Electric power tool

A power tool and action technology, applied in the direction of manufacturing tools, striking tools, lightweight impact tools, etc., can solve the problems of increased assembly time, poor operability, and increased number of parts, and achieves excellent operability and reliability. Reduced assembly time and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will be described below based on the drawings.

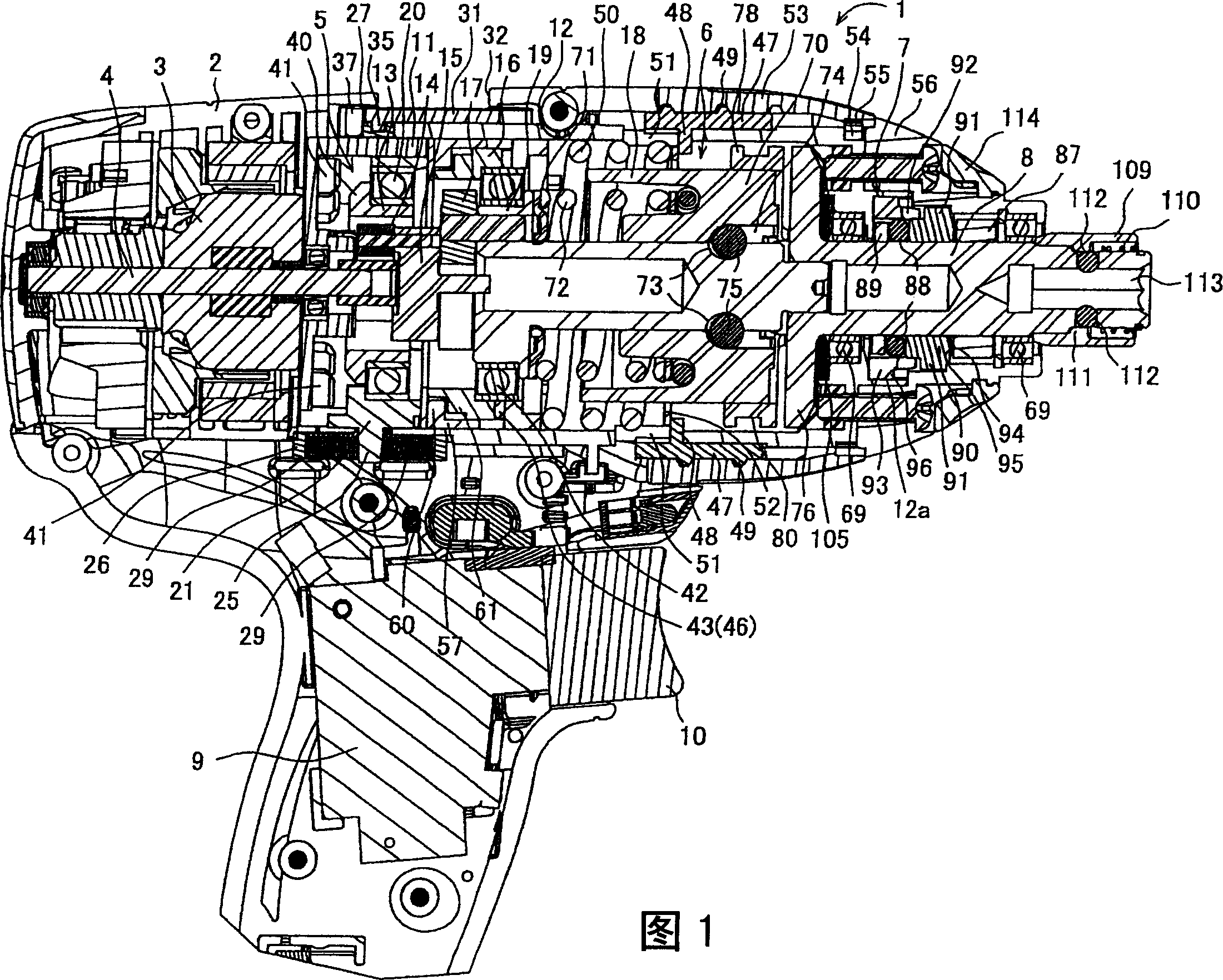

[0049] Fig. 1 is a longitudinal sectional view showing an example of an electric tool, that is, an impact screwdriver. The impact type screwdriver 1 is at the rear of a main body casing 2 composed of a pair of left and right half-cut casings (the right side of Fig. 1 is referred to as the front) A motor 3 is accommodated, and a planetary gear reduction mechanism 5 with a clutch mechanism, a striking mechanism 6, and a vibration mechanism 7 are respectively built in the front of the motor 3, so that the hammer anvil 8 coaxial with the motor shaft 4 of the motor 3 is forward protrude. 9 is a switch of the drive circuit of the motor 3, and 10 is a trigger which turns on the switch 9 by pressing operation.

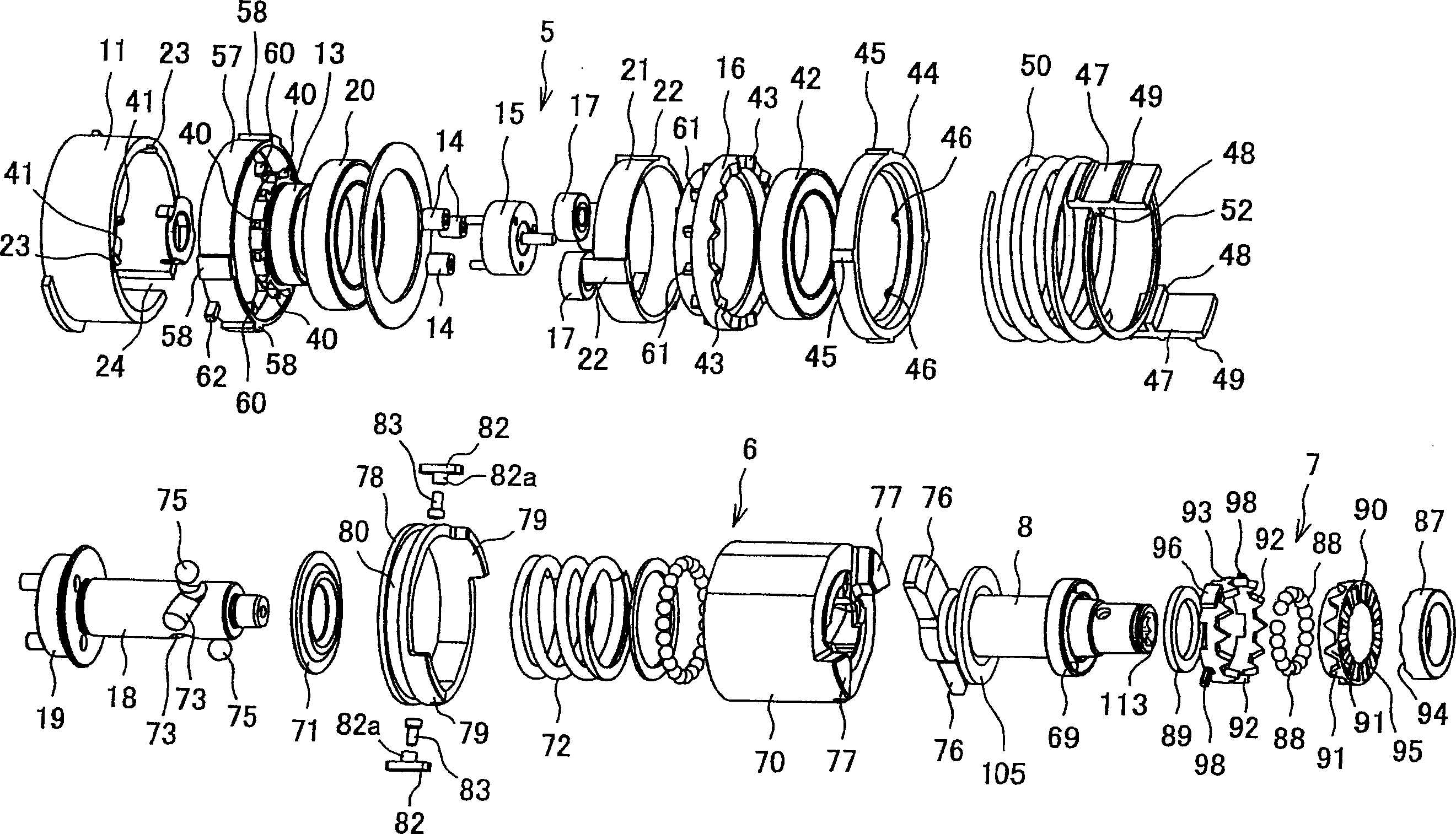

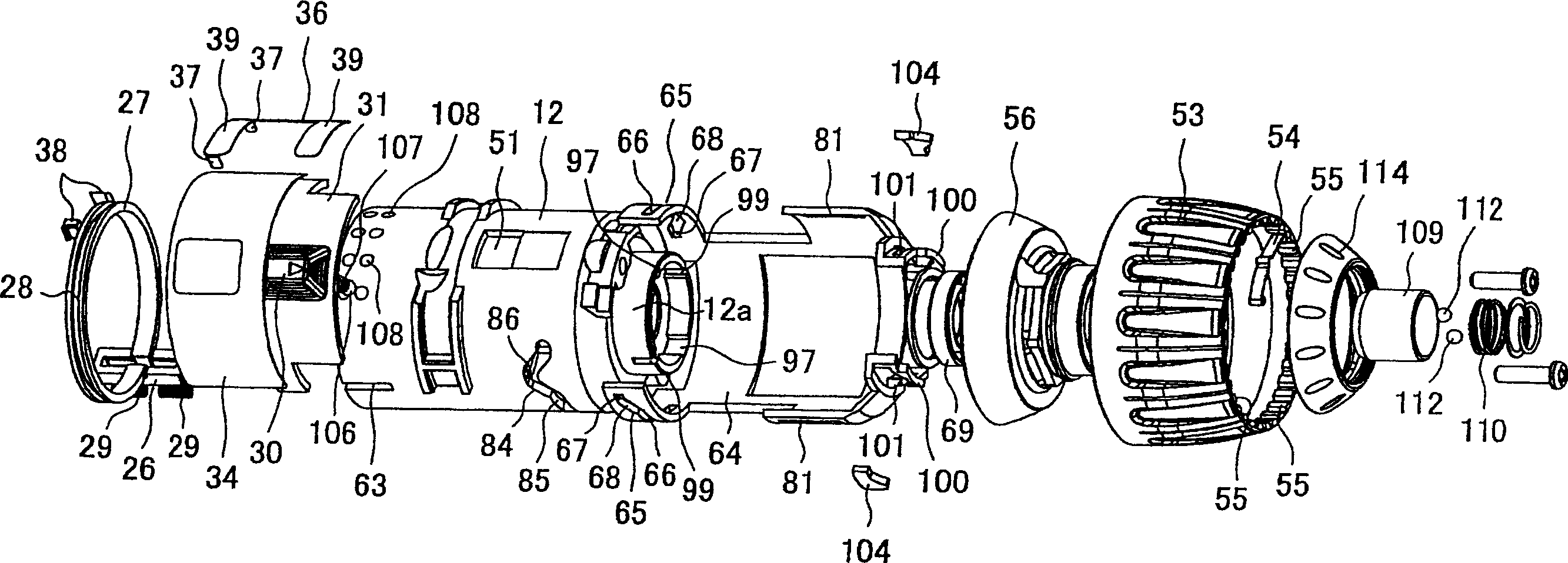

[0050] at the same time as figure 2 , 3 As shown, the planetary gear reduction mechanism 5 is accommodated inside a cylindrical motor bracket 11 and a cylindrical gear box 12. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com