Patents

Literature

2290results about How to "Reduce the risk of contamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

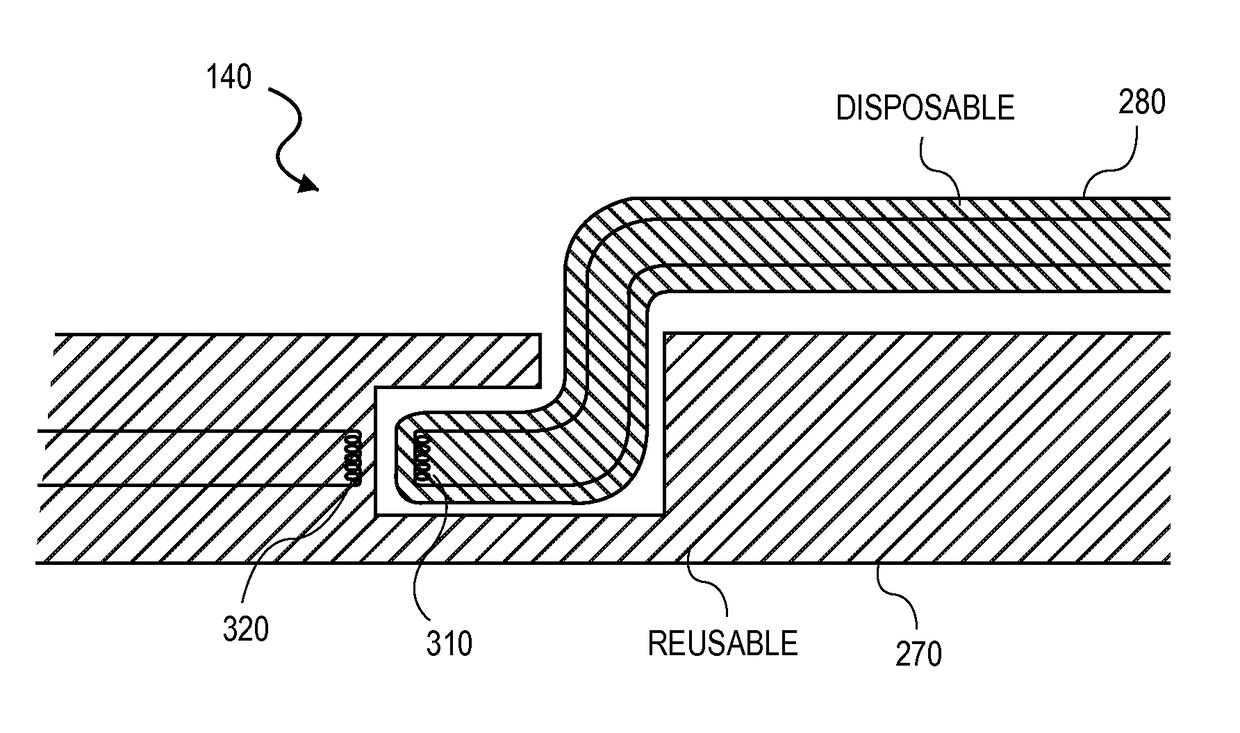

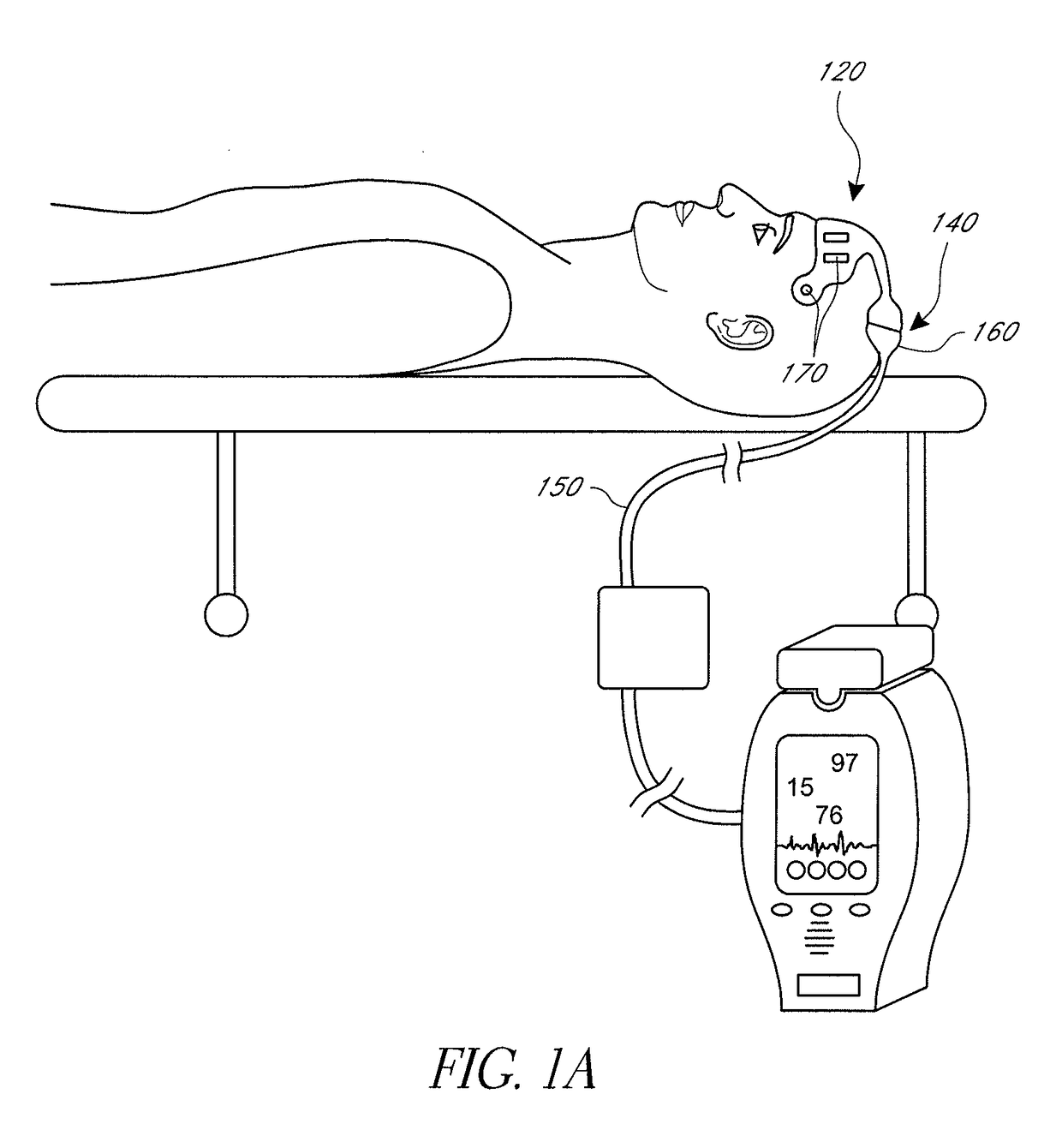

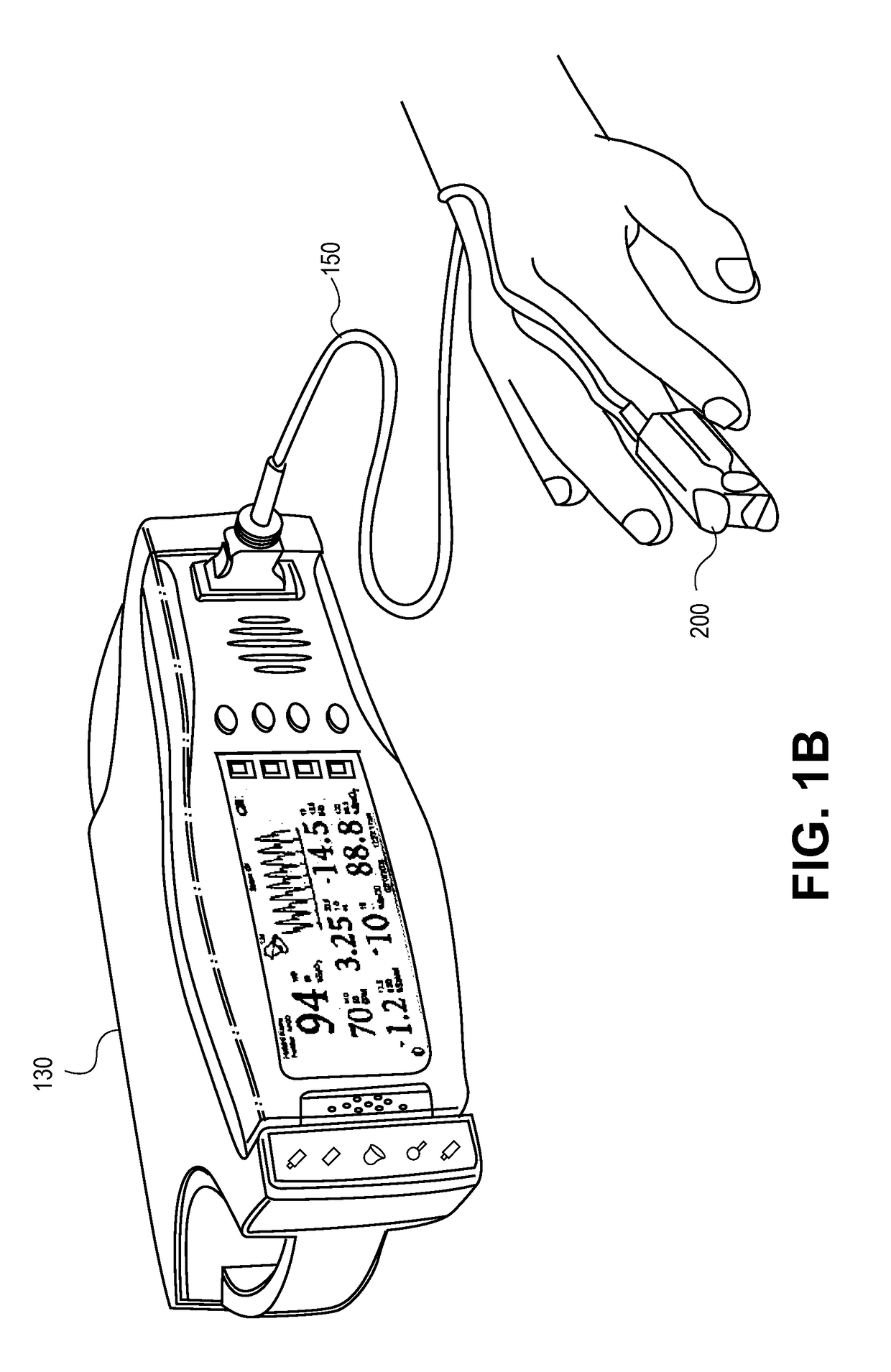

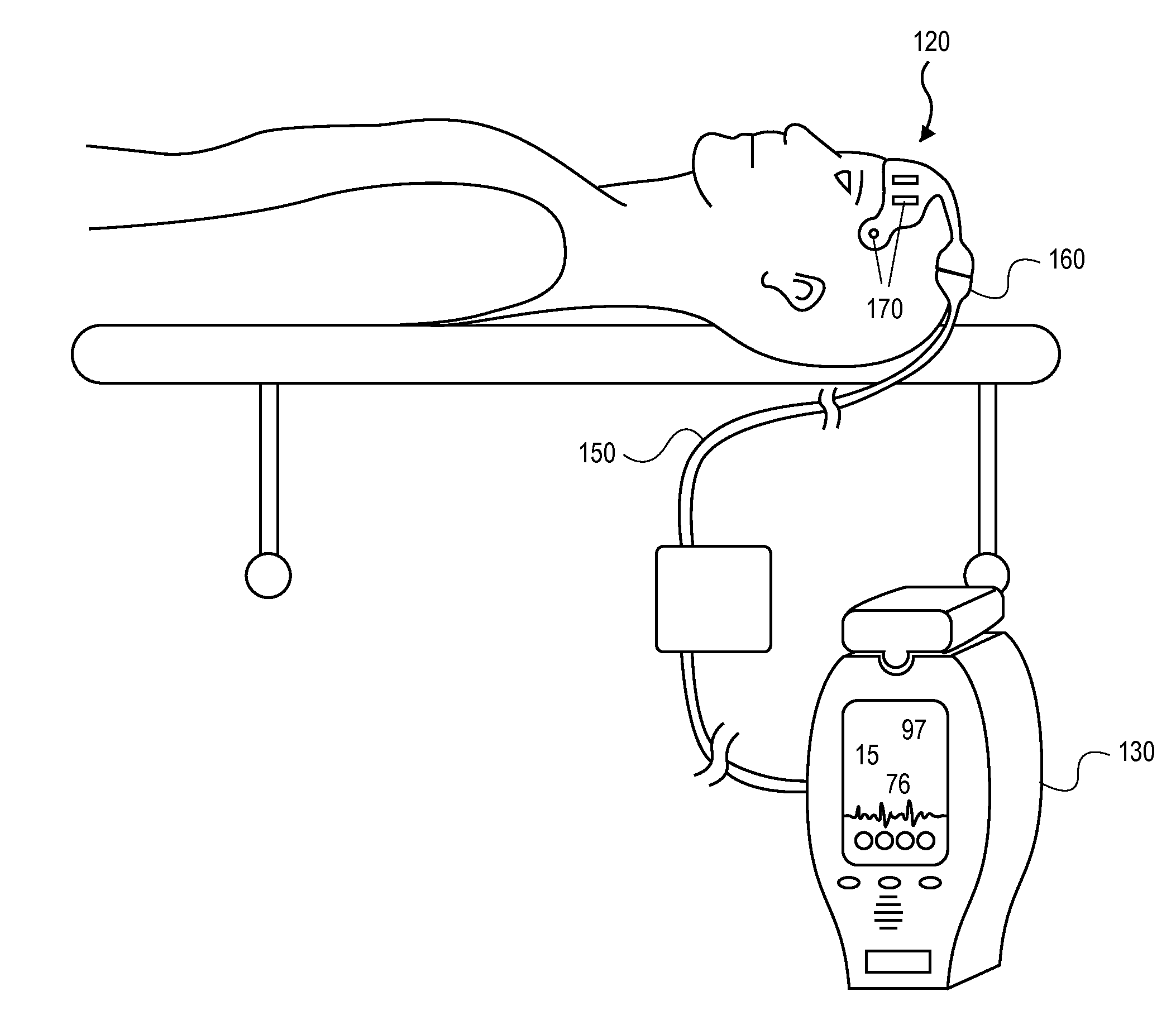

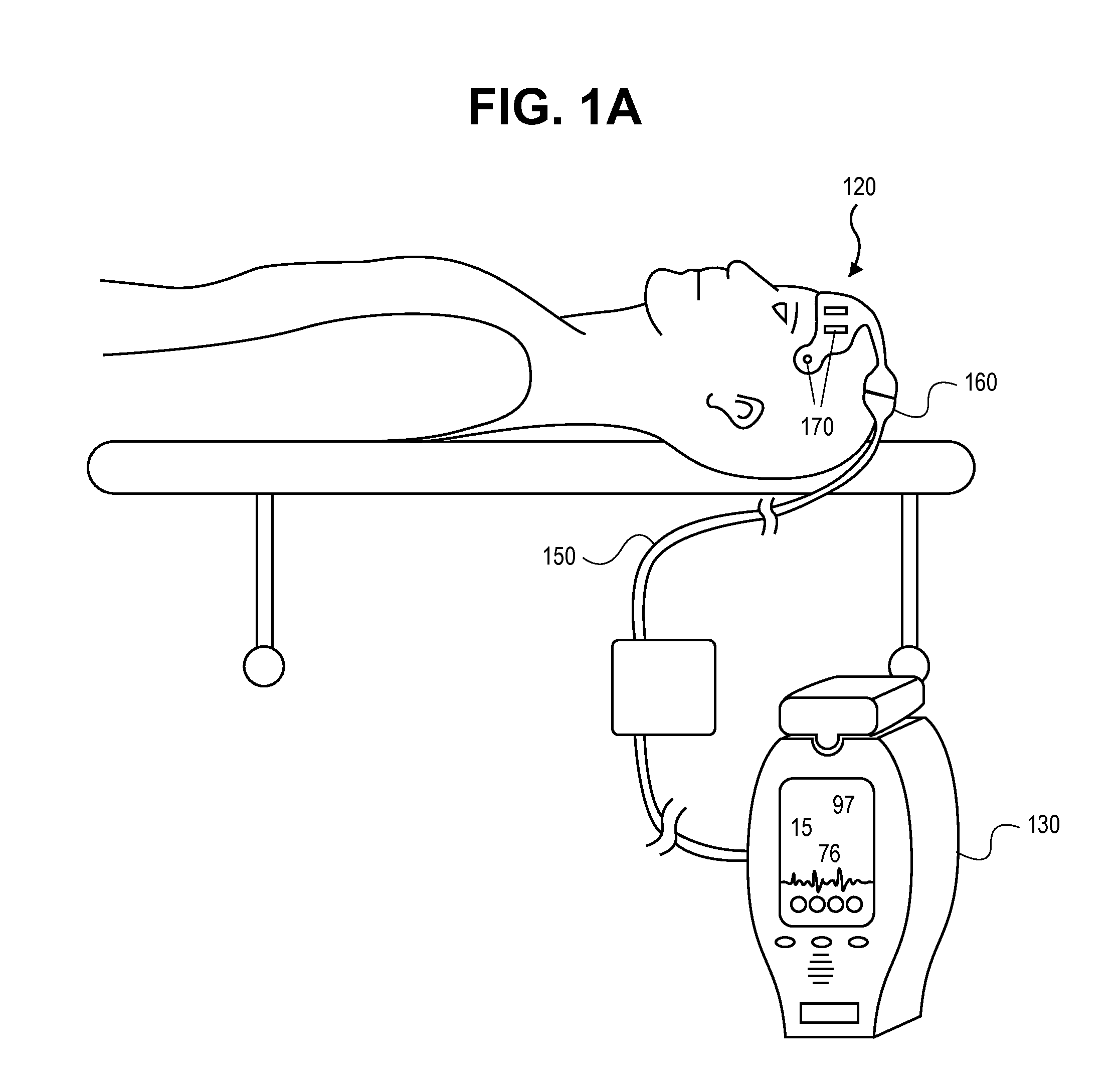

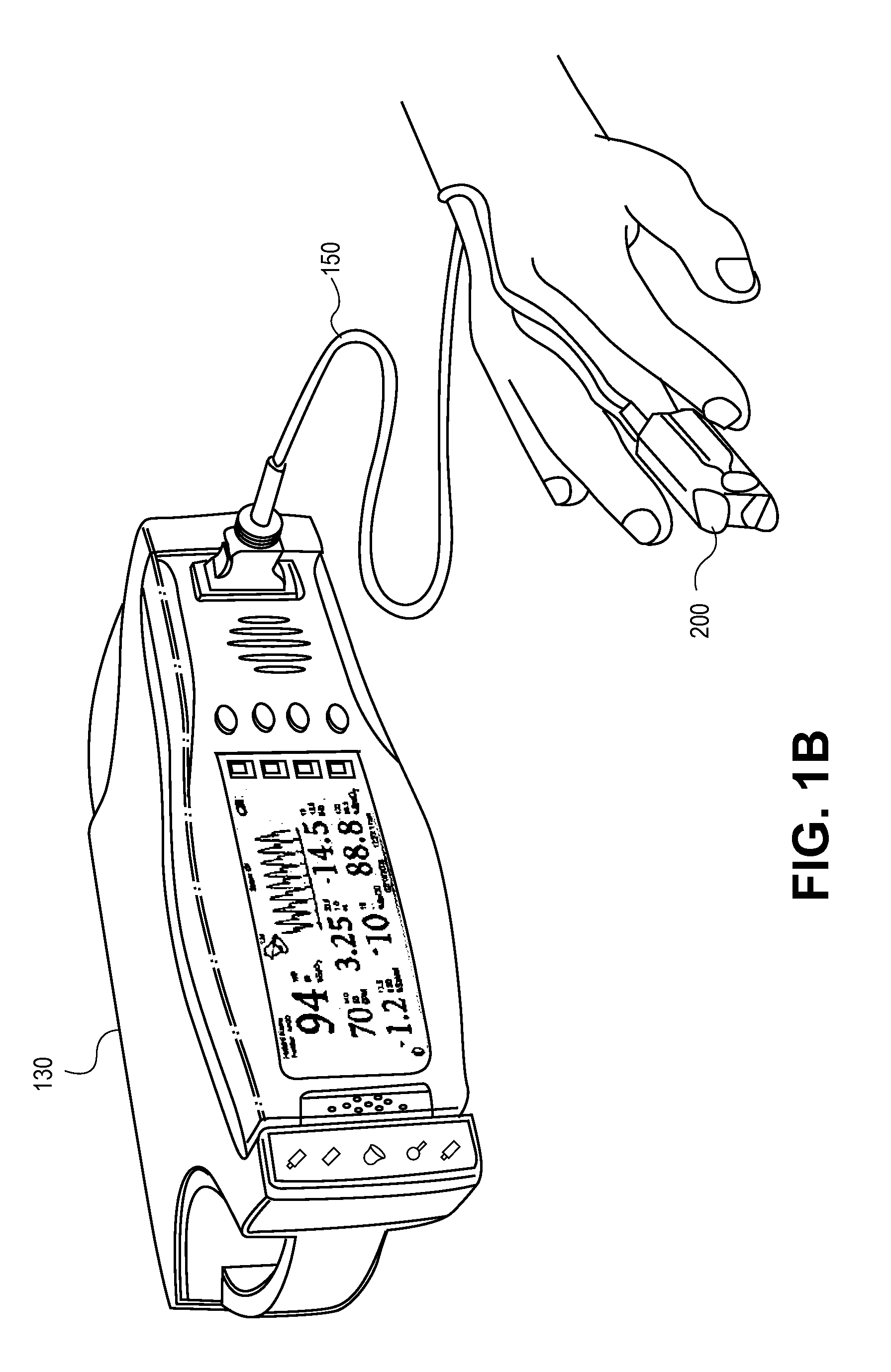

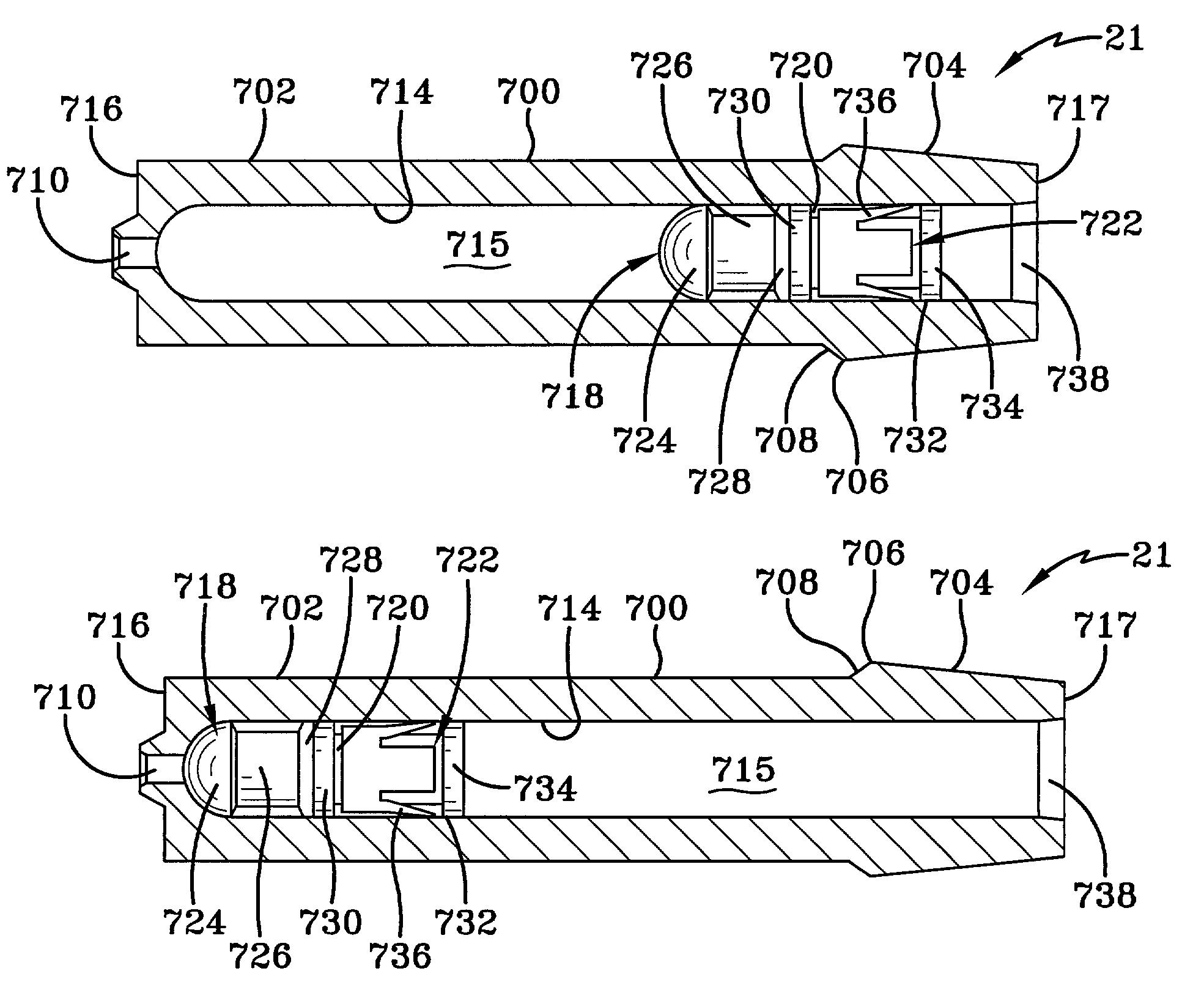

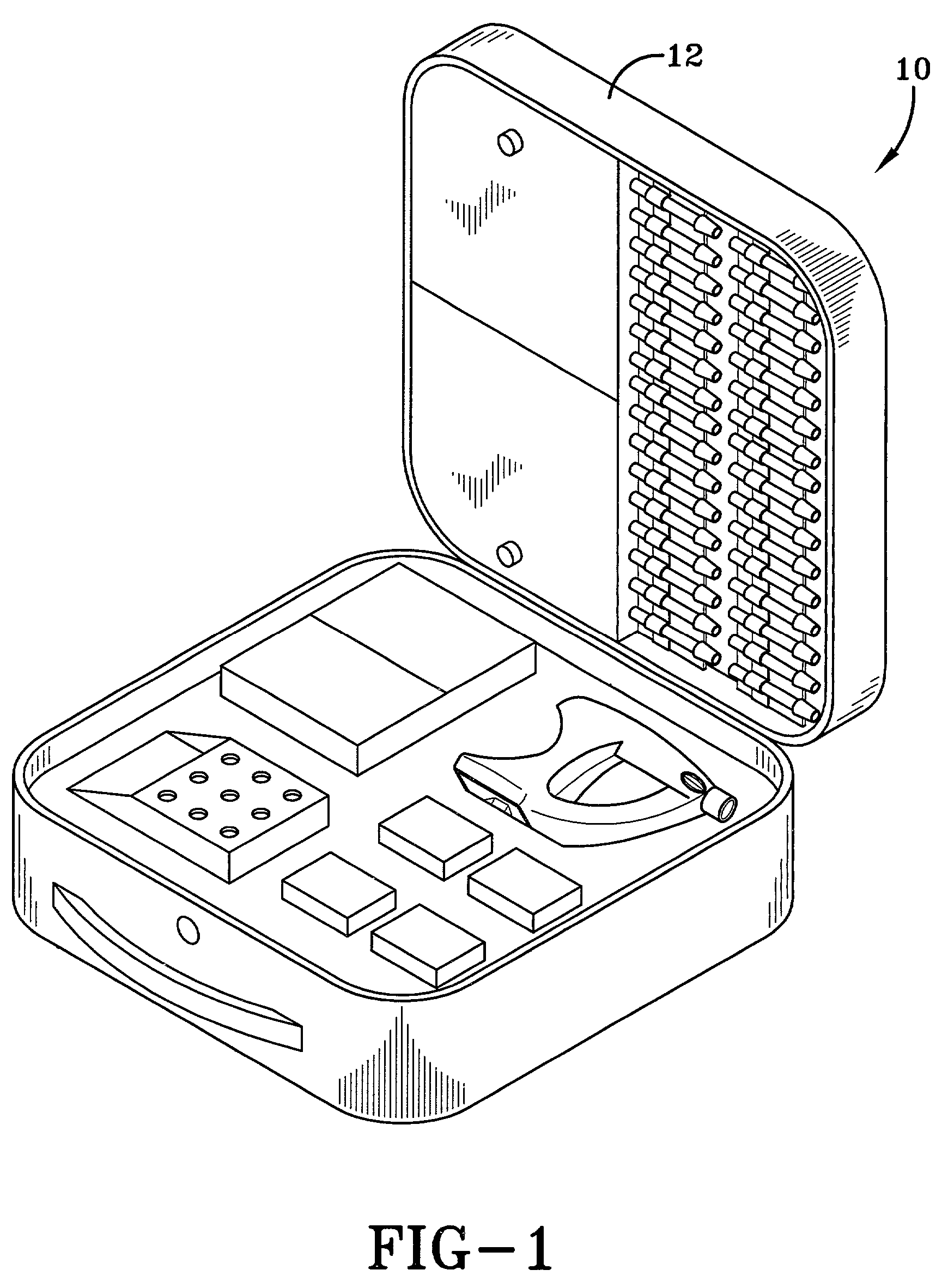

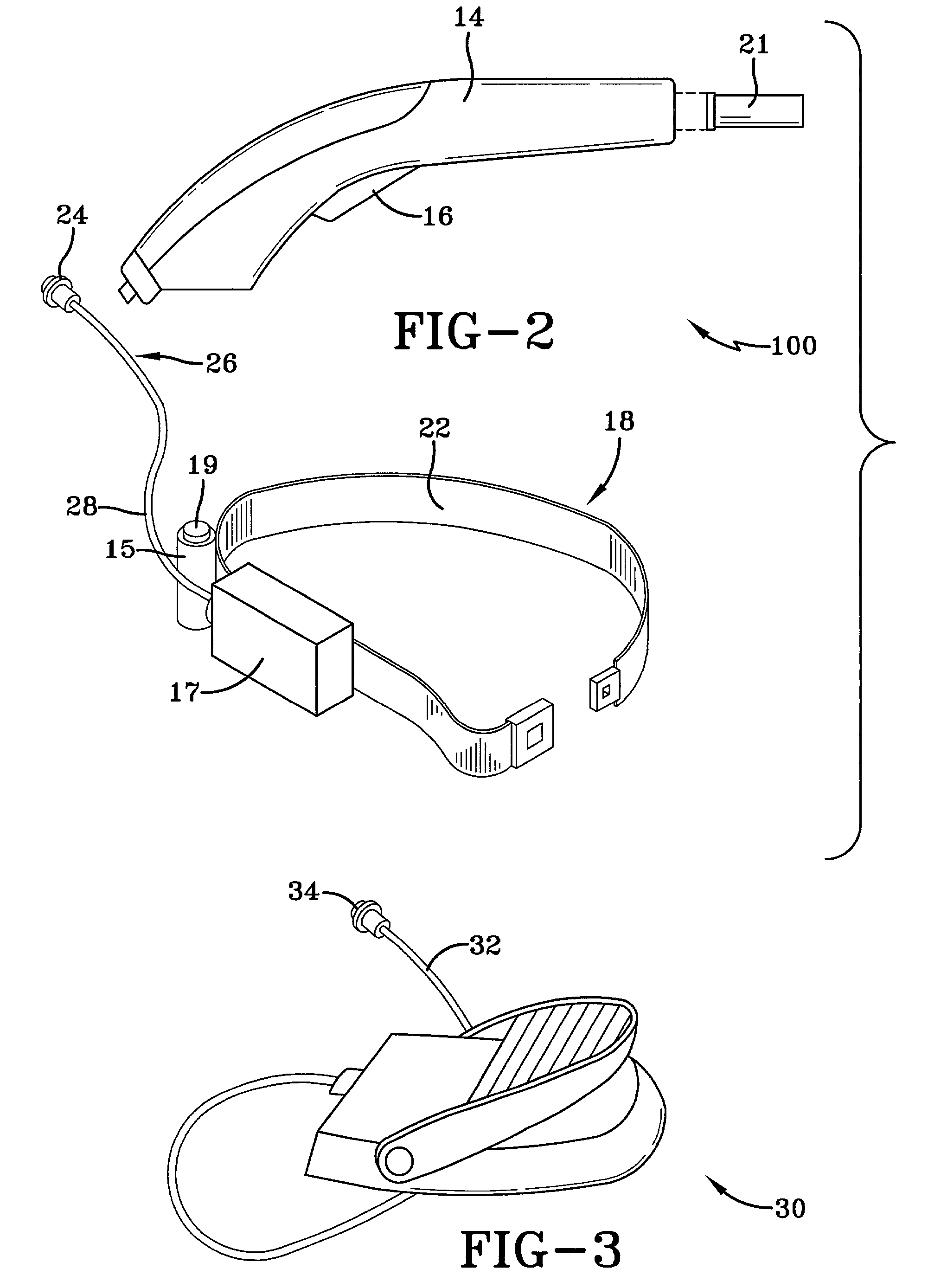

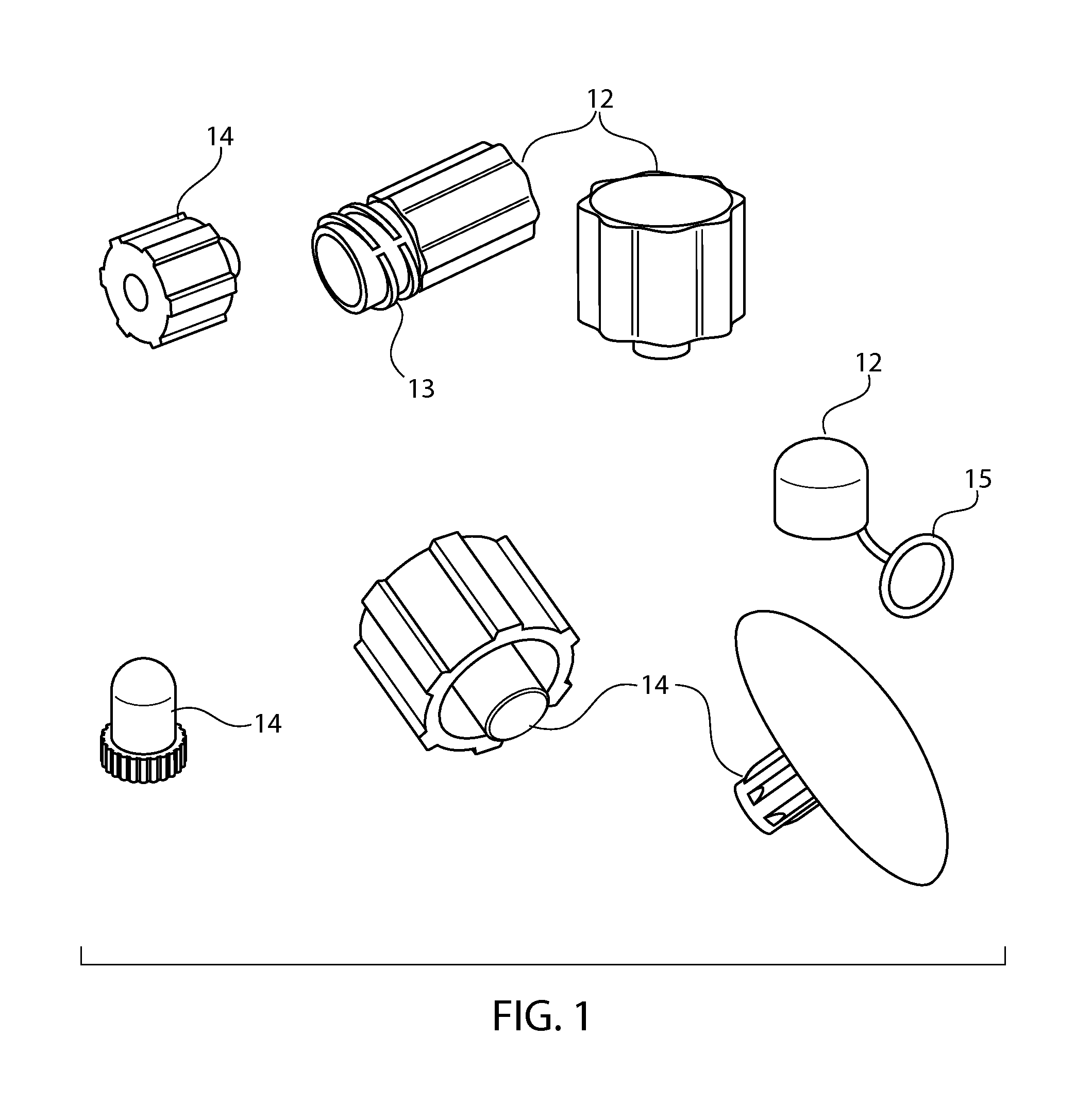

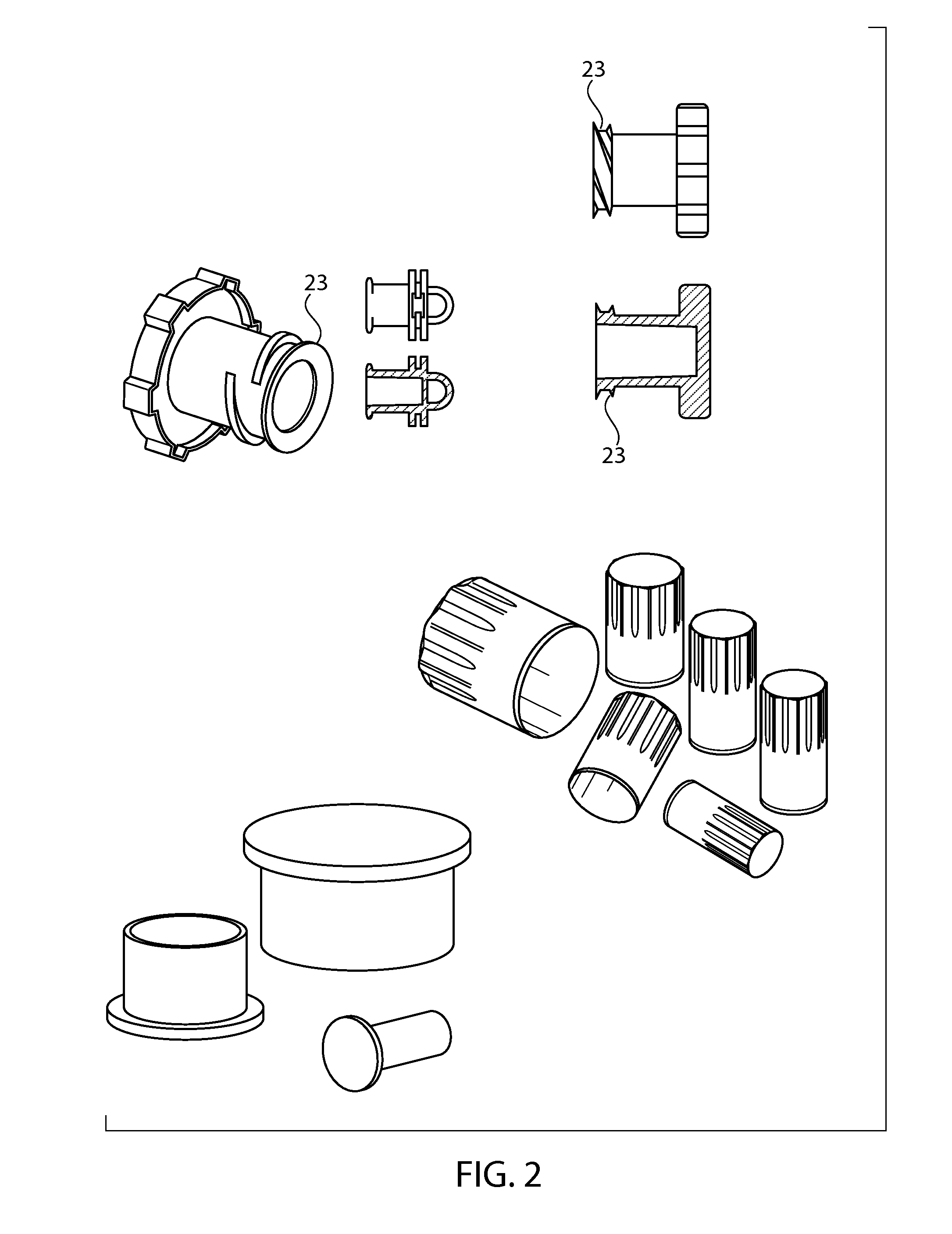

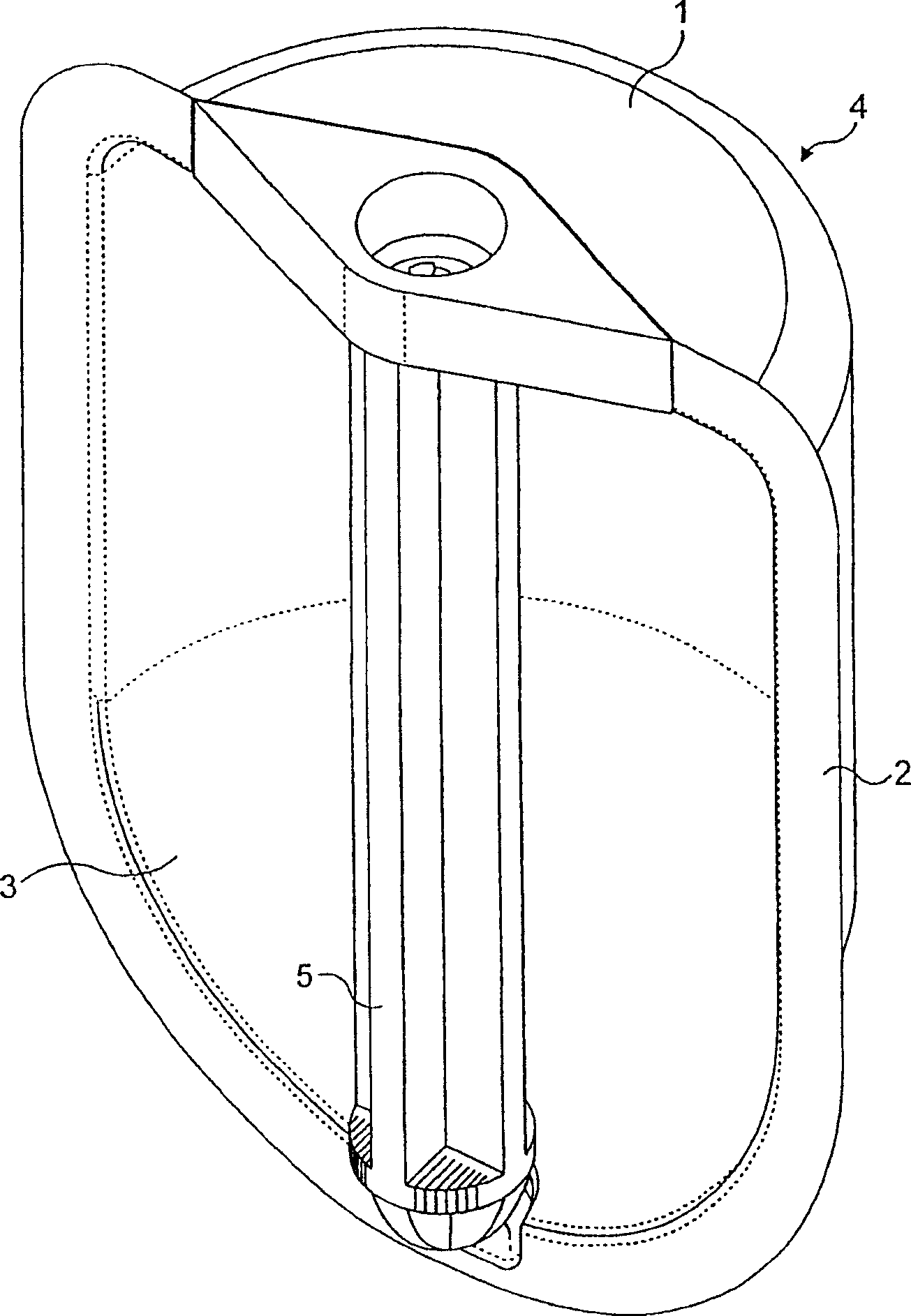

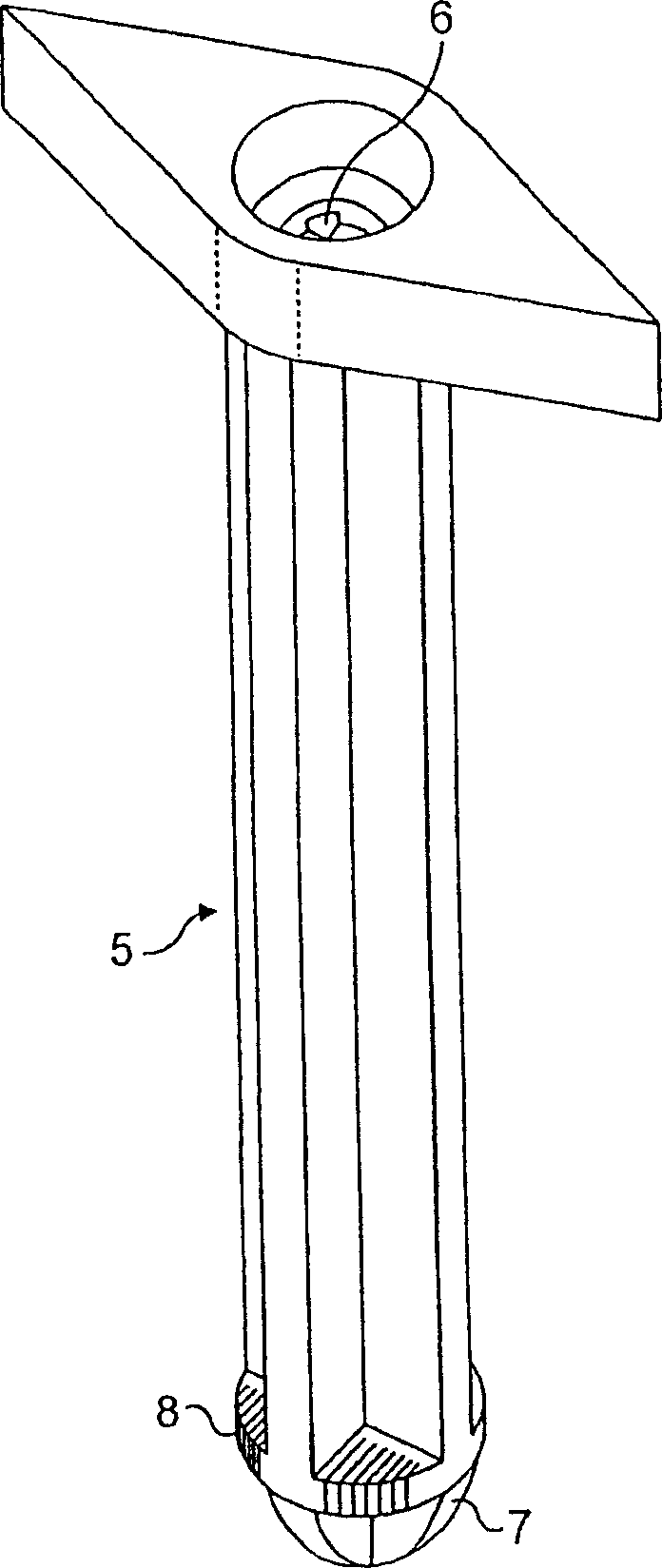

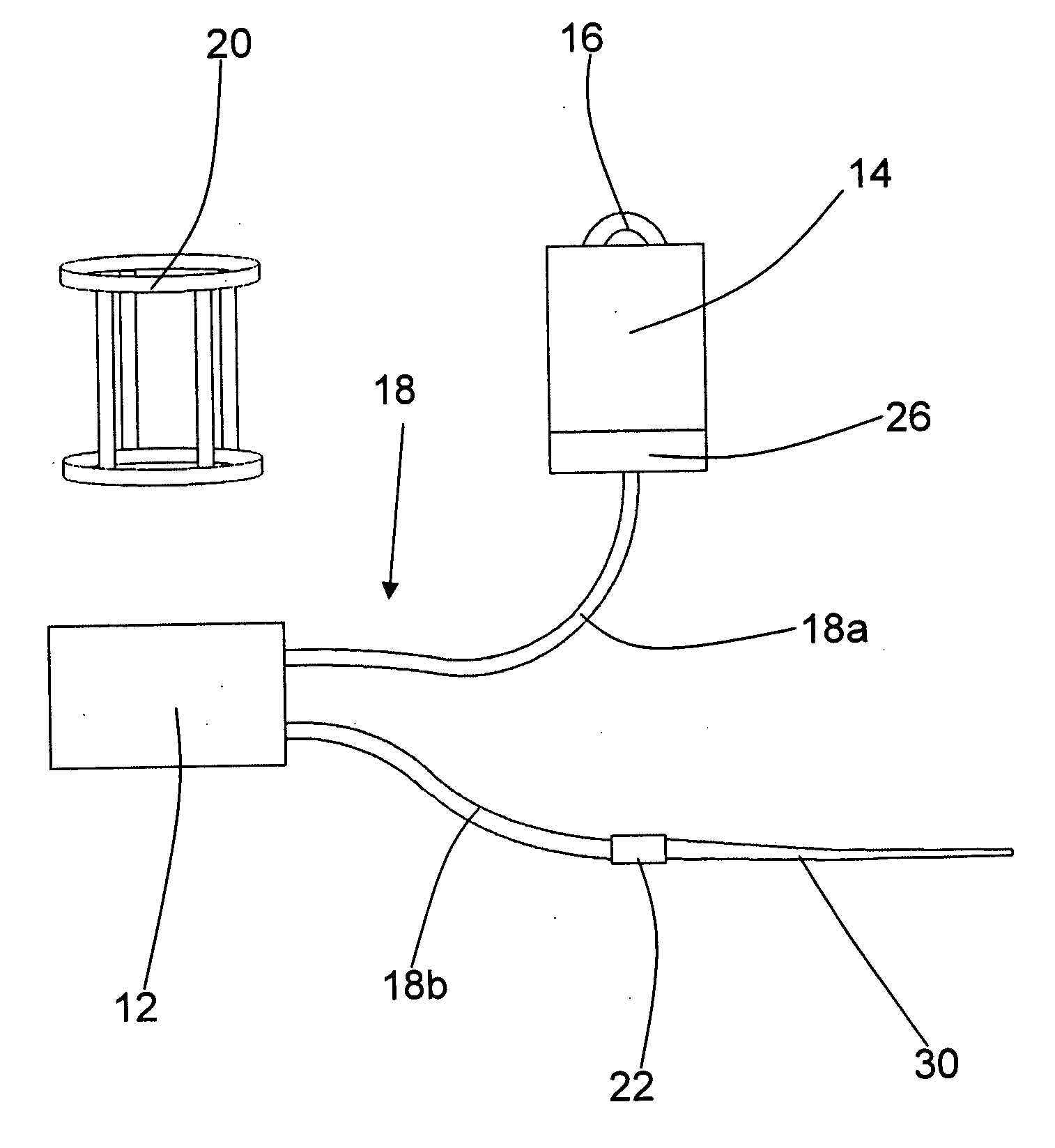

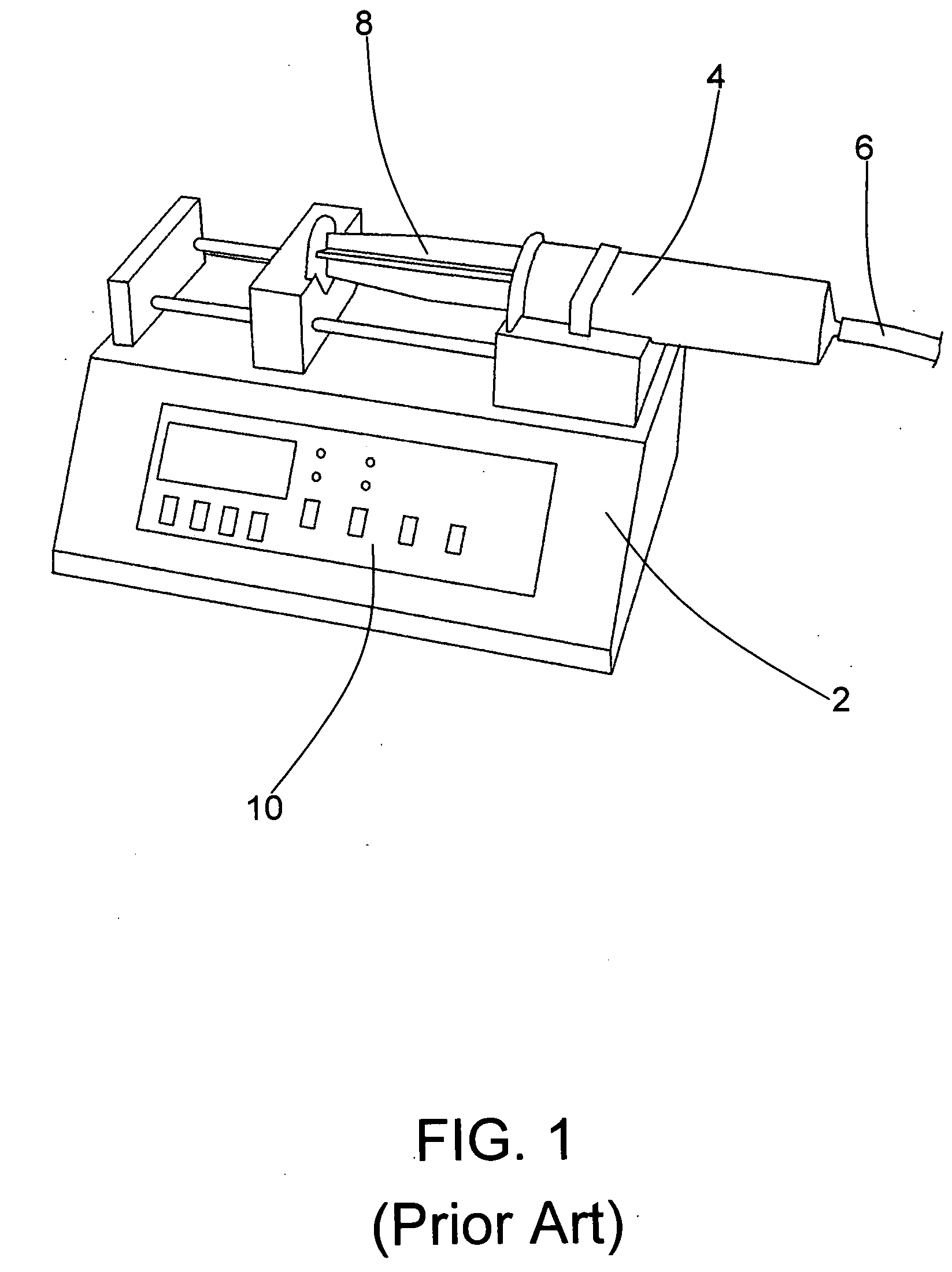

Magnetic electrical connector for patient monitors

ActiveUS9775545B2Reduce the risk of contaminationImprove efficiency and benefitElectroencephalographySensorsElectricityMonitoring system

The present disclosure relates to an electrical connector for providing signal isolation between various components of a physiological monitoring system. In an embodiment, the electrical connector is placed between a sensor and associated monitoring system and includes a physical barrier and inductive components.

Owner:JPMORGAN CHASE BANK NA

Megnetic electrical connector for patient monitors

ActiveUS20120088984A1Easy to cleanReduce the risk of contaminationElectroencephalographySensorsElectricityMonitoring system

The present disclosure relates to an electrical connector for providing signal isolation between various components of a physiological monitoring system. In an embodiment, the electrical connector is placed between a sensor and associated monitoring system and includes a physical barrier and inductive components.

Owner:JPMORGAN CHASE BANK NA

Continuous-Batch Hybrid Process for Production of Oil and Other Useful Products from Photosynthetic Microbes

InactiveUS20080118964A1Lower potentialIncreased complexityBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismCarrying capacity

A process for cultivating photosynthetic microbes comprising Closed Systems for continuous cultivation and Open Systems for batch cultivation, in which (a) the Closed System Area occupies no more than 20% of the Total Land Area of the cultivation facility; (b) batch cultures in the Open Systems are initiated with an inoculum from the Closed Systems containing a cell biomass of no less than 5% of the carrying capacity of said Open System; (c) the doubling rate of said photosynthetic microbe is no less than once every 16 hours; and (d) the residence time of the batch culture in said Open System is no more than a period of 5 days.

Owner:CELLANA

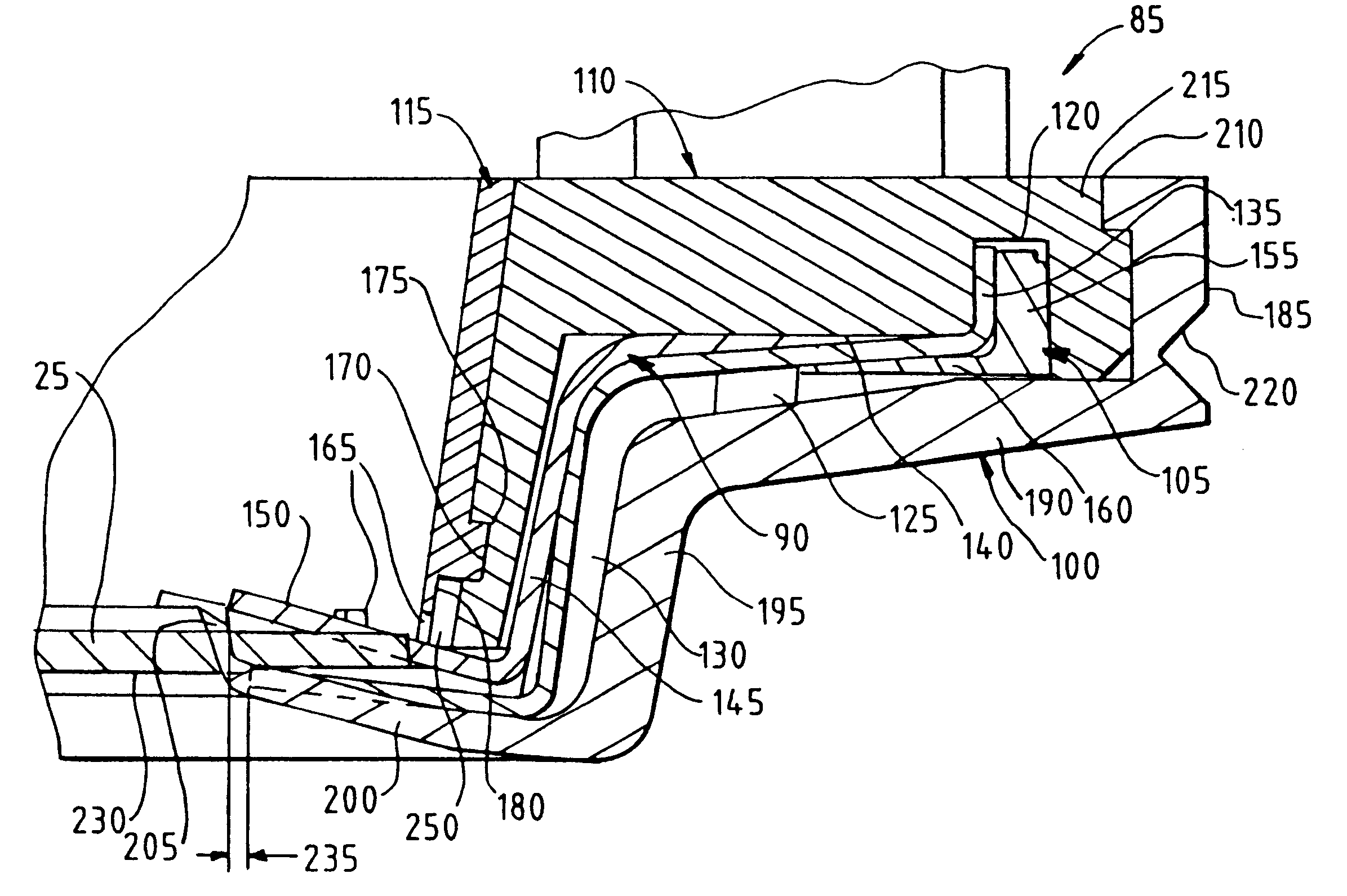

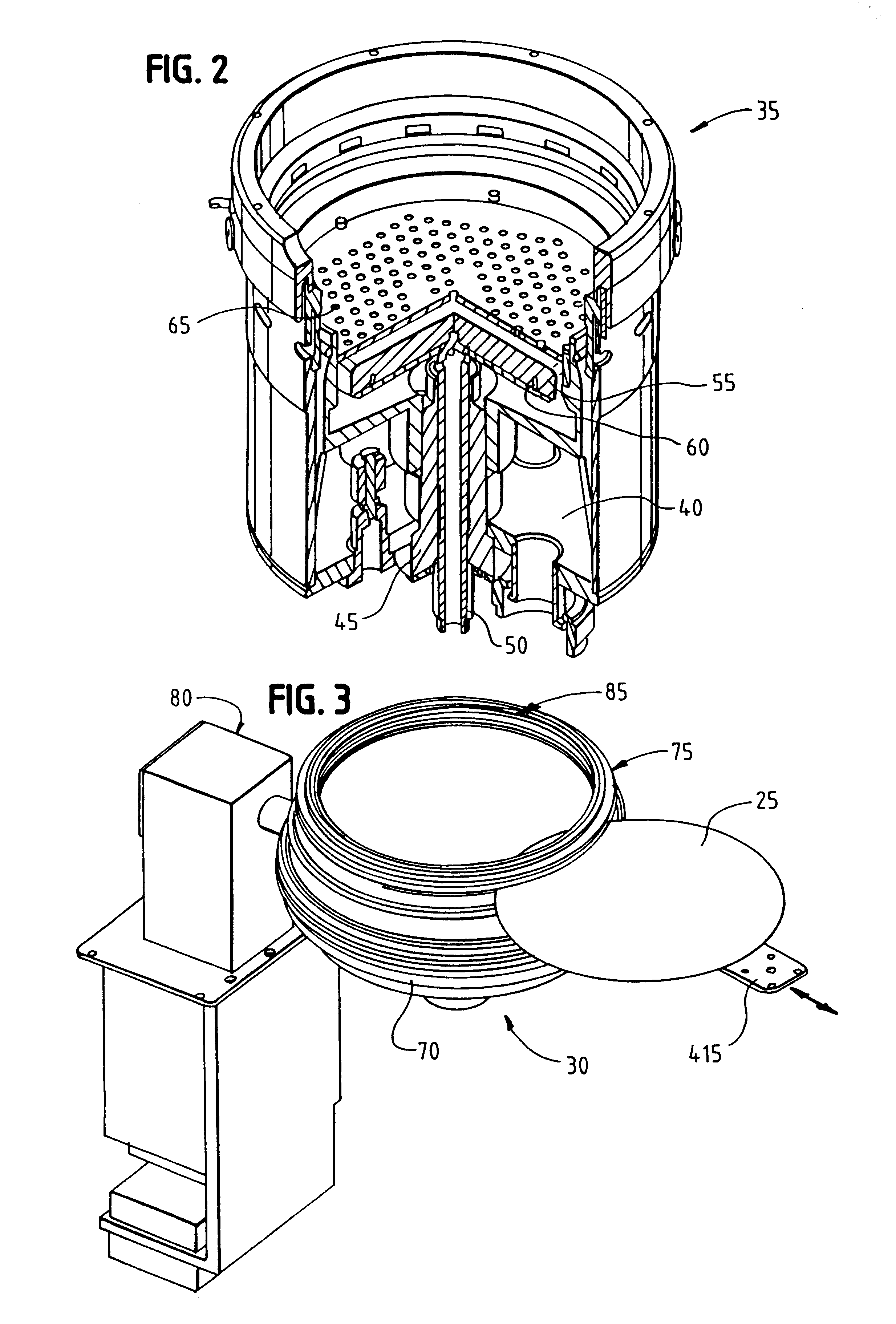

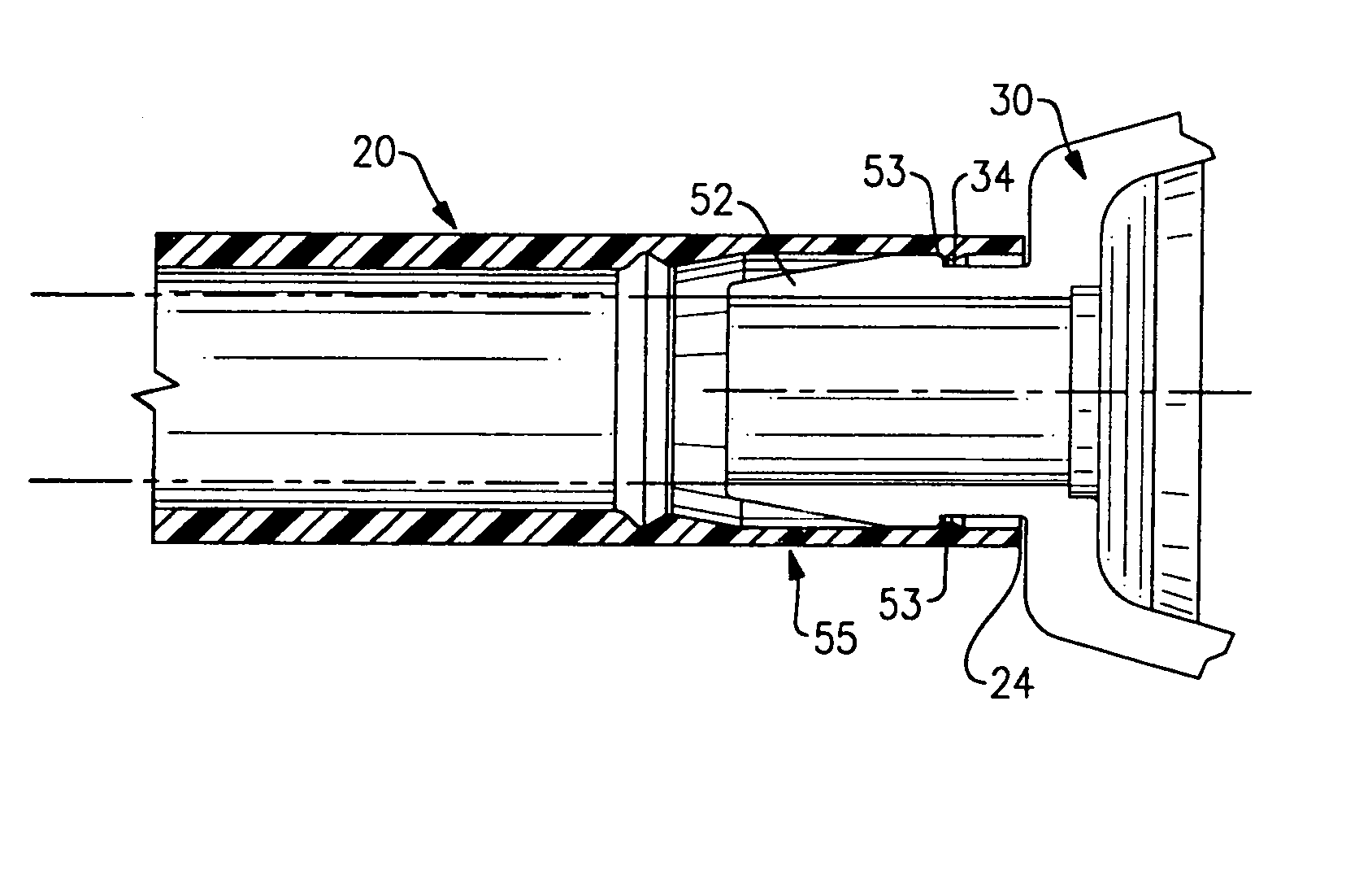

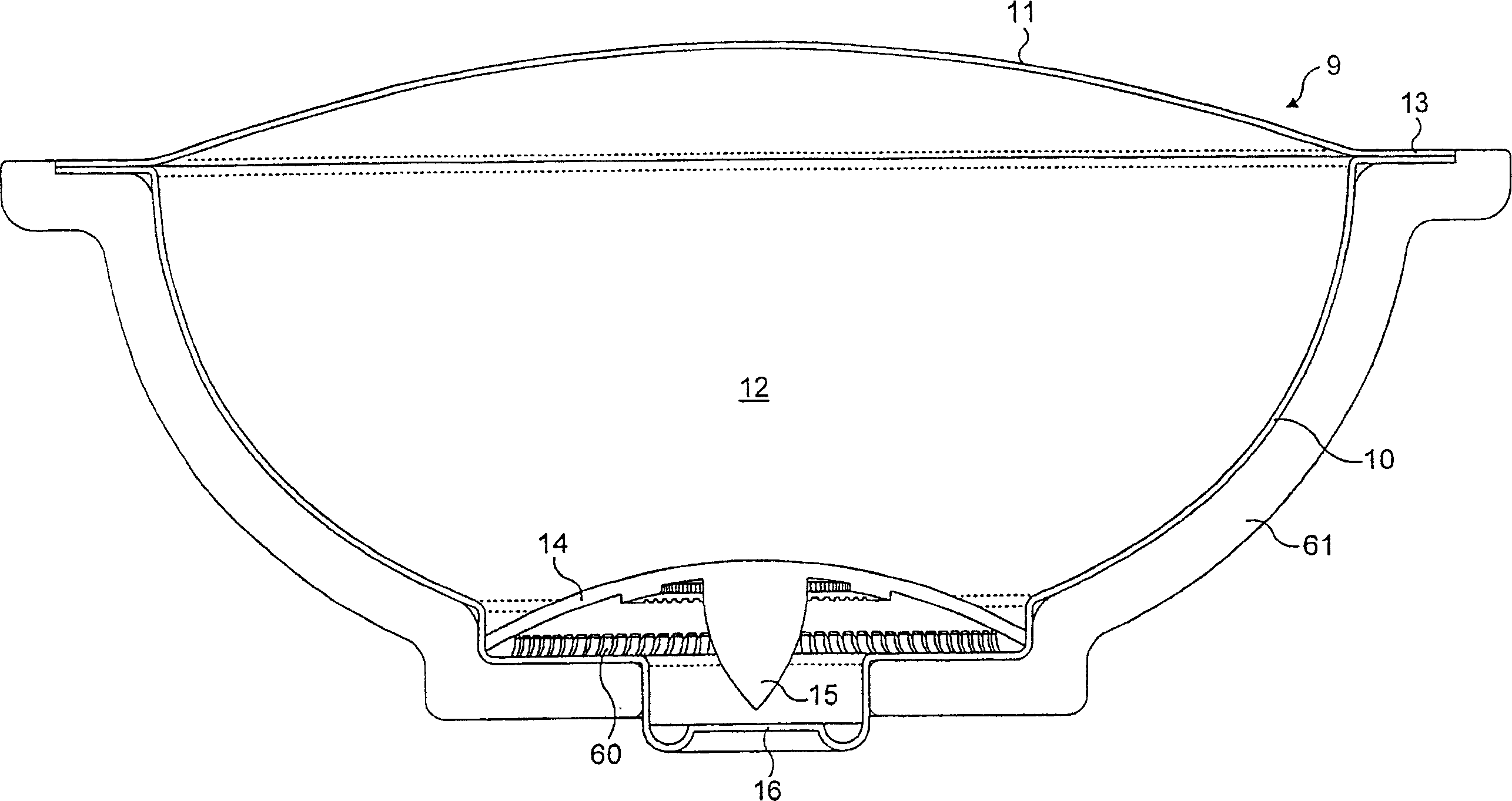

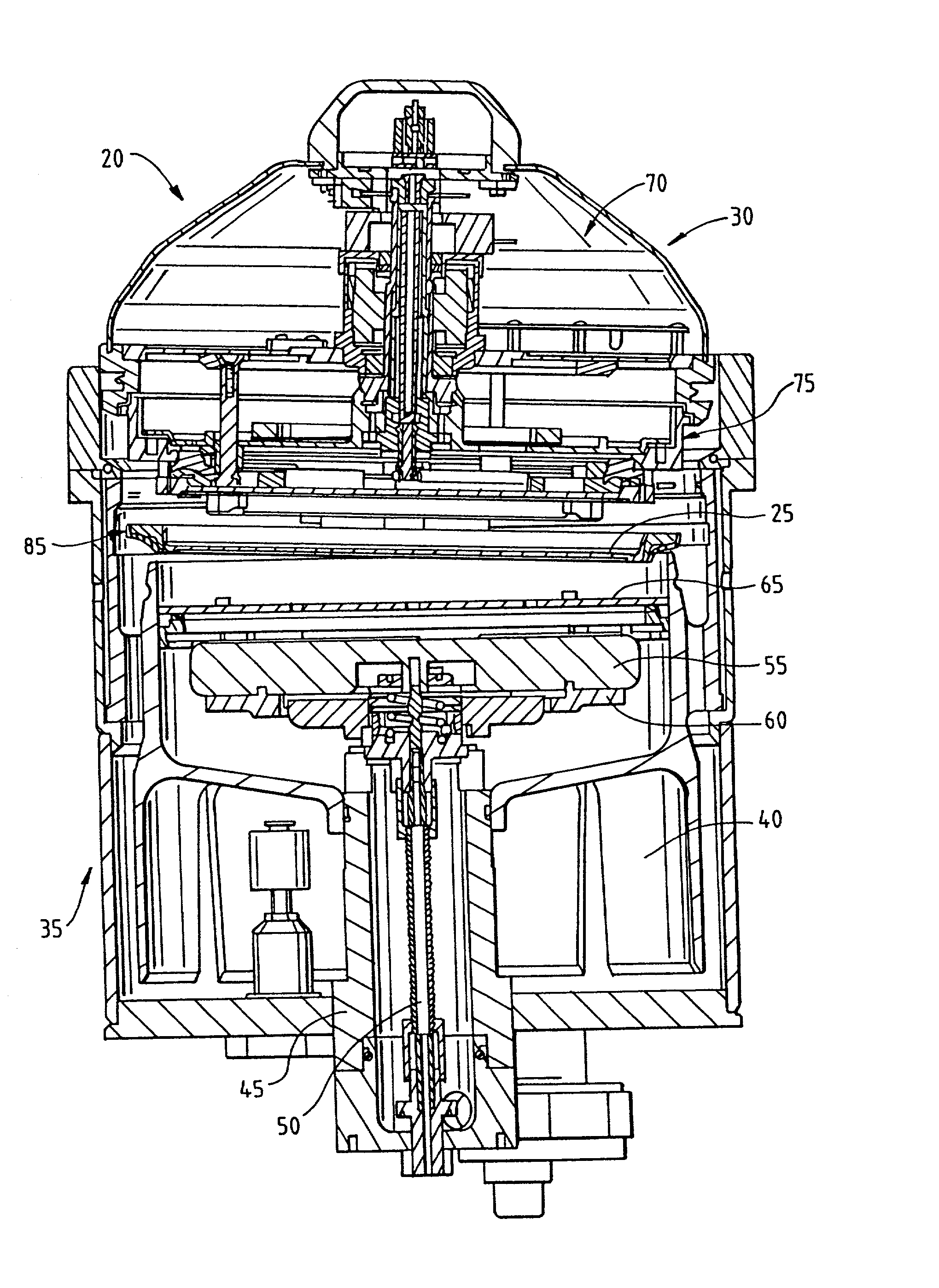

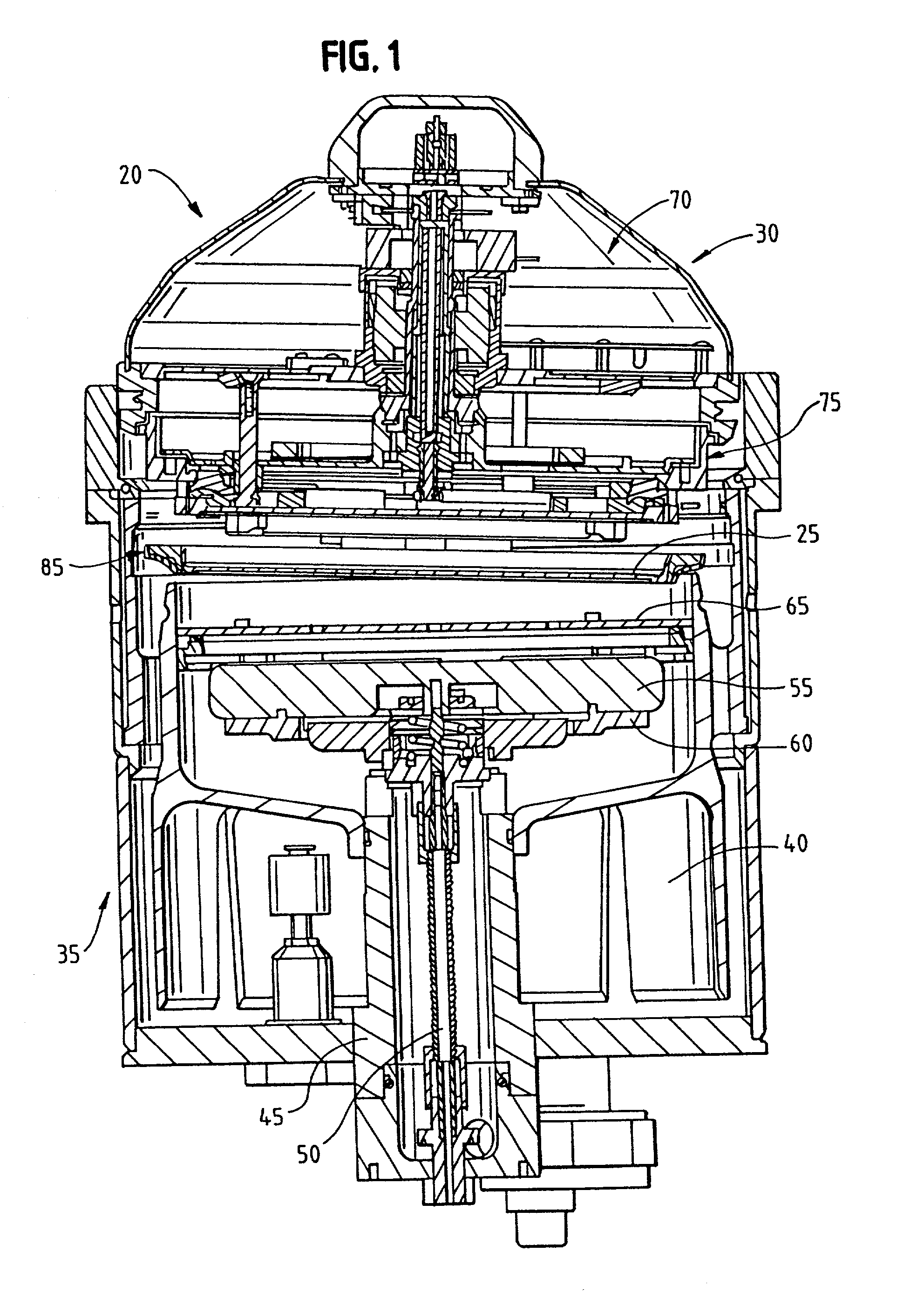

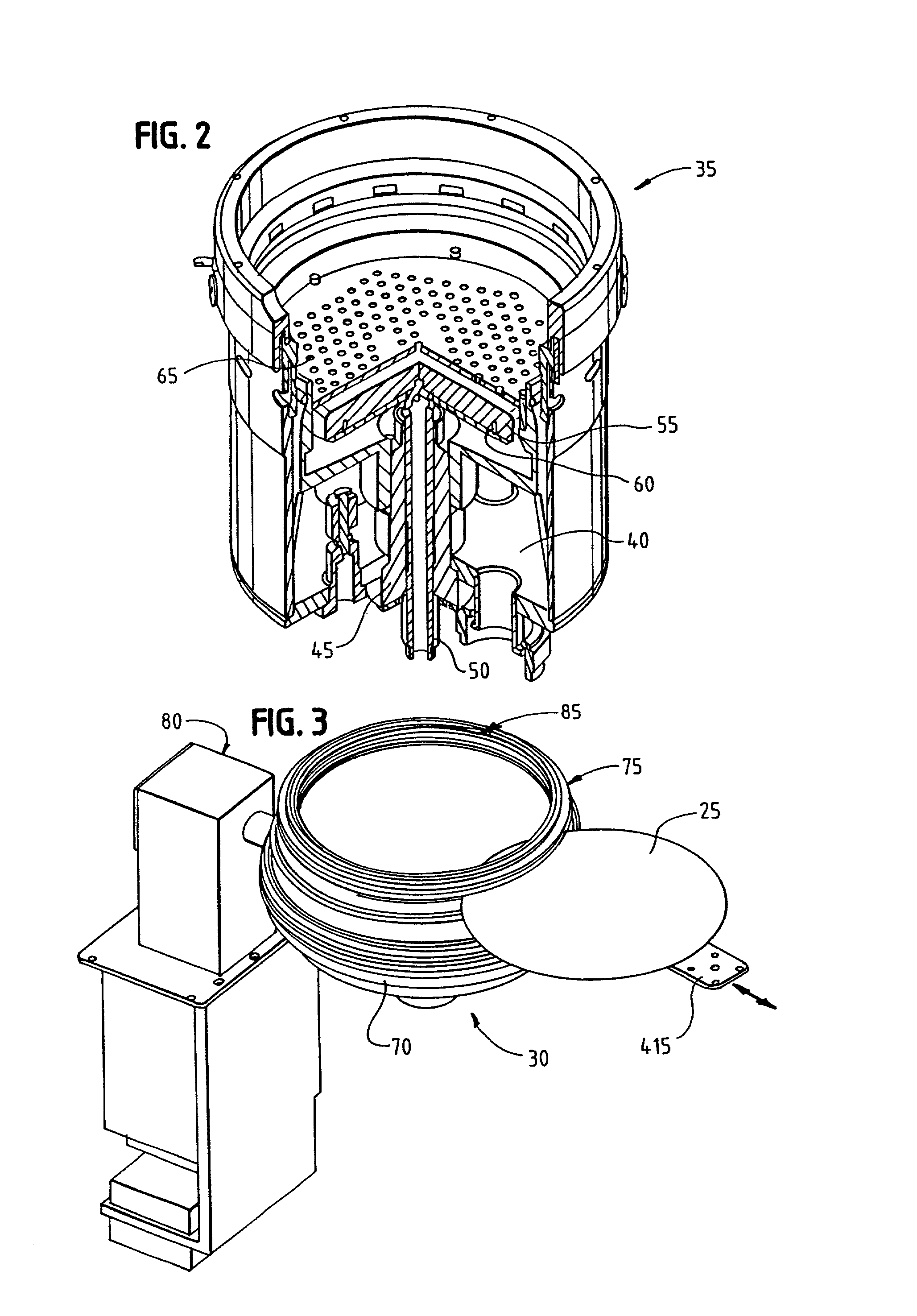

Methods and apparatus for processing the surface of a microelectronic workpiece

InactiveUS6309520B1Reduce riskReduce downtimeMachining electrodesCellsElectroless platingEngineering

A reactor for plating a metal onto a surface of a workpiece is set forth. The reactor comprises a reactor bowl including an electroplating solution disposed therein and an anode disposed in the reactor bowl in contact with the electroplating solution. A contact assembly is spaced from the anode within the reactor bowl. The contact assembly includes a plurality of contacts disposed to contact a peripheral edge of the surface of the workpiece to provide electroplating power to the surface of the workpiece. The contacts execute a wiping action against the surface of the workpiece as the workpiece is brought into engagement therewith The contact assembly also including a barrier disposed interior of the plurality of contacts. The barrier includes a member disposed to engage the surface of the workpiece to assist in isolating the plurality of contacts from the electroplating solution. In one embodiment, the plurality of contacts are in the form of discrete flexures while in another embodiment the plurality of contacts are in the form of a Belleville ring contact. A flow path may be provided in the contact assembly for providing a purging gas to the plurality of contacts and the peripheral edge of the workpiece. The purging gas may be used to assist in the formation of the barrier of the contact assembly. A combined electroplating / electroless plating tool and method are also set forth.

Owner:SEMITOOL INC

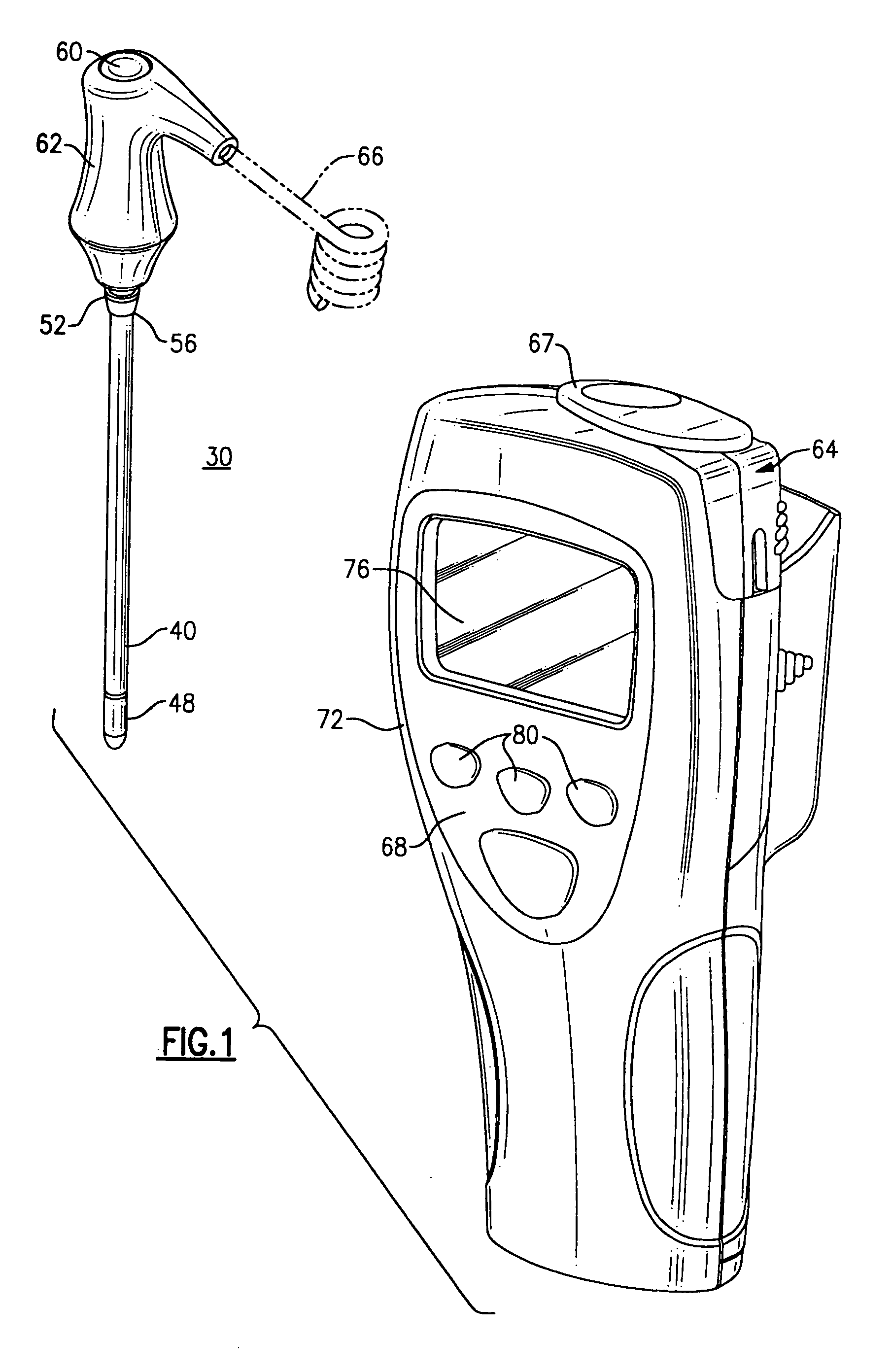

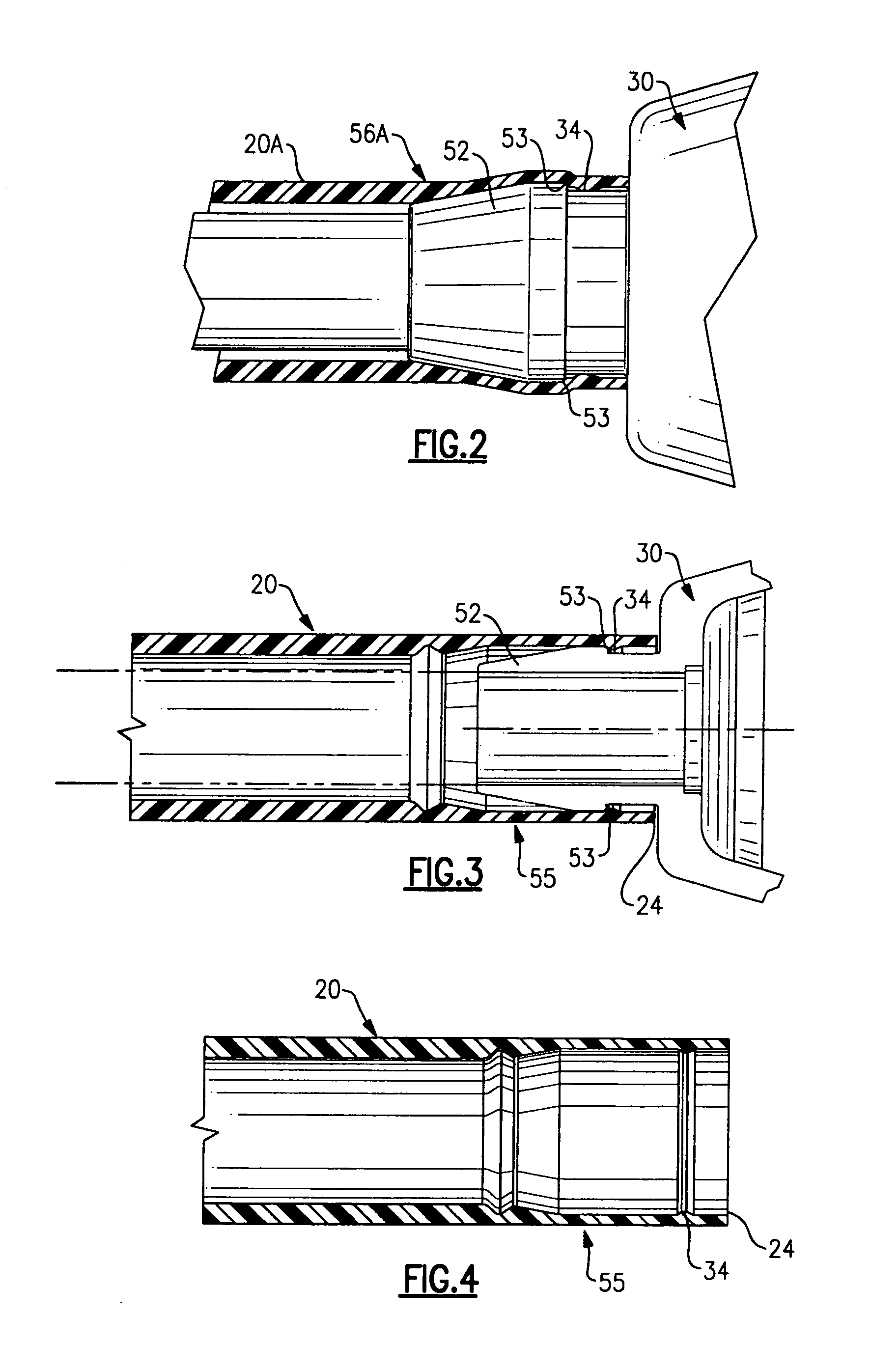

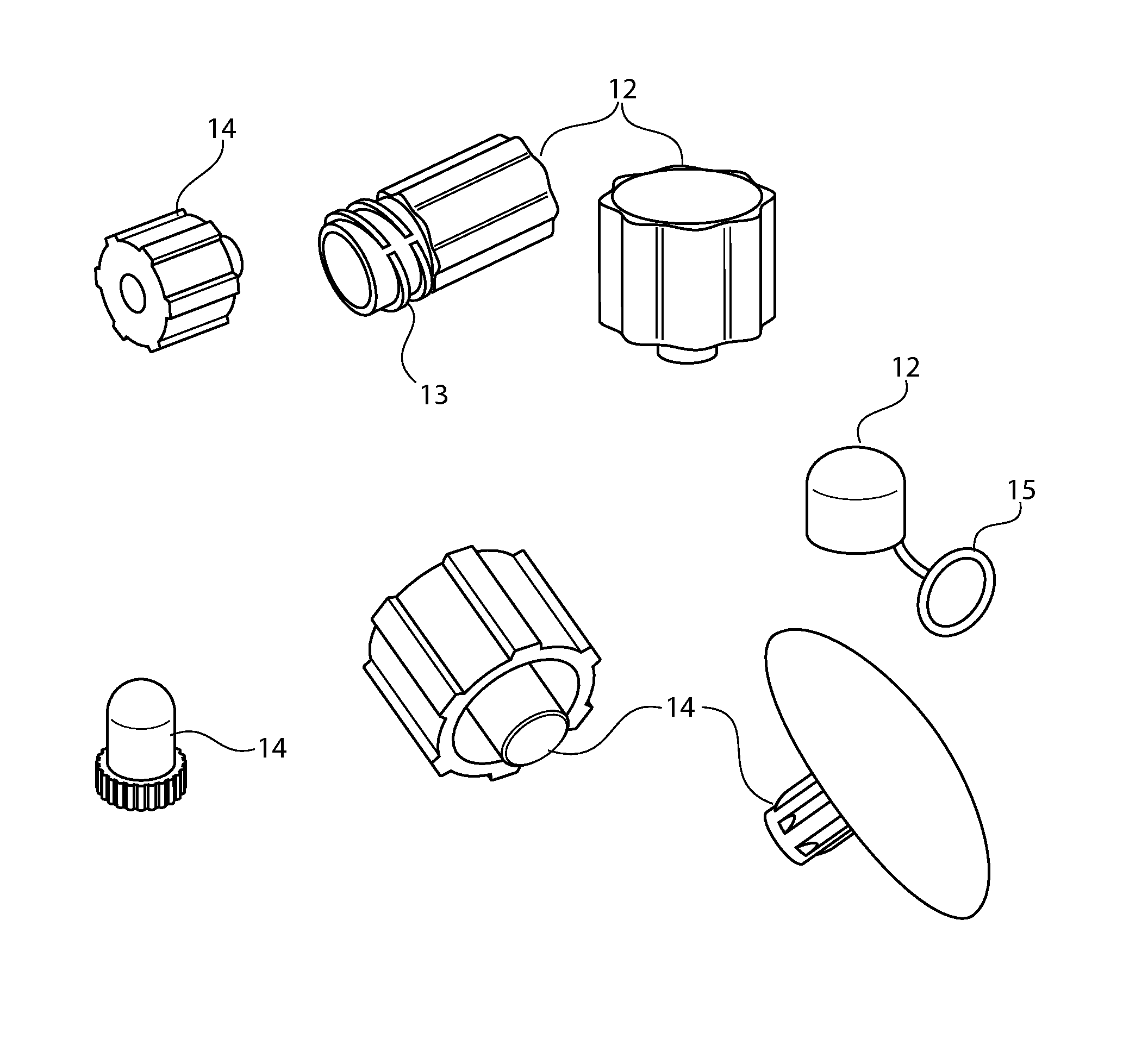

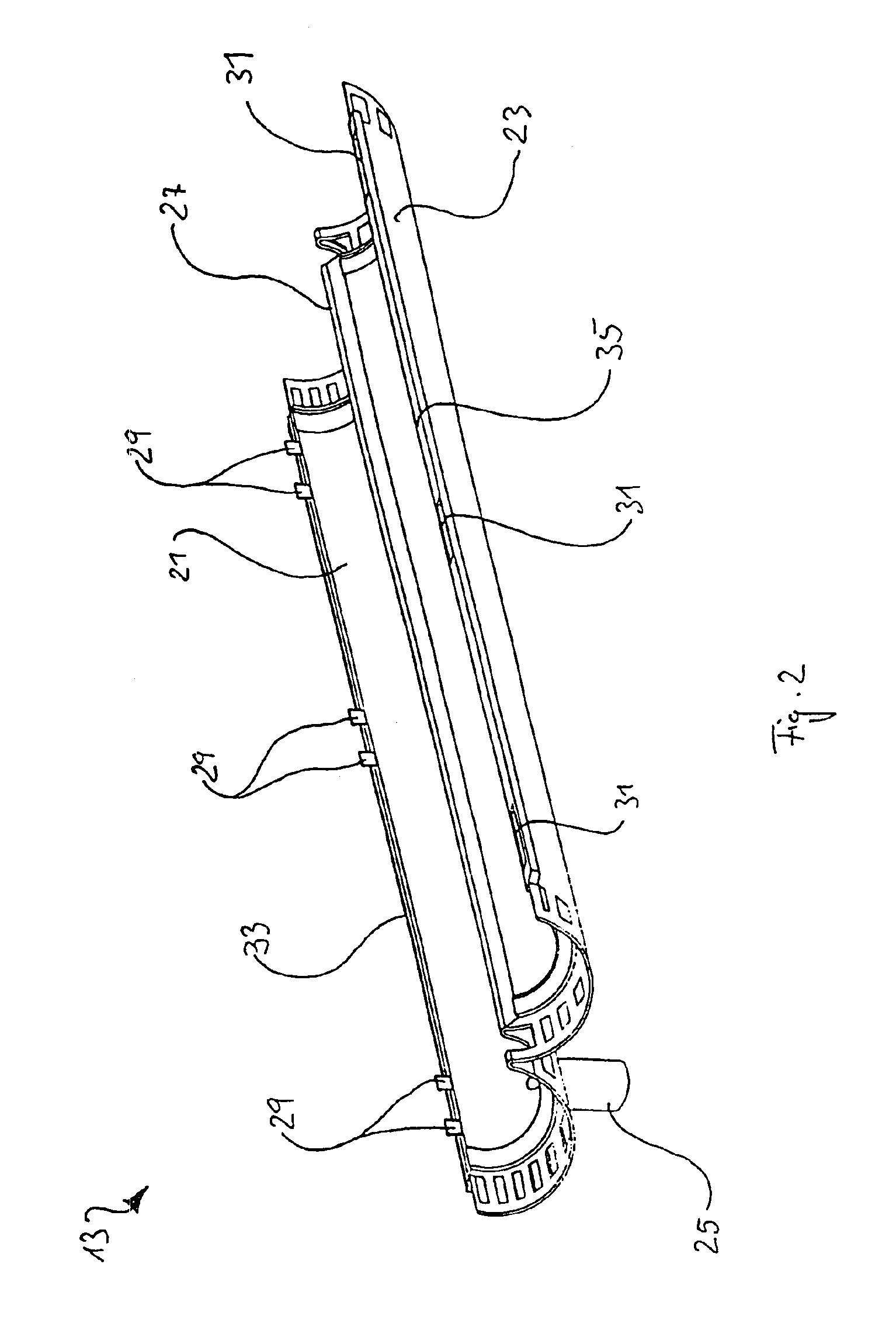

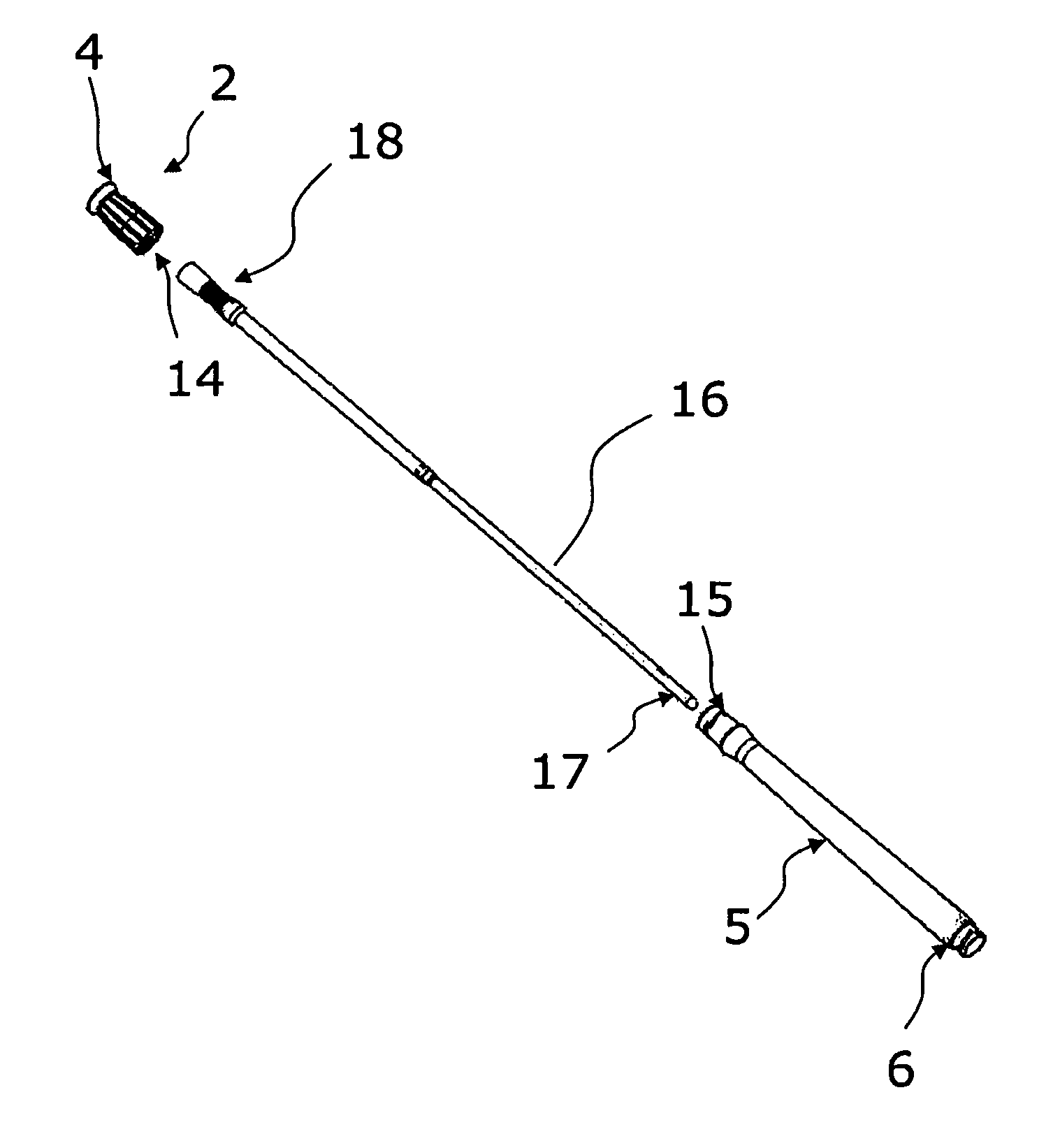

Probe cover for thermometry apparatus

InactiveUS7572056B2Reduce the risk of contaminationImprove versatilityThermometer detailsMedical devicesEngineeringAxial distance

A disposable cover for an elongated probe of a portable thermometry apparatus includes an open proximal end and a distal tip sized to fit over at least an axial portion of the elongated probe. The cover includes a transitional wall thickness at its proximal end for fitting over a holding barb of said probe, the transitional wall thickness varying between a first wall thickness adjacent the proximal end and a second wall thickness that is substantially thinner than the first wall thickness at a distal axial distance relative to the proximal end. The second wall thickness defines a weakened wall portion which is ruptured when the cover has been ejected from said holding barb by an ejection mechanism of the thermometry apparatus. The cover can also include a thinned walled portion over at least a portion of the distal tip and can also include a feature that permits the user to detect when a cover has been attached to a probe.

Owner:WELCH ALLYN INC

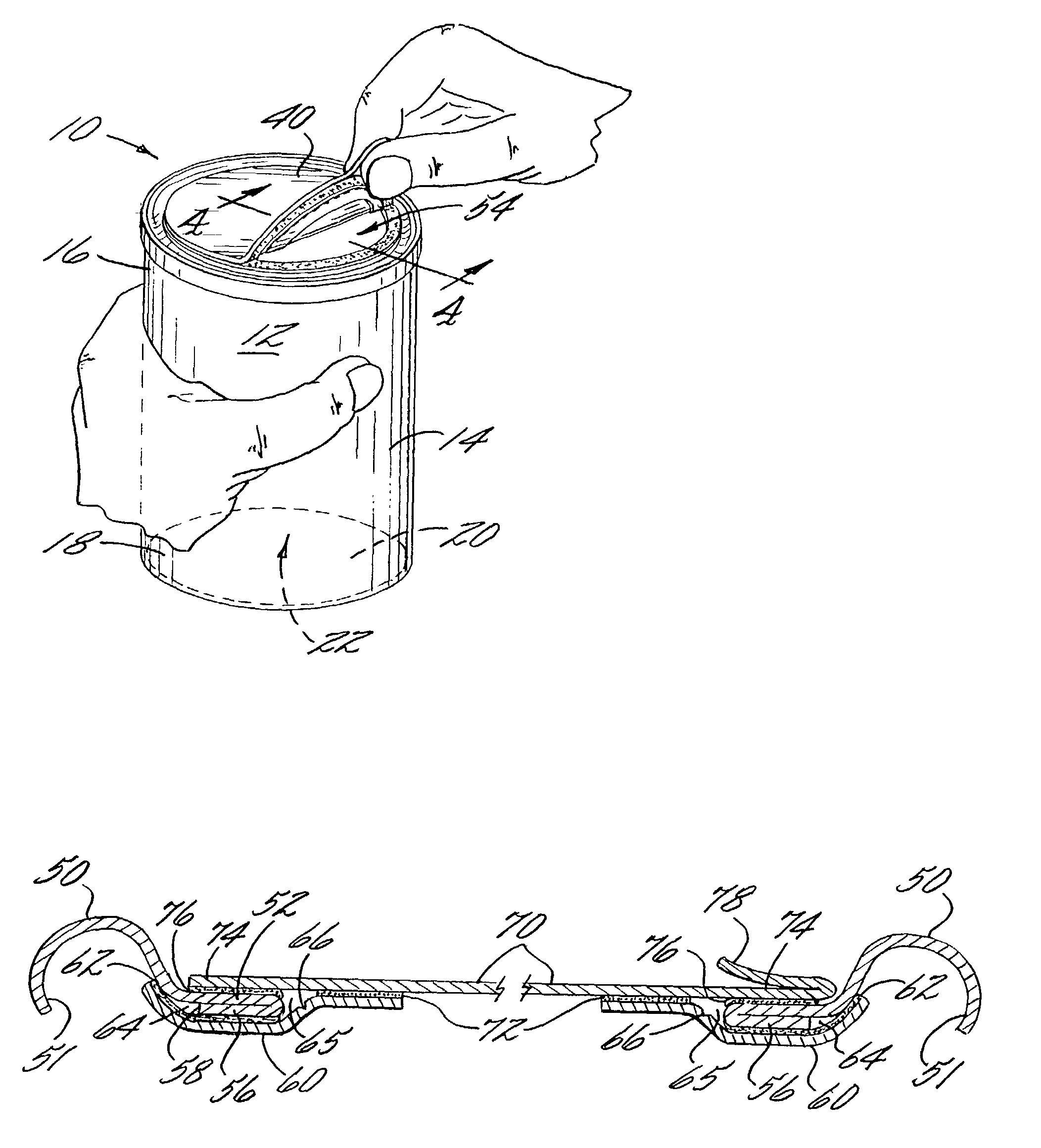

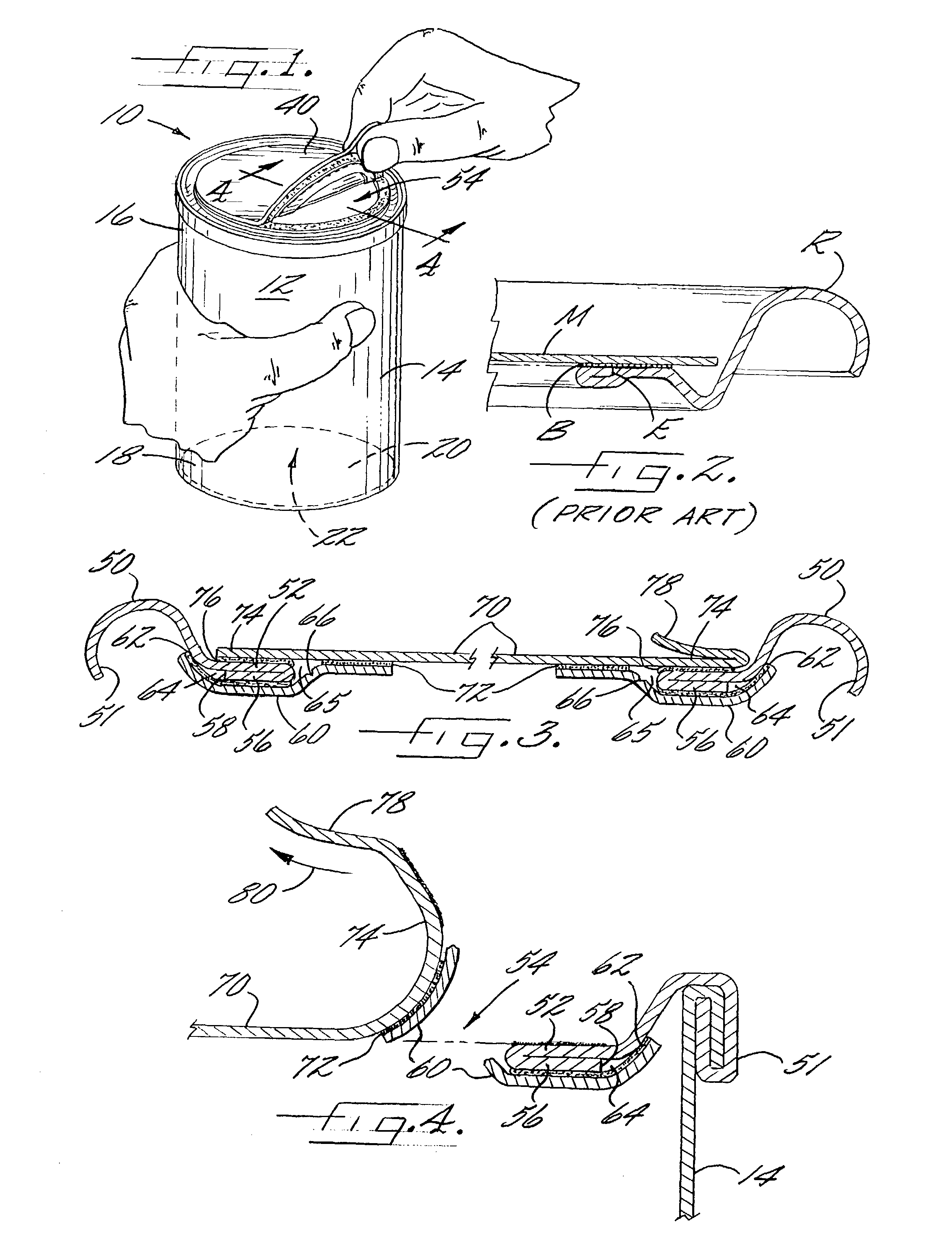

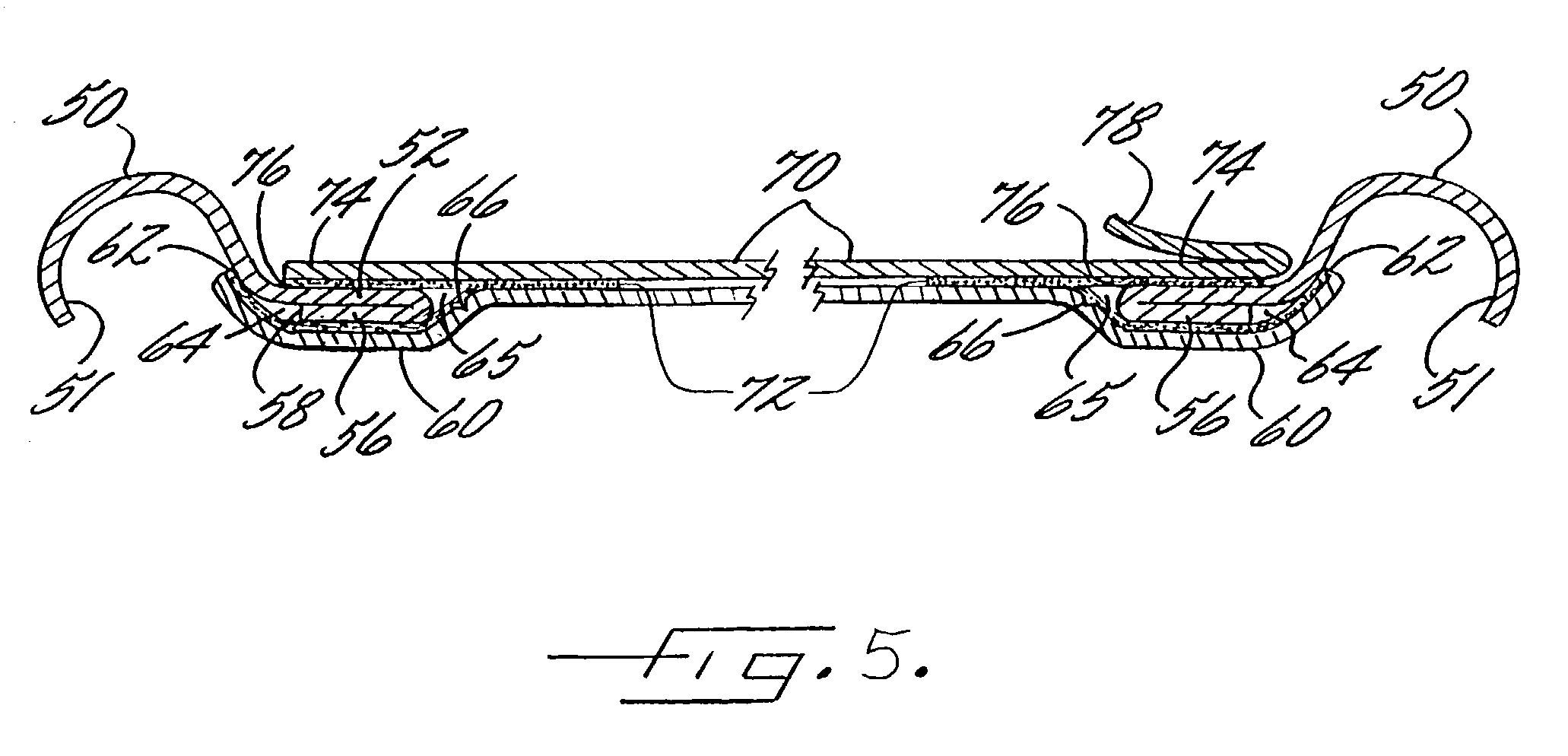

Easy-opening closure for retortable container

A retortable container and an easy-opening closure for hermetic sealing of an open end thereof. The closure includes a metal end ring adapted to be double seamed to an open end of the retortable container, an intermediate area extending radially inward and defining an opening to an interior of the container, and a folded area folded into the interior of the container. The folded area extends radially outward from the opening and substantially parallel to at least an adjacent portion of the intermediate area. A first membrane patch overlaps and is bonded to an under side of the intermediate area of the end ring such that the first membrane patch prevents contamination of contents of the container by the metal end. A second membrane patch covers the opening and is bonded to an upper side of the first membrane patch. The bonds have predetermined shear and tensile force strengths sufficient to withstand shear and tensile forces created during retort processing of the container, while allowing easy-opening of the container by peeling the second membrane patch.

Owner:SONOCO DEV INC

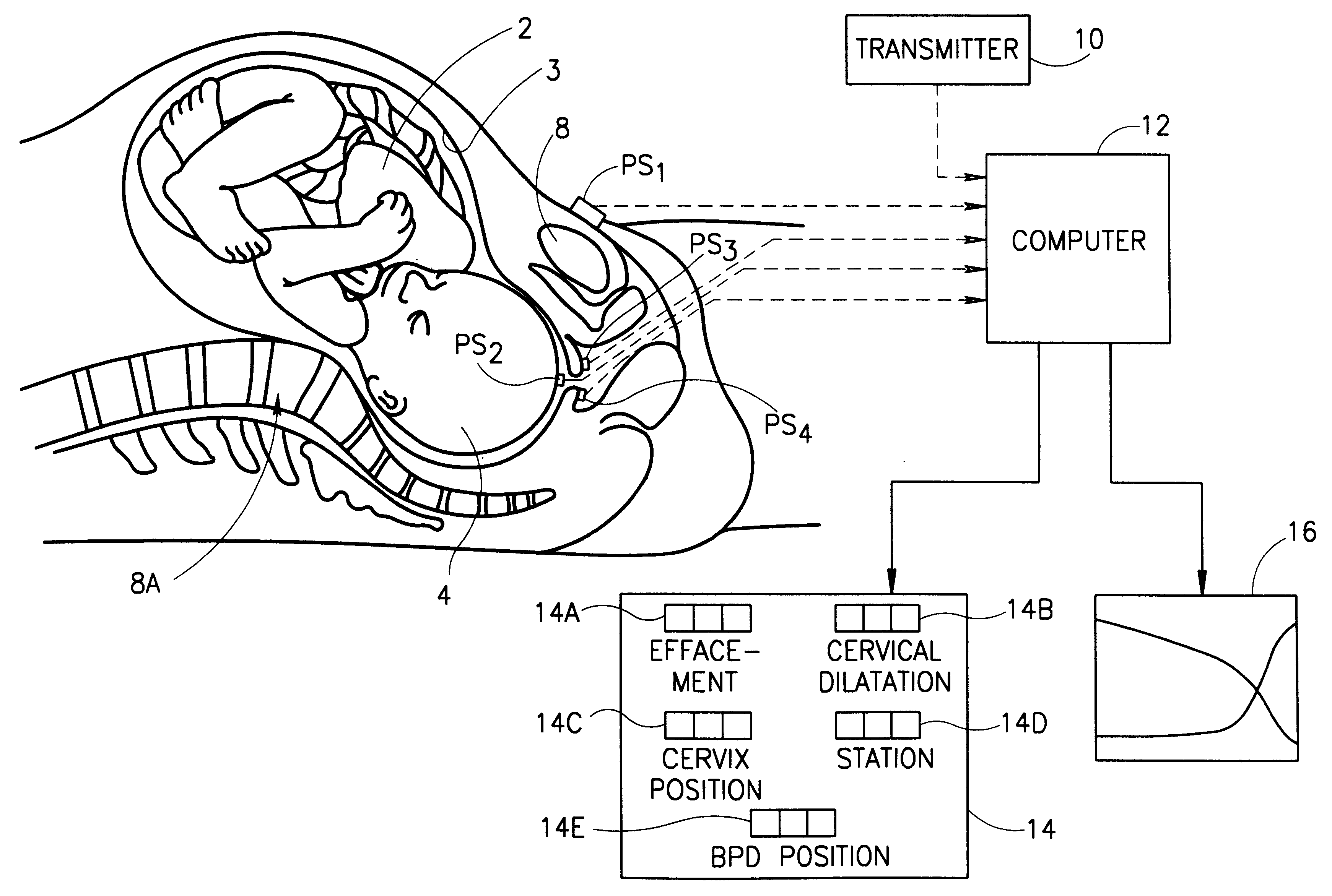

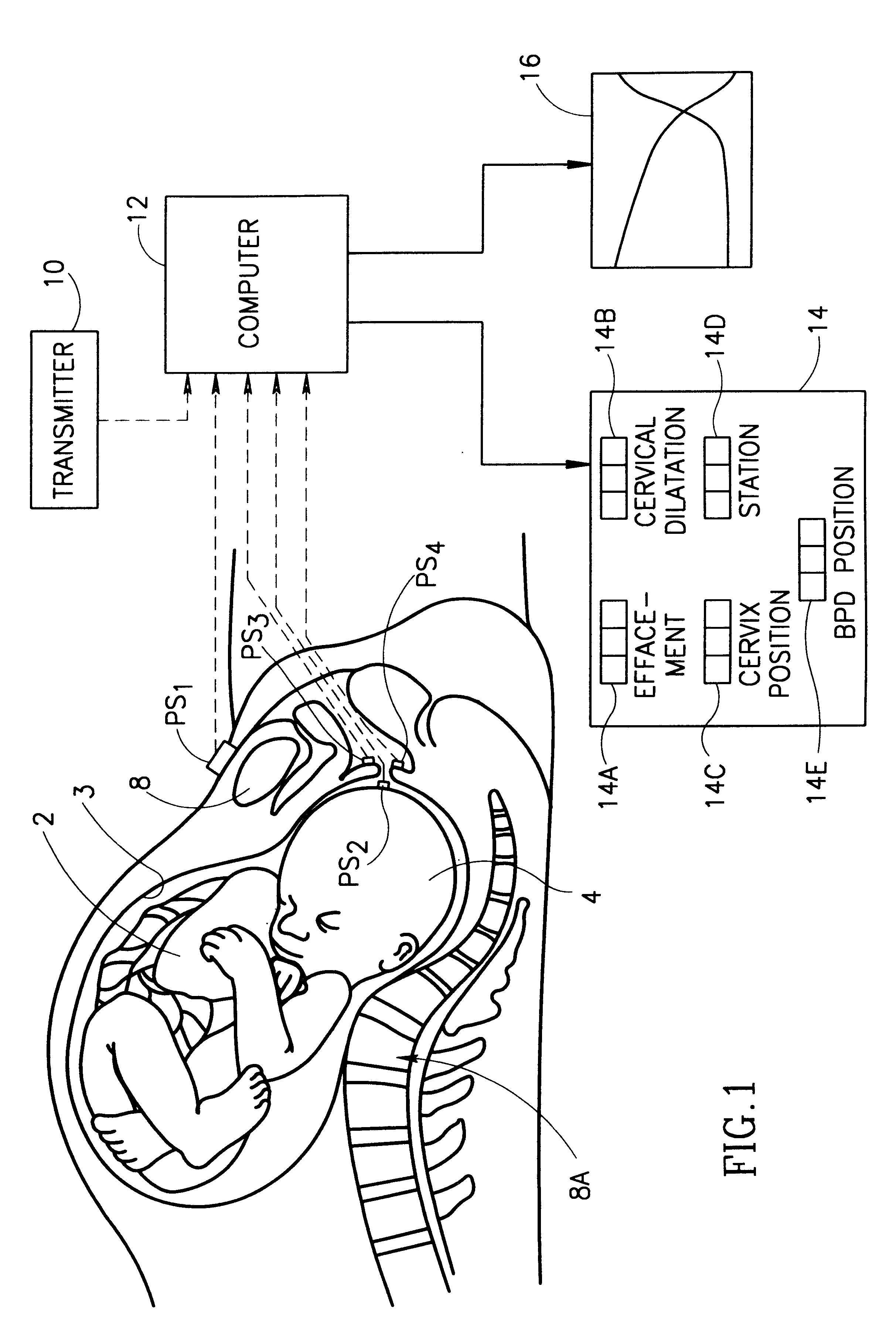

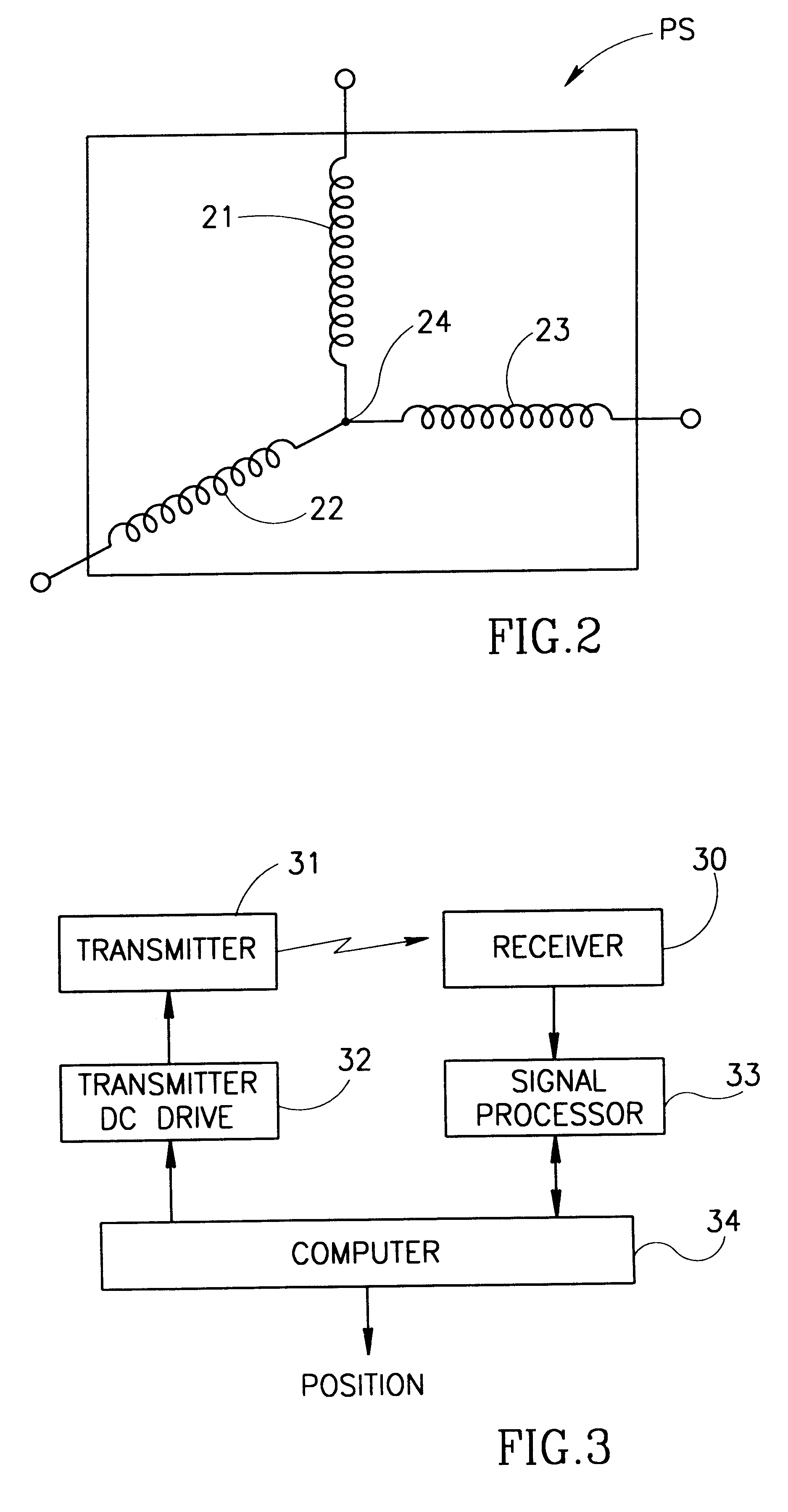

Method and apparatus monitoring the progress of labor

InactiveUS6200279B1Accuracy is dependentAccurate monitoringOrgan movement/changes detectionPerson identificationCervical dilatationObstetrics

A method of monitoring the progress of labor in a mother during childbirth, by attaching a position sensor to a predetermined point on the mother's pelvic bones; monitoring the location of the position sensor in three- dimensional space relative to a reference; and monitoring the location of the fetal presenting part with respect to the predetermined point on the mother's pelvic bones. The location of the fetal presenting part may be indicated by a similar position sensor, or by imaging. Other conditions, such as effacement, cervical dilatation, and cervical position may also be monitored in a similar manner.

Owner:TRIG MEDICAL

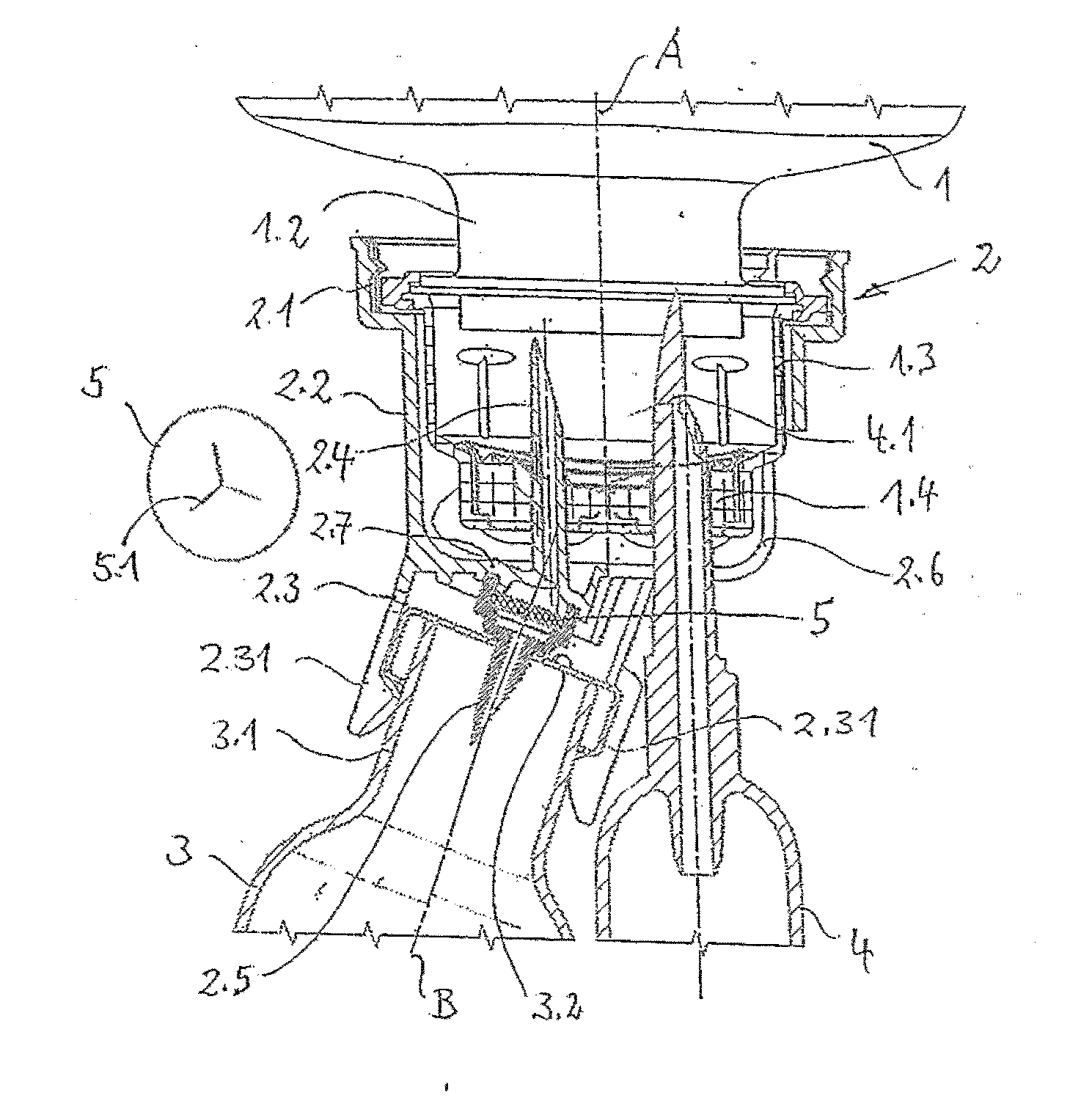

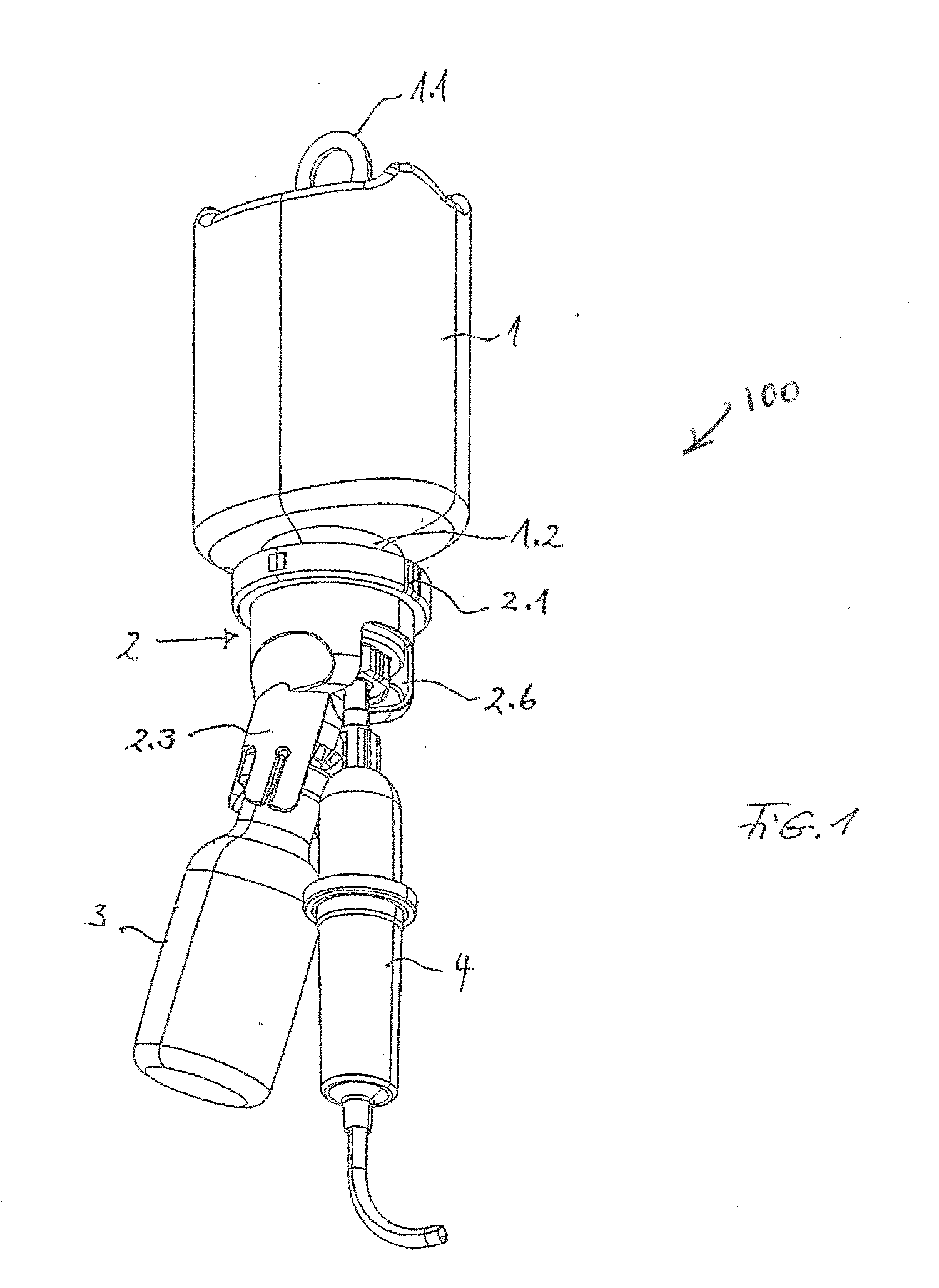

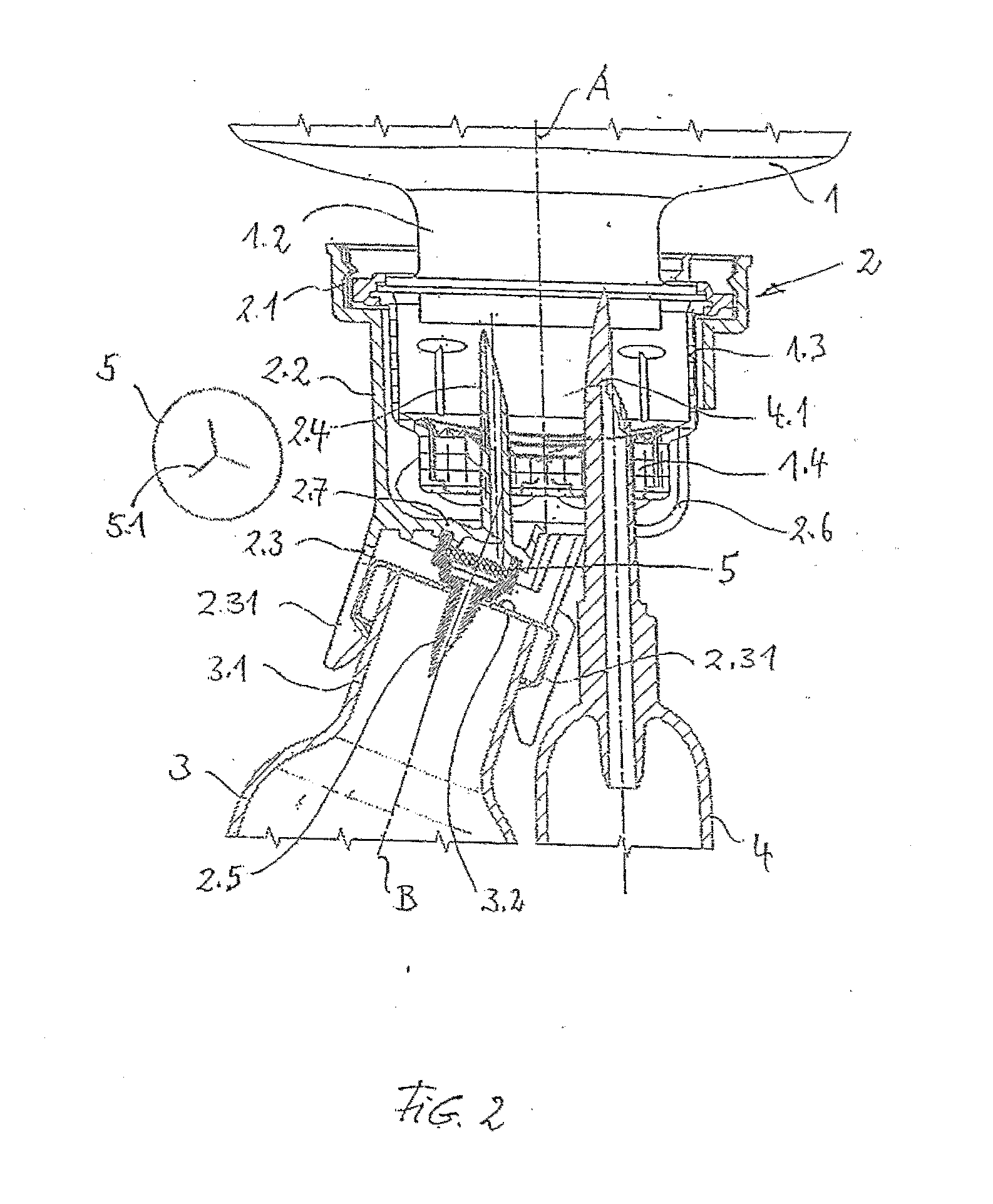

Device for introducing medicine into an infusion container

A device for adding a medicine to an infusion solution in an infusion container having a removal opening provided with a seal area. A transfer cap, which has a first hollow spike for piercing the seal area, is connected to the removal opening of the infusion container. A receiving means Dora medicine container is formed at the transfer cap, which has a second hollow spike for piercing a seal at the medicine container. A valve is arranged between the first and second hollow spikes in the transfer cap, where the valve interrupts the connection between the first and second hollow spikes and can be moved into the open position by the action of a force.

Owner:B BRAUN MELSUNGEN AG

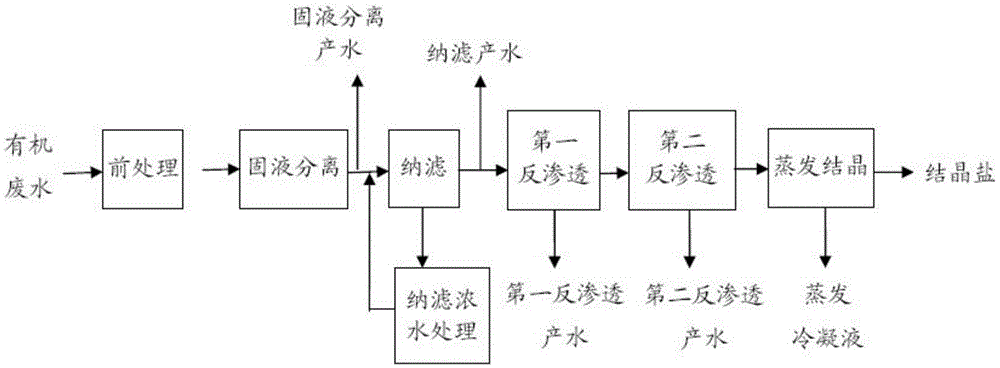

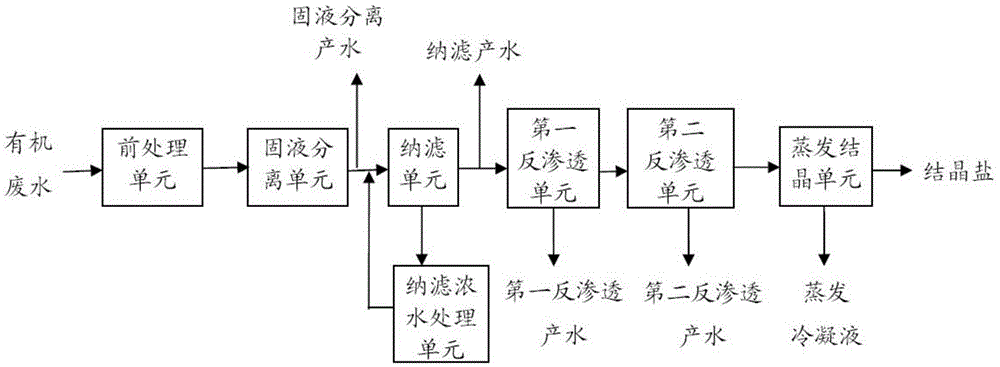

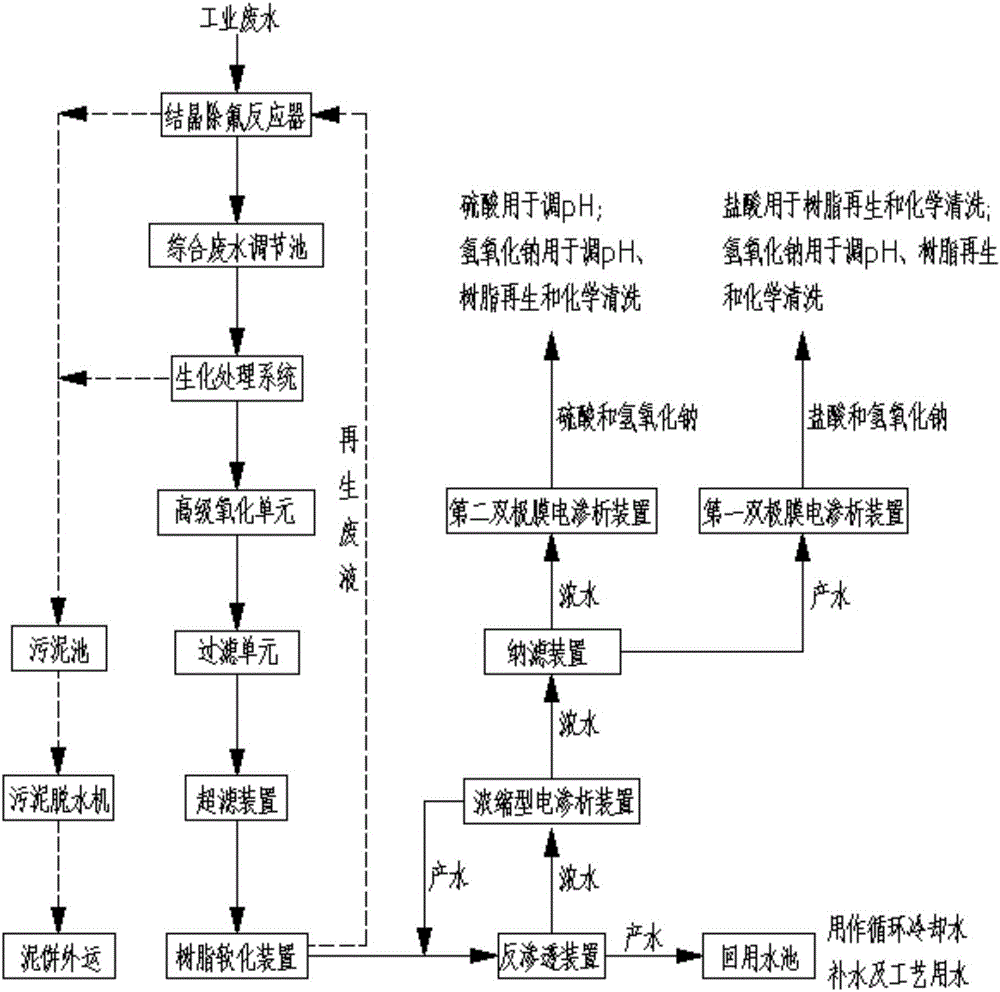

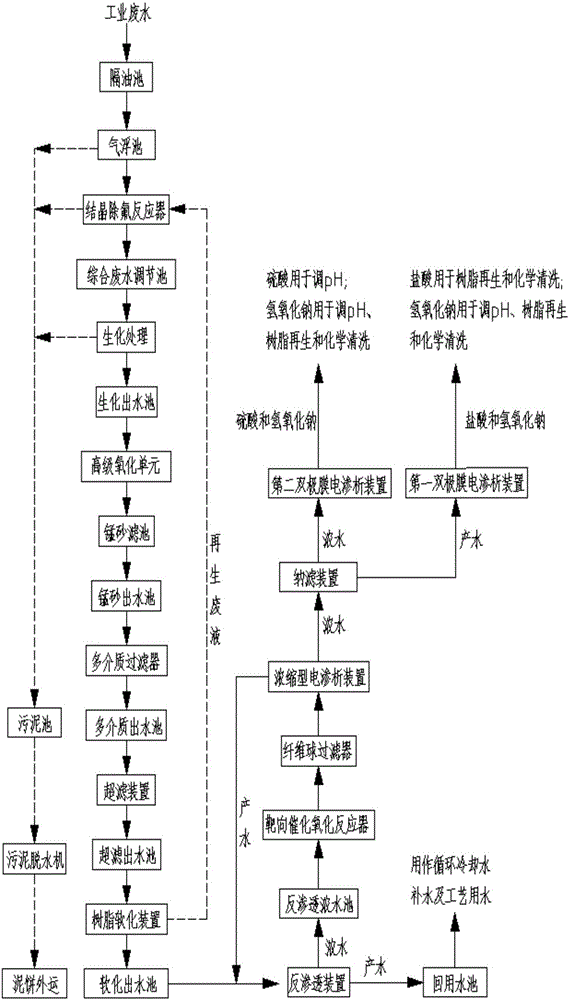

Processing method for reducing and recycling organic waste water and processing system

InactiveCN105540967AReduce foulingReduce the risk of contaminationFatty/oily/floating substances removal devicesWater contaminantsReverse osmosisWastewater

The invention provides a processing method for reducing and recycling organic waste water. The method comprises steps: (1) pre-treating waste water to obtain pre-treated out-water; (2) treating the out-water obtained from the step (1) through solid-liquid separation; (3) nano-filtering the out-water obtained from step (2); (4) treating nano-filtered concentrated water obtained from the step (3) to obtain out-water subjected concentrated water nano-filtering, returning to the step (3) for mixing the out-water subjected to concentrated water nano-filtering with the out-water subjected to solid-liquid separation, and performing nano-filtering; (5) performing first reverse osmosis treatment on out-water obtained from the step (3) through nano-filtering; (6) performing second reverse osmosis treatment on concentrated water obtained from the step (5) through first reverse osmosis treatment; and (7) evaporating and crystallizing a concentrated liquid obtained from the step (6) through second reverse osmosis treatment in order to obtain crystallized salt and evaporated concentrated water. The invention further provides a processing system of the method. Through the method and system, waste water is truly reduced and recycled.

Owner:DATANG INT CHEM TECH RESINST

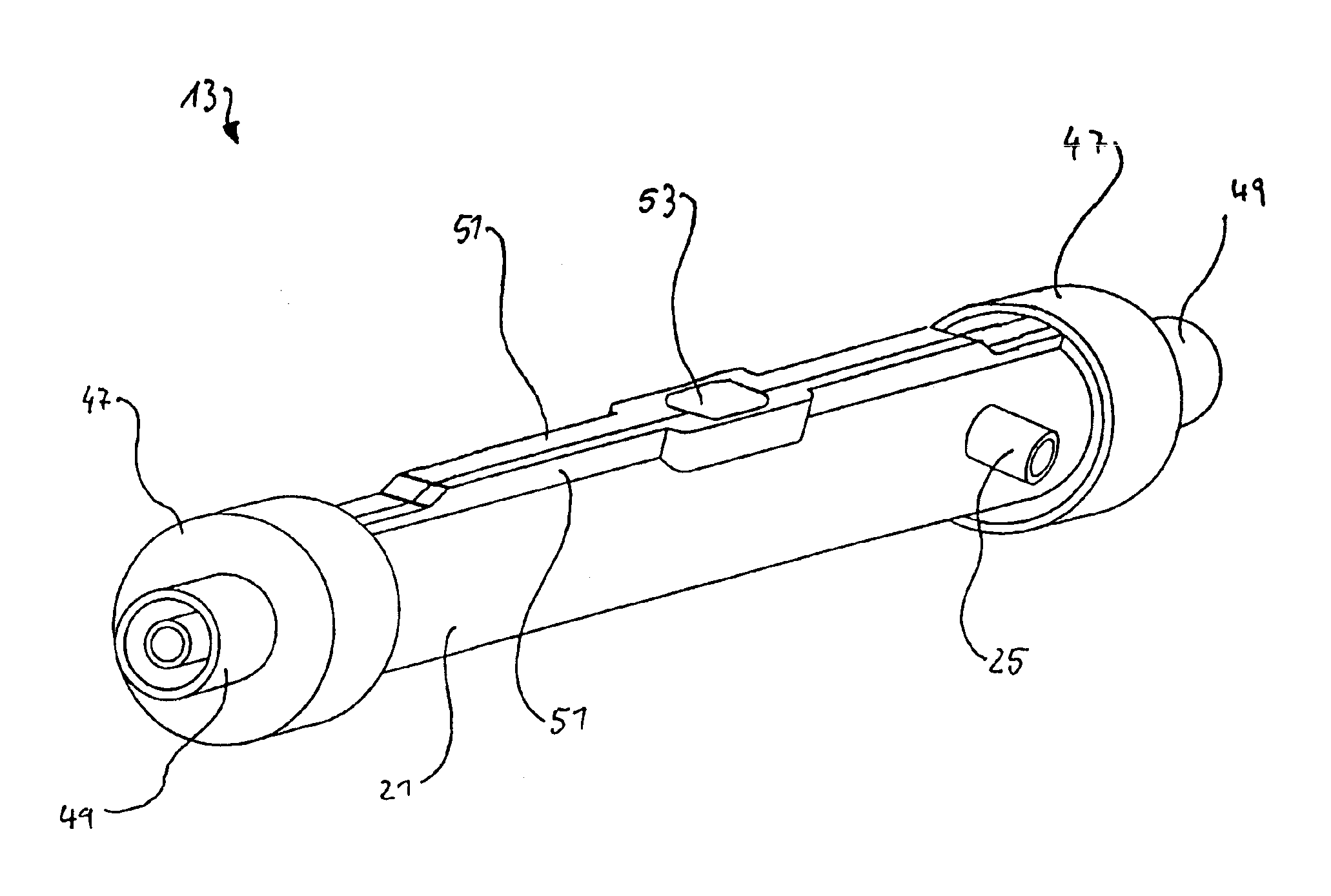

Hypodermic injection system

InactiveUS7235063B2Sufficient forceEliminate the problemAmpoule syringesJet injection syringesMultiple injectionHypodermoclysis

A hypodermic injection system particularly for use in mass immunizations having a handpiece with a grasping mechanism for holding ampules filled with injectate, a plunger for driving into the ampule to discharge the injectate in an injection process, an injection spring mechanism for driving the plunger, a motor and / or manual mechanism for cocking the injection spring mechanism, and an ampule ejection mechanism for ejecting ampules after use under control of a release mechanism. Ampules can be loaded, used and ejected without contact by the user of the system or the patient being injected. Also disclosed are a filling station for filling ampules through their injection orifices, and an arming device for setting the injection spring. Ampules are disclosed having a piston which is drivable towards an orifice to discharge injectate through the orifice. Ampules are also disclosed having enlarged proximal portions for easy grasping by the grasping mechanism of the injector. Ampules are further disclosed with separators for mixing lyophilized medication and a diluent. Further disclosed are magazines for holding ampules for sequential use by the hypodermic injector. The disclosed system finds particular use as a mass immunization kit for making numerous injections in the field.

Owner:DANTONIO CONSULTANTS INT INC

Sintered porous polymeric caps and vents for components of medical devices

ActiveUS20140188089A1Reduce and eliminate laborLiquid flow quicker and moreInfusion syringesInfusion devicesMedical deviceMaterials science

Owner:POREX CORP

Closed capsule with opening mean

InactiveCN1612831AEasy to manufactureWon't get dirtyClosuresBeverage vesselsBiomedical engineeringClosed system

The present invention relates to a closed capsule designed to be extracted under pressure in an extraction device, containing a substance 43 for the preparation of a beverage, comprising a closed system 44, 45 containing the said substance and a means 46, 48 inside the said system allowing the said capsule to be opened at the time of its use and allowing the said beverage to flow out without contact with its extraction system.

Owner:SOC DES PROD NESTLE SA

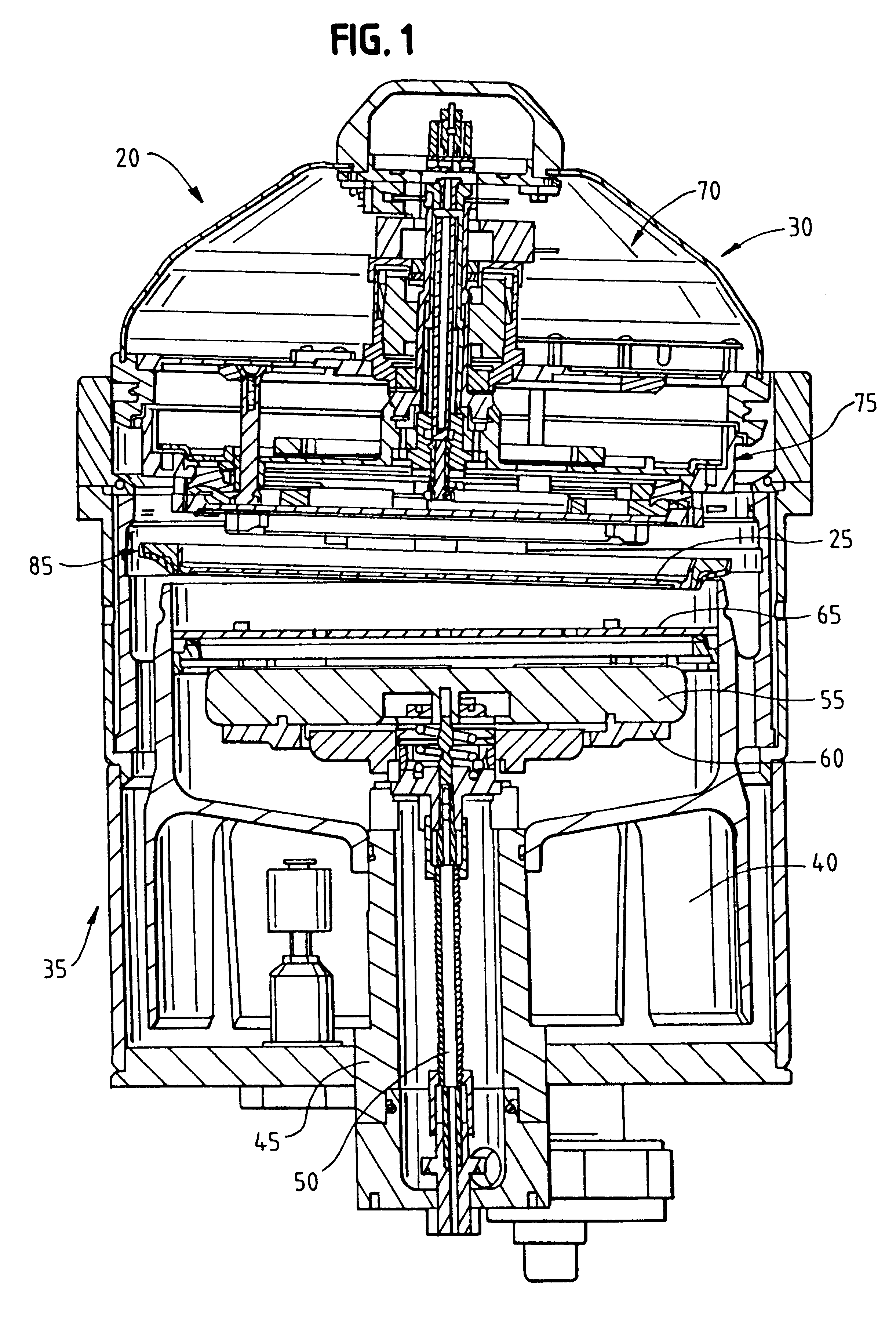

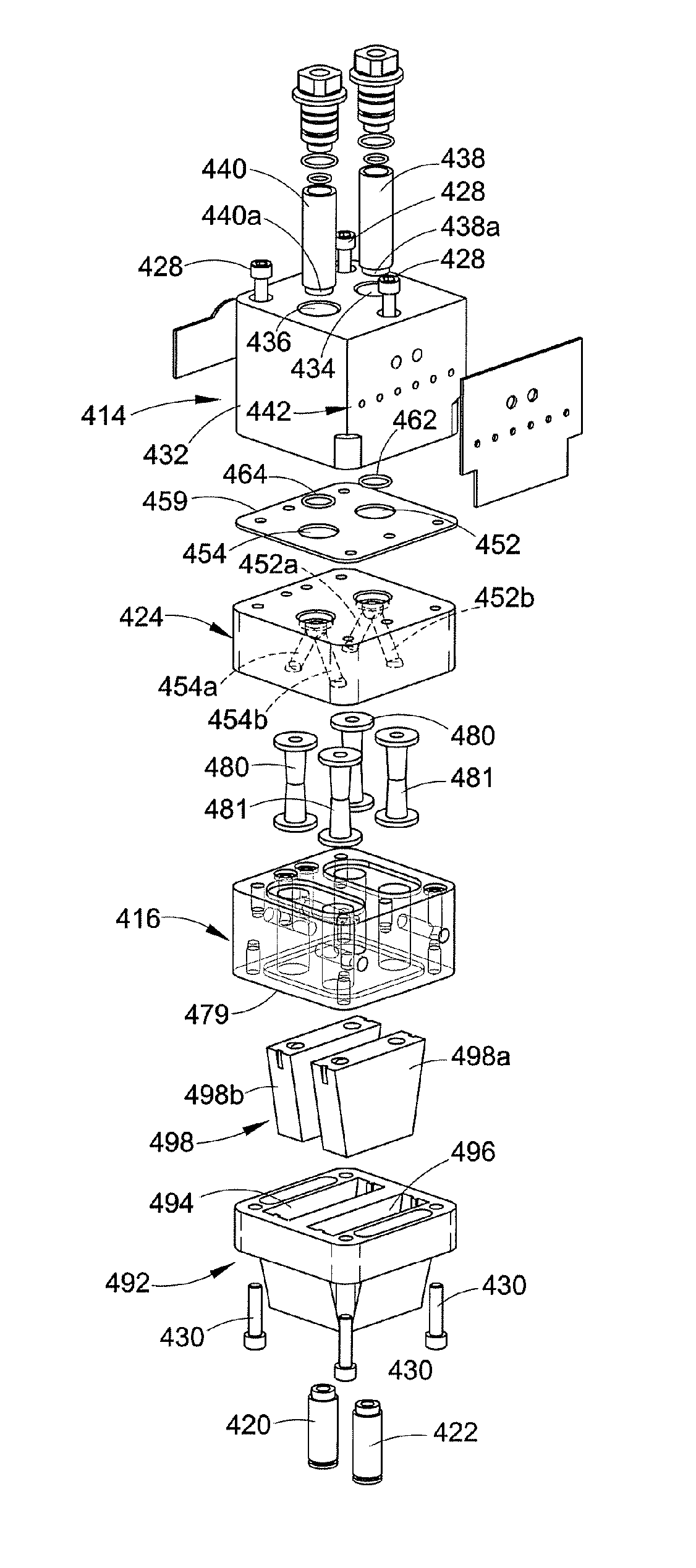

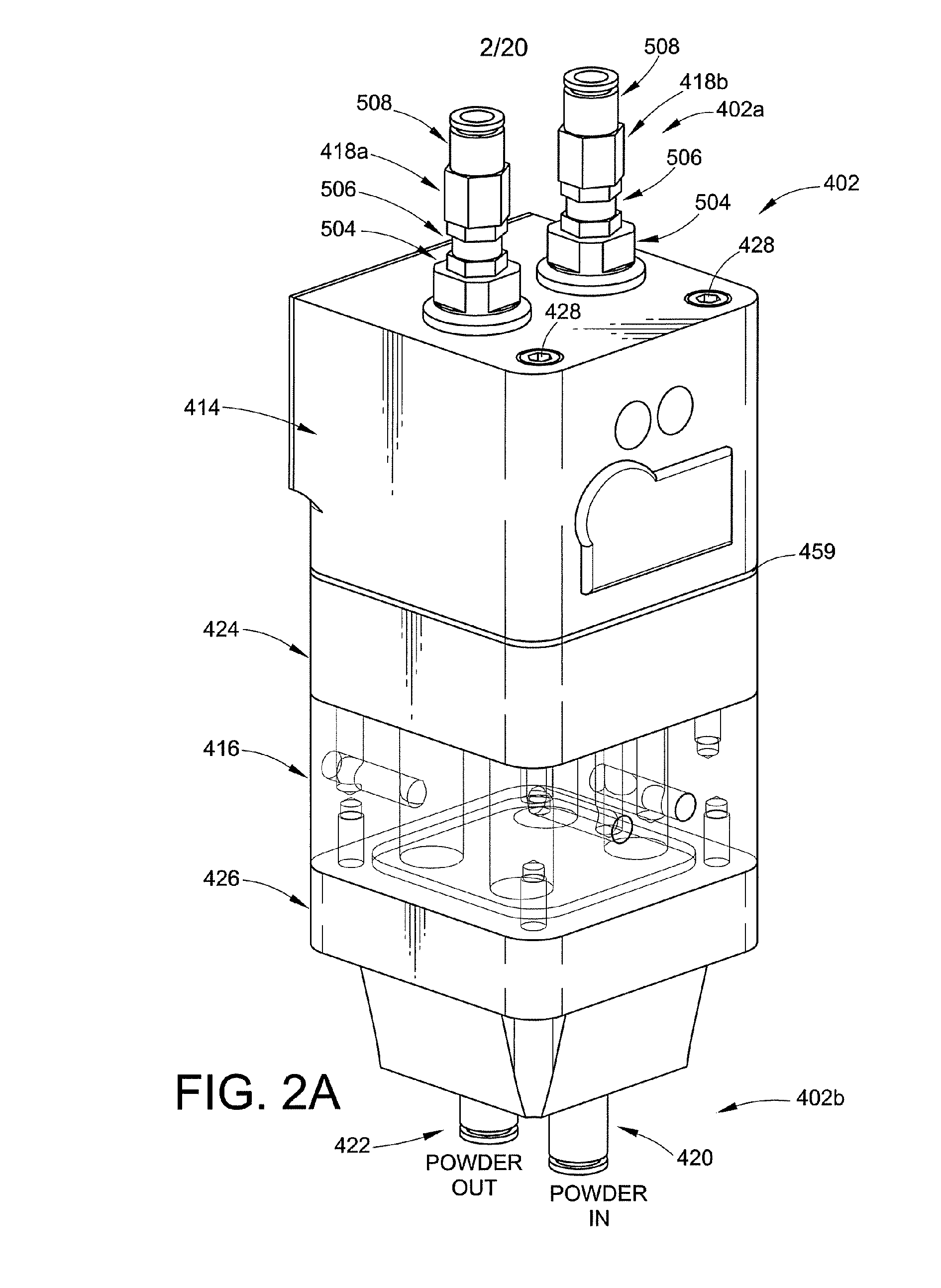

Dense phase pump for dry particulate material

InactiveUS20050158187A1Improve cleanabilityImprove serviceabilityLiquid surface applicatorsPositive displacement pump componentsCycle ratePump chamber

A dense phase pump for particulate material includes a pump chamber wherein material flows into the pump chamber under negative pressure and flows out of the pump chamber under positive pressure. A plurality of pinch valves are provided to control flow of material into and out of the pump chamber. The pinch valves are operated independent of each other and of the pump cycle rate. A modular design of the pump is provided.

Owner:NORDSON CORP

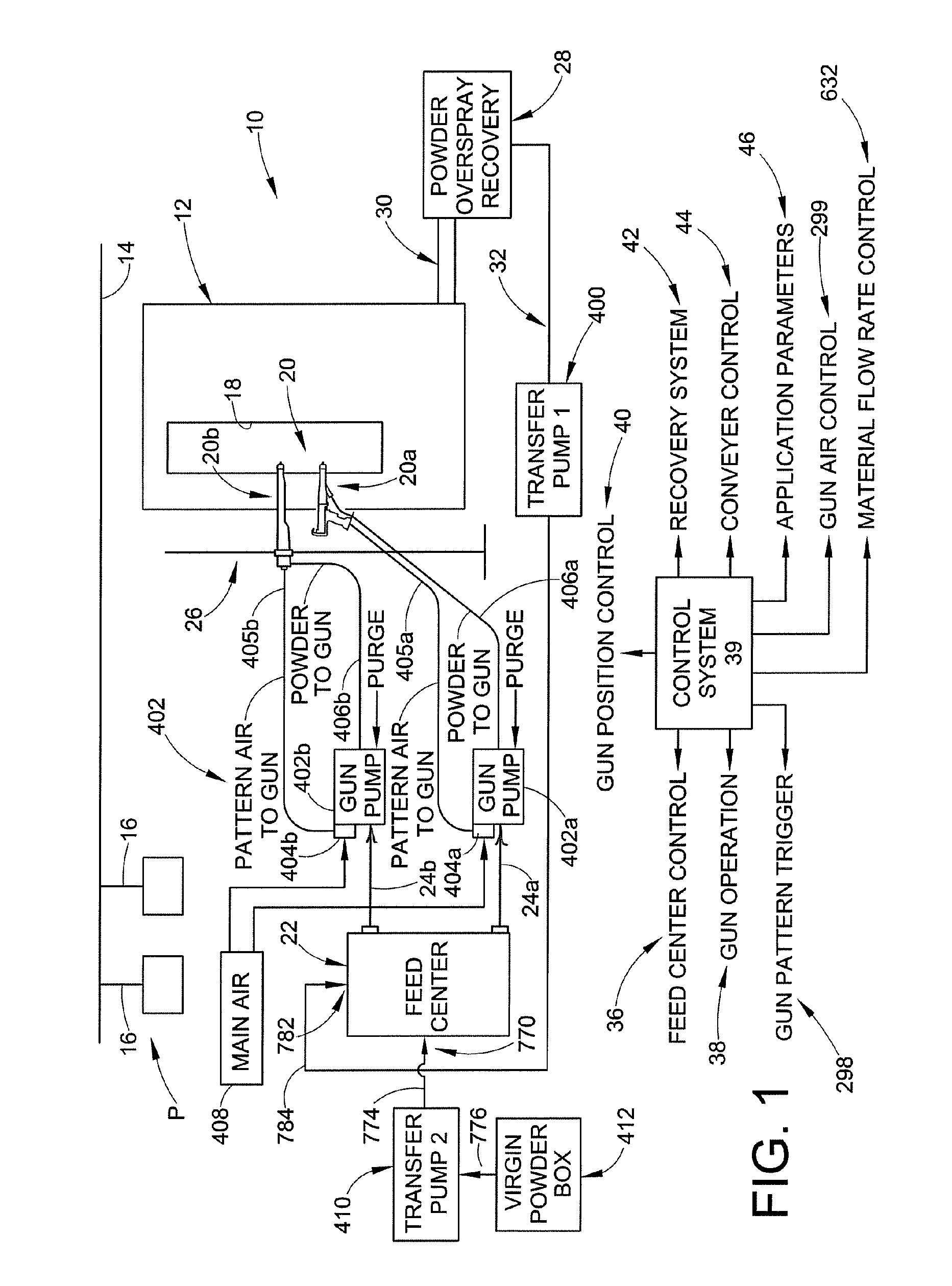

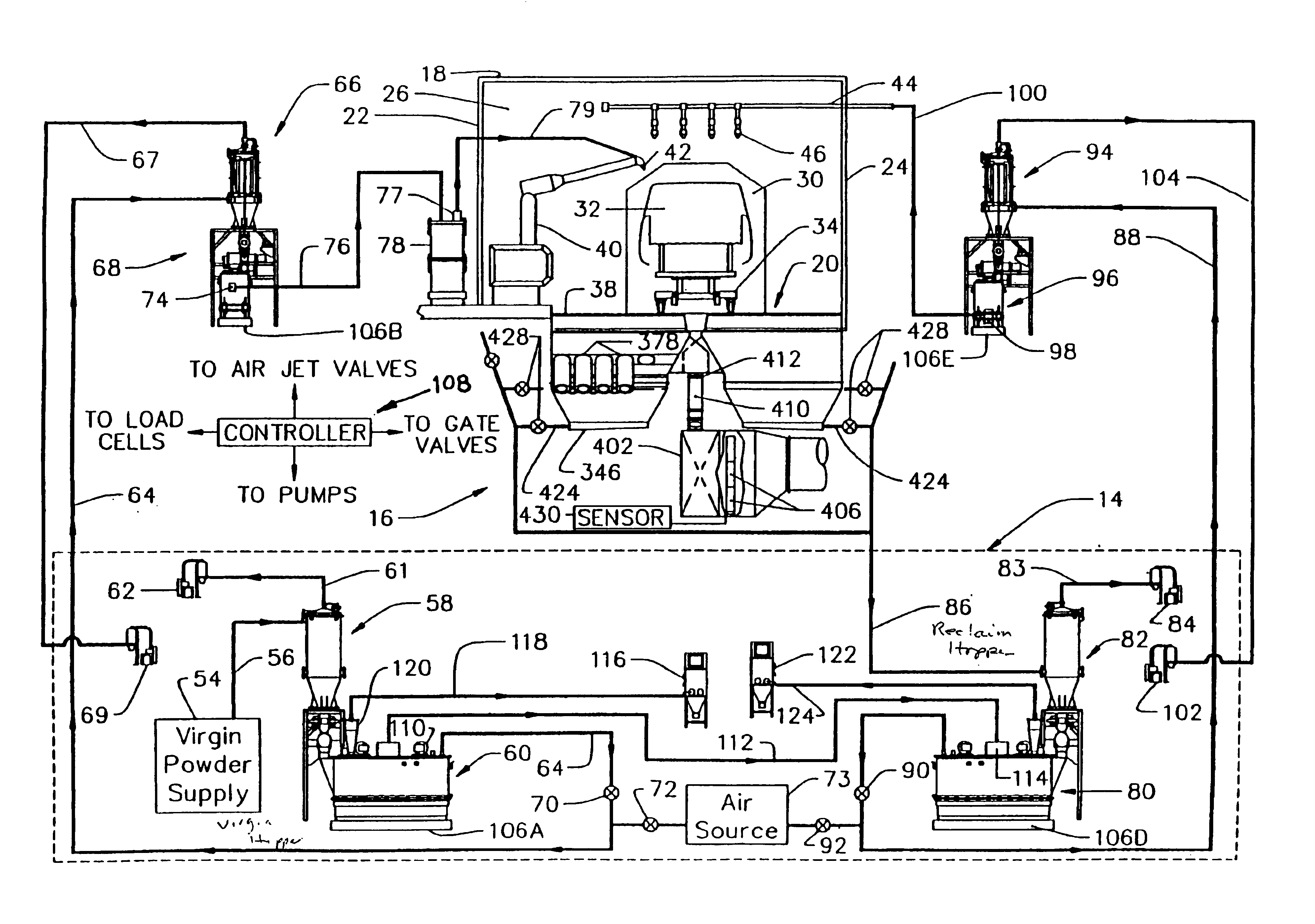

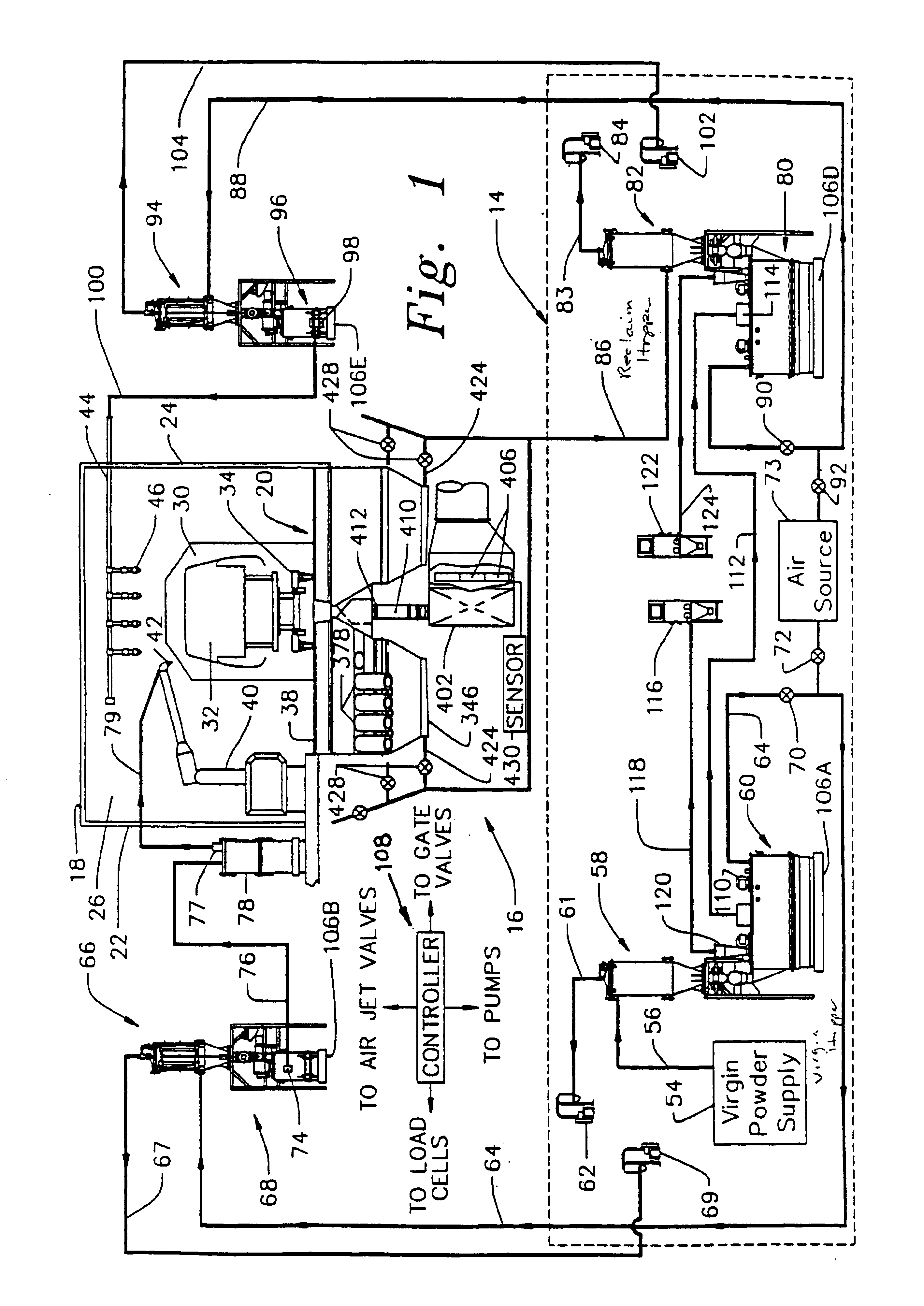

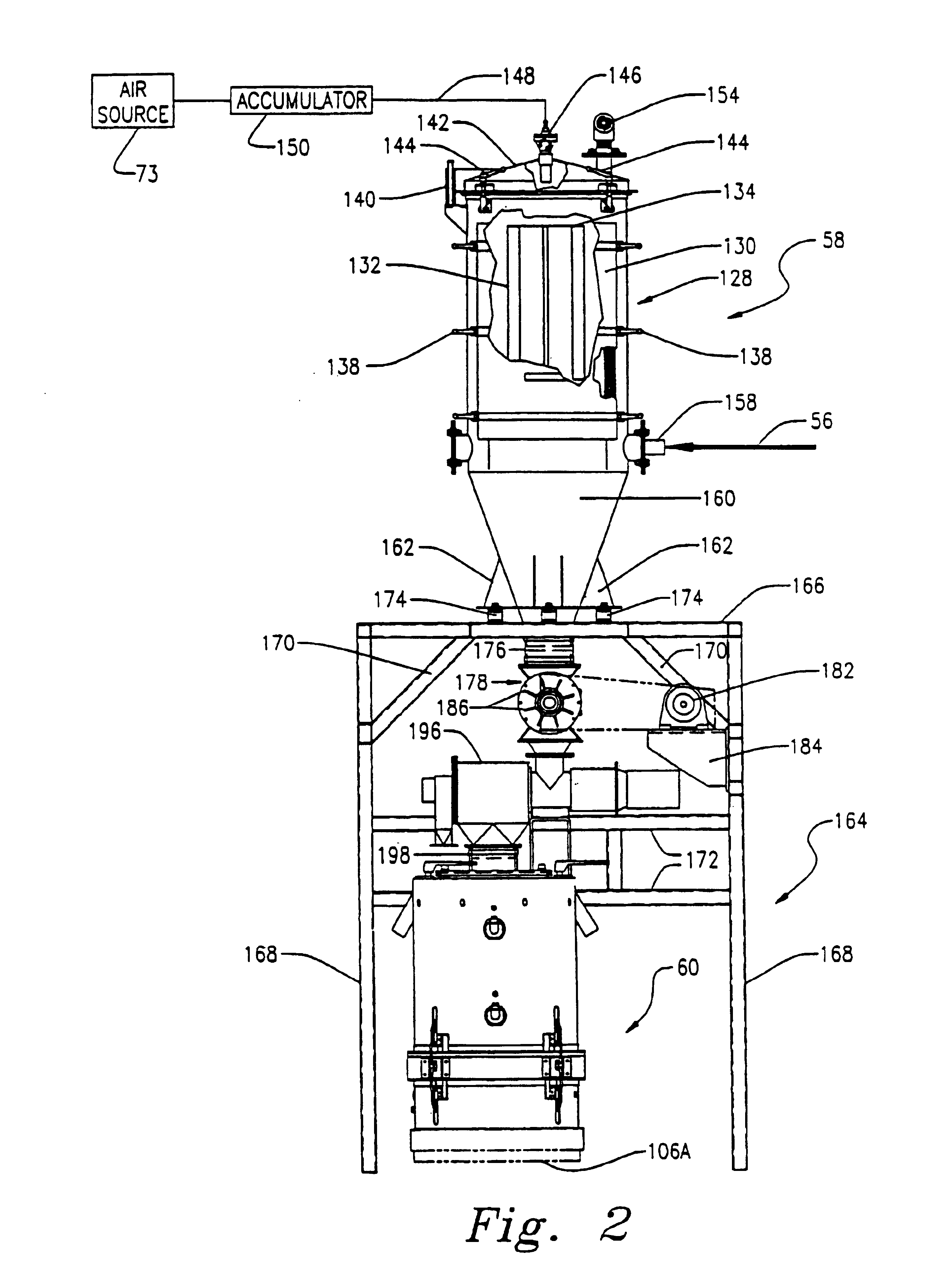

Vehicle powder coating system

InactiveUS6929698B2Easily serviceHigh flow rateLiquid surface applicatorsBulk conveyorsTruckMetallurgy

An apparatus for applying powder coating material onto large objects such as automotive, truck or other vehicle bodies includes a powder spray booth defining a controlled area within which to apply powder coating material onto the vehicle bodies, a powder kitchen located at a remote position from the powder spray booth, and, a number of feed hoppers located proximate the booth which receive powder coating material from the powder kitchen and supply it to automatically or manually manipulated powder spray guns associated with the booth. Oversprayed powder coating material is removed from the booth interior by a powder collection and recovery system which transmits the oversprayed powder back to the powder kitchen for recirculation to the powder spray guns.

Owner:ABB INC

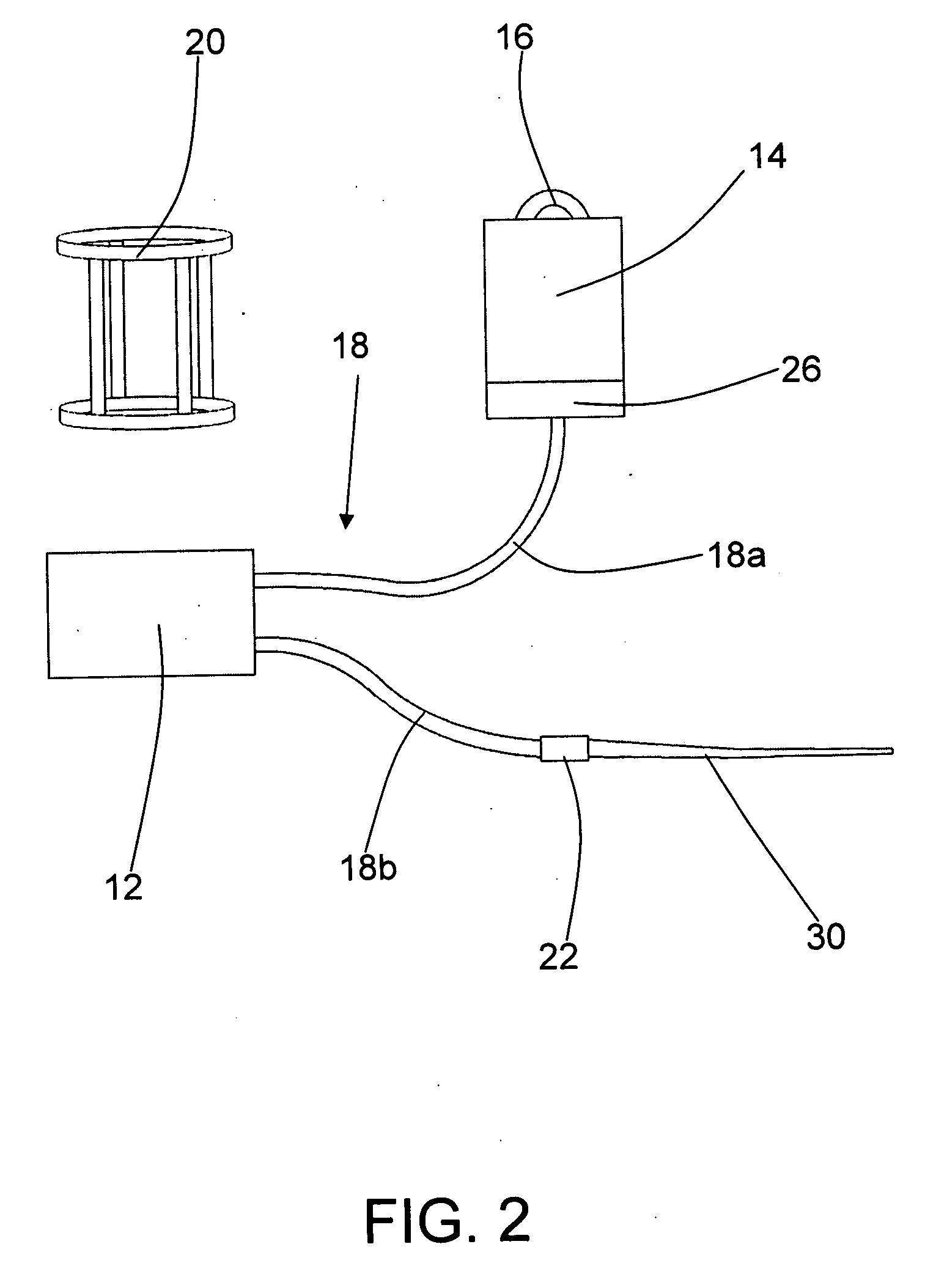

Method and apparatus for controlled feeding of an infant

InactiveUS20070118078A1Easy to useReliable nutritionMilking pumpMedical devicesEnteral feedingsPeristaltic pump

A method and apparatus for controlled feeding of an infant provides a safer and less expensive apparatus for the enteral feeding of a neonatal infant, as well as a mechanism for minimizing separation of fluid for any enteral feeding patient. The apparatus allows for dispensing the feeding solution from conventional baby bottles or breast pump reservoirs, or other convenient reservoirs in combination with a peristaltic pump. The feeding system helps reduce the risk for contaminating the feeding solution by minimizing the handling of the feeding solution. By utilizing a pump which is less expensive than current neonatal feeding pumps, the feeding system is more cost effective in all environments and more suitable for home use.

Owner:ZEVEX

Filters and method for producing filters

InactiveUS6951611B2Spend lessEasy to produceSemi-permeable membranesMembranesFiberHollow fibre membrane

Methods and apparatus are disclosed for producing hollow fiber membrane-containing filters. The methods include laying a plurality of hollow fibers in a first portion of a filter housing to form a bundle, forming first and second portions into a filter housing, sealing the portions together, connecting the plurality of hollow fibers together at at least one end of the filter housing, connecting the hollow fibers to the filter housing, and simultaneously adhering the first and second portions of the filter housing together by applying a potting compound thereto, and cutting the ends of the hollow fibers at at least one end thereof, whereby the hollow fibers include open ends.

Owner:GAMBRO DIALYSATOREN

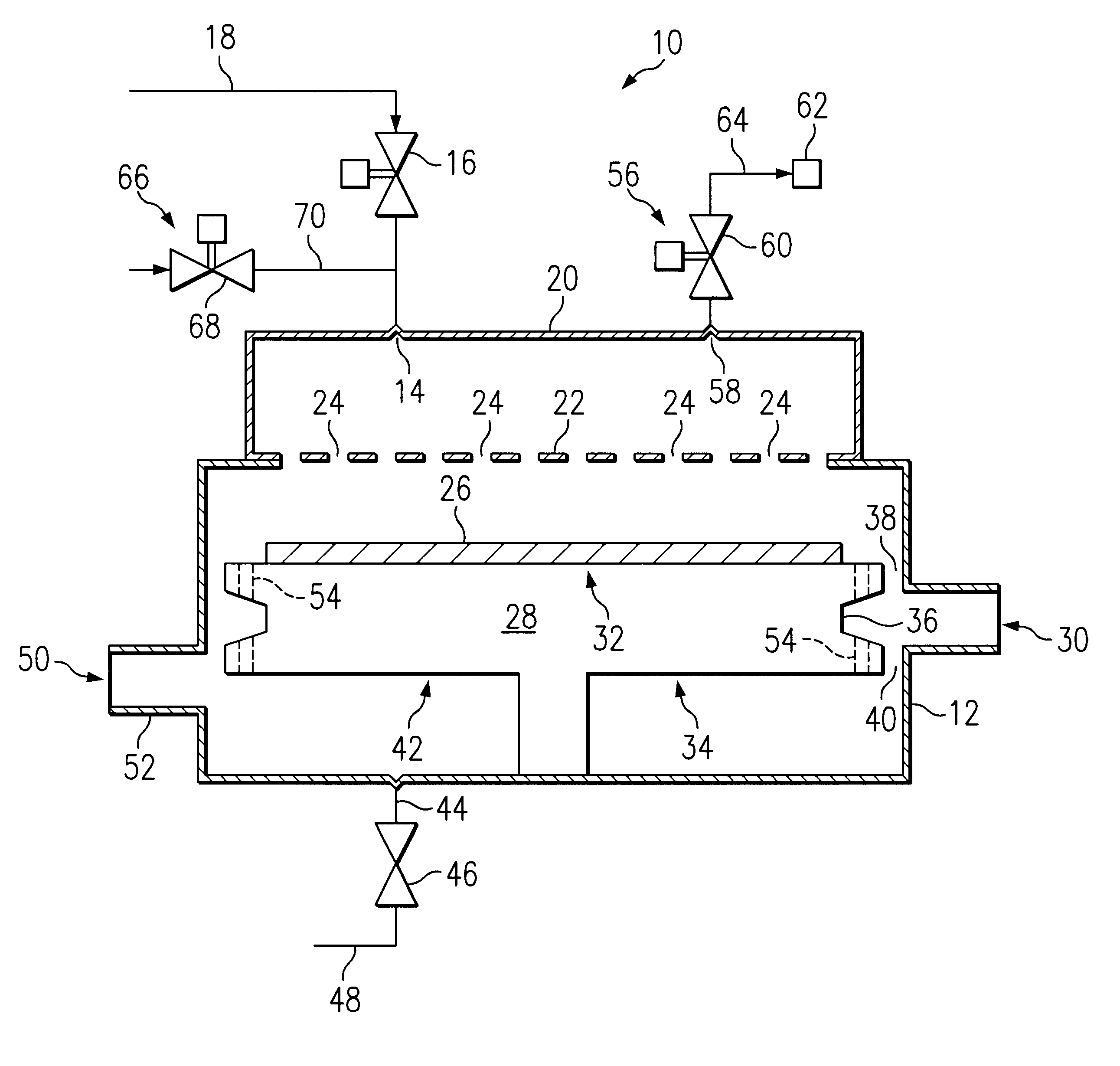

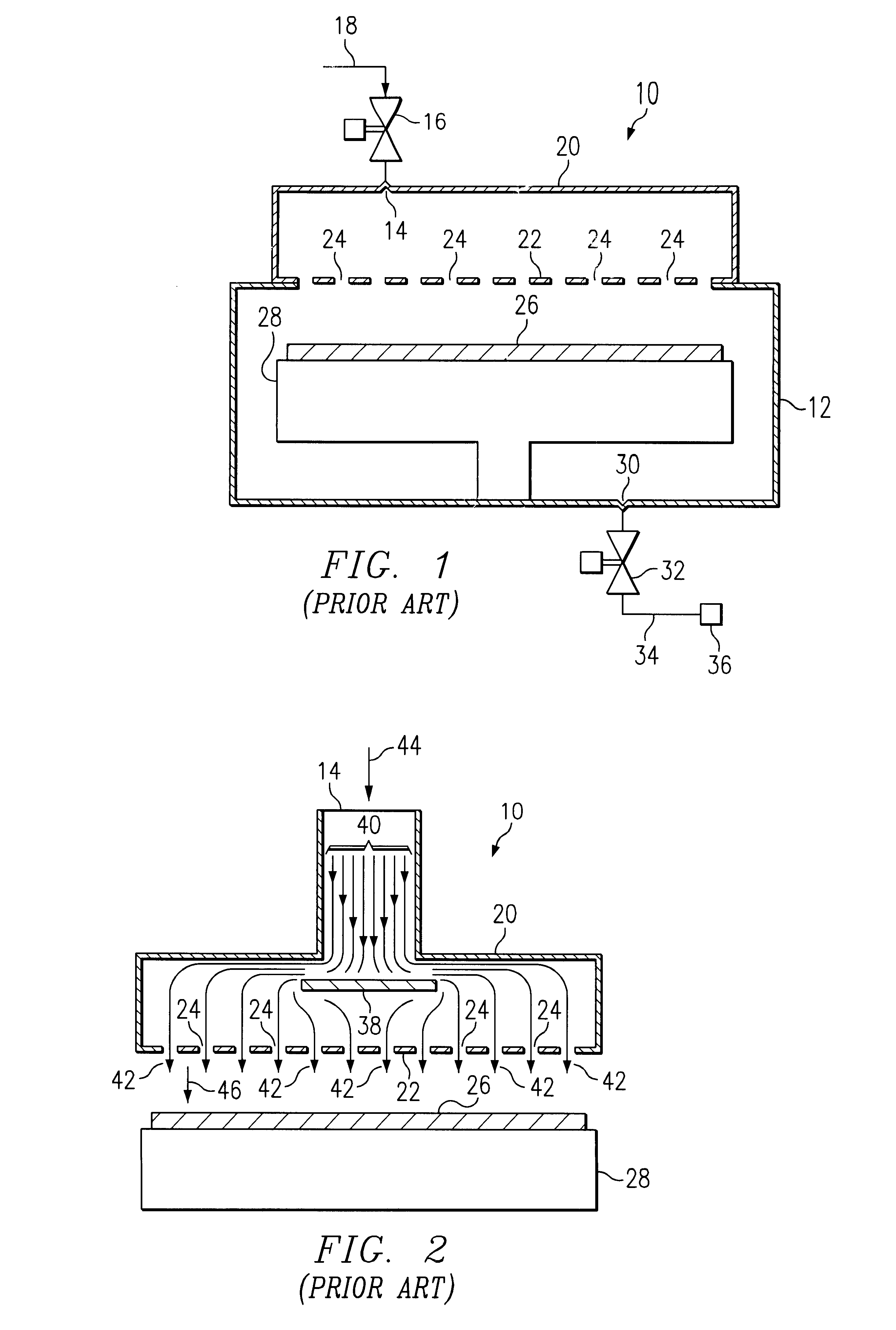

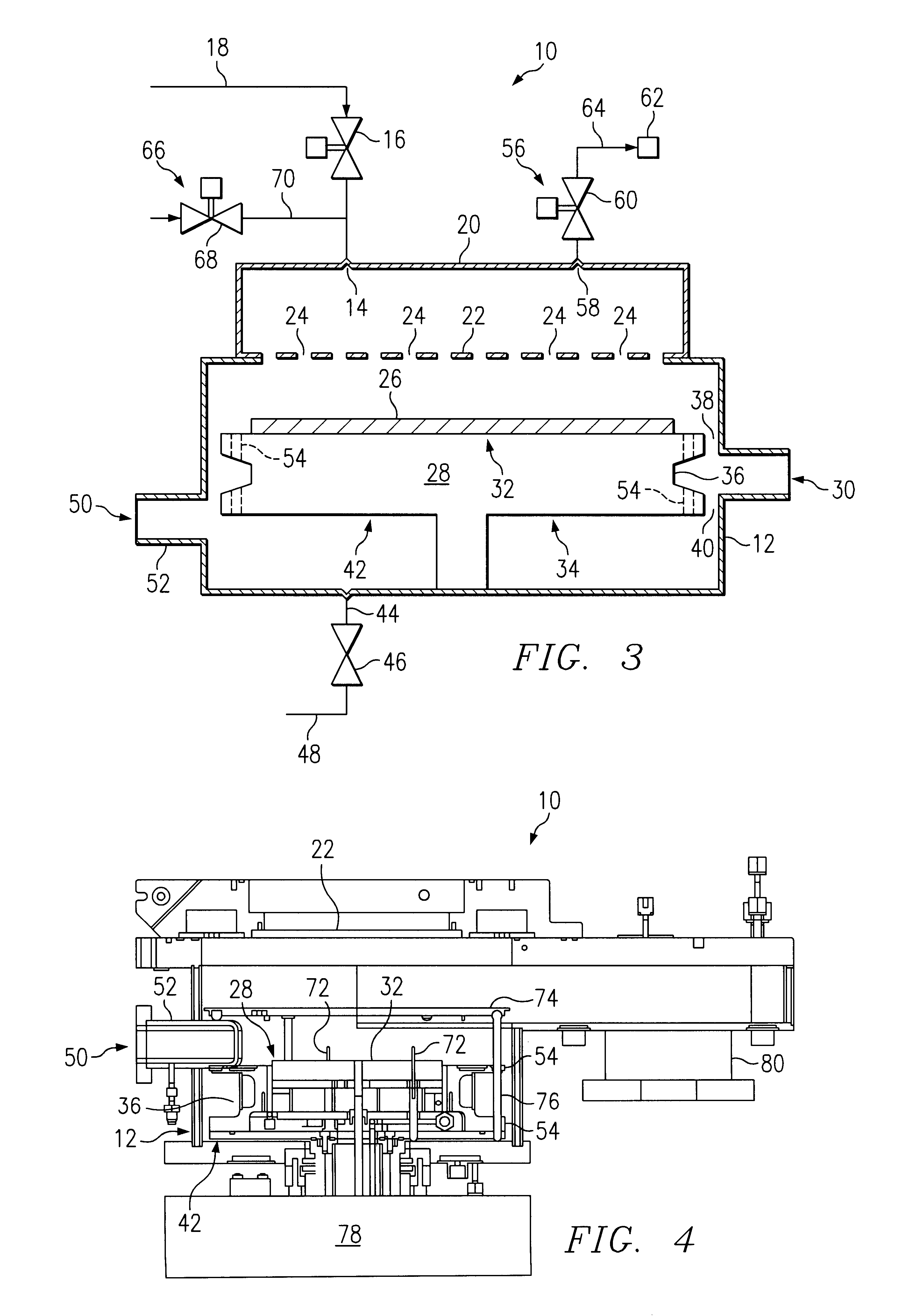

System for fabricating a device on a substrate with a process gas

InactiveUS6544341B1Improve abilitiesExpedite evacuationChemical vapor deposition coatingSemiconductor devicesProduct gasChemical vapor deposition

A method and system for fabricating a device on a substrate with a process gas, such as with chemical vapor deposition. A reaction chamber and support chuck cooperate to form a low conductance configuration for axisymetric process gas flow over the substrate and to form a high conductance configuration for enhanced evacuation of residual process gas from the reaction chamber upon completion of the process. A dual conductance chuck has an indented region that aligns with the exhaust port of the reaction chamber to restrict process gas flow in the low conductance configuration, and that moves distal a showerhead and the exhaust port to provide reduced restriction of process gas flow for reaction chamber evacuation. The chuck includes thermal control for enhancing film deposition on the substrate and for reducing residual film deposition on the chuck. An evacuation opening in the housing provides independent evacuation of residual gas from the housing. The present invention enhance throughput of device formation by reducing purge and process cycle times.

Owner:CVC PRODS

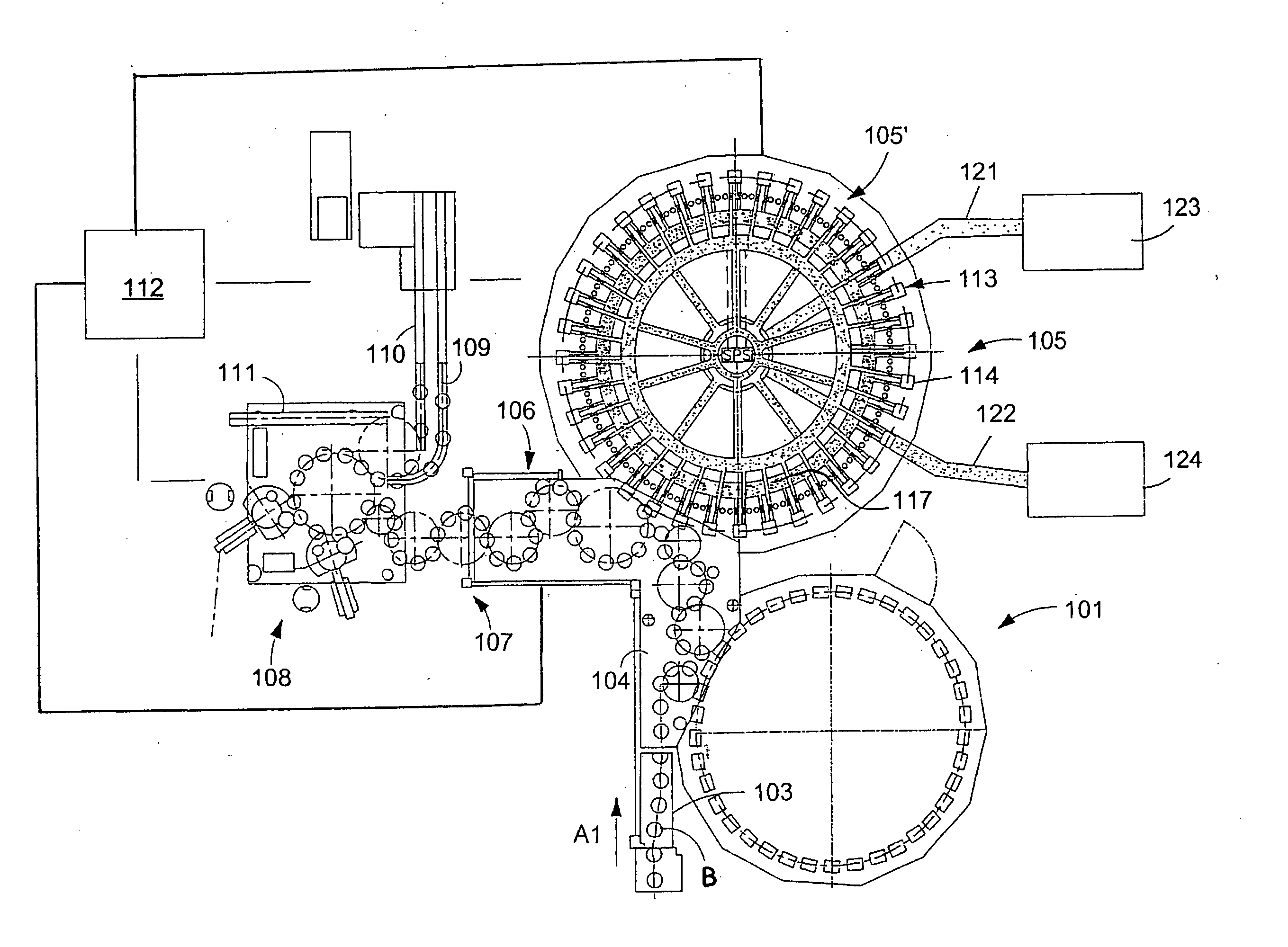

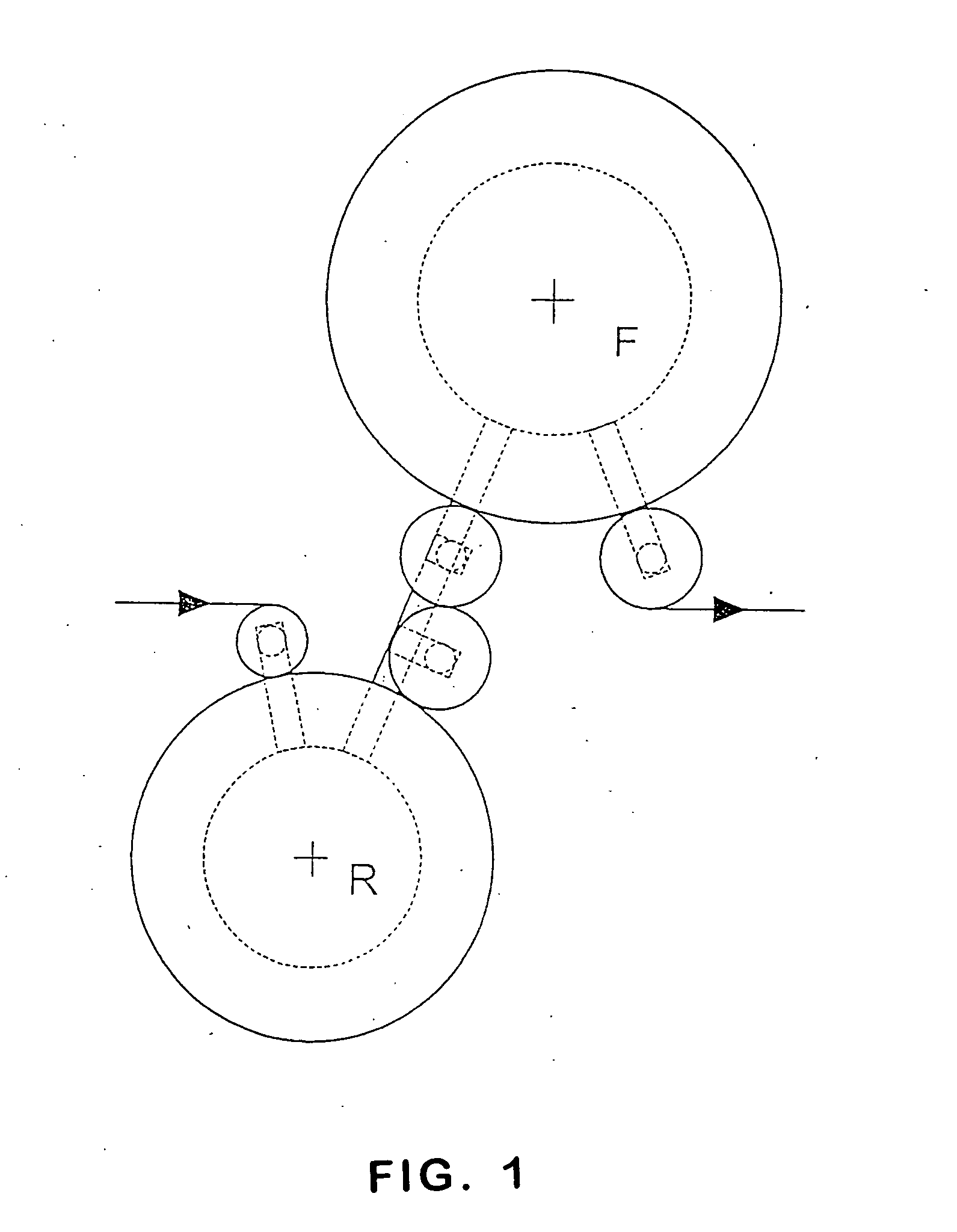

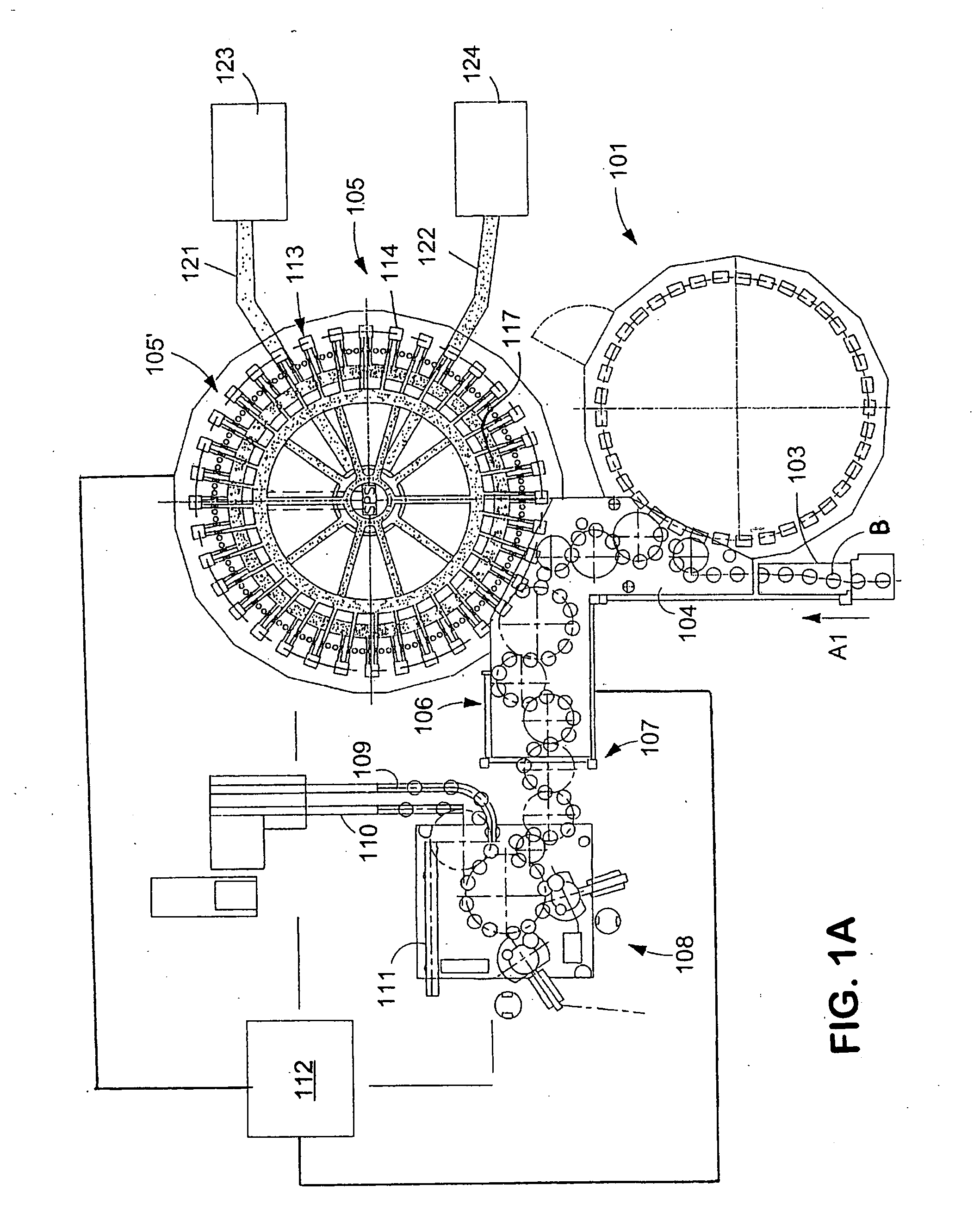

Container filling plant, such as a beverage bottling plant, for filling containers with a liquid beverage and for closing filled containers

Container filling plant, such as a beverage bottling plant, for filling containers with a liquid beverage and for closing filled containers. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): “A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims.” Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

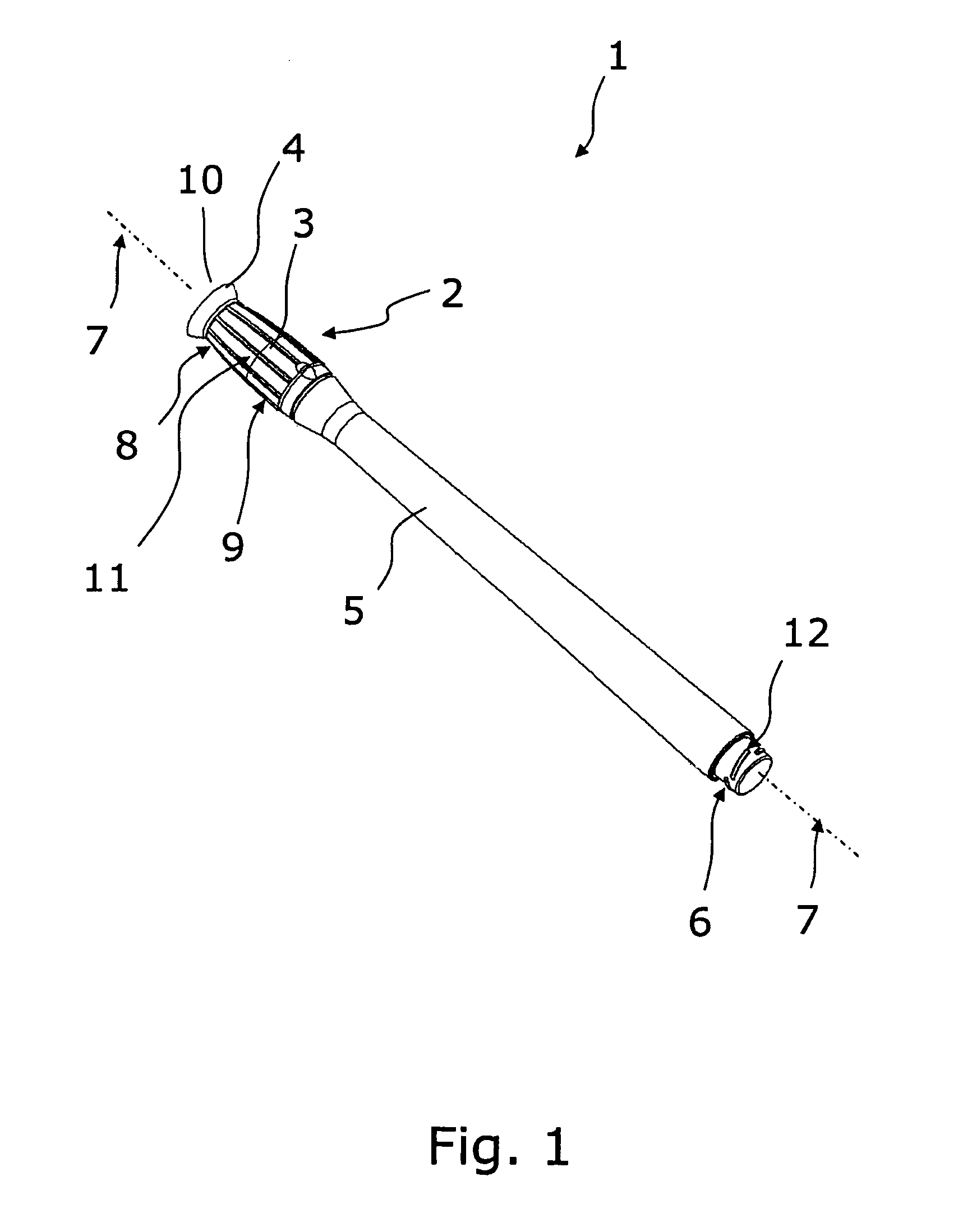

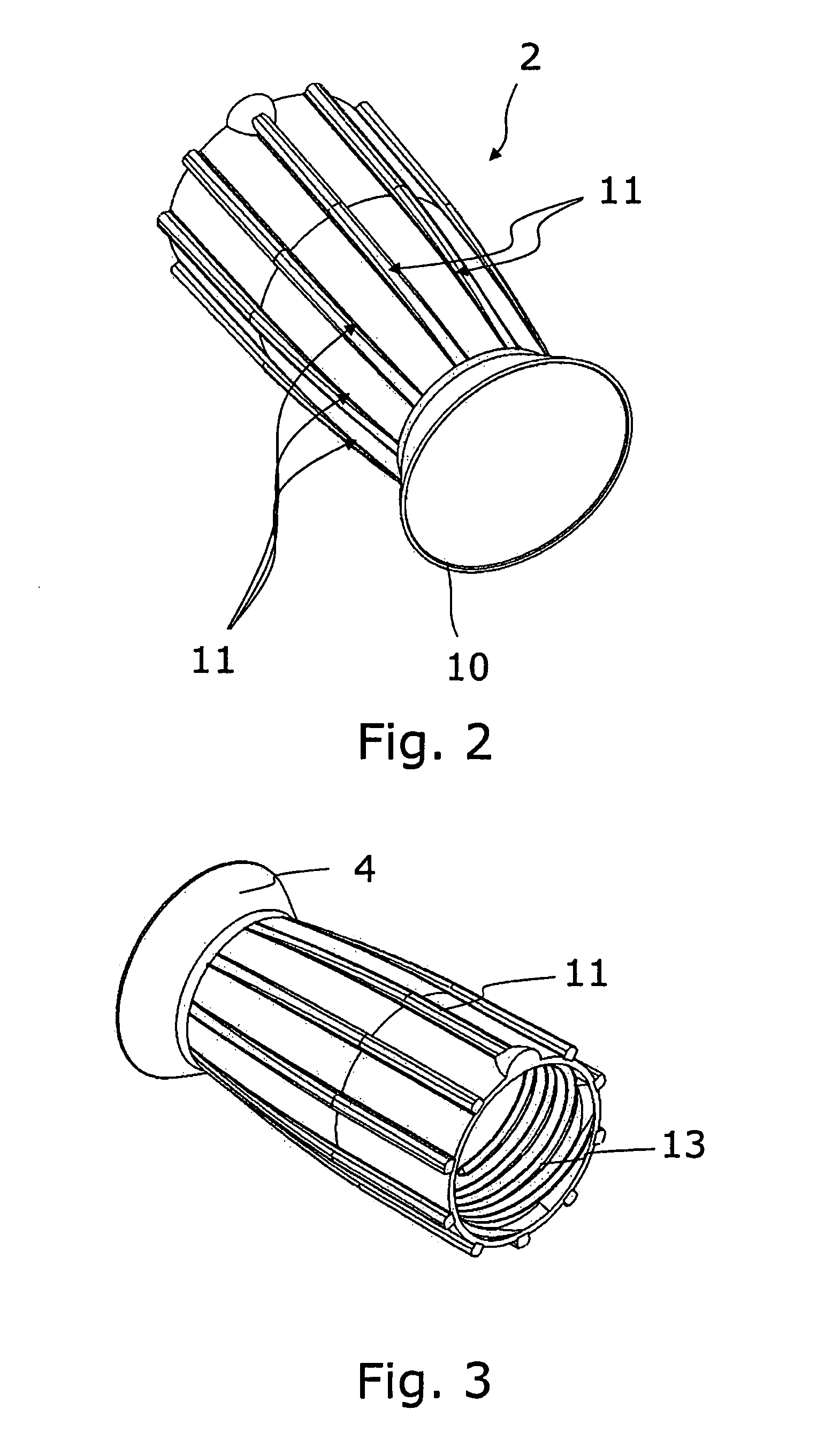

Packaging for a medical article and a catheter in such a packaging

ActiveUS8398615B2Easy to handleReduce the risk of contaminationDiagnosticsSurgical needlesUrinary catheterBiomedical engineering

Owner:COLOPLAST AS

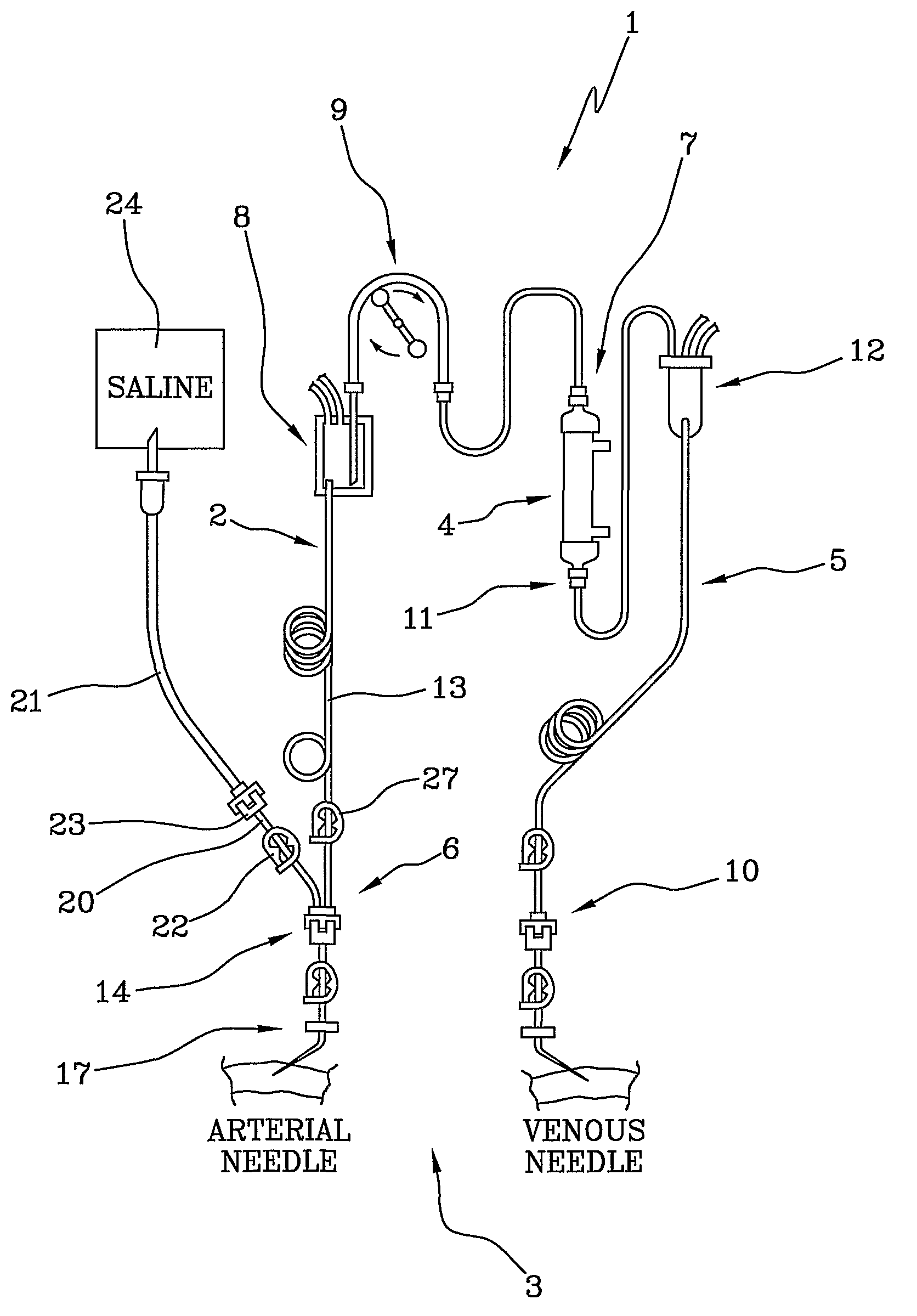

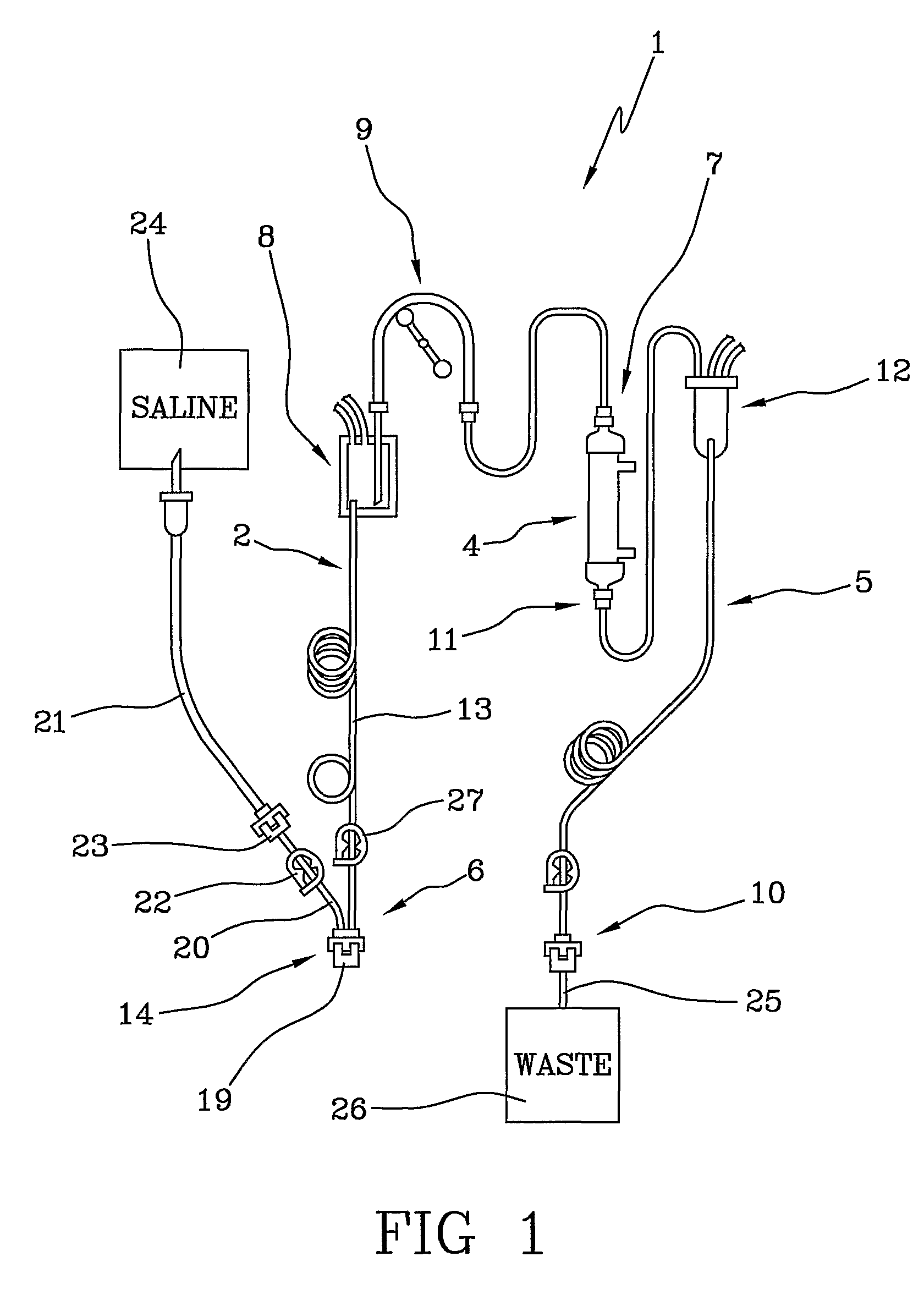

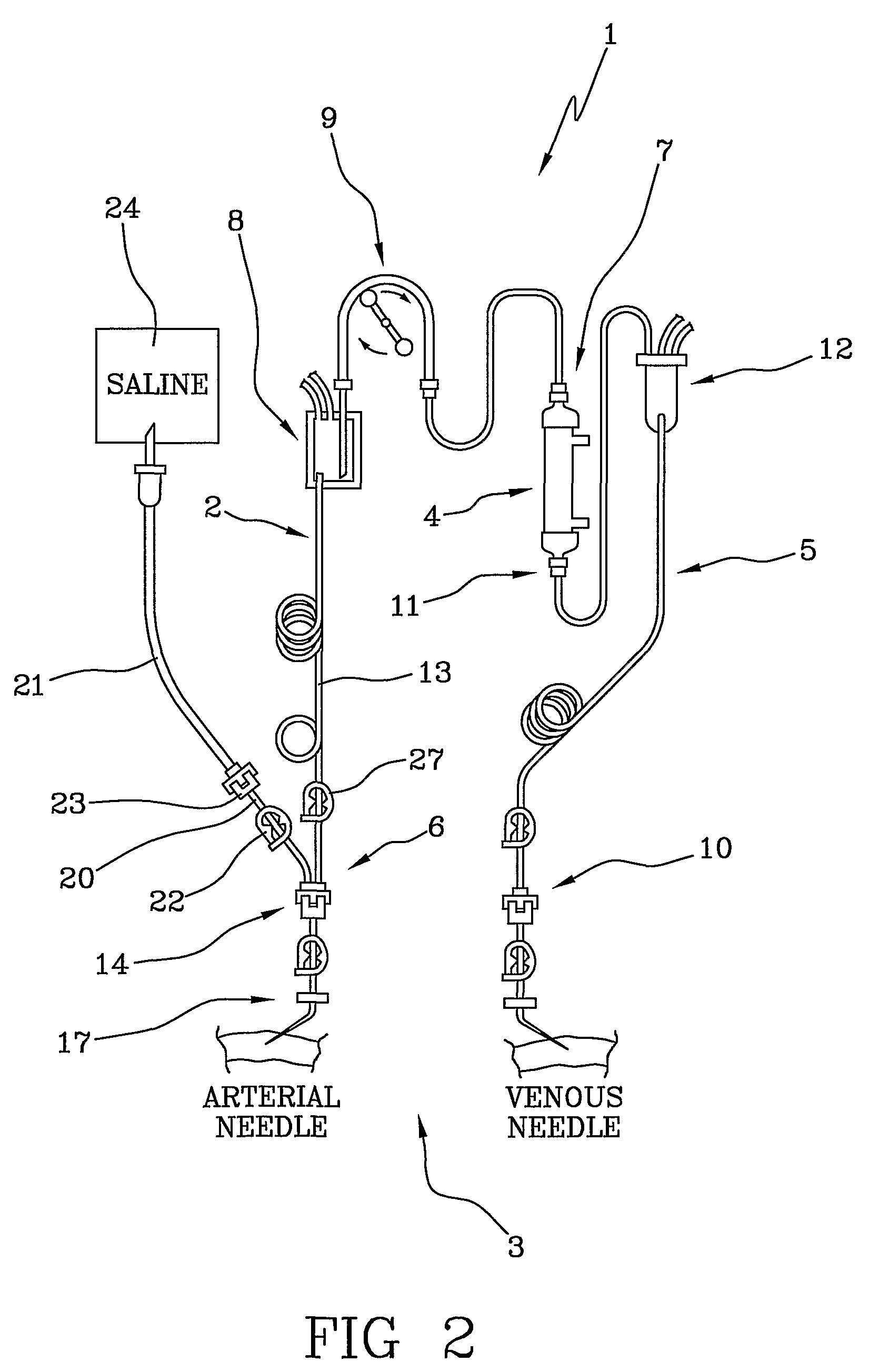

Extracorporeal blood set

InactiveUS8021319B2Constructionally simple and economicalShorten the timeMedical devicesTube connectorsVascular Access DevicesContamination

A blood set comprises an arterial line having a patient end provided with a multiport connector (14) having first port (15) connected to a blood transport tube (13), a second port (16) bearing a male luer connector for connecting to a vascular access device (17), and a third port (18) connected to a service tube (20) terminating with female luer connector (23) for connection with a priming liquid supply line. The blood set operates rapidly and with a small risk of contamination for the patient.

Owner:GAMBRO LUNDIA AB

Selenium-enriched rice and production method thereof

ActiveCN101791081APromote absorptionForm securityFood preparationRice cultivationNutritionPaddy field

The invention discloses a selenium-enriched rice which is produced by processing selenium-enriched paddy rice, the selenium-enriched paddy rice is obtained by applying a nutritional agent for the selenium-enriched paddy rice in the soil of a paddy field for cultivation after land preparation and before irrigation, and the weight composition of the nutritional agent for the selenium-enriched paddy rice is as follows: nano-selenium plant nutritional agent: nitrogen-phosphorus-potassium compound fertilizer is equal to 0.1-1: 1, wherein the weight concentration of selenium in the nutritional agent for the selenium-enriched paddy rice is 2000-10000mg / kg. The selenium content of the selenium-enriched rice is 0.04-0.300mg / kg, the proportion of organic selenium is more than 80%, and the form is safer. The production method of the selenium-enriched rice is simpler, the using amount of the nutritional agent for the selenium-enriched paddy rice is small, and the environmental pollution is small.

Owner:SUZHOU SETEK

Methods and apparatus for processing the surface of a microelectronic workpiece

InactiveUS20020108851A1Reduce downtimeEasy to replaceCellsLiquid surface applicatorsEngineeringMechanical engineering

Owner:SEMITOOL INC

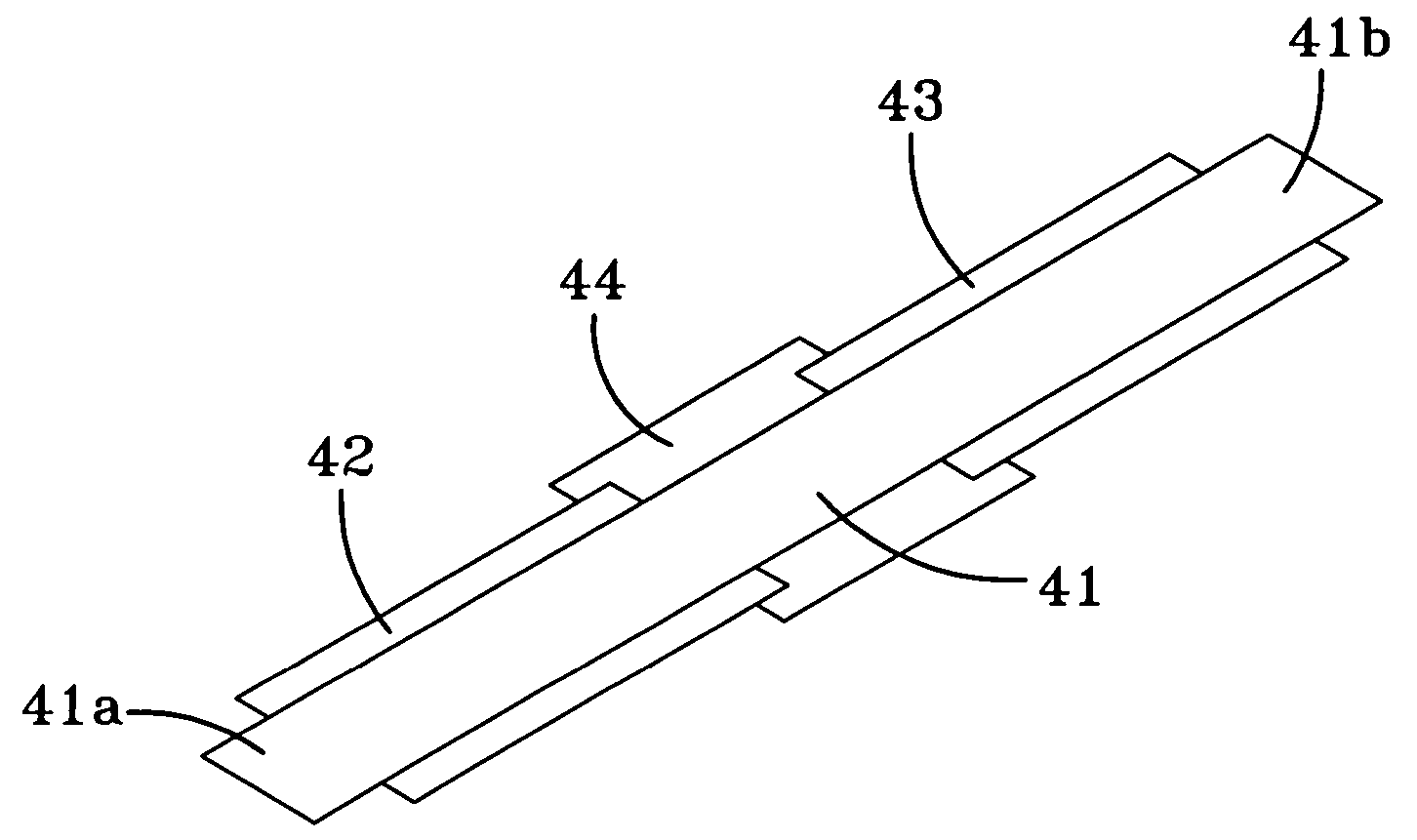

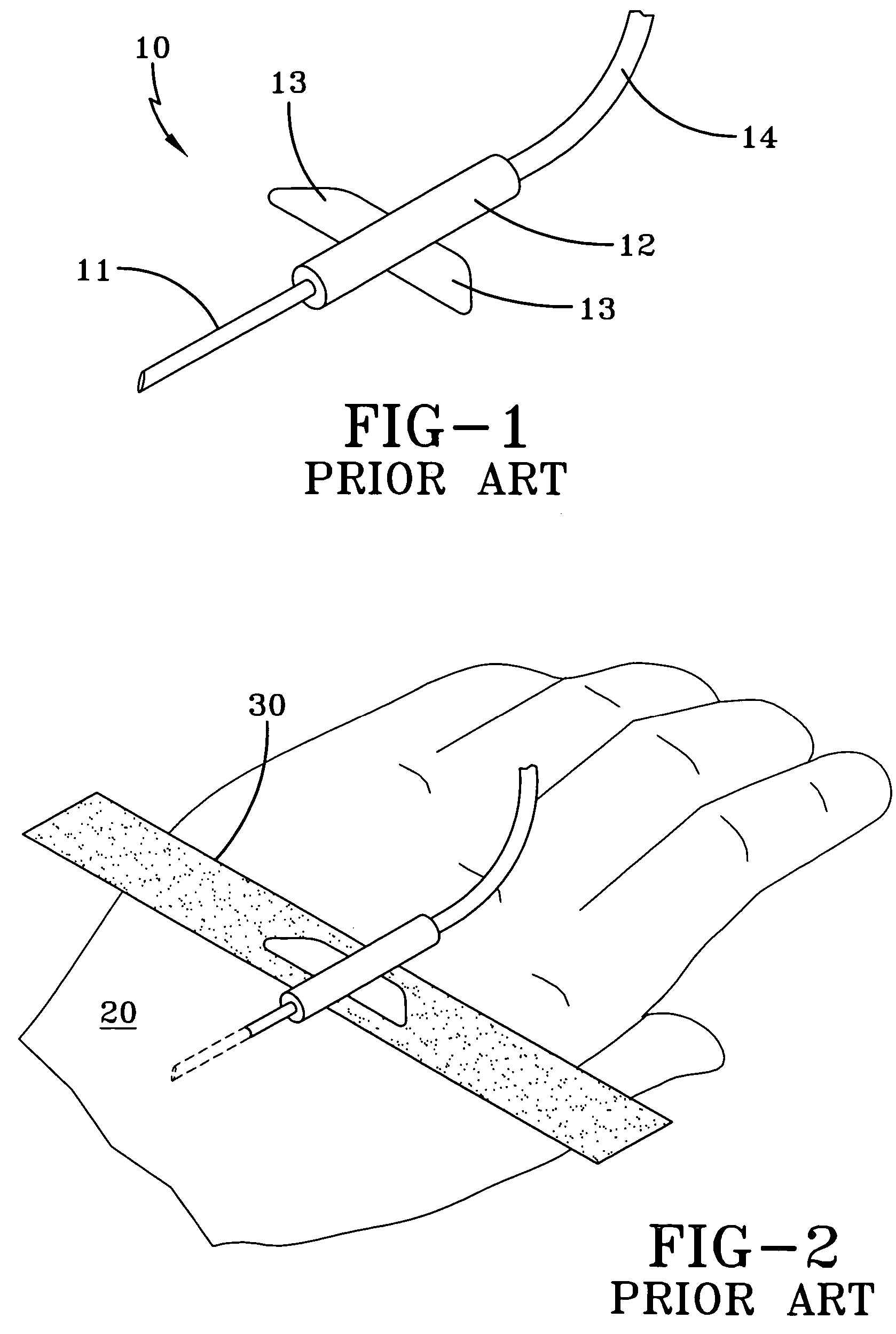

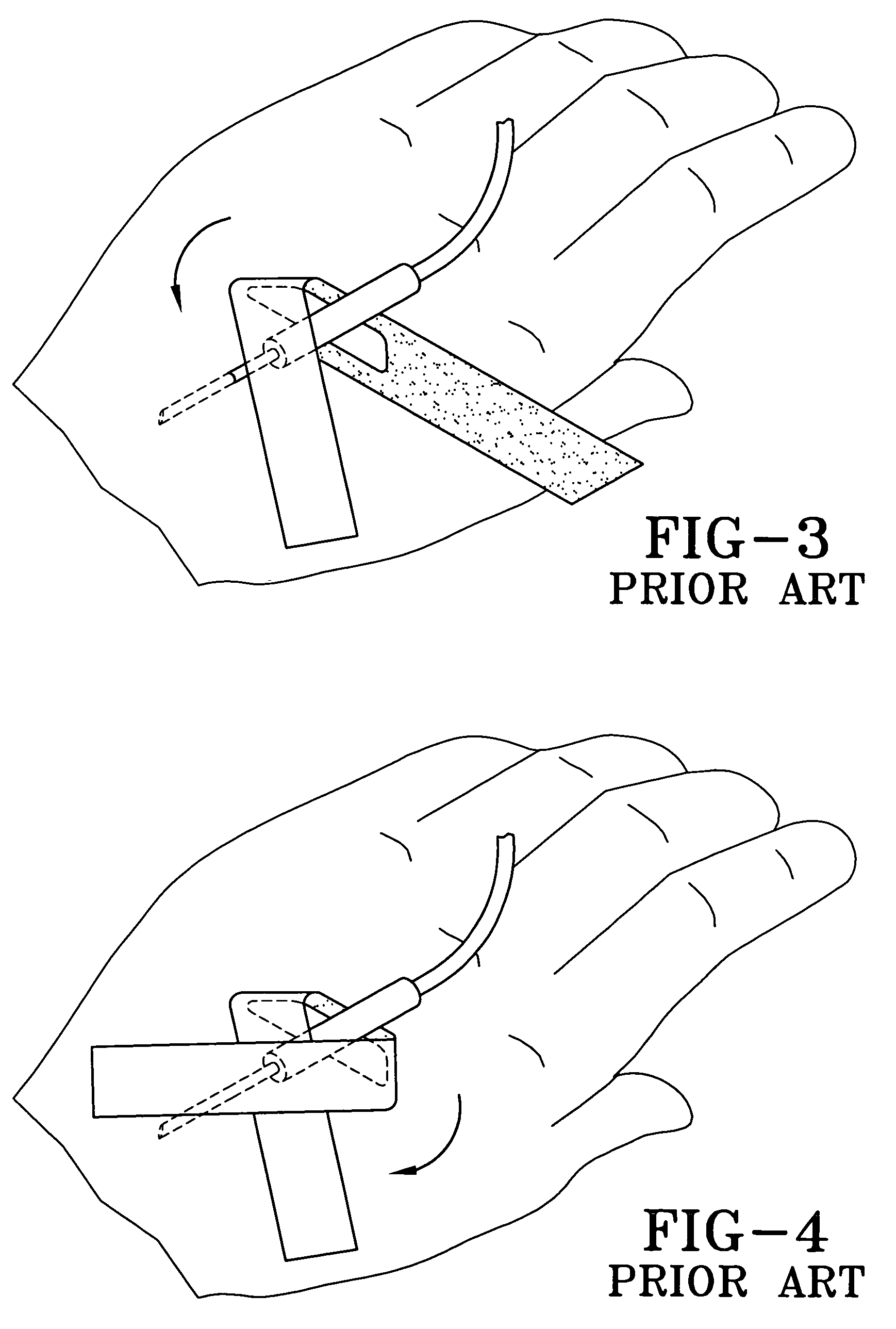

Adhesive tape for an intravascular catheter

InactiveUS7524307B2Easy to useReduce the risk of contaminationSurgeryCatheterAdhesive beltOcclusive dressing

The present invention discloses an adhesive tape to secure an intravascular catheter to the skin of a patient at an intravascular site comprising: (a) a strip of tape having adhesive on all of one side except for portions at the ends, the strip of tape having a length of about 15 to about 300 mm and width of about 4 to about 30 mm; (b) two removable covers affixed near the ends of the adhesive side of the strip, wherein the removable covers are separated from each other by a centrally located portion of the strip of tape; and (c) a third removable cover affixed to the central portion of the adhesive side of the strip of tape. The subject invention further reveals a sterile intravascular starter kit, said kit being comprised of the adhesive tape for an intravascular catheter, a tourniquet, a gauze pad, an antiseptic skin preparation device, optionally a towel, and a clear occlusive dressing.

Owner:PERRY VENTURES +4

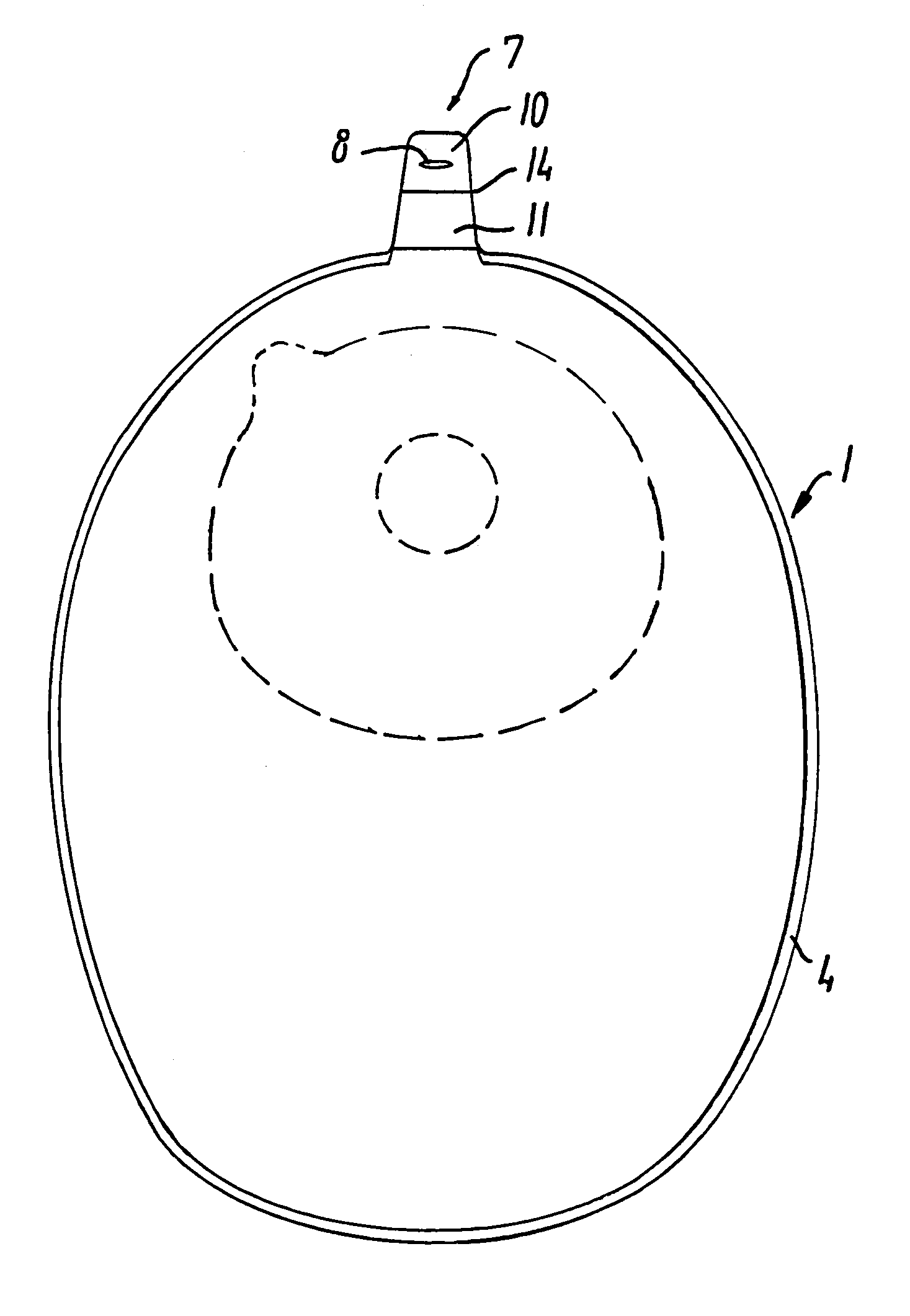

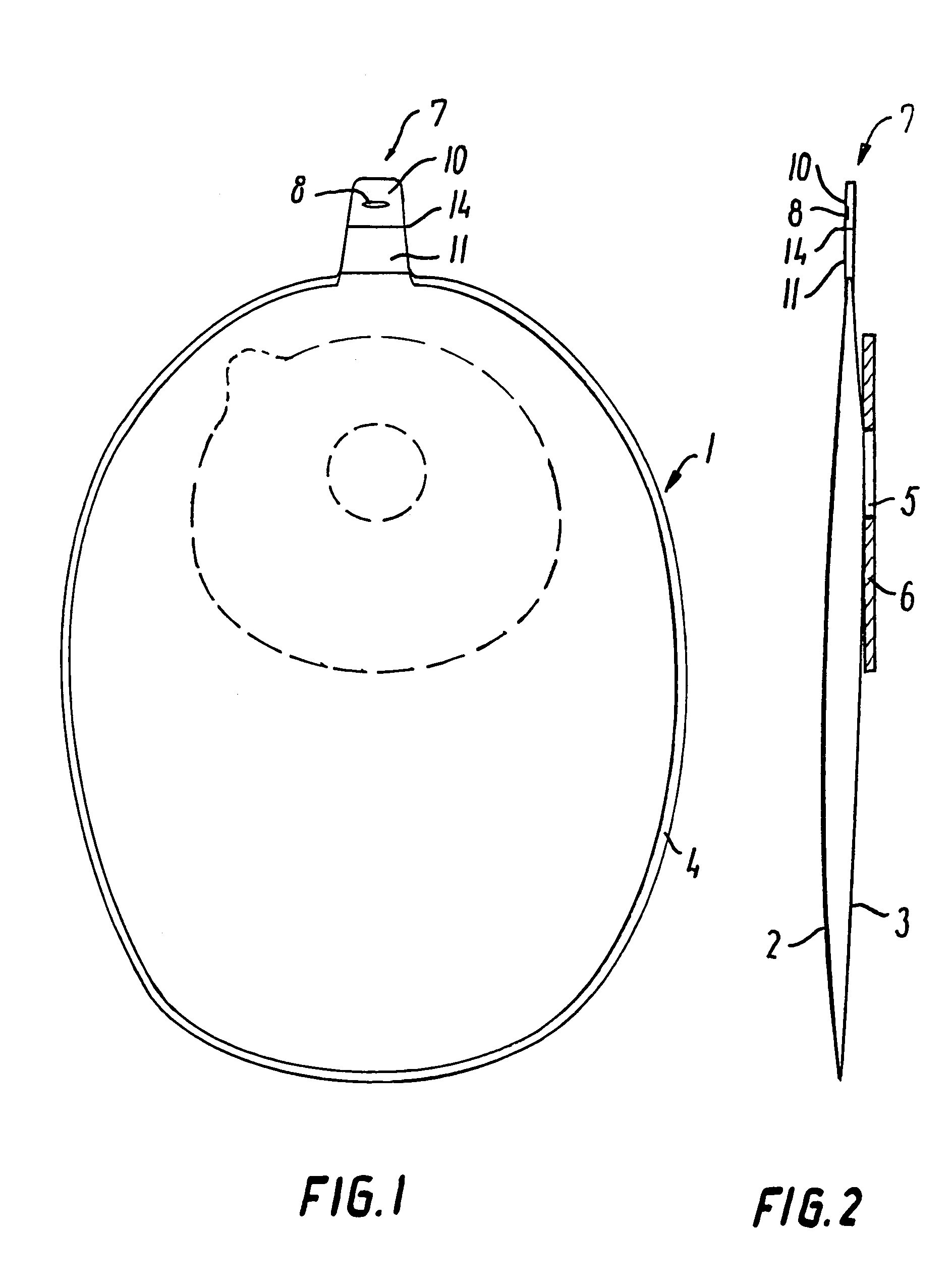

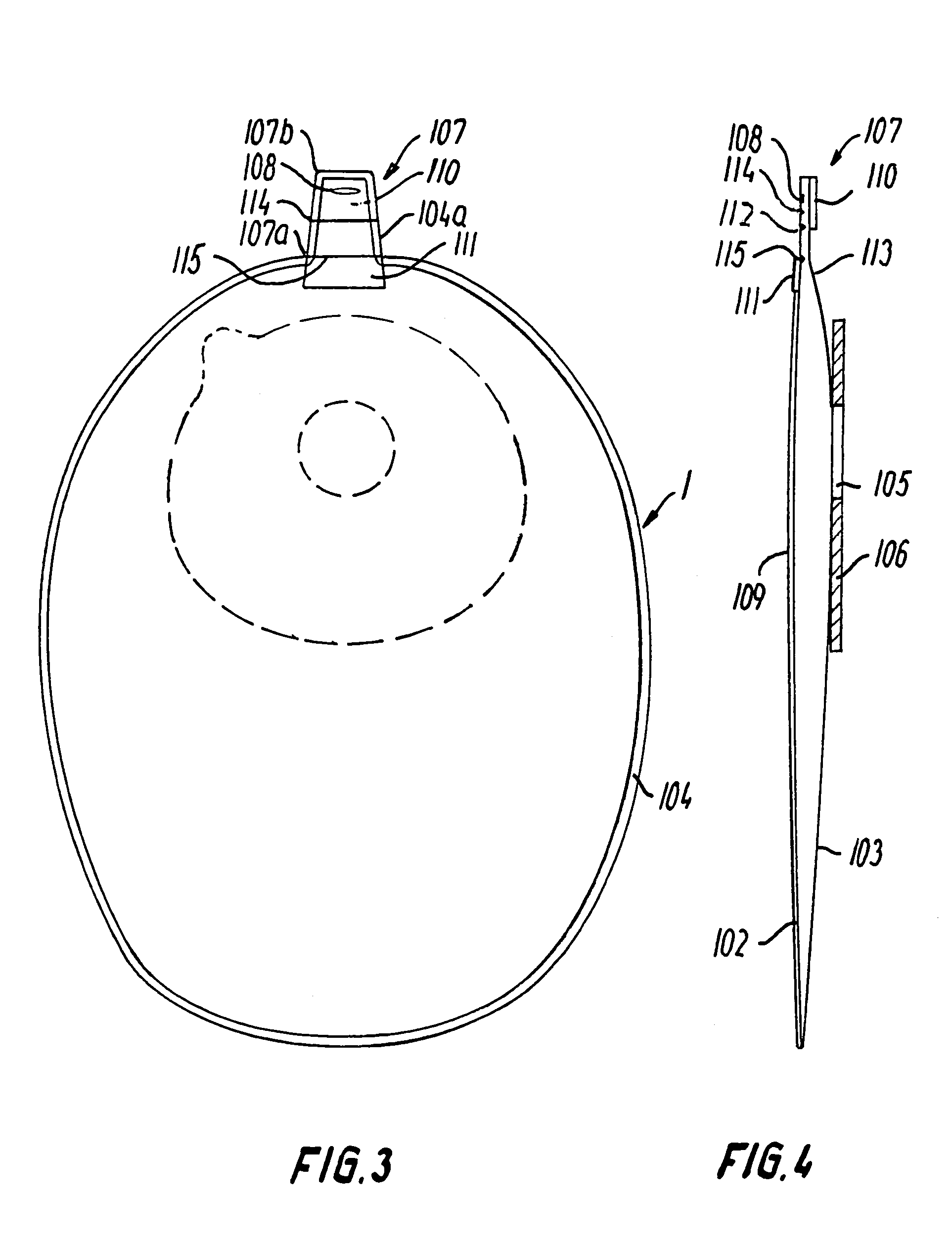

Collecting bag having a vent aperture

InactiveUS7150728B2Improve securityReduce the risk of contaminationNon-surgical orthopedic devicesBodily discharge devicesEngineeringMechanical engineering

Owner:COLOPLAST AS

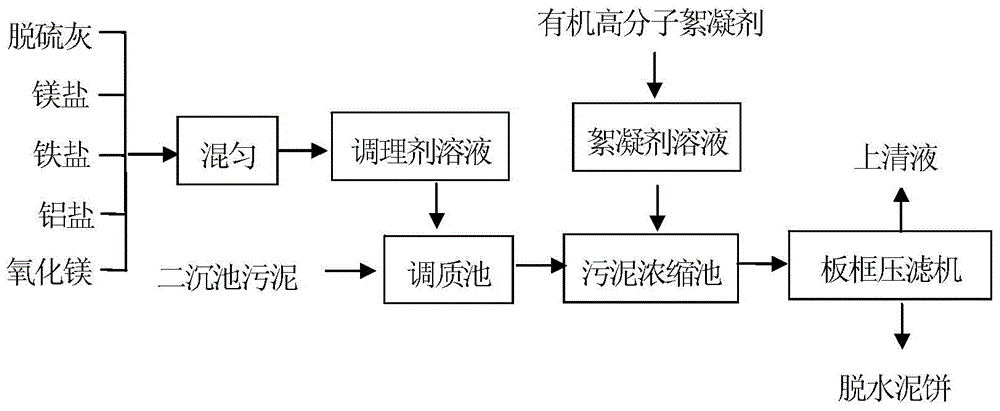

Sludge dewatering conditioning agent and dewatering method thereof

ActiveCN105314815AThe conditioning process is simpleReduce dosageSludge treatment by de-watering/drying/thickeningChemistryIron salts

The present invention discloses a sludge dewatering conditioning agent, which comprises, by weight, 30-70% of desulfurization ash, 5-15% of a magnesium salt, 5-30% of an iron salt, 2-20% of an aluminum salt, and 0.1-15% of magnesium oxide. The invention further provides a dewatering method of the conditioning agent, wherein the dewatering method comprises conditioning agent solution preparing, sludge conditioning, flocculant solution preparing, sludge dewatering and other steps. According to the present invention, the characteristics of wide used raw material source, and low raw material price, low preparation cost and good dewatering effect are provided, the method can be performed through the existing sludge dewatering facility, the implementation process is simple, the stability and the reliability of the sludge dewatering process can be effectively improved, and the sludge dewatering conditioning agent and the dewatering method can be widely used for treatments of various wastewater, sewage and sludge.

Owner:BAOSHAN IRON & STEEL CO LTD +1

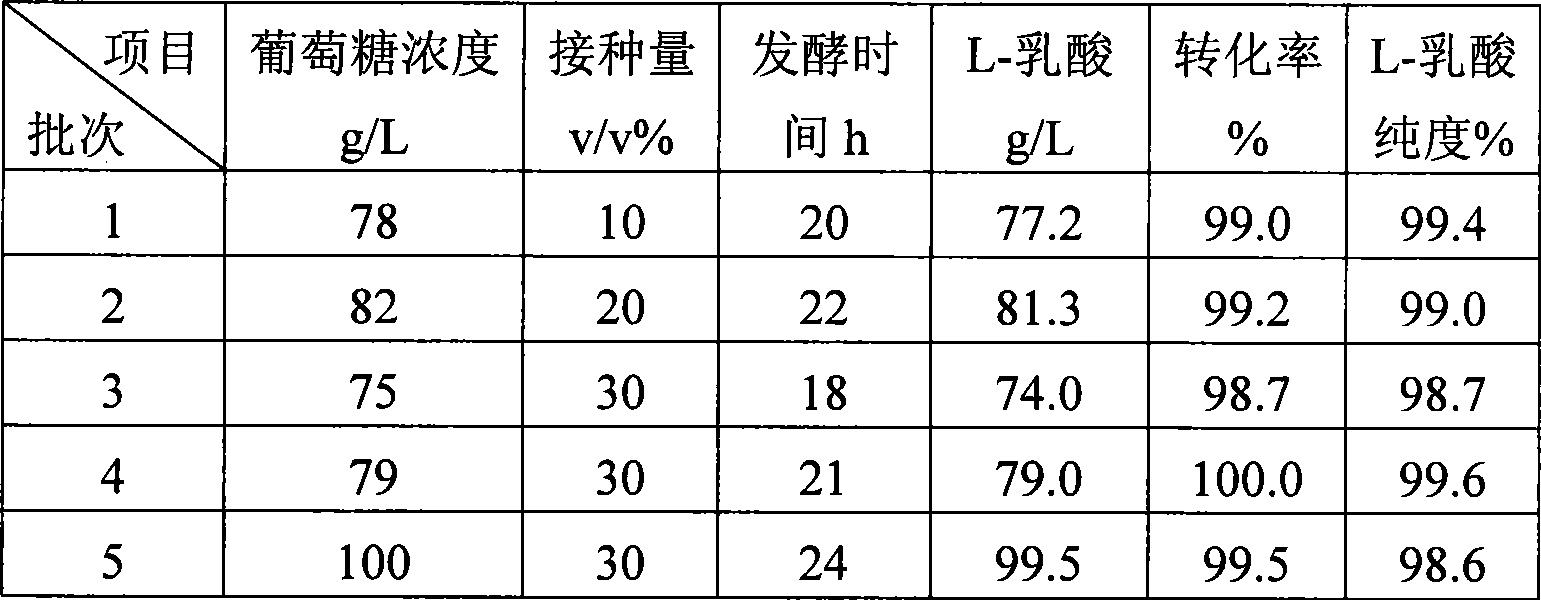

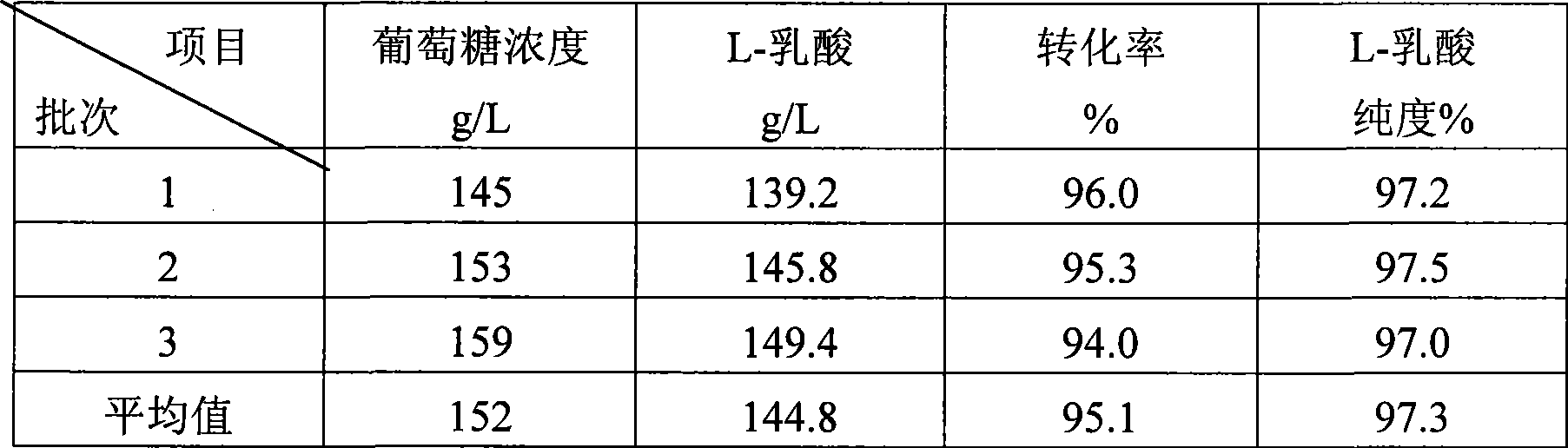

Method for producing L-lactic acid by Bacillus coagulans CGMCC No.2602

ActiveCN101544993AReduce fermentation costsSimple nutritional requirementsMicroorganism based processesFermentationMicroorganismGlucose polymers

A method for producing L-lactic acid by Bacillus coagulans CGMCC No.2602 belongs to the technical field of microorganisms. In the invention, Bacillus coagulans CGMCC No.2602 is adopted, and under the condition of no oxygen supply, starchiness hydrolyzed sugar or dextrose is fermented by a semicontinuous intermittent fermentation way or an inter-sugar-compensating fermentation way to generate L-lactic acid with high optical purity. The invention has the advantages that the gemma property of the Bacillus coagulans is stable, and the L-lactic acid obtained by inoculating and fermenting the starchiness hydrolyzed sugar has high optical purity and rate of conversion of sugar and acid and short fermentation period; in addition, the semicontinuous intermittent fermentation way saves the time for preparing seeds by a continuous reladling and subculturing method, shortens the fermentation period, enhances the fermentation strength and obtains the L-lactic acid with both relatively high rate of conversion of sugar and acid and purity.

Owner:江苏省苏微微生物研究有限公司

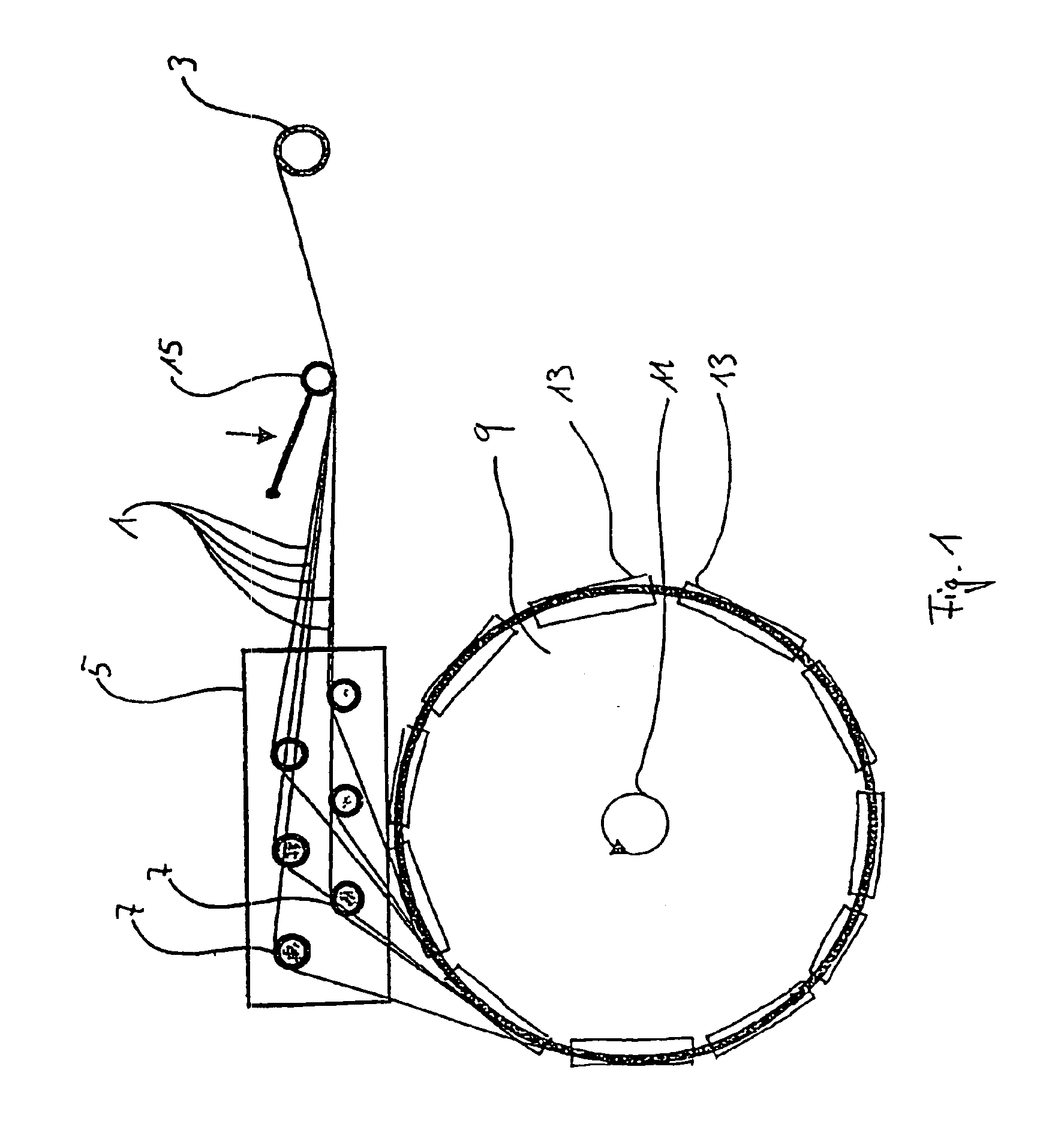

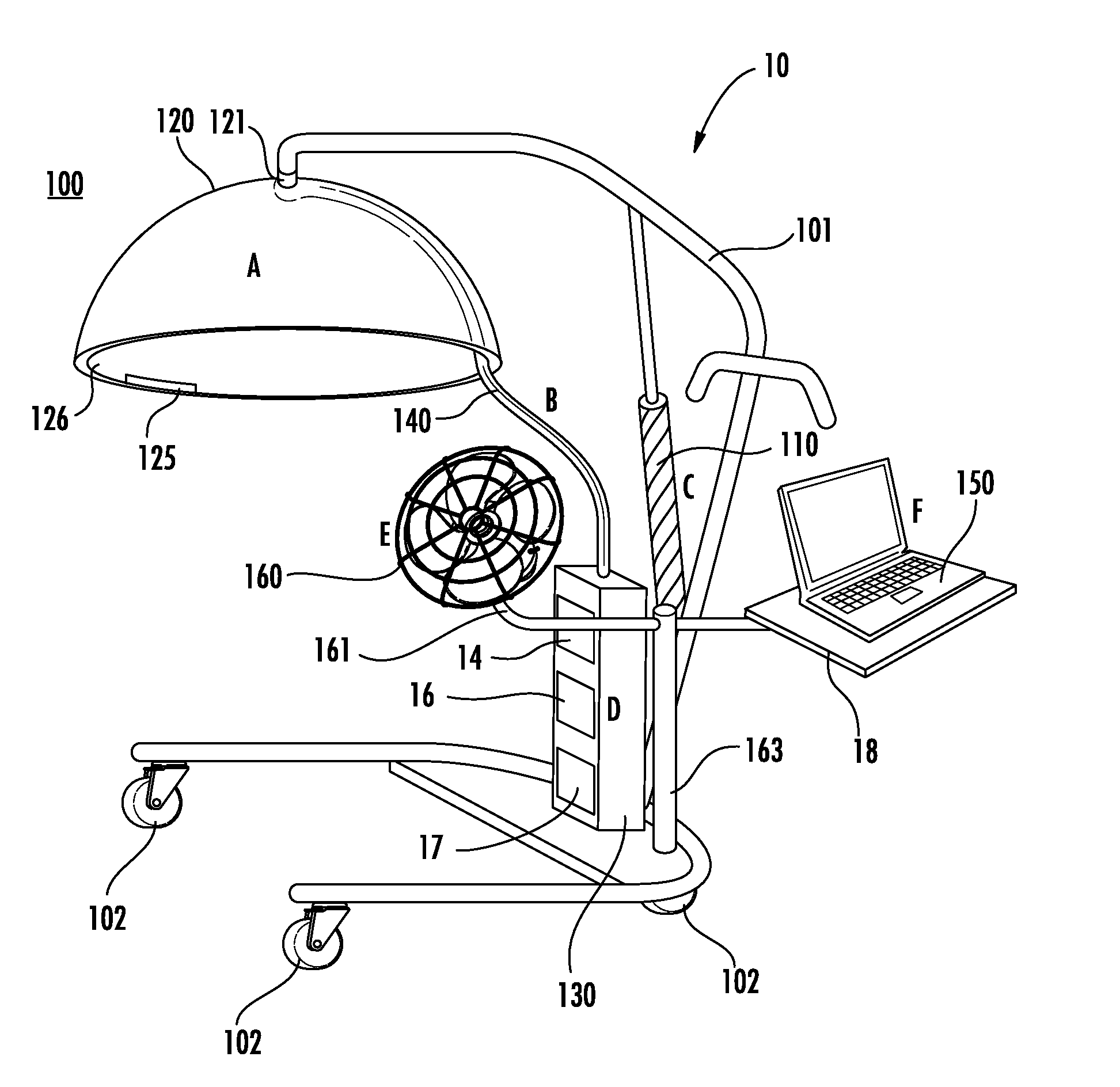

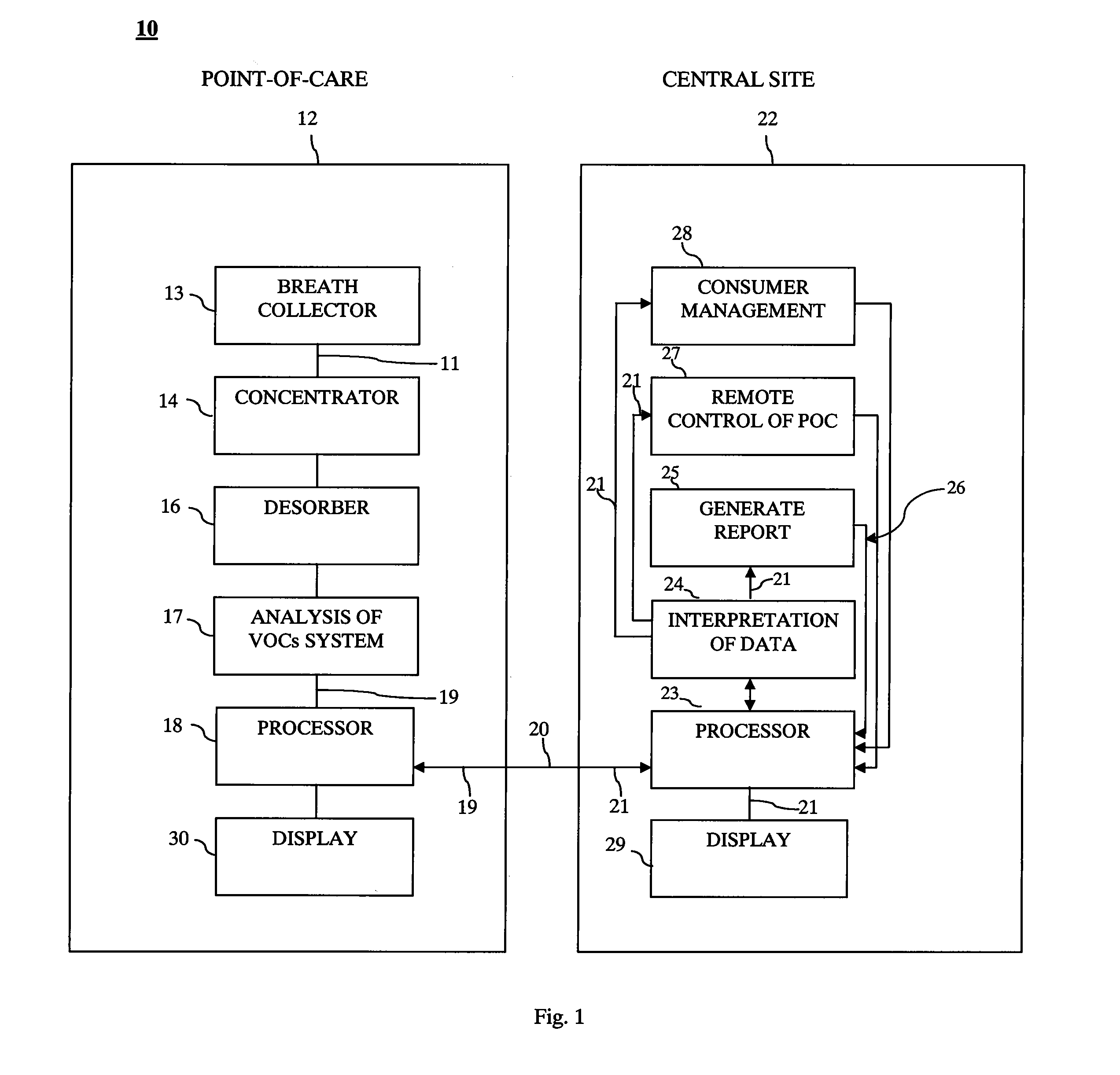

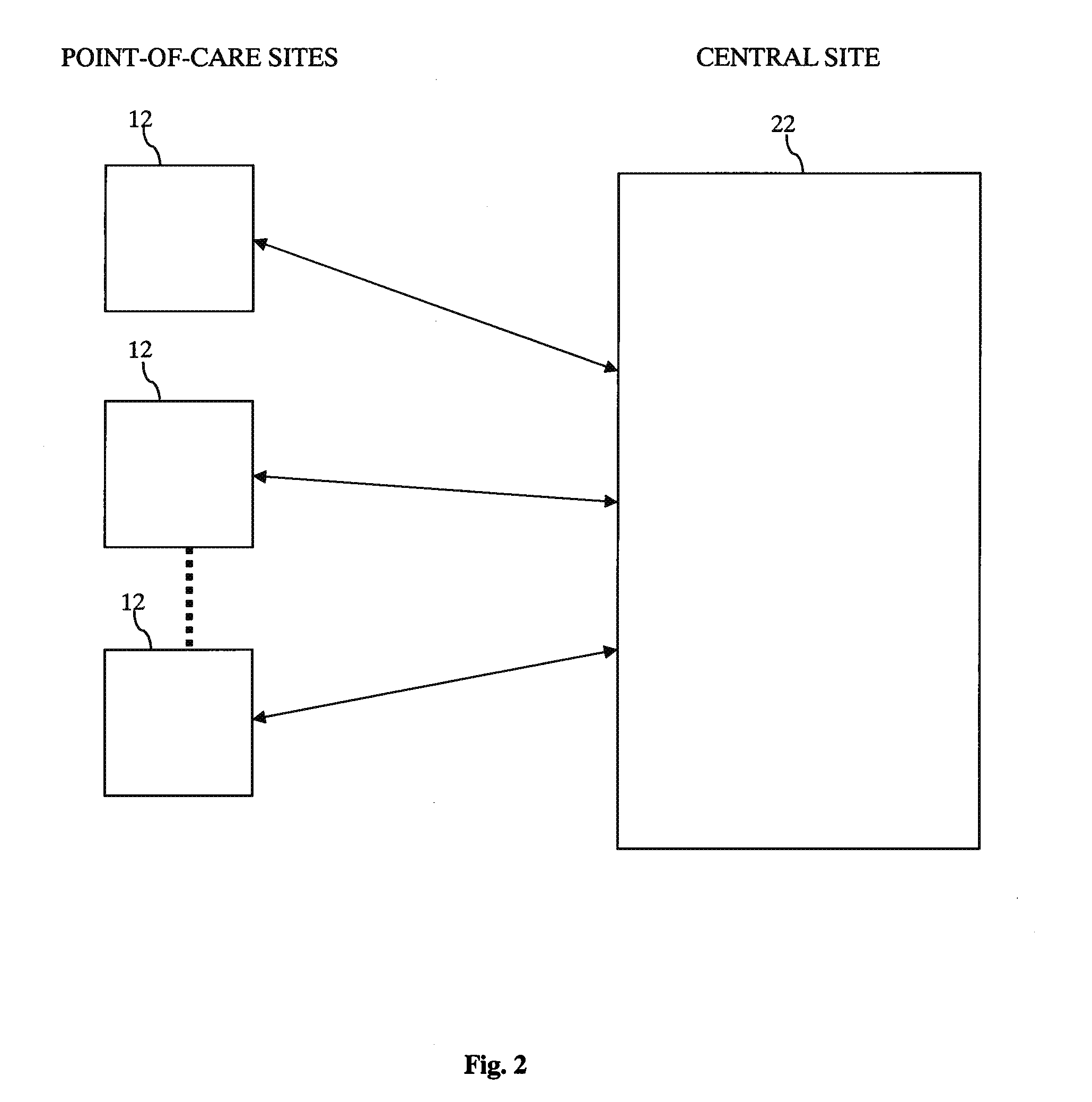

System and method for remote collection and analysis of volatile organic components in breath

InactiveUS20130253358A1Reduce usageOvercome resistanceRespiratory organ evaluationSensorsCollection systemEngineering

A tool for telemedicine including an improved breath collection system of human breath to facilitate the analysis of volatile organic components (VOCs) contained in human breath in which breath tests can be performed at remote sites for rapid detection of different diseases. The system can include a standoff breath collection device including an arcuate structure for concentration and analysis of volatile organic components (VOCs) at the point-of-use that avoids the use of mouthpieces found in conventional breath collection apparatuses.

Owner:MENSSANA RES

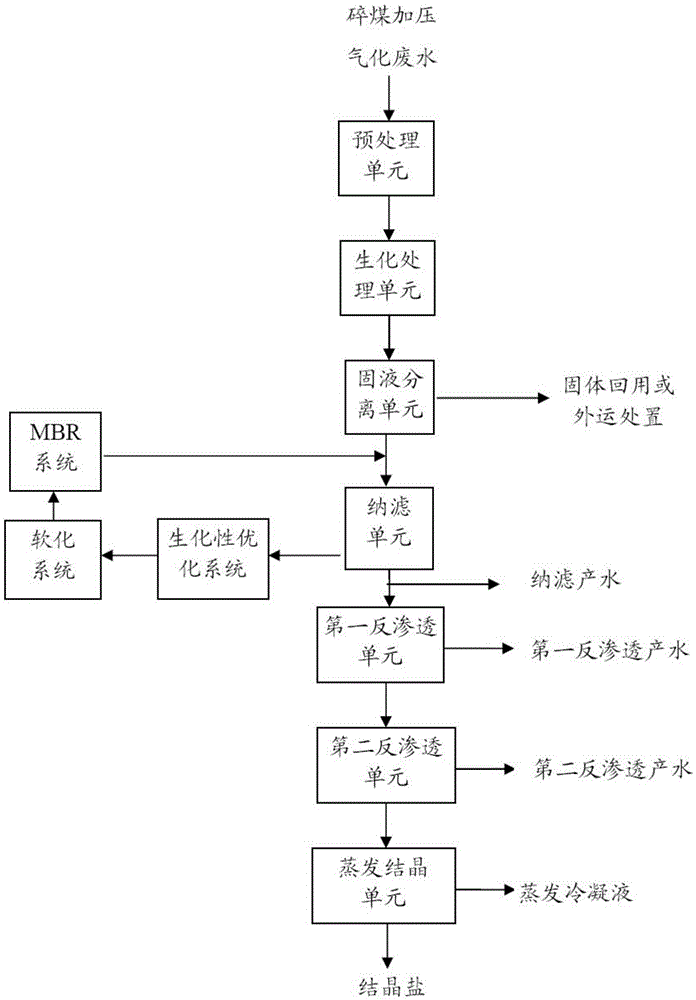

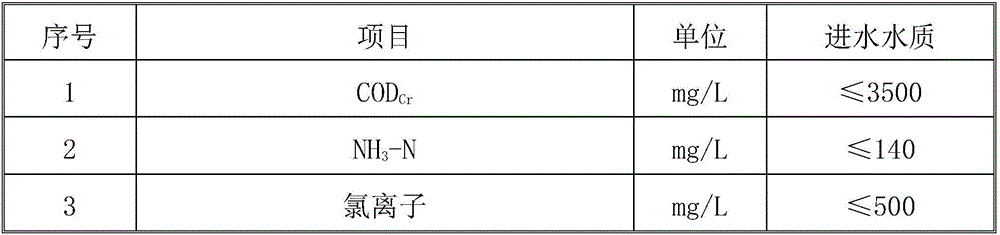

Resource recycling and treatment technology of high-concentration degradation-resistant salt-containing organic waste water

ActiveCN105800886ARealize inner loopImplement resourcesFatty/oily/floating substances removal devicesGeneral water supply conservationHigh concentrationWater quality

Provided is a resource recycling and treatment technology of high-concentration degradation-resistant salt-containing organic waste water.The technology comprises the following steps of the pretreatment process, the biochemical treatment process, the advanced pretreatment process, the advanced treatment process and the concentrated water treatment process.According to the technology, multiple process combinations are optimized, degradation-resistant organic matter and inorganic salts in the waste water can be removed step by step, and resource recycling of the high-concentration degradation-resistant salt-containing organic waste water is achieved on the basis of nearly zero emission; the recycling rate of produced water produced after the treatment process can reach 95% or above, and the produced water can be used as water for a production technology and replenishing water for circulating cooling water.According to the resource recycling and treatment technology of the high-concentration degradation-resistant salt-containing organic waste water, the water quality requirement of biochemical reaction inlet water is guaranteed; due to the fact that fluorine ions are removed through a fluorine removing reactor, and calcium and magnesium ions are removed through a resin softening device, the risk of inorganic salt scaling of a subsequent desalination system is greatly reduced; the risk of organic matter contamination of the subsequent desalination system is effectively reduced by means of biochemical treatment and an advanced oxidation reaction.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

High specific surface area mixed oxide of cerium and of another rare earth, preparation method and use in catalysis

ActiveUS20100329954A1Effective supportReduce the risk of contaminationNitrogen compoundsInternal combustion piston enginesMixed oxideLiquid medium

The mixed oxide of the invention mainly consists of cerium oxide and of at least one oxide of another rare earth. It has a specific surface area of at least 20 m2 / g after calcining at 1000° C. for 5 hours. It is obtained by forming a liquid medium comprising a cerium compound; by heating this medium; by adding to the precipitate obtained a compound of the other rare earth, by heating the medium thus obtained and by bringing its pH to a basic value and by calcining the precipitate. The mixed oxide may be used as a catalyst support.

Owner:ANAN KASEI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com