Patents

Literature

661results about "Attachable milling devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

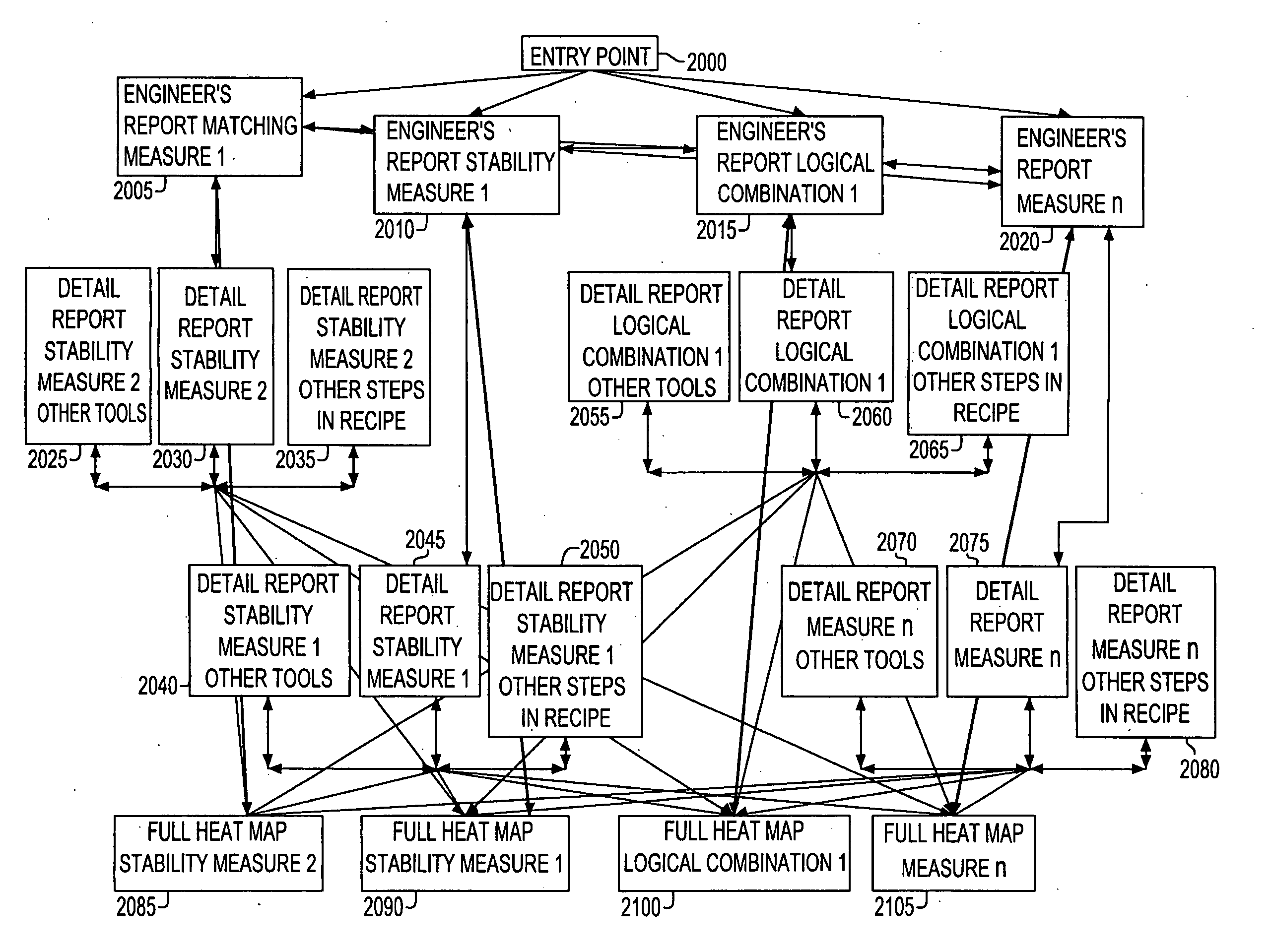

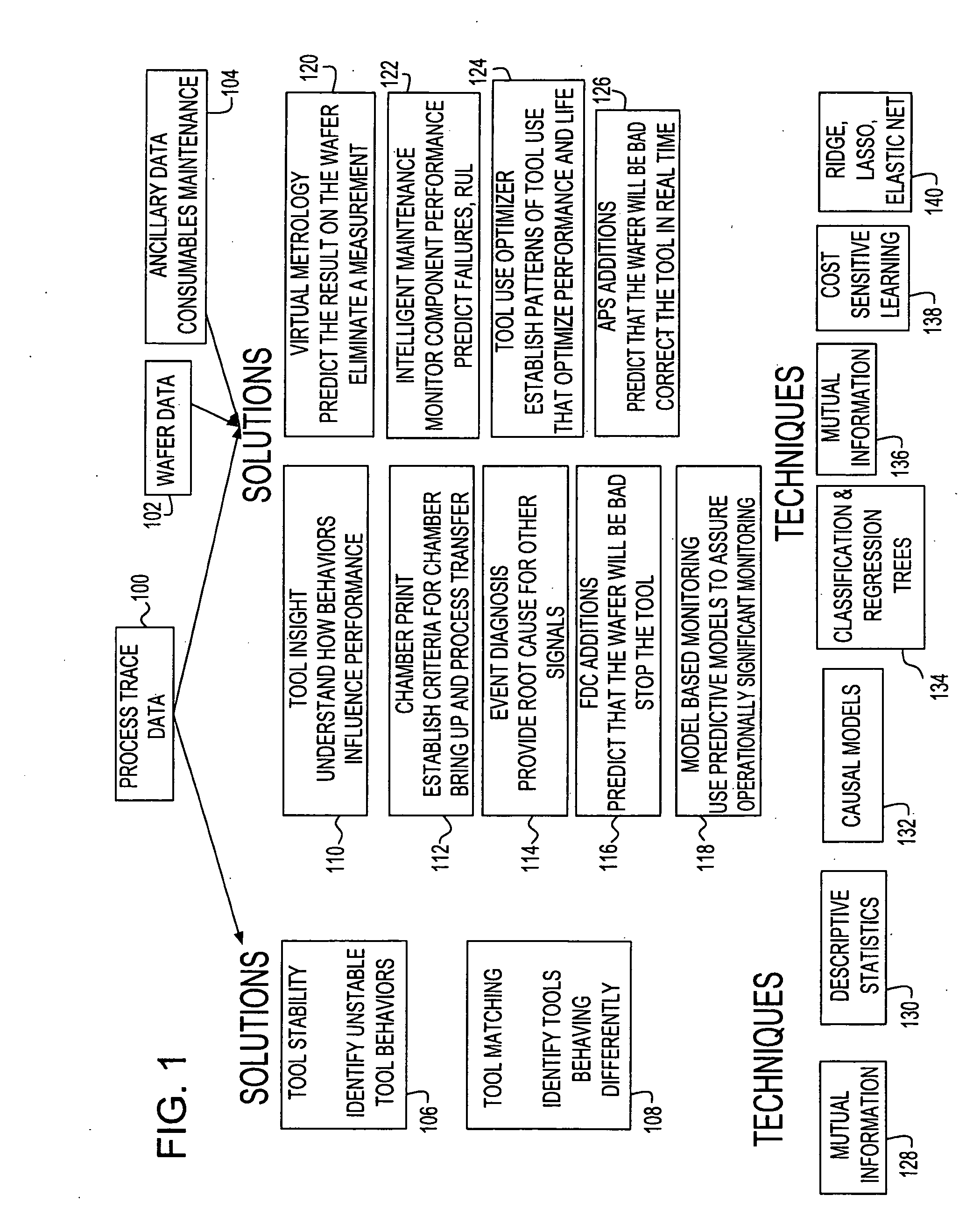

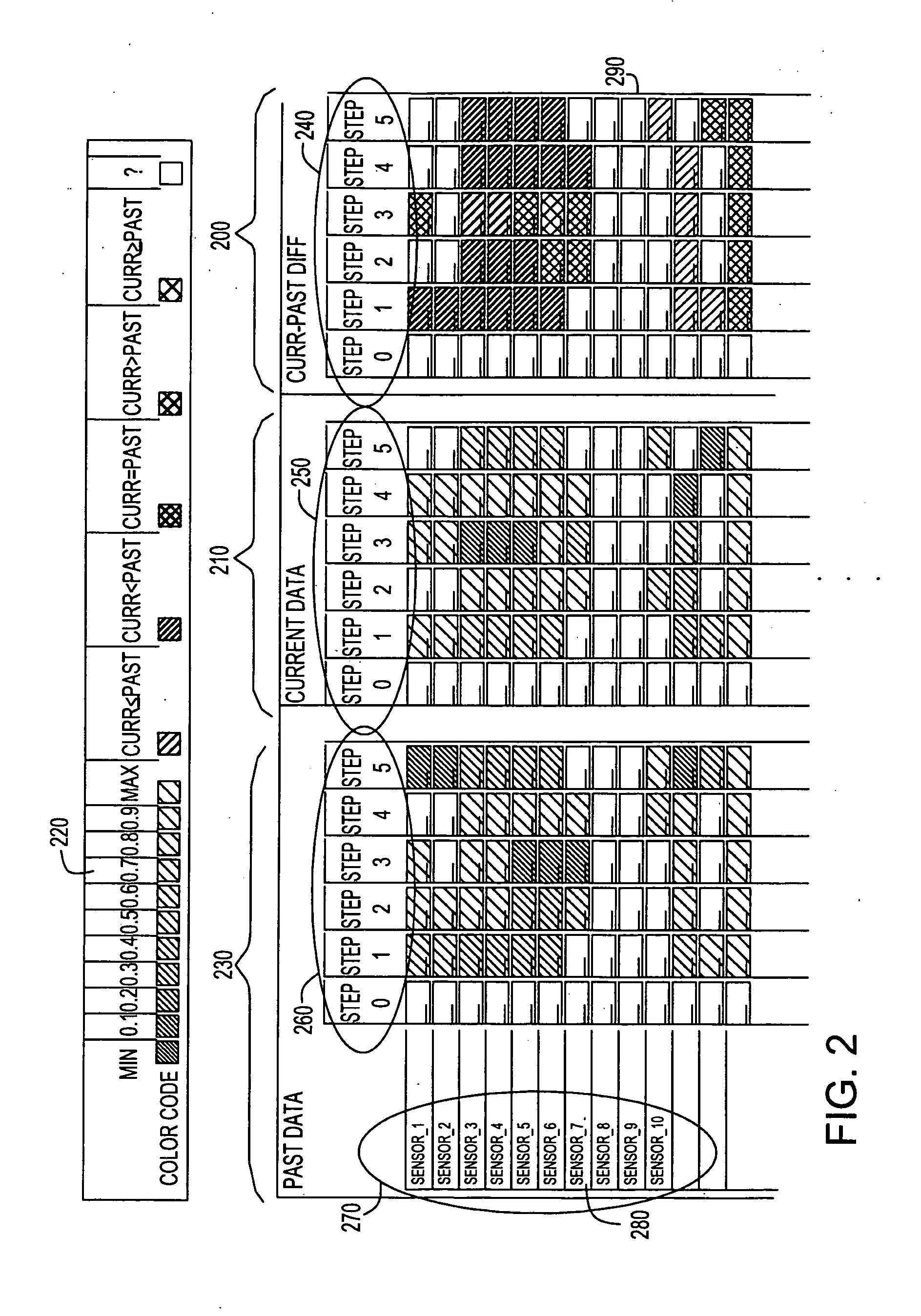

Method and system for evaluating a machine tool operating characteristics

A method and system for evaluating a performance of a semiconductor manufacturing tool while manufacturing microelectronic devices are disclosed. At least one report is generated based on executions of at least one statistical test. The report includes at least one heat map having rows that correspond to sensors, columns that correspond to trace data obtained during recipe steps, and cells at the intersection of the rows and the columns. At least one sensor in the tool obtains trace data of a recipe step while manufacturing at least one microelectronic device. A computing device analyzes the obtained trace data to determine a level of operational significance found in the data and assigns a score to the trace data that indicates a level of operational significance. Then, the computing device places the score in a corresponding cell of the heat map. A user uses the cell for evaluating the tool performance.

Owner:GLOBALFOUNDRIES INC

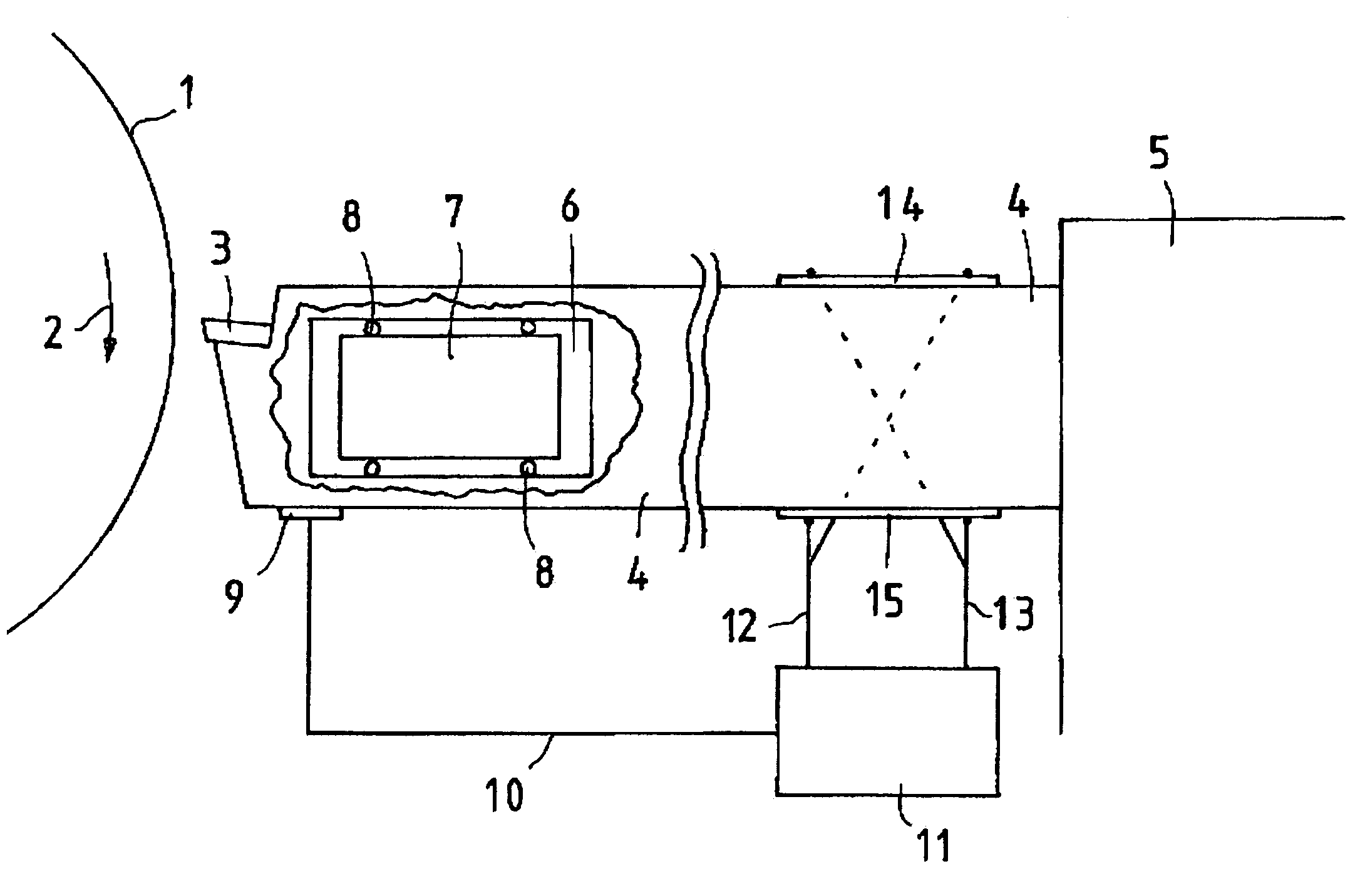

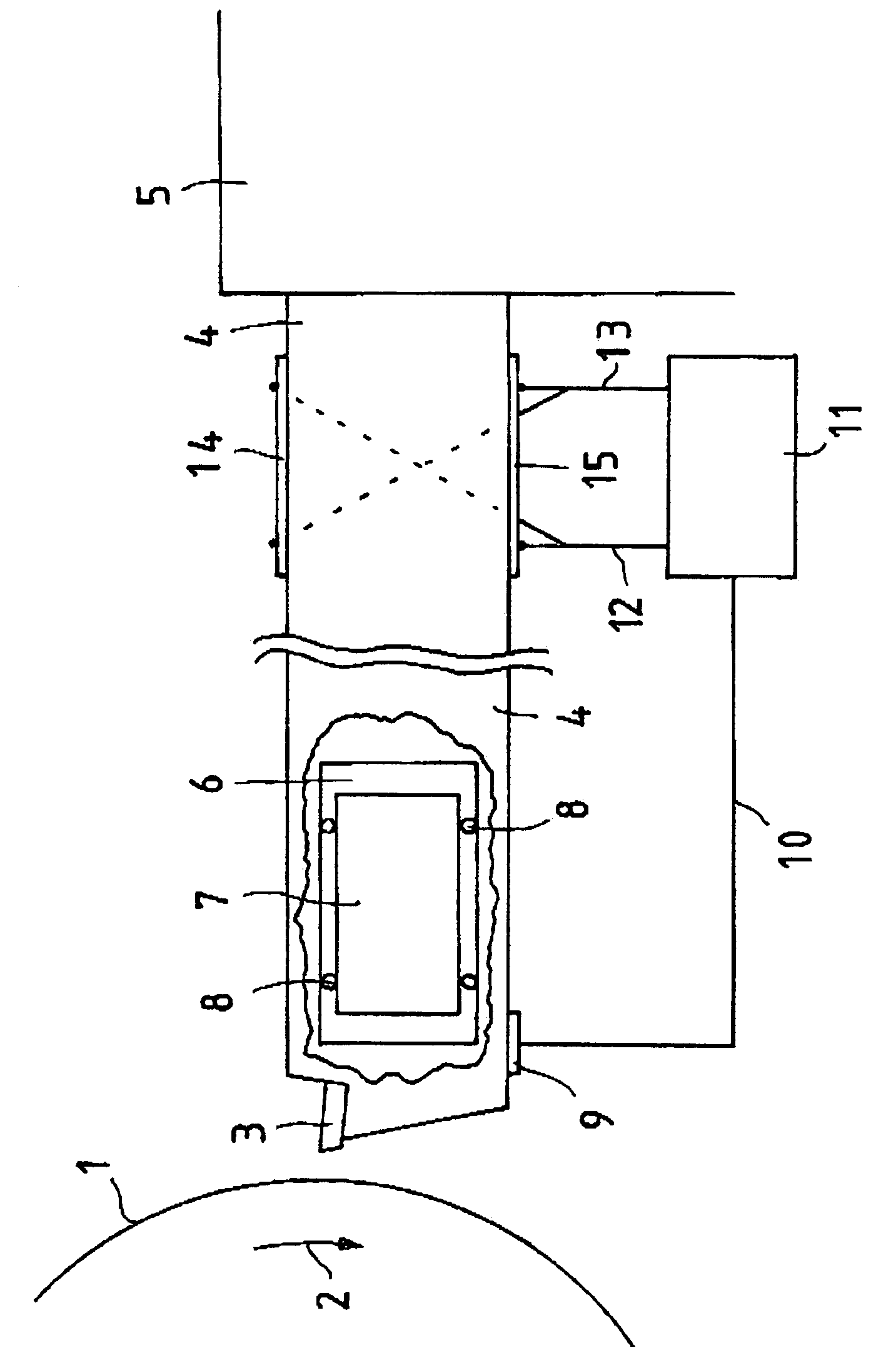

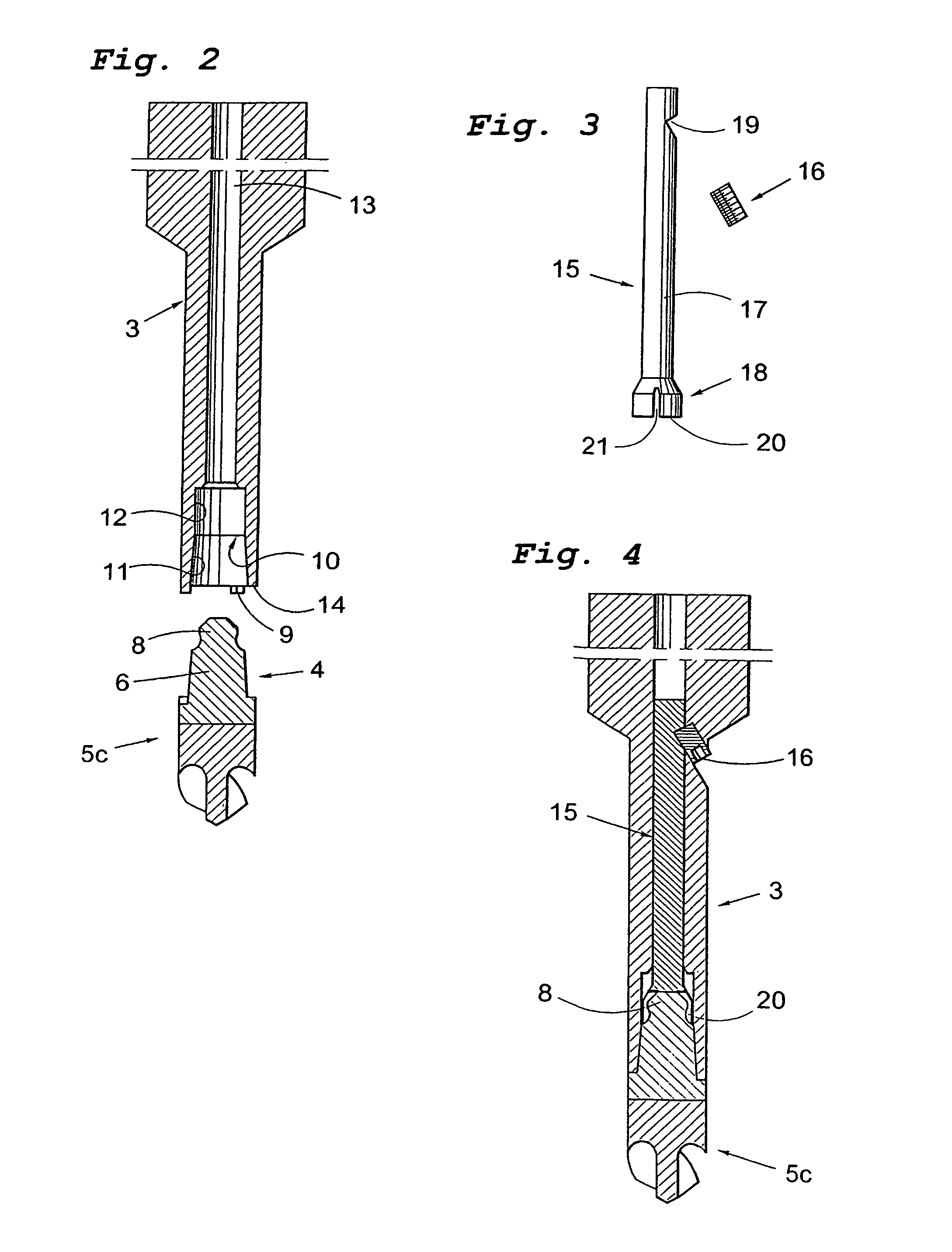

Device and a method for preventing or reducing vibrations in a cutting tool

An arrangement for reducing vibrations in a tool holder (4) with a cutting tool (3) and has a vibration sensor on the tool holder (4) that is connected to a guide unit (11). The tool holder (4) has further two piezo-electric actuators 14 and 15.Under the influence of the vibration sensor (9), the guide unit (11) provides an electric alternating current that is actively guided over time so that the actuators movably affect the tool holder (4) to reduce the vibrations in this. To also be able to dampen transients in the tool holder (4) this is movably connected with a passive dampening arrangement that is independent of the guide unit (11) and that is based on the principle of a springing (8) suspended mass (7). The invention also relates to a method for reducing vibrations. The vibrations in the tool holder are sensed and a corresponding signal is provided to a guide unit that over time provides actively guided signals to the actuators. The tool holder is also passively influenced by a dampening arrangement that is independent of the guide unit.

Owner:CLAESSON INGVAR +4

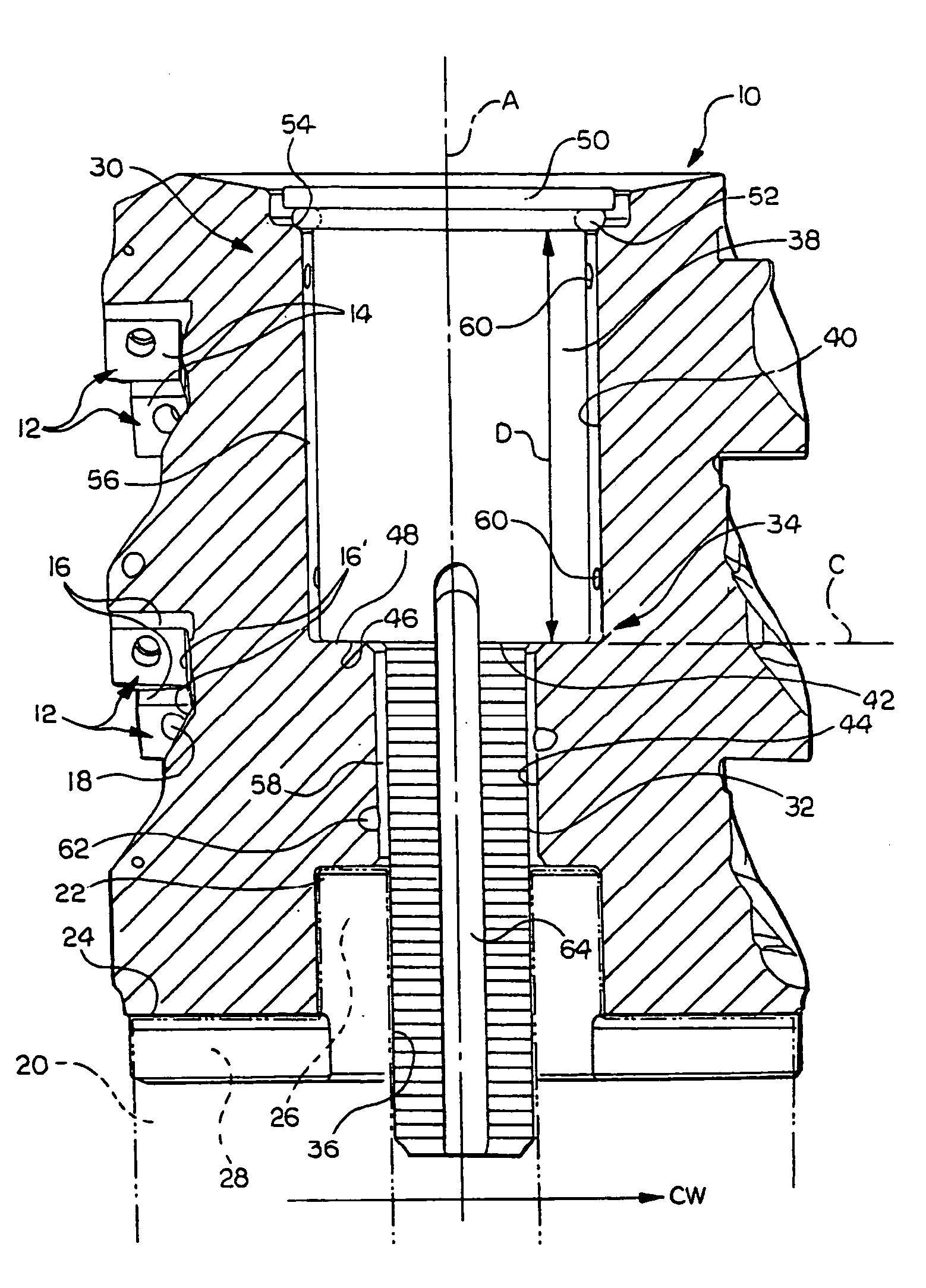

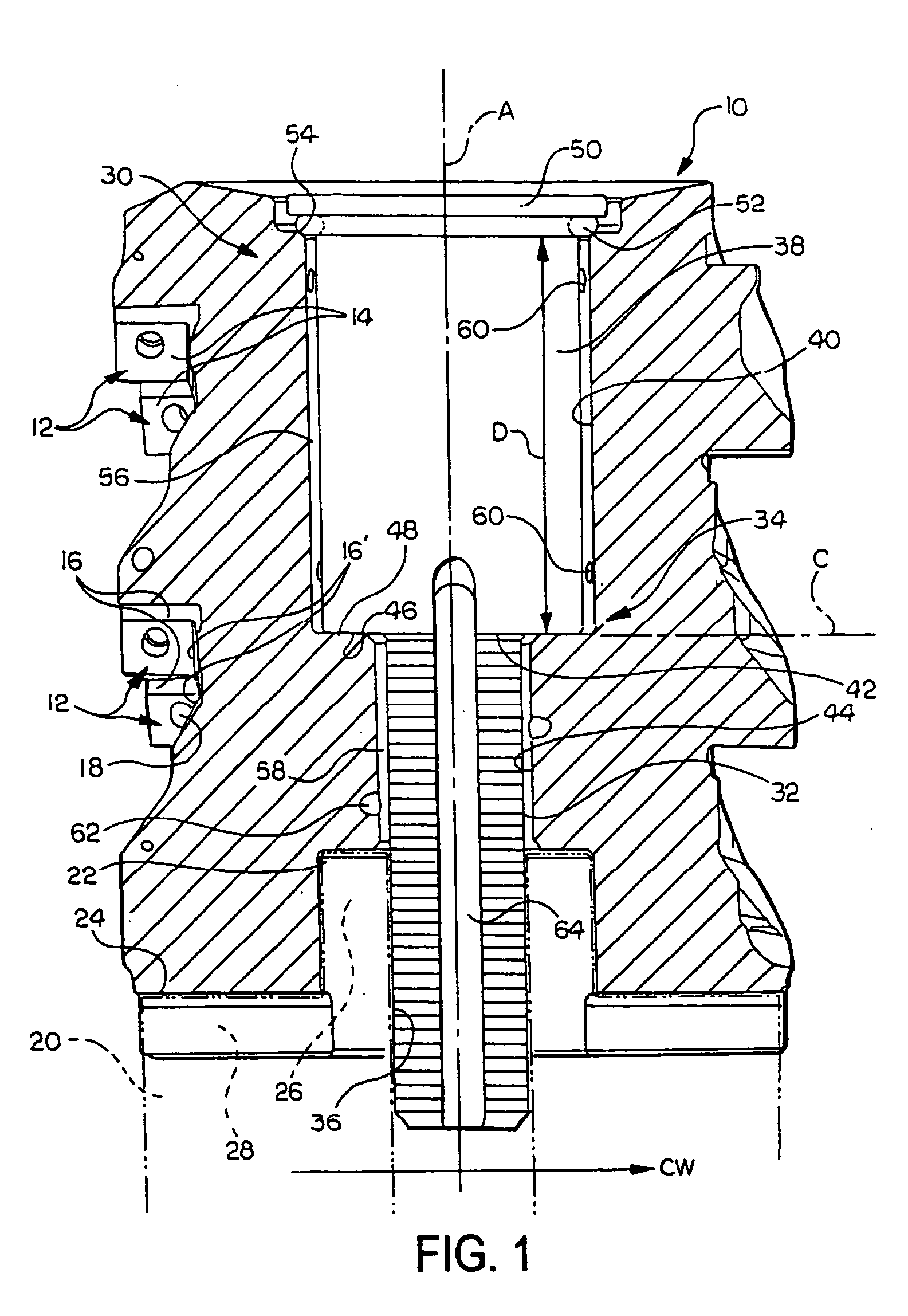

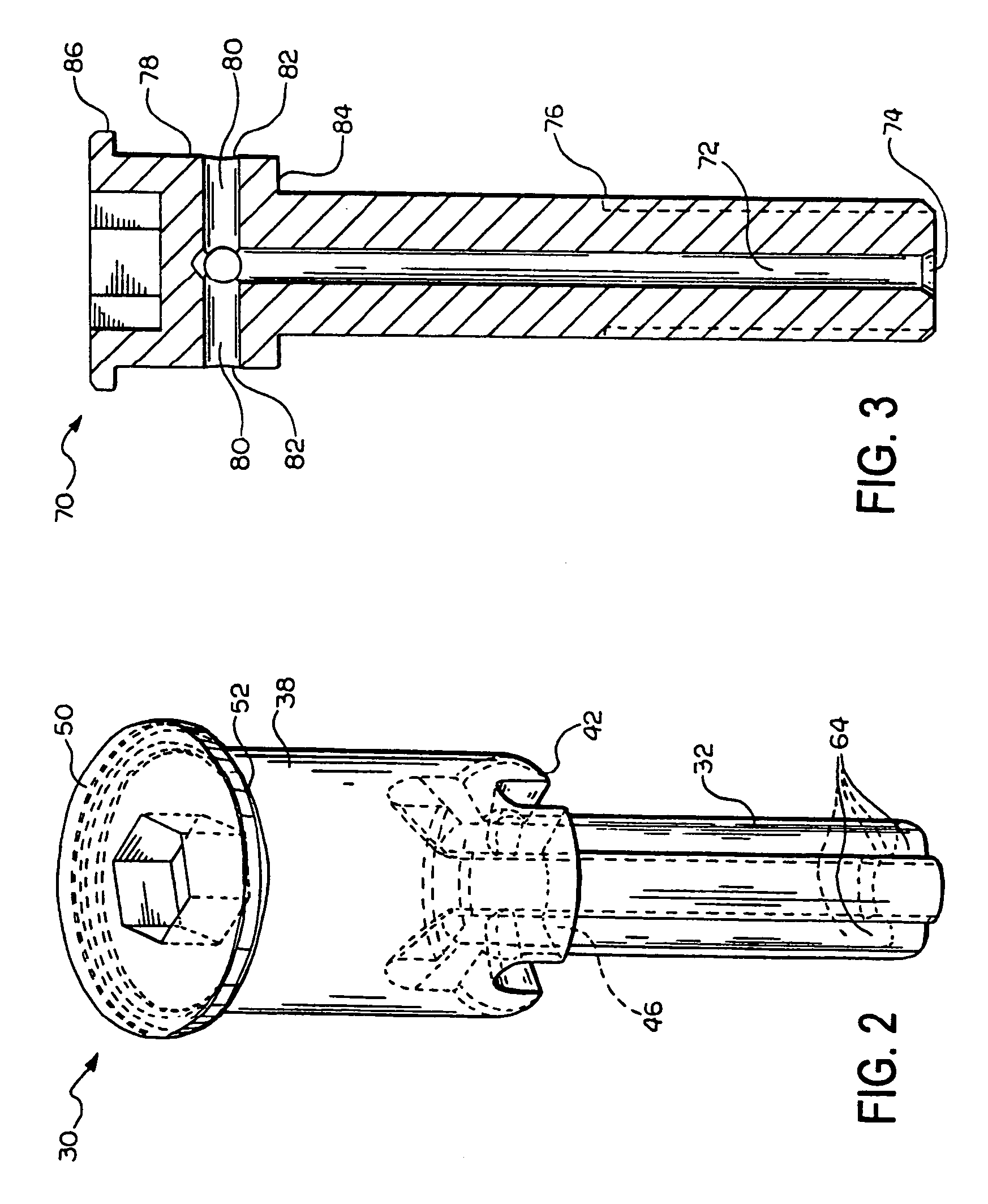

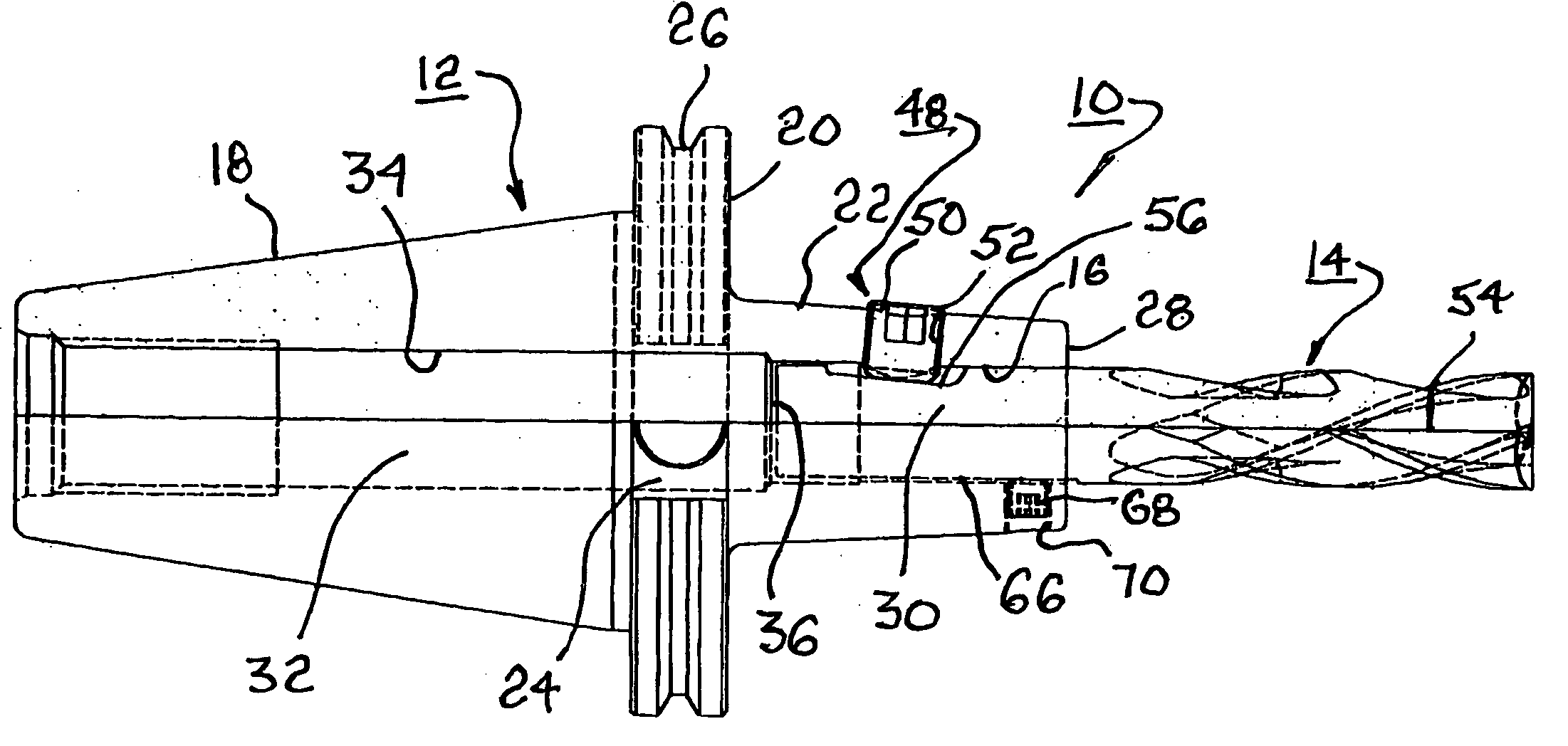

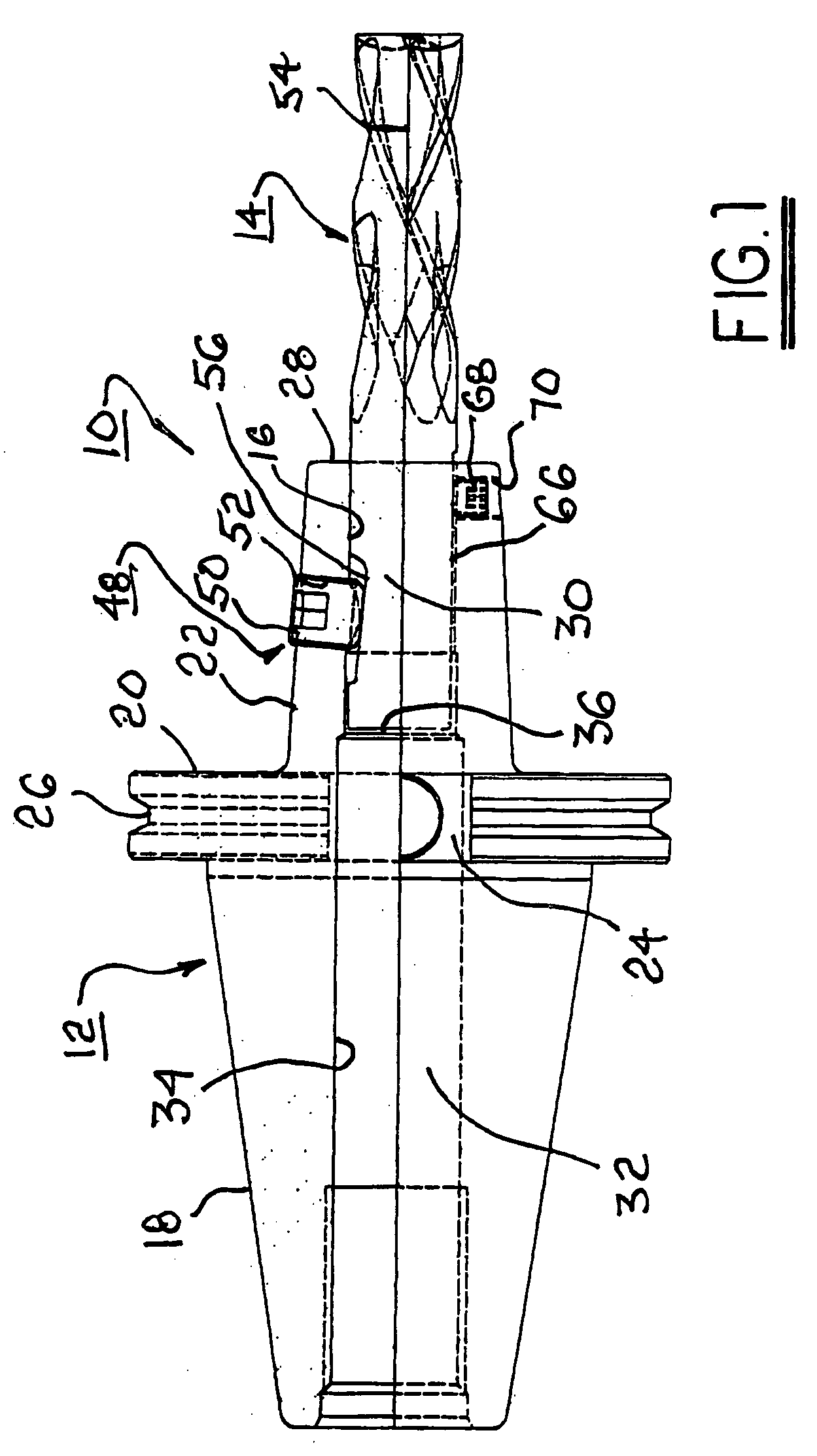

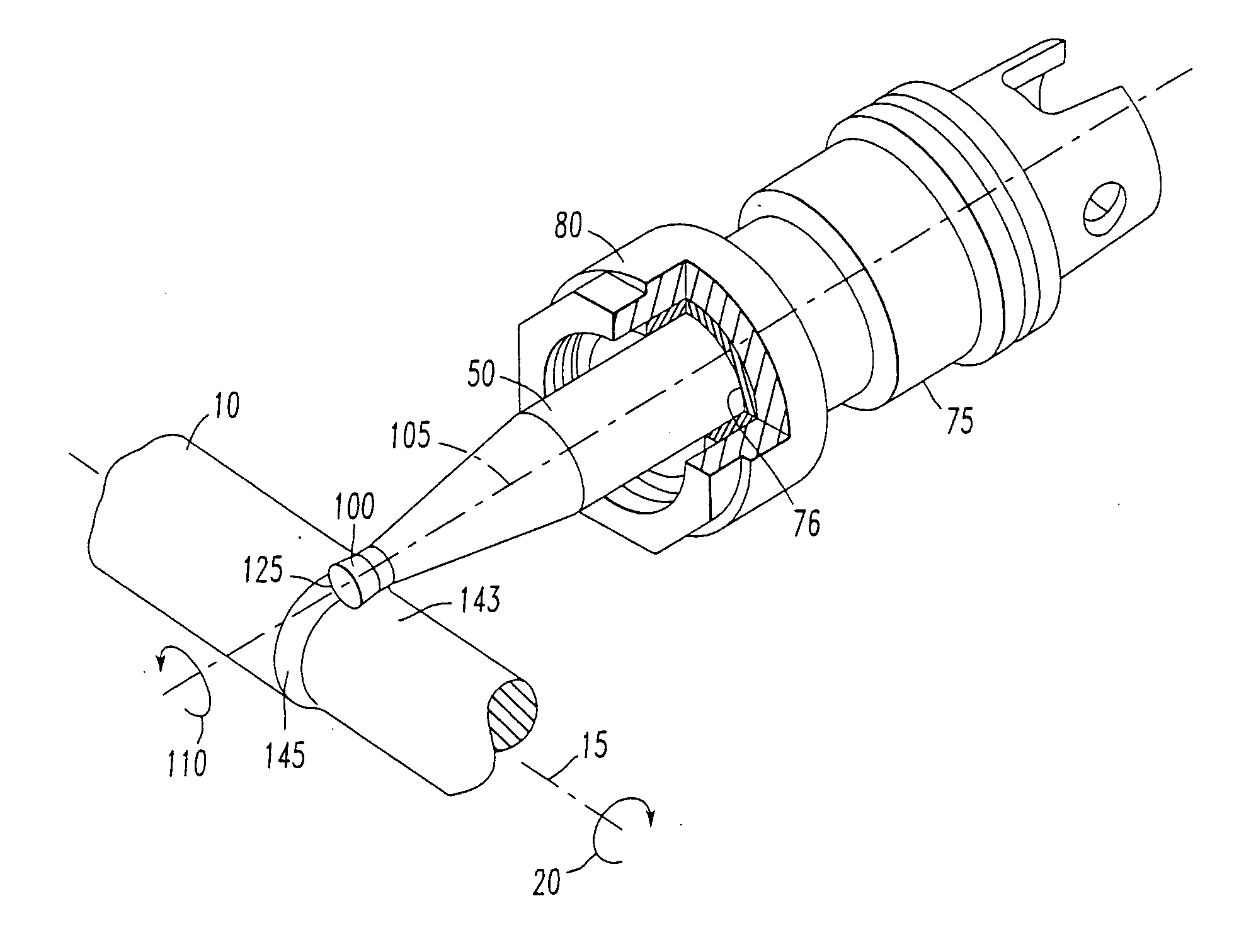

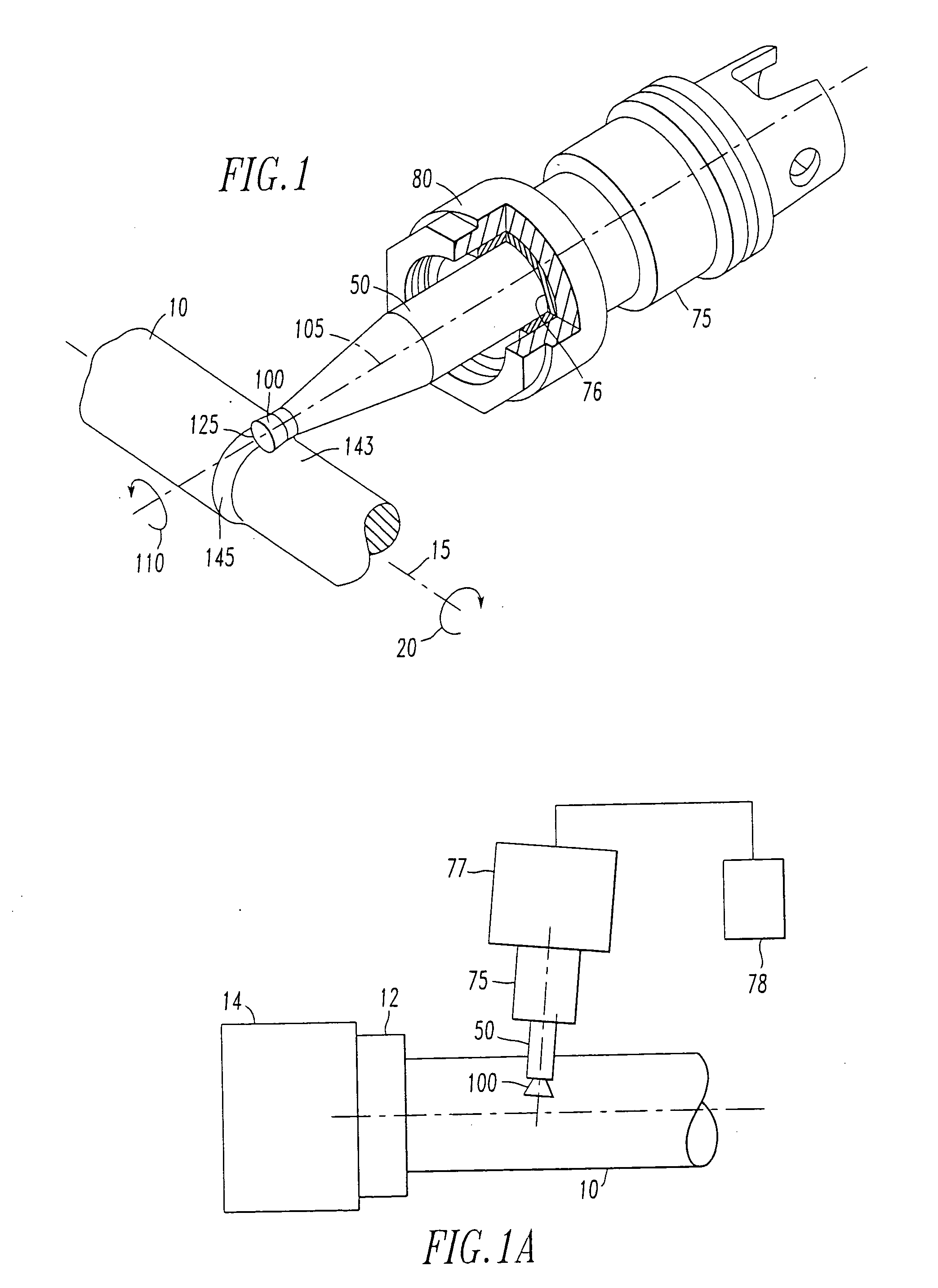

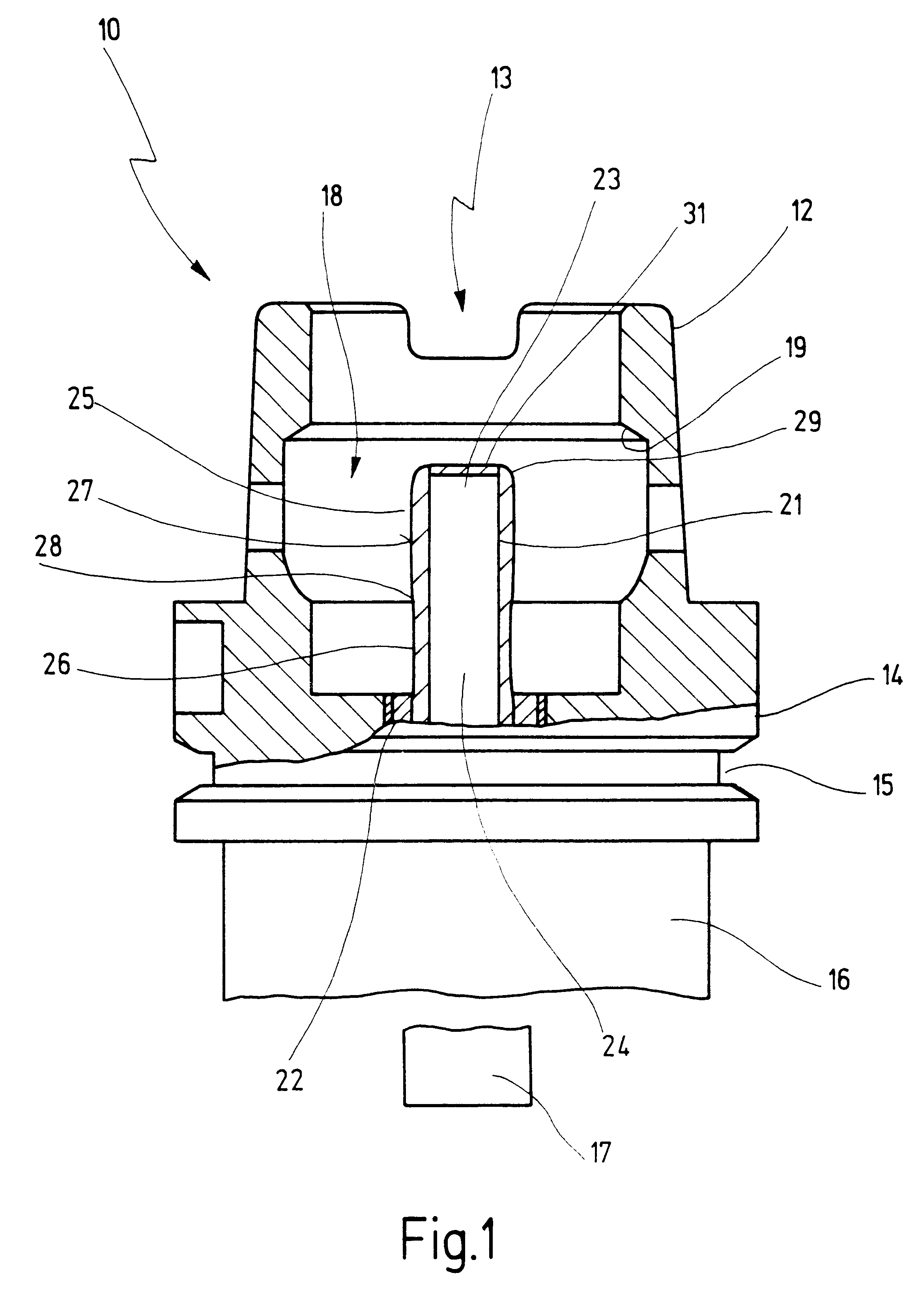

System for mounting a machine tool in a tool holder

InactiveUS20050238451A1Accurate centerAvoid turningSleeve/socket jointsTransportation and packagingSet screwEngineering

A system for mounting a tool in a tool holder combining a means for high-precision centering of the tool and a means for positive restraint of the tool from rotation within the tool holder. The tool holder includes a cylindrical aperture having a diameter slightly less than the diameter of the shank of a cylindrical tool. The tool is installed into the tool holder by heating the tool holder to a temperature sufficient to increase the pocket diameter sufficiently to accept the tool shank. In a first shrink-fit embodiment, the tool shank is further provided with an angular flat for engagement with a set screw to prevent the tool from being turned in the holder in use. In a second shrink-fit embodiment, a groove extending partially around the tool receives a tangential pin through a passage in the tool holder. The tool is rotated in the holder until the pin binds in the groove, thus preventing any further rotation of the tool in the holder during use.

Owner:PARLEC

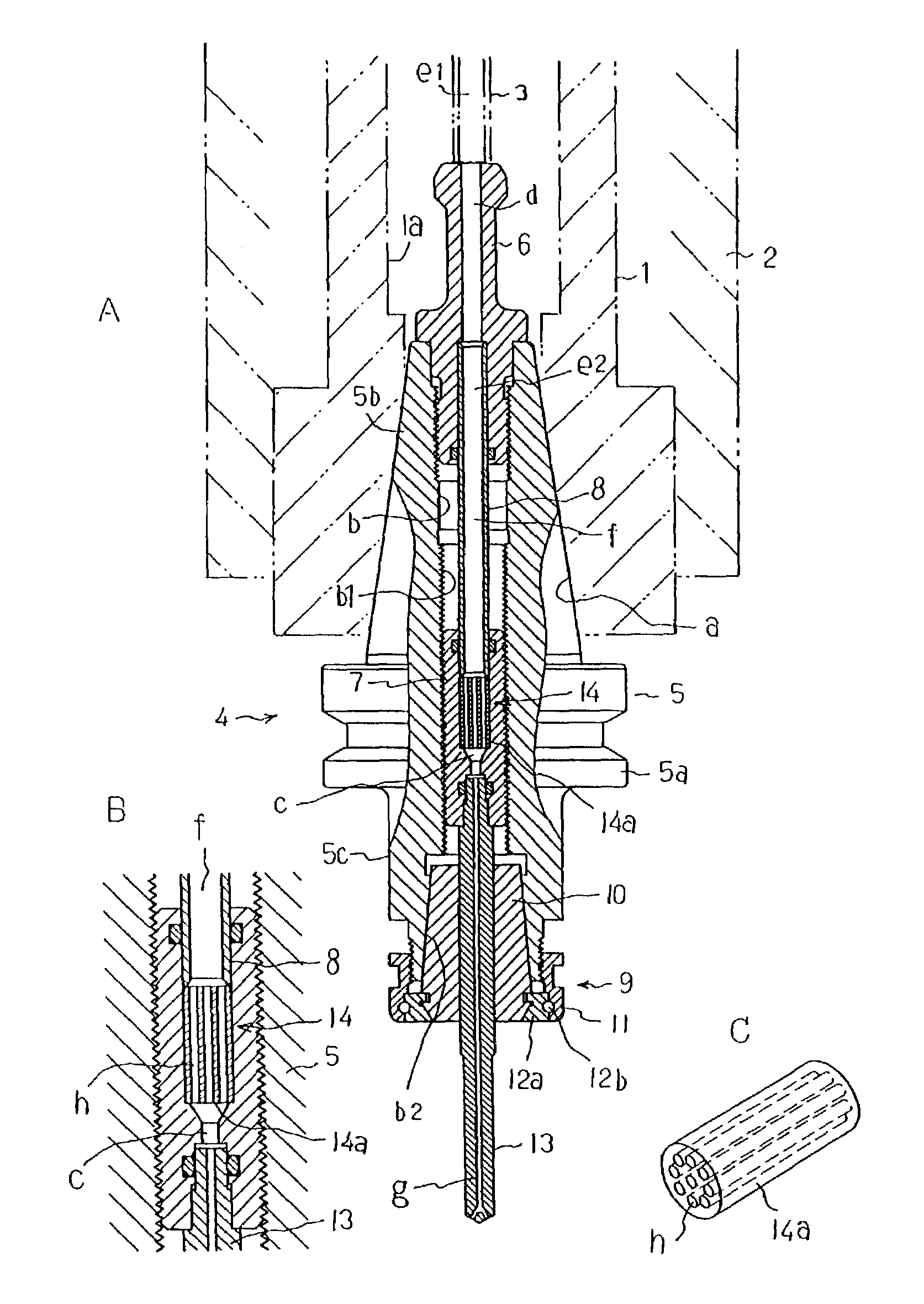

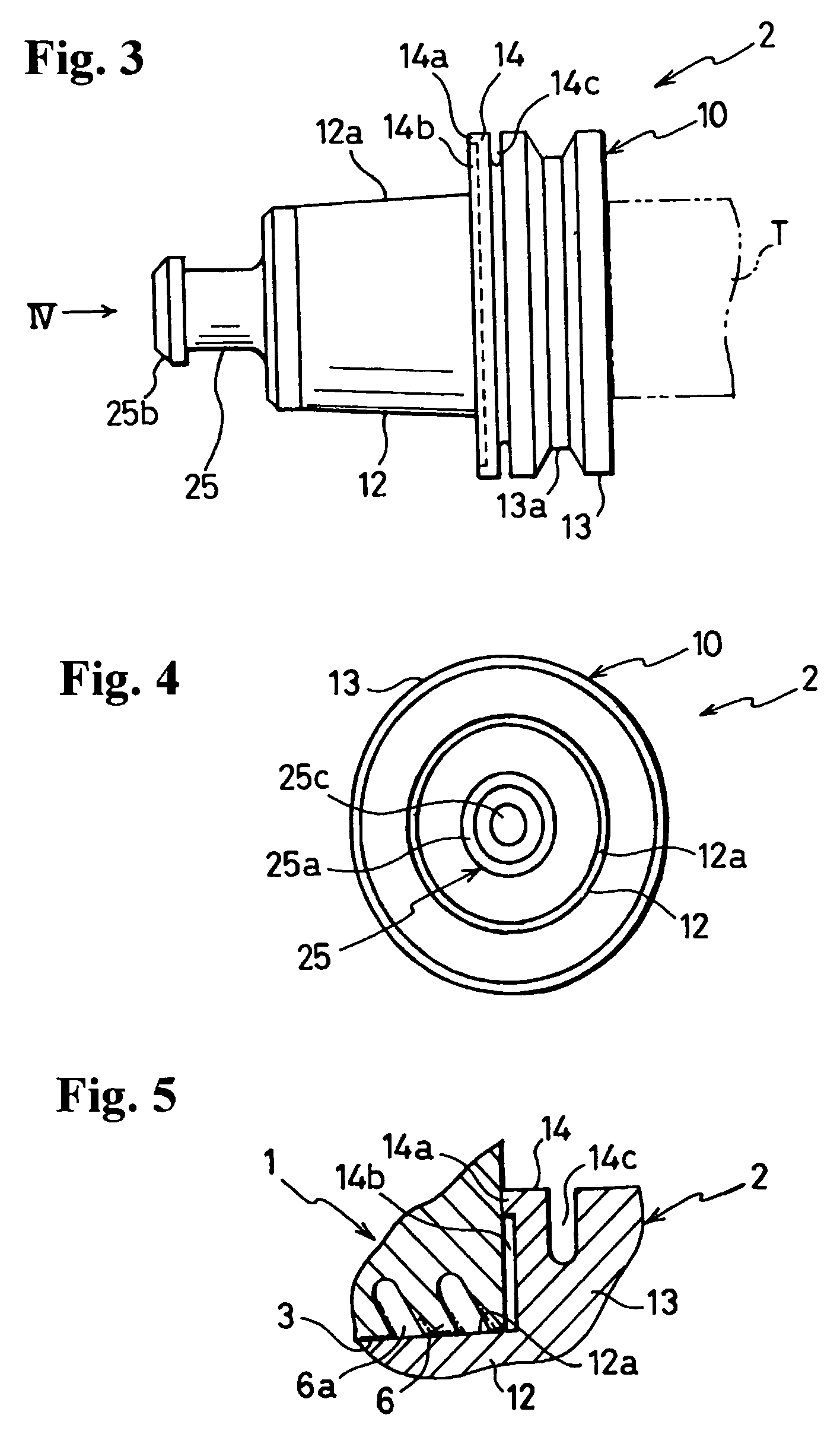

Cutting fluid device for a spindle of a machine tool

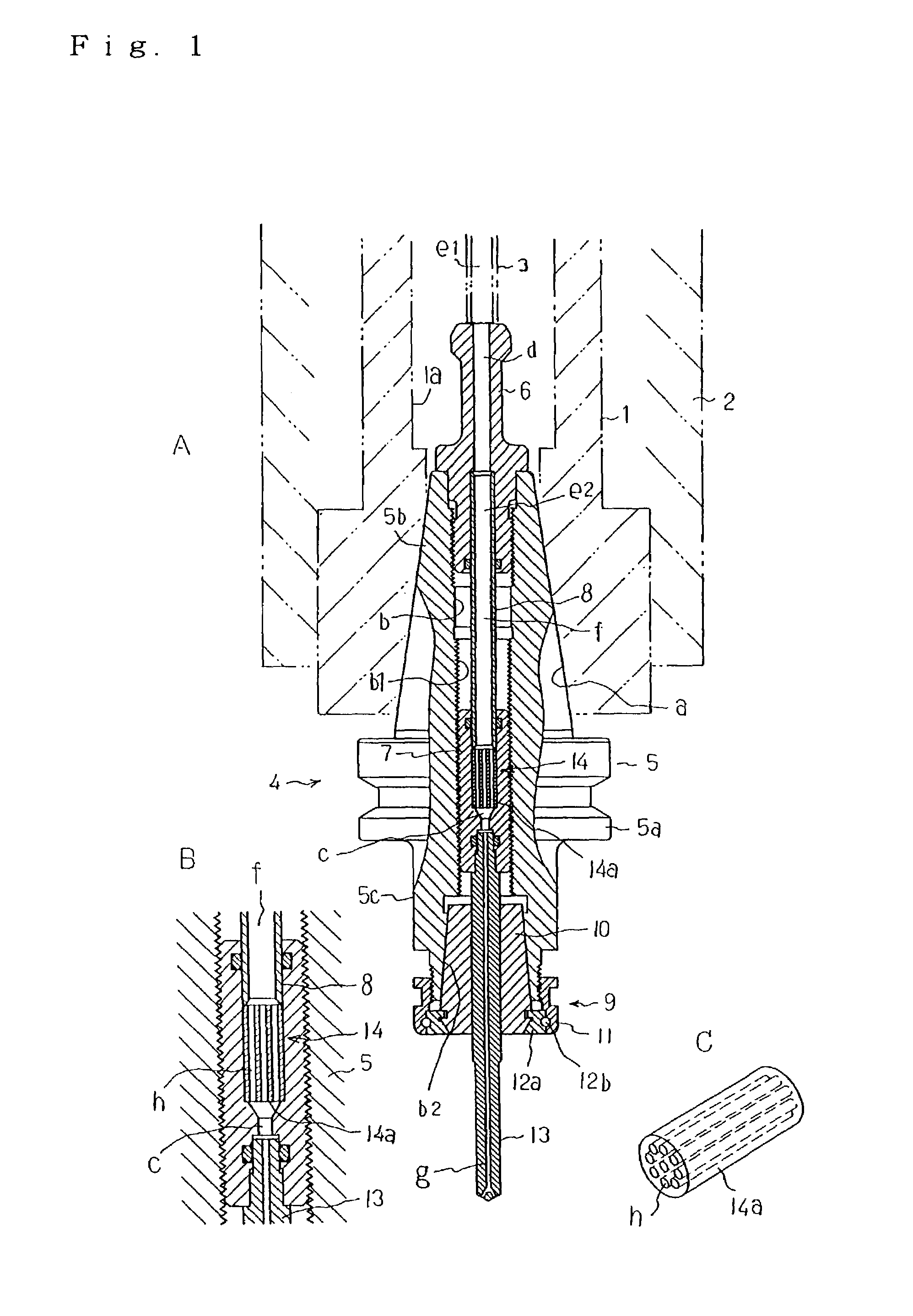

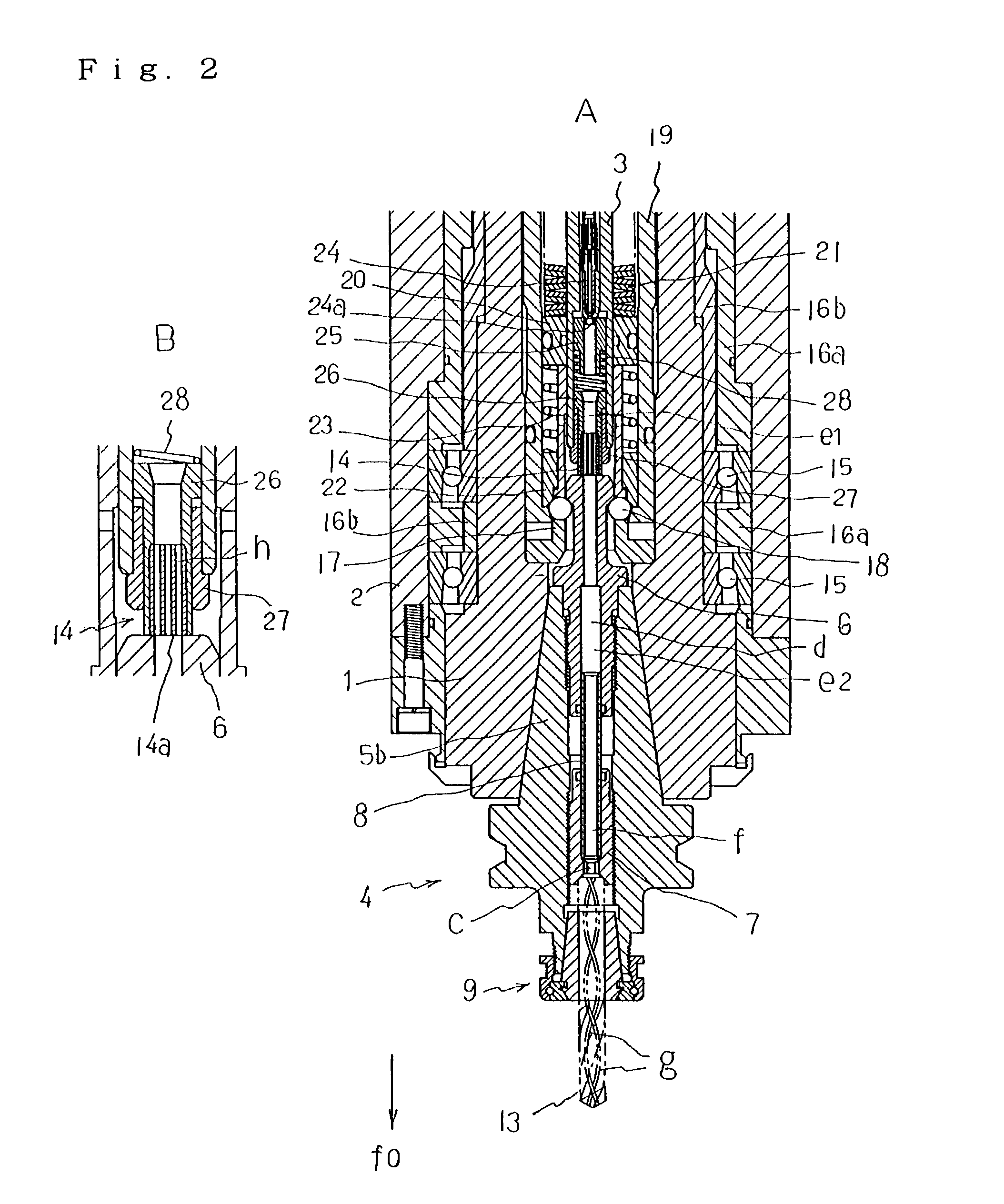

InactiveUS7048481B2Easy to producePrevent liquefactionTransportation and packagingMulti-purpose machinesMachine toolCutting fluid

A spindle device of a machine tool, which can prevent the liquefaction of atomized cutting fluid in atomized cutting fluid passage downstream of a straightening unit 14, enhance a responsiveness to an ejecting start or stop instruction, and prevent a waste of cutting fluid. The spindle device for a machine tool has atomized cutting liquid passage (e1, e2) each having a single-shape passage section and formed inside the device ranging from the spindle 1 to the tip end of a cutting tool 13 mounted thereto in one piece, and is operated so as to eject atomized cutting tool 13 via the atomized cutting fluid passages (e1, e2), wherein a straightening unit 14 formed with a plurality of small-diameter passages h are provided in the middle of the cutting liquid passages (e1, e2).

Owner:HORKOS

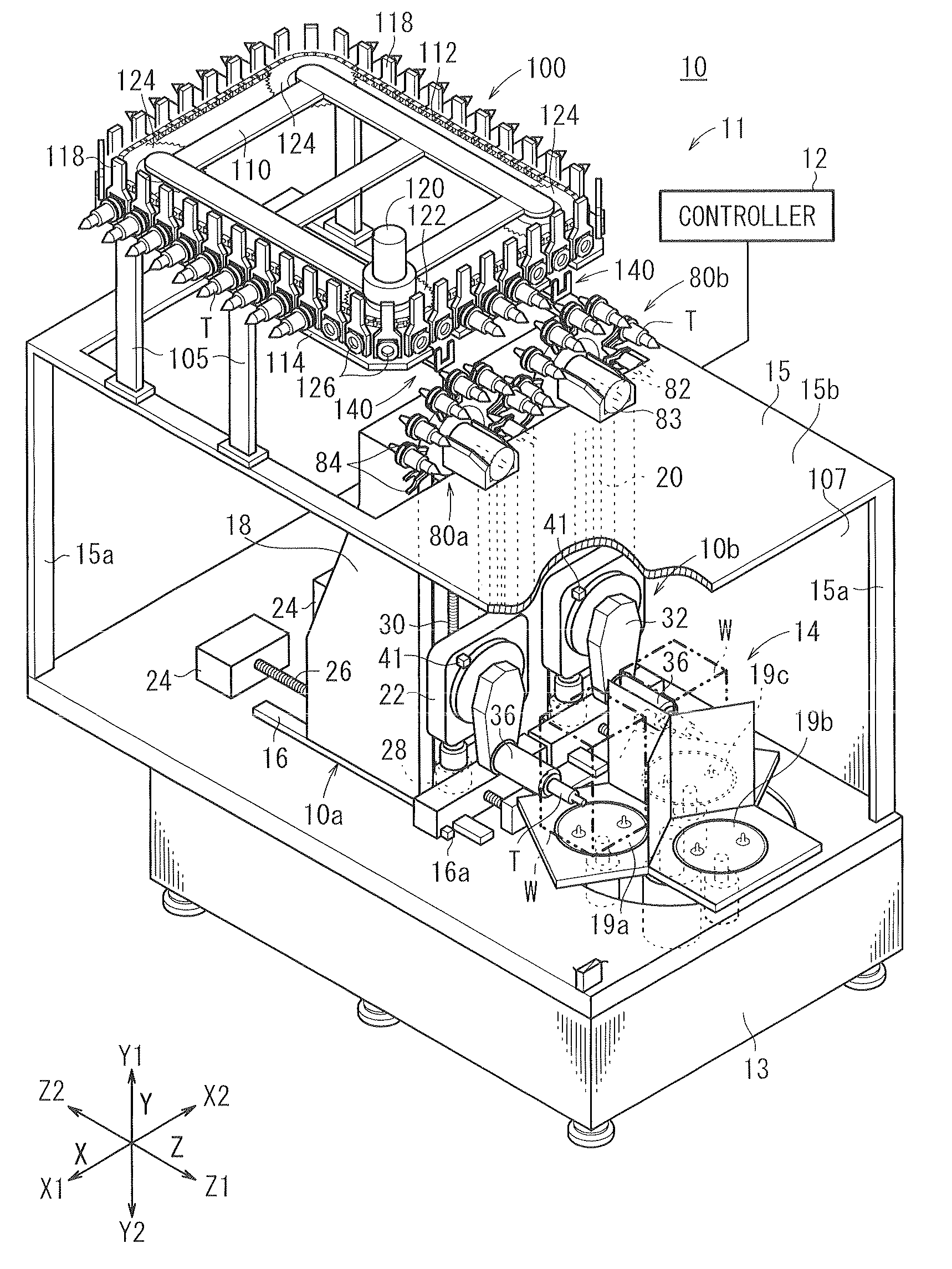

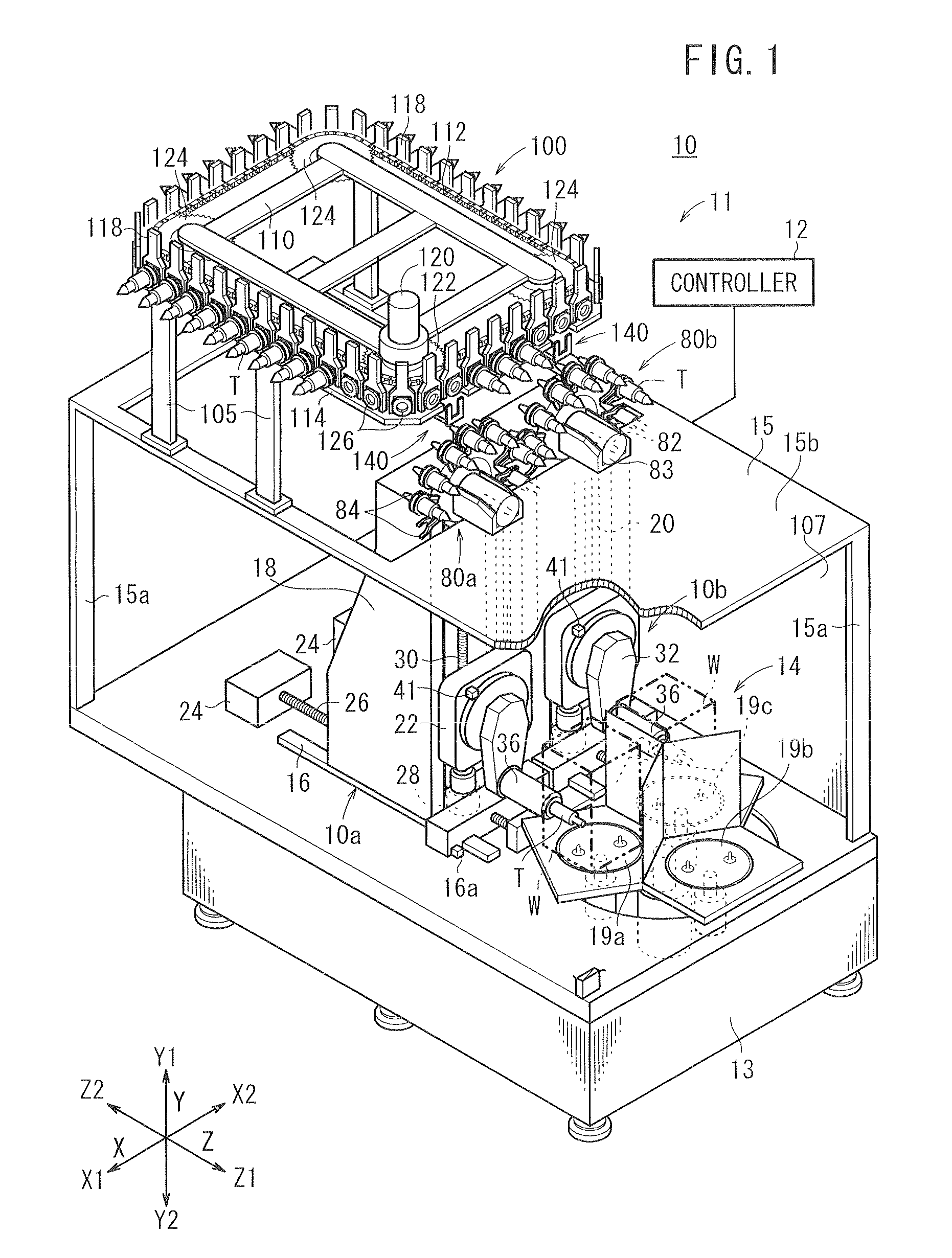

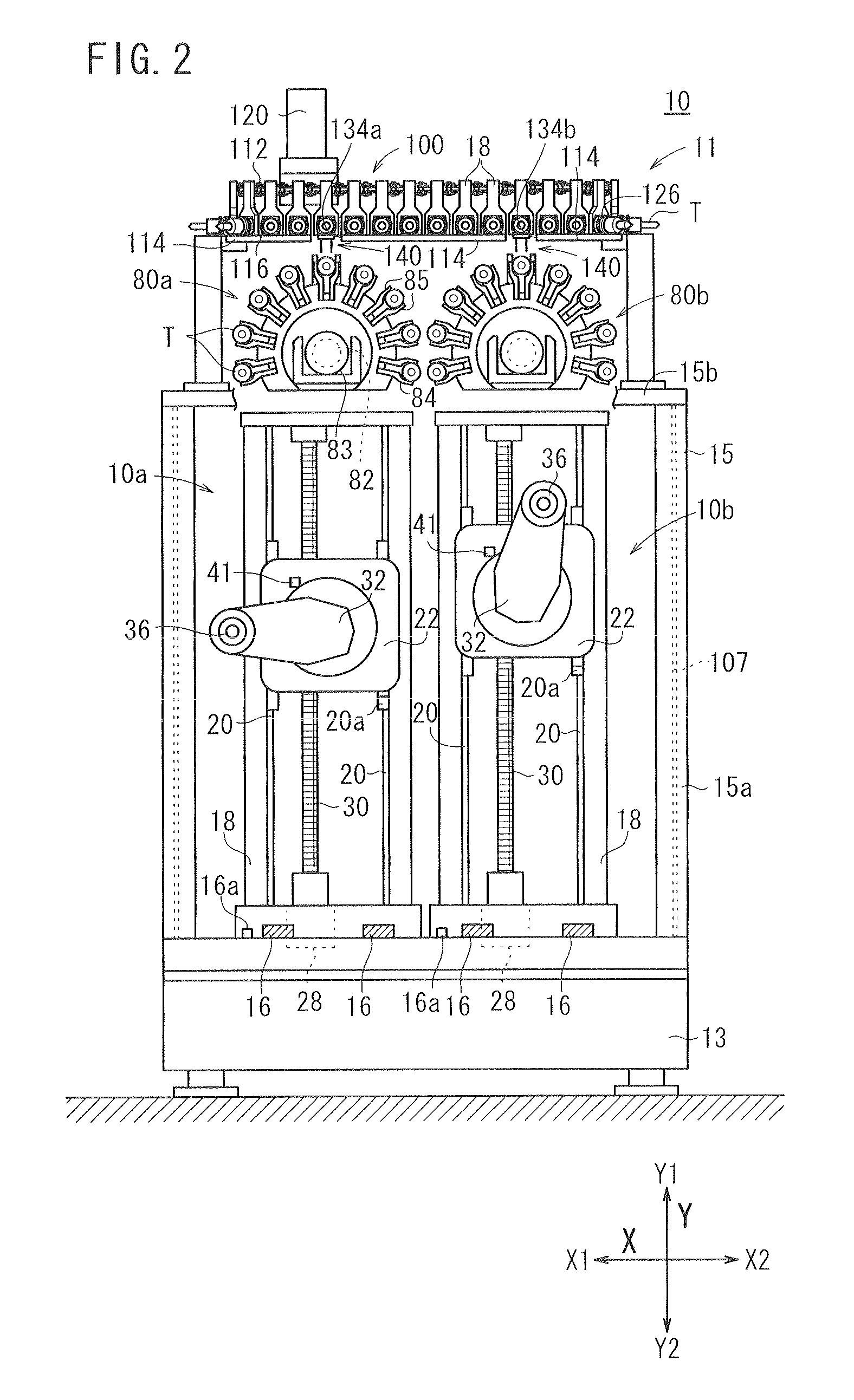

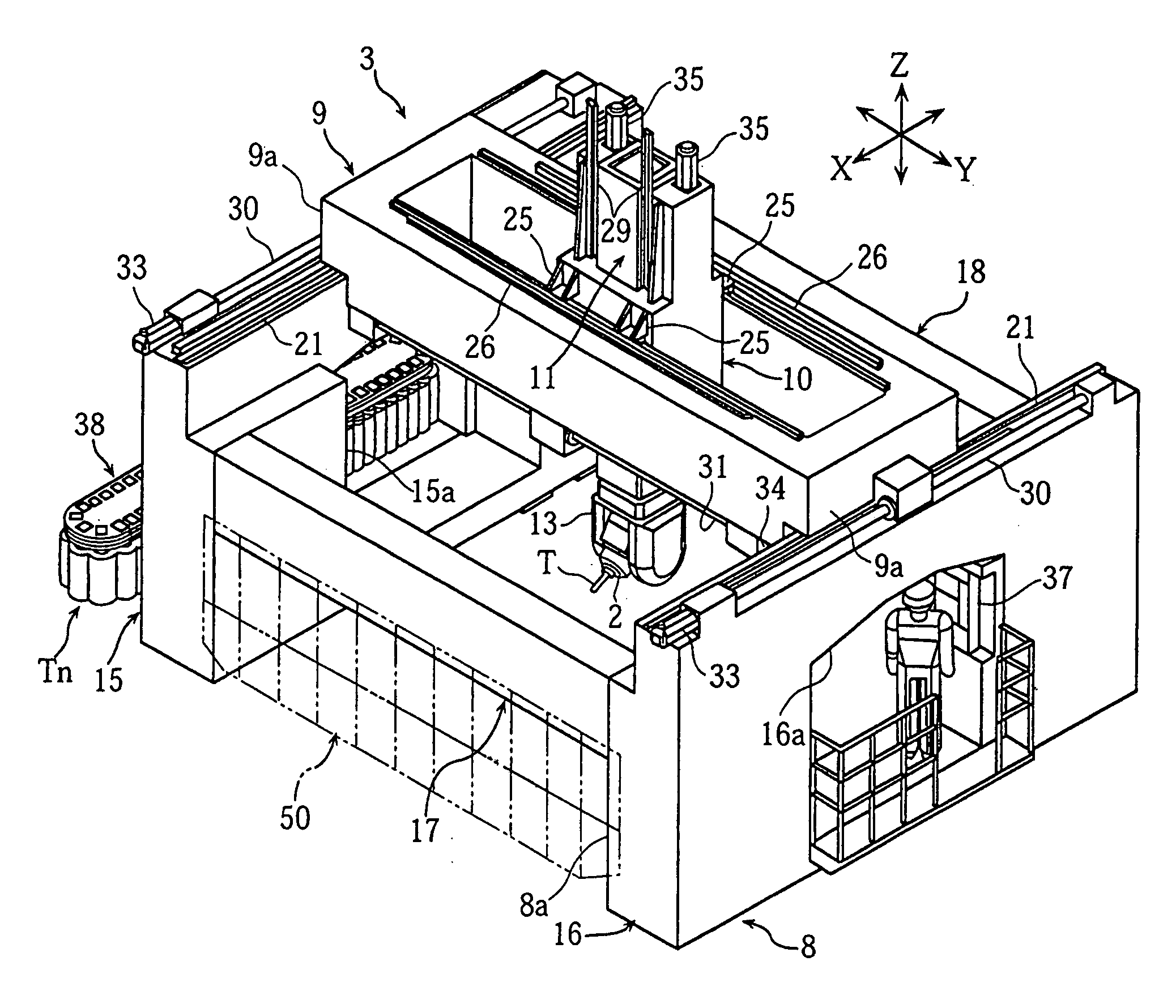

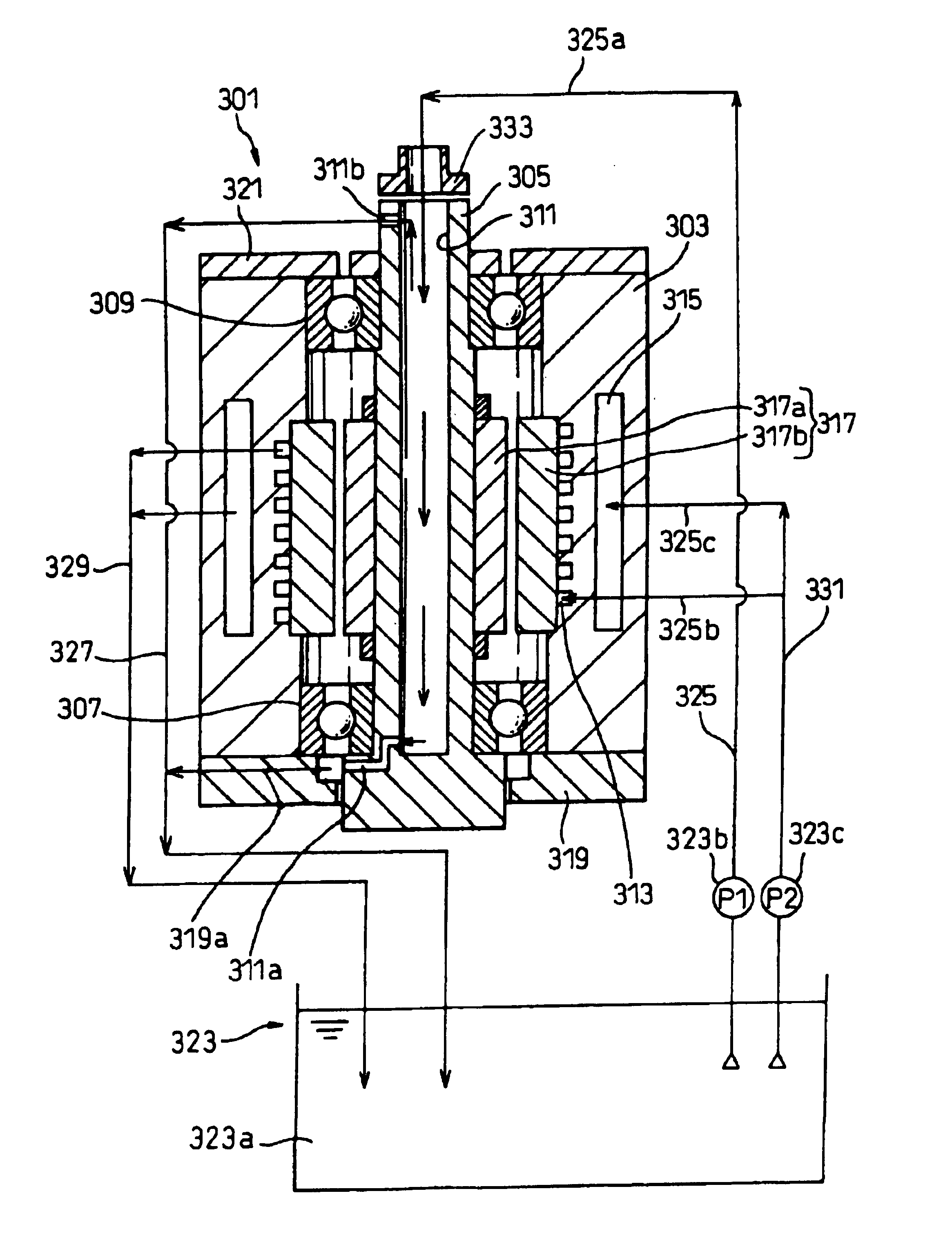

Tool stocker, machine tool system, and tool damage detecting apparatus

ActiveUS20100145498A1Easy and stable transferSmooth transferAttachable milling devicesMilling machinesTransfer mechanismMachine tool

A tool stocker includes main stockers for holding a plurality of tools detachably mounted on a main spindle for machining a workpiece, an auxiliary stocker for holding and transferring tools to and from the main stockers, and a tool transfer mechanism for transferring tools between the main stockers and the auxiliary stocker. The auxiliary stocker includes a plurality of tool pods for removably supporting the tools therein, a rail in sliding engagement with outer surfaces of the tool pods, a chain for moving the tool pods in sliding engagement with the rail, and a motor for actuating the chain. The rail has a recess defined therein in alignment with the tool transfer mechanism, such that the tools transferred by the tool transfer mechanism pass through the recess.

Owner:HONDA MOTOR CO LTD

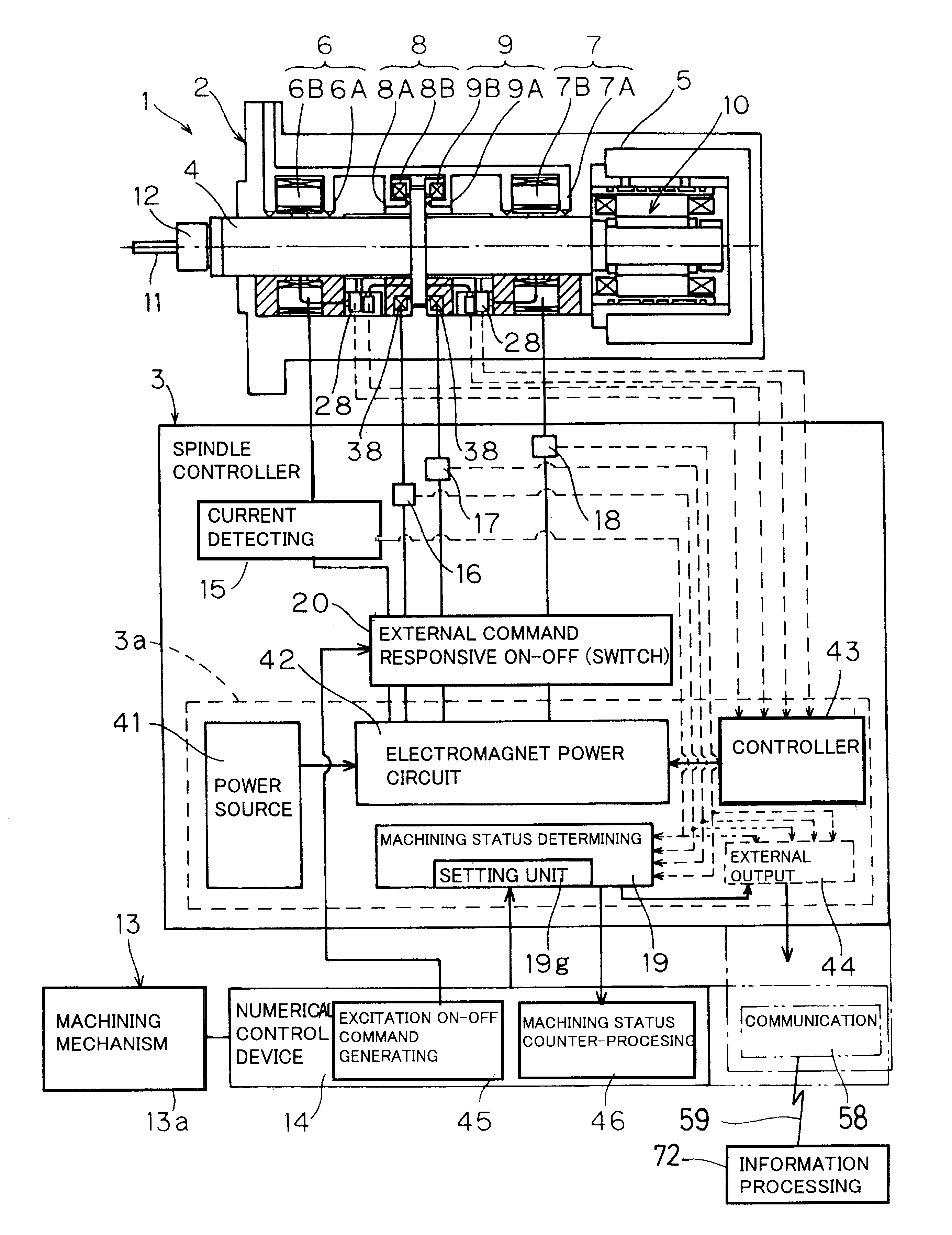

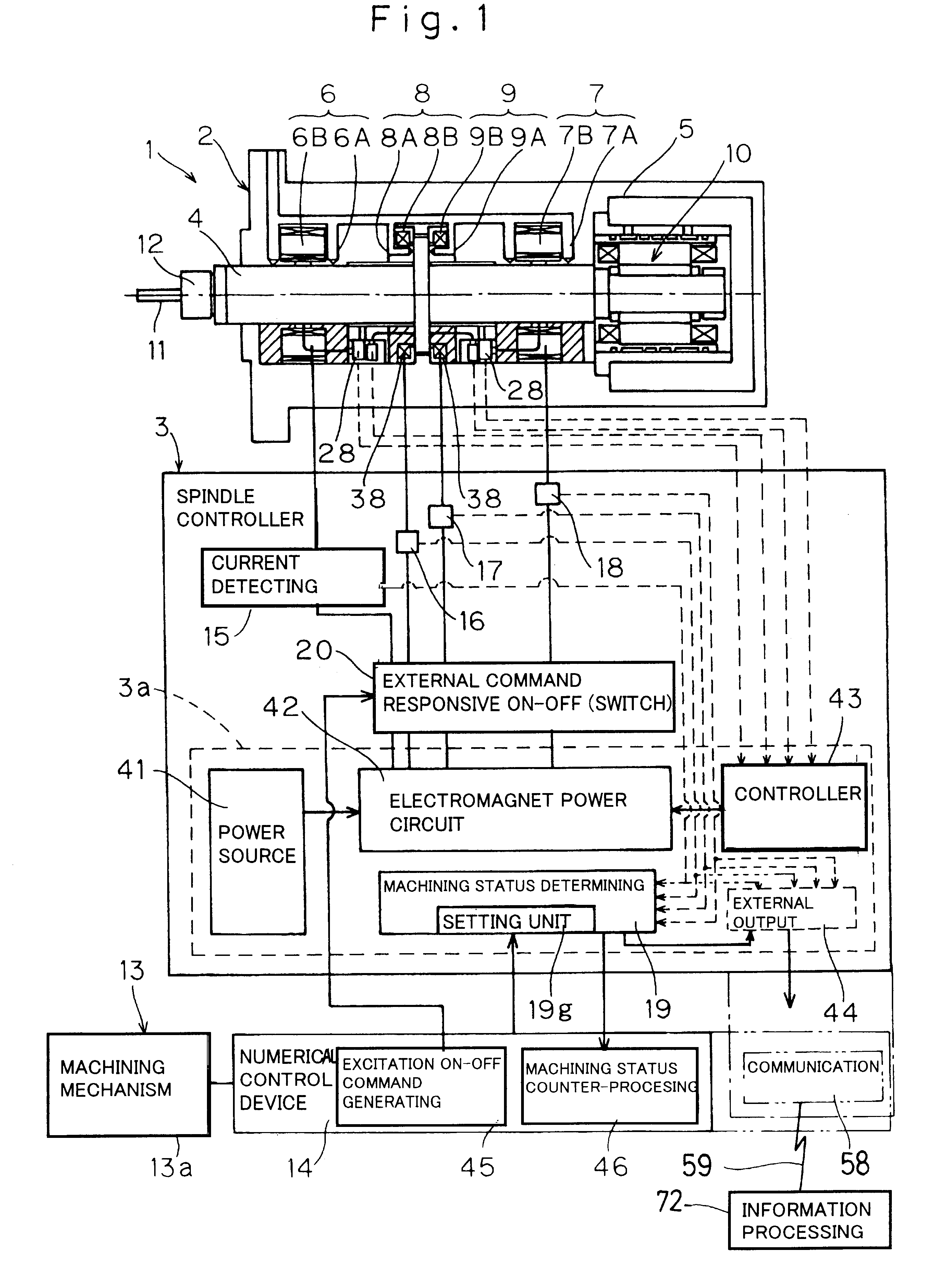

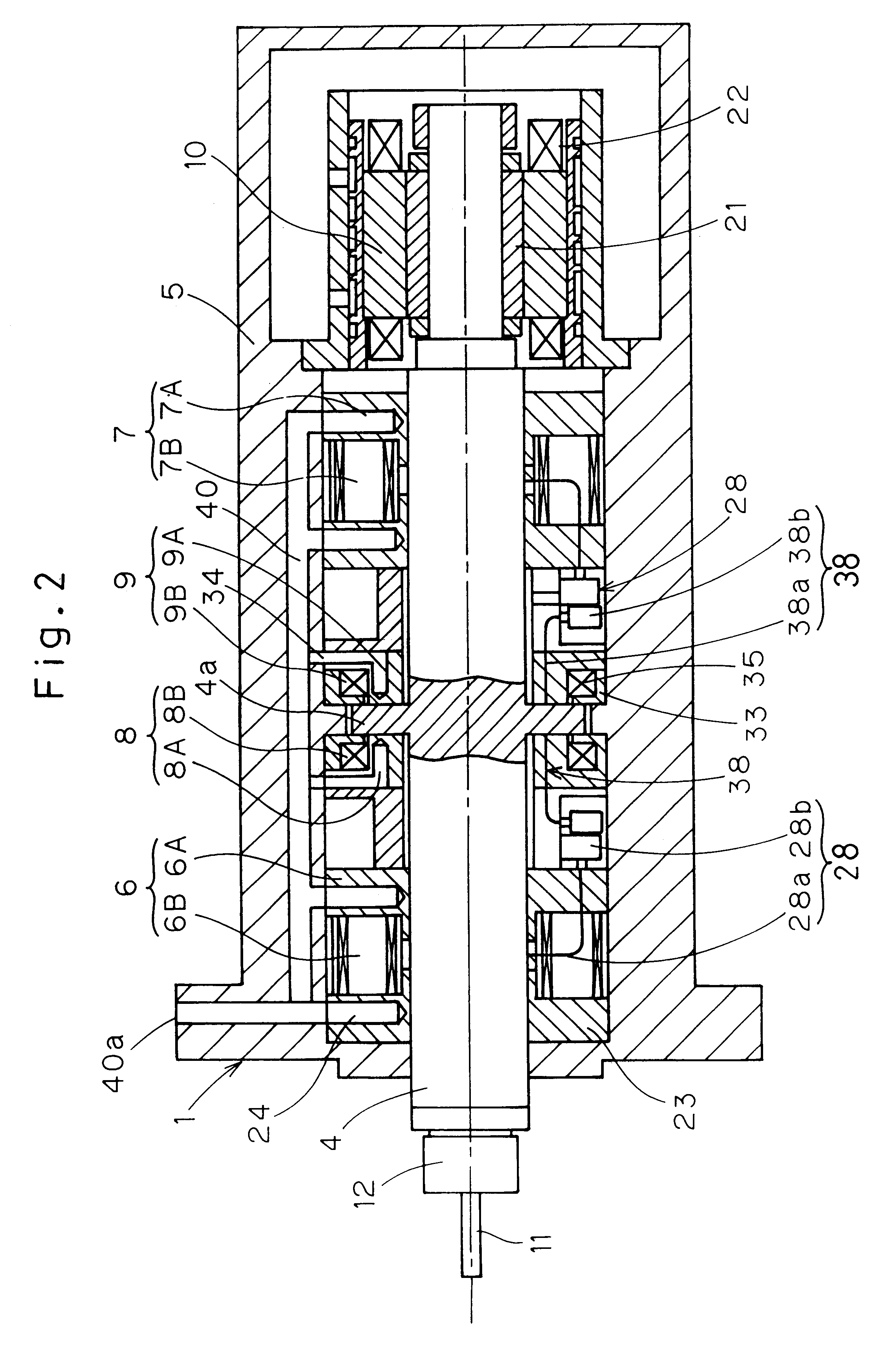

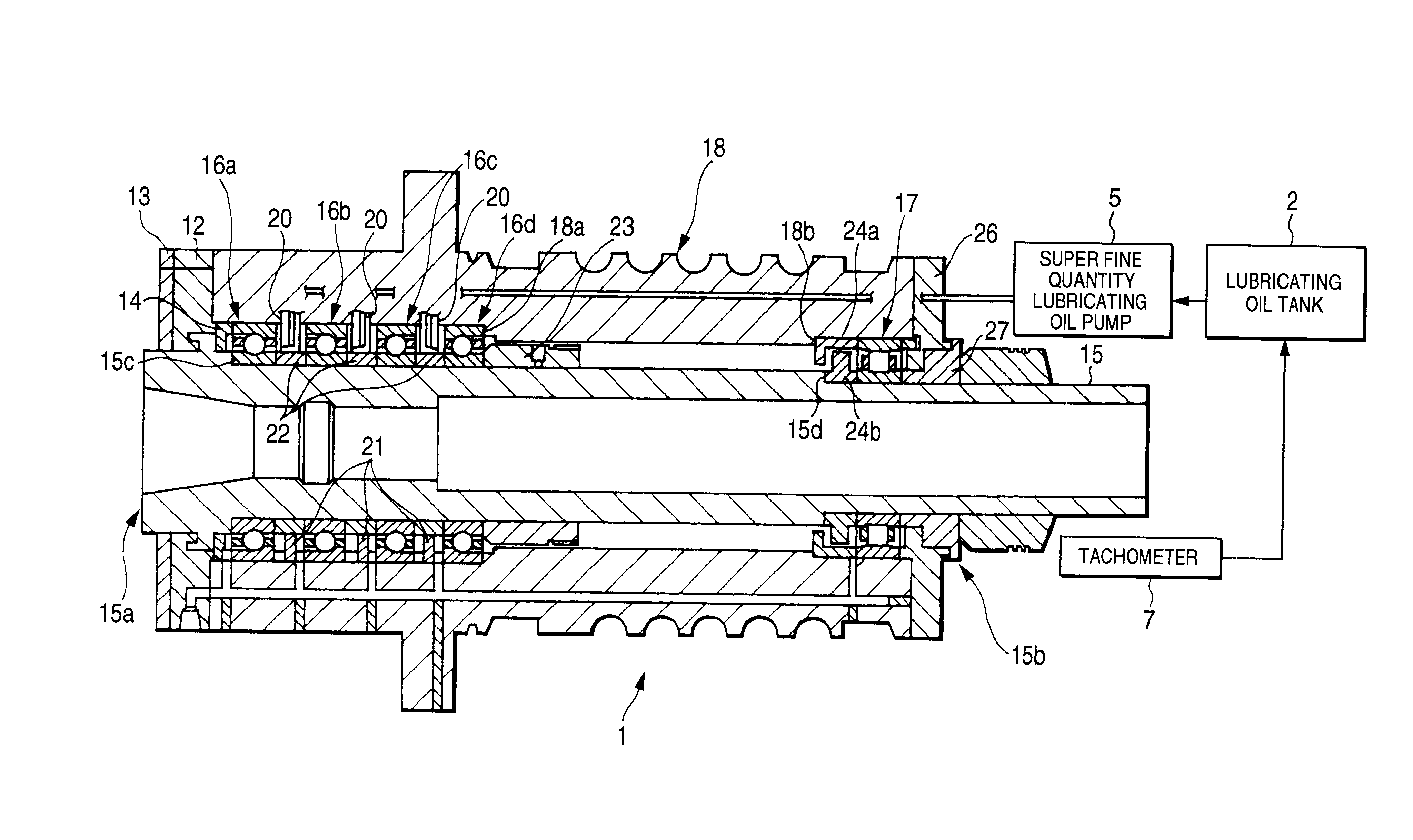

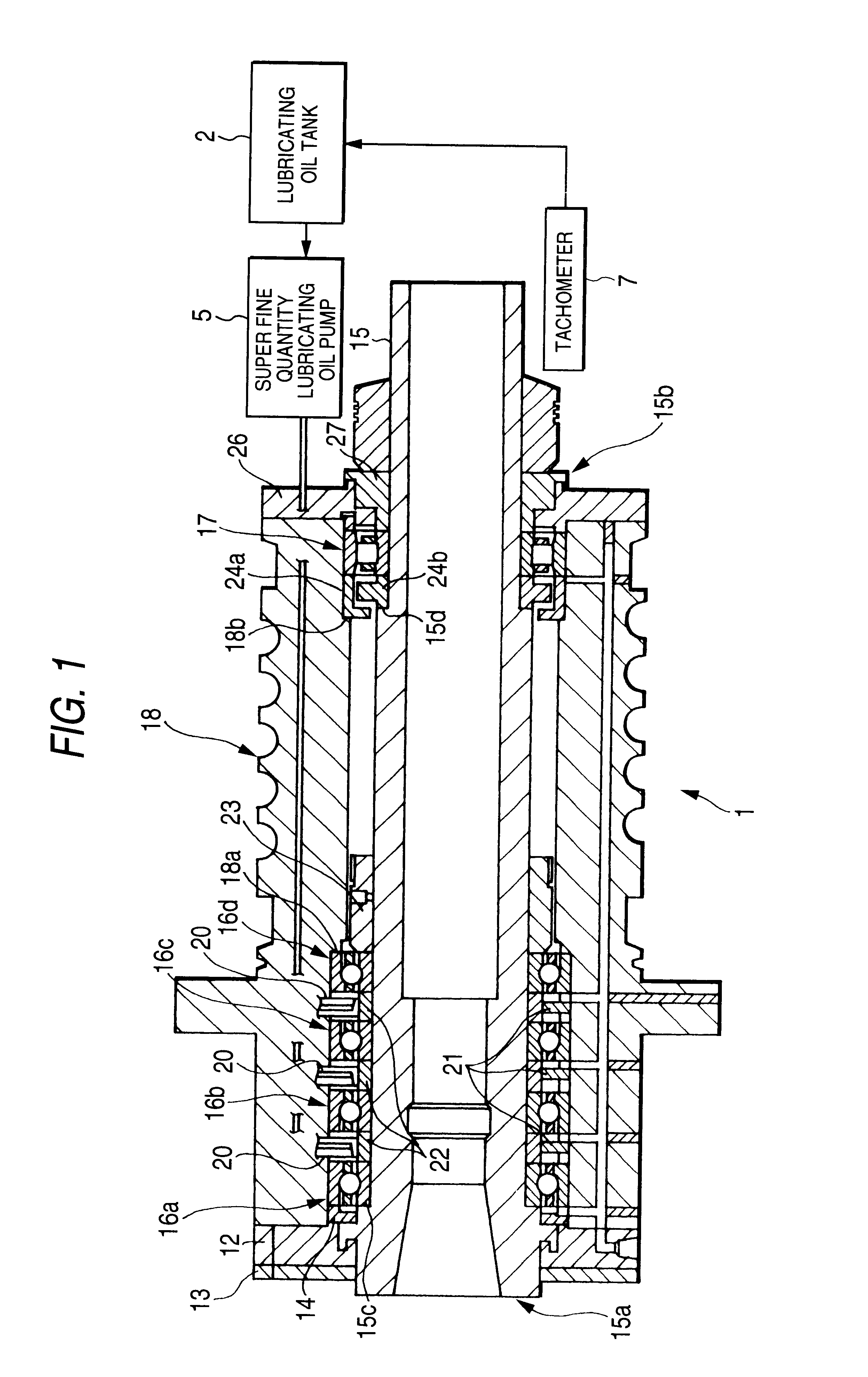

Spindle device and machine tool utilizing the same

A spindle device equipped with a combined externally pressurized gas-magnetic bearing assembly, and a machining apparatus utilizing the spindle device. The spindle device is capable of accomplishing a high speed rotation with high rotational precision and includes a main shaft (4) rotatably supported by the combined bearing assembly (6 to 9), an electric current detecting device (15 to 18) disposed in a spindle controller (3) for detecting a current supplied to electromagnets of the combined bearing assembly (6 to 9). Also provided is a machining status determining device (19) for determining the machining status in reference to the current detected by the current detecting device (15 to 18). The machining status may be an indication of the extent to which a machining tool is impaired.

Owner:NTN CORP

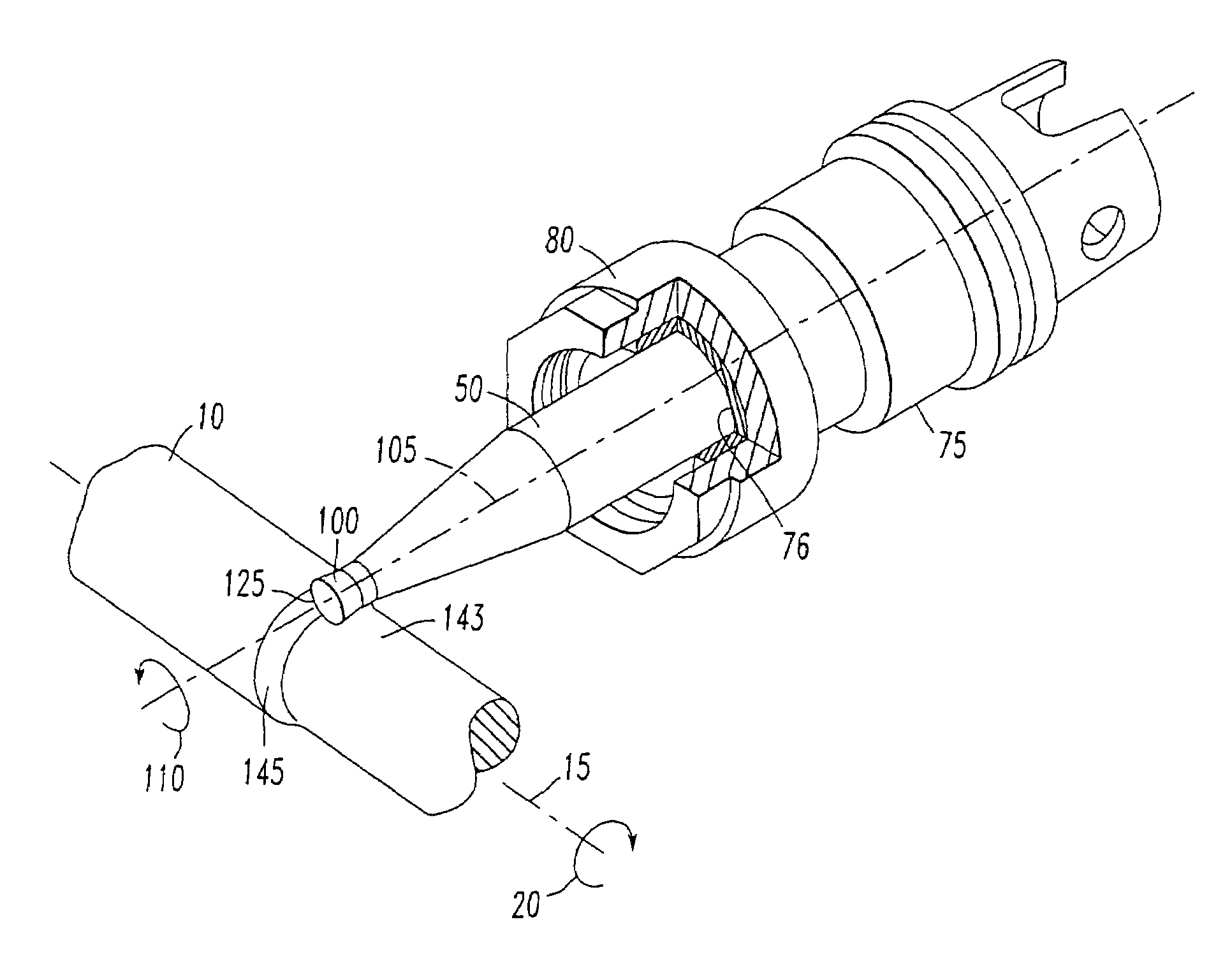

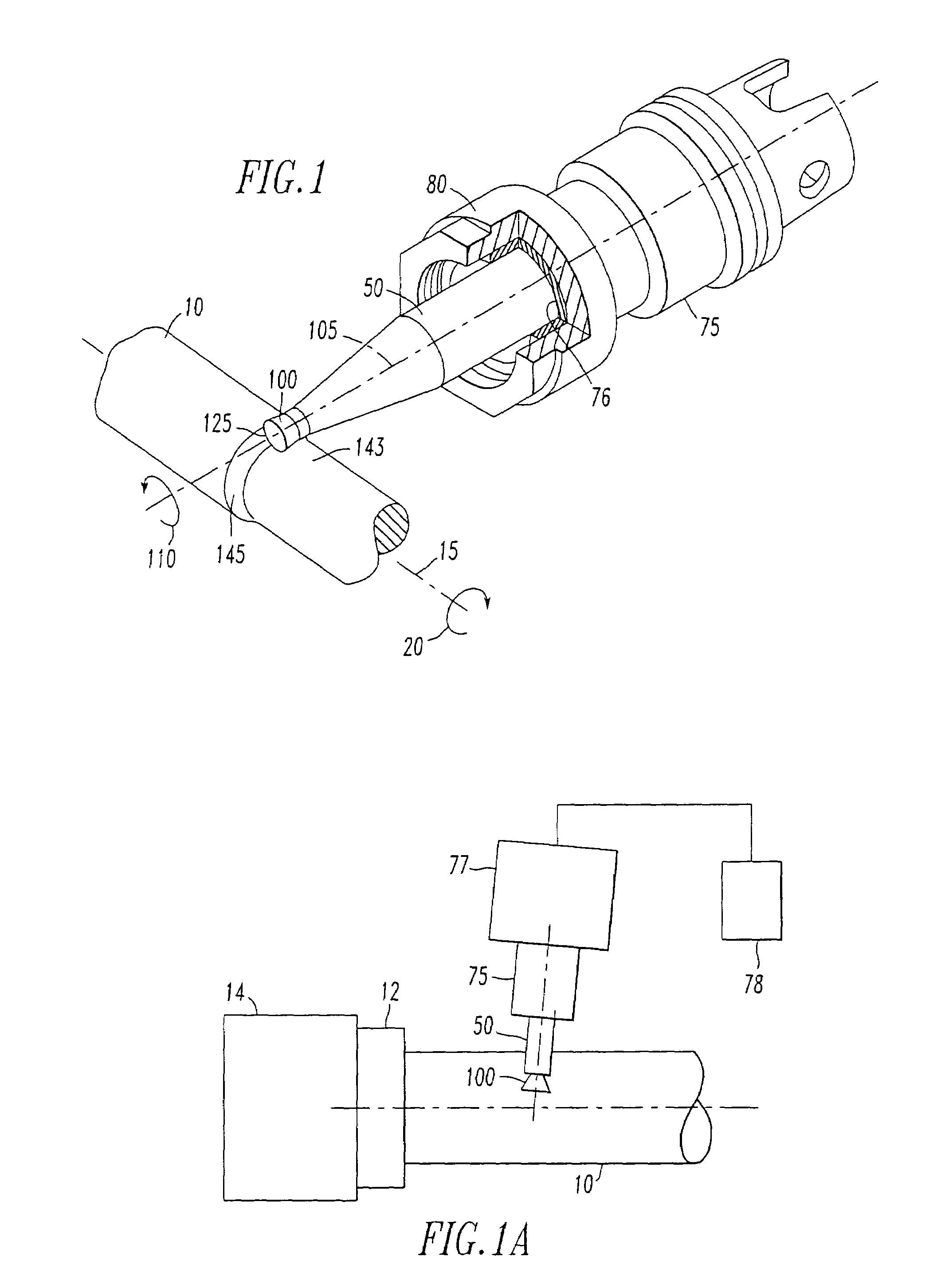

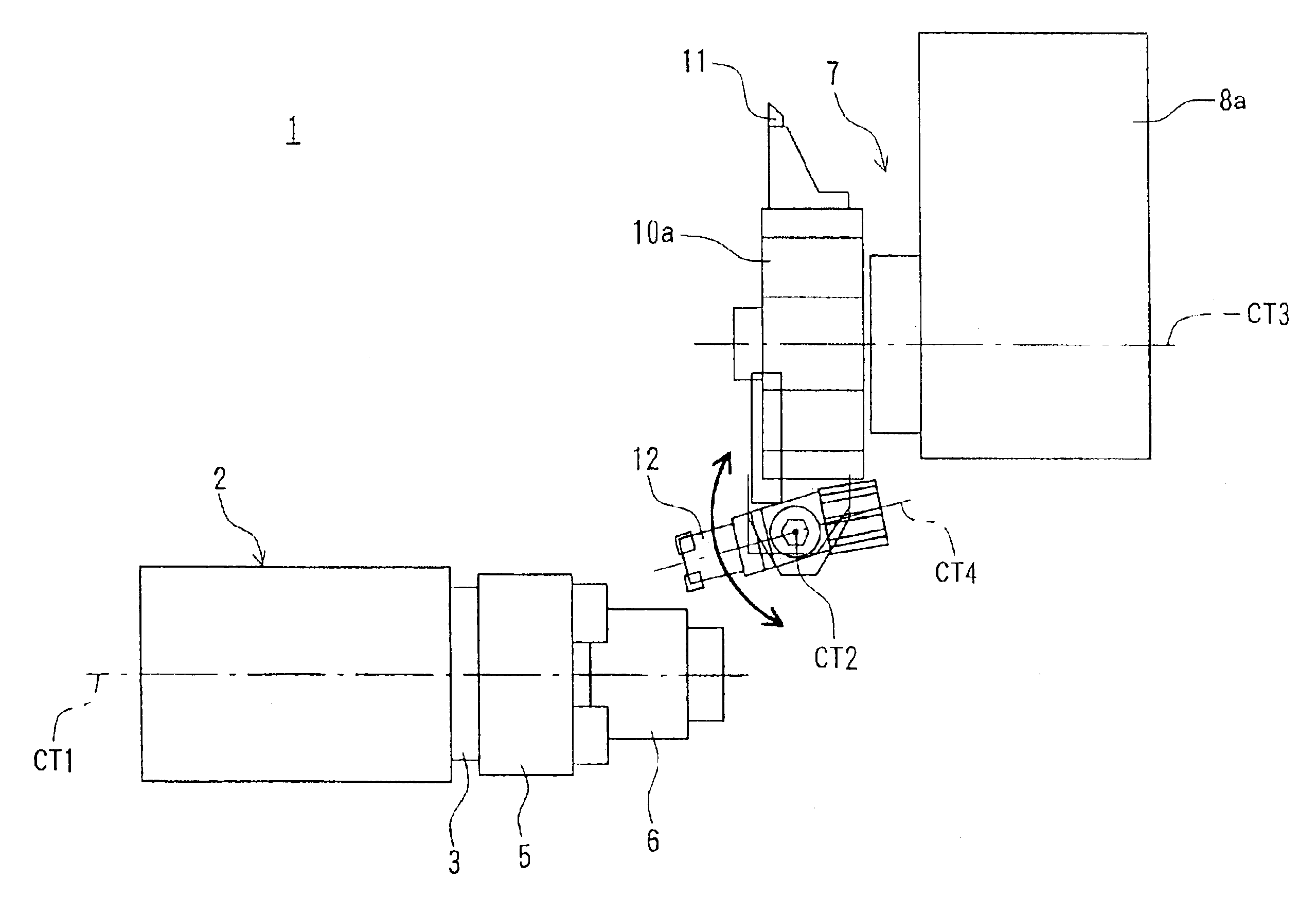

Method and assembly for rotating a cutting insert during a turning operation and inserts used therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. A method, including an assembly with a rotatable insert mounted to a toolholder may be utilized to achieve this result.

Owner:KENNAMETAL INC

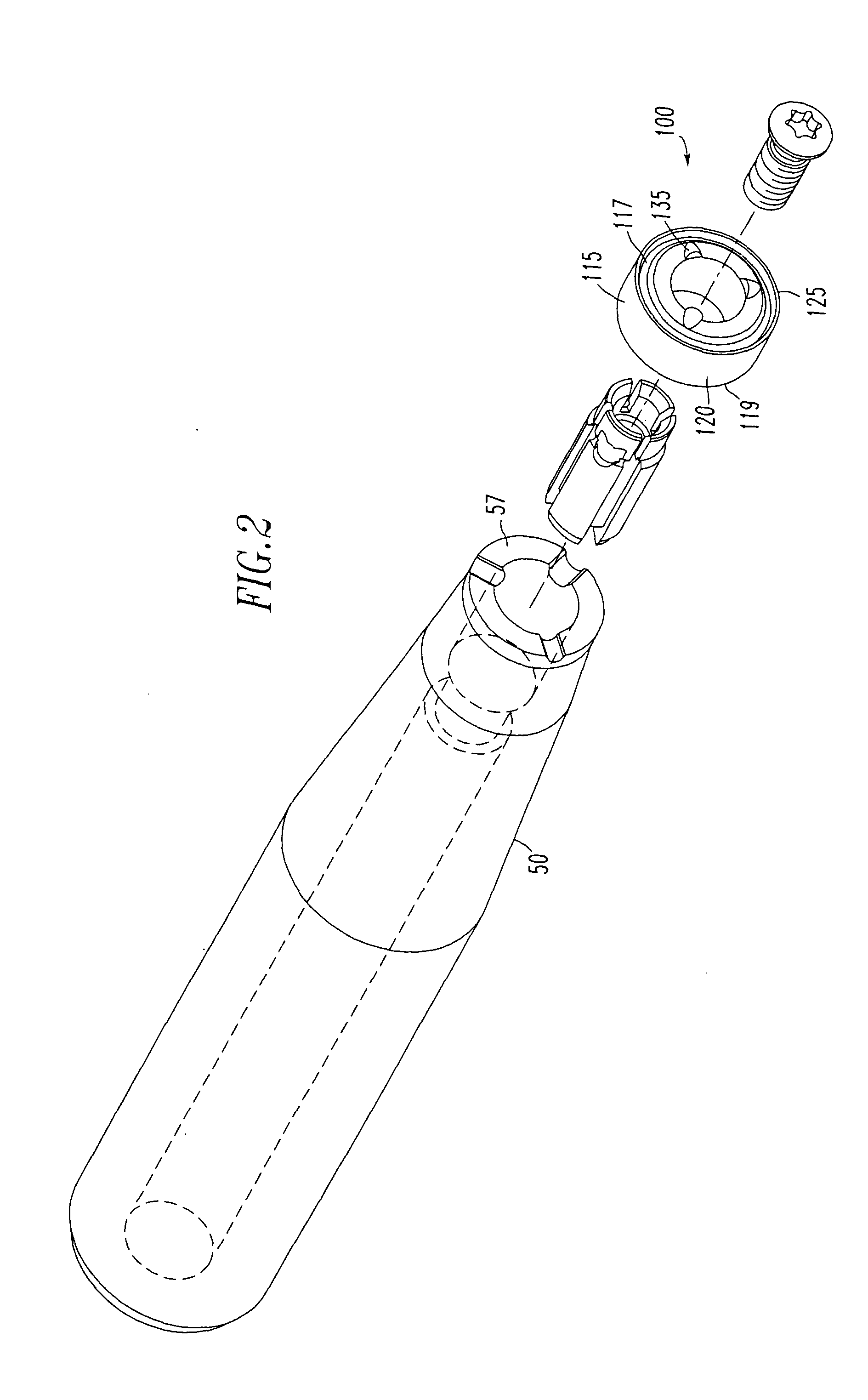

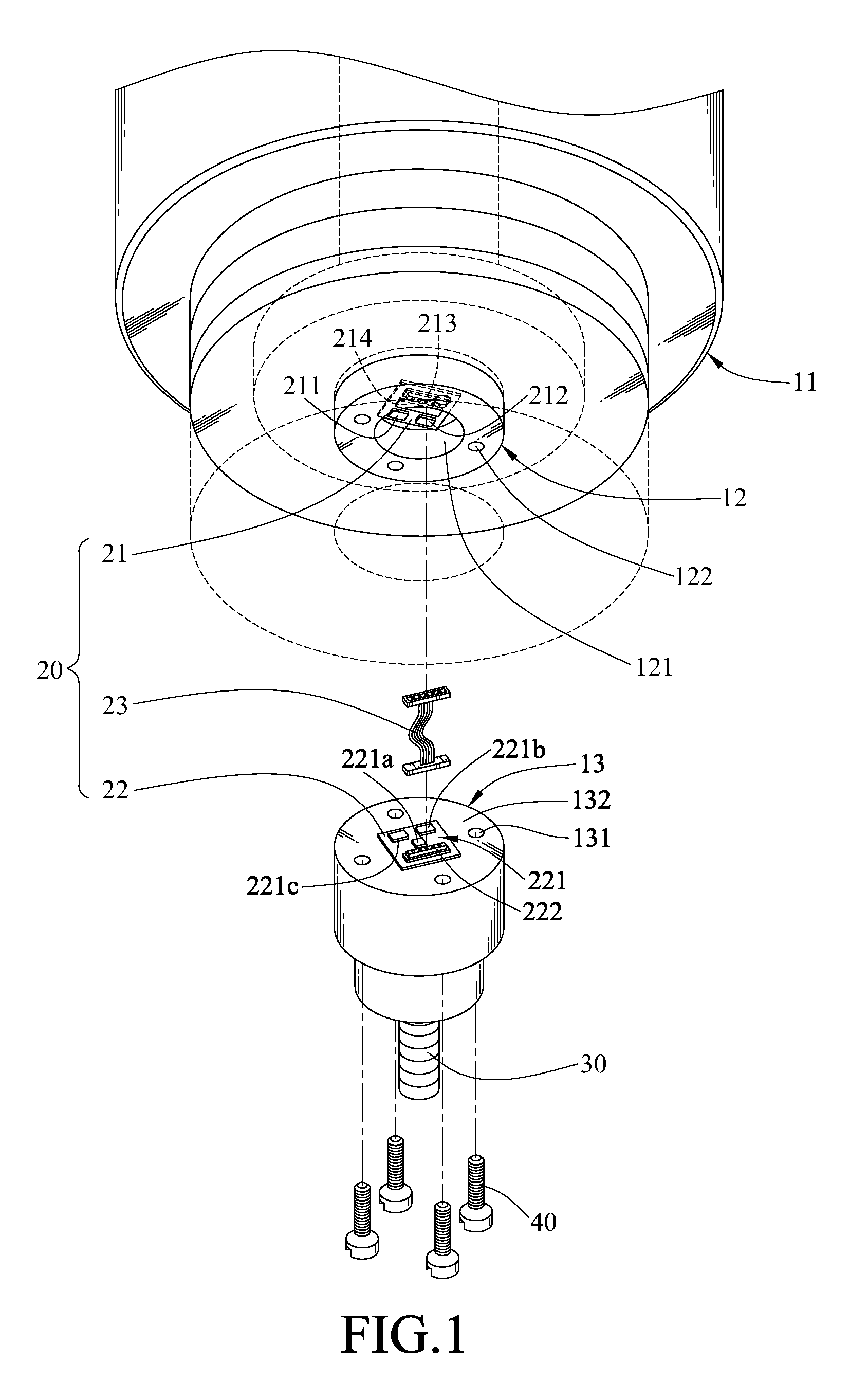

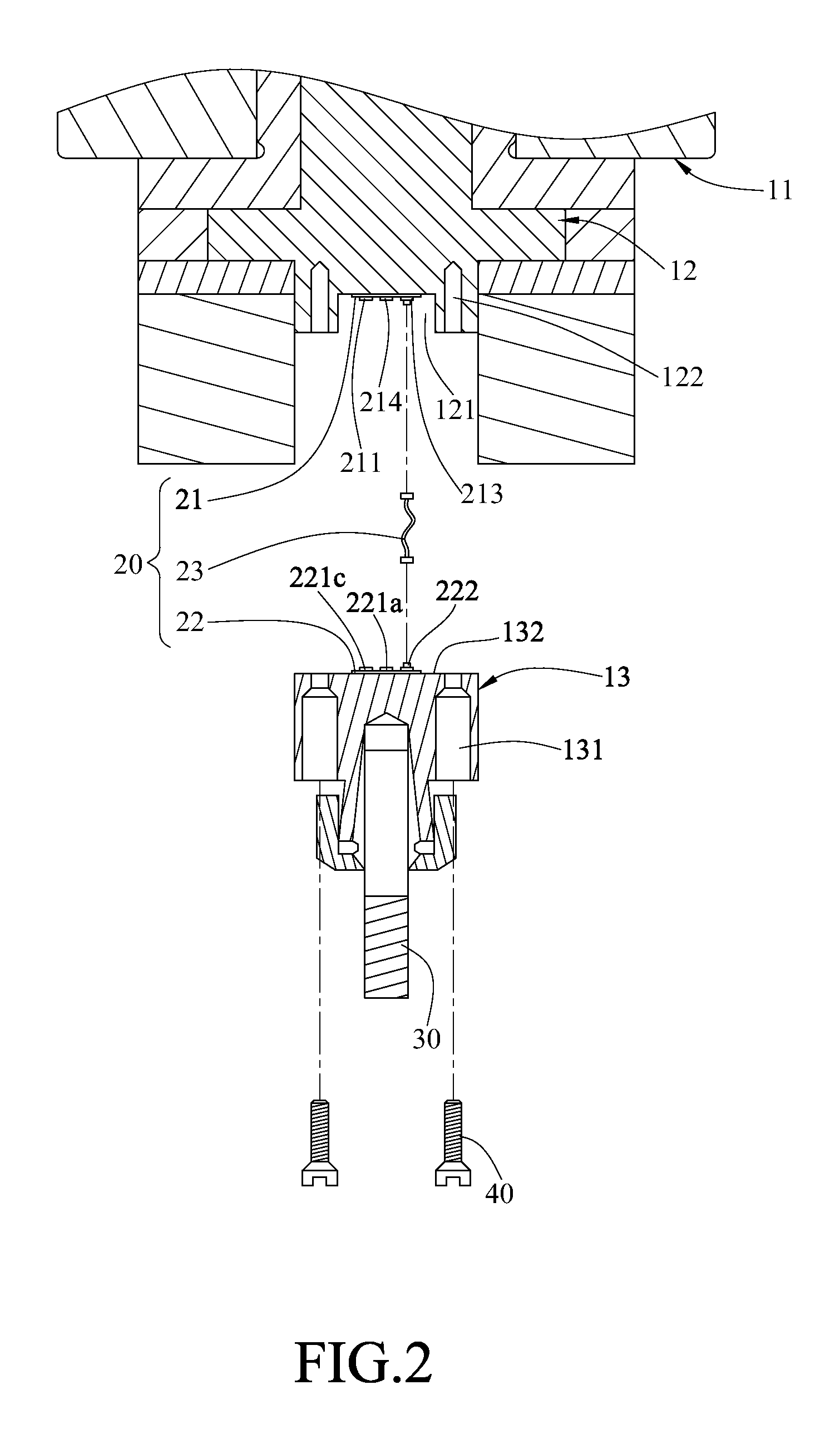

Machine tool spindle structure capable of monitoring working state in real time

InactiveUS20100145496A1Reduce the impactAccurate measurementThread cutting machinesAttachable milling devicesInformation deviceMachine tool

A machine tool spindle structure capable of monitoring a working state in real time includes a spindle body, a rotating mandrel, a cutter base, and an internal inspecting device. The cutter base is combined with the rotating mandrel and rotates with the rotating mandrel. The rotating mandrel has a chamber, and the internal inspecting device is disposed in the chamber. Inspecting chips in the internal inspecting device are directly disposed on the cutter base, so as to measure working parameters during a processing process. The working parameters are transmitted to an external information device by a wireless transmission module in the internal inspecting device, thereby accurately giving a feedback of the working state of a processing cutter in real time.

Owner:IND TECH RES INST

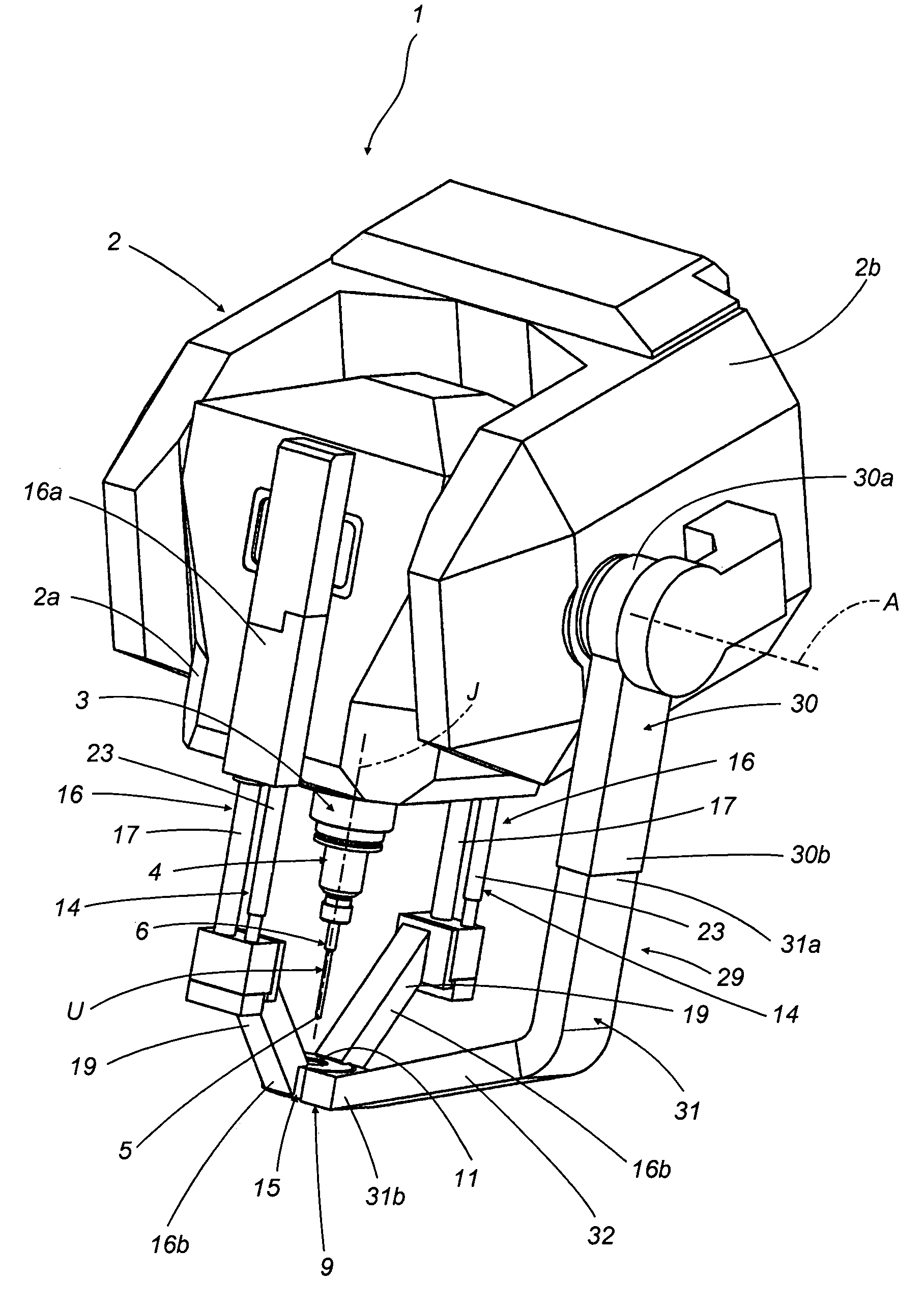

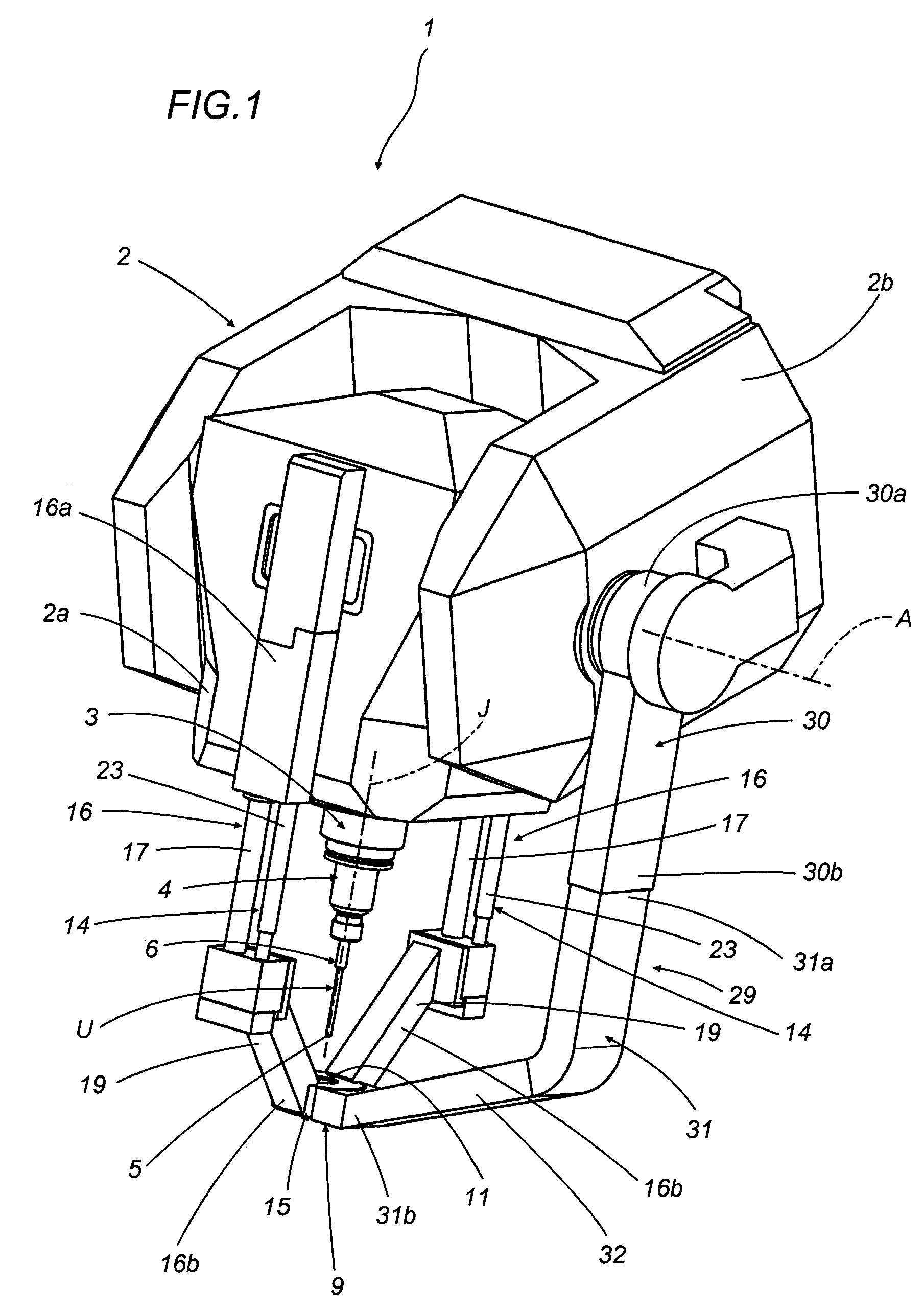

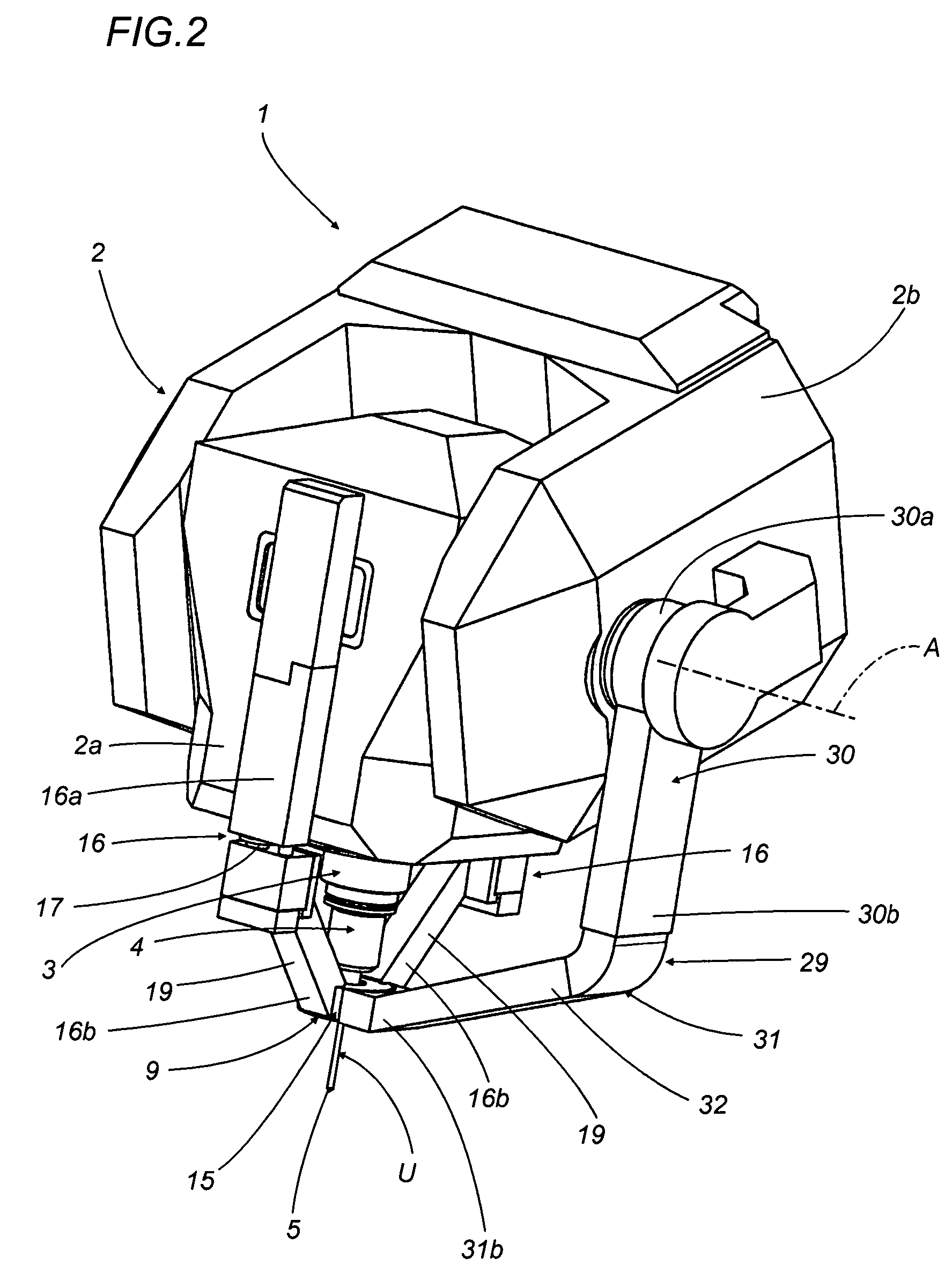

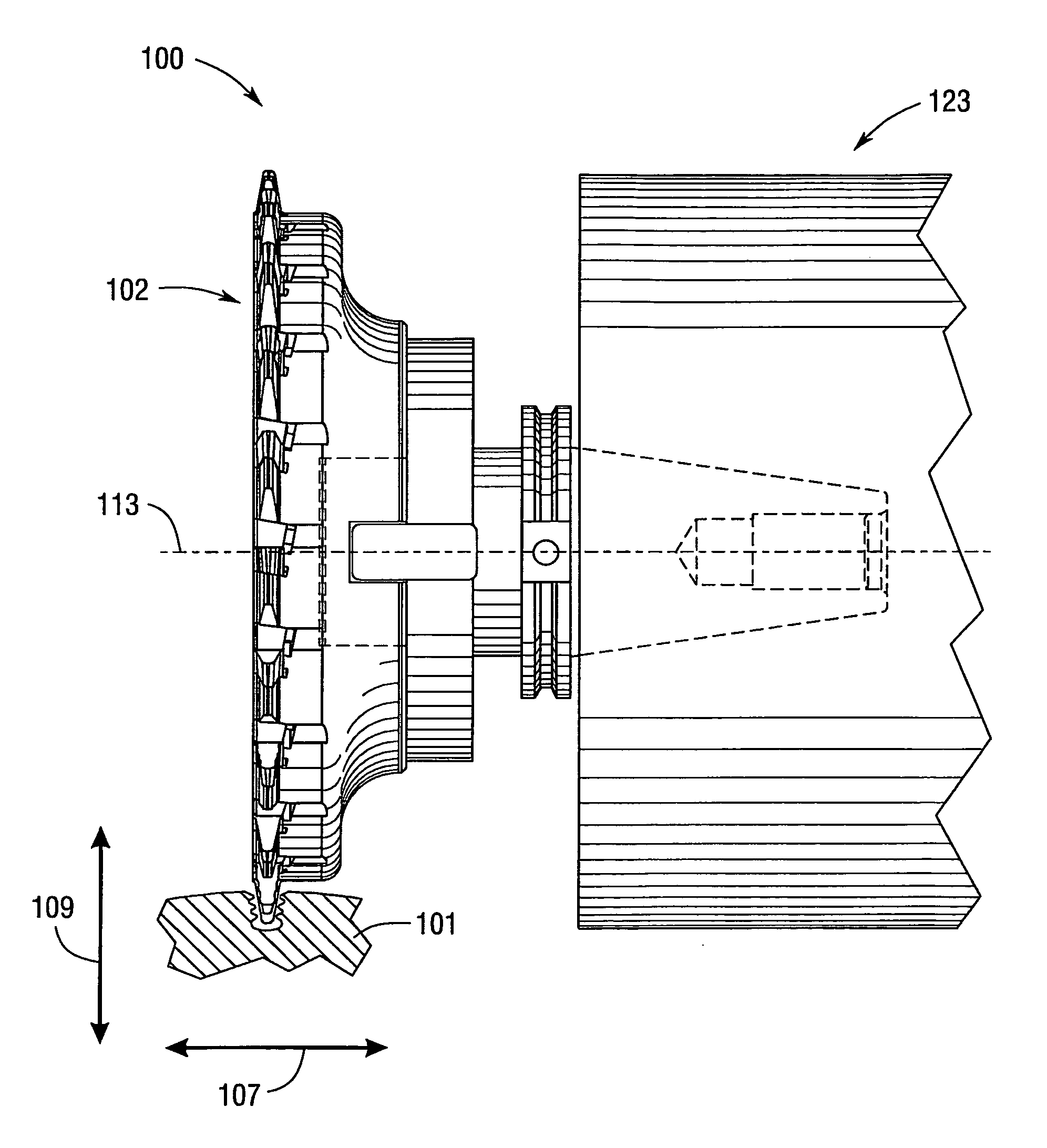

Toolhead for multi-axis machine tools

ActiveUS7220088B2Easy to getSmall and lightAircraft componentsDrilling/boring measurement devicesTransducerEngineering

Owner:JOBS SPA

Method and assembly for rotating a cutting insert during a turning operation and inserts used therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. A method, including an assembly with a rotatable insert mounted to a toolholder may be utilized to achieve this result.

Owner:KENNAMETAL INC

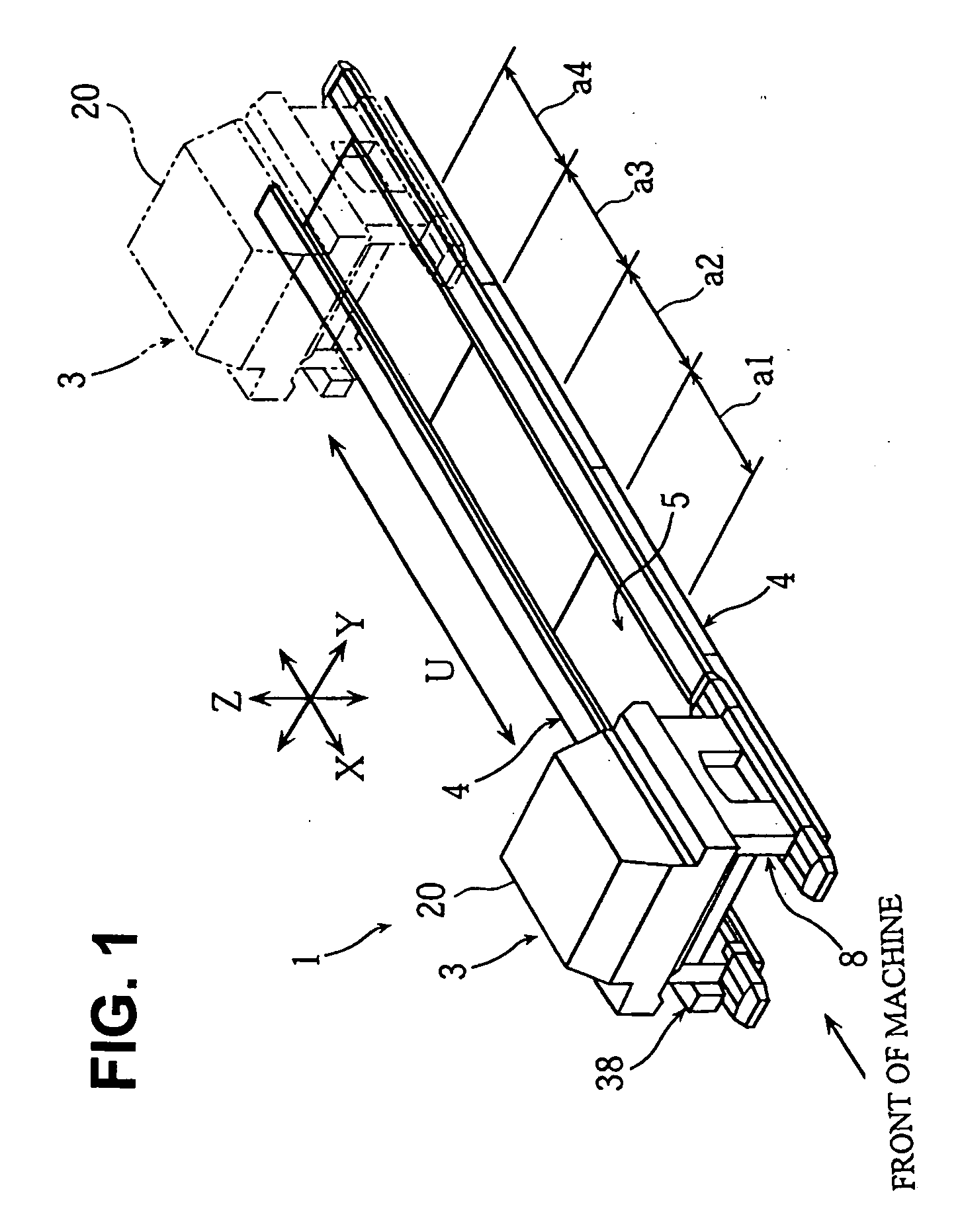

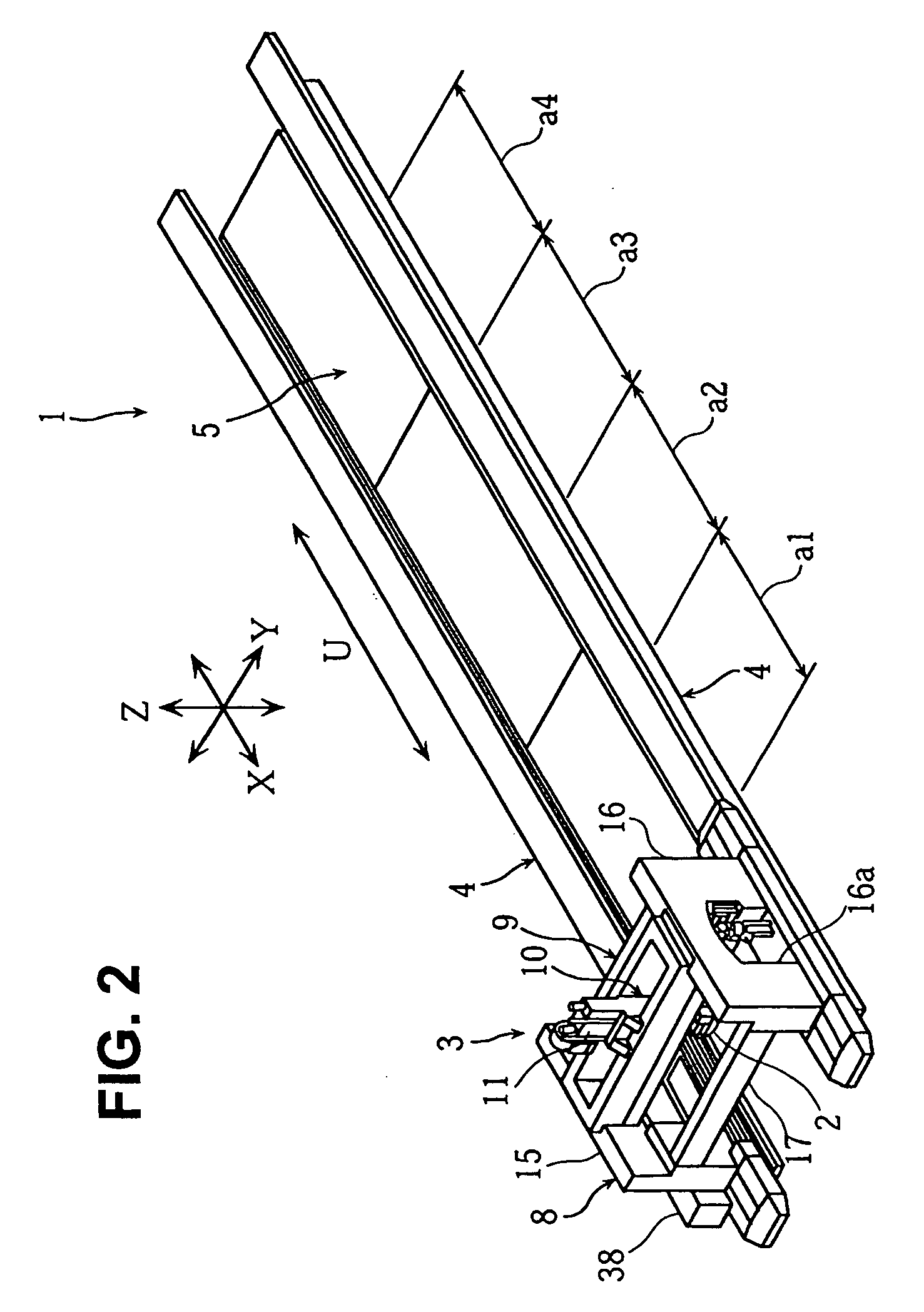

Machine tool

The present invention provides a machine tool realizing high-speed movement of a spindle and thus reducing the machining time without any increase in size of the whole machine. A machining unit 3 by which a spindle 2 with a tool T attached thereto is supported to be relatively movable in X-axis, Y-axis, and Z-axis directions is mounted on a long bed 4 having a plurality of machining areas a1 to a4 arranged in one direction, and the machining unit 3 is movable in the arrangement direction of the machining areas.

Owner:DMG MORI CO LTD

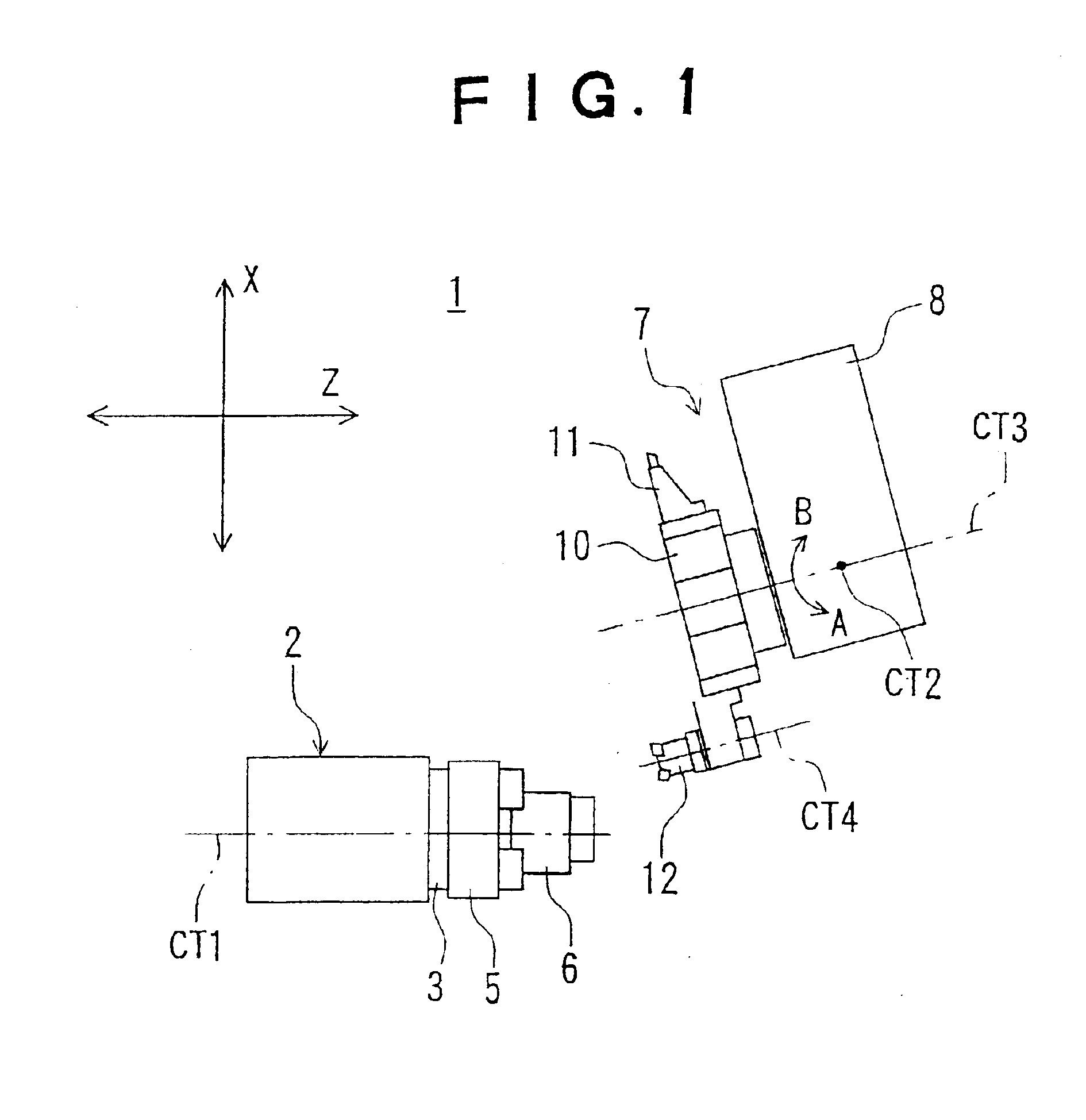

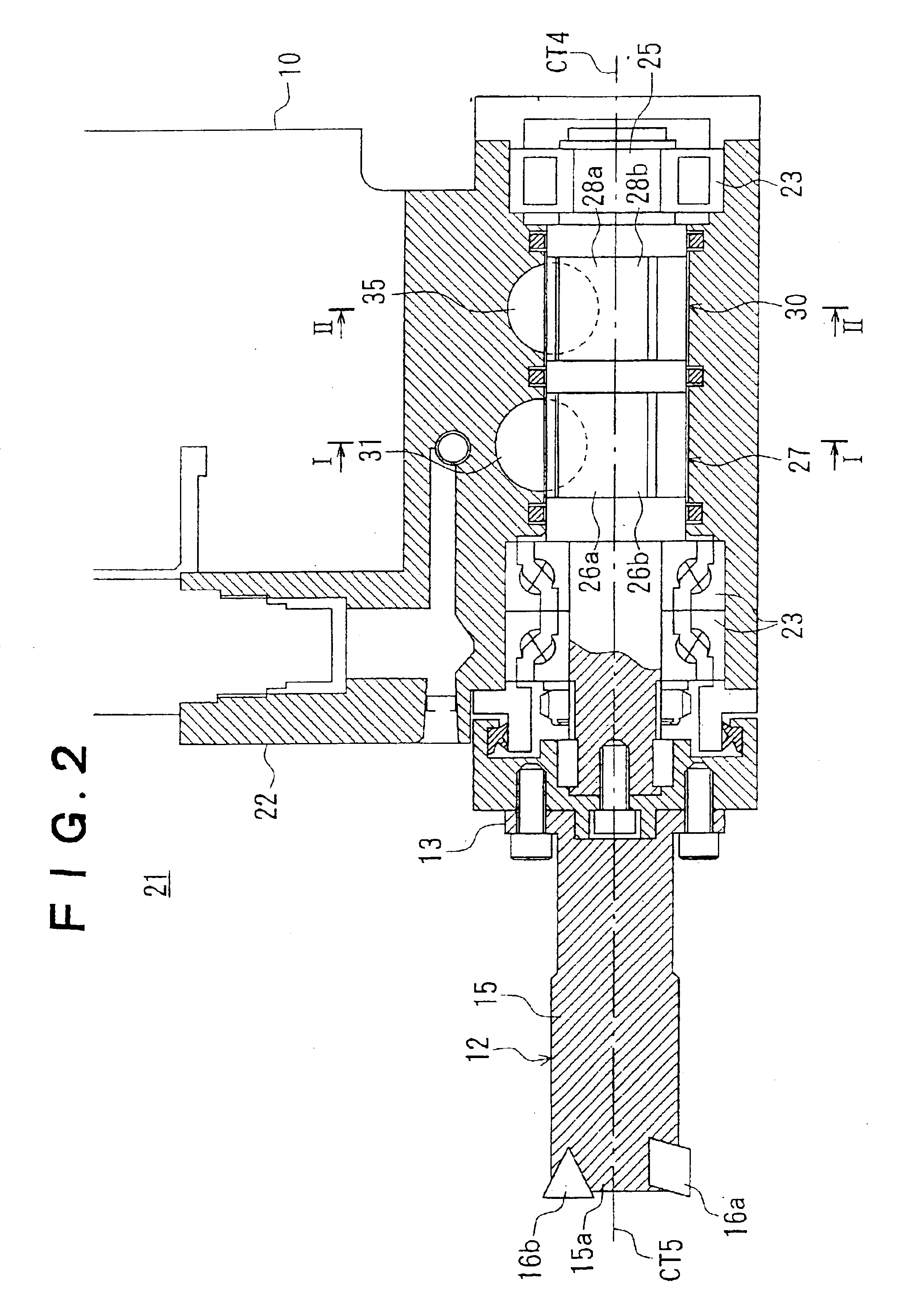

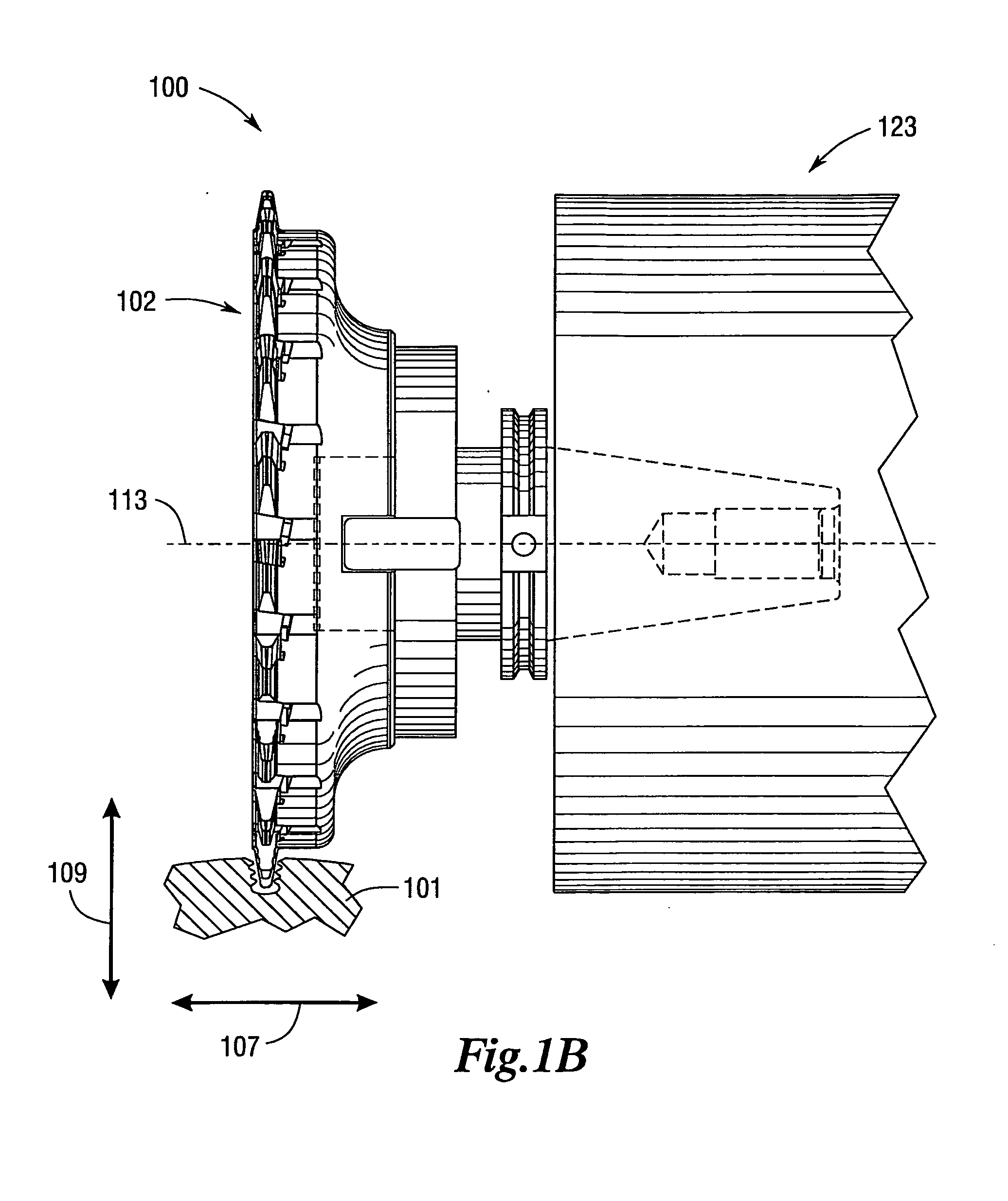

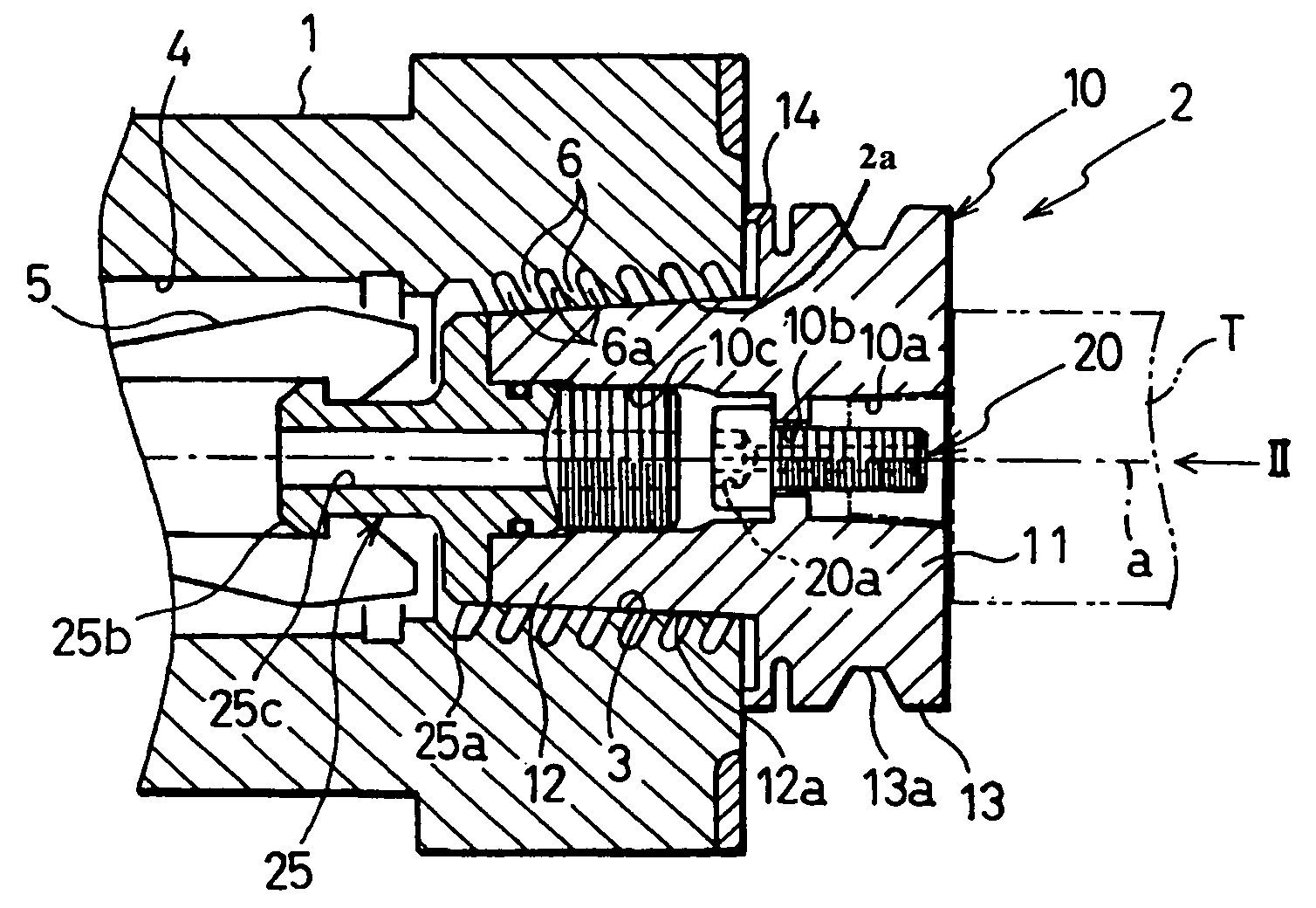

Tool holder for turret lathe

InactiveUS6865789B2Improve machine efficiencyAvoid long exchangesAutomatic/semiautomatic turning machinesPrecision positioning equipmentRotation functionEngineering

A tool holder for attaching a complex tool having a plurality of kinds of cutting edges to a turret, has a base portion attachably and detachably formed at the turret. The base portion has a rotatable tool spindle attachably and detachably installing the complex tool thereon. The tool spindle is provided with indexing means for indexably rotating the tool spindle at an indexed position corresponding to each cutting edge of the complex tool. And, clamping means for clamping the tool spindle at a predetermined indexed position is provided. Indexing rotational function and clamping function owned by the tool holder makes the use of the complex tool in the lathe possible.

Owner:YAMAZAKI MAZAK KK

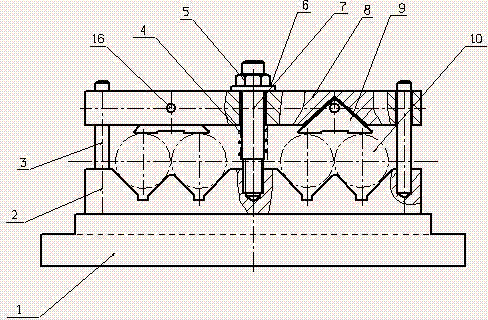

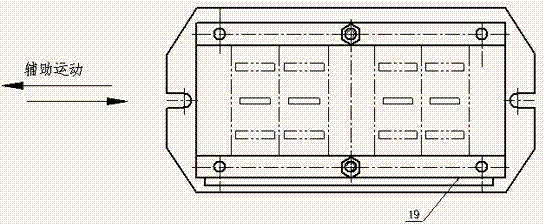

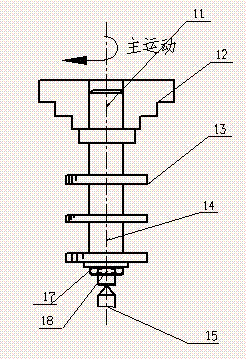

Rotating cup bearing shell milling device for lathe

InactiveCN102416498AImprove work efficiencyAttachable milling devicesPositioning apparatusMoving partsEngineering

The invention relates to a rotating cup bearing shell milling device for a lathe. The device comprises a main moving part and an auxiliary moving part, wherein the main moving part comprises a cutter rod and a cutter disc; and the auxiliary moving part is a multi-clamp fixture. The common lathe can be used for milling operation when the main moving part and the auxiliary moving part consisting of the multi-clamp fixture are combined and arranged on the lathe, so that the application range of the lathe is expanded, and work efficiency is improved; and a plurality of pieces of V-shaped iron are arranged on a bottom plate and matched with an upper part frame pressing plate structure, so that a plurality of workpieces can be fixed in the fixture at one time, and machining efficiency is improved exponentially.

Owner:JINZHONG RENHE TEXTILE MACHINERY BEARING

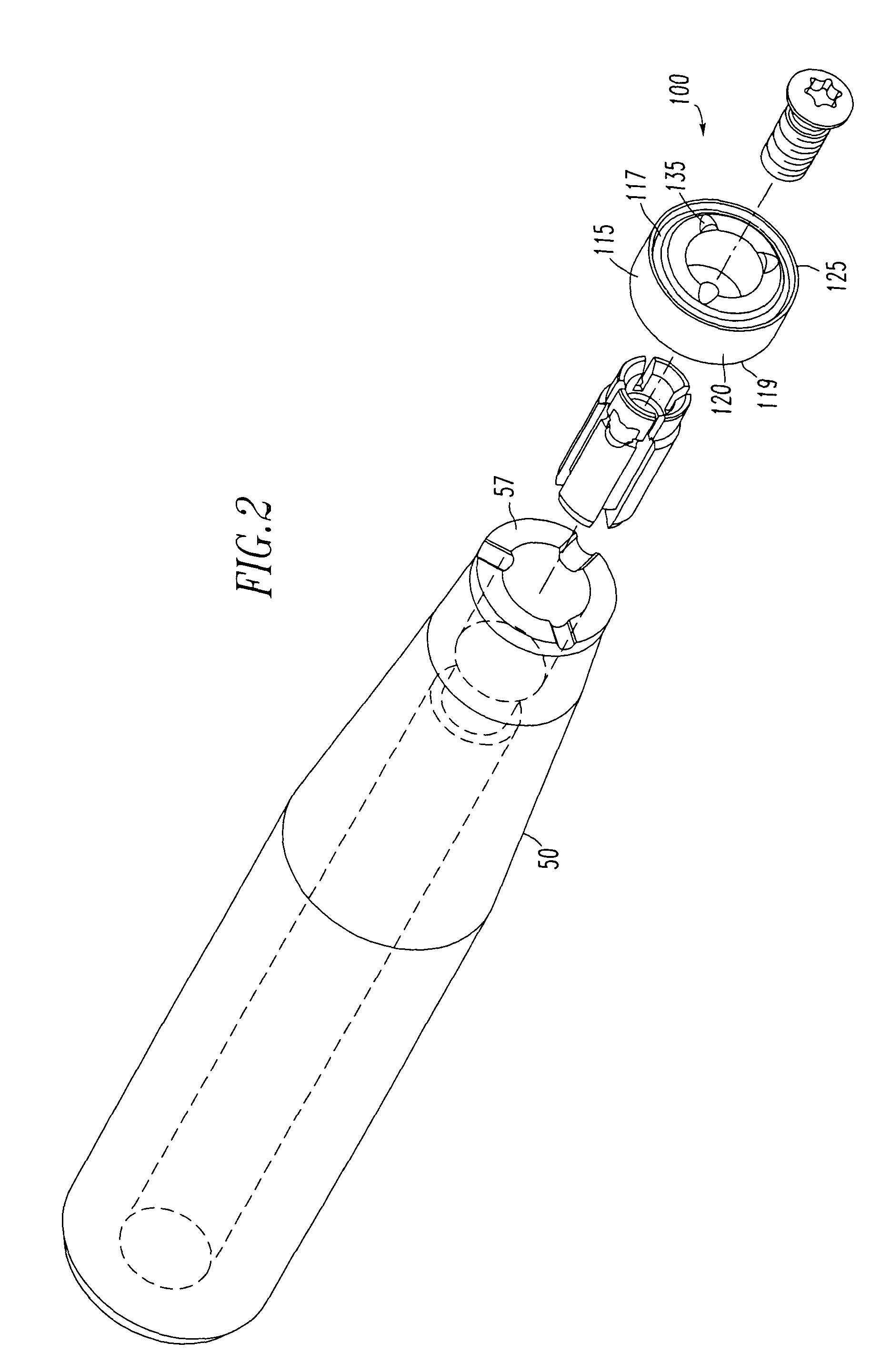

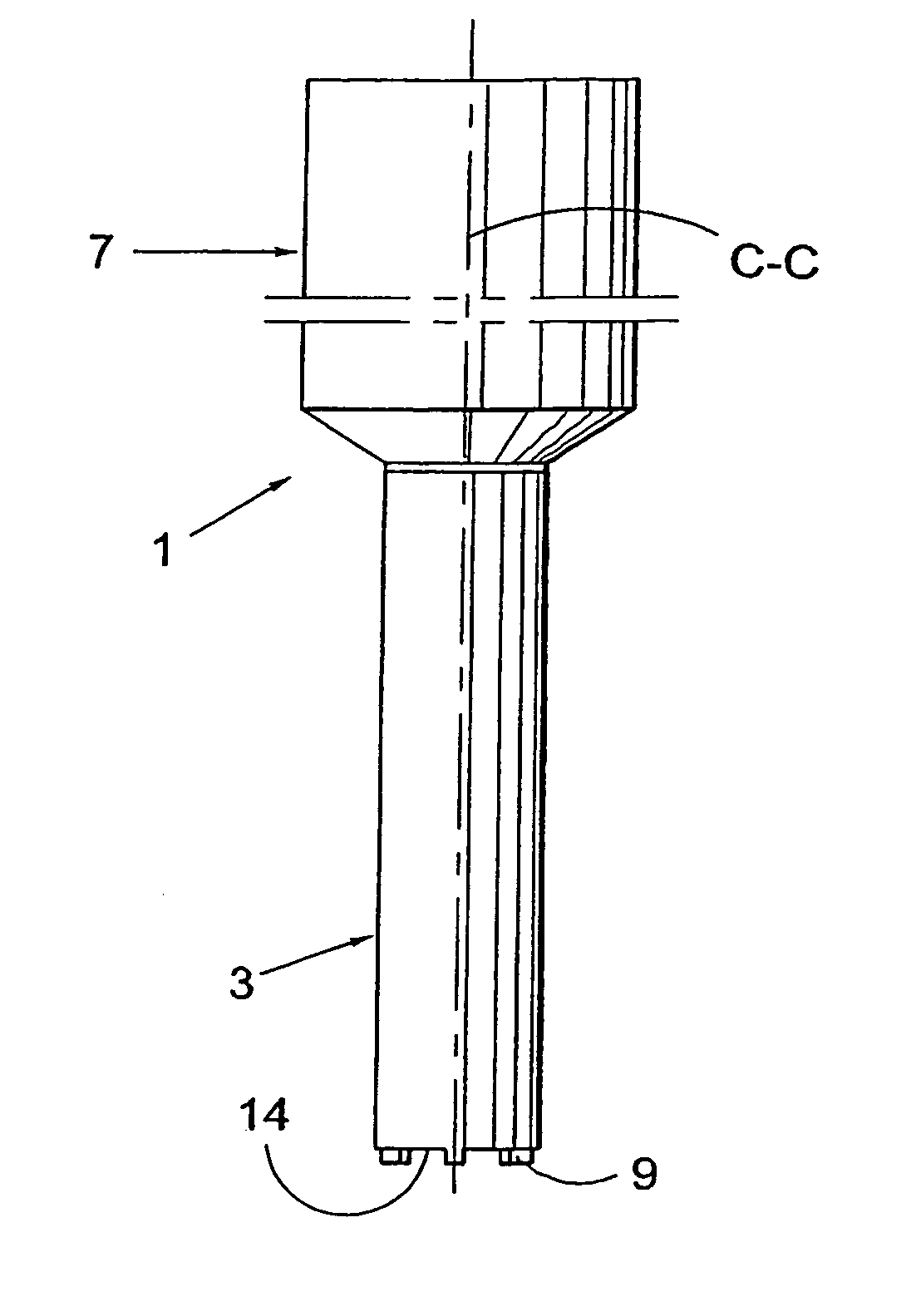

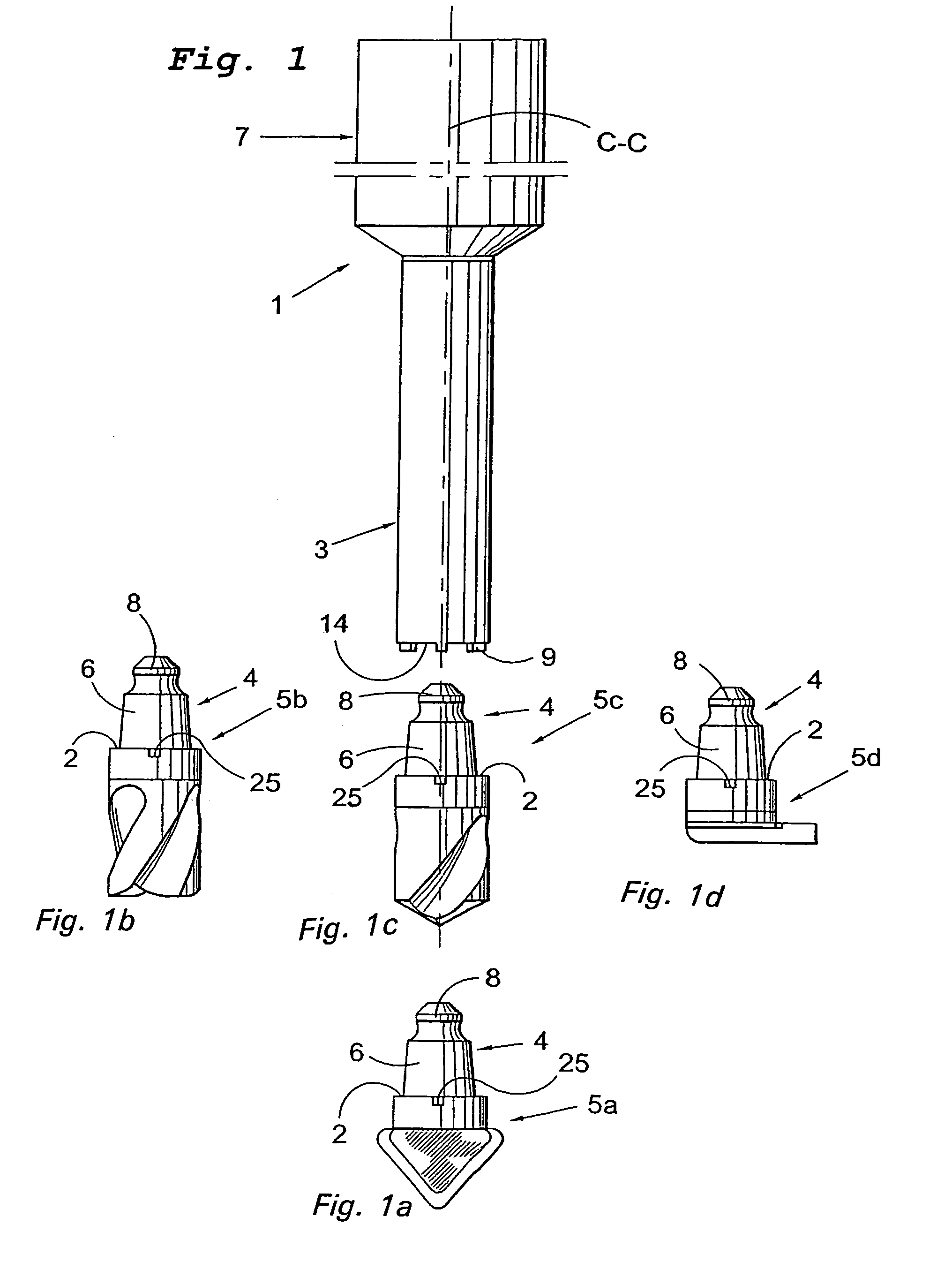

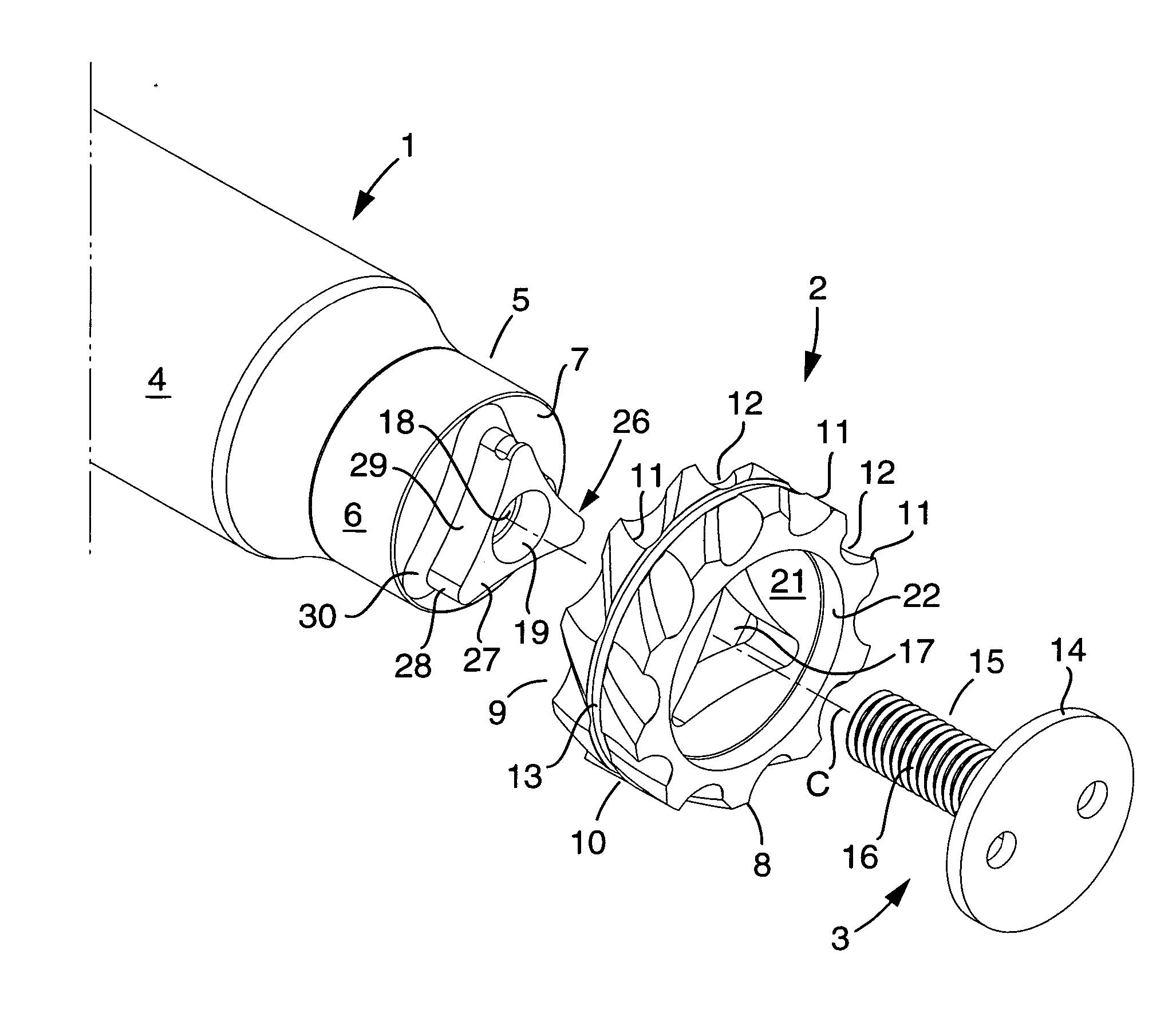

Cutting tool and cutting head thereto

InactiveUS7101128B2Improve stabilityThread cutting machinesTransportation and packagingEngineeringAxial projection

A tool such as a milling or drilling tool includes a shaft having a front recess in which a cutting head is disposed. A drawbar disposed in the shaft includes a plurality of flexible tongues disposed in the recess. The tongues form a recess in which a rear knob of the cutting head is received. A retainer urges the drawbar axially rearwardly to retain the cutting head in the recess. The shaft includes axial projections at its front end which are received in respective rearwardly open recesses of the cutting head to prevent relative rotation between the shaft and the cutting head.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

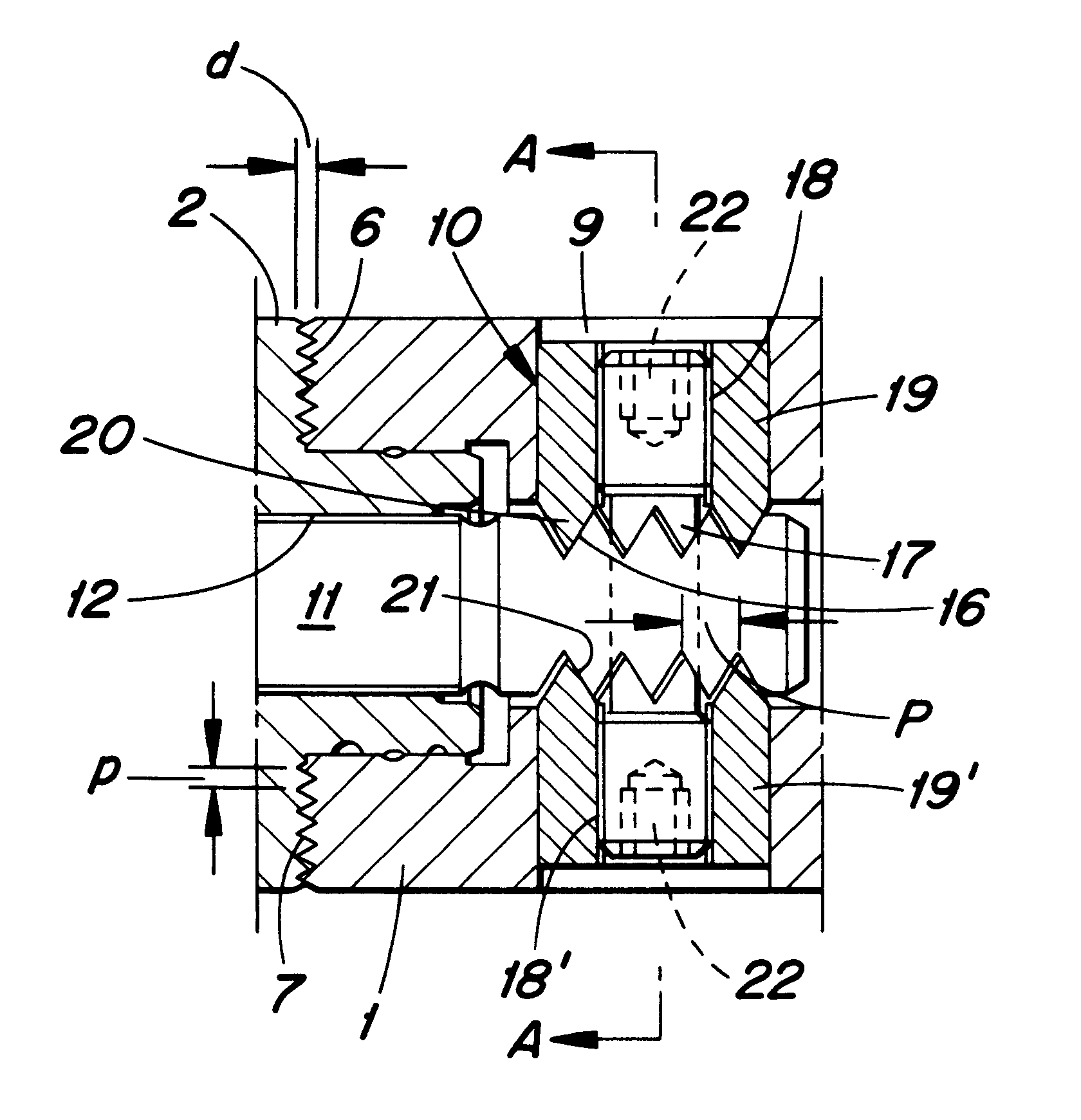

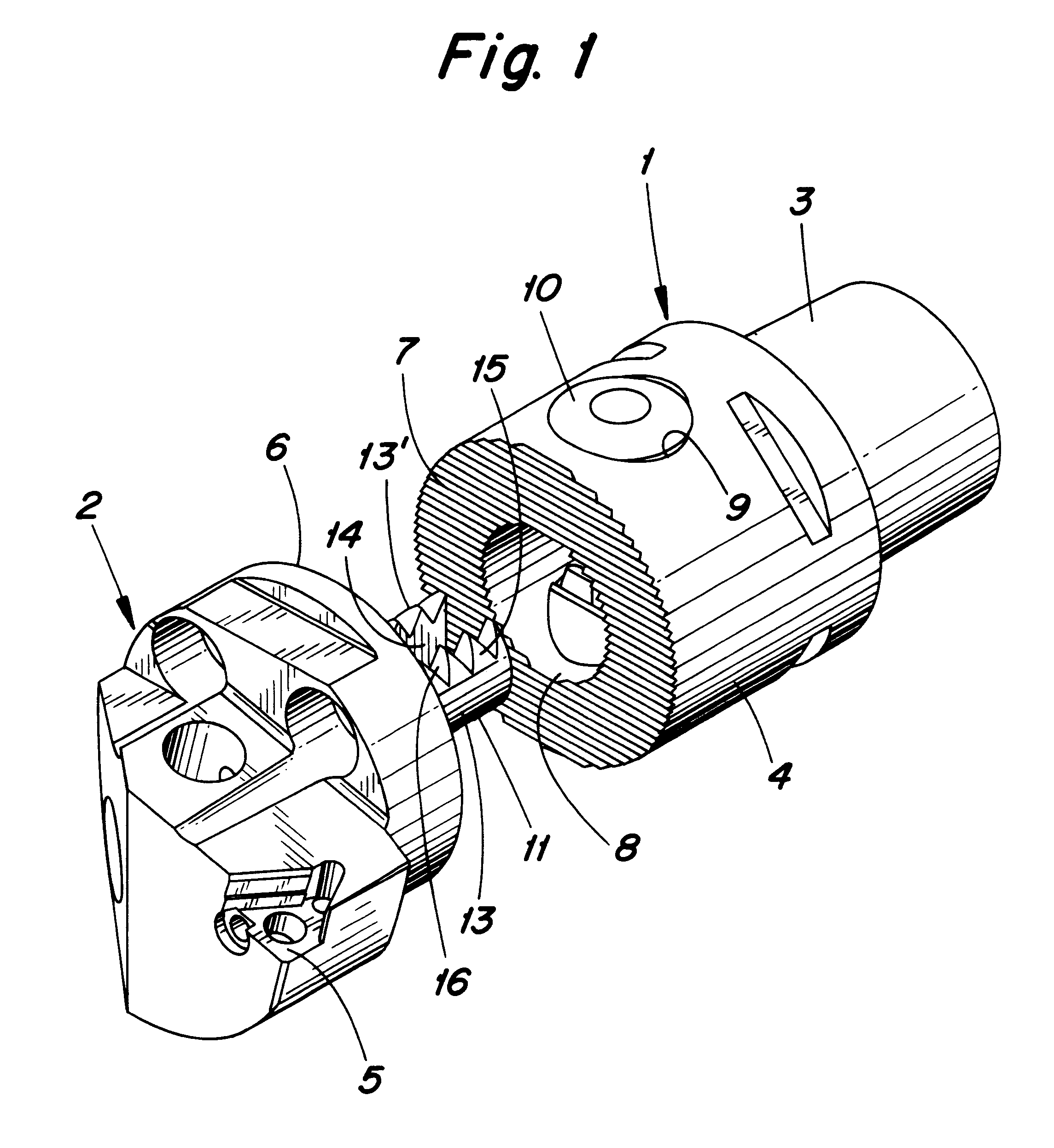

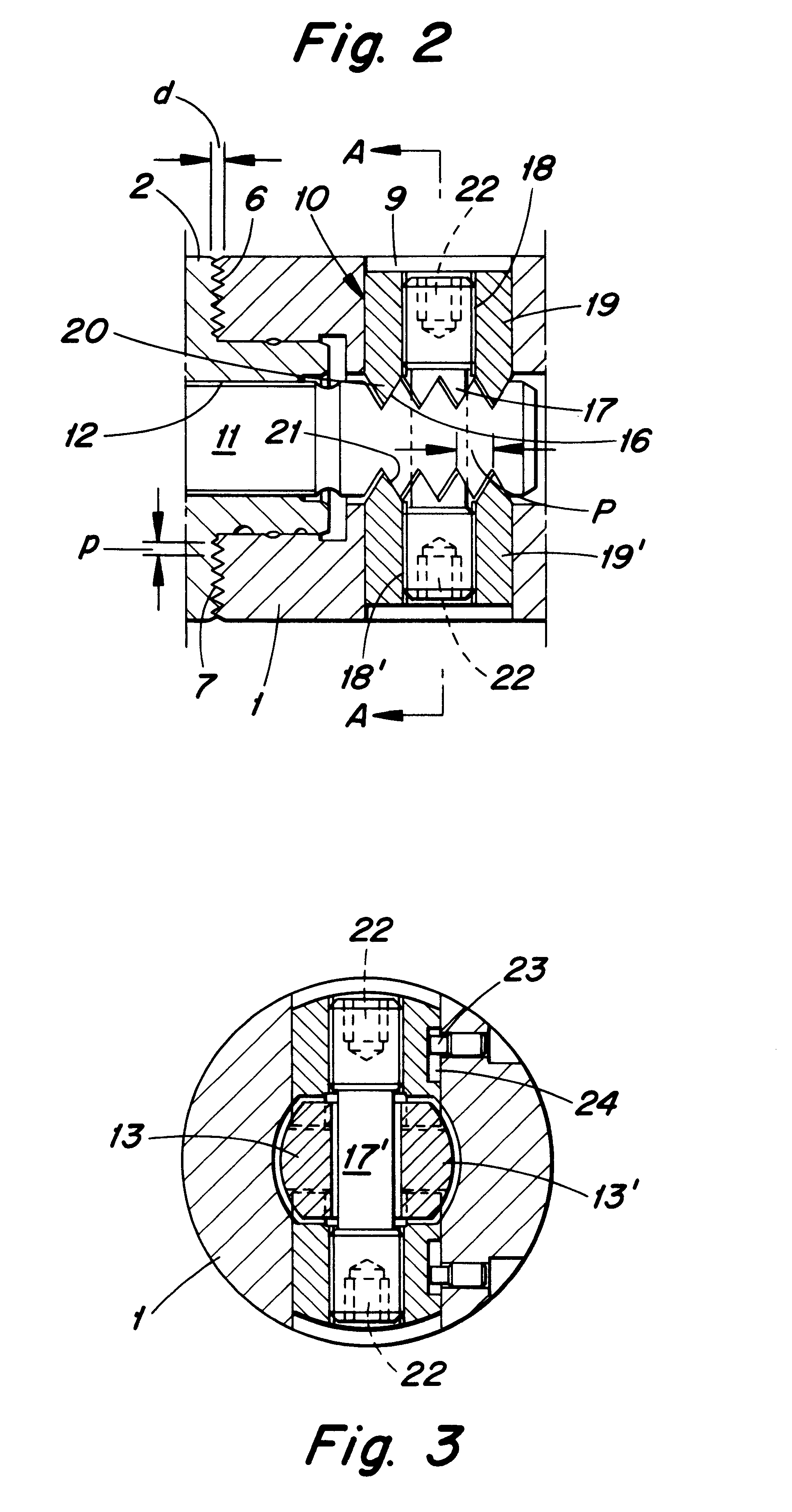

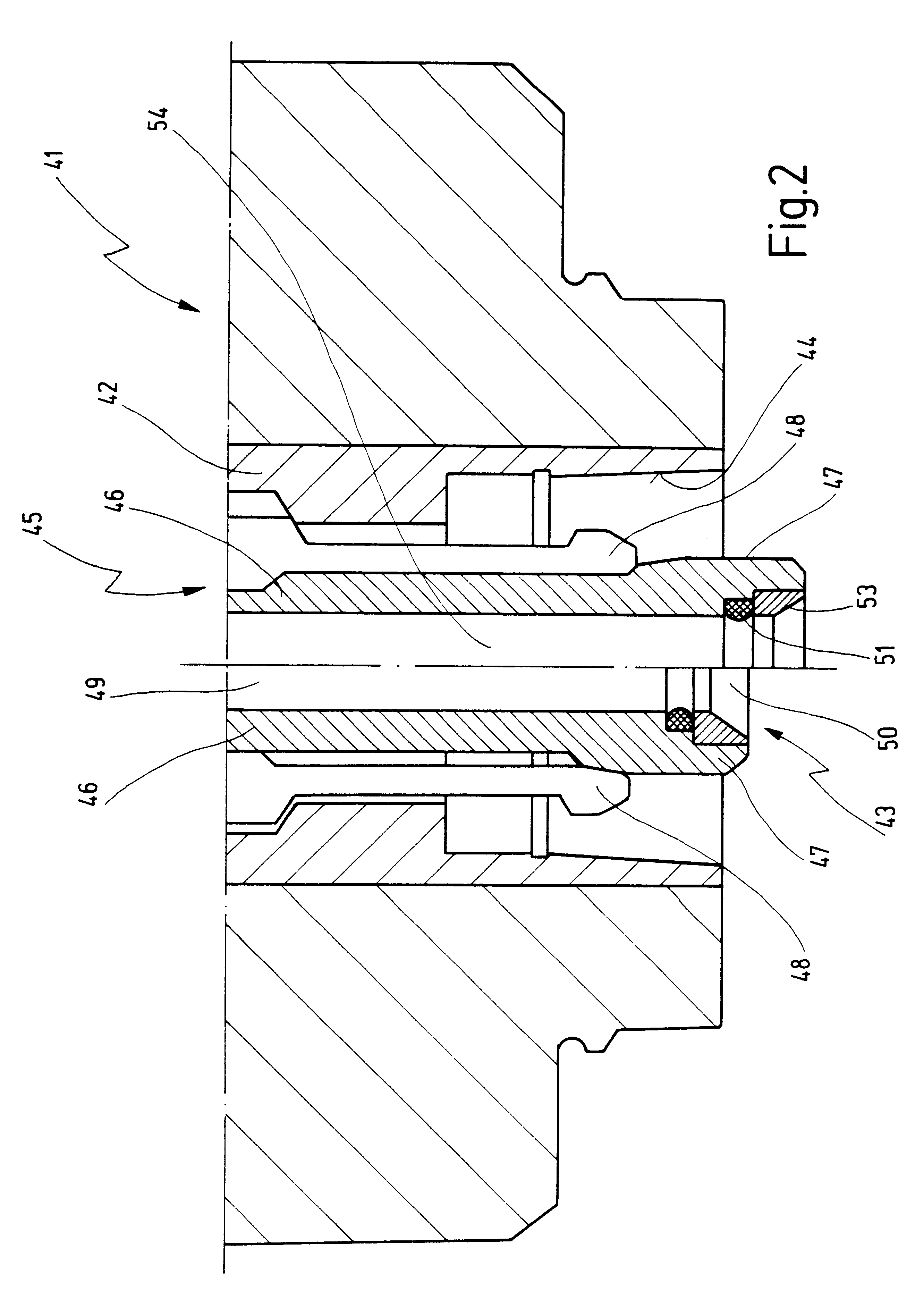

Tool coupling having serrated surfaces adapted to be pulled into meshing relationship

InactiveUS6244780B1Enhanced couplingThread cutting machinesTransportation and packagingCouplingEngineering

A tool coupling includes first and second bodies held together by a clamping mechanism. The first body includes a first surface having a first serration formed therein, a first hole extending through the first surface, and a side surface having a second hole extending therethrough and intersecting the first hole. The second body includes a second surface facing the first surface and including a second serration configured to mesh with the first serration. A drawbar projects from the second surface and extends into the first hole. The drawbar includes a plurality of wedge surfaces. The clamping mechanism includes a screw disposed in the second hole and nuts threadedly mounted thereon for movement toward and away from the drawbar. Each nut includes a plurality of wedge surfaces arranged to engage the wedge surfaces of the drawbar to pull the second body toward the first body in a manner bringing the first and second serrations into meshing engagement with one another.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Slotting cutter and inserts for same

The present invention is directed to an insert, a slotting cutter assembly and a method for machining a plurality of slots in a metallic alloy part. The insert may comprise a cutting edge, at least one primary radius, at least two secondary radii and a clearance angle. The cutting edge may form a narrow outer end at a tip of the insert and a larger width region at a distance inward from the narrow outer end. The clearance angle may extend rearward from the cutting edge. The slotting cutter assembly may comprise a plurality of inserts and a cutter body. The cutter body may comprise a plurality of retaining slots and a plurality of support portions. The retaining slot may be configured to receive the insert. The support portion may provide support for the insert.

Owner:GREENLEAF TECH CORP

Tool holder attachment structure

InactiveUS7284938B1Eliminate vibrationEliminating attachment failureAttachable milling devicesMilling machinesEngineeringFlange

A main shaft includes a plurality of elastic engagement pieces arrayed along an outer perimeter of an attachment hole. During and after assembly, the elastic engagement pieces elastically abut at least an outer surface of a tapered shank in a tool holder and deform slightly in a radial direction. The elastic engagement pieces provide uniform engagement force between the main shaft and the tool holder over a broad surface area. An elastic flange provides additional elastic engagement and easy separation from the main shaft. Together, the elastic engagement pieces and elastic flange reliably engage and securely attach the main shaft to the tool holder while aiding disengagement.

Owner:PASCAL ENG

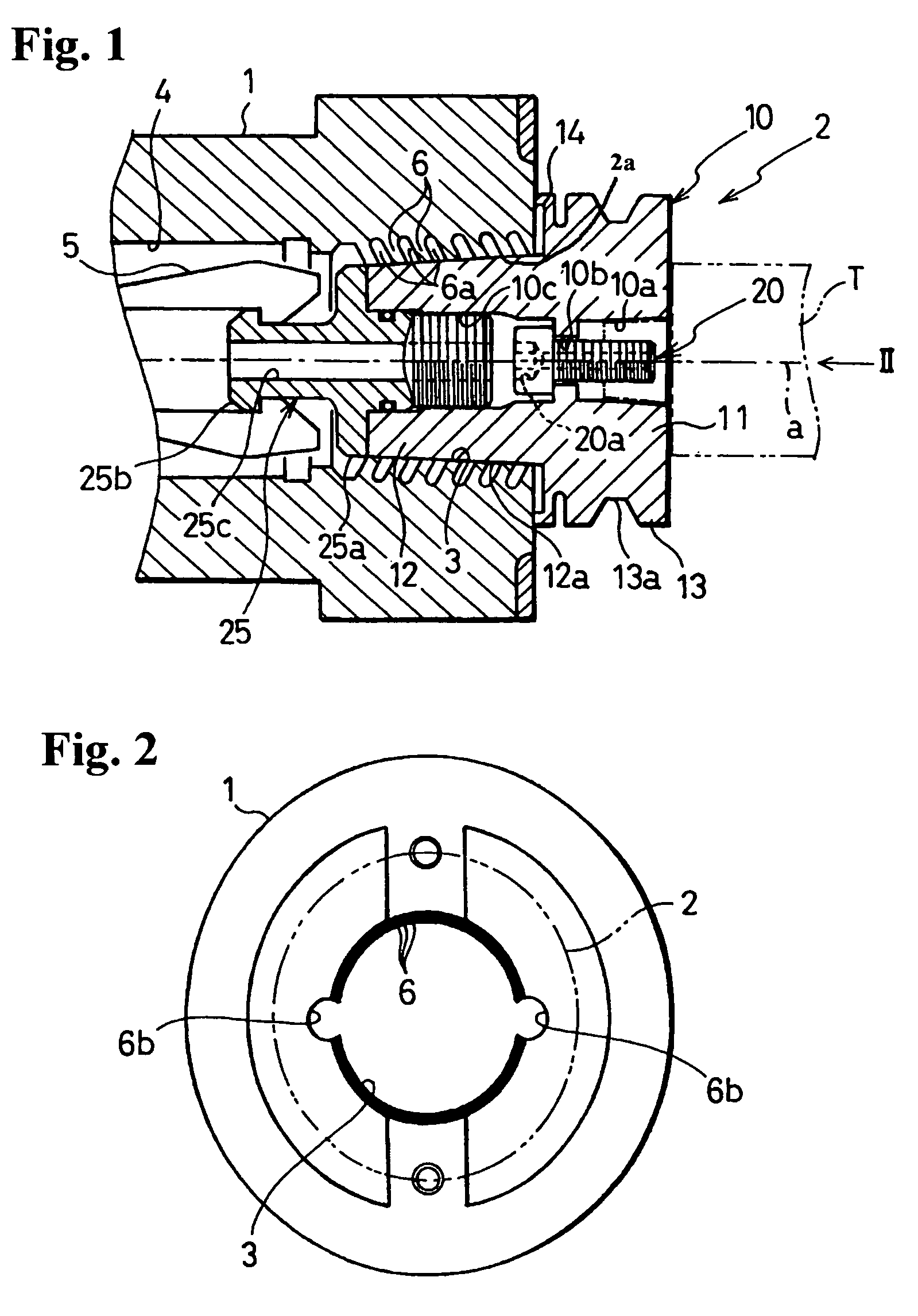

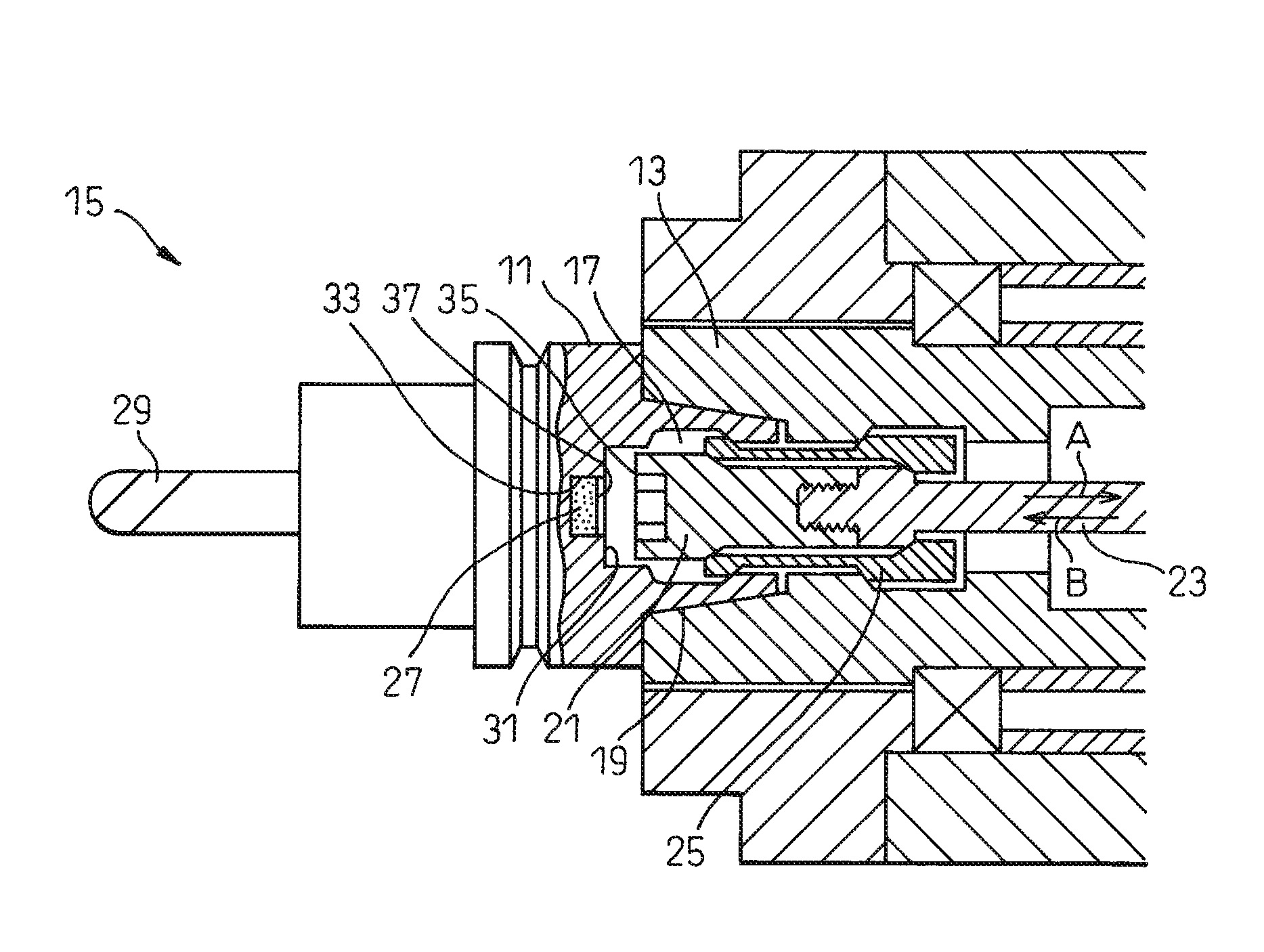

Machine tool clamping device

A machine tool tool changing device including a circular array of multiple collet fingers (5) housed in the shaft hole (12) of a spindle (1) capable of turning between a clamped position in which a tool holder (2) knob (22) is clamped and an unclamped position in which the knob is released, a collet sleeve (6) which surrounds the circular array of collet fingers and arrests the turning of same, an air cylinder which moves the collet sleeve axially relative to the collet fingers and releases the arresting of the collet fingers, a first plate spring (43) which exerts a strong force on the knob toward the spindle through the collet fingers, an air cylinder which removes the force exerted by the first plate spring, and a second plate spring (46) which exerts a force to maintain the collet fingers in the clamped position in opposition to the weight of the tool holder even if the collet fingers rotate and the force exerted by the first plate spring is removed.

Owner:SODICK CO LTD

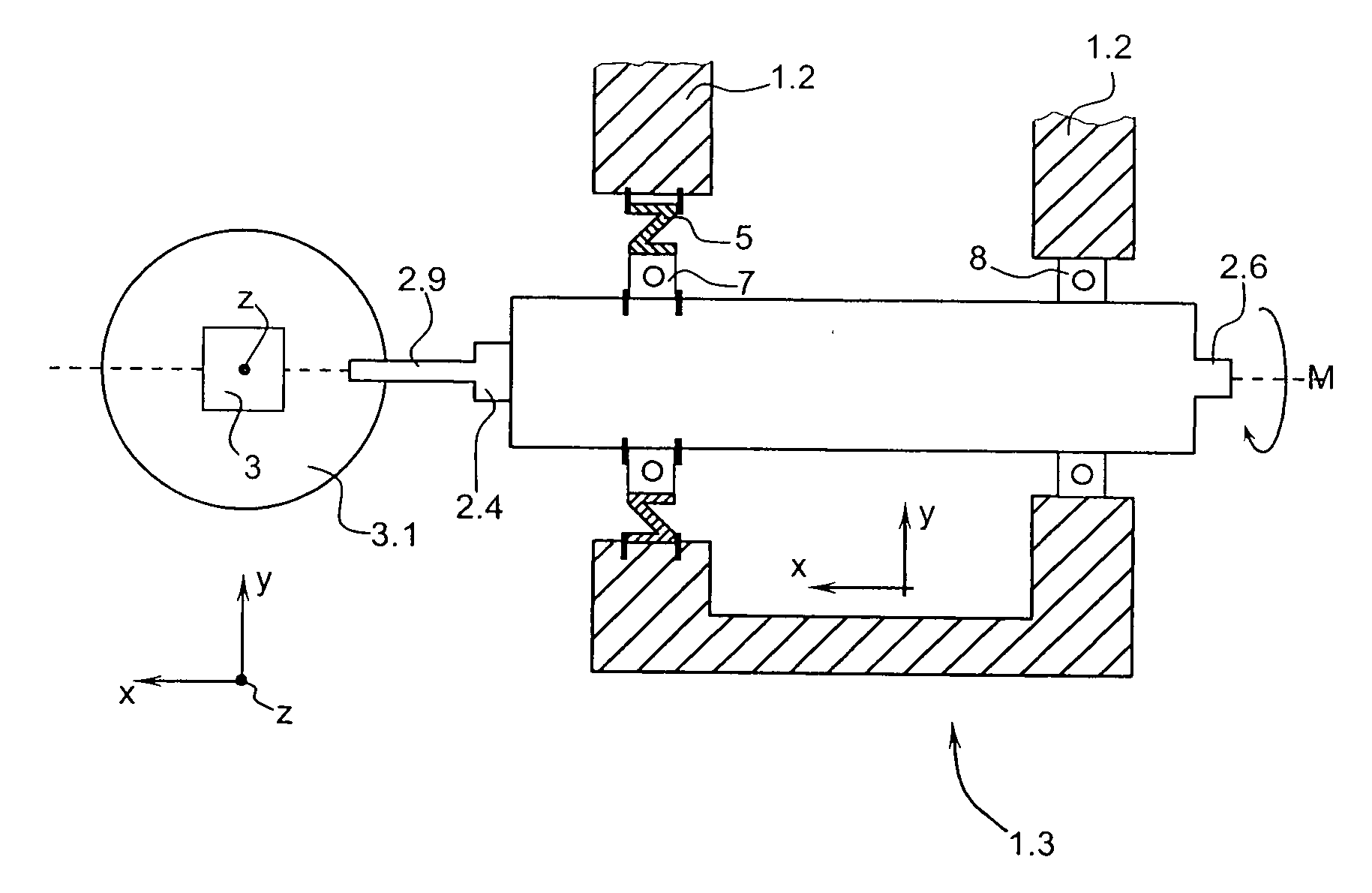

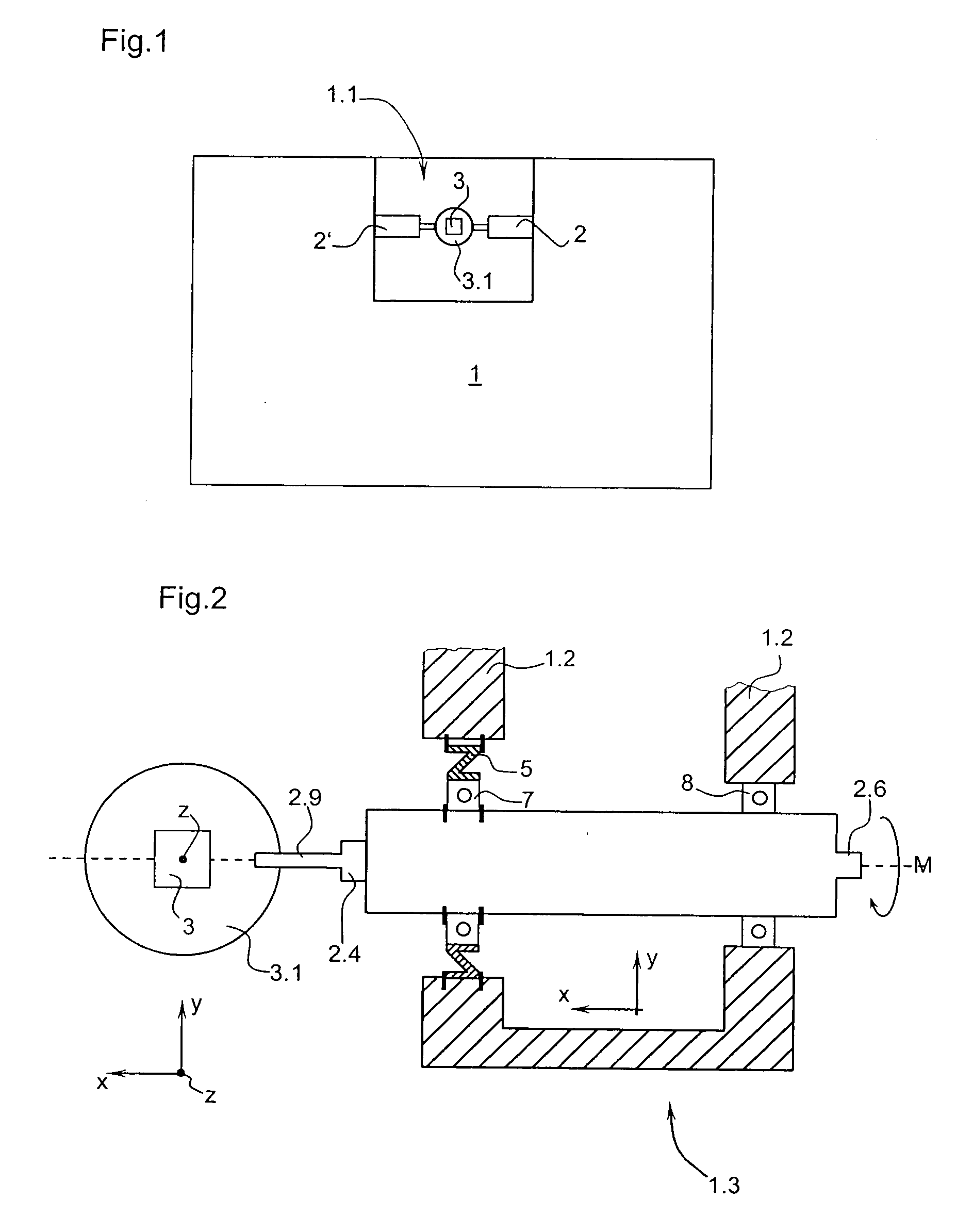

Dental machining unit with tool spindle

ActiveUS20080226409A1Evenly distributedAssures necessary stabilityRolling contact bearingsDiagnosticsEngineeringForce sensor

The present invention relates to dental machining apparatus (1) for blanks (3) comprising a tool spindle (2) having an axis of rotation (2.8) and mounted in a bearing housing (1.2) disposed on the machine housing side. A force sensor (5) is also provided, which is disposed between the tool spindle (2) and the bearing housing (1.2) for the purpose of detecting the machining force acting on the tool spindle (2), wherein the tool spindle (2) can be supported against the bearing housing (1.2) directly or indirectly via the force sensor (5).

Owner:SIRONA DENTAL SYSTEMS

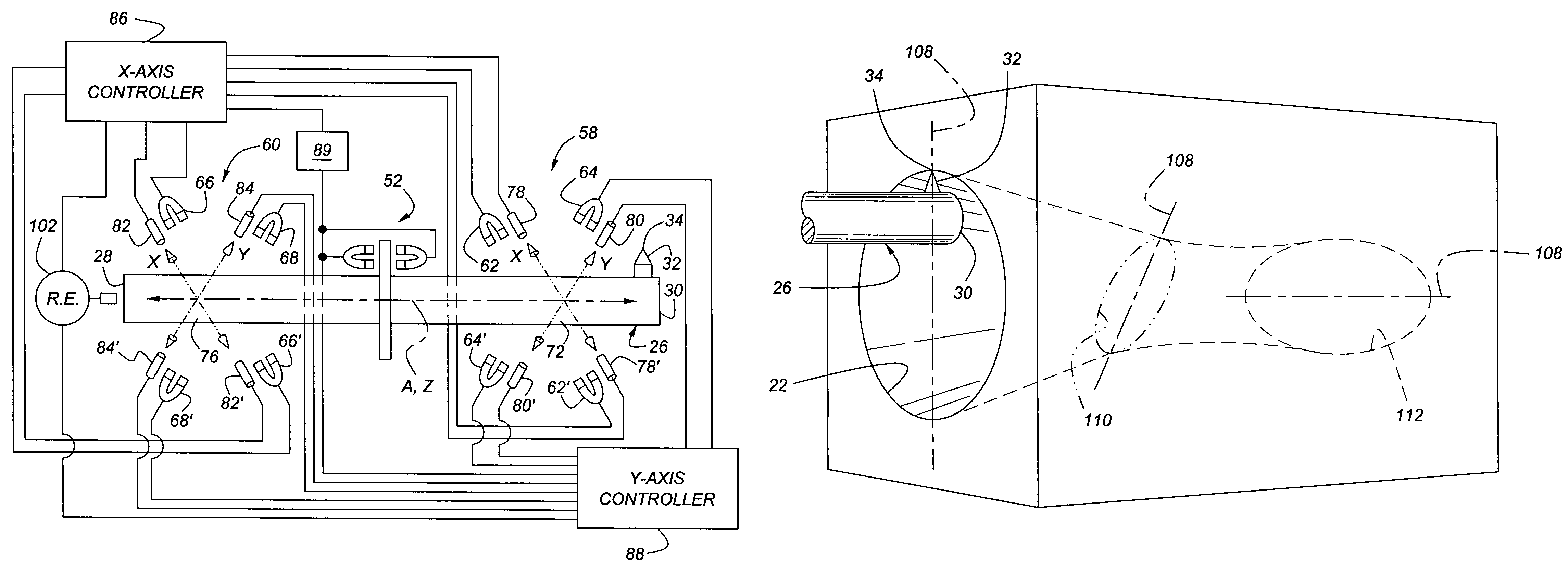

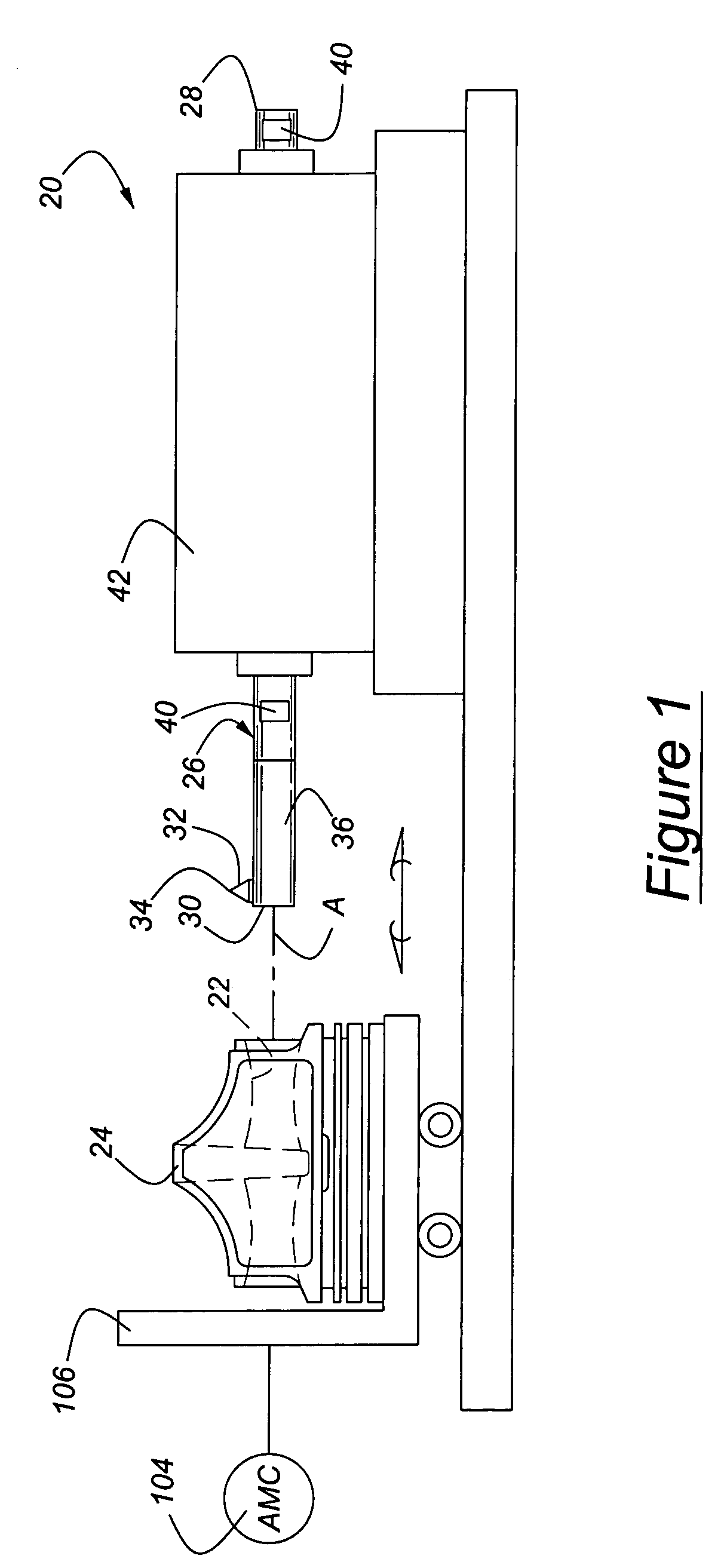

Magnetically levitated high-speed spindle for shaping irregular surfaces

InactiveUS7264430B2High precisionIncrease speedThread cutting toolsTurning machine accessoriesMagnetic bearingEngineering

Owner:FEDERAL MOGUL WORLD WIDE

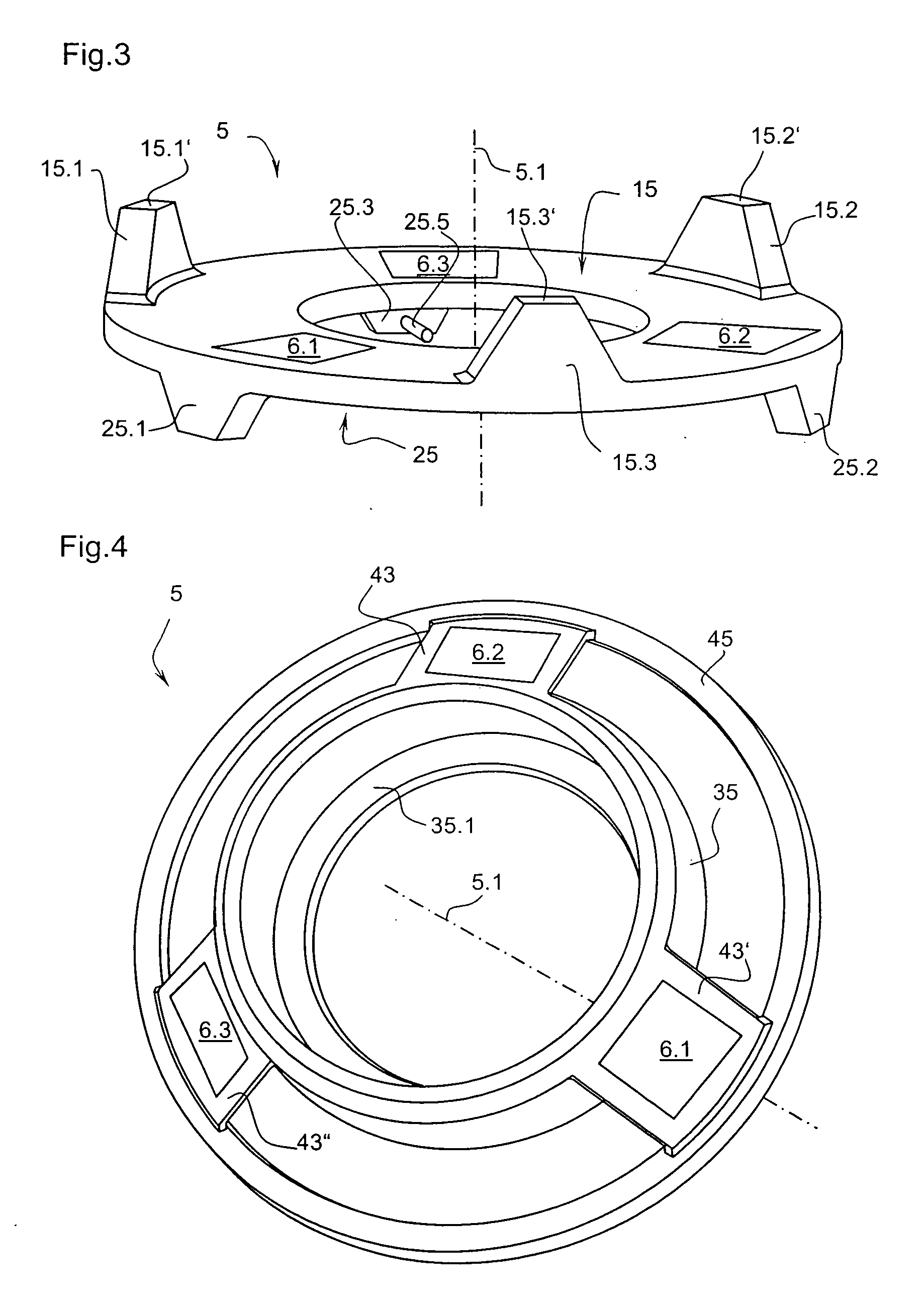

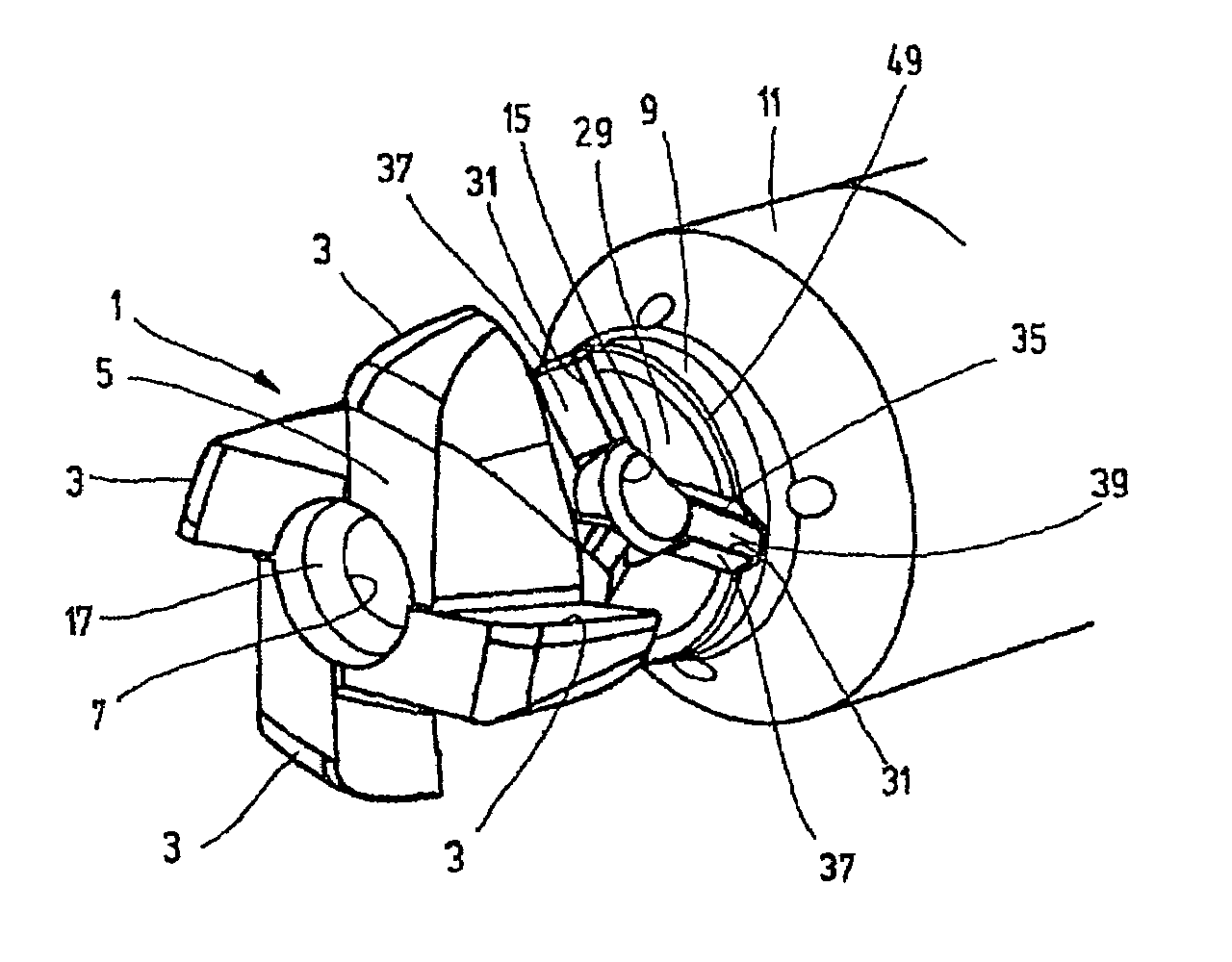

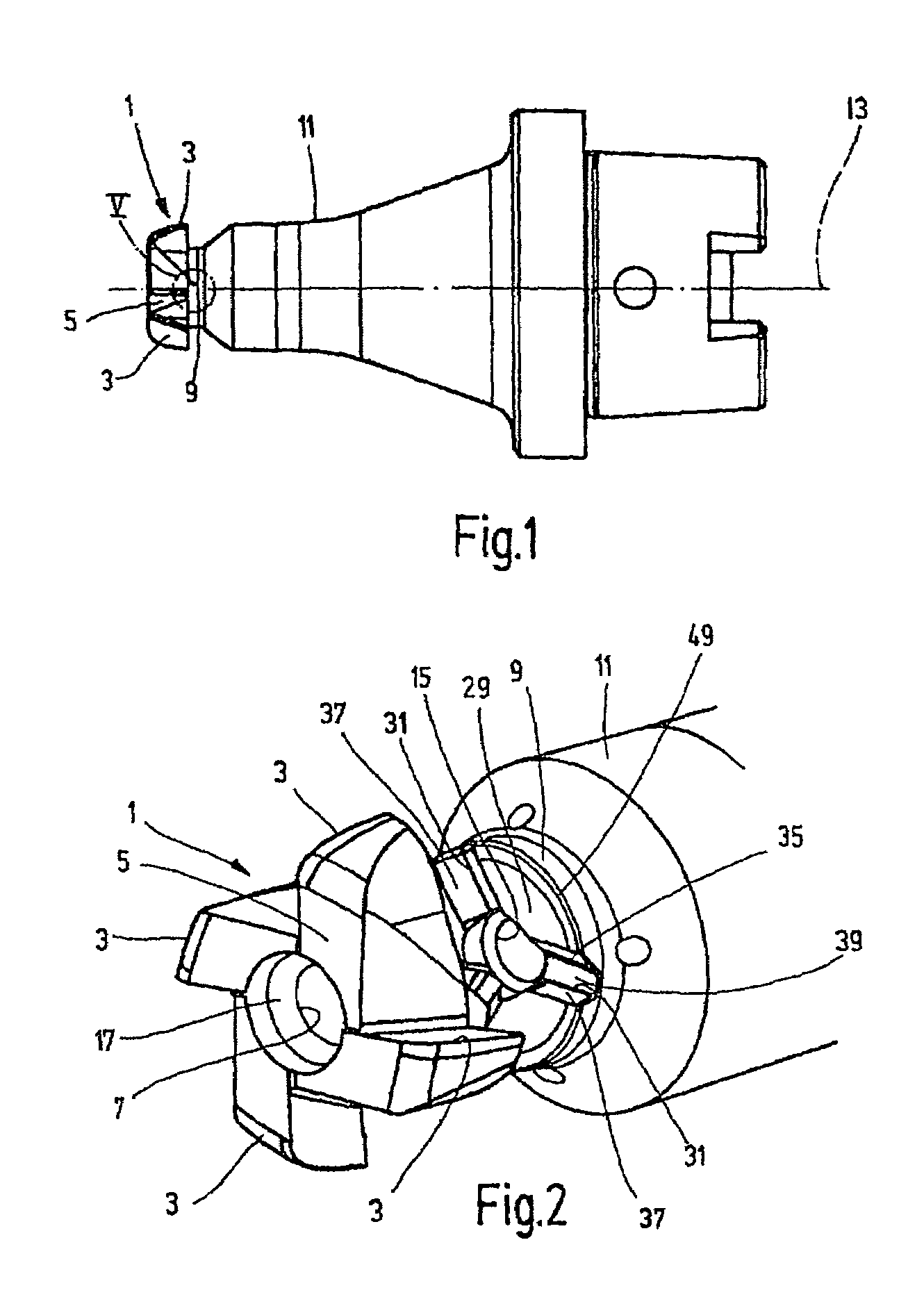

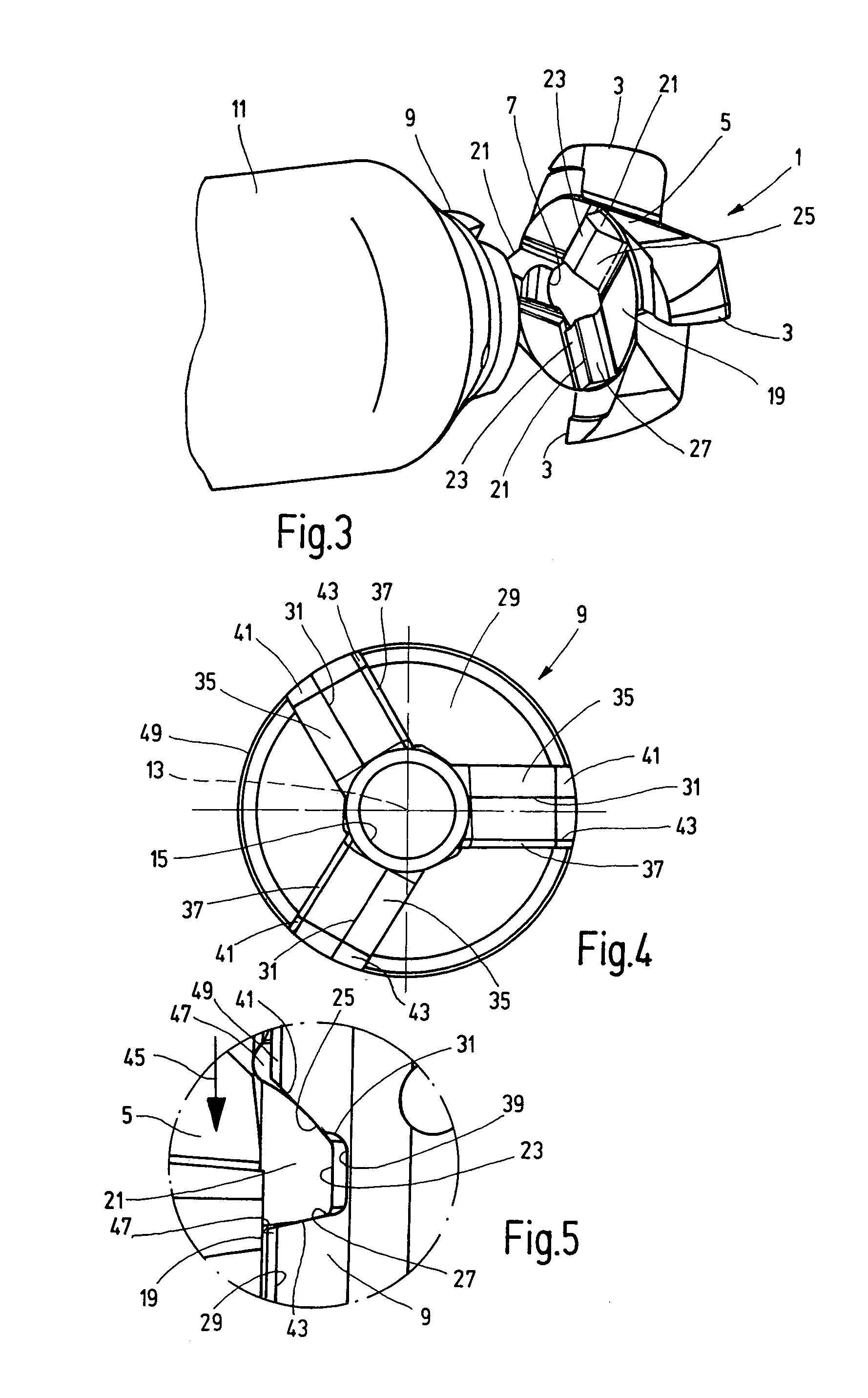

Machining tool, especially a milling tool

InactiveUS7150590B2Enhanced couplingEasy to manufactureThread cutting machinesTransportation and packagingEngineeringMachine tool

A machining tool, especially a milling tool, includes a shaft-like holder defining a longitudinal axis (13). A seat (9) is provided in the front face of the holder for a cutting plate that can be inserted into the holder. The cutting plate has a coupling part for mounting in the seat (9) of the holder. The coupling part has three ribs which project axially from the end surface of the cutting plate that is opposite the holder and which extend radially. The ribs are provided for engagement in complementary grooves (31) configured in the seat (9) of the holder. Their side walls (37 and 35) form driving surfaces and support surfaces, which interact for transmitting a machining torque, or as axial position safety-catch, with corresponding surfaces of the flanks of the ribs of the cutting plate. The driving surfaces and the supporting surfaces are formed by limited partial surfaces (43 and 41) of the side walls (37 and 35) of the grooves (31) whose other surfaces are retracted in relation to the partial surfaces (43 and 41) to form a spacing between the ribs and the walls of the grooves (31).

Owner:HARTMETALL WERKZEUGFAB PAUL HORN

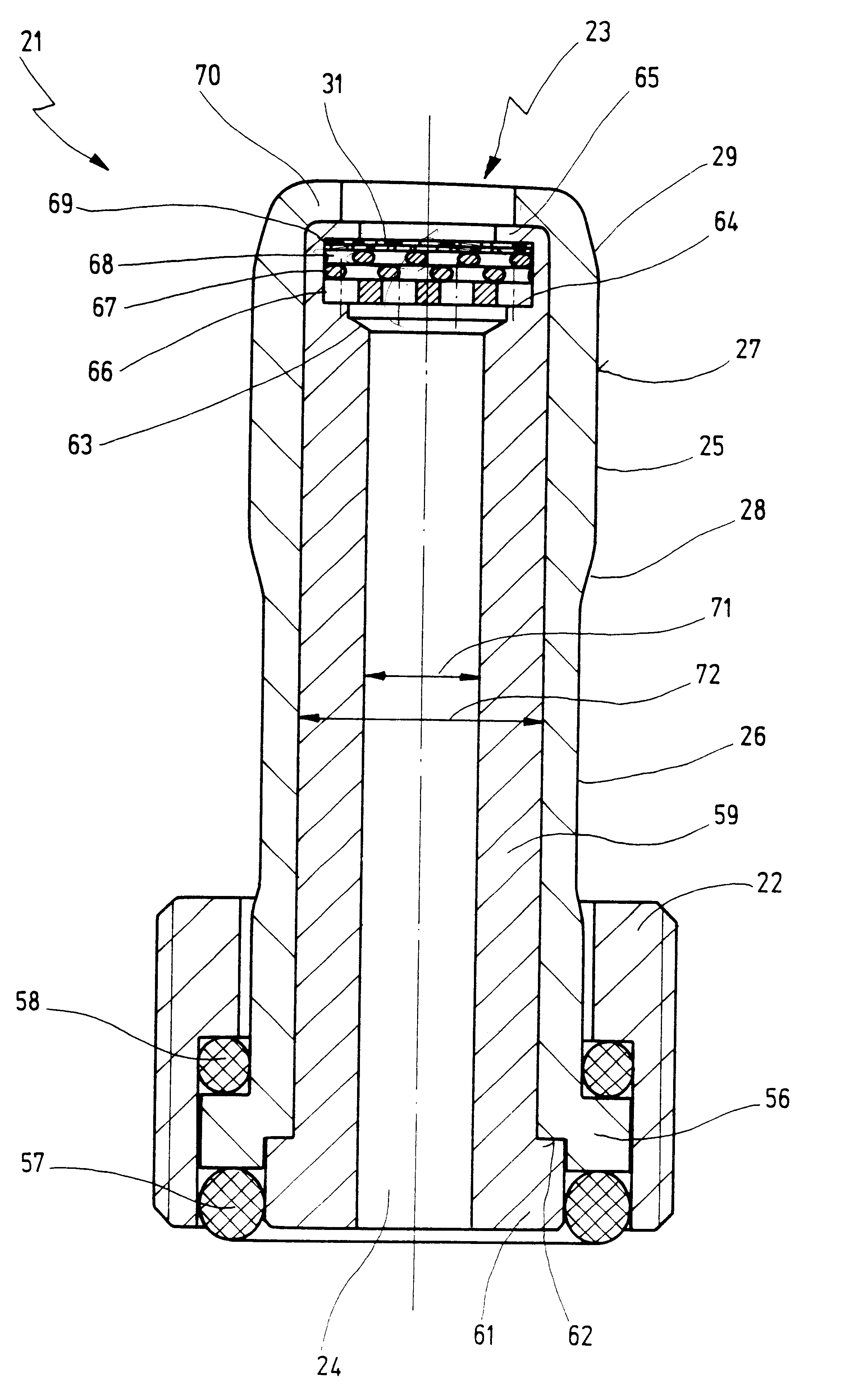

Tool holder with coolant tube

InactiveUS6648565B2Reduce net widthStable supportTransportation and packagingMilling cuttersKnife holderCoolant

A coolant tube (21) is to be arranged in a tool holder, the coolant tube (21) having an inlet opening (23) for coolants, a cover (31) at the inlet opening (23) for preventing chips from entering into the coolant tube (21), and an exchangeable insert tube (59) arranged within the coolant tube (21) and holding the cover (31).

Owner:CHIRON WERKE

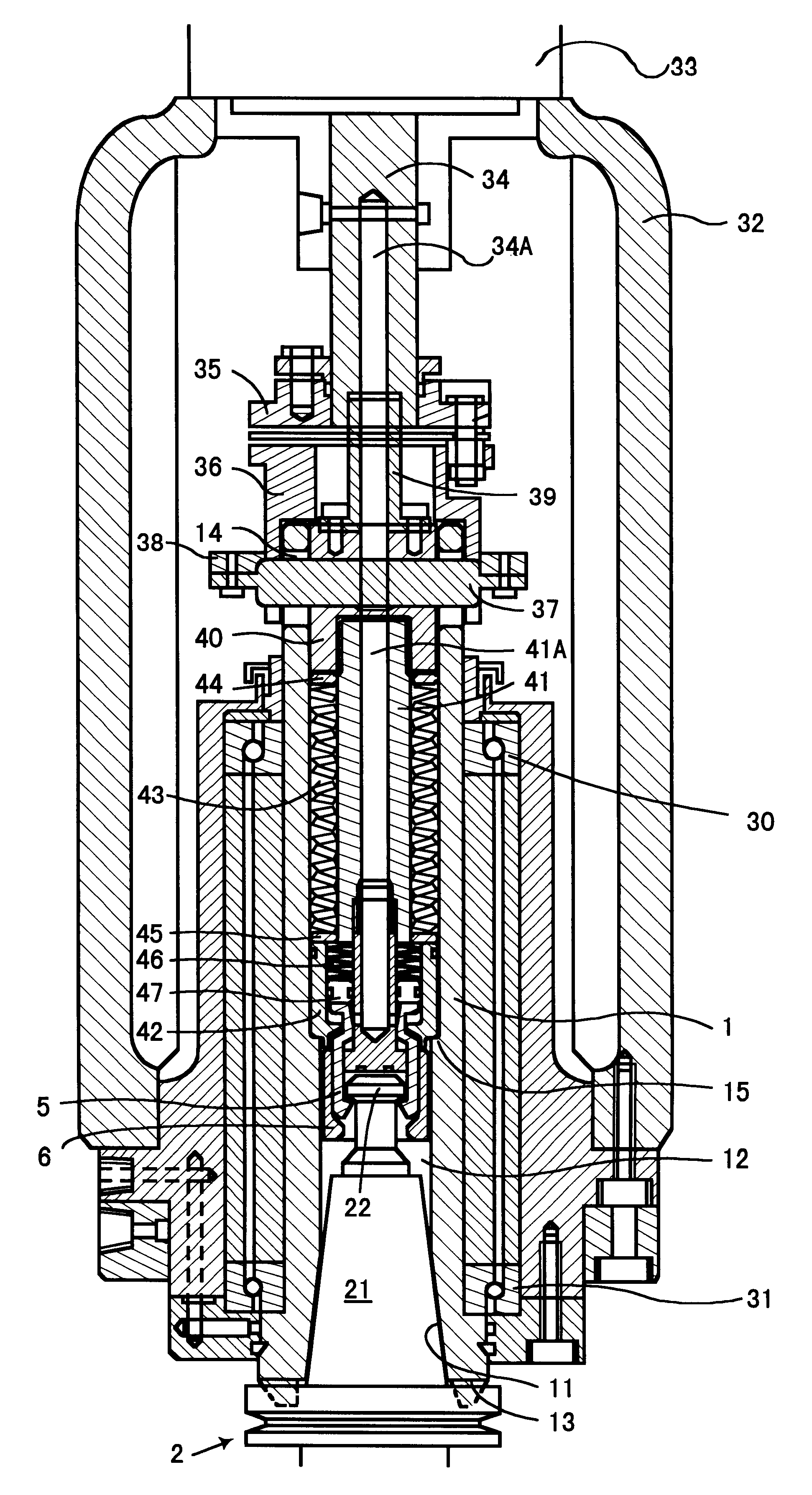

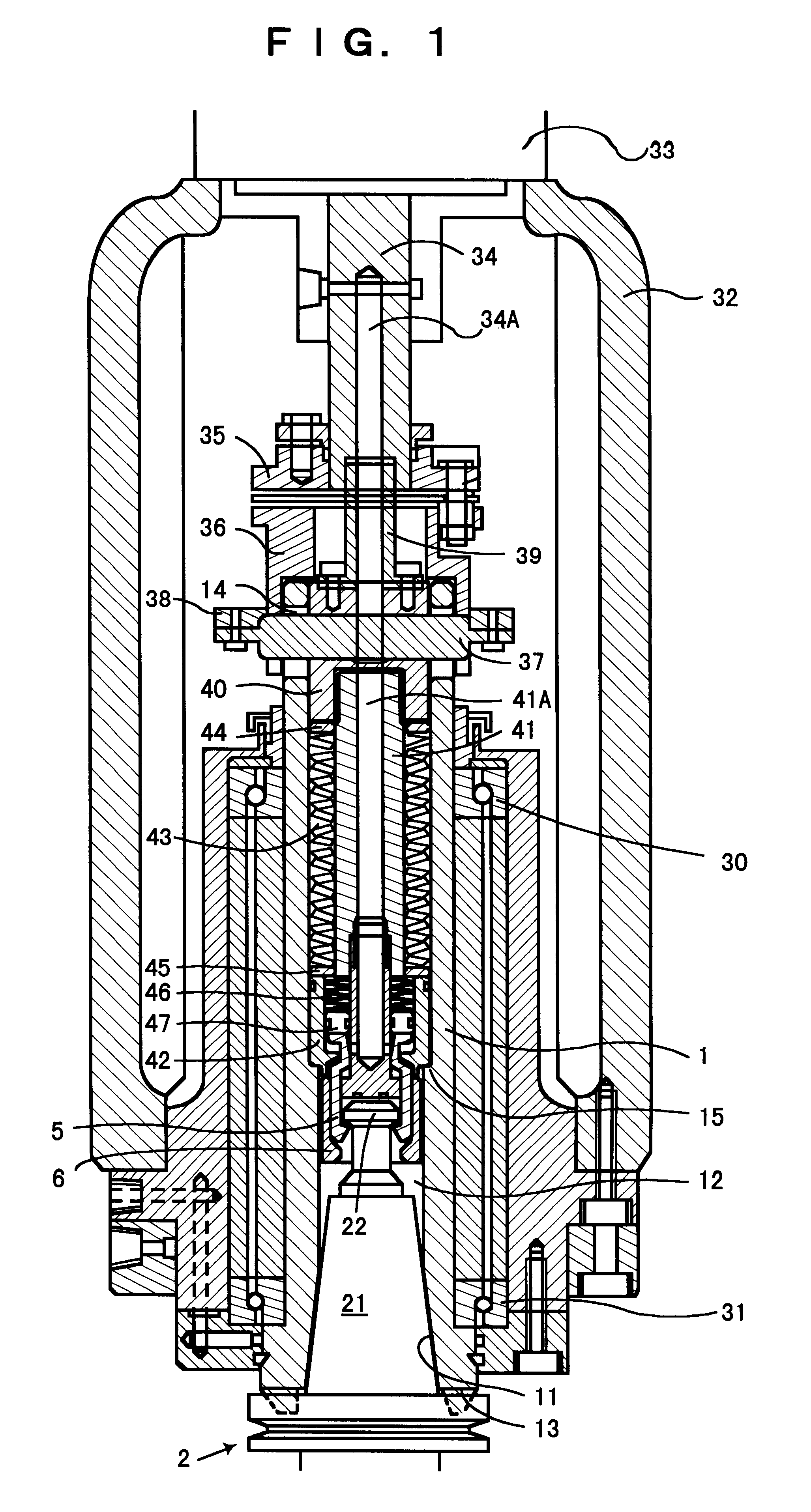

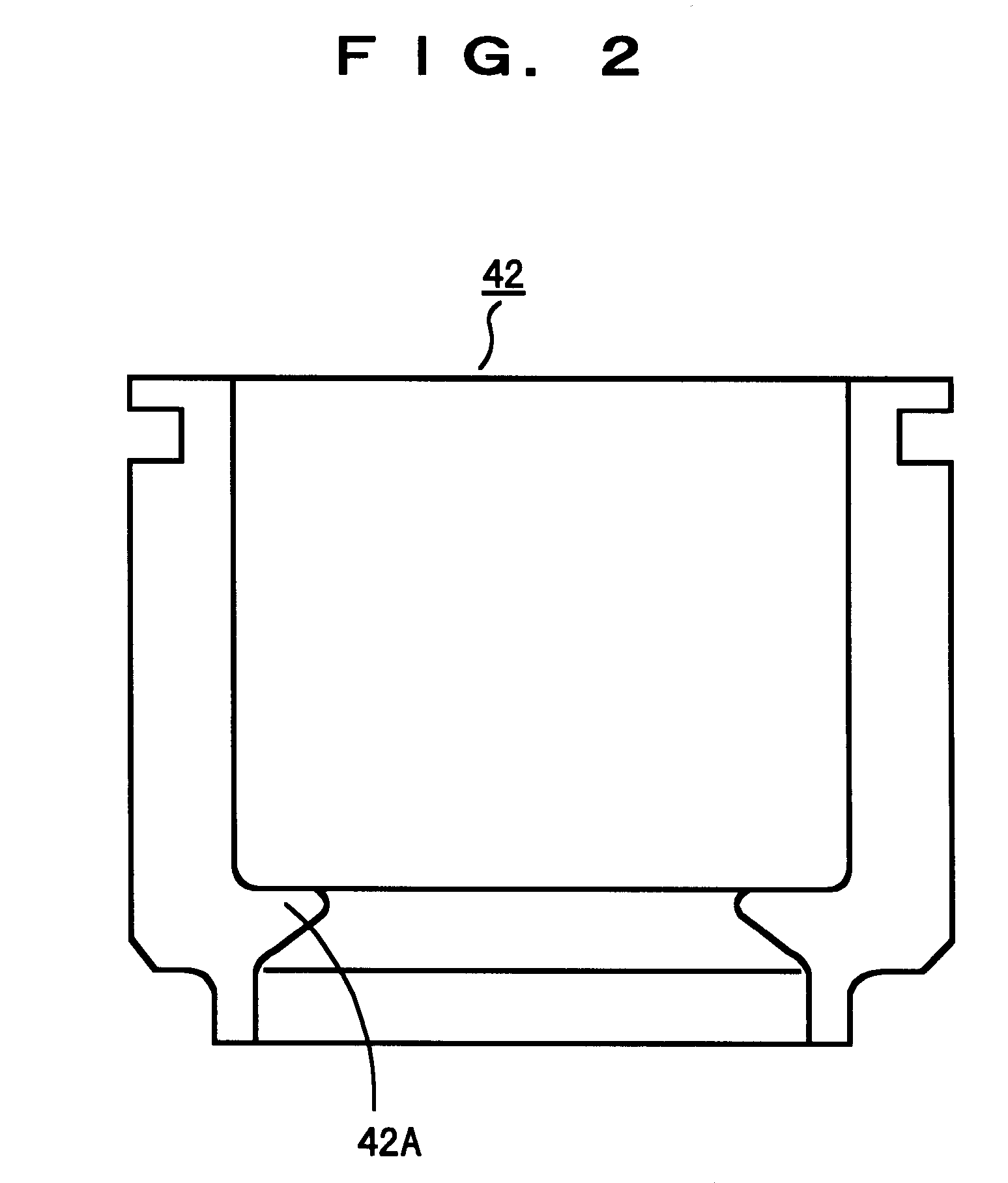

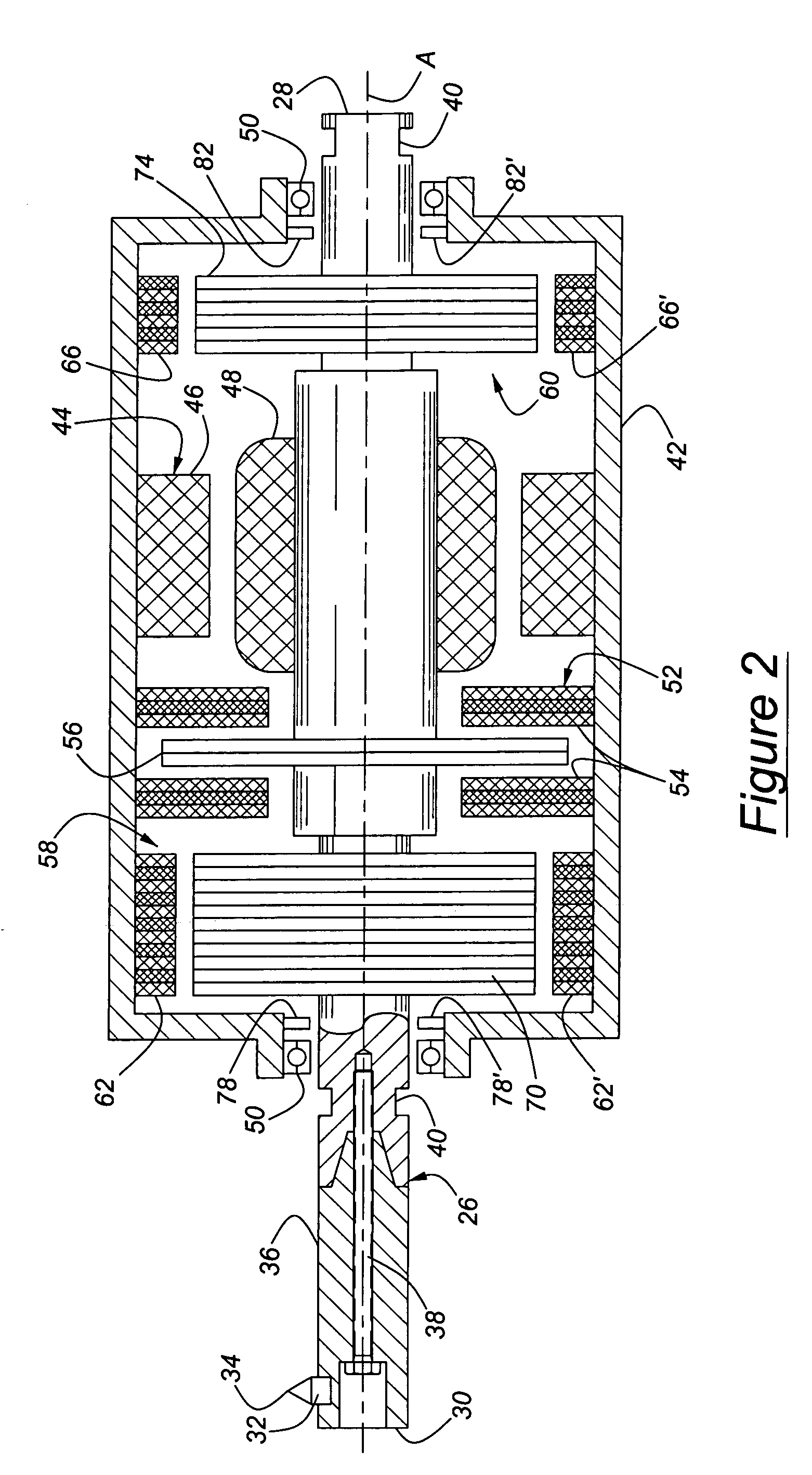

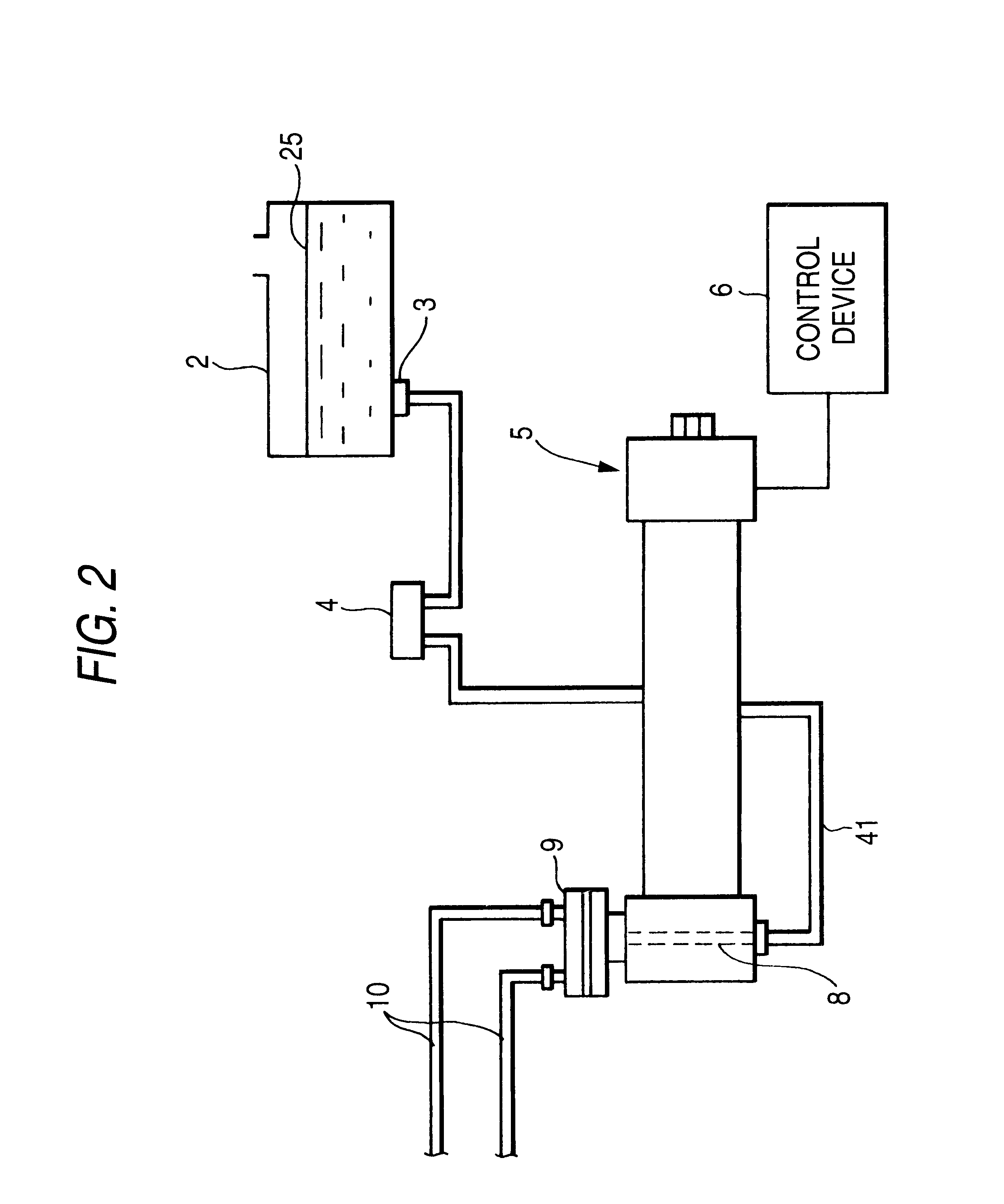

Spindle apparatus

InactiveUS6623251B2Reduce noiseMinimize an increase in torque and bearingPiezoelectric/electrostriction/magnetostriction machinesAttachable milling devicesPump chamberEngineering

A rod body (30) is formed of magnetostrictive material and includes one end portion (30a) fixed, and a piston (35) is fixed to the other end portion (35b) of the rod body (30). The piston (35) is slidably disposed within a cylinder (36) in which there is formed a pump chamber (37). A suction port (39) for sucking lubricating oil into the pump chamber (37) is formed in the cylinder (36), while a suction valve (40) for preventing the lubricating oil from flowing out from the suction port (39) is disposed in the suction port (39). In the cylinder (36), there is disposed a nozzle (20) which communicates with the pump chamber (37) and has a sectional area smaller than the lubricating oil passage sectional area of the suction valve (40). There is disposed a coil (43) outside the rod body (30) and, to the coil (43), there is connected a control device (6) for controlling the supply of a current to be supplied to the coil (43).

Owner:NSK LTD

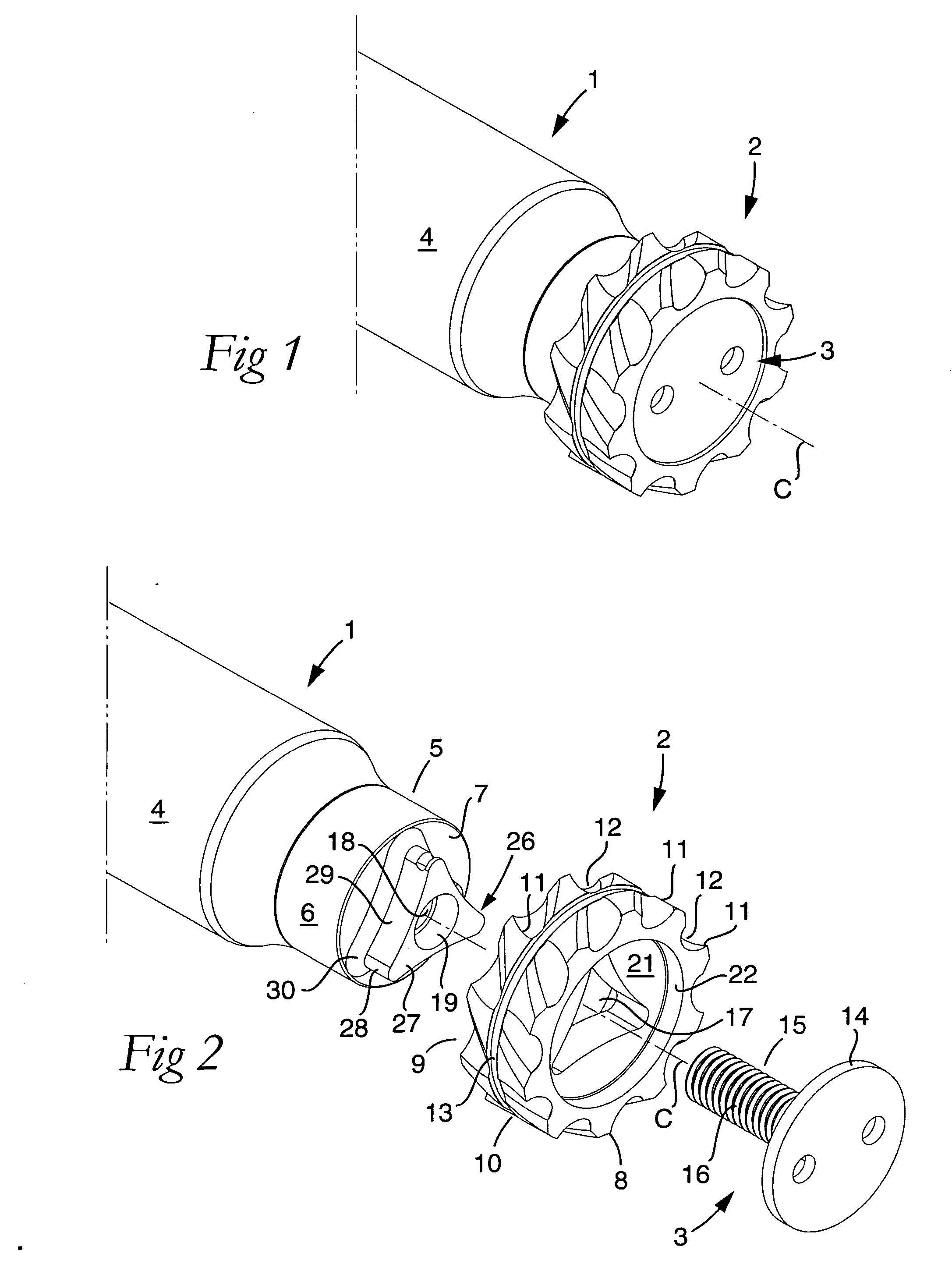

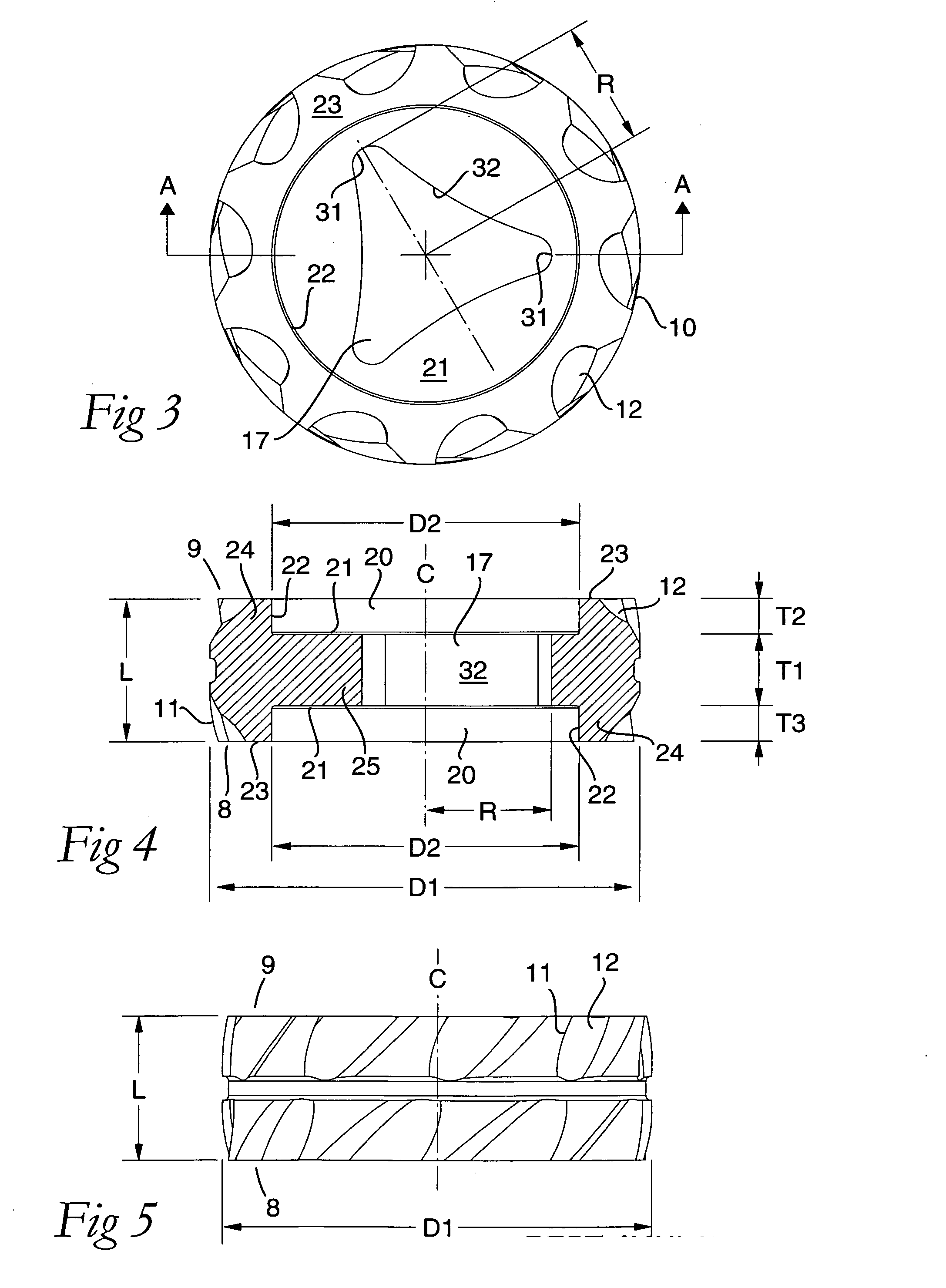

Milling cutter head and a milling cutter tool

InactiveUS20070081873A1Large formatEliminate shortcomingsMilling cuttersAttachable milling devicesFluteTool bit

A milling cutter head in the form of a body, which has an external envelope surface having a rotationally symmetrical basic shape in respect of a central axis, and includes a plurality of peripherally spaced-apart cutting edges and chip flutes. The cutter head includes two axially spaced-apart ends in which hollow spaces open, which are arranged to receive male elements included in a basic body, and are spaced-apart by a partition wall in which a through hole is formed. The through hole mouths in bottom surfaces in the hollow spaces. The cross-section area of each individual hollow space, in a plane perpendicular to the center axis, amounts to at least 25% of the total cross-section area of the body, as defined by the greatest diameter of the envelope surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

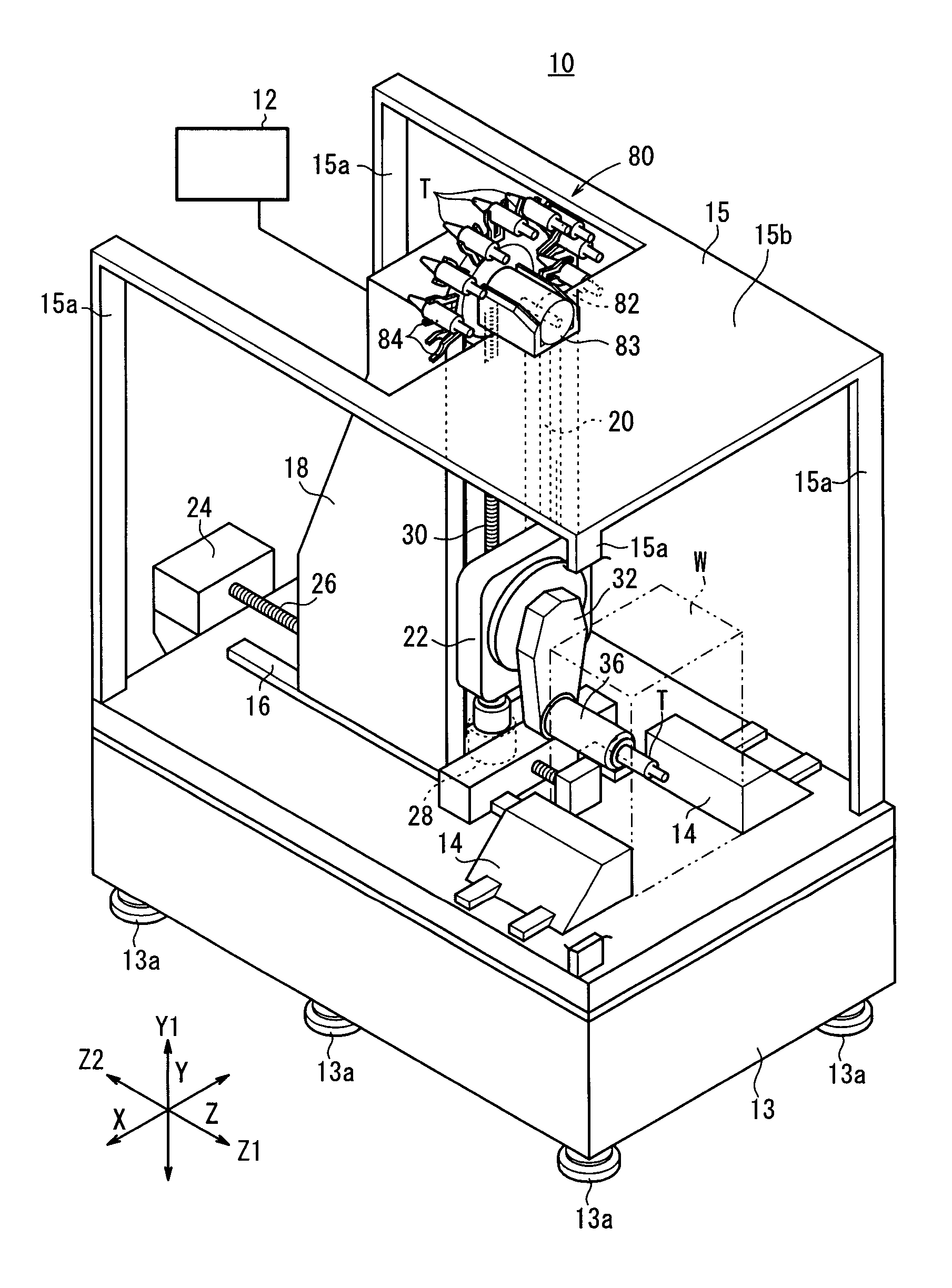

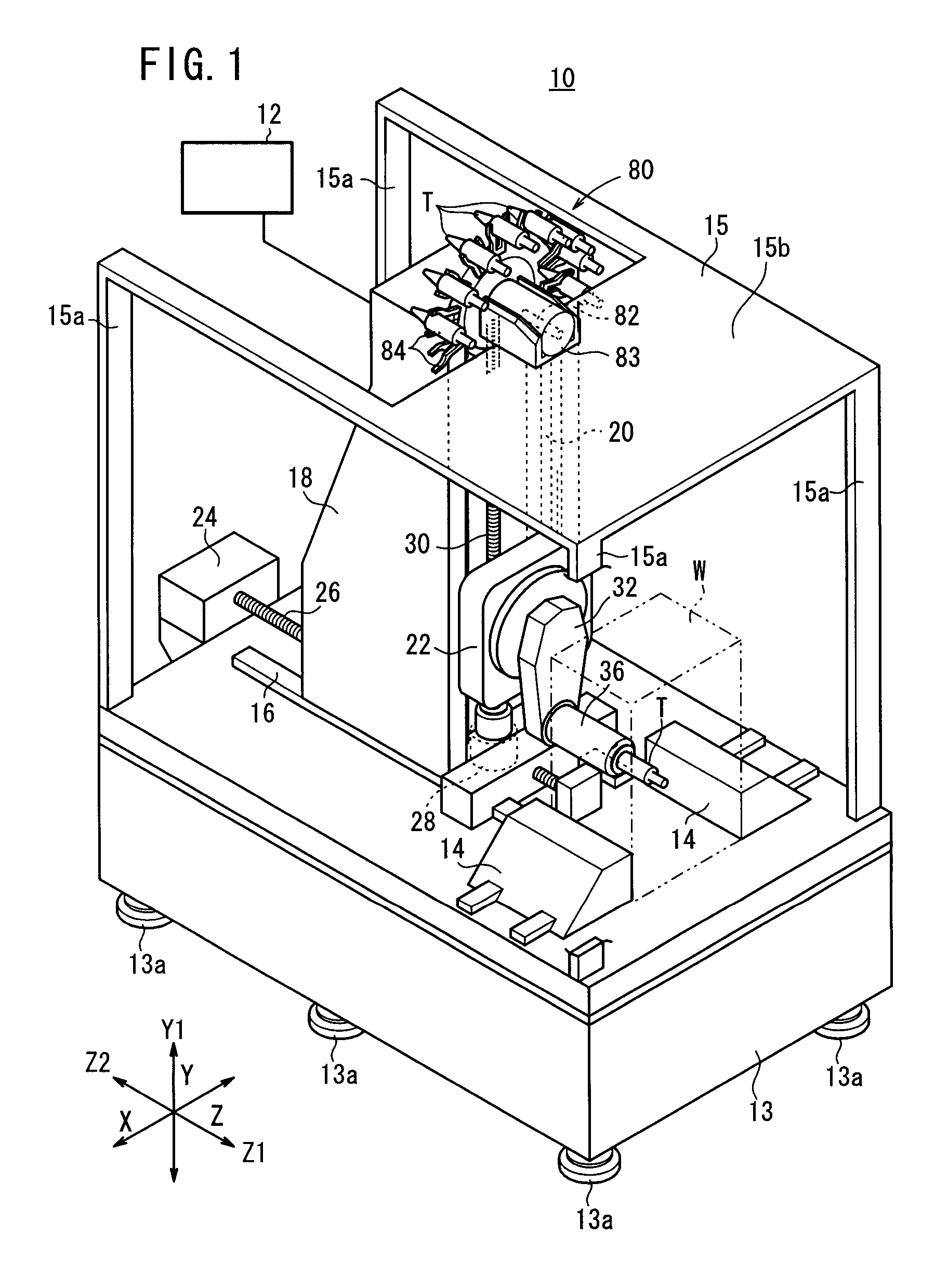

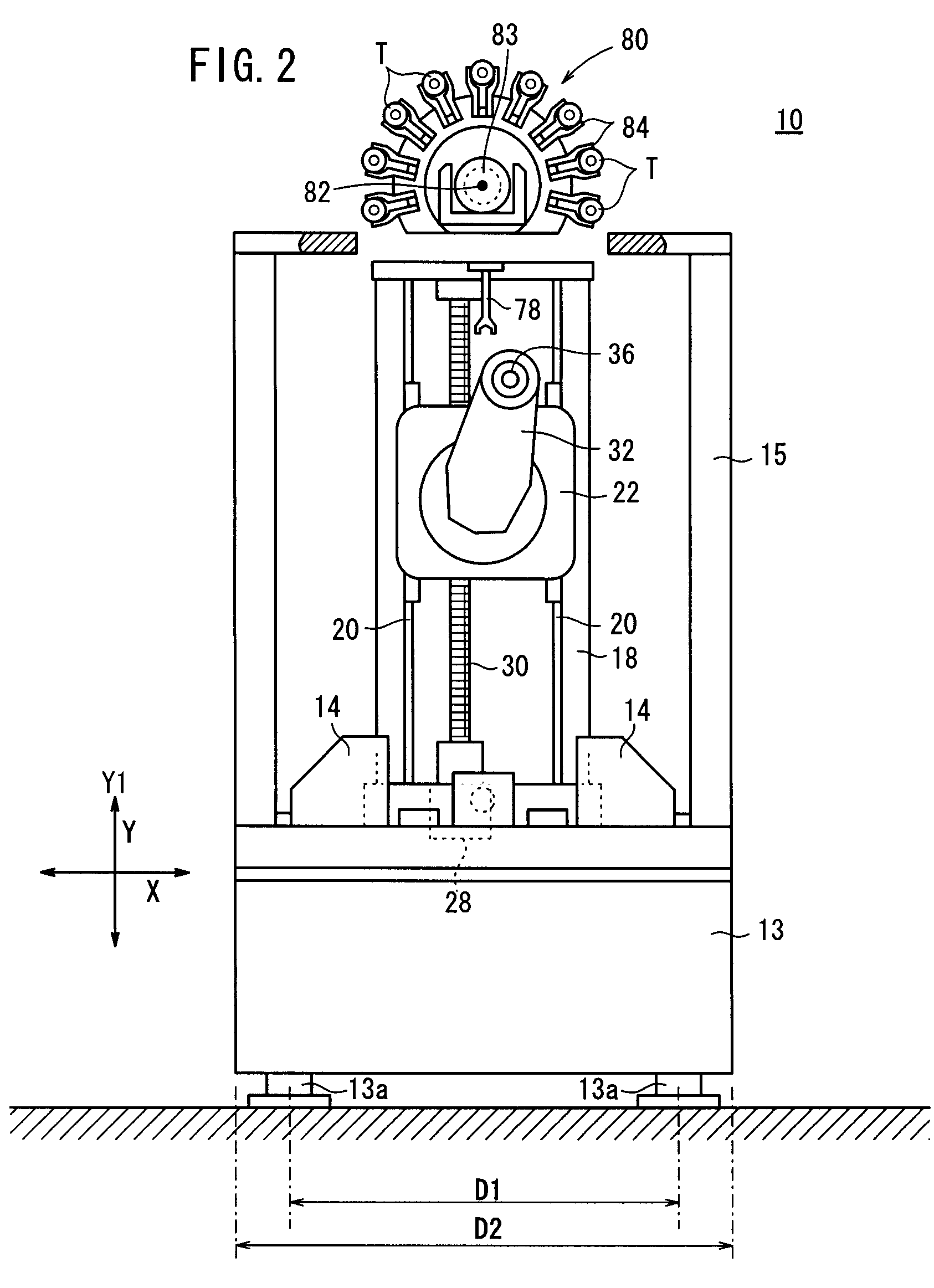

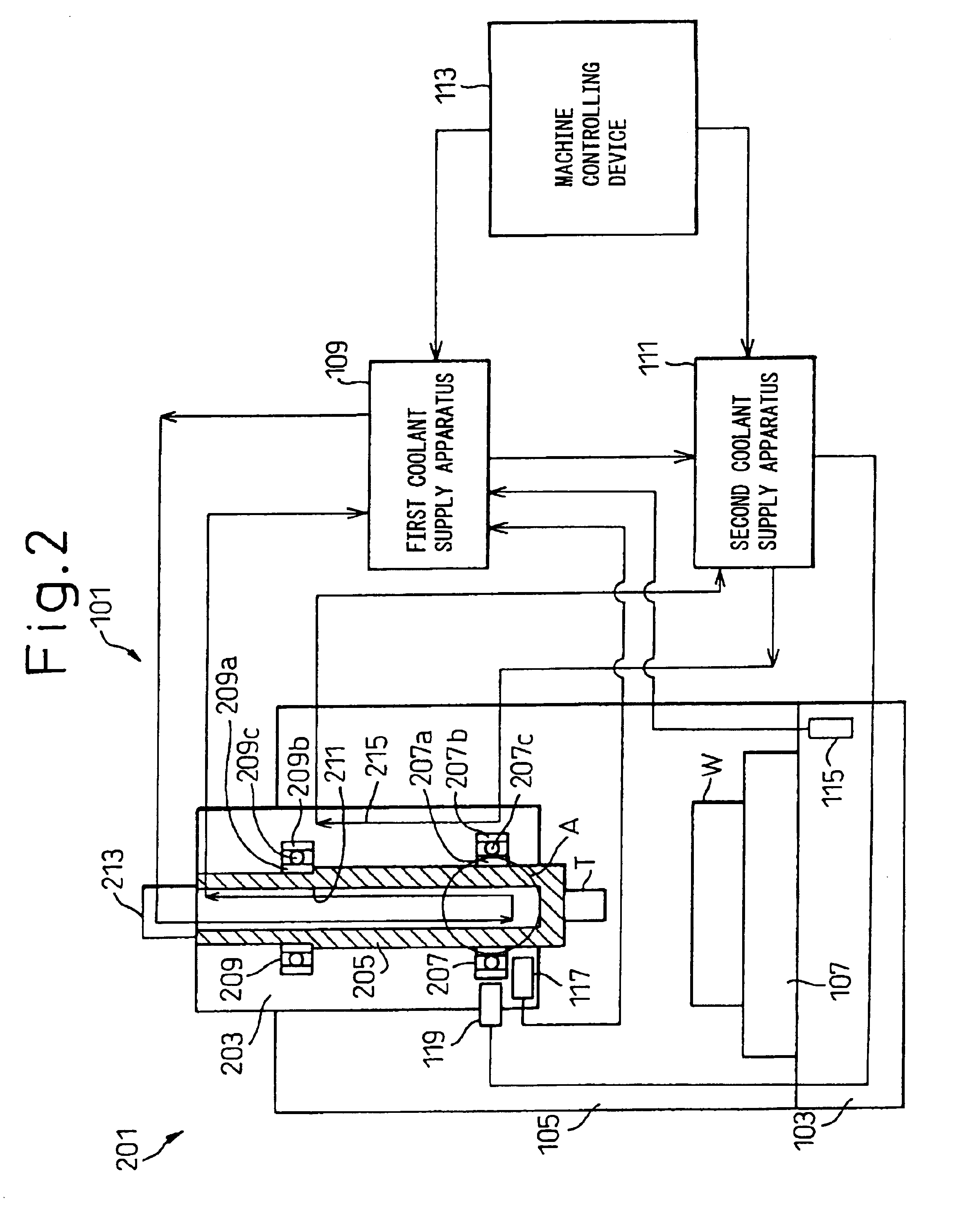

Machine tool and method of controlling machine tool

InactiveUS20090053004A1Compact structureImprove space efficiencyAttachable milling devicesTool changing apparatusVertical planeEngineering

A machine tool (10) has a Z table (18) sliding in the Z direction in a horizontal plane, a support body (22) provided on the Z table (18) and sliding in the vertical direction, a rotation arm (32) supported at the support body (22) and endlessly rotatable in a vertical plane facing work (W), an arm motor (34) for rotating the rotation arm (32), a processing spindle (36) rotatably supported and placed at a position of a distance R from the center C of rotation of the rotation arm (32), and a spindle motor (38) for rotating the processing spindle (36).

Owner:HONDA MOTOR CO LTD

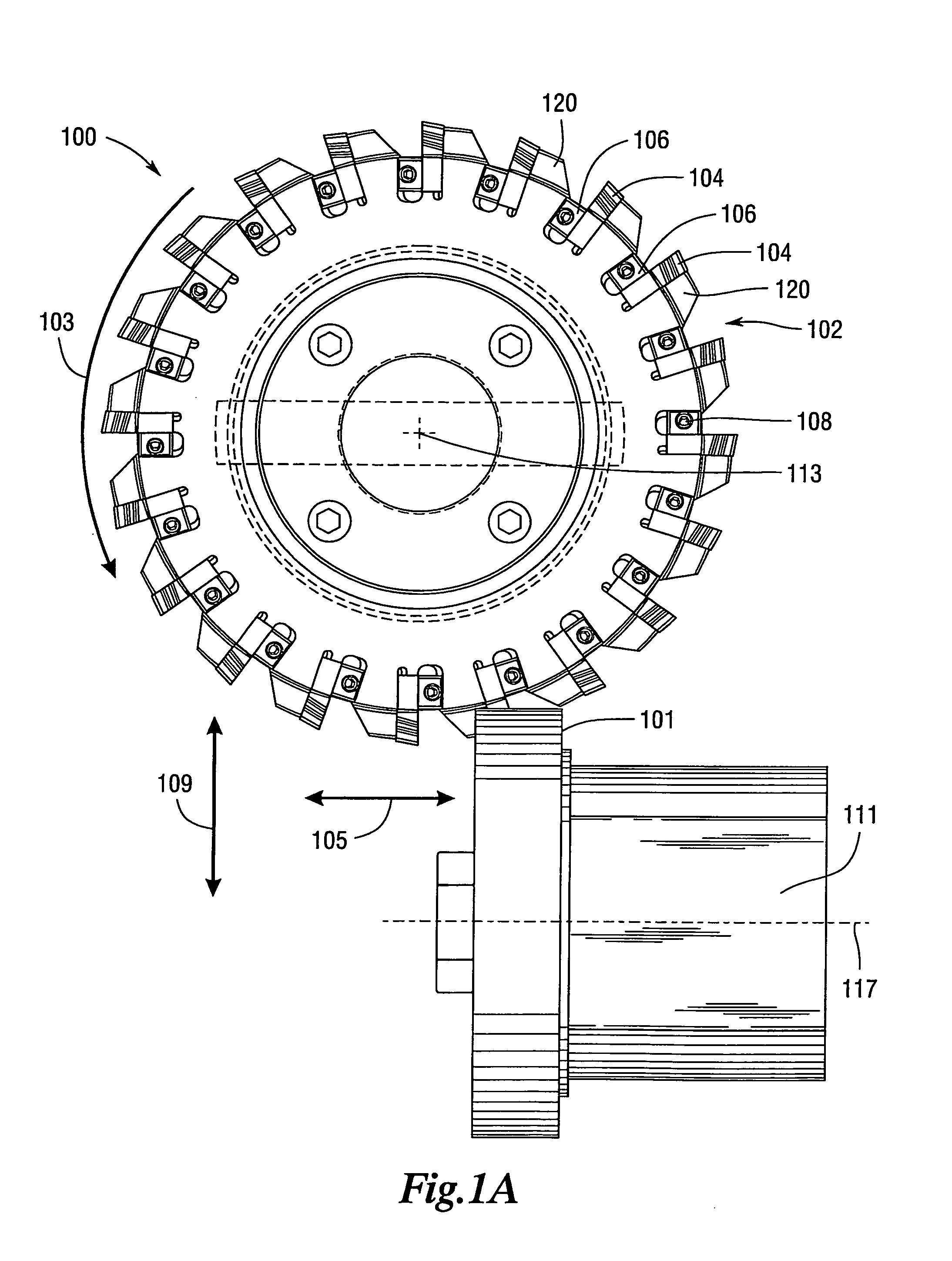

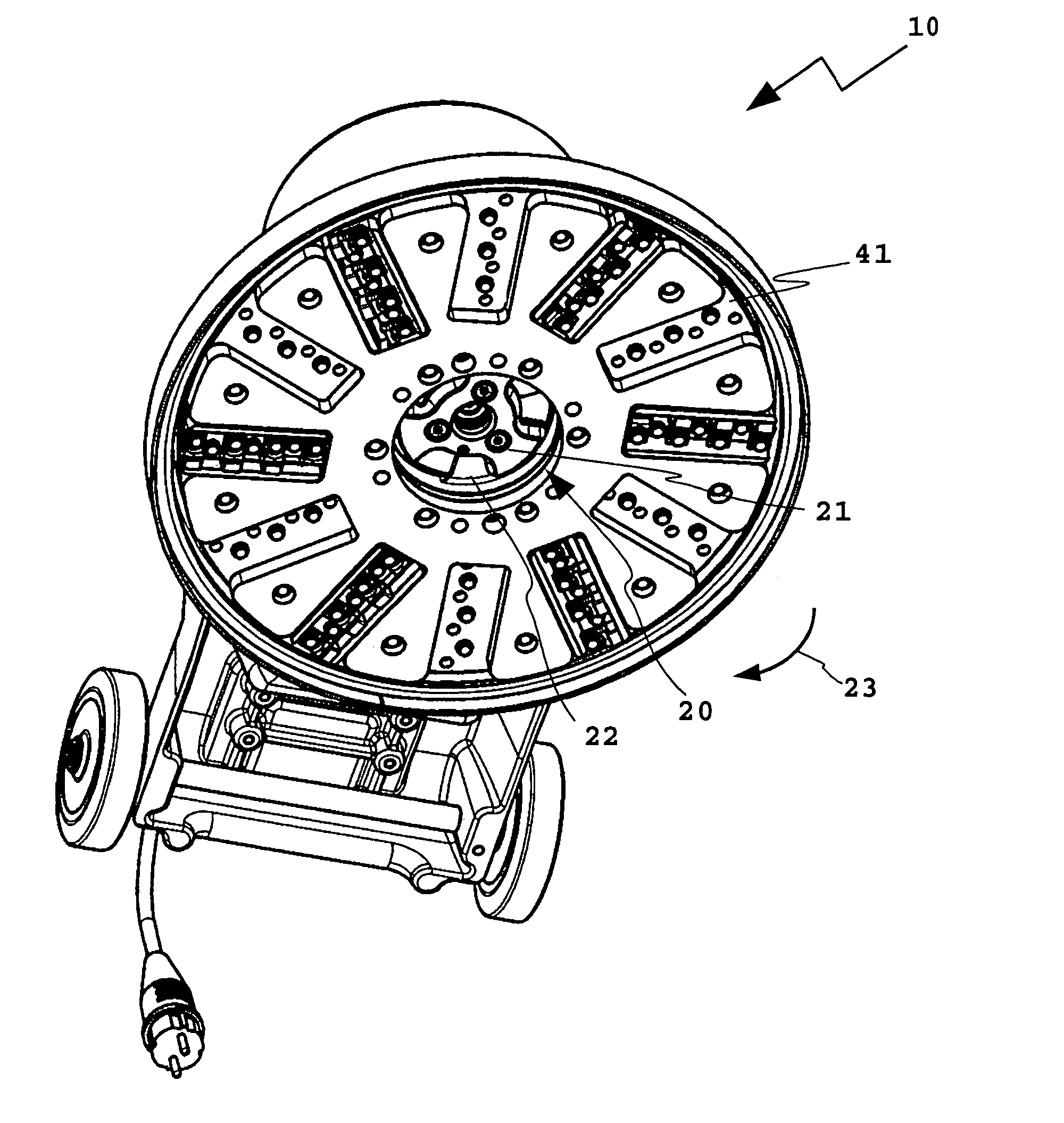

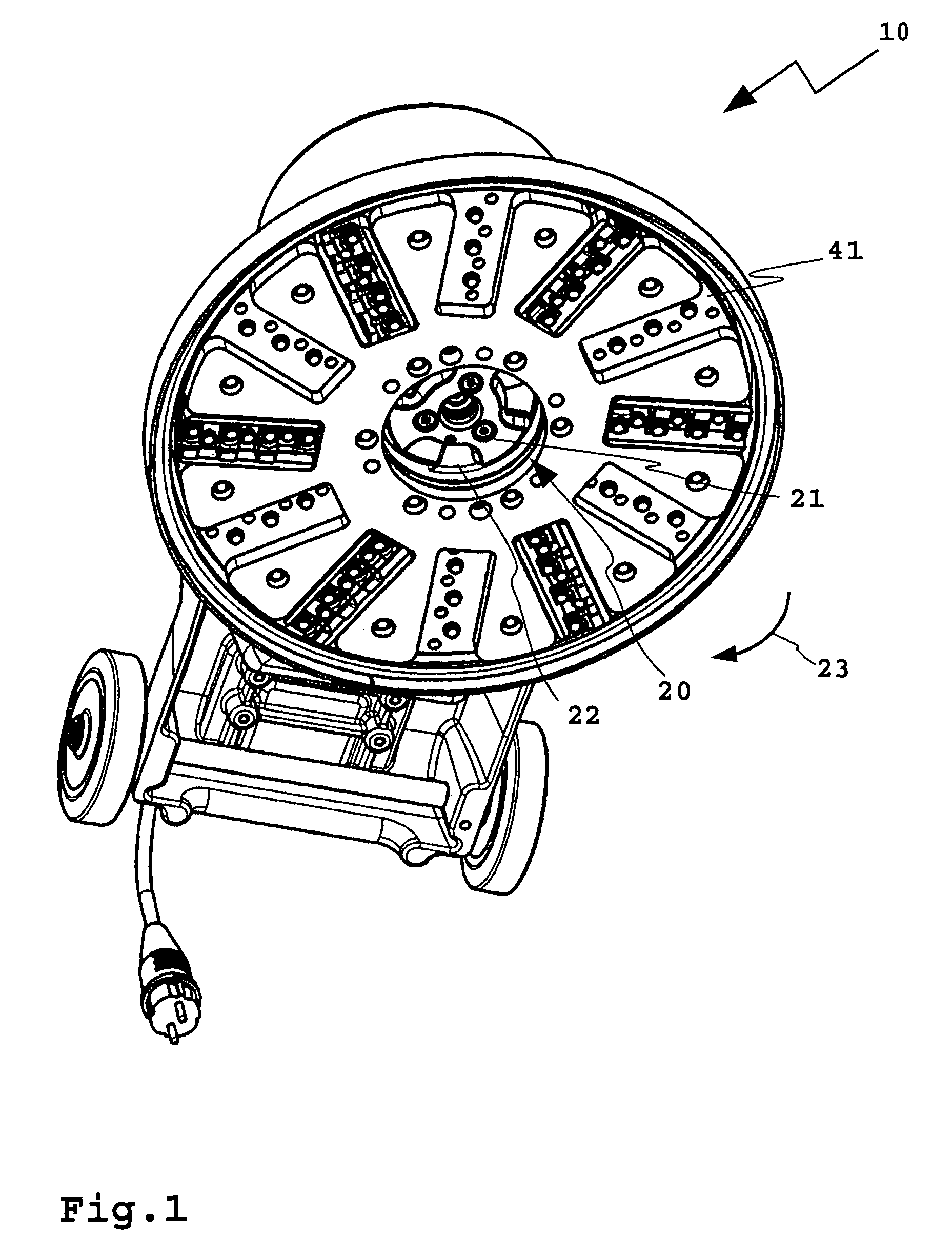

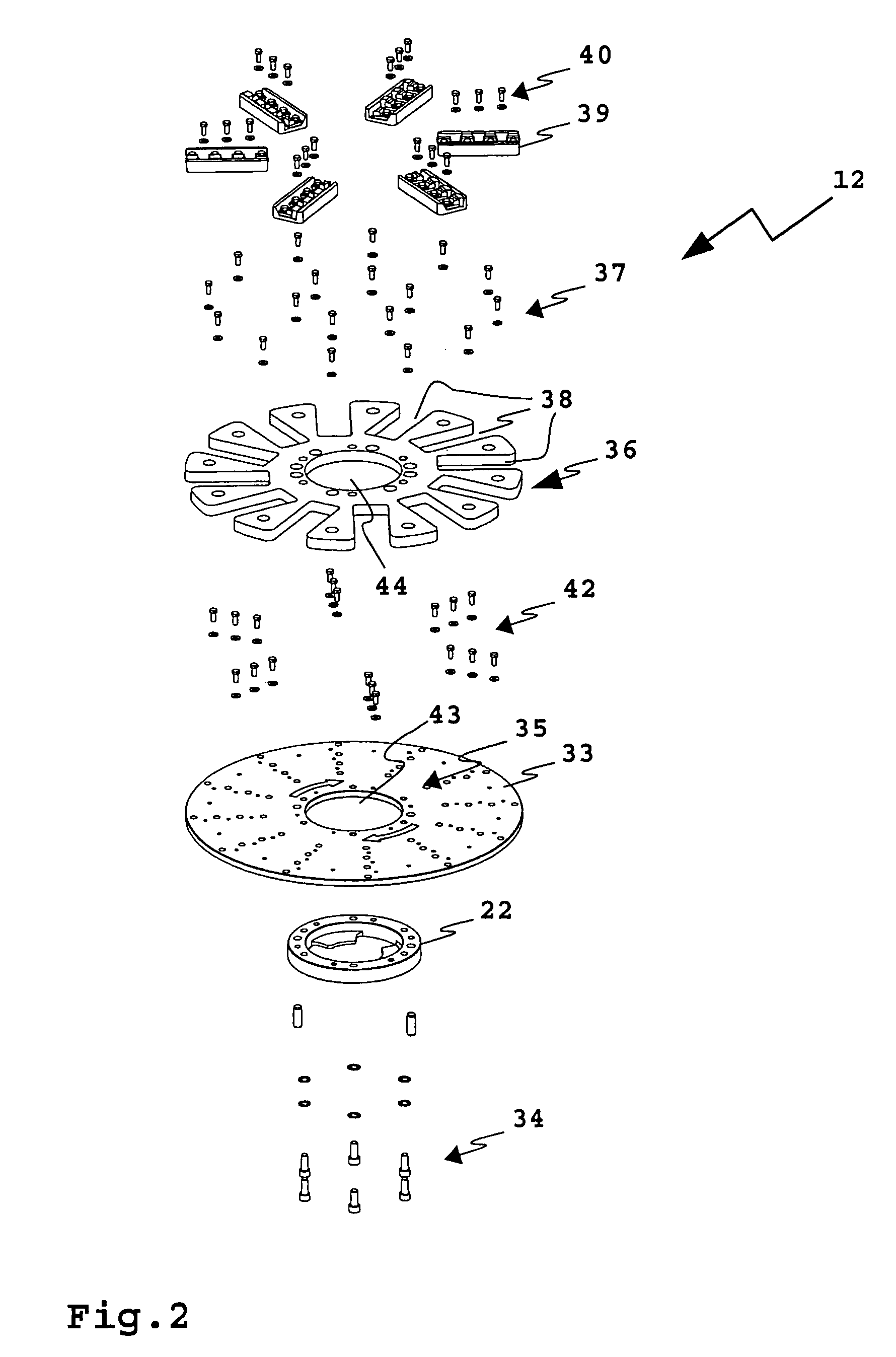

Milling disk for a floor machining appliance

ActiveUS7104739B2Avoid excessive wearHeavy loadMilling cuttersAttachable milling devicesEngineeringSubstructure

A milling disk for a floor machining appliance has a plurality of mounts for holding interchangeable plate-like milling tips, the milling disk being driven for rotation by the floor machining appliance and being held substantially parallel to the substructure to be machined so that the milling tips may bite into the substructure and remove matter from the surface thereof. The milling tips are constituted by ceramic cutting tips.

Owner:EUGEN LAEGLER

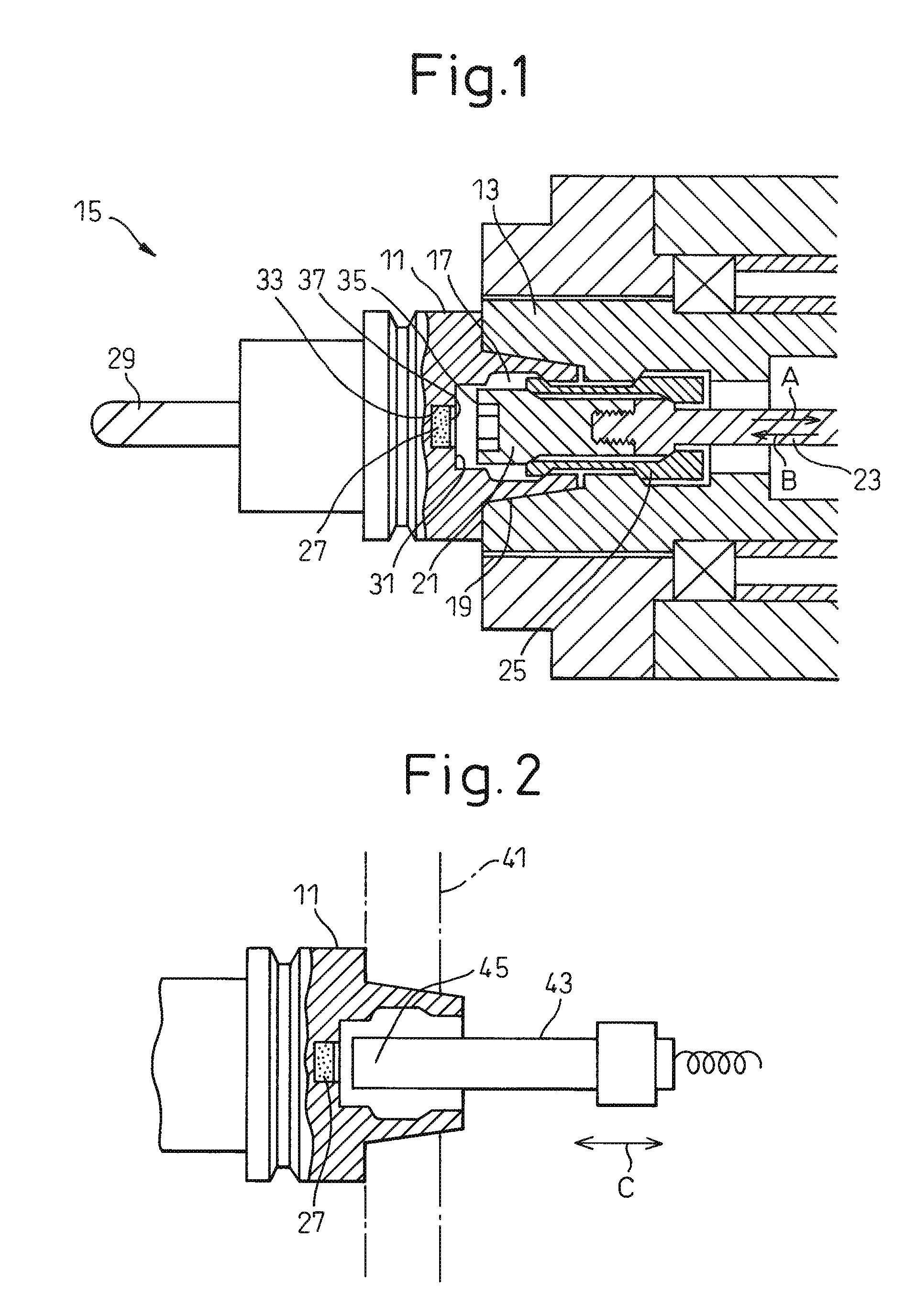

Tool holder

ActiveUS8376671B2Rotational balance thereof can not be deterioratedNot to damageTurning machine accessoriesThread cutting machinesEngineeringKnife holder

An ID tag (27) is attached to a bottom surface (31) of a hollow portion (17) of a tool holder (11) having a hollow taper shank. Concretely, a circular recess (33) is formed on bottom surface (31) of hollow portion (17), and ID tag (27) is attached in recess (33) by means of adhesive or the like. The center of circular recess (33) coincides with a rotation axis of tool holder (11).

Owner:MAKINO MILLING MASCH CO LTD

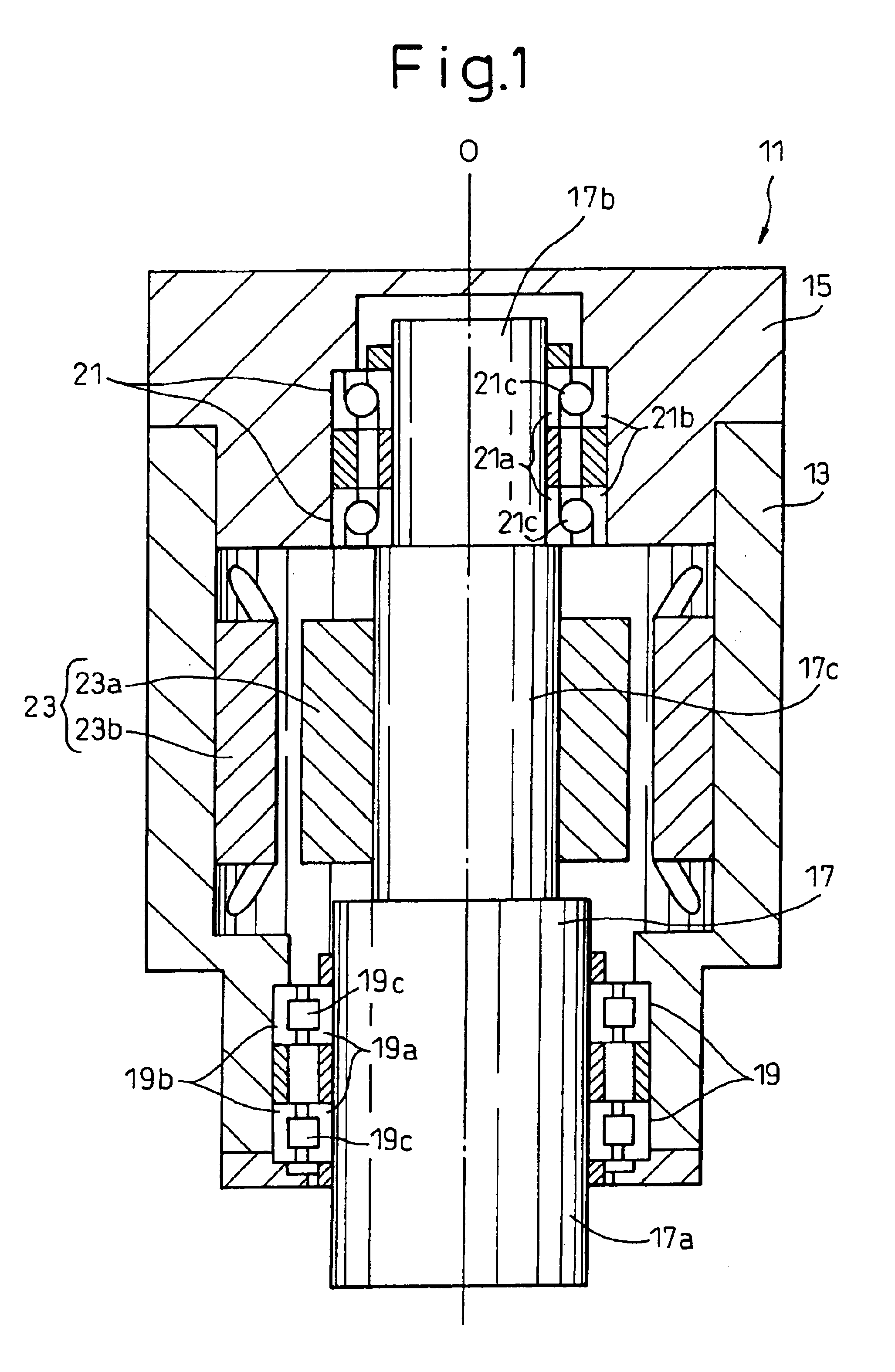

Rotating shaft apparatus

InactiveUS6913390B2Ensures rigidityLow heat generationCrankshaftsRolling contact bearingsBall bearingEngineering

A shaft 17 defines a front end portion 17a having a larger diameter and an opposite tail end portion 17b having a smaller diameter, the shaft 17 being rotatably supported by the housing 13 through a radial bearing 19 and a pair of angular ball bearings 21 at the front side large diameter portion 17a and the small diameter portion 17b, respectively.

Owner:MAKINO MILLING MASCH CO LTD

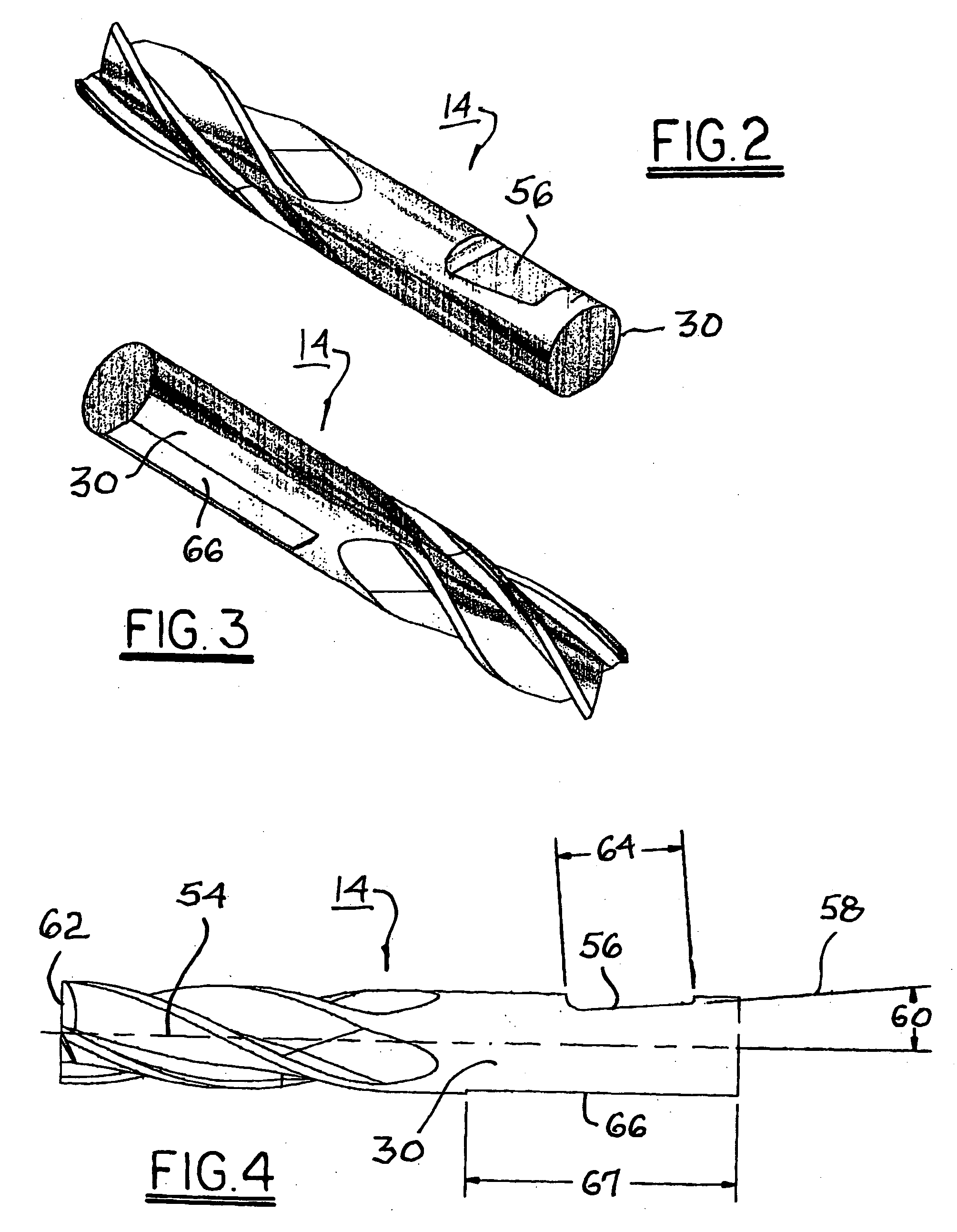

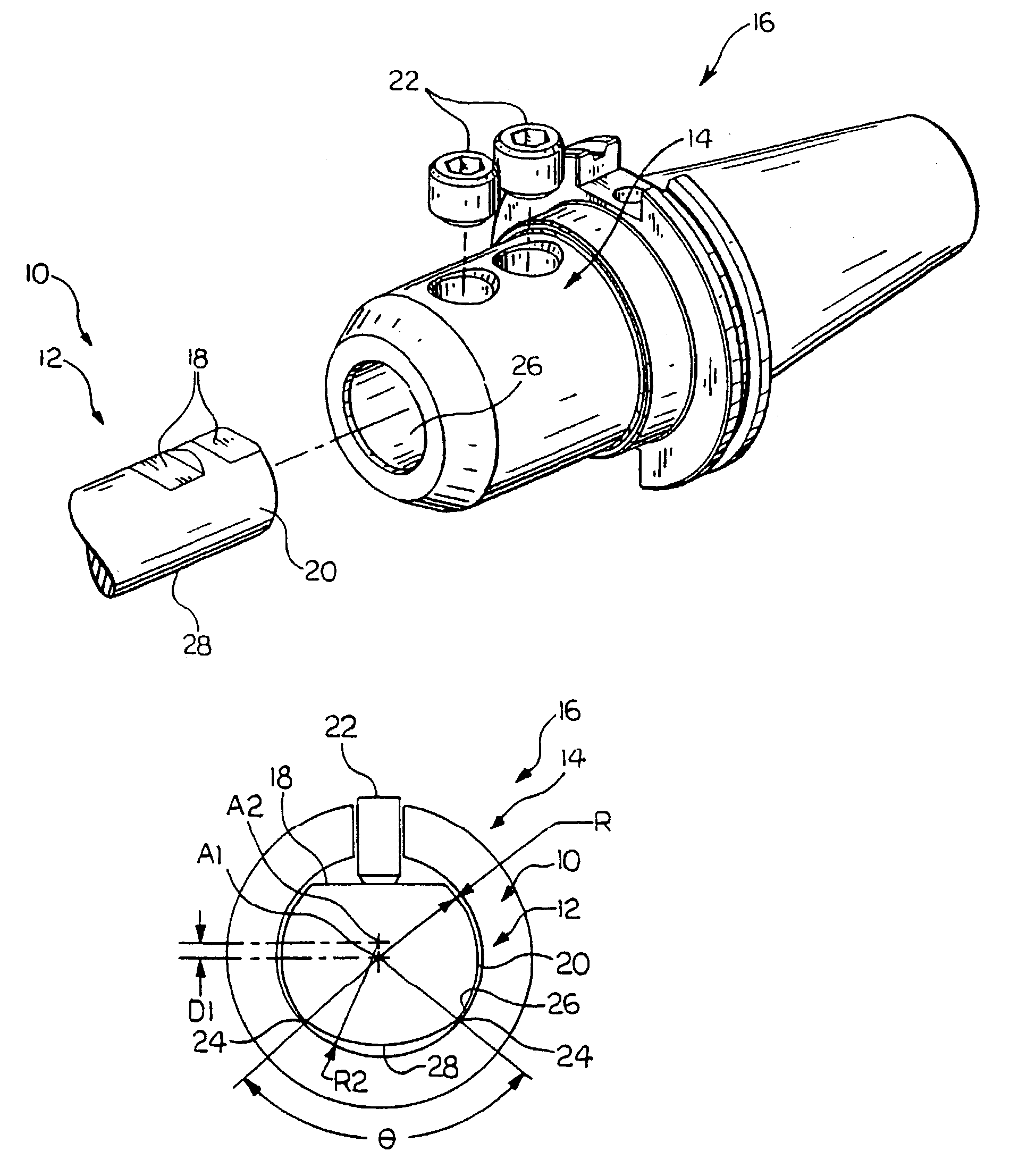

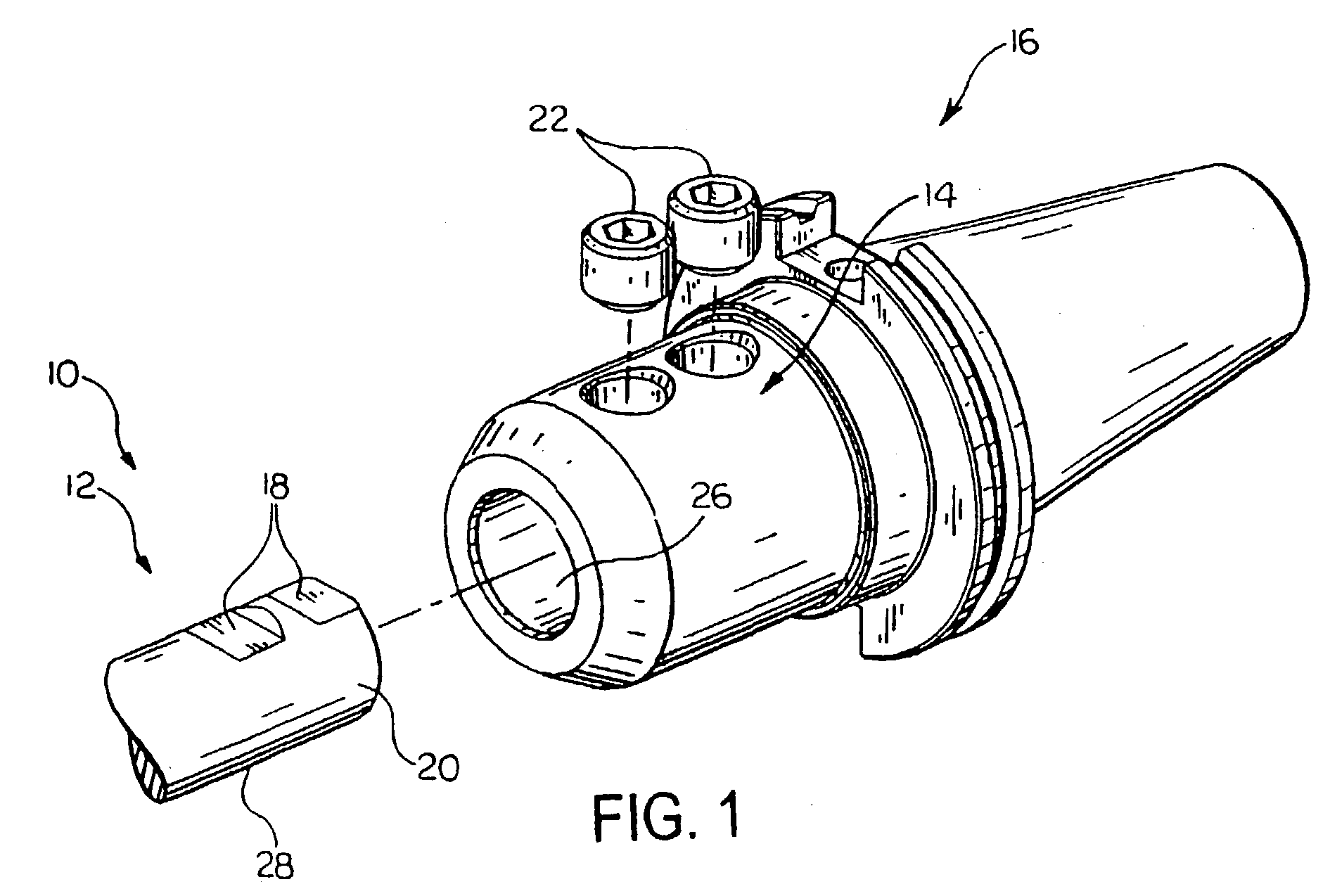

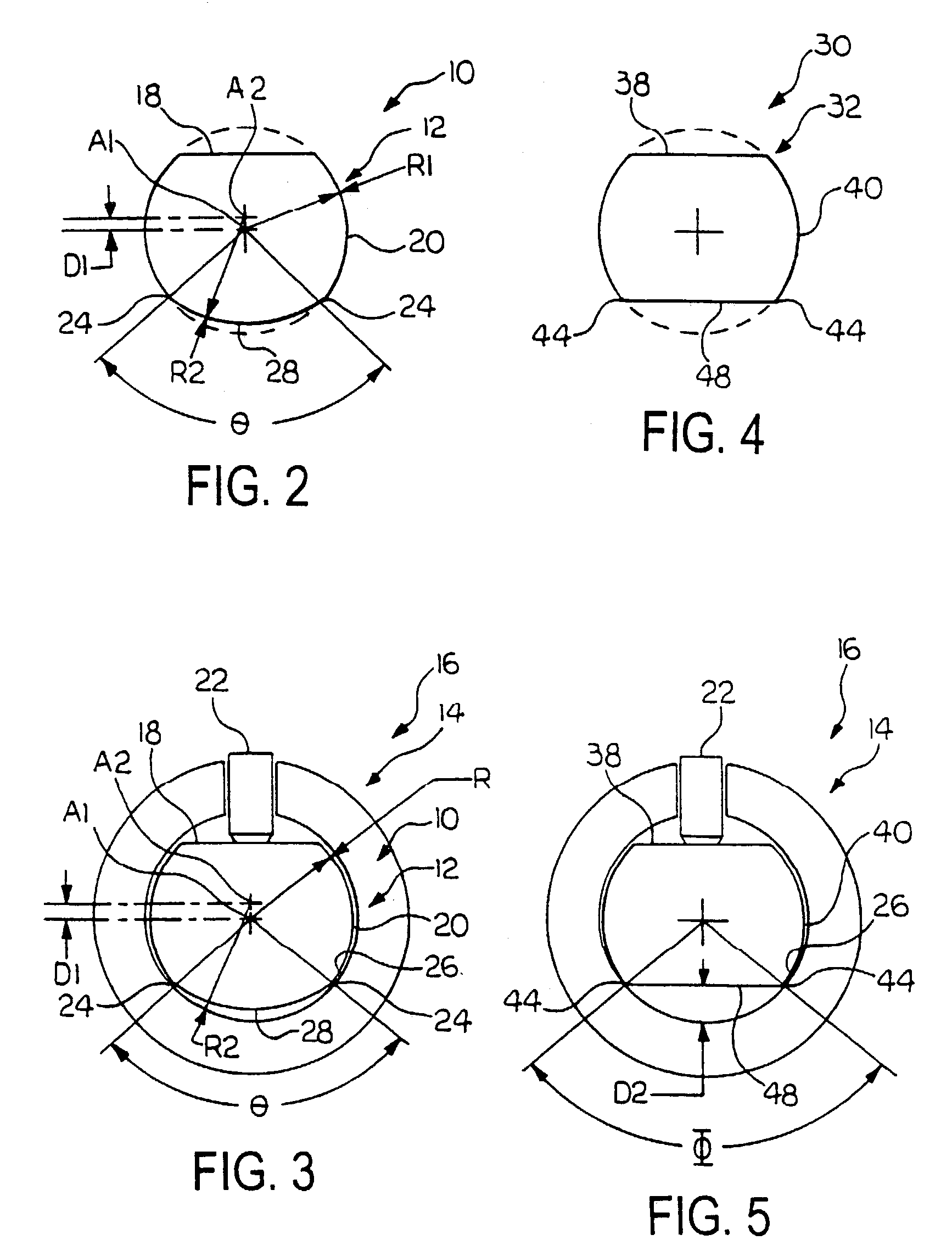

Cutting tool configured for improved engagement with a tool holder

A cutting tool has a shank with a cylindrical portion that is adapted to fit closely within a tool holder. The shank is adapted to be engaged by a setscrew of the tool holder at a first contact point. A clearance surface is provided opposite the first contact point. The clearance surface terminates adjacent two circumferentially spaced points that make contact with the tool holder upon tightening the setscrew. These contact points are circumferentially spaced from the first contact point angular distances greater than 90 degrees and less than 270 degrees.

Owner:KENNAMETAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com