Patents

Literature

479results about "Thread cutting auxillary apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

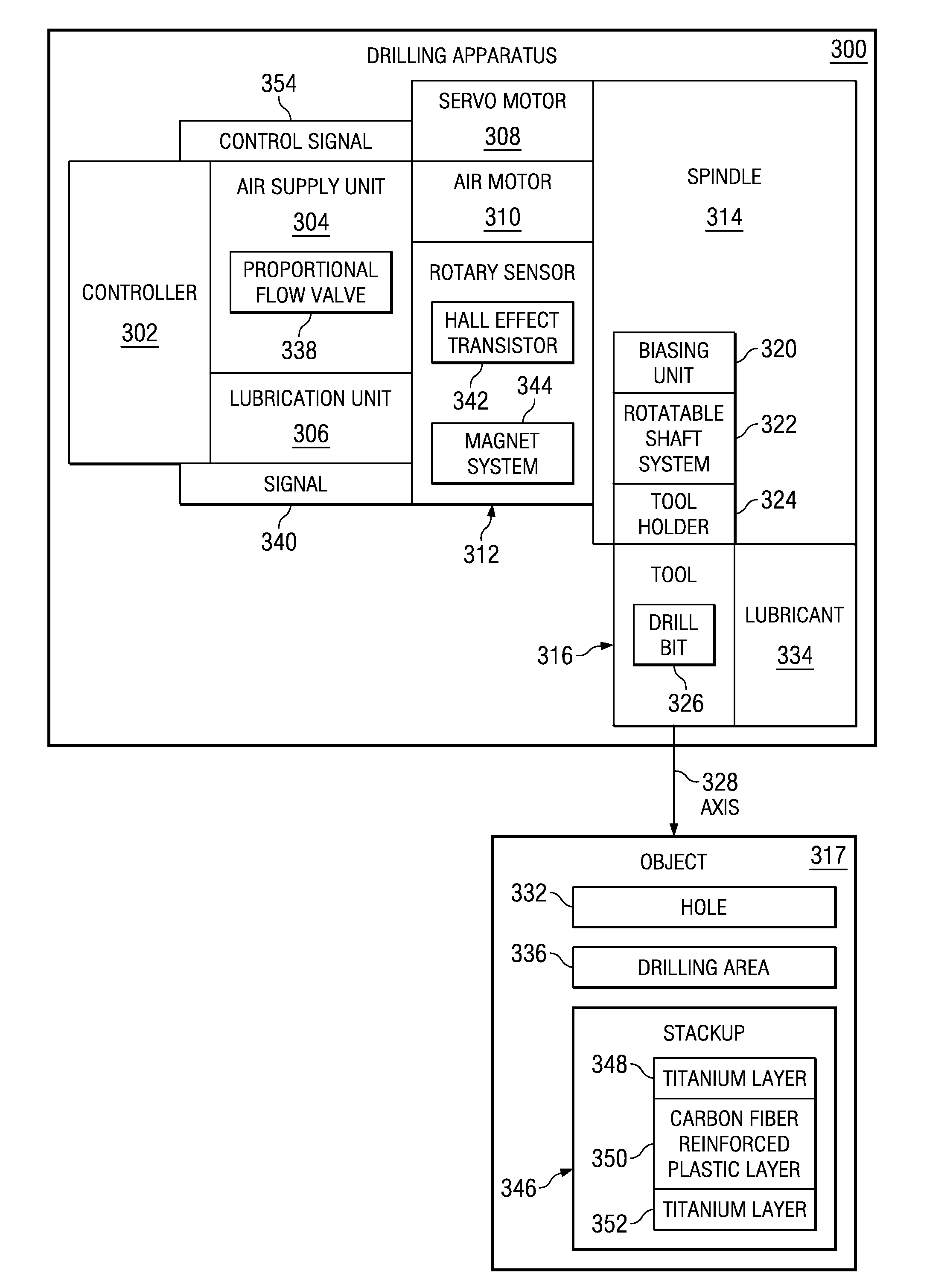

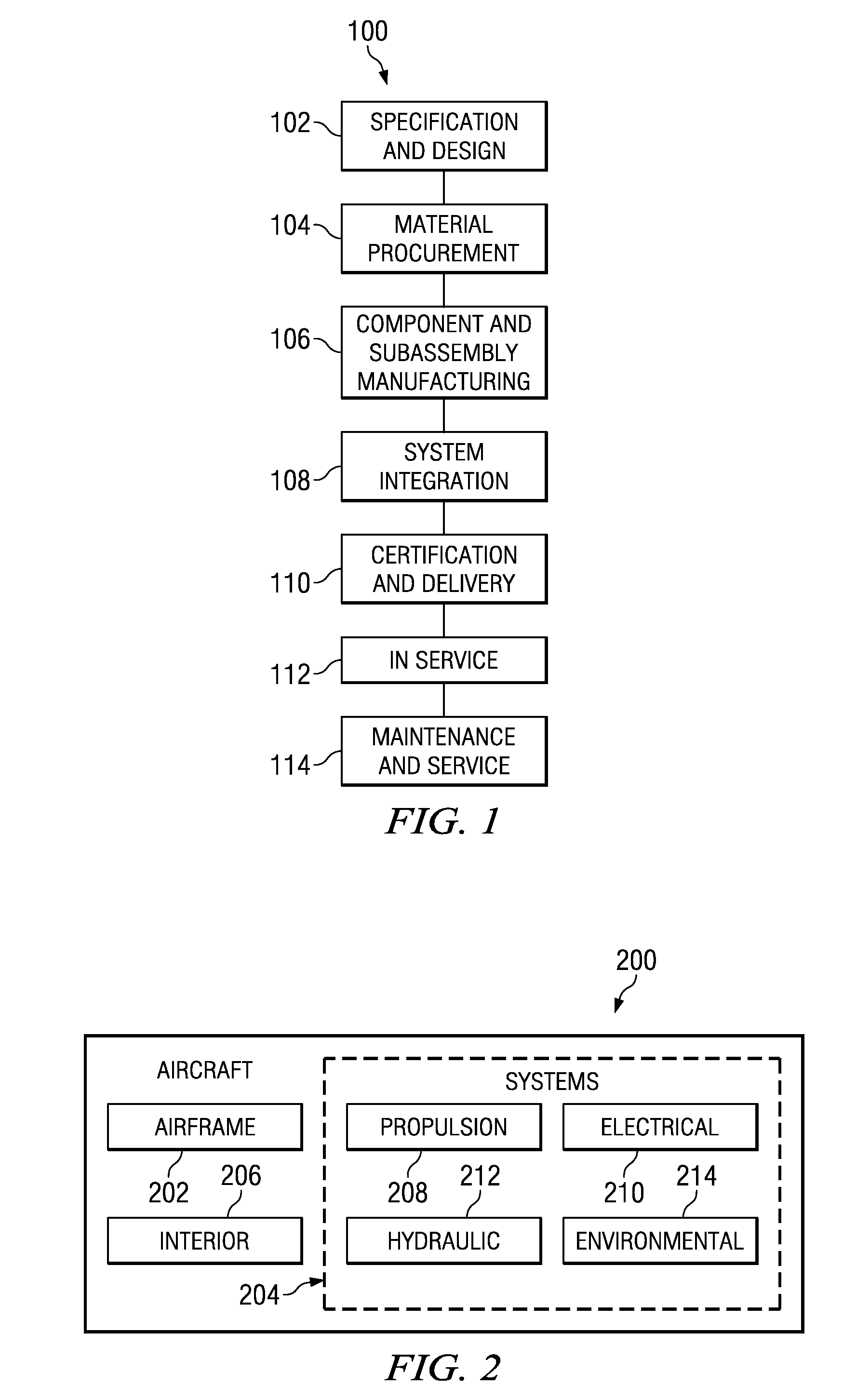

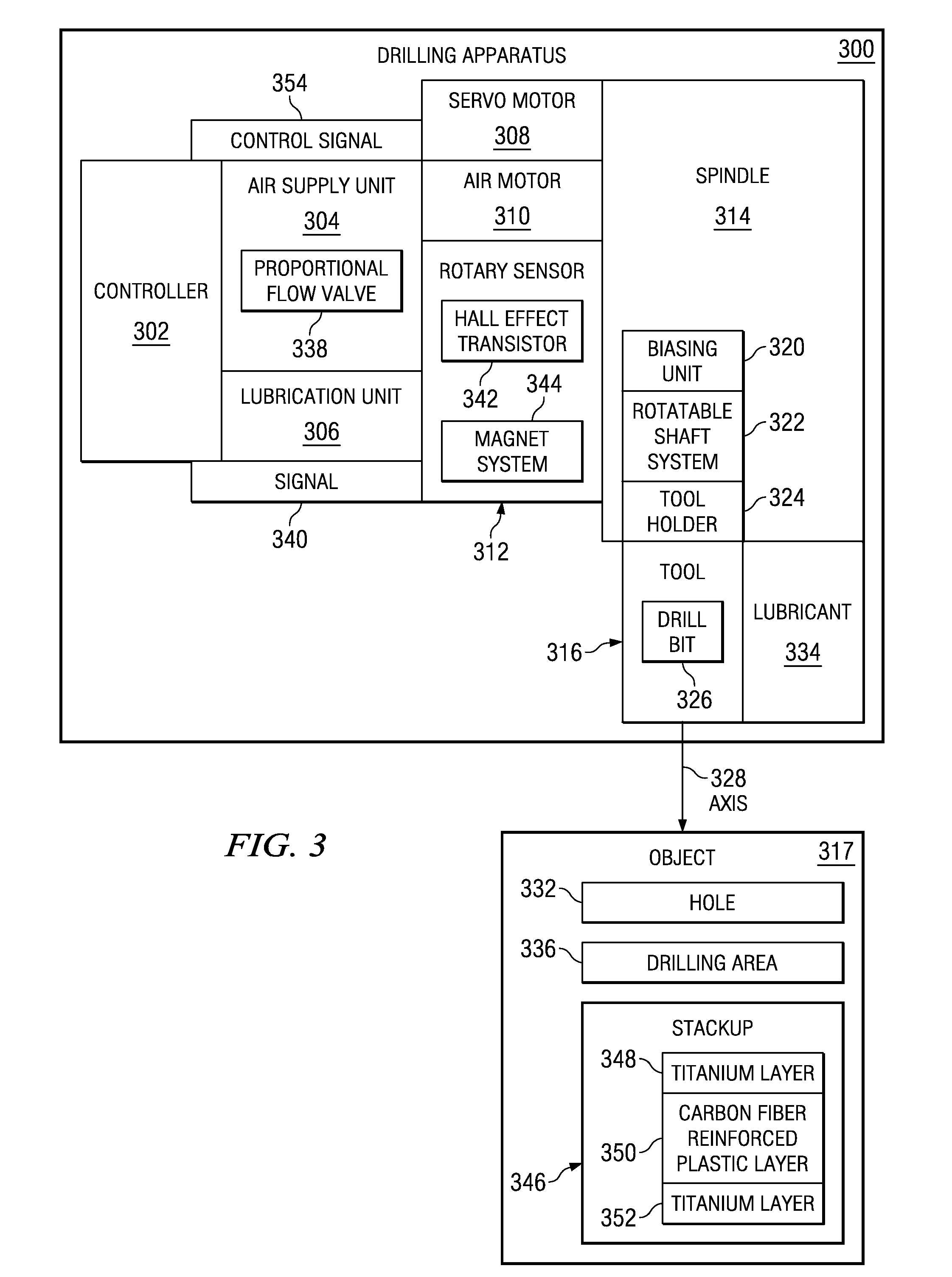

Adaptive positive feed drilling system

An apparatus for a drilling operation. In one advantageous embodiment, the drilling operation includes a motor, a rotary sensor, and a controller connected to the rotary sensor. The rotary sensor may be capable of generating a signal in response to rotary movement of the drill motor. The controller may be capable of monitoring a speed of the air motor from the signal generated by the rotary sensor and may be capable of identifying a change from a current layer in a stackup to a new layer in the stackup using the signal.

Owner:THE BOEING CO

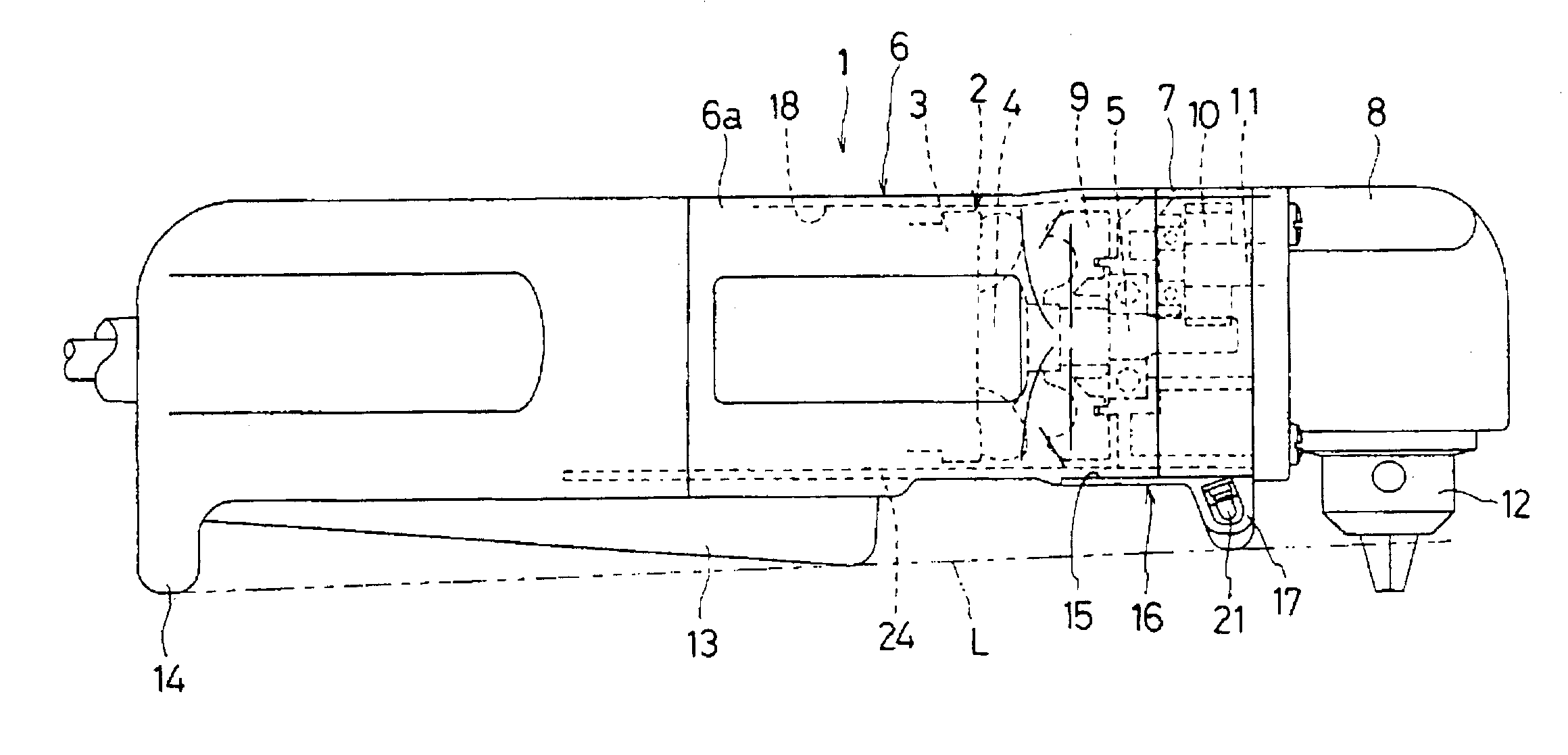

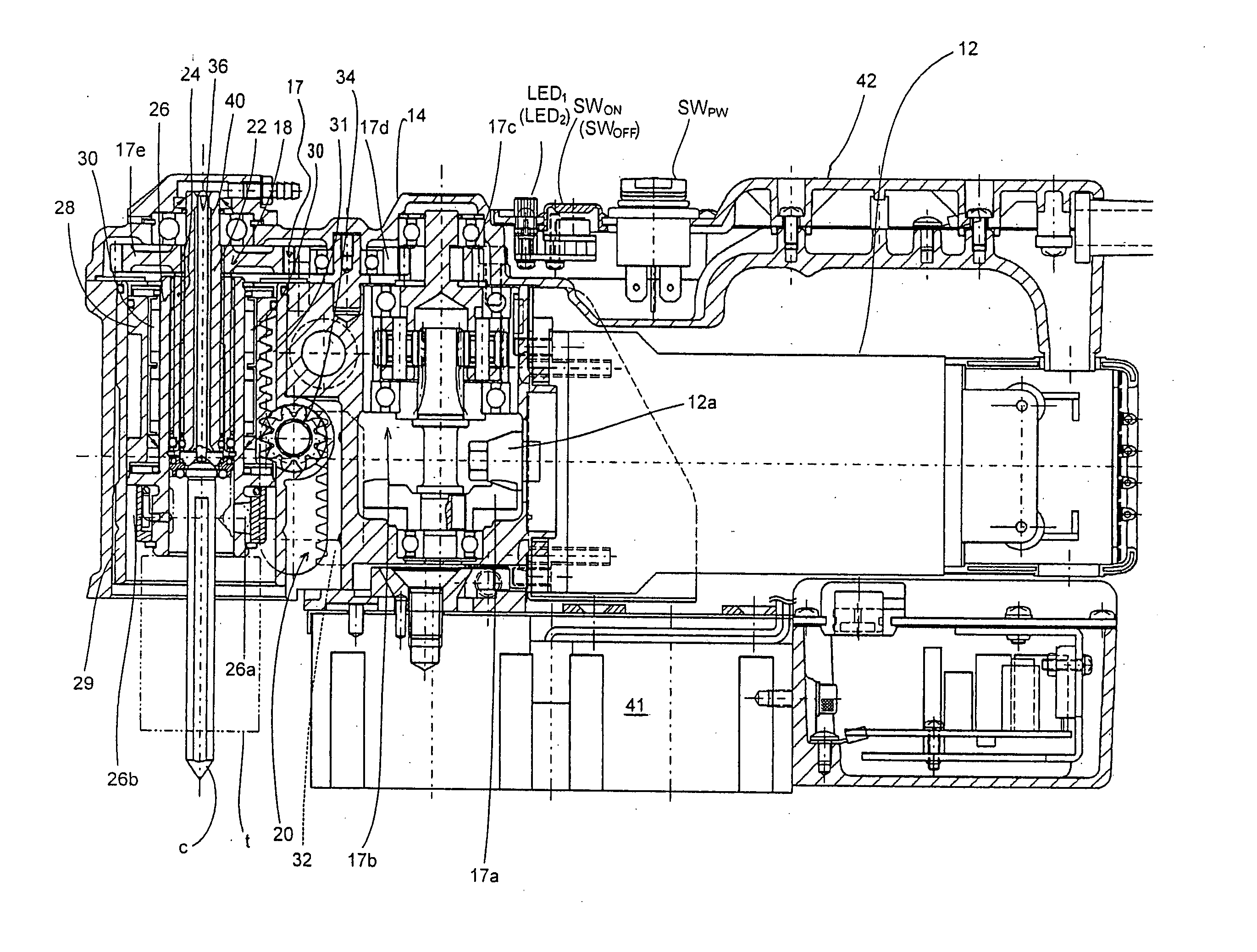

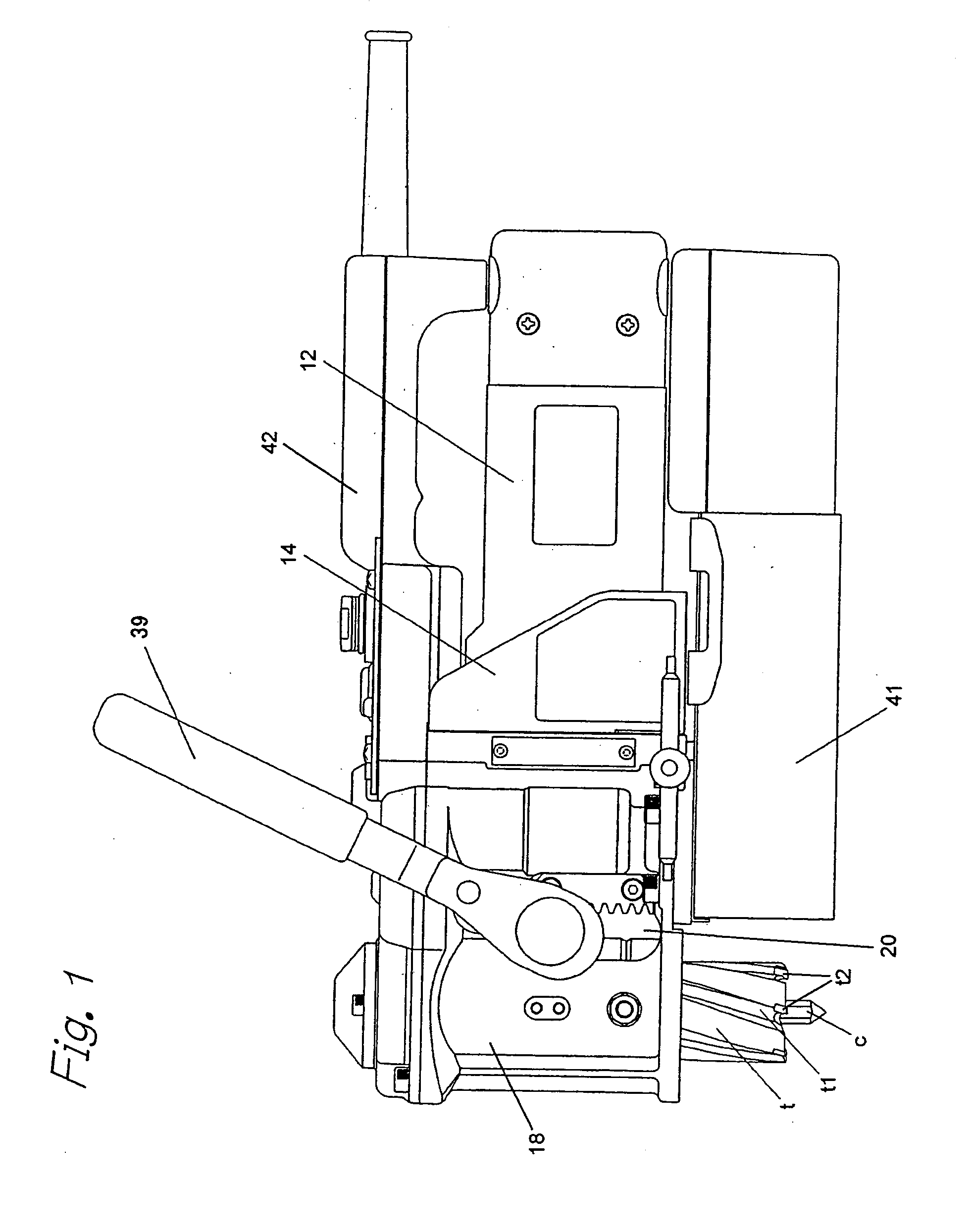

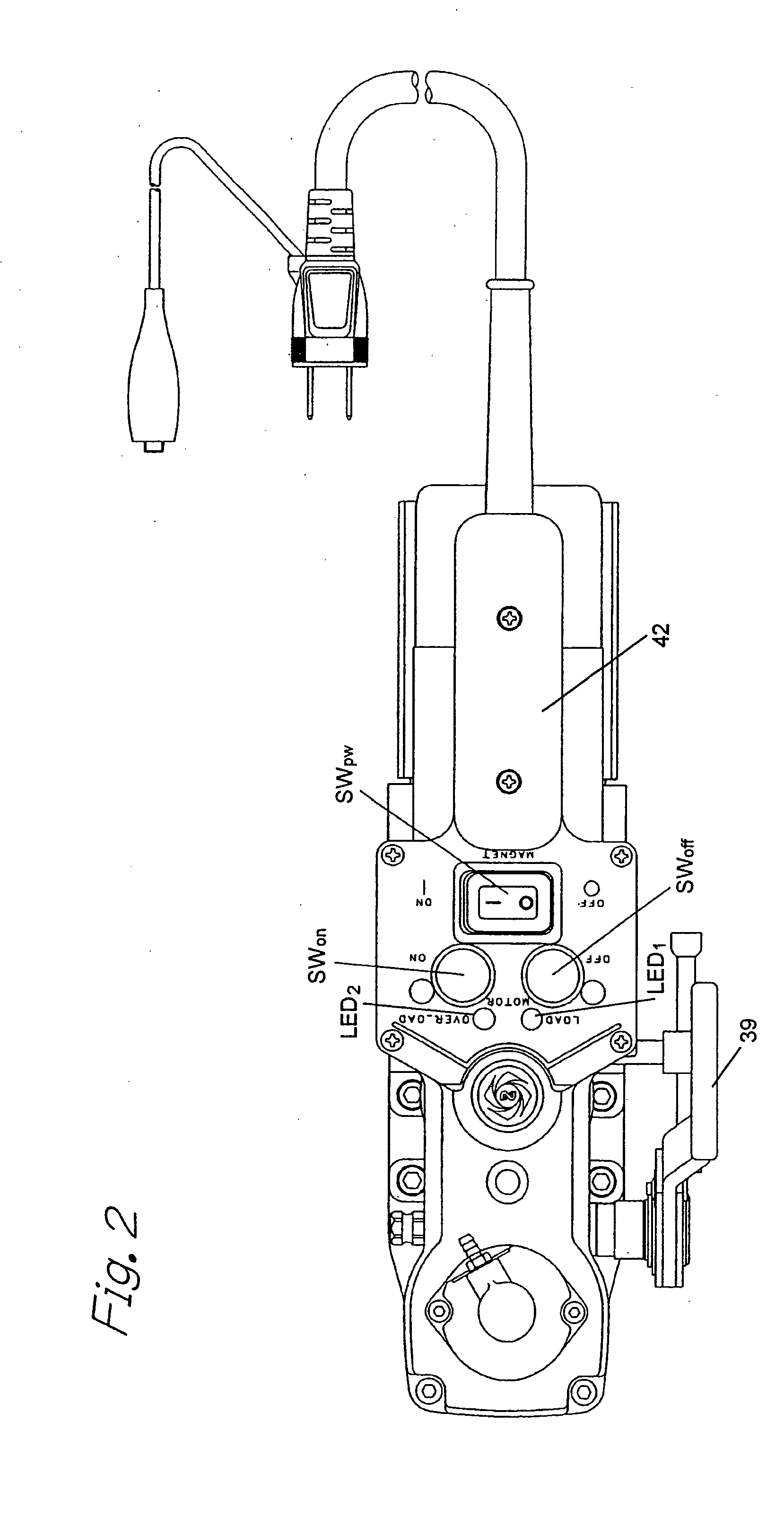

Electric drill apparatus

InactiveUS7121773B2Reduce weight and sizeLow profileDrilling/boring measurement devicesThread cutting machinesRotational axisAnnular cutter

An electric drill apparatus having a low profile is provided which comprises an annular cutter, a motor for rotating the annular cutter, a rotary shaft assembly for rotating the annular cutter attached to its leading end about a rotating, a rotation reduction mechanism disposed between the motor and rotary shaft assembly for transmitting a driving force of the motor to the annular cutter through the rotary shaft assembly, a feed mechanism responsive to an operation of a manual handle, for moving the rotary shaft assembly along with a straight line to advance or retract the annular cutter attached to the rotary shaft assembly with respect to a workpiece, and an adhesion base for securing the electric drill apparatus to the workpiece. The annular cutter has a plurality of cutting blades comprised of cemented carbide tips fixed on its lower end, thereby it is capable of rotating at a high speed. The rotary shaft assembly has a rotating shaft which rotates in a direction different from that of a rotating shaft of the motor, thereby the drill apparatus has a low profile.

Owner:NITTO KOHKI CO LTD

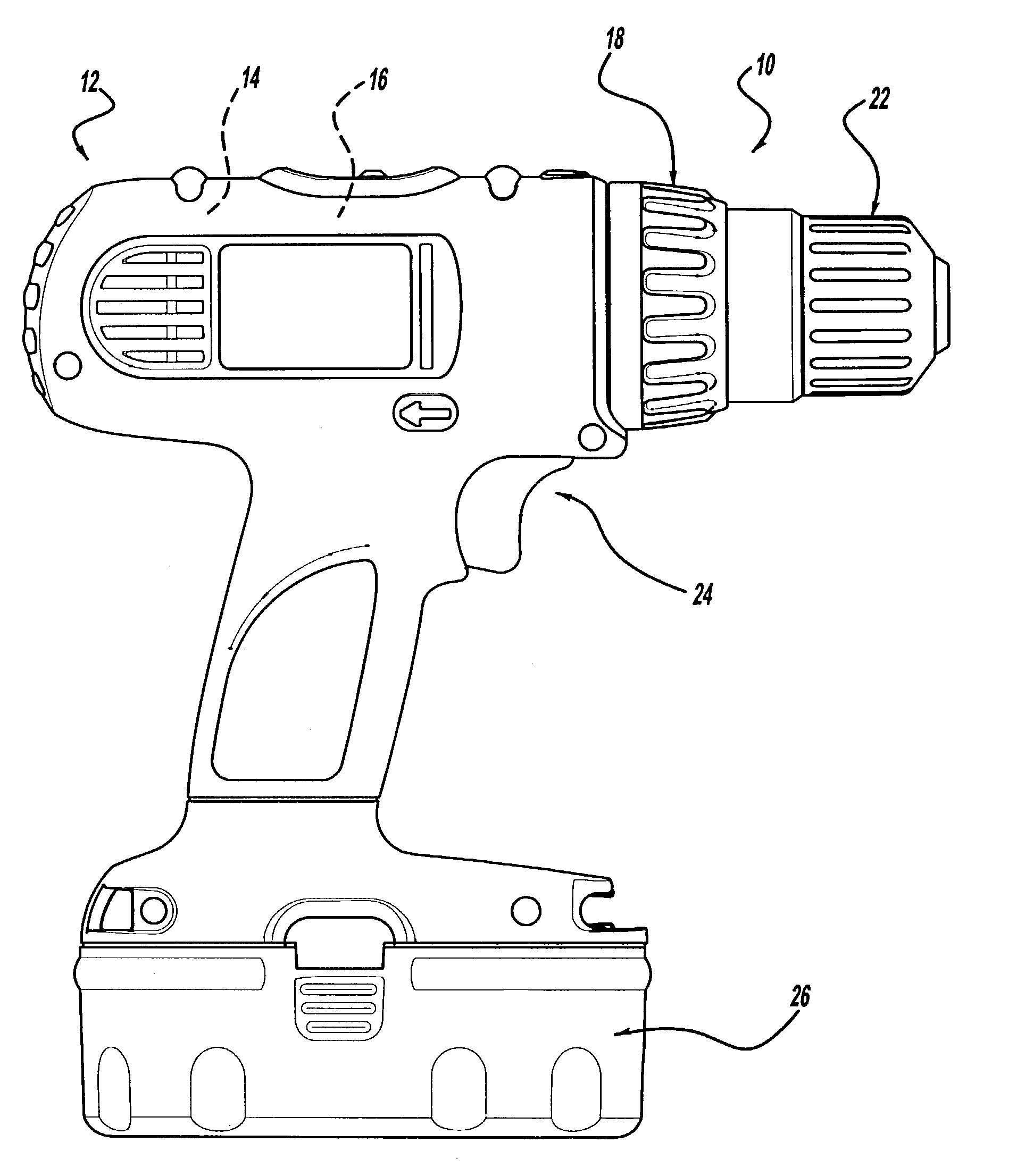

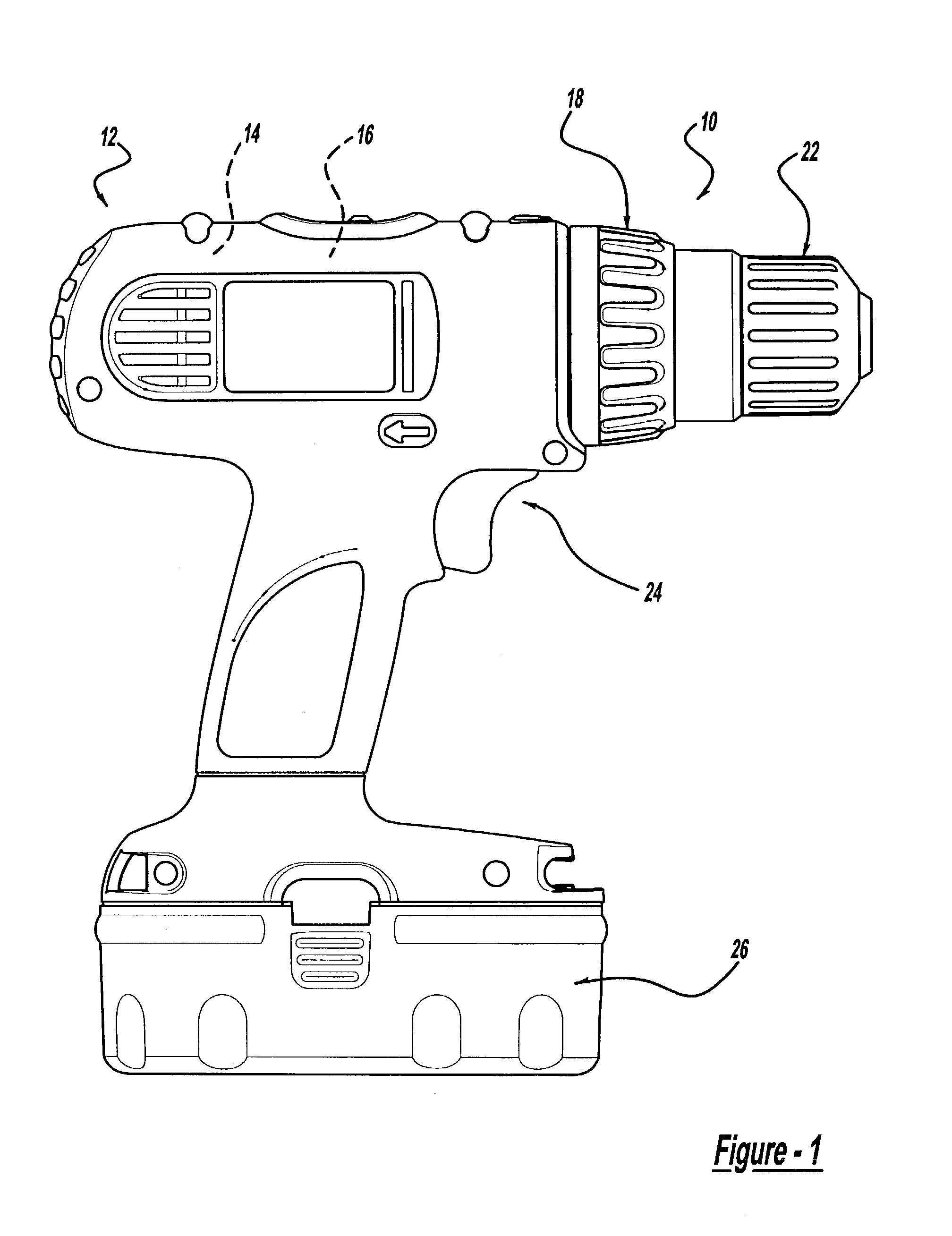

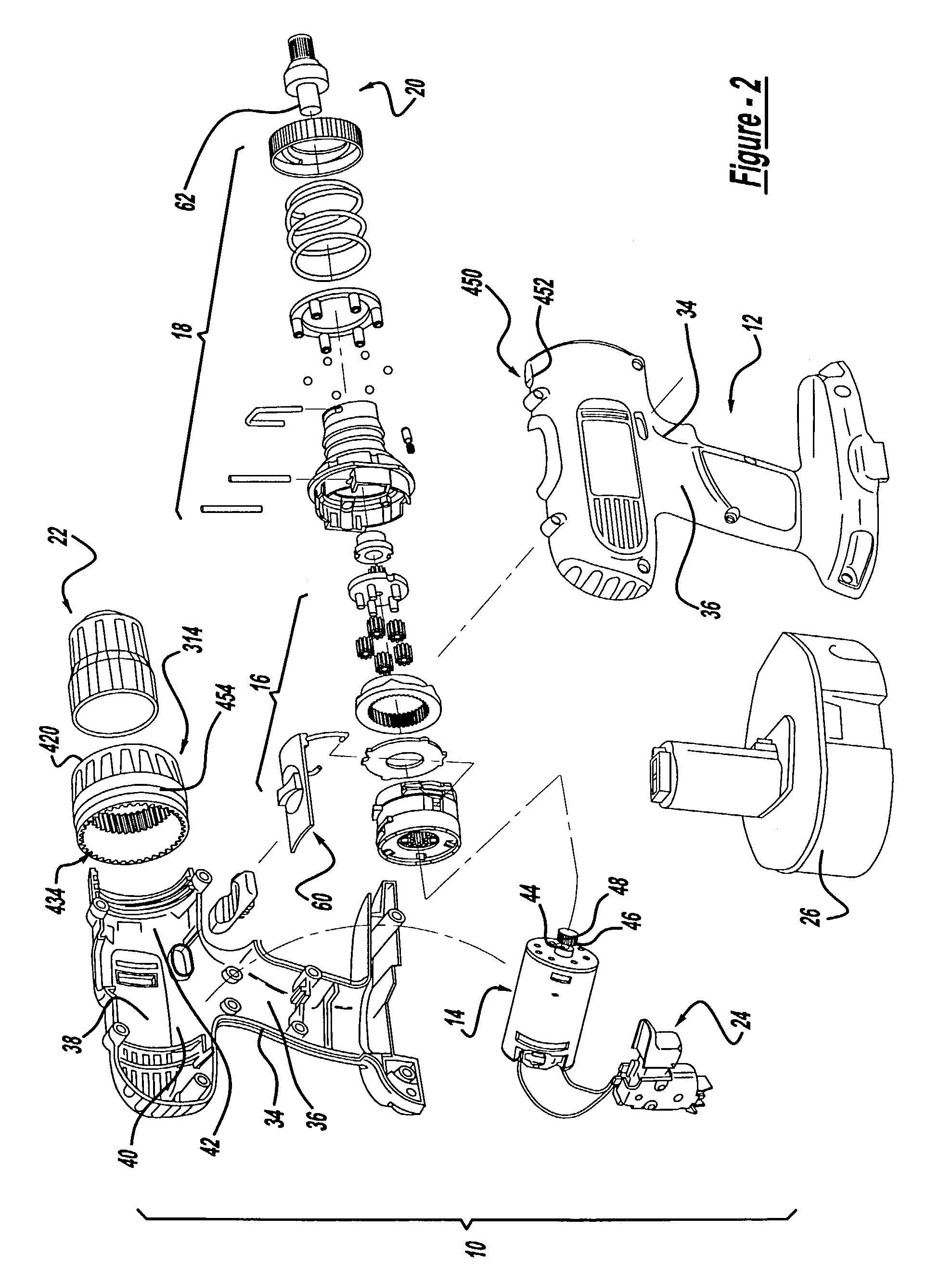

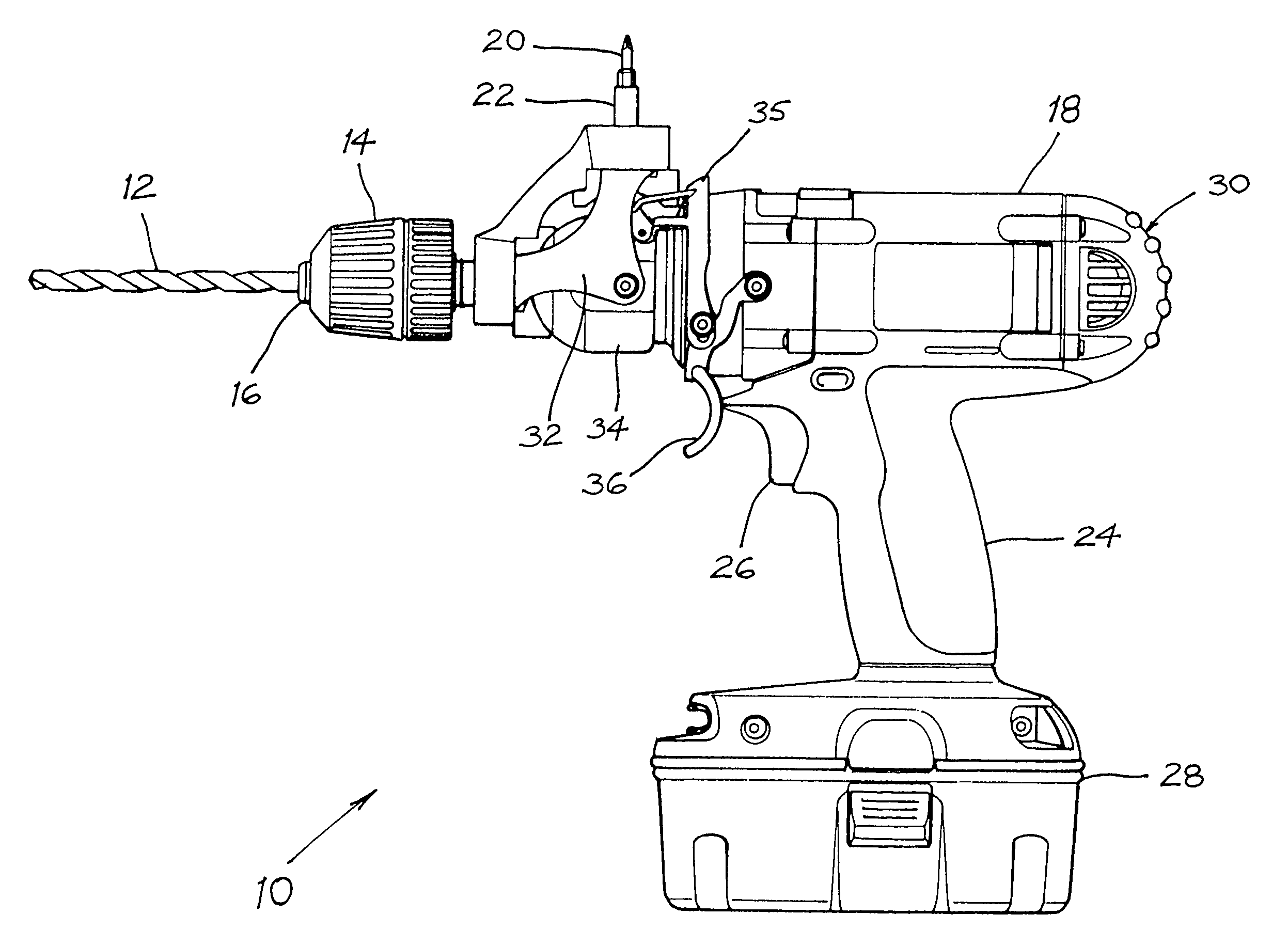

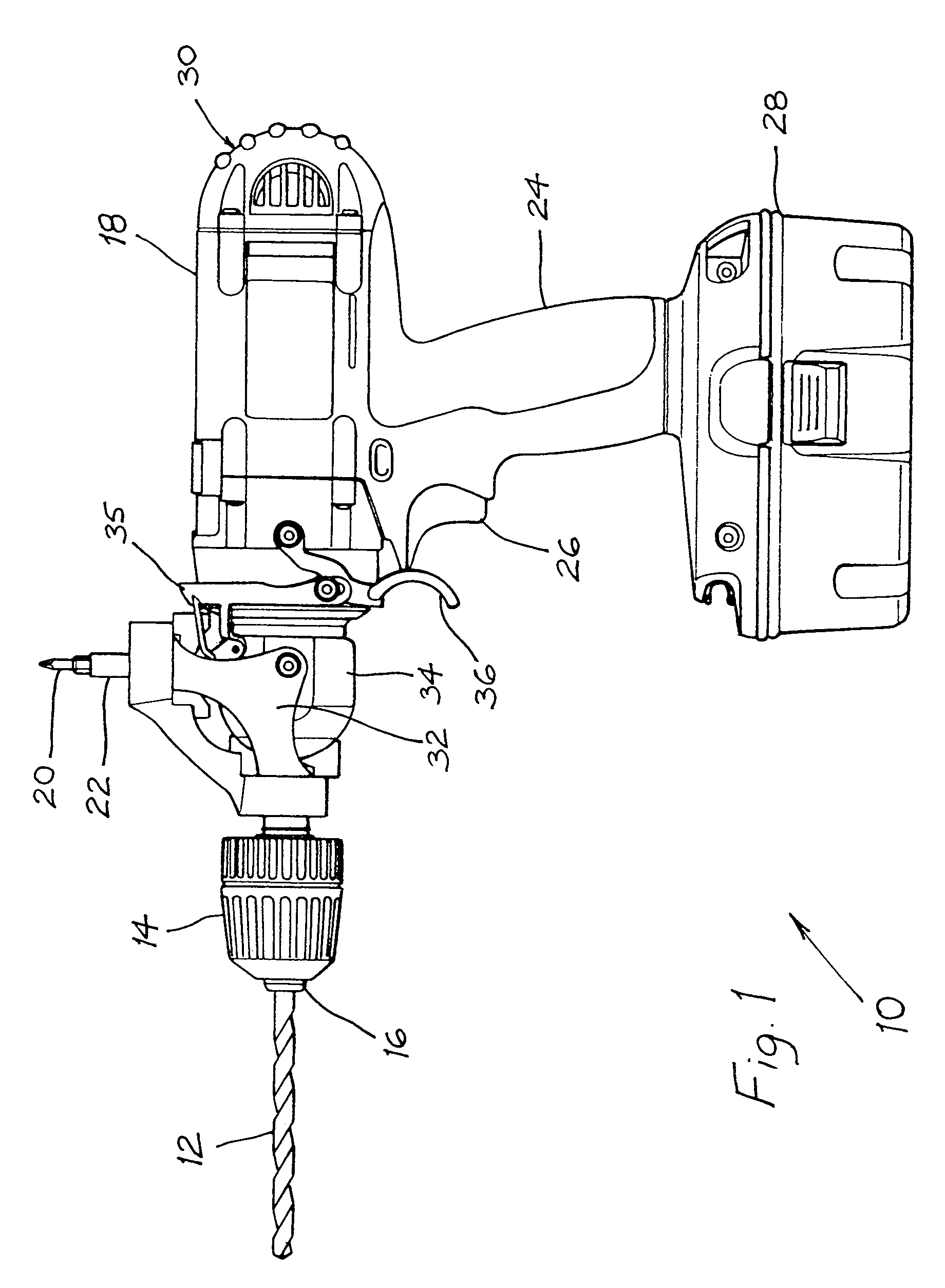

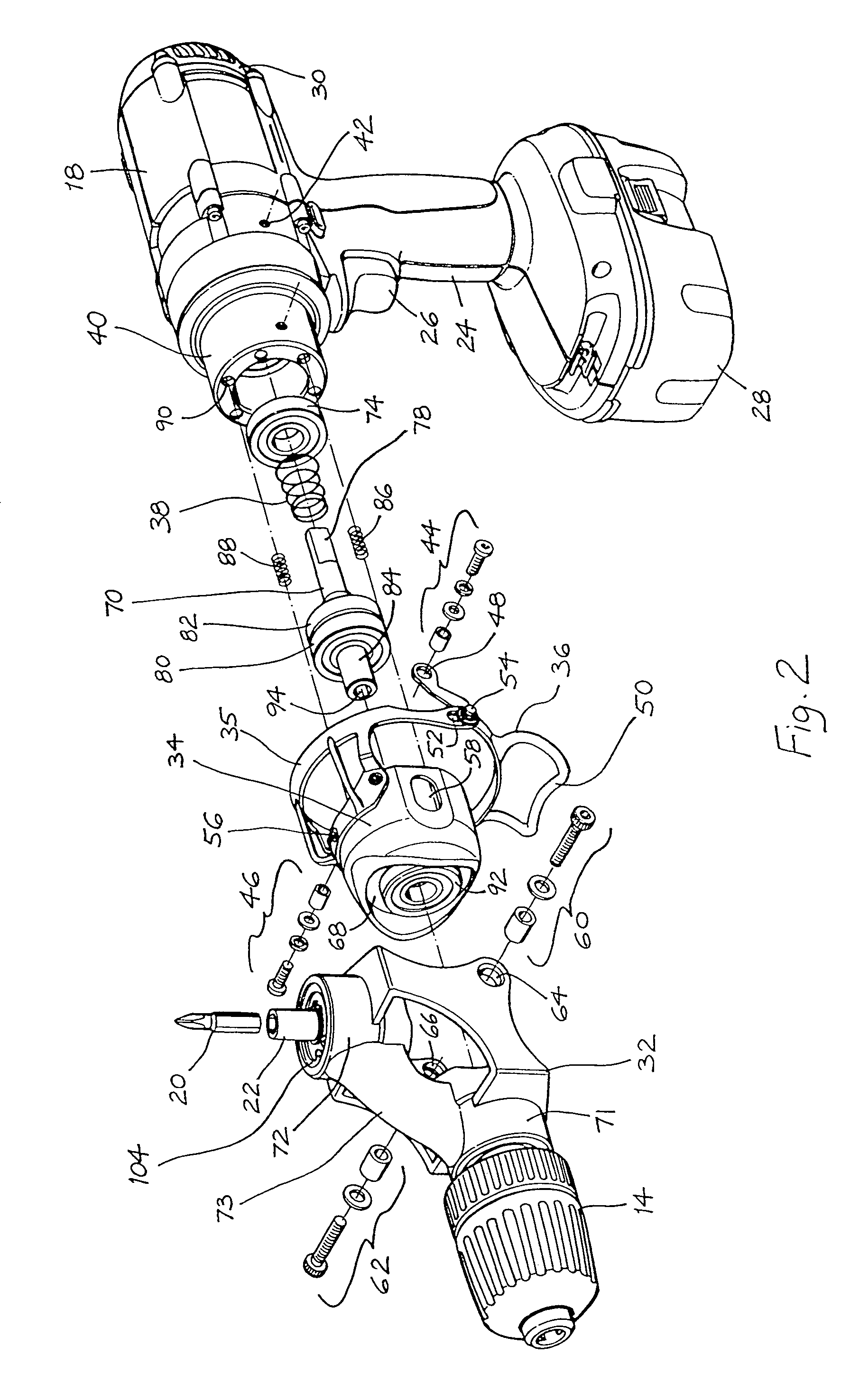

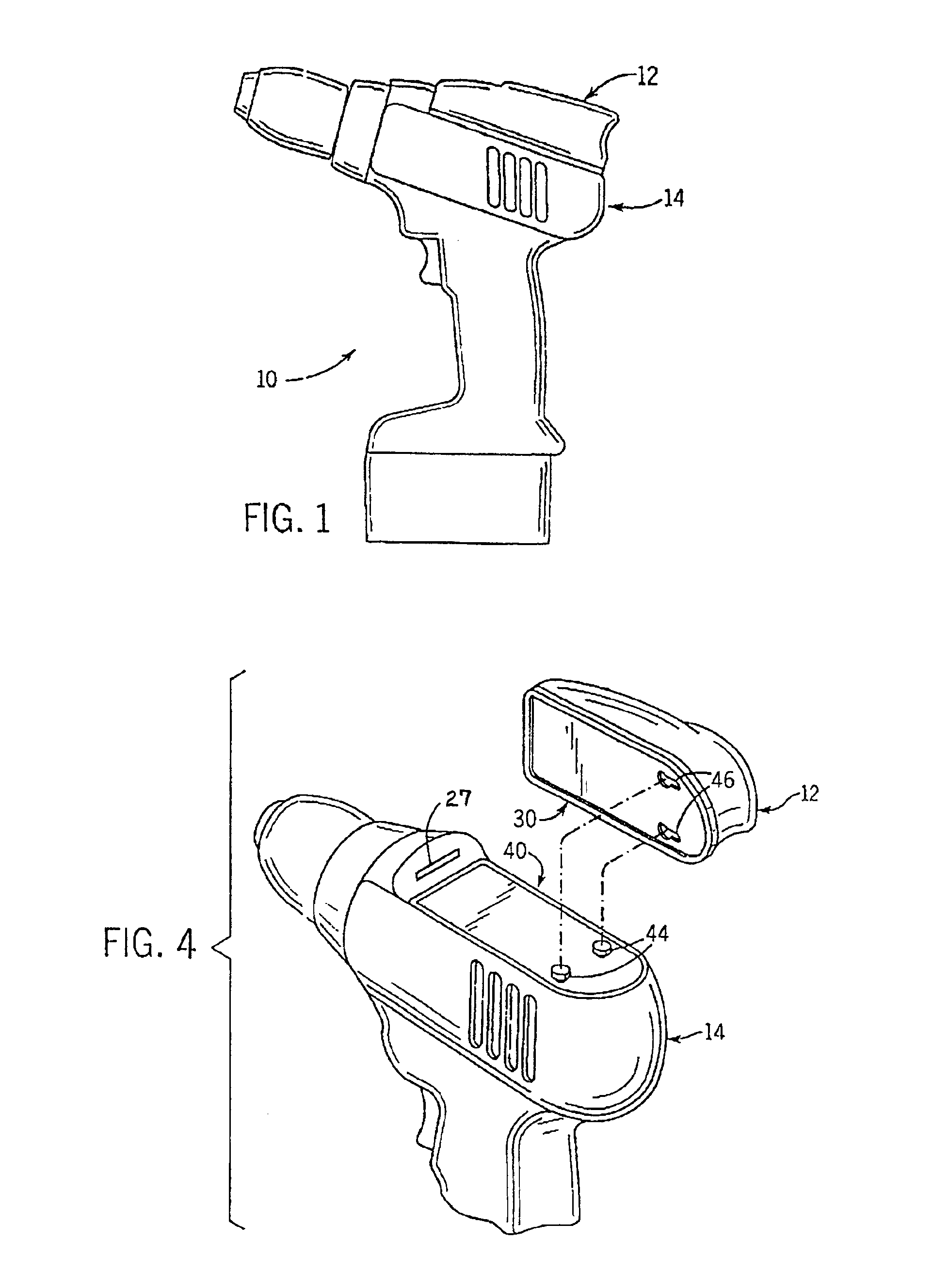

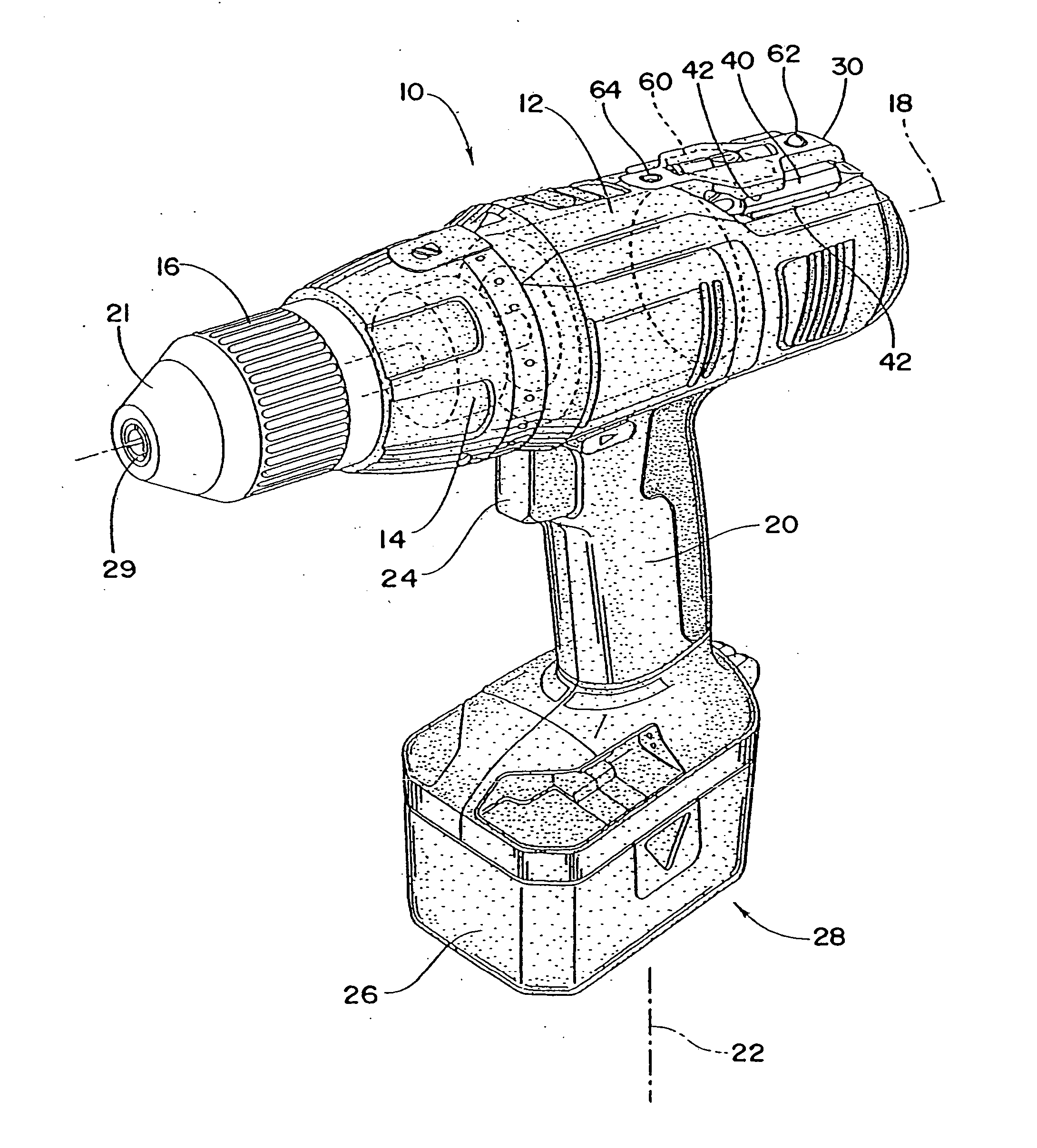

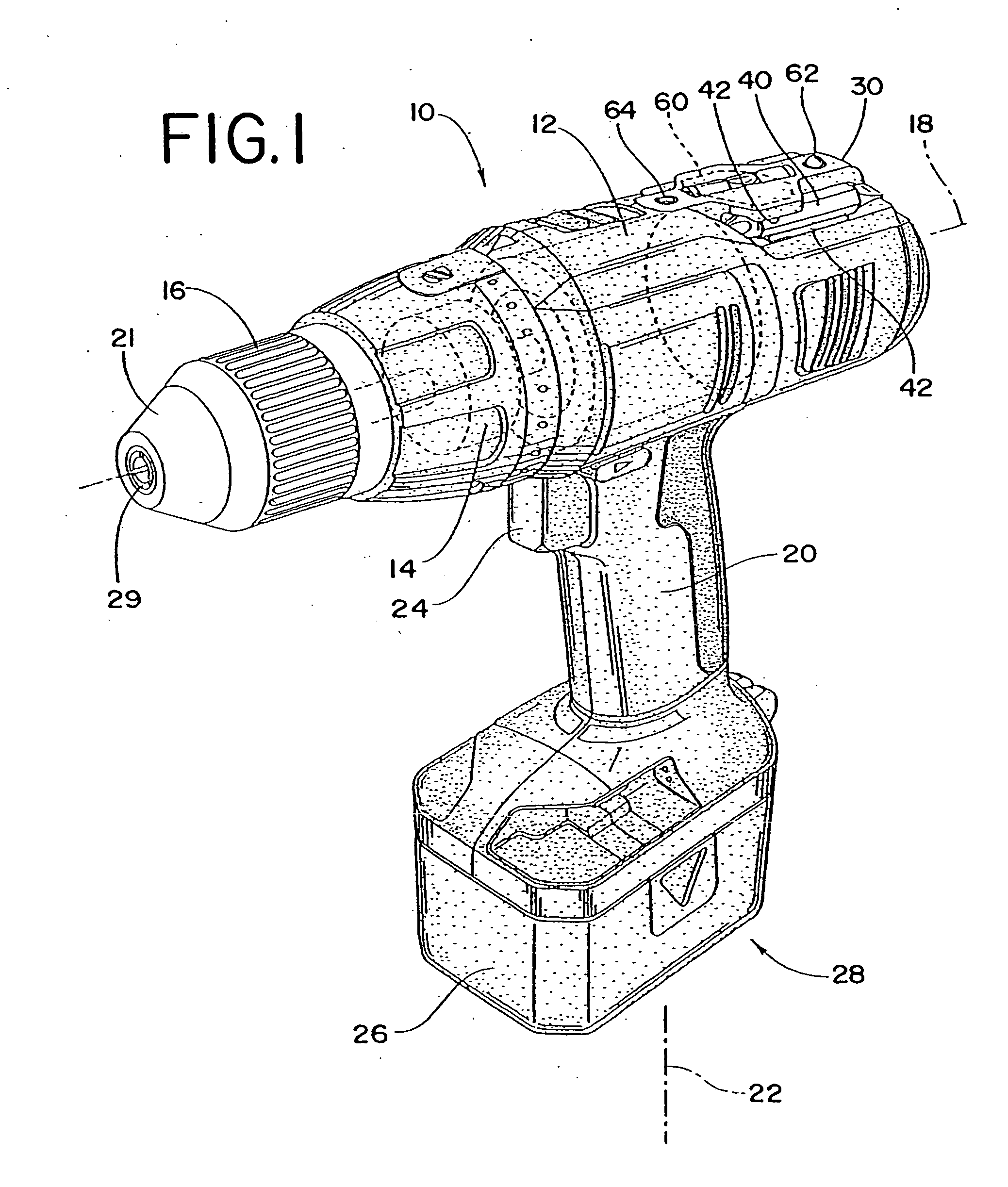

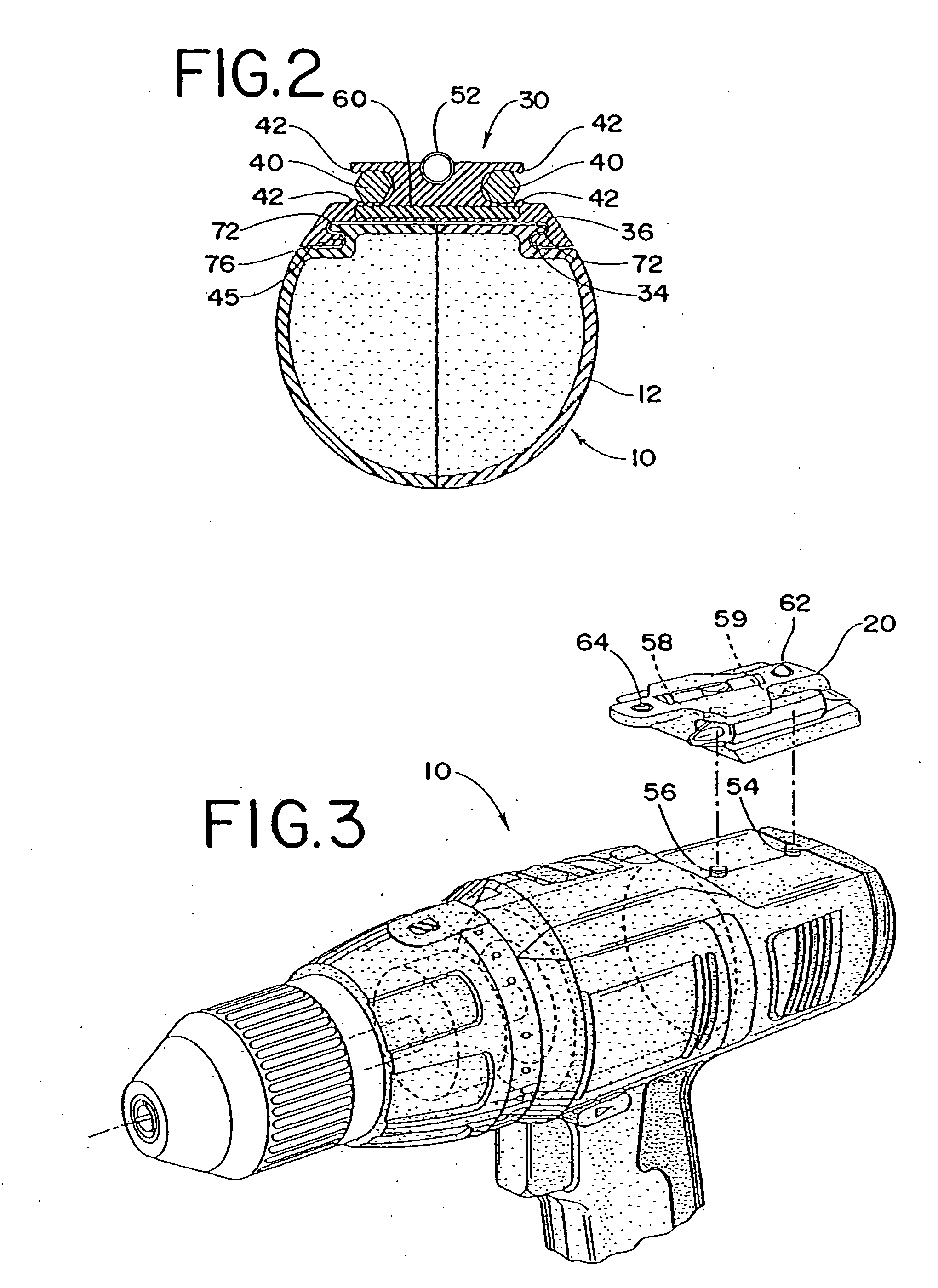

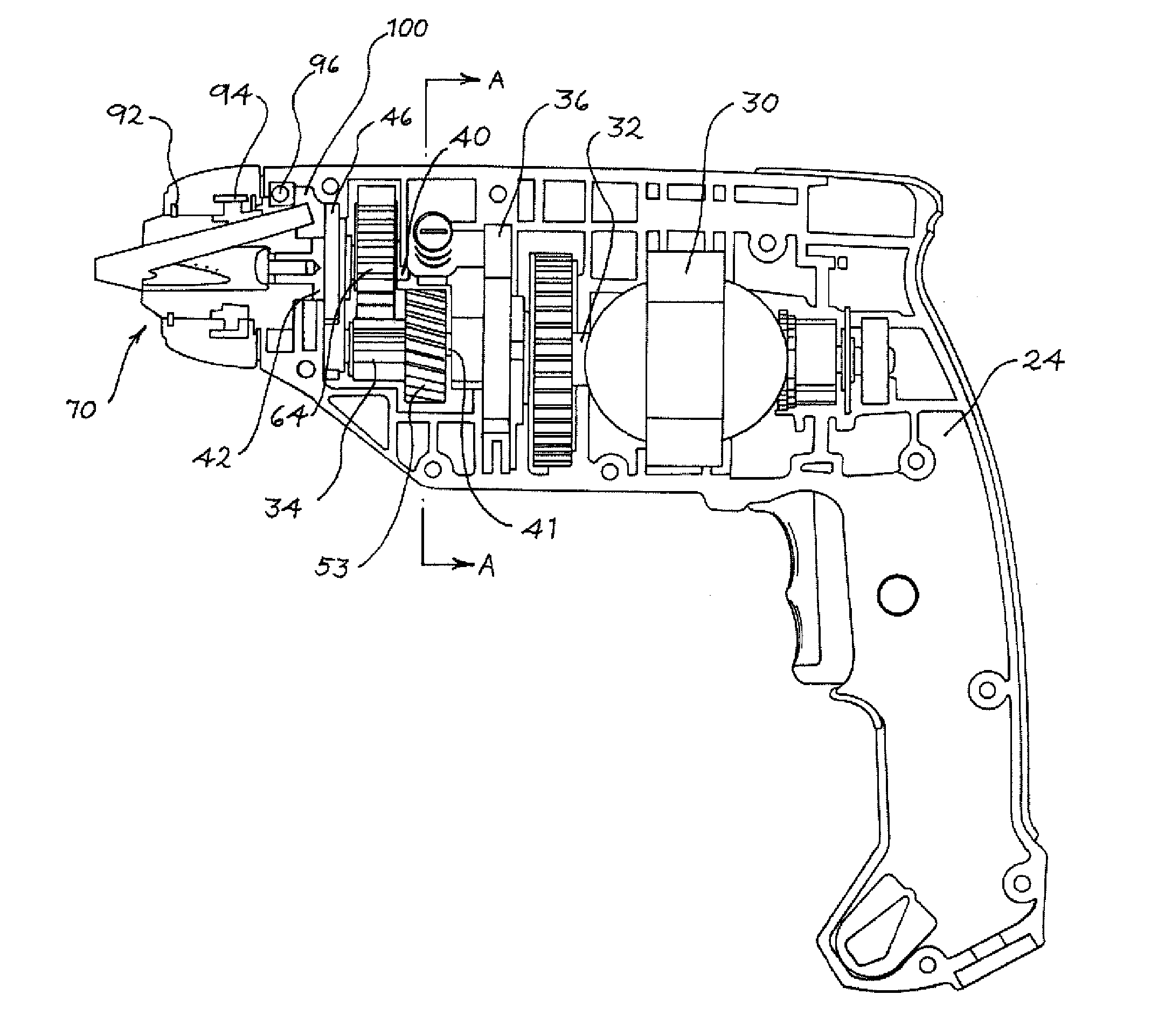

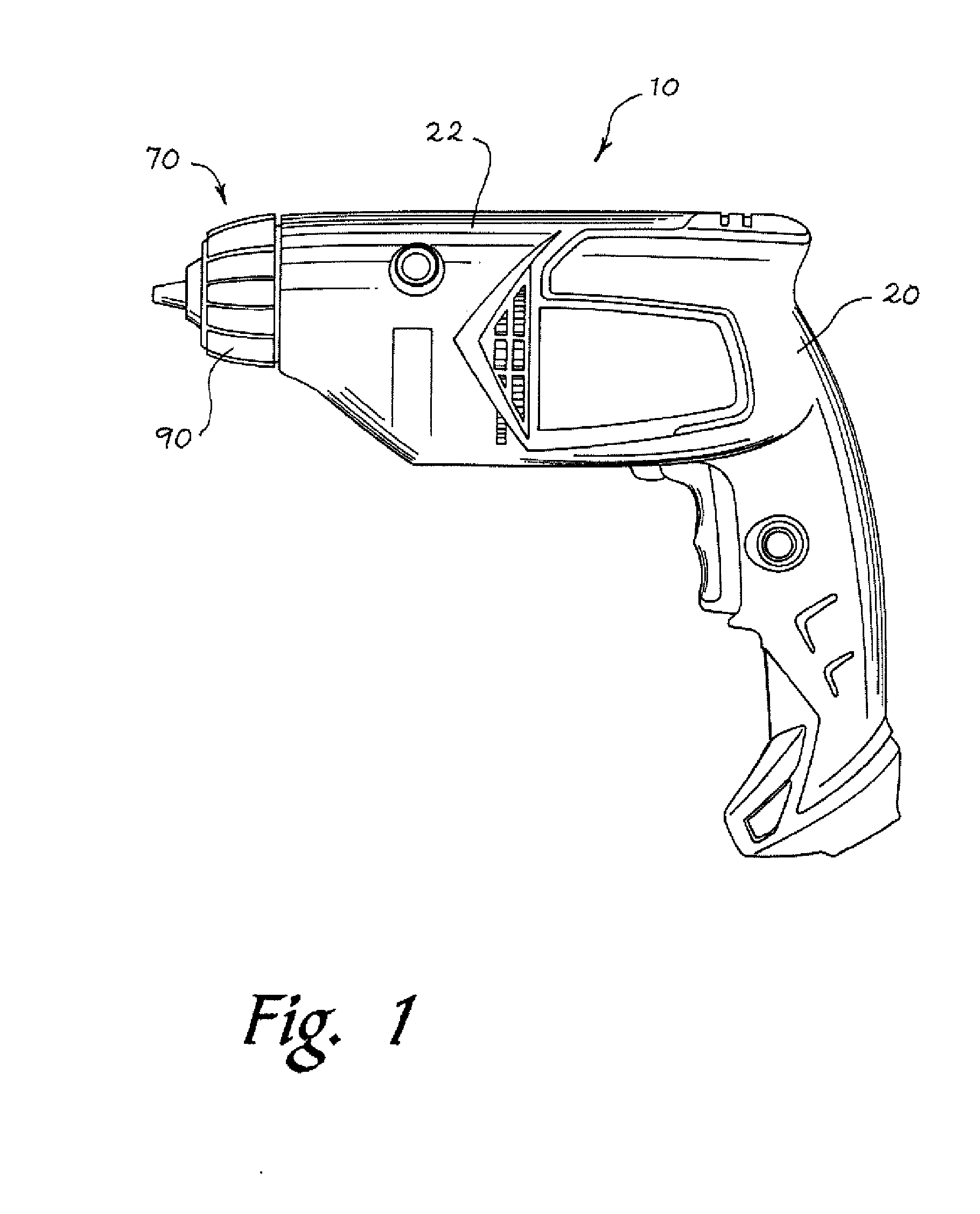

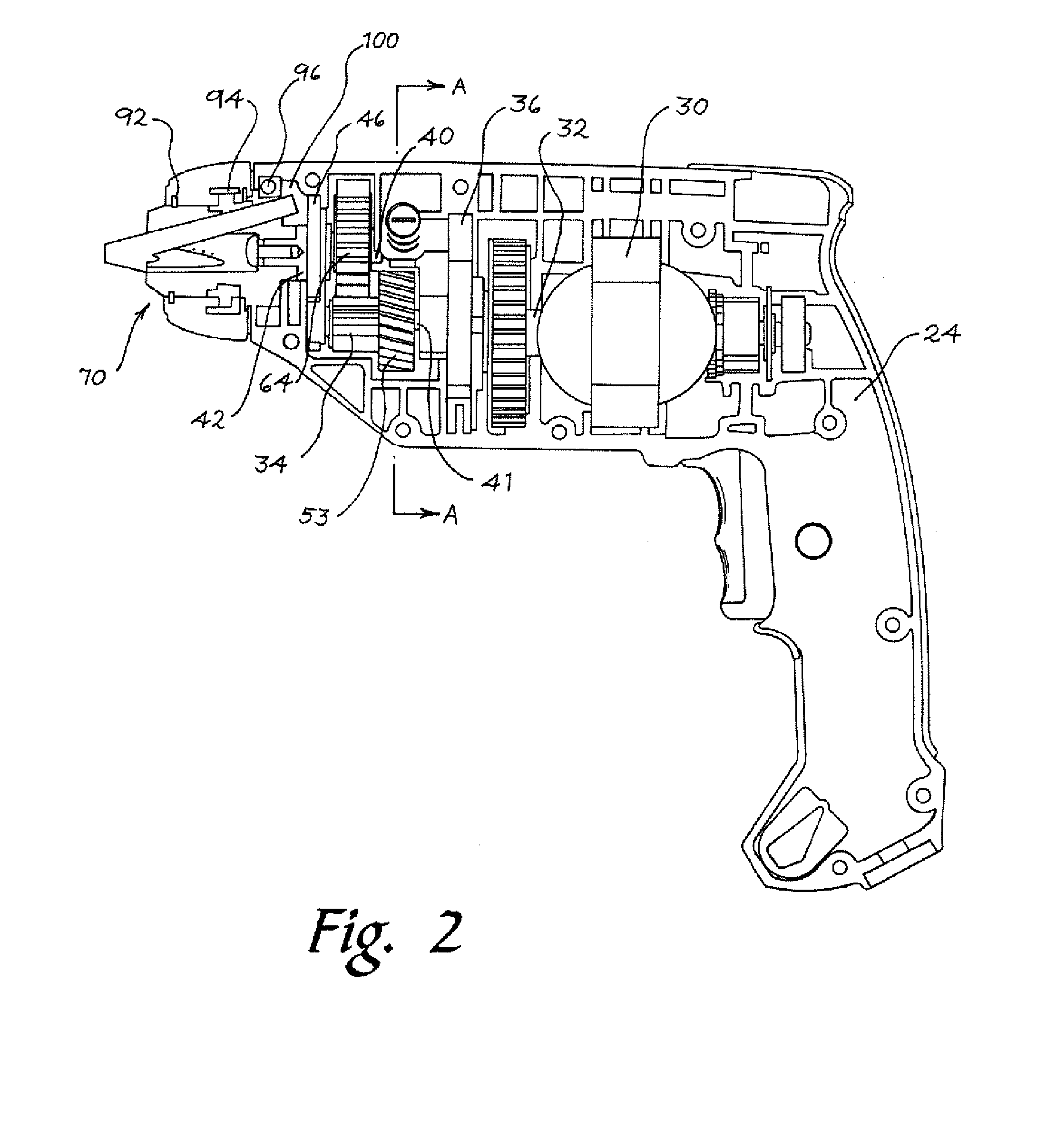

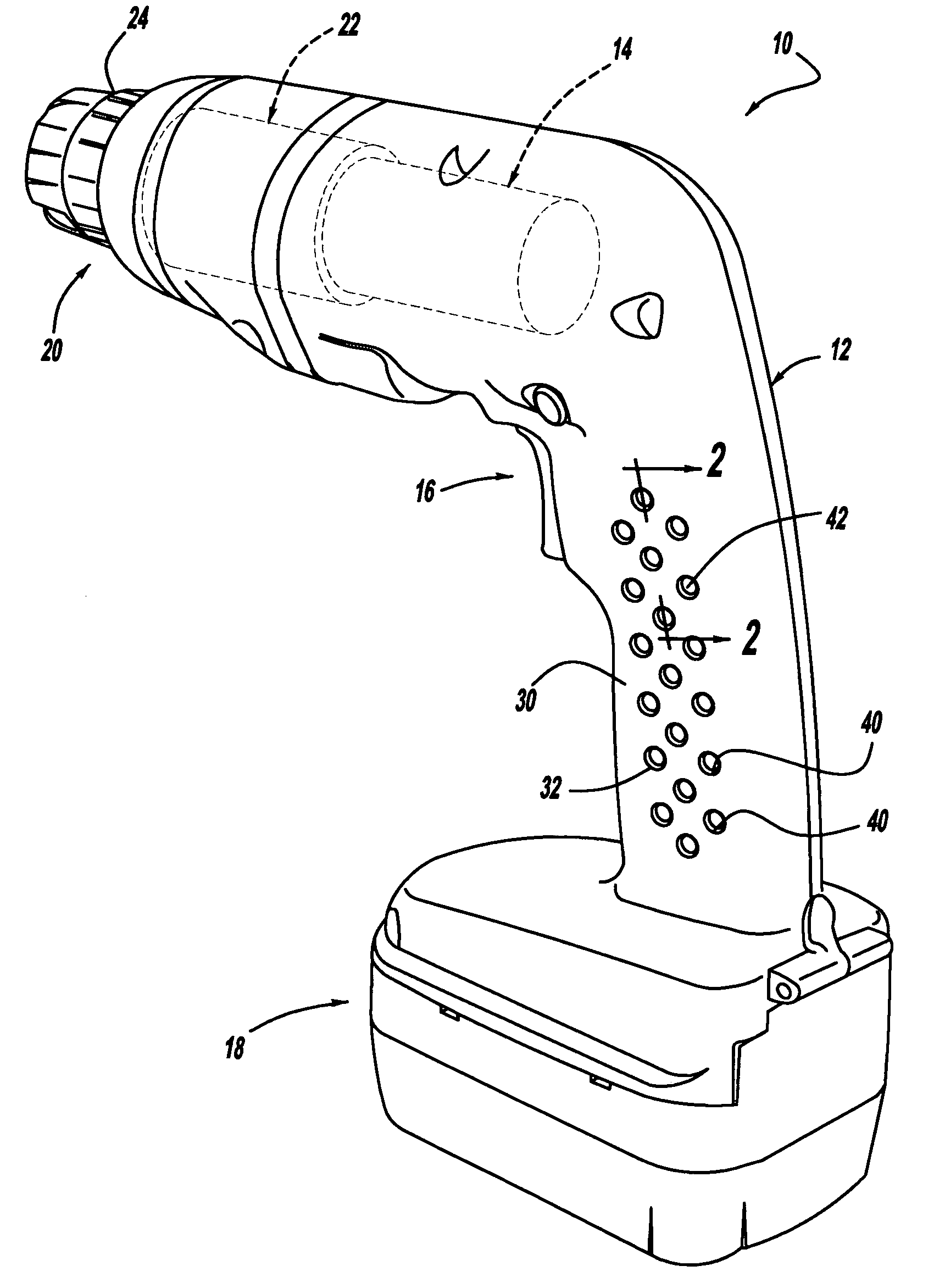

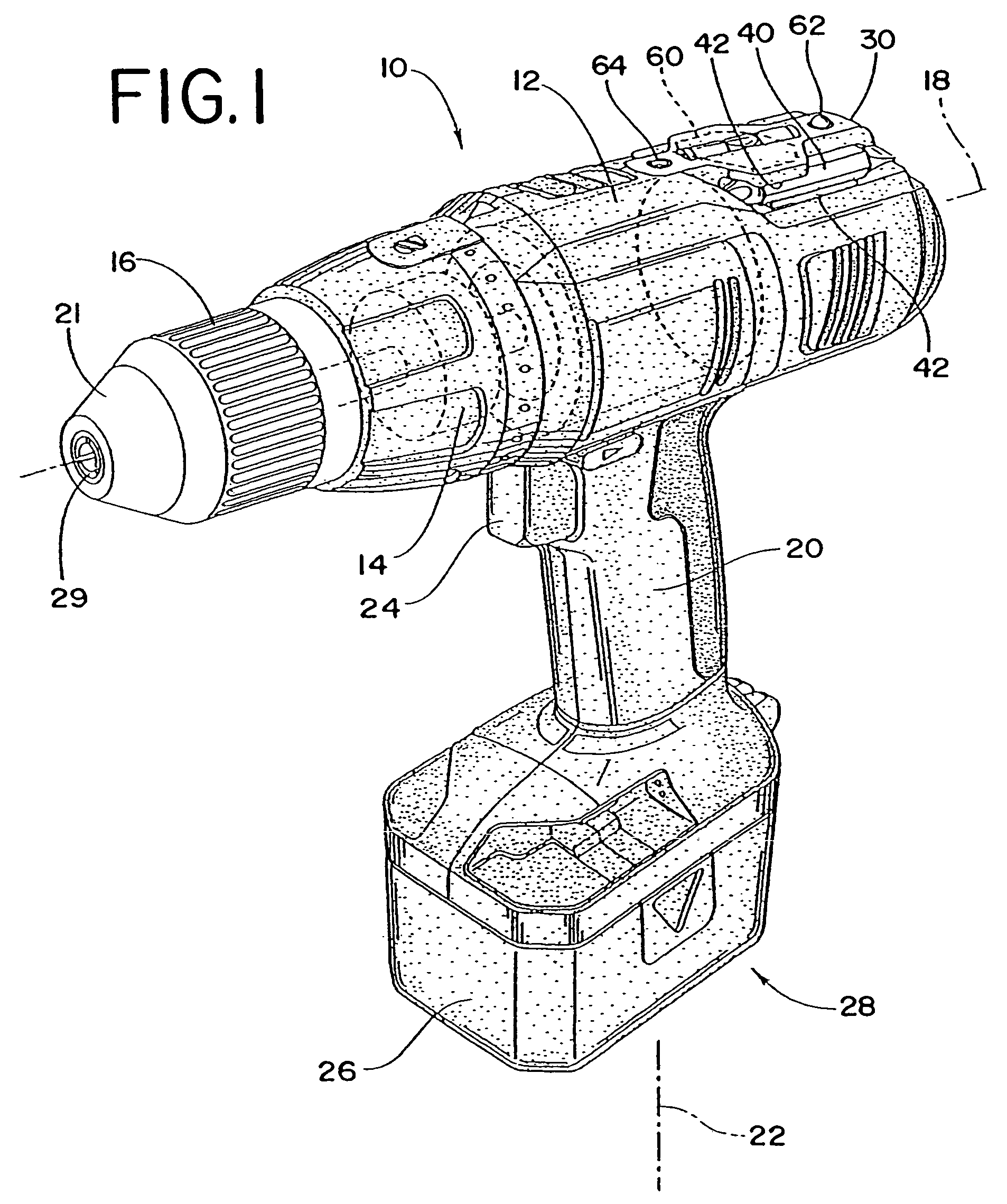

Power drill/driver

ActiveUS7066691B2Limit torsional outputOptimization mechanismThread cutting auxillary apparatusSlip couplingHand heldEngineering

A hand-held power tool having a multi-speed transmission and a clutch. The multi-speed transmission and the clutch are coupled to one another via a set of interconnecting tabs that are slidingly engaged to one another and secured with pins to inhibit the withdrawal of the tabs from one another. The clutch may include a clutch member, a unitarily formed clutch plate and a plurality of engagement members. The clutch plate includes an annular plate member and a plurality of leg members that extend generally perpendicularly from the annular plate member and which bias the engagement members into engagement with the clutch member. The clutch member may be coupled to an element of the multi-speed transmission, such as to the ring gear of a planetary gear set, so as to reduce the overall size of the power tool.

Owner:BLACK & DECKER INC

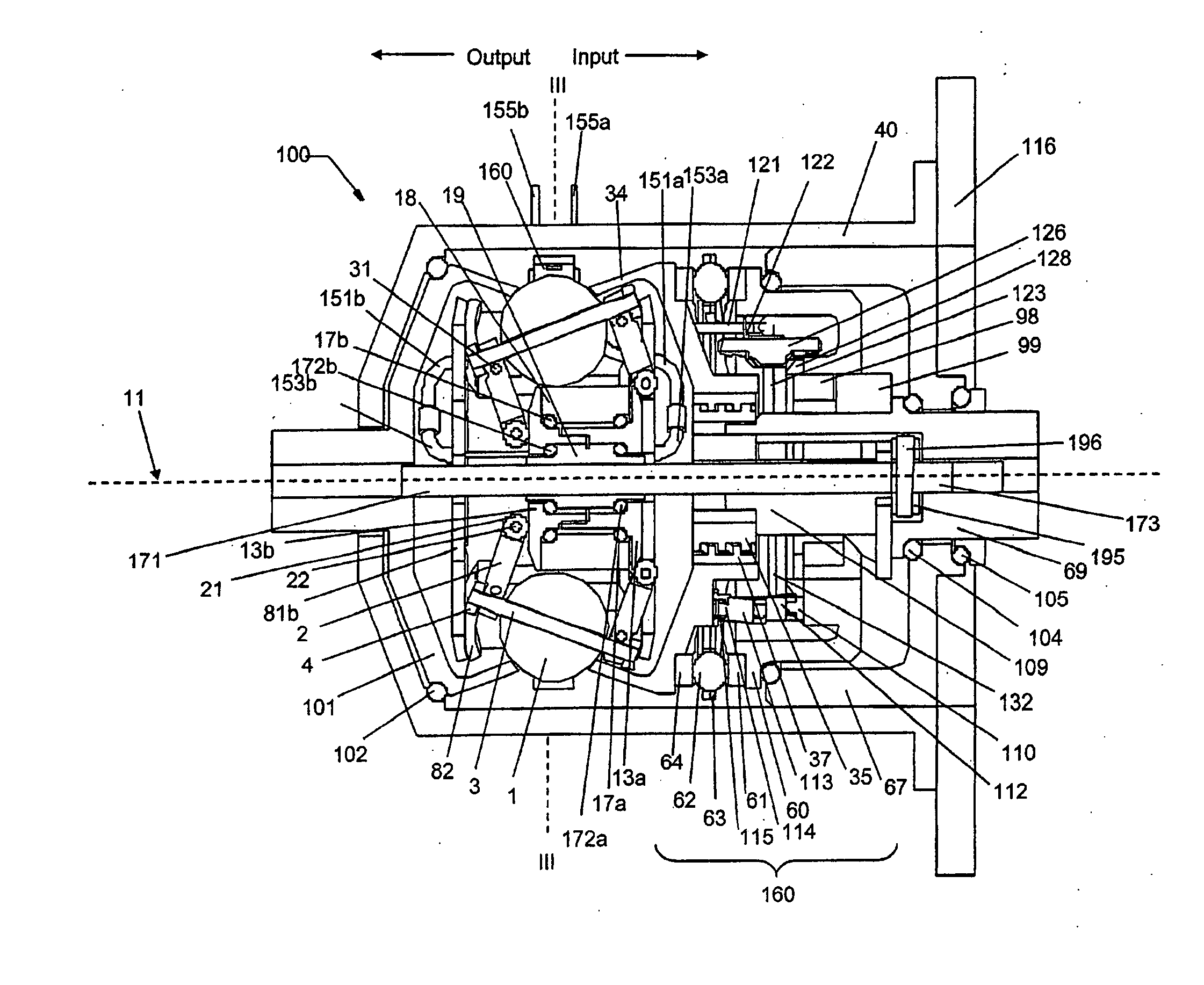

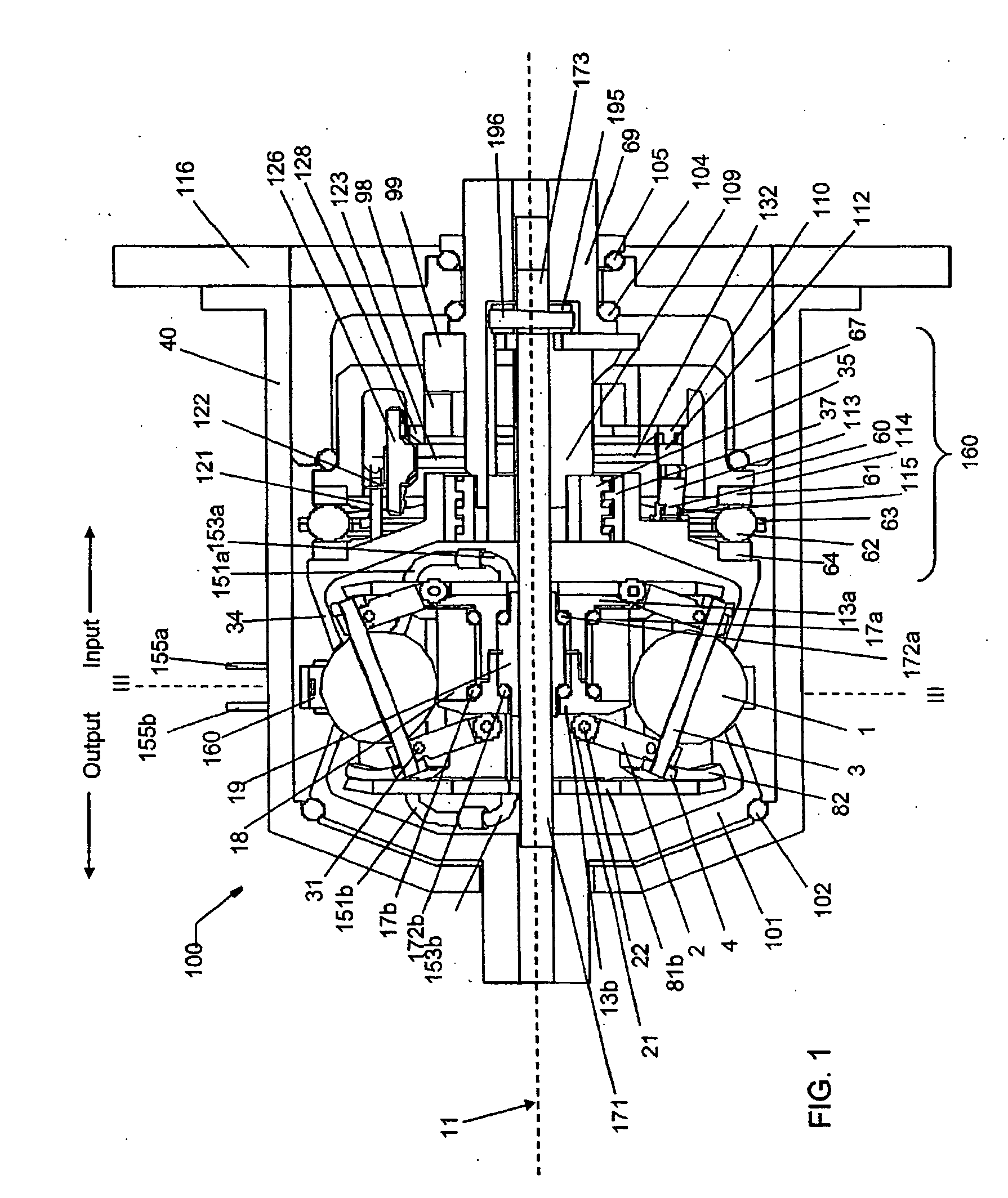

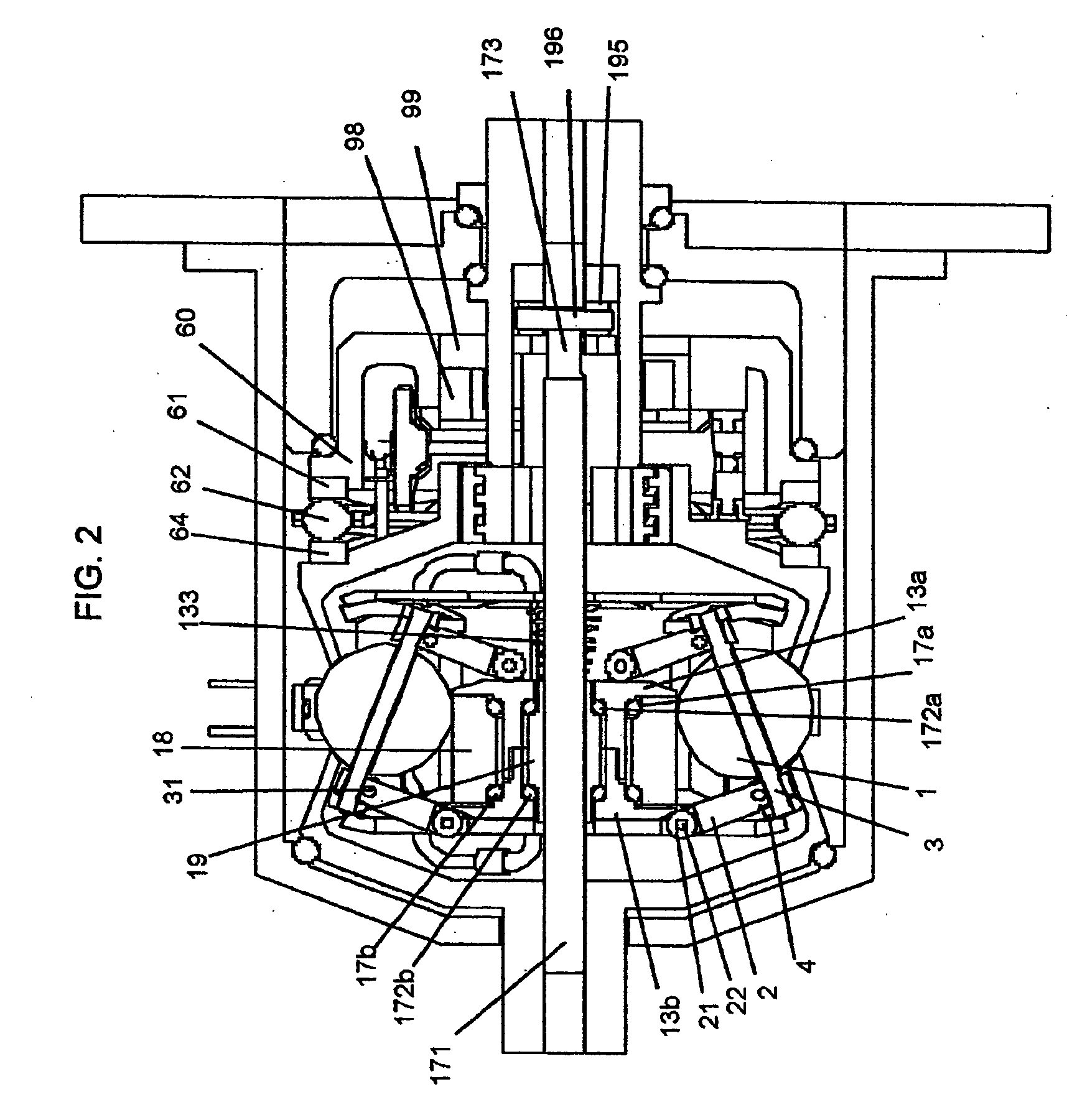

Continuously variable transmission

A variable speed transmission having a plurality of tilting balls and opposing input and output discs is illustrated and described that provides an infinite number of speed combinations over its transmission ratio range. The use of a planetary gear set allows minimum speeds to be in reverse and the unique geometry of the transmission allows all of the power paths to be coaxial, thereby reducing overall size and complexity of the transmission in comparison to transmissions achieving similar transmission ratio ranges.

Owner:FALLBROOK INTPROP COMPANY

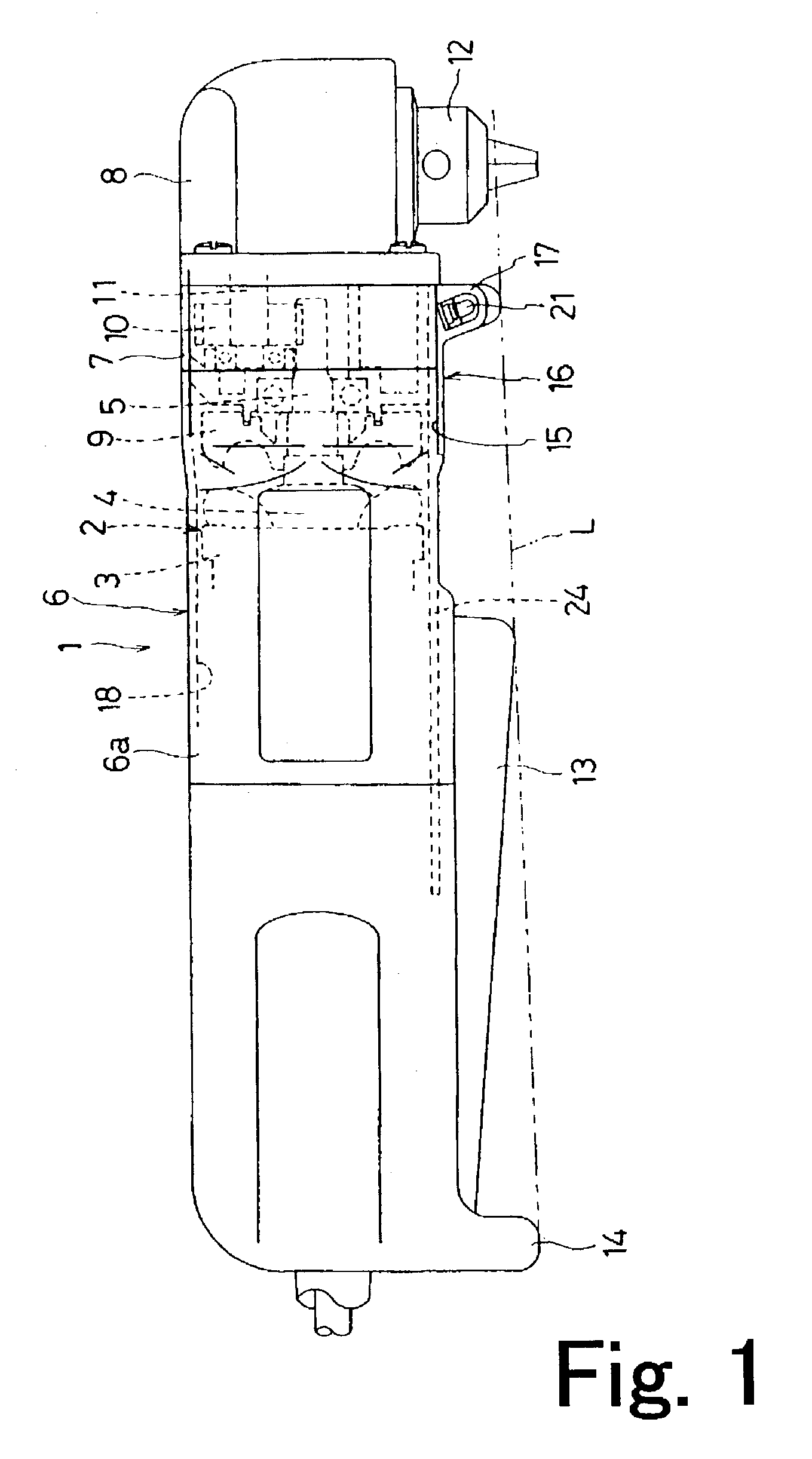

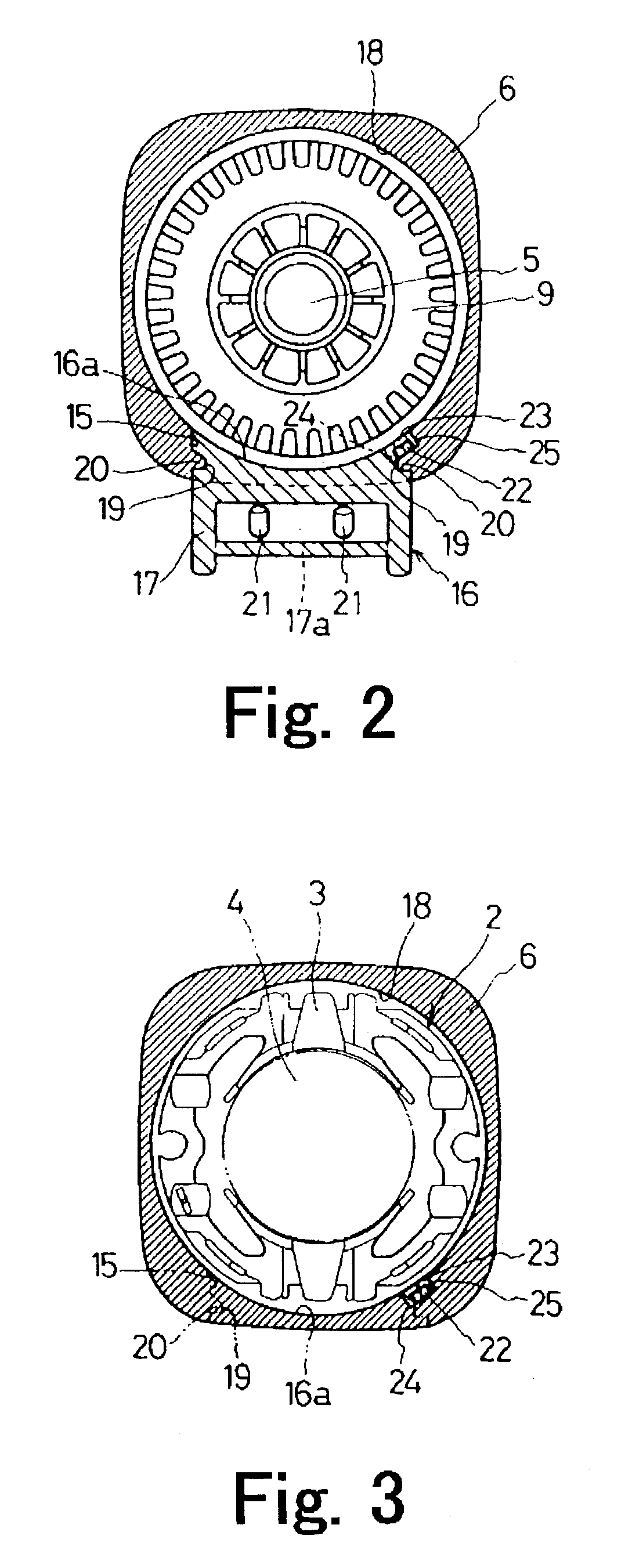

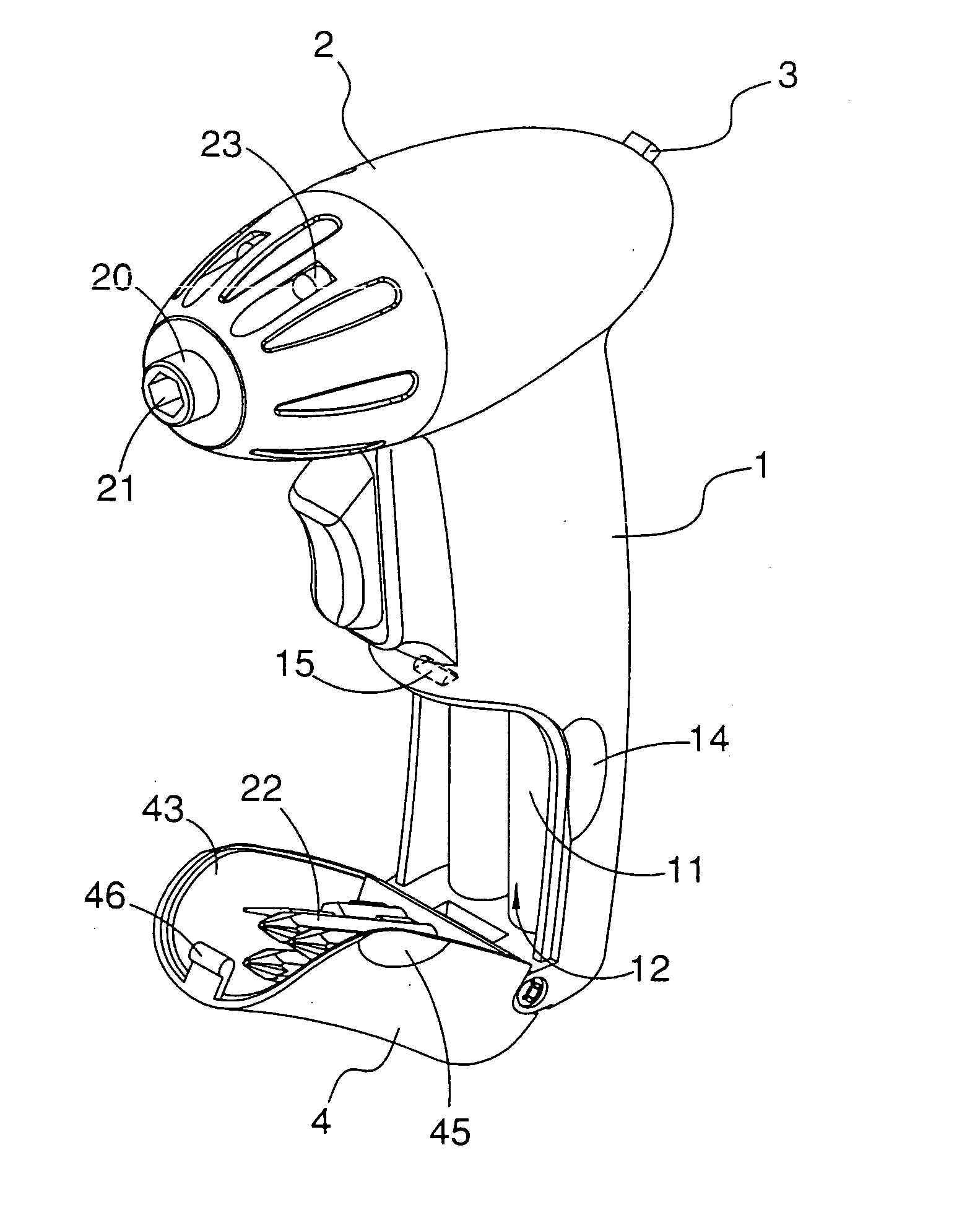

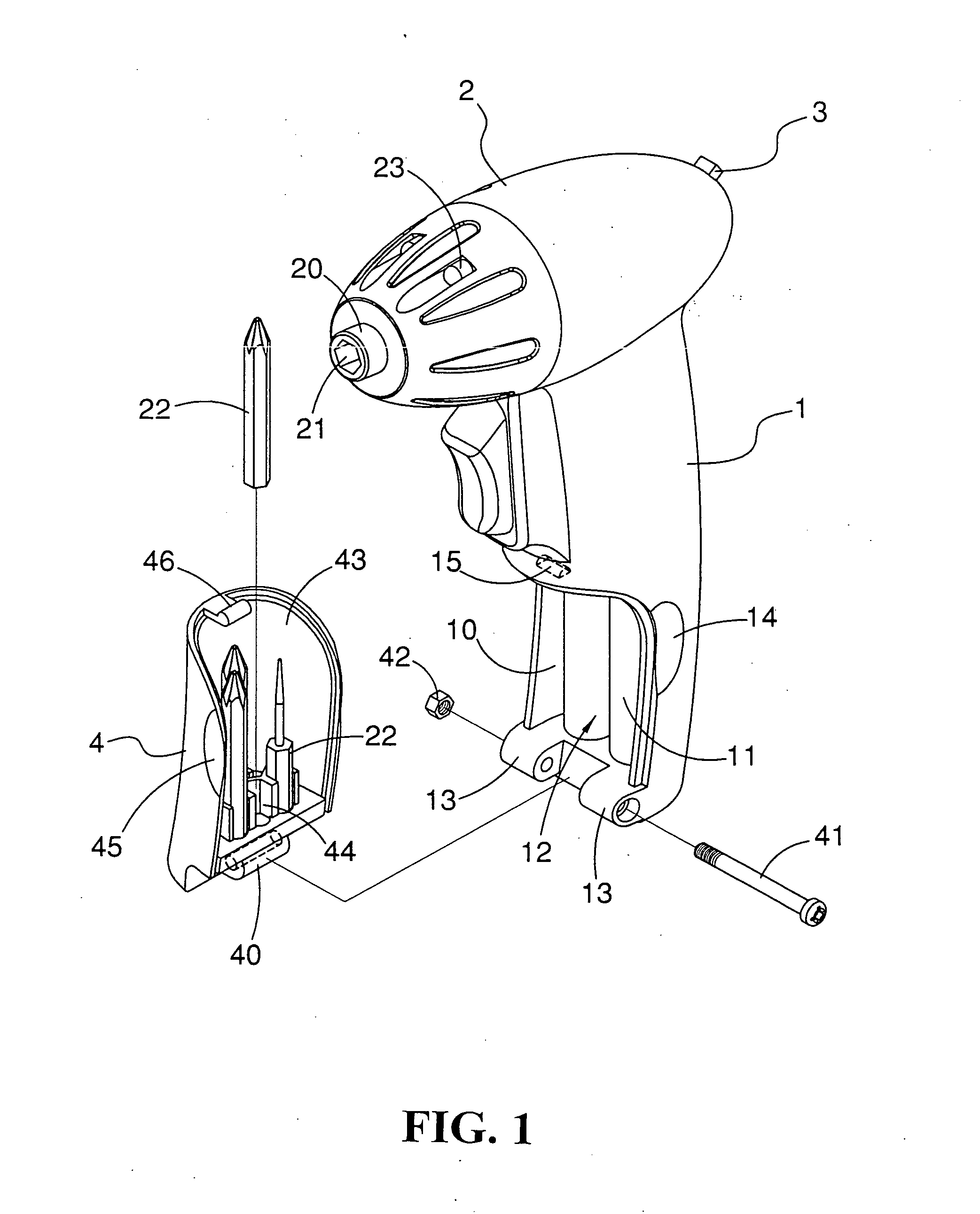

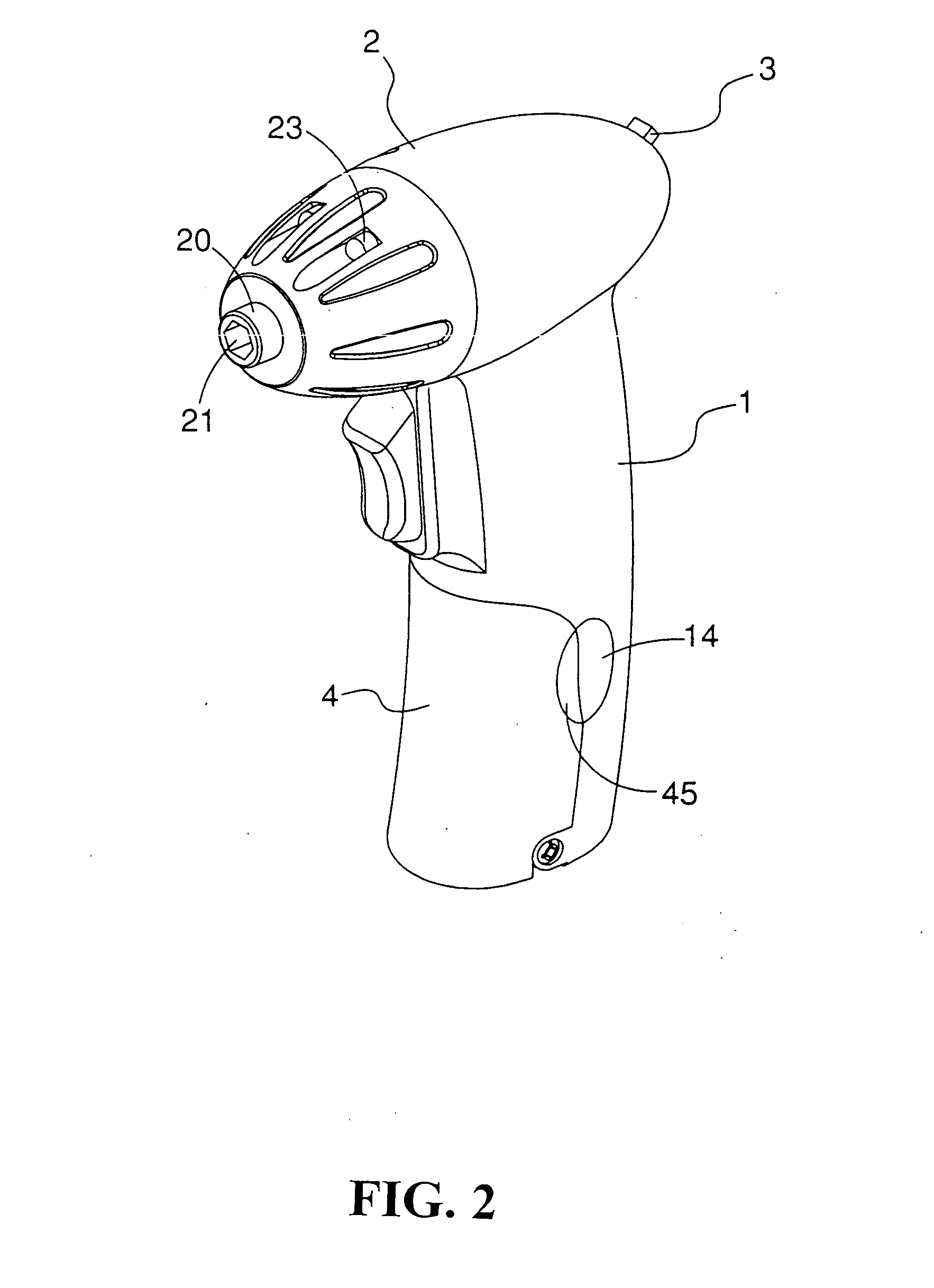

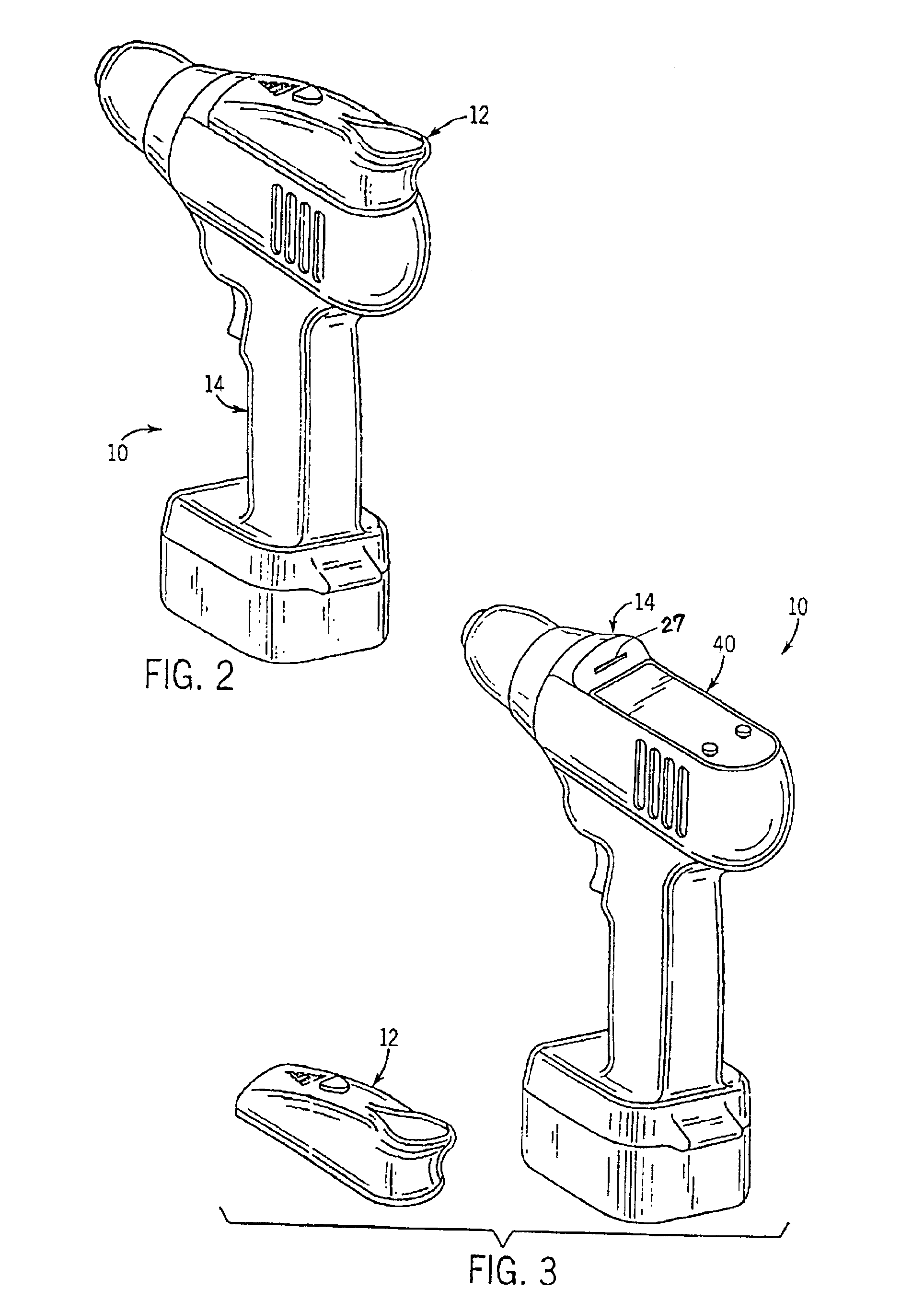

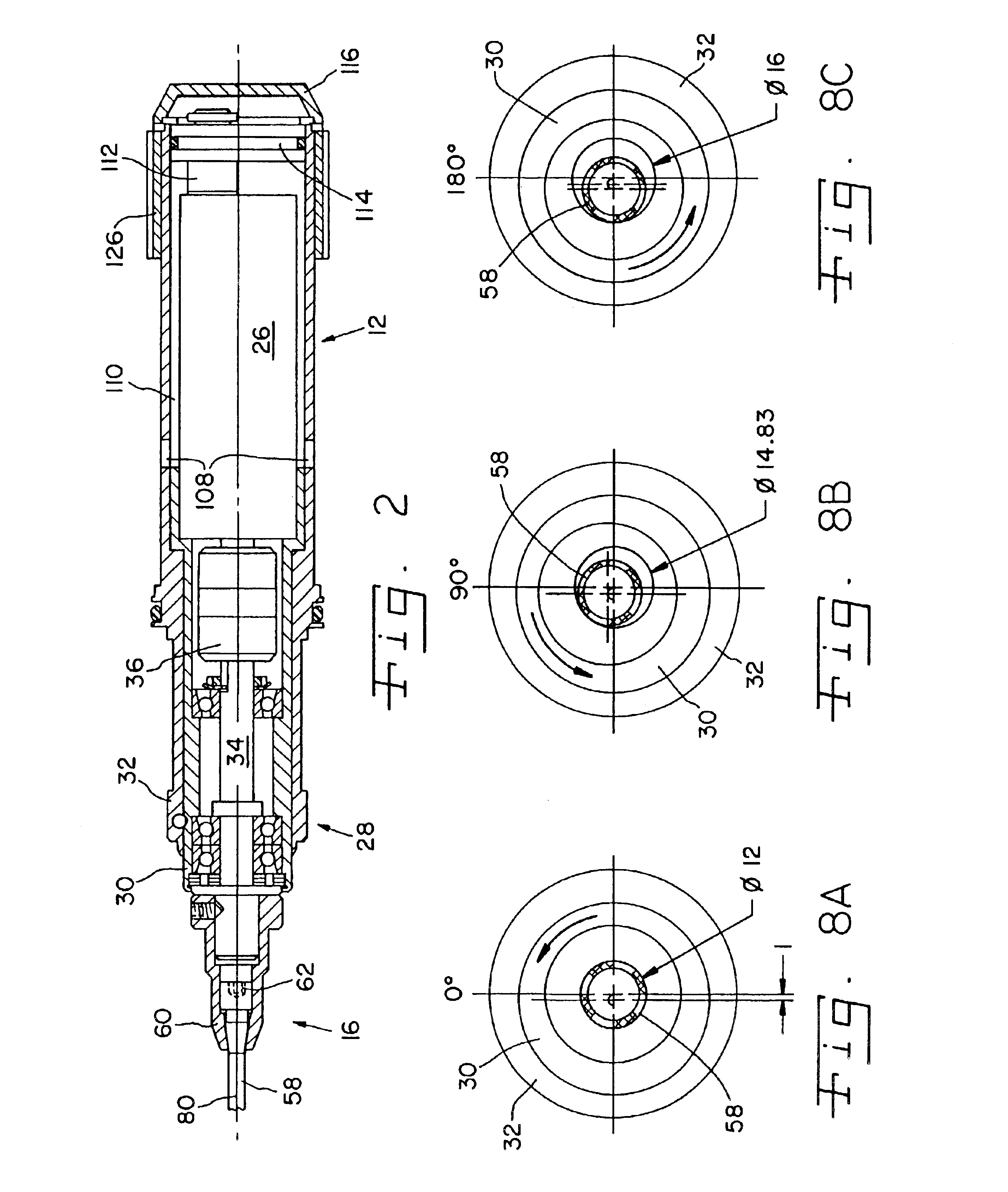

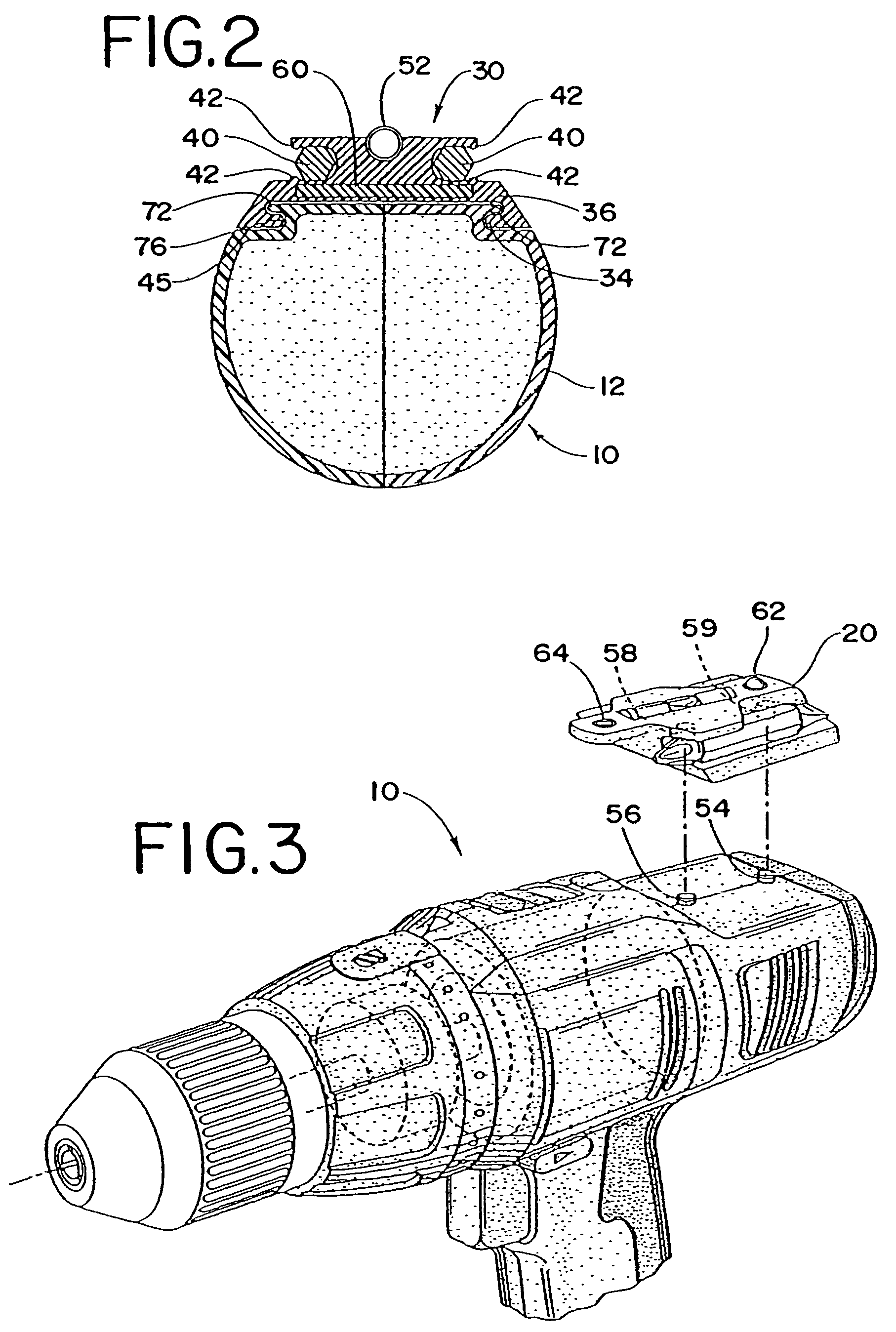

Right angle drill with an improved structure for accommodating a light assembly

InactiveUS7137761B2Inhibition of activationReduce manufacturing costDrilling/boring measurement devicesThread cutting machinesDrill bit

A right angle drill (1) includes a motor housing (6) which defines therein a hole (18) for accommodating a motor field system (3), a cut-out (15) formed in the underside of the motor housing (6) from the front end toward the rear of the tool (1), and a light unit (16) slidably fitted in the cut-out (15). The light unit (16) is a plate member having an arcuate cross section so as to define an inwardly curved rear (i.e., inner) surface (16a) along its entire length. The unit's inner surface (16a) conforms to the inner surface of the accommodating hole (18) of the motor housing (6). The light unit (16) additionally includes a protrusion (17) at the front outer surface thereof. Furthermore, the protrusion (17) contains a pair of LEDs (21) for illuminating objects below an output spindle (12) to which a bit can be attached.

Owner:MAKITA CORP

Electric drill with modified bit gripping assembly

Owner:PHILLIPS SEAN PETER

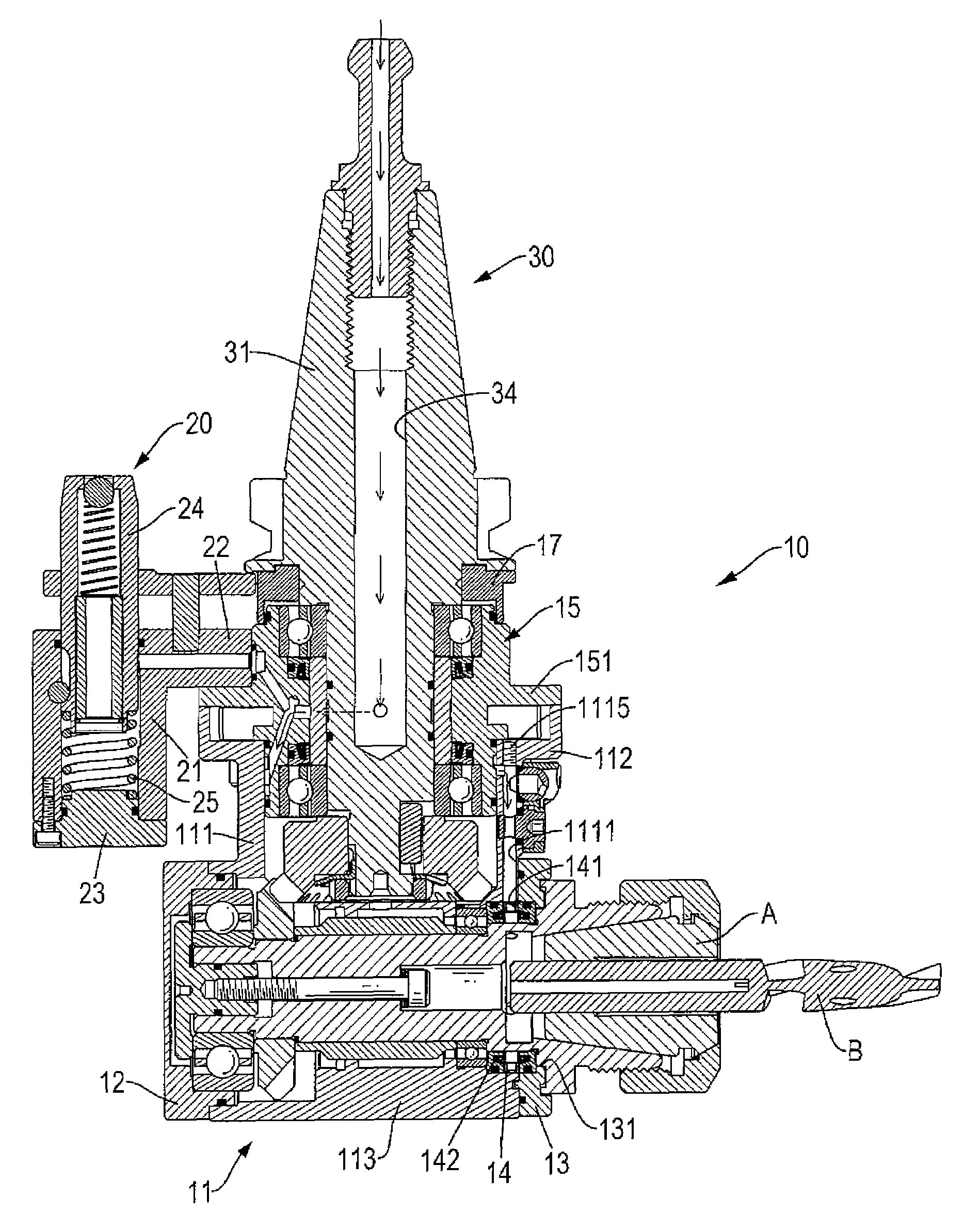

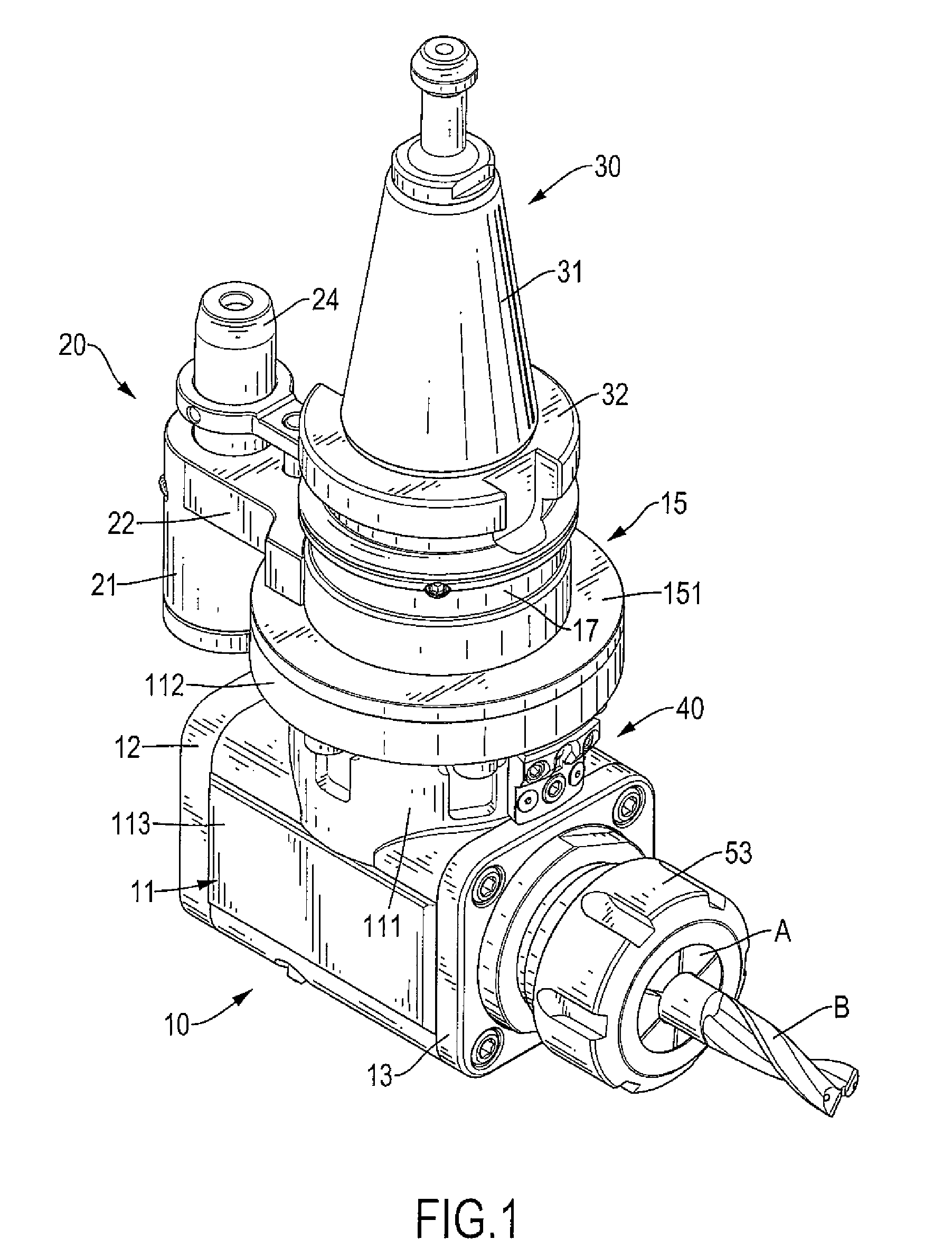

Milling head

InactiveUS7563062B1Good choiceThread cutting auxillary apparatusTransportation and packagingDrive shaftGear wheel

A milling head has a body, a holding device, a driving axle, a spraying device and a tool adaptor. The body has a base, a rear cover, a front cover, a bearing seat and a middle liner ring. The holding device is connected to the body and has a linking arm, a mounting jacket, a bottom cap, a positioning shaft and a locating spring. The driving axle is rotatably mounted in the body and has a transmission shaft and a driving bevel gear. The spraying device is mounted on the base and has a mounting cover and an spraying ball. The tool adaptor is rotatably mounted in the base below the spraying device and has a transmitting bevel gear, a holding head and a connecting segment.

Owner:CHEN CHIN CHIU

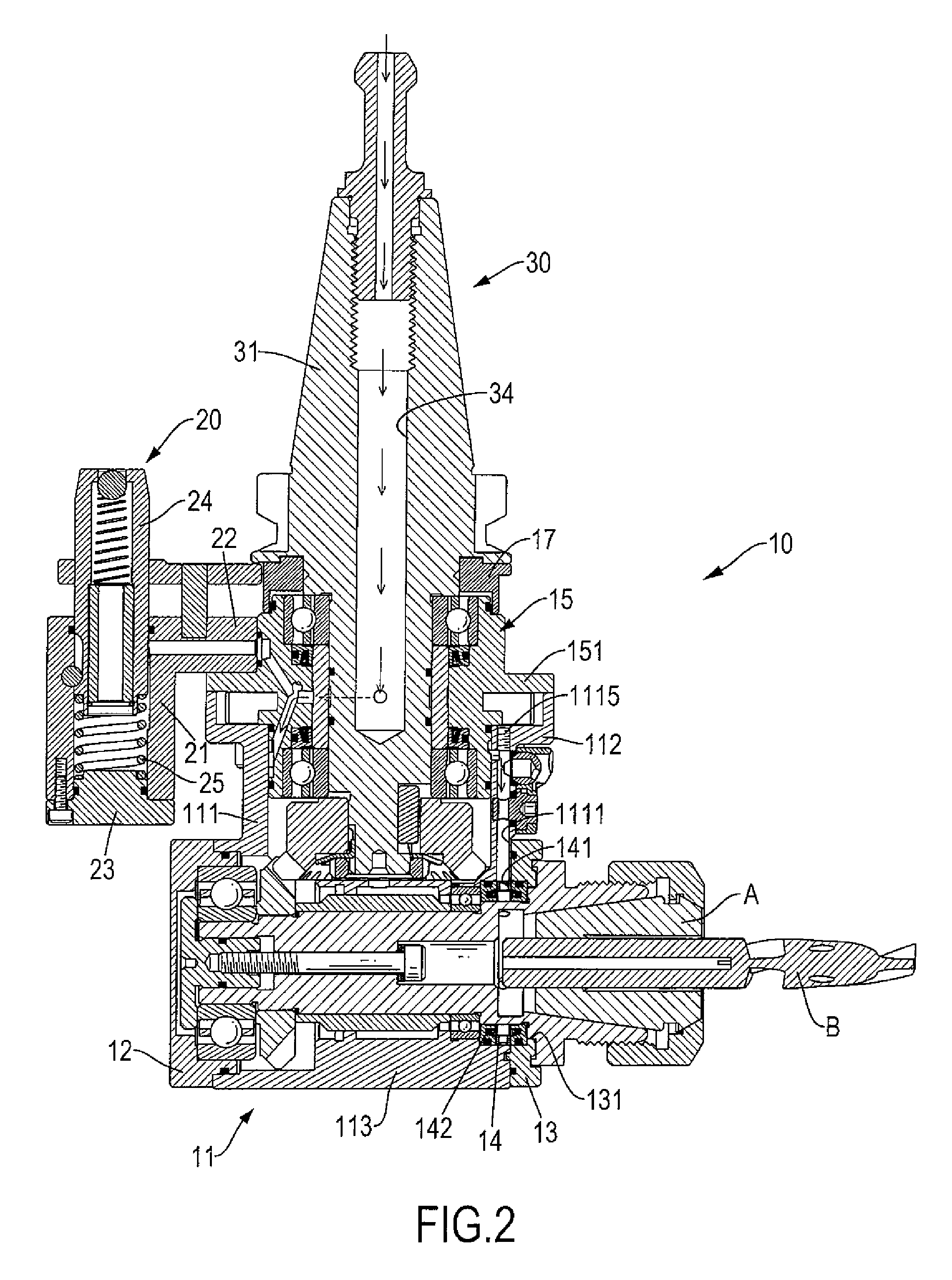

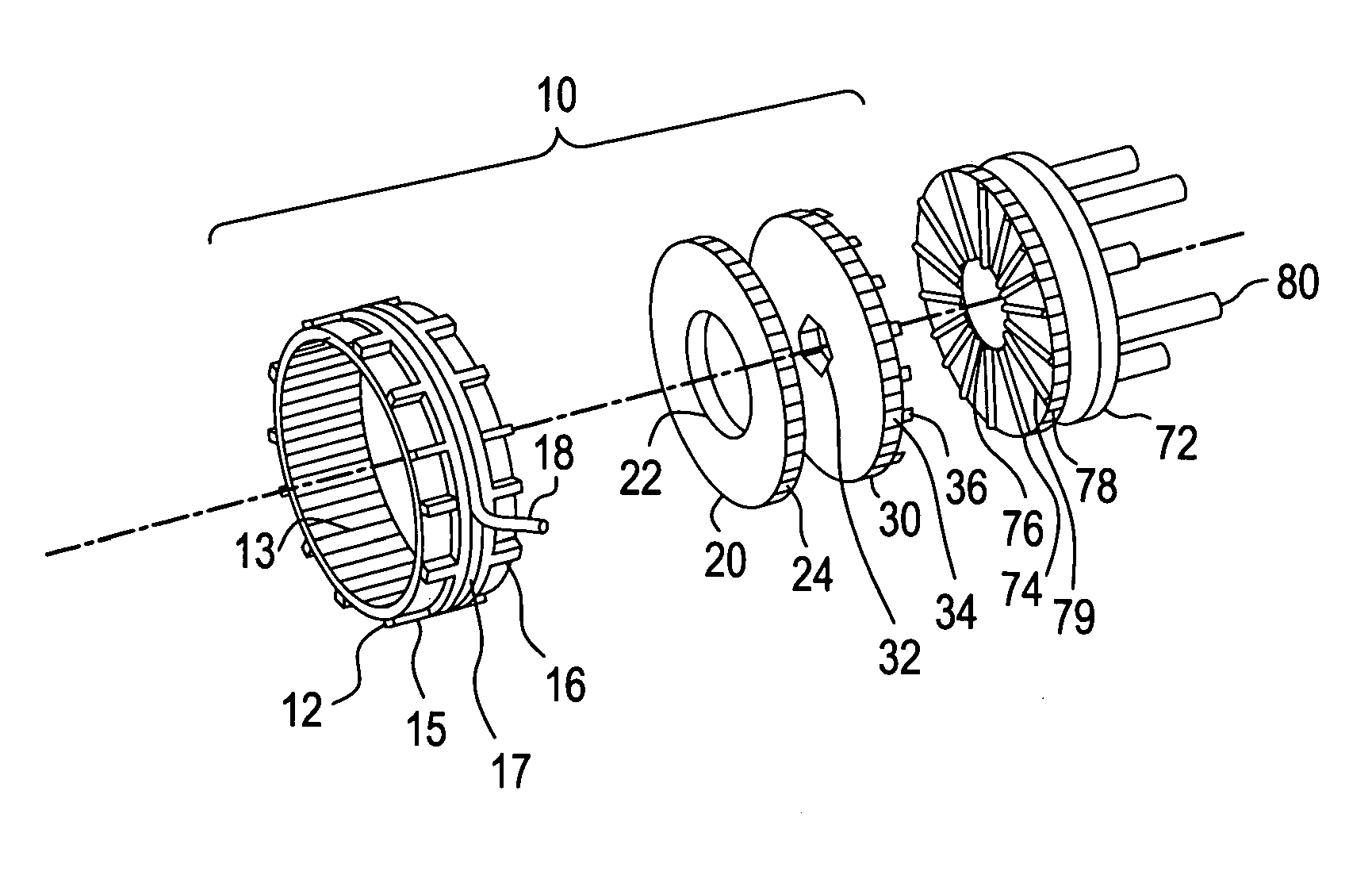

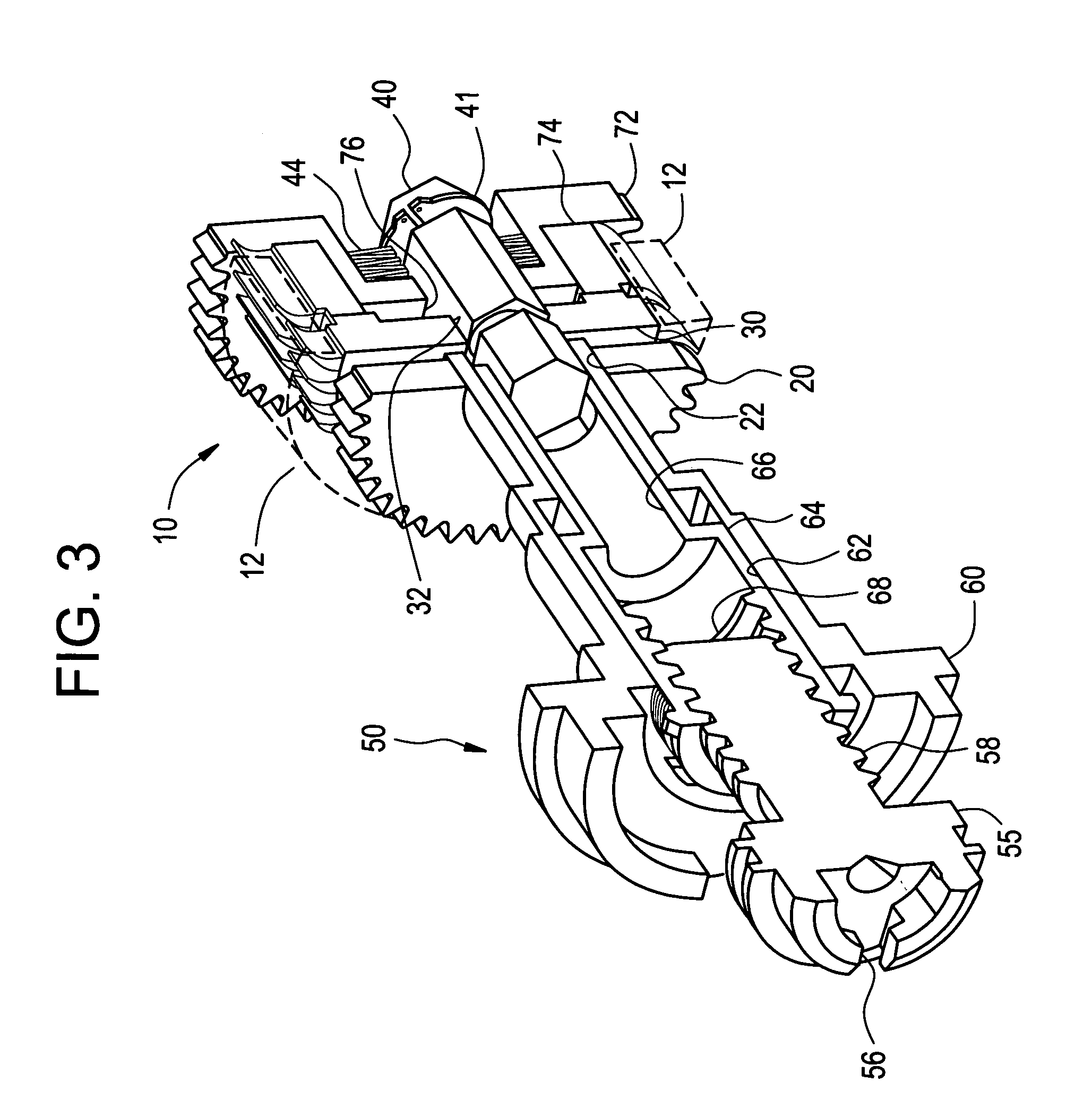

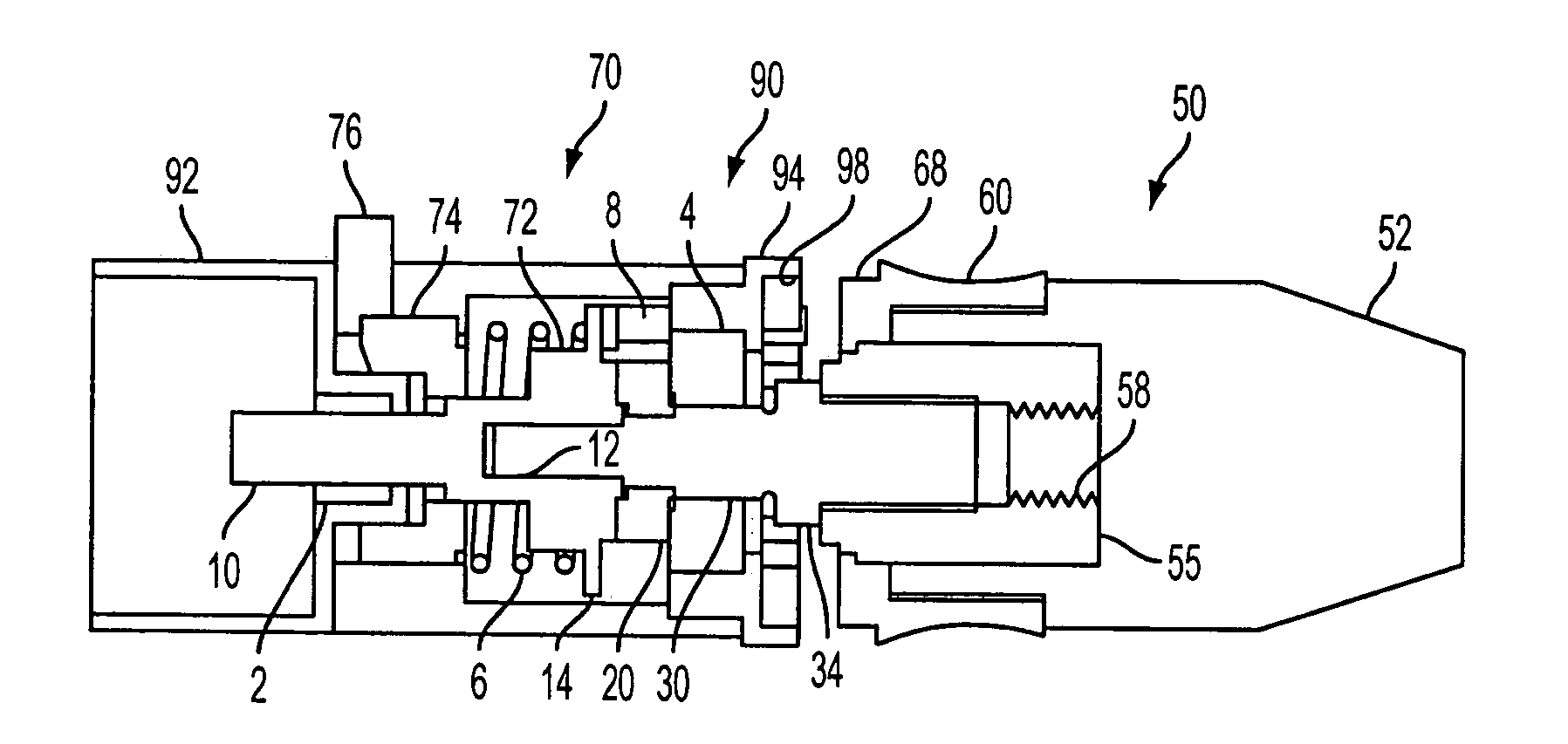

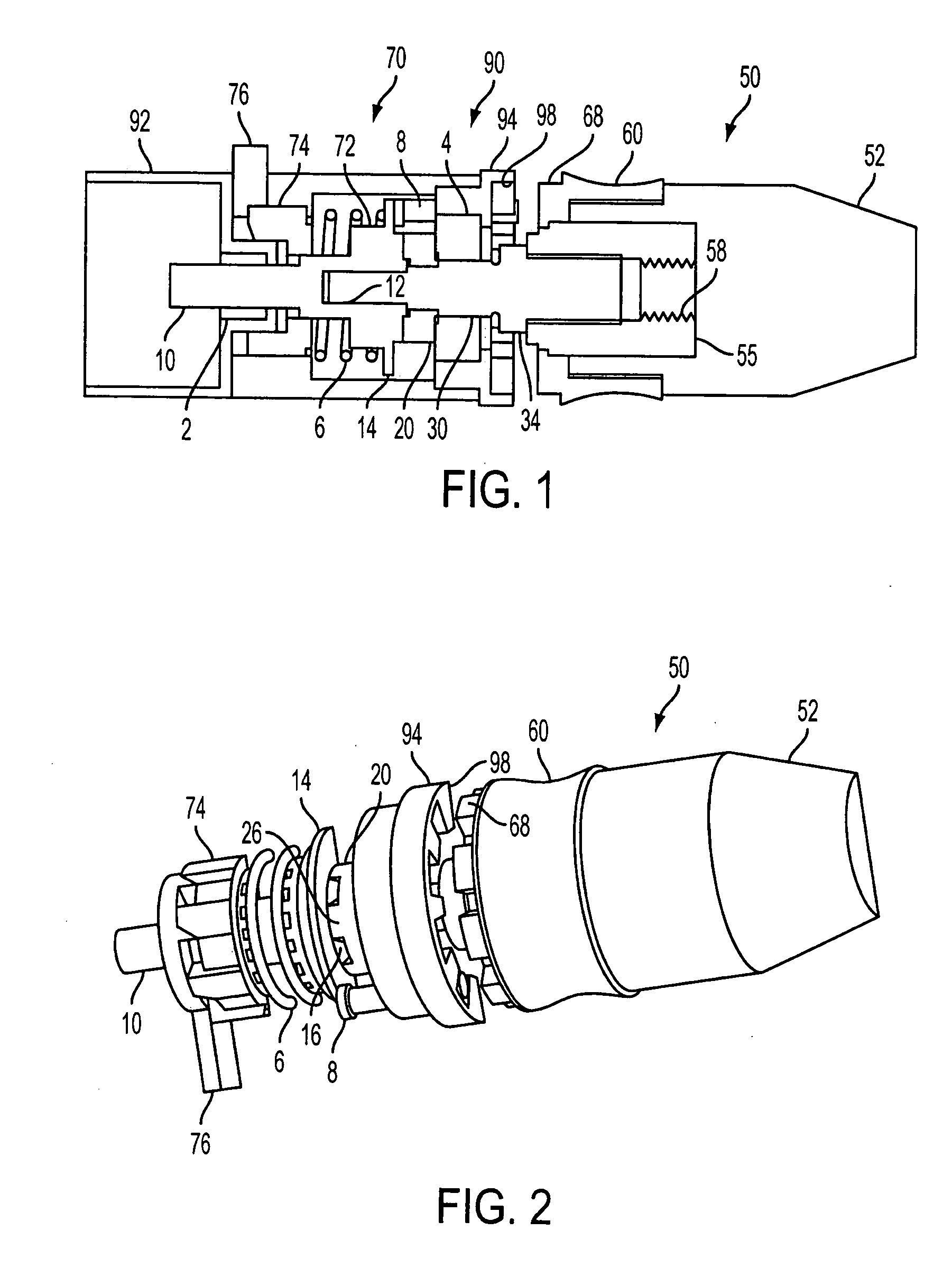

Tool chuck with power take off and dead spindle features

A power driver may include a housing, a tool chuck and a power take off mechanism. The tool chuck may have an input shaft mounted for rotation on the housing. The input shaft may support chuck jaws. A chuck actuating shaft may be mounted for rotation on the input shaft. The power take off mechanism may be connected to the tool chuck. The power take off mechanism may be adjustable into a DRILL DRIVE MODE to rotationally drive the input shaft and the chuck actuating shaft together as a unit, and a CHUCK MODE to rotationally drive the chuck actuating shaft relative to the input shaft. The power take off mechanism may be internal of the housing. The power take off mechanism in the CHUCK MODE may rotationally fix the input shaft to the housing.

Owner:BLACK & DECKER INC

Power Tool

InactiveUS20060104732A1Consumes least space consumingEasy to installThread cutting auxillary apparatusPortable power-driven toolsEngineeringPower tool

A power tool including a pistol grip handle containing a chamber connected to external opening to permit easy installation of batteries; a drive head provided at its end a rotation chuck to adapted to a bit of a hand tool, and multiple projection lights to project light to the bit; a control switch to control the on and off of the projection lights, a cover pivoted to the handle to cover up the opening; the cover swings on one side of the opening of the pistol grip handle; and multiple channels provided on the inner side of the cover for storage of bits.

Owner:BIRDSKY CORP

Hand drill attachment

InactiveUS6926473B2Efficiently finding locationDrilling/boring measurement devicesThread cutting machinesEngineeringDrill bit

A power hand drill has a subsurface object locator for detecting the presence of an object beneath a surface being probed with the locator. The drill has a housing with a flat accessory mounting surface having a pair of attachment tabs. The locator has a locator housing with a flat base and a pair of key hole slots engaged with the tabs for detachably mounting the locator housing to the accessory mounting surface of the drill housing. The locator includes sensing circuitry contained within the locator housing for detecting subsurface objects and has an object indicator mounted to the locator housing and connected to the sensing circuitry for indicating the presence of a subsurface object. A contoured surface on the locator housing provides a handrest for gripping when operating the drill.

Owner:ACTUANT CORP

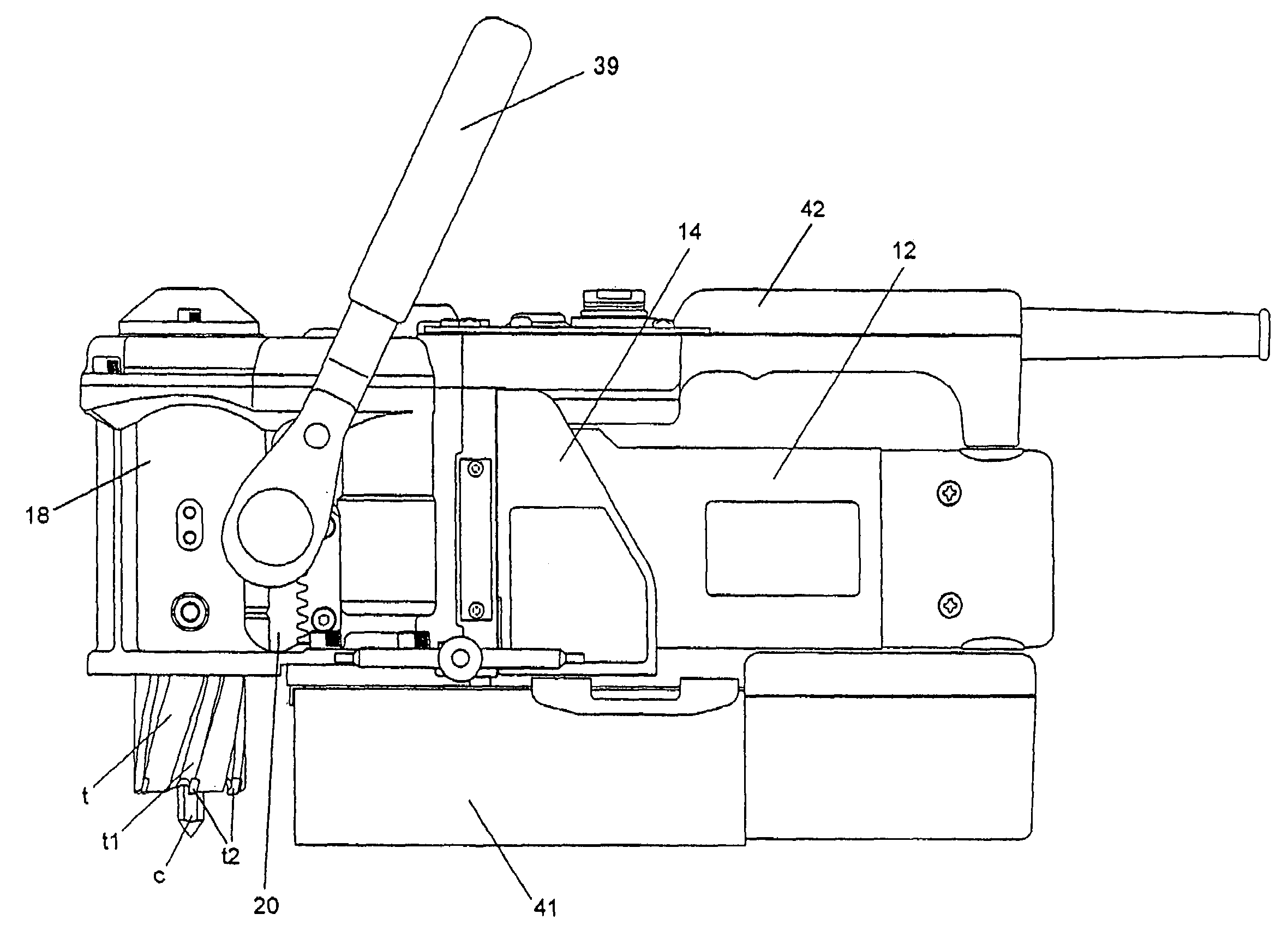

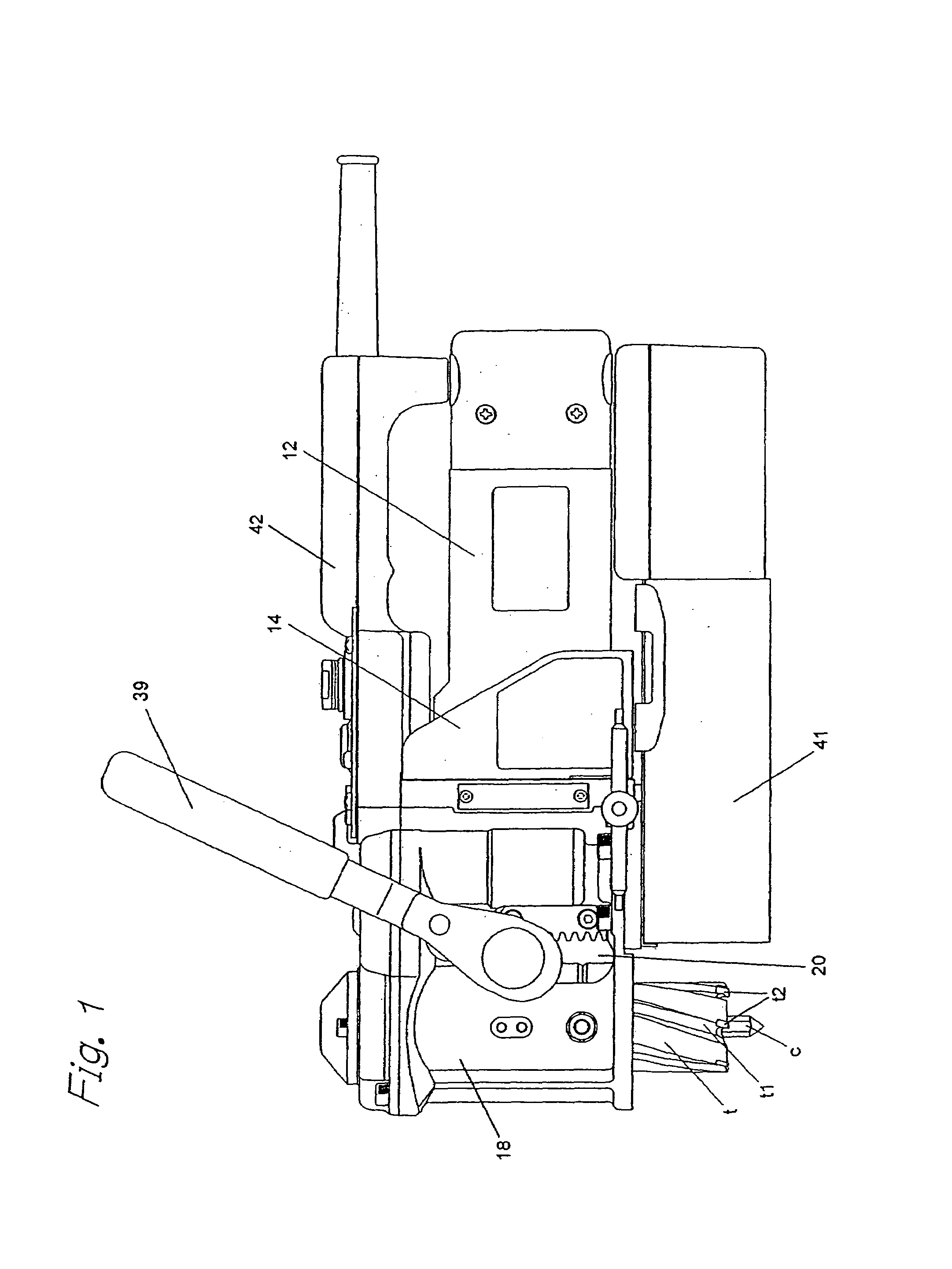

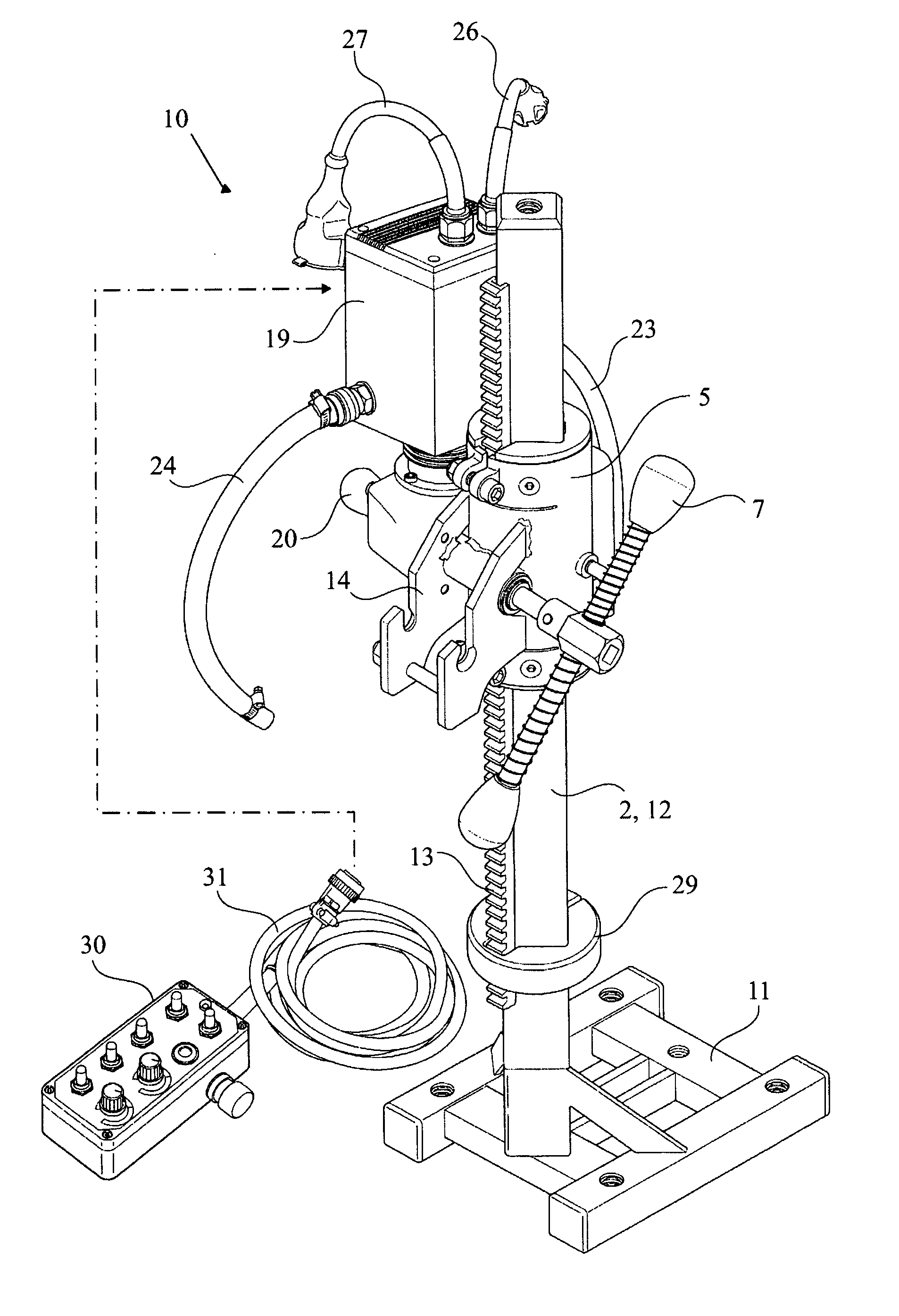

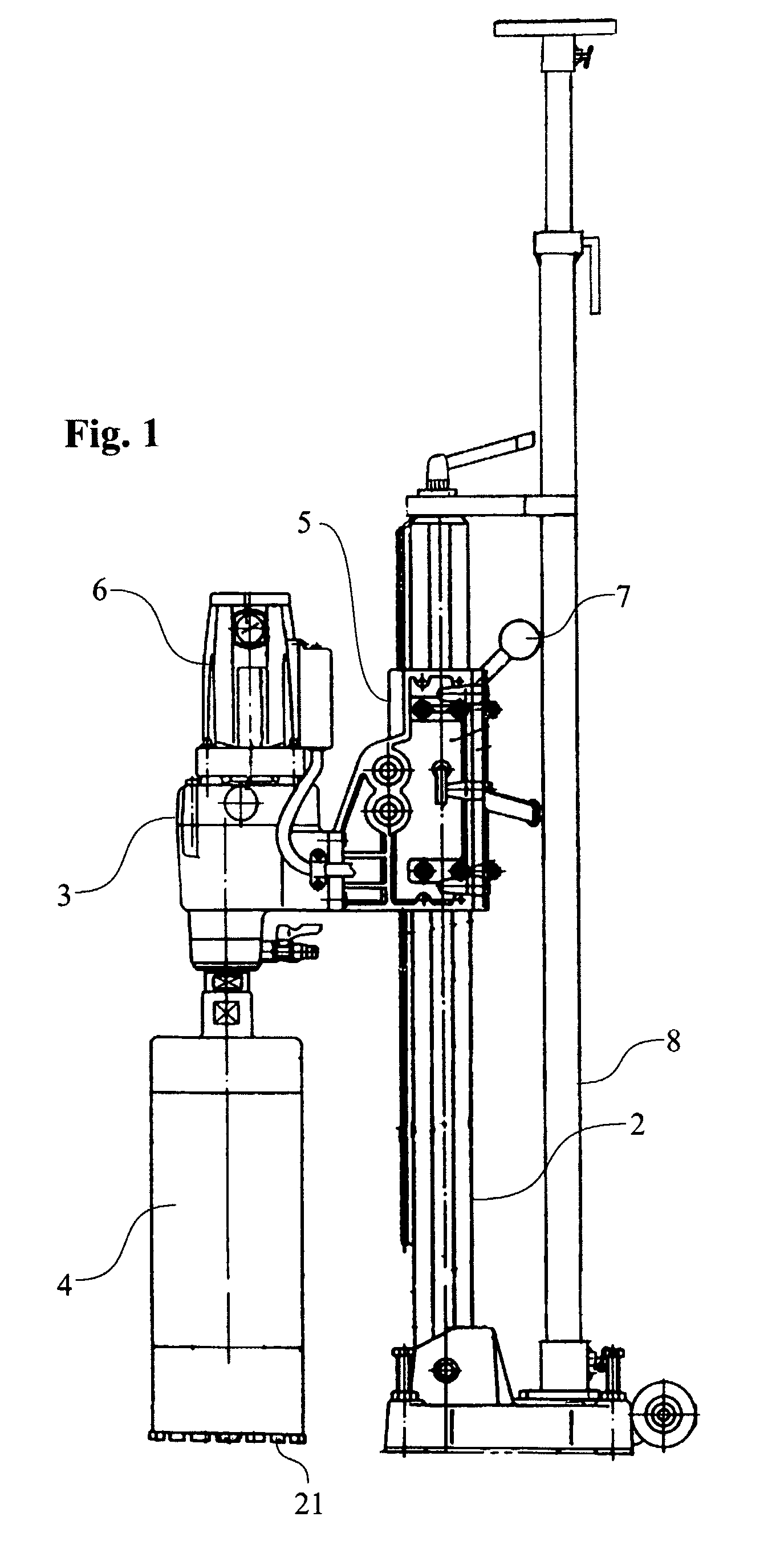

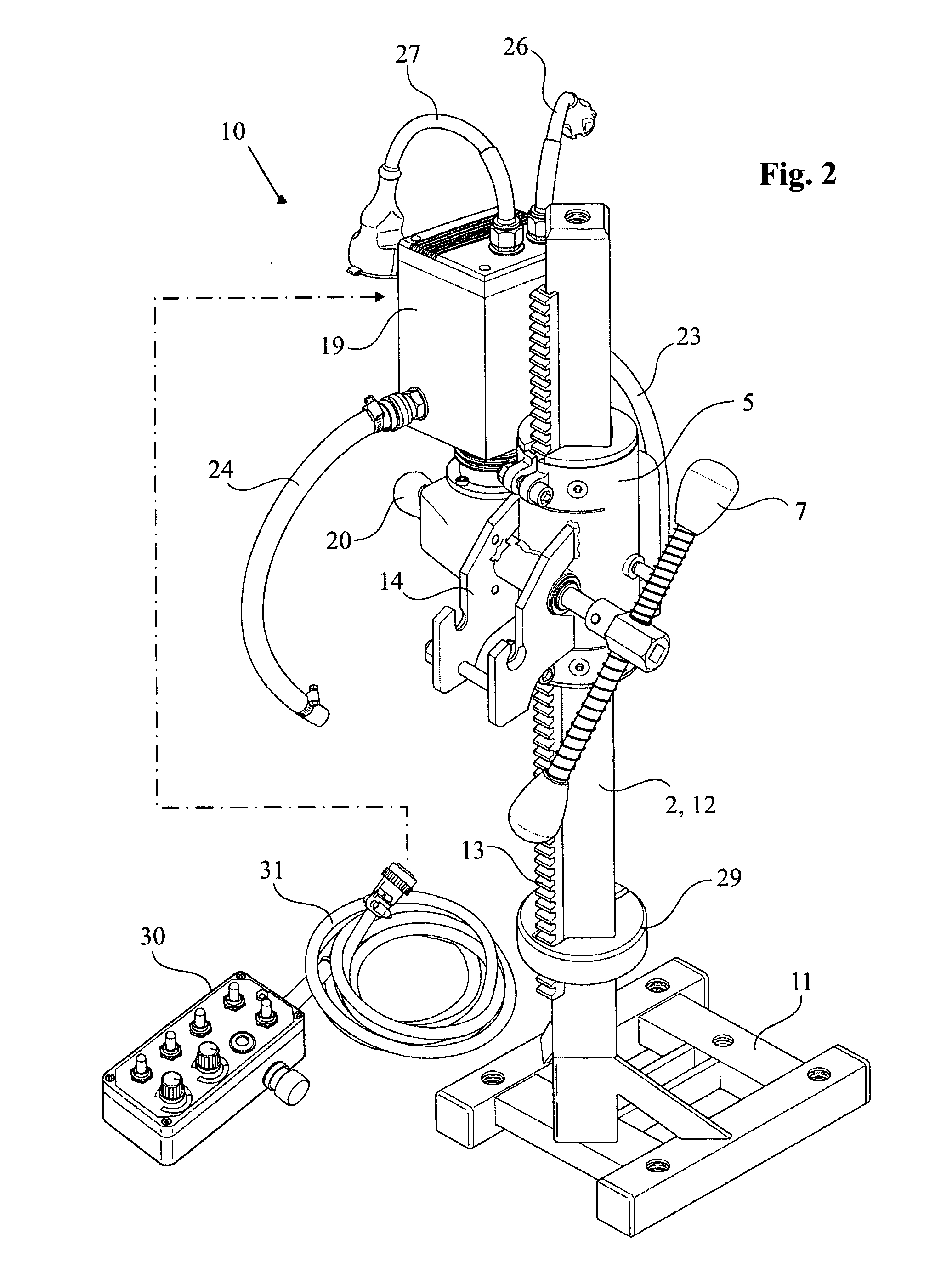

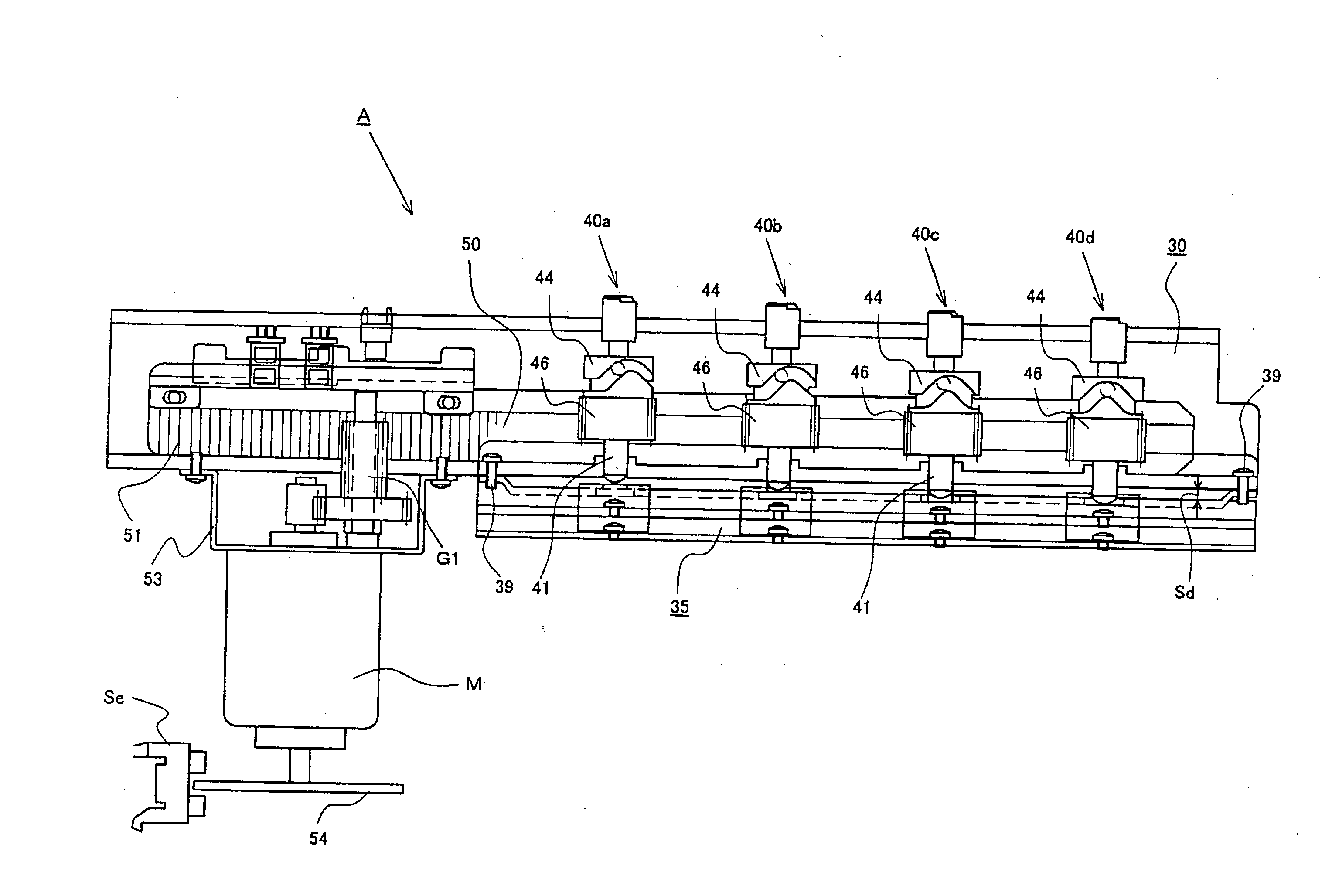

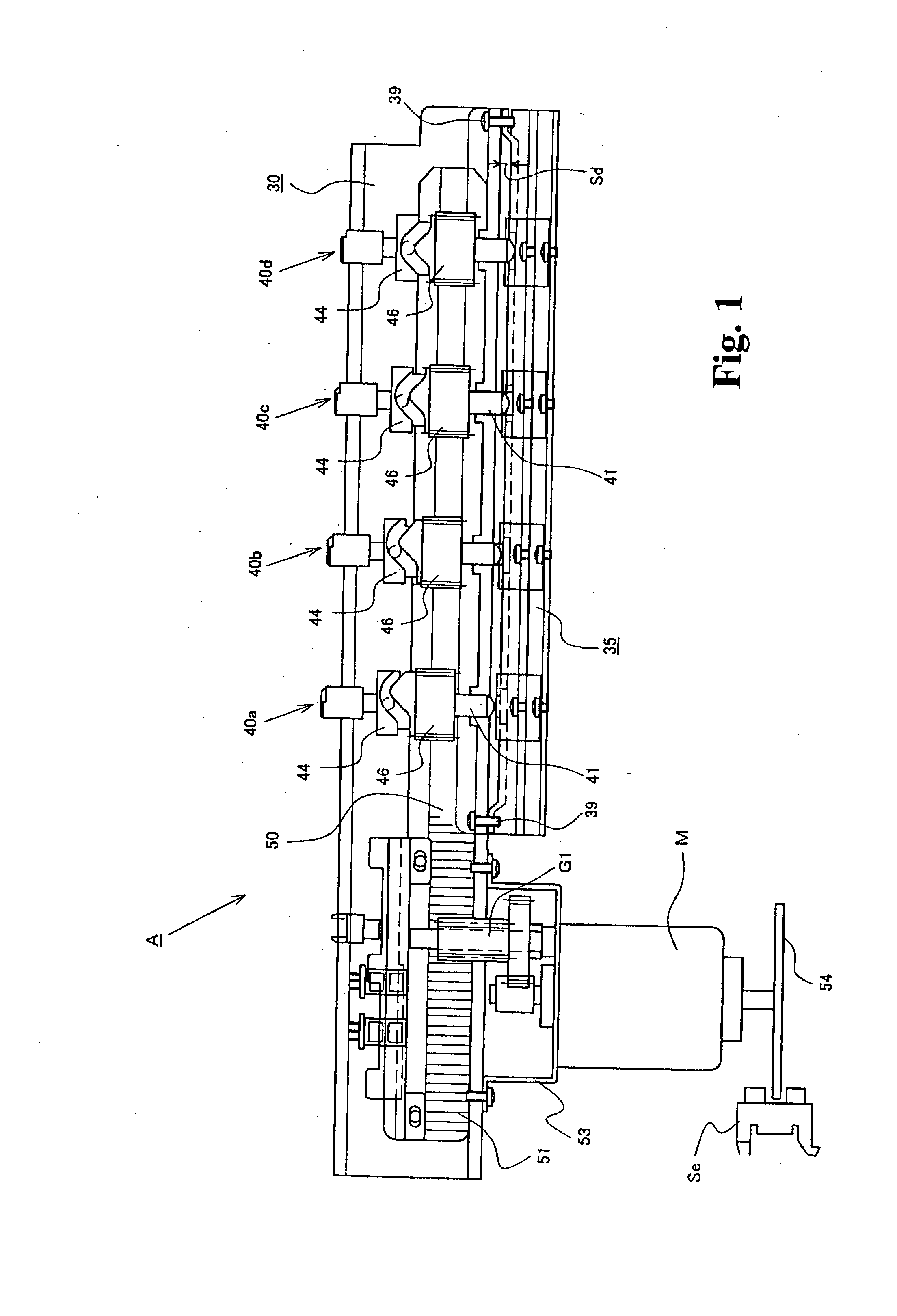

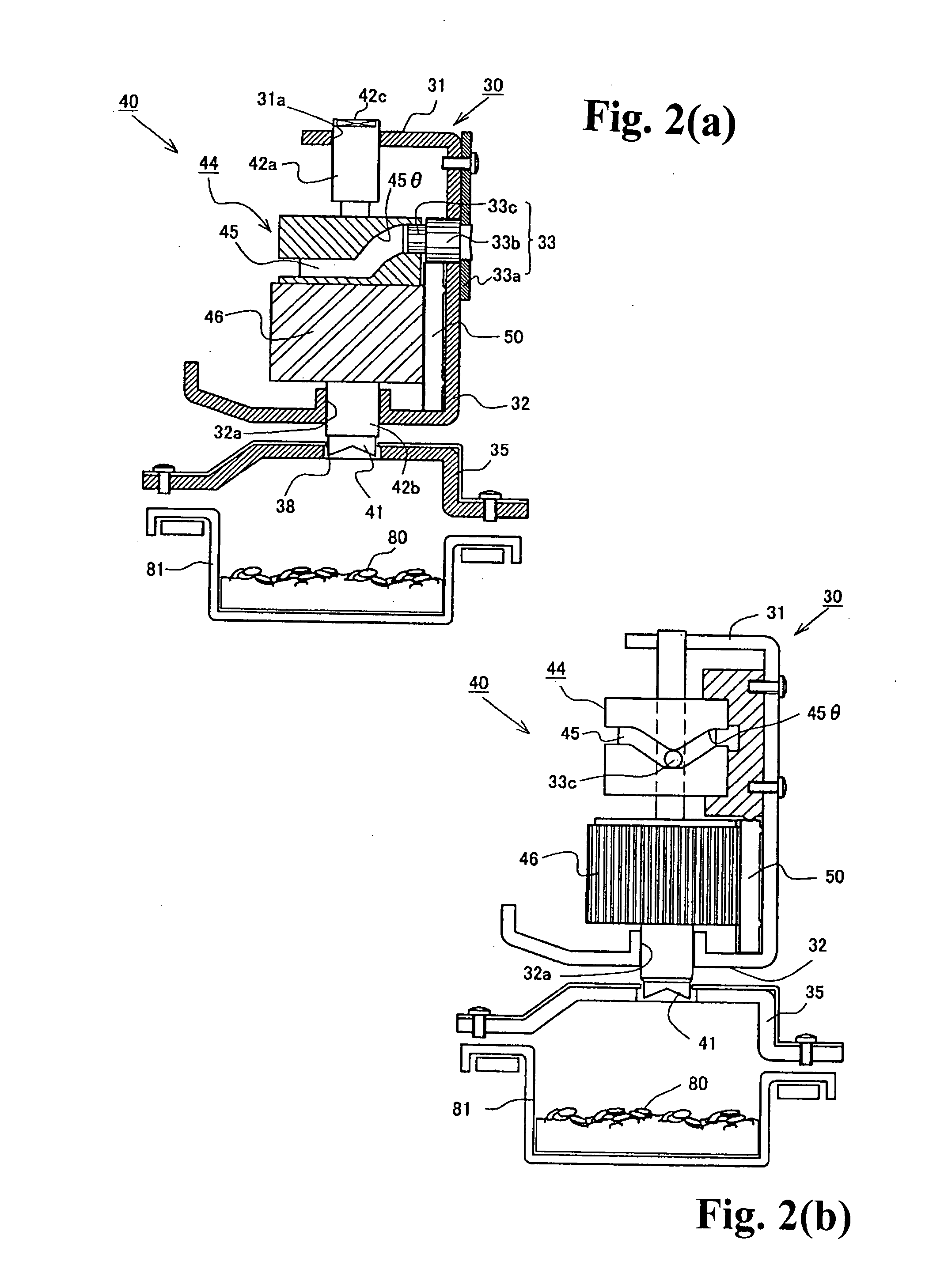

Core Drilling Device With Electrical Feeding That Is Manually Controlled

InactiveUS20070217879A1Thread cutting auxillary apparatusWorking accessoriesElectricityFeeding force

A core-drilling device (10) comprising a drilling machine (3) with a core drill (4), a drill stand (2), a feeding housing suspending the drilling machine and which is movable along the stand, an electric drilling motor for rotation of the core drill in the drilling machine and a feeding unit (19) with an electric feeding motor (17) for the feeding of the feeding housing along the stand. A control unit (30), which is electrically connected to the feeding unit, comprises at least a first control (33) for manual influence of the feeding motor's (17) feeding force.

Owner:HUSQVARNA AB

Electric drill apparatus

ActiveUS20050025586A1Small sizeReduce weightDrilling/boring measurement devicesThread cutting machinesRotational axisAnnular cutter

An electric drill apparatus having a low profile is provided which comprises an annular cutter, a motor for rotating the annular cutter, a rotary shaft assembly for rotating the annular cutter attached to its leading end about a rotating, a rotation reduction mechanism disposed between the motor and rotary shaft assembly for transmitting a driving force of the motor to the annular cutter through the rotary shaft assembly, a feed mechanism responsive to an operation of a manual handle, for moving the rotary shaft assembly along with a straight line to advance or retract the annular cutter attached to the rotary shaft assembly with respect to a workpiece, and an adhesion base for securing the electric drill apparatus to the workpiece. The annular cutter has a plurality of cutting blades comprised of cemented carbide tips fixed on its lower end, thereby it is capable of rotating at a high speed. The rotary shaft assembly has a rotating shaft which rotates in a direction different from that of a rotating shaft of the motor, thereby the drill apparatus has a low profile.

Owner:NITTO KOHKI CO LTD

Automatic universal multi-purpose ground stand

InactiveUS20050040297A1Quickly and easily securedSimple materialTravelling sacksThread cutting auxillary apparatusEngineeringDC motor

An automatic, universal, multi-purpose ground stand to securely affix an umbrella, or any like device, into any malleable surface such as sand, grass, gravel or dirt. The device is intended to accommodate any size or shape of commercially available beach or sun umbrellas. This device also contemplates the securement of other devices such as fishing poles. The device is comprised, primarily, of a main tube with a helical auger screw bit and a DC electric motor to turn the screw. A user of said device would extend the helical auger screw bit, engage the DC electric motor, and allow the action of the DC electric motor to secure the helical auger screw into a malleable surface.

Owner:SARAF JAMES

Sheet hole punching apparatus and sheet hole punching method

InactiveUS20070227324A1Reduce loadLarge storageThread cutting toolsThread cutting auxillary apparatusEngineeringCam

A cylindrical punch member equipped at the leading end thereof with a hole-punching blade is movably supported on a base frame in a hole-punching direction. A drive means is equipped that applies thrusting force to the punch member; a cam follower member disposed between the base frame and punch member engages a cam means disposed at either the base frame or punch member. An oblique cam surface inclined at a predetermined angle with regard to a hole-punching direction is equipped in cam means to give rotational drive force around an axis of rotation to the punch member that is moved in the hole-punching direction by the drive means. This configuration causes each of a plurality of cylindrical punch members to rotate around their axes of rotation when moved in a hole-punching direction by drive means thereby punching a hole in a sheet with a reduced shear force; the centrifugal force of that punch member rotation causing paper cutting debris to be scattered evenly under the punch member.

Owner:SEIKO CORP

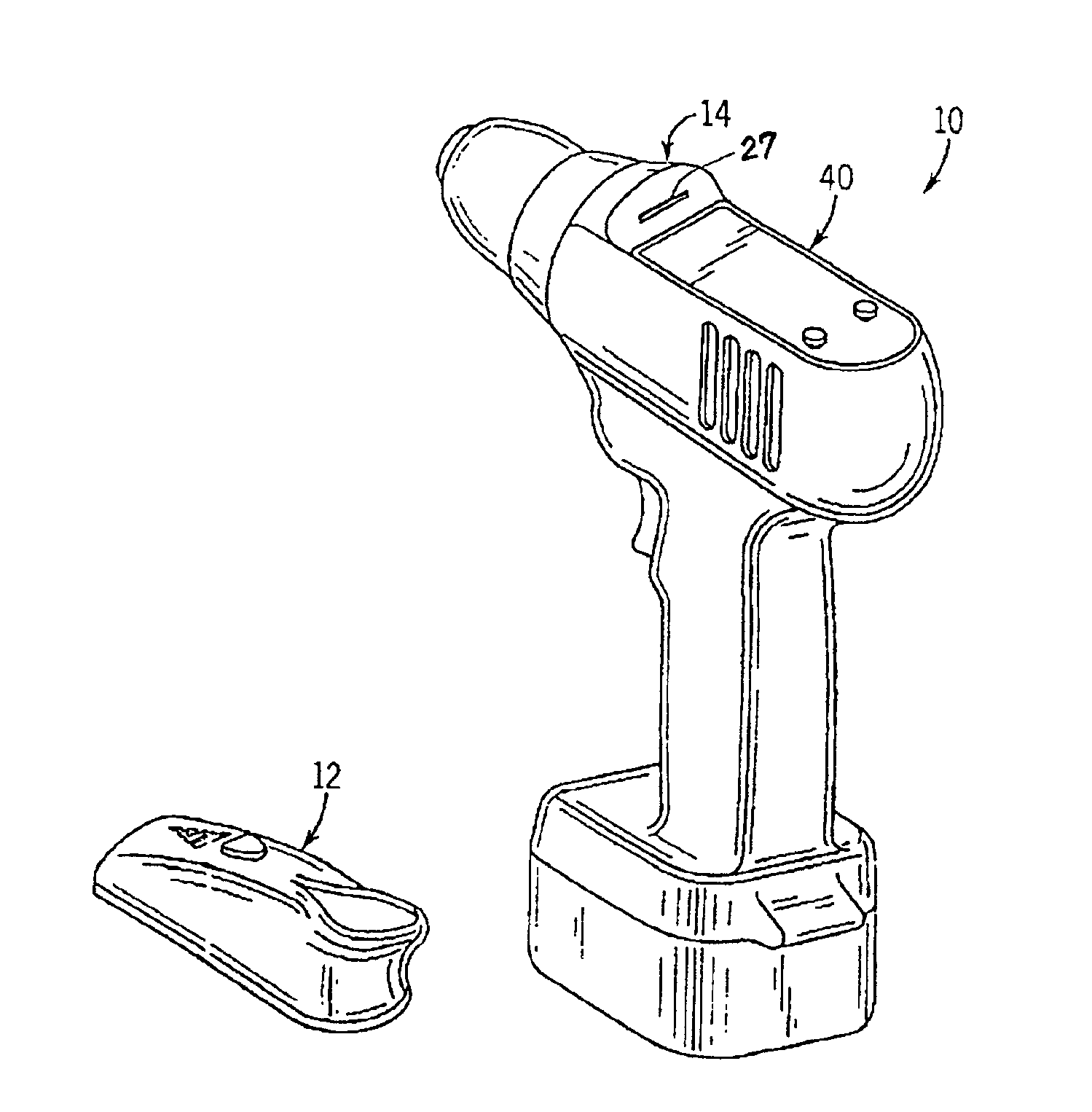

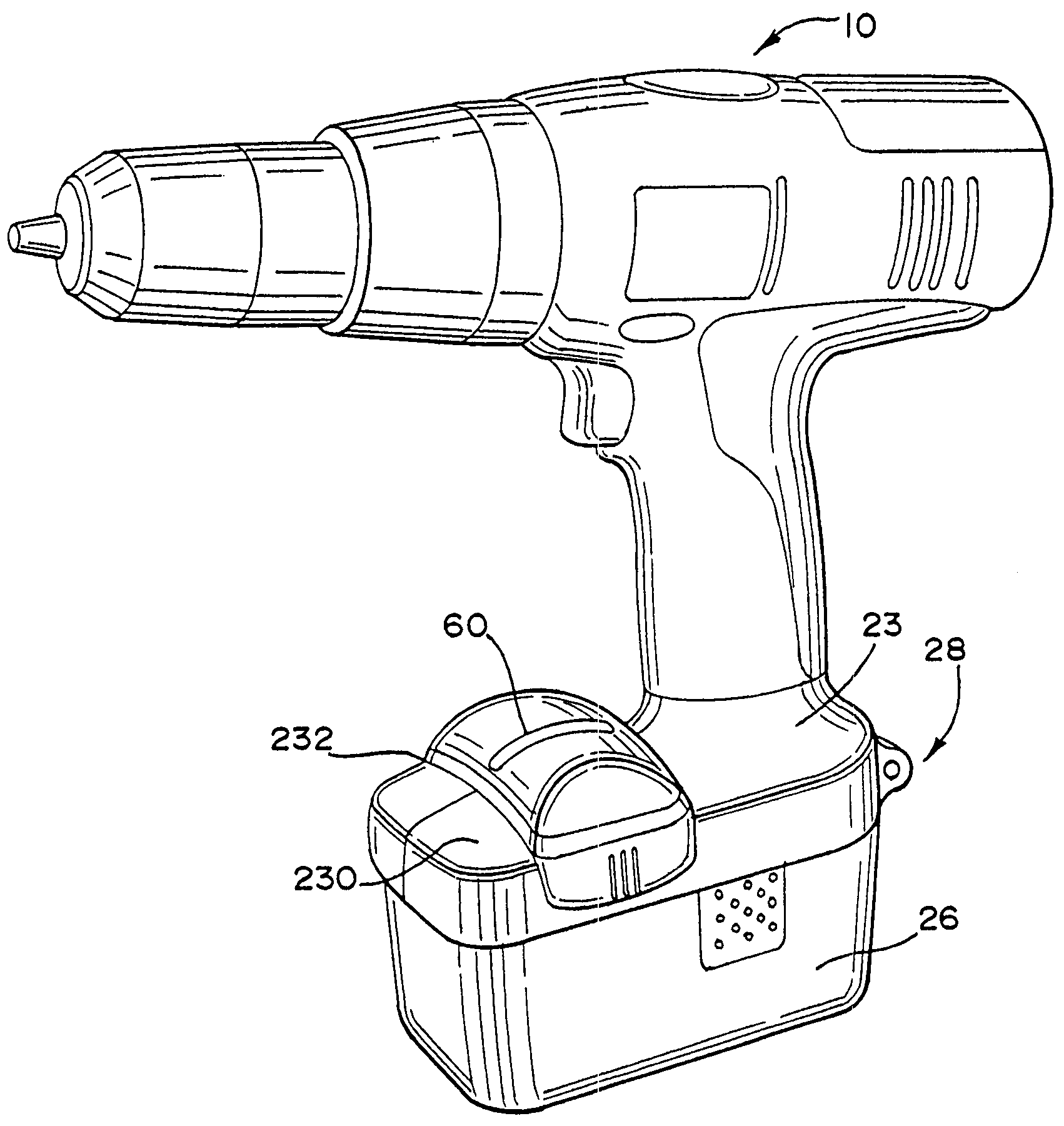

Hand-held tool with a removable object sensor

InactiveUS20050069391A1Easy to manufactureDrilling/boring measurement devicesThread cutting machinesHand heldPower tool

A hand-held power tool is provided with a housing, an attachment member, and an object sensor that is removable from the attachment member. The attachment member may be removable from the tool. The object sensor, which can be used to detect studs hidden behind walls, electrical lines, and other materials, is readily accessible to tradesmen.

Owner:ONE WORLD TECH

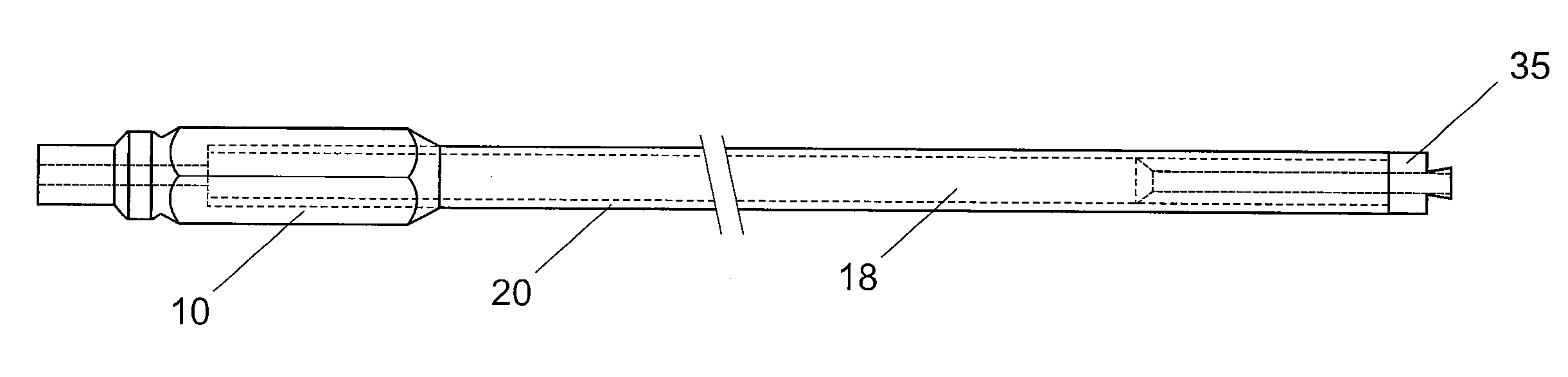

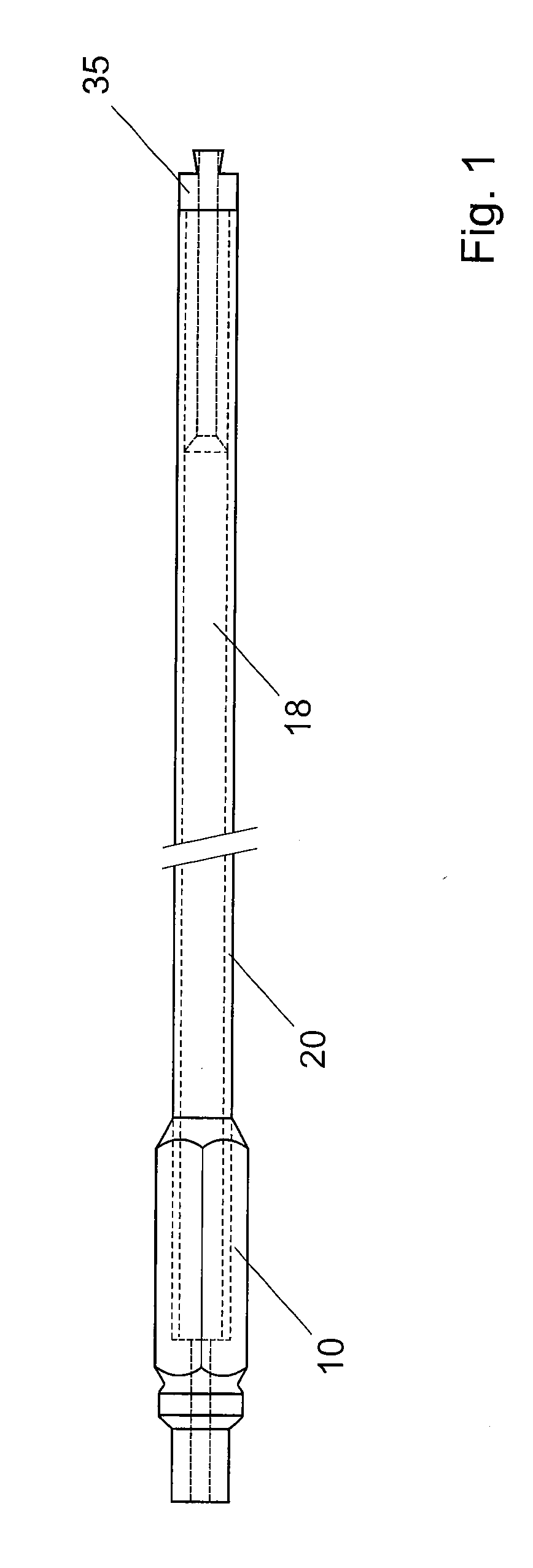

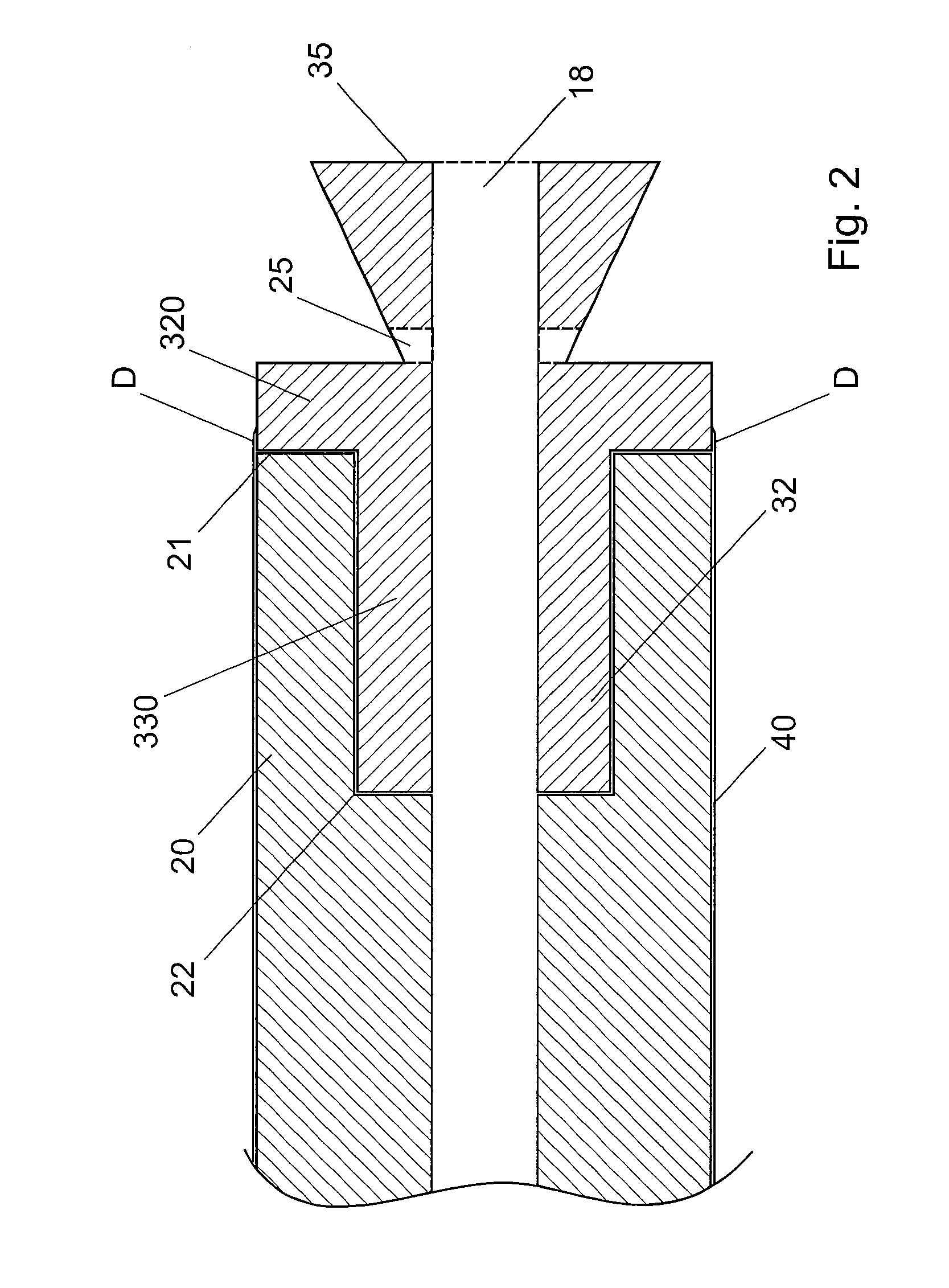

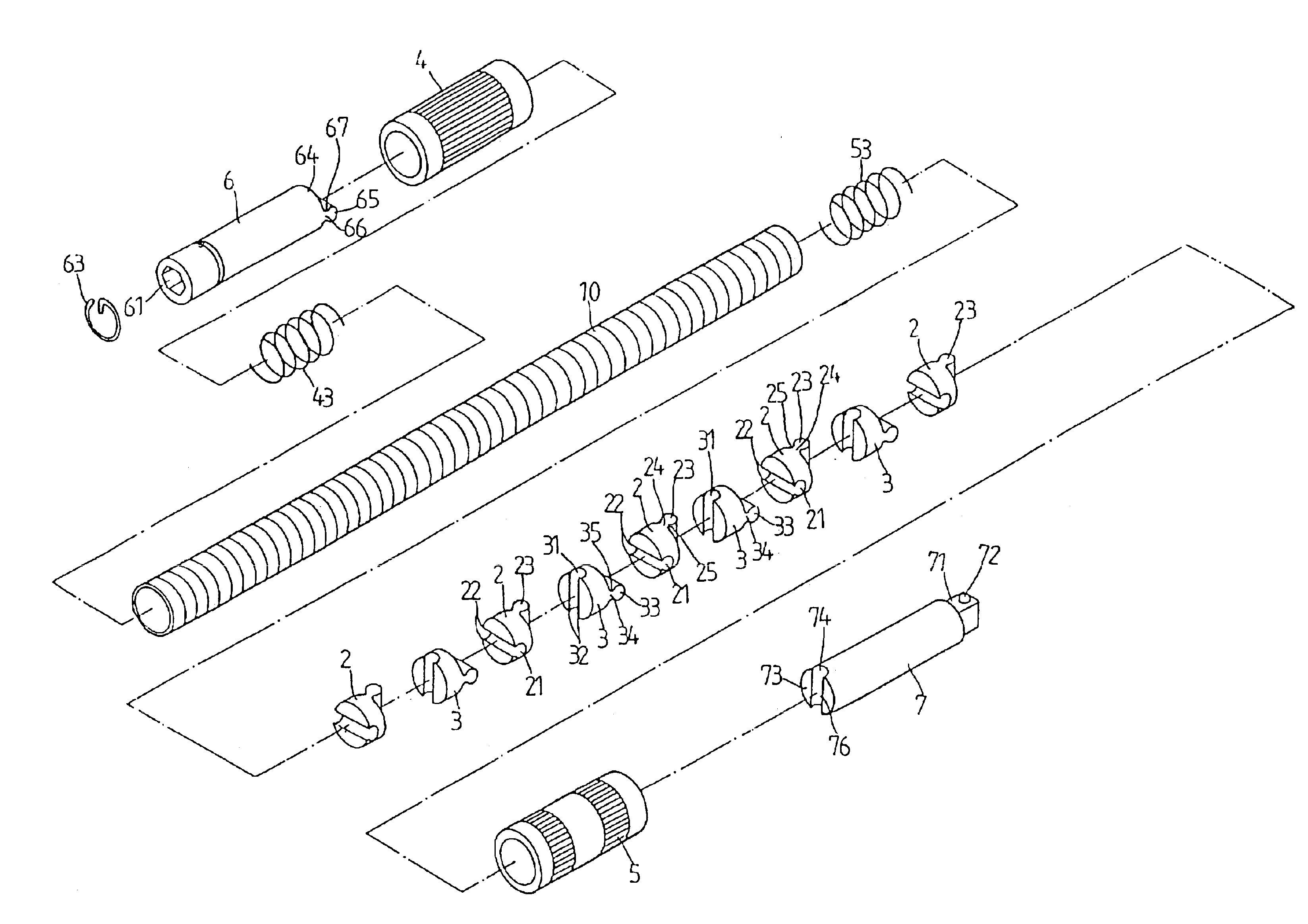

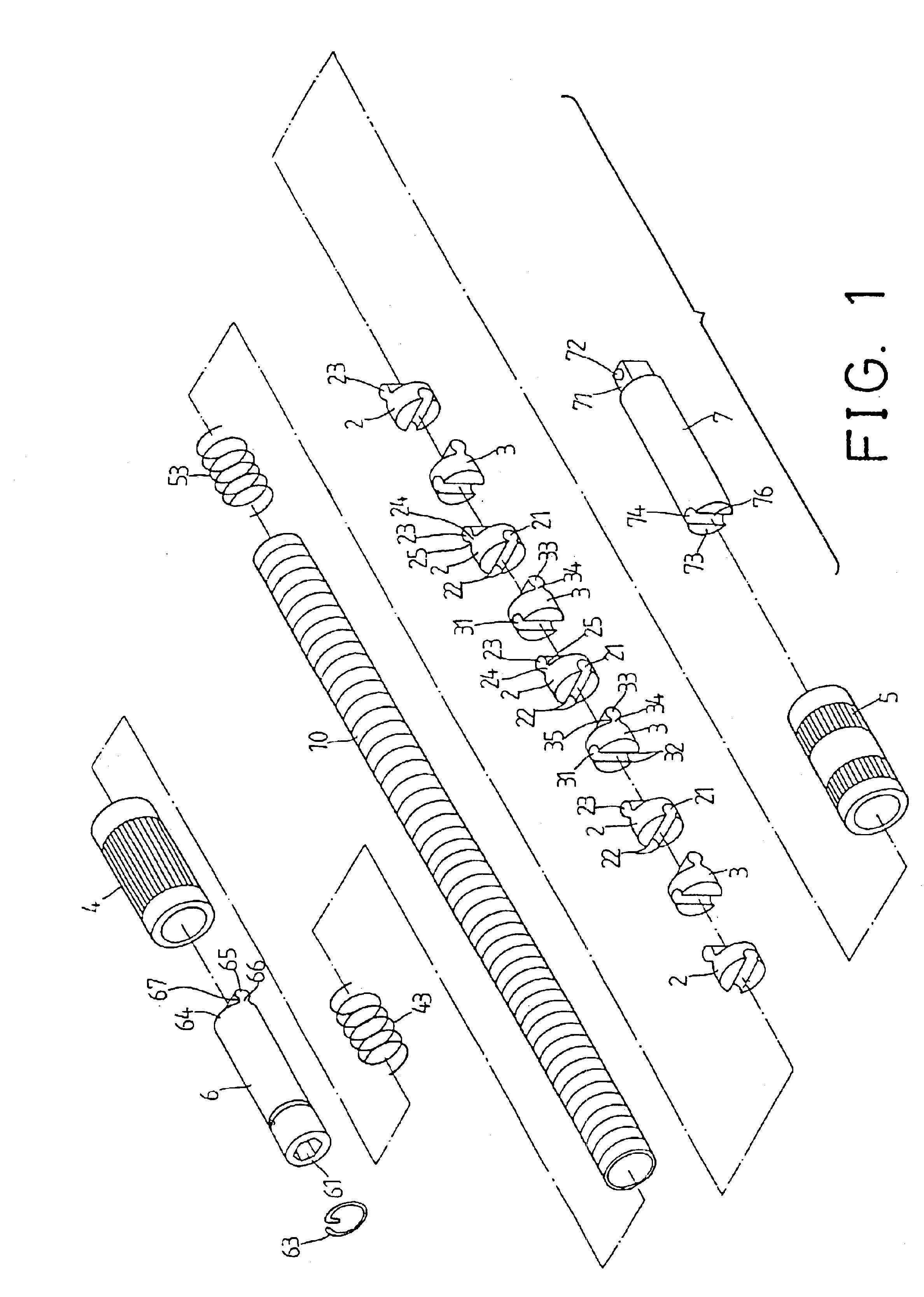

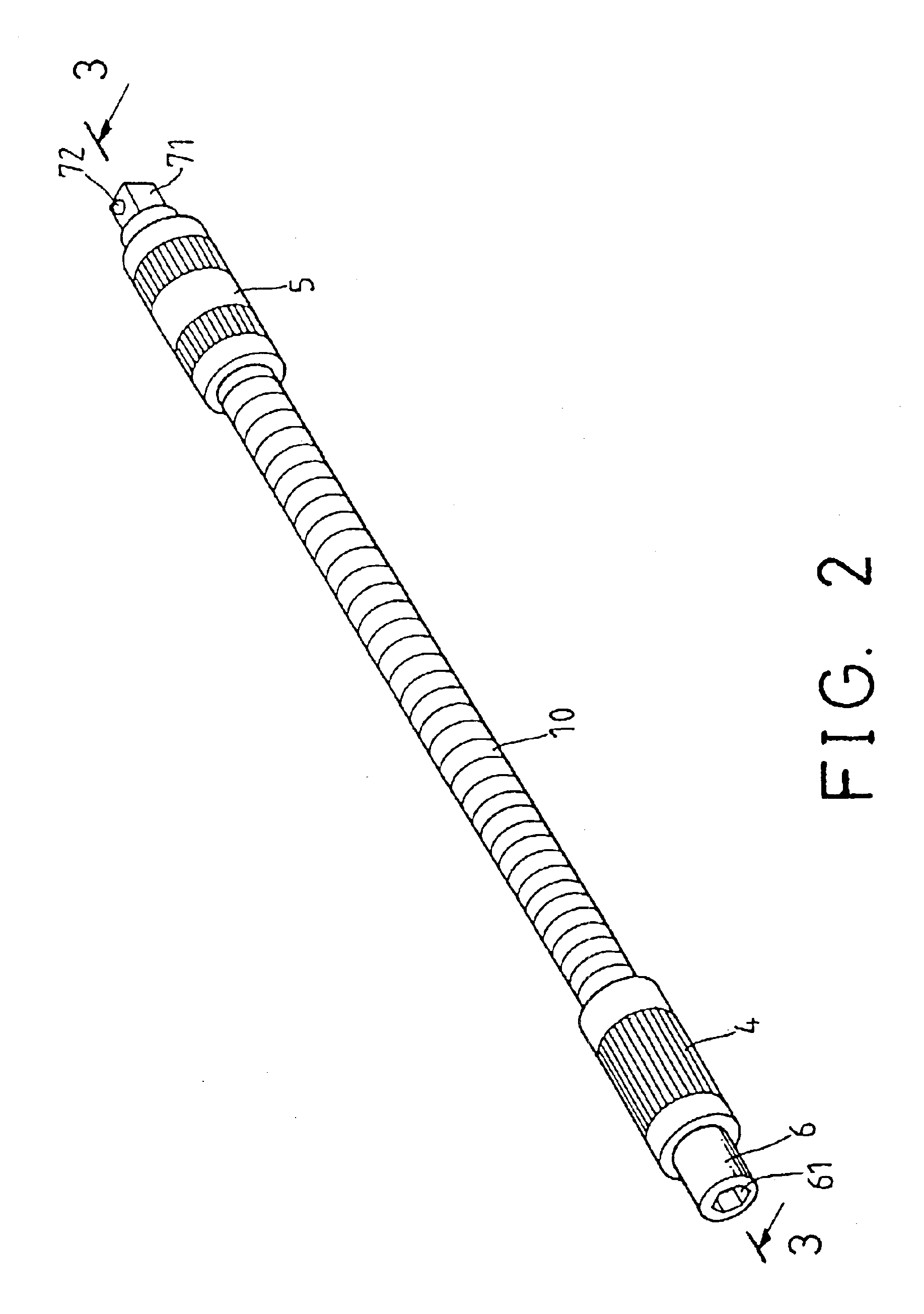

Drive shaft for a surgical reamer

InactiveUS20120253348A1Lighter and less-expensiveDifficulty costThread cutting auxillary apparatusSurgeryGlass fiber reinforced polymerCoupling

Drive shaft for interchangeable reaming heads intended for surgical use, in particular a reaming head used prior to the positioning of an intramedullary nail in the femur or in a long bone. The shaft has a rod (20) made from composite material, e.g. carbon and / or glass fiber reinforced polymer, and a connection element (35) for the coupling of an interchangeable reaming head. One portion (32) of said connection element (35) is inserted into a cavity in the first end (21) of said rod (20). The inventive shaft has a constant diameter, a smooth external surface and a low cost such that it can be disposed of after use.

Owner:CHIRMAT

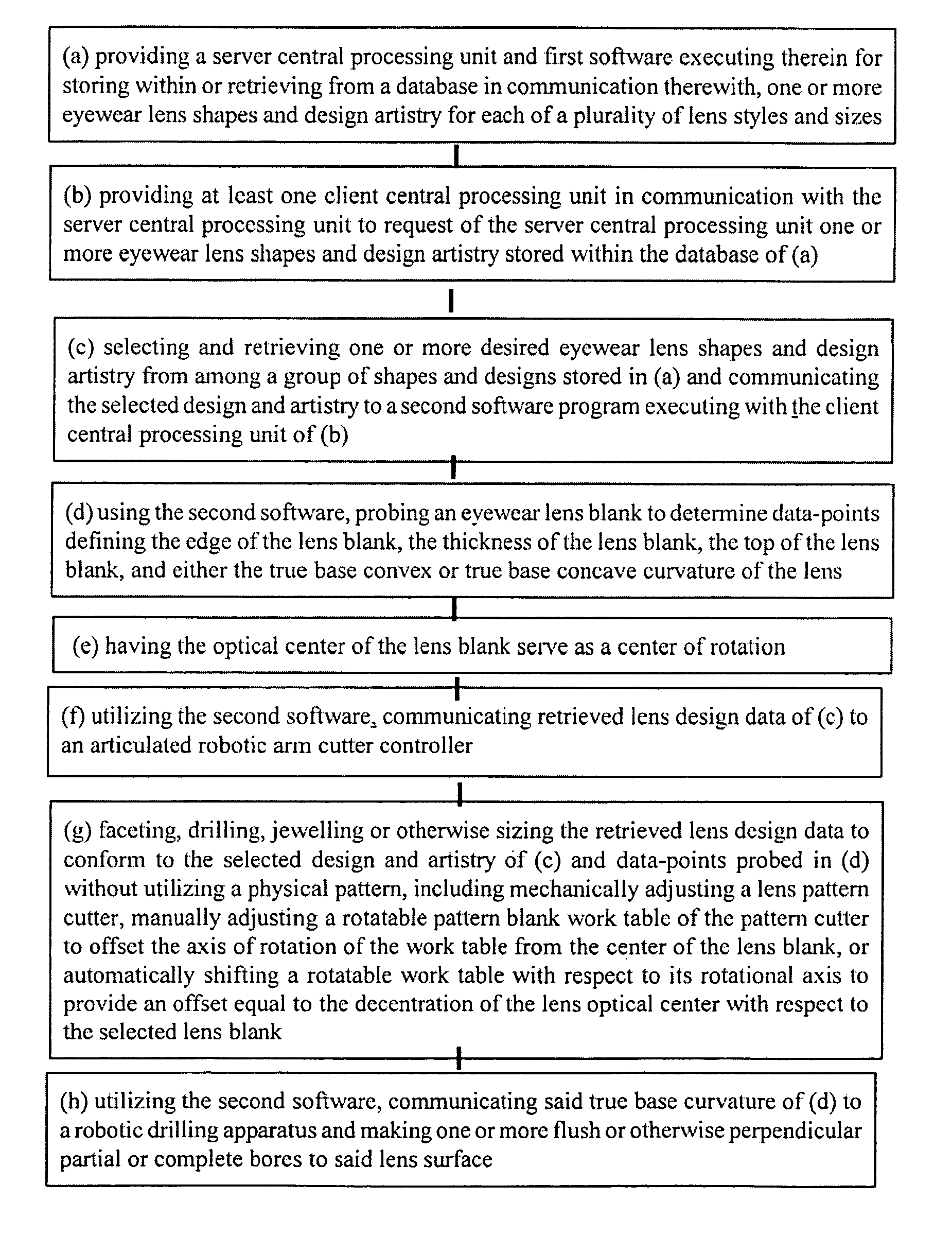

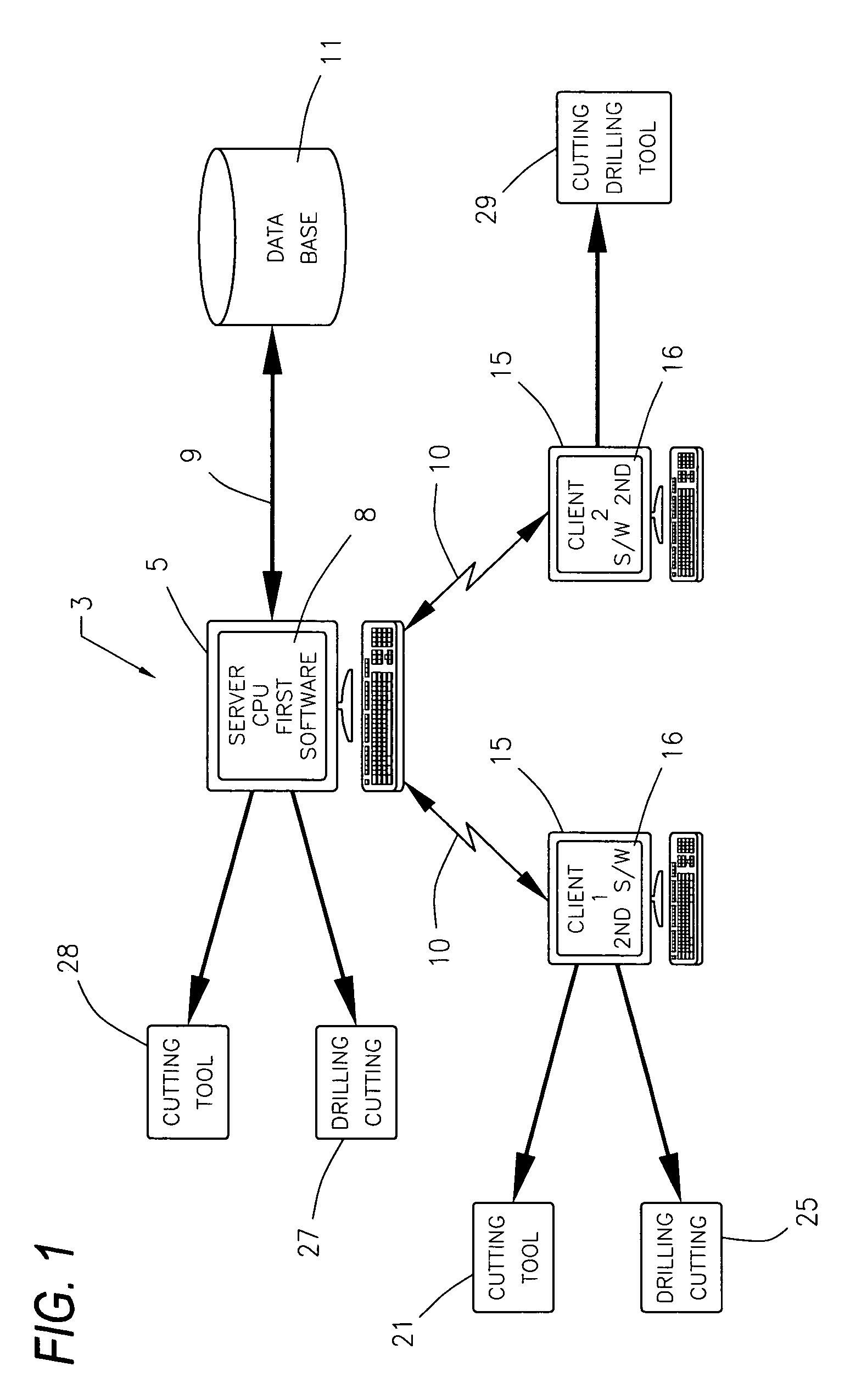

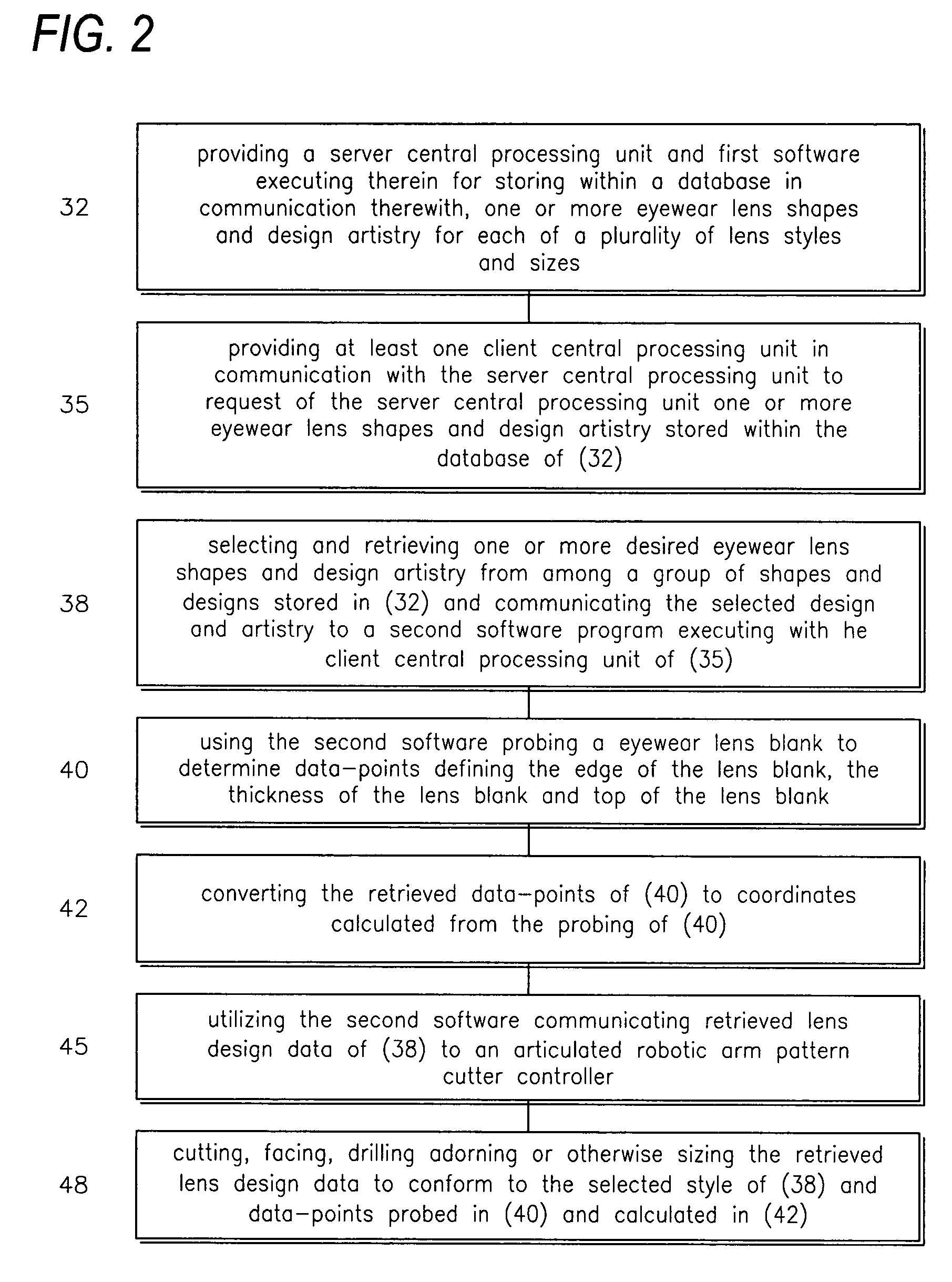

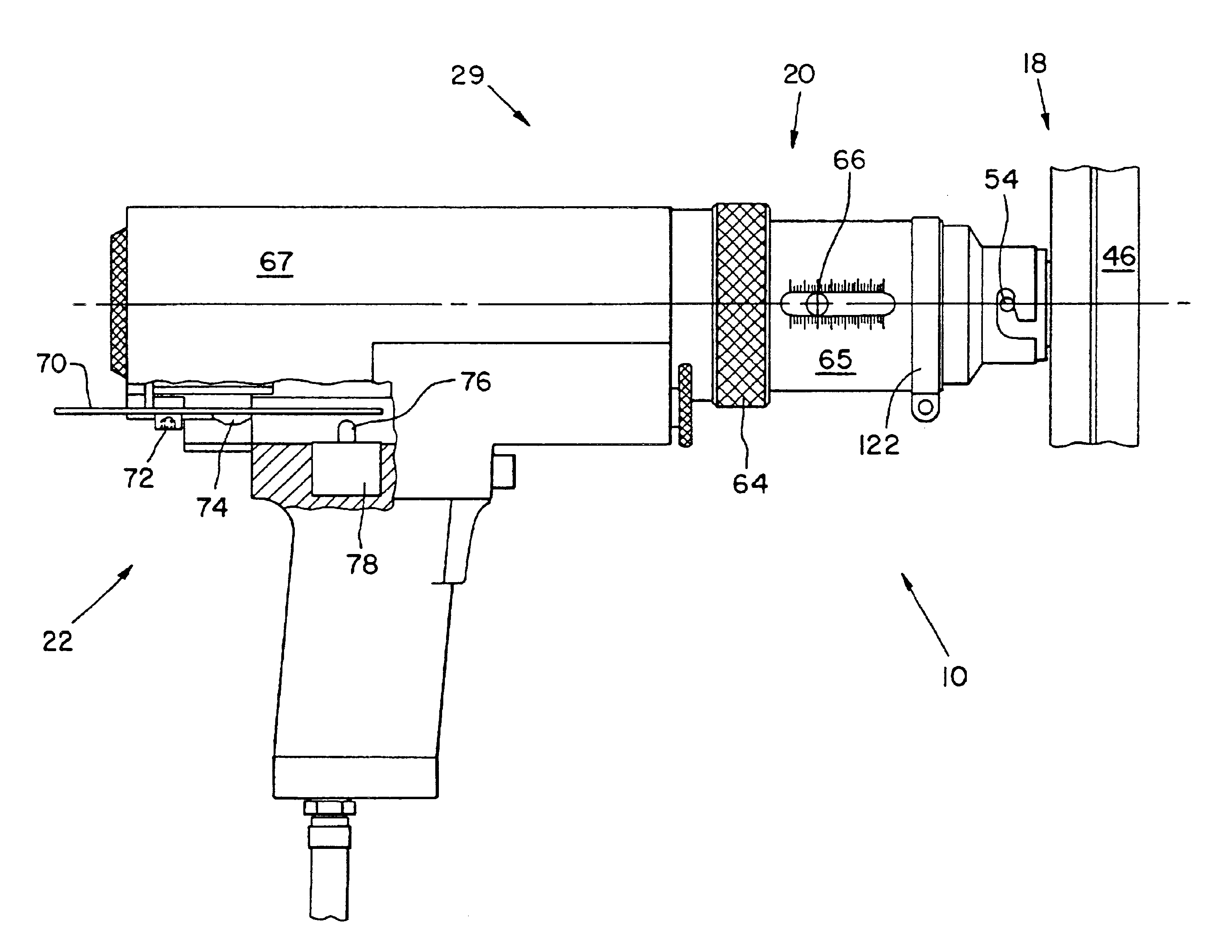

E-facet optical lens

A method and system design and manufacture of the monogrammed faceted and stone adorned eyeglass lenses via a computer program allowing a design, intricate facet cuts and stone placement on a computer lens model. Software may utilize a touch probe or laser scanner to gather point data from a previously designed lens, converting the data to a computer model. The data is then used to send signals to an articulated robotic arm holding a lens shape. The robotic arm receives the commands from the computer, moving and rotating the lens shape against an abrasive wheel, rotating cutter blade or rotating drill thereby duplicating the facet cuts, slots notches or depressions or other designs contained in the computer lens model. Varying pressure is applied by the articulated arm and various degrees of abrasiveness of the abrasive wheel.

Owner:YANCY VIRGIL T

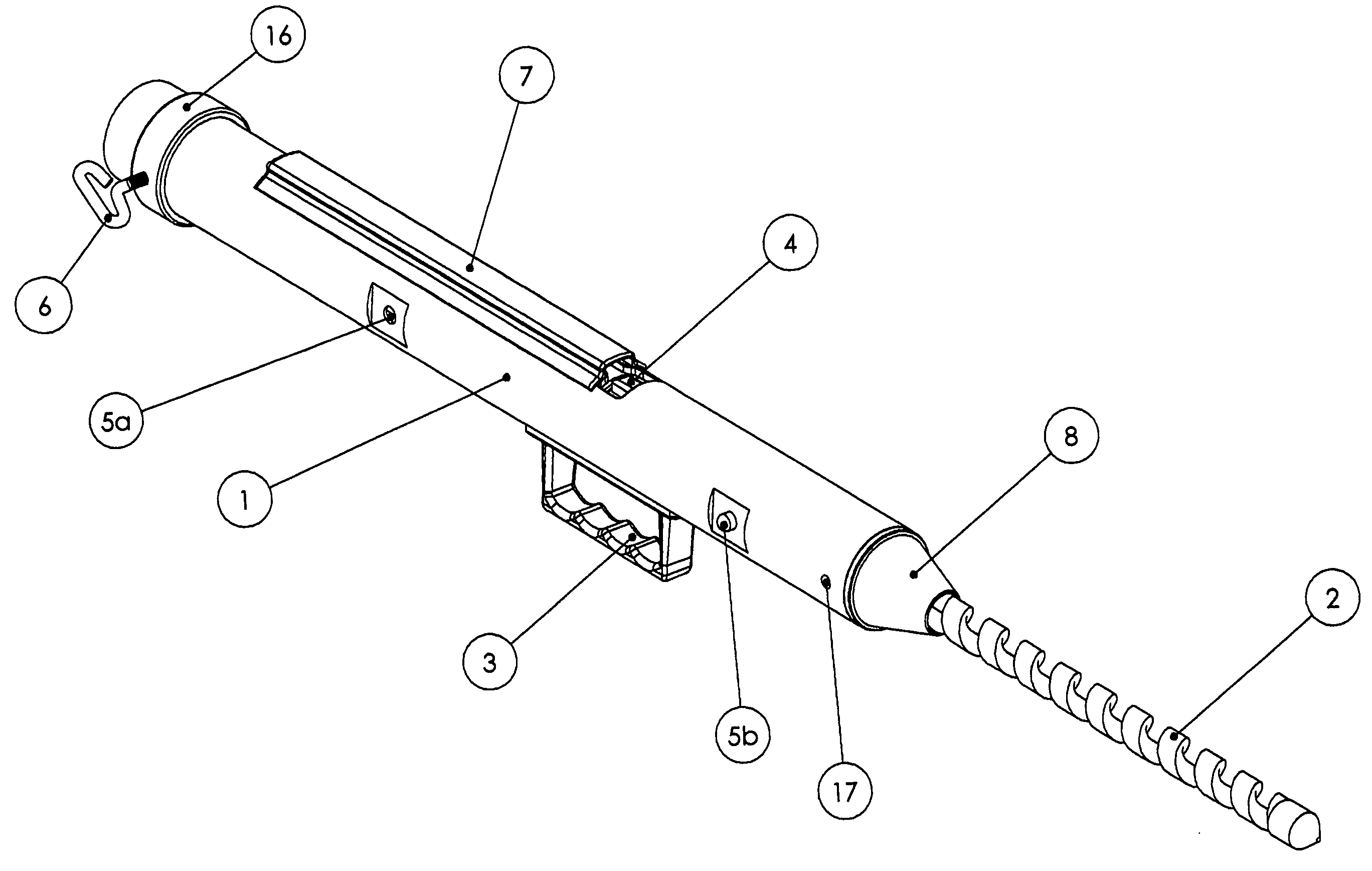

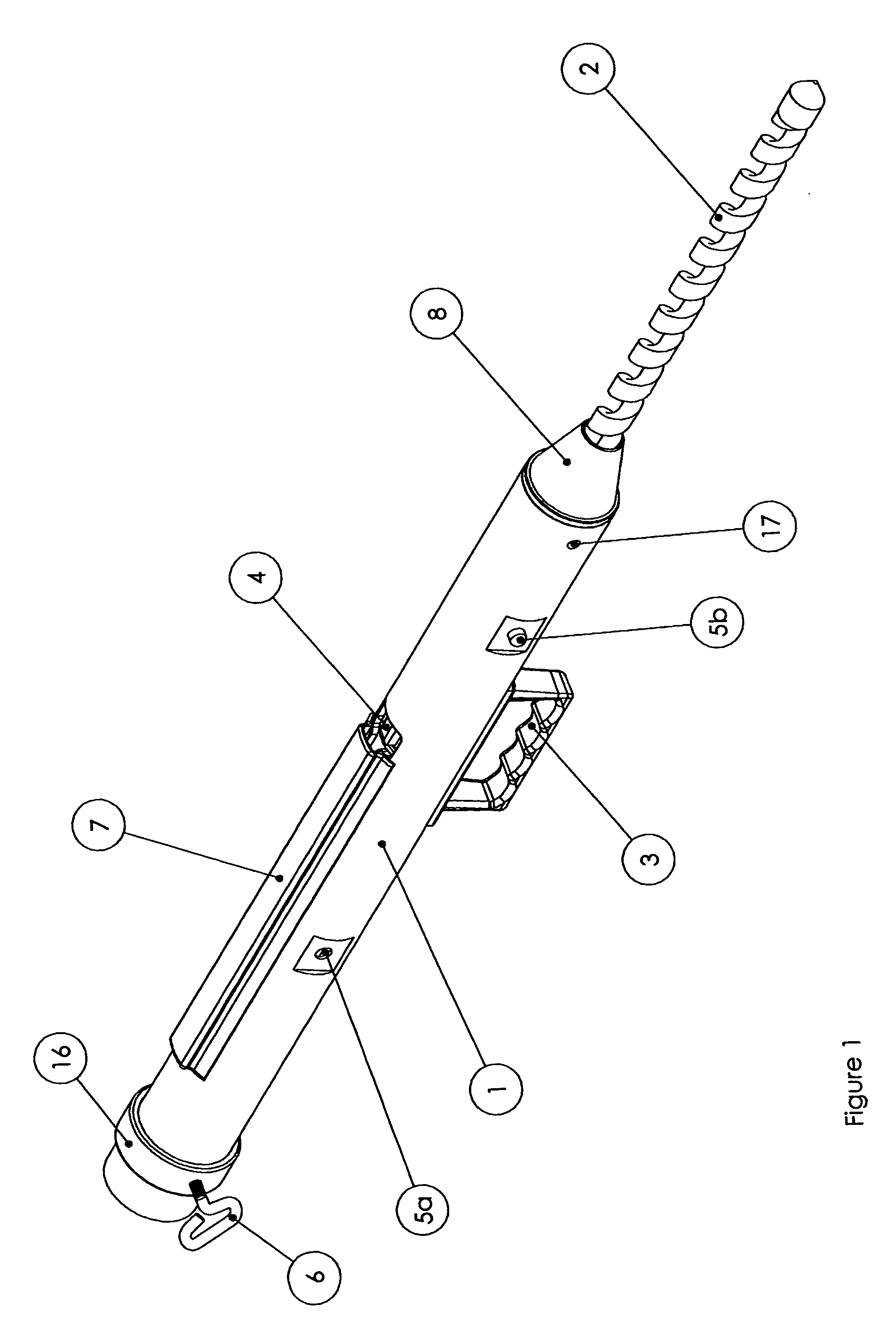

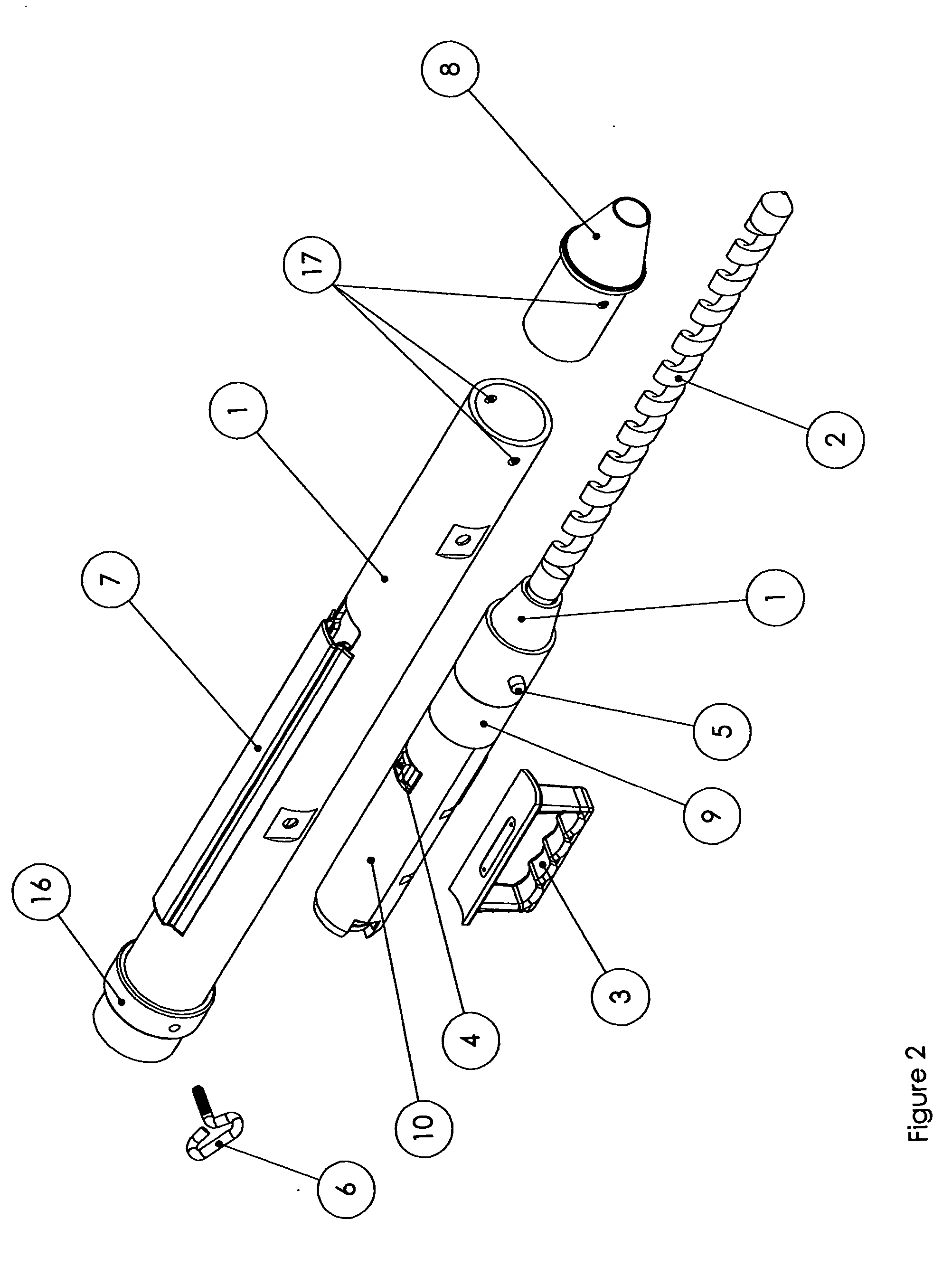

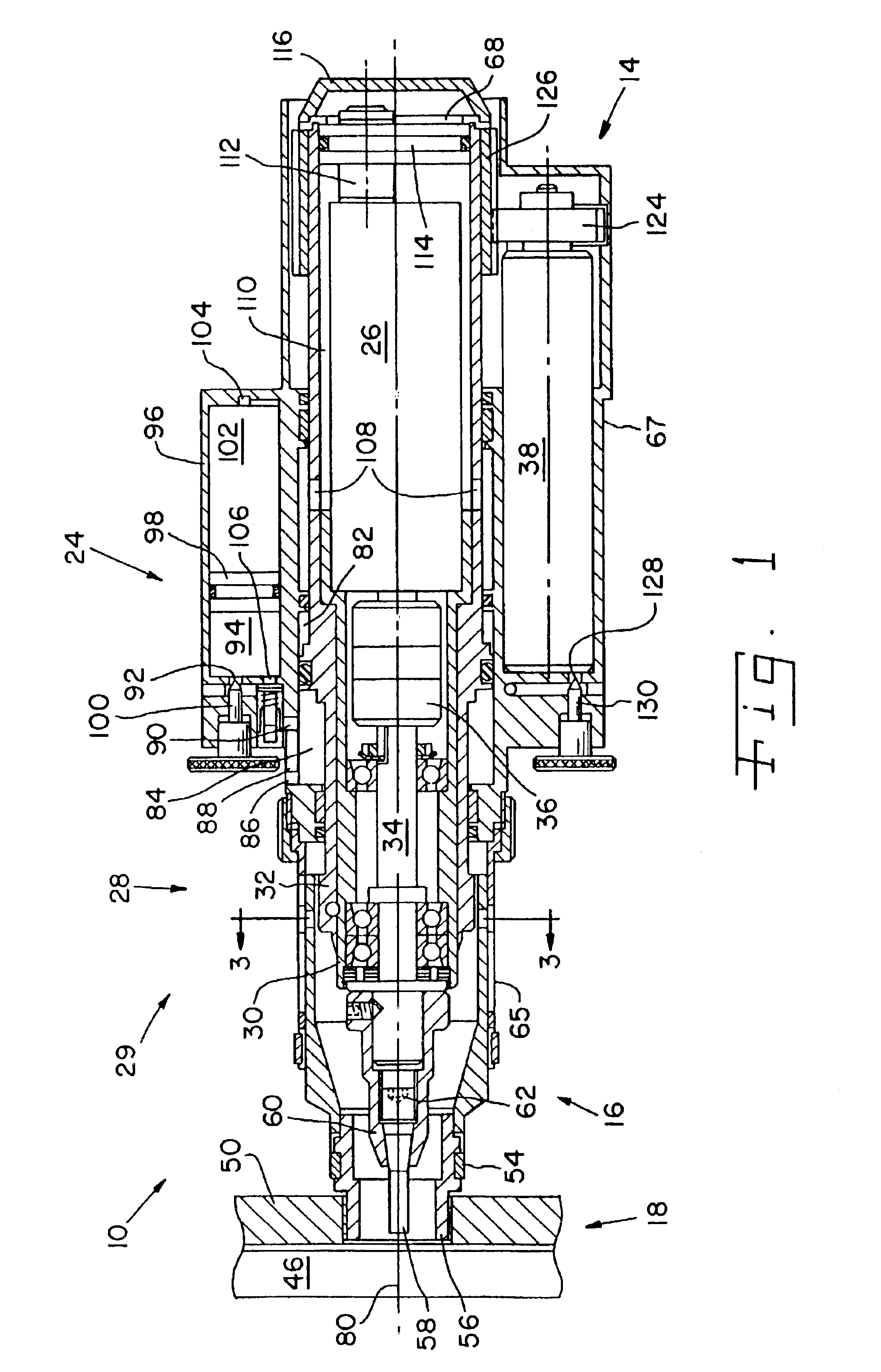

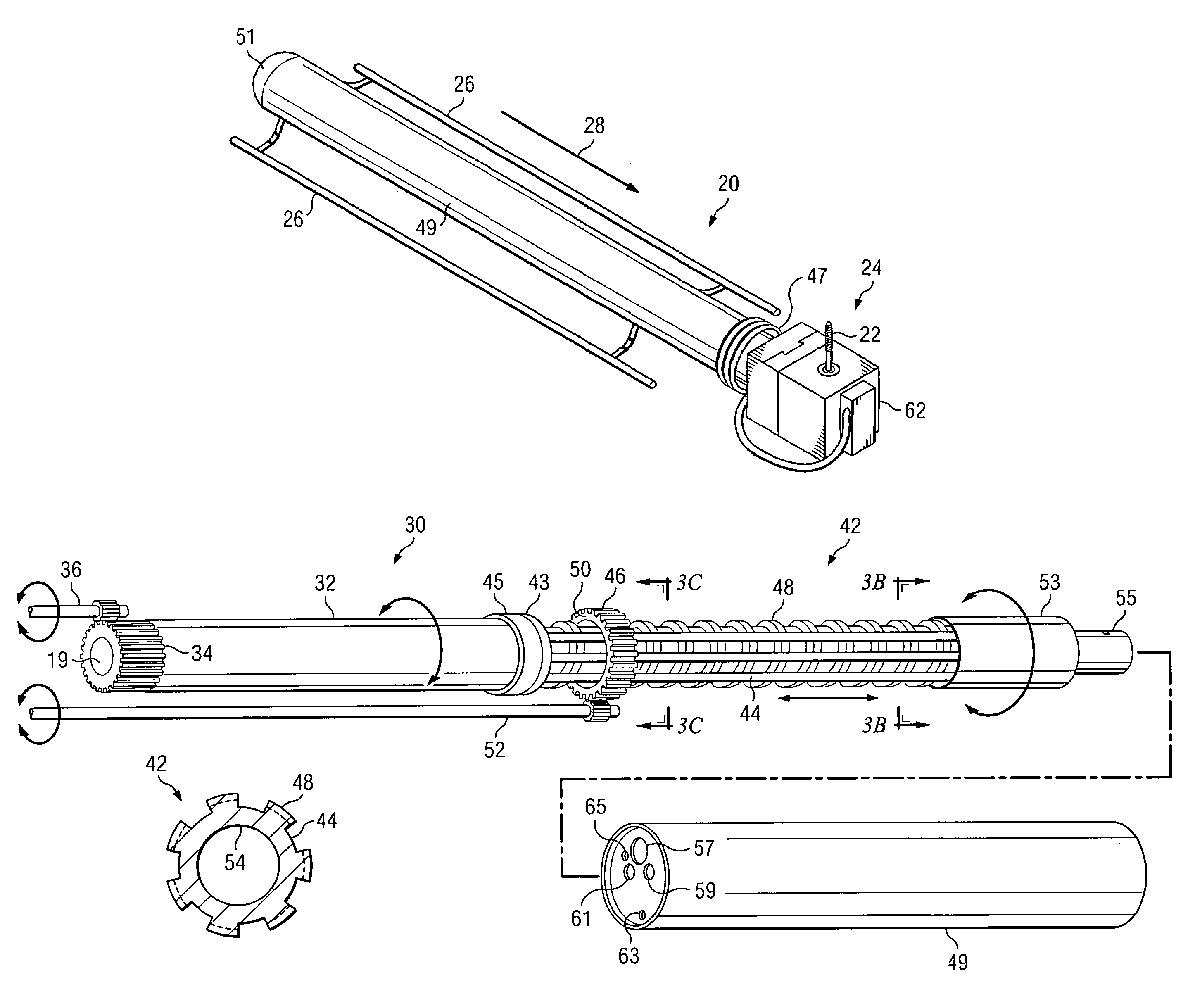

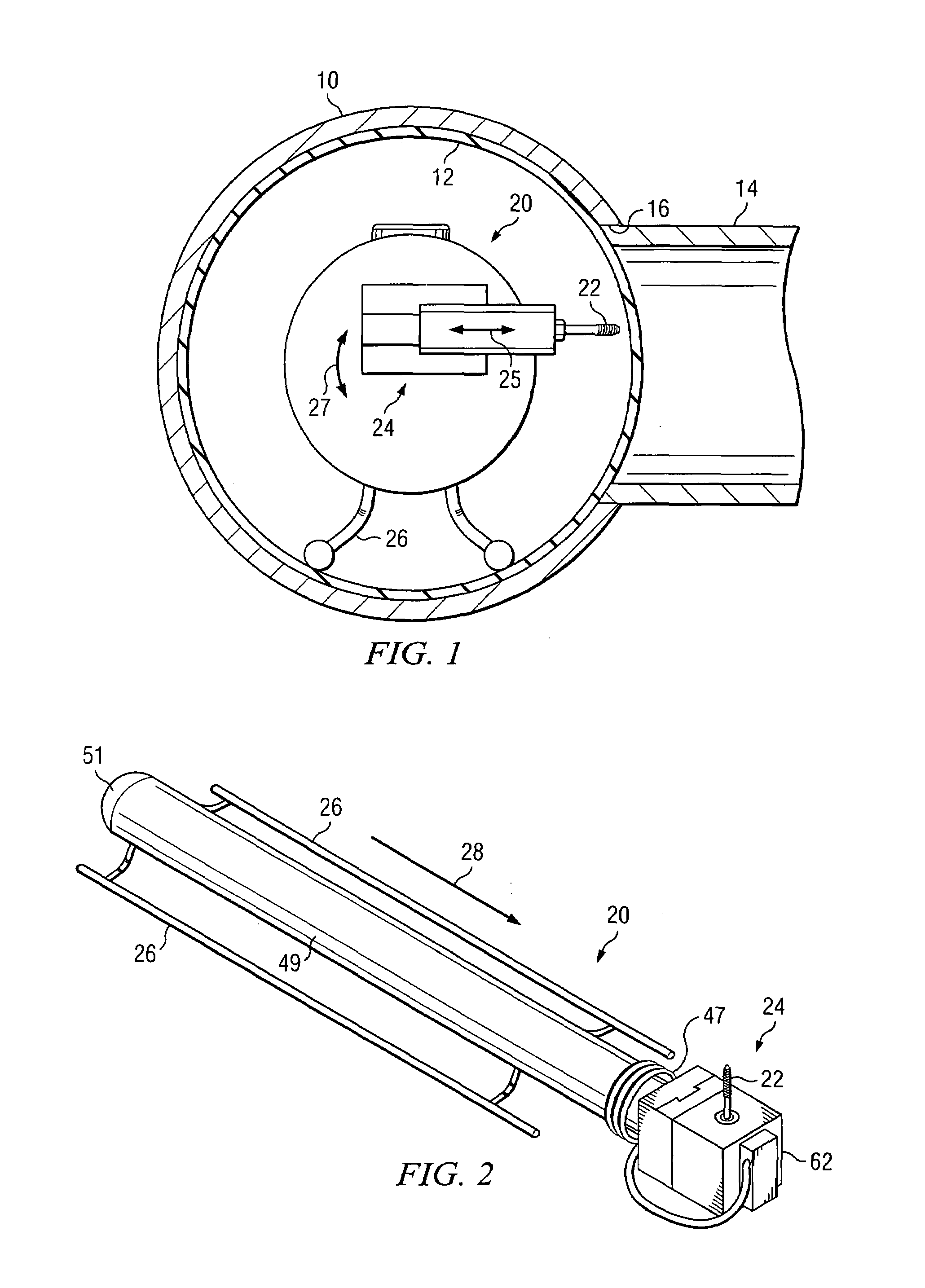

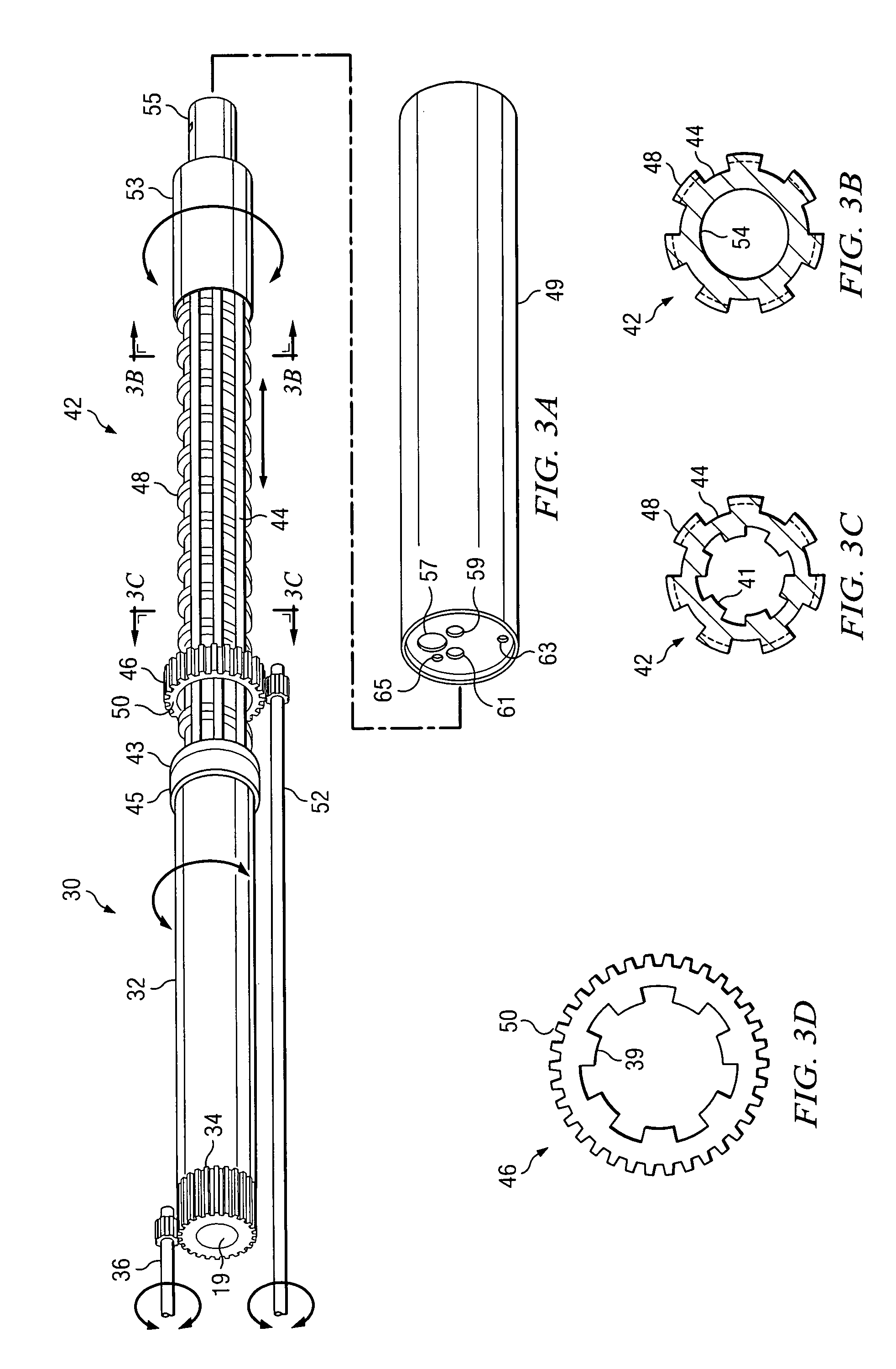

Hand tool apparatus for orbital drilling

InactiveUS6872036B2More lightweight and compactReduce bendingDrilling/boring measurement devicesTurning machine accessoriesEngineeringHand tool

A hand tool apparatus uses a cutting tool with a first width and a tool axis to machine a hole in an object. The hole has a second width at least as large as the first width of the cutting tool. The tool axis passes through a predetermined point on a surface of the object. The apparatus includes an actuating assembly including a housing. The housing contains an axial feed mechanism configured for moving the cutting tool in an axial direction, a spindle motor configured for rotating the cutting tool about the tool axis, and a radial offset mechanism. The radial offset mechanism is configured for moving the axial feed mechanism in a radial direction such that the tool axis is offset from a principal axis. A motor is configured for rotating said axial feed mechanism and the cutting tool about the principal axis.

Owner:NOVATOR

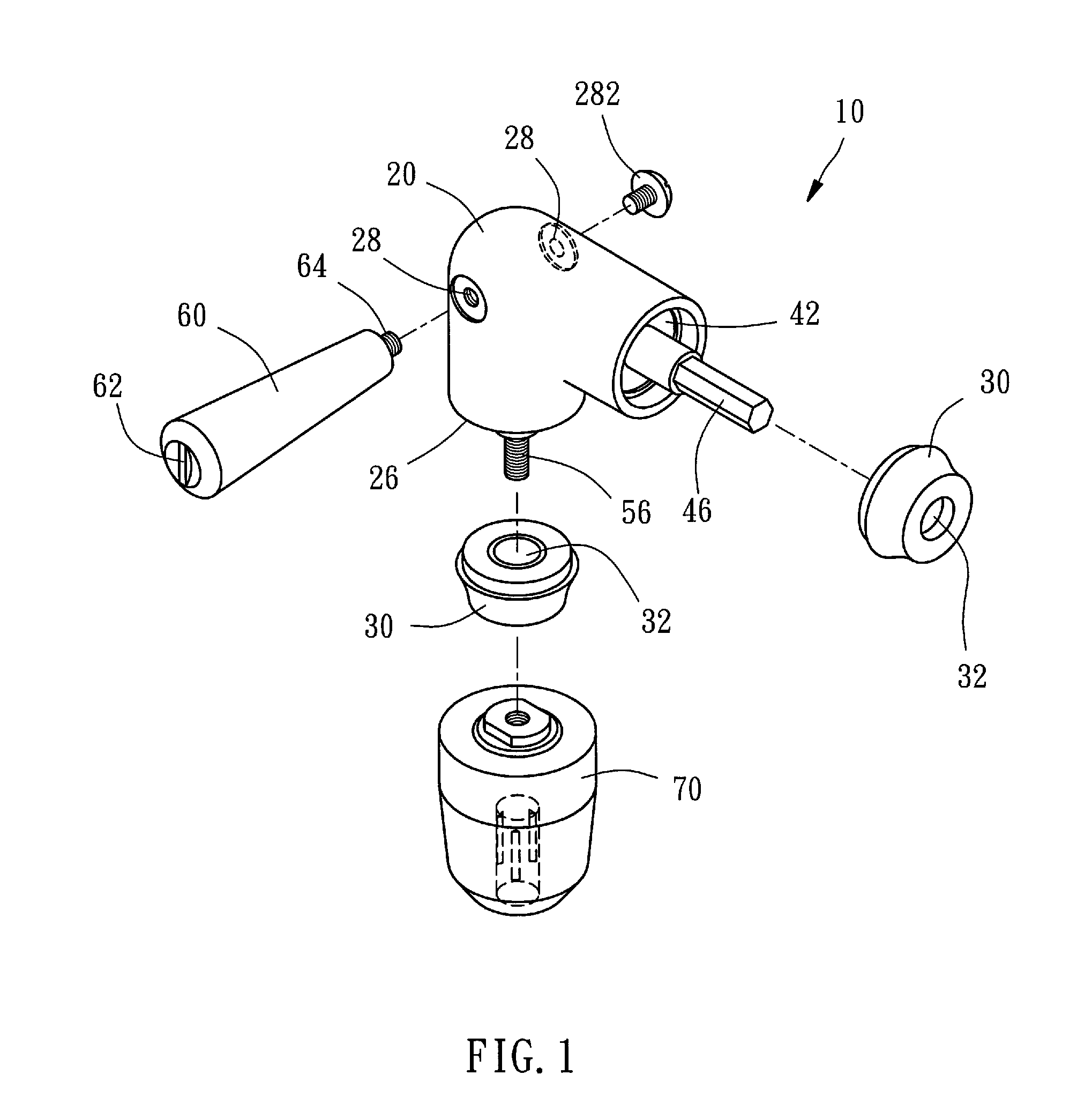

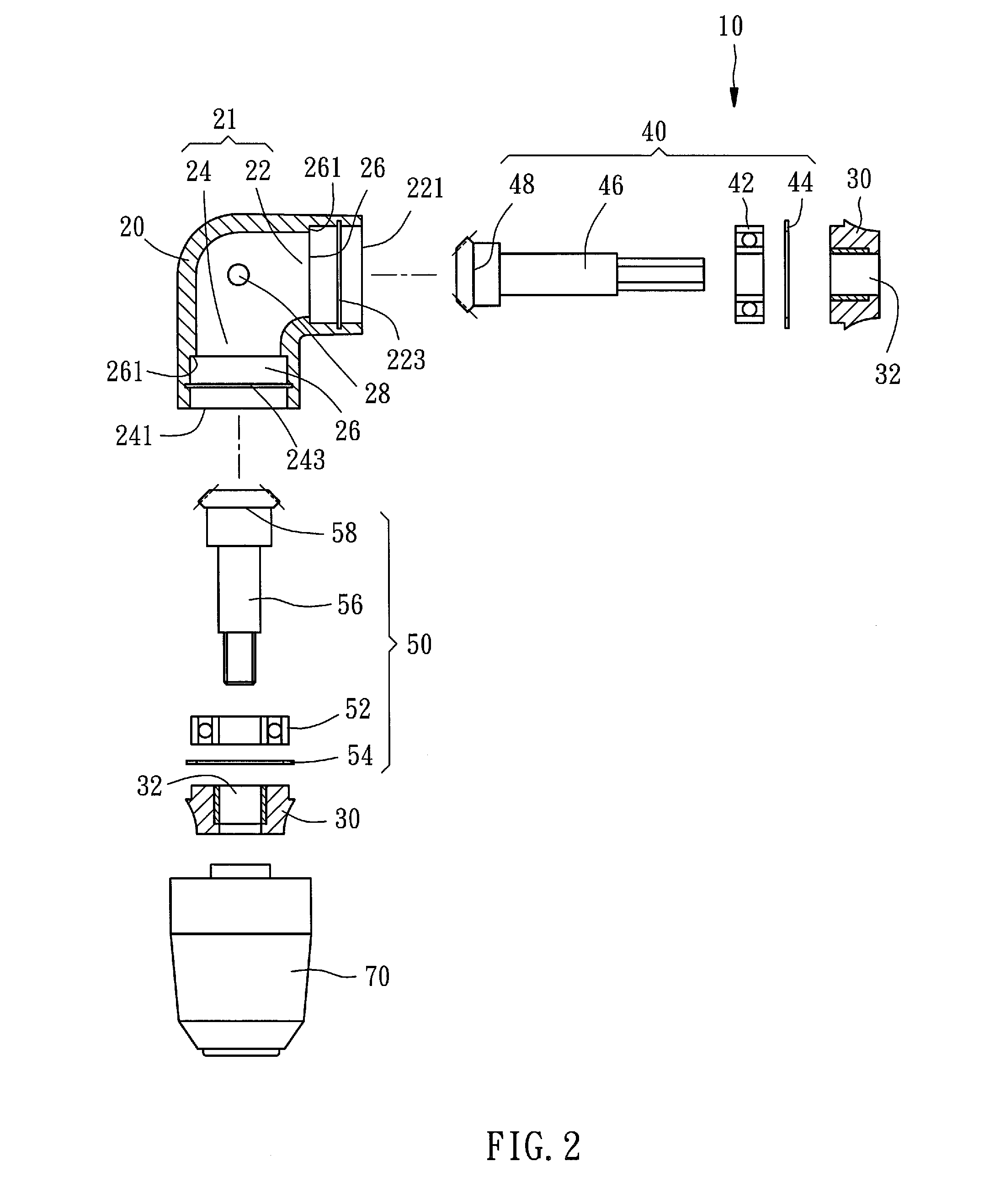

Tool adapter

InactiveUS20080003070A1Stable structureConveniently and rapidly assembledThread cutting auxillary apparatusPortable power-driven toolsEngineeringMechanical engineering

Owner:HOR BUNG JZYY

Tool setting method for repairing thread by using numerically controlled lathe

ActiveCN102350548AExtended service lifeQuality improvementThread cutting auxillary apparatusNumerical controlEngineering

The invention discloses a tool setting method for repairing thread by using a numerically controlled lathe. The method comprises the following steps of: measuring the error of a thread track line of thread to be repaired and a reference track line by taking the thread track line of firstly processed thread as a reference; and adjusting an initial position of a tool nose to enable a processed thread track to be overlapped with the thread track to be repaired by changing the pulse phase of a zero phase of a main shaft encoder or changing a Z coordinate of the initial position of the tool nose. The method is specially designed for repairing the thread of a drilling tool by using the numerically controlled lathe, and has the characteristics of easiness in operation, accuracy in tool setting, high efficiency, quickness, light labor intensity of operating personnel, high practicability and the like; large-scale repair processing is facilitated; the thread of the drilling tool repaired through tool setting by using the method has higher quality; the repair frequency of a drilling tool joint is increased; and the service life of the drilling tool is prolonged. The method can be used for repairing the thread of the drilling tool joint under numerical control, and can also be applied to thread repair of all other parts of which the thread repair track is required to be overlapped with the original thread track in numerical control.

Owner:SOUTHWEST GASOLINEEUM BUREAU TOOLS OF SINOPEC GROUP

Flexible socket extension

InactiveUS6952986B2Avoid separationPrevent disengagementThread cutting auxillary apparatusPlungersControl theory

Owner:KUN CEN ENTERPRISE

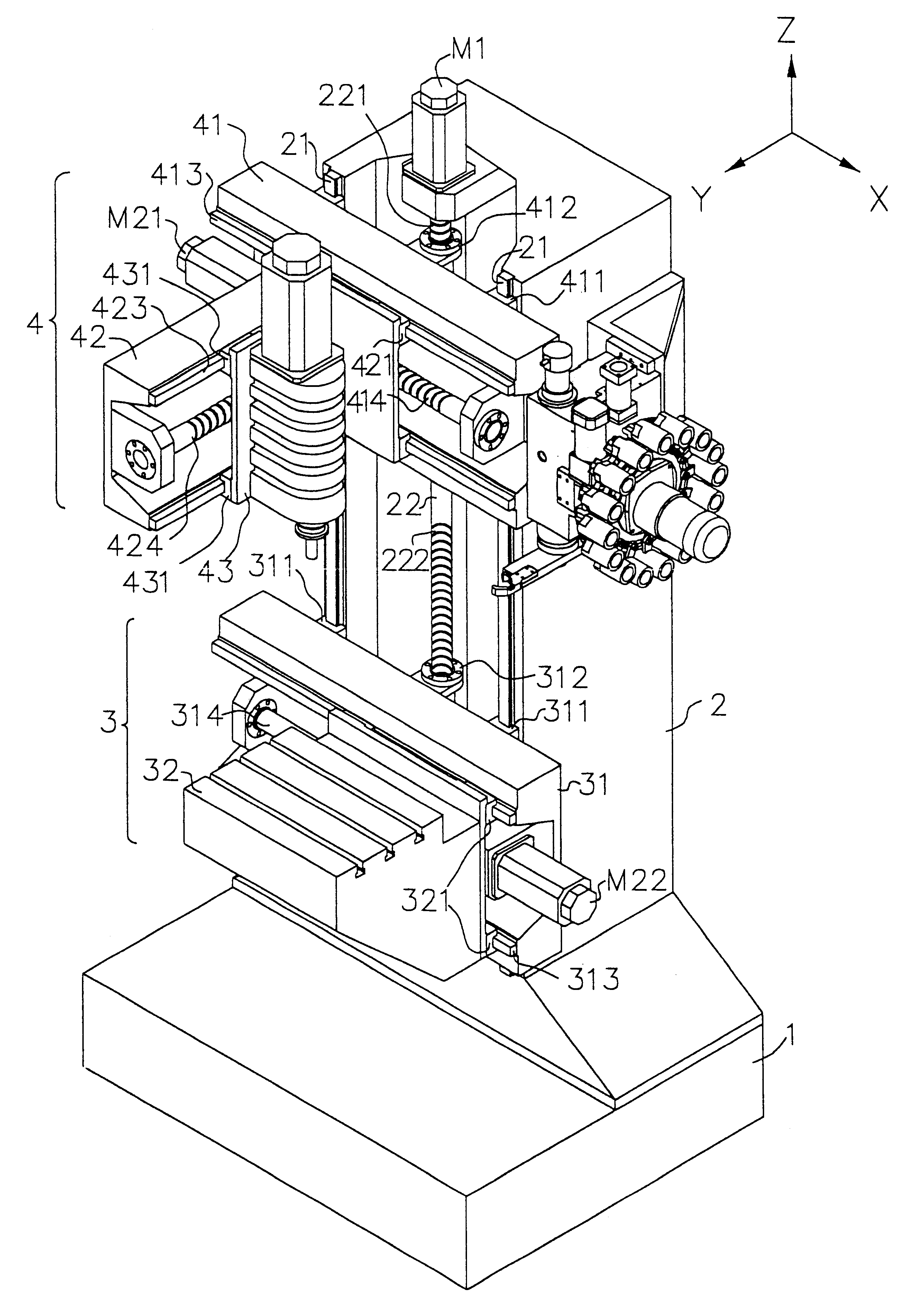

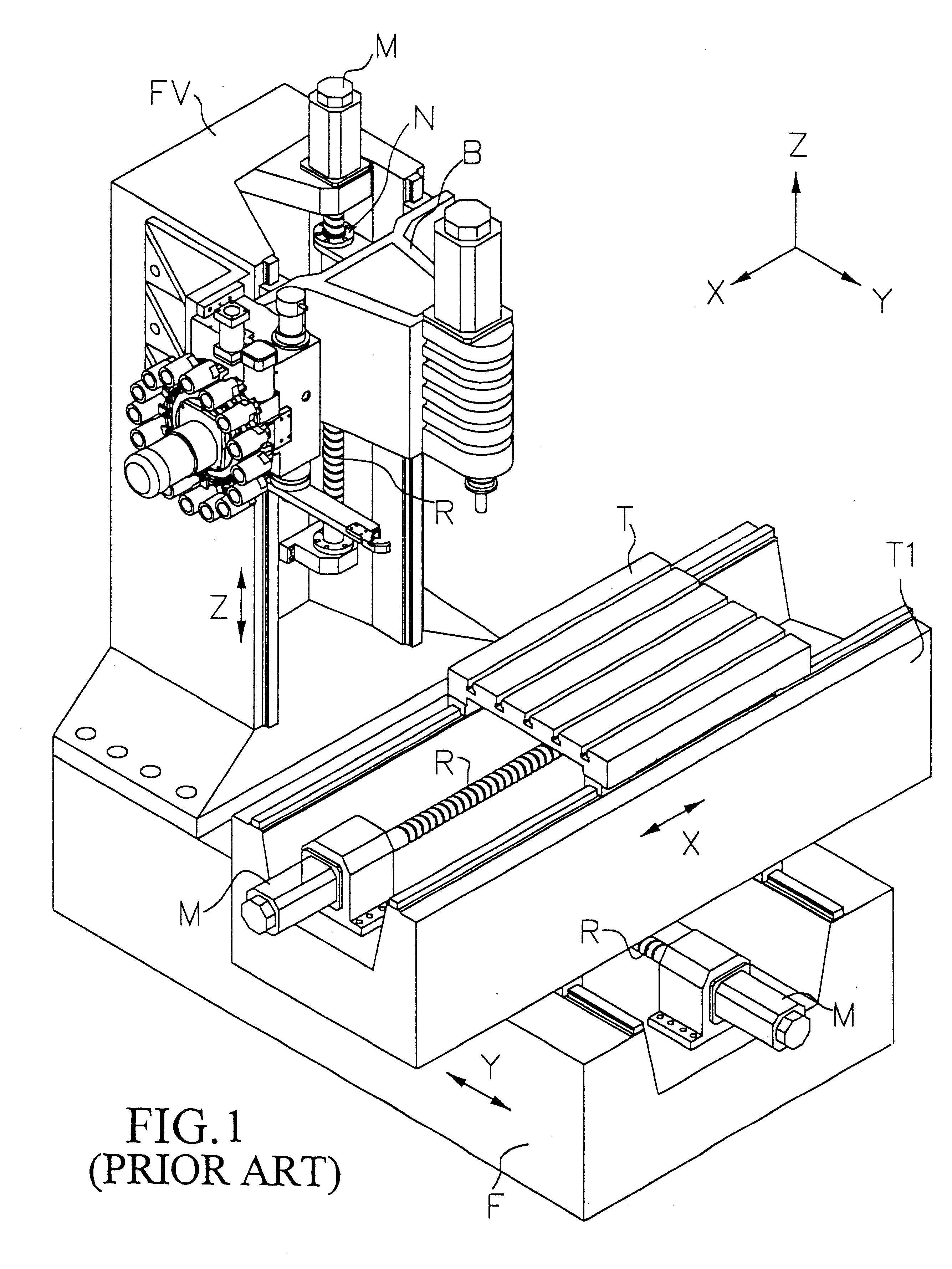

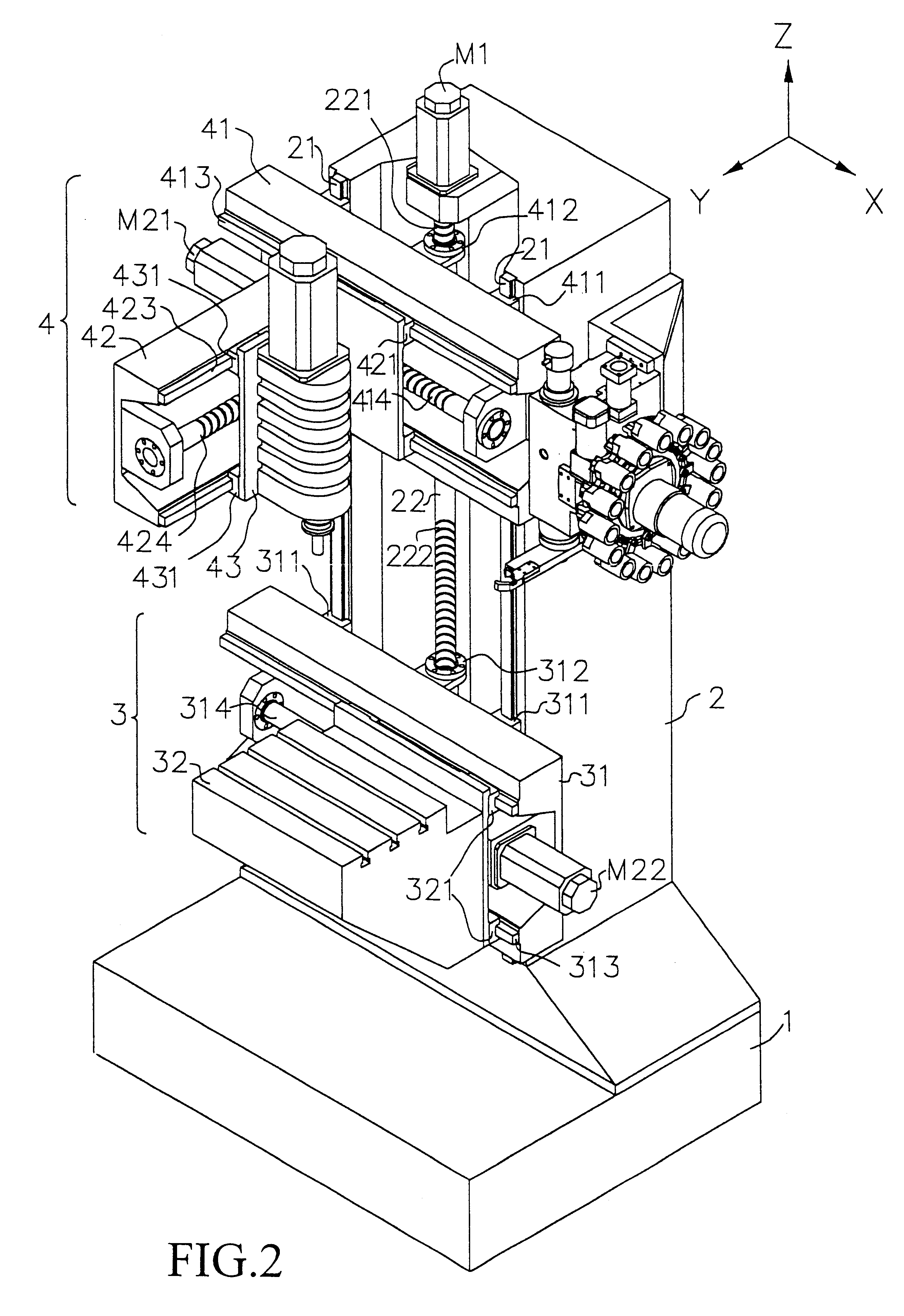

CNC machine center with double-speed shifting feature in X and Z axes

InactiveUS6364818B1Automatic/semiautomatic turning machinesThread cutting auxillary apparatusNumerical controlEngineering

A CNC machine center with double-speed shifting feature in X and Z axes, comprises an upright stand for disposing a worktable assembly and a tool holder assembly. The worktable assembly and the tool assembly are relatively movable with each other in two perpendicular coordinate axes, i.e., X-axis and Z-axis. It is characterized in that in at least one of X-axis and Z-axis, the tool holder assembly and the worktable assembly are interconnected with each other by a screw rod having a positive thread section and a counter thread section, thereby the tool holder assembly and worktable assembly can be simultaneously shifted in opposite directions to obtain a relative shifting speed double of conventional one, so that the non-cutting operation time of a machine center is greatly reduced, and so that the overall machining speed and efficiency are improved.

Owner:CHANG CHUN HSIANG

Multi-Speed Drill and Chuck Assembly

ActiveUS20090003950A1Prevent rotationThread cutting machinesThread cutting auxillary apparatusEngineeringDrill bit

A chuck assembly configured to provide a shorter longitudinal profile. The chuck assembly includes a chuck body with a support bearing mounted to a rear portion of the chuck body and mounted to a portion of a housing such that a cavity is defined axially rearward of the support bearing and is configured to receive the jaws when the rear portion of the jaws extend axially rearward. The chuck assembly can be incorporated into a tool driven by a motor. In some aspects, the tool may include a speed change mechanism, a torque adjustment mechanism, or both.

Owner:TECHTRONIC POWER TOOLS TECHNOLOGY LTD

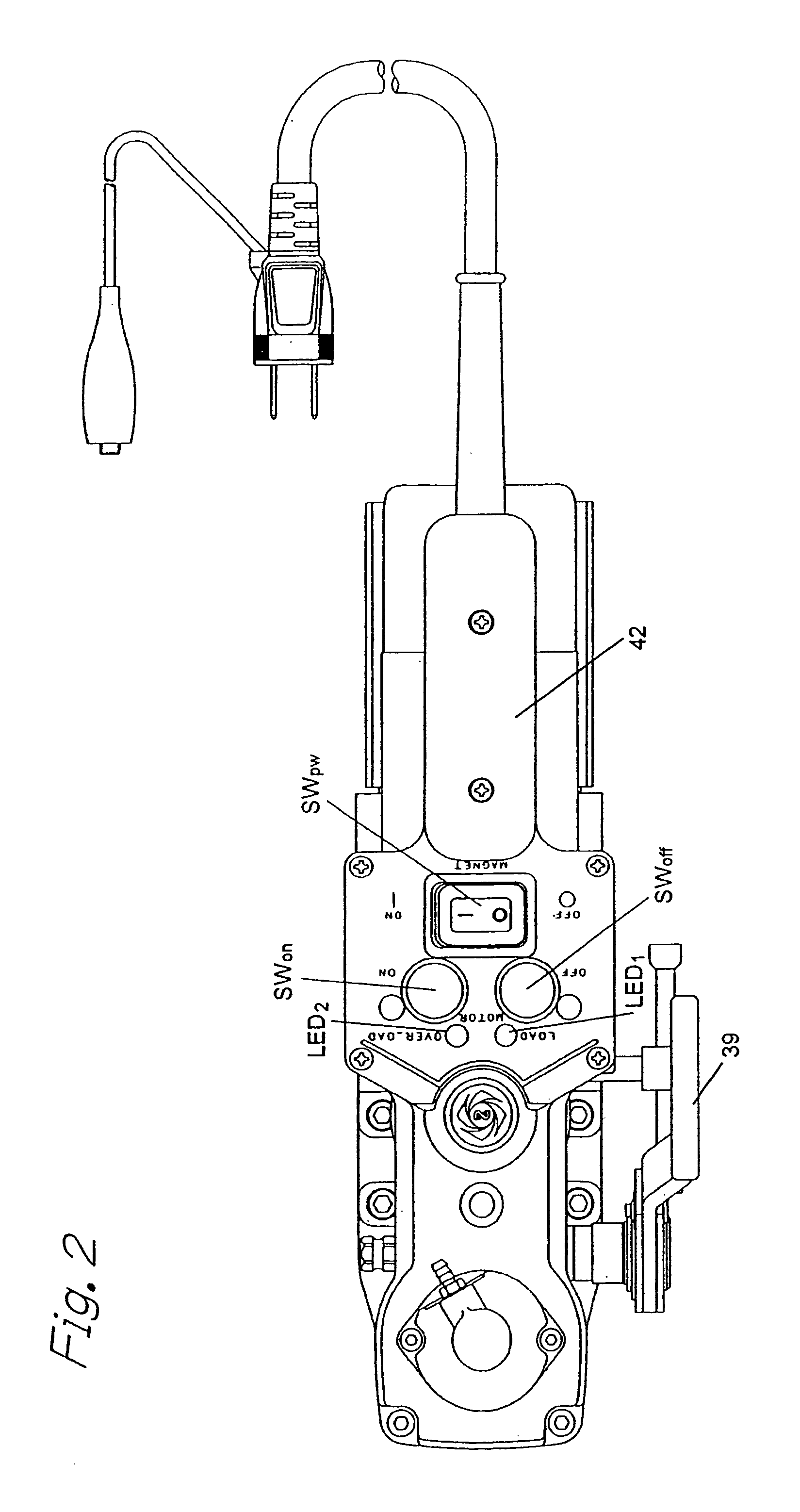

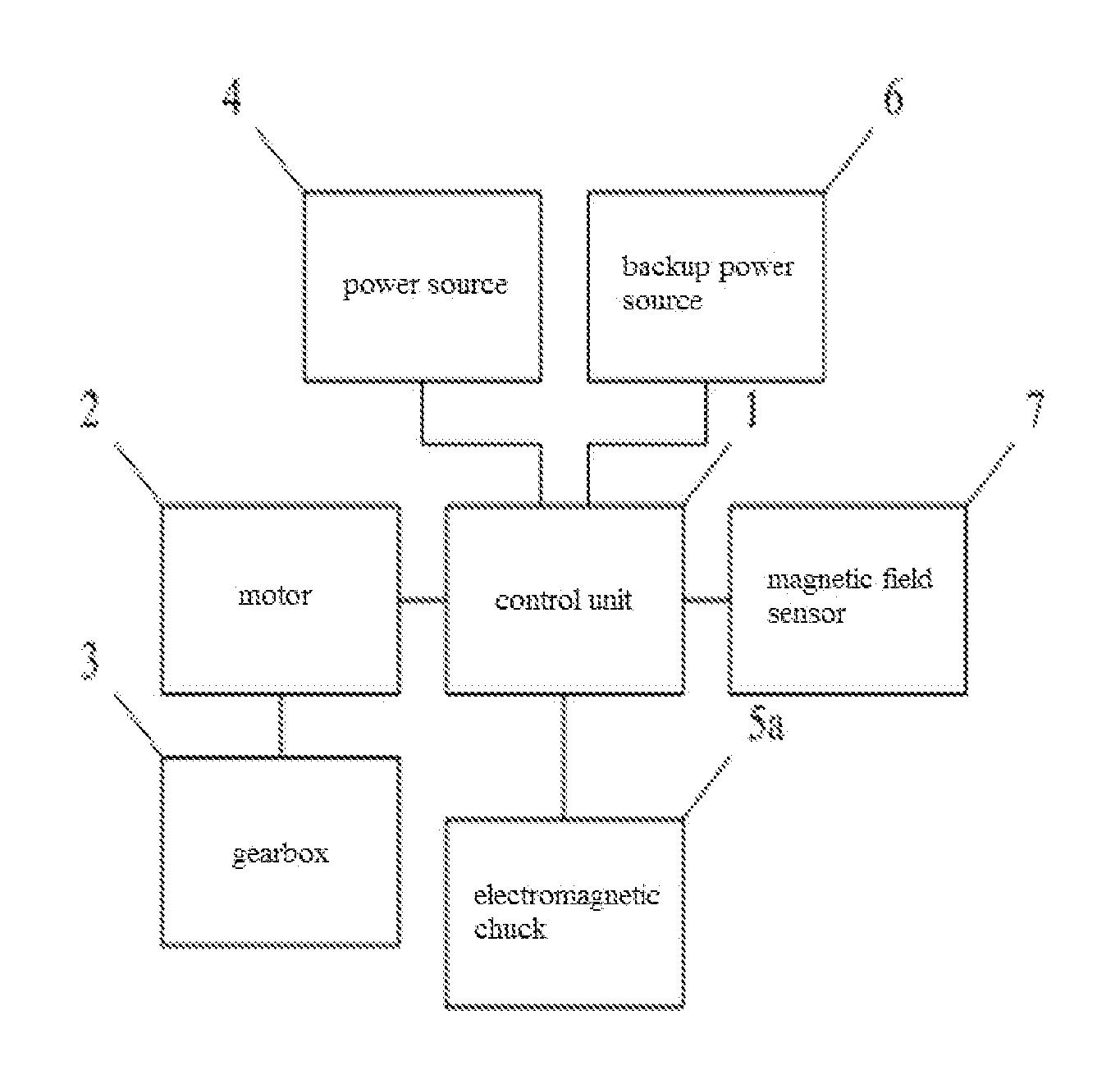

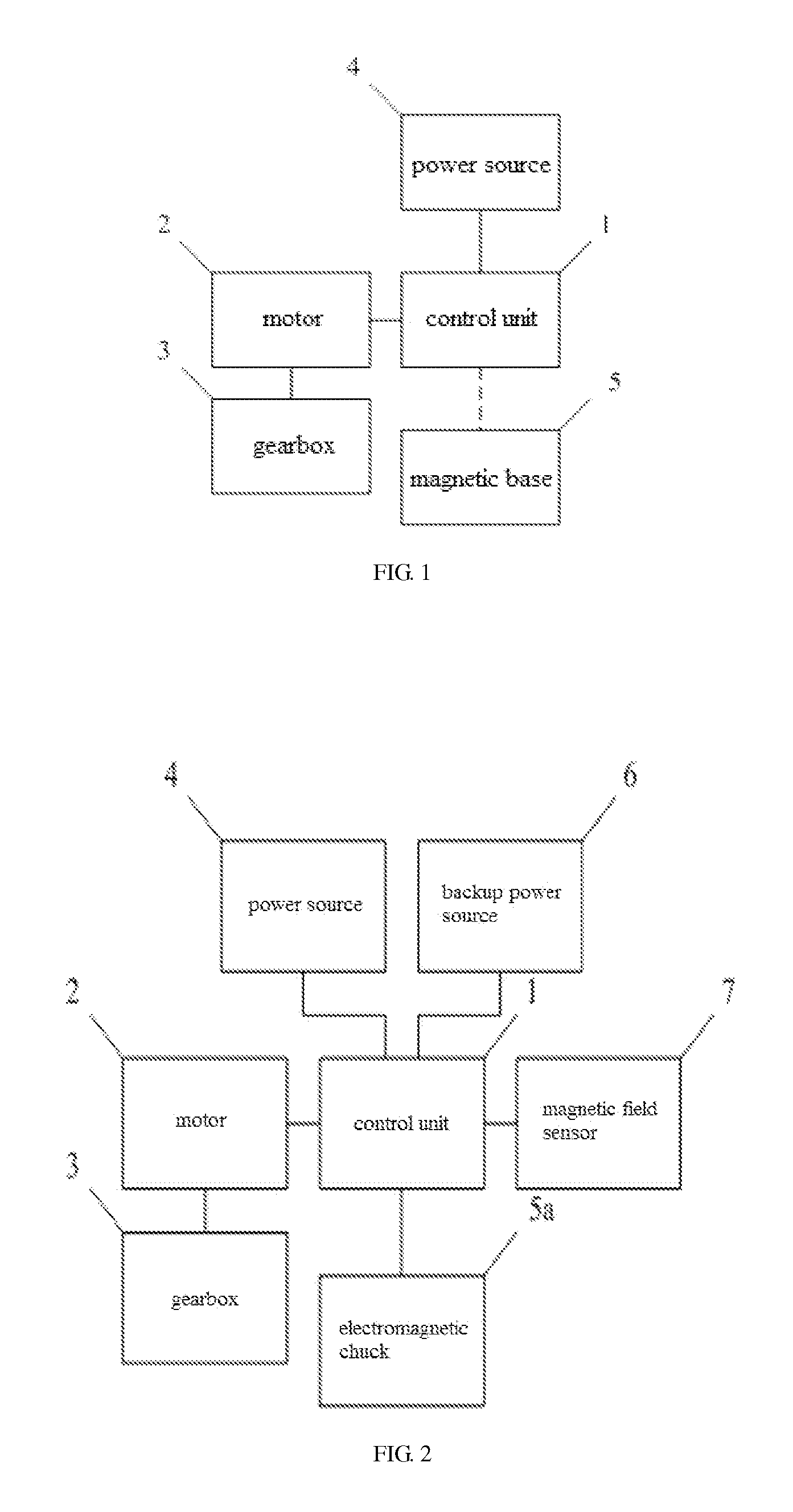

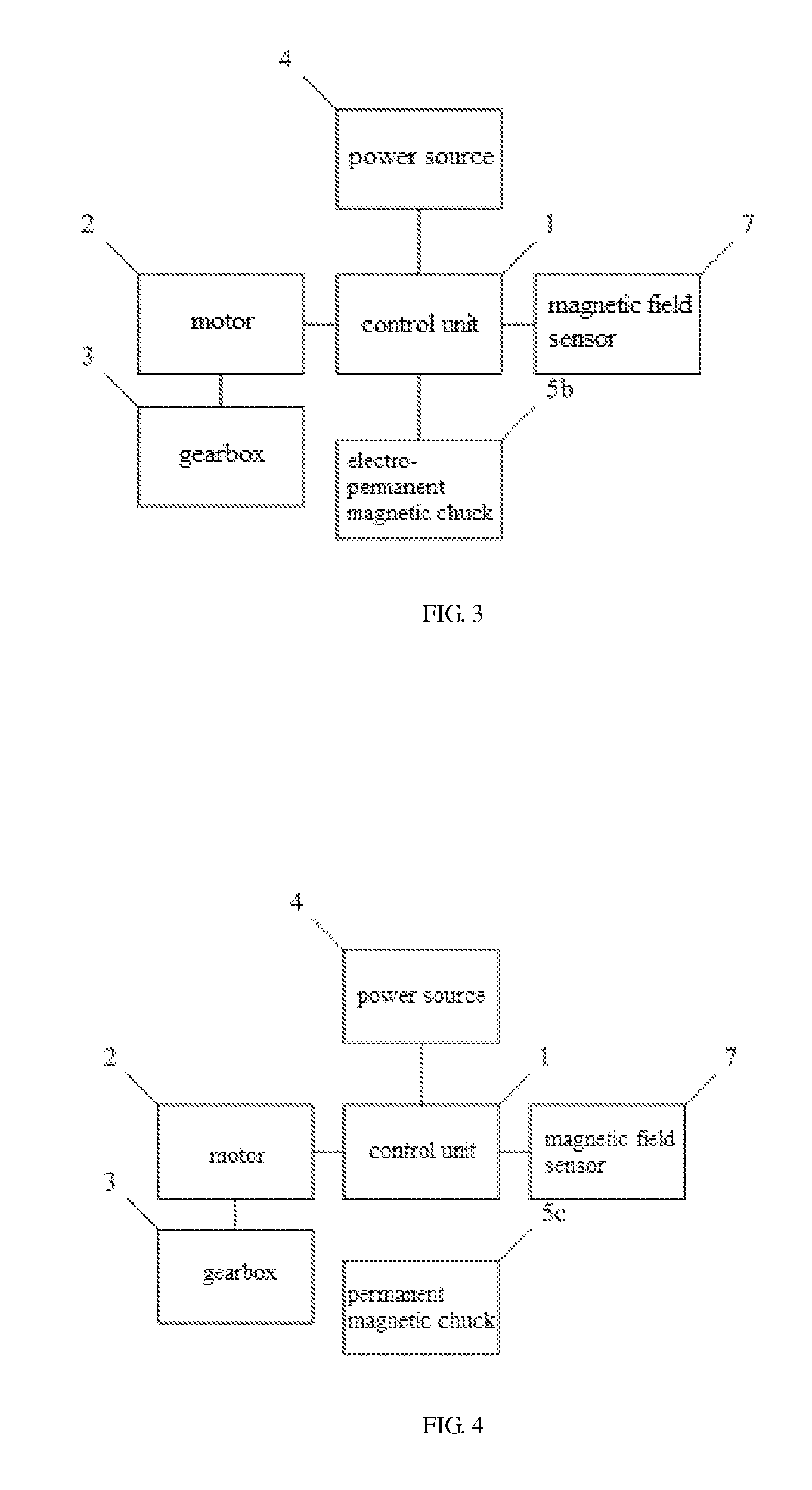

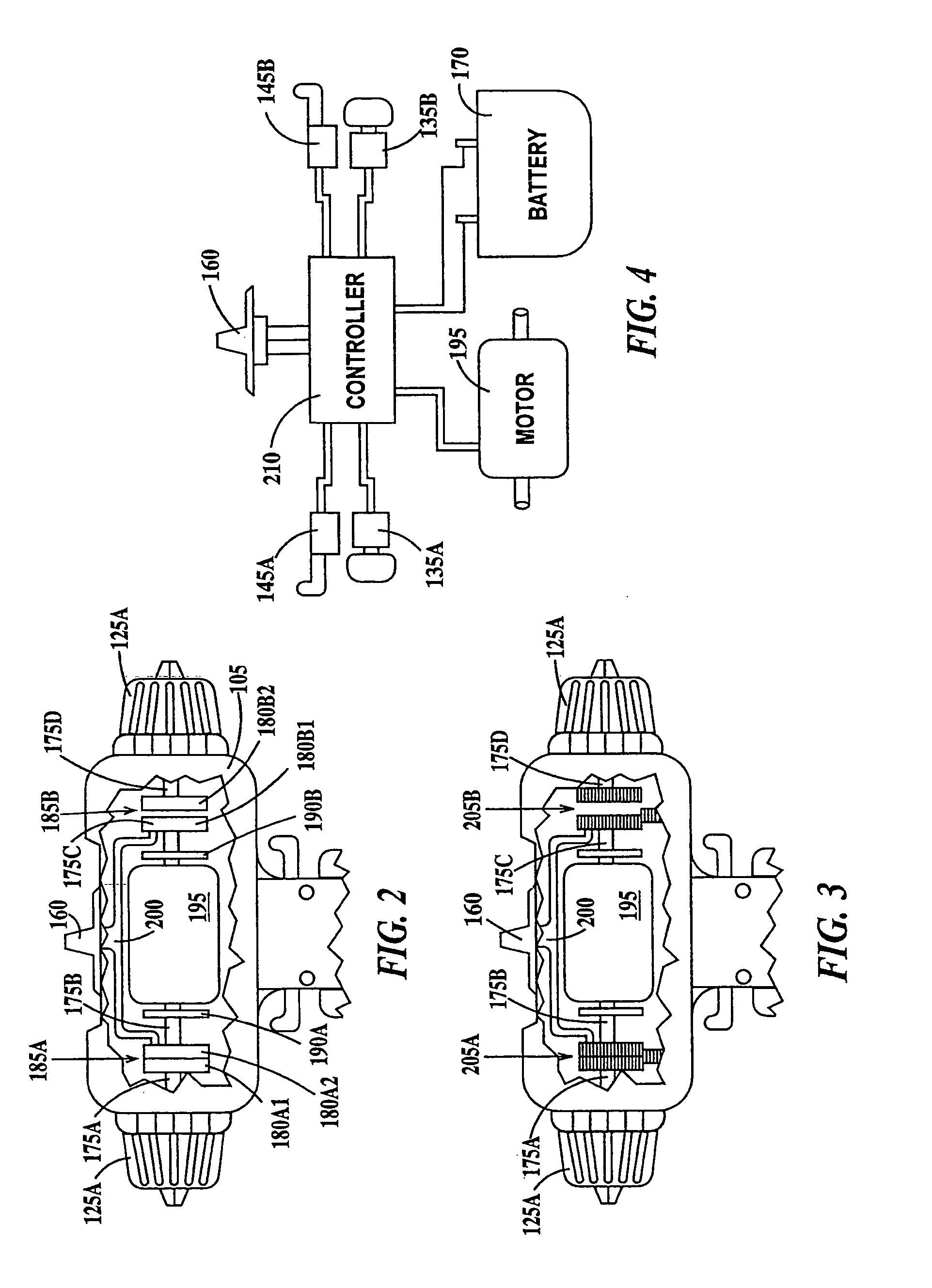

Cordless magnetic drill

InactiveUS20130108385A1Improve the safety of useImprove ease of useAutomatic control devicesDrilling/boring measurement devicesElectric machineControl cell

A cordless magnetic drill is disclosed. The drill comprises a control unit, a motor which is connected with the control unit, a gearbox which is connected with the motor, a power source which is connected with the control unit, and a magnetic base. The gear box is used for regulating the output rotation speed of the motor. The power source is used for supplying power to the motor. The magnetic base can be an electromagnetic chuck, an electro-permanent magnetic chuck, a permanent magnetic chuck or the combination of a permanent magnetic chuck and an electromagnetic chuck. The control unit is used for controlling the operations of the motor and the power source and establishing or cutting off the connection between the power source and the motor. The cordless magnetic drill of the present invention is convenient and very safe to use.

Owner:WOELDERS NIELS J

Dead spindle chucking system with sliding sleeve

A power driver may include a housing, a tool chuck and a sleeve. The tool chuck may have a chuck body mounted for rotation on the housing and supporting threadless chuck jaws, and a chuck drive shaft mounted for rotation on the chuck body. The sleeve may be mounted on the tool chuck for adjustment into a DRILL DRIVE MODE to rotationally lock together the chuck body and the chuck drive shaft, and a CHUCK MODE to rotationally lock together the chuck body and the housing.

Owner:BLACK & DECKER INC

Cutting machine

InactiveUS7249918B1Increase speedThread cutting auxillary apparatusAttachable milling devicesEngineeringMotor shaft

Cutting apparatus having a ram axis gear tube (32) equipped with internal threads engageable with external threads (48) of a main shaft (42). A tool can be fixed to the main shaft (42). The external threads (48) of the main shaft (42) are formed on external splines (44). A main shaft rotation gear (46) has internal splines (41) mating with the external splines (44) of the main shaft (42). Rotation of the ram axis gear tube 32 thus causes the main shaft (42) to move axially via the internal and external threads. Rotation of the main shaft rotation gear (46) causes rotation of the main shaft (42). The tool fixed to the main shaft (42) can thus undergo axial and rotational movements. A motor (74) can be coupled to main shaft (42) and a motor shaft (63) extended through the ram axis gear tube (32) and the main shaft (42). The motor shaft (63) can drive a linear gear (68) of a cross slide assembly (24) and thus radially move a tool fixed to the cross slide assembly (24).

Owner:BOWMAN THOMAS W

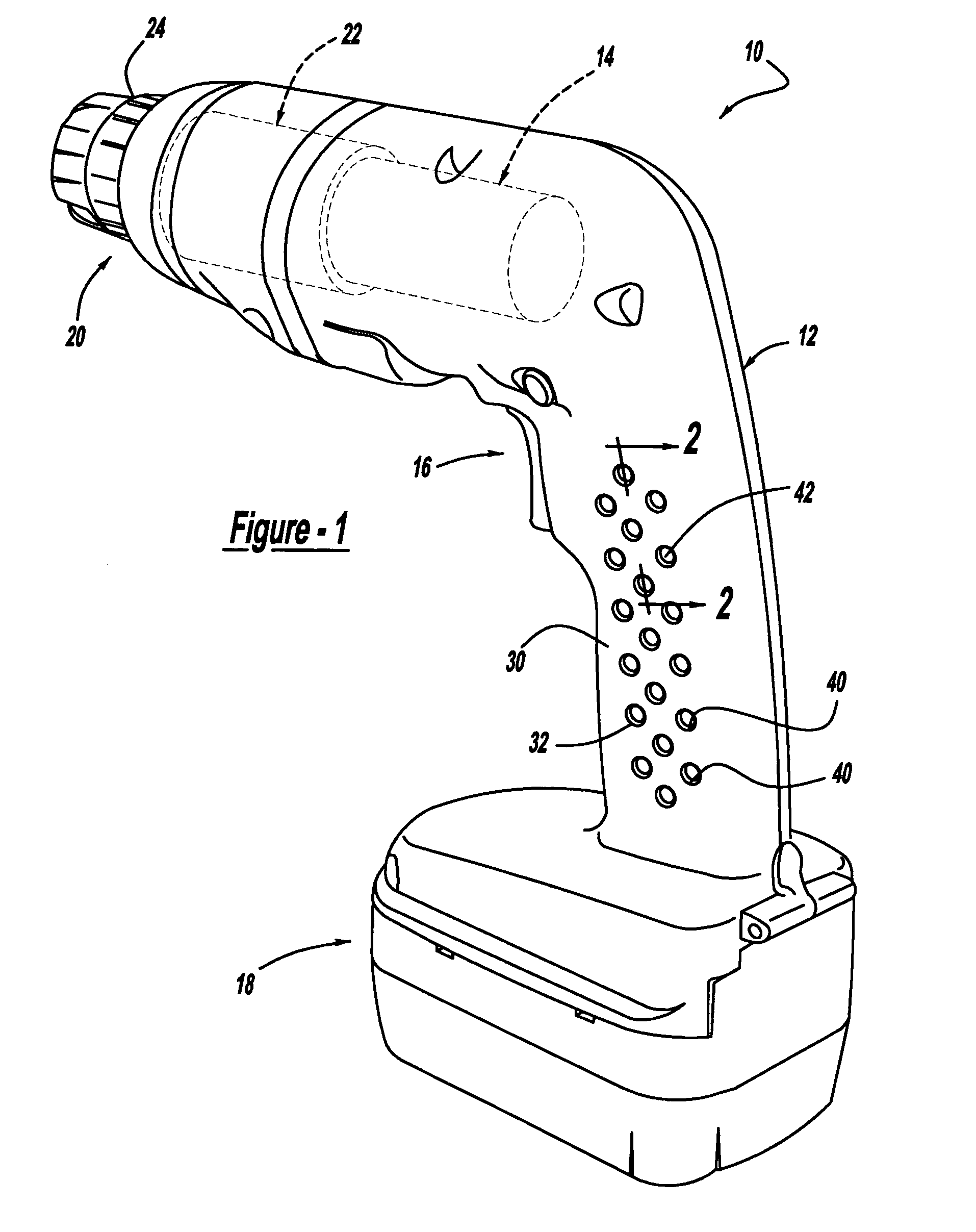

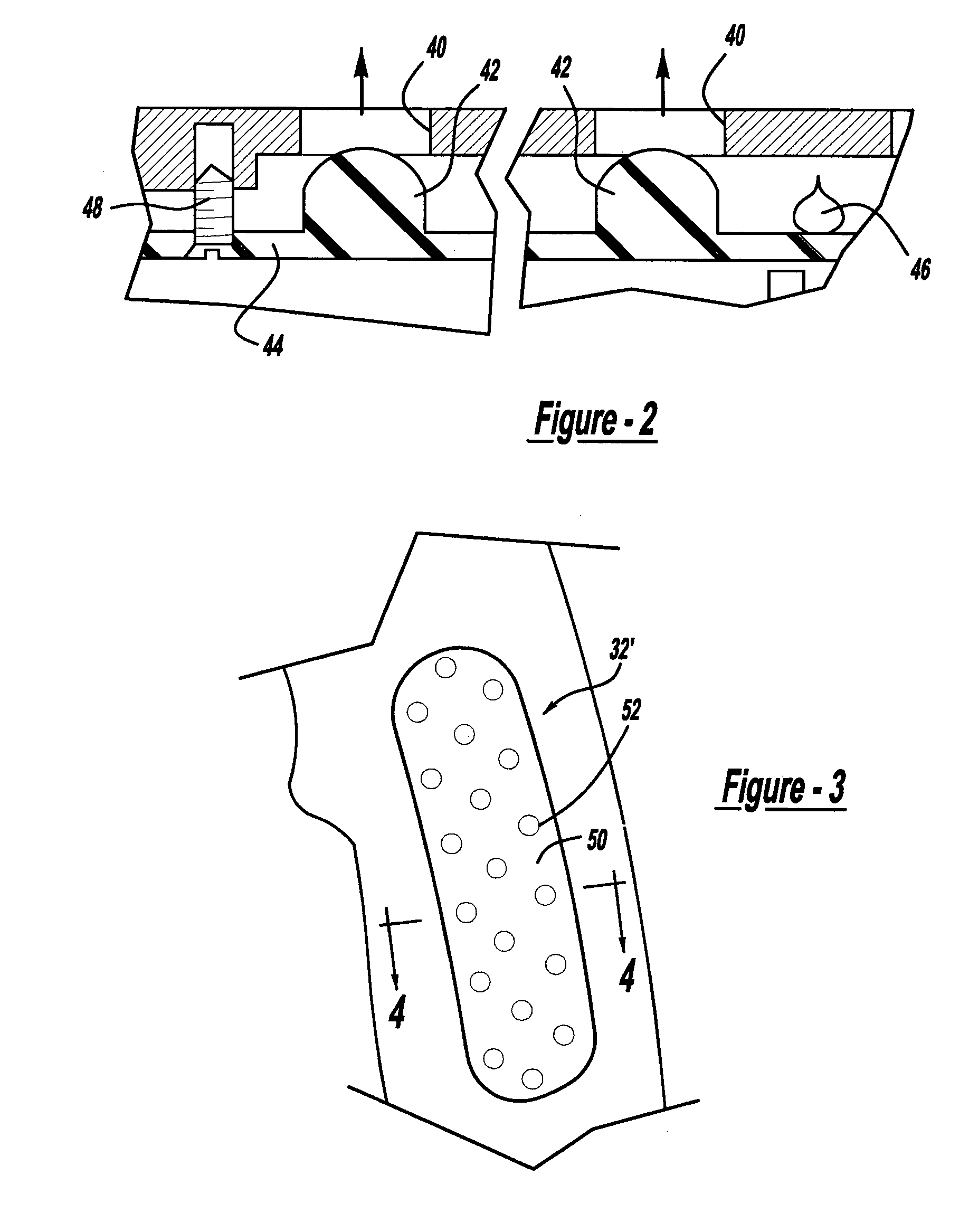

Power tool with integral gripping member

A power tool has a housing with at least one aperture in the housing. A gripping member is positioned with respect to the outer surface of the housing such that the gripping member is contacted by a user when the power tool is used. At least one member is coupled with the gripping member. The at least one member extends through the at least one housing aperture to enable the gripping member to be positioned with respect to the outer surface of the housing.

Owner:BLACK & DECKER INC

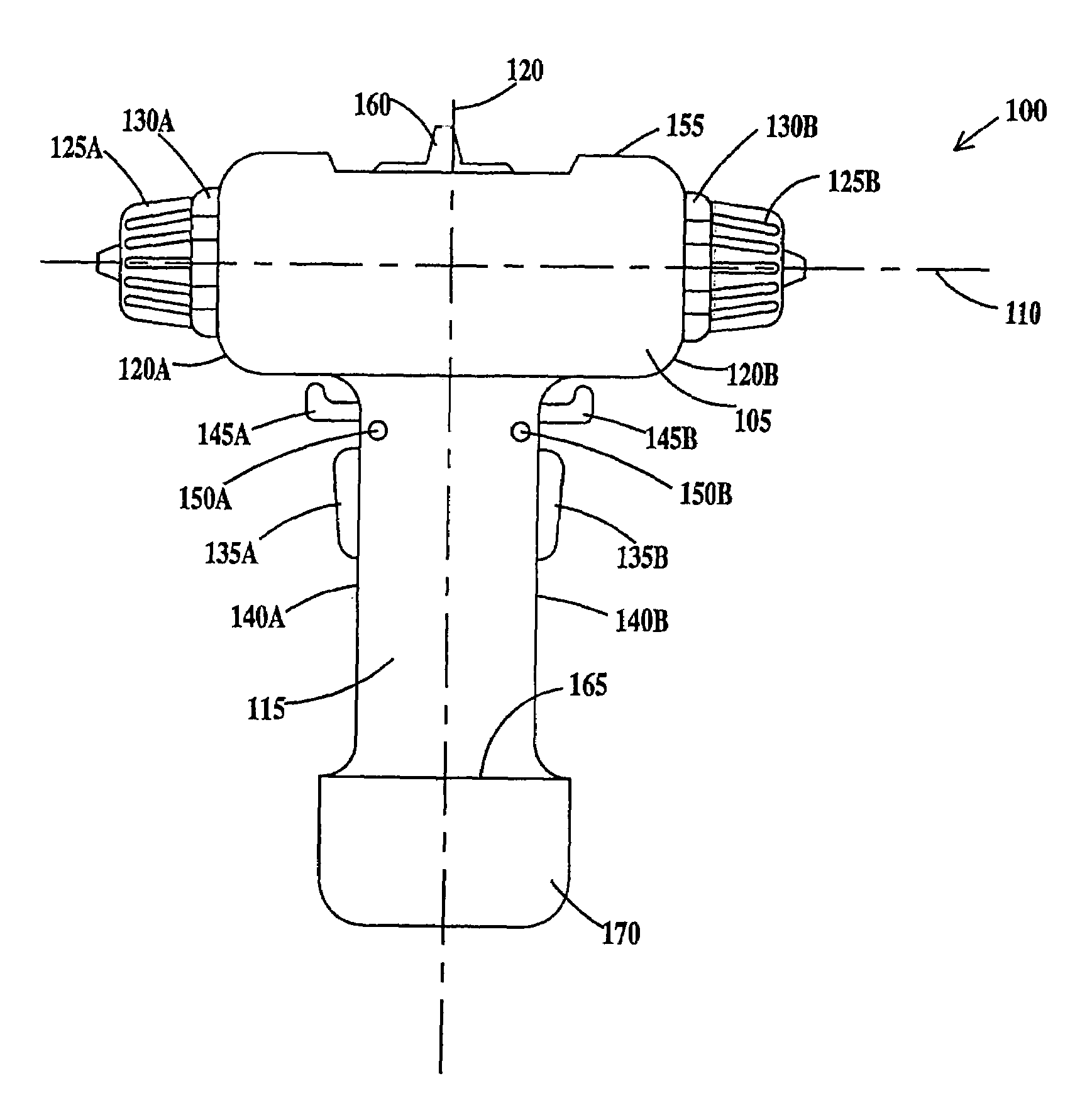

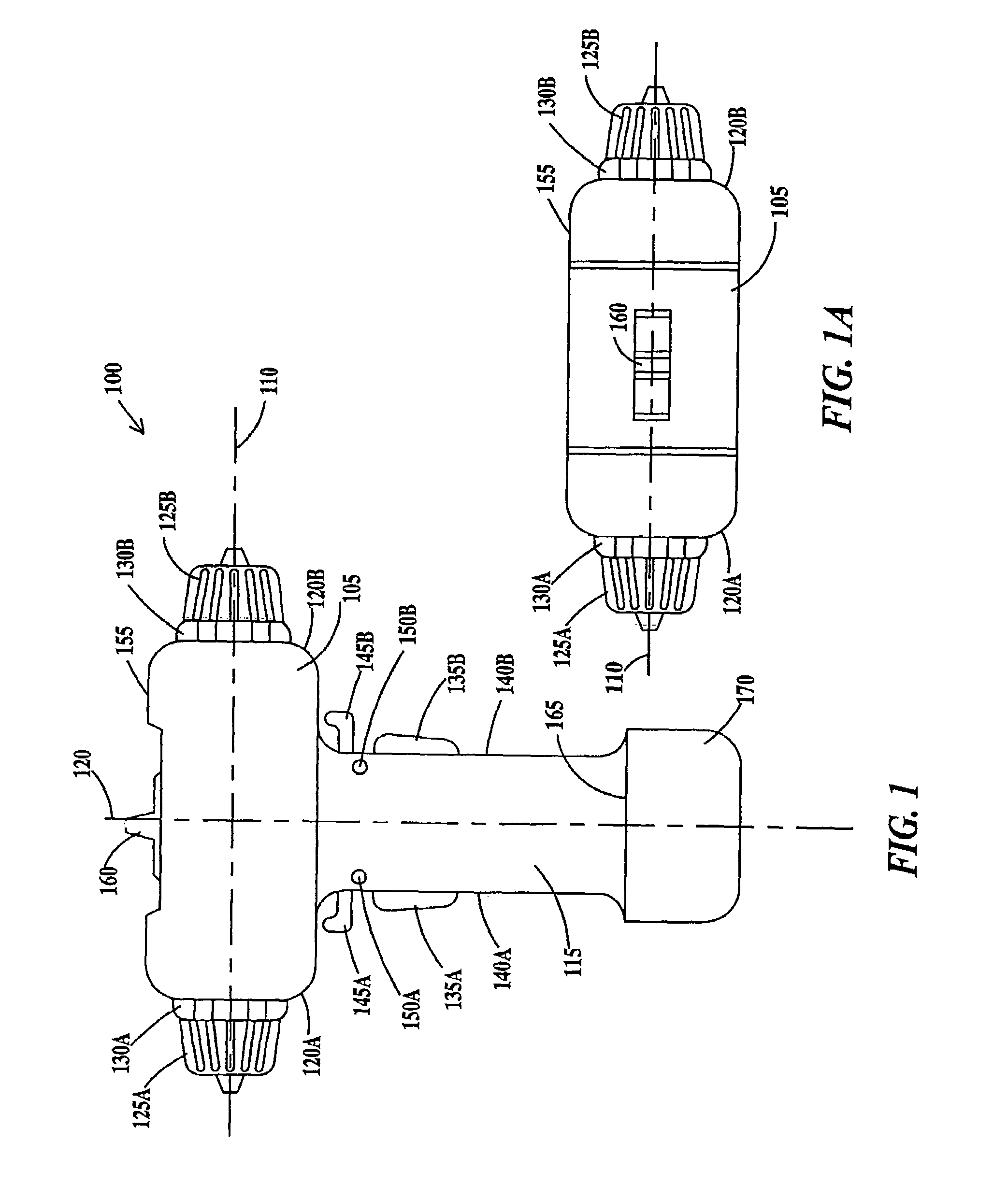

Dual chuck electrical hand drill

A drill comprising: a power head having a first chuck positioned on a first end and a second chuck positioned on an opposite second end of the power head; a handle attached to the power head, the handle having a trigger switch for controlling a drive motor coupled to the first and second chucks.

Owner:KUHN JAYME K

Hand-held tool with a removable object sensor

A hand-held power tool is provided with a housing, an attachment member, and an object sensor that is removable from the attachment member. The attachment member may be removable from the tool. The object sensor, which can be used to detect studs hidden behind walls, electrical lines, and other materials, is readily accessible to tradesmen.

Owner:ONE WORLD TECH

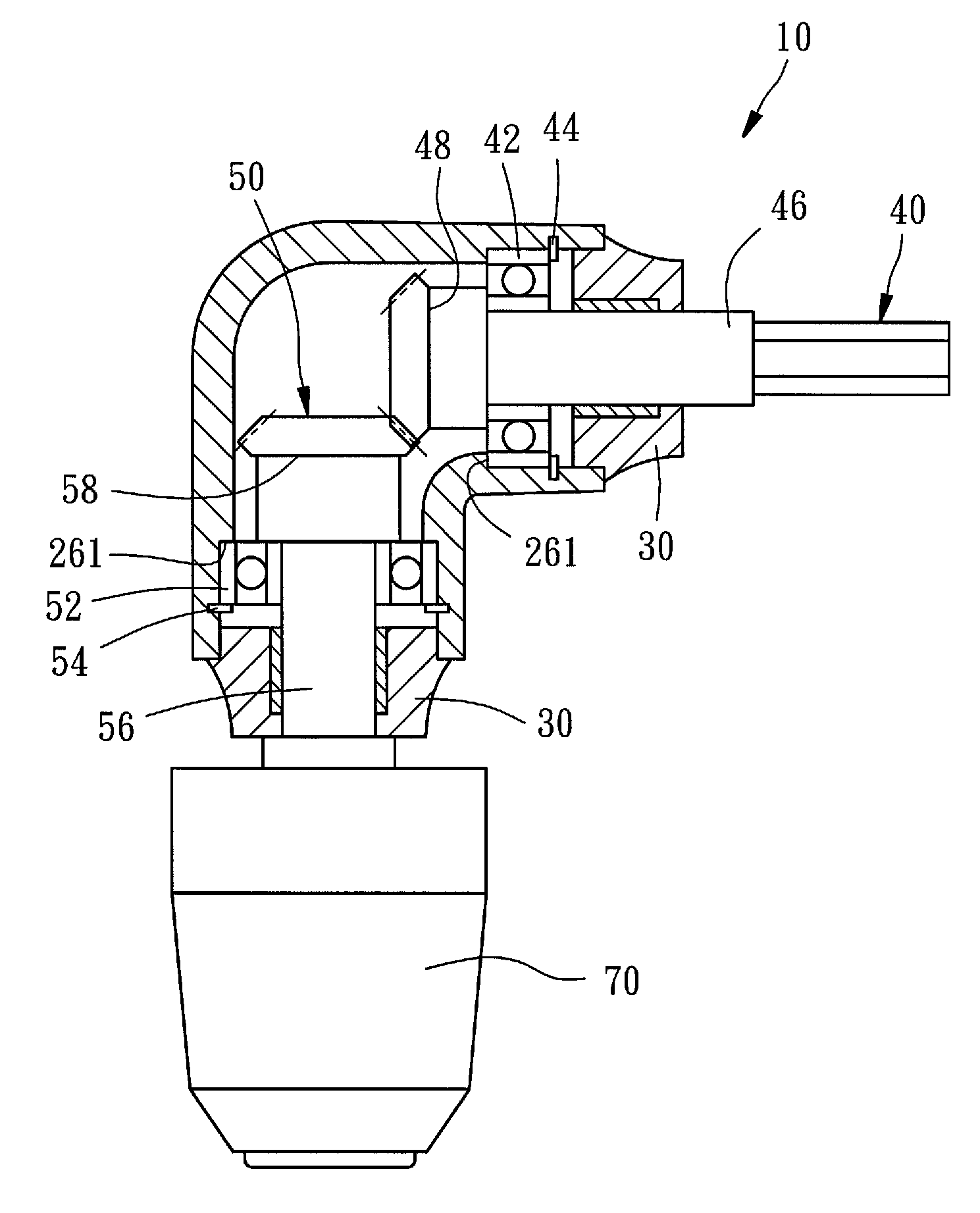

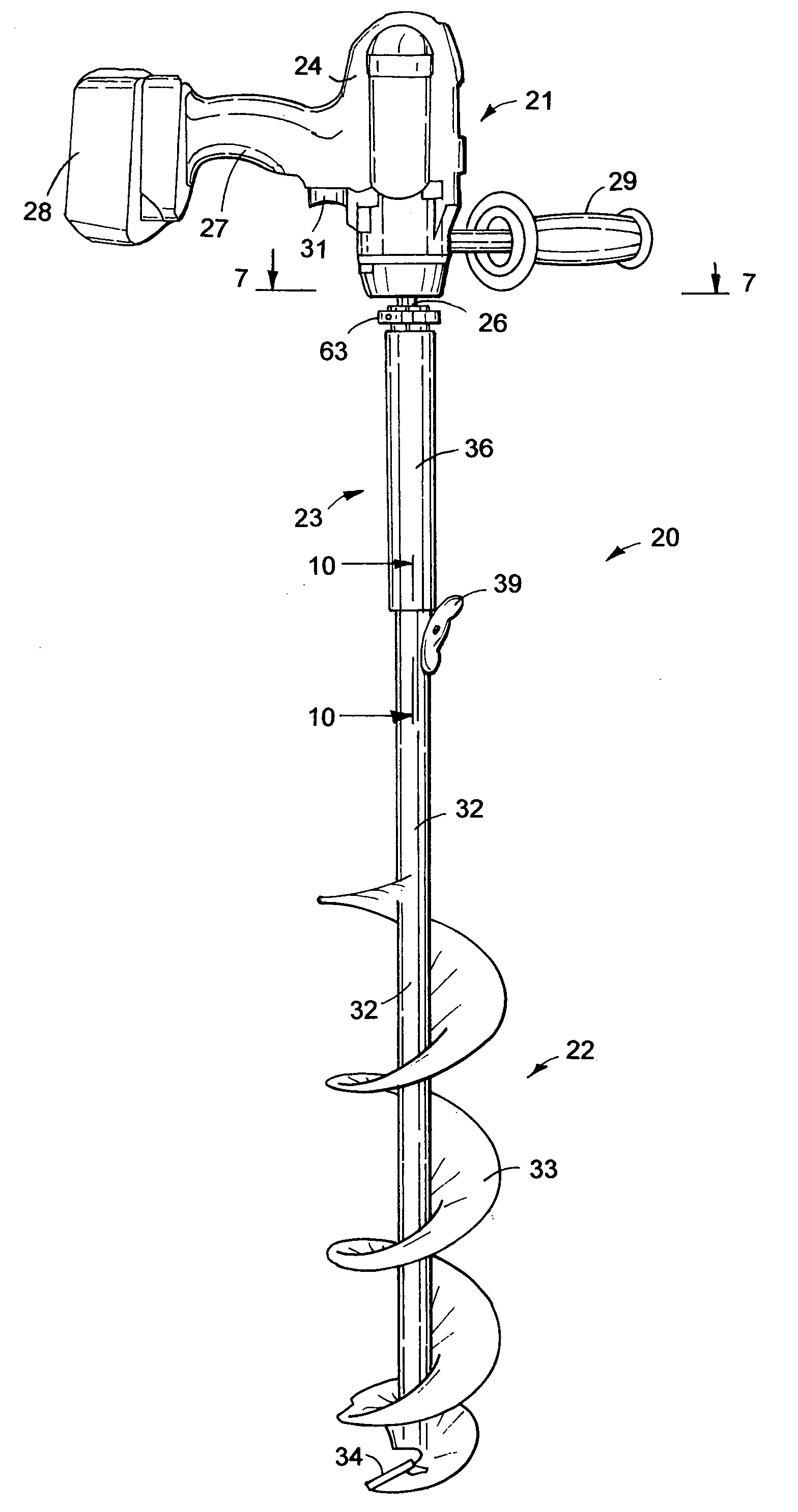

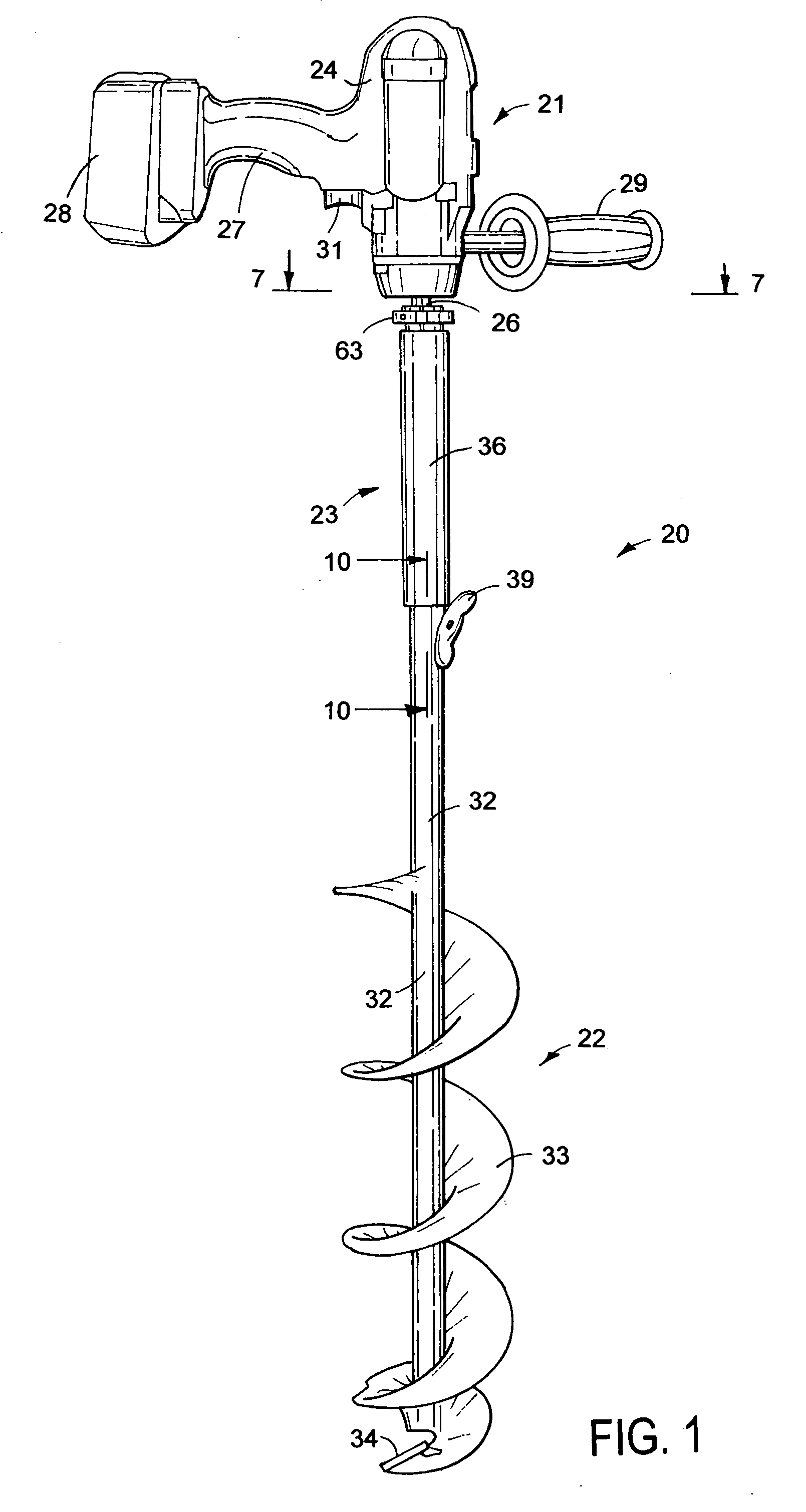

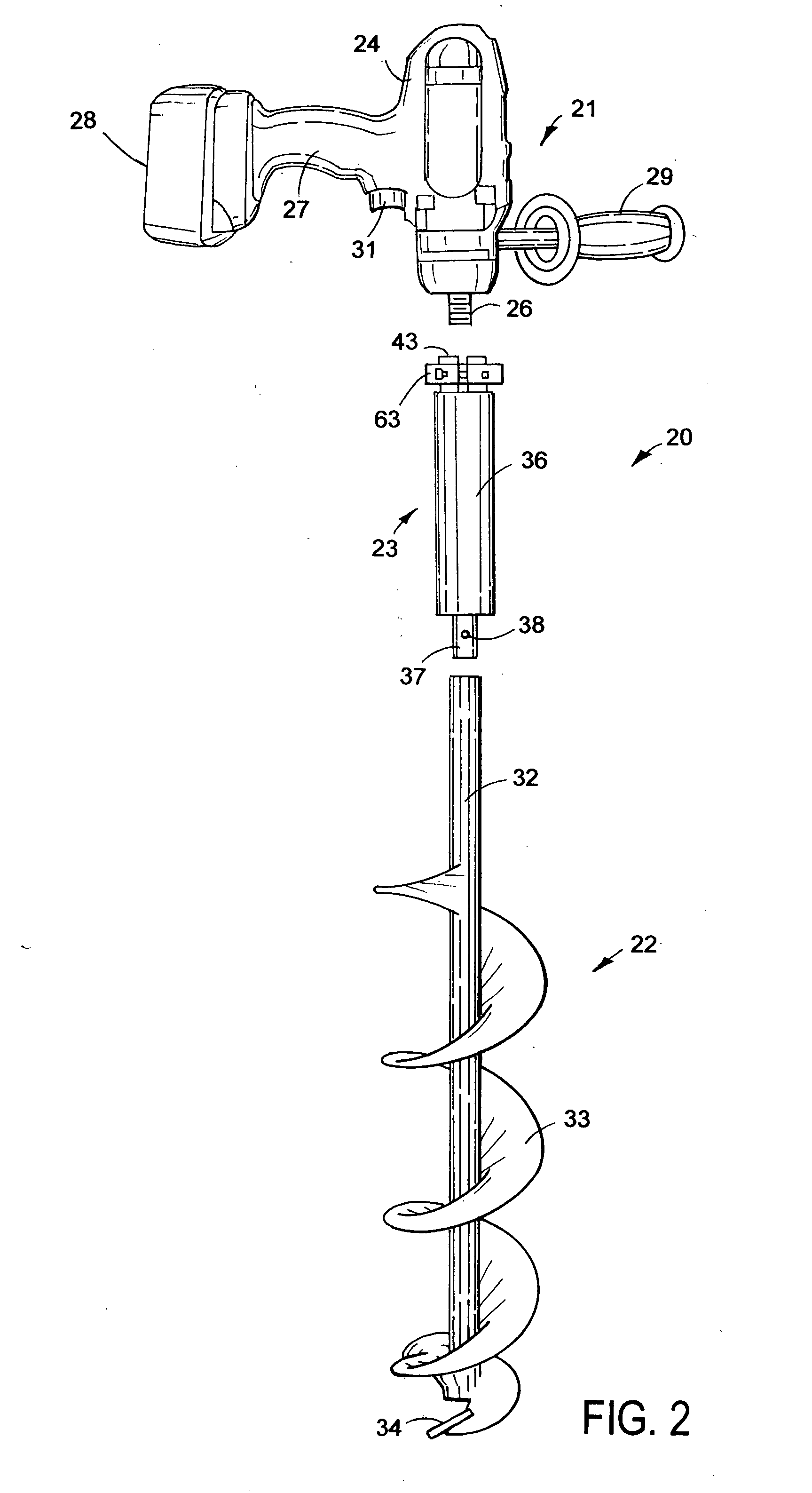

Spindle drive coupling

InactiveUS20100074702A1Light weightAvoid accidental separationConstructionsThread cutting auxillary apparatusDrive shaftCoupling

A spindle drive coupling releasably connects a cordless electric motor to an auger assembly used to drill holes in ice on a body of water. The coupling has a sleeve supporting a split head onto the drive shaft of the motor with a clamp assembly.

Owner:KLUGE DOUGLAS J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com