Patents

Literature

554 results about "Multiple injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

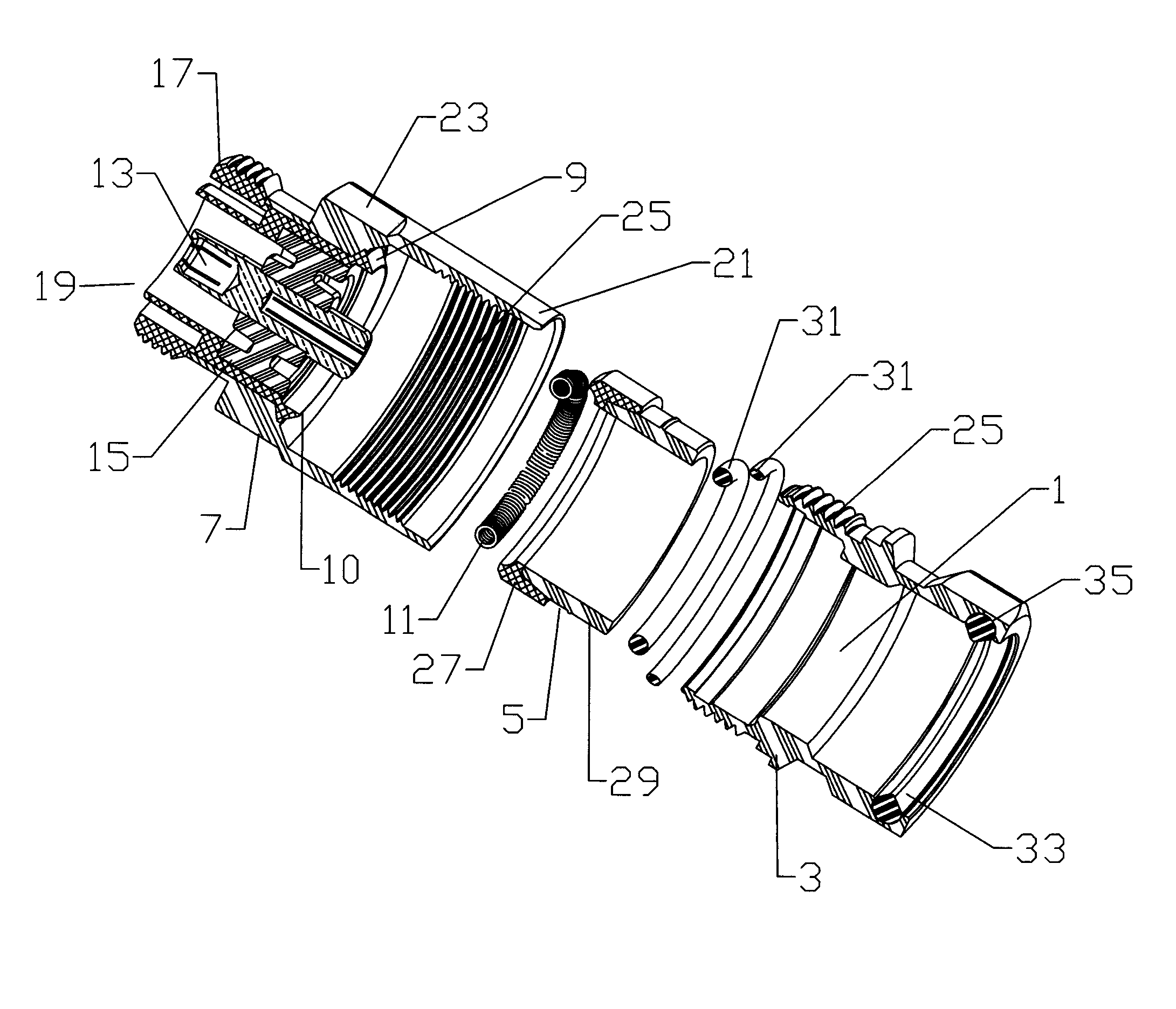

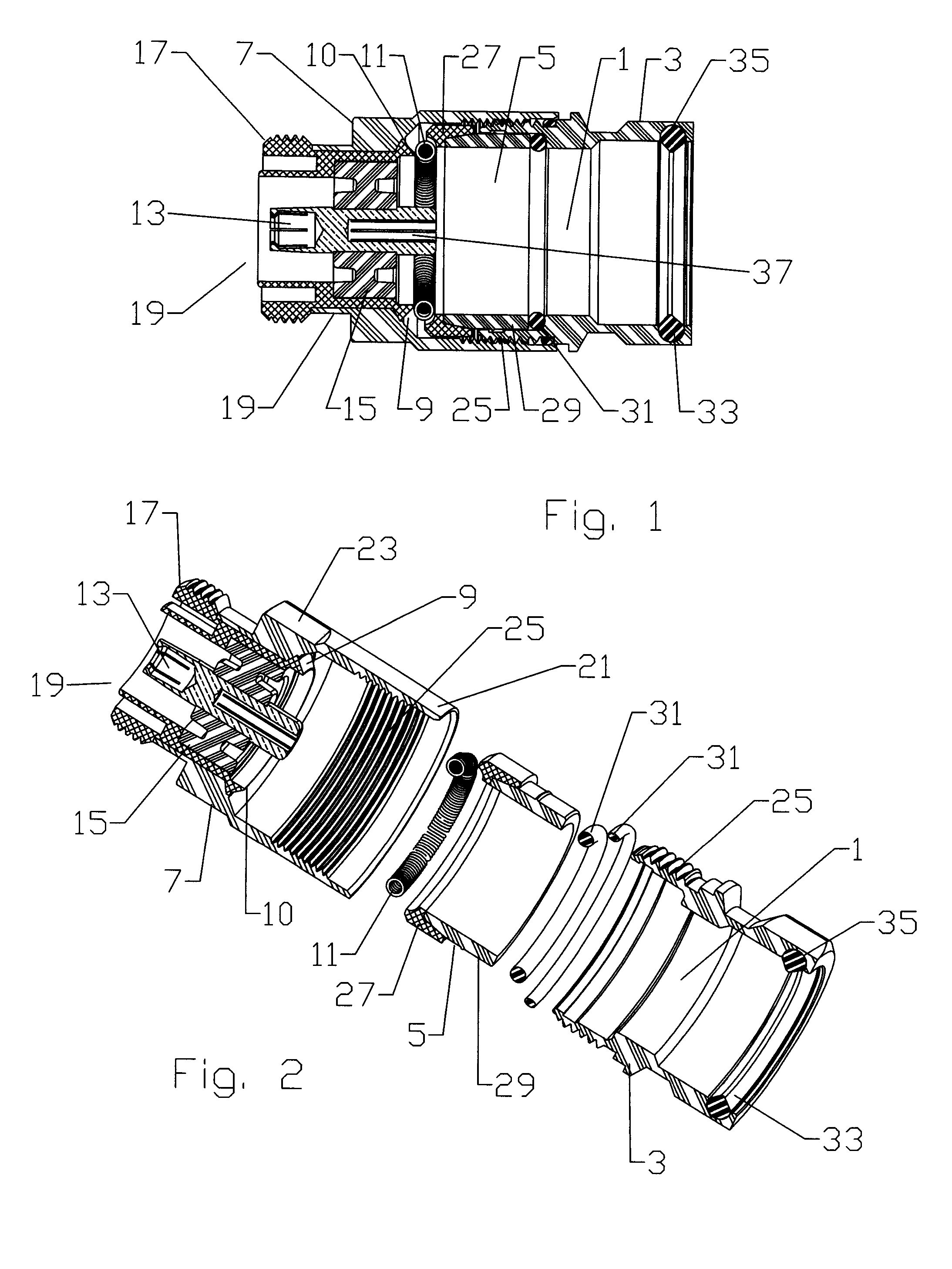

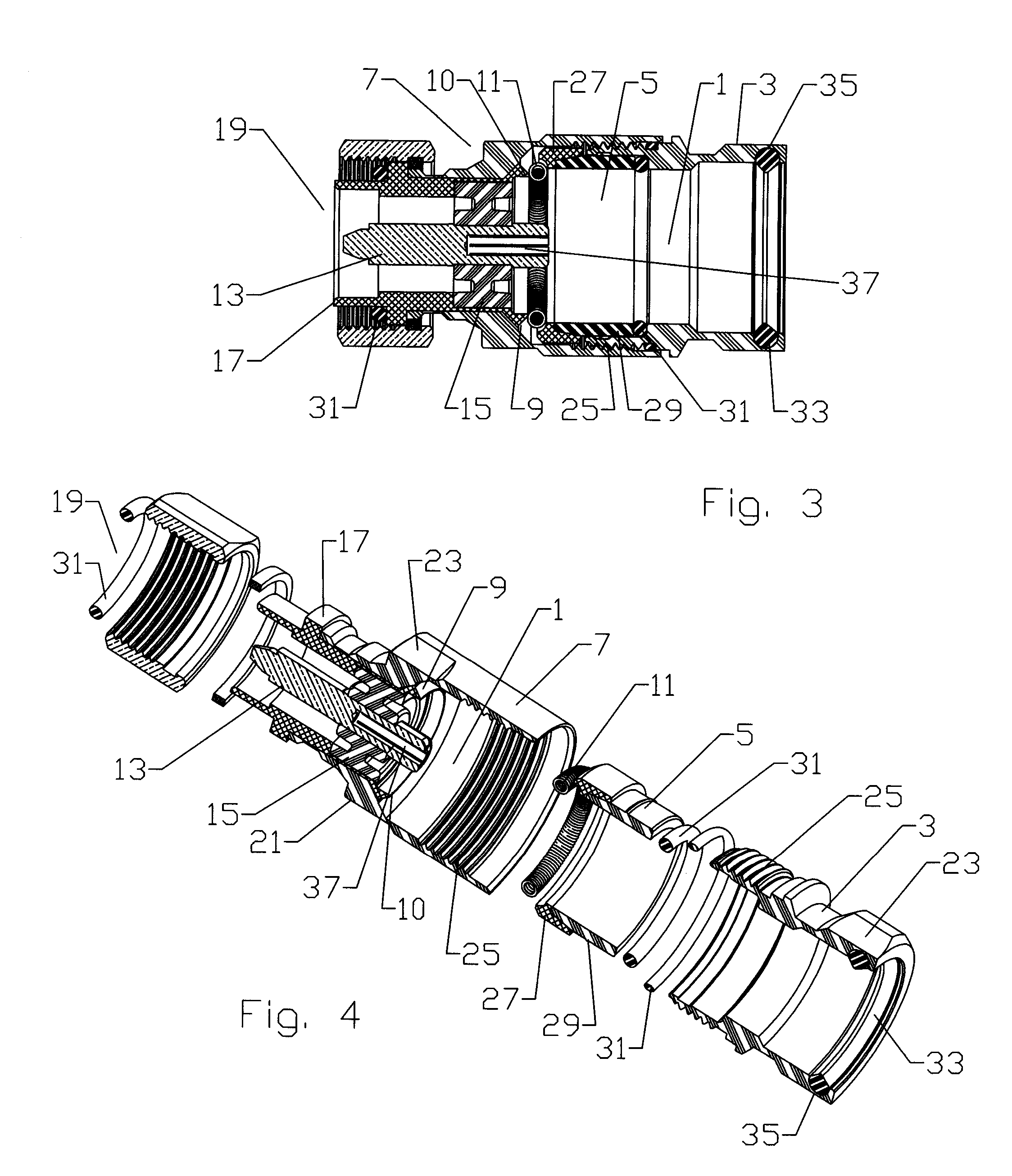

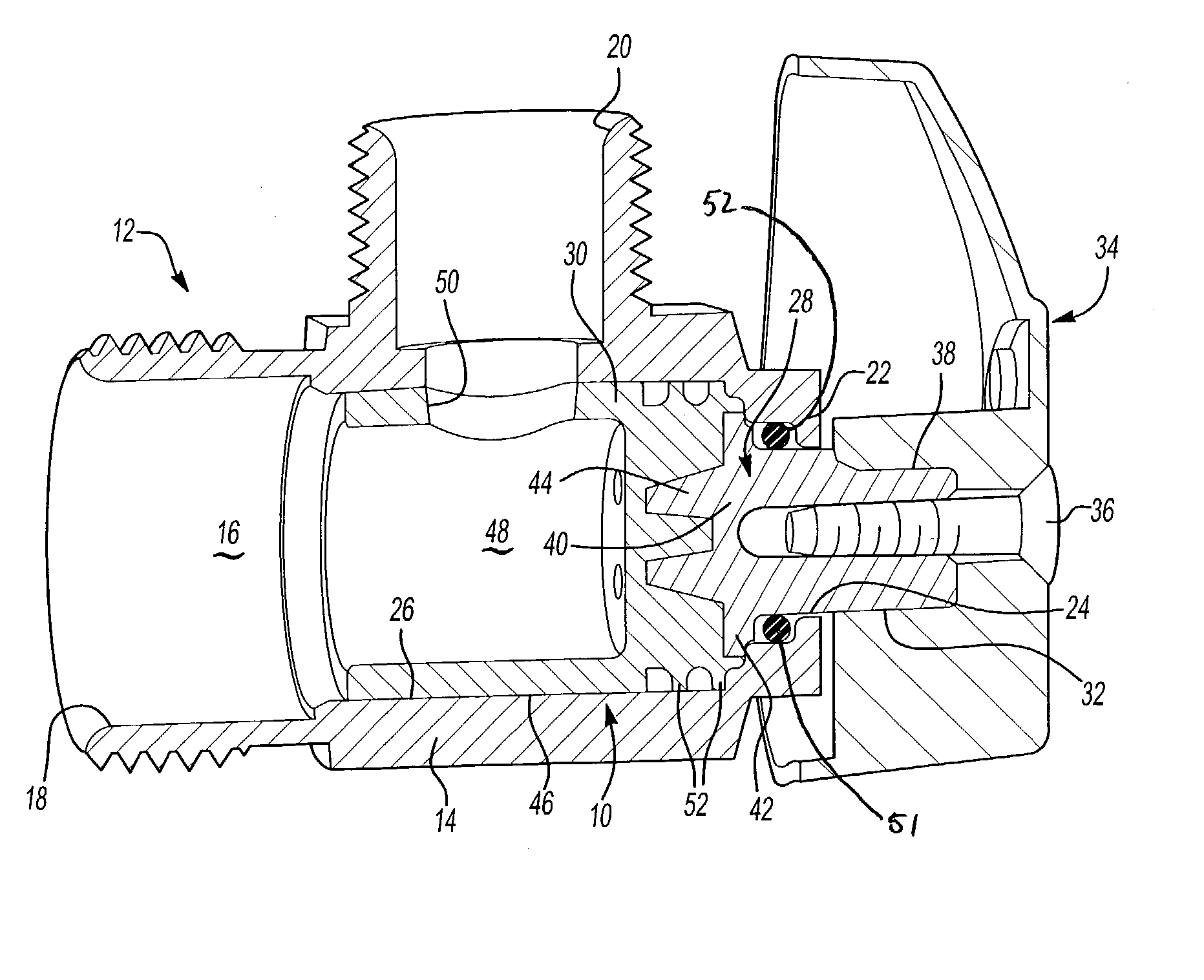

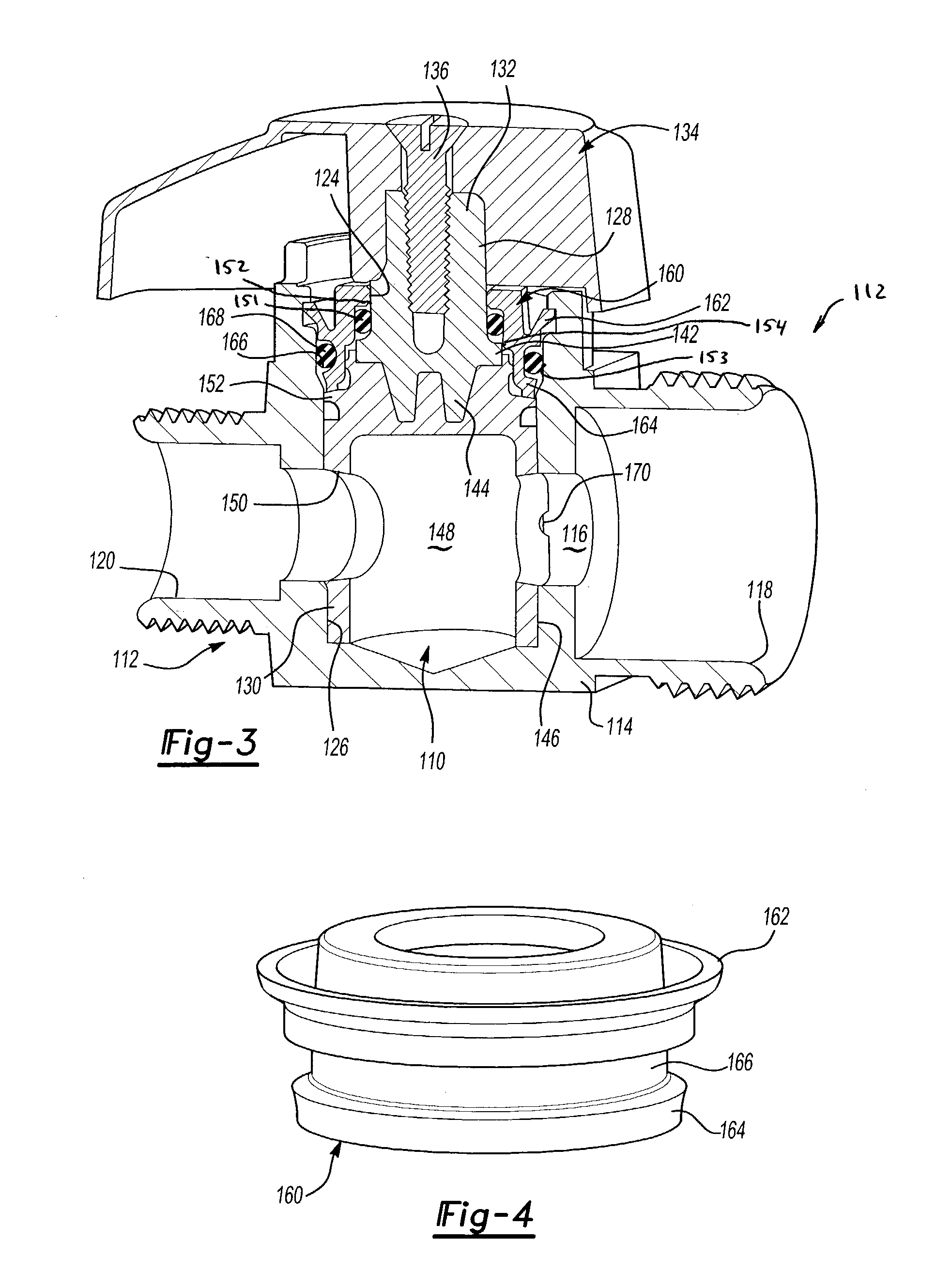

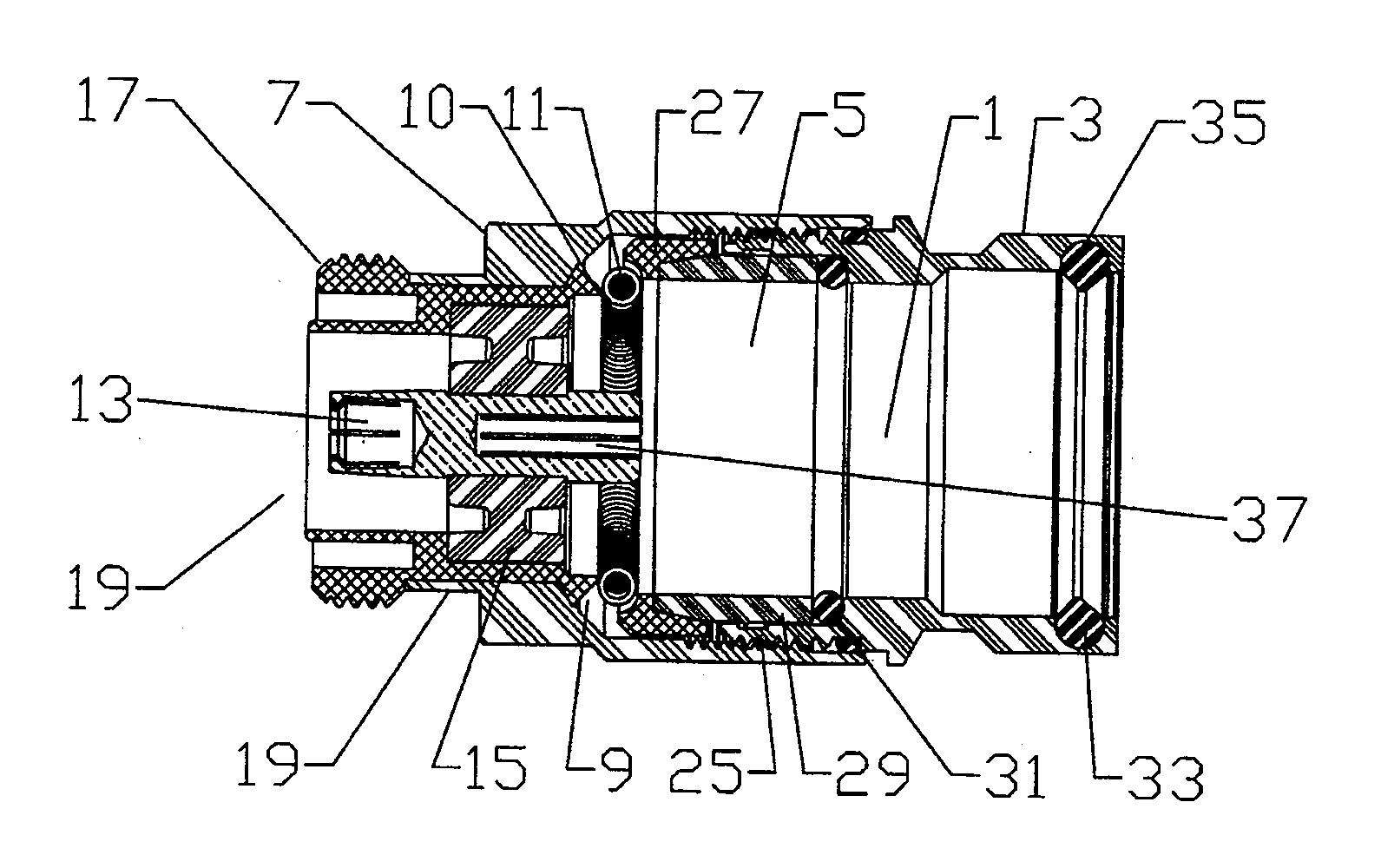

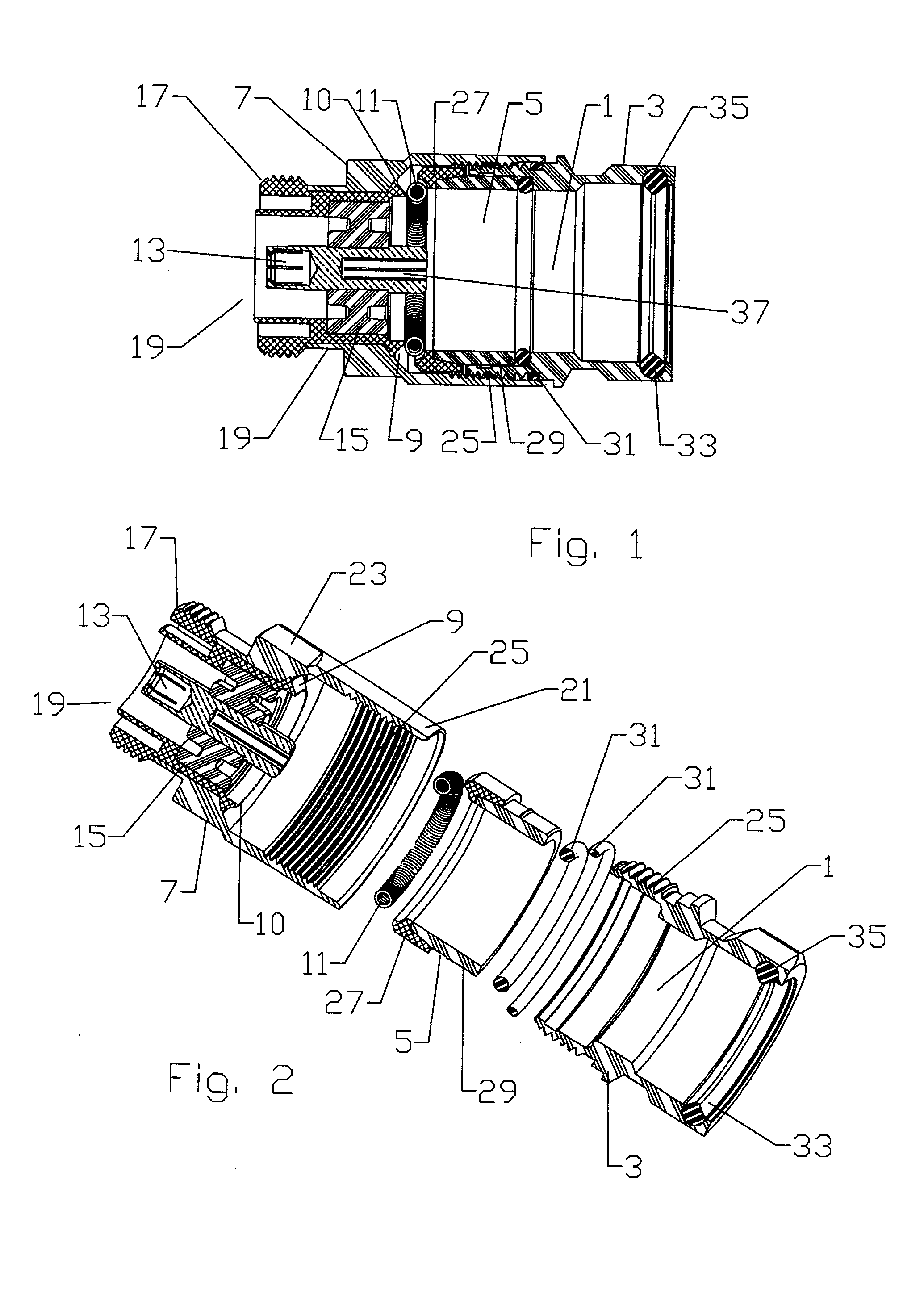

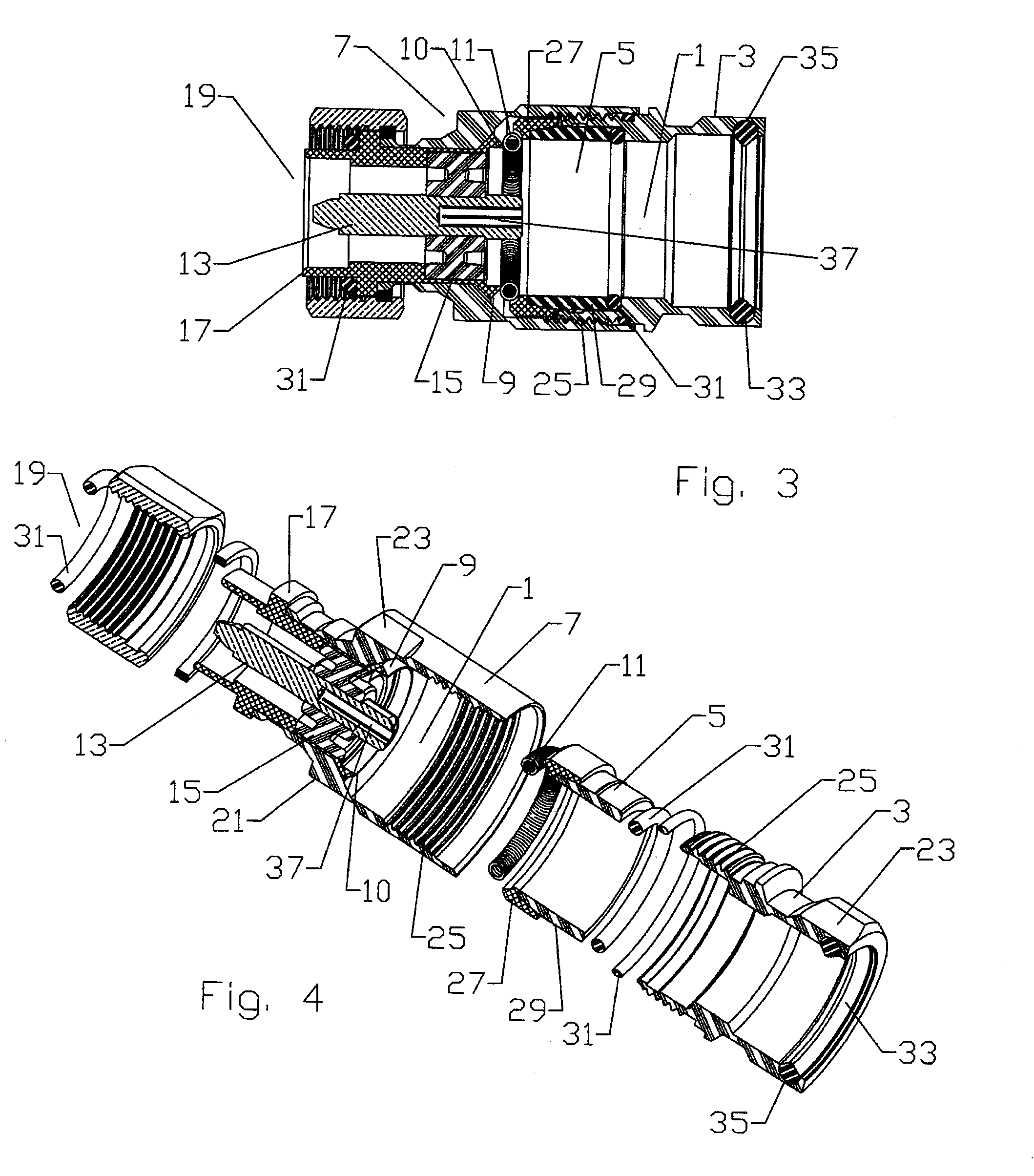

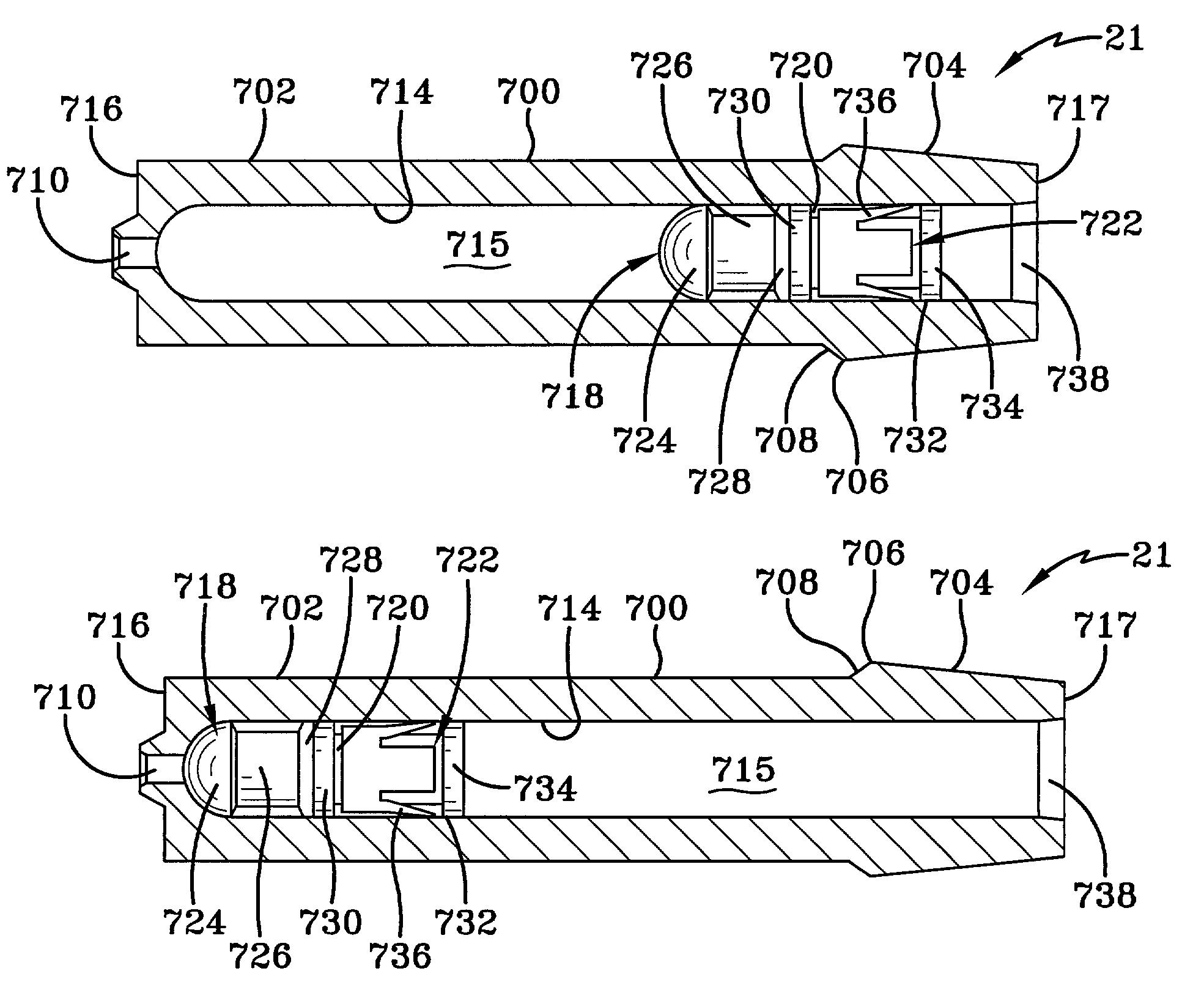

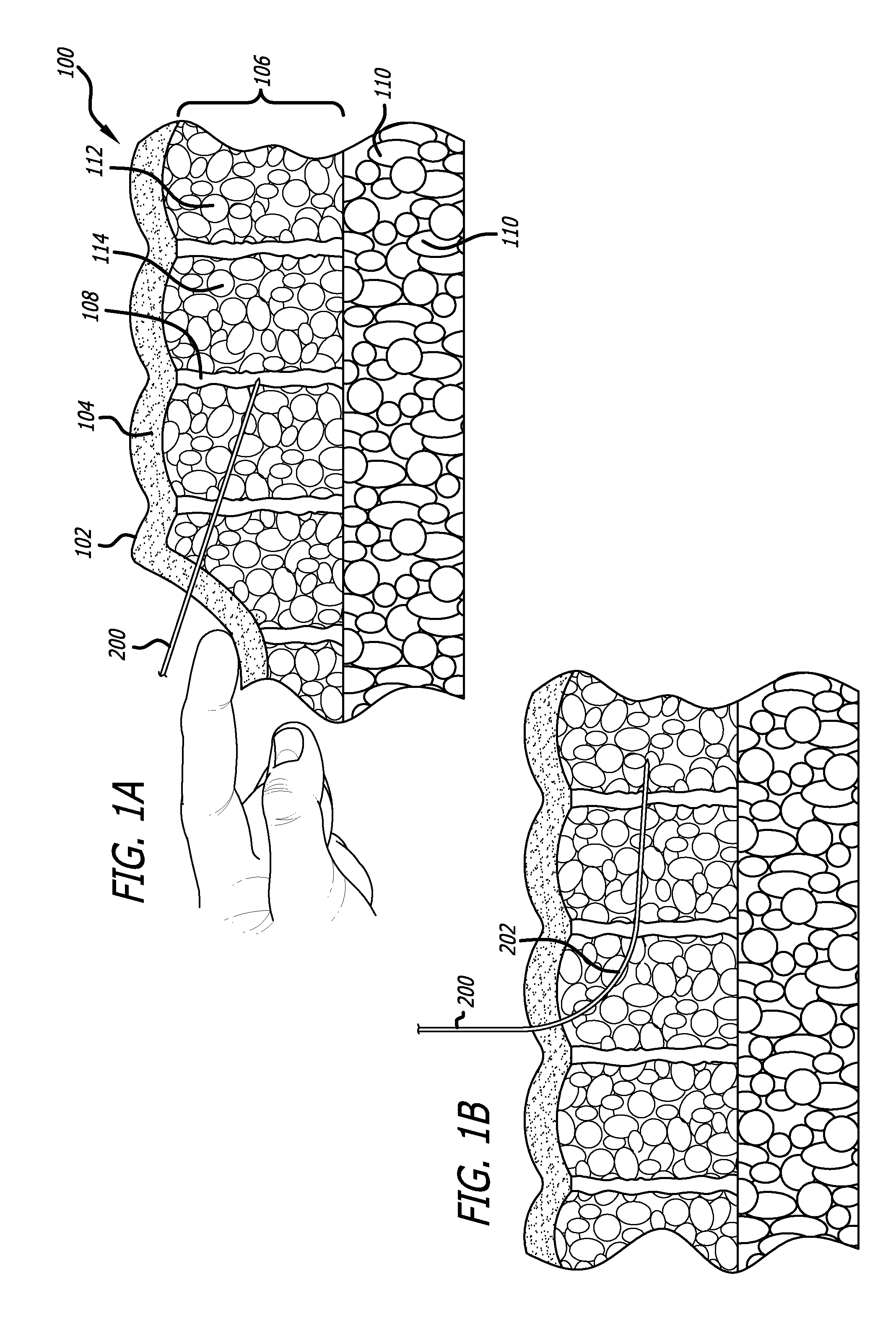

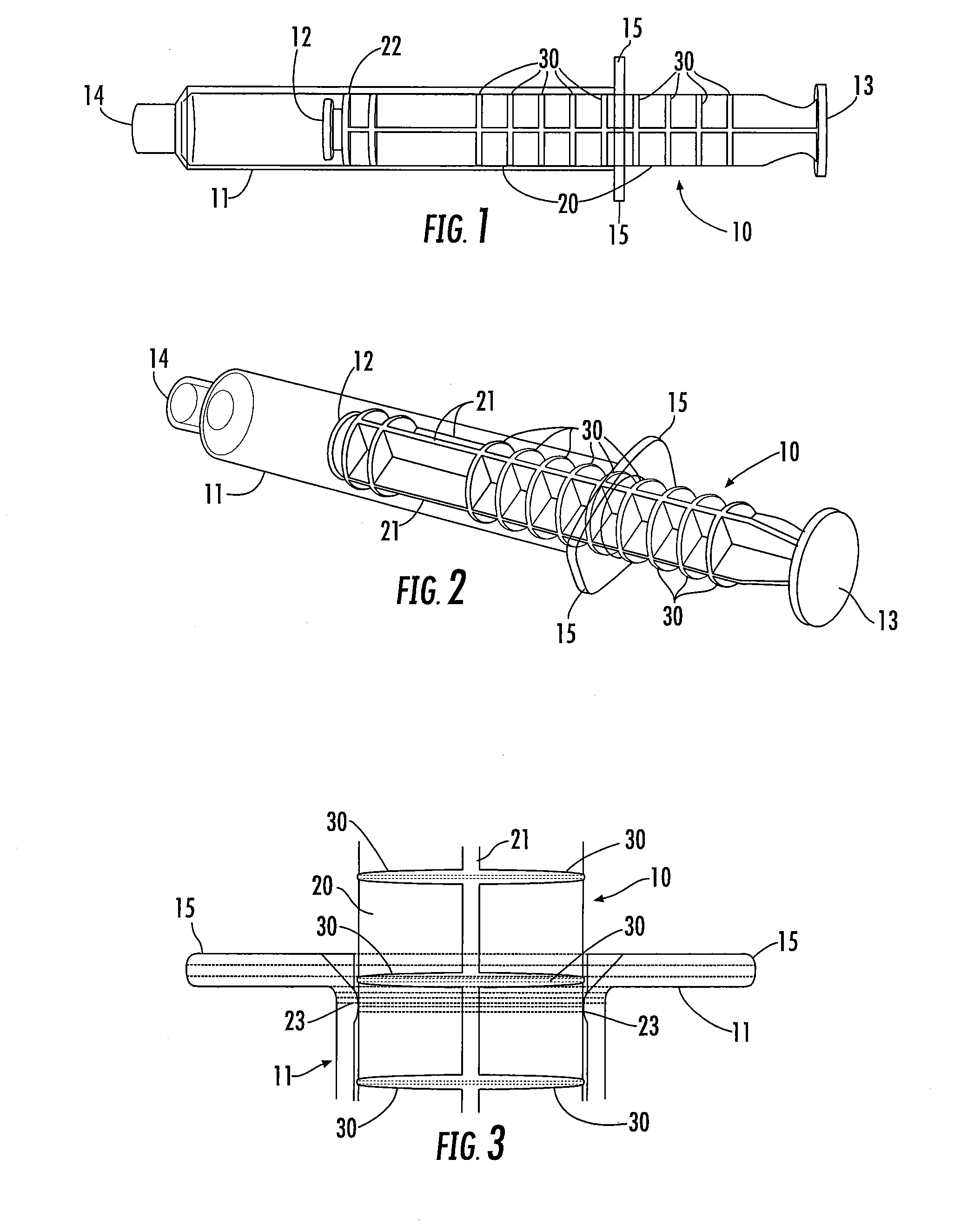

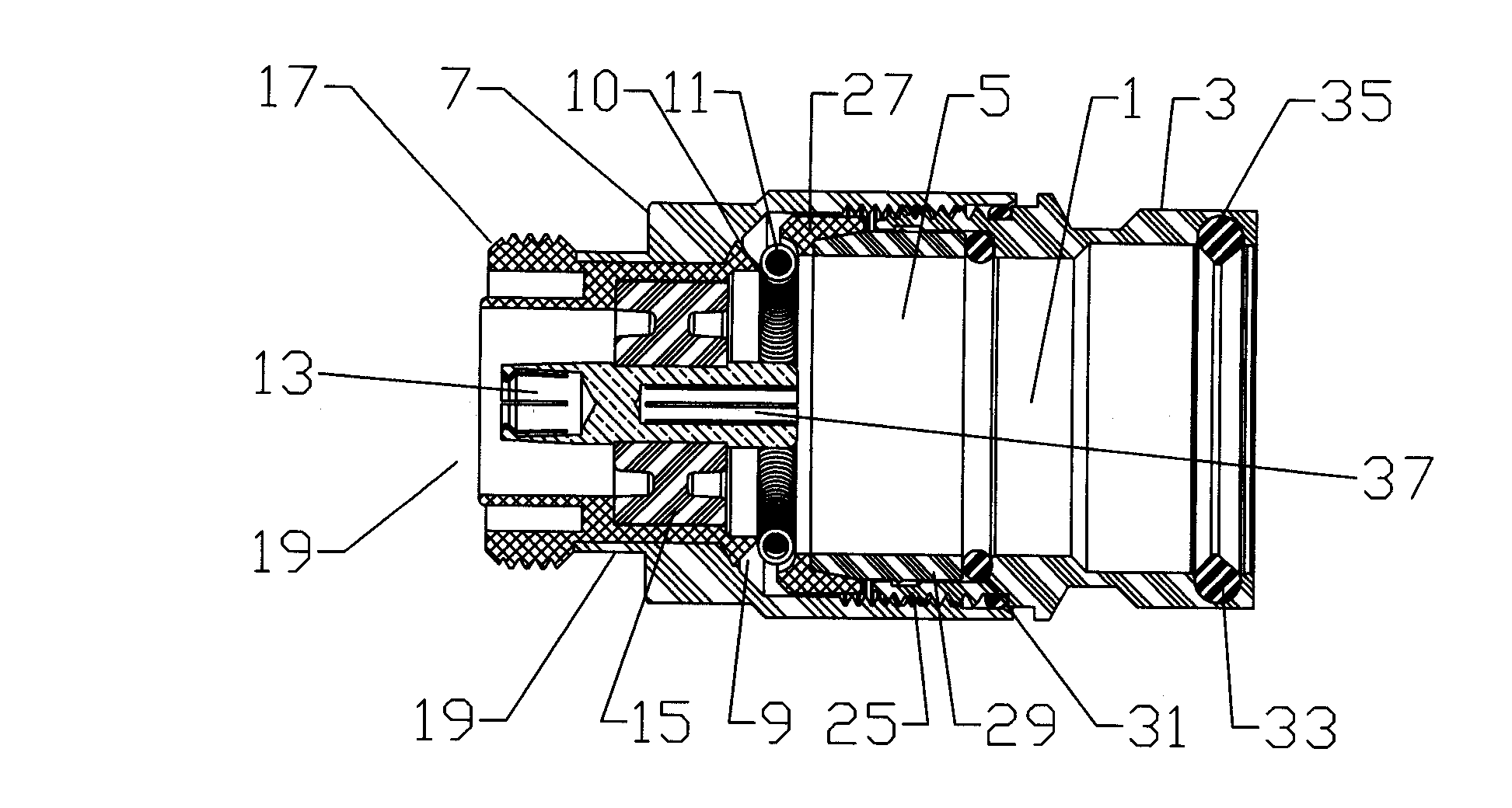

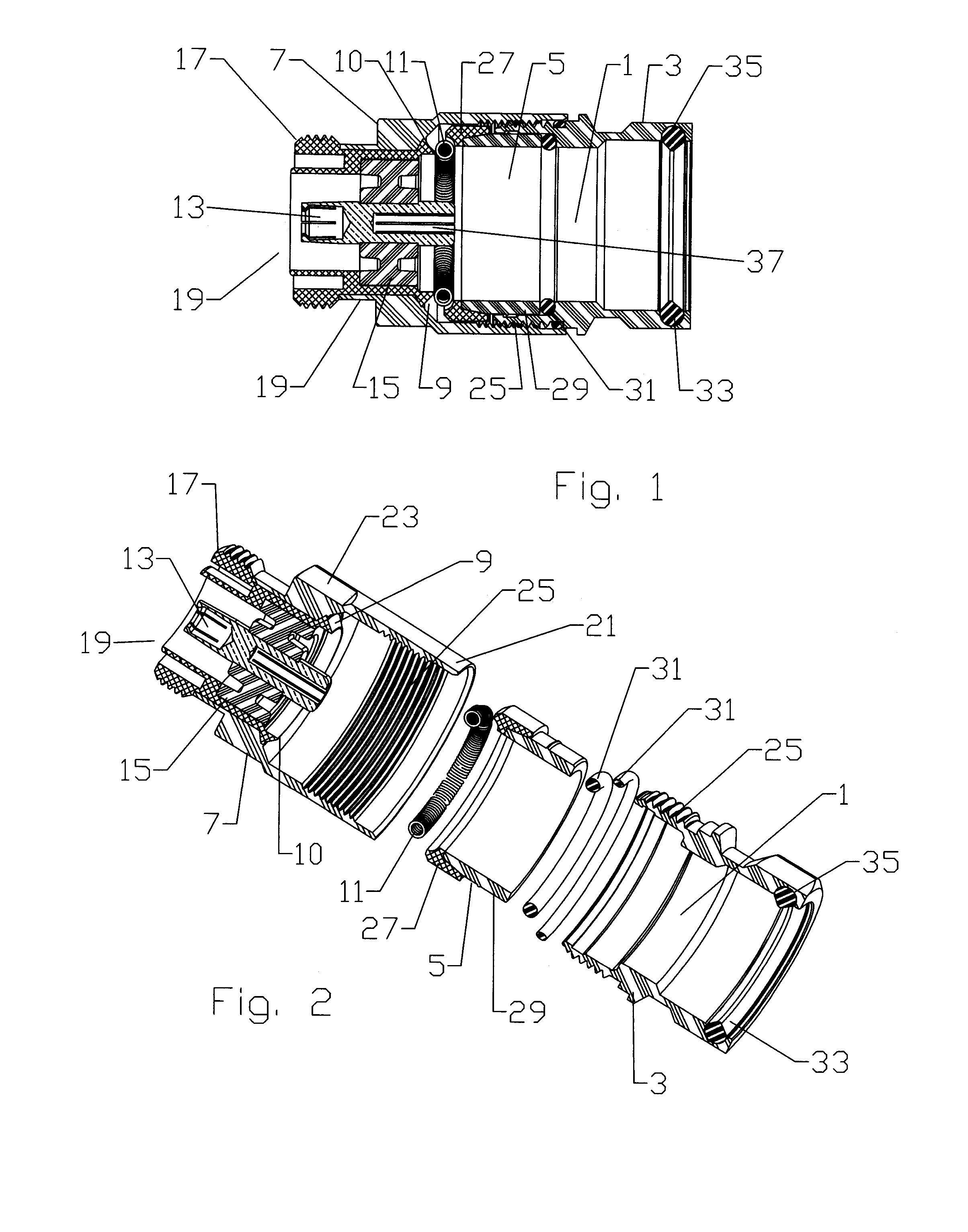

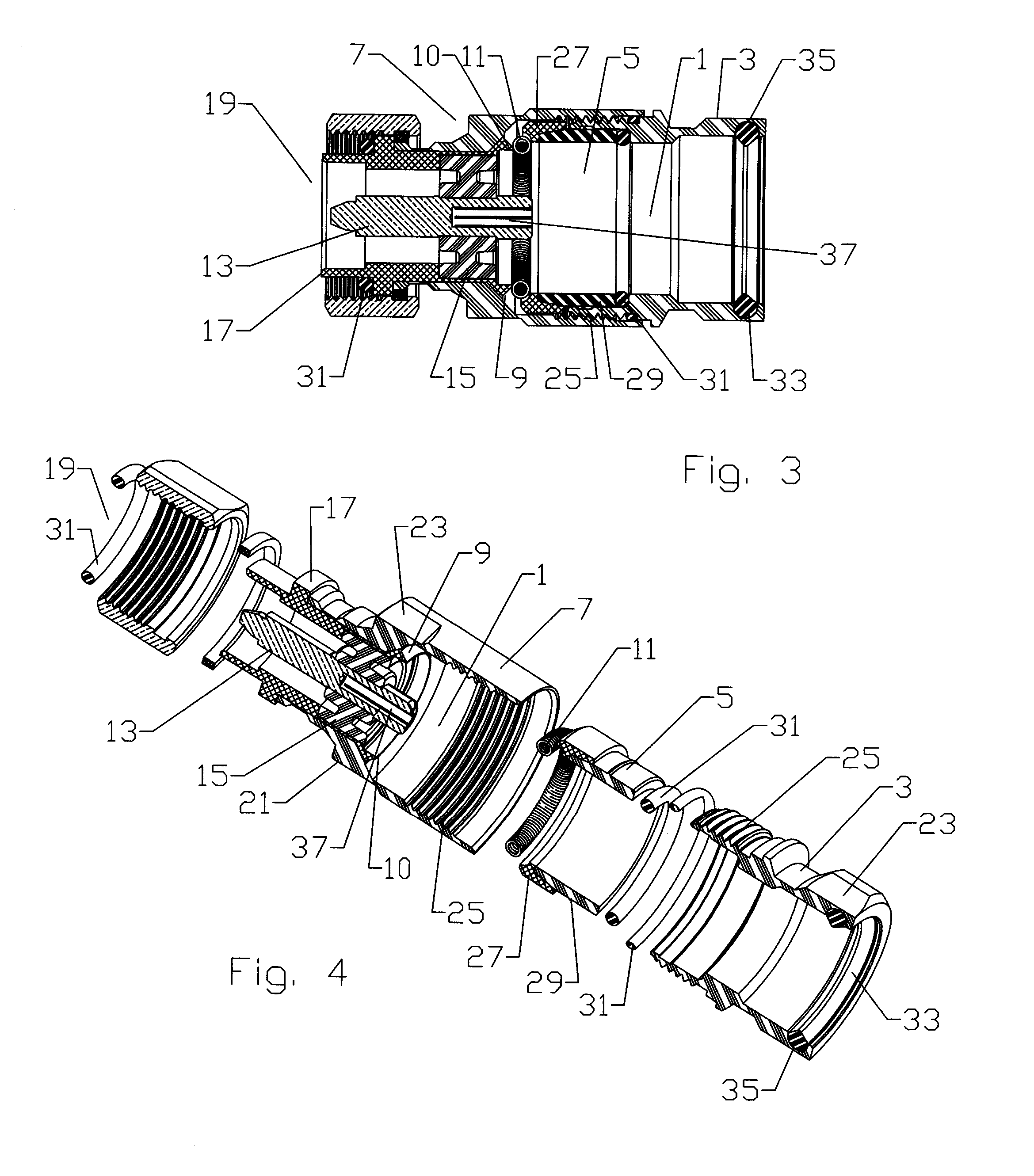

Multi-shot coaxial connector and method of manufacture

ActiveUS7607942B1Significant costSignificant materialElectrically conductive connectionsContact member cases/bases manufactureMultiple injectionCoaxial cable

A coaxial cable connector formed via multi-shot injection molding has a body formed by multiple injection molding layers of different injection moldable materials about a central inner contact to form an integral connector body. The connector body is provided with a coaxial dielectric spacer of dielectric polymer surrounding the inner contact; a coaxial inner body of injectable molded metal composition surrounding an outer diameter of the dielectric spacer; and an outer body of polymer surrounding the inner body. A range of different coupling bodies compatible with the connector body may also be formed via injection molding to provide connectors compatible with a range of different coaxial cable configurations.

Owner:COMMSCOPE INC

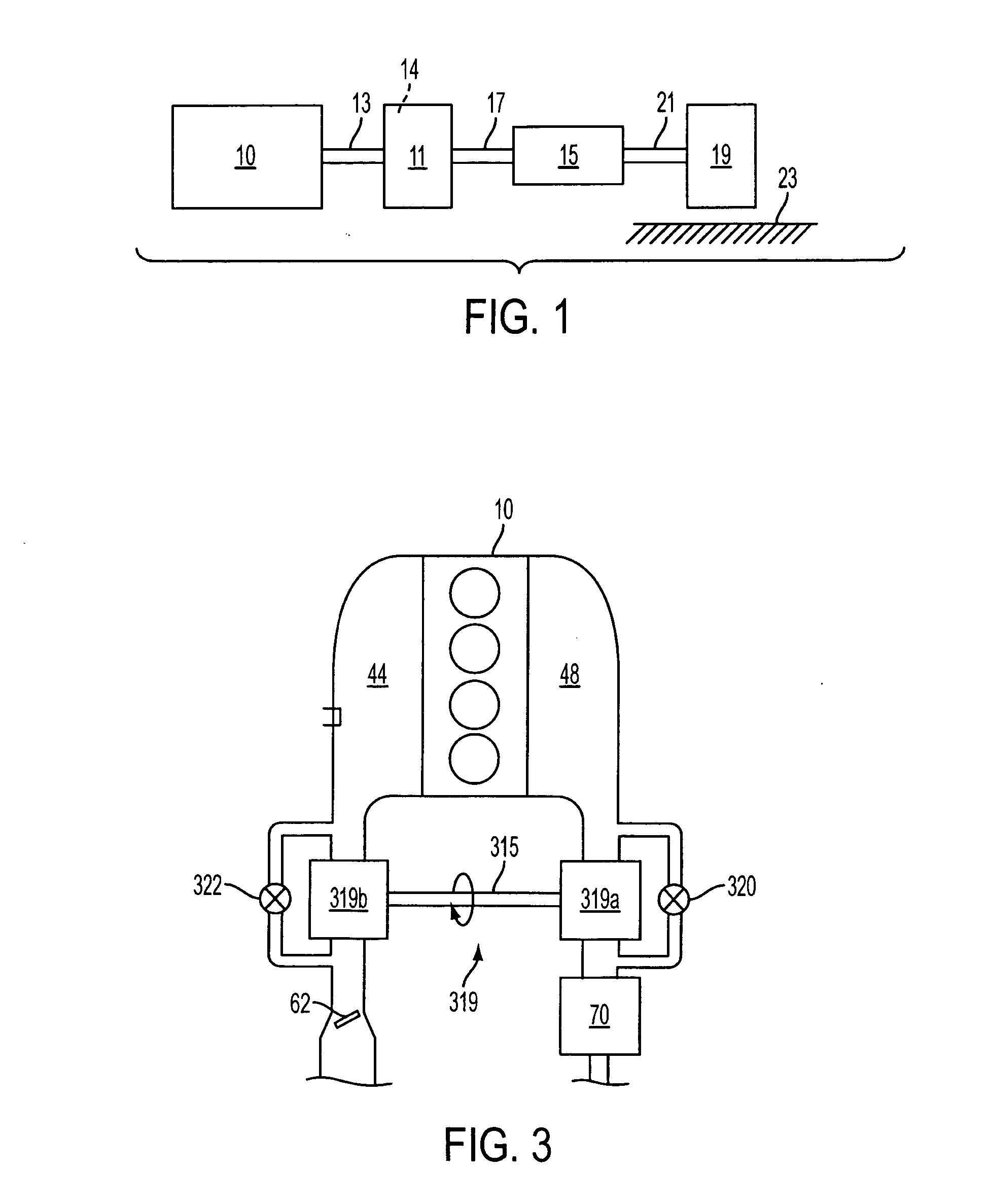

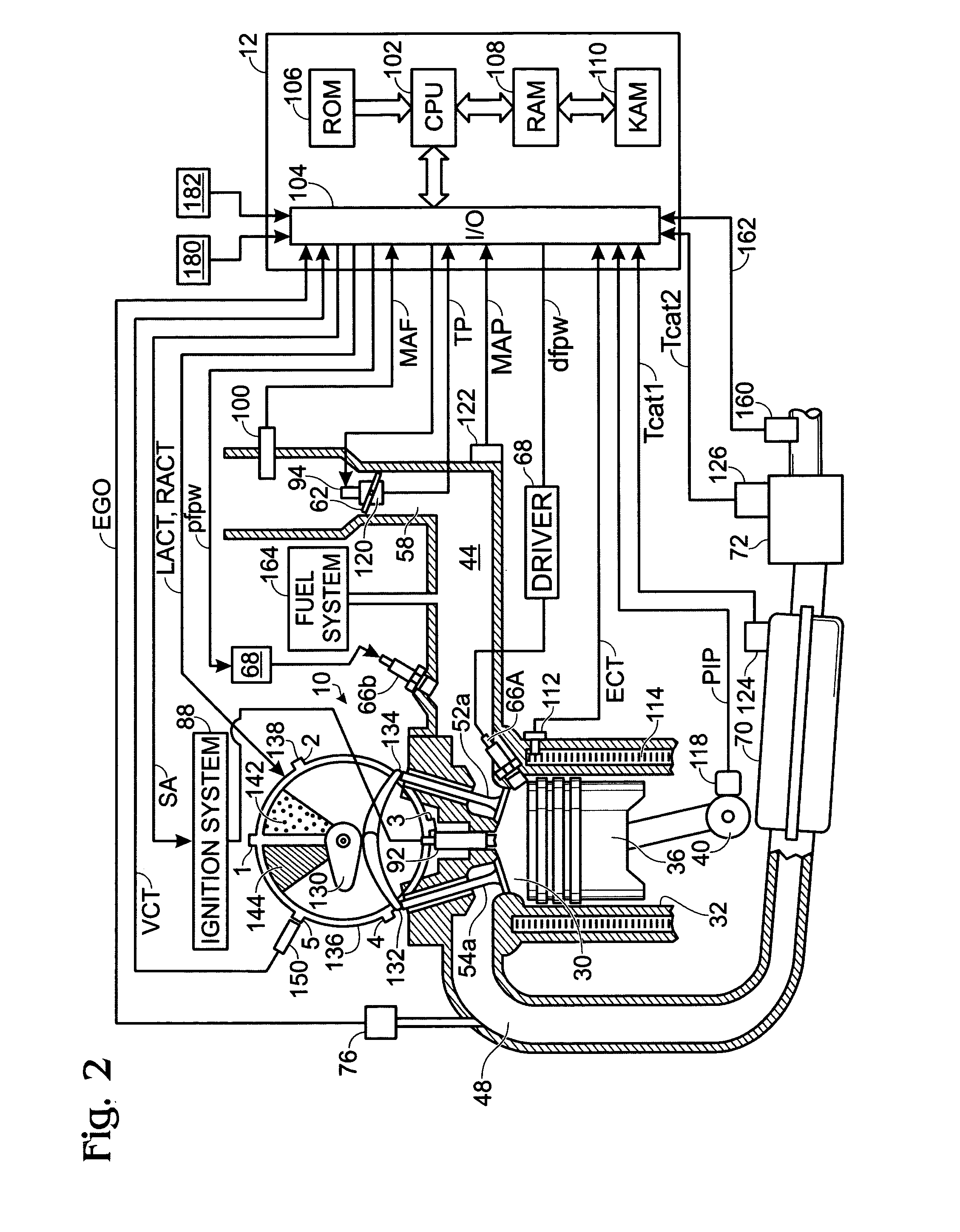

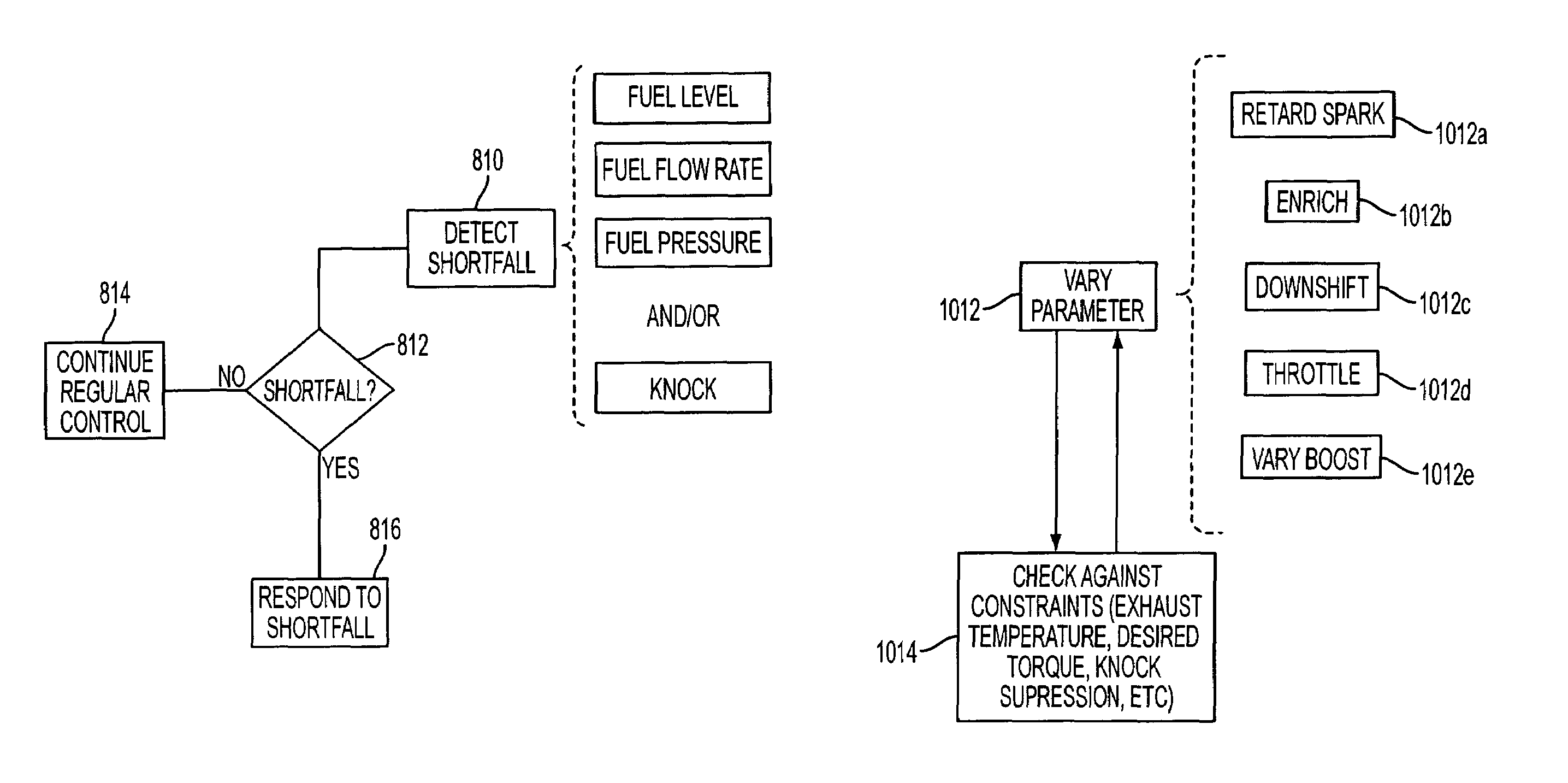

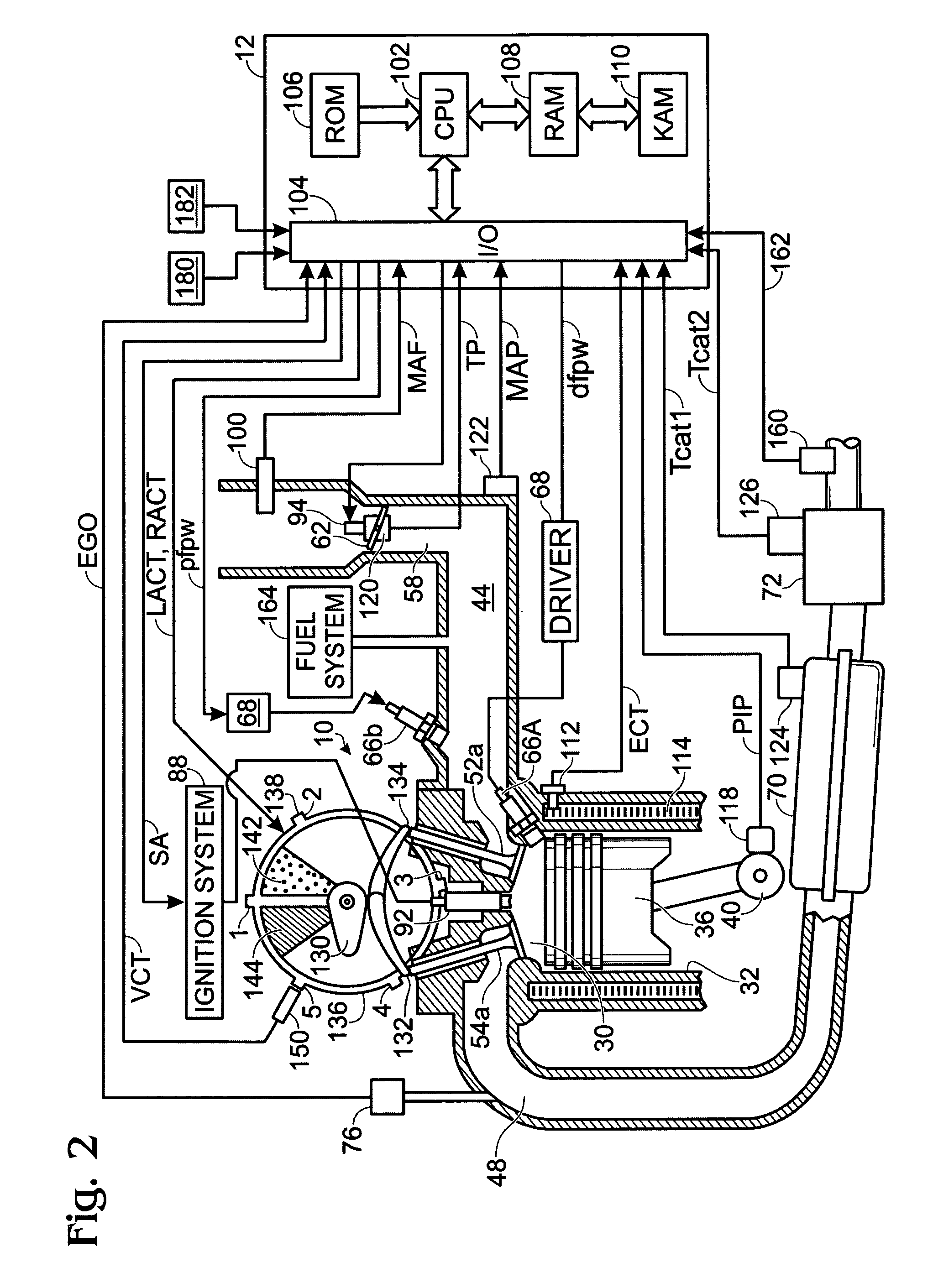

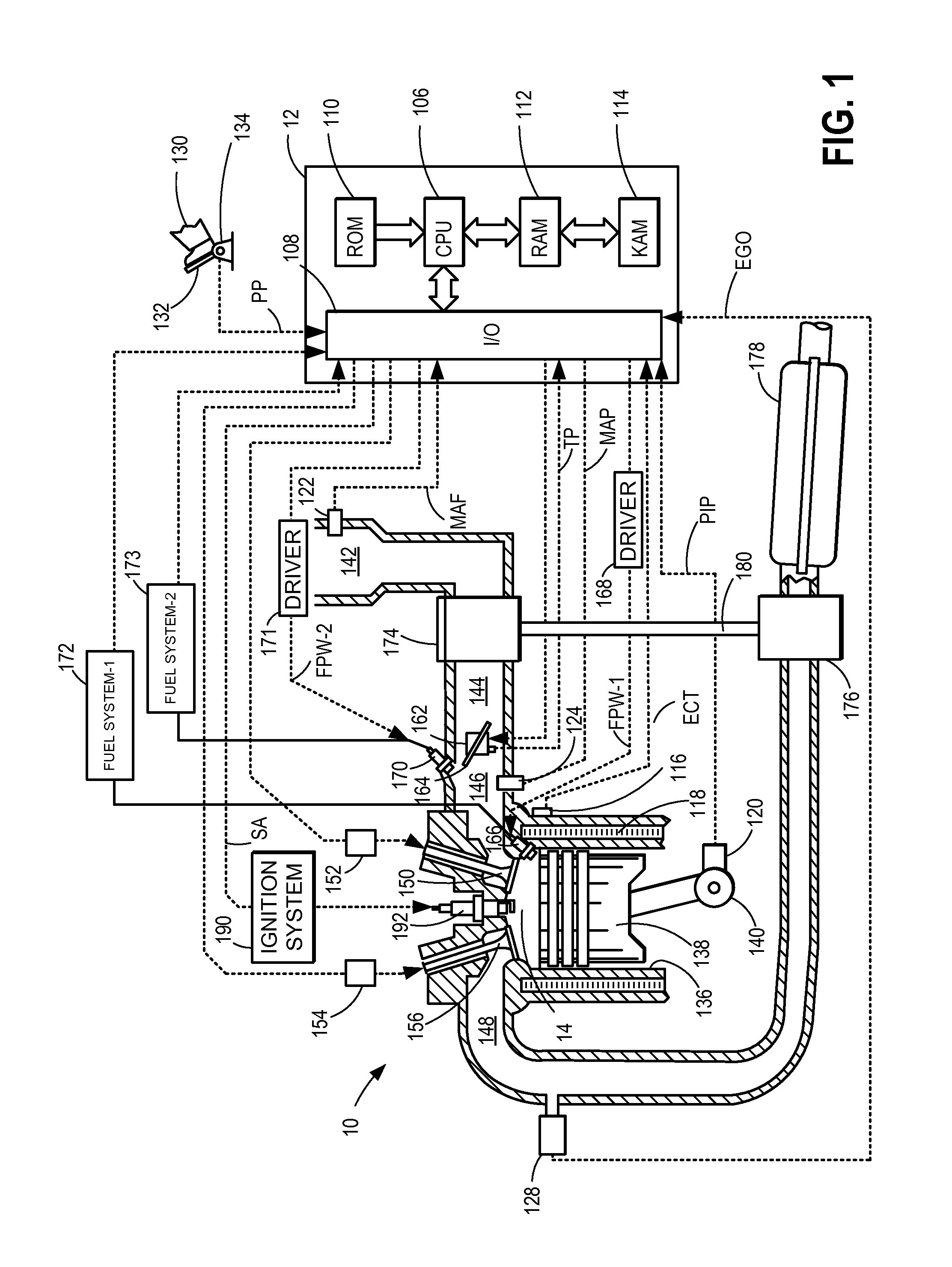

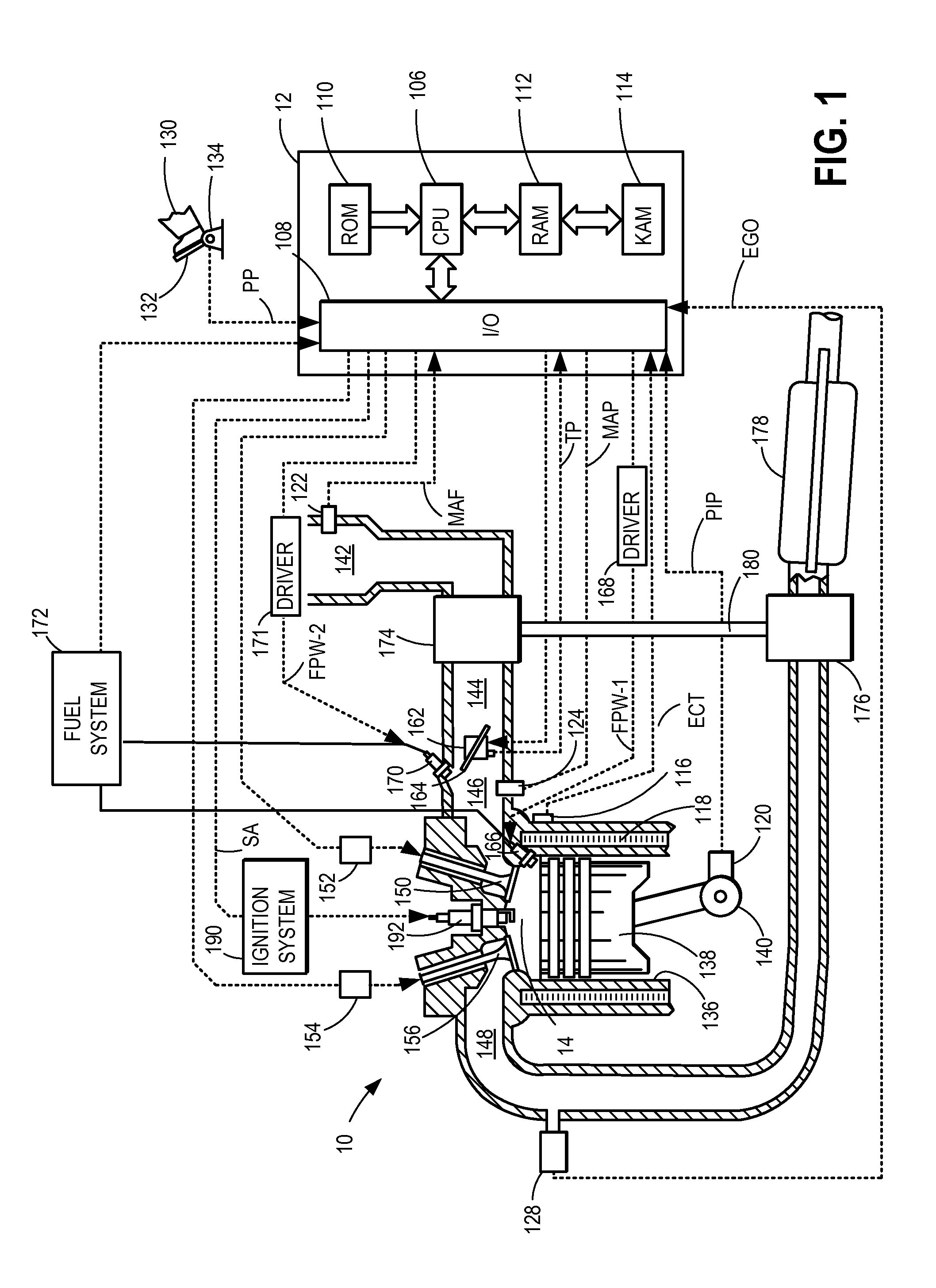

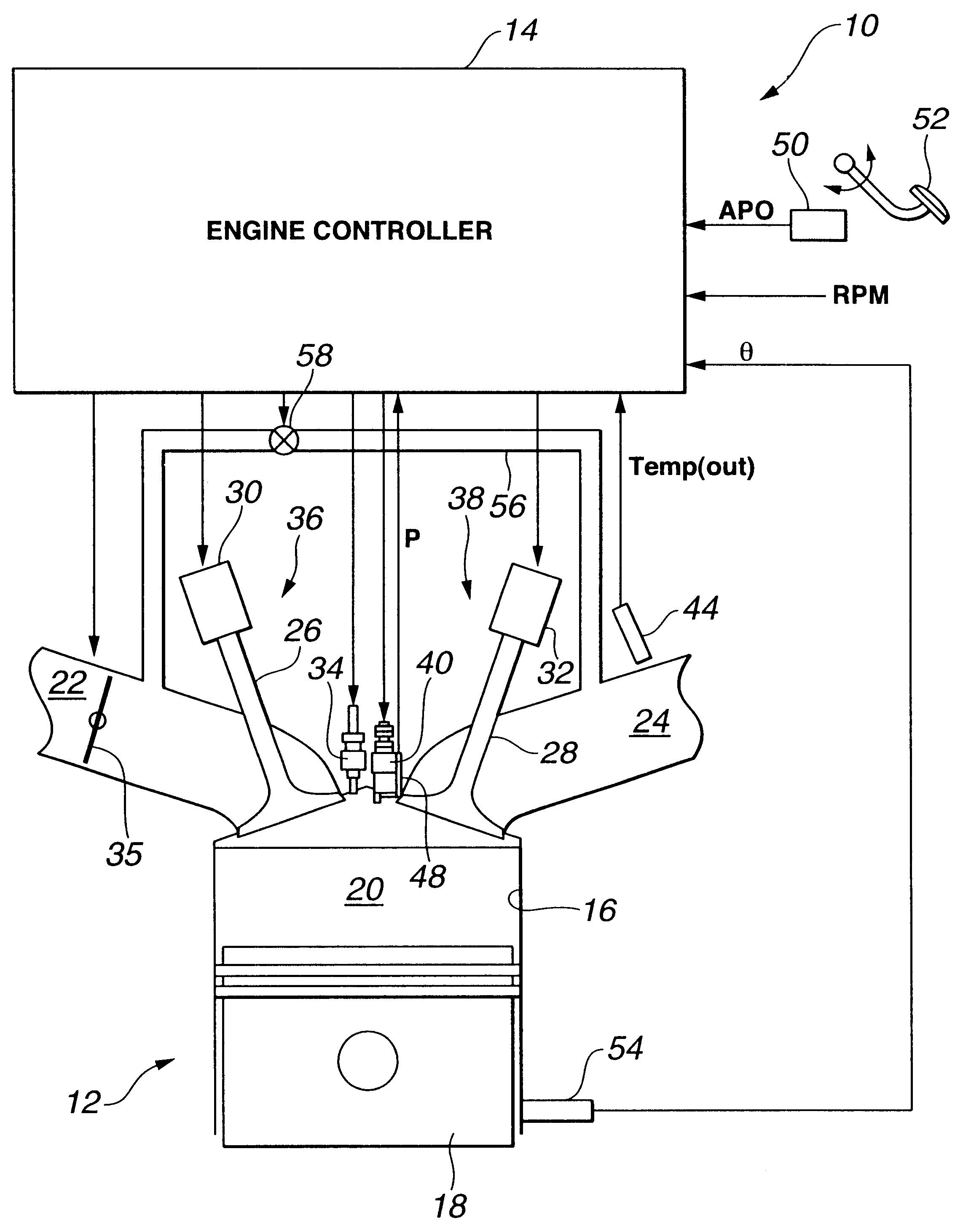

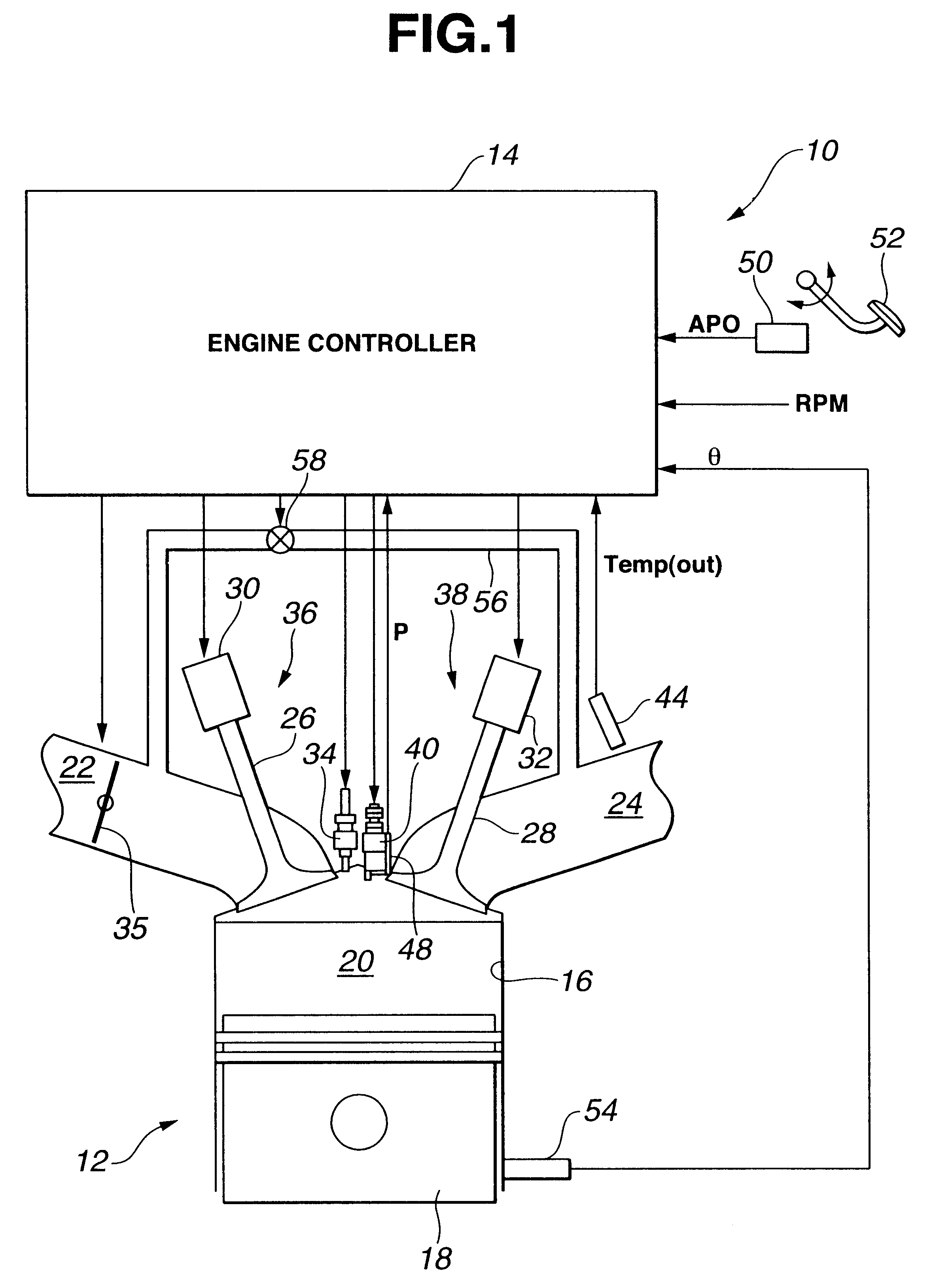

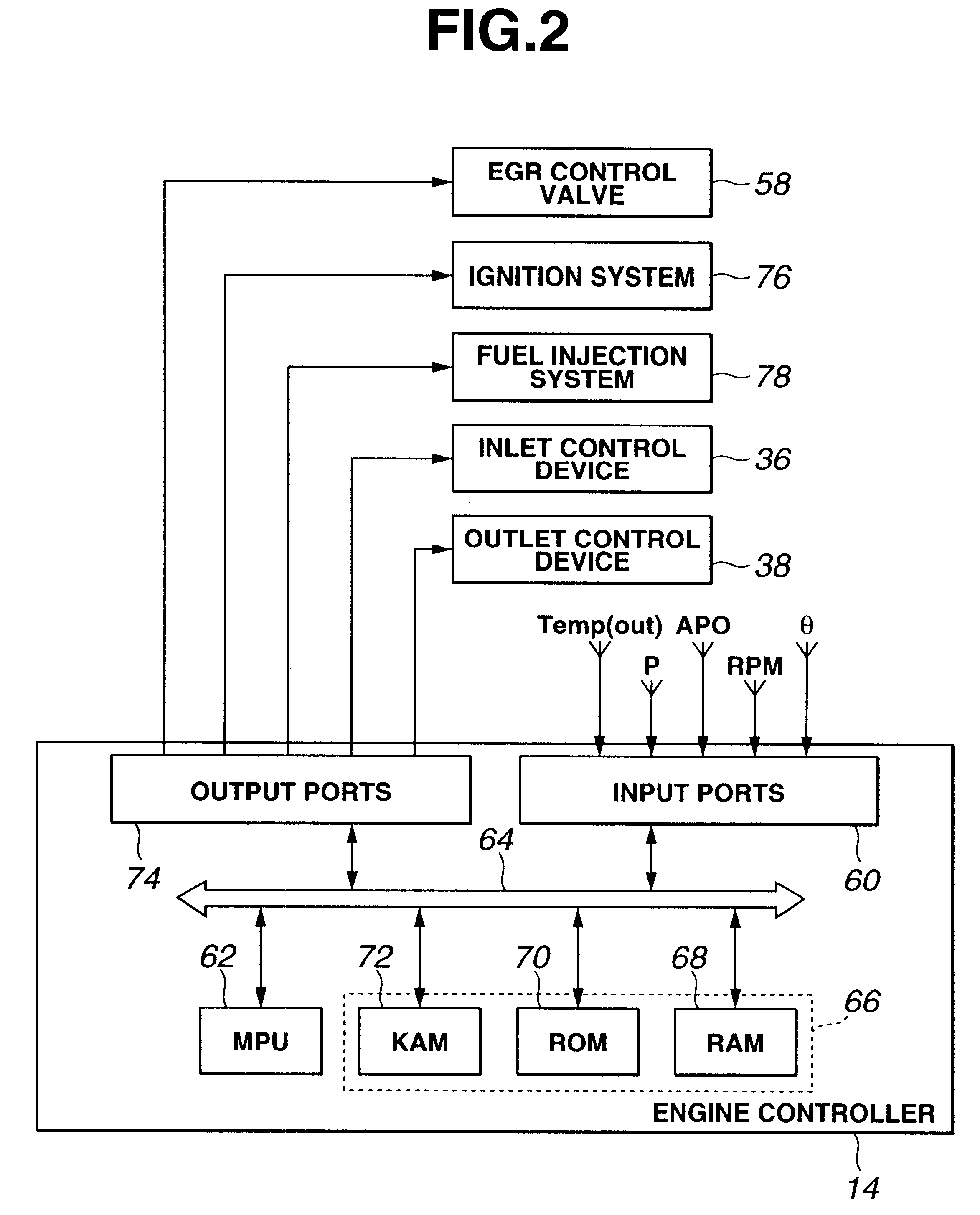

Control strategy for engine employing multiple injection types

ActiveUS20070215110A1Improve engine performanceLow costElectrical controlInternal combustion piston enginesMultiple injectionAutomotive engineering

A system for an engine, comprising a cylinder, a first injection subsystem for injecting a first substance into the cylinder, a second injection subsystem for injecting a second substance into the cylinder, and an electronic engine controller configured to control a plurality of operating parameters of the engine, where the electronic engine controller is configured to cause variation of at least one of the operating parameters in response to a shortfall condition of the second injection subsystem.

Owner:FORD GLOBAL TECH LLC

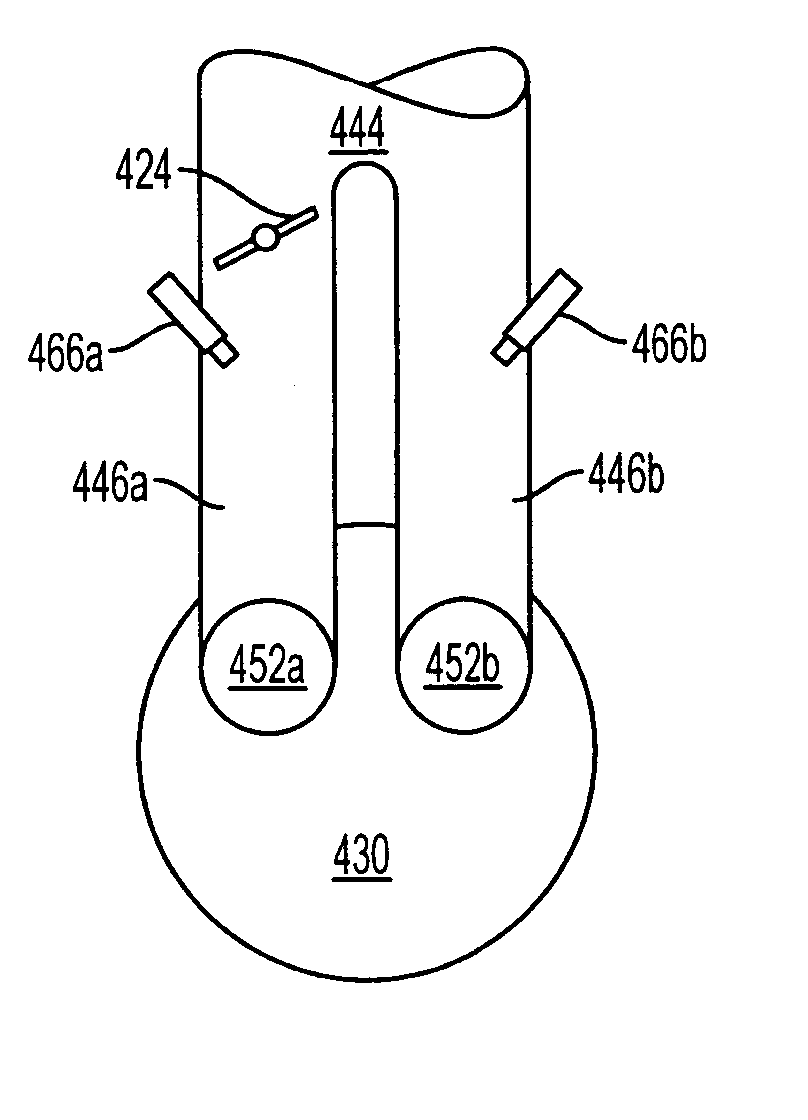

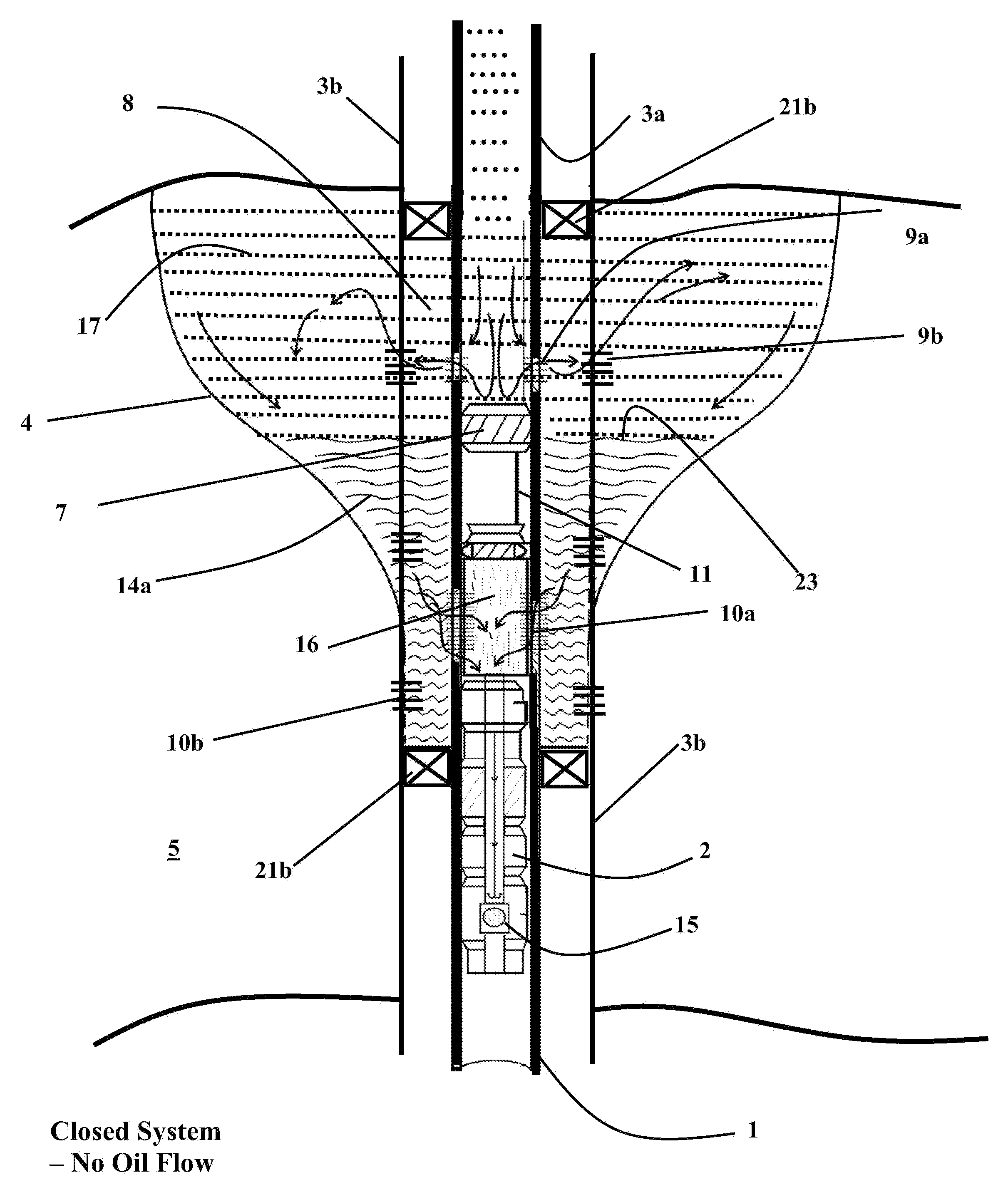

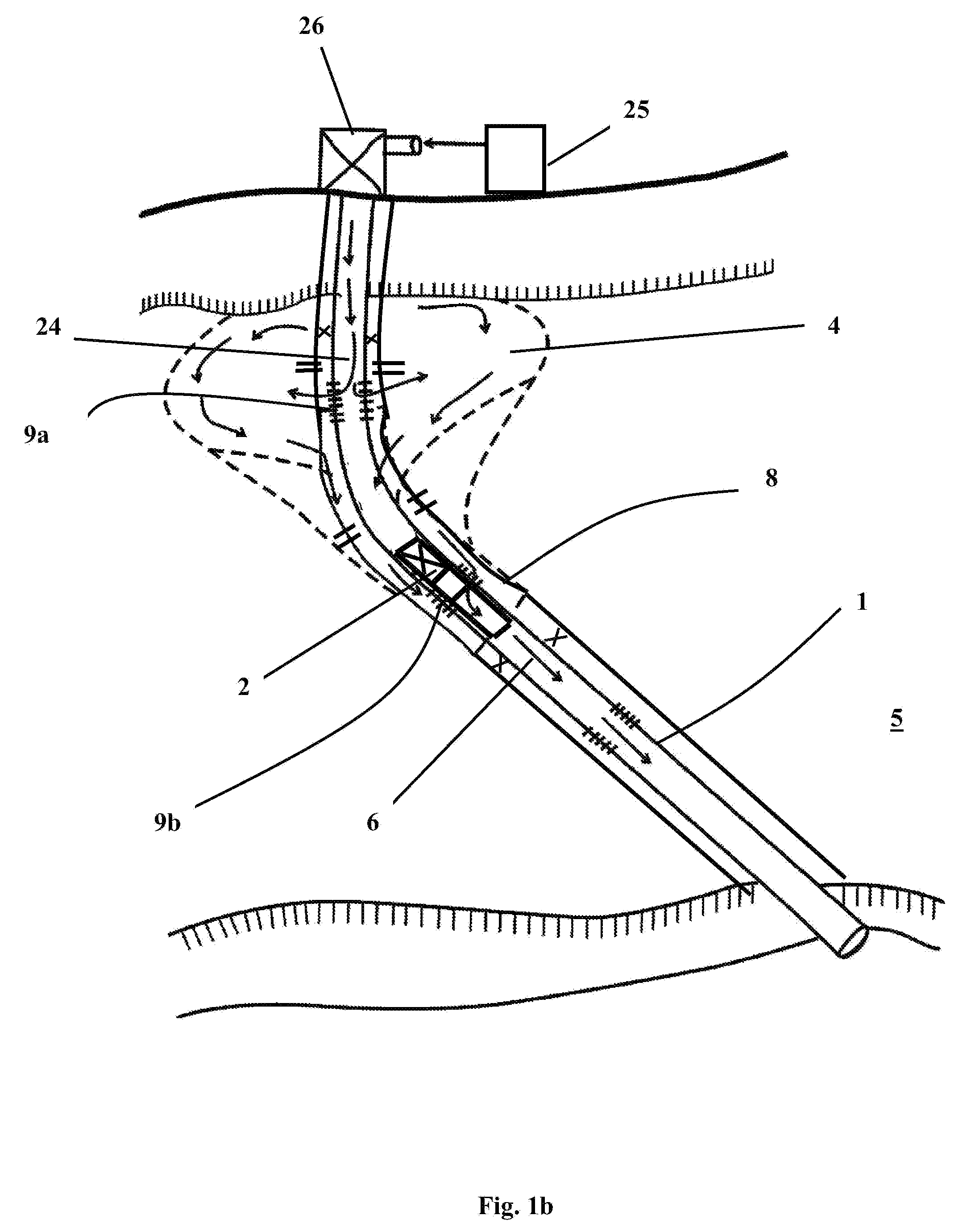

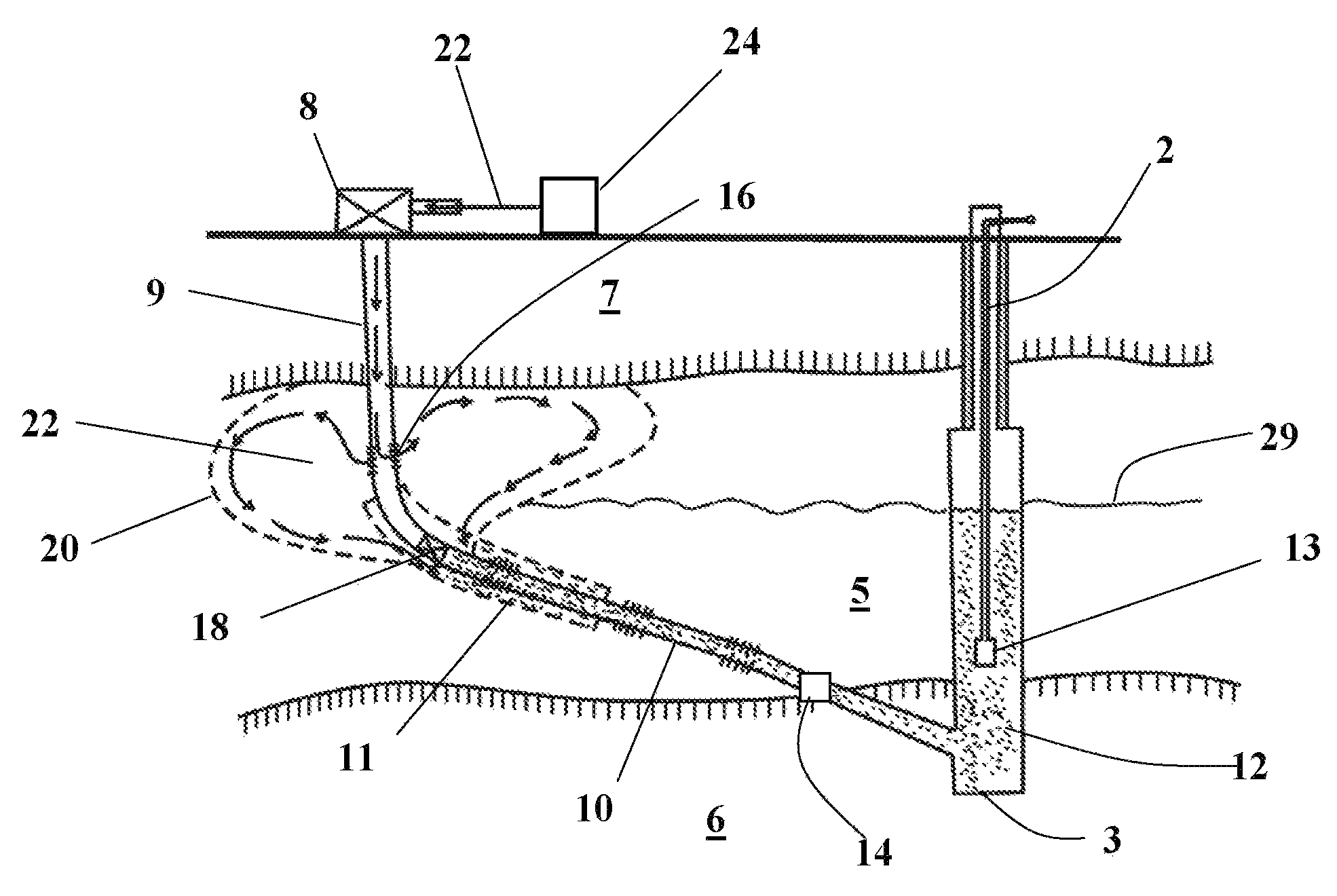

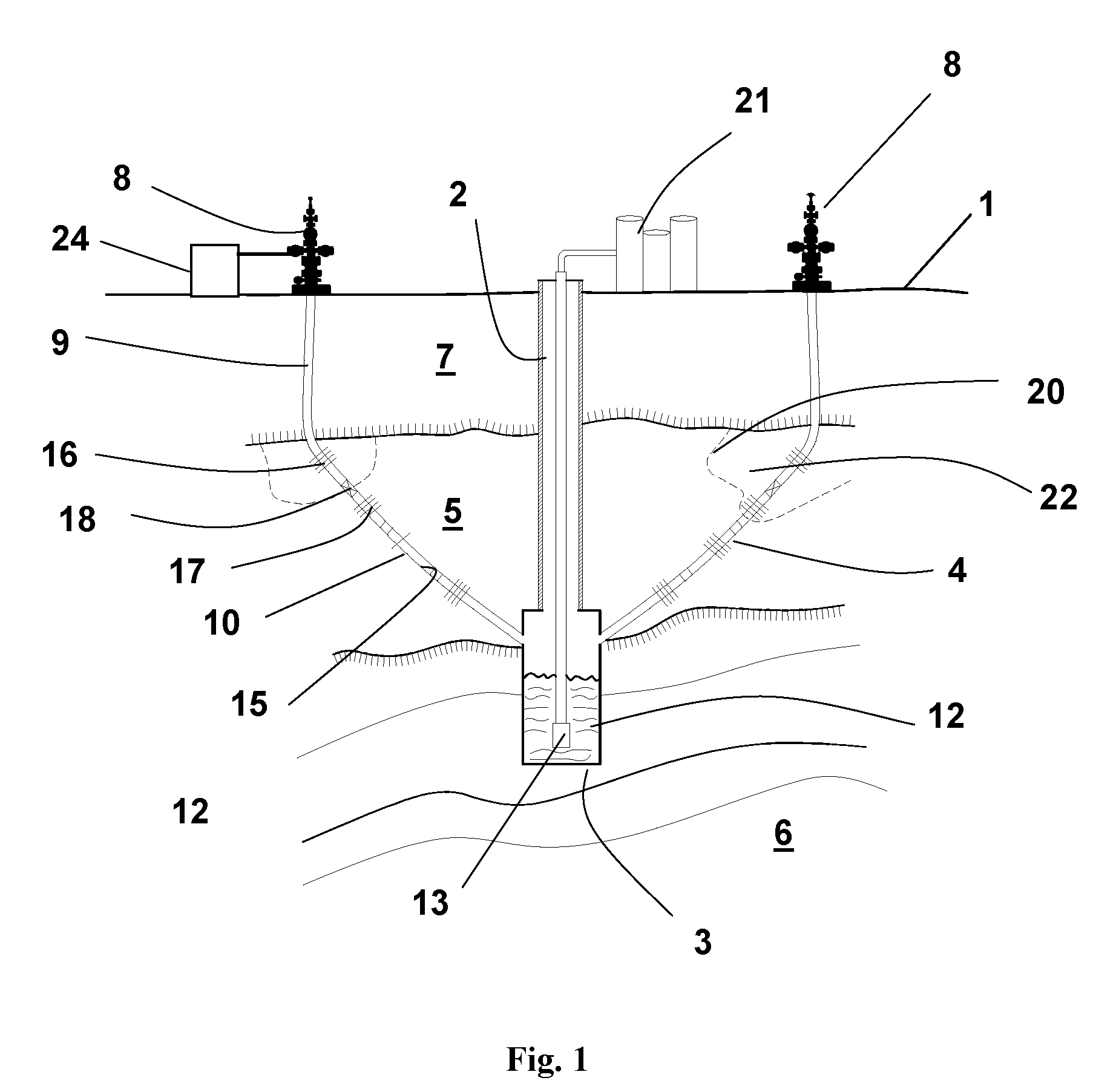

Heavy Oil Recovery and Apparatus

A thermal in-situ method and apparatus are provided for recovering hydrocarbons from subterranean hydrocarbon-containing formations such as oil sands, oil shale and other heavy oil systems. Recovery of viscous hydrocarbon by hot fluid injection into subterranean formations is assisted by using a specially designed wellbore with an active hydraulic seal, with a axial communication zone with multiple injection perforations separated from the production perforations by a moveable packer. In addition, a novel downhole thermal sensing apparatus is used to monitor and control oil production. A producing mechanism including pumping equipment lifts the produced oil from the central cavity to the surface.

Owner:CRICHLOW HENRY B

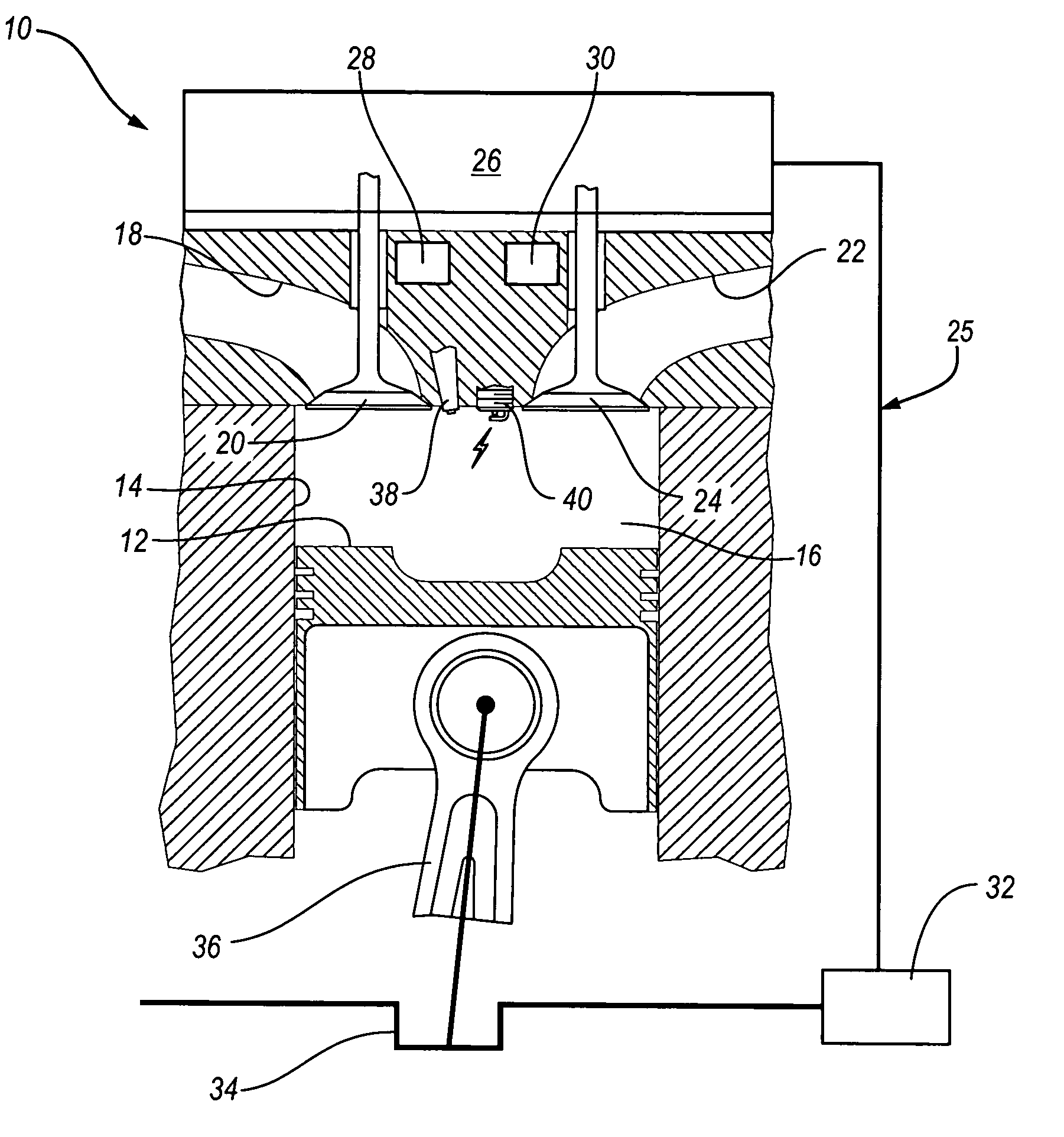

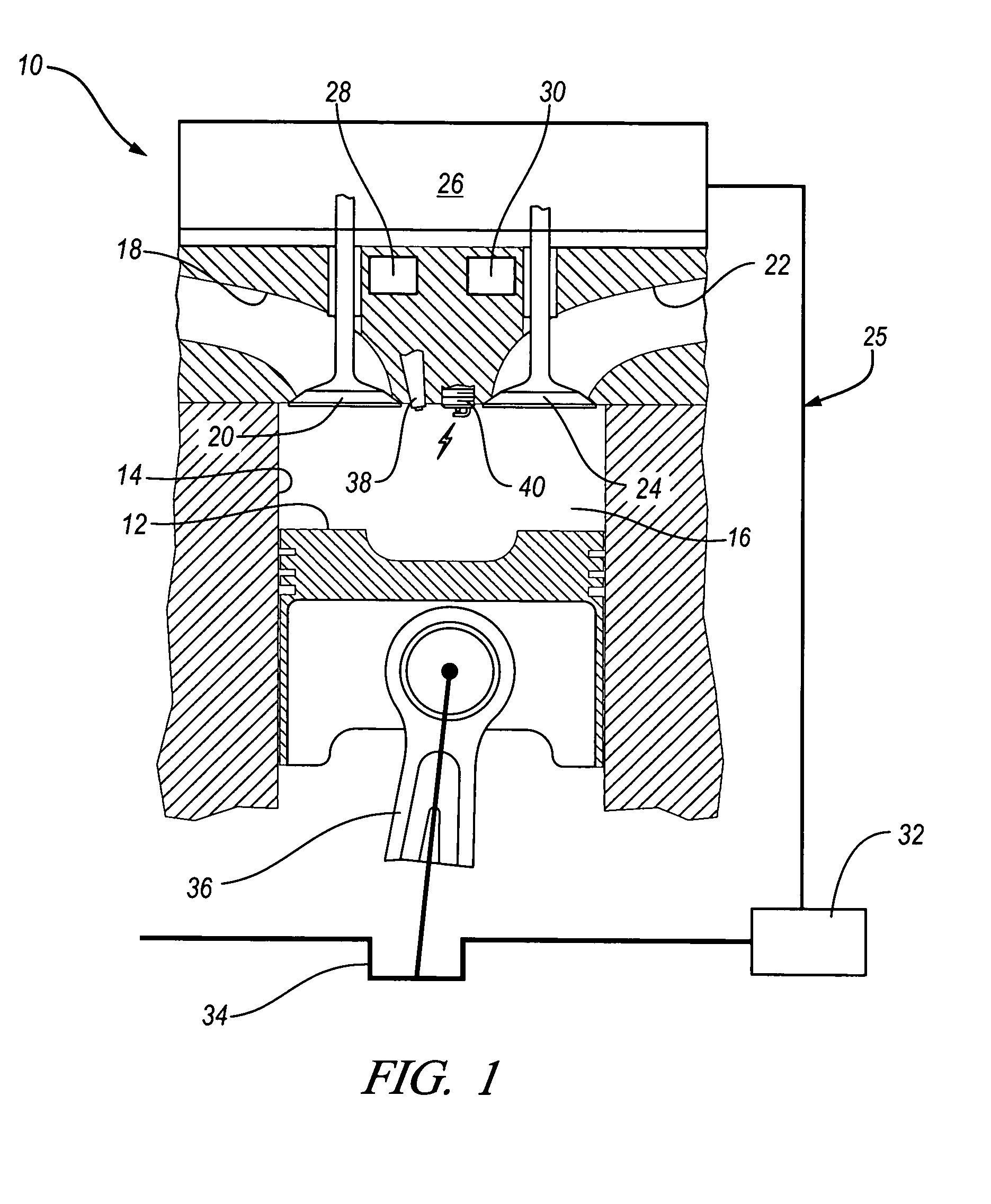

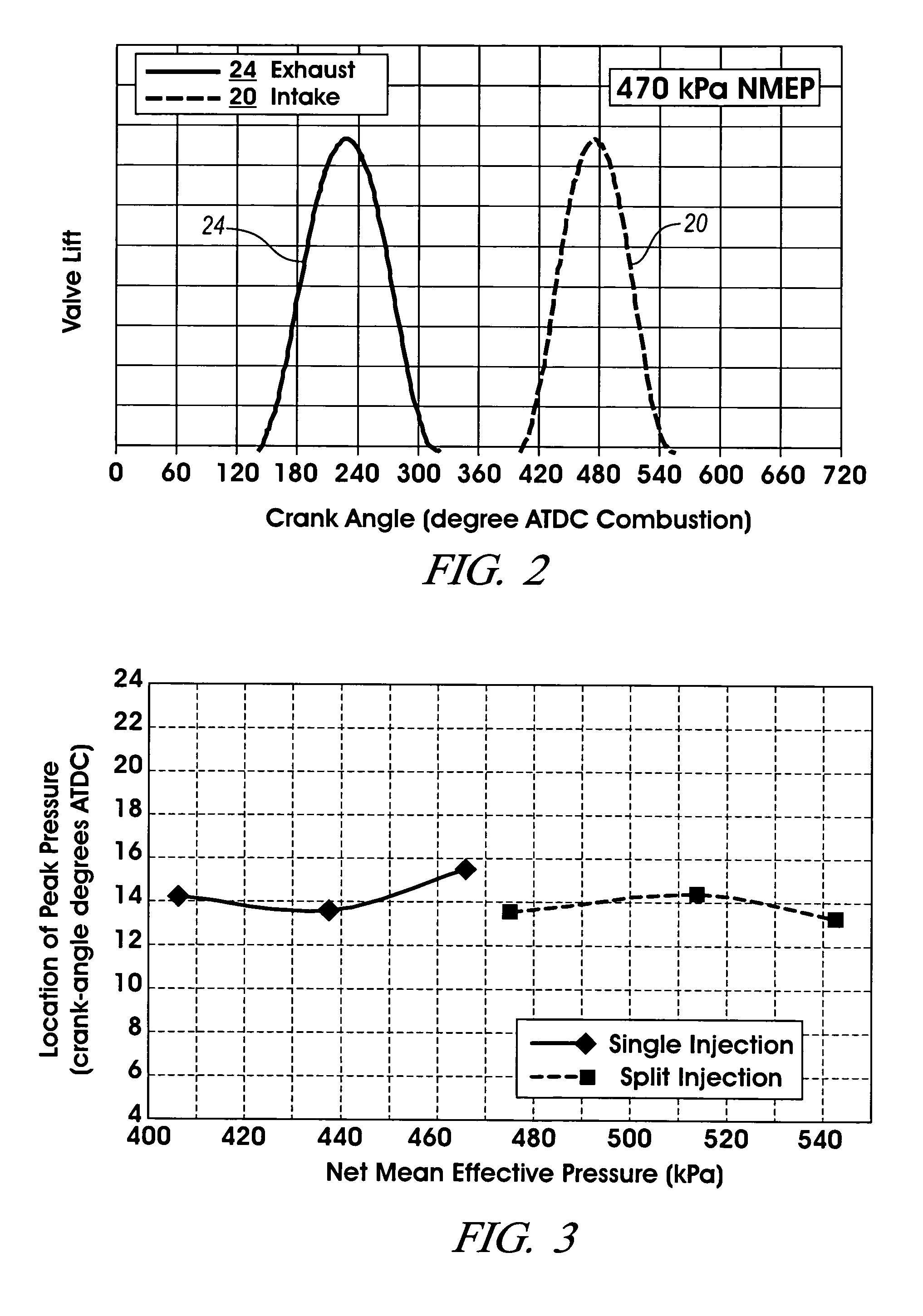

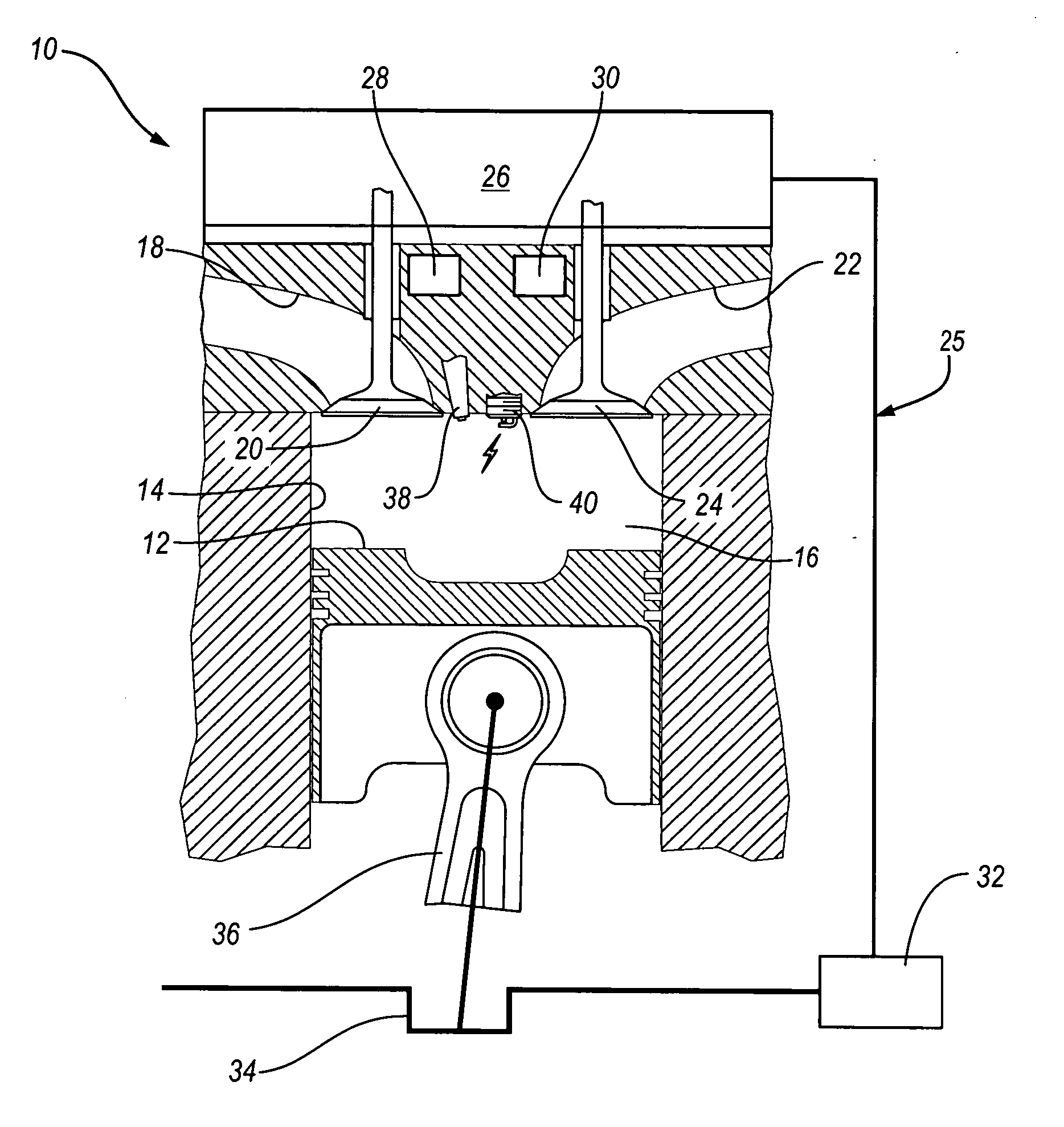

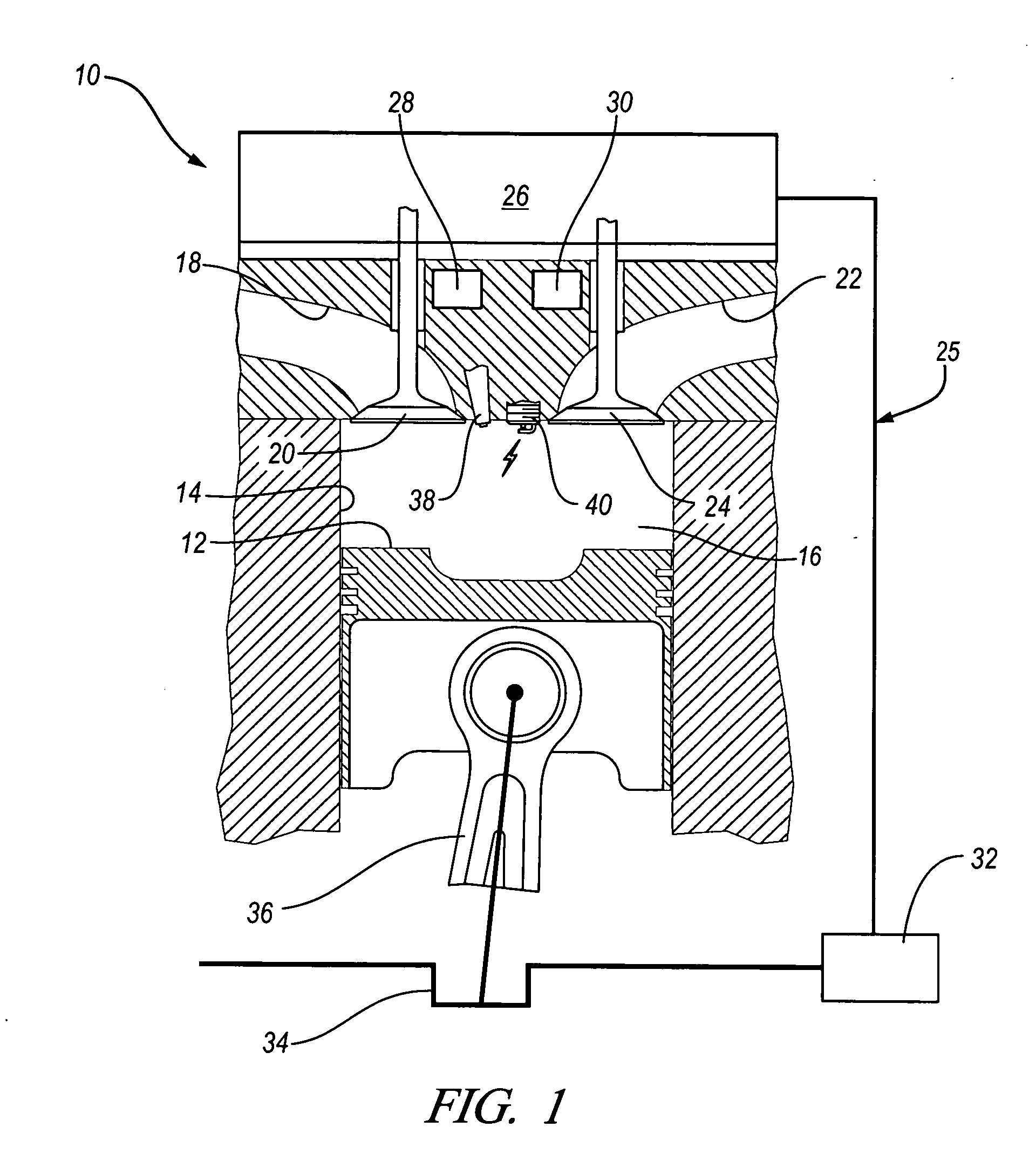

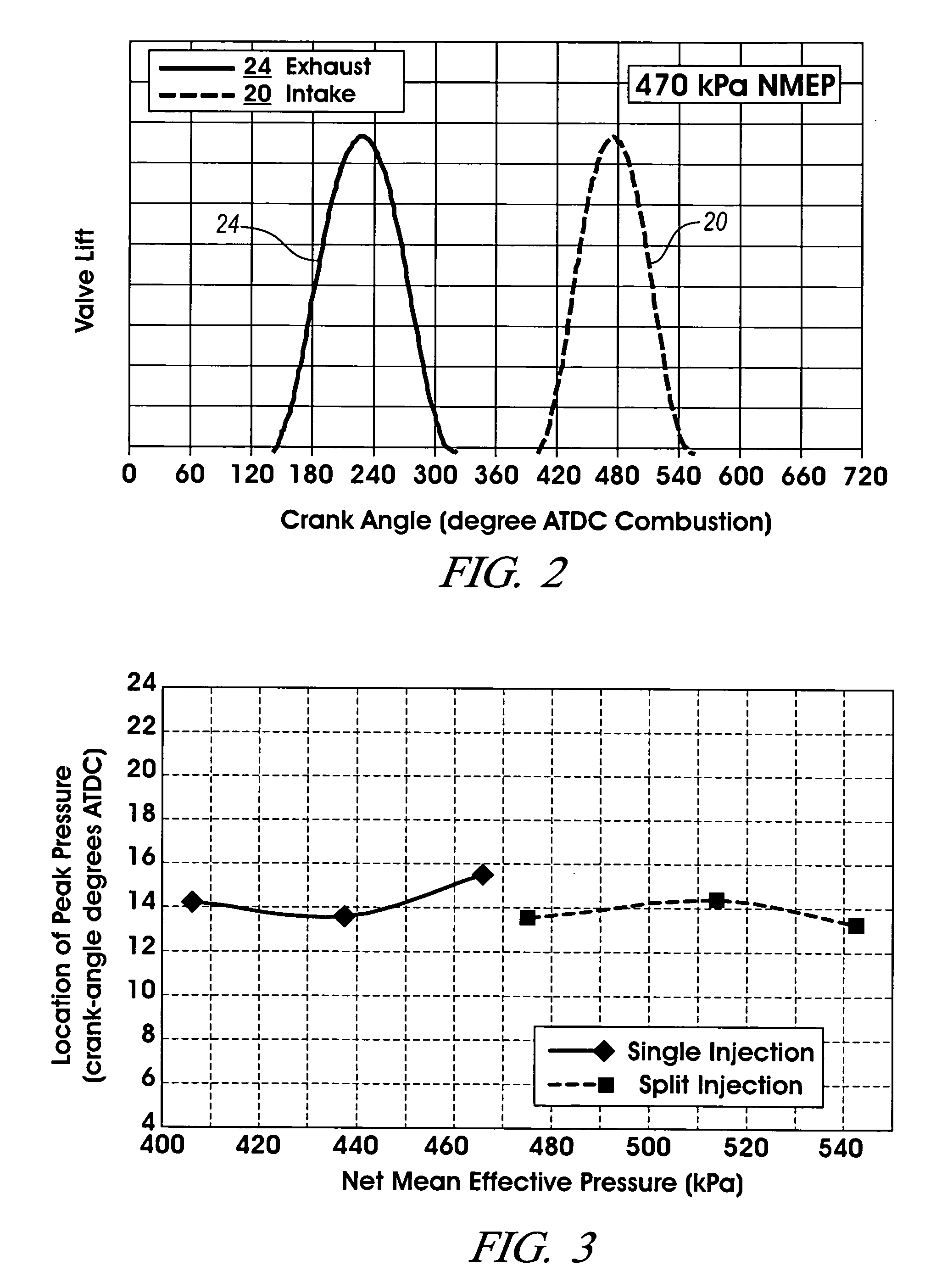

Method for mid load operation of auto-ignition combustion

ActiveUS6994072B2Electrical controlNon-fuel substance addition to fuelPressure riseMultiple injection

A method is disclosed for expanding the mid load operation limit in a four-stroke gasoline direct-injection controlled auto-ignition combustion engine. A system is employed for variably actuating the intake and exhaust valves and for operating the valves with an exhaust re-compression or exhaust re-breathing valve strategy. A spark plug is provided. A fuel injector having multiple injection capability is employed. A first fuel charge is injected into the combustion chamber to form a lean air-fuel mixture. A second fuel charge is injected into the combustion chamber to form a stratified air-fuel mixture having an ignitable mixture located near the spark plug. The ignitable mixture is ignited at the spark gap, thereby causing spark-ignition combustion that causes a sufficient increase in chamber pressure and temperature to trigger auto-ignition of the lean air-fuel mixture, resulting in the obtaining of a higher engine load before a pressure rise rate in the combustion chamber exceeds a prescribed threshold value.

Owner:GM GLOBAL TECH OPERATIONS LLC

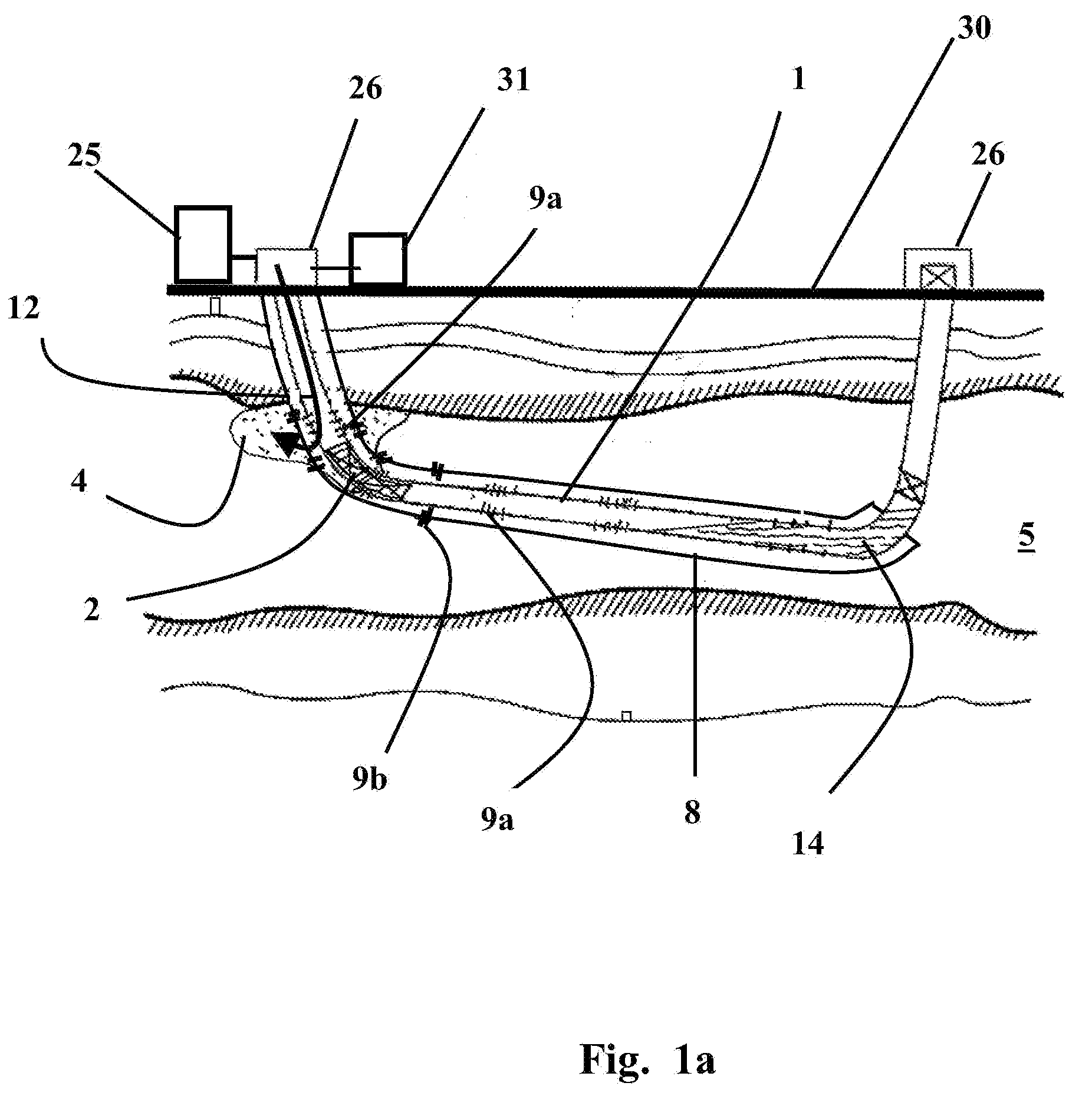

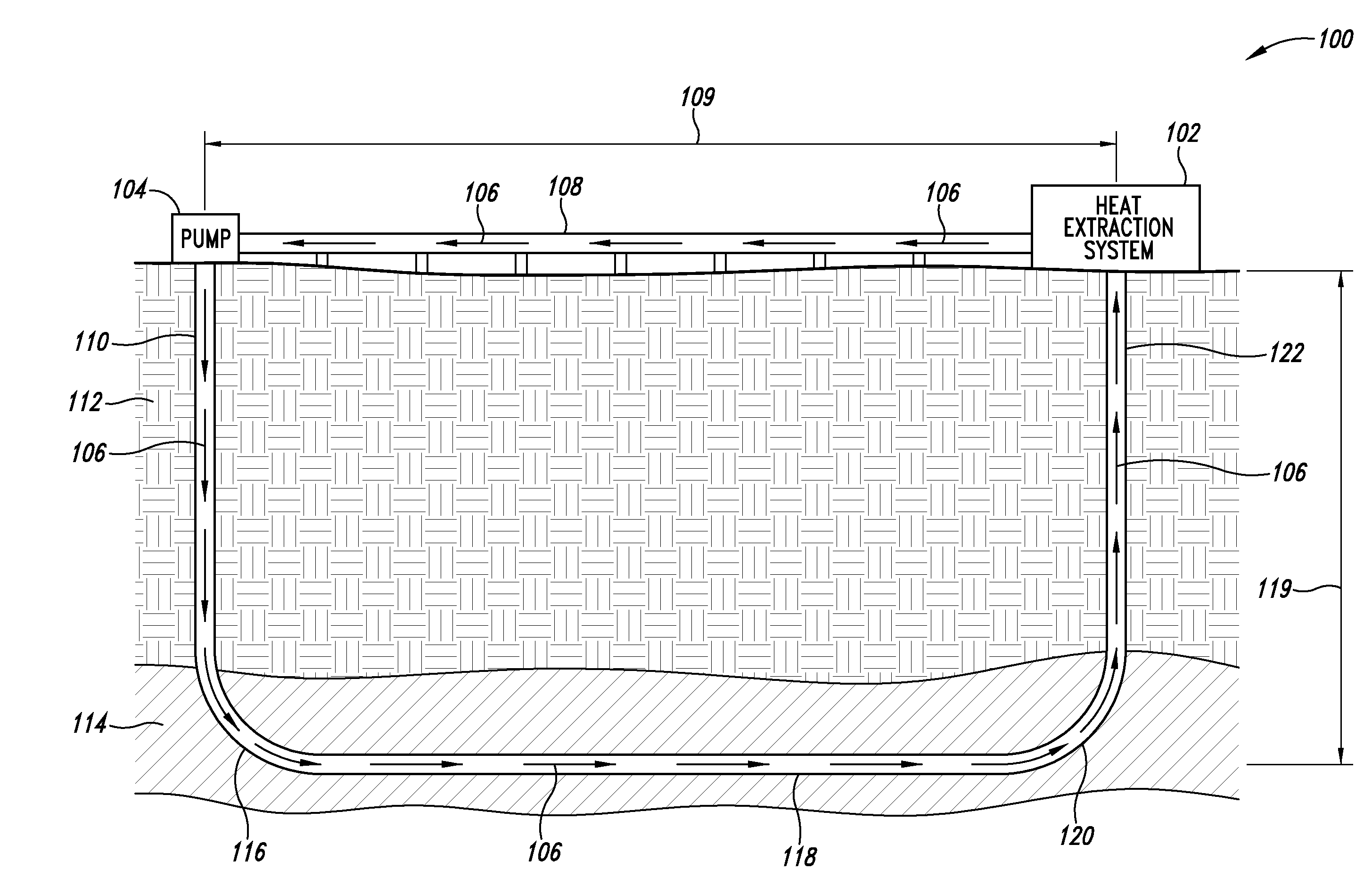

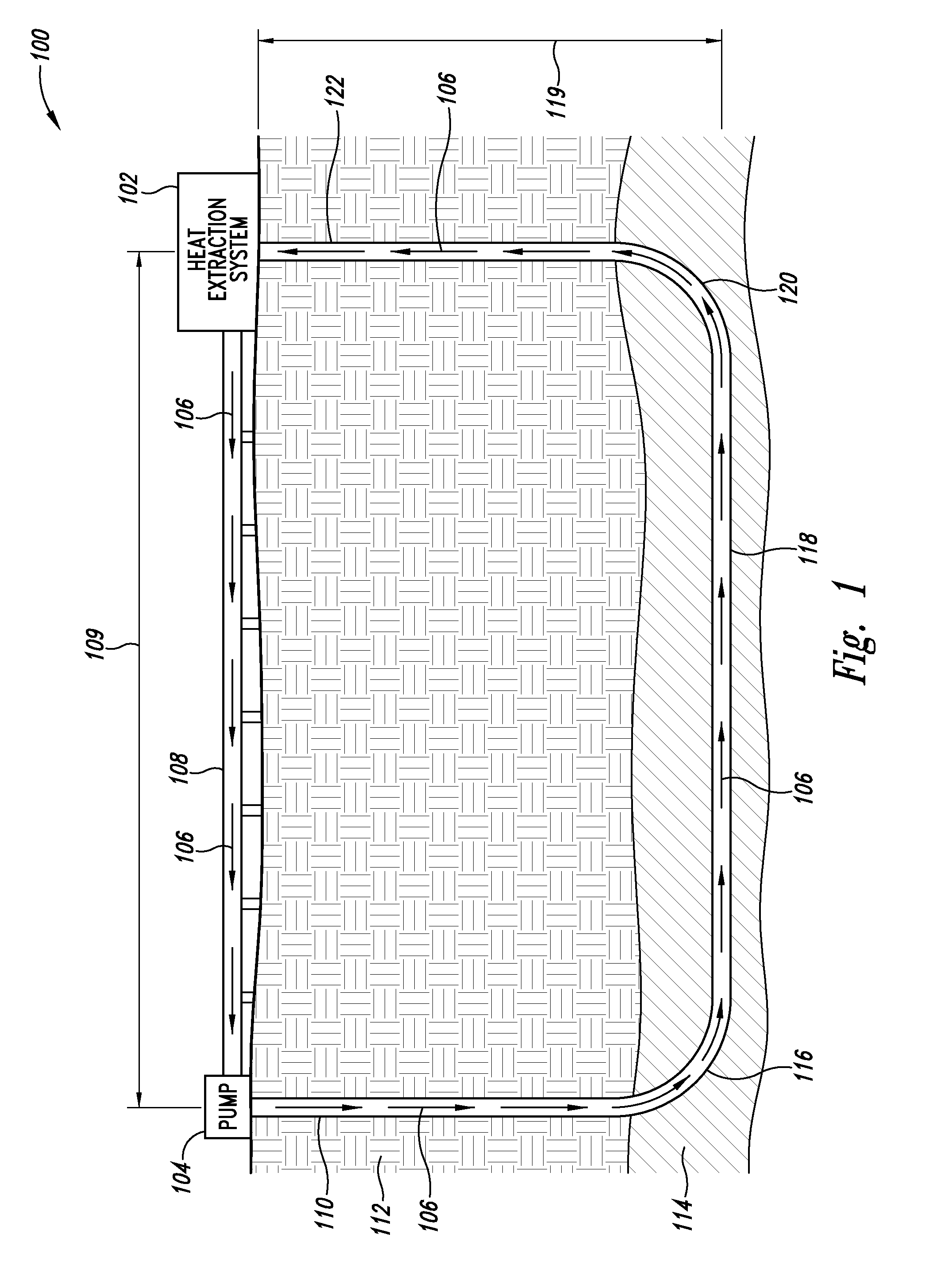

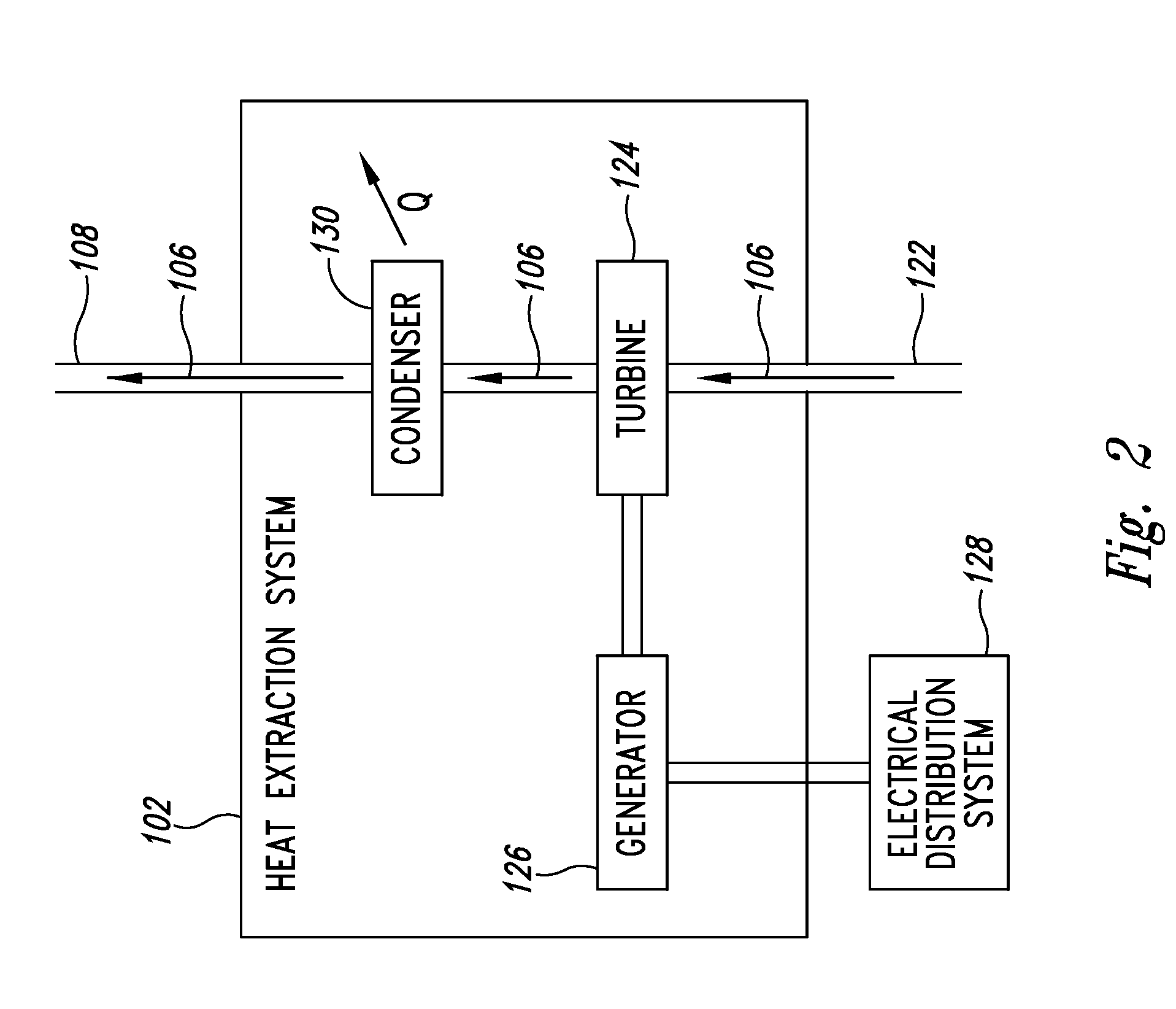

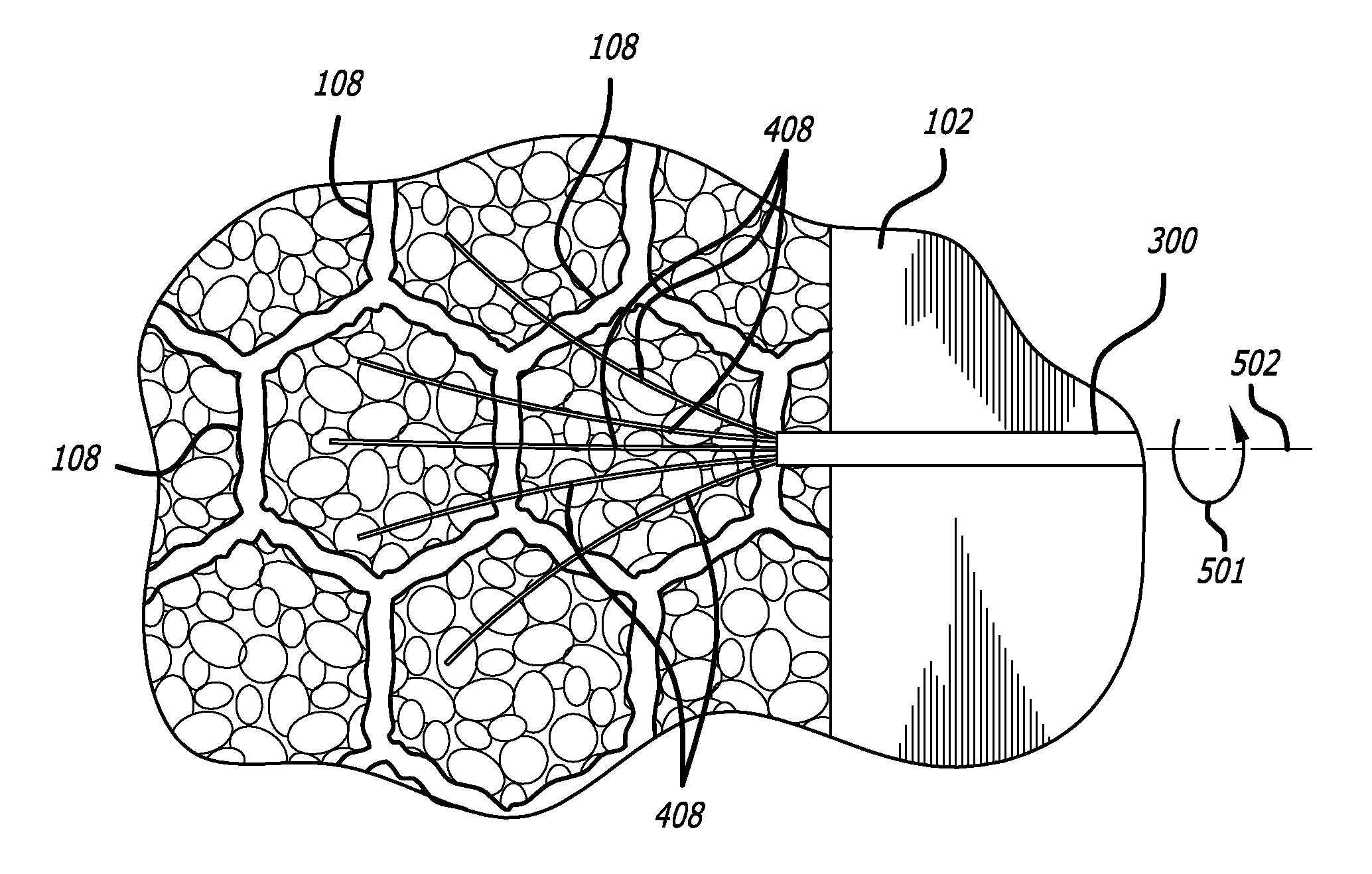

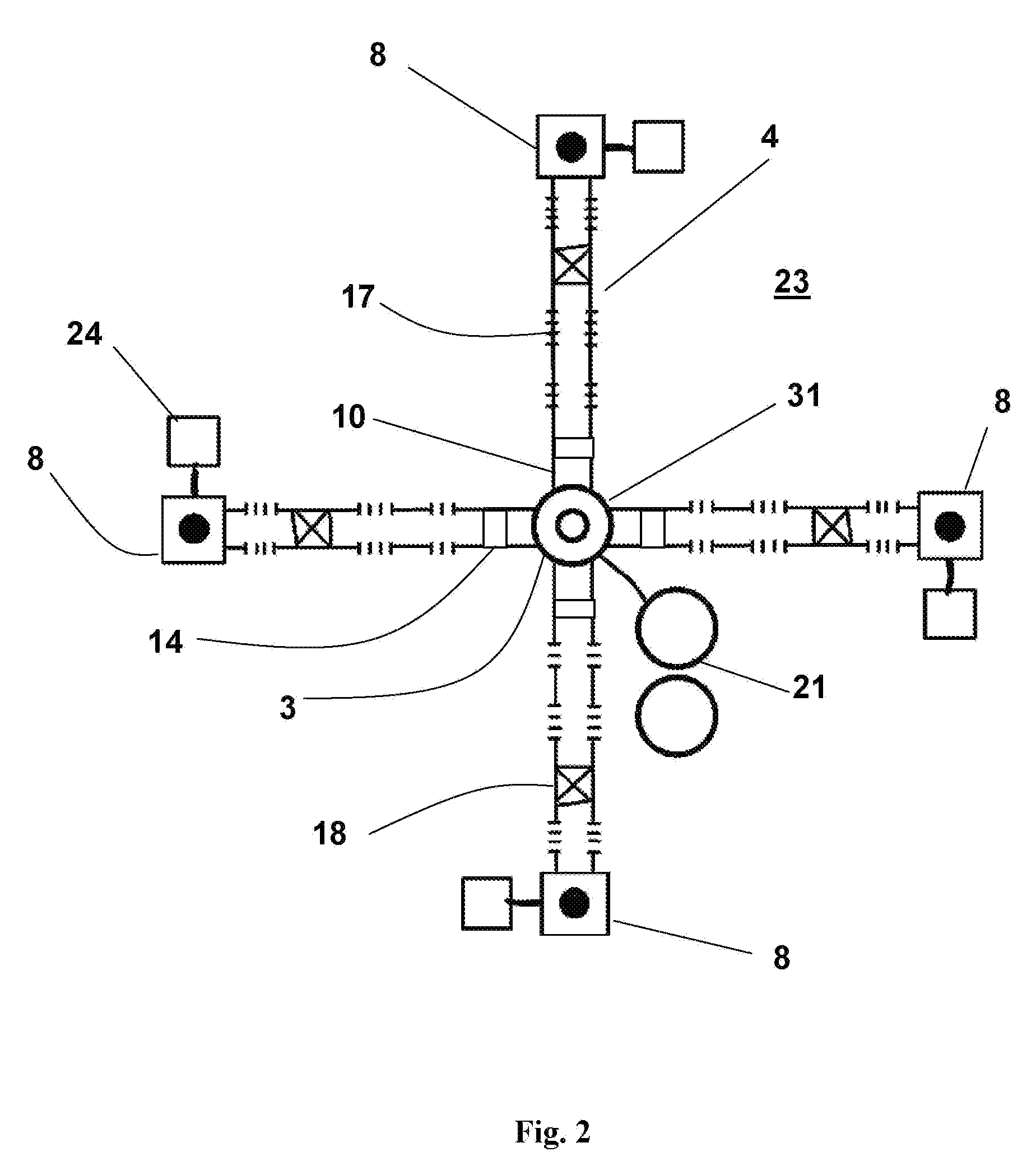

Directional geothermal energy system and method

InactiveUS20070245729A1Collector components/accessoriesGeothermal energy generationMultiple injectionTransport time

A directional geothermal energy system and method helps to increase control in paths to be taken by geo-fluid flow through hot rock to create engineered geothermal reservoirs and networks to mine heat from hot rock resources. The system uses directional drilling techniques to create a spanning borehole extending between an injection borehole and a production borehole. The spanning borehole typically extends through hot rock for a distance on the order of kilometers to allow the geo-fluid flowing through the spanning borehole adequate transit time and surface contact to obtain sufficient heat given a certain flow rate for the geo-fluid. In some implementations, multiple injection boreholes can supply geo-fluid to a single production borehole. Individual geo-fluid networks can be so sized, shaped, and located with respect to one another to form a collection of geo-fluid networks to mine heat from very large hot rock resources.

Owner:MICKLESON D LYNN

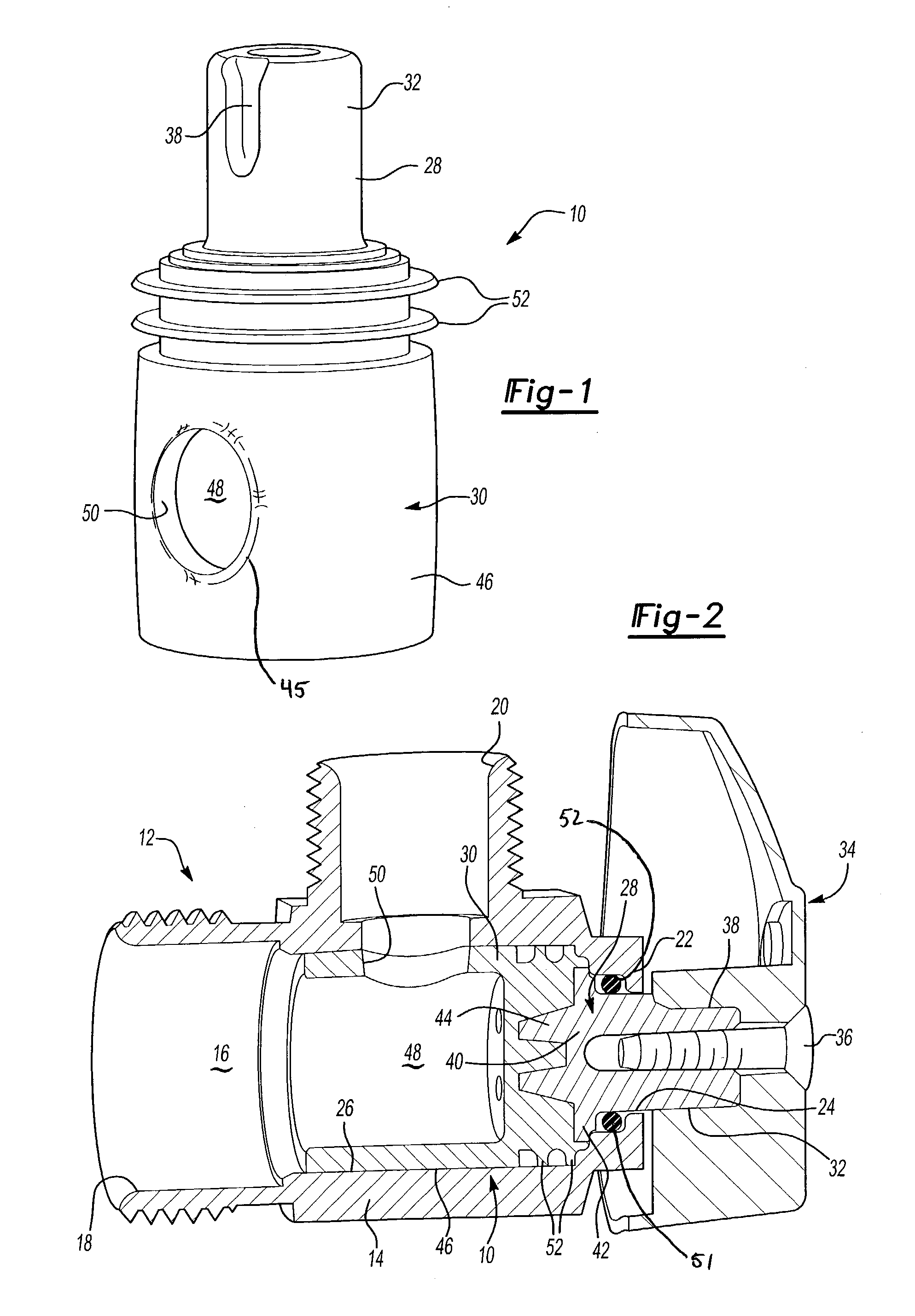

Stop valve

A stop valve includes a valve body, a multi shot resilient control sleeve, O-ring and handle. The control sleeve is molded to the valve stem to create an integral but separately molded fluid control member. Inlet line pressure resiliently biases the side walls of the control sleeve and a circumferential sealing flap formed thereon into sealing engagement with the valve bore to prevent leakage. The control sleeve consists of a hard plastic cylinder and a flexible barrel member molded as one consistent piece by a multishot molding process. The O-ring also serves as a backup seal to prevent leakage to atmosphere. A valve handle is secured to the valve by either a screw or a snap protrusion.

Owner:BRASSCRAFT MFG CO

Control strategy for engine employng multiple injection types

ActiveUS7581528B2Electrical controlInternal combustion piston enginesMultiple injectionVariation of parameters

A system for an engine, comprising a cylinder, a first injection subsystem for injecting a first substance into the cylinder, a second injection subsystem for injecting a second substance into the cylinder, and an electronic engine controller configured to control a plurality of operating parameters of the engine, where the electronic engine controller is configured to cause variation of at least one of the operating parameters in response to a shortfall condition of the second injection subsystem.

Owner:FORD GLOBAL TECH LLC

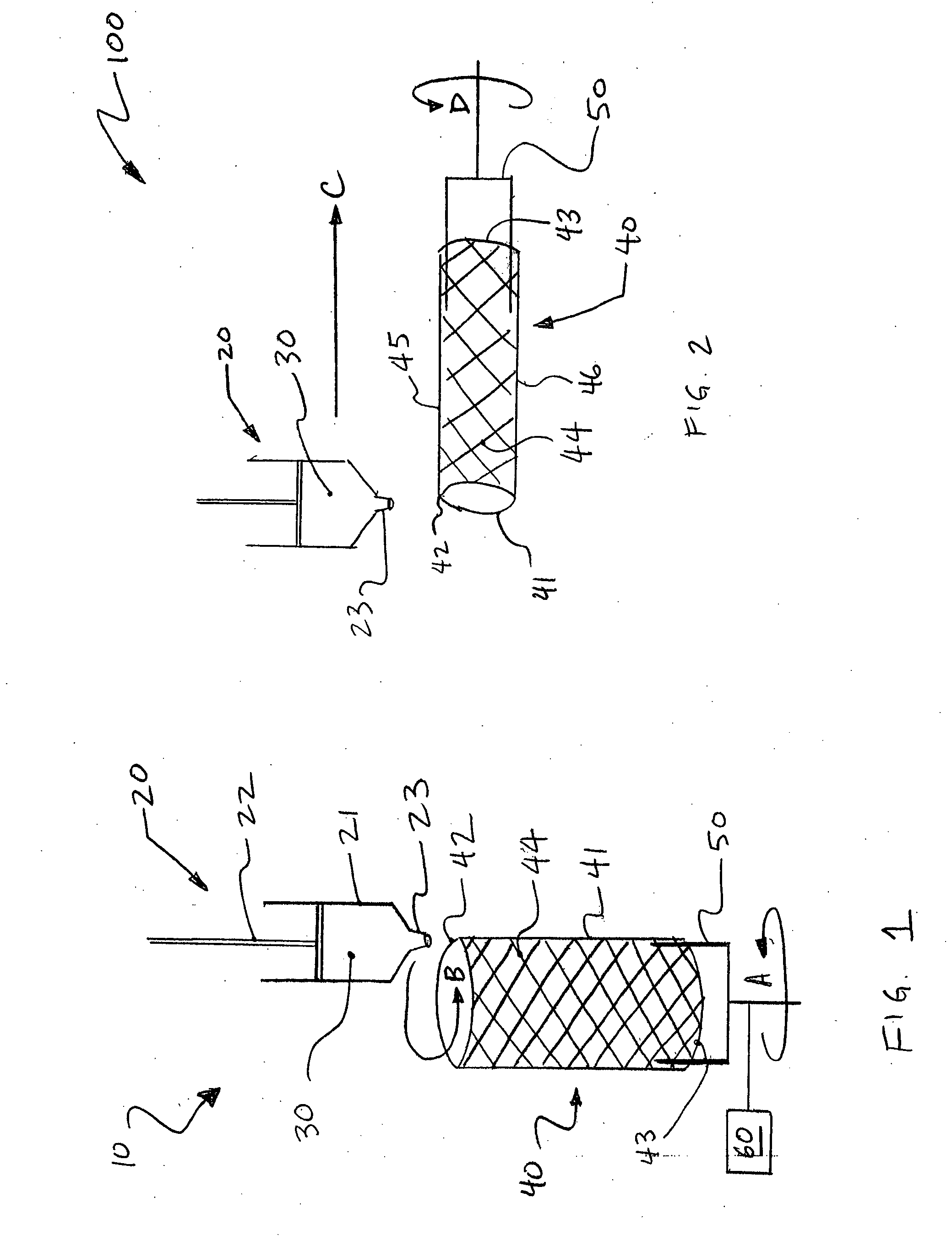

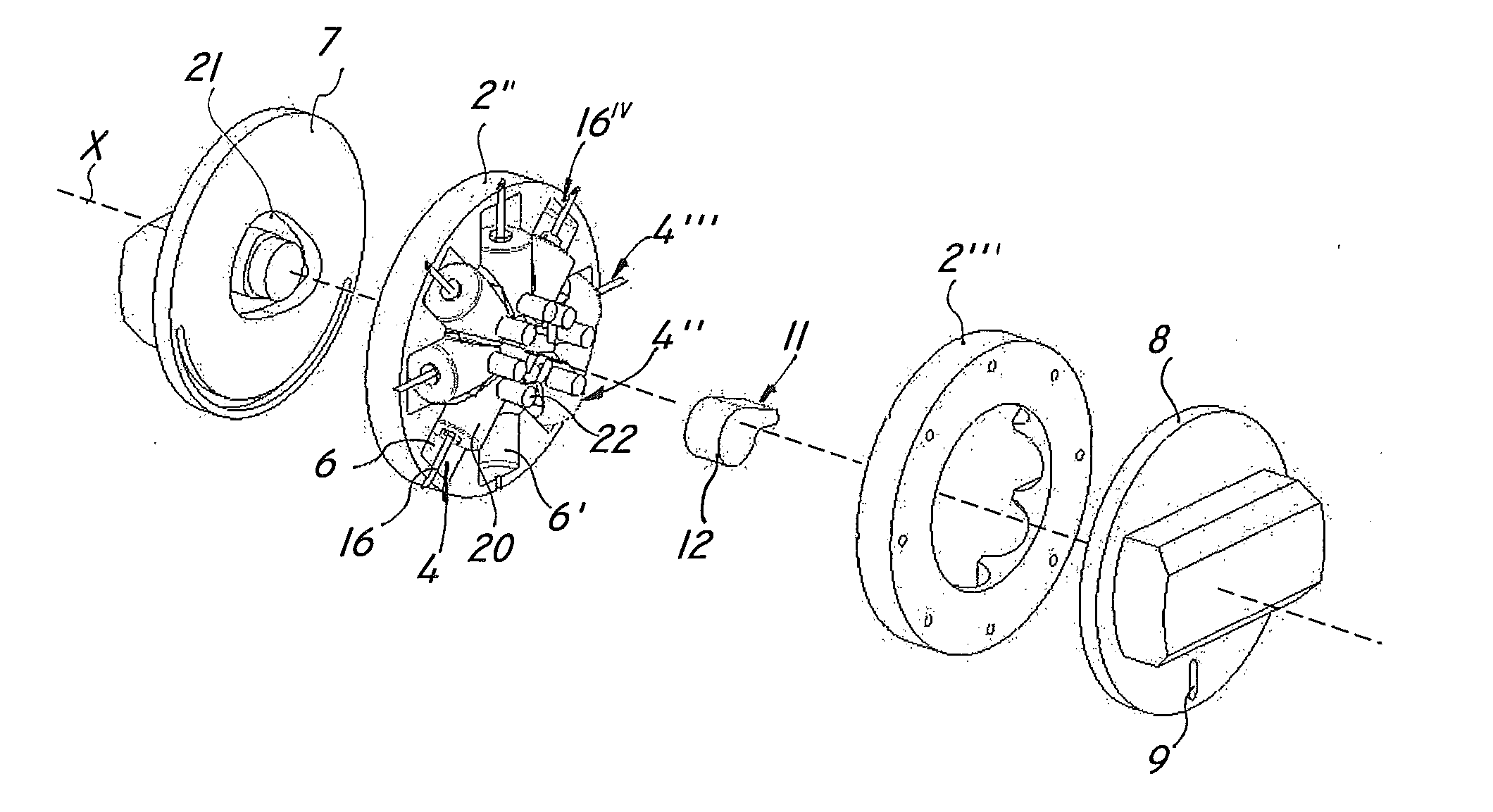

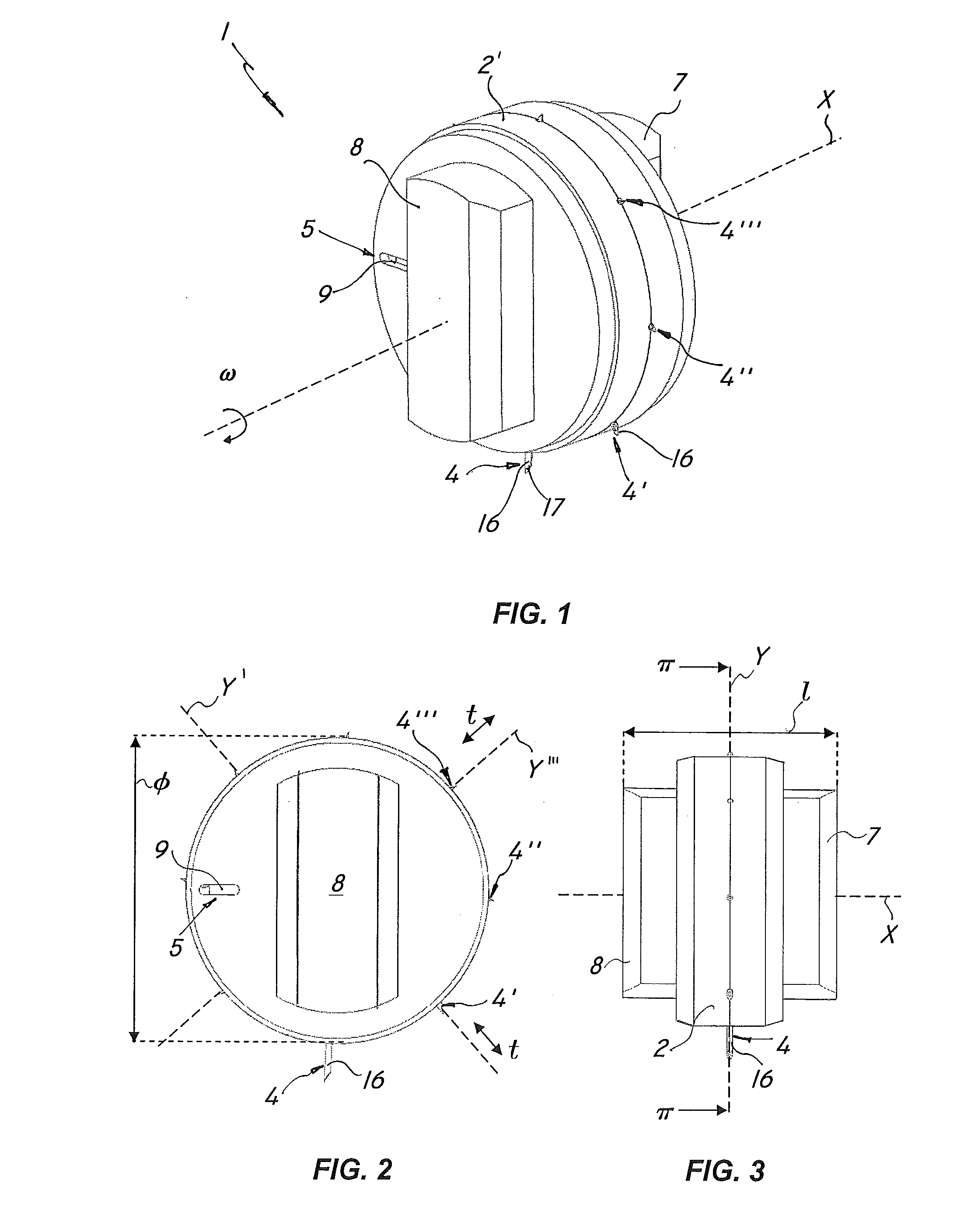

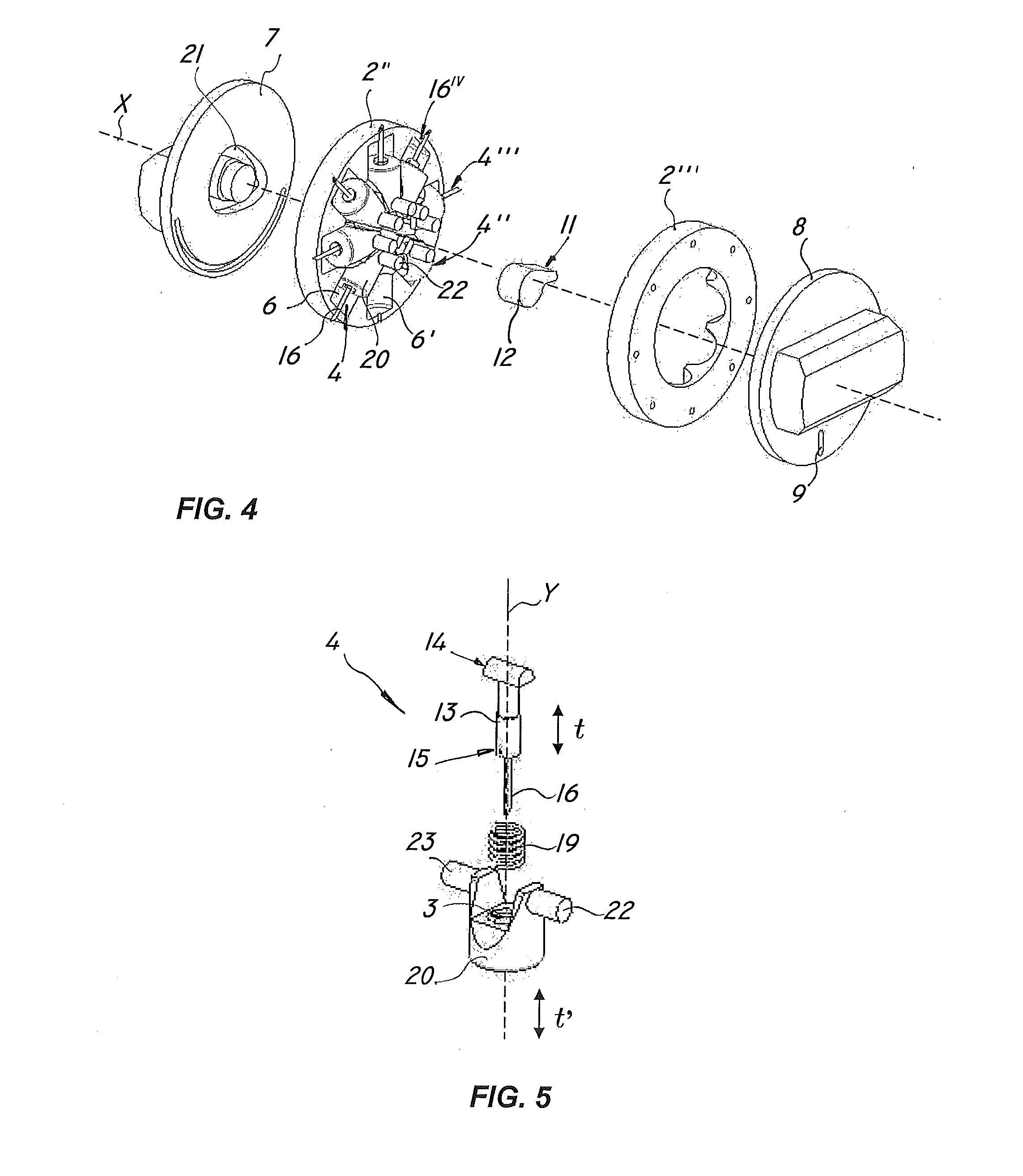

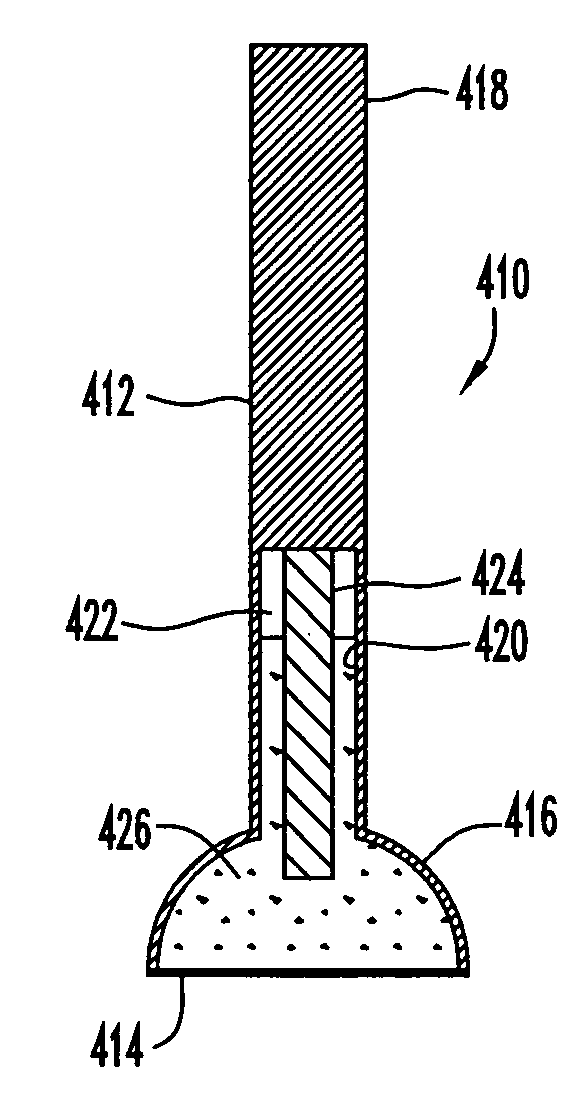

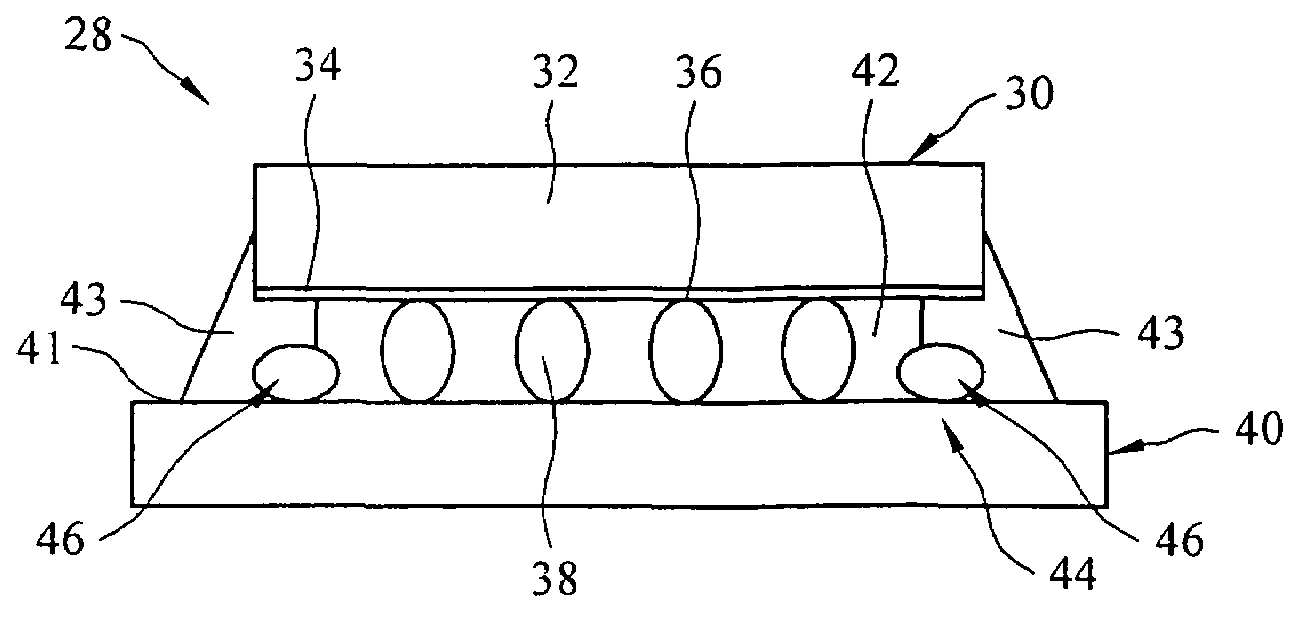

Multi-shot Connector Assembly and Method of Manufacture

InactiveUS20110003507A1Significant costSignificant materialTwo pole connectionsContact member cases/bases manufactureMultiple injectionCoaxial cable

A coaxial cable connector formed via multi-shot injection molding has a body formed by multiple injection molding layers of different injection moldable materials about a central inner contact to form an integral connector body. The connector body is provided with a coaxial dielectric spacer of dielectric polymer surrounding the inner contact; a coaxial inner body of injection molded metal composition surrounding an outer diameter of the dielectric spacer; and an outer body of polymer surrounding the inner body. Interlock features provide axial and / or rotational interlock between the layers of the connector.

Owner:ANDREW LLC

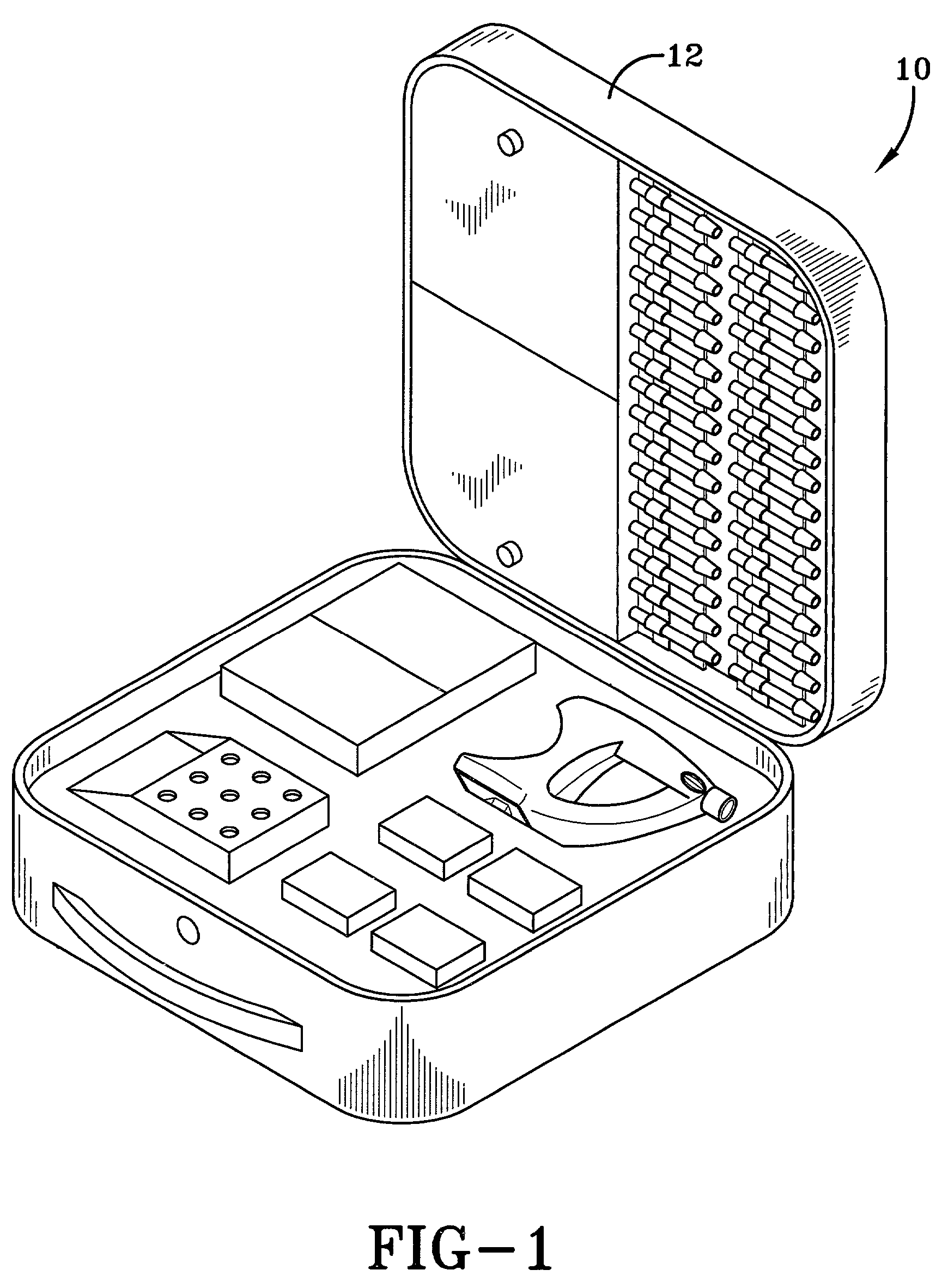

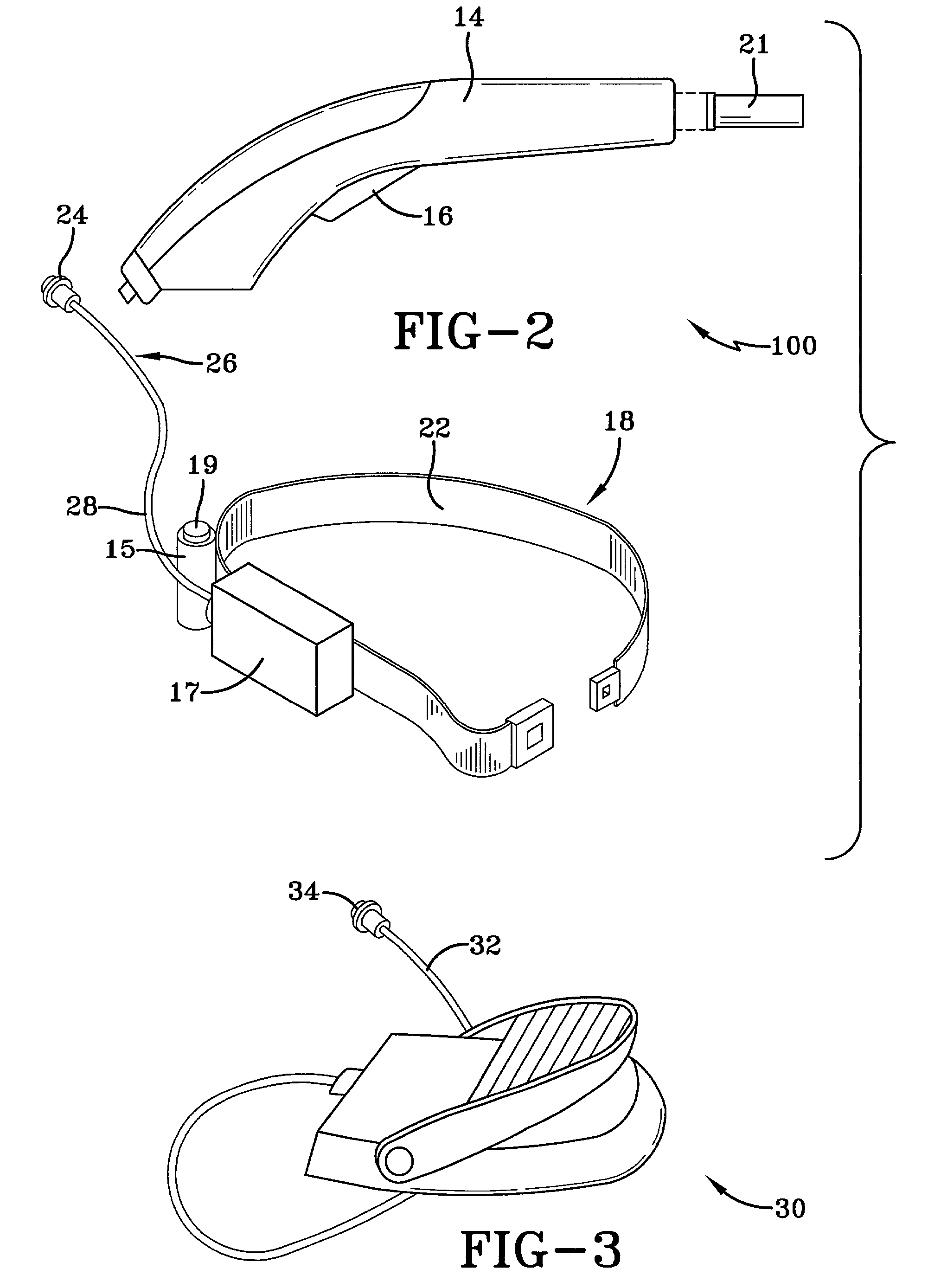

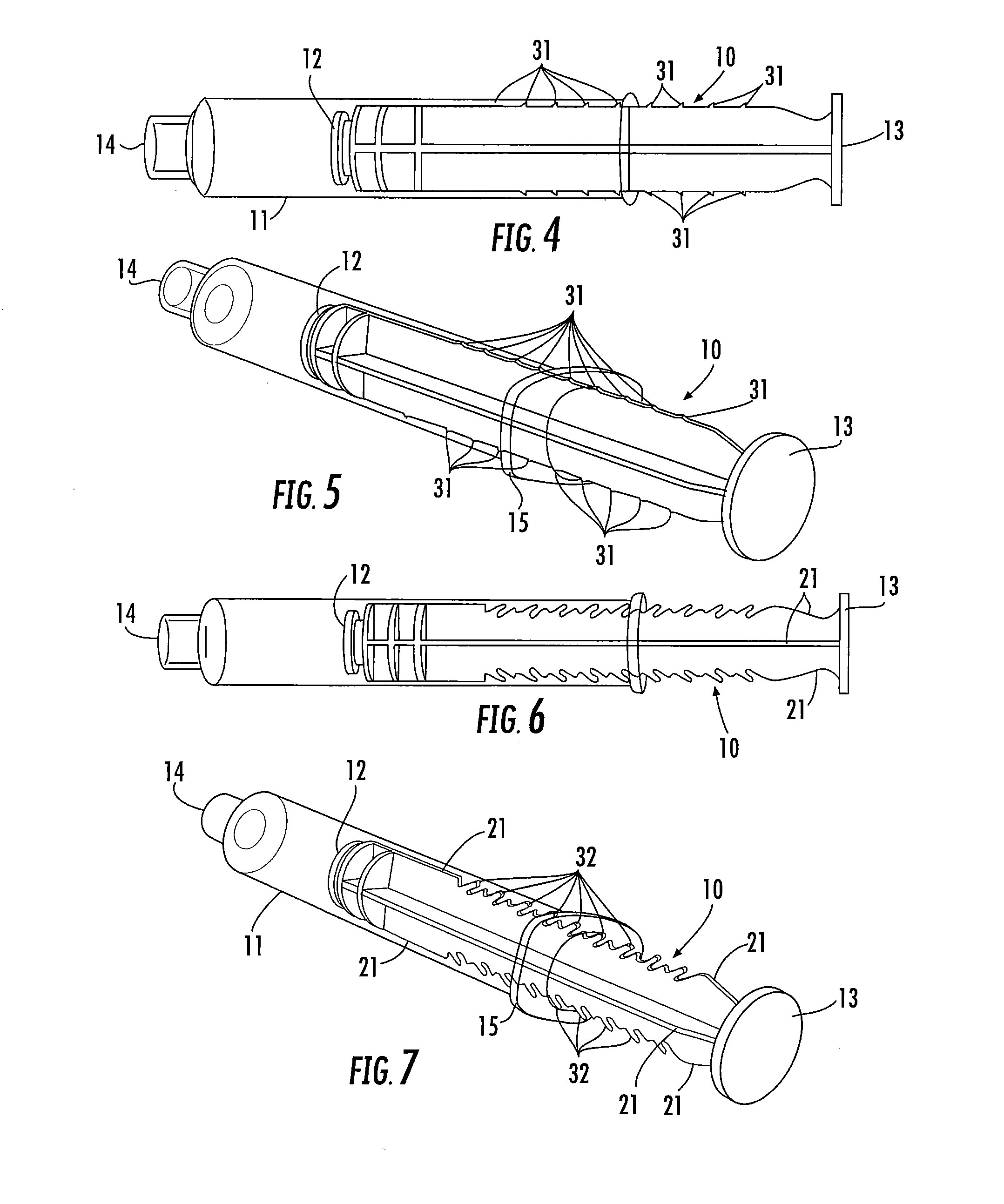

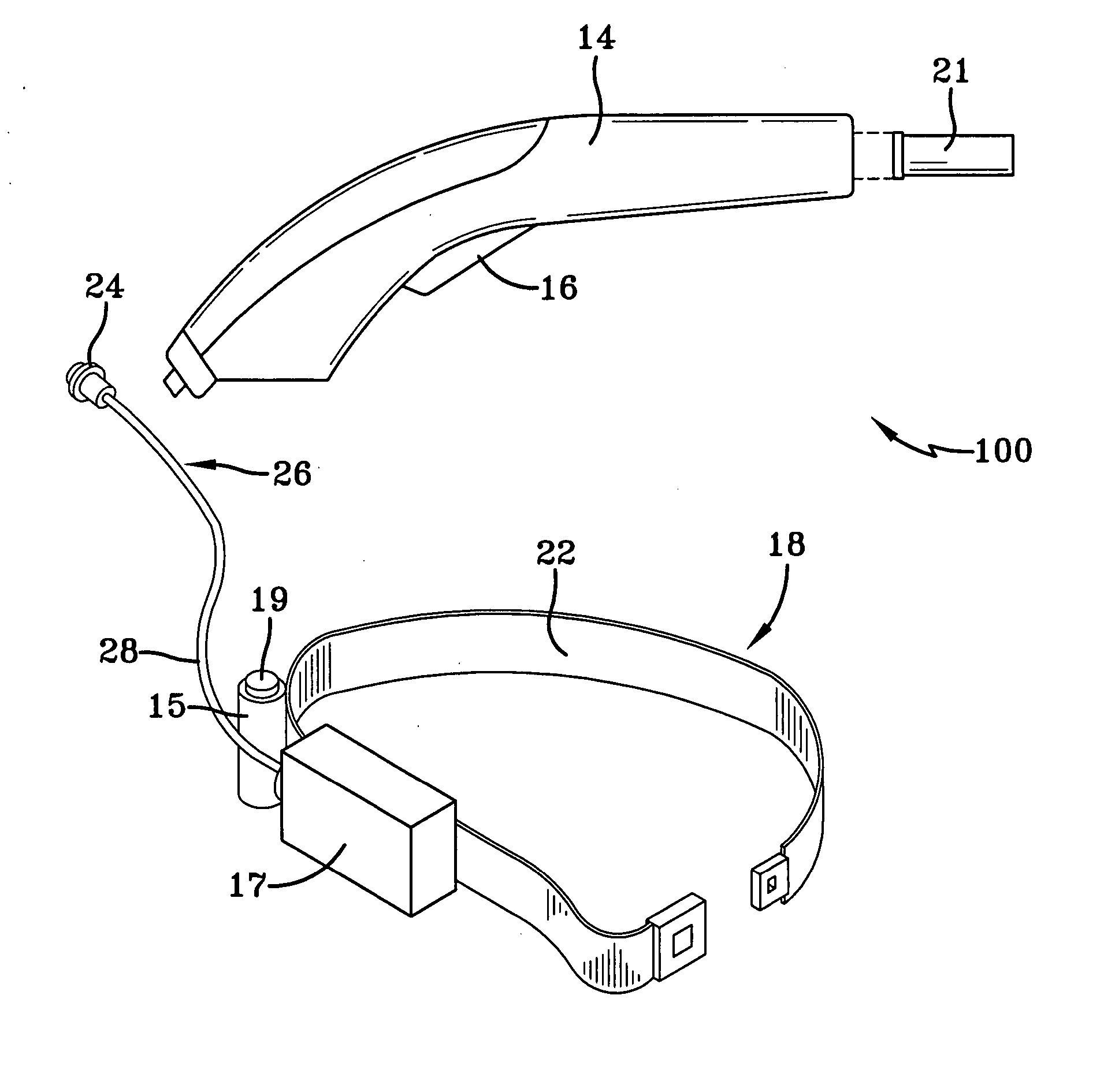

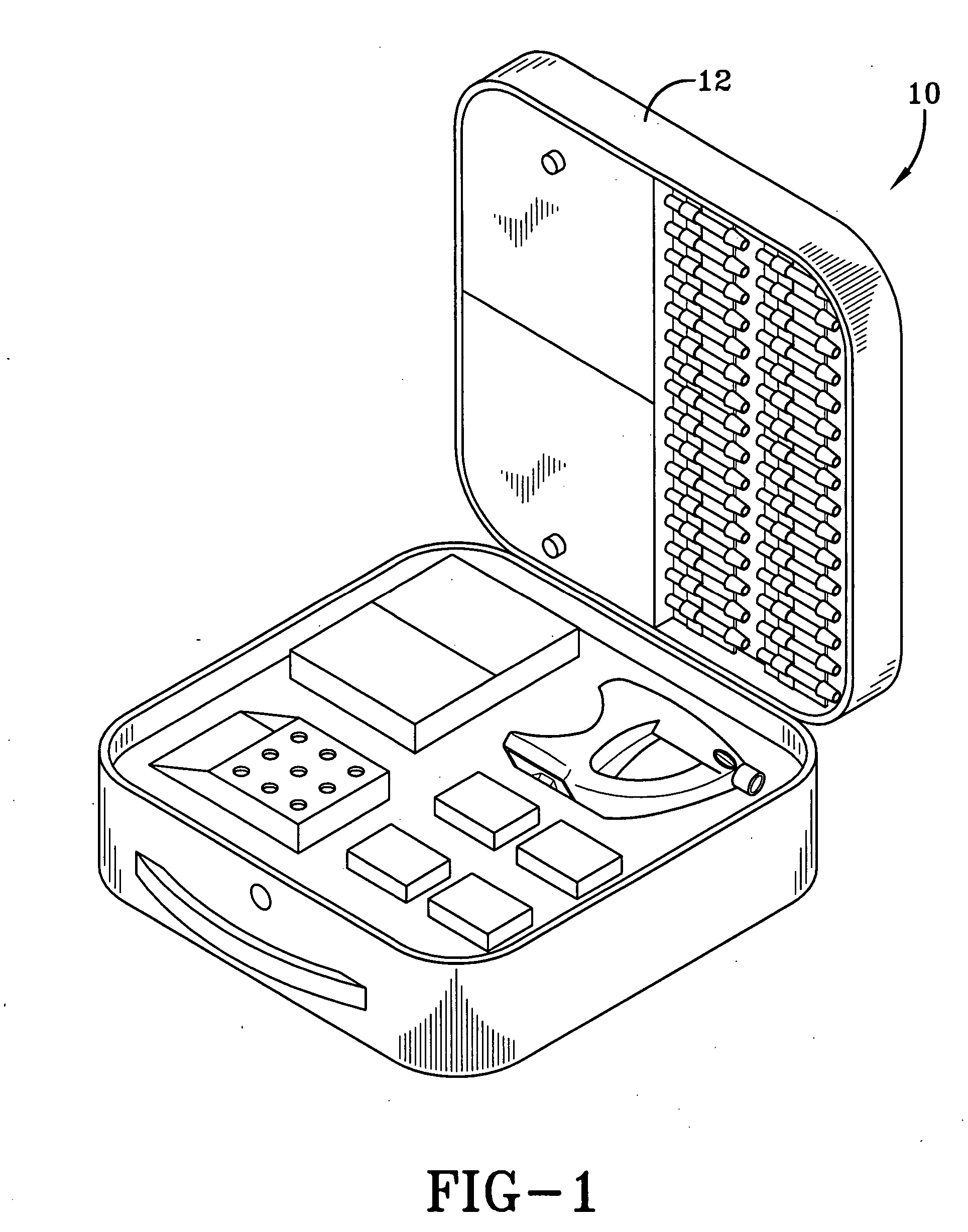

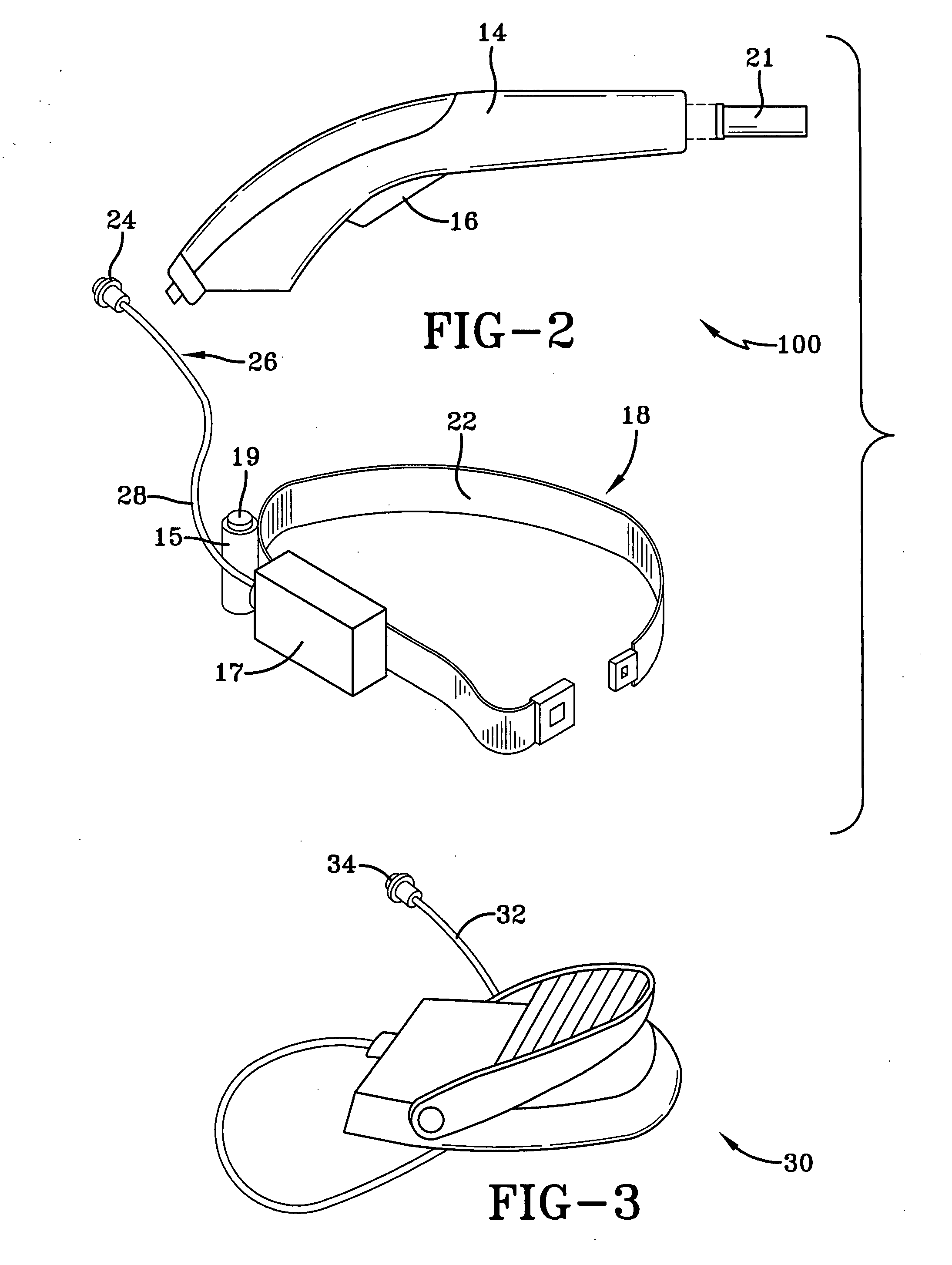

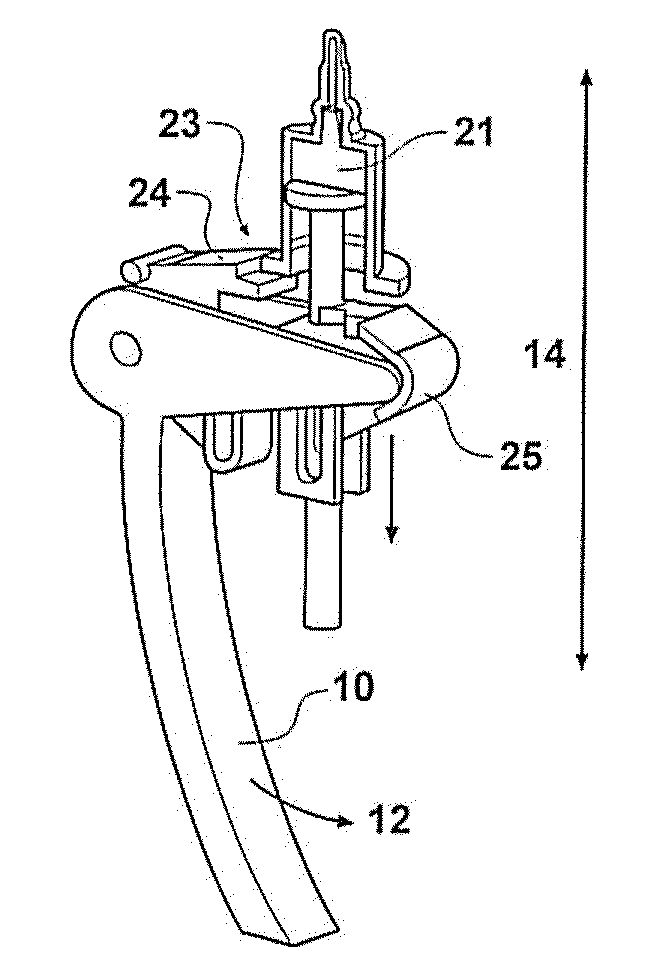

Hypodermic injection system

InactiveUS7235063B2Sufficient forceEliminate the problemAmpoule syringesJet injection syringesMultiple injectionHypodermoclysis

A hypodermic injection system particularly for use in mass immunizations having a handpiece with a grasping mechanism for holding ampules filled with injectate, a plunger for driving into the ampule to discharge the injectate in an injection process, an injection spring mechanism for driving the plunger, a motor and / or manual mechanism for cocking the injection spring mechanism, and an ampule ejection mechanism for ejecting ampules after use under control of a release mechanism. Ampules can be loaded, used and ejected without contact by the user of the system or the patient being injected. Also disclosed are a filling station for filling ampules through their injection orifices, and an arming device for setting the injection spring. Ampules are disclosed having a piston which is drivable towards an orifice to discharge injectate through the orifice. Ampules are also disclosed having enlarged proximal portions for easy grasping by the grasping mechanism of the injector. Ampules are further disclosed with separators for mixing lyophilized medication and a diluent. Further disclosed are magazines for holding ampules for sequential use by the hypodermic injector. The disclosed system finds particular use as a mass immunization kit for making numerous injections in the field.

Owner:DANTONIO CONSULTANTS INT INC

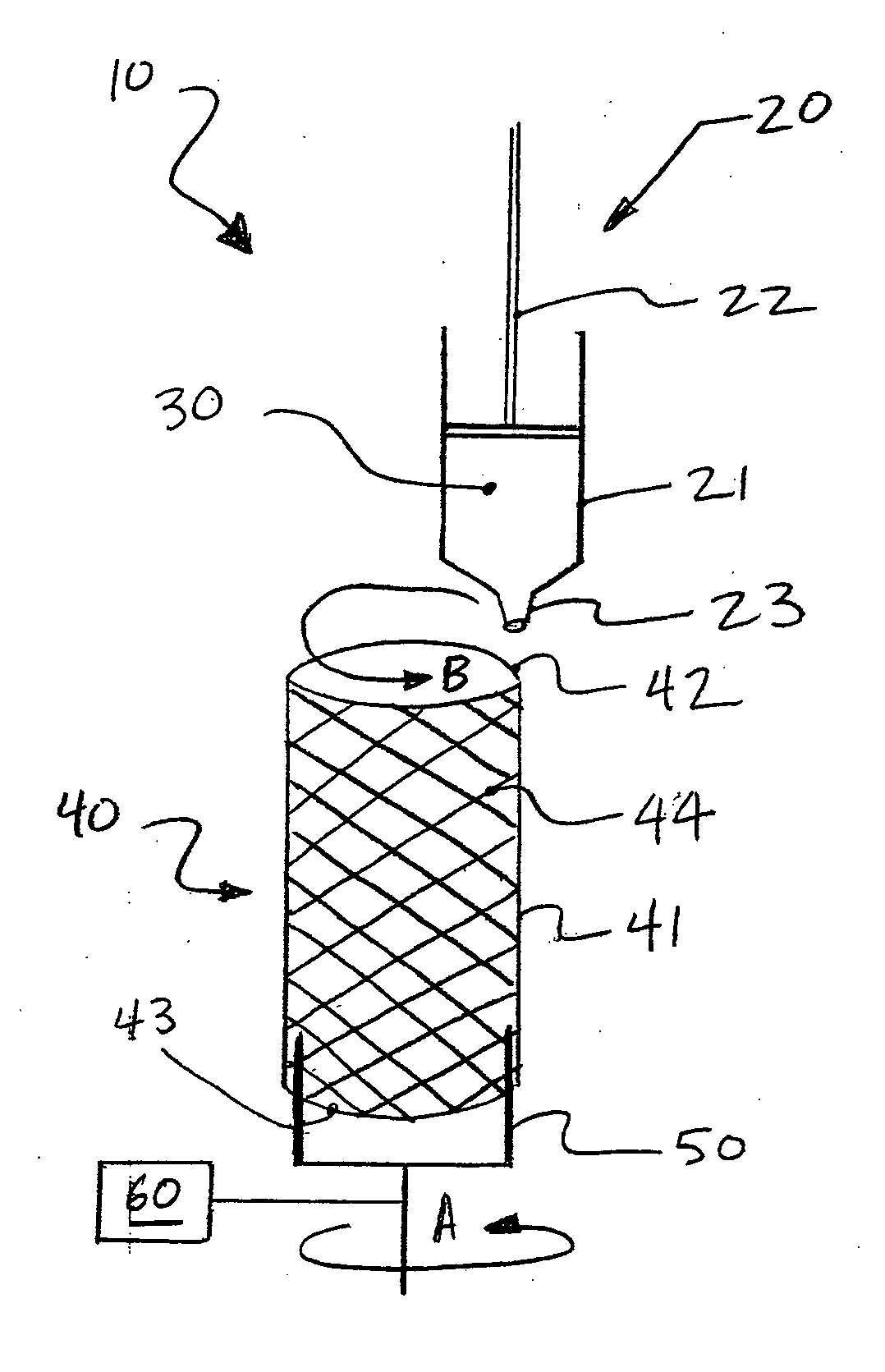

Methods and apparatus for injection coating a medical device

InactiveUS20060029720A1High degree of automationRapid through-putStentsPharmaceutical containersMultiple injectionActive agent

Methods and apparatus for coating at least a portion of the surface of medical devices using an injection coating device are disclosed. In one embodiment, the invention includes a coating method wherein an orifice of the injection coating device is placed adjacent a vertically positioned medical device, coating material is ejected from the orifice onto the medical device, and the coating material gravitationally flows downward coating the medical device. In another embodiment, an orifice of an injection coating device is positioned adjacent a horizontally positioned medical device to gravitationally flow and deposit coating material onto the medical device. These methods may be used to apply one or more coating materials, simultaneously or in sequence. In another embodiment, multiple injection coating devices may be utilized. In certain embodiments of the invention, the coating materials include therapeutic or biologically active agents.

Owner:BOSTON SCI SCIMED INC

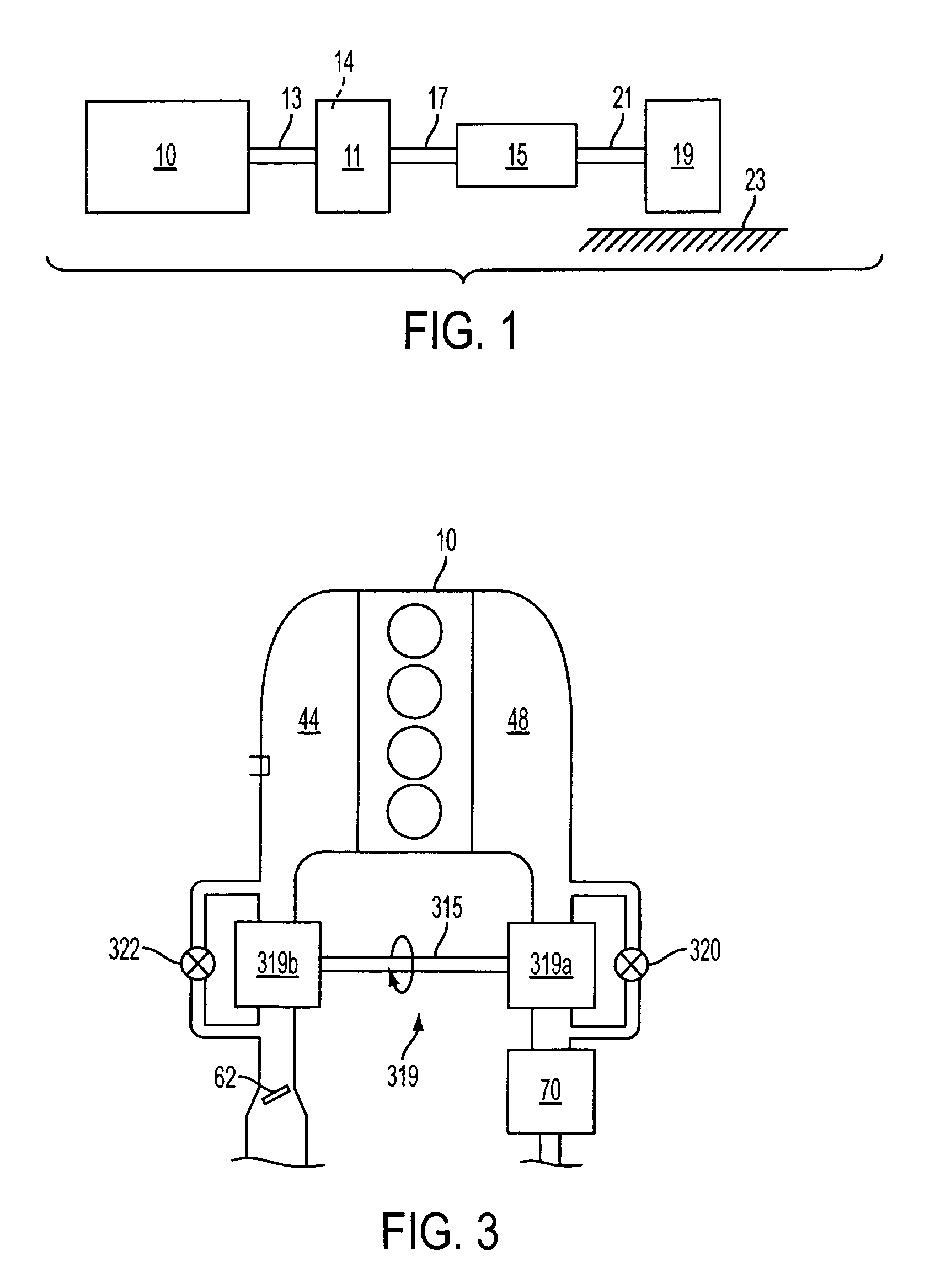

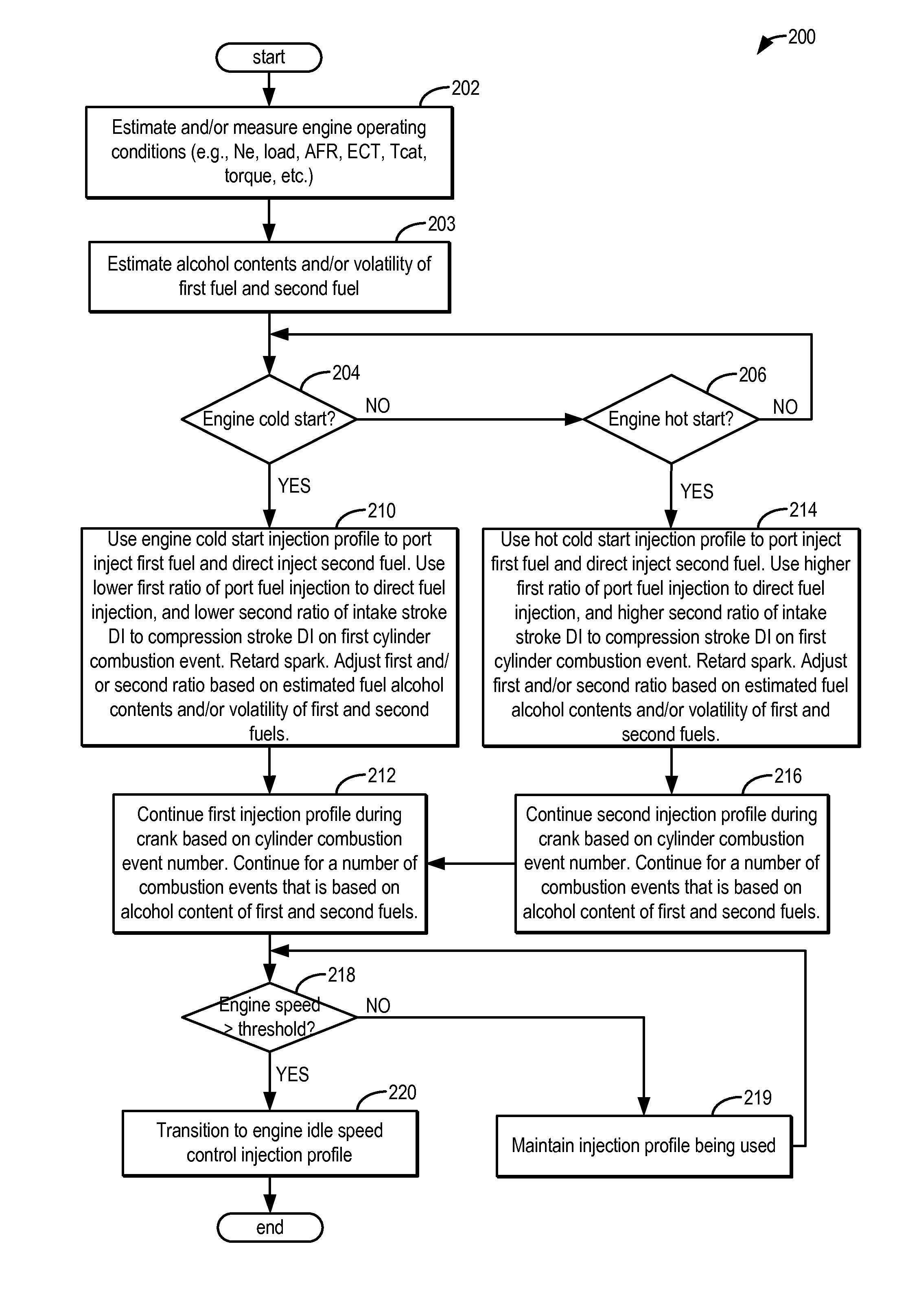

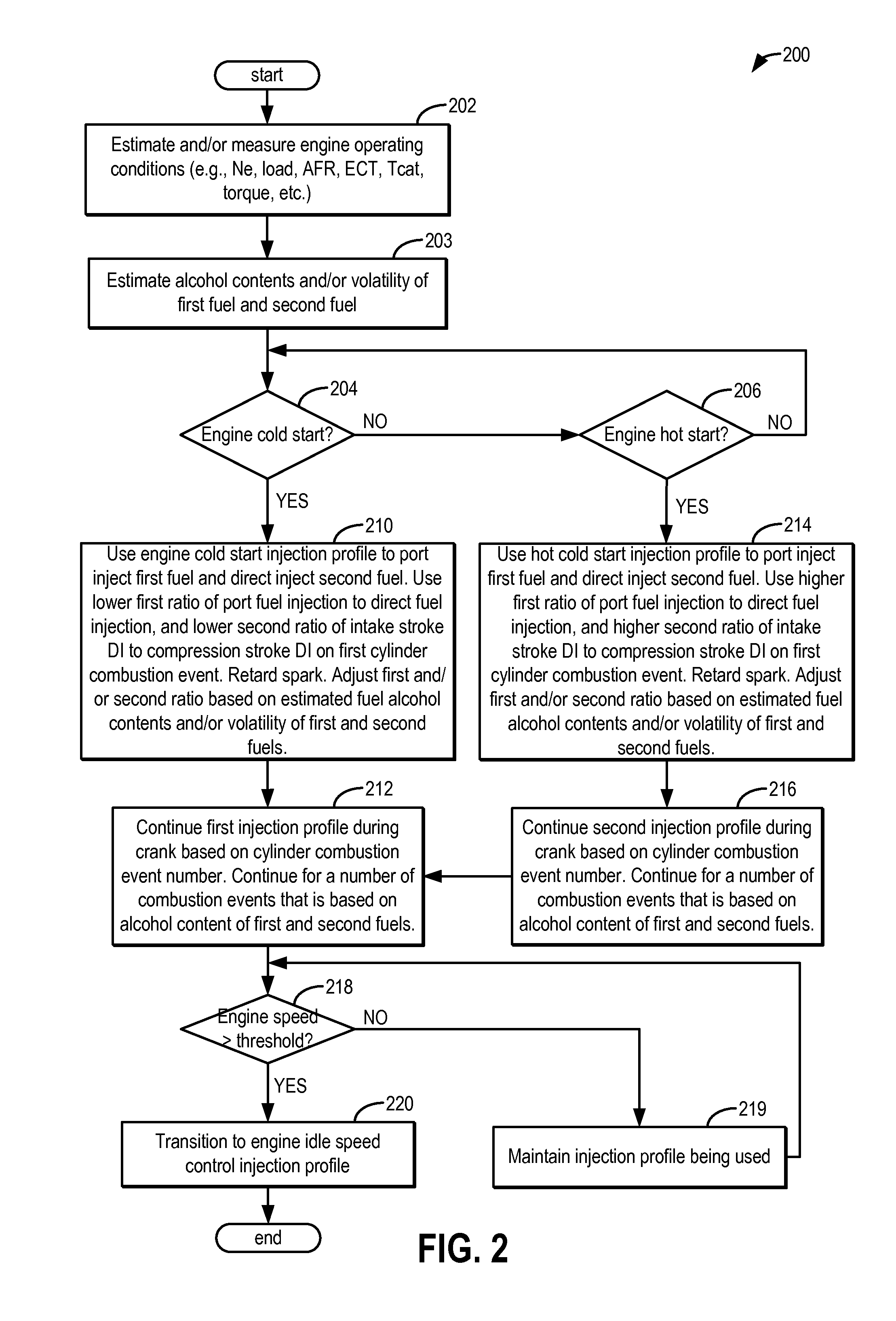

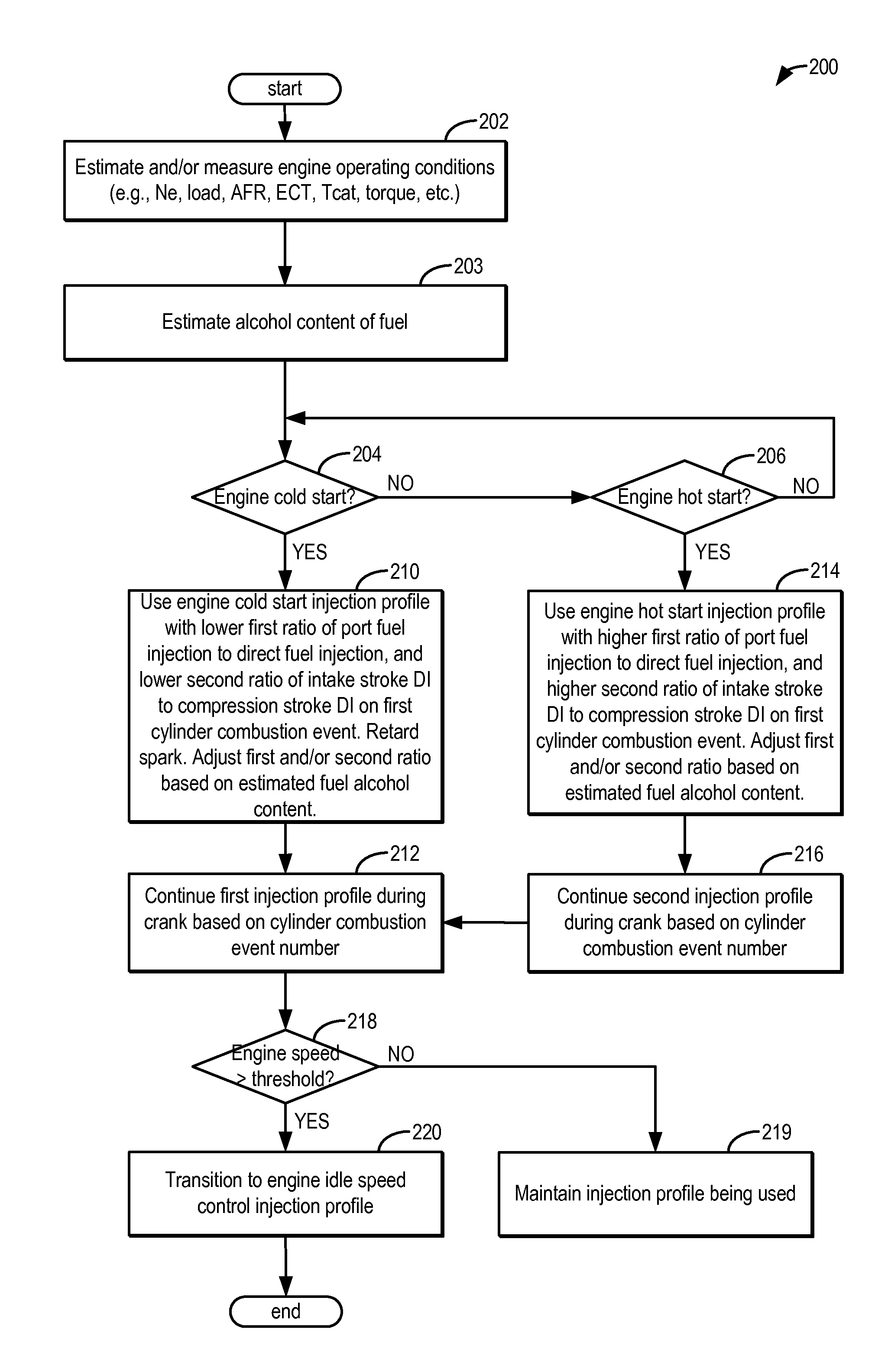

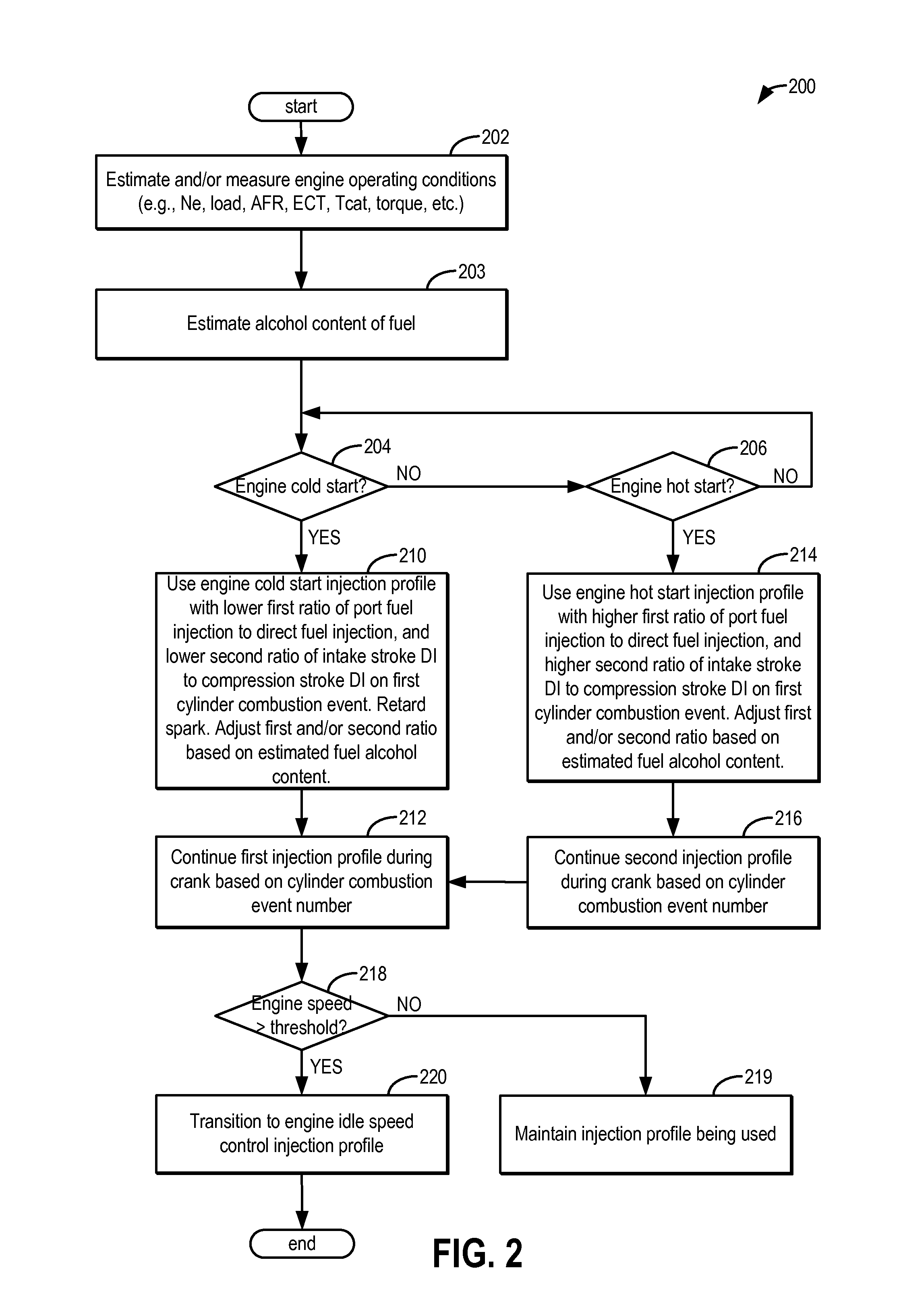

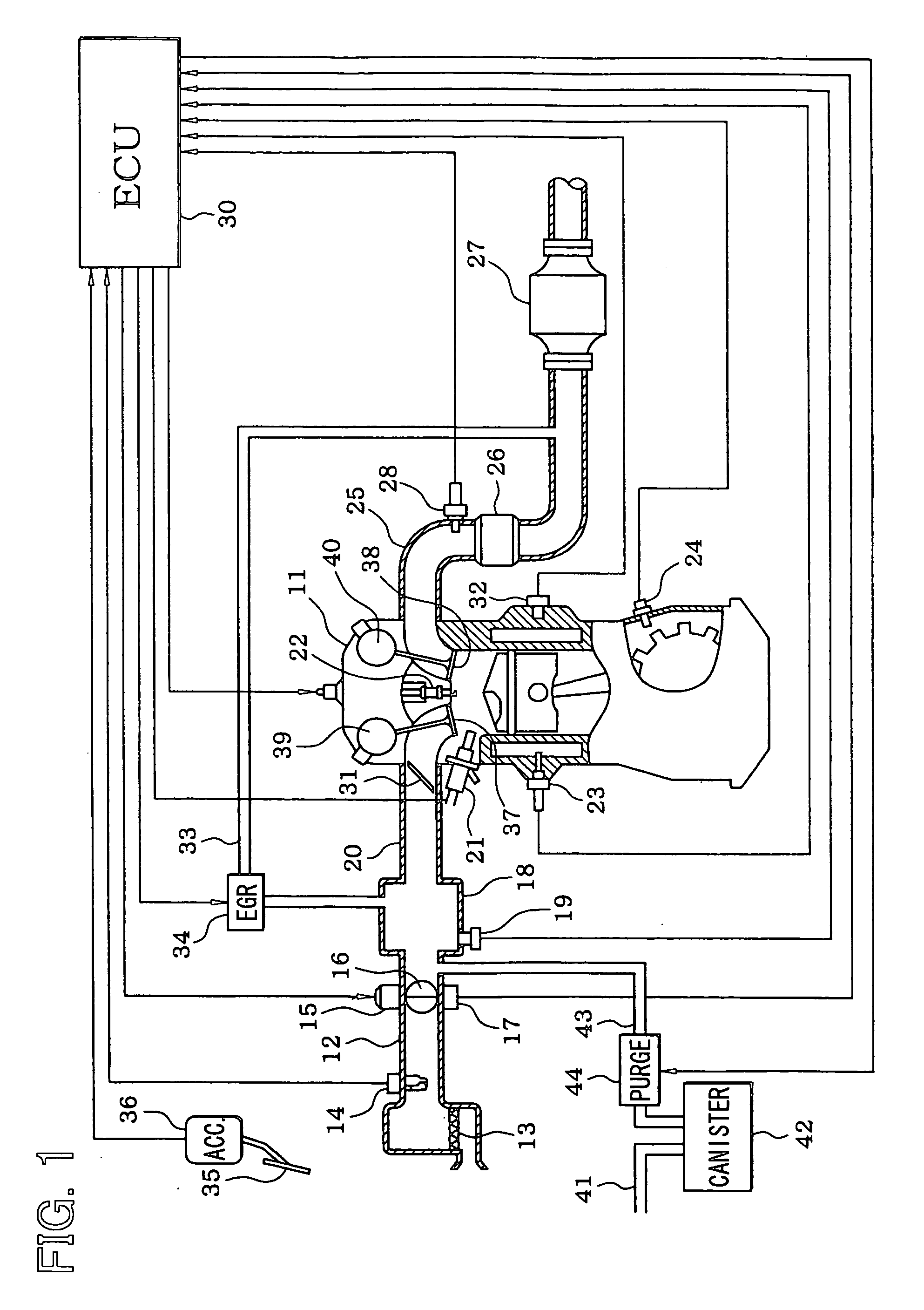

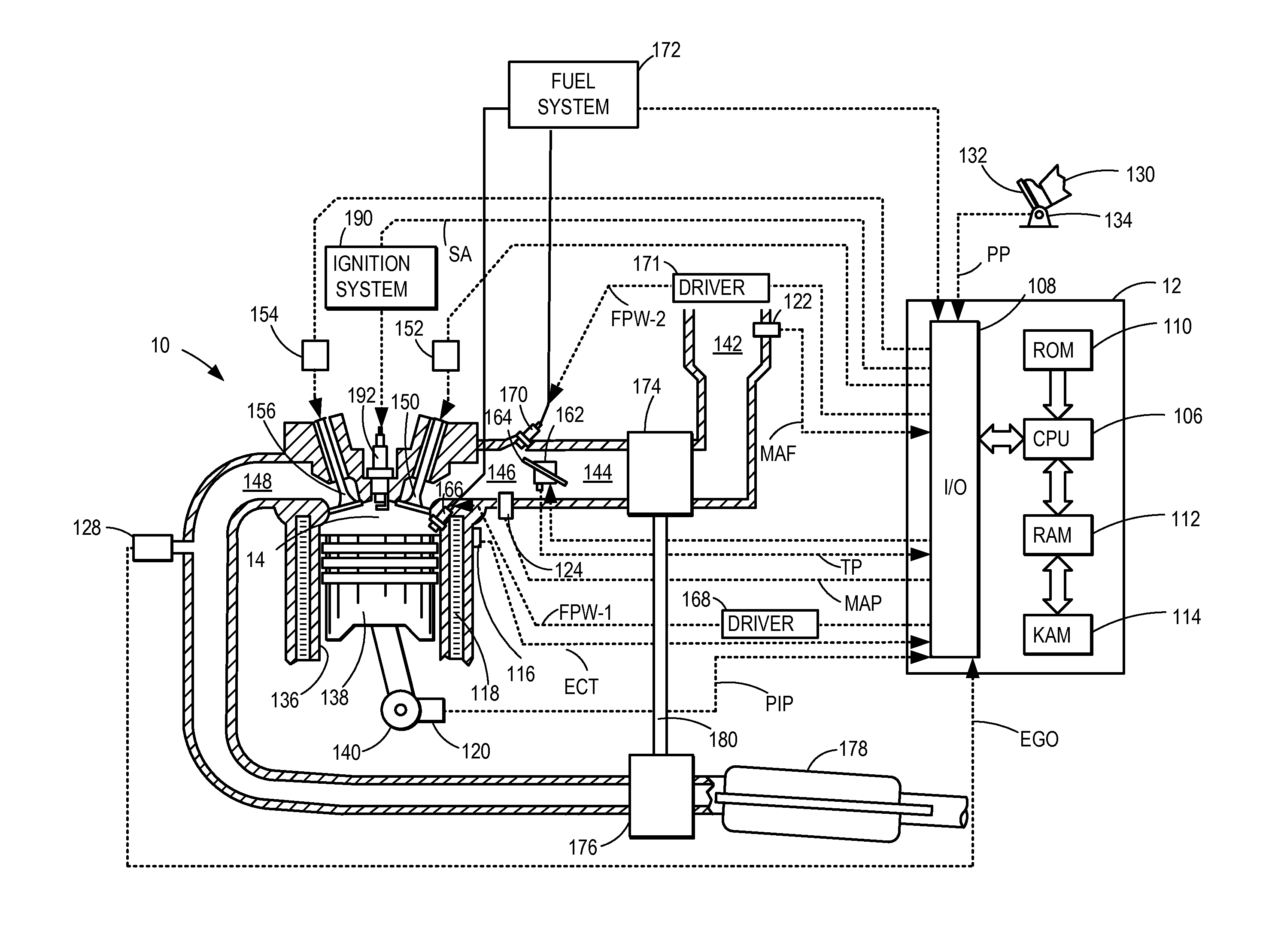

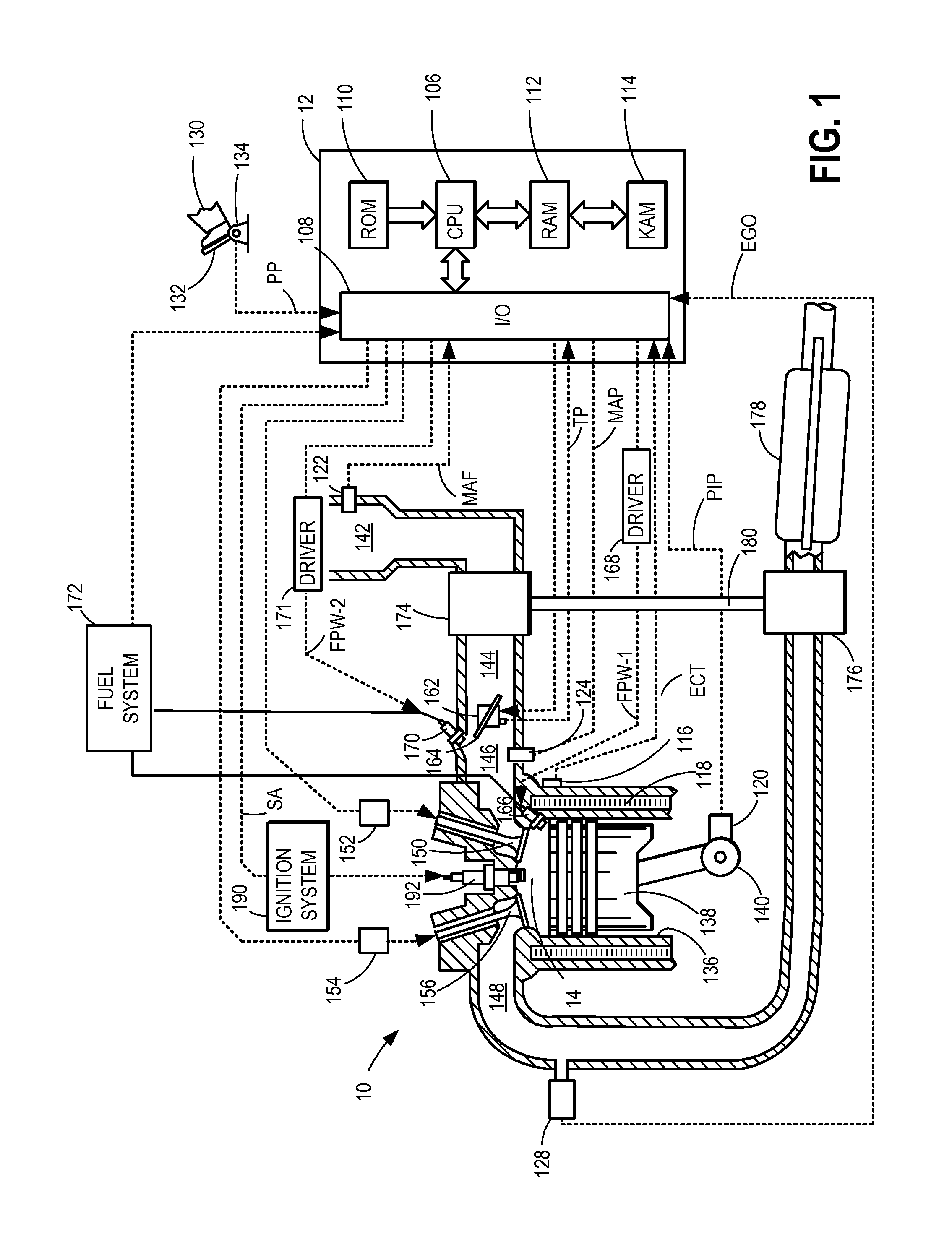

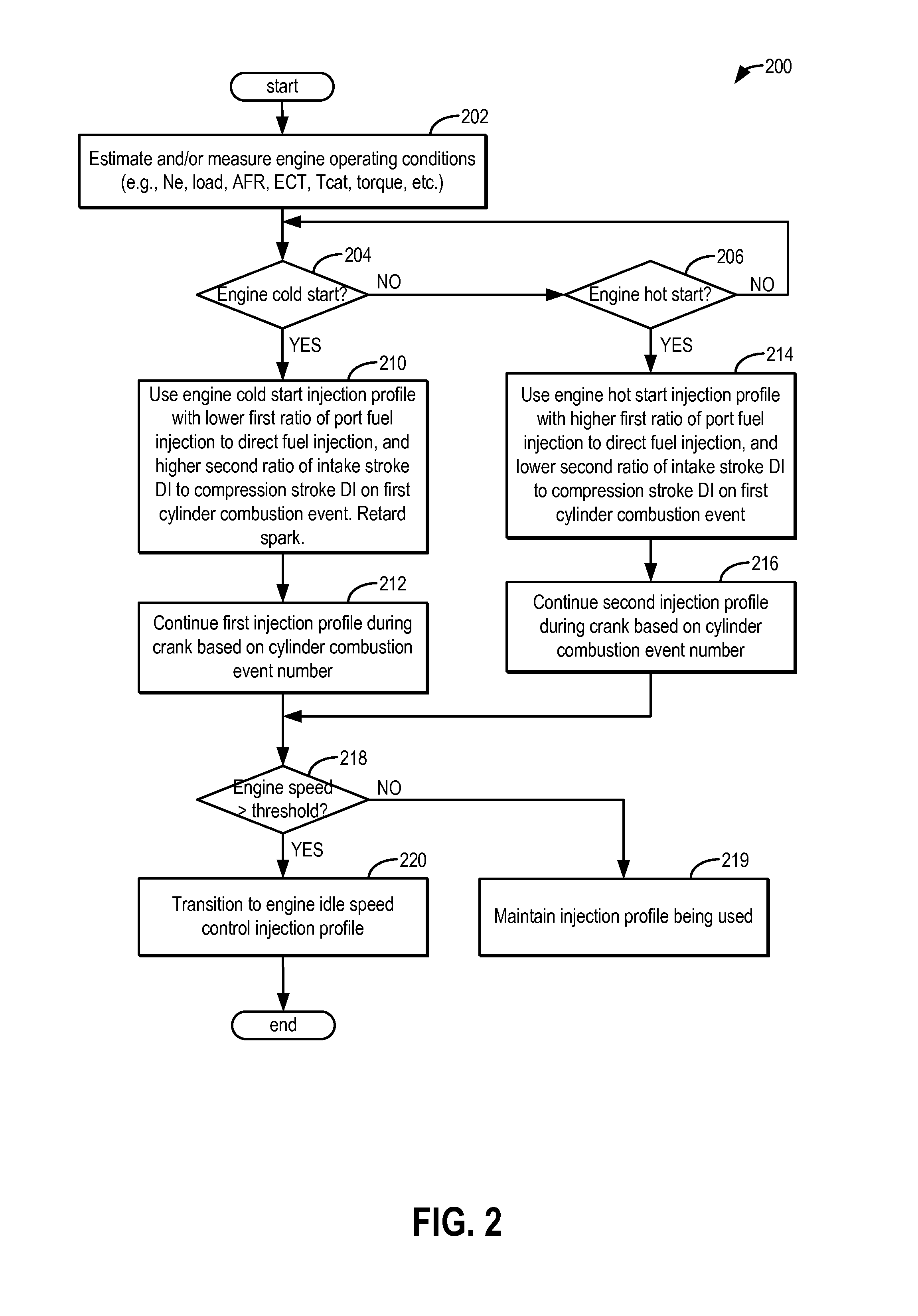

Method and system for engine control

ActiveUS20140297159A1Improve cooling effectIncrease heatValve arrangementsElectrical controlAlcohol contentMultiple injection

Methods and systems are provided for controlling exhaust emissions by adjusting an injection profile for different fuels injected into an engine cylinder from different fuel injectors during engine start and crank. By splitting fuel injection during start and cranking so that fuel of lower alcohol content is port injected and fuel of higher alcohol content is direct injected as one or multiple injections, the soot load of the engine can be reduced and fuel economy can be improved.

Owner:FORD GLOBAL TECH LLC

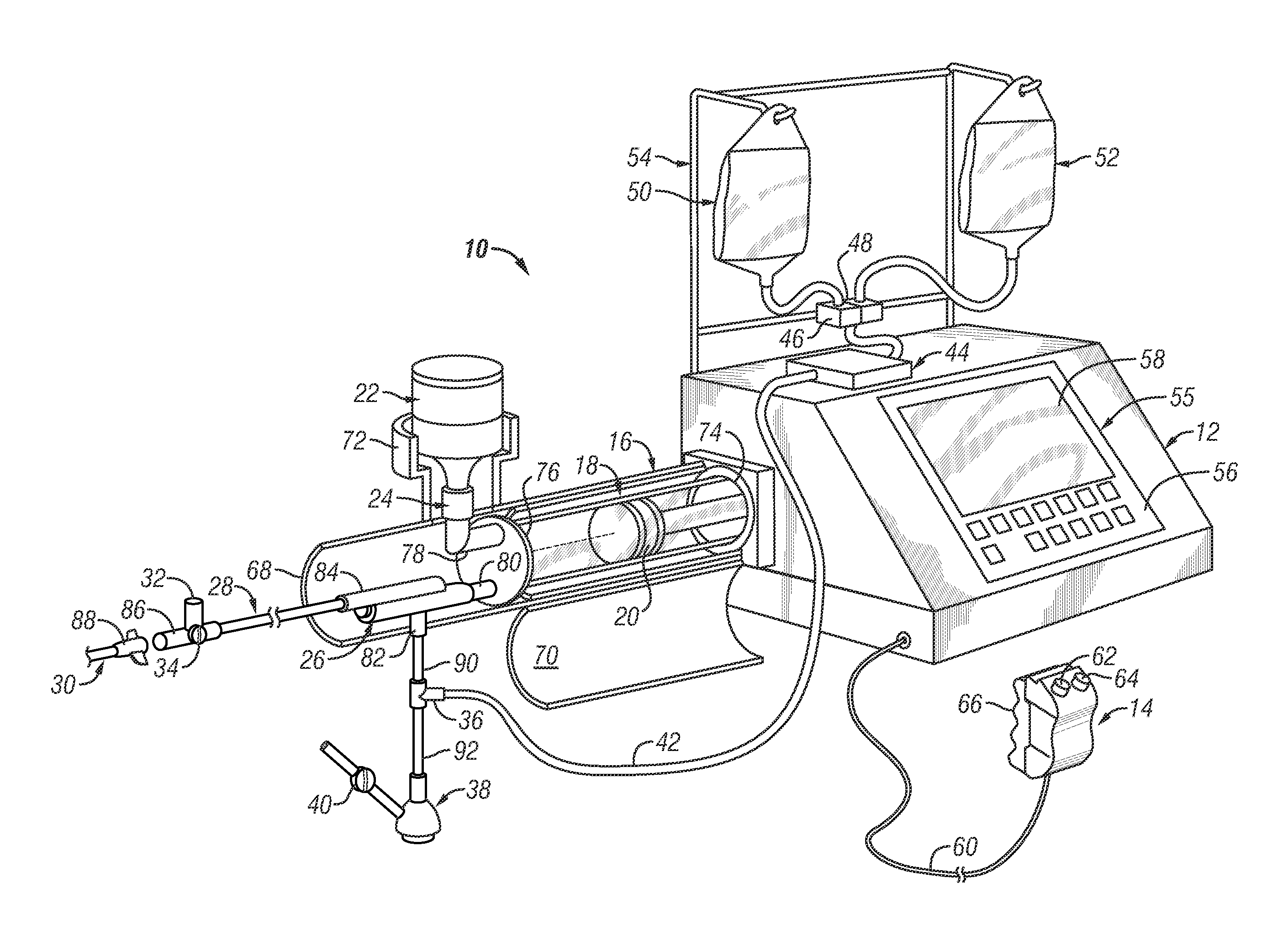

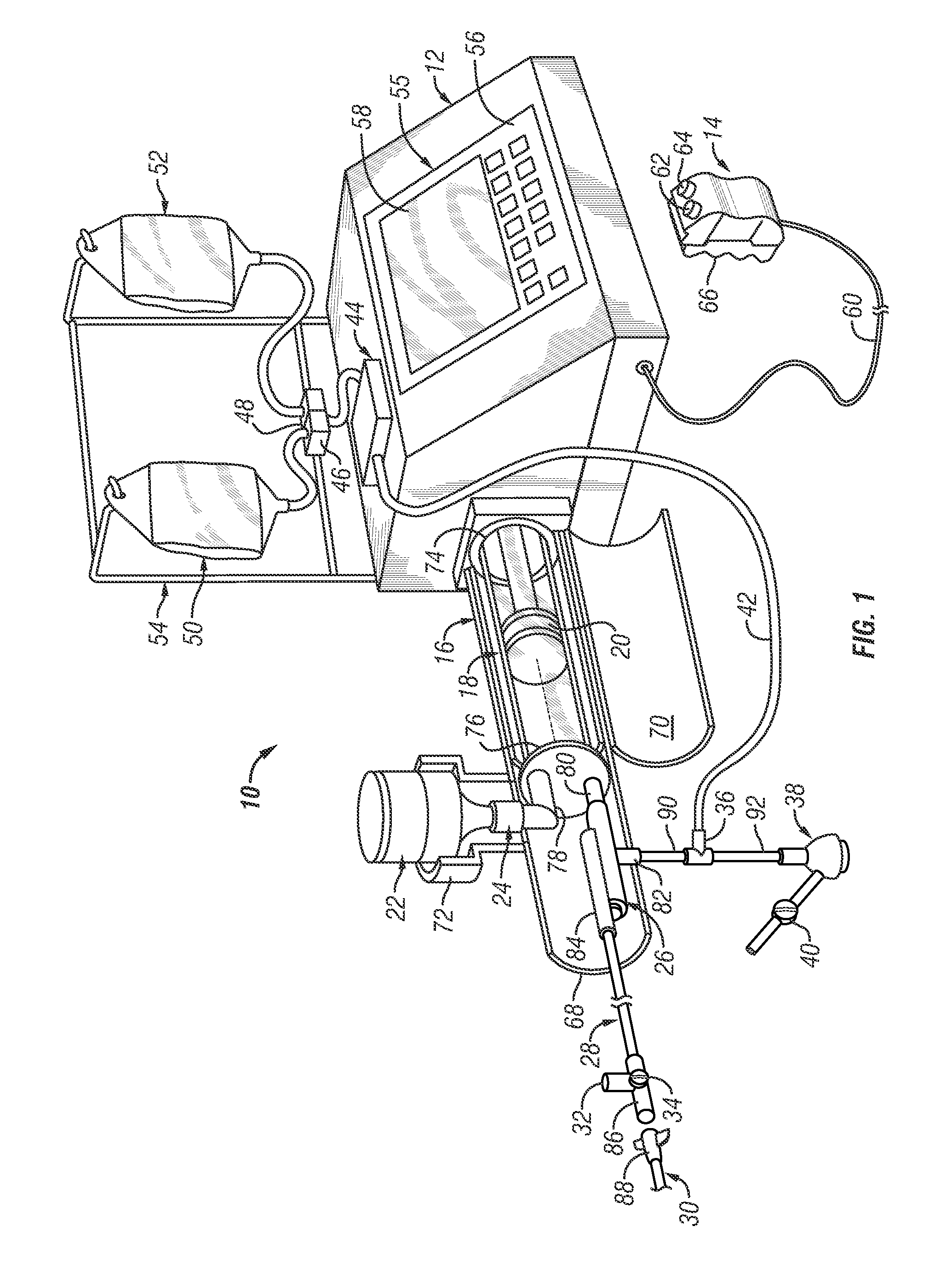

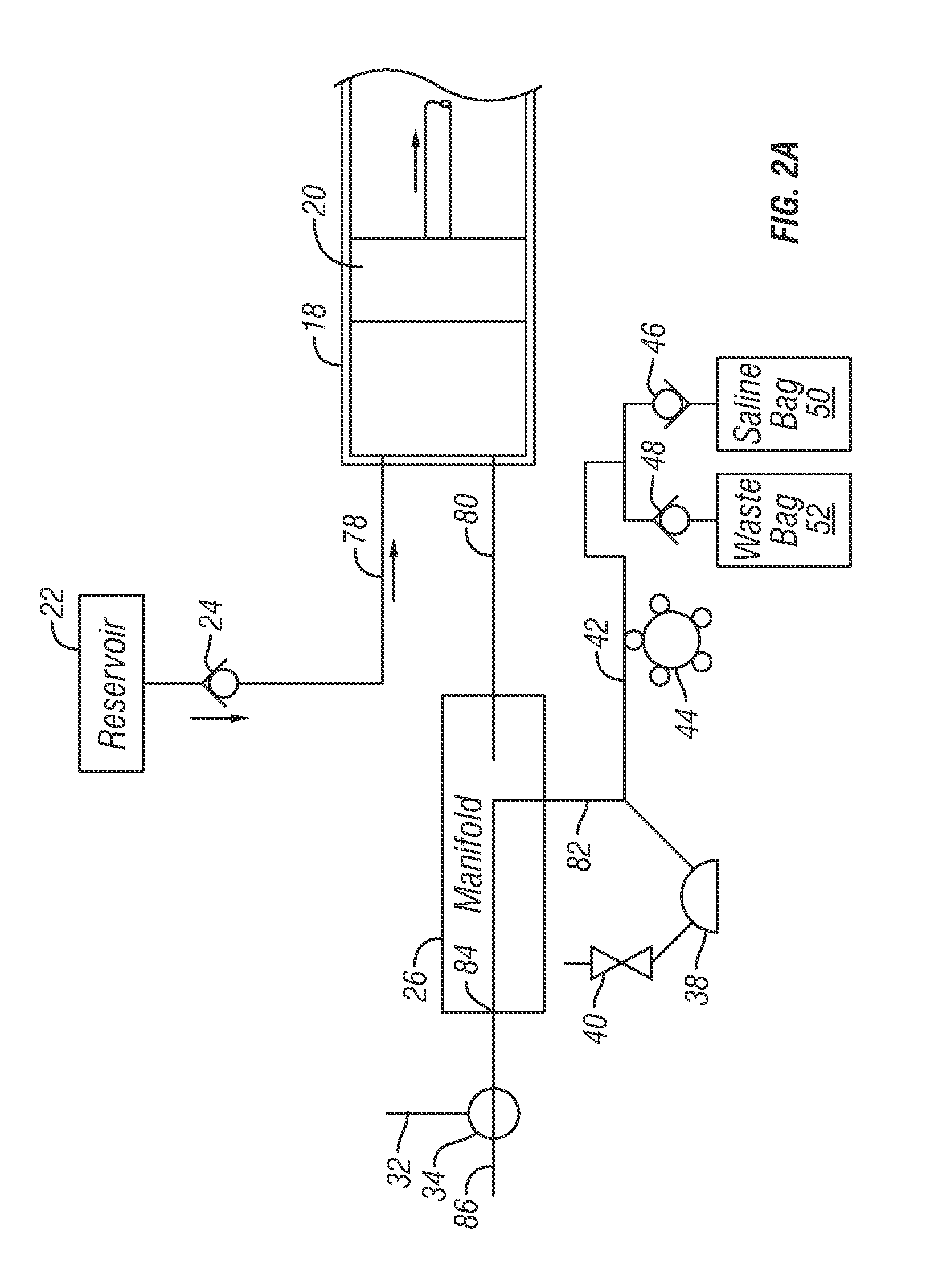

System and method for multiple injection procedures on heart vessels

InactiveUS8082018B2Readily and accurately permittedFlexible and user friendlyElectrotherapyElectrocardiographyMultiple injectionOperation mode

An angiographic injector system and a method of controllably delivering medical fluid to a patient from an angiographic injector system are disclosed. A multiple processor control system is used to actively control the injection process and to monitor sensed functions of the system. The multiple processors provide dual redundancy safety circuits for critical control functions such as syringe motor drive speed and current. A motor / servo-amplifier nested control function is also disclosed. A unique method and apparatus are disclosed for establishing injection parameter default values just prior to an injection procedure that are based on physiological values of the patient to be treated. The injector system uses an interactive display panel that presents sequenced set-up screens to the user and which enables the user to select injection procedures, parameters and other modes of operation directly through the interactive panel.

Owner:ACIST MEDICAL SYST

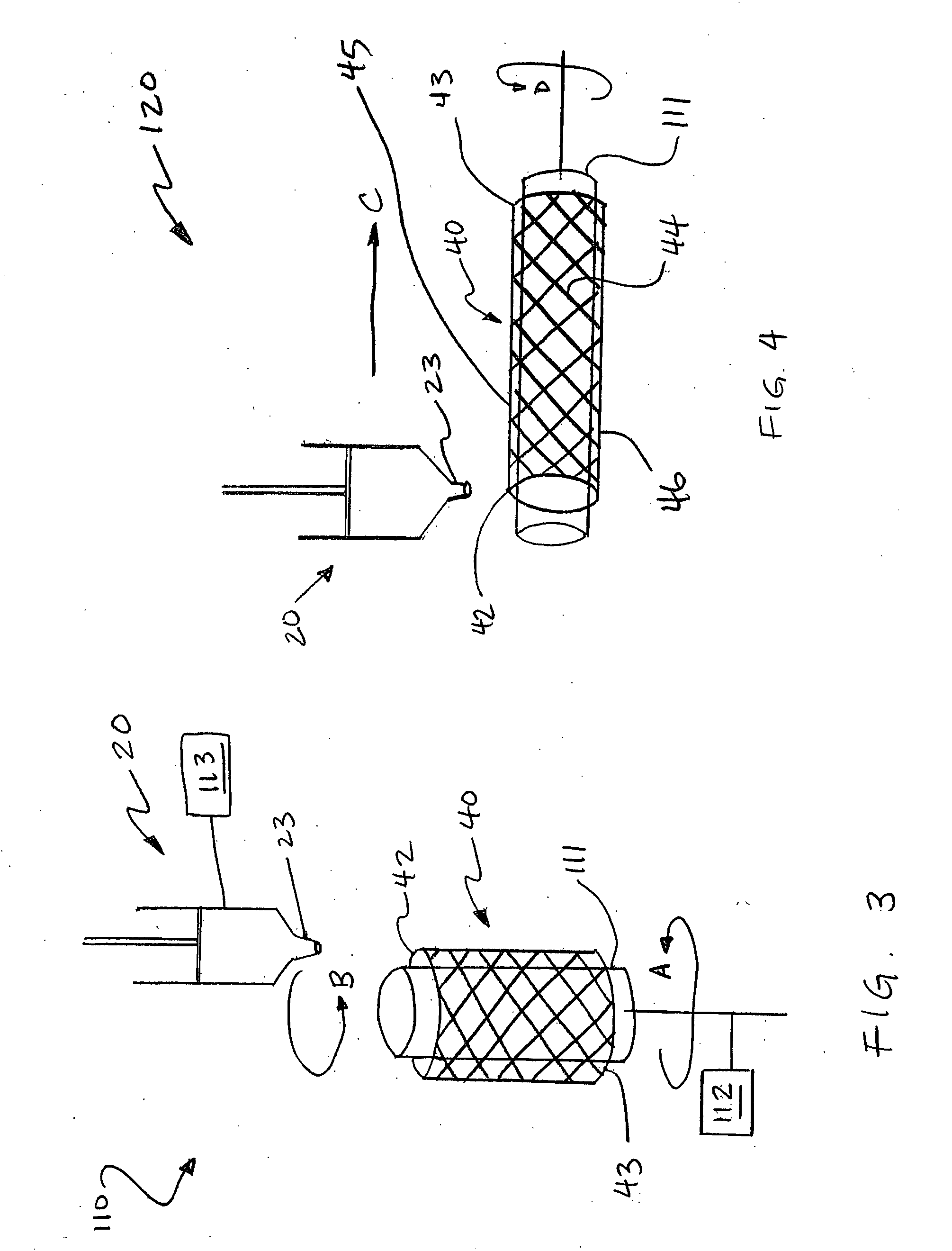

Method and system for engine control

ActiveUS20140297162A1Improve cooling effectIncrease heatElectrical controlInternal combustion piston enginesAlcohol contentMultiple injection

Methods and systems are provided for controlling exhaust emissions by adjusting an injection profile for fuel injected into an engine cylinder from a plurality of fuel injectors during engine start and crank. By splitting injection of fuel during start so that a portion of fuel is port injected and a remaining portion is direct injected as one or multiple injections, the soot load of the engine can be reduced and fuel economy can be improved. The injections are adjusted based on the alcohol content of the injected fuel to take advantage of the charge cooling properties of the fuel.

Owner:FORD GLOBAL TECH LLC

High pressure pre-burst for improved fluid delivery

ActiveUS20090326439A1Little fall timeLittle rise timeUltrasound therapyElectrotherapyMultiple injectionInjection port

A needle with multiple injection ports is used in connection with a high-pressure injection system to infuse a treatment solution into a treatment area below the dermis of the skin. The needle has multiple tines that extend outwardly from the injection ports while inside the treatment area to disrupt tissue in the treatment area and to create multiple pathways of infusion. The tines are withdrawn and the needle is partially withdrawn, and solution is injected from the needle into the treatment area at high pressure to infuse the tissue within the treatment area. The burst, infusion, and a treatment such as an energy or third solution may be interleaved and repeated multiple times.

Owner:ULTHERA INC

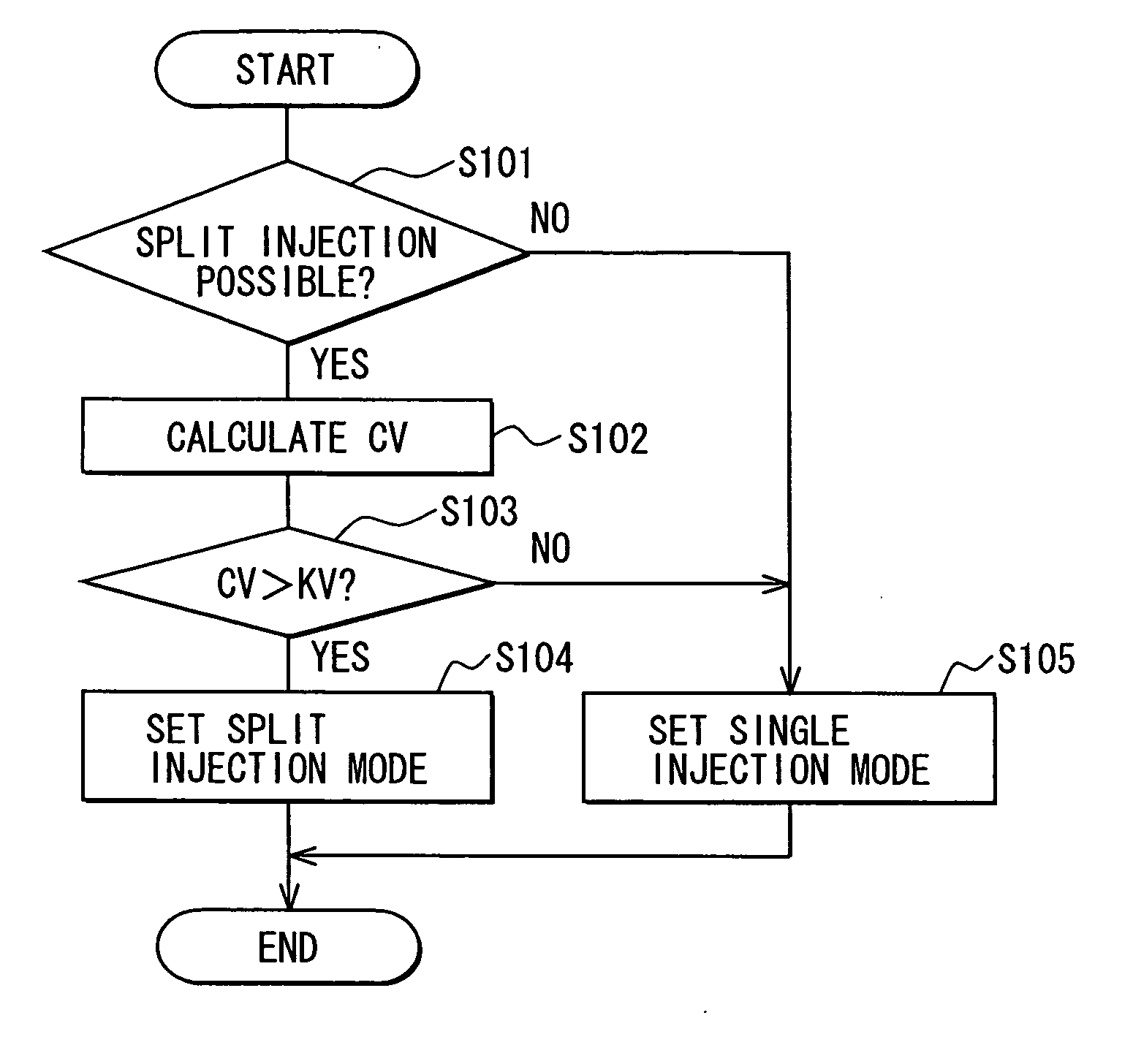

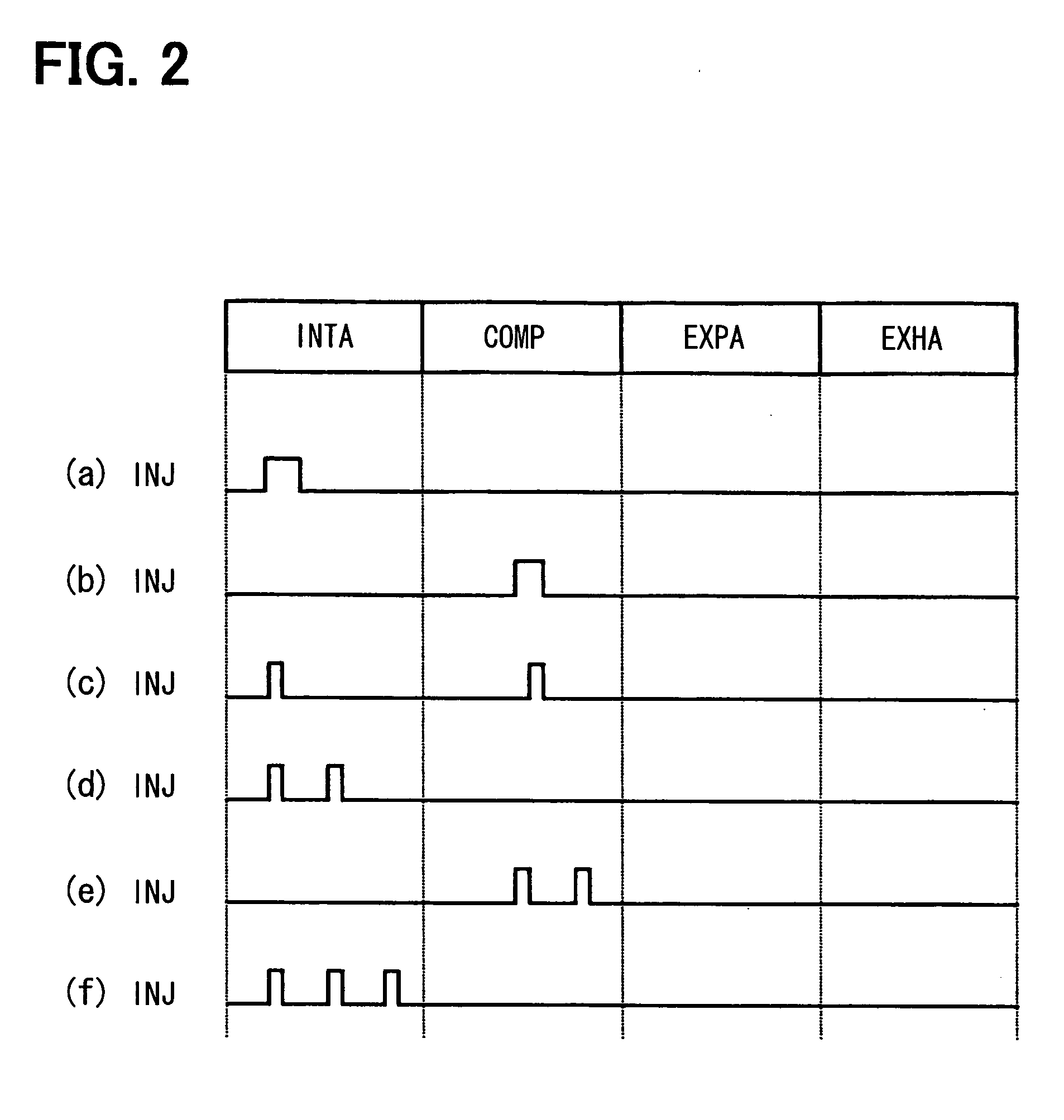

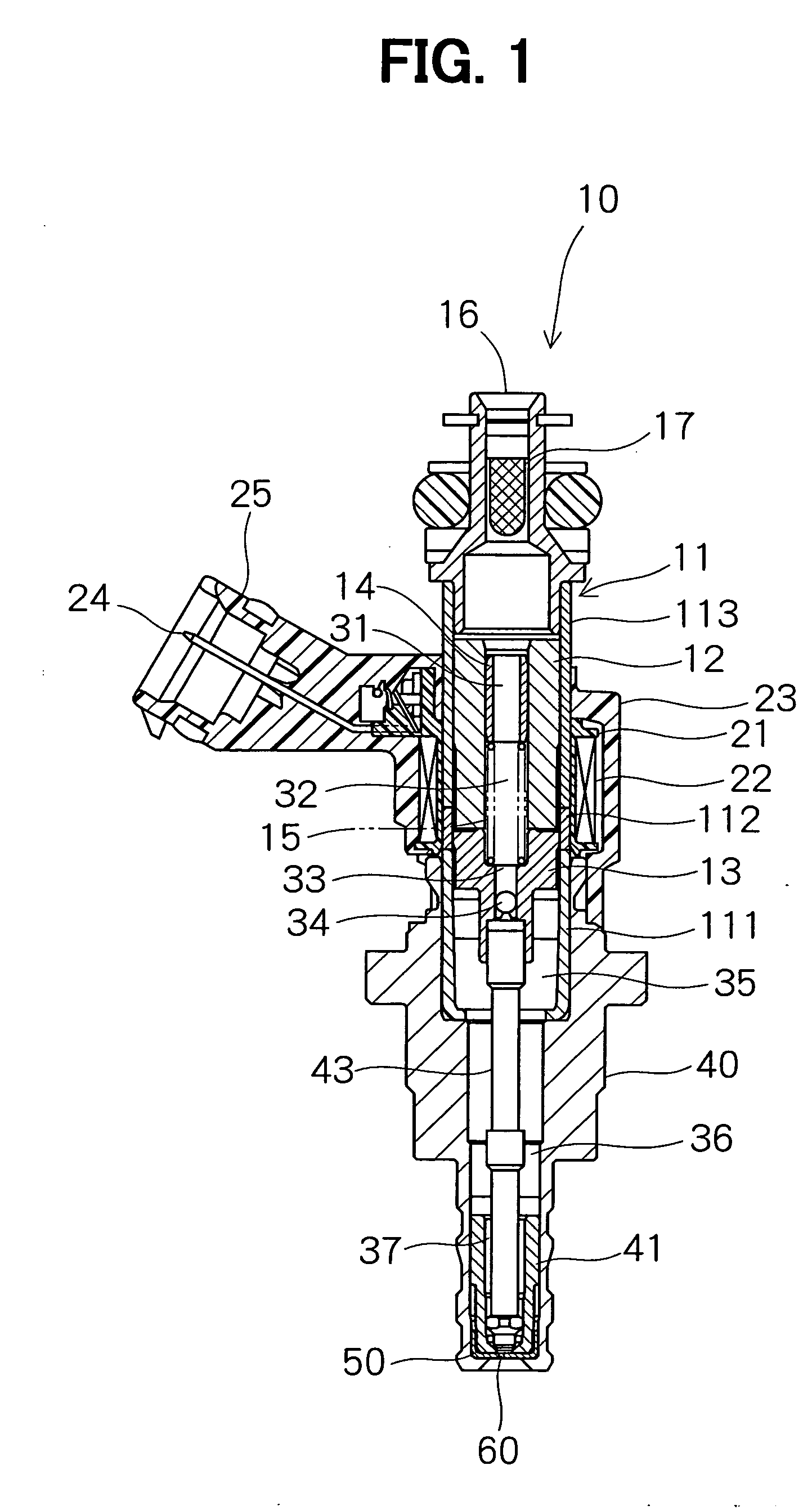

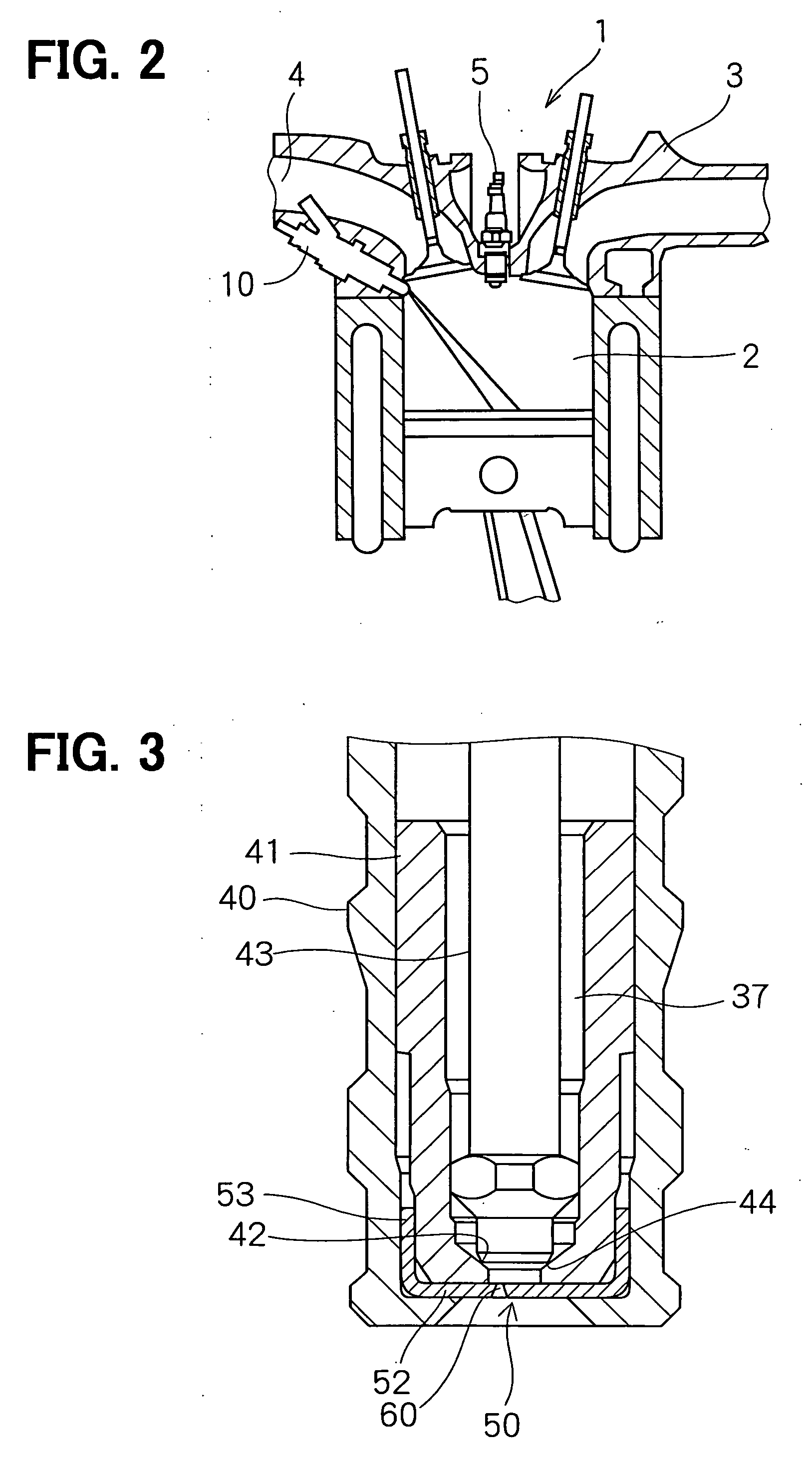

Fuel injection controller for in-cylinder injection engine

InactiveUS20060243243A1Improve the state of combustionEmission reductionElectrical controlInternal combustion piston enginesMultiple injectionCombustion

A fuel injection controller of an in-cylinder injection engine determines that a combustion state has deteriorated and executes a split injection for injecting fuel in split amounts into each cylinder in multiple injection events in a cycle of the cylinder if it is determined that a combustion fluctuation is greater than a predetermined determination value during operation of the engine. The fuel injection controller increases a ratio of an injection amount of the first injection event in the split injection and lengthens an injection interval between the injection events as the combustion fluctuation increases. Thus, a wet amount of the injected fuel is reduced to expedite atomization of the injected fuel and to homogenize an in-cylinder mixture gas. As a result, the combustion state is improved.

Owner:DENSO CORP

Multiple-injection medical apparatus

InactiveUS20110218497A1Limited amountHighly efficient and simple to useAutomatic syringesSurgeryMultiple injectionBiomedical engineering

Owner:ASSAF ANTOINE

Preparation method of an in situ pore-forming self-setting calcium phosphate composite tissue engineering scaffold

The invention discloses a making method of composite tissue engineering rack of original poring self-solidifying calcium phosphate, which comprises the following steps: placing porous rack of calcium phosphate cement into drier to dry; immersing porous rack into macromolecular solution; extracting into vacuum for 0.5-6h; injecting macromolecular material into the pore of porous rack of calcium phosphate cement; drying the surface of porous rack through filter paper; pre-freezing under -60- -4 deg.c for 1-48h; drying the frozen material to do multiple injections until the pore is filled with cement; obtaining the product.

Owner:SOUTH CHINA UNIV OF TECH

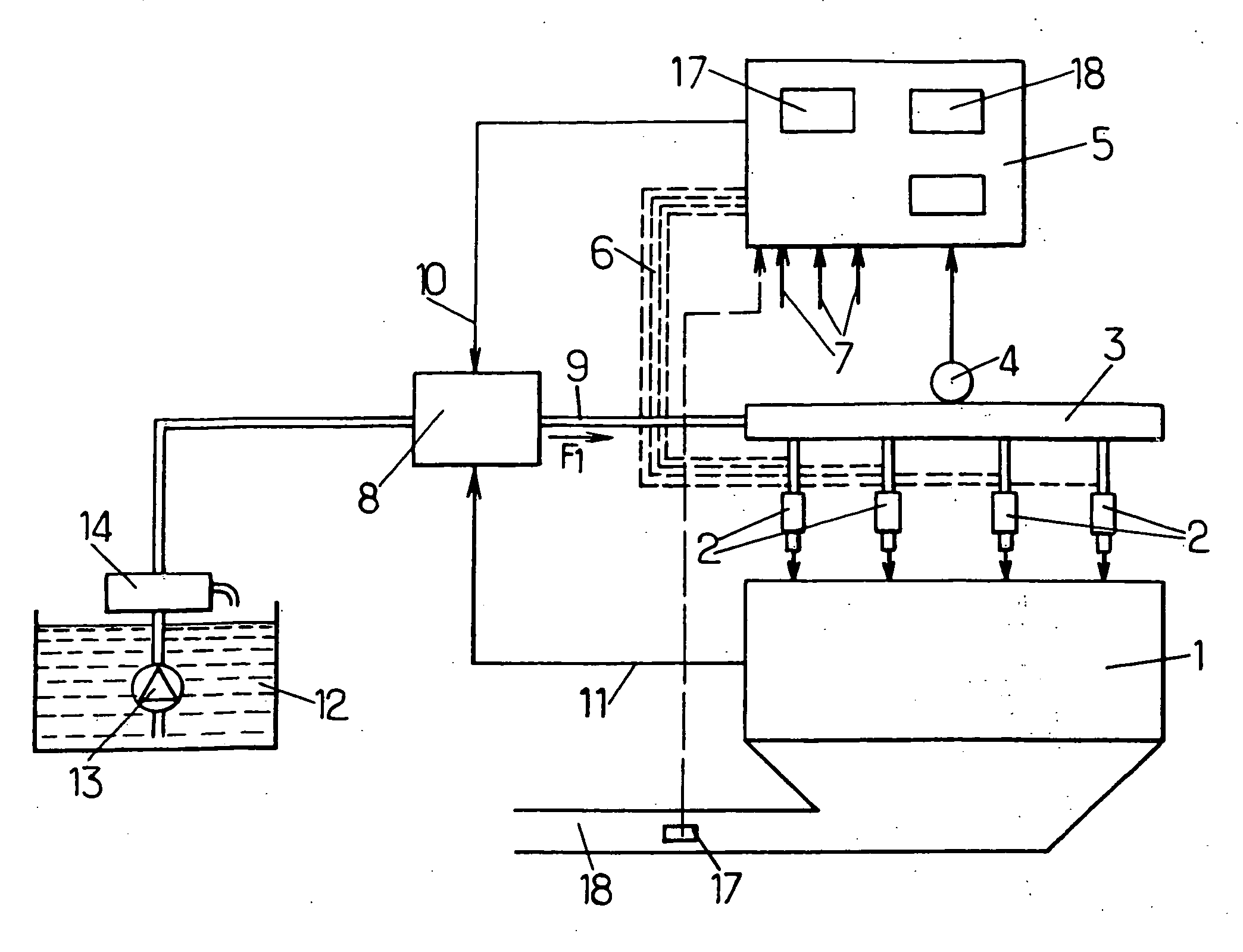

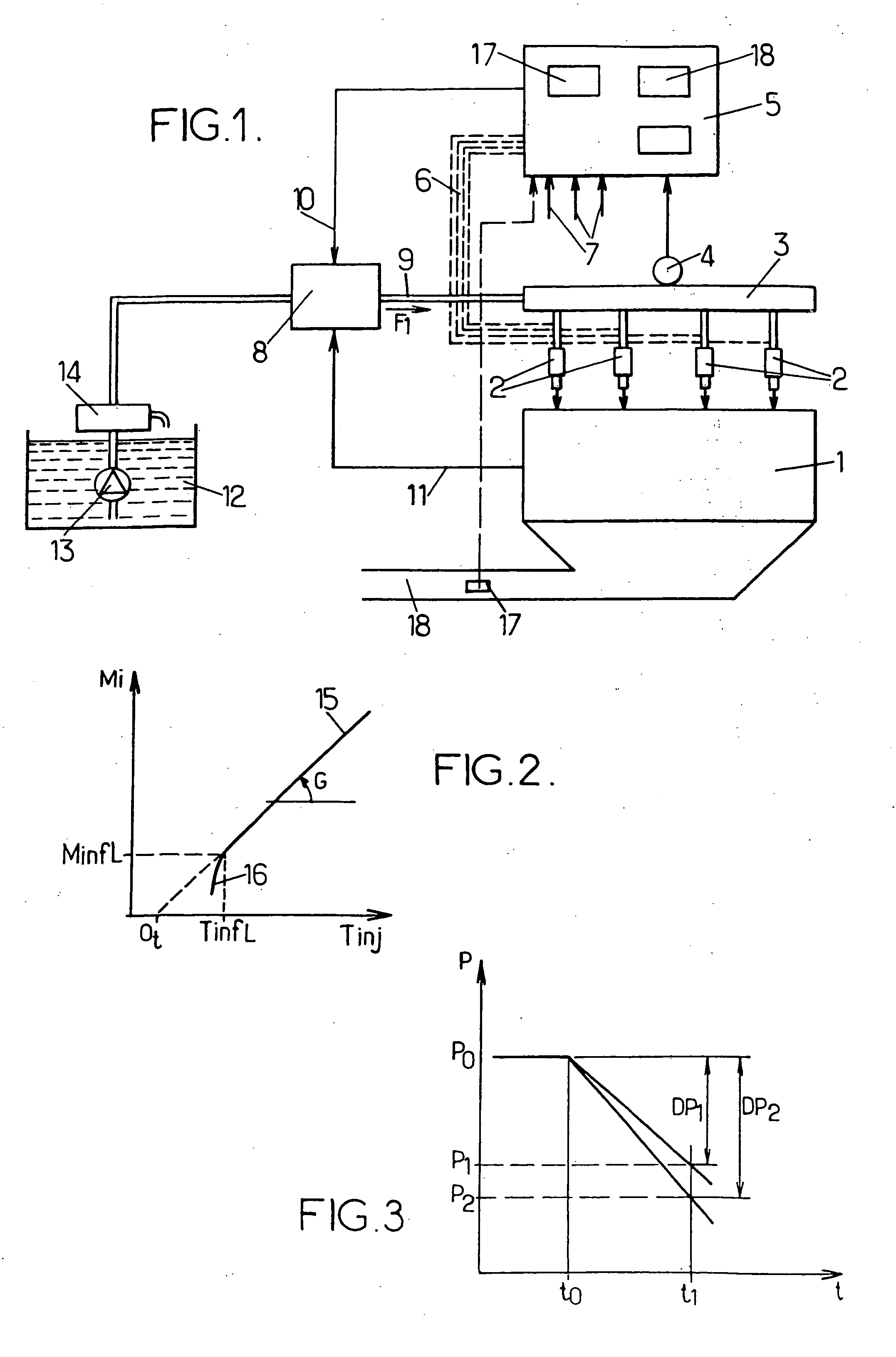

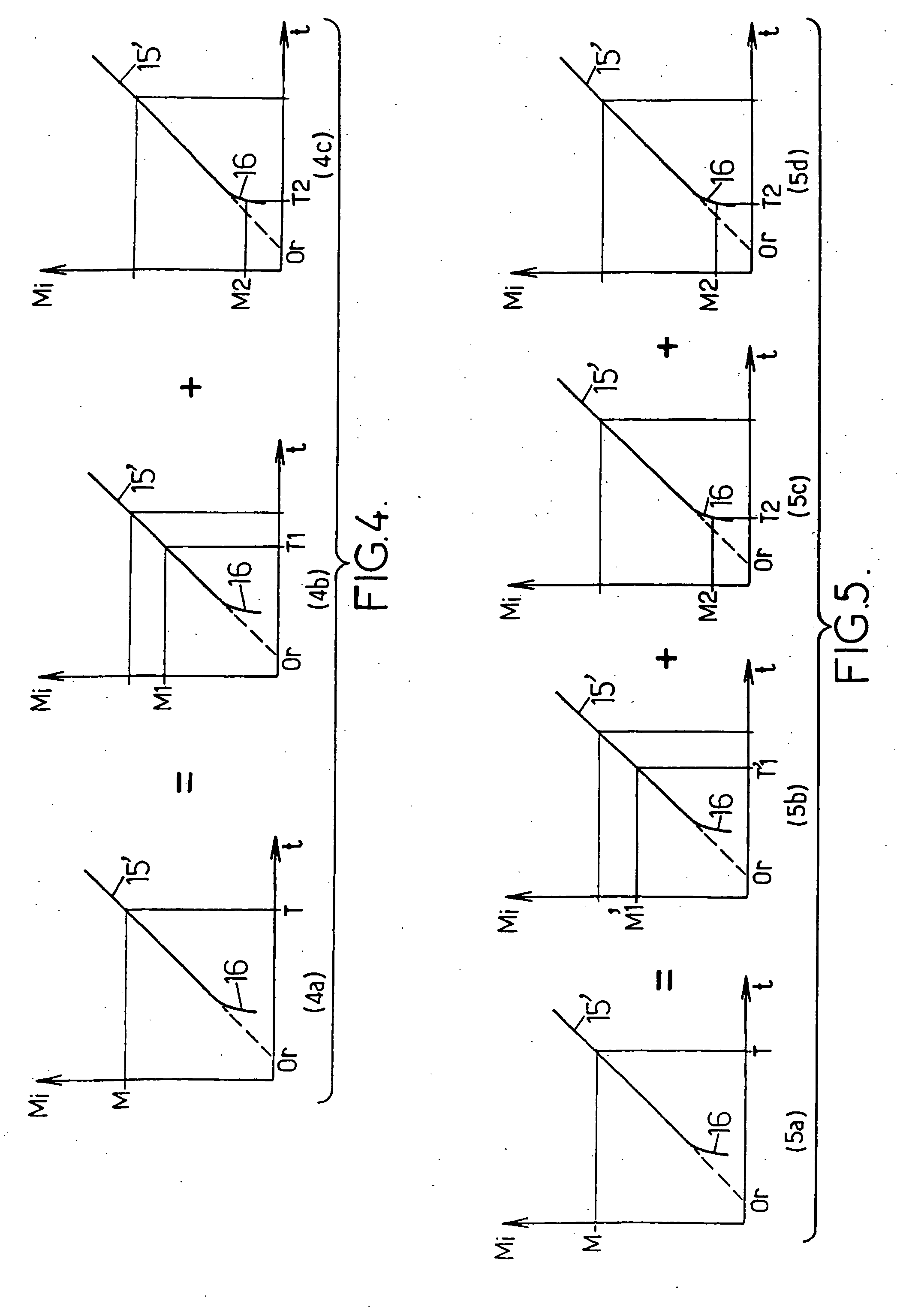

Method of determining in real time the flow rate characteristic of a fuel injector

ActiveUS20060107936A1Good knowledgeEasy to controlElectrical controlInternal combustion piston enginesMultiple injectionCombustion

The method comprises the steps consisting in assuming that the gain of at least one injector is equal to a theoretical gain or an updated gain, and in replacing each of at least one reference injection of injection control duration controlled by the engine control unit in application of a stored characteristic, with a multiple injection comprising a succession of at least two injections of injection control durations that are assumed to cause the same mass of fuel to be injected as by the replaced reference injection, in determining the fuel mass difference between the reference injection and the multiple injection, in deducing therefrom an error in determining the characteristic, and in modifying the gain and / or the offset of the linear zone of the initial characteristic or at least a table or mathematical relationship for the non-linear zone of said characteristic, so as to compensate the error, and storing the new characteristic as determined in this way. Applications to real time determination as a function of the injection control duration of the flow rate characteristic of fuel injectors for internal combustion engines fed by injection.

Owner:MAGNETI MARELLI MOTOPROPULSION FRANCE

Ice pain management device and method

InactiveUS20050182364A1Relieve painReduce manufacturing costMedical devicesSurgical instrument detailsMultiple injectionInjection site

An inexpensive and disposable cooling device for relieving pain associated with hypodermic injection that can be used with any hypodermic syringe includes a body and a sterile cooling medium within the body. A removable cover closes the body and maintains the sterility of the cooling medium before use. The device can be used to simultaneously cool a number of injection sites, eliminating the additional time required to serially cool the multiple injection sites.

Owner:BURCHMAN COREY A

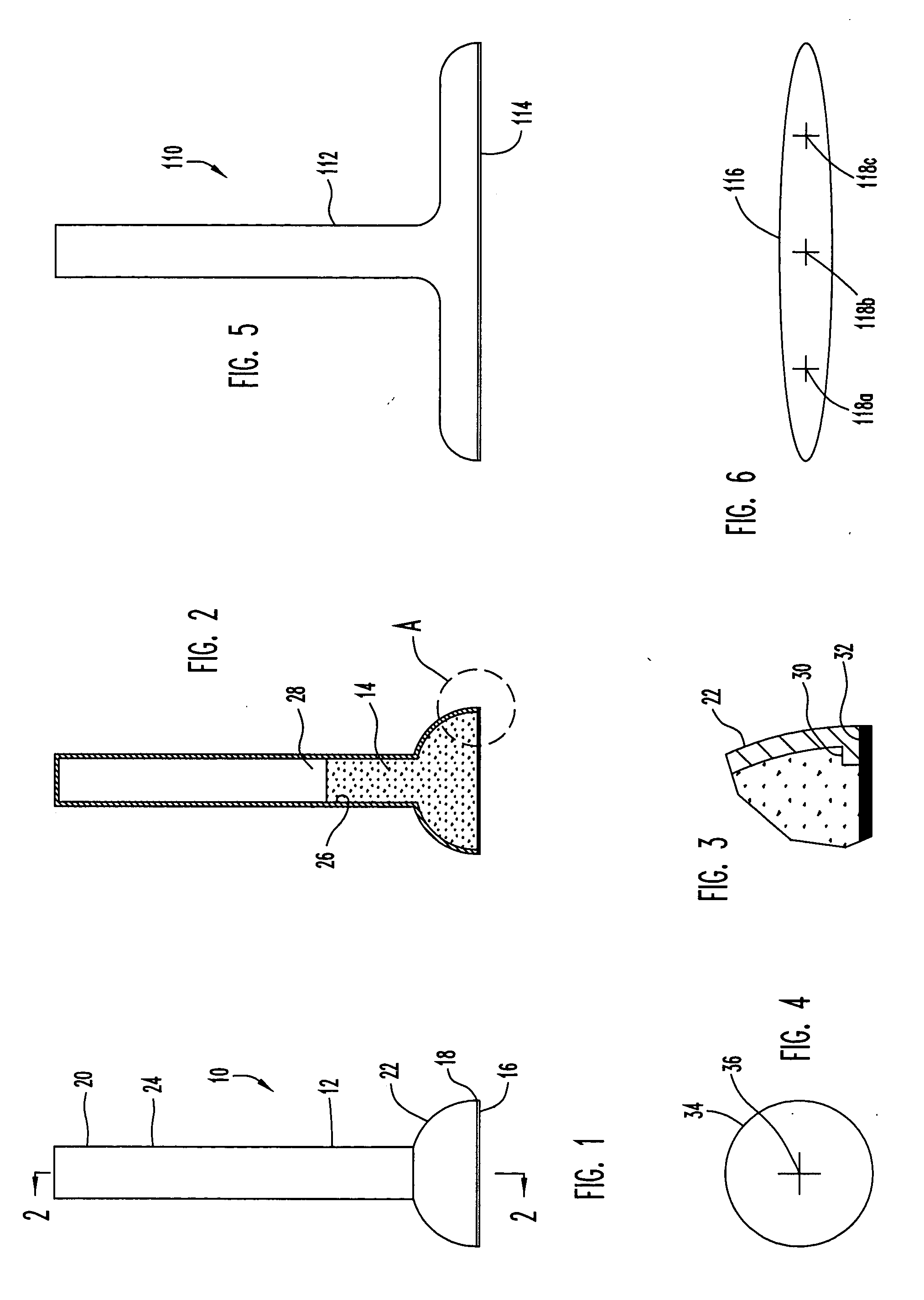

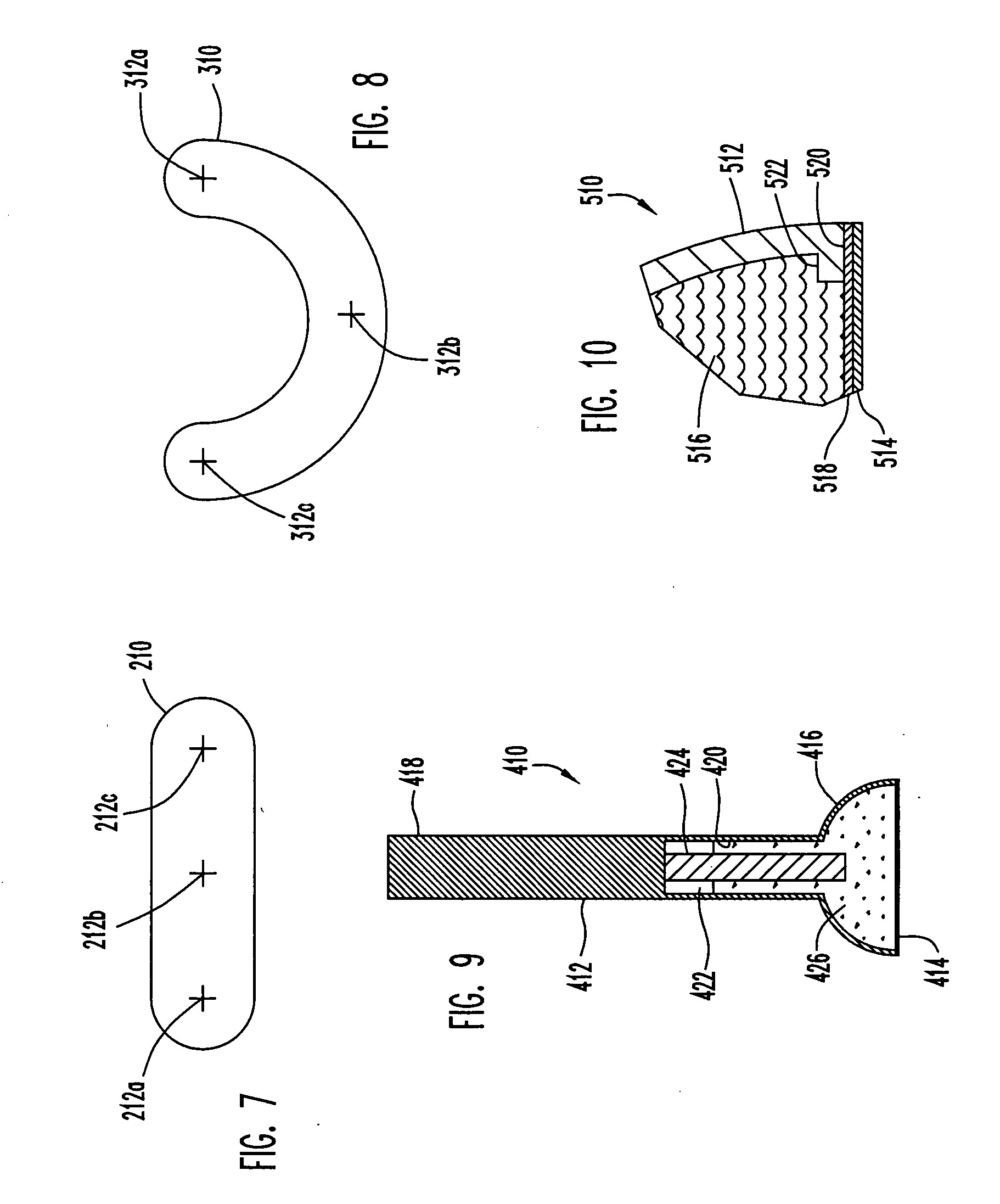

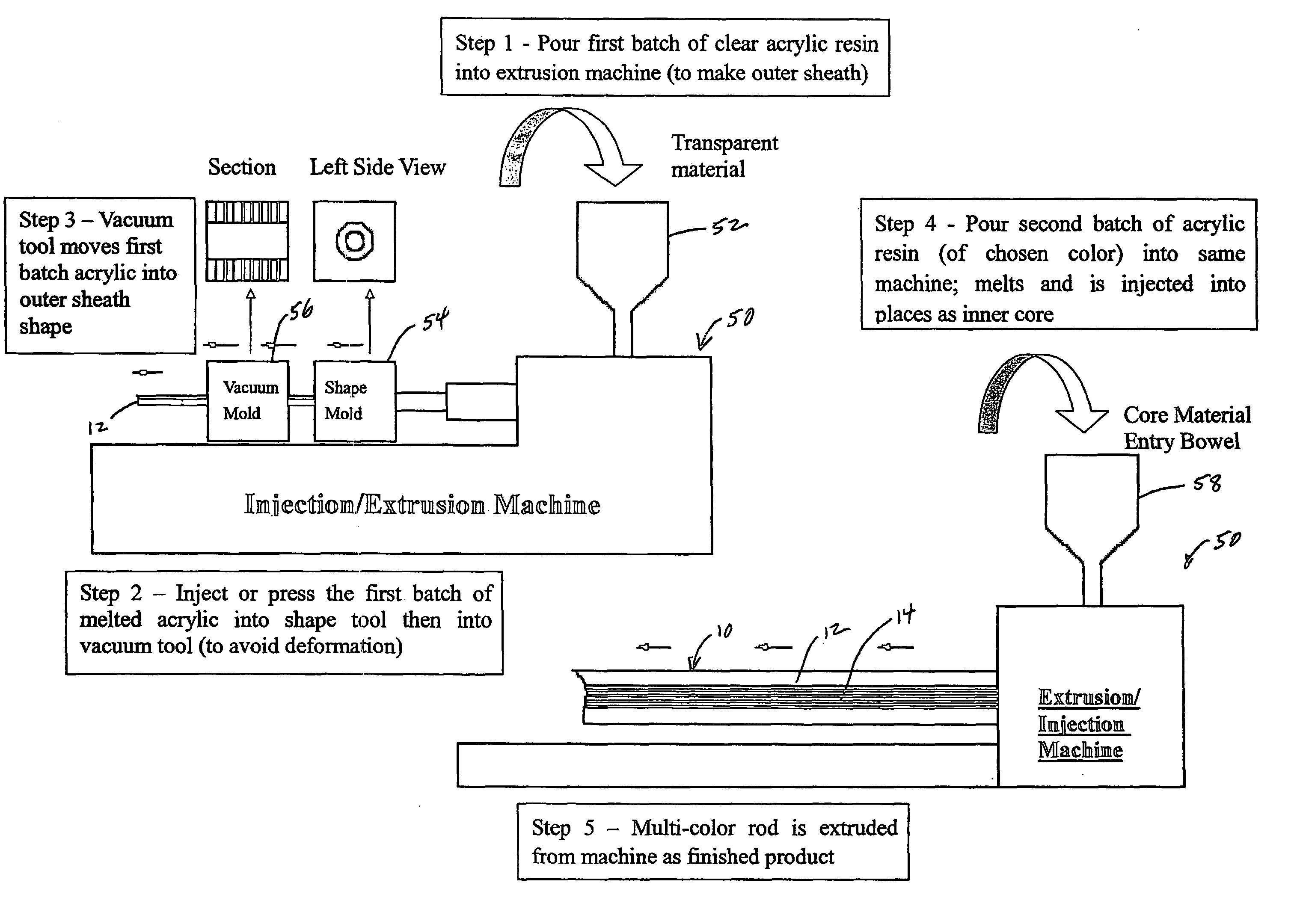

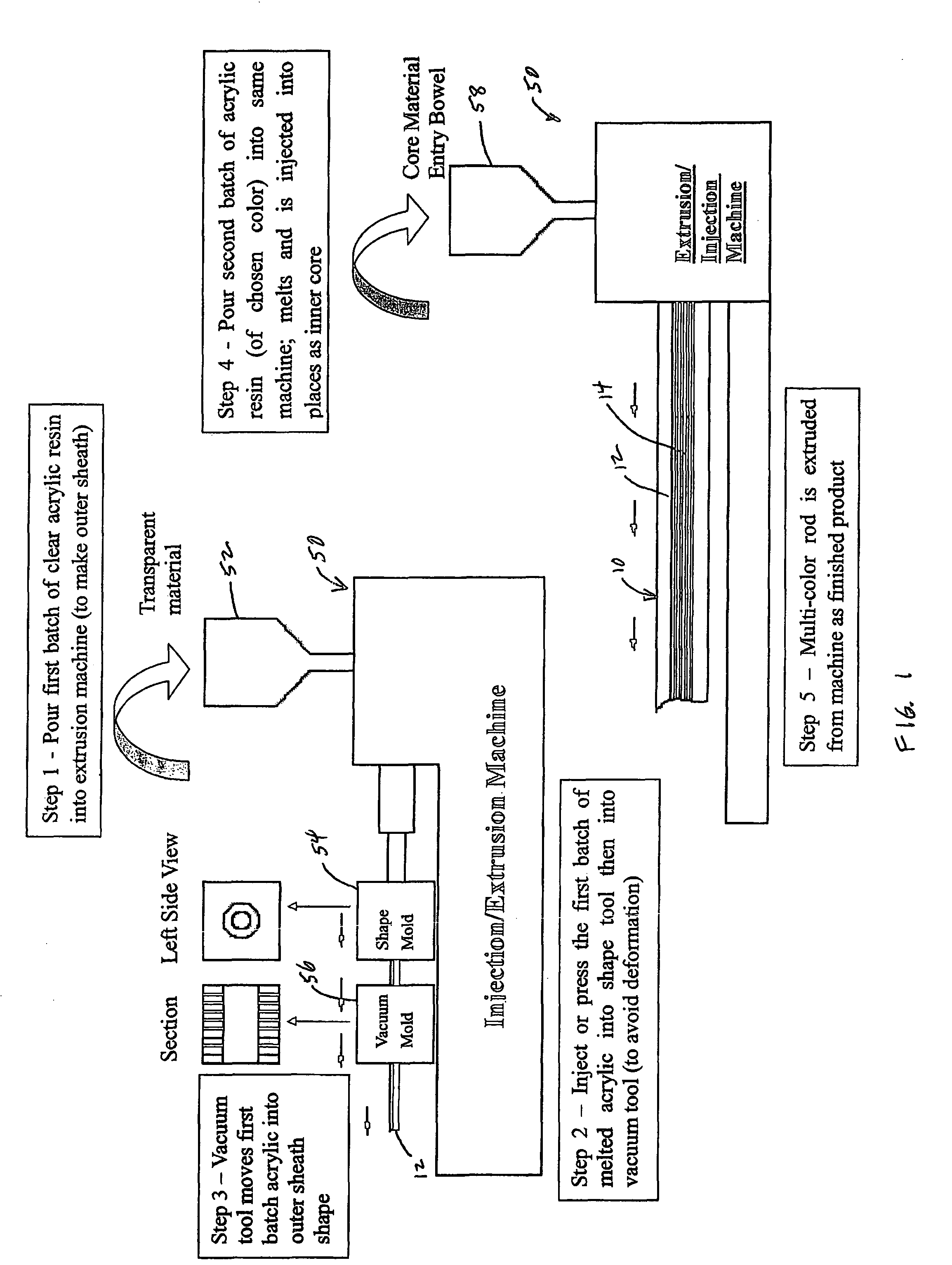

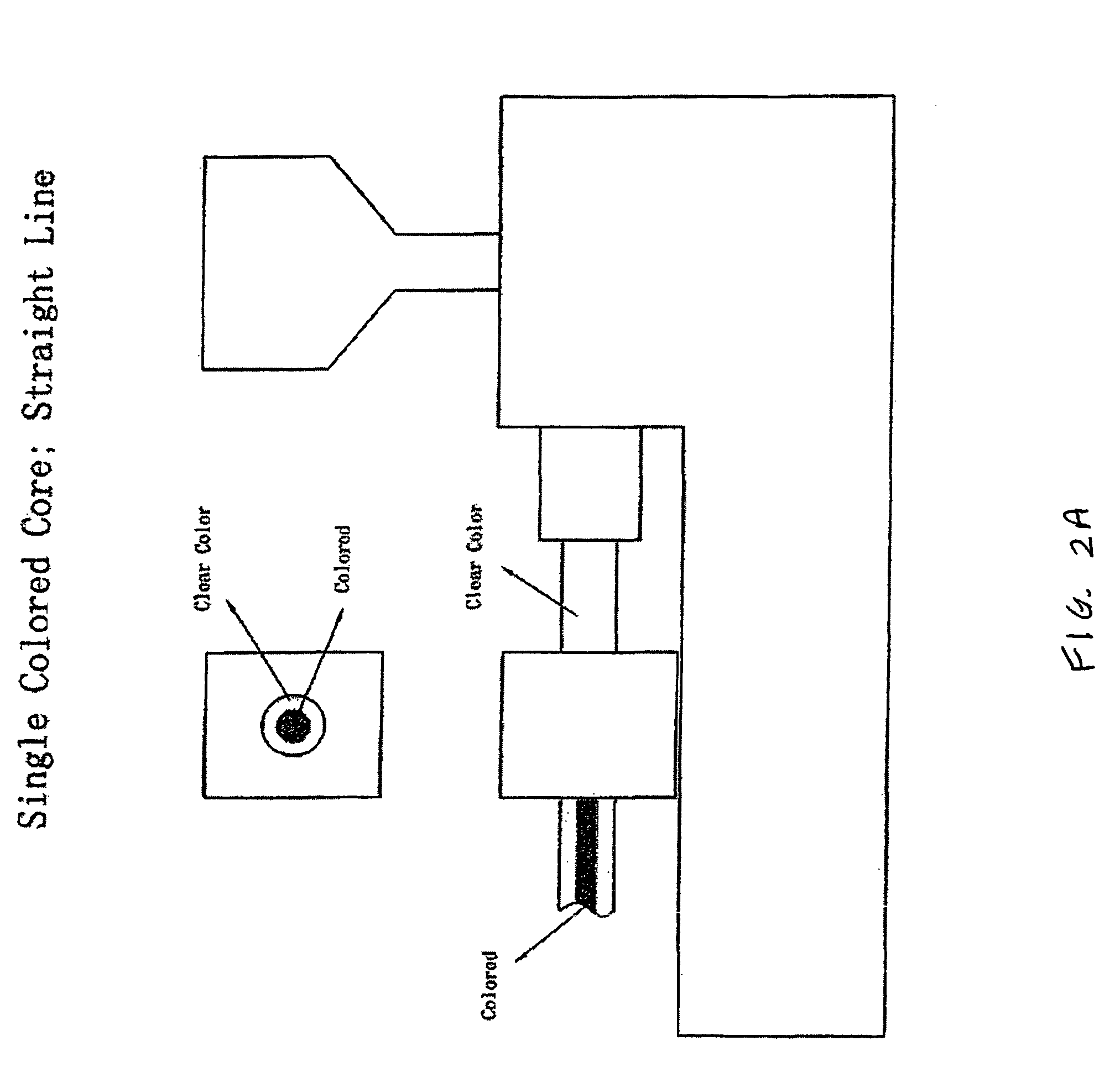

Manufacturing method for multi-color extruded acrylic cosmetic brushes and brush handles

Provided is a method for manufacturing a multi-colored acrylic cosmetic brush handle comprising supplying two or more differently colored resins to an extrusion / injection machine, providing the machine with an open multi-chamber tool, extruding the two or more resins through the tool by multiple injection nozzles to form a multi-colored rod, cutting the rod to a desired length; and polishing the outer surface of the rod; and the multi-color cosmetic brush handle produced thereby. Also provided is a method of producing a cosmetic brush including the cosmetic brush handle of the present invention, and the multi-color cosmetic brush produced thereby.

Owner:ANISA INT

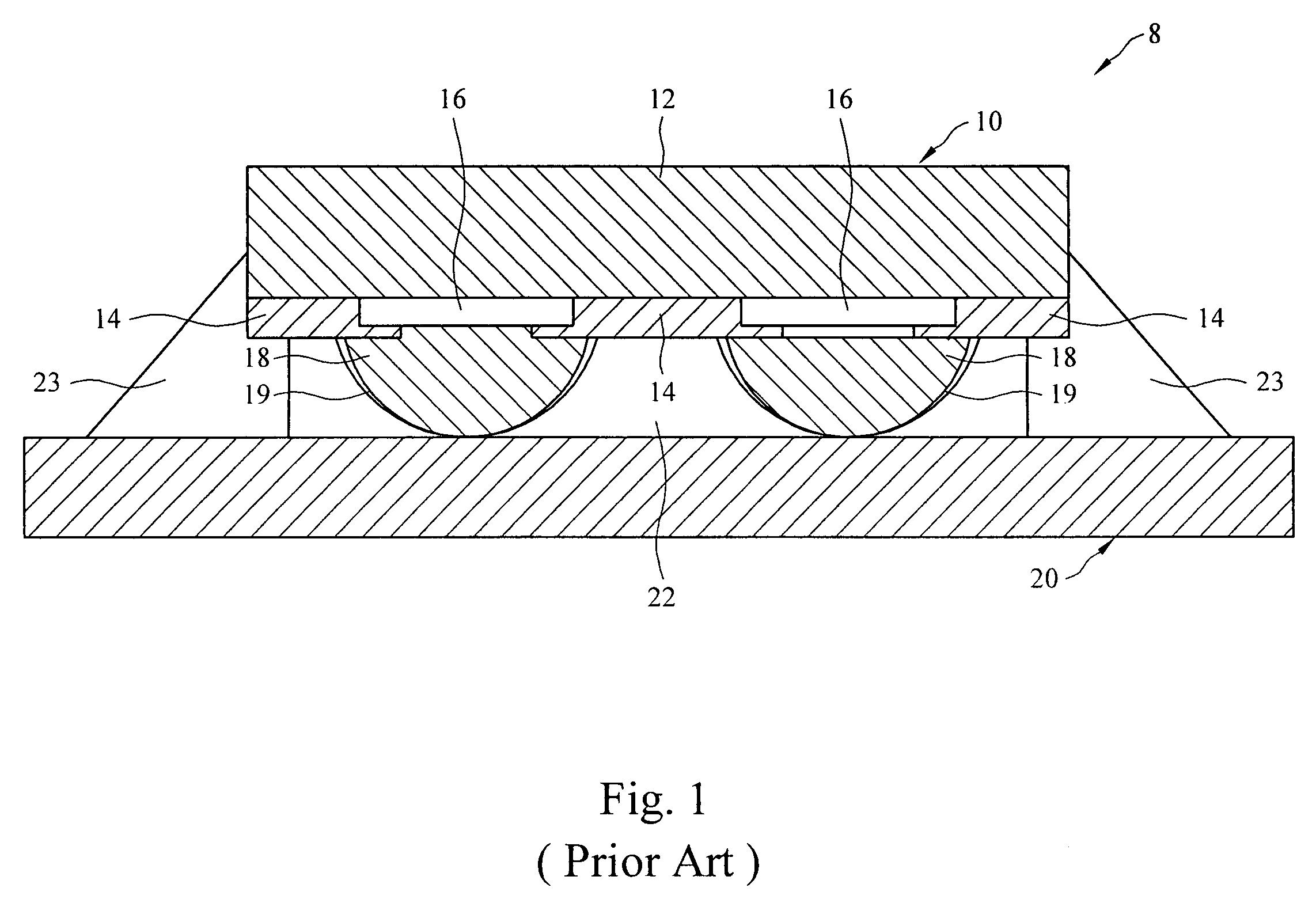

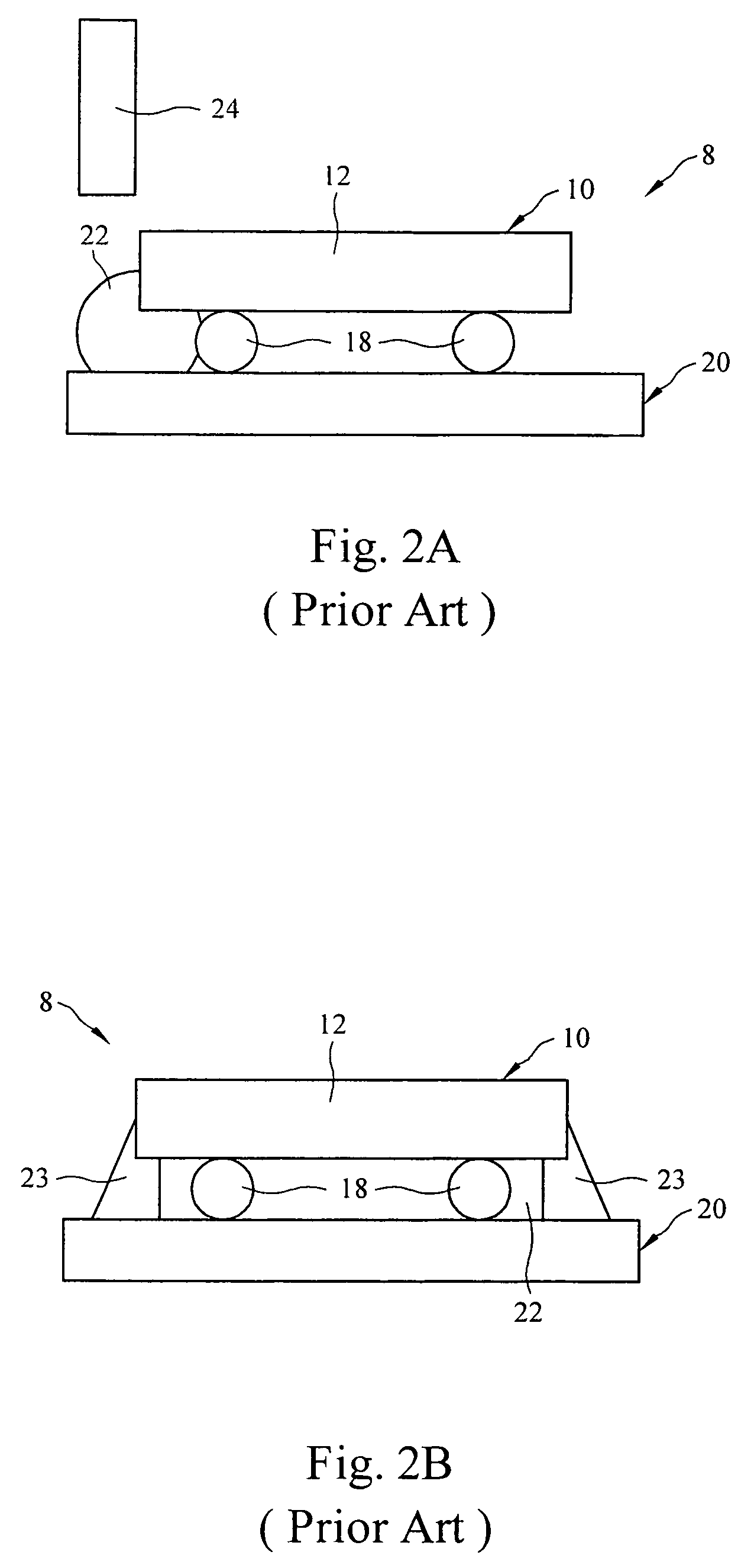

IC chip package structure and underfill process

ActiveUS7148560B2Relieve pressurePrevents orSemiconductor/solid-state device detailsSolid-state devicesMultiple injectionInjection point

A novel integrated circuit (IC) chip package structure and underfill process which reduces stress applied to corners of a flip chip in an IC package structure during the application of an adhesive material between the flip chip and a carrier substrate is disclosed. The process includes providing a dam structure on a carrier substrate; attaching solder bumps of an inverted flip chip to the carrier substrate; injecting an adhesive material between the flip chip and the carrier substrate at multiple injection points located along adjacent edges of the flip chip; and injecting a sealant material around the adhesive material. During application of the adhesive material and the sealant material to the IC package structure in the underfill process, the dam structure reduces stress applied to the corners of the flip chip. This prevents or at least reduces de-lamination of dielectric layers on the flip chip.

Owner:TAIWAN SEMICON MFG CO LTD

Method and system for engine control

ActiveUS20140172275A1Improve fuel efficiencyImprove cooling effectElectrical controlInternal combustion piston enginesMultiple injectionSoot

Methods and systems are provided for controlling exhaust emissions by adjusting an injection profile for fuel injected into an engine cylinder from a plurality of fuel injectors during engine start and crank. By splitting injection of fuel during start so that a portion of fuel is port injected and a remaining portion is direct injected as one or multiple injections, the soot load of the engine can be reduced and fuel economy can be improved.

Owner:FORD GLOBAL TECH LLC

Method for mid load operation of auto-ignition combustion

ActiveUS20060005804A1Easy loadingElectrical controlNon-fuel substance addition to fuelPressure riseMultiple injection

A method is disclosed for expanding the mid load operation limit in a four-stroke gasoline direct-injection controlled auto-ignition combustion engine. A system is employed for variably actuating the intake and exhaust valves and for operating the valves with an exhaust re-compression or exhaust re-breathing valve strategy. A spark plug is provided. A fuel injector having multiple injection capability is employed. A first fuel charge is injected into the combustion chamber to form a lean air-fuel mixture. A second fuel charge is injected into the combustion chamber to form a stratified air-fuel mixture having an ignitable mixture located near the spark plug. The ignitable mixture is ignited at the spark gap, thereby causing spark-ignition combustion that causes a sufficient increase in chamber pressure and temperature to trigger auto-ignition of the lean air-fuel mixture, resulting in the obtaining of a higher engine load before a pressure rise rate in the combustion chamber exceeds a prescribed threshold value.

Owner:GM GLOBAL TECH OPERATIONS LLC

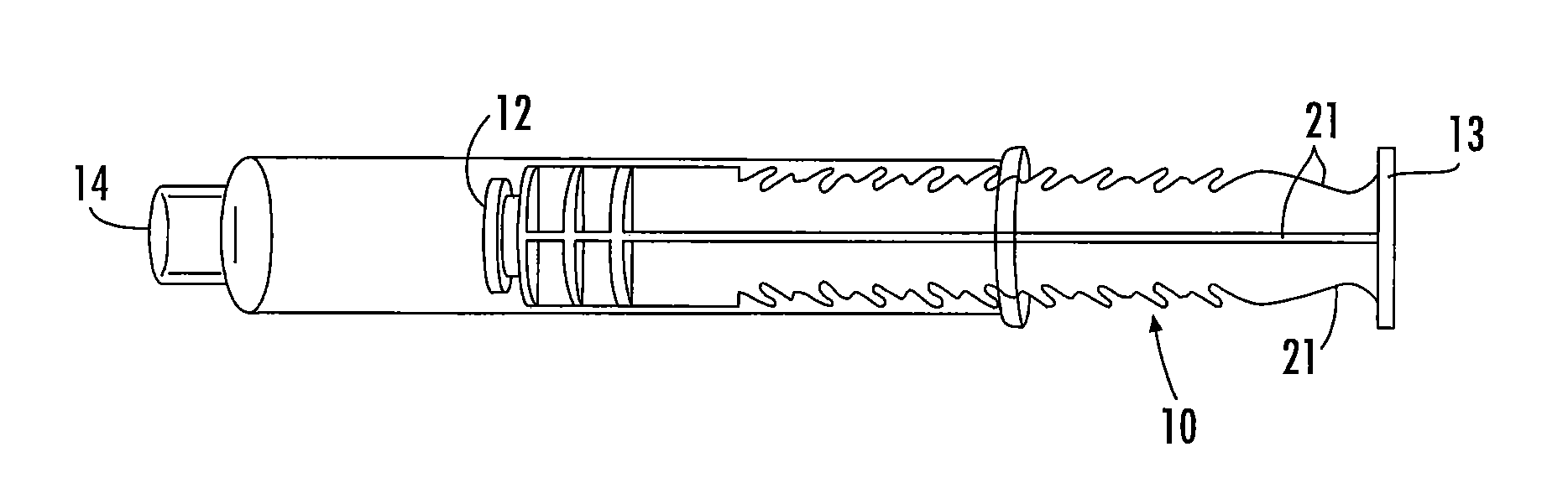

Incremental syringe

ActiveUS20160166772A1Easy to useGuaranteed to workInfusion syringesMedical devicesMultiple injectionBotulinum toxin

An incremental syringe useful for multiple injections of medications like botulinum toxin is provided. The syringe includes detents on the syringe plunger which provide a tactile feeling, a discrete audible sound or “click,” or preferably both, for every unit of medication aspirated or injected to or from an individual syringe. Hence, there is no need to look at the syringe, or bring it to the eye level, during use thereof. In some embodiments, a second set of detents is included, and in some embodiments a third set of detents is included. Syringe plungers useful for combining with a syringe body to produce such an incremental syringe are also described.

Owner:WAKE FOREST UNIV HEALTH SCI INC

Hypodermic injection system

ActiveUS20080015512A1Increase speedMeet needsAmpoule syringesJet injection syringesMultiple injectionDiluent

A hypodermic injection system particularly for use in mass immunizations having a handpiece with a grasping mechanism for holding ampules filled with injectate, a plunger for driving into the ampule to discharge the injectate in an injection process, an injection spring mechanism for driving the plunger, a motor and / or manual mechanism for cocking the injection spring mechanism, and an ampule ejection mechanism for ejecting ampules after use under control of a release mechanism. Ampules can be loaded, used and ejected without contact by the user of the system or the patient being injected. Also disclosed are a filling station for filling ampules through their injection orifices, and an arming device for setting the injection spring. Ampules are disclosed having a piston which is drivable towards an orifice to discharge injectate through the orifice. Ampules are also disclosed having enlarged proximal portions for easy grasping by the grasping mechanism of the injector. Ampules are further disclosed with separators for mixing lyophilized medication and a diluent. Further disclosed are magazines for holding ampules for sequential use by the hypodermic injector. The disclosed system finds particular use as a mass immunization kit for making numerous injections in the field.

Owner:DANTONIO CONSULTANTS INT INC

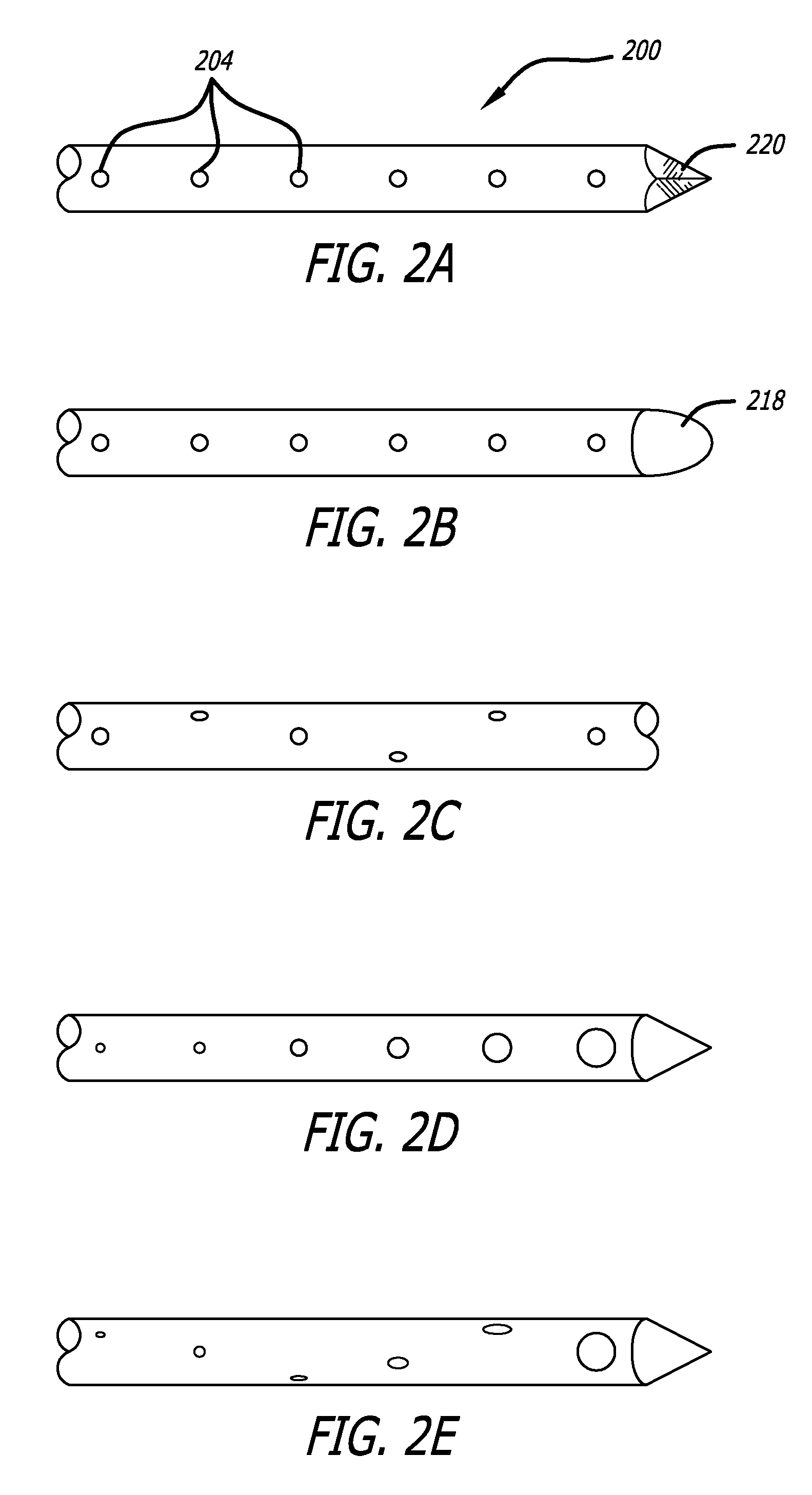

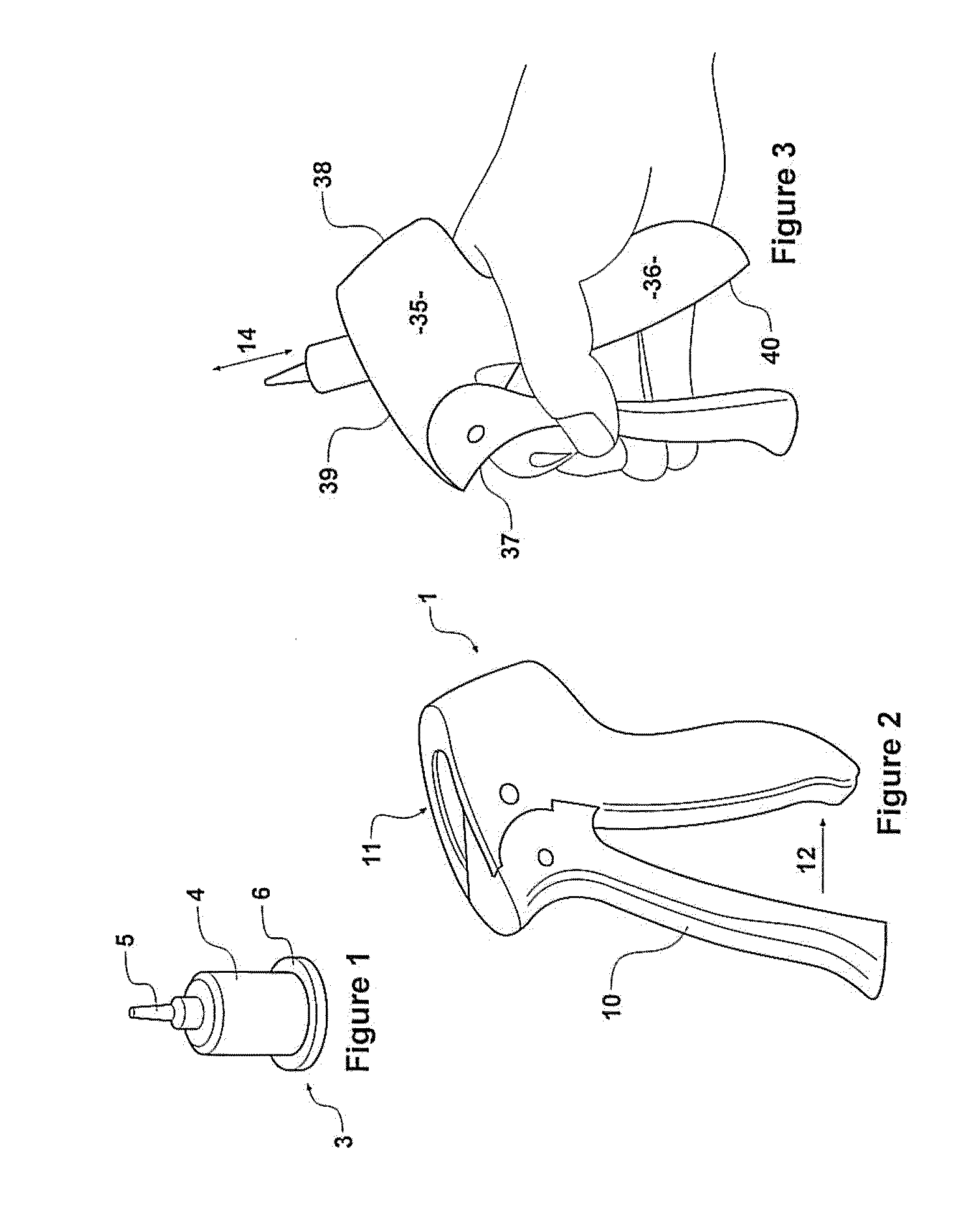

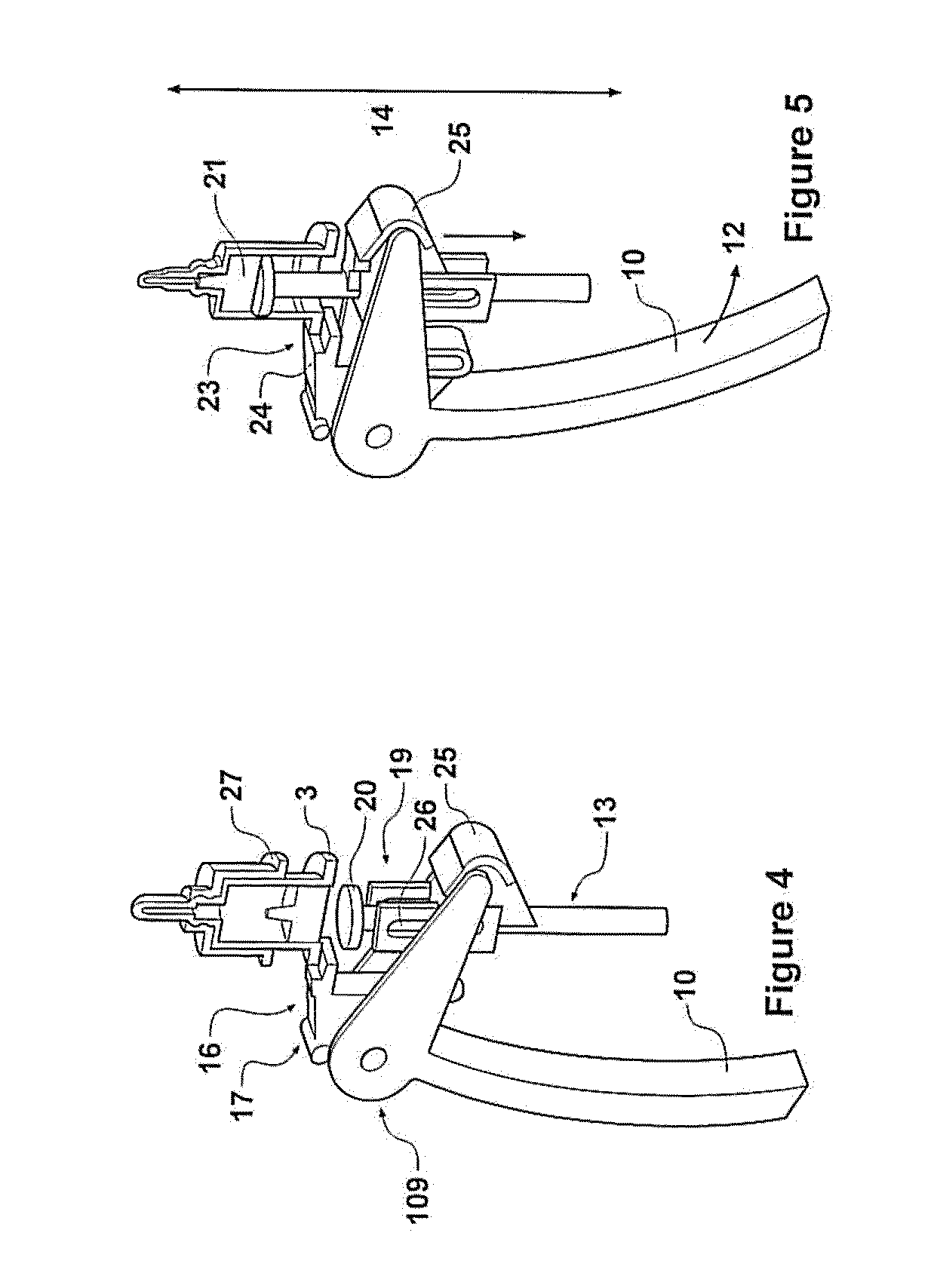

Veterinary syringe for multiple injections

A trigger operated syringe (100) for intramammary injection of antibiotics has a fluid containing syringe cartridge (203) activated by a plunger (206) which is inserted into the syringe cartridge (203A) and expels fluid when the trigger (205) is pulled. A syringe cartridge holding mechanism (223) holds the syringe cartridge in place until the trigger (205) is released and the plunger (206) retracted. Single syringe cartridge (203) and multiple syringe cartridge (204) versions are disclosed. The plunger moves in a direction which is effectively perpendicular to the direction of movement of the trigger, allowing for ease of injection to a cow's teats, and ejection of the spent cartridges.

Owner:BOEHRINGER INGELHEIM ANIMAL HEALTH USA INC

Enhanced multiple injection for auto-ignition in internal combustion engines

InactiveUS6636797B2Increase fuel injectionImprove operationElectrical controlInternal combustion piston enginesMultiple injectionCombustion chamber

Owner:NISSAN MOTOR CO LTD

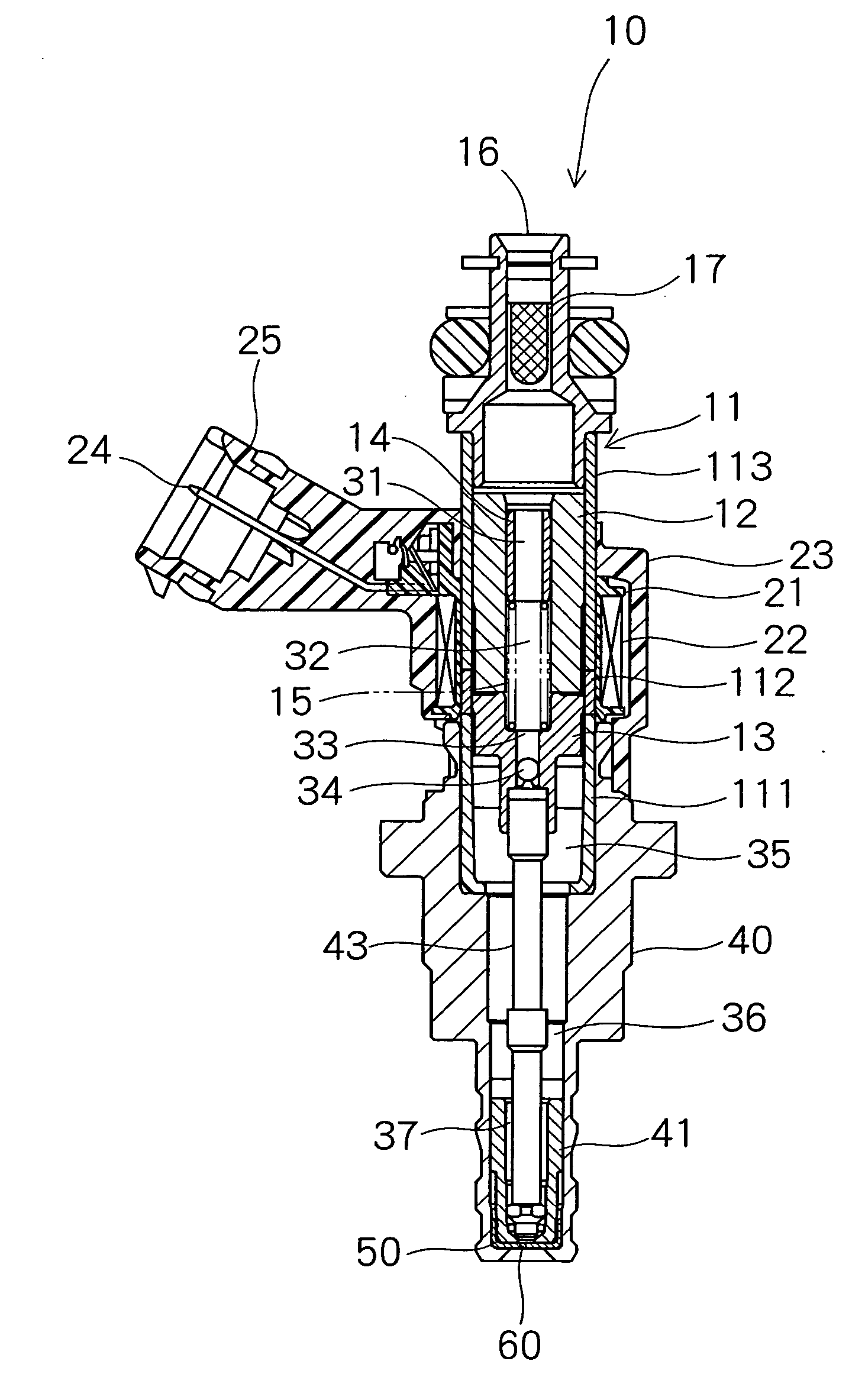

Fuel injection device of internal combustion engine

ActiveUS20040178287A1Promote atomizationWell formedSpray nozzlesFuel injection apparatusMultiple injectionEngineering

Multiple injection holes are formed in an injection hole plate. Each injection hole penetrates the injection hole plate. The injection hole is formed with an inlet side opening and an outlet side opening. The outlet side opening is formed in the shape of a flattened rectangle having a major axis and a minor axis. Therefore, the fuel flowing into the injection hole through the inlet side opening is injected in the shape of a film from the outlet side opening. Thus, liquid film splitting is promoted, so atomization of the fuel is promoted. Since the multiple injection holes are formed in the injection hole plate, the shape of a great fuel spray, which is formed by combining fuel sprays injected from the respective injection holes, can be adjusted easily.

Owner:DENSO CORP

Multi-shot Coaxial Connector and Method of Manufacture

InactiveUS20100041271A1Significant costSignificant materialElectrically conductive connectionsTwo pole connectionsMultiple injectionCoaxial cable

A coaxial cable connector formed via multi-shot injection molding has a body formed by multiple injection molding layers of different injection moldable materials about a central inner contact to form an integral connector body. The connector body is provided with a coaxial dielectric spacer of dielectric polymer surrounding the inner contact; a coaxial inner body of injection molded metal composition surrounding an outer diameter of the dielectric spacer; and an outer body of polymer surrounding the inner body. Interlock features provide axial and / or rotational interlock between the layers of the connector.

Owner:ANDREW LLC

Petroleum extraction from hydrocarbon formations

InactiveUS7621326B2Increase displacementSpeed up the processInsulationFluid removalMultiple injectionControl flow

Recovery of viscous hydrocarbon by hot fluid injection from subterranean formations is assisted by using a specially designed and under-reamed vertical well to form a central production cavity; combined with a plurality of specially perforated horizontal wells drilled from the surface down to the producing formation, and then drilled laterally to intersect and be operatively connected to the central production well cavity. These continuous horizontal uniwells™ behave as single wells with two wellheads, each with multiple injection-production perforation pairs, between which the controlled flow of hot oil via a specialized annular communication zone. The production process is controlled by modulating the hot oil flow where the wellbore fluids act as a hydraulic “P-trap” seal limiting steam bypass. The hot displaced oil is allowed to drain from the lateral horizontal wells in to the central collection cavity.

Owner:CRICHLOW HENRY B

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com