Patents

Literature

116results about How to "Eliminate the risk of contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

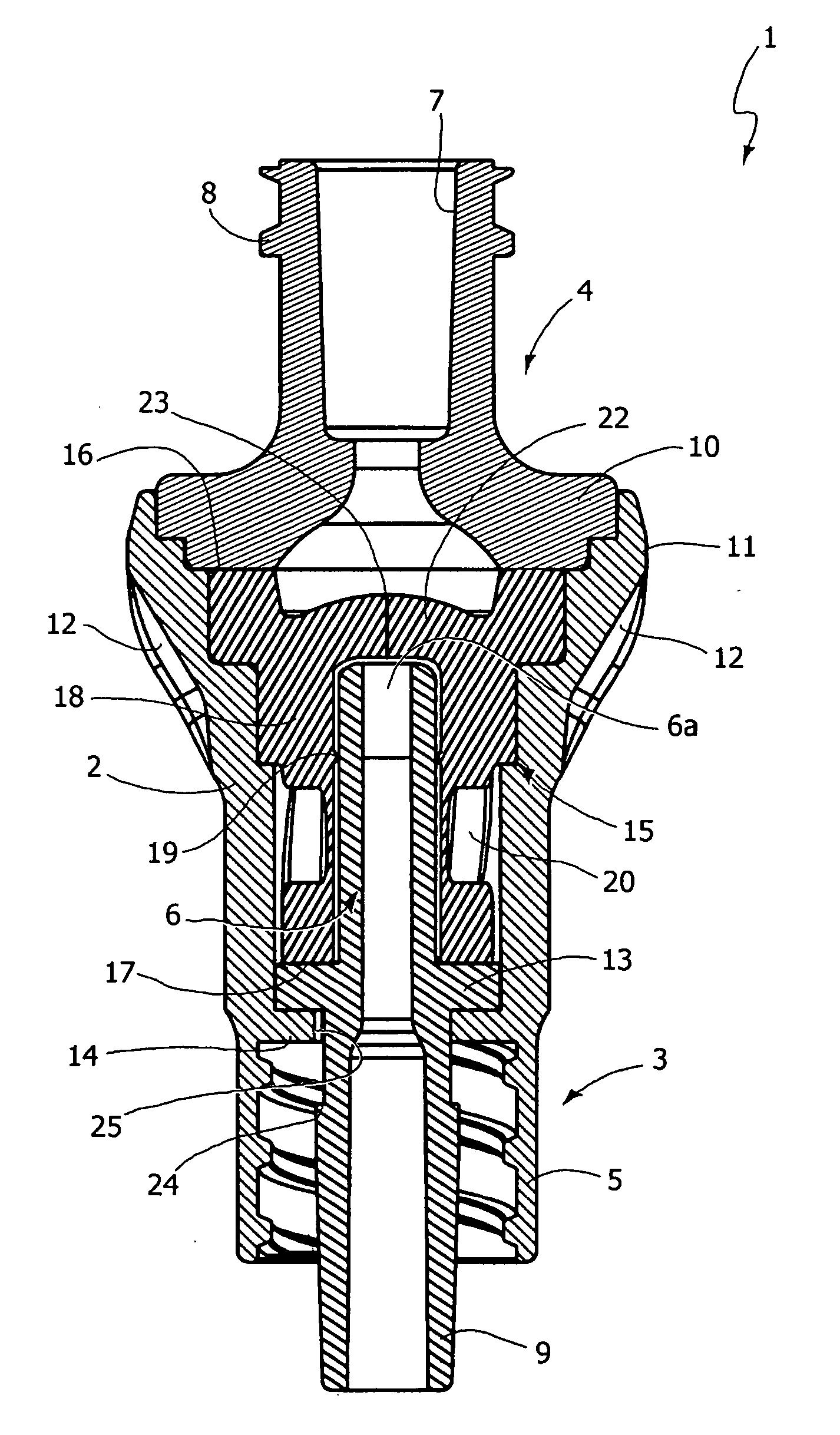

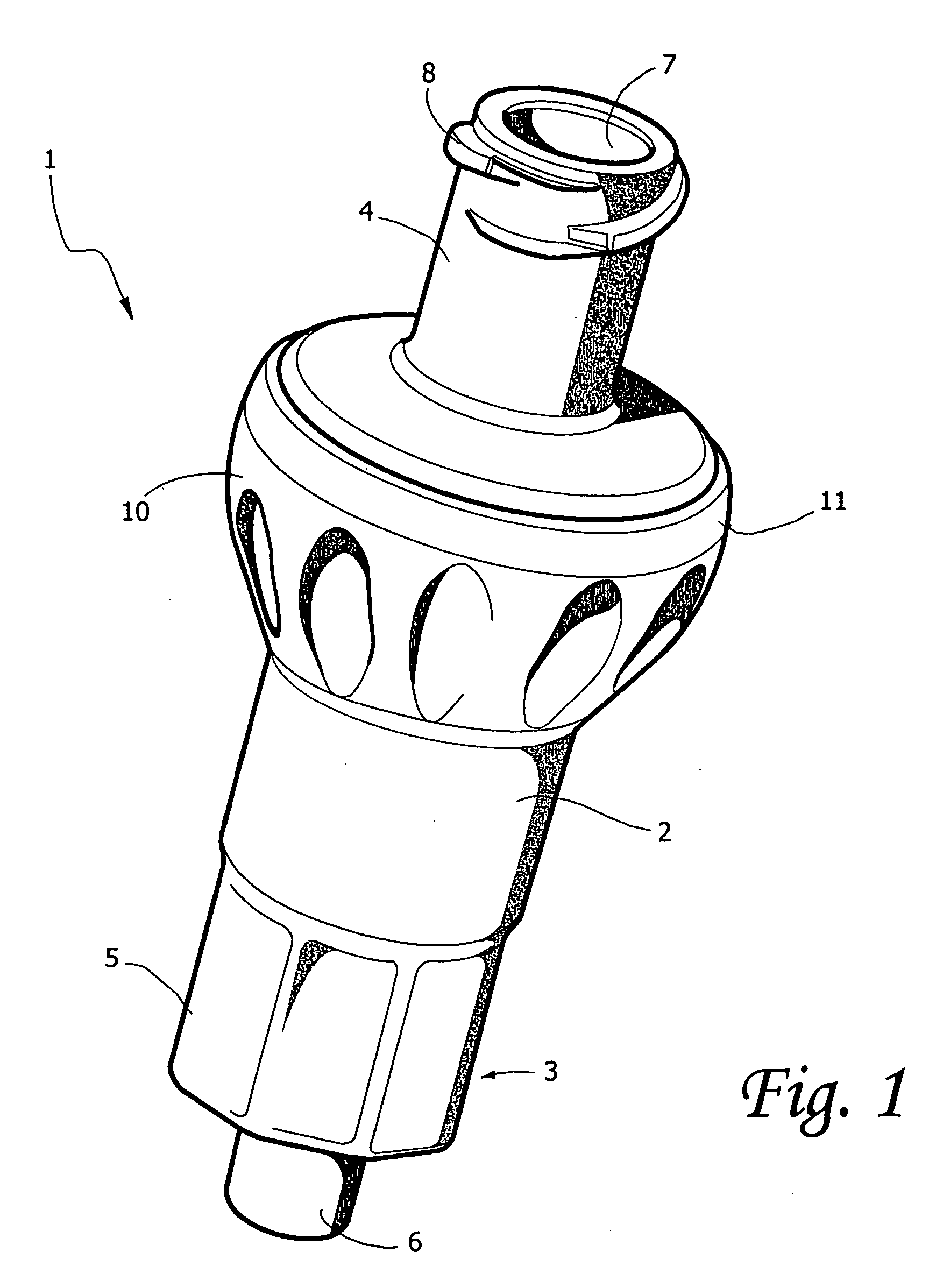

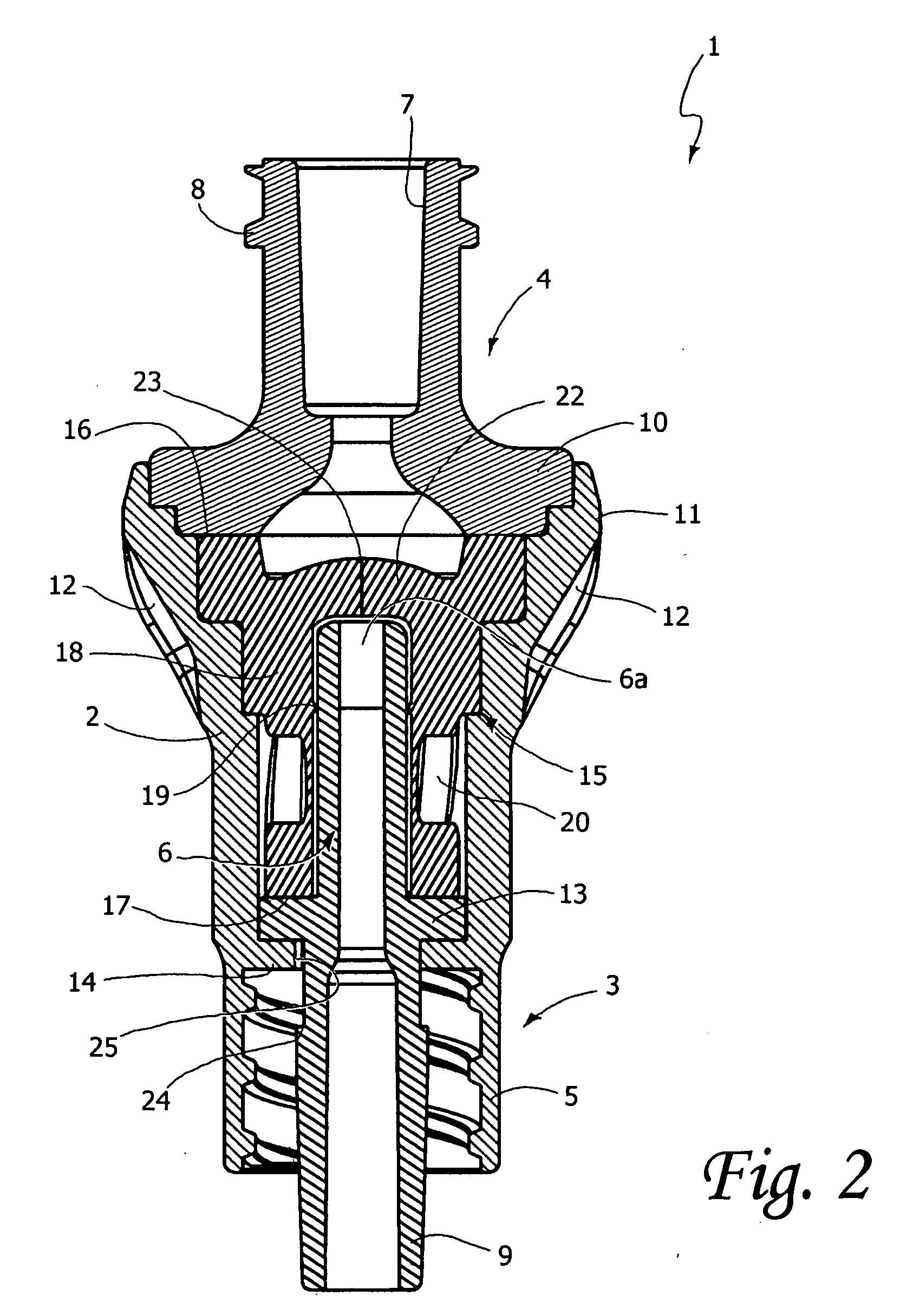

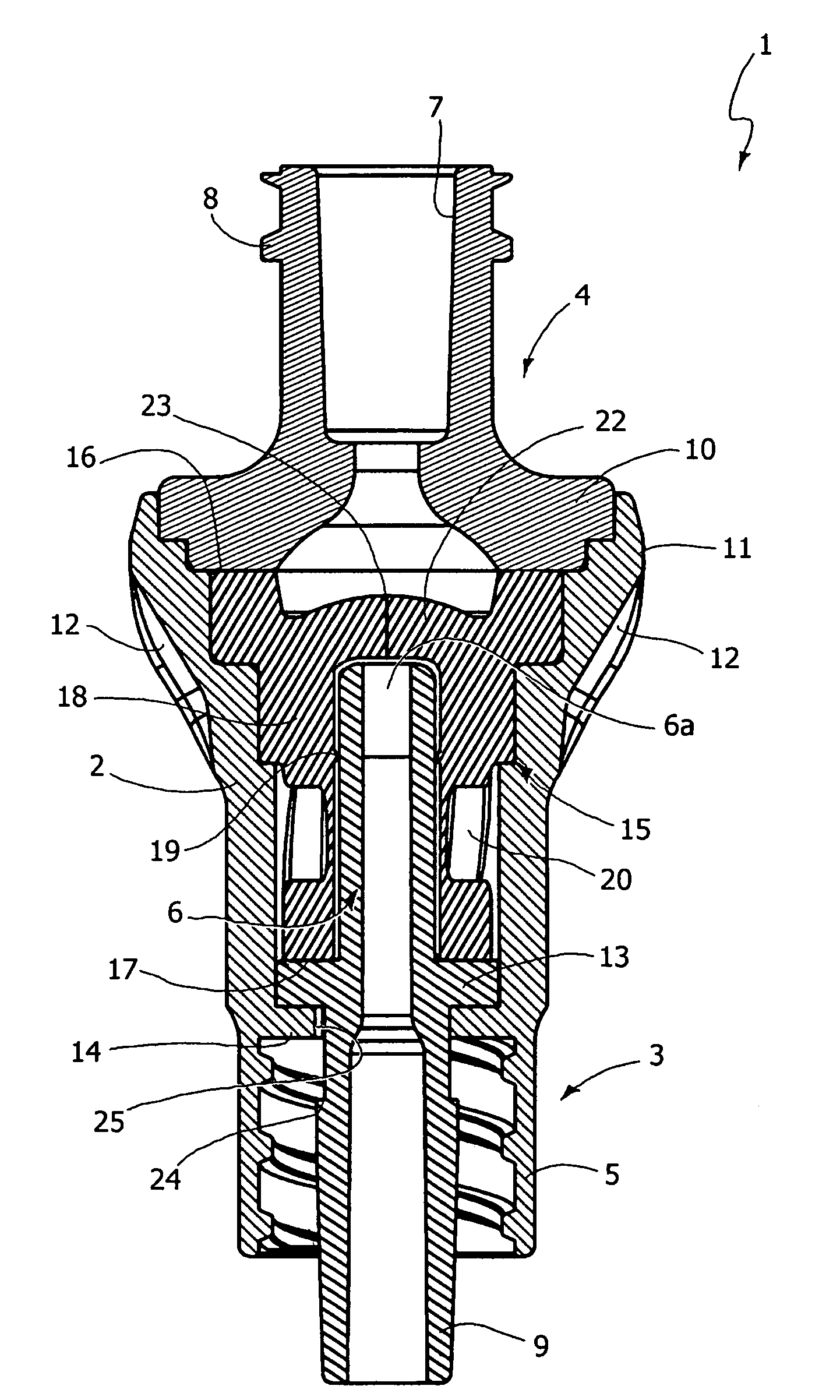

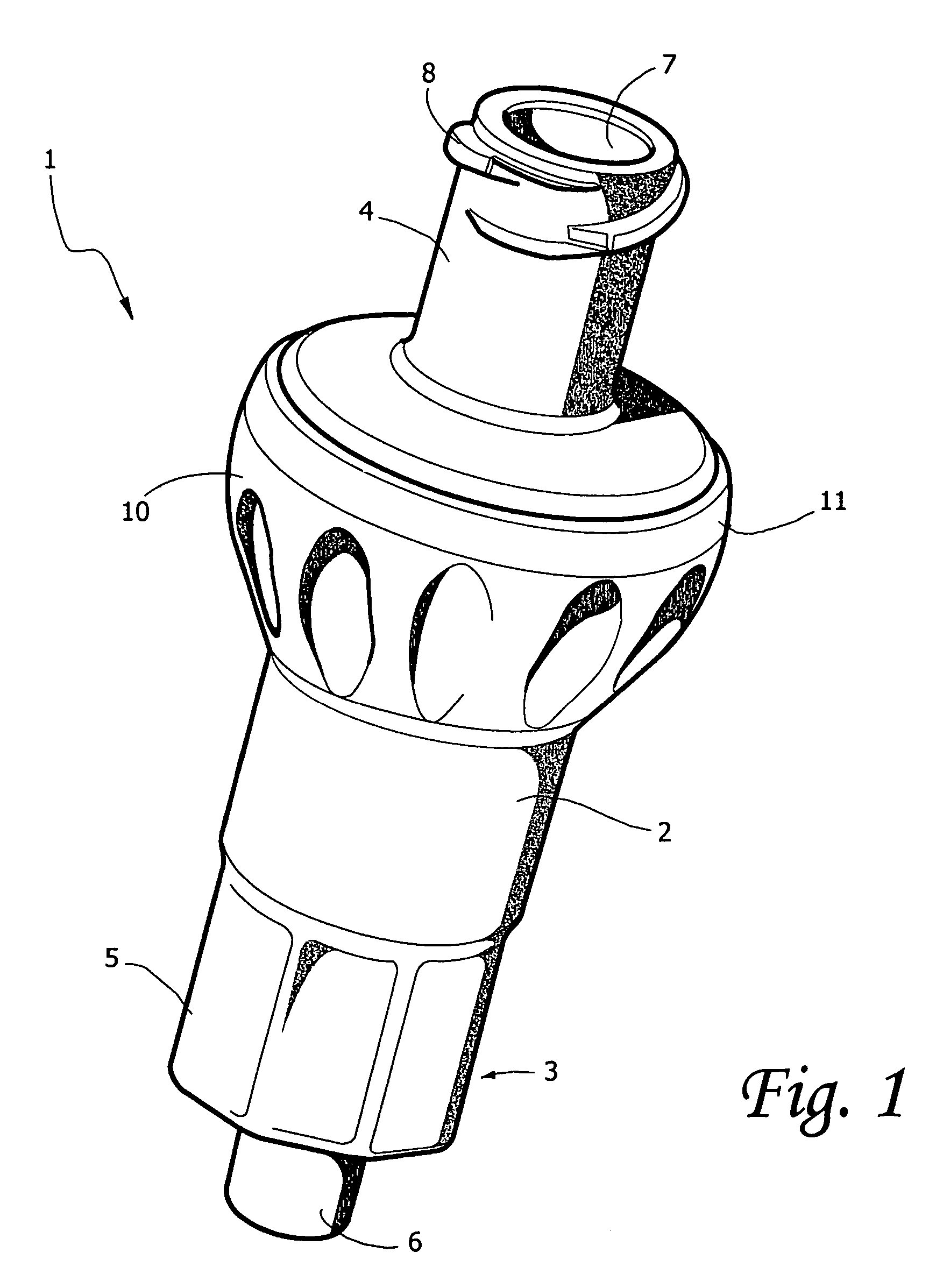

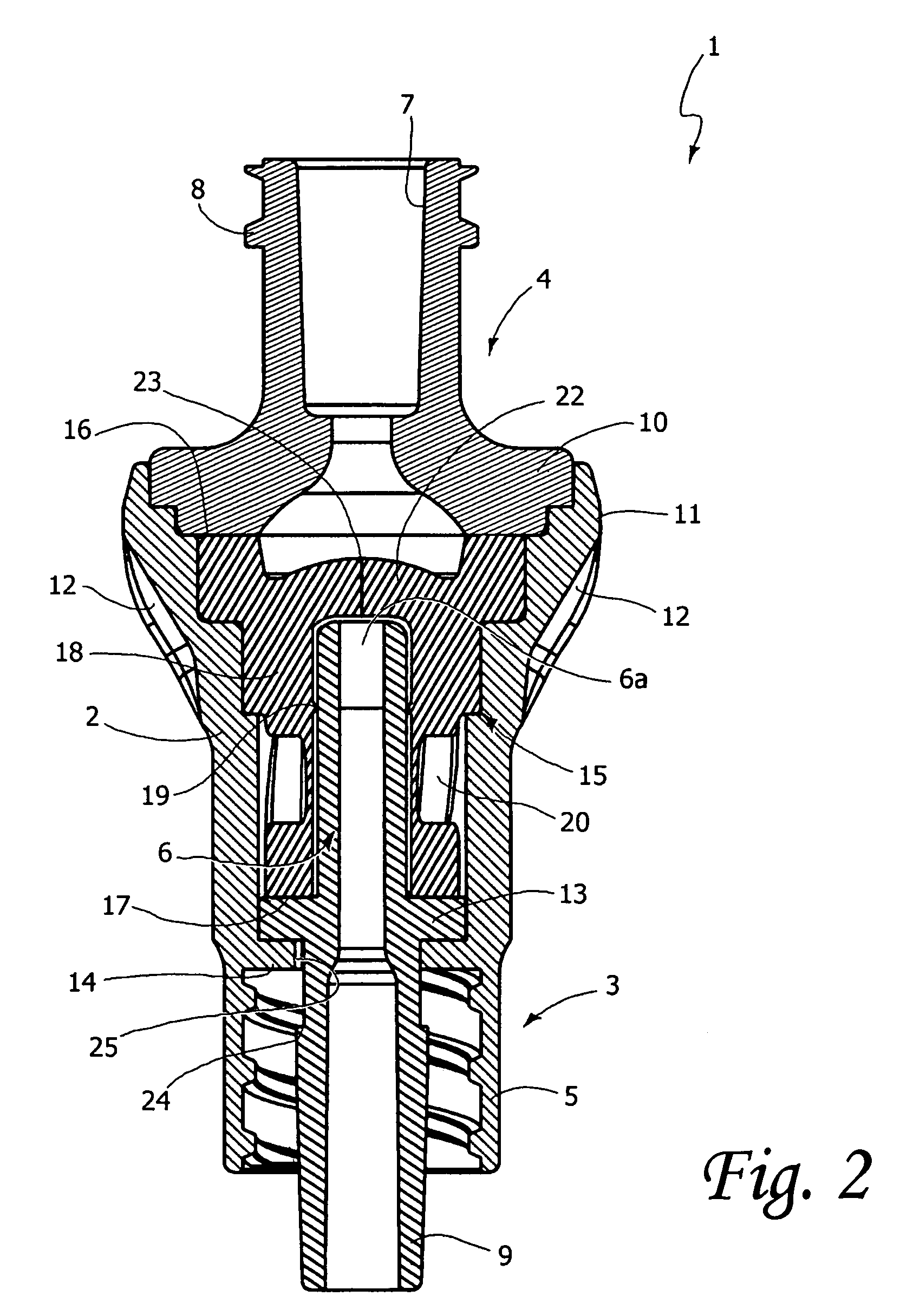

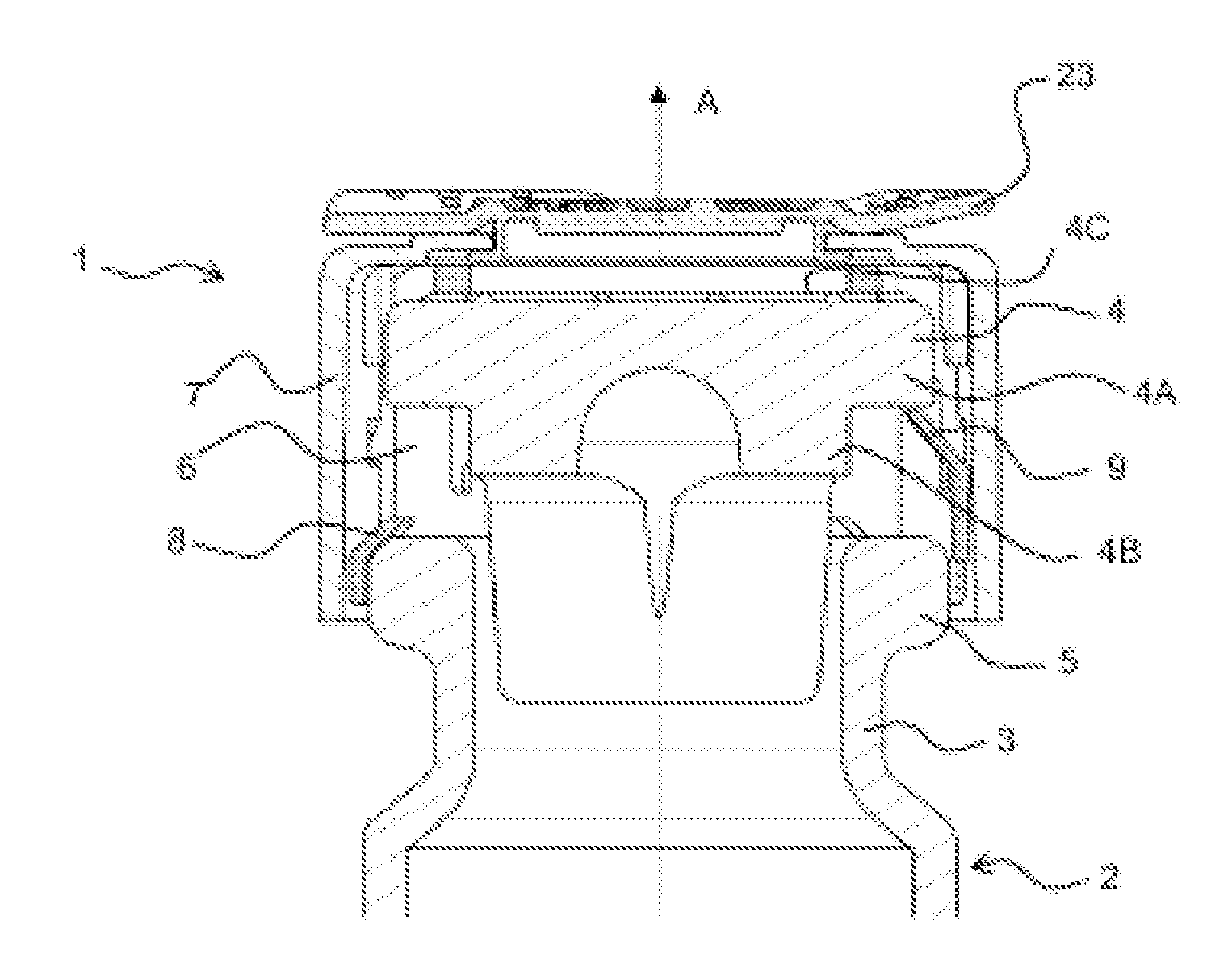

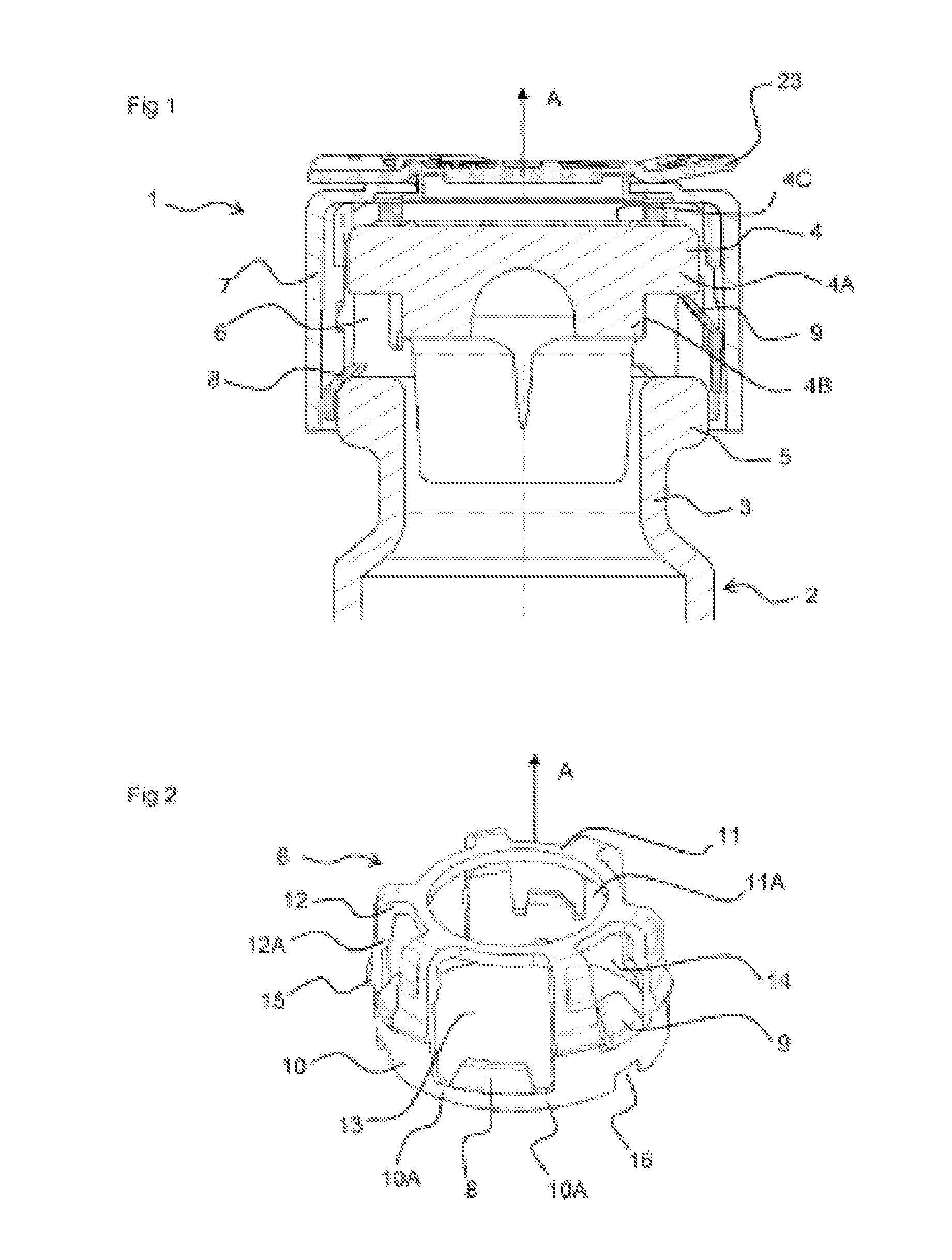

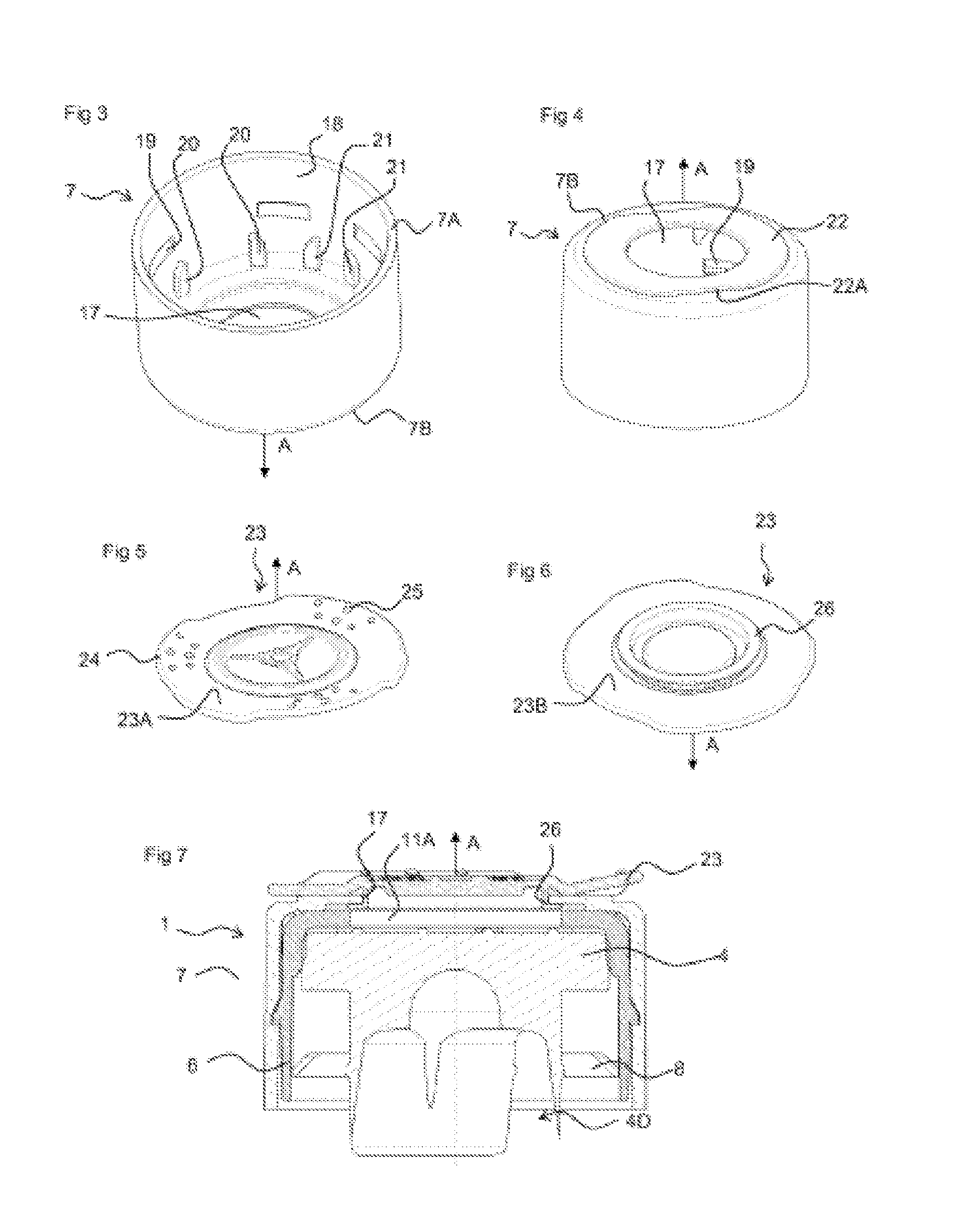

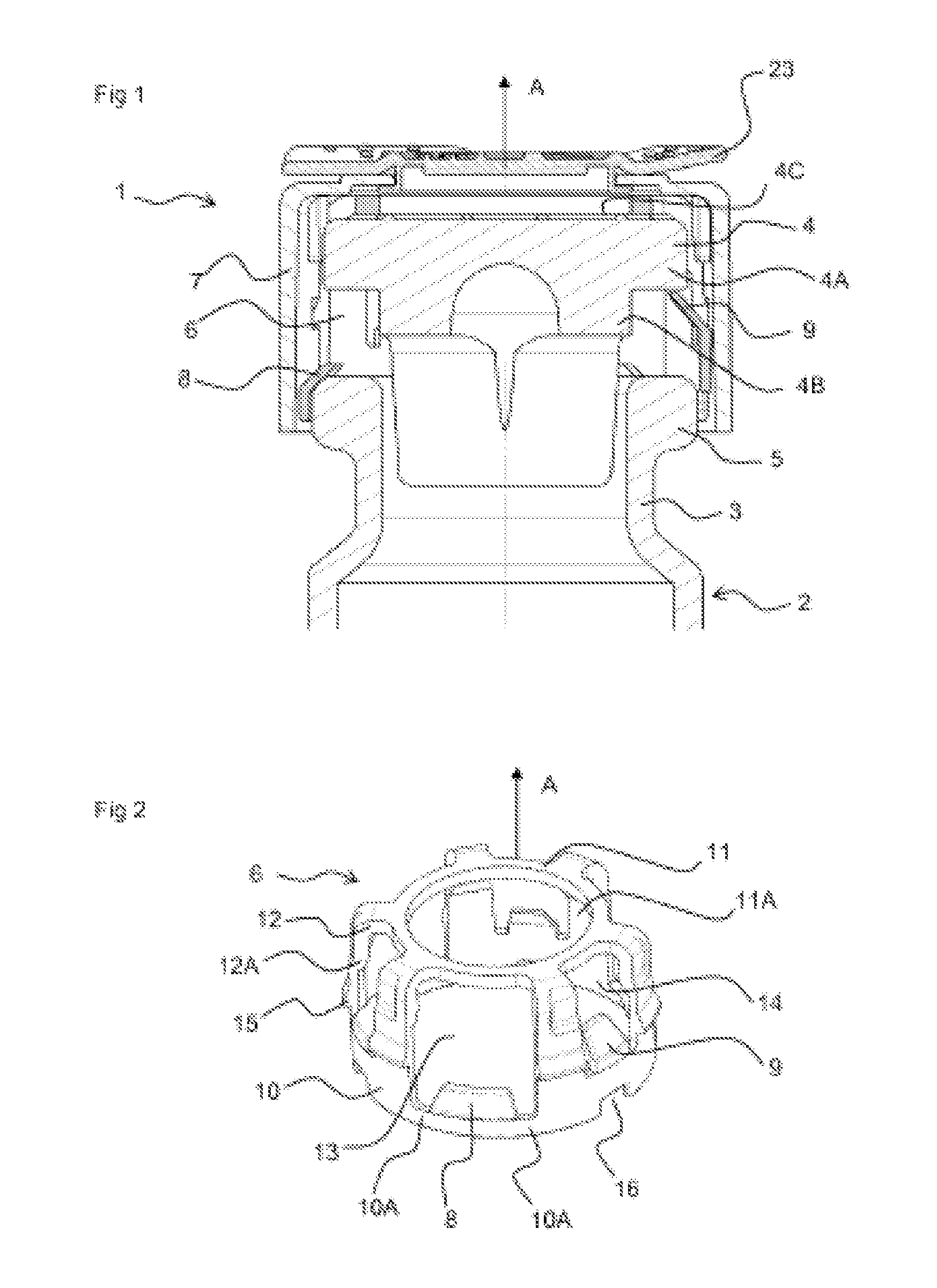

Medical valve connector

ActiveUS20070043334A1Avoid accidental separationPrevents undesirable separationCatheterIntravenous devicesEngineeringVALVE PORT

Owner:IND BORLA

Medical valve connector

ActiveUS7666170B2Eliminate the risk of contaminationAvoid separationCatheterIntravenous devicesEngineeringVALVE PORT

Owner:IND BORLA

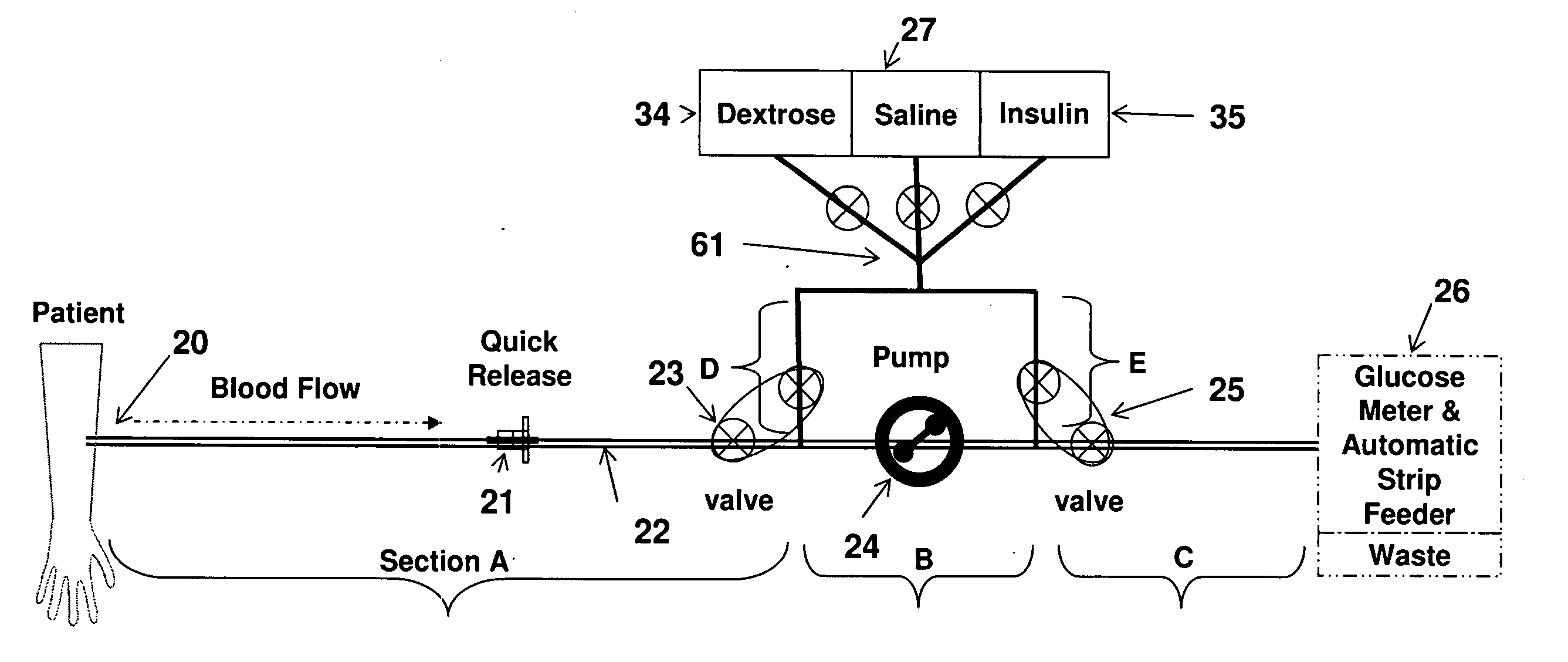

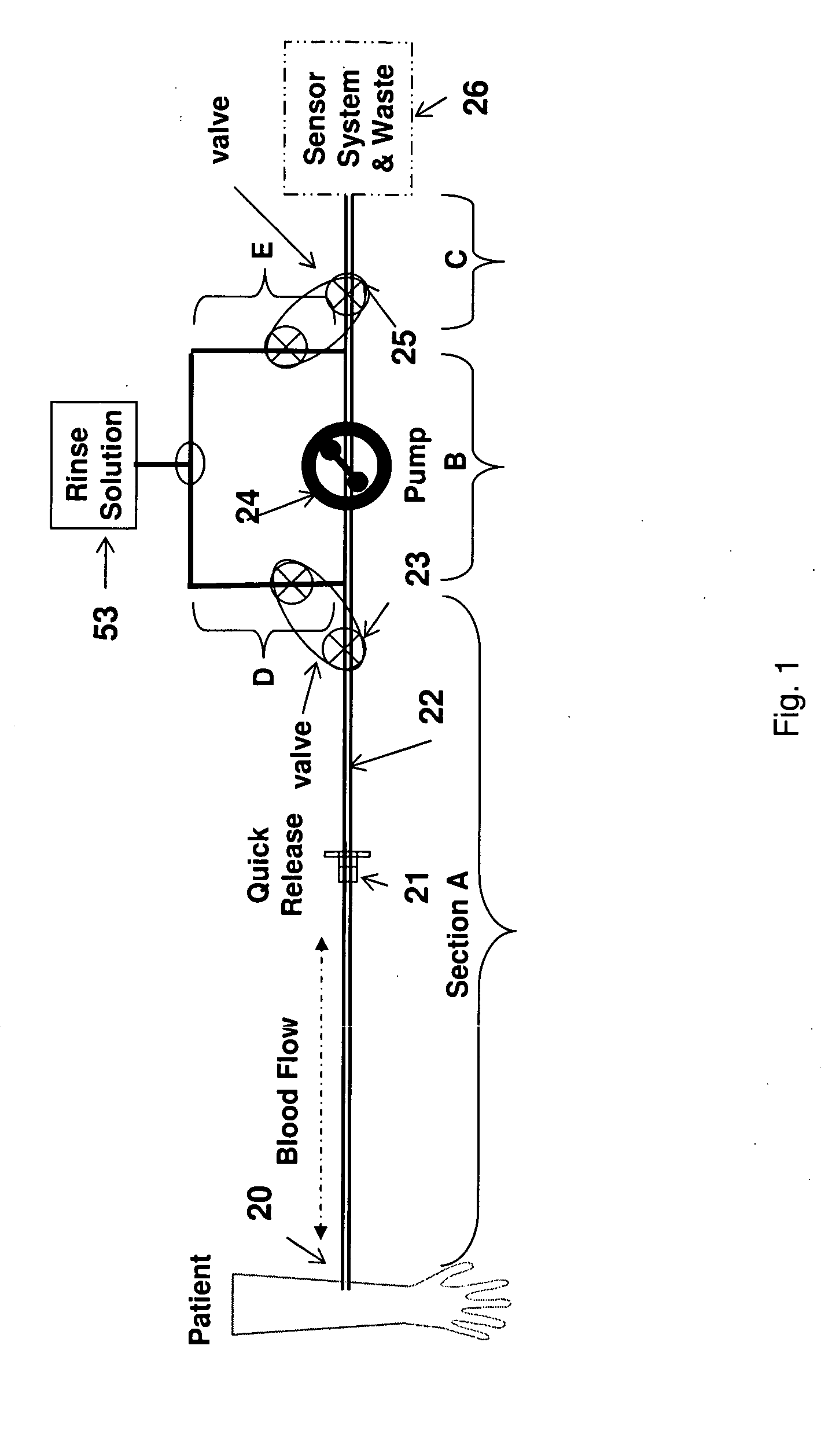

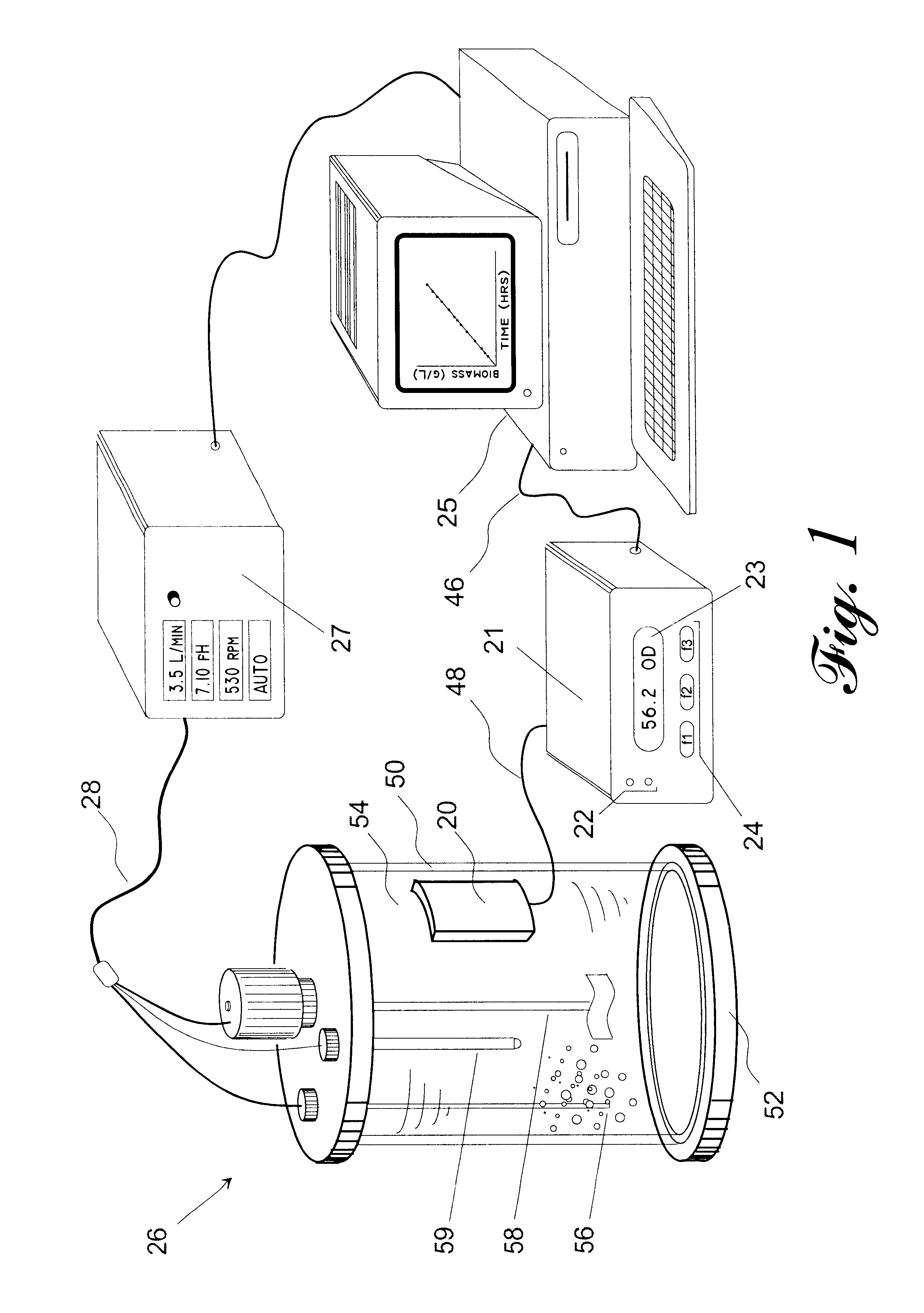

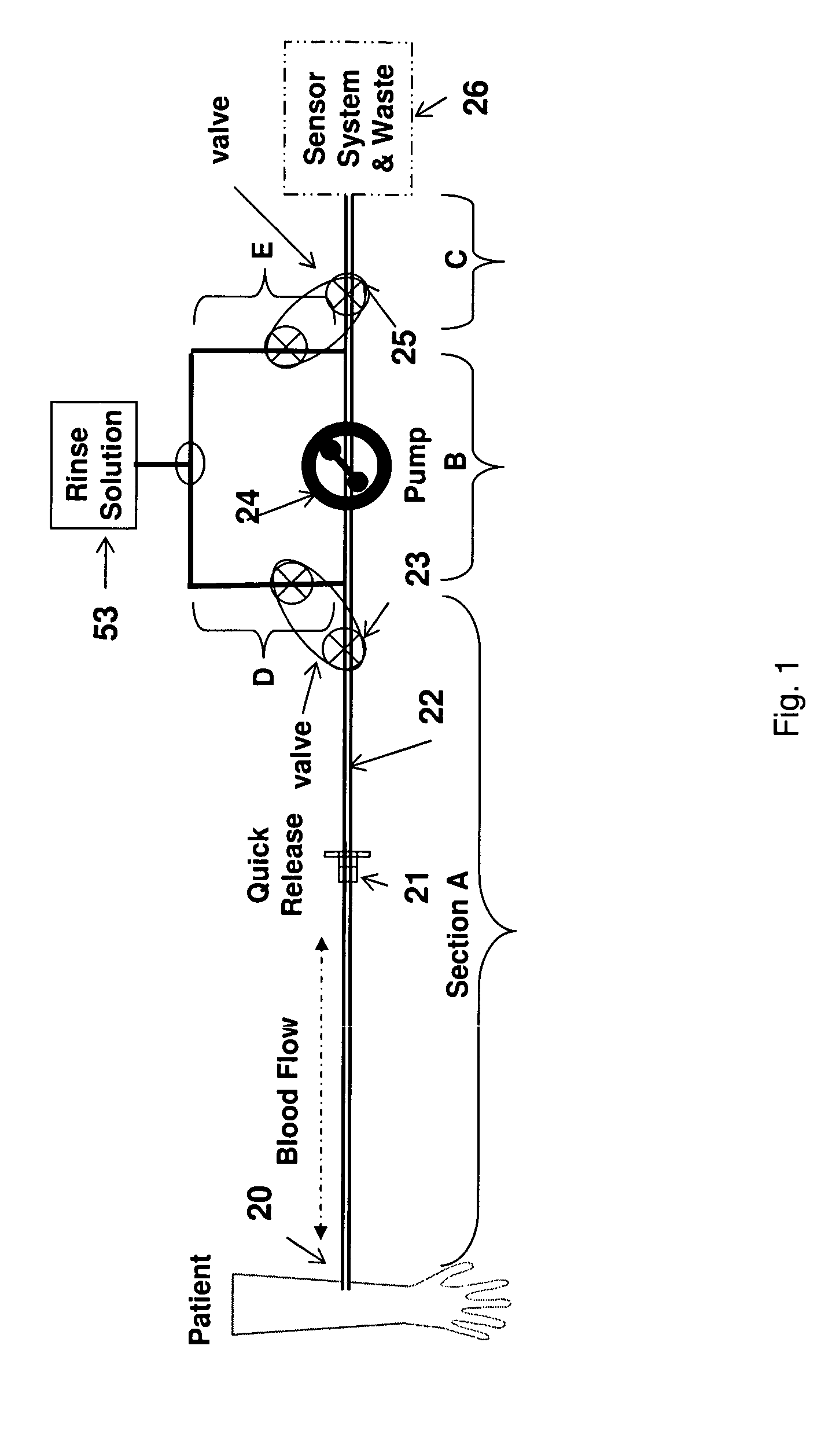

Automated Blood Sampler and Analyzer

ActiveUS20100137778A1Eliminate riskEliminate the risk of contaminationBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpVein

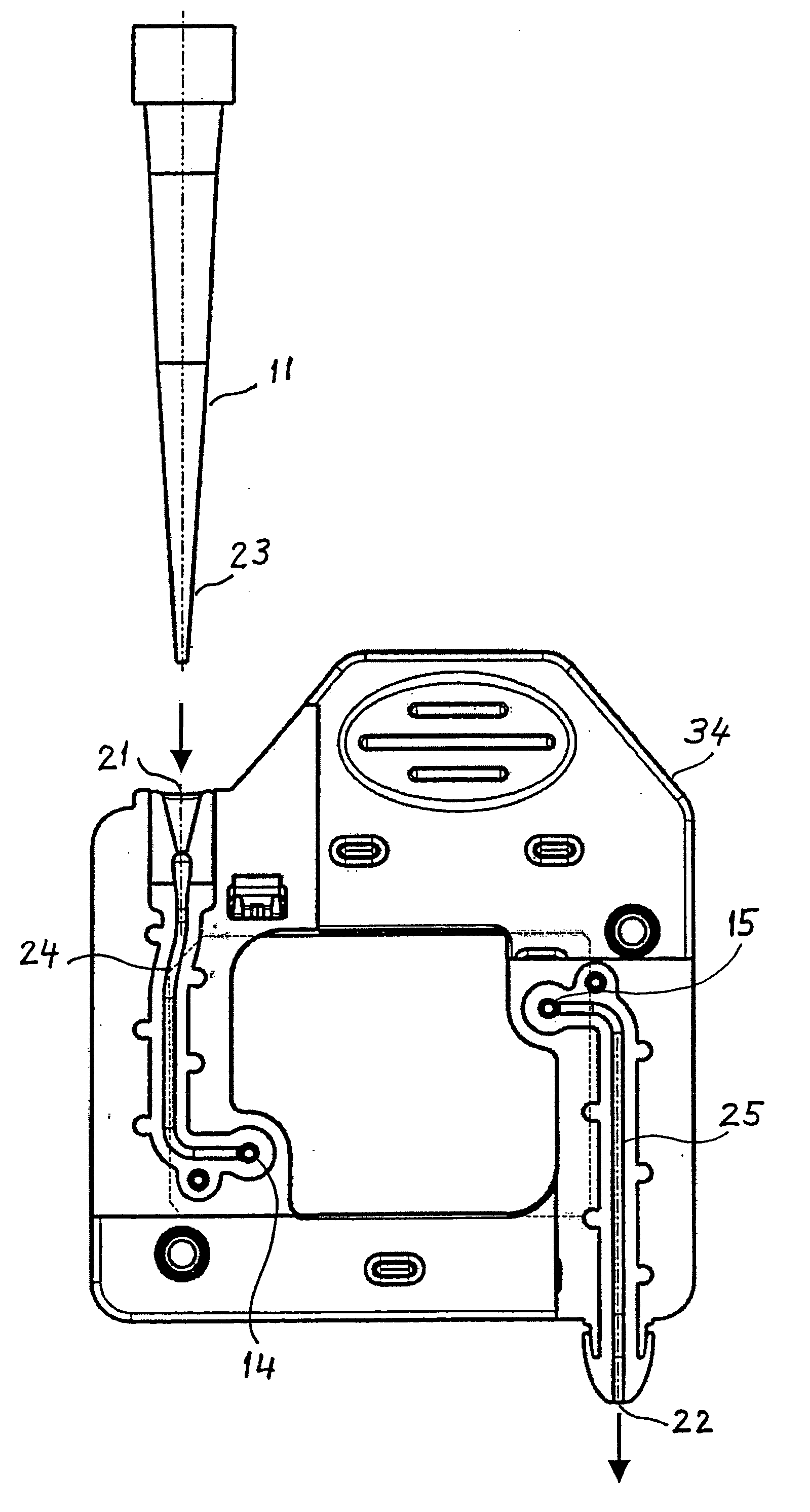

An automated blood sampler integratable with a glucose monitor comprises a catheter connected to a tube-set forming a single blood passageway; a clamp-on air-bubble sensor and a occlusion sensor externally attached to the tube set; a single peristaltic pump and two 3-way pinch valves attached to the tube set and control fluid flow. The sampler draws blood from a stationary patient, samples the blood for analytical measurement of blood parameters; after which the passageway is rinsed, the blood re-infused, and slow saline infusion prevents vein collapse. The cycle repeats at user or predefined intervals. In another preferred embodiment, blood is not re-infused, and only one 3-way pinch valve is used.

Owner:CASCADE METRIX LLC

System and cartridge for processing a biological sample

InactiveUS20040141880A1Eliminate the risk of contaminationGuaranteed uptimeMaterial analysis by observing effect on chemical indicatorChemiluminescene/bioluminescencePipetteEngineering

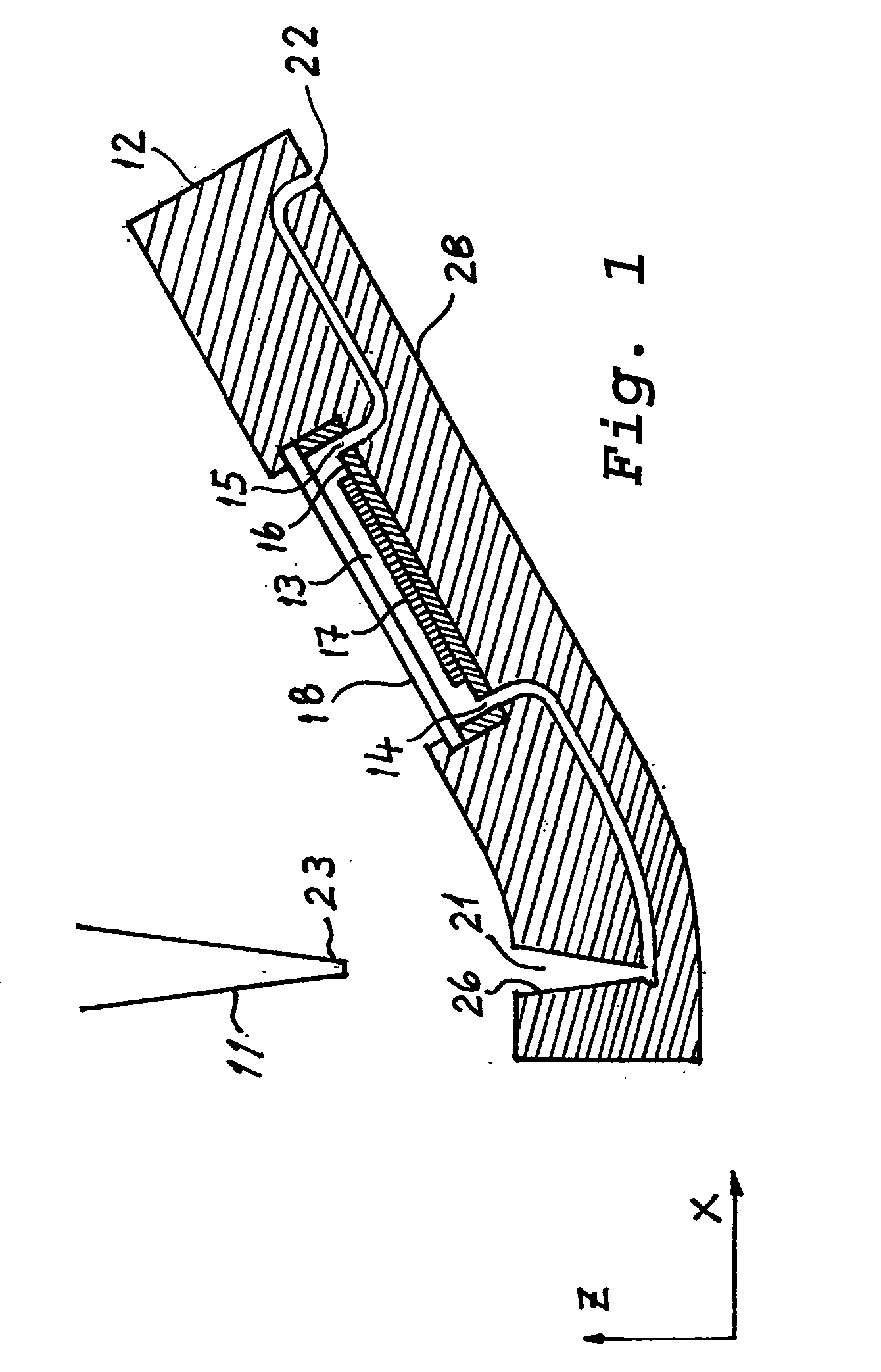

There is disclosed a sample processing system for processing a sample contained in a liquid. Specifically, there is disclosed a sample processing system comprising a pipettor, and a cartridge. The cartridge comprises a chamber which has an inlet and an outlet. The chamber contains a microarray device having an active surface. The active surface is accessible to liquid contained in the chamber. The cartridge further comprises an optical interface that provides optical access to the active surface of the microarray device, an inlet port and an outlet port. The inlet port is so configured and dimensioned that it forms an air-tight connection with a pipette tip when the pipette tip is inserted into the inlet port.

Owner:COMBIMATRIX CORP

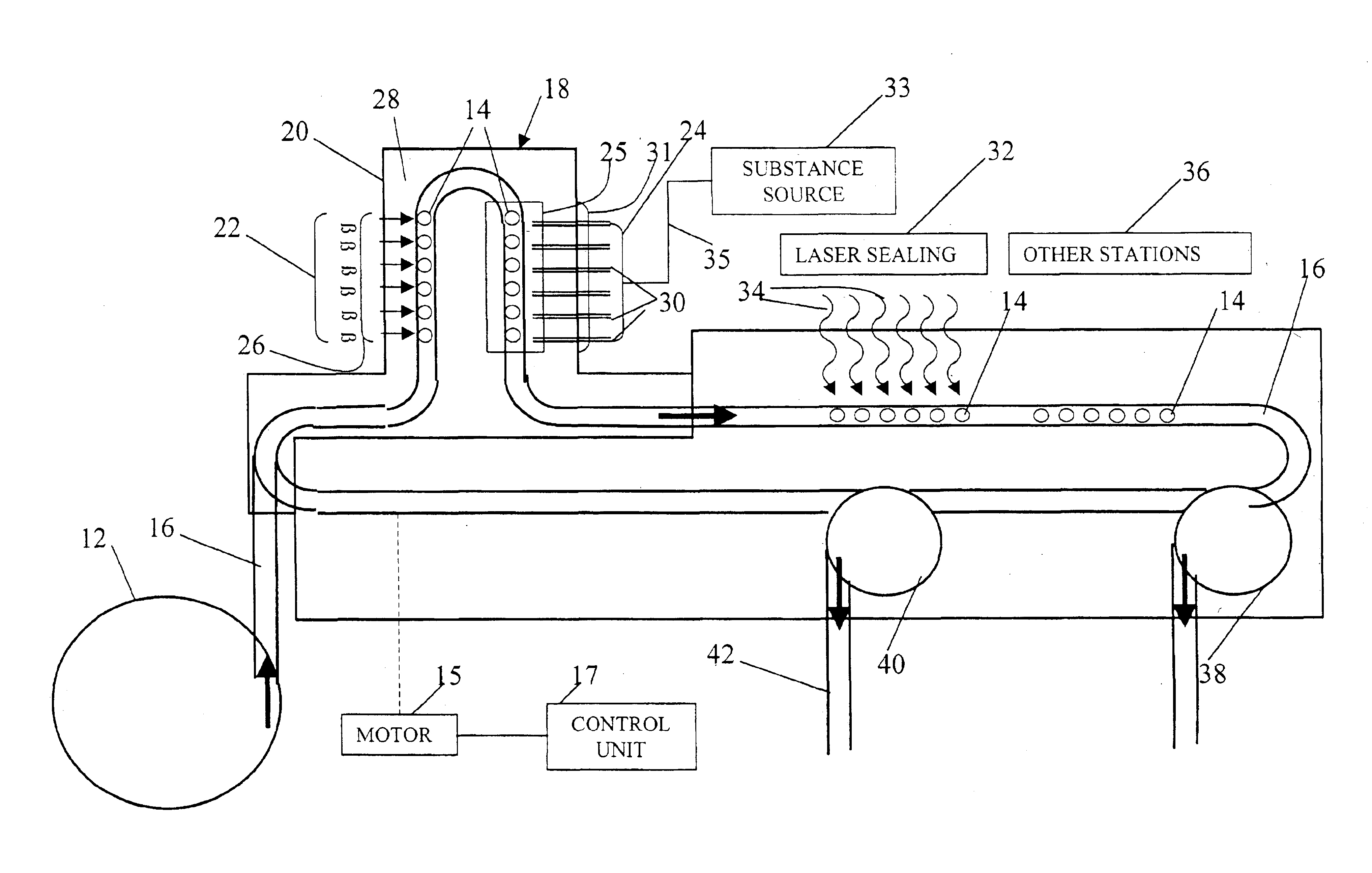

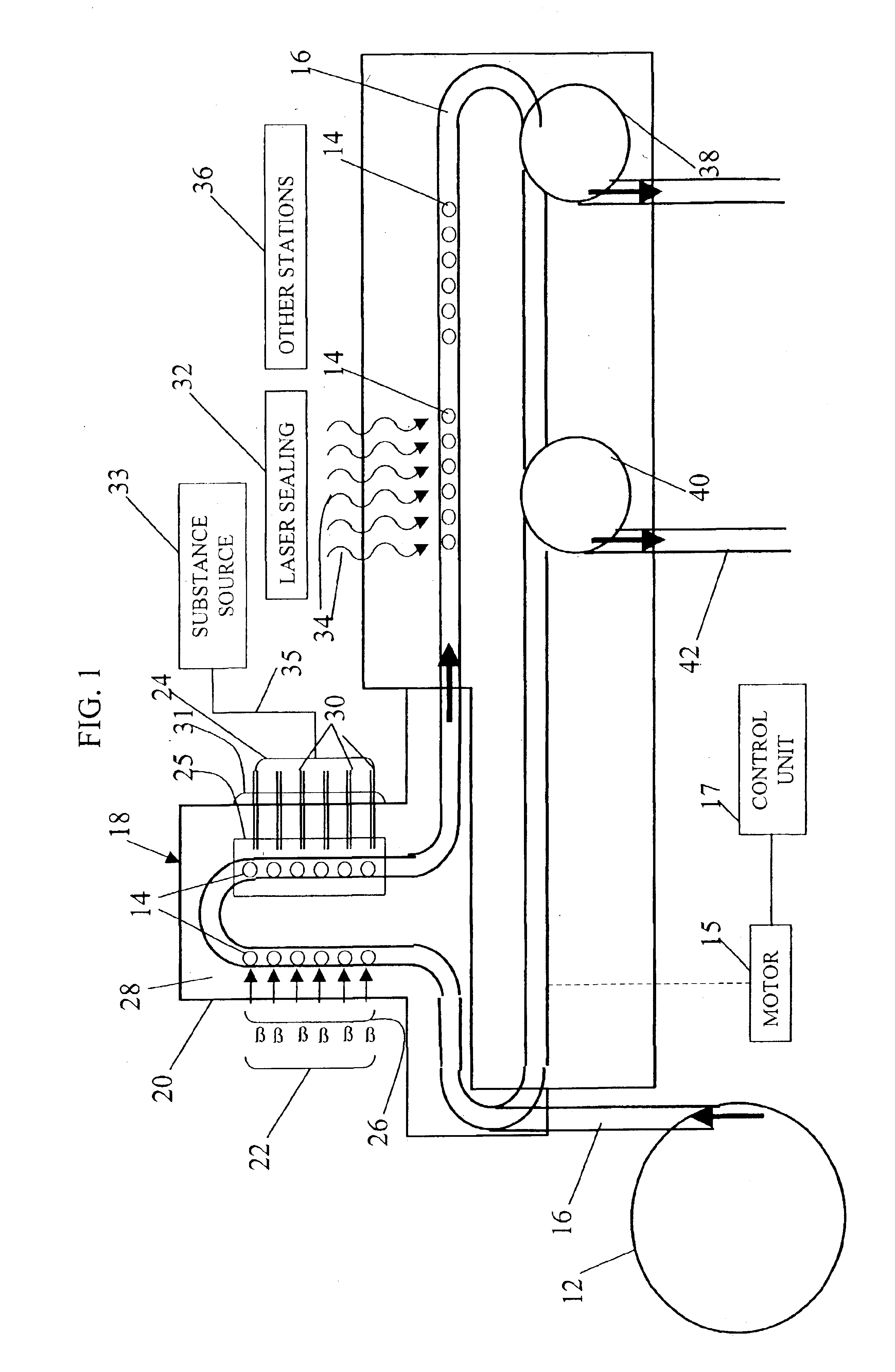

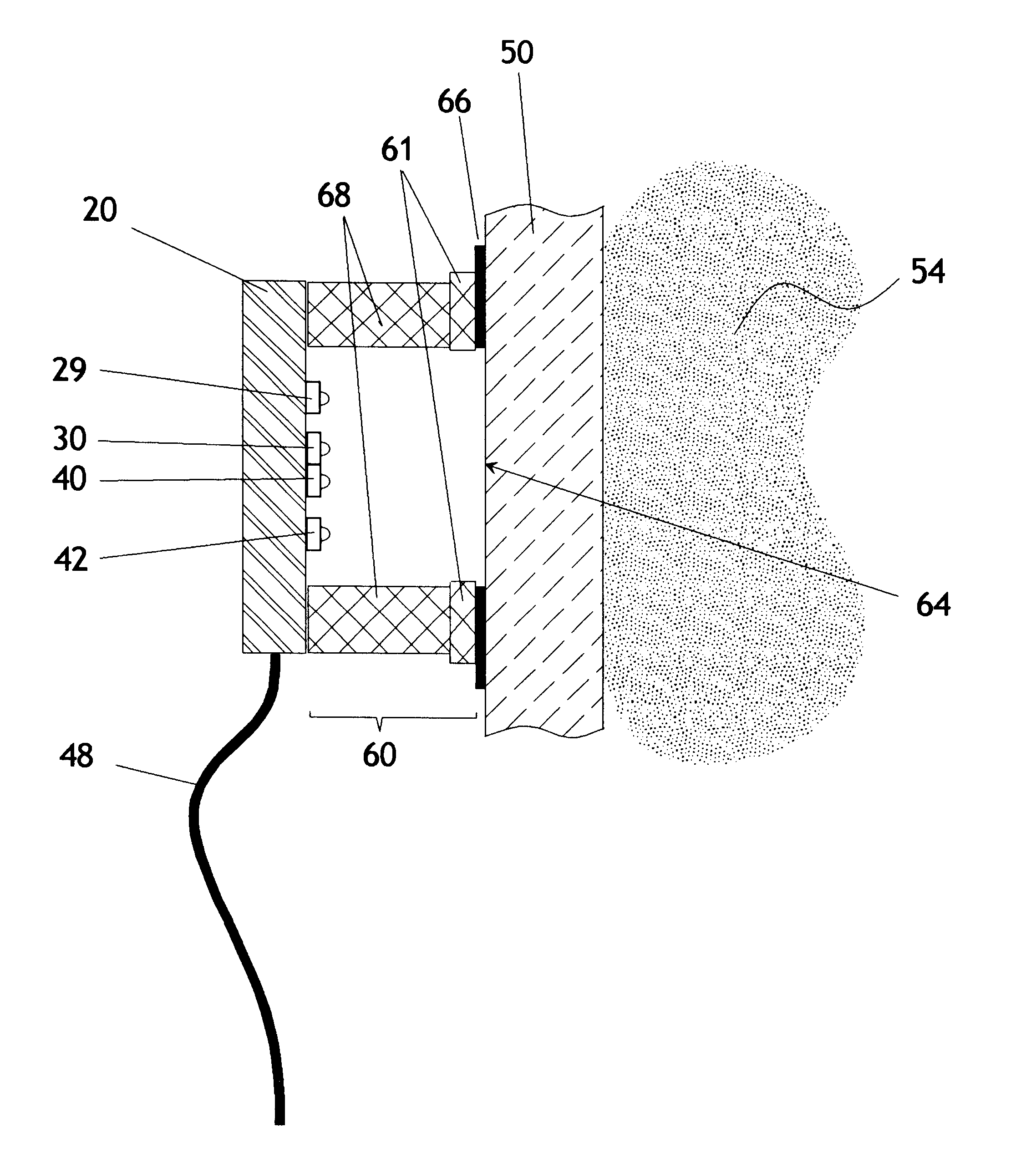

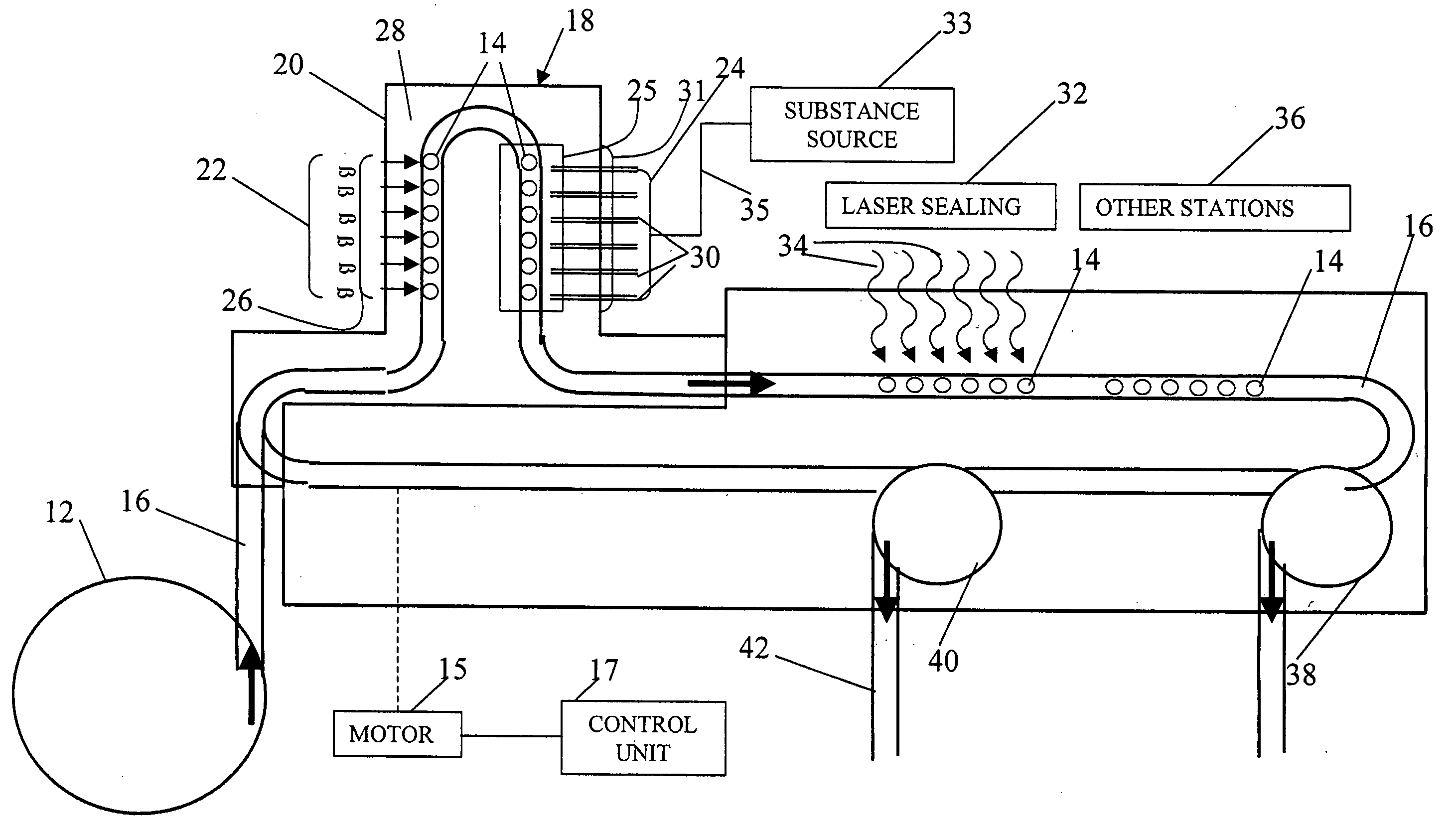

Sterile filling machine having needle filling station within e-beam chamber

InactiveUS6929040B2Obstruct passageEliminate the risk of contaminationLiquid fillingPackage sterilisationEngineeringSyringe needle

A sterile filling machine and related method are provided for sterile filling a container with a substance. The container includes a heat resealable stopper and a chamber for receiving the substance therein. The sealed, empty containers are subjected to radiation capable of penetrating through the stopper and chamber for sterilizing the container. The previously sterilized containers are then transported through an e-beam chamber, wherein an electron beam is directed onto a penetrable surface of the stopper to sterilize the penetrable surface. A needle is mounted within the e-beam chamber and moved into engagement with the stopper to pierce the sterilized penetrable surface of the stopper and inject the substance through the needle and into the chamber of the container. The needle is then withdrawn from the stopper and the filled container is transported outside of the e-beam chamber. Laser energy is then transmitted onto the penetrated surface of the stopper to fuse the stopper material and hermetically re-seal the stopper.

Owner:MEDINSTILL DEV

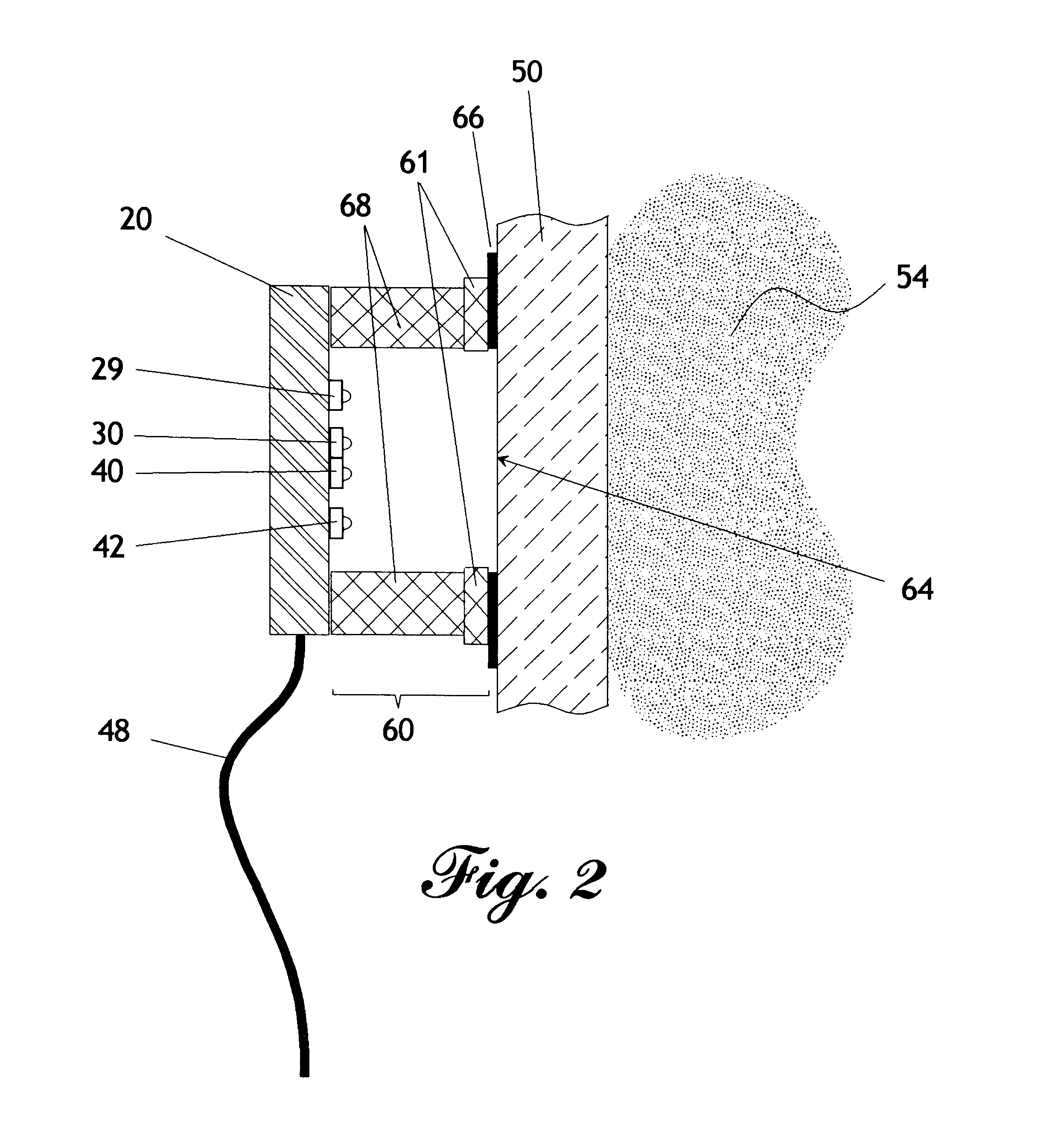

Self-compensating radiation sensor with wide dynamic range

InactiveUS6573991B1Improve accuracyEliminate needMaterial analysis by optical meansParticle size analysisLiquid cellRadiation sensor

A radiation sensing method and device that is used to measure physical properties of materials over a wide dynamic range. The sensor (20) comprises multiple radiation sources and multiple detectors at multiple separation distances. The detected signals from the different sources are separated and then combined mathematically in a manner such that the combination is self-compensated for both component drift and changes in radiation coupling efficiency between the source or detector and the material of interest. In a preferred embodiment, the biomass in a liquid cell culture (54) is measured with high accuracy over a wide dynamic range using optical wavelength radiation. The measurement can be made with the sensor external to the liquid culture container in a manner that is compensated for the thickness of the container window (50).

Owner:DEBRECZENY MARTIN PAUL +2

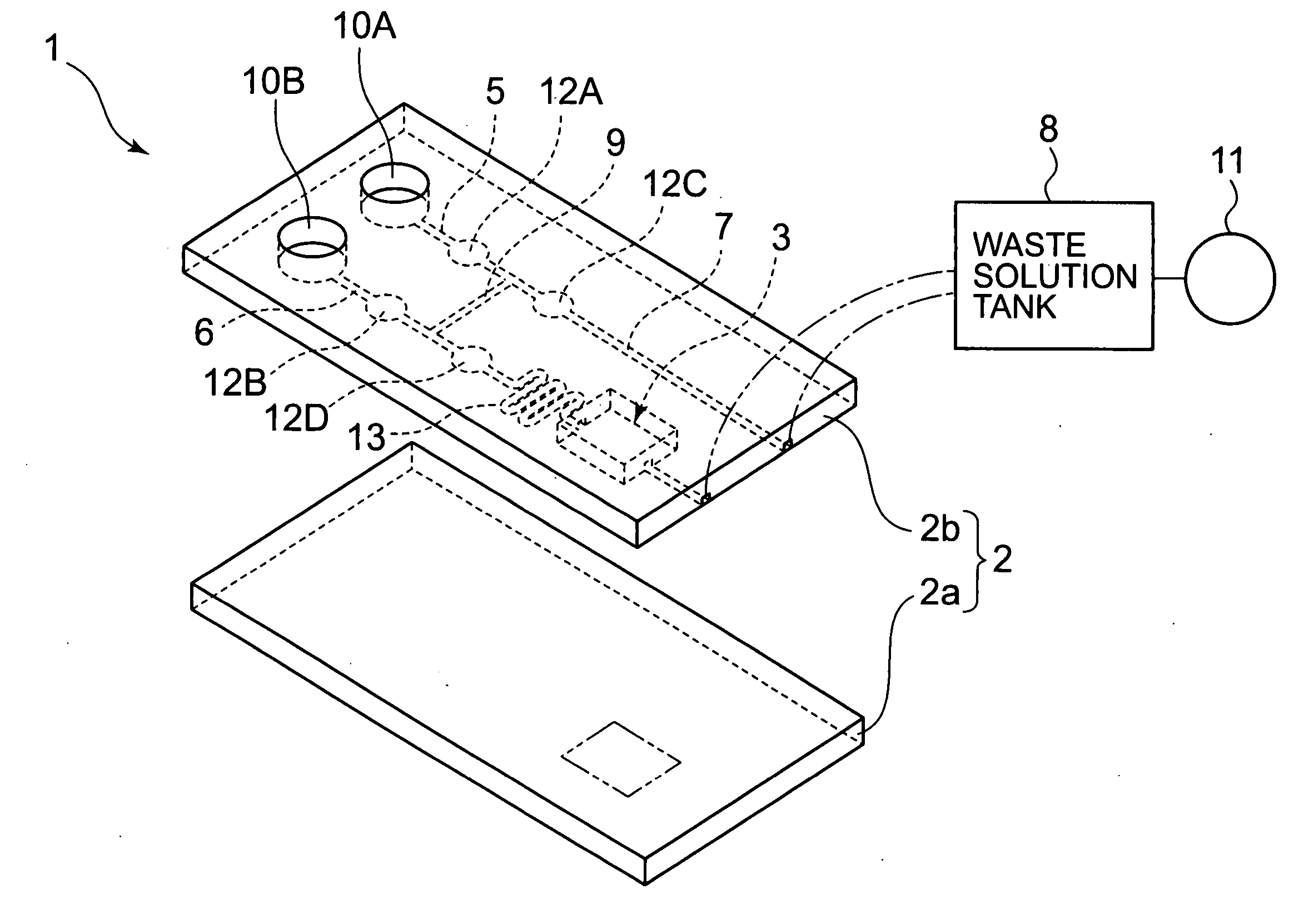

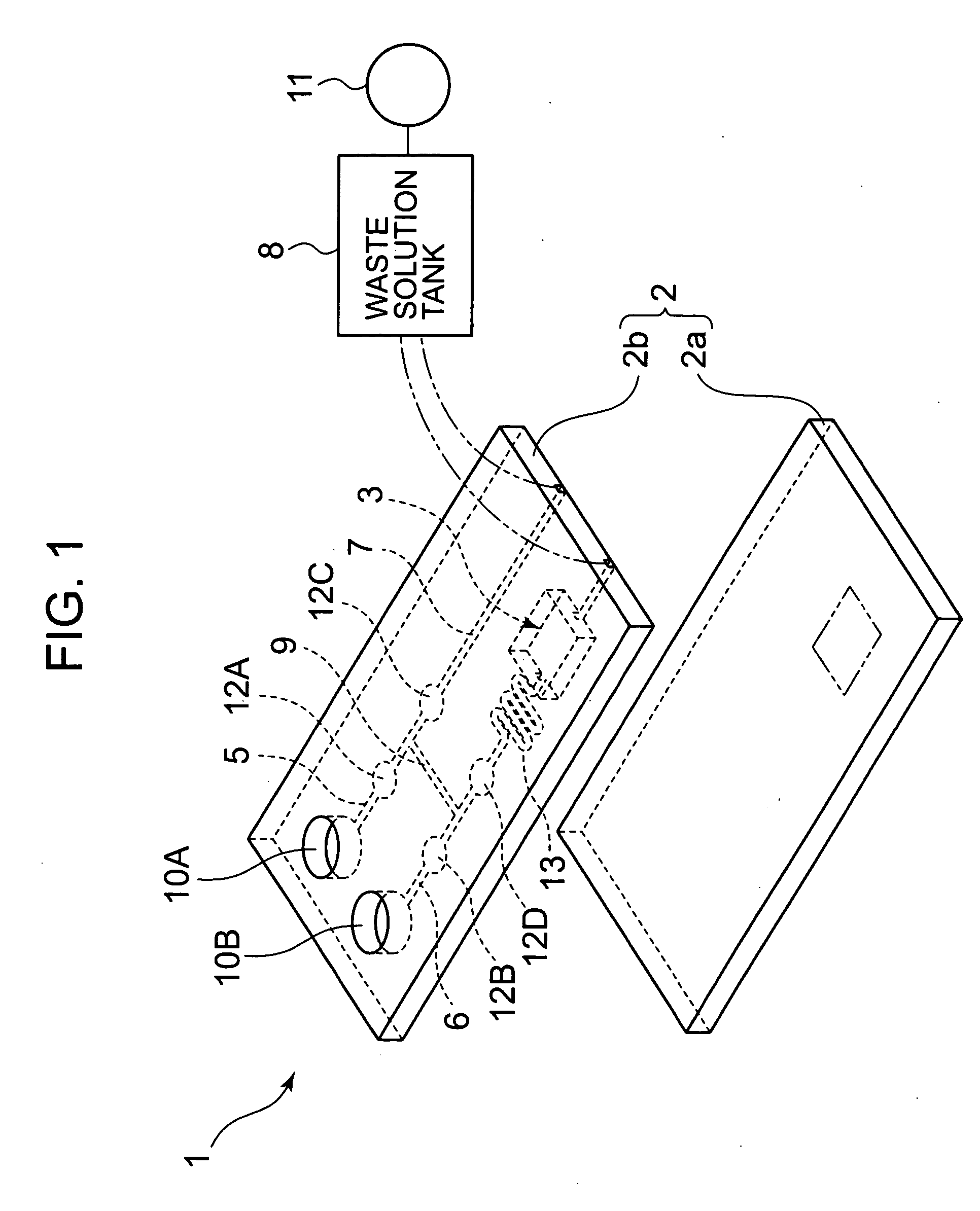

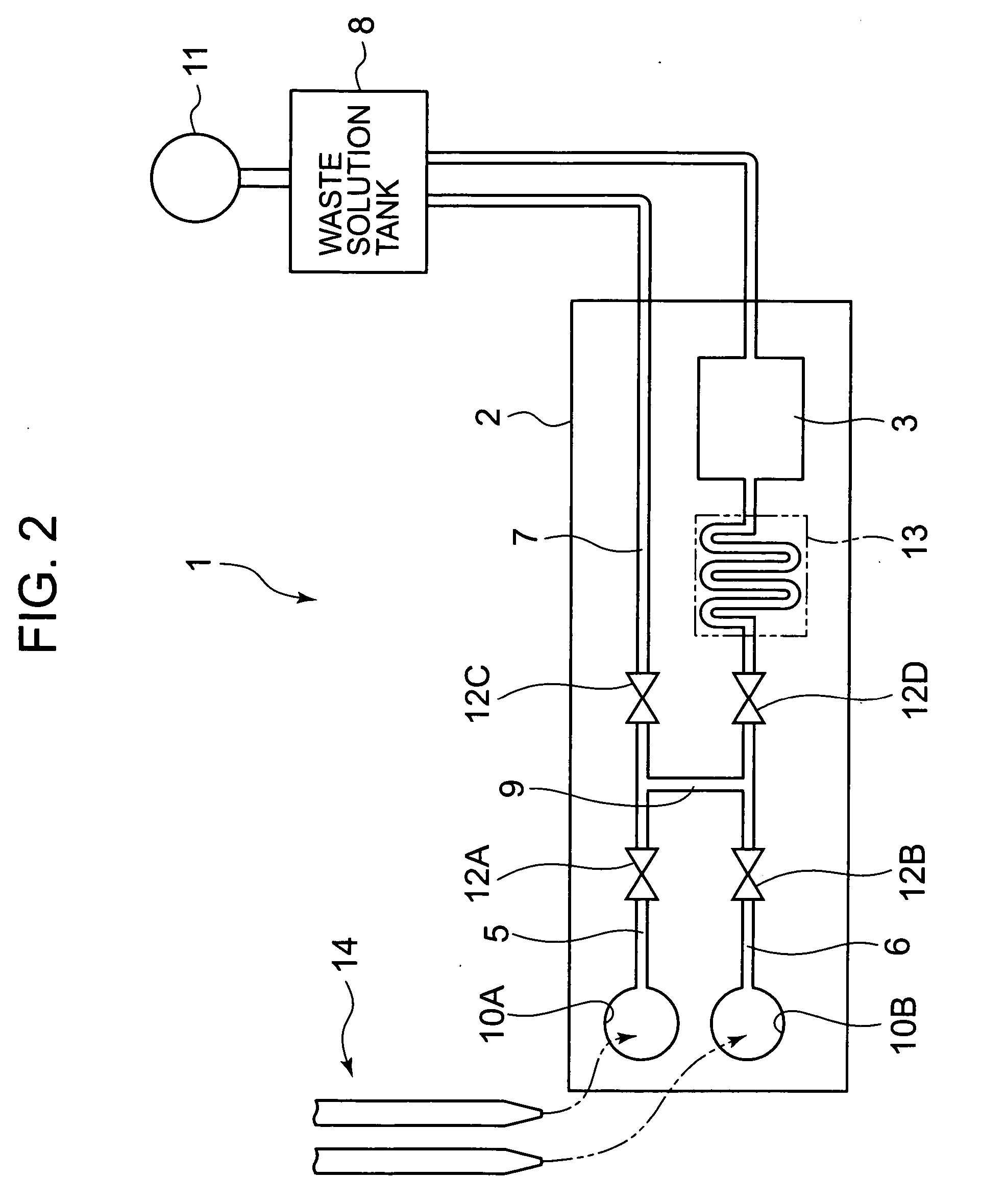

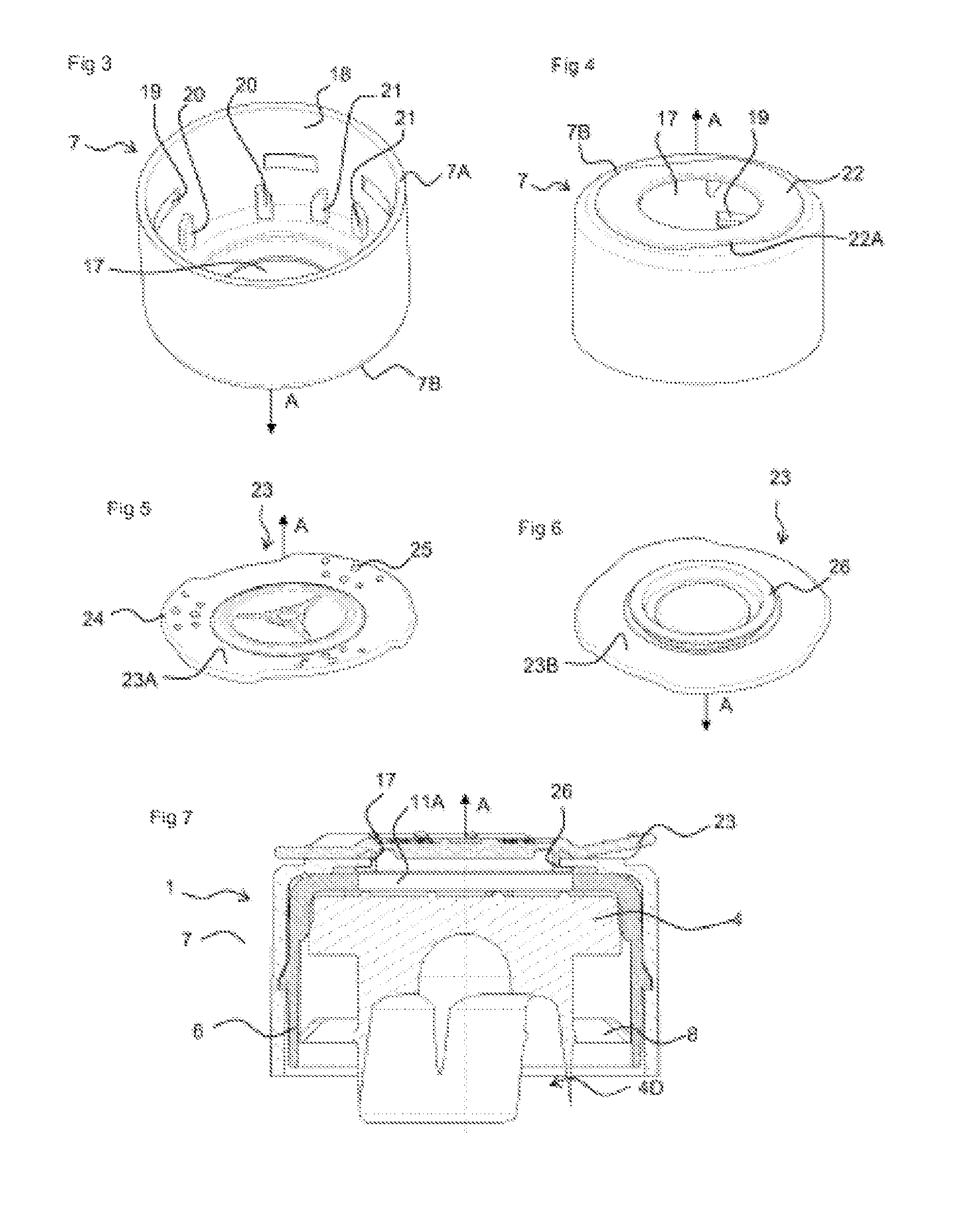

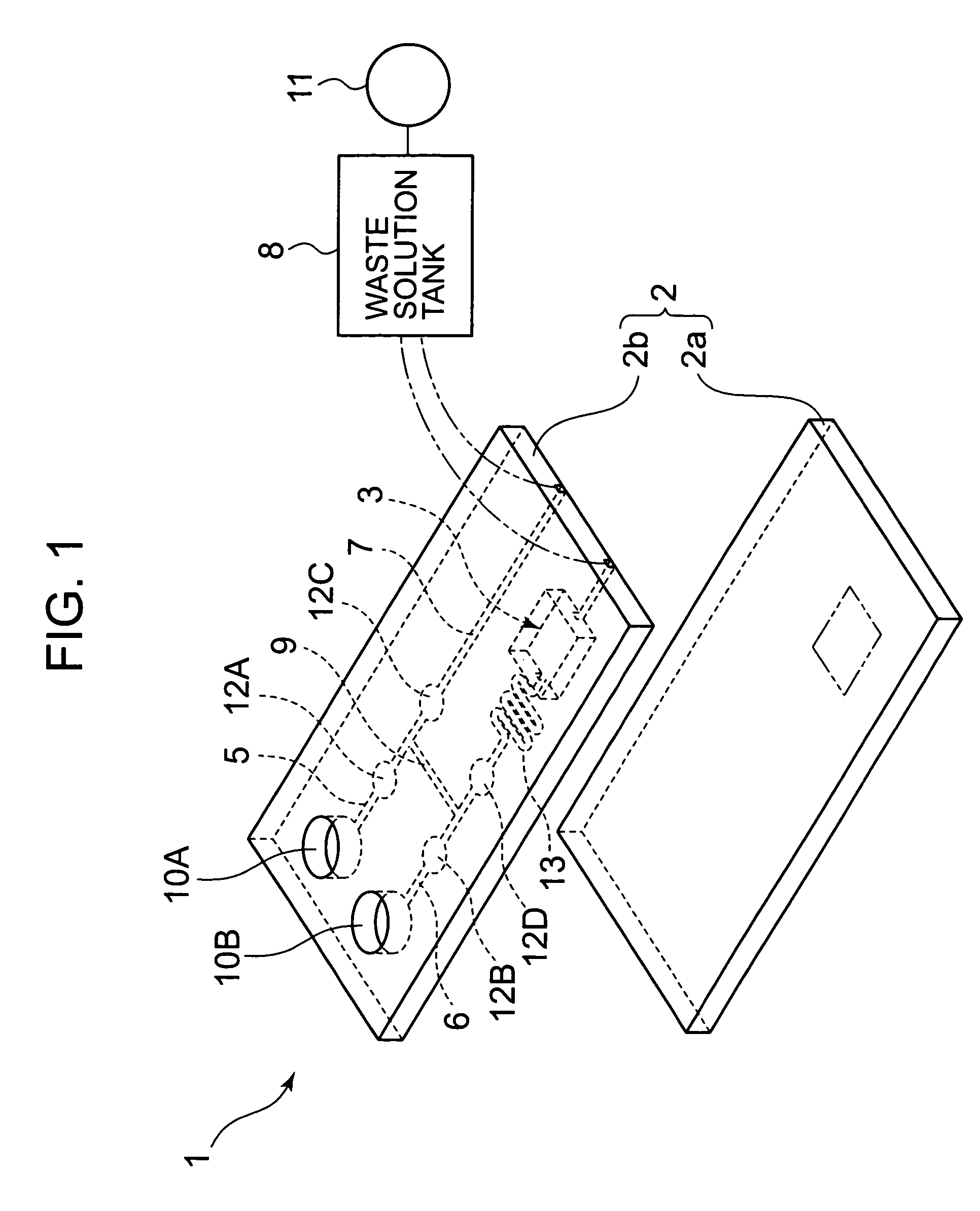

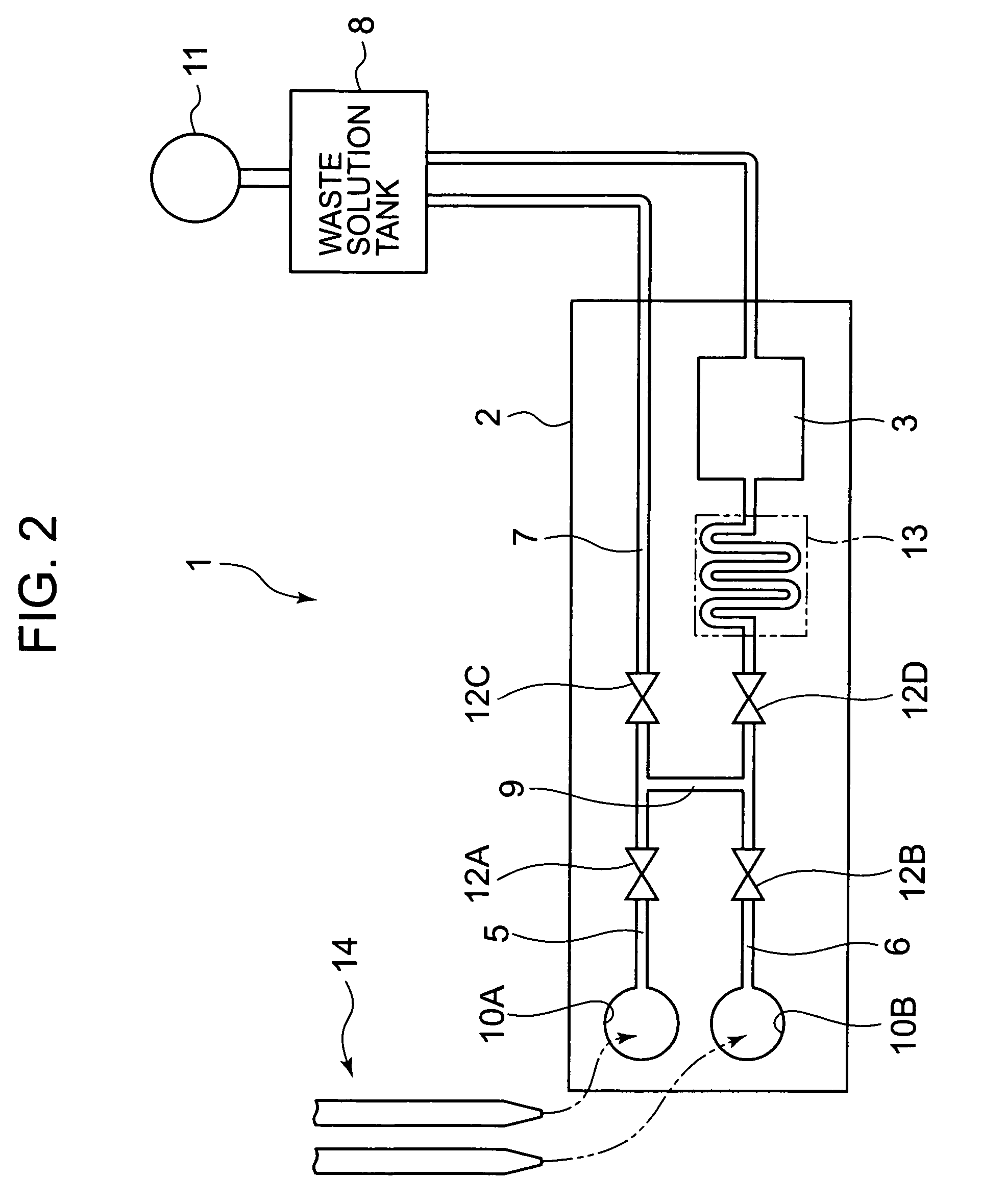

Microchip for analysis, analysis system having the same, and analysis method

InactiveUS20050255000A1Simple configurationEasy to useMaterial nanotechnologyAnalysis using chemical indicatorsAnalyteEngineering

It is a problem to provide a microchip for analysis which is miniaturized, is disposable for ease to use, and does not have a risk of contamination in flow channels. On a substrate 2, a first flow channel having a buffer solution supply channel 6 and a reaction bath section 3, a second flow channel having a sample solution supply channel 5 and a waste solution channel 7, and a connecting channel 9 connecting both the flow channels upstream of the reaction bath section 3 are provided. The waste solution channel 7 and the reaction bath section 3 are connected to a waste solution tank 8 and a pump 11. After a ligand is modified in the reaction bath section 3, a sample solution is allowed to flow in the sample solution supply channel 5 and the waste solution channel 7, and a buffer solution is allowed to flow in the buffer solution supply channel 6, the connecting channel 9 and the waste solution channel 7, subsequently to flow in the buffer solution supply channel 6 and the reaction bath section 3. Then, a temperature adjusting section 13 and the pump 11 are set such that a desired temperature of a fluid and a flow rate are obtained. Subsequently, the sample solution is supplied to the sample solution supply channel 5, the connecting channel 9, and the reaction bath section 3, a binding reaction is brought between the ligand and an analyte in the sample solution, and the state of binding is detected.

Owner:SEIKO INSTR INC

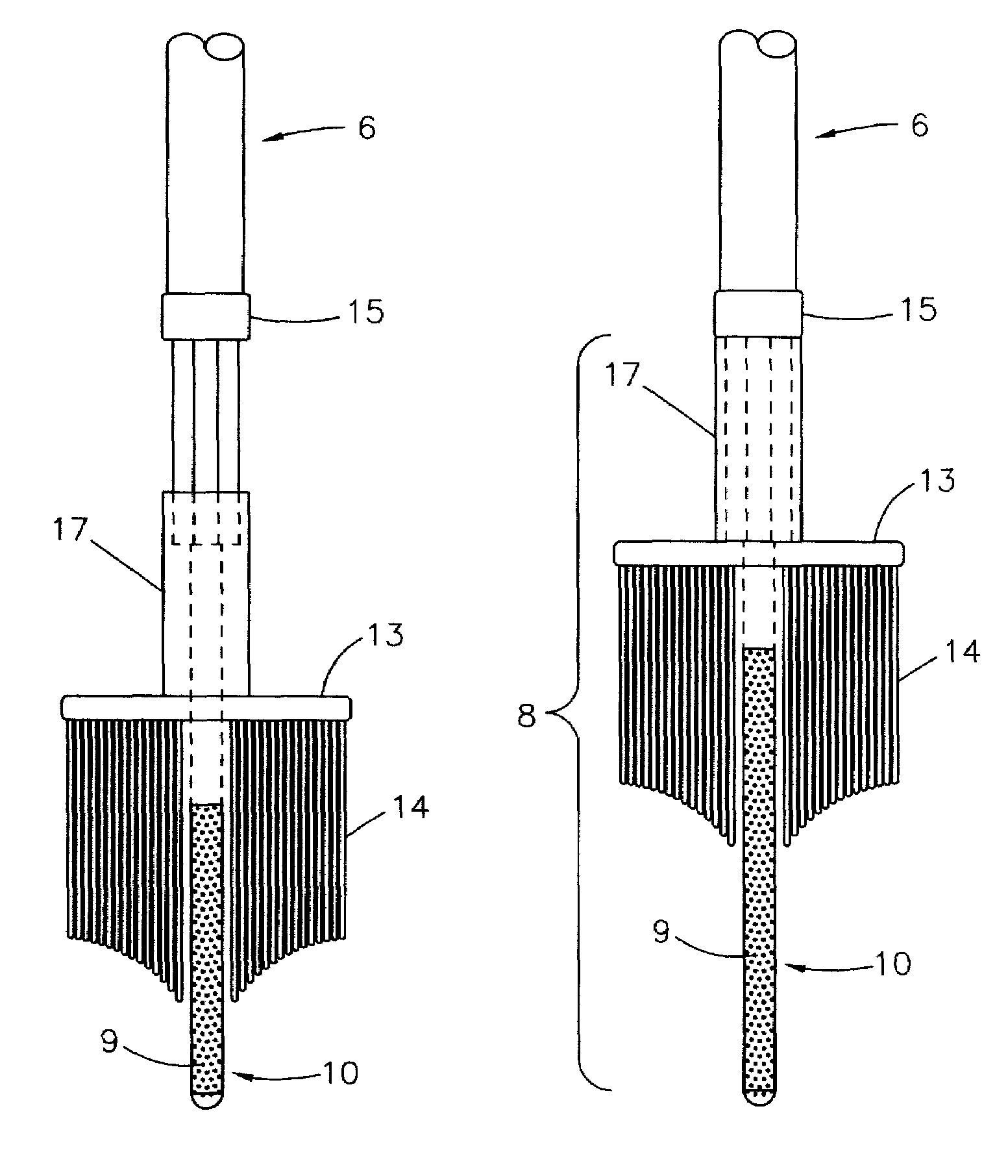

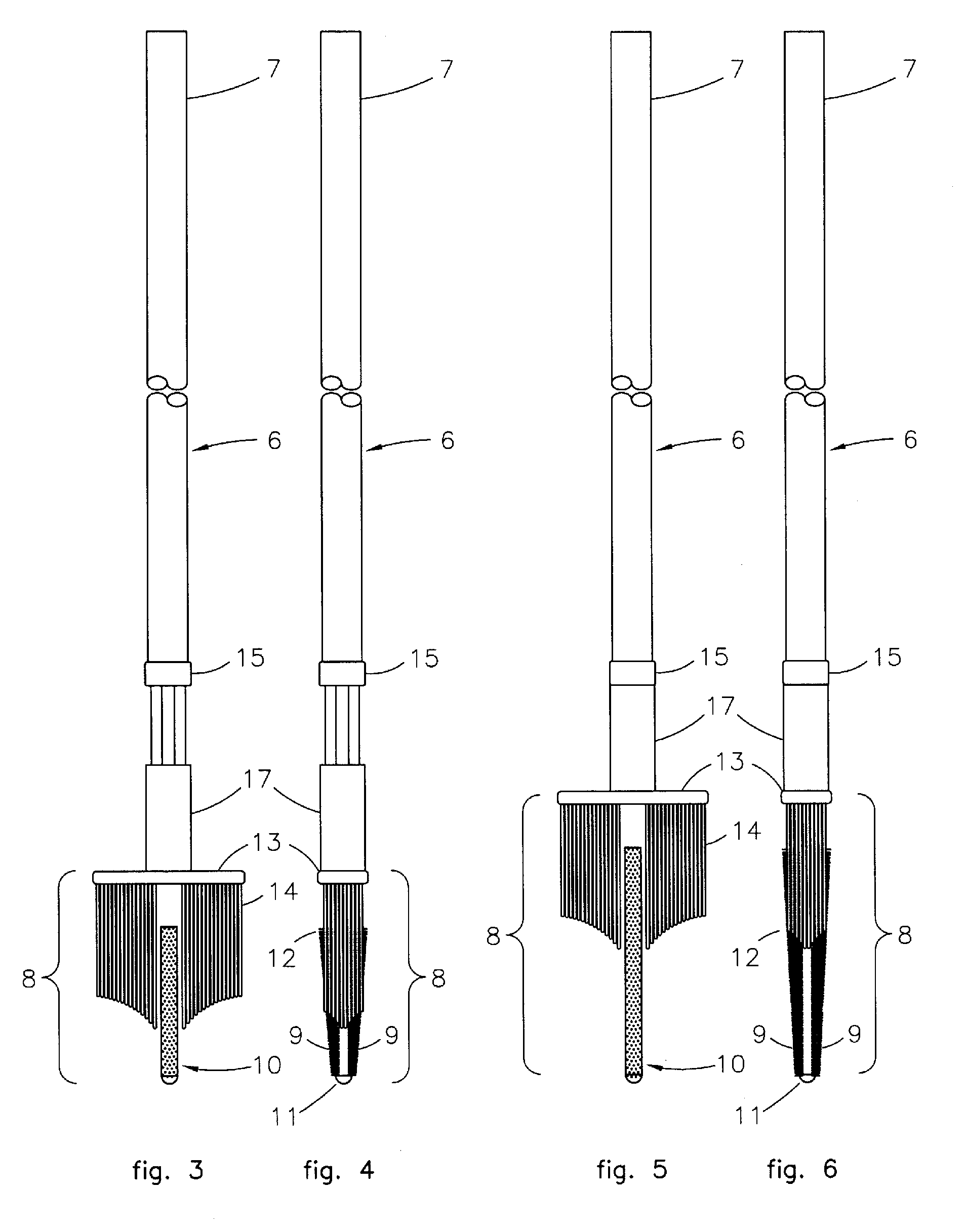

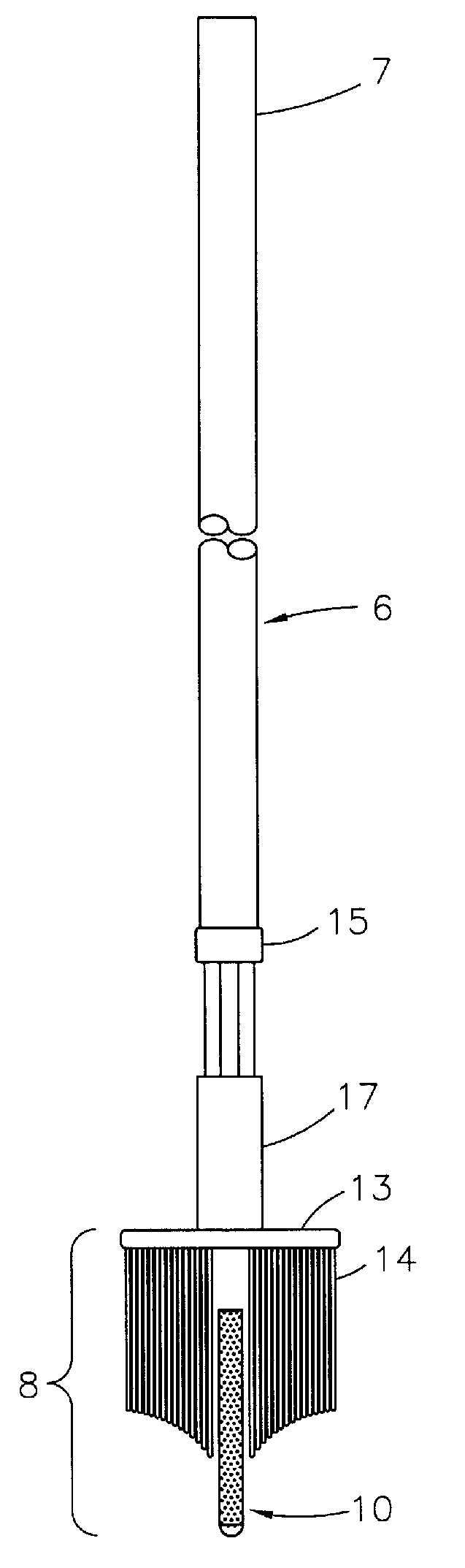

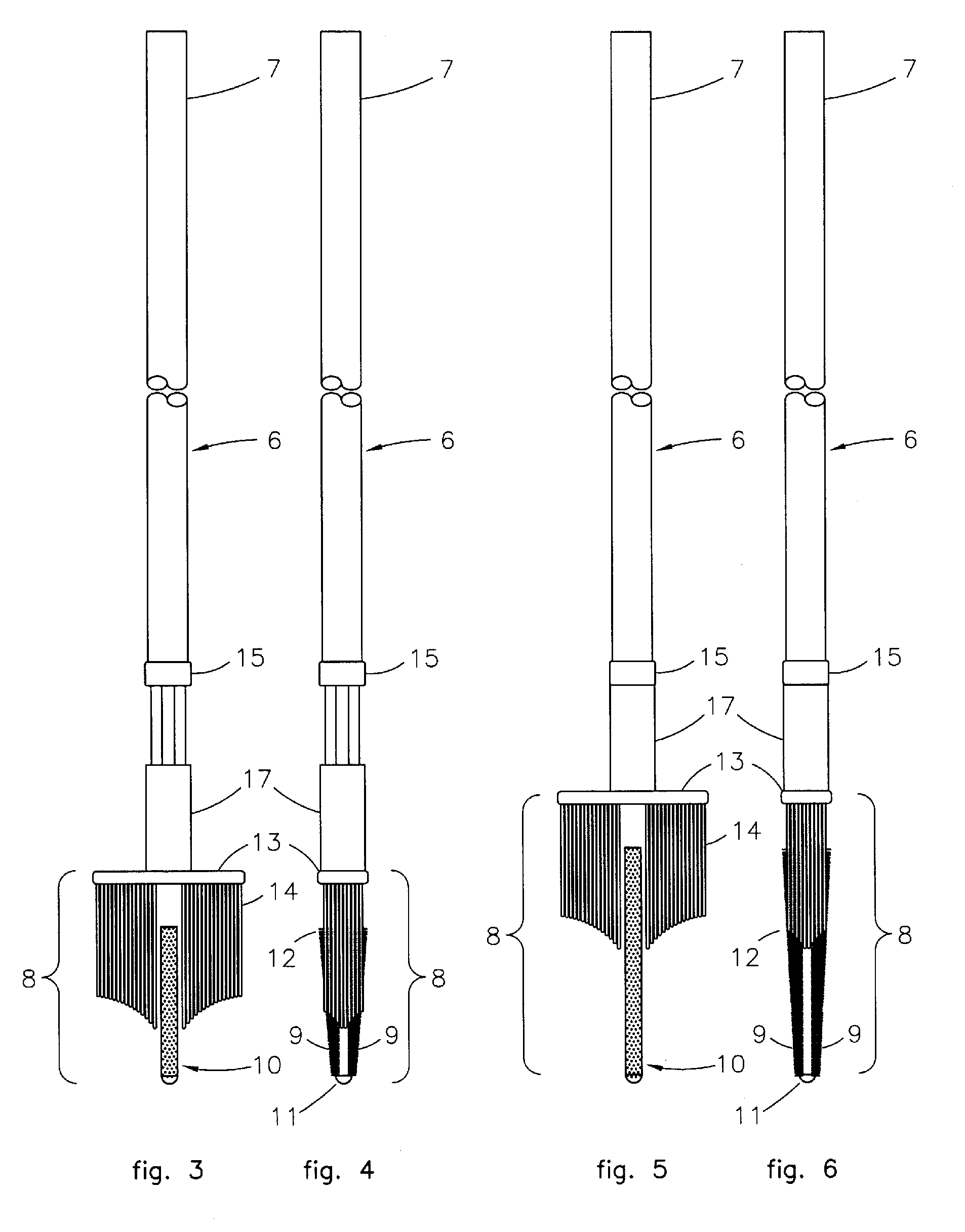

Combination self adjusting endocervical / exocervical sampling device and cell transport / preservation system

InactiveUS7413551B2Eliminate riskFacilitates collection and preservation and transportationSurgeryVaccination/ovulation diagnosticsEndocervixCritical position

The device consists of a shaft with a detachable brush head. The brush head is a new design incorporating the utility of an expandable self adjusting area that yields a complete sample of the endocervix and exocervix regardless of varying individual anatomy. The brush head has protrusions disposed at strategic positions with flat surface collection areas. A ledge with protrusions samples the exocervical area and a middle portion samples the endocervical area. The middle portion automatically elongates from approximately 2 cm to 5.5 cm as to adjust to individual anatomies as the brush head is inserted into the cervical canal. The brush head is matched to a special collection container that permits the brush head to be detached and deposited into the container without the handling of the brush / head area. The special conical insert within the container automatically orients brush head for passage through horizontal slot at bottom of insert without operator's need to manually align. In this fashion the sampled cellular material can be completely, safely, and securely transported for laboratory evaluation.

Owner:DECKER +1

A Combination Self Adjusting Endocervical / Exocervical Sampling Device and Cell Transport / Preservation System

InactiveUS20070073186A1Easy to collectFacilitates preservationSurgeryVaccination/ovulation diagnosticsEndocervixEngineering

The device consists of a shaft with a detachable brush tip. The brush tip is a new design incorporating the utility of an expandable self adjusting area that yields a complete sample of the endocervix and exocervix regardless of varying individual anatomy. The head will have protrusions disposed at strategic positions with flat surface collection areas. A ledge with protrusions will sample the exocervical area and a middle portion will sample the endocervical area. The brush tip is matched to a special collection container that permits the brush tip to be detached and deposited into said container without the handling of the brush / head area. In this fashion and utility the sampled cellular material can be completely, safely, and securely transported for laboratory evaluation.

Owner:DECKER +1

Automated blood sampler and analyzer

ActiveUS8348844B2Eliminate riskEliminate the risk of contaminationCatheterDiagnostic recording/measuringVeinPeristaltic pump

An automated blood sampler integratable with a glucose monitor comprises a catheter connected to a tube-set forming a single blood passageway; a clamp-on air-bubble sensor and a occlusion sensor externally attached to the tube set; a single peristaltic pump and two 3-way pinch valves attached to the tube set and control fluid flow. The sampler draws blood from a stationary patient, samples the blood for analytical measurement of blood parameters; after which the passageway is rinsed, the blood re-infused, and slow saline infusion prevents vein collapse. The cycle repeats at user or predefined intervals. In another preferred embodiment, blood is not re-infused, and only one 3-way pinch valve is used.

Owner:CASCADE METRIX LLC

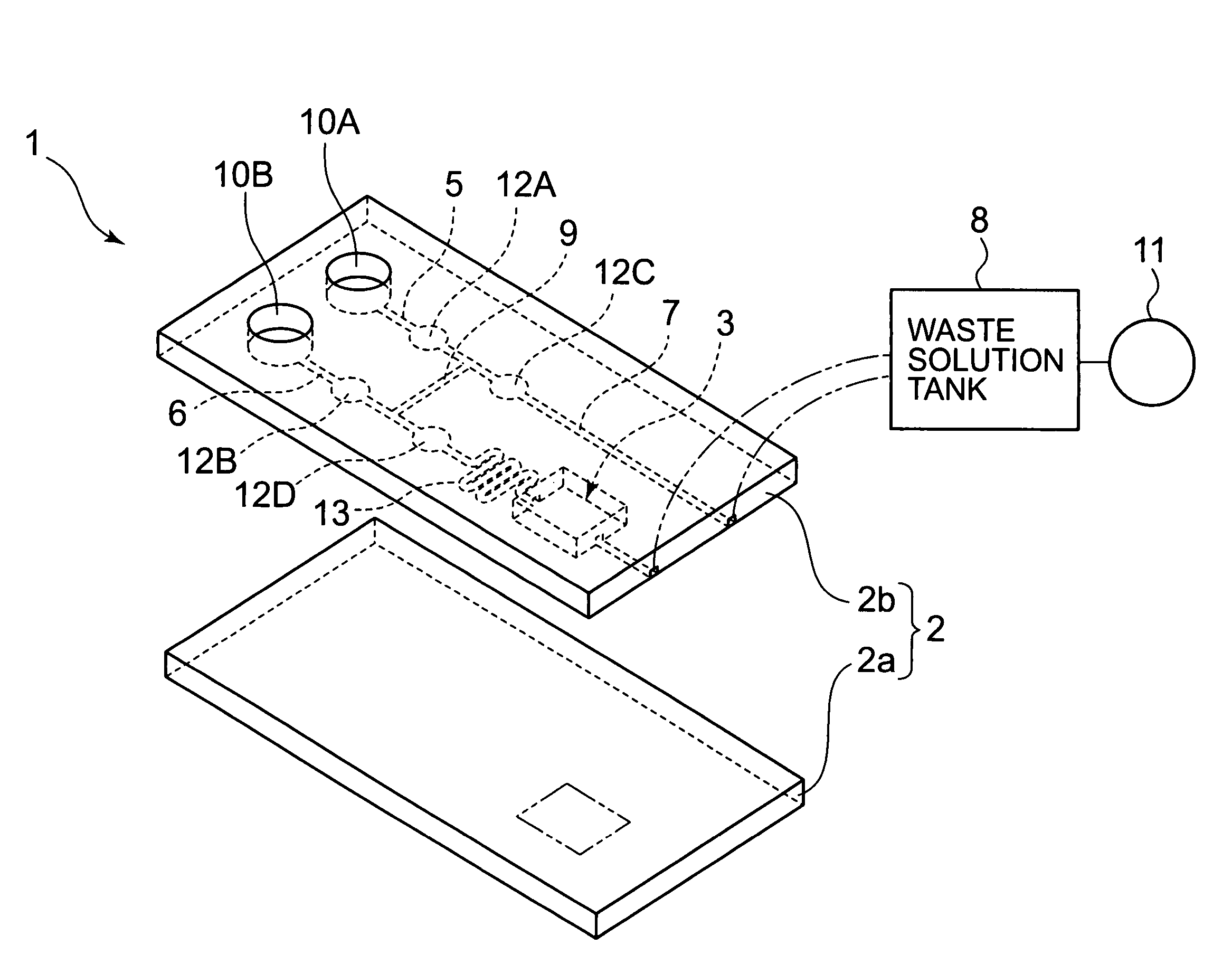

Locking cap for a vessel having a neck

ActiveUS20120160850A1Easy and fast accessEasy to installClamping mechanismLocking devicesPlastic materialsEngineering

Owner:A RAYMOND & CO

Sterile filling machine having needle filling station within E-Beam chamber

InactiveUS20050173020A1Eliminate the risk of contaminationObstruct passageLiquid fillingPackage sterilisationBiomedical engineeringElectron

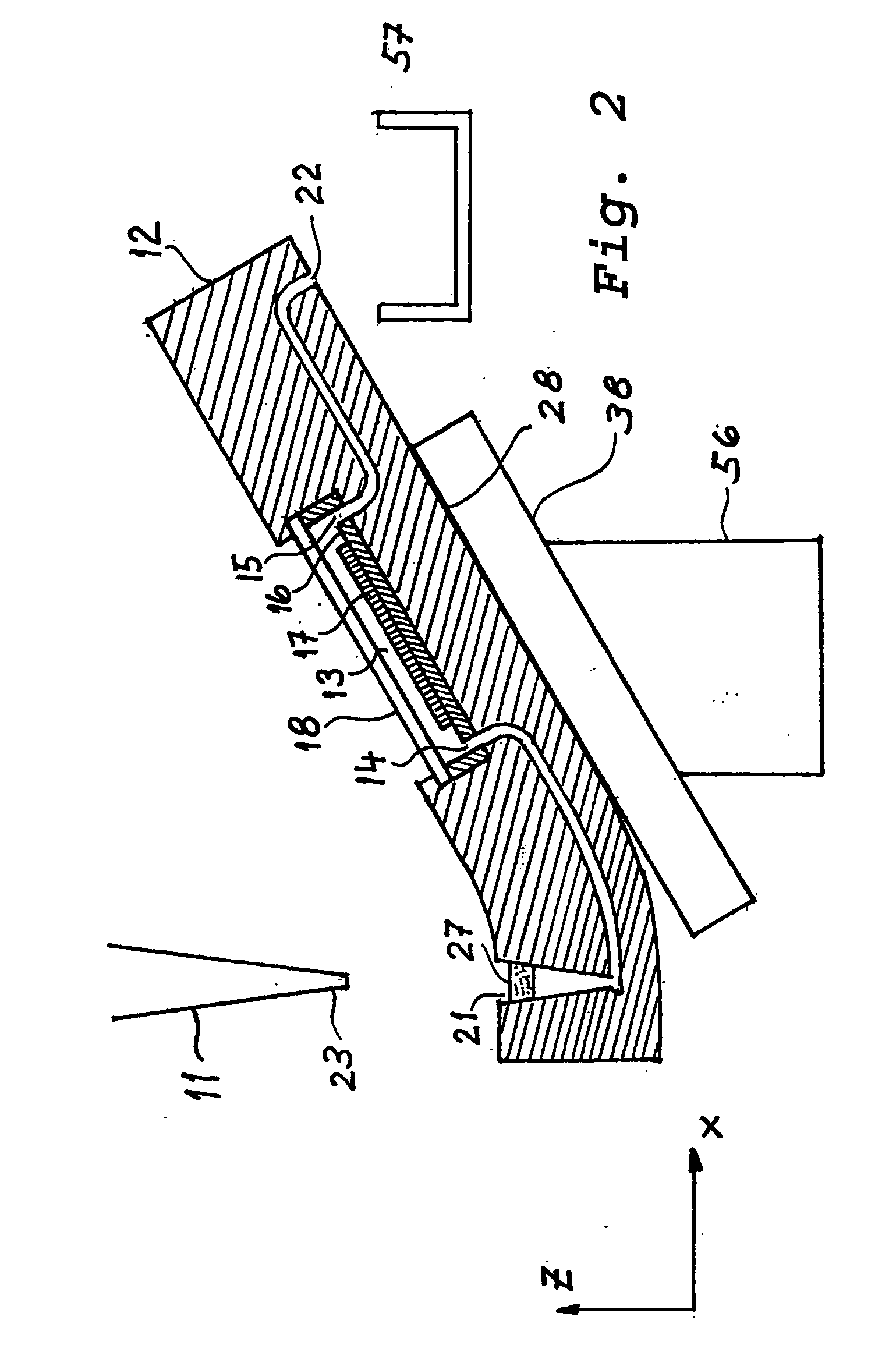

A sterile filling machine and related method are provided for sterile filling a container with a substance. The container includes a heat resealable stopper and a chamber for receiving the substance therein. The sealed, empty containers are subjected to radiation capable of penetrating through the stopper and chamber for sterilizing the container. The previously sterilized containers are then transported through an e-beam chamber, wherein an electron beam is directed onto a penetrable surface of the stopper to sterilize the penetrable surface. A needle is mounted within the e-beam chamber and moved into engagement with the stopper to pierce the sterilized penetrable surface of the stopper and inject the substance through the needle and into the chamber of the container. The needle is then withdrawn from the stopper and the filled container is transported outside of the e-beam chamber. Laser energy is then transmitted onto the penetrated surface of the stopper to fuse the stopper material and hermetically re-seal the stopper.

Owner:MEDICAL INSTILL TECH

Processing method for cephalosporin dreg

ActiveCN103146761AEasy to handleDeal with economical and thoroughWaste based fuelSludge processingActivated sludgeResource utilization

The invention discloses a processing method for cephalosporin dreg. The processing method comprises the following process steps of: (A) thermal alkaline hydrolysis and separation treatment: uniformly mixing cephalosporin dreg, water and alkali, carrying out constant-temperature alkaline hydrolysis reaction, and carrying out solid-liquid separation at a certain temperature after the constant-temperature alkaline hydrolysis reaction, so as to obtain sediments to be standby; and (B) anaerobic digestion treatment: inoculating anaerobic activated sludge into an anaerobic fermentation tank, mixing the sediments obtained in the step (A) with excess sludge produced by utilizing wastewater biological treatment, injecting the mixture into the fermentation tank, carrying out constant-temperature stirring, and carrying out biogas residue discharging and feeding during fermentation. According to the processing method for the cephalosporin dreg, drug residues in the cephalosporin dreg can be completely removed, the problem that the anaerobic fermentation of single cephalosporin dreg cannot be effectively sustained is solved, and the reduction and innocent treatment to the cephalosporin dreg are realized; and biogas residues produced during the processing process can be used for preparing raw materials of organic fertilizers, the produced sewage gas can be used as clean fuels, and safe and effective disposition and resource utilization to the cephalosporin dreg are realized.

Owner:河北华药环境保护研究所有限公司

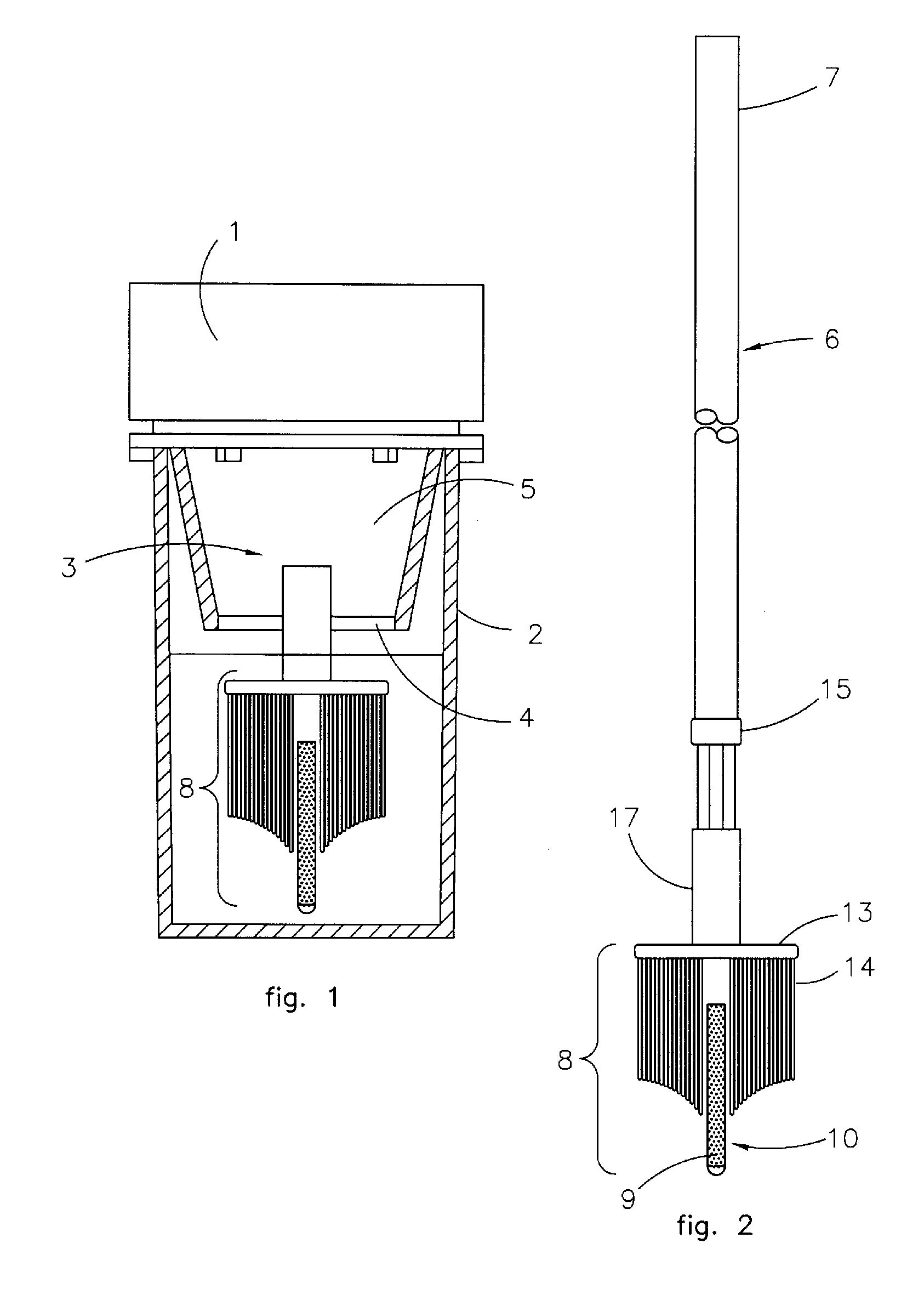

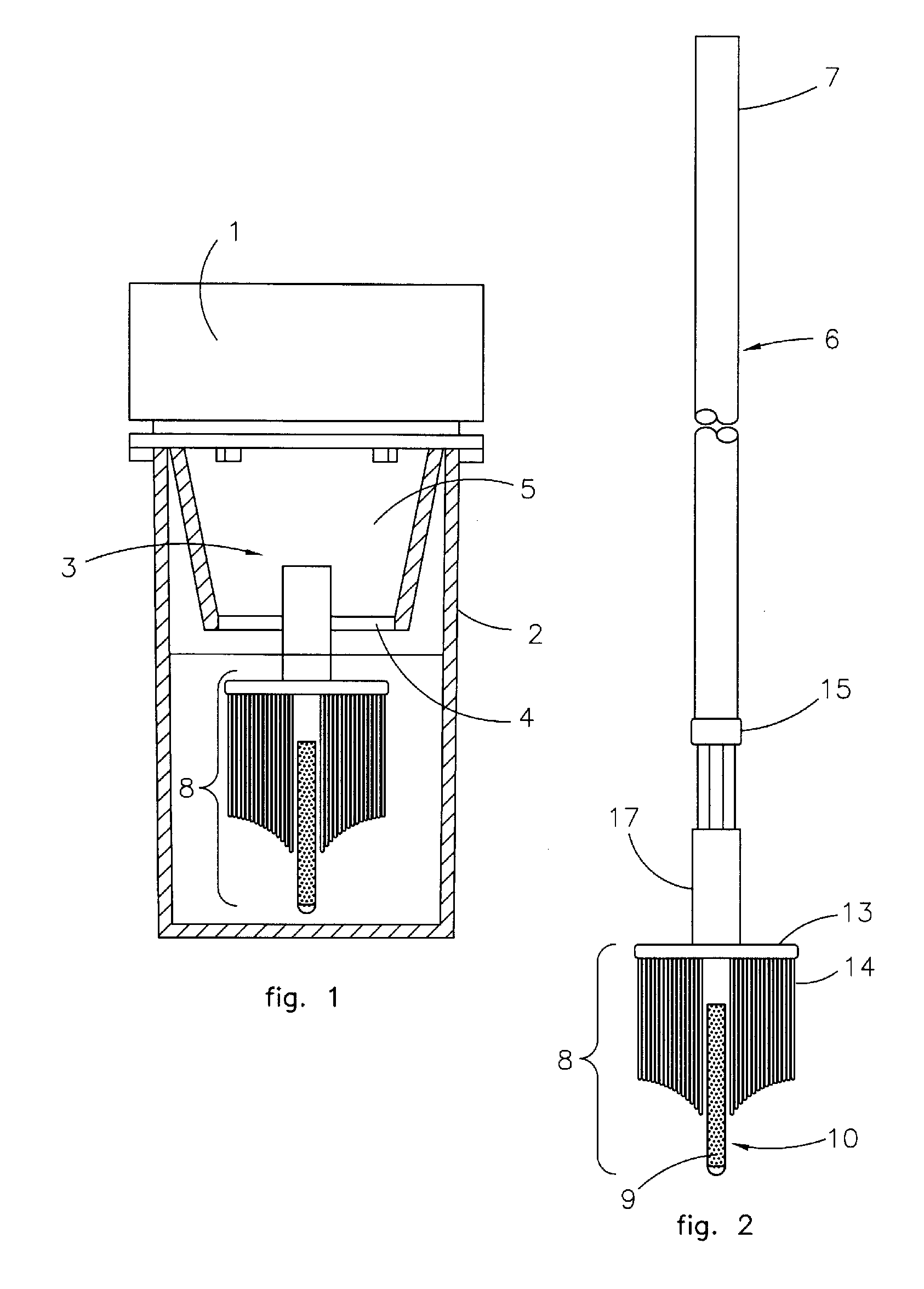

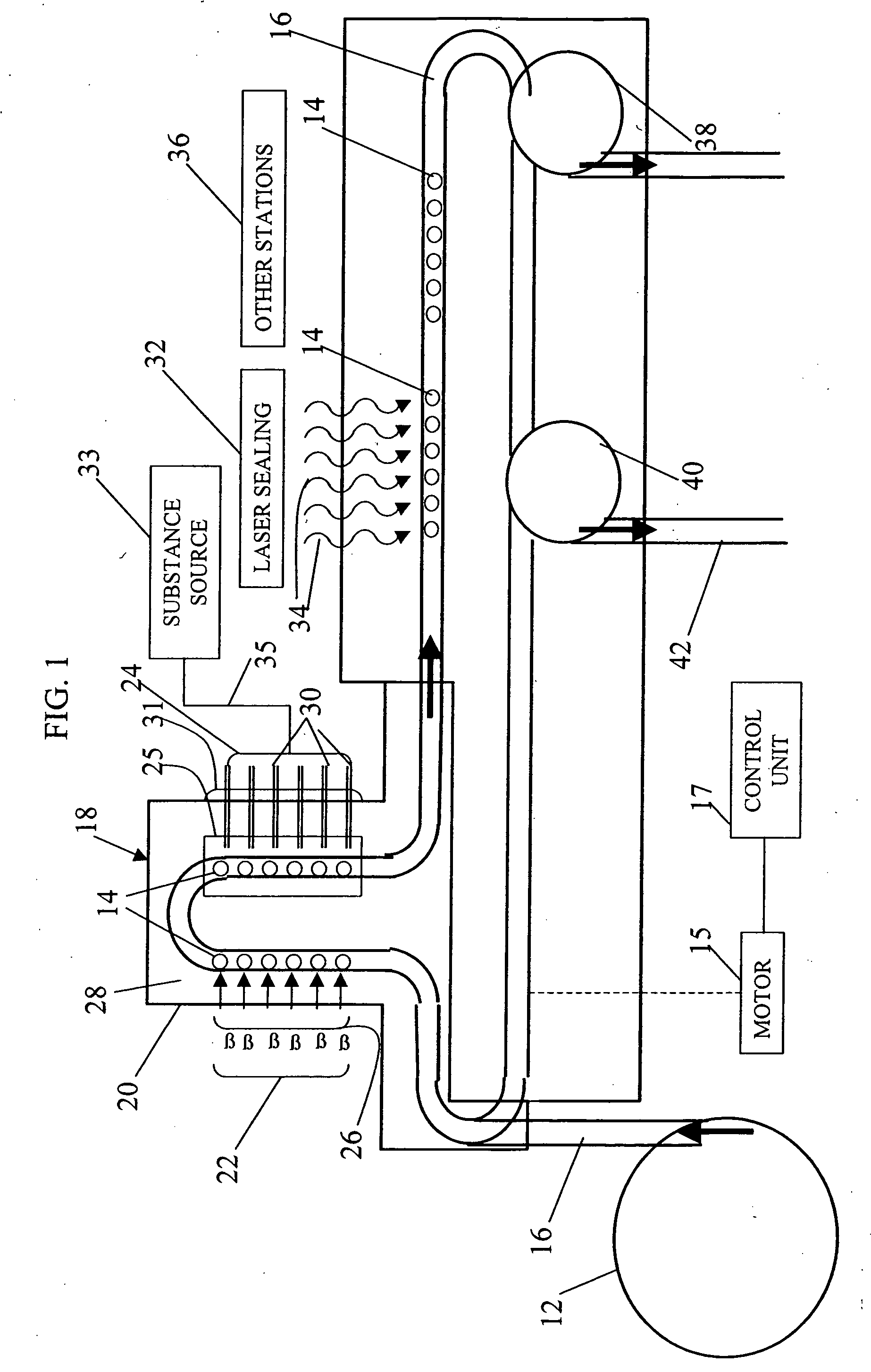

Device for cell culture

InactiveCN1894397AEliminate the risk of contaminationAutomate operationBioreactor/fermenter combinationsBiological substance pretreatments3D cell cultureWastewater

A device for cell culture capable of automatically performing operations for cell culture over several days to several months while minimizing the risk of contamination. A new medicine can be supplied to an incubator means by using a medicine supply means or unnecessary wastewater can be discharged from the incubator means by using a wastewater discharge means without taking out the incubator means disposed in heat insulation box means from a heat insulation box, and the state of the cell culture can be observed with the incubator means formed in the heat insulation box means. Accordingly, the outside air does not enter directly into the incubator means during culturing, and the risk of contamination is completely eliminated. As a result, the culturing operations can be automatically performed over a long period.

Owner:KANEKA CORP

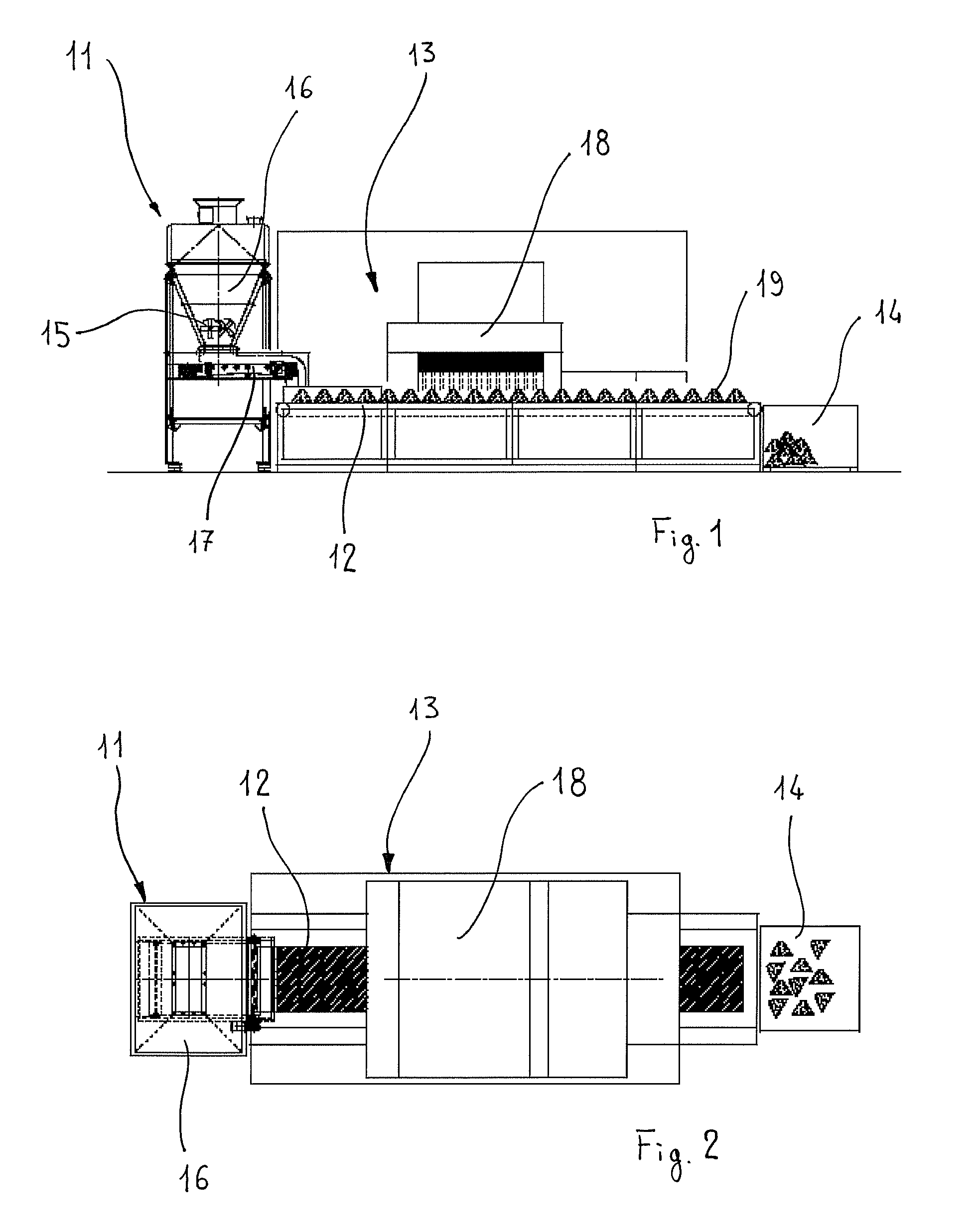

Method and plant for rendering inert toxic substances in uncompacted residual material containing hardenable resin and aggregrates

ActiveUS8030441B2Eliminate the risk of contaminationDielectric heating circuitsSolid waste disposalOrganic solventToxic material

A loose mixture formed of one or more solid inert materials and a hardenable resin dissolved in an organic solvent, in particular the remainder of the initial mix used for the manufacture of conglomerate stone sheets, is rendered inert by means of dielectric heating at a frequency of less than 300 MHz. A plant for implements a method where a loose mixture is formed of one or more solid inert materials and a hardenable resin dissolved in an organic solvent, in particular the remainder of the initial mix used for the manufacture of conglomerate stone sheets, is rendered inert by means of dielectric heating at a frequency of less than 300 MHz.

Owner:TONCELLI DARIO

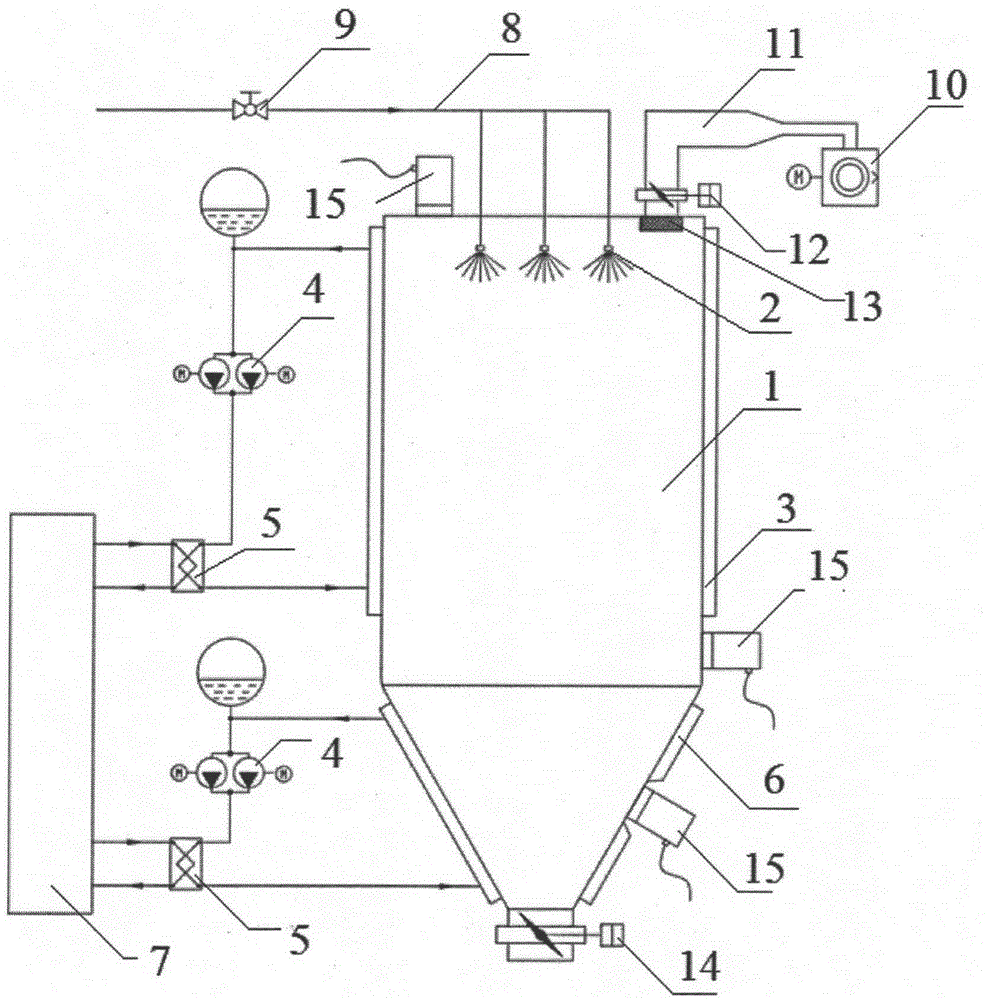

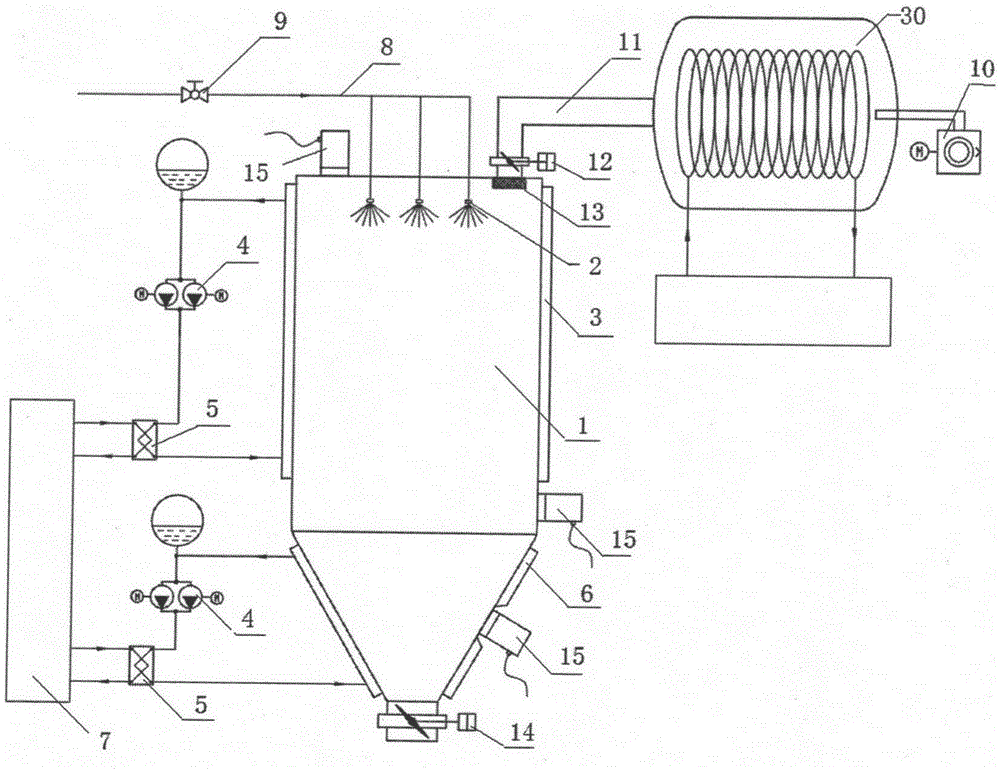

Clarification method and apparatus for material contaminated with heavy metals

InactiveUS20070142693A1Reduce concentrationEliminate the risk of contaminationContaminated soil reclamationElectrolysisSludge

A clarification method and apparatus, which can reliably remove heavy metals, including their sparingly soluble fractions, from a contaminated solid material containing the heavy metals, such as soil, sludge, sediments, wastes, or incineration ash, are provided. A reaction vessel 2 is divided into an anode zone 10 containing an anode A, and a cathode zone 20 containing a cathode C, by a diaphragm M provided between the anode A and the cathode C. The cathode zone 20 is supplied with a contaminated solid material containing heavy metals via a contaminated solid material supply means 22, an acidic substance or an alkaline substance via an acidic substance or alkaline substance supply means 24, and in some cases, water via a water supply means 26. A slurry of their mixture is maintained in the condition of a reducing atmosphere and a strongly acidic or strongly alkaline atmosphere to dissolve the heavy metals and electrolytically deposit the heavy metals on the surface of the cathode, thereby separating the heavy metals from the contaminated solid material and interstitial water.

Owner:EBARA CORP

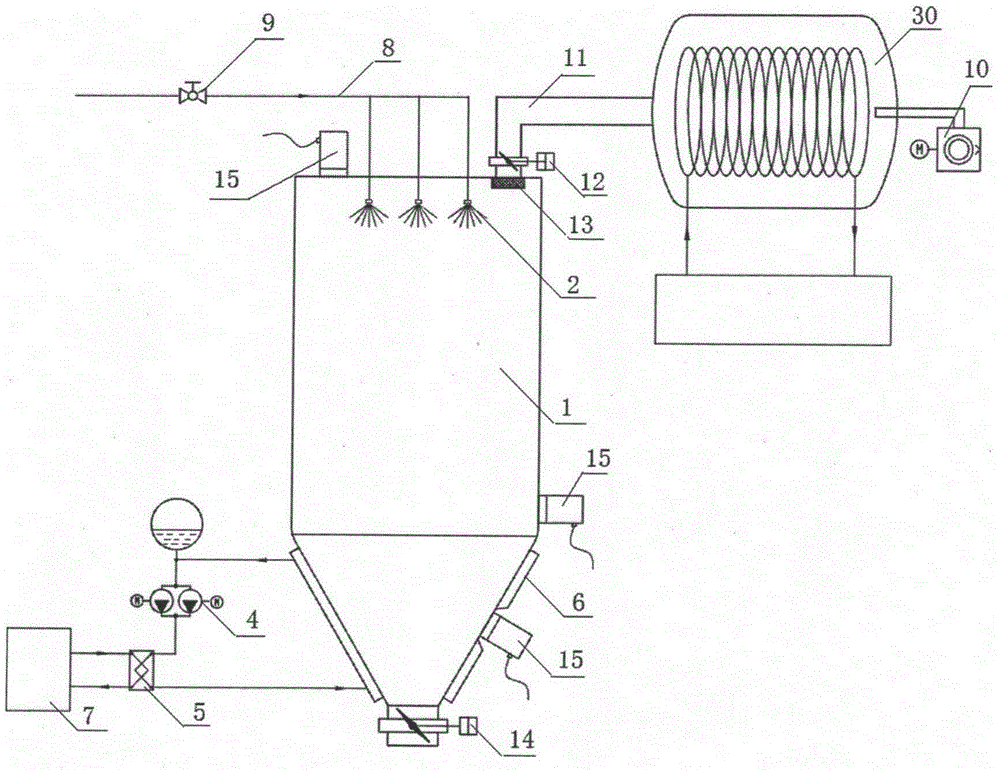

Vacuum spray-freezing granulation device and method thereof

InactiveCN105289410AIncrease freezing ratePrevent materials from being pollutedDrying solid materials without heatGranulation by liquid drop formationEngineeringFreeze dry

The invention provides a vacuum spray-freezing granulation device and a method thereof. The device of the invention is characterized in that the device comprises a container; multiple atomizing nozzles used for atomizing and dispersing a liquid to be freeze-dried into liquid drops are arranged inside the container; and the container is connected to a vacuum system used for forming a vacuum environment in the container to make part components in the liquid drops to be vaporized and absorb heat in the vacuum environment so as to further cool and freeze the liquid drops to form granules. The method of the invention is completely different from a traditional freeze-drying granulation technology. By vacuum-pumping to freeze atomized liquid drops into granules, freezing rate of the liquid to be freeze-dried is greatly raised. According to the vacuum spray-freezing granulation device, a refrigerant nozzle is not arranged therein, a liquid nitrogen low-temperature zone is not arranged in the device, and a refrigerant is completely not used to contact with a material during the quick-freezing process so as to completely eradicate the risk that the material is polluted. Therefore, sterility of the freeze-drying process is raised, production energy consumption is reduced, and the environment will not be polluted.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

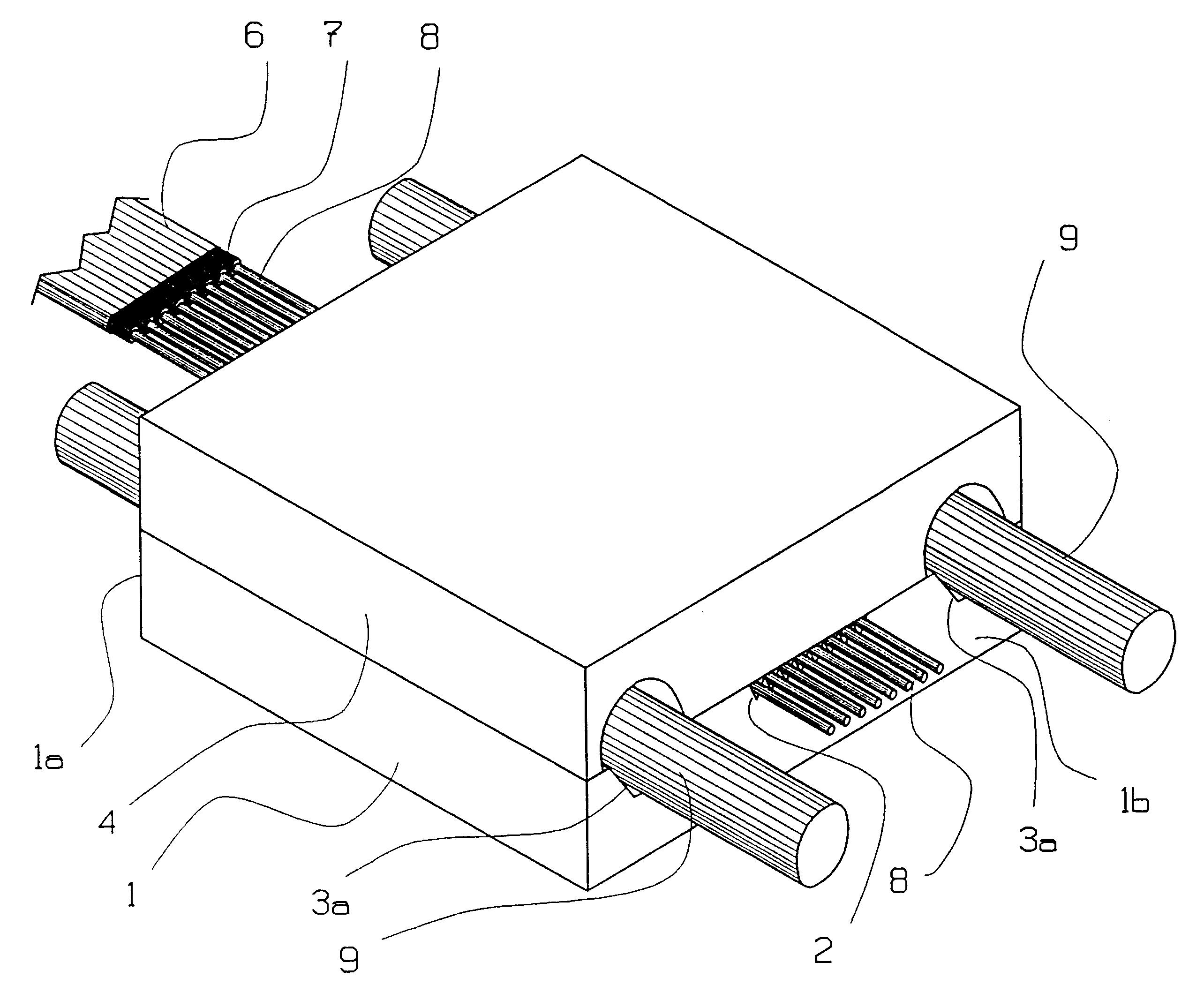

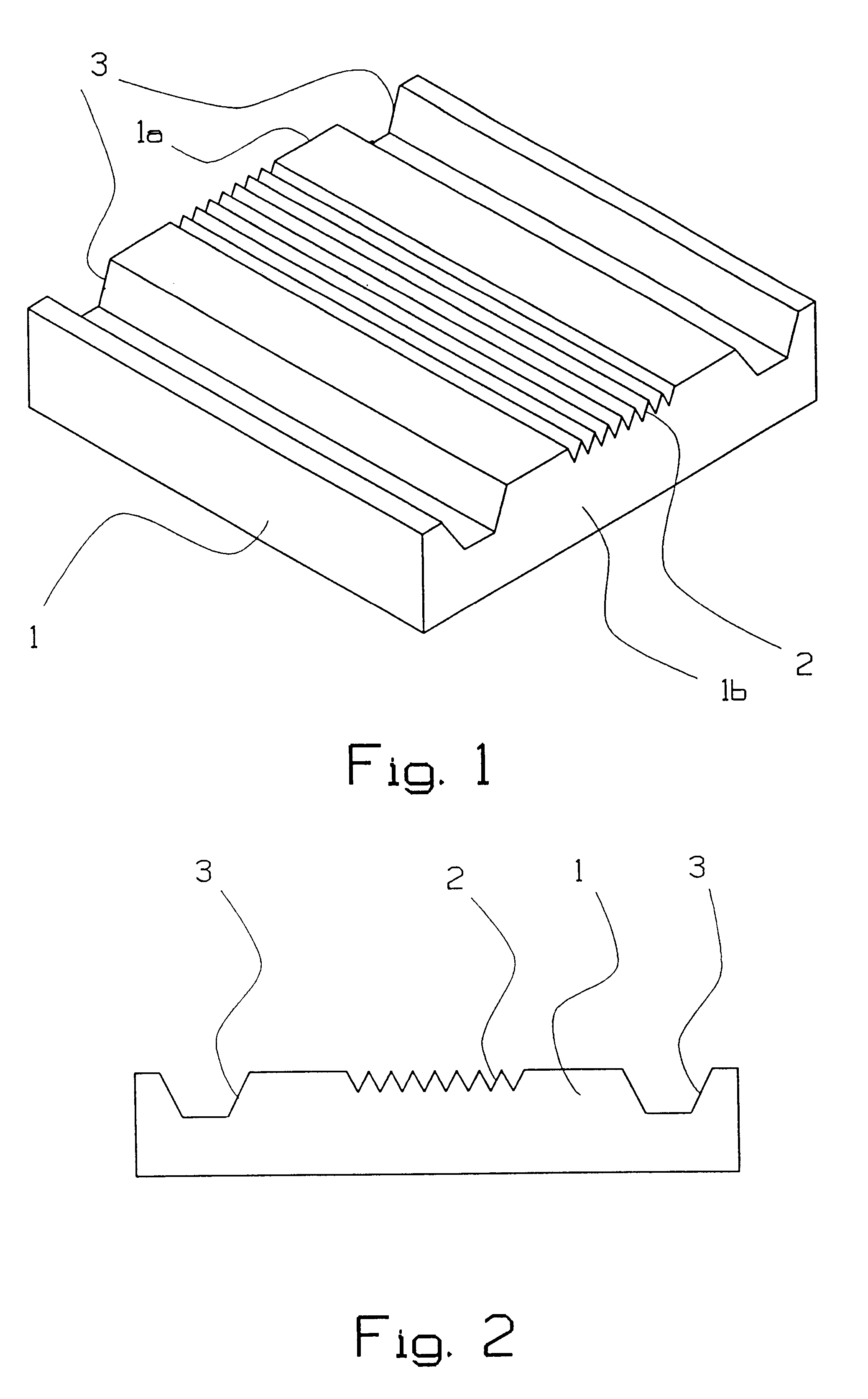

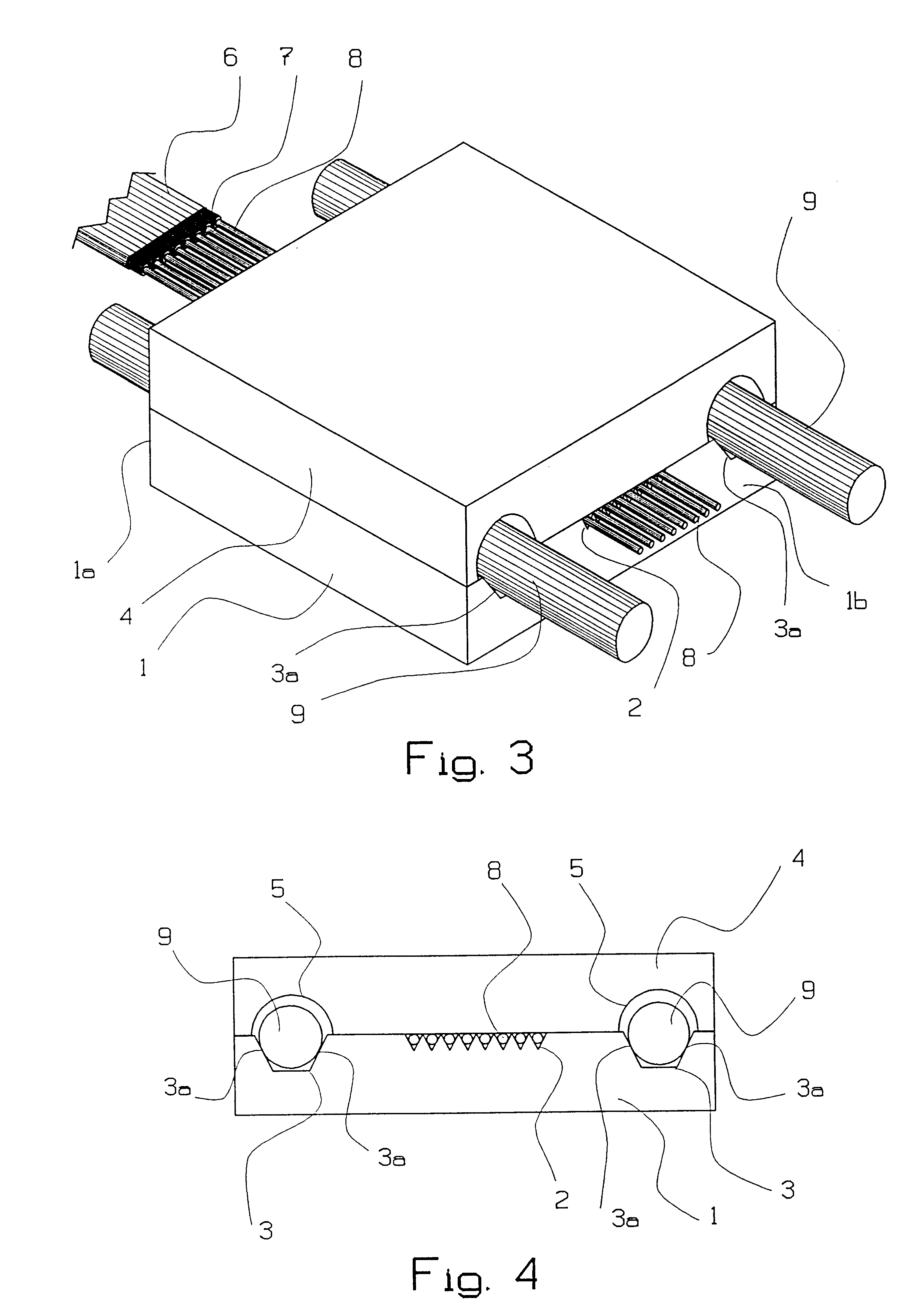

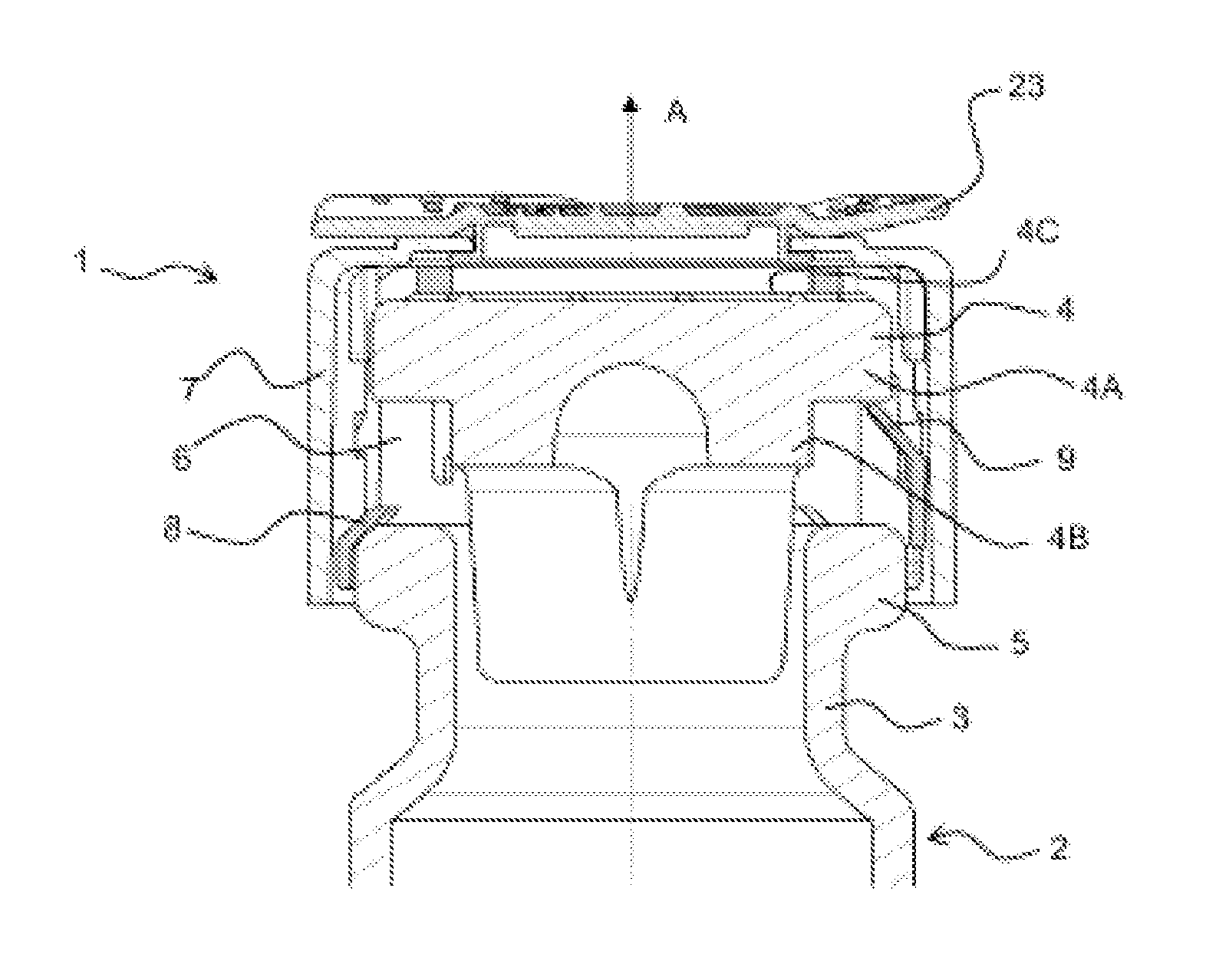

Opto-mechanical device

The present invention relates to a manufacturing method for an opto-mechanical connector (10) and to the connector itself. The invention includes that a fixture (1) is manufactured with straight and parallel grooves (2,3) running on the upper side of the fixture (1) from a first fixture side (1a) to a second fixture side (1b), and which grooves (2,3) are intended partly for optical fibers and partly for guide pins. A lid (4) is attached above the fixture (1), whereafter optical fibers (8) from, for example, a fiber ribbon cable (6) are introduced into the grooves (2) intended for the fibers from the first fixture side (1a) so that the fiber ends (8) extend out through the second fixture side (1b). Guide pins (9) are furthermore introduced into the grooves (3) intended for the guide pins. The structure obtained (fixture (1), lid (4), fiber ends (8) and guide pins (9)) is completely or partially enclosed by a plastic capsule (11).

Owner:TELEFON AB LM ERICSSON (PUBL)

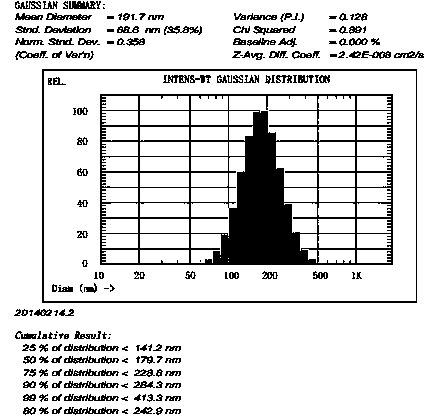

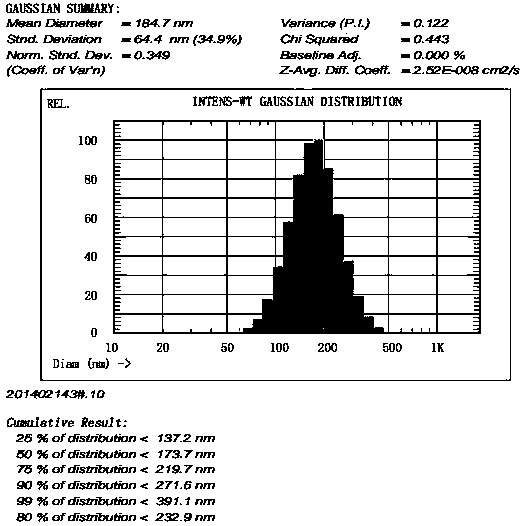

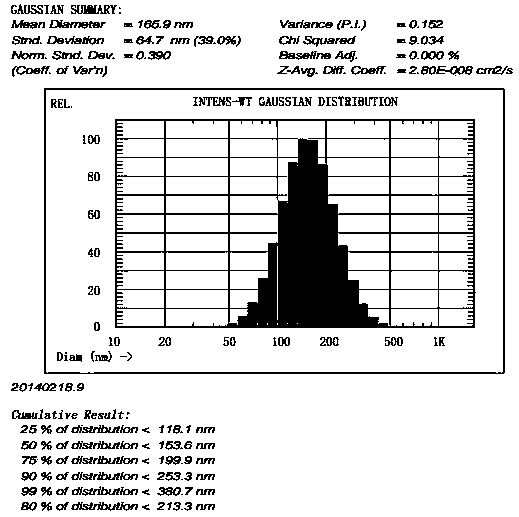

Bottled grease micro emulsion freeze-dried preparation with 13 composite vitamins

ActiveCN104337829AImprove stabilitySolve the problem of co-dissolutionPowder deliveryHydroxy compound active ingredientsBiotechnologyVitamin A Alcohol

The invention discloses a bottled grease micro emulsion freeze-dried preparation with 13 composite vitamins. The preparation is prepared by wrapping lipid-soluble vitamins A, D, E and K in grease micro emulsion of which the particle size is smaller than 120nm, mixing with water-soluble vitamins B and C, folic acid, nicotinamide and the like, adding a freeze-drying forming agent and a redissolution additive, and freeze-drying. The novel freeze-dried preparation, which contains 13 vitamins and is developed according to the above formula and the preparation method, is simple in process, the stability of the vitamins can be improved, and the side effect caused by medicine decomposition and decomposition products is alleviated; the problem of codissolution of lipid-soluble vitamins and water-soluble vitamins is effectively solved, sufficient dissolution of medicine compounds is ensured, and the side effect of undissolved substances on human bodies is avoided.

Owner:XIAN LIBANG ZHAOXIN BIOTECH CO LTD

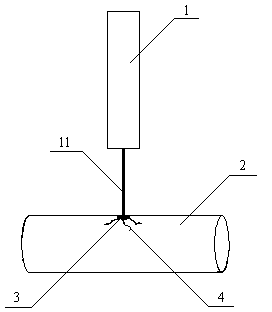

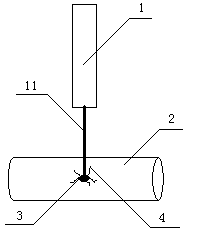

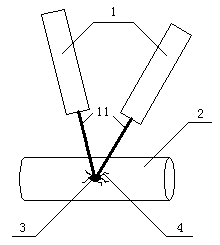

Method for contactlessly breaking polycrystalline silicon

InactiveCN103816973ALow purityEliminate the risk of contaminationGrain treatmentsLaser technologyThermal expansion

The invention discloses a method for contactlessly breaking polycrystalline silicon, and more specifically discloses a method for breaking polycrystalline silicon by using laser technology. According to the method for contactlessly breaking polycrystalline silicon, at least one laser beam is irradiated to a polycrystalline silicon rod or polycrystalline silicon ingot; and once local area on the surface of or in the polycrystalline silicon rod or polycrystalline silicon ingot absorbs laser energy, the local area of the polycrystalline silicon rod or polycrystalline silicon ingot is heated instantaneously. The heated local area of the polycrystalline silicon rod or polycrystalline silicon ingot expands; and thermal expansion stress is generated on the surface of or in the polycrystalline silicon rod or polycrystalline silicon ingot, so that the polycrystalline silicon rod or polycrystalline silicon ingot is broken.

Owner:ASIA SILICON QINGHAI

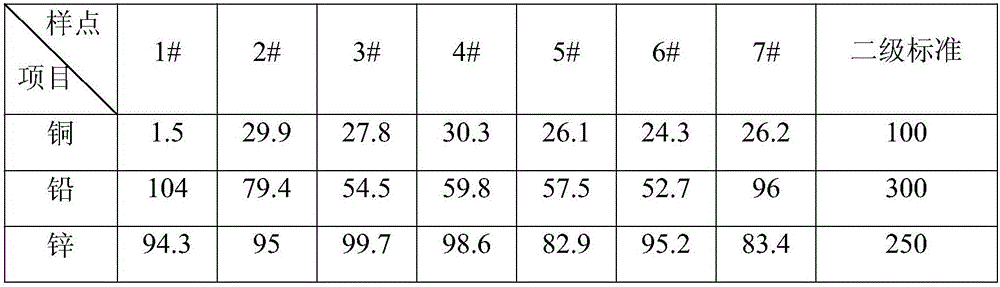

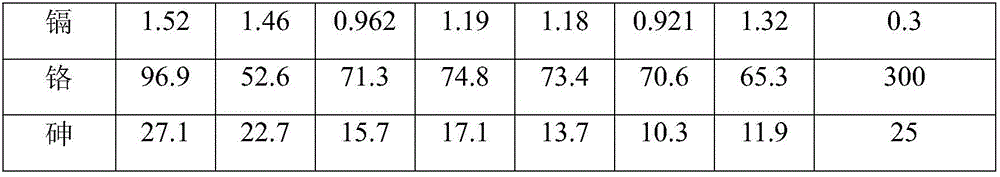

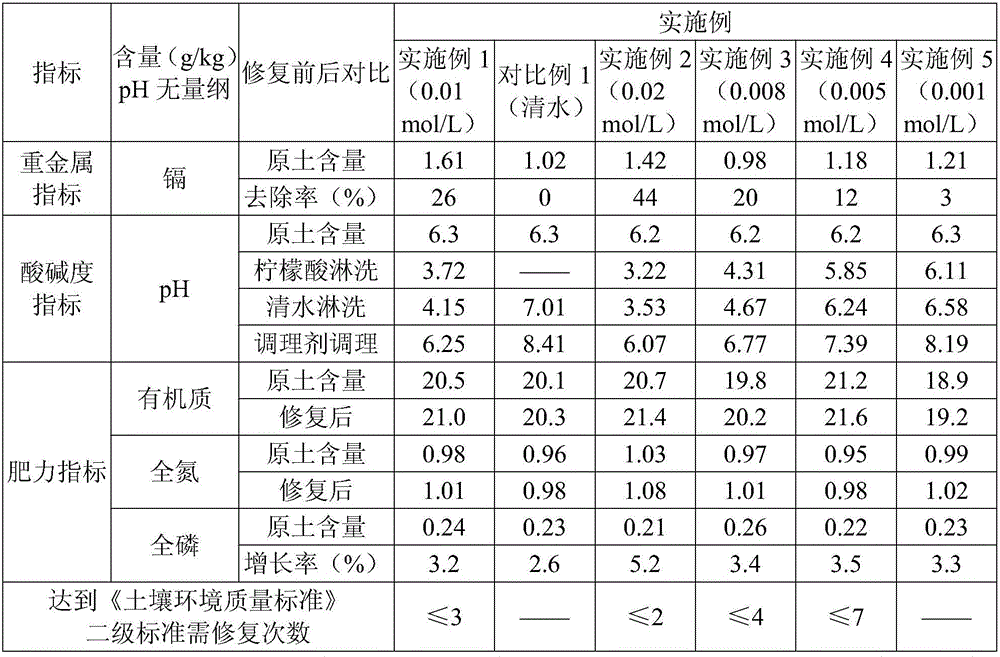

Method for repairing cadmium-polluted farmland soil

InactiveCN106694532AIncreased fertility indicatorsImprove fertilityContaminated soil reclamationSurface layerSoil science

The invention discloses a method for repairing cadmium-polluted farmland soil. The method comprises the following steps: selecting a cadmium-polluted farmland soil region, arranging soil ridges on the periphery of the region, and compacting and covering the peripheries of the soil regions by using waterproof films; after adding clear water which submerges the surface layer of the soil, turning over the soil; uniformly sprinkling a drip washing agent in the soil which is turned over, and fully stirring evenly, standing and discharging; and adding clear water in the soil, carrying out drip washing for 1-3 times, and fully stirring evenly, standing and discharging; and adding a conditioning agent in the soil, fully stirring evenly, standing, and moisturizing and maintaining to obtain the repaired farmland soil. The whole treatment process is simple, the cost is low, the period is short, the structure and the character of the soil are not affected, normal farming and planting of the land are not obstructed, heavy metals can be removed perpetually, and therefore, the method can be widely used for repairing the cadmium-polluted farmland soil.

Owner:HUNAN JINLV ENVIRONMENTAL PROTECTION CO LTD

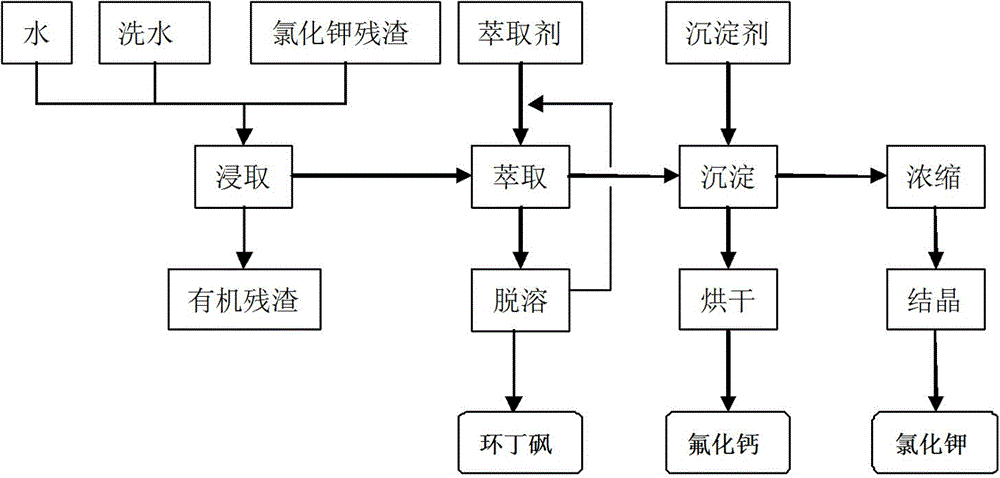

Method for treating potassium chloride residues in organic fluorination reaction

ActiveCN104477942AEliminate the risk of environmental contaminationGood economic benefitsCalcium/strontium/barium fluoridesAlkali metal halide purificationTarChemistry

The invention discloses a method for treating potassium chloride residues in an organic fluorination reaction. The potassium chloride residues are soaked with water in a soaking kettle, potassium chloride, potassium fluoride and sulfolane are dissolved in the water, carbide and water-insoluble organic impurities of tar are filtered and separated, the impurities are washed in hot water and then sent to a qualified solid waste treatment plant, and the washing water is used for soaking of the residues; soaking solutions enter an extraction kettle, sulfolane dissolved in water is extracted with an organic solvent and stands still for layering, an oil phase is desolventized, the organic solvent is recycled and returned for extraction, and the remainder is sulfolane; a water phase enters a settlement kettle, and precipitants are added into the settlement kettle and stirred until a precipitation reaction is sufficient; sediments are separated, washed and dried to obtain calcium fluoride, and the washing water is used for soaking of the residues; separating media enter an evaporator and are condensed to crystalize and dried centrifugally, and potassium chloride is obtained. According to the method, sulfolane, potassium chloride and potassium fluoride in the residues are all converted into qualified chemical materials except the organic impurities, so that the risk of environmental pollution is eliminated and considerable economic benefits are achieved.

Owner:JIANGSU HENGAN CHEM

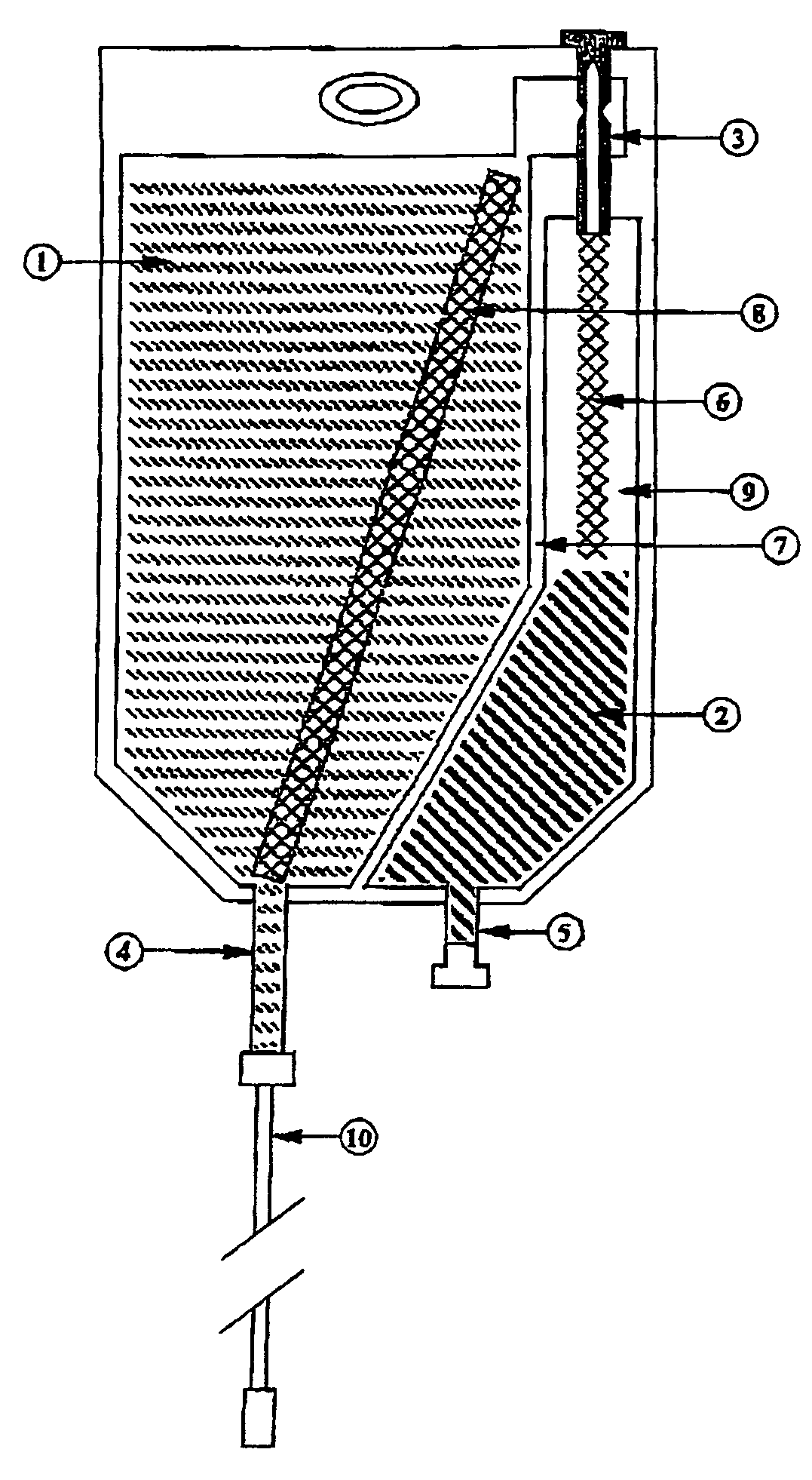

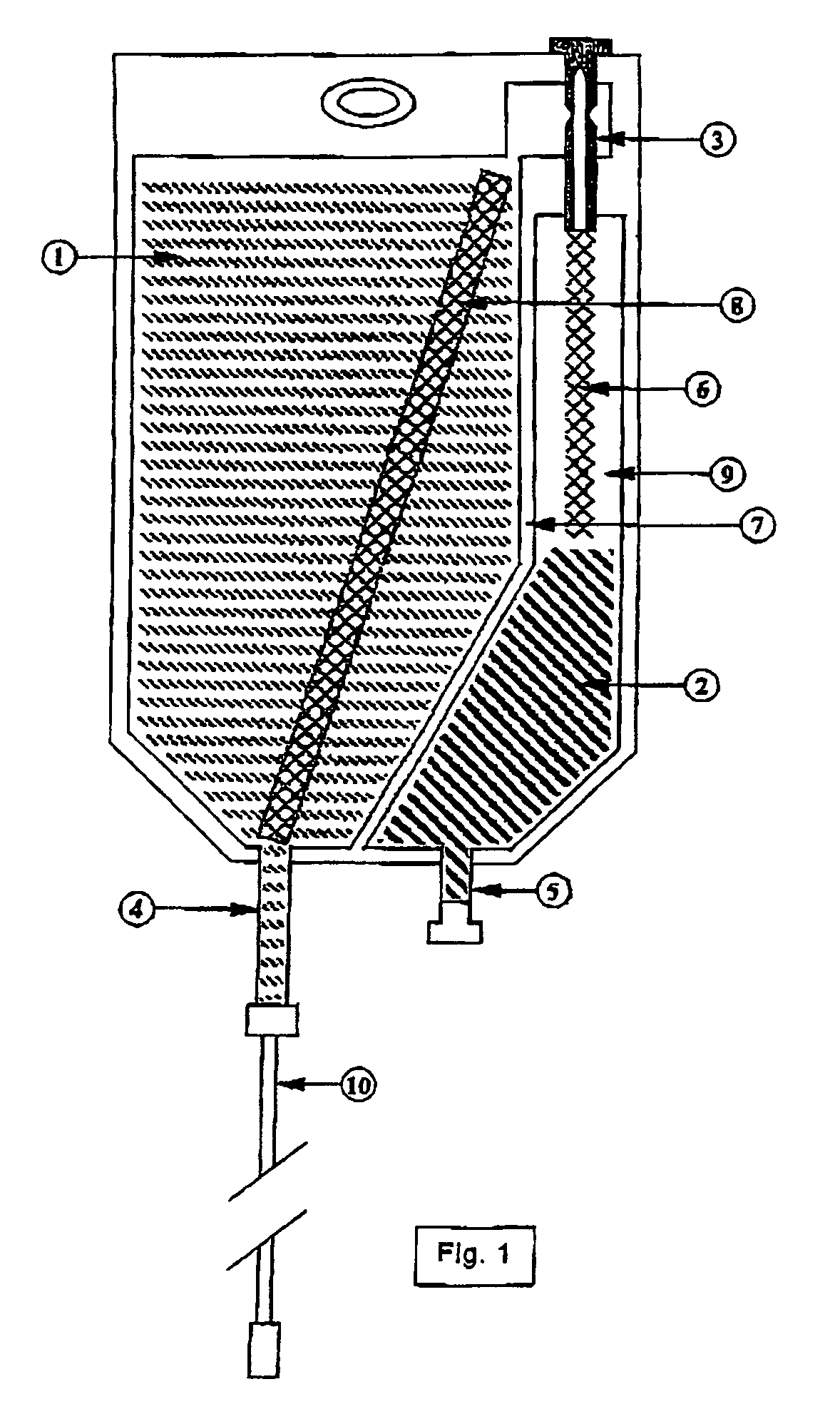

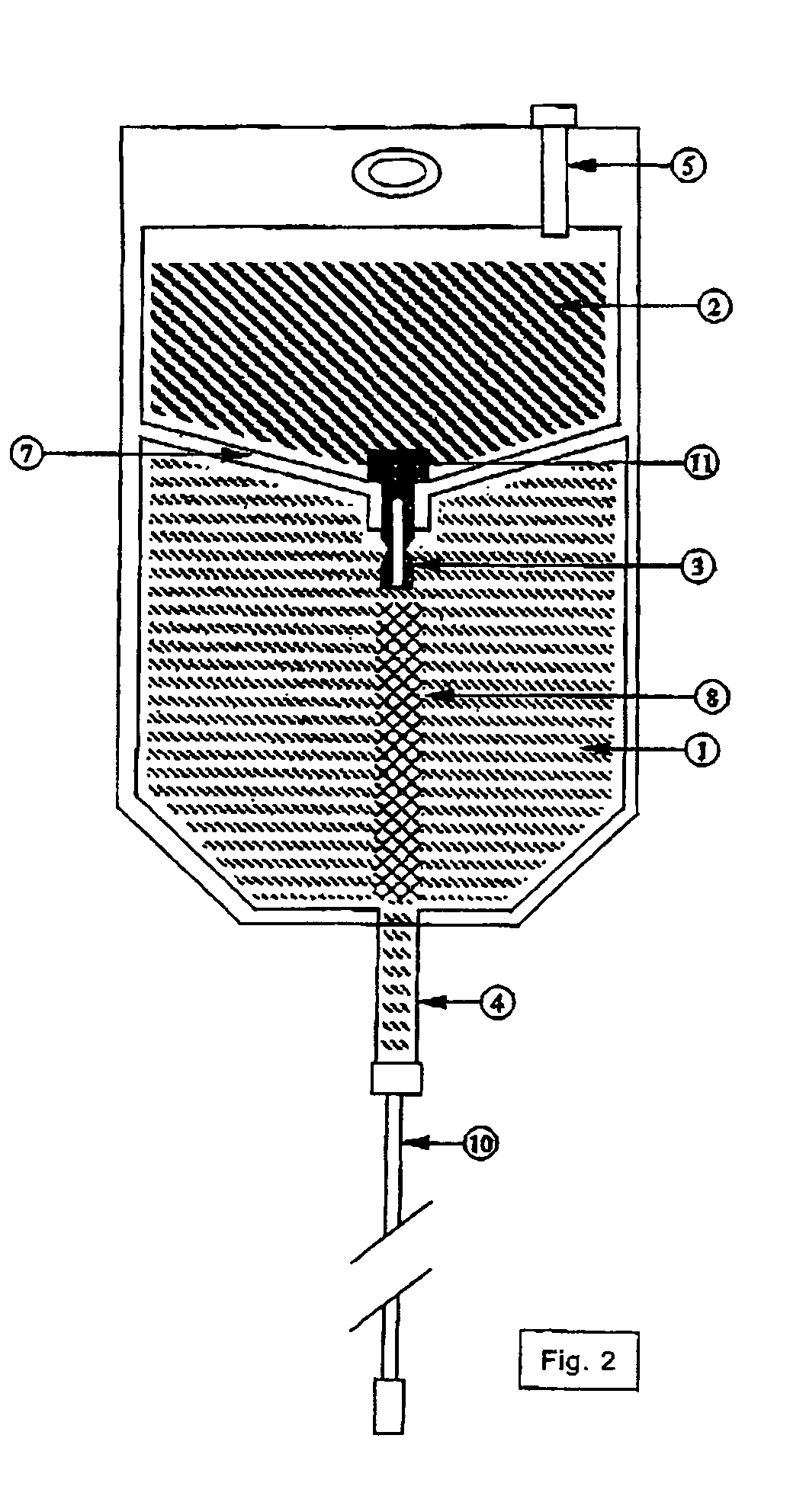

Infusion bag with integrated rinsing system

InactiveUS7722594B1Improve securityImprove effectivenessWrappersDiagnosticsLine tubingBiomedical engineering

The invention relates to a medical bag which is intended for the infusion of a medicament by means of gravity. The inventive bag comprises: at least two compartments, namely a first compartment (1) containing a medicament in the form of a solution and a second compartment (2) containing a rinsing solution; and means for separating / communicating the compartments, which prevent the rinsing solution from automatically entering the medicament compartment except at the end of the infusion period. The rinsing solution ends the infusion, by rinsing the medicament bag and the infusion line, such as to prevent any risk of contamination or leakage of residual medicament from the bag or line.

Owner:LAB AGUETTANT SA

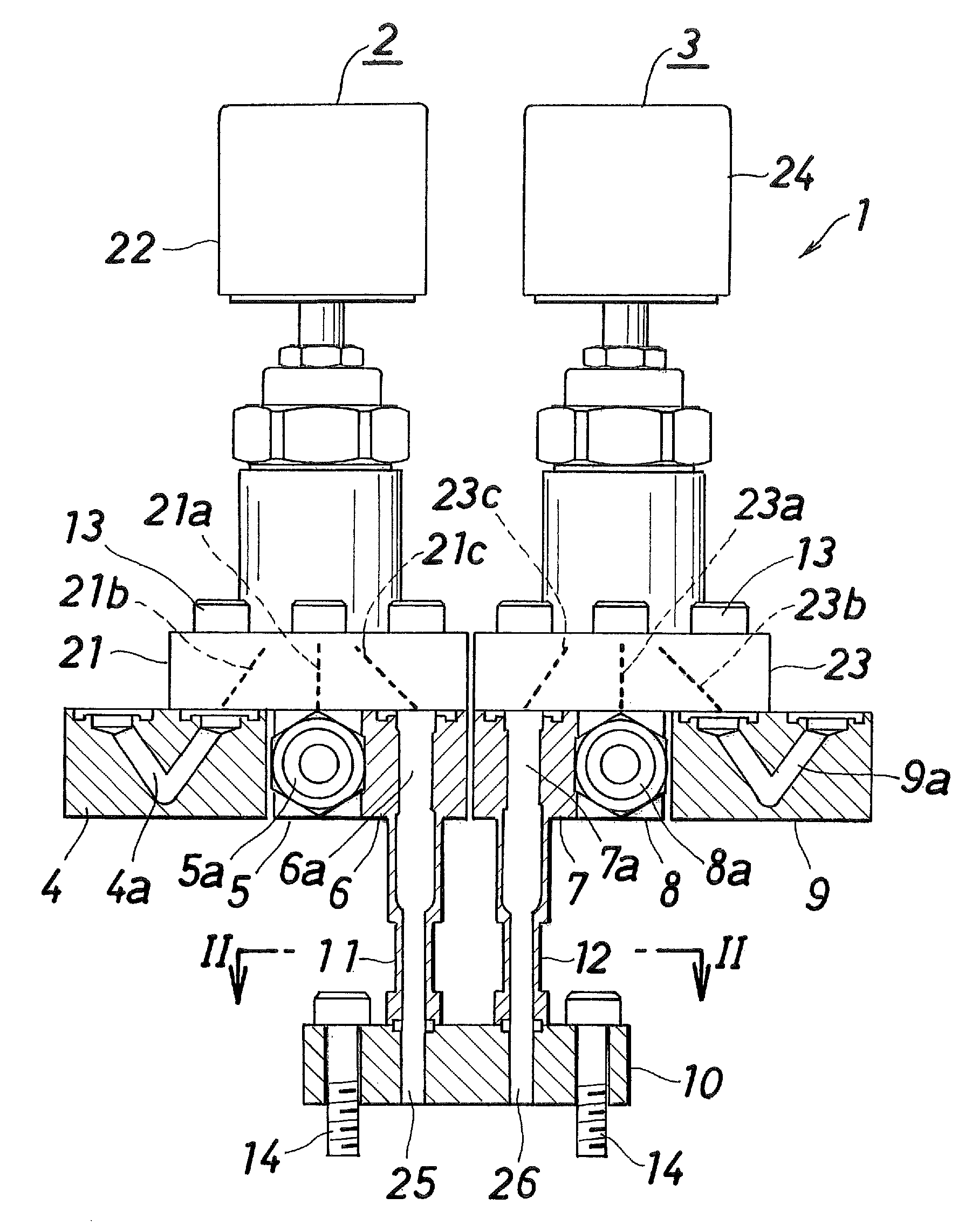

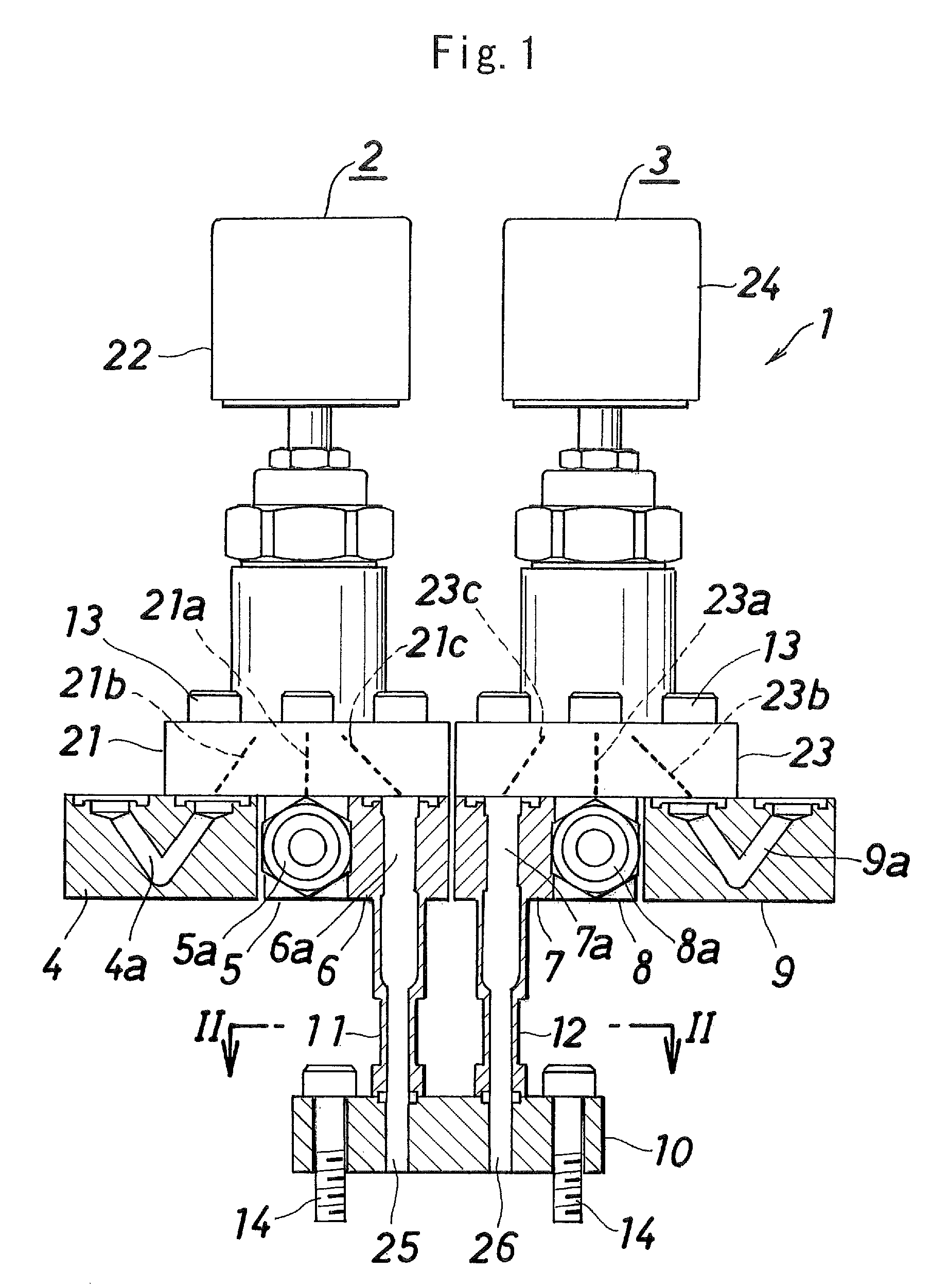

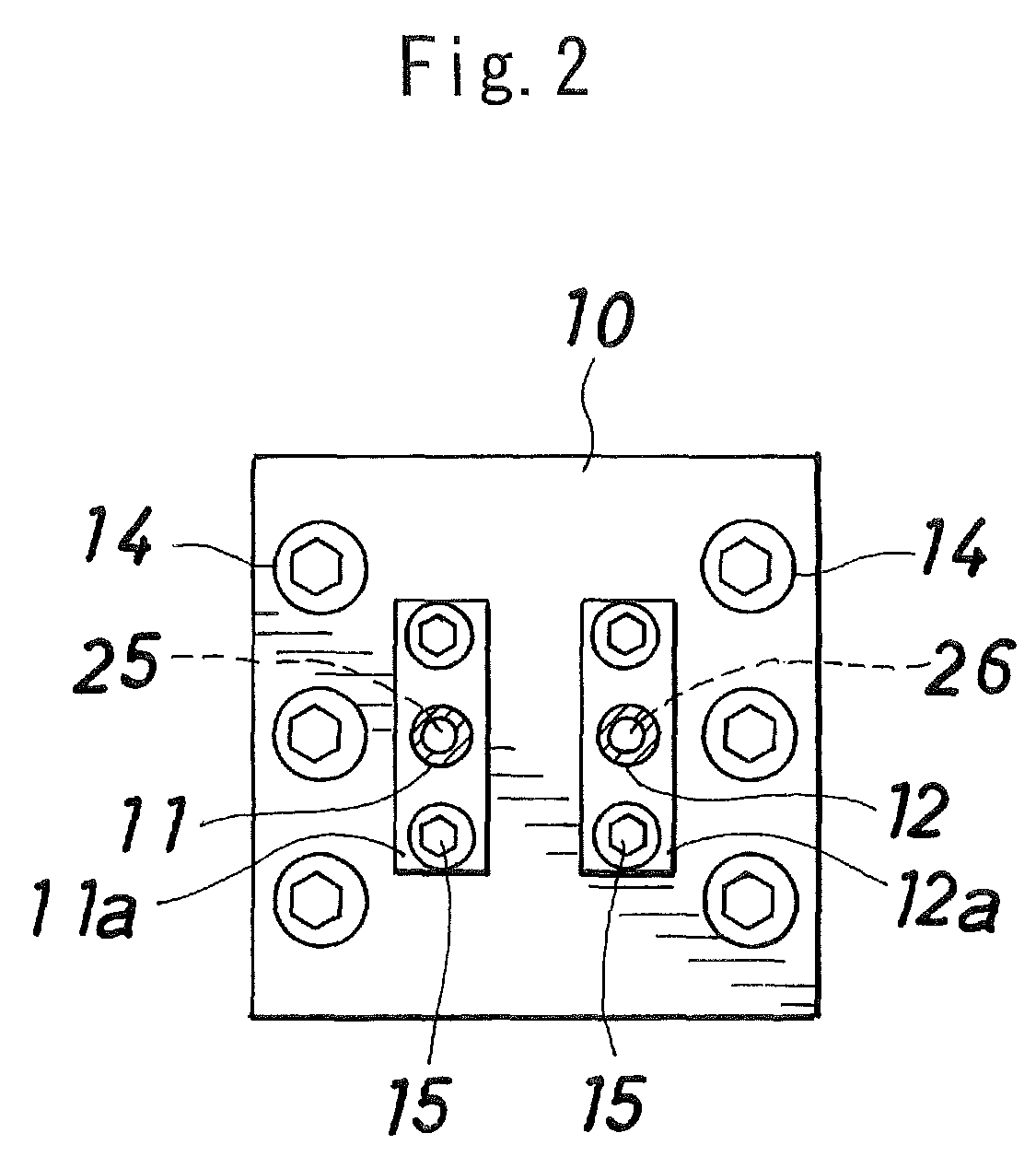

Fluid control device

ActiveUS9212755B2Eliminate the risk of contaminationFlow control of the two different fluids is facilitatedSemiconductor/solid-state device manufacturingMultiple way valvesFluid controlTwo fluid

A fluid control device includes two opening and closing valves 2, 3 disposed symmetrical to each other and having an identical shape, two fluid discharge passages 6, 7, 11, 12 having an equal length and provided in parallel with each other in outlets of the opening and closing valves 2, 3, and a connection member 10 attachable to a chamber and having two fluid passages 25, 26 formed in an equal length to and communicating with the two fluid discharge passages 6, 7, 11, 12, the connection member being provided in outlets of the two fluid discharge passages 6, 7, 11, 12.

Owner:FUJIKIN INC

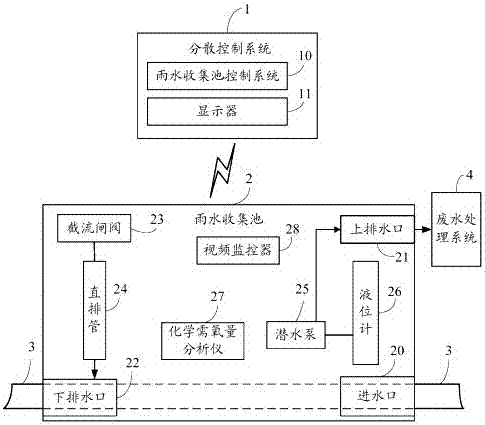

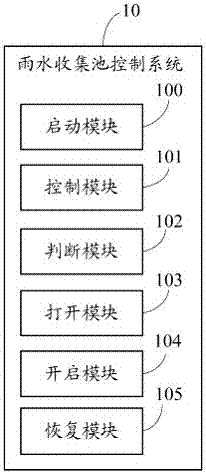

Rainwater collection and processing control method

InactiveCN107882146AGuaranteed validityAvoid dangerSewerage structuresElectric programme controlControl systemEmission standard

The invention provides a rainwater collection and processing control method. A rainwater collection and processing system applied by the control method comprises a control module, a sub-station systemand a start module, wherein the control module controls a chemical oxygen demand analyzer in a rainwater collection pool to sample rainwater in the rainwater collection pool, and analyzes a chemicaloxygen demand concentration value of the rainwater; the sub-station system comprises a sub-station controller, a waste flow controller well, a rainwater storage pool, a purifying device, a clean waterstorage pool and a sub-station control system; the start module starts a submerged pump in the rainwater collection pool when a chemical oxygen demand concentration value of the rainwater excesses arainwater emission standard and a rainwater level reaches a high liquid level of a liquidometer in the rainwater collection pool. The invention further provides a rainwater collection pool control method. Rainwater can be collected and processed and environmental pollution can be prevented.

Owner:安徽德司节能科技有限公司

Locking cap for a vessel having a neck

ActiveUS8684225B2Avoid accessEliminate the risk of contaminationCapsClosure using stoppersPlastic materialsEngineering

Owner:A RAYMOND & CO

Microchip for analysis, analysis system having the same, and analysis method

InactiveUS7842240B2Low production costEasy to useMaterial nanotechnologyAnalysis using chemical indicatorsEngineeringBuffer solution

A microchip has a substrate on which there are formed a reaction bath section, a first flow channel to which are connected a supply channel that supplies a buffer solution and the reaction bath section, a second flow channel to which are connected a supply channel that supplies a sample solution containing a first substance and a channel that discharges the sample and buffer solutions to an exterior of the substrate, and a connecting channel connecting the first flow channel to the second flow channel. The reaction bath section receives the first and second substances so that the first and second substances react in the reaction bath section. The first and second flow channels are provided with valves disposed relative to the connecting channel such that selective opening and closing of the valves causes the buffer solution to flow first into the reaction bath section at a preselected speed and the sample solution to flow second into the reaction bath section at the preselected speed to cause the first and second substances to react in the reaction bath section.

Owner:SEIKO INSTR INC

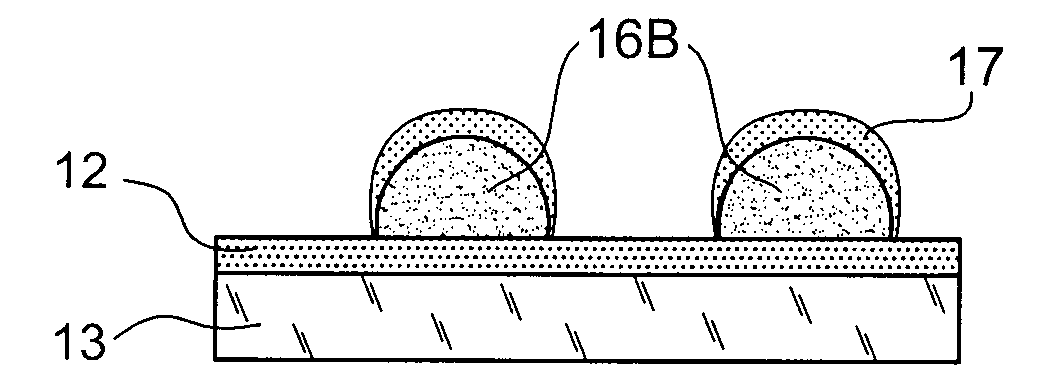

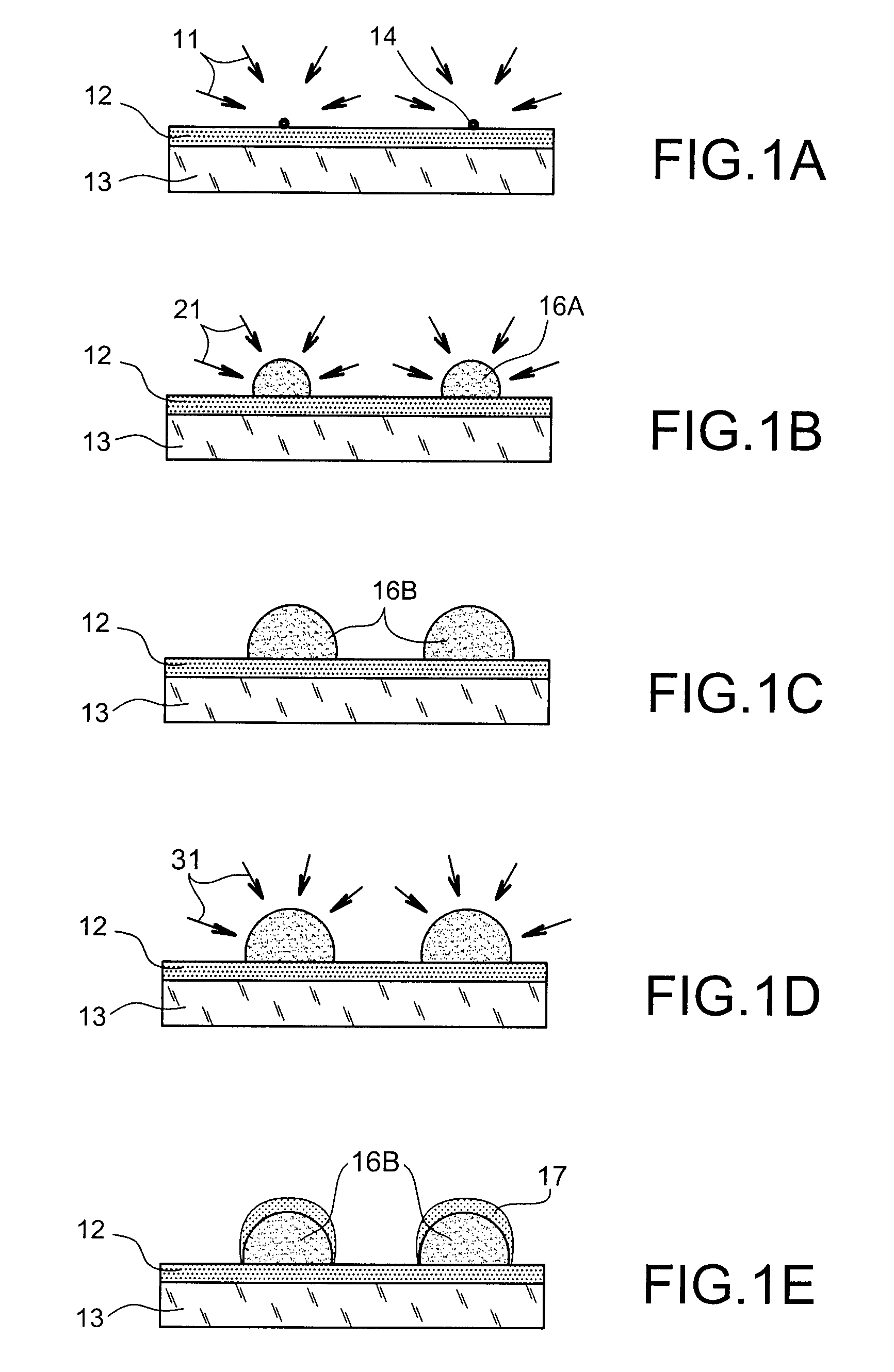

Manufacturing method for a nanocrystal based device covered with a layer of nitride deposited by CVD

InactiveUS20080203460A1Eliminate the risk of contaminationPromote formationTransistorNanoinformaticsSemiconductor materialsMemory cell

The invention relates to a manufacturing method for a structure comprising semi-conductor material nanocrystals on a dielectric material substrate by chemical vapour deposition (CVD), the nanocrystals being covered by a layer of semi-conductor material nitride. The method comprises a step for forming stable nuclei on the substrate by CVD from a first gaseous precursor of the nuclei; a step of nanocrystal growth from stable nuclei by CVD from a second gaseous precursor; and a step for forming a layer of semi-conductor material nitride on the nanocrystals. The method is characterised in that the passivation step is carried out by selective and stoichiometric CVD of semi-conductor material nitride only on the nanocrystals from a mixture of the second and a third gaseous precursor selected to cause selective and stoichiometric deposition of the nitride only on said nanocrystals, wherein steps for forming the nuclei, forming the nanocrystals and passivation are carried out inside a same, single chamber.The invention also relates to the formation of memory cells and flash memories comprising nanocrystals made according to the method of the invention.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

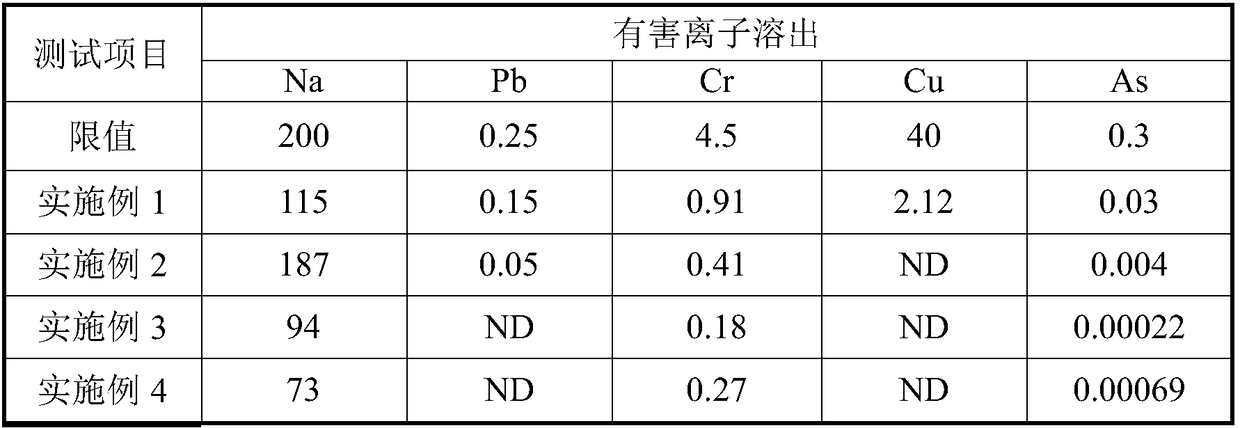

Ionic curing agent and red mud fly ash gel material

The invention discloses an ionic curing agent used for a red mud fly ash gel material. The material mainly consists of layered double metal hydroxide and ammonium chloride. The volume weight is 1170 kg / m3-1230 kg / m3. The percentage of the layered double metal hydroxide in the total content of the ionic curing agent is 50%-60%. The percentage of the ammonium chloride in the total content of the ionic curing agent is 40%-50%. 0.25-0.5% of the ionic curing agent is added into the red mud fly ash gel material after mixing the ionic curing agent with a percentage of the total content. The dissolution amount of Na+ ions and harmful ions (Na, Cu, Pb, Cr, As) of hardened gel material can be reduced. The risk of environmental pollution can be eliminated. The usage field of industrial wastes such asred mud can be widened.

Owner:WUHAN UNIV OF TECH

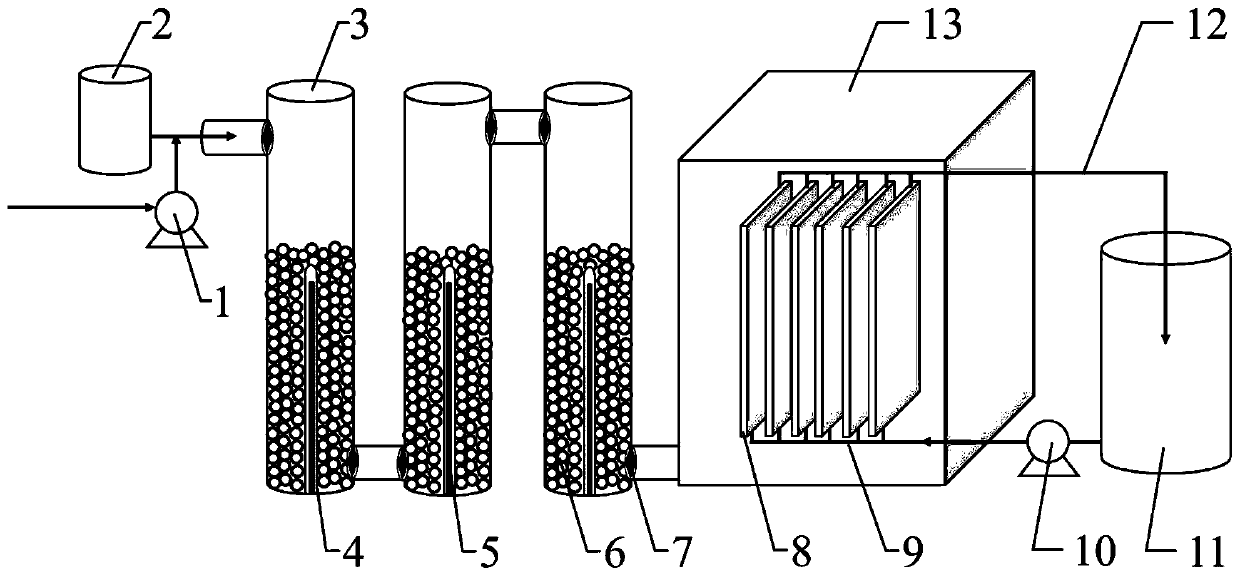

Photo-Fenton-positive permeation integrated device for treating organic wastewater difficult to biodegrade and using method of device

InactiveCN110204031AReduce the risk of contaminationEfficient removalWater/sewage treatment by irradiationWater treatment compoundsTherapeutic effectCirculating pump

The invention relates to a photo-Fenton-positive permeation integrated device for treating organic wastewater difficult to biodegrade and a using method of the device. The device comprises a photo-Fenton unit and an immersed positive permeation unit. The method for treating the water by using the device comprises the photo-Fenton process and the positive permeation process, and while organic pollutants are effectively degraded or converted by using the photo-Fenton unit, the organic pollutants which are not completely degraded or converted in the photo-Fenton process are permselectively intercepted by using a positive permeation membrane. The immersed positive permeation unit adopts an immersed positive permeation structure, a water inlet end circulating pump or an inlet water tank is notneeded, the overall structure is compact, the energy consumption is low, and the photo-Fenton-positive permeation integrated device is easily combined with other technologies or devices. Active substances generated by the photo-Fenton unit are used up in the pollutant degradation and converting process and in the positive permeation unit migration process, the strong oxidizing property of the photo-Fenton unit cannot affect the stability of the membrane, the wastewater treatment efficiency is high, the wastewater treatment effect is good, and the device is suitable for application and popularization.

Owner:CHANGCHUN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com