Weld seam surface detect feature extraction method based on grayscale image morphology

A grayscale image and weld surface technology, applied in the field of non-destructive testing, can solve the problems of few researches on the detection and identification of weld surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below in conjunction with concrete experiment the present invention will be further described:

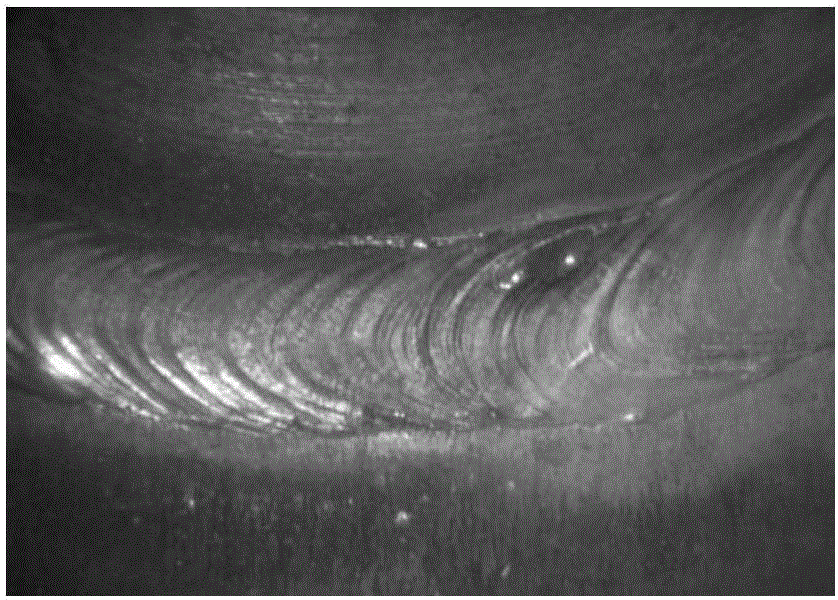

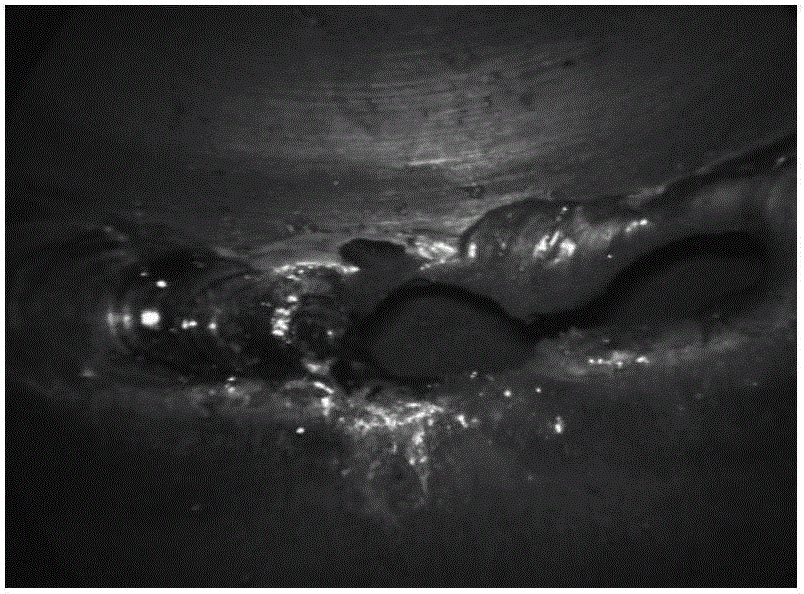

[0053] In this experiment, the samples with holes on the surface of the weld and the weld bead on the surface of the weld are selected as feature extraction images, and the samples with good surface welding quality are selected as the verification images of the edge extraction algorithm in the early stage. Such as figure 1 shown. Step 1: Image acquisition.

[0054] An industrial CCD camera is used to collect images of defects such as holes and welding spots on the internal weld surface of the transducer. The collected images are true-color RGB images, with image size 480*360, hue 4, saturation 100, contrast -4, and each value is fixed. constant.

[0055] Step 2: Image pre-processing.

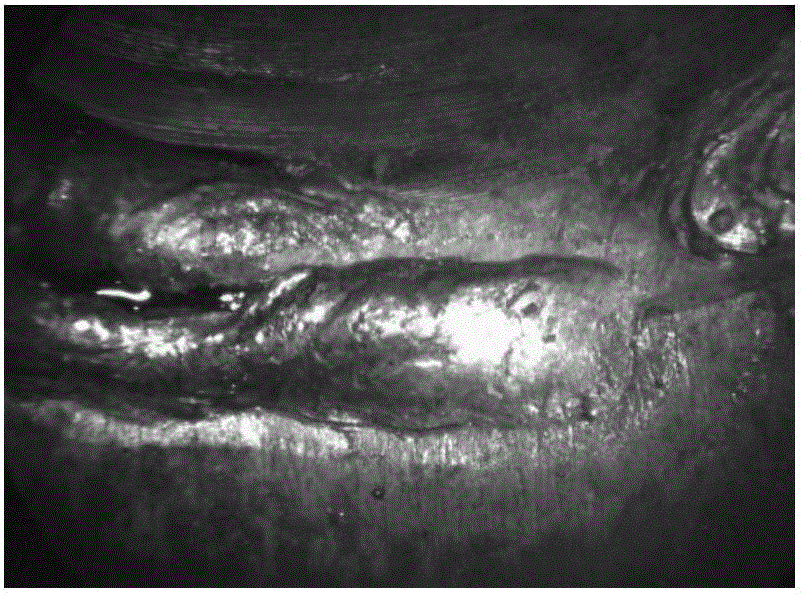

[0056] According to the formula (1), the true color RGB image is converted into a grayscale image. as shown in picture 2.

[0057] Step 3: Image preprocessing.

[0058] Median filterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com