Patents

Literature

4683results about "Driving apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tool drive system

A tool drive system for transferring rotational power from a rotational tool, such as a drill or ratchet, to at least one input drive shaft which then transfers the power to at least one output drive shaft. The angle of at least one input drive shaft being adjustable relative to at least one output shaft. The tool drive system comprises a round housing with an angle adjuster attached to the input shaft that assists in adjusting and locking the angle of the input shaft relative to the output shaft in an almost circular span. The input and output shafts may be positioned in a user-selected gear ratio from the input to output shafts or vice versa.

Owner:ULLAH RIZWAN

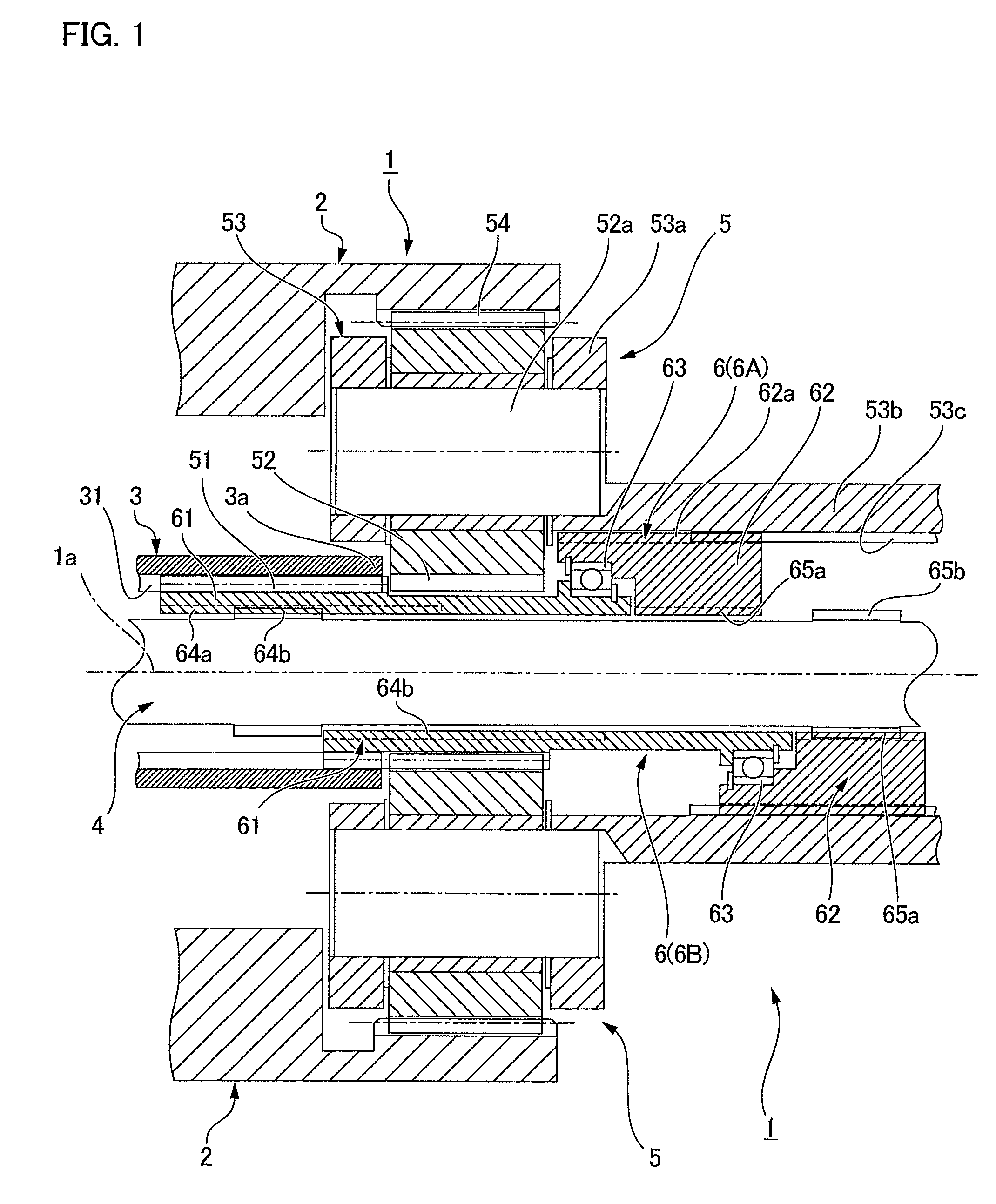

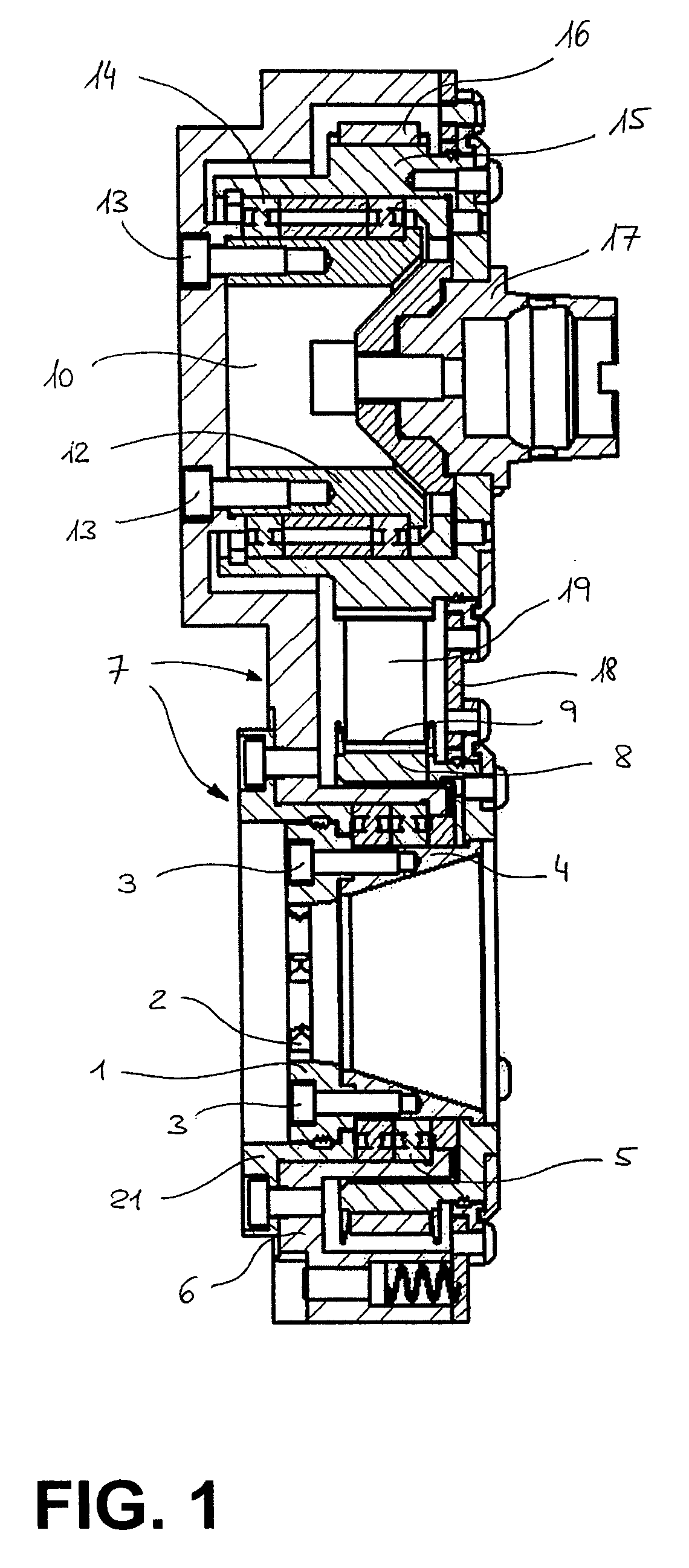

Switchable rotation drive device

InactiveUS20100179022A1Simple switching mechanismSmall sizeToothed gearingsFeeding apparatusLow speedSpur gear

Owner:HARMONIC INC

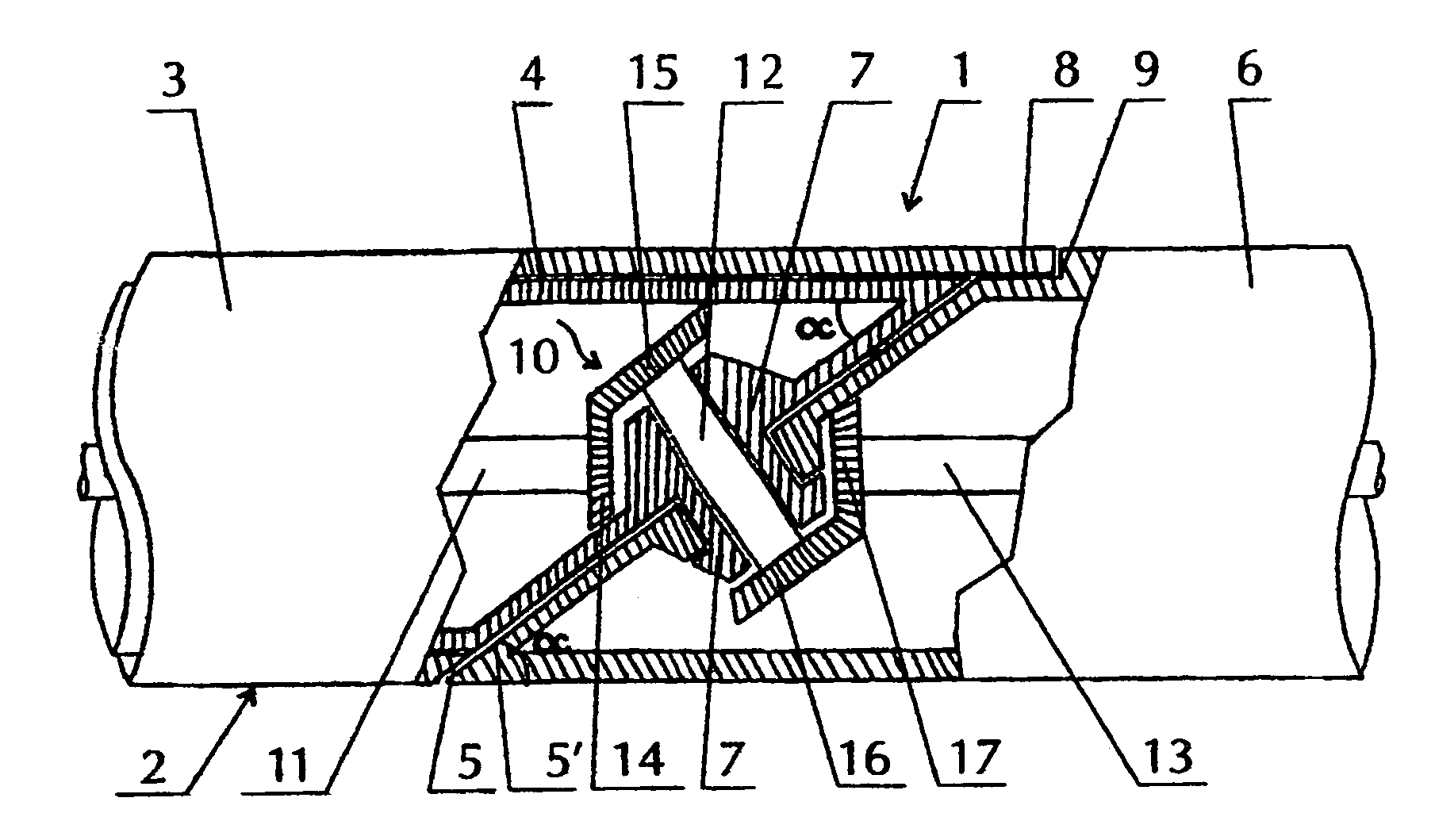

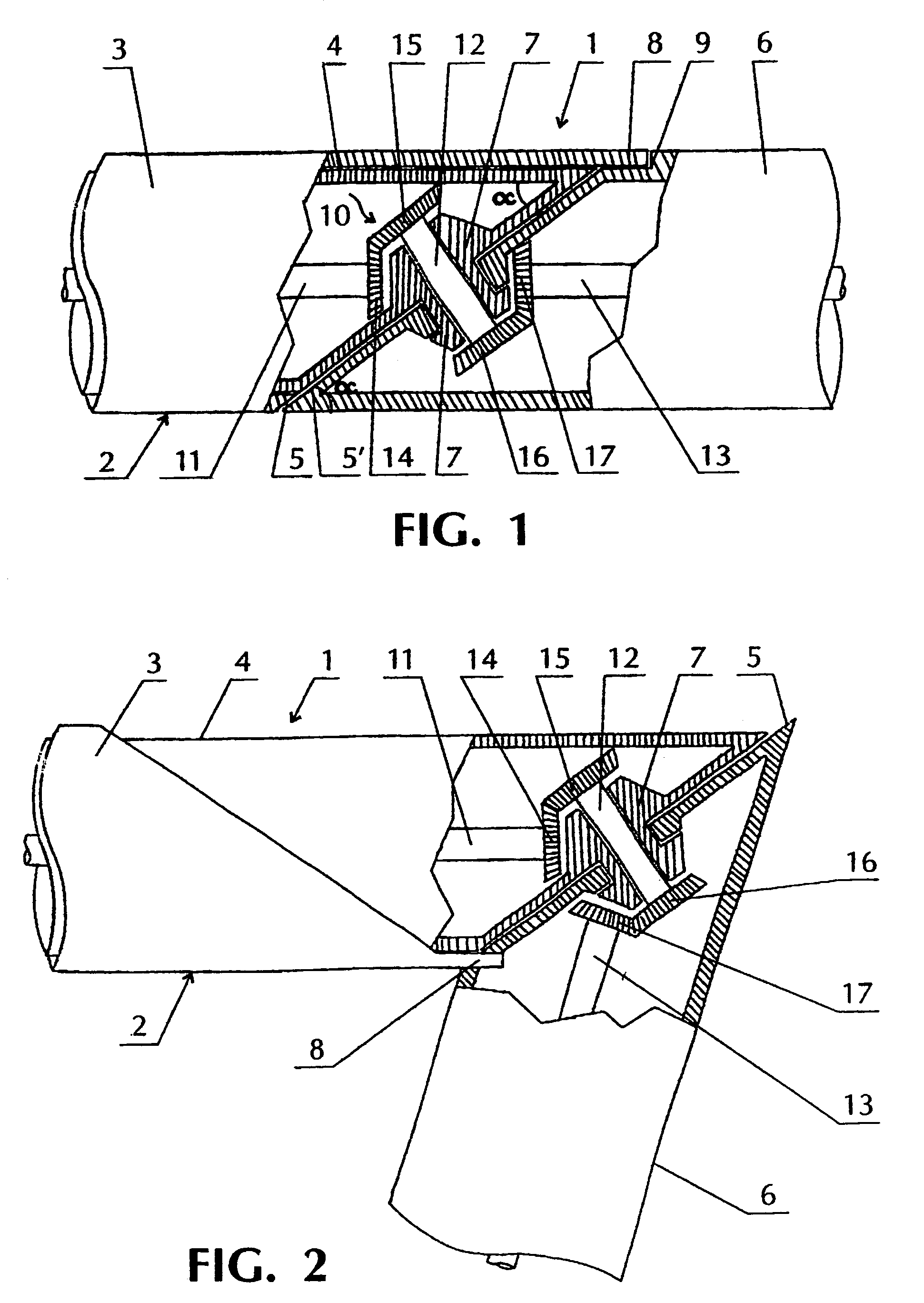

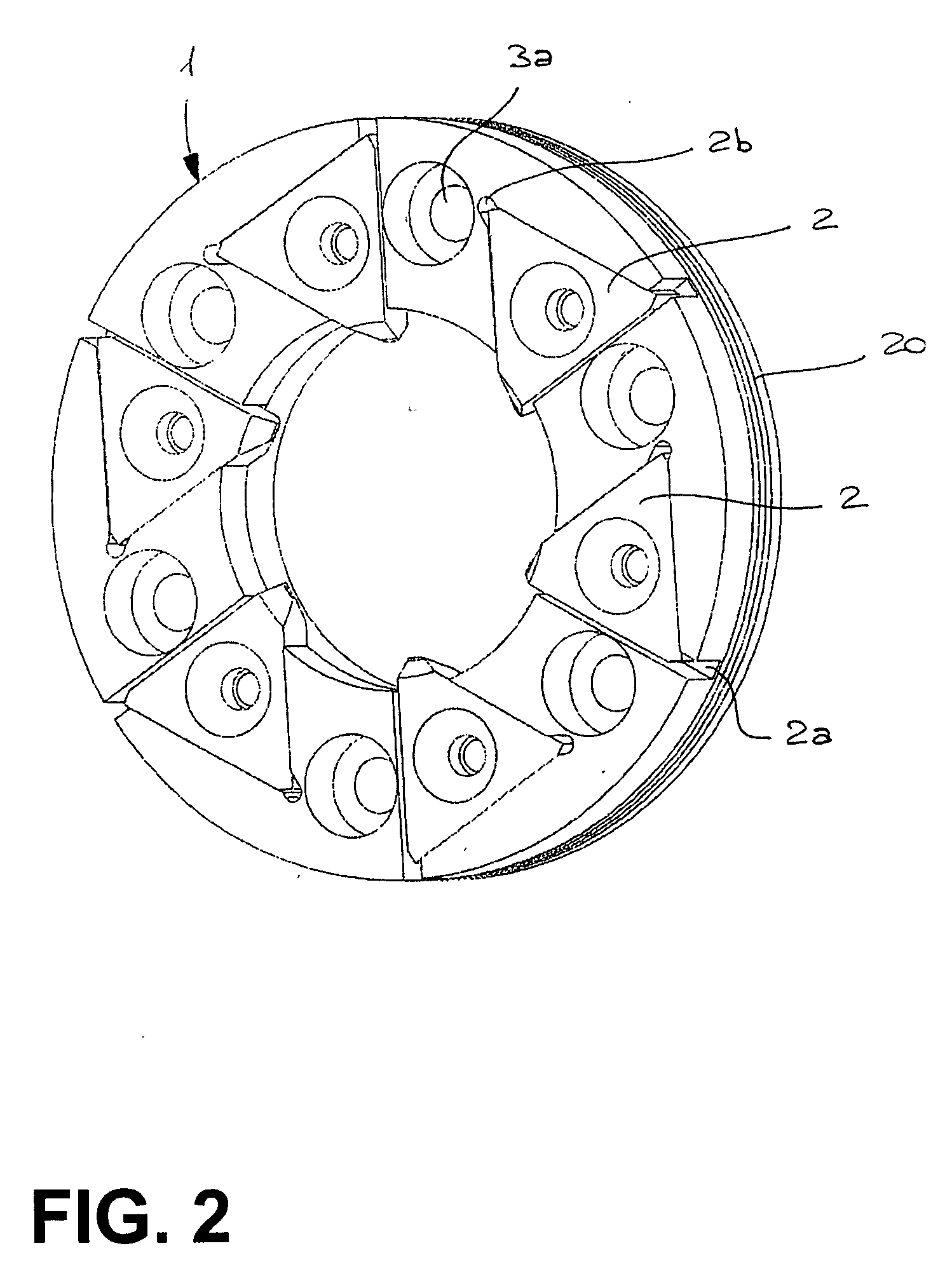

Remote controlled device for tool rotating

InactiveUS7300431B2Minimal lossLess labour-consumingYielding couplingToothed gearingsRemote controlEngineering

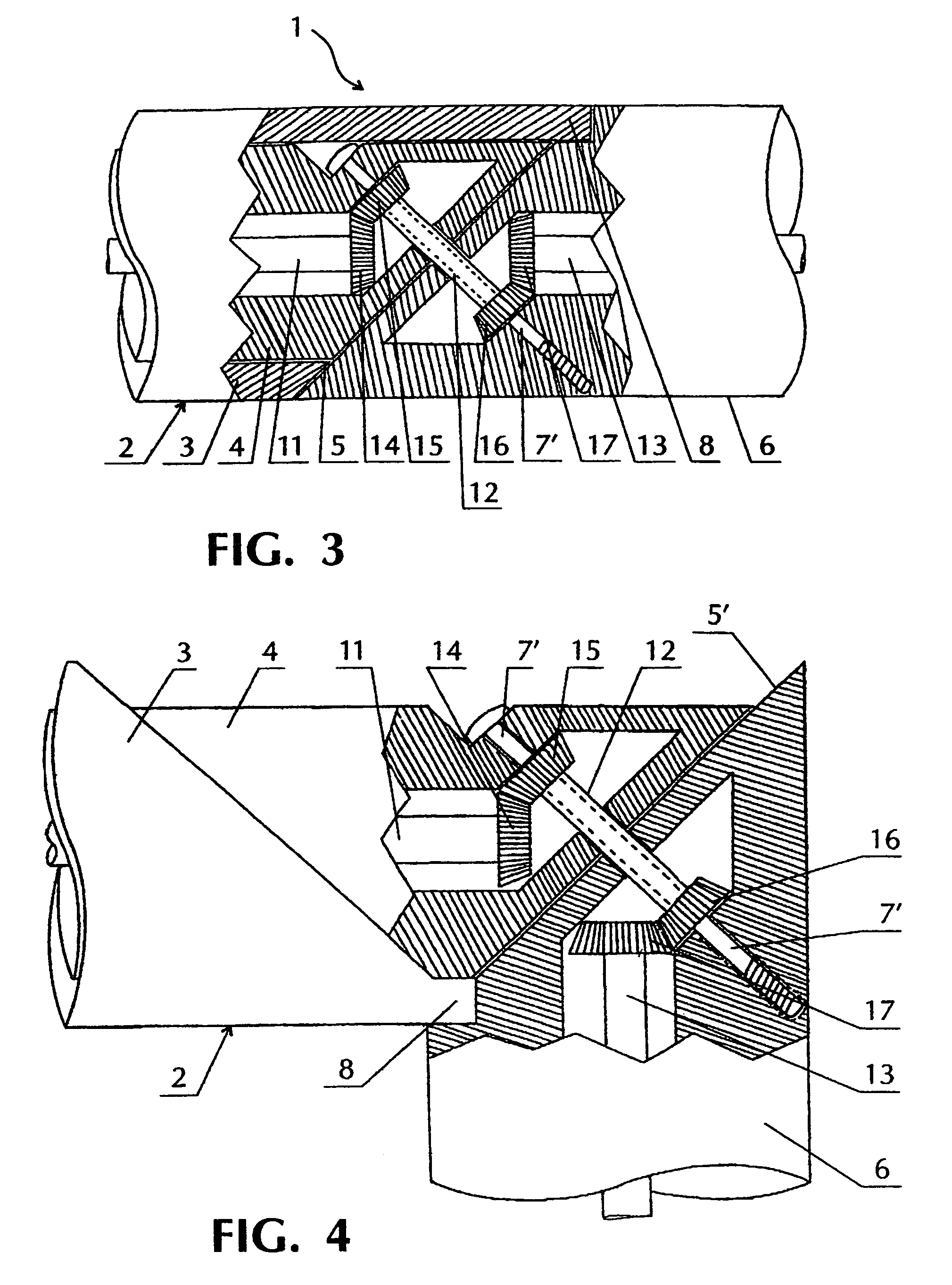

A remote-controlled device for rotating tools, preferably medical tools, comprising a hollow body (1) which is embodied in the form of pivotally connected proximal and distal parts (2, 6) provided with a pair of adjacent end surfaces (5, 5′) which are angularly disposed with respect to the longitudinal axis of the body (1), and an axis (7) which is perpendicularly oriented with respect to the end surfaces (5, 5′) and provided with a central channel and a remote control mechanism. A shaft (10) arranged in the central channel of the device comprises driven, driving and transmitting sections (11, 12, 13) respectively, and operates as a link for transferring working rotational motion at a variable angle. The tilt angle between the distal part (6) and the longitudinal axis of the proximal part (2) can be equal to 180°.

Owner:DUBROVSKY ARKADY VENIAMINOVICH

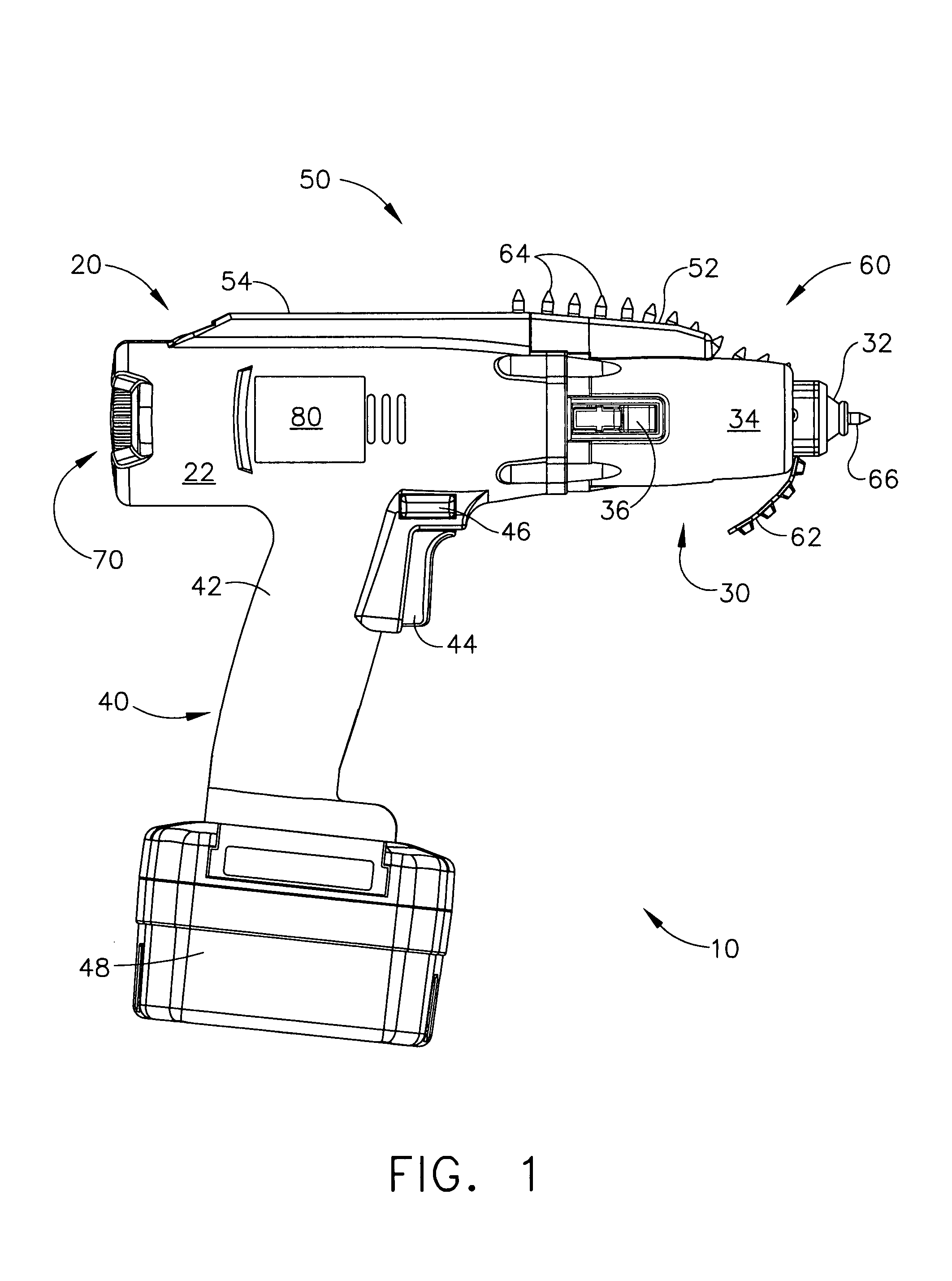

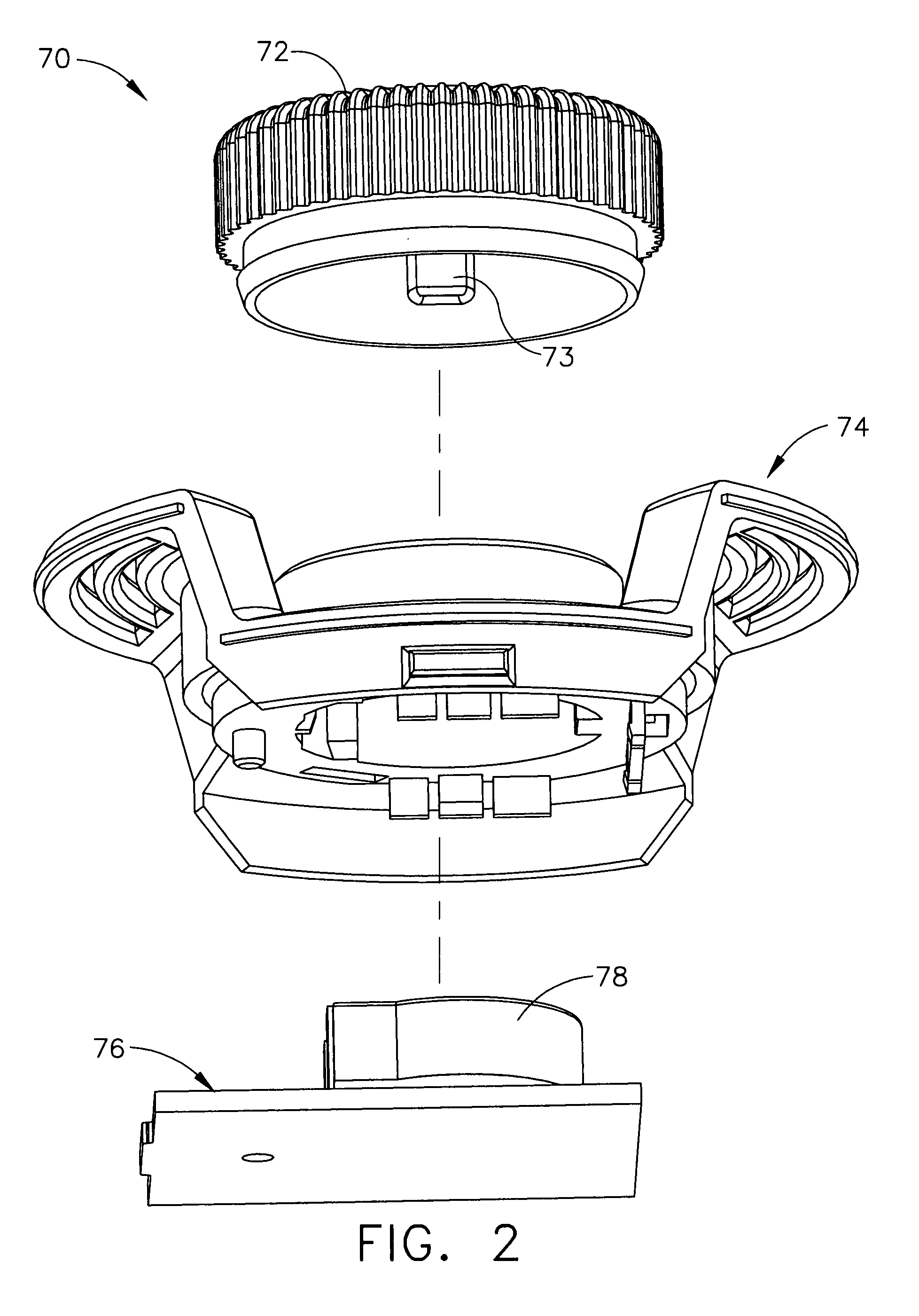

Apparatus for controlling a fastener driving tool, with user-adjustable torque limiting control

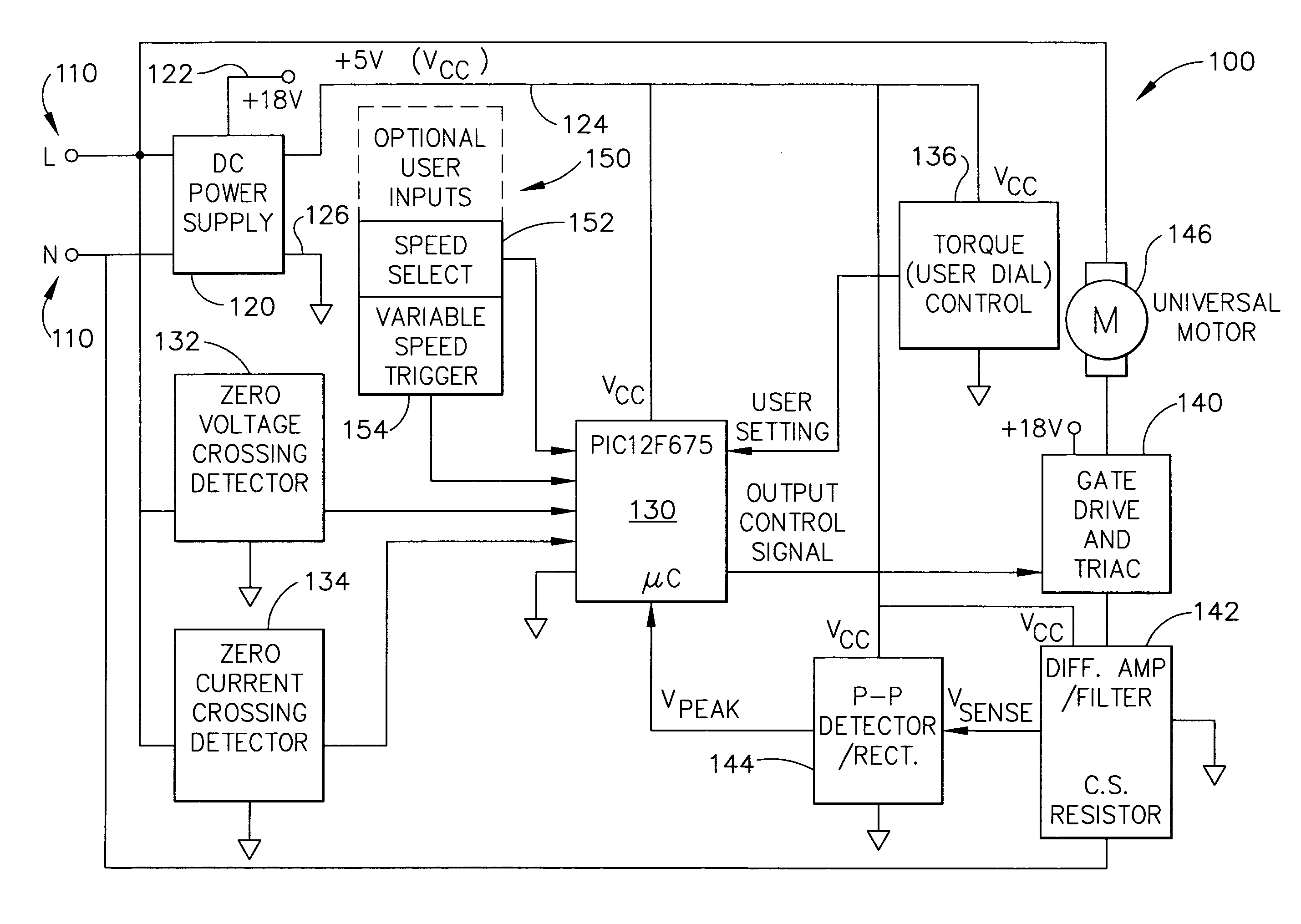

An improved hand-held fastener driving tool is provided with an adjustable torque limiting control. The tool is portable, and is electrically powered using either a battery pack or a power cord as a power source. The tool drives collated fasteners (e.g., screws) into solid objects. The motor current is measured to determine the amount of torque being applied to a screw by the motor and mechanical drive components. As the screw bottoms out, the motor torque increases to a point where it exceeds the user-adjusted torque limiting control. The motor is automatically turned off at that point, thereby preventing the screw from being stripped.

Owner:KYOCERA SENCO IND TOOLS INC

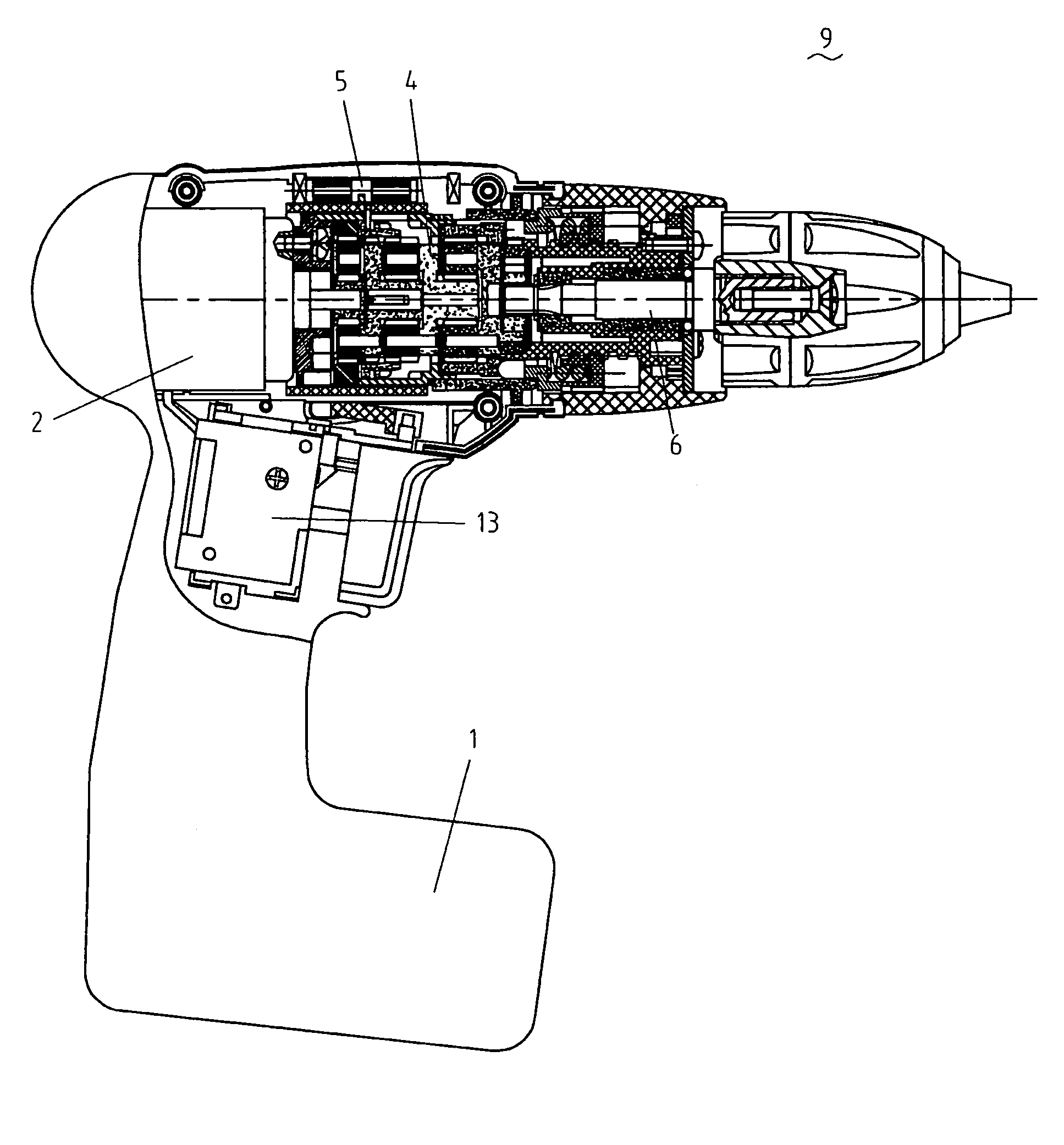

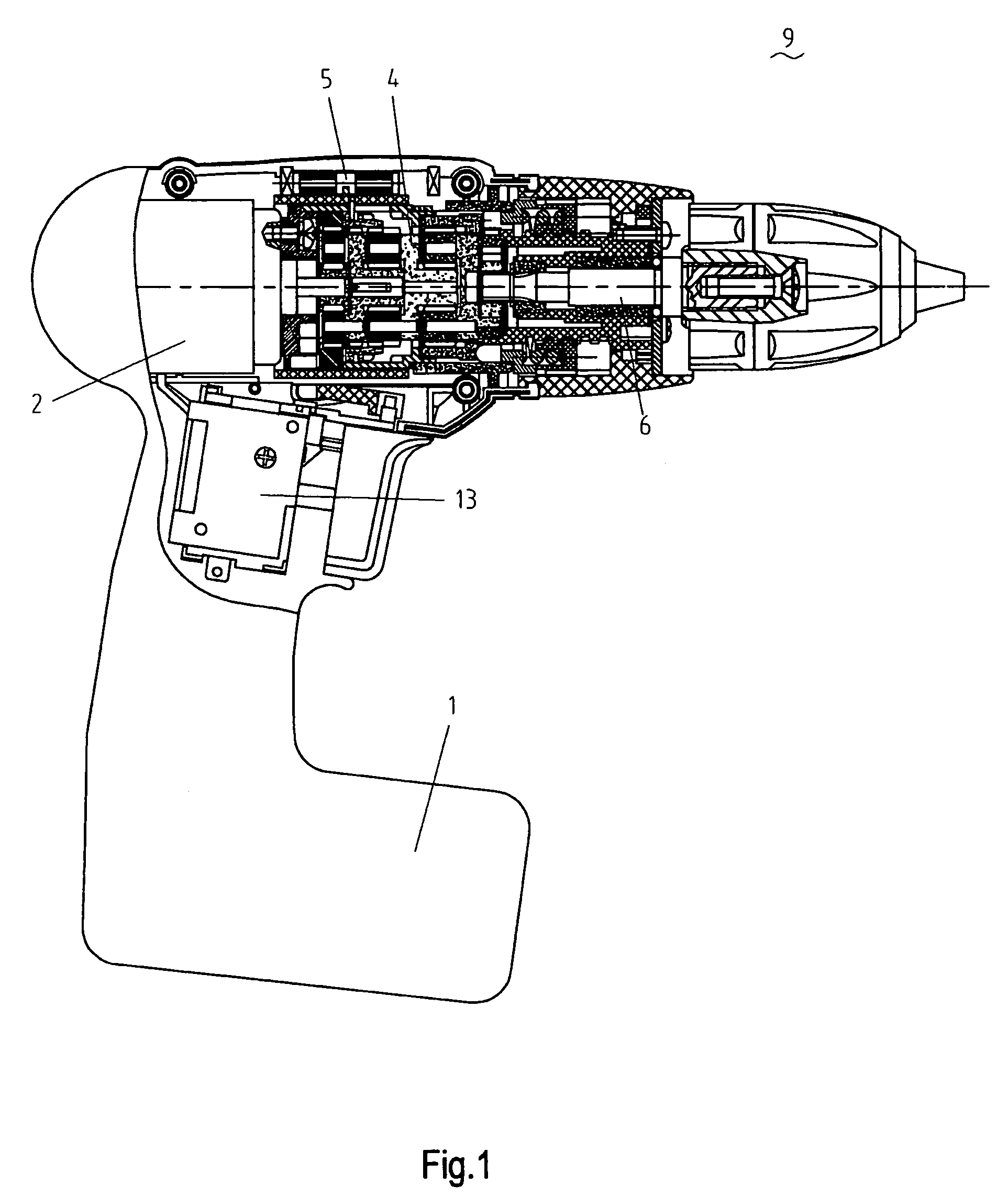

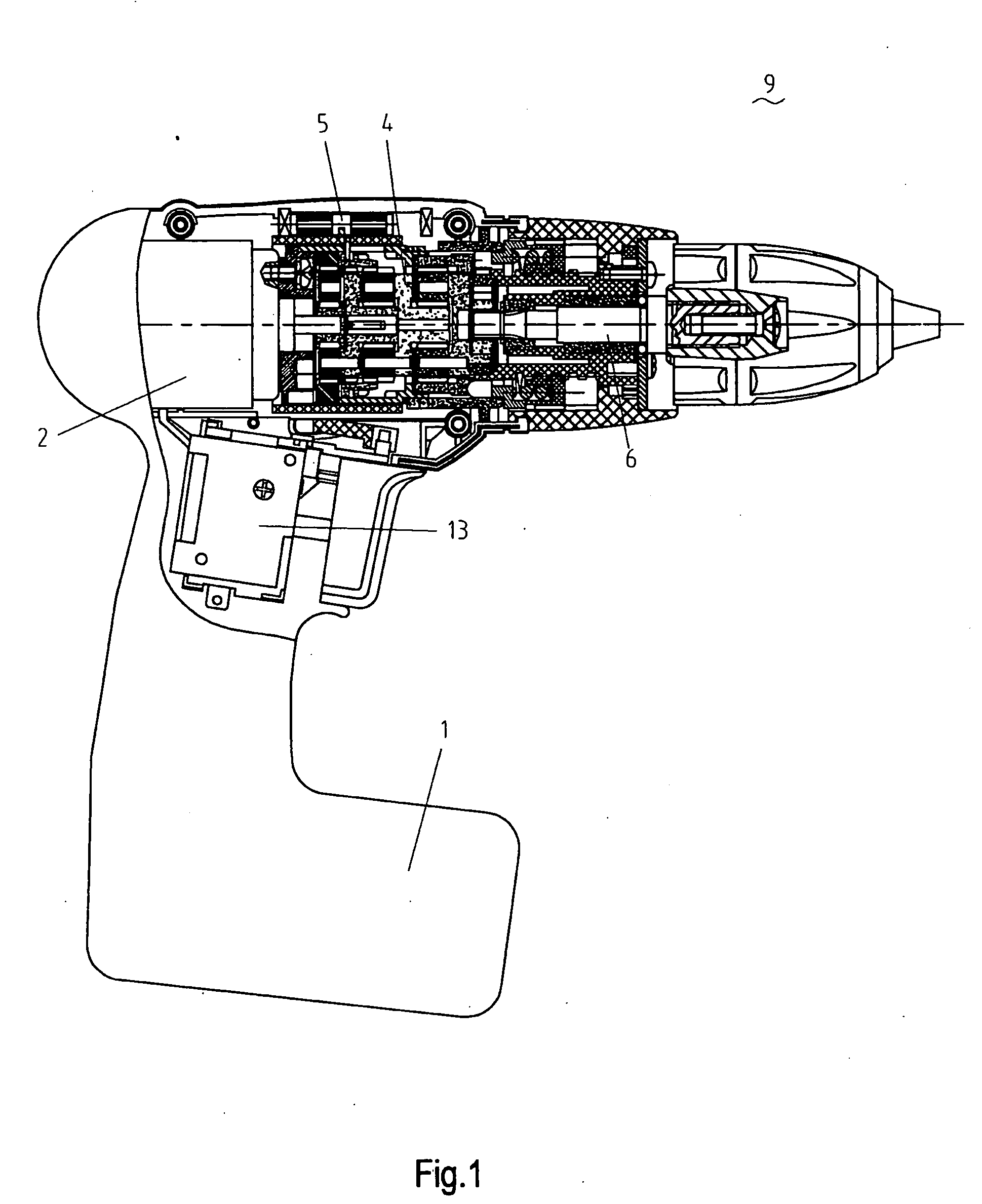

Power tool having control system for changing rotational speed of output shaft

ActiveUS7882899B2Extend the life cycleReduce speedDerricks/mastsGearing controlLow speedControl system

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

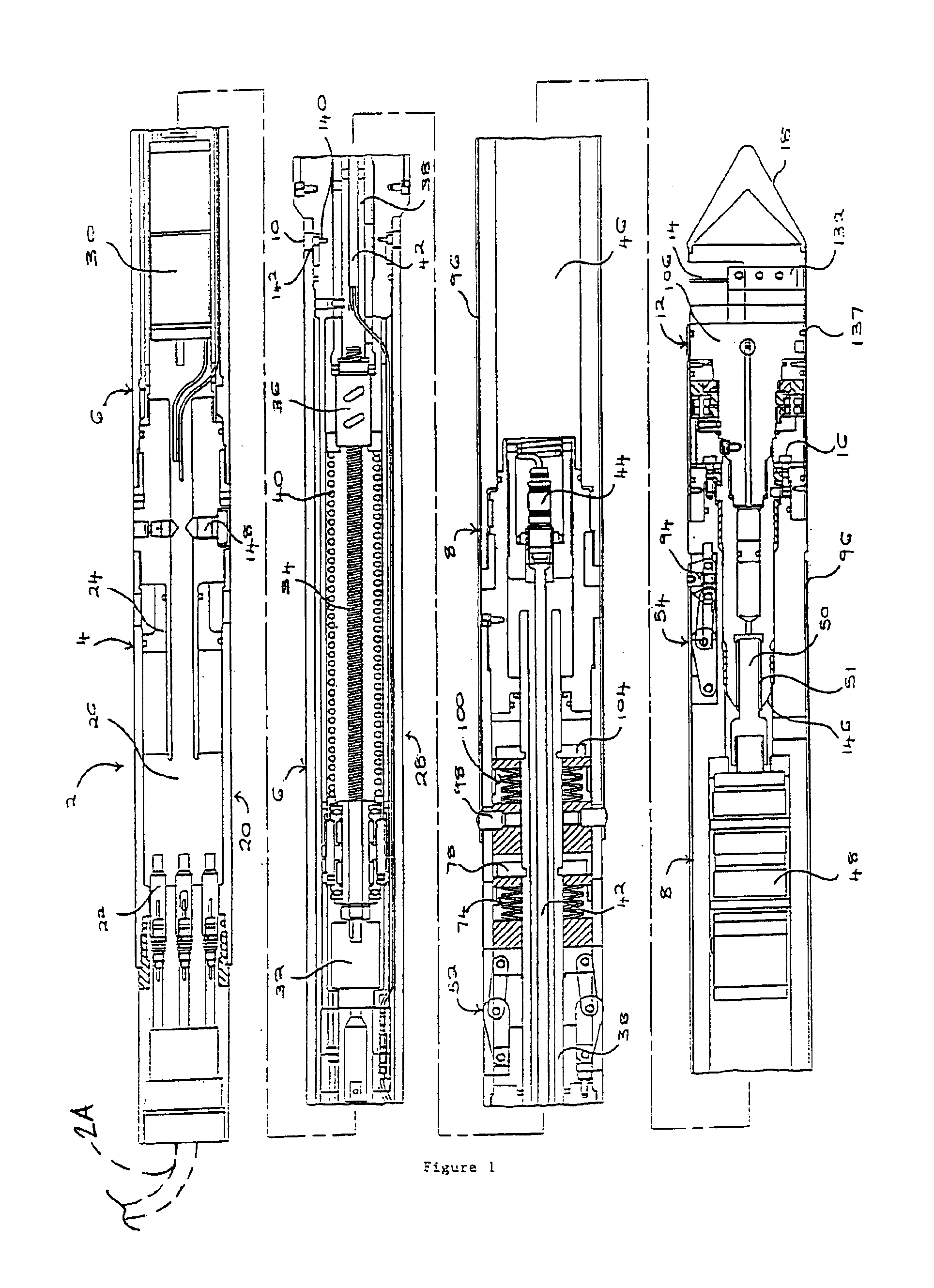

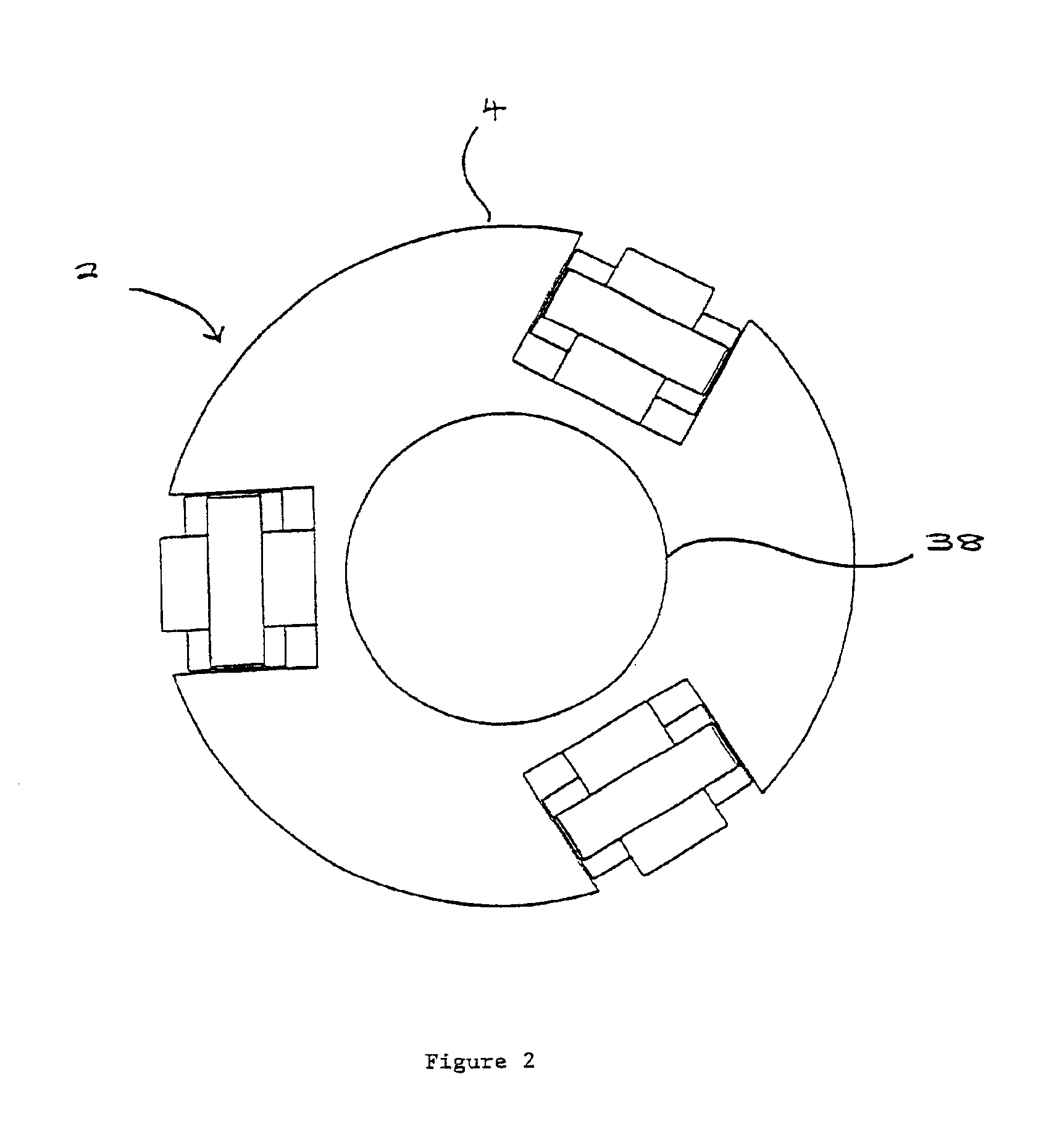

Tubular cutting tool

InactiveUS6868901B2Overcome difficultiesFluid removalBorehole drivesEngineeringMechanical engineering

A tubular cutting tool includes two or more sets of electrically actuated retractable anchoring legs mounted at longitudinally spaced apart locations and an electrically driven rotary cutting head with a retractable cutting blade. The anchoring legs can be arranged such that they are capable of compensating for variations in the internal radii of the tubular to be cut, thereby ensuring that the cutting tool is clamped rigidly in position.

Owner:SONDEX

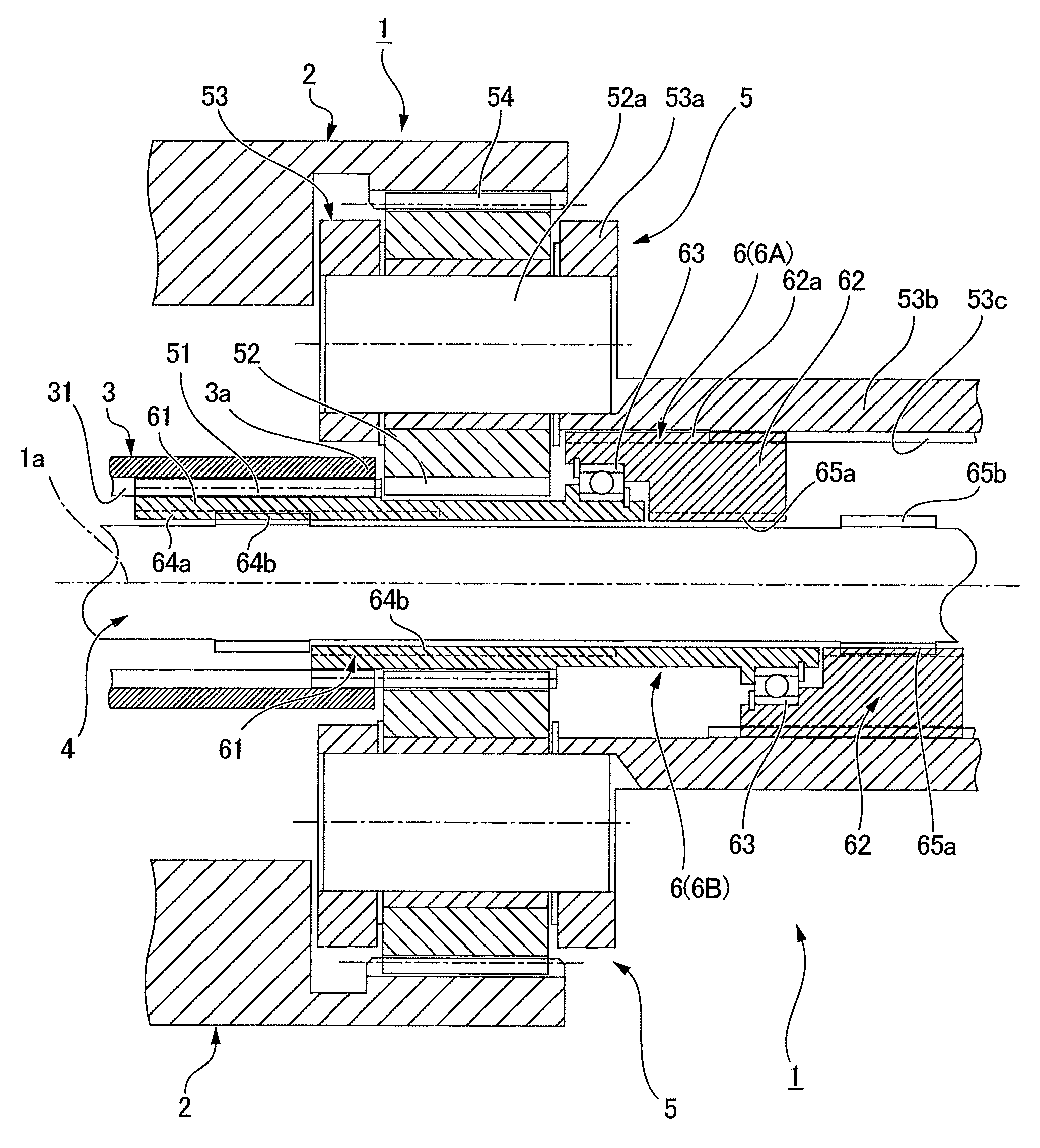

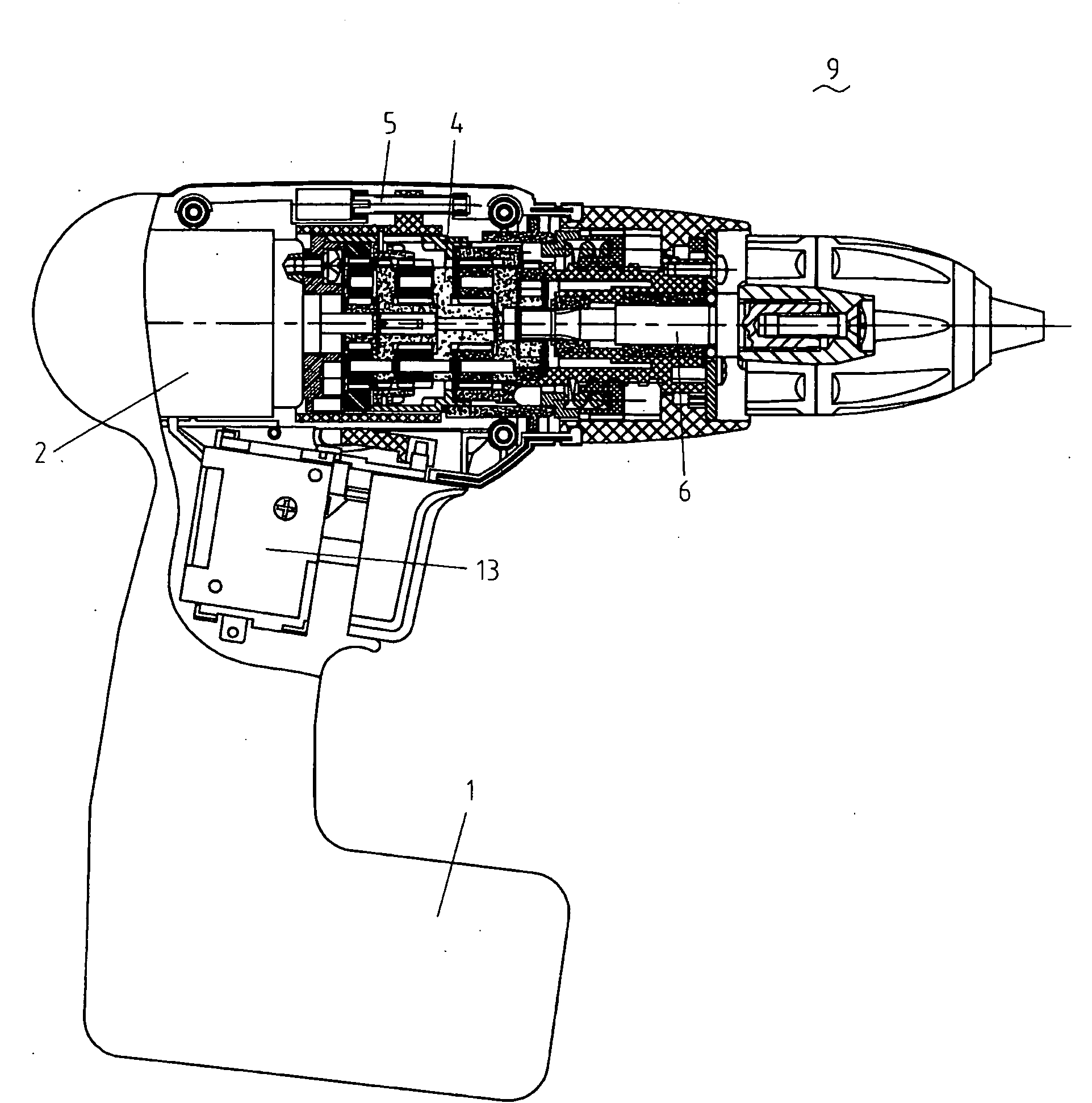

Power tool

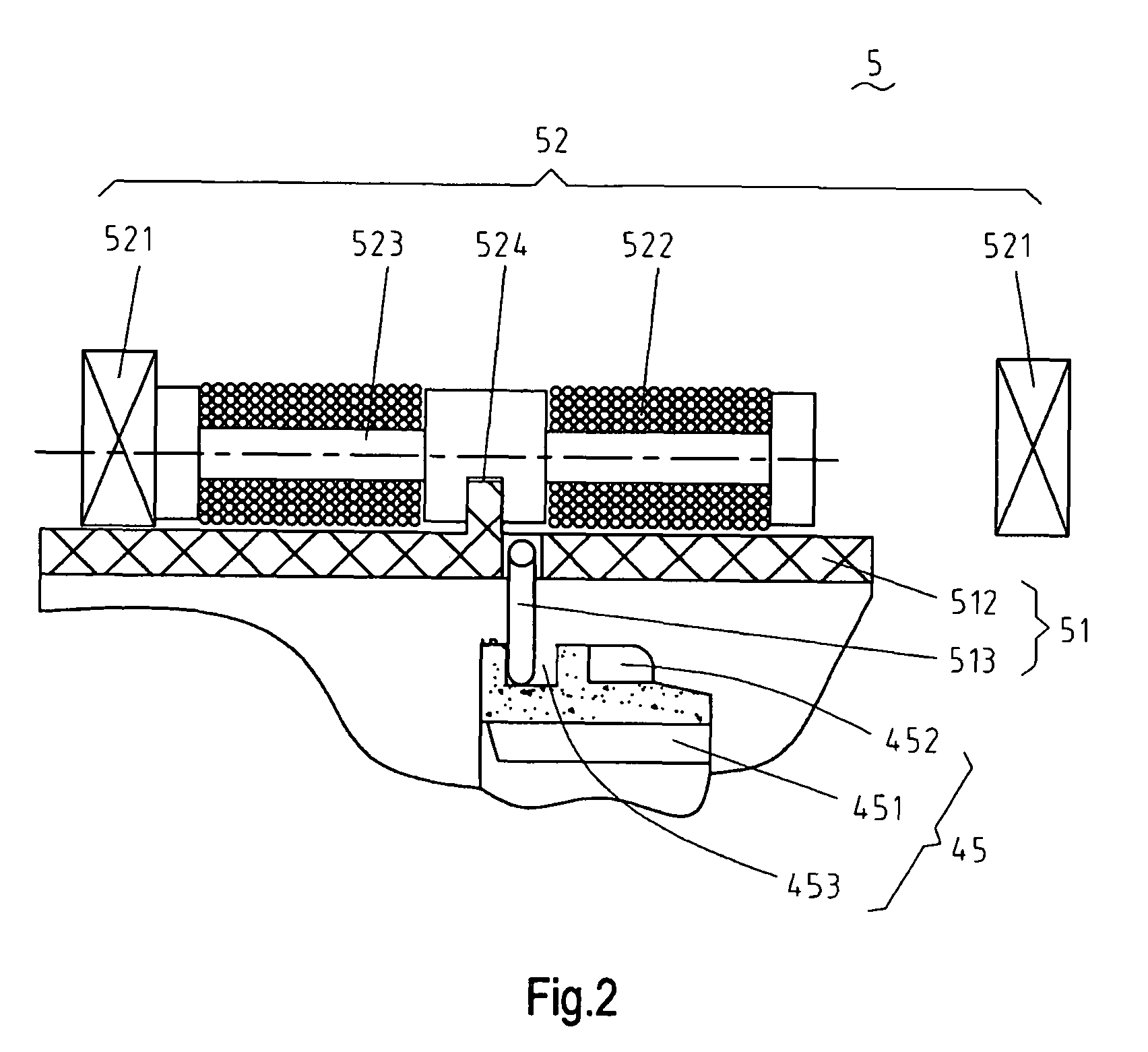

ActiveUS20090071671A1Avoids gear clashExtend the life cycleDerricks/mastsGearing controlLow speedControl system

A power tool comprising a housing, a motor, an output shaft, a gear transmission mechanism and a control system. The gear transmission mechanism is connected between the motor and the output shaft to transmit the rotary power of the motor to the output shaft. The gear transmission mechanism has a high speed position and a low speed position. The control system is coupled to the gear transmission mechanism for detecting an operating characteristic of the power tool to actuate a ring gear to automatically move from the high speed position to the low speed position and to reduce the rotational speed of the ring gear when the operating characteristic exceeding a predetermined value.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

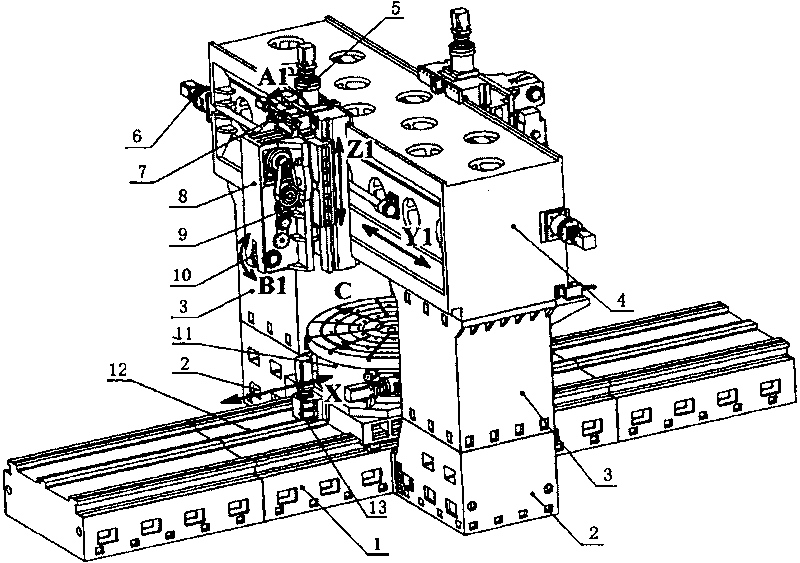

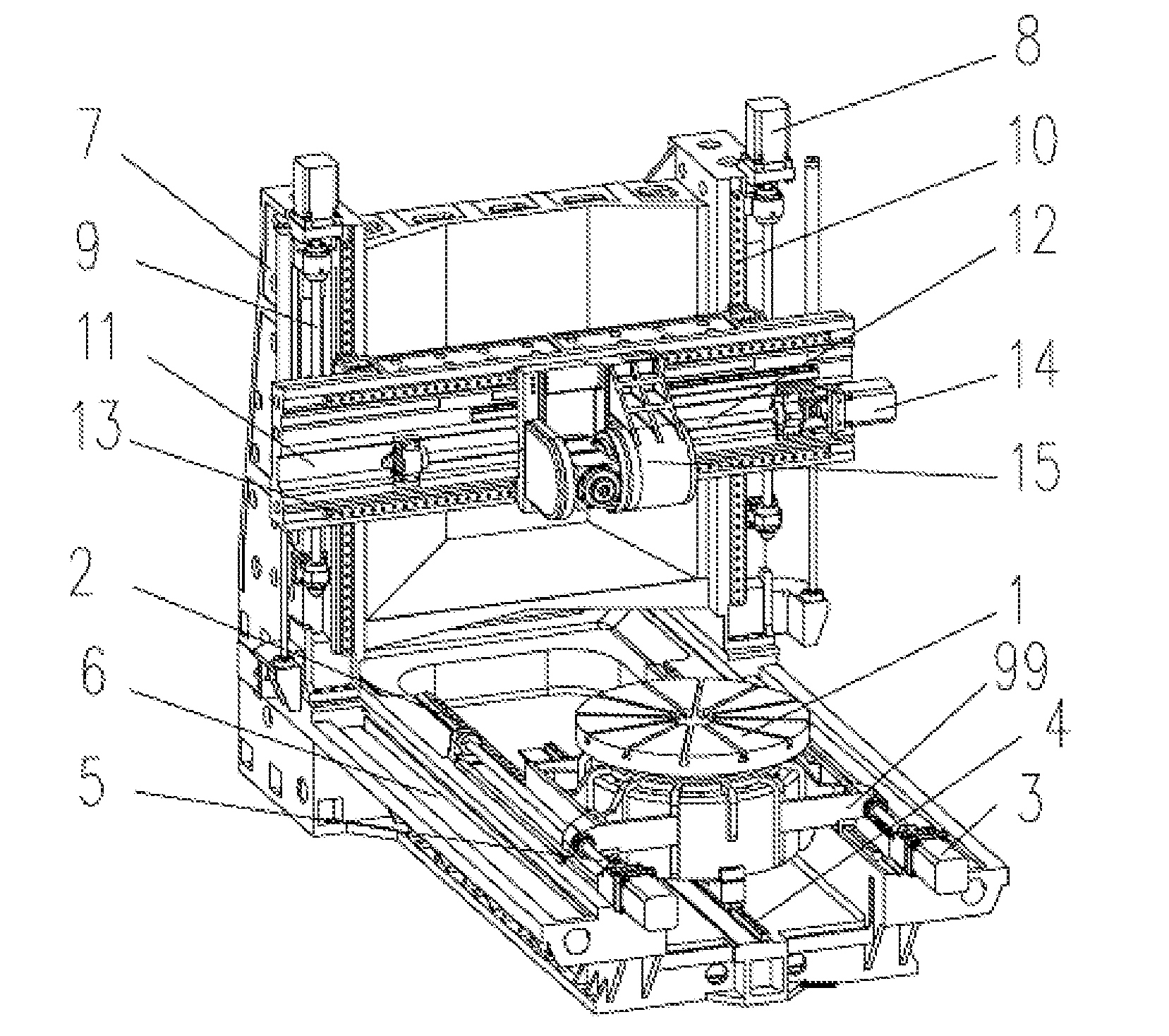

Large gantry polar-coordinate digital-control milling, hobbing and grinding gear combined machine

ActiveCN101700620AImprove machining accuracyImprove processing efficiencyOther manufacturing equipments/toolsLarge fixed membersHobbingGear wheel

The invention relates to a large gantry polar-coordinate digital-control milling, hobbing and grinding gear combined machine adopting a beam both-side bearing structure by respectively hanging a milling gear headstock and a hobbing and grinding gear headstock at the left side and the right side of a beam. Compared with the prior art, the invention adopts the design concepts of polar coordinates and modularization and enables the connection sizes of lathes, bases, and the like as well as Y-direction and Z-direction feeding systems of a milling gear and a hobbing and grinding gear to have interchangeability, thereby decreasing the manufacture cost, lowering the assembly difficulty and improving the machining precision and the machining efficiency of large-module large-diameter gears. The invention integrates the machining characteristics for roughly and finely machining a milling gear, precisely spreading into a hobbing gear and molding a grinding gear with respective optimal process velocities and reasonably arranges a milling, hobbing and grinding gear headstock transmission chain capable of satisfying the requirements for molding the milling gear, spreading into the hobbing gear and molding the grinding gear.

Owner:NANJING UNIV OF TECH

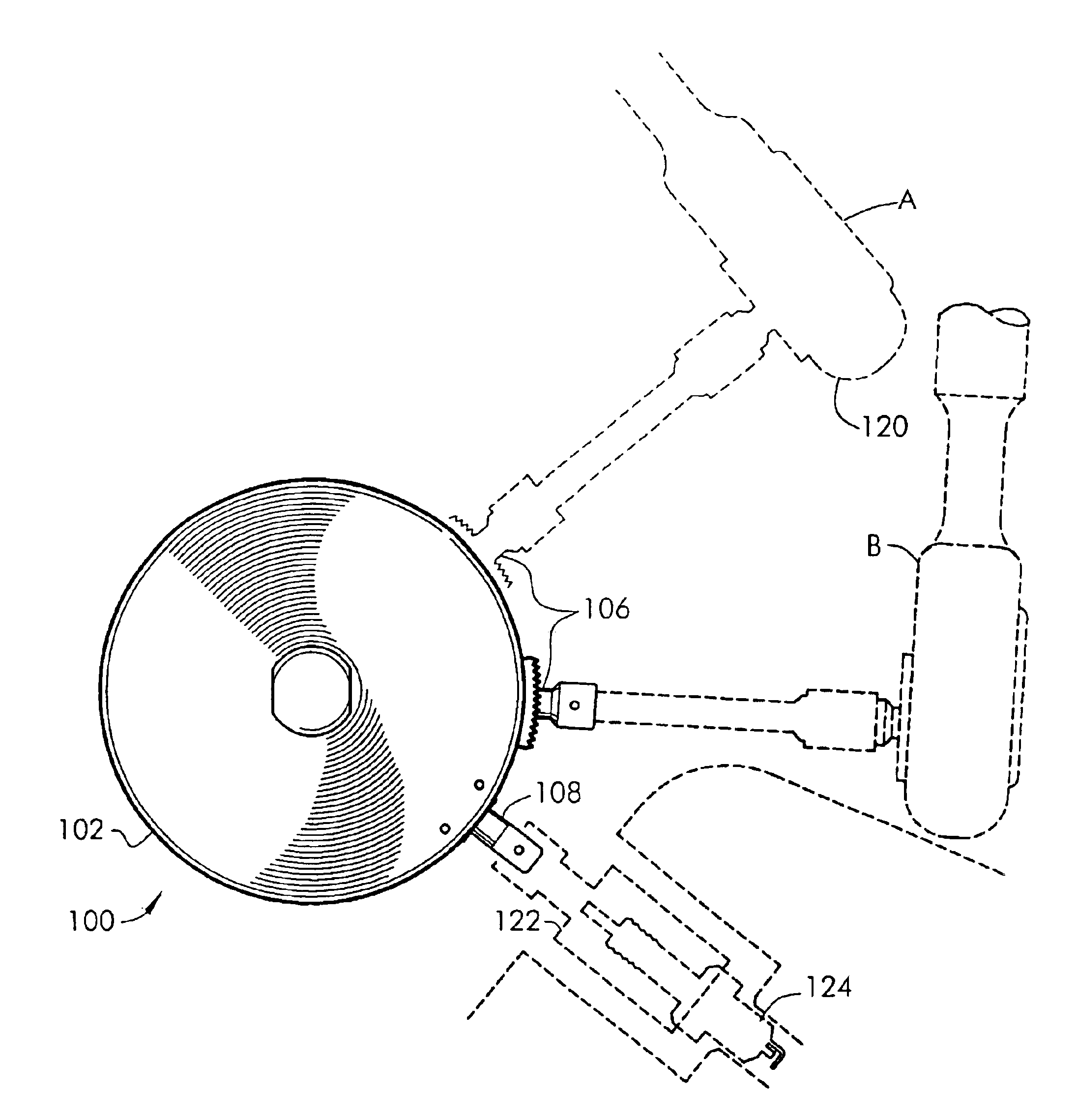

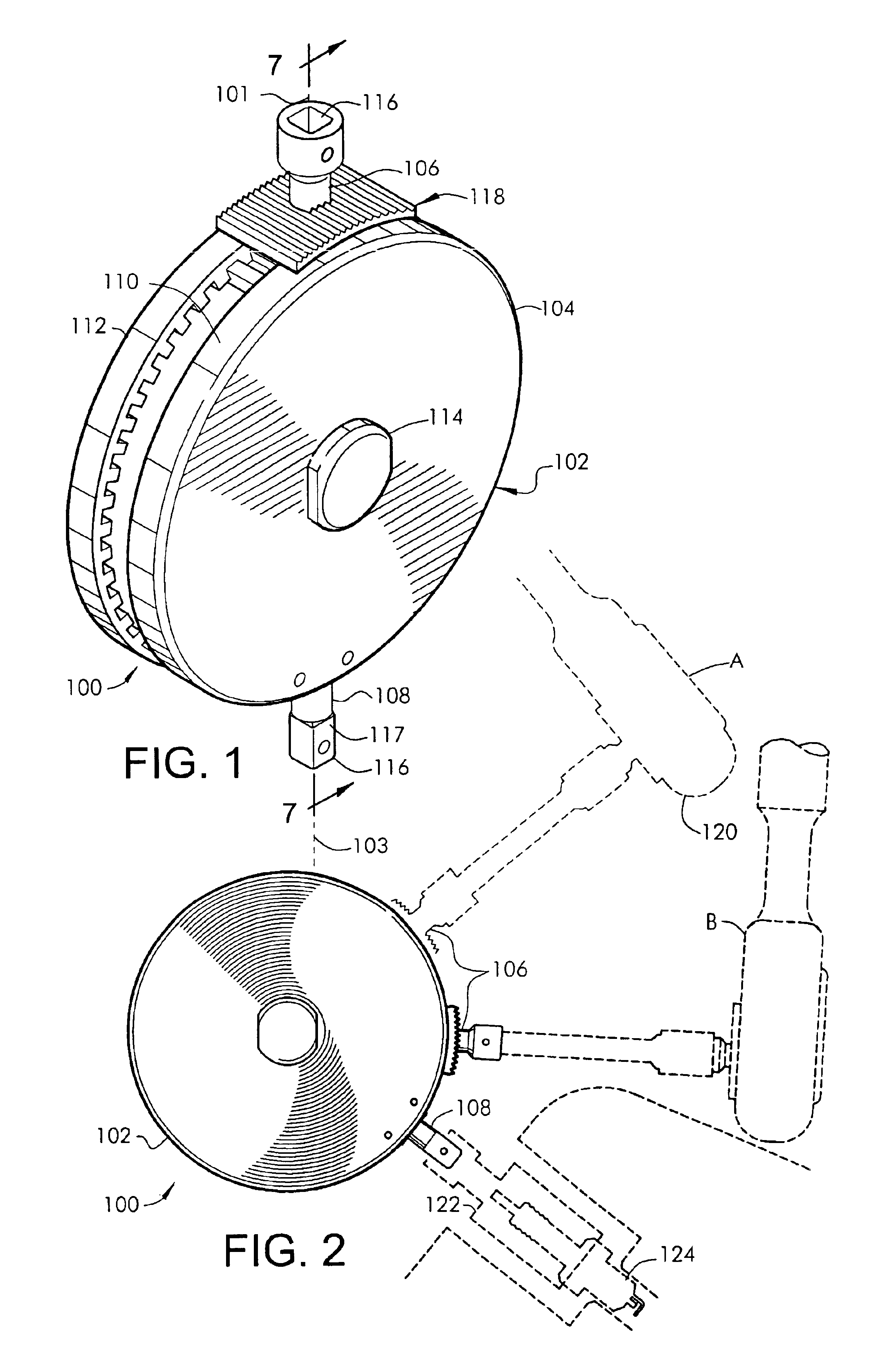

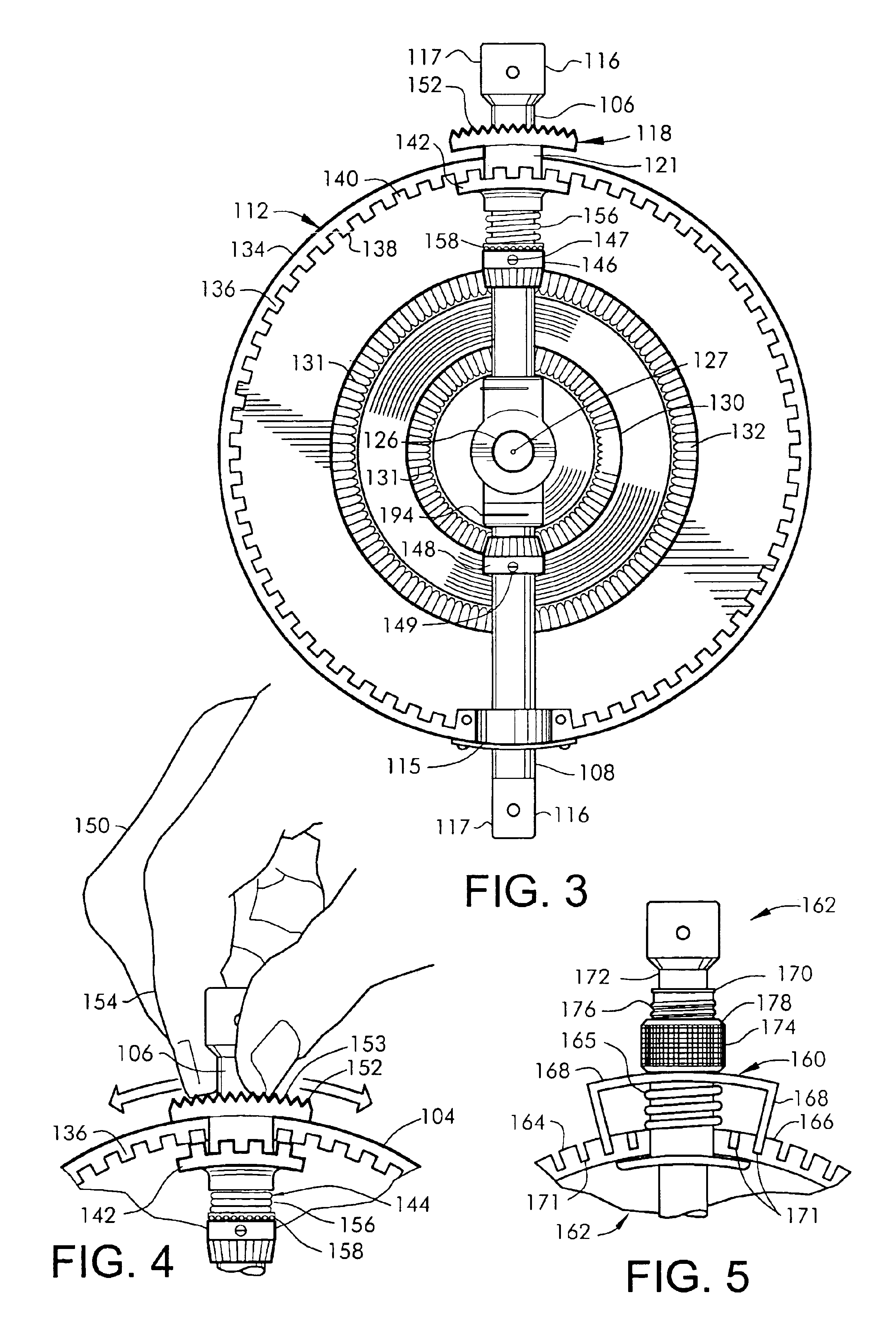

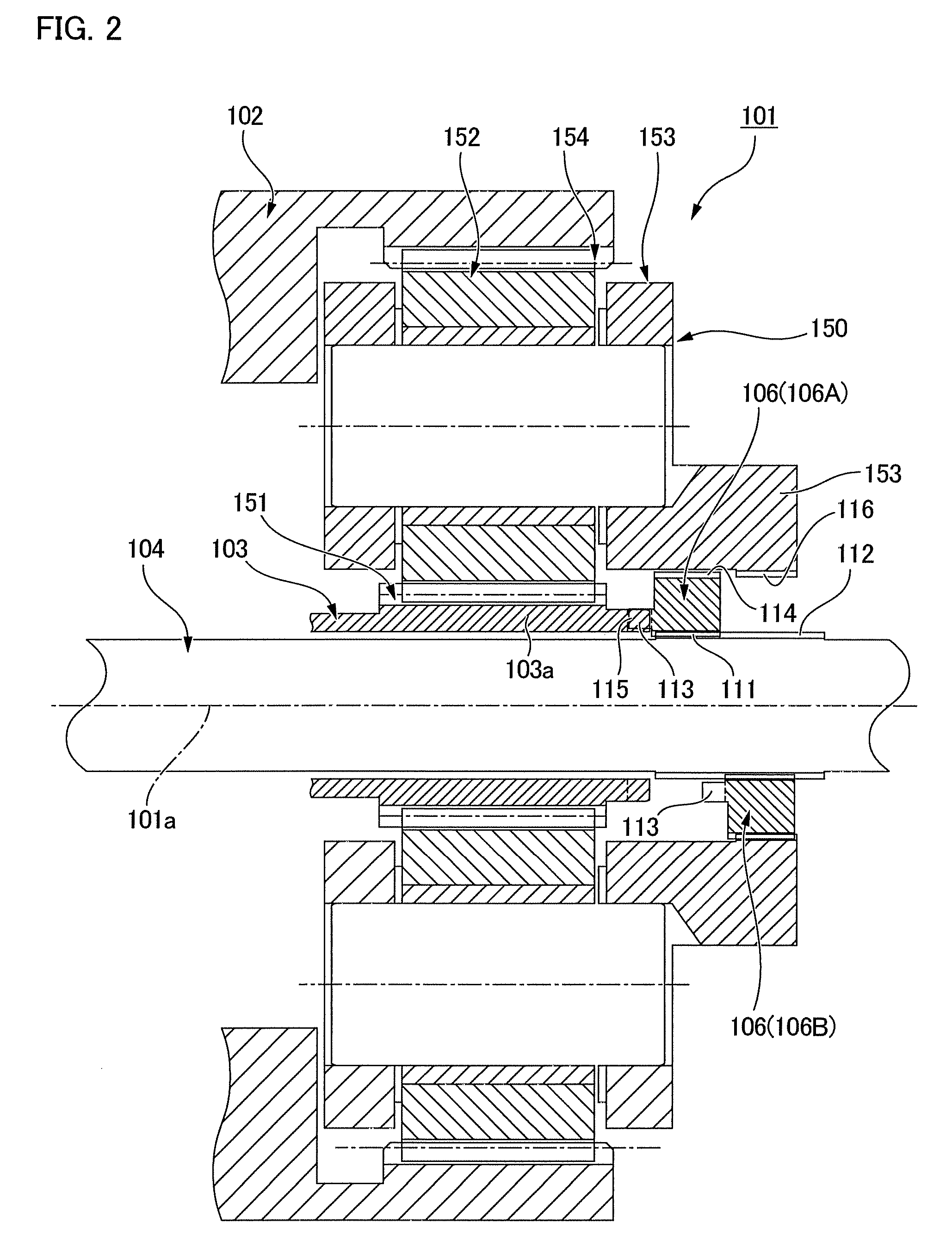

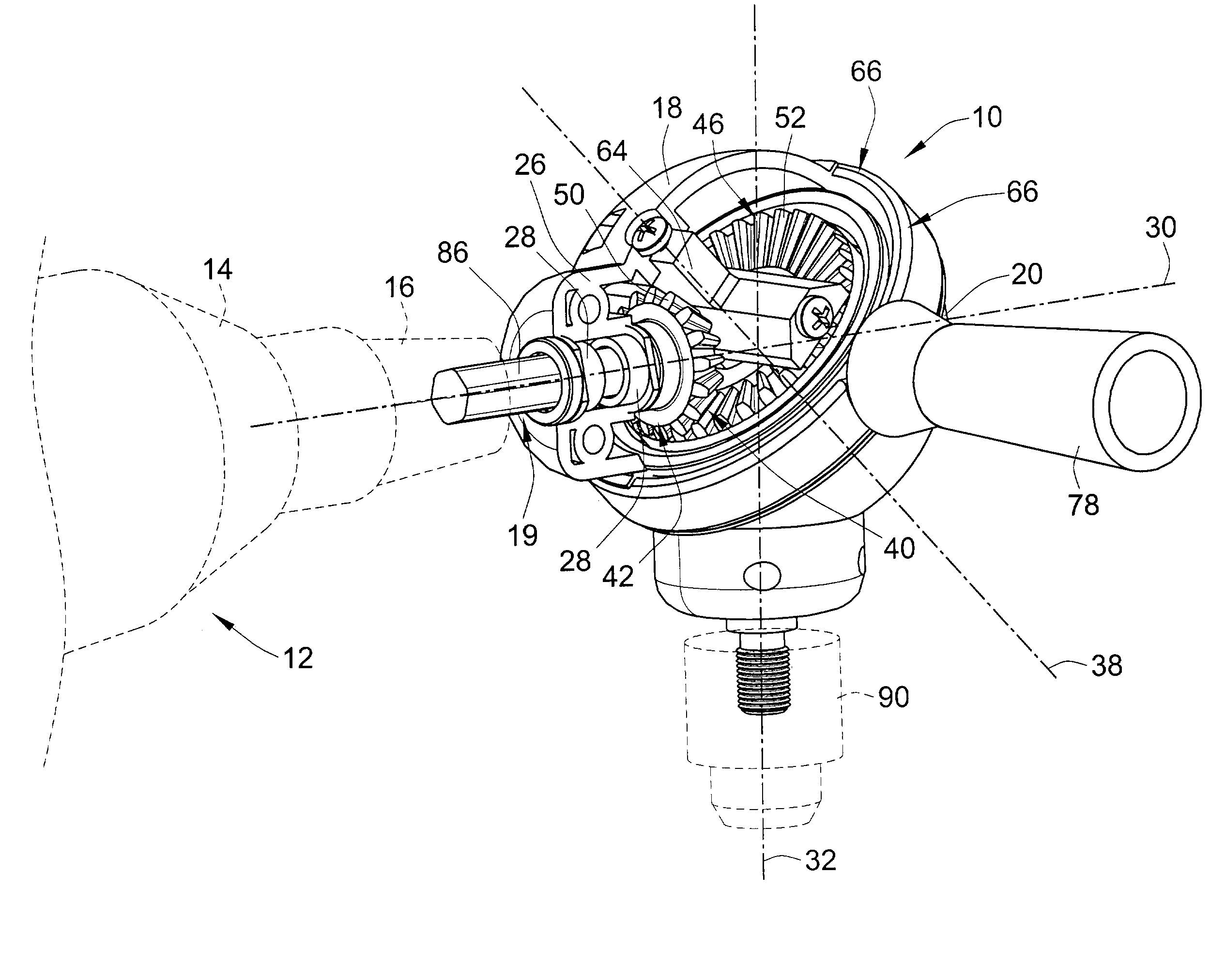

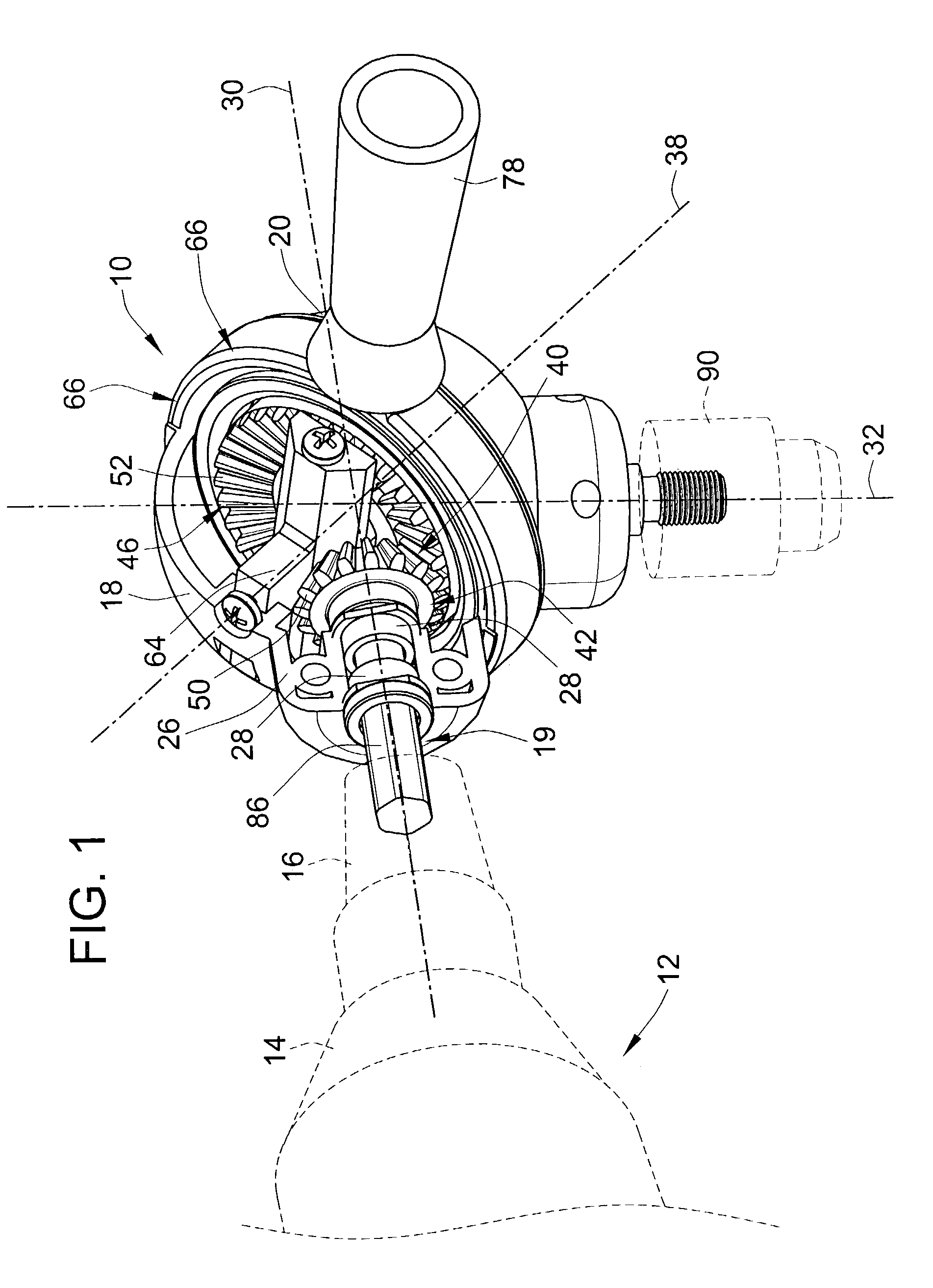

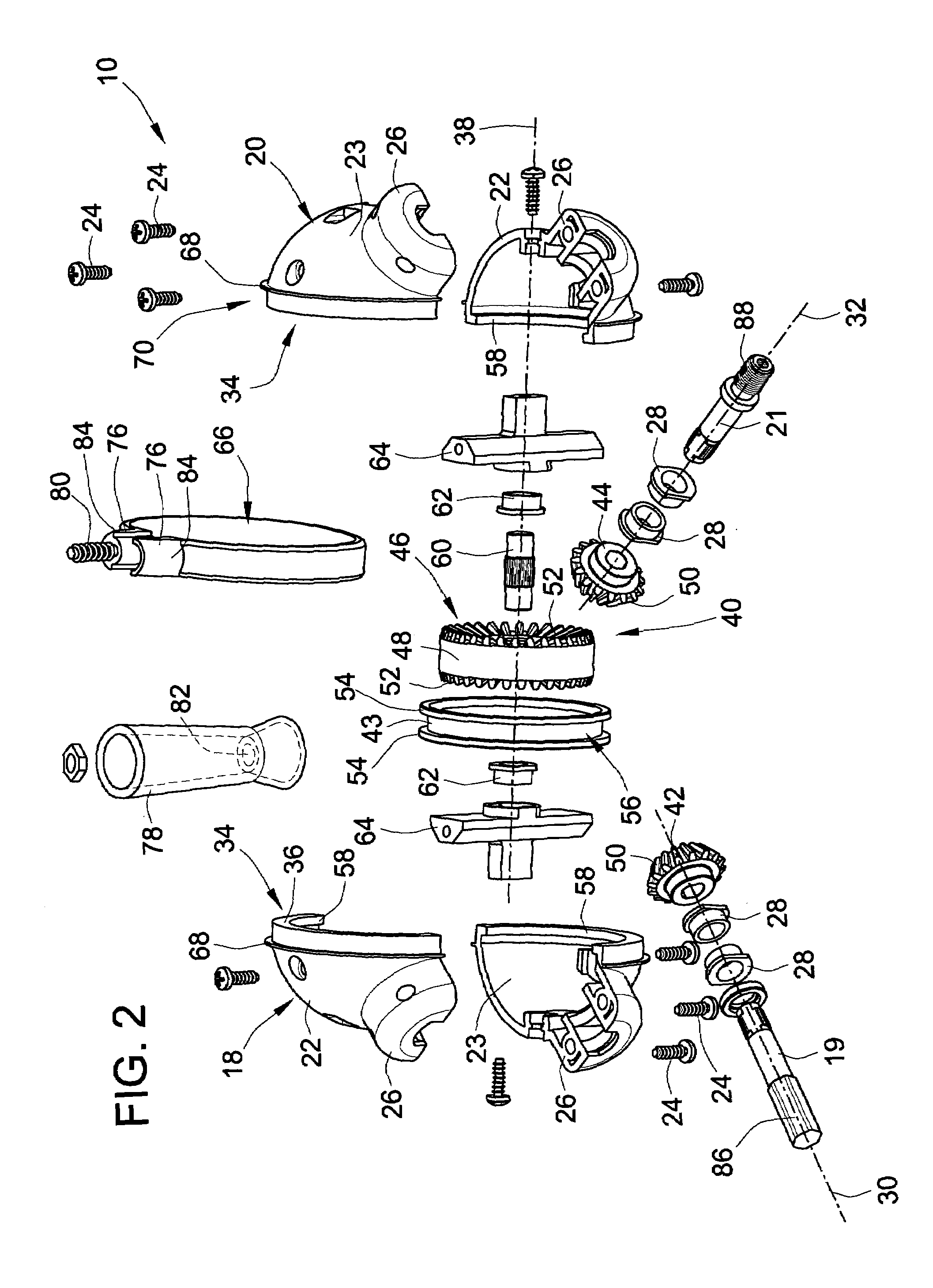

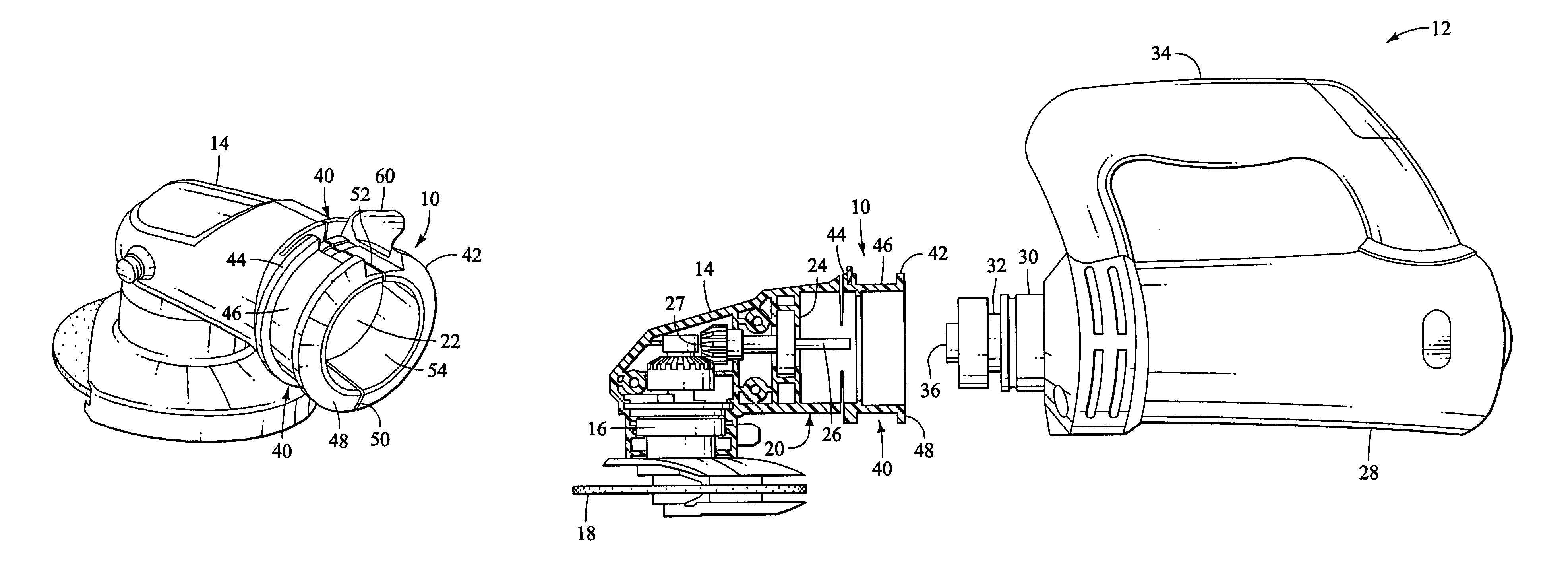

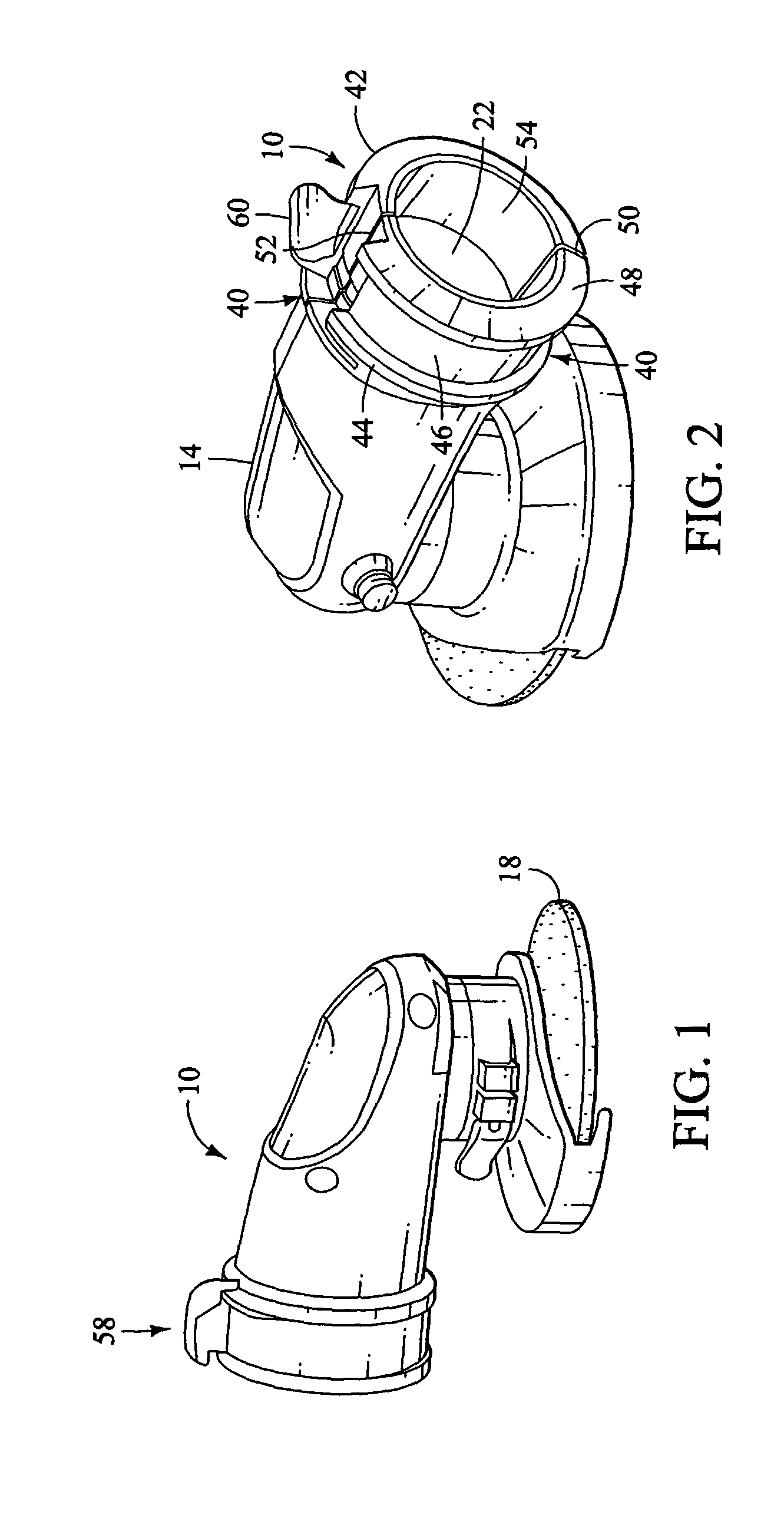

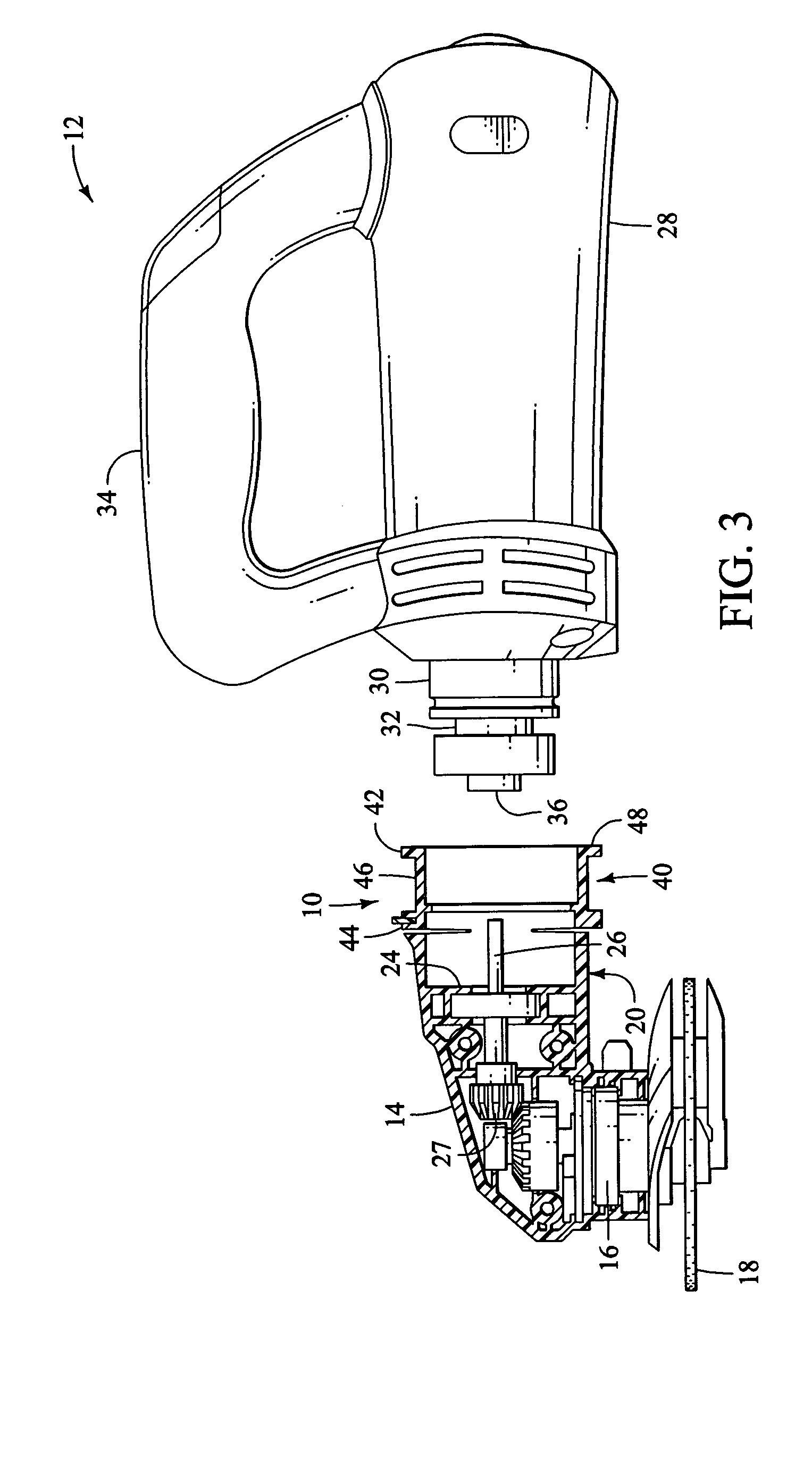

Adjustable angle drive for a rotary power tool

The present invention provides an adjustable angle drive for a rotary power tool such as a drill. The adjustable angle drive includes input and output shafts journalled for rotation in input and output housings. The input and output shafts are rotatably coupled through gearing and are adjustable among different angular positions.

Owner:NOMIS

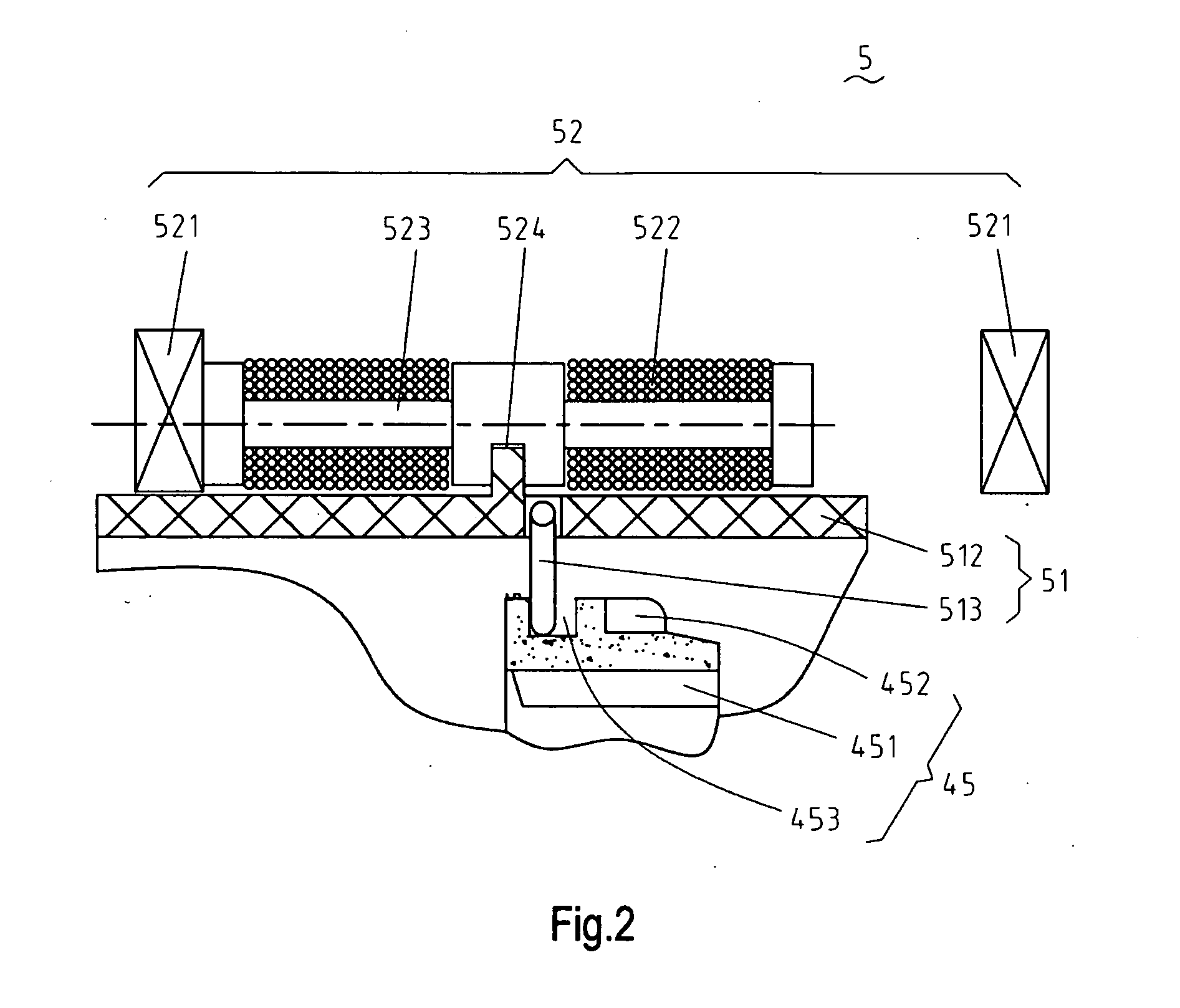

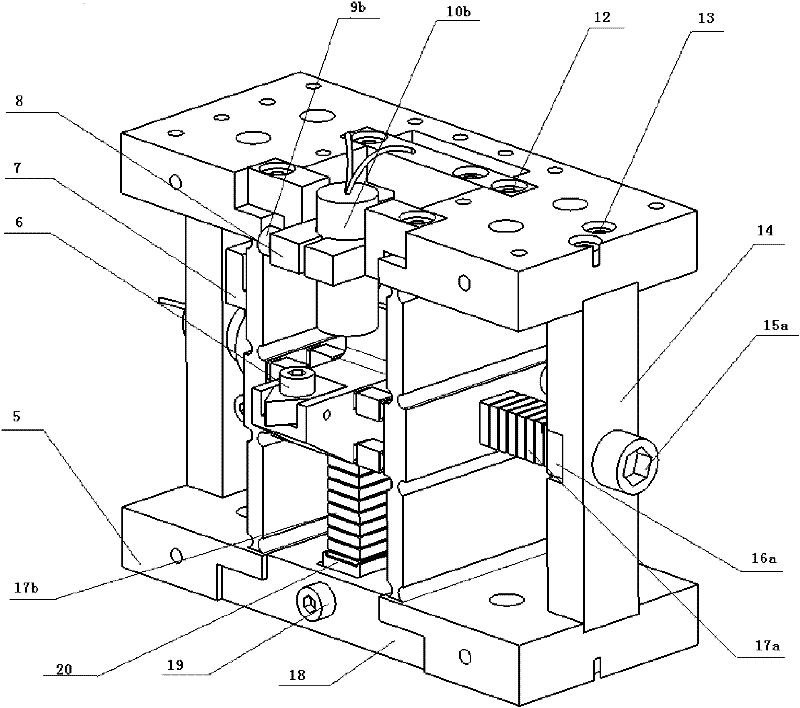

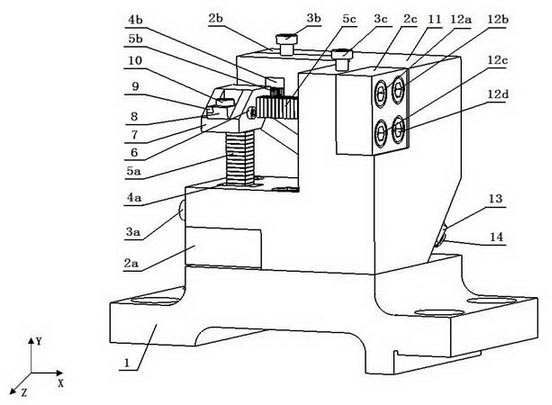

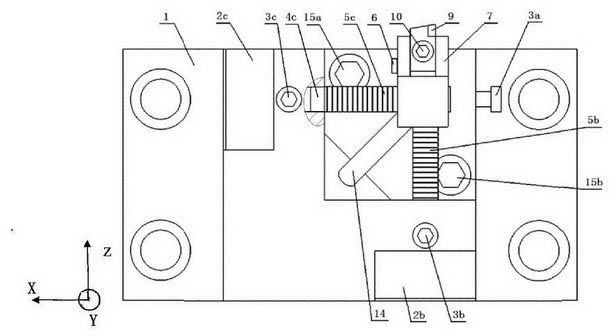

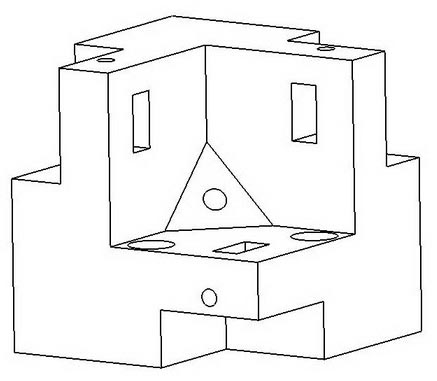

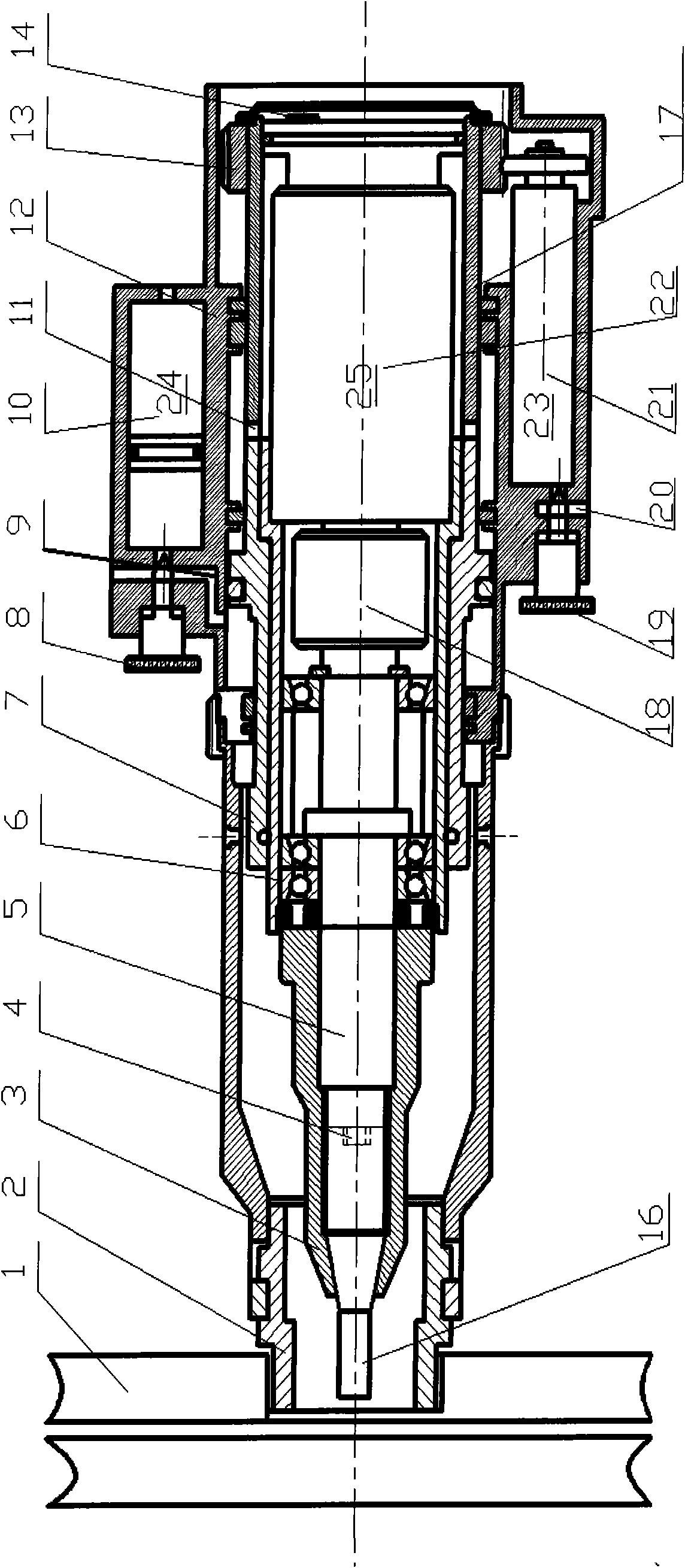

Three-dimensional elliptical vibration cutting device

ActiveCN102371359AImprove machinabilitySimplify the modeling processMeasurement/indication equipmentsTurning toolsLinear motionEllipse

The invention relates to a three-dimensional elliptical vibration cutting device, belonging to the field of cutting and ultra-precision cutting machining of materials which are difficult to machine. A diamond cutter is guided through flexible hinge mechanisms respectively along an X direction, a Y direction and a Z direction, and further, is driven by three piezoelectric stacks respectively alongthe X direction, the Y direction and the Z direction; the piezoelectric stacks of the X direction and the Z direction are preloaded by preloading screw bolts along respective axial direction; the piezoelectric stack of the Y direction is preloaded through a screw bolt screwing wedge; the preloading processes of the three directions are mutually independent; through regulating and matching the initial phase position and the amplitude of a driving signal for each of the three piezoelectric stacks, the projections of the cutter location point movements of the diamond cutter in an X-Y plane and aY-Z plane are elliptical motions, and the projection of the cutter location point movements of the diamond cutter in an X-Z plane is reciprocating elliptical motion or linear motion. The three-dimensional elliptical vibration cutting device has a novel and simple structure, is easy to implement, and is beneficial to obtaining the best cutting machinability of the diamond cutter.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

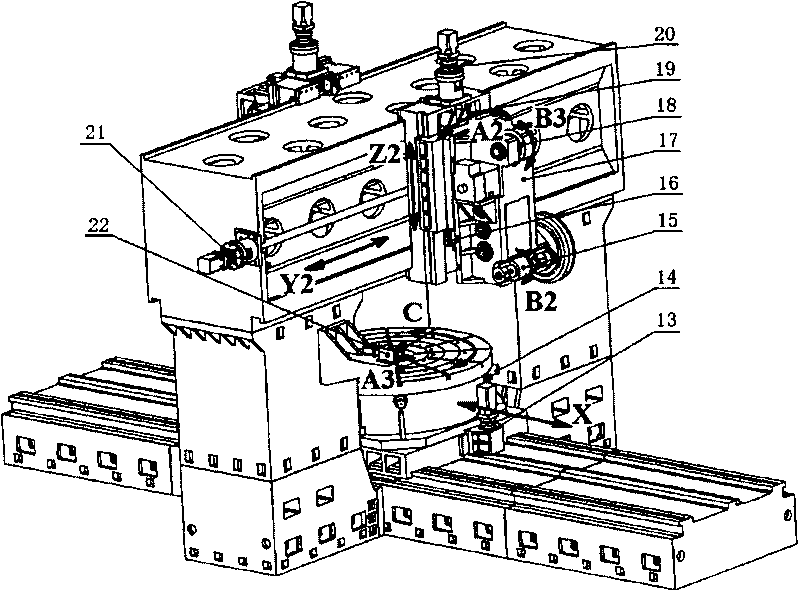

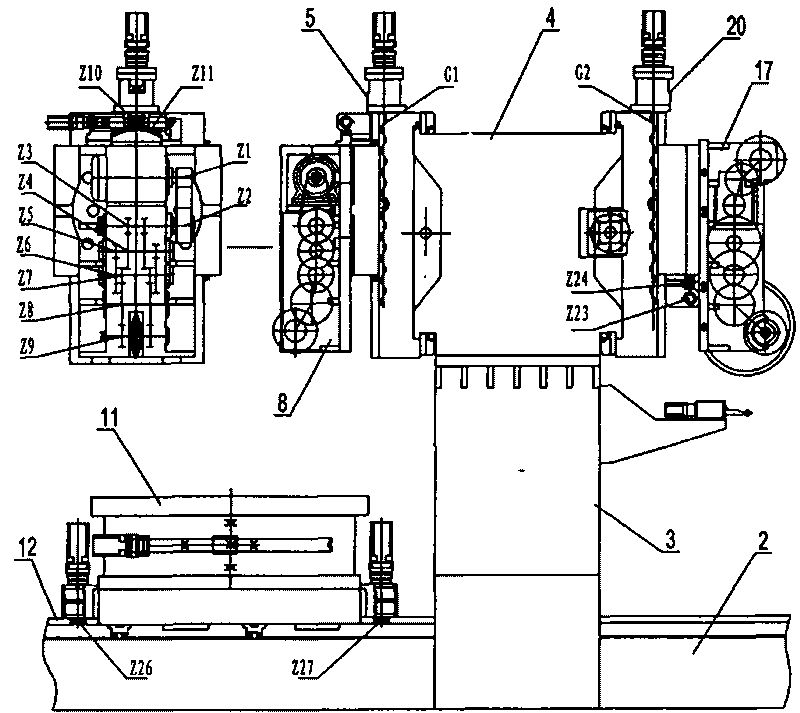

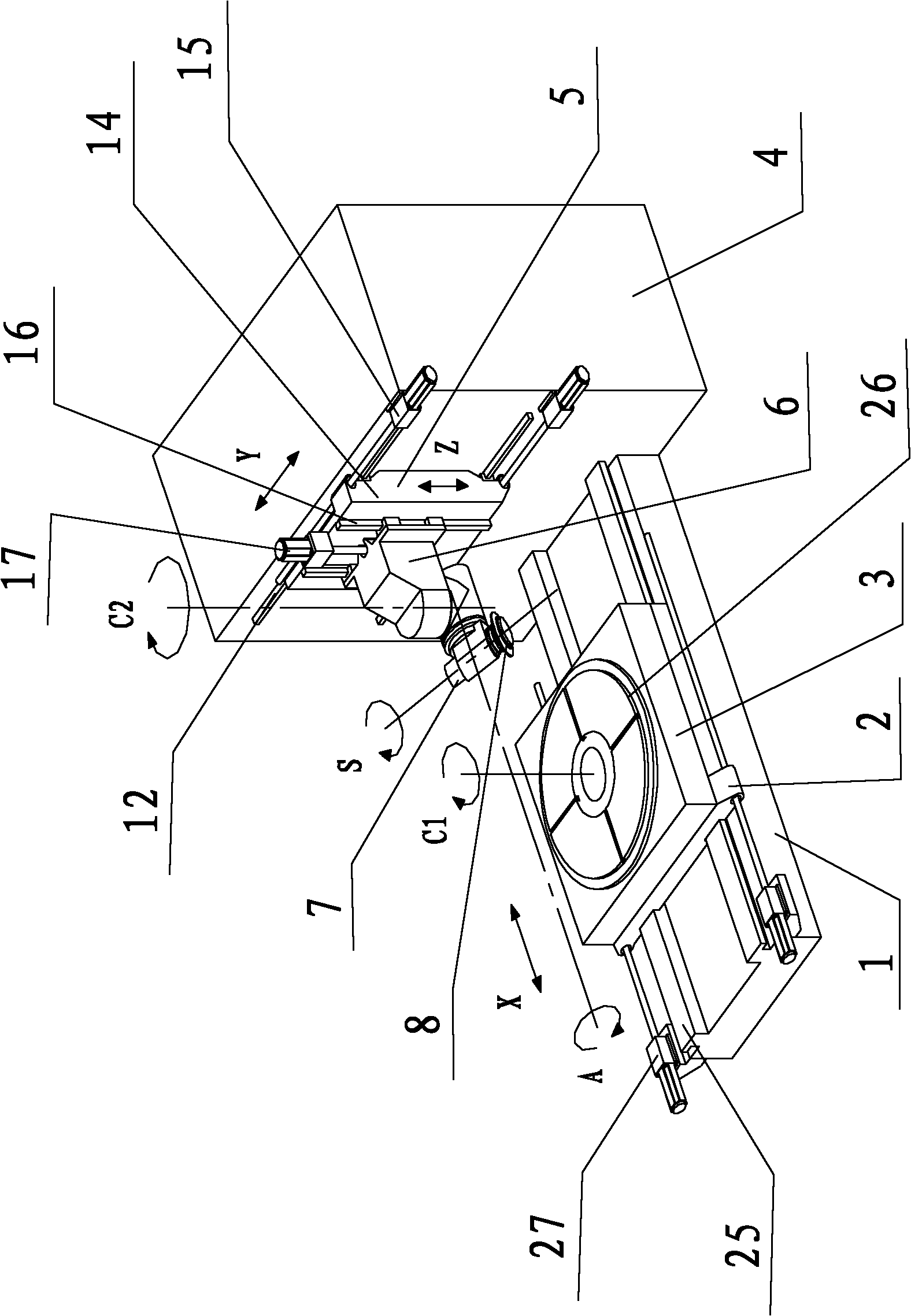

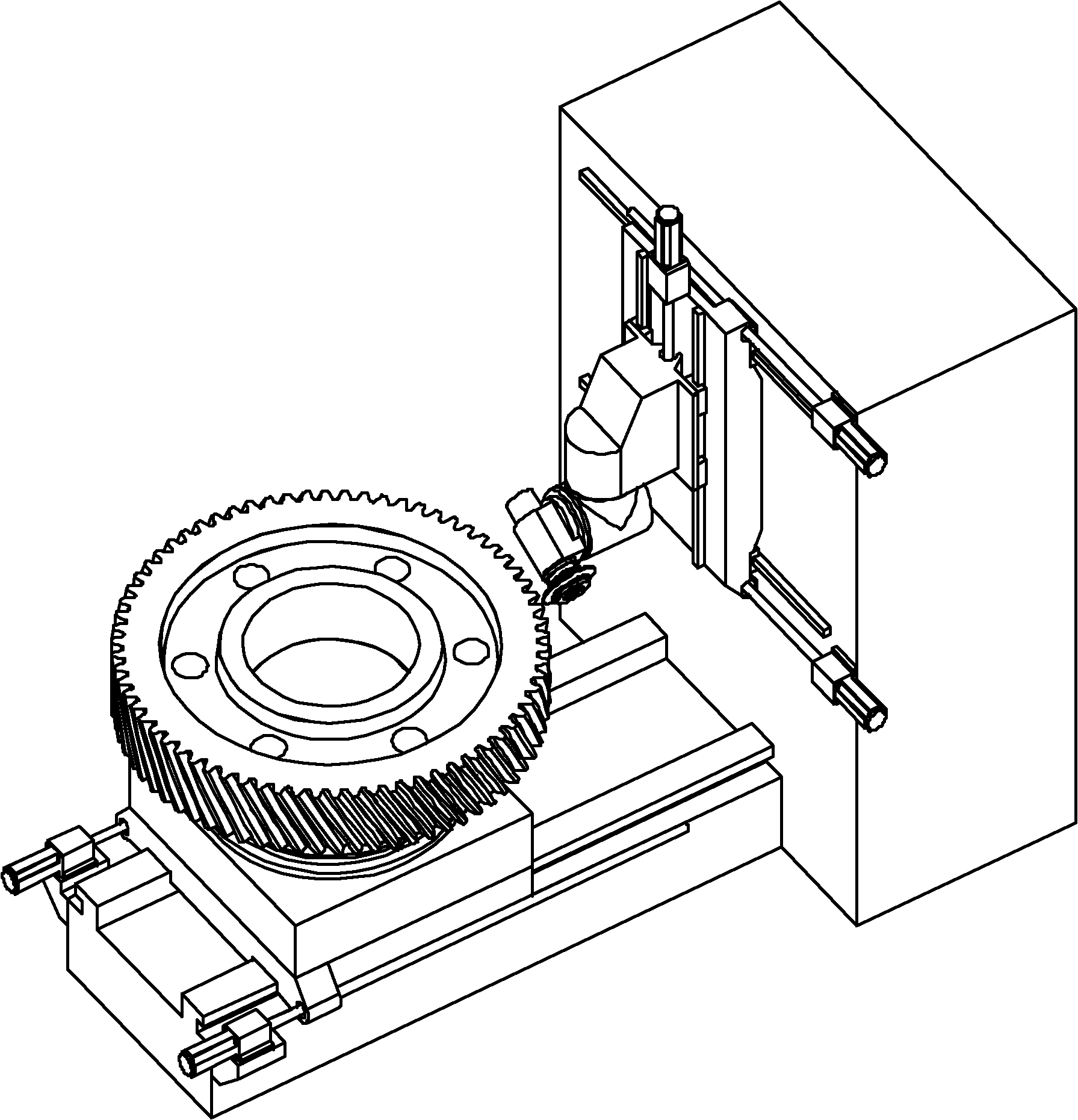

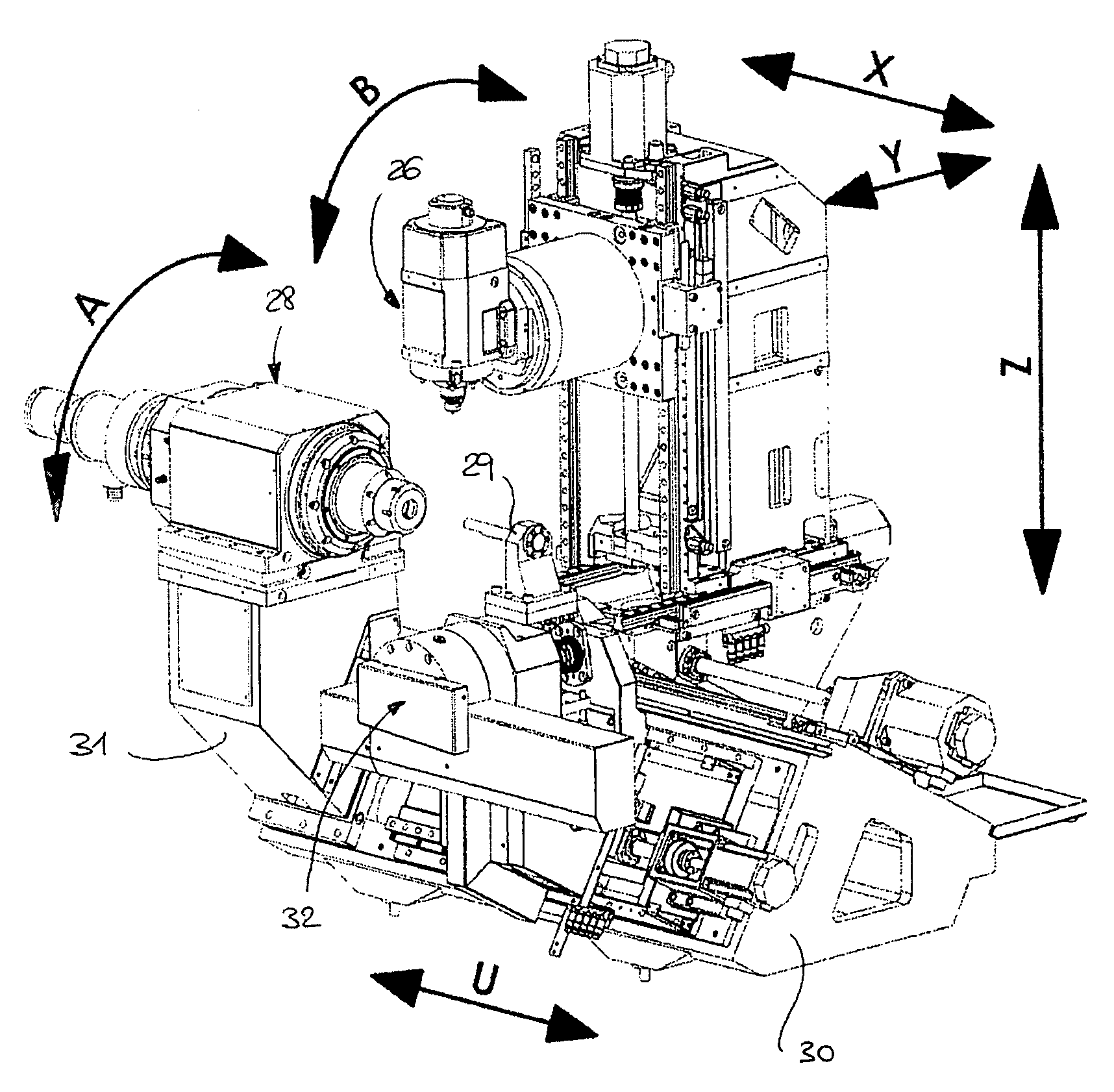

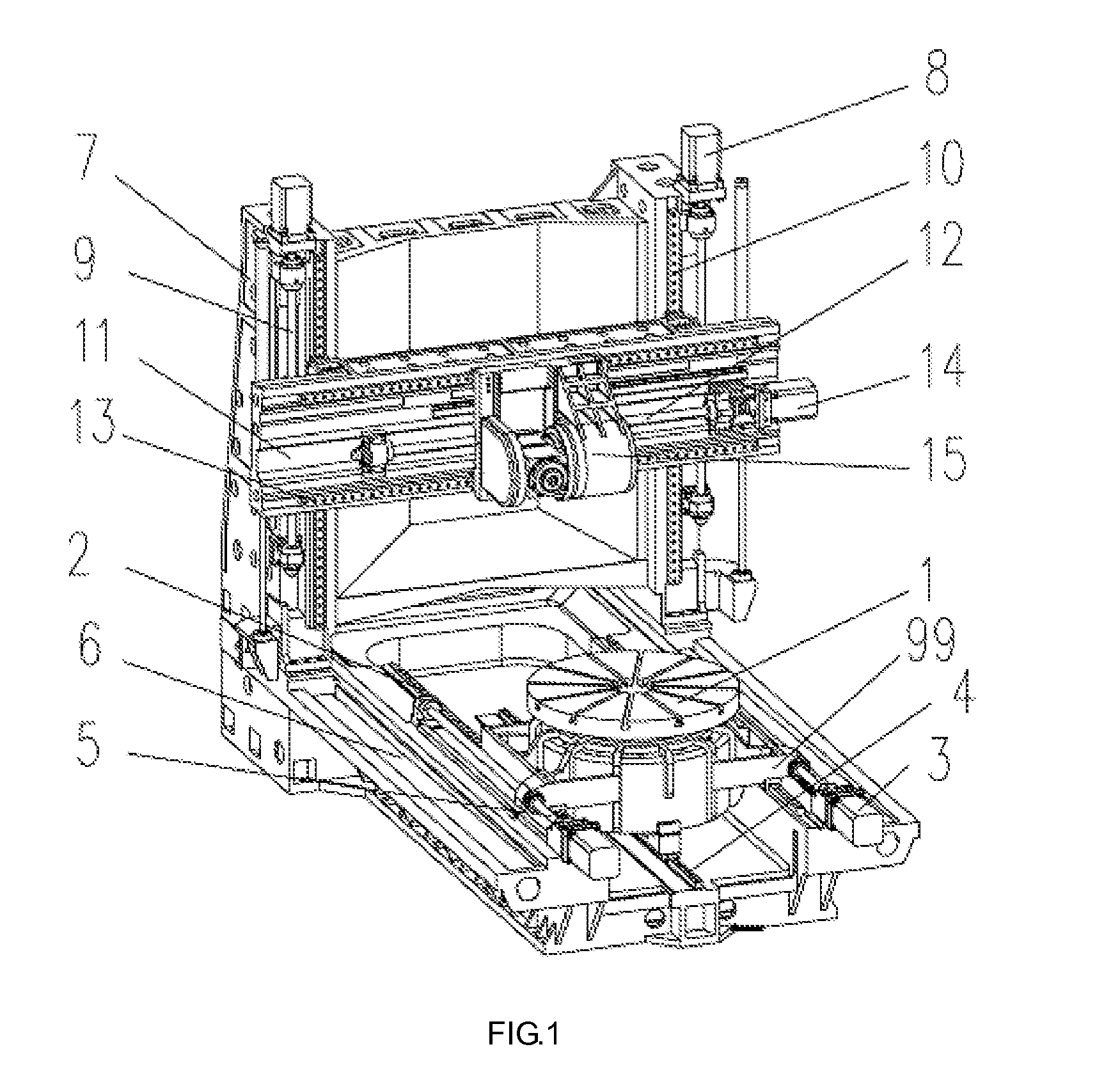

Large-scale numerical control gear machining machine tool

ActiveCN102151909AImprove machining accuracyImprove processing efficiencyLarge fixed membersDriving apparatusLinear motionImpeller

The invention provides a large-scale numerical control gear machining machine tool which has six numerical control coordinate axes, namely X, Y, Z, A, C1 and C2 and adopts a two plus four layout manner. A workpiece has two freedom motion, namely linear motion along the X axis and rotational motion around the C1 axis; and a tool has four freedom motion, namely linear motion along the X axis and the Z axis and rotational motion around the A axis and the C2 axis. The large-scale numerical control gear machining machine tool adopts a six-axis (X, Y, Z, A, CI and C2 axis) five-linkage (X, Y, Z, A and C2 axis linkage) structure; the five numerical control coordinate axes, namely the X, Y, Z, A and C2 axes carry out interpolation motion; and the indexing movement of the workpiece is controlled by the C1 axis to process all tooth surfaces. The rotational axis of the workpiece, namely the C1 axis only finishes the indexing movement and does not participate in the interpolation motion formed bythe tooth surfaces so as to improve the processing precision and the processing efficiency of a large-scale gear. The large-scale numerical control gear machining machine tool can be constructed intoa gear miller or a gear grinder, thereby realizing the curved surface machining of a cylindrical gear, a bevel gear, an impeller and others with the indexing features.

Owner:秦川机床工具集团股份公司

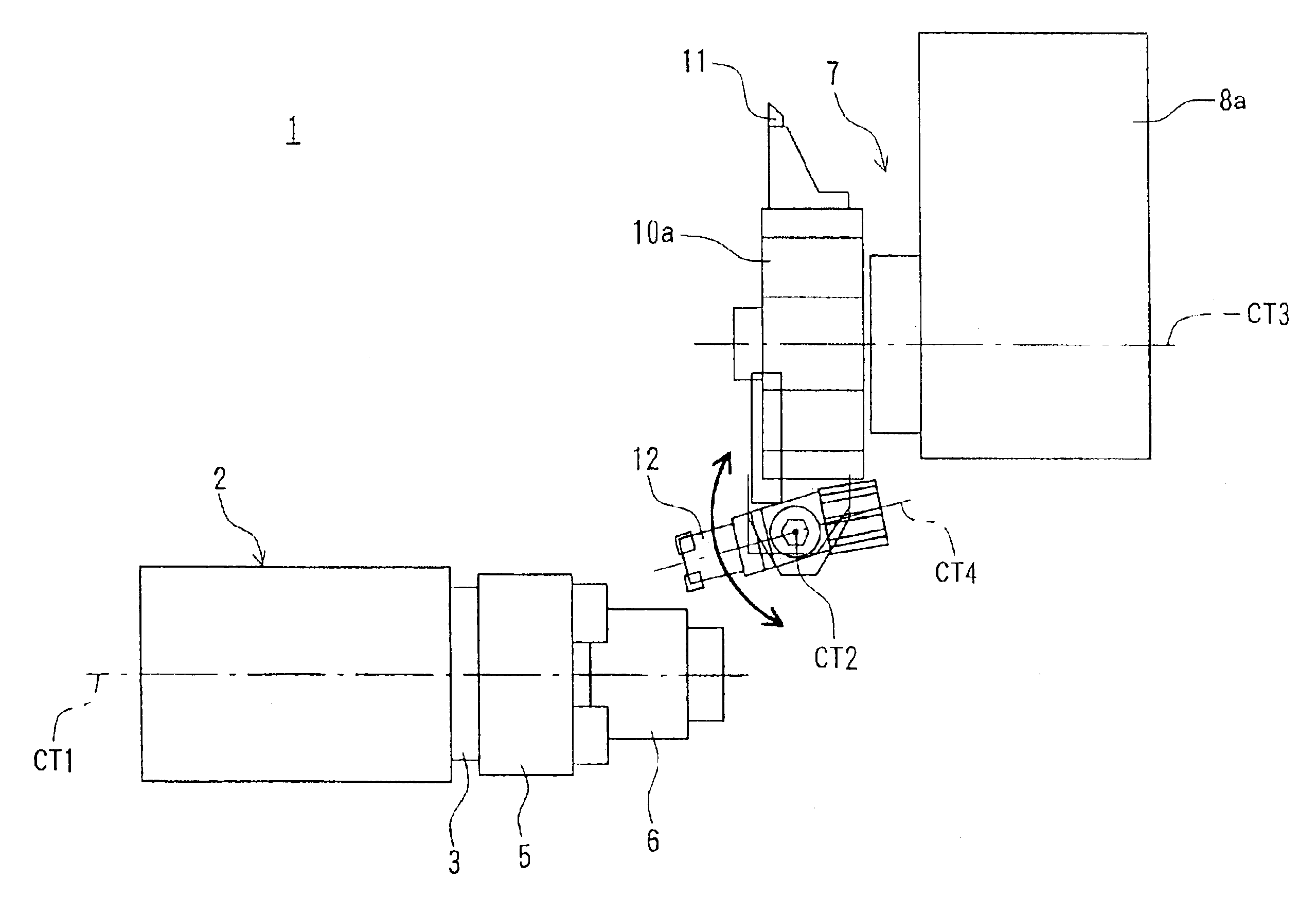

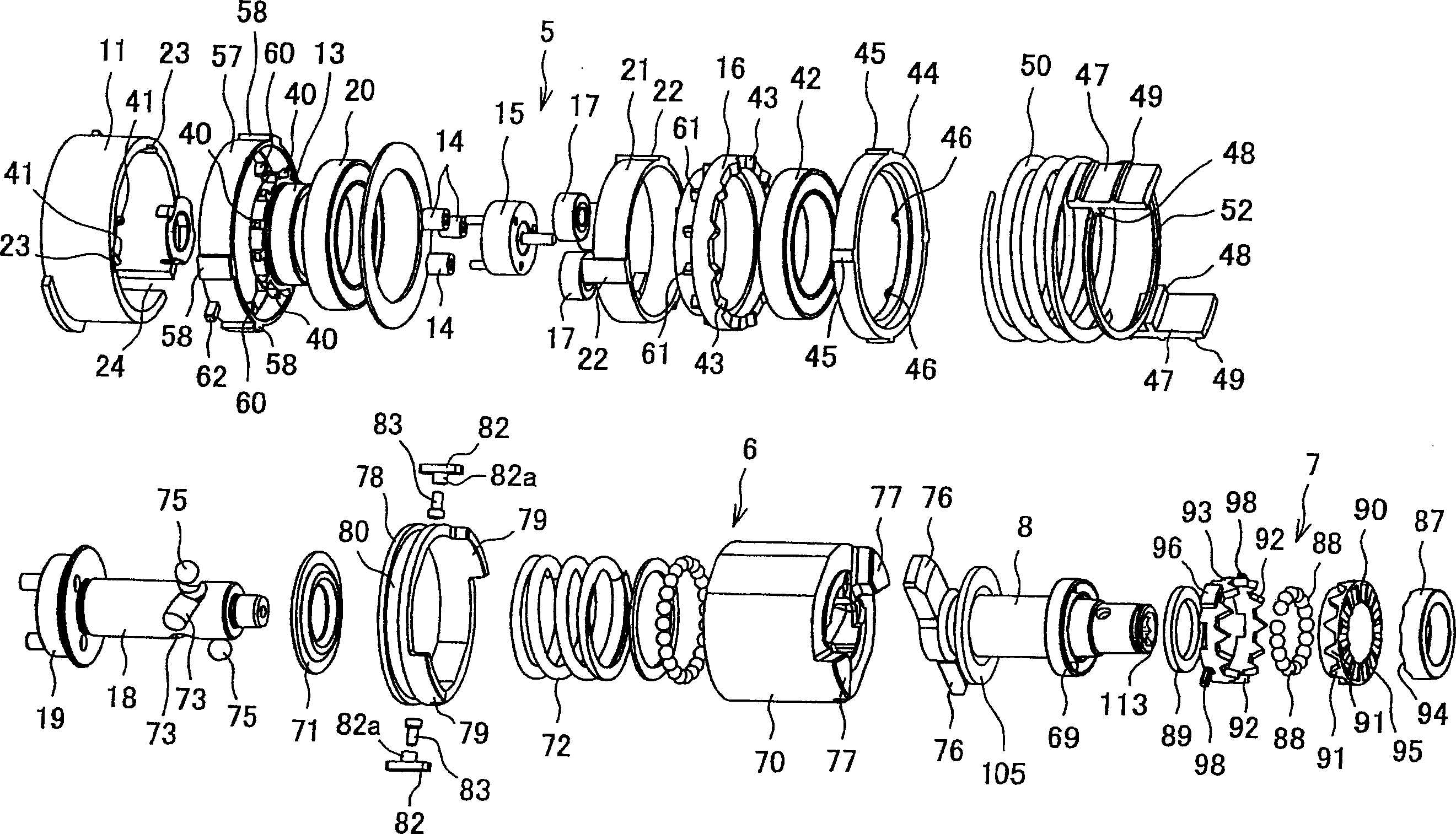

Tool holder for turret lathe

InactiveUS6865789B2Improve machine efficiencyAvoid long exchangesAutomatic/semiautomatic turning machinesPrecision positioning equipmentRotation functionEngineering

A tool holder for attaching a complex tool having a plurality of kinds of cutting edges to a turret, has a base portion attachably and detachably formed at the turret. The base portion has a rotatable tool spindle attachably and detachably installing the complex tool thereon. The tool spindle is provided with indexing means for indexably rotating the tool spindle at an indexed position corresponding to each cutting edge of the complex tool. And, clamping means for clamping the tool spindle at a predetermined indexed position is provided. Indexing rotational function and clamping function owned by the tool holder makes the use of the complex tool in the lathe possible.

Owner:YAMAZAKI MAZAK KK

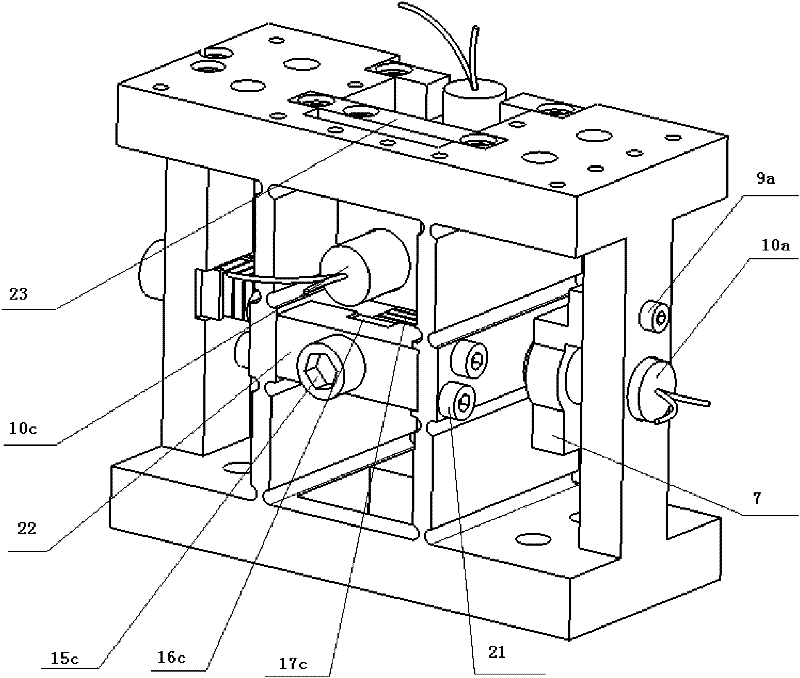

Three-dimensional elliptic motion generating method and device for diamond cutter

ActiveCN102059575AAchieve autonomous controlThe generation method is simpleDriving apparatusLinear motionElectricity

The invention relates to a three-dimensional elliptic motion generating method and a three-dimensional elliptic motion generating device for a diamond cutter, which belong to the field of ultraprecise cutting and cutting of materials difficult to machine. The diamond cutter is directly driven by three piezoelectric stacks which are arranged vertically, the three piezoelectric stacks are pre-tightened by a pre-tightening bolt at the same time, and the pre-tightening forces of the three piezoelectric stacks are finely adjusted by three wedge mechanisms respectively; by actively controlling the initial phase of a three piezoelectric stack driving signal, the projections of the motion of the diamond cutter on an X-Y plane and a Y-Z plane are elliptic motions, and the projection of the motion of the diamond cutter on an X-Z plane is a reciprocating linear motion; and by regulating the parameters such as frequency and amplitude of the three piezoelectric stack driving signal, the automatic control over the three-dimensional elliptic motion track parameter of the cutter is realized. The method and the device are very simple, easy to implement and favorable for obtaining the optimal cutting machinability of the diamond cutter.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

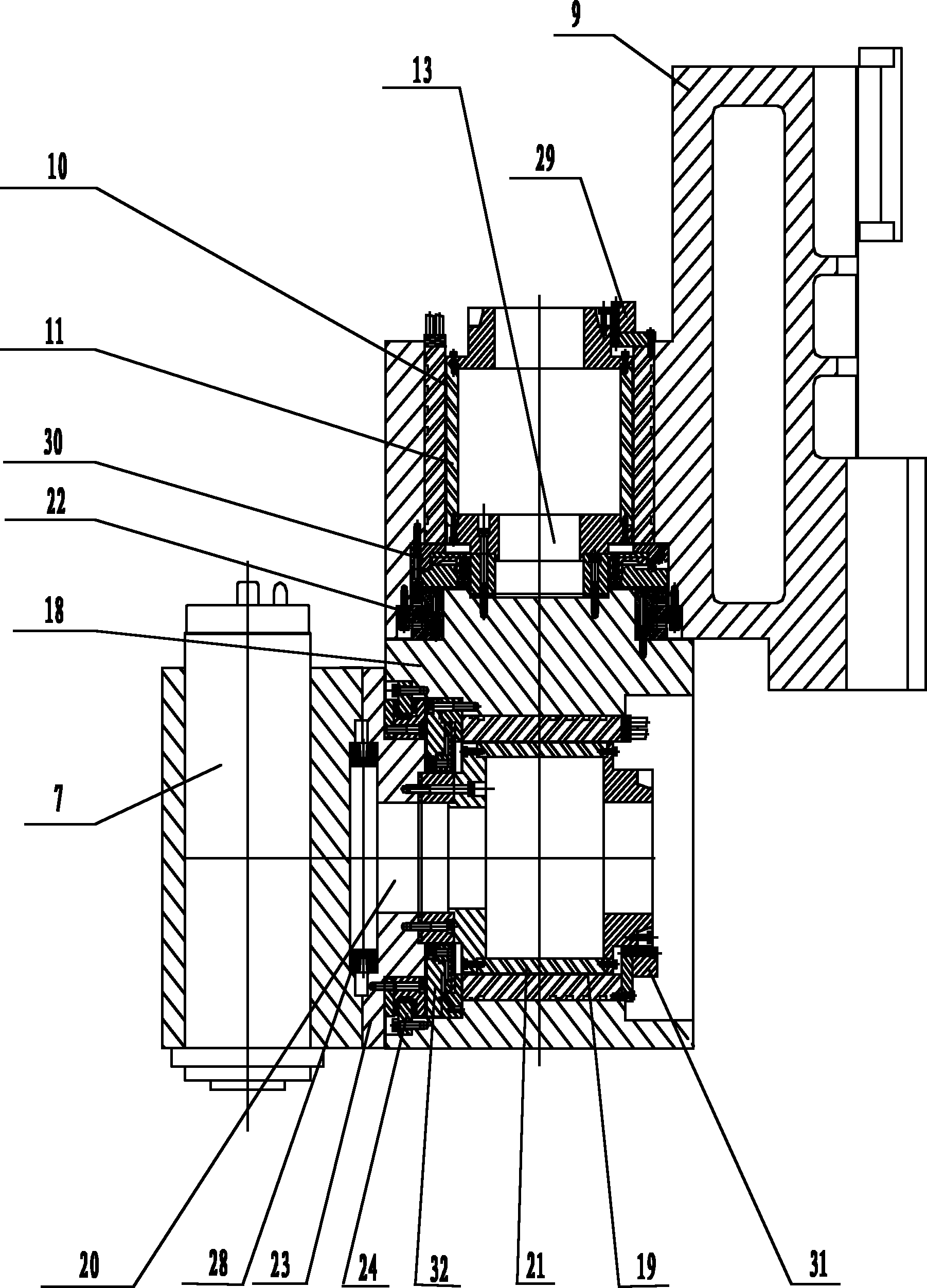

Whirling head and its use

The frame of the whirling head comprises the rigid casing (7), in which the part (10) contains the drive pulley (15) solidly attached to the coupling member (17) connected to the drive shaft of the spindle (26). By means of the belt (19), this pulley (15) drives the pulley (8) solidly attached to the connecting cone (4), which in turn comprises the internal milling cutter (1) which cuts the thread of the screw shaft (27) supported between the bar advance unit (28) and the tailstock centre (29). The latter is mounted as an exchangeable tool on the return unit (32).

Owner:WILLEMIN MACODEL

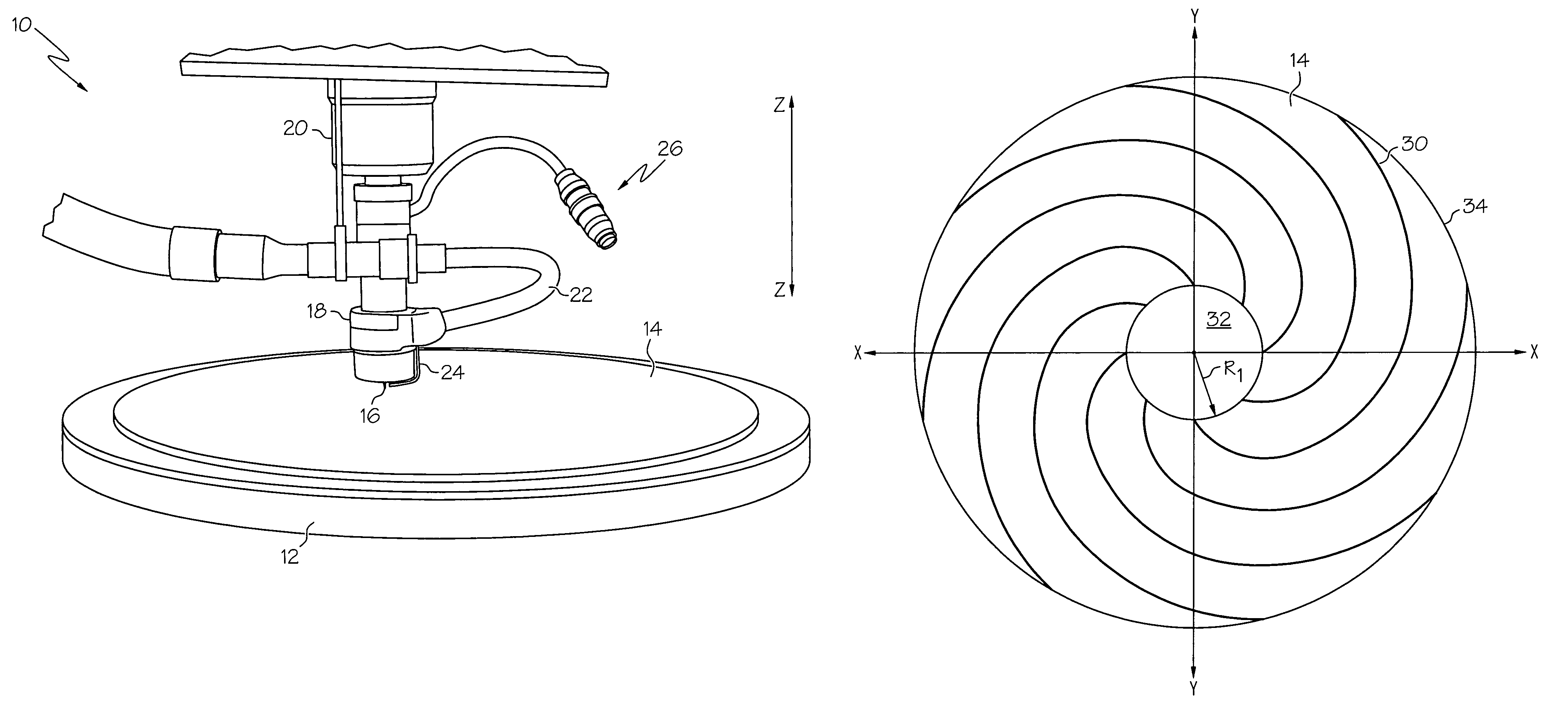

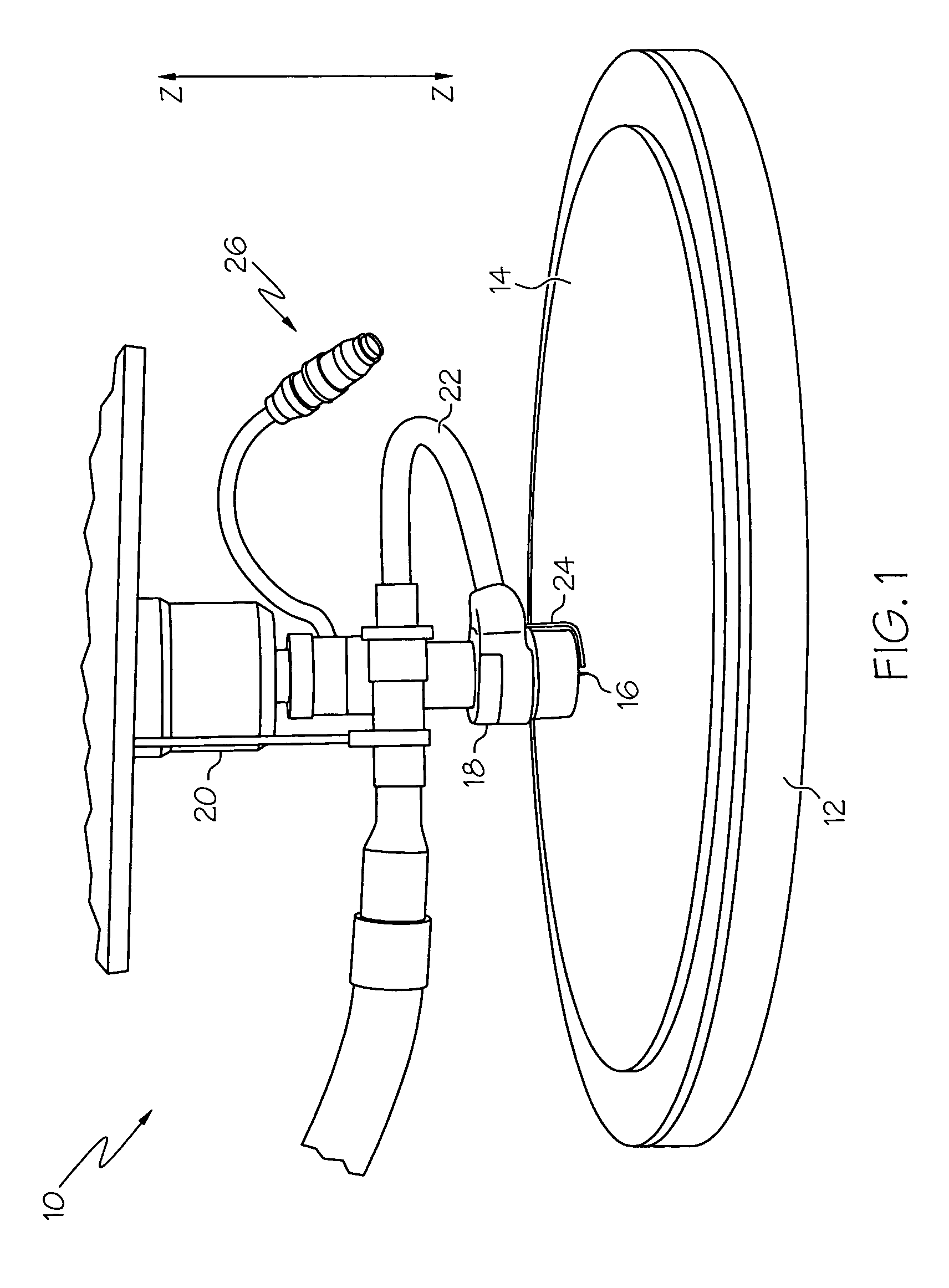

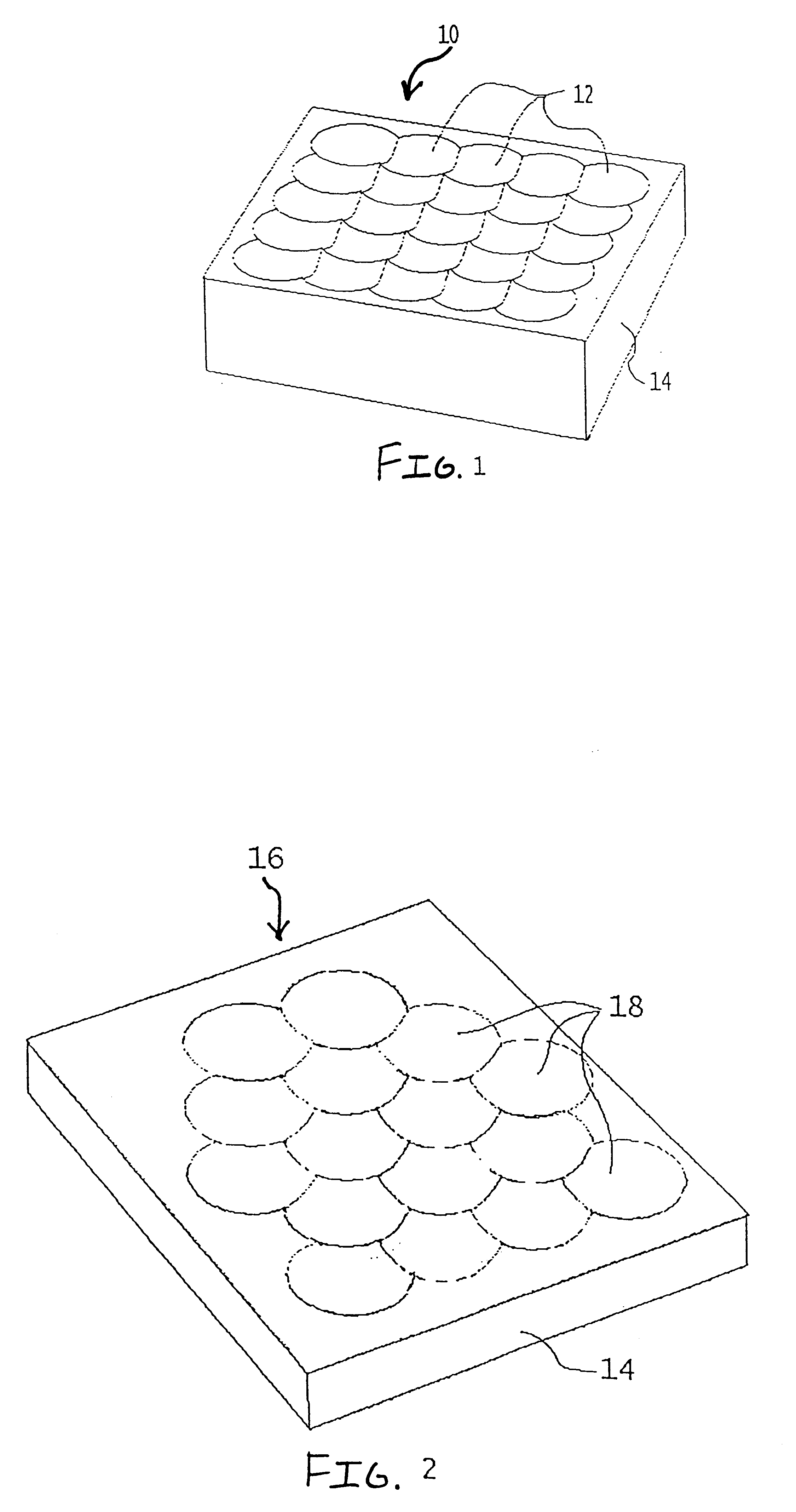

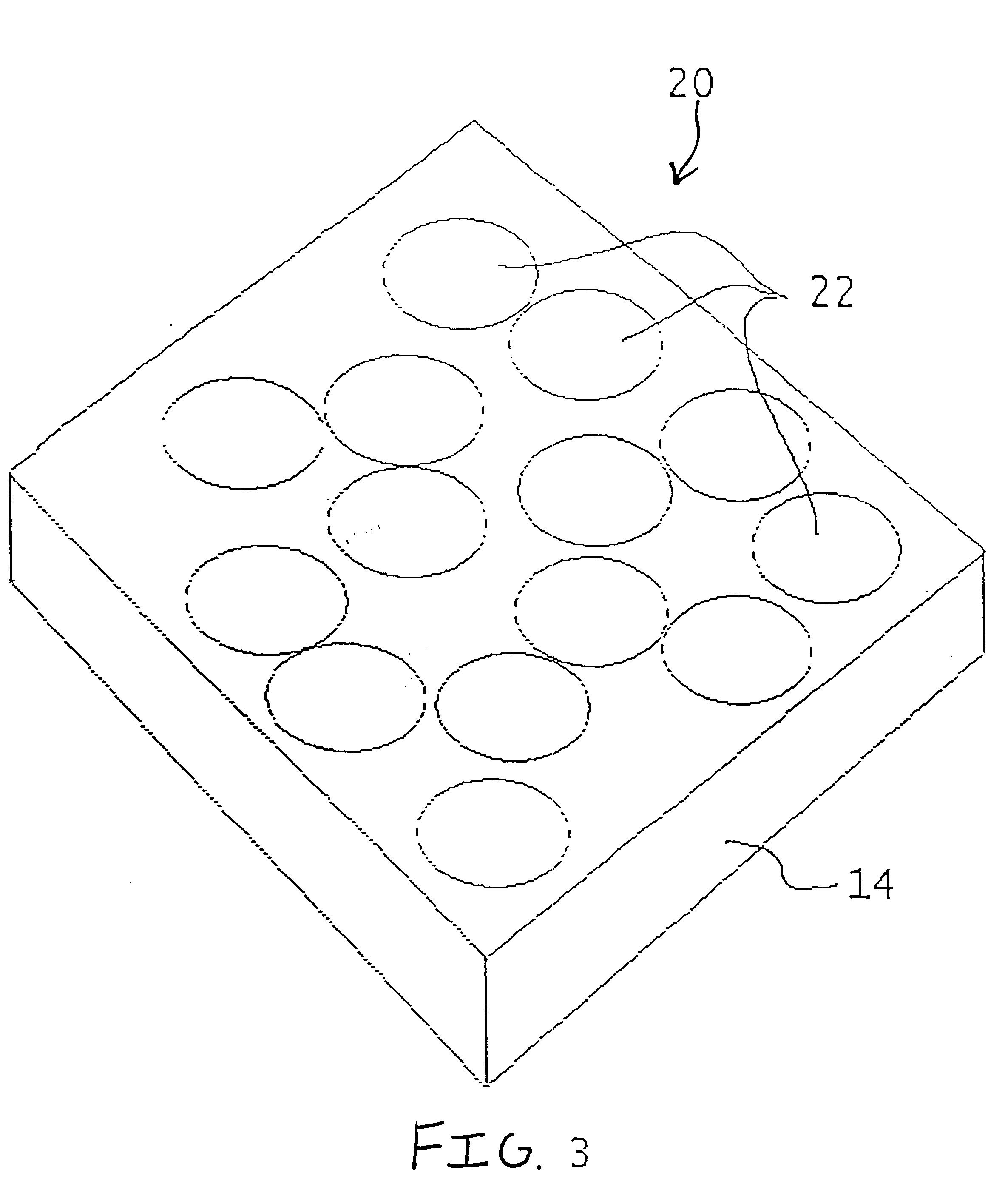

Curved grooving of polishing pads

ActiveUS7234224B1Improve productivityEfficiently formedMilling cuttersAbrasion apparatusHigh rateEngineering

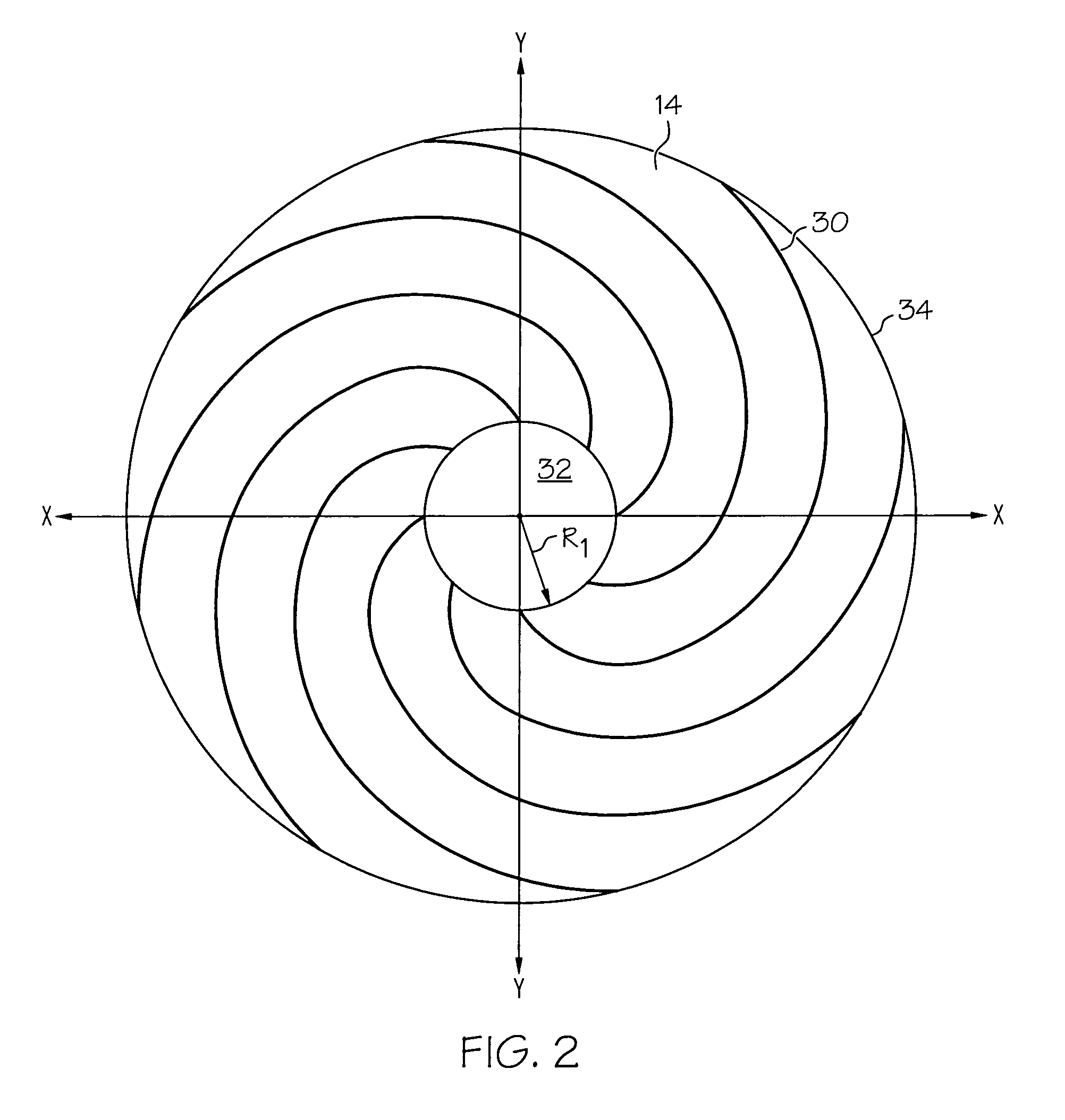

A method is provided for forming grooves in a polishing pad useful for planarizing a substrate in a chemical mechanical planarization process. The method maintains average velocity as a function of bit diameter to enable groove formation using a rotating bit, whereby grooves can be formed at a higher rate while maintaining high groove quality and low defectivity.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Hand-held tool

ActiveUS20110114347A1Accurate detectionReduce usageAutomatic control devicesDerricks/mastsHand heldControl theory

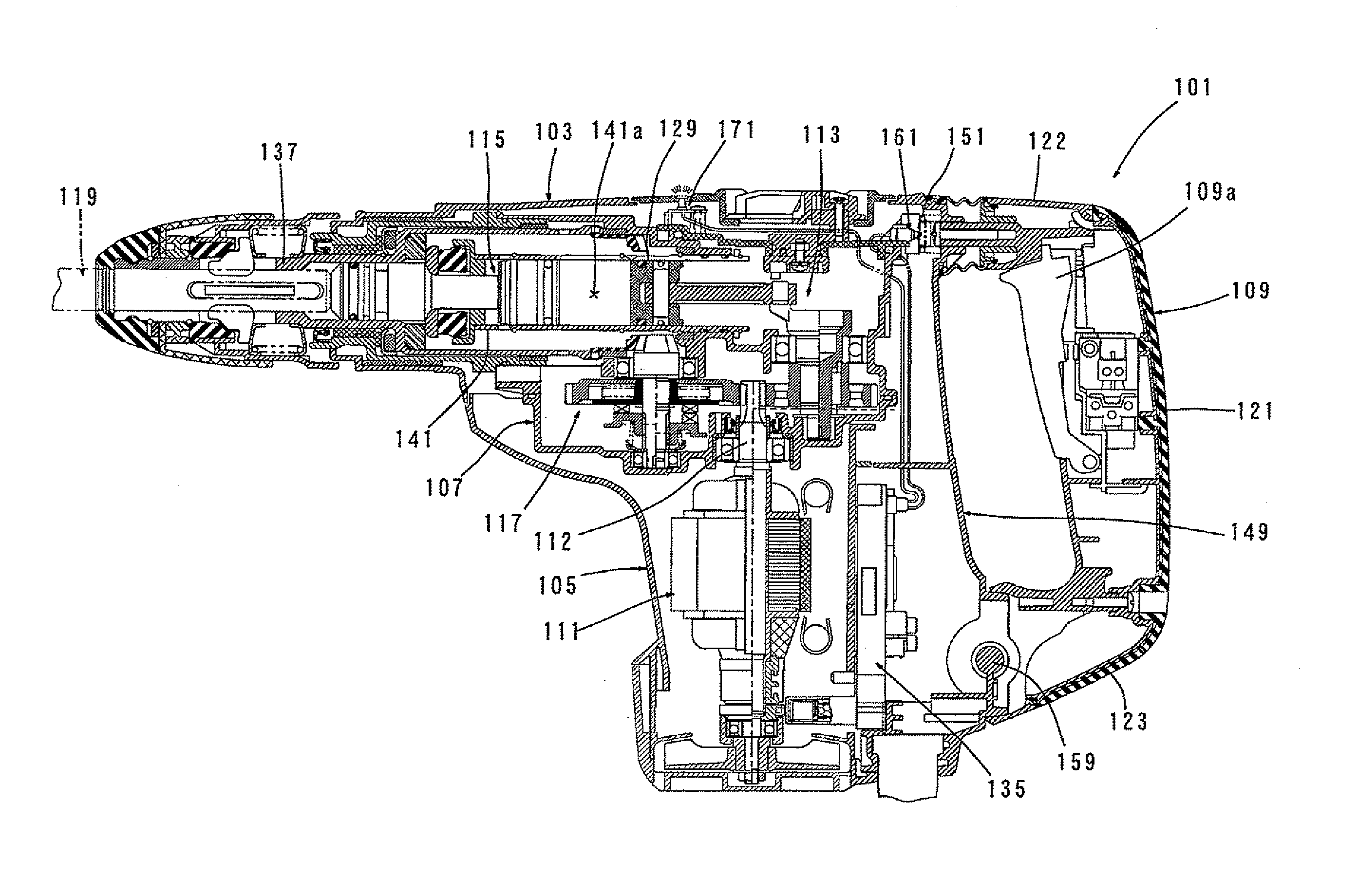

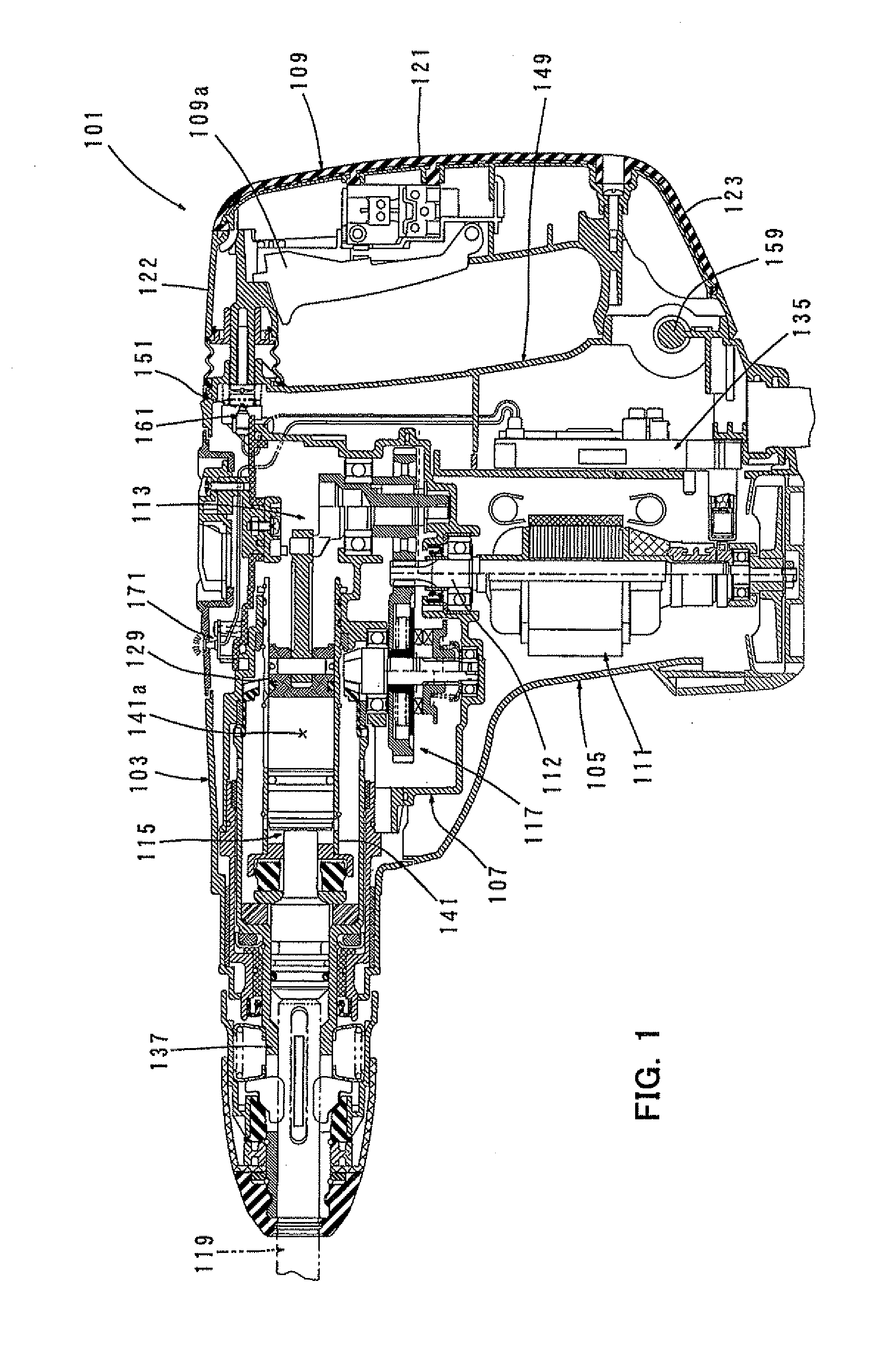

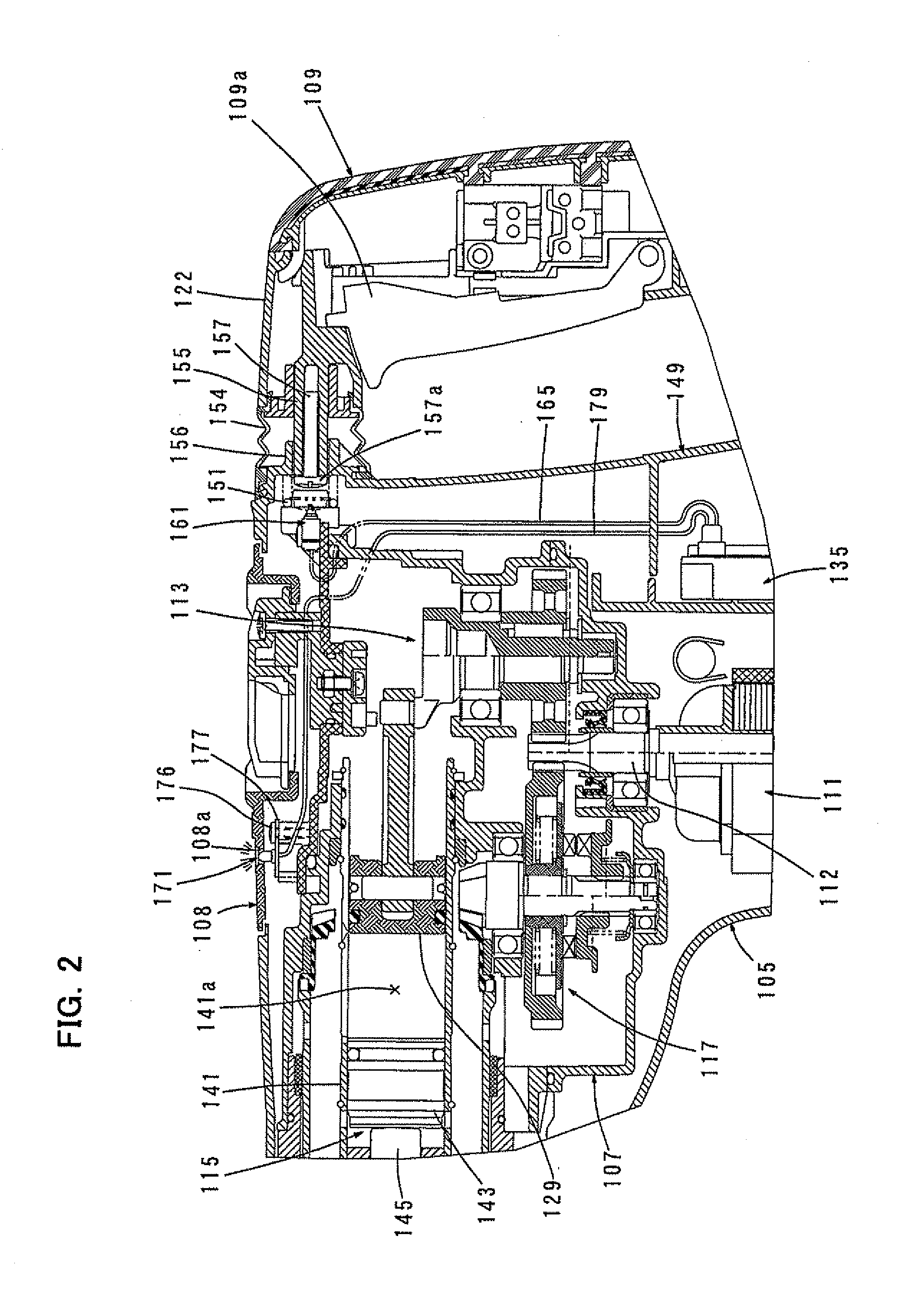

An effective technique for detecting several load conditions different in presence or absence and magnitude of load applied to a tool bit is provided in a hand-held tool. A hand-held tool 101 performs a predetermined operation while pressing a tool bit 119 mounted in a front end region of a tool body 103 against a workpiece. A plurality of detecting sensors 161 of different kinds detect several load conditions different in presence or absence and magnitude of load applied to the tool bit 119. The hand-held tool 101 includes at least one of an indicating device 171 which indicates the load conditions based on a result detected by the detecting sensors 161, and a driving control device 135 which controls driving of the tool bit 119 based on the detected result.

Owner:MAKITA CORP

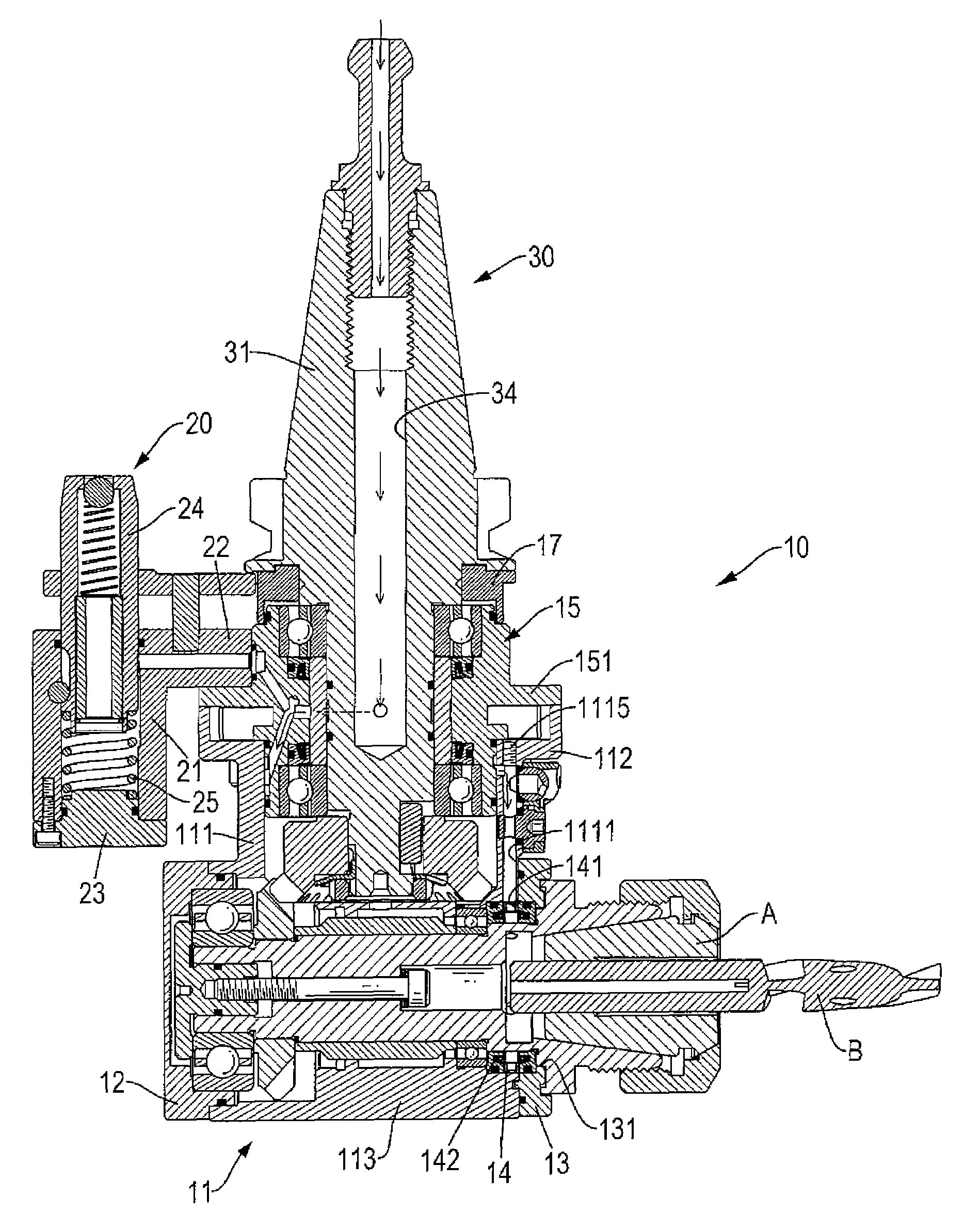

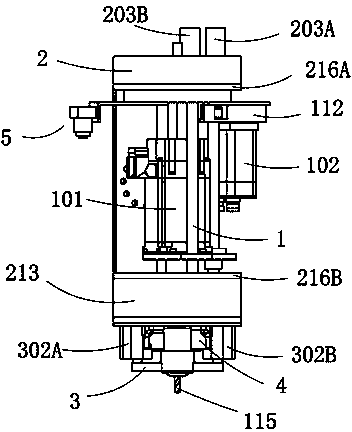

Vertical turning-milling complex machining center

ActiveUS20120210551A1Avoid vibrationDeformation MinimizationLathesAutomatic/semiautomatic turning machinesReciprocating motionTorque motor

A vertical turning-milling complex machining center comprises a horizontally-arranged bed body (6) and a vertically-arranged column (7). The bed body (6) is provided with an X-axis lateral supporting linear track (2) and an X-axis guide screw (5). The bed body (6) is also provided with a uniaxial rotating table (1) which can reciprocate and is driven directly by a first external rotor torque motor. The column (7) is vertically provided with a Z-axis lateral supporting linear track (10), a Z-axis guide screw (9) and a crossbeam (11) that reciprocates up and down. The crossbeam (11) is provided with a transverse Y-axis linear track (13), a Y-axis guide screw (12) and a single-pendulum milling head seat frame that can reciprocate along the Y-axis guide screw (12). The single-pendulum milling head is driven directly by a second external rotor torque motor. The vertical turning-milling complex machining center uses direct-drive technology applied to a B-axis and a C-axis, the motor torque is greatly increased and functional parts can stably operate, therefore the integral rigidity and stability of the machining center are improved.

Owner:KEDE NUMERICAL CONTROL CO LTD

Milling head

InactiveUS7563062B1Good choiceThread cutting auxillary apparatusTransportation and packagingDrive shaftGear wheel

A milling head has a body, a holding device, a driving axle, a spraying device and a tool adaptor. The body has a base, a rear cover, a front cover, a bearing seat and a middle liner ring. The holding device is connected to the body and has a linking arm, a mounting jacket, a bottom cap, a positioning shaft and a locating spring. The driving axle is rotatably mounted in the body and has a transmission shaft and a driving bevel gear. The spraying device is mounted on the base and has a mounting cover and an spraying ball. The tool adaptor is rotatably mounted in the base below the spraying device and has a transmitting bevel gear, a holding head and a connecting segment.

Owner:CHEN CHIN CHIU

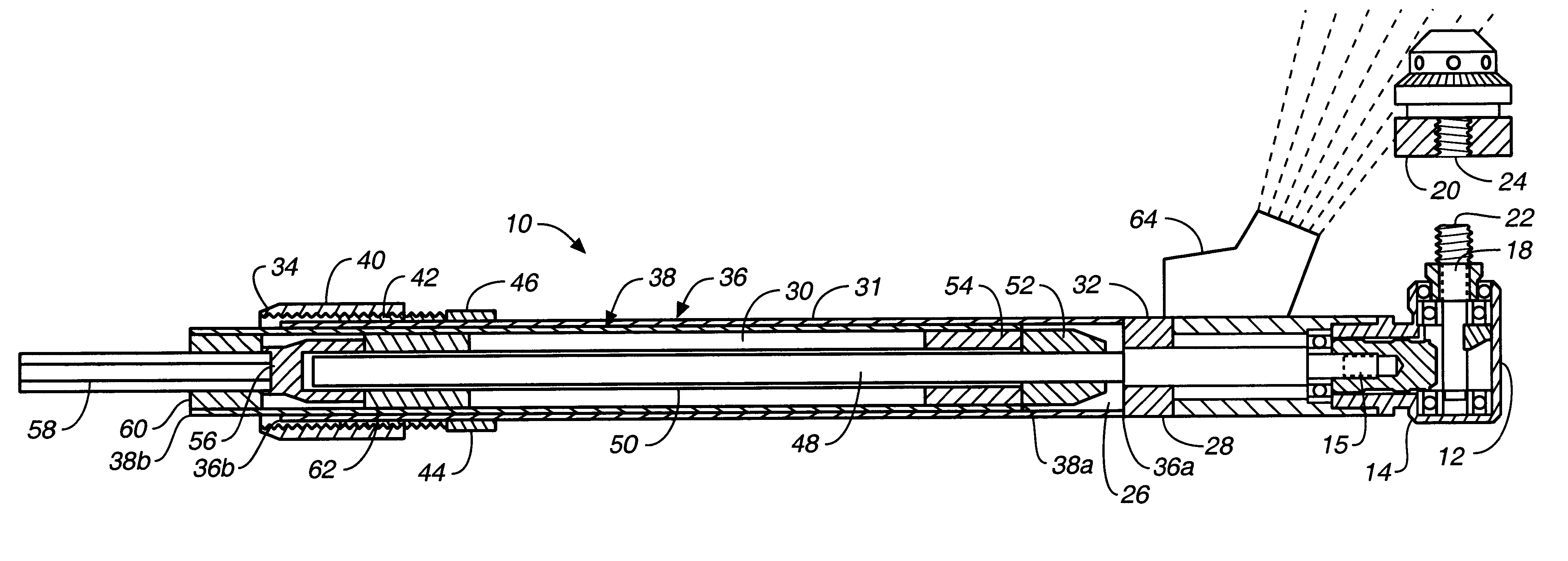

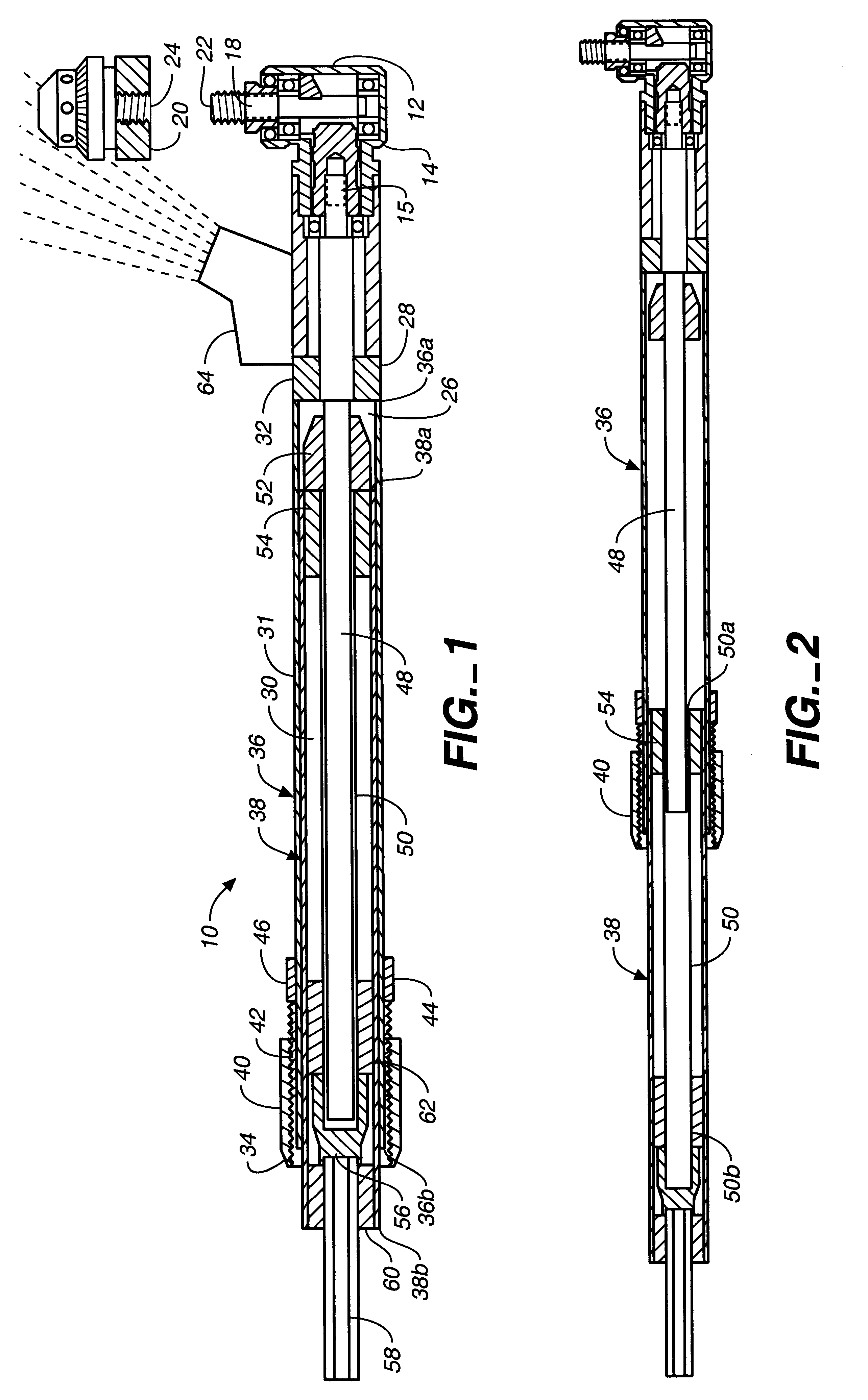

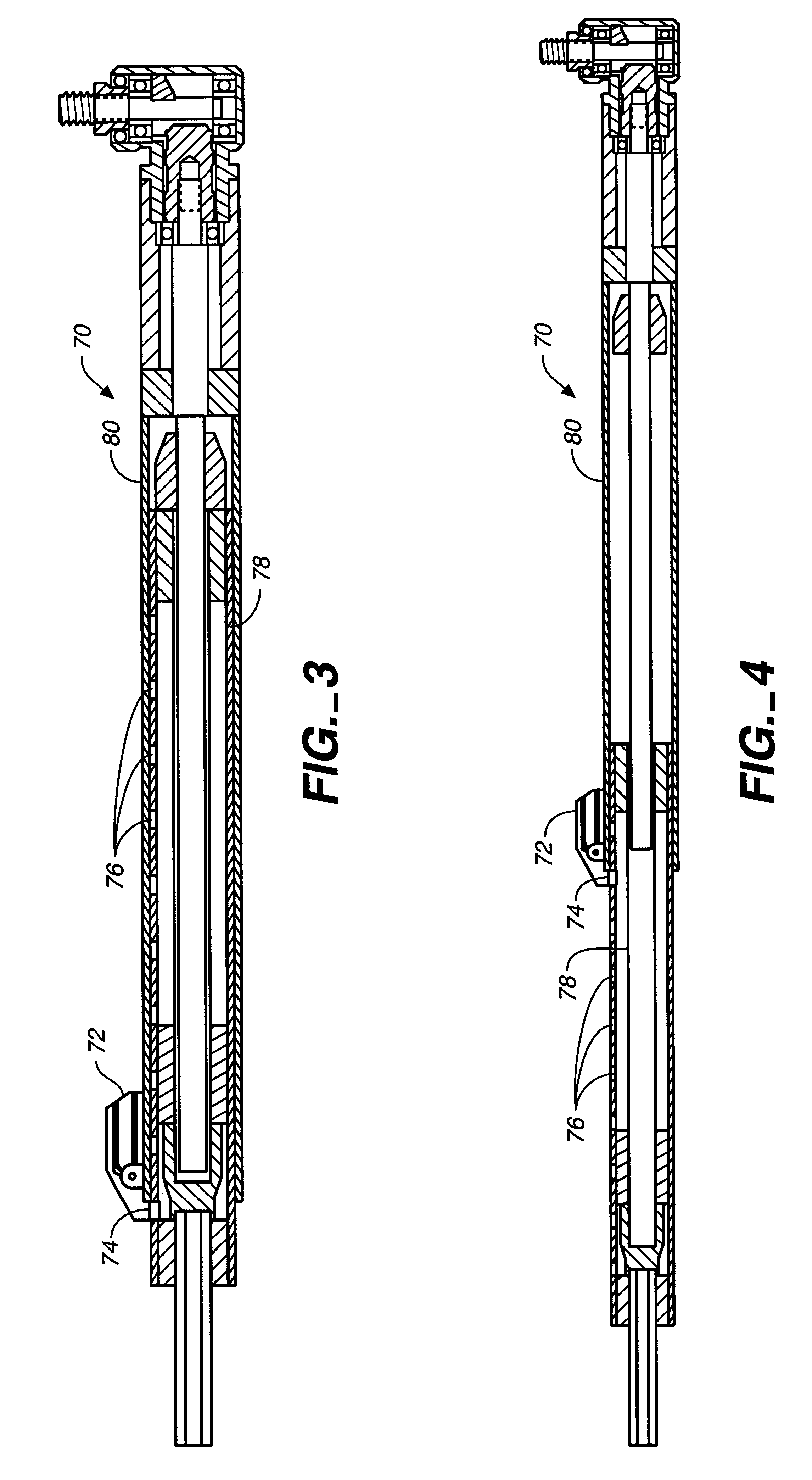

Telescopic pocket door angle drill

InactiveUS6293172B1Easy to install and removeOvercome limitationsMeasurement/indication equipmentsSpannersGear wheelDrive shaft

A pocket door angle drill having a right angle driver with a truly telescopic handle portion that may be extended to reach into confined spaces. The right angle driver has a casing and an internal gear assembly for translating rotary motion from a horizontal drive shaft to a vertical drive shaft. The drill further includes a telescopically extendable primary drive shaft portion that may be operatively connected to a power rotary device, and, optionally, an extension pole having an extension drive shaft for providing access to remote confined spaces.

Owner:SMITH JAMES C

Slotting cutter and inserts for same

The present invention is directed to an insert, a slotting cutter assembly and a method for machining a plurality of slots in a metallic alloy part. The insert may comprise a cutting edge, at least one primary radius, at least two secondary radii and a clearance angle. The cutting edge may form a narrow outer end at a tip of the insert and a larger width region at a distance inward from the narrow outer end. The clearance angle may extend rearward from the cutting edge. The slotting cutter assembly may comprise a plurality of inserts and a cutter body. The cutter body may comprise a plurality of retaining slots and a plurality of support portions. The retaining slot may be configured to receive the insert. The support portion may provide support for the insert.

Owner:GREENLEAF TECH CORP

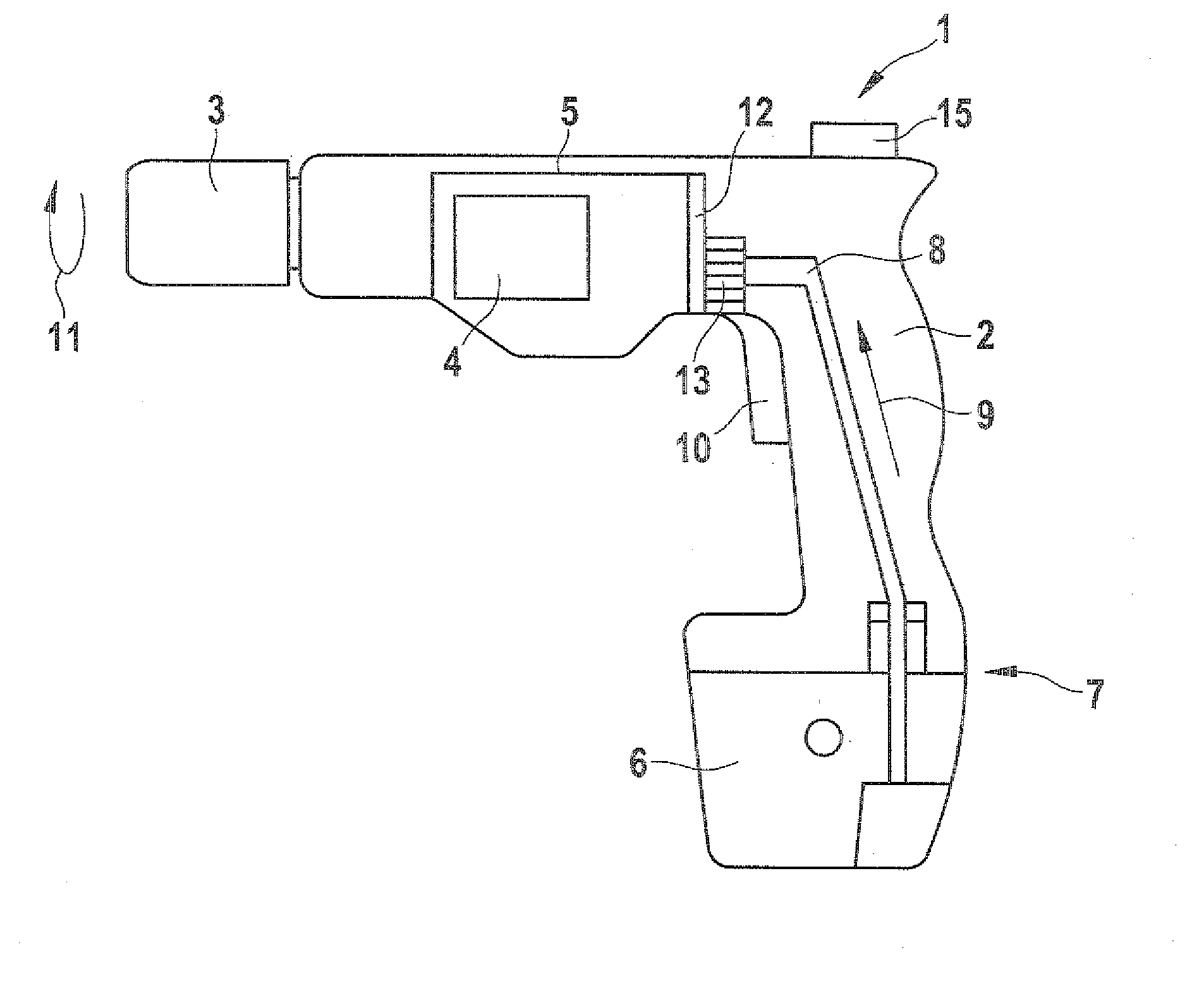

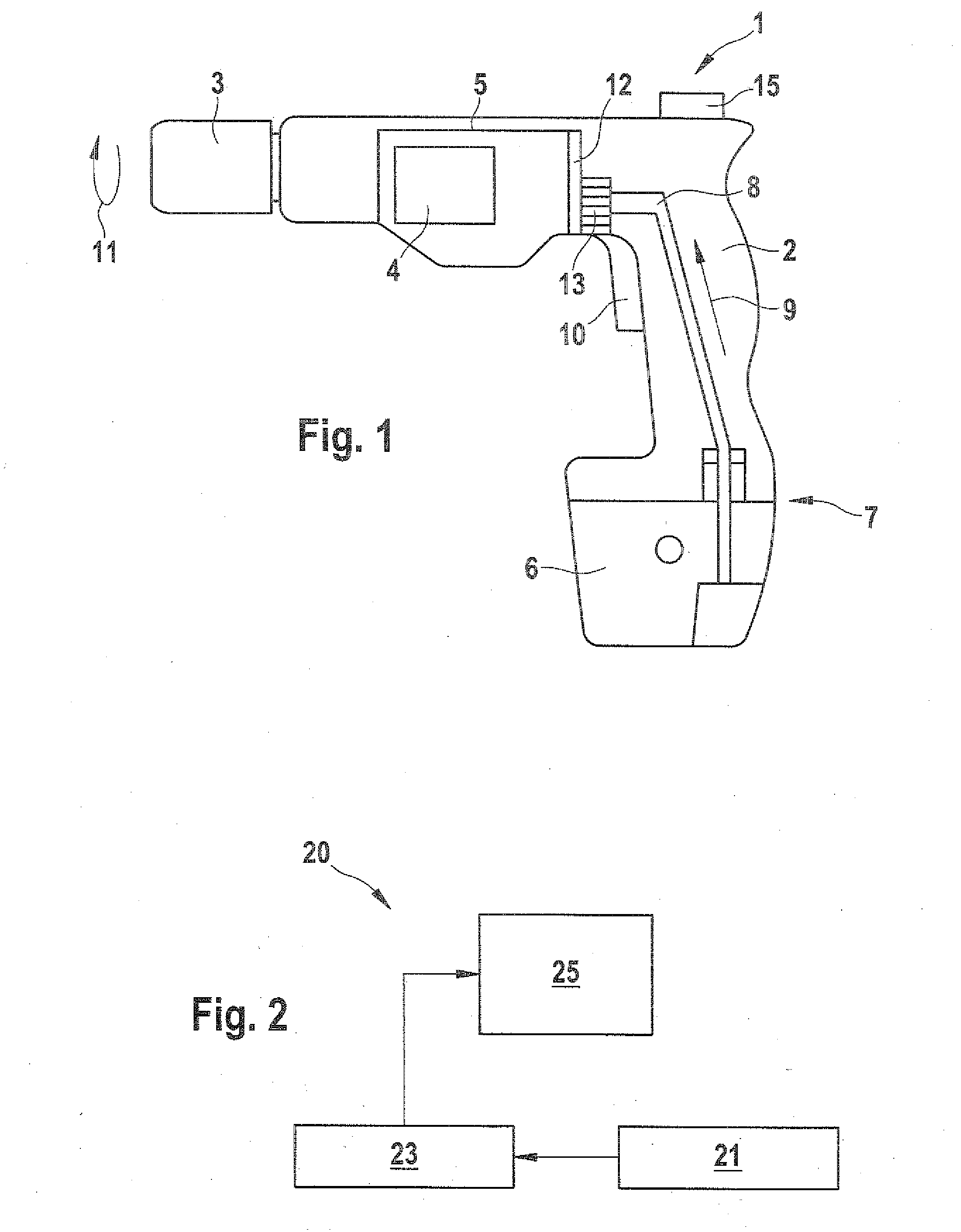

Method for operating an electrical power tool, and a drive unit for an electric power tool

InactiveUS20100065293A1Shutoff is preventedRestraint torsionDC motor speed/torque controlDrilling rodsMaximum torqueElectric power system

The invention relates to a method for operating a handheld electric power tool, having an electric motor that is drivable at a rated torque as the maximum allowable motor torque by the application of a maximum allowable motor current. The method includes the steps of manually furnishing a specification of a maximum torque, in which the maximum torque is within a setting range between a minimum set torque and the rated torque, operating the electric motor by applying a motor voltage which corresponds to an rpm desired by the user, and limiting the motor current to a current value that depends on the furnished specification of the maximum torque.The invention also related to a drive unit for an electric power tool, which includes an electric motor drivable at a rated torque as a maximum allowable motor torque by application of a maximum allowable motor current. A setting element manually furnishes a specification of a maximum torque, the maximum torque being within a range between zero and the rated torque. A triggering unit operates the electric motor by applying a motor voltage that corresponds to an rpm desired by the user. A motor controller limits the motor current to a current value that depends on the furnished specification of the maximum torque.

Owner:ROBERT BOSCH GMBH

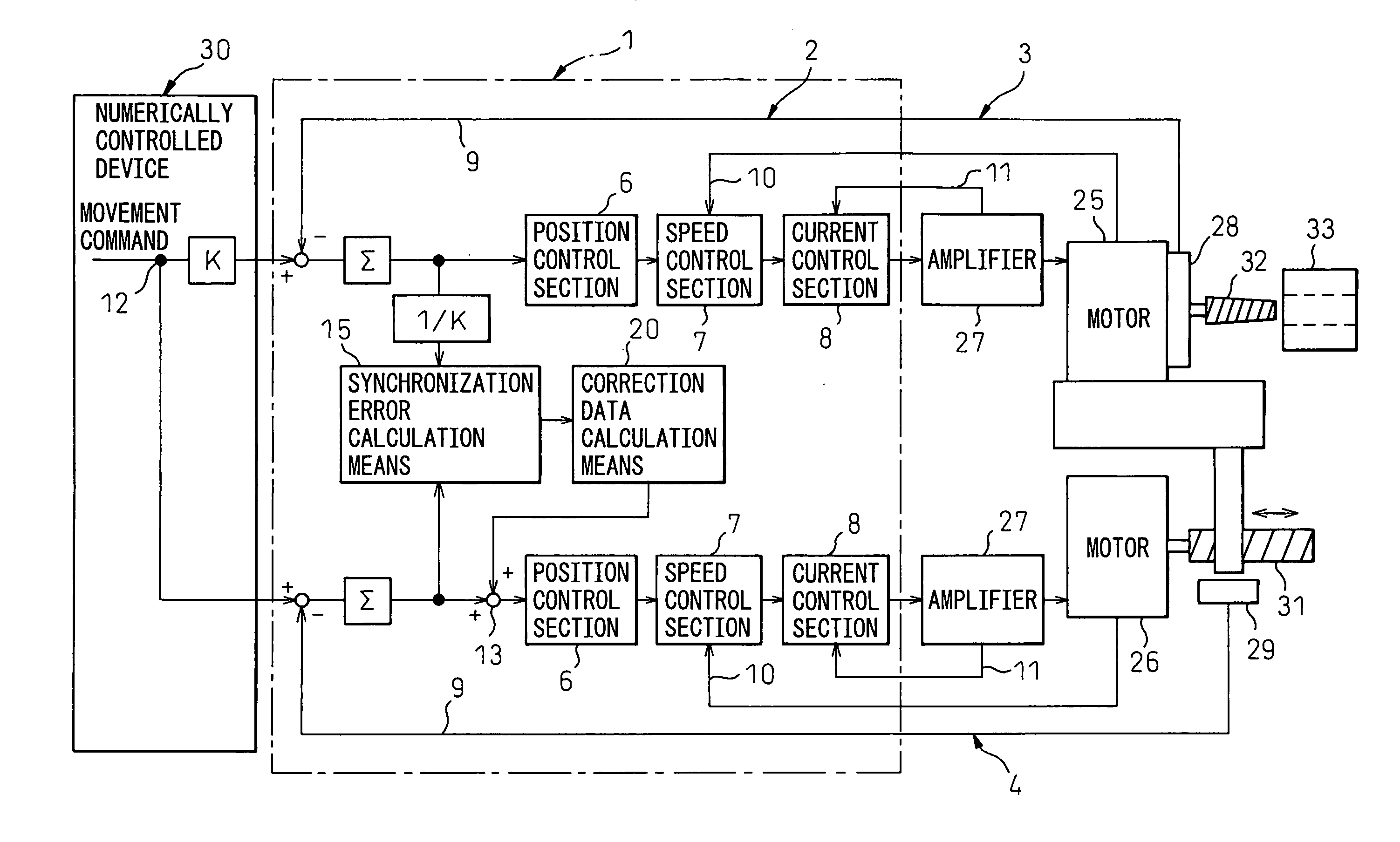

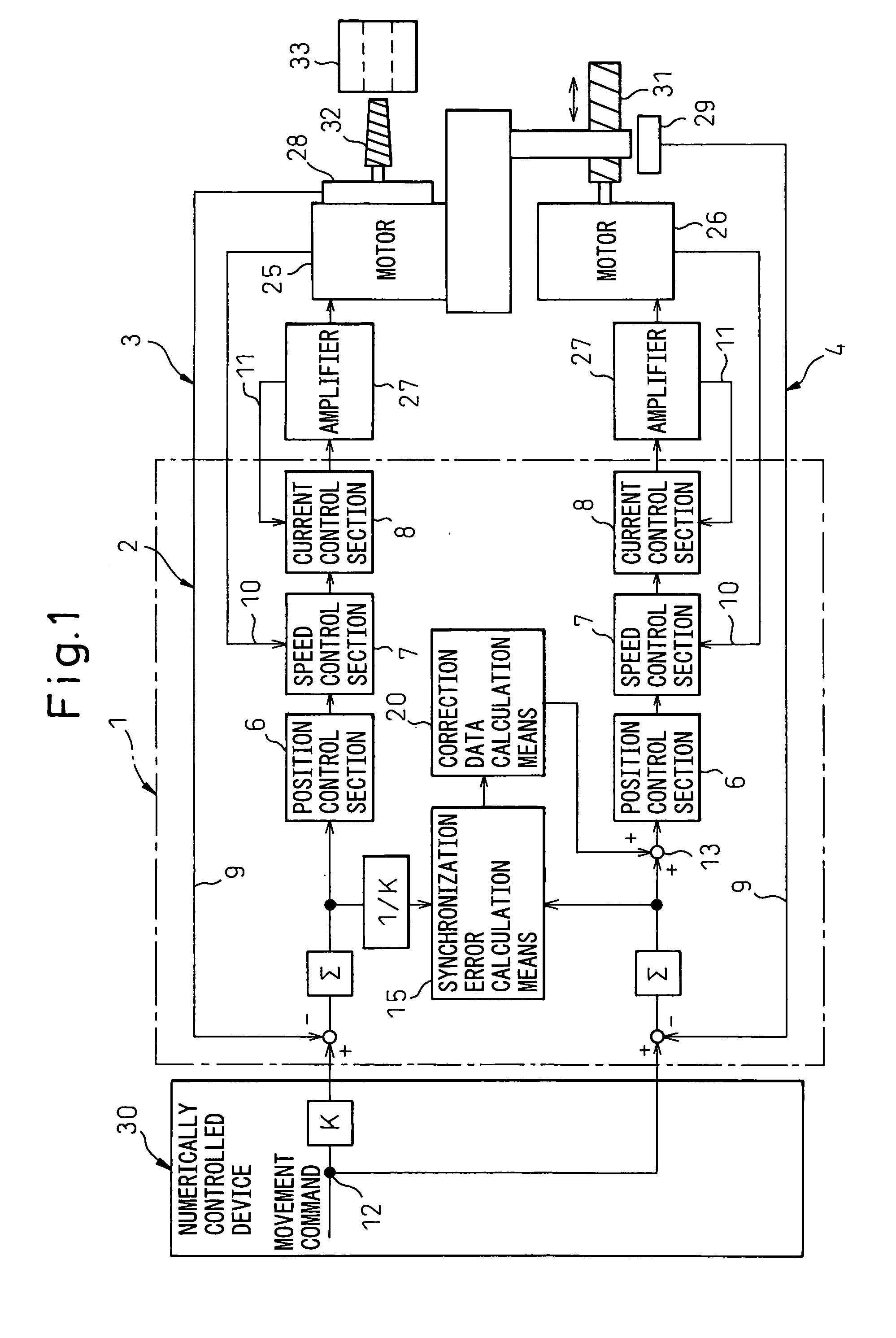

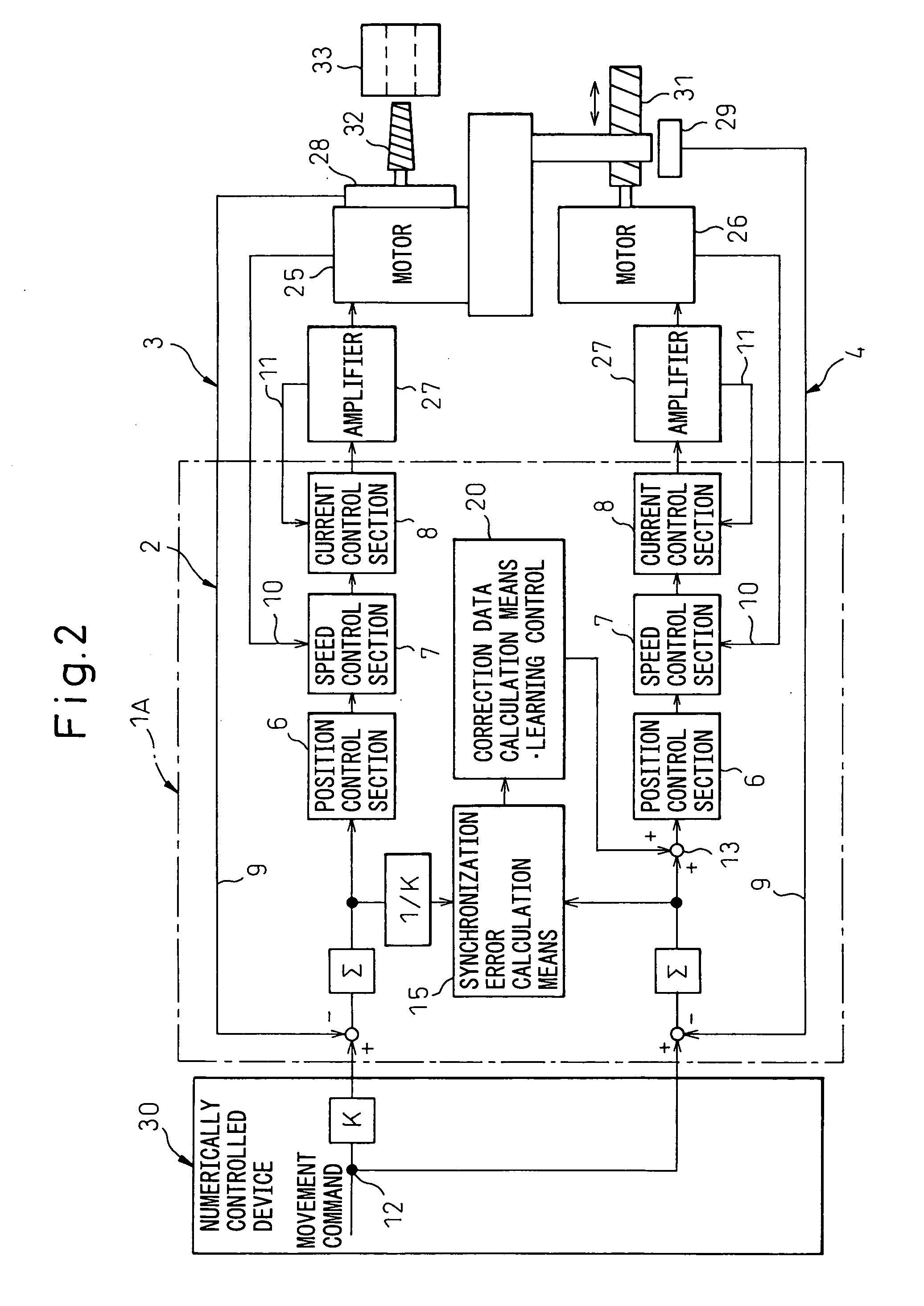

Servo controller

InactiveUS20070007926A1Highly accurately and efficiently conducting machiningReducing a synchronization errorComputer controlSimulator controlSynchronous controlServo control

There is provided a servo controller for synchronously controlling a master side drive source to drive one drive axis and a slave side drive source to drive the other drive axis. The servo controller includes a correction data calculation means for calculating correction data to correct a positional deviation of a slave side drive source according to a synchronization error which is a difference between a positional deviation of a master side drive source and a positional deviation of the slave side drive source, in which the correction data is added to the positional deviation of the slave side drive source.

Owner:FANUC LTD

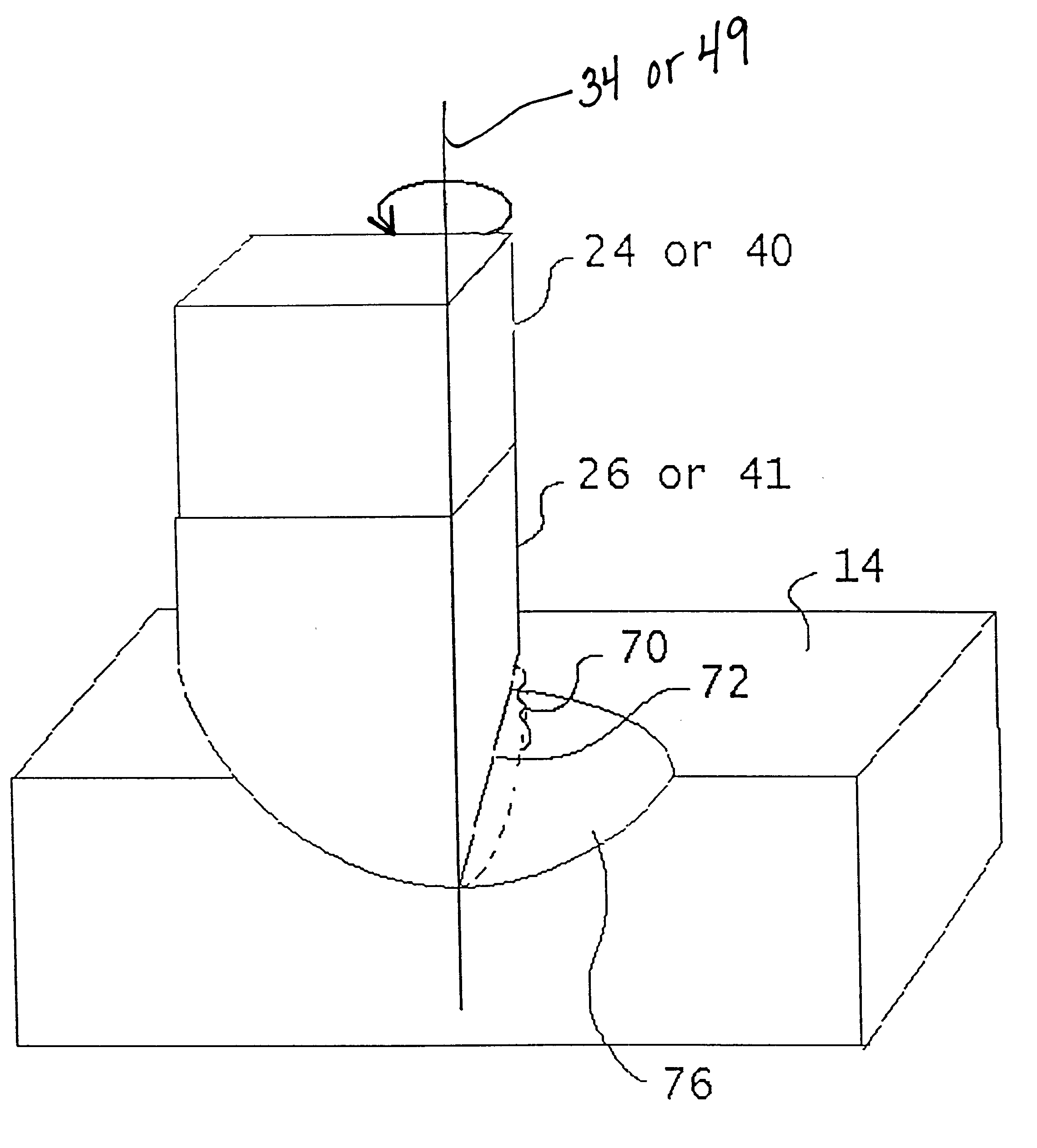

Apparatus for forming a microlens mold

InactiveUS6846137B1Precise processQuality improvementMilling cuttersOptical articlesDiamond cuttingFill factor

An apparatus for making microlens molds and microlens array molds is described which utilizes a forming element having a rotating half radius diamond cutting member. A substrate is alignably arranged with the diamond cutting member so that the cutting member can mill a mold cavity in the substrate. The apparatus can be used to make high sag lens molds with high accuracy and a nearly 100% fill factor.

Owner:EASTMAN KODAK CO

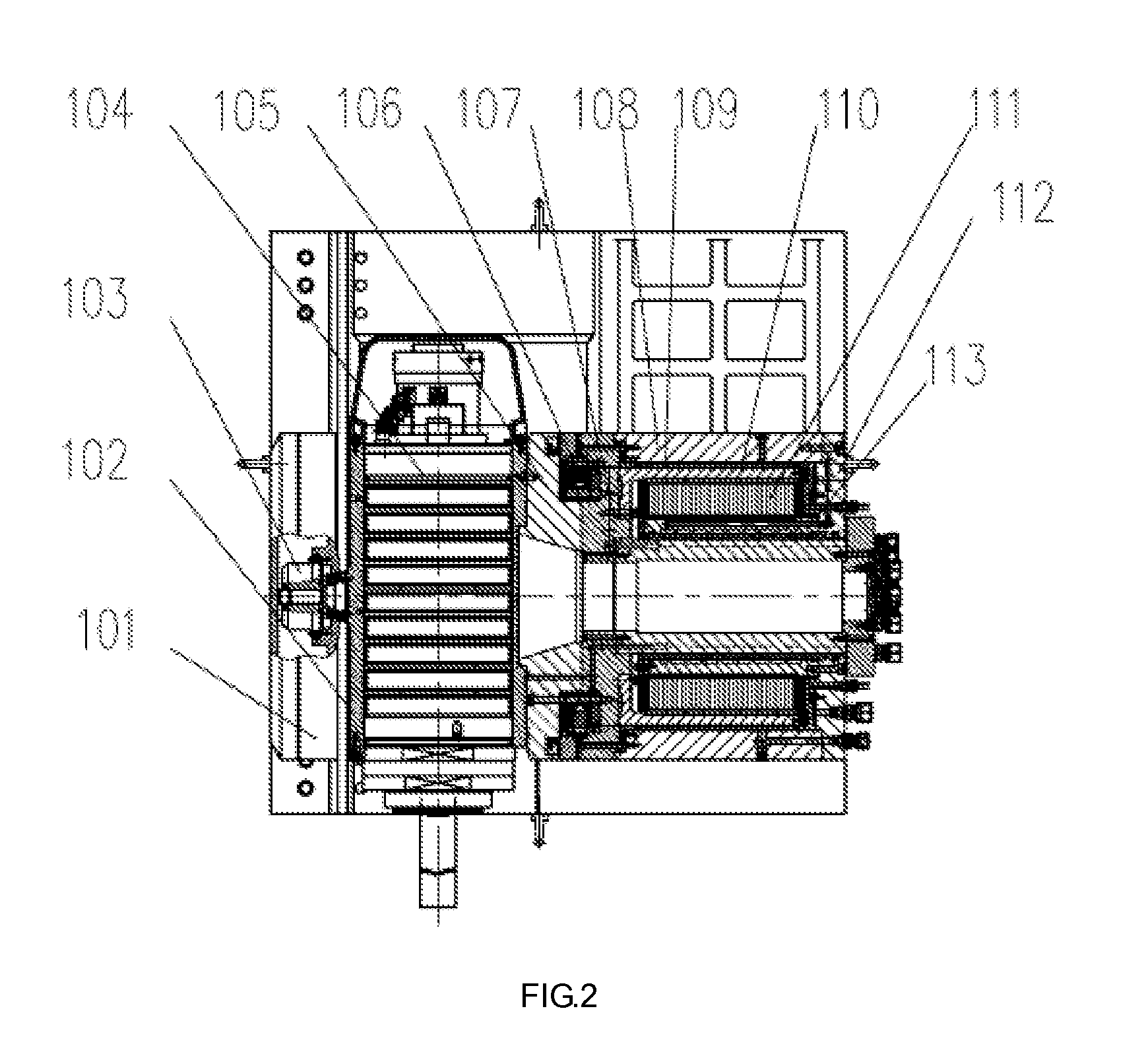

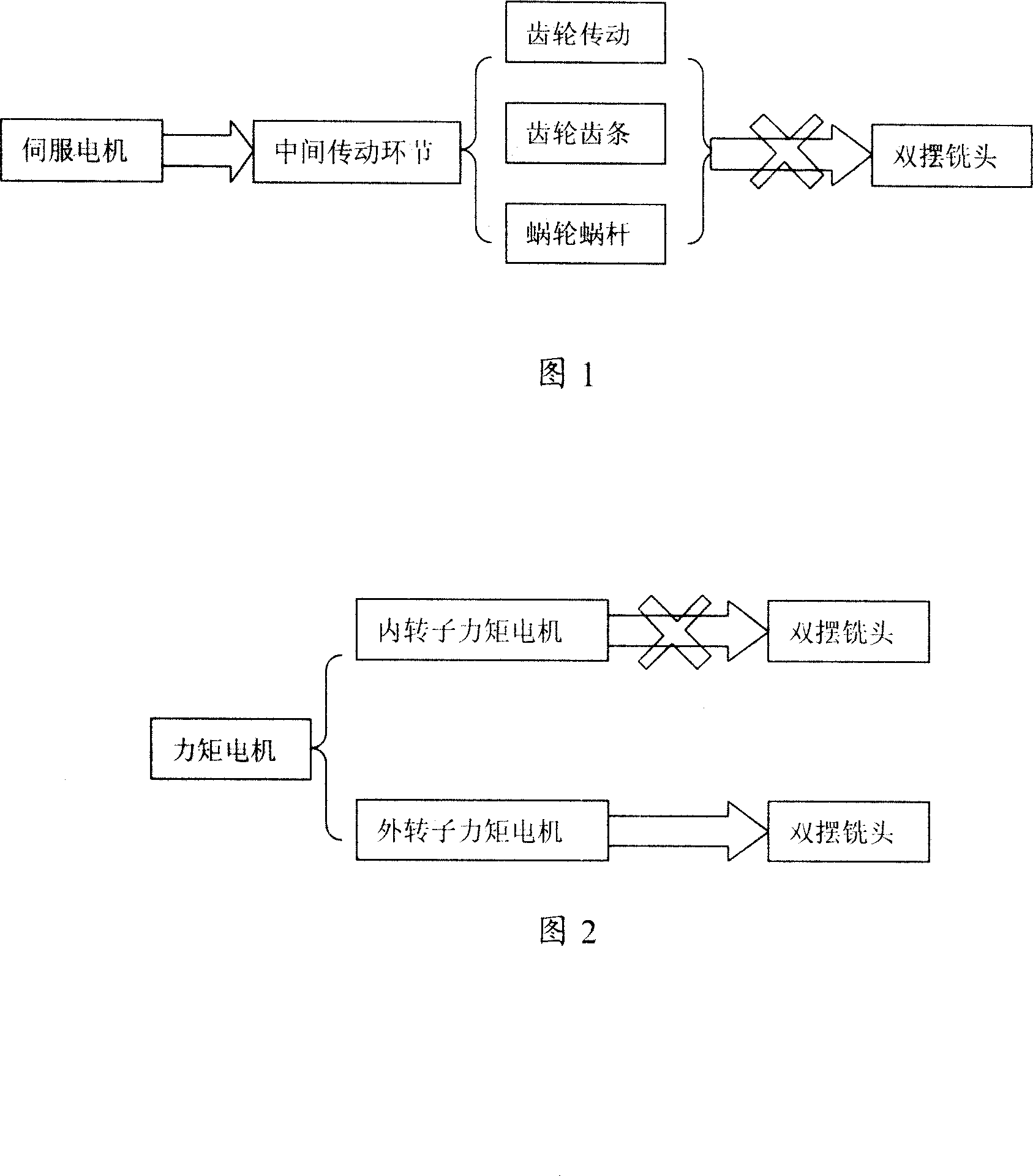

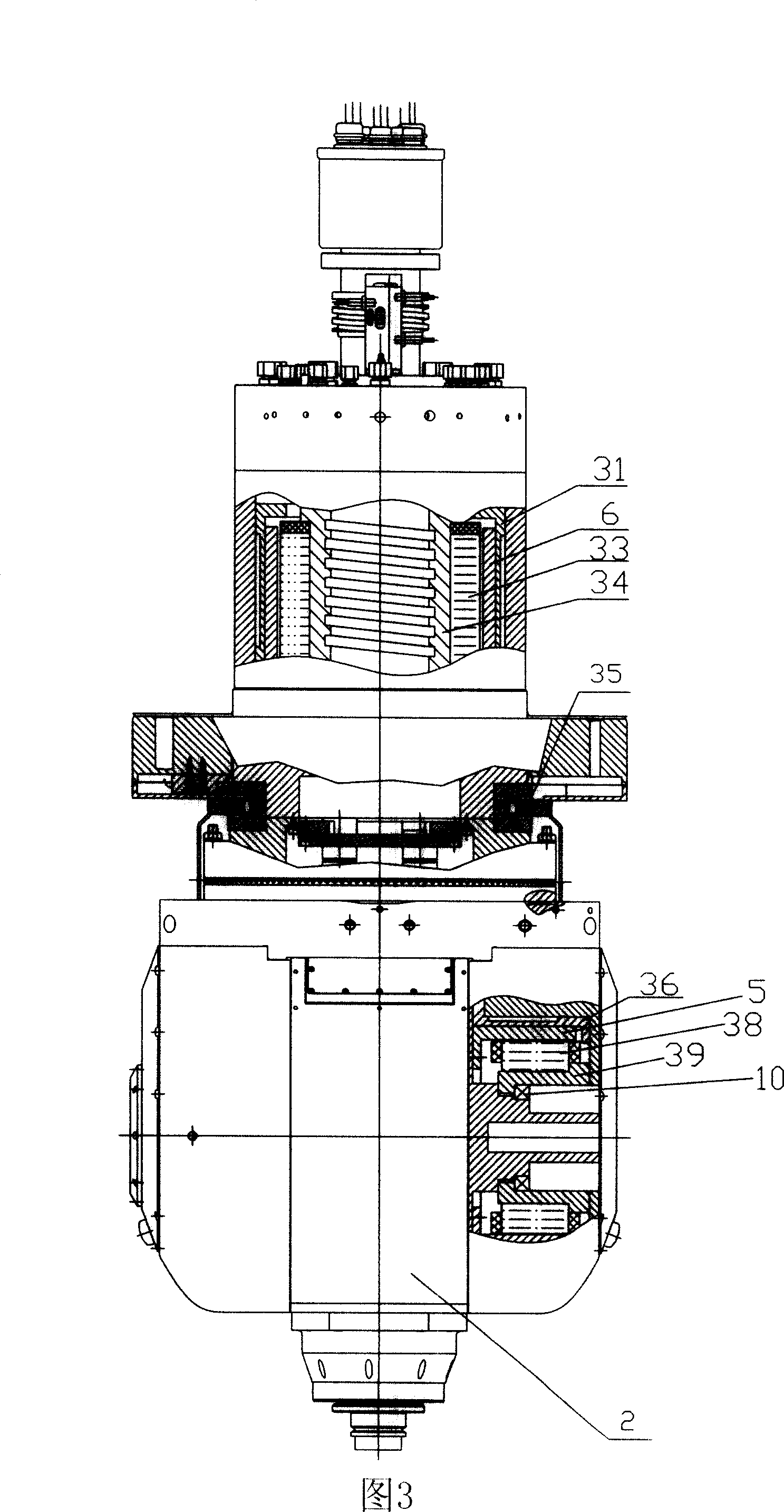

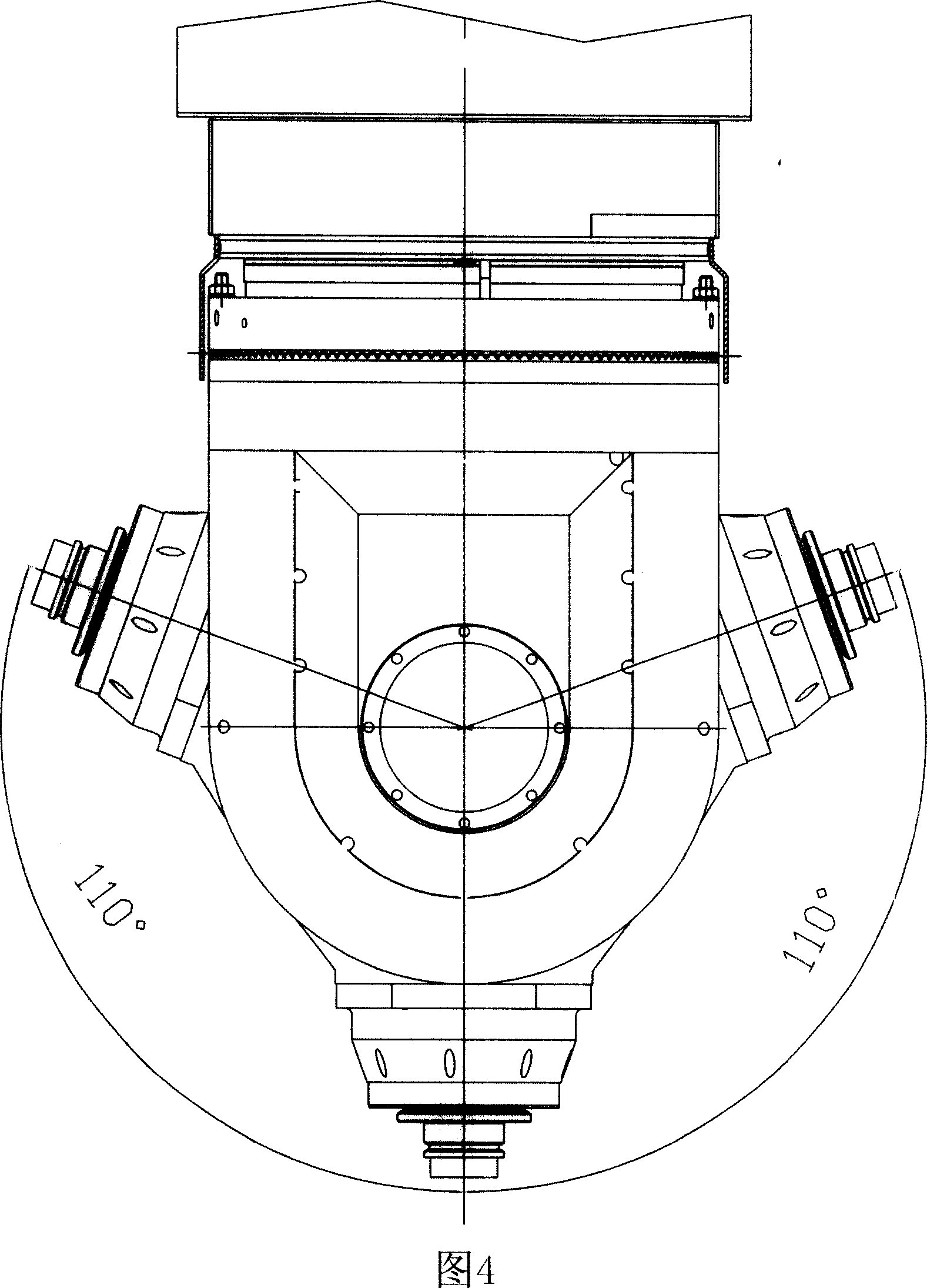

Double pendulum milling head of AC permanent magnetic synchronization external-rotor-type force moment motor drive

ActiveCN101011795AImprove running accuracyImprove stabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityNumerical control

The double pendulum milling head driven by the AC permanent syntactic rotor torque motor having a cross hollow shaft, whose both ends fixed on the rotor of the horizontal torque motor at both ends of the A shaft. Acting as an integral, they are fixed on the rotor of the vertical torque motor of C shaft. In this way, vertical motor driving the milling head to rotate around C shaft, and A shaft horizontal motor driving the pendulum of milling head around A shaft. It complete the complex machining of the working piece through compound motion in two directions matching the high speed revolution of the shaft itself. It is compact in structure, simple of drive, good in rigidity, smaller in mechanical components quantity, higher reaction sensitivity, free from wear and reverse gap, being able to machining for a five-face body with high precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

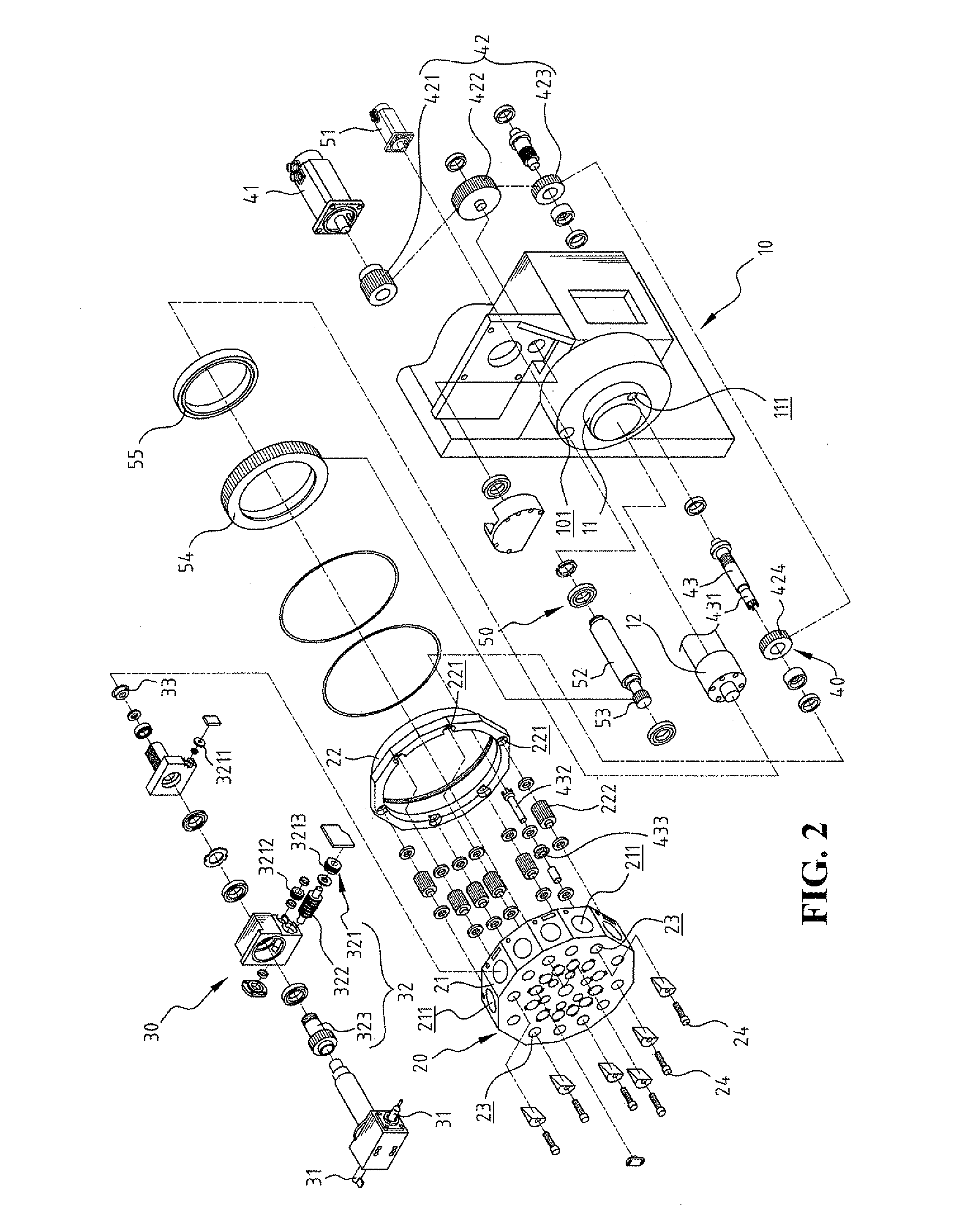

End effector for forming holes for aircraft assembly and using method thereof

ActiveCN103990829AGuaranteed verticalityLight in massAutomatic control devicesMeasurement/indication equipmentsBall screwEngineering

The invention relates to an end effector for forming holes for aircraft assembly, wherein the end effector is combined with an industrial mechanical arm. The end effector comprises a spindle-feeding module, a dual-eccentric-disk posture adjusting module, a scrap sucking and pressing module, a normal detection module and a visual detection module. The spindle-feeding module comprises a spindle motor, a feeding motor, a ball screw, a drill and the like and achieves the hole drilling function. The dual-eccentric-disk posture adjusting module comprises a posture adjusting motor, a large eccentric disk, a small eccentric disk and the like and achieves the drill posture adjusting function. The scrap sucking and pressing module comprises a pressing air cylinder, a pressing head and the like and achieves the workpiece pressing function and the drilling and cutting scrap sucking function. The normal detection module comprises a laser sensor and the like and achieves the function of calculating the normal direction of a hole forming point. The visual detection module comprises an industrial camera and the like and achieves the function of displaying the hole forming effect in real time. After the end effector is combined with the industrial mechanical arm, the error of perpendicularity of a hole in the hole forming process can be smaller than 0.5 degree, and according to the hole forming efficiency, five to six holes can be formed per minute. Not only is the hole forming quality for aircraft assembly improved, but also labor force is greatly reduced.

Owner:SHANGHAI AIRCRAFT MFG +1

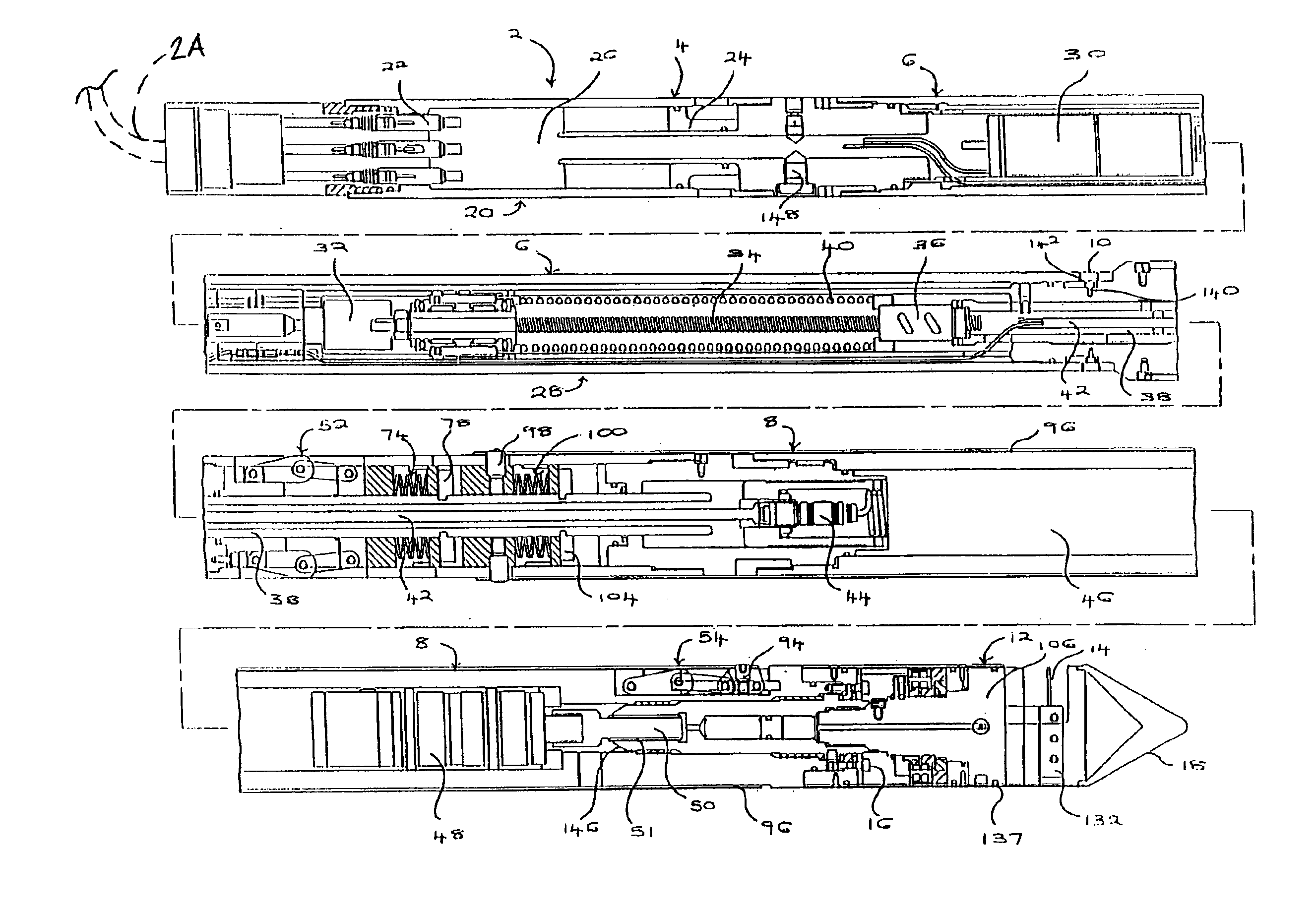

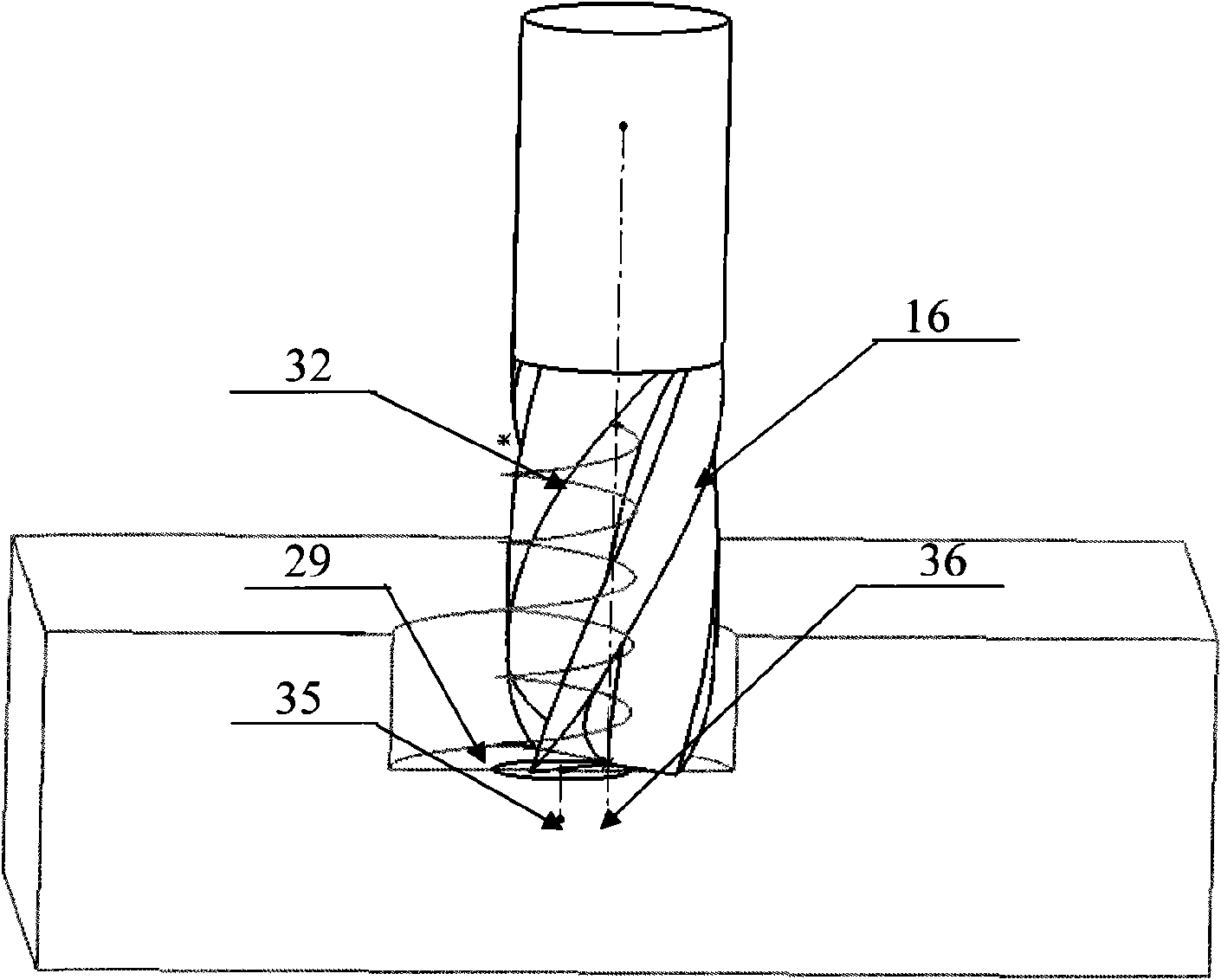

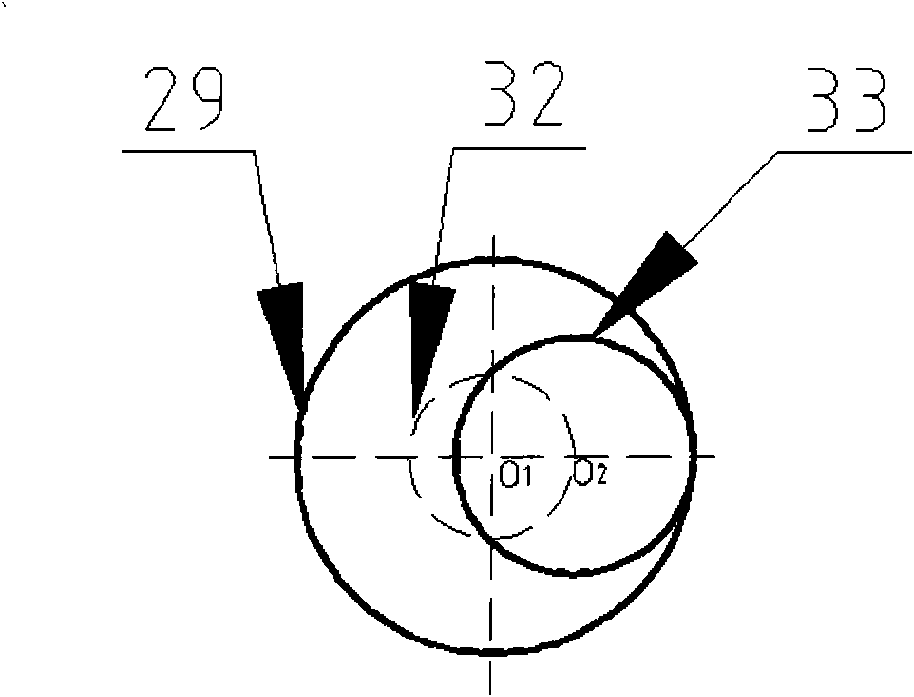

Method for helically milling hole and device thereof

InactiveCN101537512AShorten the development cycleLow costFeeding apparatusLarge fixed membersFiberEngineering

The invention discloses a method for helically milling a hole and a device thereof. The method comprises the following steps: a cutting tool automatically rotates around the center line of the cutting tool and rotates around the center of a machining hole; when the size of the hole which is to be machined changes, a distance that the center line of the cutting toll departures from the center line of a stander is adjusted and the hole is continuously to be machined; and the cutting tool is used for continuously milling the hole according to predetermined feed rate until that the hole is machined. By adopting the method and the device, the cutting tool with diameter from 6mm to 8mm is used for machining the holes with different specifications, therefore, tool changing time is reduced, finish machining is avoided, and efficiency is greatly improved. The device also can have holes with high quality on the new materials such as carbonized fiber, titanium alloy, etc. Simultaneously, the device is portable, under the condition with the same precision, greatly reduces dependence to machine tools with large scale and high precision, can combine with manipulators, and can complete the work for milling holes with high precision in the whole assembly of an airplane whole components assembly.

Owner:TIANJIN UNIV

Accessory attachment for rotary hand tools

Owner:CREDO TECH CORP

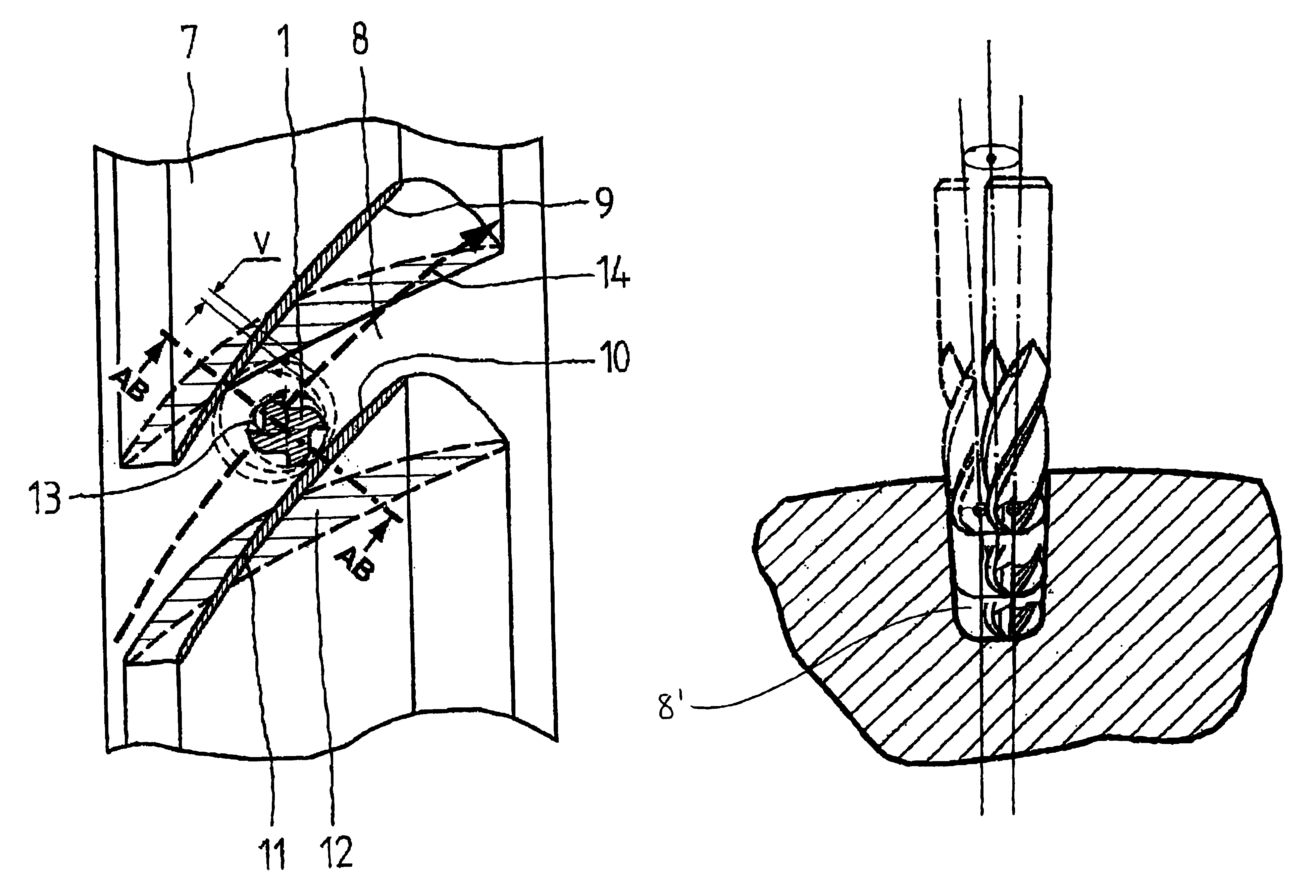

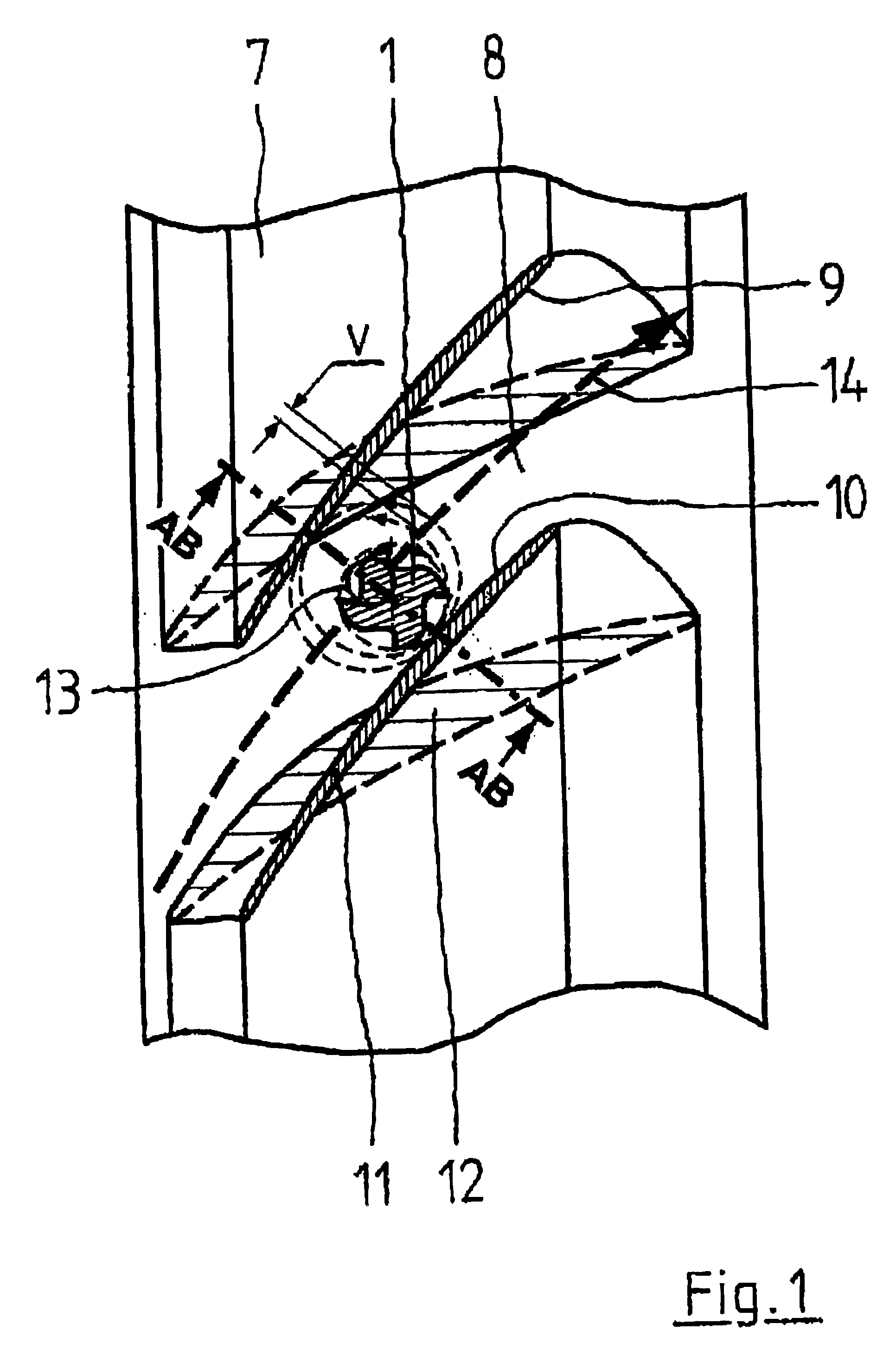

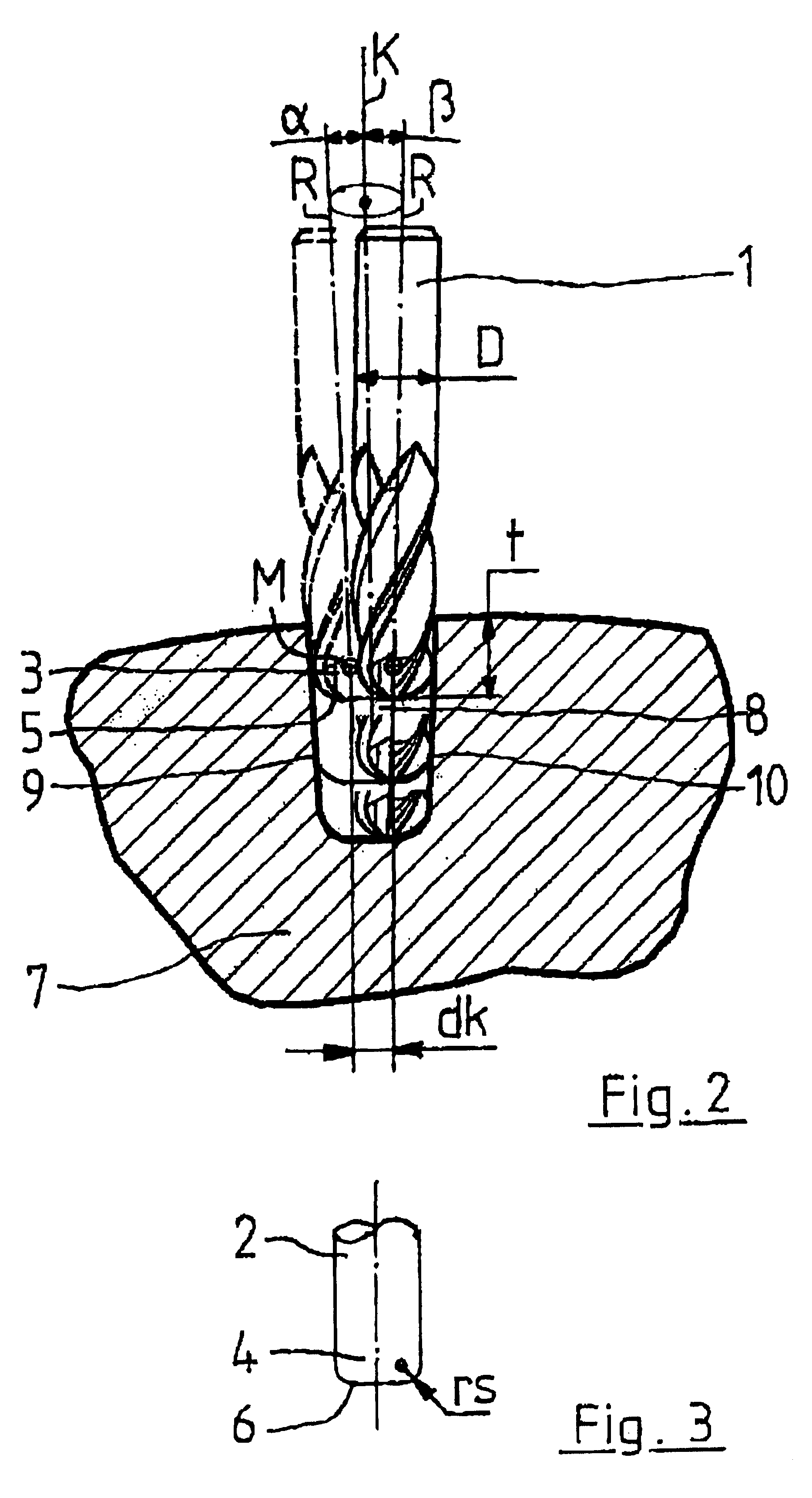

Milling method

A milling method is provided for the manufacture of components composed of difficult-to-cut materials for turbomachines, aircraft and spacecraft by producing recesses with one or more side walls. An end milling cutter which cuts at the circumference and at the tip and has a tip contour which is rounded towards the circumference is used as the rotating milling tool. In addition to rotation about its axis, the milling tool performs an eccentric orbiting motion about an orbital axis spaced apart from its axis. The opposite senses of rotation lead to downcut milling, and the orbital axis performs a translational advance motion on a straight and / or curved path transversely to its longitudinal direction, with or without a swivelling motion.

Owner:MTU AERO ENGINES GMBH

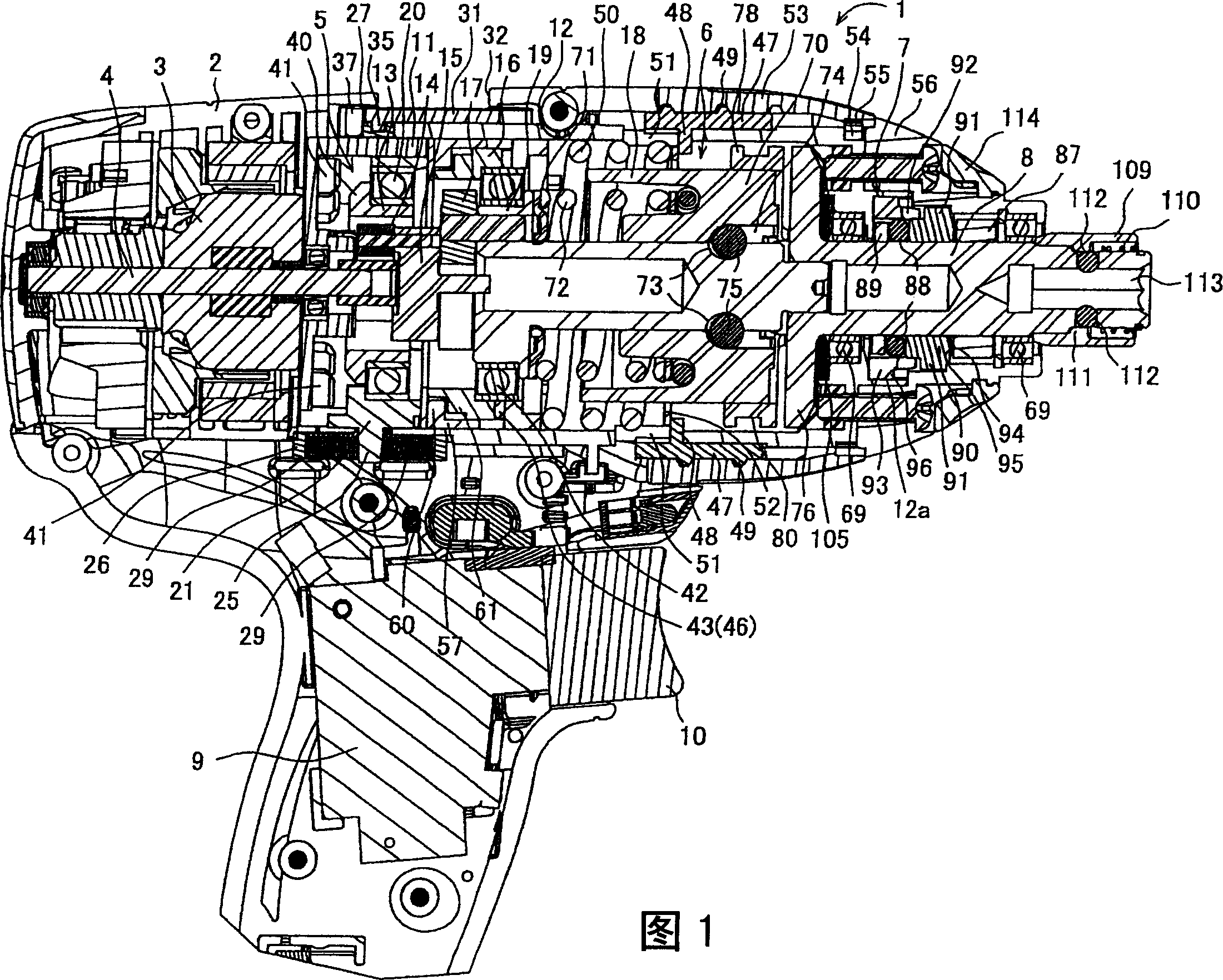

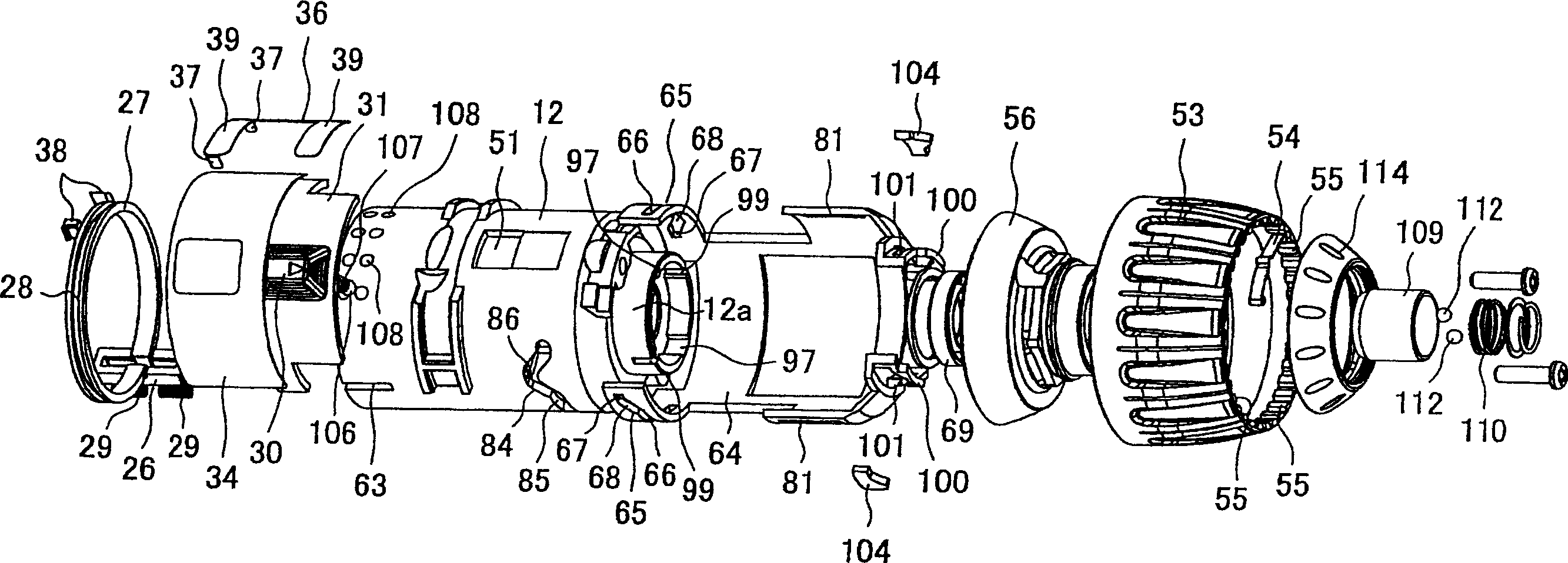

Electric power tool

InactiveCN1765590AEasy to operateImprove reliabilityPortable percussive toolsPortable power-driven toolsSwitch boxElectric power system

An electric power tool capable of selecting an operation mode with good operability without risk of erroneous operation even though there are many operation modes. The gear box (12) in the housing respectively has: the clutch switching groove (65) engaged with the operation protrusion (62) of the clutch switching handle (57); ) of the notch (81) of the guide body (82) of the stepped pin (83) engaged; the vibration switching groove (101) engaged with the operation protrusion (98) of the vibration switching handle (93), and the The integrated rotary position of the switching plate (31) can change the combined switching box (64) of the sliding position of each switching member, and use the switching button (30) to rotate and operate the switching plate (31) and the switching box (64) from the outside of the housing, so that Only the operation of one switch button (30) can select all action modes of drilling mode, impact mode, vibration drilling mode and clutch mode.

Owner:MAKITA CORP

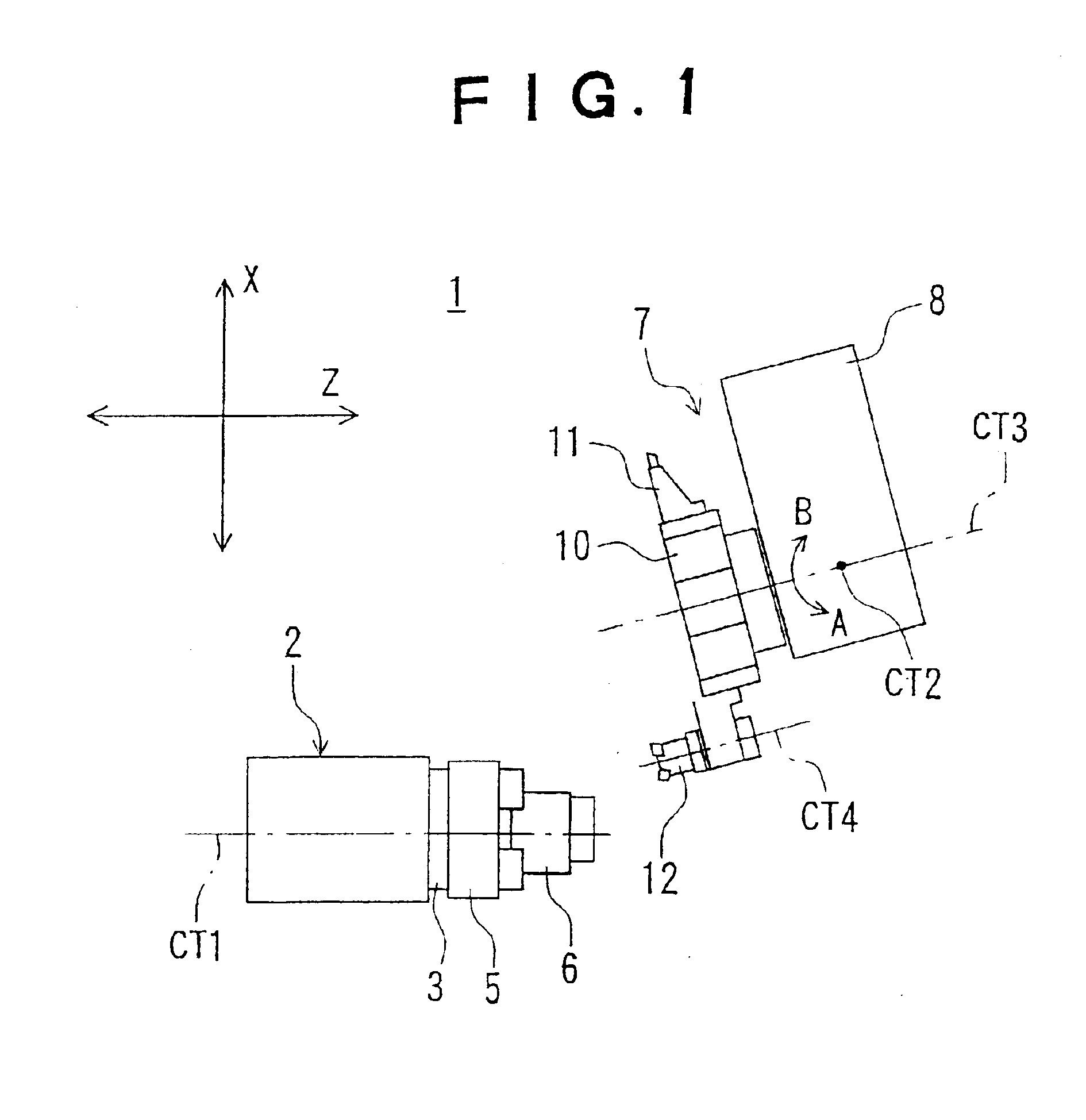

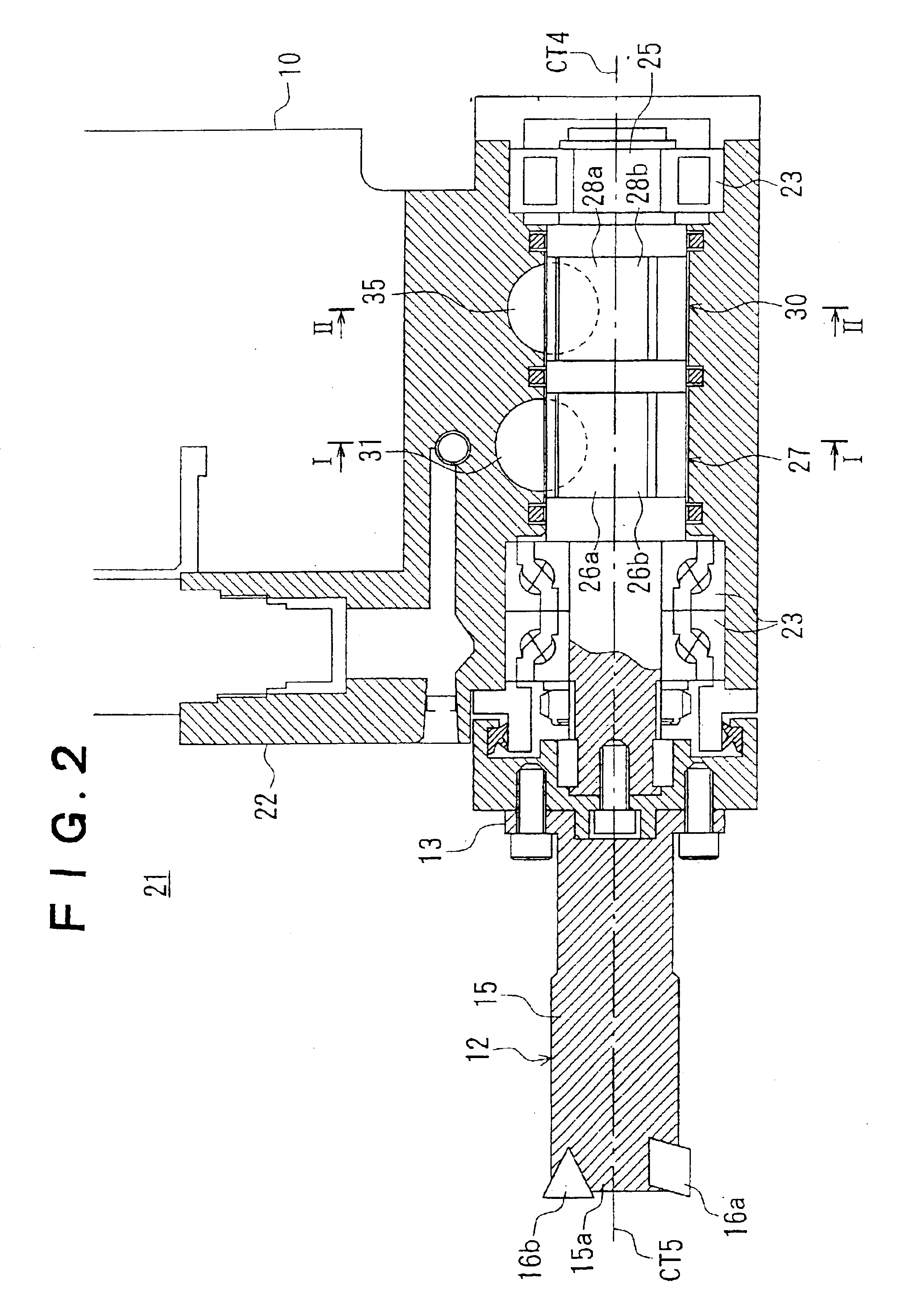

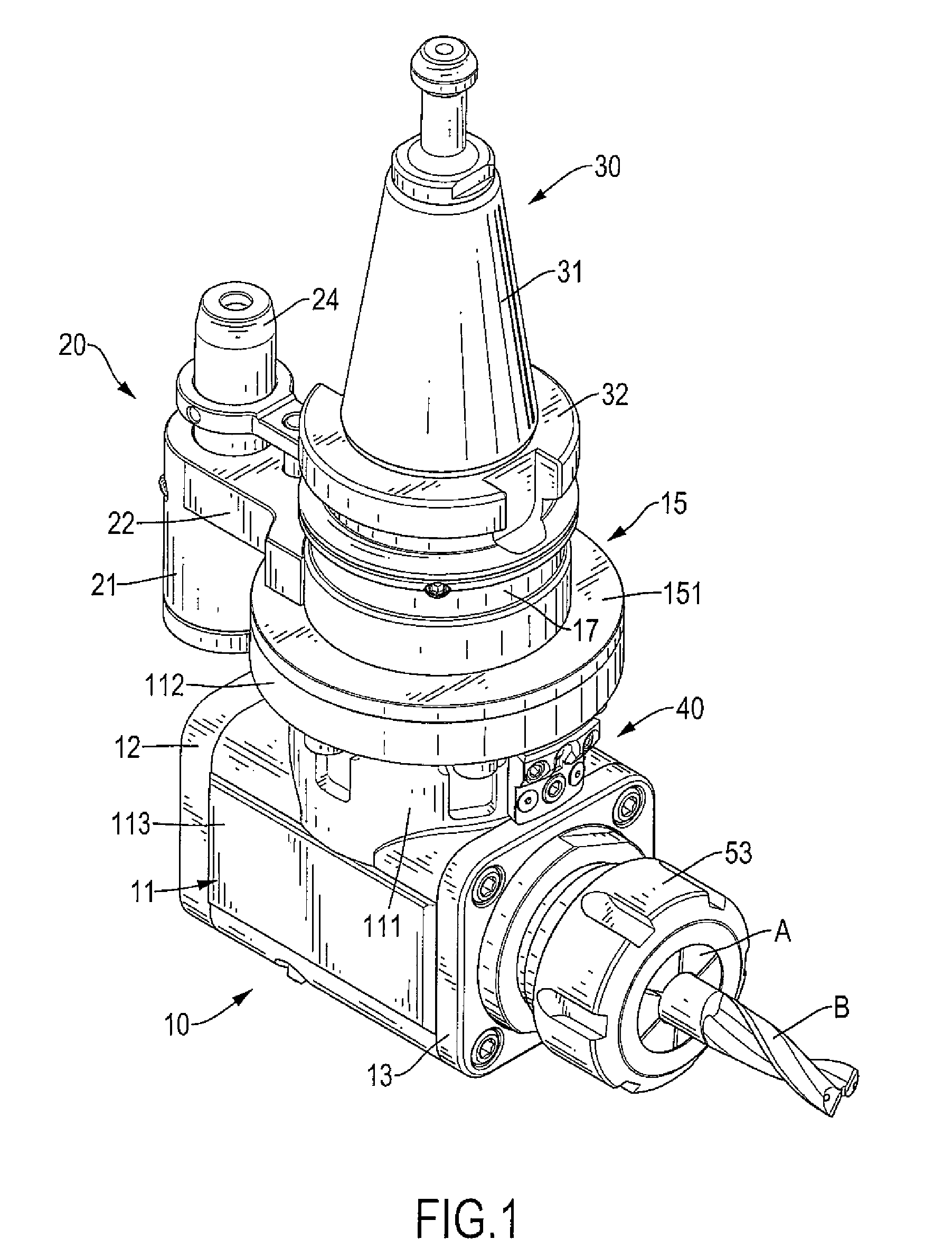

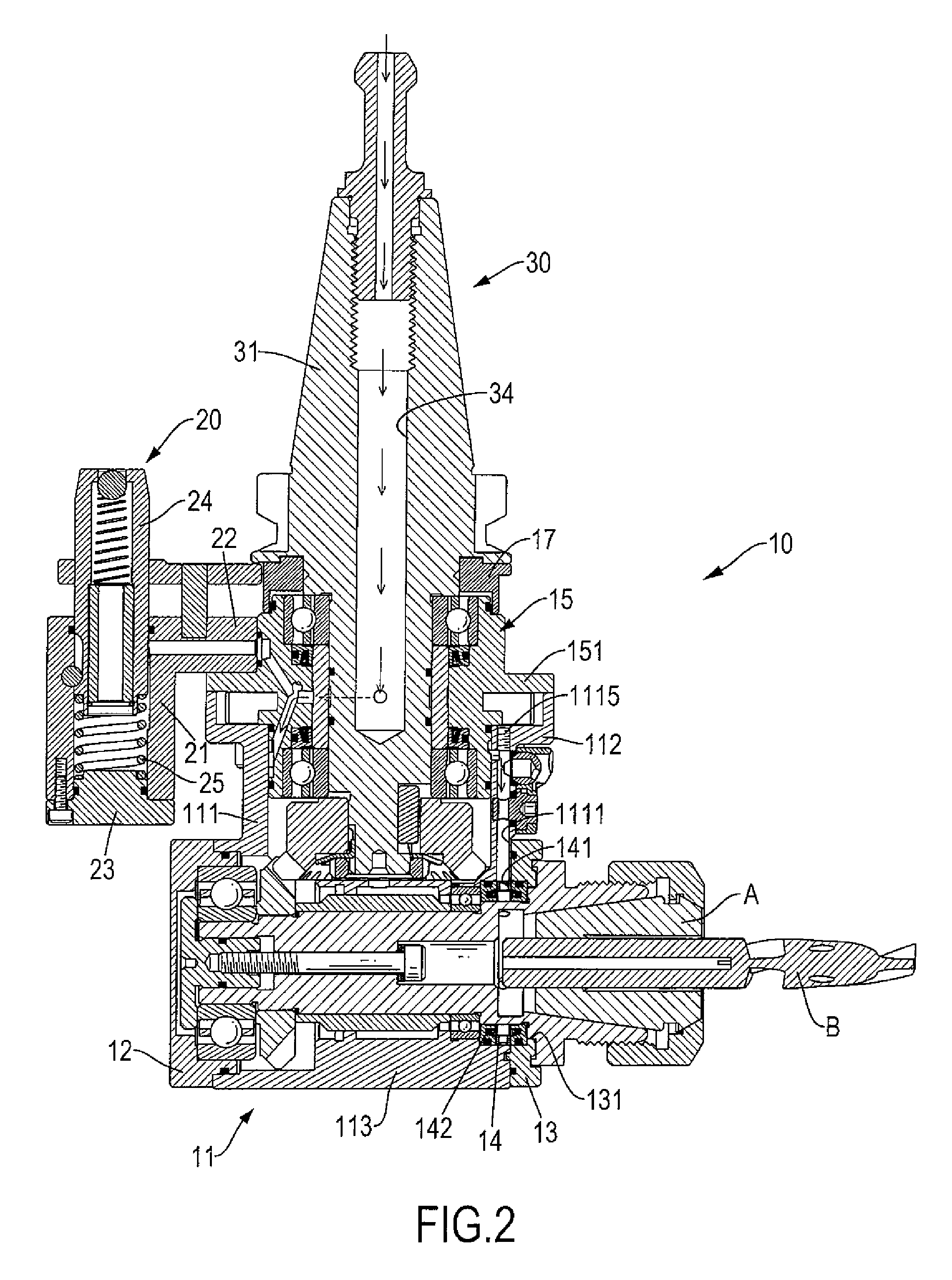

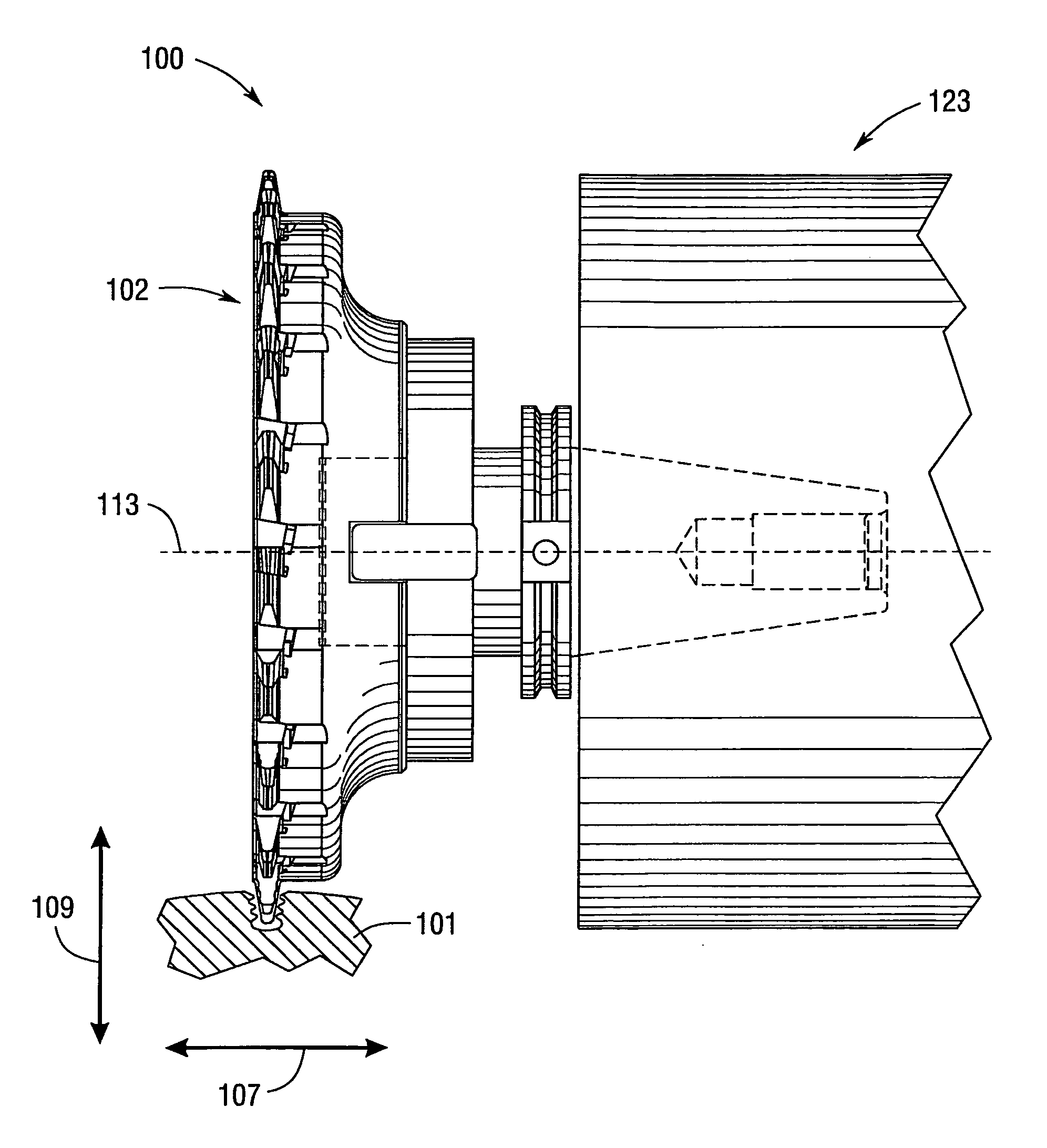

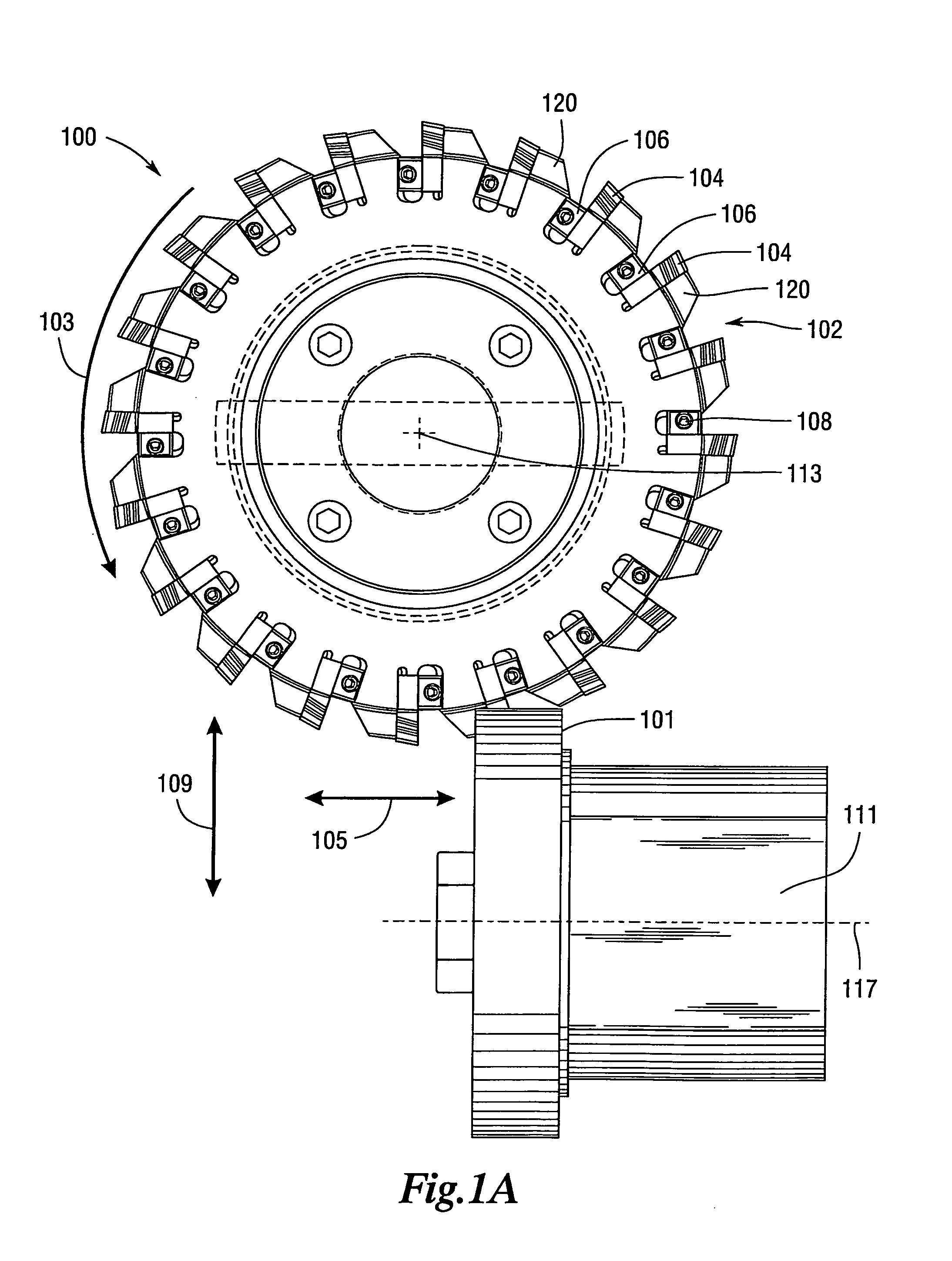

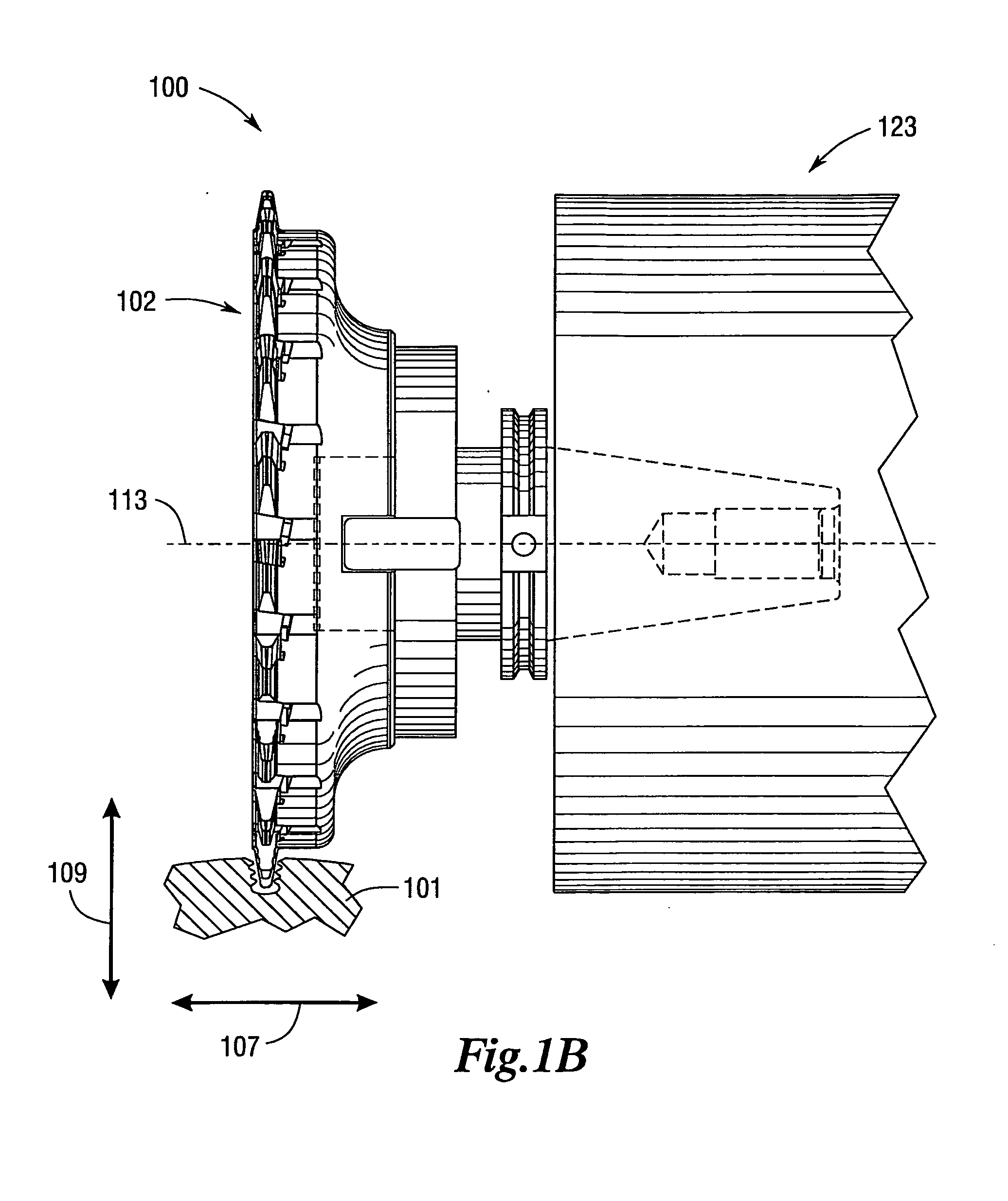

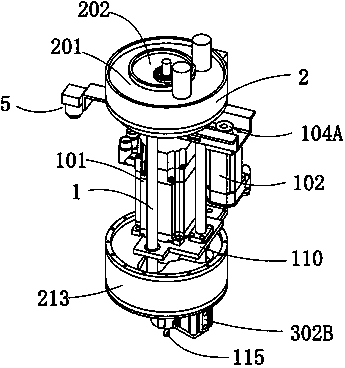

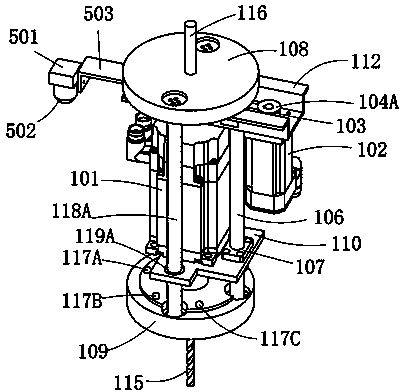

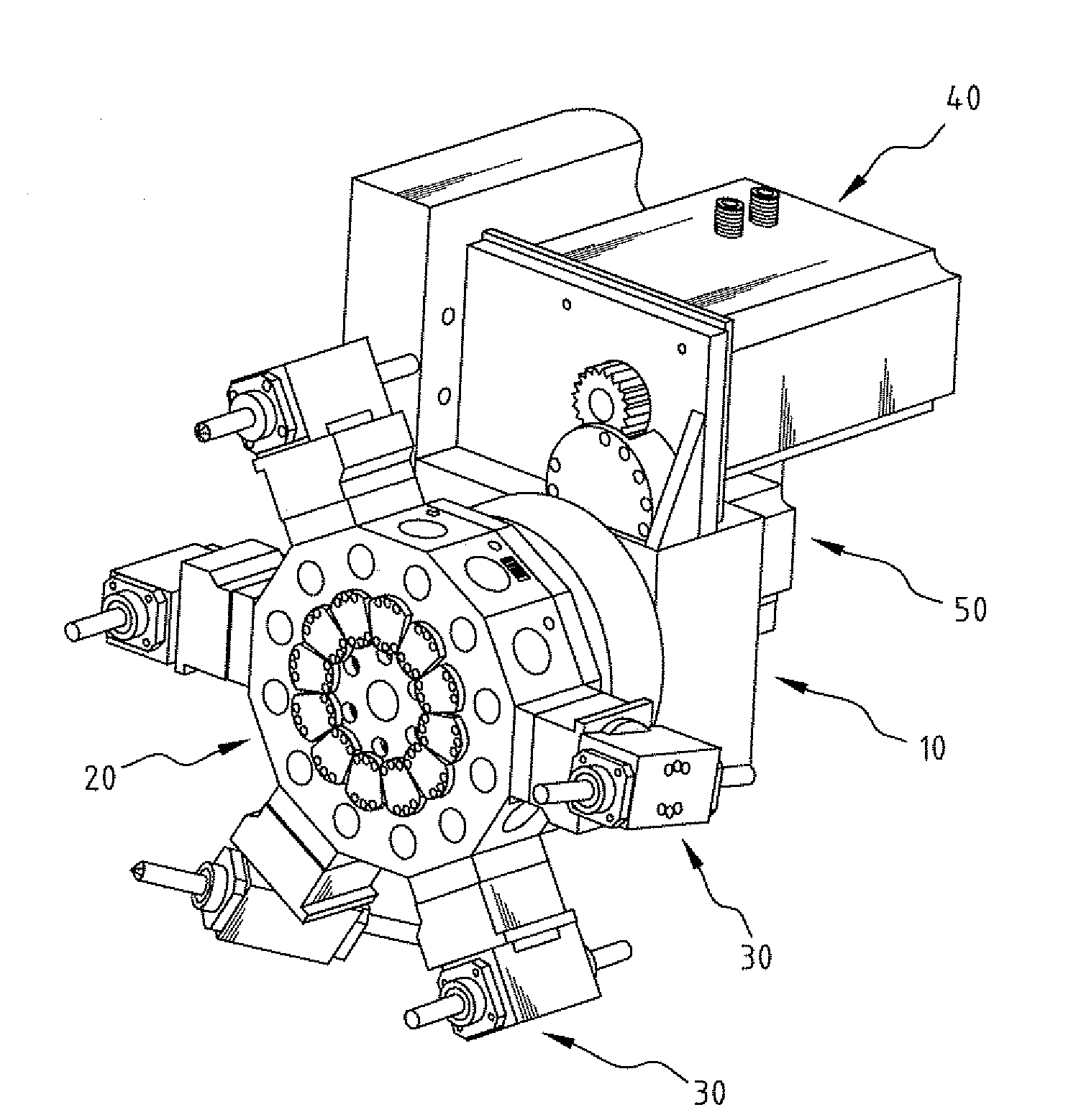

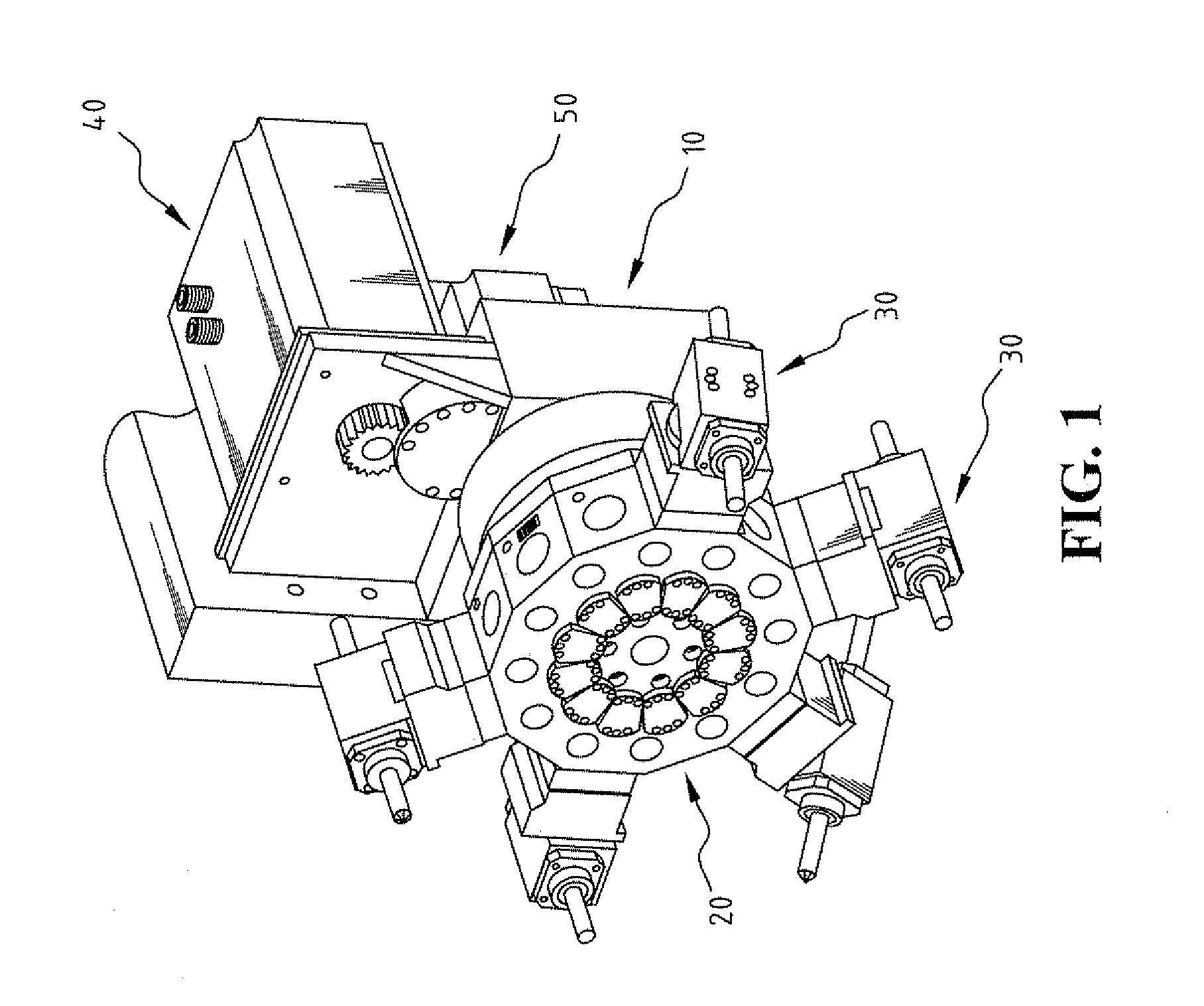

Rotational power servo toolpost

InactiveUS7395589B1Limited rangeWork lessAutomatic/semiautomatic turning machinesMachine tool componentsTurretTool holder

A rotational power servo toolpost includes a plurality of rotational tool holders, which can freely rotate 360 degrees, to cut a workpiece from various angles. The rotational power servo toolpost has a turret base, a turret, tool holders mounted on a side surface of the turret and having a variety of needed tools, a tool-holder-rotating device, and a tool-rotating device. When the tool holder with the needed tool rotates along with the turret to the preset area, a servo motor of the tool-holder-rotating device drives the related members to freely rotate the tool holder around 360 degrees according to the machining requirements. The tool-driving device then drives the tool, thereby cutting the workpiece from various angles.

Owner:KUO CHING HUI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com