Patents

Literature

984 results about "Fuel spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

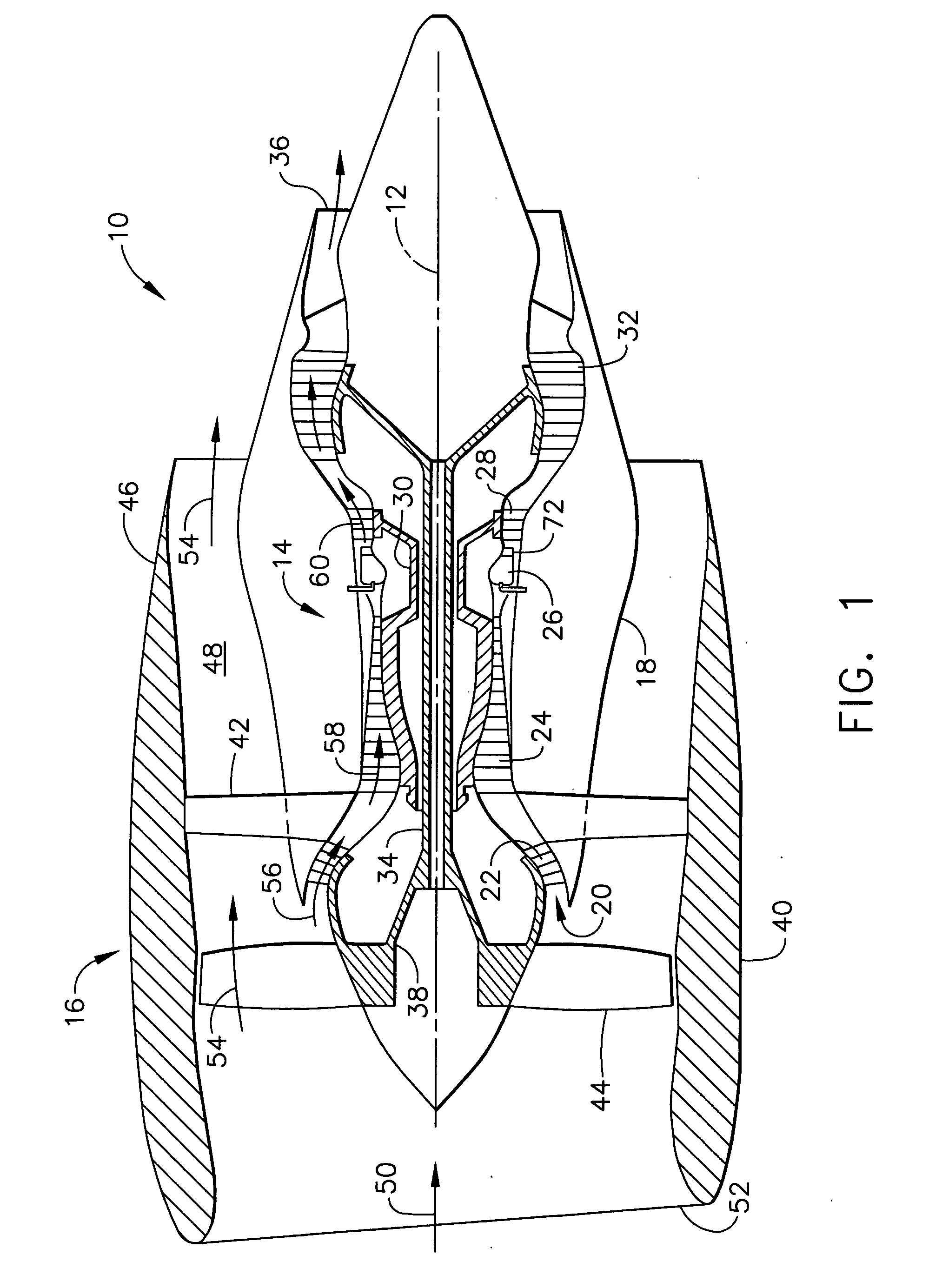

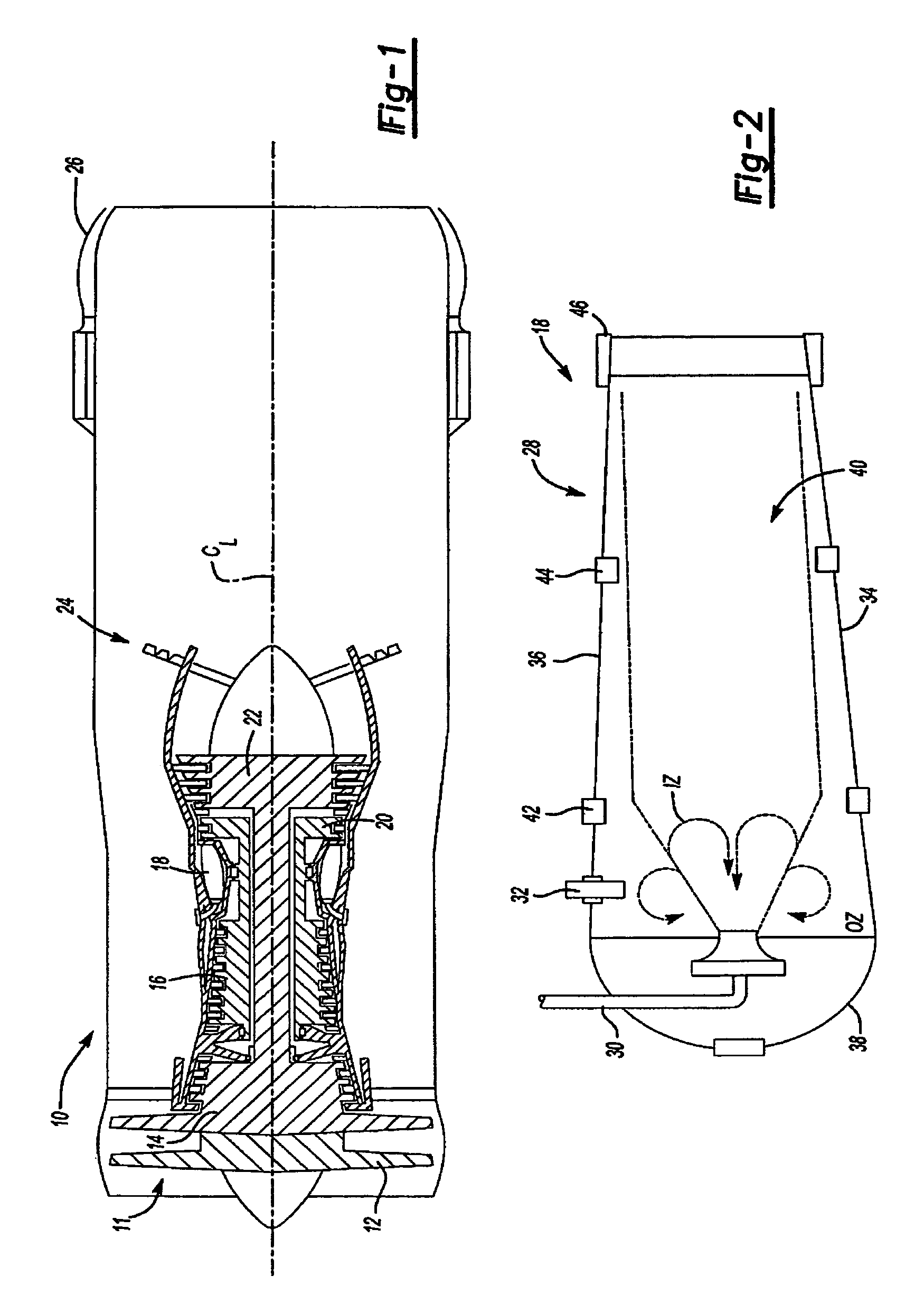

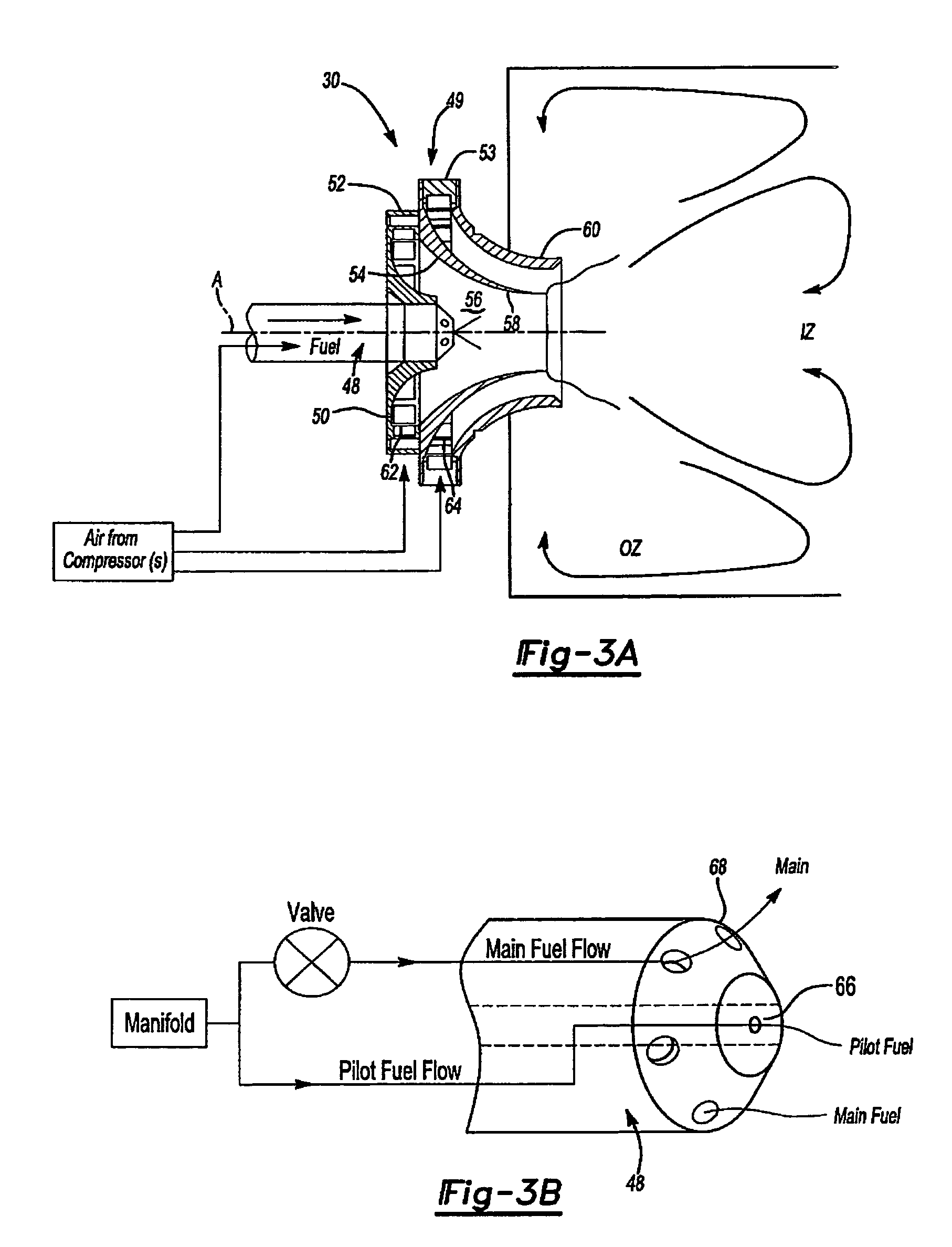

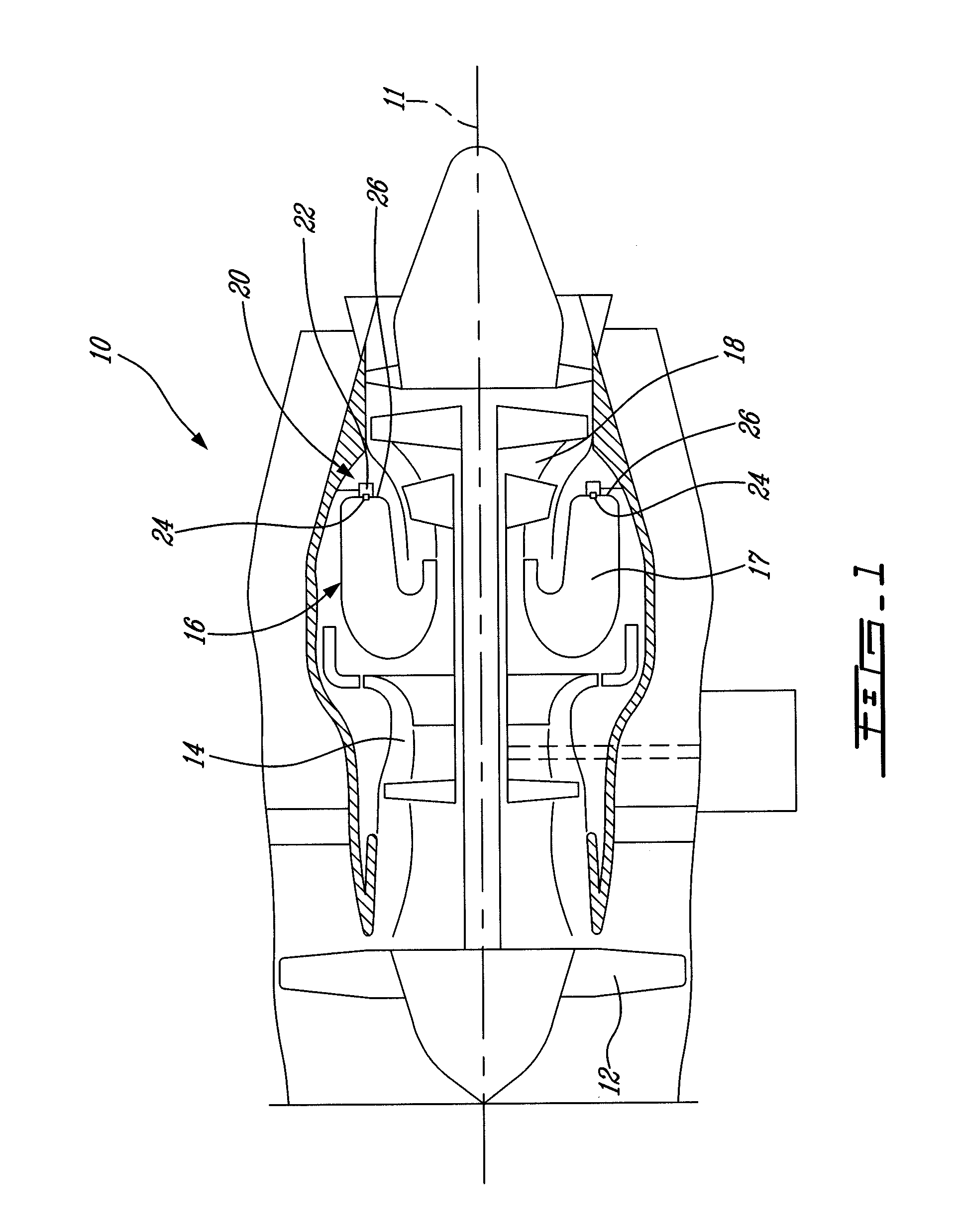

Pilot fuel injector for mixer assembly of a high pressure gas turbine engine

ActiveUS20070137207A1Continuous combustion chamberEfficient propulsion technologiesHigh pressureTurbine

A mixer assembly for a gas turbine engine, including: a primary fuel injector having a central axis for injecting a primary fuel spray into a primary air stream, wherein fuel is provided at a desired rate and droplets of the fuel spray are within a desired size range; a secondary fuel injector positioned radially outwardly of the primary fuel injector for injecting a secondary fuel spray into a secondary air stream spaced radially outwardly of and surrounding the primary air stream; and, a primary air jet positioned between the primary fuel injector and the secondary fuel injector to direct a portion of an incoming air stream between the primary air stream and the secondary air stream.

Owner:GENERAL ELECTRIC CO

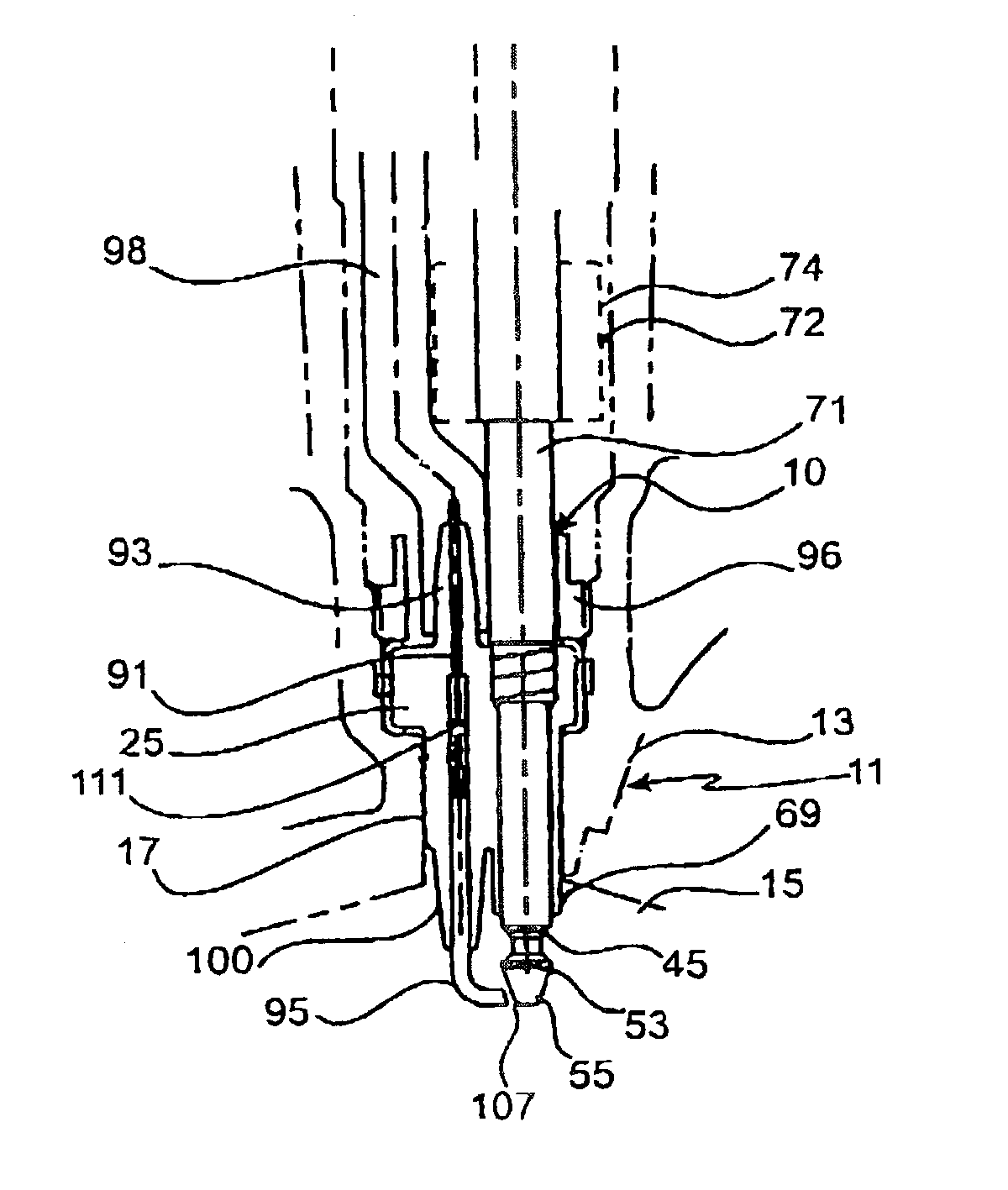

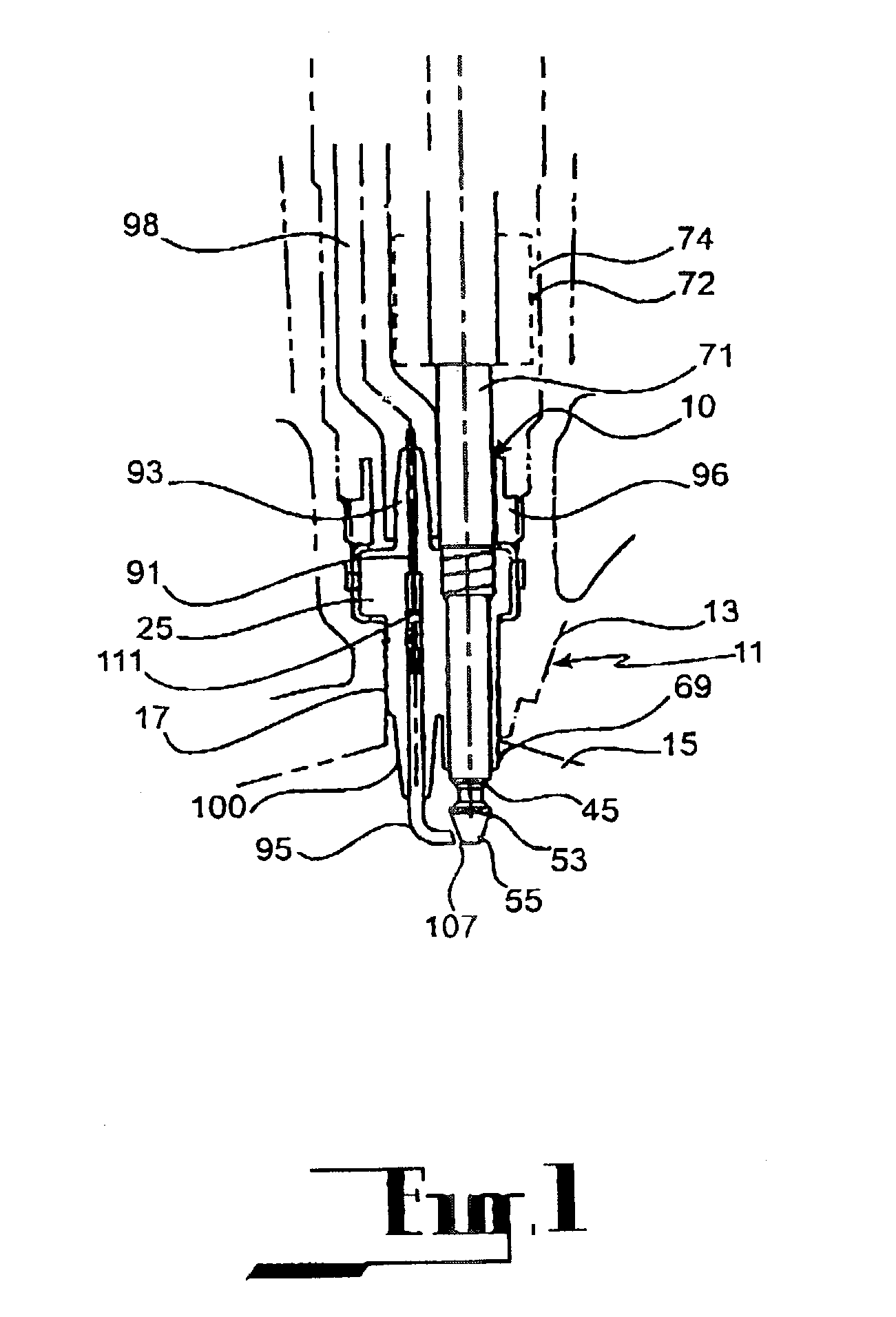

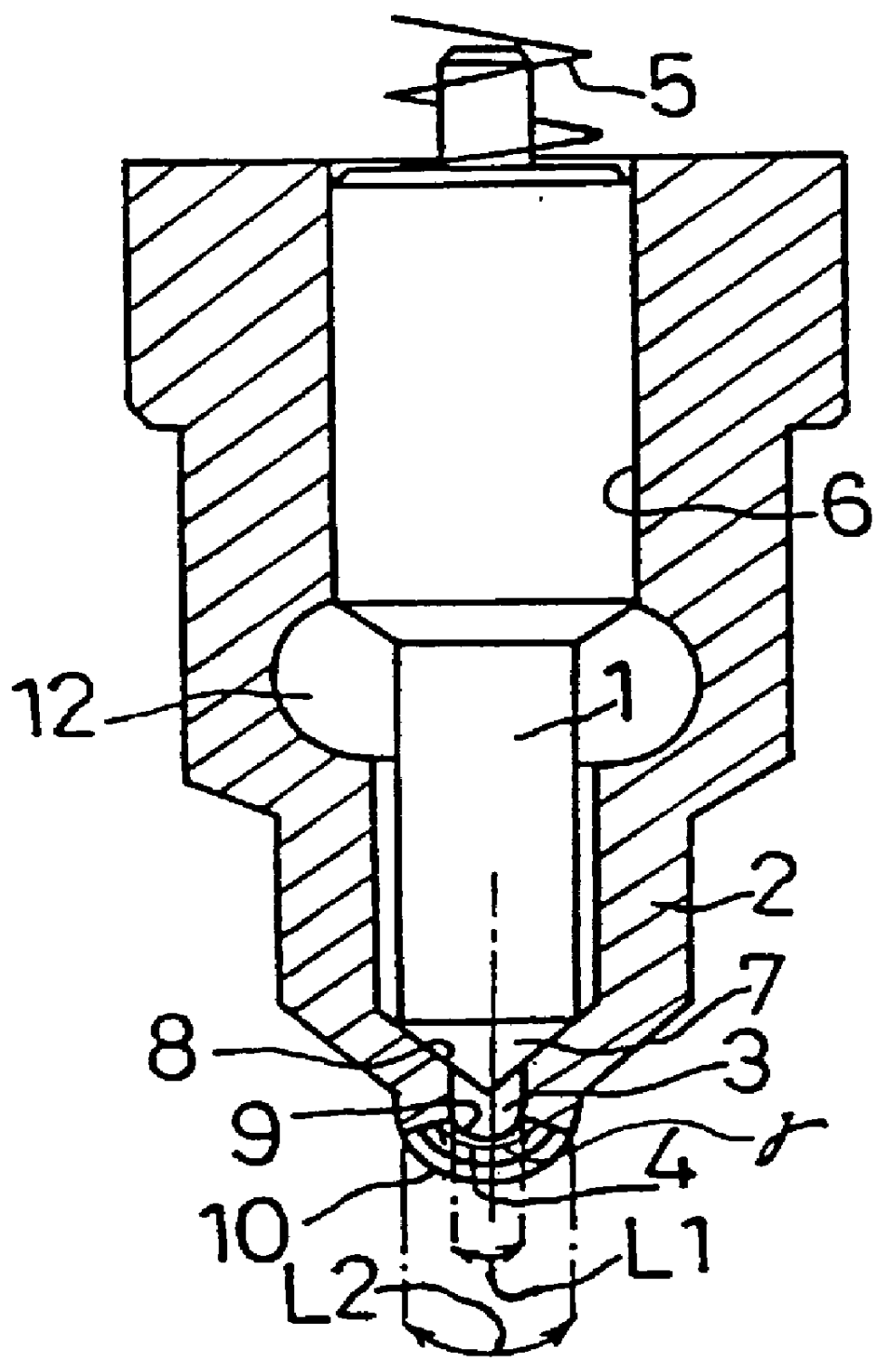

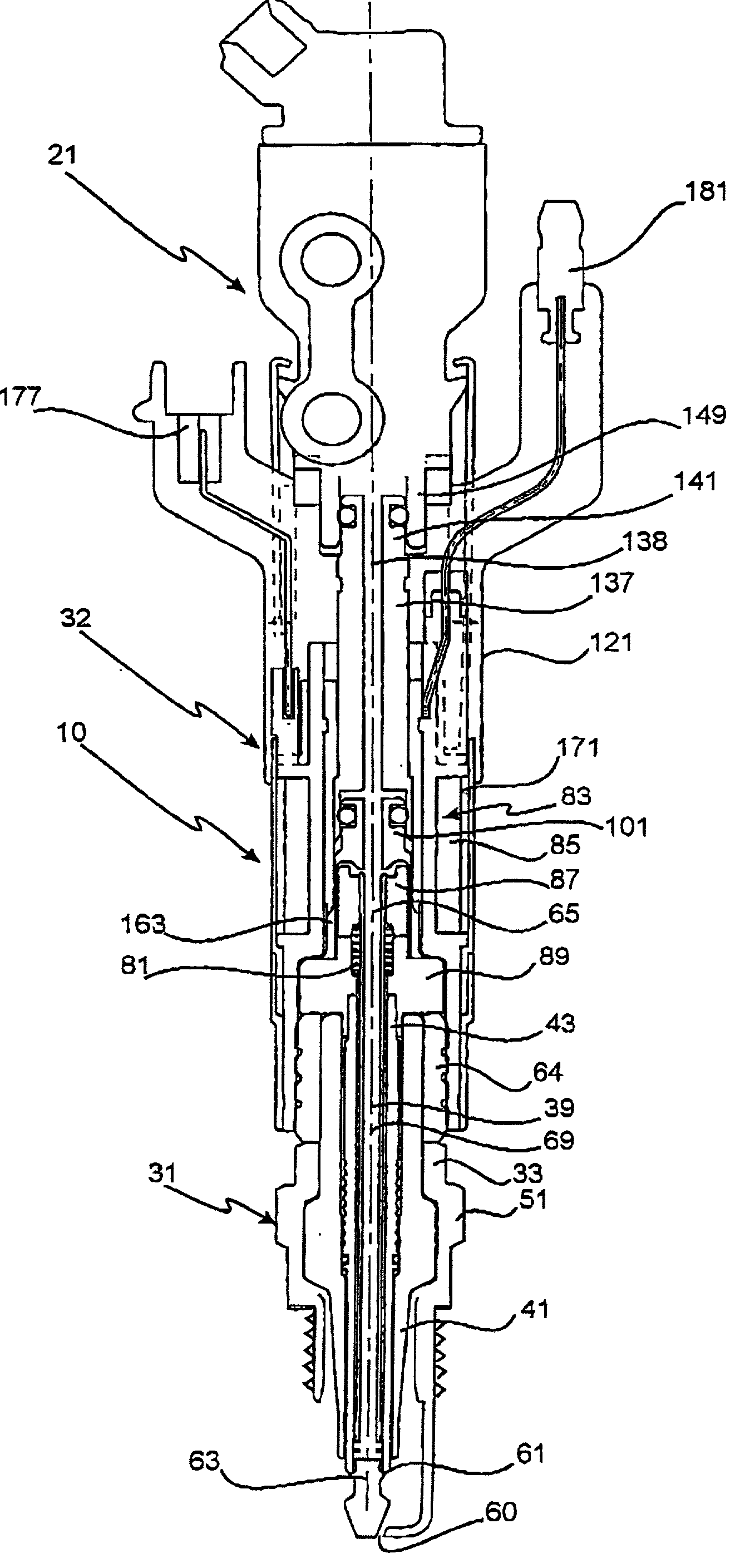

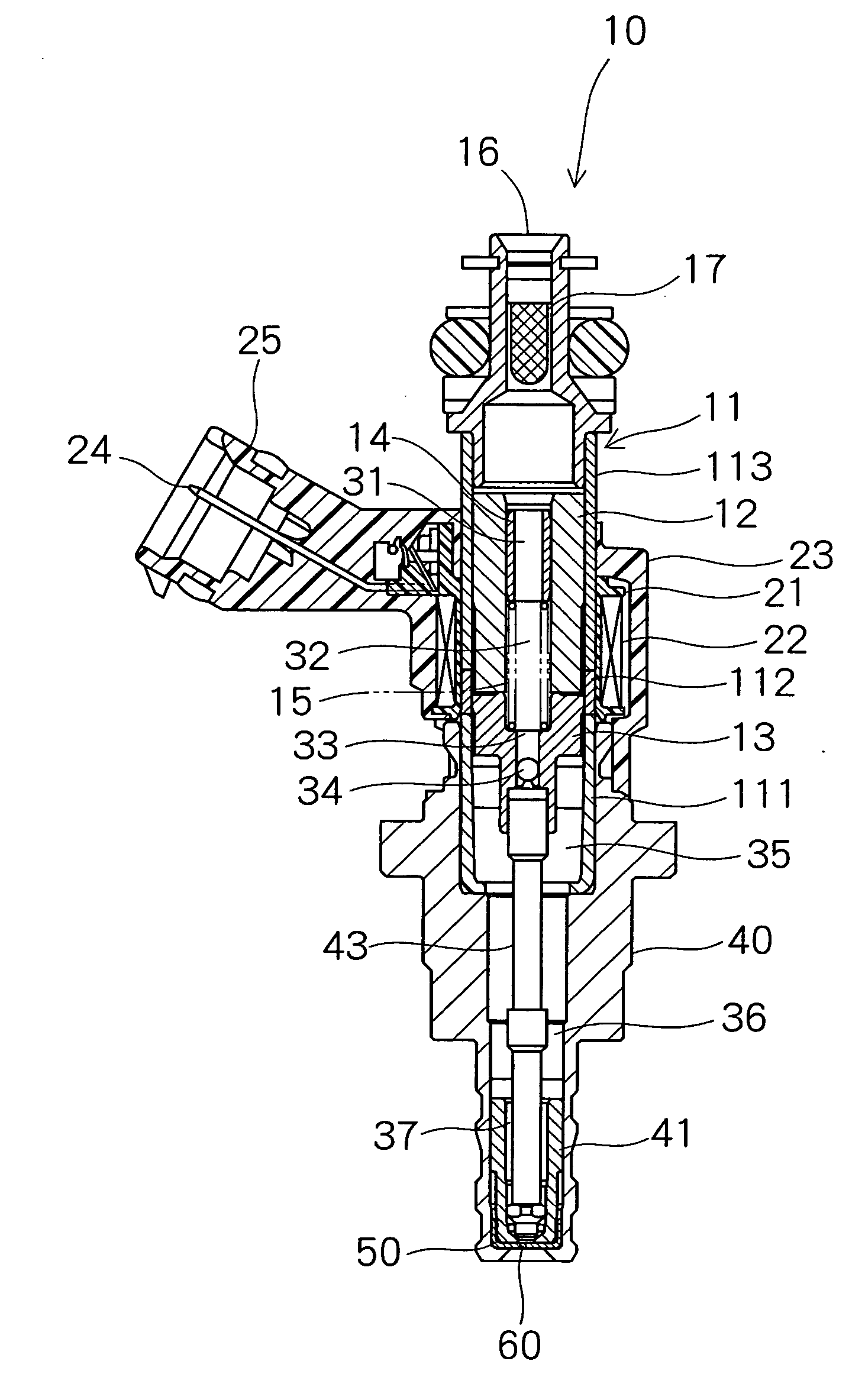

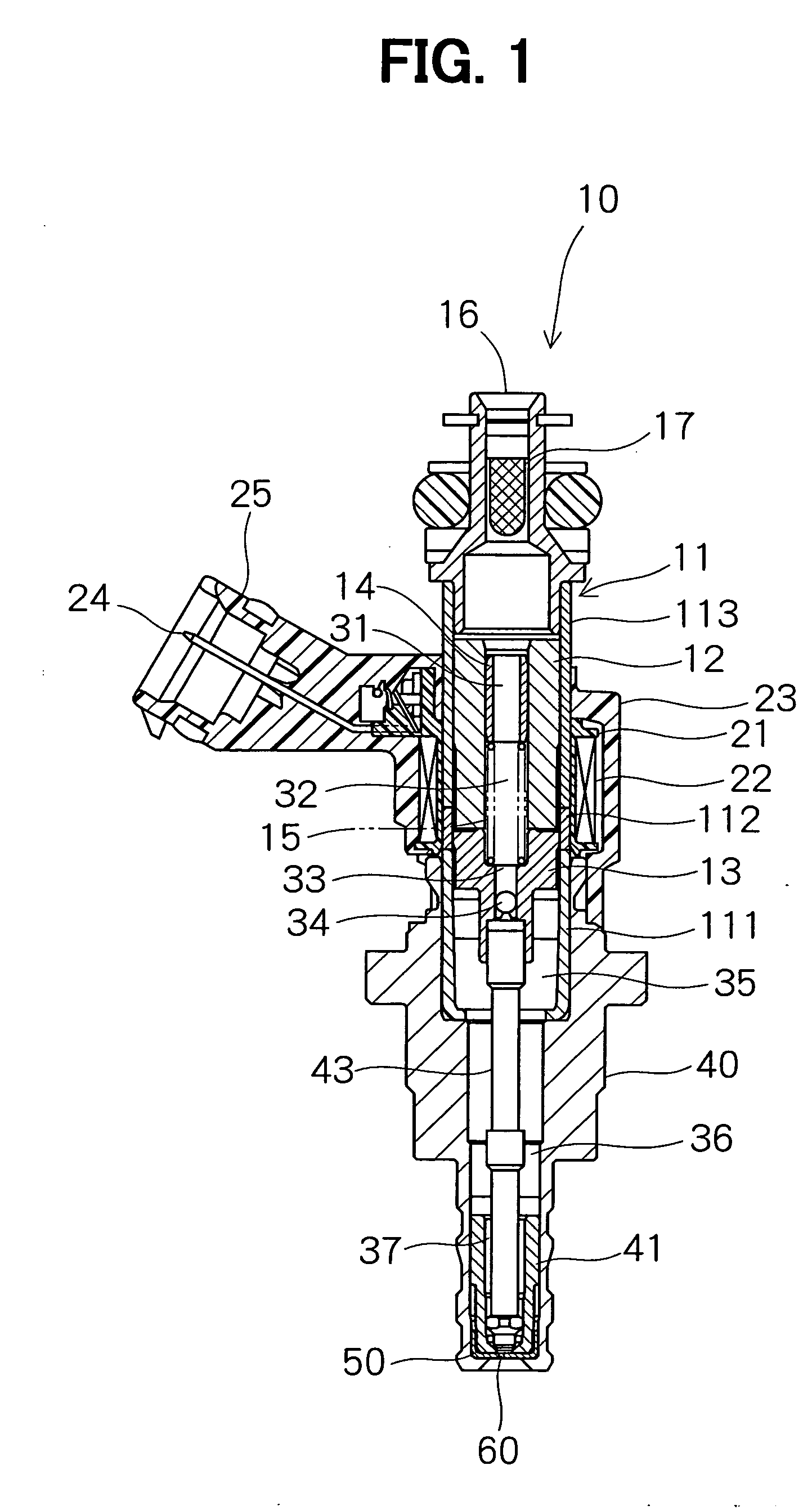

Combined fuel injection and ignition means

InactiveUS7086376B2Reduce capacityConstruction is difficultHigh pressure gas fuel injectionMachines/enginesEngineeringInternal combustion engine

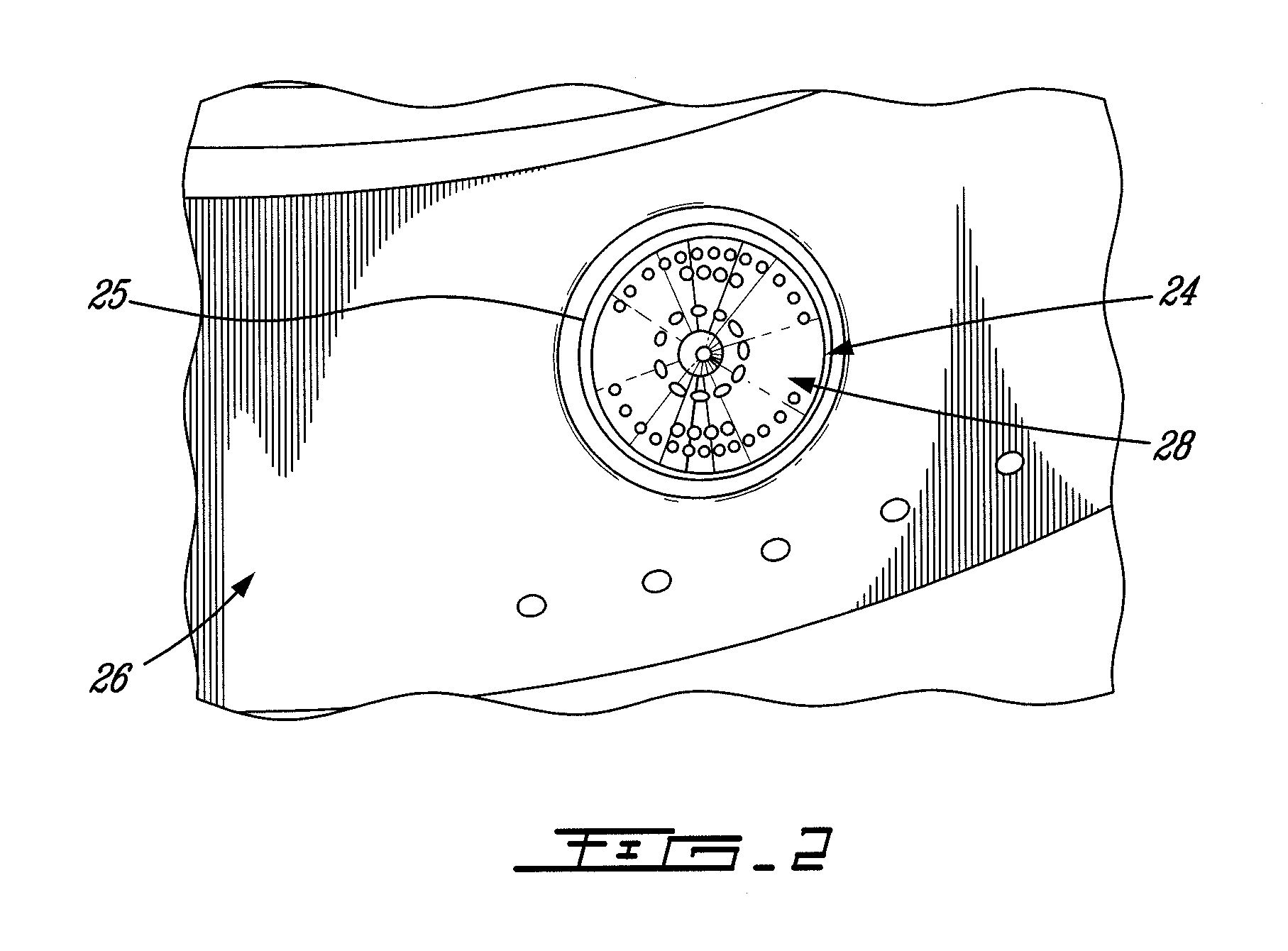

A device (10) providing a combined fuel injection and ignition means for a spark-ignition internal combustion engine. The device (10) comprises a insulator body (25) of ceramic material, a fuel flow path (24) having a section thereof encased in the insulator body (25) and terminating at a delivery port (45) disposed outwardly of the insulator body (25), and, an ignition path (23) having a section encased in the insulator body (25) in a spaced apart relationship with respect to the section of the fuel path (24). The fuel path (24) is defined within a valve structure (33) detachably secured to the insulator body (25) so as to be selectively removable therefrom. The ignition path (23) terminates at an electrode (95) disposed outwardly of the insulator body (25). The insulator body has a nose portion (100) and a skirt portion (69) beyond the delivery port (45). The nose (100) and the delivery port (45) are positioned relative to each other such that all or at least part of the fuel spray issuing from the delivery port (45) avoids impingement on the nose (100).

Owner:ORBITAL ENGINE CO PTY LTD

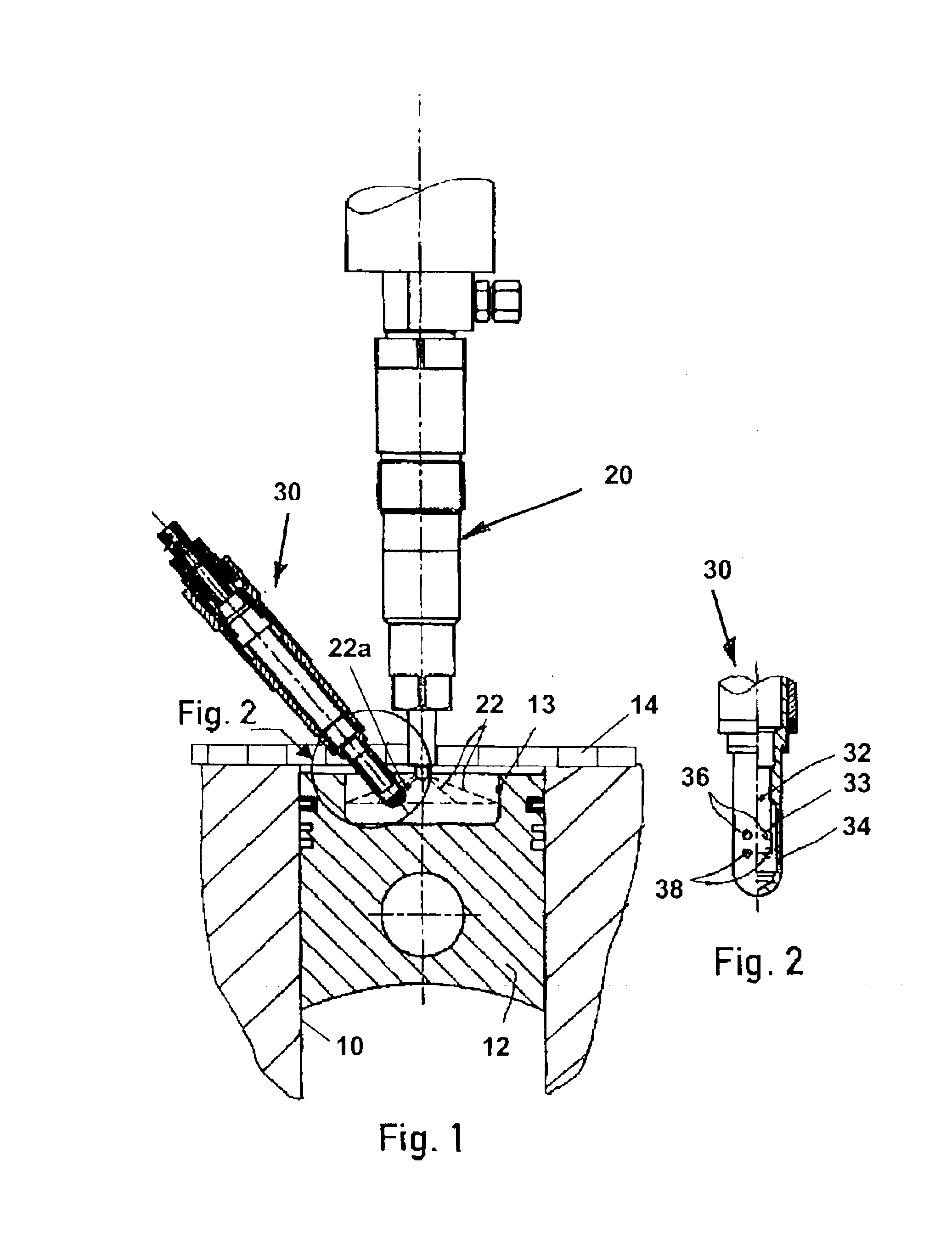

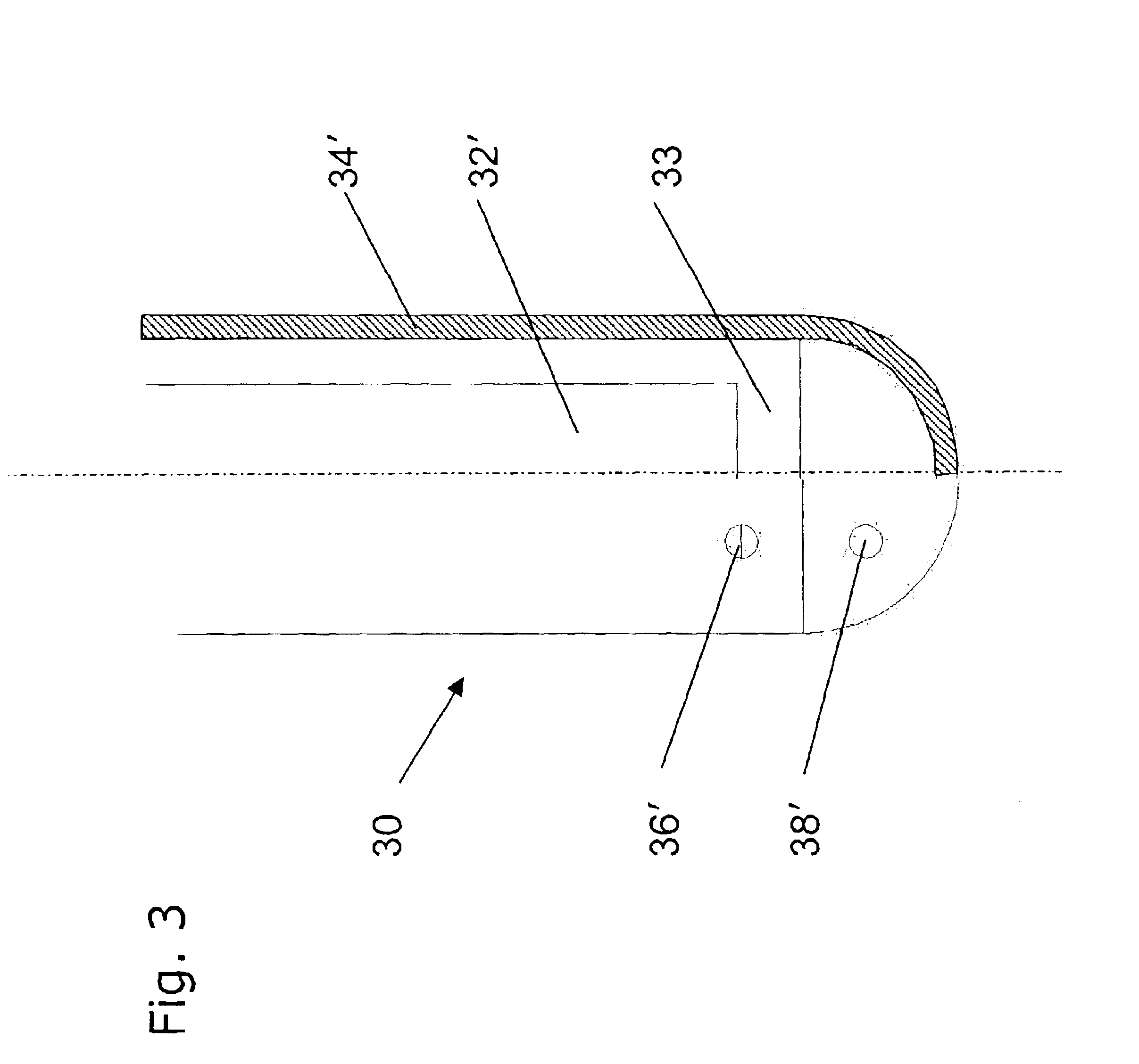

Internal combustion engine with injection of gaseous fuel

InactiveUS6854438B2Reduce modificationReduce manufacturing costIncandescent ignitionInternal combustion piston enginesInternal combustion engineFuel injection

An internal combustion engine comprises a fuel injection nozzle for injecting a gaseous fuel directly into the combustion chamber. shield, is installed in close proximity to the fuel injection nozzle, provides a shielded space around a hot surface igniter and restricts flow between the shielded space and the combustion chamber. The nozzle comprises a fuel injection port oriented to direct a fuel spray against a surface of the sleeve An inlet in the sleeve allows air and fuel to enter the shielded space to form a combustible mixture therein. The sleeve contains a substantial amount of the combustible mixture within the shielded space until it ignites and pressure builds within the shielded space to propel a combustion flame through at least one discharge opening and into contact with the fuel sprays emerging from the fuel injection nozzle.

Owner:WESTPORT POWER

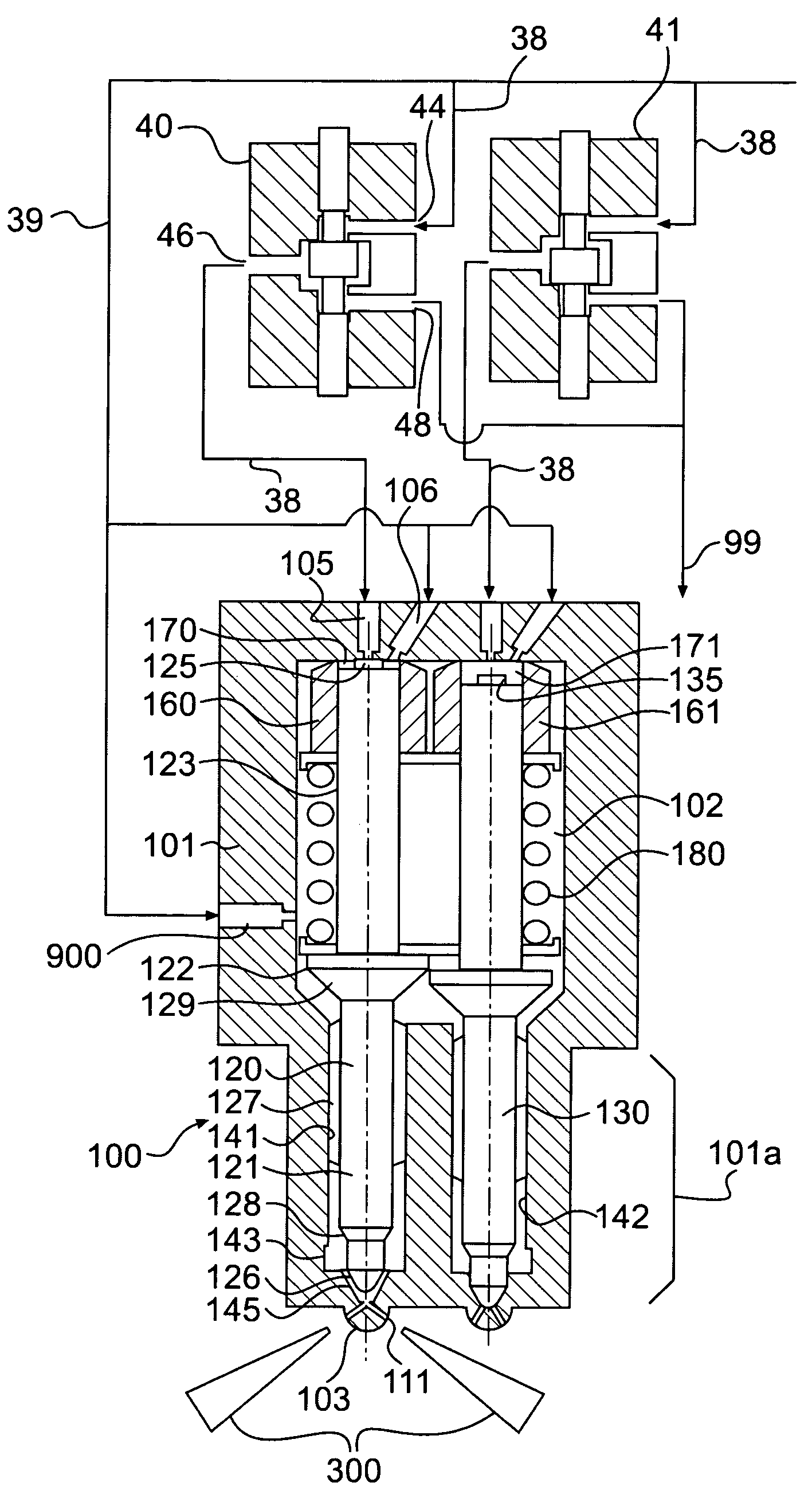

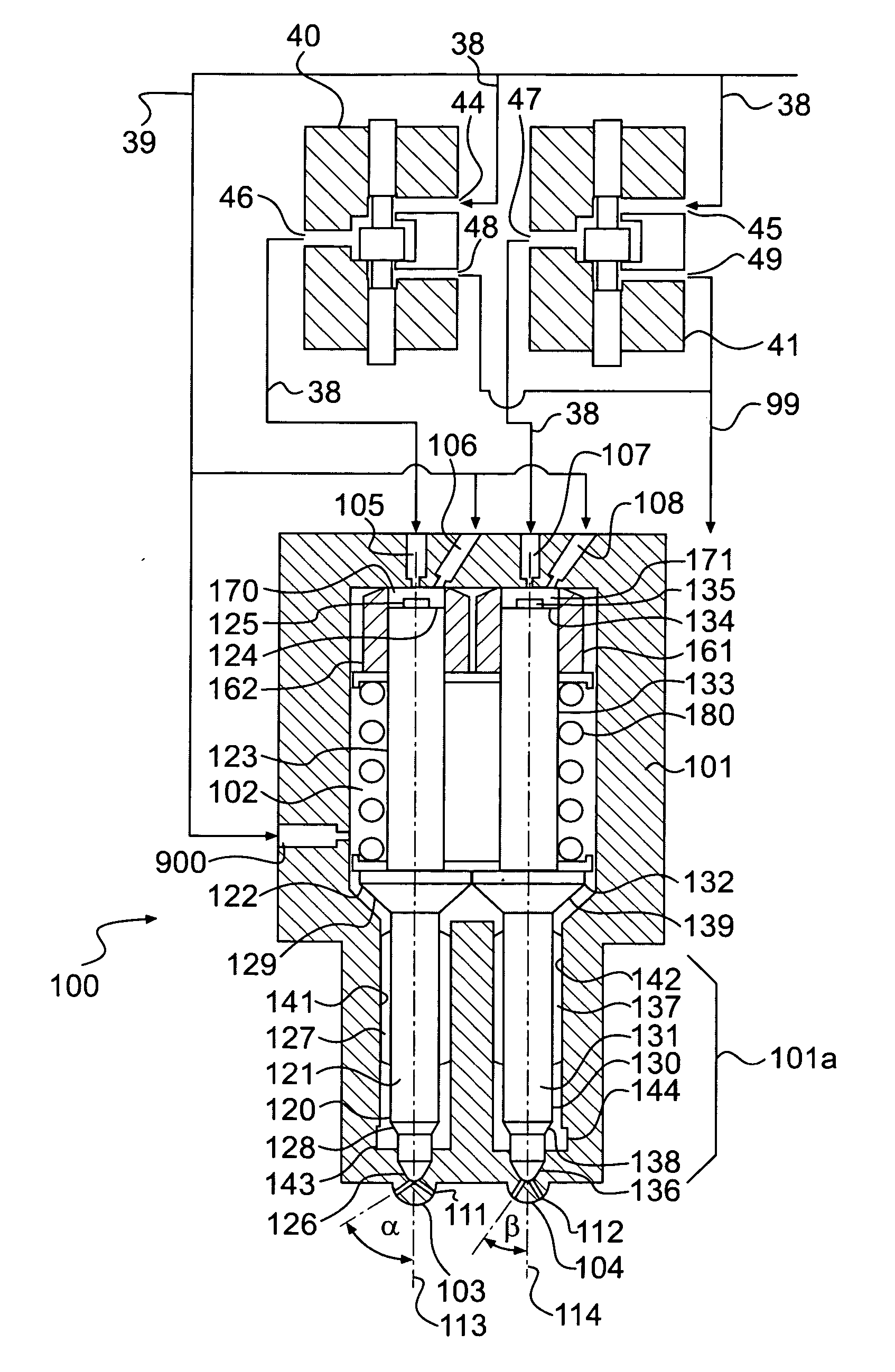

Twin needle valve dual mode injector

A fuel injector having an injector body defining a hollow interior configured to receive pressurized fuel, a first nozzle configured for providing a first fuel spray pattern, and a second nozzle configured for providing a second fuel spray pattern different from the first fuel spray pattern. The first and second nozzles may be configured to inject fuel supplied from a common source into a combustion space. The fuel injector may further include first and second needle valve members corresponding to the first and second nozzles, respectively. The first and second needle valve members may be positioned within the hollow interior of the injector body, with the second needle valve member being spaced from, but adjacent to the first needle valve member.

Owner:CATERPILLAR INC

Thermally applied coating of mechanically alloyed powders for piston rings

InactiveUS6887585B2Improve the immunityTrend downMolten spray coatingPiston ringsCombustionWear resistant

The invention relates to a wear-resistant coating used for bearing surfaces and flanks of piston rings in internal combustion engines. The wear-resistant inventive coating is obtained by mechanically alloying powders which form a metallic matrix with hard material dispersoids and lubricant material dispersoids. The coating is then thermally applied to the workpieces, especially by means of high velocity oxygen fuel spraying (HVOF). The workpieces coated are bearing surfaces and parts of flanks pertaining to piston rings in internal combustion engines.

Owner:FEDERAL MOGUL BURSCHEID

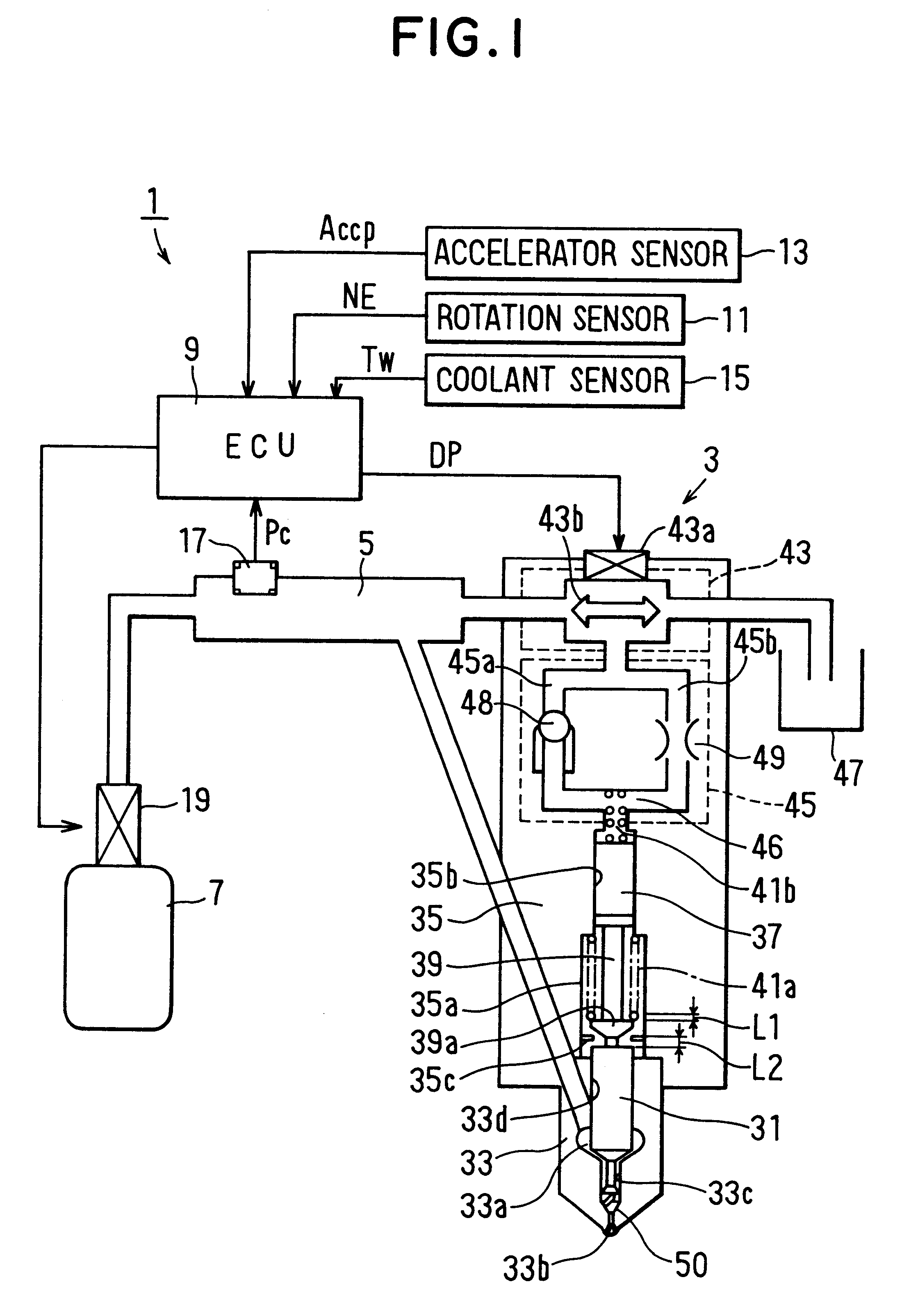

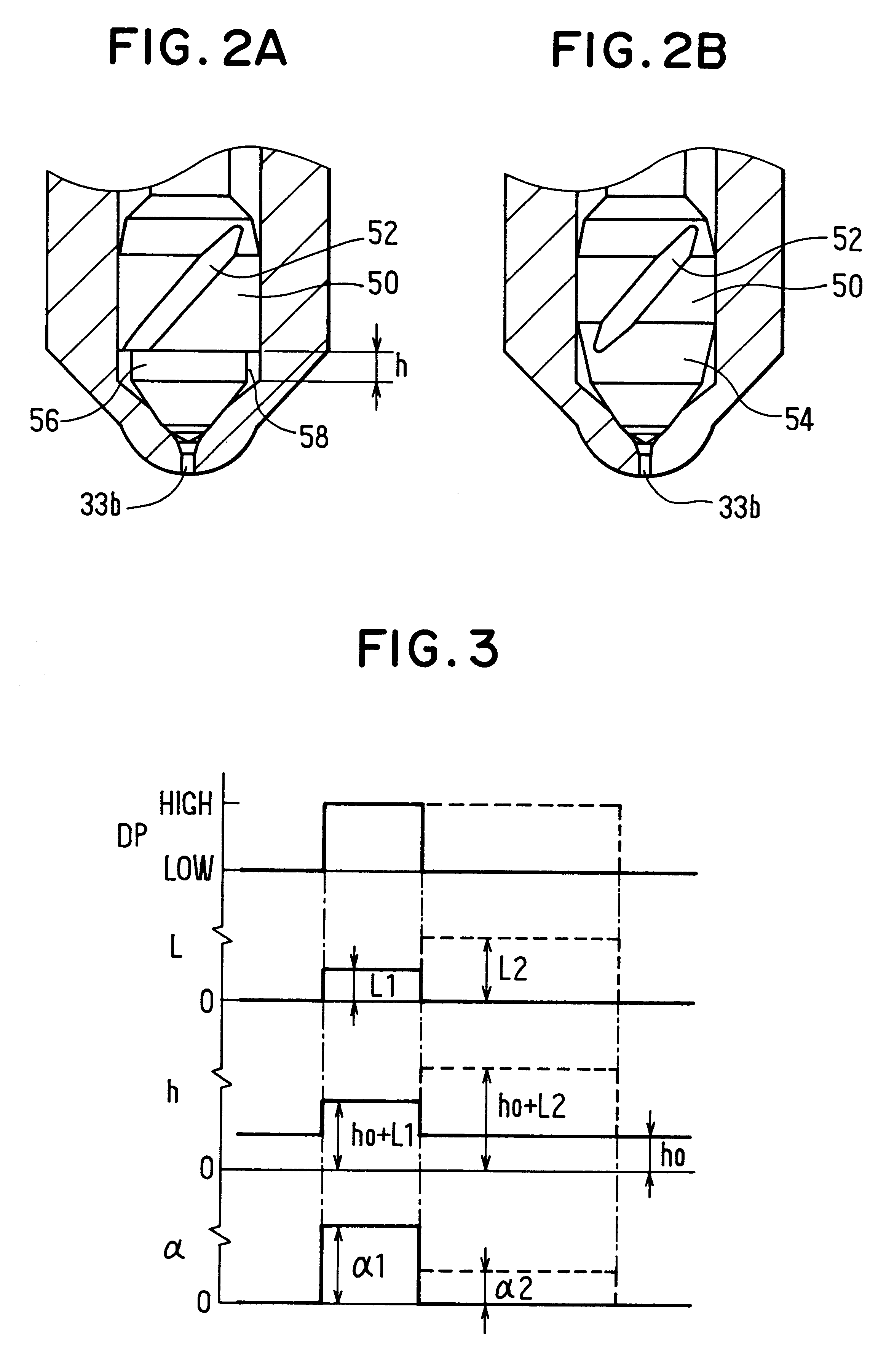

Fuel injection system having pre-injection and main injection

InactiveUS6302080B1Improve permeabilityIncrease the angleElectrical controlInternal combustion piston enginesTop dead centerEngineering

The angle of fuel spray at the time of pre-injection is set to a wider angle of spray and the angle of fuel spray at the time of main injection is set to a narrower angle of spray. The pre-injection timing is set so that when fuel spray after the pre-injection is diffused in a cylinder and stratified, the stratified fuel spray is ignited by a rise in the pressure in the cylinder in association with movement of a piston from the bottom dead center to the top dead center. The main injection timing is set so that when the spray stratified by the pre-injection is burned, the fuel spray injected by the main injection passes through the combustion zone while being ignited in the combustion zone, reaches a combustion chamber of the piston, and is burned in the combustion chamber.

Owner:DENSO CORP

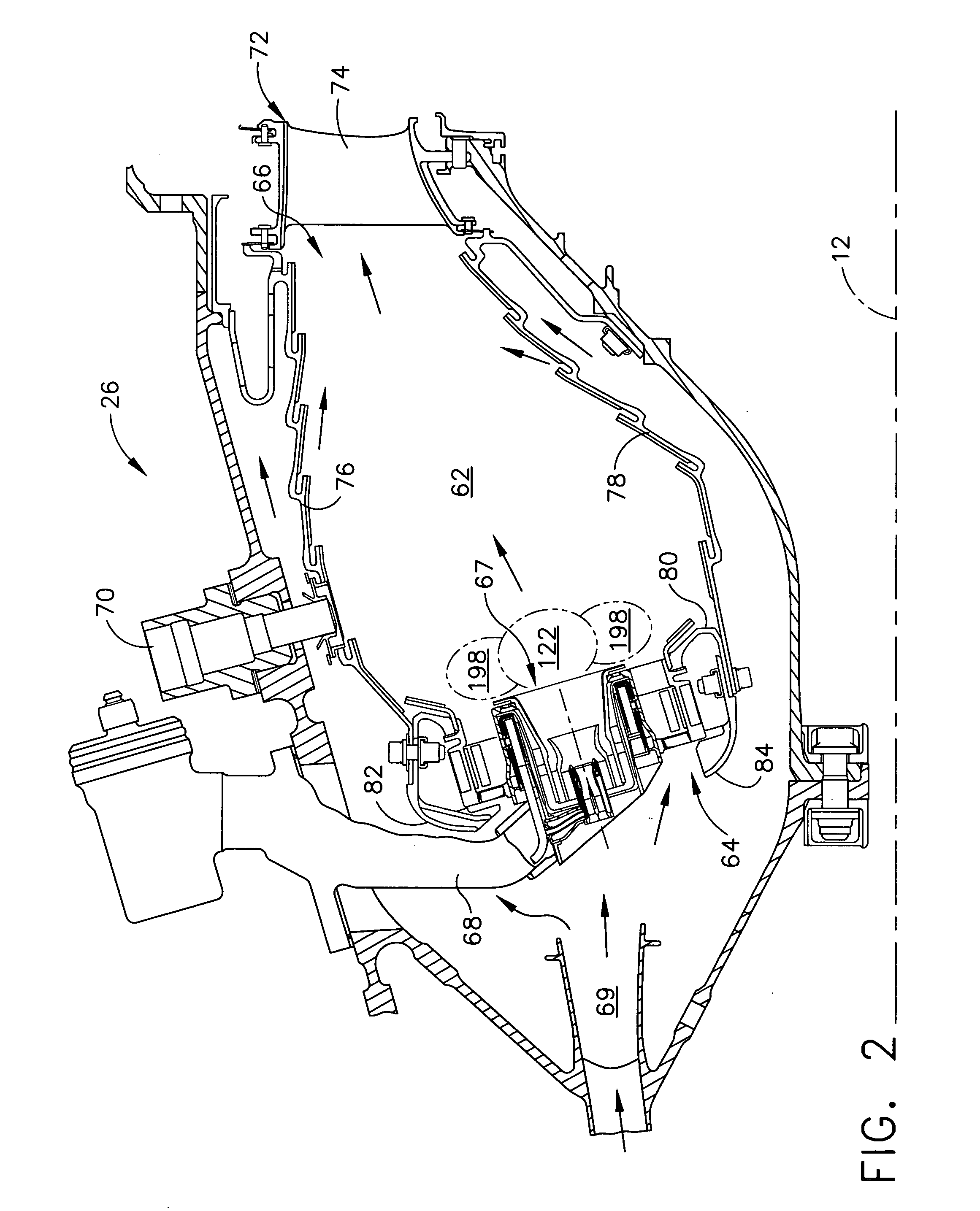

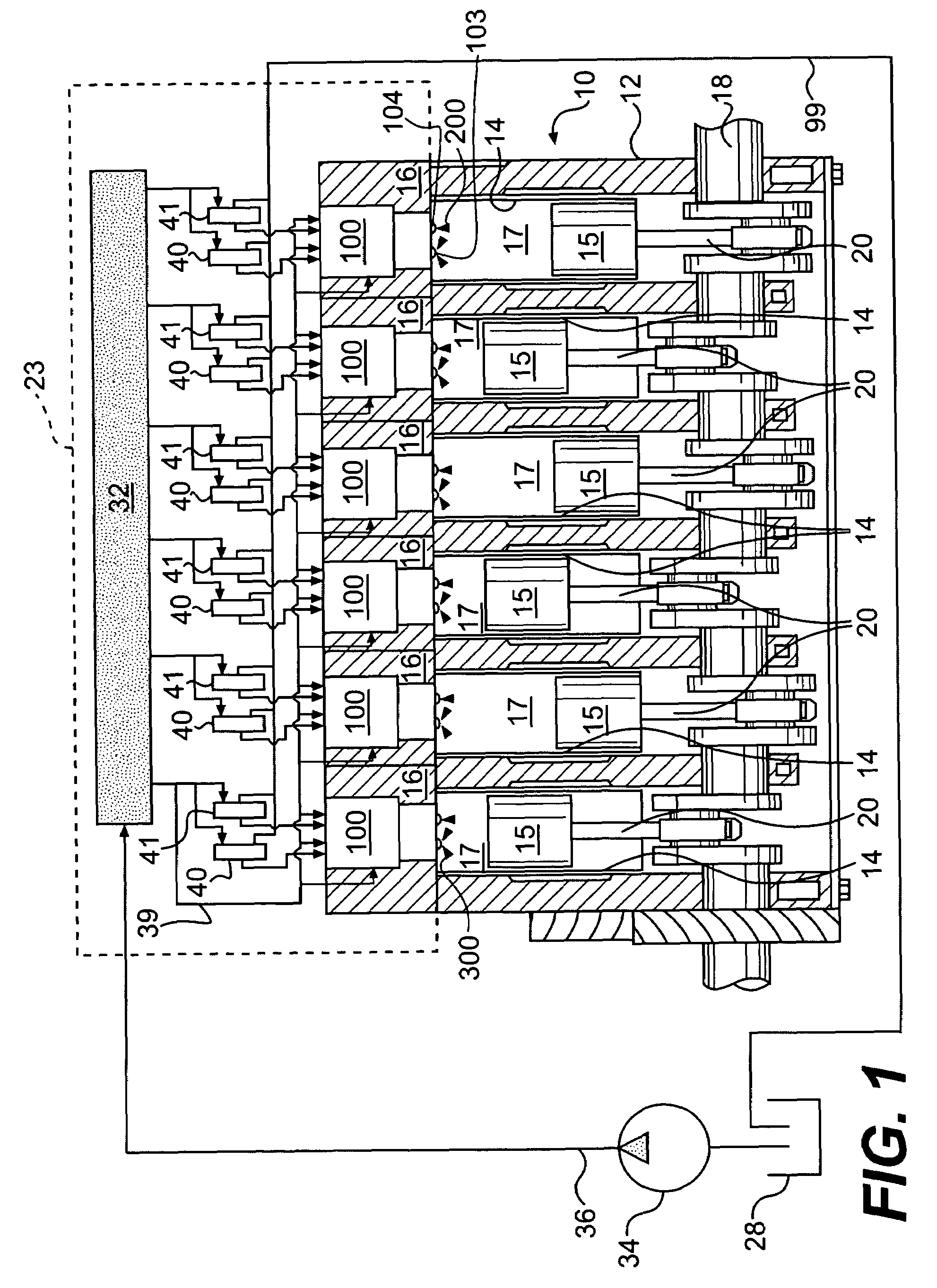

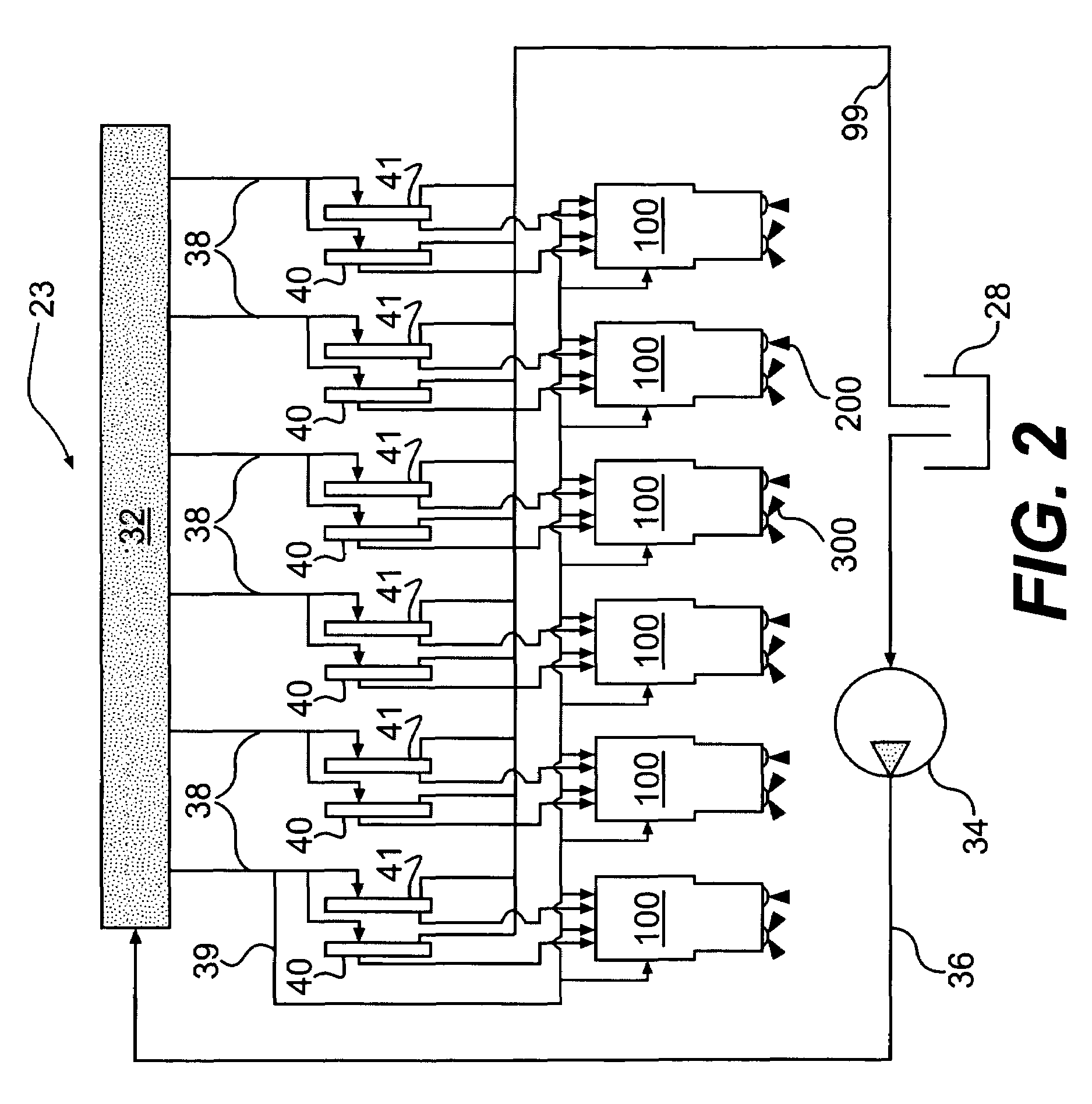

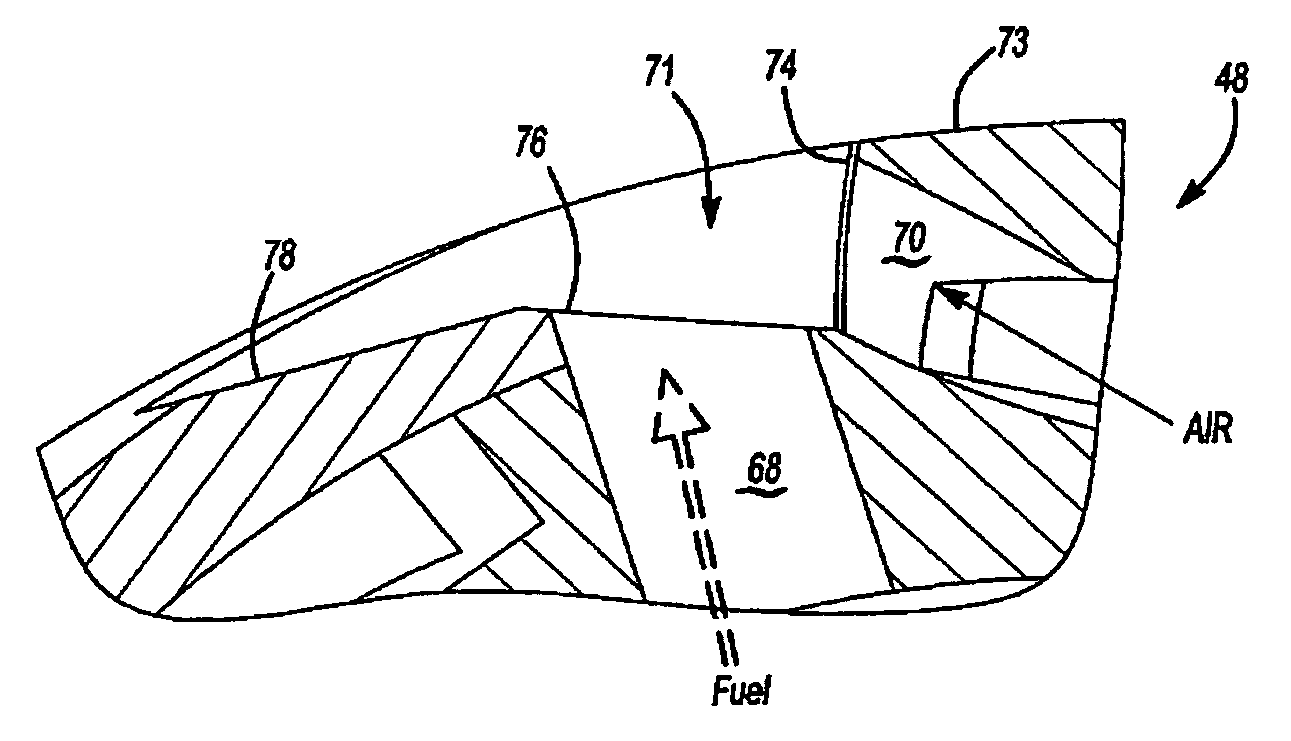

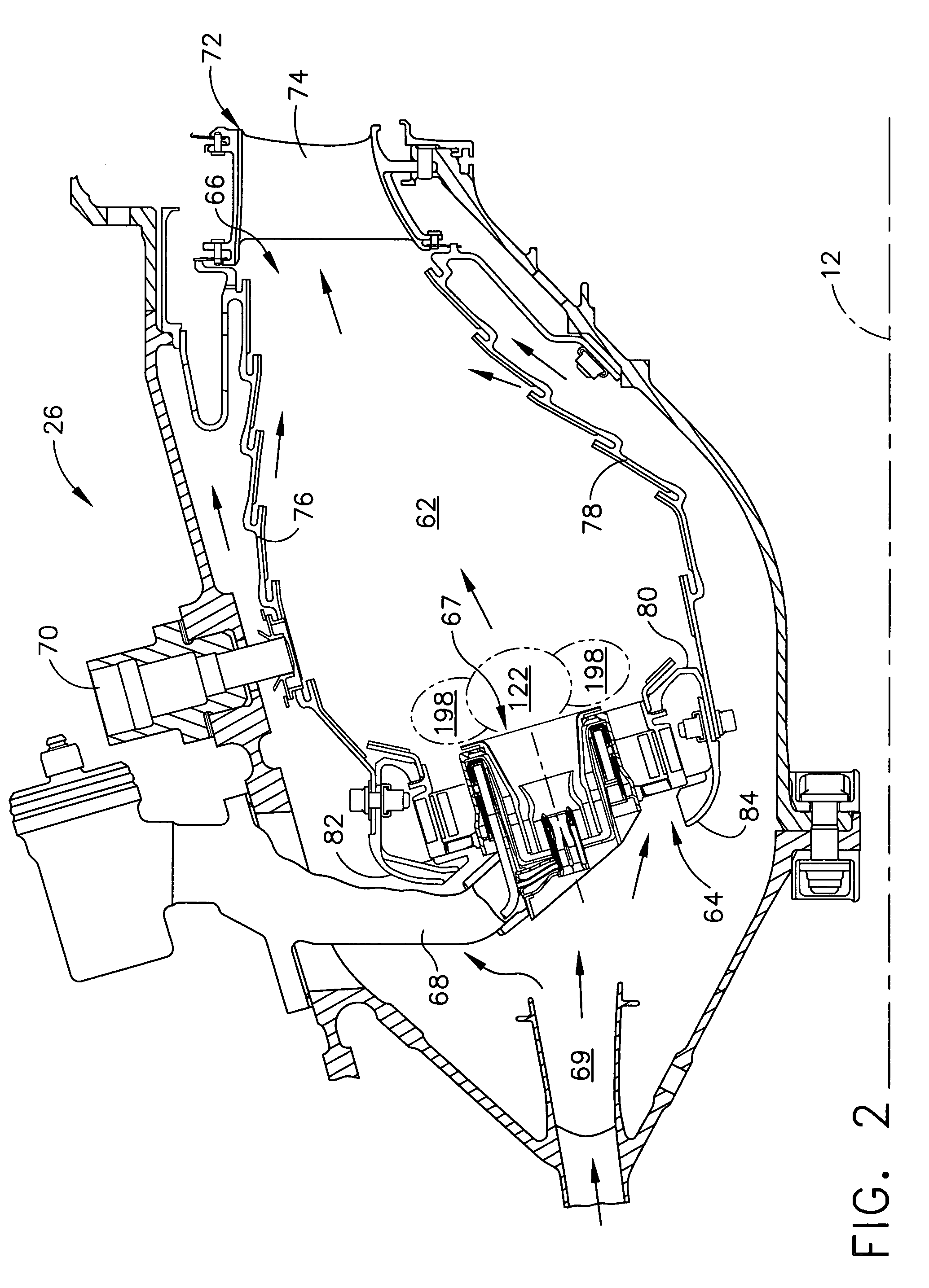

Air assist fuel injector for a combustor

ActiveUS7251940B2Increase pressureHigh speedBurnersTurbine/propulsion fuel supply systemsCombustorEngineering

A fuel injector system provides an air assist fuel nozzle which includes a fuel shroud and an air portion. Air passes around the fuel shroud to air jets in the air portion to provide a focused application of air directly onto a fuel spray from each of a multiple of main fuel jets to impart additional velocity to the fuel as it is flowing out of the fuel nozzle. The air jets increase the resulting fuel spray velocity to a level high enough to reach a prefilmer wall of a swirler even during snap deceleration conditions.

Owner:RTX CORP

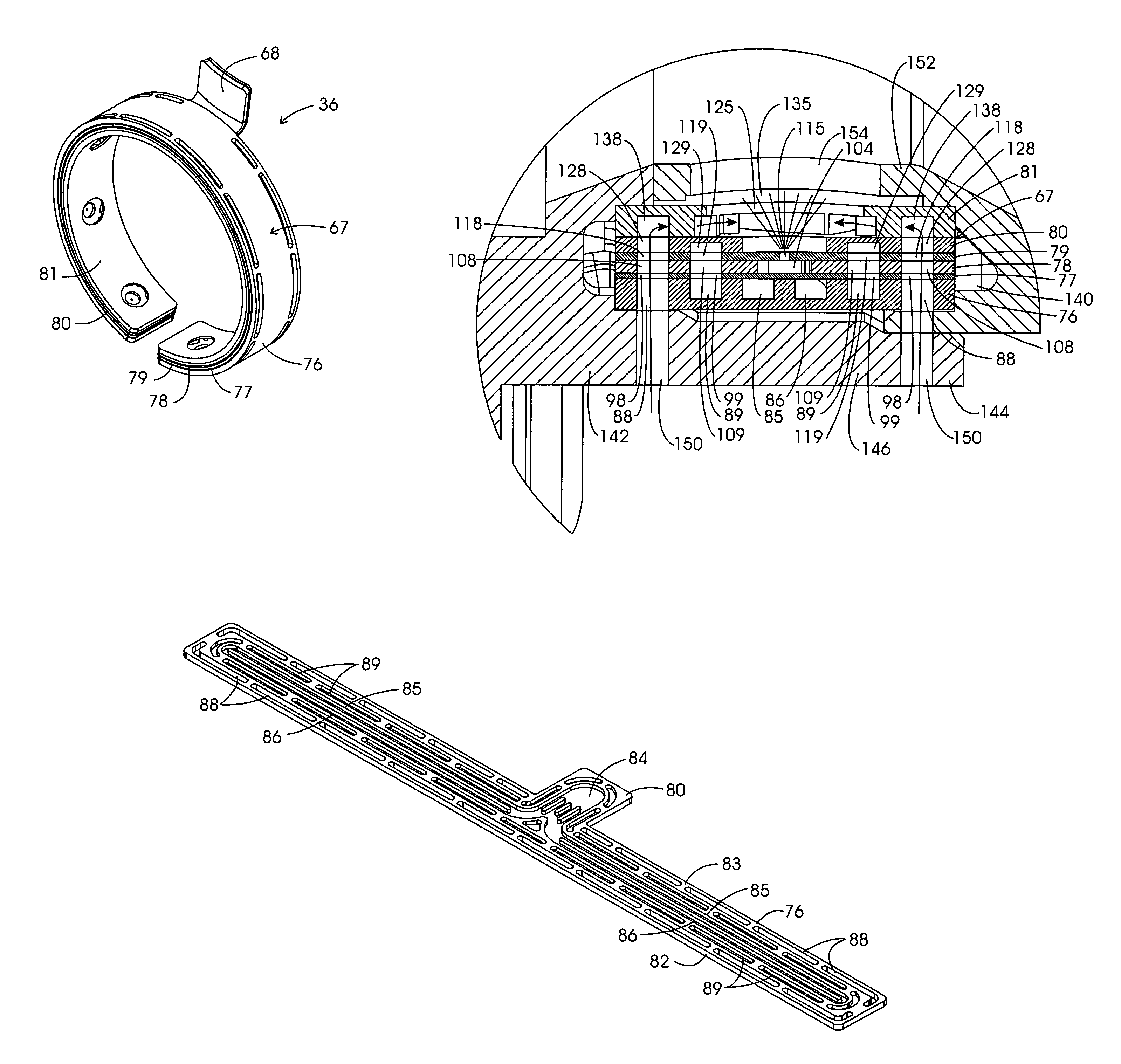

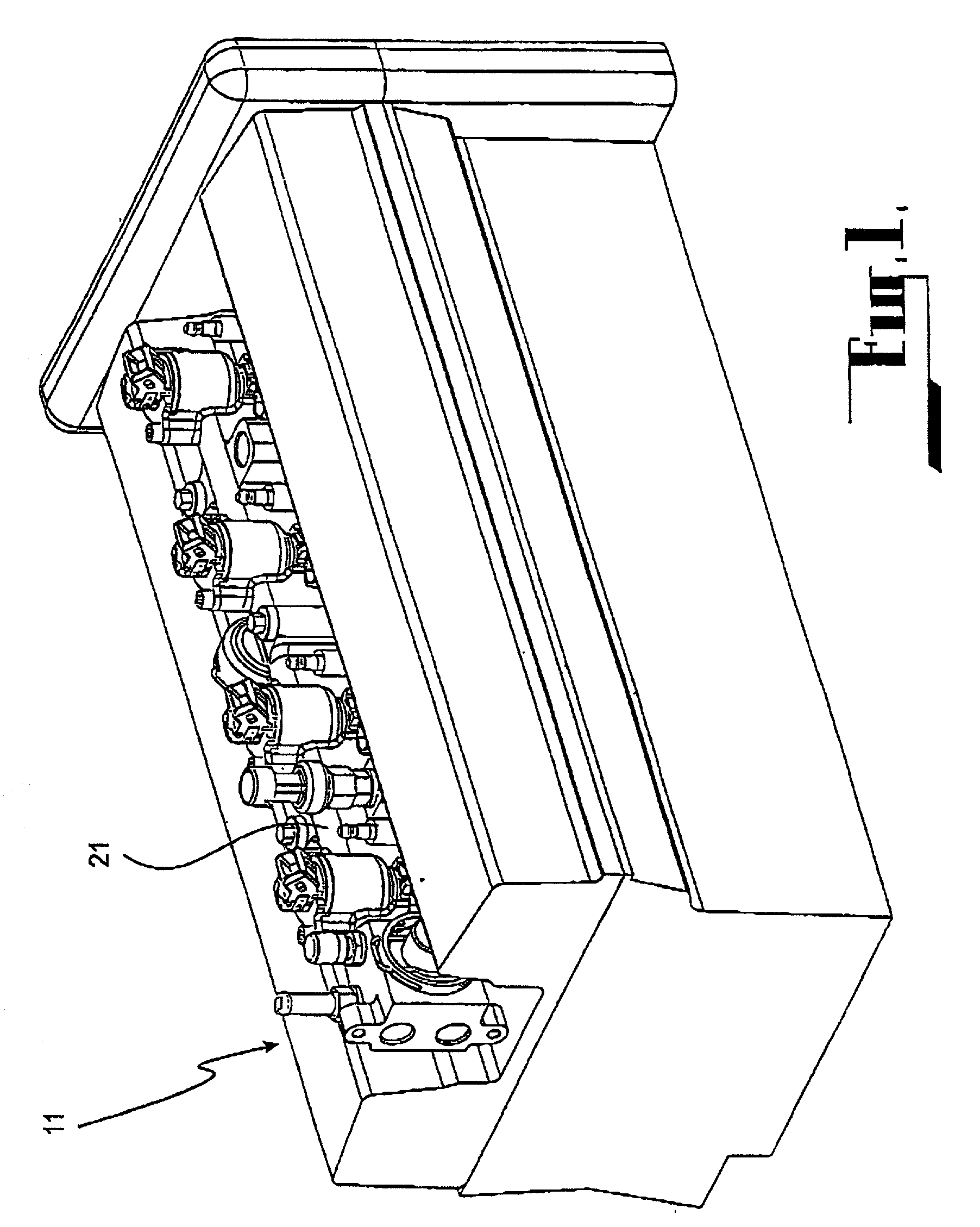

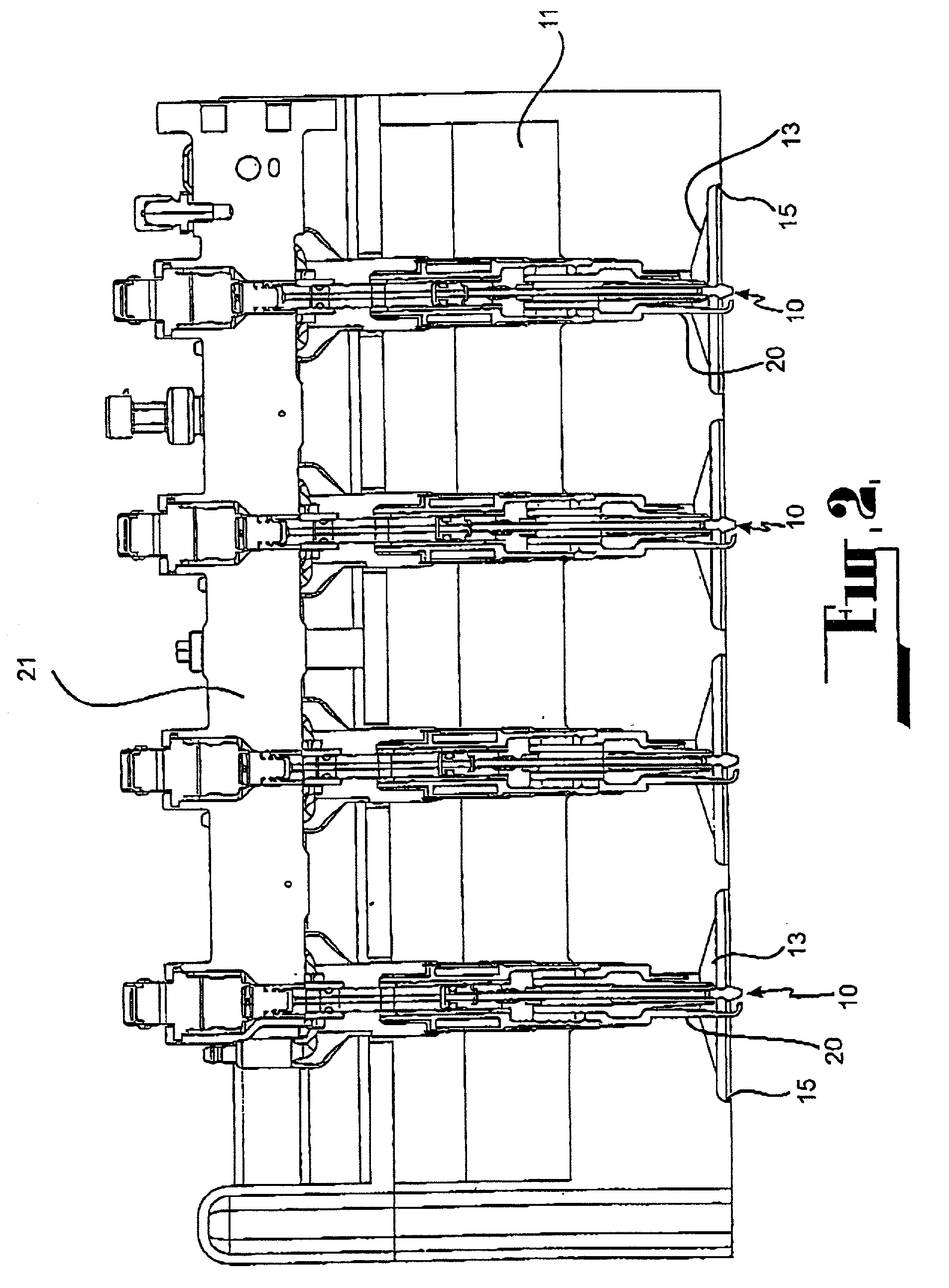

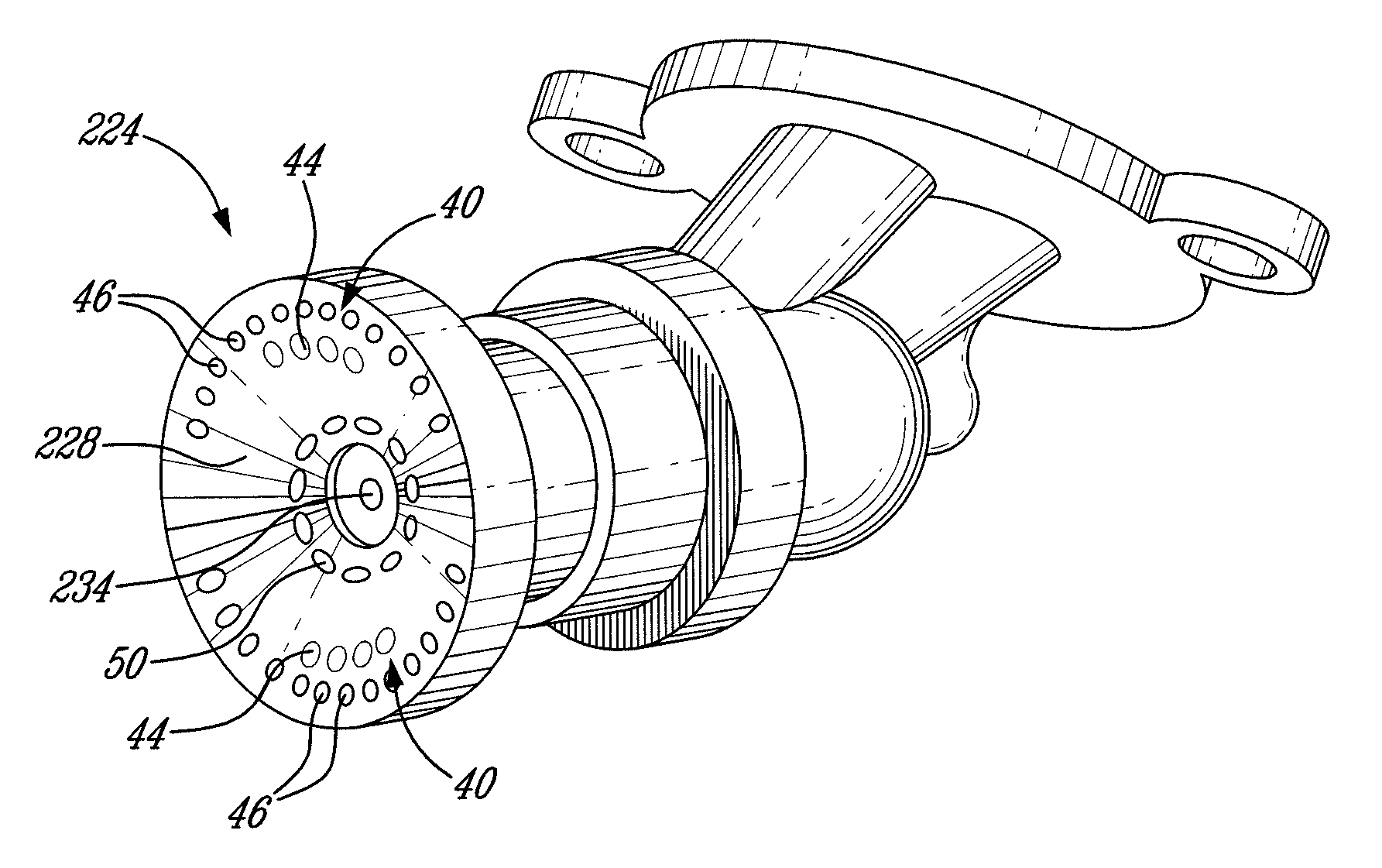

Macrolaminate radial injector

ActiveUS7028483B2Good dispersionAccurately and repeatably manufacturedTurbine/propulsion fuel supply systemsContinuous combustion chamberEngineeringBarrel Shape

An injector assembly includes a barrel-shaped housing and an injector, the injector including a feed ring formed of multiple, etched, T-shaped plates. A plurality of nozzles are arranged in an evenly-spaced array around the injector and direct fluid radially inward into the central annulus of the injector assembly. The injector includes an air inlet port with an internal feed passage fluidly connected to swirl chambers and exit orifices to provide individual sprays of fuel from the nozzles. Integral air swirlers impart a swirling component of motion to the fuel sprays. A venturi configuration is provided by the housing. The nozzles are provided along the venturi configuration, which maintains fluid separation from the walls of the housing downstream from the venturi.

Owner:PARKER INTANGIBLES LLC

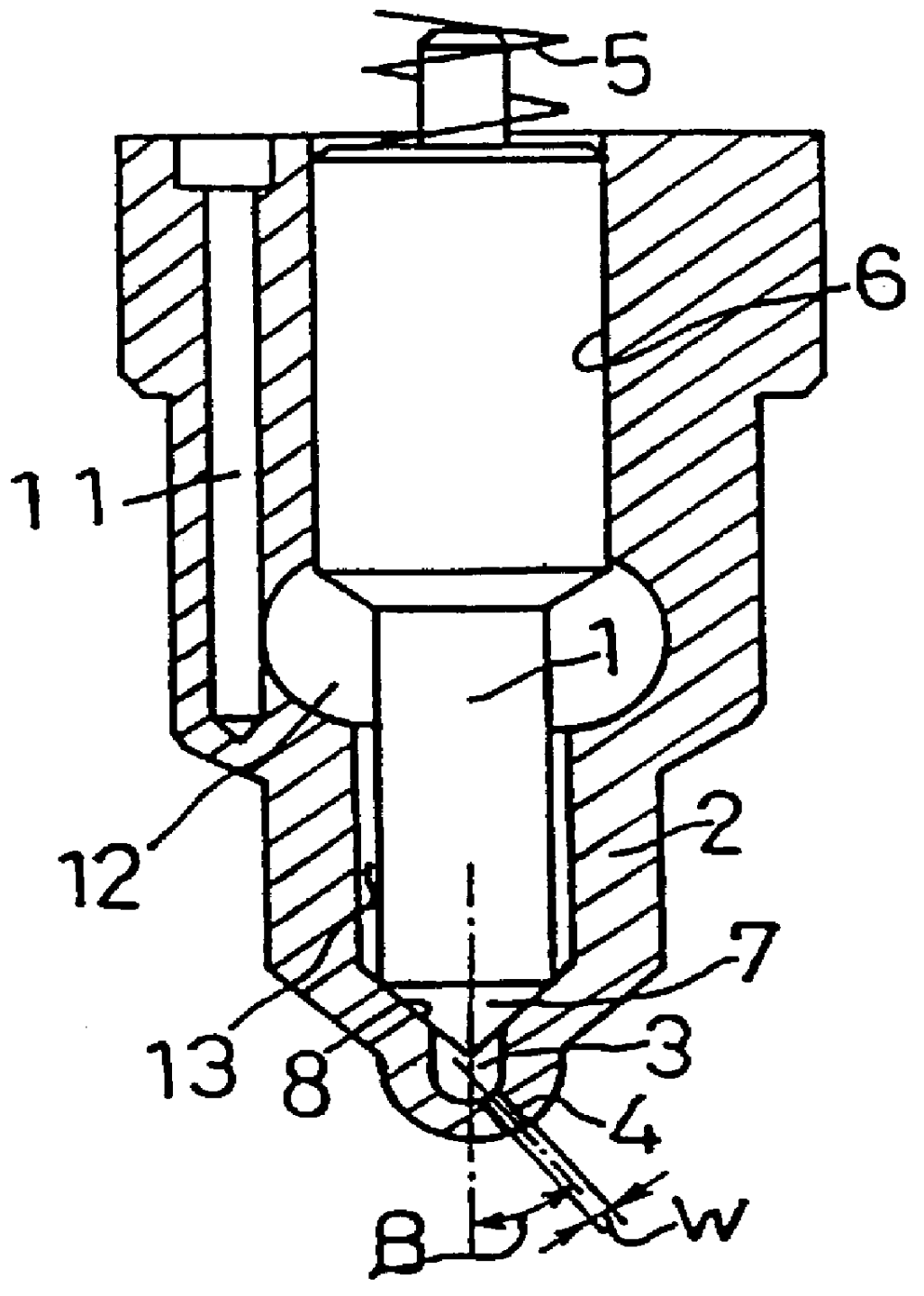

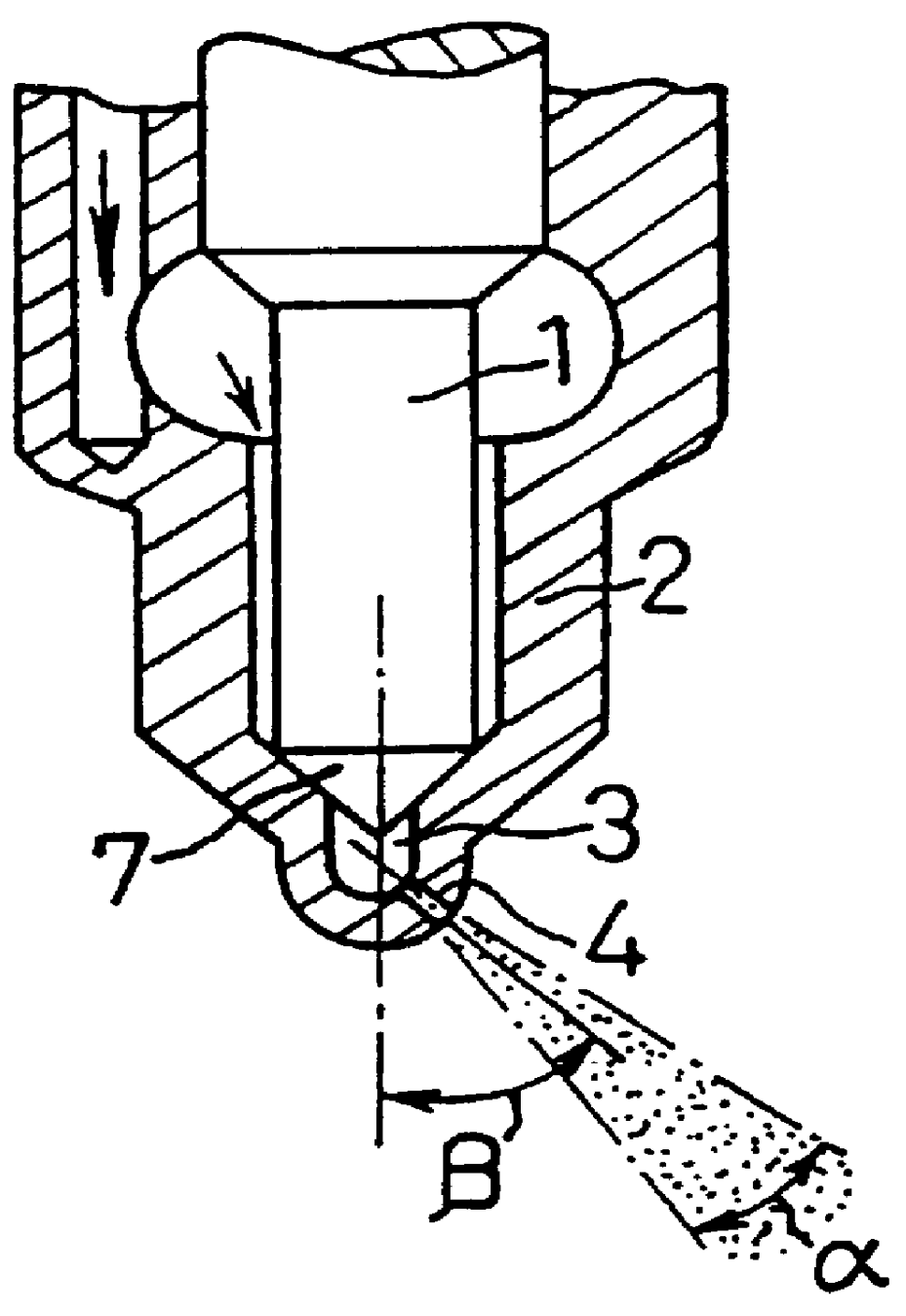

Fuel injection valve and nozzle

InactiveUS6045063AReduce traffic lossLower resistanceInternal combustion piston enginesSpray nozzlesEngineeringFuel injection

A fuel injector which is enabled to form a fuel spray efficiently and properly into a flat sector shape by improving the angle, dispersion and atomization of the spray and by optimizing the spray tip penetration. A slit-shaped nozzle outlet 4 is constructed such that its transverse walls from its inner end 9 to its outer end 10 have an included angle gamma of 20 to 180 degrees, such that an angle beta of 0 to 90 degrees is made between the axis of the fuel injector and the opening direction of the slit-shaped nozzle outlet 4, such that the nozzle outlet 4 is diverged outward from a plane joining the axis to the fuel injector and the inner end 9, and such that the opposite portions of the inner end 9 have a width W of 0.05 mm to 0.24 mm. By combining these constructions suitably, the fuel spray can be formed efficiently and properly into a flat sector shape thereby to improve the fuel injection characteristics.

Owner:TOYOTA CENT RES & DEV LAB INC

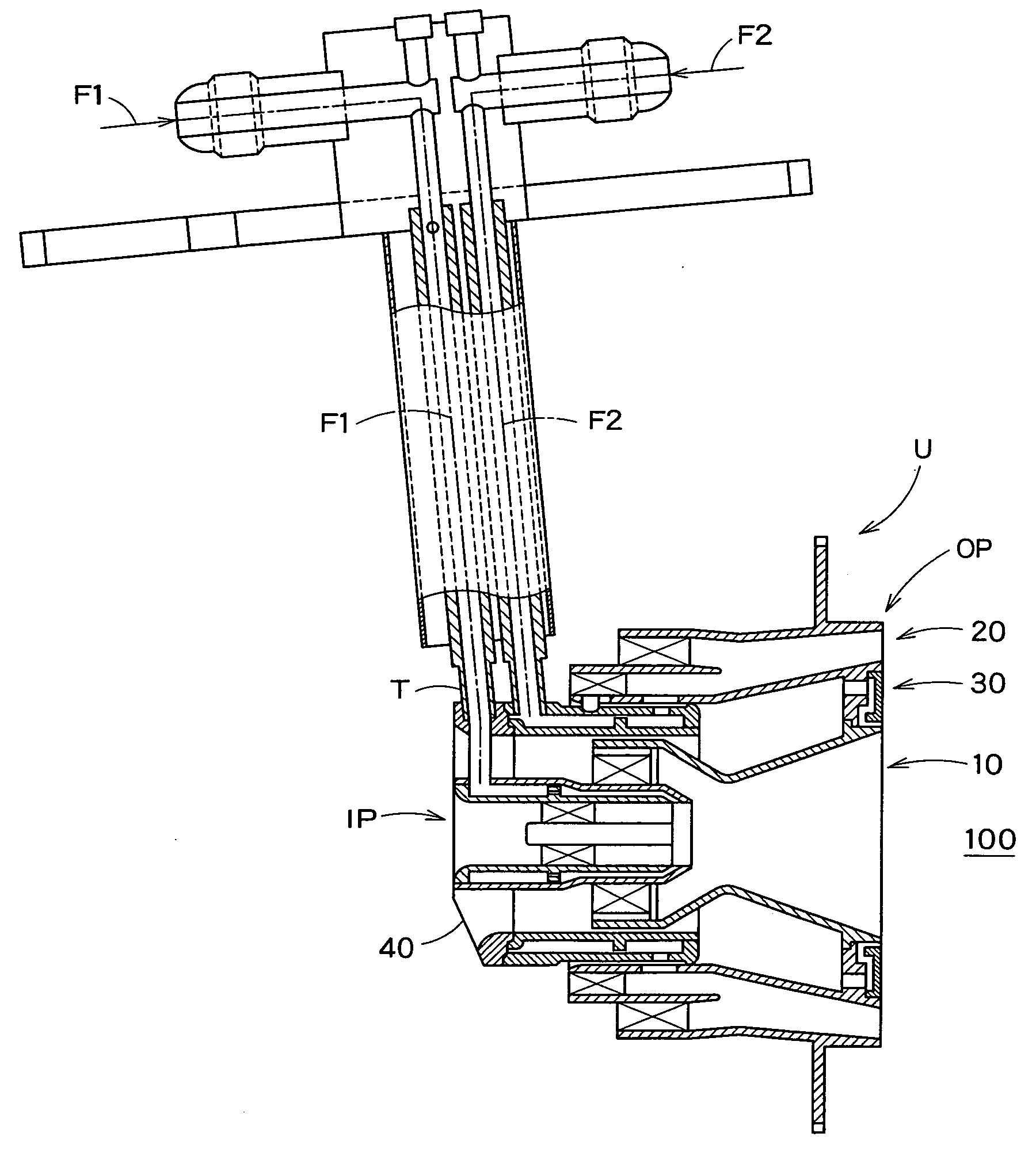

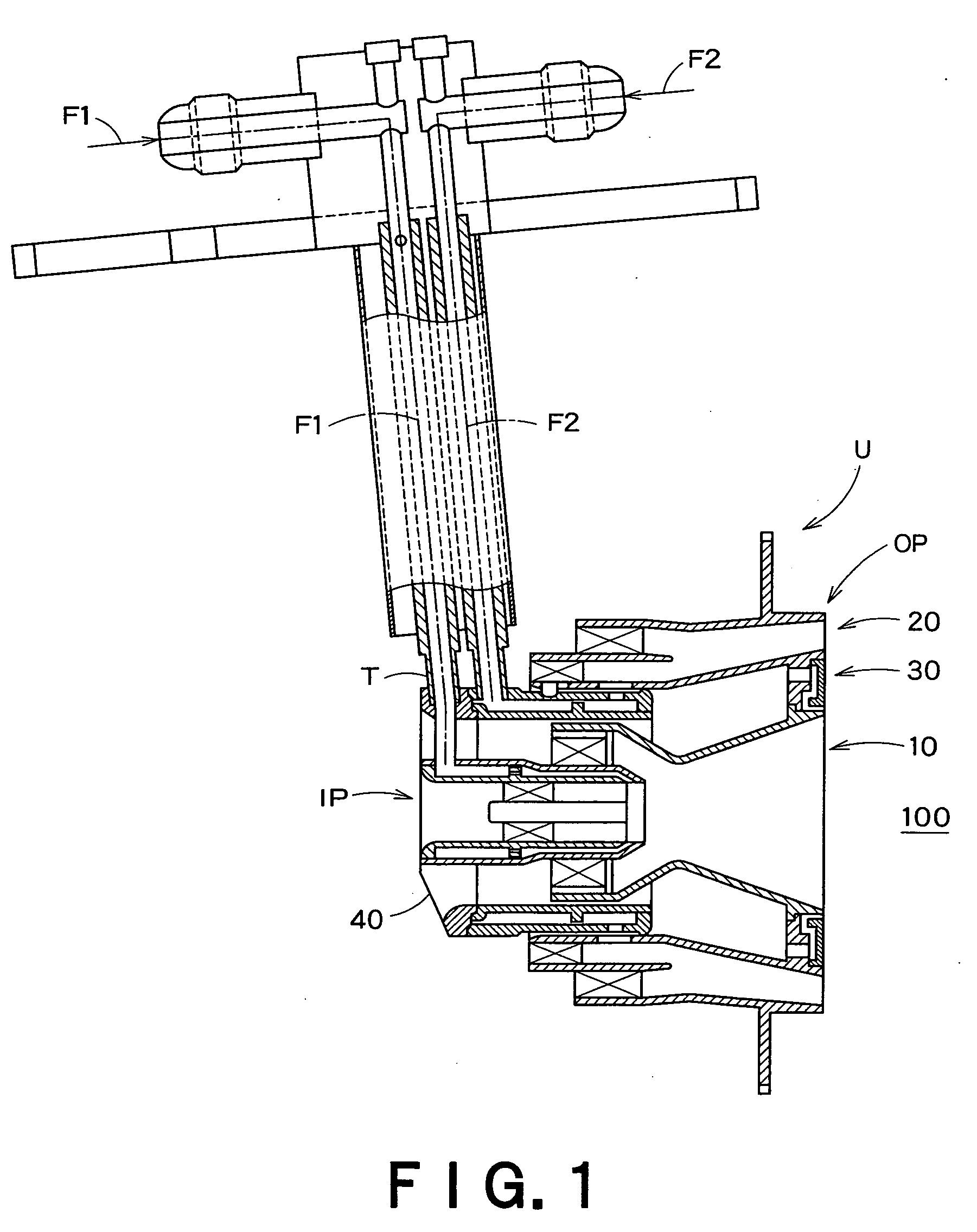

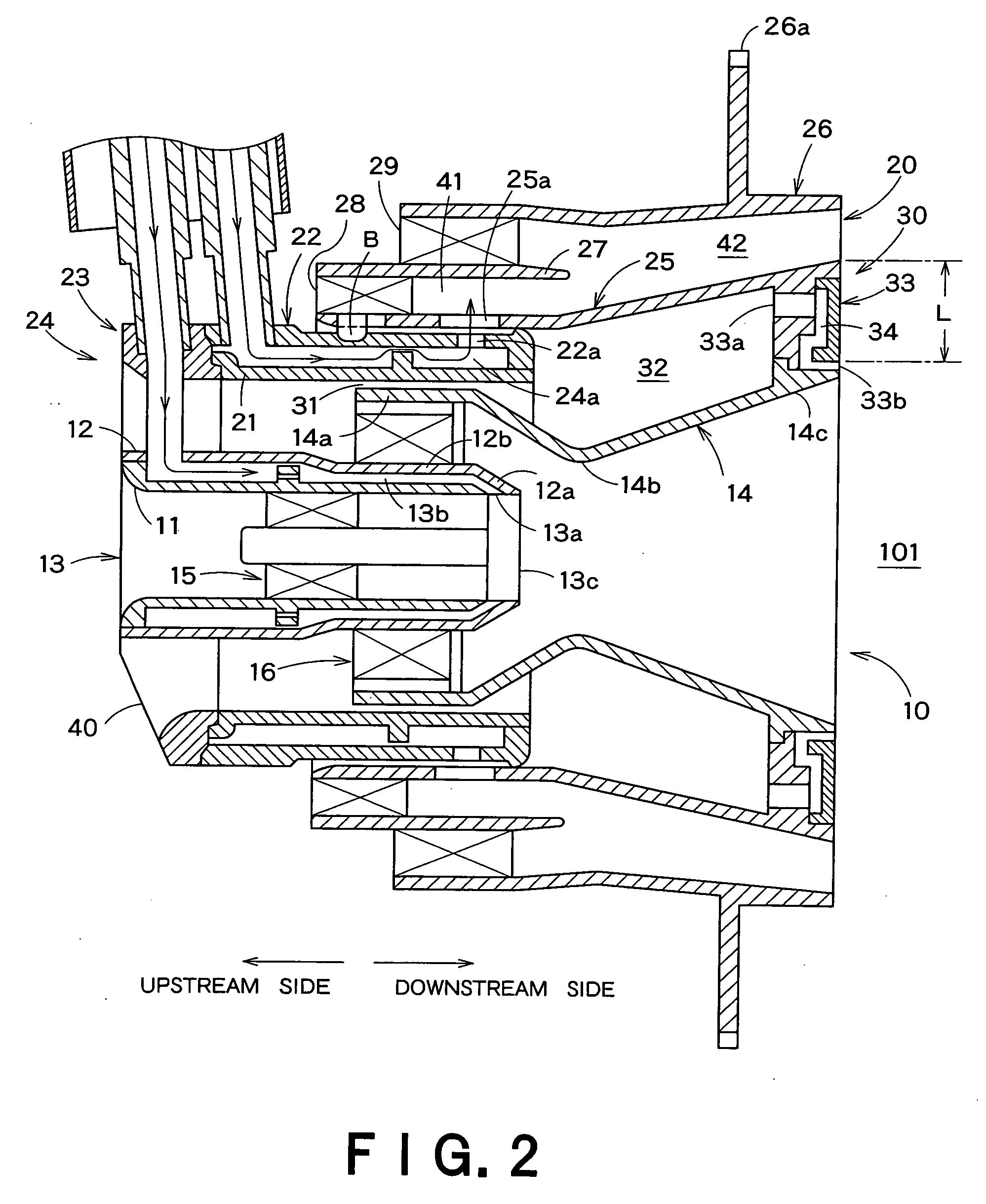

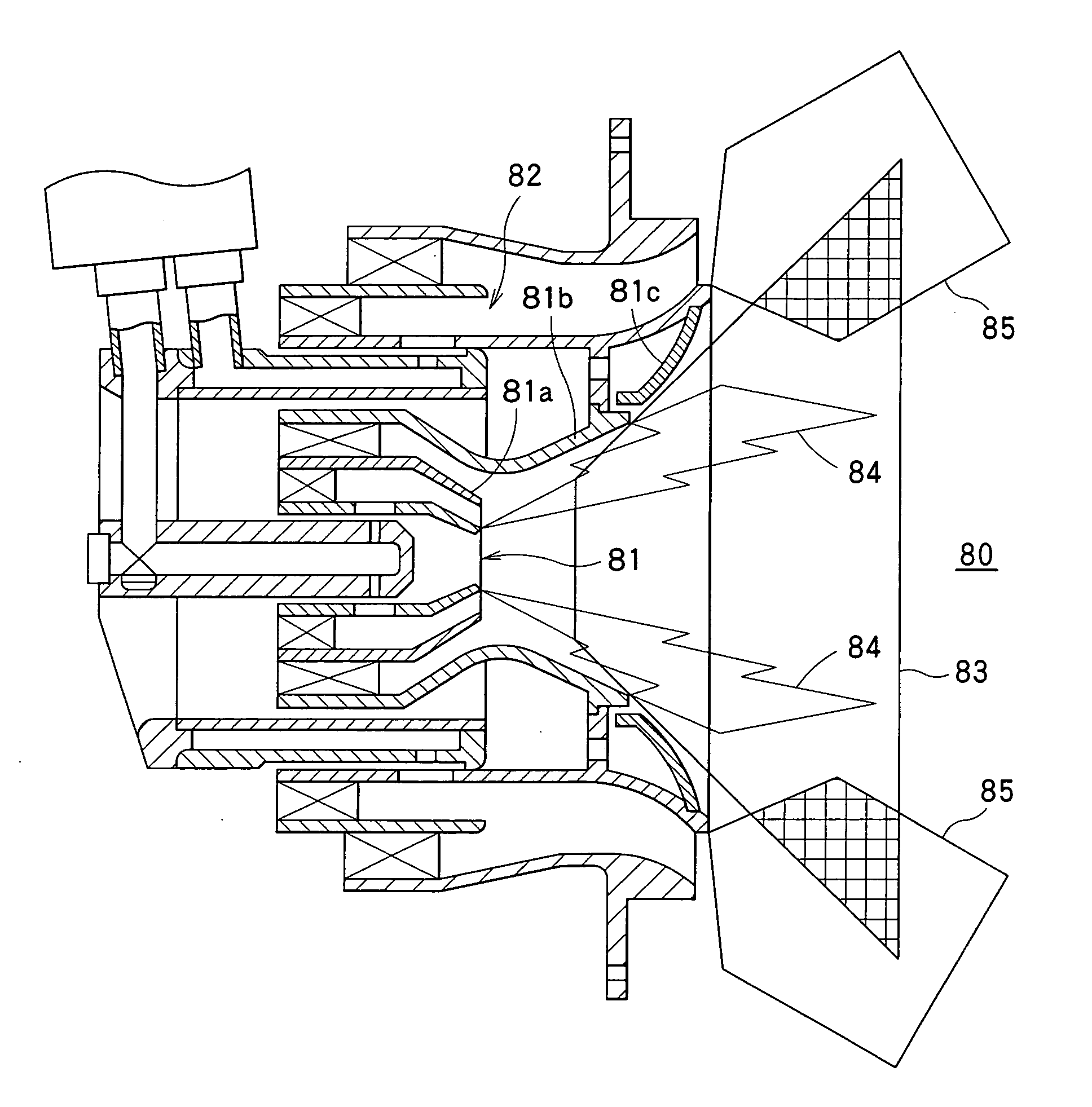

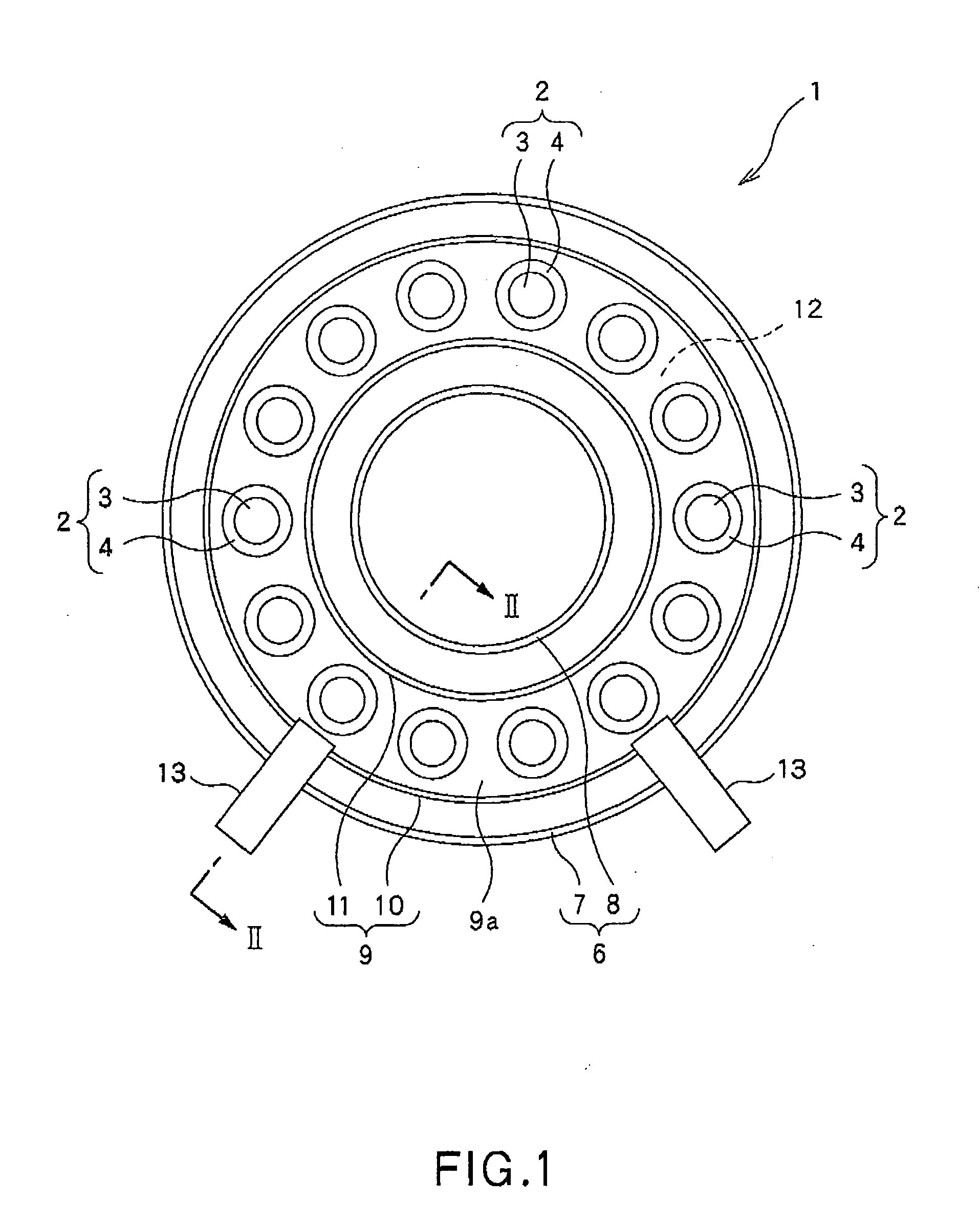

Fuel spraying apparatus of gas turbine engine

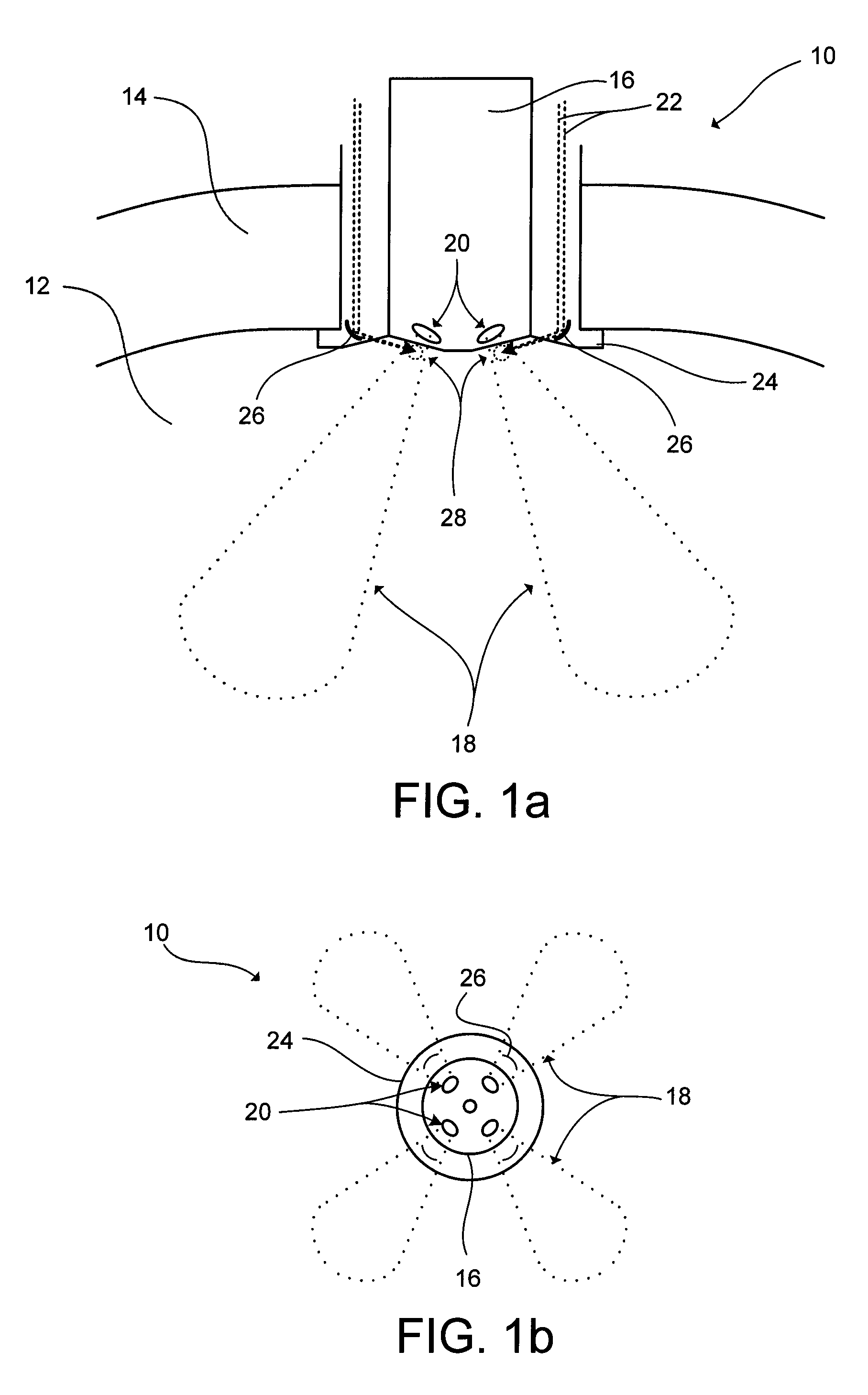

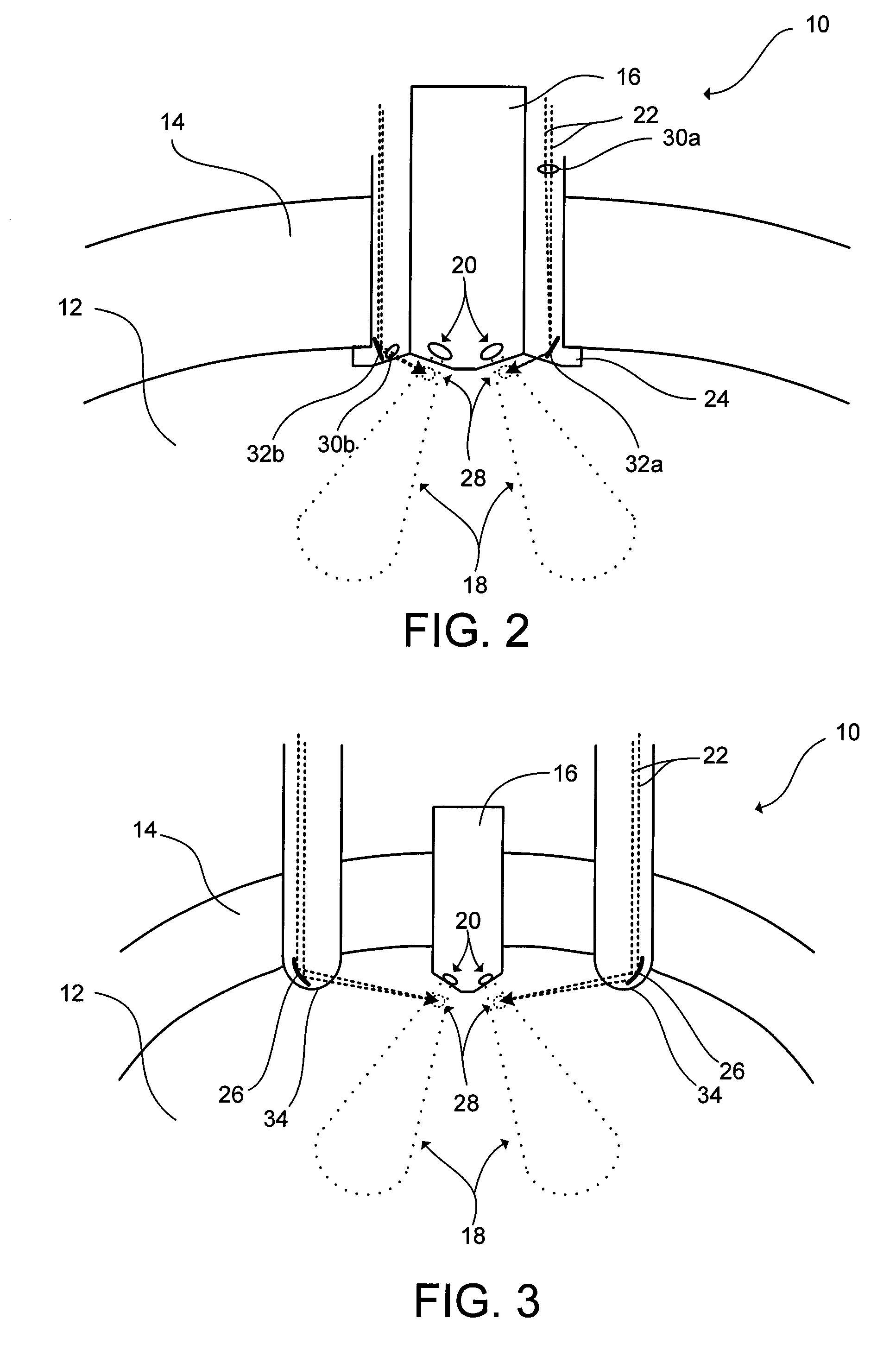

ActiveUS20070289305A1Improving flamablenessImproving ignitablenessBurnersContinuous combustion chamberGas turbinesFuel gas

A fuel spraying apparatus of a gas turbine engine includes a first fuel spraying section configured to spray fuel for diffusion combustion and a second fuel spraying section configured to spray fuel for premixed combustion. The second fuel spraying section is disposed so as to surround the first fuel spraying section. The apparatus further includes an air curtain generating section disposed between the first fuel spraying section and the second fuel spraying section. The air curtain generating section configured to generate an air curtain which defines an outer edge of a diffusion combustion area in a combustion chamber.

Owner:KAWASAKI HEAVY IND LTD

Twin needle valve dual mode injector

A fuel injector having an injector body defining a hollow interior configured to receive pressurized fuel, a first nozzle configured for providing a first fuel spray pattern, and a second nozzle configured for providing a second fuel spray pattern different from the first fuel spray pattern. The first and second nozzles may be configured to inject fuel supplied from a common source into a combustion space. The fuel injector may further include first and second needle valve members corresponding to the first and second nozzles, respectively. The first and second needle valve members may be positioned within the hollow interior of the injector body, with the second needle valve member being spaced from, but adjacent to the first needle valve member.

Owner:CATERPILLAR INC

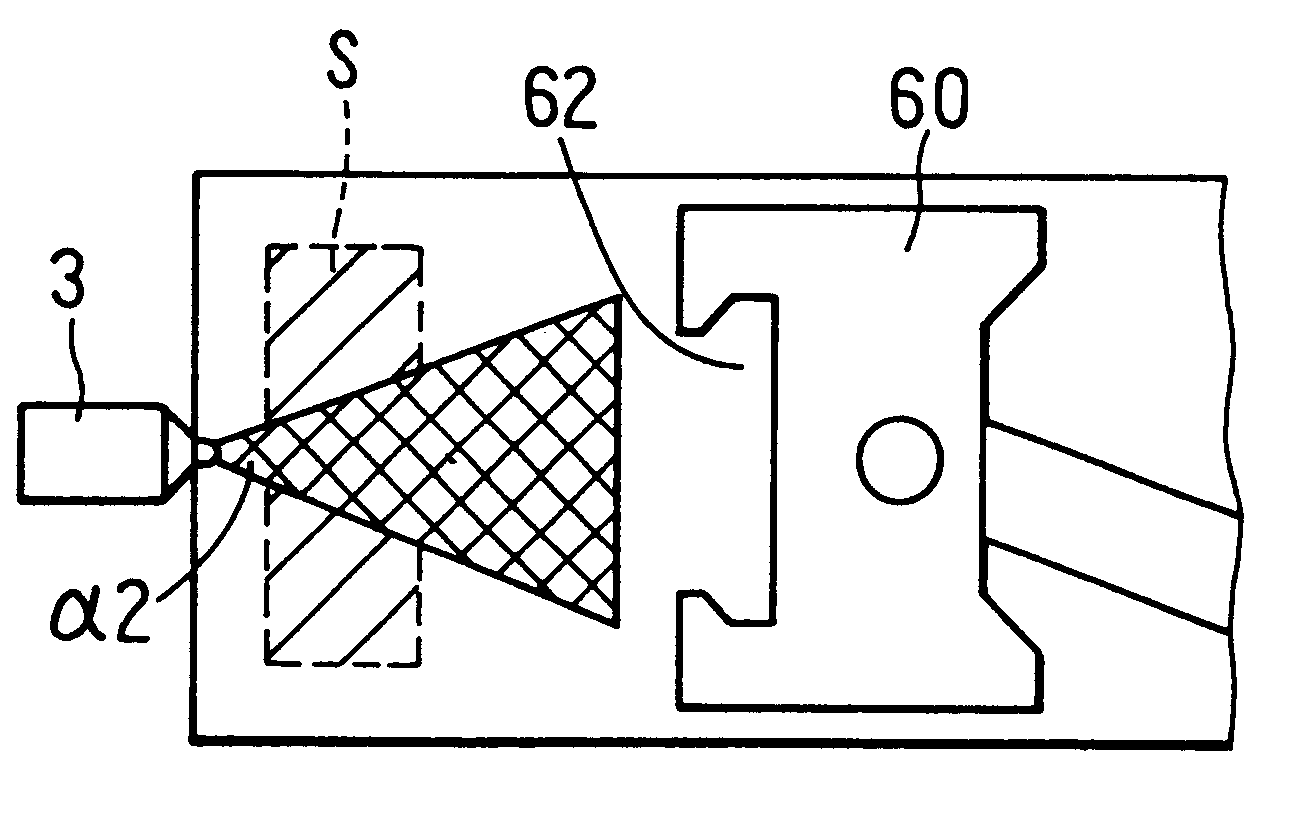

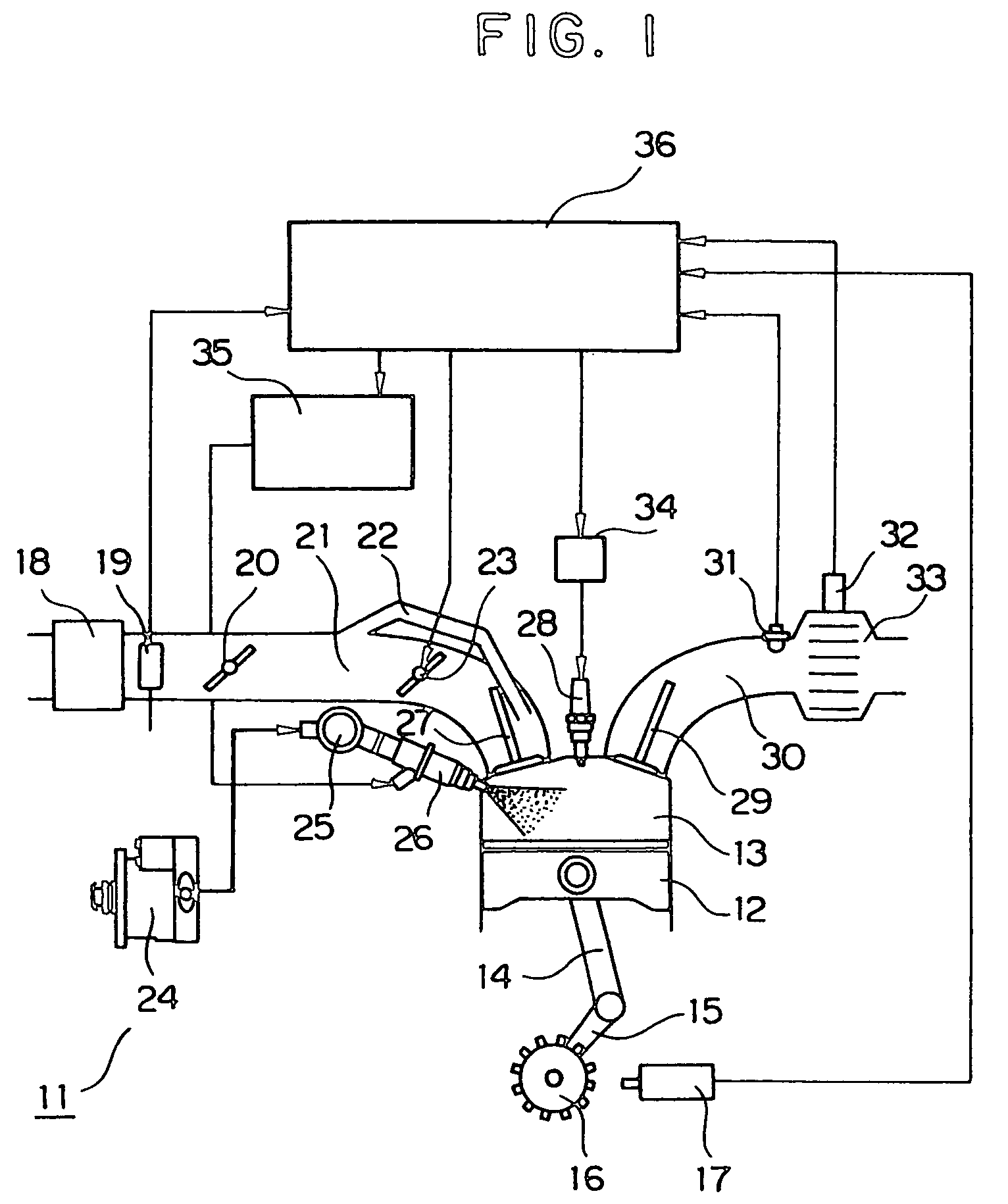

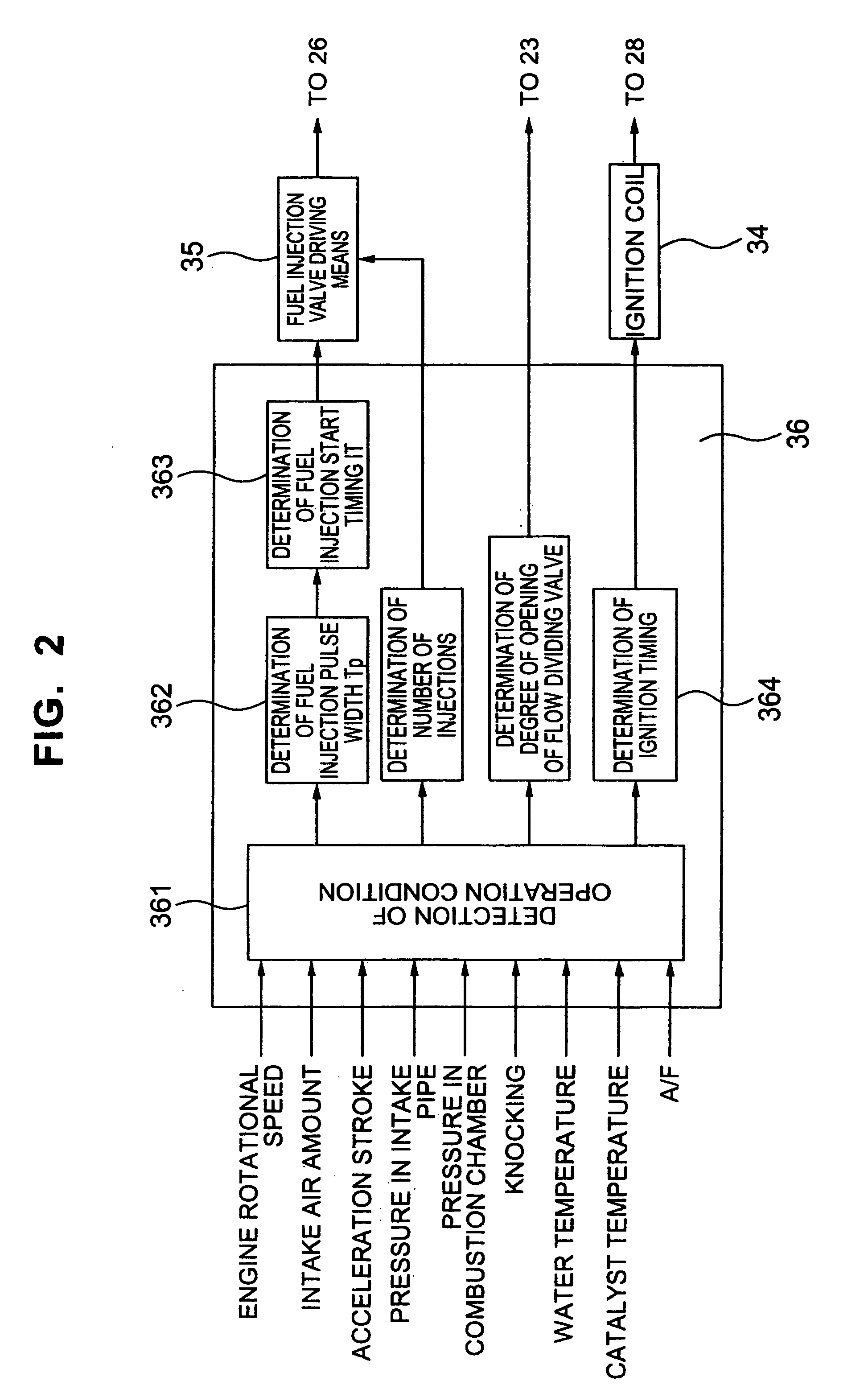

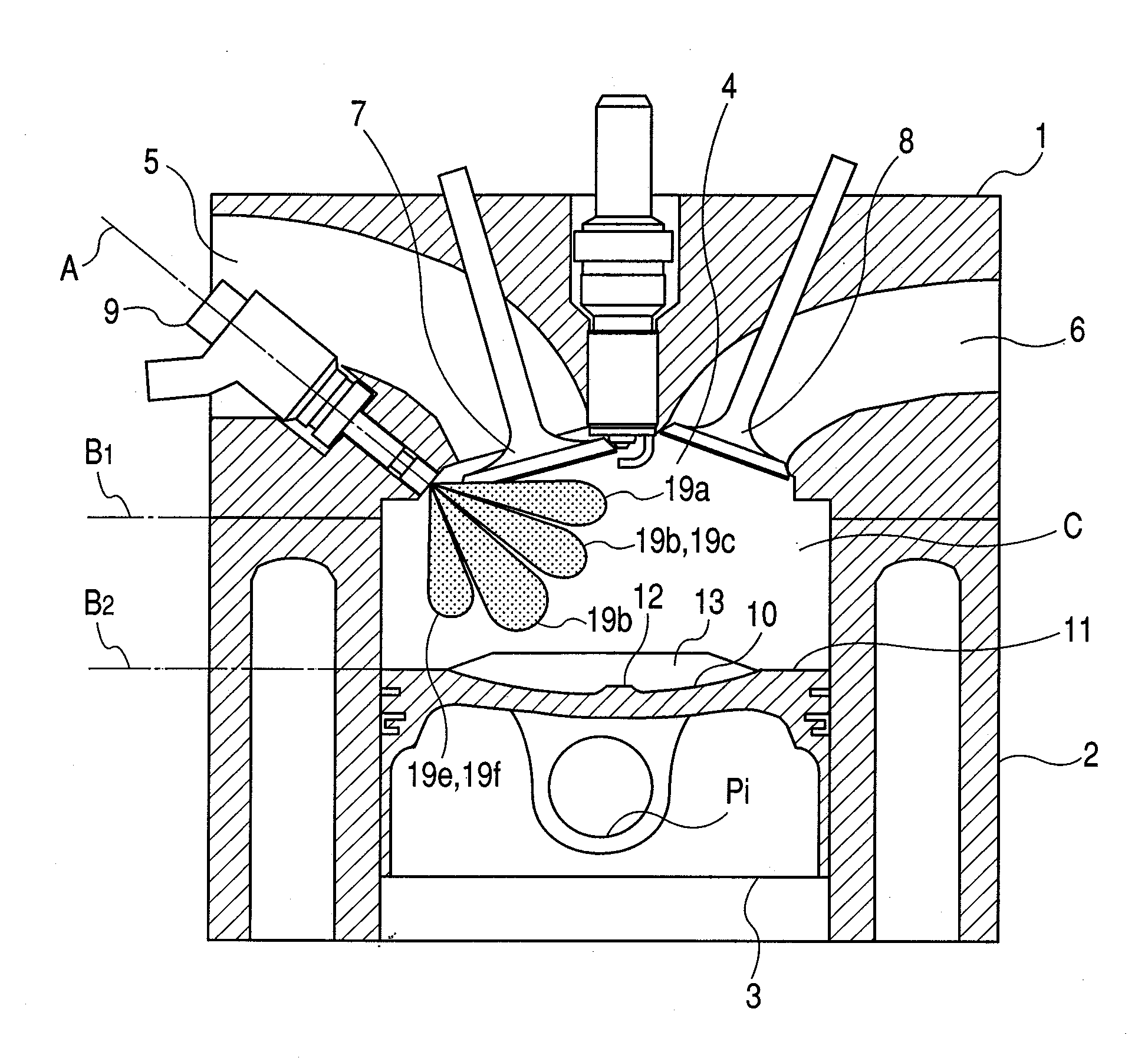

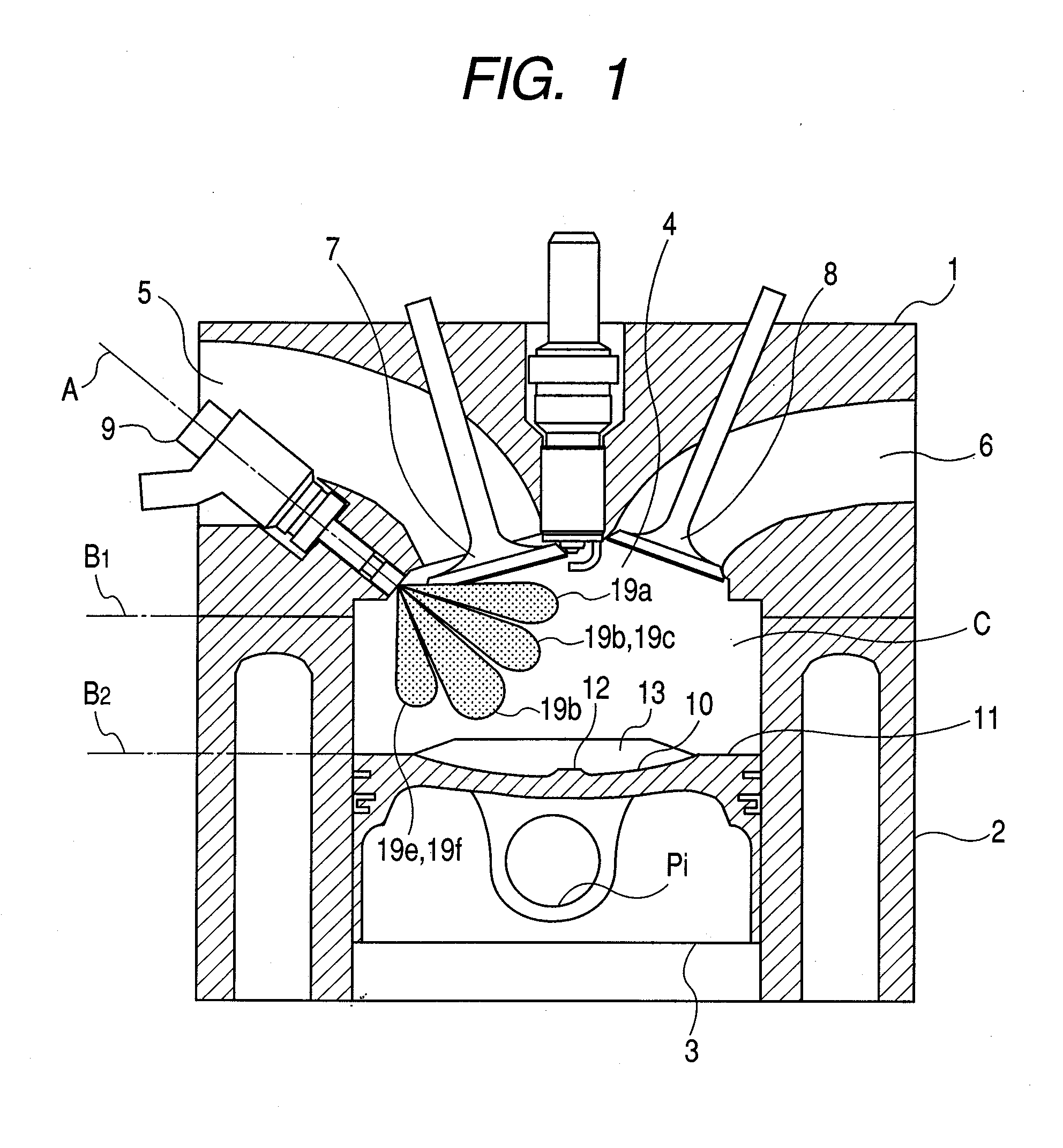

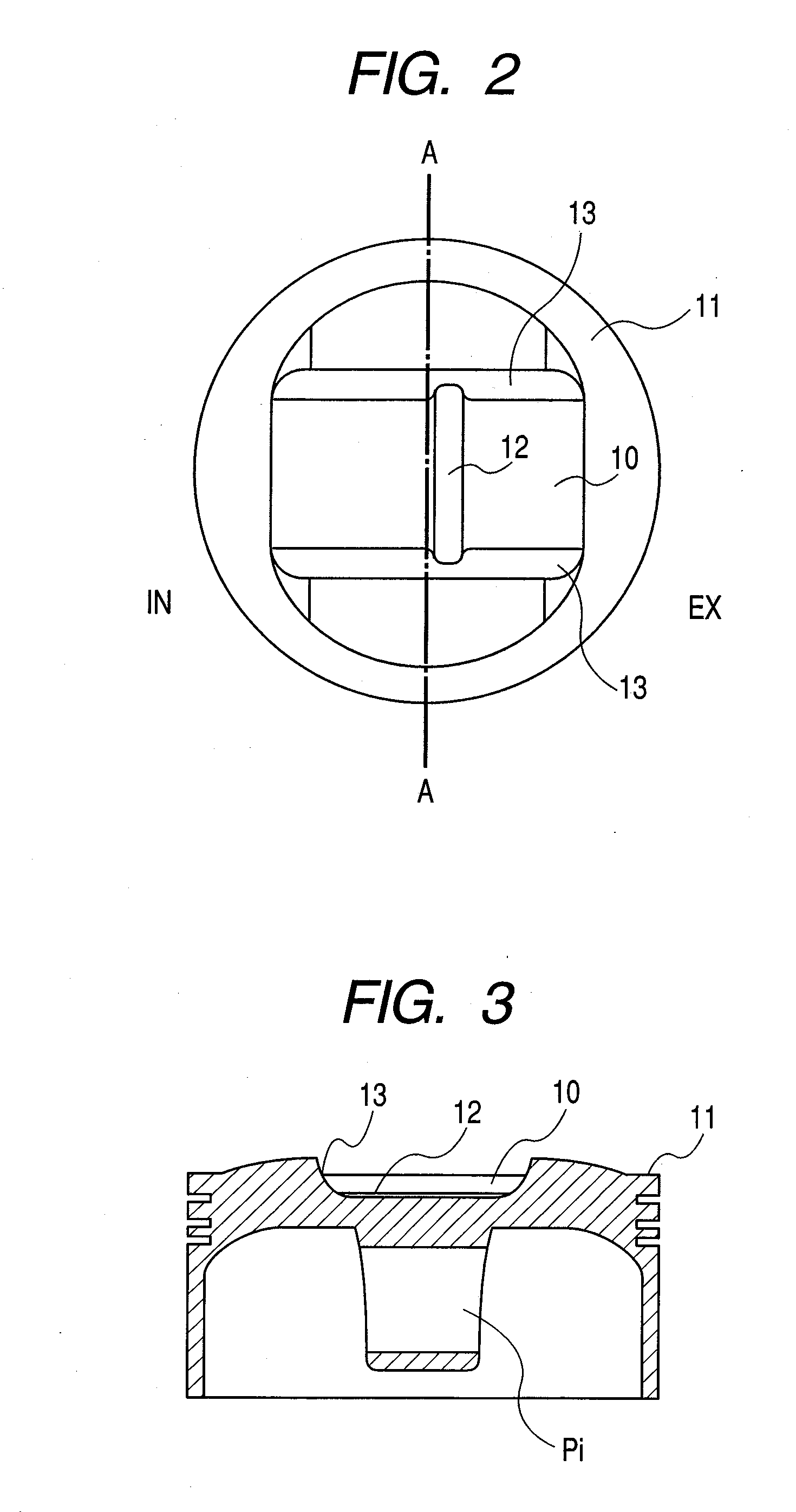

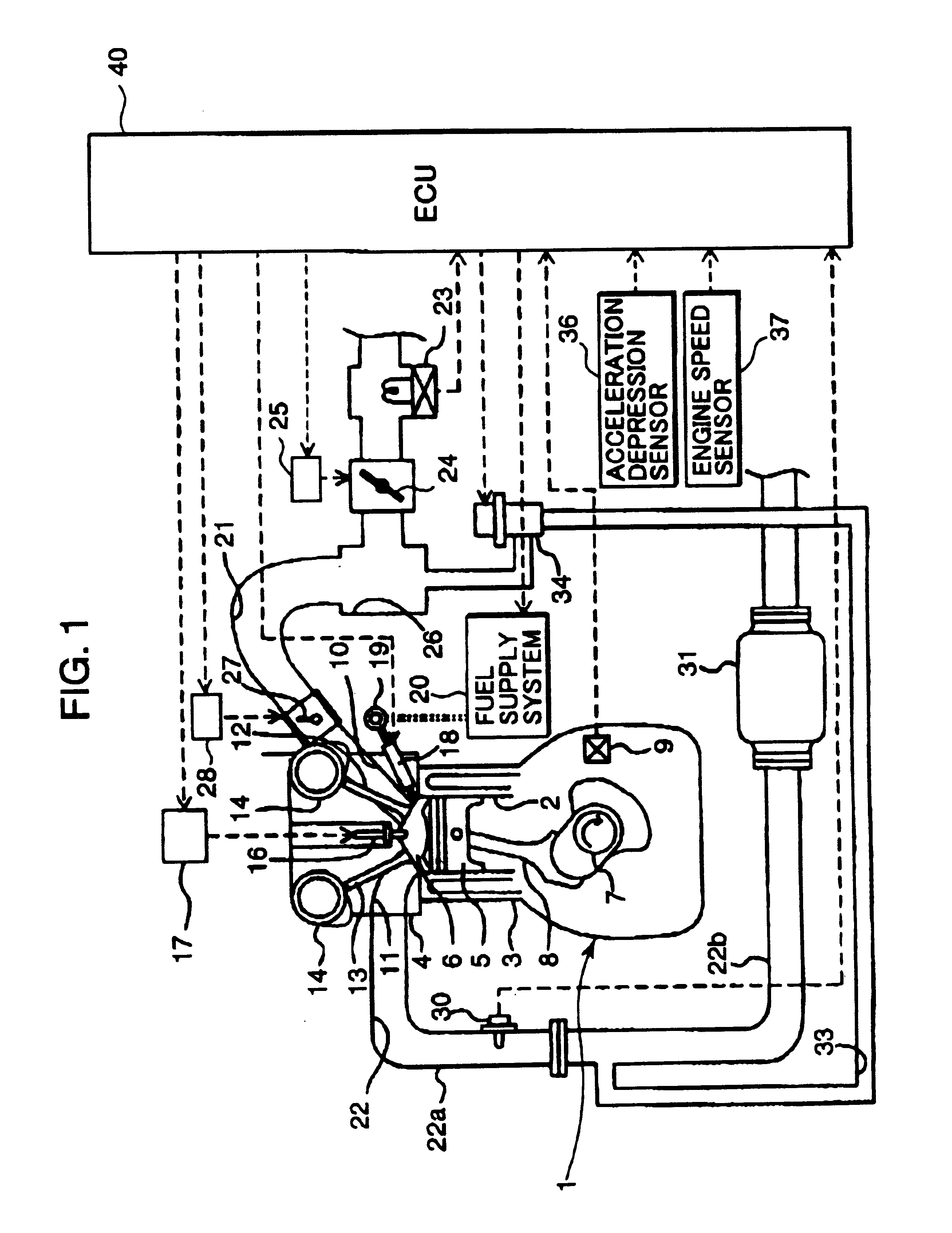

Cylinder injection type internal combustion engine, control method for internal combustion engine, and fuel injection valve

InactiveUS7013863B2Electrical controlInternal combustion piston enginesExternal combustion engineFuel efficiency

There is provided a cylinder injection type internal combustion engine capable of performing stratified charge operation at the time of a vehicle speed of 120 km / h and / or an engine rotational speed of 3200 rpm to enhance the fuel efficiency and / or to observe the emission regulations. In the internal combustion engine, a stratum of air and / or air flow is formed between a fuel spray injected from an injection valve and the top face of a piston and / or the wall surface of a combustion chamber, and a face shape contrived to guide the air flow is formed on the top face of the piston.Also, the stratified charge operation can be performed even at the time of cold start or cranking.

Owner:HITACHI LTD

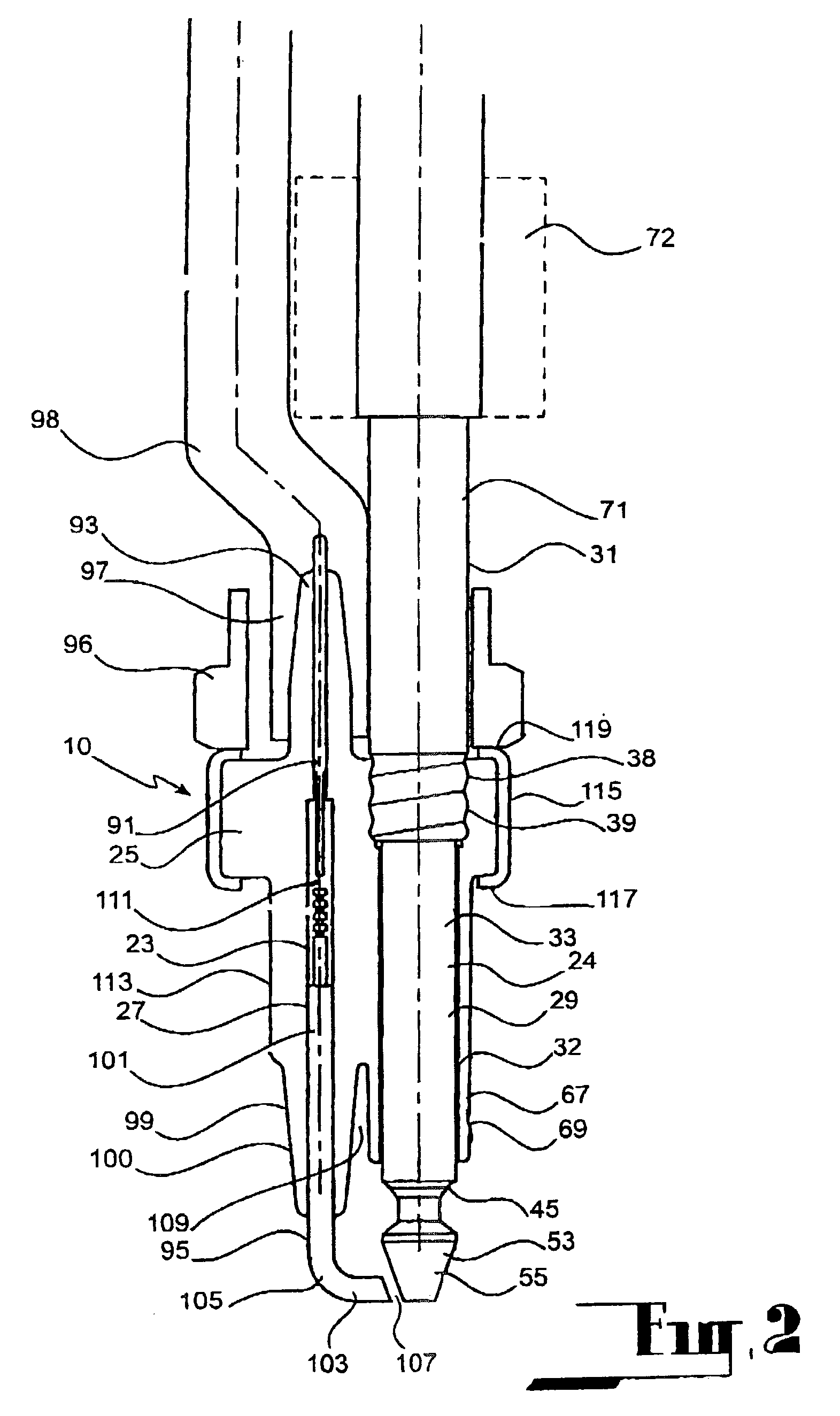

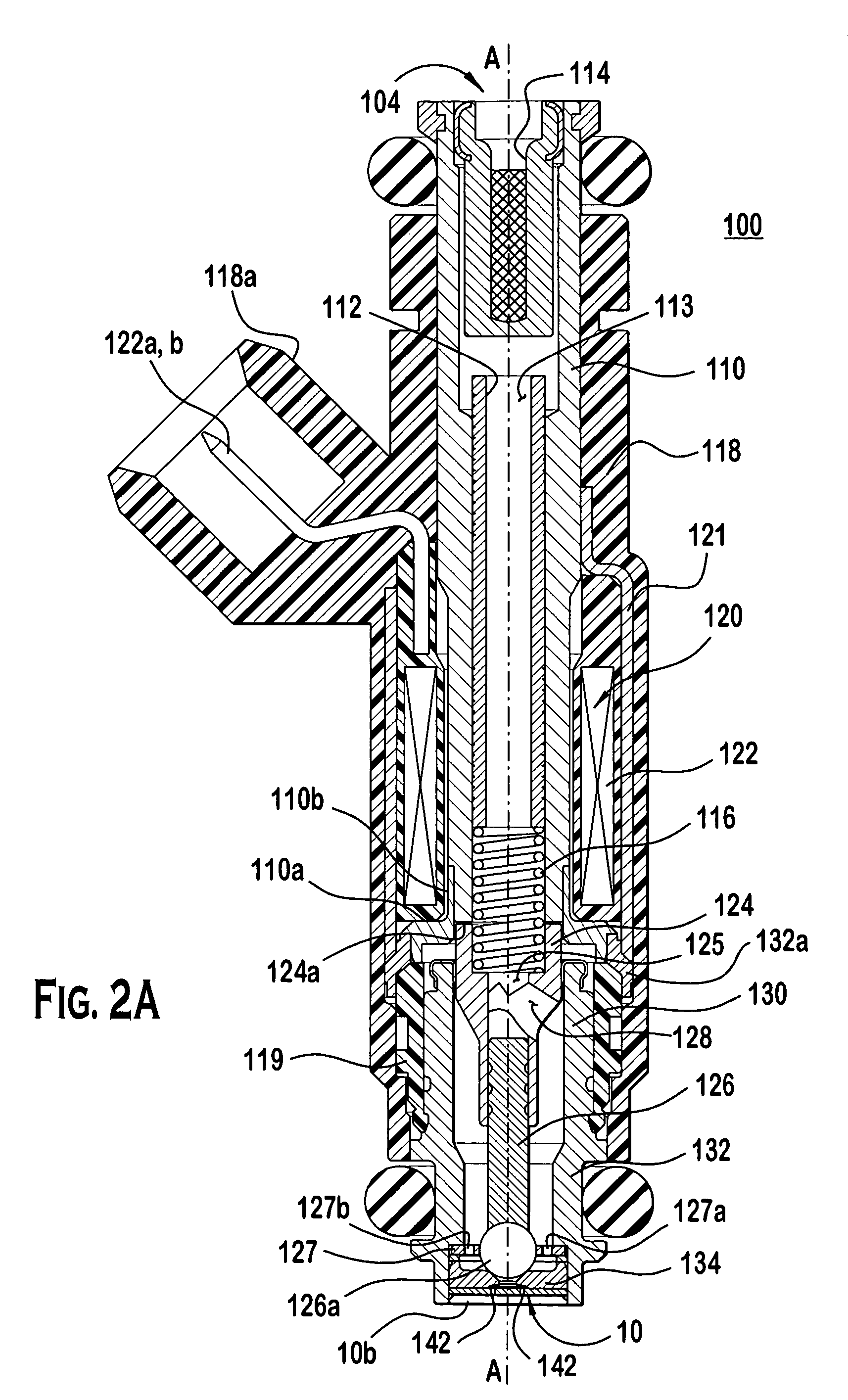

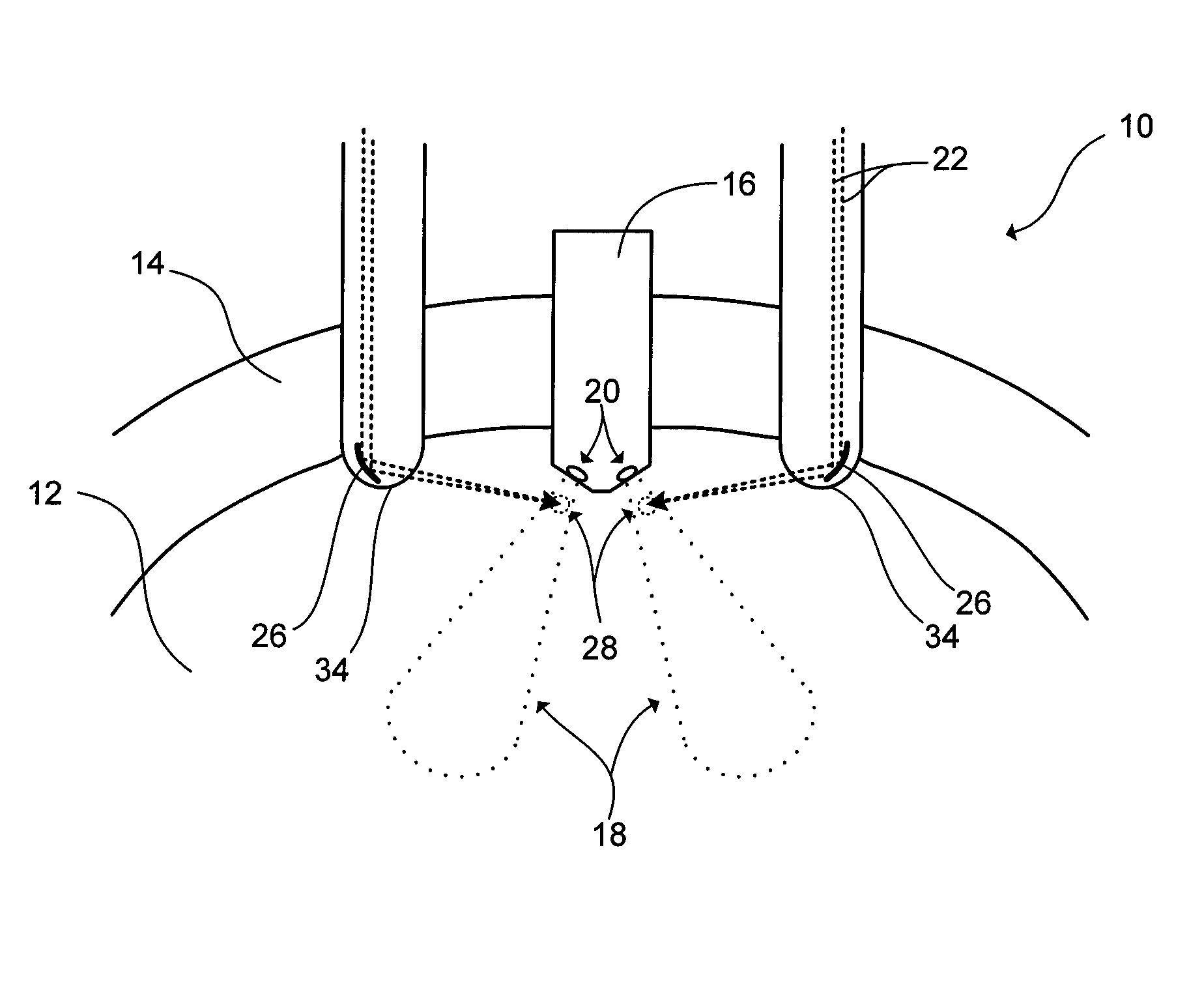

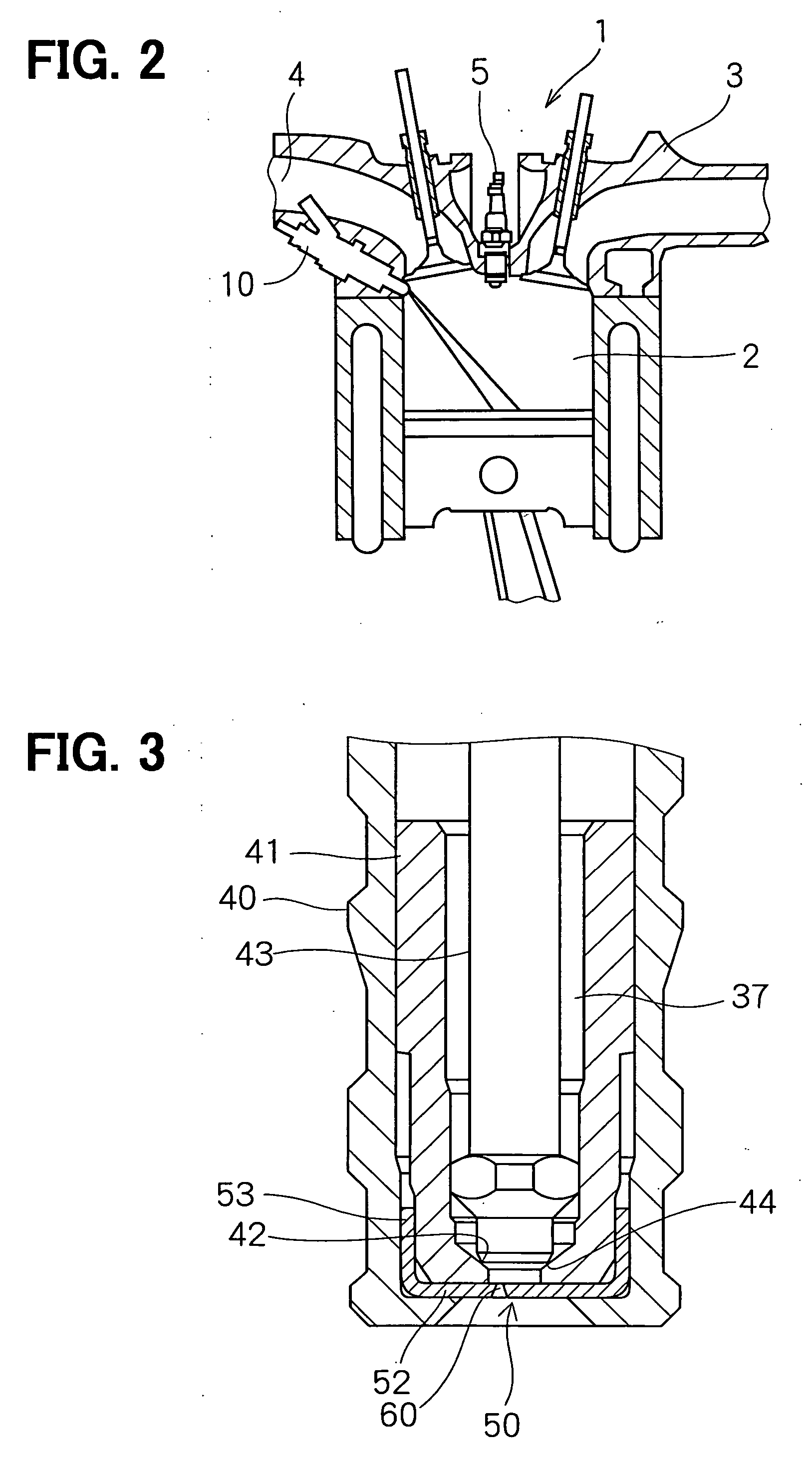

Direct injection of fuels in internal combustion engines

InactiveUS20050045146A1Maintain integritySparking plugsHigh pressure gas fuel injectionCombustionEngineering

A fuel delivery injector for an internal combustion engine. The fuel injector forms pan of a device (10) which provides a combined injection and ignition means for the engine. The fuel delivery injector comprises a first portion (31) and a second portion (32) adapted to be detachably connected together. The first portion has a delivery port (37) defined between a valve seat (61) and a valve member (63) movable with respect to the valve seat (61) for opening and closing the delivery port (37). An actuating member (87) is provided in the first portion (31) and is operatively connected to the valve member (63). An actuating means (85) is provided in the second portion (32). When the first and second portions (31, 32) are connected together, the actuating mean (85) is operably associated with the actuating member (87) to provide an actuating assembly (83). Typically, the actuating assembly (83) comprises an electromagnetic means in which the actuating member (87) comprises a solenoid armature and the actuating means (85) comprises a solenoid oil, whereby connection of the first and second portions (31, 32) together completes assembly of the electromagnetic means. Where the device (10) provides a combined fuel injector and ignition me the device (10) is provided with a primary electrode (58) which cooperates with a secondary electrode (57) to define a spark gap (60). A popper projection (62) provided on the valve member (63) is utilized to define the primary electrode (58), as well as to provide spray guidance effects on the fuel spray issuing from the delivery port (37). The device (10) providing the combined fuel injection and ignition means is also described and claimed.

Owner:ORBITAL ENGINE CO PTY LTD

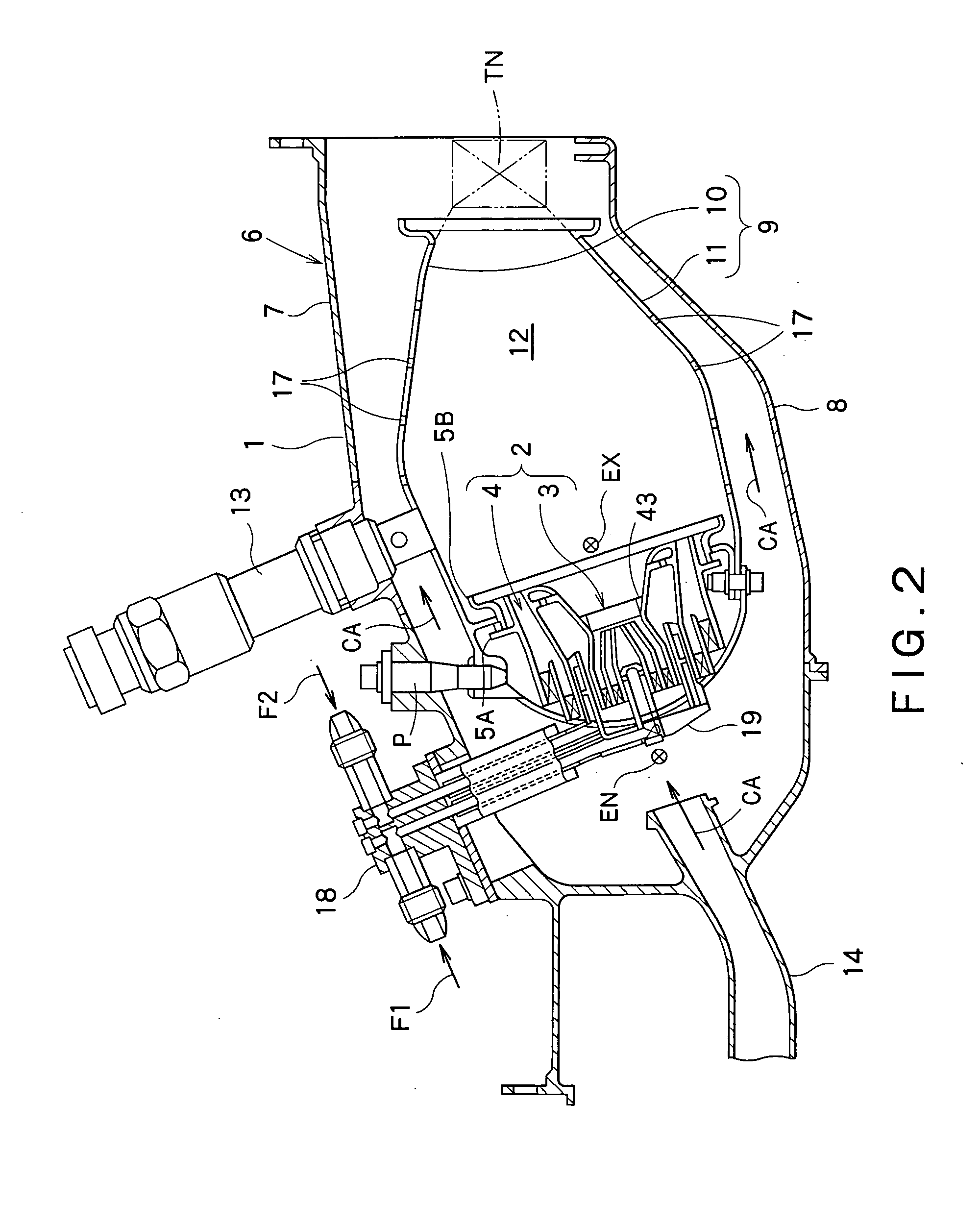

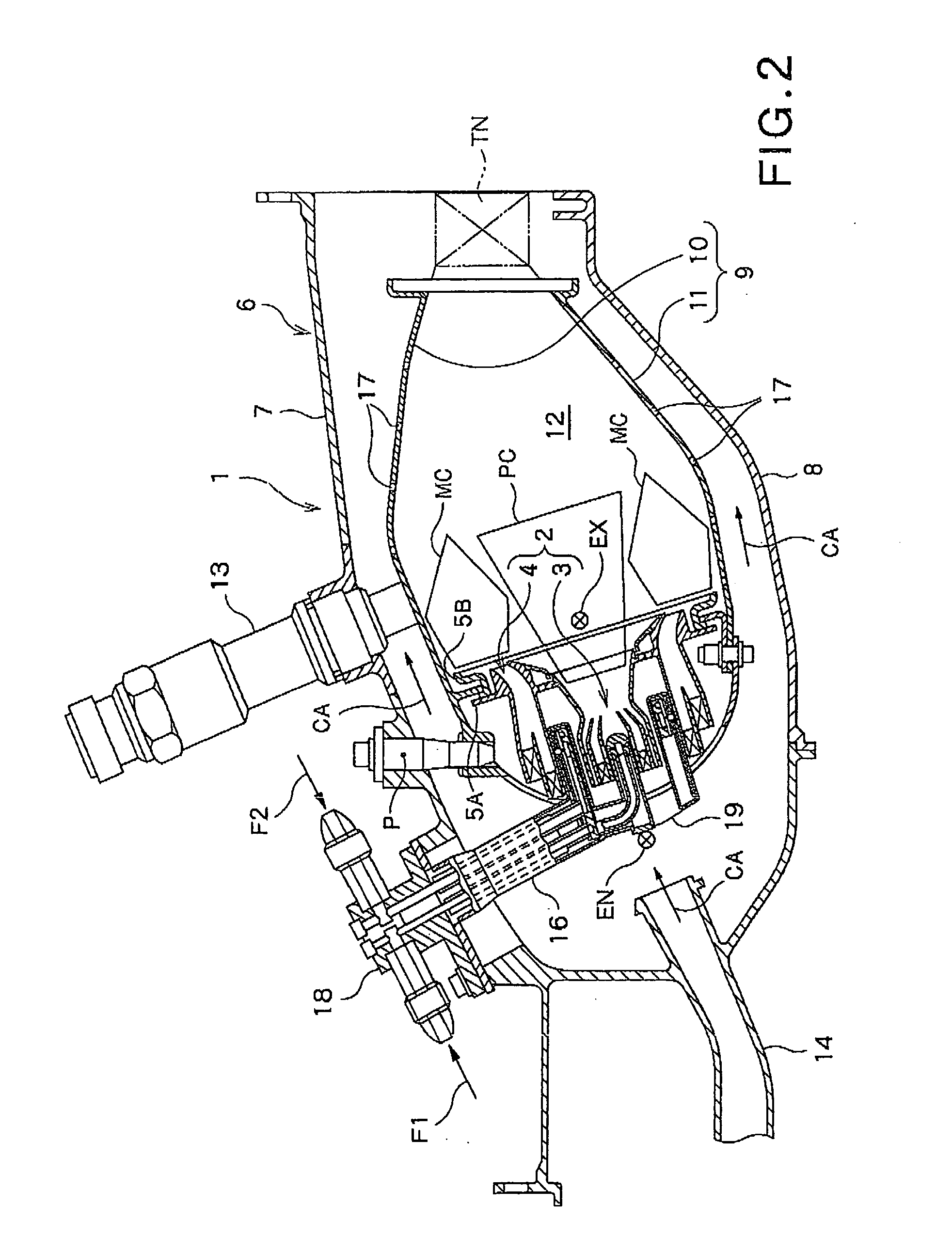

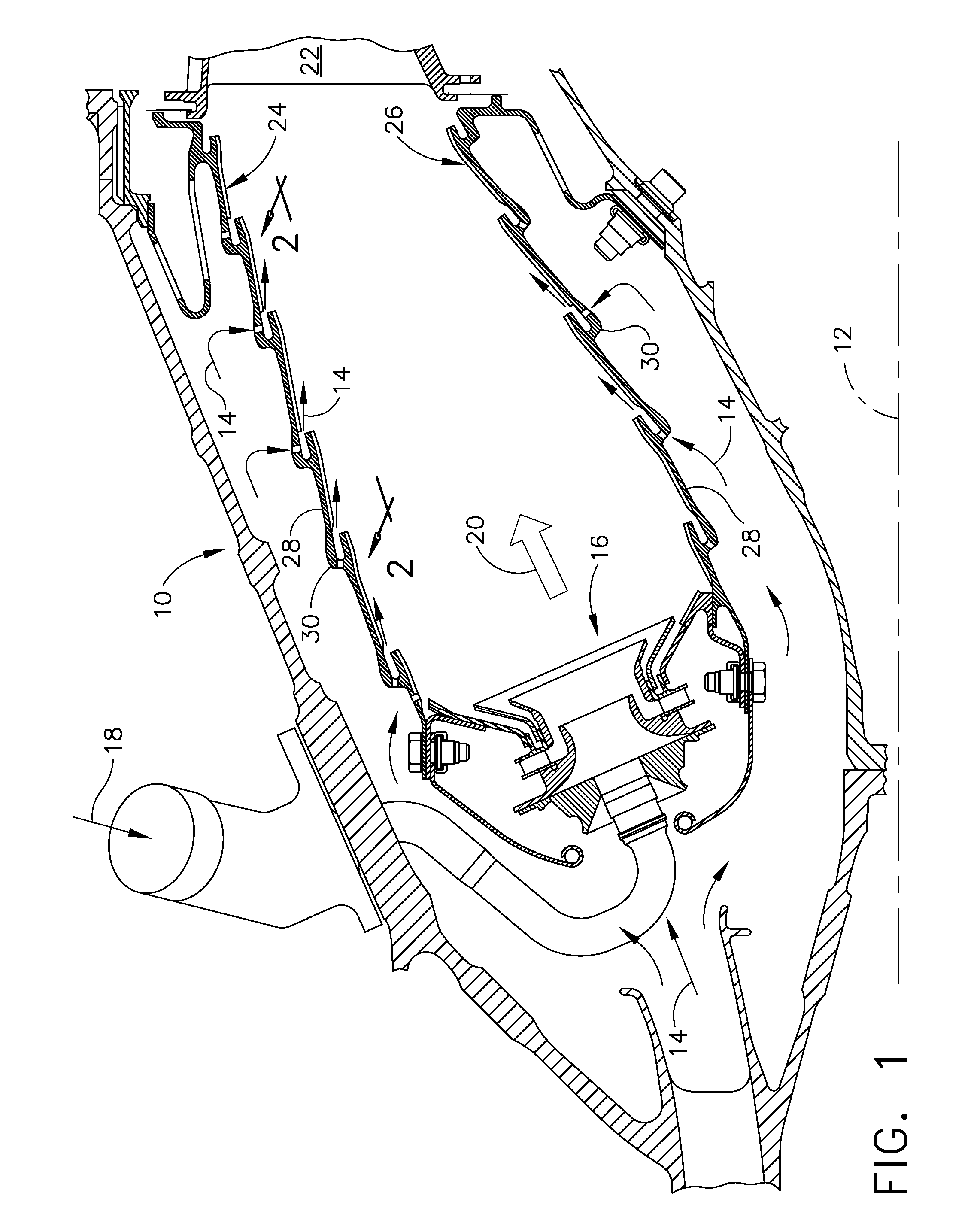

Combustor of a gas turbine engine

ActiveUS20080302105A1Effectively restraining diffusion of fuelImprove combustion efficiencyBurnersTurbine/propulsion fuel supply systemsCombustorMixed gas

The present invention provides a combustor of a gas turbine engine, including: a fuel spray portion configured to spray a fuel so as to create a diffusion combustion region in a combustion chamber, the fuel spray portion including a fuel atomizing portion configured to atomize the fuel, and a diffusion passage portion disposed downstream of the fuel atomizing portion, the diffusion passage portion having a spreading trumpet-like shape and being configured to diffuse the fuel and the air; a pre-mixture supply portion configured to supply a pre-mixture gas including the fuel and an air so as to create a pre-mixture combustion region in the combustion chamber, the pre-mixture supply portion being positioned concentrically with the fuel spray portion so as to surround the fuel spray portion; and fuel diffusion restraining member disposed on an inner circumferential face of the diffusion passage portion for restraining a diffusion of an injected fuel by separating a stream of the injected fuel away from the inner circumferential face.

Owner:KAWASAKI HEAVY IND LTD

Multi-Hole Injector, in-Cylinder Gasoline Injection Type Internal Combustion Engine and Control Method for the Engine

InactiveUS20090025680A1Suppression amountLarge flow path areaInternal combustion piston enginesSpraying apparatusCombustionGasoline

Improvement of combustion stability in retard ignition at the time of starting in a cold state, high output in a full throttle condition, reduction of smoke, and prevention of wear of the cylinder liner caused by oil dilution, are to be attained. In connection with the flow of fuel into each hole and a fuel inflow angle which is determined by the axis of each hole formed in a plate, the fuel inflow angle of an hole directed to a spark plug is set large to reduce an effective flow path area, thereby making the amount of fuel in the hole smaller than in other holes. A shallow cavity is formed in a piston crown face and a small prominence confronting fuel sprays is formed within the cavity.

Owner:HITACHI LTD

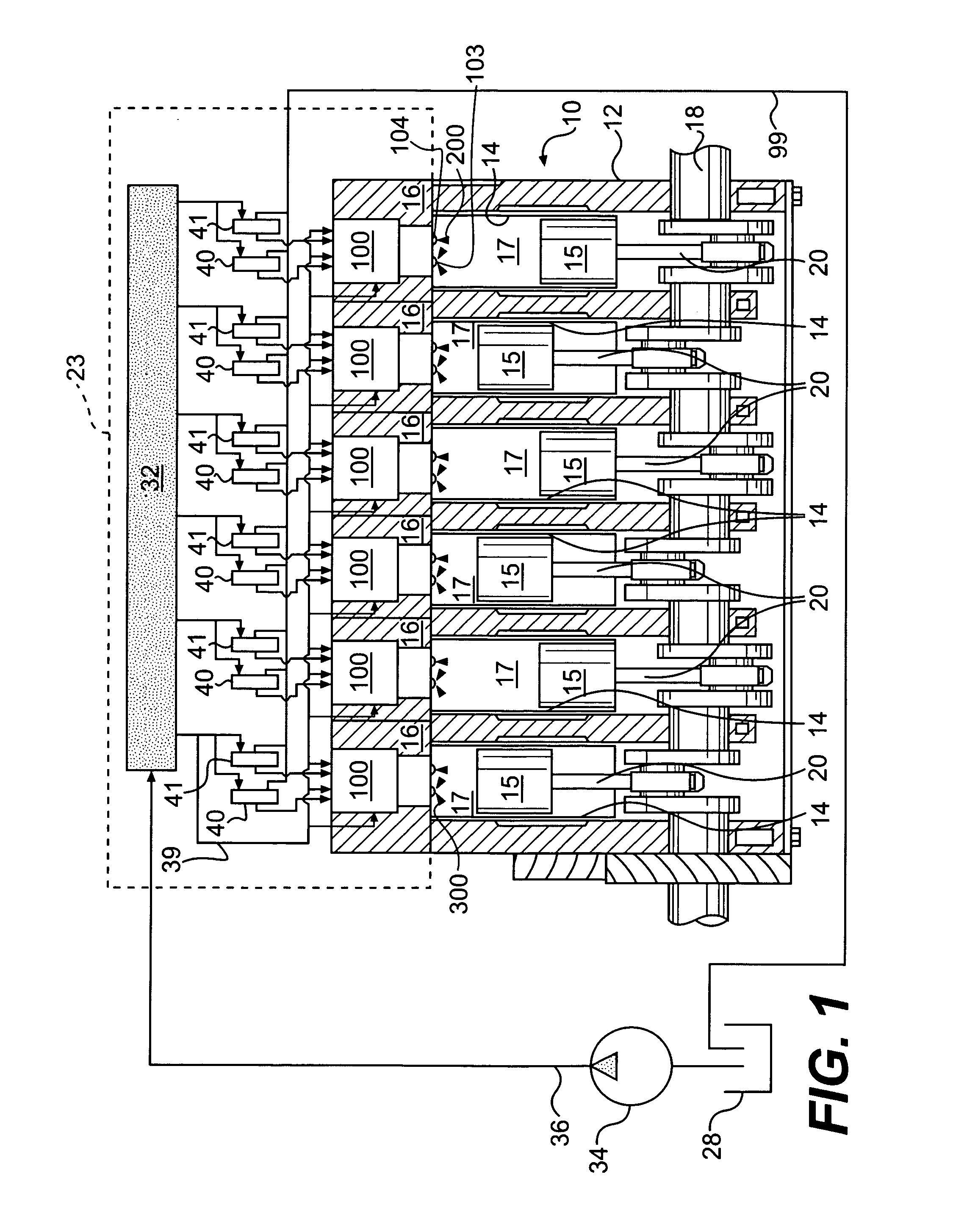

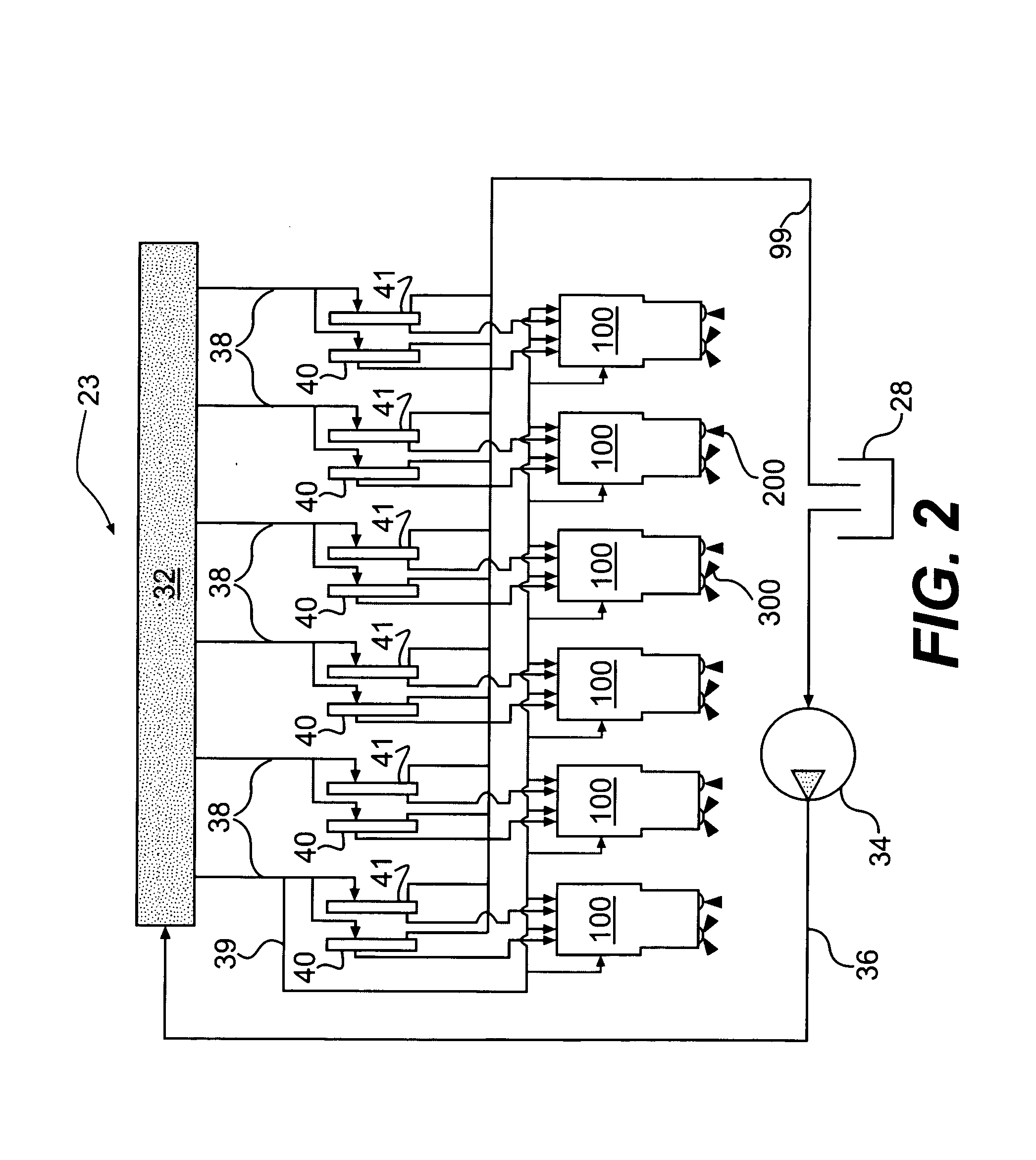

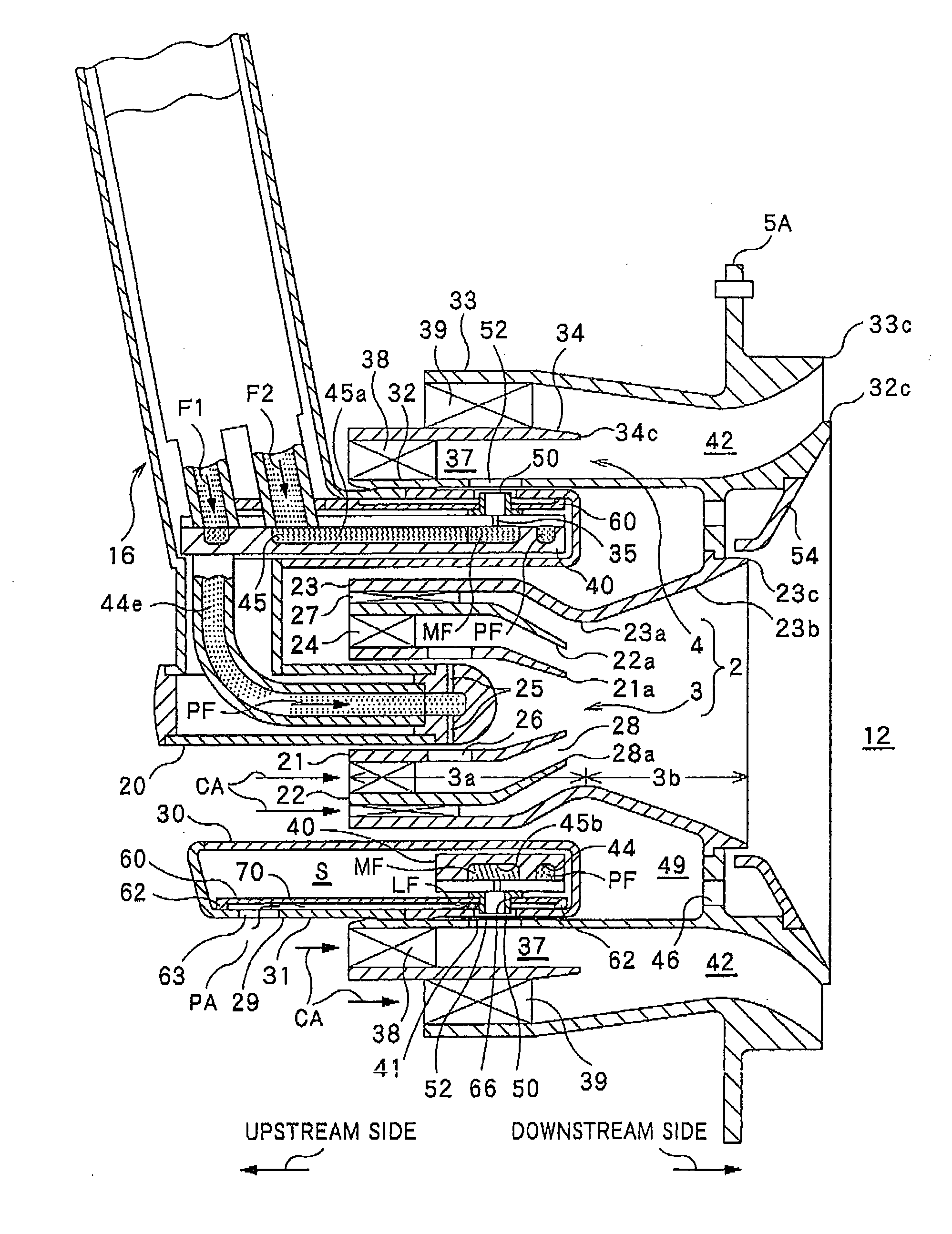

Fuel spray apparatus for gas turbine engine

ActiveUS20100269506A1Easy to provideEffectively blowing offBurner safety arrangementsBurnersProduct gasEngineering

The present invention provides a fuel spray apparatus for a gas turbine engine, including: a pilot part configured to spray a fuel to be used for a diffusion combustion; a main part provided so as to surround the pilot part and configured to inject a pre-mixed gas only upon a high power operation; and a shield body constituting a purge air passage which is configured to take therein an air flowed on an upstream side relative to a fuel injection port of the main part as a purge air, and to blow off a fuel dripping from the fuel injection port toward a main air passage of the main part. The purge air passage is provided in a position opposite to a main fuel passage communicated with the fuel injection port across the shield body.

Owner:KAWASAKI HEAVY IND LTD

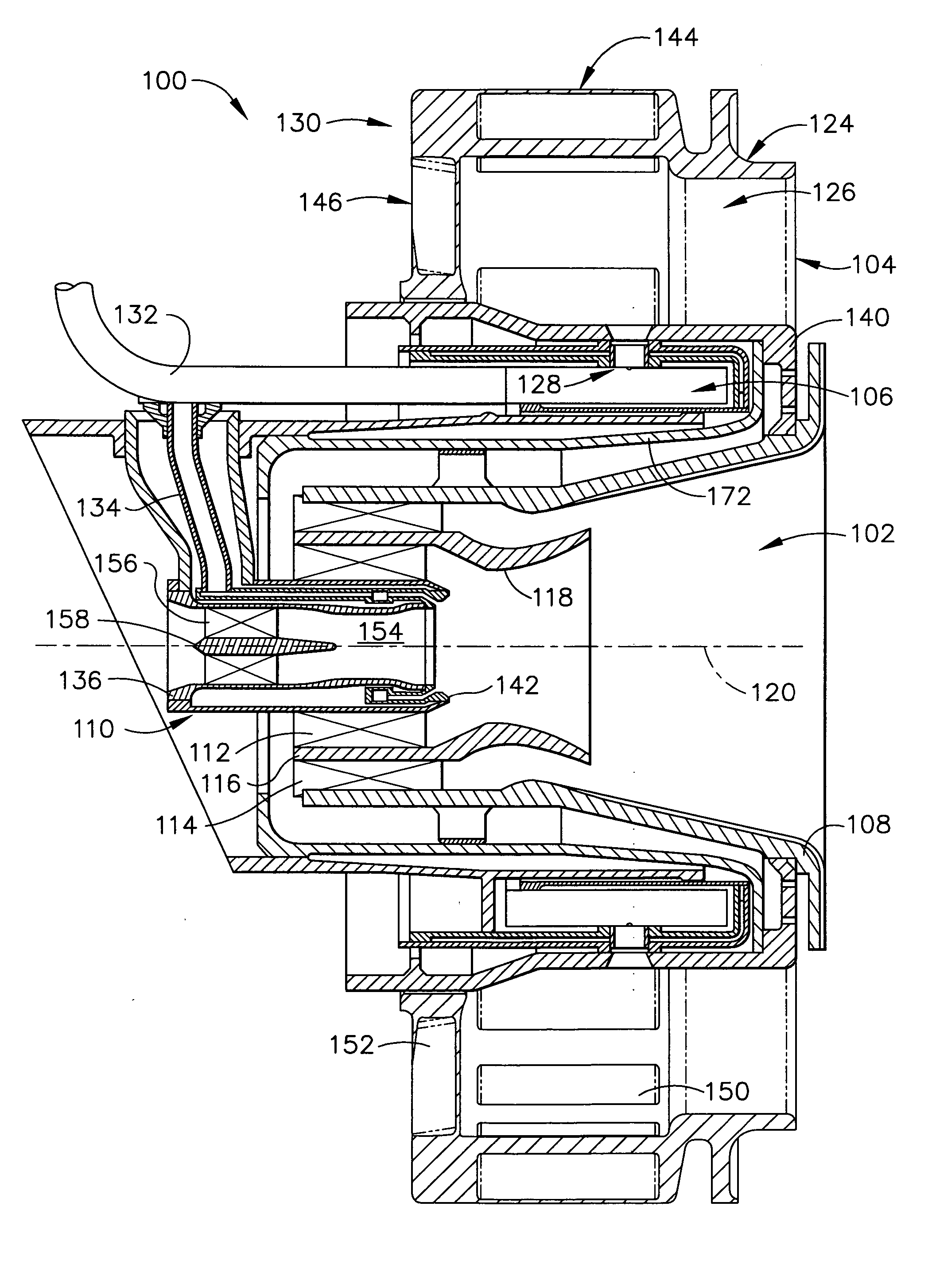

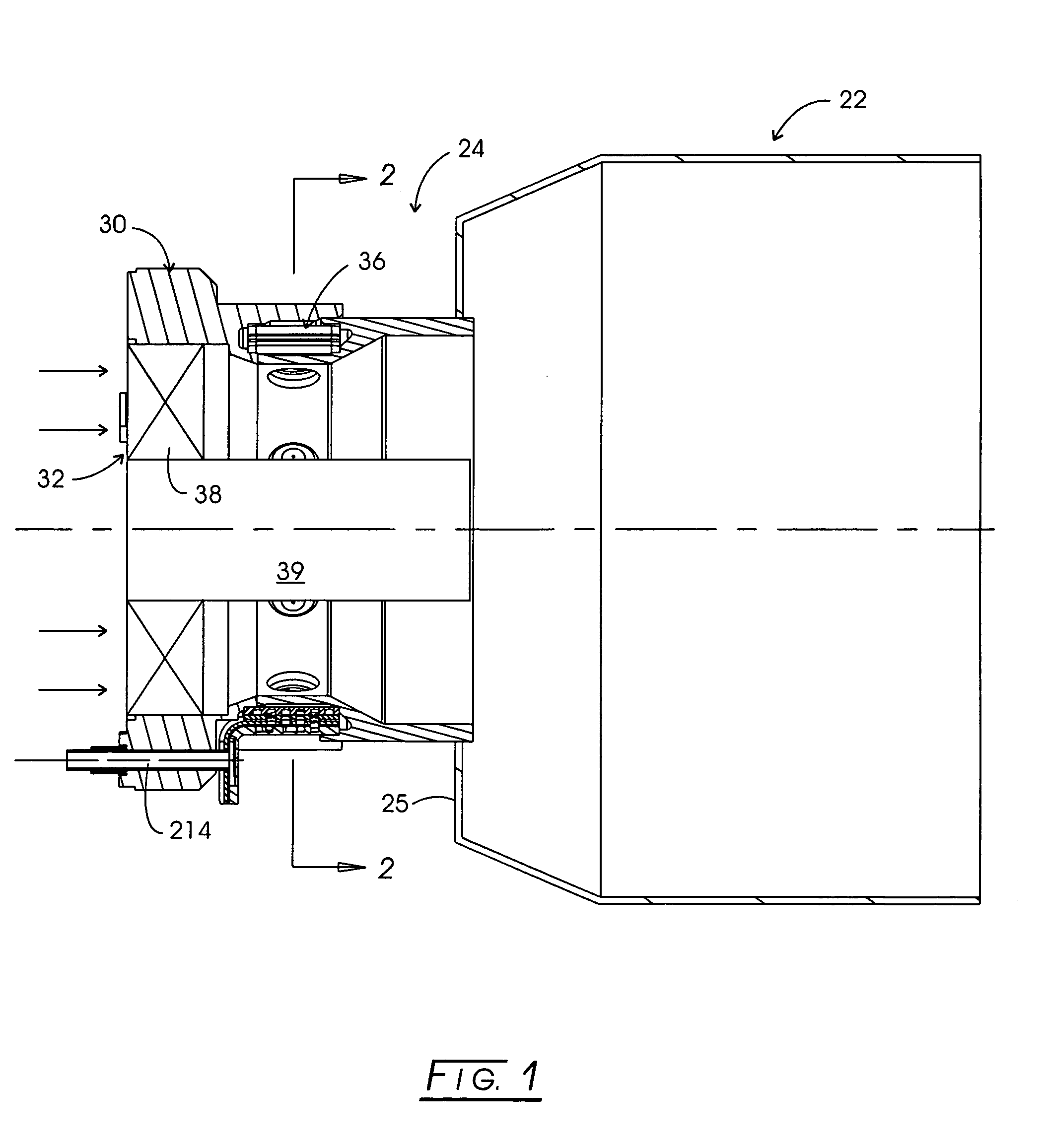

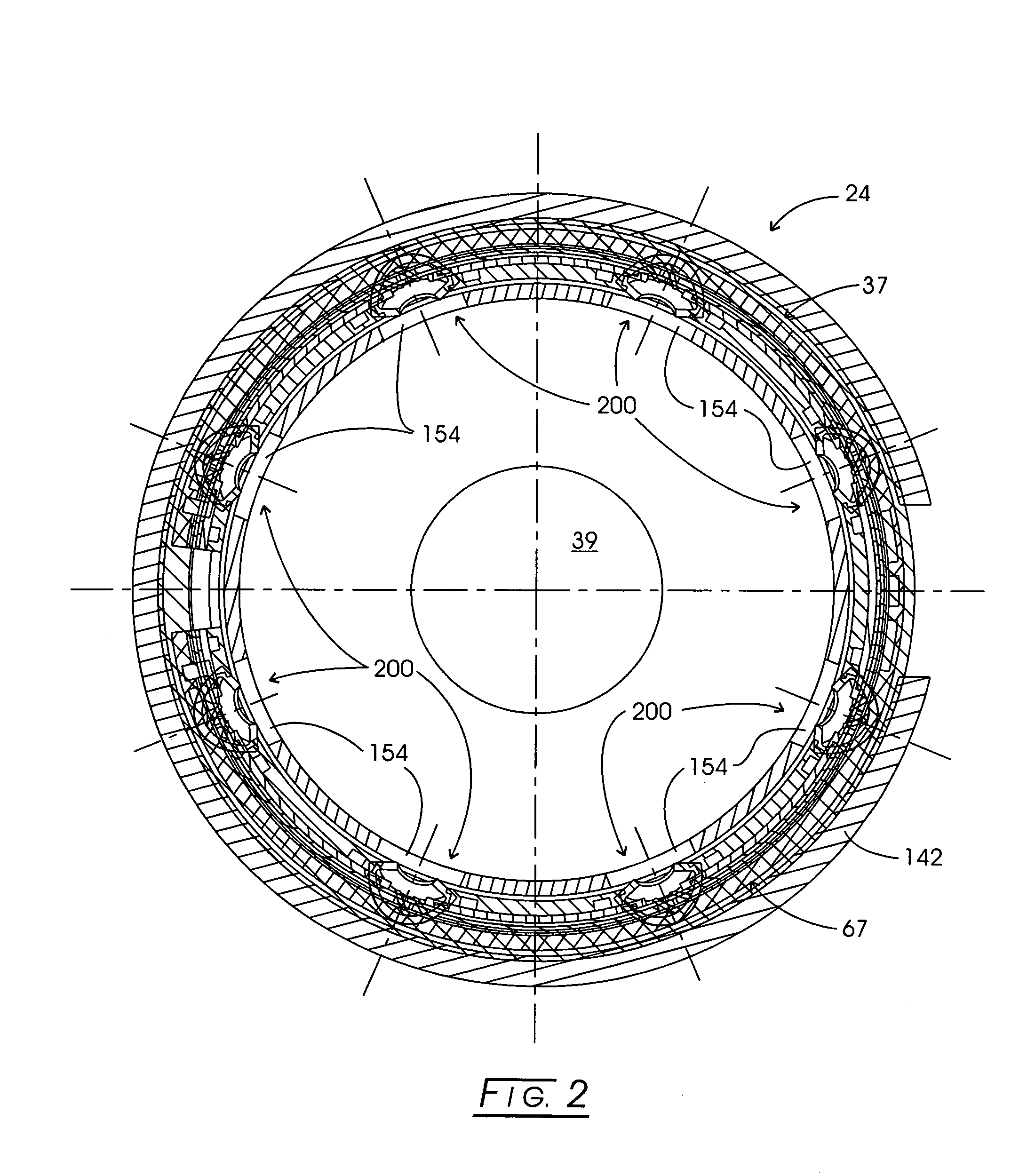

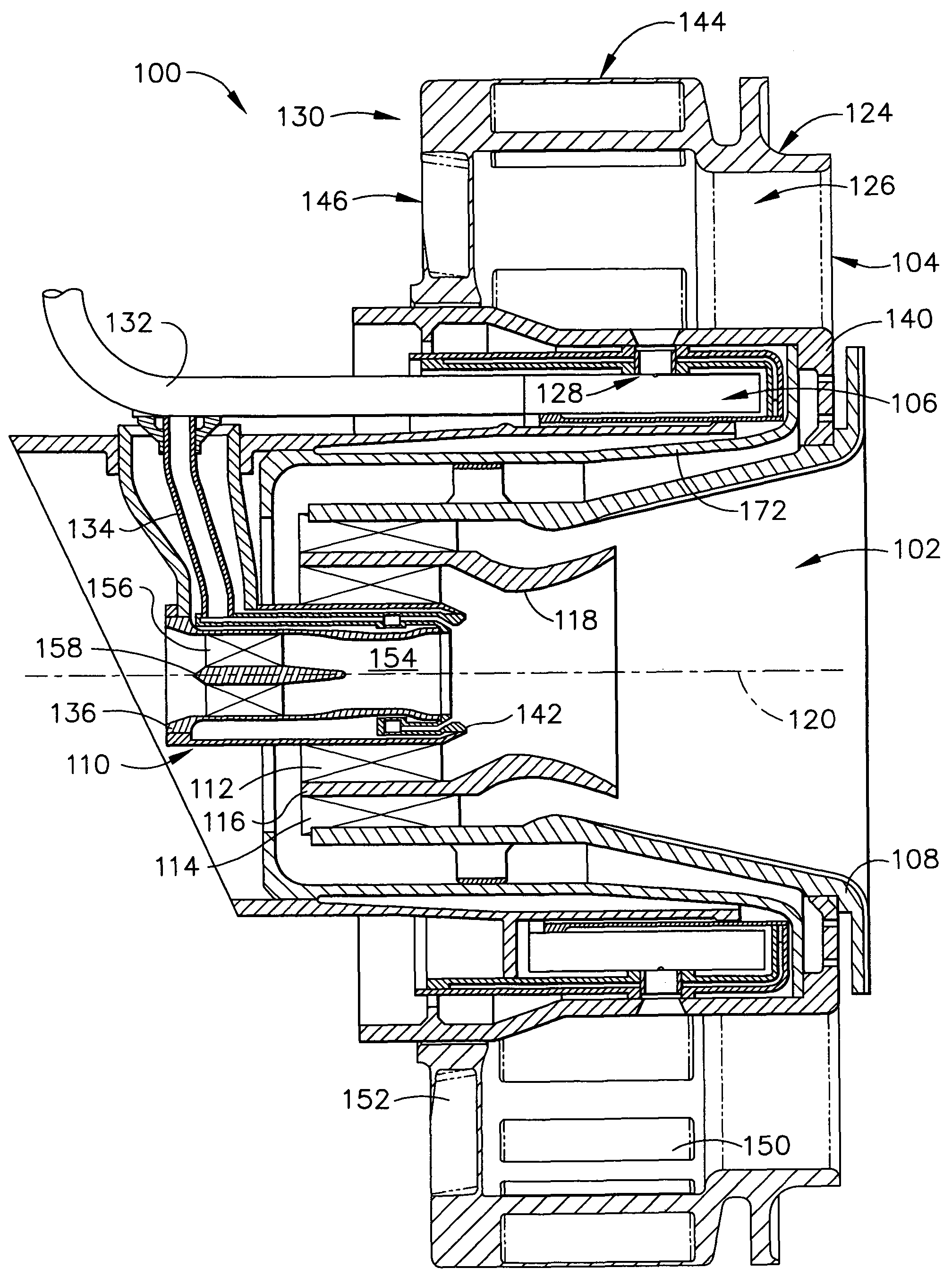

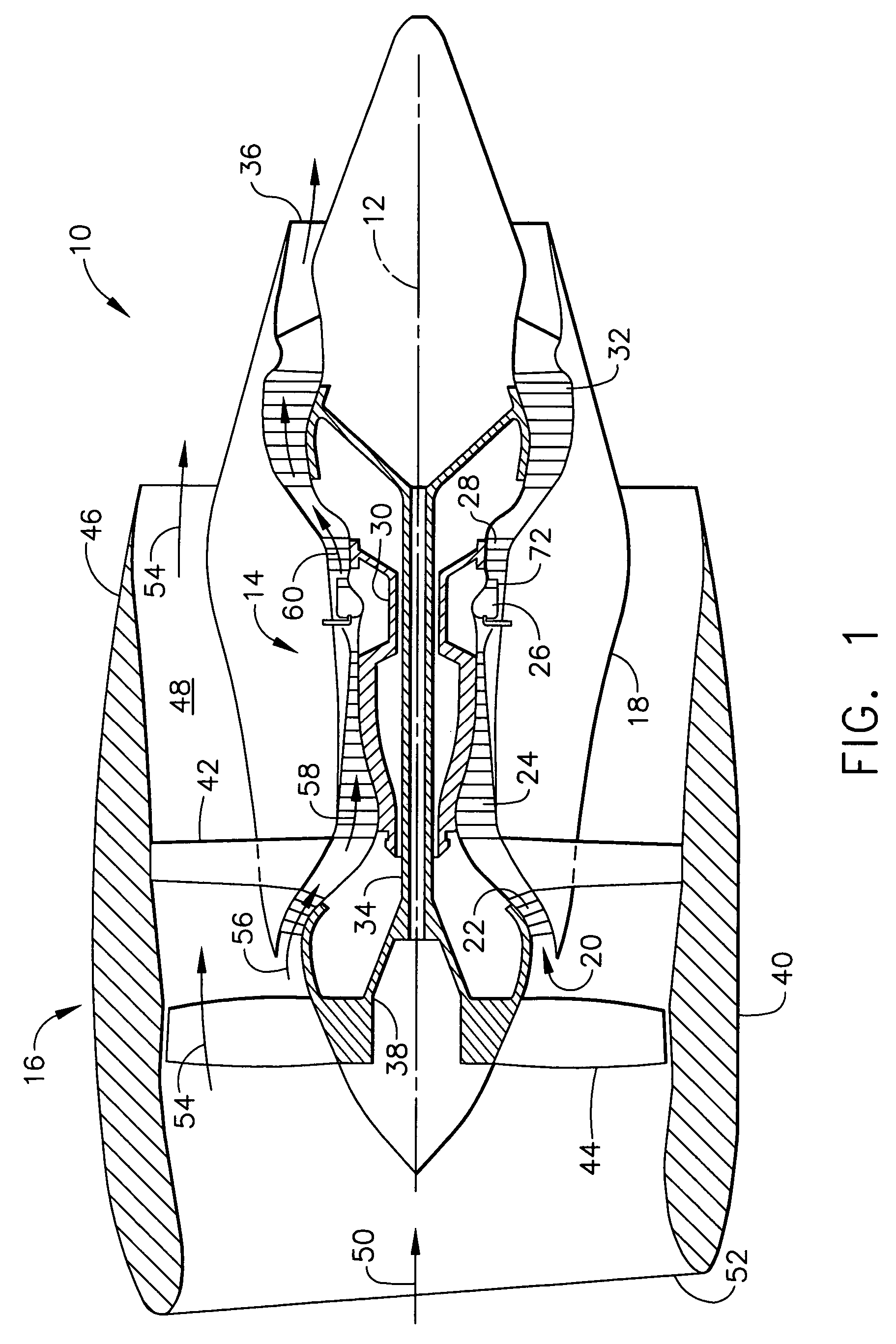

Pilot fuel injector for mixer assembly of a high pressure gas turbine engine

ActiveUS7878000B2Continuous combustion chamberEfficient propulsion technologiesEngineeringHigh pressure

A mixer assembly for a gas turbine engine, including: a primary fuel injector having a central axis for injecting a primary fuel spray into a primary air stream, wherein fuel is provided at a desired rate and droplets of the fuel spray are within a desired size range; a secondary fuel injector positioned radially outwardly of the primary fuel injector for injecting a secondary fuel spray into a secondary air stream spaced radially outwardly of and surrounding the primary air stream; and, a primary air jet positioned between the primary fuel injector and the secondary fuel injector to direct a portion of an incoming air stream between the primary air stream and the secondary air stream.

Owner:GENERAL ELECTRIC CO

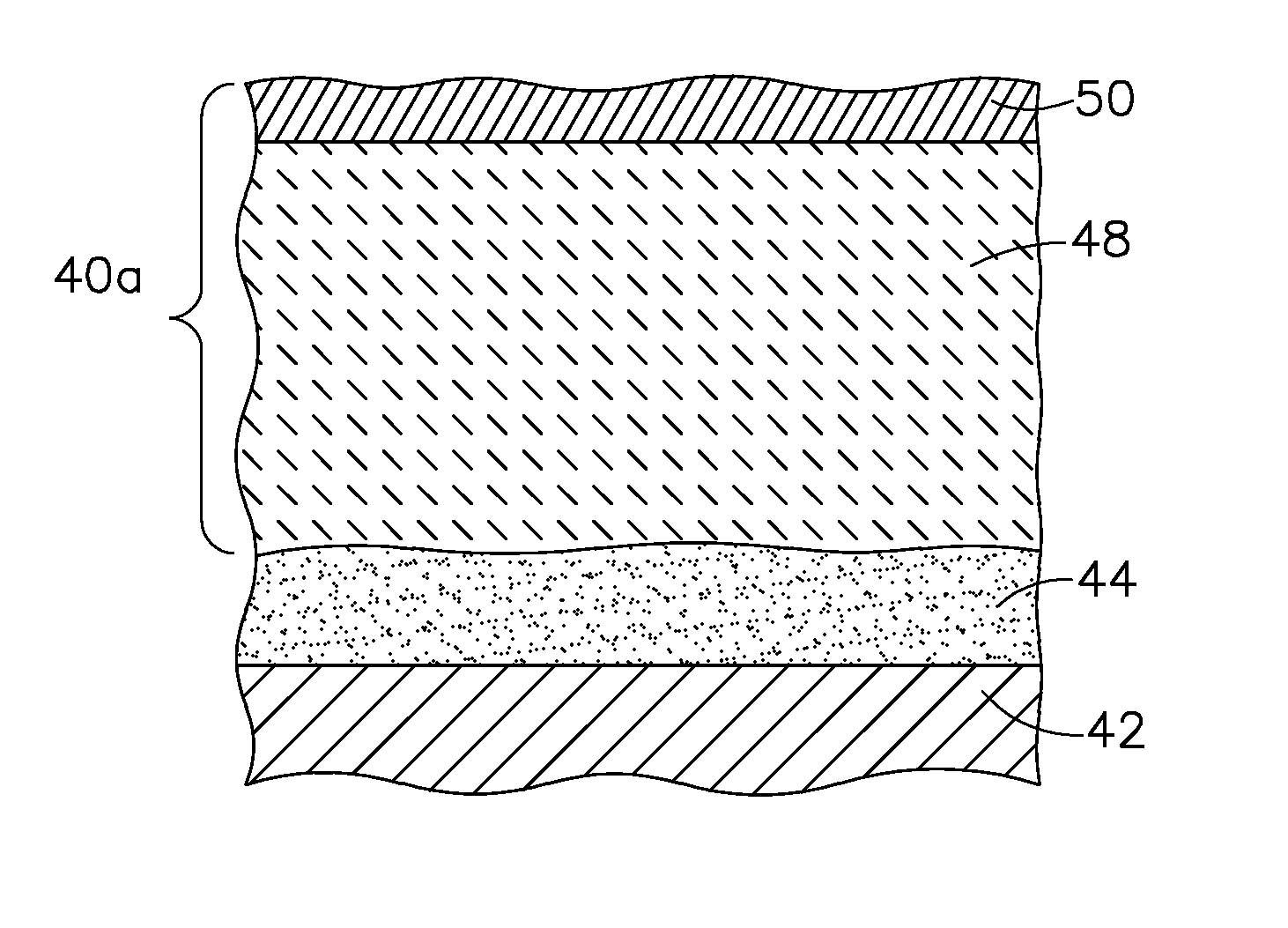

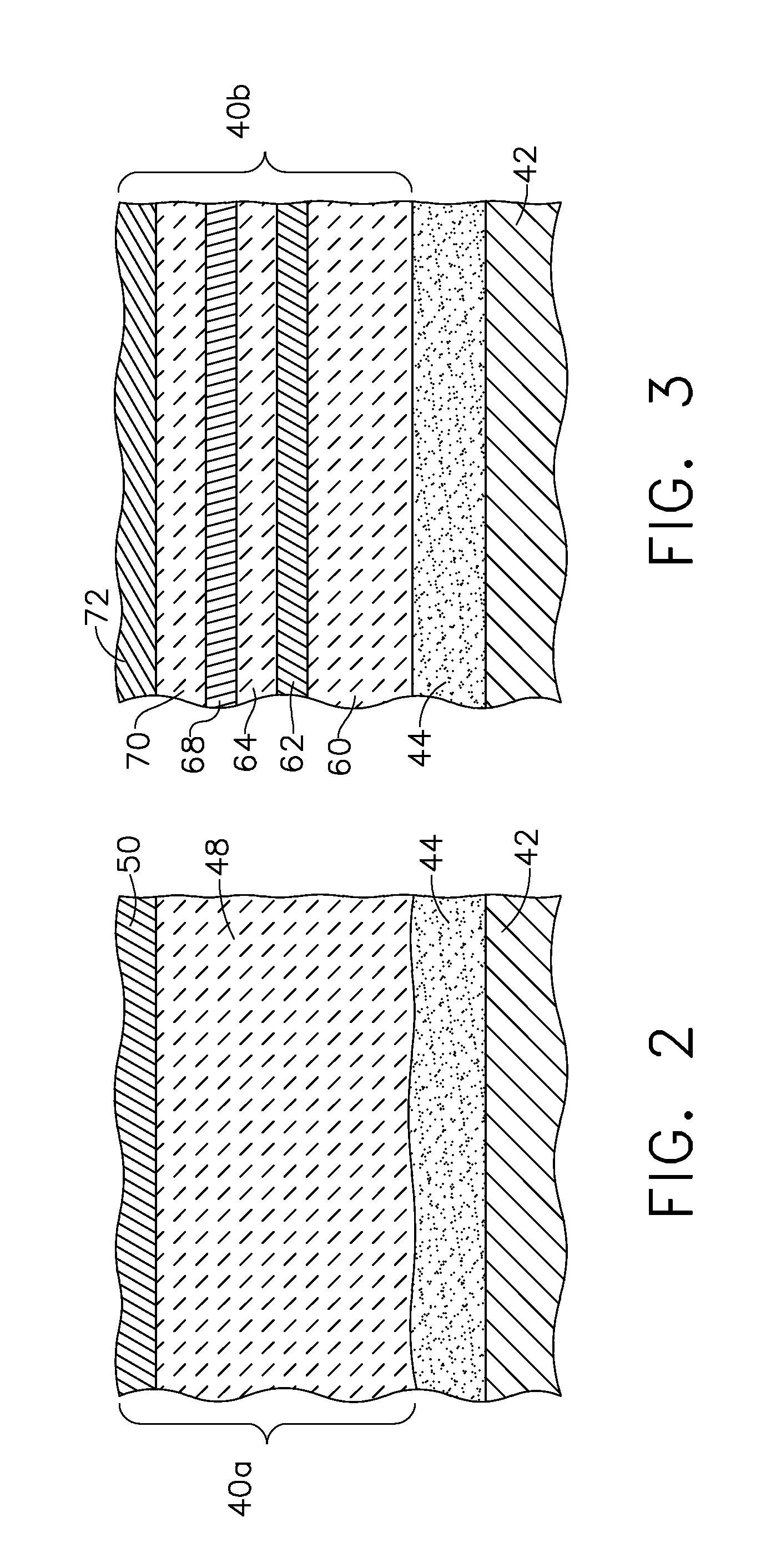

Coating Systems for Protection of Substrates Exposed to Hot and Harsh Environments and Coated Articles

InactiveUS20110151219A1Reduce the effectUsed in environmentContinuous combustion chamberMolten spray coatingCoating systemOxygen

Coating system for reducing CMAS infiltration of substrates includes at least an inner ceramic layer and an outer alumina-containing layer. The outer layer includes up to 50 percent by weight titania. Additional ceramic layers and alumina-containing layers may be provided. The coating may be used for gas turbine engine components. Deposition techniques for the coating layers may depend on the end use of the component. Coated articles include a substrate, an optional bond coat on the substrate and a coating over the bond coat or on at least a portion of the substrate in the absence of a bond coat. The inner ceramic layer(s) exhibit a microstructure indicative of a deposition technique selected from thermal spray, physical vapor deposition, and suspension plasma spray, whereas the outer alumina-containing layer exhibits a microstructure indicative of suspension plasma spray, solution plasma spray, and a high velocity oxygen fuel spray.

Owner:GENERAL ELECTRIC CO

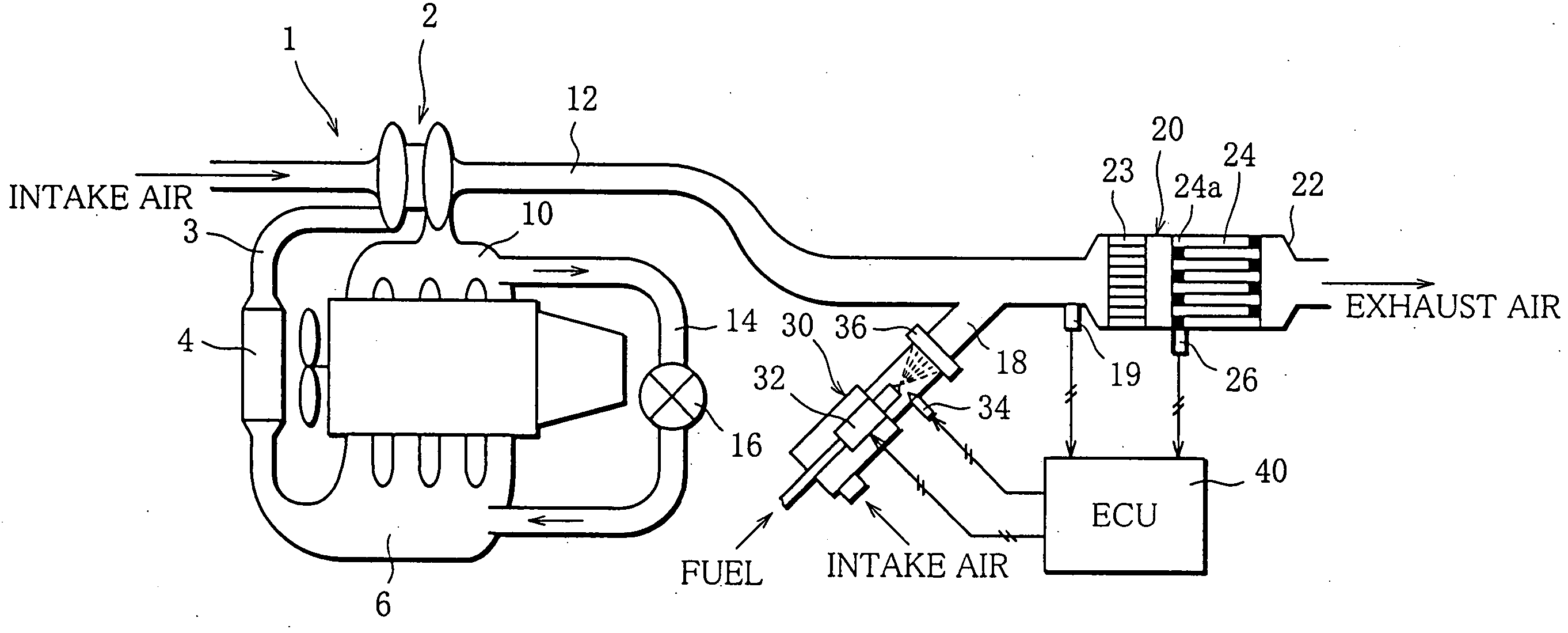

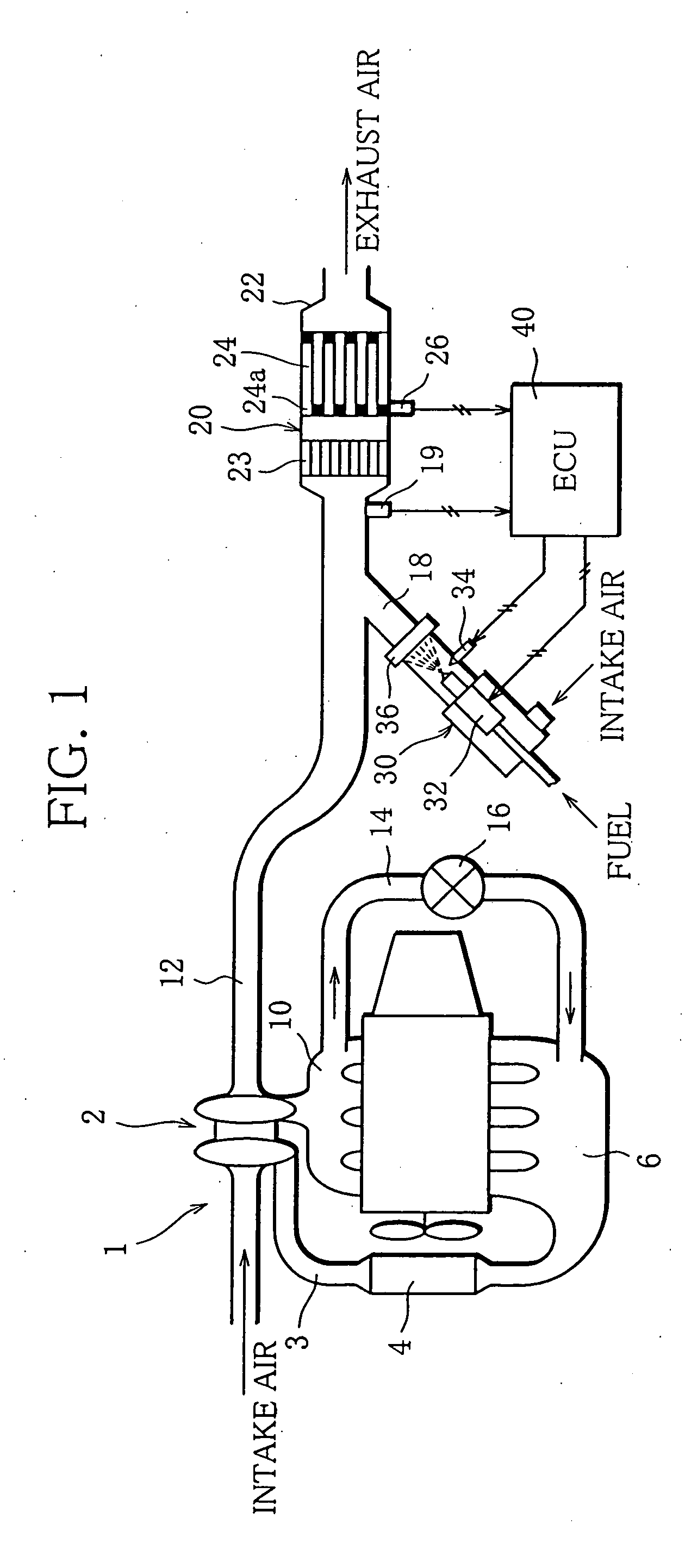

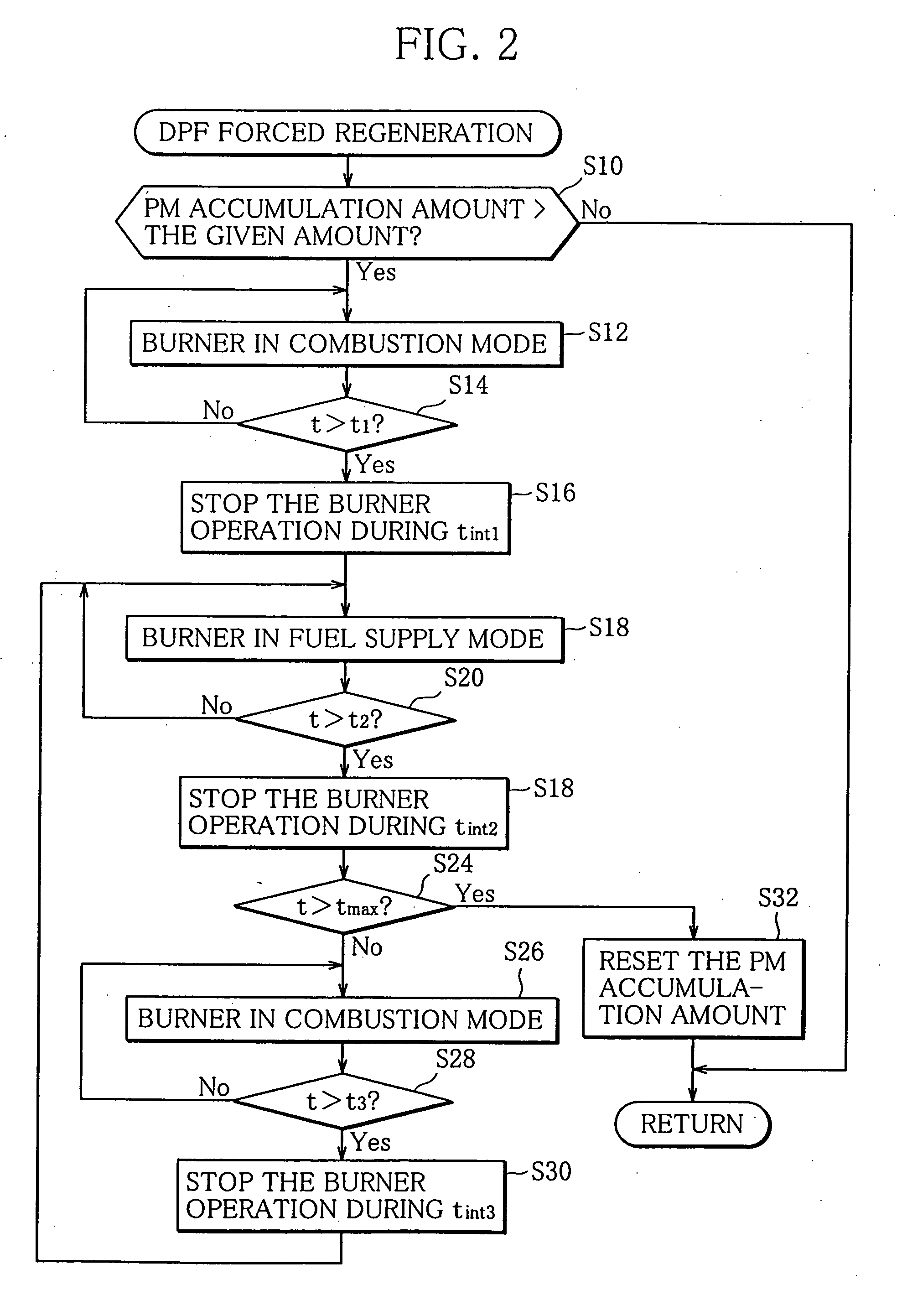

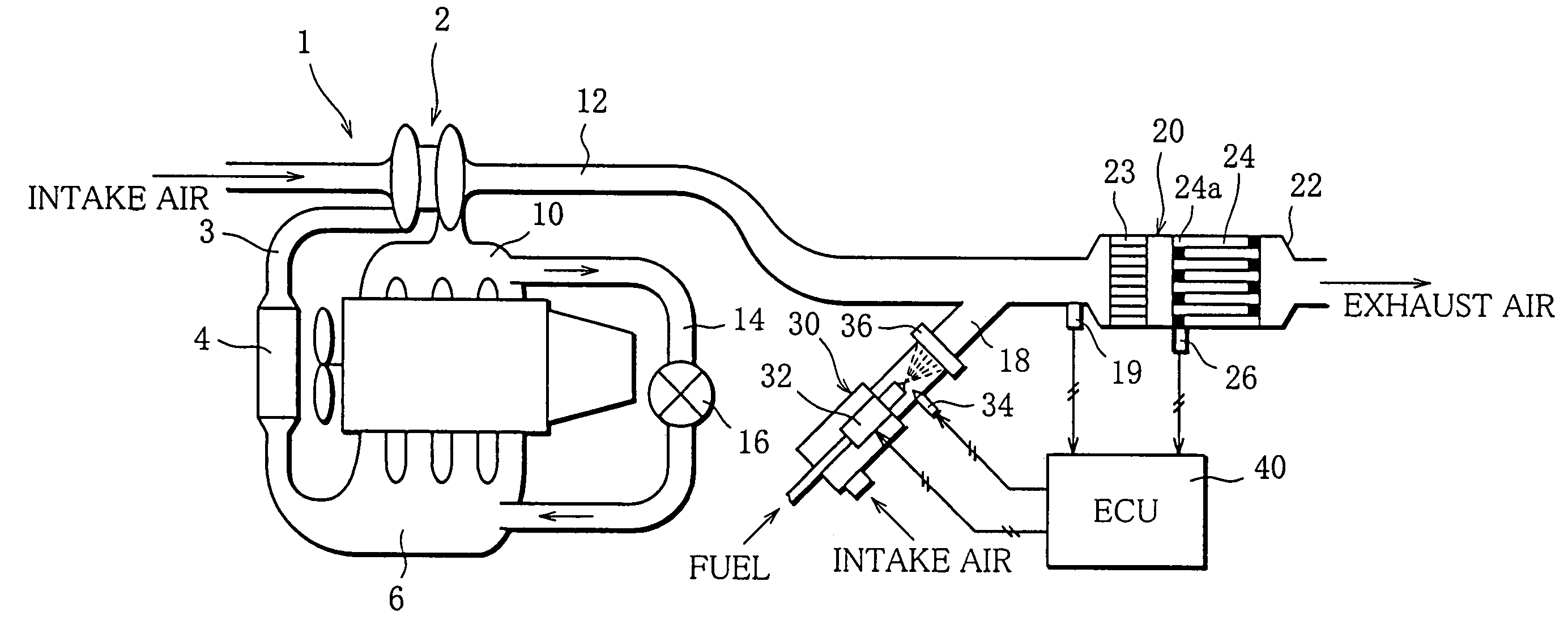

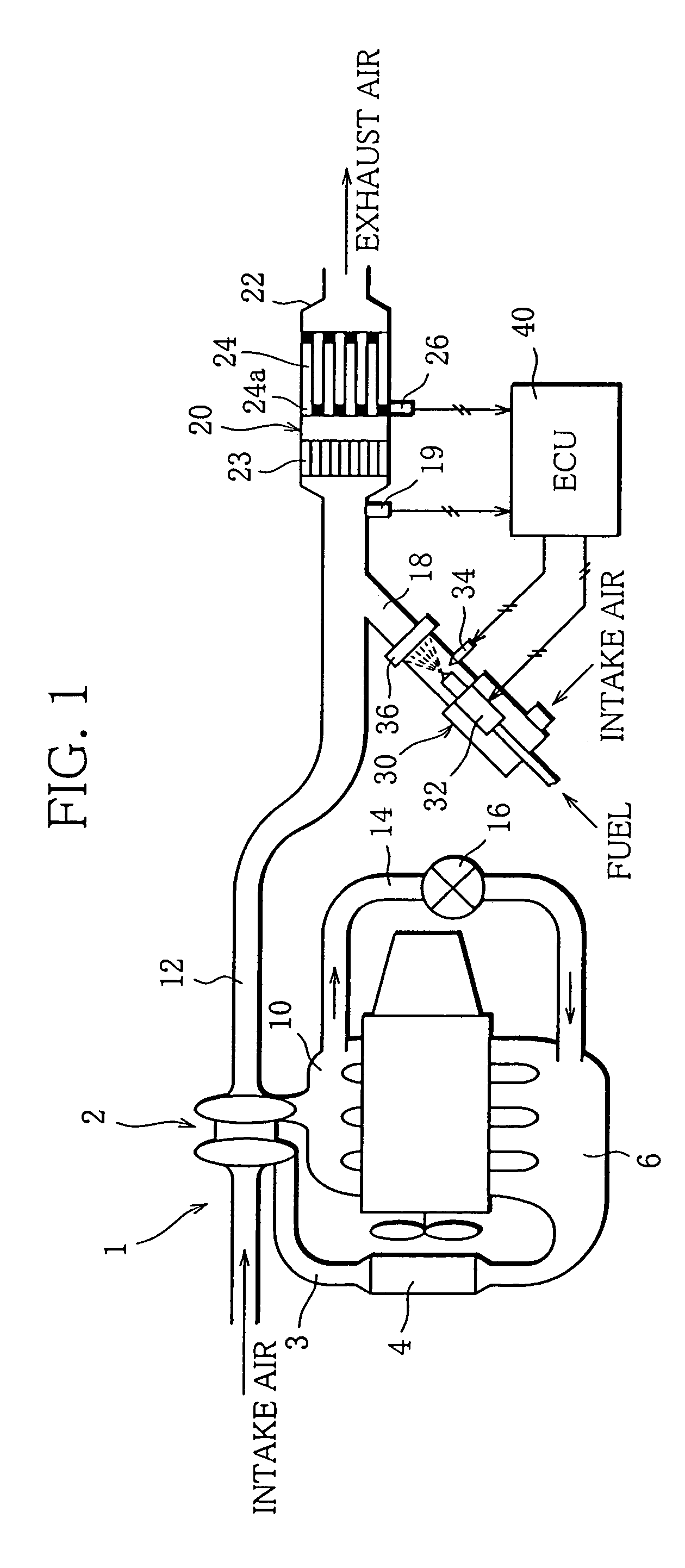

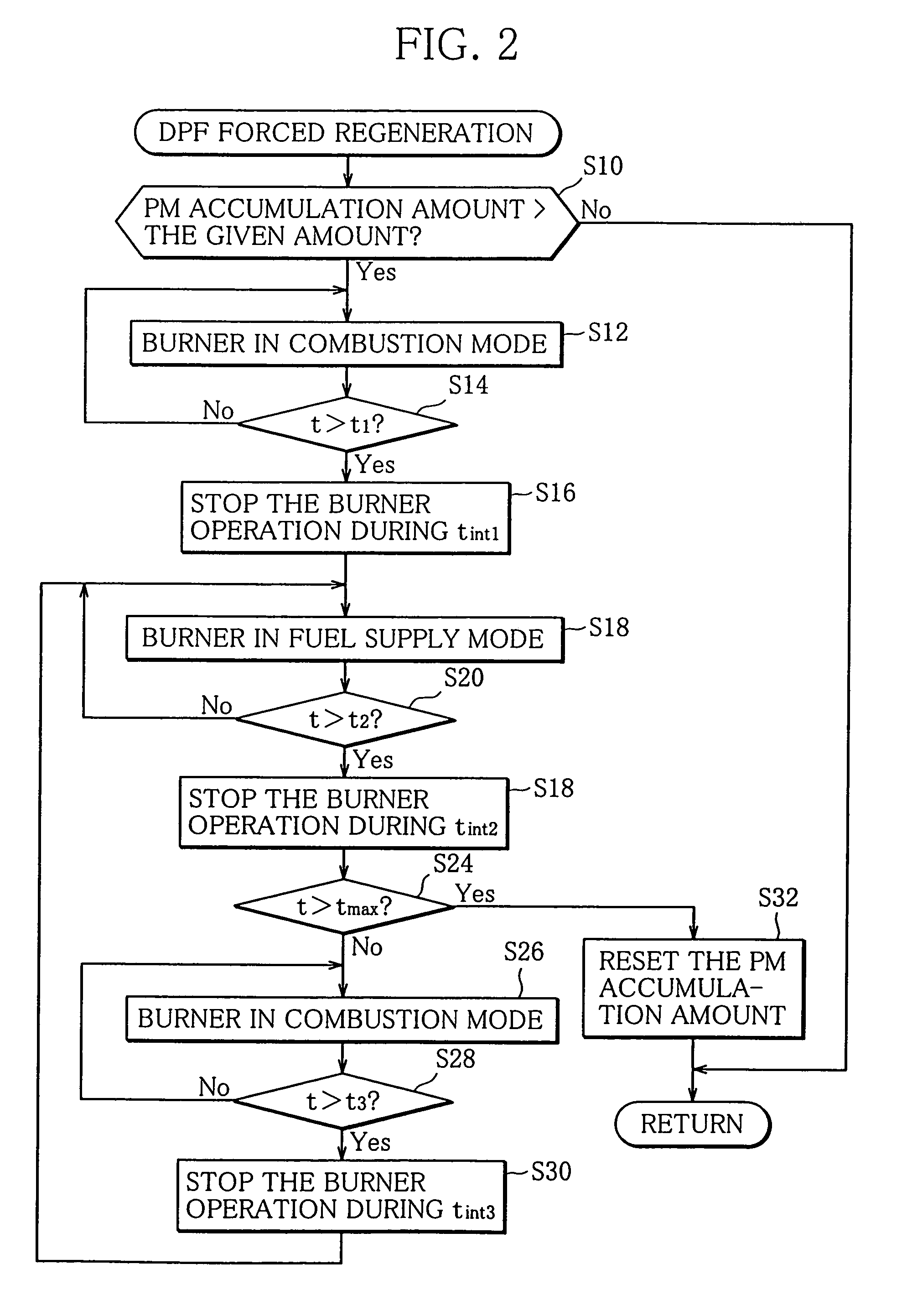

Exhaust emission control device for an internal combustion engine

InactiveUS20050000209A1Efficient regenerationSimple and inexpensive configurationCombination devicesInternal combustion piston enginesParticulatesCombustor

A forced regeneration device which performs regeneration of a particulate filter includes oxidation catalysts (23, 24a) disposed upstream from the particulate filter or in said particulate filter and a burner (30) located upstream from the oxidation catalysts and operable switching between a combustion mode for combusting a fuel spray by inflammation to raise temperature of exhaust gases in an exhaust passage and a fuel supply mode for supplying only a fuel spray to the exhaust passage without inflammation. After the burner operates in the combustion mode, the burner operation is switched to the fuel supply mode.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

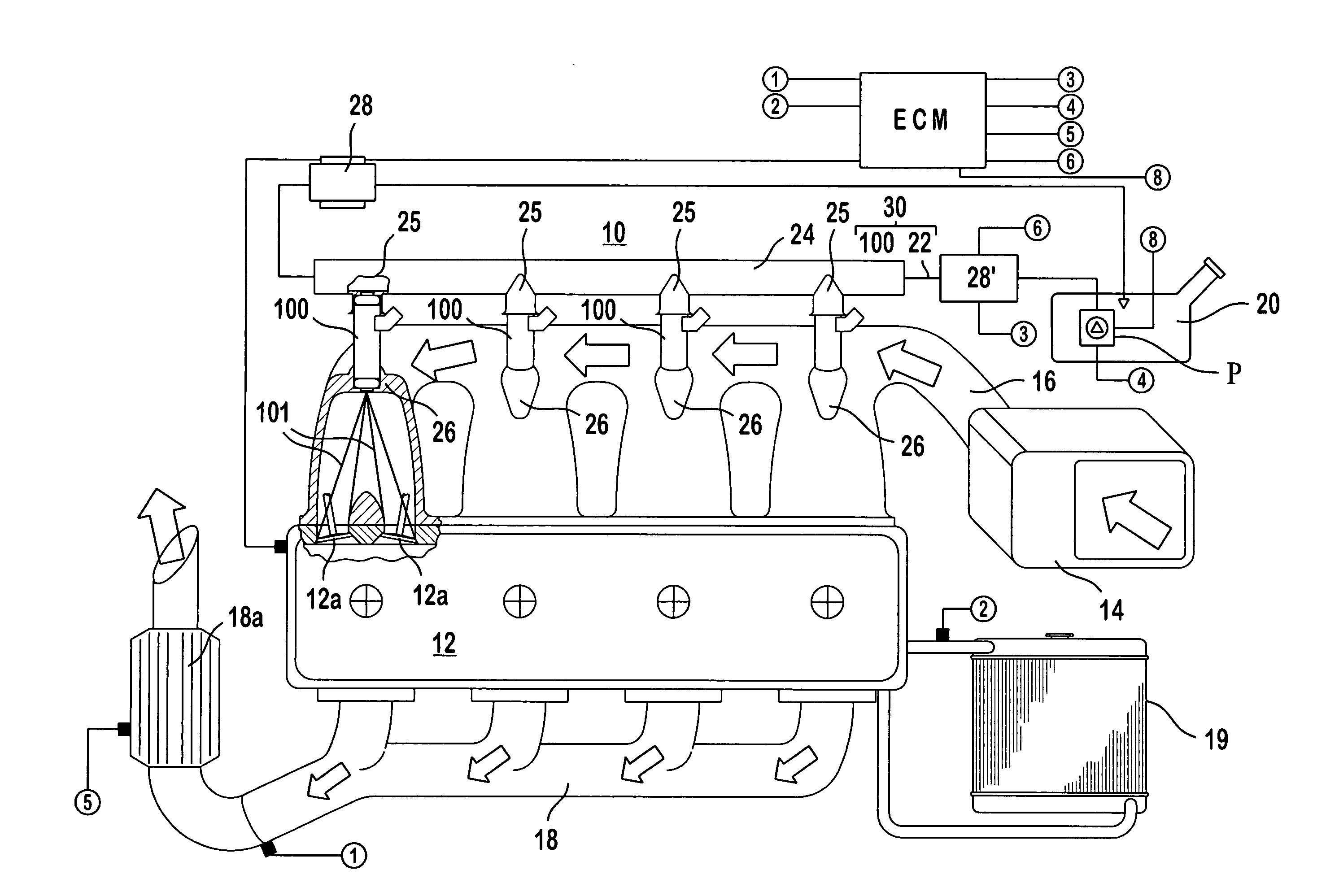

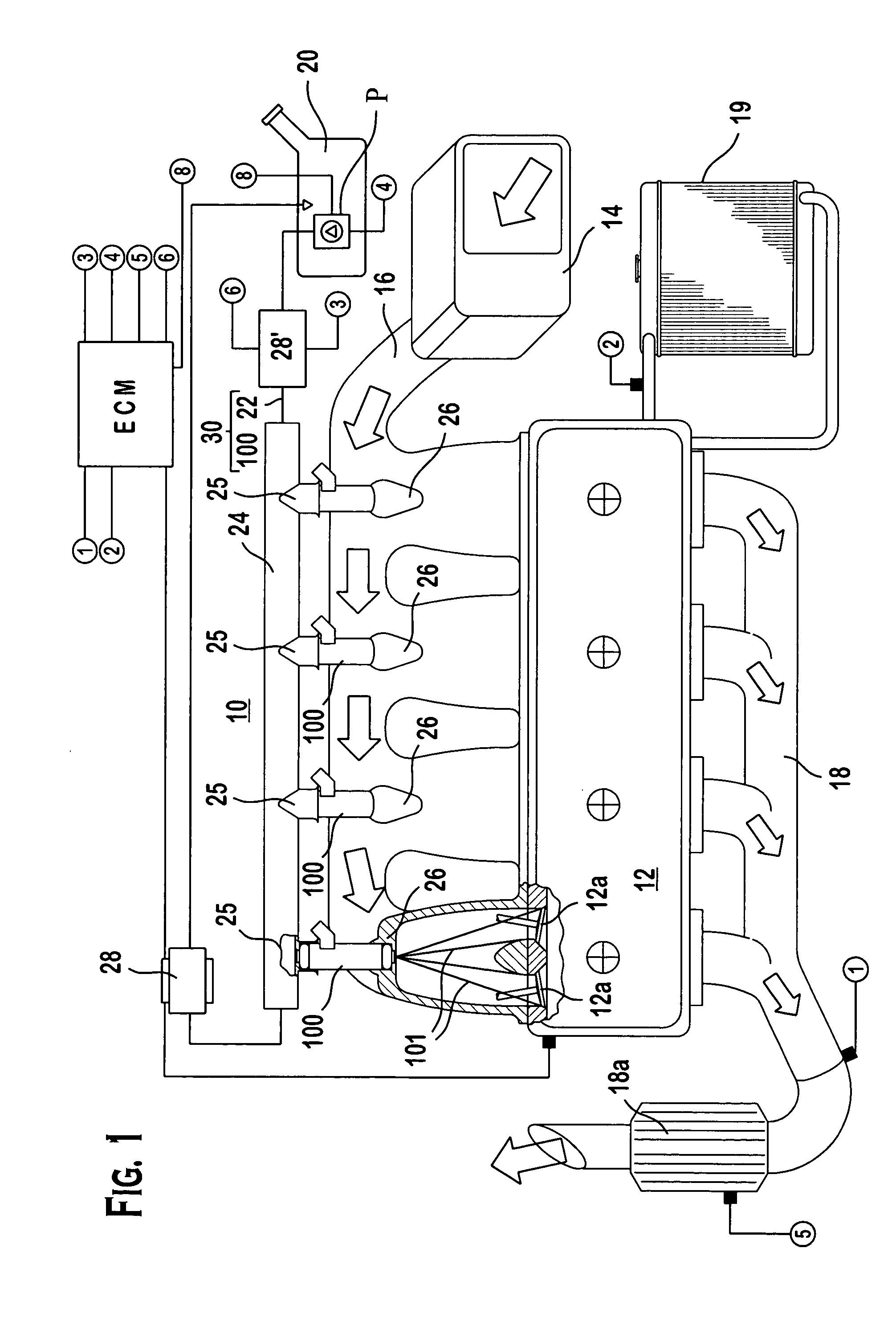

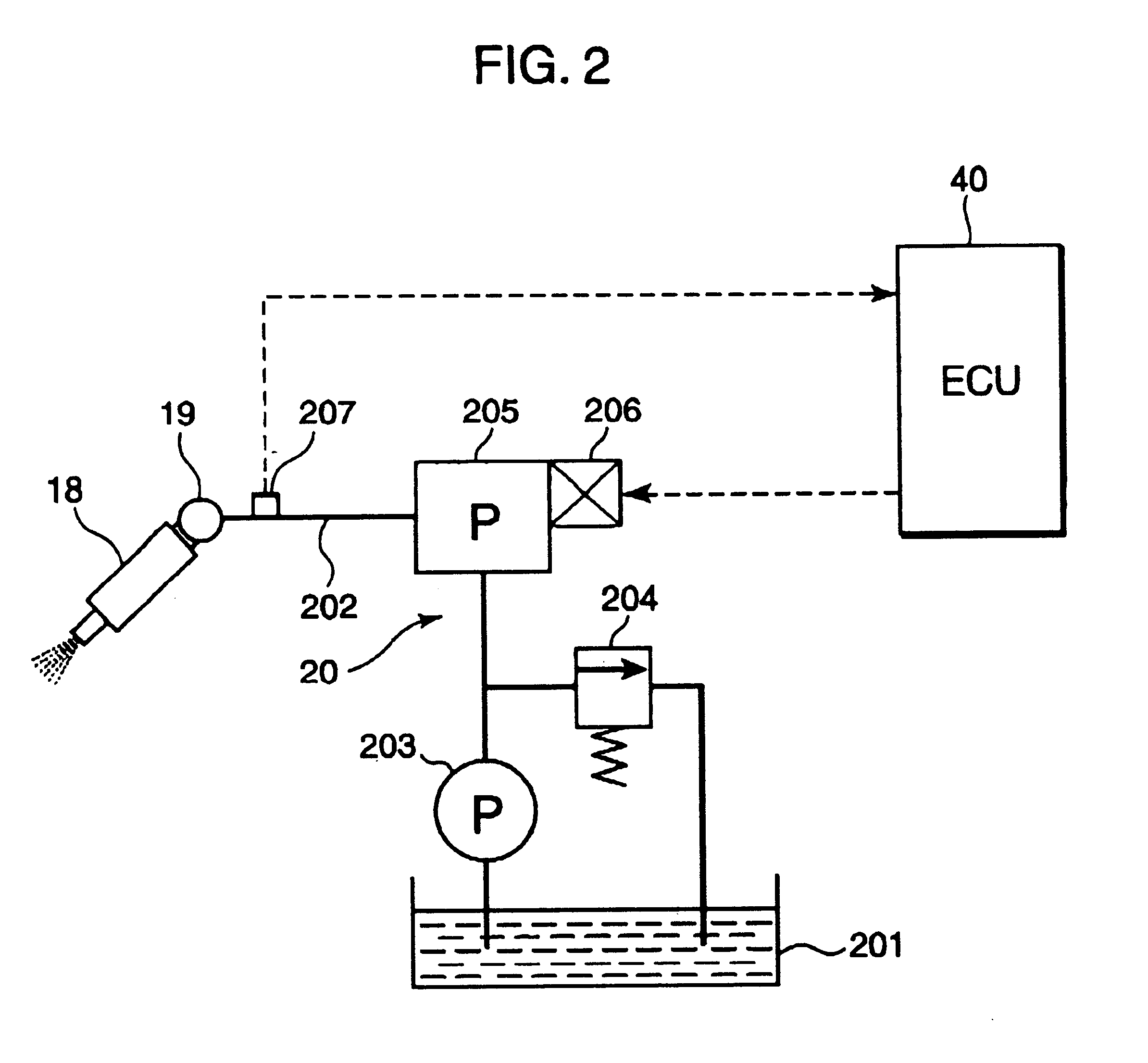

Reduction in hydrocarbon emission via spray pattern control through fuel pressure control in fuel injection systems

InactiveUS7303144B2Electrical controlInternal combustion piston enginesHot startPressure controlled ventilation

Among other aspects shown and described, a fuel supply apparatus that provides multiple fuel spray targeting angles as a function of fuel pressure towards a combustion chamber of an engine to reduce hydrocarbon emission during cold-start or hot-start. A method and fuel system are also shown and described.

Owner:SIEMENS VDO AUTOMOTIVE CORP

Devices and methods for conditioning or vaporizing liquid fuel in an intermittent combustion engine

InactiveUS7404395B2Improve efficiencyAccelerate emissionsElectrical controlInternal combustion piston enginesLiquid fuelInternal combustion engine

A device and method for conditioning and / or volumetric heating fuel within an intermittent combustion engine in order to enhance fuel combustion and emission performance is provided. Such a device can include a fuel injector configured to eject a fuel spray having a trajectory within a combustion chamber, an energy source capable of emitting electromagnetic energy, and an optical fiber configured to transmit electromagnetic energy emitted from the energy source into the combustion chamber, and is also configured to cause fuel conditioning.

Owner:YOSHIMOTO HITOSHI

Fuel nozzle providing shaped fuel spray

A fuel injection nozzle for a gas turbine engine has a central fuel ejection nozzle and a plurality of airflow passages within the spray tip that include a first and second group of circumferentially spaced apart fuel-spray forming airflow passages disposed on opposite sides of a transverse axis and oriented towards each other such as to produce opposed fuel spray shaping air jets which generate a shaped final fuel spray.

Owner:PRATT & WHITNEY CANADA CORP

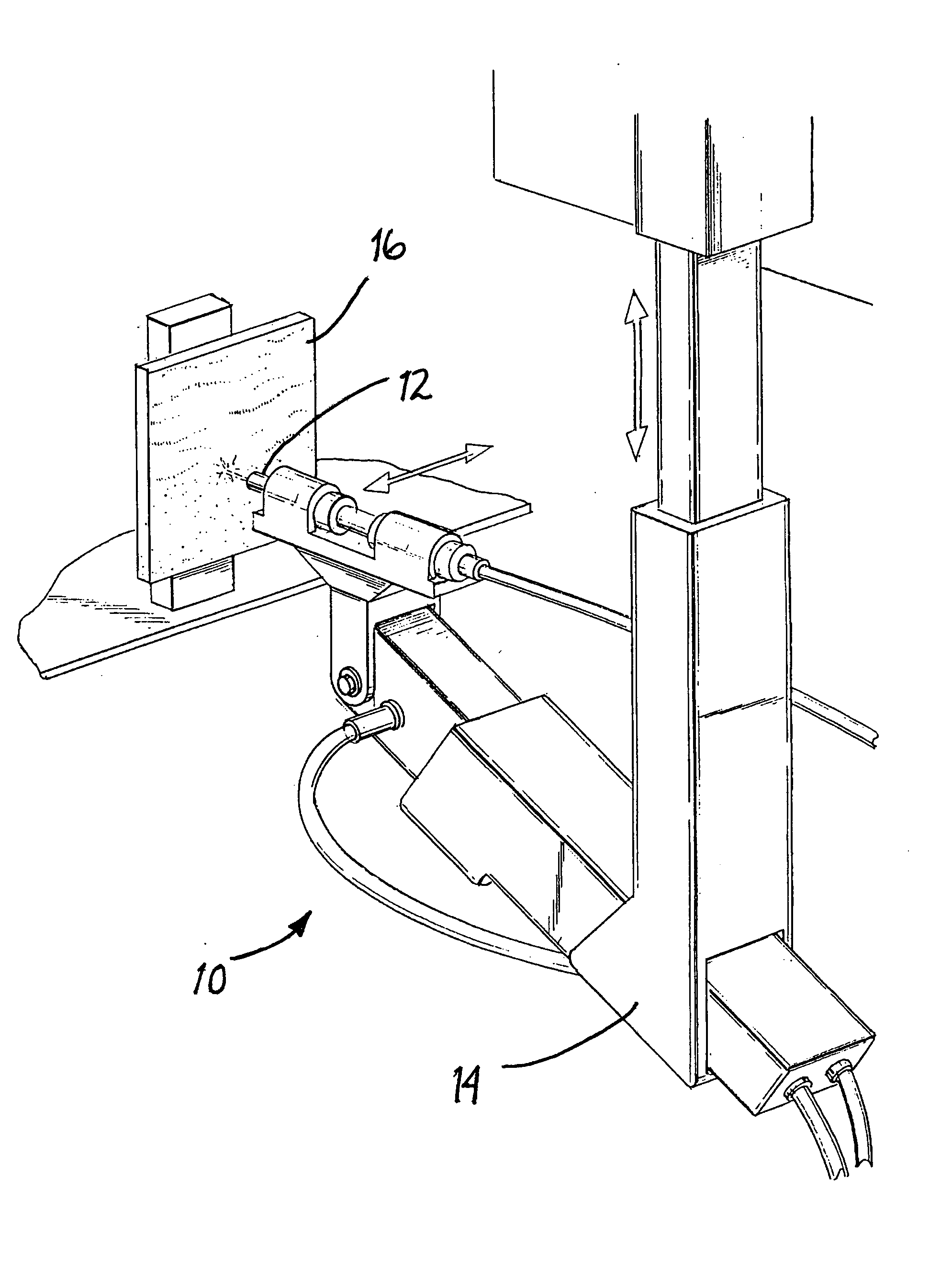

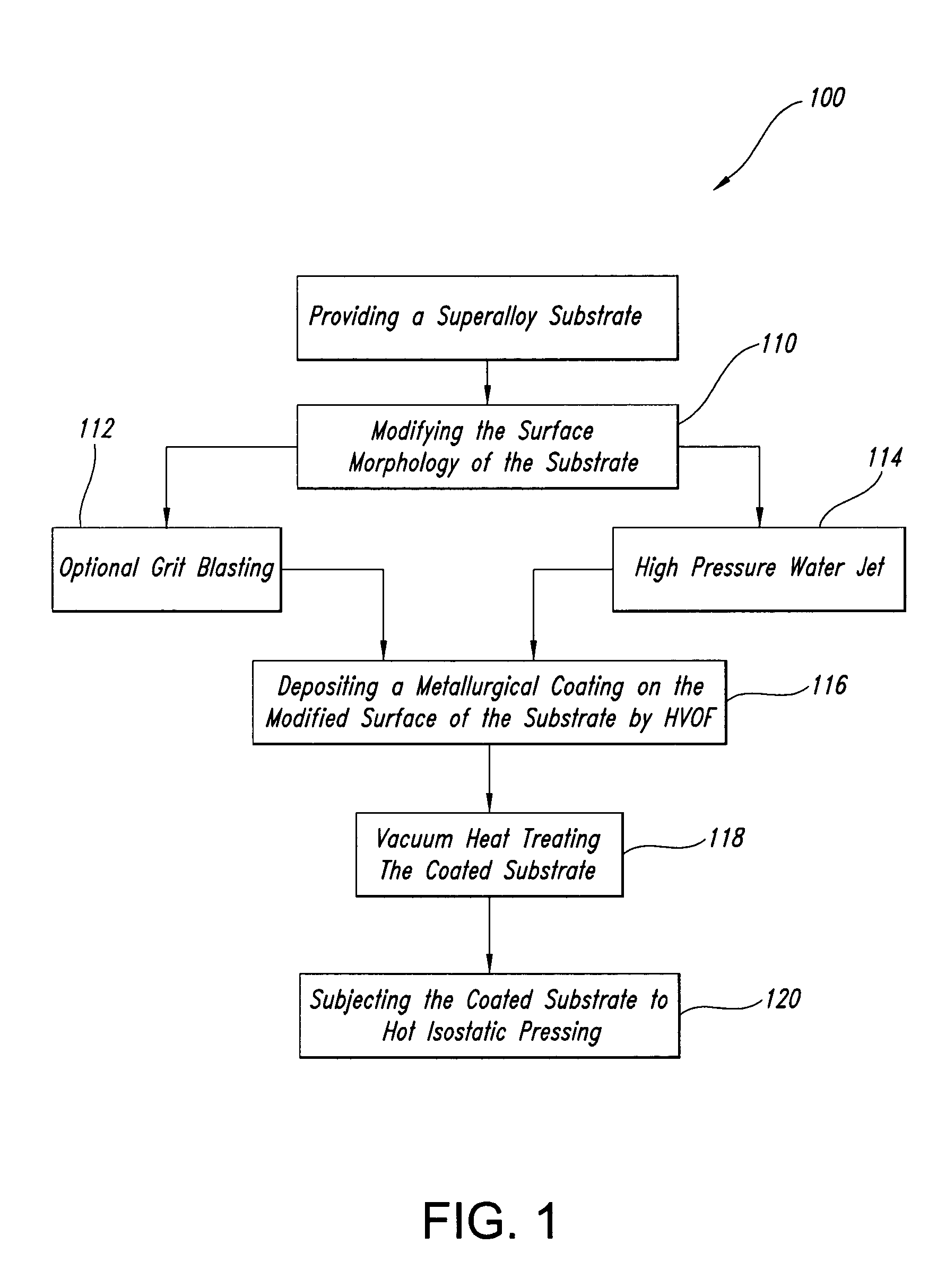

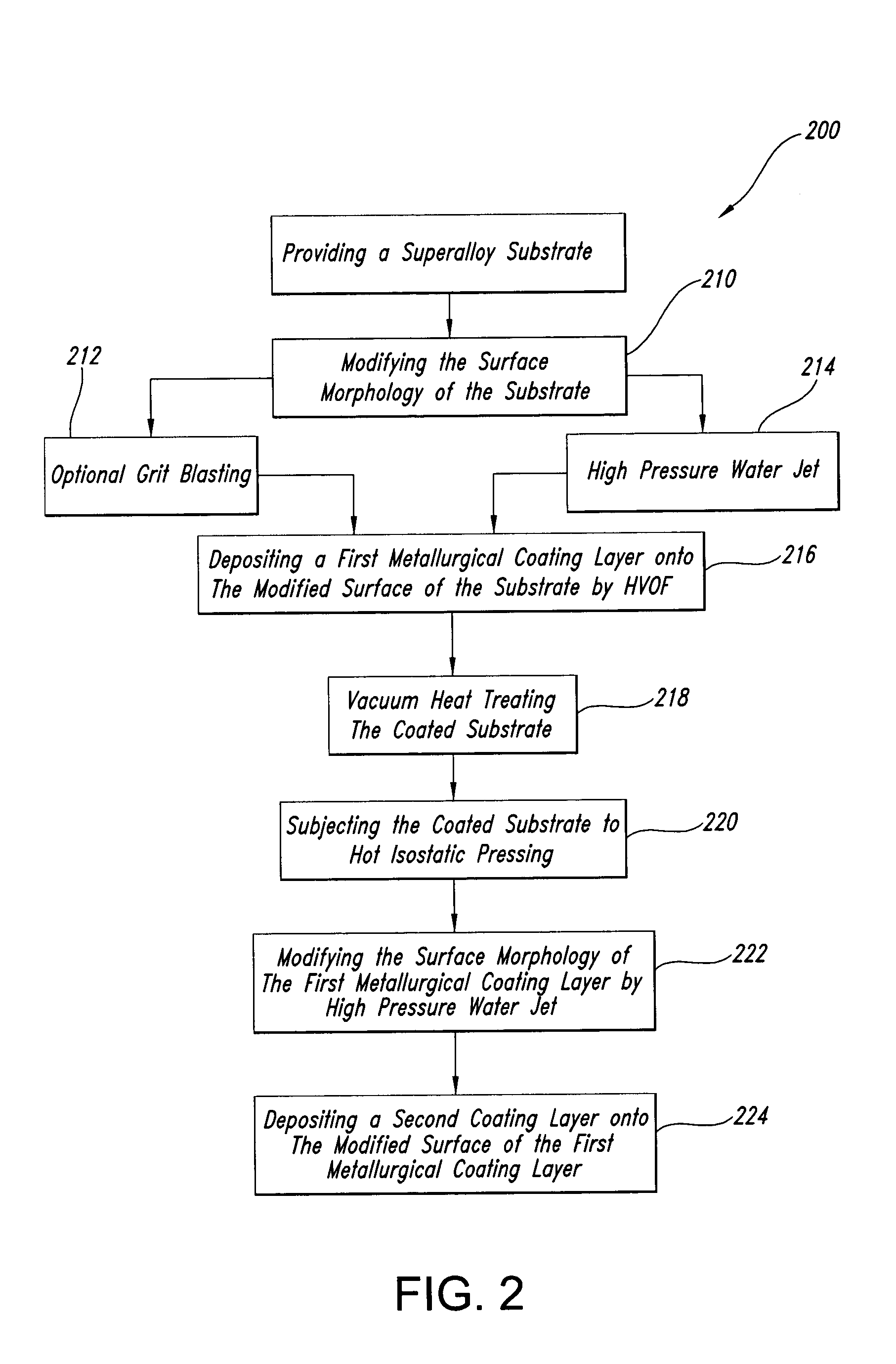

Method for applying metallurgical coatings to gas turbine components

InactiveUS20050036892A1Improve surface roughnessPropellersMolten spray coatingSufficient timeTime segment

A method is disclosed for applying a metallurgical coating to a superalloy substrate that includes the steps directing a water jet having a sufficient pressure against the surface of the superalloy substrate for a sufficient time period to modify the surface morphology of the substrate in a such a manner so that the surface roughness and surface volume of the substrate are increased at a microscopic and macroscopic level, and depositing a metallurgical coating on the modified surface of the substrate using a high velocity oxygen fuel spray.

Owner:WALBAR METALS

Exhaust emission control device for an internal combustion engine

InactiveUS7367182B2Efficient regenerationSimple and inexpensive configurationCombination devicesNon-fuel substance addition to fuelParticulatesCombustor

A forced regeneration device which performs regeneration of a particulate filter includes oxidation catalysts (23, 24a) disposed upstream from the particulate filter or in said particulate filter and a burner (30) located upstream from the oxidation catalysts and operable switching between a combustion mode for combusting a fuel spray by inflammation to raise temperature of exhaust gases in an exhaust passage and a fuel supply mode for supplying only a fuel spray to the exhaust passage without inflammation. After the burner operates in the combustion mode, the burner operation is switched to the fuel supply mode.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

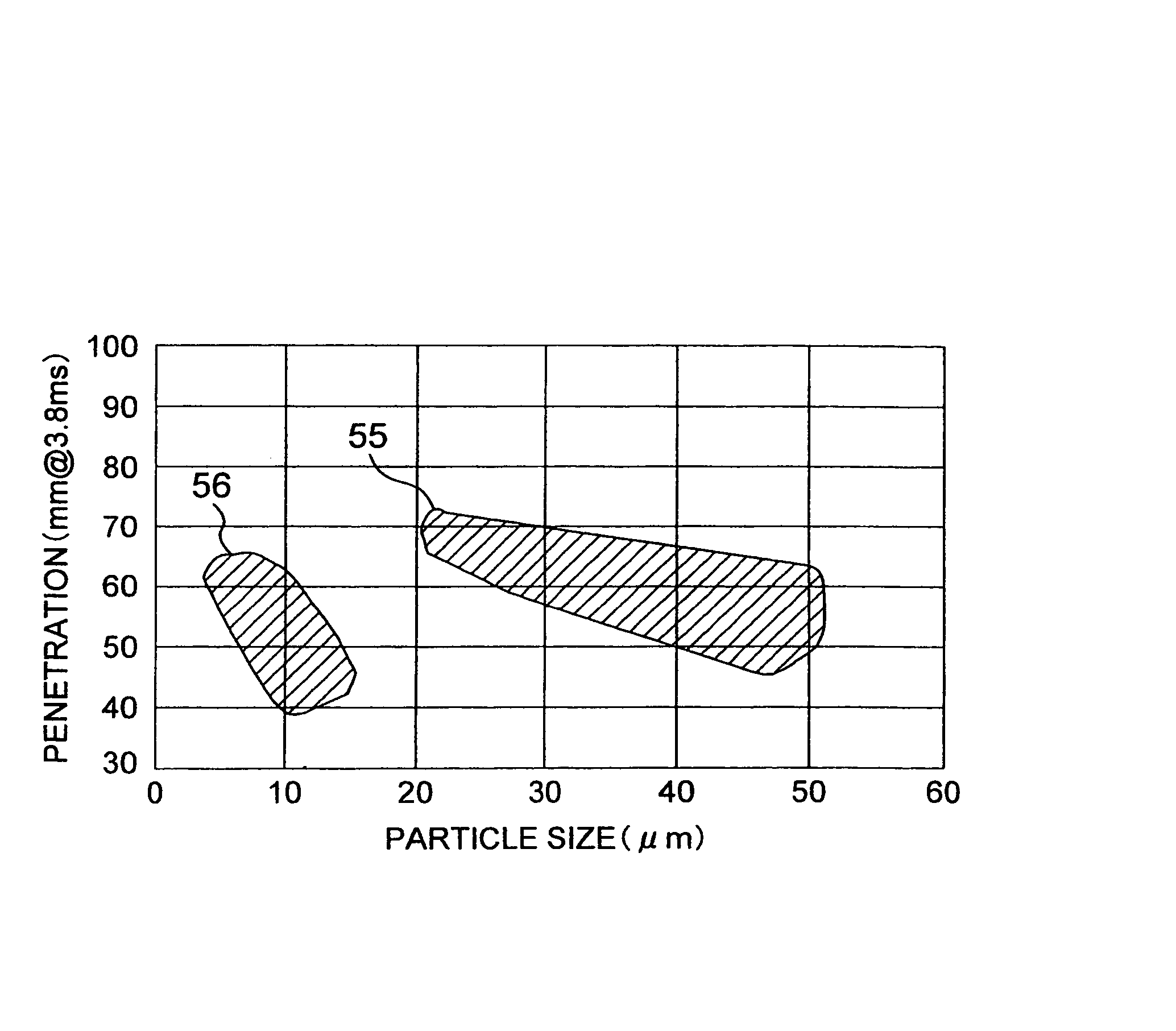

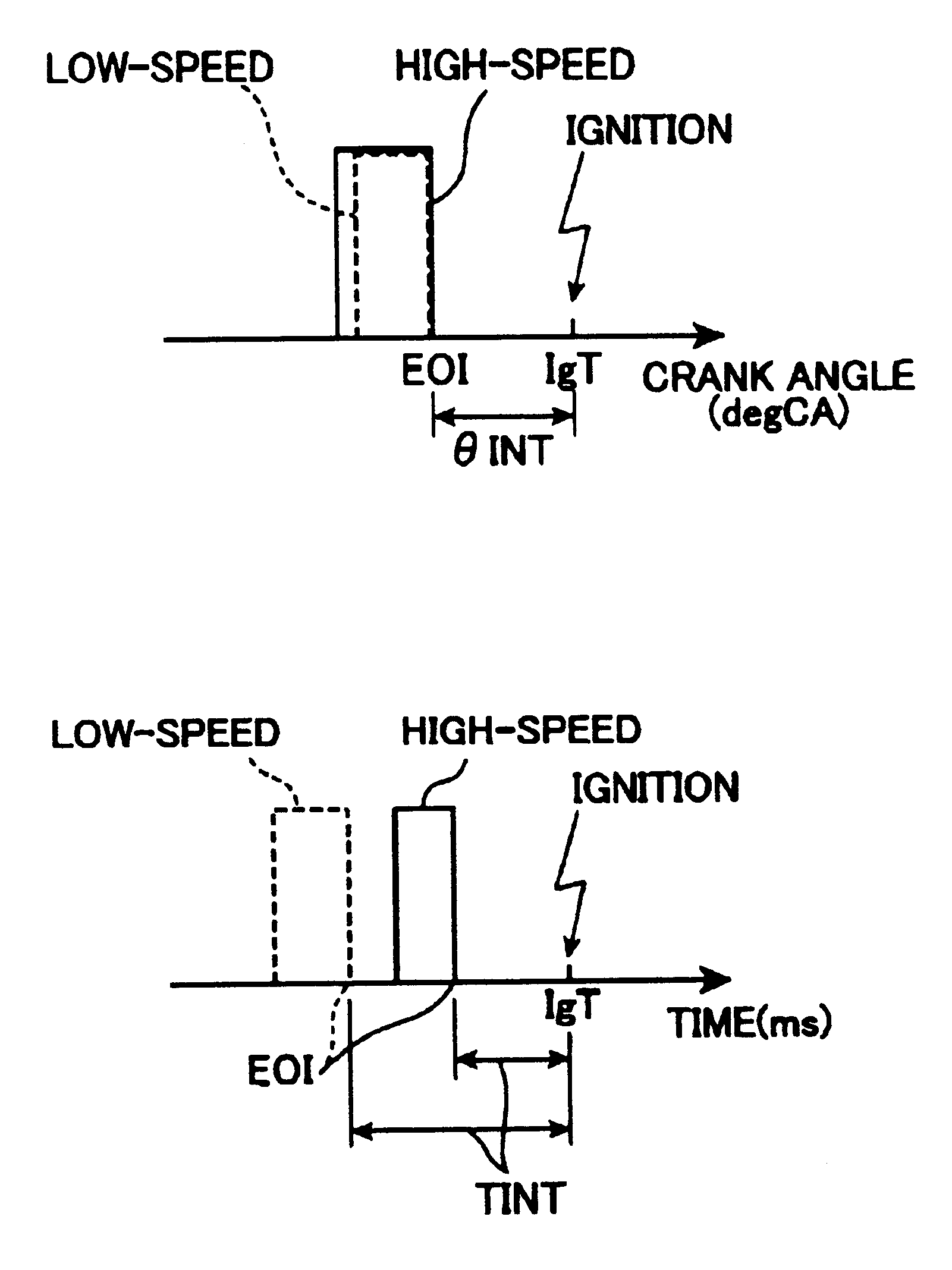

Control device for direct-injection spark-ignition engine and method of setting fuel injection timing of the same

InactiveUS6681739B2Improve fuel economyElectrical controlNon-fuel substance addition to fuelFuel injectionIgnition point

A direct-injection spark-ignition engine in which a combustible mixture is produced around a spark plug at an ignition point by causing a tumble and a fuel spray to collide with each other in a combustion chamber during stratified charge combustion comprises a fuel pressure controller which controls fuel pressure such that penetration of the fuel spray from a fuel injector is progressively intensified with an increase in engine speed in a stratified charge combustion region and means for controlling fuel injection timing including an injection timing setter. The means for controlling fuel injection timing controls the injection timing in such a way that the interval between a fuel injection ending point and the ignition point becomes progressively shorter as engine speed increases under the same engine load conditions in the stratified charge combustion region.

Owner:MAZDA MOTOR CORP

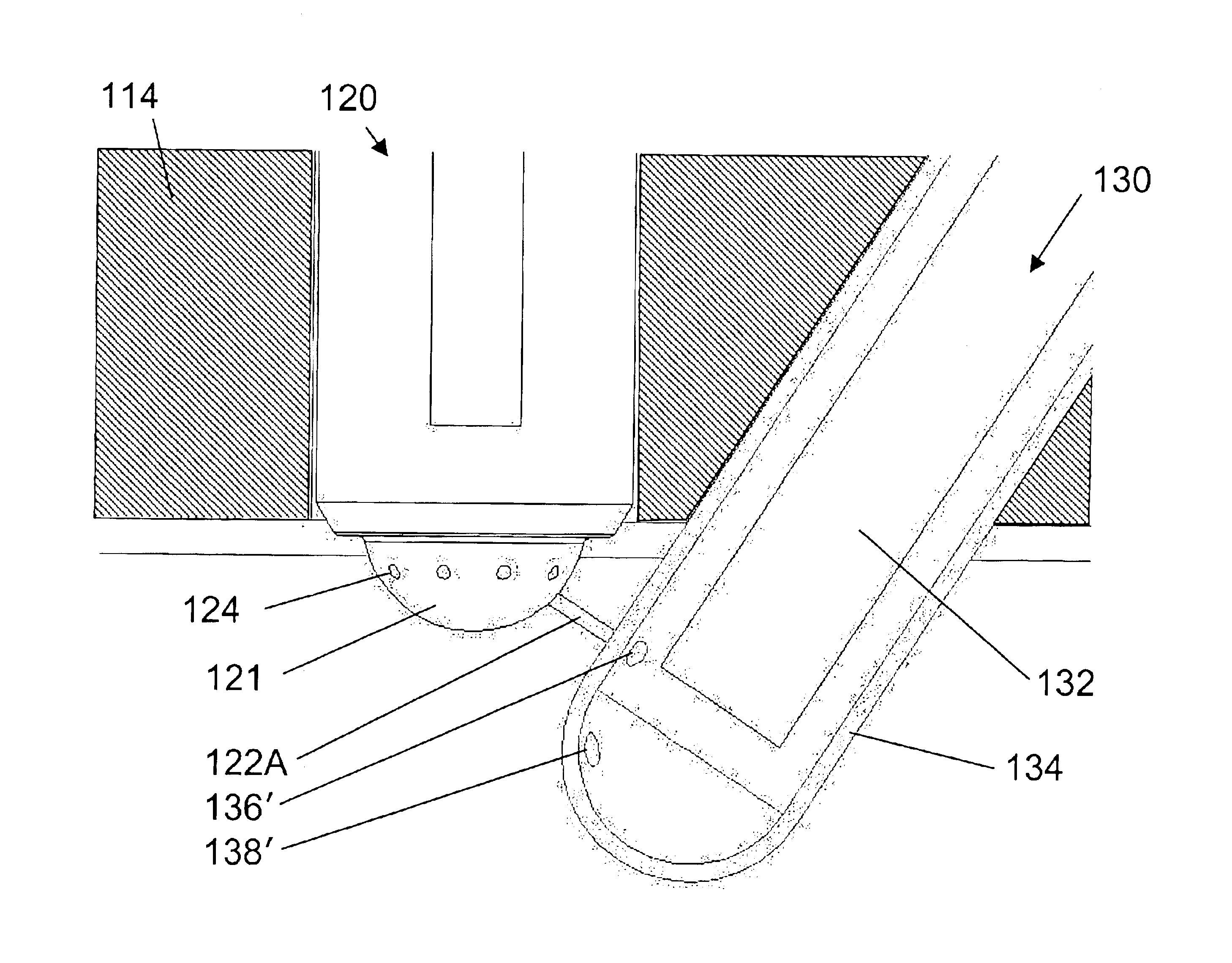

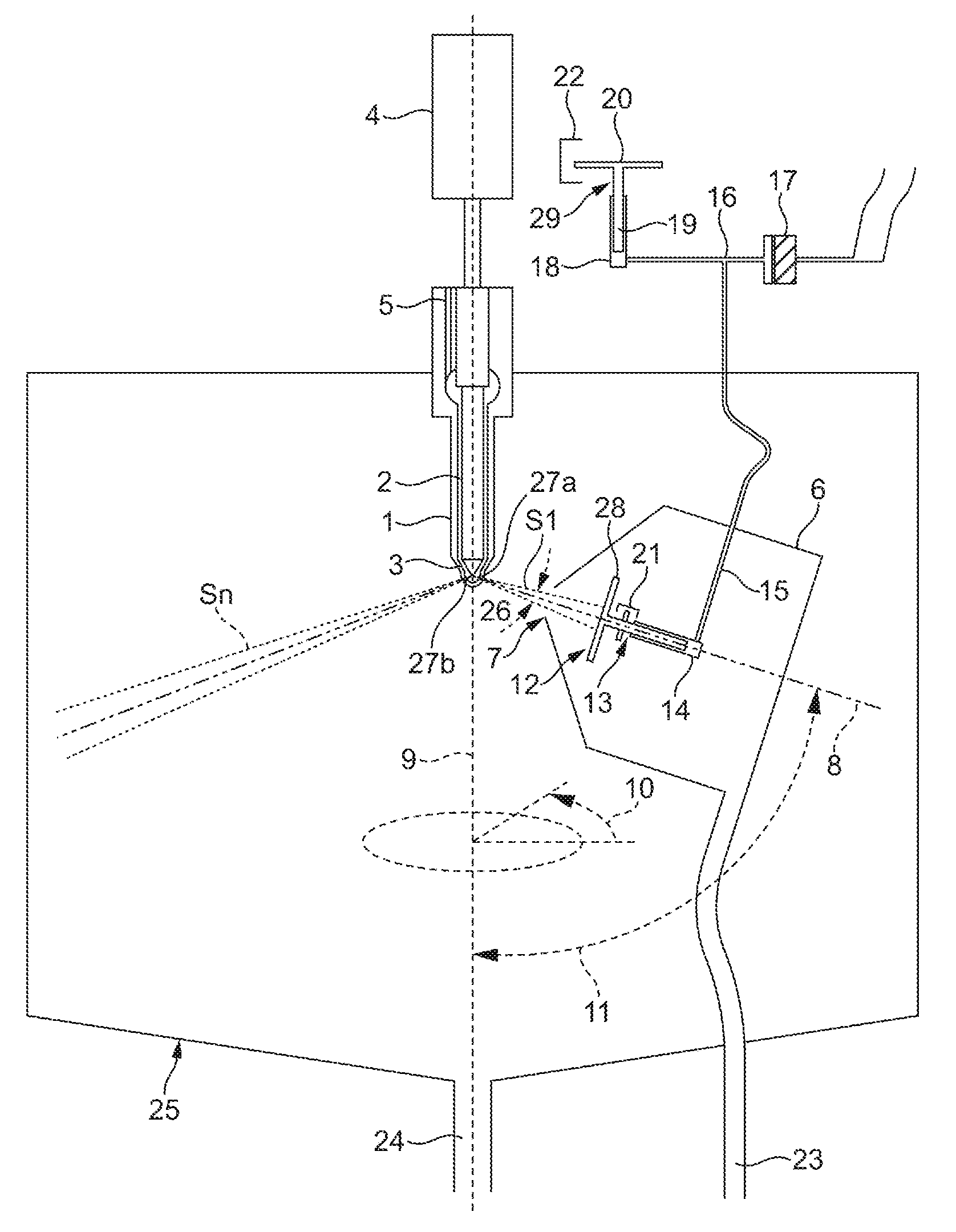

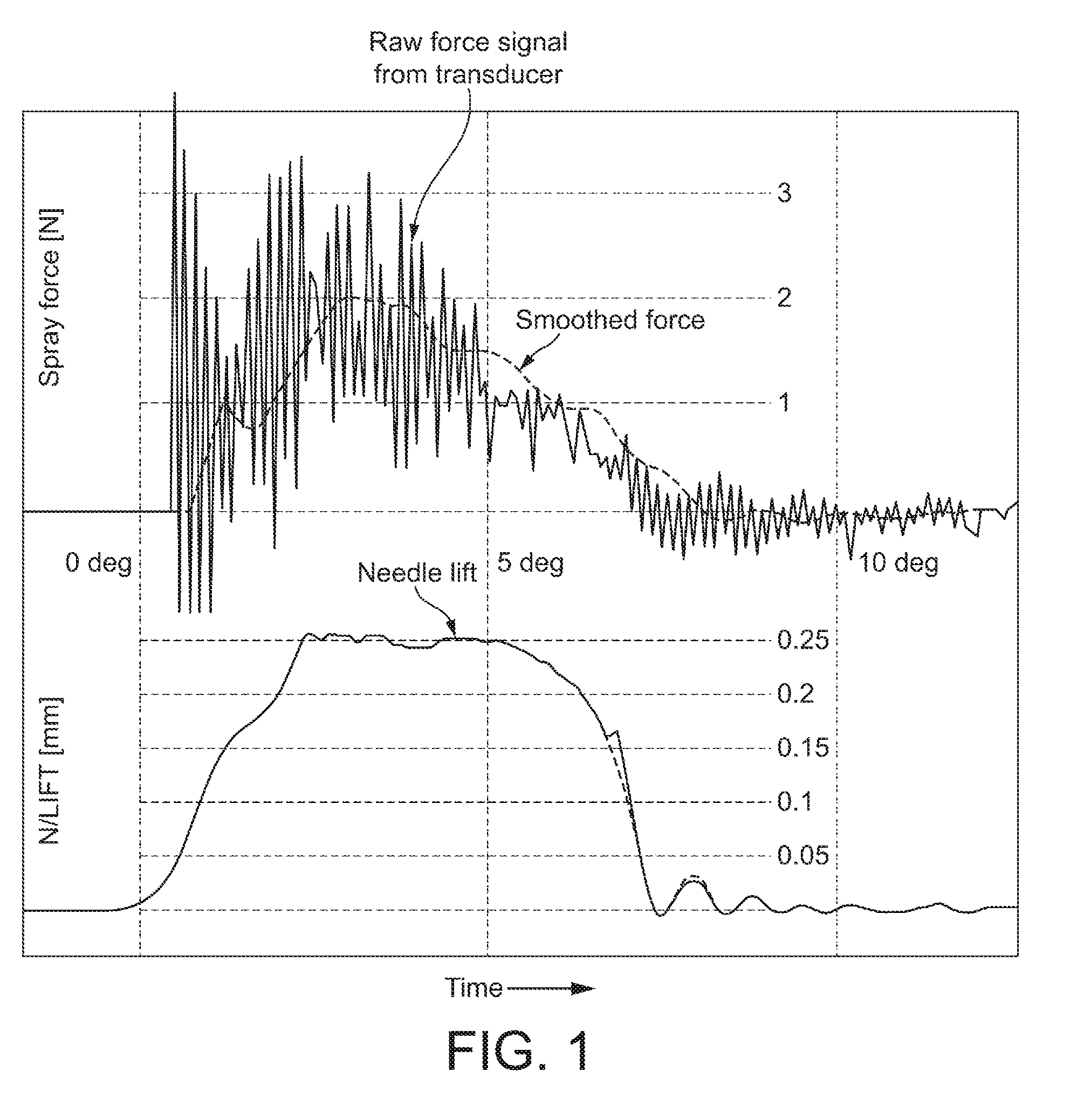

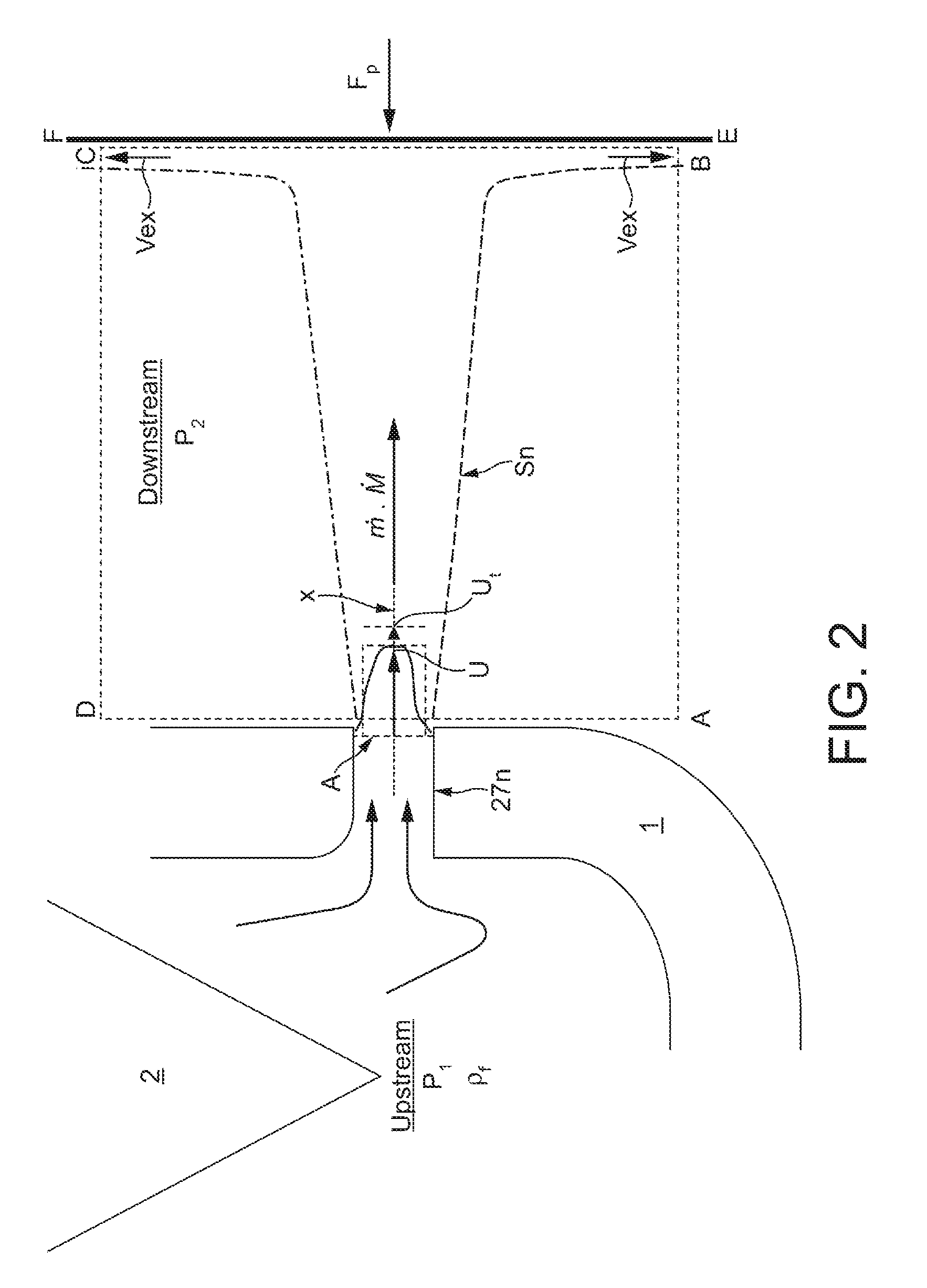

Apparatus and methods for testing a fuel injector nozzle

InactiveUS20100170329A1Quick changeMinimizes static frictionInternal-combustion engine testingFuel injection apparatusMomentumInjector nozzle

An apparatus and method is described for testing a multi-hole fuel injector nozzle. The apparatus comprises mounting means for the multi-hole nozzle and fuel supply means for supplying fuel to the multi-hole nozzle. The multi-hole nozzle is mounted outside a measurement chamber for capturing the fuel spray from an individual spray hole outlet of the multi-hole nozzle. In one embodiment, the apparatus includes a spray target plate, located within the measurement chamber, at which the fuel spray is directed. The spray target plate (28) is connected to a remote pressure sensor, which is used to determine the spray force of the fuel spray acting on the spray target plate. The apparatus is further arranged to determine the mass flow rate of the fuel spray. A new parameter, referred to as ‘momentum efficiency’ is defined, and calculated using the determined values of spray force and mass flow rate.

Owner:DELPHI TECH IP LTD

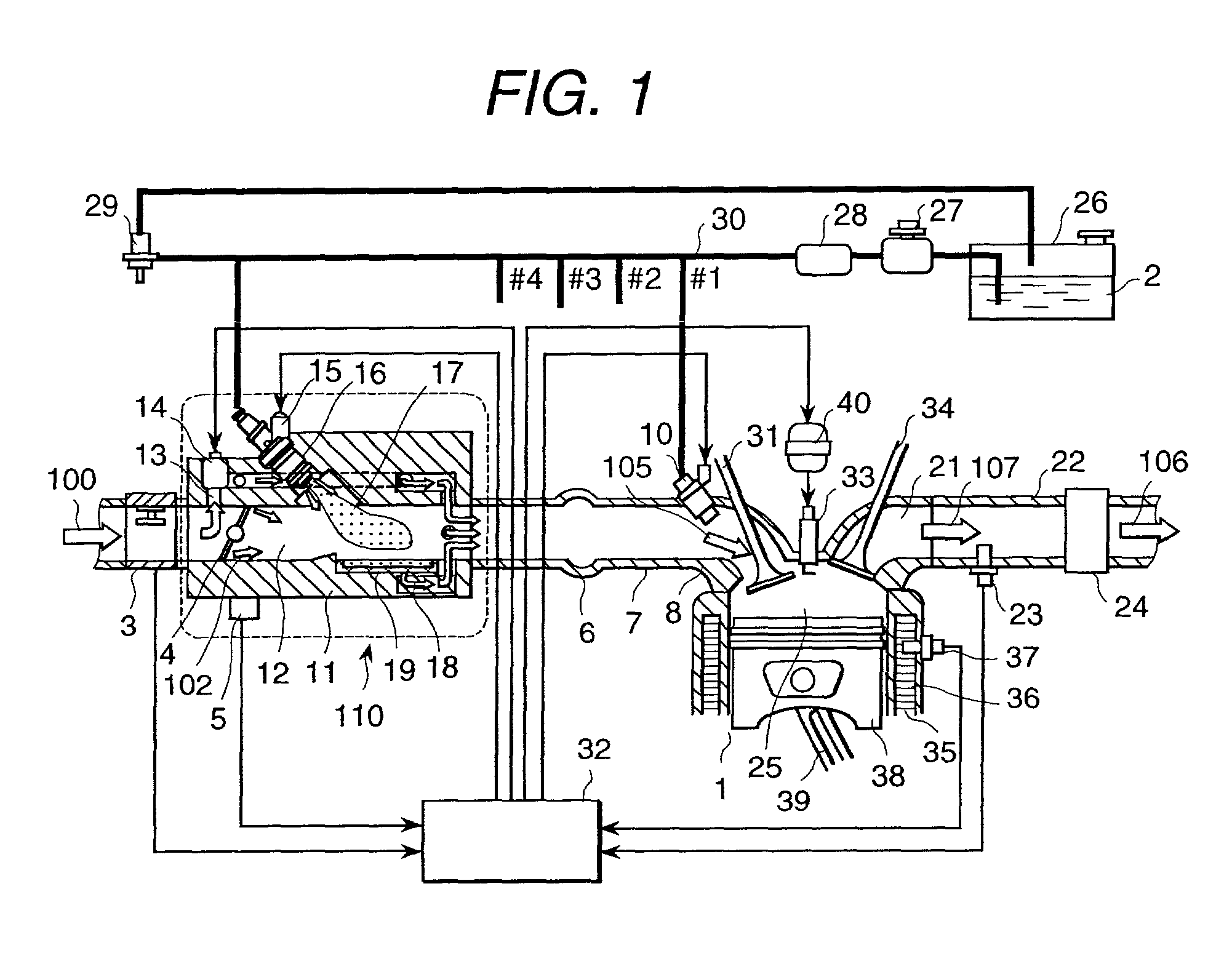

Intake air control device and internal combustion engine mounting the same

InactiveUS20010027776A1Easy to manufactureEasily dismountedElectrical controlInternal combustion piston enginesExternal combustion engineInternal combustion engine

A main passage mounting a throttle valve and an air bypass flow passage for reducing HC emission by promoting atomization of the fuel spray injected from the assembly pipe fuel injector are integrated in a body of an intake air control device arranged upstream of an assembly pipe in one-piece structure to form a unit. Thereby, the intake air control device can be easily manufactured, and easily mounted on and dismounted from the intake air system. An amount of HC emitted at warming-up operation of an internal combustion engine is reduced by efficiently supplying fuel spray injected from an assembly pipe fuel injector at starting and warming-up operations to the internal combustion engine.

Owner:HITACHI LTD +1

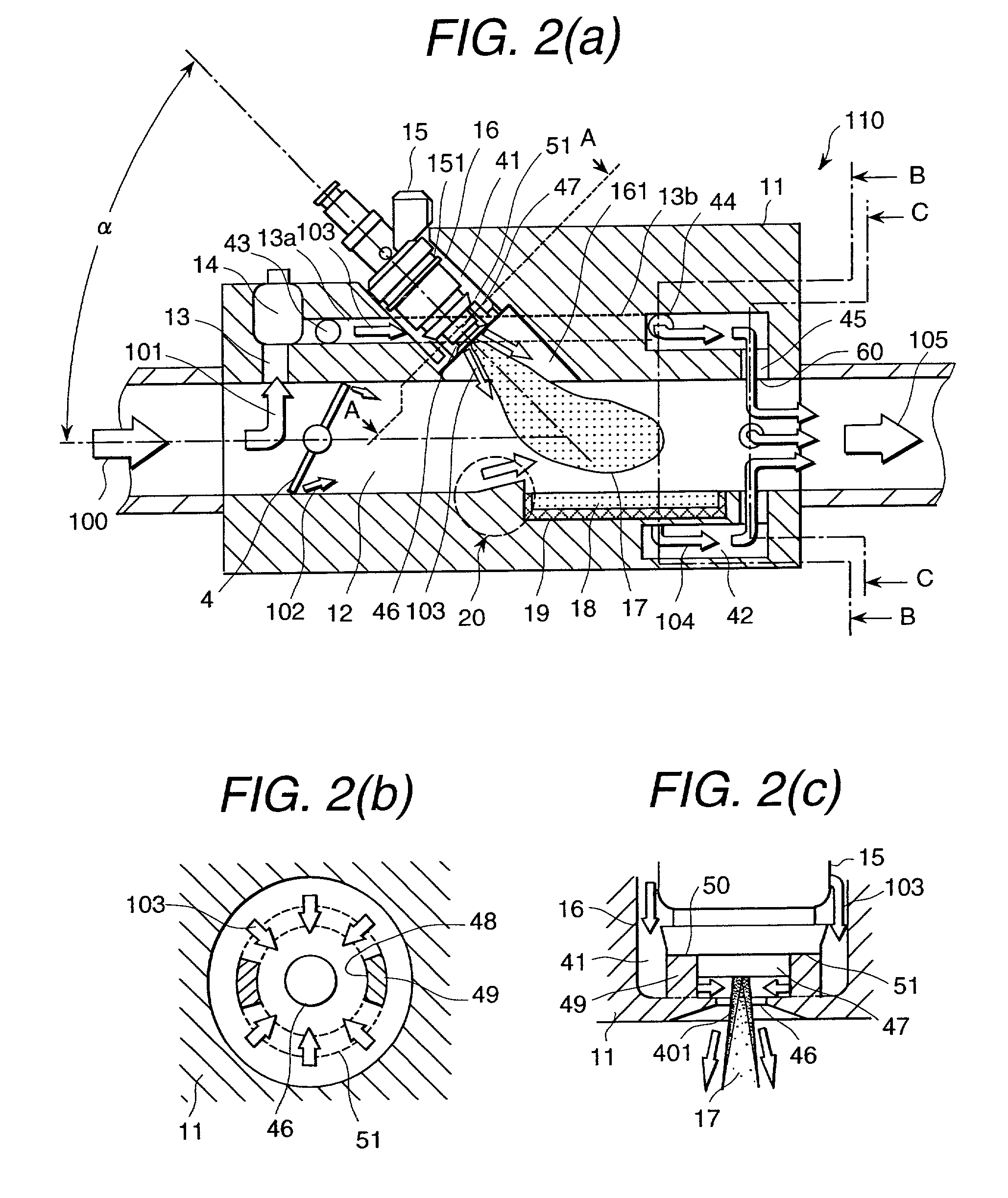

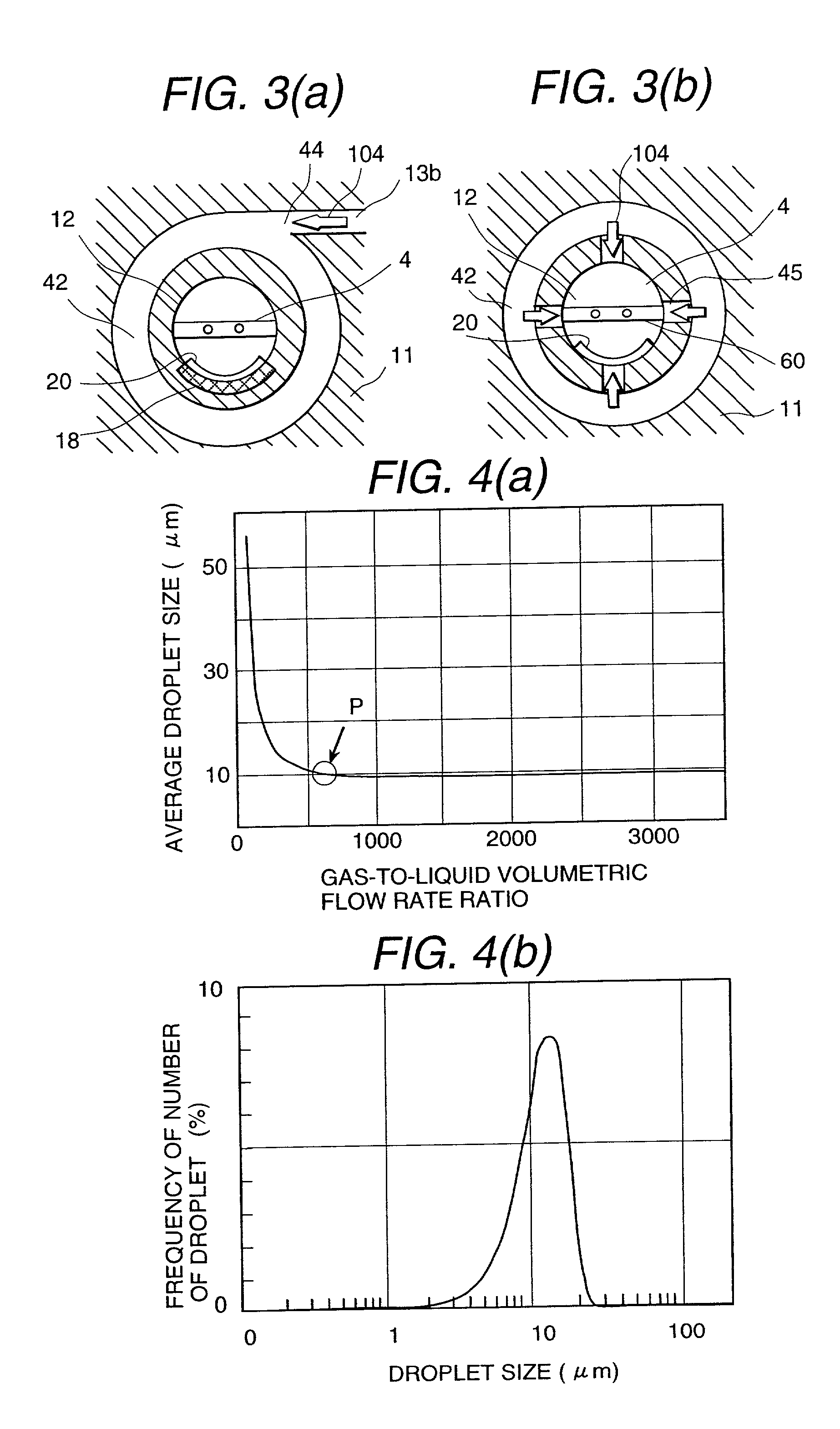

Fuel injection device of internal combustion engine

ActiveUS20040178287A1Promote atomizationWell formedSpray nozzlesFuel injection apparatusMultiple injectionEngineering

Multiple injection holes are formed in an injection hole plate. Each injection hole penetrates the injection hole plate. The injection hole is formed with an inlet side opening and an outlet side opening. The outlet side opening is formed in the shape of a flattened rectangle having a major axis and a minor axis. Therefore, the fuel flowing into the injection hole through the inlet side opening is injected in the shape of a film from the outlet side opening. Thus, liquid film splitting is promoted, so atomization of the fuel is promoted. Since the multiple injection holes are formed in the injection hole plate, the shape of a great fuel spray, which is formed by combining fuel sprays injected from the respective injection holes, can be adjusted easily.

Owner:DENSO CORP

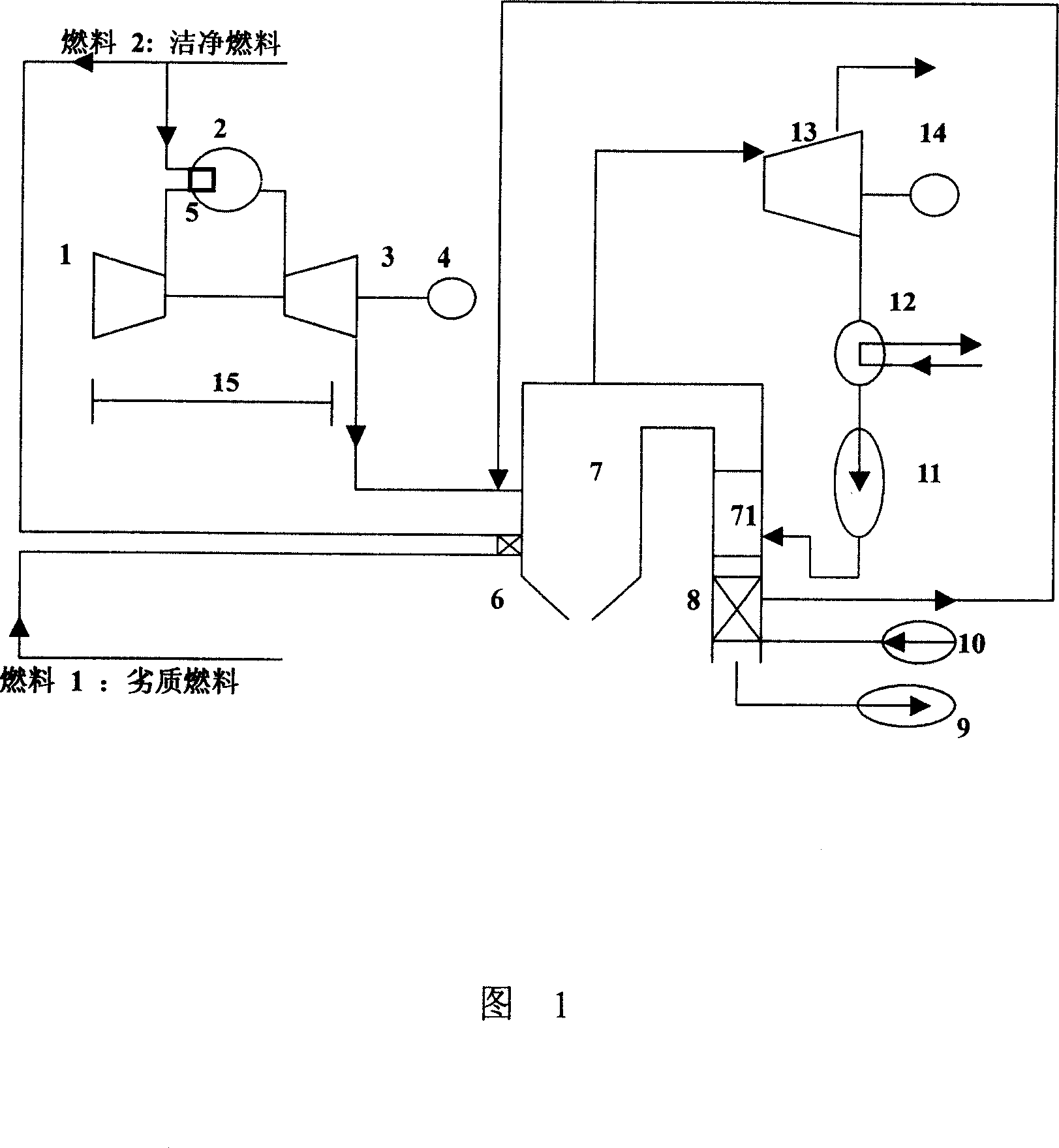

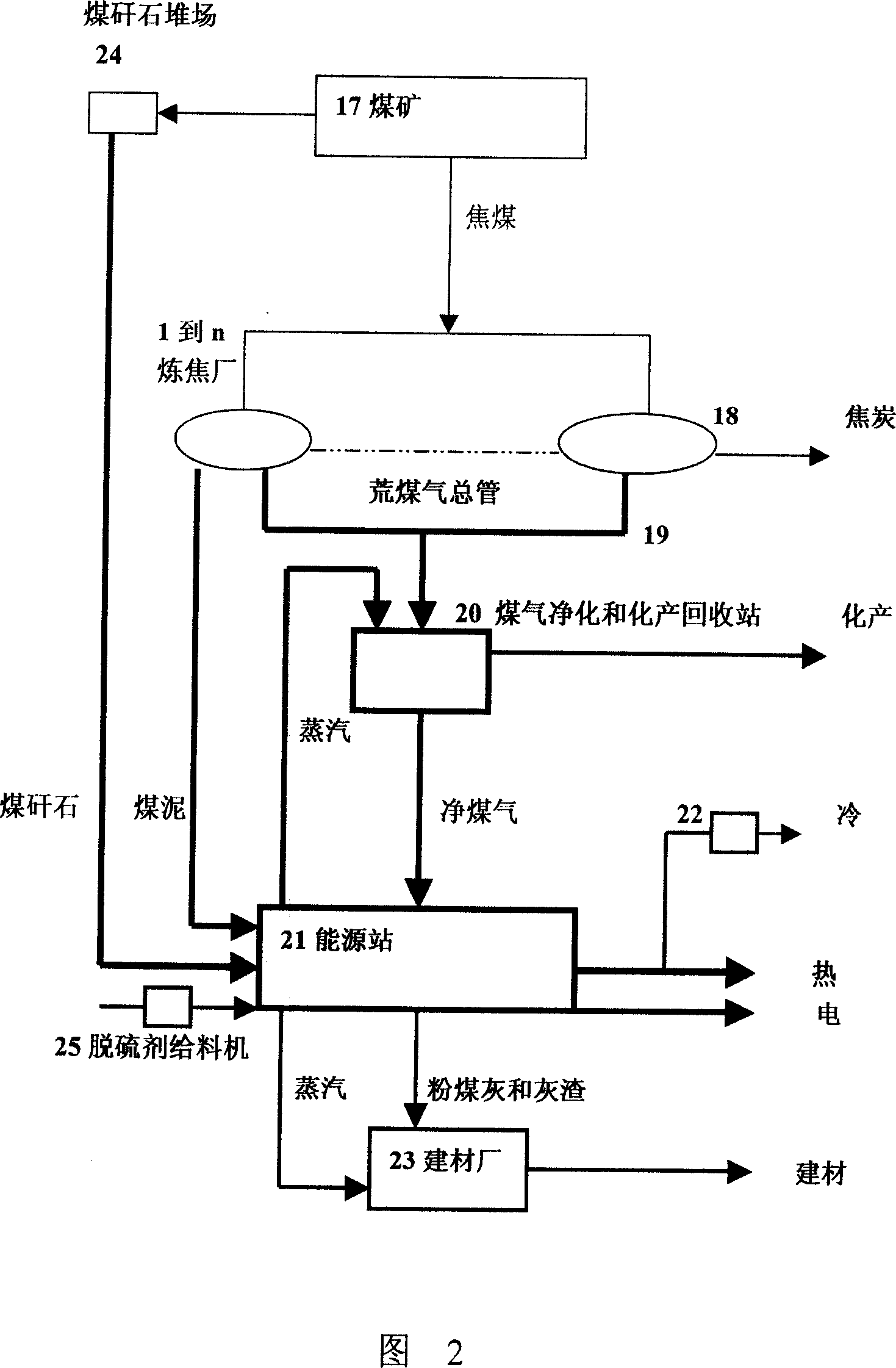

Double-fuel combustion-supporting type gas-steam combined cycle system

InactiveCN101144396AEliminate wasteNo wasteFluidized bed combustionSteam engine plantsCoalFuel supply

The invention relates to a dual fuel combustion-supporting type gas-steam combined cycle system, and belongs to the energy comprehensive utilization technical field. The invention is characterized in that the invention comprises a gas turbine power generating system, a steam turbine power generating system and a circulating fluidized bed boiler; the exhaust tube of the gas turbine of the gas turbine power generating system is communicated with the secondary air inlet tube of the circulating fluidized bed boiler through an exhaust pipeline, the circulating fluidized bed boiler is connected with the steam turbine of the steam turbine power generating system through a steam pipeline, and the steam turbine of the steam turbine power generating system is connected into the economizer of the circulating fluidized bed boiler through a condenser and a feed water pump; a lean fuel supply pipeline is divided into two branch lines, one branch line is led to the combustion engine fuel spraying nozzle of the gas turbine power generating system, and the other branch line is led to the burner of the circulating fluidized bed boiler; an inferior coal-related supply pipeline is accessed to the burner of the circulating fluidized bed boiler. The invention uses the wastes as raw materials to generate electric energy and steam, and thereby primary resource waste and environmental pollution are eliminated, the invention has no secondary pollution, as well as the environment is protected.

Owner:马龙根

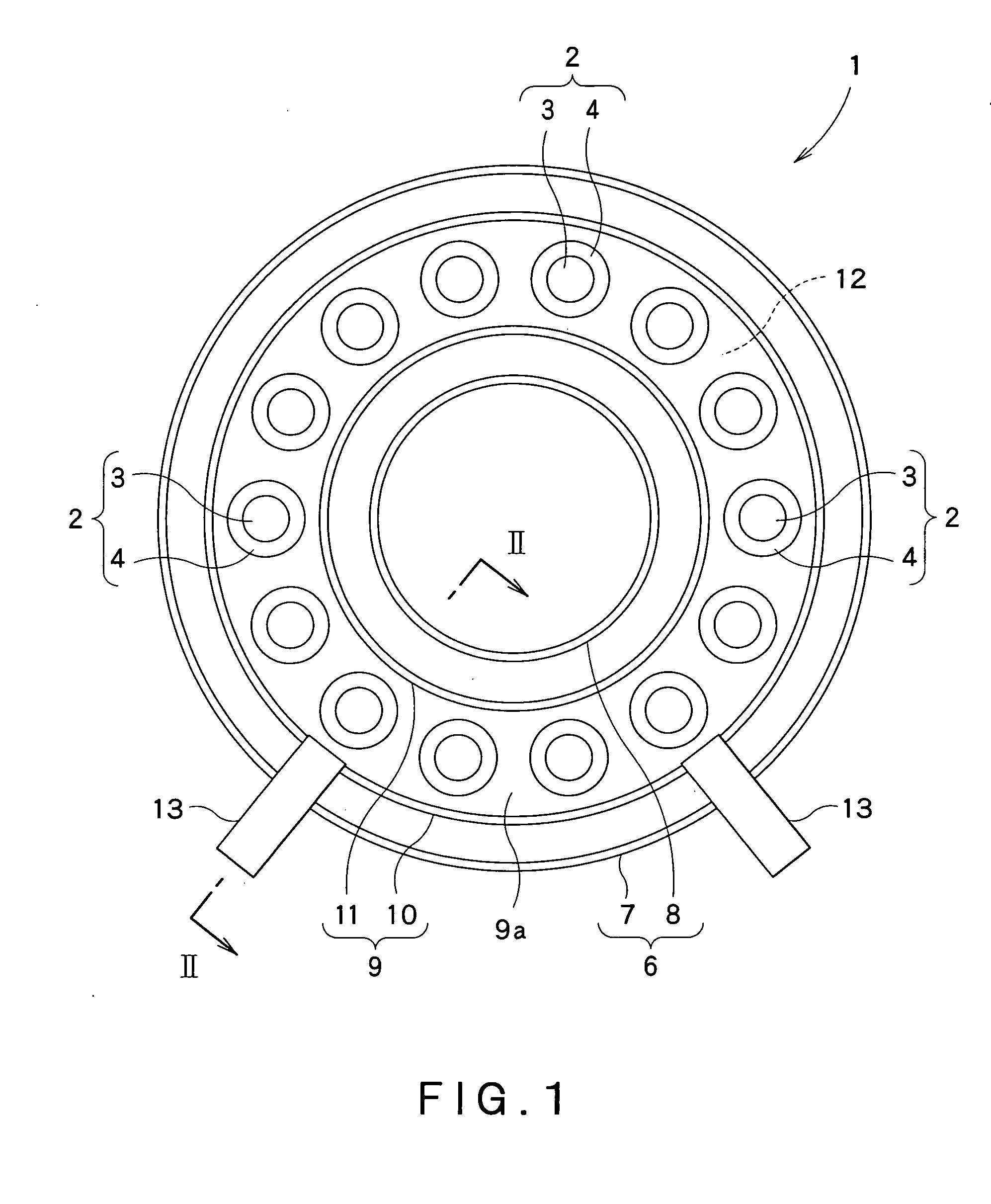

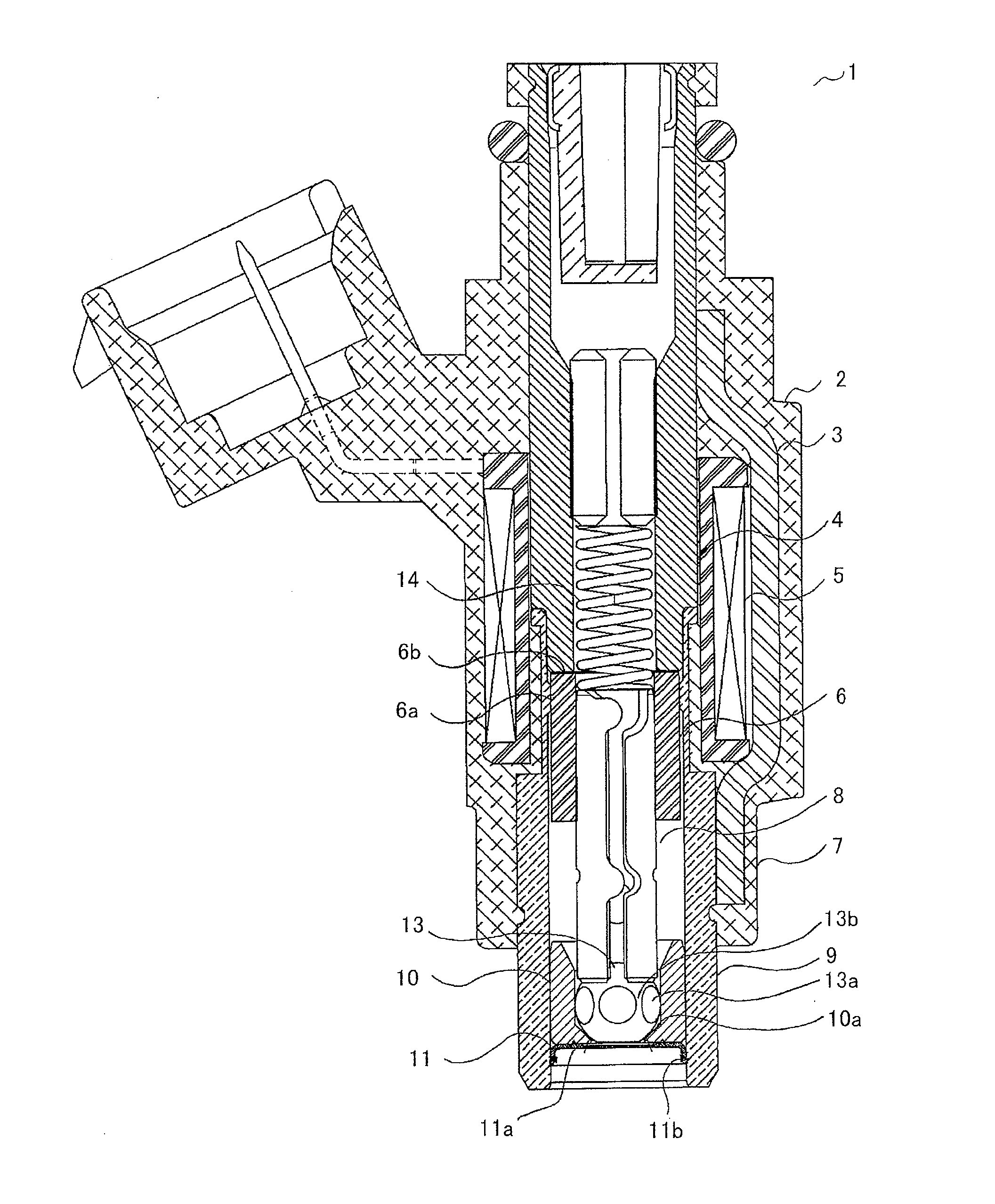

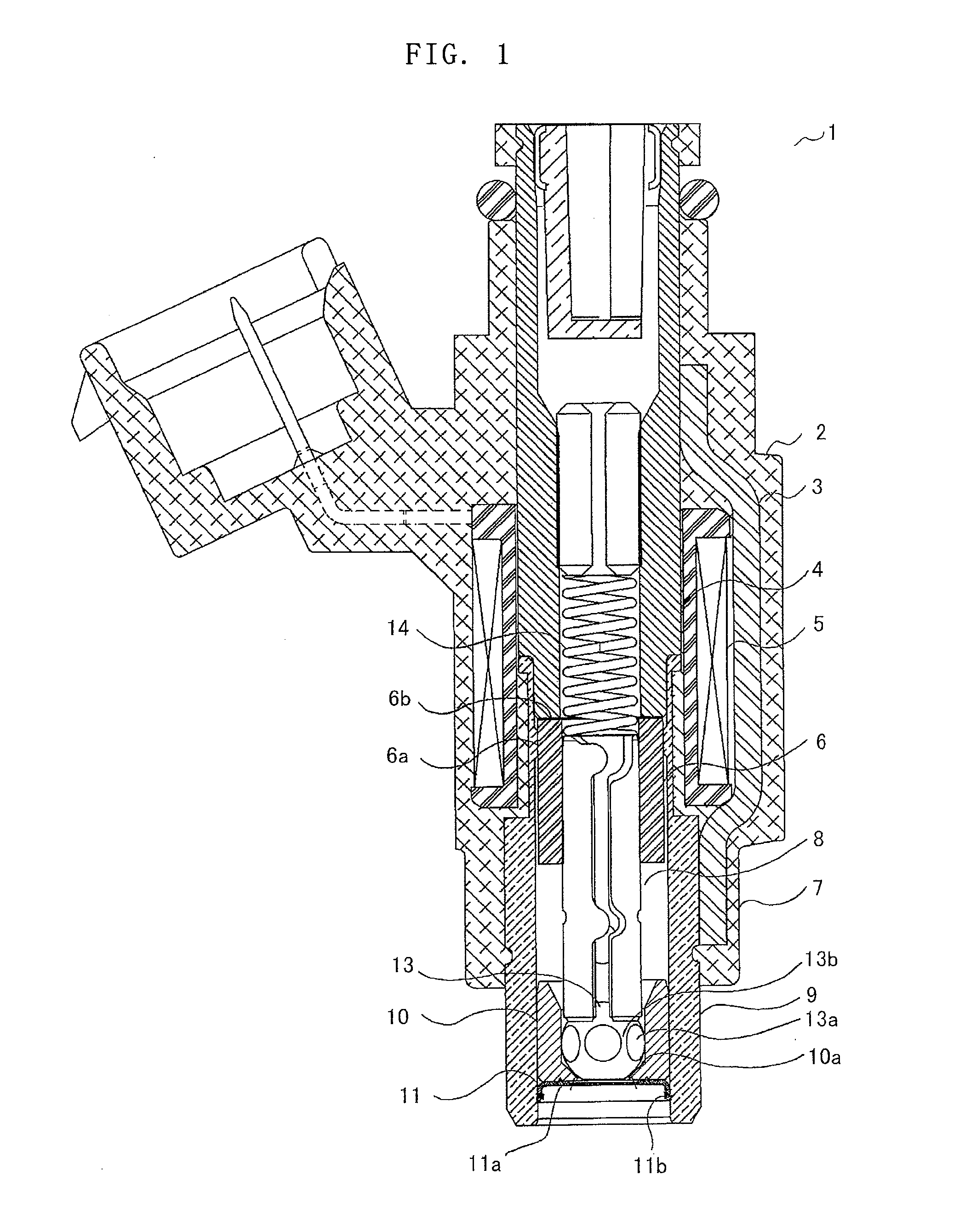

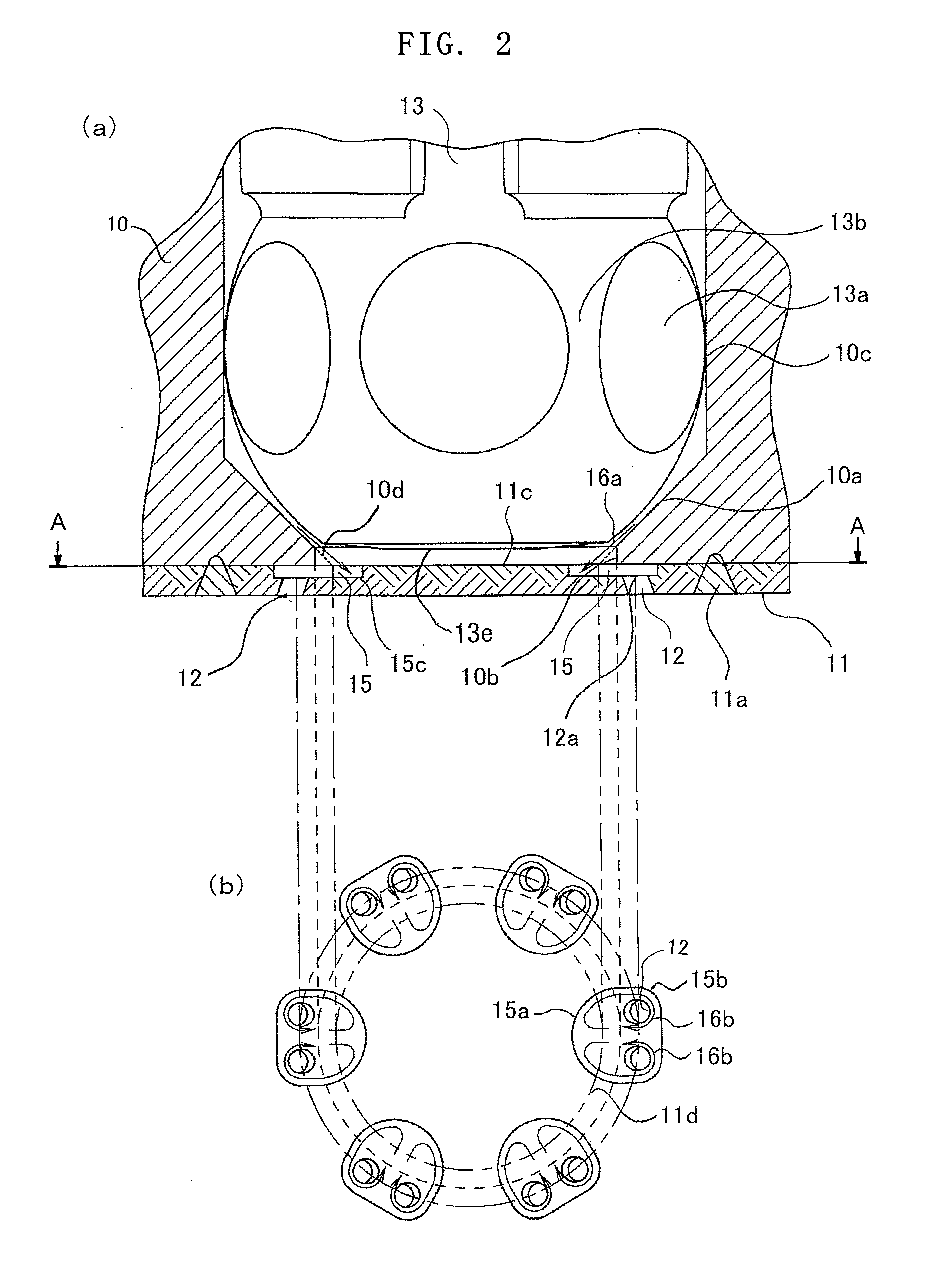

Fuel injection valve

ActiveUS20100288857A1Deterioration of dynamic rangeAdd partsSpray nozzlesFuel injection apparatusAtmospheric airEngineering

There is obtained an internal combustion engine fuel injection valve in which, by suppressing increase in production costs, deterioration in the accuracy of a flow rate, and variations in various kinds of characteristics caused by a change in the atmospheric air pressure, the quality of atomized fuel spray is improved.An injection hole plate 11 is disposed in such a way that an extended line 10d along the plane of a valve seat portion of a valve seat whose diameter is gradually reduced in the downstream direction and an upstream plane 11c of the injection hole plate 11 intersect each other so that a virtual circle 11d is formed; by recessing part of the upstream side of the injection hole plate 11 at a plurality of positions along the valve seat opening portion 10b, a plurality of fuel chambers 15 is formed; the fuel chamber 15 is in a shape, the halves of which are symmetric with each other with respect to a line that radially extends from the center of the injection hole plate 11, and is disposed in a place that ranges from the inside of the virtual circle 11d to the outside of the inner circumference of the valve seat opening portion 10b; and in each of the fuel chambers 15, two injection holes 12 are arranged outside the inner circumference of the valve seat opening portion 10b in such a way as to flank the radial center line of the fuel chamber 15.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com