Vacuum spray freeze-drying device and method

A technology of vacuum spraying and drying equipment, applied in drying solid materials, lighting and heating equipment, drying solid materials without heating, etc., can solve the problems of affecting the quality of freeze-dried products, low standing drying efficiency, low slow freezing efficiency, etc. , to achieve the effect of improving heat and mass transfer, shortening freeze-drying cycle, and improving sterility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

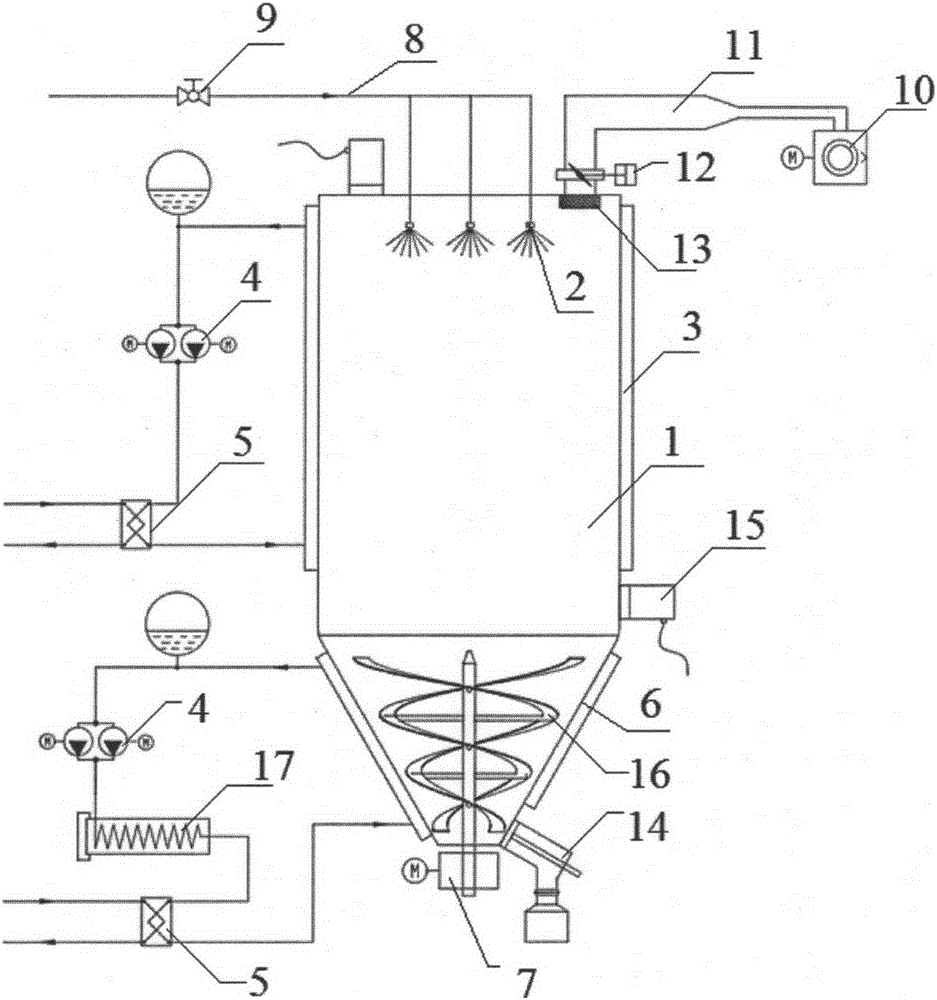

[0040] Such as figure 2 As shown, it is a schematic structural diagram of the vacuum spray freeze-drying equipment in Example 1. The vacuum spray freeze-drying equipment includes: a closed container 1 for holding materials in the vacuum spray freeze-drying process; The liquid is atomized and dispersed into droplets and sprayed into the atomizing nozzle 2 in the container 1; it is used to form a vacuum environment in the container 1 during the vacuum spray freezing granulation stage to vaporize the water in the droplets and absorb heat Then the droplets are cooled and frozen to form granules, and the vacuum system is continuously evacuated to maintain the vacuum environment in the drying stage; The drying stage provides the temperature-regulating jacket 6 for the sublimation heat of the ice in the particles, and in the vacuum spray freeze granulation stage, the evaporated water vapor is condensed and the water in the particles after sublimation is condensed in the drying stage...

Embodiment 2

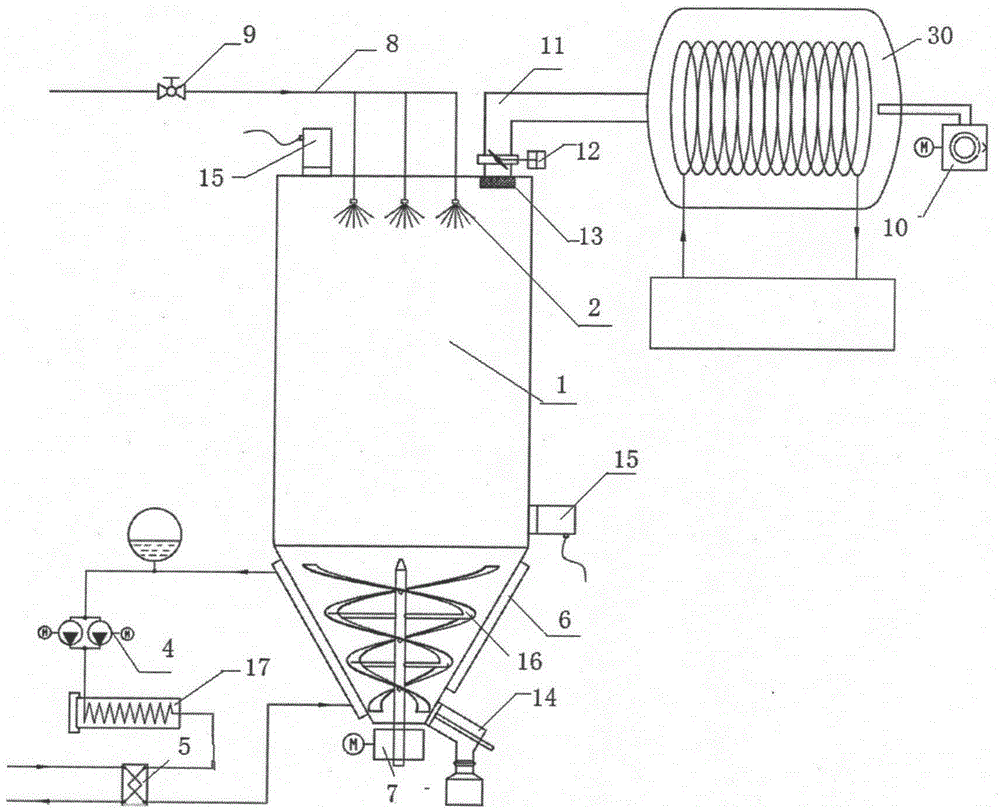

[0050] Such as image 3 As shown, it is a schematic diagram of the structure of the vacuum spray freeze-drying equipment in Example 2. The vacuum spray freeze-drying equipment is similar to Example 1, the difference is that the condensing device is located outside the container 1 and is connected with the The condenser 30 connected to the container 1, the condenser 30 is connected to the connection port of the container 1 through the pipeline 11, the vacuum pump 10 is connected to the condenser 30 through another pipeline, and the condenser 30 A valve 12 is provided on the pipeline 11 between the connection port of the container 1 , and no refrigeration jacket 3 is provided outside the upper part of the container 1 .

[0051] Take the ivy powder aqueous solution that 125g ivy powder is dissolved in the gained ivy powder in 2L water as example, when described equipment is used, implementation step is similar to embodiment 1, and difference is:

[0052] Step 1: In the stage of ...

Embodiment 3

[0055] Such as Figure 4 As shown, it is a schematic diagram of the structure of the vacuum spray freeze-drying equipment in Example 3. The vacuum spray freeze-drying equipment is similar to that of Example 1, the difference is that the condensing device is the one in the refrigeration jacket 3 and the condenser 30. In combination, the refrigeration jacket 3 is arranged outside the upper part of the container 1, the condenser 30 is arranged outside the container 1, and the condenser 30 is connected to the container 1 through a pipeline 11. The connection port of the vacuum pump 10 is connected to the condenser 30 through another pipeline, and a valve 12 is provided on the pipeline 11 between the condenser 30 and the connection port of the container 1 .

[0056] Take the ivy powder aqueous solution that 125g ivy powder is dissolved in the gained ivy powder in 2L water as example, when described equipment is used, implementation step is similar to embodiment 1, and difference is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com