Patents

Literature

773results about How to "Improve machine efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

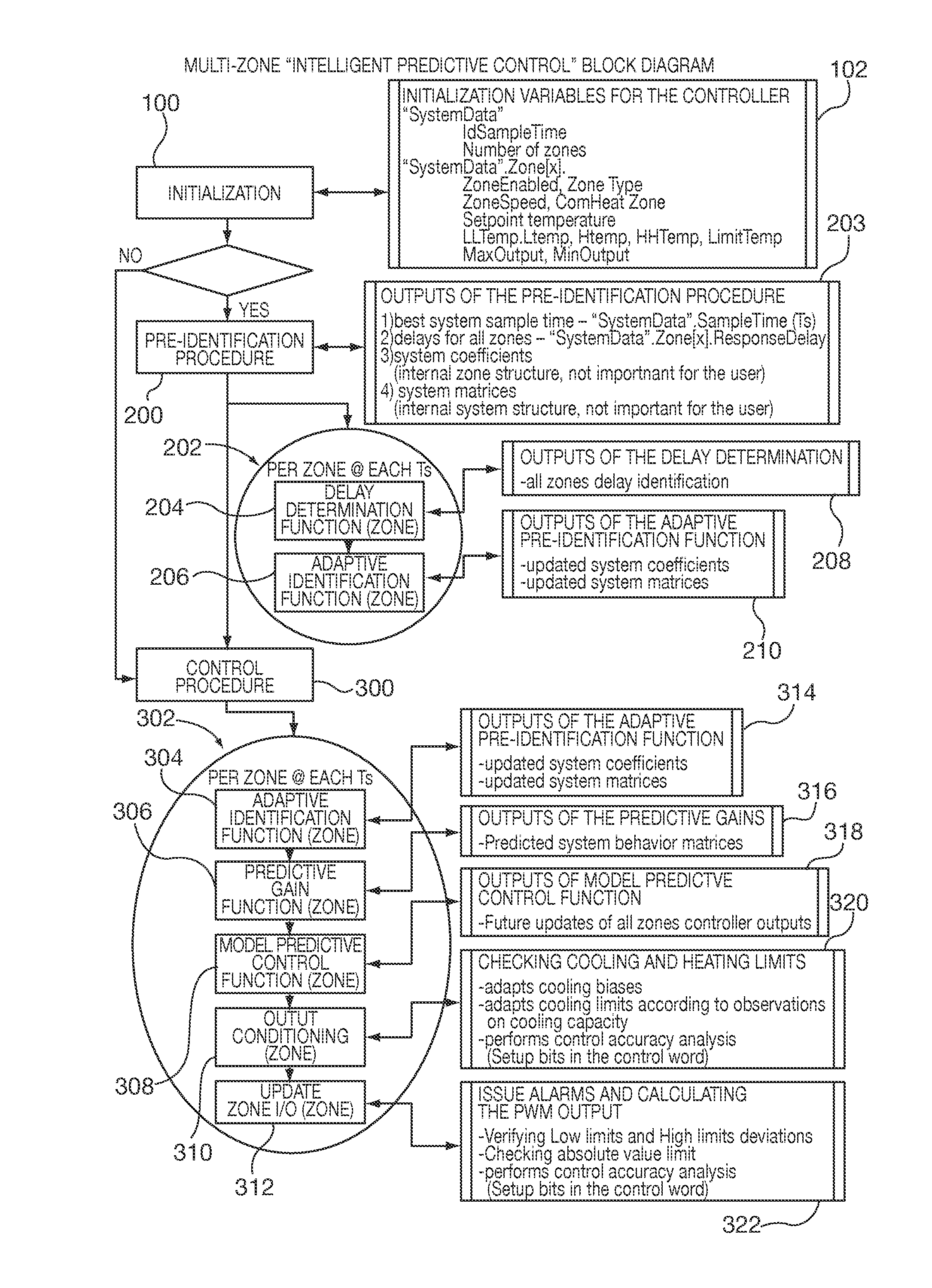

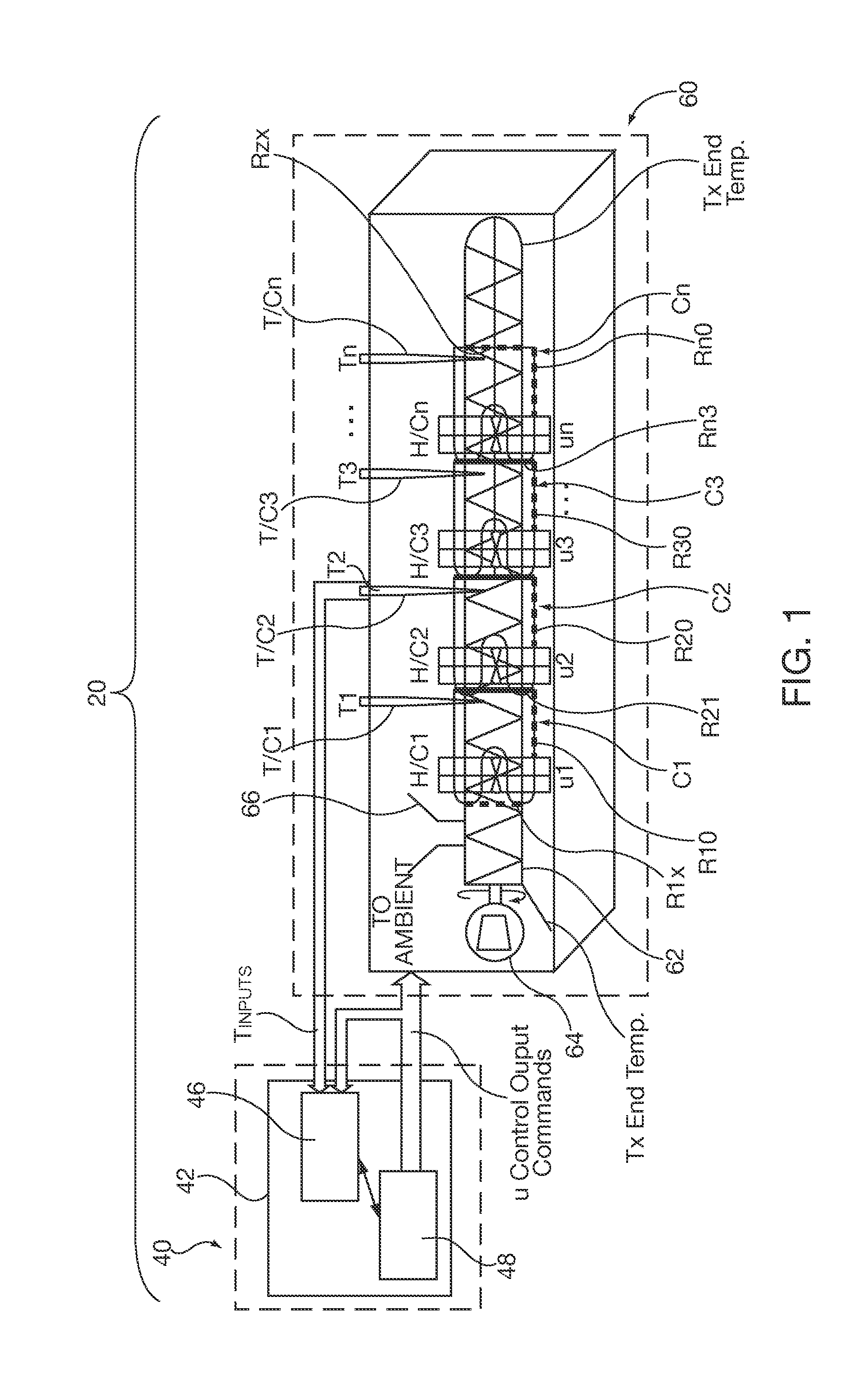

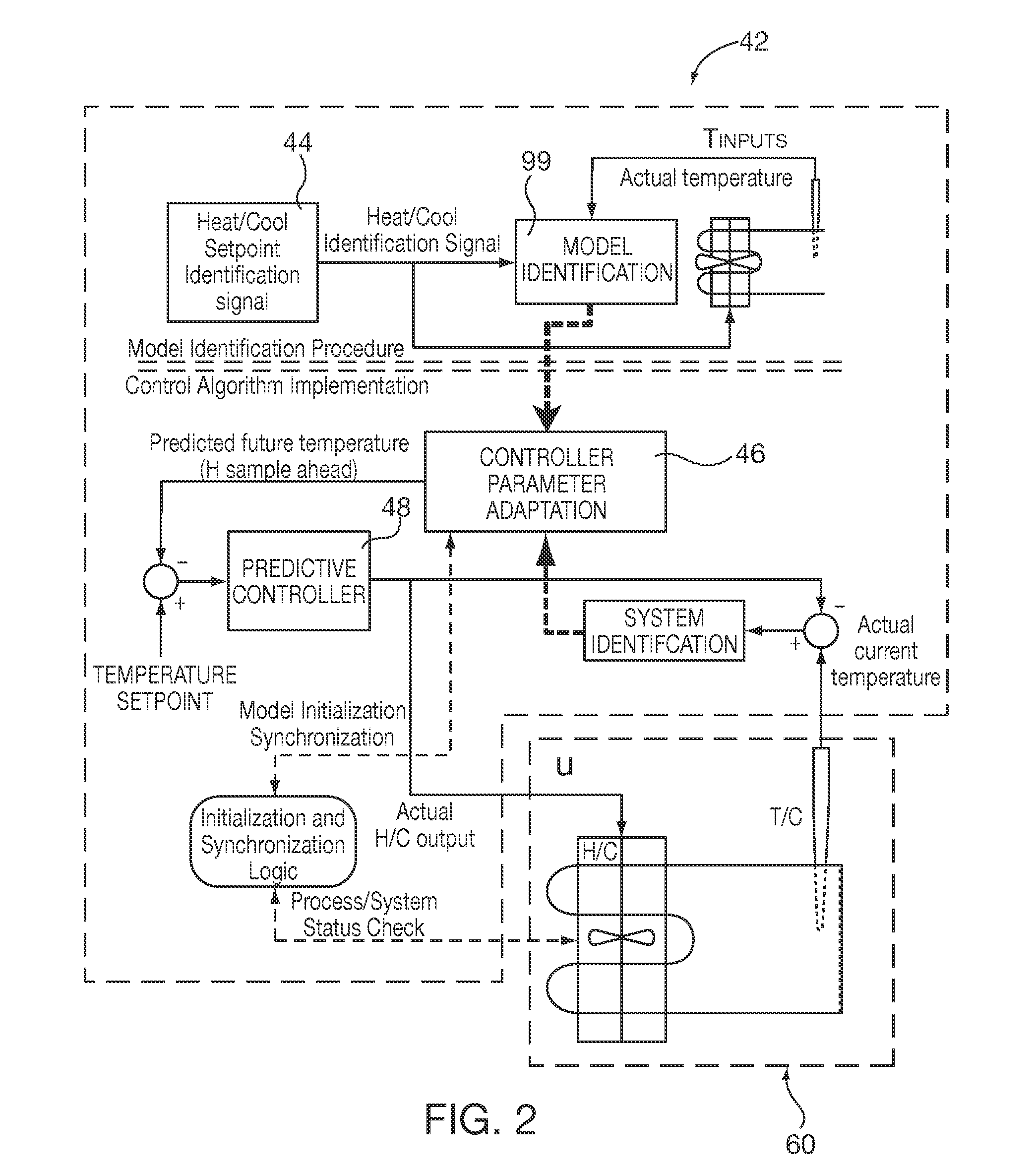

Method and apparatus of a self-configured, model-based adaptive, predictive controller for multi-zone regulation systems

InactiveUS20110022193A1Easy to addPrecise processingSampled-variable control systemsTravelling carriersHorizonPlastic injection molding

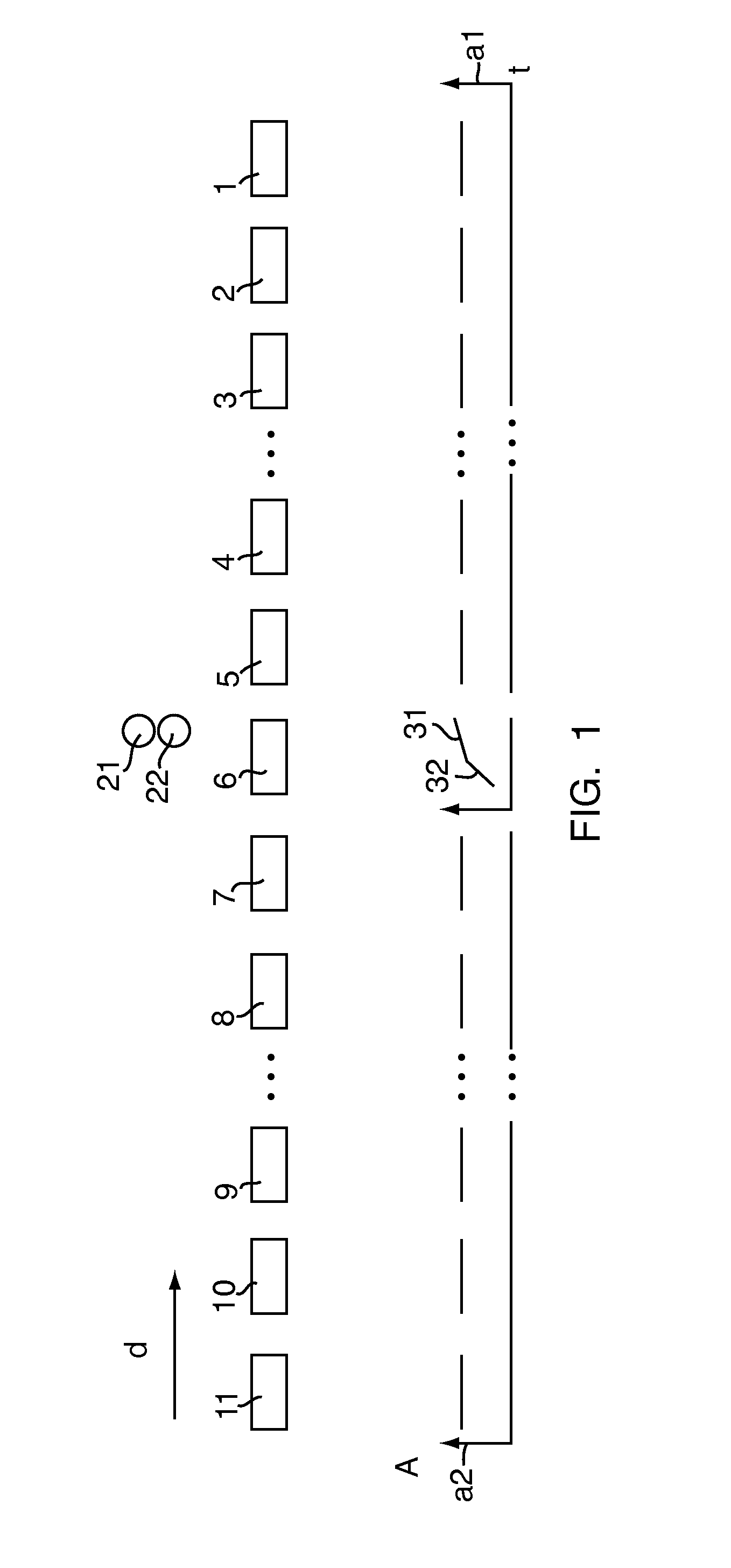

A control system simultaneously controls a multi-zone process with a self-adaptive model predictive controller (MPC), such as temperature control within a plastic injection molding system. The controller is initialized with basic system information. A pre-identification procedure determines a suggested system sampling rate, delays or “dead times” for each zone and initial system model matrix coefficients necessary for operation of the control predictions. The recursive least squares based system model update, control variable predictions and calculations of the control horizon values are preferably executed in real time by using matrix calculation basic functions implemented and optimized for being used in a S7 environment by a Siemens PLC. The number of predictions and the horizon of the control steps required to achieve the setpoint are significantly high to achieve smooth and robust control. Several matrix calculations, including an inverse matrix procedure performed at each sample pulse and for each individual zone determine the MPC gain matrices needed to bring the system with minimum control effort and variations to the final setpoint. Corrective signals, based on the predictive model and the minimization criteria explained above, are issued to adjust system heating / cooling outputs at the next sample time occurrence, so as to bring the system to the desired set point. The process is repeated continuously at each sample pulse.

Owner:SIEMENS IND INC

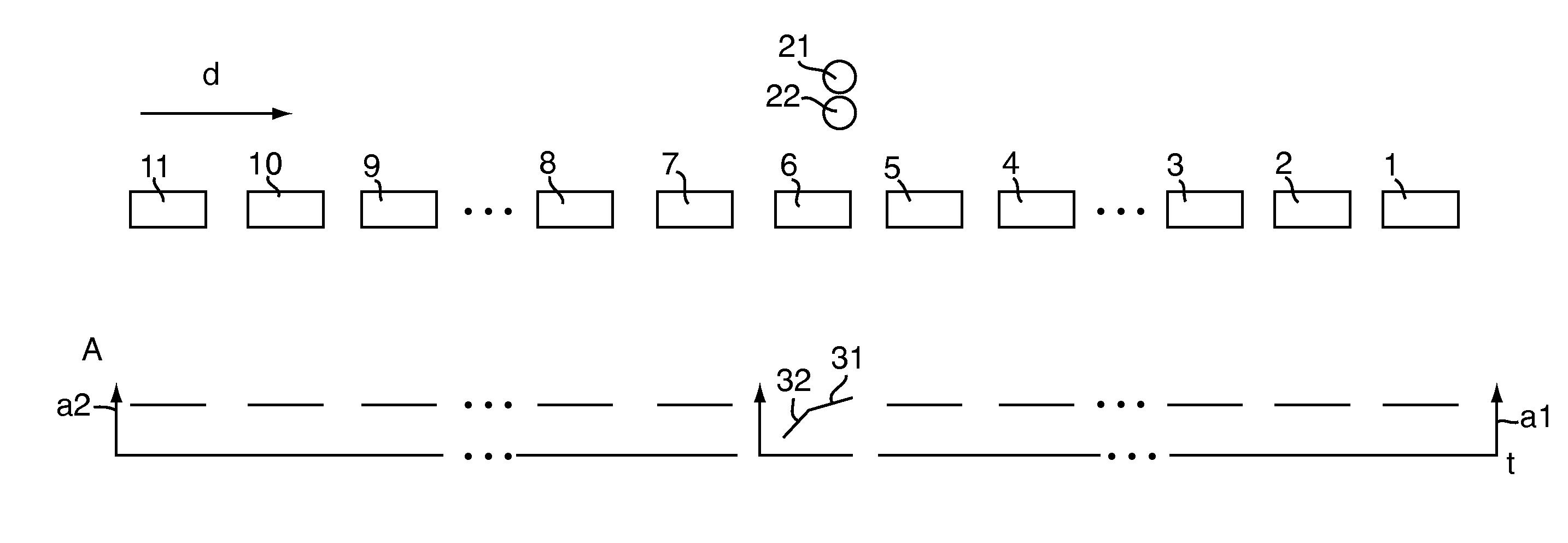

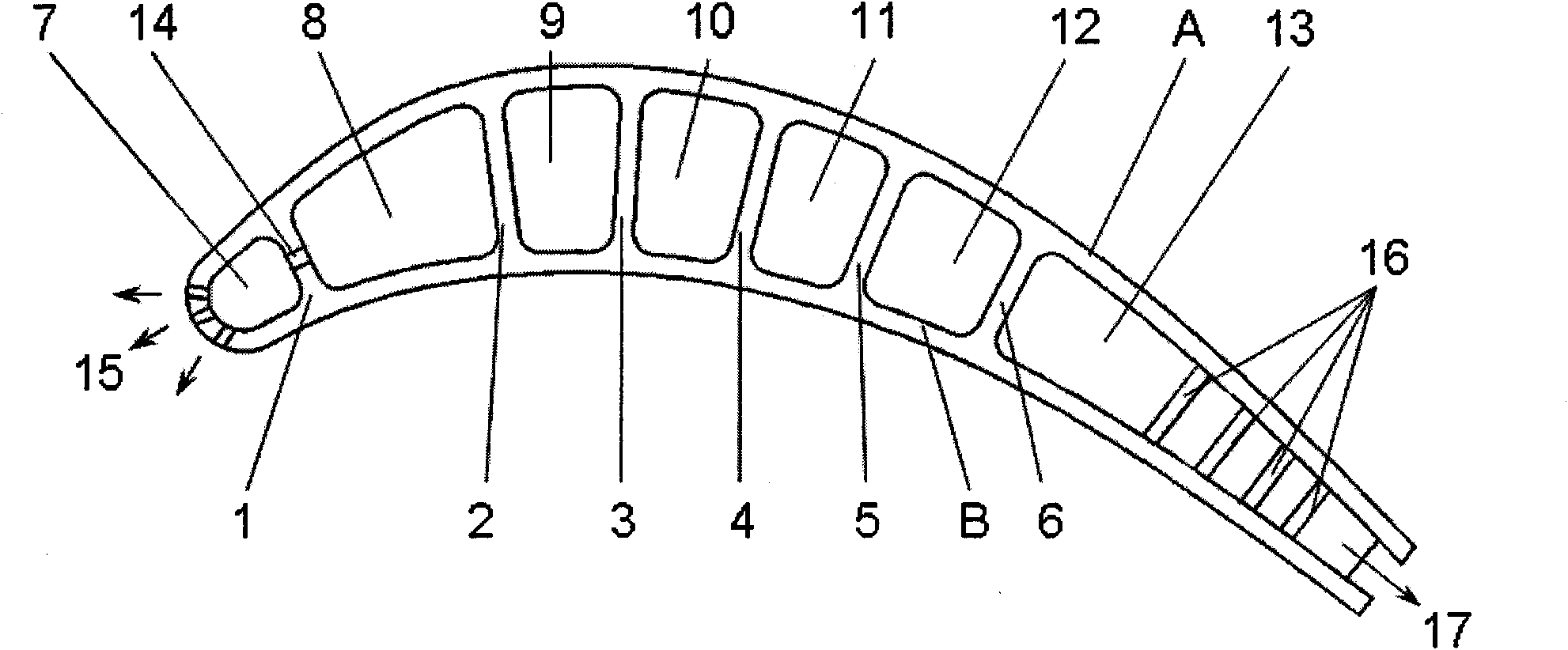

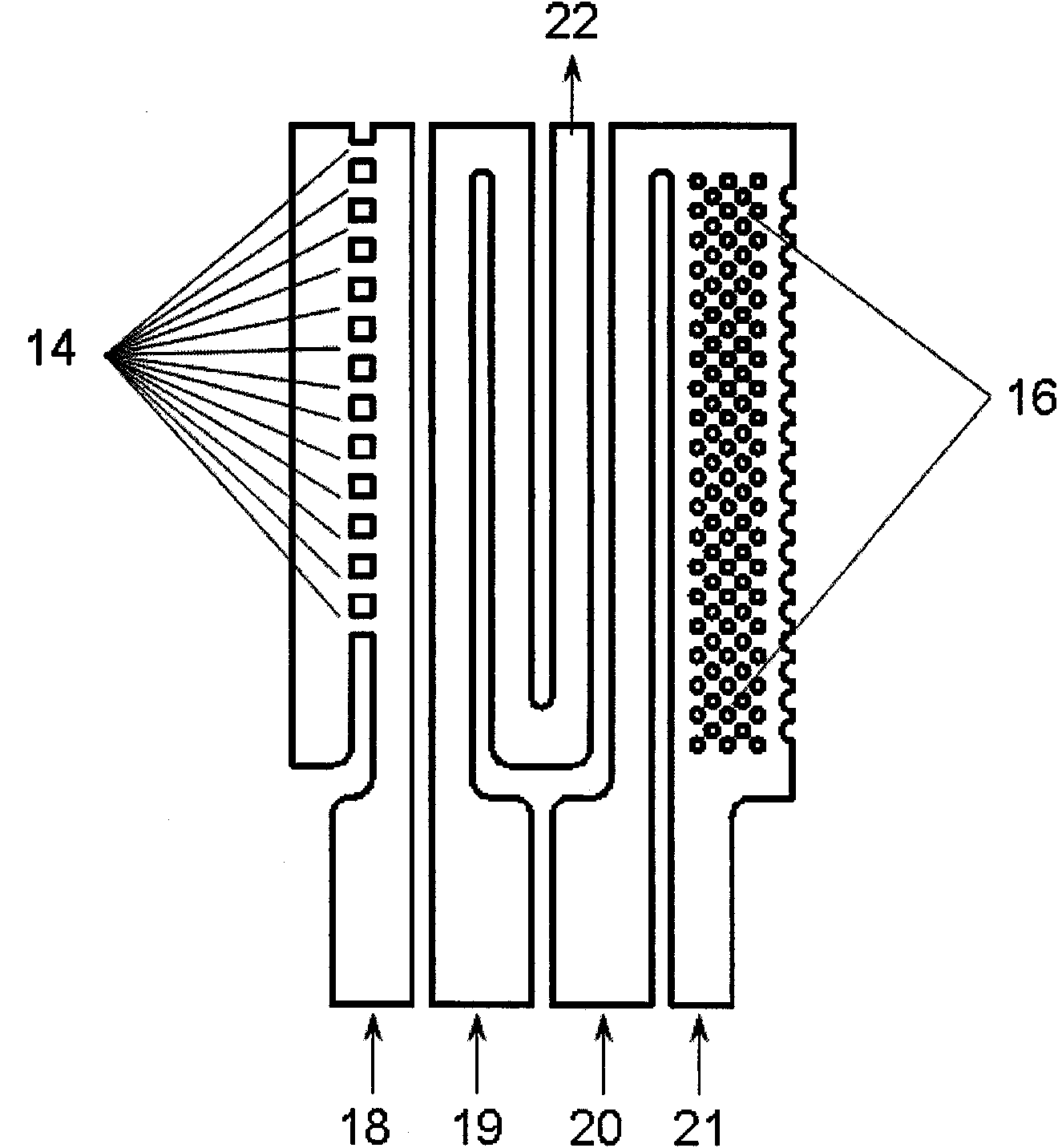

Method and welding device for the evaluation of the welding current intensity during the welding of container bodies

ActiveUS20110000892A1Compensate for changeManipulation errorSoldering apparatusElectrode supporting devicesSeam weldingElectric energy

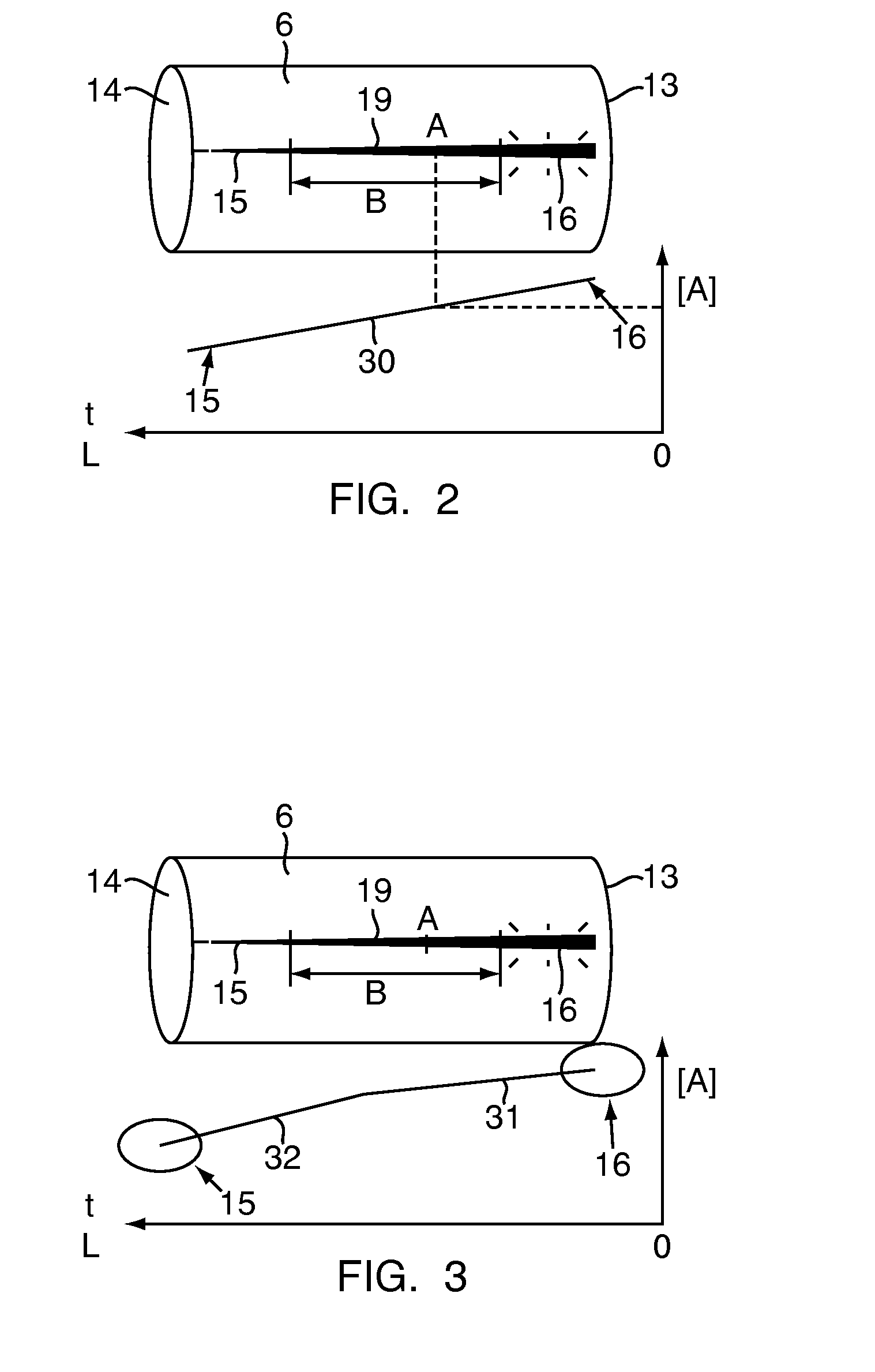

In order to evaluate the welding current for the resistance seam welding of an overlap seam of container bodies, a welding with changing welding current intensity is carried out for a container body of the production series, resulting in a changing welding of the seam, ranging from the welding with a too high temperature to the welding with a too low temperature. The electric energy for this welding is determined several times during this welding and / or the temperature of the weld seam is determined several times and the welding current intensity is determined at which the welding of the individual container body is too cold and the welding current intensity at which the welding is too hot. This determination is based on the determined electric energy values and / or on the determined temperature values and based on this determination a preferred range for the welding current intensity within these limits of too hot and too cold is determined. By this, an evaluation if the welding current intensity is correct may take place in a simple way during the production. After the welding of the individual container bodies a changed welding current intensity lying between the welding current intensity of the too hot and of the too cold welding may optionally be set and used for the following series of container bodies of the production series.

Owner:SOUDRONIC

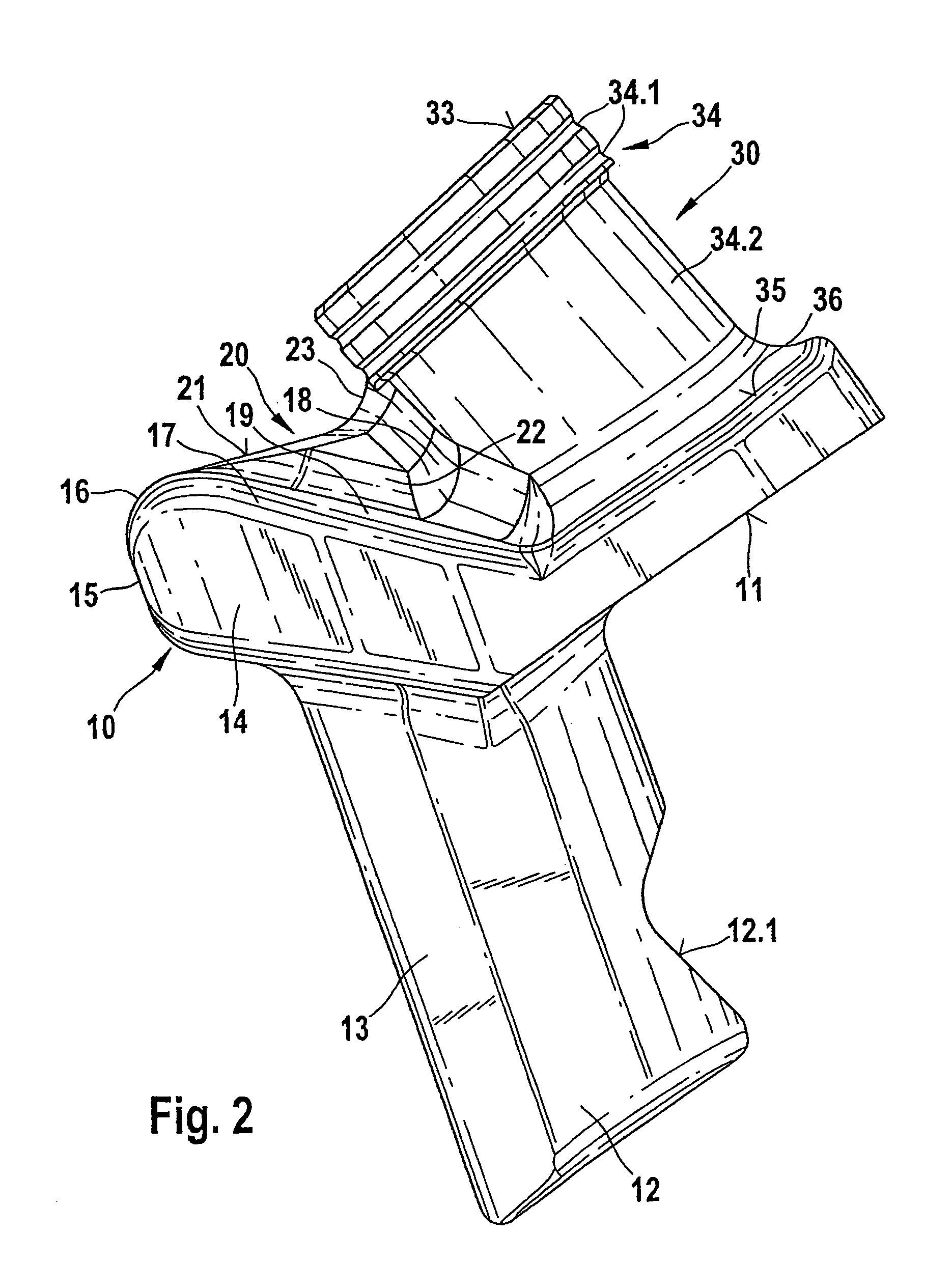

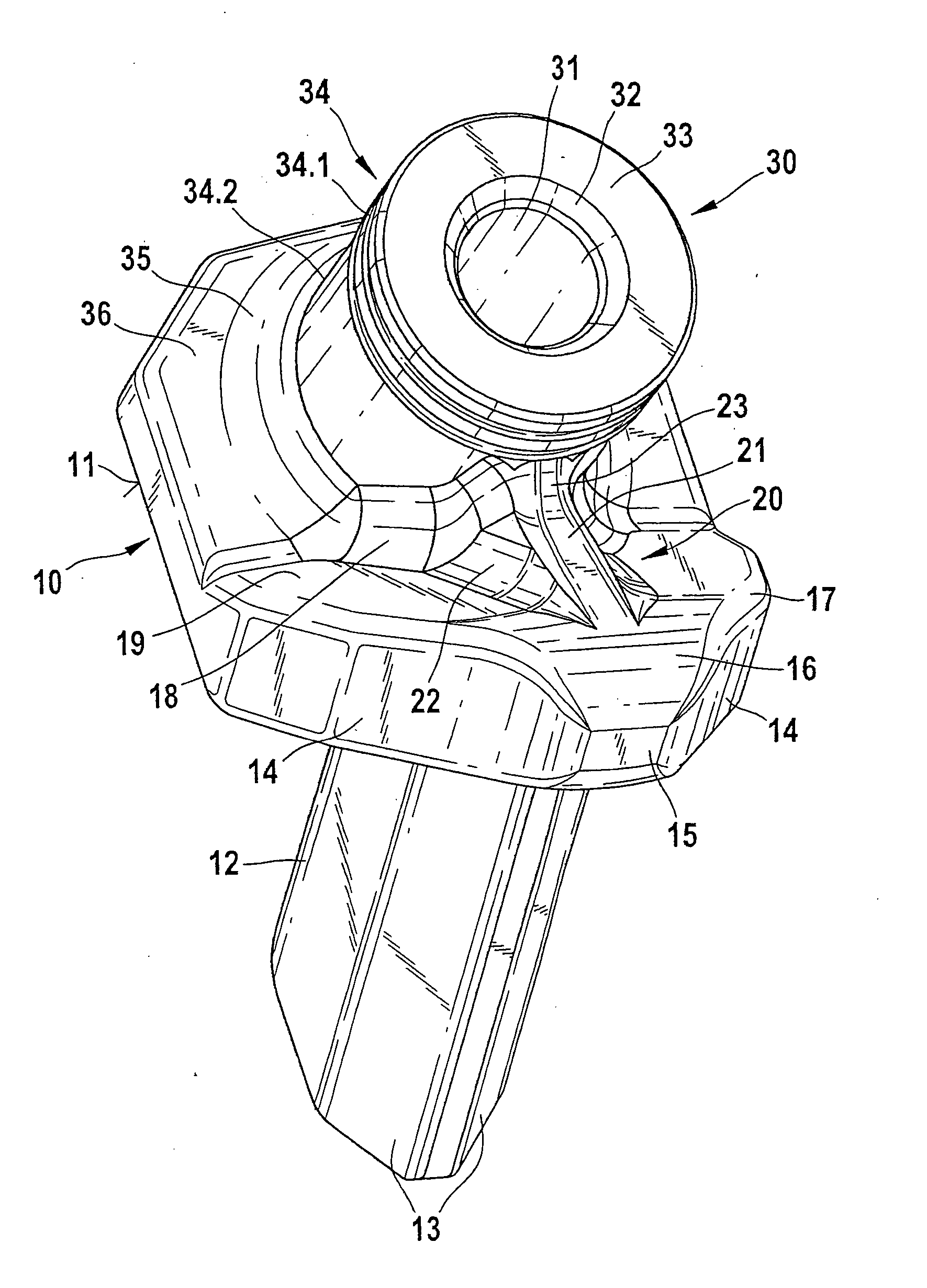

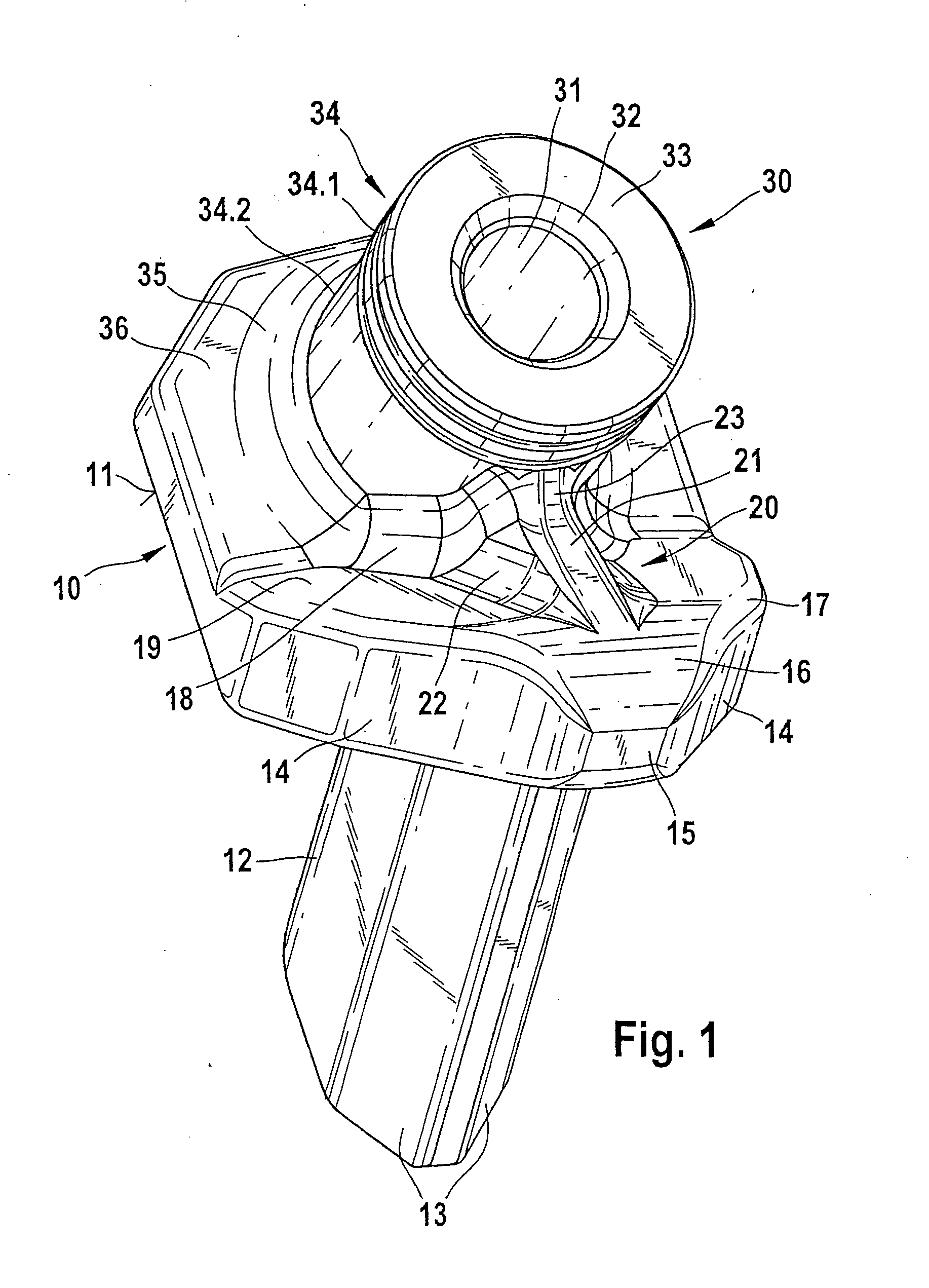

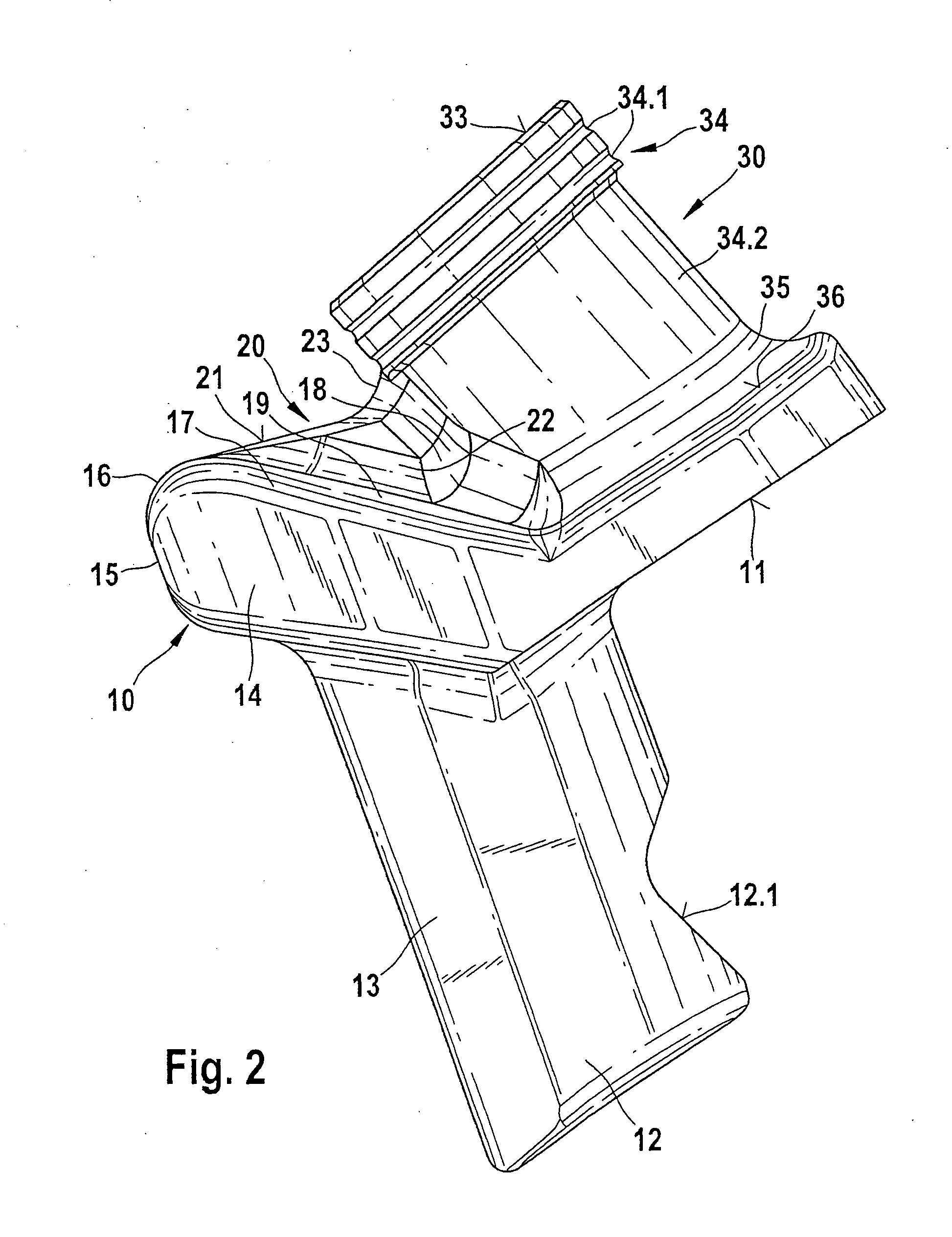

Chisel holder

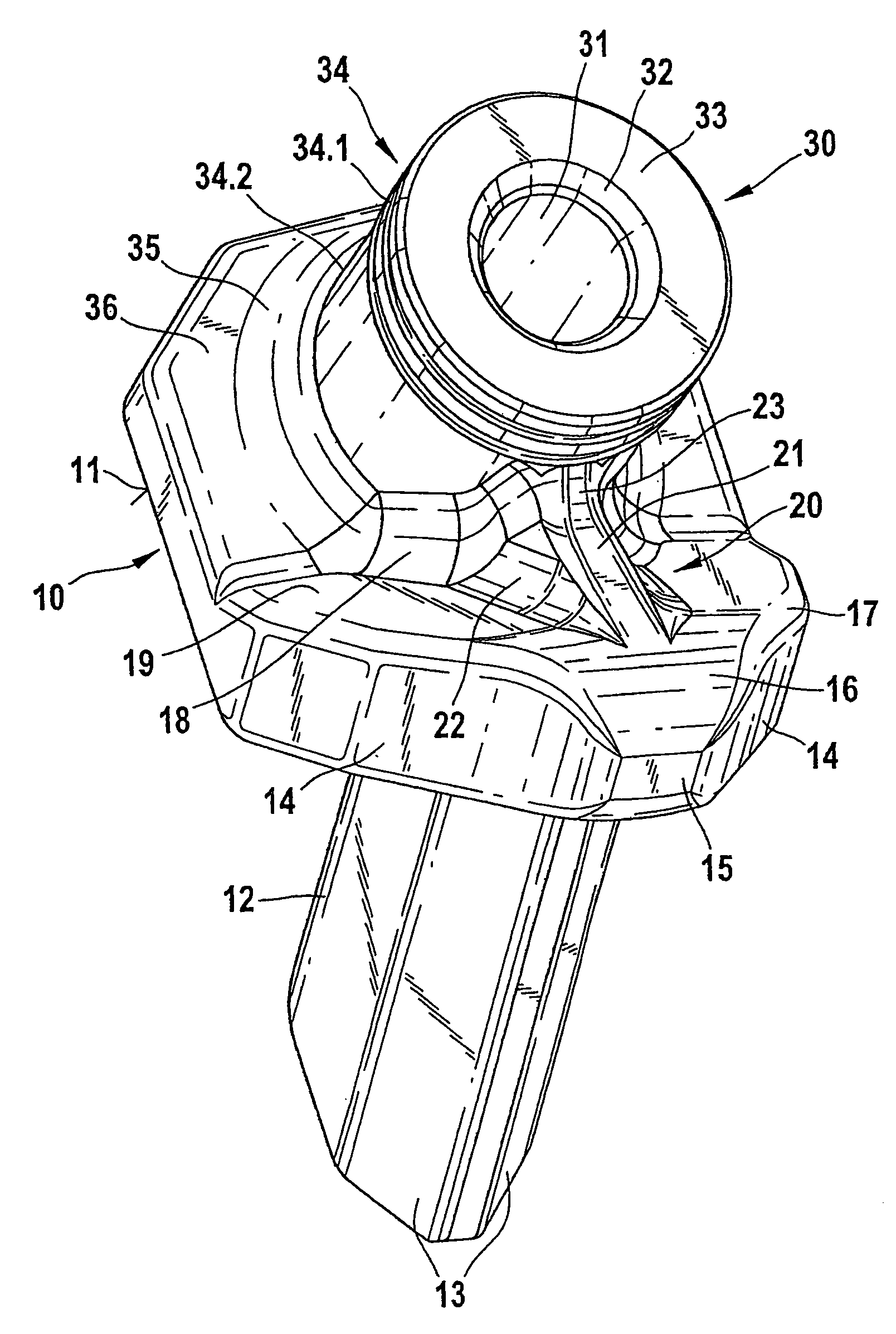

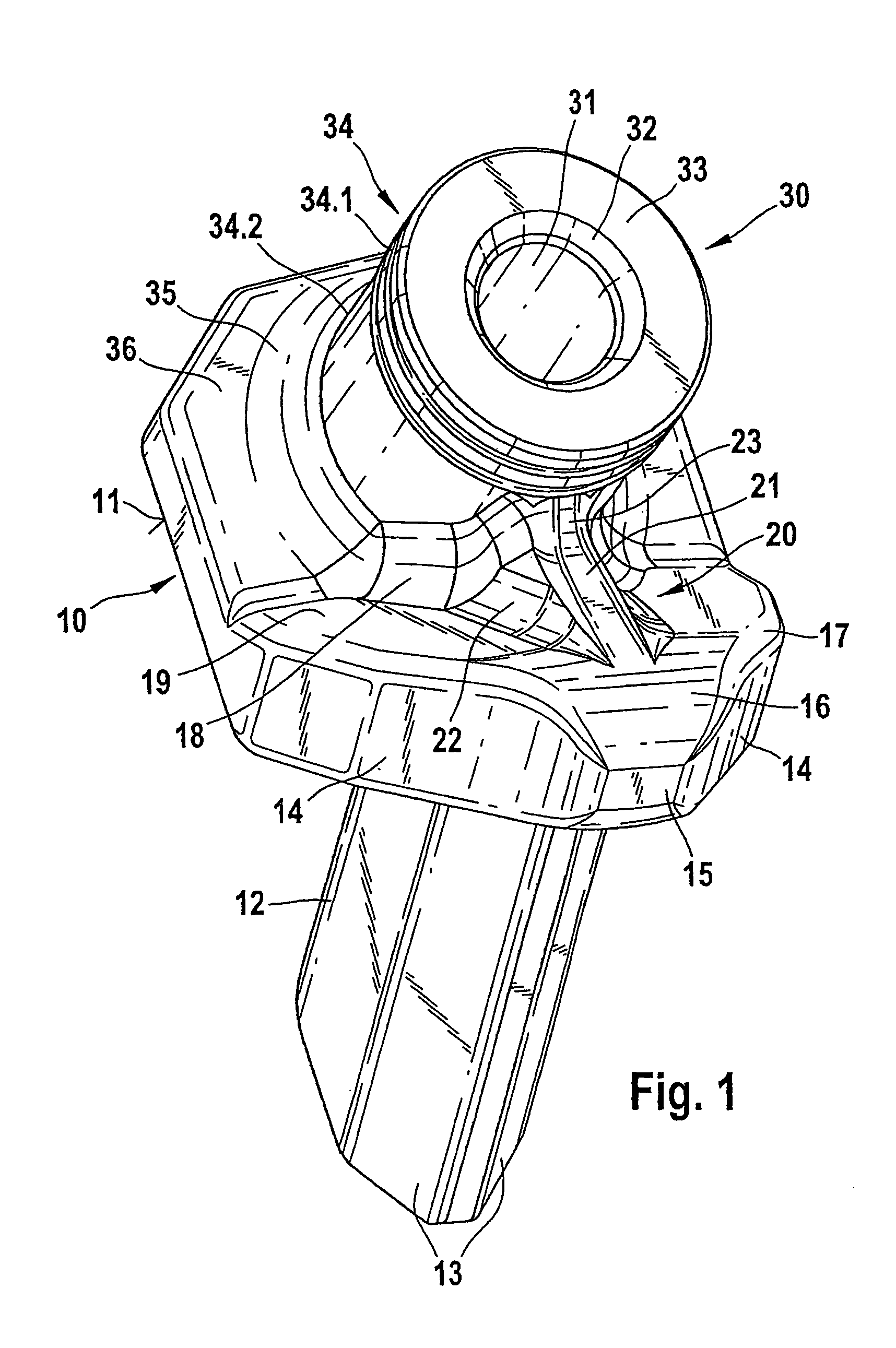

A chisel holder for a road milling machine or the like, having a base element which supports a holding neck, wherein the holding neck has a chisel receiver and a protrusion is connected to the base element upstream of the holding neck when viewed in an advancing direction of the tool. For improving the cutting output, in particular in connection with rough-chipped milling materials, the base element has a connecting section designed as a chip breaker, which is formed on the base element and extends, starting at the holding neck, at least partially over the protrusion.

Owner:WIRTGEN GMBH

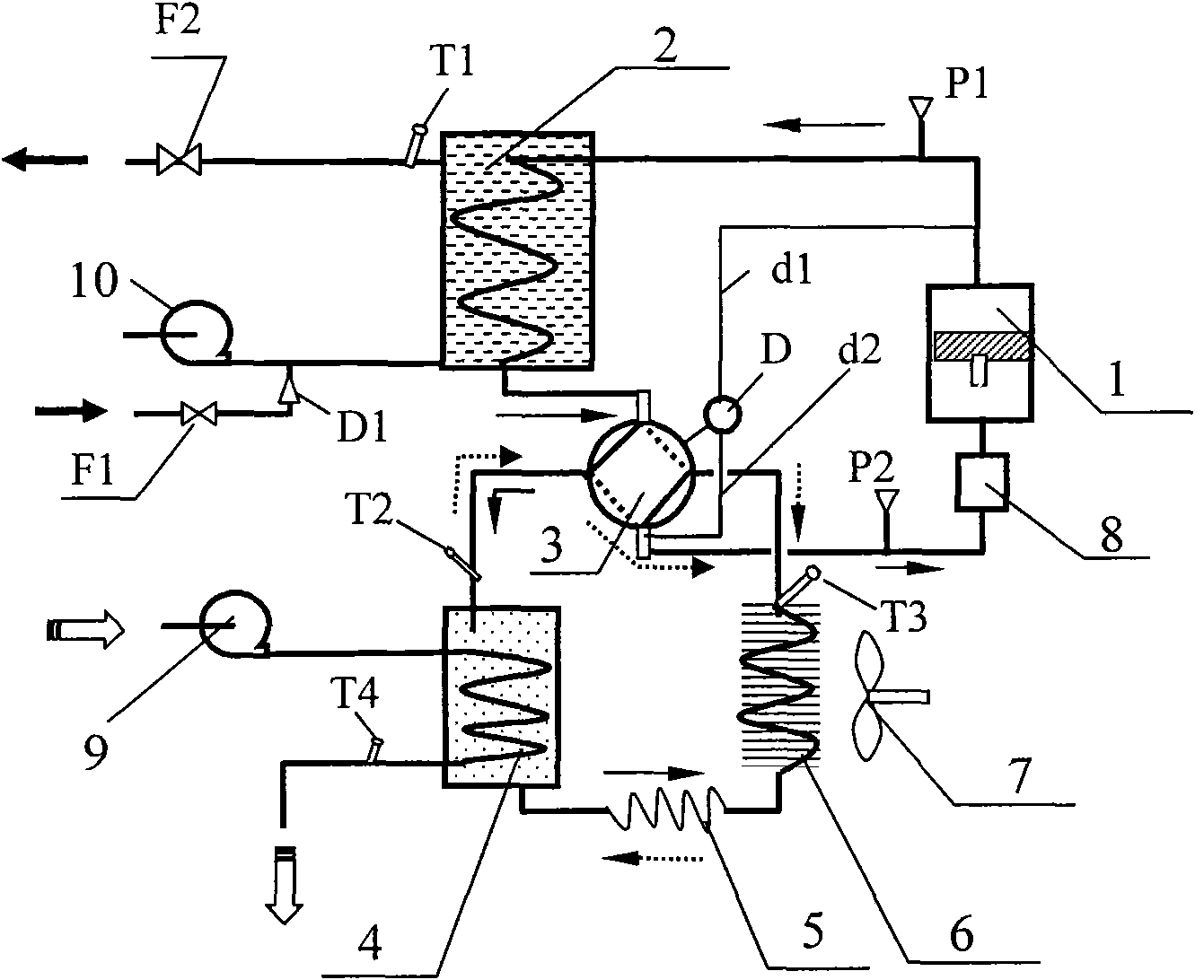

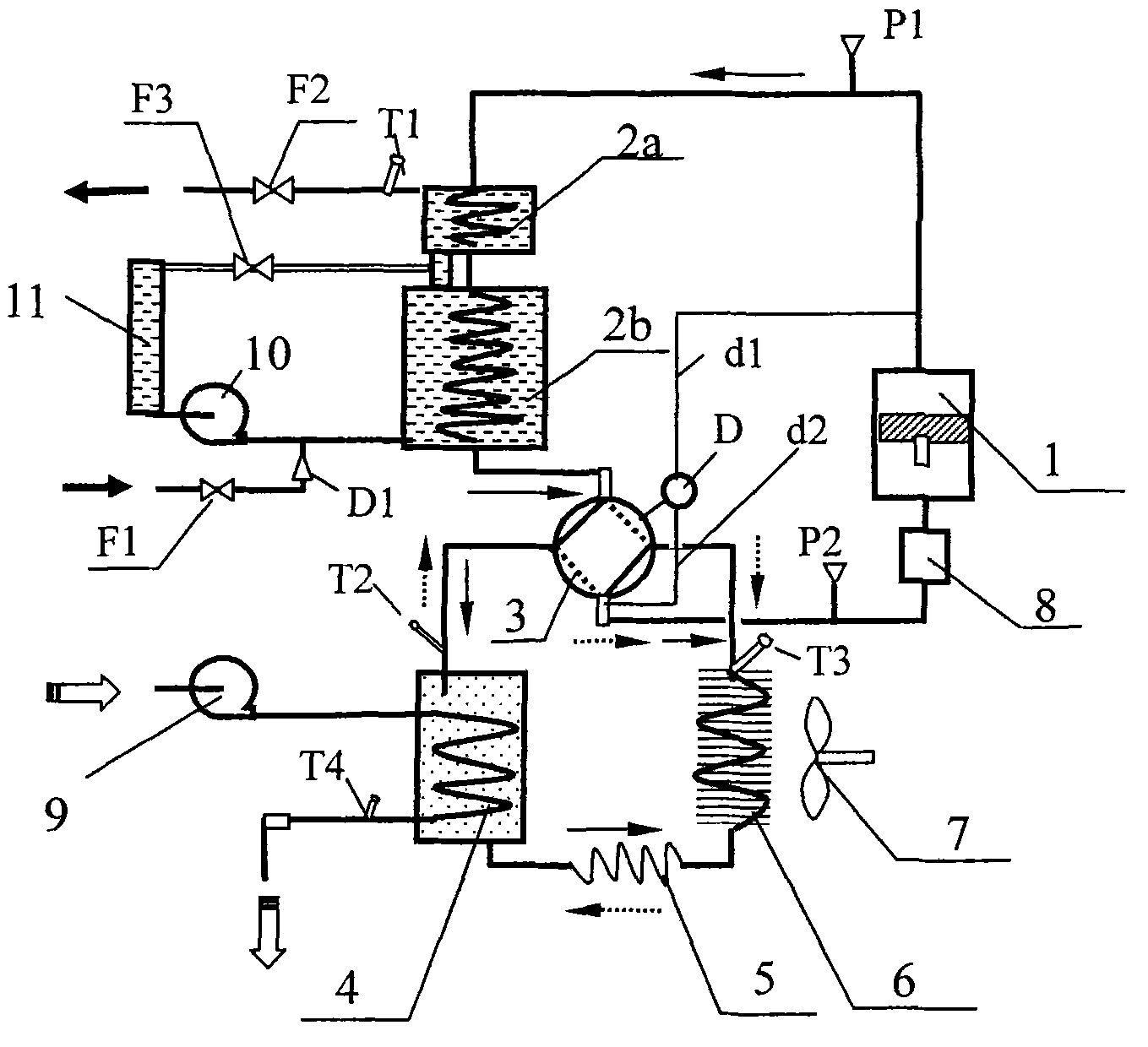

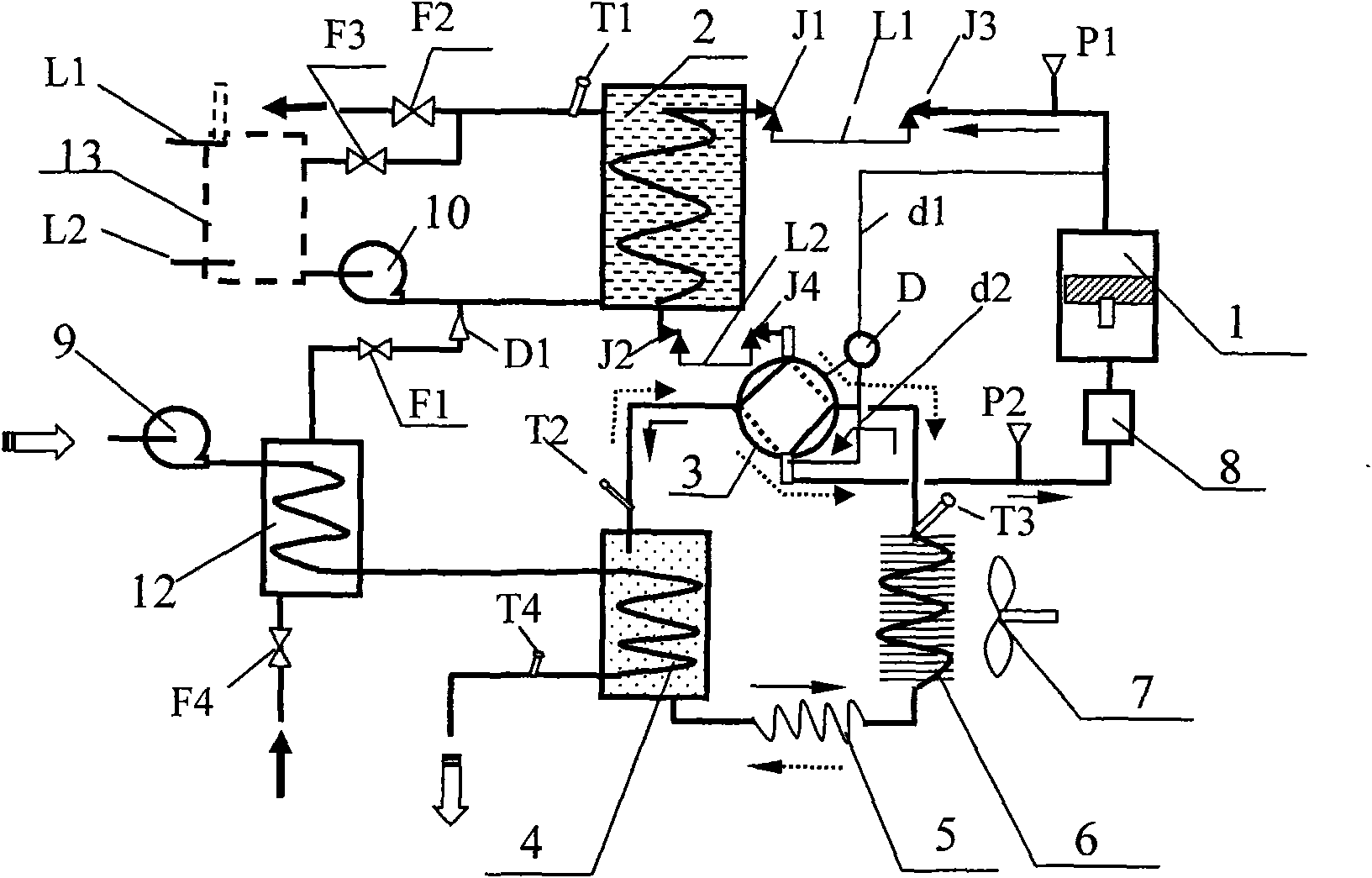

Dual heat-source heat-pump hot water device with extremely simple refrigerating loop

InactiveCN101943471AFix switching issuesSolve defrosting problemsFluid heatersHeat recovery systemsFour-way valveWater source

The invention discloses a dual heat-source heat-pump hot water device with an extremely simple refrigerating loop. The device is characterized by mainly comprising a compressor, a hot water condenser, a wind heat exchanger, a water heat exchanger, a four-way valve, a bidirectional throttle and the like, wherein a high pressure inlet of the four-way valve is connected with the outlet of the hot water condenser, and the other three ports thereof are connected with air inlets of the wind heat exchanger, the water heat exchanger and the compressor respectively; other ports of the wind heat exchanger and the water heat exchanger are connected with the bidirectional throttle; the exhaust port of the compressor is connected with the inlet of the hot water condenser, and is connected with high pressure air inlet of an electromagnetic pilot valve of the four-way valve; four functions of manufacturing hot water by utilizing water source or air energy and providing air-conditioning cool water by utilizing air-cooling or heating water can be realized by only switching the four-way valve, defrosting can be performed completely and quickly; and a water pre-heater is added to the device to reclaim the heat of waste hot water. The heat pump has the advantages of dual heat sources compensation and wide application range, has multiple functions, extremely simple structure, extremely convenient switching and over 5 of annual comprehensive energy efficiency ratio, and has great popularization value.

Owner:陈则韶

Chisel holder

A chisel holder for a road milling machine or the like, having a base element which supports a holding neck, wherein the holding neck has a chisel receiver and a protrusion is connected to the base element upstream of the holding neck when viewed in an advancing direction of the tool. For improving the cutting output, in particular in connection with rough-chipped milling materials, the base element has a connecting section designed as a chip breaker, which is formed on the base element and extends, starting at the holding neck, at least partially over the protrusion.

Owner:WIRTGEN GMBH

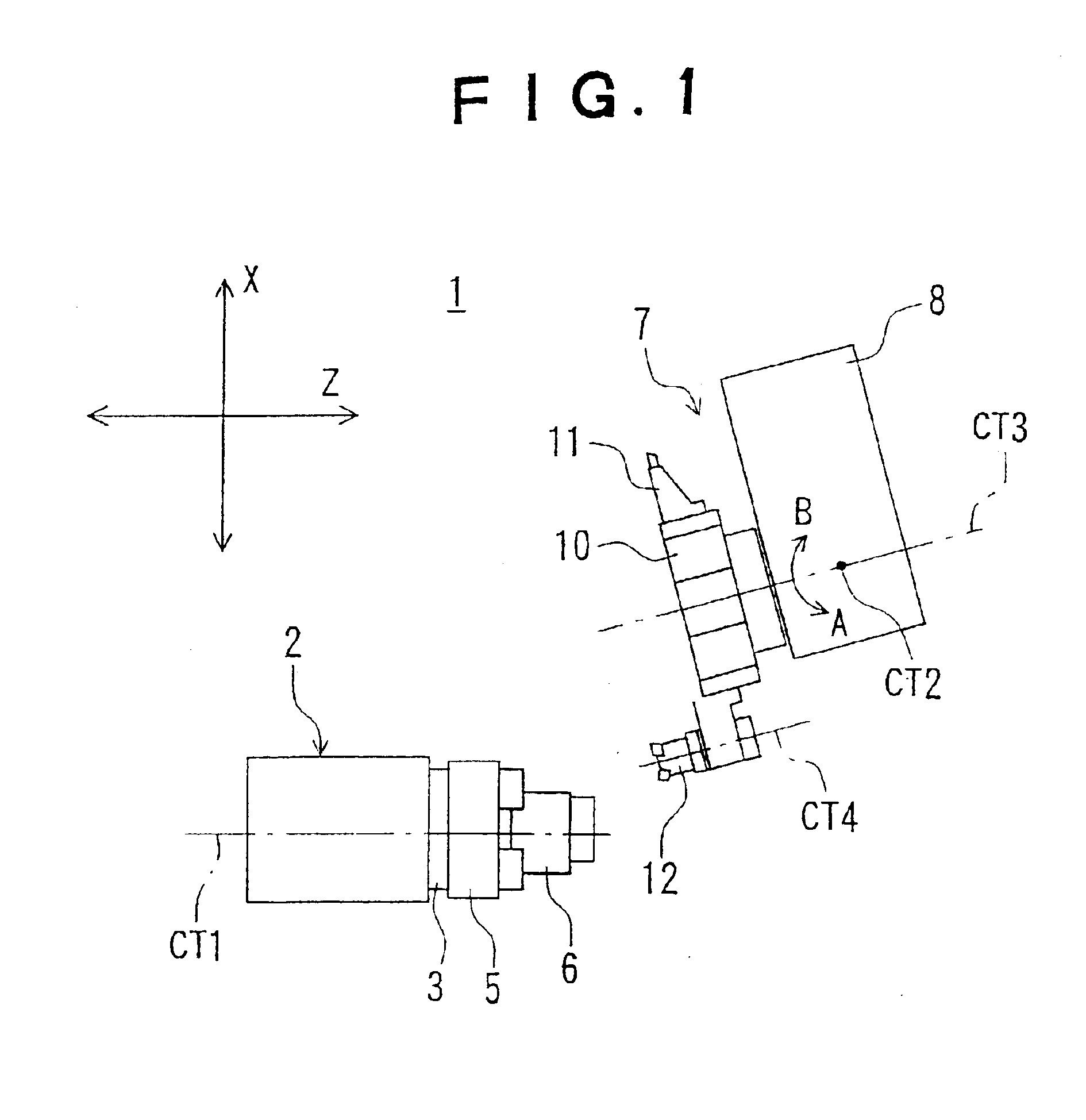

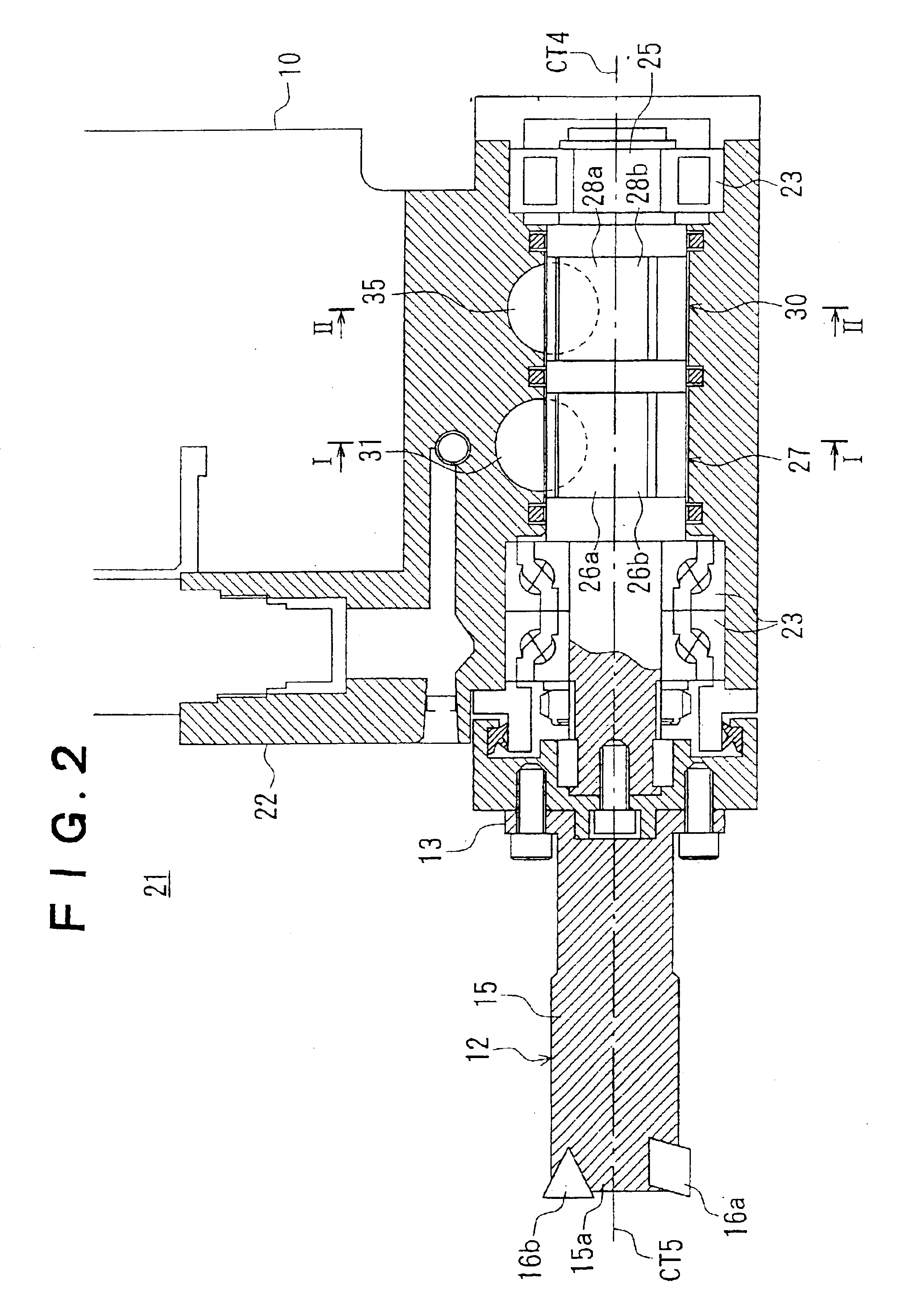

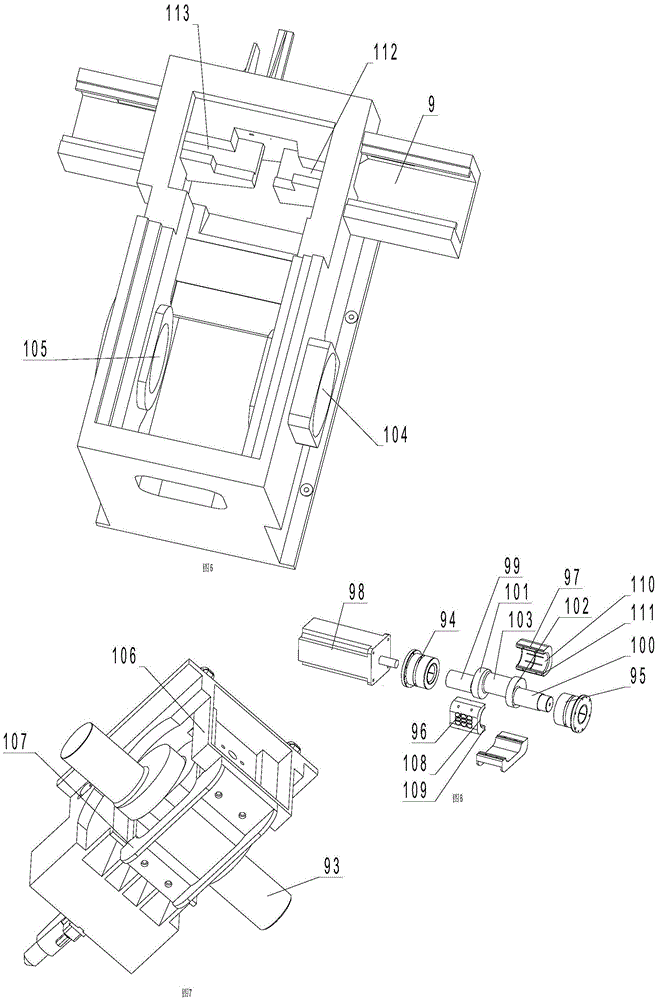

Tool holder for turret lathe

InactiveUS6865789B2Improve machine efficiencyAvoid long exchangesAutomatic/semiautomatic turning machinesPrecision positioning equipmentRotation functionEngineering

A tool holder for attaching a complex tool having a plurality of kinds of cutting edges to a turret, has a base portion attachably and detachably formed at the turret. The base portion has a rotatable tool spindle attachably and detachably installing the complex tool thereon. The tool spindle is provided with indexing means for indexably rotating the tool spindle at an indexed position corresponding to each cutting edge of the complex tool. And, clamping means for clamping the tool spindle at a predetermined indexed position is provided. Indexing rotational function and clamping function owned by the tool holder makes the use of the complex tool in the lathe possible.

Owner:YAMAZAKI MAZAK KK

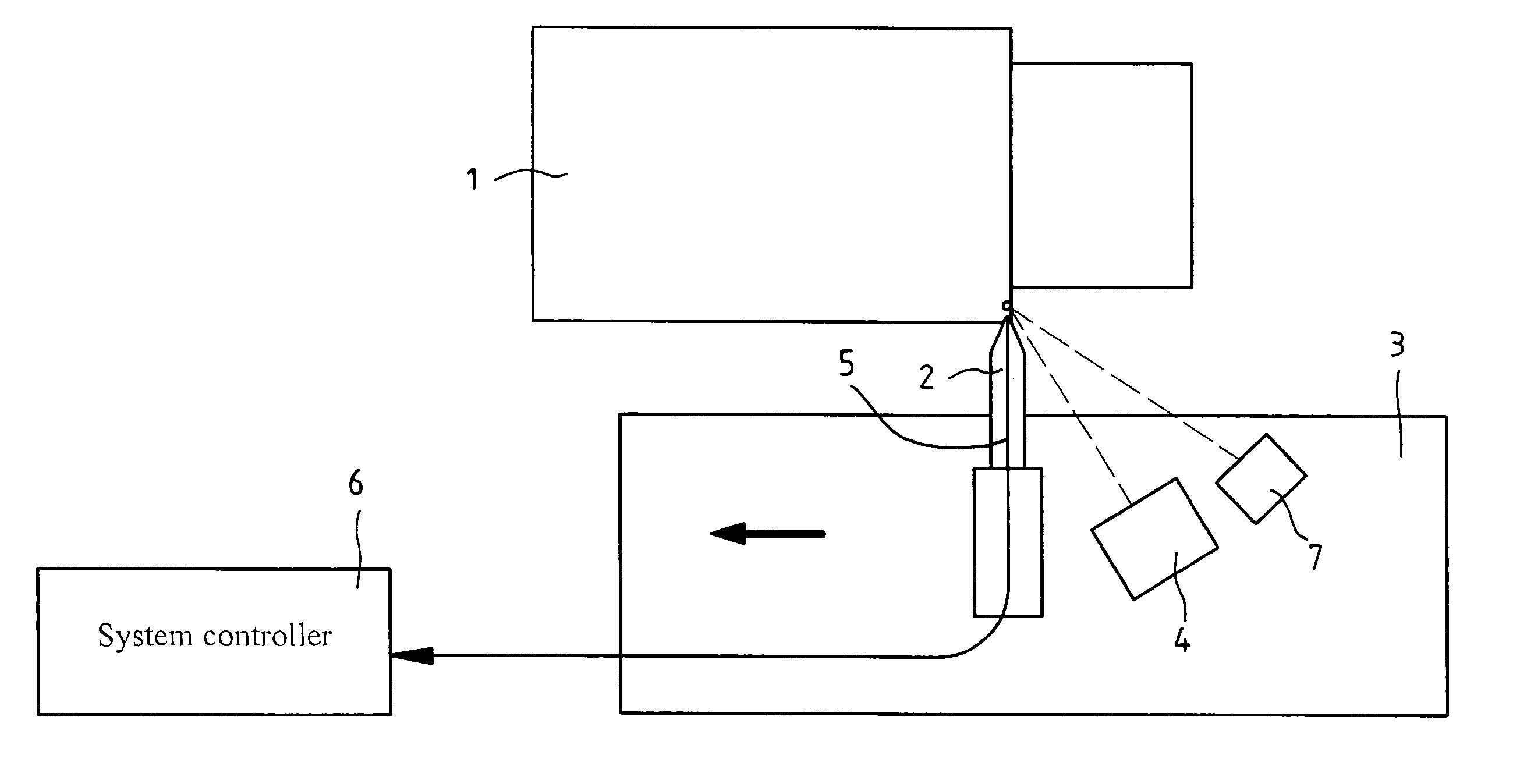

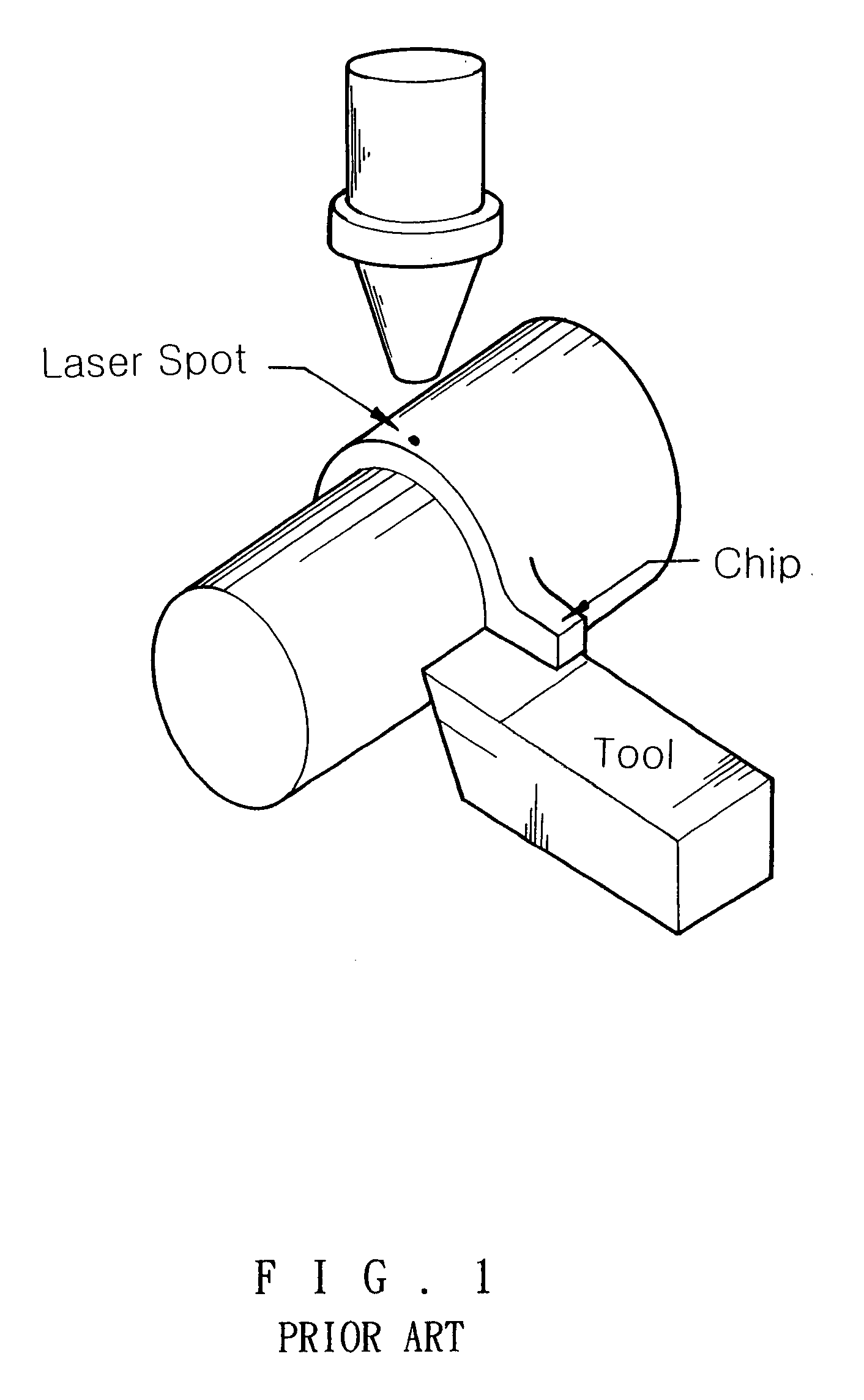

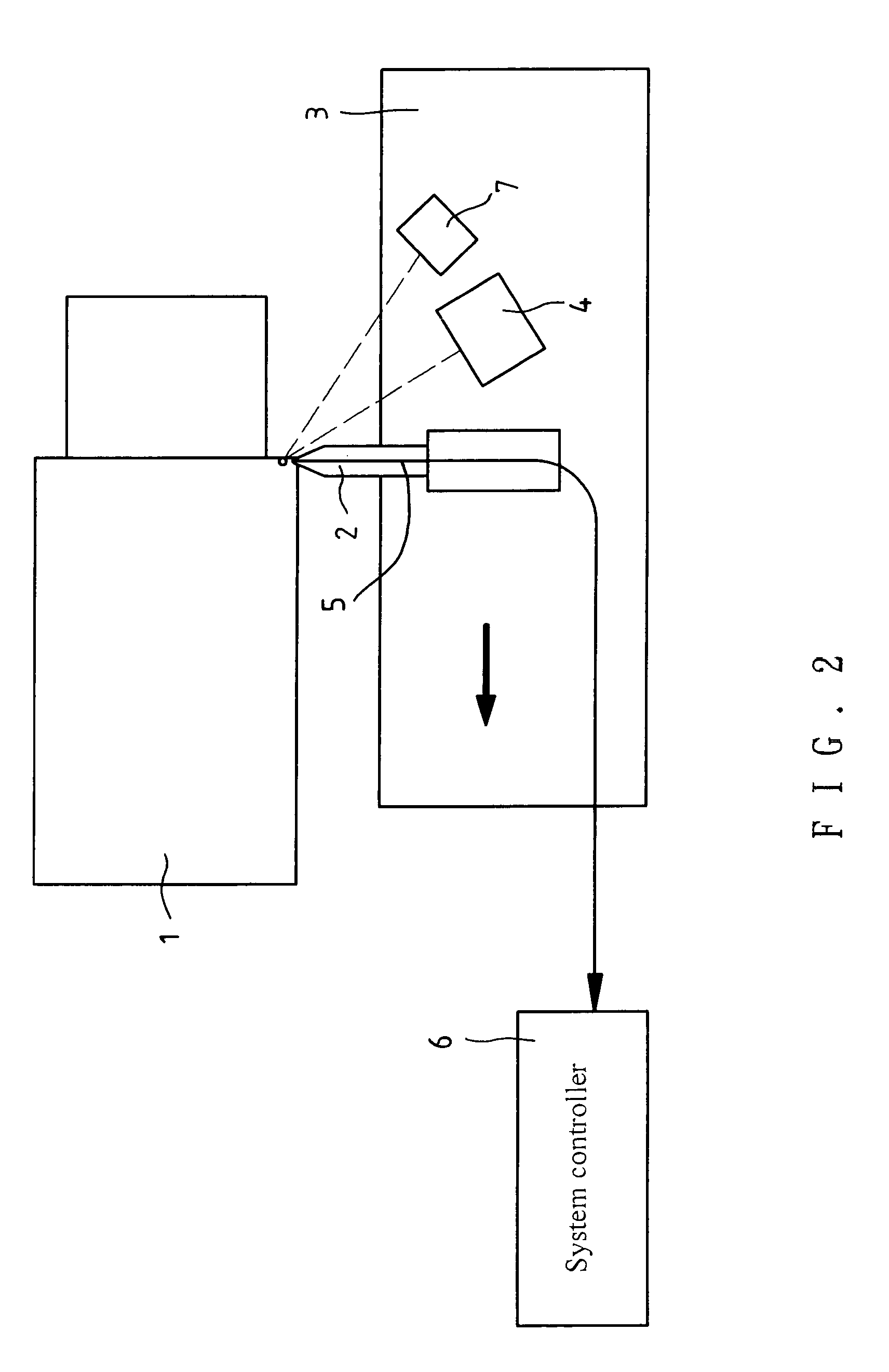

Laser assisted machining method and device

ActiveUS7002100B2Prolong service life spanAlleviate effectWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlLaser assisted

A laser assisted machining method and device comprise a tool mount on which a laser head is disposed. A digital thermometer is disposed in a machining tool or on the tool mount for feeding data to a system controller. A laser is used to enable the blade of the machining tool to heat and soften a workpiece instantaneously. As the machining process is in progress, the chip is rapidly removed. The temperature of the tool tip is monitored by the digital thermometer for automatic control of the temperature of heating the workpiece by the laser, thereby keeping the temperature of the tool tip in a specific allowable range. The efficiency of the machining process and the surface precision are thus enhanced.

Owner:IND TECH RES INST

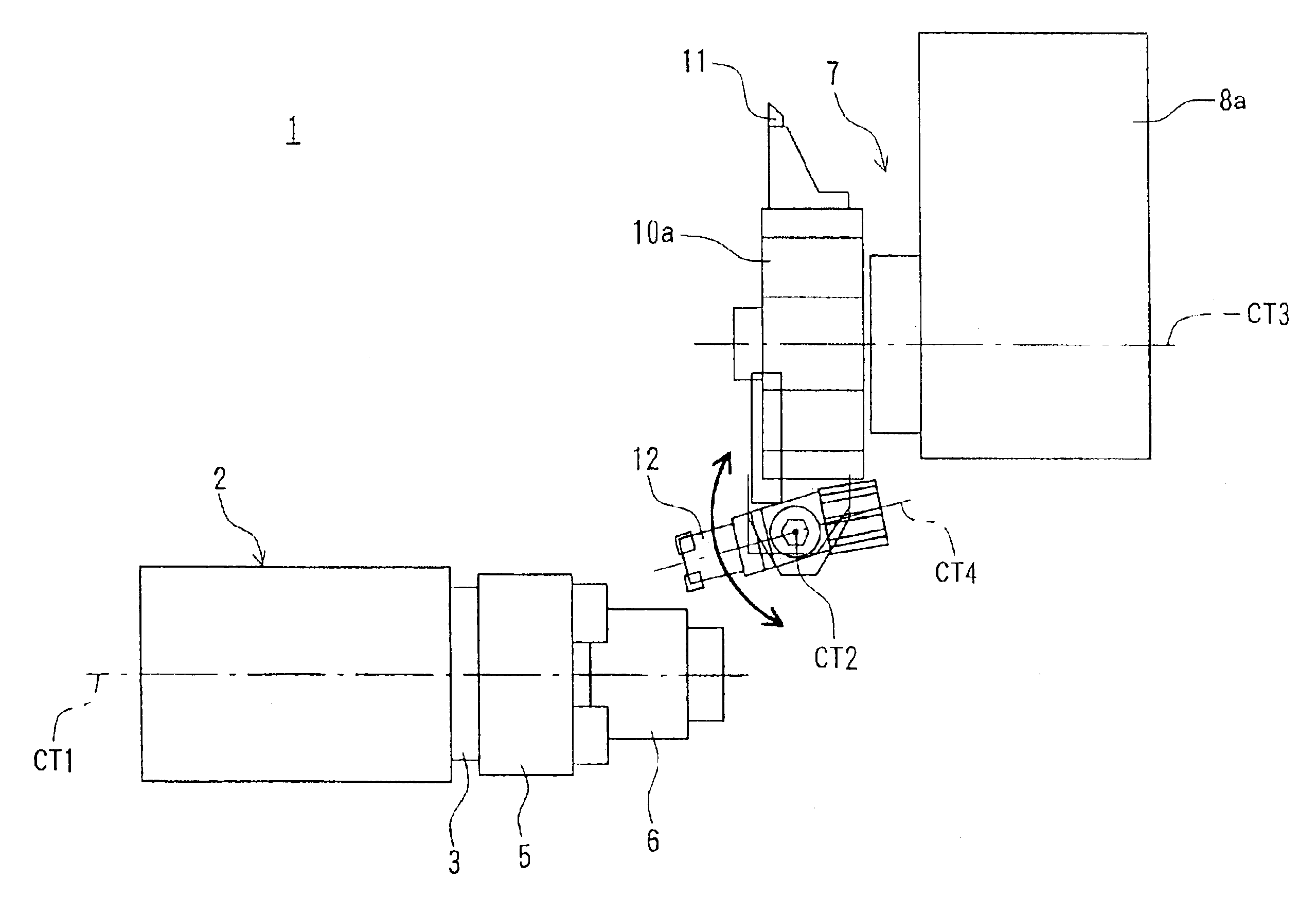

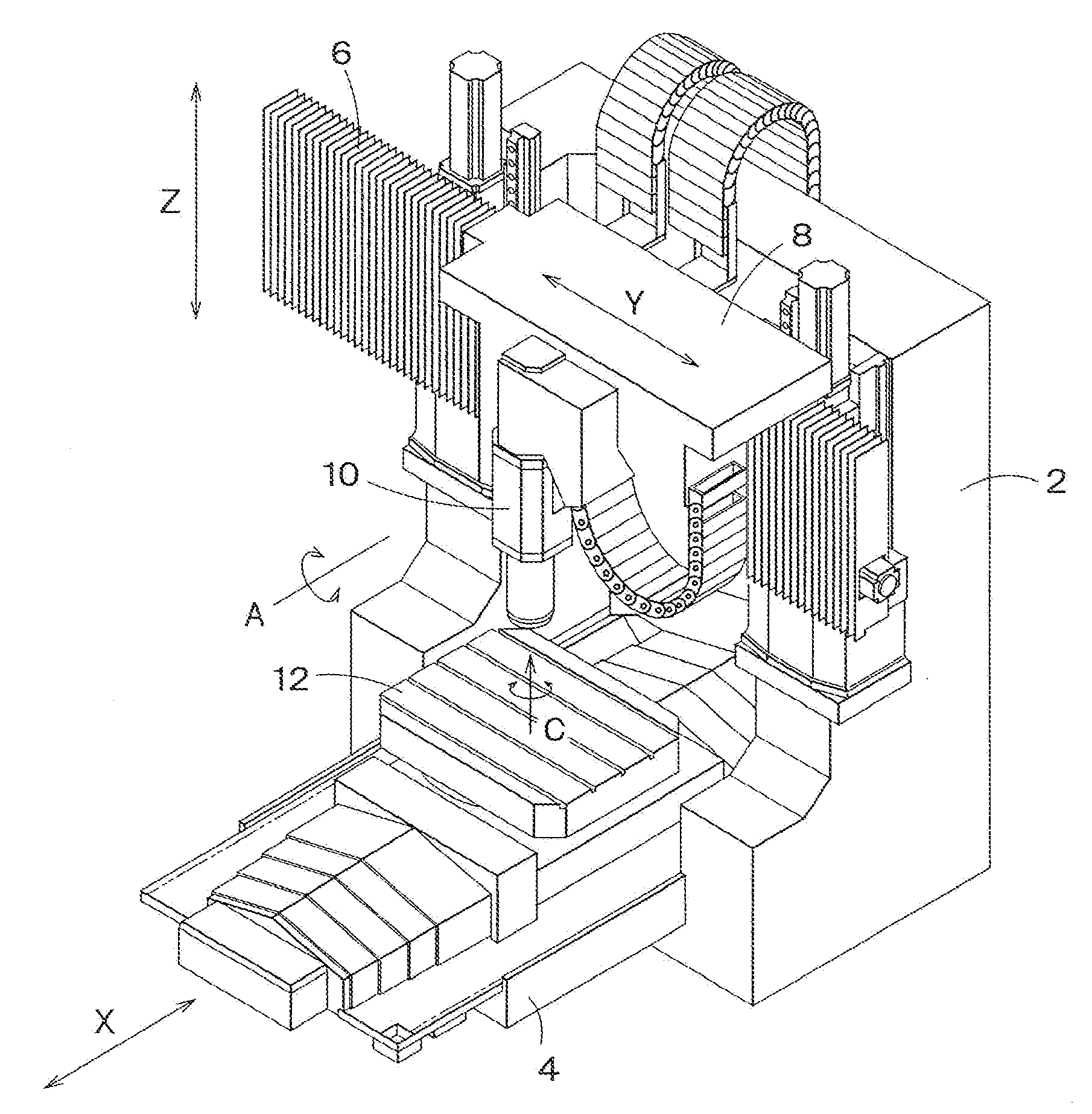

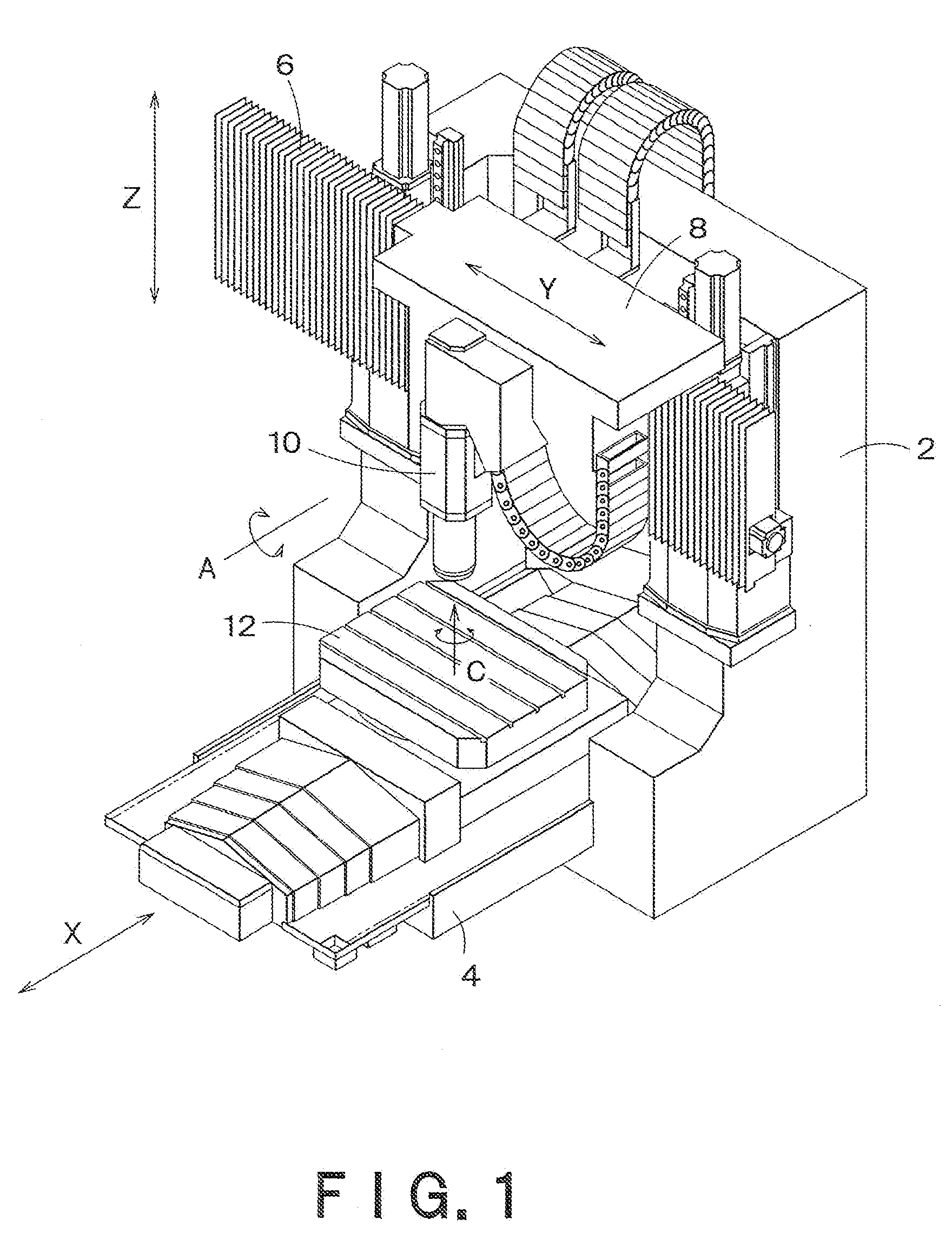

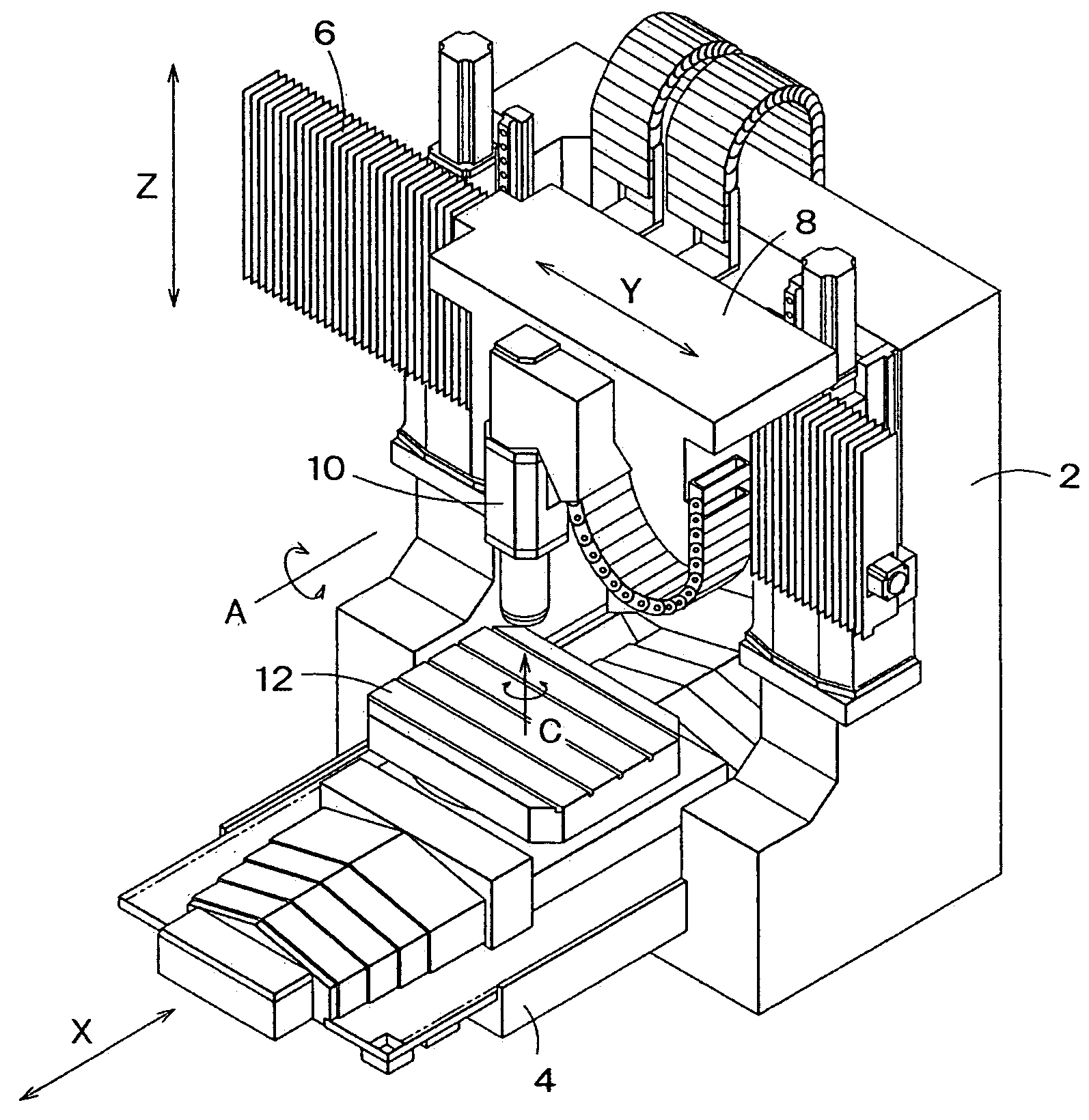

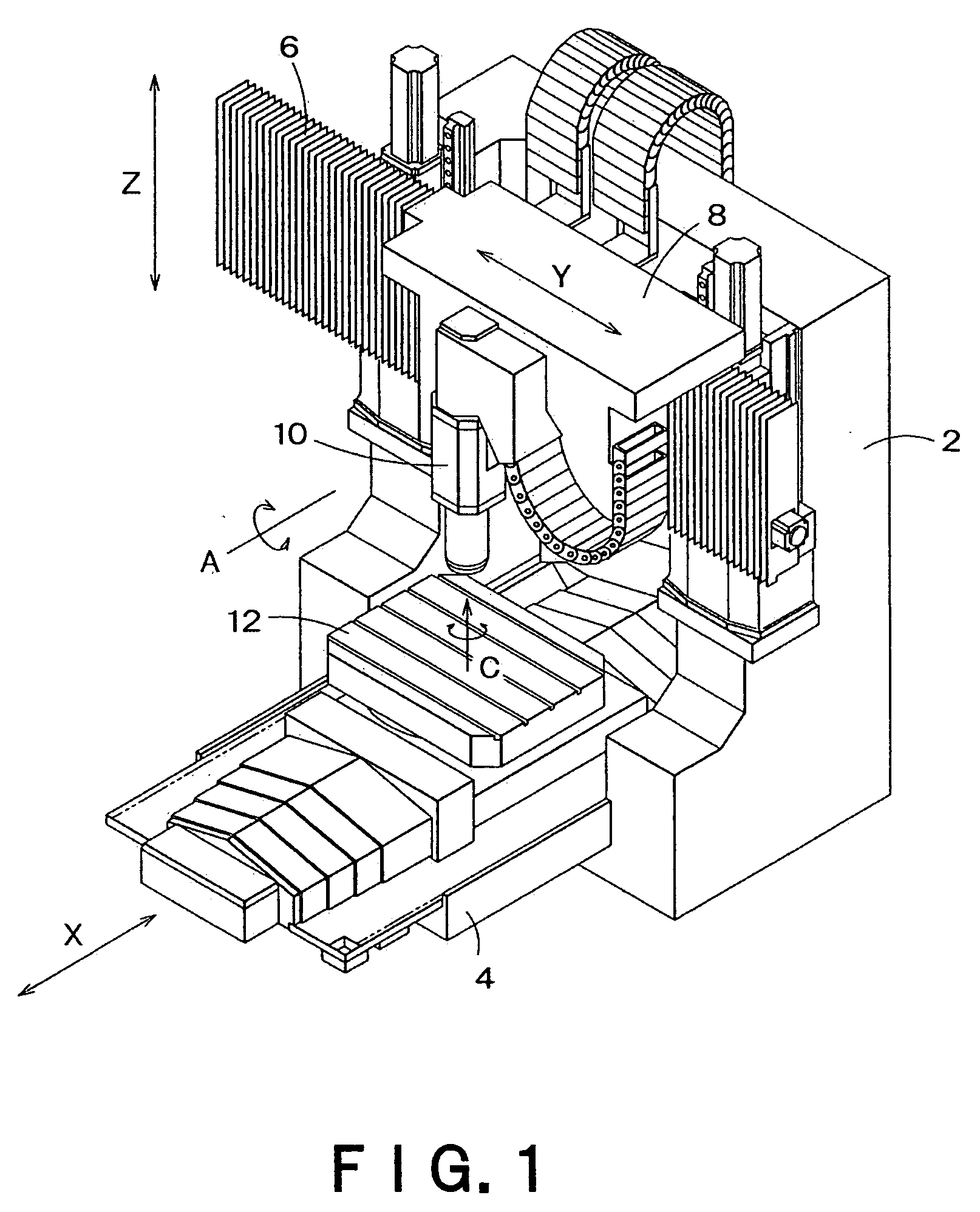

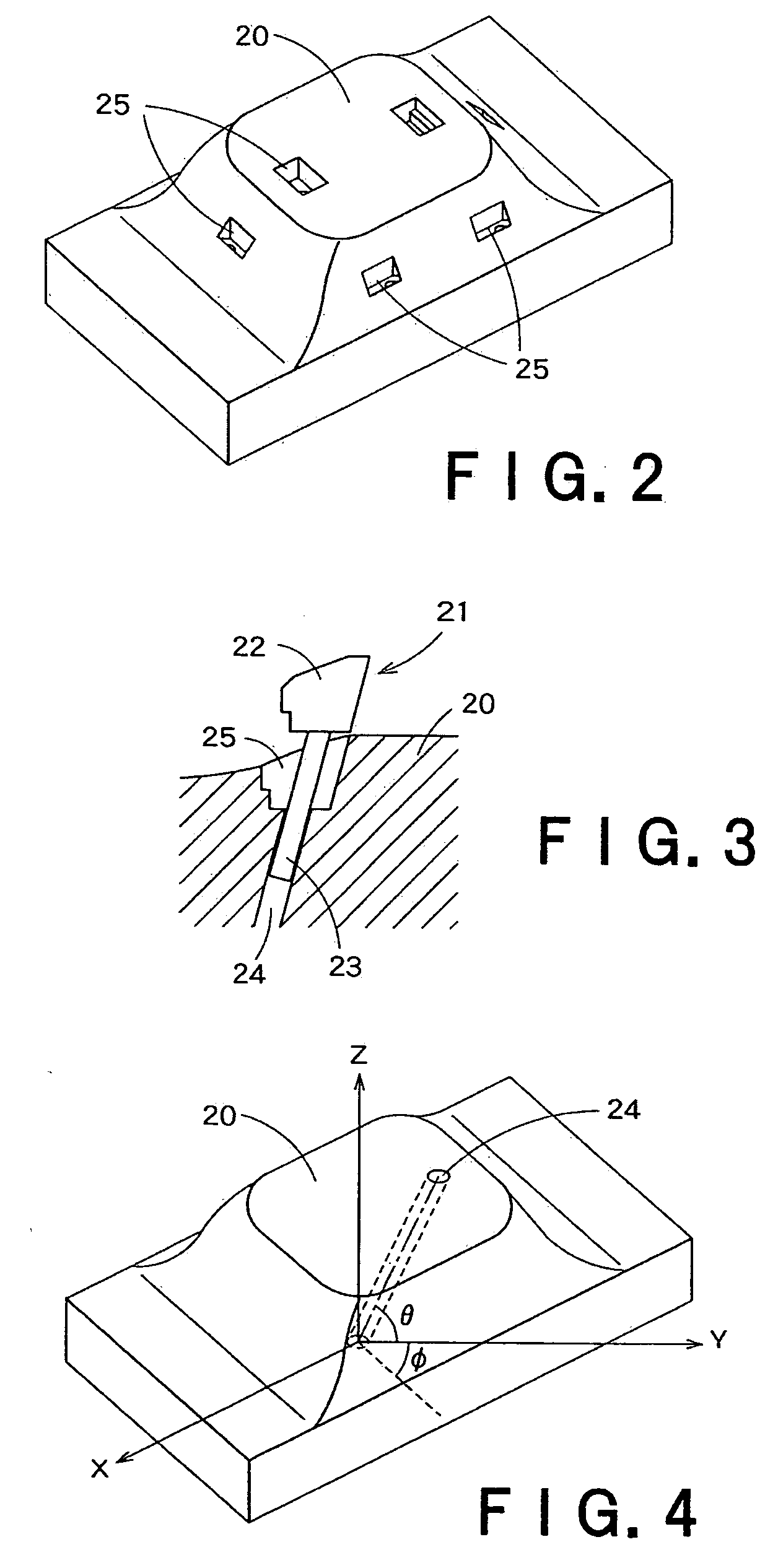

Position ensuring system for oblique machining in five-axis machine tool

ActiveUS20080114485A1Improve machine efficiencyTake advantage ofProgramme controlAngles/taper measurementsData preparationControl theory

There is provided a position ensuring system for oblique machining in a five-axis machine tool which, based on the inclination and the direction of an inclined hole to be machined, carries out measurement of an error in the pivot angle of a spindle head and an error in the rotation angle of a table before initiating machining of the hole, and can automatically correct the pivot angle of the spindle head and the rotation angle of the table upon machining of the hole, thereby precisely ensuring the position of the spindle head and the position of the table in the machining.The position ensuring system includes: an A-axis calibration means for measuring a displacement angle, which is an error between a target value and a measured value of the pivot angle of the spindle head about the A-axis as the spindle head is pivoted to meet the inclination angle of an inclined hole to be machined in a workpiece, and correcting the pivot angle about the A-axis in such a manner that the displacement angle as measured with the corrected pivot angle as a target value fall within a tolerable range, before initiating machining of the workpiece, the measurement of displacement angle being carried out for all the inclined holes to be machined by execution of a measurement program prepared based on data on the shapes, including the inclination angles and the directions, of the inclined holes to be machined; a corrected data storage means for storing the corrected pivot angle about the A-axis for each of the inclined holes to be machined; and an A-axis control means for reading out the corrected pivot angle about the A-axis for each inclined hole upon executing a machining program for the workpiece by means of an NC apparatus, and instructing the corrected pivot angle about the A-axis to pivot the spindle head when executing oblique machining of the inclined hole.

Owner:TOSHIBA MASCH CO LTD

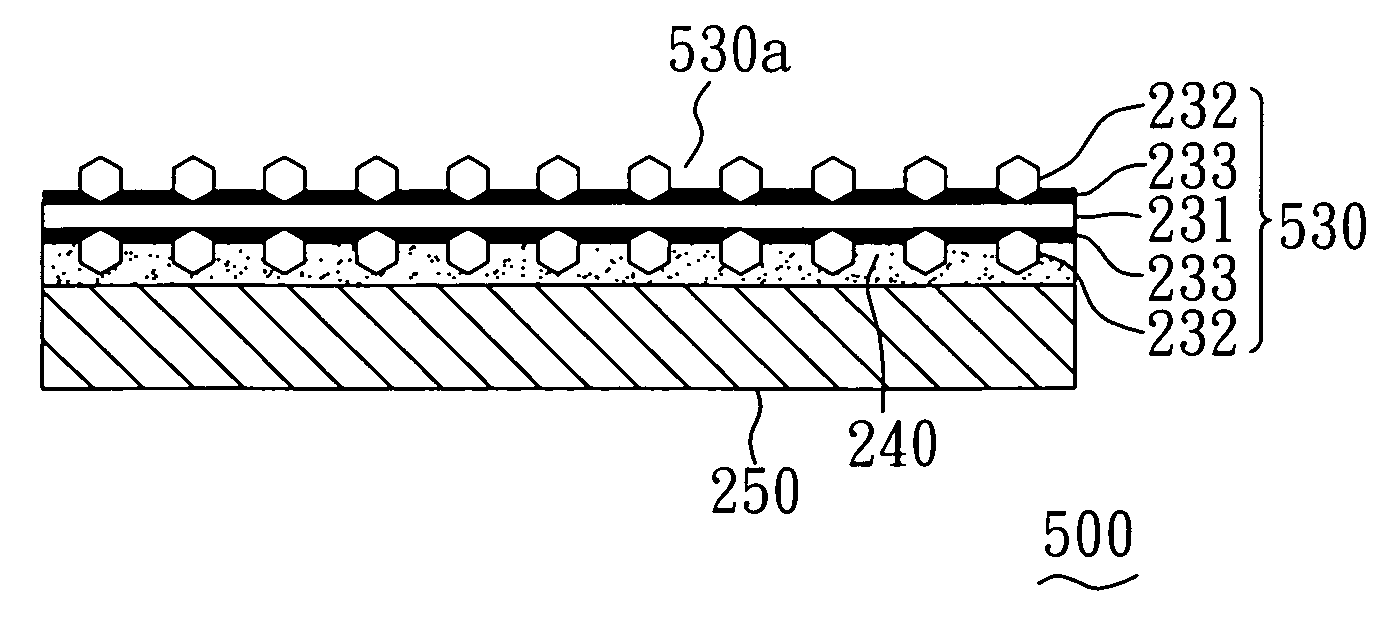

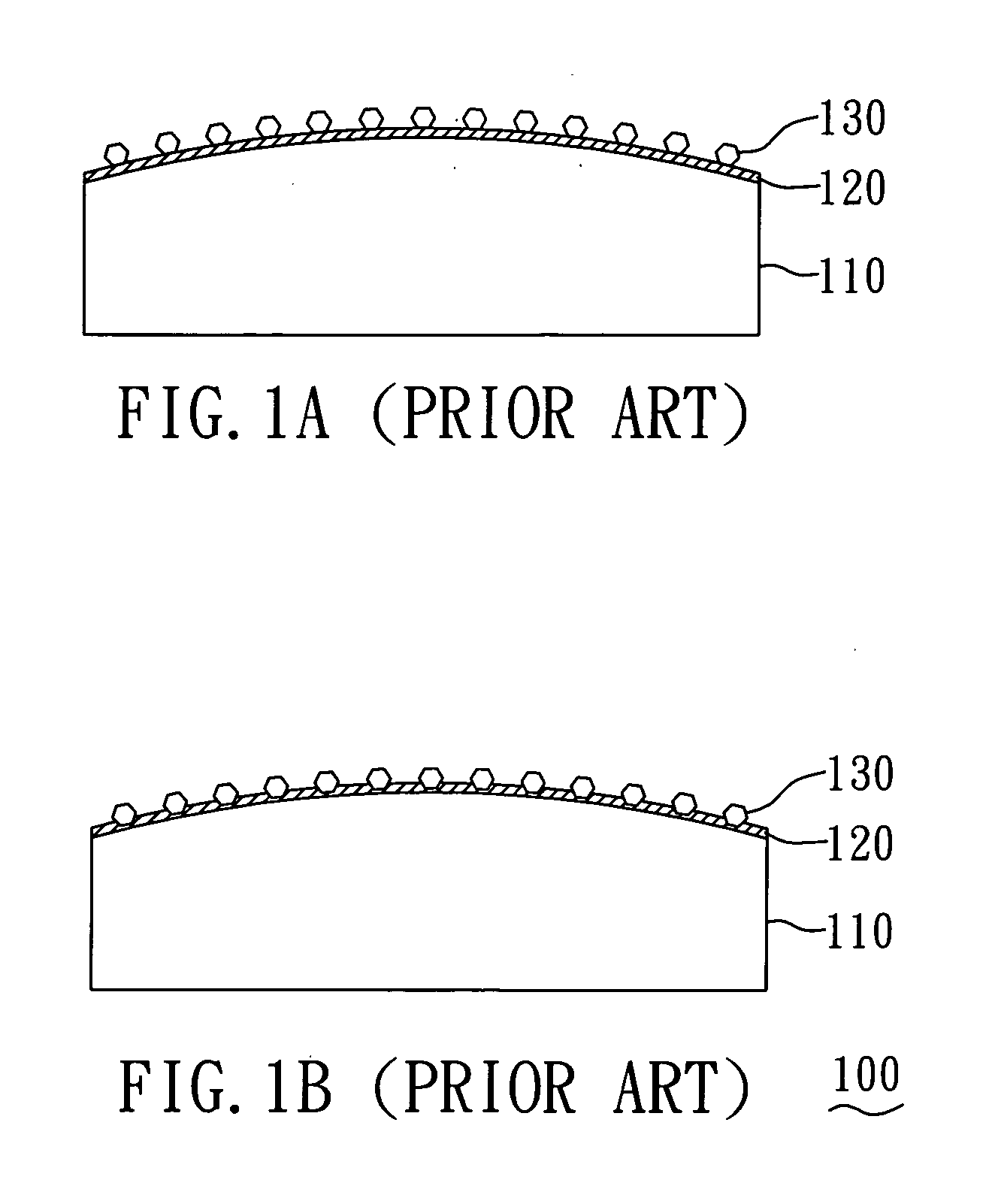

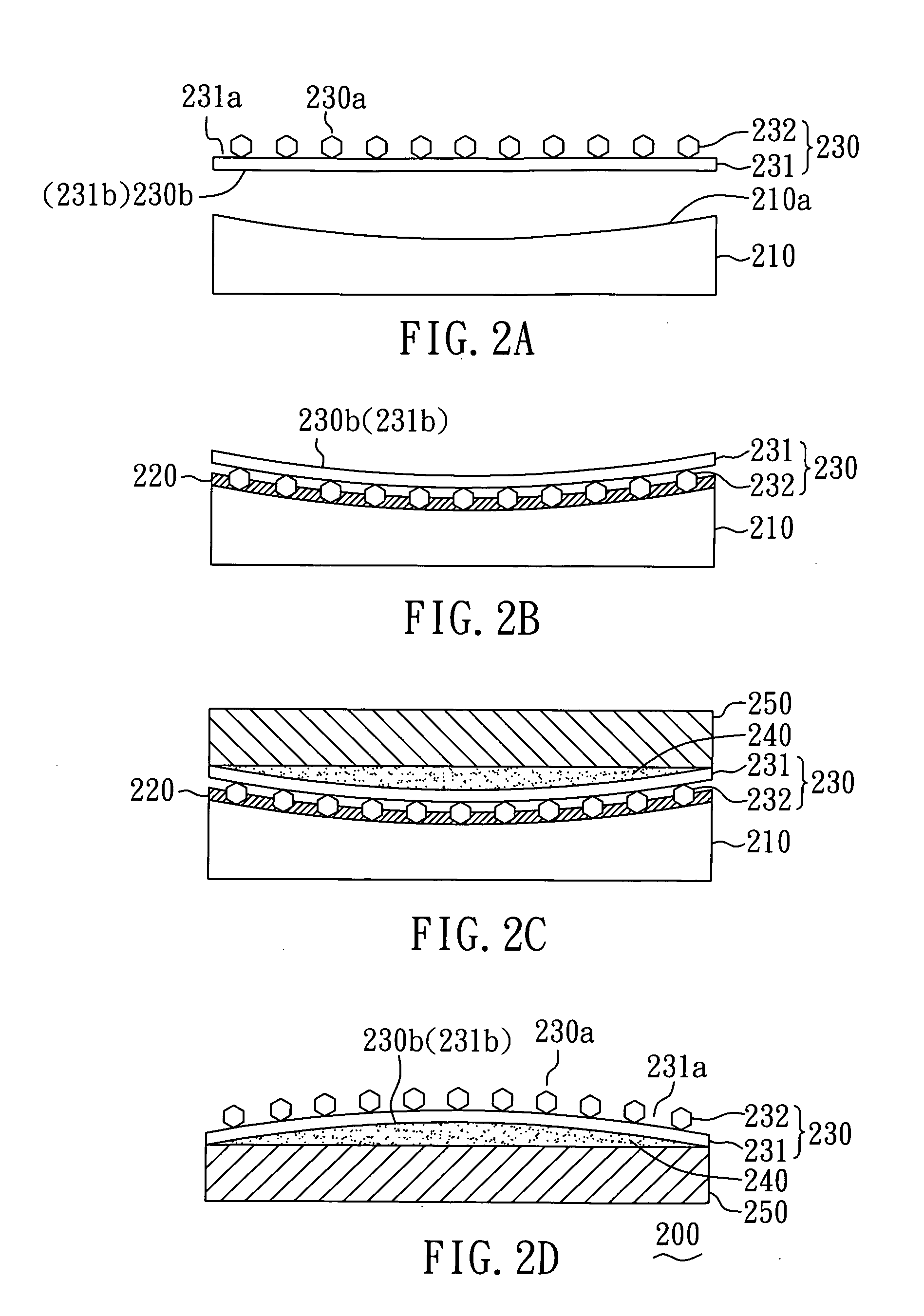

Grinding tool and method for fabricating the same

InactiveUS20100022174A1Efficient processingImprove machine efficiencyRevolution surface grinding machinesAbrasion apparatusComposite materialBackplane

The present invention relates to a grinding tool and a method for fabricating the same. The method comprises: (A) providing a grinding plate having a working surface and a non-working surface, a mold having an adjustment surface, and a backplane; (B) getting the working surface of the grinding plate to fit precisely and be retained on the adjustment surface of the mold by a binder; (C) forming an adhesive layer on the non-working surface of the grinding plate; (D) disposing the backplane on a surface of the adhesive layer to retain the backplane over the non-working surface of the grinding plate by the adhesive layer; and (E) removing the binder to separate the mold from the grinding plate. Accordingly, the present invention can significantly improve the precision and lifetime of products, reduce the cost of production, and enhance the machining efficiency.

Owner:KINIK

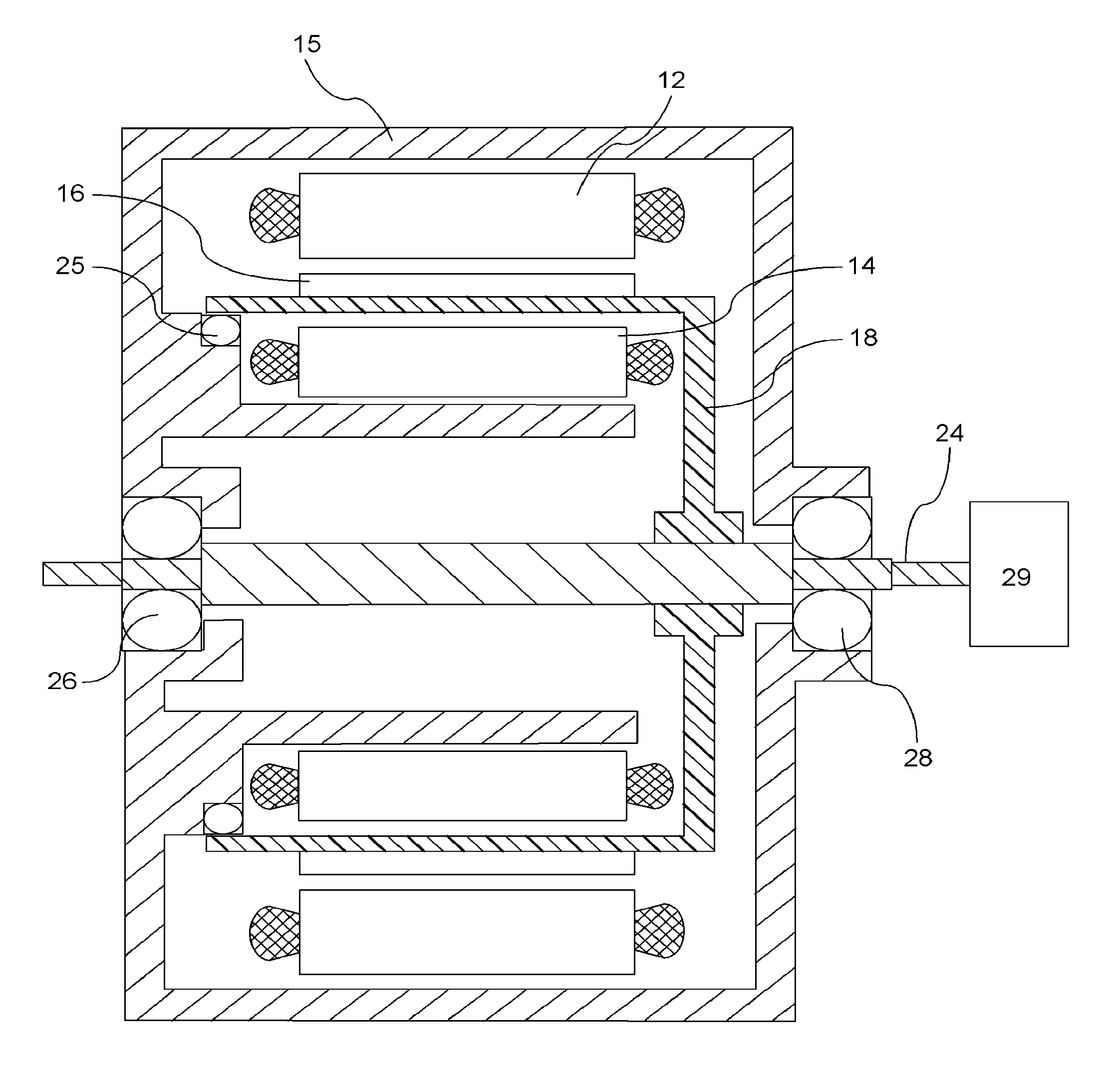

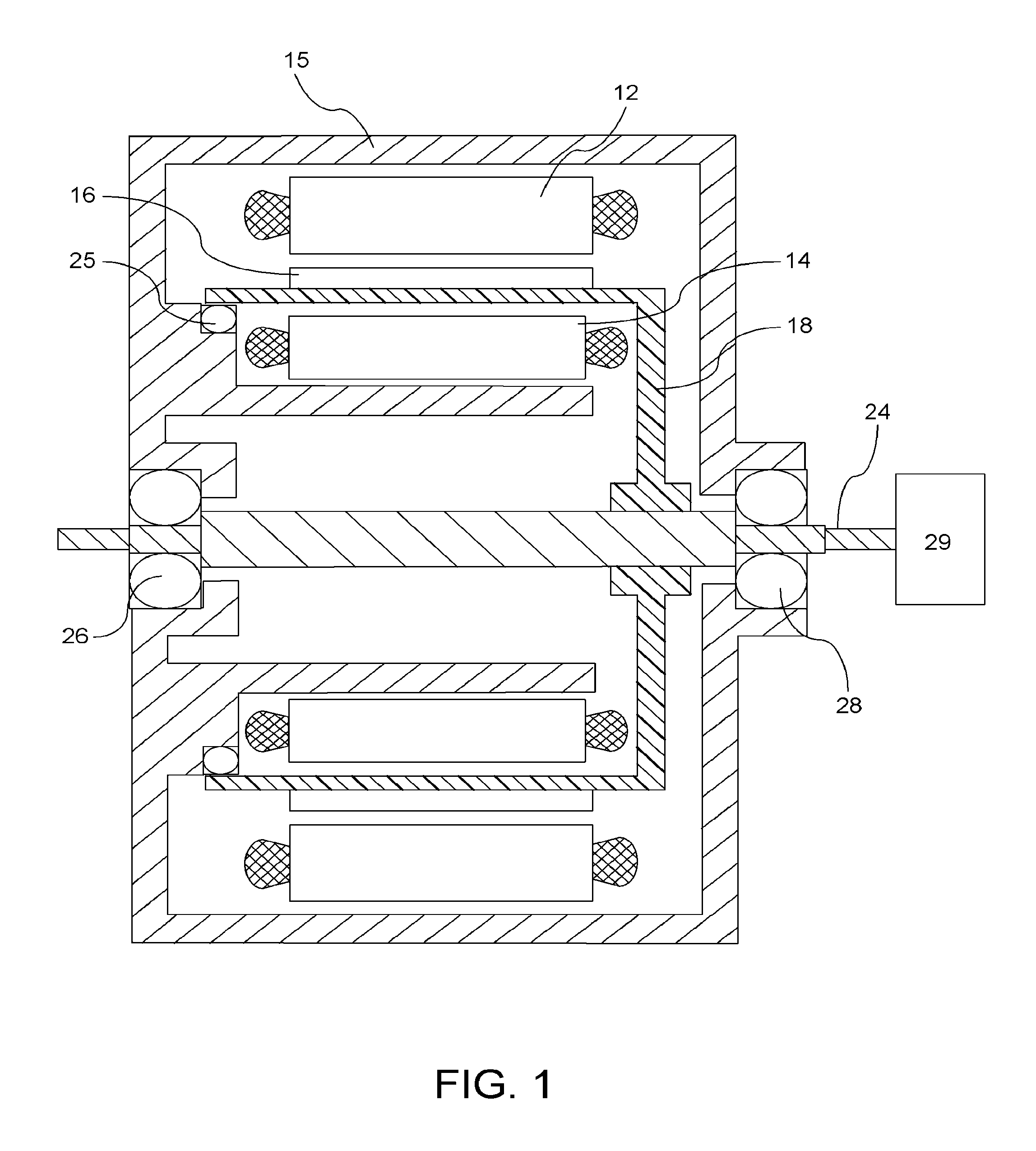

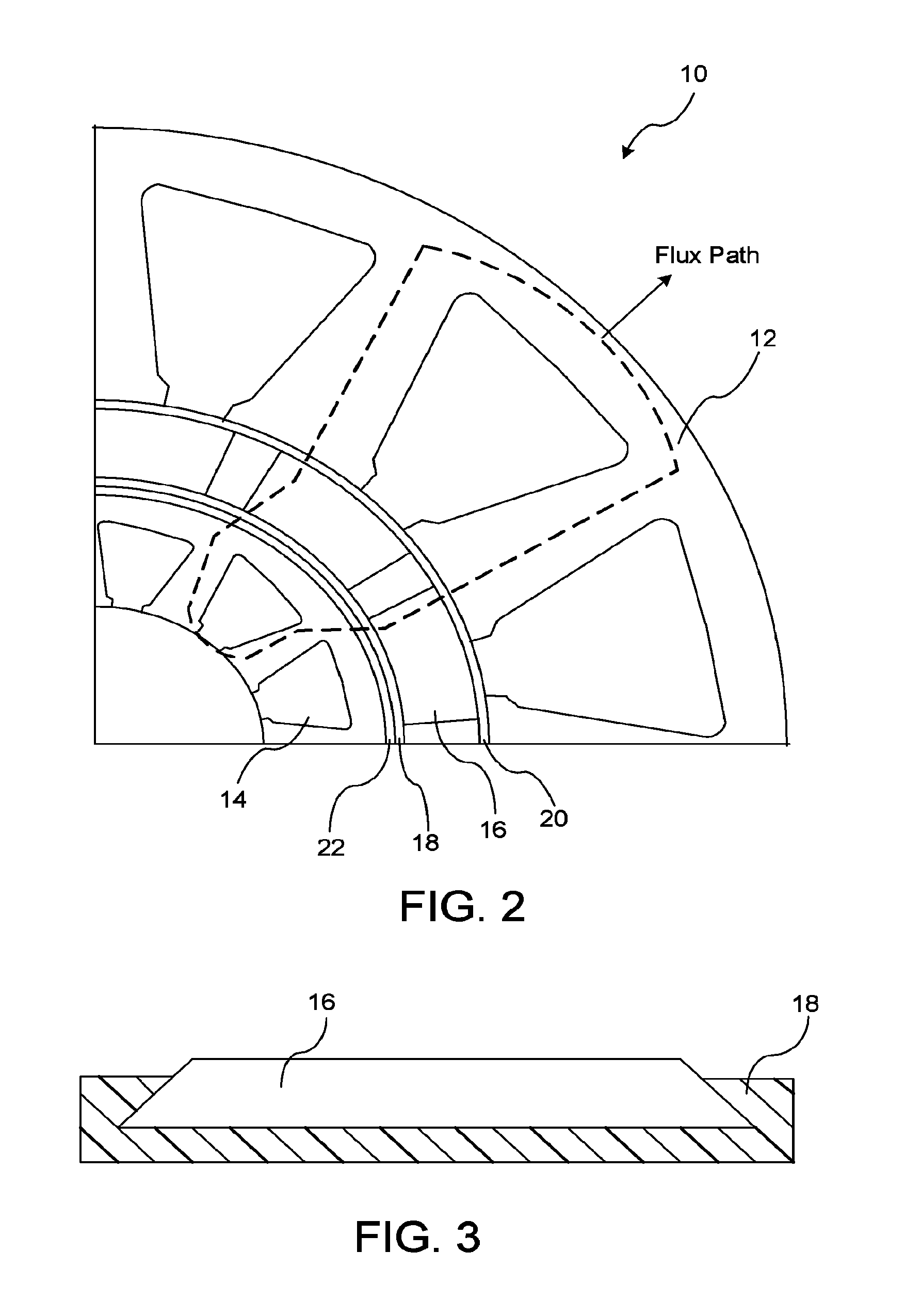

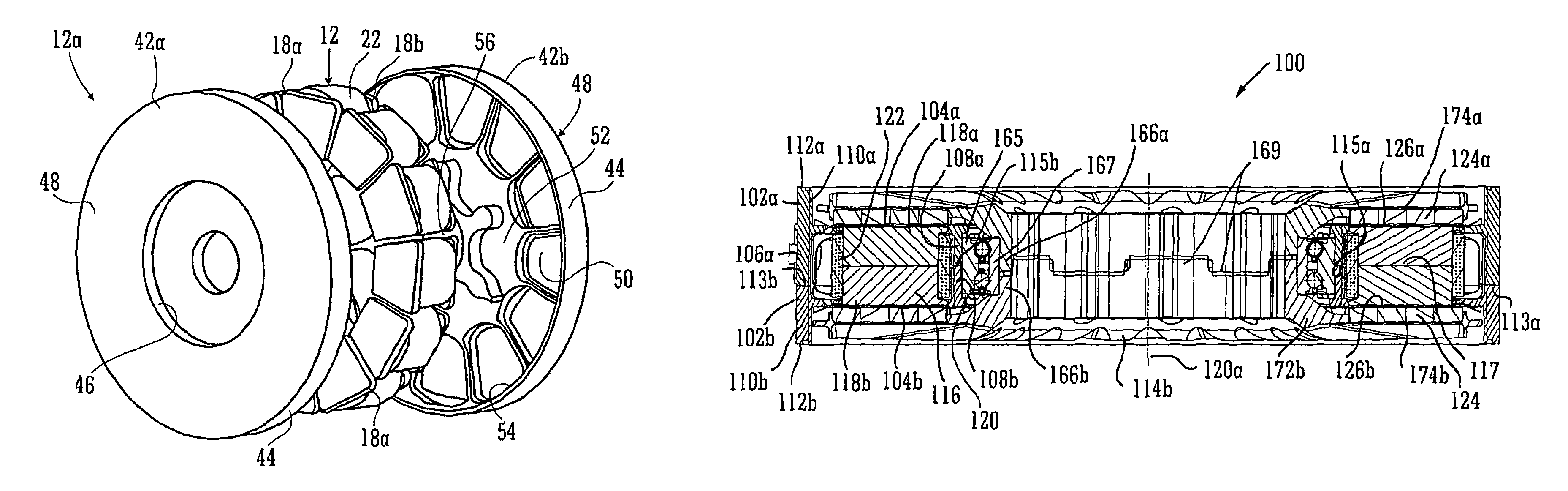

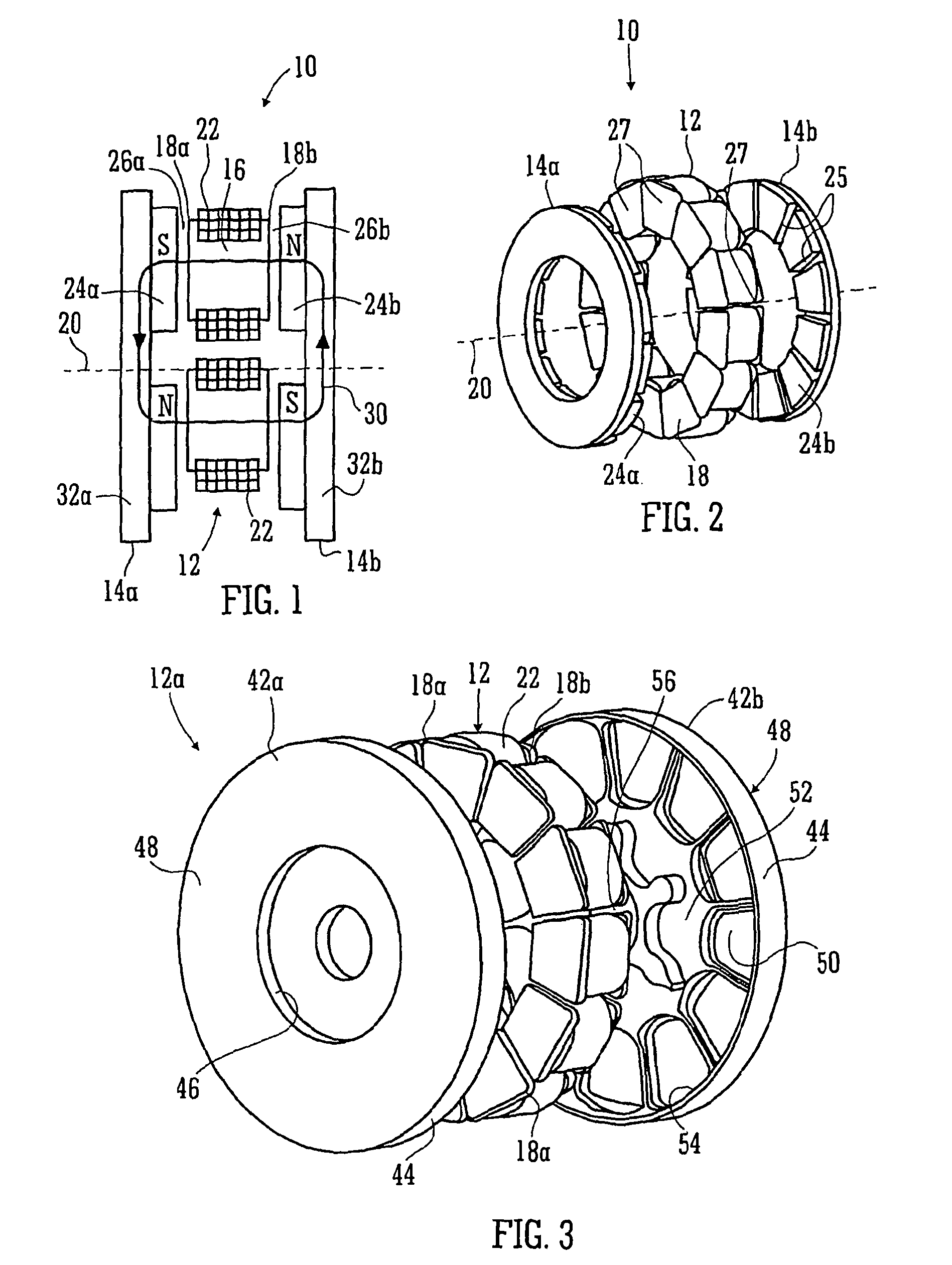

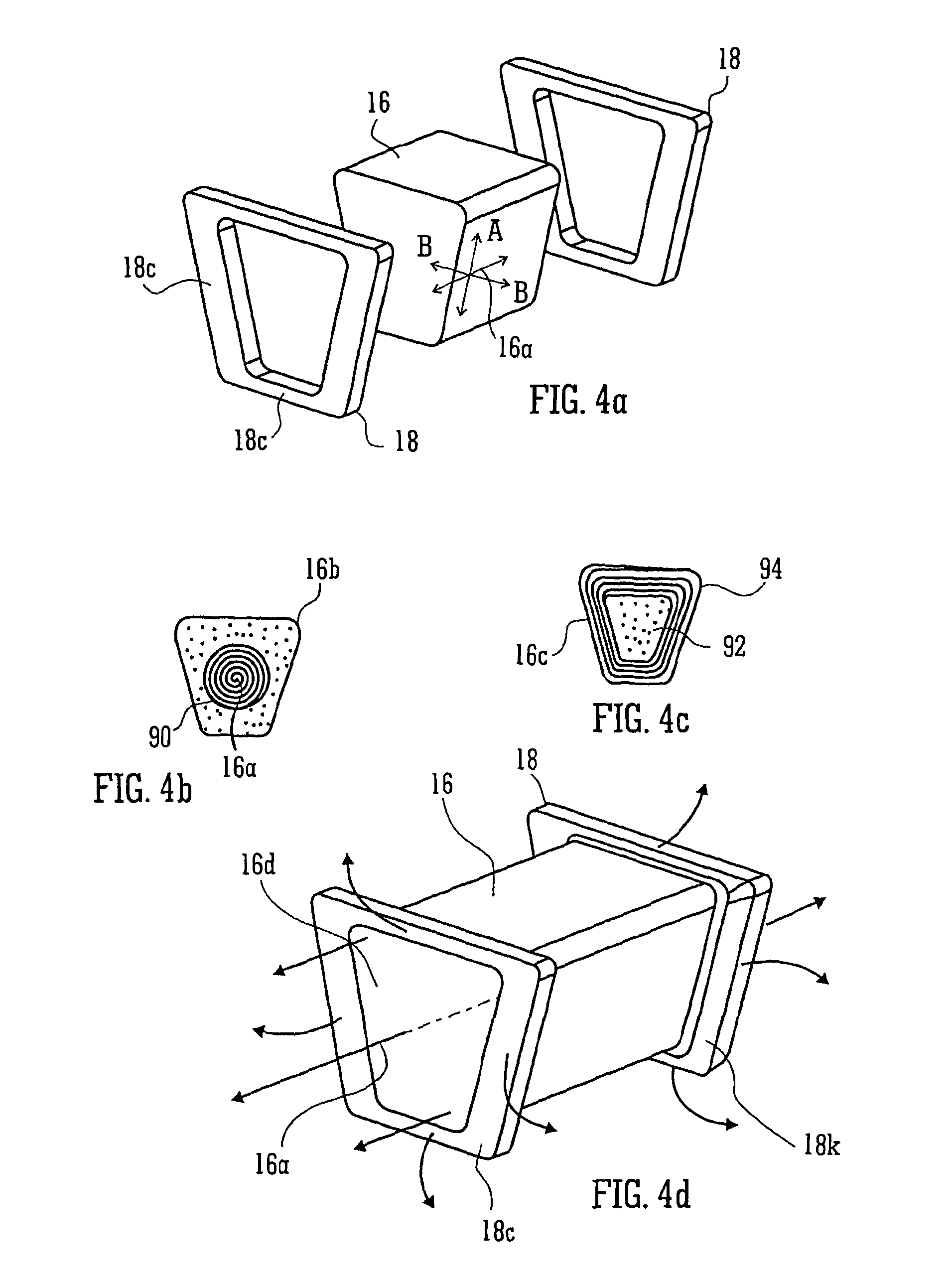

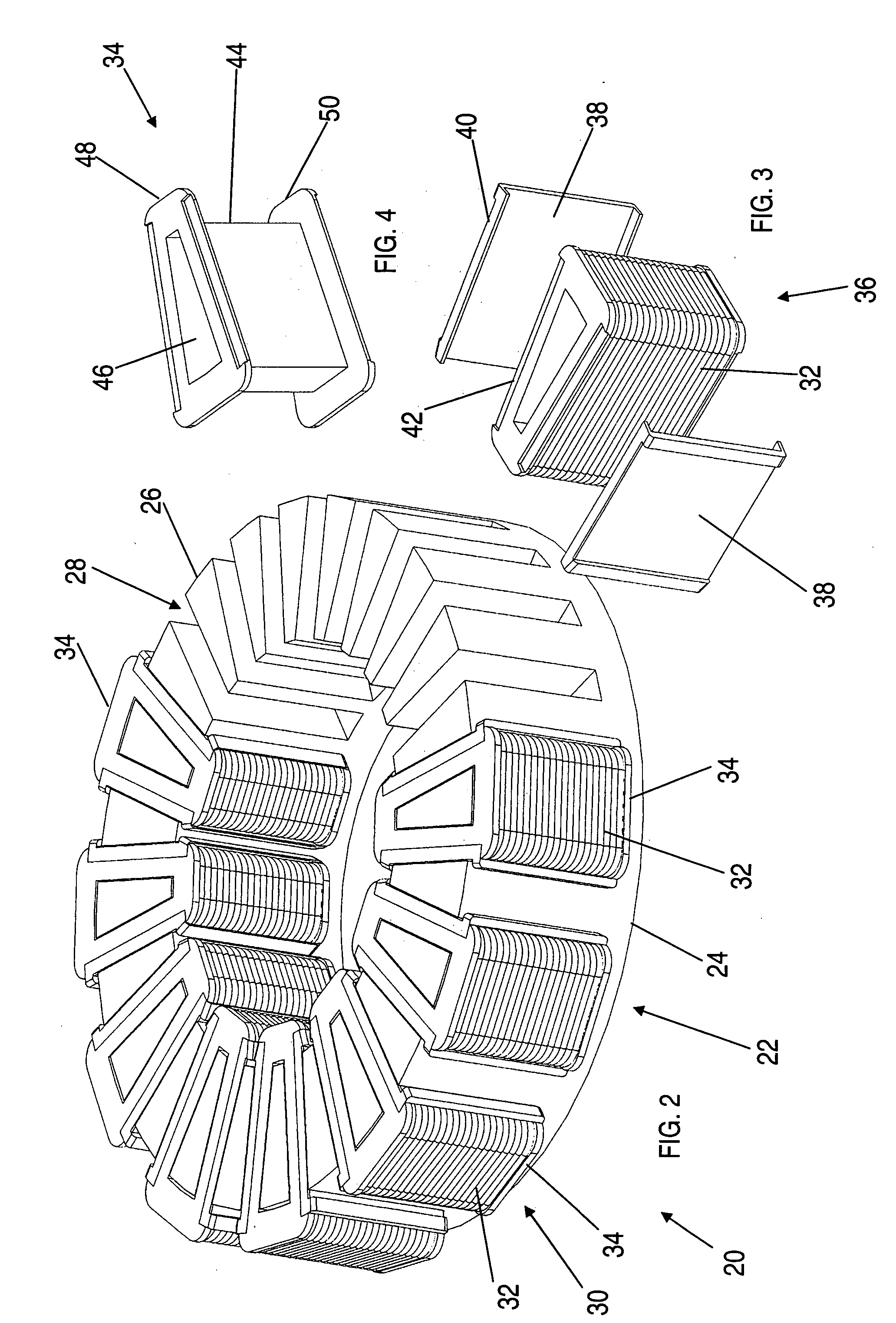

Optimized electric machine for smart actuators

InactiveUS7791245B1Optimal operating characteristicRaise the ratioSynchronous generatorsMagnetic circuit rotating partsElectric machineEngineering

An electric machine includes a plurality of magnets for generating a first magnetic field. A magnet holder retains the plurality of magnets. A first stator is disposed radially outward from the magnet holder for generating a second magnetic field. The first stator includes a plurality of stator poles separated by slots with each of the stator poles having a concentrated winding with a respective number of turns formed around each respective stator pole. A second stator is disposed radially inward from the magnet for generating a third magnetic field. The second stator has a plurality of stator poles separated by slots with each of the stator poles having a concentrated winding with a respective number of turns formed around each respective stator pole. The magnet holder and magnets retained therein are rotatable between the first stator and second stator.

Owner:GM GLOBAL TECH OPERATIONS LLC

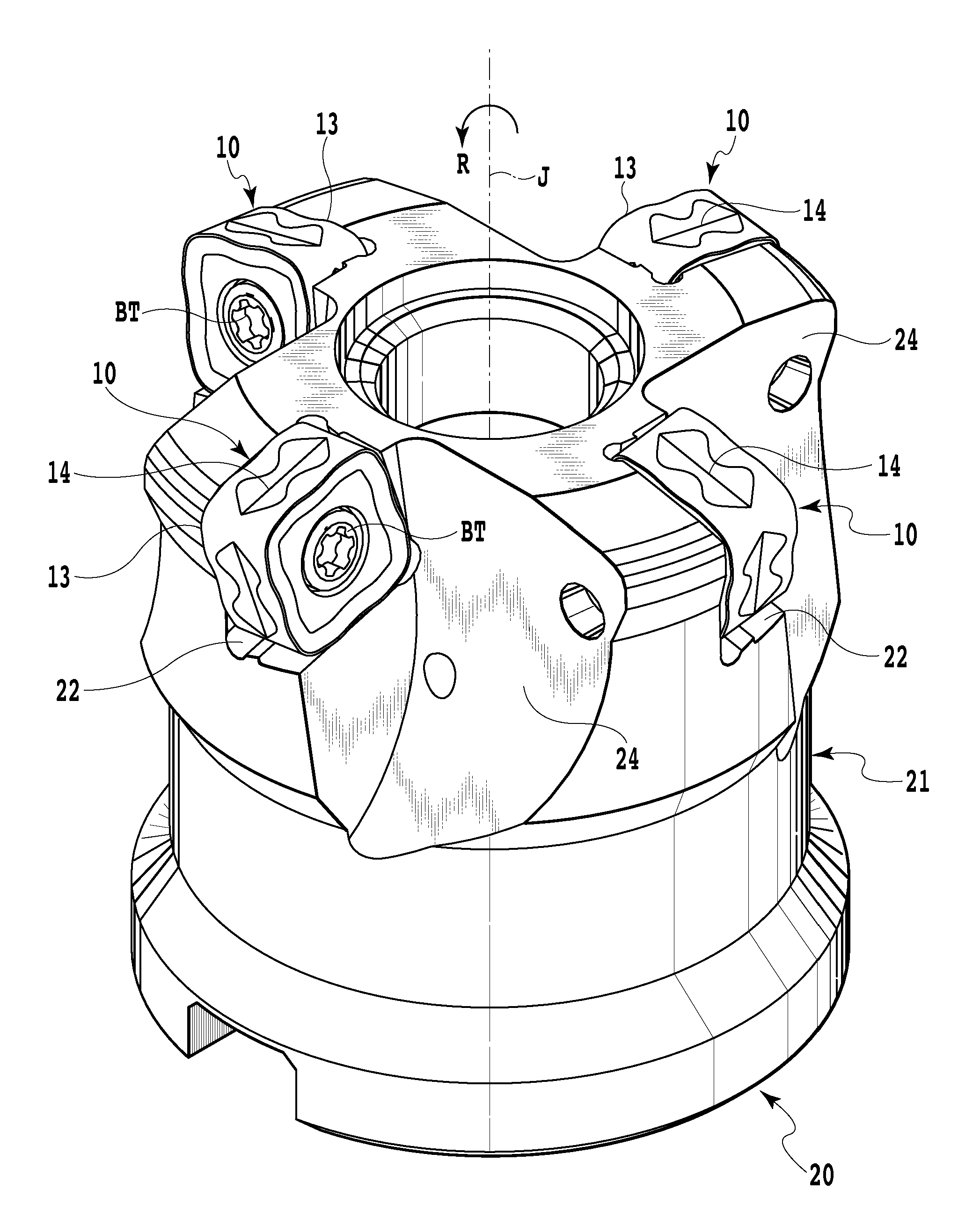

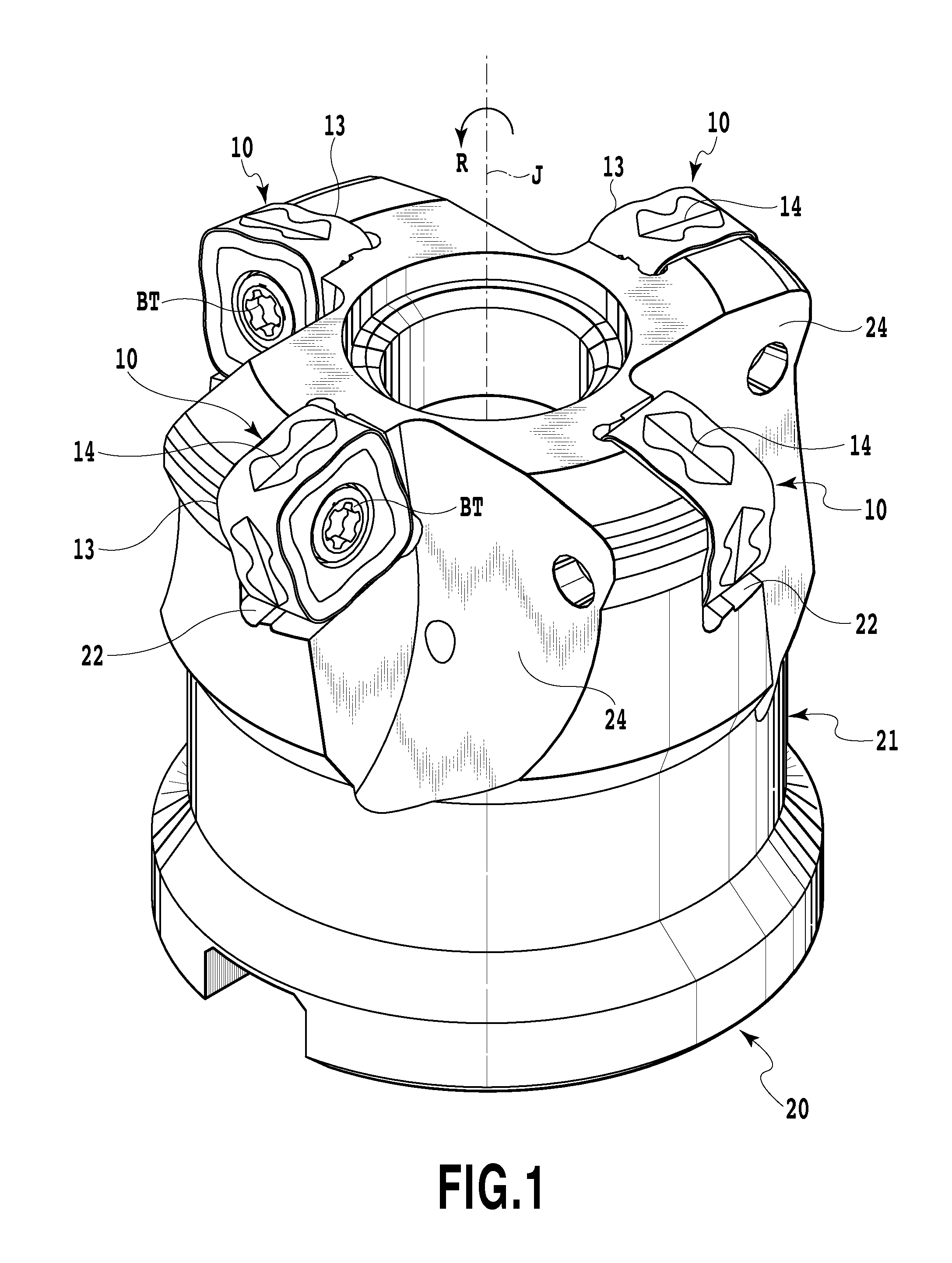

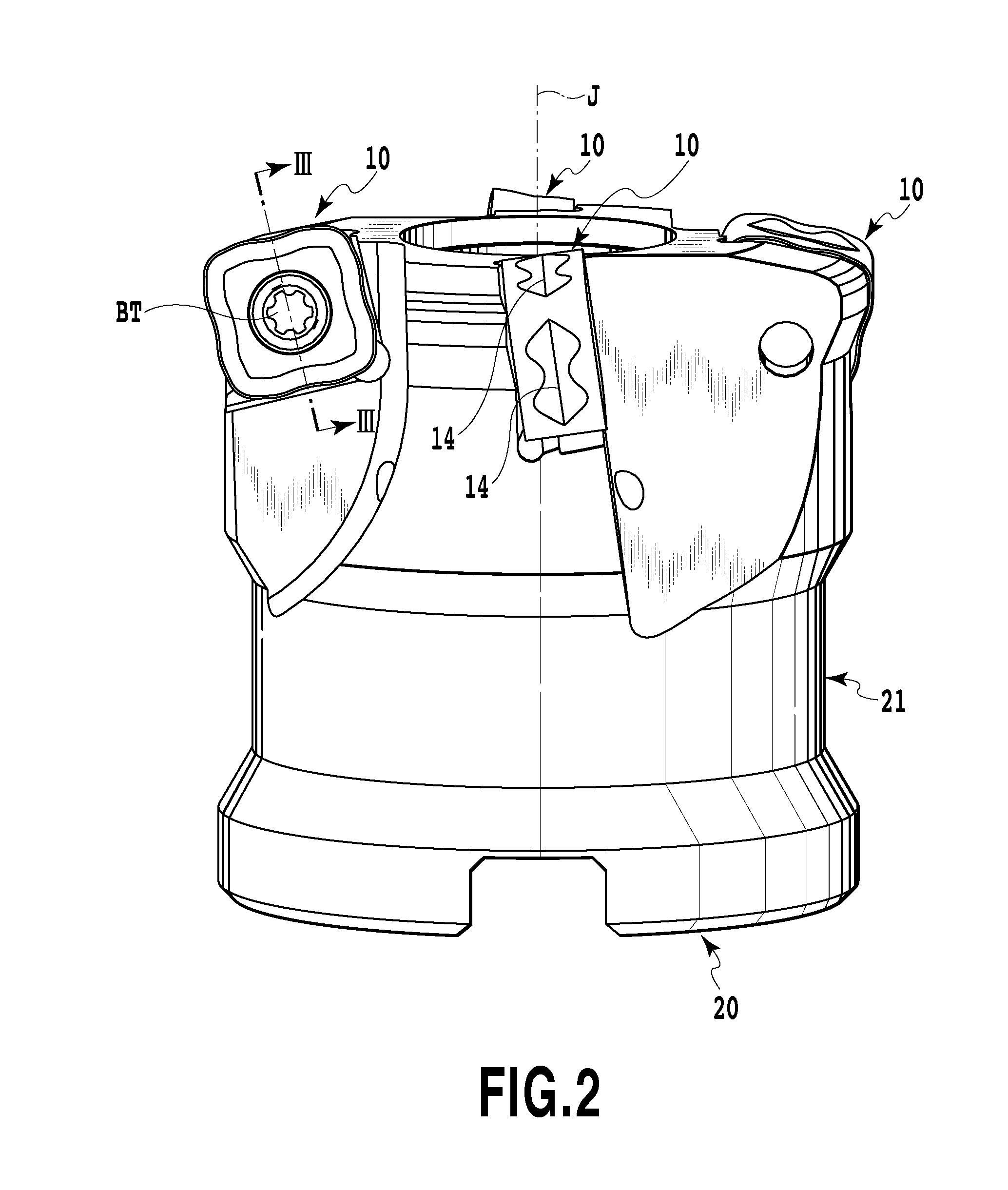

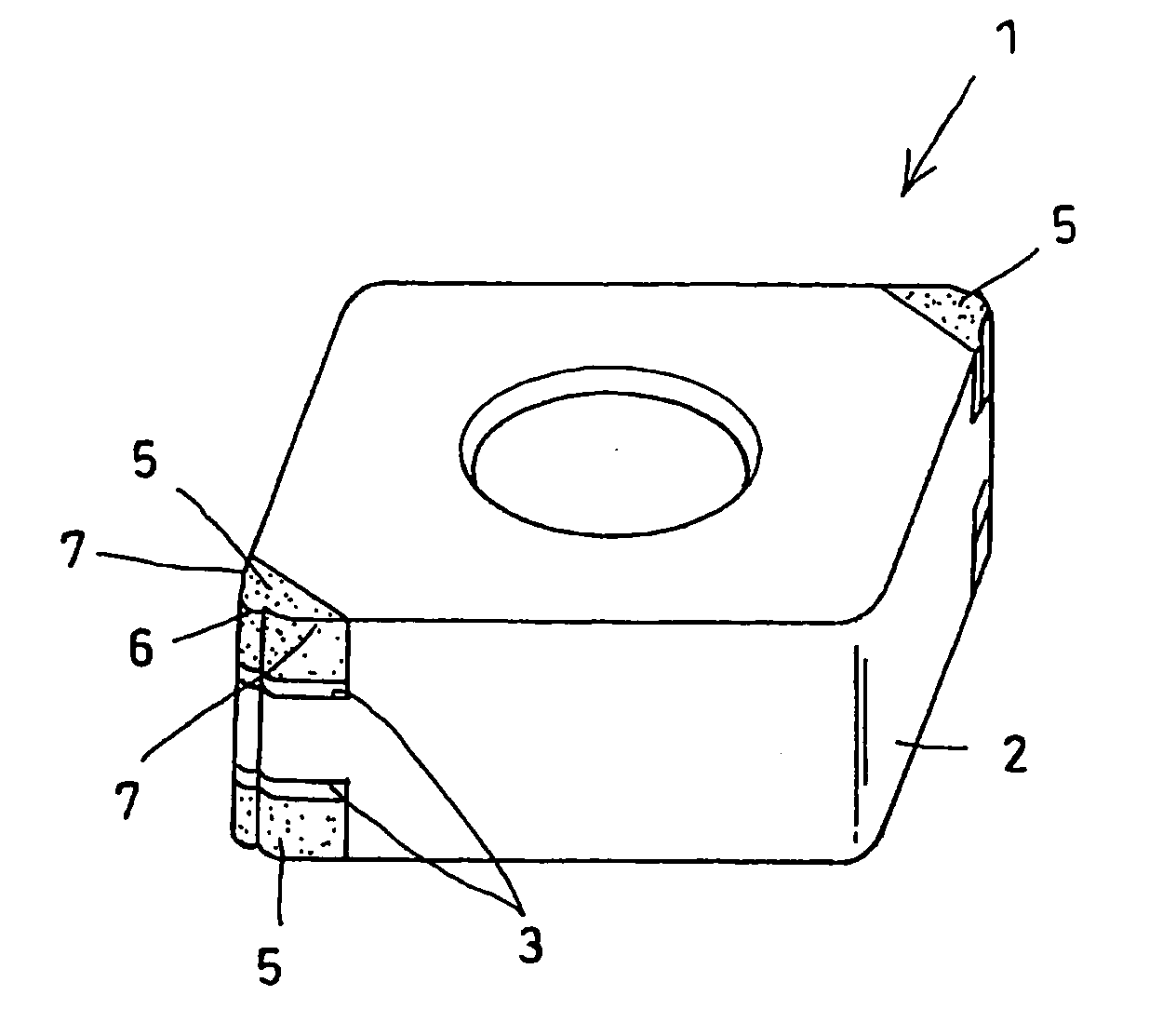

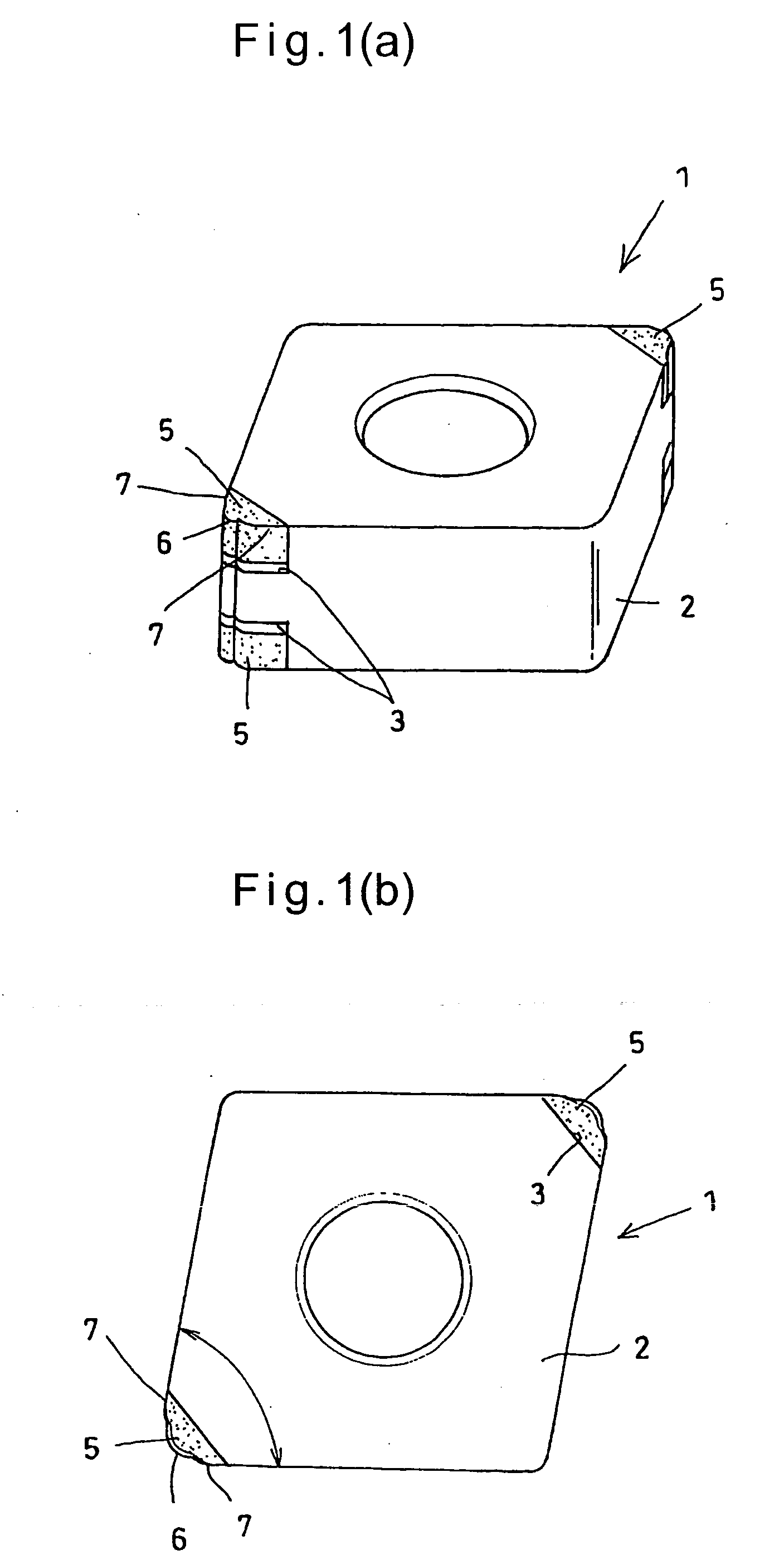

Cutting Insert and Cutting Tool

InactiveUS20120301235A1Cut resistance increaseReduce resistanceMilling cuttersTurning toolsEngineeringMechanical engineering

A cutting insert has a cutting edge configured to suppress an increase in cutting resistance applied to a cutting boundary portion with an increase in a depth of cut. The cutting insert has a rake face, a flank, and a cutting edge formed at an intersection portion between the rake face and the flank and is removably attachable to a mounting seat. The cutting edge has an angle decreasing portion in which a cutting edge angle gradually decreases in a direction in which the depth of cut of the cutting edge increases. In one embodiment, the rake face includes an upper rake face and a lower rake face. The flank is formed on a side surface between the top and bottom surfaces. The cutting edge is formed at an intersection portion between the upper rake face and the flank.

Owner:TUNGALOY CORP

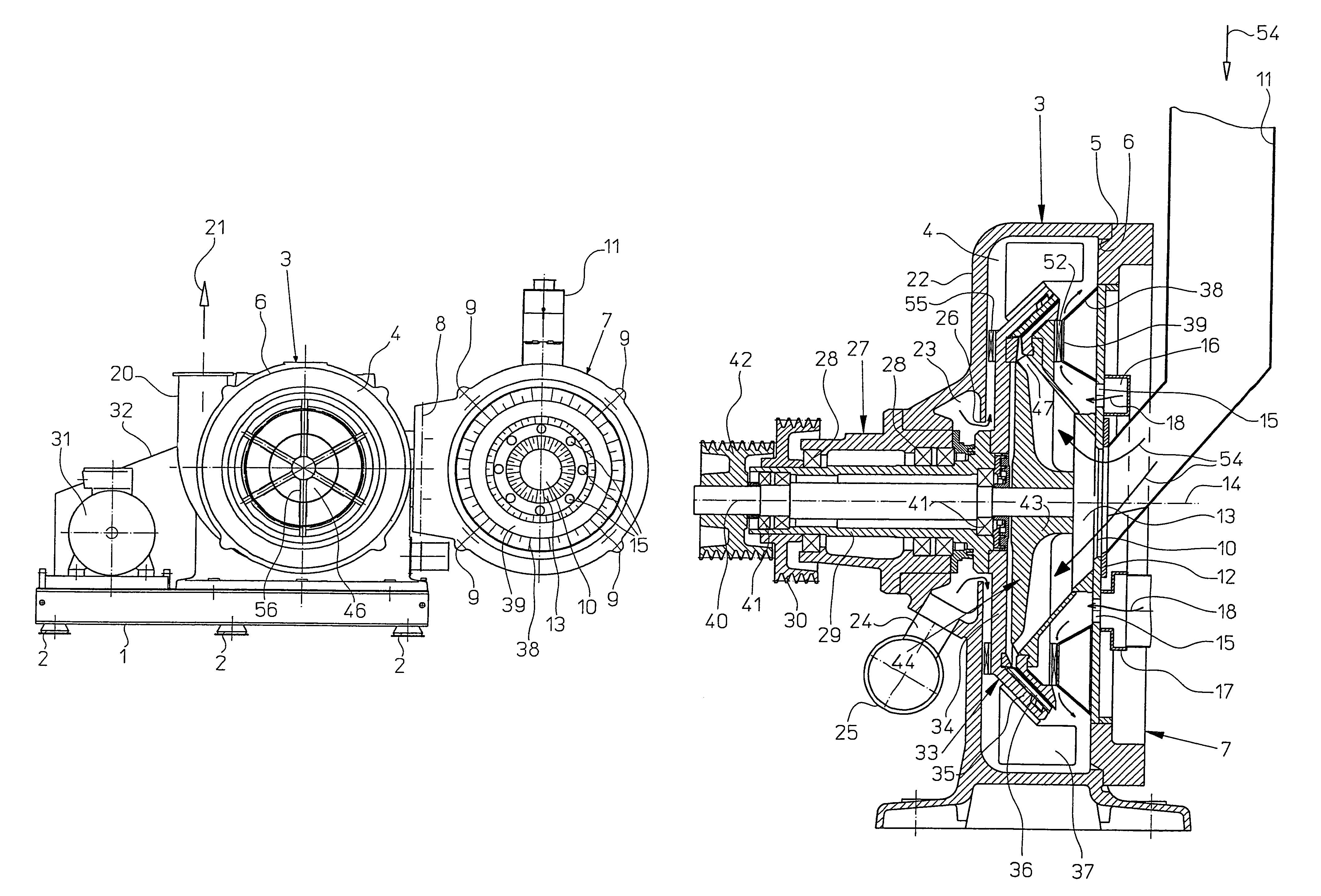

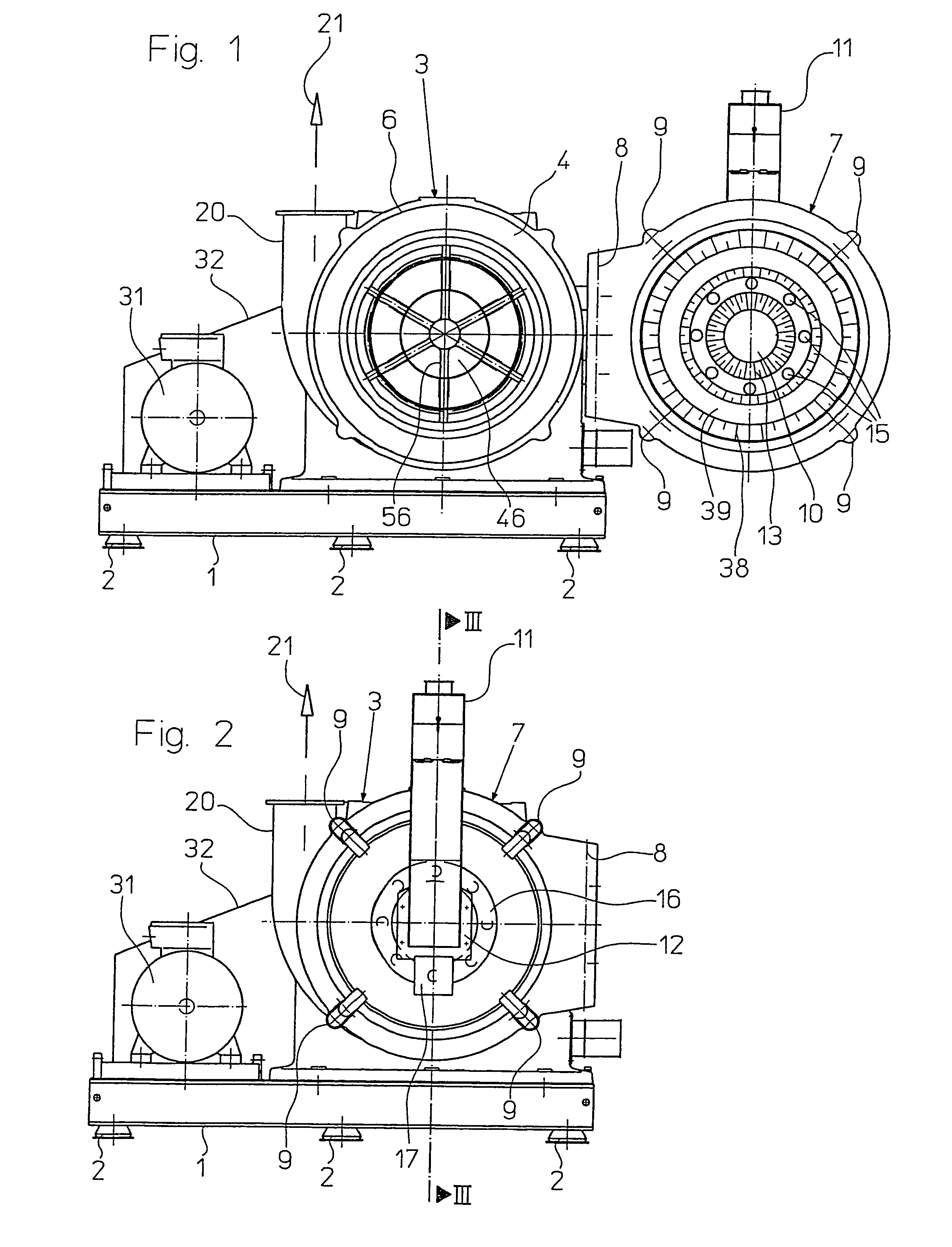

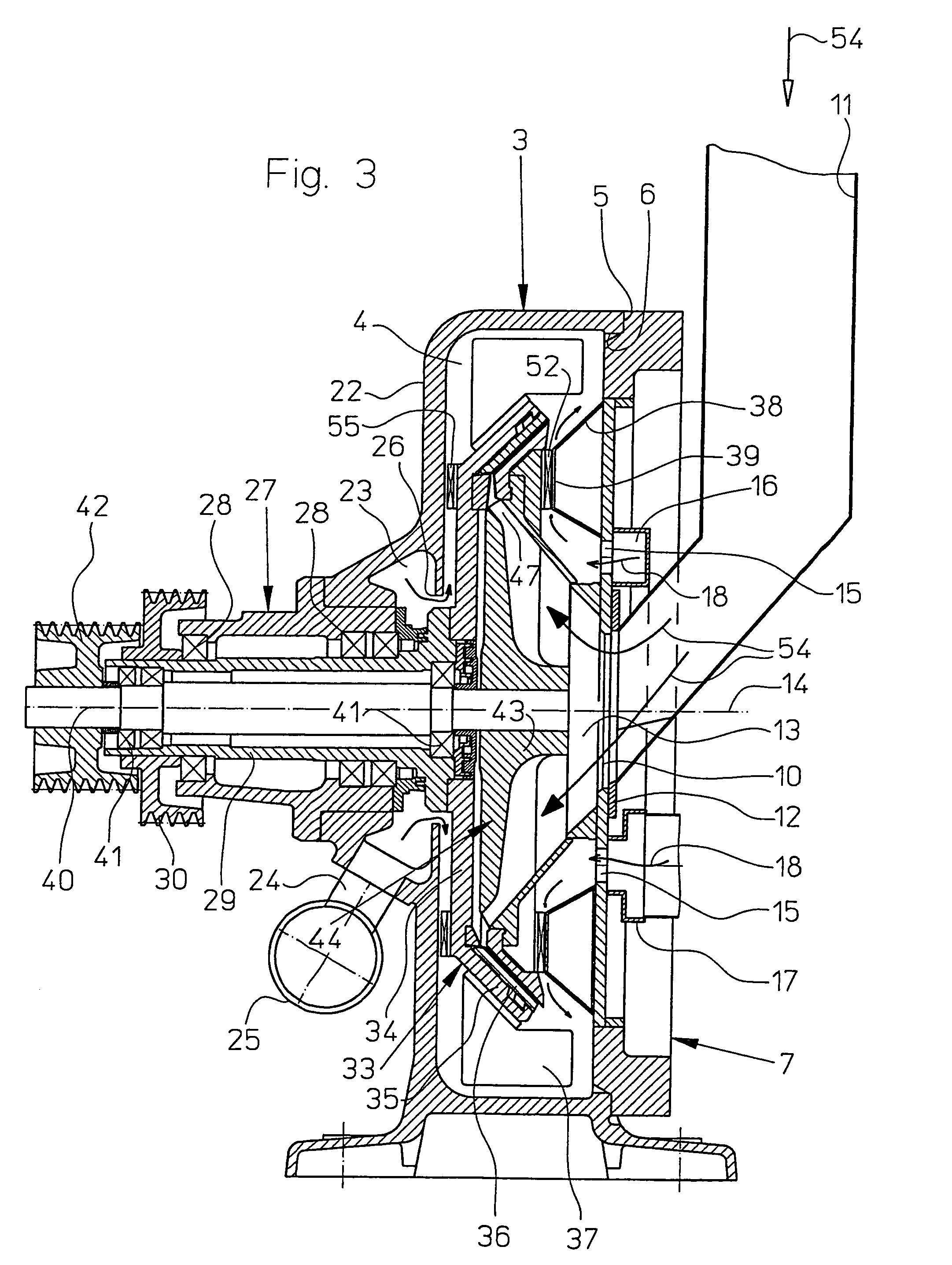

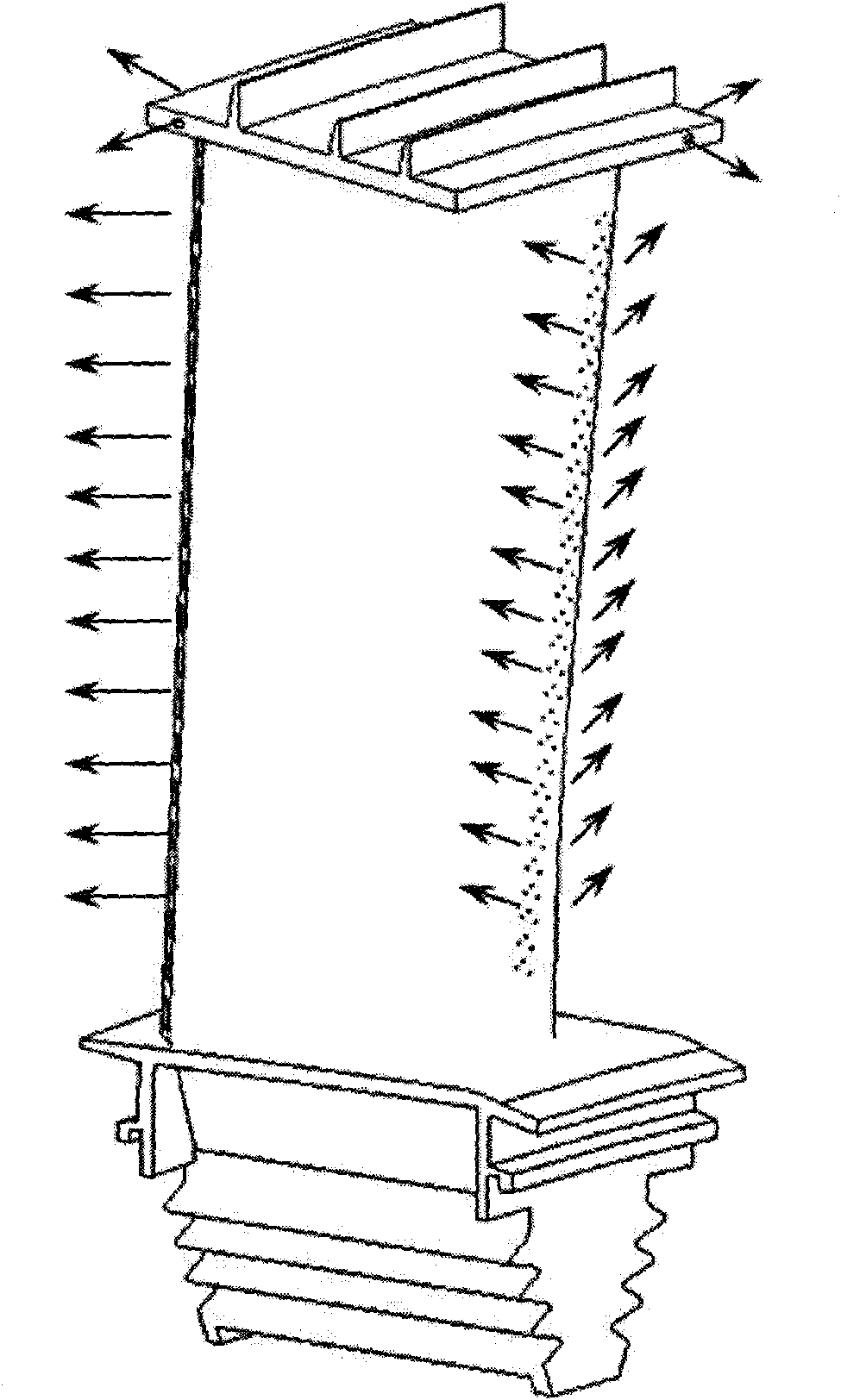

Apparatus for comminuting material having a cool air channel

ActiveUS7510133B2Improve machine efficiencyImprove business performanceGas current separationGrain millingCold airEngineering

An apparatus for comminuting material is provided. The apparatus includes two disks, which are arranged coaxially to one another inside a housing that encloses a comminuting room. The rim areas of the disks are positioned opposite one another, thus forming a milling gap, and are provided with interacting comminuting tools. To generate a mutual relative movement of the disks, at least one of the disks carries out a rotational motion around the mutual axis. To comminute the material, it is first fed into the comminuting room and subsequently radially channeled to the milling gap. For additional cooling, the disk on the intake side is arranged at an axial distance to the intake side of the housing front wall, thus forming a ringwheel-shaped cool air conduit. This can be charged with cool air, which flows through the conduit in a radial direction. In this way, the machine capacity can be increased without causing thermal damage to the material to be processed.

Owner:PALLMANN MASCHFAB GMBH & CO KG

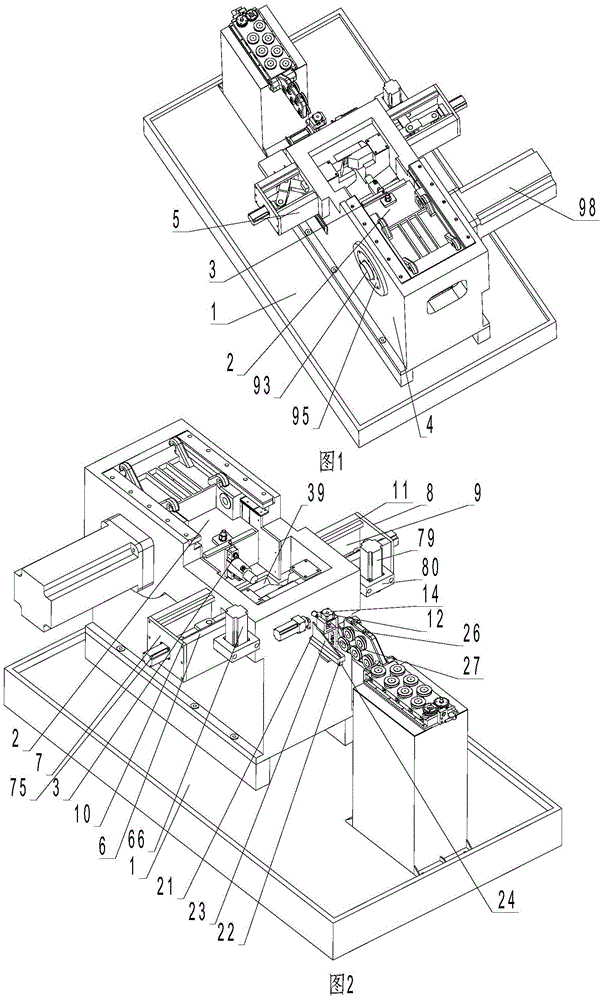

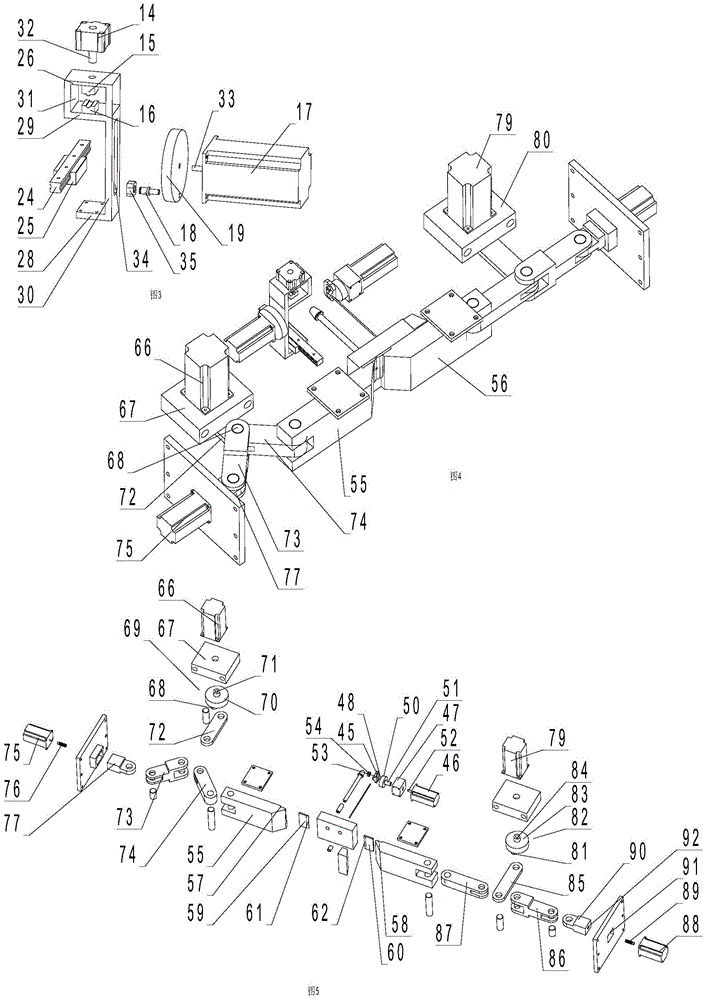

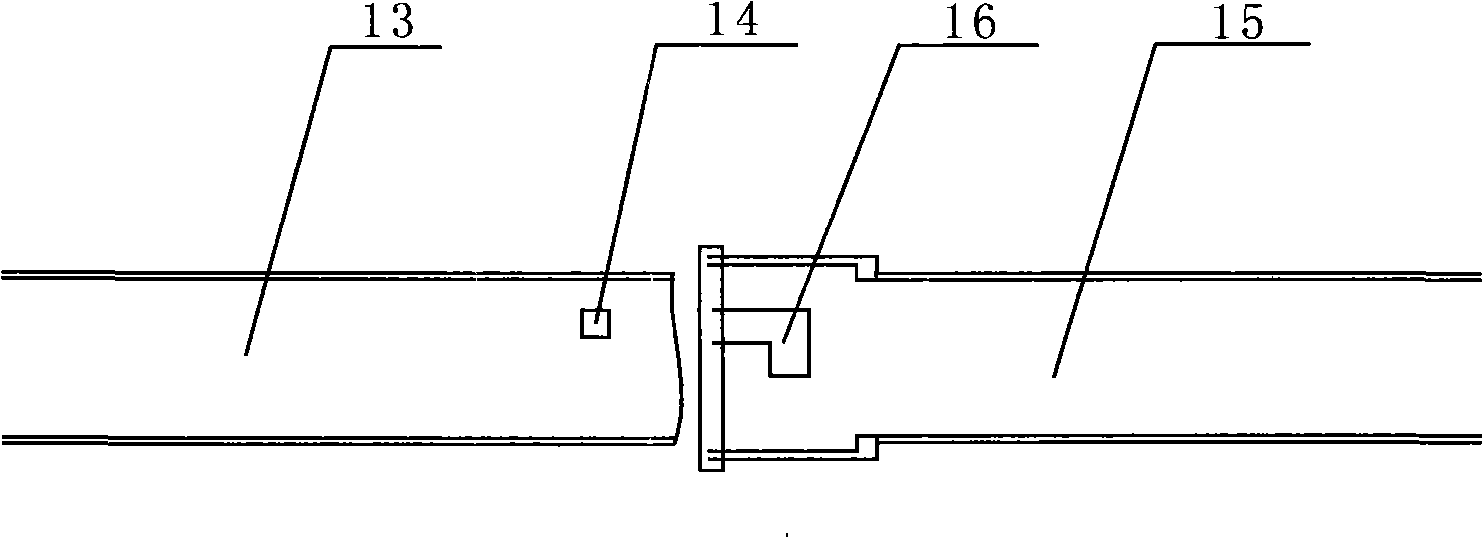

Die assembly upsetting and forging machine and working method thereof

InactiveCN105642807AEasy to installEasy to debugUpsetting pressesSwagging pressesEngineeringMechanical engineering

The invention discloses a die assembly upsetting and forging machine and a working method thereof. The die assembly upsetting and forging machine comprises a machine body, a punch die assembly, a punch die assembly driving mechanism, a feeding mechanism and a material shearing sleeve; the machine body is provided with a die assembly device; the die assembly device comprises a first die assembly base and a second die assembly base; a first installation space is arranged on the side face, close to the second die assembly base, of the first die assembly base; a second installation space is arranged on the side face, close to the first die assembly base, of the second die assembly base; and the die assembly upsetting and forging machine is further provided with a first die assembly driving mechanism for driving the first die assembly base to horizontally move and a second die assembly driving mechanism for driving the second die assembly base to horizontally move. The working method comprises the steps that displacement whole-circle material shearing and material transferring of station parts are achieved through horizontal movement of the die assembly device, and then upsetting and forging are conducted. According to the working method, an independent material shearing mechanism and an independent material clamping and blank transferring mechanism are omitted, and the functions of die assembly material shearing and die assembly upsetting and forging and the function of a clamp are achieved.

Owner:杨东佐

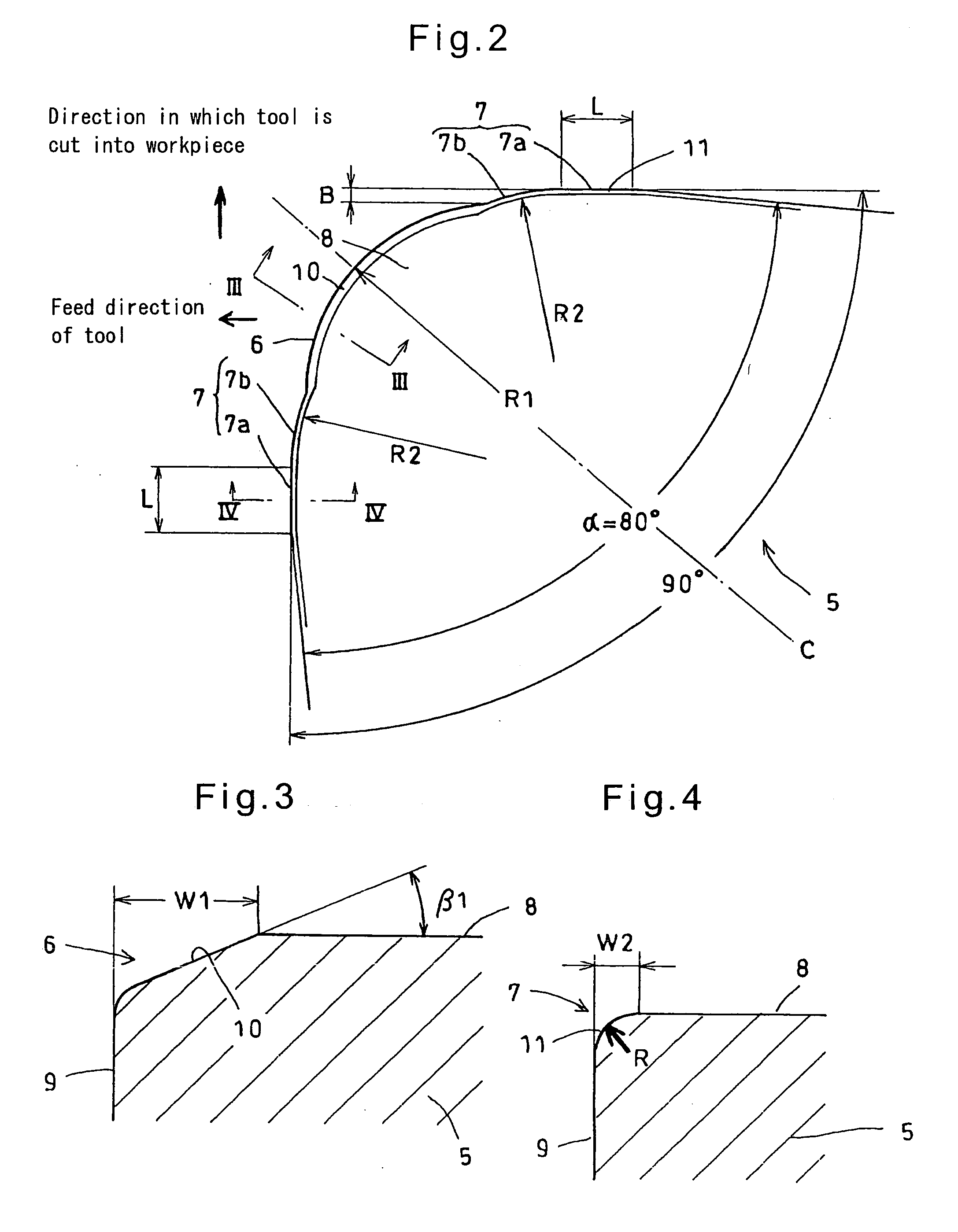

Cutting Tool for High-Quality High-Efficiency Machining and Cutting Method Using the Same

ActiveUS20080292415A1Improve machine efficiencyLarge widthTool workpiece connectionCutting insertsHardened steelEngineering

It is an object to provide a cutting tool which can perform high-quality, high-efficiency machining of a workpiece such as hardened steel.The cutting tool includes a finishing cutting edge 6 which initially cuts into the workpiece, and superfinishing cutting edges 7 for finishing the workpiece cut by the finishing cutting edge. The superfinishing cutting edges 7 project from the finishing cutting edge by a predetermined amount B in such a direction that the depth of cut of the superfinishing cutting edges increases. Each superfinishing cutting edge includes a burnishing portion 7a having a predetermined width L in the feed direction of the tool, and a wiper portion 7b. The superfinishing cutting edges 7 burnish the finished surface formed by the finishing cutting edge, while removing a affected layer formed by the finishing cutting edge.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

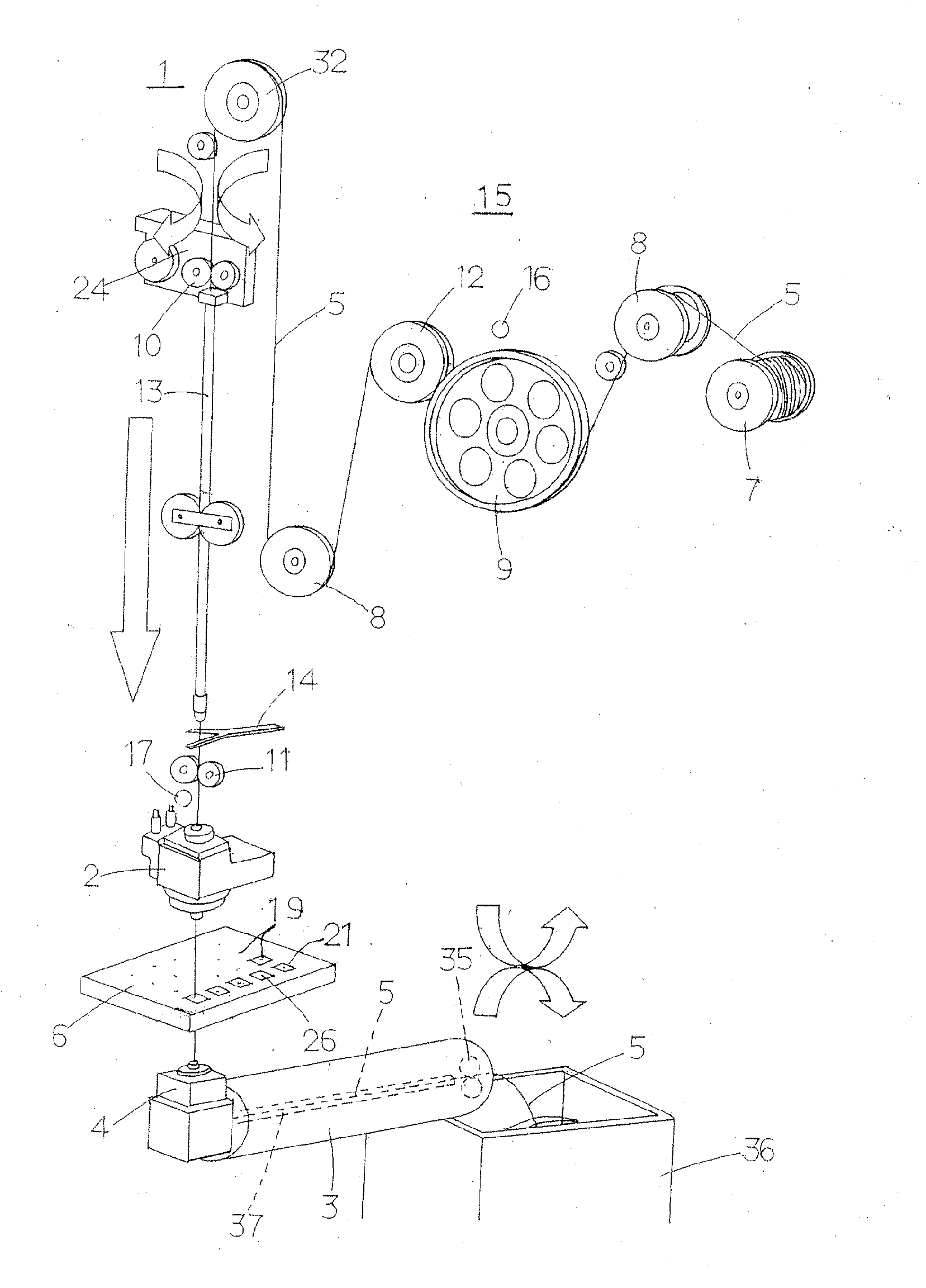

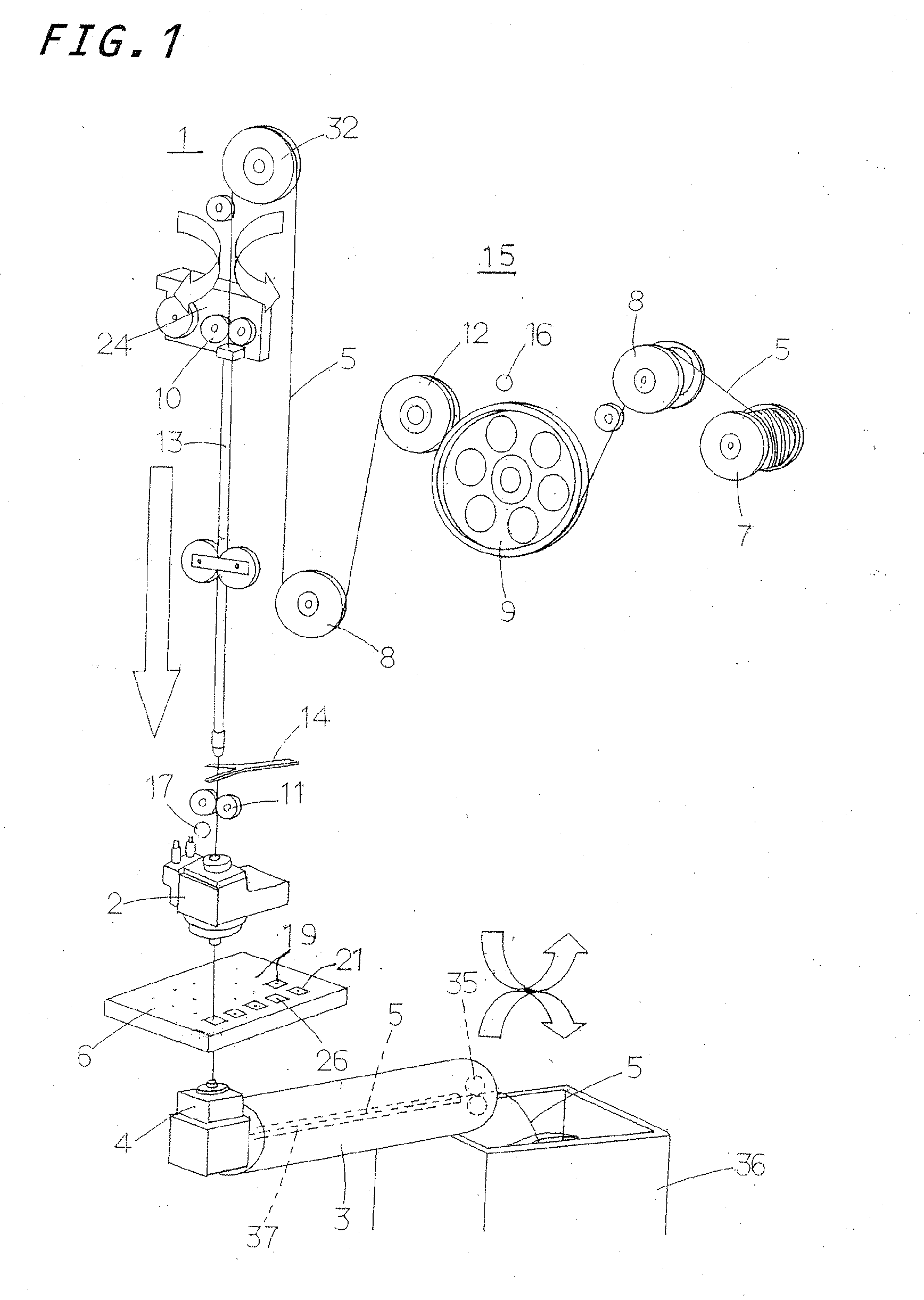

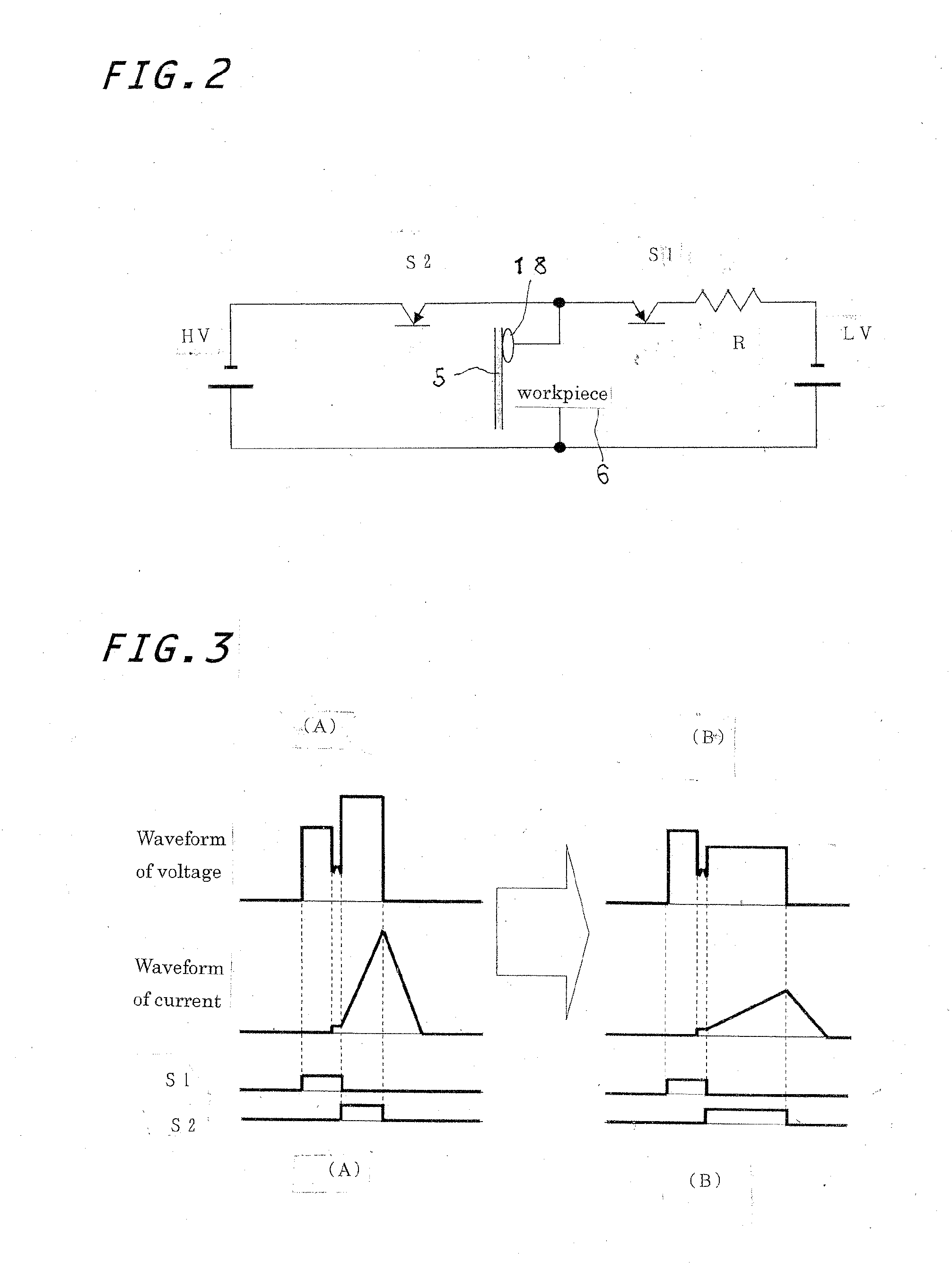

Method of cutting out part with making partially welded spots in wire-cut electrical discharge machining

ActiveUS20120193326A1Shorten totalityImprove machine efficiencyArc welding apparatusElectrical-based machining electrodesEngineeringMechanical engineering

A method of cutting out a part from a workpiece with making partially welded spots in wire electrical discharge machining to keep the part against falling apart away from the workpiece. There is no need to cut anew the welded spot left as in the conventional process. The cut-out parts are cut off at a time after breakage of the welded spots caused by an external impact. The electric processing condition applied across an inter-electrode space between the wire electrode and the workpiece is changed from a cutting phase to a welding phase in which the wire electrode is fused partially at some spots along a cutting path of a predetermined contour on the workpiece to weld together the cut-out part and the workpiece at the fused spot on the wire electrode.

Owner:WEST ELECTRIC CO LTD

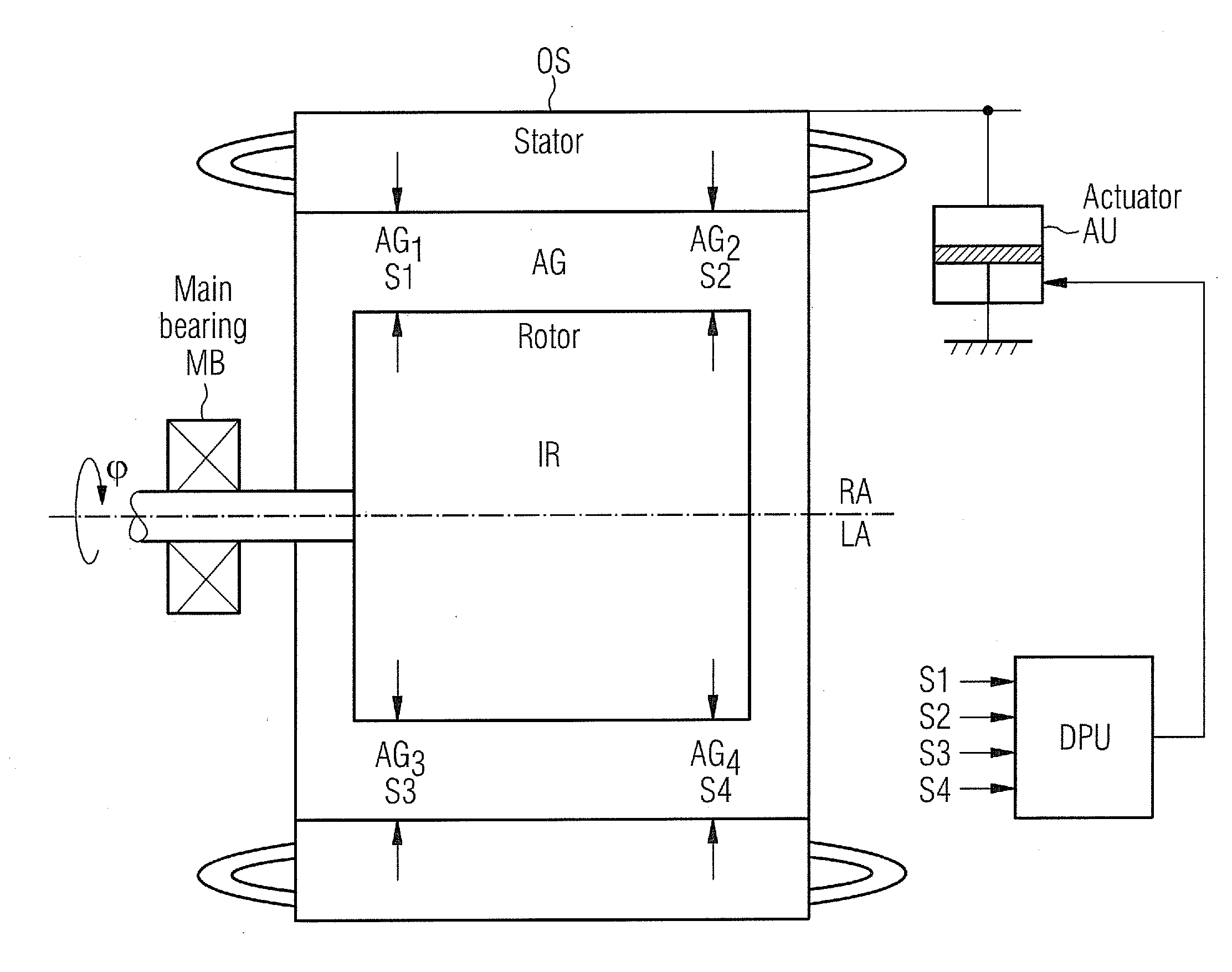

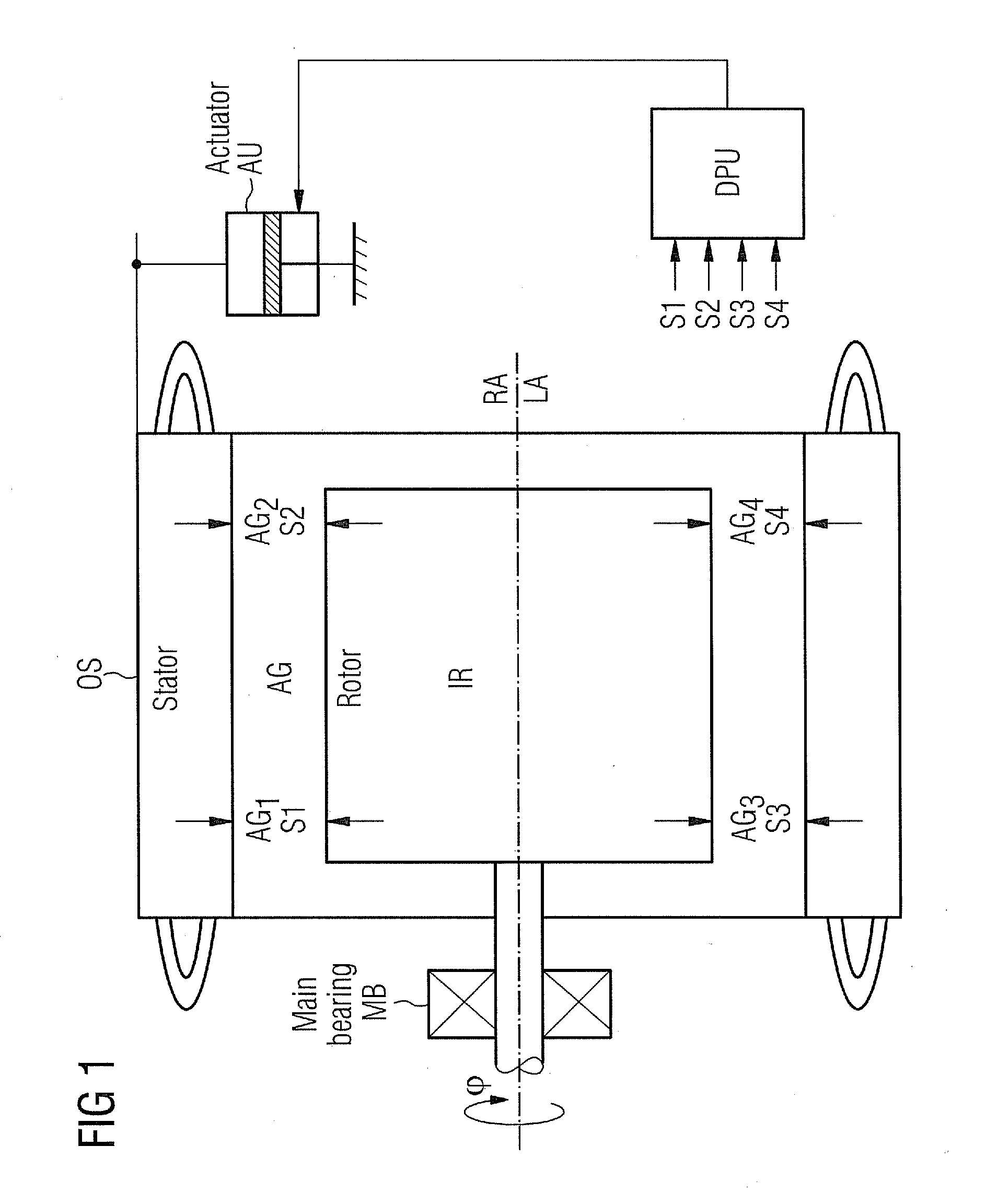

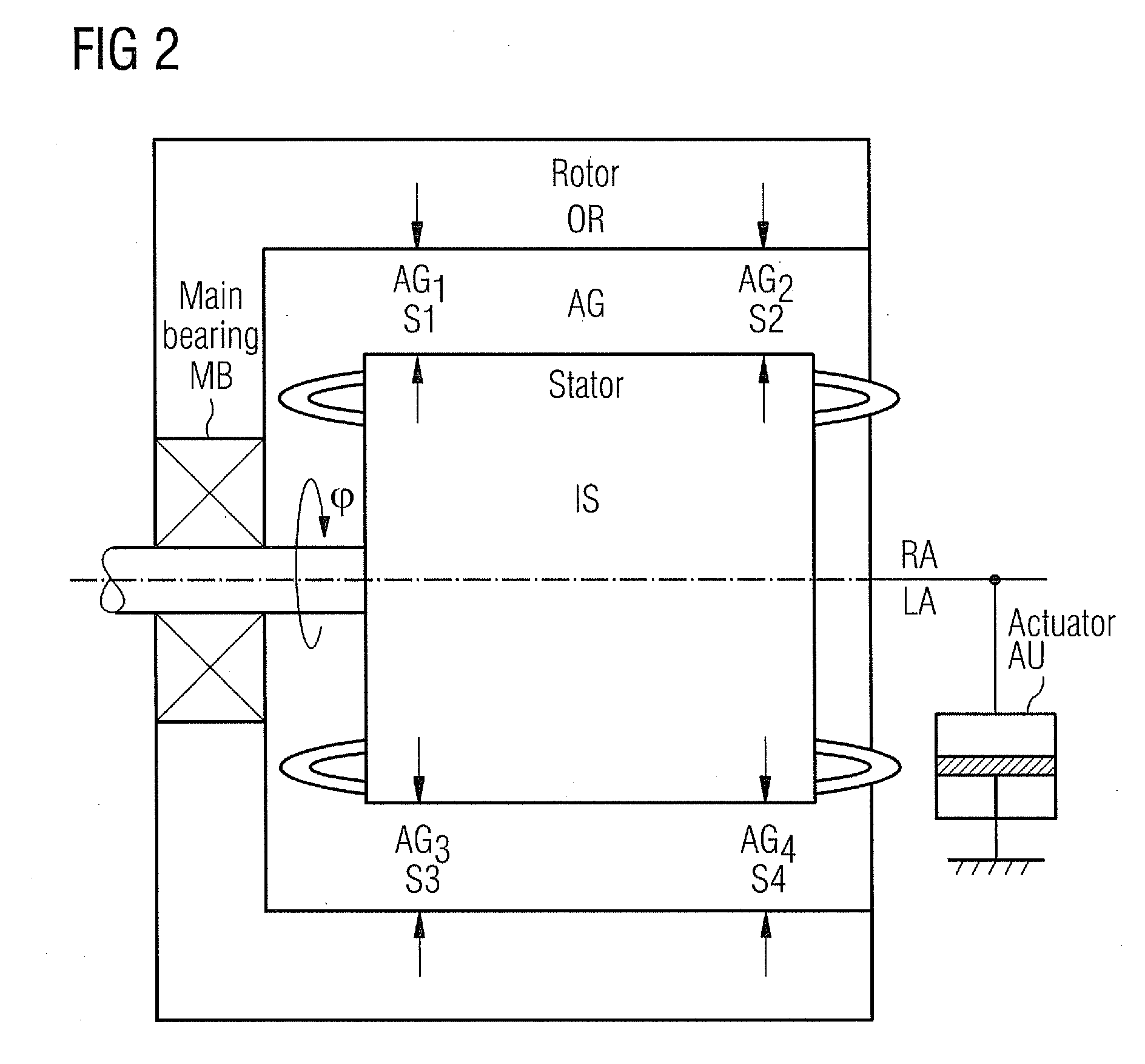

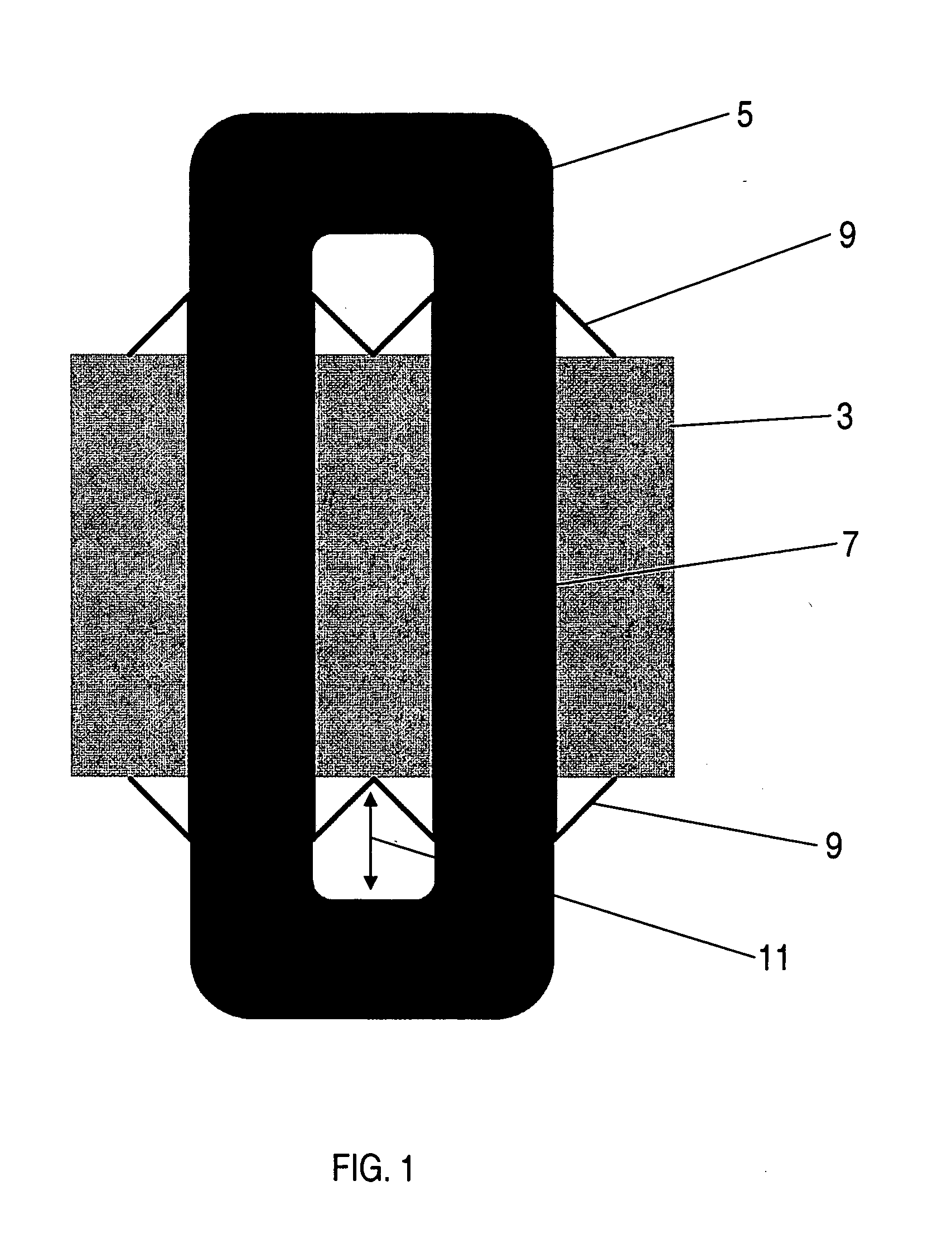

Method and Arrangement to Adjust an Air-Gap

InactiveUS20100253272A1Reduce machine loadLife time is improvedDC motor speed/torque controlMachines/enginesEngineeringMechanical engineering

The electrical machine includes a movable part and a static part. The movable part rotates in relation to the static part around a dedicated rotary axis. An air-gap is located between the rotating and the static part of the machine. A device is positioned and used to measure the spacing of the air-gap. The static part and / or the movable part is coupled with an actuating-unit, which changes the relative position of the static part in relation to the movable part to adjust the spacing of the air-gap.

Owner:SIEMENS AG

Electric machine—over-moulding construction

ActiveUS9287755B2Gap minimizationImprove machine efficiencyMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectric machineStator coil

Owner:YASA LIMITED

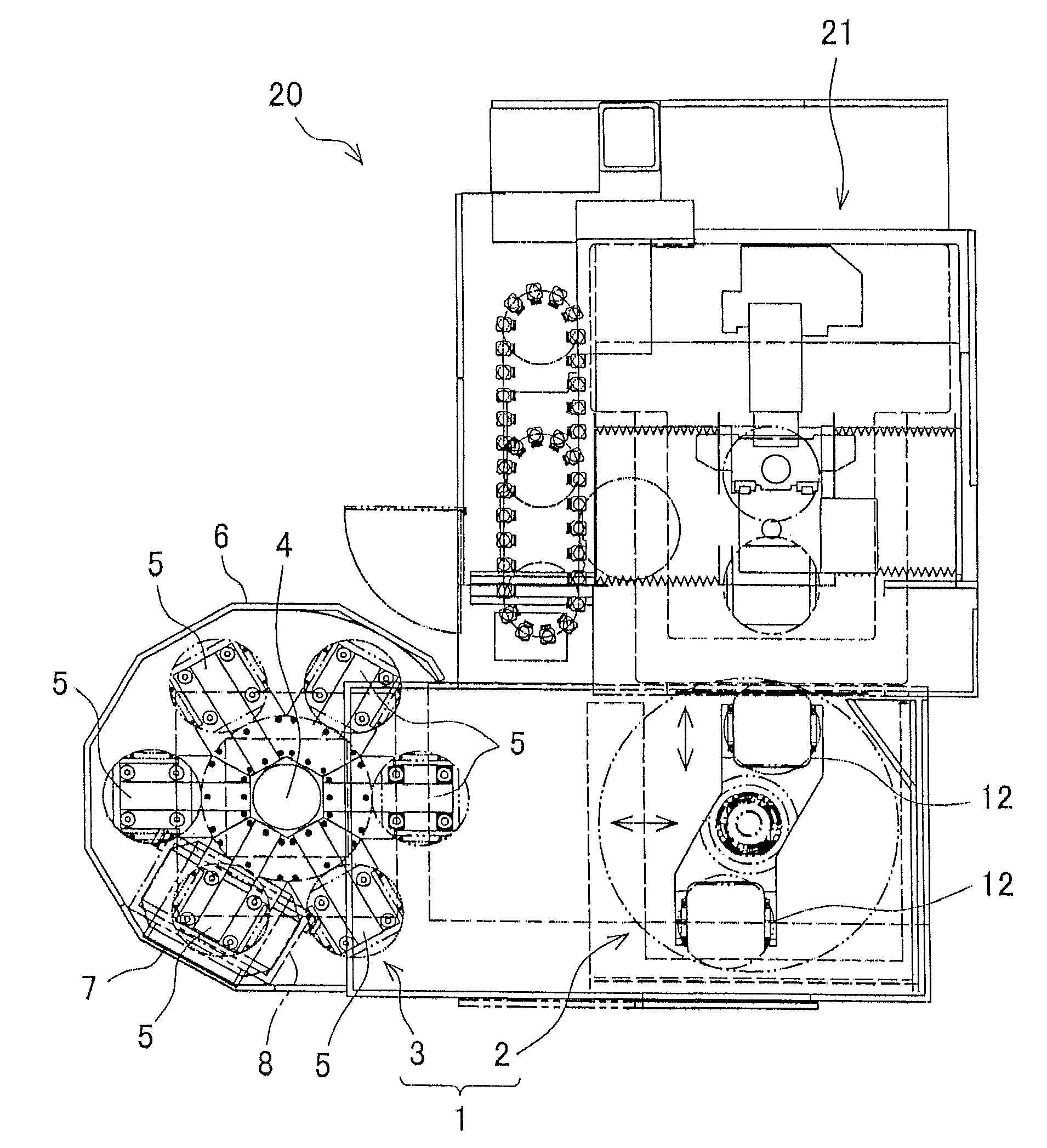

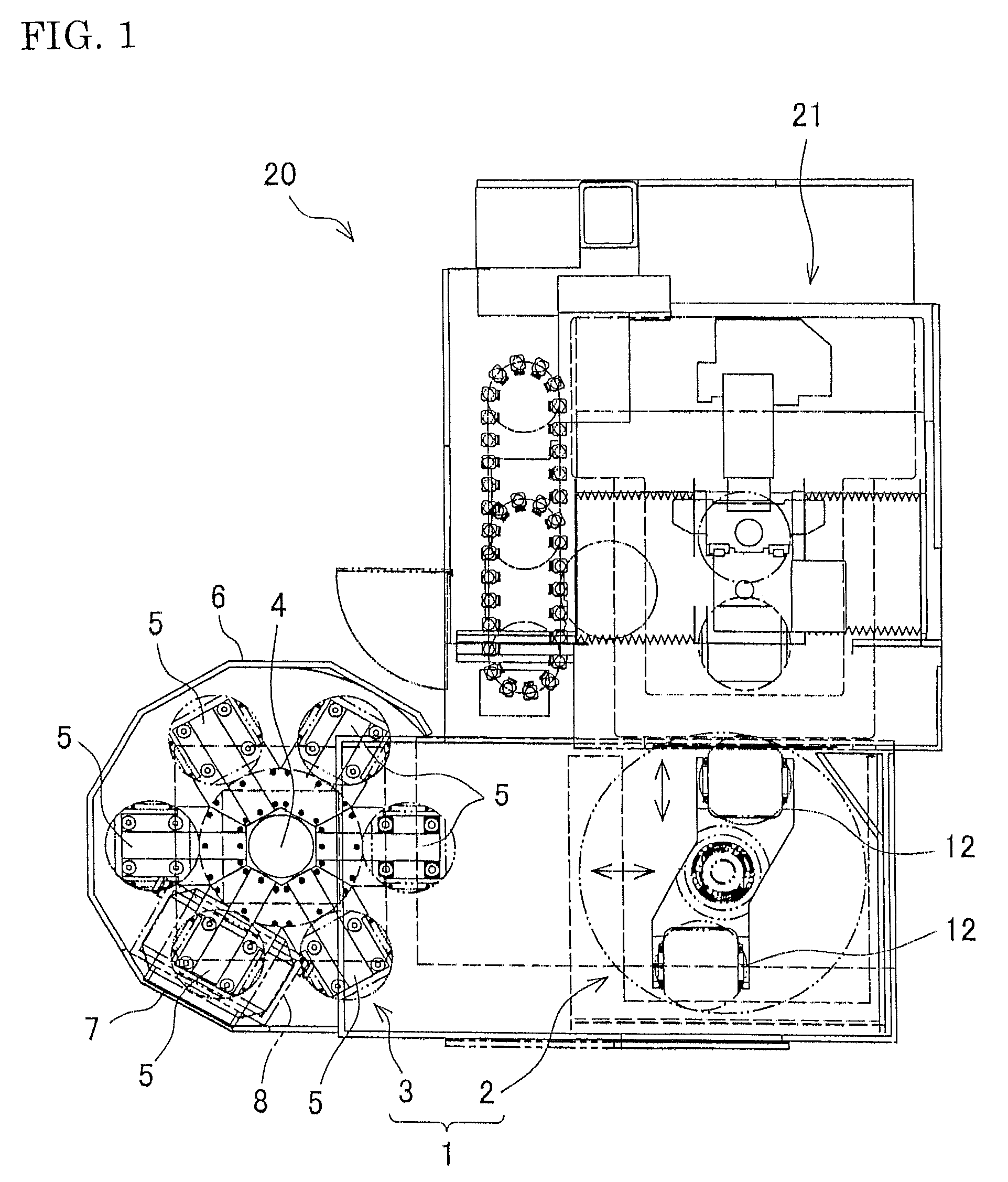

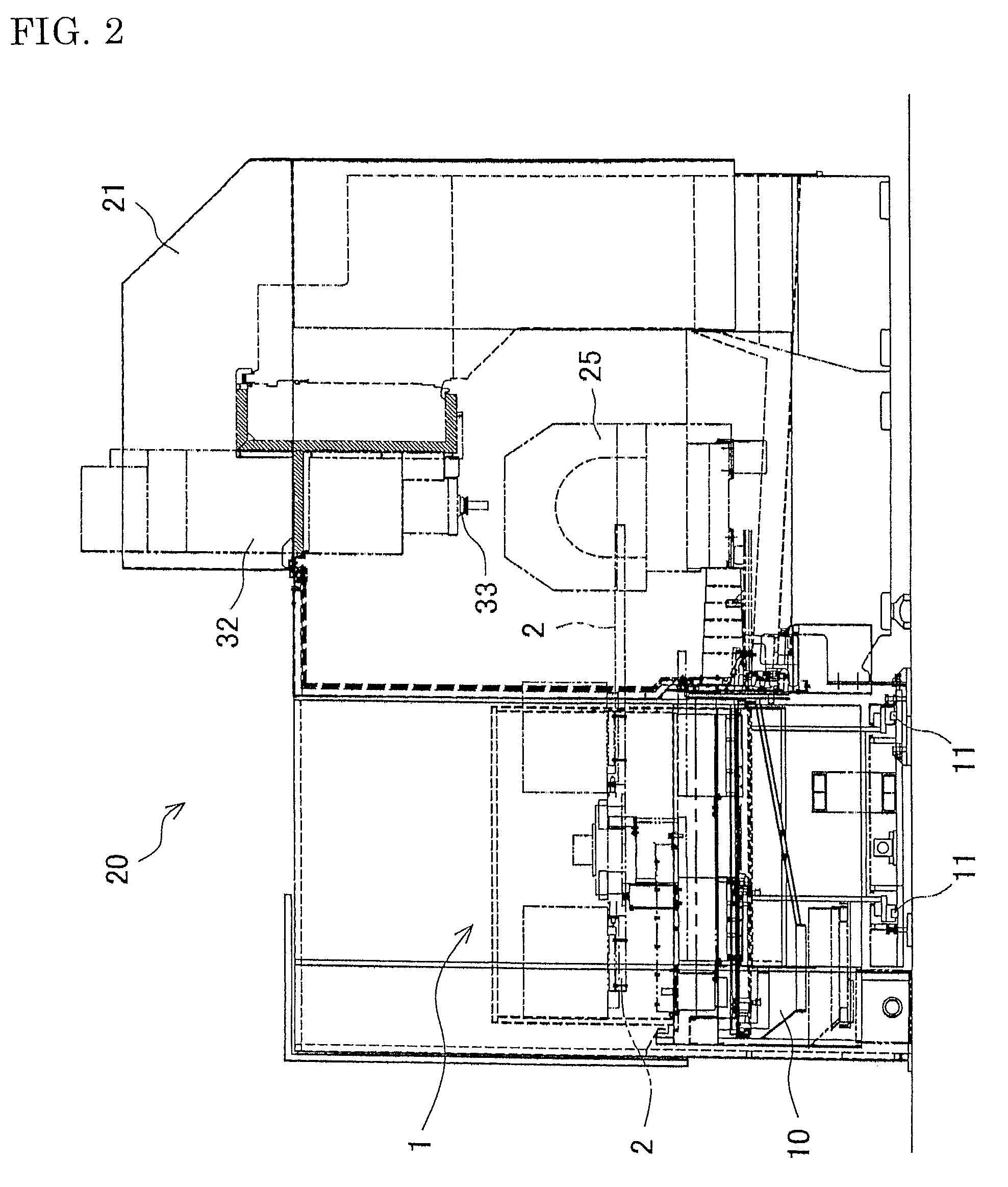

Pallet exchanging device

InactiveUS7621031B2Solve the lack of spaceImprove machine efficiencyControl devices for conveyorsCharge manipulationMulti phaseWorking space

Owner:OKUMA CORP

Gas turbine cooling blade with crown

InactiveCN102128055AReduce air leakage lossImprove overall machine efficiencyBlade accessoriesMachines/enginesLeading edgeTurbine blade

The invention discloses a gas turbine cooling blade with a crown. A plurality of clapboards which are arranged along the radial direction respectively are arranged from the leading edge of a blade body to the tail edge on the inner wall of the blade body; the inner cavity of the blade body is divided into three return flow type cooling channels which are formed along the longitudinal direction of the blade body; a clapboard at the headmost end is provided with impingement cooling holes, and the leading edge of the blade body is provided with air film holes; the tail end of a cooling channel on the middle part of the blade body is connected with a blade crown cooling cavity; partition ribs and turbulent flow posts are arranged and air vent holes are formed in the blade crown cooling cavity; an air vent seam is formed at the tail edge of the blade; and the turbulent flow posts are arranged in the air vent seam. The blade has a simple structure; and by the blade, the cooling efficiency is improved, the temperatures of the blade body and the blade crown are reduced, the loss of air leakage of a blade tip is reduced, and the properties of the turbine blade and the complete machine are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

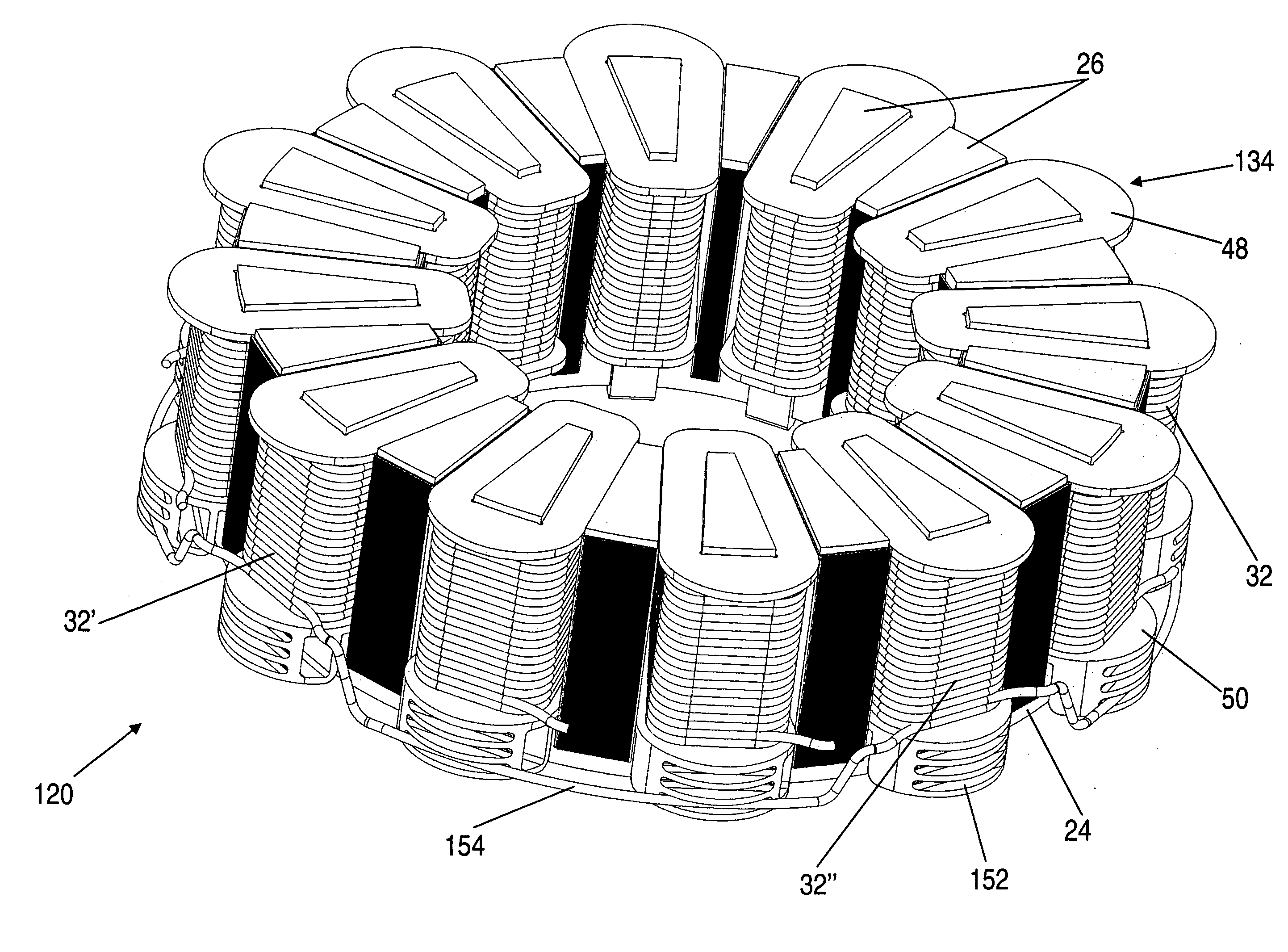

Winding insulation arrangement for axial flux machines

InactiveUS20110221297A1Reduce resistanceImprove machine efficiencyWindings insulation shape/form/constructionMagnetic circuitRotational axisAxial flux

A stator 20 for an axial flux machine such as a motor or generator. The stator includes a stator core 32 having a back plane 24 which in use is disposed perpendicularly about a rotational axis of the machine. A plurality of teeth 26 extend axially from the back plane so as to form winding receiving slots 28 between adjacent teeth. The stator also includes an electrical winding 30 including a plurality of coils 32, each coil being located about a tooth of the stator core and being electrically isolated from the stator tooth by means of an insulating former 34 having a shape which closely conforms to the shape of the stator tooth. The coils 32 are interconnected to form the winding 30. A method of constructing a stator is also disclosed.

Owner:REGAL BELOIT AUSTRALIA PTY LTD

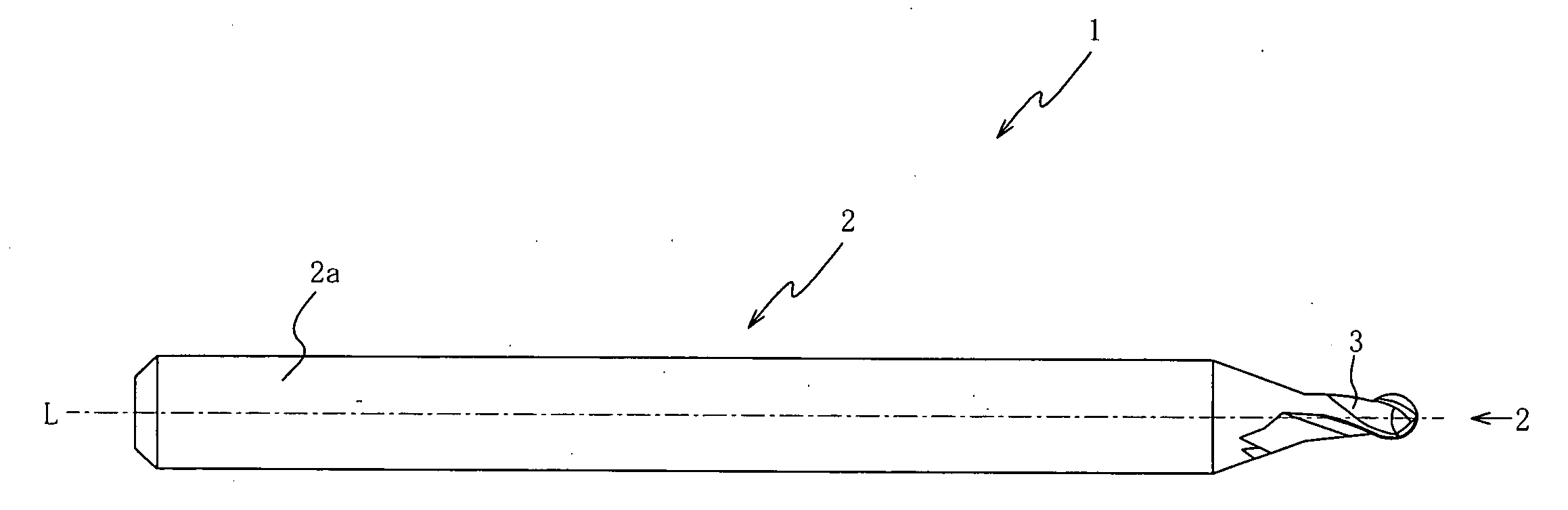

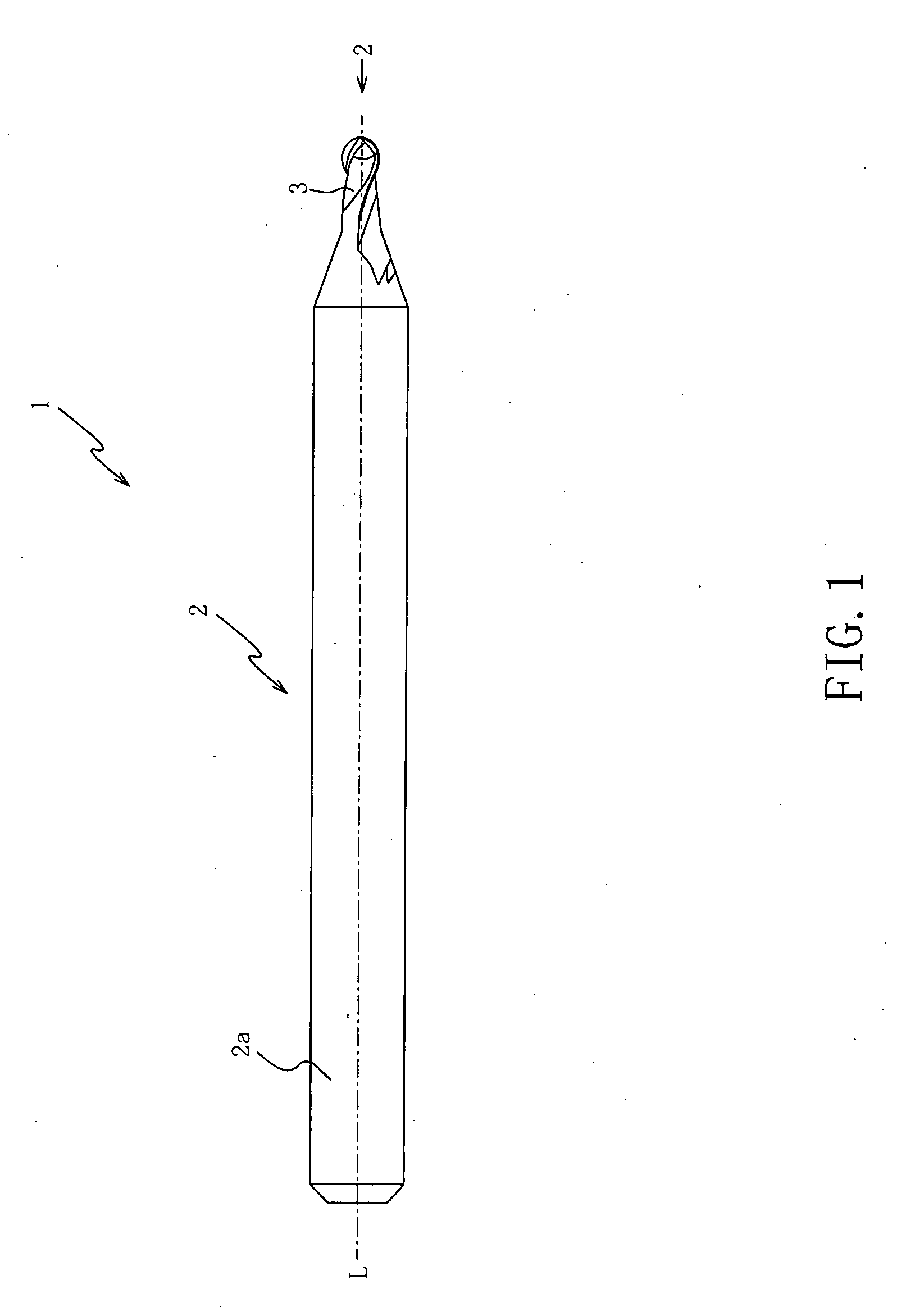

Ball endmill

InactiveUS20070172321A1Increase speedLarge depth of cutMilling cuttersWorkpiecesEngineeringSpherical shaped

A ball endmill includes a cylindrical tool body that is to be rotated about its axis, ball-nosed end cutting edges located in an axially distal end portion of the tool body and describing a semi-spherical-shaped locus during rotation of the tool body, and spiral gashes located in the axially distal end portion of the tool body and defining rake faces of the respective ball-nosed end cutting edges. The tool body is made, at least at its part providing each ball-nosed end cutting edge, of a hard sintered body. Each ball-nosed end cutting edge is inclined with respect to the axis by a helix angle in a range from about 10° to about 30°. The tool body has, in its distal end, a non-gashed central area in which the spiral gashes do not exist. A ratio of a size of the non-gashed central area to a ball nose radius is in a range from about 0.03 to about 0.1.

Owner:OSG +1

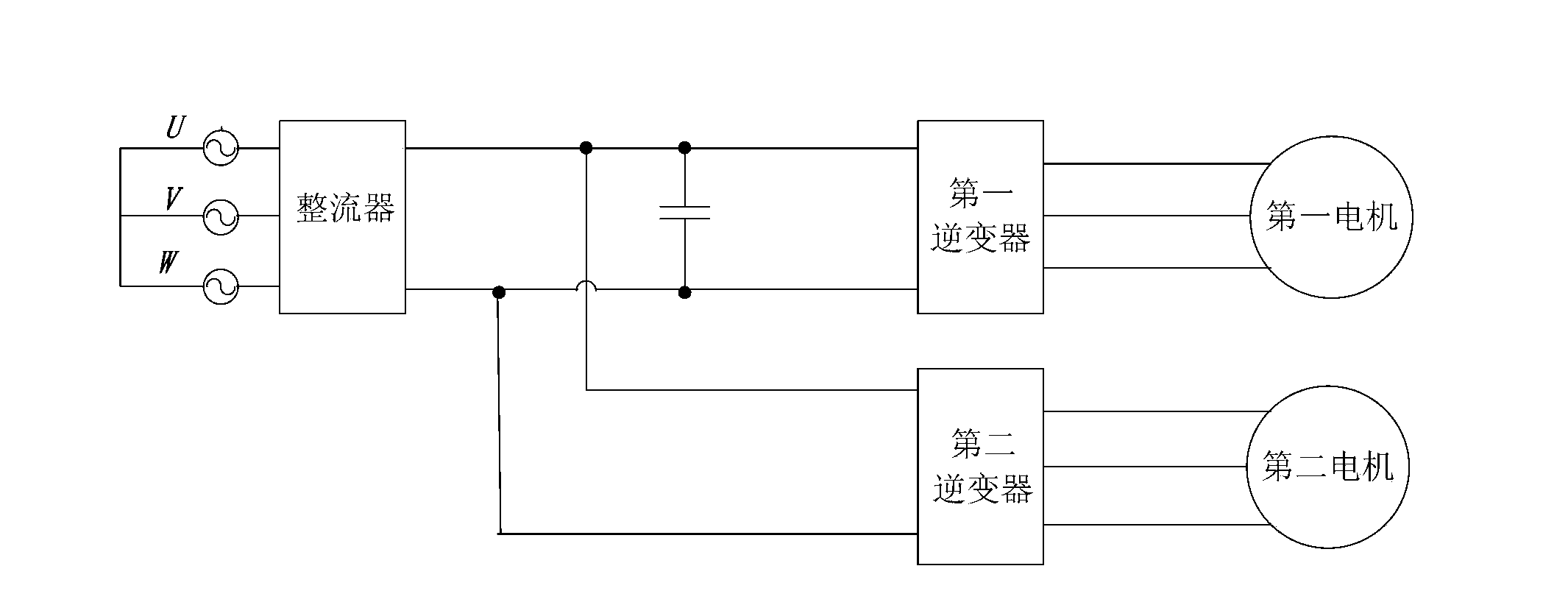

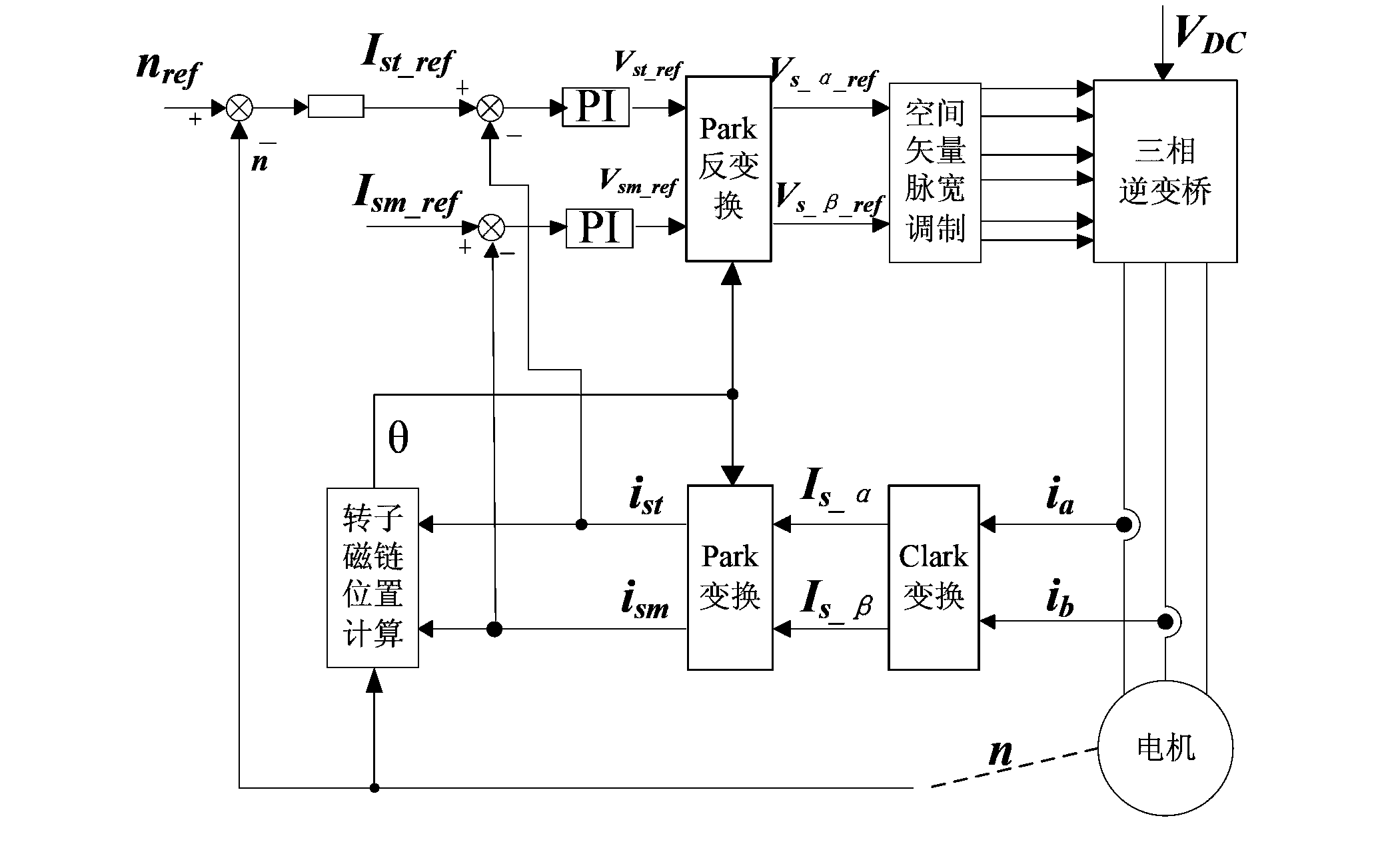

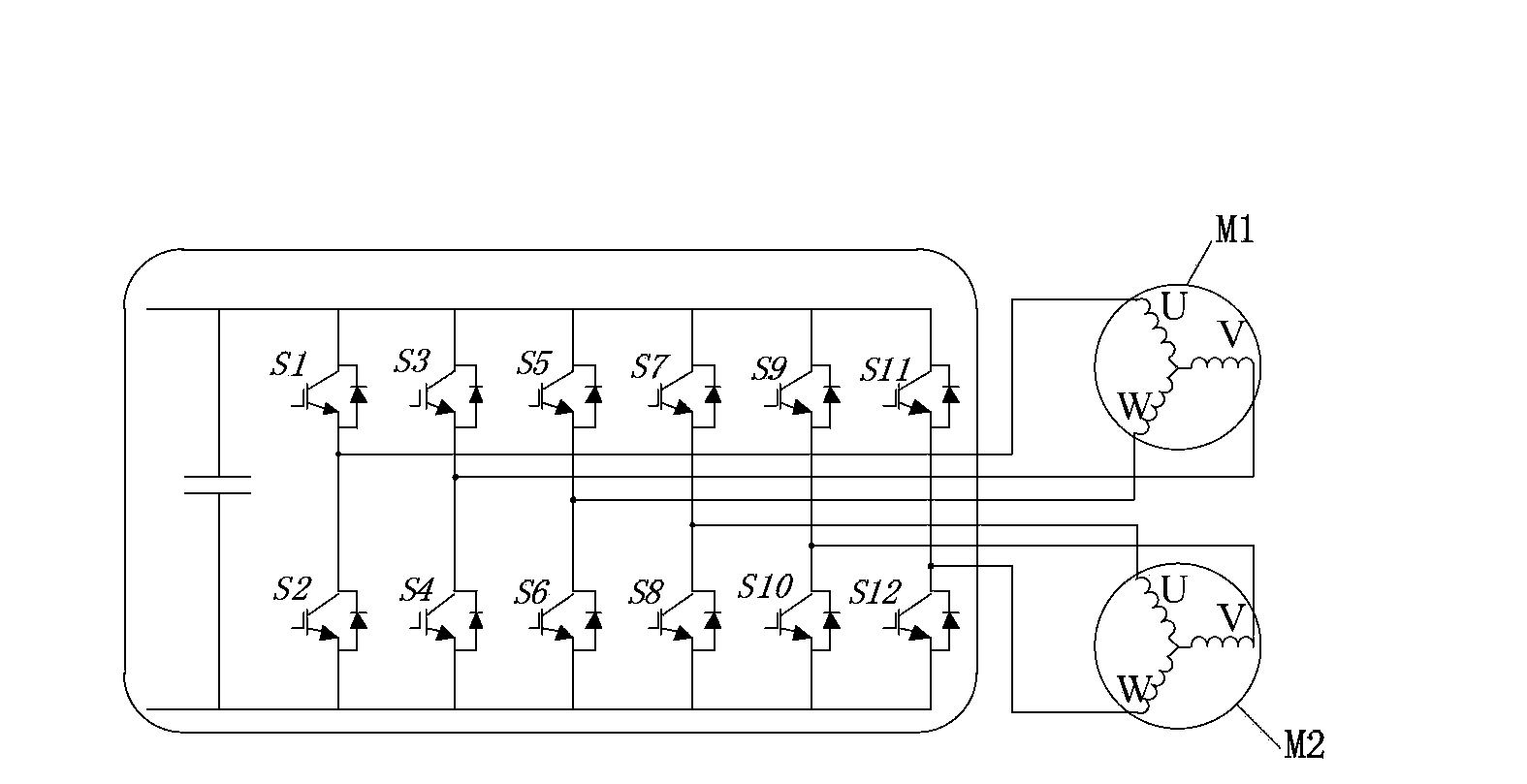

Control method for inverter and inverter

InactiveCN103904960AReduce volumeOptimal control methodMultiple ac dynamo-electric motors controlHysteresisPulse control

The invention aims to provide a control method for an inverter and the inverter. The inverter is used in two three-phase alternating-current motors including the first motor and the second motor at the same time. The inverter comprises five sets of inverter bridge arms, a current sampling device and a hysteresis controller. The output end of the first set of inverter bridge arms is connected with a U-phase winding of the first motor. The output end of the second set of inverter bridge arms is connected with a V-phase winding of the first motor. The output end of the third set of inverter bridge arms is connected with a U-phase winding of the second motor. The output end of the fourth set of inverter bridge arms is connected with a V-phase winding of the second motor. The output end of the fifth set of inverter bridge arms is connected with the W-phase winding of the first motor and a W-phase winding of the second motor. The current sampling device is used for sampling a current. The hysteresis controller is connected with the current sampling device and the control ends of the five sets of inverter bridge arms and is used for obtaining the objective current and the output current of each phase winding of the two three-phase alternating motors and sending corresponding pulse control signals to the five sets of inverter bridge arms through hysteresis control according to the output currents and the objective currents.

Owner:北京君泰联创低碳节能科技有限公司

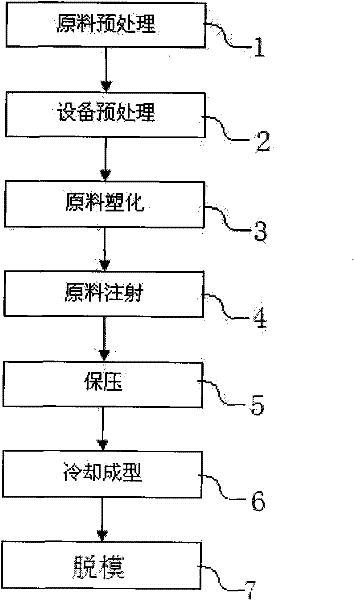

Injection molding technology for acrylonitrile butadiene styrene (ABS) plastic air conditioner shell

ActiveCN102407588AThe process steps are simpleEasy to implementCoatingsEngineeringInjection molding process

The invention discloses an injection molding technology for an acrylonitrile butadiene styrene (ABS) plastic air conditioner shell, and the technology comprises the following steps of: (1) pretreating raw materials; (2) pretreating an injection molding system and an injection molding mould; (3) plasticizing; (4) injecting; (5) maintaining the pressure; (6) molding by cooling; and (7) demoulding. The injection molding technology is simple in implementation steps, and can be used for effectively reducing the molding period and the production cost, and effectively improving the quality of finished products by virtue of the corresponding technological condition.

Owner:SHANGHAI PUDONG MEILING PLASTIC PROD

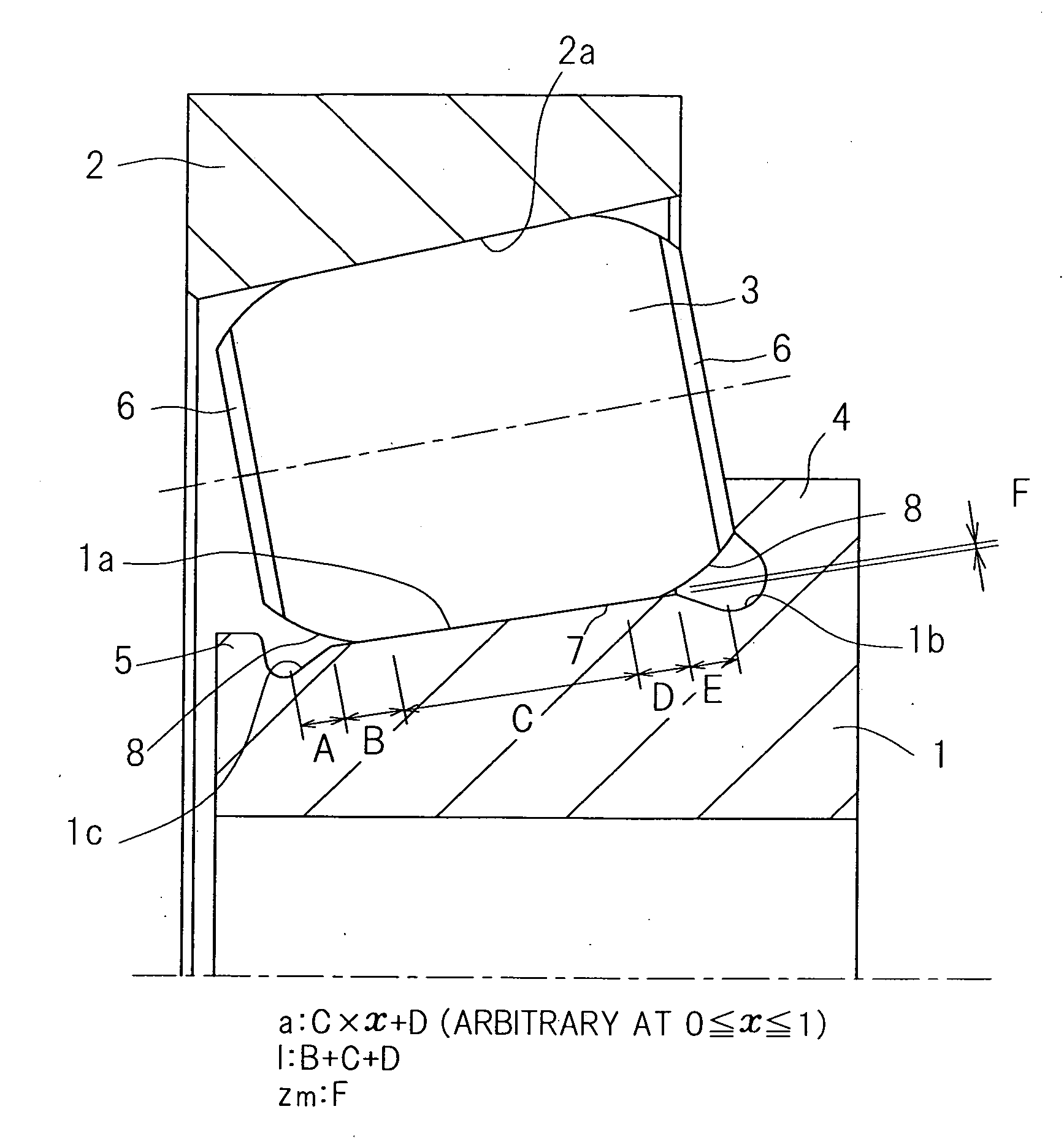

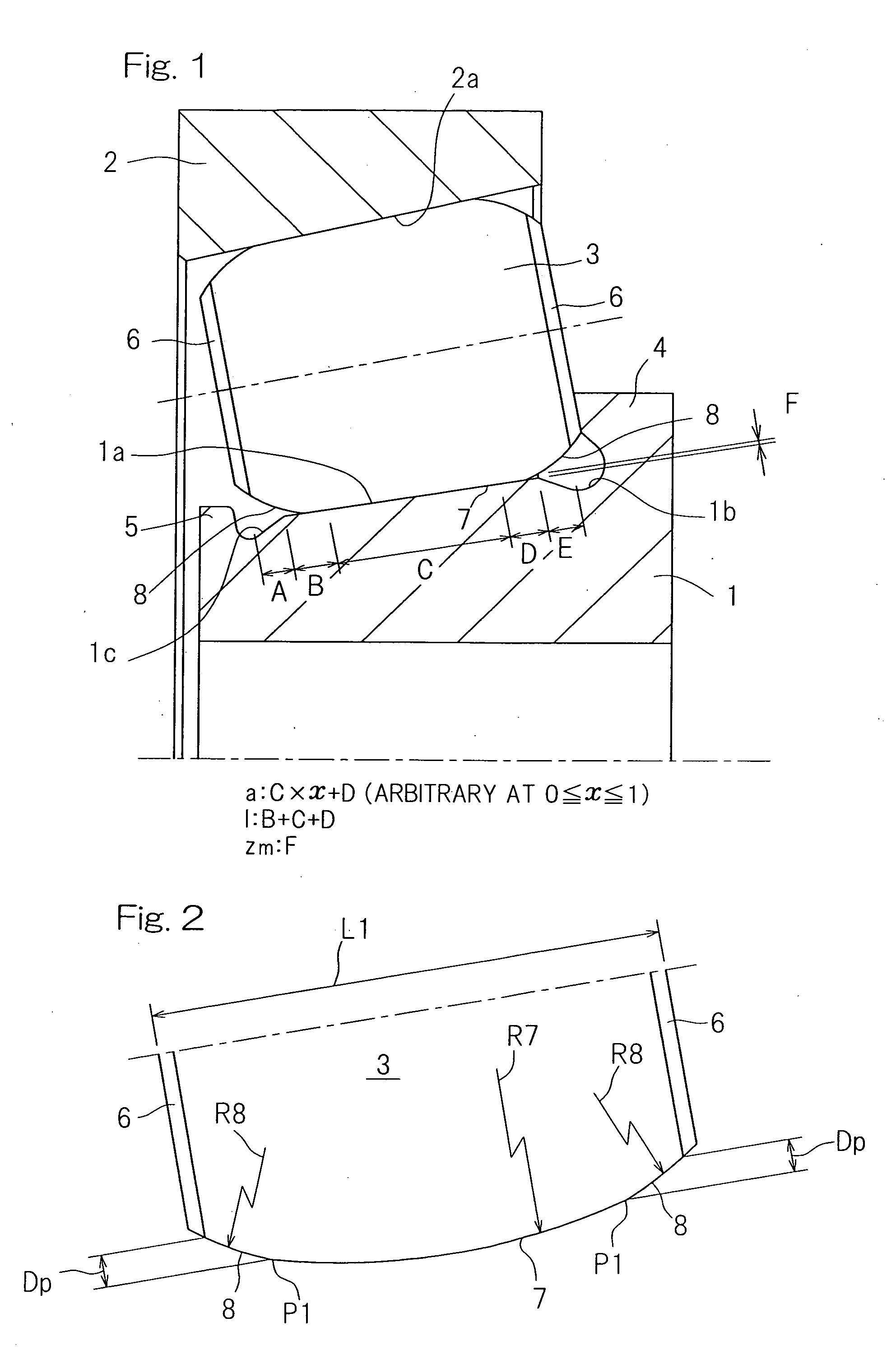

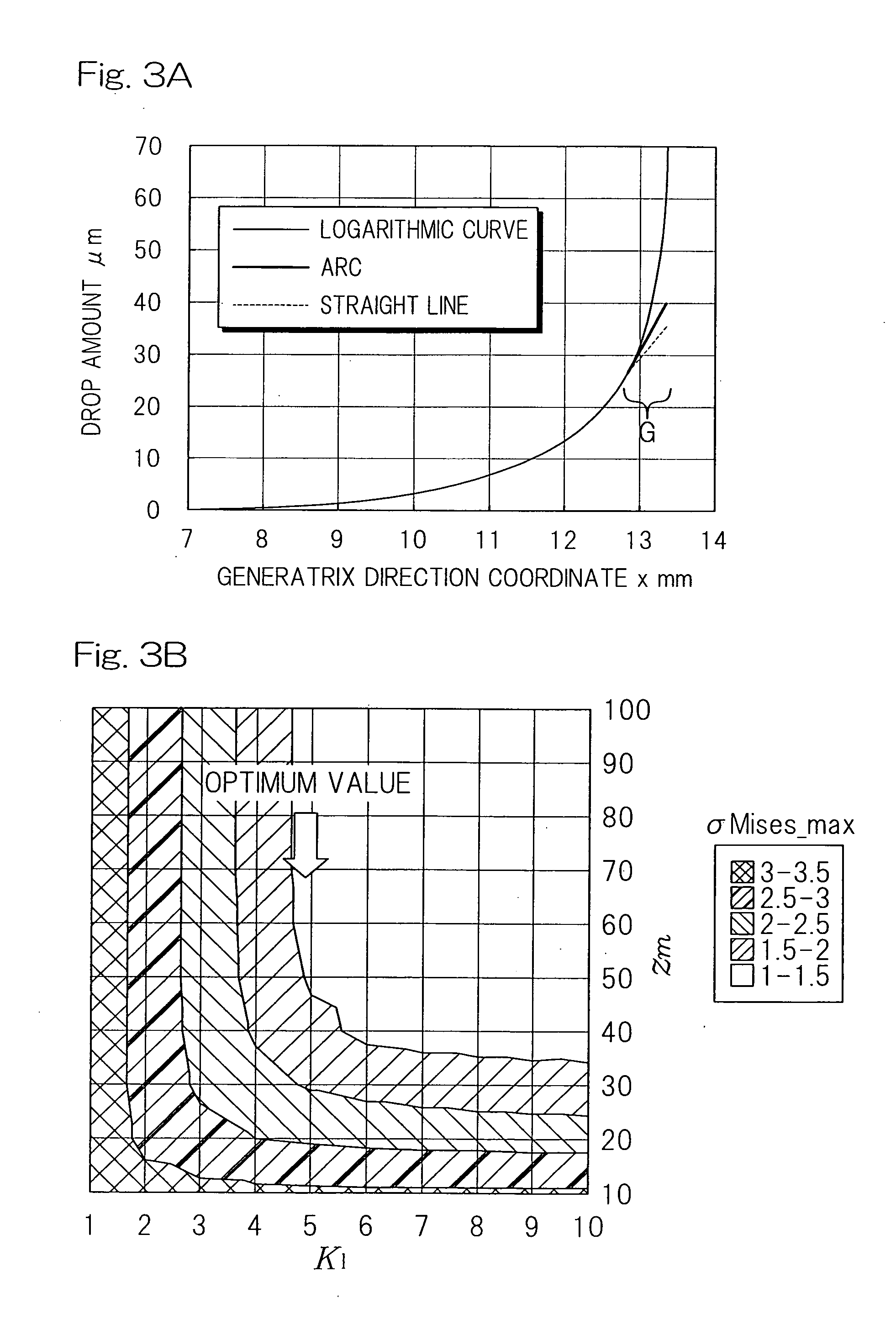

Tapered roller bearing and method of designing the same

ActiveUS20120033909A1Design be relatively longCost reductionRolling contact bearingsShaftsMechanical engineeringContact region

In a tapered roller bearing assembly, a crowning profile formed portion of the roller rolling surface is made up of a contact area crowned portion (7), which is held in contact with an inner ring raceway surface (1a), and a non-contact area crowned portion (8) which is held in non-contact with the inner ring raceway surface (1a). The contact area crowned portion (7) and the non-contact area crowned portion (8) have their generatrices extending in an axial direction of a roller (3), which generatrices are represented by corresponding continuous lines represented by different functions and continued smoothly at a point of connection, and the curvature of the generatrix of the non-contact area crowned portion (8) in the vicinity of the connection point is chosen to be smaller than the curvature of the generatrix of the contact area crowned portion (7).

Owner:NTN CORP

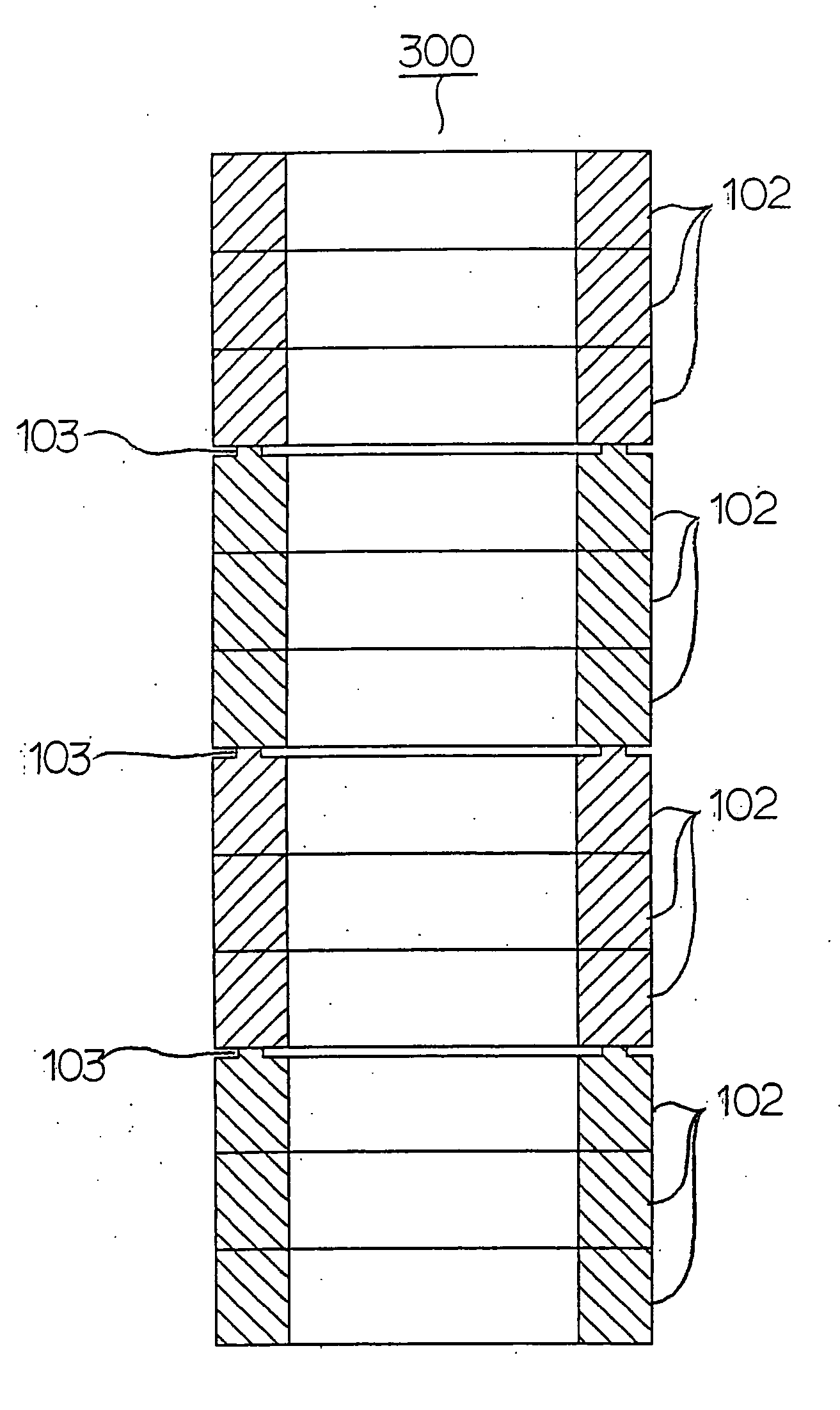

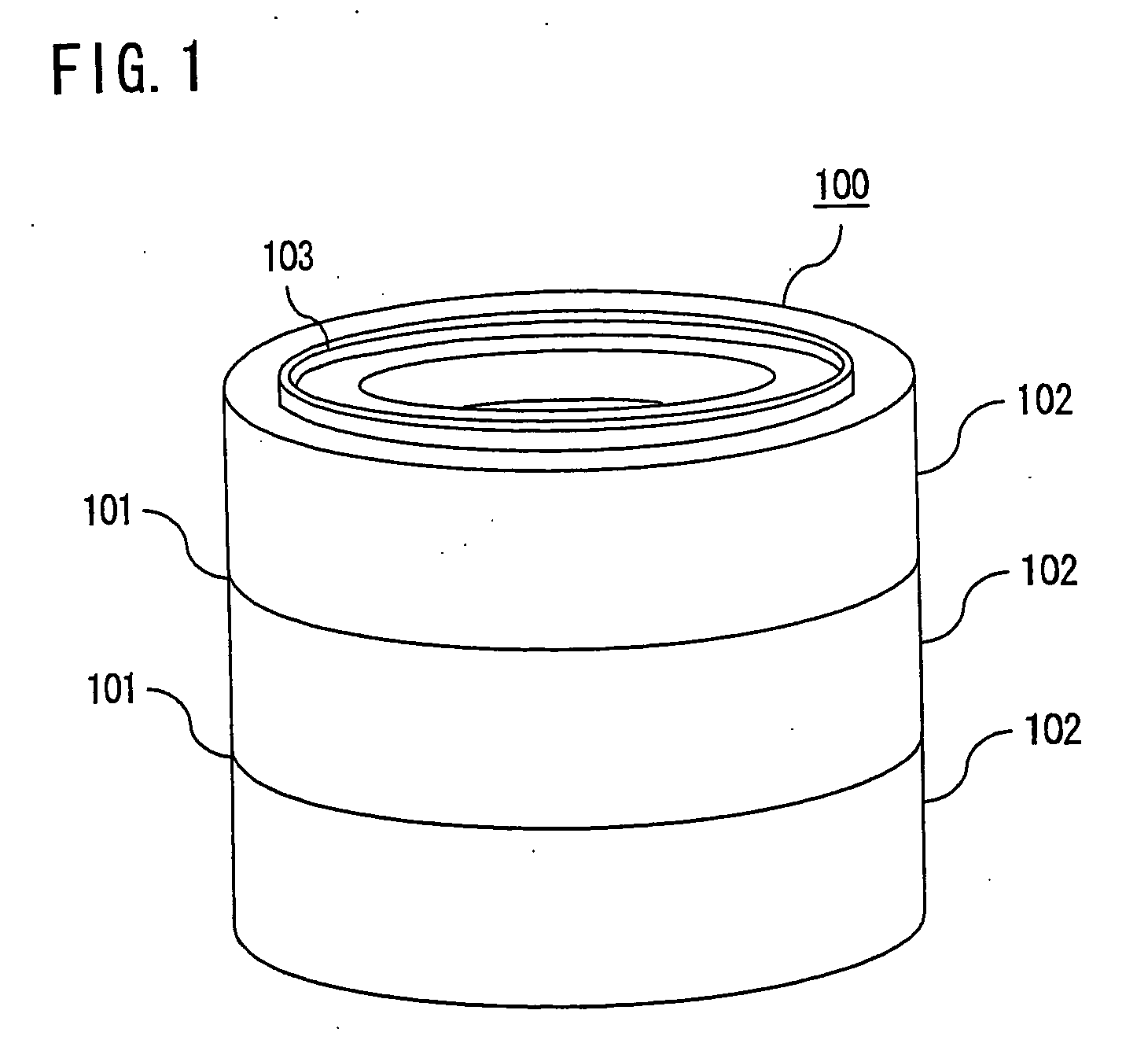

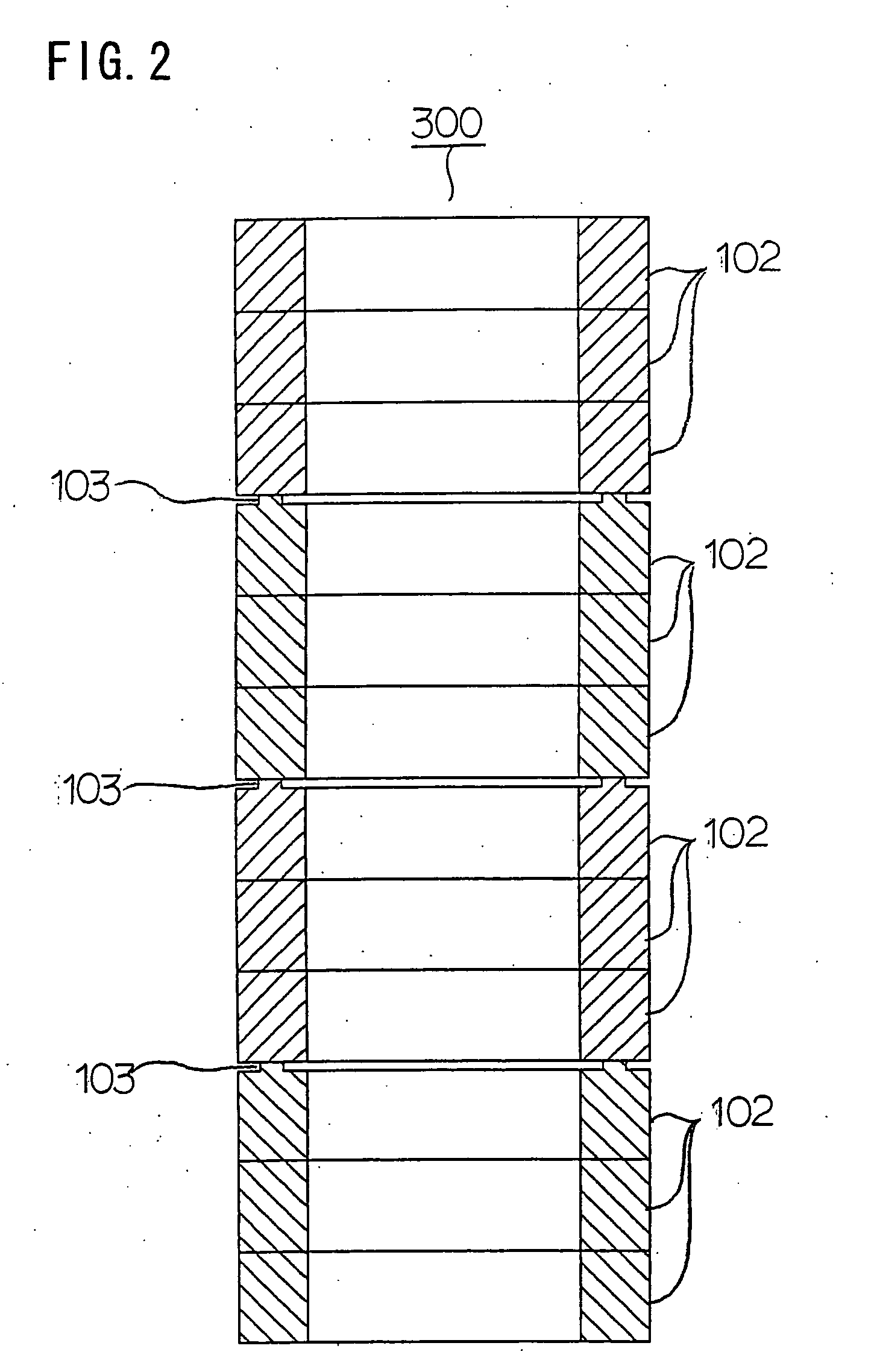

Sintered ring magnet and method of manufacturing the same

InactiveUS20060051233A1High shape accuracyImprove efficiencyPermanent magnetsInorganic material magnetismMetallurgyBoundary region

A ring magnet manufacturing method includes the steps of stacking a plurality of radially oriented ring-shaped powder compacts (102) in an axial direction thereof to produce a ring-shaped powder compact rod, sintering the ring-shaped powder compact rod to produce a sintered ring-shaped powder compact rod (300) in which the ring-shaped powder compacts (102) are joined together, and dividing the sintered ring-shaped powder compact rod (300). In this ring magnet manufacturing method, protruding parts (103) are formed on upper end surfaces of the ring-shaped powder compacts (102) which will be located in uppermost layers of individual sintered ring magnets (100), for example, such that the ring-shaped powder compacts (102) are joined with a reduced joint strength at specific boundary regions of the sintered ring-shaped powder compact rod (300) where the protruding parts (103) are located than at the other boundary regions. The sintered ring magnets (100) are obtained by dividing the sintered ring-shaped powder compact rod (300) at the specific boundary regions having the reduced joint strength.

Owner:MITSUBISHI ELECTRIC CORP

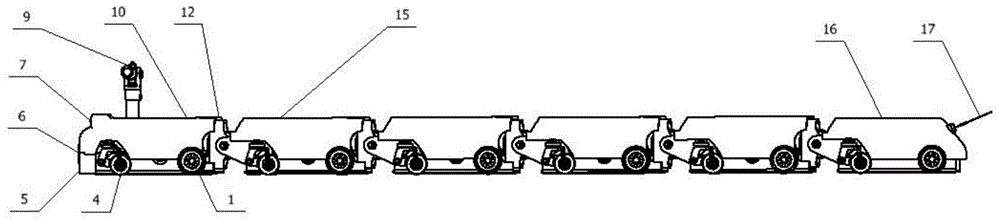

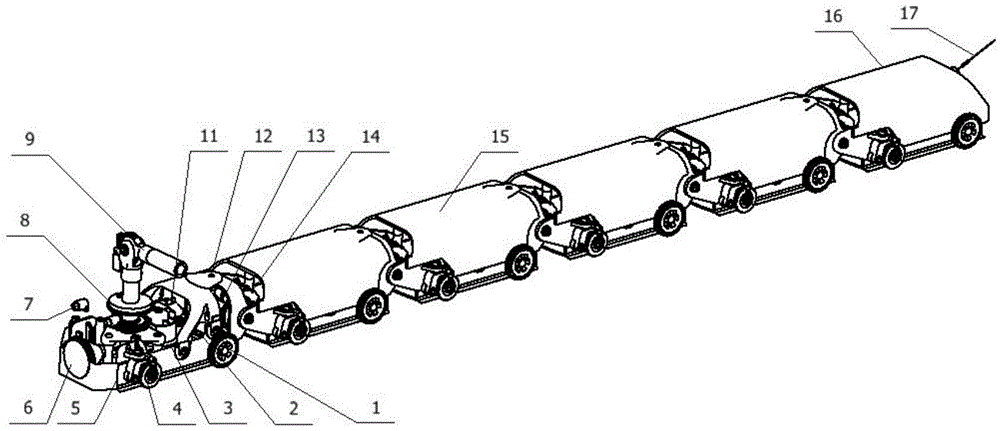

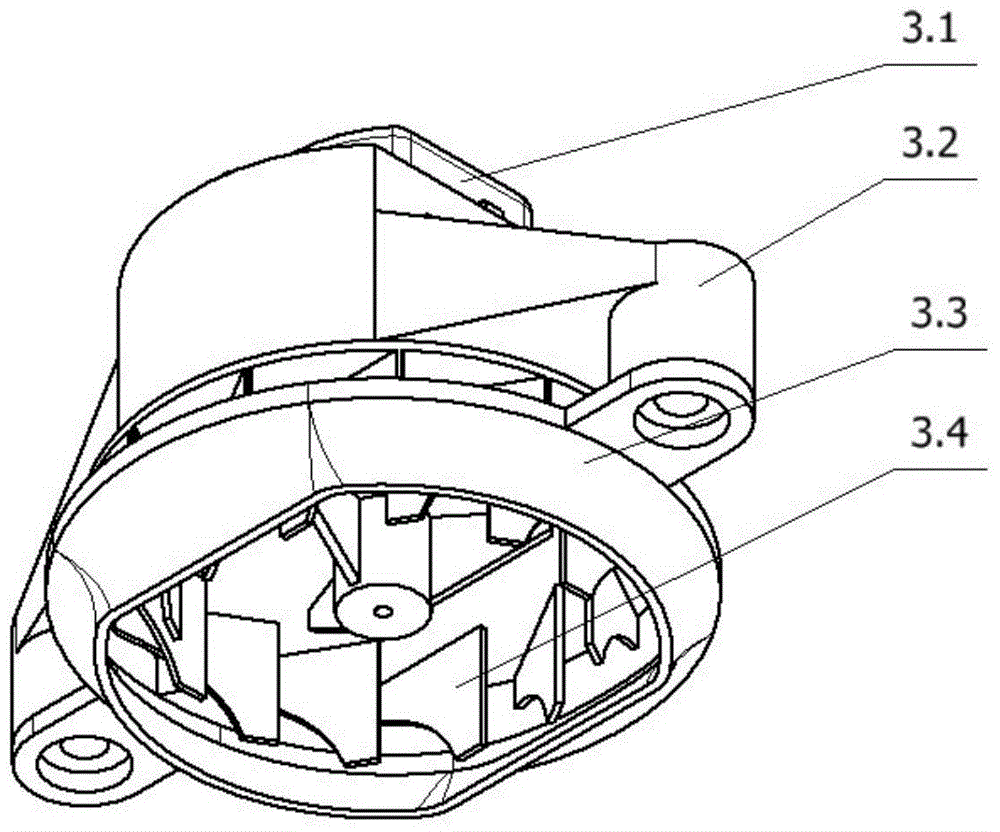

Reconnaissance type obstacle-surmounting machine snake

ActiveCN104925159AFlexible and accurate movementImprove migration abilityVehiclesEngineeringTorsion spring

The invention discloses a reconnaissance type obstacle-surmounting machine snake, and belongs to the field of robots. Because the conventional wall climbing robots cannot surmount walls of 90 degrees, the conventional wall climbing robots are difficult to move a single step on modern buildings in a common right-angle design; the capability of surmounting obstacles is weak, so that the conventional wall climbing robots cannot perform search, inspection and maintenance tasks at dangerous locations, and the application range is narrow. In order to overcome the defects of the conventional wall climbing robots, the wall climbing machine snake is designed by combining a snake-shaped robot which is high in stability, small in cross section, and high in flexibility. The machine snake can simulate a snake to raise the head and swing the head. The machine snake can raise the head like the snake, so that the machine snake can freely turn on walls of different angles, and the mobility is high. The machine snake walks by adopting wheels, and a buffering torsion spring is arranged at each joint, so that the turning accuracy is guaranteed. On the aspect of adsorption, the machine snake is adsorbed on a wall by utilizing a vacuum negative pressure theory; through comparison and analysis, a base structure is designed, so that the adsorption is firmer. A camera can rotate 360 degrees.

Owner:河北航轮科技有限公司

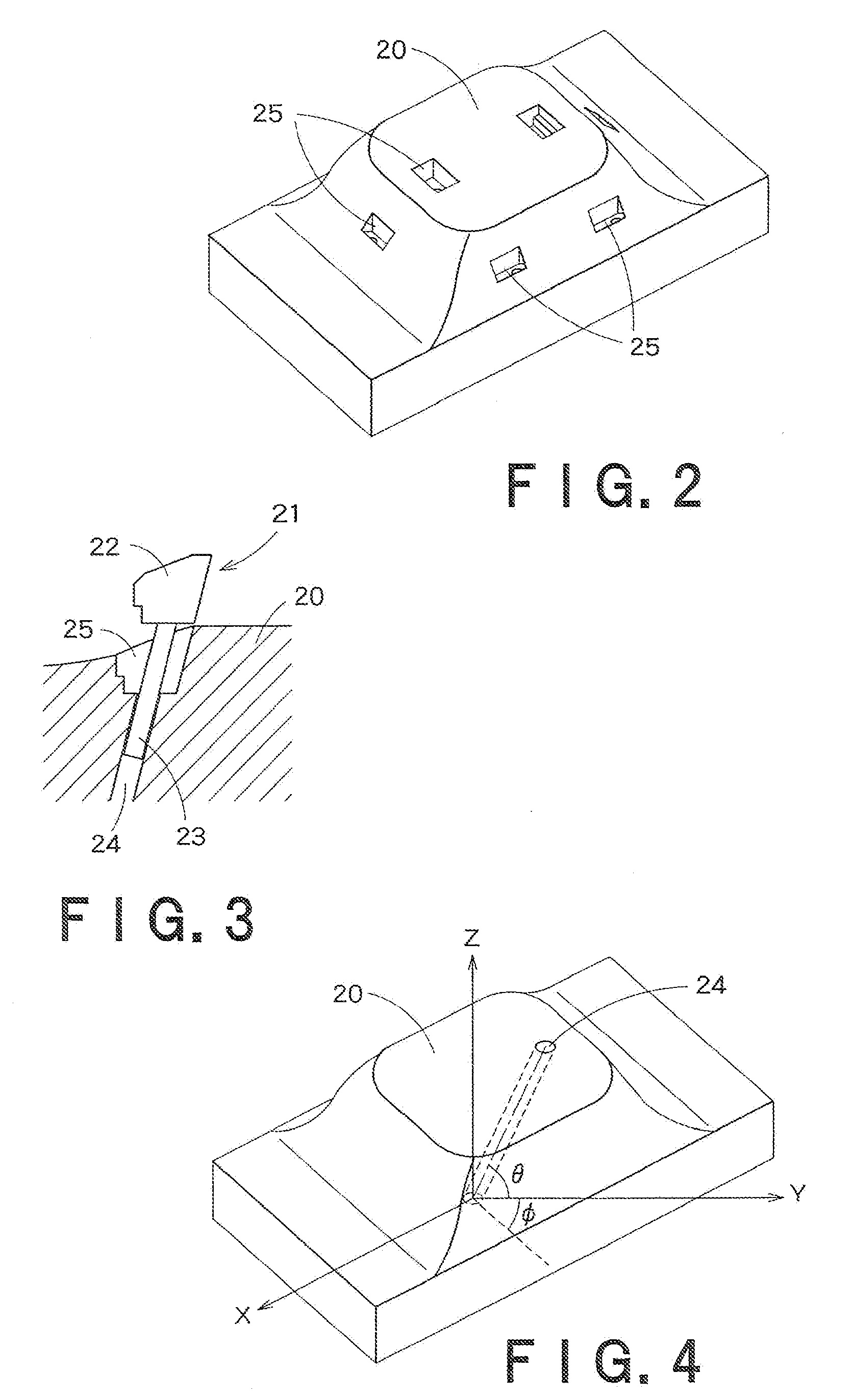

Method for machining slide core hole and measurement/correction system for use in machining of slide core hole

ActiveUS20080199266A1Improve efficiencyHigh precisionProgramme controlSampled-variable control systemsGun drillReamer

There are provided a method for machining a slide core hole and a measurement / correction system for use in machining of a slide core hole, which enable efficient machining of a slide core hole while utilizing the high-speed cutting performance of a five-axis machine tool. The method for machining an inclined slide core hole, comprised of a core pocket and a rod hole, in a mold as a workpiece by means of a five-axis machine tool having, in addition to X-axis, Y-axis and Z-axis, an A-axis for pivoting of a spindle head and a C-axis for rotation of a table, includes the steps of: pivoting the spindle head to meet the inclination angle of the slide core hole to be machined in the mold, and fixing the A-axis angle; spot-facing a shallow flat-bottomed spot-faced hole in the surface of the mold by using an end mill as a tool; drilling a guide hole in the bottom surface of the spot-faced hole by using a drill or a reamer as a tool; drilling said rod hole by using a gun drill as a tool with the guide hole as a guide for the gun drill; carrying out, as pre-machining before machining of said core pocket, shaping machining to form an intermediate pocket hole while expanding the spot-faced hole by using an end mill as a tool; correcting a reference point for use as a reference in machining of the core pocket based on measurement of the shape of the intermediate pocket; and executing a corrected machining program with the corrected reference point to carry out precision shaping machining of the core pocket while expanding the intermediate pocket by using an end mill as a tool.

Owner:TOSHIBA MASCH CO LTD

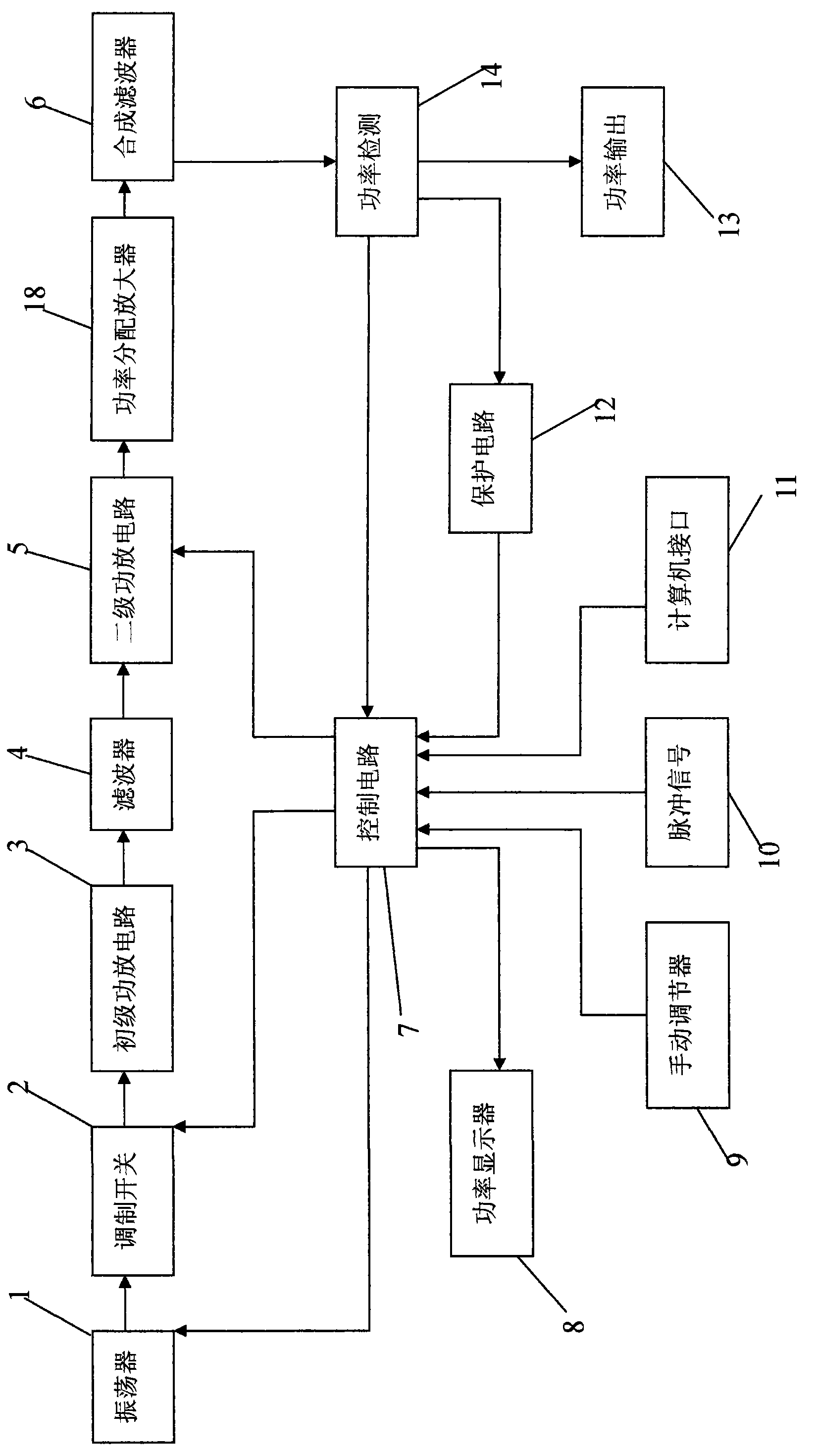

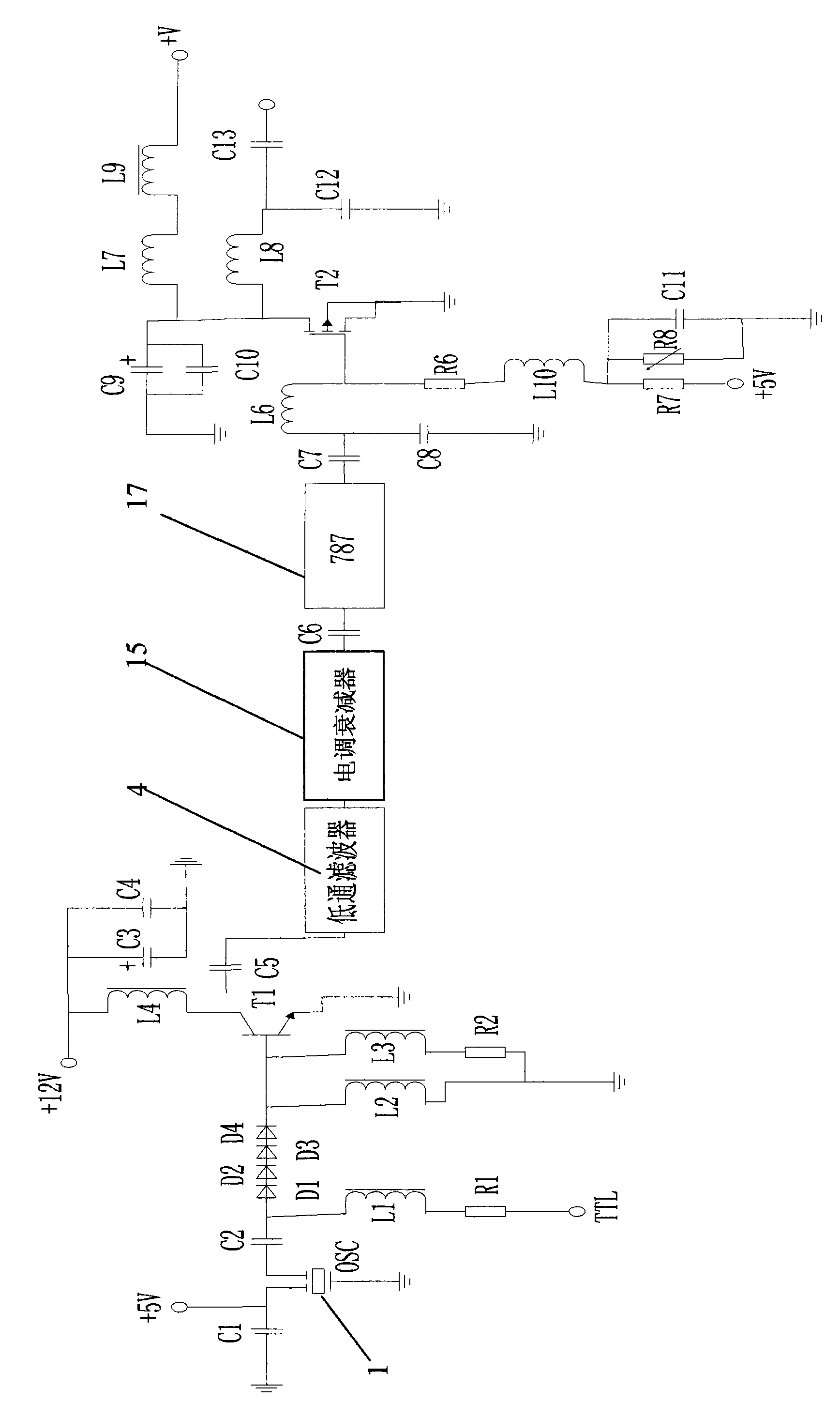

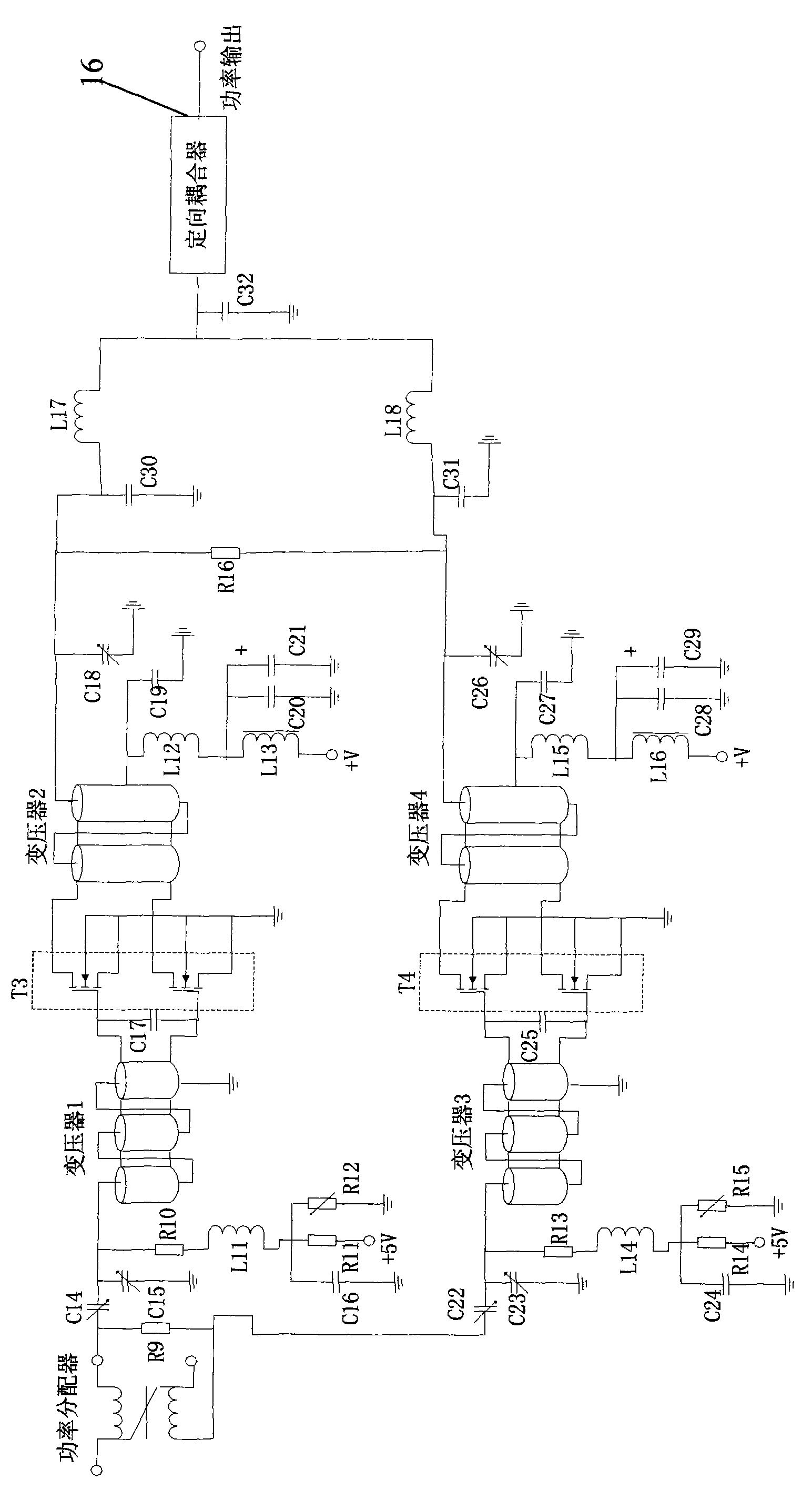

Full solid-sate radio frequency power supply

ActiveCN101594127AExtend working lifeLong working hoursPulse automatic controlPower amplifiersRadio frequencyStanding wave

The invention relates to a radio frequency power supply, in particular to a large-power full solid-state radio frequency power supply based on an MOS-FET amplifier, which comprises a signal source, a control circuit, a modulation switch, a wave filter, a primary power amplification circuit, a secondary power amplification power, a synthetic wave filter, a power detector and other modules; and the radio frequency power supply has the advantages that the radio frequency power supply has long service life, long continuous working time, stable power frequency and power and simple operation, does not need preheating, reduces the labor intensity of engineering operators, has high efficiency of the whole machine and also has the functions of standing wave protection and overheating protection.

Owner:常州瑞思杰尔电子科技有限公司

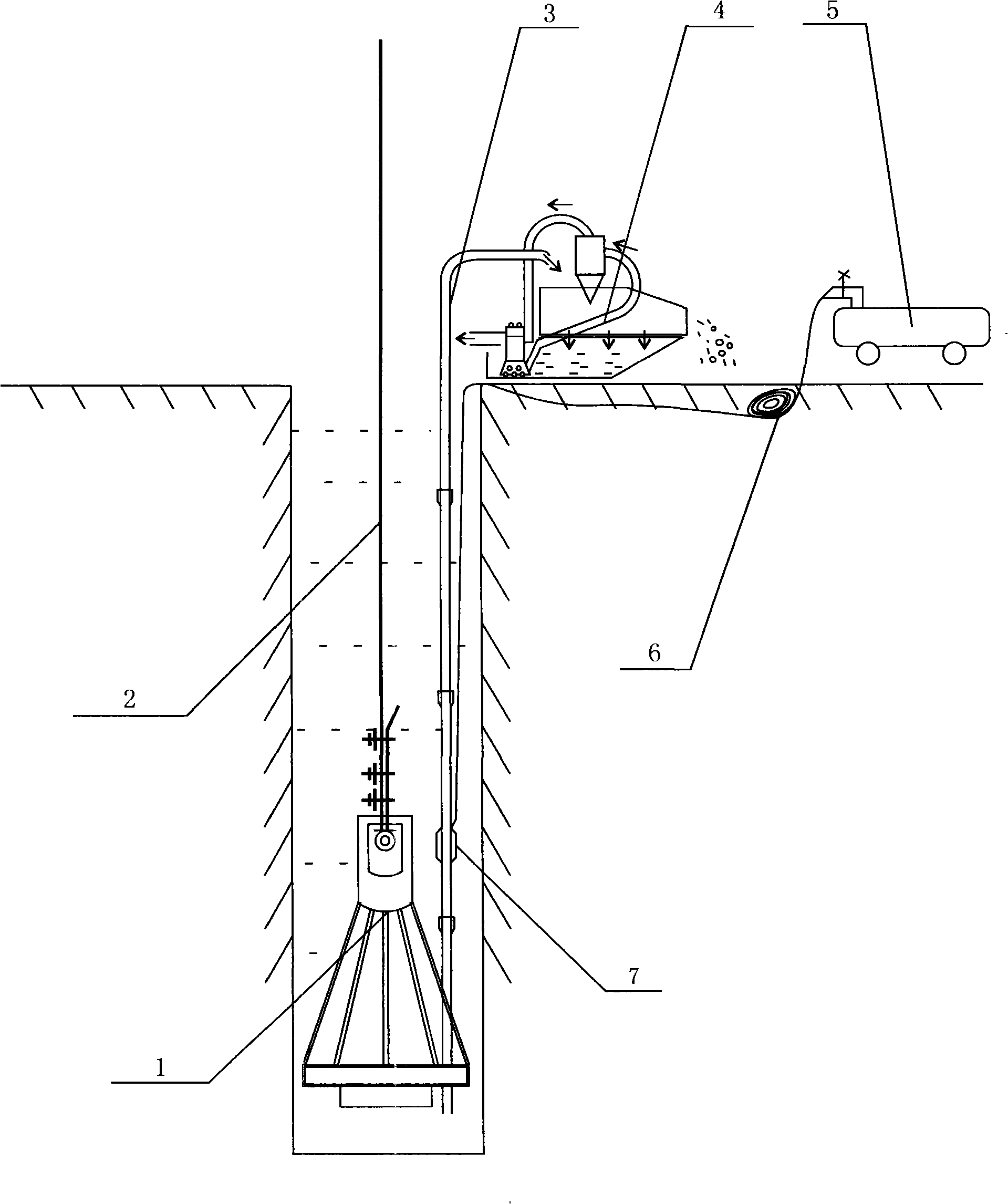

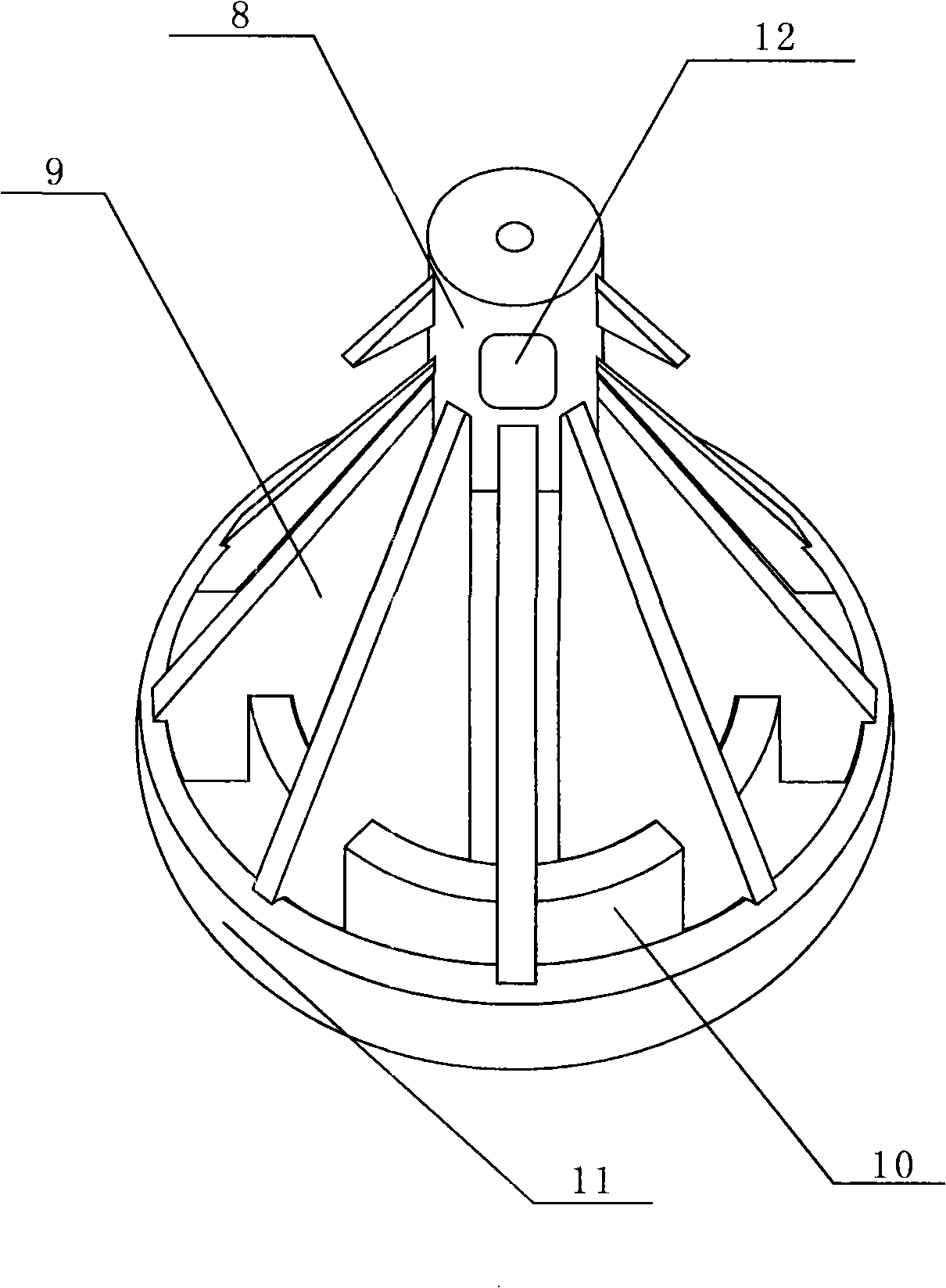

Reverse circulation construction technique and apparatus of single rope impact drill

InactiveCN101275458ARotation does not generateAvoid entanglementConstructionsReciprocating drilling machinesSlagEngineering

The invention discloses a process and a device for the reverse circulation execution of a single rope impact drill, the reverse circulation execution device comprises a percussion drill, a slurry pumping pipe at the hole bottom and a slurry purifier at the hole mouth, the drill bit is composed of a drill bit body and a cutting blade, the drill bit body is composed of a hammer body, corner boards and a base, the upper end of the hammer body is provided with a connecting hold connected with a non-rotating rope, the corner boards are distributed in the same angle axially on the cylindrical or circular-tube-shaped hammer body, the base is composed of coaxial inner base and outer base, which are tube-shaped, the upper surfaces of the two base are in the same plane, the inner base is higher than the outer base, the lower ends of the corner boards are connected with the two bases, the hammer body, the corner plate and the base are integrated by welding, casting or riveting, the lower end of the base is evenly equipped with multiple cutting blades; pile types of various section shapes can be dilled by the drill bit, the reverse circulation process of hole bottom slag pumping is used when drilling, the execution process is fastened, the energy consumption is reduced, the slag is cleaned completely and clearly, the time for cleaning the hole is shortened.

Owner:张安禄

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com