Patents

Literature

92 results about "Fast freezing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fast Freeze (for the skin) is a combination medicine used to relieve minor muscle or joint pain. Fast Freeze may also be used as a chest rub to soothe chest congestion and relieve cough caused by the flu or common cold. Fast Freeze may also be used for purposes not listed in this medication guide.

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1672531AReduce drying loadReduced moisture removal requirementsFruits/vegetable preservation by dehydrationWater contentFood processing

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

Ultrasonic thawing device and method and application in ice breaking and defrosting

PendingCN106721903AKeep it authenticEasy to break awayOverhead installationFood freezingProcess engineeringFreezing environment

The invention relates to a thawing technology, in particular to an ultrasonic thawing device and method and application in ice breaking and defrosting. The ultrasonic thawing device comprises a machine body and a freezing area arranged on the machine body, wherein the freezing area comprises a thawing cabinet and a cold storage cabinet capable of freezing food, the thawing cabinet is provided with an ultrasonic thawing apparatus, the ultrasonic thawing apparatus breaks ice on the frozen food in the thawing cabinet under the freezing environment, so that nutritional substances of the food can be prevented from being lost along with the water, the original taste of the food is ensured, the taste is good, and the thawing efficiency is improved. The ultrasonic thawing method can be used for ice breaking of ocean, rivers, roads, railways, bridges, electric power and telecommunication circuits, can also be used for defrosting of fast-freezing tunnels, subzero storages, refrigerators, and air conditioner condensers, is not only short in ice breaking time and high in efficiency, but also low in energy consumption and convenient in operation.

Owner:HUNAN JIASHENG FRESH PRESERVATION TECH

Method for preparing purple sweet potato crispy chips

The invention discloses a method for preparing purple sweet potato crispy chips. The method comprises the following steps: picking raw materials, washing, peeling, slicing, blanching, cooling, draining, fast-freezing, deep-frying in oil under vacuum, deoiling and packaging. The purple sweet potato crispy chips have a crisp taste and a mellow fragrance, have the effects of clearing the bowels, eliminating toxins in the liver, lowering blood lipid level, reducing blood pressure, promoting digestion, protecting against oxidation and relieving constipation, are snacks beneficial for health and suitable for people of all ages, and have broad market prospects.

Owner:徐静

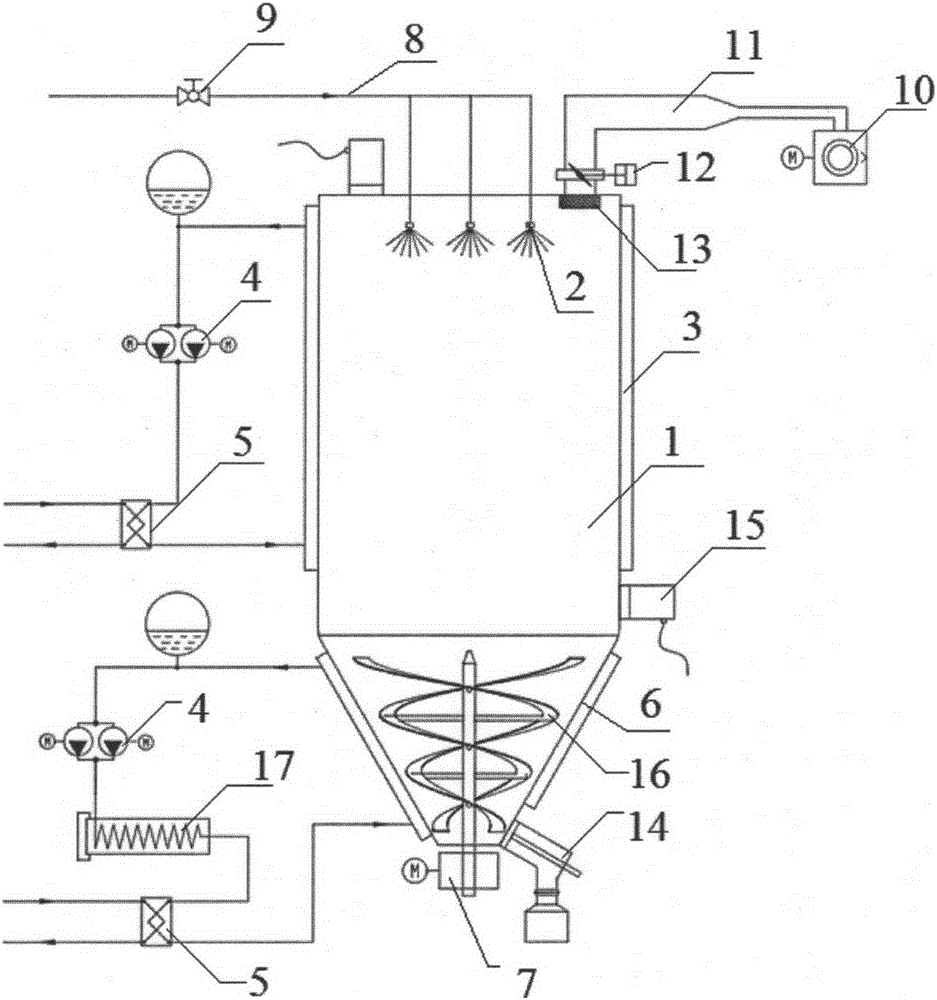

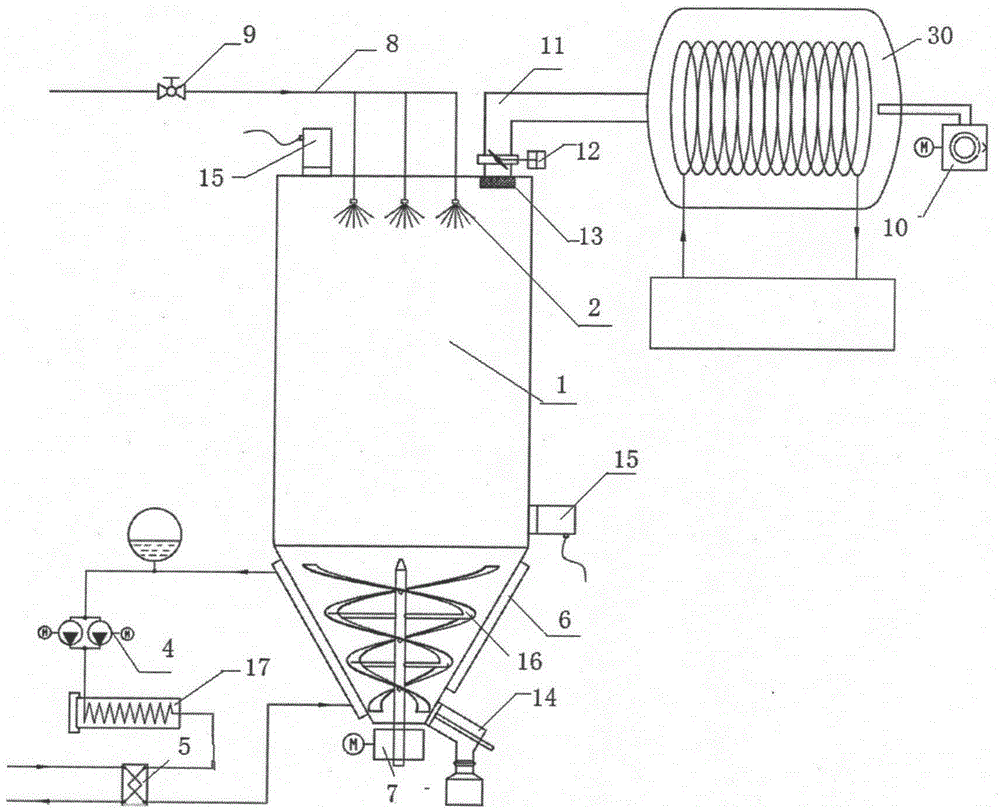

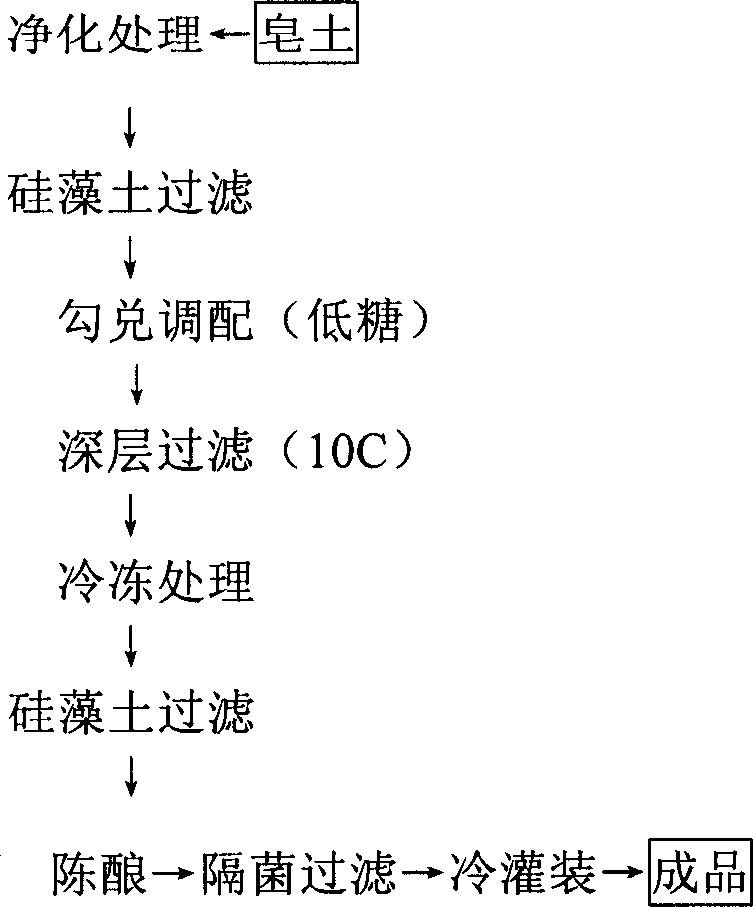

Vacuum spray freeze-drying device and method

InactiveCN105318666AImprove sterilityEliminate the risk of contaminationDrying solid materials without heatFreeze-dryingEngineering

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

A method for preparing fermented meat cake or meat ball

InactiveCN1864549ASolve the problem of low absorption utilization rateIncrease appetiteFood scienceGlucose polymersFermentation

The present invention relates to fermented meat product, and is especially the making process of fermented meat pie or fermented meat ball. The making process includes the following steps: 1. cutting and chopping to obtain meat paste; 2. adding glucose and salt into meat paste, mixing and heating to sterilize; 3. inoculating lactic acid bacteria and saccharomycete; 4 fermenting; 5. making no-fermentation meat paste; 6. mixing the fermented meat paste and no-fermentation meat paste; and 7. adding supplementary material, forming and fast freezing to obtain fermented meat pie or fermented meat ball. The fermented meat pie and fermented meat ball have attractive fragrance, rich nutrients and unique sourish taste.

Owner:HARBIN UNIV OF COMMERCE

Preparation technology for beef balls

The invention relates to a preparation technology for beef balls, which is characterized by comprising the following steps: (1) preprocessing: selecting and cleaning fresh rump steak and fresh chicken breast, wherein the weight ratio of the fresh rump steak to the fresh chicken breast is (3:1)-(3:2); (2) curing: curing the obtained beef and chicken in an aqueous solution of prickly ash and nitrite for 1-1.5 h at 0-4 DEG C; (3) meat grinding; (4) chopping and mixing; (5) beef ball shaping: extruding meat paste manually or mechanically into beef balls with diameters of 2-2.5 cm; (6) cooking and cooling; (7) vacuum packing and then sterilizing; (8) fast freezing. The preparation technology provided by the invention can be used for producing beef balls which contain rich nutrient substances, high-quality animal protein, mineral substances, vitamins and various amino acids necessary for human bodies, and the beef balls are convenient, fast, safe and sanitary to eat and are not required to be secondarily processed.

Owner:王婵

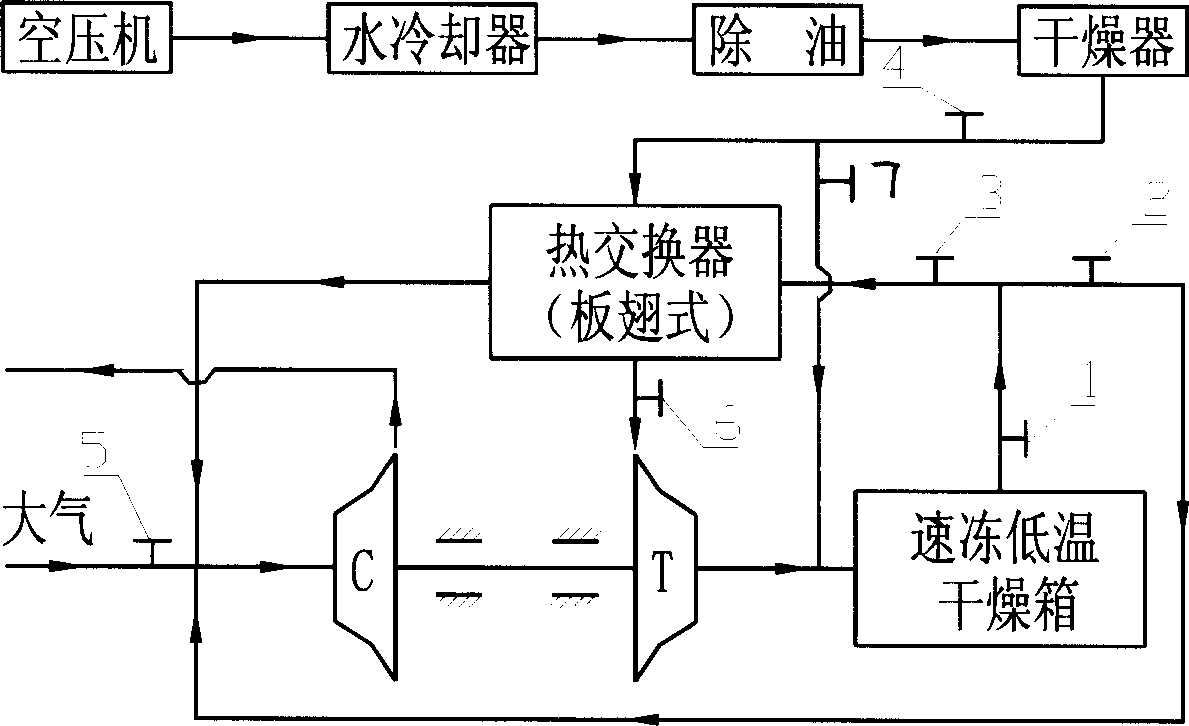

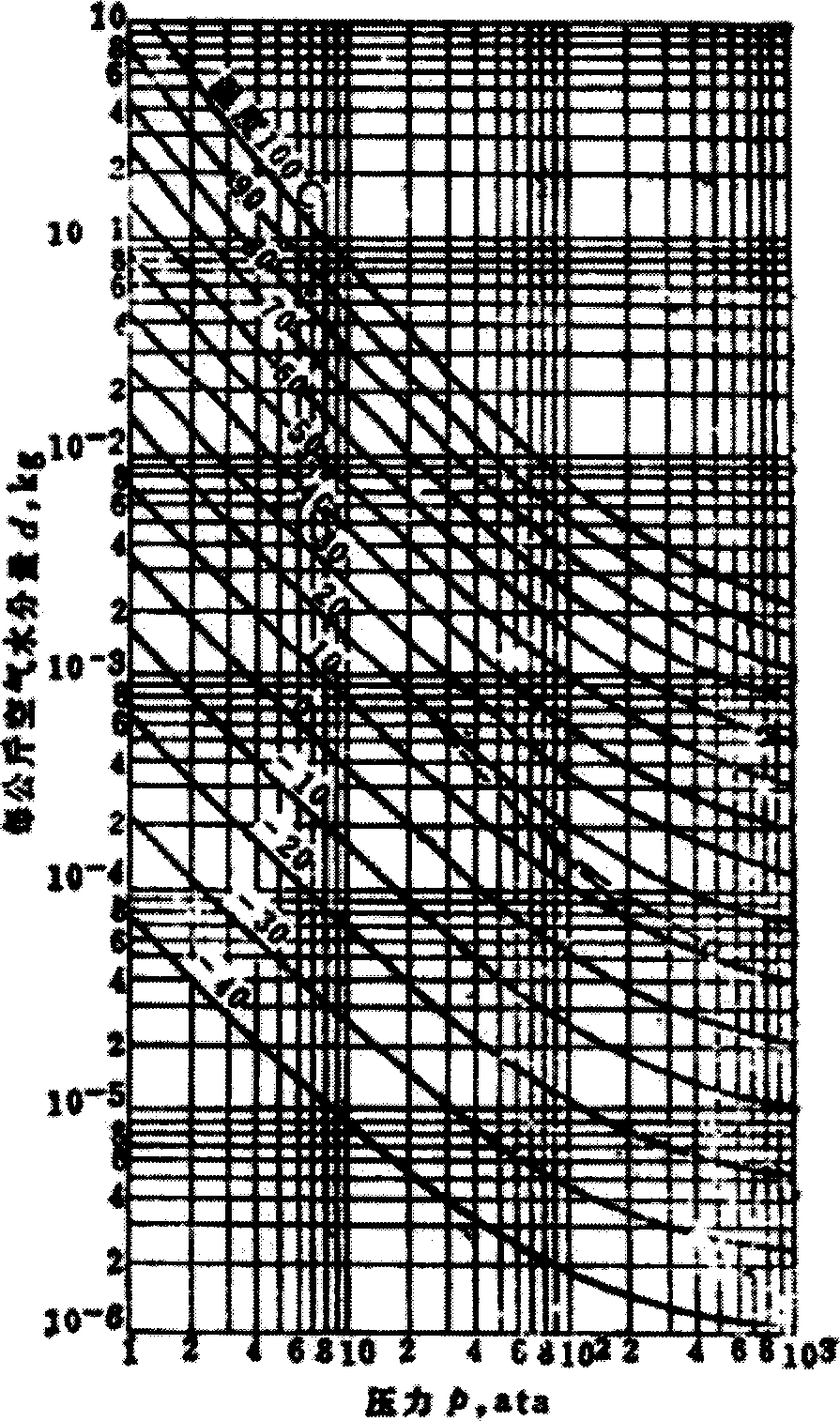

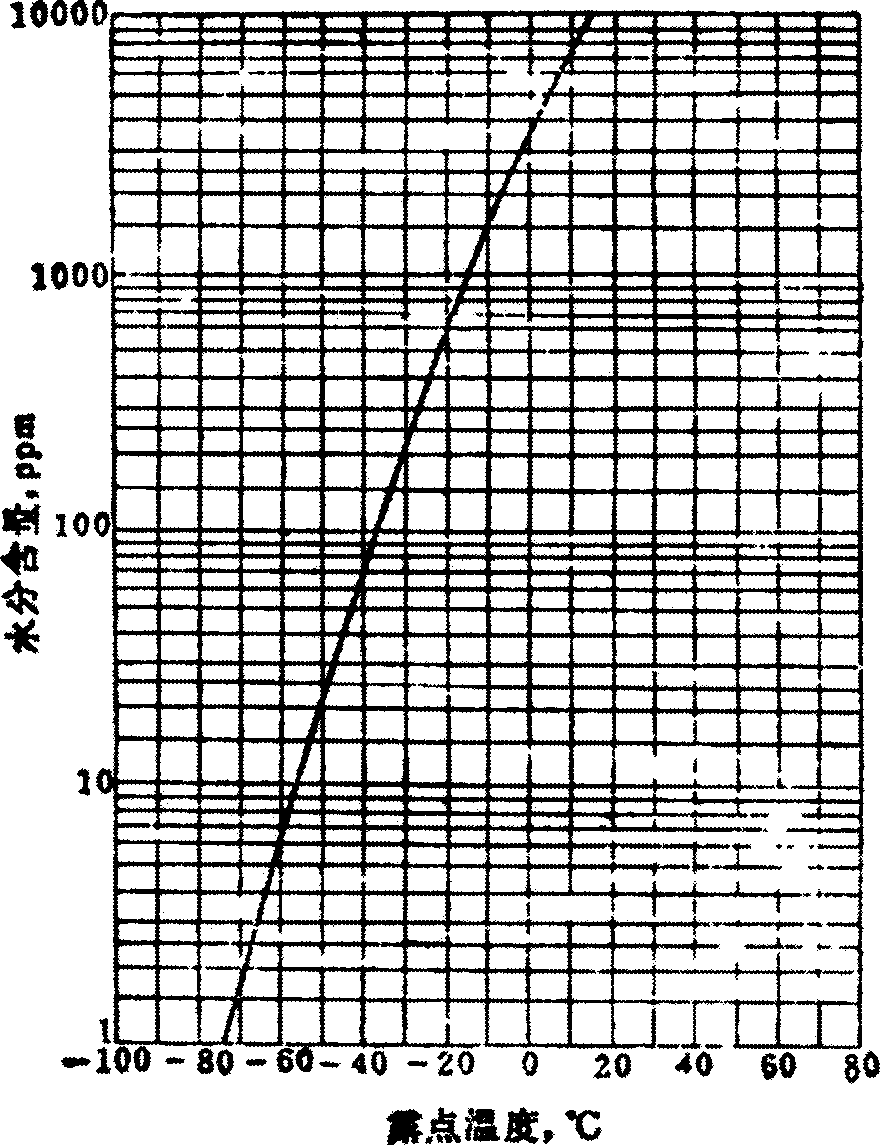

Method and apparatus for cryogenic fast freezing preservation and refrigerating dry of Chinese medicines and food

InactiveCN1439316AReduce energy consumptionLow costFruit and vegetables preservationCompression machines using turbinesFreeze-dryingCell membrane

A process for antistaling and drying the Chinese-medicinal materials or food features that an air turbine with reflux condenser is used for refrigerating, which can quickly freeze the Chinese-medicinal materials or food for antistaling them, and said drying them features the direct sublimation. Its advantages are no damage to cell membrane, very low water content, and long storage period.

Owner:BEIHANG UNIV

Pet feces fast freezer

InactiveCN101574059AEasy to handleReduce pollutionDomestic cooling apparatusLighting and heating apparatusAnimal fecesEngineering

The invention relates to a pet feces fast freezer which comprises a tank body, a handle, a bottle neck, a mesh bag and a nozzle. The handle is installed on the tank body, the upper part of the tank body is connected with the nozzle which is used for spraying refrigerant through the bottle neck, the mesh bag used for containing feces after fast freezing is hung on the bottle neck, and the pet feces is fast refrigerated into a harder solid state, thereby the feces can be treated in time, and environmental pollution caused by feeding a pet is reduced.

Owner:ADOLESCENT SCI & TECH GUIDE STATION BAOSHAN DISTRICT SHANGHAI CITY

Instant sea cucumber with primary taste and is manufacturing method

InactiveCN1653960AMaintain molecular structureReserve statusFood preservationFood preparationFast FreezeSea cucumber

The instant sea cucumber with primary taste is made through cleaning, water boiling and fast freezing. Specifically, the making process includes eliminating internal organs of live sea cucumber and cleaning; boiling first in water at 30-40 deg.c for 5-10 min on slow fire and then at 50-60 deg.c for another 5-10 min until sea cucumber stretches to live state; fast freezing at temperature from -40 deg.c to -30 deg.c in fast freezing machine for 15-20 min; and packing. The said making process can maintain the molecular structure, nutritious components and taste of live sea cucumber radically, and the sea cucumber may be eaten in different modes after being defrozen.

Owner:许毅

Method for preserving and evenly thawing fast-frozen side dishes

InactiveCN101715807AInorganic saltMeet needsFruit and vegetables preservationFood processingSide dishHorticulture

The invention relates to a method for preserving and evenly thawing fast-frozen side dishes, belonging to the technical field of the further processing of agricultural products. The method comprises the following main steps of: selecting fresh vegetables as raw materials, washing, cutting, blanching, color conserving, cooling, draining, matching, packing, fast-freezing, storing and micro-wave thawing. According to the method, vegetables with different nutrients, textures and colors are matched together and are good for health after being eaten; and different vegetables are cut in different sizes to improve the thawing effect, and the combined thawing of samples is carried out by three-segment dielectric heating. The invention has the advantages that by the segmented combined thawing of dielectric heating, the colors of thawed fast-frozen side dishes are similar to that of fresh vegetables, the nutrients of the side dishes are well kept, the thawing is carried out evenly, the textures of the vegetables are well kept, the thawing quality of the fast-frozen side dishes is improved, thereby achieving the characteristics of effectively reduced thawing time, good original shape after the thawing, low production cost, energy saving and the like.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

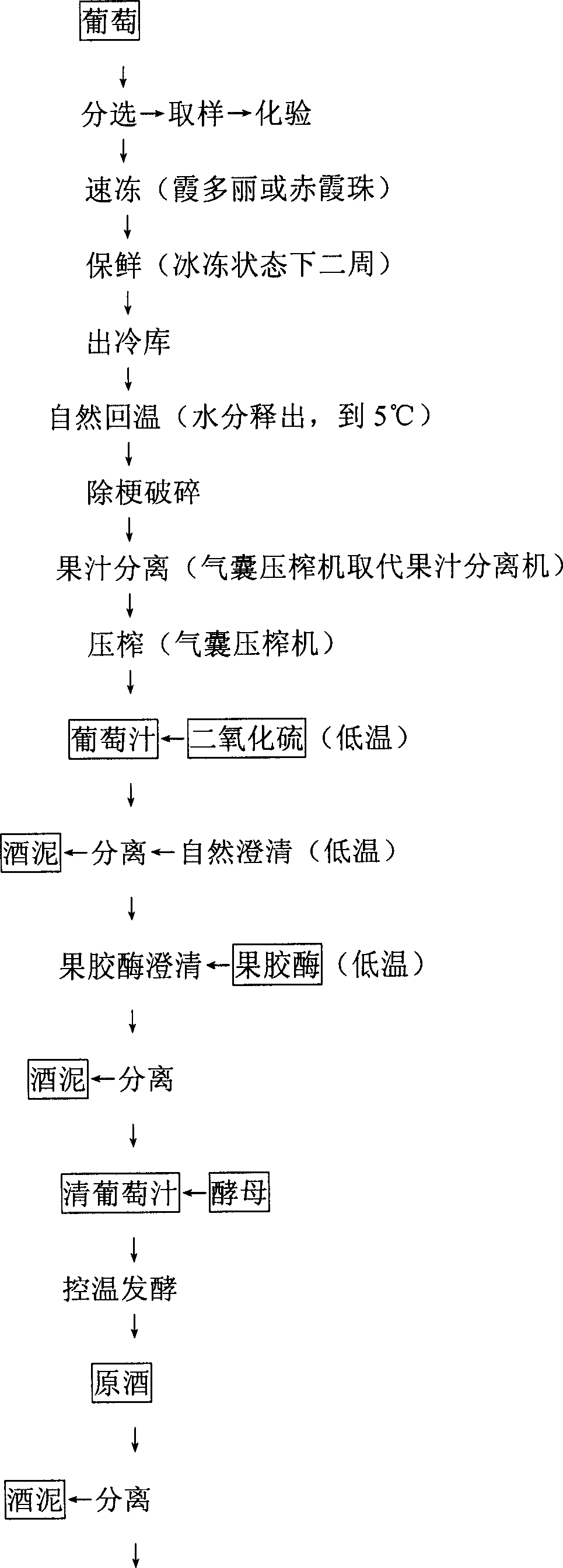

Frozen wine and its preparing method

The invention relates to a freeze grape wine and the method to manufacture that belongs to wine producing field. The process includes the following steps: selecting grape and taking fast freezing to keep fresh in low temperature, warming in natural temperature, reducing peduncle, compressing, separating the flesh and the juice, purifying, fermenting at a certain temperature, separating to kettle and storage, mixing, taking second freezing process, filtering and bottling. The invention has taken strict test from the four aspects of color aroma, taste and alimentation. And it has all the features of the existing freeze wine.

Owner:马玉祥 +1

Clean silkworm cocoon cooking method

ActiveCN106012037AGood relaxing effectQuality improvementSilk filament obtainingVacuum pressureMicrowave

The invention discloses a clean silkworm cocoon cooking method. The method comprises the following steps: putting selected silkworm cocoons in a home-made soaking agent to be soaked, then washing the silkworm cocoons with clear water and drying the silkworm cocoons by microwave and far infrared optical wave and then sending the silkworm cocoons to be directly steamed; putting the silkworm cocoons in a vacuum cocoon cooking permeator after direct steaming is completed, adding proper amount of unwinding agent, controlling the water temperature at 30-50 DEG C, carrying out vacuum permeation, and when the vacuum pressure is -0.1Mpa, taking out the silkworm cocoons to enter the next cocoon cooking procedure after continuing for 1-5 minutes, after cocoon cooking is completed, putting the obtained silkworm cocoons in a fast freezing tank at 23 DEG C to be fast frozen for seven hours, then putting the silkworm cocoons in an environment at minus 10.5 DEG C and with vacuum degree of 270pa to be sublimated for 230 minutes and sending the silkworm cocoons to a silk reeling workshop. The method has the beneficial effects that by adopting the cocoon cooking method to cook cocoons, the obtained cooked cocoons have high silk yields and good quality; the quality indicator levels of the cooked cocoons are greatly improved; the cleaning, strength and cohesion indexes are improved by more than or equal to one grade.

Owner:SHANGLIN ZHONGXING SILK

Livestock embryo vitrifying freeze process on metal surface

InactiveCN101066052AImprove survival ratePromote commercial applicationDead animal preservationEmbryoDomestic animal

The present invention is livestock embryo vitrifying freeze process on metal surface, and belongs to the field of biotechnology. The livestock embryo vitrifying freeze process includes replacing freeze protectant for liquid inside and outside the embryo cell and fast freezing of the embryo liquid drop. During the fast freezing, the embryo liquid drop is dropped onto the exposed upper surface of one metal block with lower part soaked inside liquid nitrogen. The present invention can cool embryo in high speed while avoiding contamination of impurity in liquid nitrogen to the embryo. Besides, adding cytochalasin B as cytoskeleton protectant into the frozen liquid can raise the freezeproof capacity of the embryo and raise vitrification freezing effect. The present invention is used for freezing livestock embryo.

Owner:BEIJING JINXIU DADI AGRI CO LTD

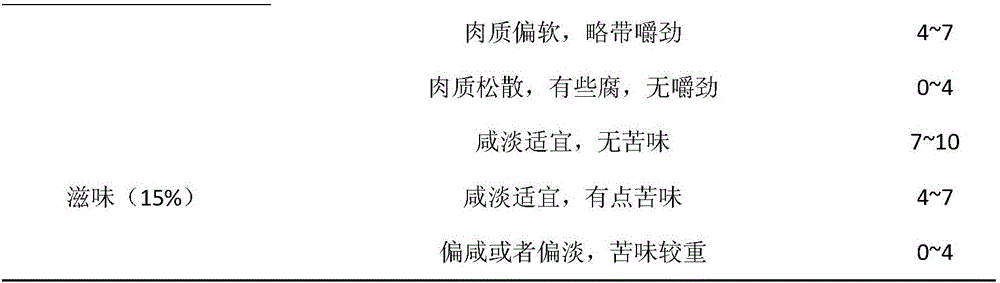

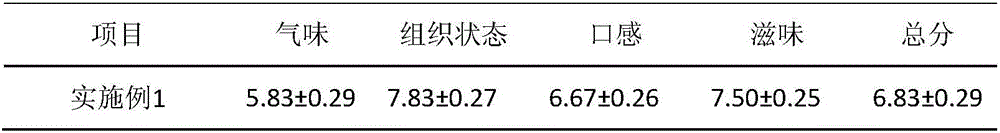

Production method of Hubei flavored fermented mandarin fish

The invention provides a production method of Hubei flavored fermented mandarin fish. The production method comprises the following steps: pretreatment, bacteria-reducing treatment, composite fishy smell removal, pickling, gradient temperature-controlled humidity-controlled fermentation, bittern washing, vacuum sealing, fast freezing and the like. The bacteria-reducing treatment is adopted to effectively reduce the initial bacterial colonies on the fish body surface. The composite fishy smell removal is adopted to treat the fish body, thereby effectively lowering the fishy smell. The wet pickling treatment is adopted to effectively isolate oxygen, thereby decelerating deterioration of the fish, and enabling the salt and spices to uniformly penetrate into the fish tissues. The gradient temperature-controlled humidity-controlled fermentation is adopted, and the microbes and endogenous enzyme are used for fermenting the fish under appropriate conditions to generate the special flavor substance.

Owner:WUHAN ACADEMY OF AGRI SCI

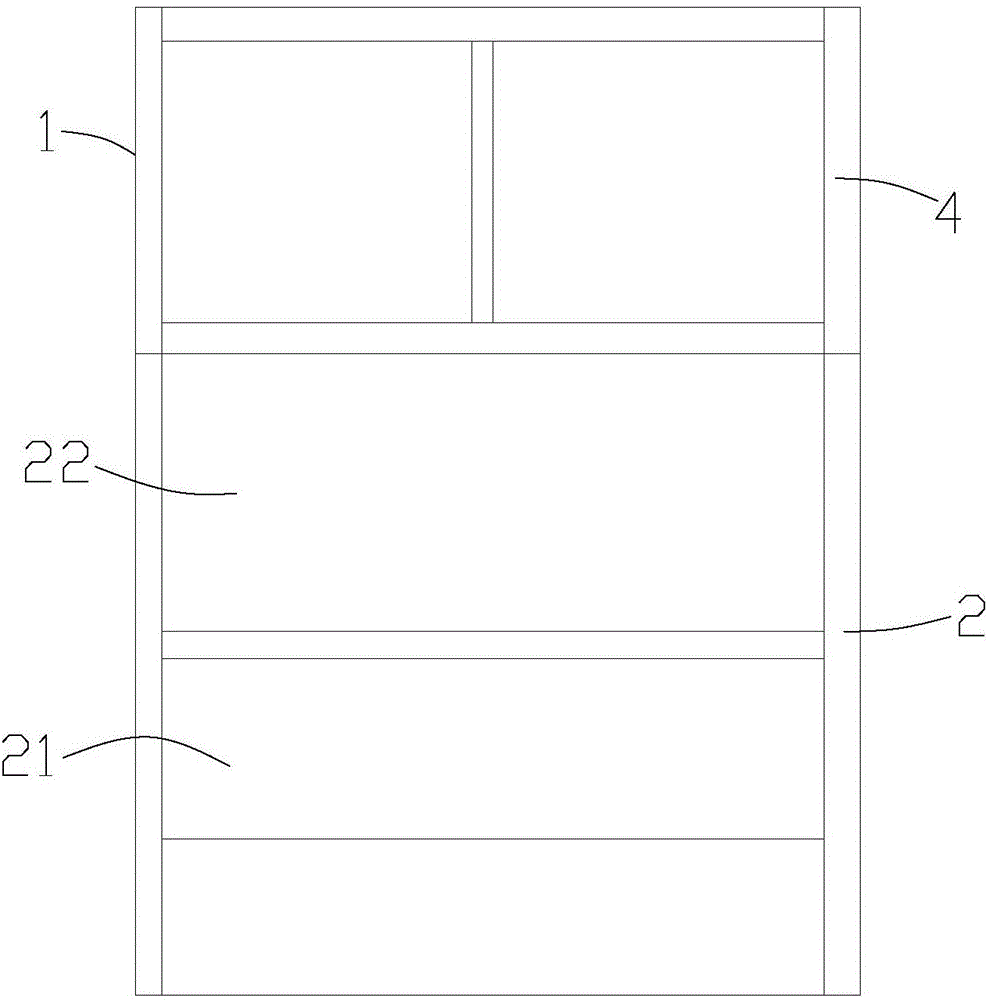

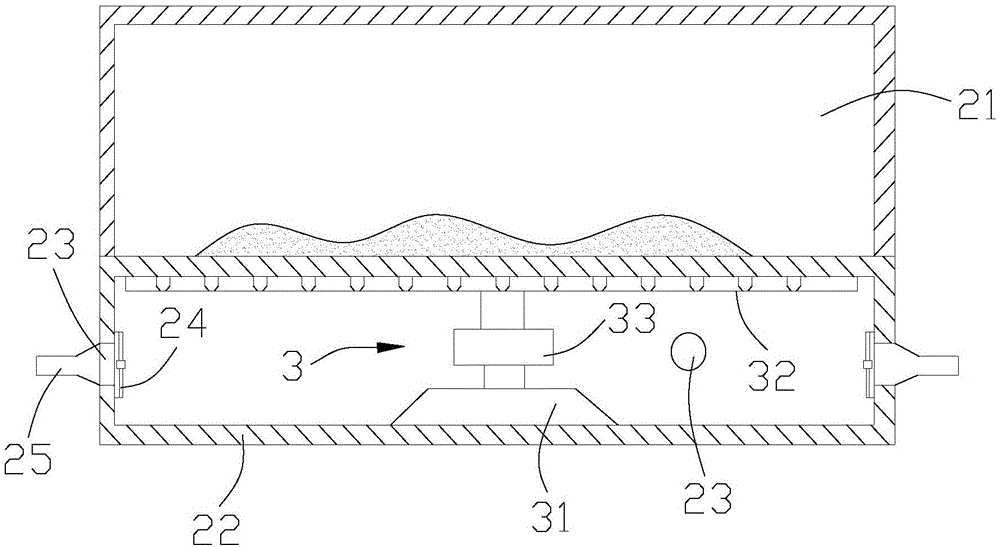

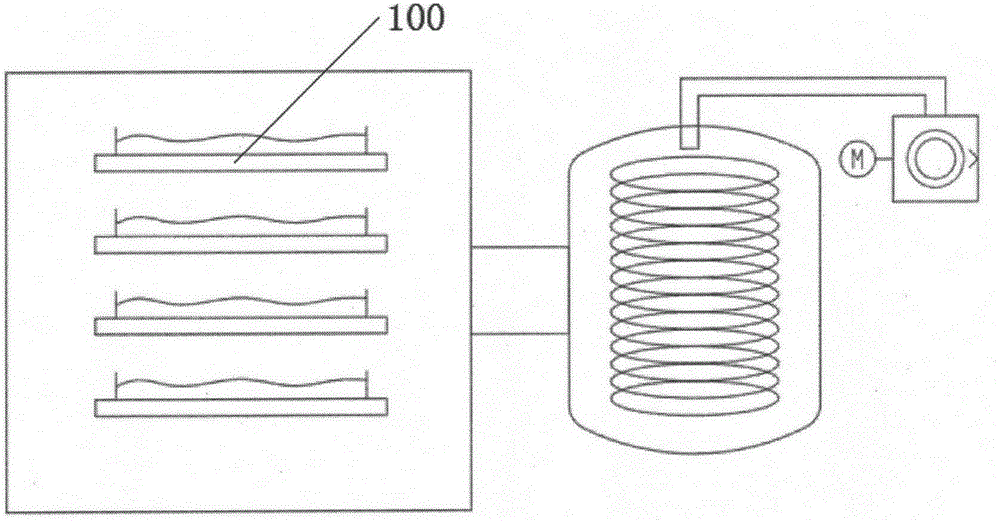

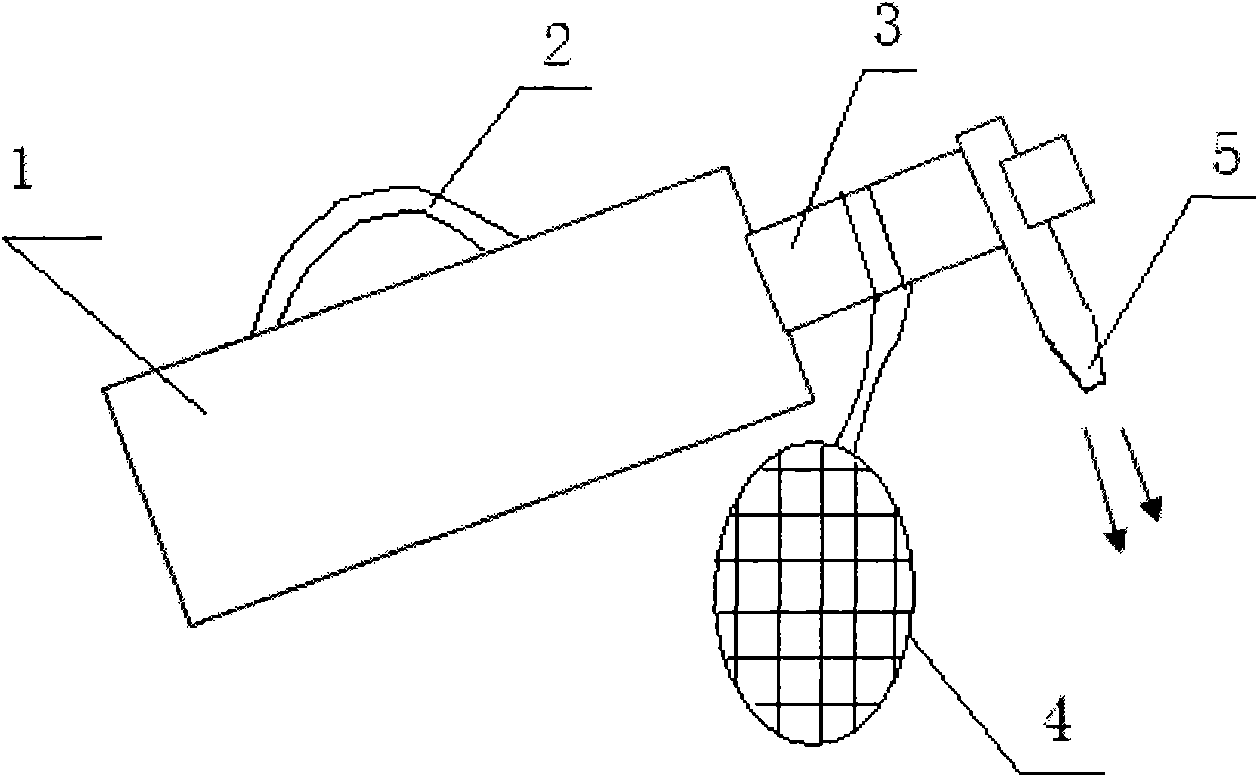

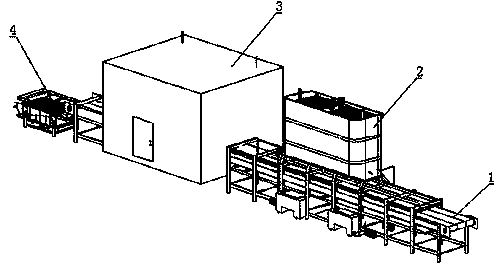

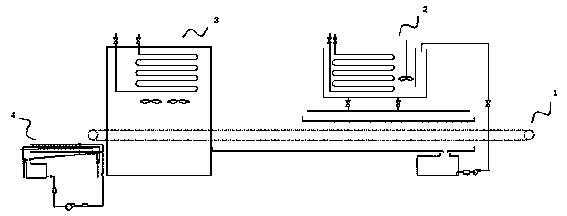

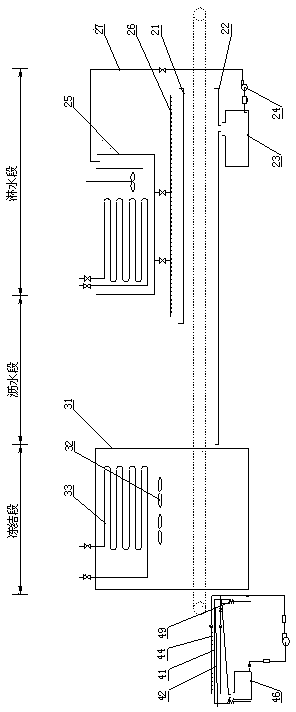

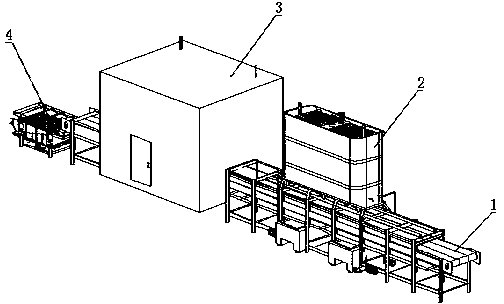

Refrigeration pretreatment production line for shrimps

ActiveCN103431495AWeaken the U-turn phenomenonCurb corruptionFood preservationQuick FreezeEngineering

The invention relates to a refrigeration pretreatment production line for shrimps. The production line is characterized in that: the production mainly comprises a conveying mesh belt, the conveying mesh belt is divided into a water spraying segment conveying mesh belt, a water draining segment conveying mesh belt and a freezing segment conveying mesh belt from the front to the rear according to technological requirements; the water spraying segment conveying mesh belt and the water draining segment conveying mesh belt are provided with a salt brine spraying, cooling and water draining device; the freezing segment conveying mesh belt is provided with a fast freezing device; the discharging end of the freezing segment conveying mesh belt is provided with a vibration ice coating device; and thus the refrigeration pretreatment production line for the shrimps is formed, and the whole refrigeration pretreatment on the shrimps in the production line is realized, the treatment efficiency on the shrimps is substantially improved, and the health status of the shrimps is improved. Also, the salt brine sprayed on the surface of the shrimps helps to inhibit corrosion caused by biological action and enzyme action, weaken the generation conditions of large ice crystal in the freezing segment, reduce possibility of damages to shrimp tissues and guarantee the quality of the shrimps; and the shrimps do not need secondary freezing because of vibration ice coating, and thus energy consumption is reduced.

Owner:NANTONG SINROFREEZE EQUIP

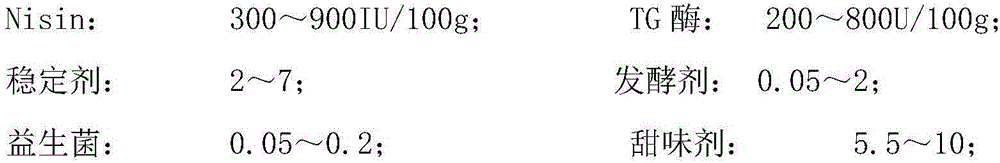

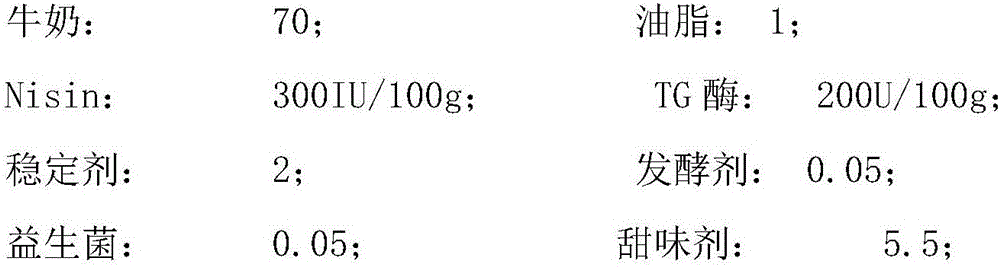

Freeze-thawing-resistant probiotics yoghourt and production method thereof

The invention discloses freeze-thawing-resistant probiotics yoghourt and a production method thereof. The yoghourt is produced by milk, grease, Nisin, TG enzymes, stabilizer, probiotics, a fermentation agent and a sweetening agent. The production method includes preparing the materials, standardizing, mixing, homogenizing and degassing, fermenting, performing after-ripening and fast freezing. The freeze-thawing-resistant probiotics yoghourt and the production method have the advantages that the yoghourt forms fine ice crystals during the freezing, the thawed yoghourt has the structure, taste and flavor of conventional yoghourt, and the yoghourt has better taste as compared with the conventional yoghourt; the probiotics are protected through embedding; the yoghourt can be stored for 12 months at -18 DEG C, can keep the good structure, taste and flavor after freeze thawing for 3 times, the thawed yoghourt can be stored for 7-12 days at 4 DEG C, quality deterioration and selling limitation caused by the short shelf life of the yoghourt, convenience is brought to consumers, and consumers in remote and backward regions can consume the high-quality yoghourt; the production method is simple to operate, convenient in production, low in cost and suitable for industrial large-scale production.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES +1

Vacuum fast freezing, storing and freshening new technology of fresh osmanthus flowers

InactiveCN101796976AFlower preserving apparatusFruits/vegetable preservation by freezing/coolingFood flavorOsmanthus

The invention aims at providing a vacuum fast freezing, storing and freshening new technology of the fresh osmanthus flowers, belonging to the technical field of freshening and storing fresh flowers. The stored fresh osmanthus flowers has the characteristics of small storing volume, no brown stain, no flavor reversion and long storing time.

Owner:四川日香桂农业科技开发有限公司

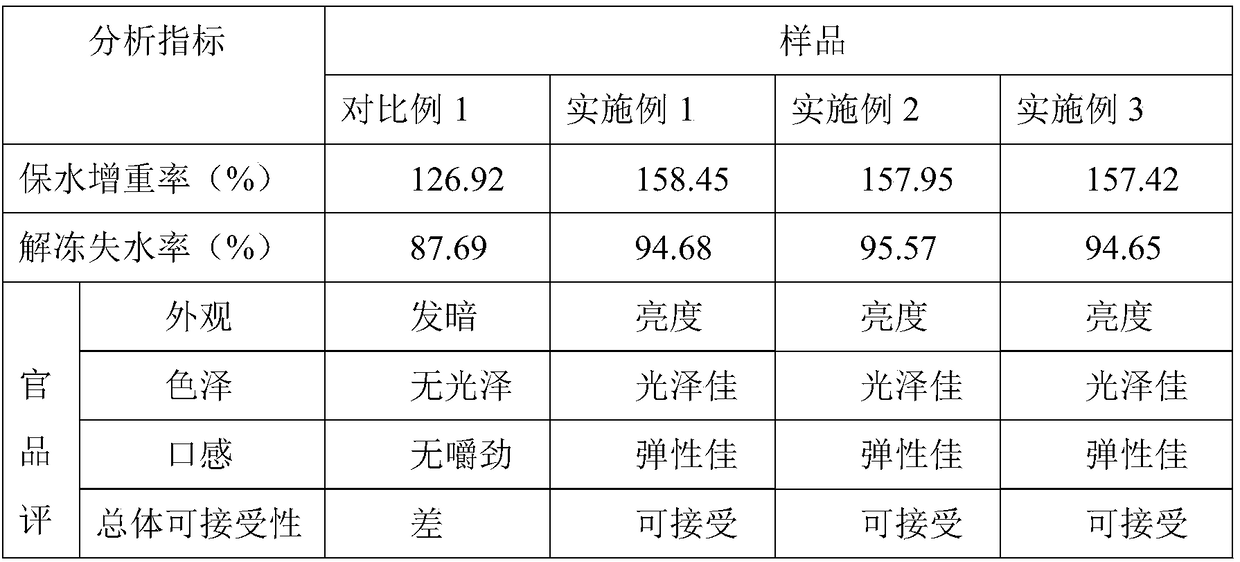

Method for improving frozen prepared fish fillets

The present invention discloses a method for improving frozen prepared fish fillets. The method comprises the following steps: step 1: selecting a fresh live fish, removing scales, head, internal organs and bones, cutting the fish into 2-3mm fillets, and conducting washing and draining; step 2, adding, in parts by mass, 1.5-2 parts of a compound fish fillet tissue improver into every 100 fish fillets, adding 1.0-1.2 parts of salt, 0.5-0.6 part of monosodium glutamate, 0.01-0.1 part of I+G, 0.08-0.15 part of white pepper powder, 3-8 parts of starch and 30-65 ice water, and conducting vacuum rolling and pickling; step 3, conducting vacuum packaging, and conducting pickling 12-16h; and step 4, fast freezing the fillets until the center temperature of the fish fillets is -18 DEG C or below, and conducting freezing storage. The method maintains the nutritional value, the flavor and the taste of the prepared fish fillets during freezing and transportation process. The fish fillets are extremely resistant to boiling, the cooked fish fillets are still fresh, the fish fillets are shrunk-proof and fuller, and the yield is increased. The fillets are slightly brittle and free from peculiar taste in mouth feel, have no loss of raw material nutrients, and are suitable for a plurality of cooking methods such as hot pot.

Owner:杭州众香科技有限公司

Copious cooling fast freezing infrared drying technology

InactiveCN109780821AImprove protectionNo pollution in the processDrying solid materials without heatLiquid waterFreeze-drying

The invention discloses a copious cooling fast freezing infrared drying technology and belongs to the technical field of chemical engineering and light industry machining. The copious cooling fast freezing infrared drying technology is characterized in that a gas turbine expanding refrigerating technology is adopted for performing copious cooling fast freezing on materials, compressed air at 0.5-0.9 Mpa is used, the initial air expanding pressure intensity ratio is 3-9, and fresh product vegetables and fruits and traditional Chinese medicinal materials except mineral drug are fast cooled to minus 20- minus 120 DEG C within 5-30 min, so that liquid water in a raw material organization structure fast solidifies, and becomes extremely micro ice crystal; and then, the materials are fed into aninfrared vacuum freezing drying bin to be heated, so that solid water in the materials sublimates into vaporous water, and the water content of the materials is lowered to 0-10%. The copious coolingfast freezing infrared drying technology has the characteristics of being high in freezing speed, low in cooling temperature, high in drying speed, uniform in material heating, uniform in material product quality and good in drying effect.

Owner:海尔生物医疗科技(成都)有限公司

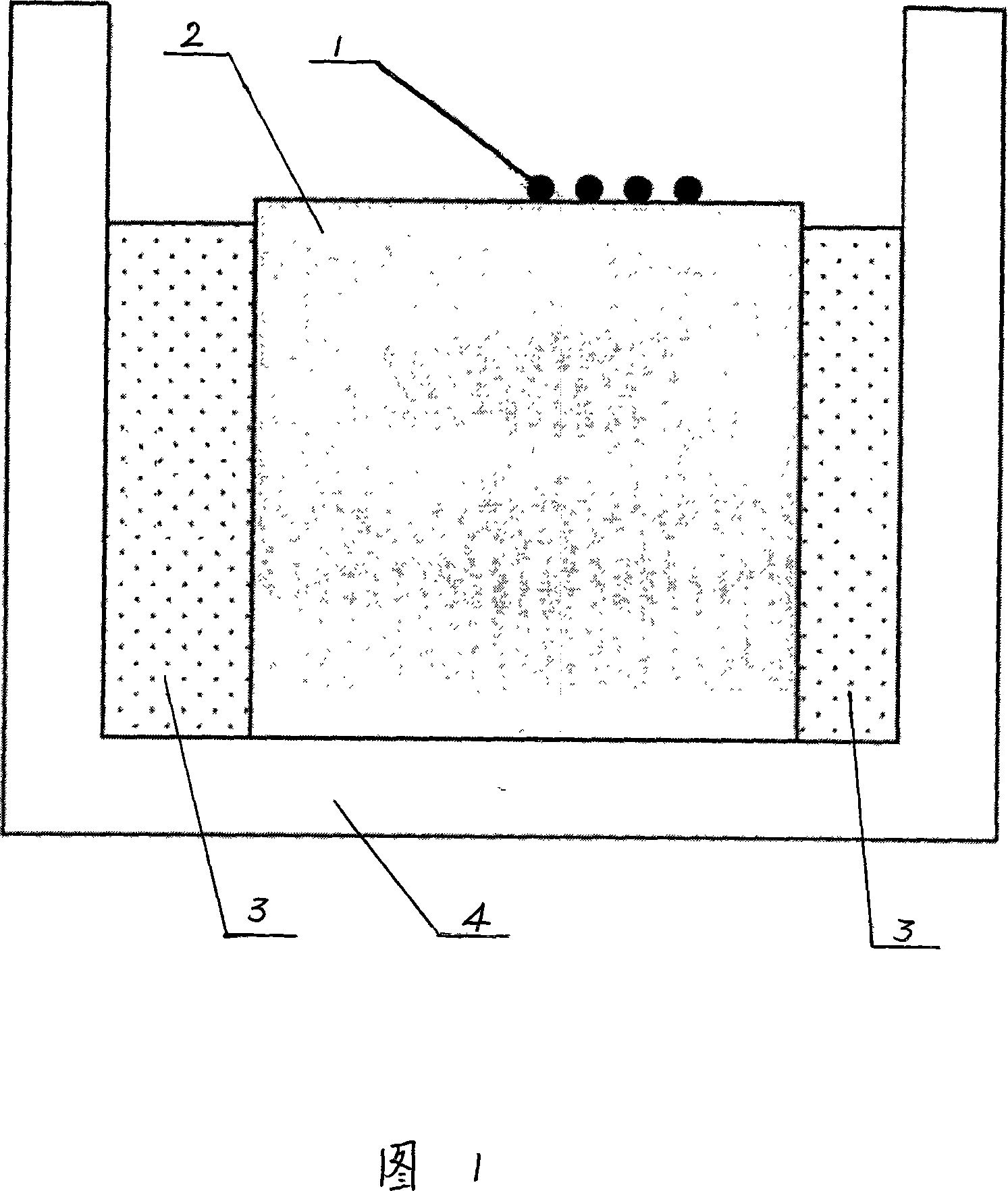

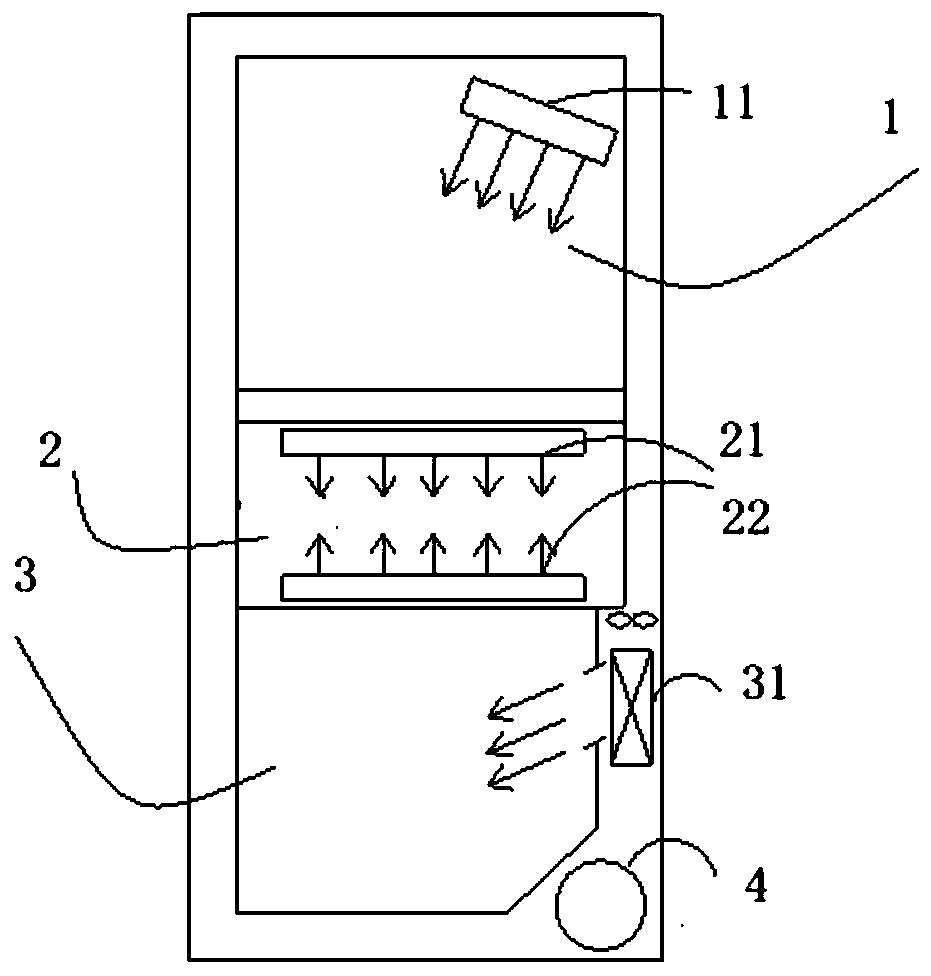

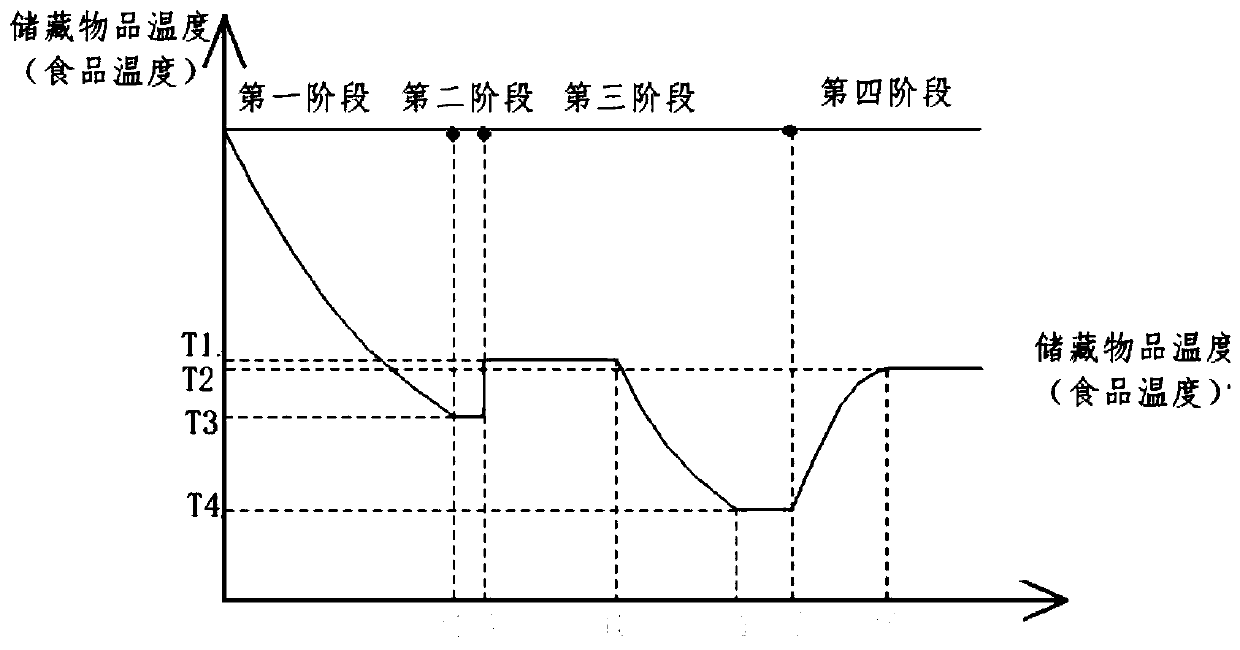

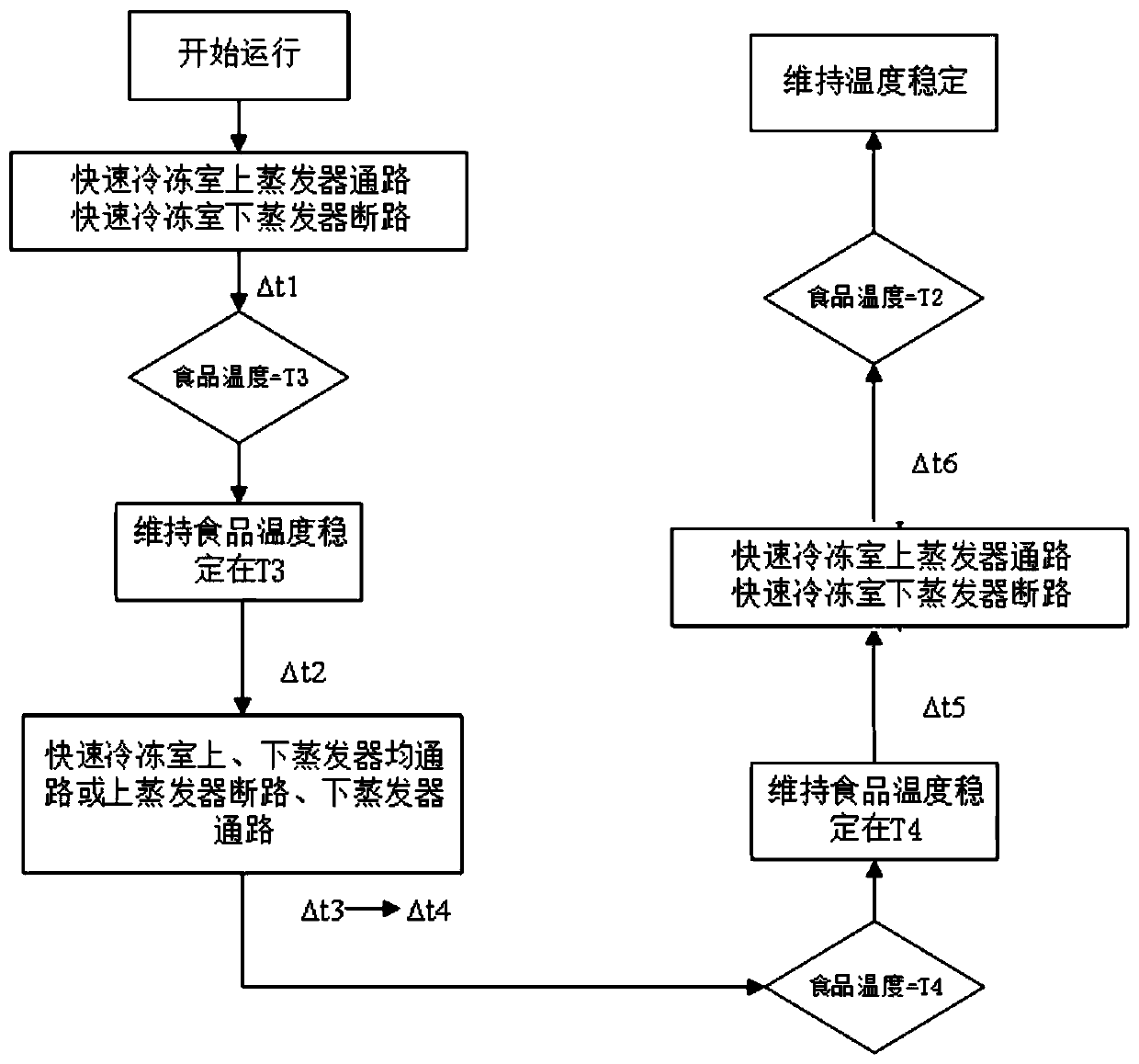

Overcooling freezing method, refrigerator and refrigerator control method

ActiveCN110671877AUniform and stable temperatureAvoid churnLighting and heating apparatusDomestic refrigeratorsFreezing chamberFast freezing

The invention provides an overcooling freezing method, a refrigerator and a refrigerator control method. Direct-cooling-type evaporators are adopted, and the direct-cooling-type evaporators at different positions are controlled to work in different overcooling freezing processes. A top evaporator is used for reducing temperature, so that the temperature reducing conditions of food in a freezing room are as close as possible to natural convection, the situation that the temperature reducing rate is too high due to the fact that the food is in contact thermal conductance with a refrigerated evaporator or the food is too close to the refrigerated evaporator, and keeping the stability of the food overcooling state is facilitated. A bottom evaporator or both the top evaporator and the bottom evaporator are used for reducing temperature at a fast freezing stage of the food to ensure the food to be quickly frozen, ice crystals are smaller and more rounded, the frozen food can be cut with a knife and cooked immediately, the waste of time and loss of food nutritional value caused by the thawing process are avoided.

Owner:GREE ELECTRIC APPLIANCES INC

Refrigeration pretreatment method for shrimps

InactiveCN103431496AExtension of timeGuaranteed qualityFood preservationSaline waterPretreatment method

The invention relates to a refrigeration pretreatment method for shrimps. The method is characterized in that: the pretreatment method employs a shrimp pretreatment line for treating of the shrimps, the main steps of the method comprise a water spraying process, a water draining process, a freezing process and a vibration ice coating process; a salt brine with a concentration of 3%-4% is cooled to 0 DEG C-2 DEG C, and are uniformly sprayed over the shrimps which pass therebeneath; after water is drained, the shrimps are transported to a fast freezing apparatus with a temperature of -30 DEG C or less; and after fast frozen, the shrimps are put in a vibration ice coating apparatus of the shrimp pretreatment line, the vibration ice coating apparatus sprays potable water approximating mist or a salt brine with a concentration of 0-4% to the surface of the frozen shrimps for formation of ice coating. The whole pretreatment method helps to substantially improve the quality of the treated shrimps, and is beneficial to improvement on quality of the shrimps.

Owner:NANTONG SINROFREEZE EQUIP

Preparation method of fast-frozen fried chicken lotus root box

The invention relates to a preparation method of fast-frozen fried chicken lotus root box. The preparation method comprises the following steps: selecting chicken skin, chicken breast and chicken thigh to stir to muddy flesh, then mixing the muddy flesh with raw onion, raw ginger, mustard powder, monosodium glutamate, Japanese soy sauce, red wine, Japanese red bread powder and potato starch evenlyto insert two uniform slices of lotus root, soaking in soup base, then pasting bread powder, fast-freezing and packaging, wherein the soup base is stewed by selecting wheat flour, baking soda, soybean oil, salt, monosodium glutamate and glucose and adding water. The pork and chicken lotus root box of the invention has special flavor; compared with the similar food technology, the method adopts chicken skin as the main material of meat stuffing with the function of maintaining beauty and the food is simple to carry and is suitable to eat in daily life or outdoor life containing expedition andthe like. The preparation method of the chicken lotus root box has reasonable process, low cost and strong maneuverability and is easy to realize large-scale production.

Owner:RONGCHENG BODELONG FOODSTUFF

Preparation method of graphene/silicon carbide/aluminum composite material

The invention relates to a preparation method of a graphene / silicon carbide / aluminum composite material. The preparation method includes the following preparation steps that after silicon carbide fiber / graphene oxide mixed dispersion liquid of a certain concentration is prepared according to the proportion, the mixed dispersion liquid is transferred into a PTPE mold, the mold is placed on the surface of liquid nitrogen for fast freezing, then freezing and drying are performed, pre-sintering is performed, and an oriented and orderly arranged silicon carbide fiber / three-dimensional graphene framework is obtained; and enough aluminum blocks are vertically placed on the surface of the silicon carbide fiber / three-dimensional graphene framework, pressure infiltration is performed in a vacuum pressure infiltration furnace, and the compact graphene / silicon carbide / aluminum composite material is obtained. Graphene and silicon carbide fibers in the composite material prepared through the preparation method are of a three-dimensional network crossed structure, more heat conduction channels are provided, three-dimensional network crossing of the silicon carbide fibers provides the high-strength framework, and the high temperature stability of the material is improved. The composite material prepared through the preparation method is uniform in component, low in heat expansion coefficient and high in heat conduction rate.

Owner:LANZHOU JIAOTONG UNIV

Special slow release salt for boiled dumplings and steamed stuffed buns, and preparation method thereof

PendingCN107019194AGood sustained release effectKeep the original tasteFood scienceSucroseWater soluble

The invention discloses special slow release salt for boiled dumplings and steamed stuffed buns. The slow release salt is prepared through spraying a slow release liquid on the surfaces of table salt particles. The slow release liquid is prepared from the following raw materials in parts by weight: 100 parts of water, 6 to 10 parts of gamma-polyglutamic acid, 2 to 4 parts of sucrose ester, 0.5 to 1.0 part of soluble soybean polysaccharide, and 0.3 to 0.8 part of transglutaminase. The invention also discloses a preparation method of the slow release salt. The special slow release salt for the boiled dumplings and the steamed stuffed buns has a better slow release effect, and starts to be dissolved after being added into a filling for 10 to 30min, so that the discharge of a vegetable juice in the filling is remarkably slowed down, the original taste and flavor of the filling is maximally retained, the dumplings and the steamed stuffed buns can be conveniently prepared and are delicious and juicy, the quality and the taste of the dumplings and the steamed stuffed buns are improved, and the slow release salt is not only suitable for home use but also suitable to be popularized and applied in large scale in a fast freezing industry. The slow release salt provided by the invention is simple in preparation process, stable in product quality, and suitable for larger-scale production and application.

Owner:JINAN SHUNJING PHARMA TECH

Preparation method of low-agglomeration nanoscale tea powder

InactiveCN105724627ASolve powder agglomerationSolve the two major technical problems of nano-scale particlesPre-extraction tea treatmentPrillHigh energy

The invention relates to a preparation method of low-agglomeration nanoscale tea powder and belongs to the technical field of tea leaf processing.The preparation method includes: taking matcha, black tea or other tea; crushing tea leaves with a universal crusher, and crushing with a fluidized bed type airflow ultrafine grinder under a low temperature state; adding water to the ultrafine tea powder, and grinding with a high-energy nano ball mill; fast freezing the nano tea powder to below minus 25 DEG C, and continuously drying and sublimating under a vacuum state, sieving with a sieving machine, and bagging and sealing; or directly performing spraying drying on the nano tea powder to obtain the low-agglomeration nanoscale tea powder.By the preparation method, the two technological difficulties that traditional ultrafine tea powder is prone to agglomeration and cannot reach nano scale are solved.Compared with the prior art, the method has the advantages that sufficient cell wall breaking is achieved, the tea powder can reach nano scale, the absorption rate and dispersing effect of tea healthcare factors are increased at the same time, and the prepared tea powder is original in taste, capable of being dissolved and dispersed fast and widely applicable to food and beverage.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

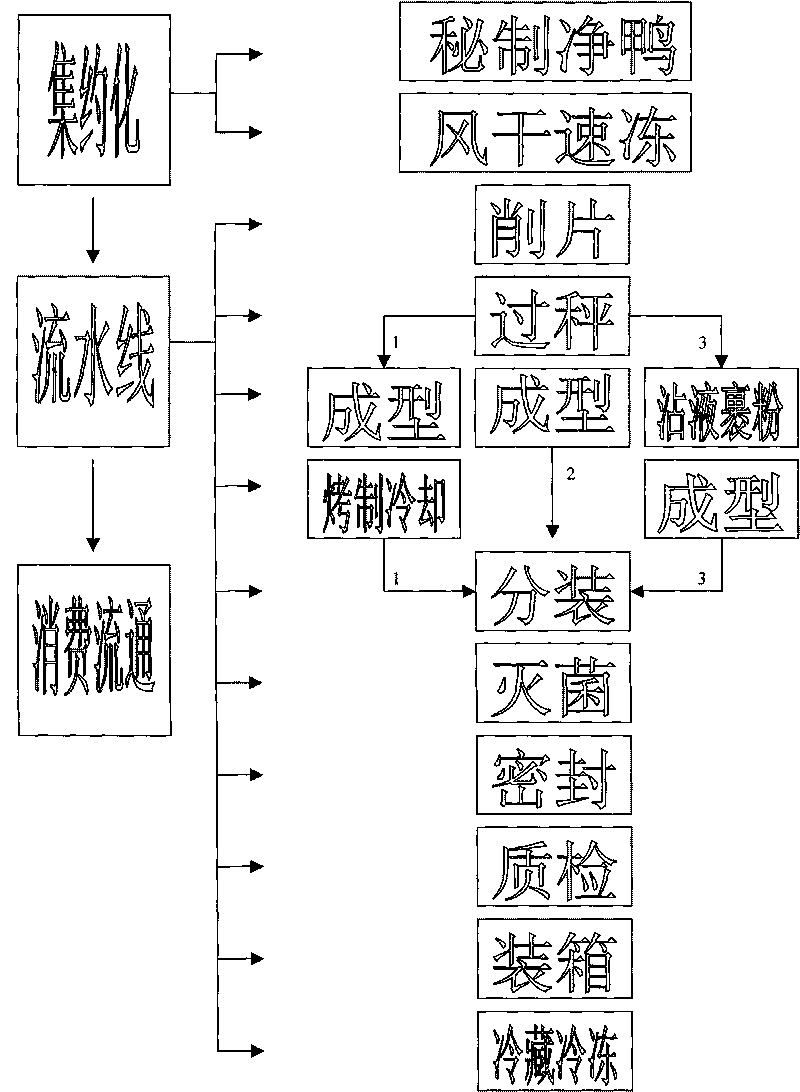

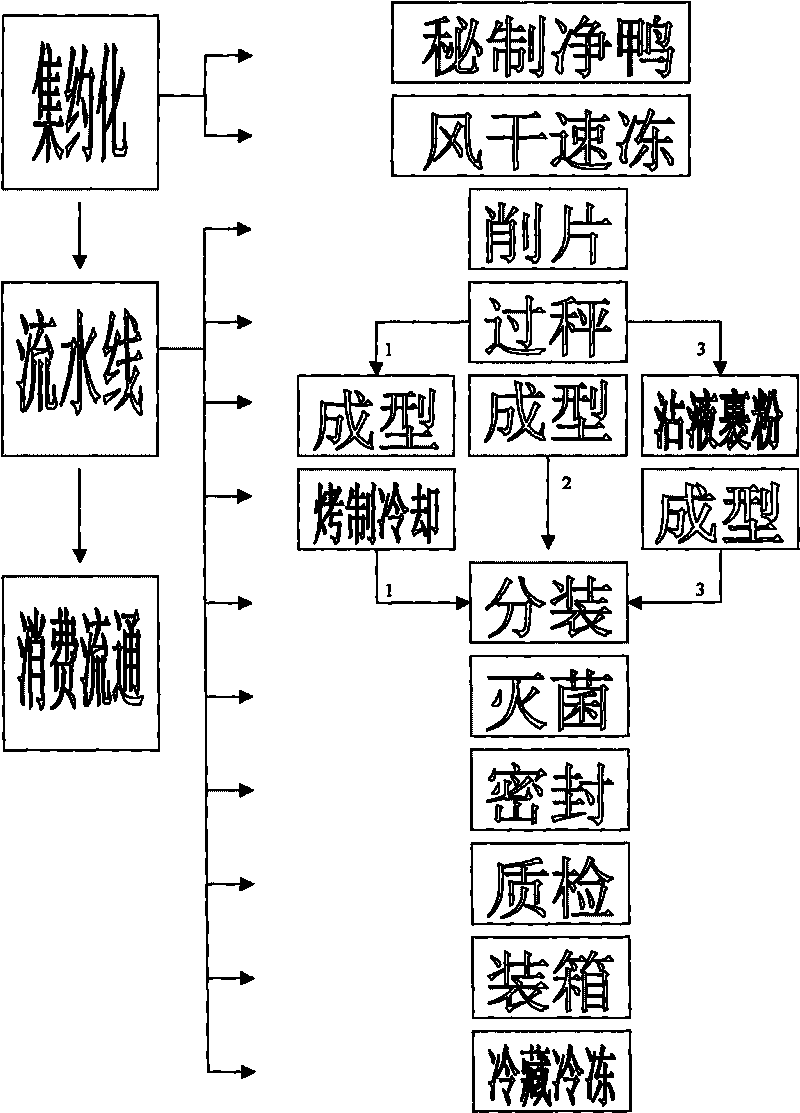

Method for supplying and producing Chinese traditional roasted duck snacks

The invention discloses a method for supplying and producing Chinese traditional roasted ducks. By using the method, the supplying mode of Chinese traditional roasted duck products can be quickened, standardized, popularized and industrialized, the sales area and the audiences of the Chinese traditional roasted duck can be remarkably enlarged, and the limitation of the supplying mode of the Chinese traditional roasted duck is remarkably improved. The invention provides delicious food to noble bachelors, provides opportunities to family snacks and provides chances to snack chain restaurants.The invention is mainly realized by the following technical scheme: intensively preparing plucked ducks by a traditional method, airing and fast freezing, stream-lined chipping, weighing, shaping, roasting and cooling, packaging, sterilizing, sealing, quality-inspecting, boxing, refrigerating, application the consumption, communication and processing method, and promotion of the edible method. The invention can ensure that all the delivered products are the same in the size, the quality, the appearance and the taste. Finished products and semi-finished products can be sold in supermarkets and chain shops, thereby meeting the different dining requirements of citizens.

Owner:徐红

Production method of fresh and tender wheat food

InactiveCN1515177AEasy to eatIncrease color varietiesFood preservationFood preparationBiotechnologyCold storage

The present invention discloses a production method of fresh tender wheat food. The method includes the following steps: harvesting the wheat being in late milk stage and prophase of full-ripe stage, threshing, then feeding the wheat groat into the cold storage whose temp. is -28 deg.C- -30 deg.C within 10 hr, fast freezing, then feeding the fast-frozen wheat groat into the cold storage with 01 deg.C- -20 deg.C for storage, then taking out said wheat groat from cold storage and peeling at 3 deg.C-15 deg.C, cleaning and centrifugally-drying, then making vacuum package so as to obtain the invented product fresh tender wheat food.

Owner:汪昌顺

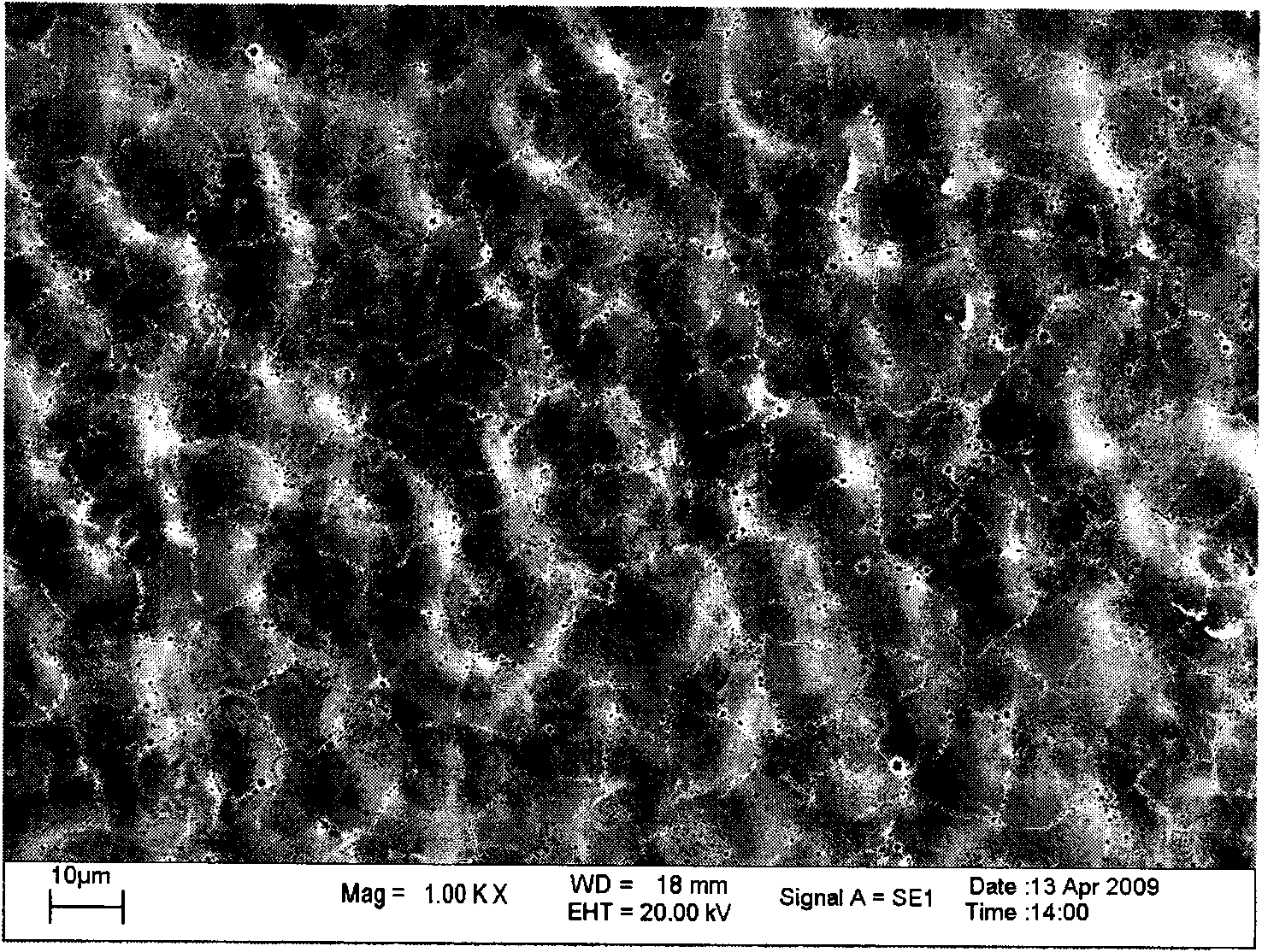

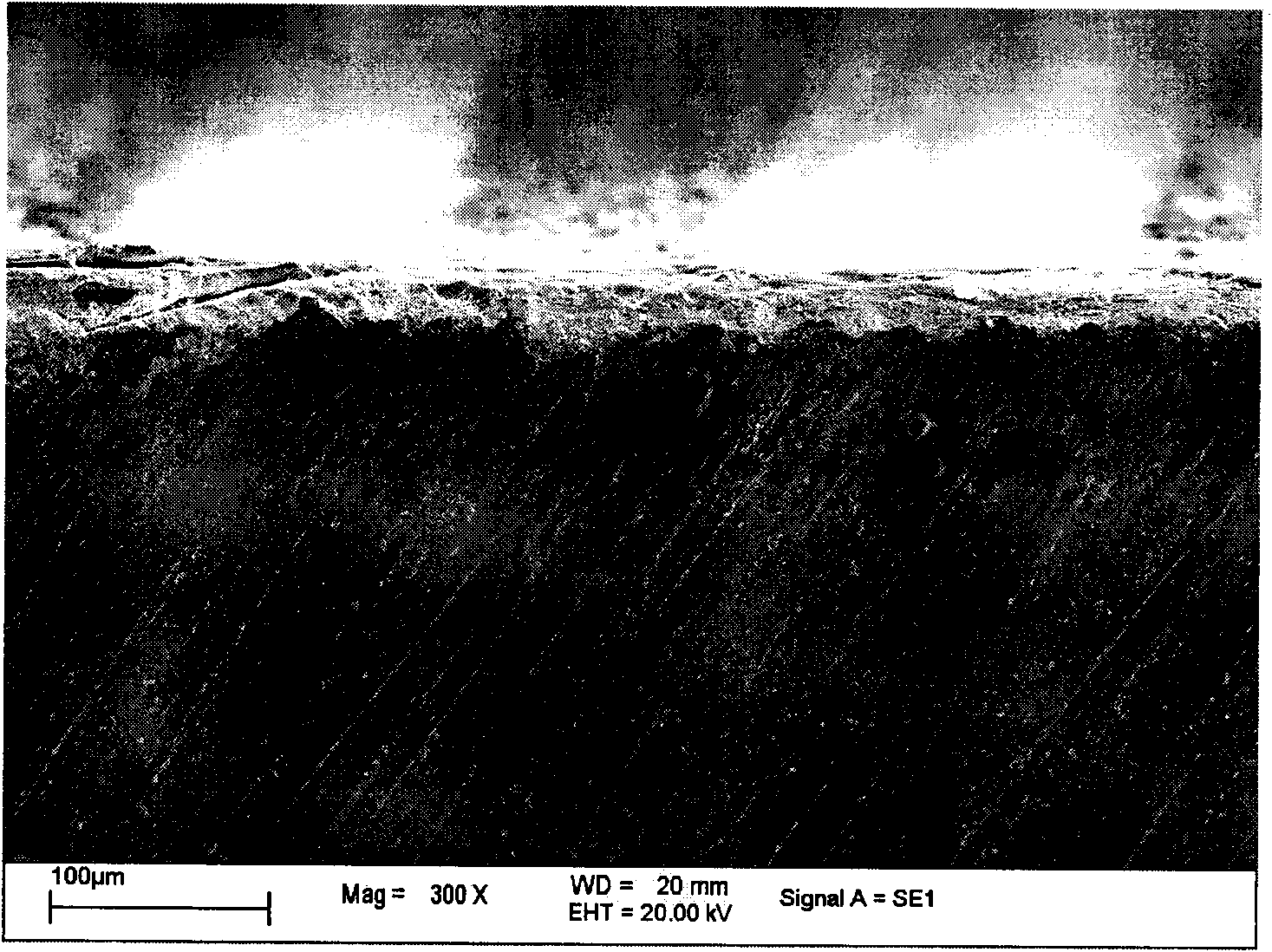

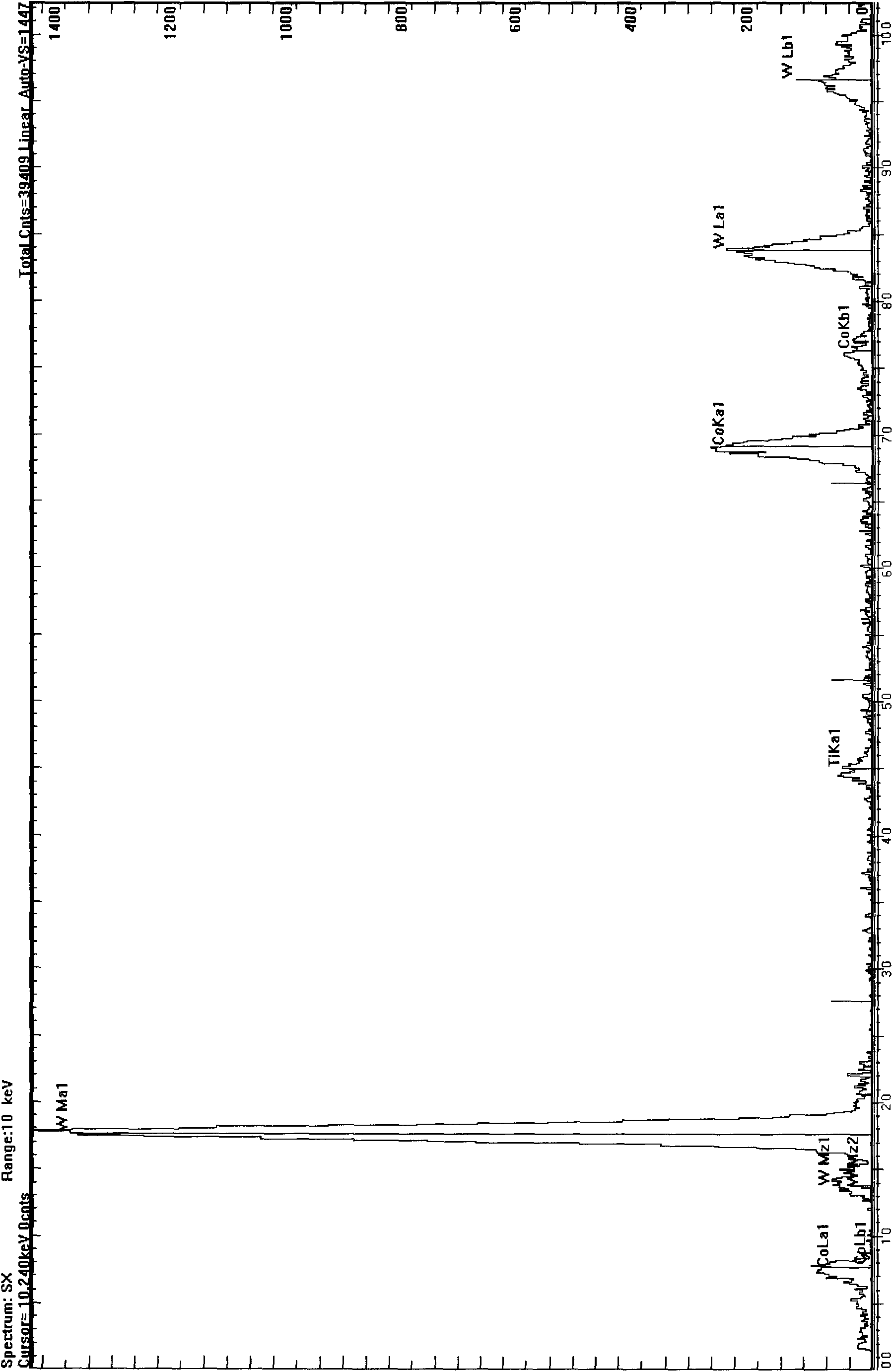

Technology method for pulse laser etching cobalt melting and fusing enhancing hard alloy

A technology method for pulse laser etching cobalt melting and fusing enhancing hard alloy relates to the laser surface processing technique of a hard alloy cutter and belongs to the technical field of the laser processing. The surface enhanced technology which is based on guaranteeing the toughness of the hard alloy appears in the practical production; generally coating is less than 10mu m; the bonding strength between the coating and the matrix of the hard alloy is lower; therefore, the service life of the hard alloy can not be substantially increased. The technology method carries out laseretching cobalt melting and fusing treatment on the external surface of the hard alloy (the mass percent of the cobalt is 10-30%); the wave length of the pulse laser is 248nm-1060nm; the power densityranges from 1.0*10<6>-9.9*10<7>W / cm<2>; the pulse width is 10 picosecond (ps)-90 nanosecond (ns); the numbers of the pulse is 10-500; and the pulse frequency is 1-20Hz. The thickness of the laser melting and fusing layer is 20-60mu m; the cobalt content in the melting and fusing layer is 3-9%; binder of Co, Ni, Cr and the like and matrix materials are of fast freezing tissues; and the hard alloycan be a cutter or a saw bit and used for processing materials such as metal, wood, etc.

Owner:BEIJING UNIV OF TECH

Mussel processing method

InactiveCN101138355AKeep the appearanceConvenient storage and transportationMeat/fish preservation by freezing/coolingBivalves processingCelsius DegreeComputer science

The present invention provides a processing method of mussel; the mussel is cleaned and cooked; the shell of cooked mussel is opened and the tendon which connects one side of the mussel meat and the shell is picked; the gill and byssus on the meat is removed and the shell is closed and fixed; a single frozen machine is used for fast freezing of the mussel and the fast freezing temperature is below minus 30 Celsius degrees; the mussel is delivered to the refrigerator for storage 2 to 3 minutes after the completion of fast freezing. With the present invention of a mussel processing method, the clean mussel meat is also connected with the shell on one side by tendon after being processed and two shells are also connected by back tendon; in this way, the product is characterized by the convenient storage and transportation of frozen product which meets the requirements that people can eat fresh mussel out of the production area, and the integral appearance of fresh mussel; with the protection of shells, the mussel meat can not be damaged by collision which has a better product image and enables people to cook the mussel with shell.

Owner:嵊泗县华利水产有限责任公司

Wildness domestic fungus fresh-keeping method

InactiveCN101138361ASuperior preservation methodRetain effective nutrientsFruits/vegetable preservation by freezing/coolingAdditive ingredientCold store

A preservation method of wild edible fungus belongs to the food processing technical field, in particular relates to a preservation method of wild edible fungus. As for the present invention of a preservation method of wild edible fungus, the process comprises impurities removing, cleaning, fast freezing, packing, cold store, cold transportation and marketing. The wild edible fungus preserved with the process keeps the fresh and delicious taste of picked wild fungus and the nutrition of fungus which is green and environment friendly and fully accords with the requirements of food health and principle of environmental protection; in addition, the wild edible fungus is also beneficial to the health of people. Therefore, the present invention is an advanced preservation method of wild edible fungus and deserves wide dissemination.

Owner:金学珍 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com