Double-fuel combustion-supporting type gas-steam combined cycle system

A circulatory system, dual-fuel technology, applied in the combustion, combustion type, and combined combustion mitigation using block fuel and gaseous fuel, can solve the problems of environmental pollution, waste of resources, etc., to protect the environment, eliminate primary environmental pollution, Eliminate the effect of a waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

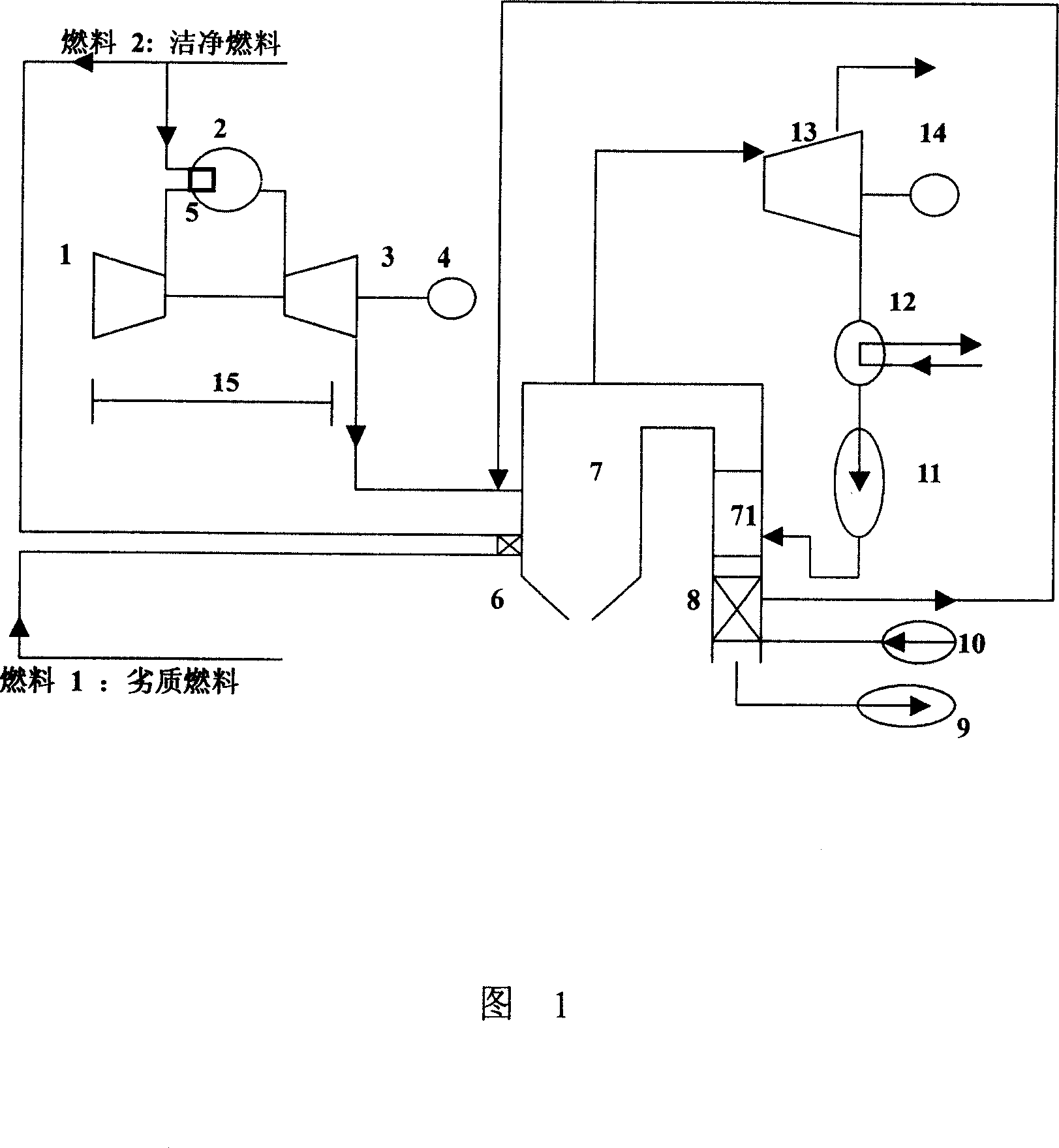

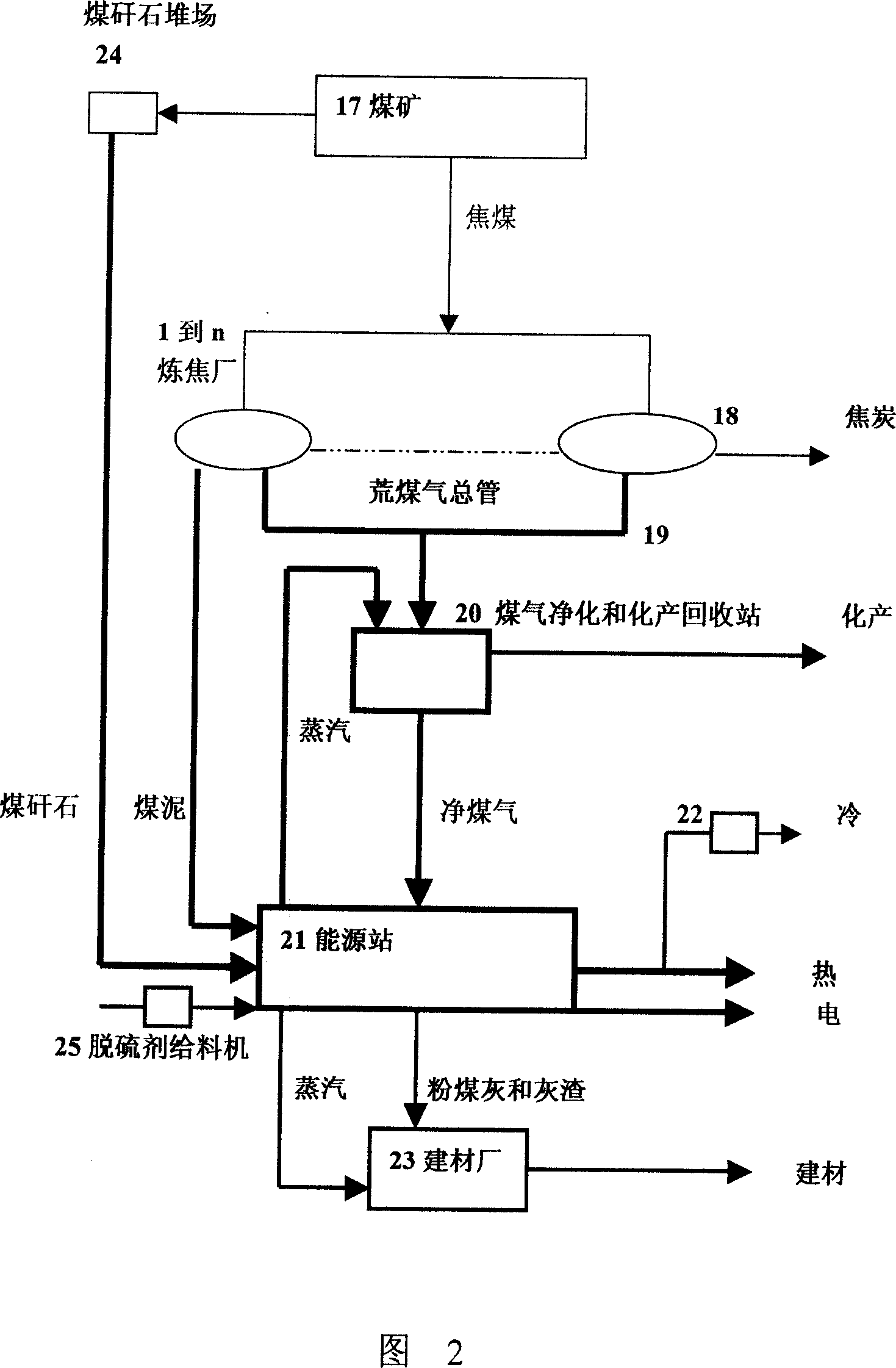

[0011] Below with accompanying drawing 1, 2 as the embodiment of the present invention, the present invention is further elaborated.

[0012] In this embodiment, it includes a gas turbine power generation system, a steam turbine power generation system and a circulating fluidized bed boiler 7; wherein the gas turbine power generation system, steam power generation system and circulating fluidized bed boiler are all prior art. The gas turbine power generation system includes a gas turbine 15 composed of a gas turbine compressor 1, a gas turbine combustor 2, and a gas turbine turbine 3; and a gas turbine generator 4; the steam power generation system includes a circulating fluidized bed boiler 7, a steam turbine 13 , Turbogenerator 14. The auxiliary equipment of this system includes gas turbine fuel nozzle 5, dual-fuel circulating fluidized bed boiler burner 6, boiler secondary air preheater 8, boiler induced draft fan 9, boiler secondary air supply fan 10, condenser 12, Water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com