Patents

Literature

609 results about "Food process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food processing is the transformation of agricultural products into food, or of one form of food into other forms. Food processing includes many forms of processing foods, from grinding grain to make raw flour to home cooking to complex industrial methods used to make convenience foods.

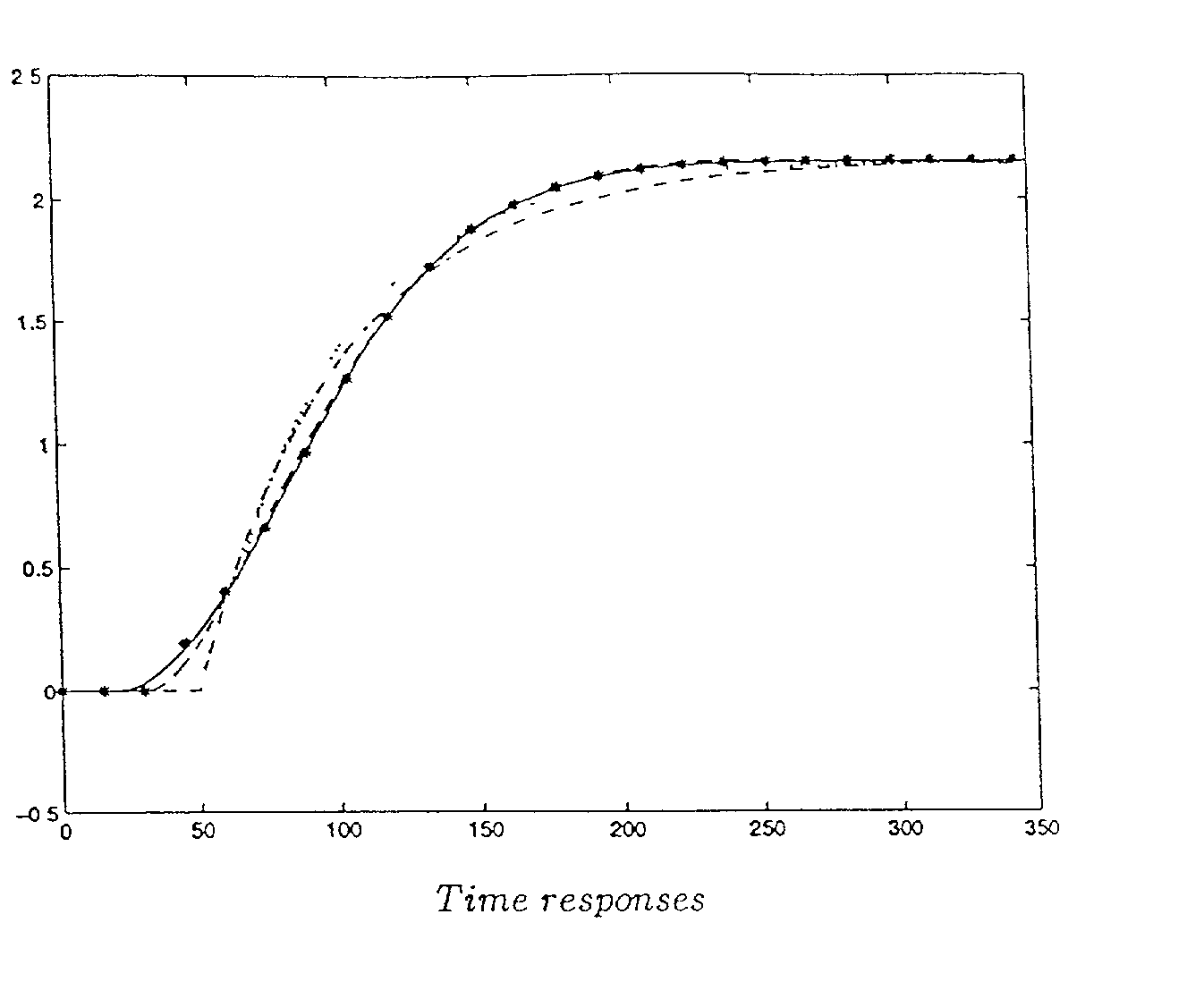

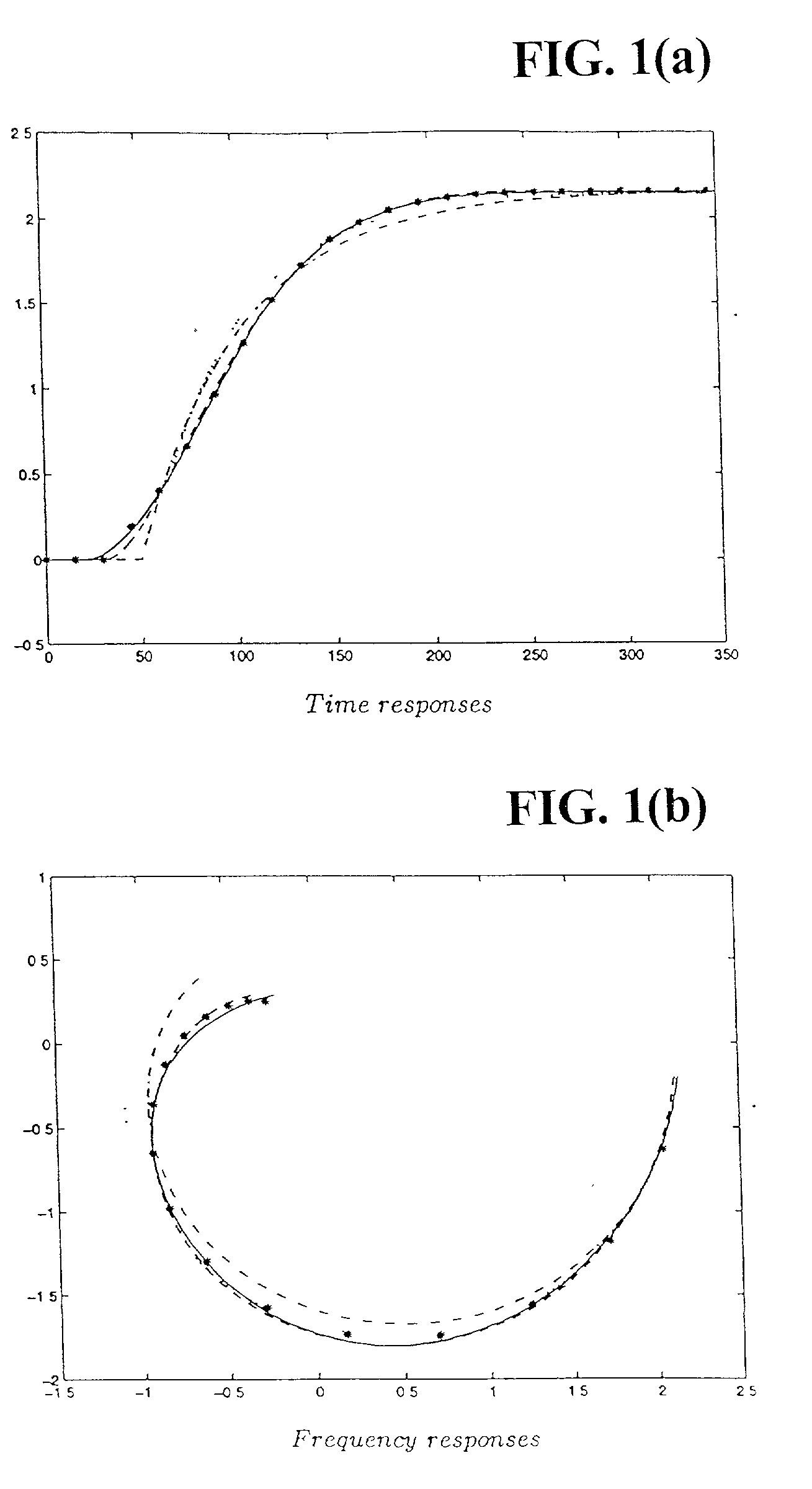

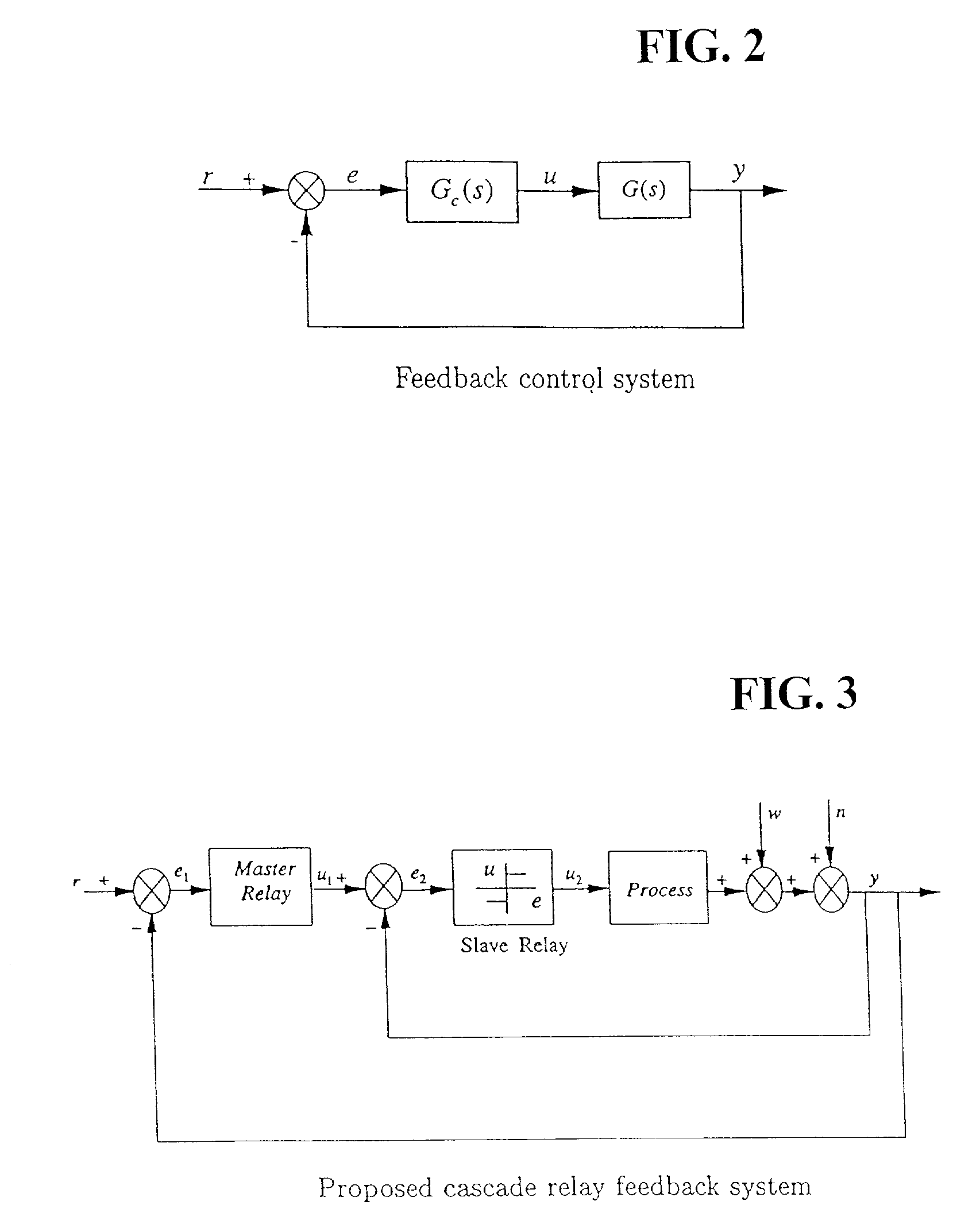

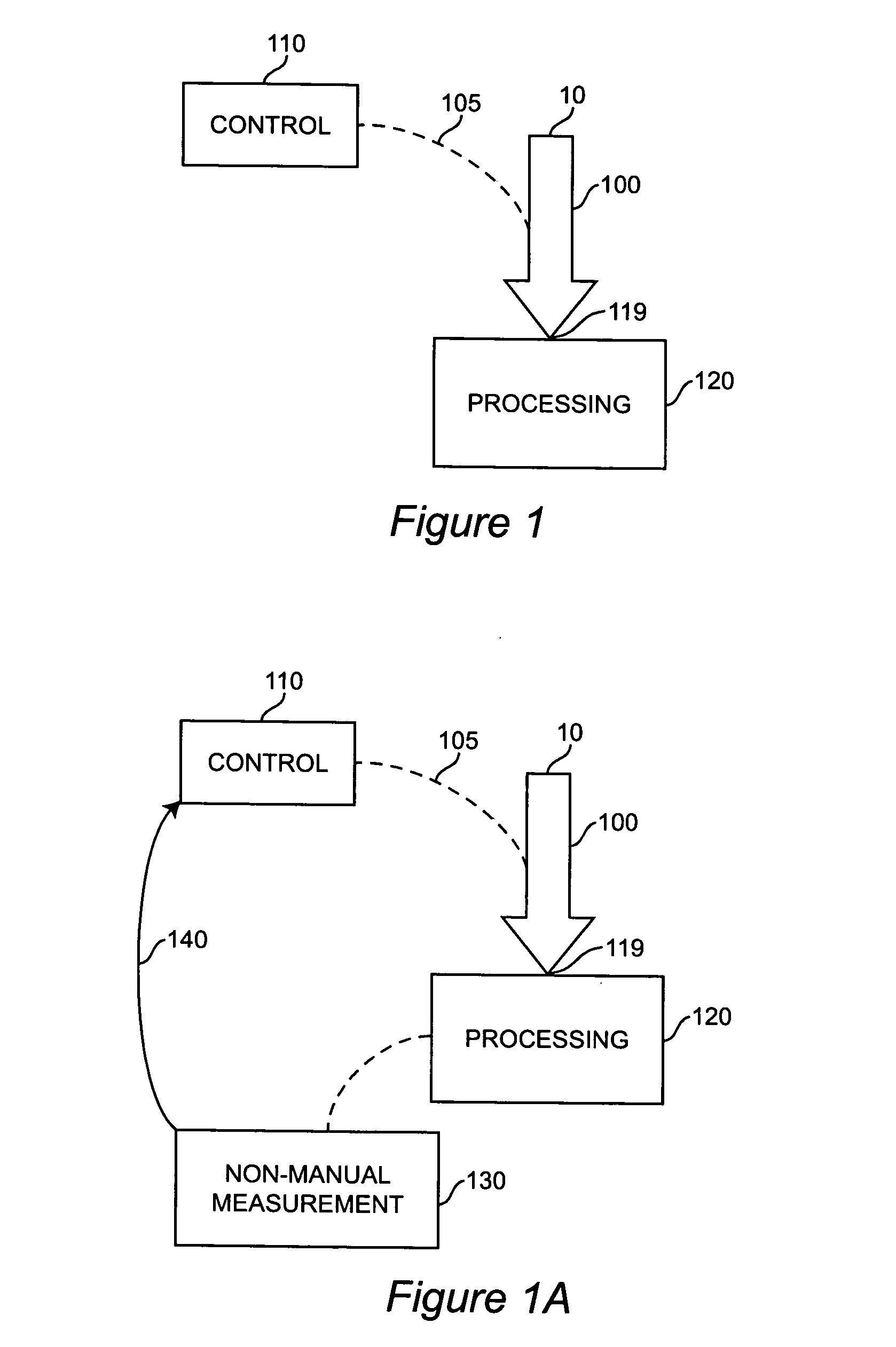

Robust process identification and auto-tuning control

InactiveUS20020111758A1Accurate estimateImprove performanceAmplifier modifications to reduce noise influenceVoltage-current phase angleGuidelineTime delays

A simple yet effective and robust identification method is presented using process step responses for process identification that can provide a continuous transfer function with time-delay without iteration. A cascade relay provides accurate and reliable more points on the process frequency response. The internal model principle is employed to design single-loop controller of PID or high-order types with best achievable control performance for controller tuning, e.g. both single and multivariable cases are covered. The process identification and control design portions can be easily integrated into a control system auto-tuning package. Further, a general control scheme for disturbance rejection is given which can significantly improve disturbance rejection performance over conventional feedback systems with time delays. Practical issues such as noises, real-time implementation and tuning guidelines are also provided. The present invention provide general, systematic, effective, and applicable methods for process identification and control for a wide range of industries such as process and chemical plants, food processing, waste water treatment and environmental systems, oil refinery, servo and mechatronic systems, where a system model is needed for analysis, prediction, filtering, optimization and management, and / or where control or better control is required for their systems.

Owner:NAT UNIV OF SINGAPORE

Feeding mechanism auto-adjusting to load for use in automatic high-security destruction of a mixed load, and other feeding systems

A inventive feeding mechanism continuously feeds and continuously subjects to shredding, cutting, recycling, sorting, or other processing, a load consisting of a mixture of different-thickness materials, such as a mixture of paper, compact disks (CDs), cassette tapes, videotapes, etc. The auto-adjusting feeding mechanism is useable in high-security destruction, food processing, recycling, sorting, processing, and other applications.

Owner:CASTRONOVO CHARLES A

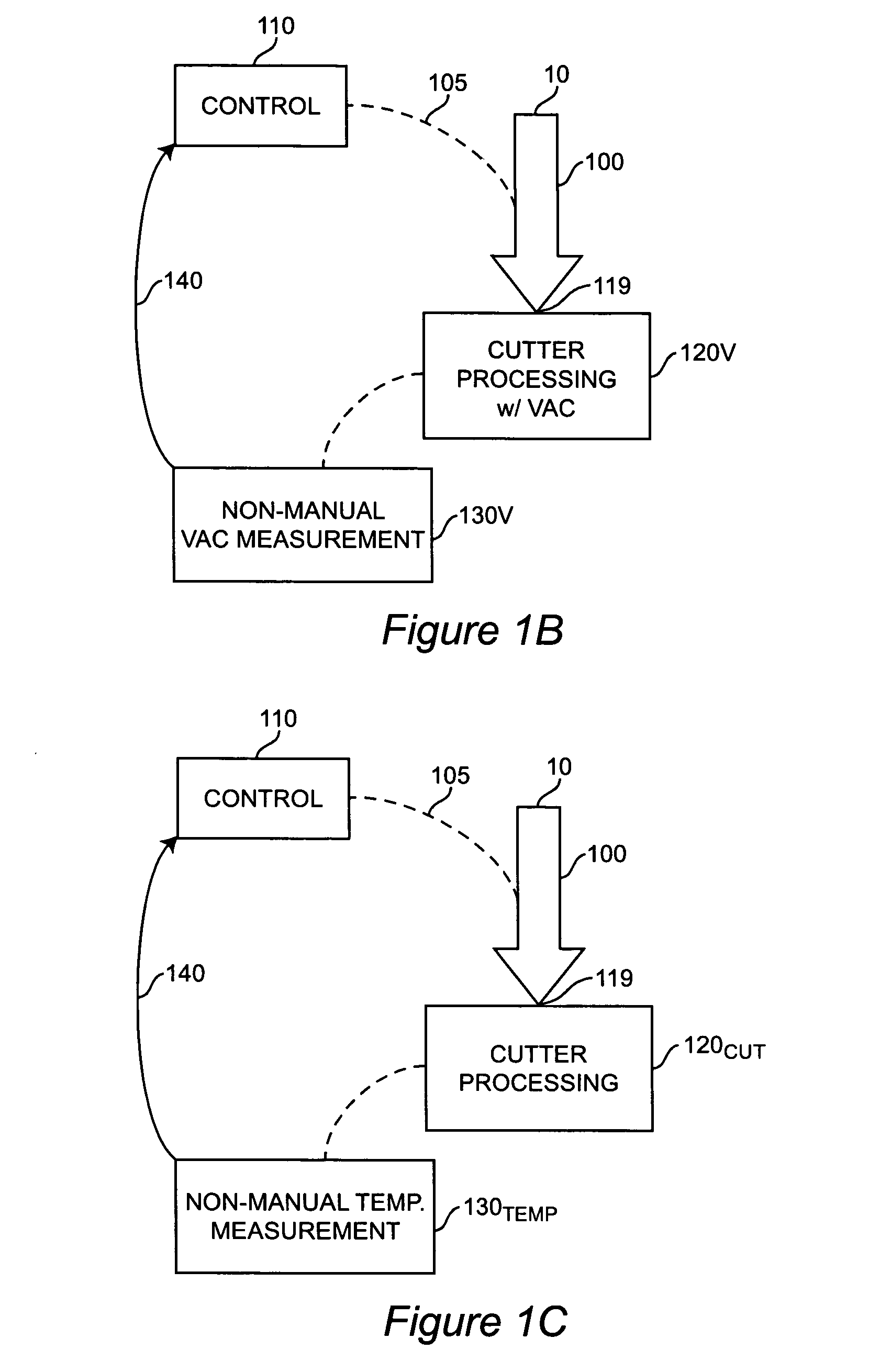

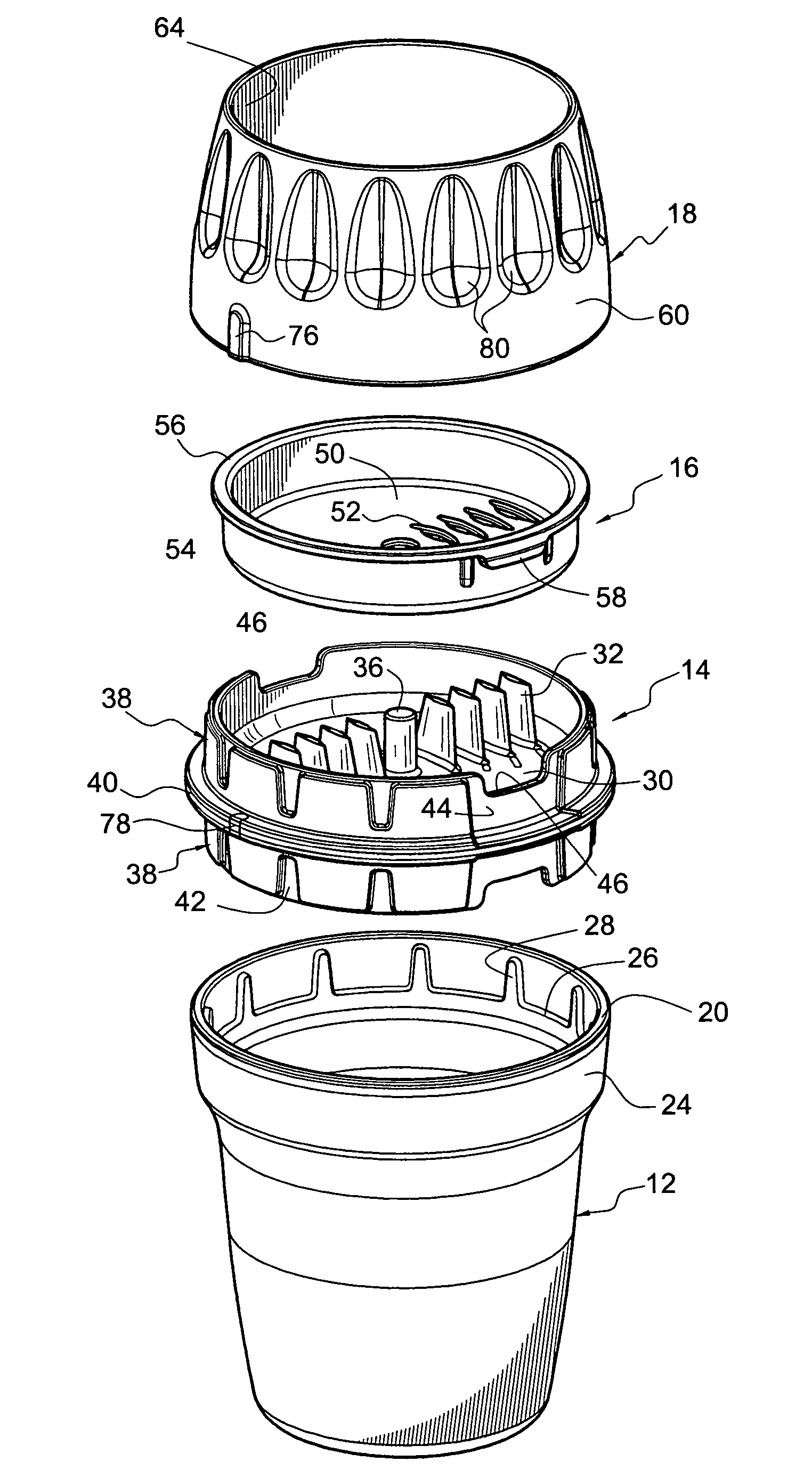

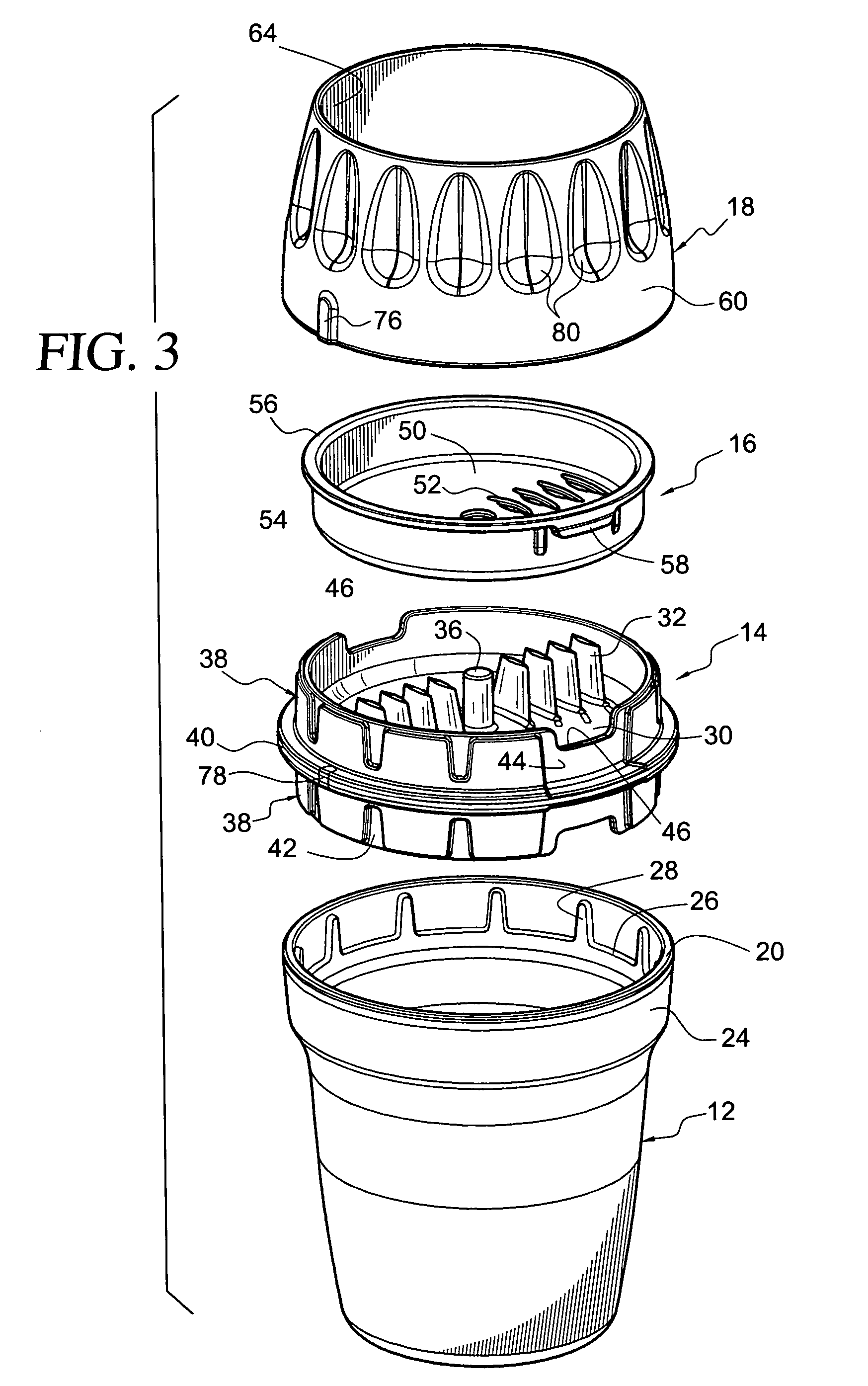

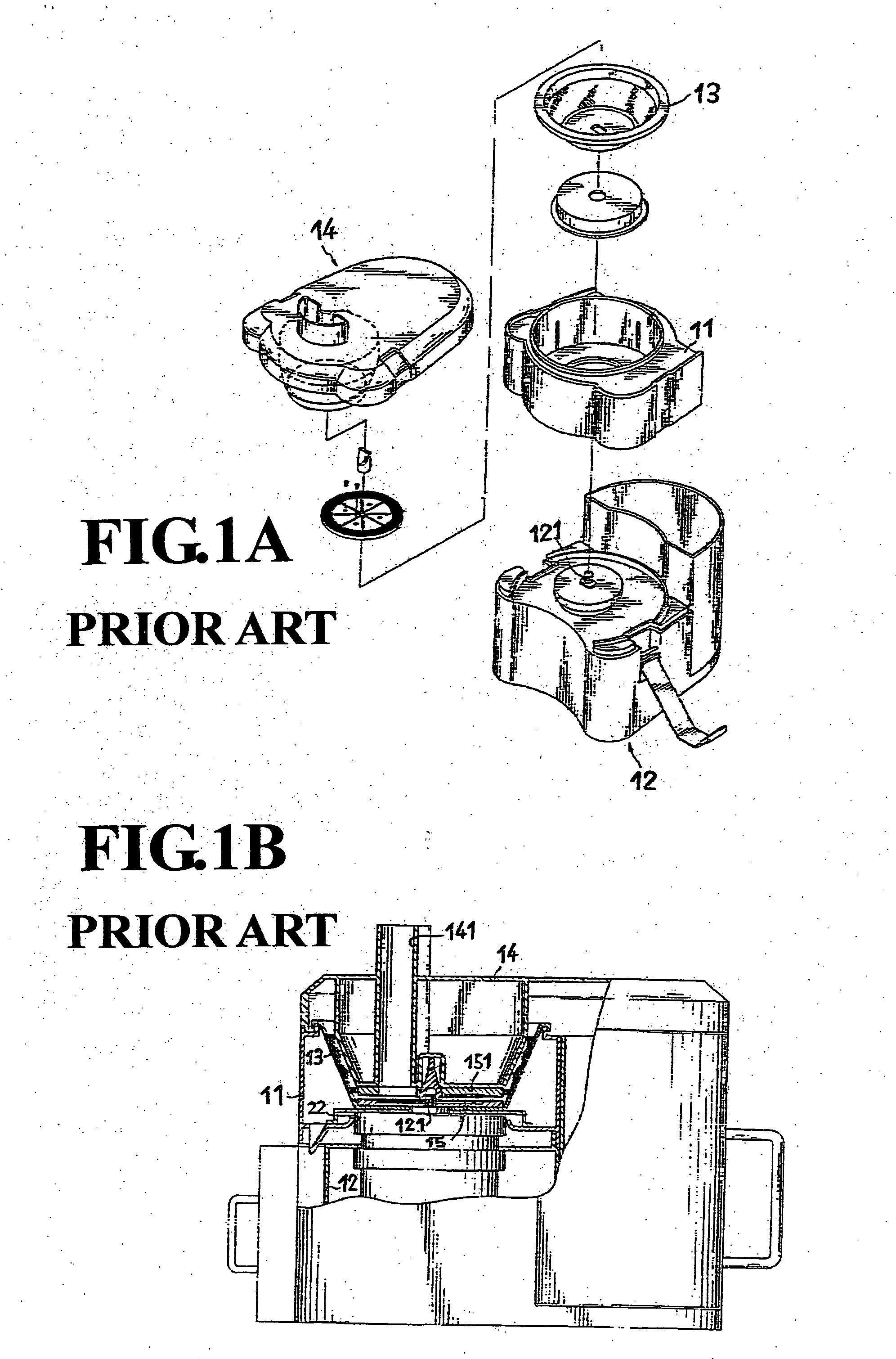

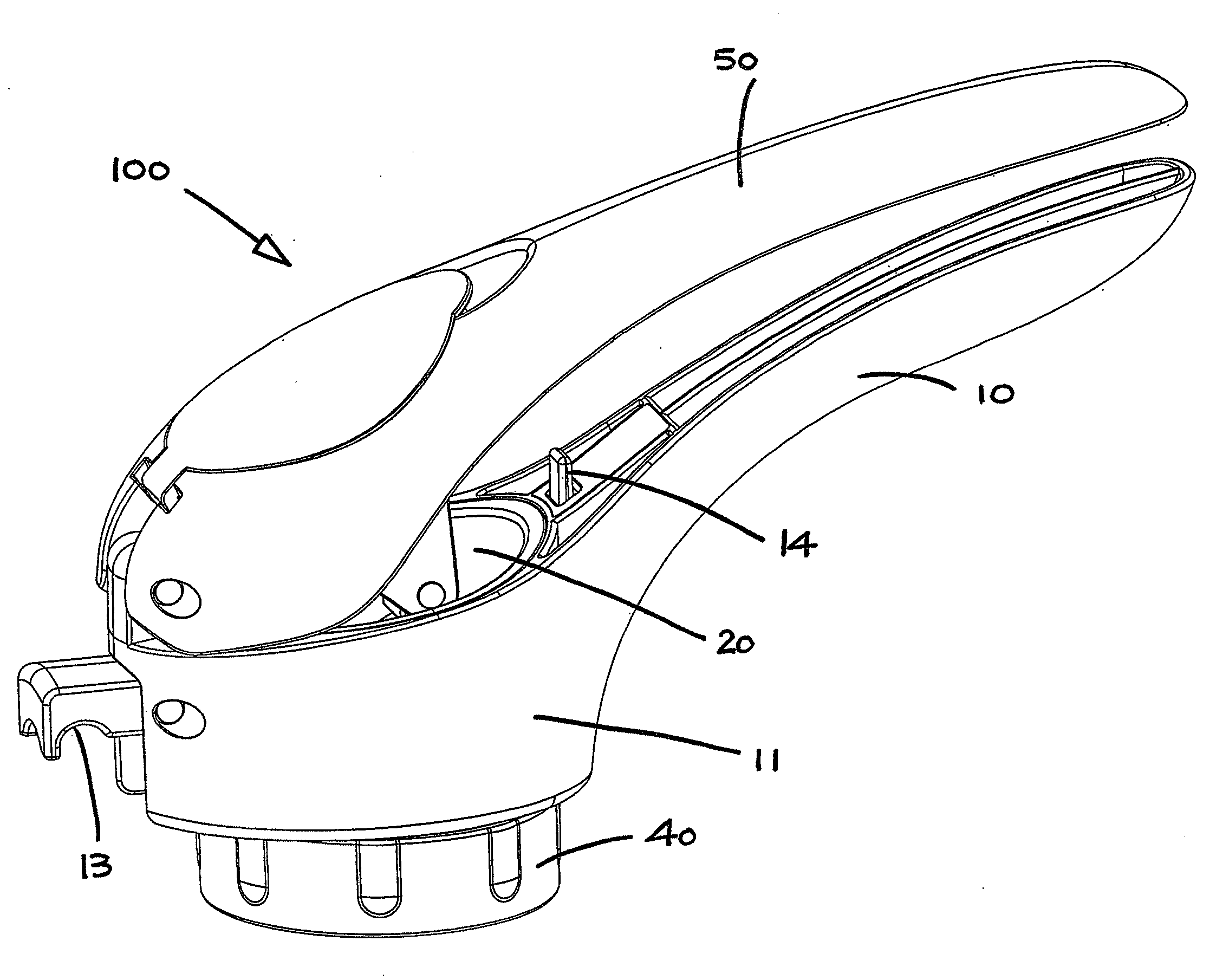

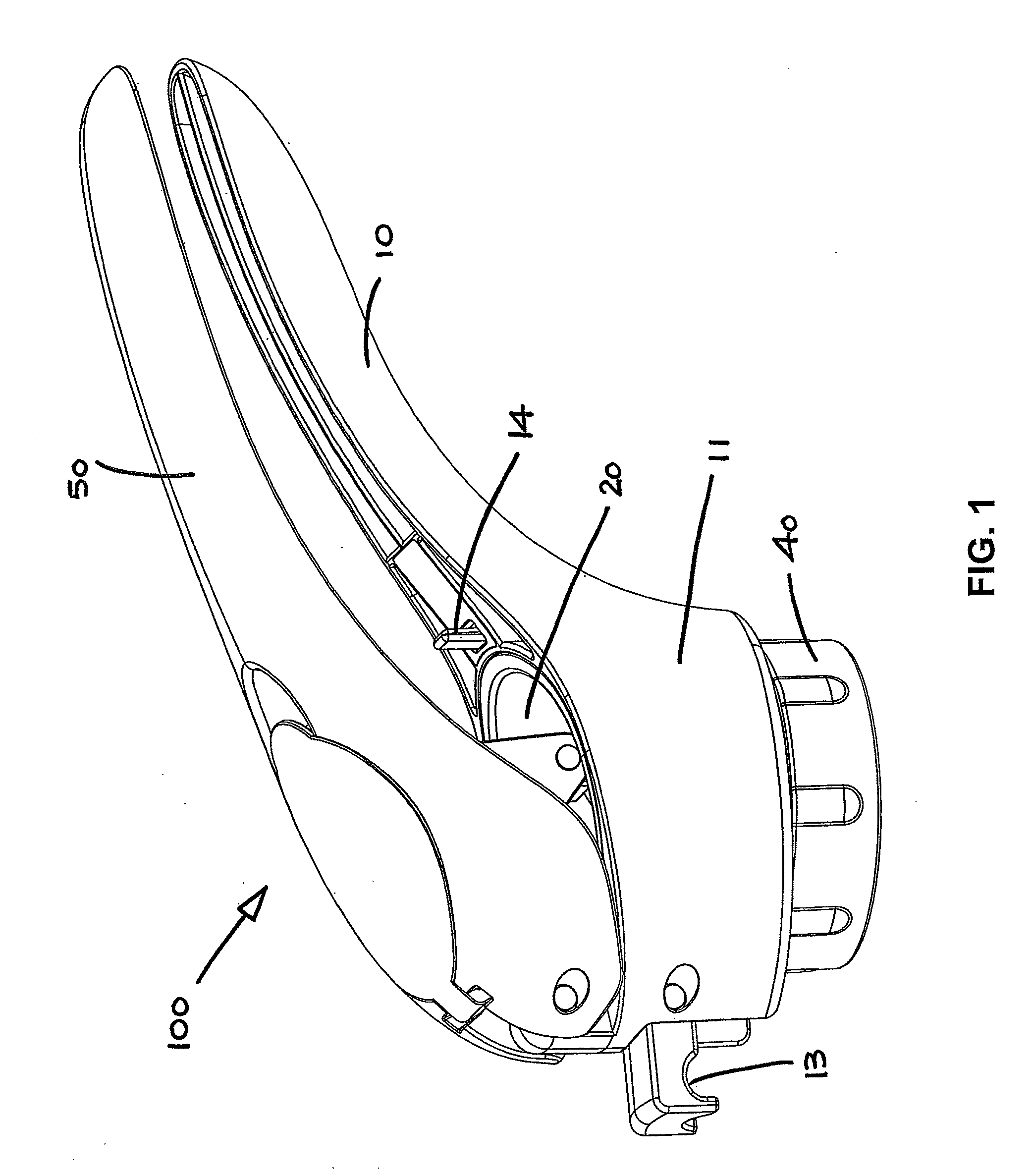

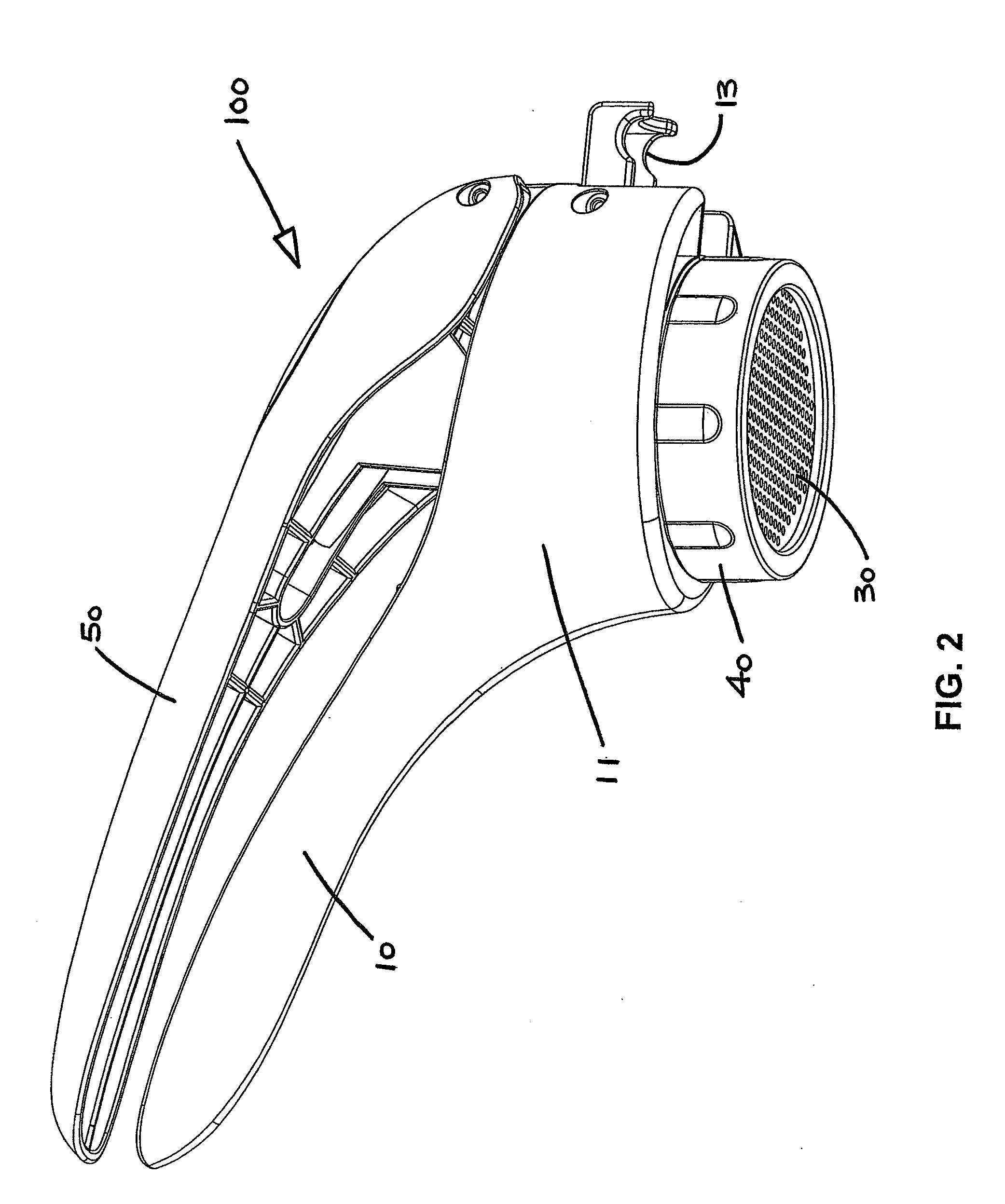

Processing tool for foodstuffs

A processing tool for garlic and like edibles including a container mounted comminuting unit having-upper-and lower sets of spaced linearly aligned blades selectively presented in an upwardly directed operating position upon an inverting of the unit, the blades of each set having a comminuting profile differing from that of the blades of the other set and are selectively engaged by a set of spaced pusher teeth aligned along a sinusoidal path and mounted on an overlying cap for, upon rotation of the cap relative to the comminuting unit, moving an edible through the comminuting blades for the desired comminution thereof, the cap including a separate chamber for preparation of the edible before the comminuting process.

Owner:DART IND INC

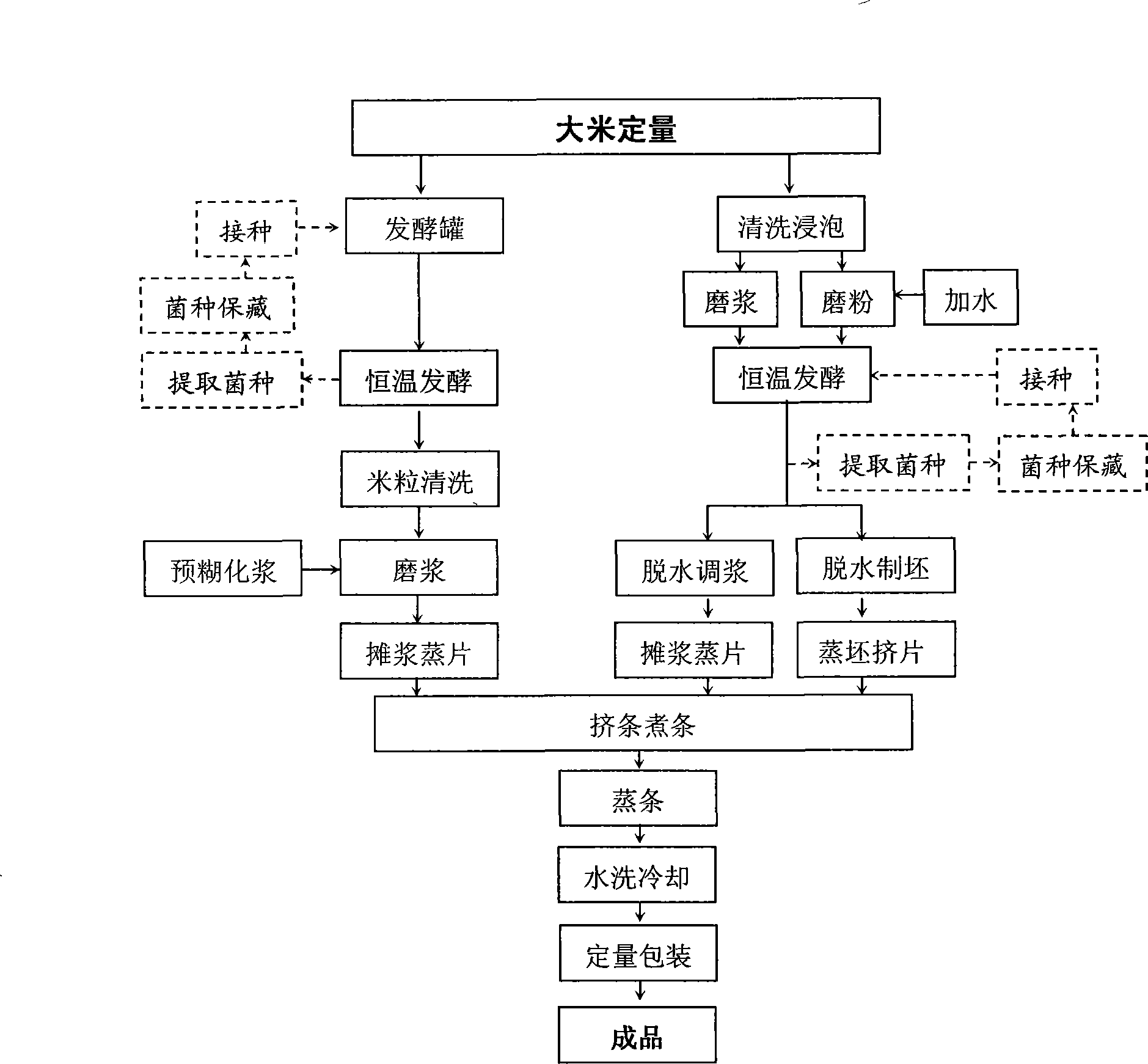

Method for processing lactic acid bacteria fermentation rice-flour noodles

InactiveCN101248852AShorten the production cycleReduce manufacturing costFood preparationBiotechnologyBroken rice

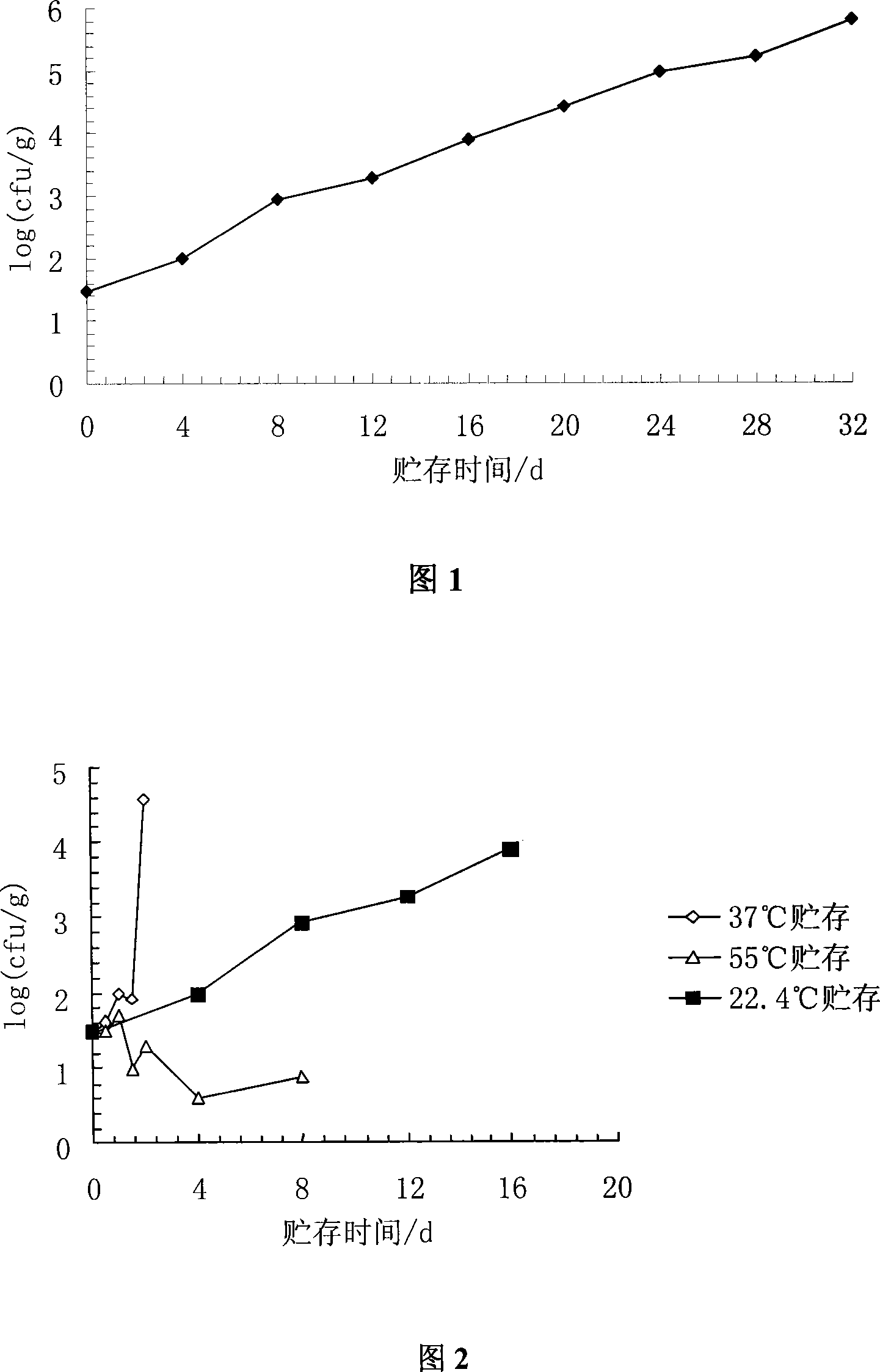

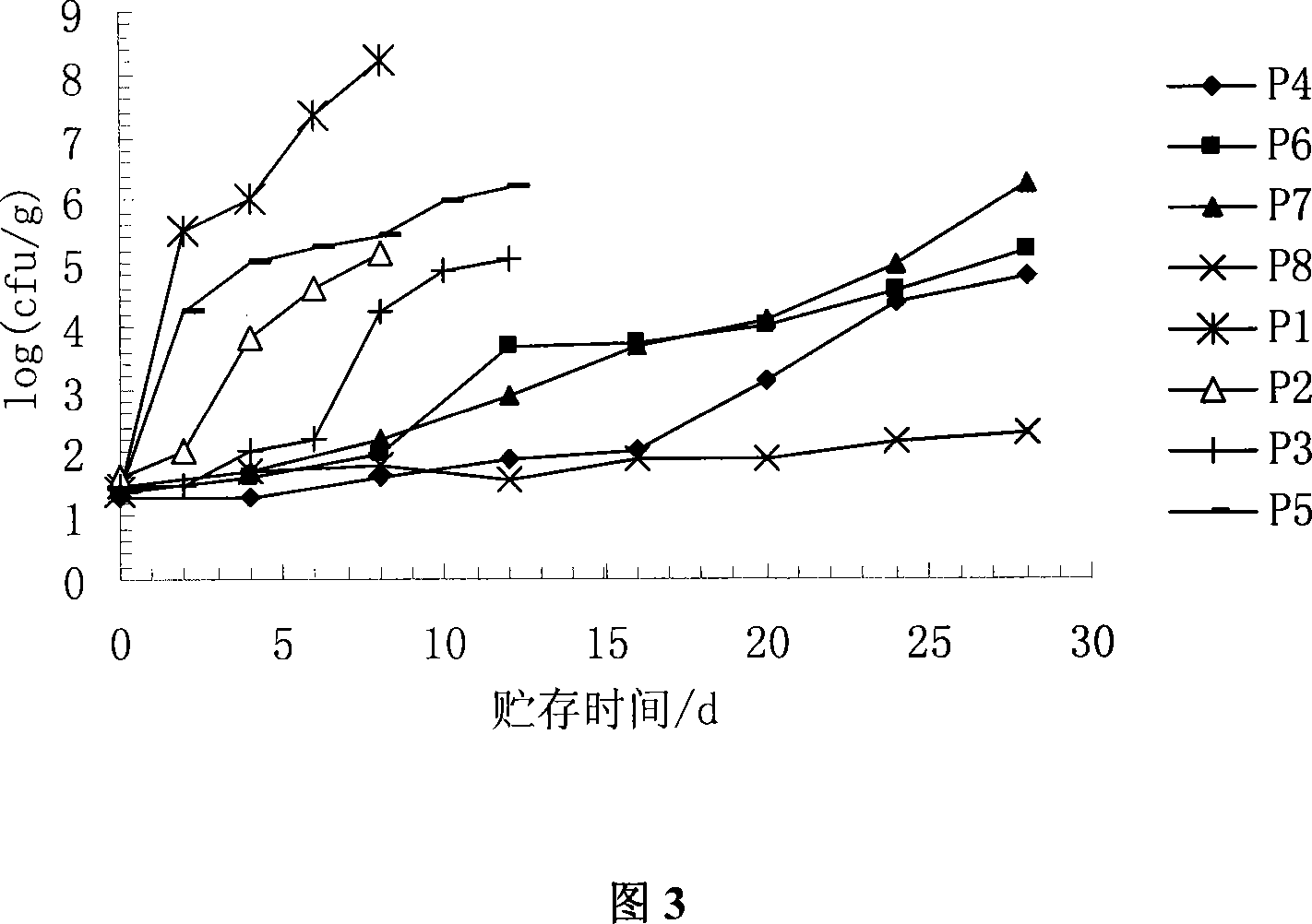

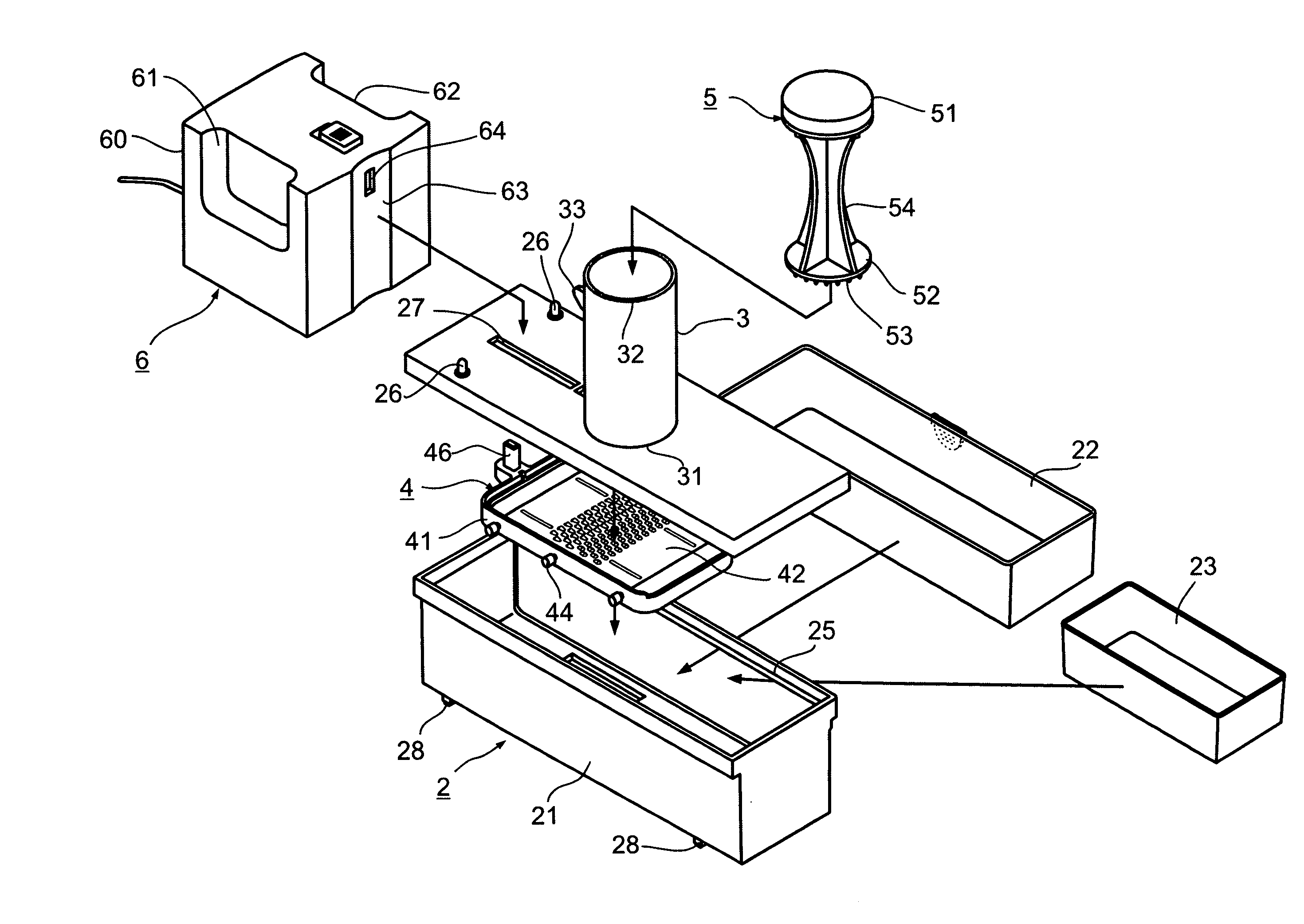

The invention discloses a processing method for fermenting rice flour by lactobacillus, namely using the lactobacillus to ferment and produce rice flour food with high quality, belonging to the technology field of food process. The technical proposal comprises the following steps of grinding the rice flour to thick liquid, spreading the thick liquid to steam a sheet, extruding and cooking rice bars, steaming the rice bars, and washing and cooling the rice bars. The processing method is characterized in that the selected material is rice or broken rice with amylose starch content more than 20%, the lactobacillus is added into the rice flour for fermentation at a constant temperature before or after grinding the rice flour to thick liquid, the number of the lactobacillus is 10<6> - 10<11>cfu / ml, the fermentation temperature is 30-50 DEG C, and the fermentation time is 8-18 hours. The processing method avoids the danger of latent miscellaneous bacteria by adopting pure strain enrichment fermentation, improves the flexibility and ensures the cleanness and the quality of the rice flour by utilizing pre-pasting rice milk instead of reserved rice sheet and fermented glutinous rice, and saves production cost due to the short production period.

Owner:CHINA AGRI UNIV

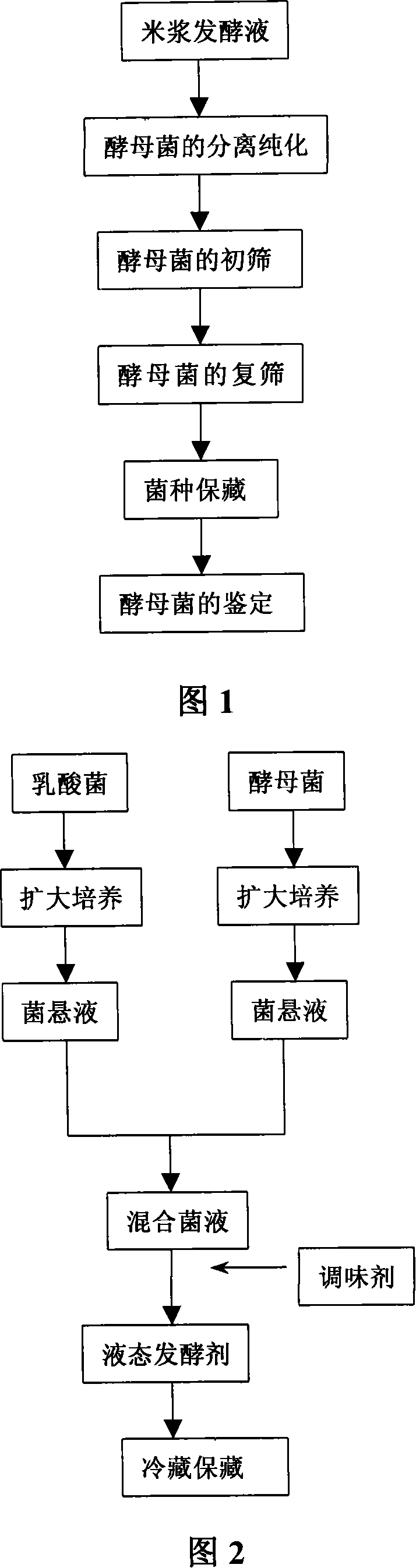

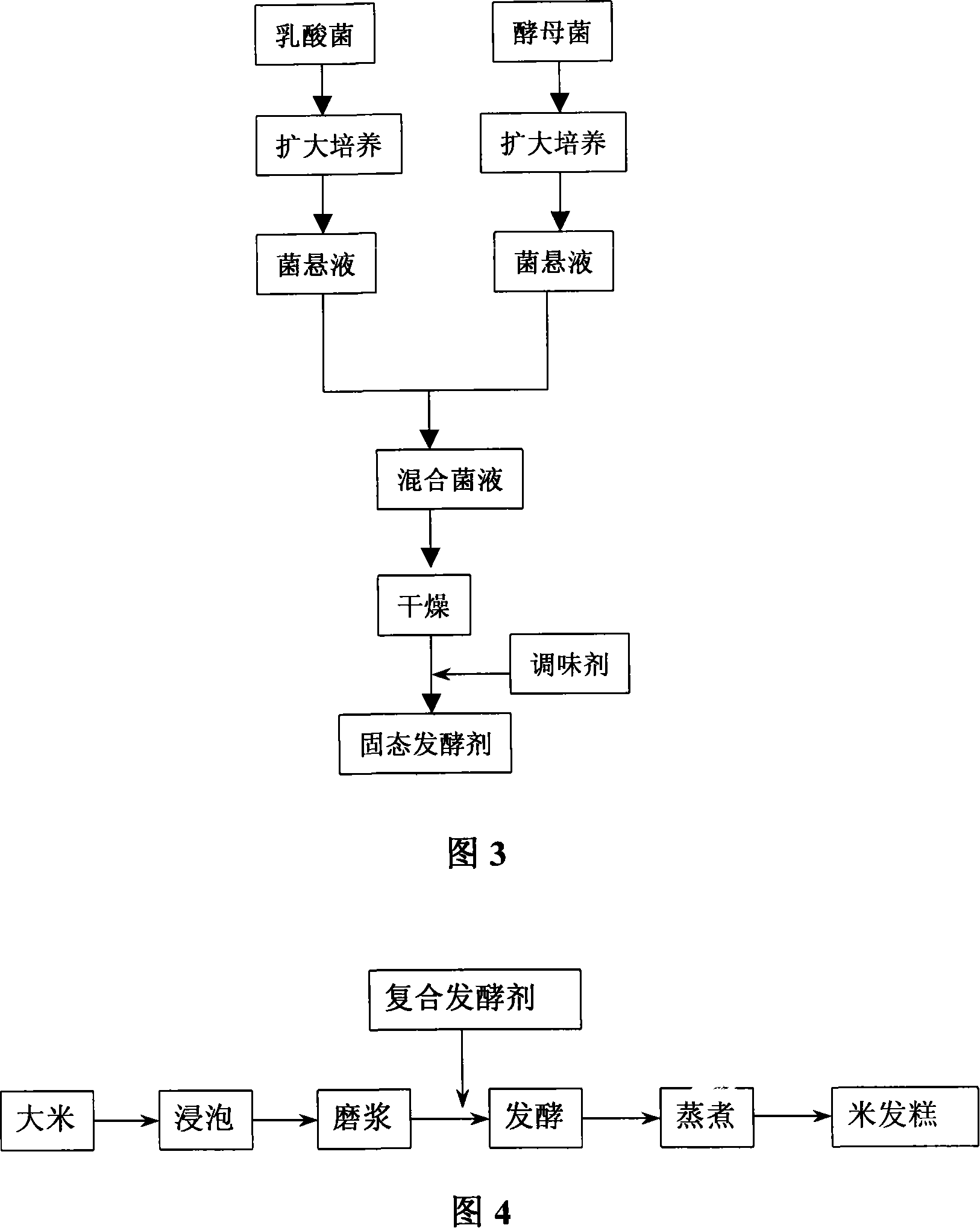

Mycopremna as microorganism leaven, composite leaven containing the mycopremna and application of the same

InactiveCN101173223AShort fermentation timeGood fermentation propertiesFungiMicroorganism based processesBiotechnologyMicroorganism

The invention relates to a strain used as hametz of microorganism, belonging to technical field of processing agricultural microorganism and food, which comprises the strain and the compound hametz ofplant lactocin as well as the application. The invention is characterized in that: the microzyme-Custer bouquet yeast strain can obtain by separating and filtering, which is suitable for fermenting the rice steamed sponge cake; the yeast strain is preserved in Chinese typical culturing and preserving centre and the preserved number is CCTCC NO: M207150. The microorganism compound hametz can be made by the ZSM-001 Custer bouquet yeast strain and AS1.510 plant lactocin (Lactobacillus plantarum), and can be used in rice fermented products, such as rice steamed sponge cakes. The invention has theadvantages of good fermenting performance and easy commercial process, and the products made by the invention have a typical sweet and sour perfume.

Owner:HUAZHONG AGRI UNIV

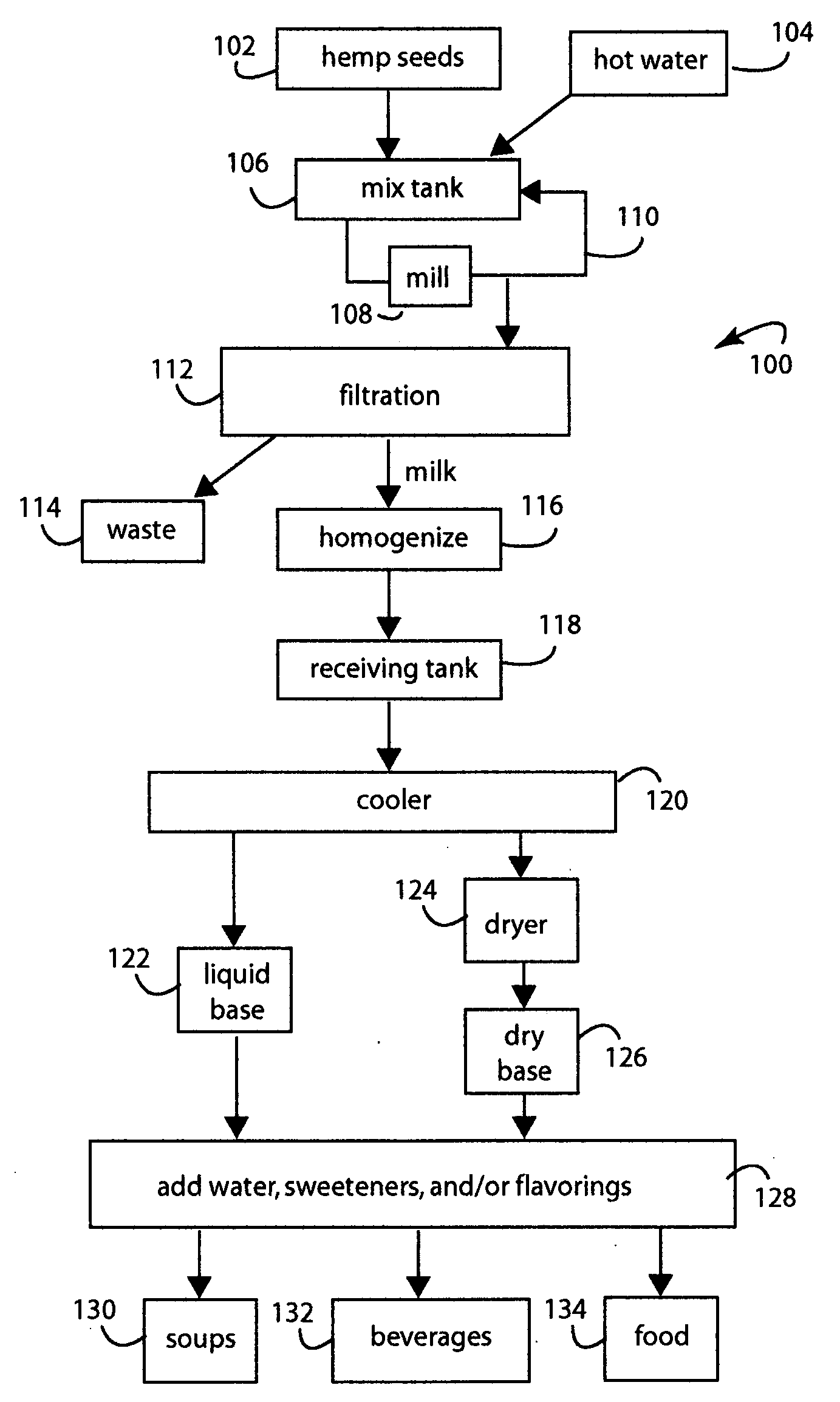

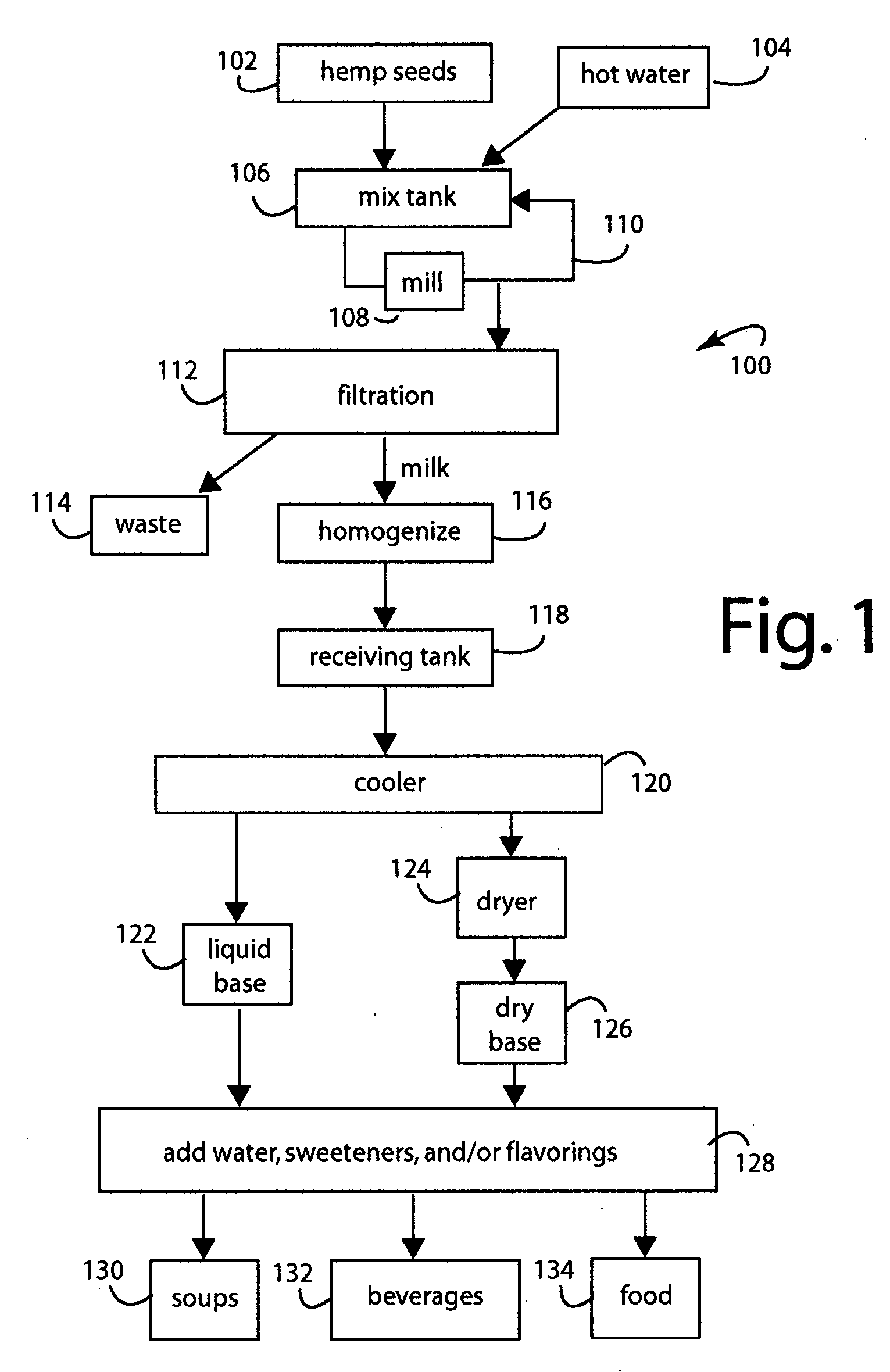

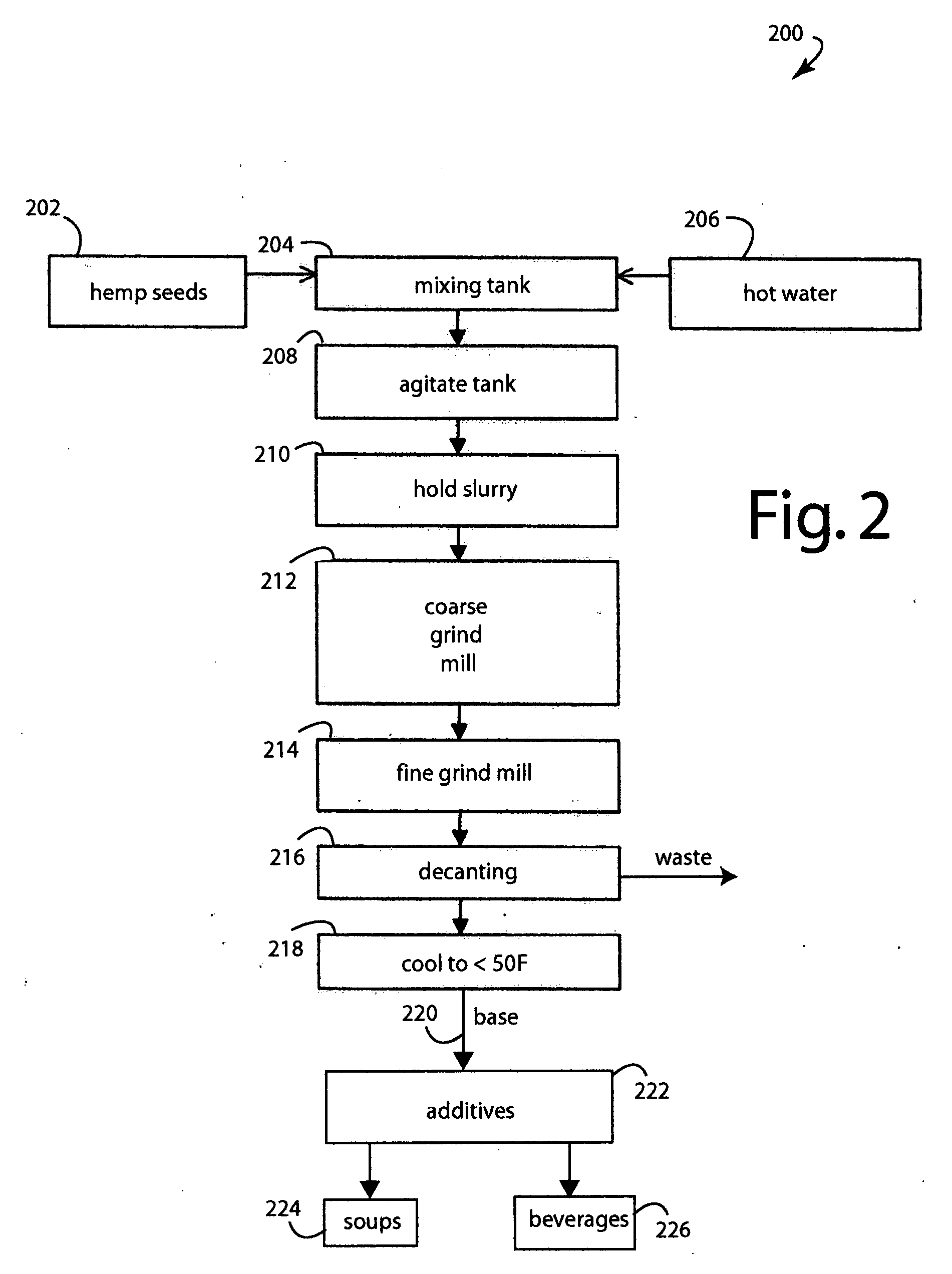

Hemp food product base and processes

InactiveUS20080241339A1Pleasant flavorLow carbohydrateFood preparationGrain millingFlavorProduct base

A food process comprises starting with hemp (Cannabis sativa) seeds that have been cultivated to have low levels of tetrahydrocannabinol (THC) alkaloid, e.g., less than 0.3%. The hemp seeds are dehulled to produce split seed kernels, mixing the split seed kernels with hot water to hydrate them into a slurry, grinding the slurry to blend and smooth it into a product base, cooking the product base to achieve a particular flavor and aroma consistent with a target food product, cooling the product base to stop cooking, and further processing the product base into a target food product like soups and beverages. The products produced have high levels of protein, vitamins, and other nutritional values.

Owner:CALIFORNIA NATURAL PRODS

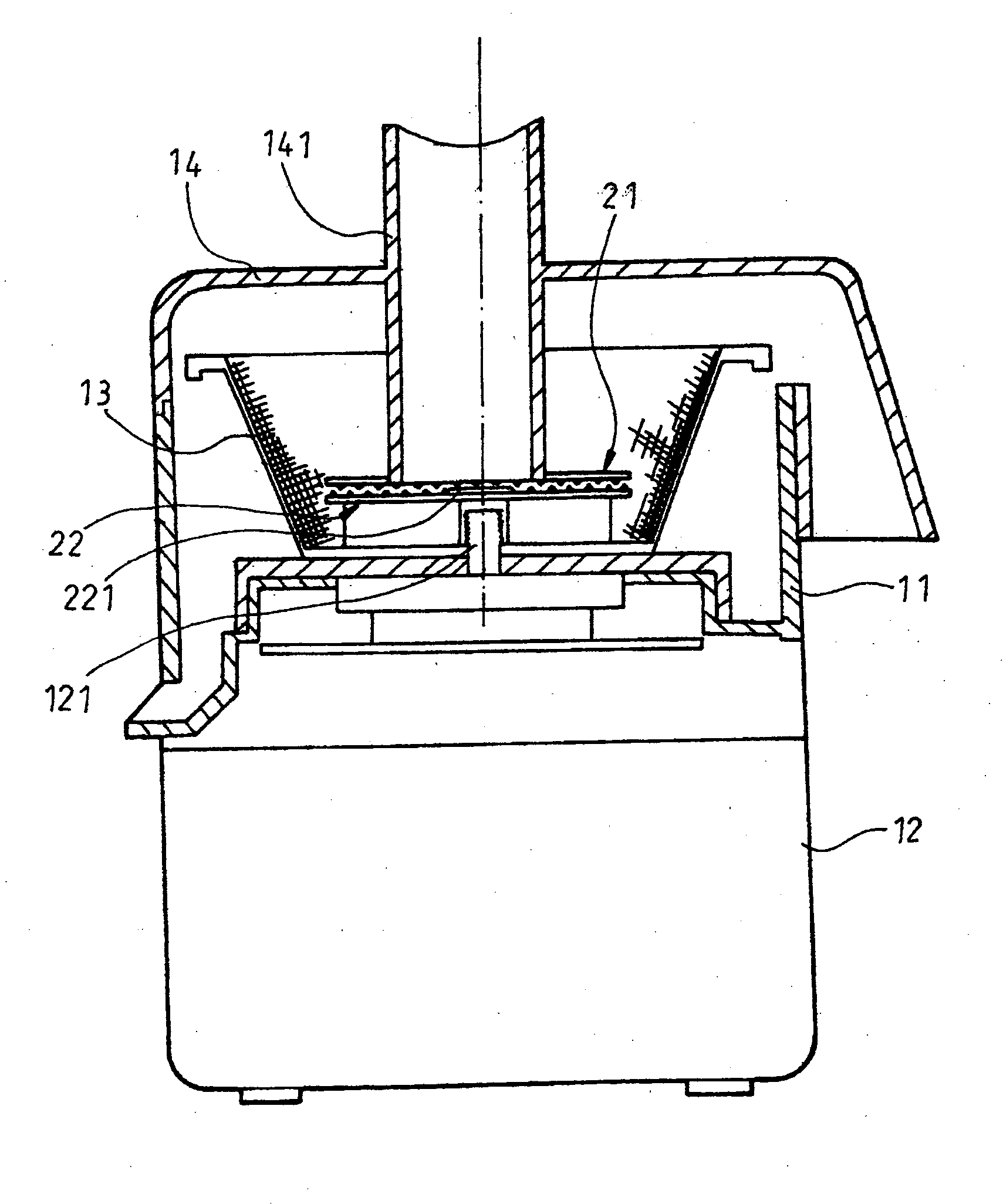

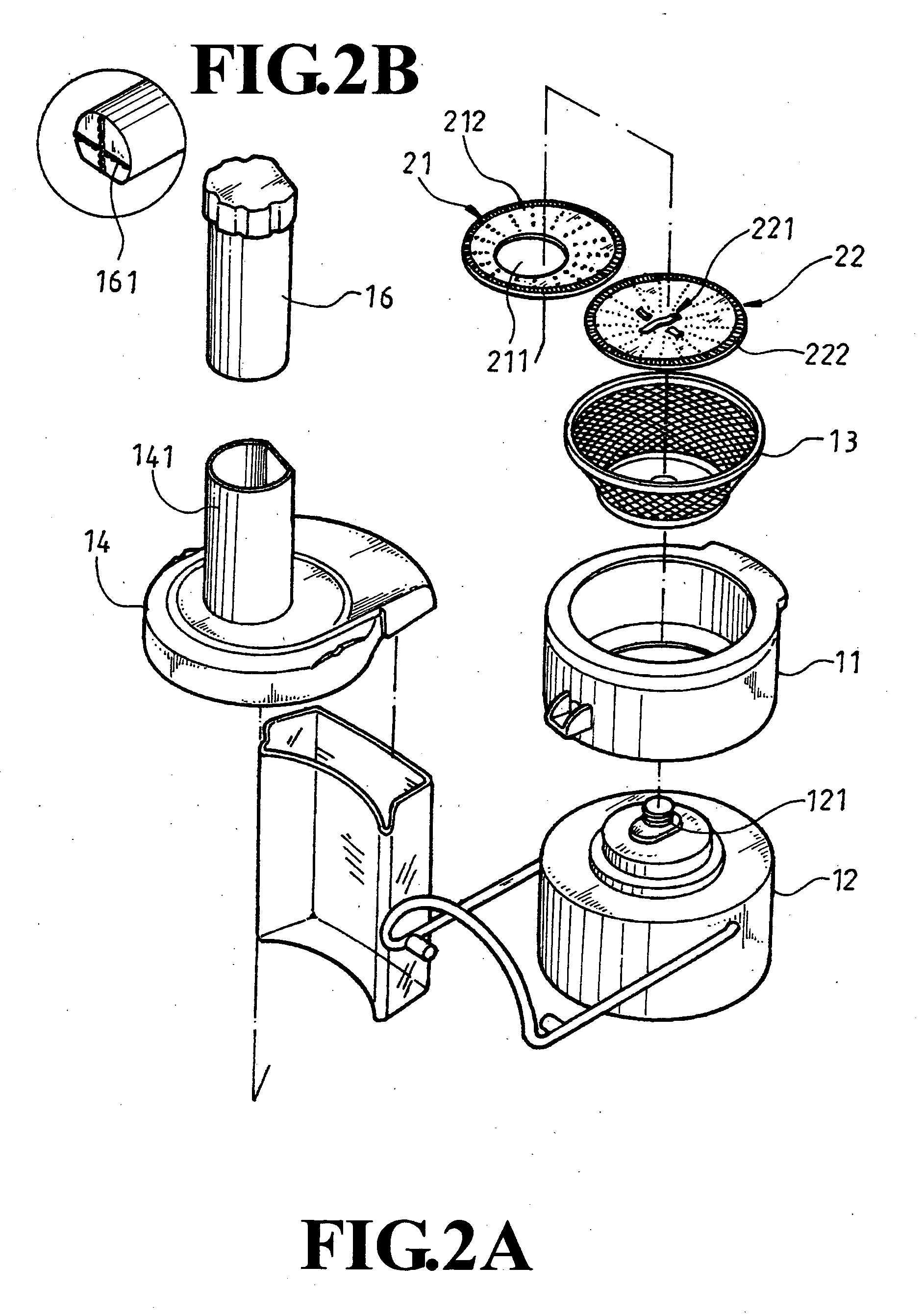

Food processor with combined grinding and juice extracting functions

InactiveUS20080115677A1Increase the areaEliminate dead areasJuice extractionGrain treatmentsEngineeringProcessor design

A food processor designed for grinding beans and cereals as well as extracting juice from fruits and vegetables includes a bowl, a base, a strainer basket, a cover, an upper grinding disc fixedly mounted around a bottom of a feed tube formed on the cover, and a lower grinding disc firmly connected to and driven by a driving mechanism on the base to rotate at high speed. Since the lower grinding disc is provided at a central area with differently shaped central blades and along a circumferential edge with multiple grinding teeth, the feed tube is offset from but overlaps a center of the lower grinding disc, and the upper grinding disc is provided with grinding teeth corresponding to the lower grinding disc, an expanded grinding area is available on and between the two grinding discs, and any dead area of grinding may be eliminated.

Owner:GREAT YEN ELECTRIC FOOD GRINDER

Production method for ocean biology nutrition wine

The present invention belongs to the field of food producing technology, and is especially production process of nutritious sea food wine, which is produced with grain liquor as the base material, abalone and sea cucumber as main material, and wolfberry fruit, Chinese yam, licorice, cassia bark, date, mulberry and kudzu vine root as supplementary material. The production process includes the following steps: 1. cooking fresh abalone and sea cucumber, puffing in dilute base solution, freeze drying, crushing, sieving and sterilizing to obtain abalone and sea cucumber powder; 2. washing and drying the supplementary material, crushing, sieving and sterilizing to form supplementary material powder; and 3. soaking the abalone and sea cucumber powder and the supplementary material powder separately in grain liquor for several days, filtering to obtain filtrates, mixing, heating to eliminate alcohol, homogenizing, filtering, seasoning, sterilizing and packing.

Owner:程玉山

Preparation method of asparagus whole powder and asparagus solid beverage

InactiveCN102266018AHigh nutritional valueRetain nutritionFood preparationAsparagus adscendensDrum drying

The invention discloses a preparation method of asparagus whole powder and asparagus solid beverage, which belongs to the technical field of food processing. A method for preparing whole asparagus powder, comprising the following steps: (1) selecting and cleaning raw materials; (2) cutting into pieces and blanching; (3) crushing and beating; (4) miniaturization treatment; (5) homogenizing; 6) Sterilization; (7) Drum drying; (8) Crushing and sieving. The first preparation method of the asparagus solid beverage is to use the above-mentioned asparagus whole powder as the main raw material, and mix it with other powdery raw materials evenly to obtain the asparagus solid beverage. The second preparation method of the asparagus solid beverage is to prepare the asparagus pulp before homogenization, so that the asparagus slurry and other powdery raw materials are evenly mixed, and other processes are similar to the preparation method of the whole asparagus powder. The production of asparagus products by the method of the invention has low cost, high production efficiency, continuous production can be realized, and the product has good quality, good brewability and rich nutritional value.

Owner:CHINA AGRI UNIV

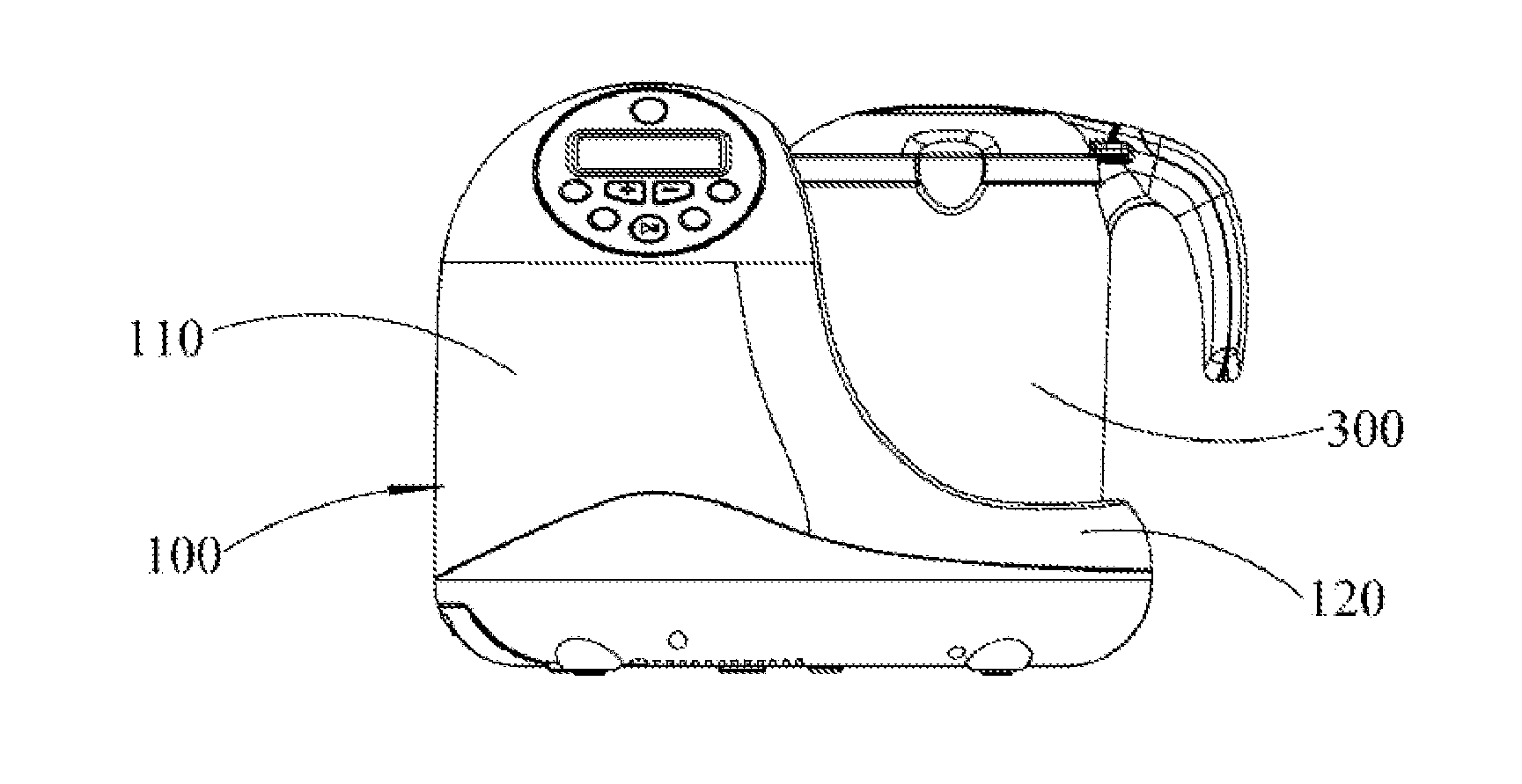

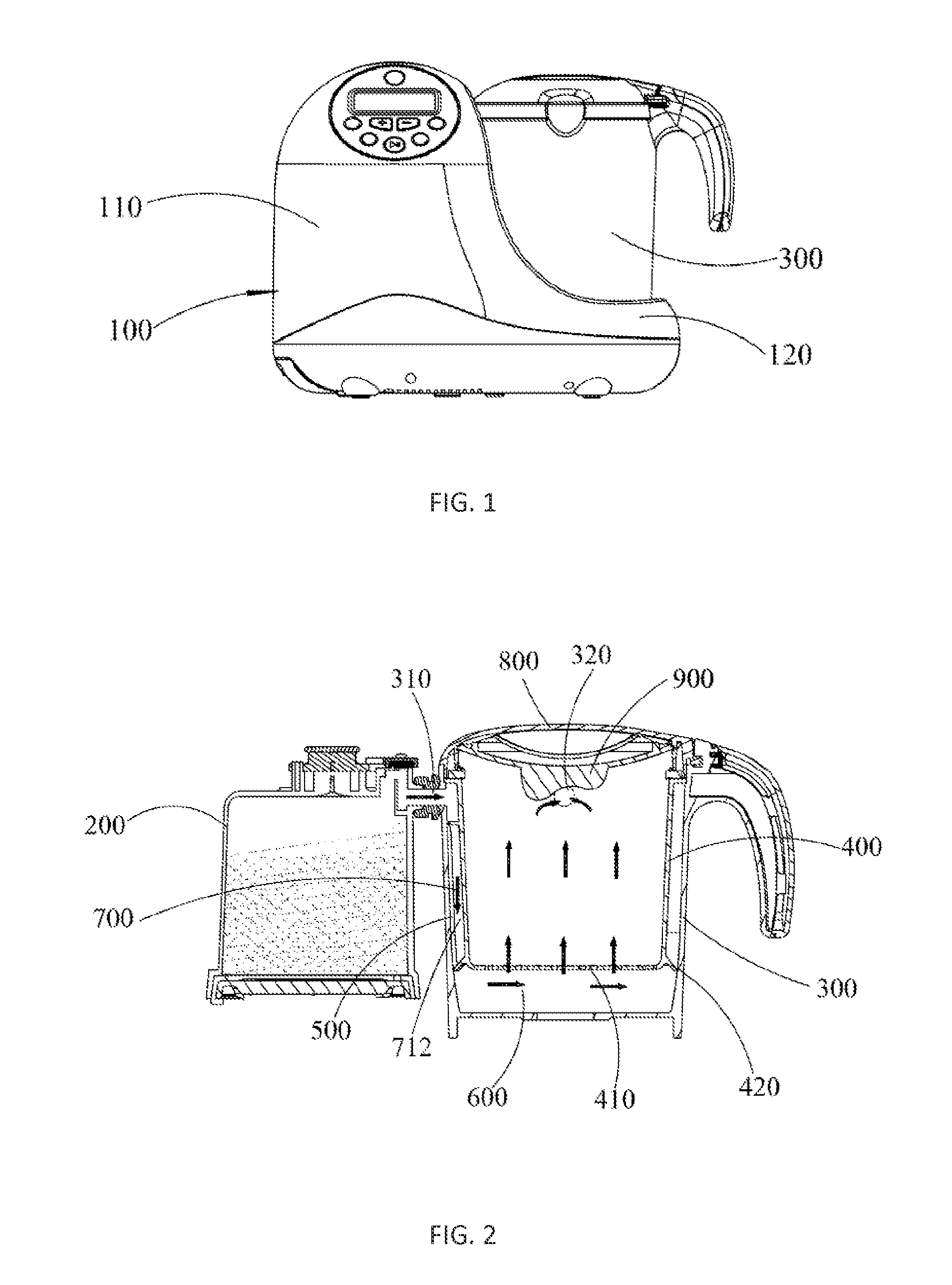

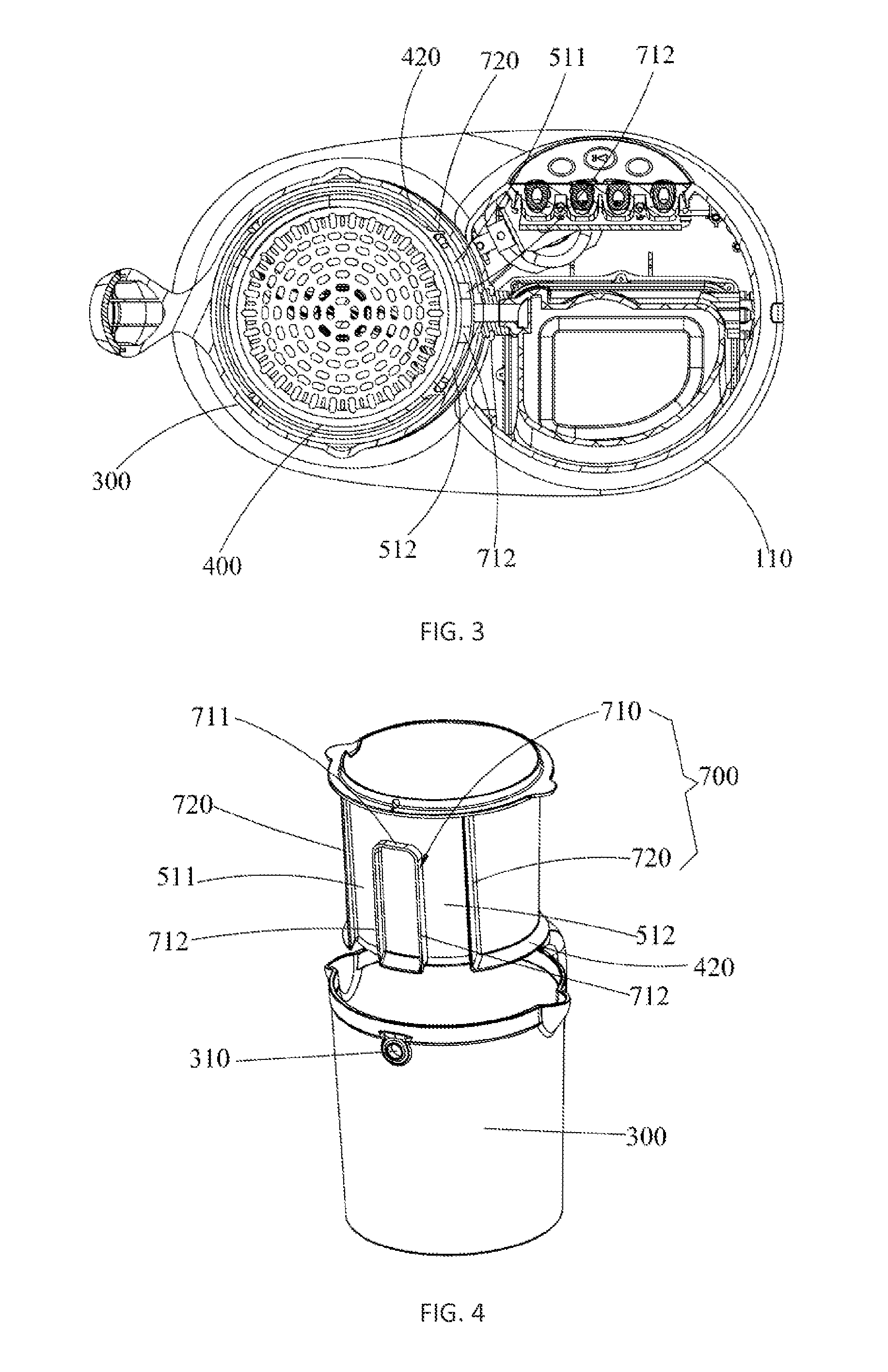

Food processor and steam channel structure thereof

InactiveUS20140251162A1Large steam flowShort pathSteam cooking vesselsDeep fat fryersHeat lossesEngineering

A food processor and a steam channel structure thereof. The food processor comprises a processor body (100), a steam generation device (200) and a heating cup (300). The heating cup is provided with a steam inlet (310) and a steam outlet (320); a steaming cup (400) is arranged in the heating cup; an air hole (410) is provided at a bottom wall of the steaming cup; a first gap (500) and a second gap (600) in communication with each other are respectively arranged between a side wall of the steaming cup and a side wall of the heating cup, and between the bottom wall of the steaming cup and a bottom wall of the heating cup; the steam channel has the following structure: a steam inflow channel is arranged in the first gap, and steam diffuses from the steam inlet on the heating cup towards two sides to enter the steam inflow channel, and enters the steaming cup through the air hole after entering the second gap from the steam inflow channel. The steam channel has a simple structure, a large steam flow, a short path, a little heat loss, and high heating efficiency.

Owner:ZHOU JIANZHANG

Method for improving quick-freezing fruit vegetables thawing quality through low-frequency ultrasound wave

InactiveCN101138362AImprove defrosting qualityShorten freeze timeFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingOperational costsUltrasonic assisted

A method for improving the unfreezing quality of fast frozen fruit and vegetables with low-frequency ultrasonic belongs to the processing technical field of fruit and vegetable food. The present invention adopts ultrasonic for freezing in the process of fast freezing; the process is that the raw materials of fruit and vegetables are selected, cleaned and burnt to kill the enzyme; and then the materials are cooled, refrigerated and frozen with ultrasonic; at last the materials are packed up. The present invention adopts the process that the ultrasonic processing is combined in the process of dipping and freezing fruit and vegetable and improves the unfreezing quality of the fast frozen fruit and vegetables; the present invention is characterized by a short freezing time, excellent initial shape maintenance and low operational cost.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

High-calcium freshwater fish ball and preparation method thereof

InactiveCN102948820AIncrease added valueSolve problems that are not being reused wellFood preparationCalcium in biologyFresh water organism

The invention relates to a high-calcium freshwater fish ball and a preparation method of the high-calcium freshwater fish ball, belonging to the technical field of the processing and the producing of food. The minced fillet and the fishbone mud are taken as raw materials. The preparation method comprises the following steps of: adding shop fat with a certain quantity and the other auxiliary materials, chopping in a mixing way, forming fish ball, curing fish ball and the like. On the basis that the peculiar taste of the fish ball is guaranteed, the high-calcium freshwater fish ball provided by the invention is rich in elasticity, and has the loose, soft, fine and smooth mouth feel when being eaten, and the pursuing of modern people to nutrition health can be met. The problems that the calcium is sufficiently ingested by people, and the problem that the fish bone generated when the freshwater is deeply processed is not well used in the prior art can be solved, the additional value of the fish bone can be improved, a feasible technical scheme can be provided for the treatment of the fish bone, and the considerable economic benefit can be brought to the enterprises.

Owner:HUBEI DAMING AQUATIC PROD TECH CO LTD

Five-color health preserving noodle

Chinese traditional saying: 'food is the most important for people', which is the most basic and the most important core for the Chinese diet culture idea. Five-color health preserving noodle keeps and improves the processing technique of instant noodles, which shows the key of the health and long life (the rational nutrient match) based on the deep research of five-element philosophy by analyzing the trend of the food process, consumption and the present state of the instant noodles market, and fills the vacancy of the instant noodles food market. The product is abrasive machined finely with green, red, yellow, white, black five color optimum material and a plurality of type vegetables, which has the rational nutrition. The aim of the invention is the nutrient diet and the health preserving. The invention changes the single nutrition state of instant noodles, which meets the needs of the equalizing nutrition, the health, the long life and the convenience.

Owner:李险峰

3D (three-dimensional) printing accurate forming regulation and control method for instant conditioning mashed potatoes

The invention discloses a 3D (three-dimensional) printing accurate forming regulation and control method for instant conditioning mashed potatoes, and belongs to the field of novel food processing technologies. The 3D printing accurate forming regulation and control method includes cleaning and peeling potatoes, then slicing and cooking the potatoes and mashing the potatoes until paste is delicate and bright; adding colloid into the paste, uniformly mixing the colloid and the paste with each other to obtain mixtures, and then cooking the mixtures to thoroughly cook the potatoes and sufficiently dissolve the colloid; cooling the mixtures until the temperature of the mixtures reaches the room temperature and then adding white chocolate powder into the mixtures. The 3D printing accurate forming regulation and control method has the advantages that the diameters of printing spray nozzles, the printing distances, the printing temperatures, the movement speeds of the spray nozzles and the discharge speeds are selected in order to finely print the conditioning mashed potatoes; the accuracy of printed objects can reach 95% at least, and the printed objects can be prevented from collapsing in 40-60 min after being printed; main printed materials include mashed potatoes with high usage in daily dining and can be used as desserts, snacks and the like for dining cold dish.

Owner:JIANGNAN UNIV

Storable bread and its making process

InactiveCN101019567AImprove storage performanceDough treatmentBakery product preservationPreservativeAcidity regulator

The storable bread has in bread flour in 1000 weight portions water keeping agent 10-200 weight portions, acidity regulator 1-10 weight portions and preservative 0.5-2.5 weight portions other than conventional bread material, and is packed in a sealed bag together with deoxidant. By means of improving the bread making and storing process with modern biotechnology, modern food making technology, and modern packing technology, the present invention raises the storing performance of bread greatly. The storable bread may be stored at normal temperature for as long as three years, and is suitable for serving in tour, field operation, military field, etc.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

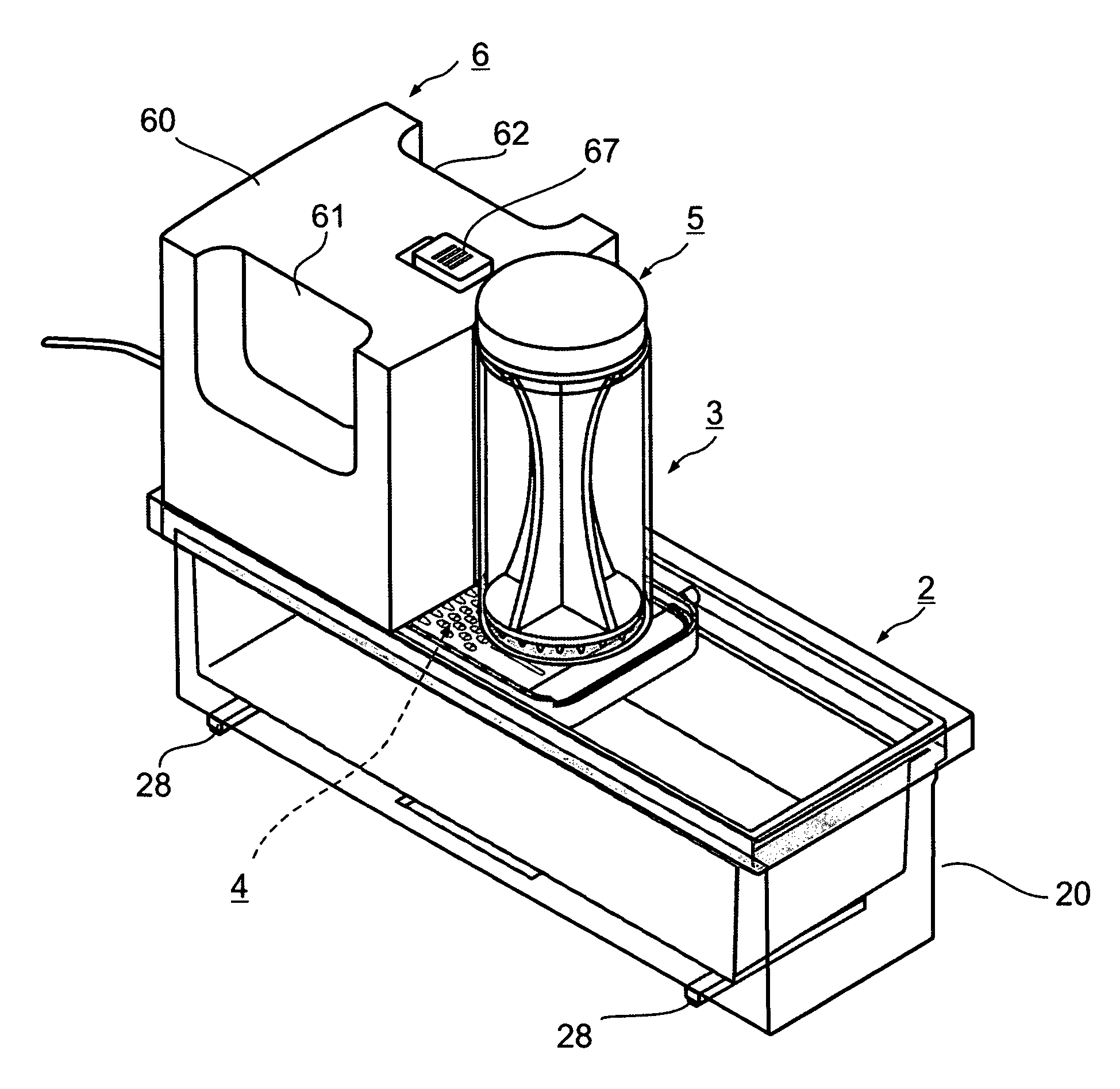

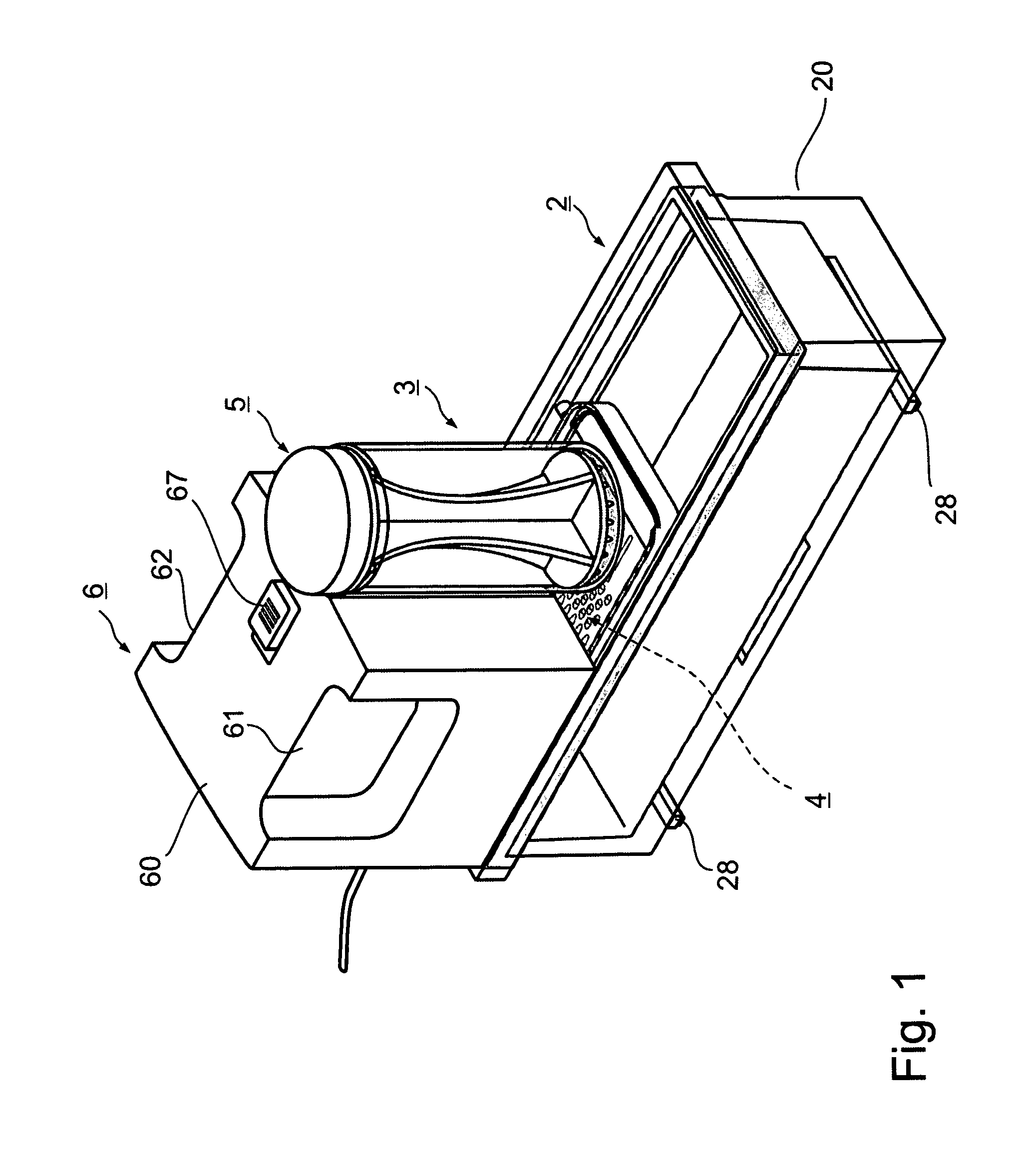

Food processor appliance for cutting food articles into desired forms

InactiveUS20080156204A1Conveniently disassembledAccurate locationAutomatic control devicesFruit stoningReciprocating motionActuator

A food processor appliance for cutting food articles into a desired form, includes a housing having a feed chute; a pusher member for pushing food articles through the feed chute into the housing; a cutter device within the housing mounted for reciprocatory movements transversely across the outlet end of the feed chute for cutting food articles fed therethrough into the desired form; and an electrical drive unit including an electrical motor removable from the housing to facilitate cleaning the cutting device. The electrical drive unit includes an interlock electrical switch normally disabling the drive unit but actuatable to enable it, and the feed chute includes an actuator laterally thereof for actuating the interlock electrical switch, and thereby the drive unit, when the drive unit is located in its proper position the top wall of the housing.

Owner:AAC TRADE LTD

Preparation method of dried rabbit meat nutritional food

The invention relates to convenience food, and in particular relates to a preparation method of dried rabbit meat nutritional food, wherein rabbit meat is taken as a main raw material and nutritious Chinese herbal medicines are taken as auxiliary materials. The preparation method comprises the following steps: (1) preparing the materials; (2) arranging and soaking; (3) preserving; (4) marinating; (5) slicing; and (6) making dried rabbit meat. The rabbit meat food processed by the preparation method has diversified flavors, namely the flavors can be changed by adding flavorings according to different tastes of various groups; and the food has the characteristics of crispy outside and tender inside without greasiness and fragrant and sweet taste, and can be easily chewed without weariness, thus being suitable for people of all ages and realizing wide application range.

Owner:马小真

Food processor appliance for cutting food articles into desired forms

InactiveUS7543768B2Accurate locationEasy to masterFruit stoningBalingReciprocating motionEngineering

Owner:AAC TRADE LTD

Method for processing acid and hot bitter bamboo shoot

InactiveCN1653946AReduce and mask bitternessMask bitternessFruit and vegetables preservationConfectioneryBamboo shootSugar

The present invention relates to food production, is especially the production process of sour and hot bitter bamboo shoot, and solves the technological problem of utilizing the resource of bitter bamboo shoot to produce delicious food product in simple process and low cost. The production process of sour and hot bitter bamboo shoot includes the following steps: slicing bitter bamboo shoot into shreds or slices; boiling in water with salt for 40-60 min; draining and cooling; mixing with sugar and pressurizing for 1-2 days; mixing with chicken bouillon, pickled chili chip and vinegar, sealing in can; sterilizing; etc.

Owner:余学军

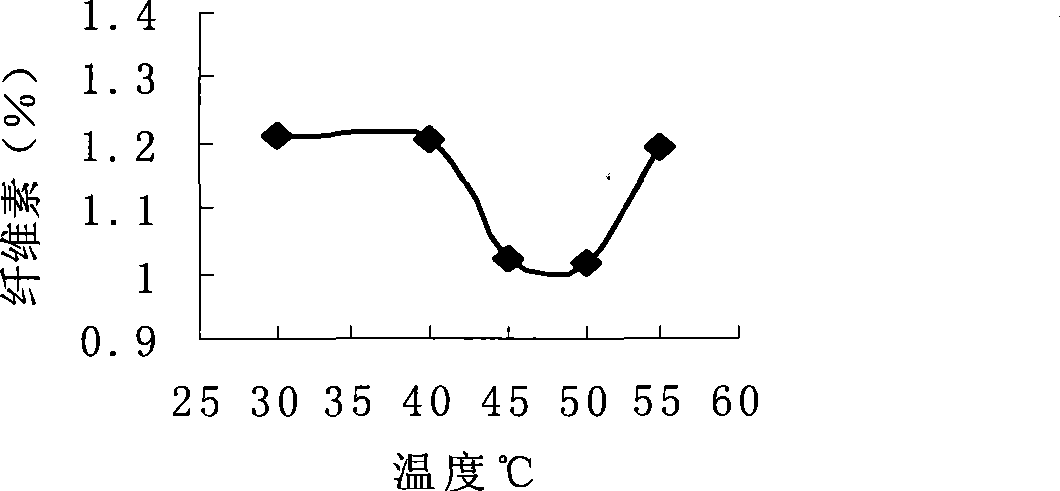

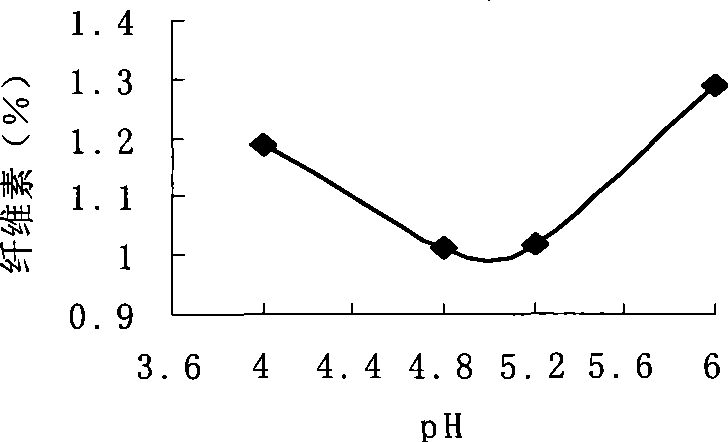

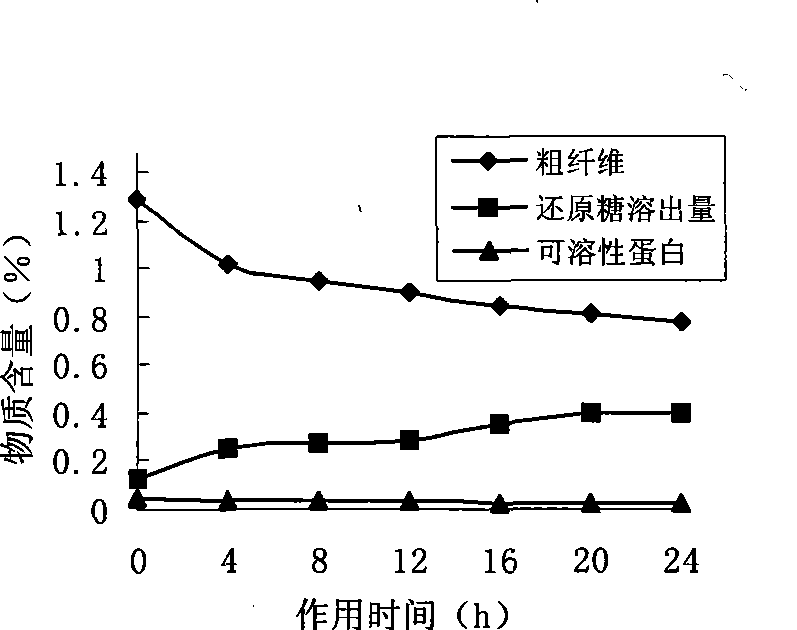

Method for improving edible quality of brown rice

The invention relates to a method to improve edible quality of brown rice, which adds enzyme in the water of 120-180 parts by volume, adds the brown rice of 100 parts by weight, mixes well, regulates the pH of mixed enzyme solution to 4.5-7.0, soaks at 30-55 DEG C for 2-5h to obtain the mixture of brown rice and enzyme solution. The invention processes the brown rice by cellulose or compound pectinase directly, degrades cellulose and pectine on the outer surface to soften tissue structure, reduce hardness after cooking and improve taste, such that the objectives of improving the edible quality of cooking foods of brown rice and keeping the nutrient contents of brown rice are achieved, and the edible quality of brown rice foods processed by enzyme is better than that of germinated brown rice.

Owner:JIAYING UNIV

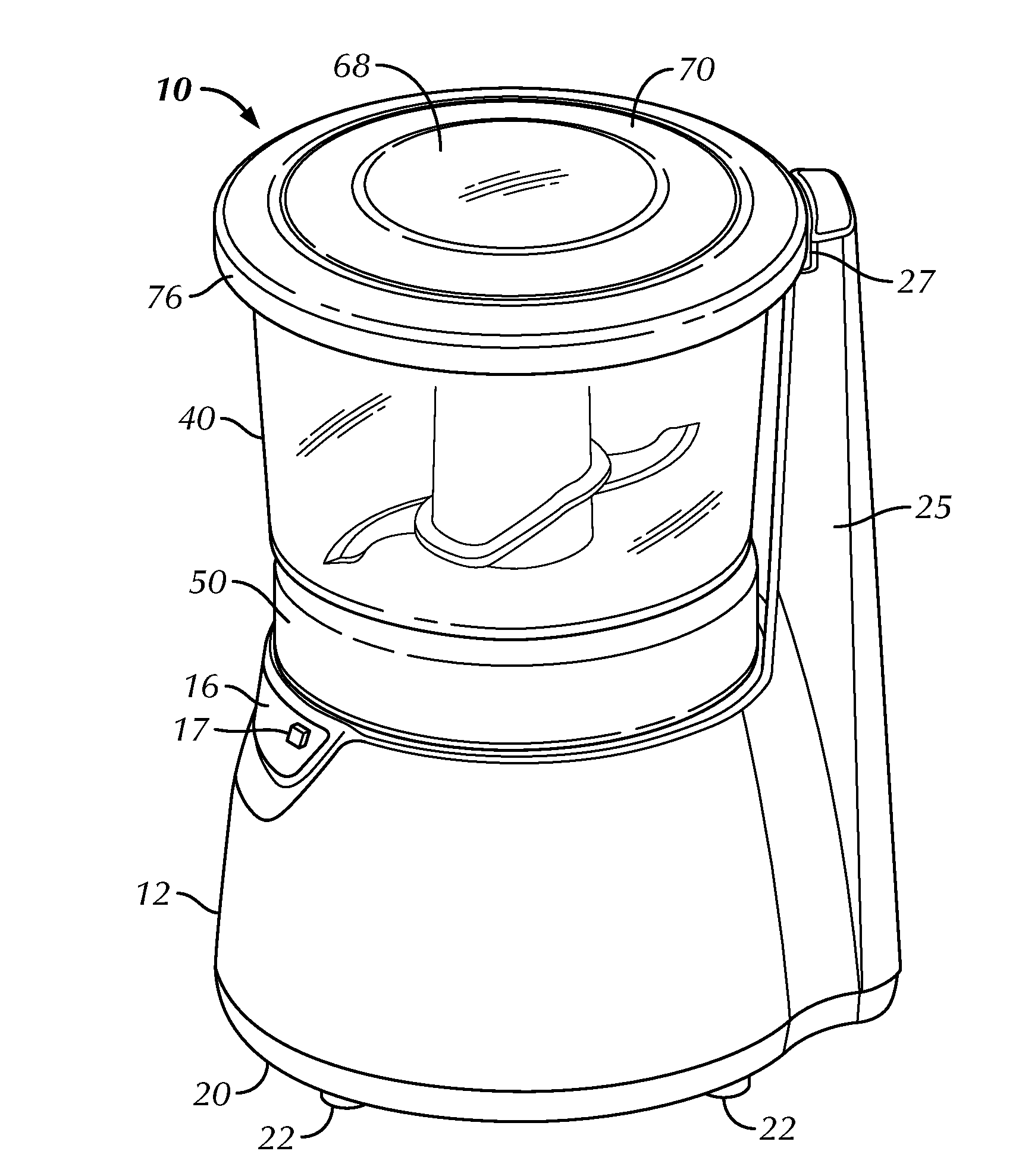

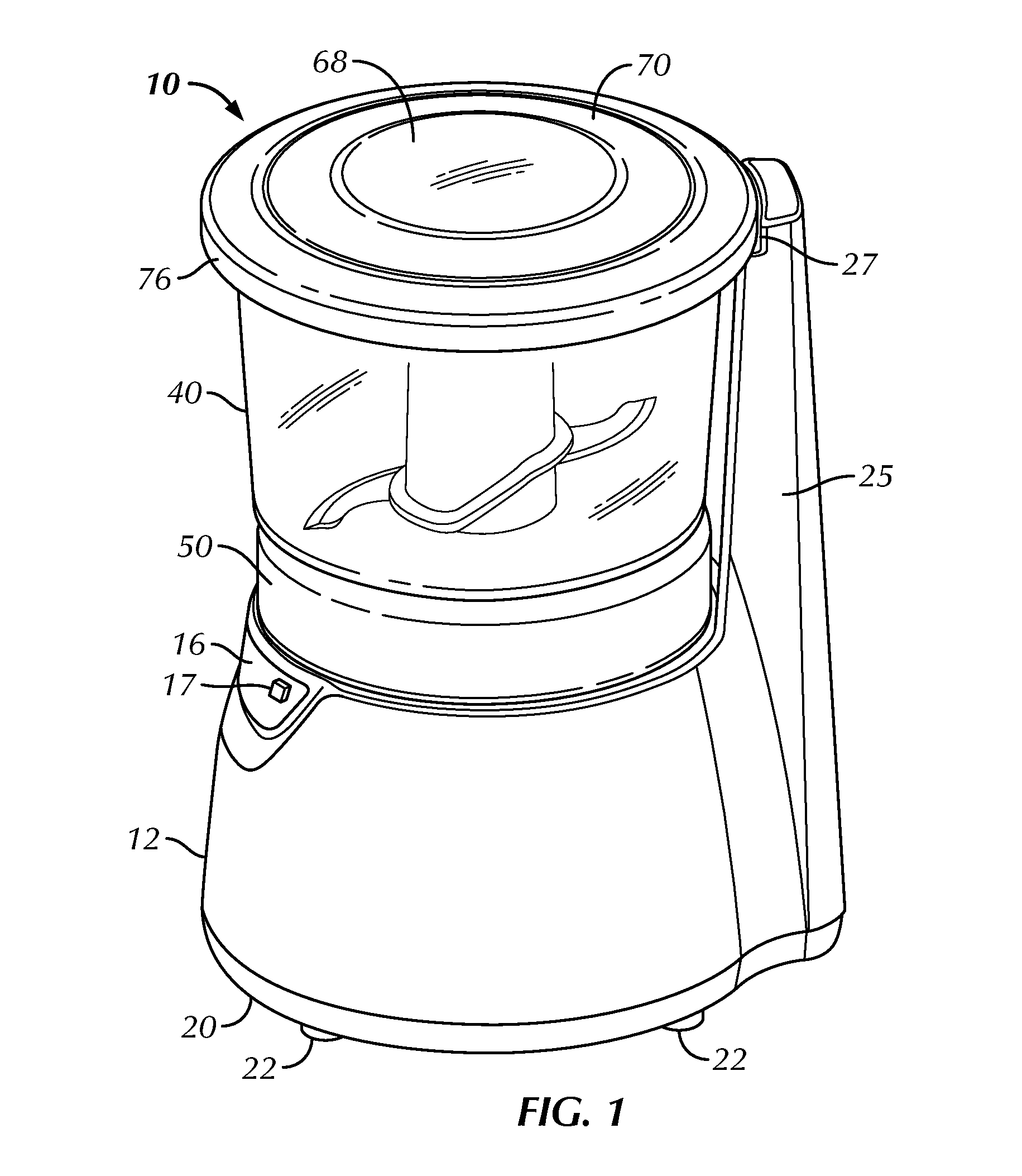

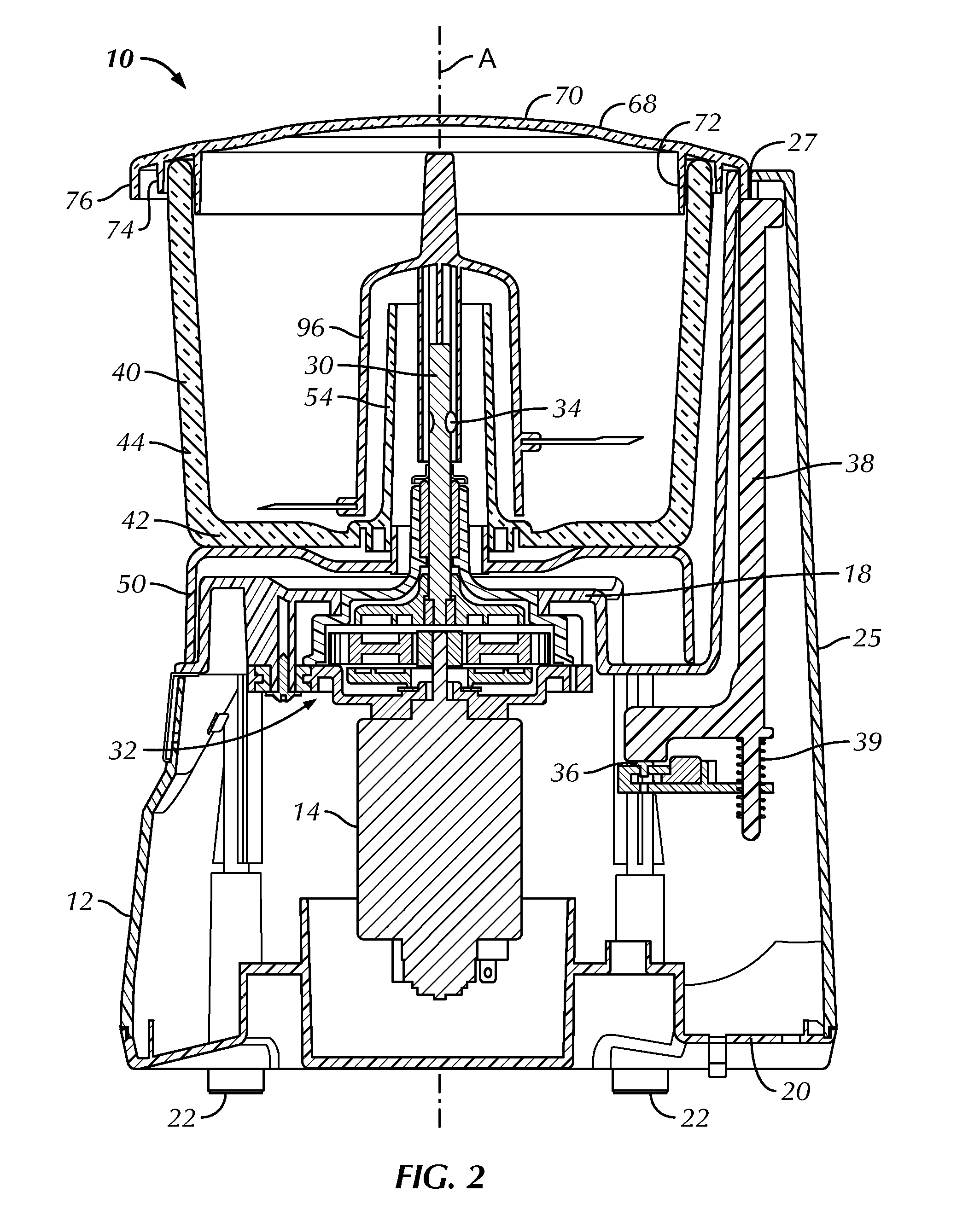

Kitchen Appliance for Processing Foodstuff and Method of Operating Same

Owner:HAMILTON BEACH BRANDS

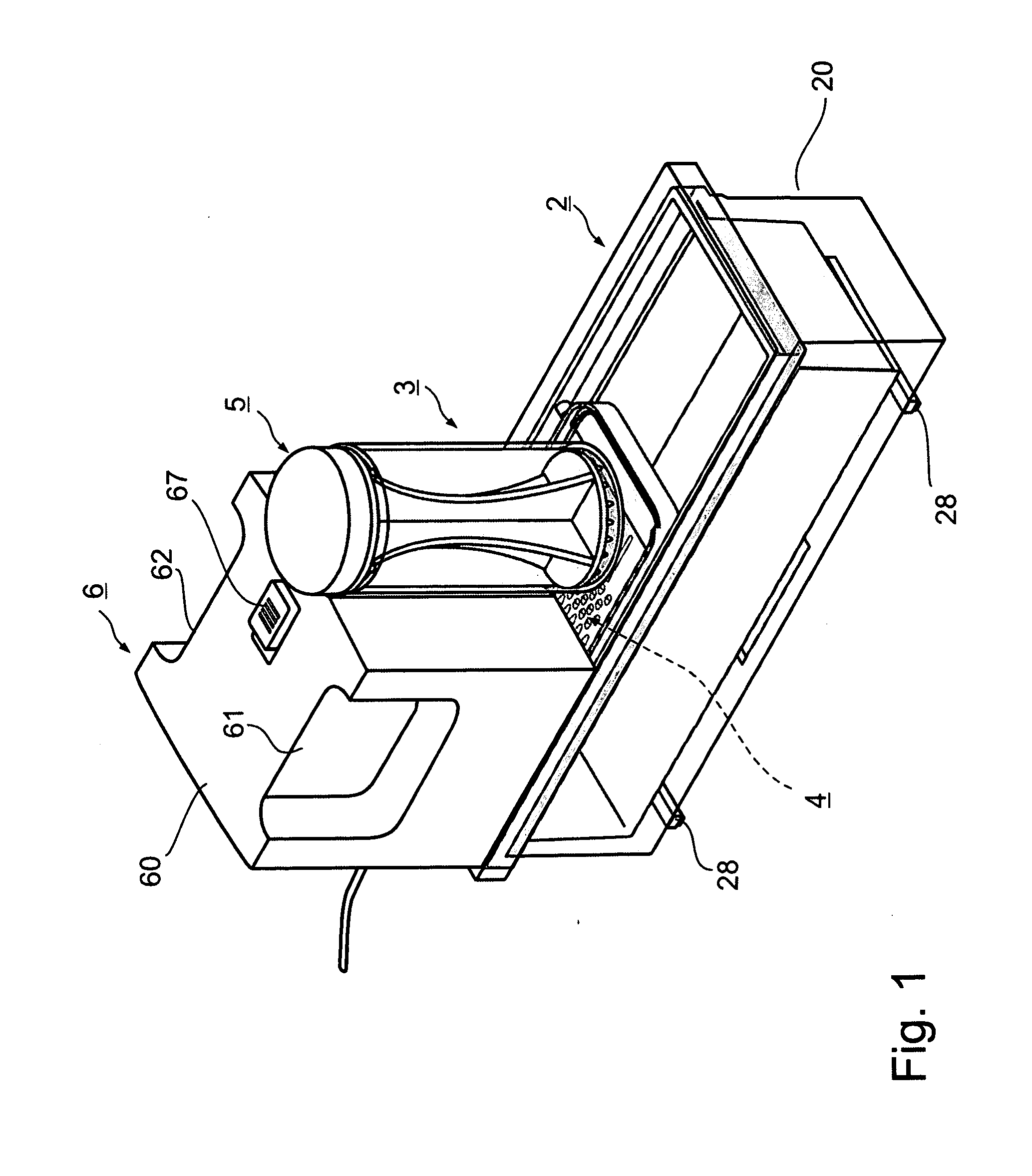

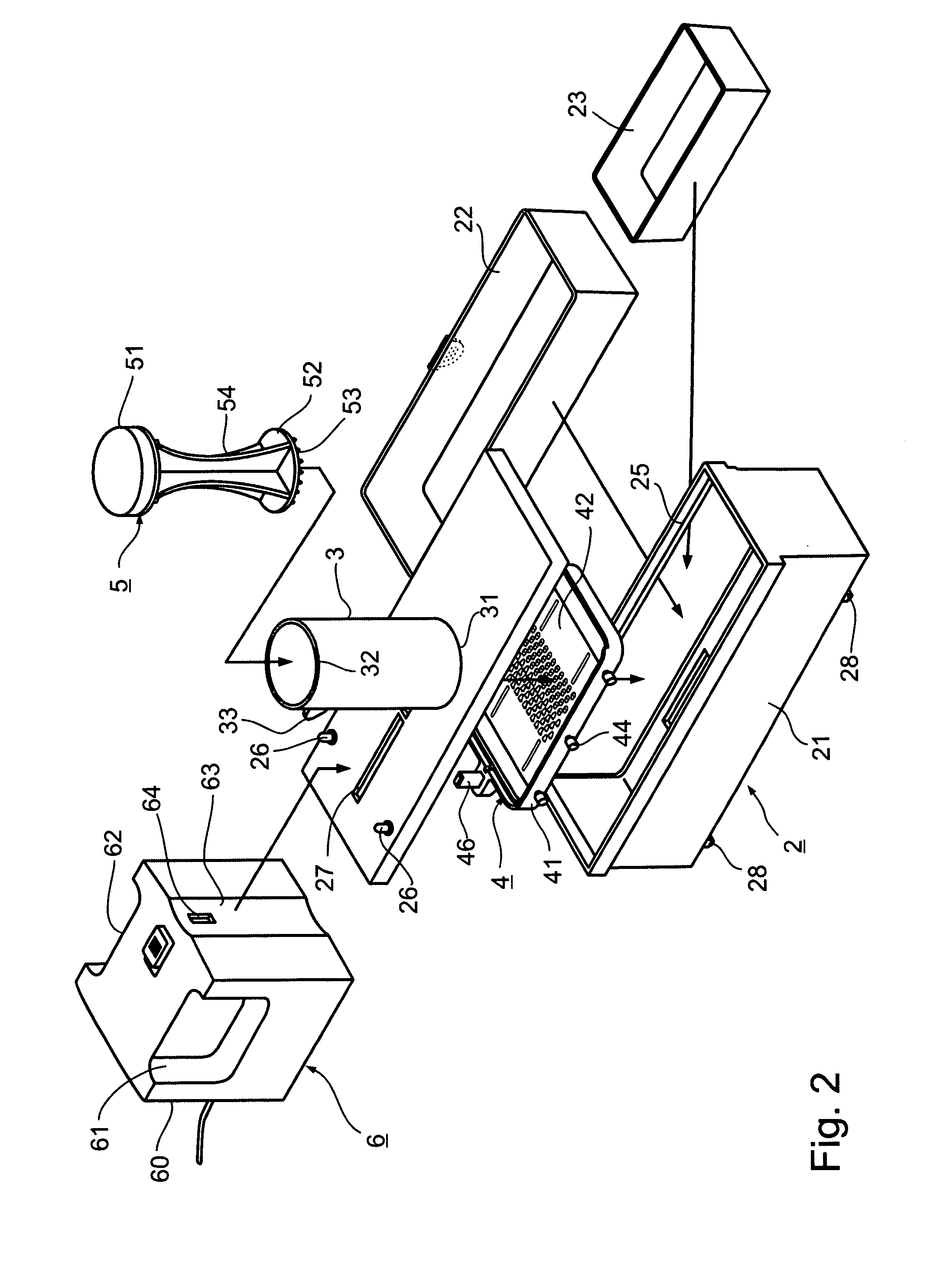

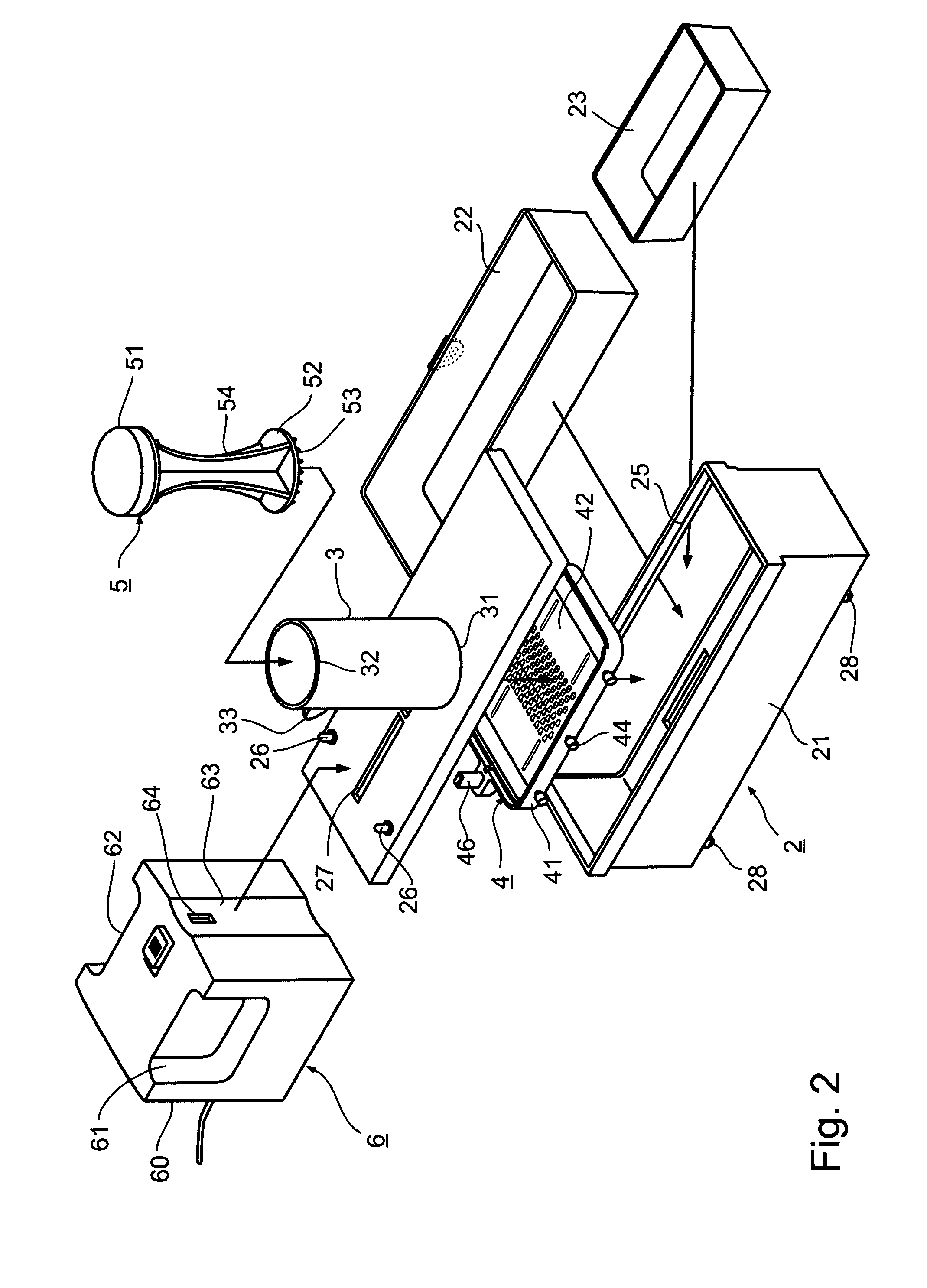

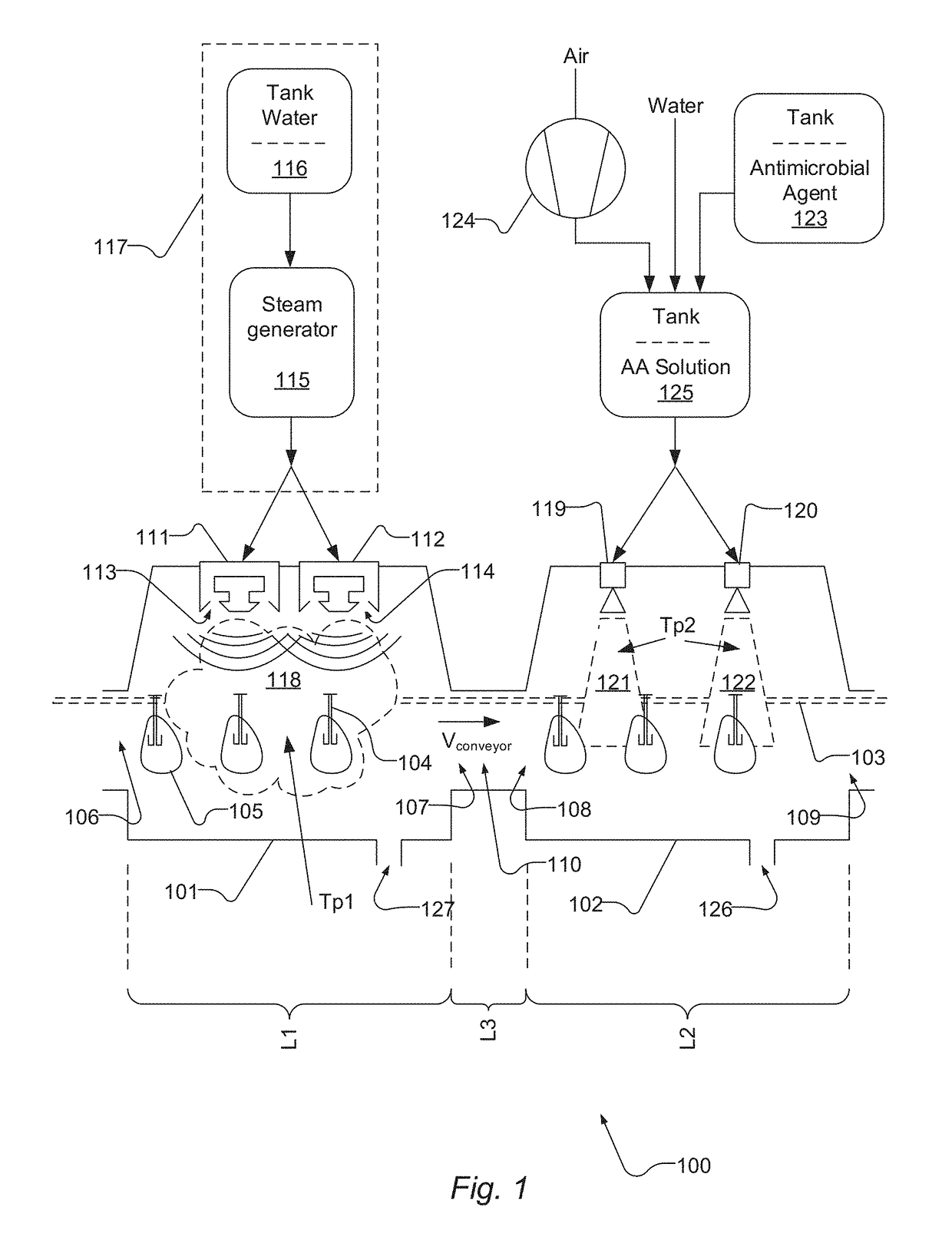

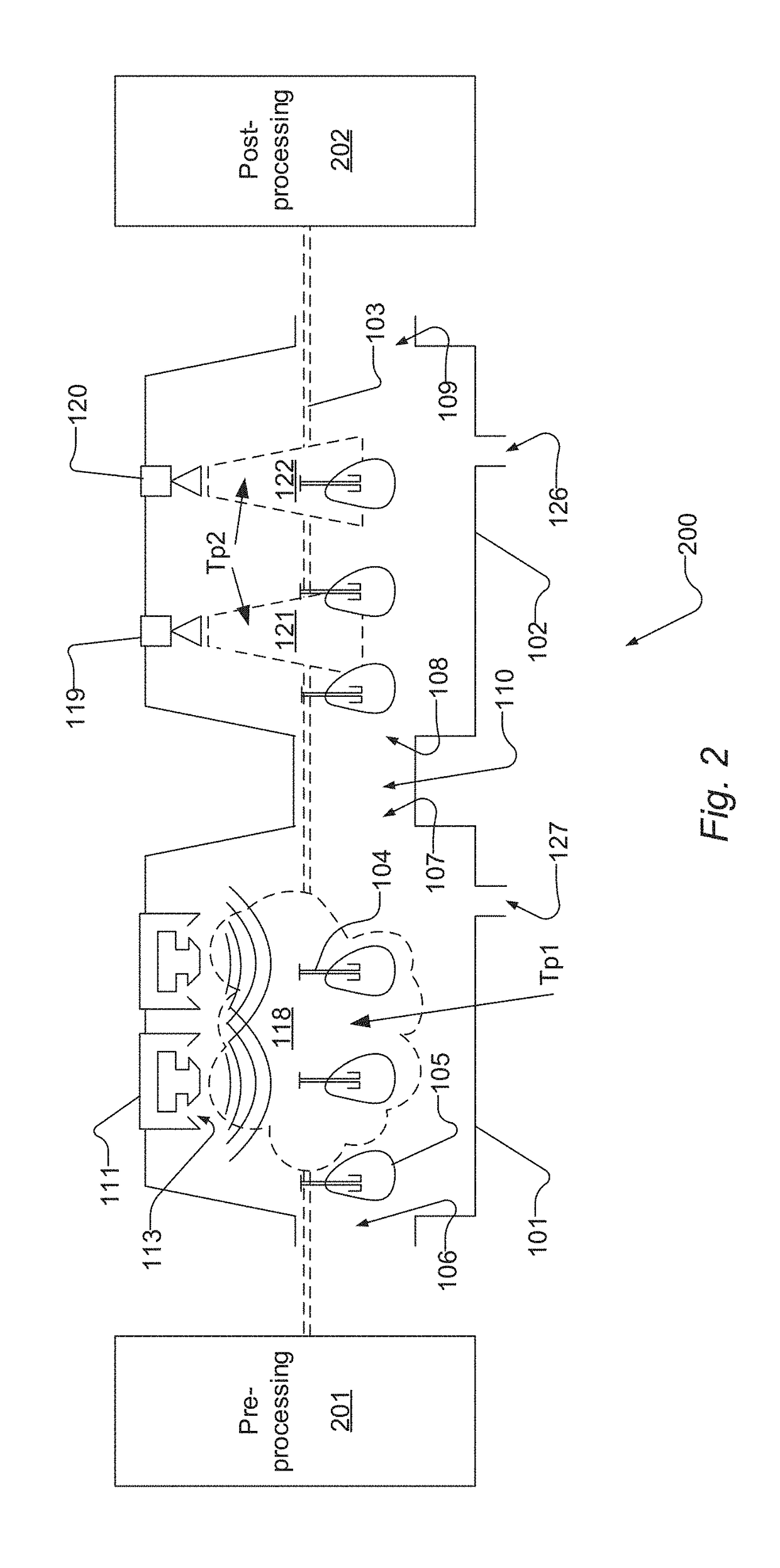

Production line and method for processing food products

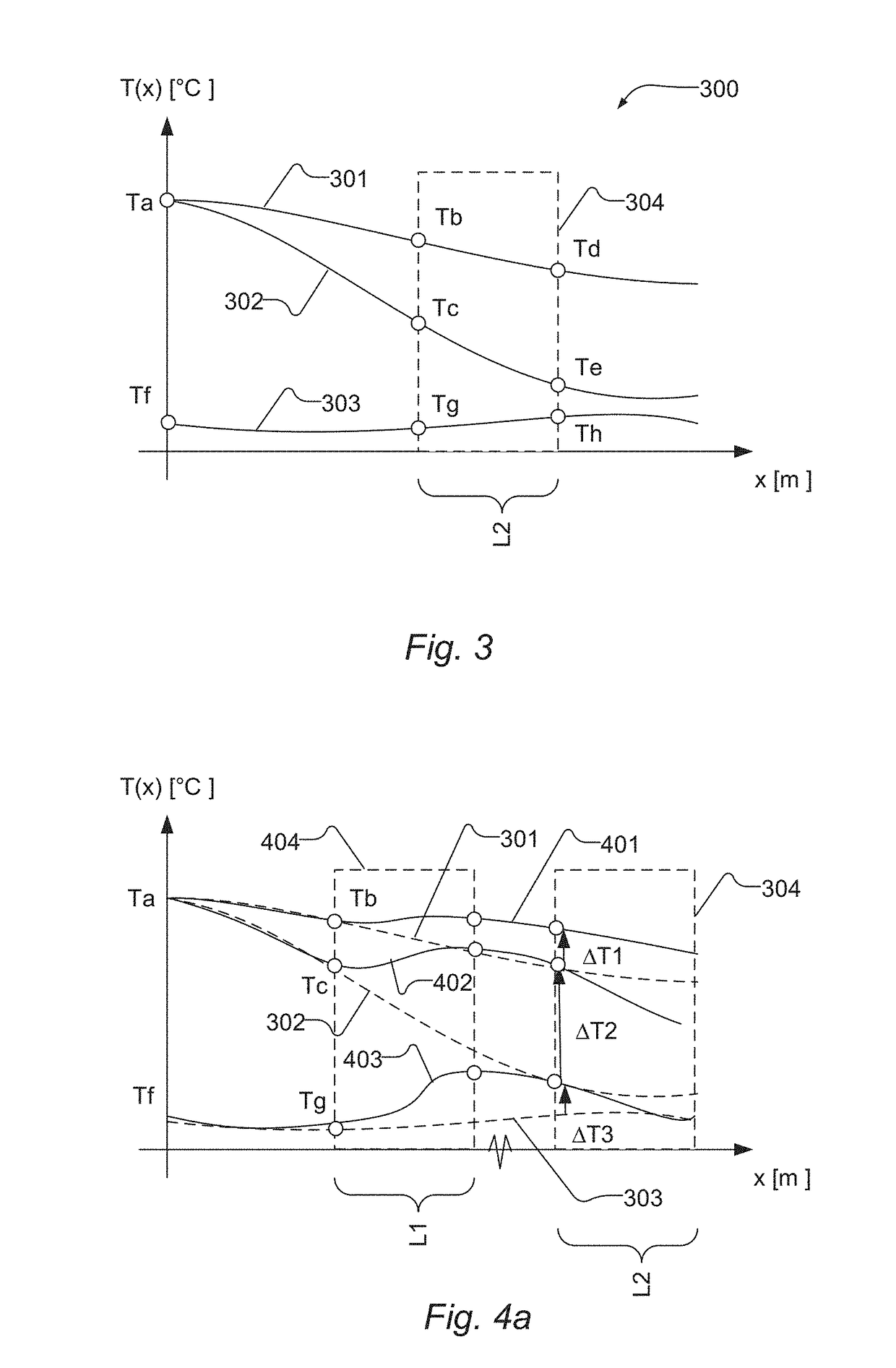

InactiveUS20180360077A1Good curative effectInhibition of inflowFood preservationHeatProduction lineCelsius Degree

A method for sanitizing food products on a production line (201), and a production line (100) for processing food products (103), comprising: a first processing enclosure (101) and a second processing enclosure (102) and a conveyor system (103) configured to move a food product through the first processing enclosure (101) and onwards through the second processing enclosure (102). The first processing enclosure (101) is coupled to a gas supply system (113) delivering a flow of gas at a gas temperature above 70 degrees Celsius via an orifice (113; 114) to generate a first processing atmosphere within the first processing enclosure (101) exposing at least a portion of the surface of the food products, while travelling through the first processing enclosure, to a first processing temperature (Ts) which is above 60 degrees Celsius. The second processing enclosure (102) is configured with an atomizing nozzle (106; 107) to deliver a spray of a supply of an antimicrobial chemical agent (123) towards the food products (103) travelling through the second processing enclosure.

Owner:SANOVO BIOSECURITY AS

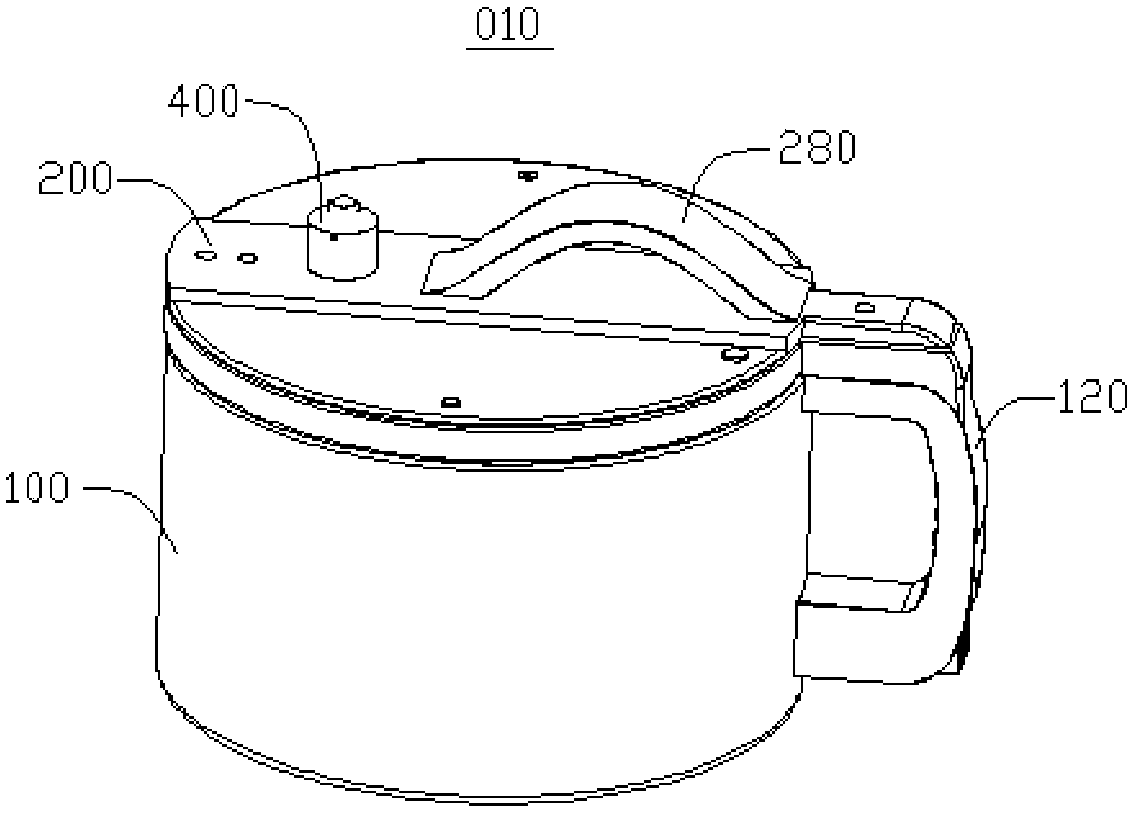

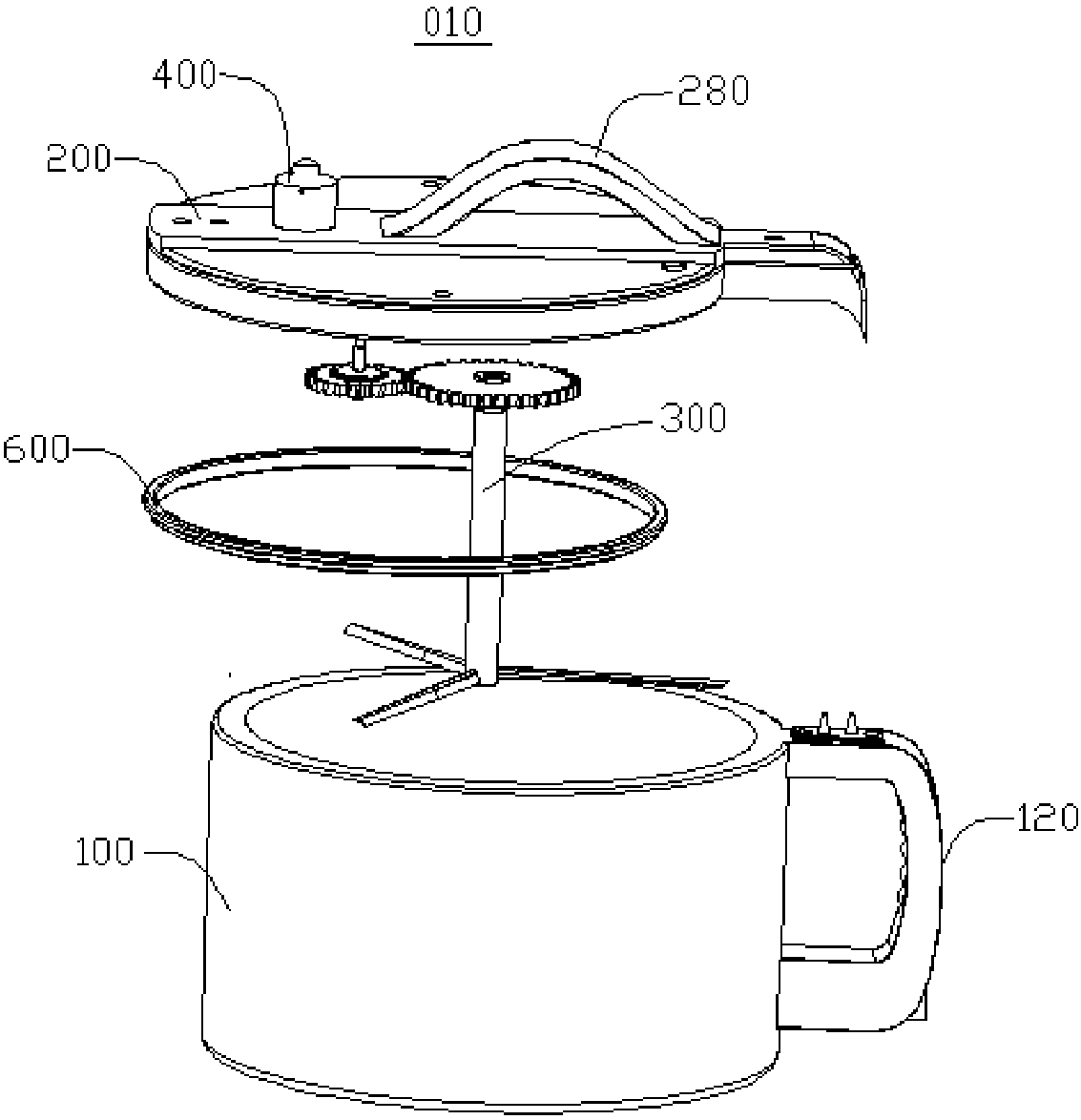

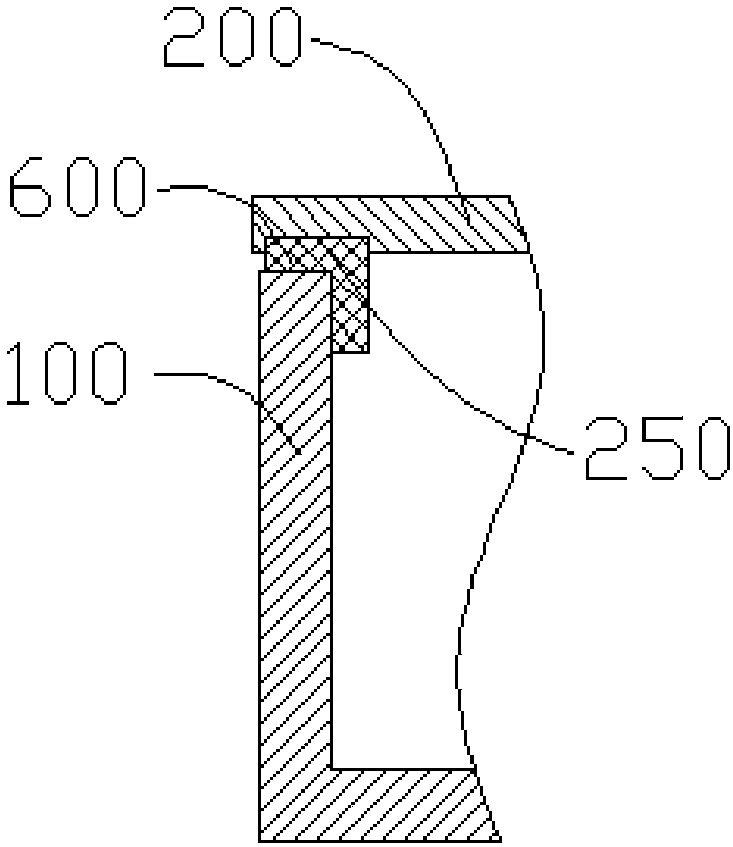

Pressure cooker

InactiveCN105942844AEvenly heatedGreat tastePressure-cookersCooking insertsEngineeringPressure cooking

The invention aims at solving the problems in the prior art that food processed by pressure cookers is poor in taste, and the food processing time is long. In order to solve the problems, the invention provides a pressure cooker which comprises a cooker body with a containing cavity and a cooker cover for covering the cooker body; the cooker also comprises a stirring device and a pressure relieving device; the stirring device is arranged in the containing cavity; the pressure relieving device comprises a valve sleeve and a valve element arranged in the valve sleeve; the valve sleeve is rotatably arranged on the cooker cover and has an air outlet; a straight line, on which the air outlet direction of the air outlet is located, is not on the plane where a rotating axis of the valve sleeve is located; the pressure relieving device has an air outlet passage, one end of the air outlet passage is communicated with the containing cavity, and the other end of the air outlet passage is communicated with the air outlet; the valve element has a first position for sealing the air outlet passage and a second position for opening the air outlet passage; the valve element can move to the second position under the action of pressure in the containing cavity, or automatically return to the first position; and the valve sleeve is in driving connection with the stirring device. The pressure cooker has the beneficial effects that the processed food is good in taste and the time needed for processing food is shortened.

Owner:江苏金海玛电器有限公司

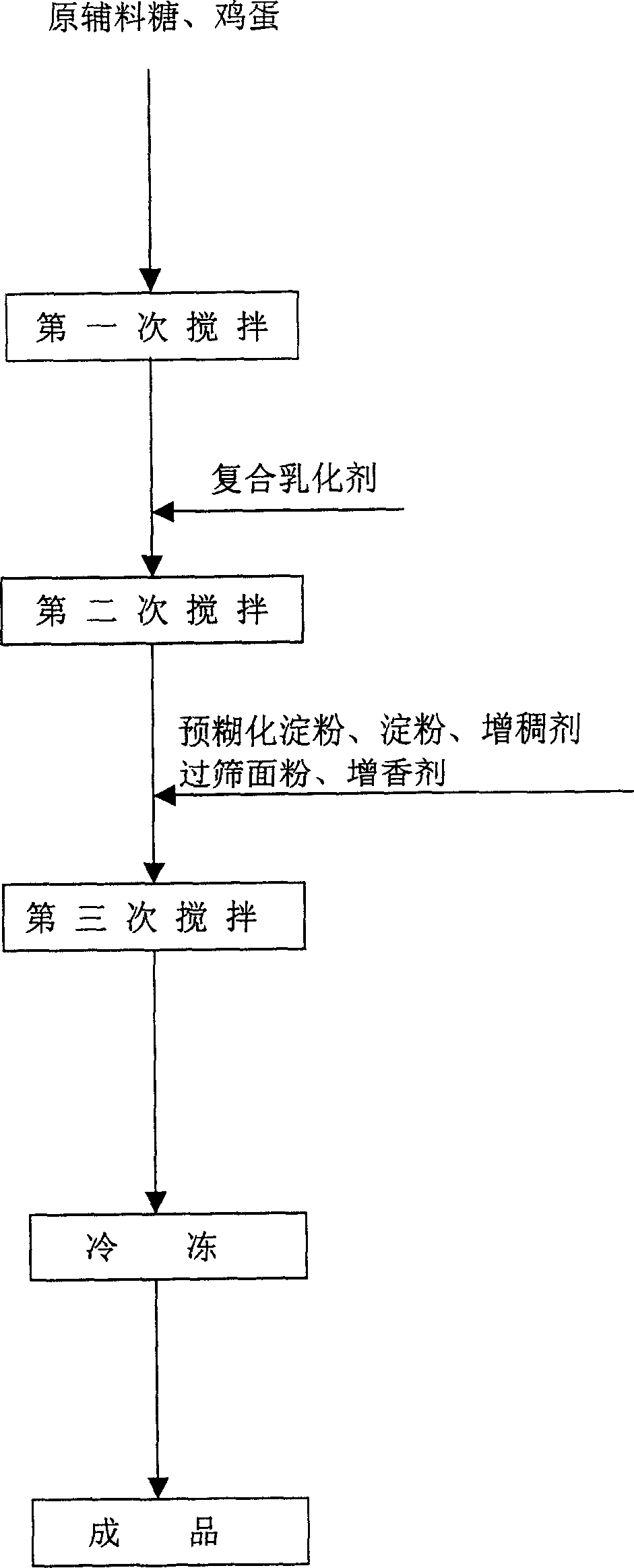

Microwave refrigerated sponge cake dough, and its making method

A frozen dough for roasting the spongy cake by microwave is prepared through removing shell of egg, mixing with sugar, stirring while sequentially adding composite emulsifier, starch, pregelatinized starch, thickening agent, wheat flour and flavouring, high-speed stirring and freezing.

Owner:JIANGNAN UNIV

Method for improving quality of fish meat by adding chitin

InactiveCN100998426AImprove gel qualityExtended price periodMetabolism disorderDigestive systemIce waterFish paste

A method for improving the quality and shelf life of fish paste used to regulate blood sugar, blood fat and enteric flora by adding chitosan includes such steps as preparing fish paste, adding chitosan, egg white powder, starch, edible salt and ice water, shaping, and heating.

Owner:ZHEJIANG UNIV

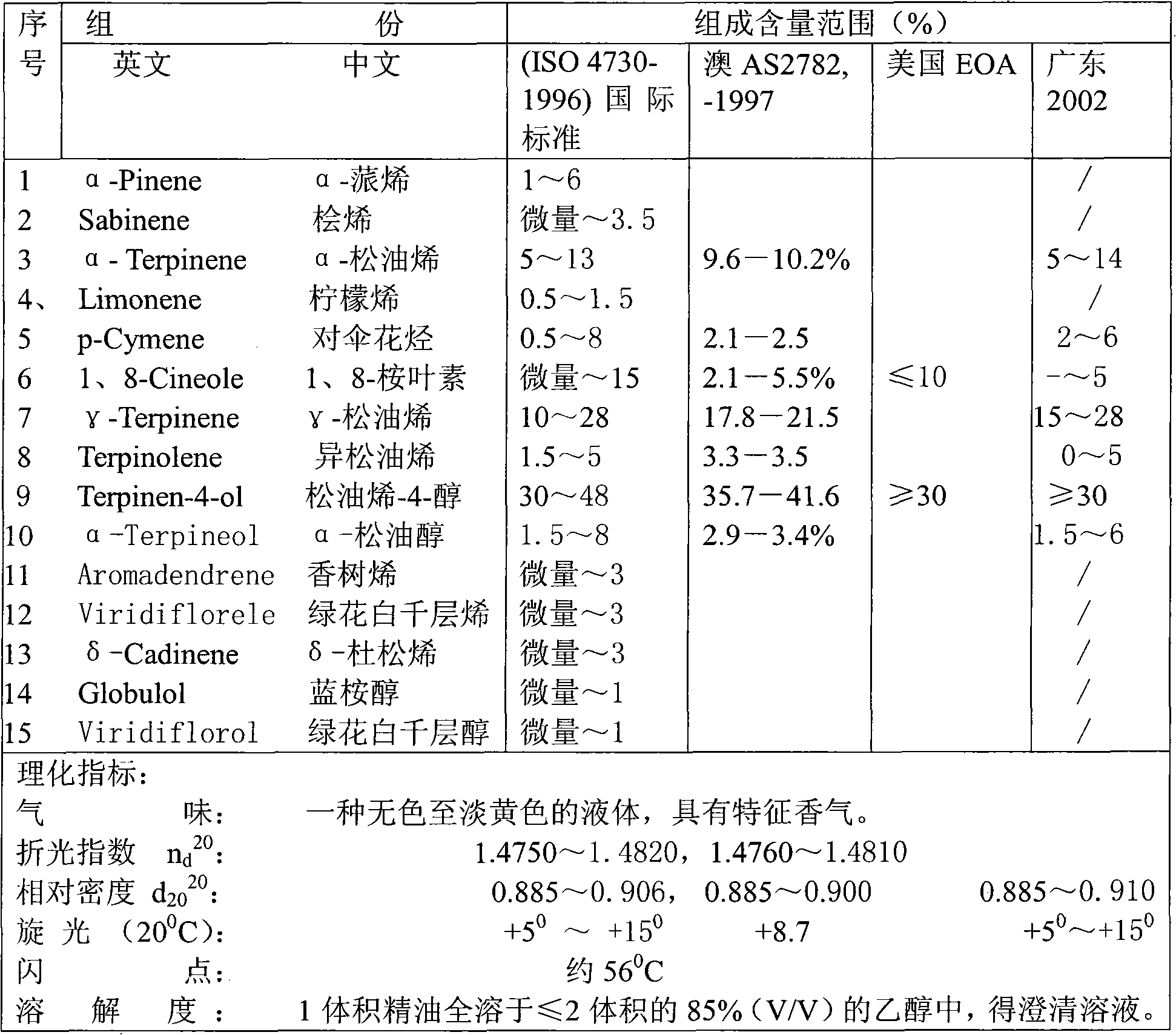

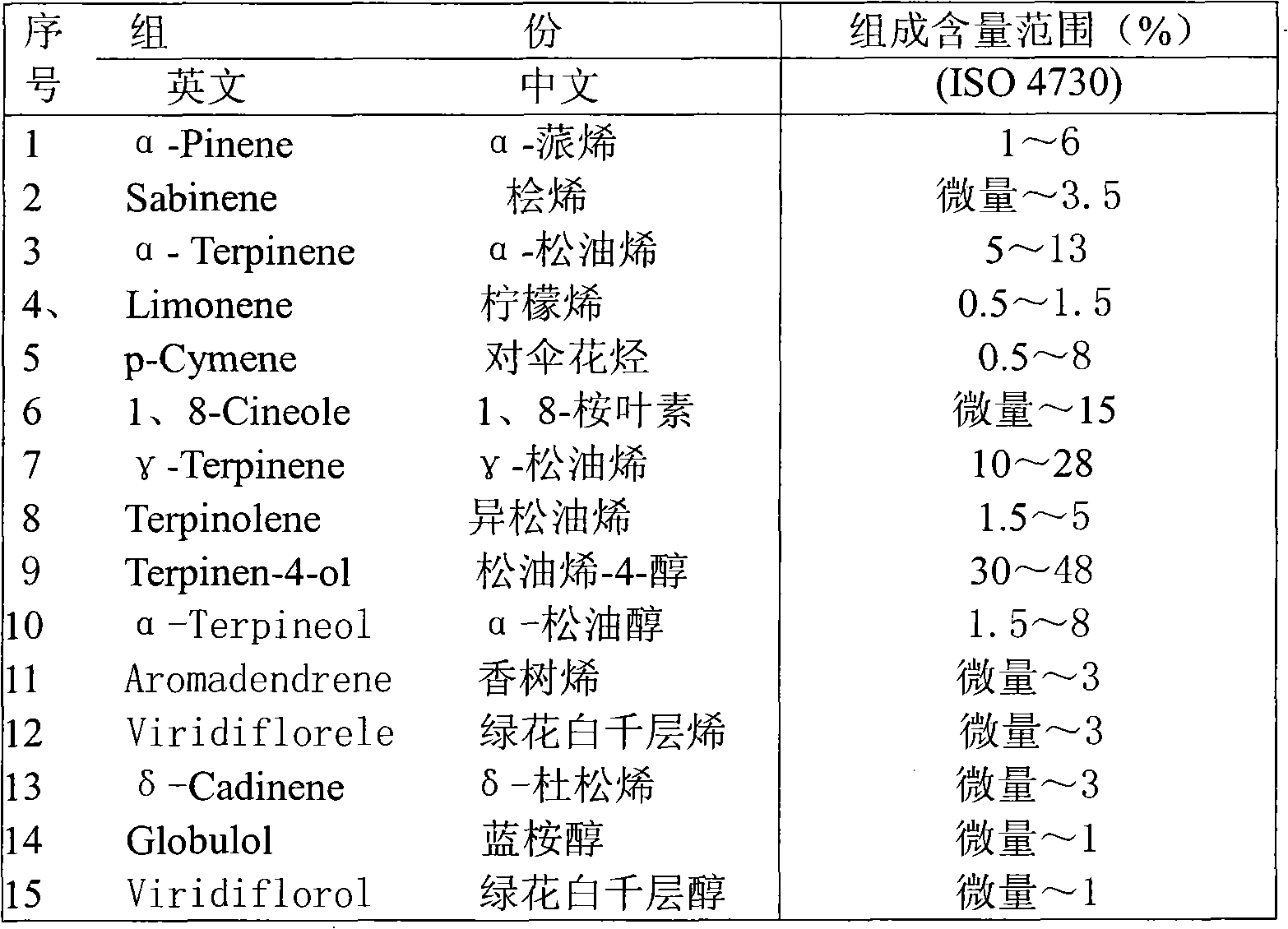

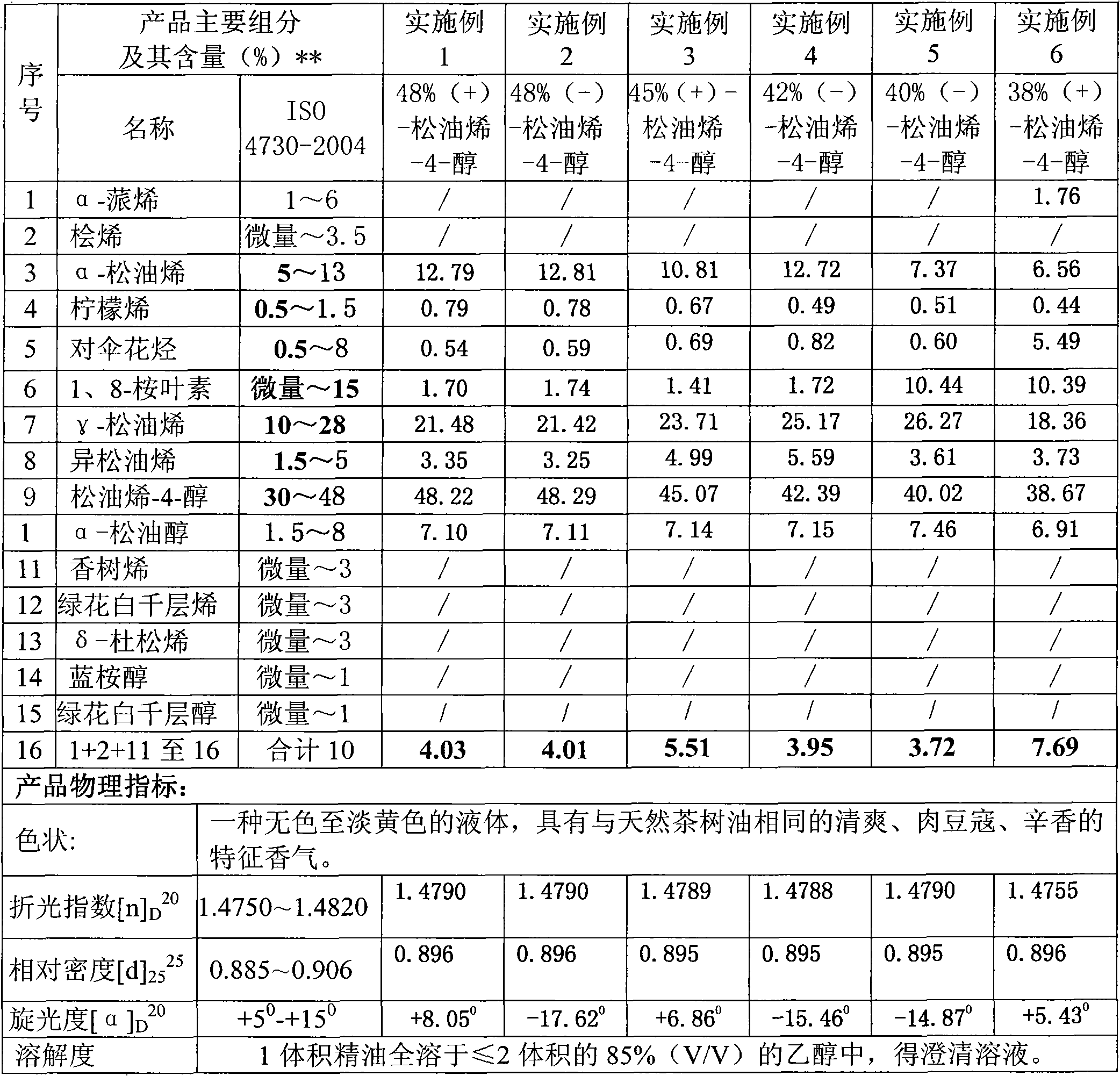

Standardized recombinant tea tree oil and preparing method thereof

InactiveCN101829074AImprove eco-efficiencyThe outstanding problem of insufficient supplementary supplyBiocideCosmetic preparationsInternational marketFood products

Tea tree oil has ultra-strong broad-spectrum antibacterial performance and the functions of sterilizing, killing mildew, resisting viruses, relieving inflammation, killing pests, repelling pests, killing mites, protecting skin, degreasing, restoring physical ability and the like, rapidly acts, is not easy to generate medicine resistance, is considered as one of the most effective natural antimicrobials discovered so far and is an ideal synthetic antibiotic substitute, thereby being widely applied in the processing of medicines, cosmetics, chemicals for daily use and foods. In order to solve the problems that along with the change of tree seeds, producing areas, climates and picking time, the content of each component of natural tea tree oil has no fixed value, the quality is not easily controlled and the requirements of various downstream product users for different specifications and different applications can not be satisfied, and the prominent contradiction that the supply of an international market is not adequate to the demand, the invention discloses standardized recombinant tea tree oil which can effectively solve or relieve the supply and demand contradiction of the international market.

Owner:南宁辰康生物科技有限公司

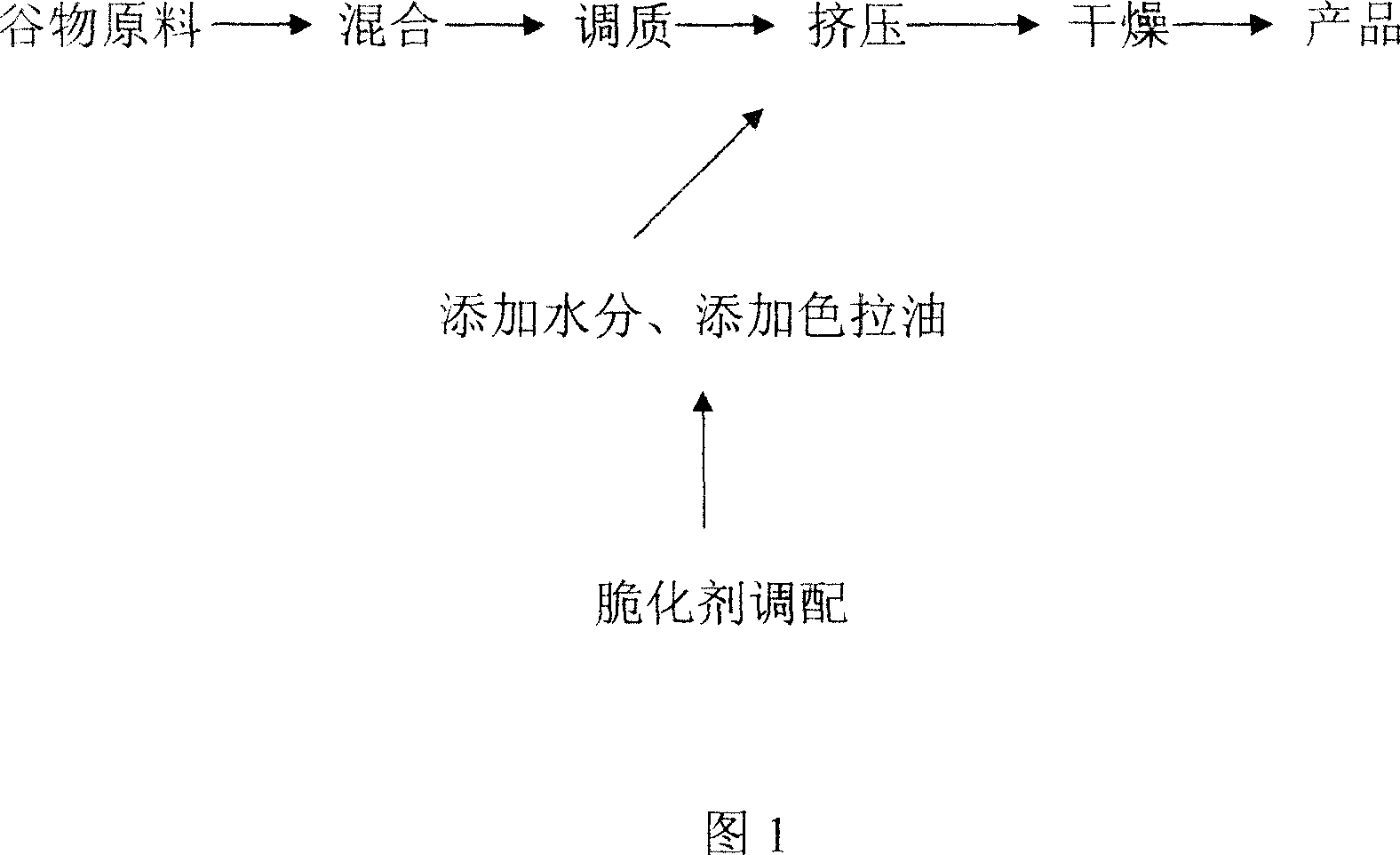

Method for producing breakfast food of slice shaped grain with excellent crisp property

InactiveCN100998386AImprove textural propertiesGood chewingFood preparationAdditive ingredientCow milk

Owner:JIANGNAN UNIV

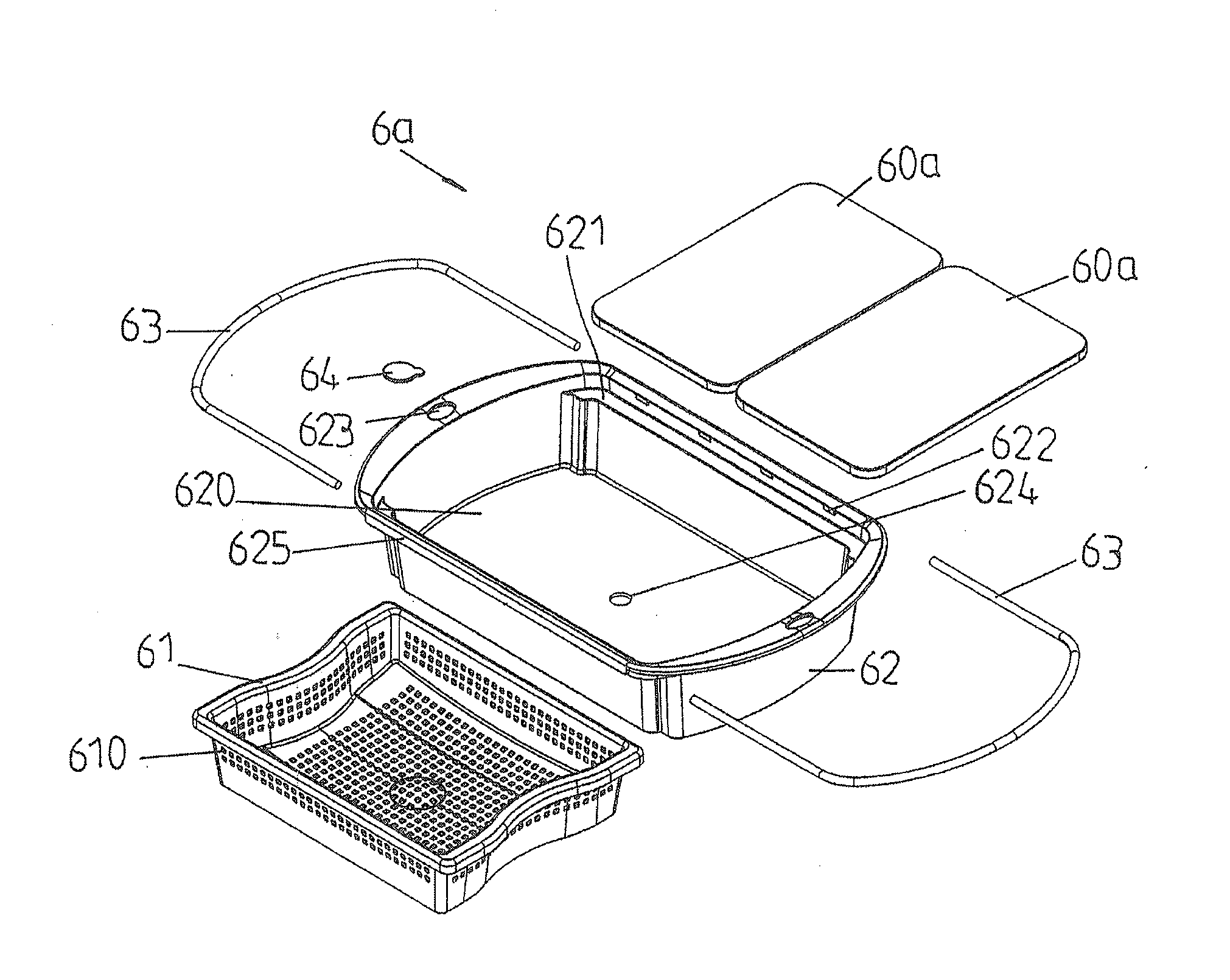

Food Processor for Processing and Cleaning Foods Easily and Quickly

InactiveUS20130241127A1Easy to processKitchen equipmentPositioning apparatusEngineeringMechanical engineering

Owner:YANG HENG DE

Food processing device

A food processing device has a handle holding a food receptacle, a cutter having perforations and extending across a bottom opening of the receptacle, and a presser extendable into the receptacle and movable towards the cutter for pressing food in the receptacle against the cutter, whereby the food is cut into smaller pieces. The presser has a press surface, which has a protruding pattern matching the perforations of the cutter for passing through the perforations to press food through the cutter.

Owner:SO

Deerskin ointment and preparation method thereof

InactiveCN101632731AEasy to eatSimple processing technologyAerosol deliveryOintment deliverySpermatorrheaMotherwort

The invention relates to a medicine adopting deerskin as a raw material and a preparation method thereof, in particular to a health product or food processed by deerskin and a preparation method thereof. Deerskin ointment is prepared by deerskin, motherwort, astragalus root, Chinese date, angelica sinensis, sugar candy, yellow wine, sweet osmanthus honey and agal-agal. The invention aims to solve the problems existing in the aspects of waste, insufficient development and utilization, difficult absorption and utilization by human bodies, and the like of a plurality of prior deerskin resources. The deerskin ointment has the obvious effect on symptoms of woman leucorrhoea, uterine bleeding, kidney deficiency, spermatorrhea, skin ulcer breeding, and the like.

Owner:辽宁鹿源参茸饮片有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com