Patents

Literature

1127results about How to "Less interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

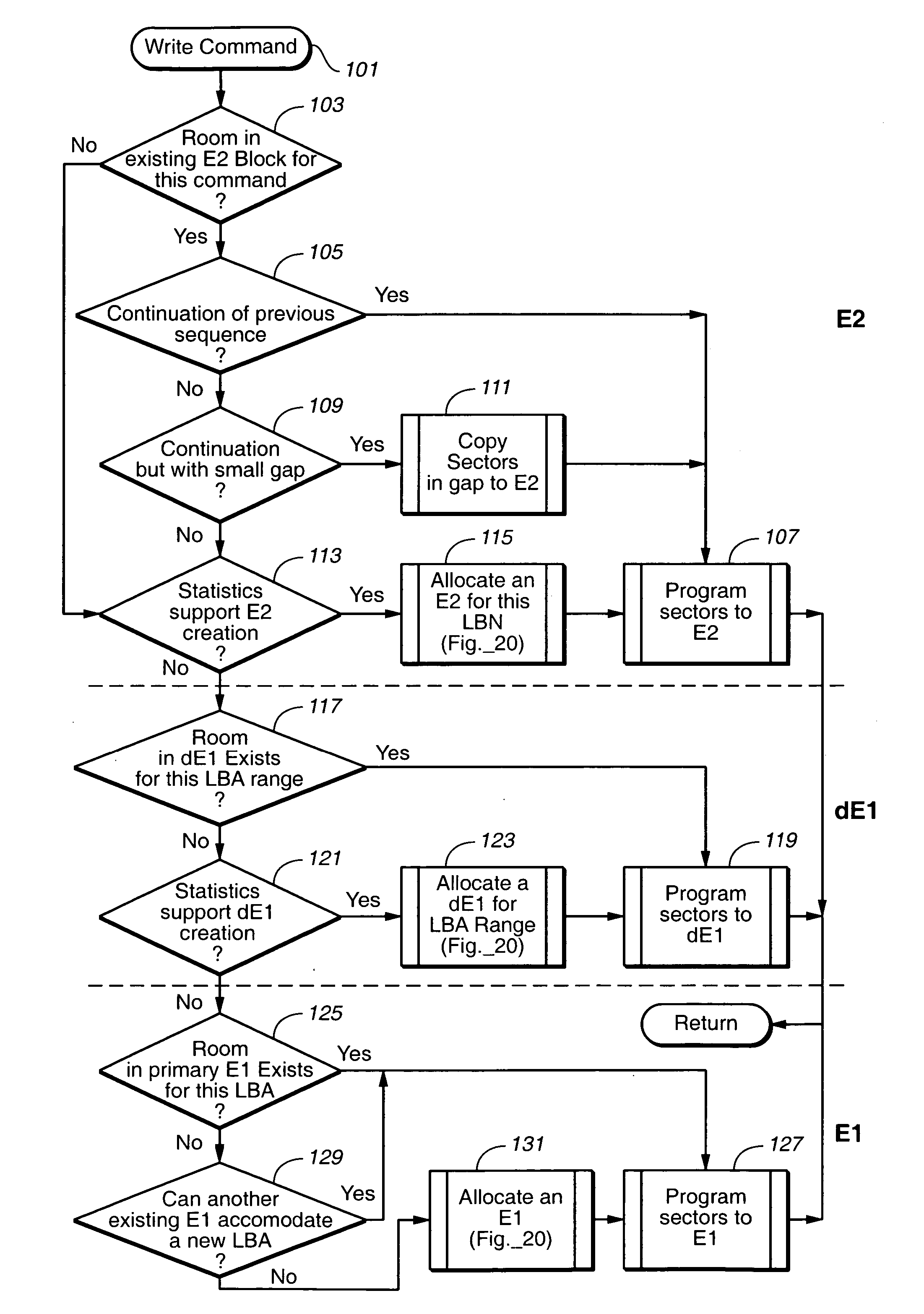

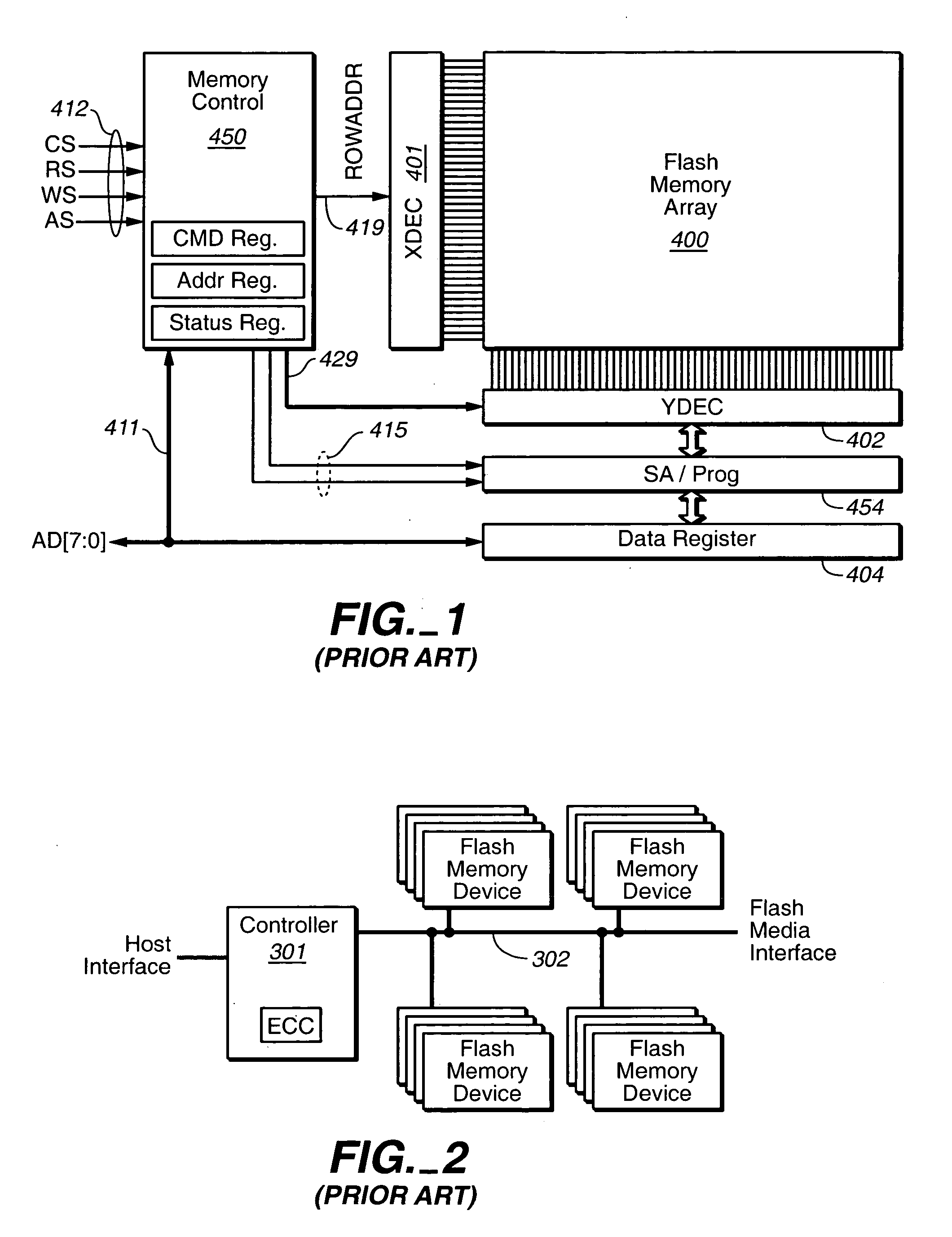

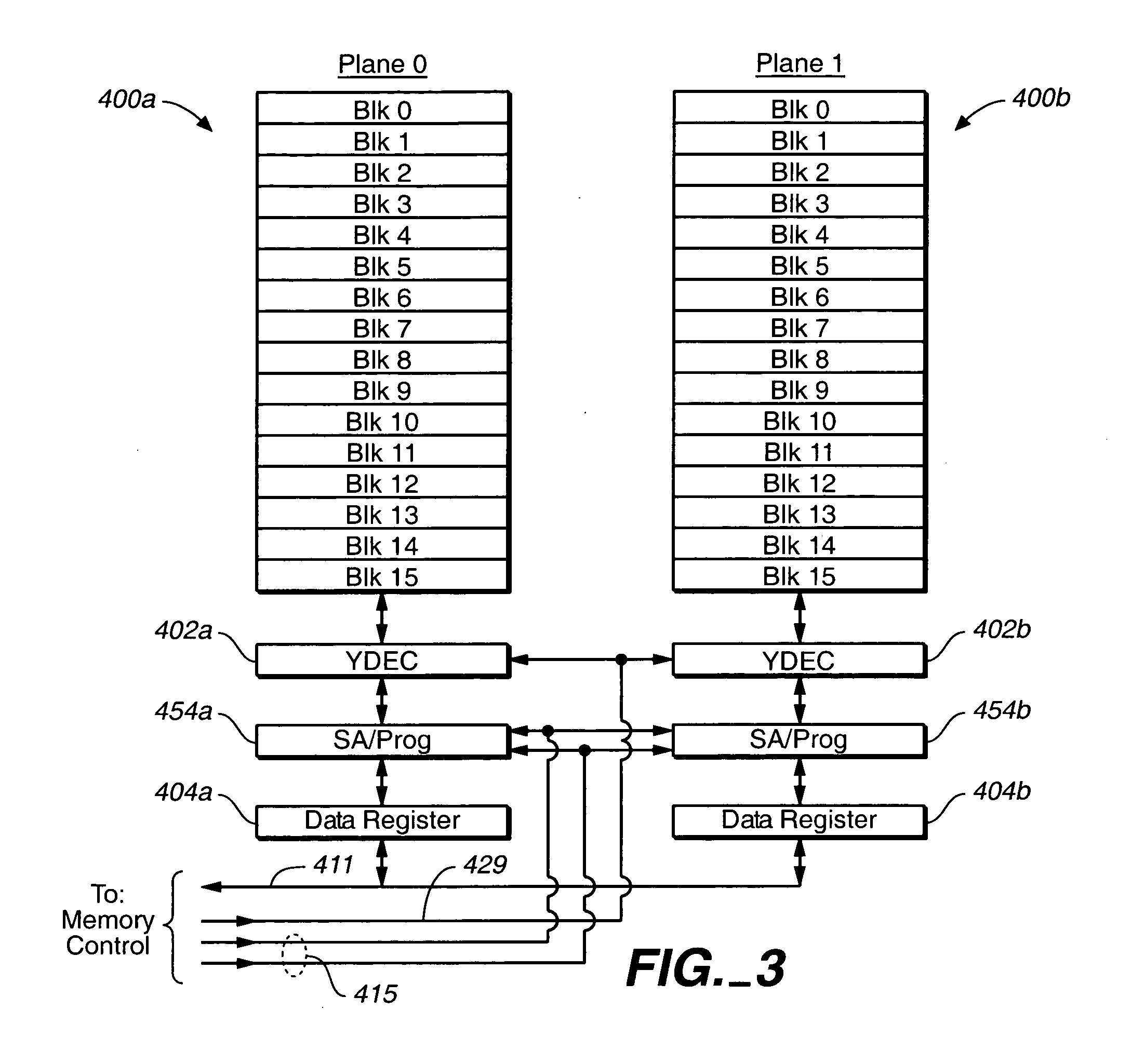

Management of non-volatile memory systems having large erase blocks

ActiveUS20050144358A1Reduce amountImprove system performanceMemory architecture accessing/allocationMemory adressing/allocation/relocationOriginal dataTerm memory

A non-volatile memory system of a type having blocks of memory cells erased together and which are programmable from an erased state in units of a large number of pages per block. If the data of only a few pages of a block are to be updated, the updated pages are written into another block provided for this purpose. Updated pages from multiple blocks are programmed into this other block in an order that does not necessarily correspond with their original address offsets. The valid original and updated data are then combined at a later time, when doing so does not impact on the performance of the memory. If the data of a large number of pages of a block are to be updated, however, the updated pages are written into an unused erased block and the unchanged pages are also written to the same unused block. By handling the updating of a few pages differently, memory performance is improved when small updates are being made. The memory controller can dynamically create and operate these other blocks in response to usage by the host of the memory system.

Owner:SANDISK TECH LLC

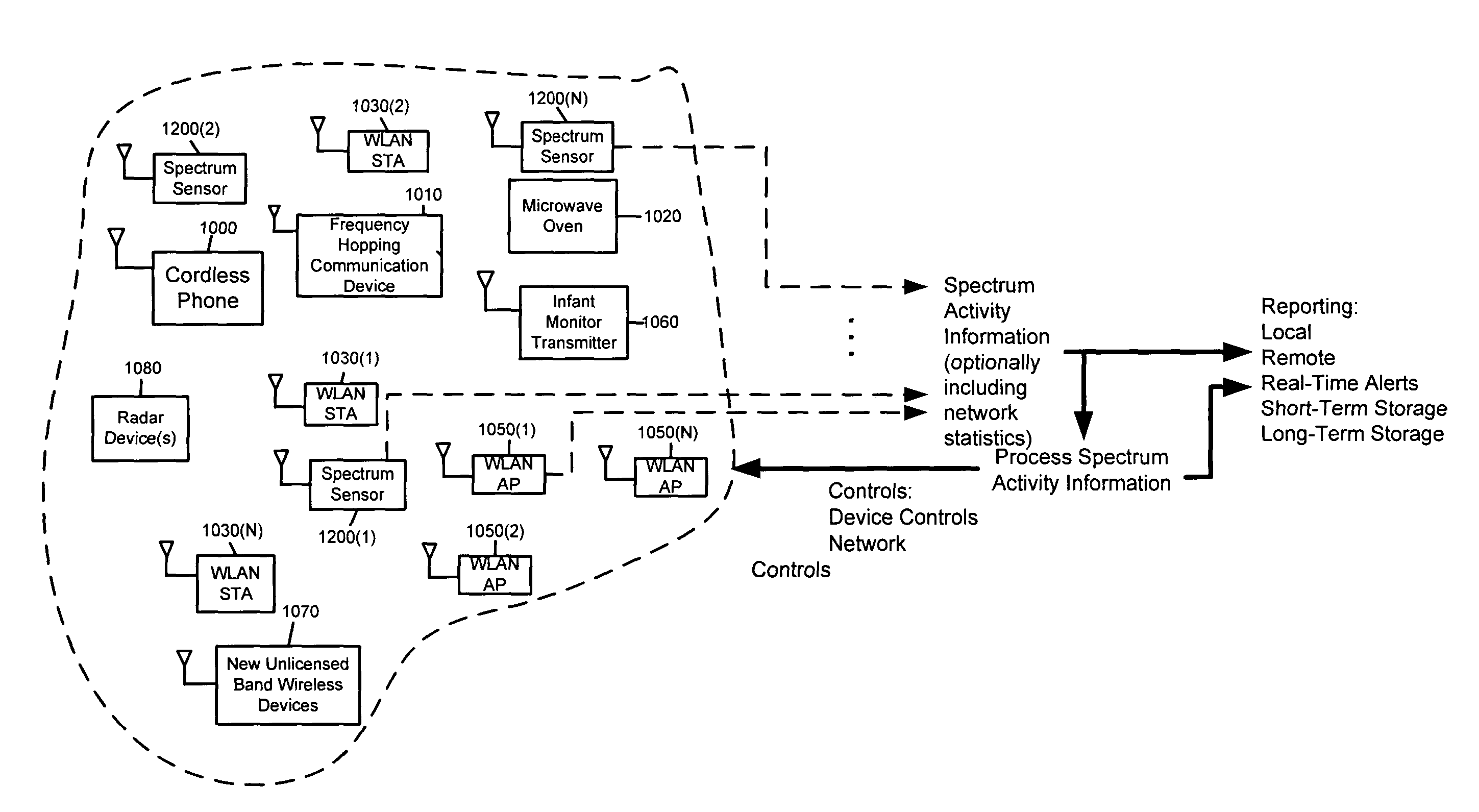

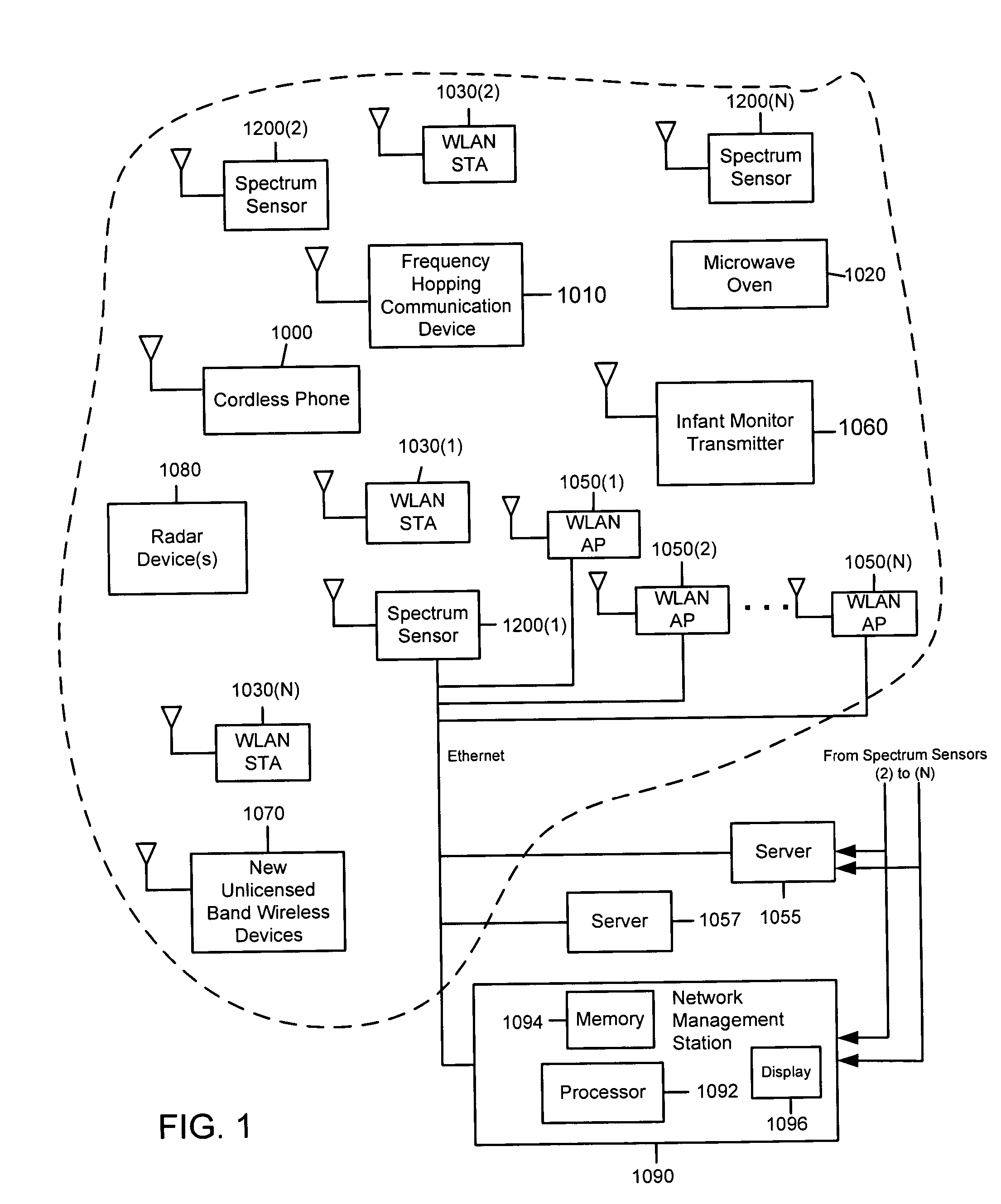

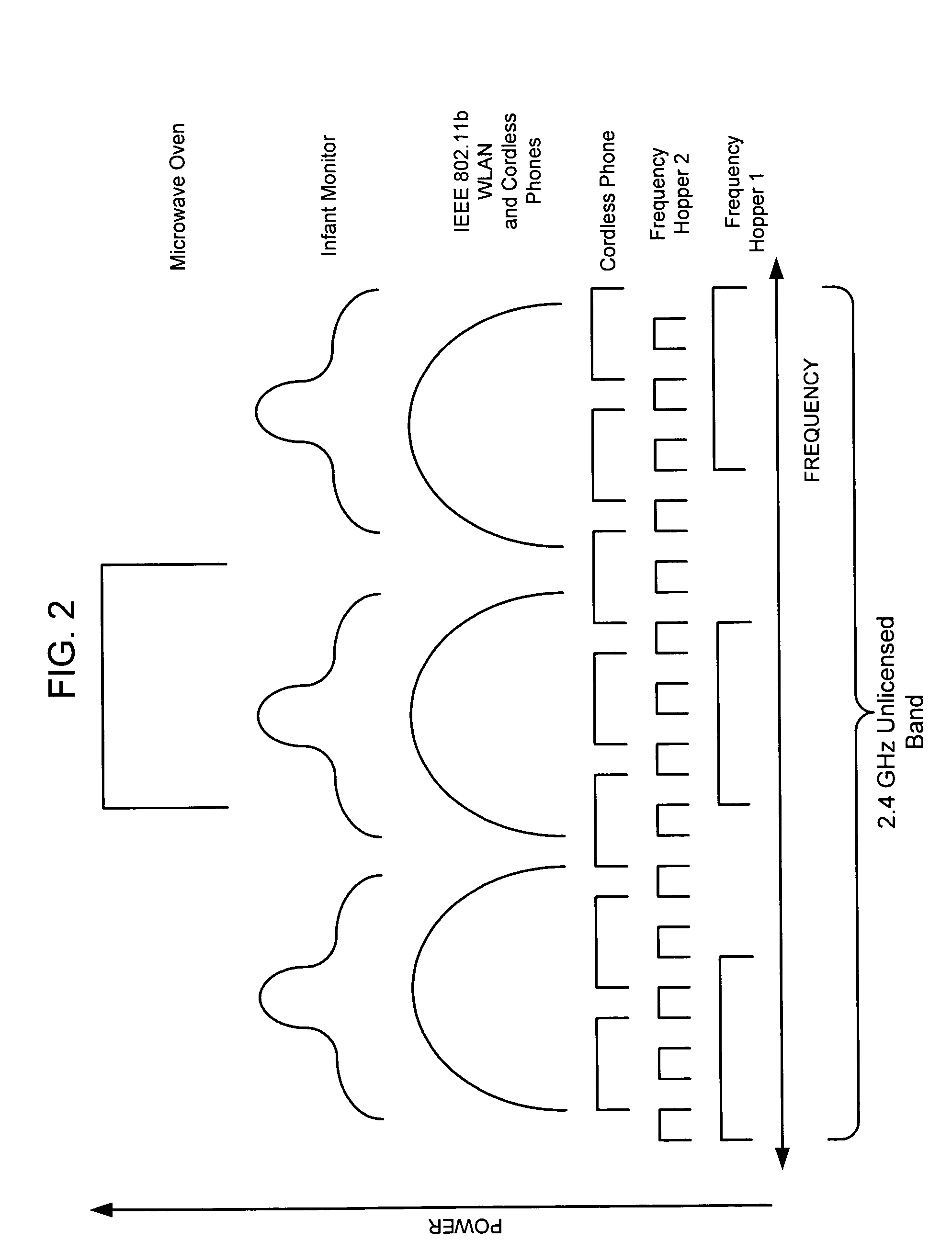

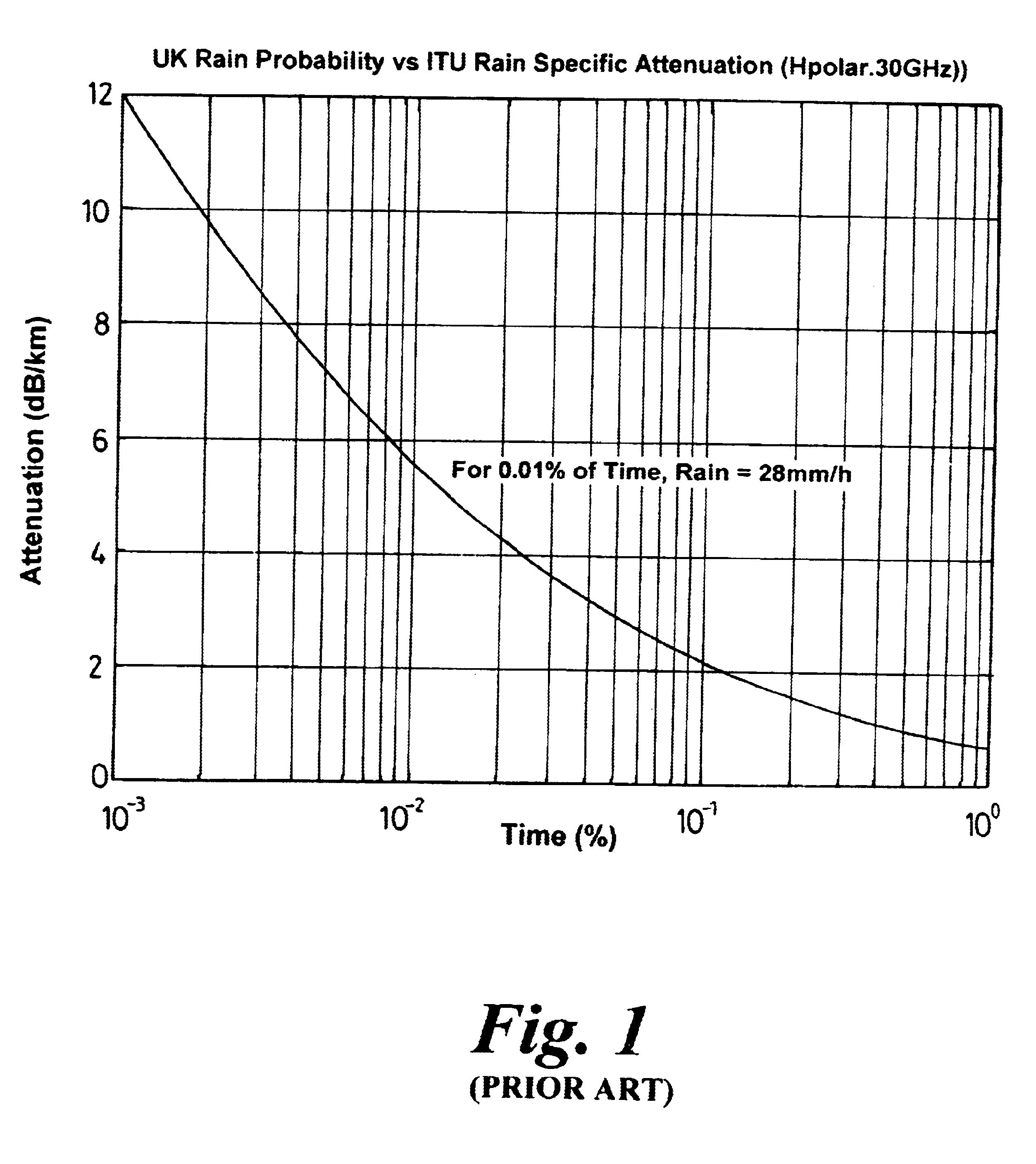

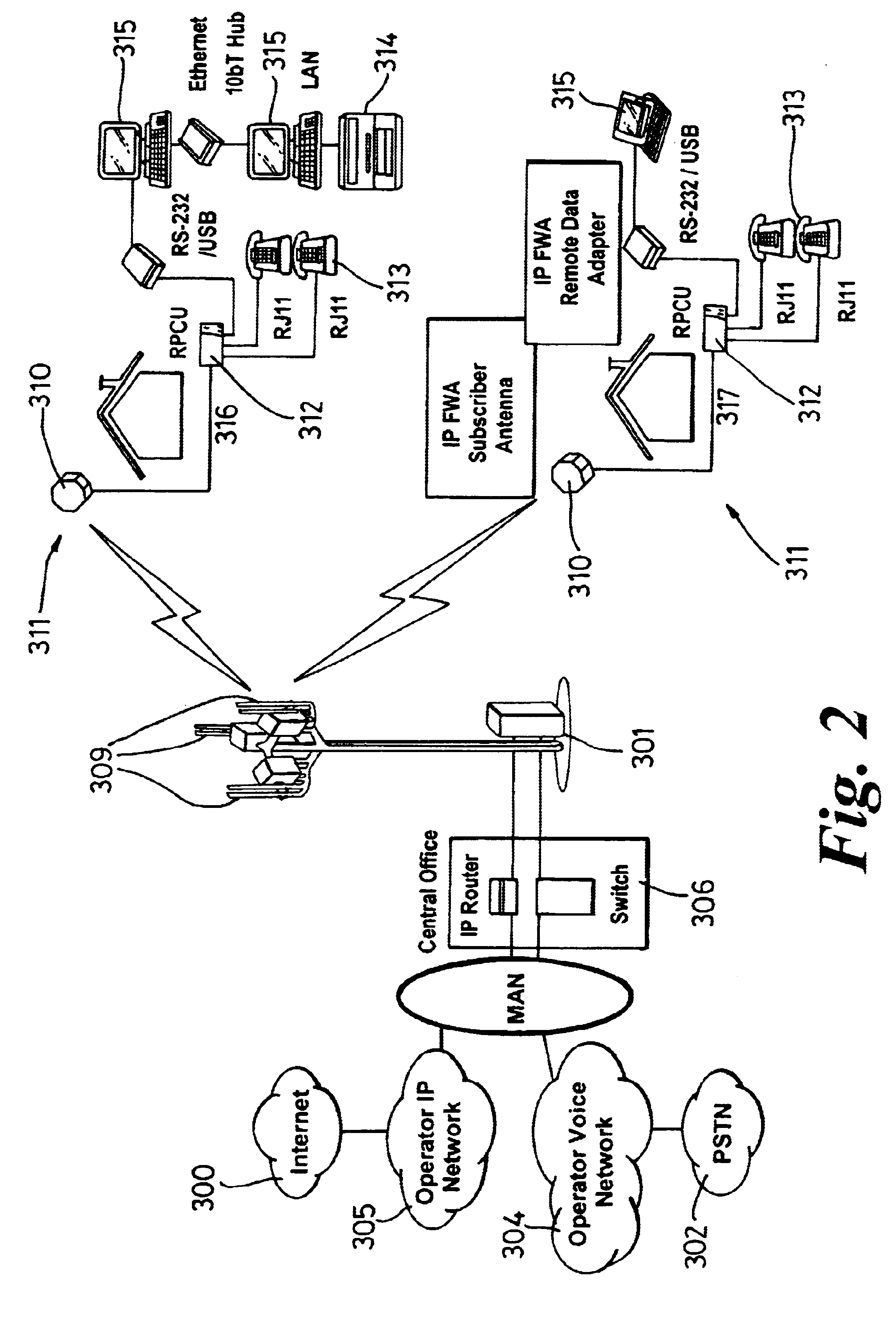

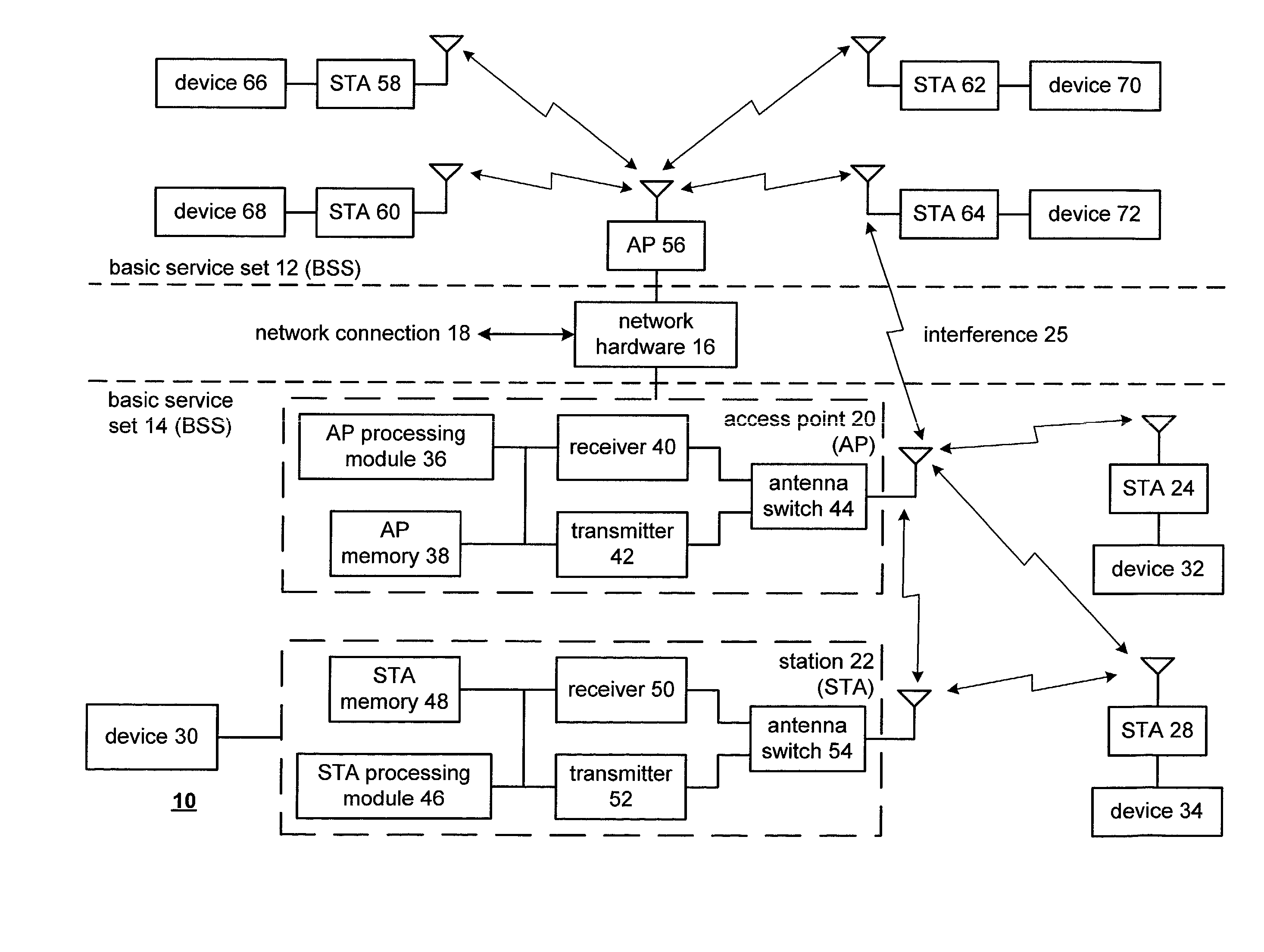

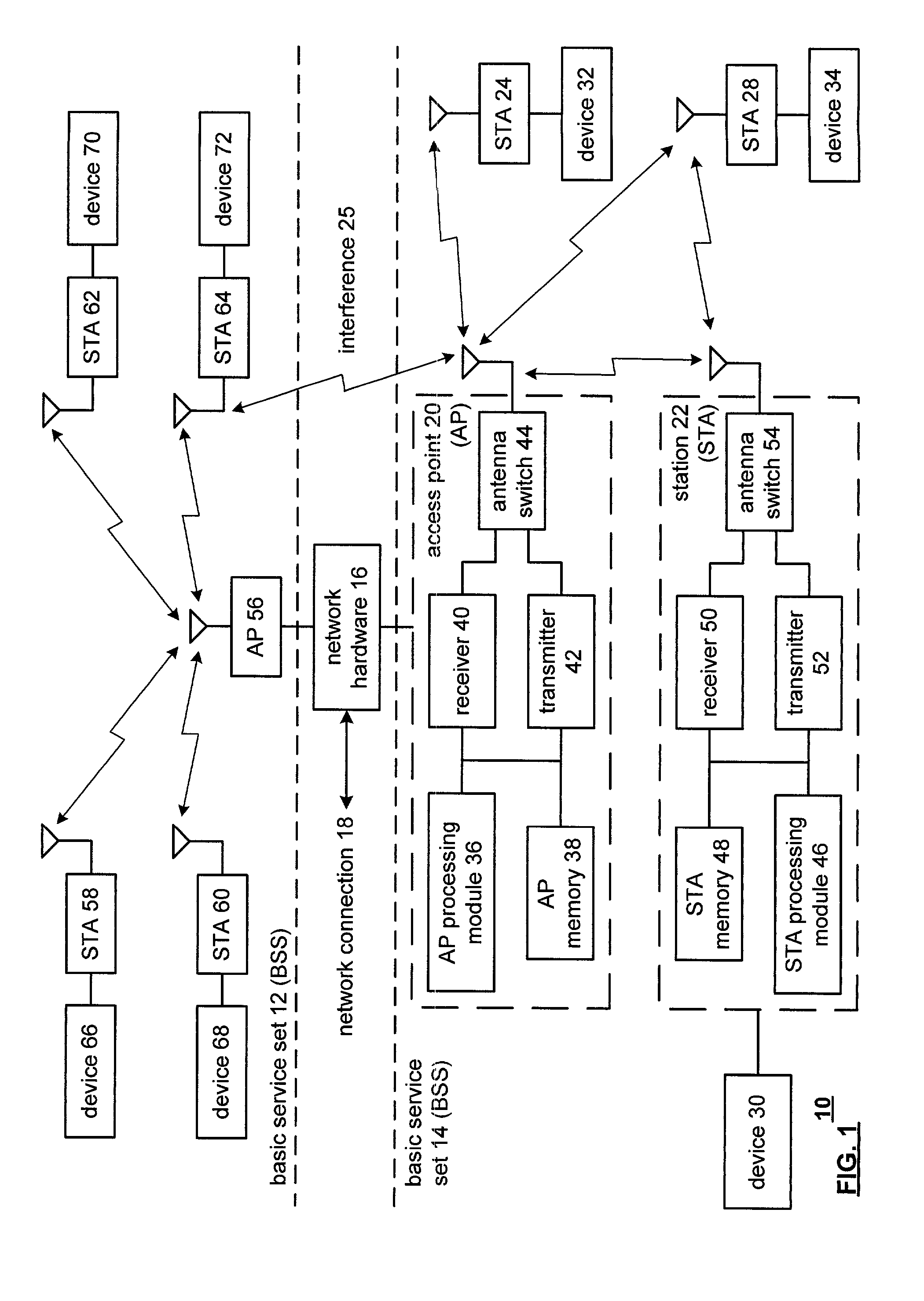

System and method for management of a shared frequency band using client-specific management techniques

ActiveUS7408907B2Increase capacityCell size be reduceError prevention/detection by using return channelNetwork traffic/resource managementClient-sideRadio frequency

Owner:CISCO TECH INC

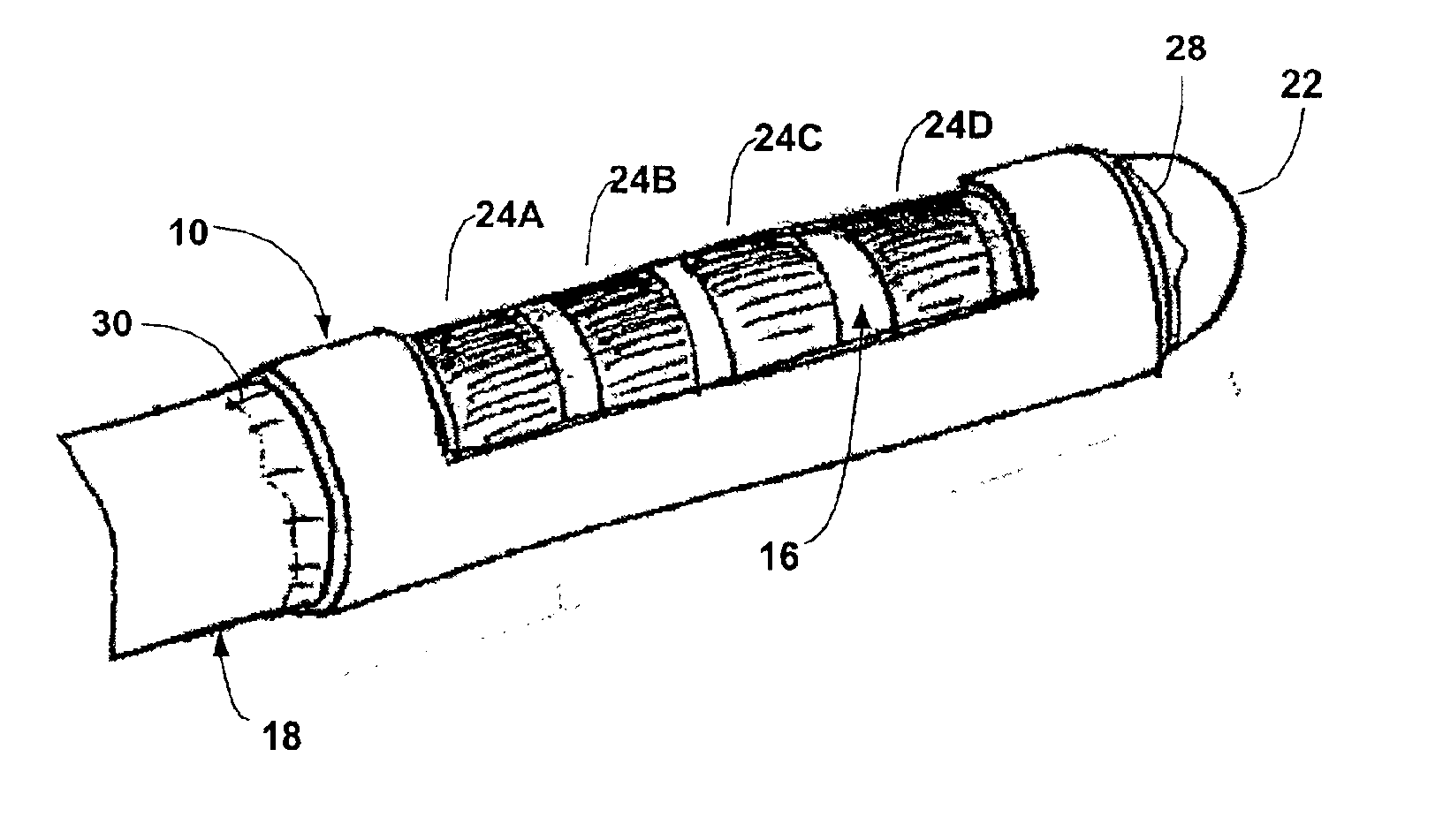

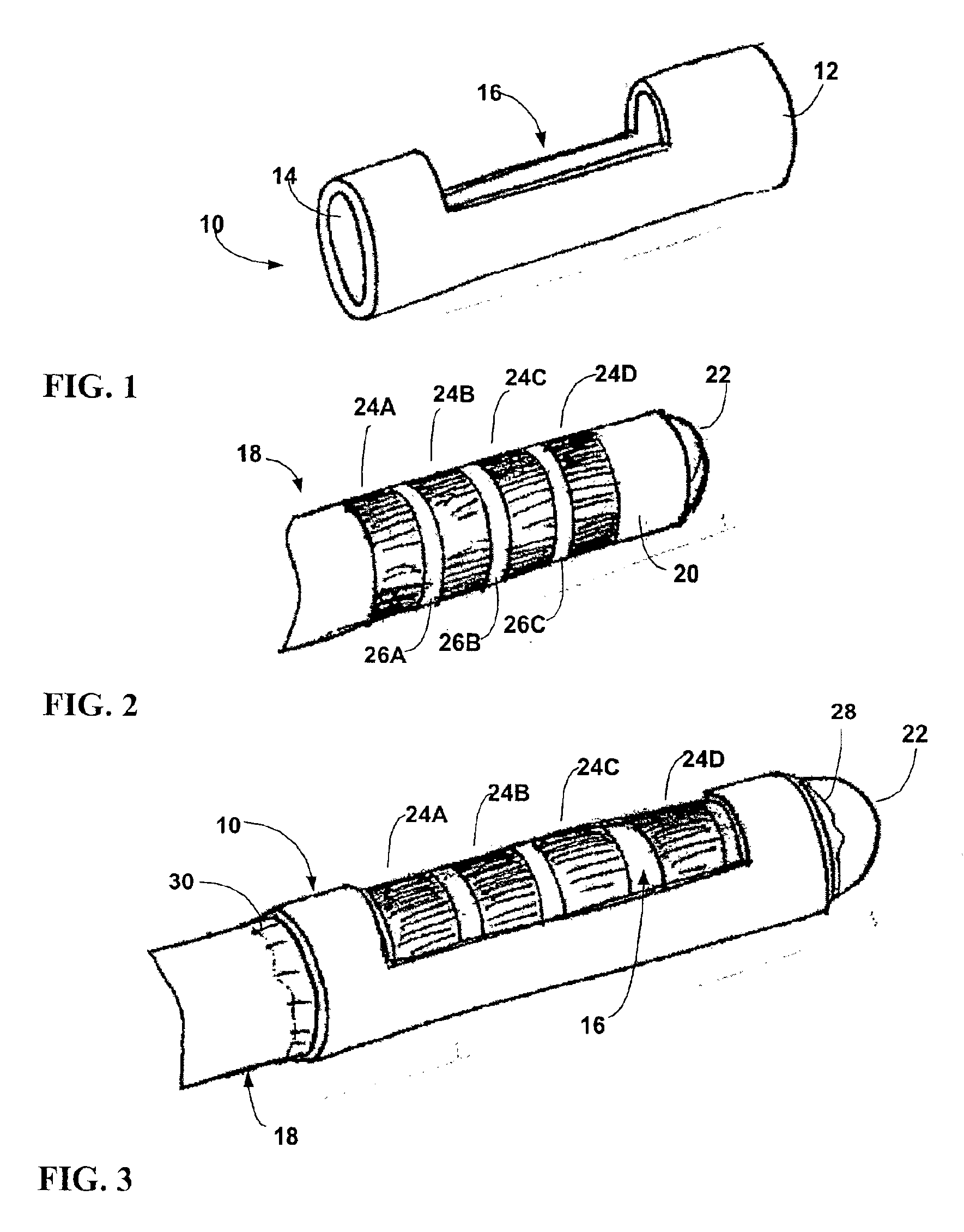

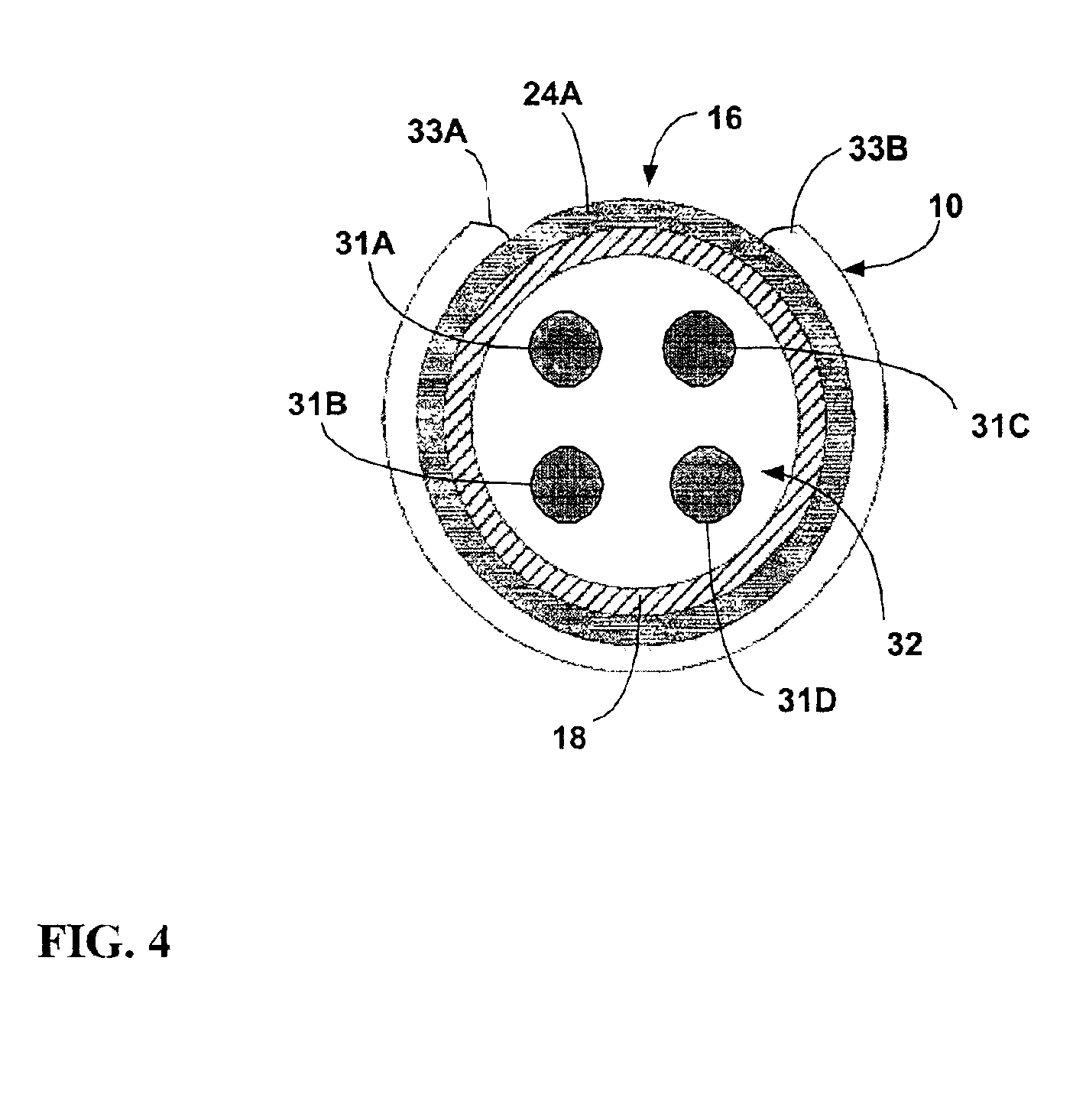

Directional brain stimulation and recording leads

InactiveUS7212867B2Improve abilitiesLess interferenceHead electrodesExternal electrodesElectricitySide effect

A directional brain stimulation lead assembly provides a lead body and an insulating member defining one or more windows that selectively expose portions of electrodes carried by the lead body to produce a directional stimulation current field. The lead assembly can achieve more effective localization of electrical stimulation to very small brain targets, and thereby reduce the incidence of material side effects caused by collateral stimulation of brain tissue adjoining a desired brain target. In addition, the directional lead can sense brain activity on a more localized basis.

Owner:MEDTRONIC INC

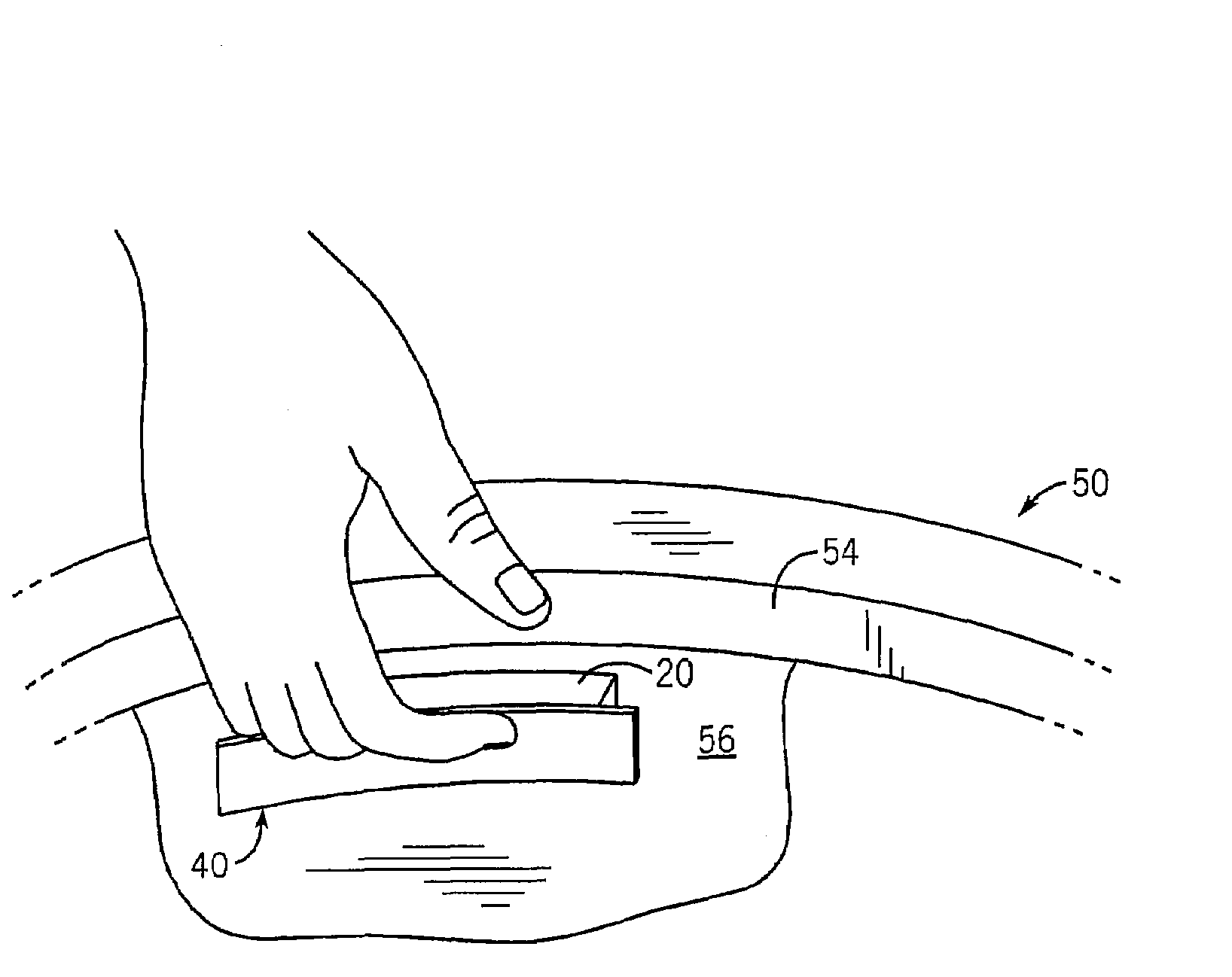

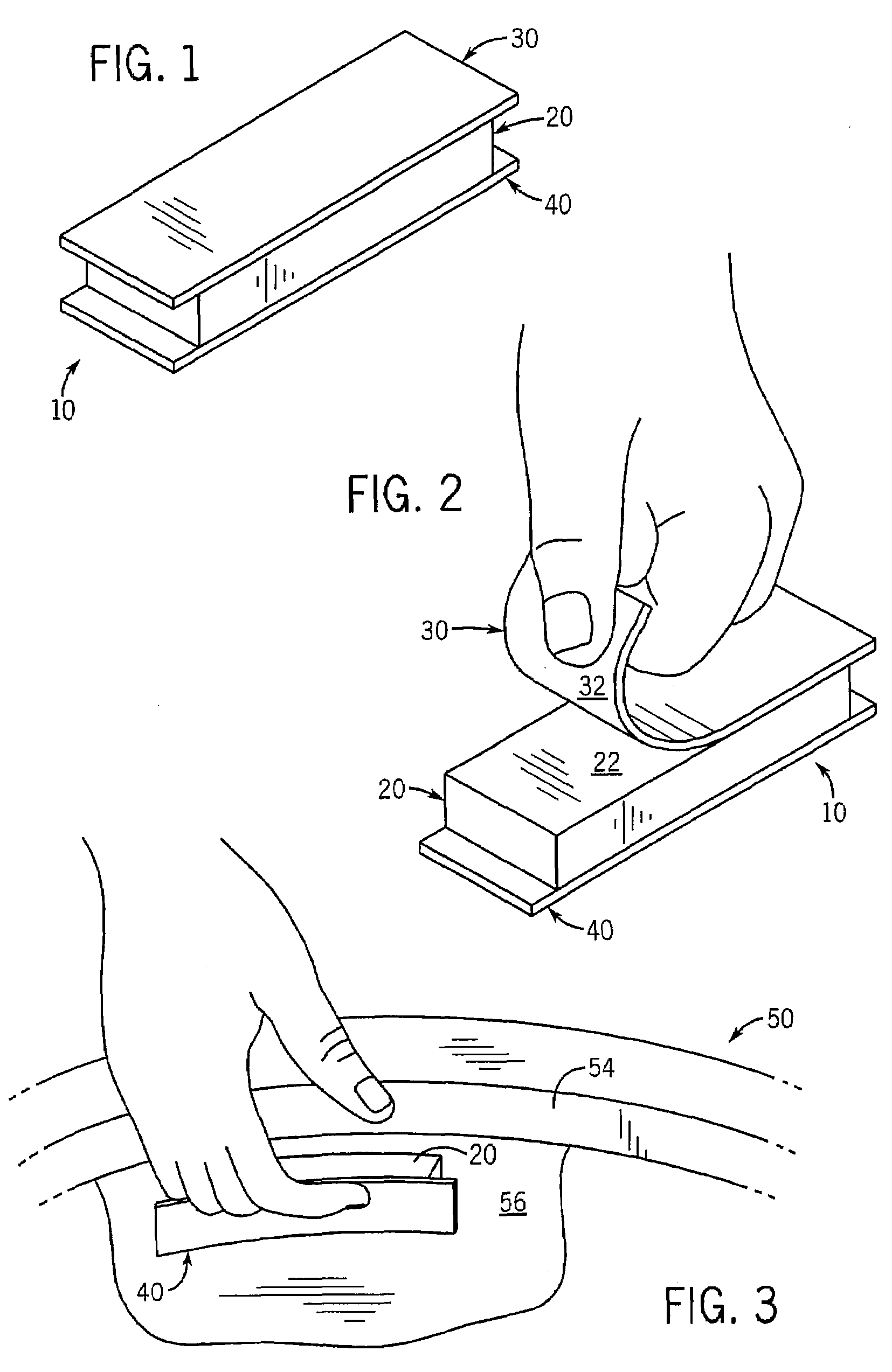

Self-sticking disintegrating block for toilet or urinal

ActiveUS20080190457A1Less erosionLess obtrusiveOrganic detergent compounding agentsNon-ionic surface-active compoundsChemistryToilet

A self-sticking disintegrating cleansing block to be attached directly to a wall of a toilet bowl or urinal, above the water-line and in the stream of flush water, by pressing the cleansing block to the wall. The cleaning block includes 25% to 99% of a solid surfactant, and 1% to 25% of a liquid component. The cleansing block may include a substrate removably attached to a surface of the cleansing block. In use, the substrate is removed from the cleansing block and the exposed surface of the cleansing block is pressed to a surface in a position above any waterline that is contacted by a rinse liquid that disintegrates the cleansing block. Rinse liquid is then allowed to contact the cleansing block such that an amount of the cleansing block is mixed with rinse fluid to clean the surface or a liquid reservoir adjacent the surface.

Owner:SC JOHNSON & SON INC

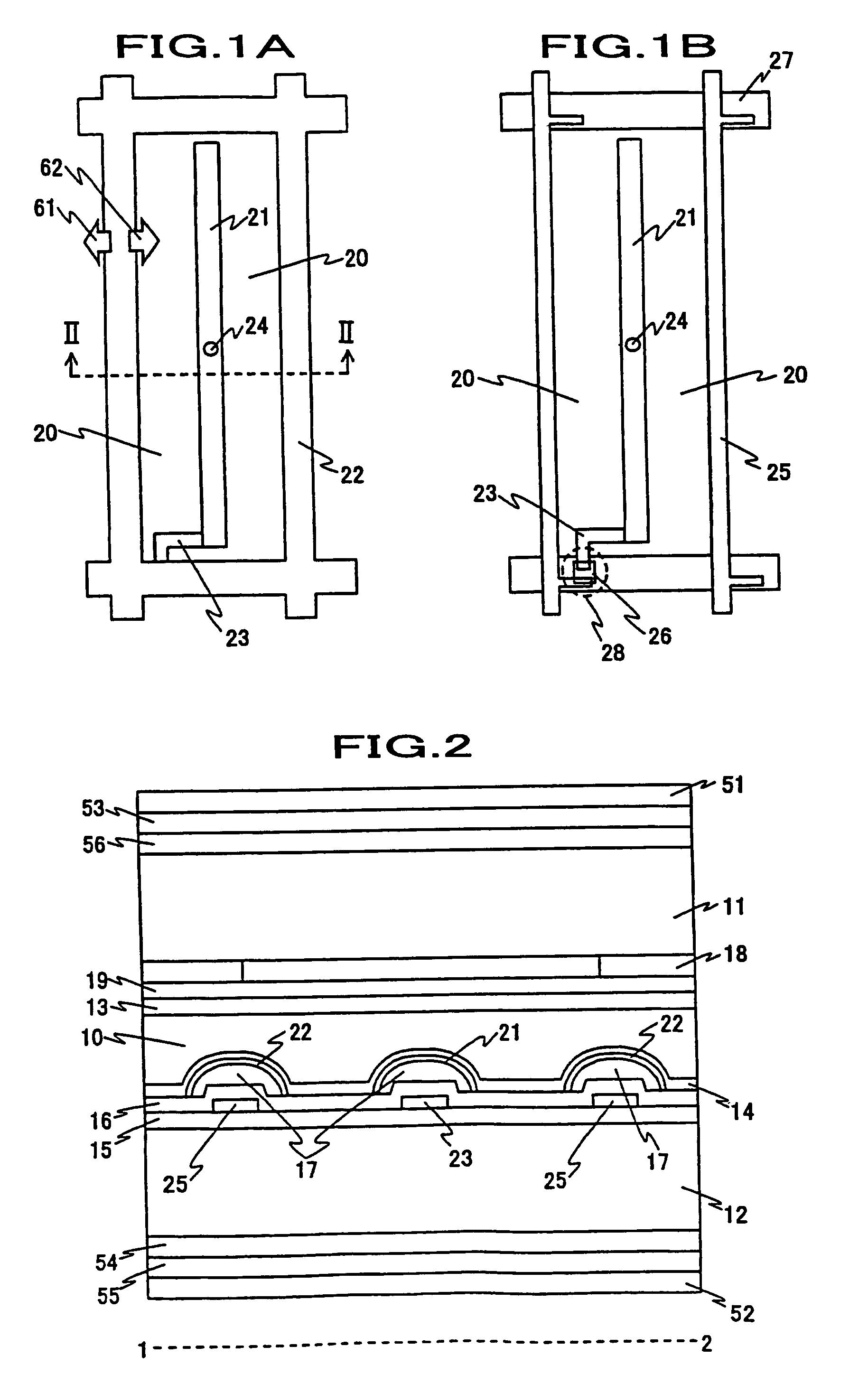

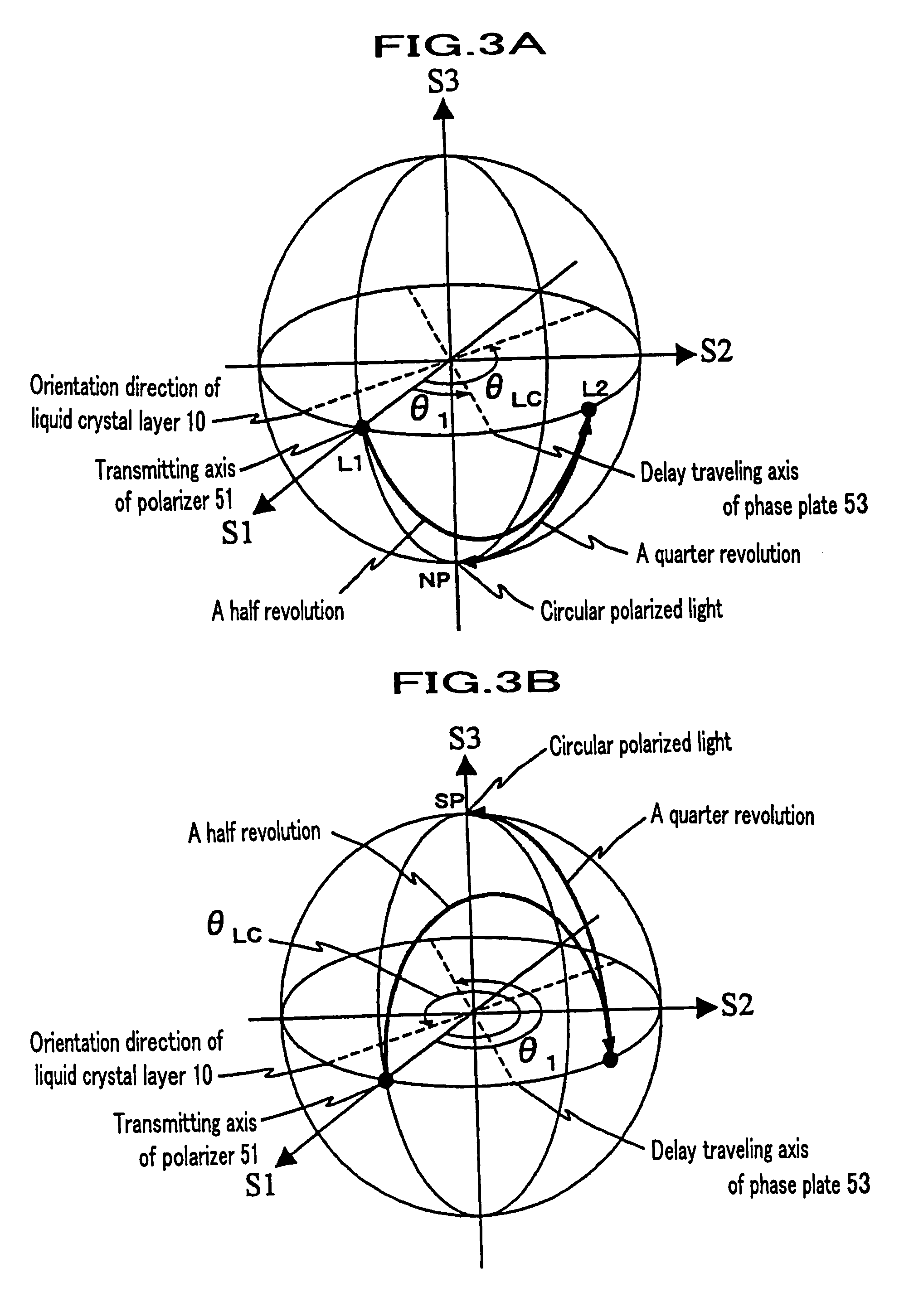

Transreflective liquid crystal display panel having a wide viewing angle

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

In vivo use of water absorbent polymers

InactiveUS6908609B2Reduce the amount requiredReduce the numberBiocideSynthetic polymeric active ingredientsFecesRemove blood

The subject invention is a method and material for removing fluid from the intestinal tract of a host and may be useful in treating animals or human patients suffering from fluid overload states. In one embodiment, the subject method involves ingesting an enterically coated non-systemic, non-toxic, non-digestible, water absorbing polymer which absorbs fluid while passing through the intestinal tract. The polymer is excreted in the feces wherein the polymer and absorbed fluid is removed from the body. Preferred polymers include super absorbent acrylic acid polymers, preferably provided in bead form. The polymers may include functional groups for selectively removing blood borne waste products, e.g. urea, from the G.I. tract.

Owner:RELYPSA INC

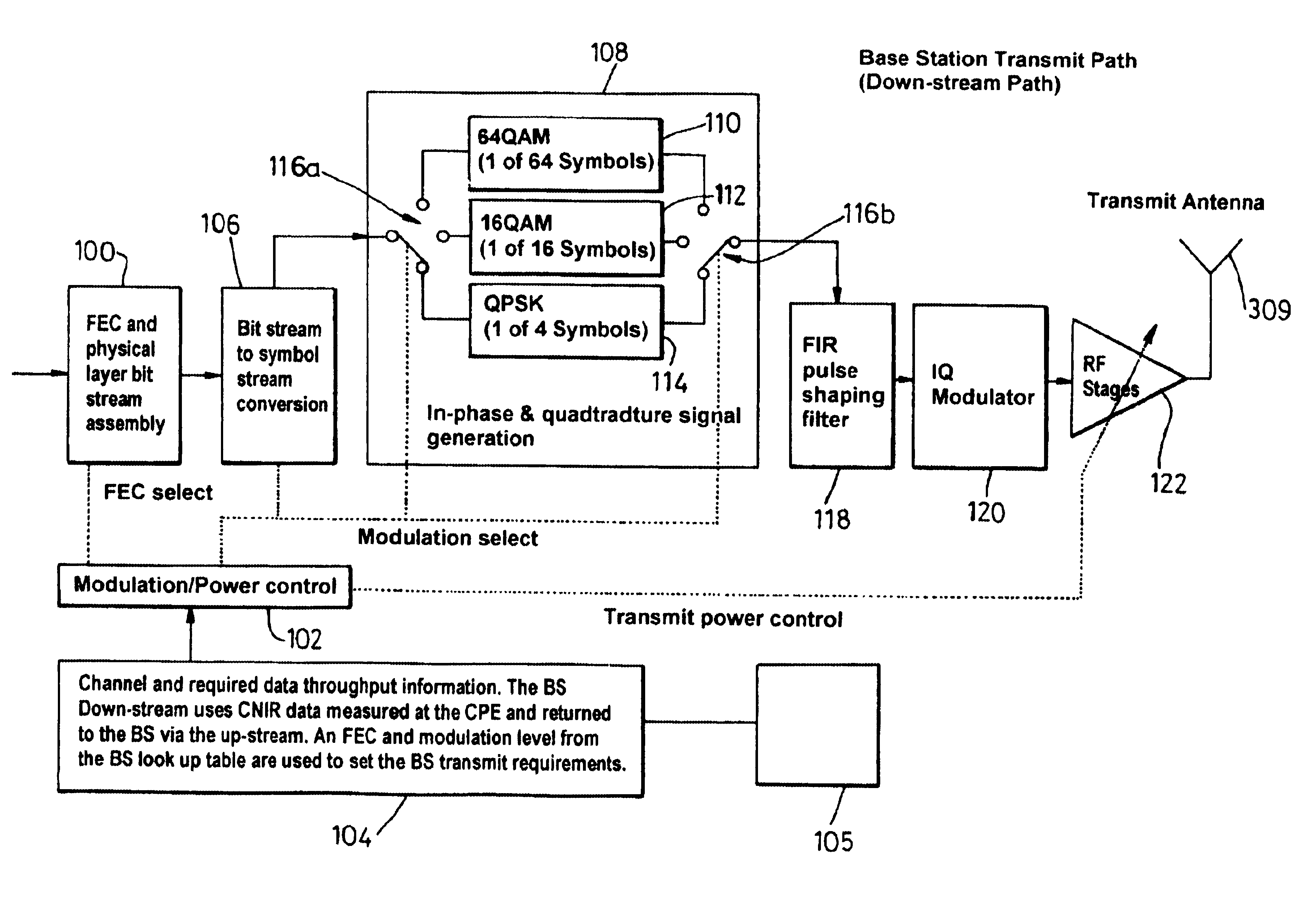

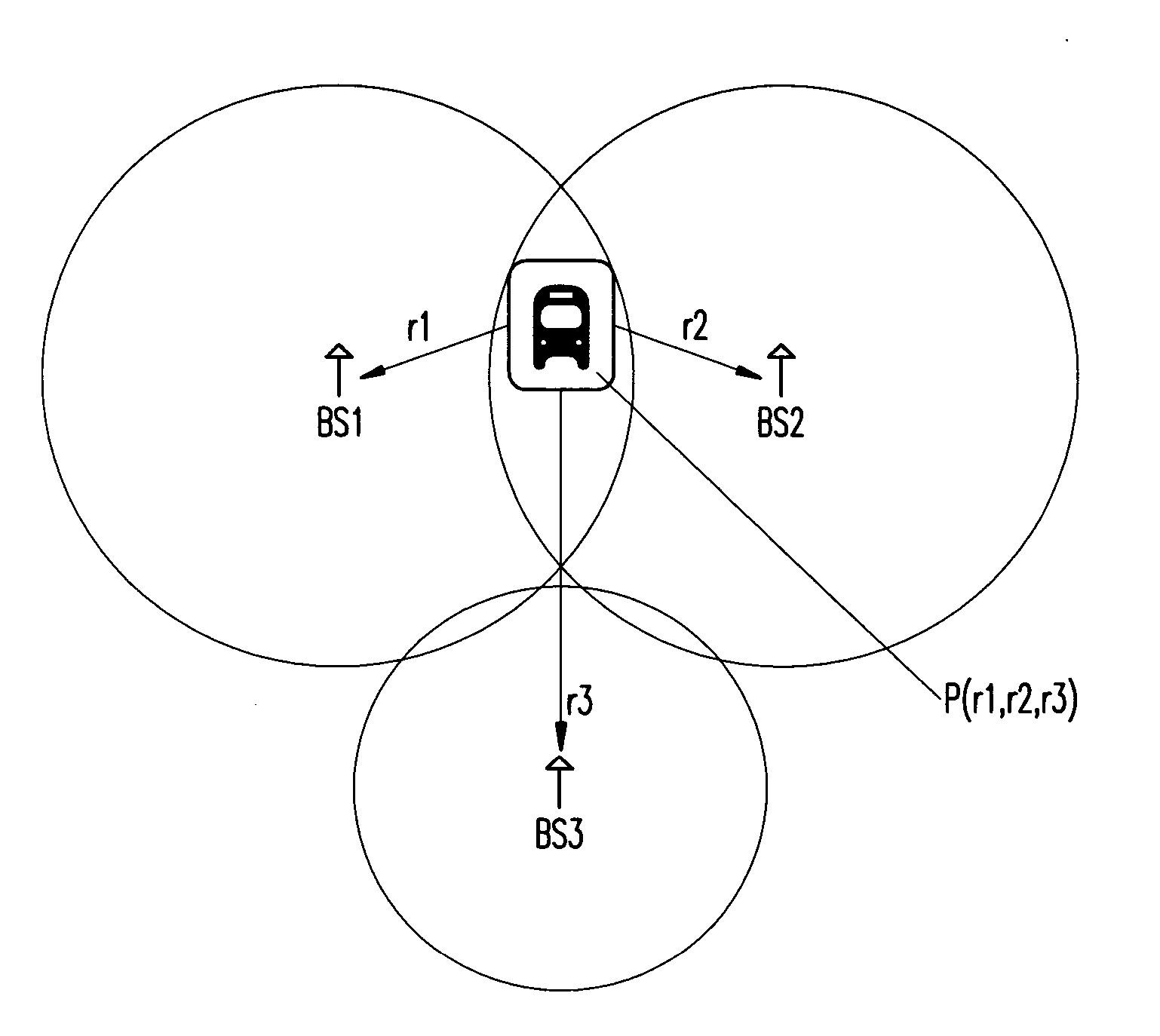

Cellular radio communications system

InactiveUS6947490B1Improve bandwidth usageReduce the required powerChannel coding adaptationSignalling characterisationCellular radioCommunications system

A cellular radio communication system for transmitting blocks of data over transmission links in which the quality of the transmission links are monitored. The system comprises a data storage means for storing sets of modulation scheme and forward error correction coding level pairs to give an optimum data rate at a predetermined bit error rate and a predetermined symbol rate for different quality transmission links. The database is interrogated and a modulation scheme and forward error correction coding level pair is allocated and applied to the blocks of data transmitted over a transmission link dependent on the monitored quality of the transmission link.

Owner:MICROSOFT TECH LICENSING LLC

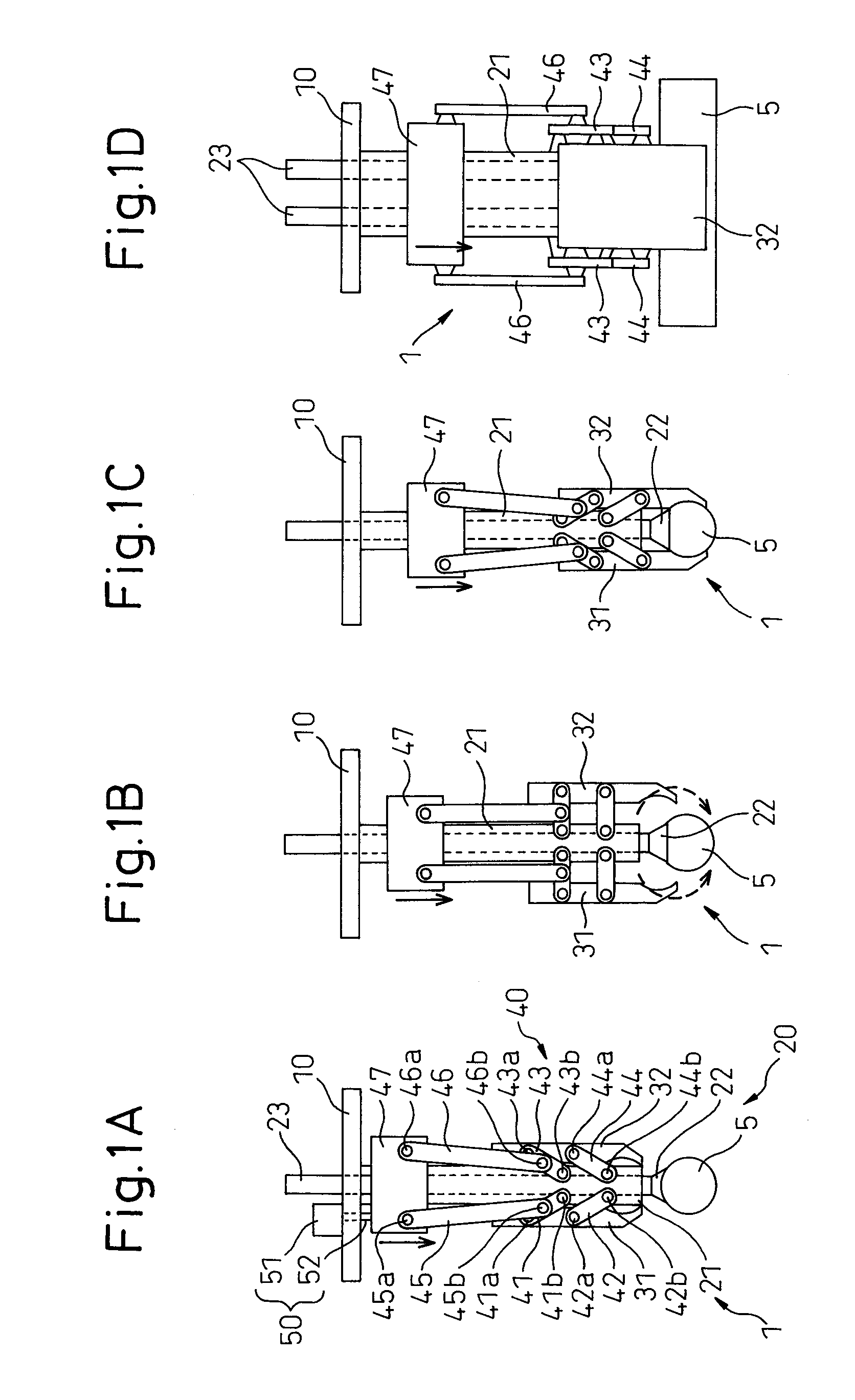

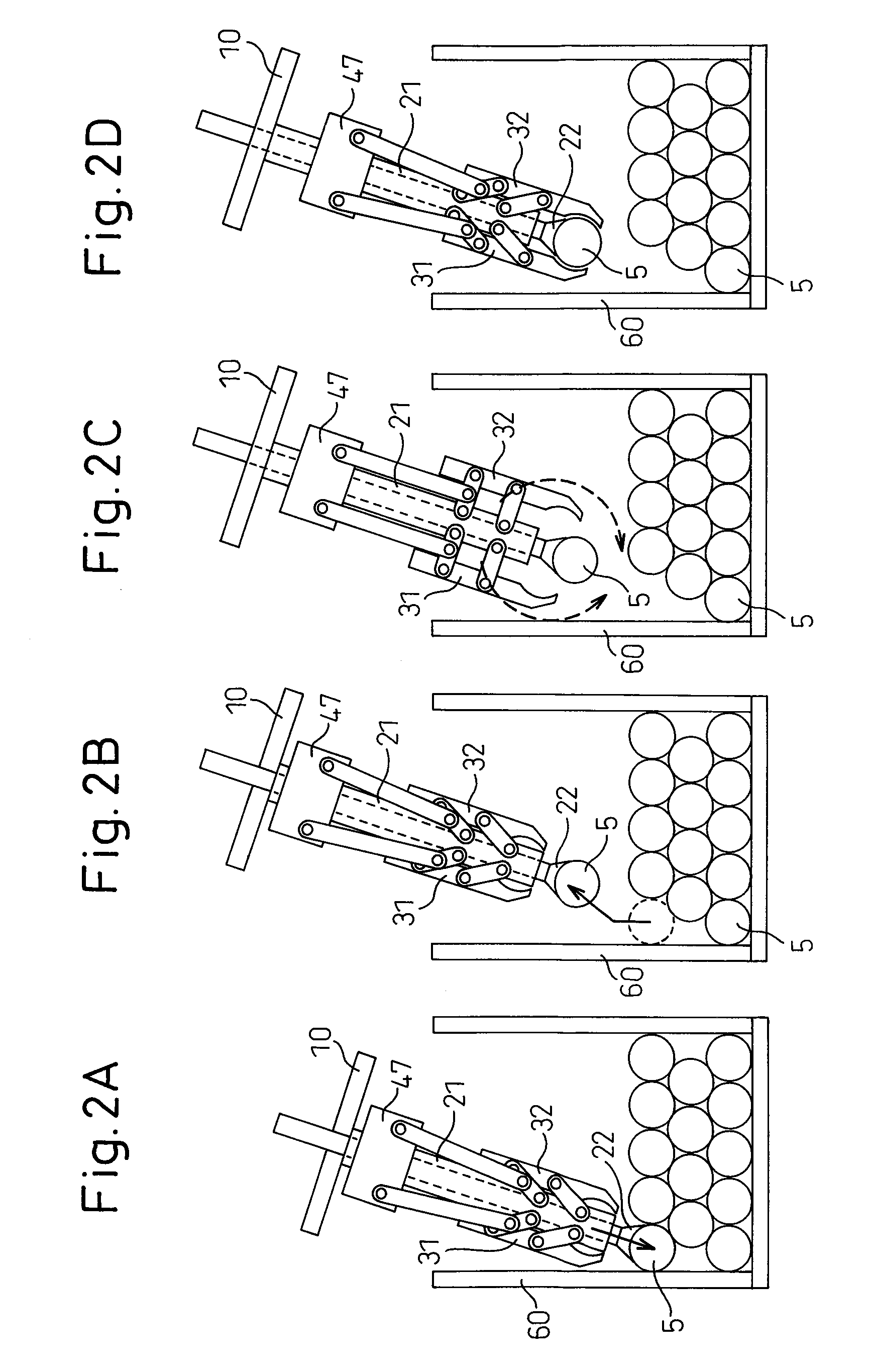

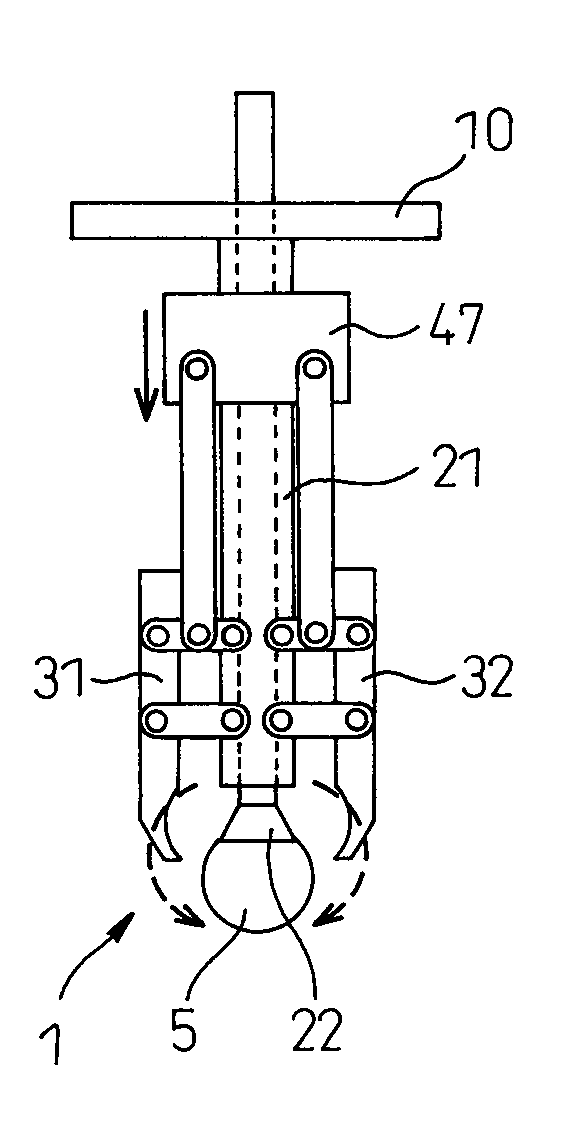

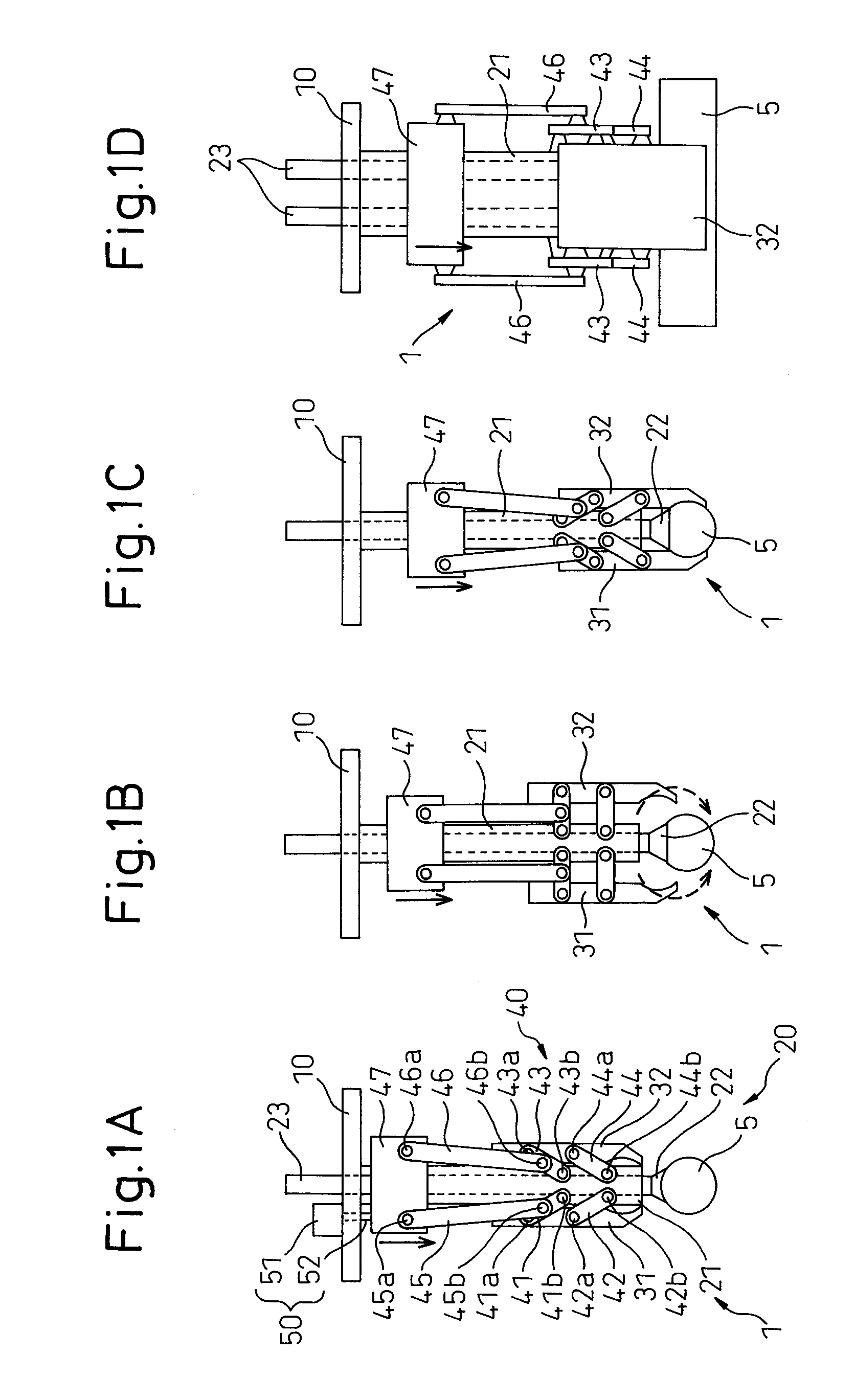

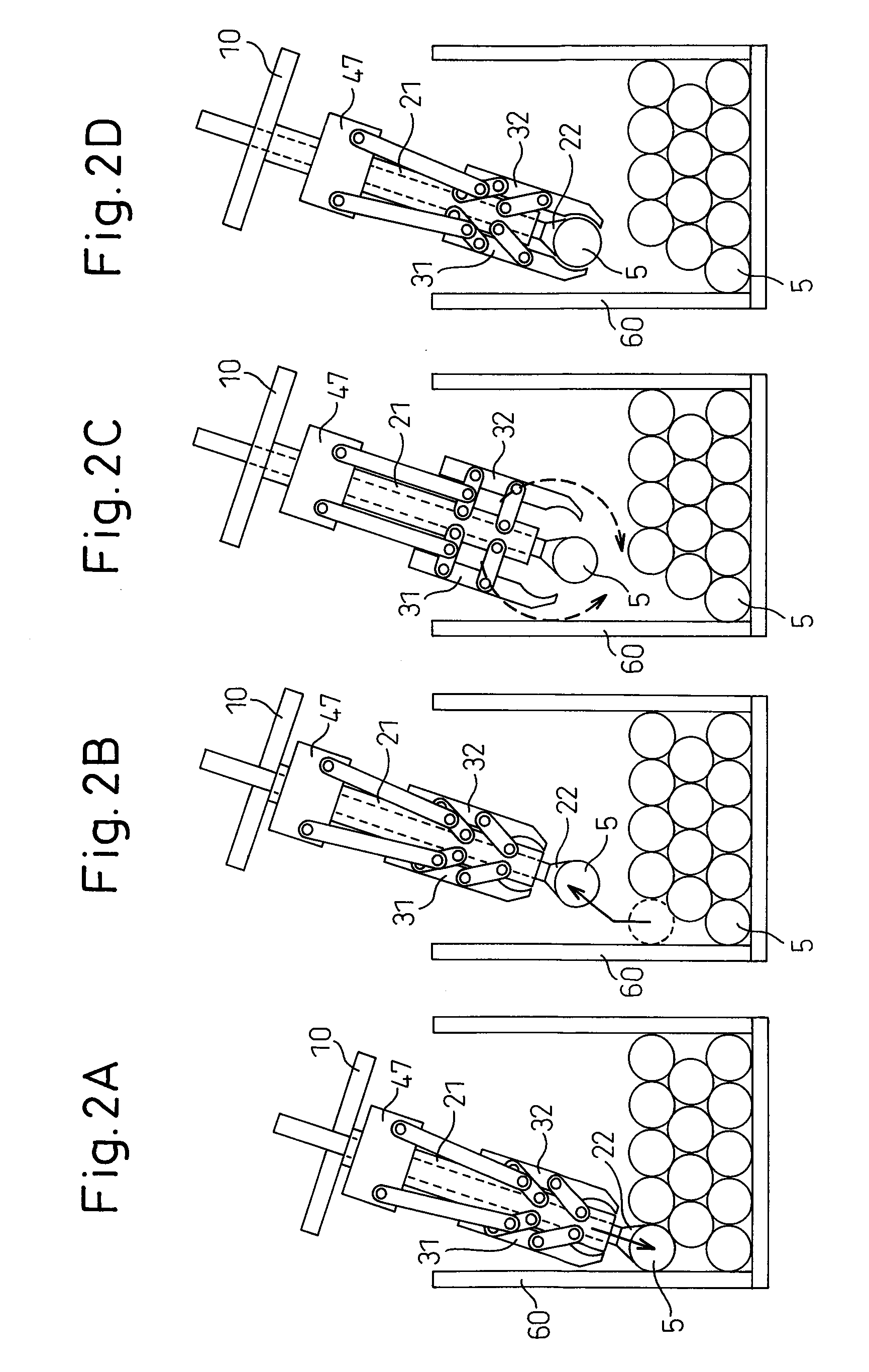

Workpiece gripping device

Owner:FANUC LTD

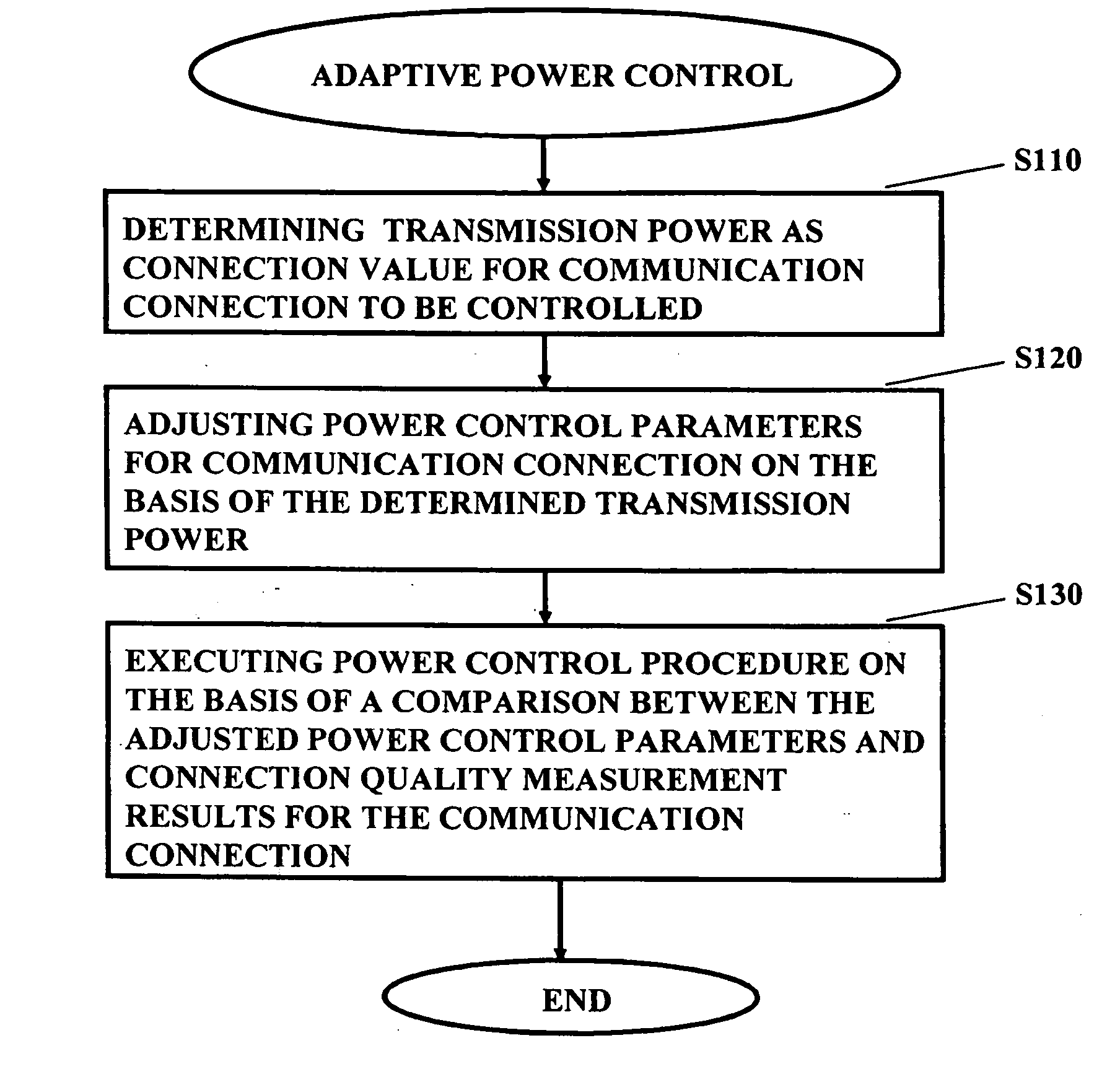

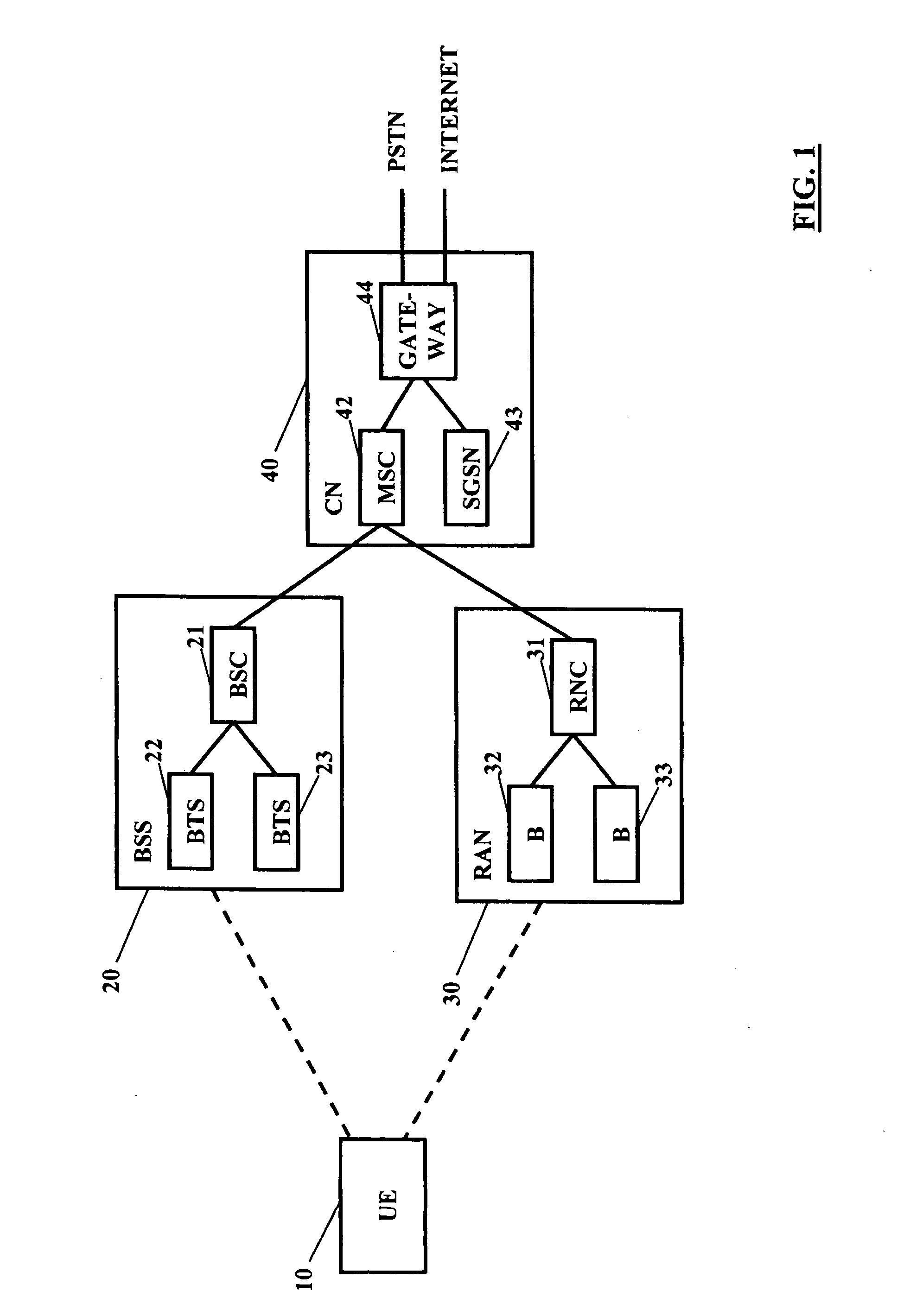

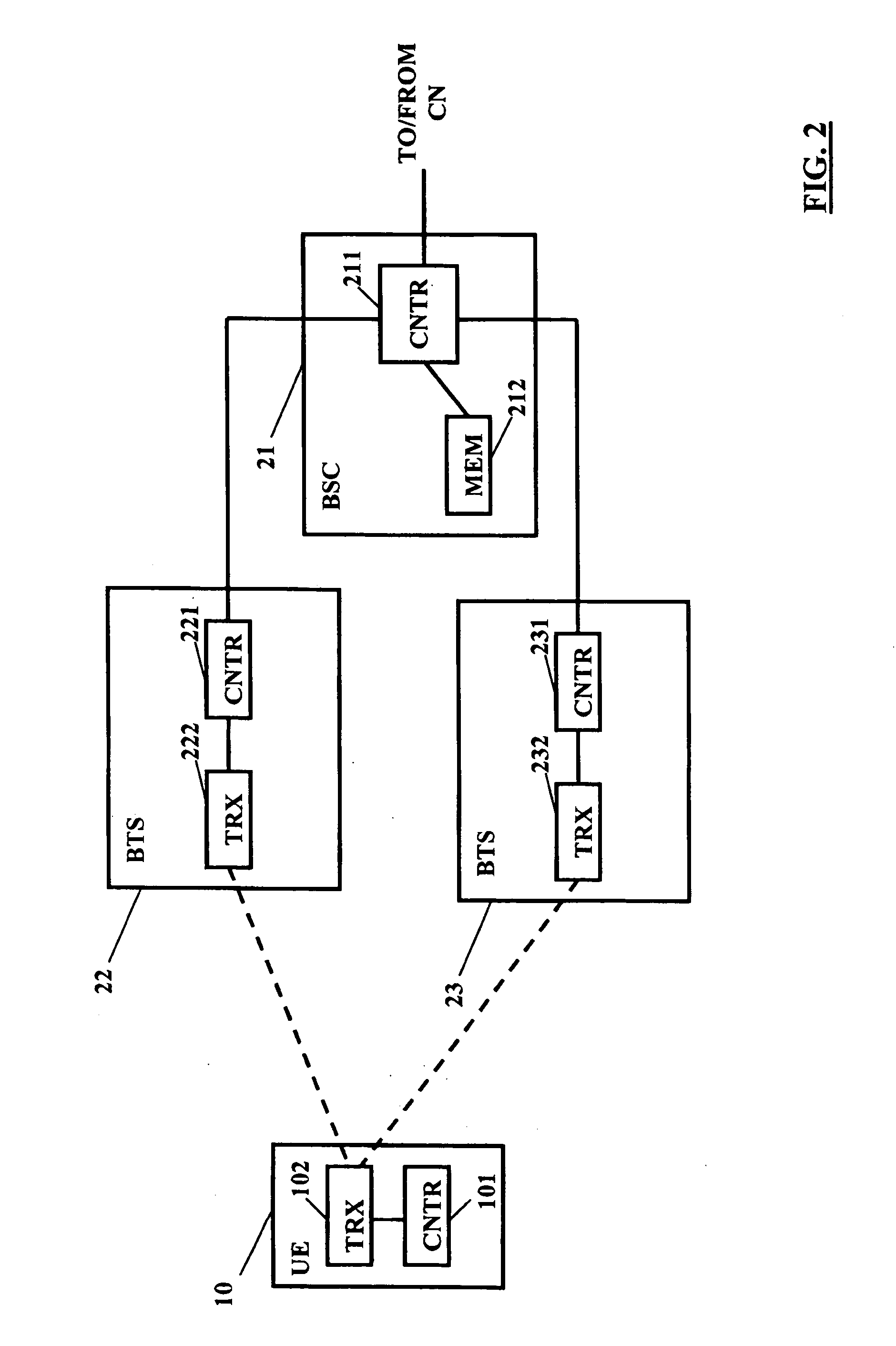

Power control in a communication network

InactiveUS20060246938A1Improve sound qualityReduce noise levelPower managementRadio/inductive link selection arrangementsTransceiverUser equipment

A method of controlling a transmission power for a communication connection in a communication network is provided. The communication network comprises a user equipment communicating with the communication network, at least one transceiver station for providing a connection with the user equipment, wherein a serving transceiver station is provided for the user equipment, and a controller for controlling the at least one transceiver station. A connection value used at the communication connection between the user equipment and the serving transceiver station is determined, and on the basis of the determined connection value, power control parameters are adjusted wherein at least one change of power control parameters is possible between respective connection value ranges. A power control of the transmission power for the communication connection is executed on the basis of a comparison between the adjusted power control parameters and connection quality measurement results determined for the communication connection. Furthermore, a corresponding system and a corresponding controller are provided.

Owner:NOKIA CORP

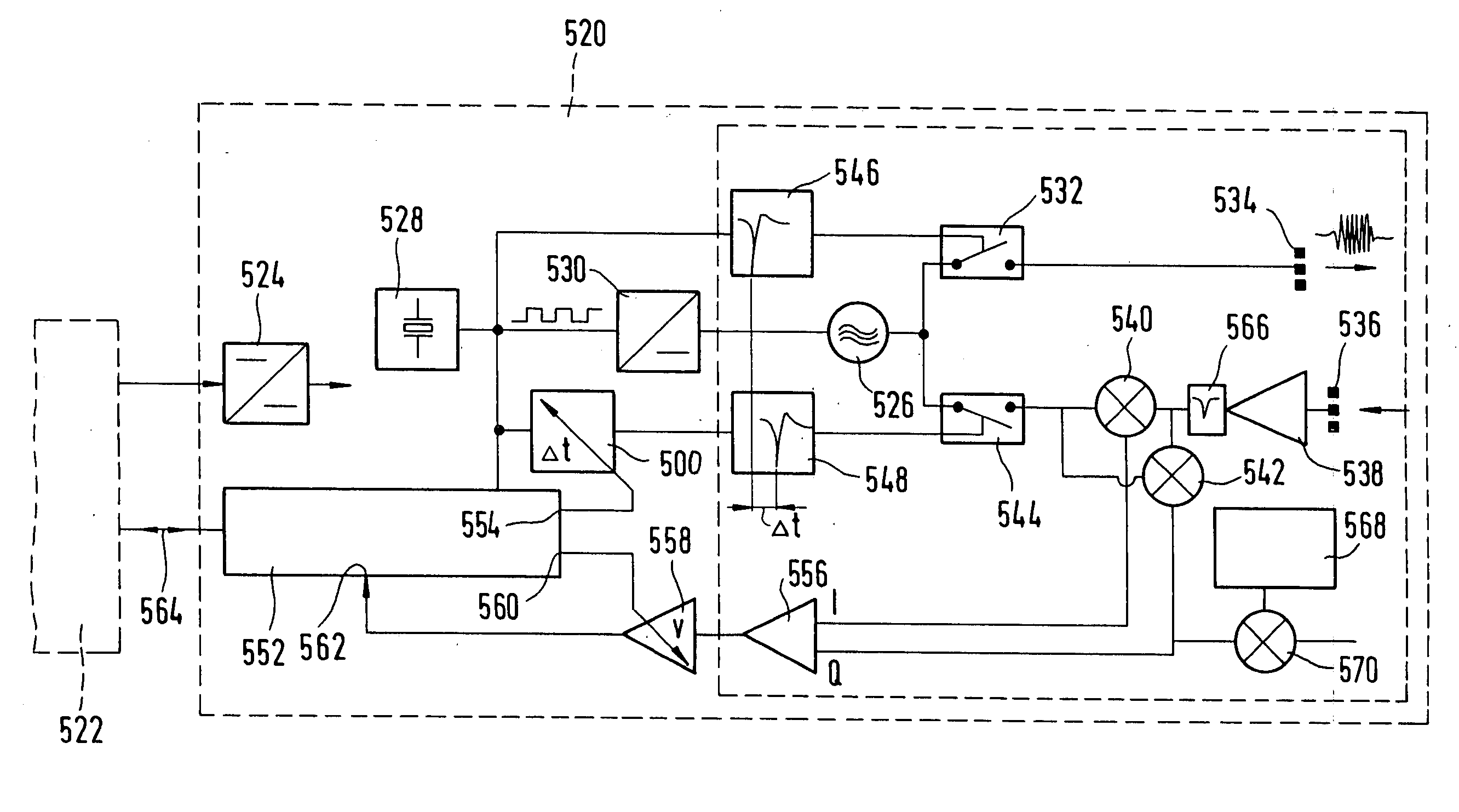

Method and device for the adaptive regulation of power

InactiveUS20060109170A1Minimizes signal irregularityLess interferenceRadio wave reradiation/reflectionBraking systemsControl powerIn vehicle

A method and a device for adaptively controlling power in a radar device having a radar transmitter and a radar receiver are provided, in particular for applications in vehicles. The radar signals are emitted, and radar signals reflected off of target objects are received and checked for irregularities. The transmitting power of the radar transmitter is reduced when irregularities occur which are attributable to interference caused by neighboring radar transmitters.

Owner:ROBERT BOSCH GMBH

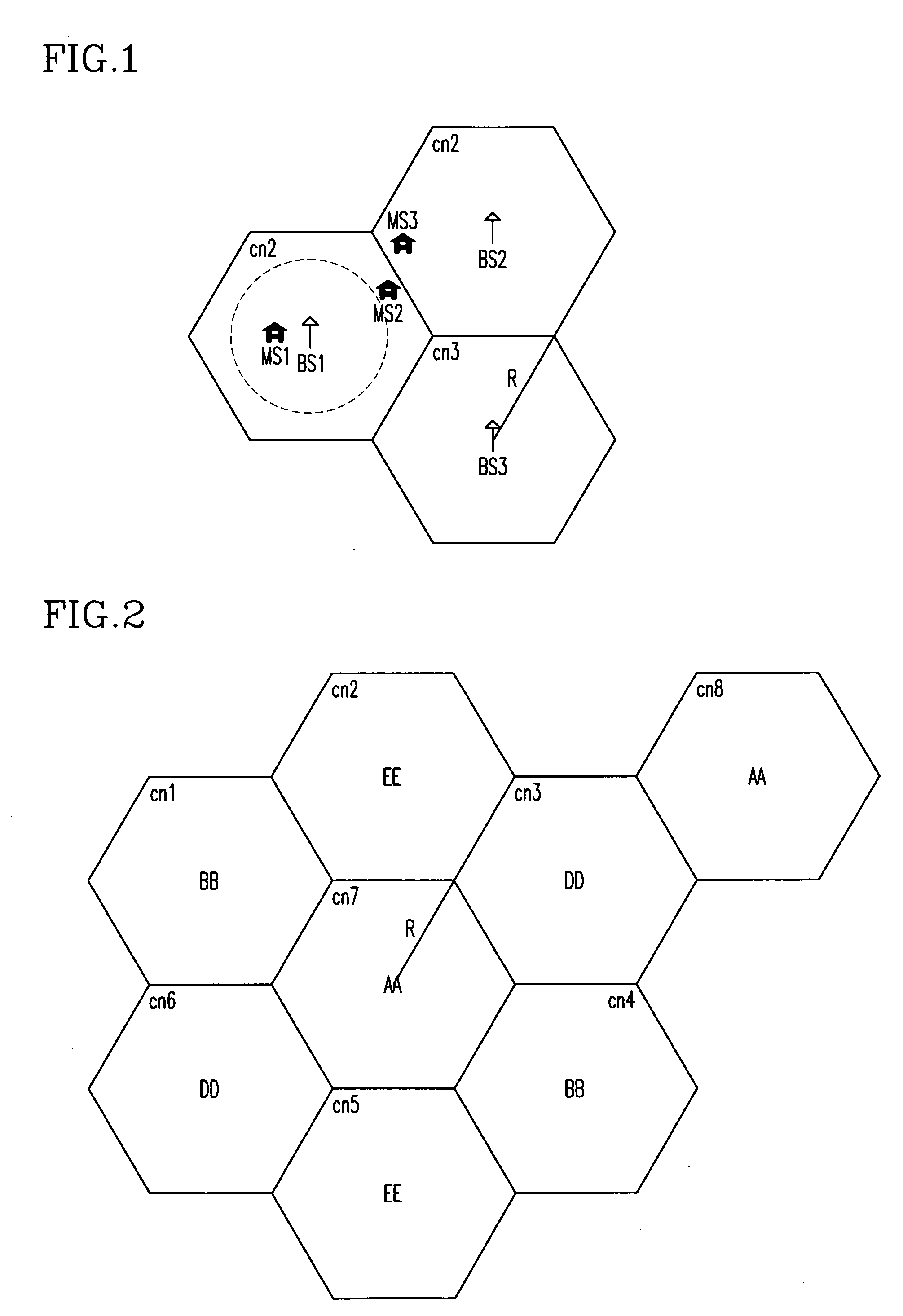

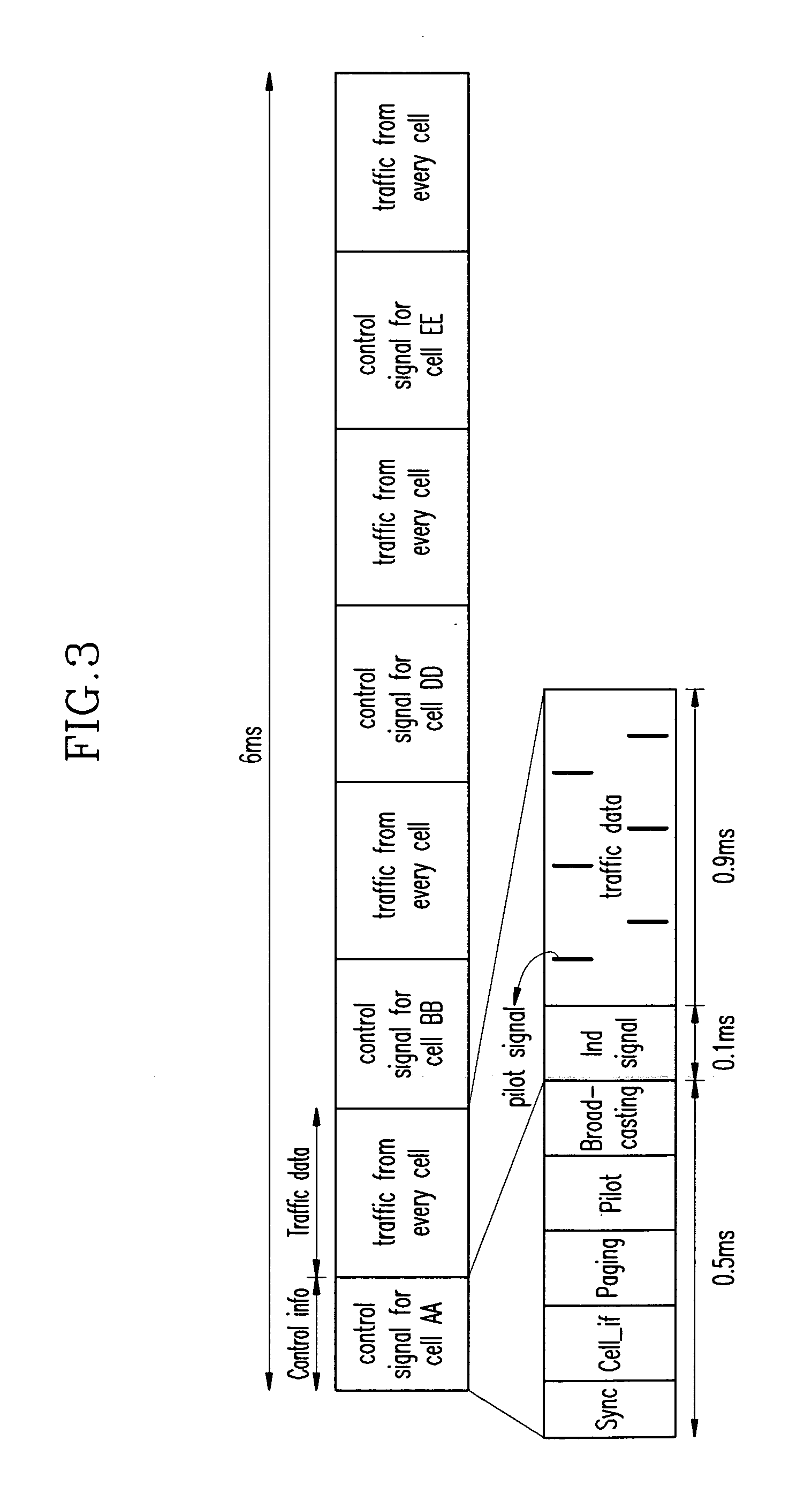

Method for configuring and allocating forward channel in orthogonal frequency division multiple access frequency division duplex system

ActiveUS20050048979A1Minimize inter-cell interferenceLess inter-cell interferenceNetwork traffic/resource managementAssess restrictionMobile stationOrthogonal frequency-division multiple access

Disclosed is a forward channel configuring method in an OFDMA FDD system. The method comprises: classifying the cells into a specific number of patterns based on location relations of the respective cells; allowing the respective base stations of the cells having different classified patterns to transmit control information to the mobile station at different times within a period of the forward channel, and allowing the respective base stations of the cells having the same classified patterns to transmit control information to the mobile station at the same time; and allowing the respective base stations to transmit traffic data to the mobile station irrespective of the classified patterns when the control information is transmitted.

Owner:PANTECH CORP

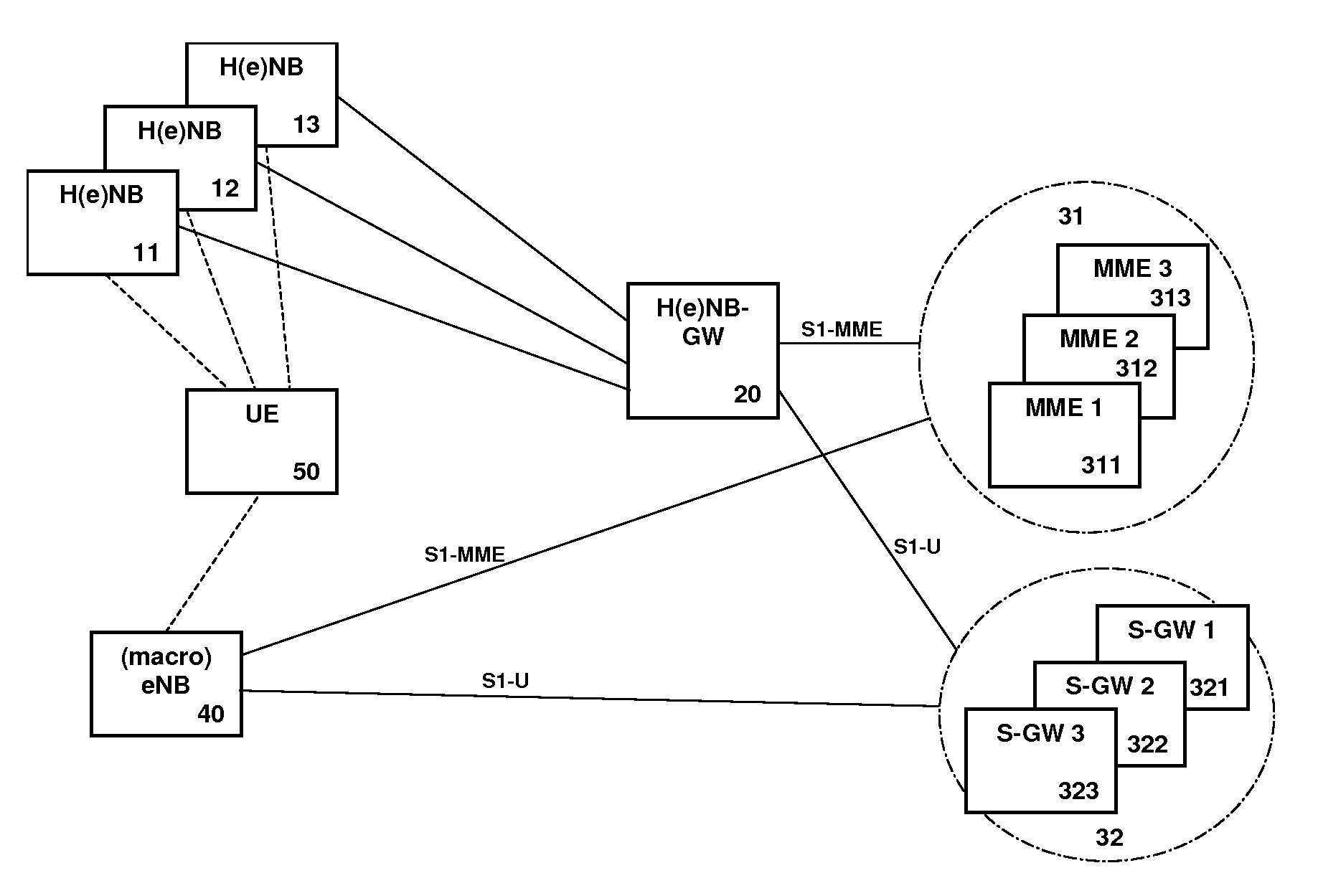

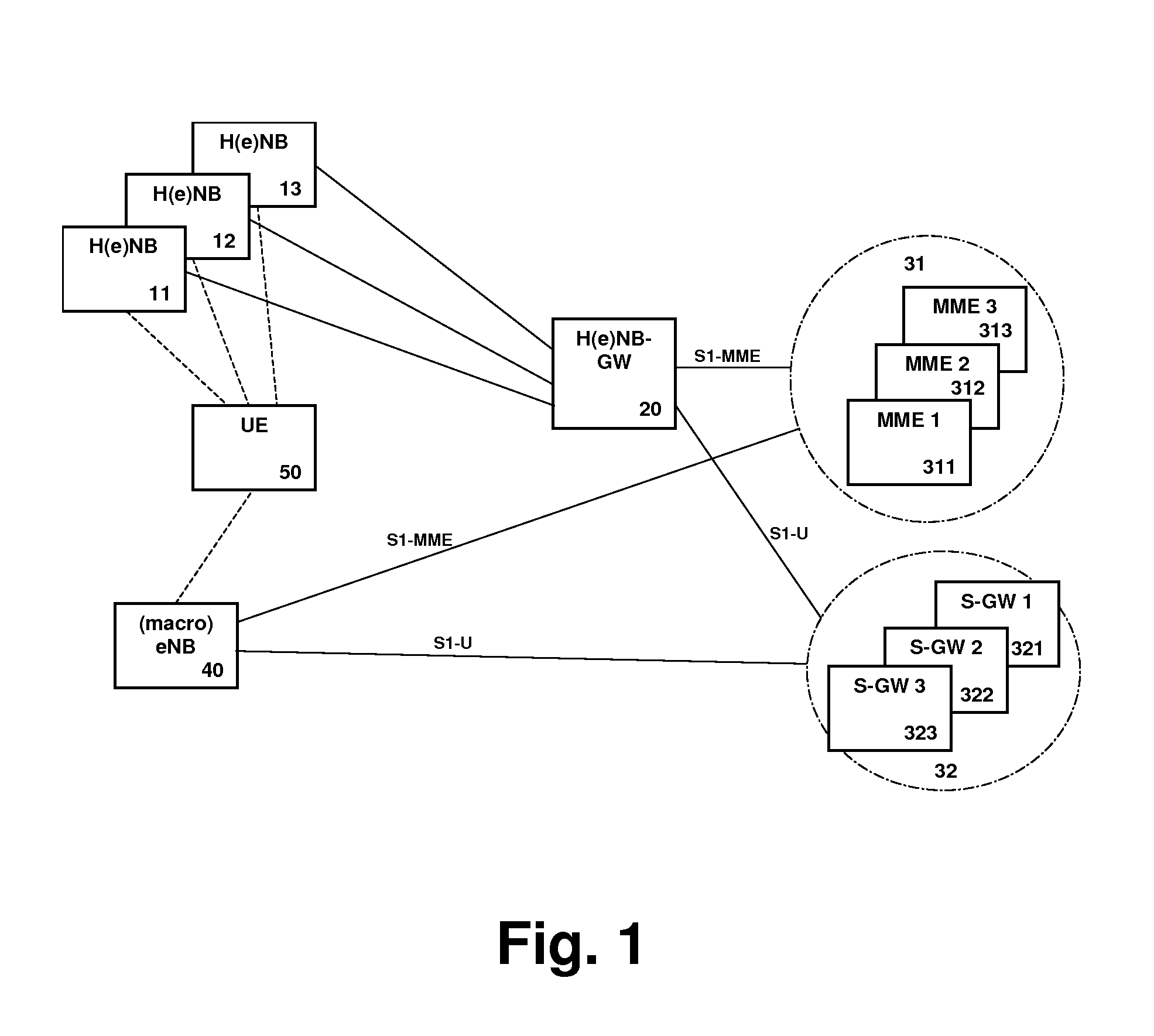

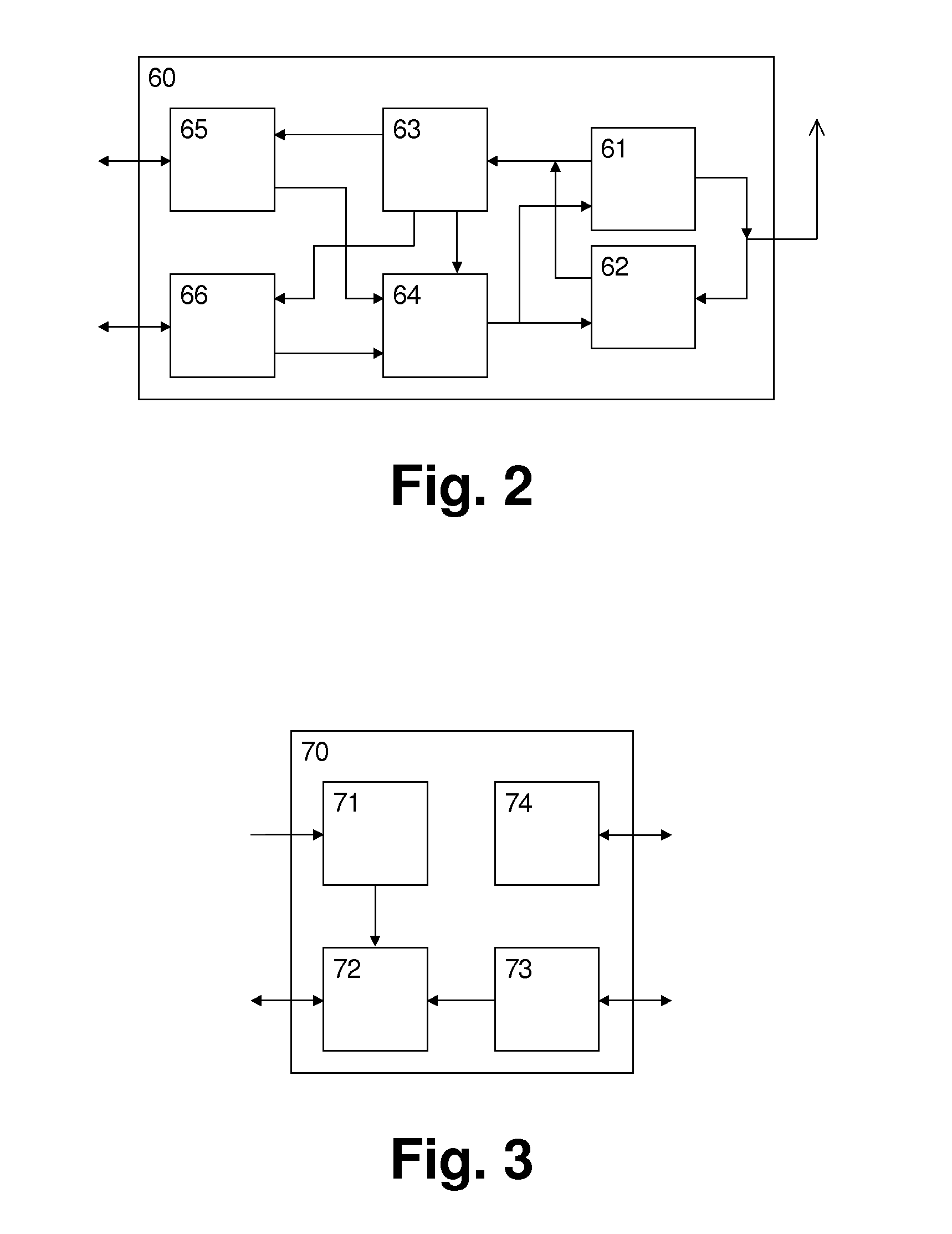

Reducing Interference and Energy Consumption for FEMTO Base Stations

ActiveUS20110211514A1Reduce interference and energy consumptionReduce consumptionEnergy efficient ICTPower managementHandshakingEnergy consumption

The present invention relates to methods, apparatuses, a system and a computer program product for reducing interference and energy consumption of wireless devices. An apparatus, namely a femto base station or home (e) NodeB, can include a transmitting unit, a receiving unit, a determining unit, a disabling unit, a disabling handshaking unit, and a reassigning unit. If the determining unit determines that there is no active communication between the apparatus and a user device, the disabling unit may disable the transmitting unit and the receiving unit while maintaining a connection between the apparatus and a network. A disabling handshaking can be performed by the disabling handshaking unit to achieve this, wherein the re-assigning unit may re-assign one or more user device(s) to a network apparatus, namely a macro (e) NodeB.

Owner:NOKIA SOLUTIONS & NETWORKS OY

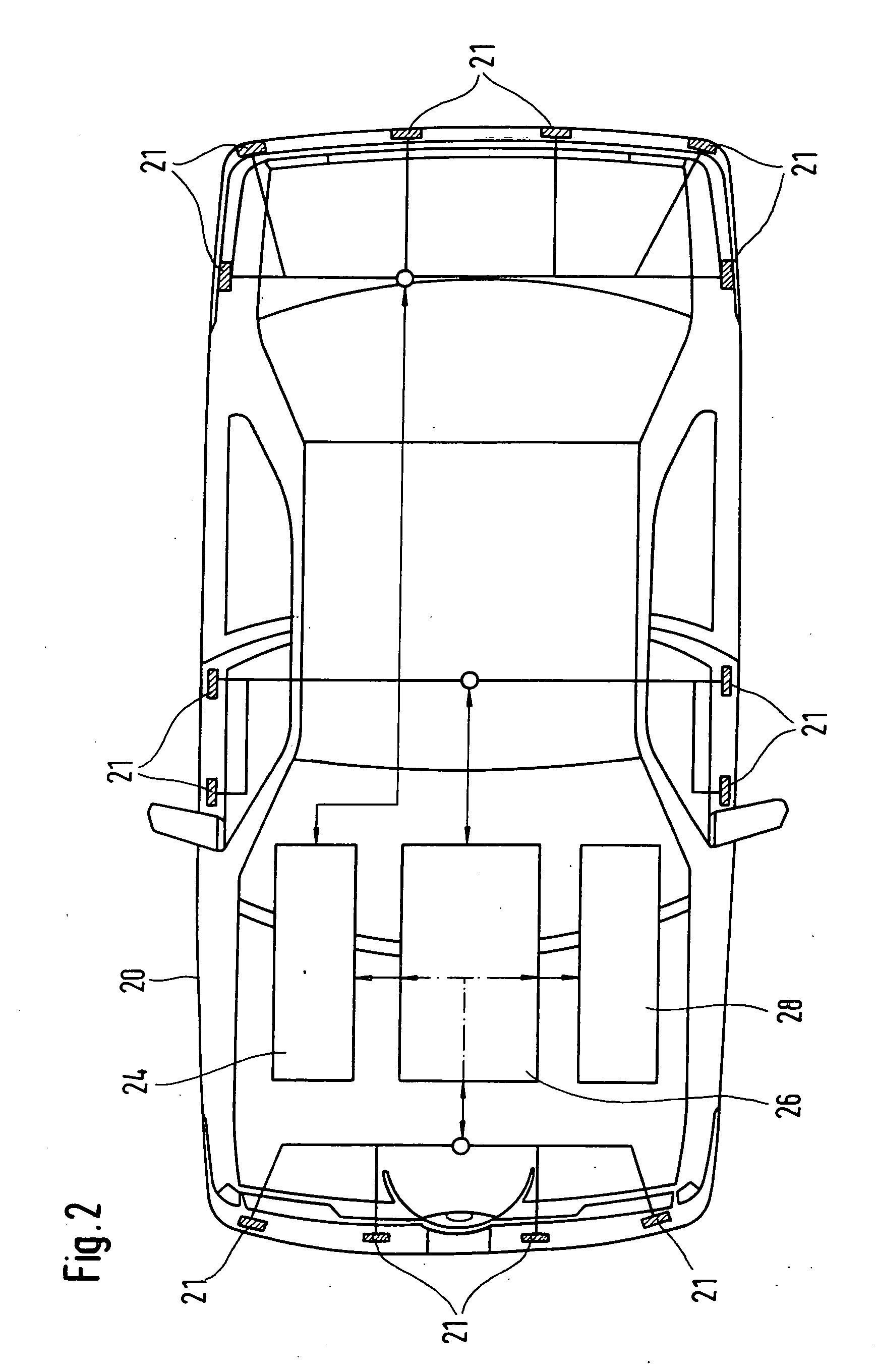

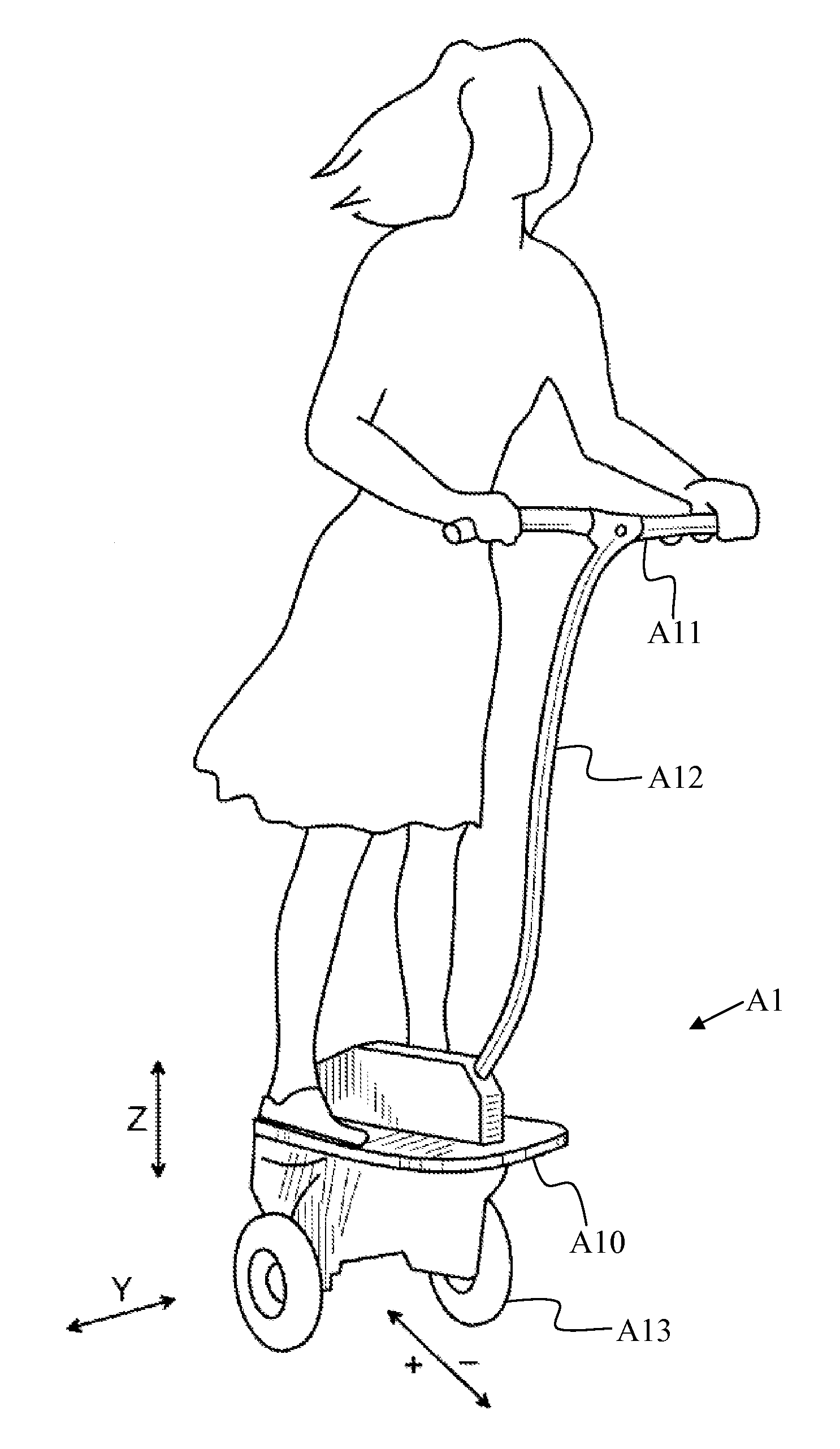

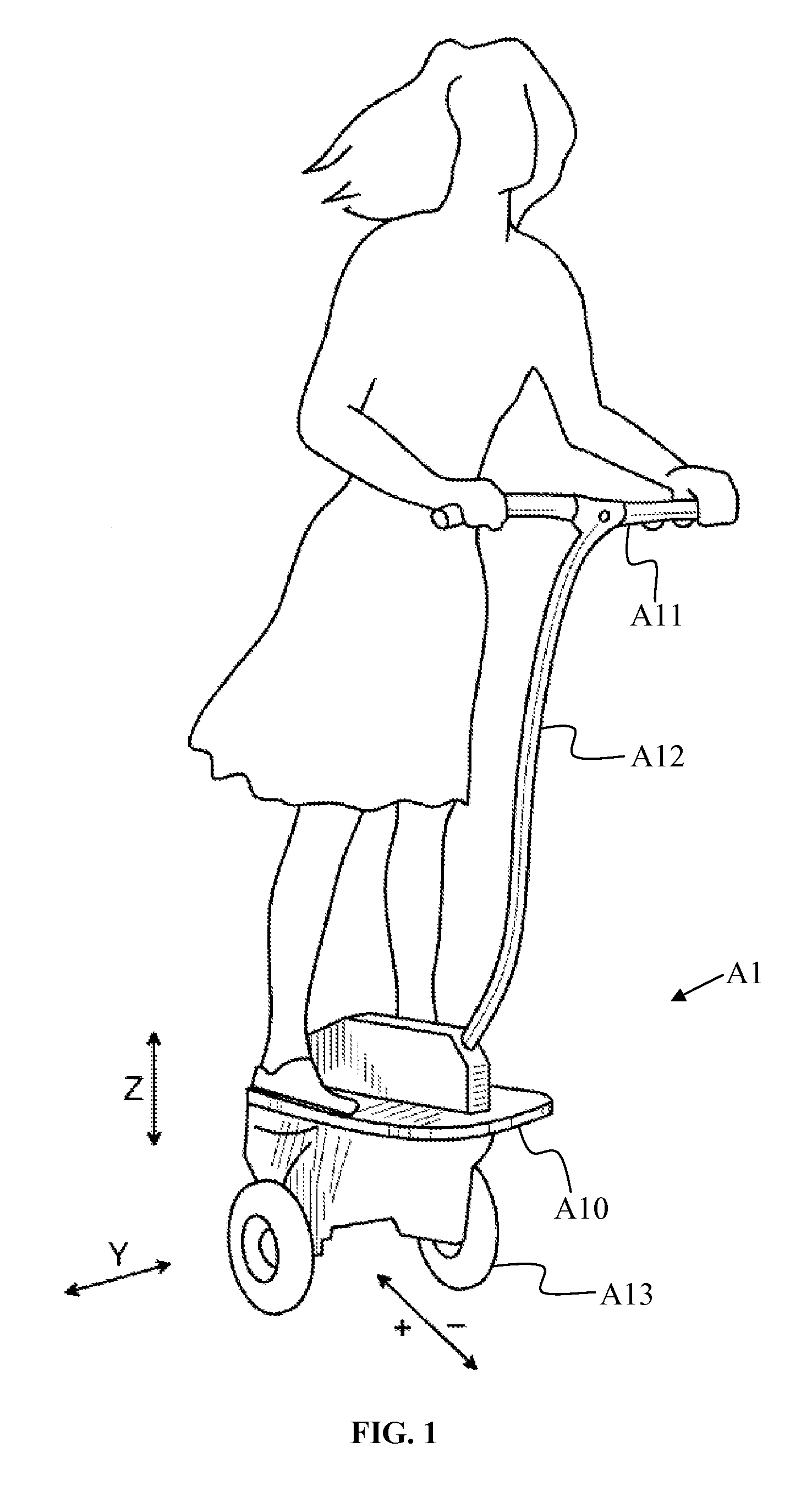

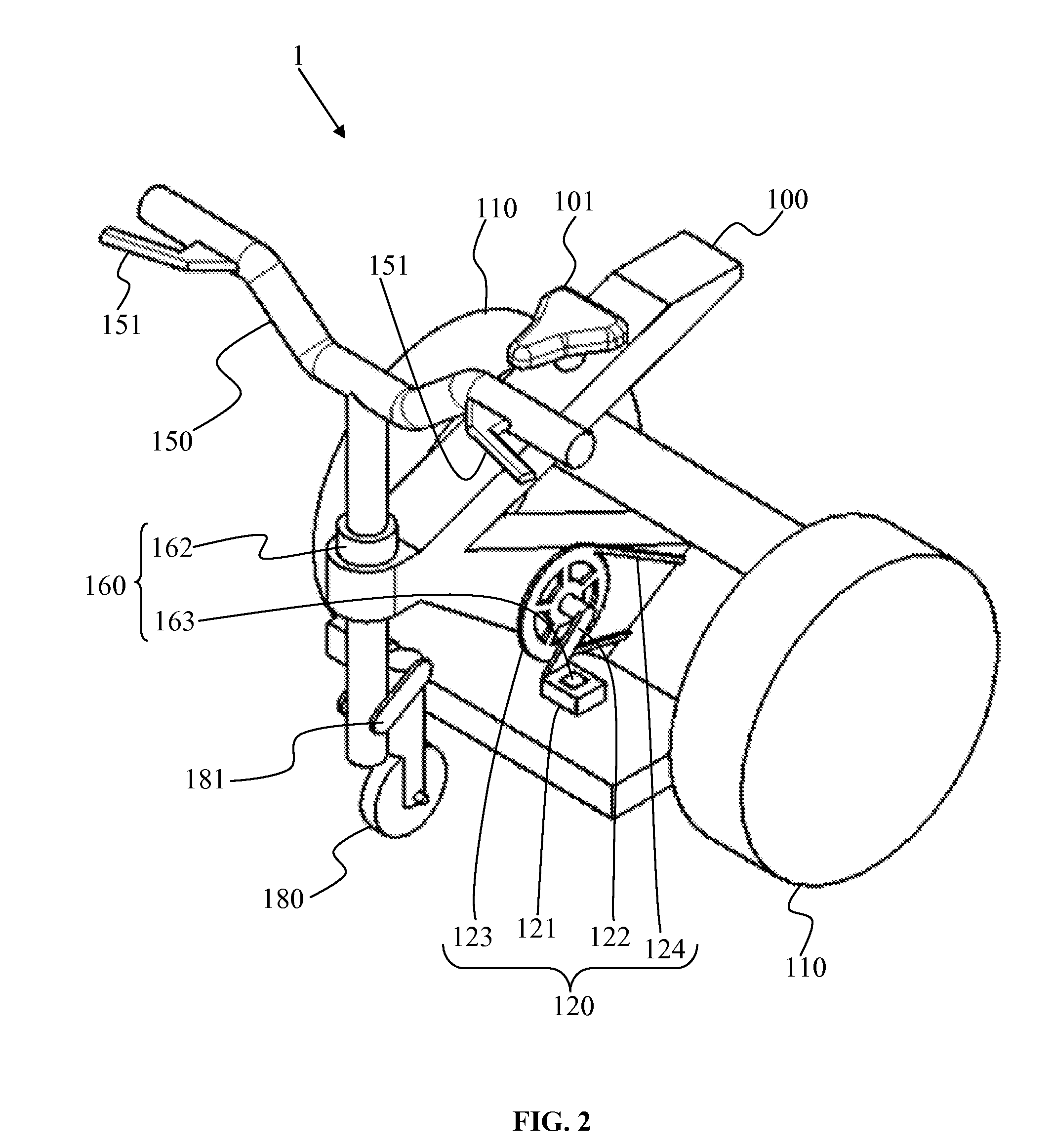

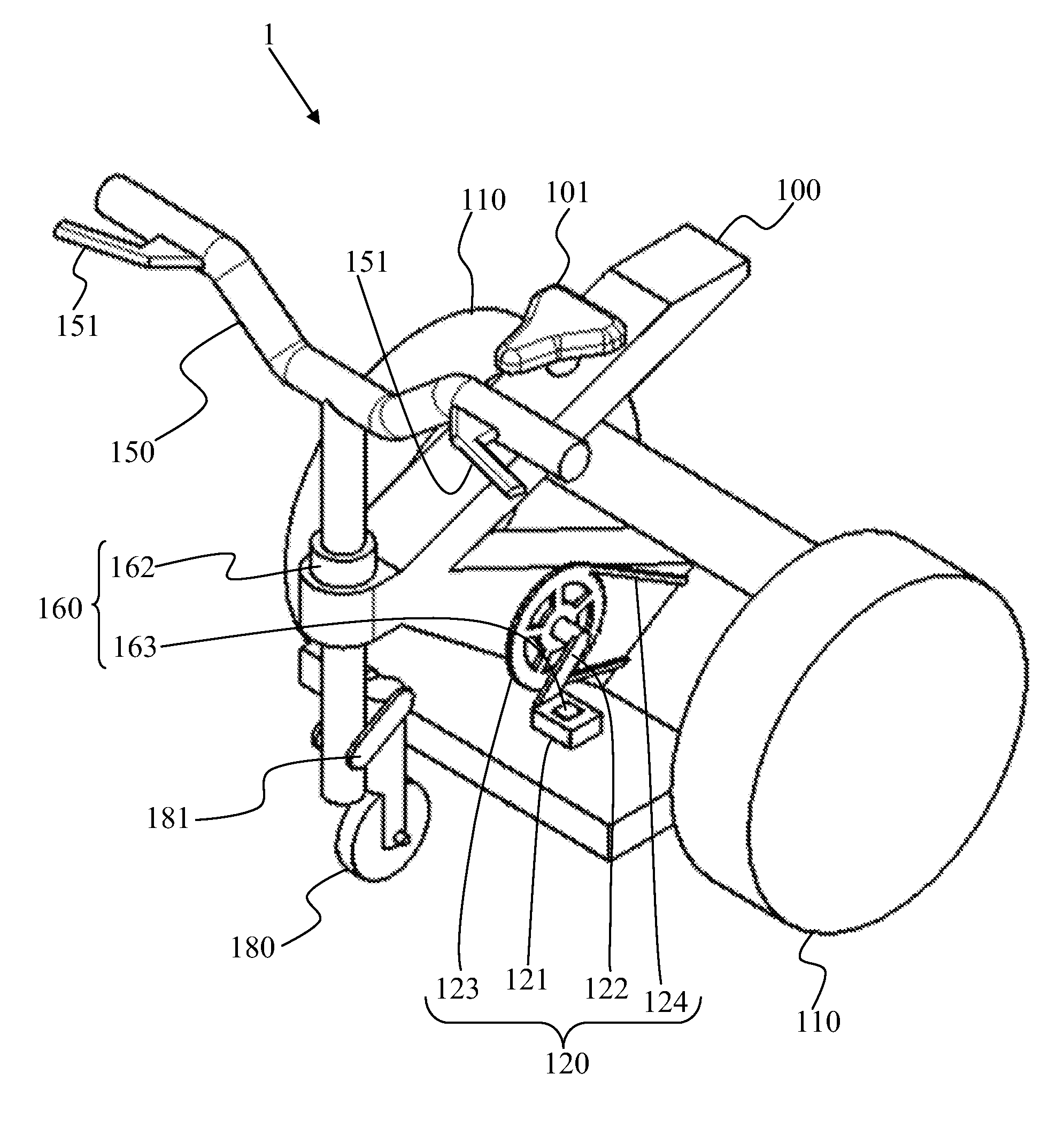

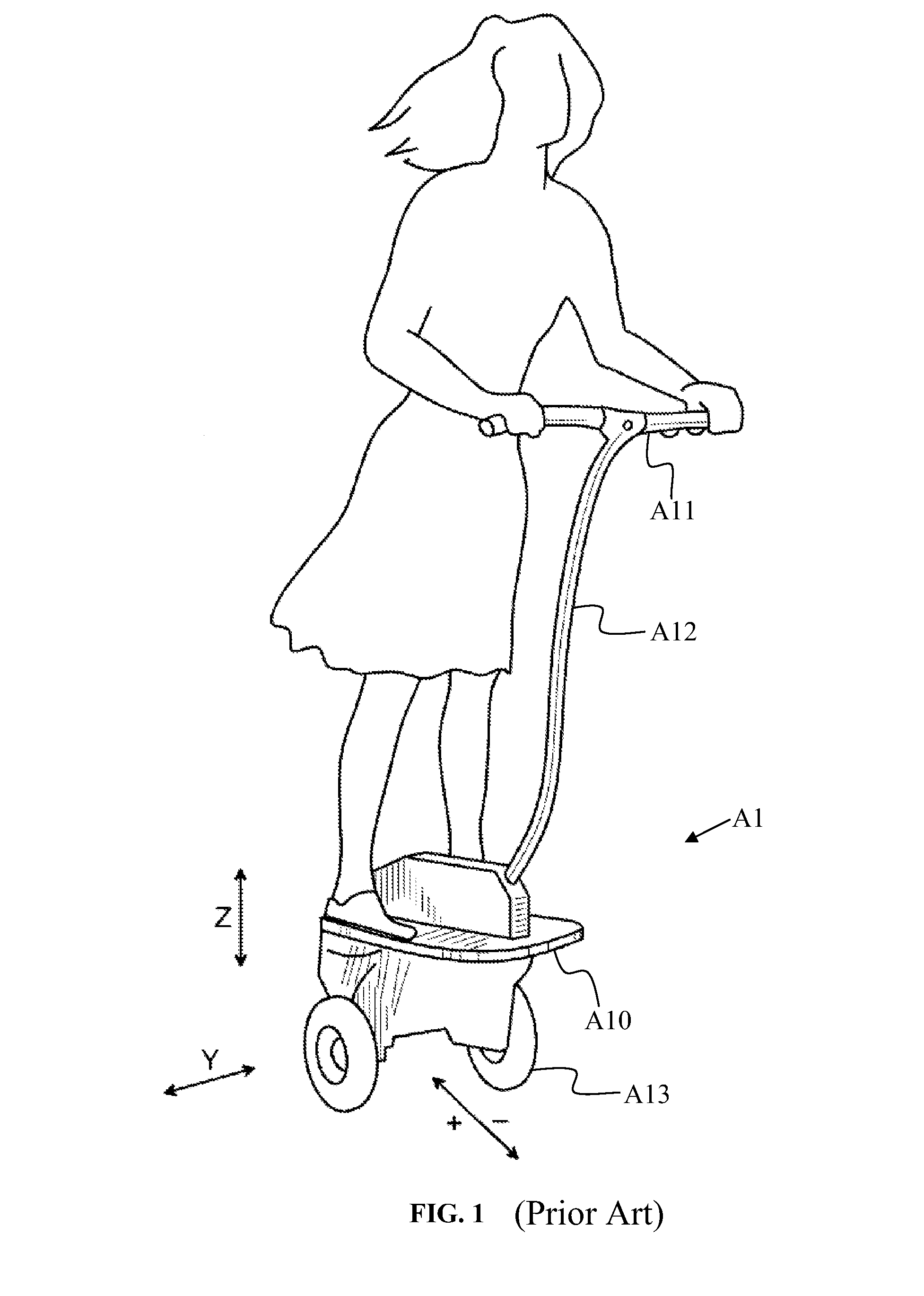

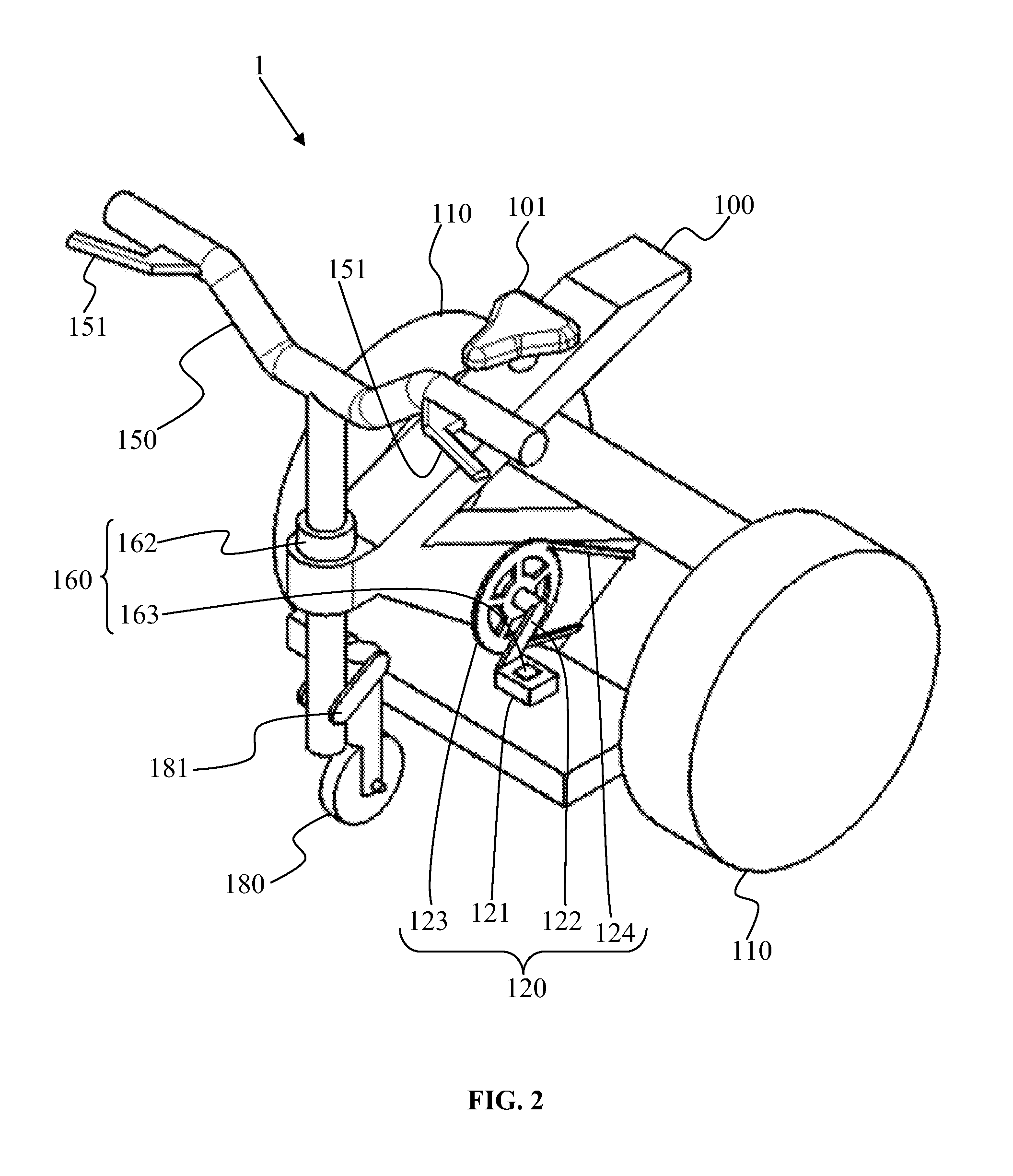

Human Powered and Electricity Balanced Personal Vehicle

InactiveUS20110221160A1Increase spaceLess interferenceUnicyclesPropulsion by batteries/cellsElectricityEngineering

The present invention discloses a human powered and electricity balanced personal vehicle, which comprises: a main body for bearing a driver; a set of powered wheels being two coaxial wheels; a manpower inputting device being provided for the driver to input manpower into the personal vehicle; an electricity converting device for converting electricity to power and inputting the power into the personal vehicle; a transmission device for receiving the manpower inputted by the manpower inputting device and the power inputted by the electricity converting device, and inputting mixed power of the manpower and power into the powered wheels; an operation device being provided for the driver to control the moving state of the personal vehicle; a plurality of vehicle movement detecting devices for detecting the moving state of the personal vehicle and the operating condition of the driver; and a control unit for receiving and analyzing the signals of the plurality of vehicle movement detecting devices and controlling the electrical output of the electricity converting device.

Owner:NATIONAL TSING HUA UNIVERSITY

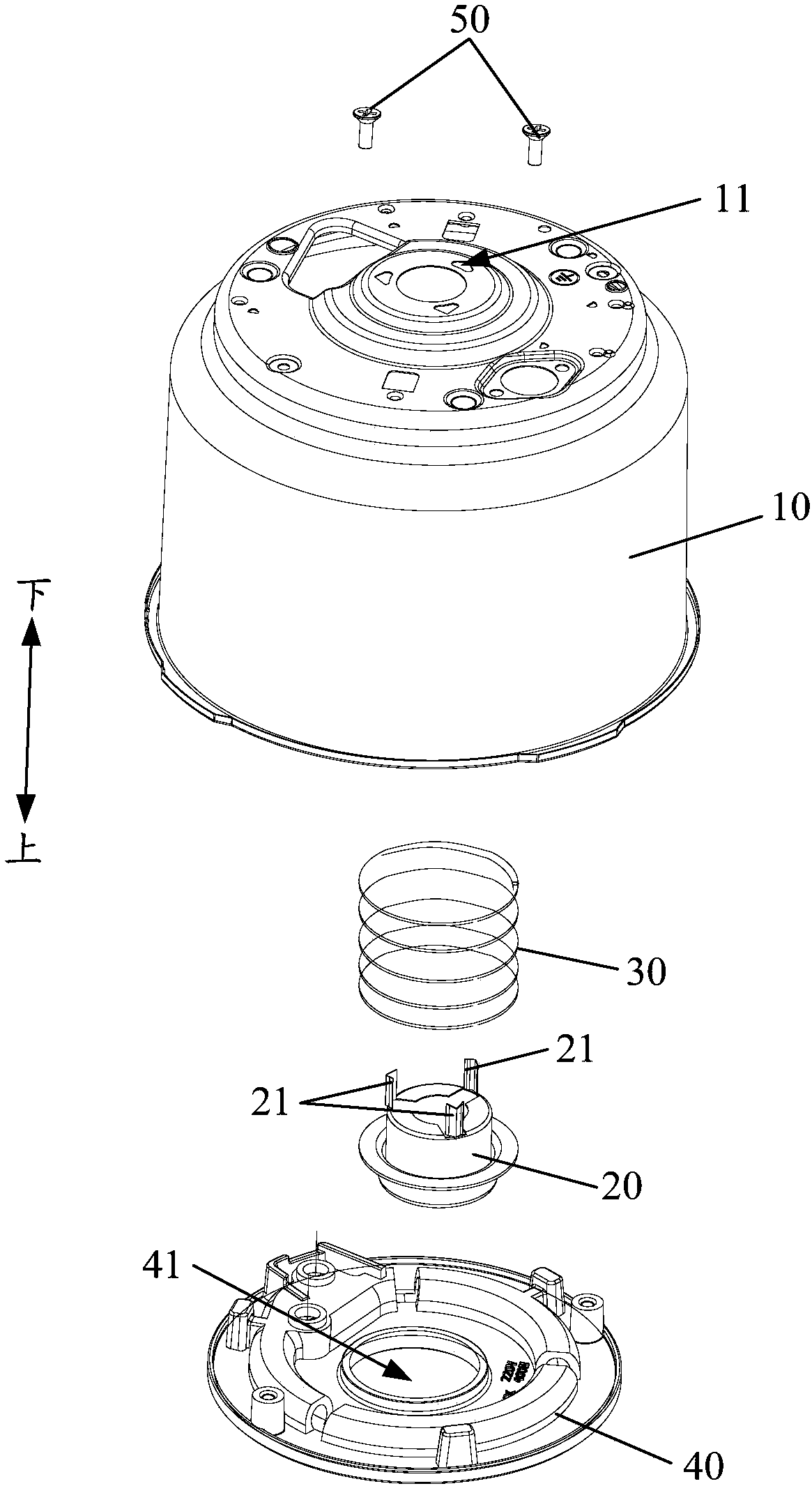

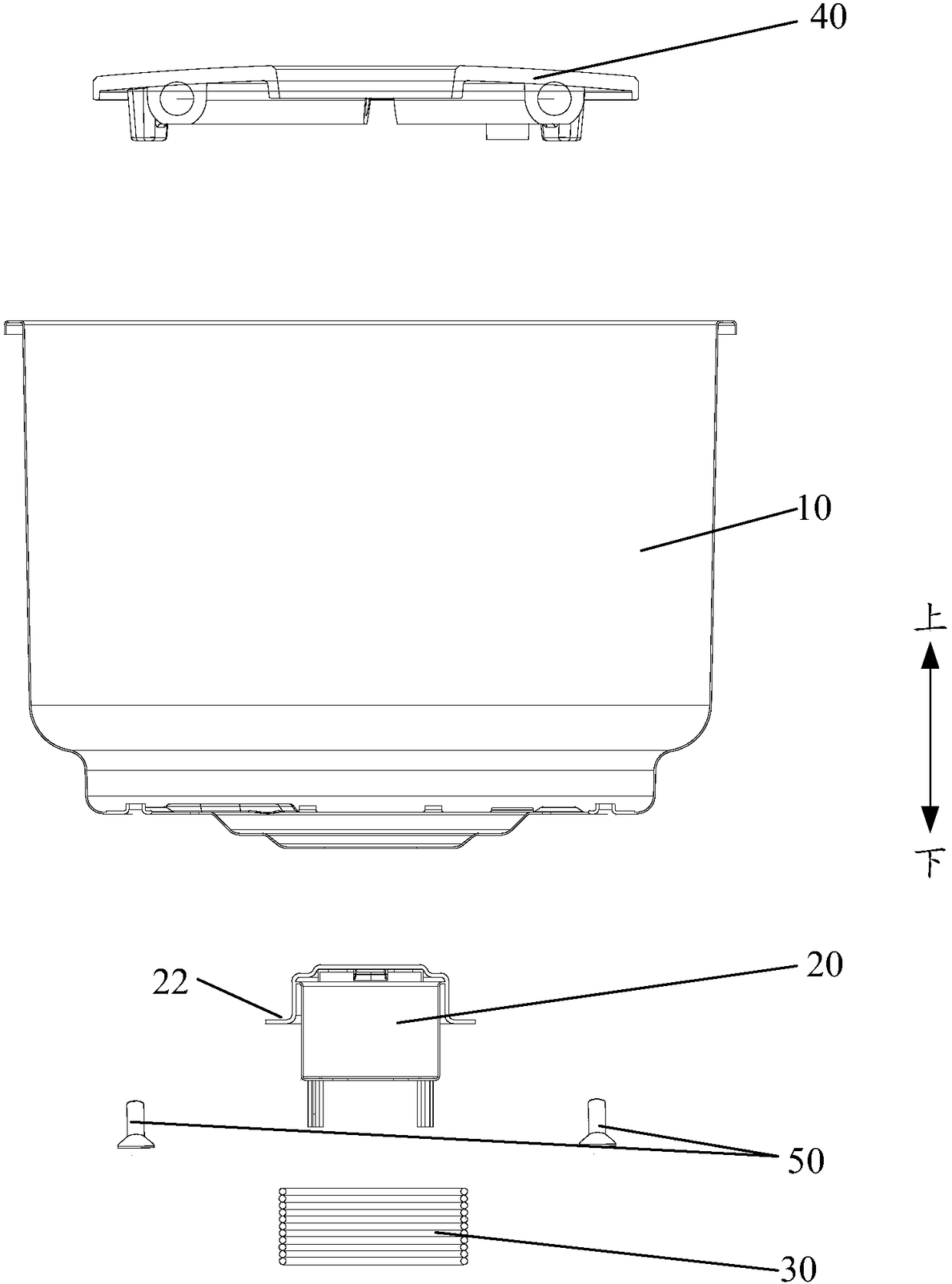

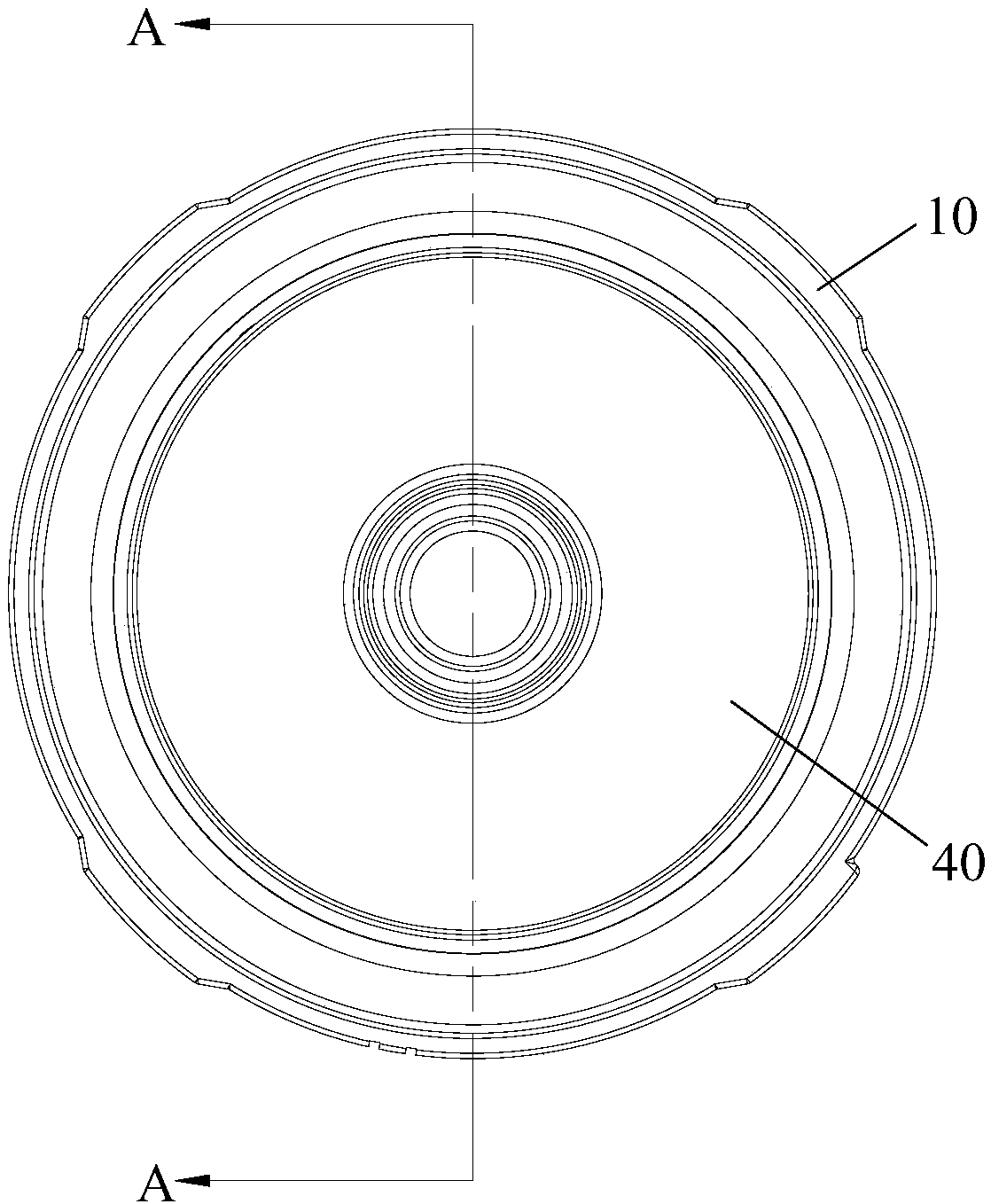

Cooking utensil

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

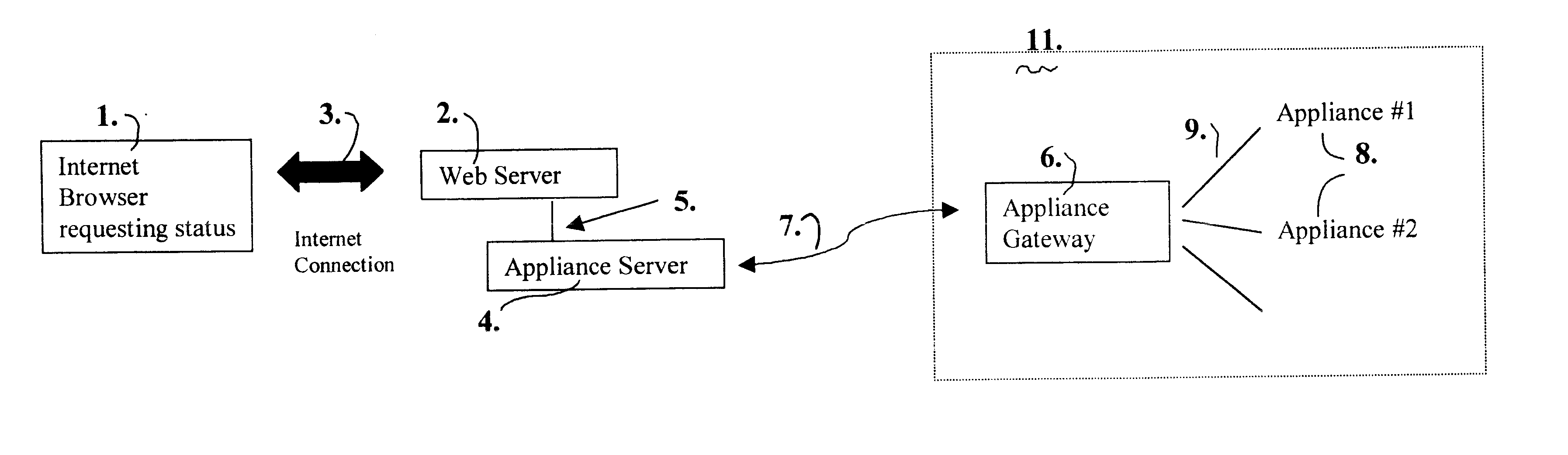

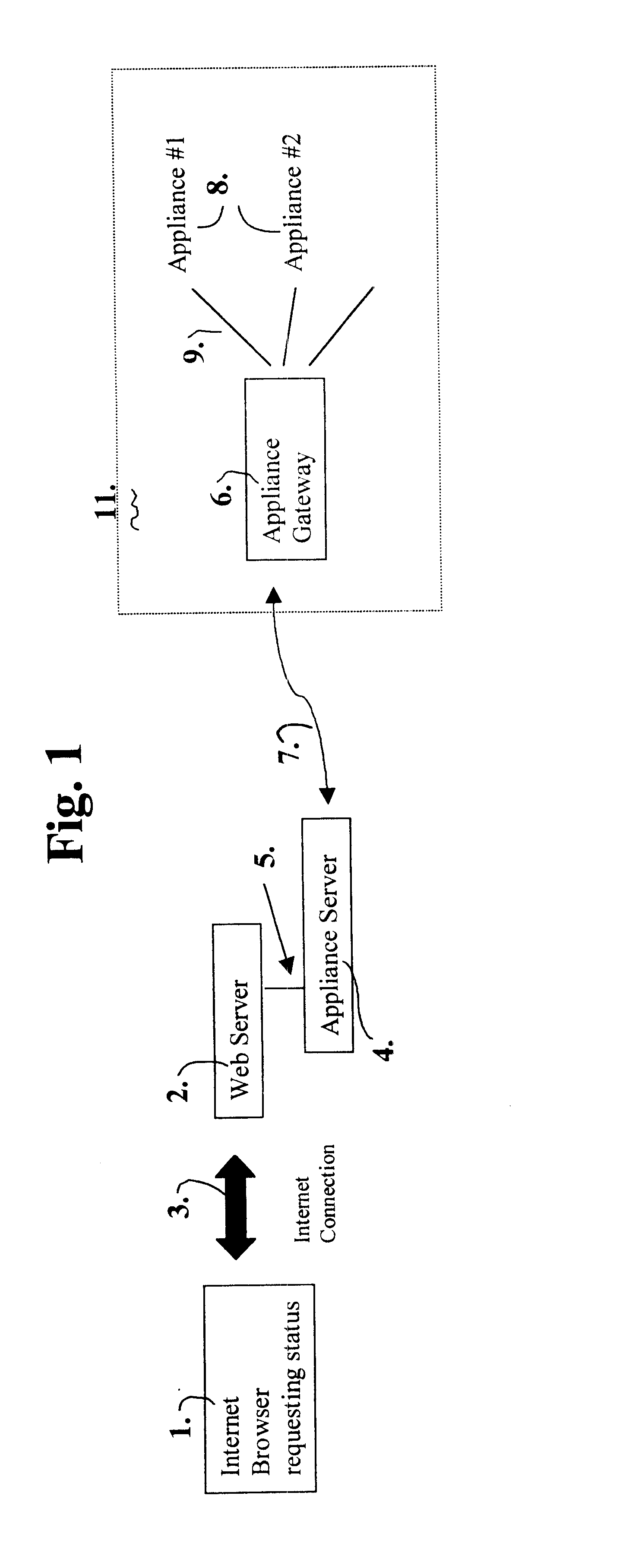

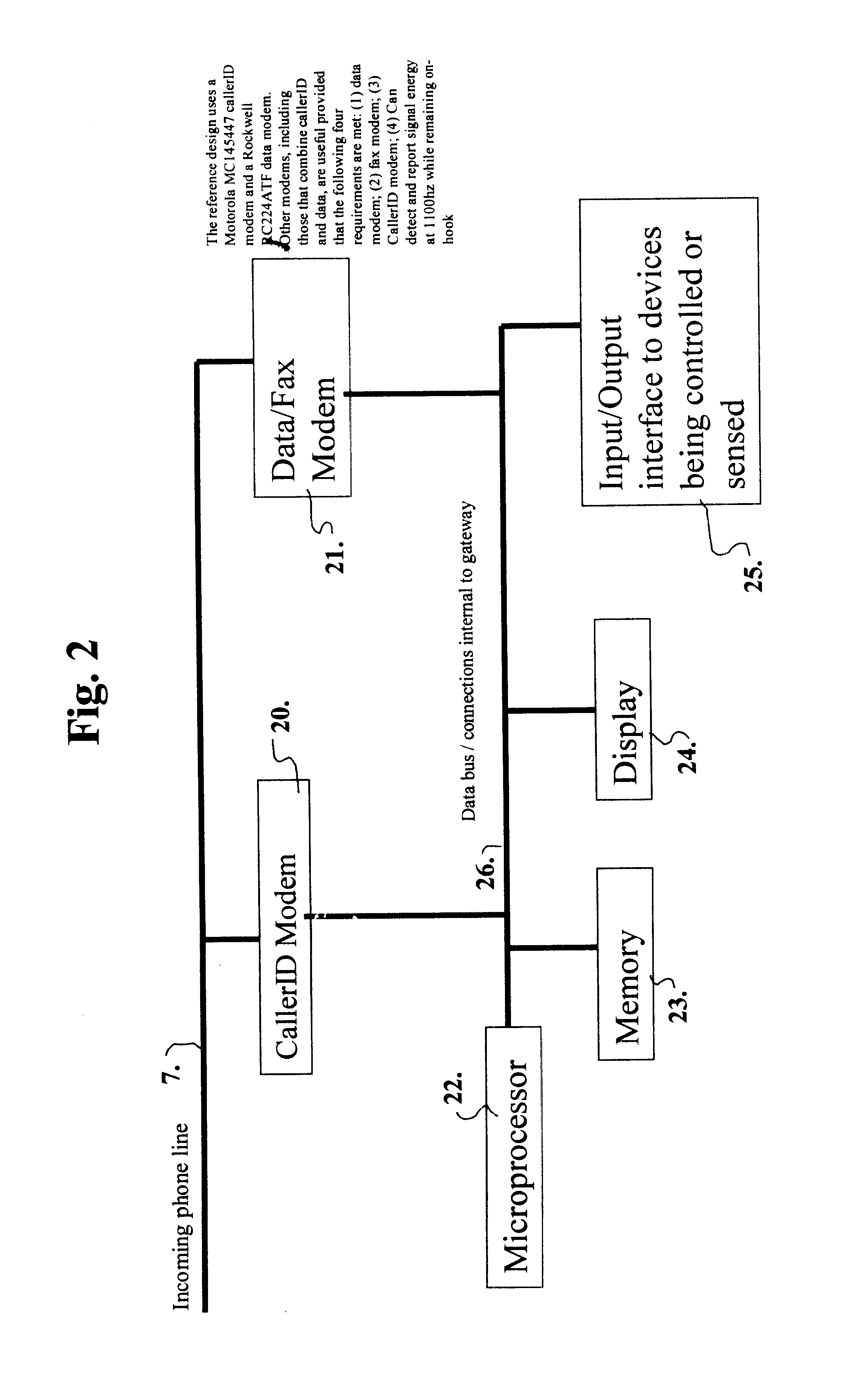

Remote initiation of communications for control of multiple appliances by telephone line

InactiveUS6480586B1Less interferenceSpecial service for subscribersData transmissionService provision

To control multiple electronic devices in homes and other buildings through telephone lines, a user may establish communication by utilizing Caller ID supplied by a local telephone service supplier and, where such Caller ID service is unavailable, user generated Caller ID tones and simultaneous FAX pilot tones and data transmission, to signal to a device to be controlled or to a receiving station that instructions are received and communication is required.

Owner:GENESIS ENG

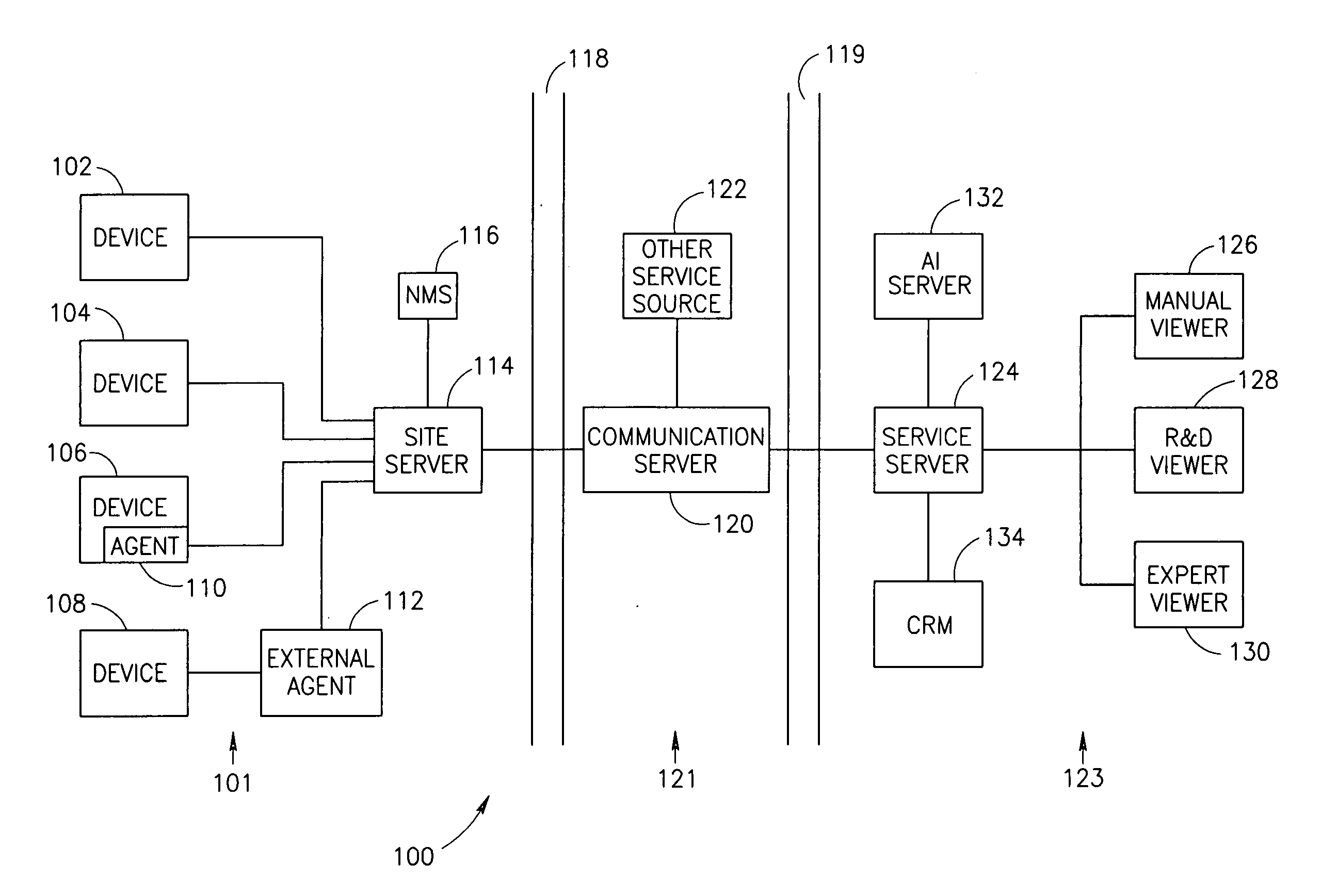

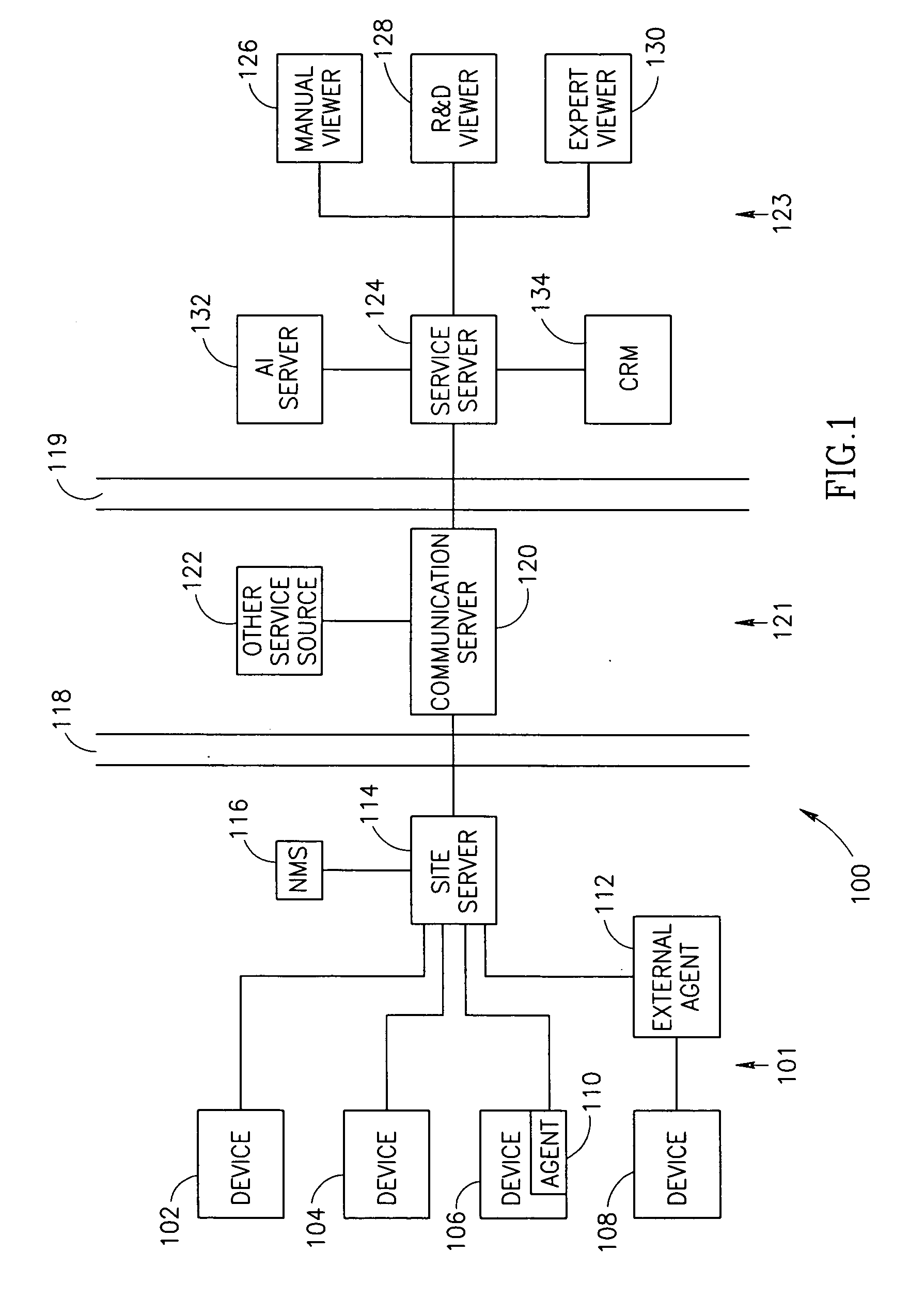

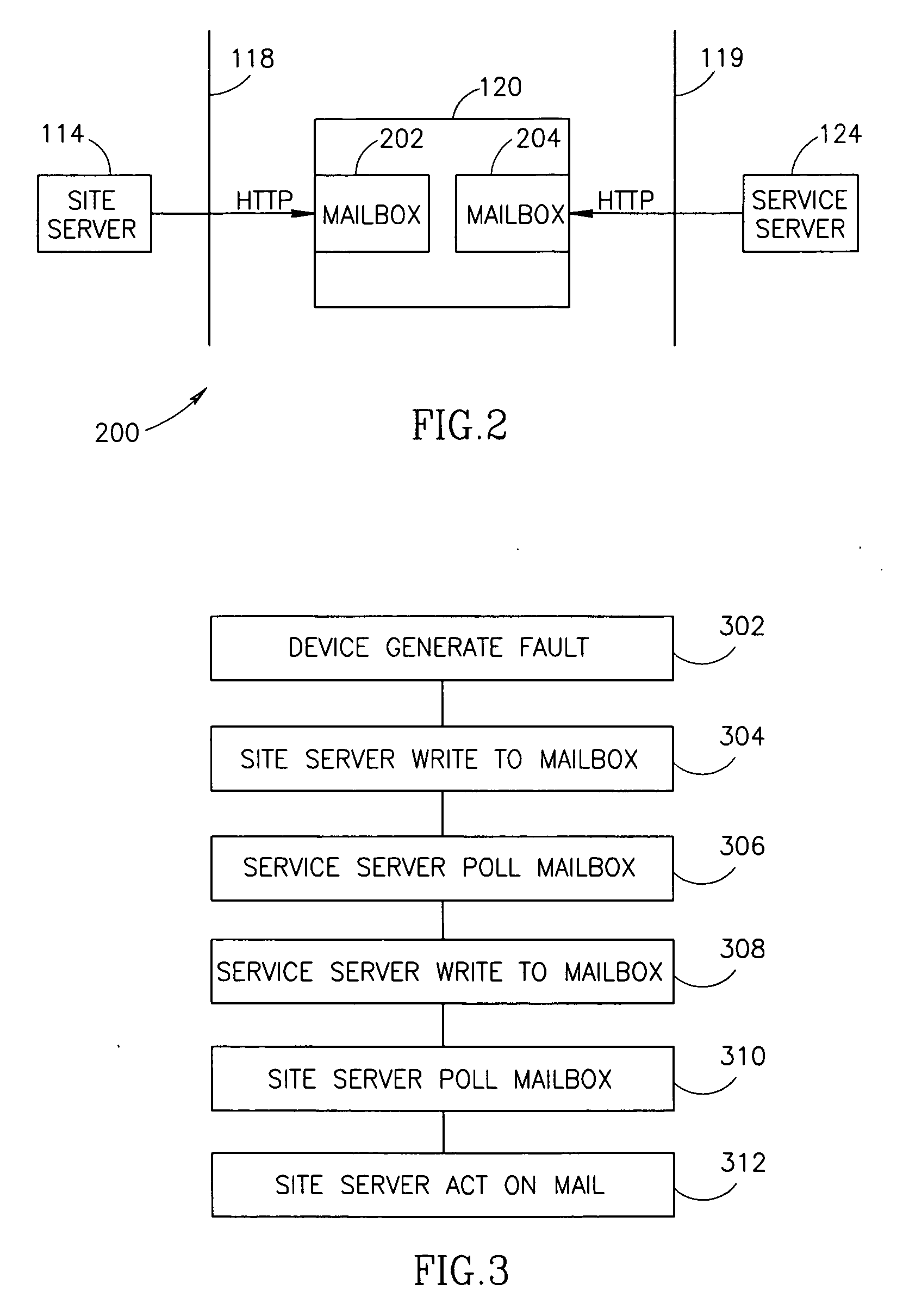

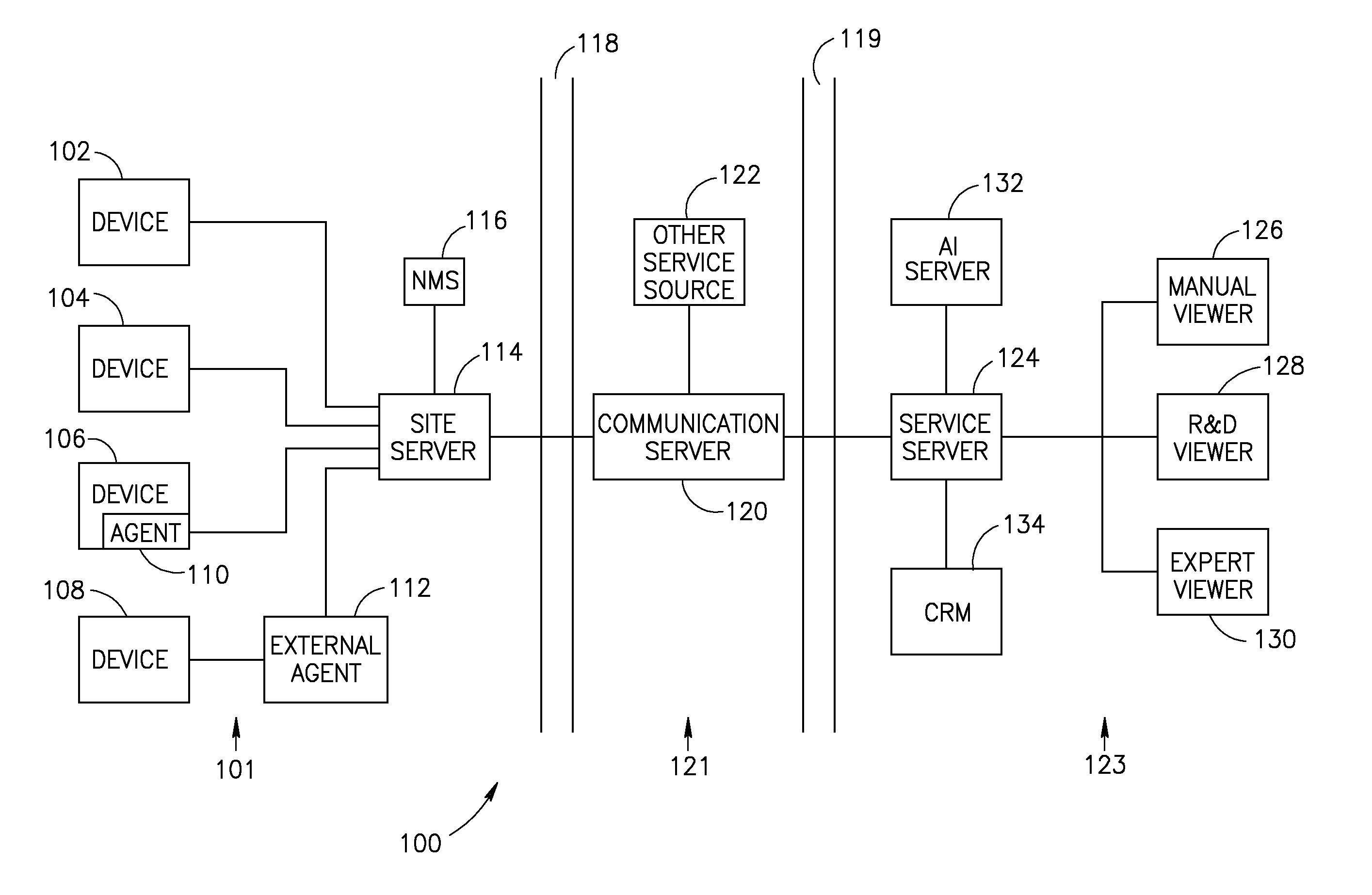

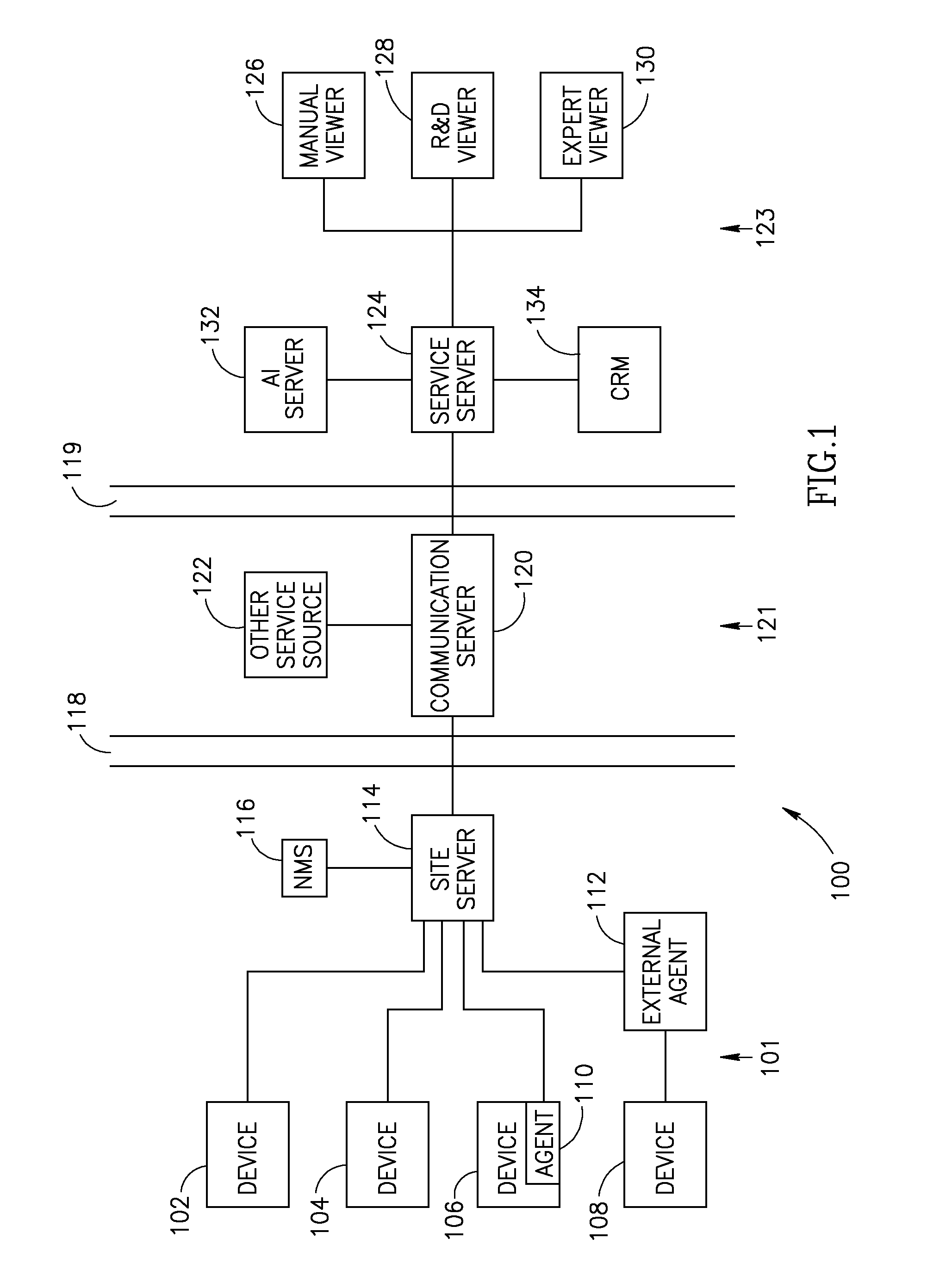

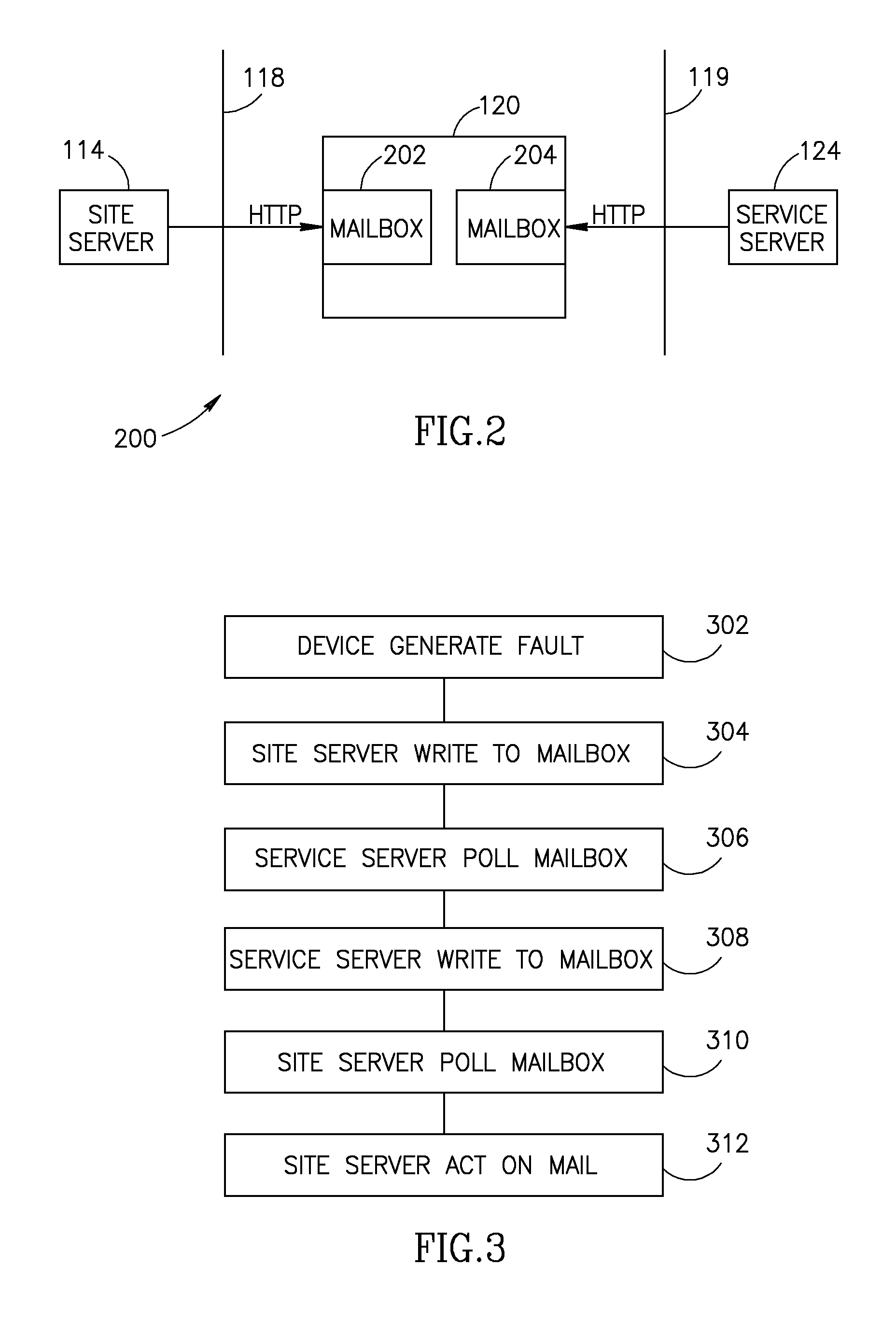

Support network

InactiveUS20060161394A1Reduce the amount requiredReduce the numberDetecting faulty hardware by remote testDigital computer detailsComputer scienceReal-time computing

Owner:NEXTNINE

Workpiece gripping device

Owner:FANUC LTD

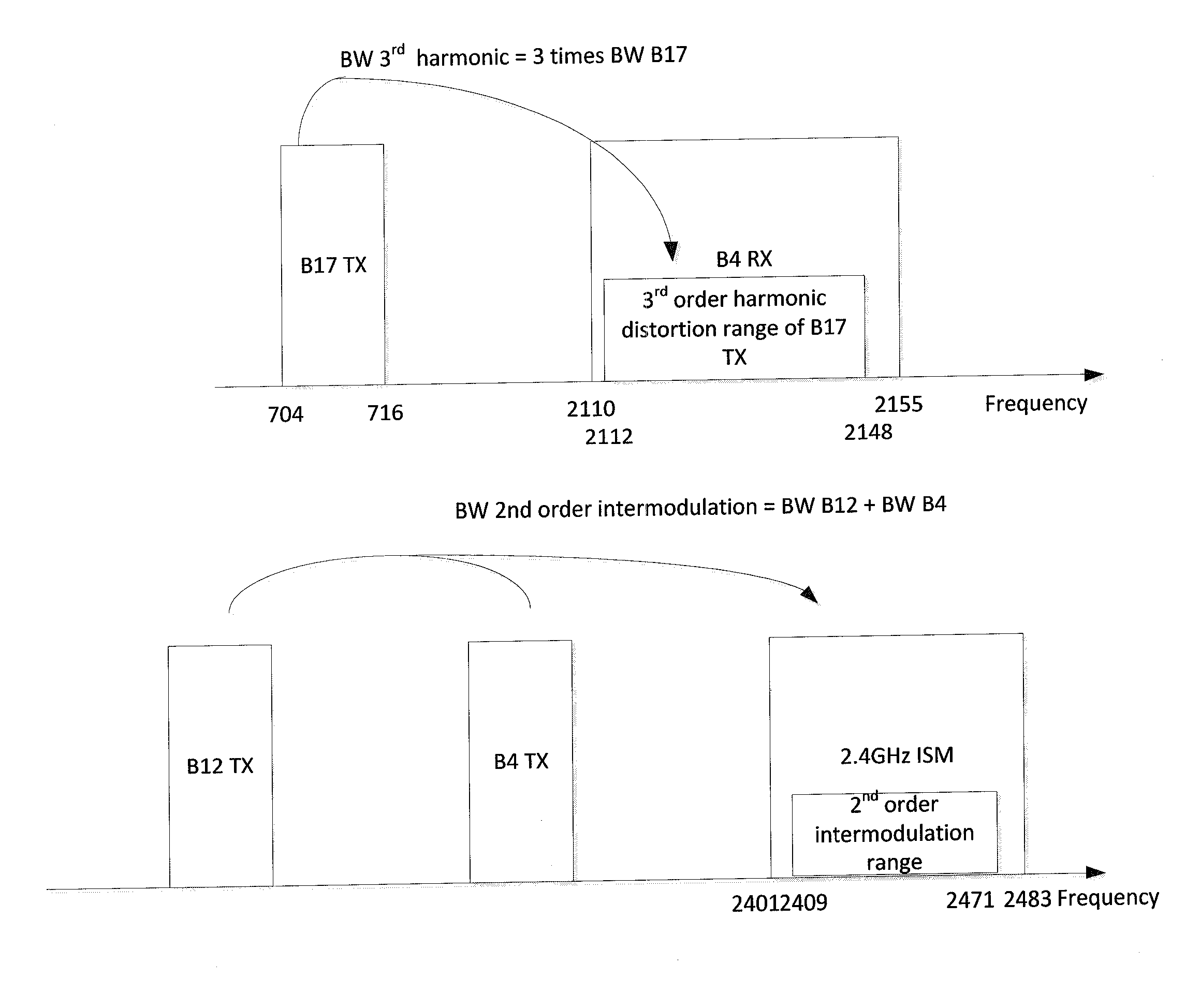

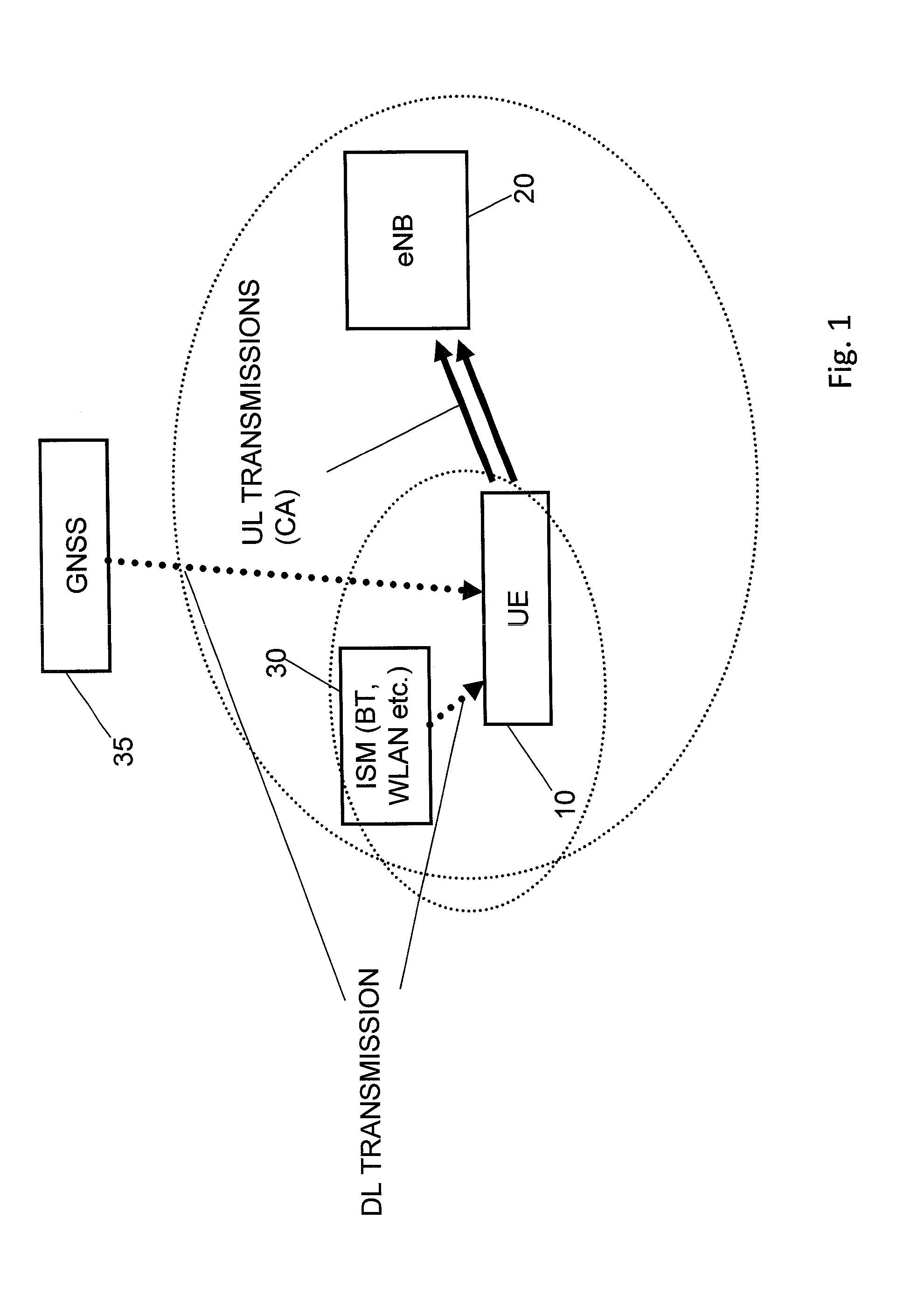

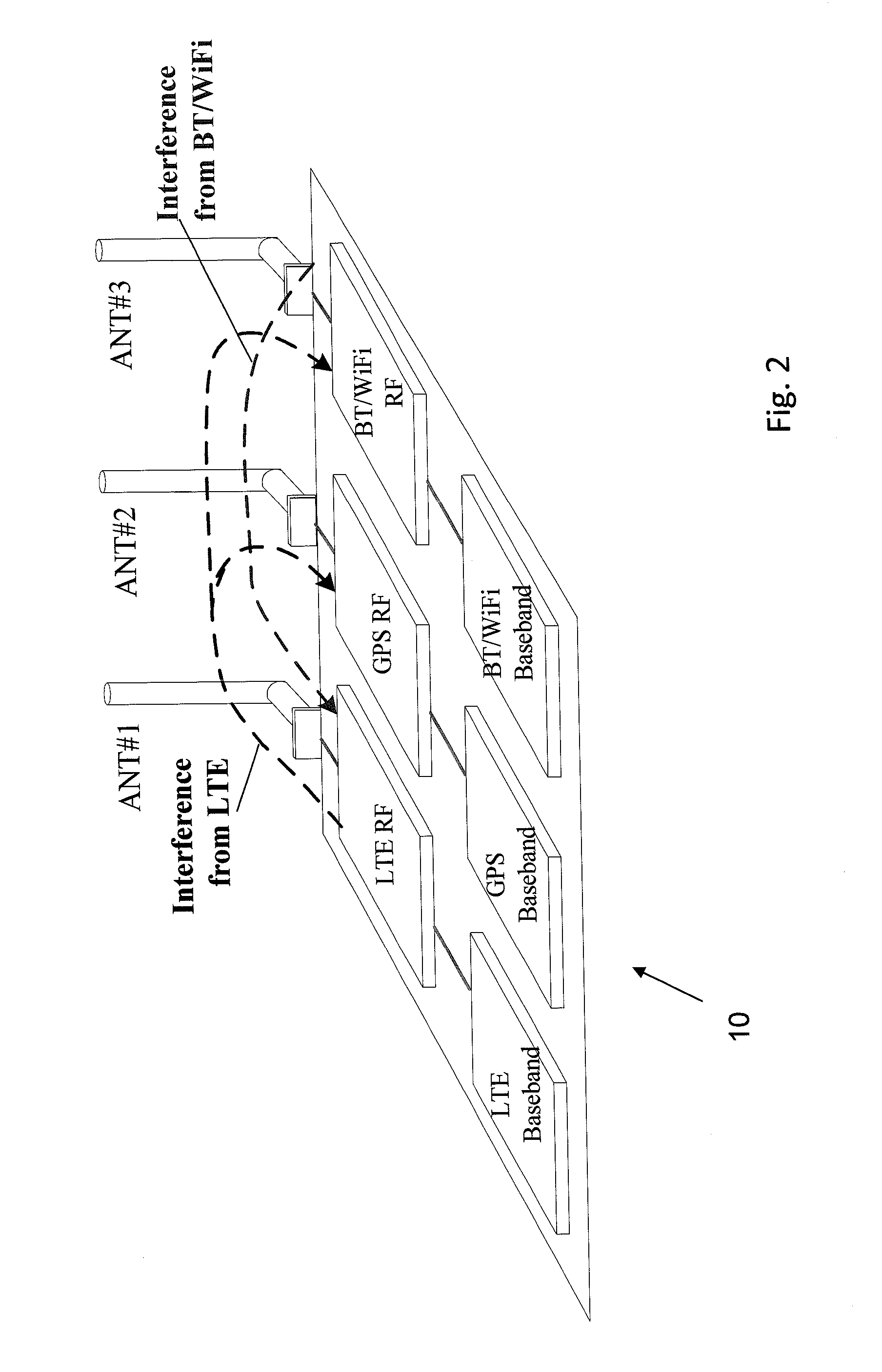

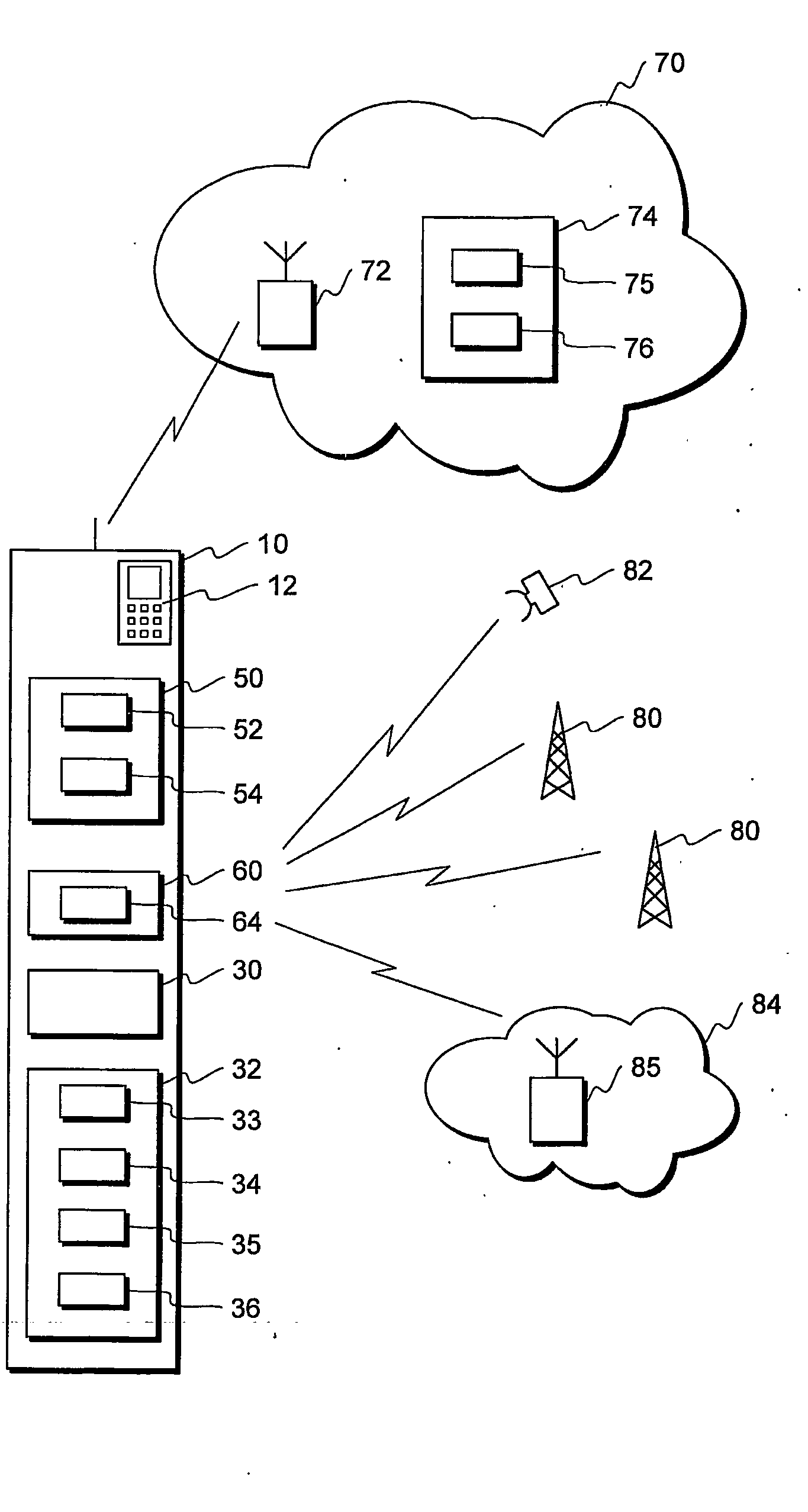

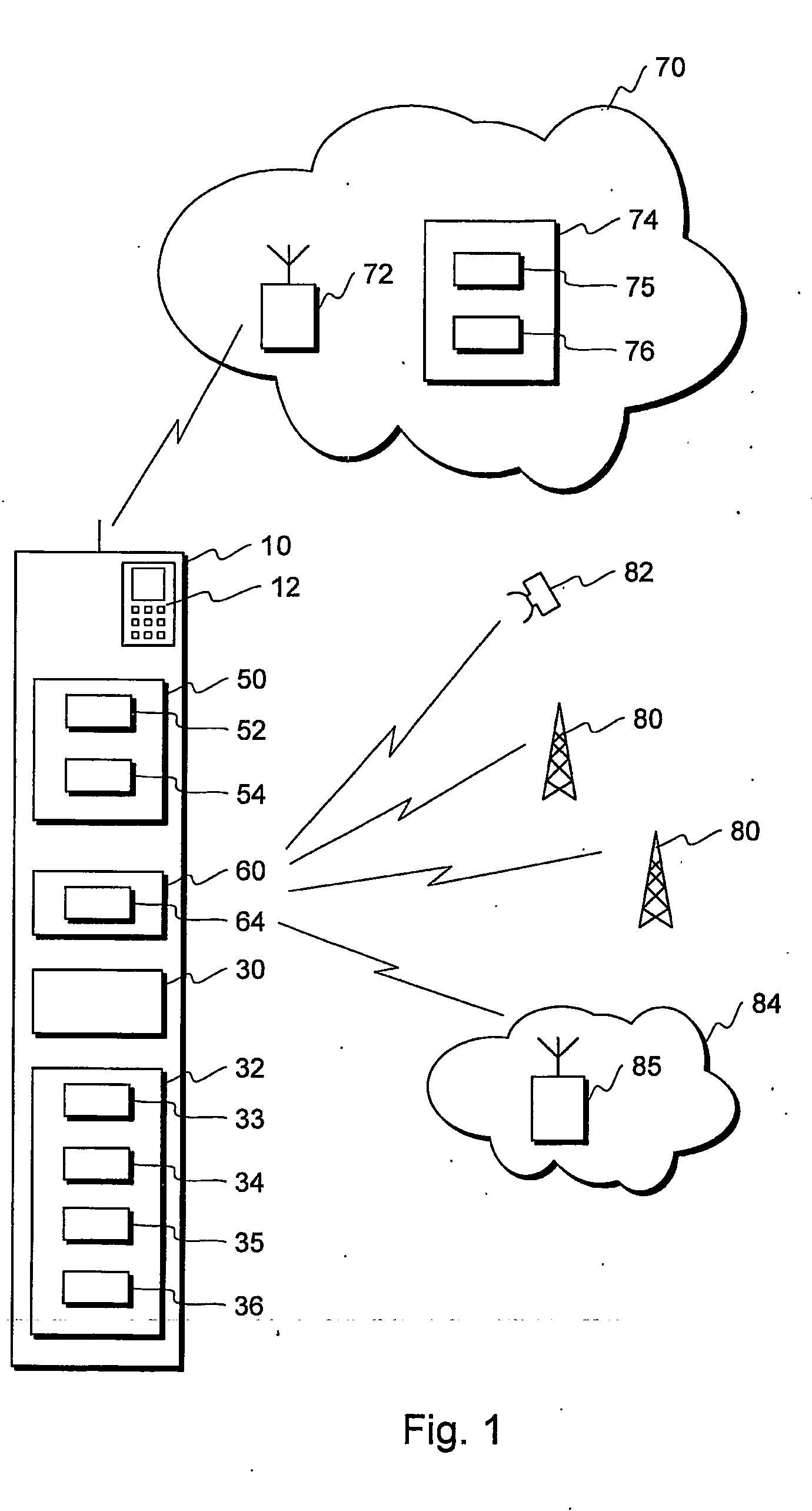

Interference Control Mechanism in Multi-Band Communication

ActiveUS20130194938A1Optimize networkHigh data rateError preventionFrequency-division multiplex detailsMulti bandCarrier signal

There is provided a mechanism for controlling communications conducted in multiple frequency bands so as to decrease an interference level between the communications. When an interference situation caused between a first set UL communications performed on at least two different frequency bands and a DL communication performed on another frequency band is determined, a frequency carrier deactivation processing is conducted so as to deactivate either one of carriers of the at least two frequency bands of the set of UL communications. The deactivation processing comprises for example an autonomous denial on the UE side or an interference reporting with deactivation on the eNB side.

Owner:AVAGO TECH INT SALES PTE LTD

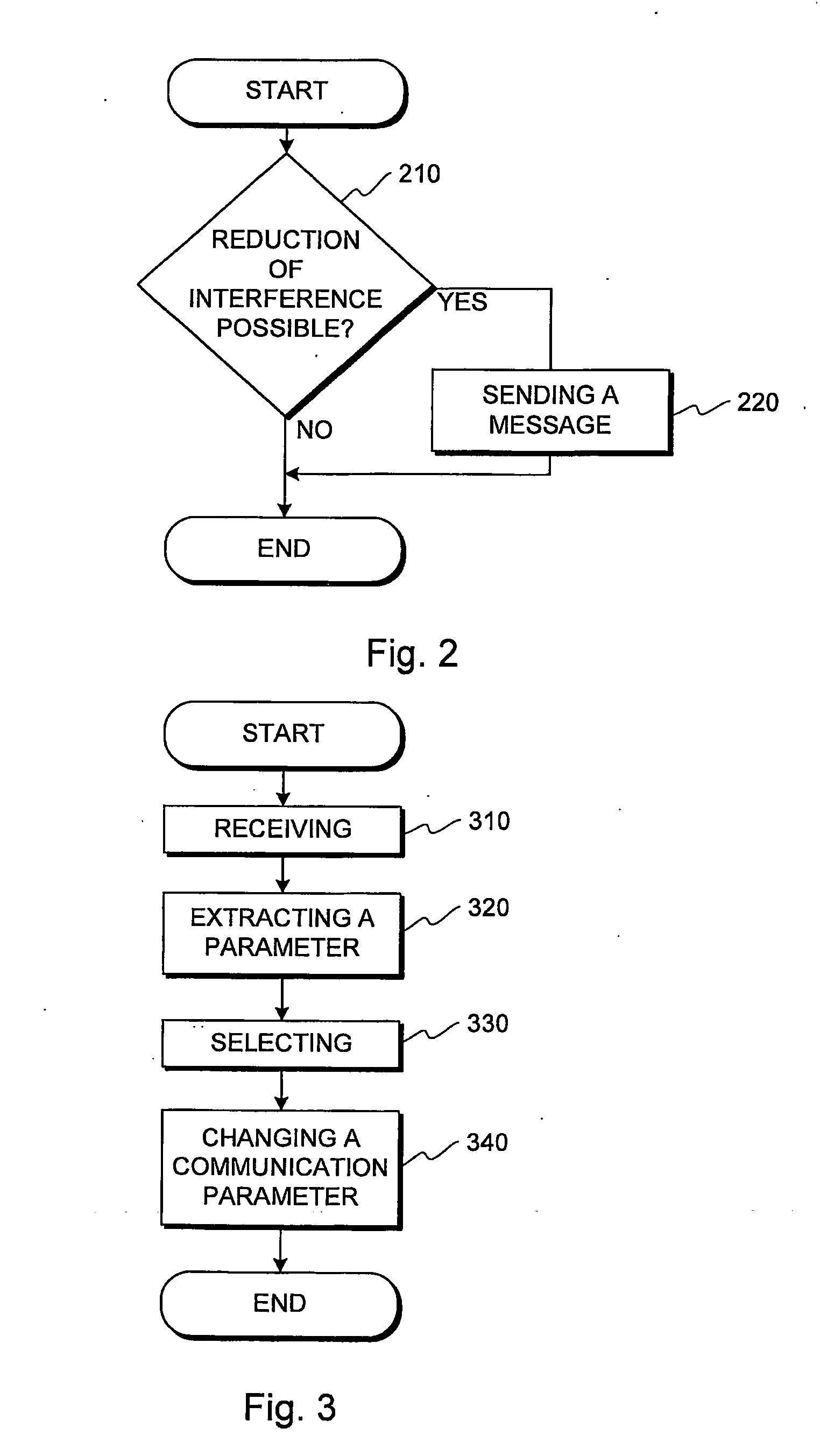

Method for reducing interference

ActiveUS20090252122A1Less interferenceFrequency-division multiplexRadio transmissionWireless communication systemsMobile station

This invention relates to wireless communication systems, specifically to methods for reducing interference. The invention allows a mobile station to determine if certain transmissions of the mobile station cause interference to reception by a second receiver in the mobile station, and indicate to the network that a change in a transmission parameter of the mobile station is desired. The network can then change a transmission parameter to reduce interference observed by the second receiver.

Owner:NOKIA TECHNOLOGLES OY

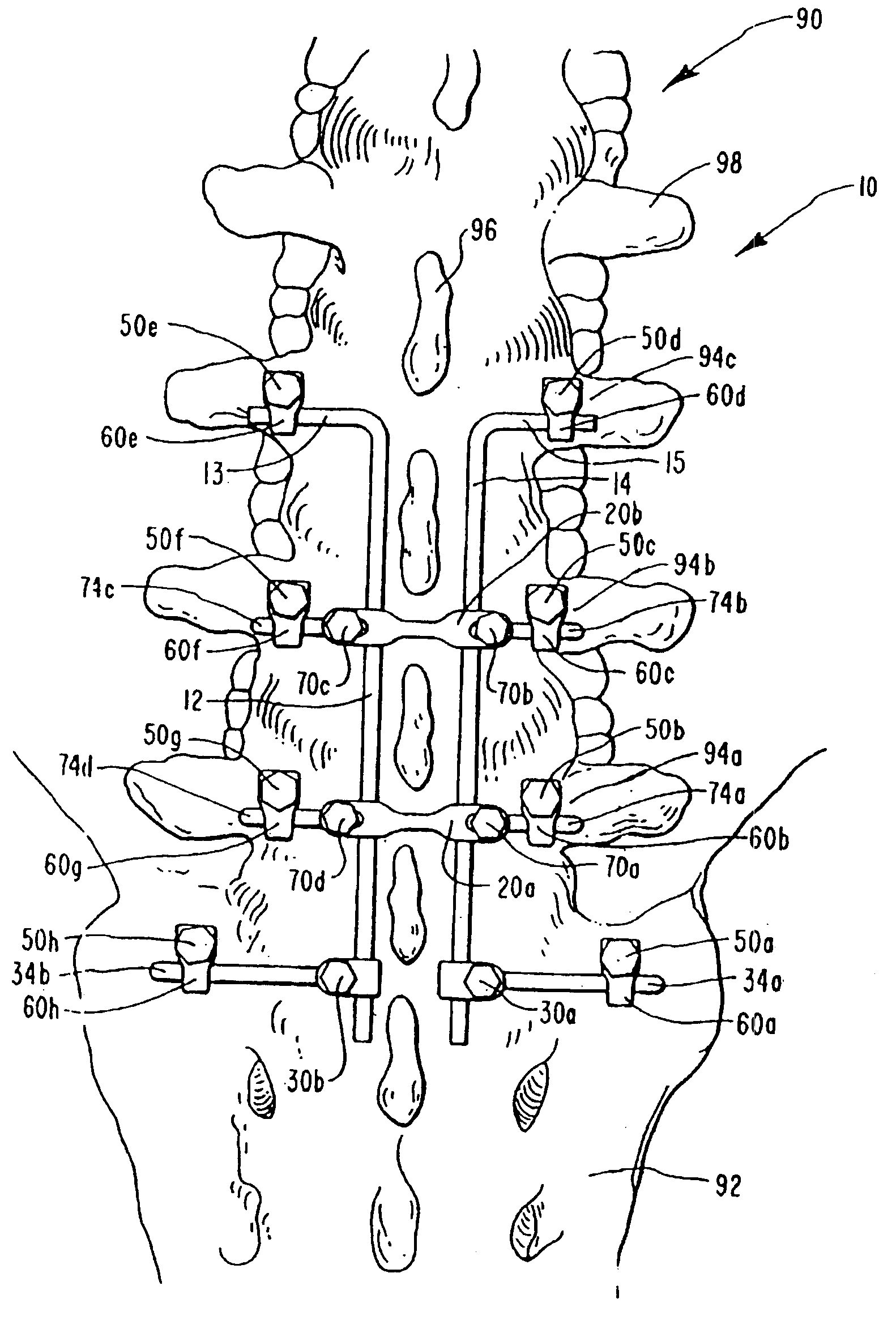

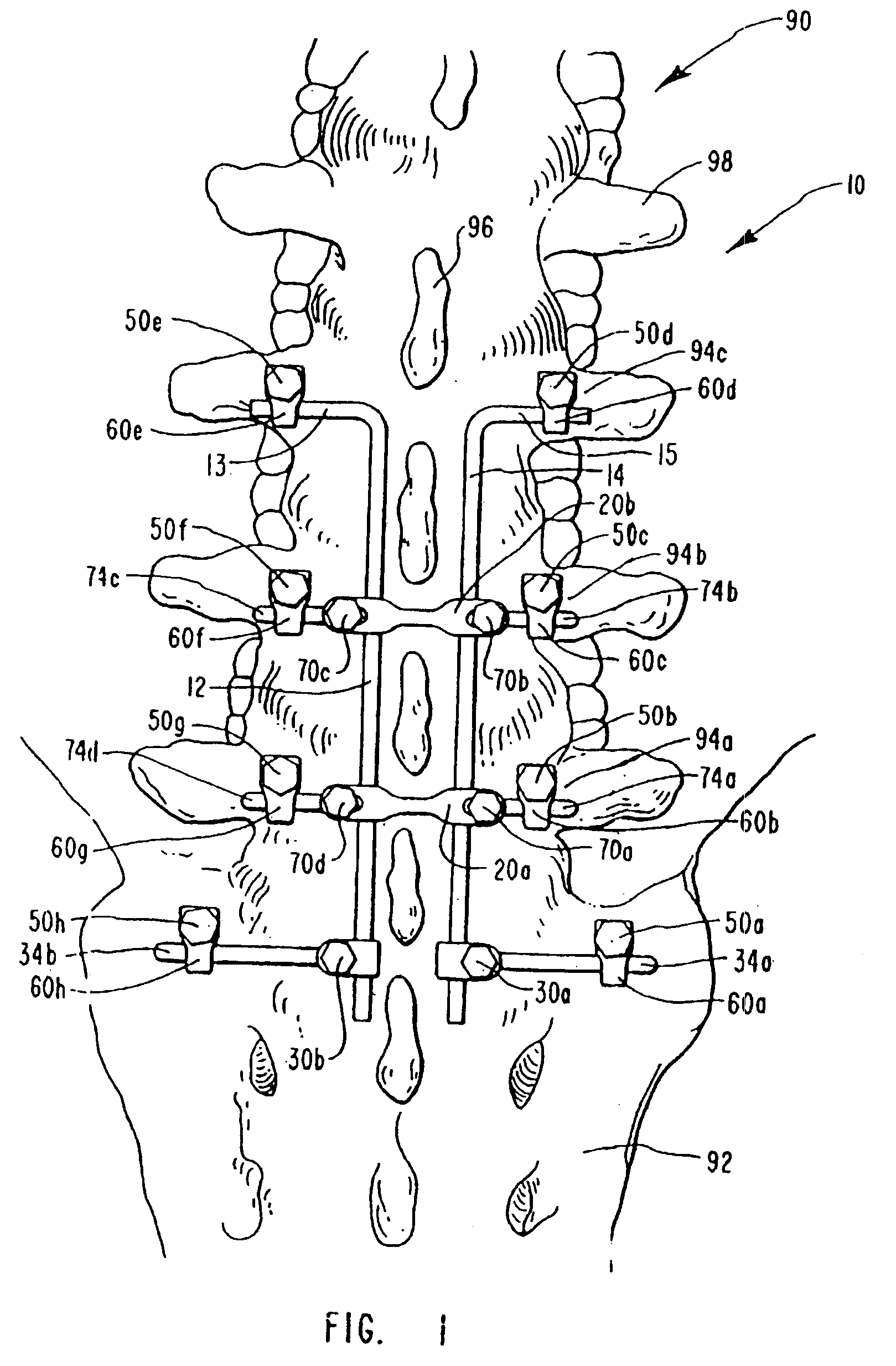

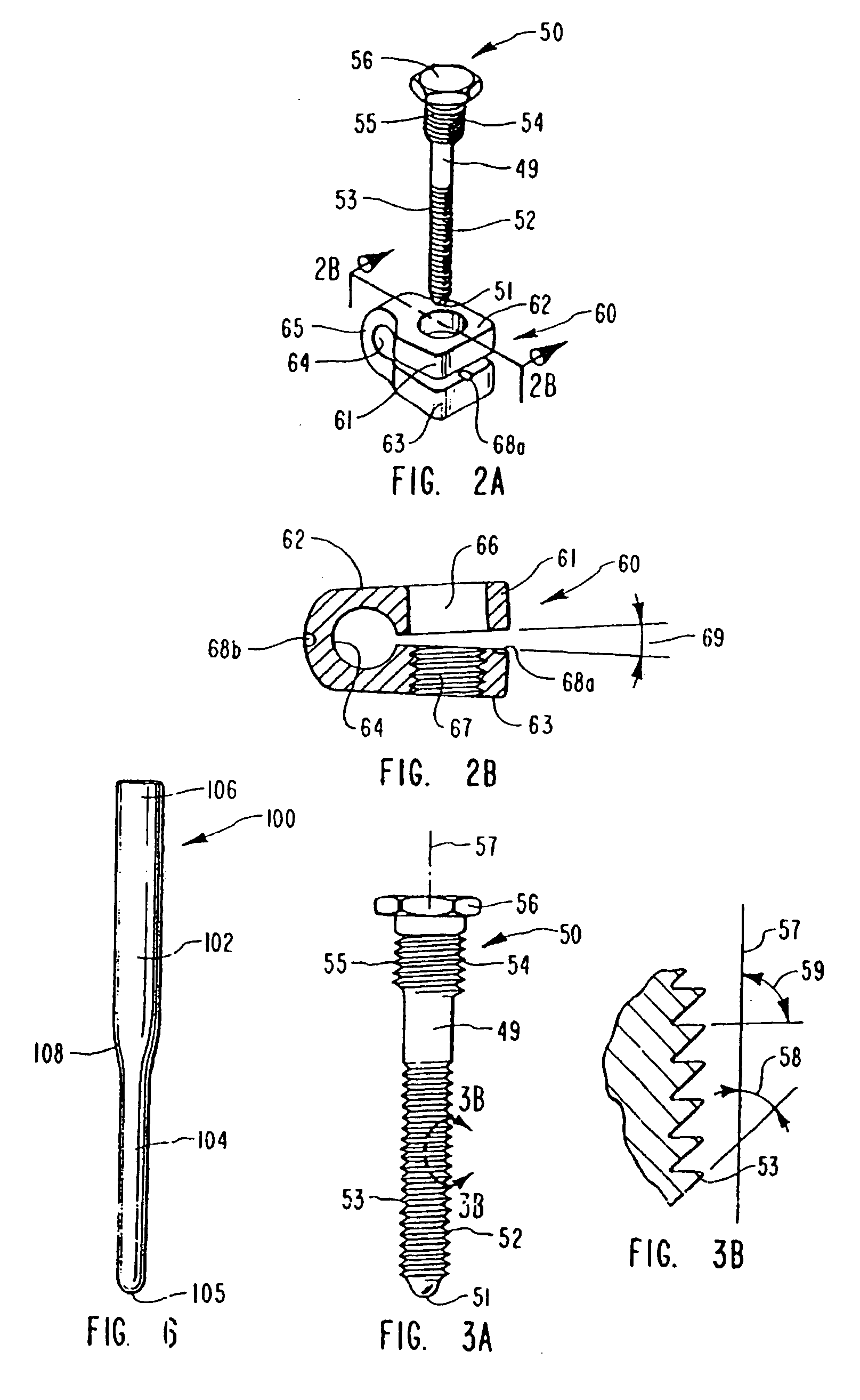

Spinal fixation apparatus and method

InactiveUSRE39325E1Easy to operateGreat gripping strength and ease of implantationInternal osteosythesisJoint implantsScrew threadSpinal implant

A spine fixation apparatus and method including at least one longitudinal rod mounted parallel to the axis of the spine and having a plurality of stem clamps adjustably mounted to the longitudinal rod. Each stem clamp has a stem extending outwardly therefrom with the diameter of the stem being identical to the diameter of the longitudinal rod. A plurality of C-clamps are provided and are mounted to the stems and to the longitudinal rods. A plurality of bone pins are provided and are used to preliminarily mount the spinal fixation construct to the spine to allow the surgeon to determine by X-ray the accuracy of the construct with regard to the spine. A plurality of innovative bone screws are used to simultaneously anchor the C-clamps to the bone and to the respective stem and longitudinal rod. The bone screws are configured with a smaller diameter at the distal end having threads thereon for threadedly engaging the underlying bone. The bone screw includes a threaded shoulder for threadedly engaging the Cclamp to clamp the same to the stems and the longitudinal rod. The thread pitch is identical for both threaded sections of the bone screw. A second longitudinal rod can also be used to create the spinal implant construct and be coupled to the first longitudinal rod through a plurality of cross-link plates.

Owner:BRYAN DONALD W

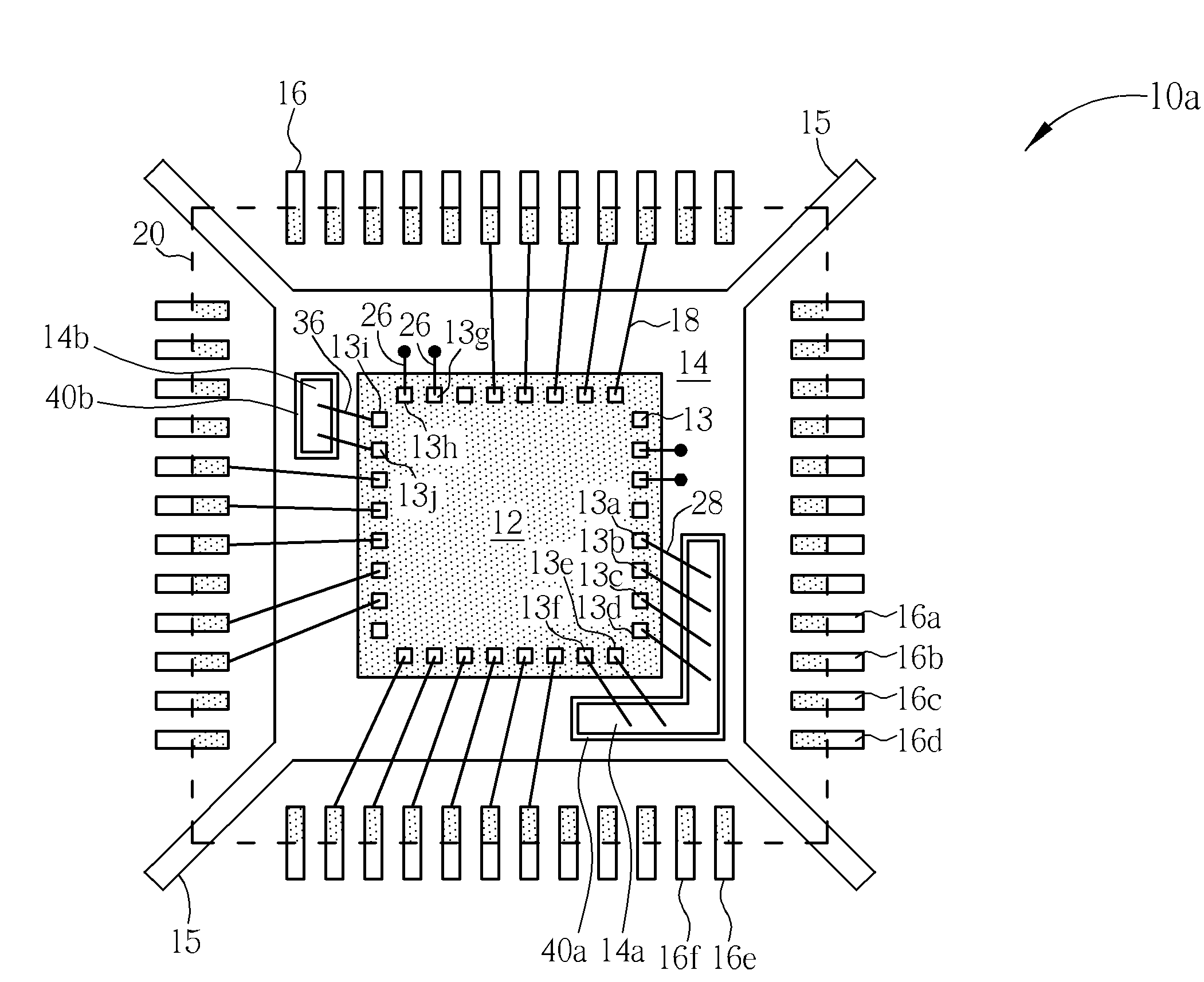

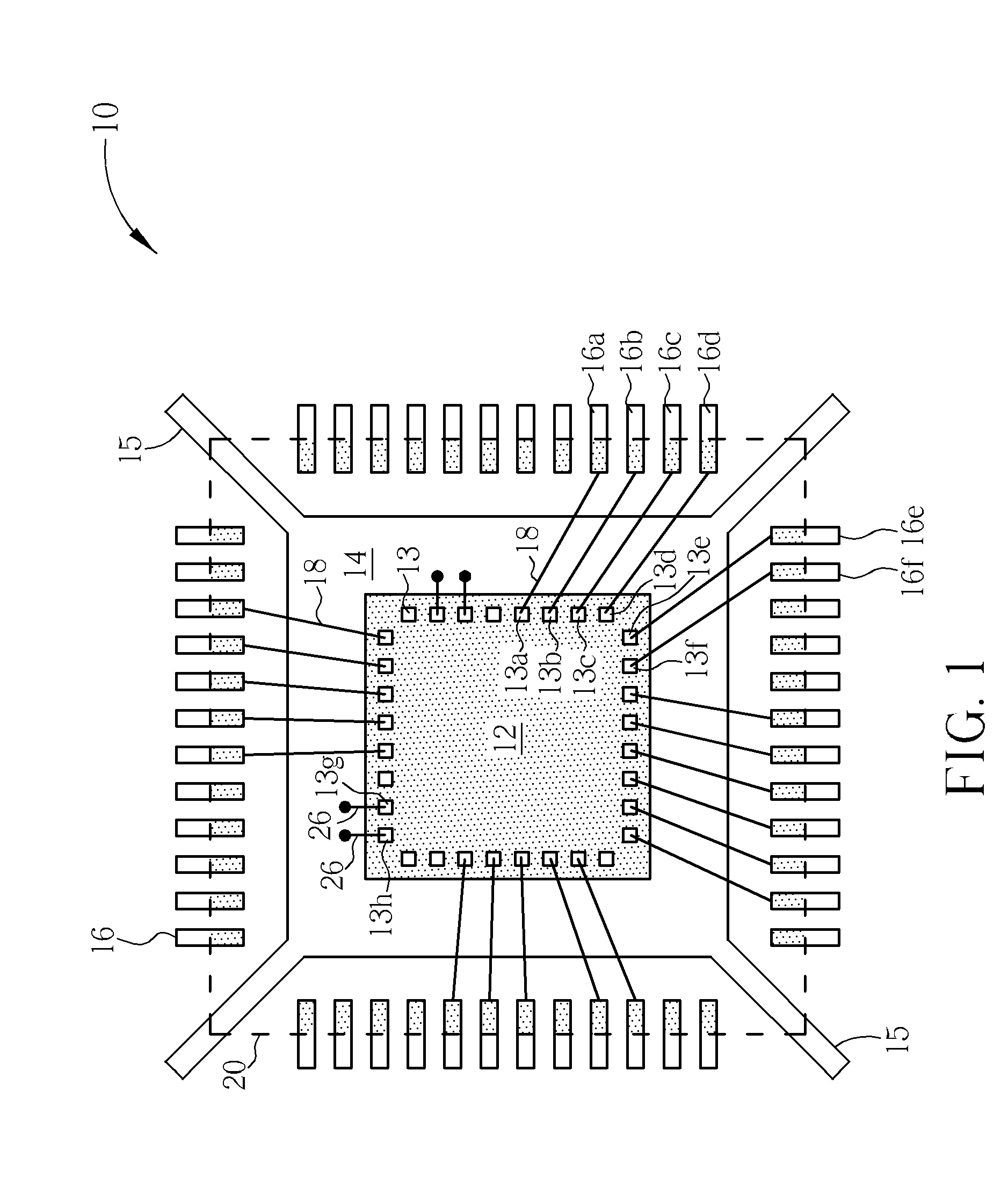

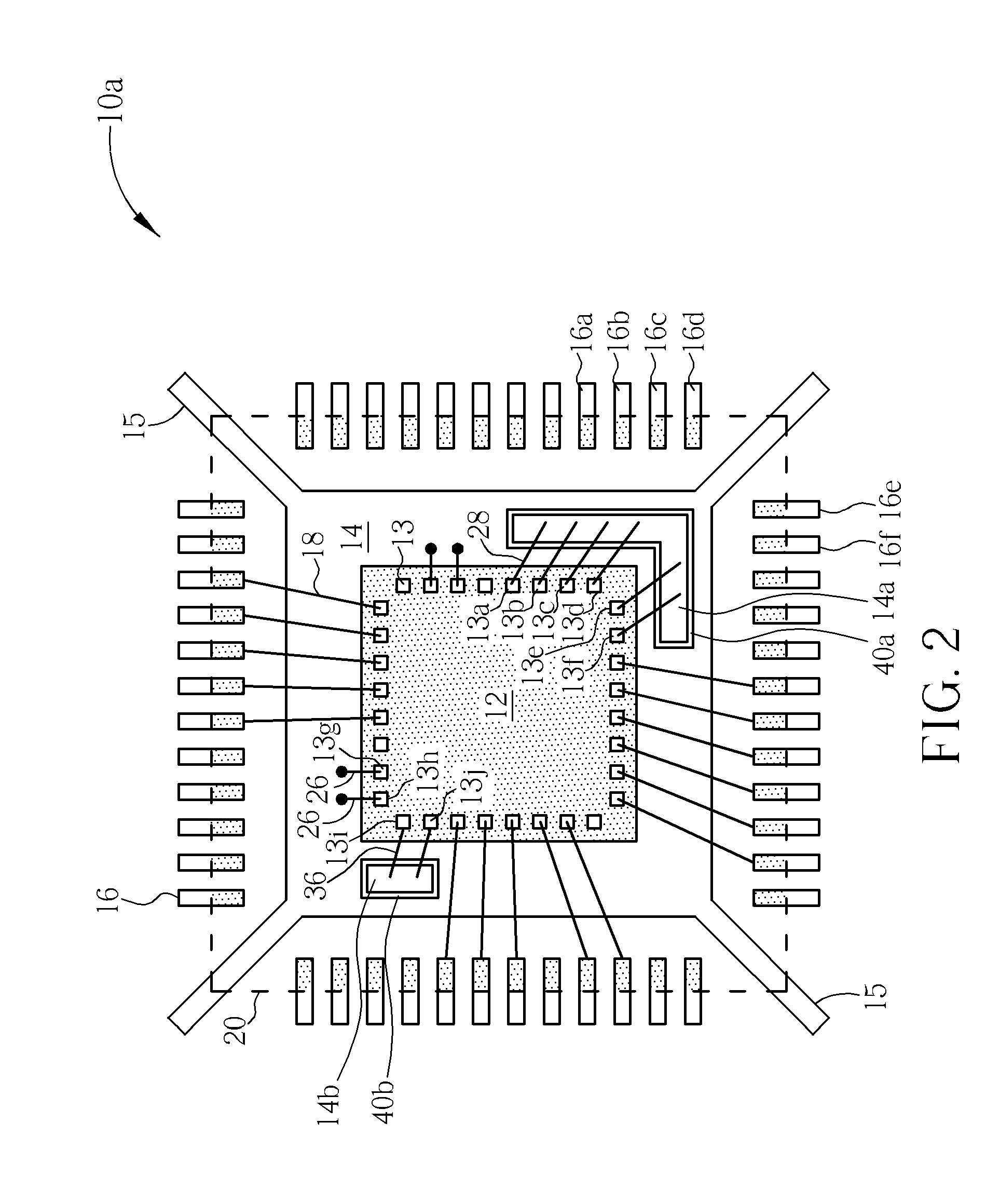

Leadframe package

ActiveUS20080290486A1Less noise interferenceElectronic signal qualitySemiconductor/solid-state device detailsSolid-state devicesLead bondingEngineering

A leadframe package includes a die pad with four unitary, outwardly extending slender bars; a plurality of leads arranged along periphery of the die pad; a separate pad segment separated from the die pad and isolated from the plurality of leads; a semiconductor die mounted on an upper side of the die pad, wherein the semiconductor die contains first bond pads wire-bonded to respective the plurality of leads and a second bond pad wire-bonded to the separate pad segment; and a molding compound encapsulating the semiconductor die, the upper side of the die pad, the first suspended pad segment and inner portions of the plurality of leads.

Owner:MEDIATEK INC

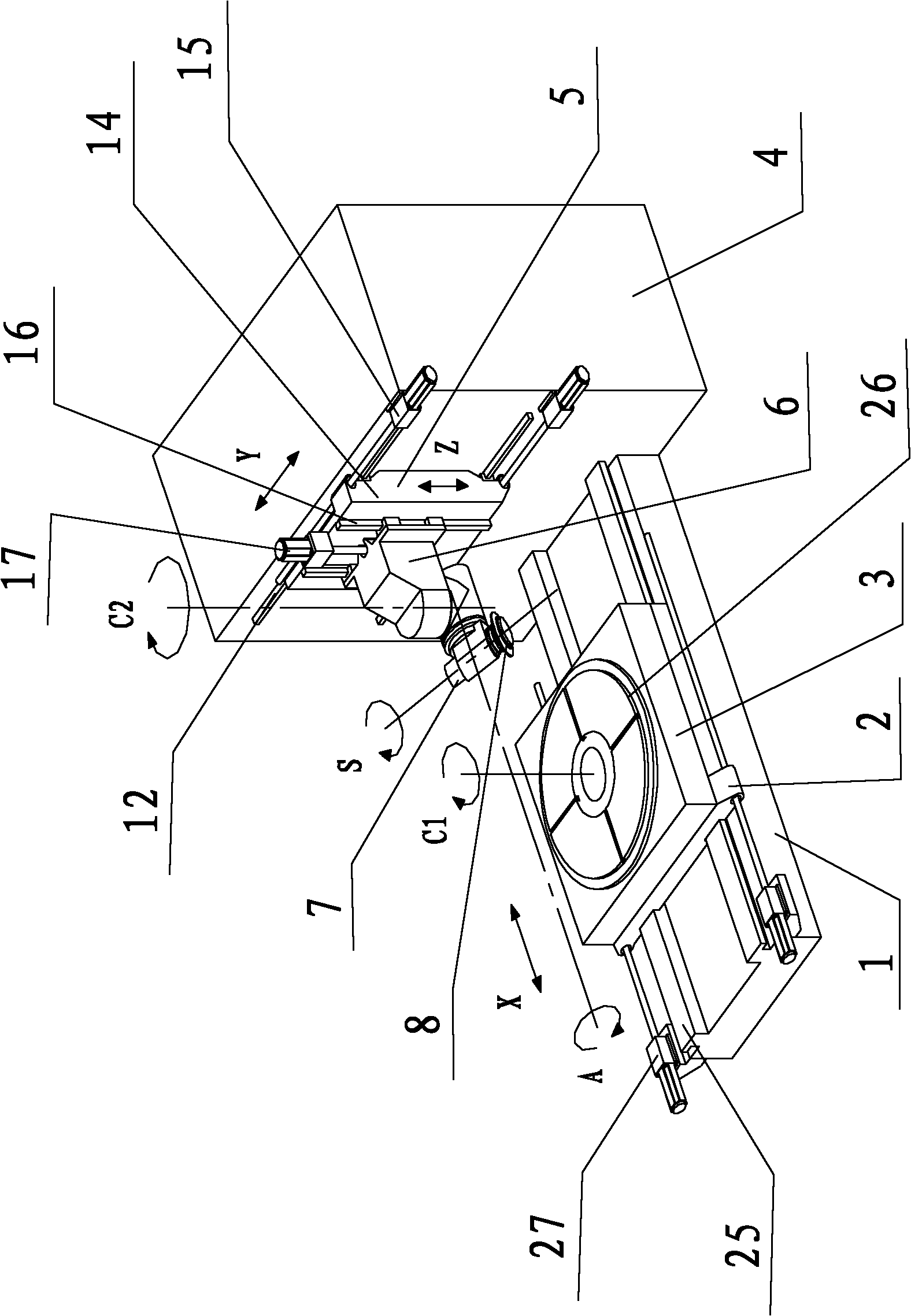

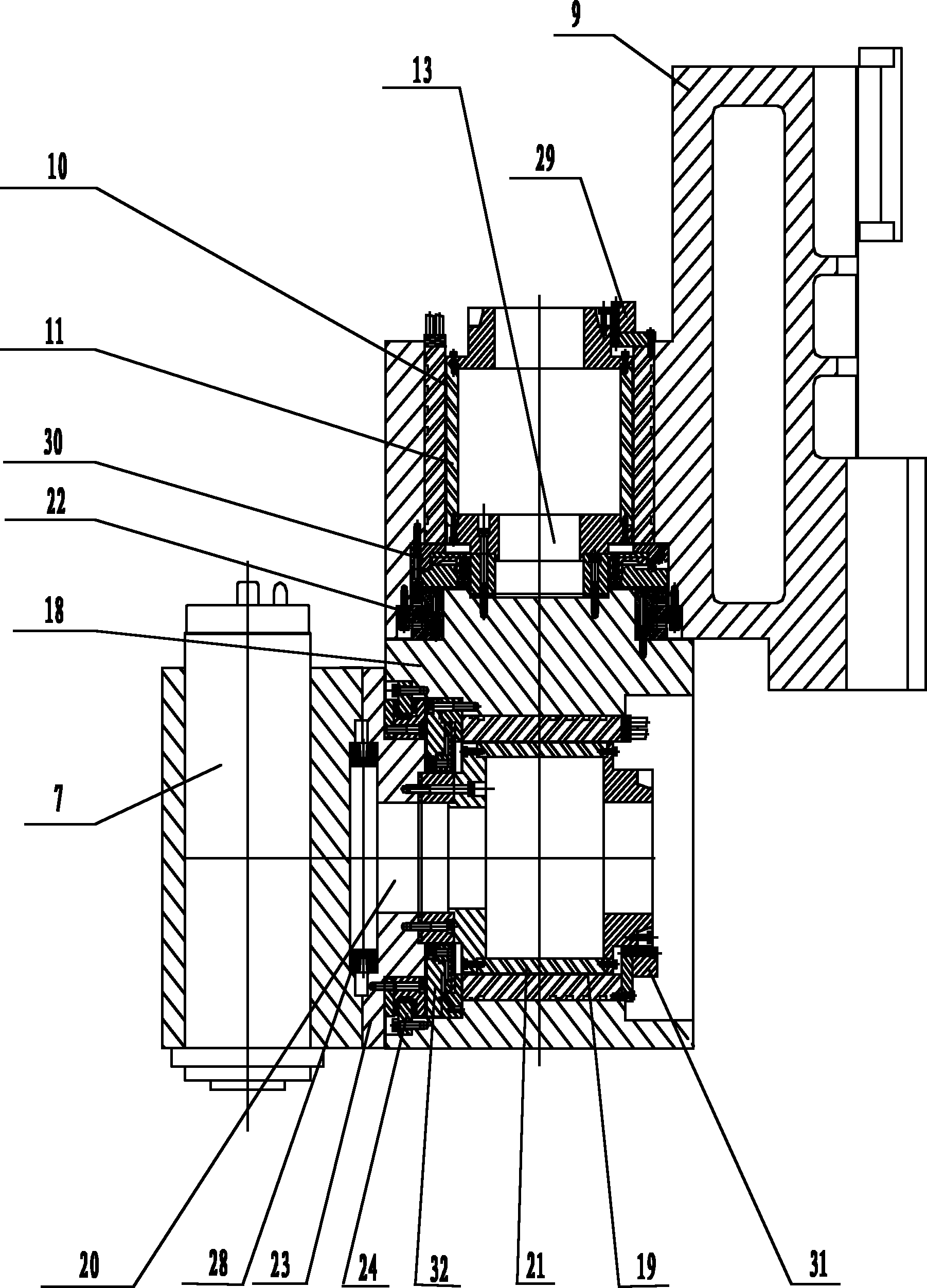

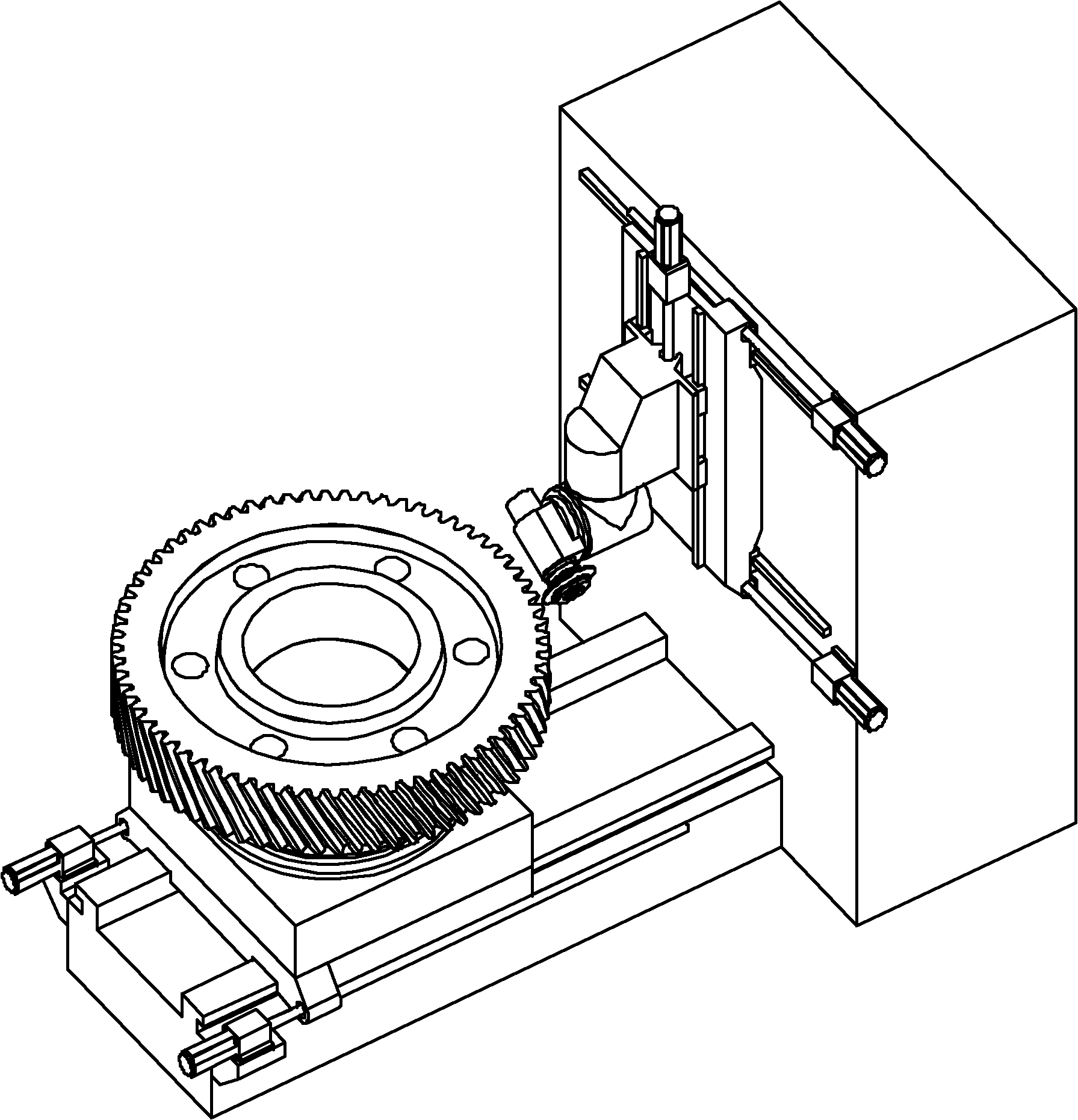

Large-scale numerical control gear machining machine tool

ActiveCN102151909AImprove machining accuracyImprove processing efficiencyLarge fixed membersDriving apparatusLinear motionImpeller

The invention provides a large-scale numerical control gear machining machine tool which has six numerical control coordinate axes, namely X, Y, Z, A, C1 and C2 and adopts a two plus four layout manner. A workpiece has two freedom motion, namely linear motion along the X axis and rotational motion around the C1 axis; and a tool has four freedom motion, namely linear motion along the X axis and the Z axis and rotational motion around the A axis and the C2 axis. The large-scale numerical control gear machining machine tool adopts a six-axis (X, Y, Z, A, CI and C2 axis) five-linkage (X, Y, Z, A and C2 axis linkage) structure; the five numerical control coordinate axes, namely the X, Y, Z, A and C2 axes carry out interpolation motion; and the indexing movement of the workpiece is controlled by the C1 axis to process all tooth surfaces. The rotational axis of the workpiece, namely the C1 axis only finishes the indexing movement and does not participate in the interpolation motion formed bythe tooth surfaces so as to improve the processing precision and the processing efficiency of a large-scale gear. The large-scale numerical control gear machining machine tool can be constructed intoa gear miller or a gear grinder, thereby realizing the curved surface machining of a cylindrical gear, a bevel gear, an impeller and others with the indexing features.

Owner:秦川机床工具集团股份公司

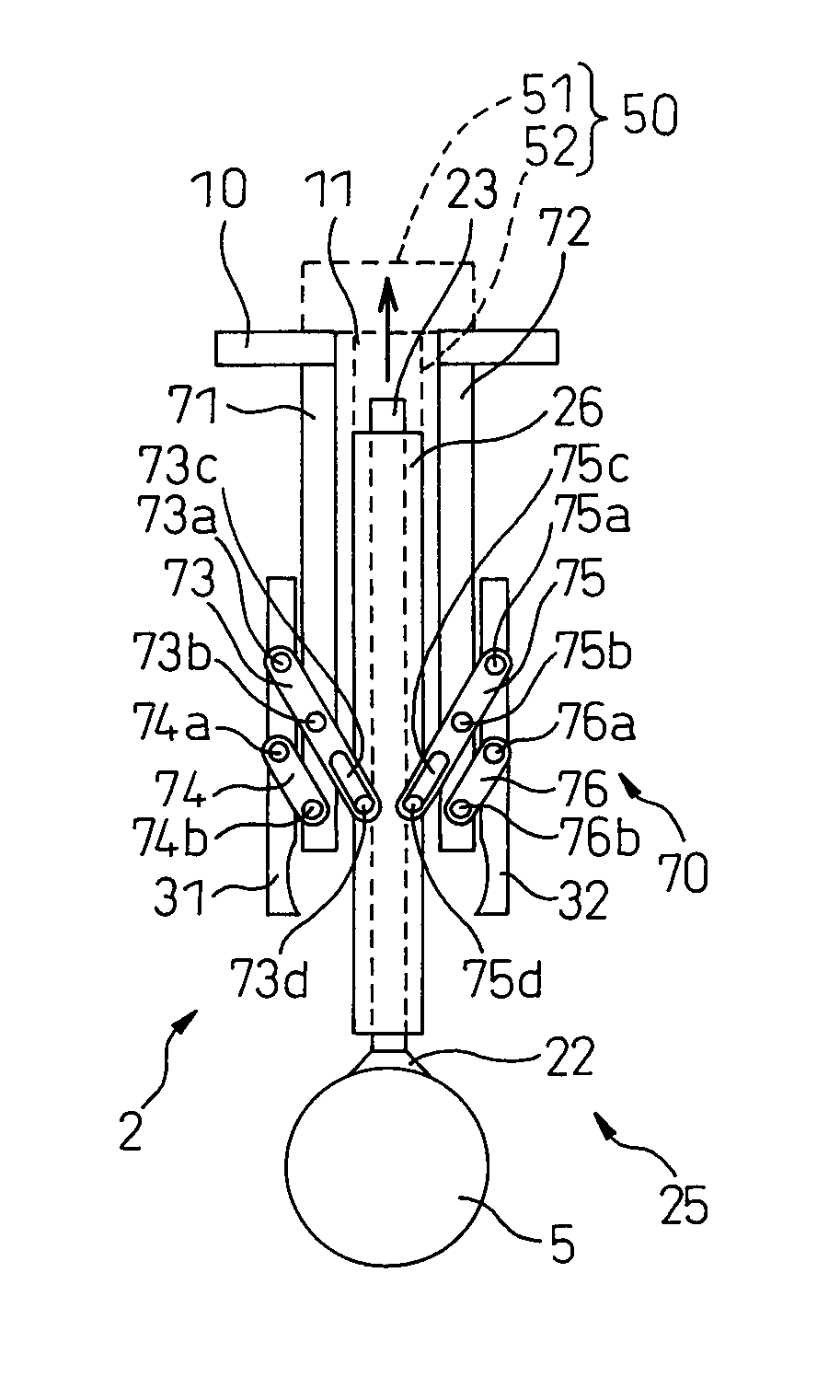

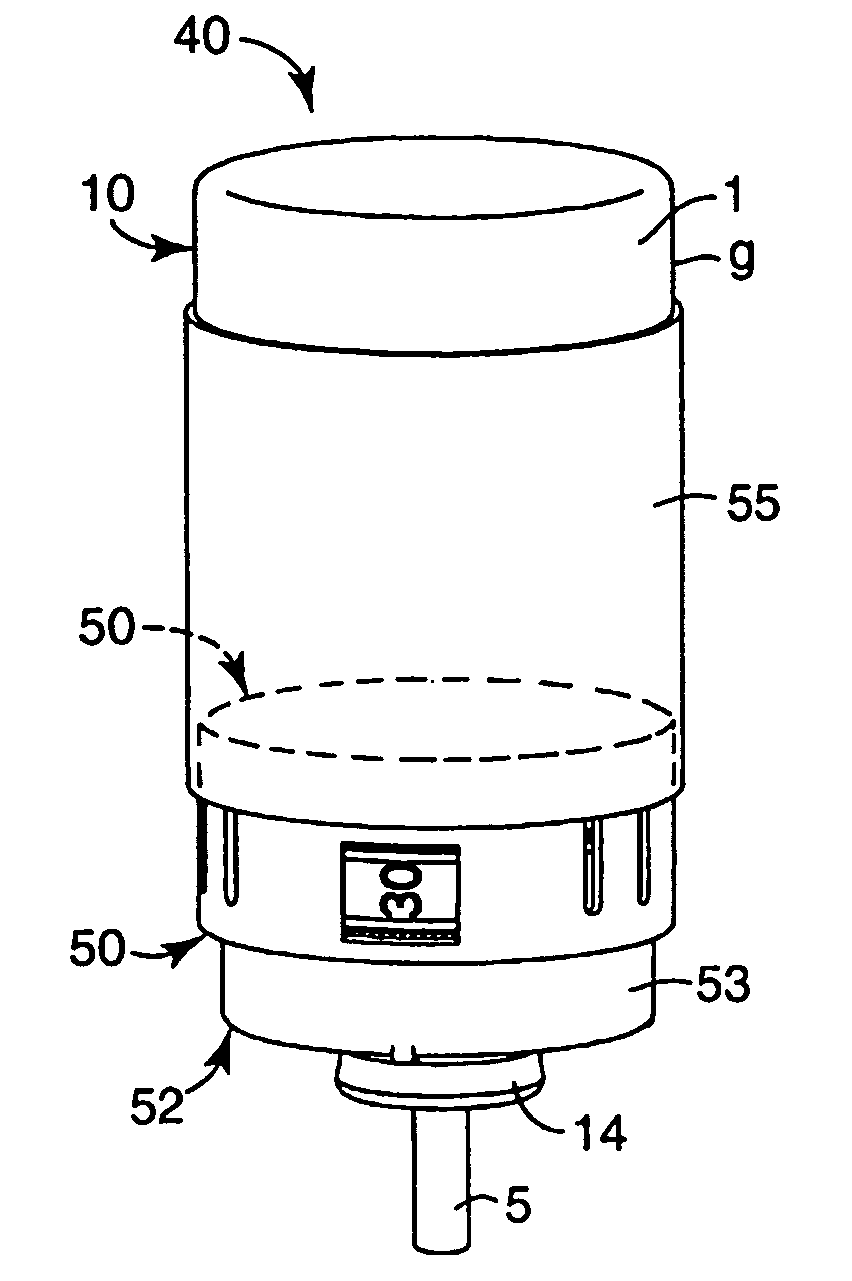

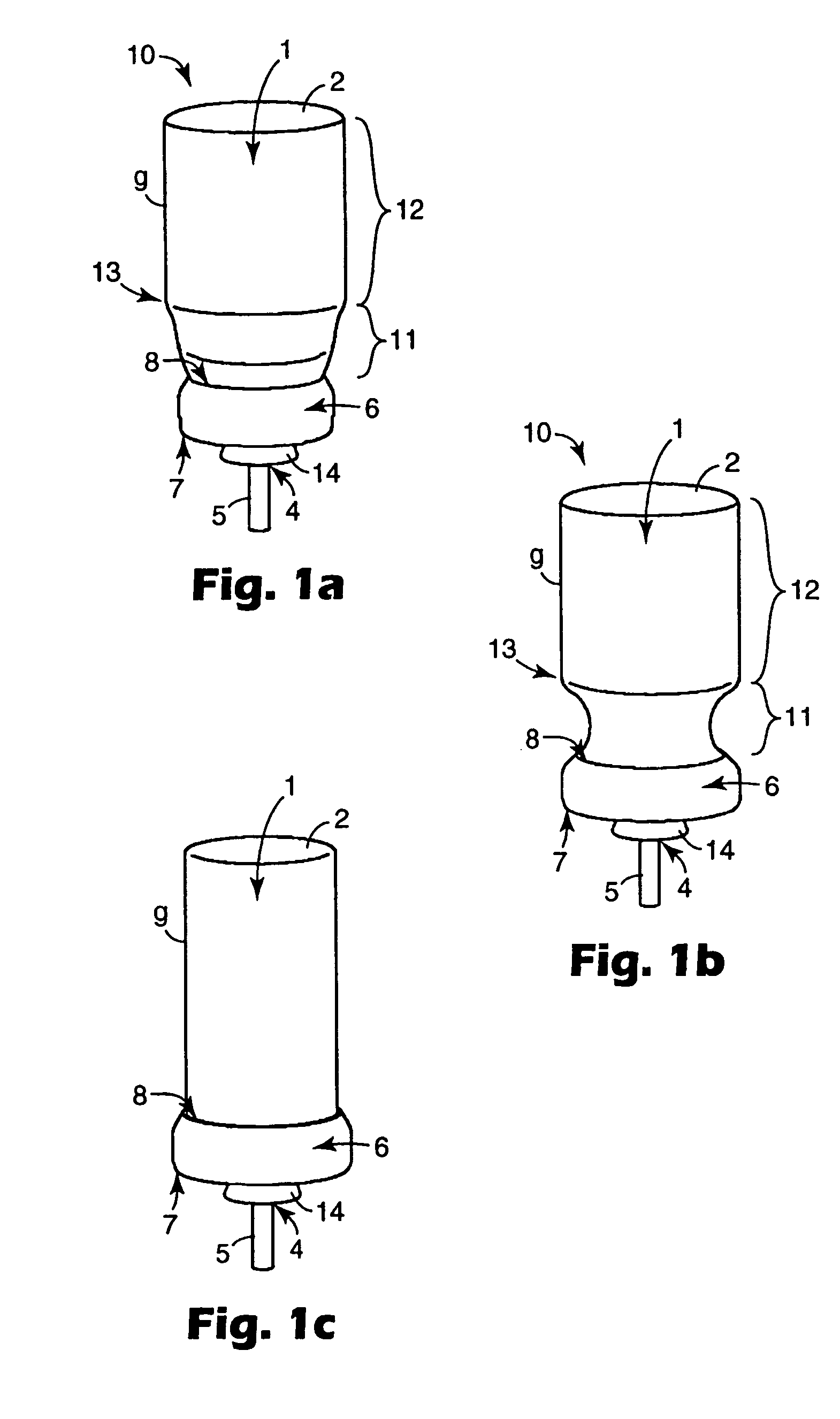

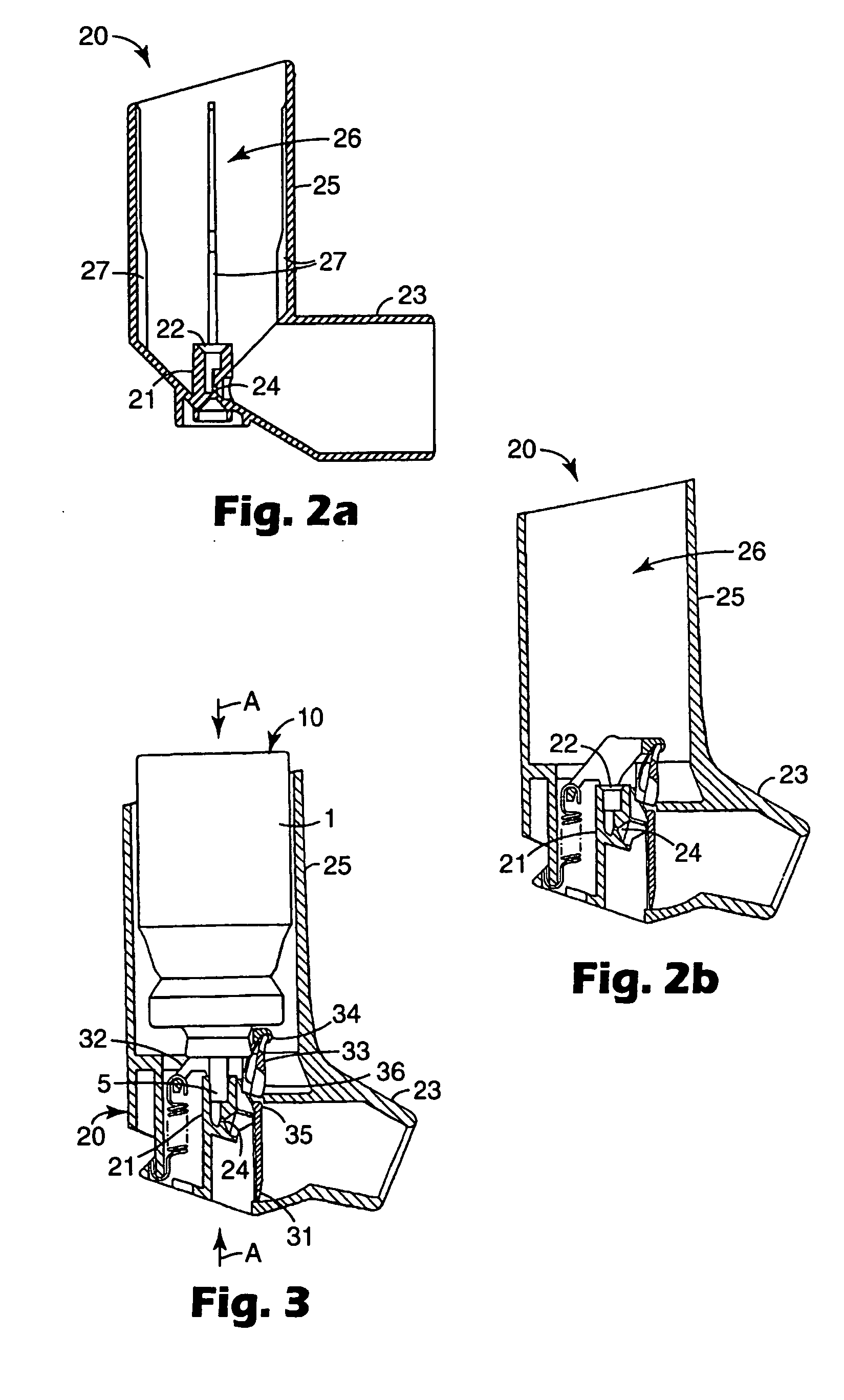

Dose indicators and dispensing canister-indicator assemblies

InactiveUS20050209558A1Easy to installSolve the complicated productionCapsSurgeryReciprocating motionEngineering

An annular dose indicator (50) for use with a dispenser comprising a dispensing canister (10) comprising a substantially cylindrical container (1) having a closed end (2) and an open end (3), said open end of the container being equipped with a dispensing means (4) that comprises an outlet member (5) movable between closed and discharge positions and an adaptor comprising a support block (21) having a socket (22) adapted to receive the outlet member, the container and support block being reciprocally movable relative to each other to cause the outlet member to move to its discharge position thereby dispensing a dose, said annular dose indicator (50) comprising an annular housing (60) having an interior surface (64) defining a substantially circumferential cavity; a counter-ring (80), said counter-ring located in the cavity and being arranged to be moveable relative to the housing by rotation about an axis parallel or substantially parallel to linear reciprocal movement of container and support block; a driving member (90) mounted on the interior surface of the housing, said driving member engaging the counter-ring and being arranged to be selectively engaged during reciprocal movement of container and support block as to drive an incremental, rotational movement of the counter-ring; wherein said indicator (50) is arranged to be circumferentially mountable about the dispensing-canister (10), such that the first edge (51) of the indicator faces towards the closed end of the container, the second edge (52) of the indicator faces towards the outlet of the dispensing canister, so that at least the outlet member of the canister will extend beyond the second edge of the indicator.

Owner:3M INNOVATIVE PROPERTIES CO

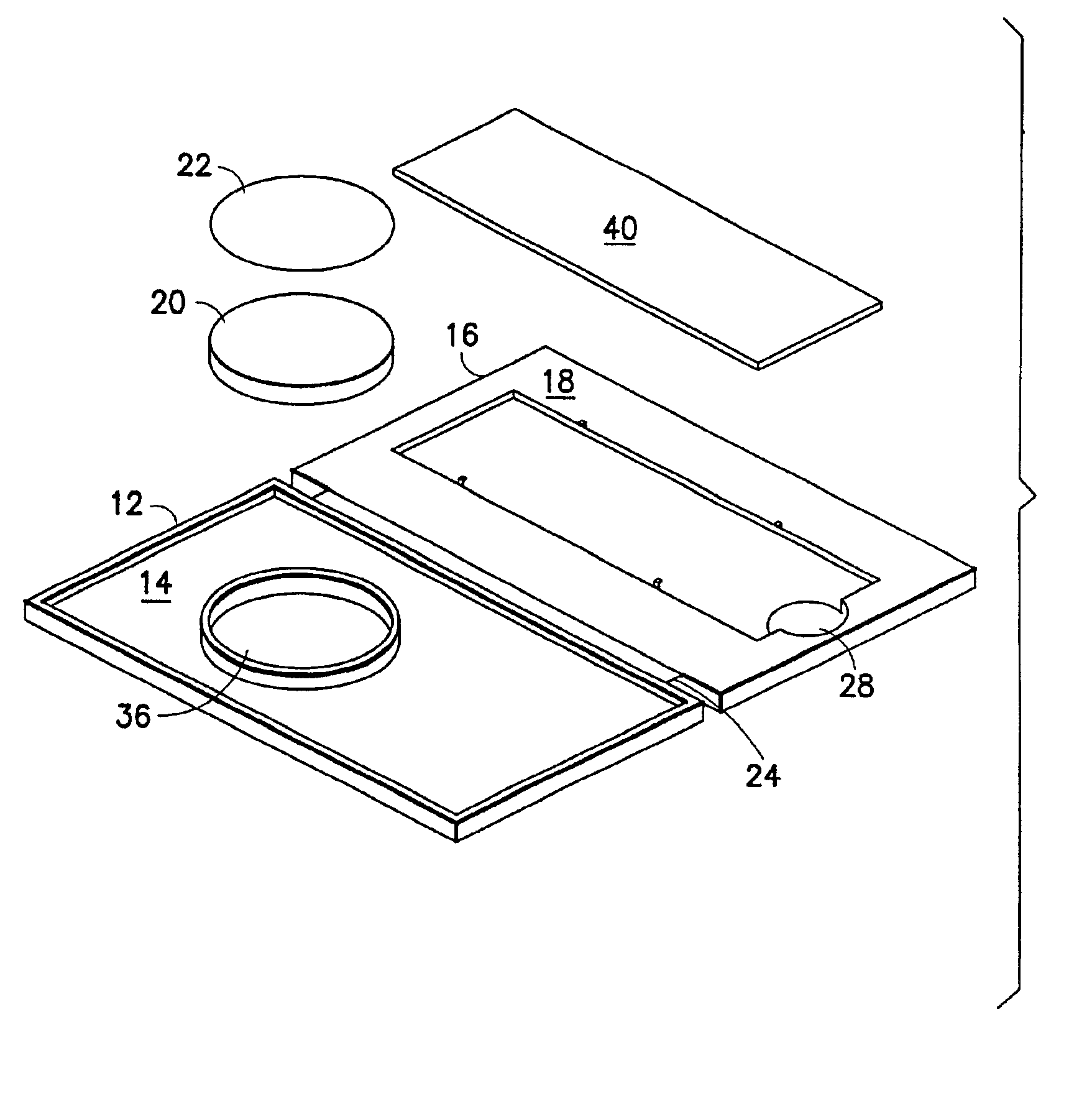

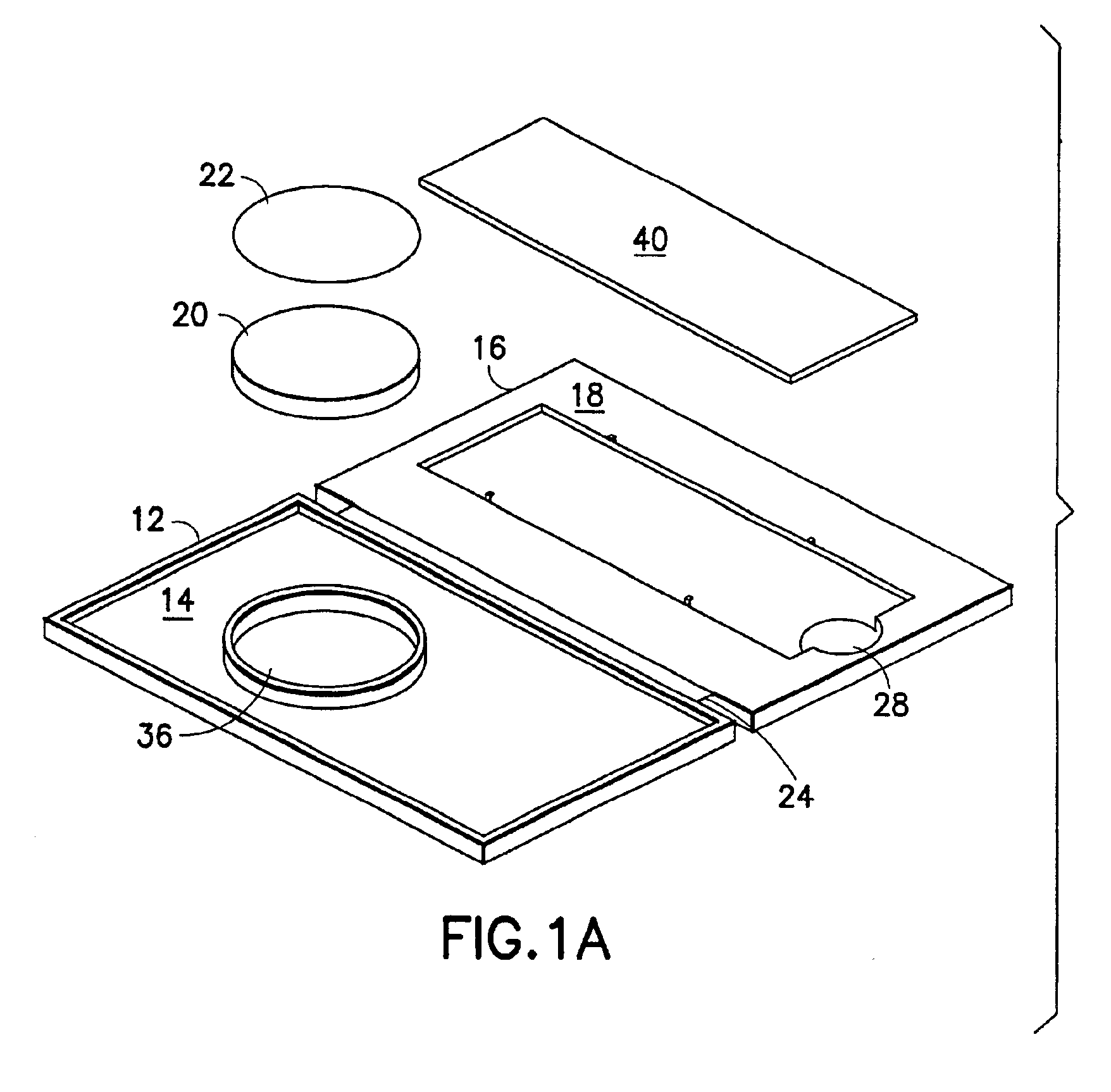

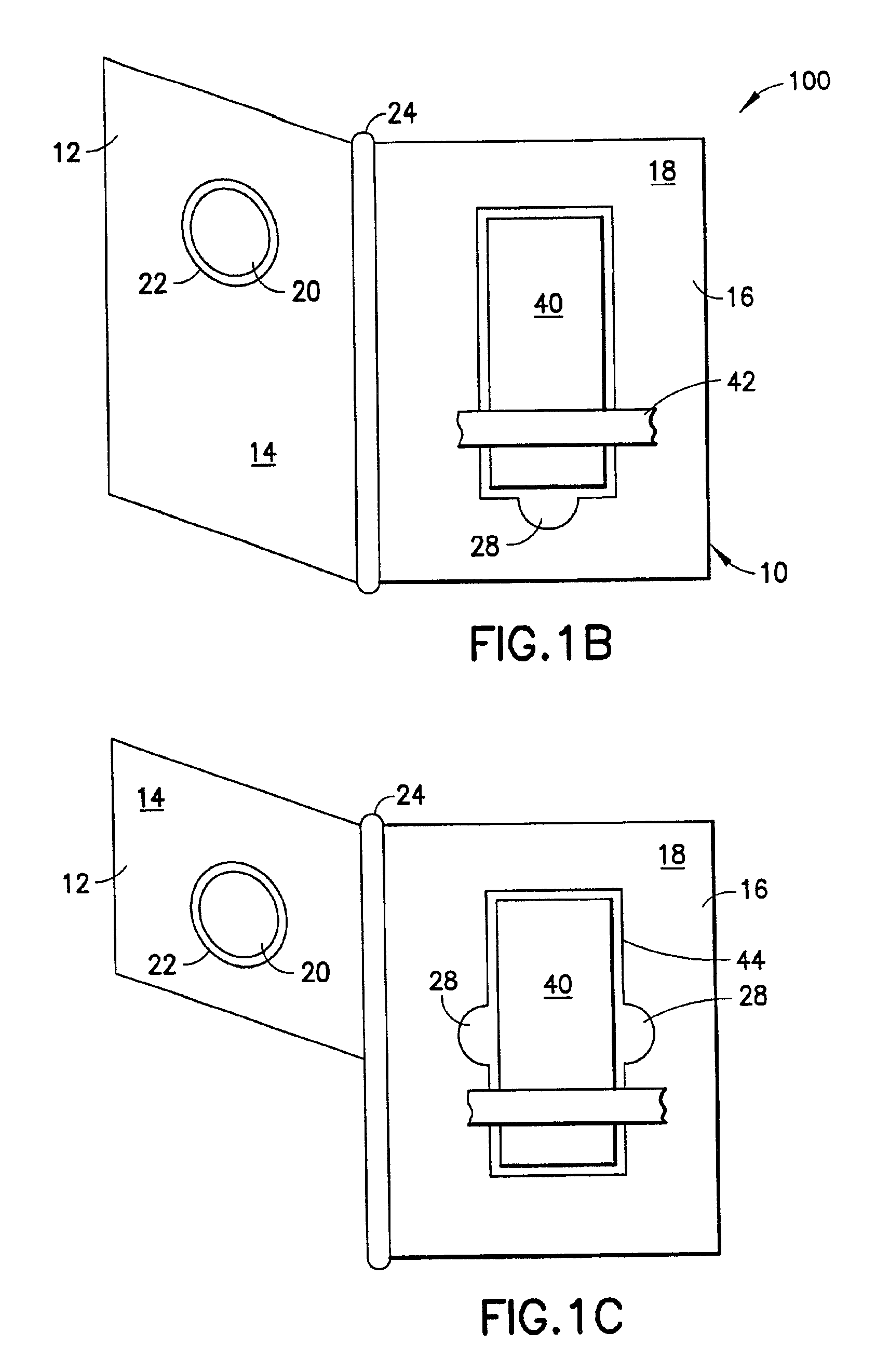

Device and method for cytology slide preparation

InactiveUS6890729B2Efficient transferPrepared quickly and reliablyBioreactor/fermenter combinationsBiological substance pretreatmentsCytologyAbsorbent material

This invention provides a novel device and method for preparing cytology slides. The device comprises a book-like form including an absorbent material and filter attached to the inside surface of a front cover and a cytology slide removeably attached to an inside surface of a back cover. A sample is removed from the body of a patient, placed in a liquid-based solution, and then on the filter. When the book-like form is closed, the sample is effectively transferred to the slide.

Owner:ABBOTT MOLECULAR INC

Support Network

InactiveUS20070100585A1Less interferenceFew connectionsDetecting faulty hardware by remote testNuclear monitoringReal-time computing

Owner:NEXTNINE

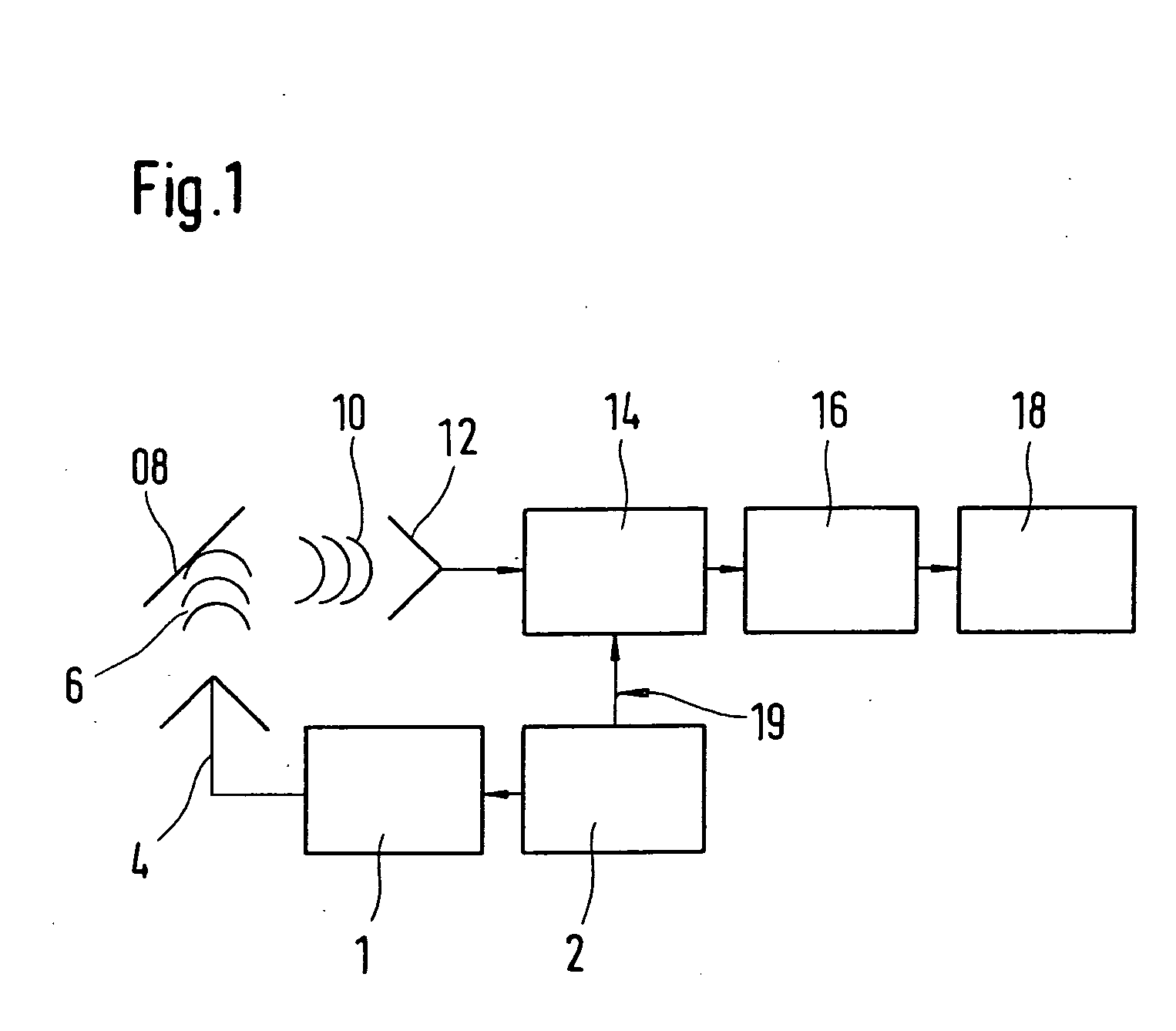

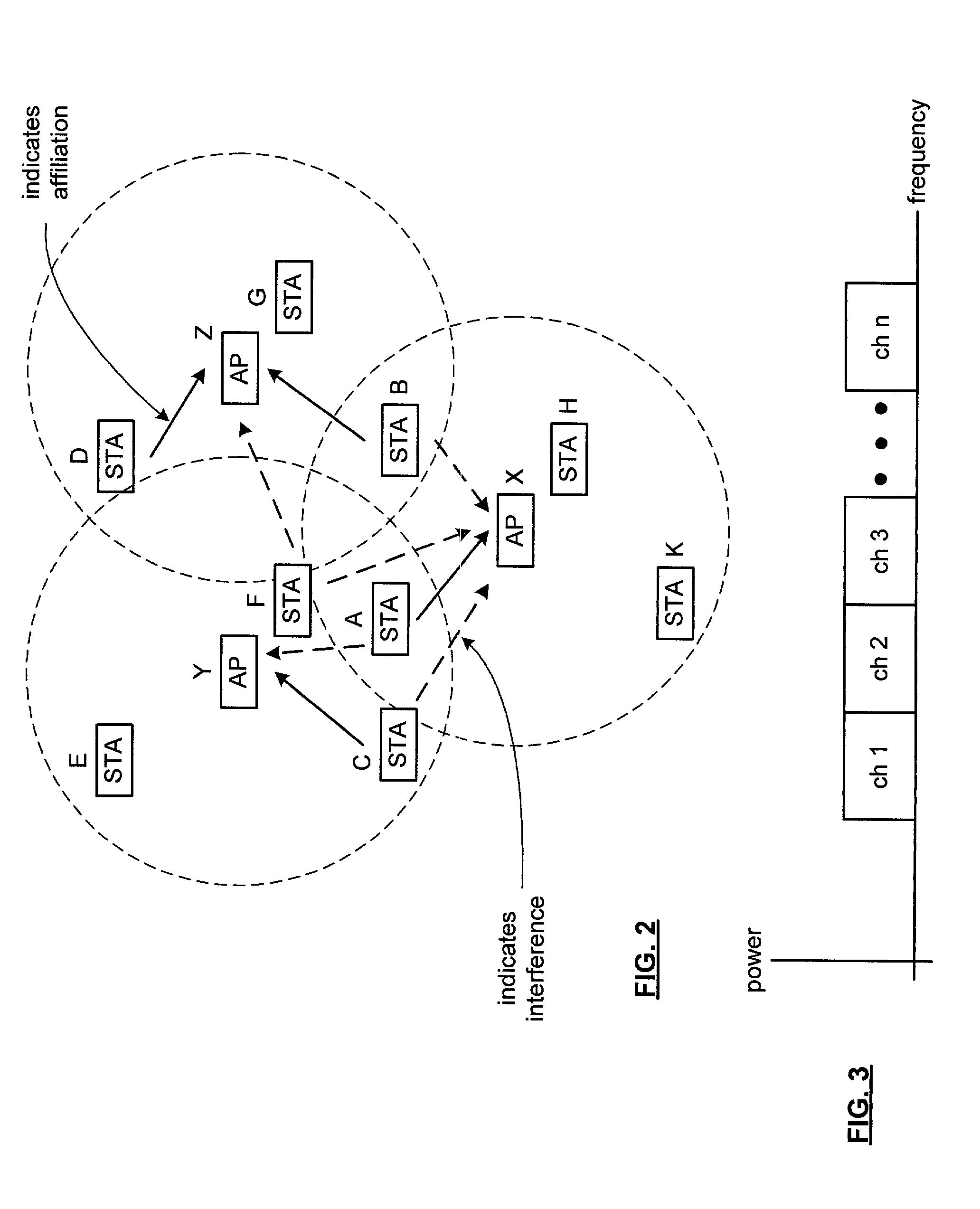

Dynamic frequency selection in a wireless communication network

InactiveUS7158759B2Quality improvementLess interferenceRadio/inductive link selection arrangementsTransmission monitoringChannel state informationFrequency spectrum

A method and apparatus for dynamic frequency selection in a wireless communication system or network includes processing that begins when an access point determines interference on a wireless channel that is being used by the access point. When the interference exceeds an interference threshold, the access point provides a request packet to affiliated stations being serviced by the access point for channel spectrum information. The processing continues as the affiliated stations generate the channel spectrum information regarding each of the wireless channels in the wireless communication network. The processing proceeds then as the affiliated stations provide the channel spectrum information to the access point via the current wireless channel. The access point interprets the channel spectrum information to determine a desired wireless channel of the plurality of wireless channels within the wireless communication network. The access point then provides a selection packet to the affiliated stations via the current wireless channel to indicate that the access point will begin using the desired wireless channel at a particular future time.

Owner:AVAGO TECH INT SALES PTE LTD

Human powered and electricity balanced personal vehicle

The present invention discloses a human powered and electricity balanced personal vehicle, which comprises: a main body for bearing a driver; a set of powered wheels being two coaxial wheels; a manpower inputting device being provided for the driver to input manpower into the personal vehicle; an electricity converting device for converting electricity to power and inputting the power into the personal vehicle; a transmission device for receiving the manpower inputted by the manpower inputting device and the power inputted by the electricity converting device, and inputting mixed power of the manpower and power into the powered wheels; an operation device being provided for the driver to control the moving state of the personal vehicle; a plurality of vehicle movement detecting devices for detecting the moving state of the personal vehicle and the operating condition of the driver; and a control unit for receiving and analyzing the signals of the plurality of vehicle movement detecting devices and controlling the electrical output of the electricity converting device.

Owner:NATIONAL TSING HUA UNIVERSITY

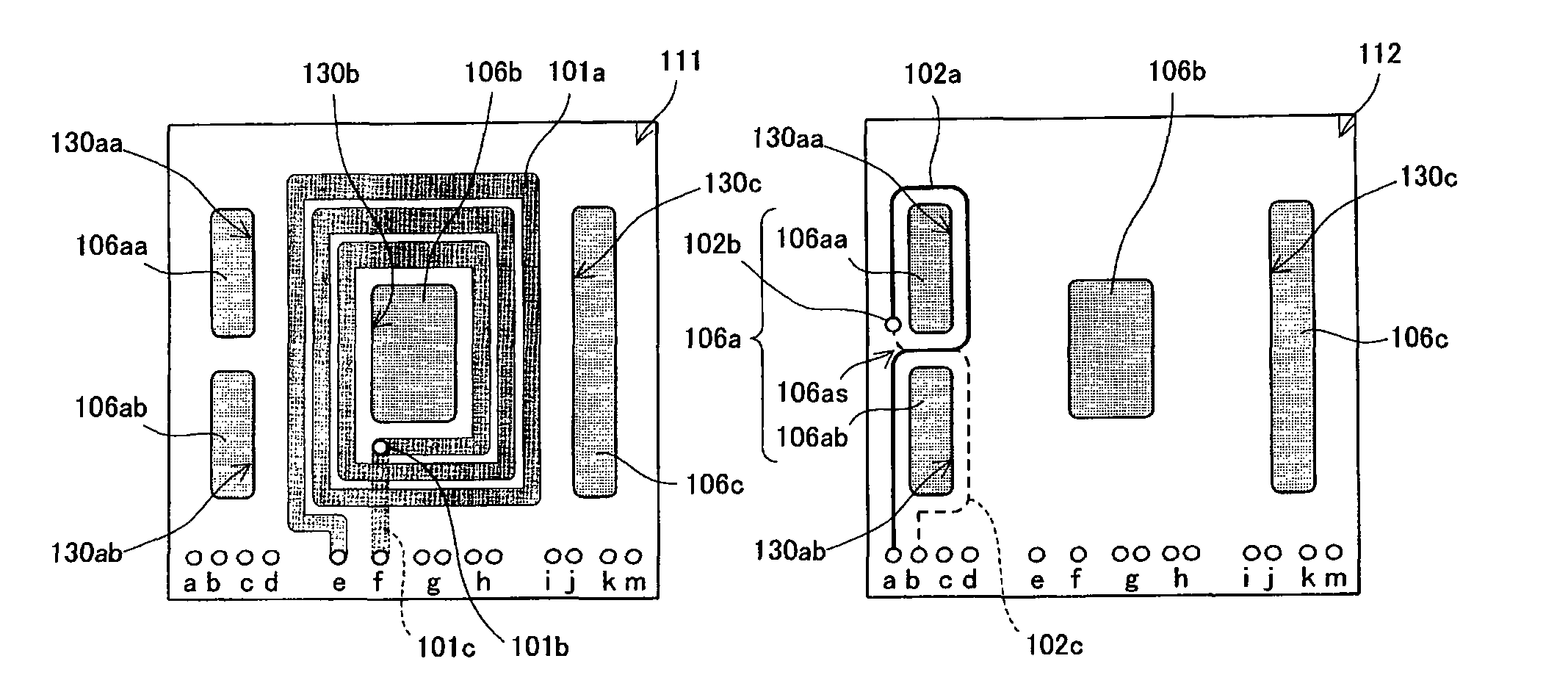

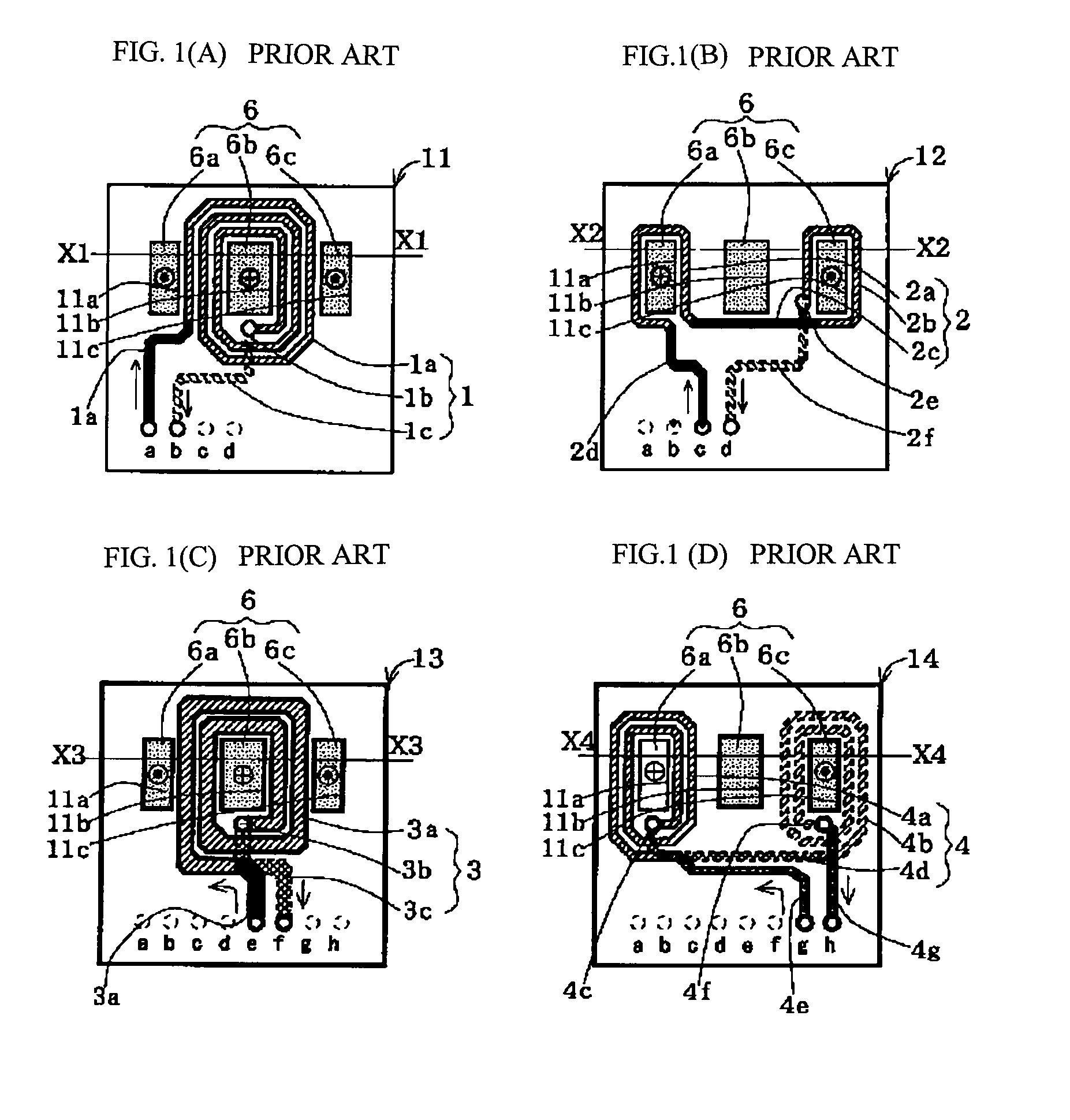

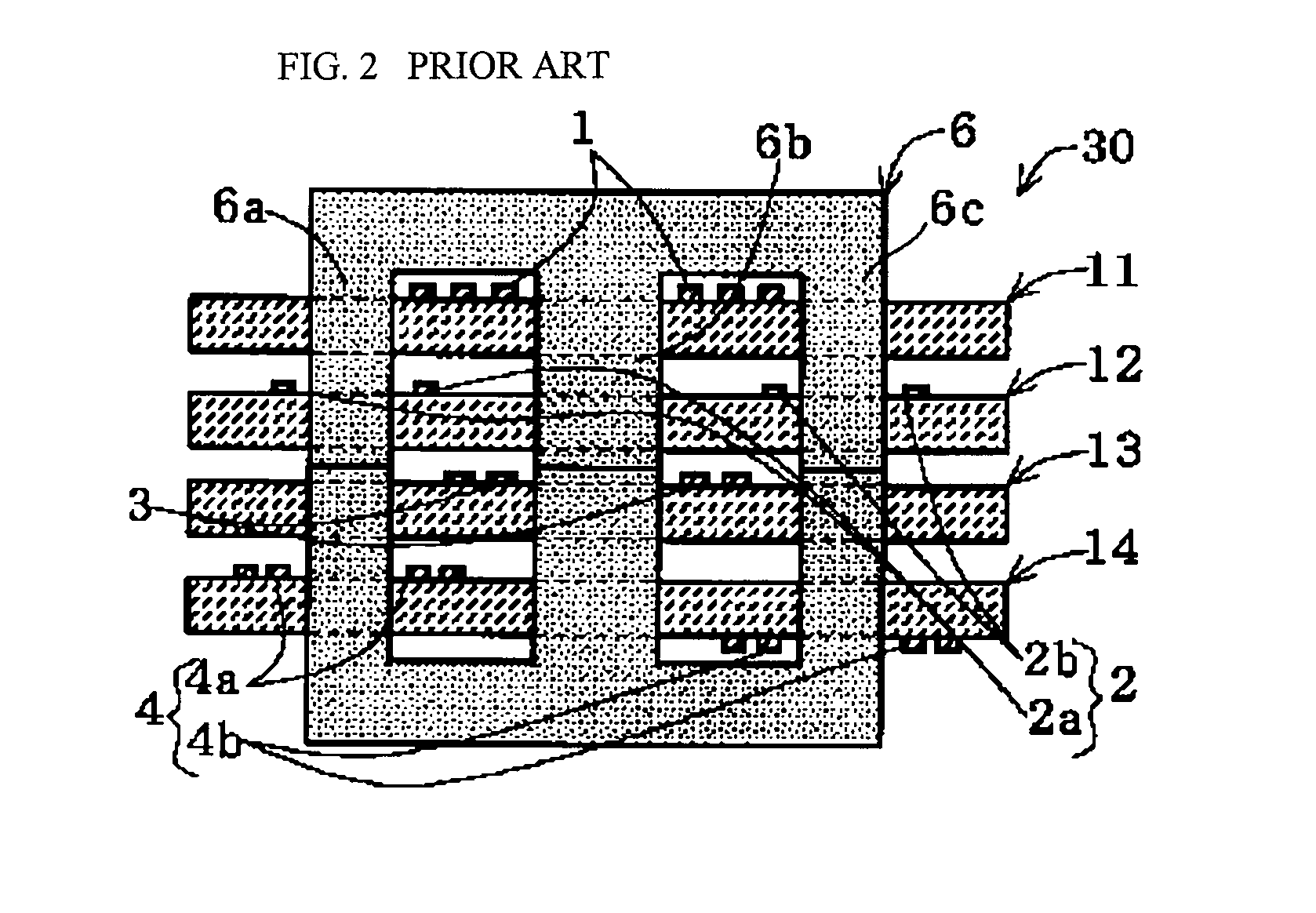

Composite transformer and insulated switching power source device

ActiveUS7872561B2Less interferenceReduce the valueEfficient power electronics conversionTransformers/inductances coils/windings/connectionsTransformerEngineering

An E-shaped transformer core has a middle leg and one pair of outer legs and on opposite sides with respect to the middle leg. A first pair of coils including at least two coils are wound around the middle leg so that a power transmission transformer unit is formed. The outer leg is divided into two outer leg portions and with a space therebetween allowing coil wiring therebetween, and a second pair of coils including two coils are respectively wound around the respective two outer leg portions and so as to have mutually opposite winding directions, so that a signal transmission transformer unit is formed.

Owner:MURATA MFG CO LTD

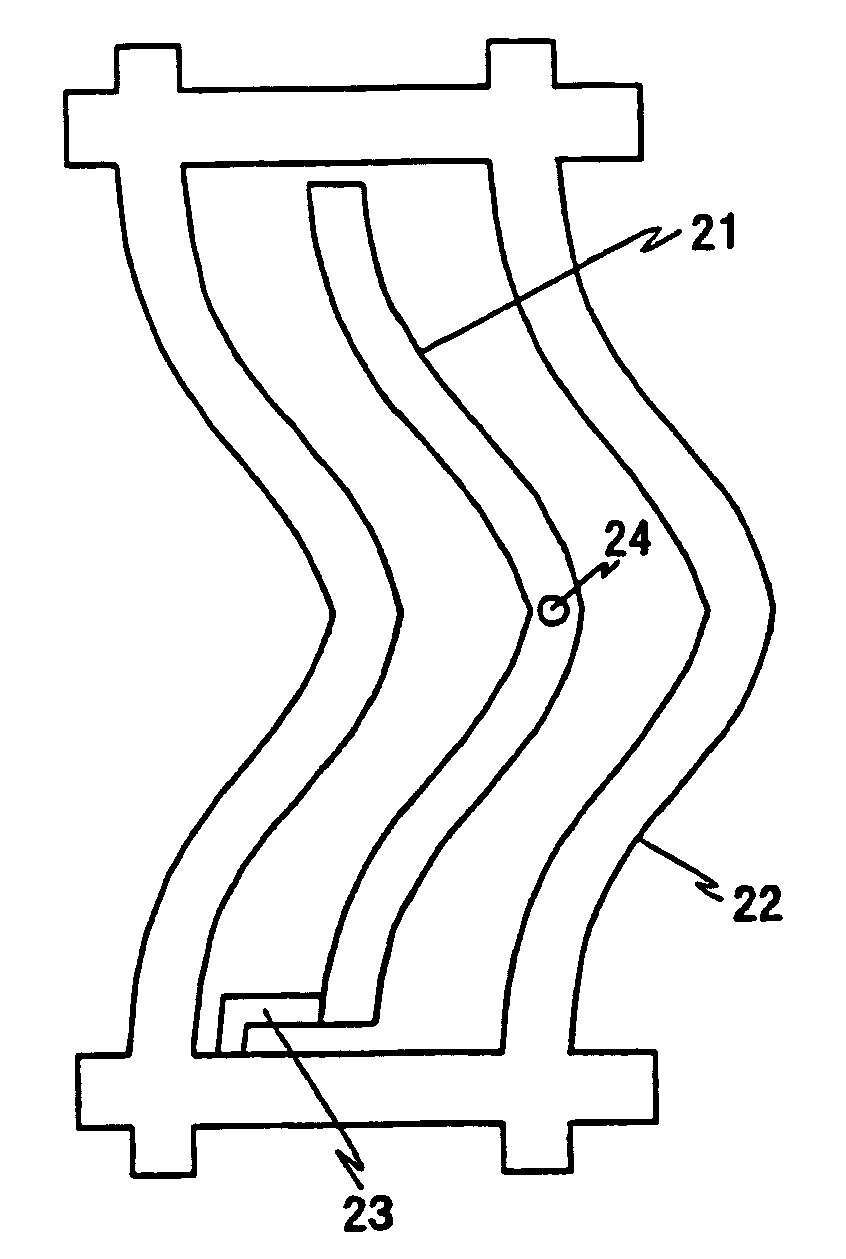

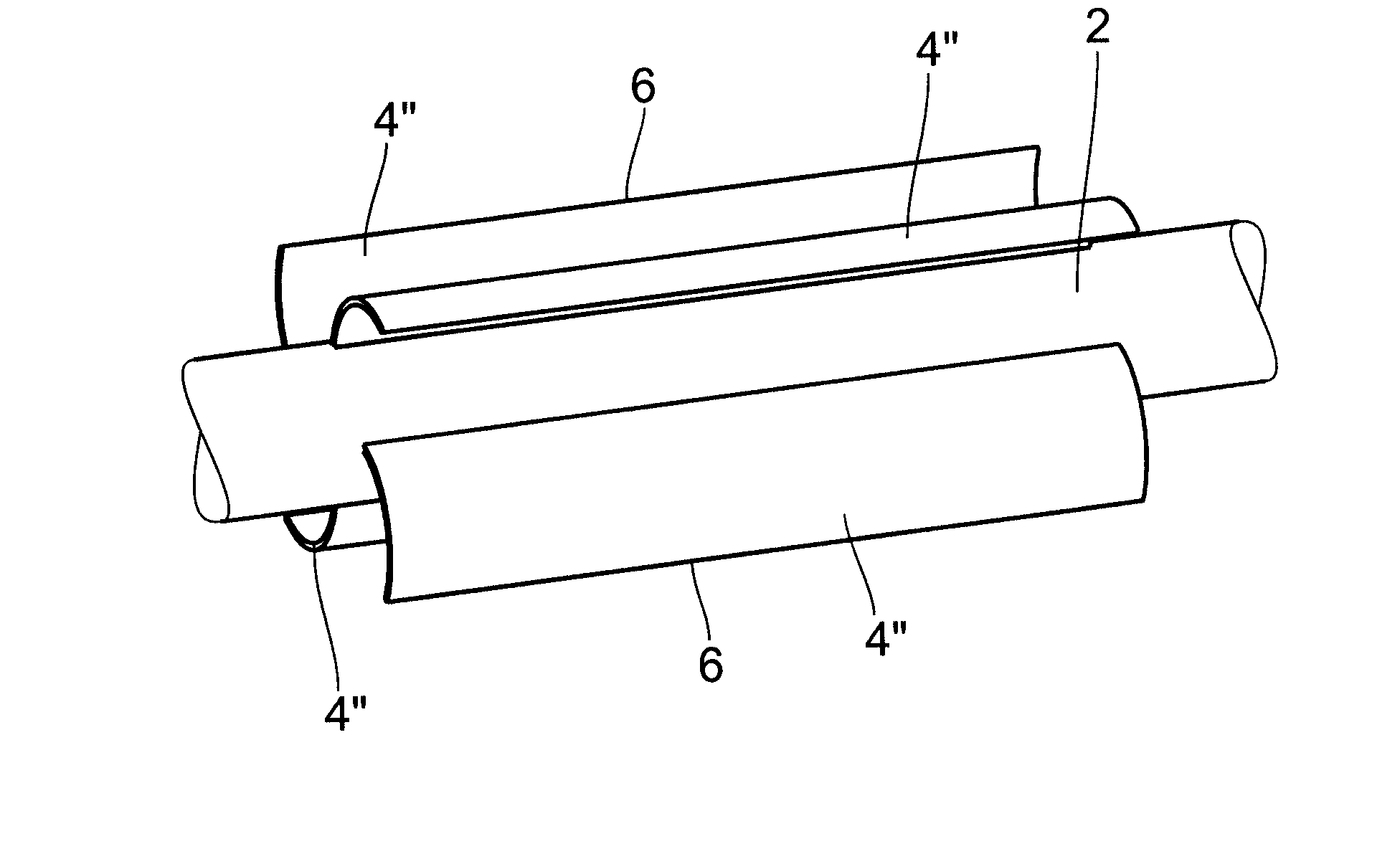

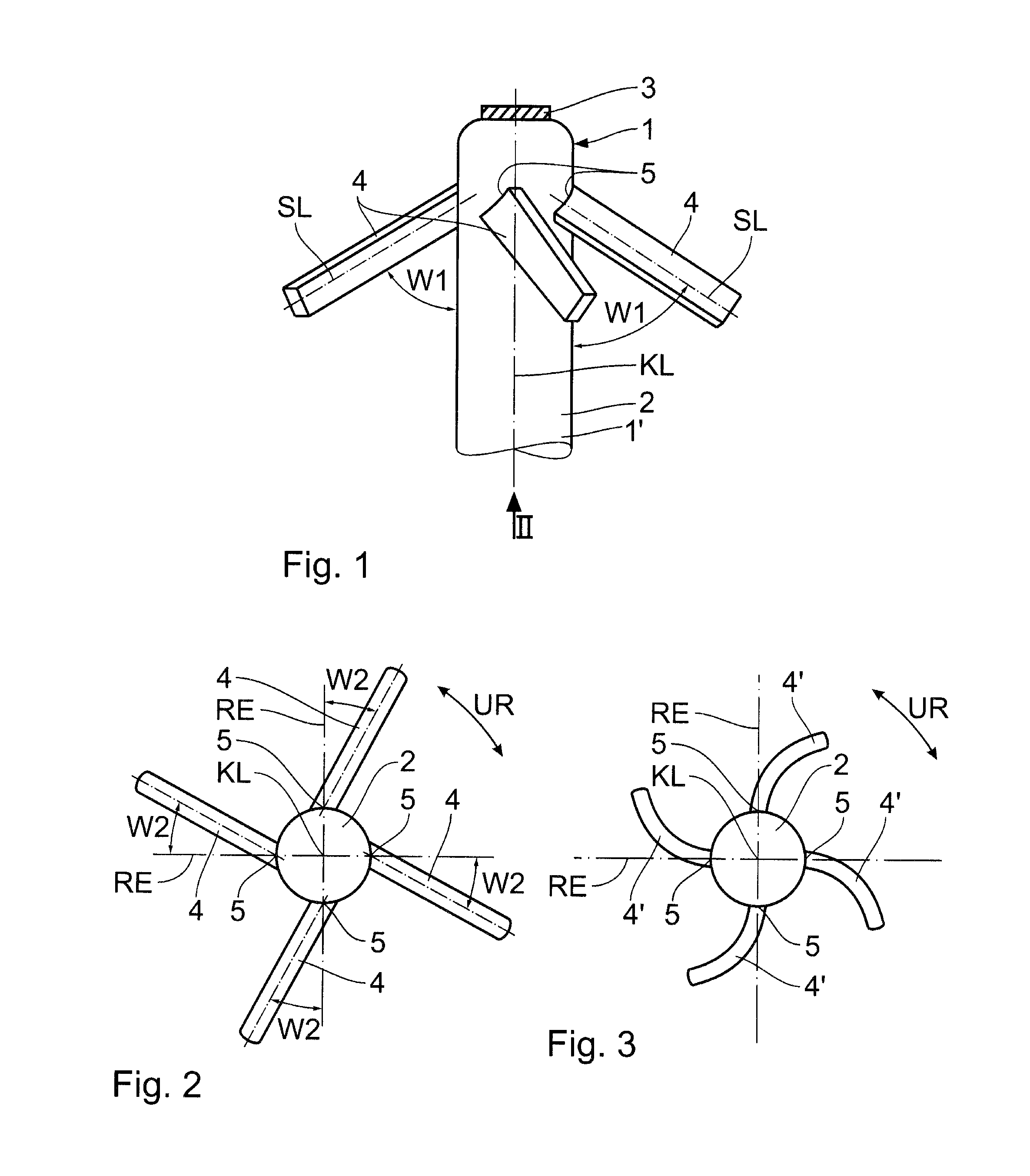

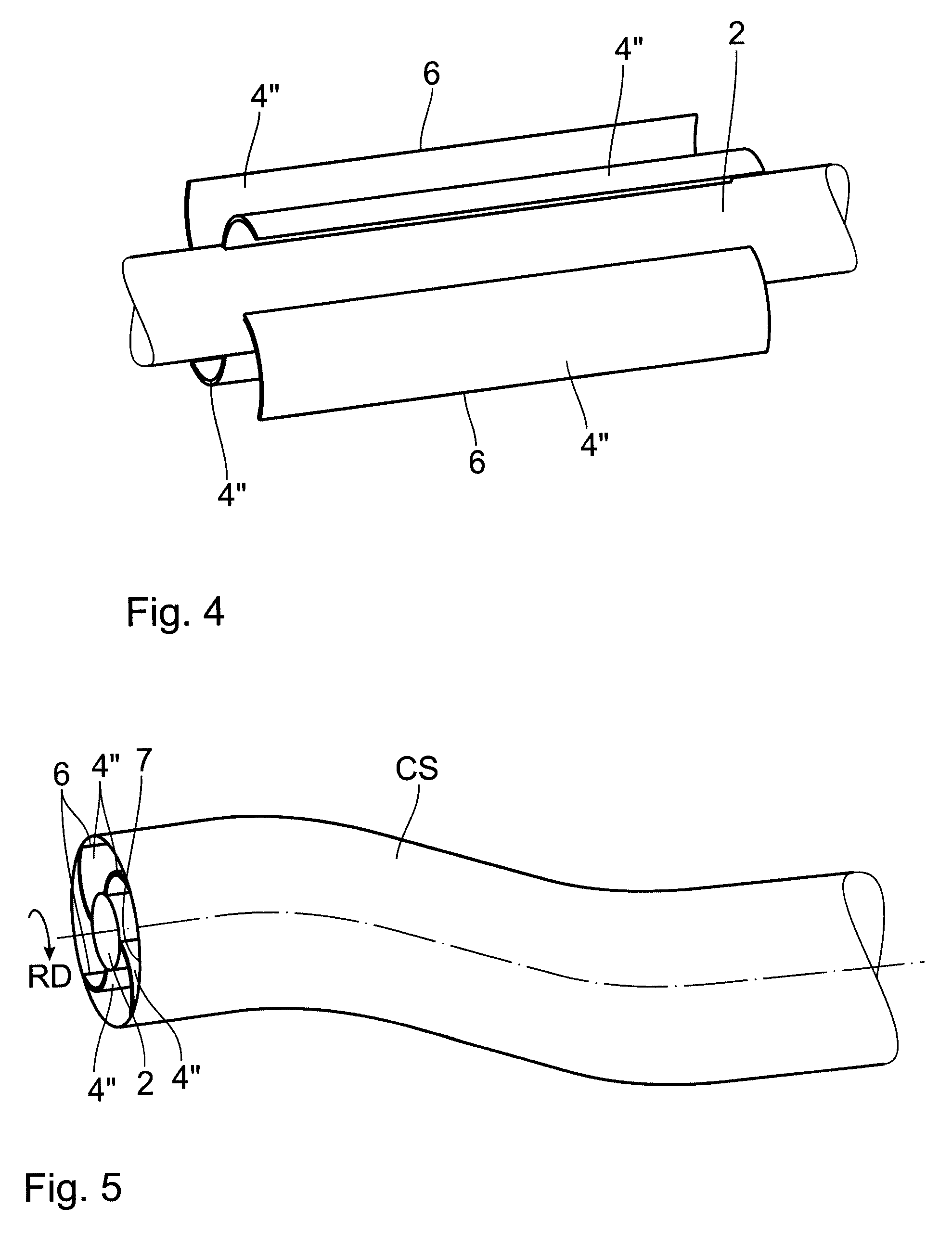

Implantable medical electrode device

InactiveUS8428750B2Less interferenceSimpler to withdrawTransvascular endocardial electrodesDiagnostic recording/measuringImplantable ElectrodesBody axis

A medical, implantable electrode device, in particular a cardiological electrode device, comprises an elongate electrode body (2) having a proximal and a distal end (1) for insertion into the body of the patient and multiple strut-like anchoring elements (4), which are attached laterally to the electrode body (2) before the distal end (1) for fixing the electrode device in the patient and are distributed around the circumference, which each project having their longitudinal axis (SL) at an acute angle (W1) opening in the direction of the proximal end in relation to the electrode body axis (KL). The anchoring elements have a preferred direction around the circumference in such a way that upon engagement of the anchoring elements (4) in a body part of the patient, a rotation of the electrode body (2) is opposed by a greater resistance in one rotational direction than in the opposite direction.

Owner:BIOTRONIK SE & CO KG

Polyester film for display

InactiveUS6921580B2Low UV transmittanceImprove light resistanceOptical filtersSynthetic resin layered productsPolyesterOptical transmittance

The present invention relates to a polyester film for display comprising:a polyester film substrate containing an ultraviolet light absorber; anda coating layer formed on at least one surface of said polyester film substrate,said polyester film having a haze of not more than 2.0% and a light transmittance at 380 nm of not more than 5.0%.

Owner:MITSUBISHI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com