Patents

Literature

11520 results about "Weld seam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

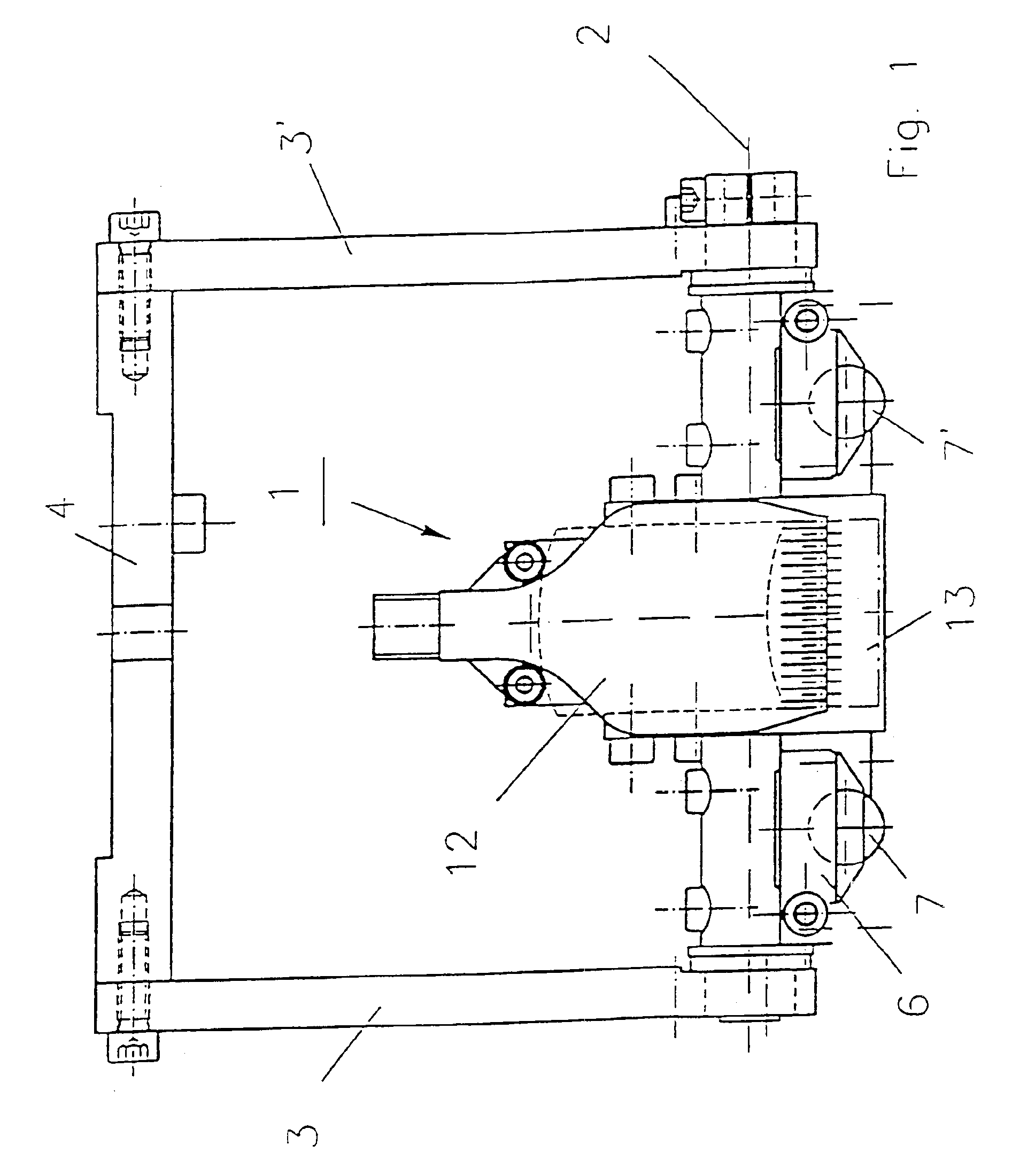

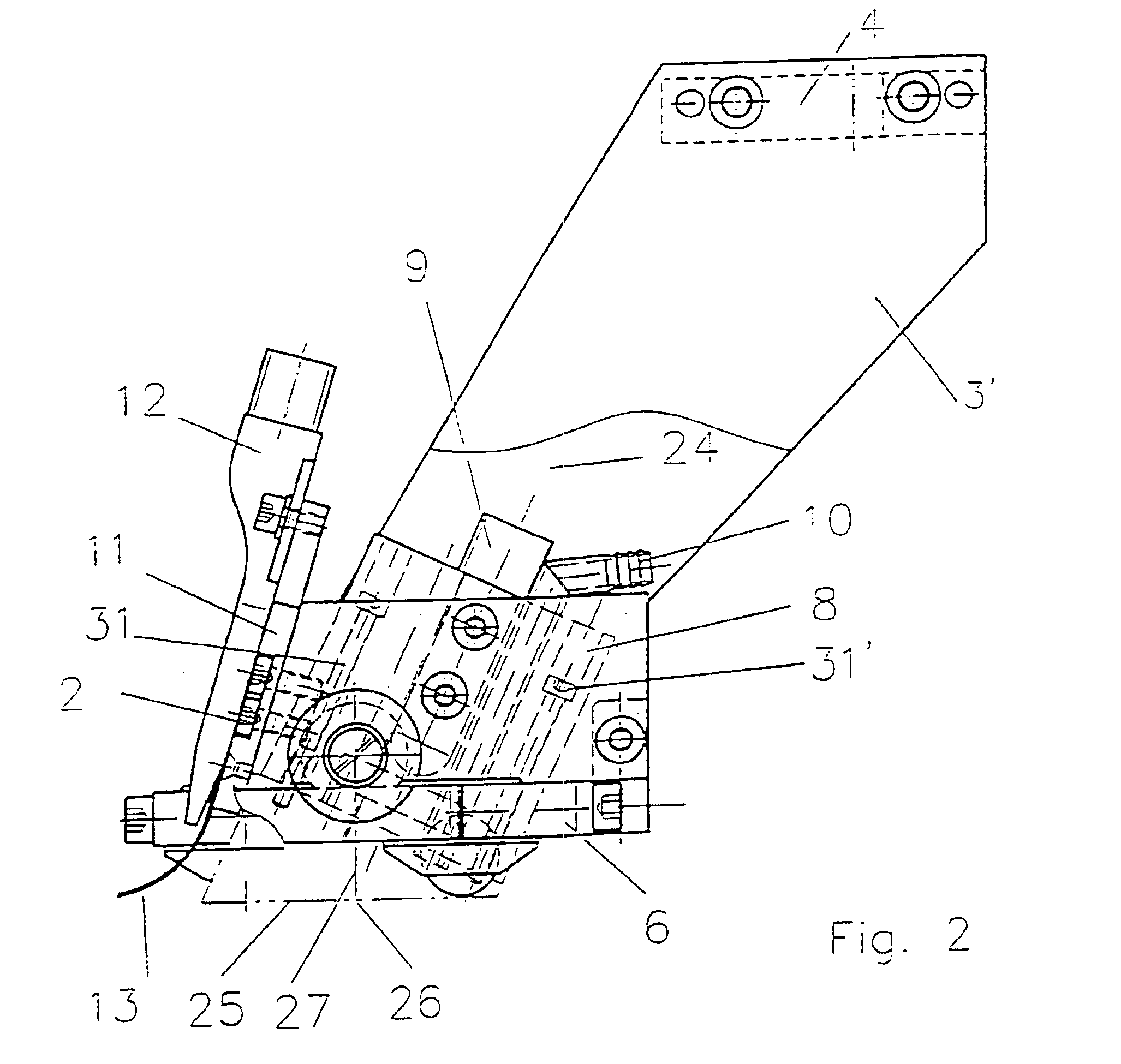

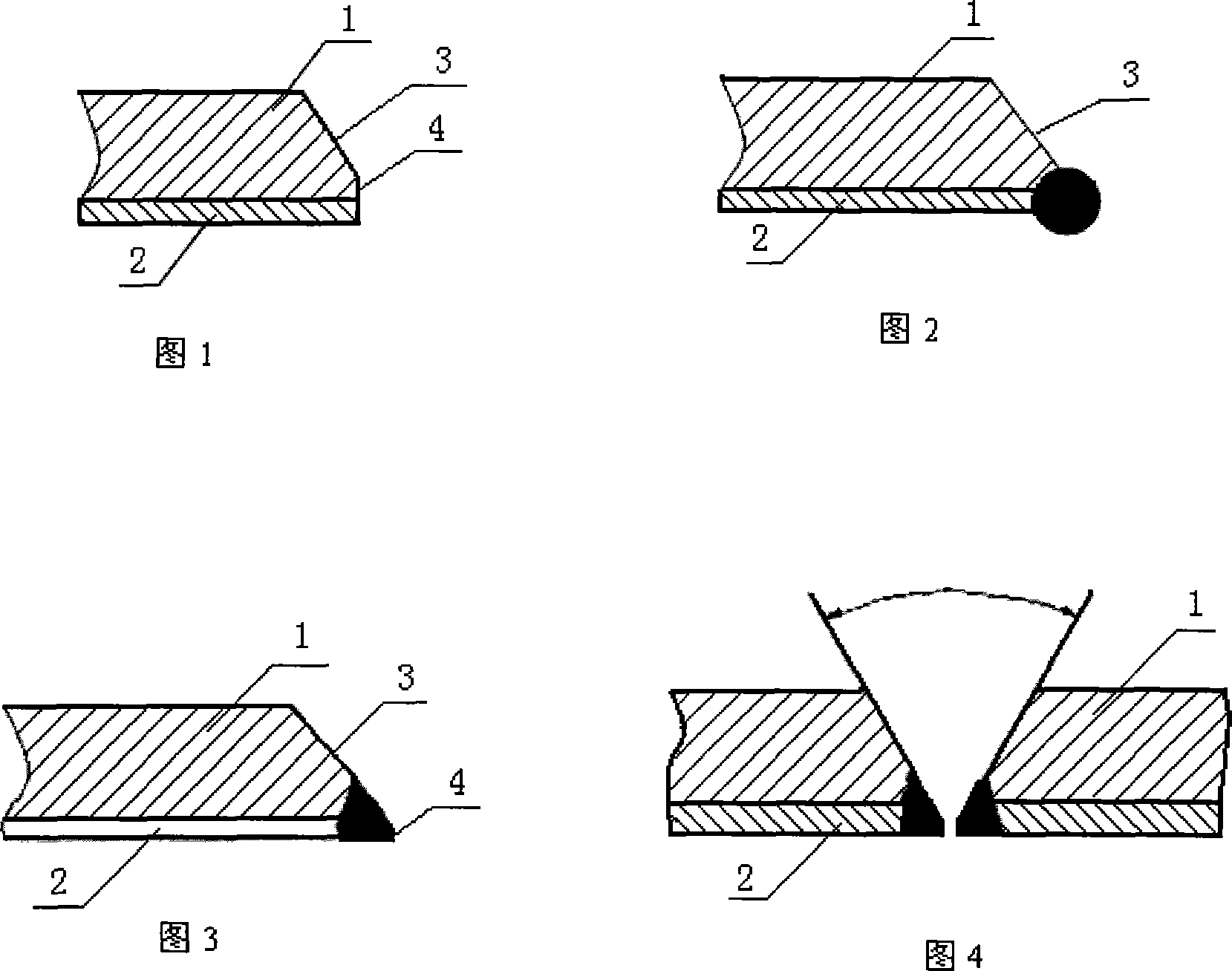

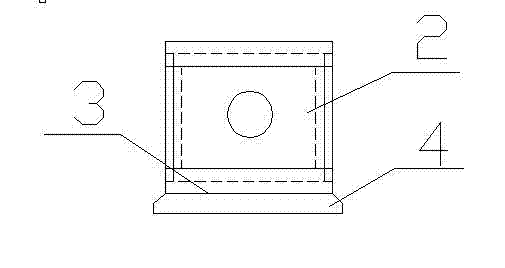

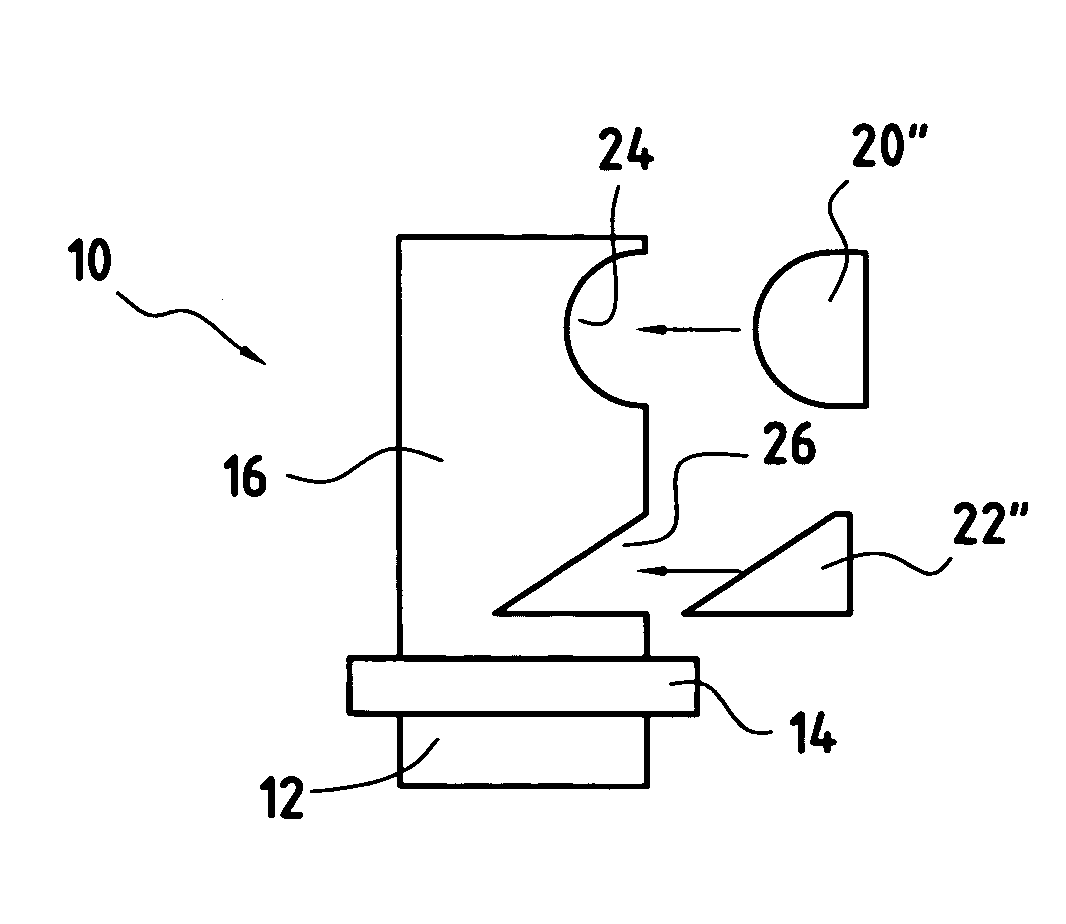

Connection between a dental implant and an abutment

InactiveUS6663388B1Increased functional reliabilityImprove reliabilityDental implantsAbutmentWeld seam

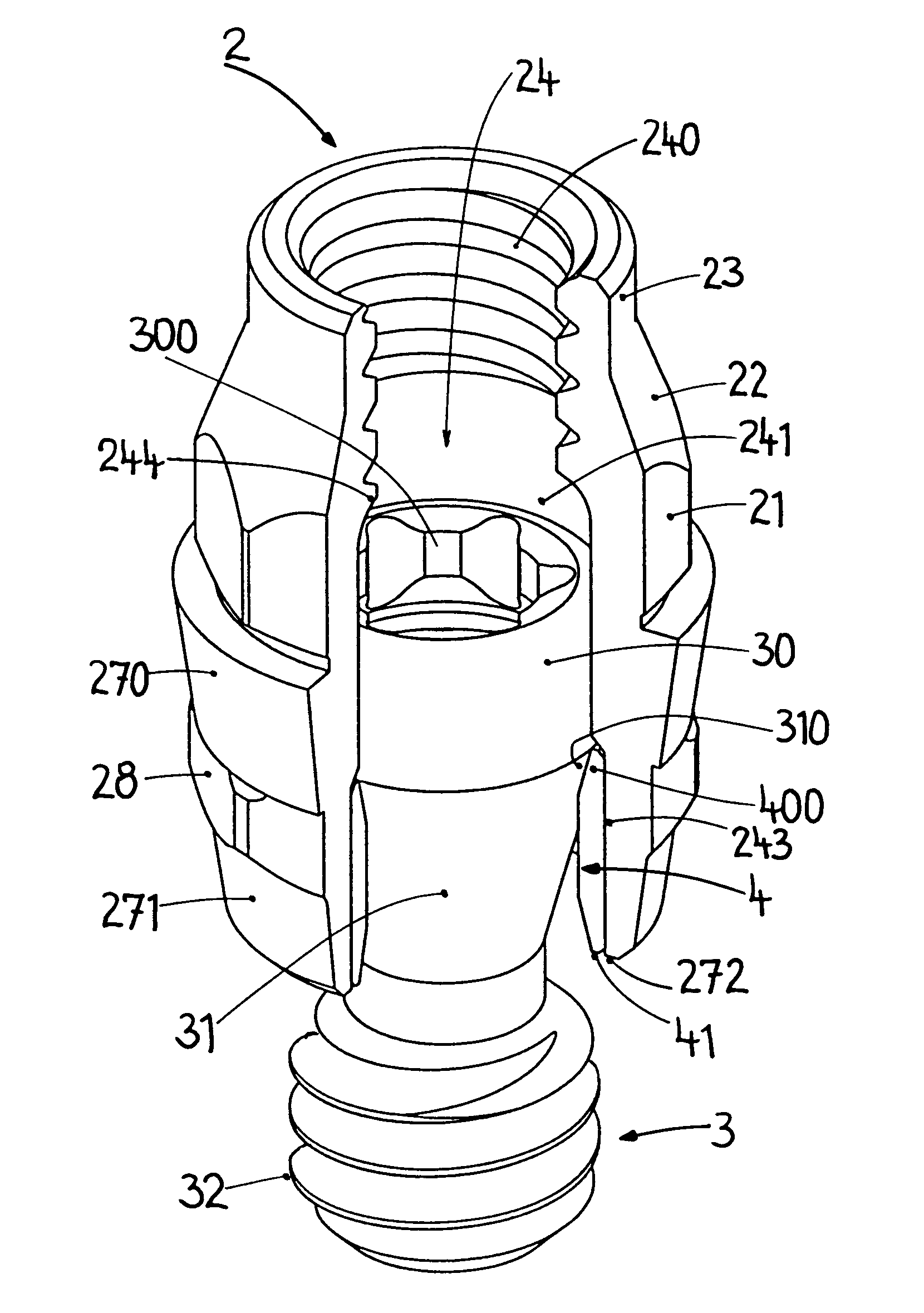

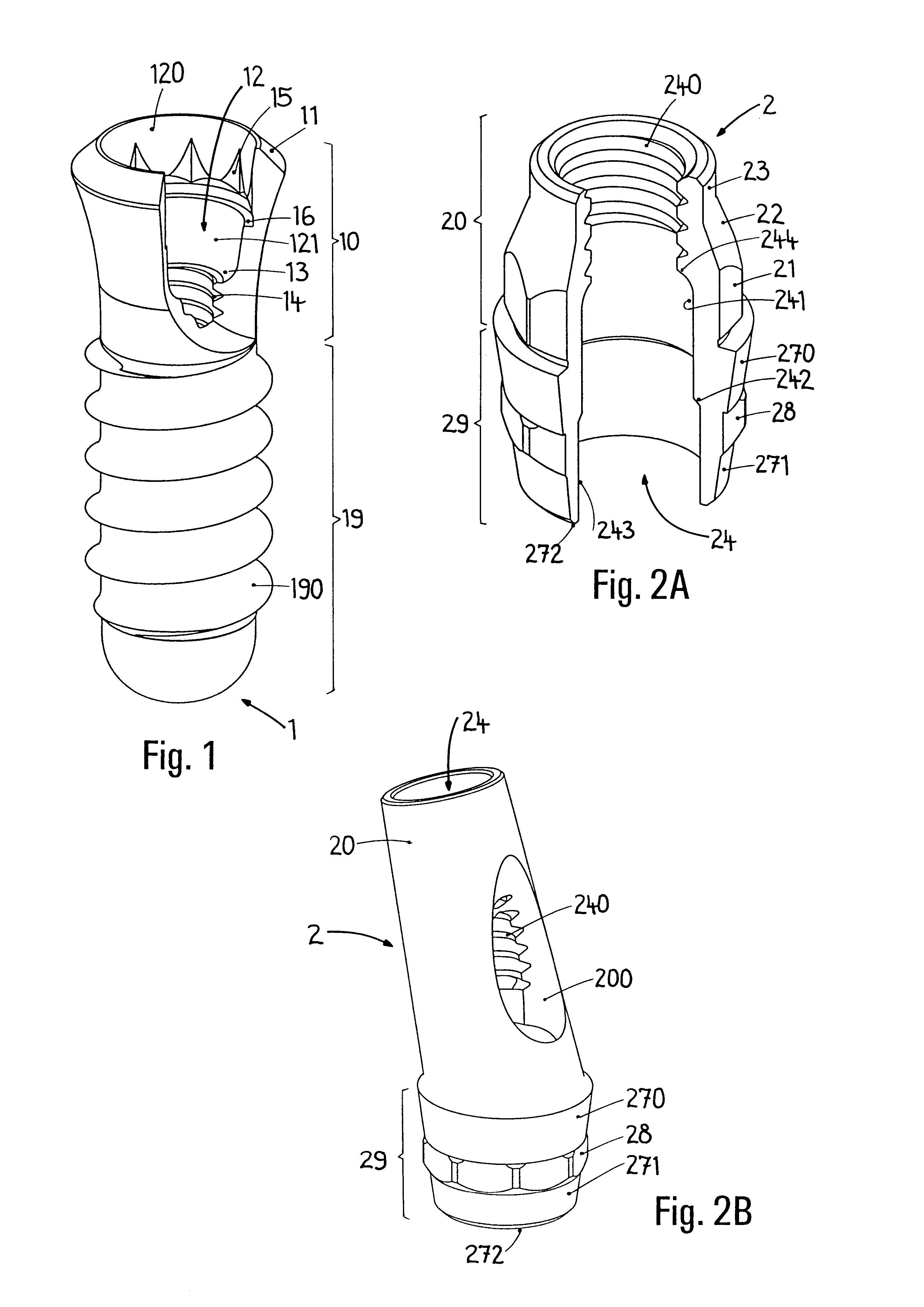

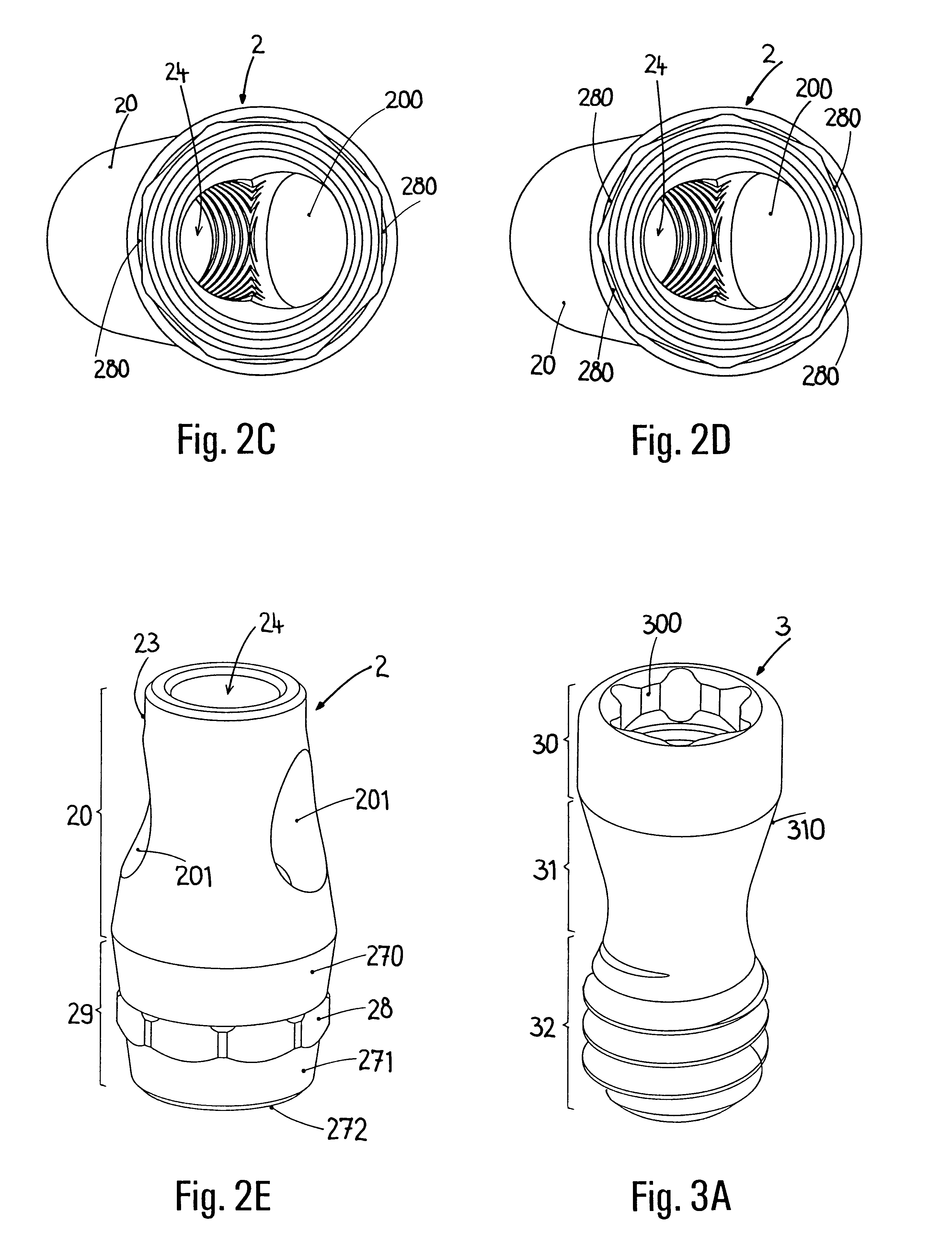

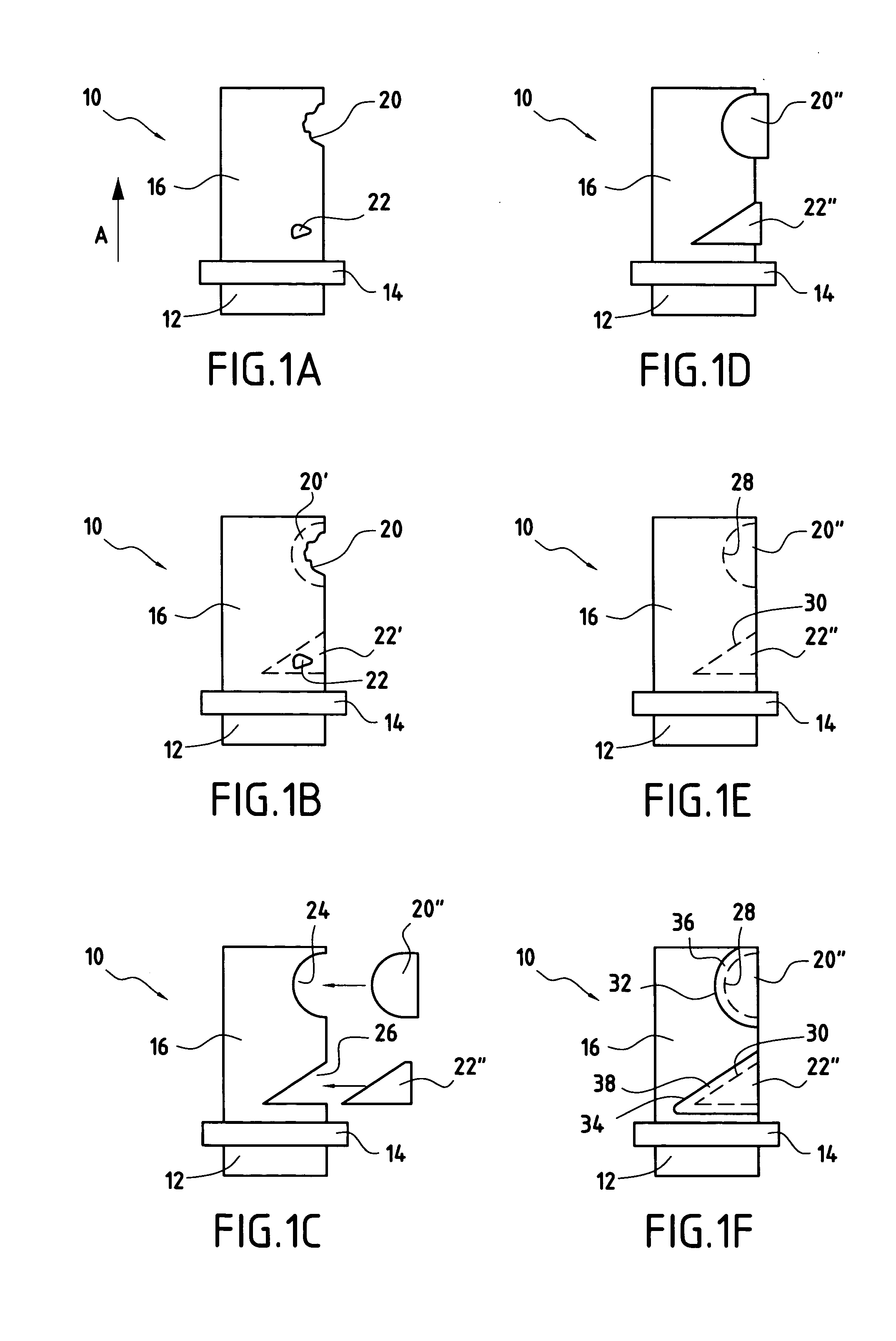

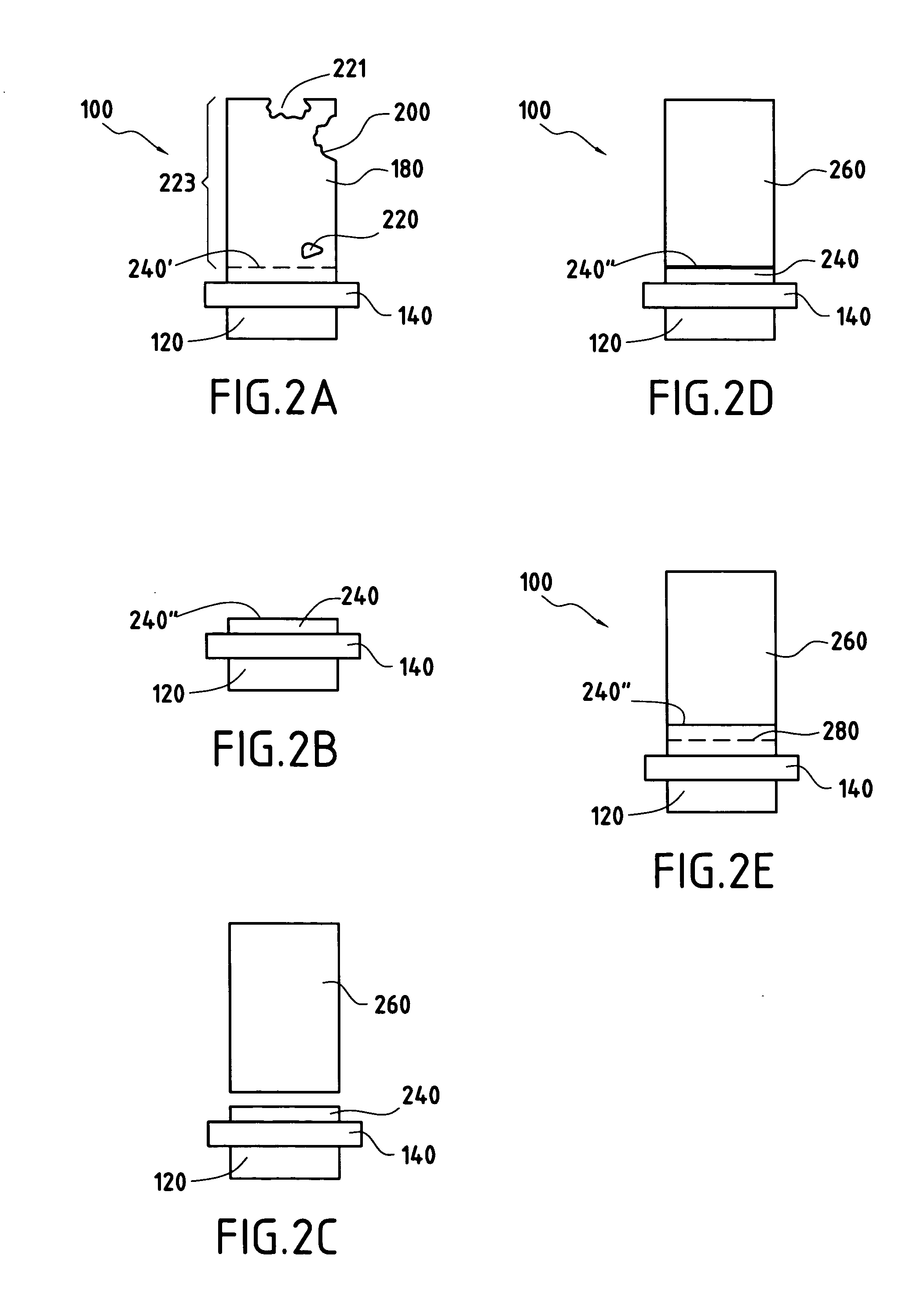

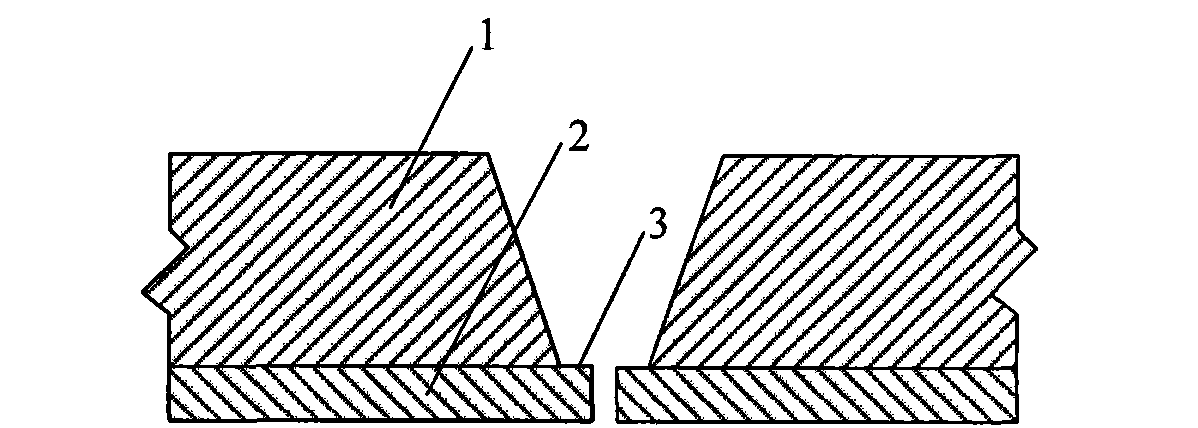

The invention relates to a connection between a known dental implant (1) and a straight or angular abutment (2) which can be established by means of a base screw (3) and a support ring (4). The support ring (4) is fixedly introduced into the inlet of the abutment (2) near the lower edge of same, preferably by welding or by bending over of the lower edge of the abutment (2). Before insertion of the support ring (4) the base screw (3) is introduced head first into the inlet (24) from the side of the root part of the abutment. The base screw is held in the abutment (2) by the support ring (4) on which the base screw (3) rests. The threaded shank (32) of the base screw (3) engages the inner thread (14) provided for in the implant (1) and draws the abutment (2) into the receiving hole (12) of the implant (1). An angled surface of the base screw (3) and a beveled surface of the support ring (4) contact each other so that the welding seam or bent over lower edge of the abutment (2) are relieved of axial stress. The above connection system is designed especially for implants (1) with a conical receiving hole (12) and internal polygon as well as abutments (2) having a complementary external conical shape and external polygon.

Owner:STRAUMANN HLDG AG

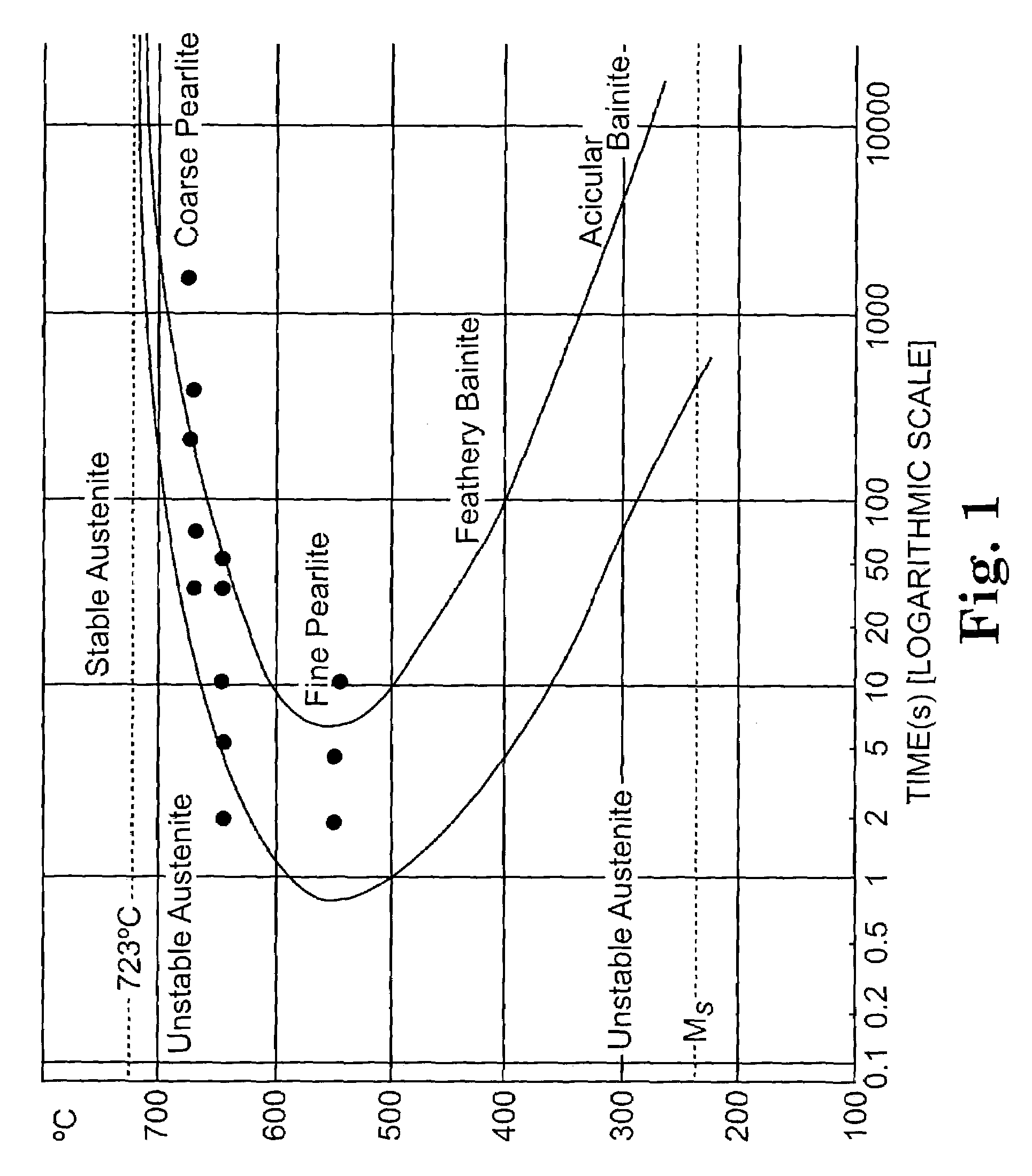

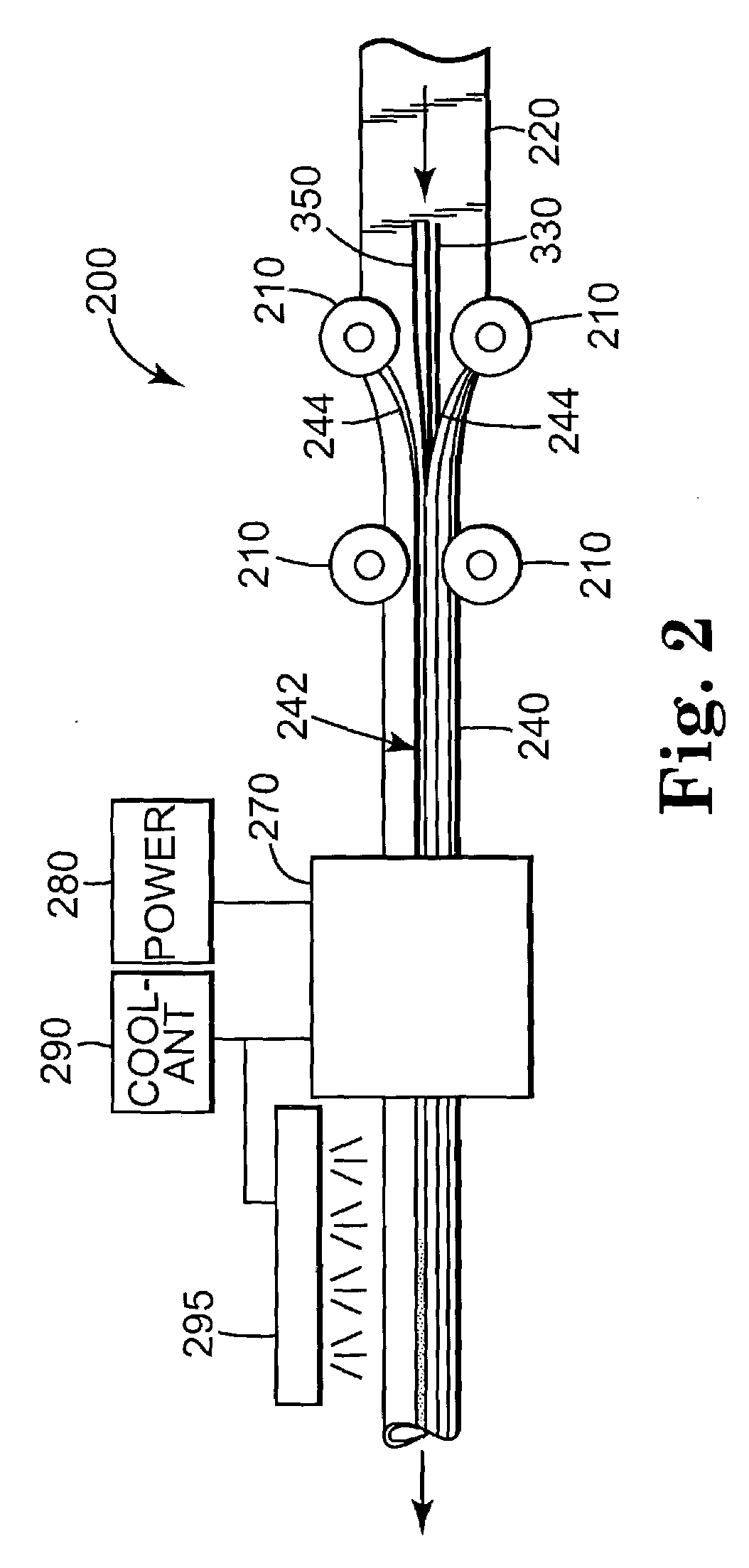

Seam-welded metal pipe and method of making the same without seam anneal

InactiveUS7032809B1Efficient processingEliminates annealing stepArc welding apparatusFurnace typesSufficient timeWeld seam

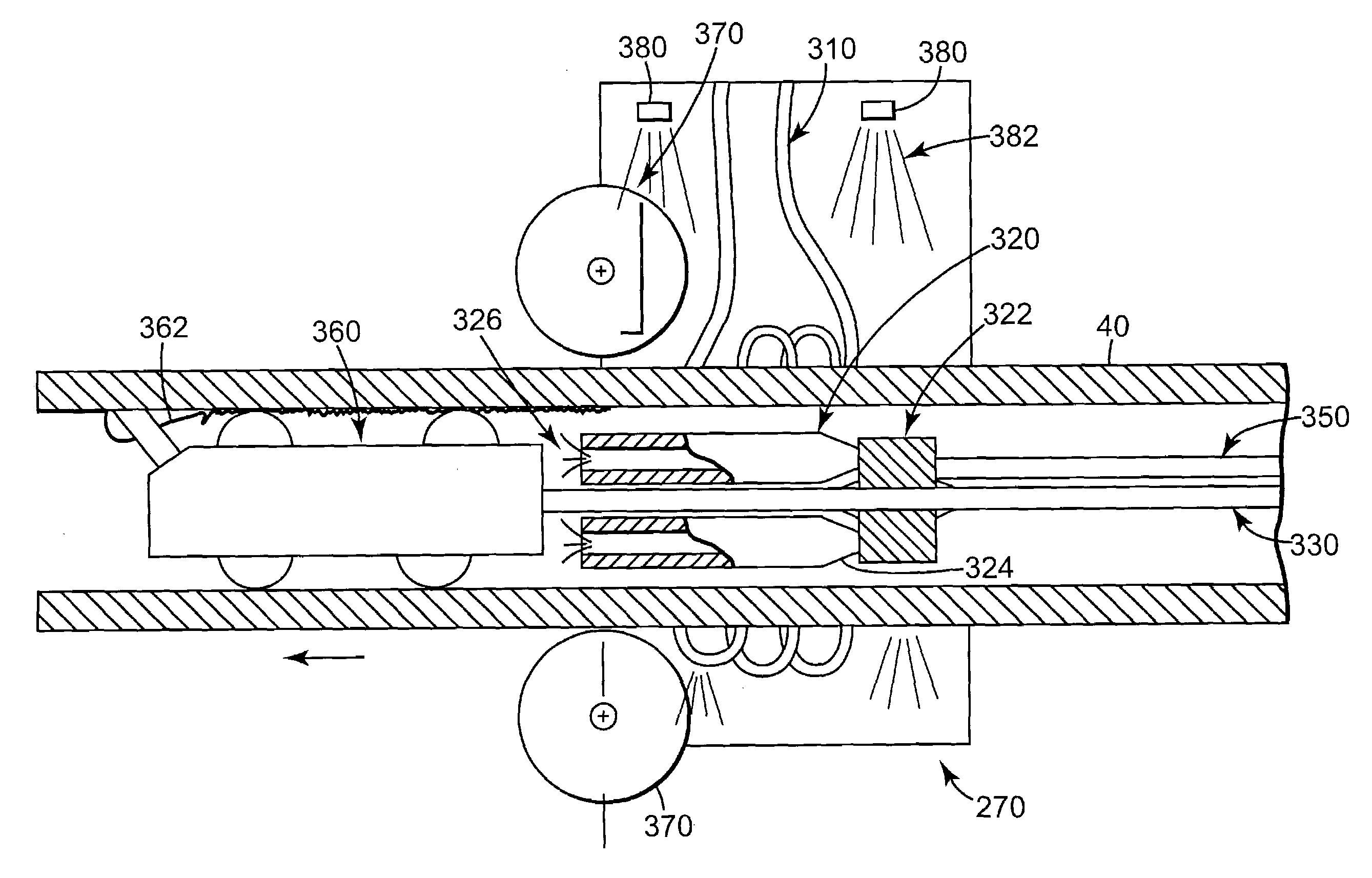

An apparatus and method for making a seam-welded steel pipe free of untempered martensite without seam anneal. The method includes selecting a steel containing a carbon concentration below a predetermined level, for example, 0.14% or 0.12% by weight. The method also includes flooding both outside and inside of the strip with a coolant while the weld seam is being formed, and continuing to immerse the welded strip for a sufficient time after the weld seam is formed to prevent the formation of untempered martensite. The apparatus includes a heater capable of heating the strip to a temperature sufficient to form a welded seam, a cooling module configured to supply a coolant to the welded seam both inside and outside of the strip as the weld seam is being formed, and another cooling module configured to immerse the welded strip in a coolant after the weld seam is formed for a sufficient length of time to prevent the formation of untempered martensite.

Owner:STEEL VENTURES

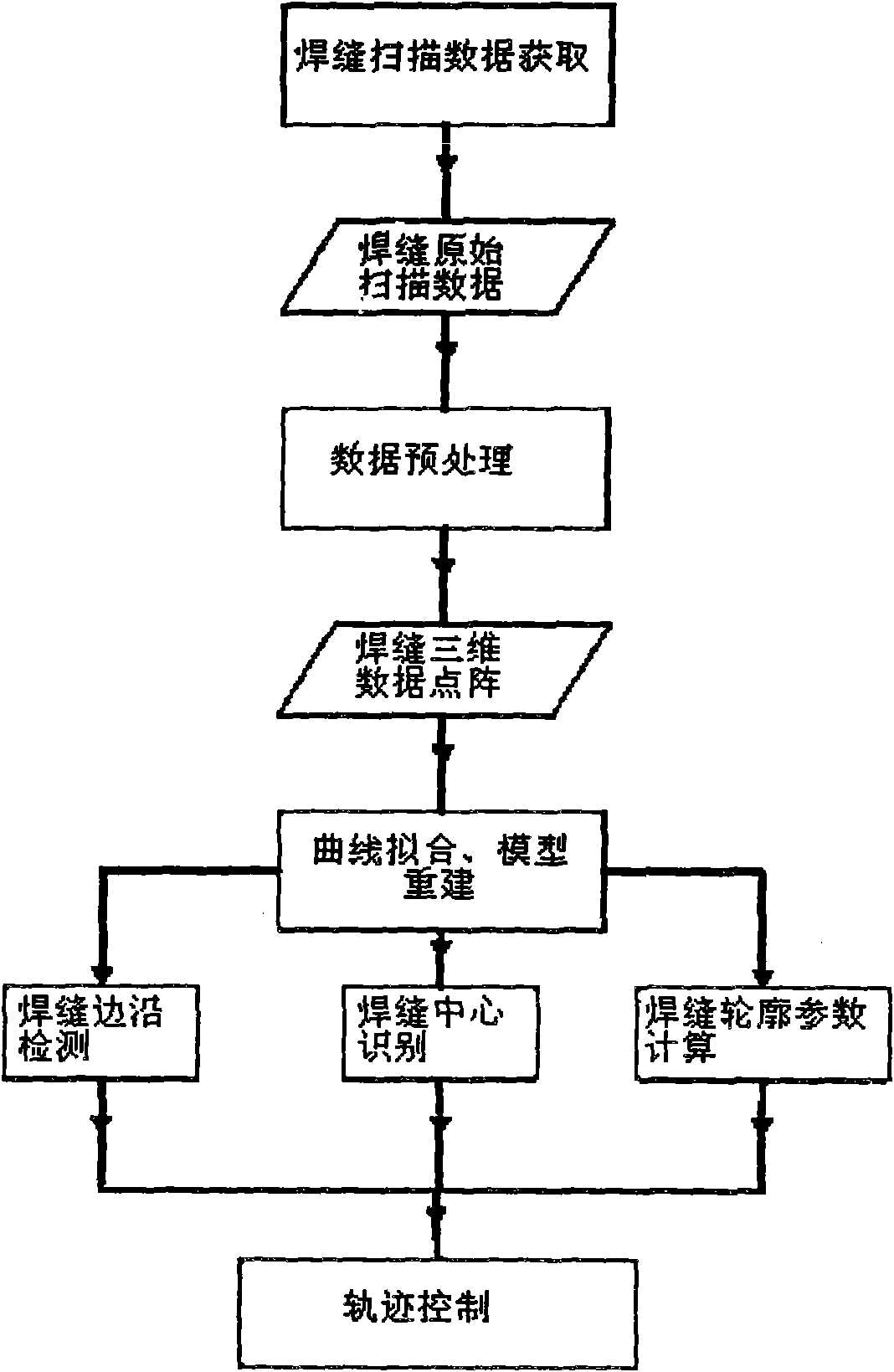

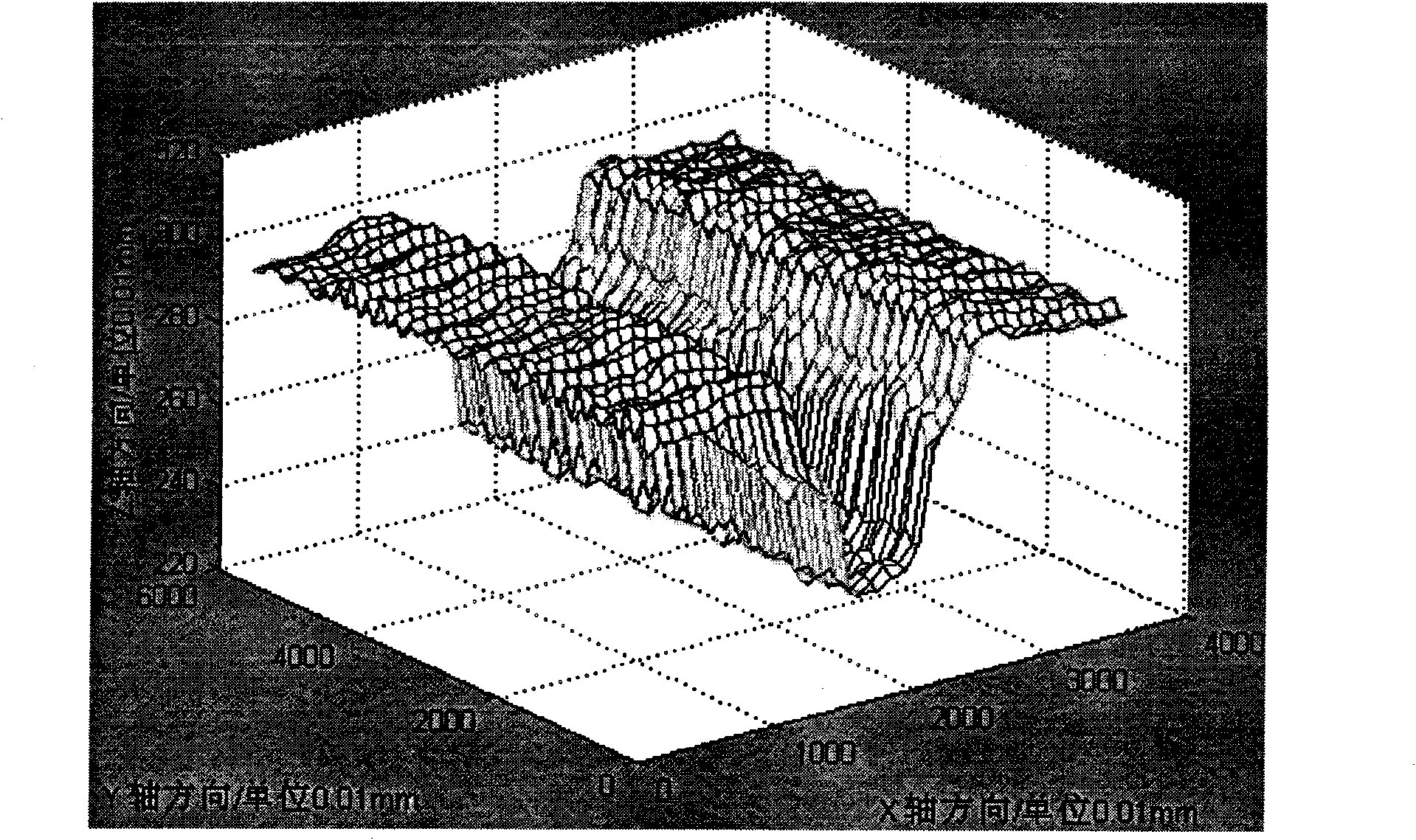

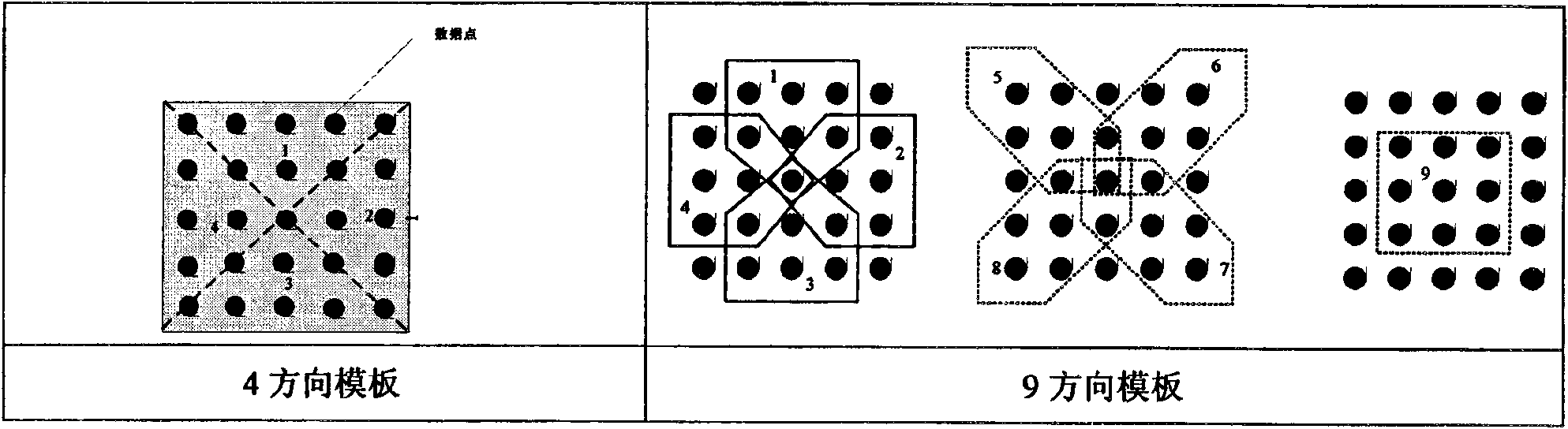

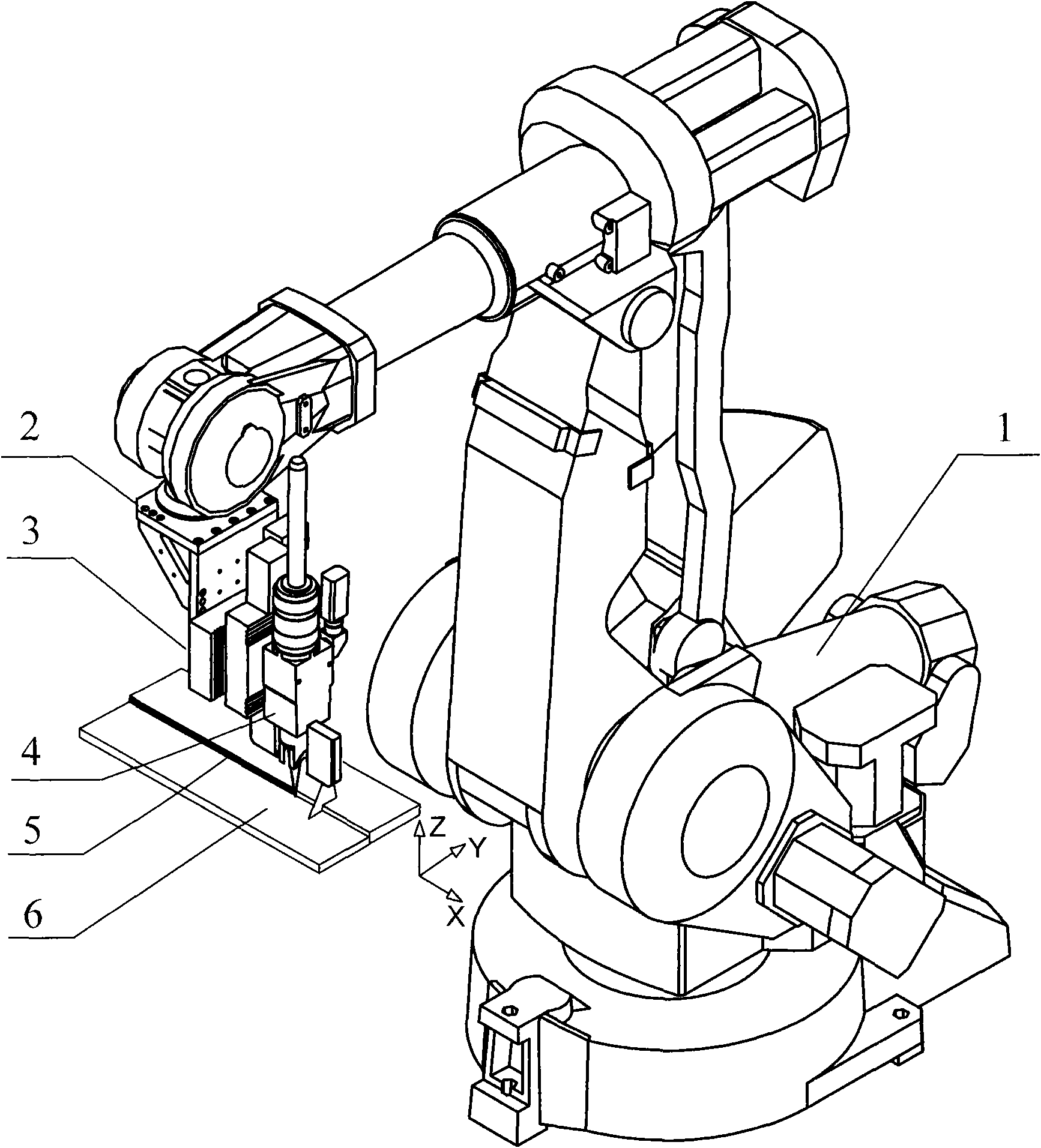

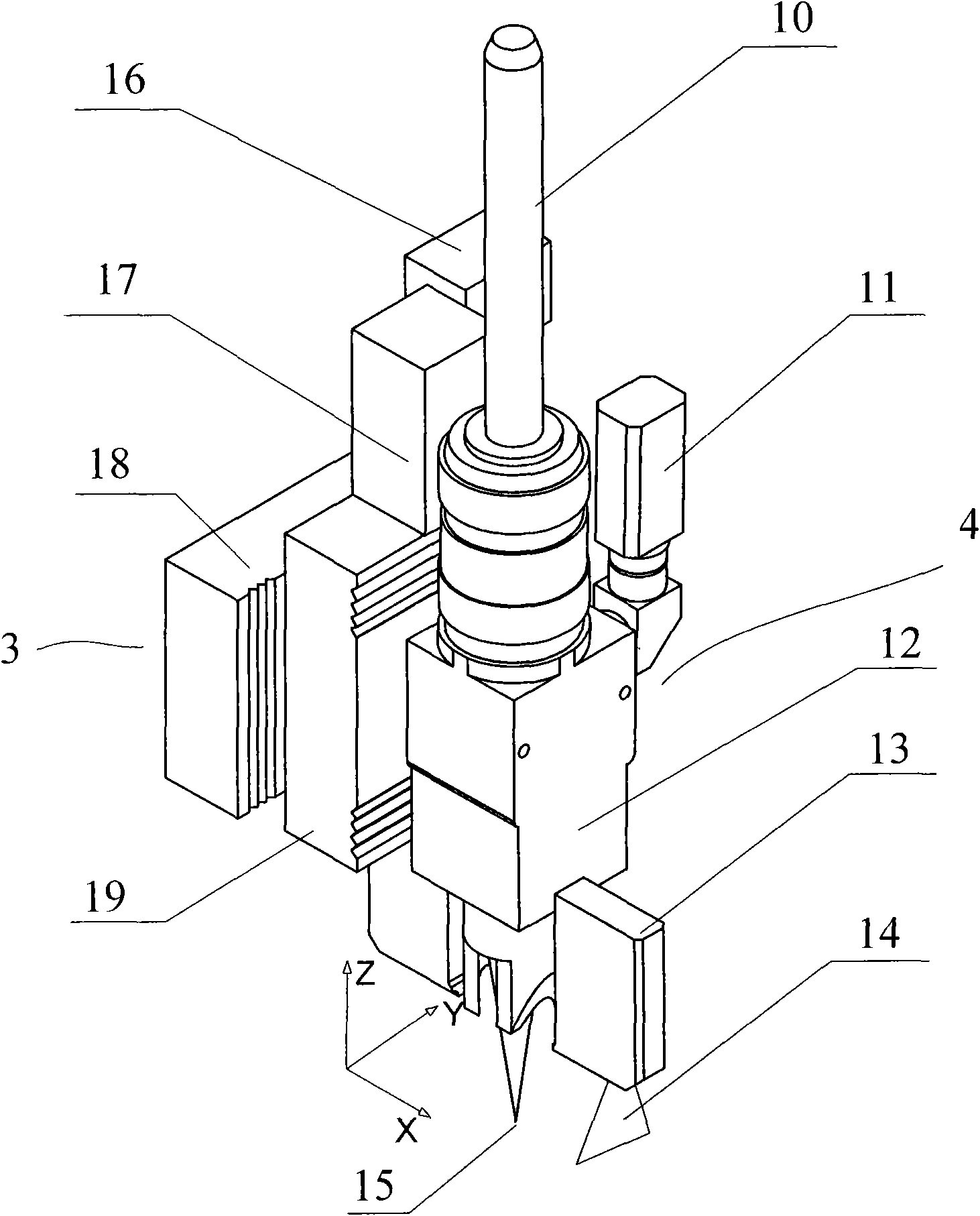

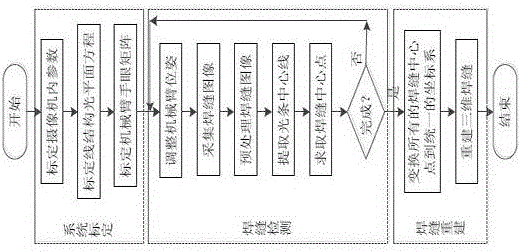

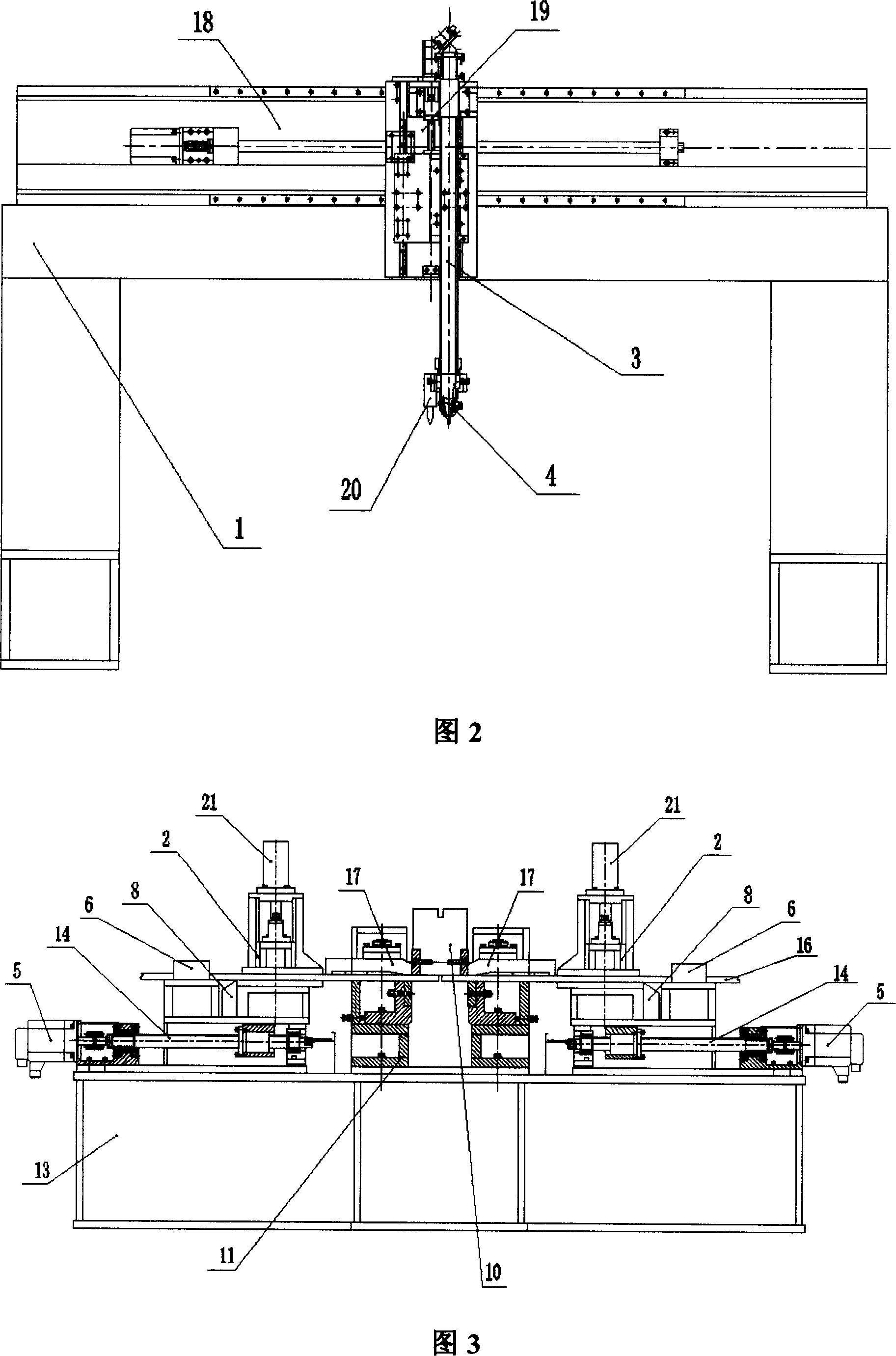

Welding track detection and control method of plate butt weld based on laser ranging

InactiveCN101559512ATo achieve the purpose of seam trackingTo achieve the purpose of trackingArc welding apparatusNumerical controlLaser rangingField tests

The invention relates to a welding track detection and control method of plate butt weld based on laser ranging, including the following steps: A. track detection is carried out; B. track identification and extraction are carried out; C. track control is carried out; D. the relative position relation between a welding gun and a welding seam is adjusted at last by performing mechanism actions. In the invention, the information of welding seam profile is obtained by transverse scanning of a laser sensor, and welding seam is rebuilt after effective wave filtering treatment to realize three-dimensional detection of the welding seam; simultaneously, the welding track curve is obtained by fit while detecting welding seam by using dynamic B spline fit algorithm, and the track control is carried out in combination with constant speed B spline track interpolation algorithm, thereby fundamentally solving the problem of track detection and control in automatic welding of plate butt weld. By using the method in the invention, the field test welding has welding profile identification precision of 0.15mm and welding track identification precision of 0.2mm, and the welding speed is more than four times of common manual welding.

Owner:SHANDONG UNIV

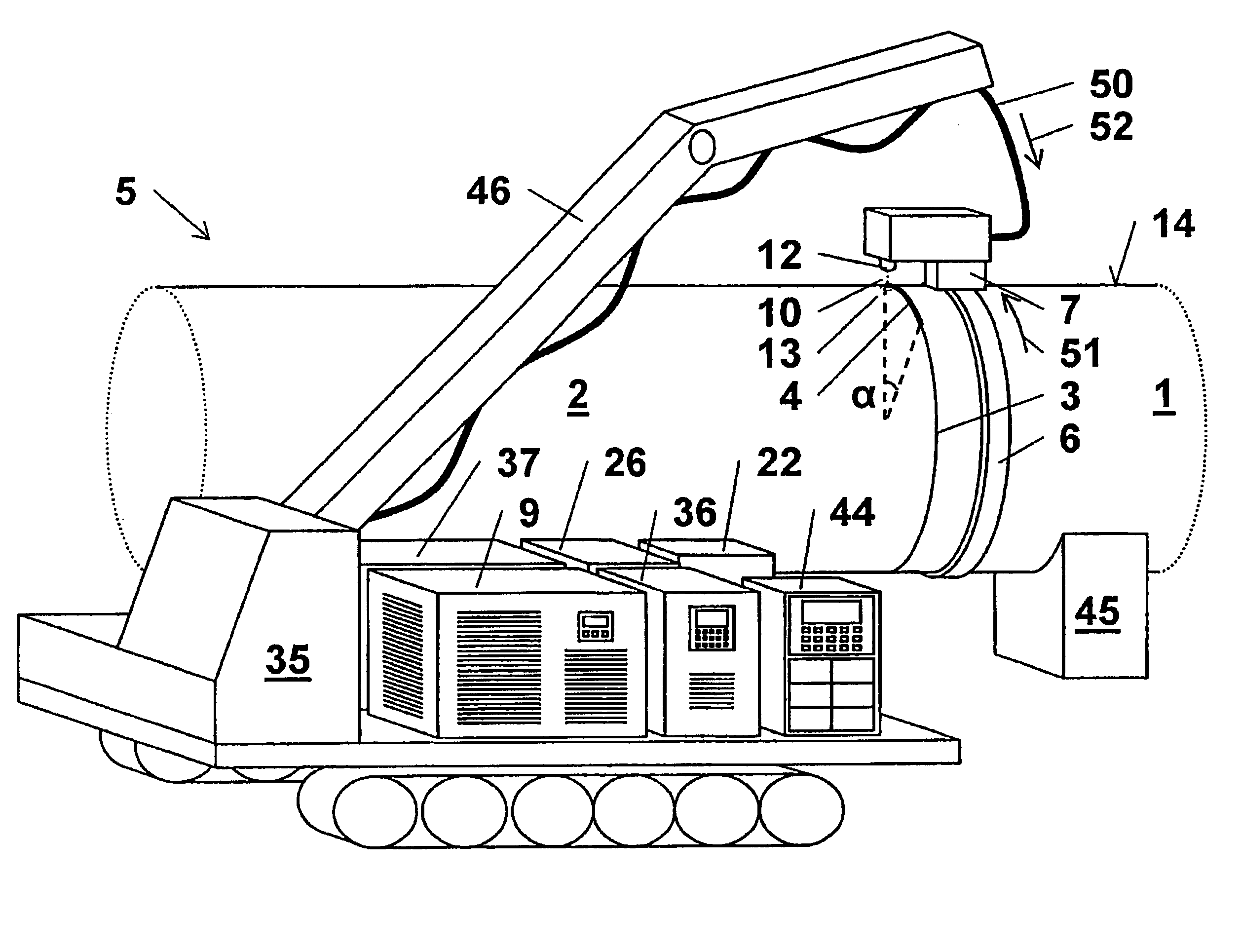

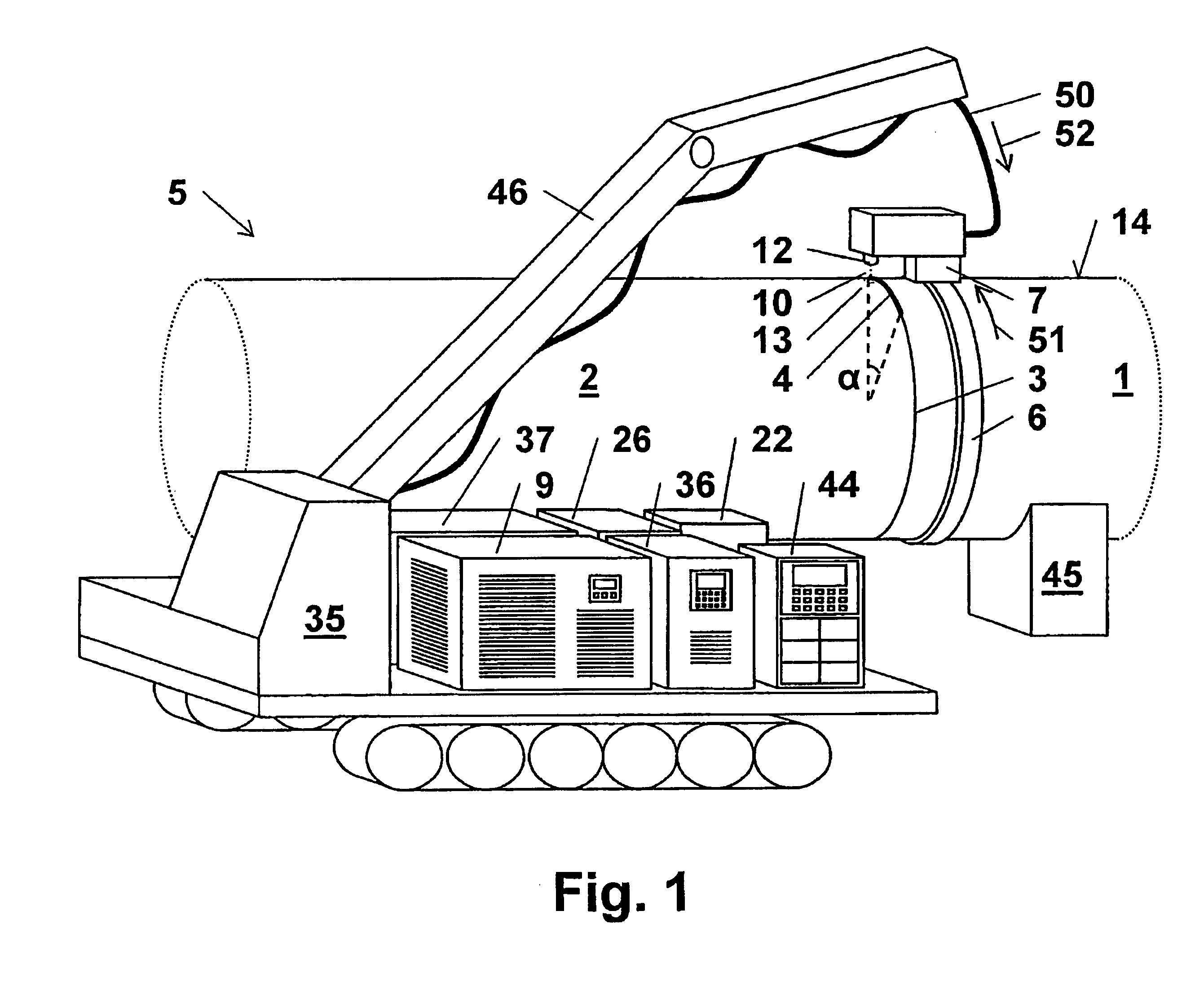

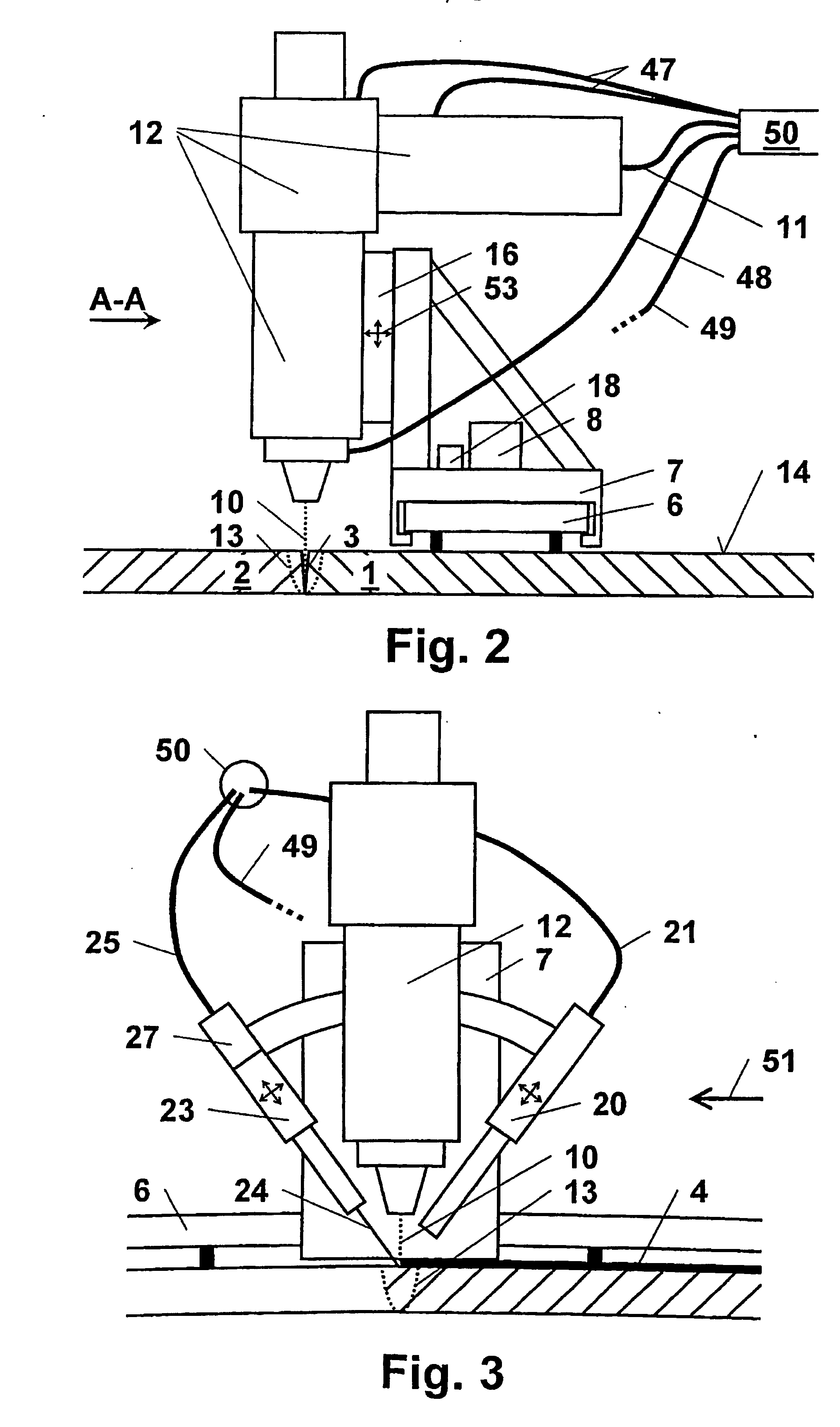

Orbital welding device for pipeline construction

InactiveUS20070119829A1Increase production speedArc welding apparatusLaser beam welding apparatusLight guideBeam source

The invention relates to an orbital welding device for mobile use in order to join a first pipe (1) and a second pipe end (2) along a circumferential joint (3) by at least one weld seam (4), particularly for producing a pipeline (5) to be placed on land. The inventive device includes a guide ring (6), which can be oriented toward the first pipe end (1) and the circumferential joint (3), and an orbital carriage (7) that can be motor-displaced along the guide ring (6) via an advancing device (8). On the orbital carriage (7), a laser welding head (12) for directing a laser beam (10) into a laser welding zone (13) is mounted in a manner that enables it to be oriented toward the circumferential joint (3) whereby enabling the production of the weld seam (4) along the circumferential joint (3) by displacing the orbital carriage (7). The laser beam (10) is produced by a high-power fiber laser beam source (9) located, in particular, on a mobile transport vehicle (35) while being situated at a distance from the orbital carriage (7), is guided by light guide (11) passing through a tube bundle (50) to the orbital carriage (7) and then supplied to the welding head (12). A significant advantage of the invention resides in the fact that the joining of two pipe ends by only one single welding process during a short period of time is made possible in the field with autonomous operation.

Owner:VIETZ

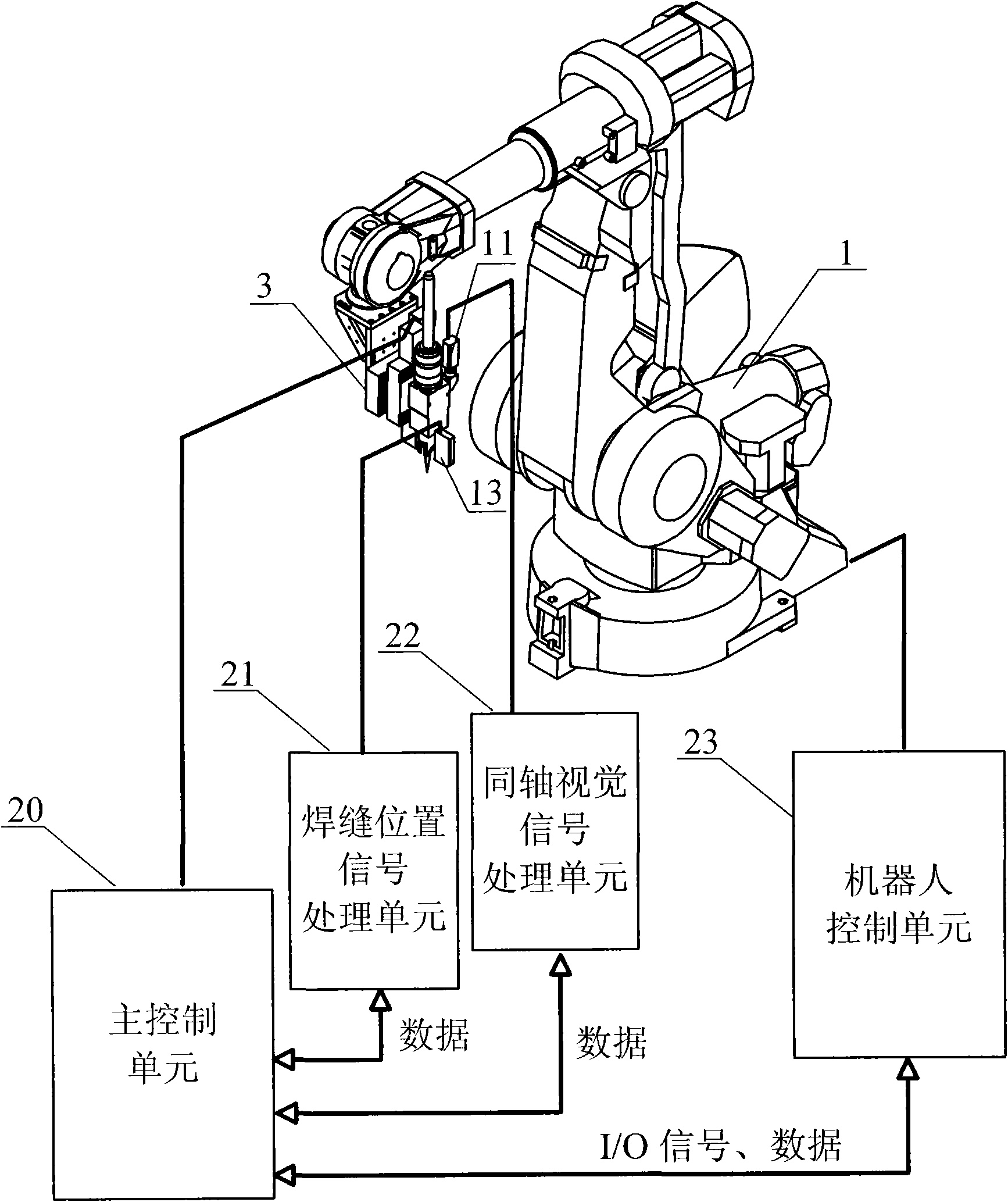

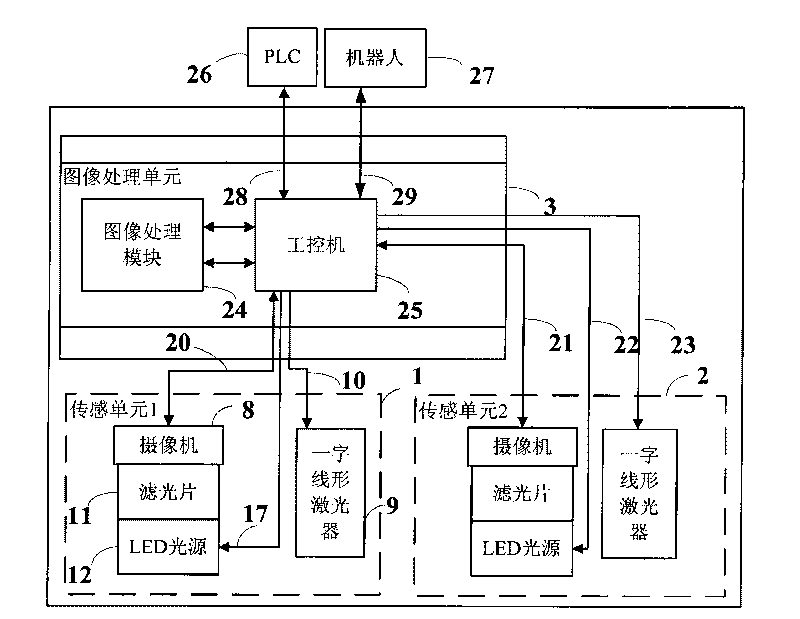

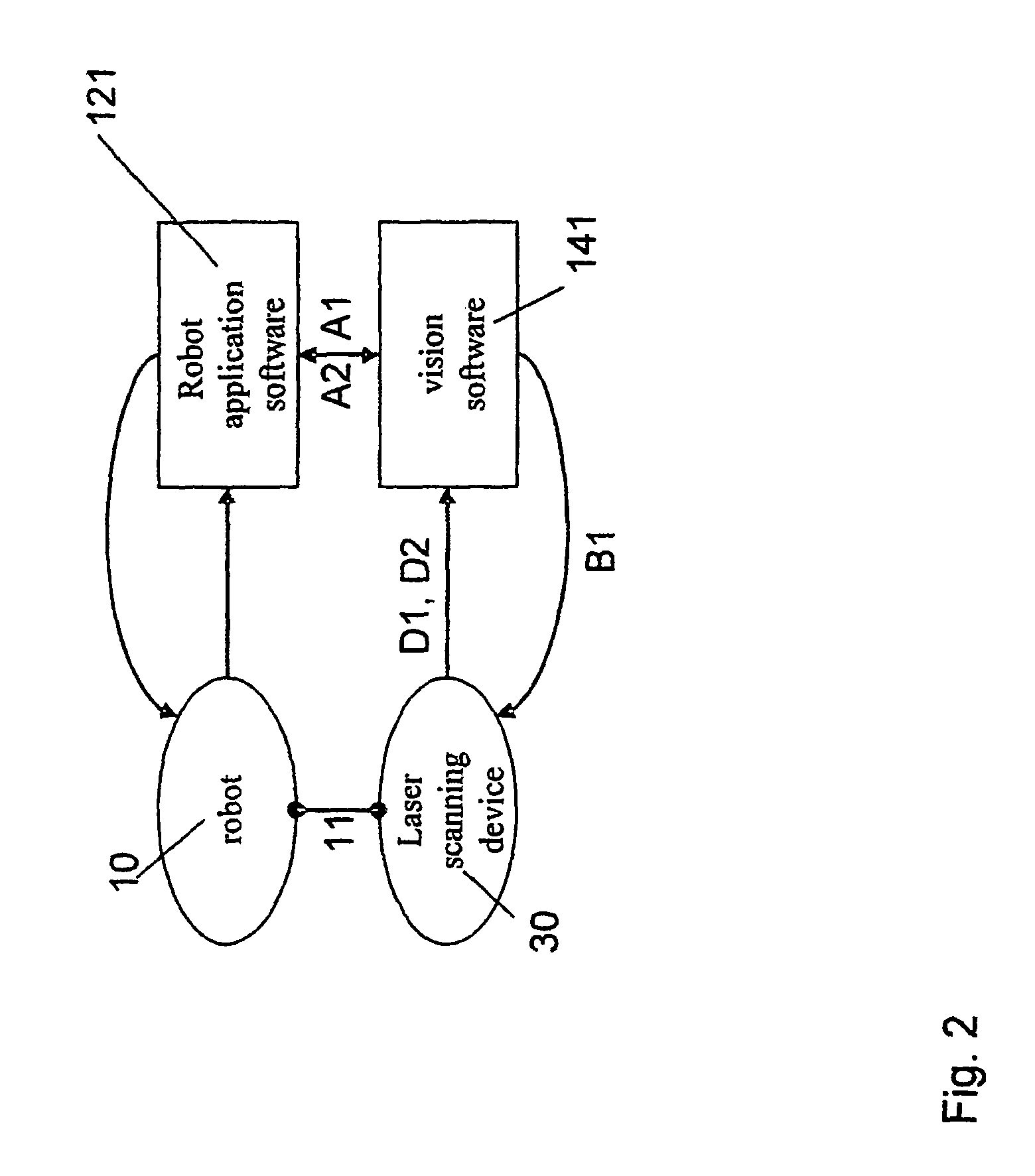

Device and method for making robot track given route at high accuracy

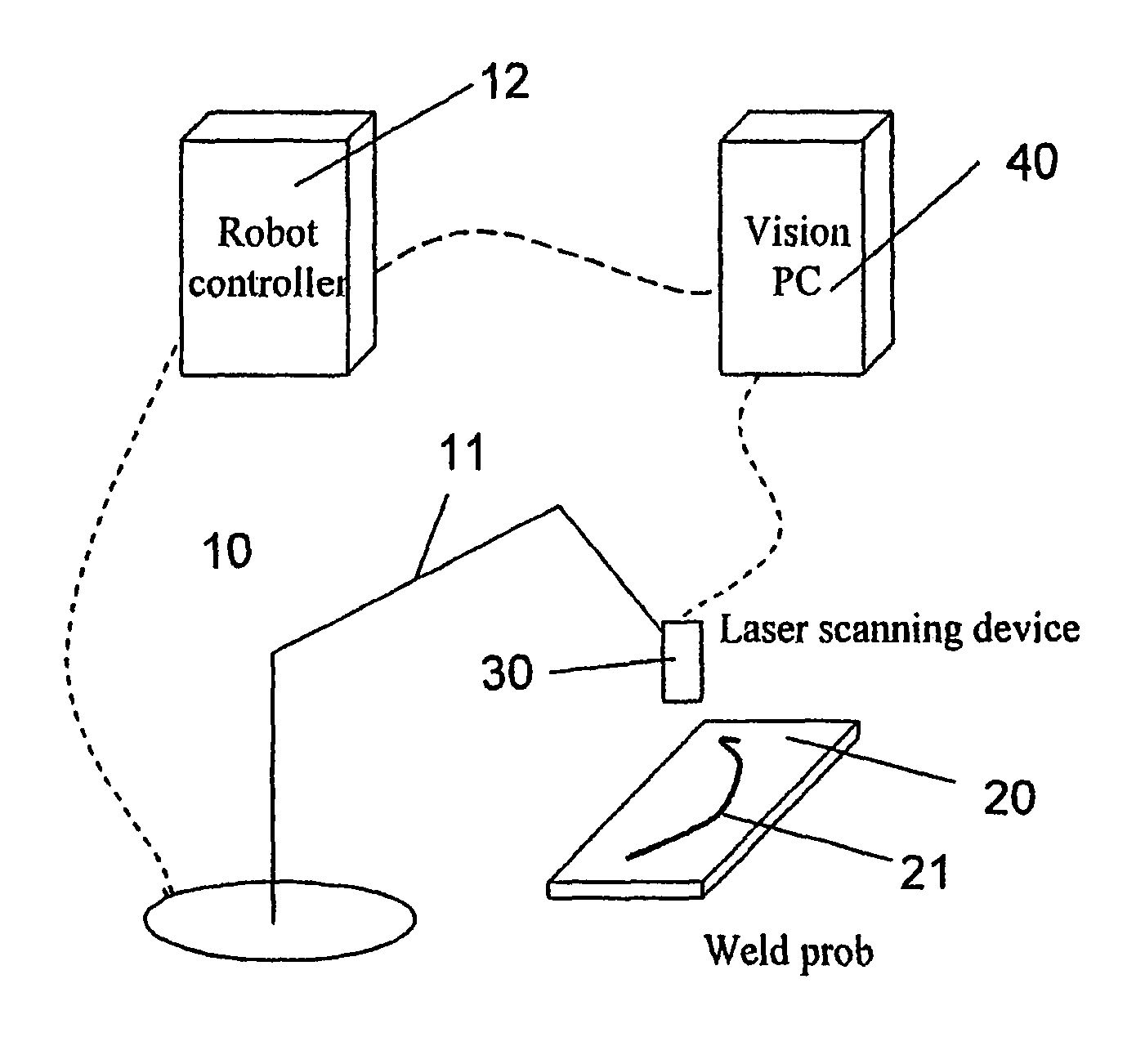

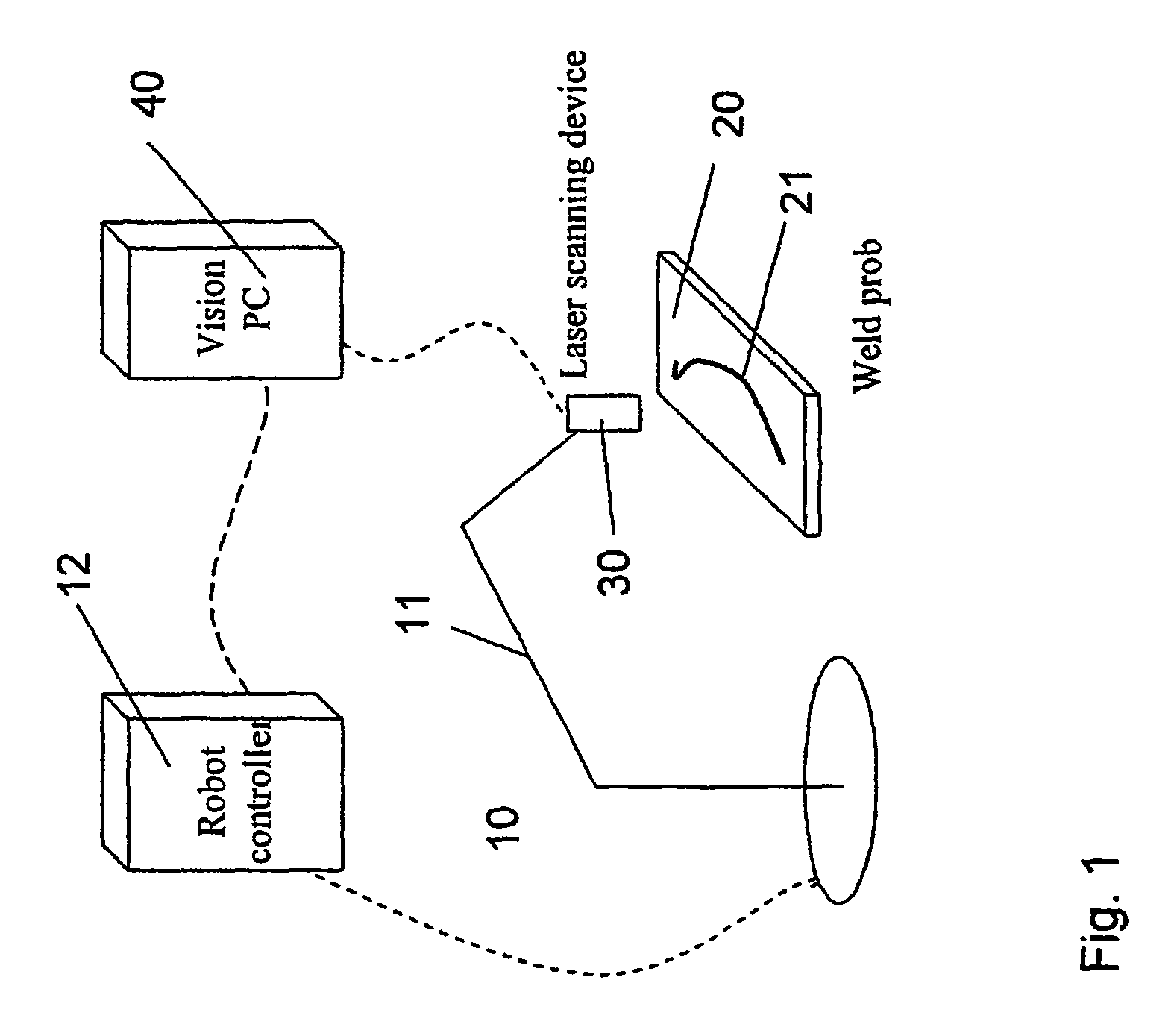

InactiveCN101623867ALow costGuaranteed to workProgramme controlProgramme-controlled manipulatorRobotic systemsThree stage

The invention relates to a device and a method for making a robot track a given route at high accuracy, in particular to a robot processing system for performing route tracking and deviation compensation by comprehensively utilizing a coaxial vision sensing system and a welding seam position measurement sensing system, and a route tracking method, which are used for high-accuracy processing of laser welding and the like. The implementation process is divided into three stages; the first two stages comprehensively utilize welding seam position measurement information and coaxial vision measurement information to calculate the deviation between the front welding seam position and the central point of a robot tool and a welding seam so as to obtain the compensation data of the track deviation of the central point of the robot tool and the welding seam position reference data; and the stage of actual welding utilizes the welding seam position measurement information and the welding seam position reference data to perform tracking and compensation control, a position correcting device corrects the motion of a robot system so that the central point of the robot tool moves forwards continuously along the given route, and the deviation of the given route is smaller than the route repeat accuracy of the robot. The device and the method can be widely applied to various occasions required to improve the motion path accuracy of the robot.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

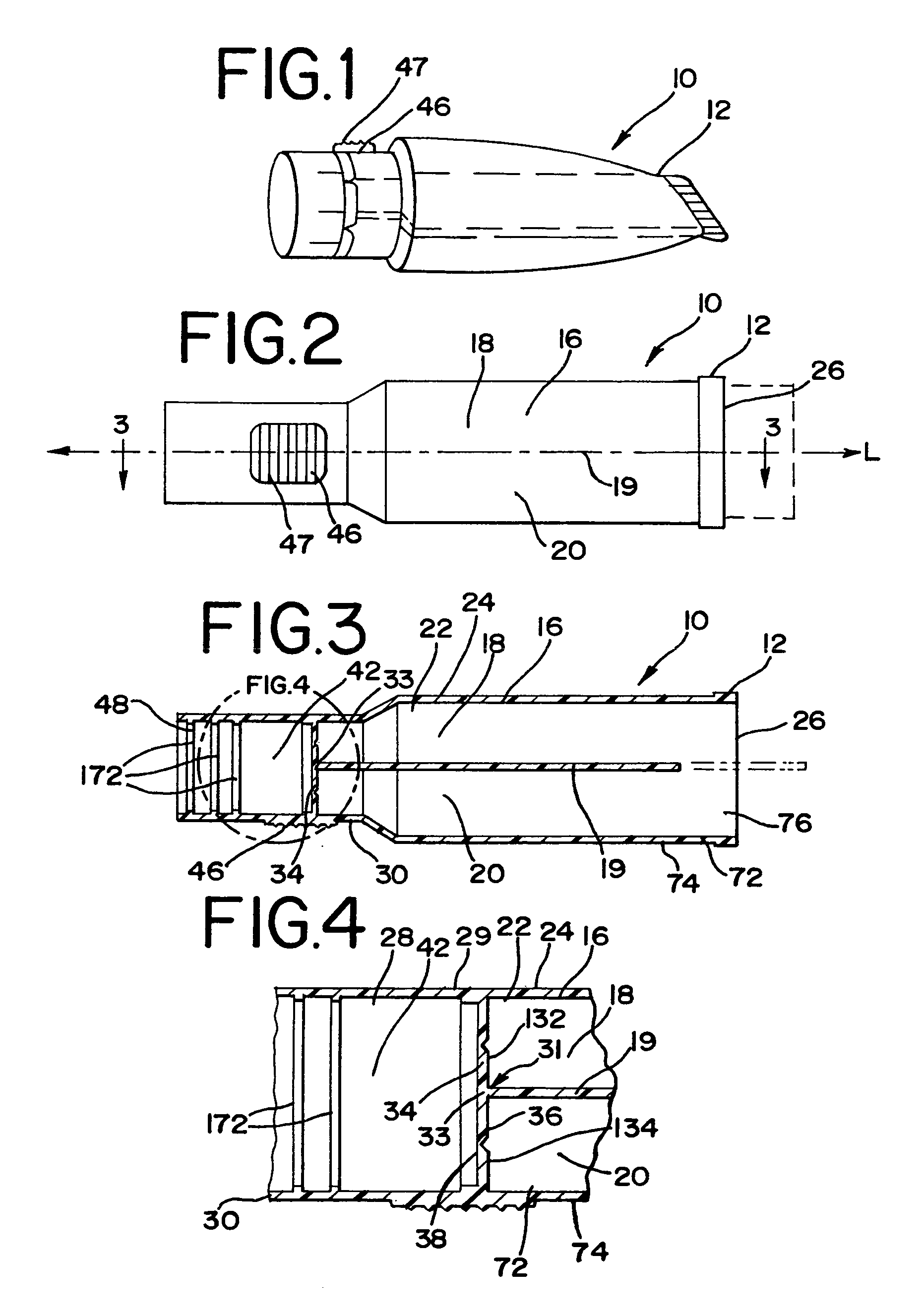

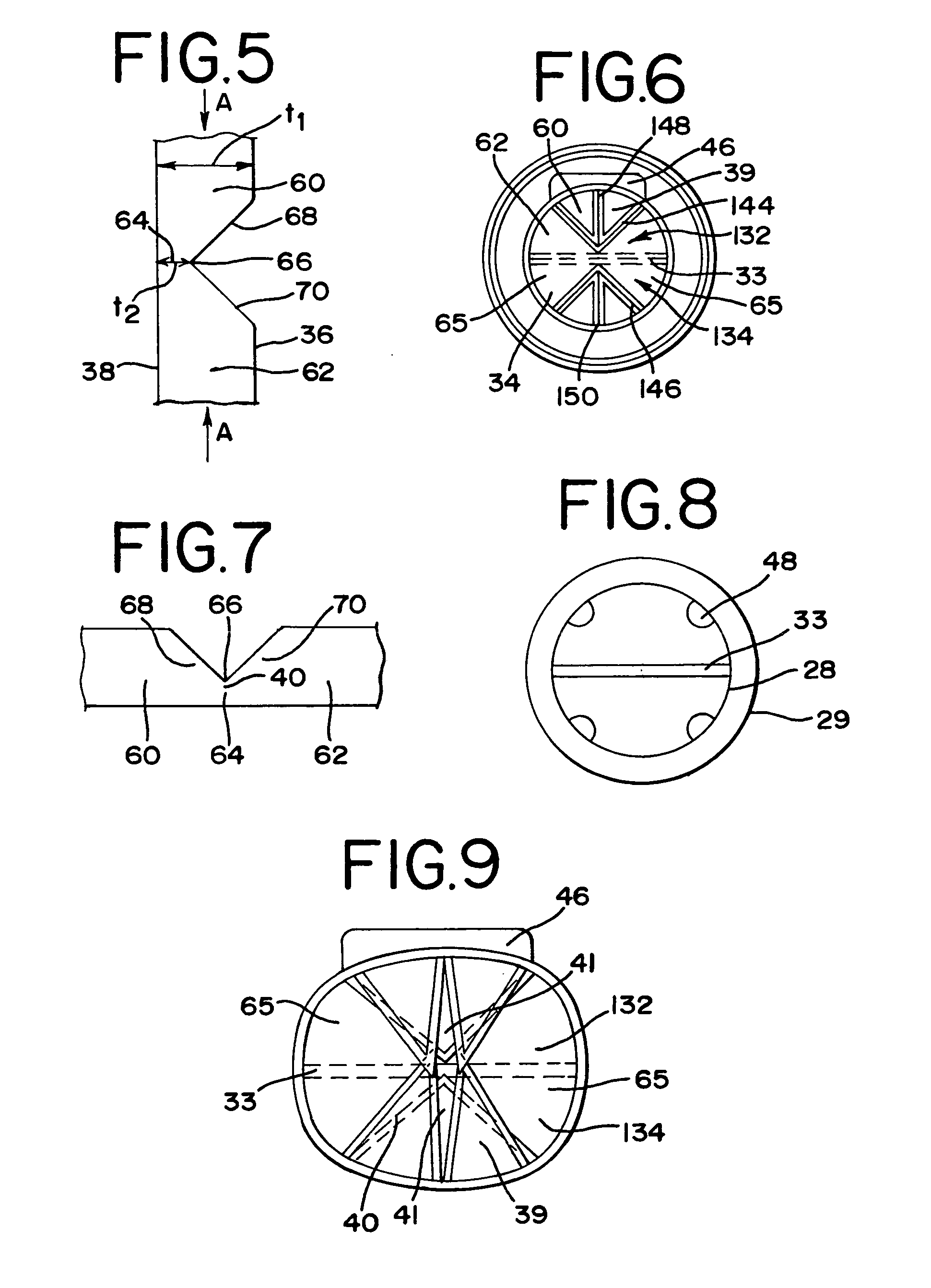

Multi-chambered dispenser and process

A dispenser (10) for dispensing flowable materials has a container assembly (12) having a dividing wall (19). A first chamber (18) and a second chamber (20) are defined in the container assembly (12). The first chamber (18) is configured to contain a first flowable material (M1) (140) and the second chamber (20) is configured to contain a second flowable material (M2) (142). A membrane (34) is positioned in the container and cooperates with the dividing wall (19) to enclose the first and second chambers (18, 20). The membrane (34) has a first section (132) having a first weld seam (148) and a second section (134) having a second weld seam (150). The first section (132) is separated from the second section (134) by a non-rupturable member (33). Rupture of the membrane (34) allows the flowable materials into a third chamber (42) in which the flowable materials mix to form a mixture, and from which the mixture is dispensed.

Owner:JAMES ALEXANDER CORP

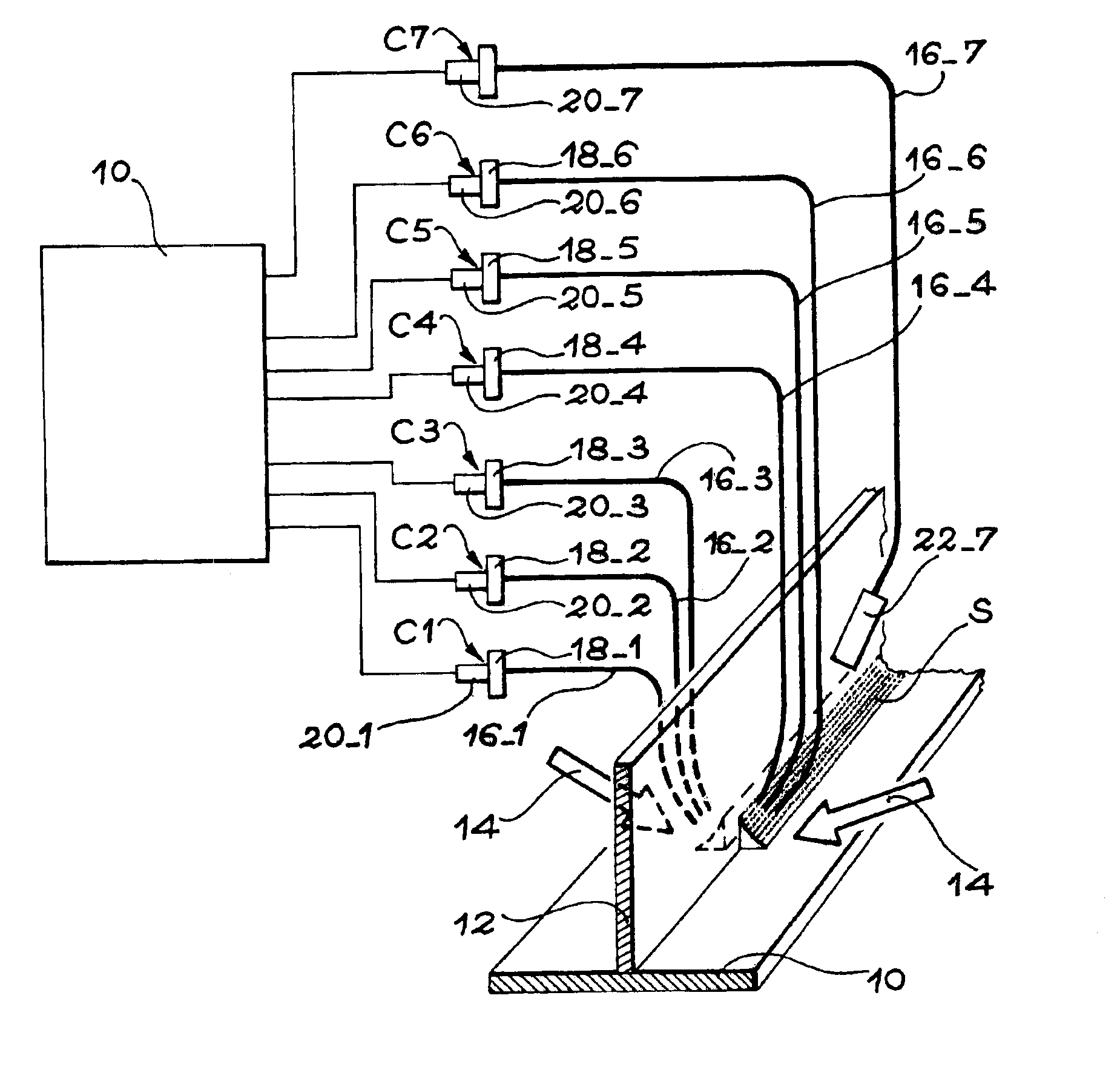

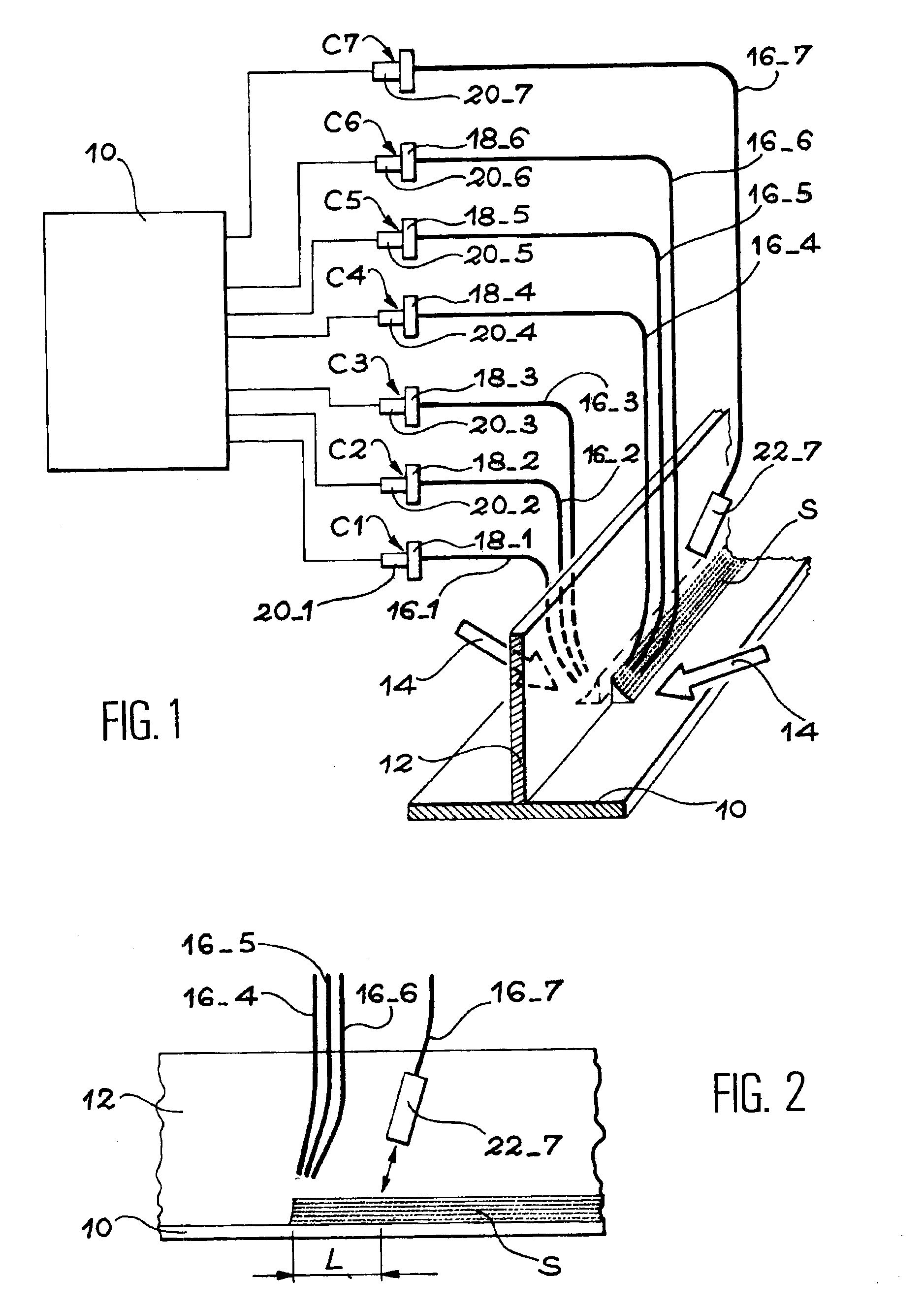

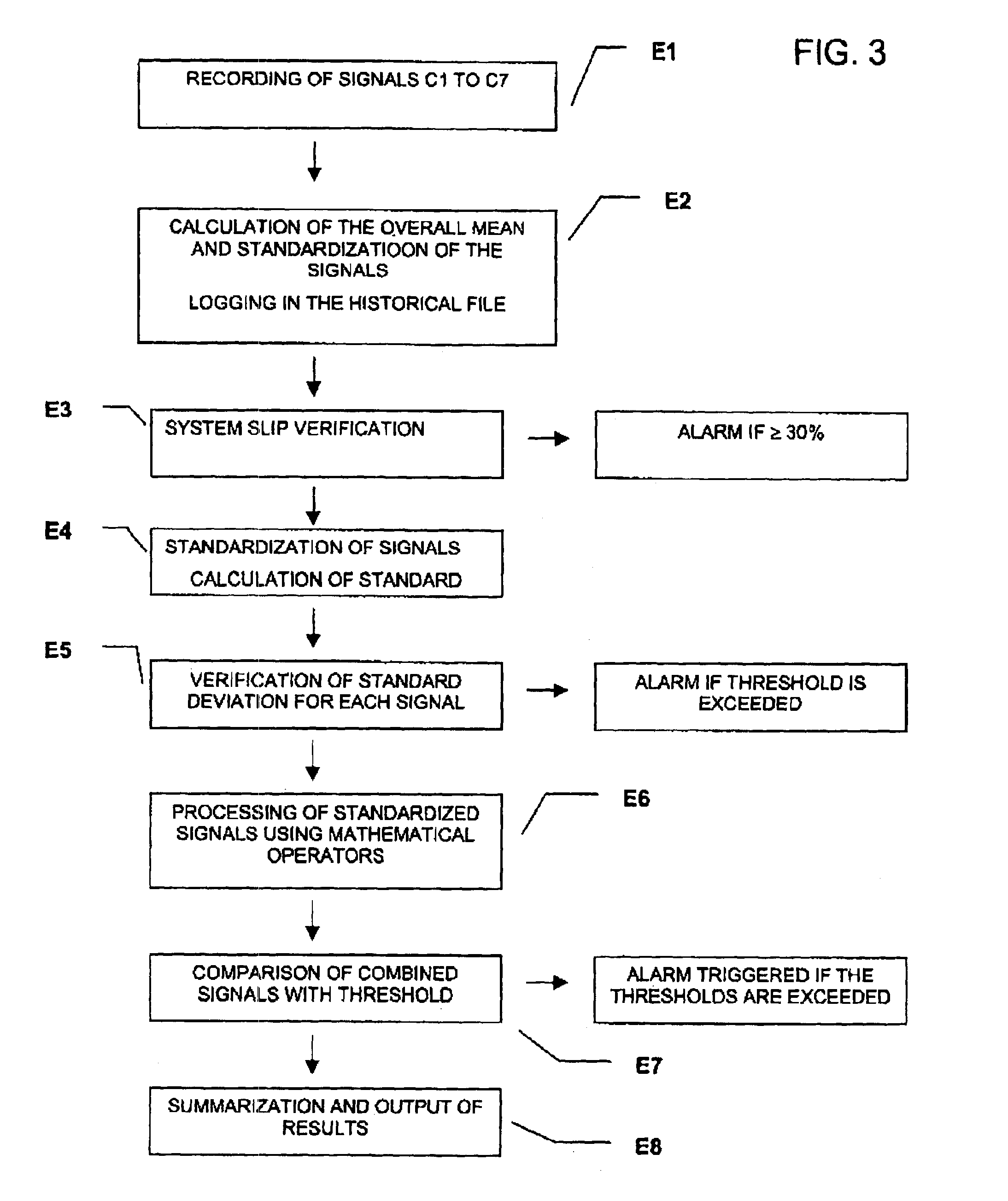

Method for detecting and identifying defects in a laser beam weld seam

A method for detection and identification of defects in a weld seam created using a laser beam.According to this method, at least two measurement signals are acquired in real time delivered by optical sensors (C1 to C6) detecting variations in luminous intensity of the plasma formed by the laser beam (14). These signals are then combined by applying a mathematical operation. The combined signal obtained is then compared to a predetermined threshold. Depending on the result of this comparison, a determination is made of the presence or absence of a defect corresponding to the operator used.

Owner:AEROSPATIALE MATRA

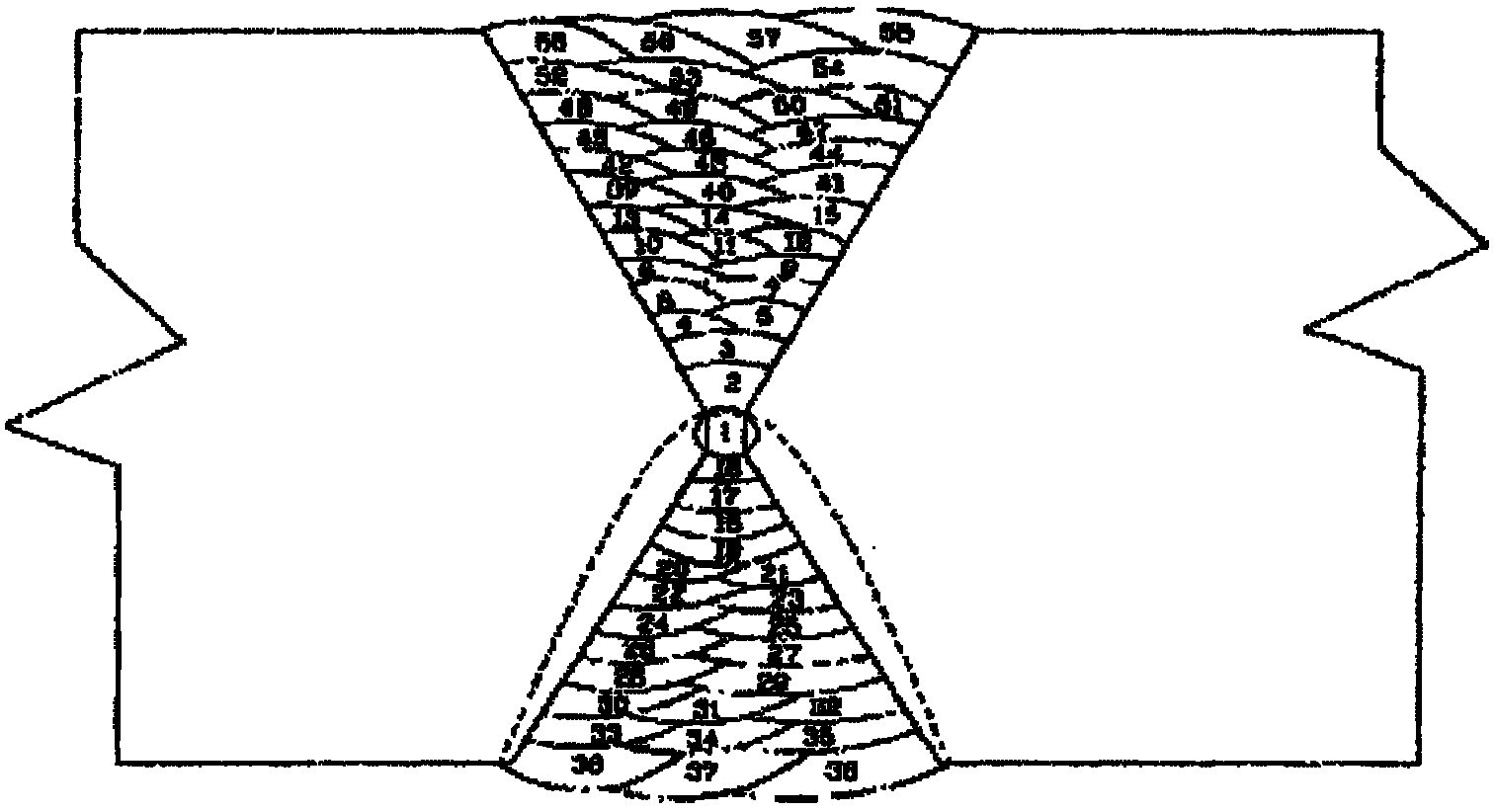

Device for ultrasonic weld seam testing of longitudinally welded pipes for longitudinal and transversal errors

InactiveUS6931931B2Simple adaptationSimplify workAnalysing solids using sonic/ultrasonic/infrasonic wavesMetal working apparatusEngineeringWeld seam

A device for ultrasonic weld seam testing of longitudinally includes two testing carriages swingably suspended and moveable on the pipe surface to the right and left of the weld seam for longitudinal flaw inspection, and one testing carriage swingably suspended in central relationship to the weld seam and moveable on the pipe surface for transverse flaw inspection. Each testing carriage has a mount for accommodating at least one testing head which includes an oscillator, and at least one coupling medium connection having a channel ending in the region of the oscillator and configured as nozzle in the outlet area. The test head for longitudinal flaw inspection can be arranged at various fixed and predefined angle positions at variable distance to the nozzle in the mount, and the test head for transverse flaw inspection can be arranged, together with the mount, at a variable distance to the pipe surface in a support element accommodating the mount.

Owner:MANNESMANN ROHRENWERKE

Laser welding control system

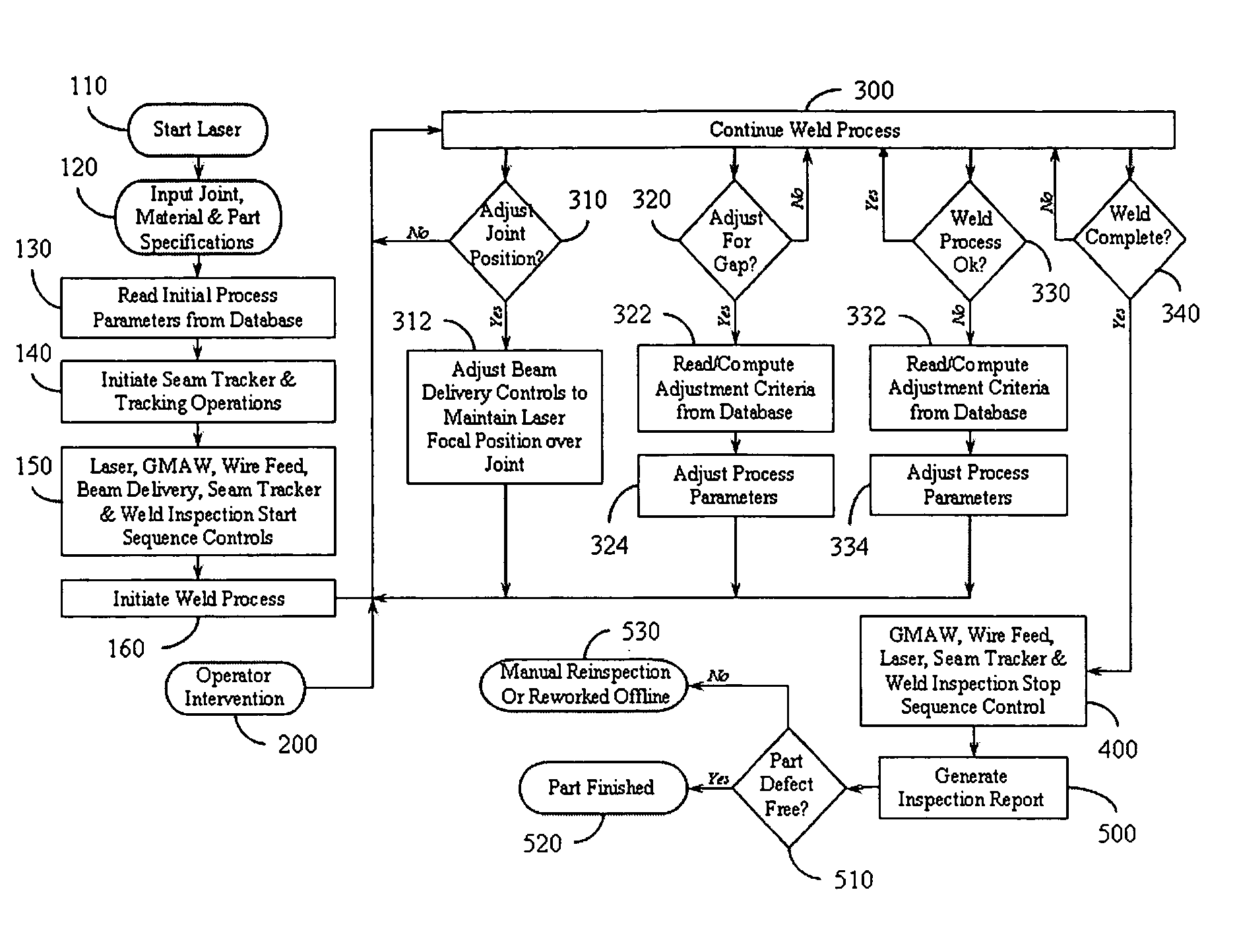

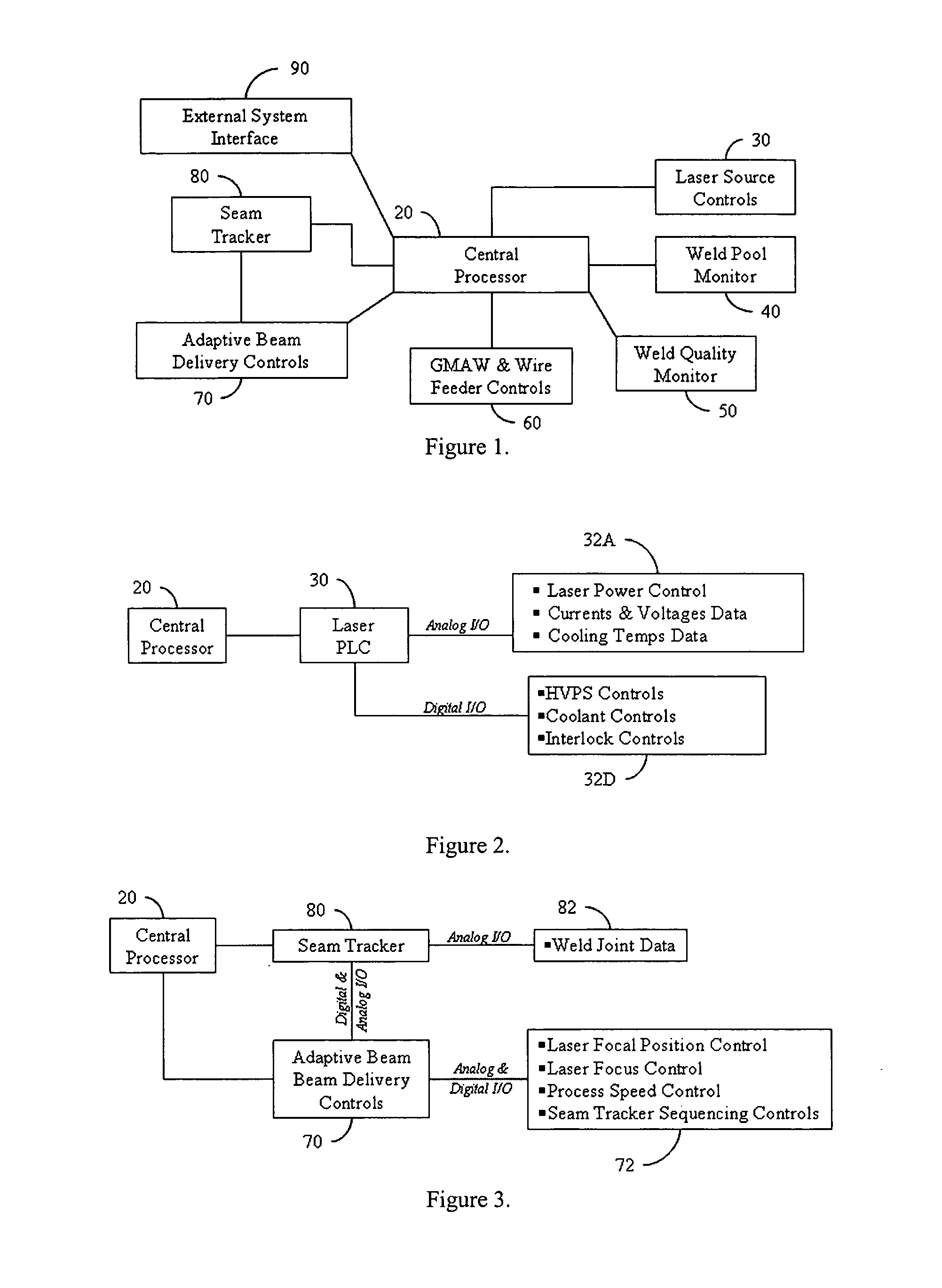

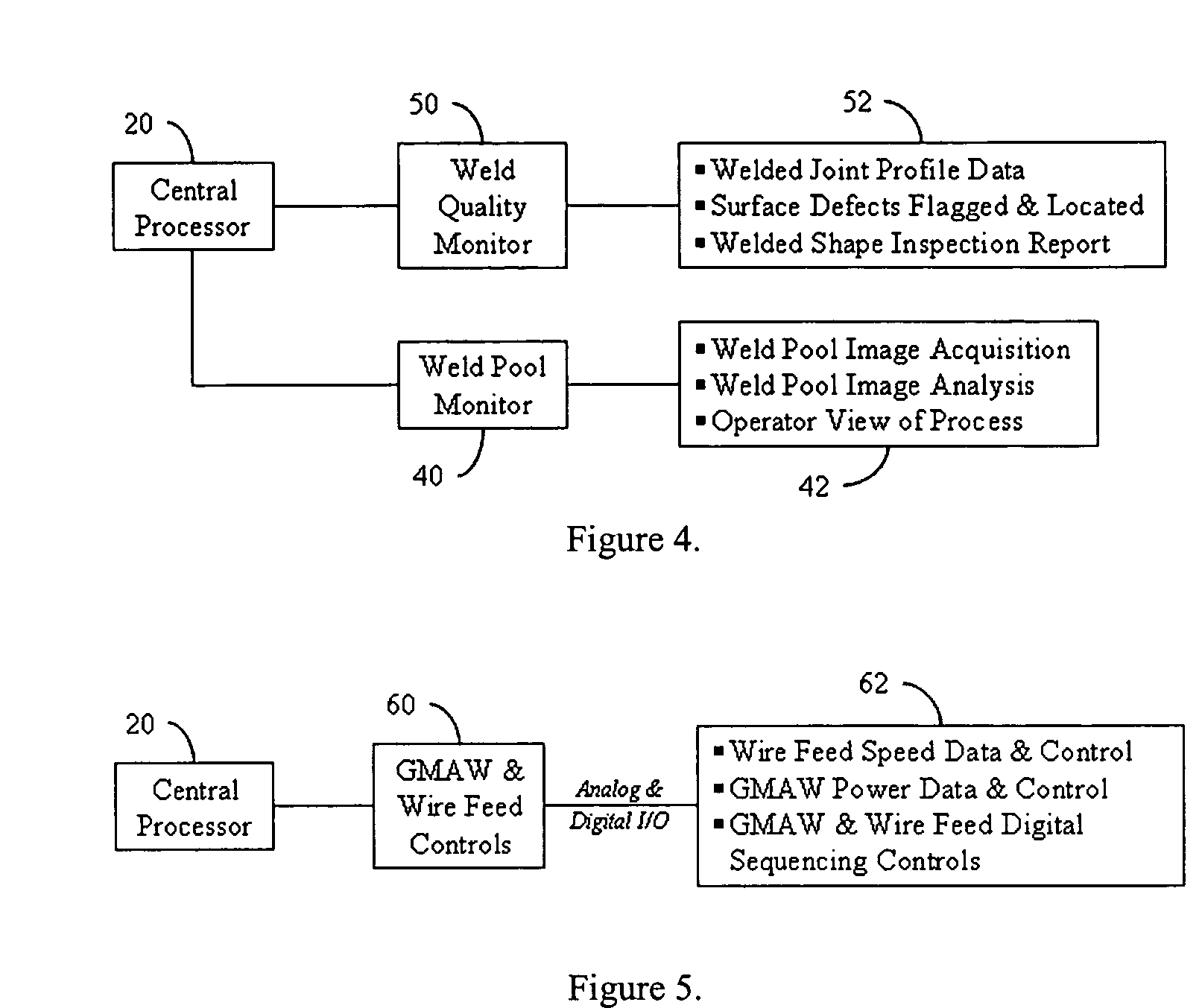

ActiveUS7107118B2Improve reliabilityReduce the amount requiredProgramme controlElectrical apparatusClosed loopVision based

A fully integrated automated laser weld process control system (LWPCS) and method of controlling the fabrication of structural parts, particularly for shipbuilding and other industries. The LWPCS defines joint and weld quality attributes as process control variables and integrates these weld quality variables, along with the more traditional process parameters such as laser power, wire feed, GMAW voltage and active seam tracking, into a closed-loop monitoring and control system. The LWPCS includes a central processor and a plurality of subsystems that control laser beam positioning, vision-based monitoring and image processing, active weld-quality monitoring and inspection, adaptive beam delivery, and seam tracking. Cross-communication between subsystems is managed by the central processor. In addition to process control, the system extracts weld quality attributes during the weld process and provides immediate documentation of the weld quality.

Owner:ESAB AB

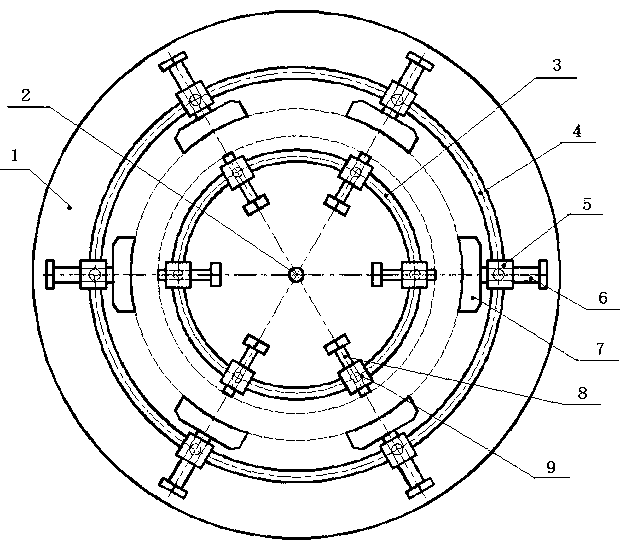

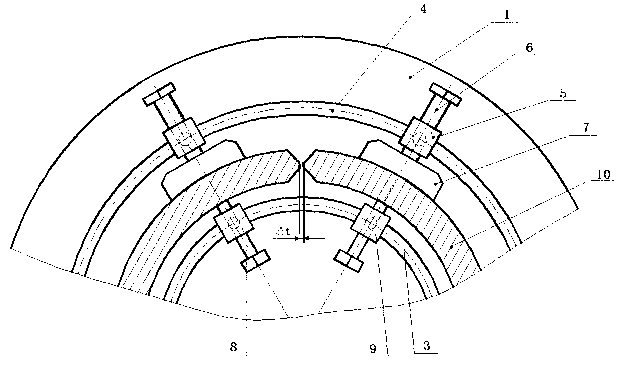

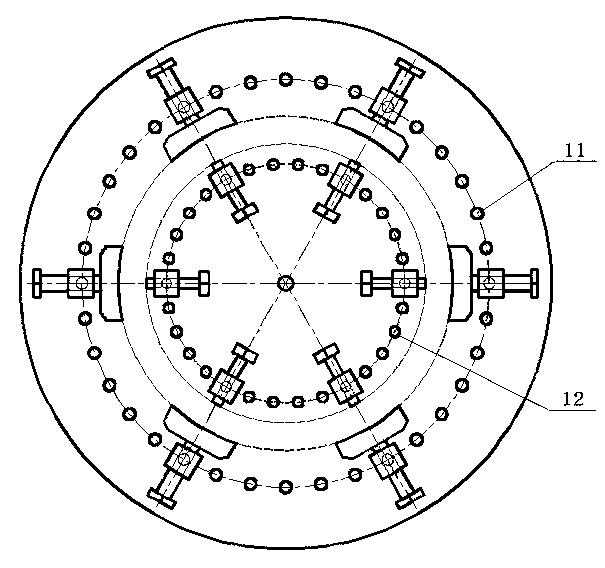

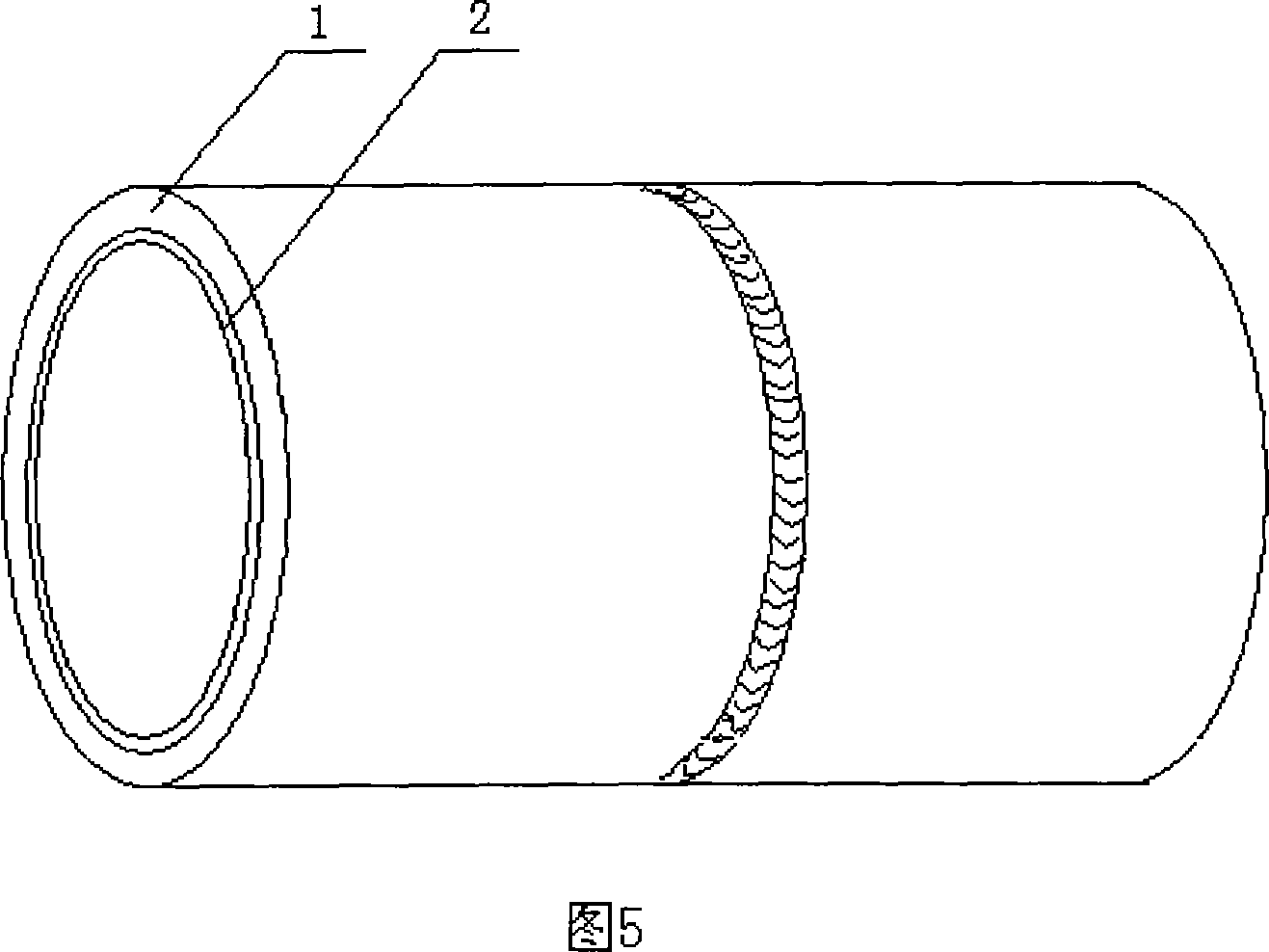

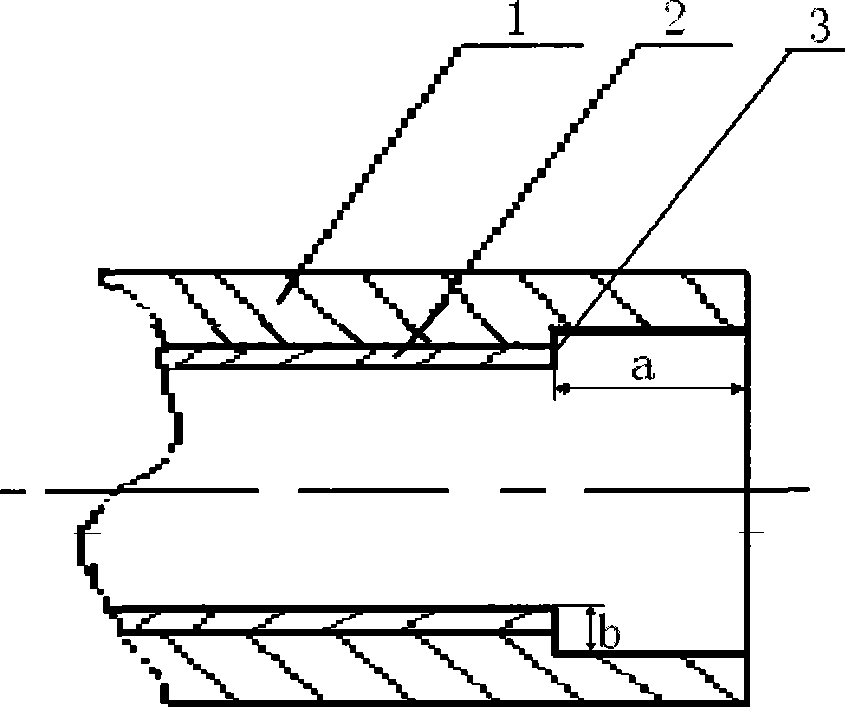

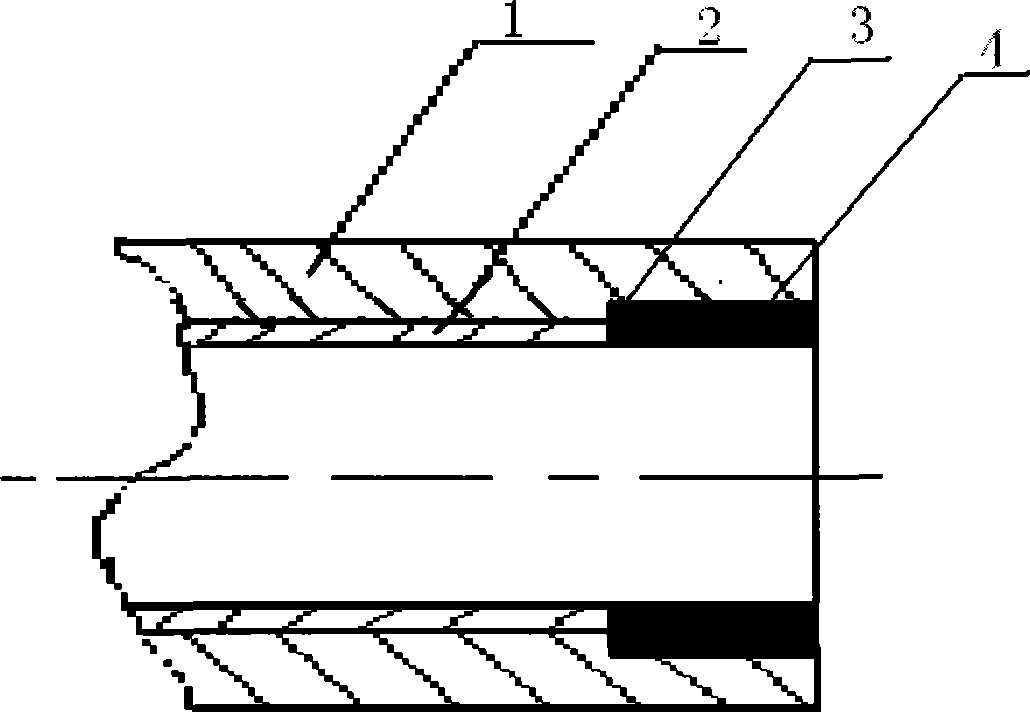

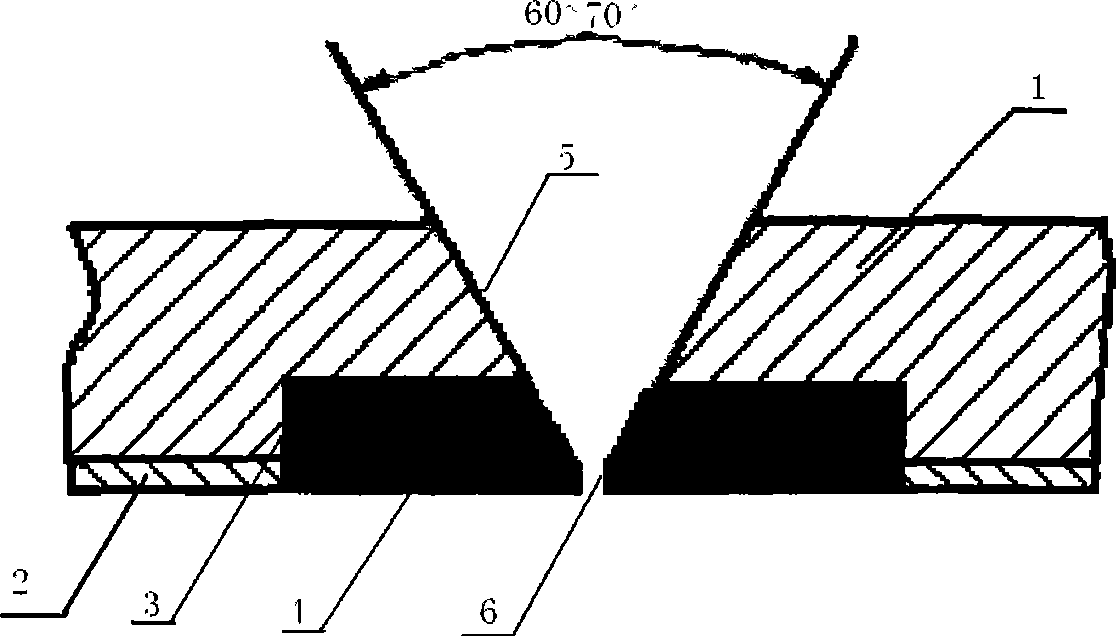

Pre-welding shaping auxiliary mold of large-scale steel cylinder and welding method

ActiveCN103273252AAvoid mechanical shaping processGuaranteed accuracy requirementsWelding/cutting auxillary devicesArc welding apparatusStructural engineeringWeld seam

The invention relates to the technical field of forming, assembling and welding of a large-scale supporting cylinder on a lightering platform on the sea, and provides a pre-welding shaping auxiliary mold of the large-scale steel cylinder and a welding method. The shaping mold is composed of a welding platform, a fixing column, a slide way, an outer lead screw, an outer arc locating block, an inner ejector rod and the like. The outer circle of the cylinder is shaped through an adjusted rigid restrained position; shaping accuracy of the cylinder is ensured through the lead screw, a seam width positioning wedge, a process support and the like; a welding process of the cylinder is made; tack welding is firstly conducted on a longitudinal seam, then the longitudinal seam is integrally welded, and the welding sequence is that welding is conducted from the middle towards the two ends at intervals; sectionalized barrel bodies are welded in an assembled mode and through an X-type double-face groove, the butt-jointing groove faces upwards, the inner side of the cylinder is welded firstly when welding is started, carbon arc air gouging back gouging is conducted on a welding seam in the outer side after the cylinder is turned over, and then the outer side of an annular welding seam is welded. Slight welding deformation is achieved through adjustment of a rigidity restraint positioning block and changes of the welding sequence, and requirements for welding accuracy of the cylinder are met.

Owner:JIANGSU DINSON HEAVY IND +1

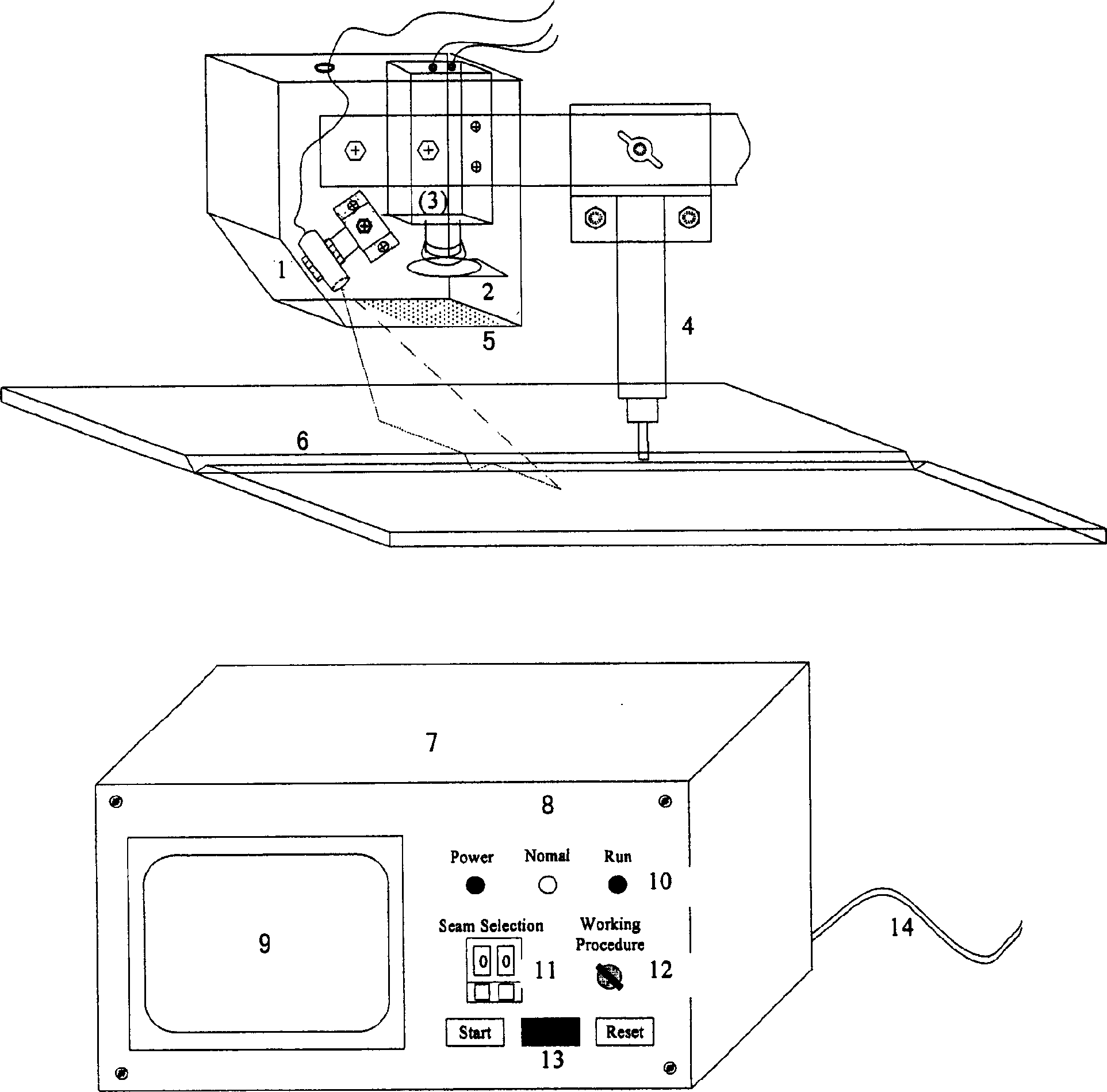

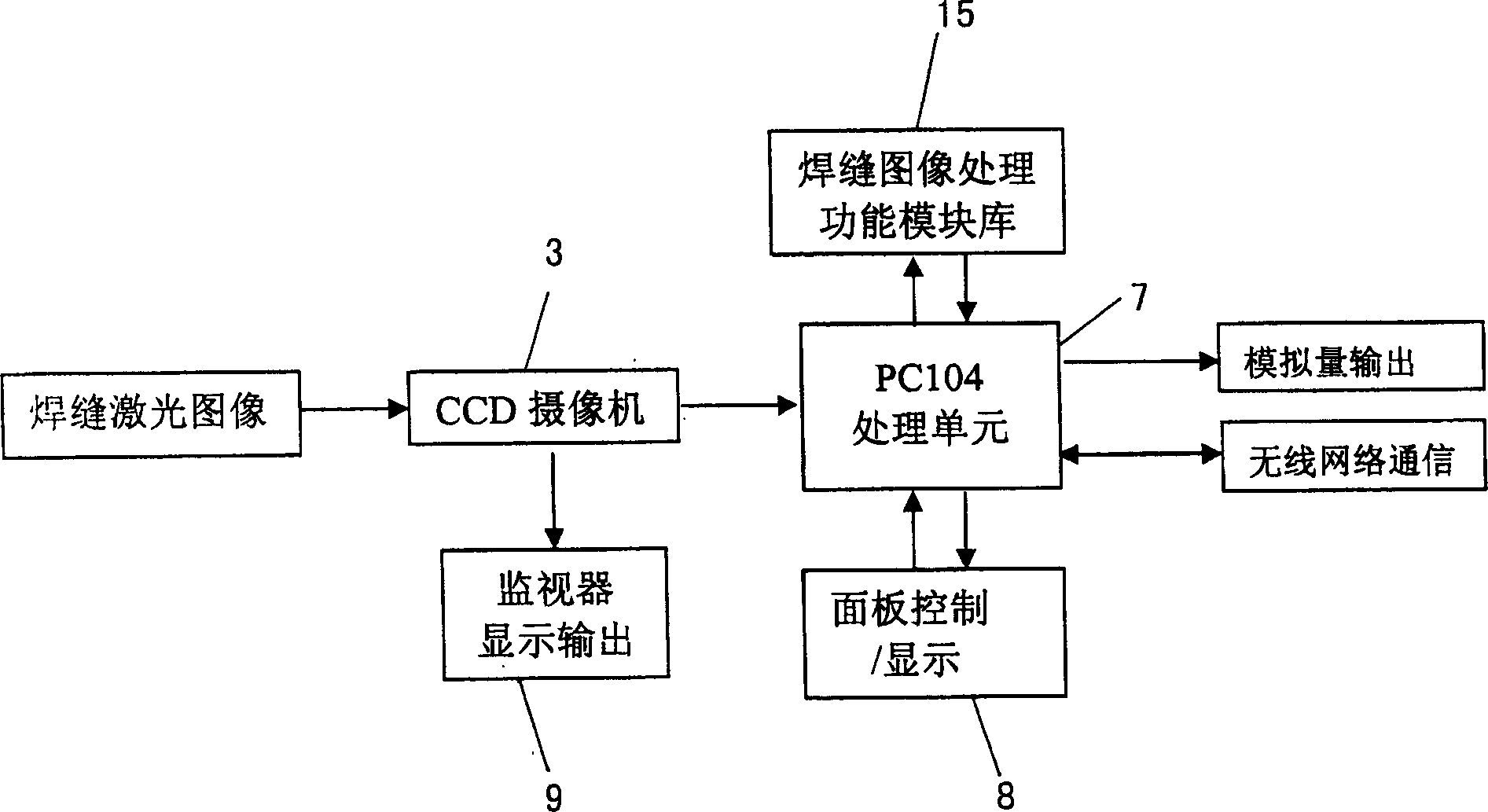

Welding seam tracking sight sensor based on laser structure light

The present invention relates to robot technology, and is weld seam tracking sight sensor based on laser structure light. The welding seam tracking sight sensor has laser as the light source of structure light, and consists of laser, video camera, monitor, treating unit, etc. By means of forming laser plane with laser beam in a cylindrical mirror, projecting the laser plane to a workpiece to generate laser fringes, acquiring the laser image of weld seam with a visual sensor, calculating weld seam positions through image processing and converting into analog signal or radio signal, the present invention controls welding robot for automatic weld seam tracking. Different weld seam processing modules for different kinds of weld seam are developed. The present invention has high weld seam position measuring precision, raised anti-jamming capacity and high versatility and flexibility.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

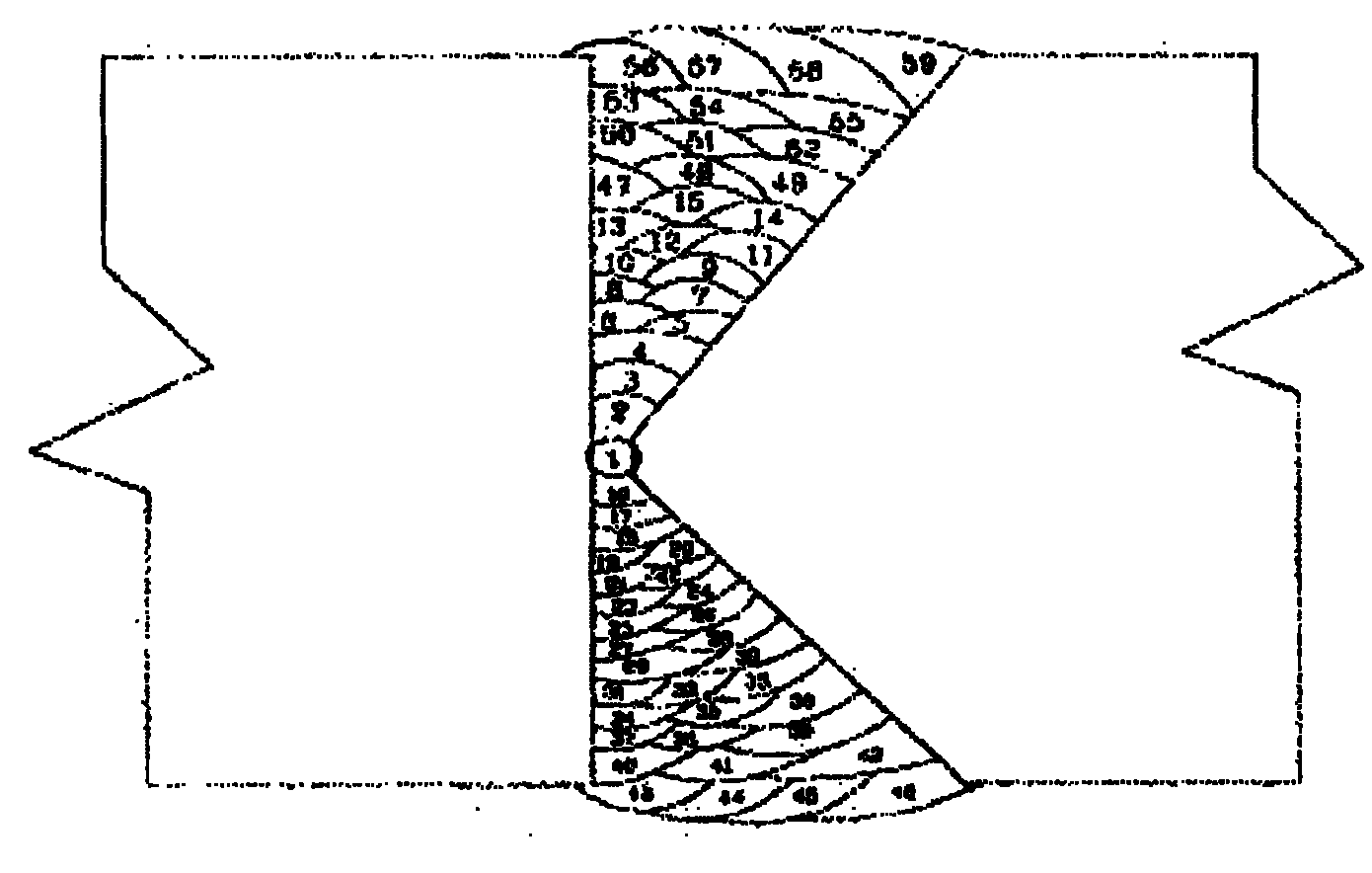

High-resolution welding seam supersonic image-forming damage-free detection method and detection system

InactiveCN101101277AImprove performancePrecise positioningAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound imagingSonification

The invention discloses a high clear weld ultrasound imaging undamaged detection method and detection system, firstly dong point by point scanning with leach focusing probe to welding seam, and sampling detecting signal of ultrasound reflect echo for every bit, composing the ultrasonic scanning image of welding line section, and then realizing to rebuild super-resolution of image by gathering tiny scanning image and multigraph rebuilding super-resolution image. The invention can breach resolution limited of existing equipment of ultrasound imaging, it improves greatly recognizability of equipment of ultrasound imaging for the small bug of welding line by multi-framing rebuilding high resolution and high quality image from fall quality image in the scene.

Owner:SOUTH CHINA UNIV OF TECH

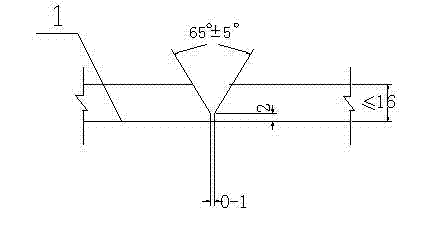

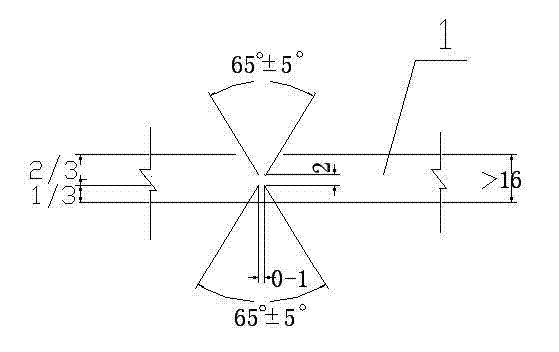

Marine engineering large thick steel plate submerged arc welding process method in low-temperature environment

InactiveCN101879645AIncrease productivityReduce labor intensityArc welding apparatusWelding/cutting media/materialsEngineeringWeld seam

The invention belongs to the field of welding, in particular to a process method applicable to marine engineering large thick steel plate submerged arc welding in low-temperature environment, which comprises a welding method, welding material selection, a welding order, a welding process and the selection and control of various welding process parameters. The method renders with carbon dioxide gas protection welding, and fills and faces through an automatic submerged arc welding; stops welding when the welding reaches more than two thirds of the thickness of a large groove during the welding process, clears chips on the back side and completes the welding of the other side; finally completes the welding of the first side; strictly controls all relevant process parameters of the welding during the welding process, and solves the problems of poorer anti-crack toughness of welding seams and heat affected zones caused by too high cooling speed of the welding seams and too high temperature; can ensure good anti-crack toughness of a welding seam connector without heat treatment after welding; and can meet the requirements of welding of an E36 plate with the thickness of 35 to 77mm under the working environment at the temperature of above -30DEG C, simplifies the production process, shortens the production cycle and reduces the cost.

Owner:PENGLAI JUTAL OFFSHORE ENG HEAVY IND CO LTD

Thin-wall stainless steel double-layer and carbon steel base layer composite tube girth weld welding method

ActiveCN101100013AEliminate gapsIncrease the effective thicknessArc welding apparatusWelding/cutting media/materialsWeld seamMaterials science

The process of ring welding composite pipe comprising one thin stainless steel layer and one carbon steel base layer includes the following steps: 1. chamfering and eliminating oil stain; 2. bead welding and trimming chamfer; 3. pairing bimetal composite pipe chamfers; 4. argon shielded tungsten arc welding in the bottom; 5. welding the second layer to weld the base layers of two composite pipes; and 6. filling welding and finishing welding. During the welding process, stainless steel electrode and 309 or 309Mo welding material are adopted for reaching high strength and high toughness of the weld seam, and the chamfers have increased effective thickness of stainless steel layer for high welding quality and high corrosion resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Weld seam surface detect feature extraction method based on grayscale image morphology

ActiveCN105976352AImplement extractionEfficient extractionImage enhancementImage analysisColor imageFeature extraction

The invention relates to a weld seam surface defect feature extraction method based on the grayscale image morphology, which comprises the steps of setting shooting parameters of a miniature CCD camera according to an acquired image; converting the acquired true color image into a grayscale image, and carrying out median filtering processing on the image; eliminating a white interference region generated by residue noise and background texture by adopting a minimum area deleting method; avoiding influences imposed on edge line extraction by an undetermined black region through region filling processing; processing a completely filled weld seam region through an expansion algorithm so as to acquire a weld seam region whose area is identical to the actual weld seam area; extracting an edge line of the filled and expanded weld seam region by adopting a Canny operator so as to realize positioning for the weld seam region; and drawing a cross section grayscale B scanning curve which is vertical with the weld seam edge, wherein a gray-scale value of the weld seam surface changes obviously on the B scanning curve when the weld seam surface has defects such as a hole and an overlap, so that different types of defects at the weld seam surface are judged. The weld seam surface detect feature extraction method realizes accurate positioning for the weld seam edge and accurate recognition for the defects such as overlaps and holes.

Owner:BEIJING UNIV OF TECH

Method for welding thin layer iron nickel base alloy carbon steel composite tube

ActiveCN101462193AIncrease the effective thicknessHigh strengthArc welding apparatusWelding/cutting media/materialsAlloyWeld seam

The invention relates to a method for welding a carbon steel composite pipe of a thin iron-nickel-based alloy. The method comprises: processing a step on the end part of the composite pipe; adopting the surfacing of argon arc welding on the surface of the step and trimming the surfacing layer; processing a groove; adopting tungsten electrode argon arc welding to carry out three-point positioning of spot welding evenly around a welding seam, and adopting the tungsten electrode argon arc welding to carry out back welding on the root; and adopting manual electric arc welding to carry out filling welding and overlay welding on the upper part of a second layer of back welding. The chemical compositions of a welding material by weight percentage: 0.02 to 0.1 percent of C, 0.2 to 1.0 percent of Si, 1.0 to 2.2 percent of Mn, 20.0 to 31.5 percent of Cr, 40.0 to 60.0 percent of Ni, 8.0 to 14.5 percent of Mo, 0.5 to 2.5 percent of Cu, 0 to 5.0 percent of Co, 0.3 to 4.2 percent of Nb, and the balance being Fe. The welding seam has the characteristics of no sensitivity to offset, favorable corrosion resistance, high strength and favorable plastic toughness.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

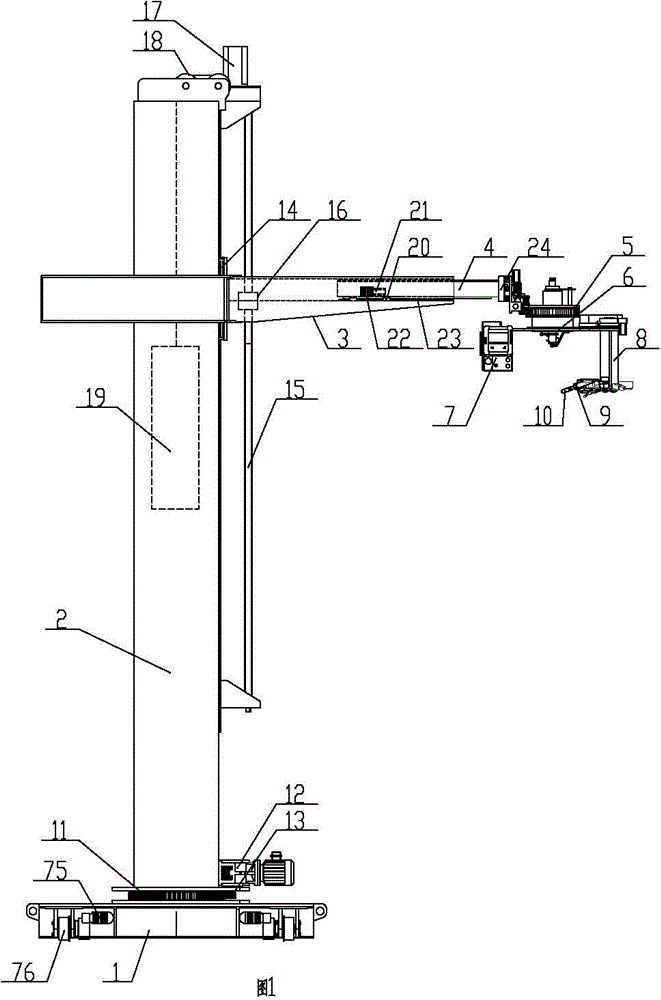

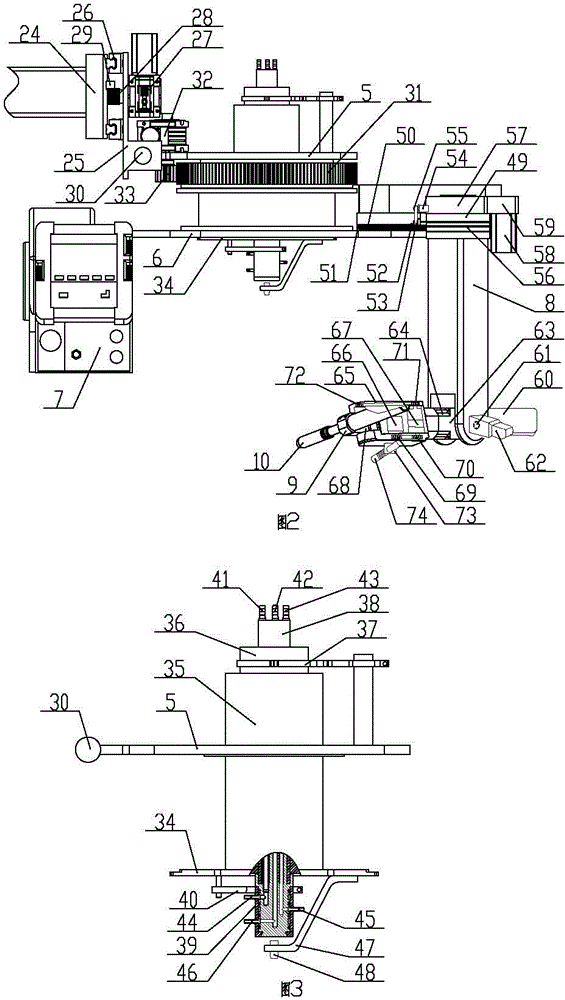

Multifunctional single-cantilever cutting and welding integrated machine

InactiveCN104308333AAvoid frequent movementReduce the number of card positioningWelding/cutting auxillary devicesAuxillary welding devicesFillet weldEngineering

The invention relates to the technical field of automated cutting and welding, and discloses a multifunctional single-cantilever cutting and welding integrated machine. The integrated machine comprises a machine frame base, a machine frame stand column, a stand column rotary device, a vertical lifting device, a machine frame transverse arm, a left-right translation device, a telescopic arm, a front-rear transverse moving device and a multi-joint machine head, wherein the machine frame stand column is mounted on the machine frame base through the stand column rotary device, and the machine frame transverse arm is mounted at the upper part of the machine frame stand column through the vertical lifting device. The integrated machine is reasonable and compact in structure and convenient to use; the welding of longitudinal, circumferential and fillet weld seams, cutting of an intersecting line hole and automatic welding of a saddle-shaped weld seam between a barrel body and a connecting pipe can be finished in a relatively fixed station through the stand column rotary device, the vertical lifting device, the left-right translation device, the front-rear transverse moving device and the multi-joint machine head, the frequent motion of a workpiece can be avoided, the clamping and positioning frequency of the workpiece is greatly reduced, the welding efficiency and quality are remarkably improved, and the labor intensity of welding workers is reduced.

Owner:新疆威奥科技股份有限公司

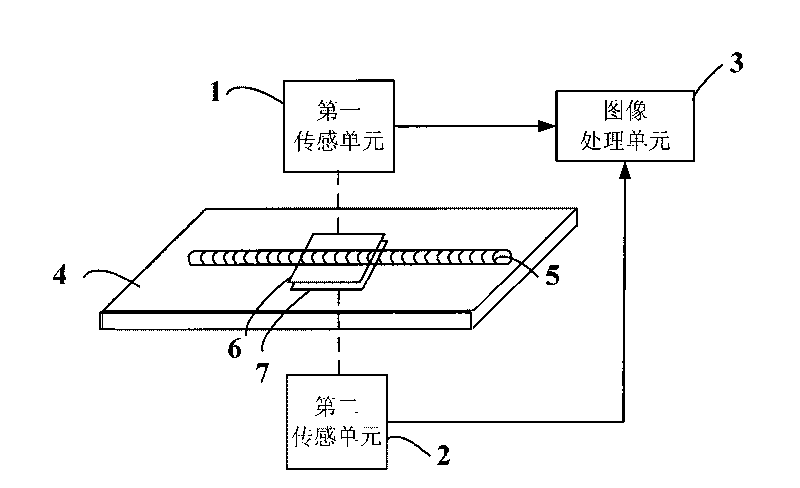

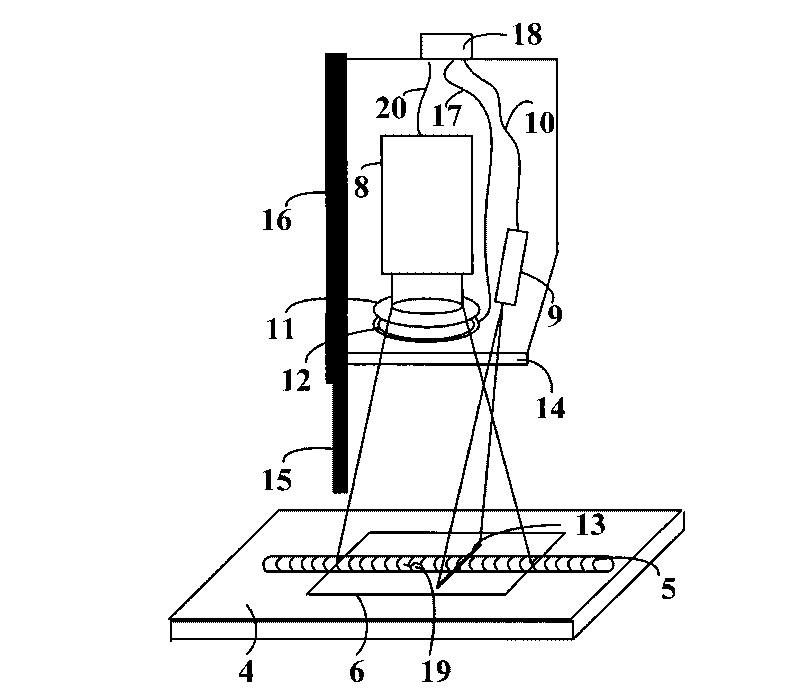

Visual welding seam surface quality detection sensor based on line structure light

InactiveCN101750416AIncrease autonomyImprove the level of intelligenceOptically investigating flaws/contaminationCamera lensWeld seam

The invention discloses a visual welding seam surface quality real-time on-line detection sensor based on line structure light, comprising sensing units and an image processing unit, wherein two sensing units are respectively vertically installed at two sides of the upper and lower surfaces of the welding seam and connected with the image processing unit; the sensing units comprise a video camera for receiving the welding seam surface gray scale image including laser stripe formed on the welding work piece; a straight linear laser for generating laser structure light stripe on the welding work piece; an optical filter in front of the video camera lens; and an LED annular light source coaxially provided with the video camera and positioned in front of the optical filter. The invention uses the straight linear laser to project onto the upper and lower surfaces of the welding seam to generate the laser stripes; the camera collects the welding seam surface gray scale image including laser stripes to finally realize automatic quality detection of the upper and lower surfaces of the welding seam; and the precision of surface quality detection of the welding seam is improved. The sensor can be widely applied to the fields such as robot automatic welding.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Manufacturing method for box type pillar beam

ActiveCN102896472AAdvanced preparation technologyReasonable preparation processArc welding apparatusNumerical controlSlag (welding)

The invention relates to a manufacturing method for a pillar beam for the building field and especially relates to the manufacturing method for a box type pillar beam. The manufacturing method comprises the processes of steel check, line marking, cutting, material receiving, assembling, welding, finishing, coating, and marking. The manufacturing method comprises the following steps: splicing big plates and cutting the box type pillar beam under numerical control; adding lining strips and leaving gaps during the grouping process of four main welding seams of the box type pillar beam; welding the four main welding seams by adopting an automatic submerged arc welding method; welding box type separating plates by adopting non-melting nozzle electro-slag welding; keeping the welding seams of the non-melting nozzle electro-slag welding under an abreast state; machining after grouping the separating plates of the box type pillar beam; and end-milling the two ends of the box type pillar beam. According to the manufacturing method, during a manufacturing process of the box type pillar beam, an advanced box type separating plate non-melting nozzle electro-slag welding technology is adopted; the welding and the assembling are alternately performed; the welding sequence is scientific and reasonable; multiple measures are simultaneously taken for preventing welding deformation; the precise equipment is adopted for processing the end part, so that the manufacturing technology for the box type pillar beam is more advanced and reasonable; and the manufacturing method is suitable for the box type pillar beams in various cross section sizes and plate thicknesses.

Owner:CHINA 22MCC GROUP CORP

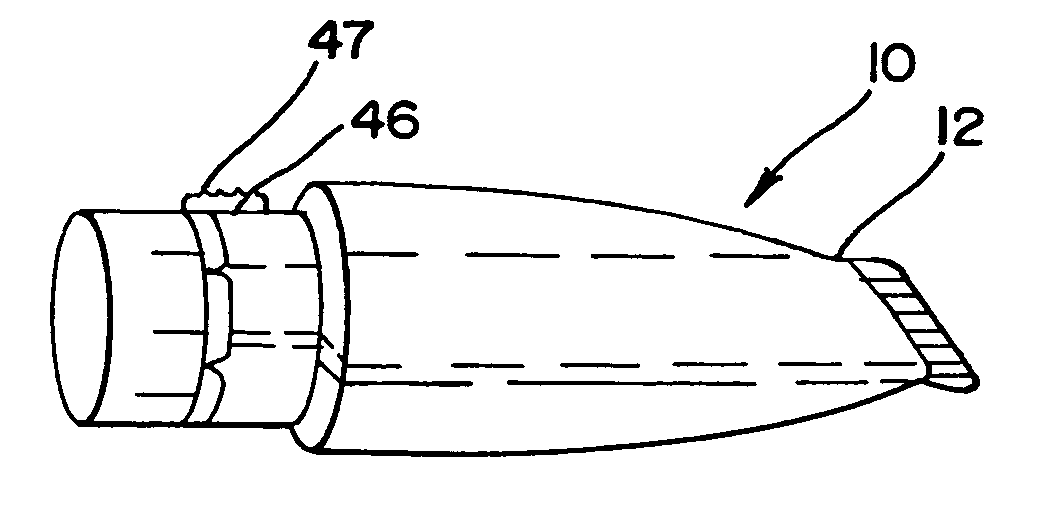

Method of repairing a blade member

InactiveUS20060277753A1Induce compression stressBlade accessoriesEfficient propulsion technologiesWeld seamResidual stress

A method of repairing blade members, especially blade members in a turbomachine is provided. In one example, a damaged portion of a blade member is cut away from the blade member, by milling for example. The extent of the cut away portion generally corresponds in size and / or shape to the damaged area. A replacement portion is then welded into place in the resultant void in the blade member. The resulting weld seam is then burnished or deep rolled in order to cold work the blade member material at the weld seam. This induces compressive residual stresses in the blade member that counteract tensile residual stresses in and around the weld seam caused by the welding, and therefore strengthens the resulting repaired structure. The disclosed process particularly useful for repairing bladed disks (bladed monoblock disks) where individual blades cannot be removed for replacement or repair.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Defect detection system for identifying defects in weld seams

ActiveUS8046178B2Increase flexibilityIncrease productivityArc welding apparatusSpecial data processing applicationsEngineeringWeld seam

A defect detection system identifies defects in weld seams. An exemplary system includes a scanner device, mounted on a displacement device of a processing unit and which can be displaced by the unit over at least one weld seam that is to be examined. The scanner unit scans the weld seam using a predefinable frequency, each scanning sweep being correlated with a time signal. The time signal is used to record the point in time when at least one location containing defects is scanned. An analysis module determines the co-ordinates of the defects from the signals that are obtained by the scanning sweeps and stores the co-ordinates of the defects and transmits them to a localisation module. The localisation module determines the spatial arrangement of the defects of the weld seam by evaluating a speed profile of the displacement device during the scanning sweeps, the time signal and the co-ordinates.

Owner:ABB (SCHWEIZ) AG

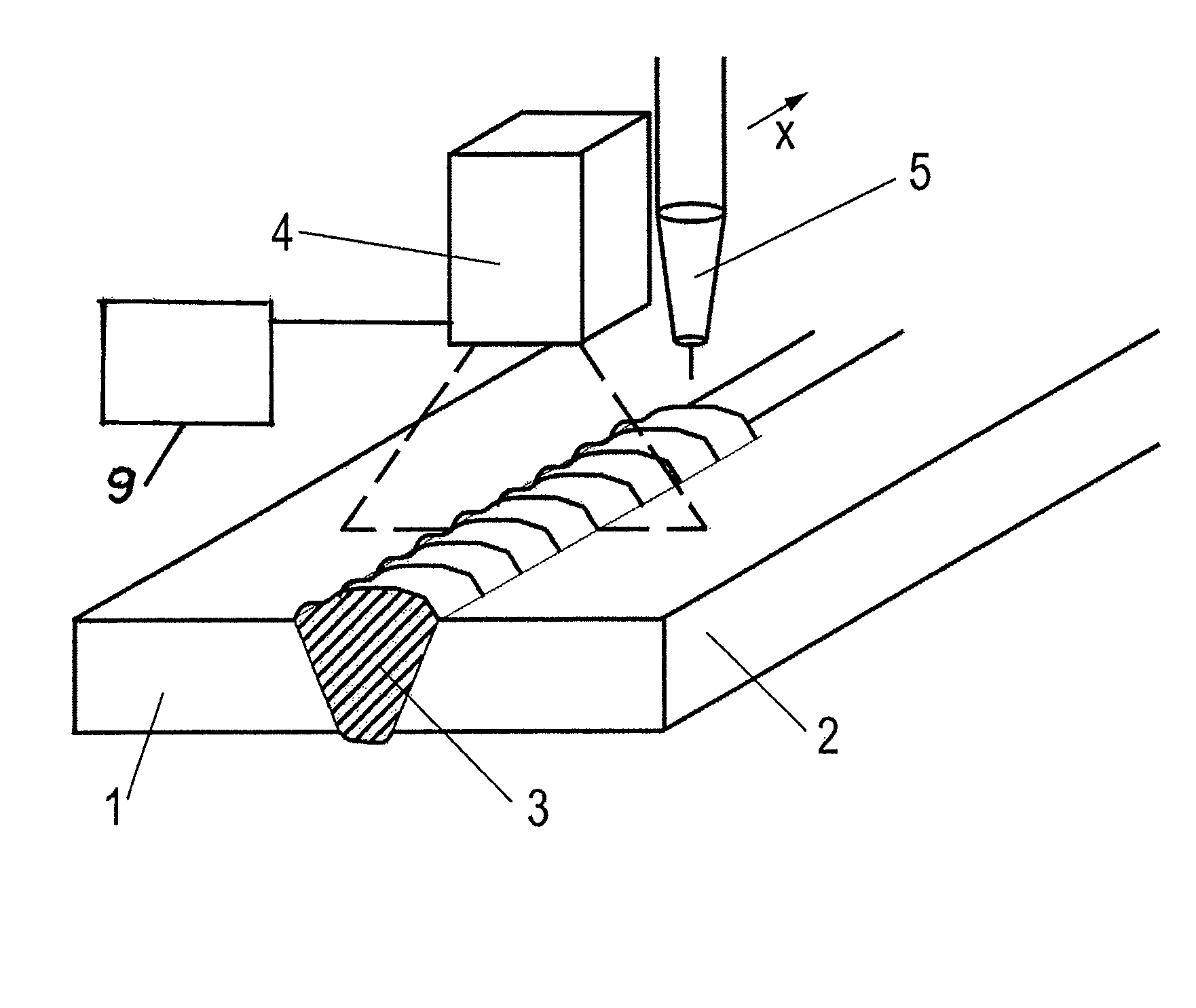

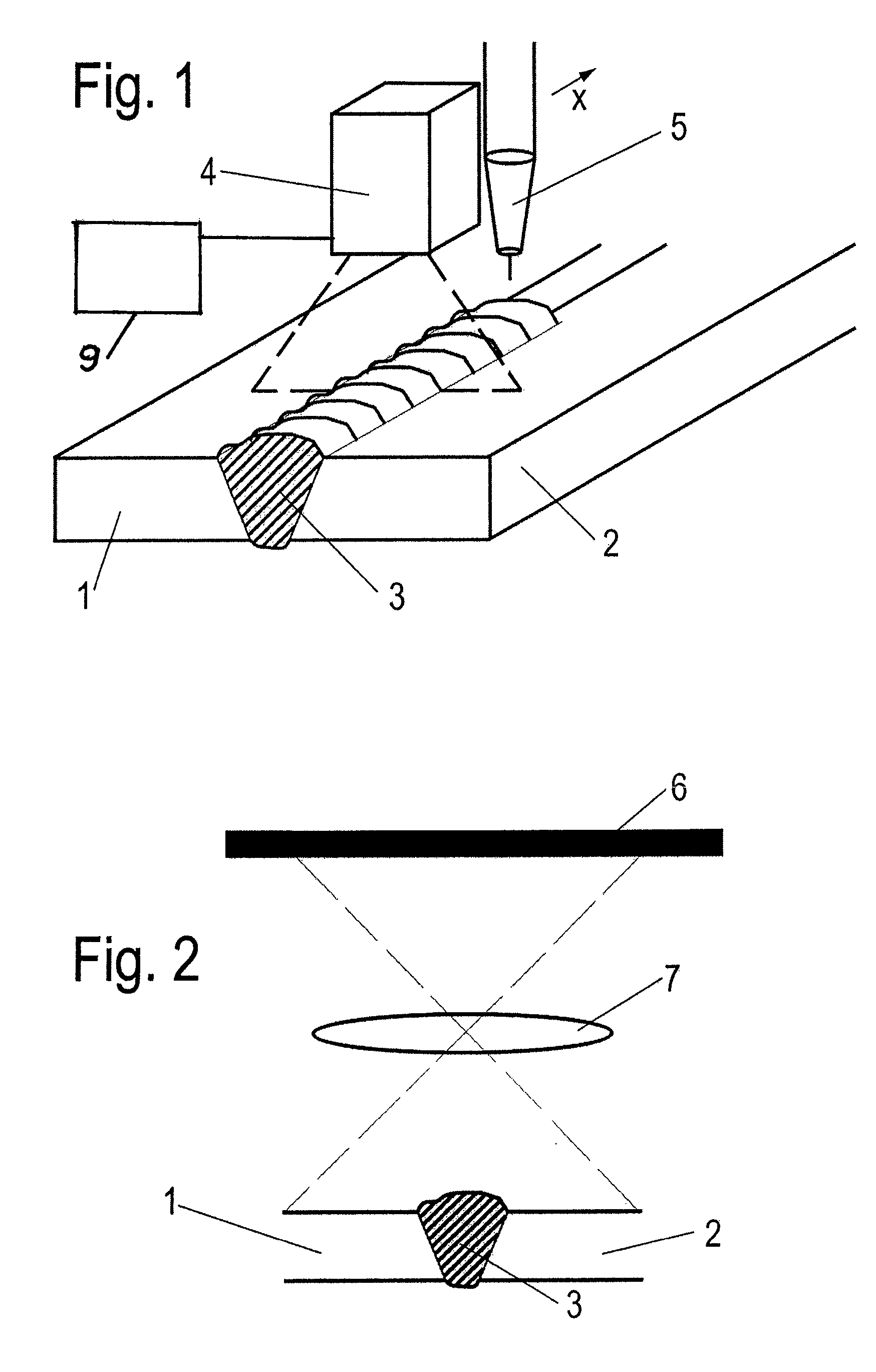

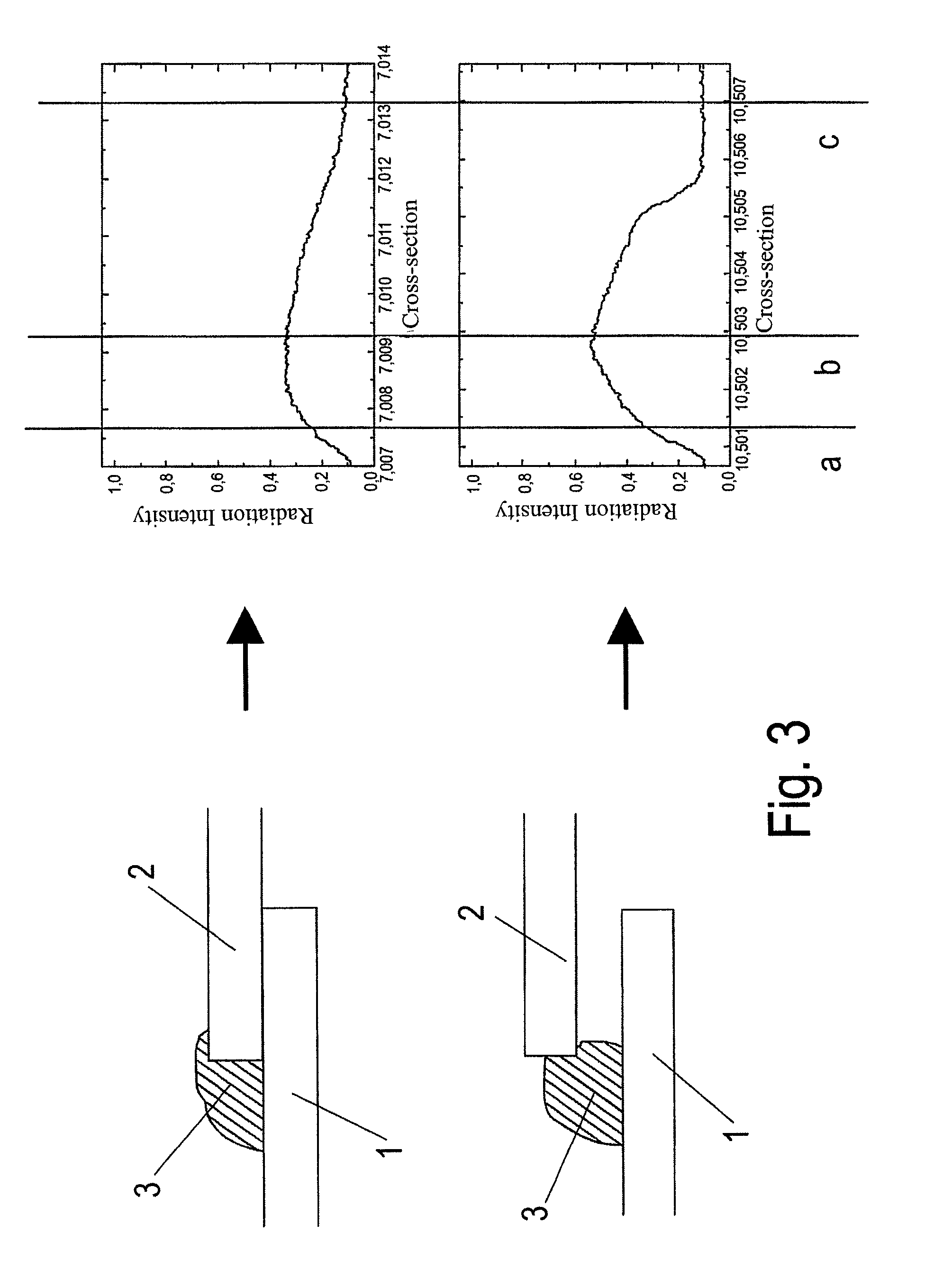

Process and system for the nondestructive quality determination of a weld seam, and a welding device

A process for the non-destructive determination of the quality of a weld seam, the process steps comprising: providing a first and a second component; connecting the first and second components by a weld seam produced by a welding operation; and measuring a surface temperature of the weld seam and surface temperatures of areas of the first and second components adjacent to the weld seam that were heated by the welding operation. A system for carrying out the process for the non-destructive determination of the quality of a weld seam, the system comprising: a measuring device, an analyzing unit, and a welding device.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

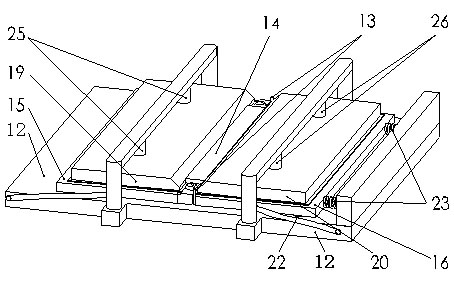

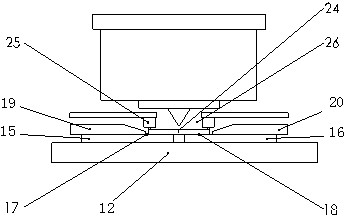

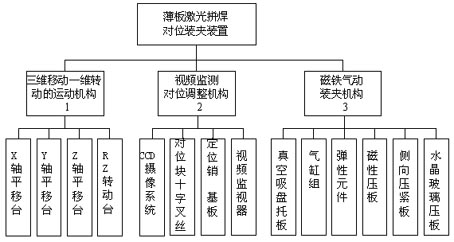

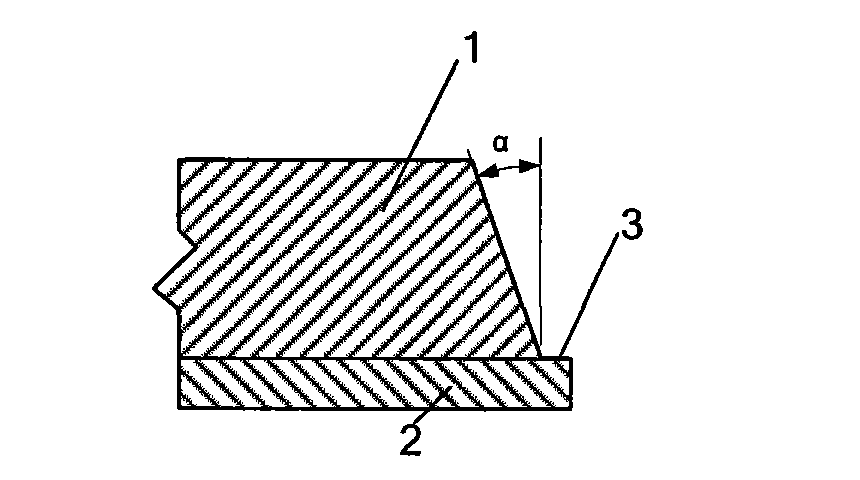

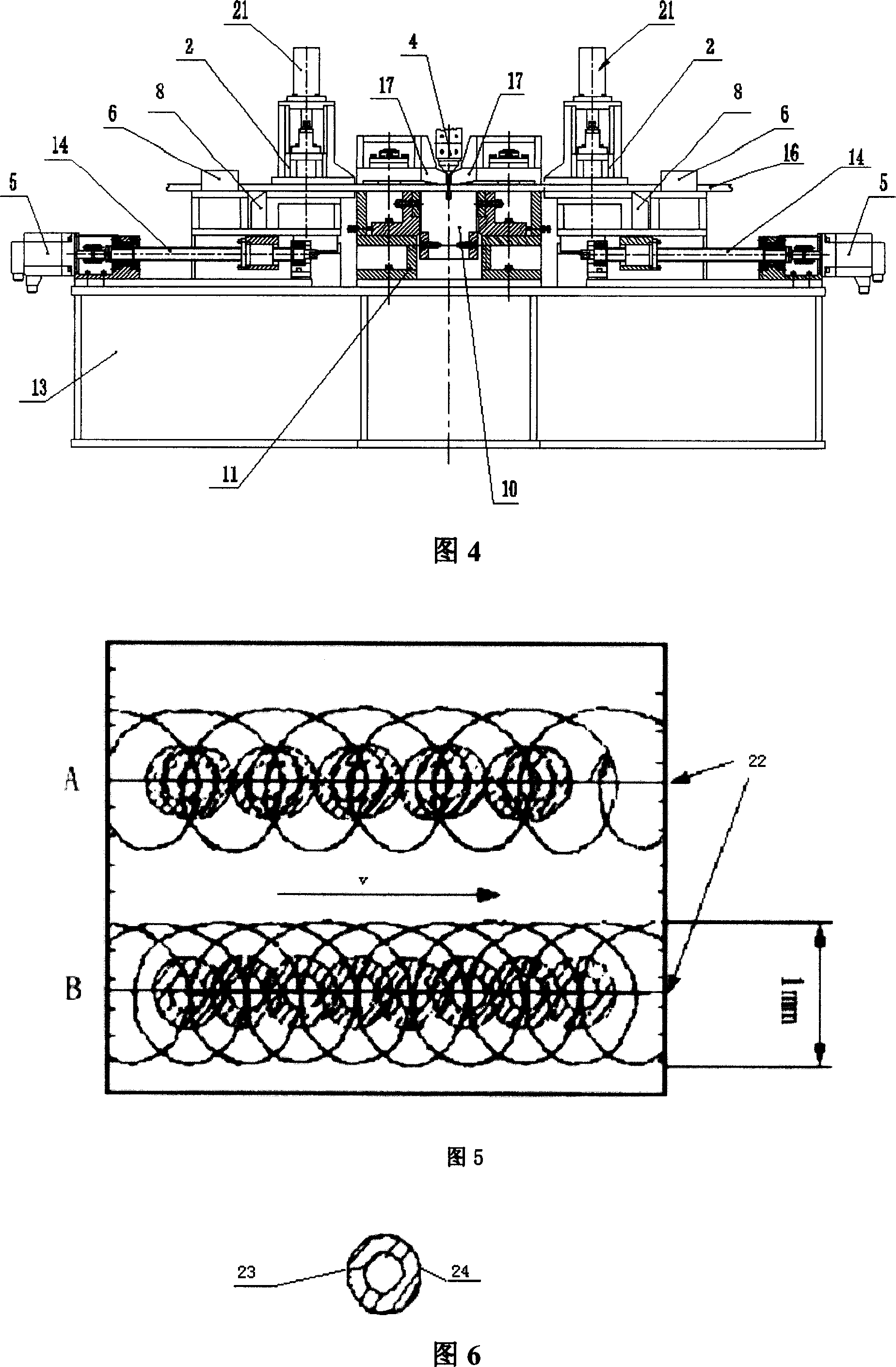

Stainless steel or nickel sheet laser tailor-welding alignment clamping device and method

ActiveCN101890576ARealize Tailored WeldingSolve the problem of difficult tailor welding of deformed thin platesWelding/cutting auxillary devicesAuxillary welding devicesVideo monitoringButt welding

The invention discloses a stainless steel or nickel sheet laser tailor-welding alignment clamping device and a method. The alignment clamping device comprises an XYZ three-dimensional translation RZ one-dimensional rotation motion mechanism, a video monitoring alignment regulating mechanism and a magnet pneumatic clamping mechanism, wherein the stainless steel or nickel sheet laser tailor-welding alignment clamping device can align and position sheets through the XYZ three-dimensional translation RZ one-dimensional rotation motion mechanism and the video monitoring alignment regulating mechanism, and then clamps and fixes the stainless steel or nickel sheets by the magnet pneumatic clamping mechanism to realize the laser tailor-welding of the stainless steel or nickel sheets. The invention can solve the problem of difficult welding of the stainless steel or nickel sheets smaller than 0.3mm in thickness in laser butt welding because the sheets are easy to deform owing to easy deformation property per se and thermal stress, and guarantees the quality of tailor-welded seams.

Owner:上海市激光技术研究所有限公司

Welding method of girth weld of inner cladding thin-walled stainless steel composite tube

InactiveCN101633074AResolving ingredient matchesSolve the corrosion resistanceWelding/cutting auxillary devicesAuxillary welding devicesChemical industryWeld seam

The invention relates to a welding method of a girth weld of an inner cladding thin-walled stainless steel composite tube. The welding method comprises the following steps: girth welds of the inner cladding stainless steel composite tube are respectively and gradually welded by three welding seams, an inner cladding layer welding seam and a transition layer welding seam are welded by argon tungsten-arc welding, the stainless steel inner cladding layer welding seam adopts welding wires with the same quality thereof, the transition layer welding seam adopts ER309 welding wires, and the base layer is welded by shielded metal arc welding or CO2 gas shielded welding and adopts a welding material matched with the strength of the base layer; and the inner cladding layer, the transition layer and the first layer of the base layer are welded under back argon gas protection. The welding method guarantees corrosion resistance of a joint of the inner cladding layer and mechanical property of a welding joint of the base layer; and the method plays an important role in promoting wide application of the inner cladding stainless steel composite tube in businesses such as oil-gas delivery, chemical industry, oil refining and the like, improving corrosion resistance of an inner wall of a pipe, and solving the problems of high cost and the like caused by adopting a full wall-thickness stainless steel pipe.

Owner:XI AN JIAOTONG UNIV

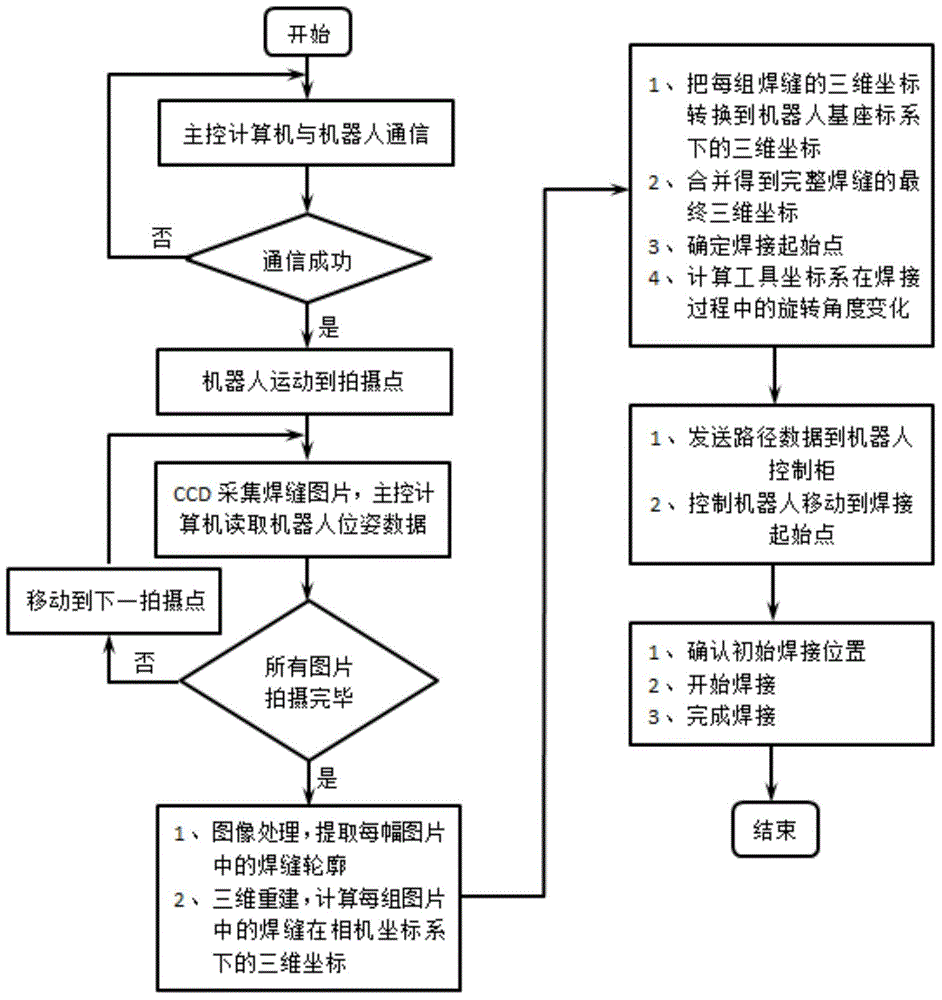

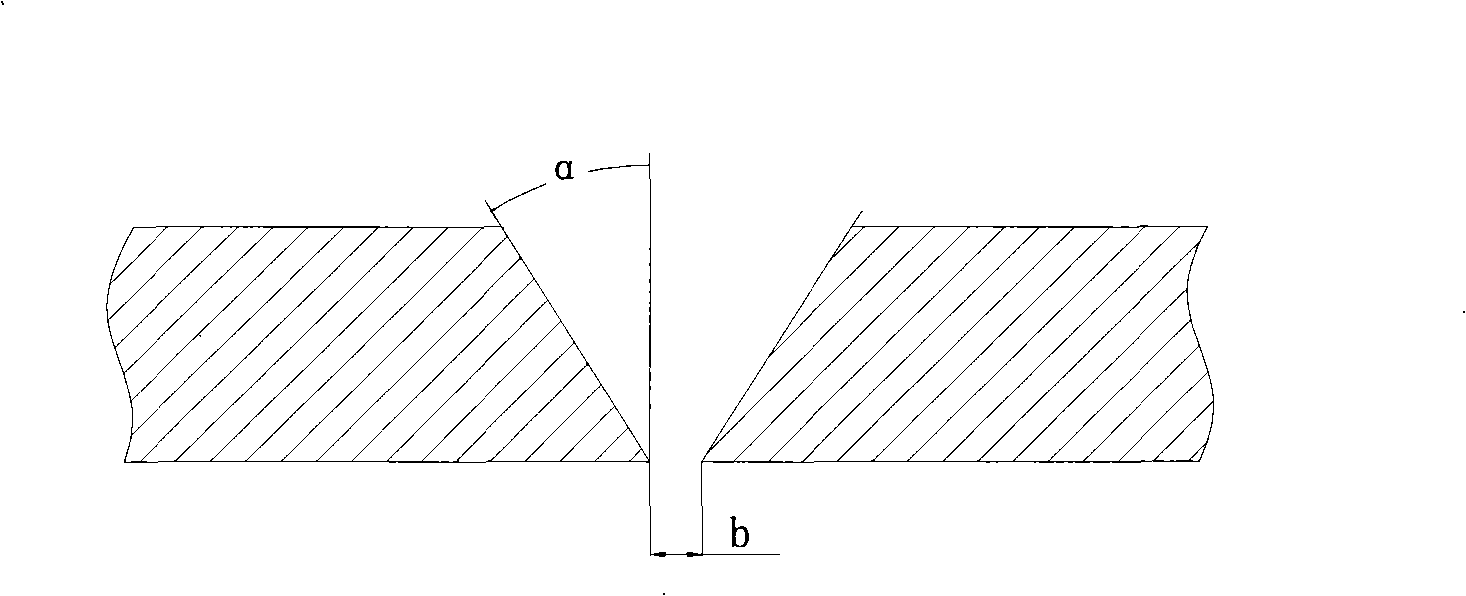

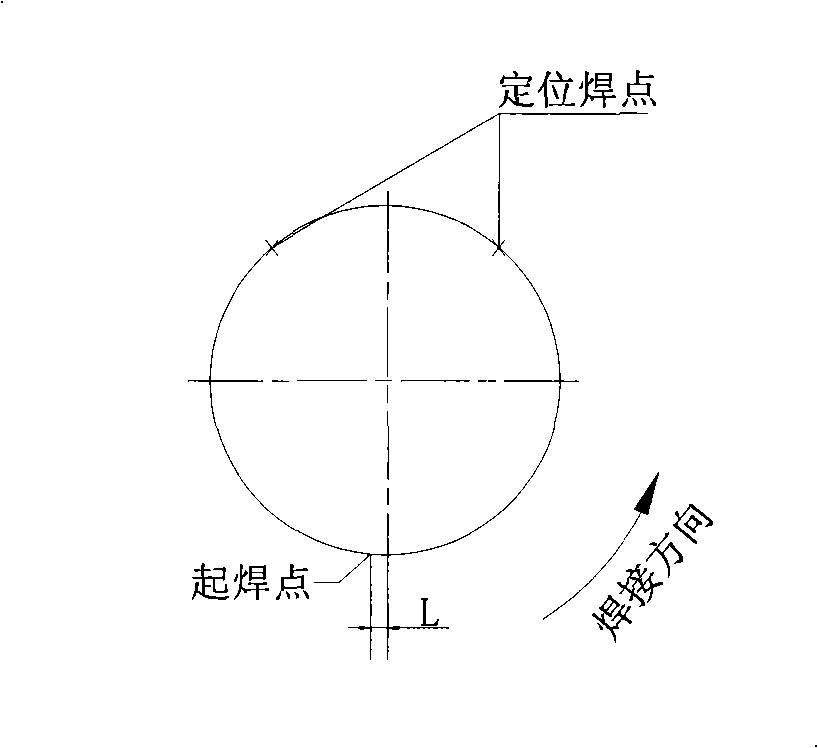

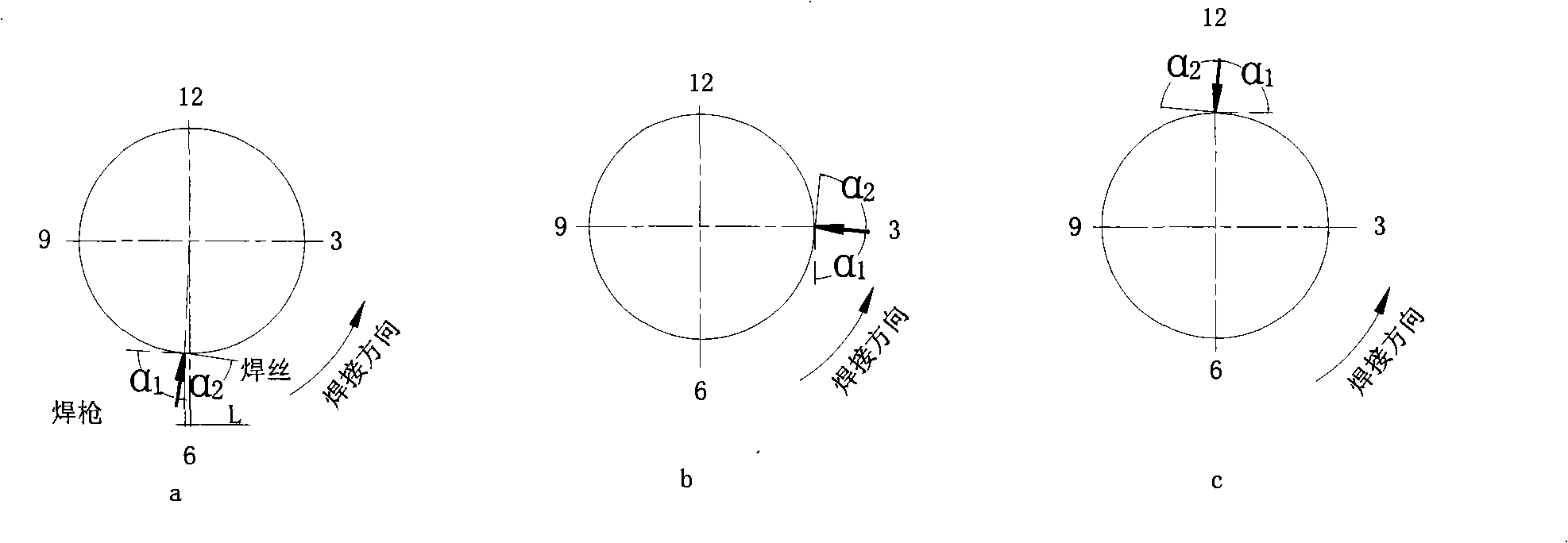

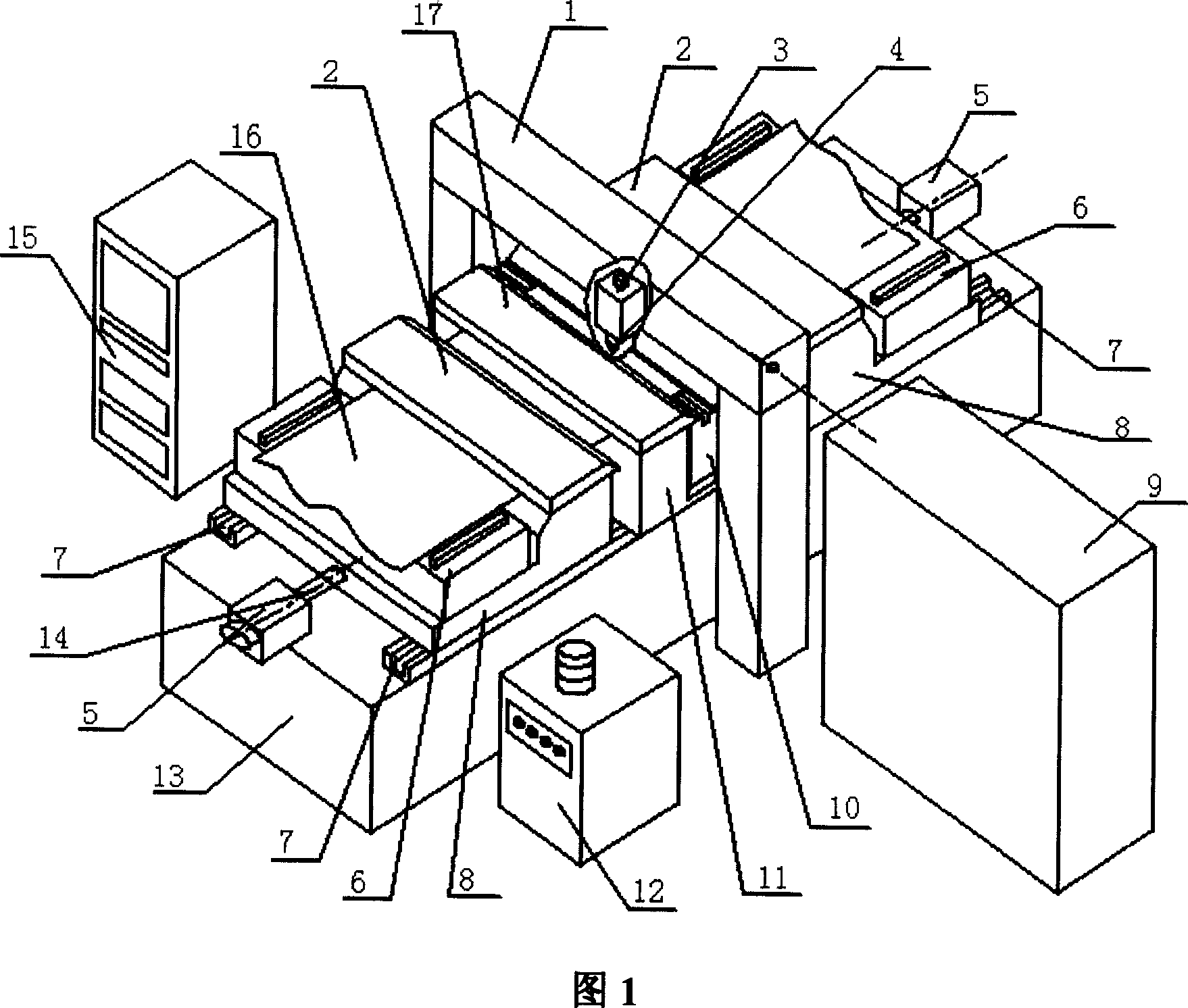

CCD-based method and system for automatic identification and track planning of pipeline space weld seams

ActiveCN104400279AMeet welding needsEliminate influence of welding qualityWelding/cutting auxillary devicesAuxillary welding devicesWeld seamEngineering

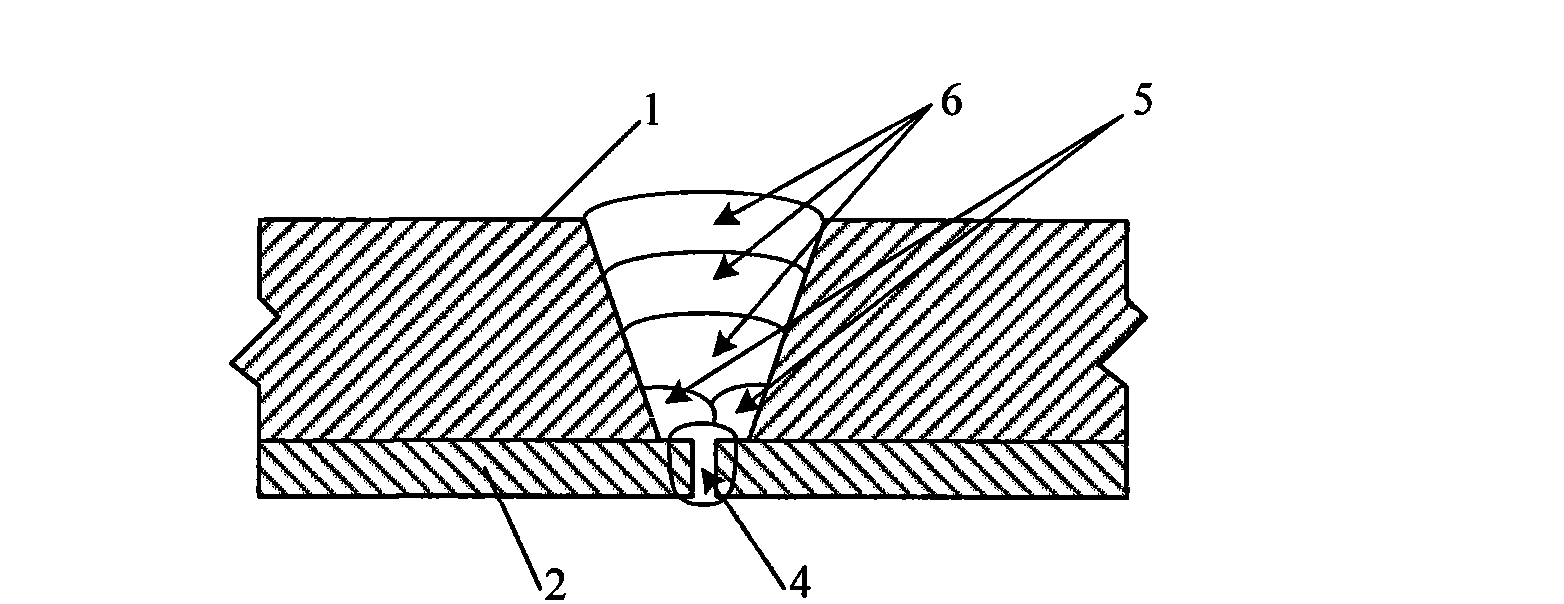

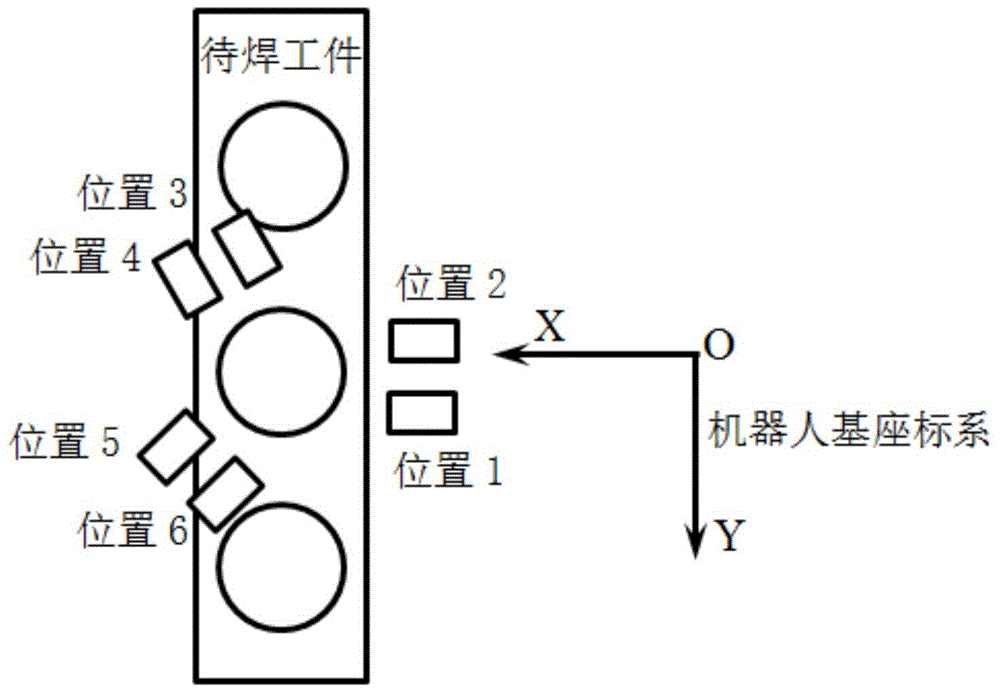

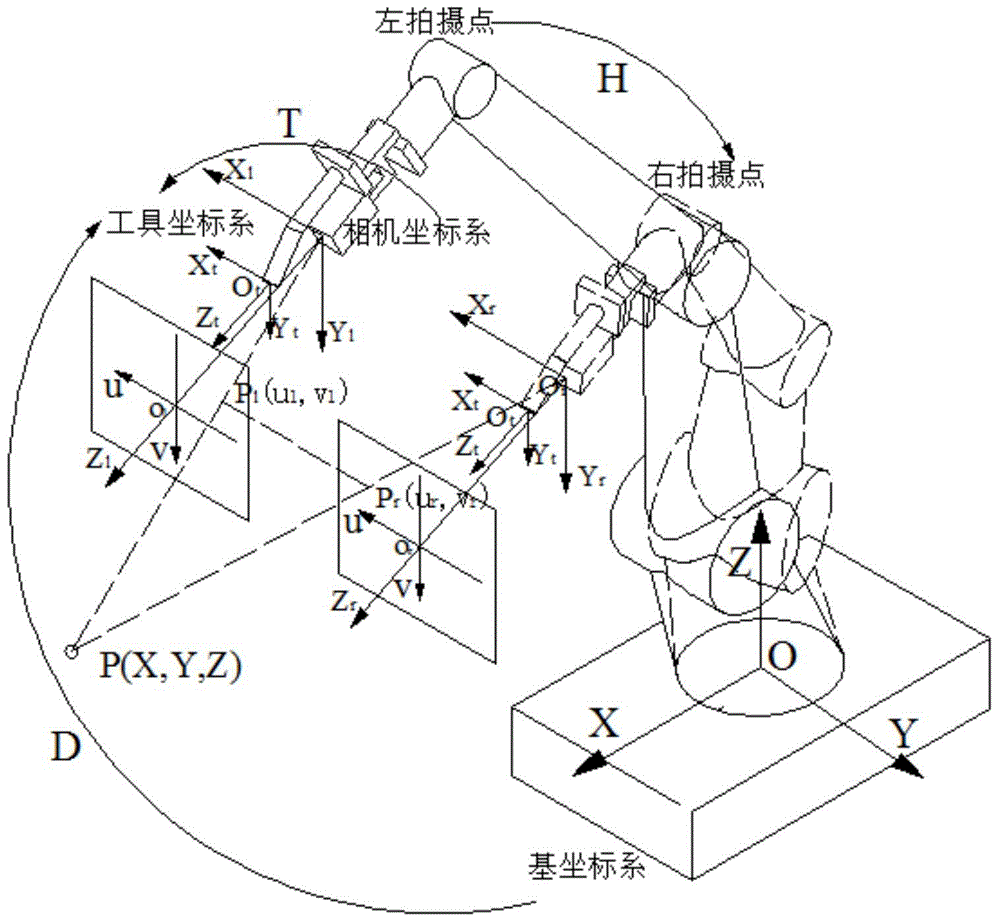

The invention discloses a CCD-based method and system for automatic identification and track planning of pipeline space weld seams and meets common welding robots' requirements on welding of the pipeline space weld seams. Before welding, a CCD collects weld seam images in a one-eye and two-position way, and transmits the weld seam images to a main control computer through a USB cable; the main control computer conducts three-dimensional reconstruction on the weld seam of a workpiece in three parts according to a general stereoscopic vision principle to obtain the three-dimensional coordinate information of the three parts of the weld seam, combines the three-dimensional coordinate information to obtain the complete three-dimensional coordinates of the weld seam to determine the starting point of welding and determine the pose change of a robot tool coordinate system in the welding process, and transmits the pose change to a robot control cabinet via the Ethernet to control a welding robot to perform welding. Through a vision sensing system, the method and the system provided by the invention can be adapted to welding of butting and intersection of pipelines of different diameters to conduct all-position automatic welding, and avoids the limitation that only single-path weld seams can be welded according manual teaching.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Large caliber aluminium alloy pipeline non-pad tungsten electrode argon arc single face welding and double face shaping method

InactiveCN101301699ABeautiful weldWell formed inside and outArc welding apparatusWelding/soldering/cutting articlesEngineeringWeld seam

The invention discloses a method for large-calibre aluminium-alloy pipeline no-liner tungsten electrode argon arc one-side welding both-side formation, comprising the following steps of: assembling of groove angle and clearance, grinding of tungsten electrode, cleaning before welding, adjusting welding process parameters, tack welding, and welding of a bottom coating, a filling layer and a covering layer. The pipe is horizontally fixed and the position is marked by hour; the welding sequence is left half-ring and right half-ring; each half-ring comprises overhead welding, vertical position welding and downhand welding; the welding is started at a position where L is equal to 5-10mm close to six of the overhead welding; the vertical position welding is then carried out; finally, the front half-ring is ended at 12 of the downhand welding; before the rear half-ring starts welding, the connection is grinded as a slope; the welding seam formed by the connection and the front half-ring welding position is overlapped by 3-5mm; the welding of the rear half-ring is started from 6 of the overhead welding and ended at 12 of the downhand welding through the vertical position welding; the welding is carried out by a continuous feeding method. The surface of the welding seam of the method has no pores or cracks, is completely welded and beautiful, and has good internal and external forming; by the non-destructive testing, the first-time qualification rate achieves 100%, the welding seam achieves the class-1 quality, the construction procedures are reduced, and the construction cost is reduced.

Owner:ANGANG CONSTR CONSORTIUM

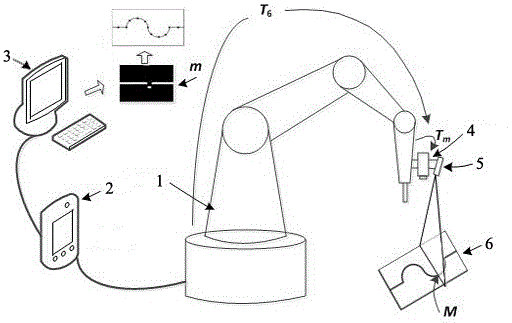

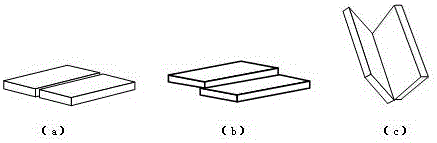

Curve-welding-seam three-dimensional reconstruction method based on line structure light vision detection

The invention provides a curve-welding-seam three-dimensional reconstruction method based on line structure light vision detection. By using the method, various kinds of welding seams can be effectively detected, reliability is high, the method is simple and detection efficiency is high. A mechanical arm and a line structure light vision system are included. A controller controls and is connected to the mechanical arm. The line structure light vision system comprises a camera and a line structure light projector. The camera is fixed to a tail end of the mechanical arm. The line structure light projector is fixed to one side of the camera and is projected to a surface of a workpiece to be welded. The curve-welding-seam three-dimensional reconstruction method comprises the steps of system calibration, welding seam detection and welding seam reconstruction so that a complete three-dimensional curve welding seam is reconstructed.

Owner:WUXI PROFESSIONAL COLLEGE OF SCI & TECH

Plate-bending online laser welding technology and its equipment

InactiveCN101100030AReduce assembly requirementsSimple structureShearing machinesOther manufacturing equipments/toolsBogieEngineering

The present invention is plate bending and laser welding process and apparatus. The technological process includes cutting with one upper shearing machine and one lower shearing machine, lowering the upper shearing machine, raising the leveling plates on two sides and pushing with bogies on two sides for matching two cut edges of the workpiece, closing two leveling plates to clamp the workpiece on the upper shearing machine, and welding with the laser head to form weld seam. The apparatus includes one shearing system comprising two shearing machines, one workpiece fixture, tracked bogies and one driving mechanism; and one welding laser set comprising one laser guide unit, one laser head, and one X and Y axis assembly. The present invention has simple technological process, compact apparatus structure and low cost, and is suitable for plate bending and welding production.

Owner:HUAZHONG UNIV OF SCI & TECH

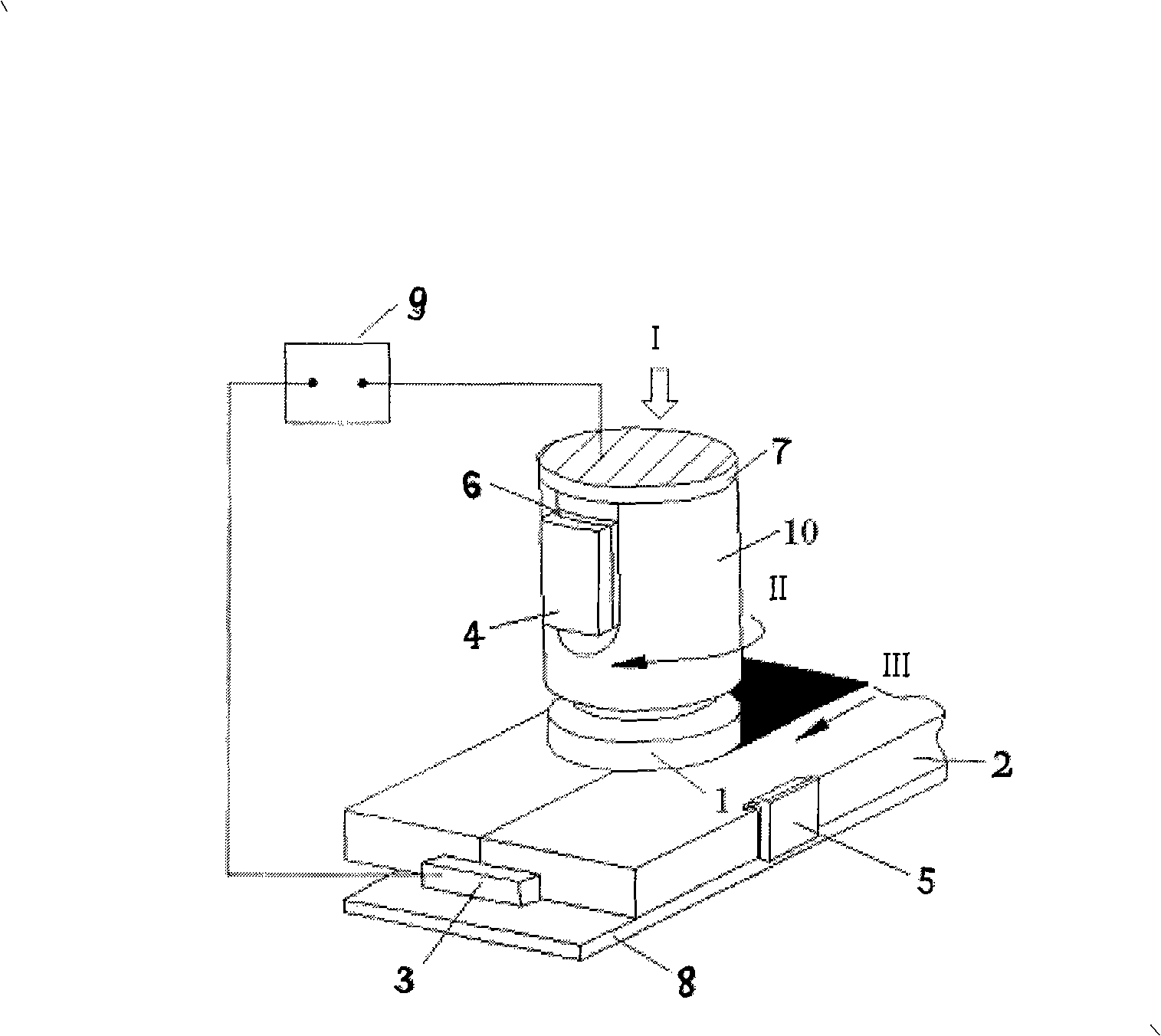

Electric conduction-stirring friction composite heat power supply welding method and equipment

ActiveCN101323054AOvercoming a lack of energy inputBreak through limitationsResistance welding apparatusNon-electric welding apparatusEngineeringWeld seam

The invention discloses a conducting-stirring friction hybrid heat source welding method and a piece of equipment, wherein, in stirring friction welding, a stir head and a workpiece are simultaneously insulated from the main body of a welding machine, the clamp of a fixed workpiece and a worktable, current is galvanized in the weld seam direction of the workpiece, the current and the weld seam through which the current flows produce resistance heat with the contact resistance of a friction stirring welding area, and the resistance heat together with stirring friction heat forms the hybrid heat source of the stirring friction welding. The method and the equipment of the invention have the following remarkable effects: 1. the limitation of the stirring friction welding on welding materials is broken through, leading the stirring friction welding to be used for welding such structural materials as black ferrous metals, superalloy, and the like; 2. the service life of the stir head can be improved; and 3. welding speed and welding quality can be further improved, thus improving the mechanical property of a welding joint. The method and the equipment of the invention can be used for the stirring friction welding, the preheating before welding, and the postweld heat treatment of such structural materials as carbon steel, stainless steel, and superalloy, etc.

Owner:罗键

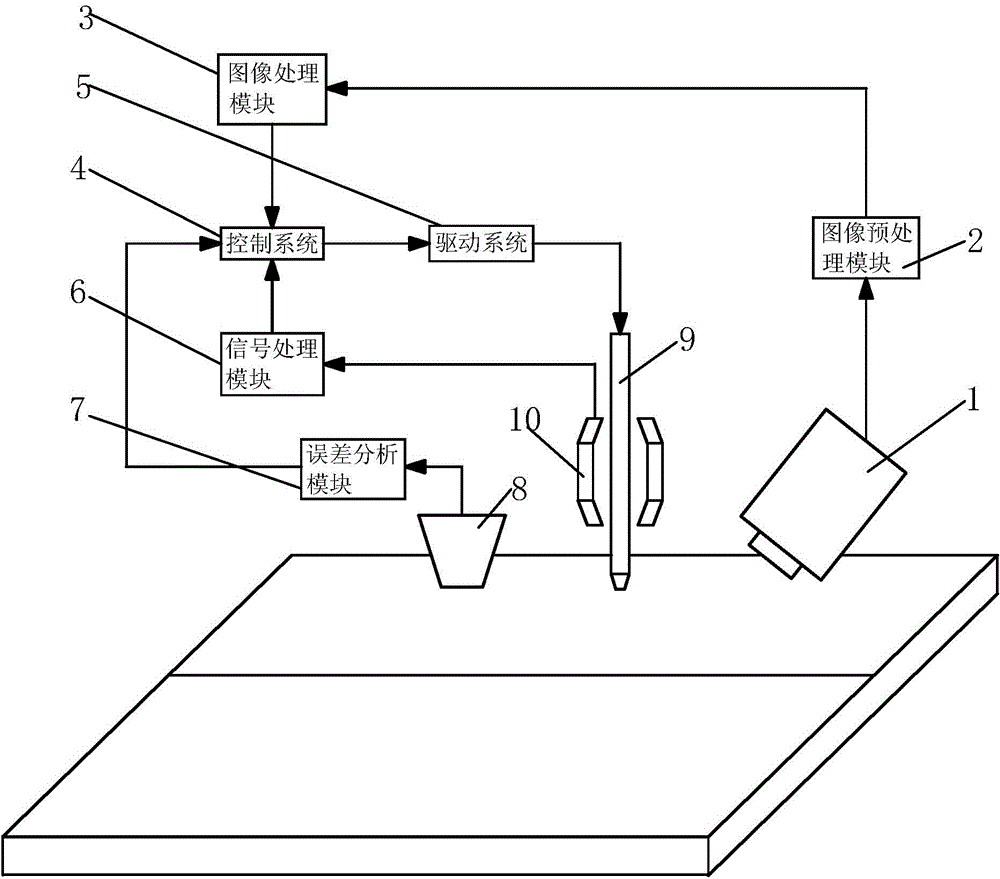

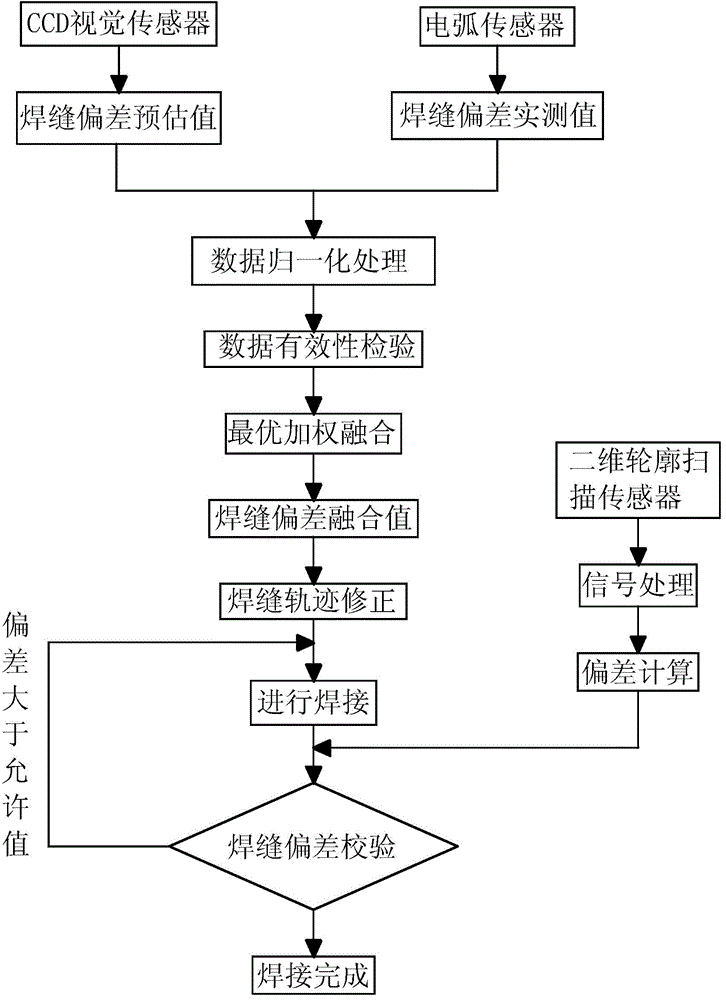

Automatic tracking control and online correction system with welding gun and control method thereof

The invention relates to an automatic tracking control and online correction system with a welding gun and a control method thereof and belongs to the technical field of robotic arc welding. The automatic tracking and control and online correction system comprises a vision sensing system, an image processing system, a tracking control system and an online correction system, wherein the vision sensing system comprises a CCD (Charge Coupled Device) vision sensor; the image processing system comprises an image preprocessing module and an image processing module; the tracking control system comprises the welding gun, a control system, a driving system, a signal processing module and an arc sensor; the online correction system comprises a laser two-dimensional outline scanning sensor and an error analysis module. According to the automatic tracking control and online correction system, butt-welded seams are predicated, tracked and corrected respectively a prewelding stage, a welding stage and a post-welding stage by virtue of error online fusion of three sensors, namely the CCD vision sensor, the arc sensor and the laser two-dimensional outline scanning sensor, so that the welded seam tracking precision and the fault tolerance of the system are improved, the welding production efficiency and the welding quality are improved, and the automatic tracking control and online correction system has generality.

Owner:WUHU ANPU ROBOT IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com