Patents

Literature

1635 results about "Seam welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seam Welding. Seam welding is a variation of resistance spot welding. In resistance seam welding, however, the welding electrodes are motor driven wheels as opposed to stationary rods. The result is a 'rolling' resistance weld or non-hermetic seam weld. This process is most often used to join two sheets of metal together:

Seam-welded metal pipe and method of making the same without seam anneal

InactiveUS7032809B1Efficient processingEliminates annealing stepArc welding apparatusFurnace typesSufficient timeWeld seam

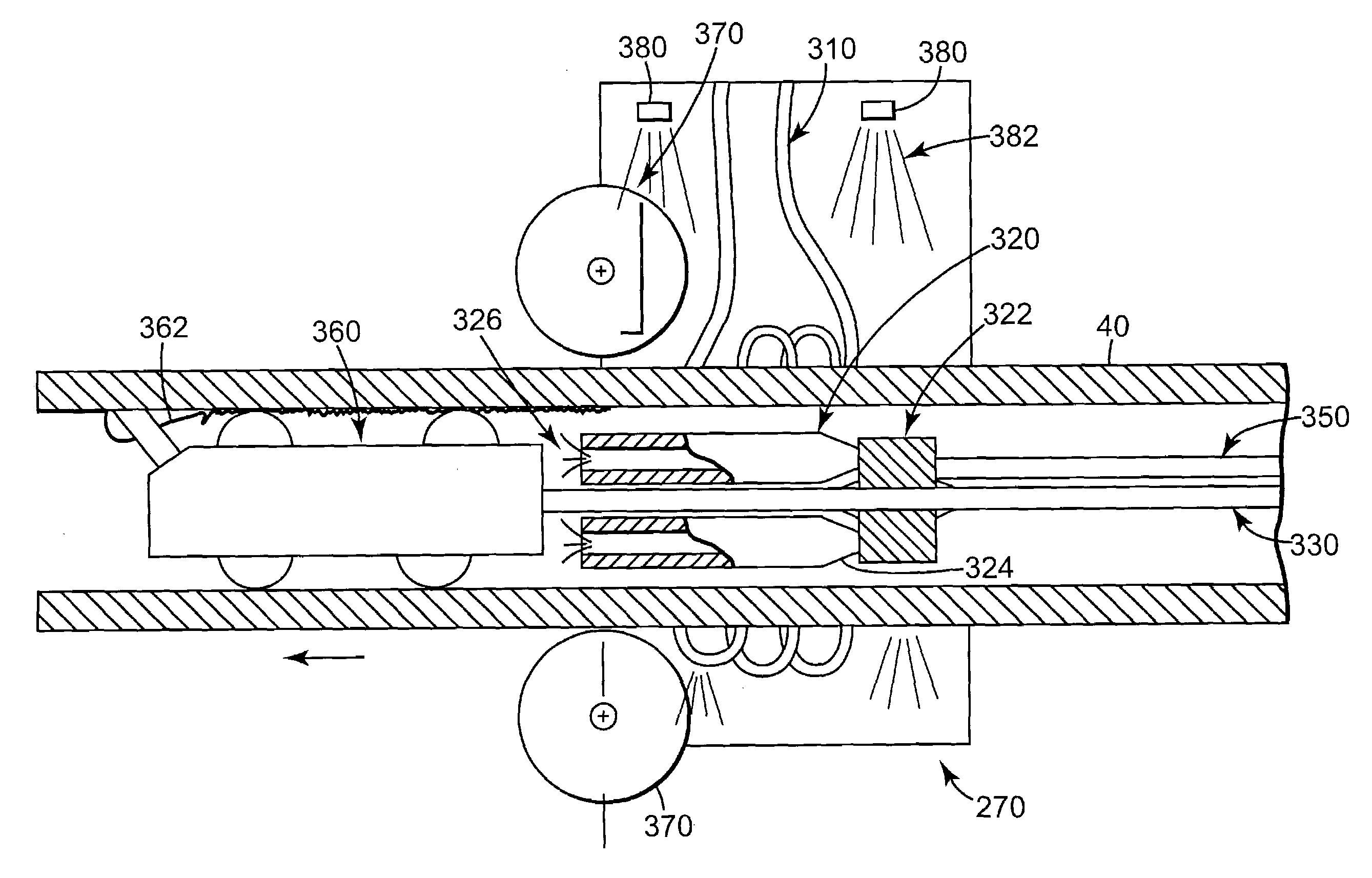

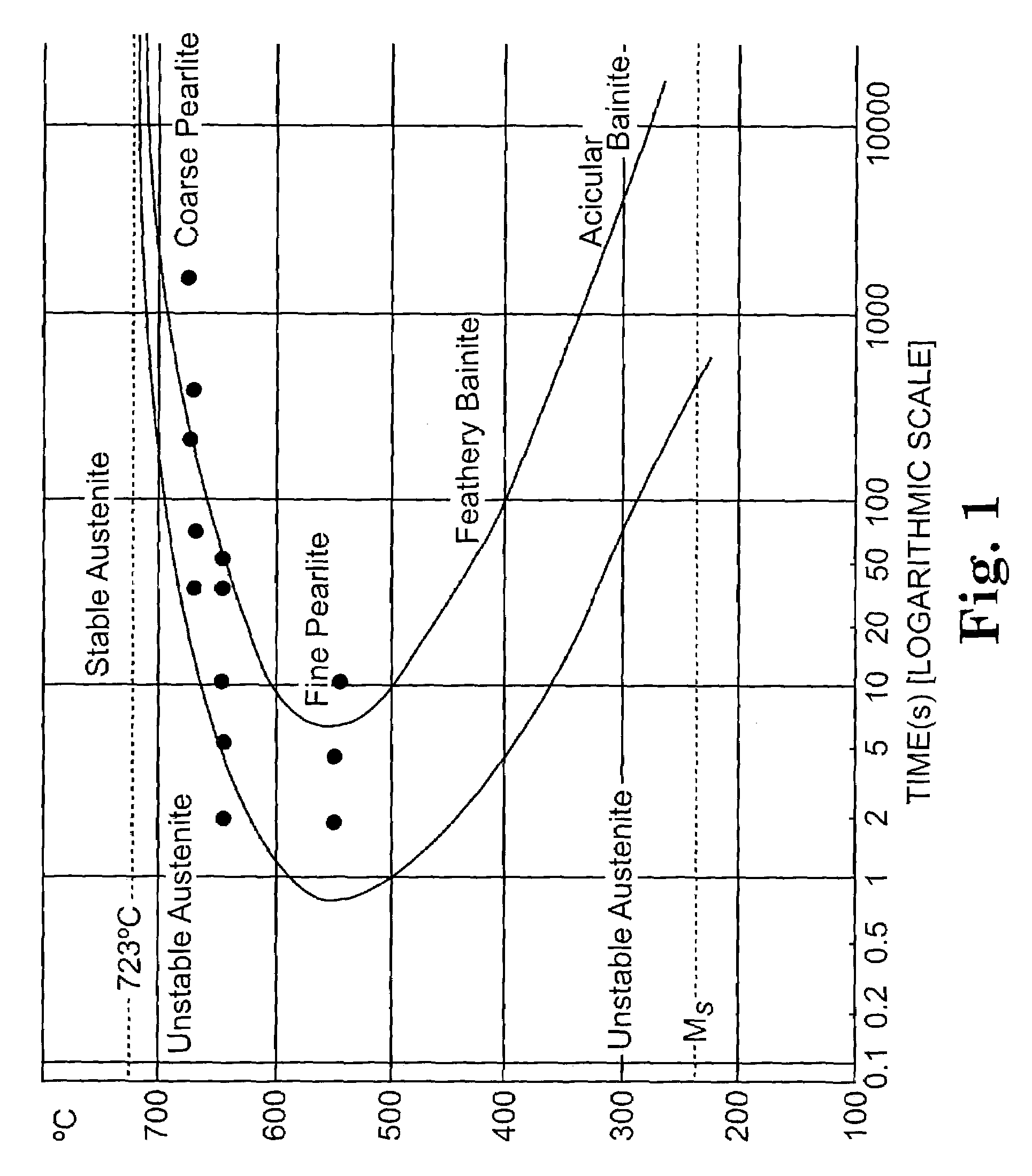

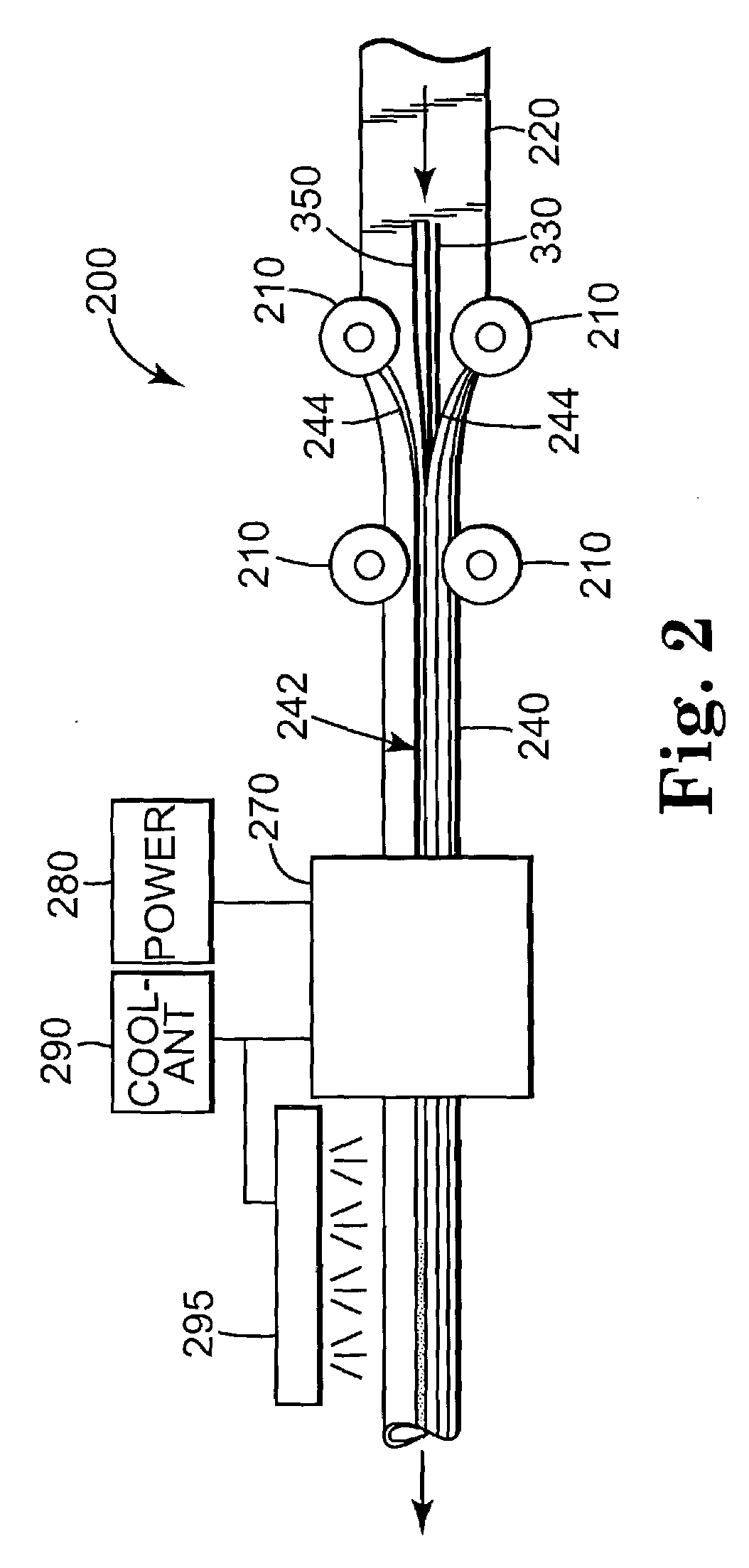

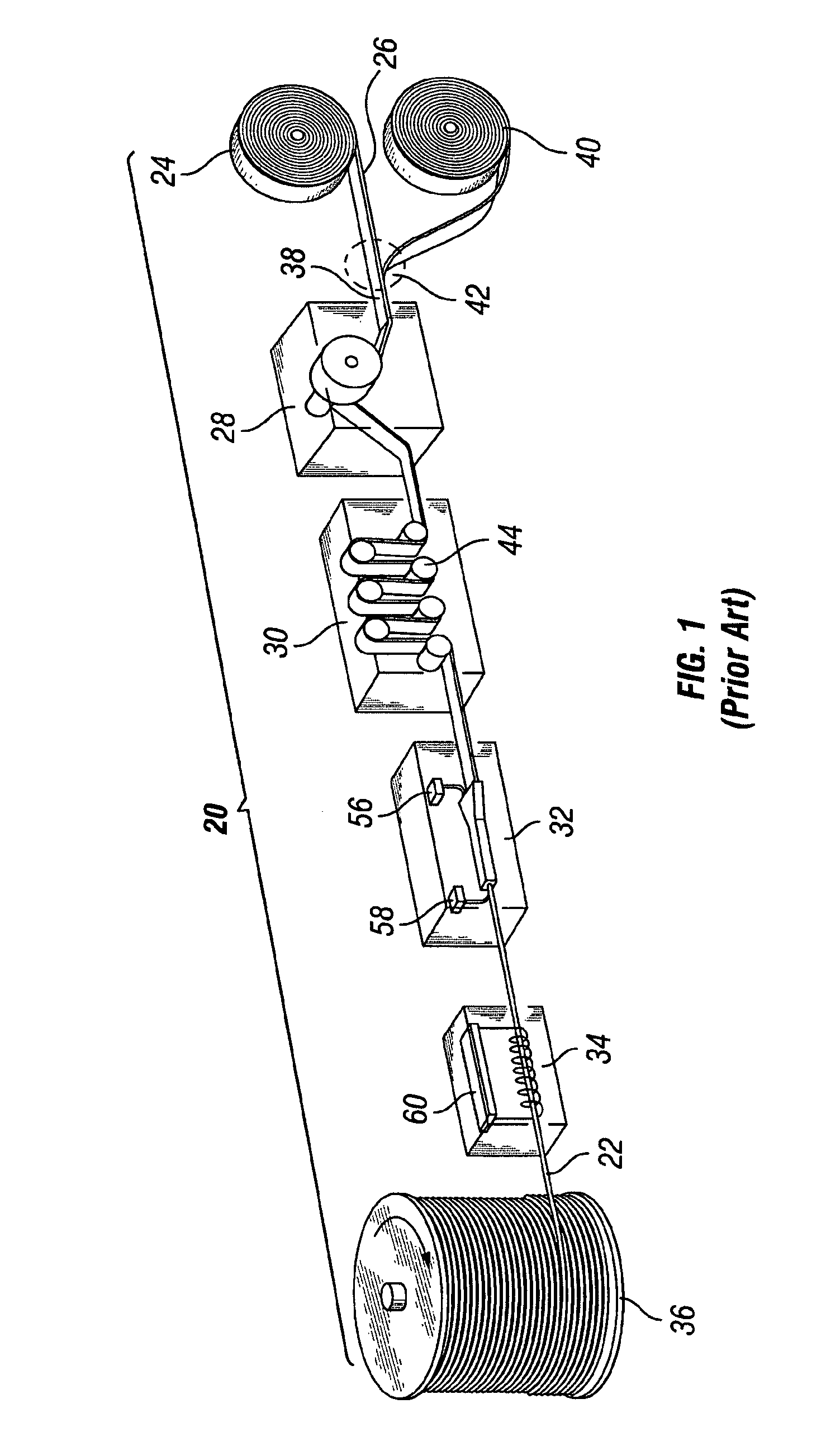

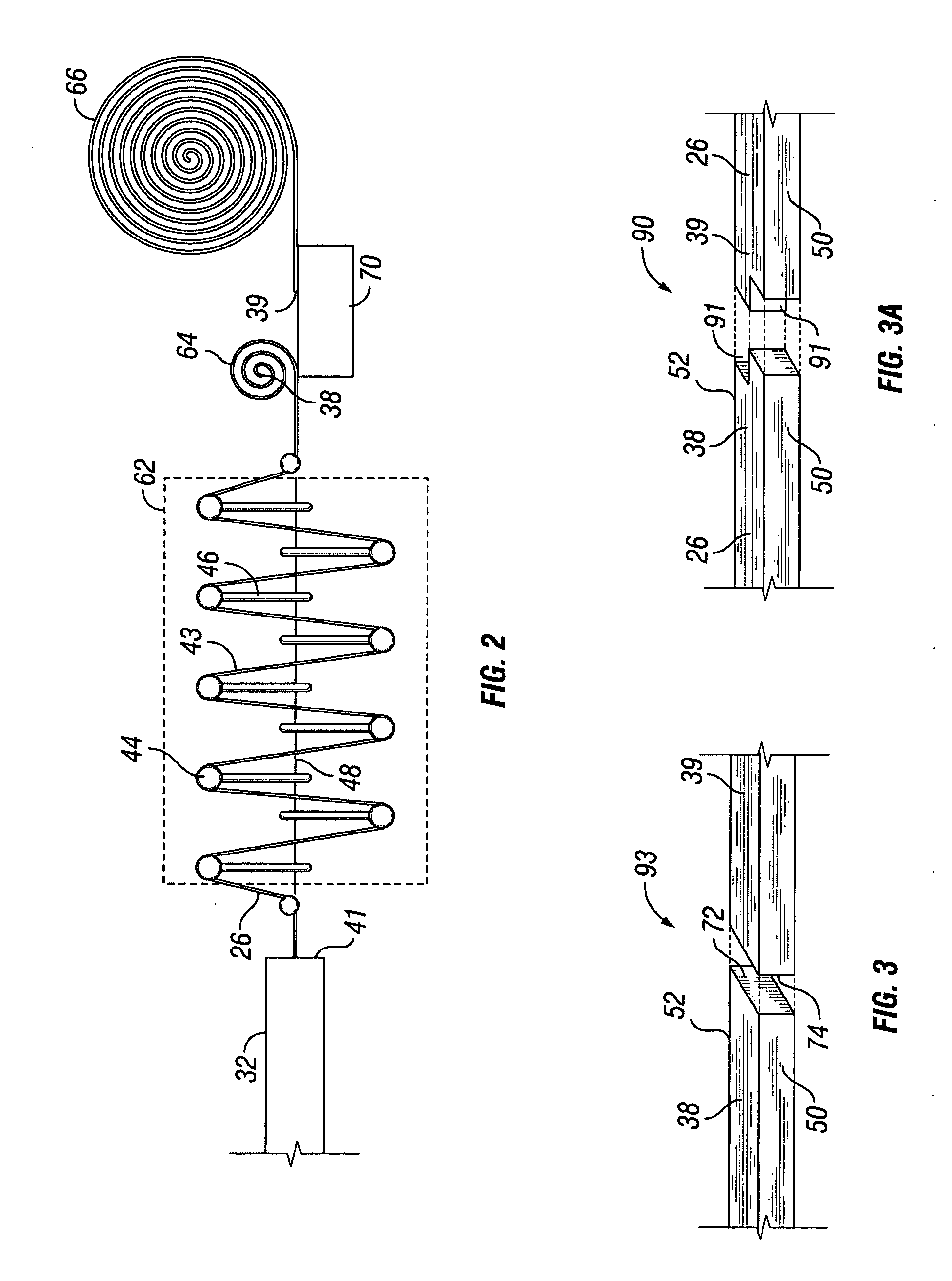

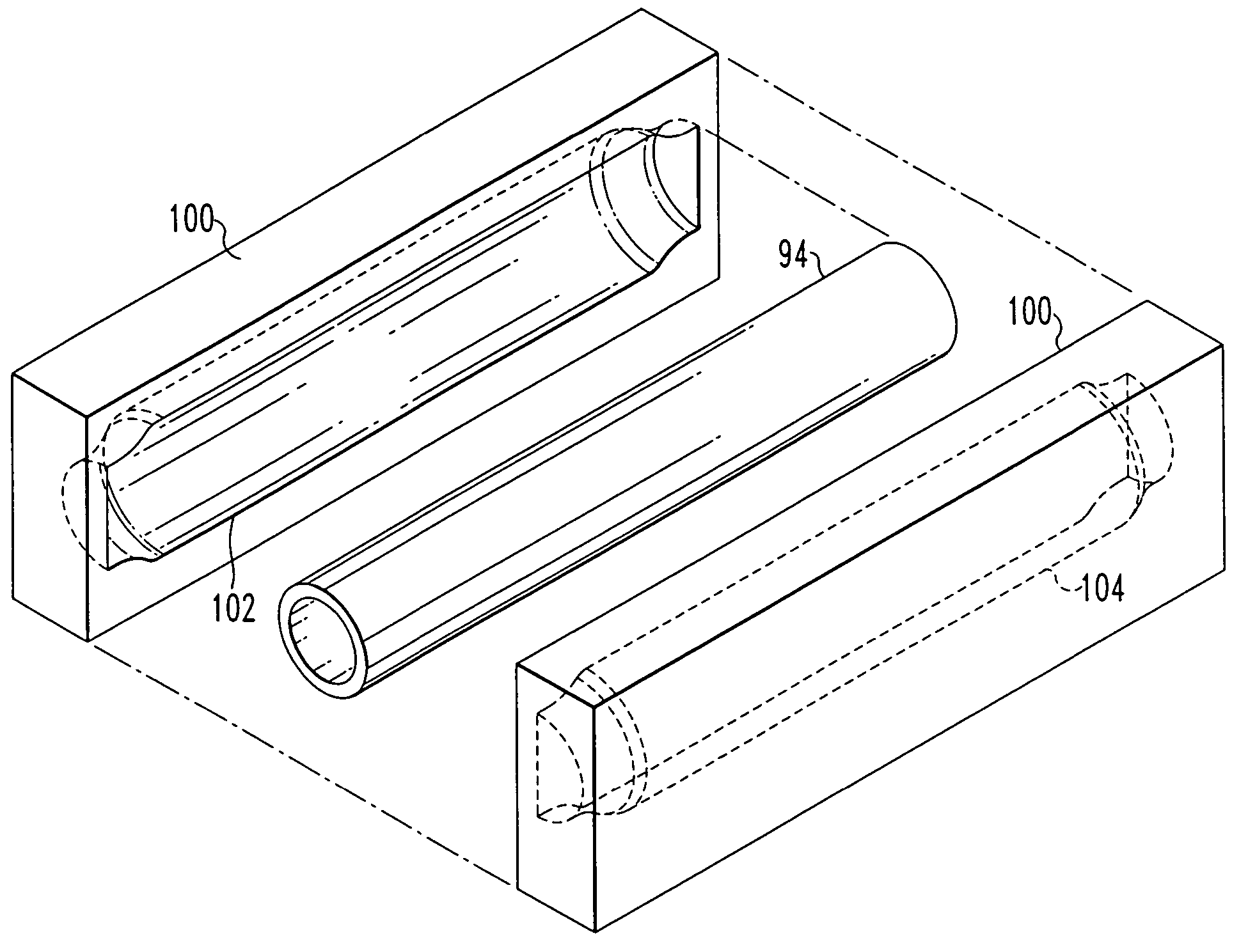

An apparatus and method for making a seam-welded steel pipe free of untempered martensite without seam anneal. The method includes selecting a steel containing a carbon concentration below a predetermined level, for example, 0.14% or 0.12% by weight. The method also includes flooding both outside and inside of the strip with a coolant while the weld seam is being formed, and continuing to immerse the welded strip for a sufficient time after the weld seam is formed to prevent the formation of untempered martensite. The apparatus includes a heater capable of heating the strip to a temperature sufficient to form a welded seam, a cooling module configured to supply a coolant to the welded seam both inside and outside of the strip as the weld seam is being formed, and another cooling module configured to immerse the welded strip in a coolant after the weld seam is formed for a sufficient length of time to prevent the formation of untempered martensite.

Owner:STEEL VENTURES

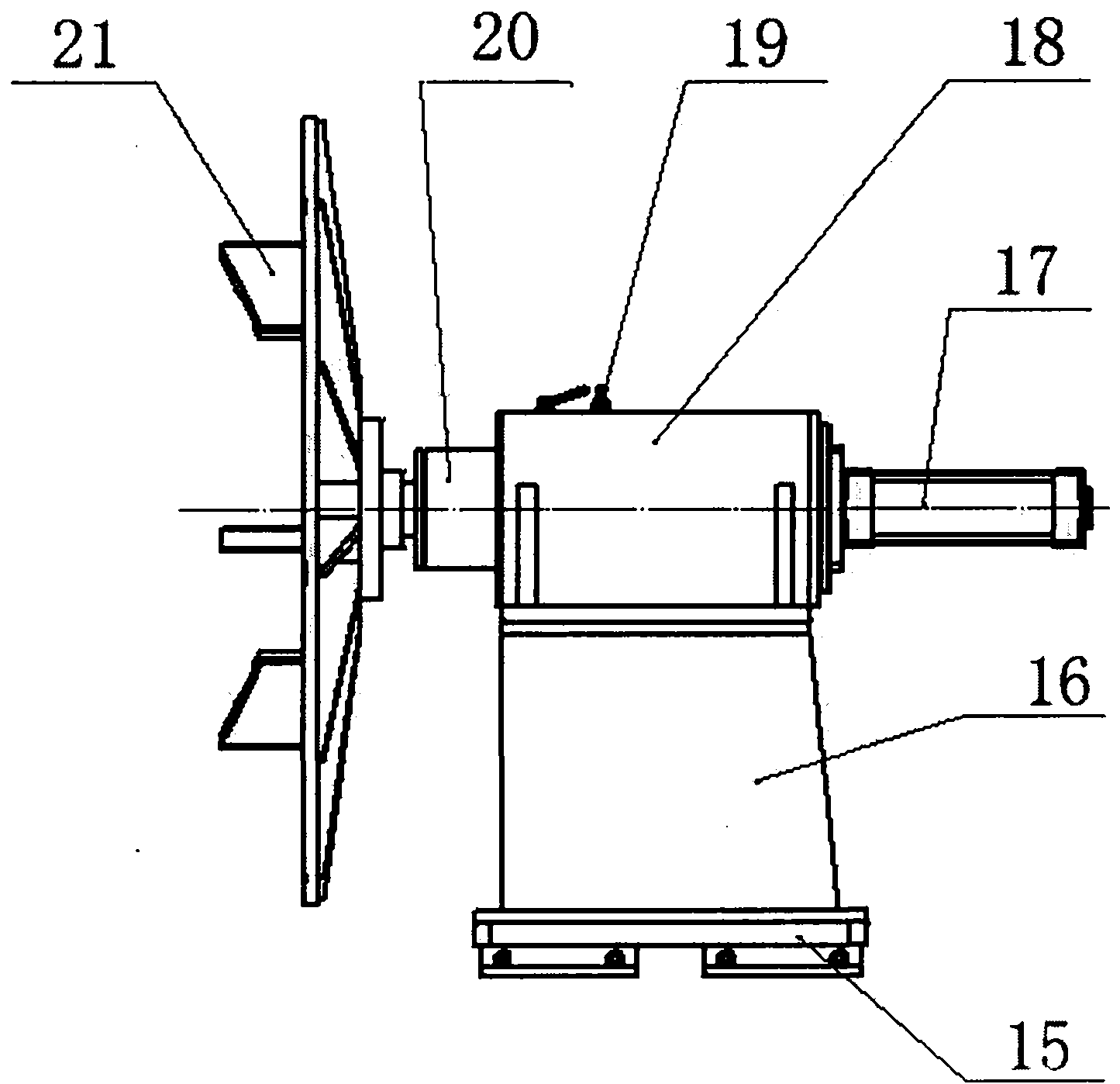

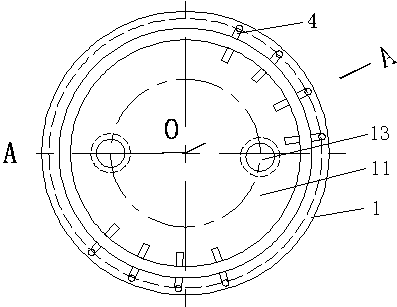

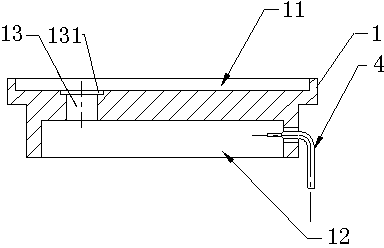

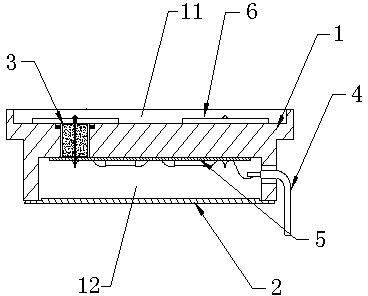

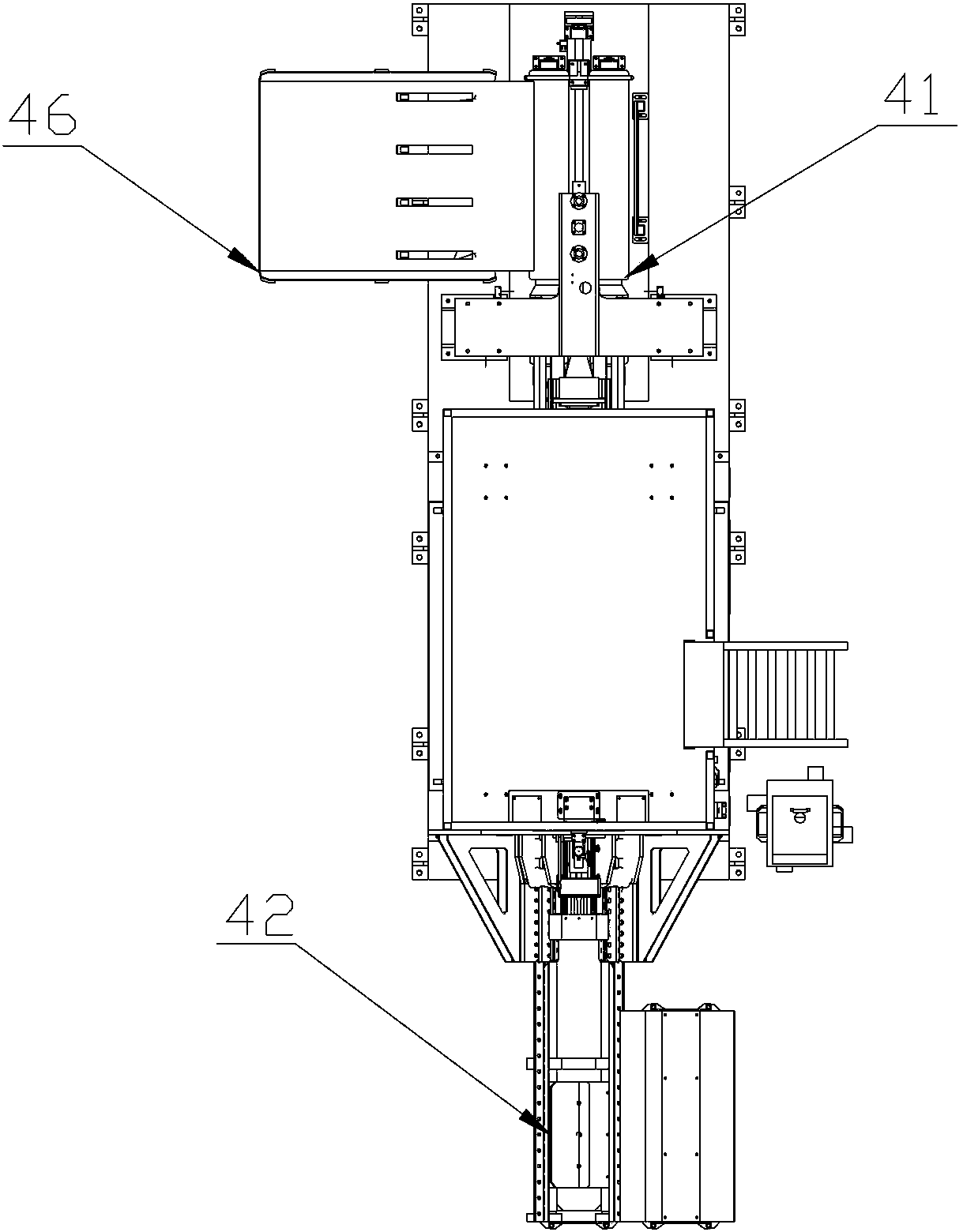

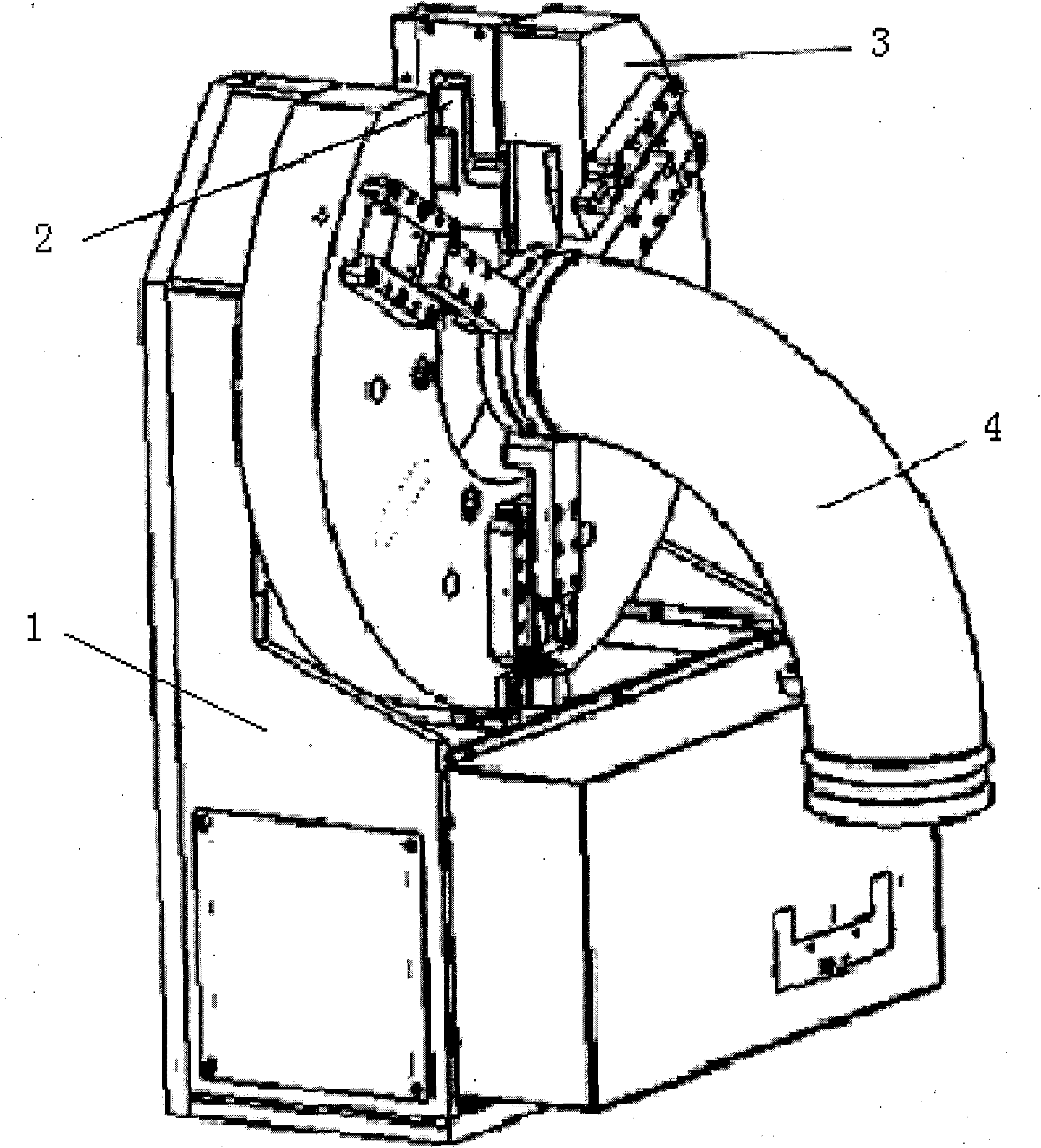

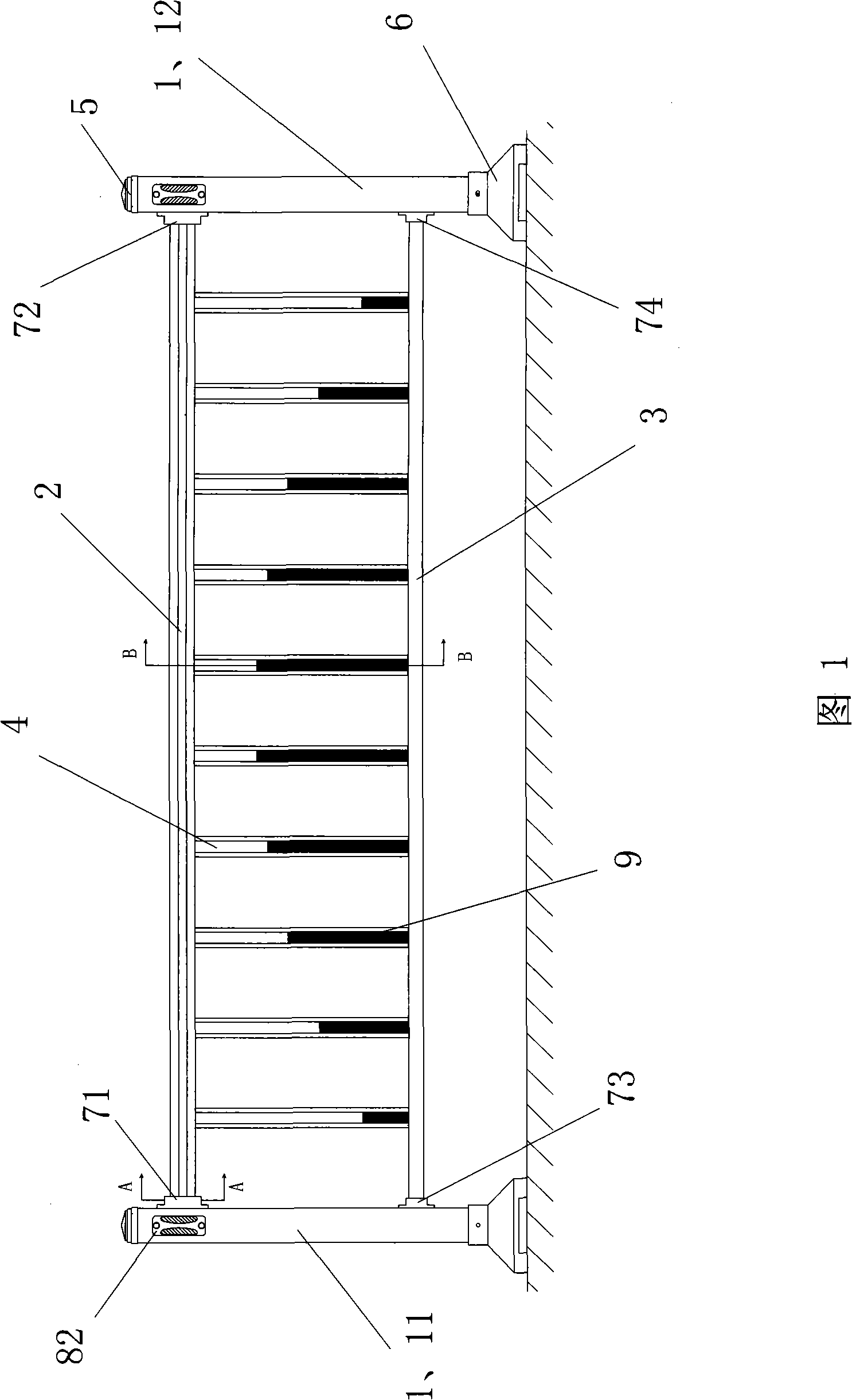

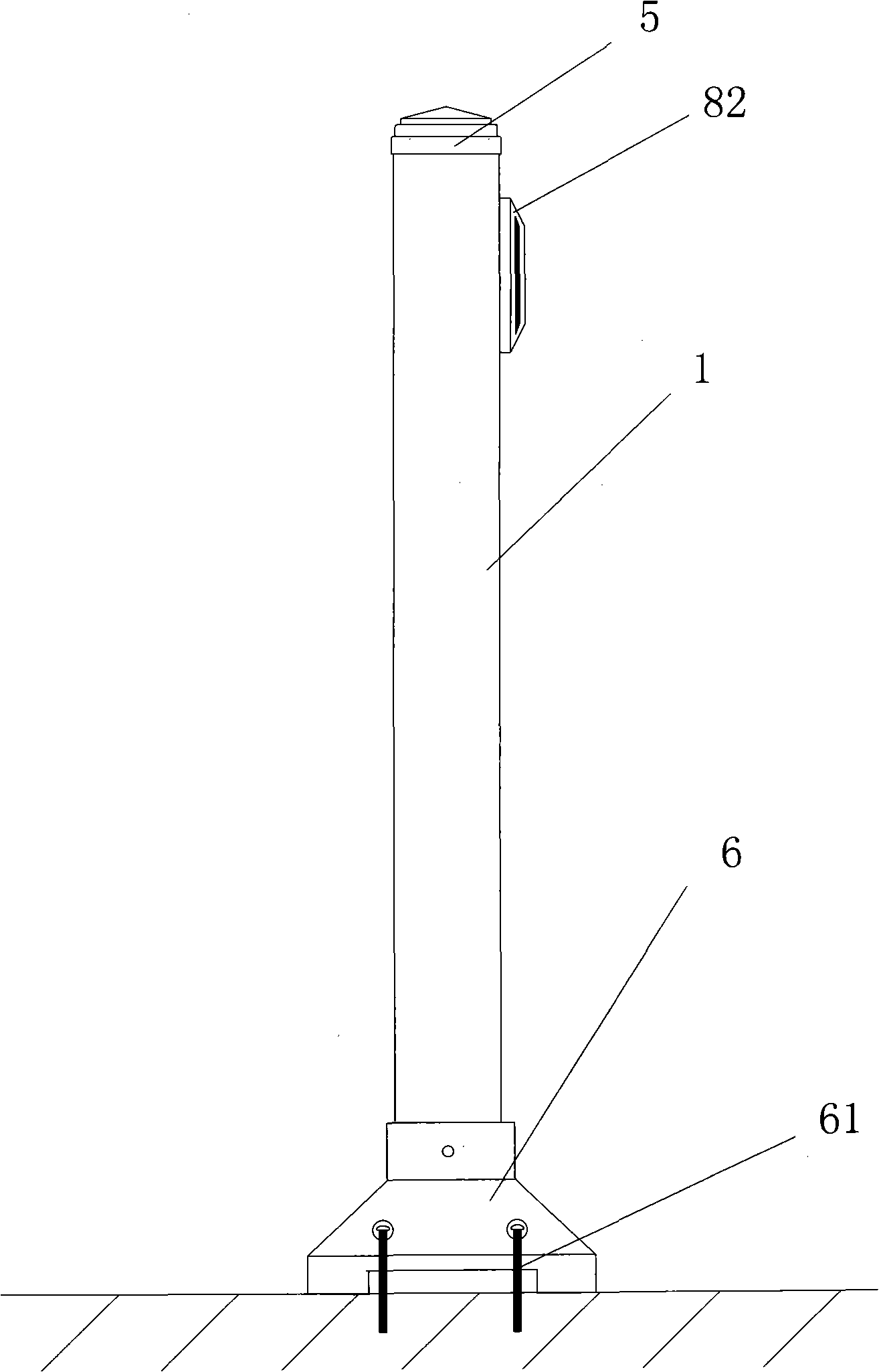

Speed-variable circular and longitudinal seam welder applied to multi-specification tank bodies

InactiveCN101913040ACompact structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSeam welding

The invention relates to a welding device, in particular to a circular and longitudinal seam welder special for automatically welding multi-specification tank bodies. The speed-variable circular and longitudinal seam welder applied to the multi-specification tank bodies mainly comprises four parts, namely a bed body (1), a headstock (2), a beam mechanism (12) and a tailstock (5). Compared with the prior art, the circular and longitudinal seam welder has the advantages of adapting to the change of the tank body diameter range of phi300 to 1,400mm and welding linear speed range of 200 to 1,200mm / min, realizing edge sealing and dual circular and longitudinal seam welding of the tank bodies, along with multiple functions, compact structure, convenient operation, high stability and low production cost.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

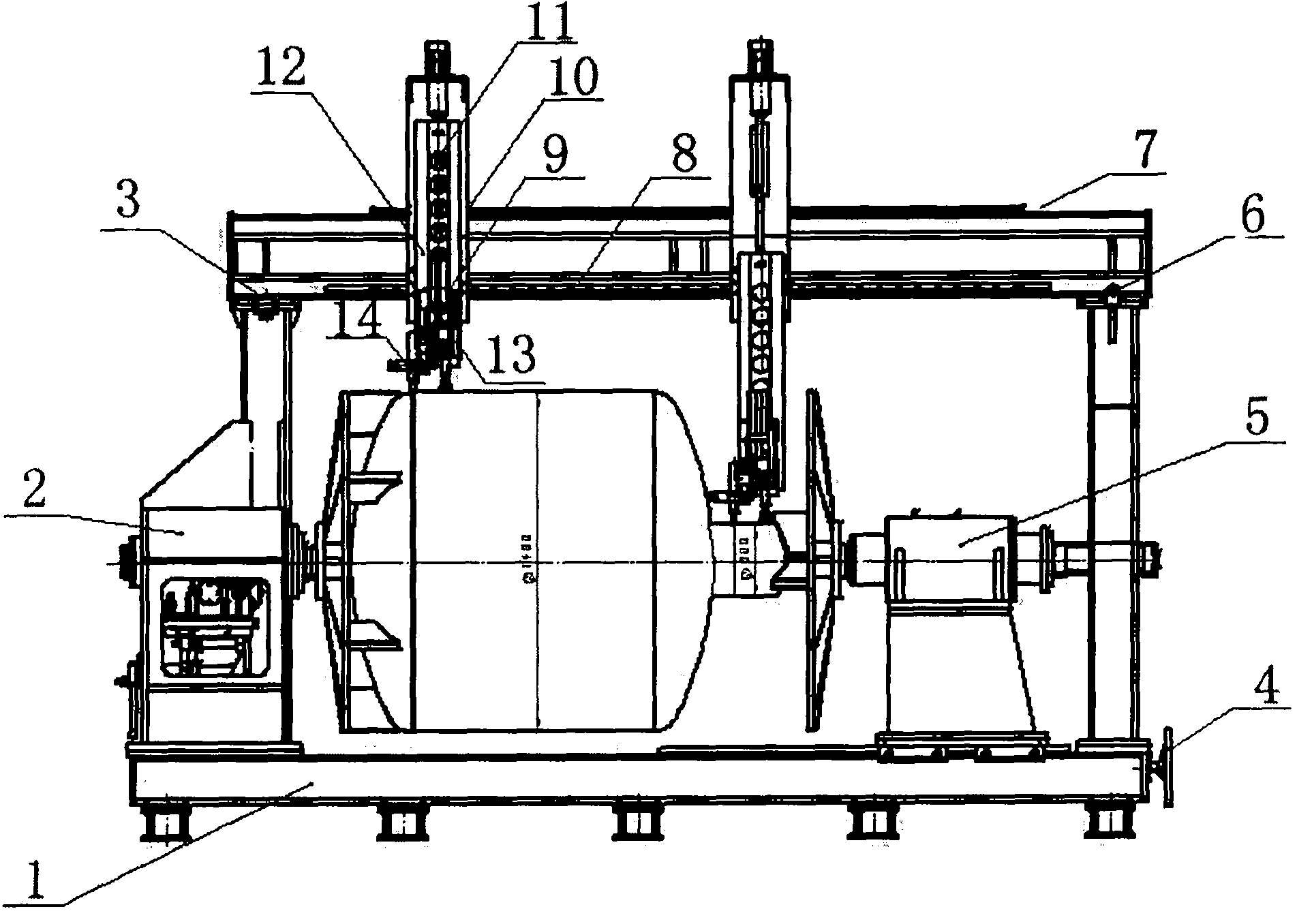

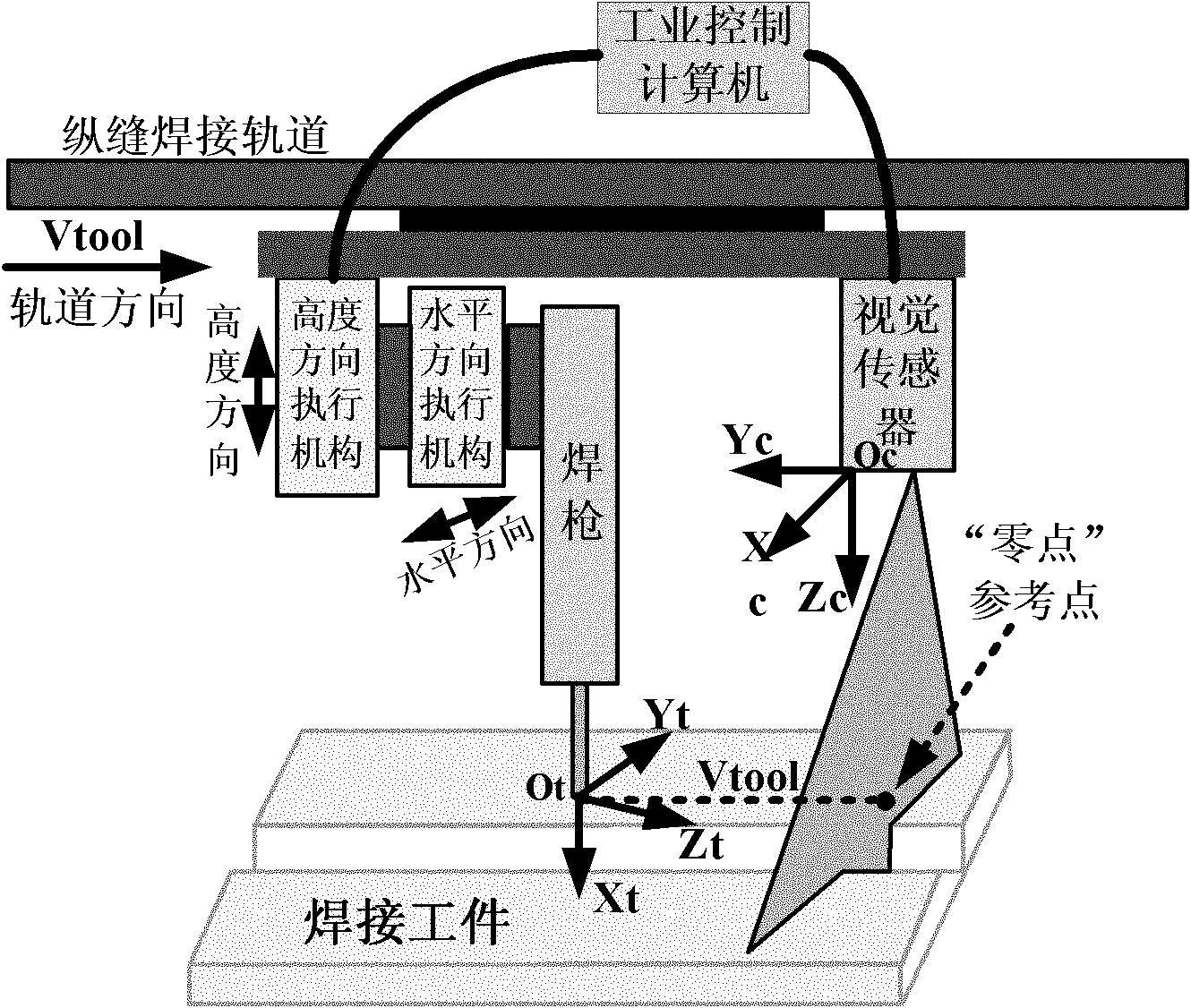

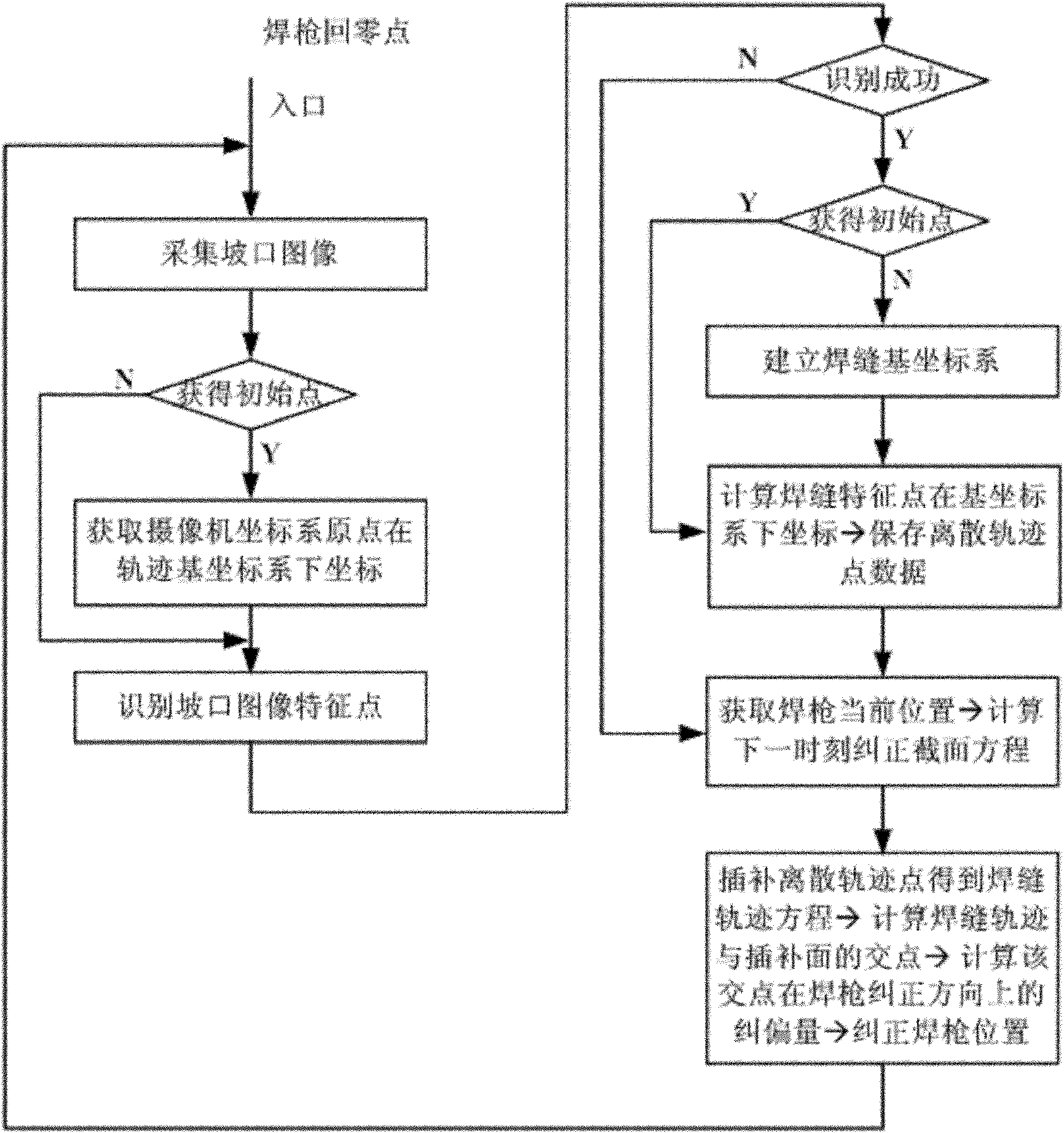

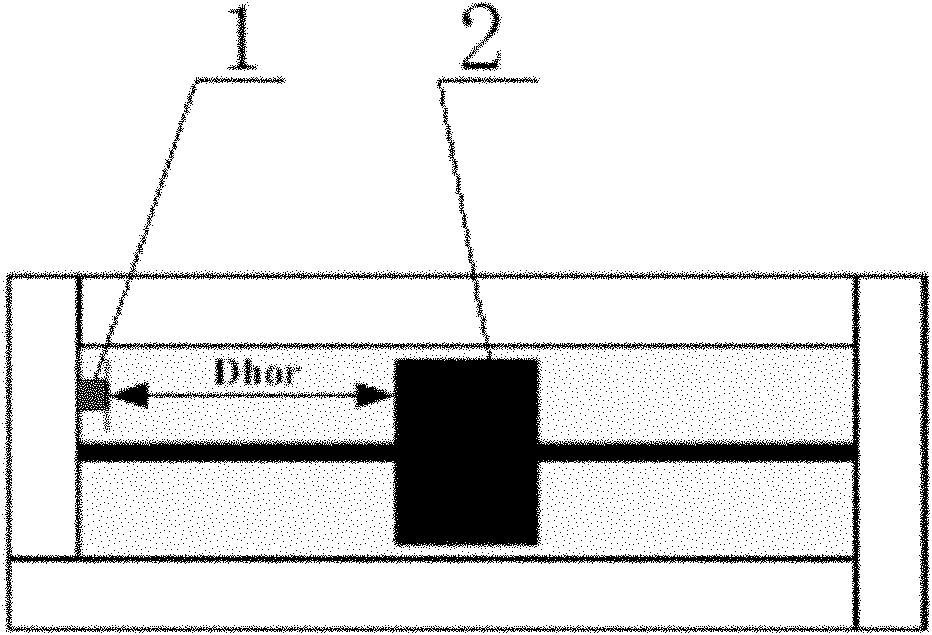

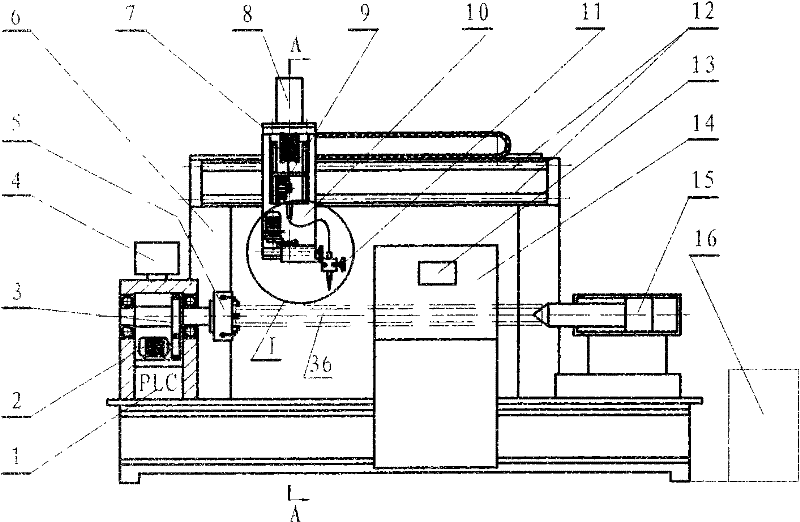

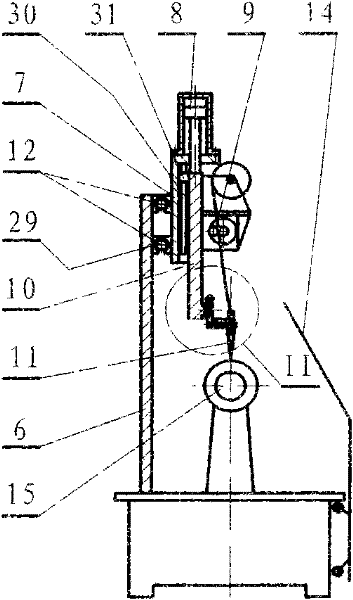

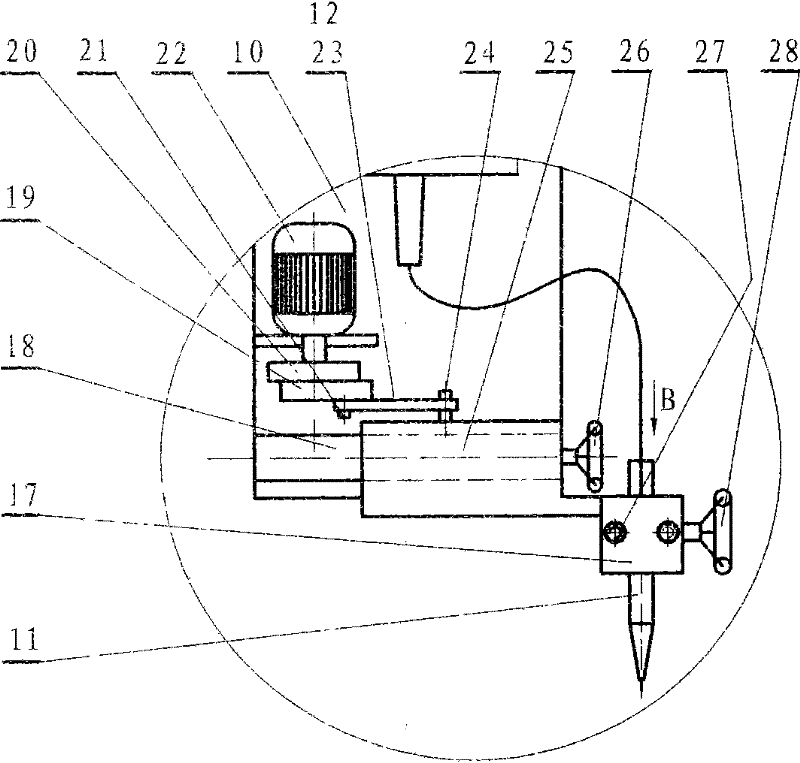

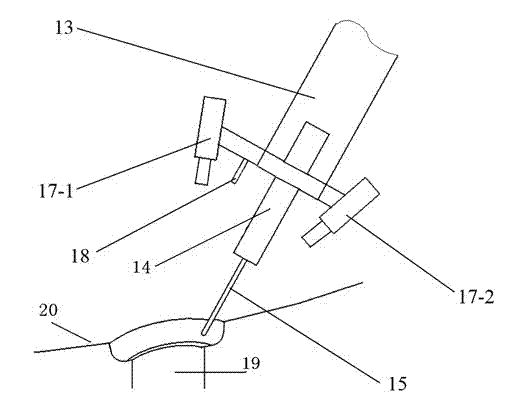

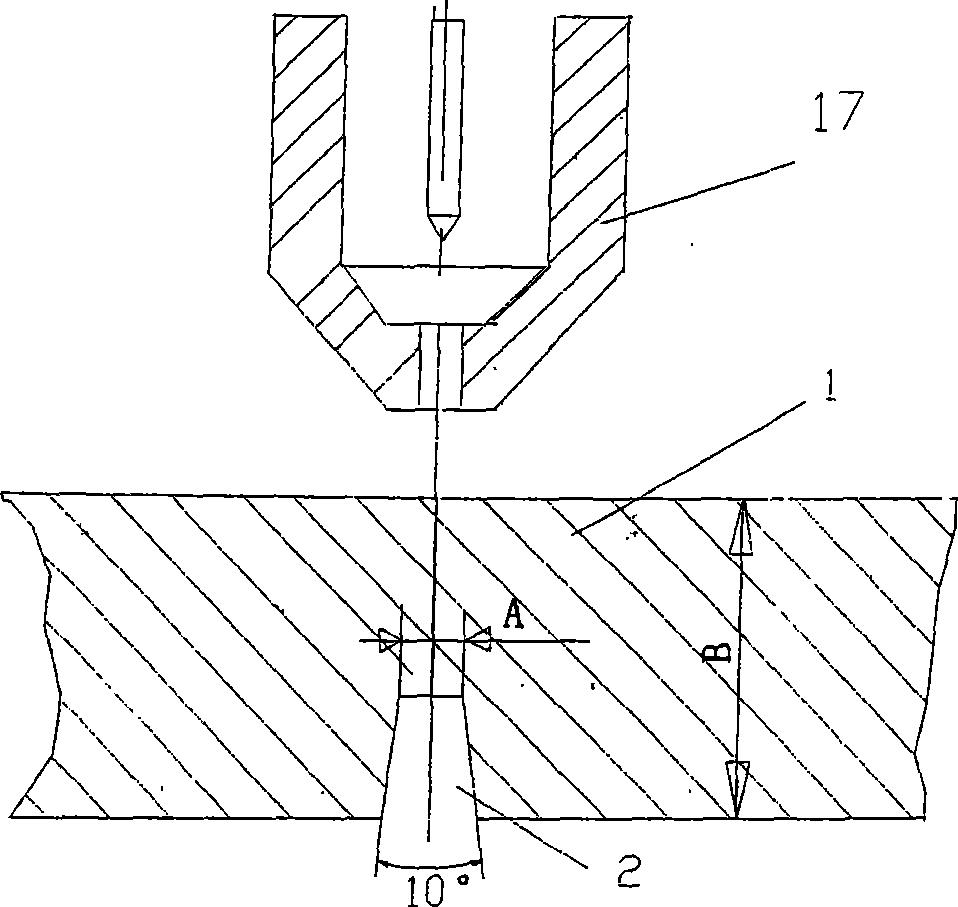

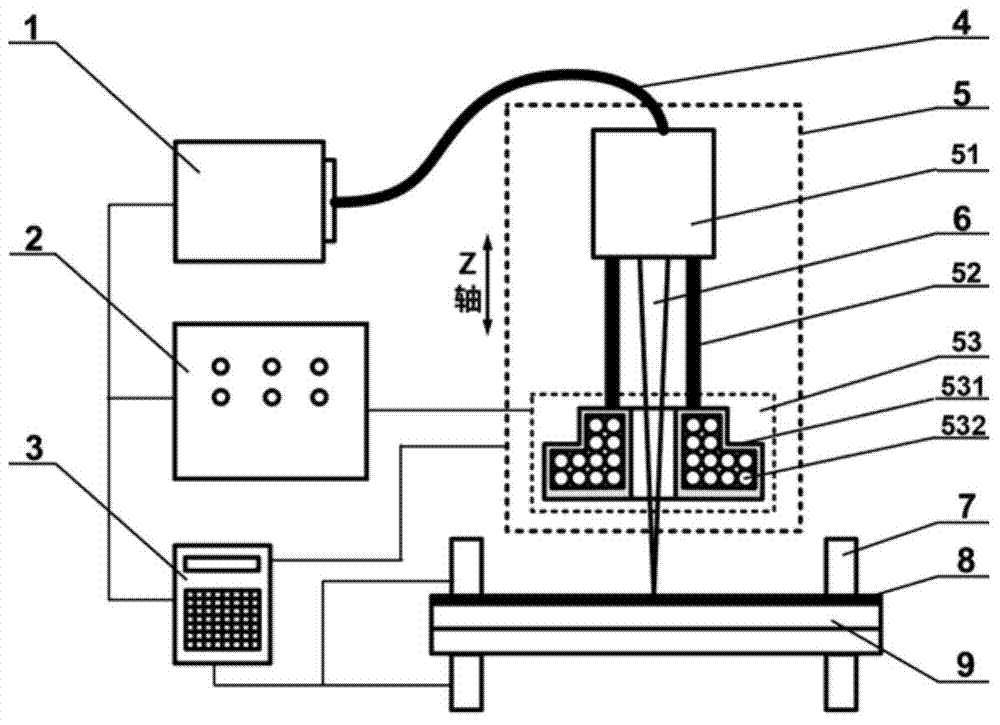

Longitudinal seam welding special machine with linear structure light type vision sensor and control method thereof

InactiveCN102059435AImplement trackingHigh degree of automationArc welding apparatusWeld seamSeam welding

The invention discloses a longitudinal seam welding special machine with a linear structure light type vision sensor and a control method thereof. The longitudinal suture welding special machine comprises a welding gun, the linear structure light type vision sensor, an industrial control computer and an execution mechanism, wherein the welding gun is fixed on the execution mechanism; the welding gun and the linear structure light type vision sensor are connected to an operation rail of the longitudinal seam welding special machine, and the linear structure light type vision sensor is arranged in front of the welding gun; and the output end of the linear structure light type vision sensor is connected with the execution structure through the industrial control computer. With the control method, the concept of a coordinate system is established, and a welding seam track is detected through the vision sensor to essentially change an application way of corresponding the welding gun to an image reference point through a rigid body relation, and the method can also be used for tracking the space curve welding seam without limitation of tracking the linear welding track. The longitudinal seam welding special machine detects the whole welding seam track, even if the sensor is out of the visual field, the last section of the welding seam can also ensure the tracking of the whole welding seam.

Owner:SOUTHEAST UNIV

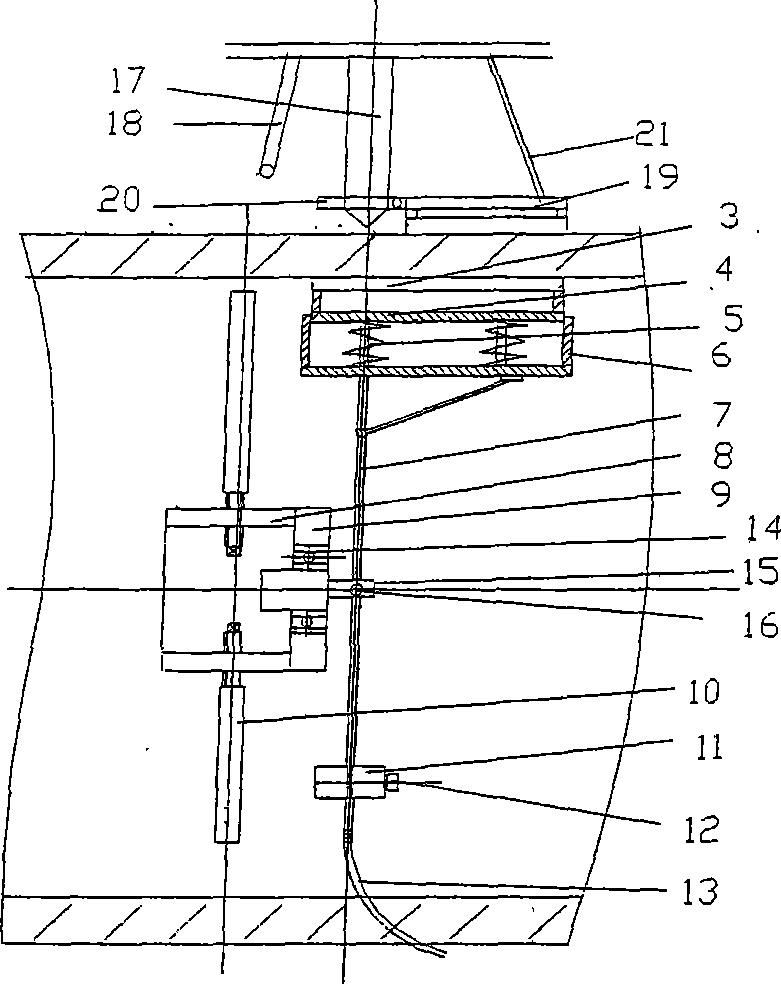

Program-controlled side-moving oil cylinder peripheral seam welding machine

InactiveCN102275032AHigh degree of automationImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlPower flow

The invention relates to a program-controlled side-moving oil cylinder circumferential seam welding machine, which consists of seven parts: an automatic control system, a power clamping mechanism, a lateral shifting device, a vertical lifting device, a welding torch swinging device, a position fine-tuning device and a welding mechanism. The invention adopts a PLC programmable controller as a main control unit, and adopts a Chinese display and video touch screen as a parameter adjustment dialogue interface. The touch screen can set the welding voltage, current welding speed and swing speed of each layer, and it is equipped with automatic and manual buttons for welding torch up and down. The invention adopts the mode of rotating the workpiece and fixing the welding torch; the welding torch is equipped with a fine-tuning mechanism and a two-axis angle adjustment device, which can adjust different welding angles; the welding torch is controlled by air pressure, and the micro DC motor drives the welding torch to swing; the tailstock is tightened by air pressure, and the machine head The three-jaw clamping method is adopted to realize automatic, manual and semi-automatic operation. The invention has the advantages of high degree of automation, good welding quality, safety and reliability.

Owner:YANCHENG EAST MACHINERY MFG CO LTD

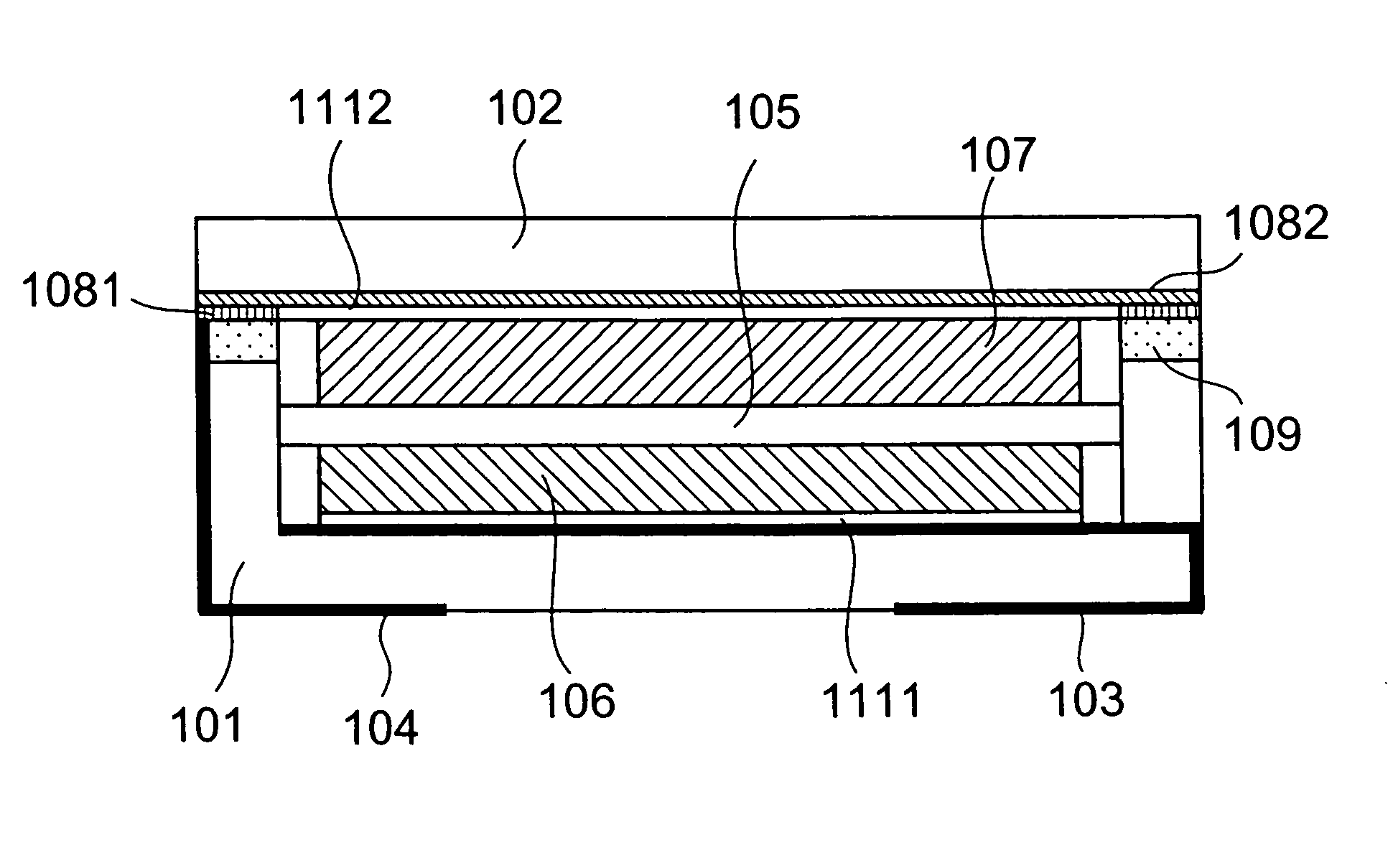

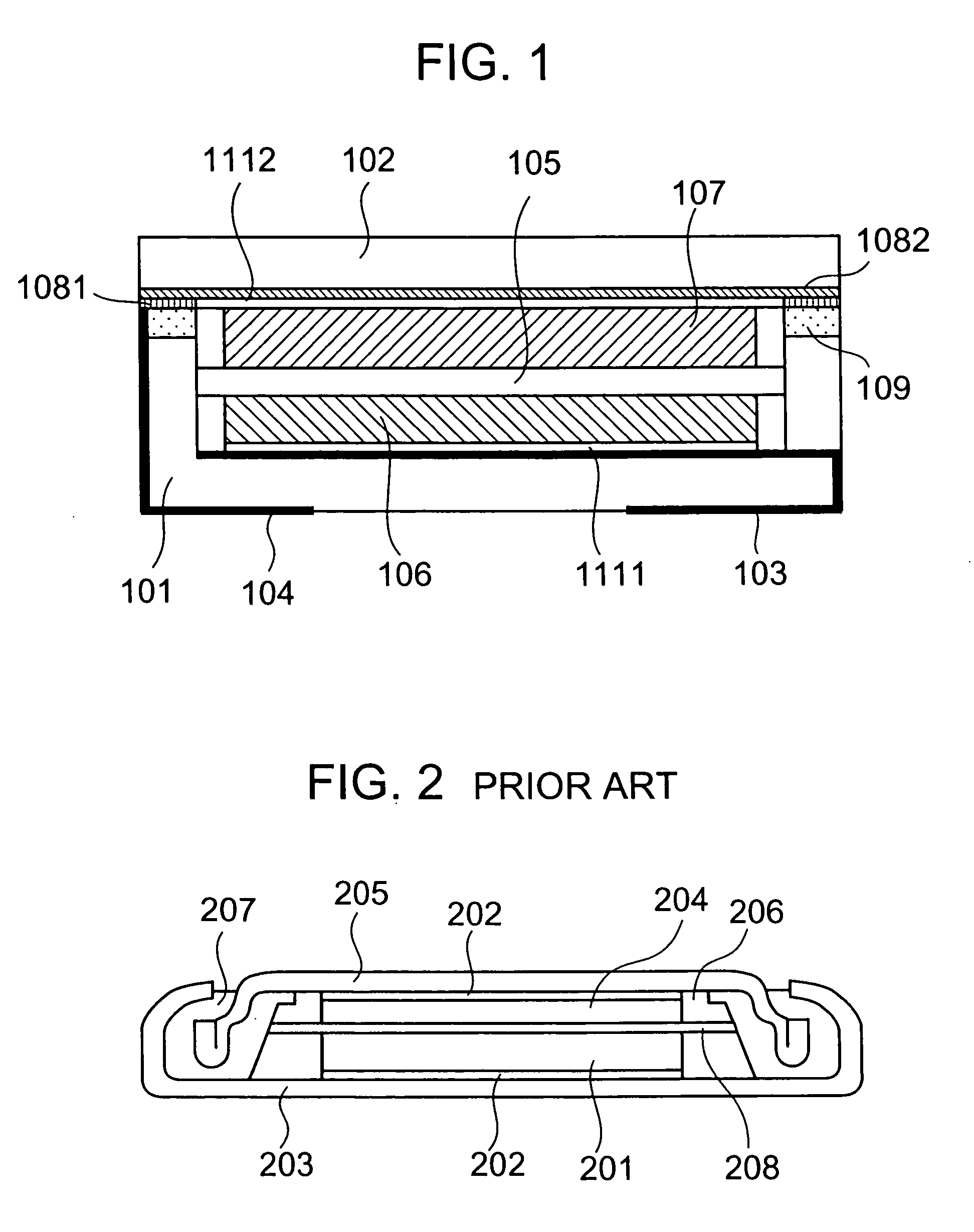

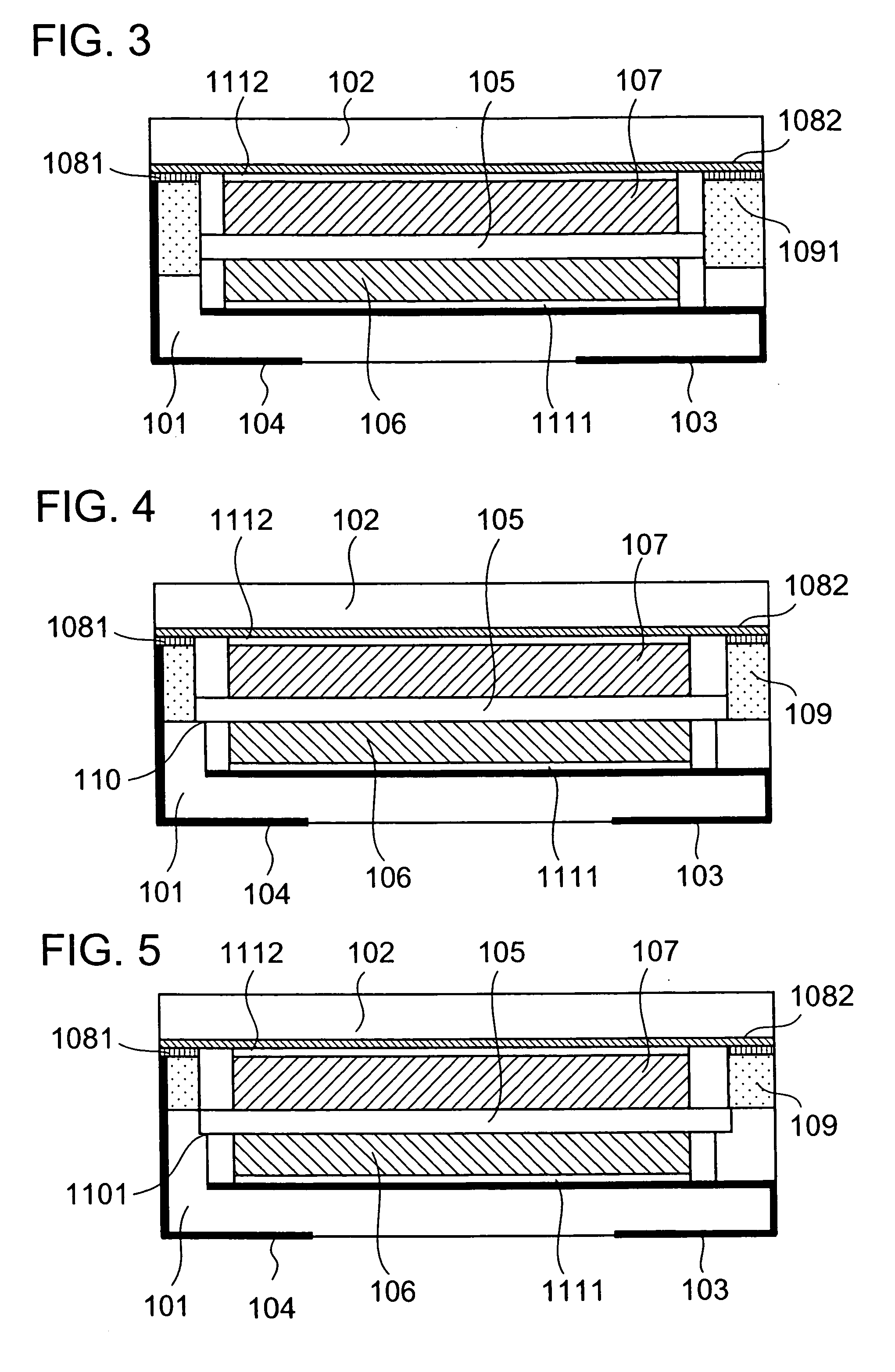

Electrochemical cell

InactiveUS20040157121A1Hybrid capacitor separatorsHybrid capacitor electrolytesElectrical resistance and conductanceSeam welding

For avoiding problems in existent non-aqueous electrolyte cells or electric double layer capacitors of a rectangular pyramidal shape that sealing at high reliability can not be attained unless a bonded portion has a margin of a certain degree in view of electrolytes contained therein, a metal layer comprising a metal ring and a brazing material having a heat expansion coefficient approximate to that of a concave vessel of a non-aqueous electrolyte cell or an electric doceble layer capacitor is disposed to the edge of the vessel, a sealing plate made of a metal having a property similar with the metal ring and having a brazing material layer at the bonded surface is also used for the sealing plate and, further, paired electrodes comprising a positive electrode and a negative electrode, a separator and an electrolyte are contained in the concave vessel, the sealing plate is placed on the vessel and seam welding is conducted by using a resistance welding method thereby capable of attaining sealing at high reliability.

Owner:WATANABE SHUNJI +3

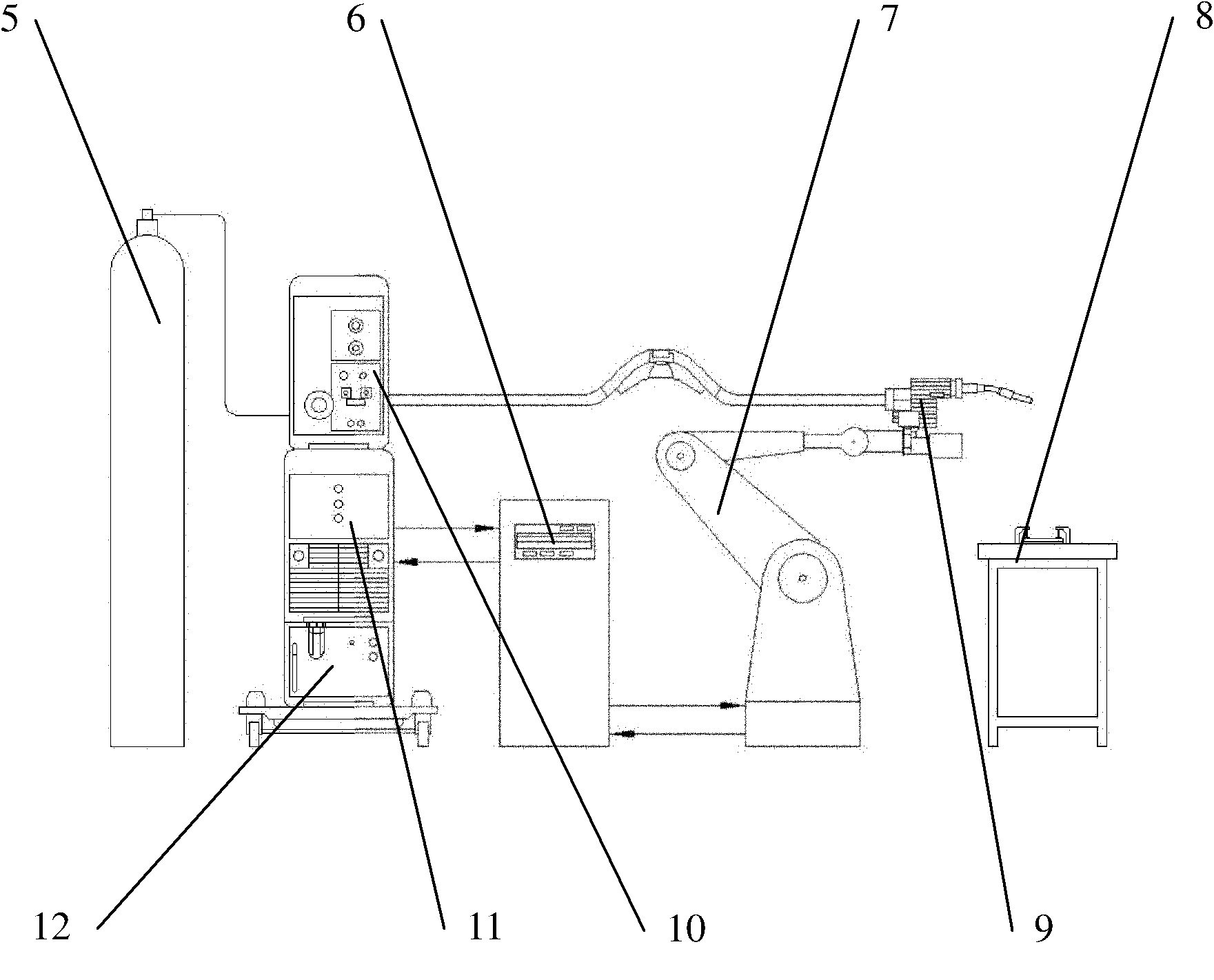

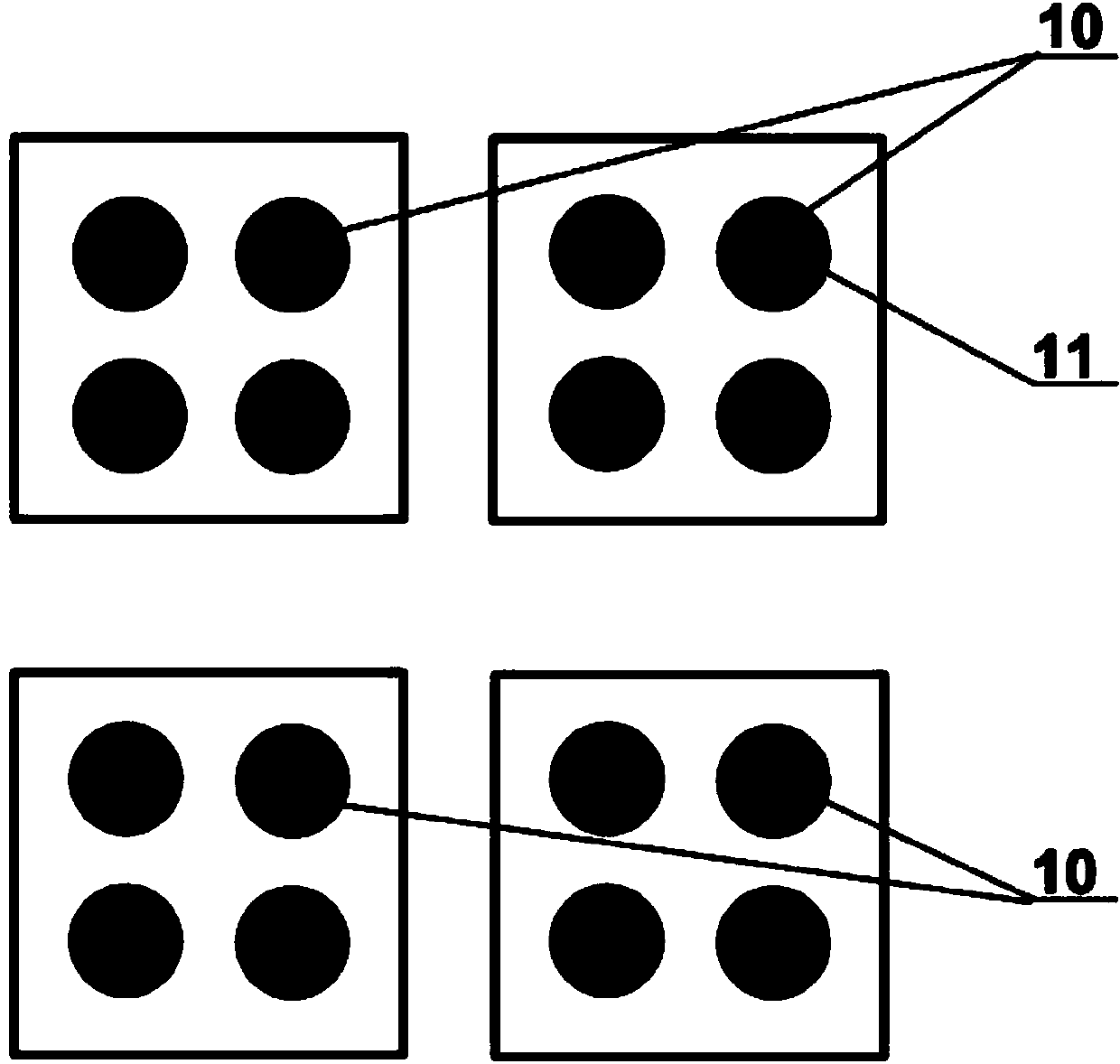

Dissimilar metal spot welding system of light metal and coated steel and welding method thereof

The invention provides a dissimilar metal spot welding system of light metal and coated steel and a welding method thereof, wherein the system comprises a CMT (cold metal transfer) arc welding system, an air bottle, a robot control module, a robot and a clamping device; the arc welding system is connected to the robot control module and used for transmitting a welding control signal; the air bottle is communicated with the CMT arc welding system; the robot control module is connected to the robot for transmitting a control signal of the movement of the robot. In the invention, a spot melting soldering joint is formed between light metal and coated steel to realize the spot connection of the light metal and the coated steel; the serious deformation of the joint during continuous seam welding is solved while the connecting quality of dissimilar metal is ensured; traditional vehicle body part joints primarily using resistance spot welding process are not influenced; and the design and manufacture costs of vehicle bodies are greatly reduced.

Owner:SHANGHAI JIAO TONG UNIV +1

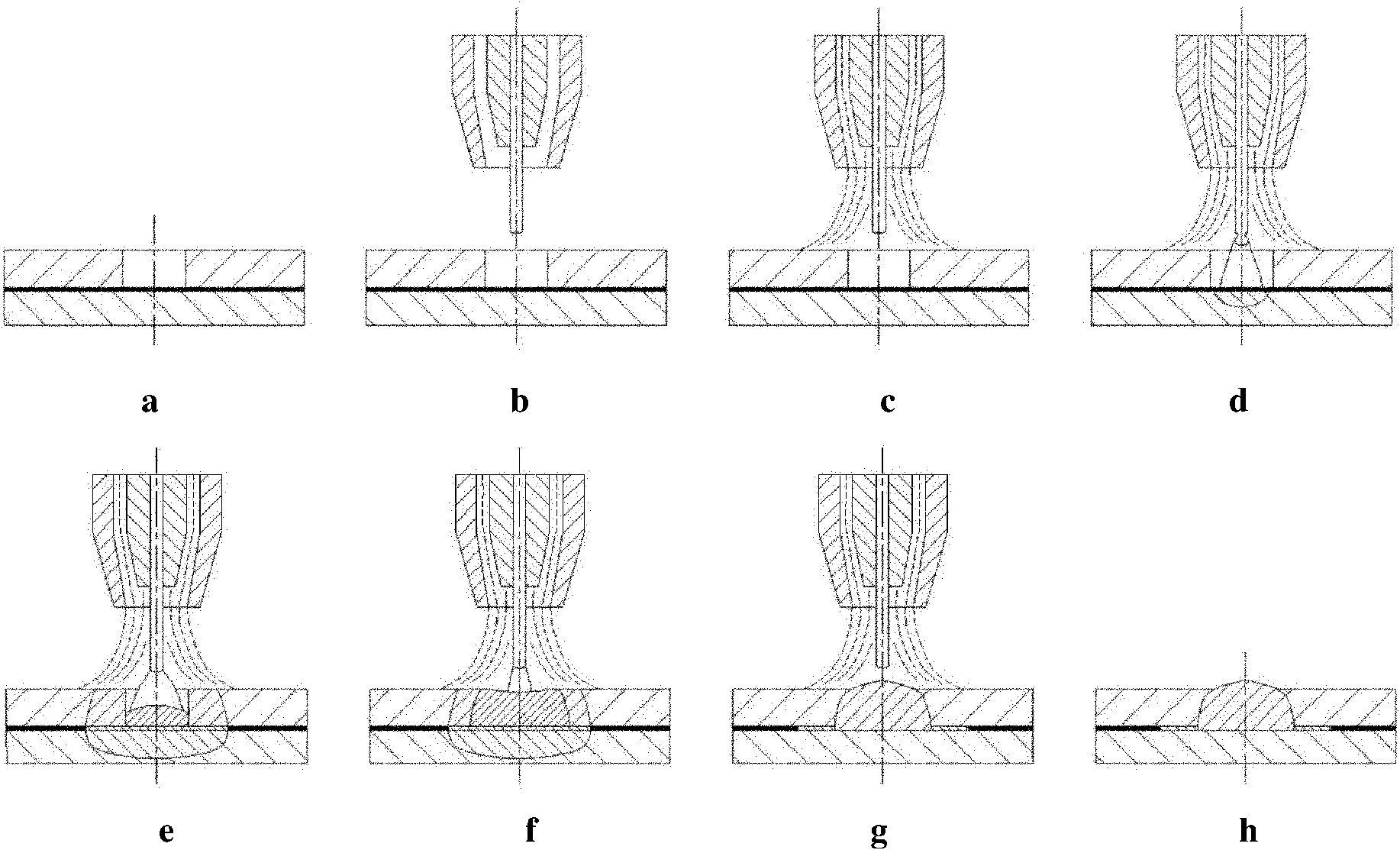

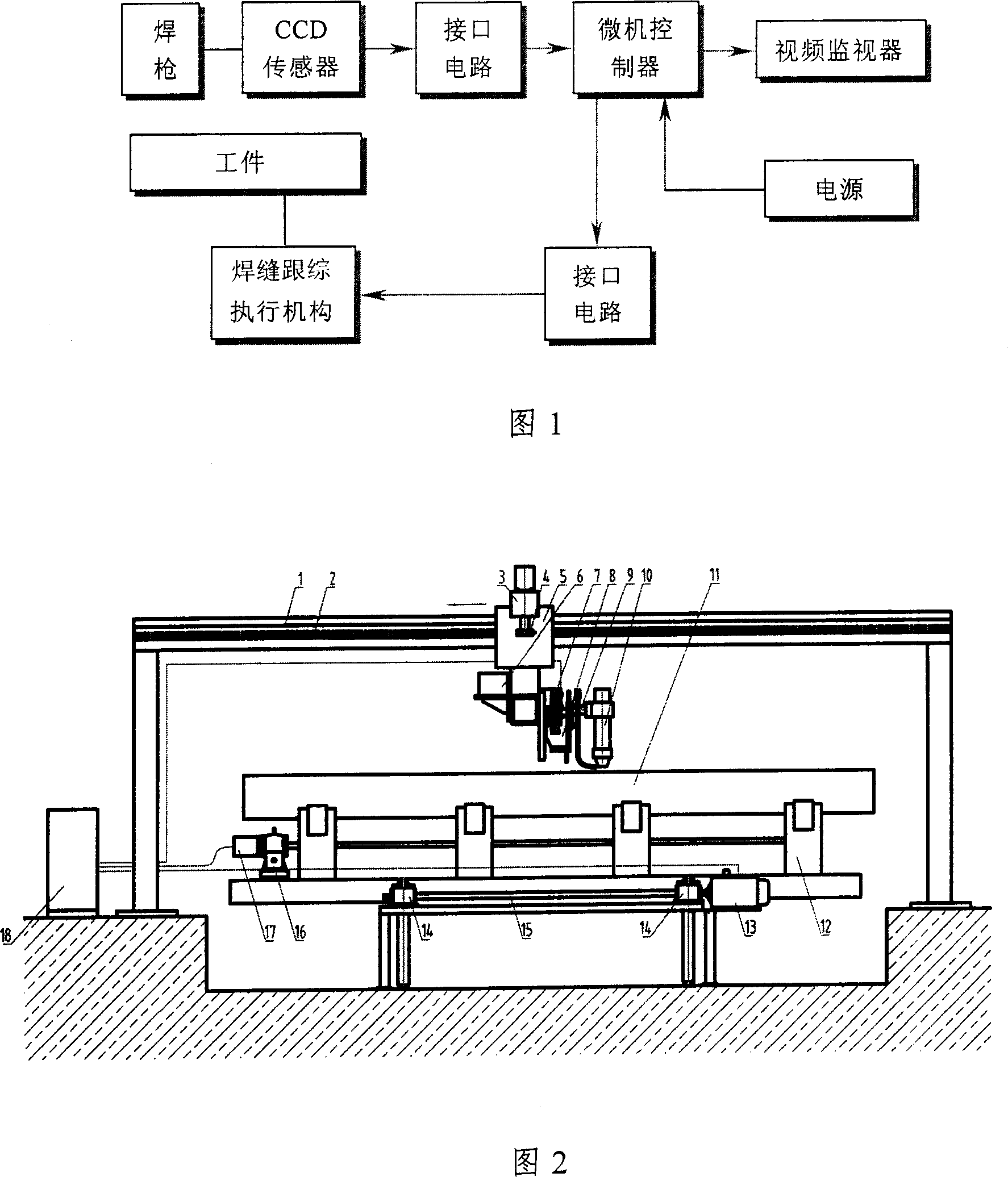

Automatic tracker of longitudinal seam welding for major diameter welding pipe

InactiveCN101011773AGuarantee welding qualityRigorous structureArc welding apparatusDevice formReduction drive

The automatic tracking device for a big diameter longitudinal seam welding comprises a visual sensor integrated with the welding gun in front of it, interface circuit, computer controller and welding seam tracking execution mechanism, with the said welding gun and visual sensor installed on the running cart along the seam direction, welding tube resting on the rolling wheel on the rack, with the weld seam track execution device made of servo motor and decelerator formed roller drive device and the frequency change motor and turbine screw lifting device formed rolling rack lifting mechanism. It is compact in structure, reliable in working.

Owner:ZHEJIANG JIULI HI TECH METALS

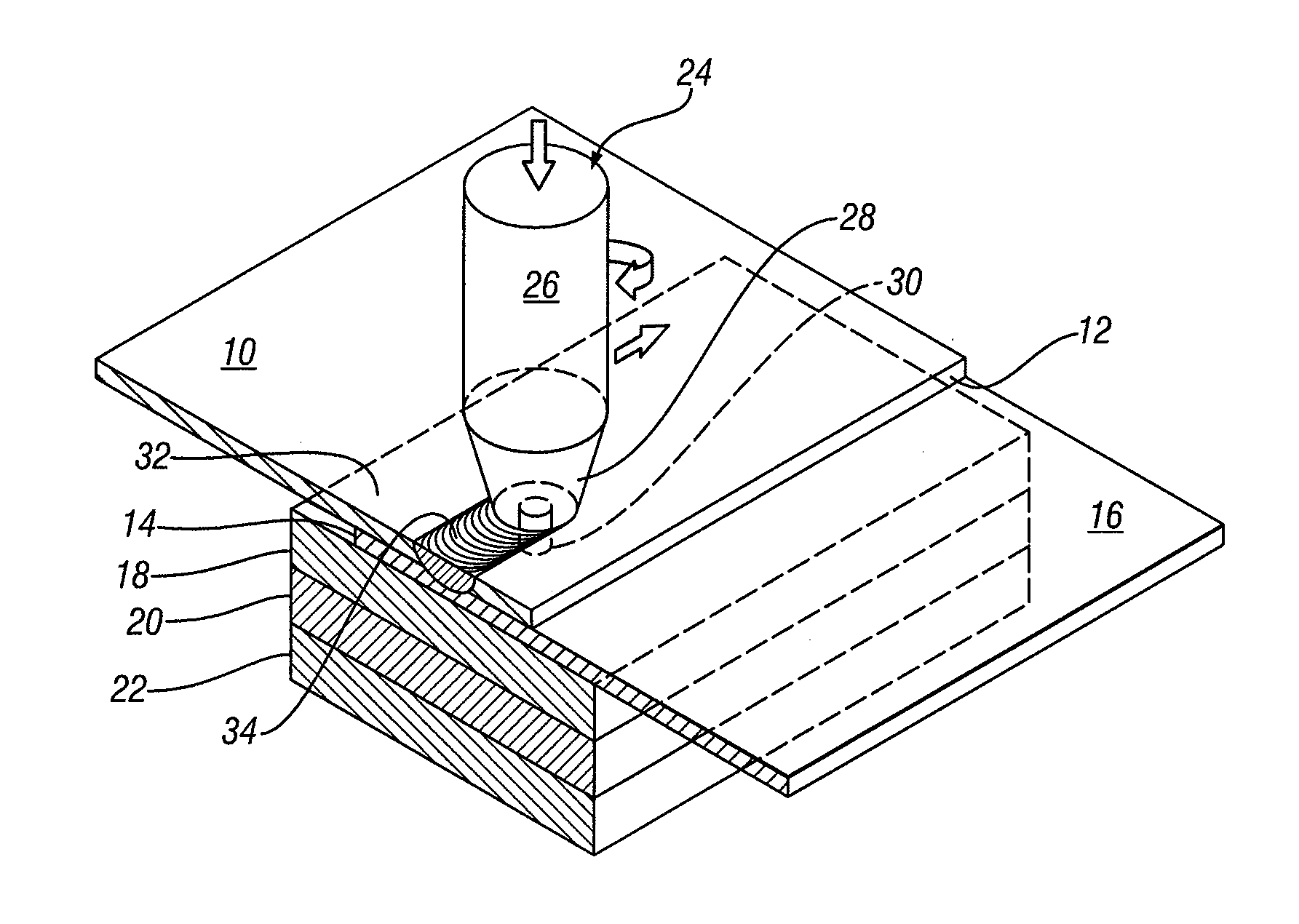

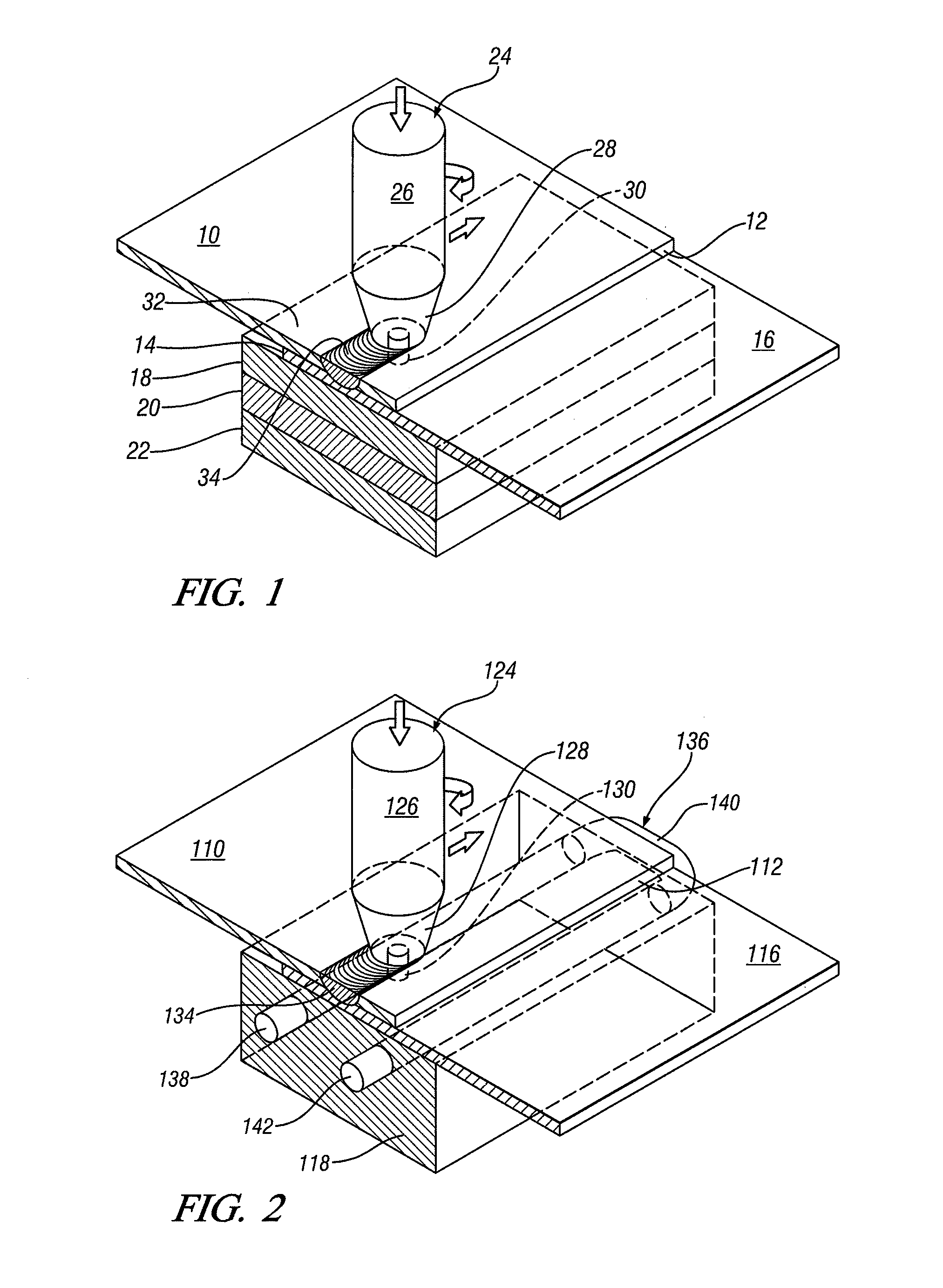

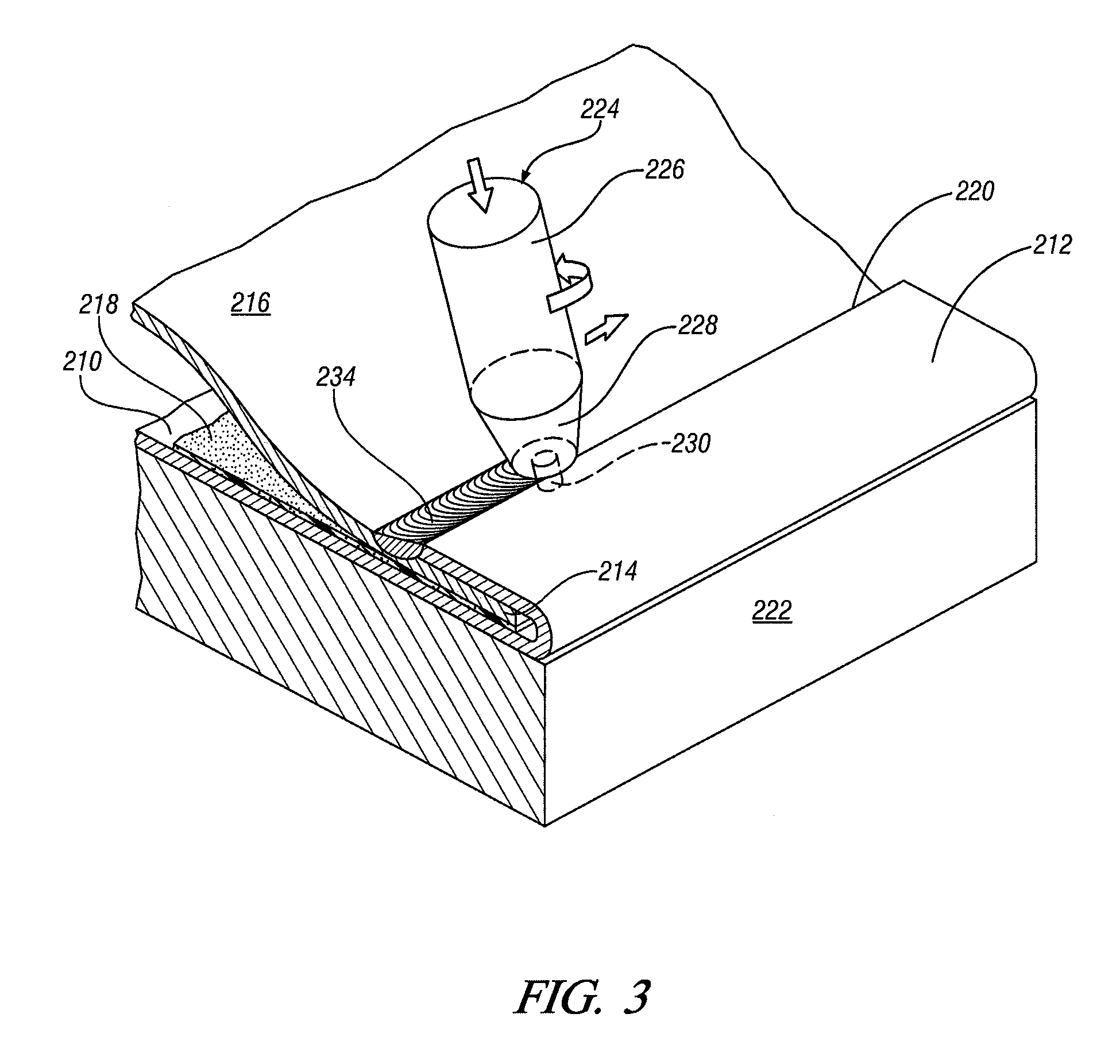

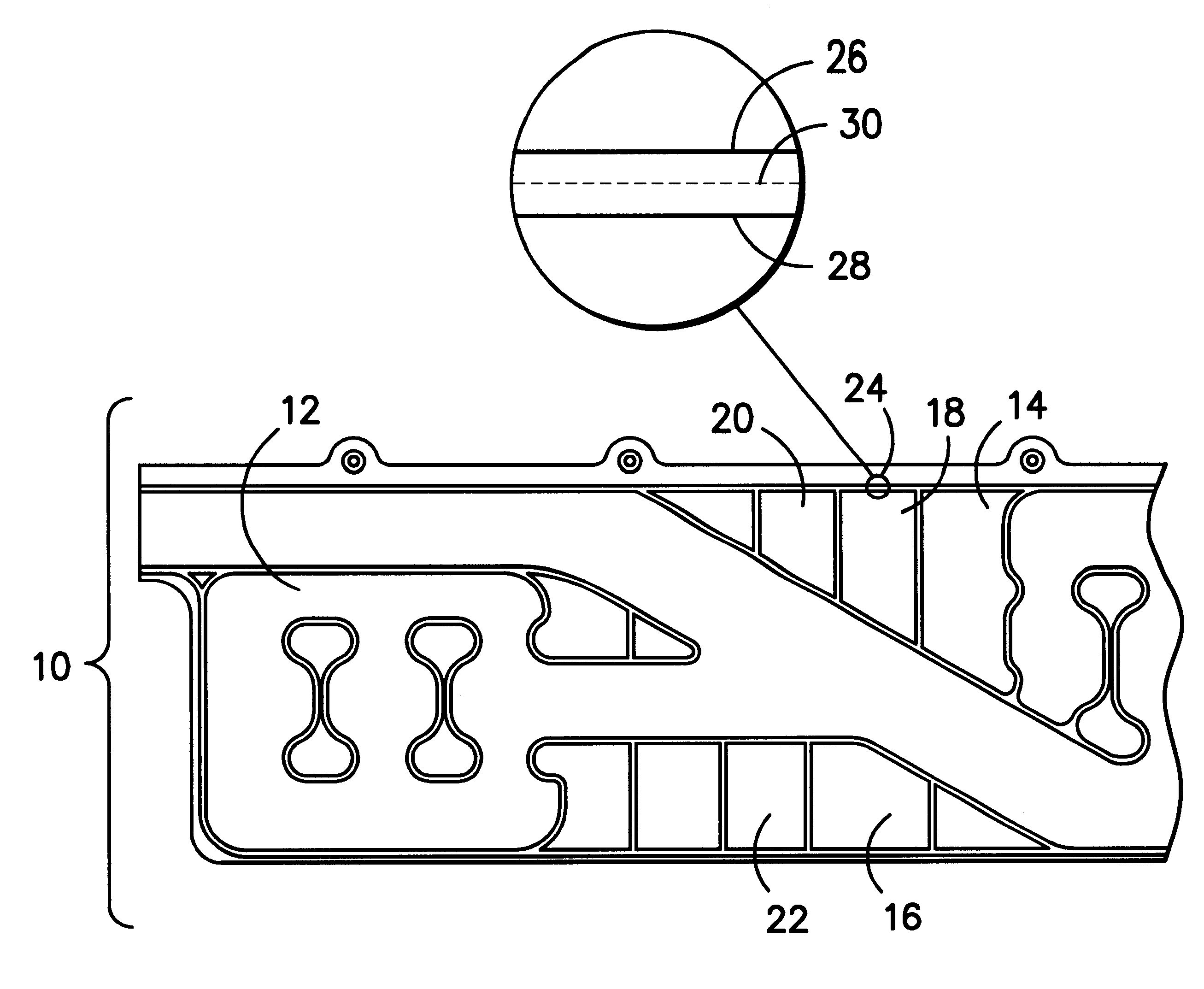

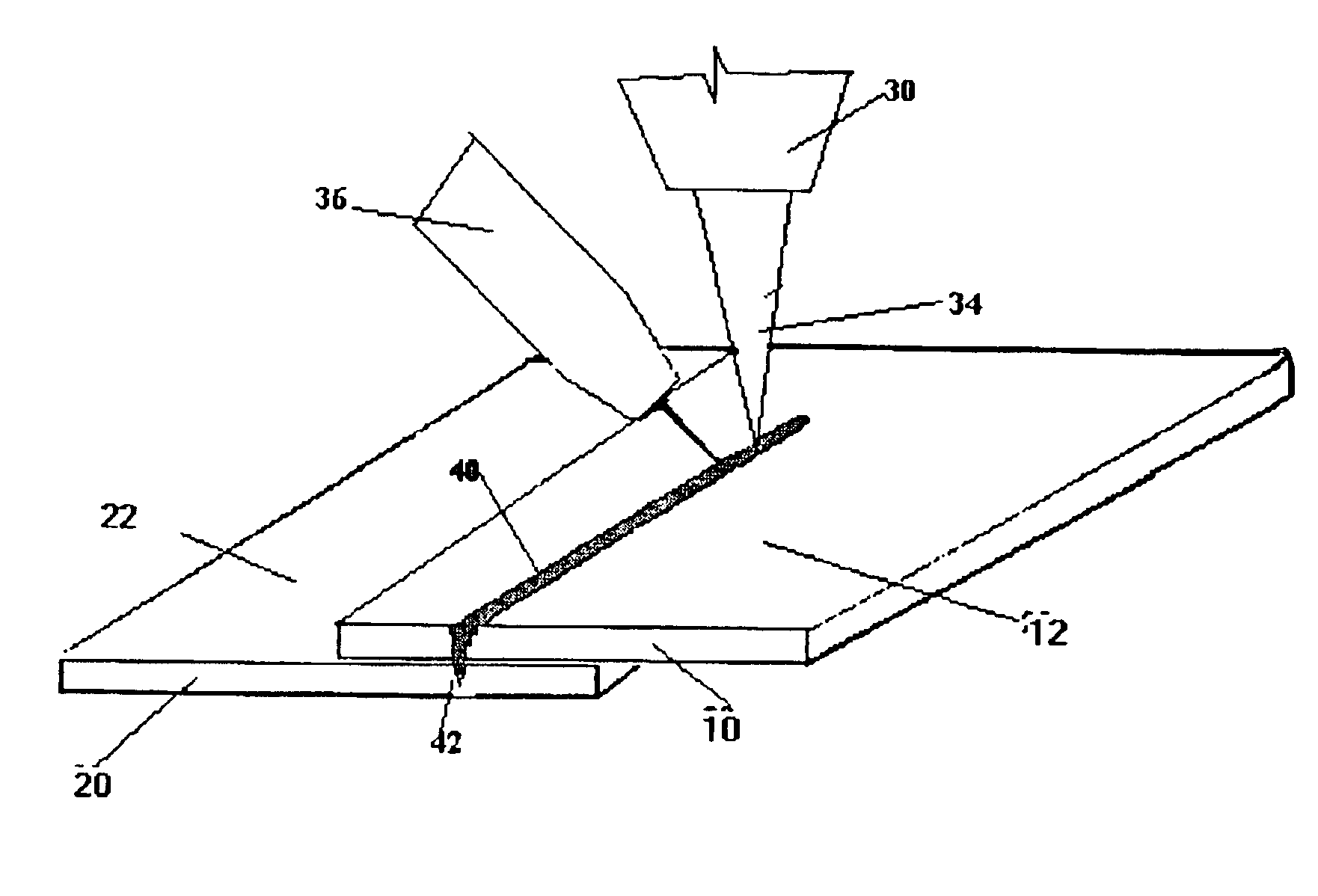

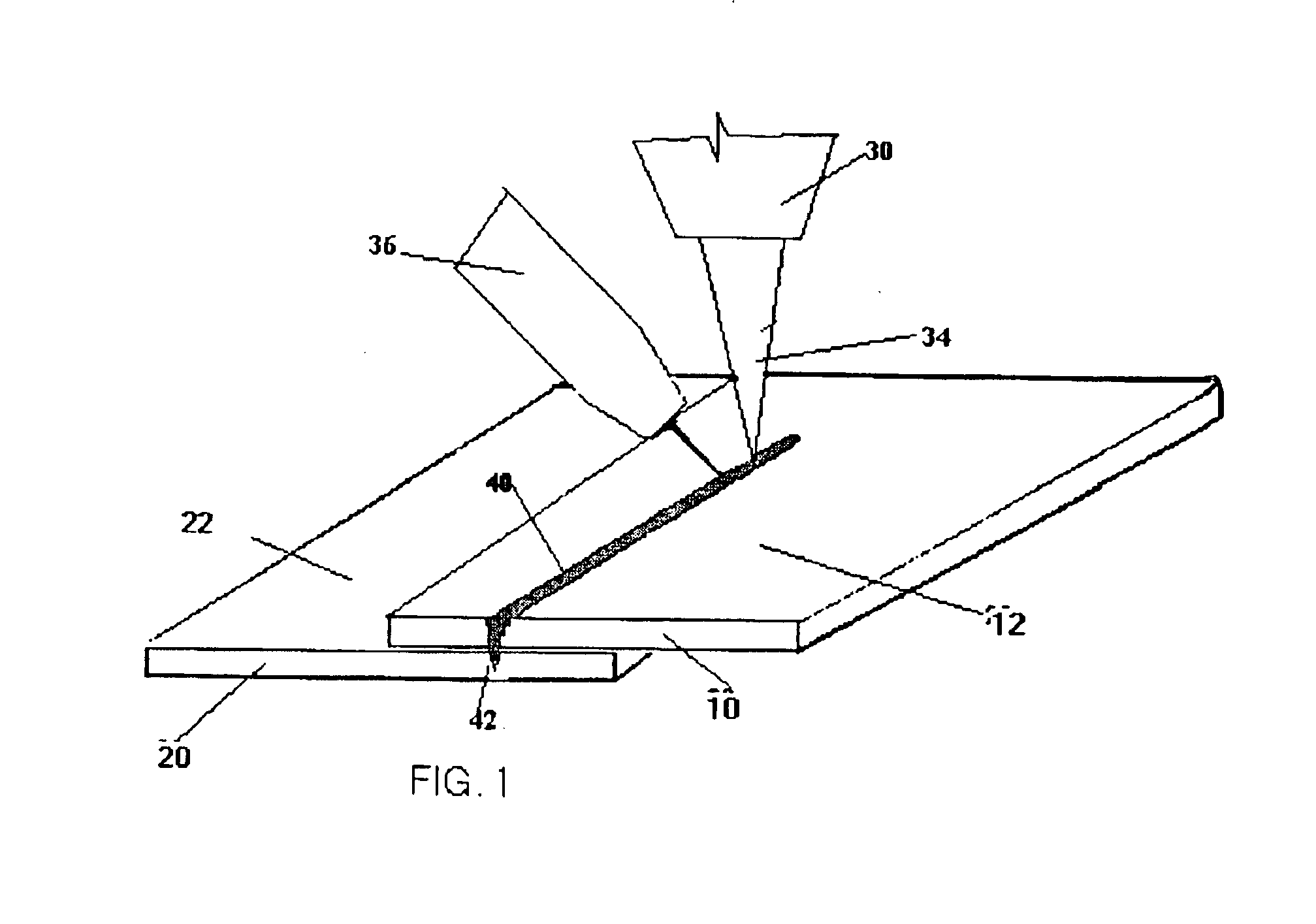

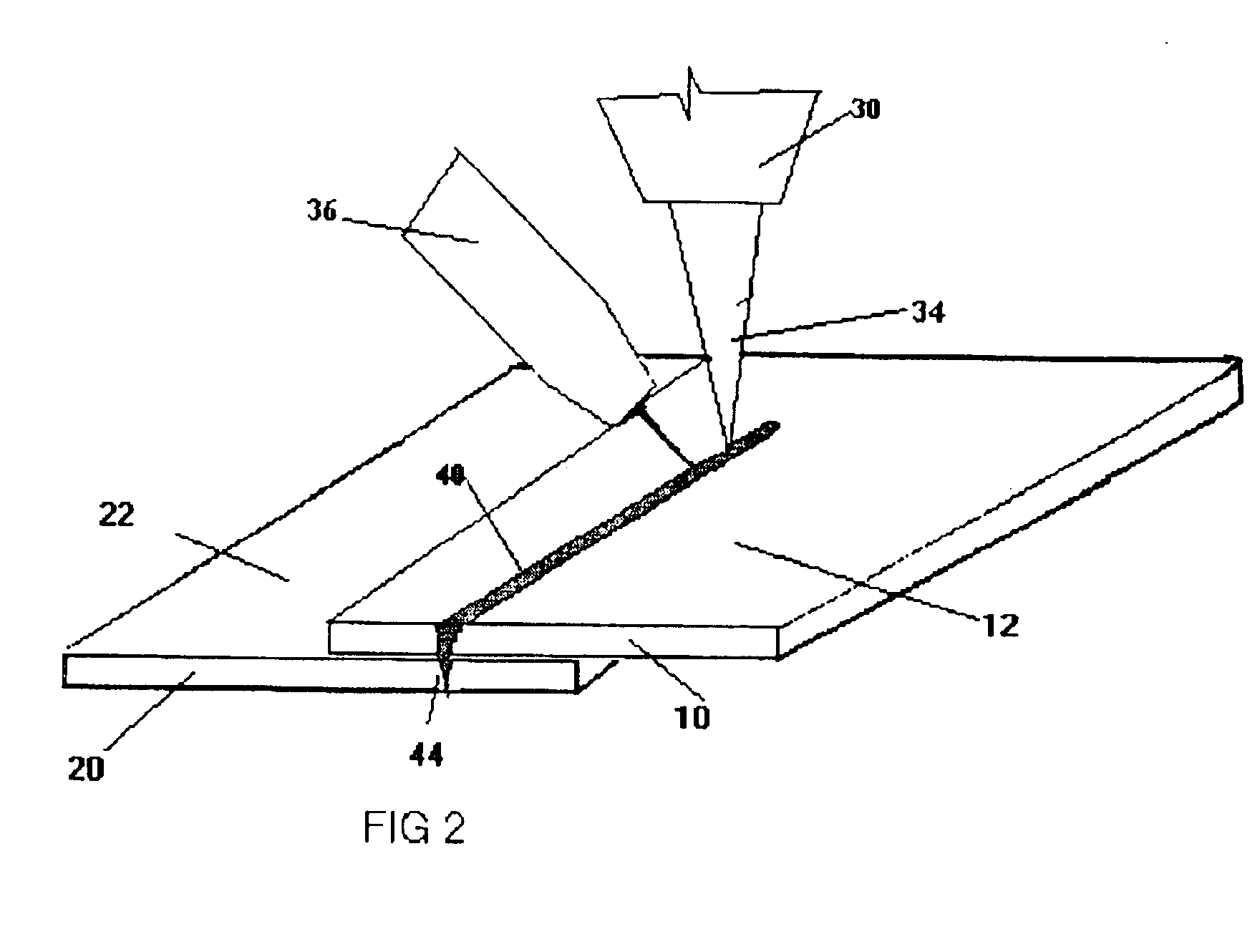

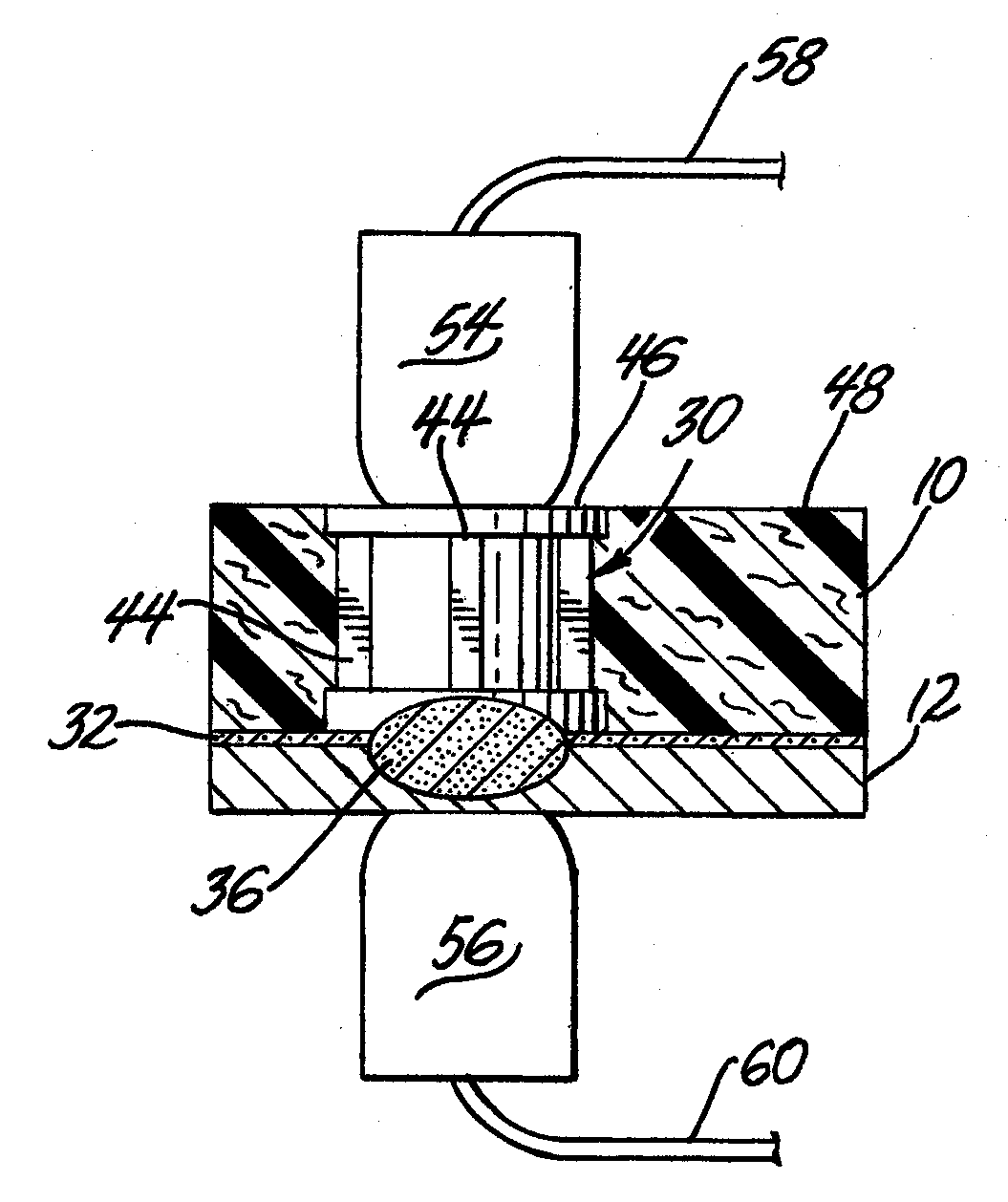

Reducing sheet distortion in friction stir processing

InactiveUS20090200359A1Lower yield strengthEnable unwanted deformationVehicle componentsWelding/soldering/cutting articlesFriction reductionSpot welding

Local heat may be generated through surfaces of sheet metal workpieces by supporting the workpiece(s) on a hard surfaced anvil and engaging the opposite surface of the workpiece with a rotating, and optionally translating, friction stir tool that is pressed against the work surface. Advantages are realized in friction stir processing (e.g. seam or spot welding) of such sheet metal workpieces by using an anvil with appreciable thermal conductivity, or a liquid cooled anvil body, to suitably cool the site(s) of the workpiece engaged by the friction stir tool to minimize or eliminate distortion of the workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

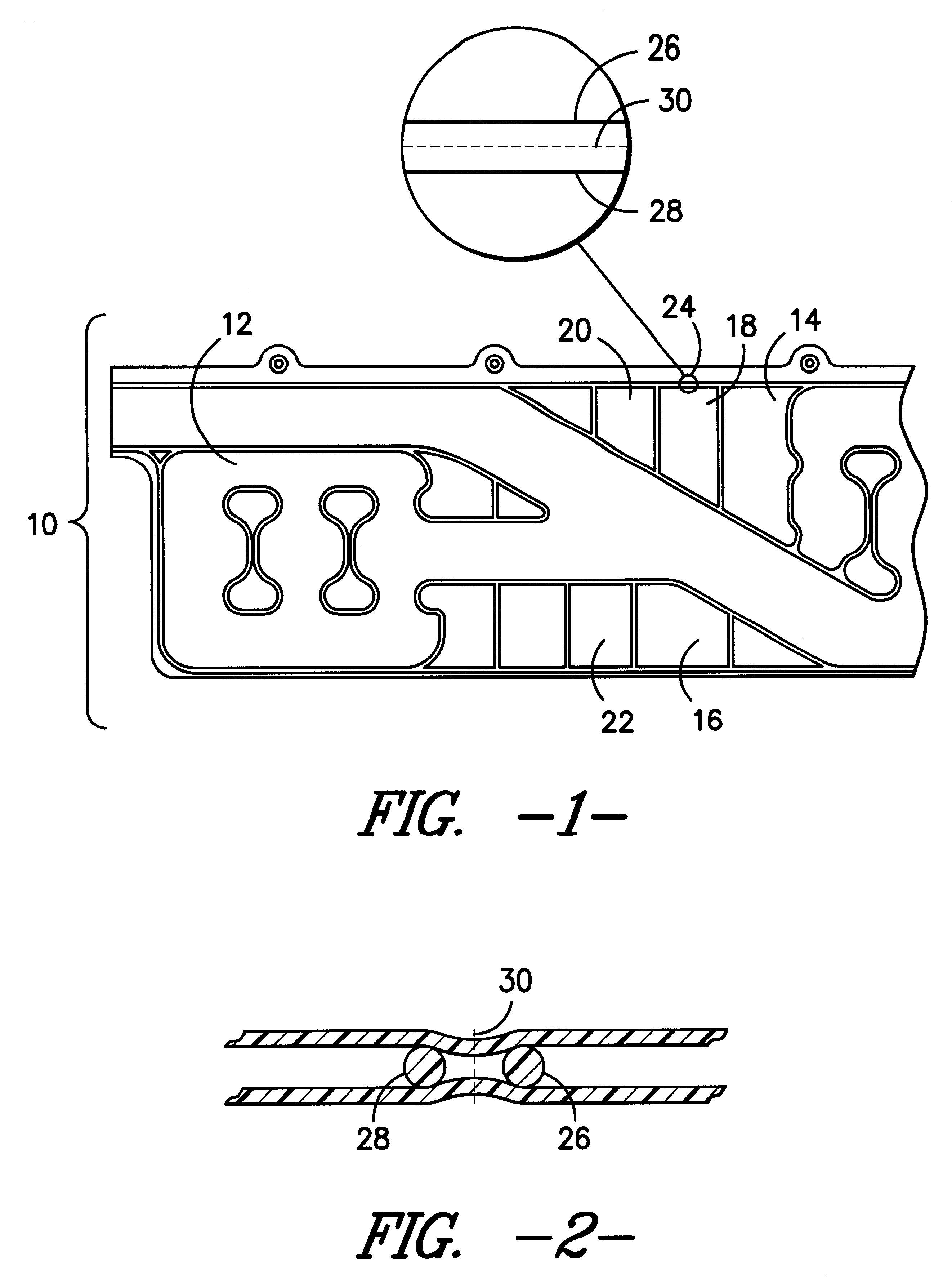

Airbag cushion comprising sewn reinforcement seams

InactiveUS6364356B1High strengthLower potentialPedestrian/occupant safety arrangementHollow articlesEngineeringWeld seam

A method utilizing welds, reinforced with sewn seams, to adhere two fabrics together to form an inflatable airbag cushion. Although welded seams provide better and more easily produced attachment points between multiple layers of fabrics, not to mention improved manners of reducing air or gas permeability as such attachment points, the utilization of sewn seams adjacent to such welded areas provides stronger reinforcement, and thus more reliable non-permeable fabrics. Seam welding generally concerns the utilization of a film on the underside of a fabric which, upon contact with a second, film-treated fabric and upon exposure to high frequency energy, forms a bead of polymeric material at the attachment point between the two fabric layers. Lower numbers of sewn seams may be utilized to permit sufficient reinforcement if the size of the formed polymeric bead if of sufficient size to permit thorough sealing and adhesion between the fabric layers. Such a specific reinforced fabric, as well as high bead-size welded airbag fabrics are encompassed within this invention.

Owner:MILLIKEN & CO

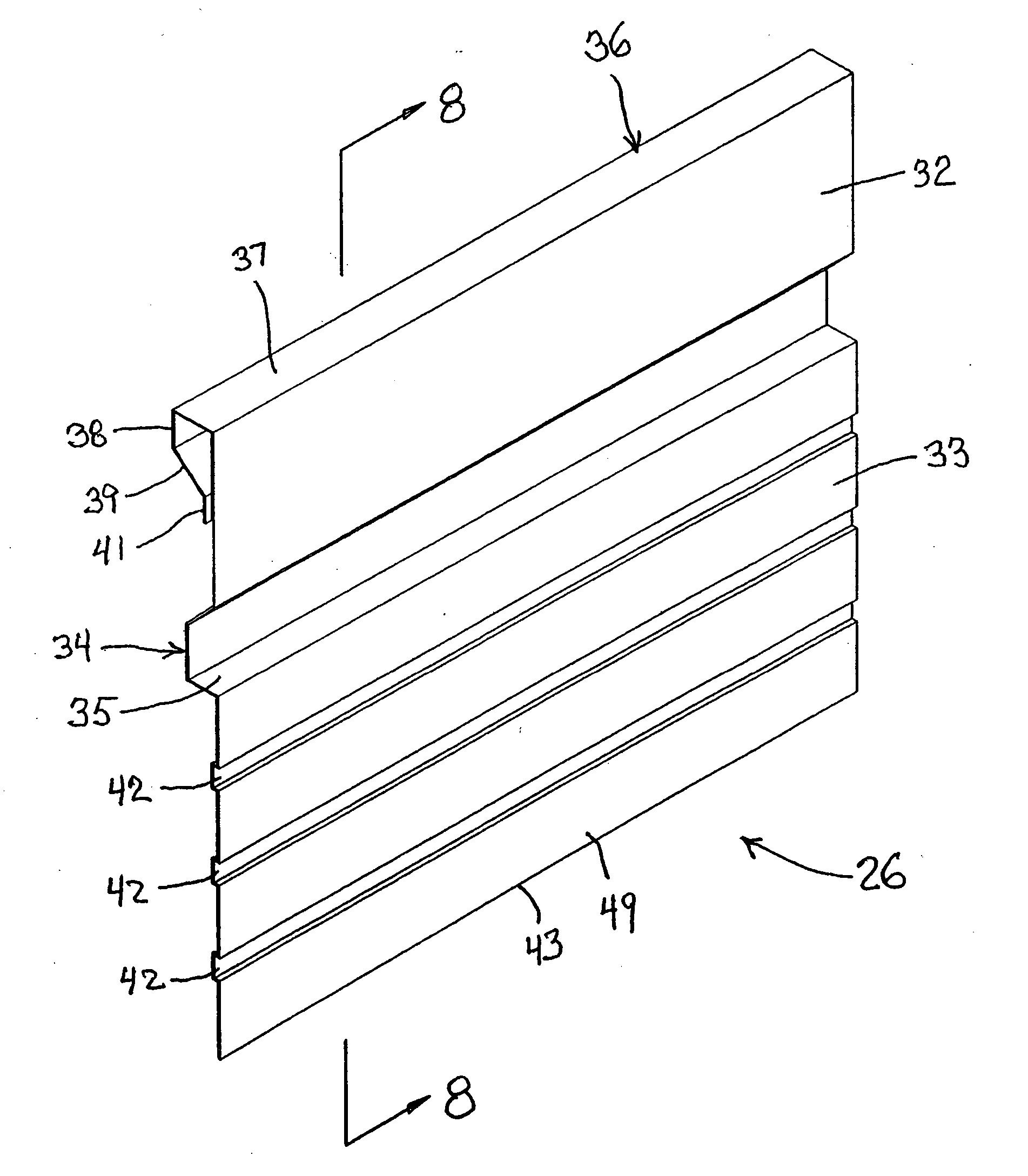

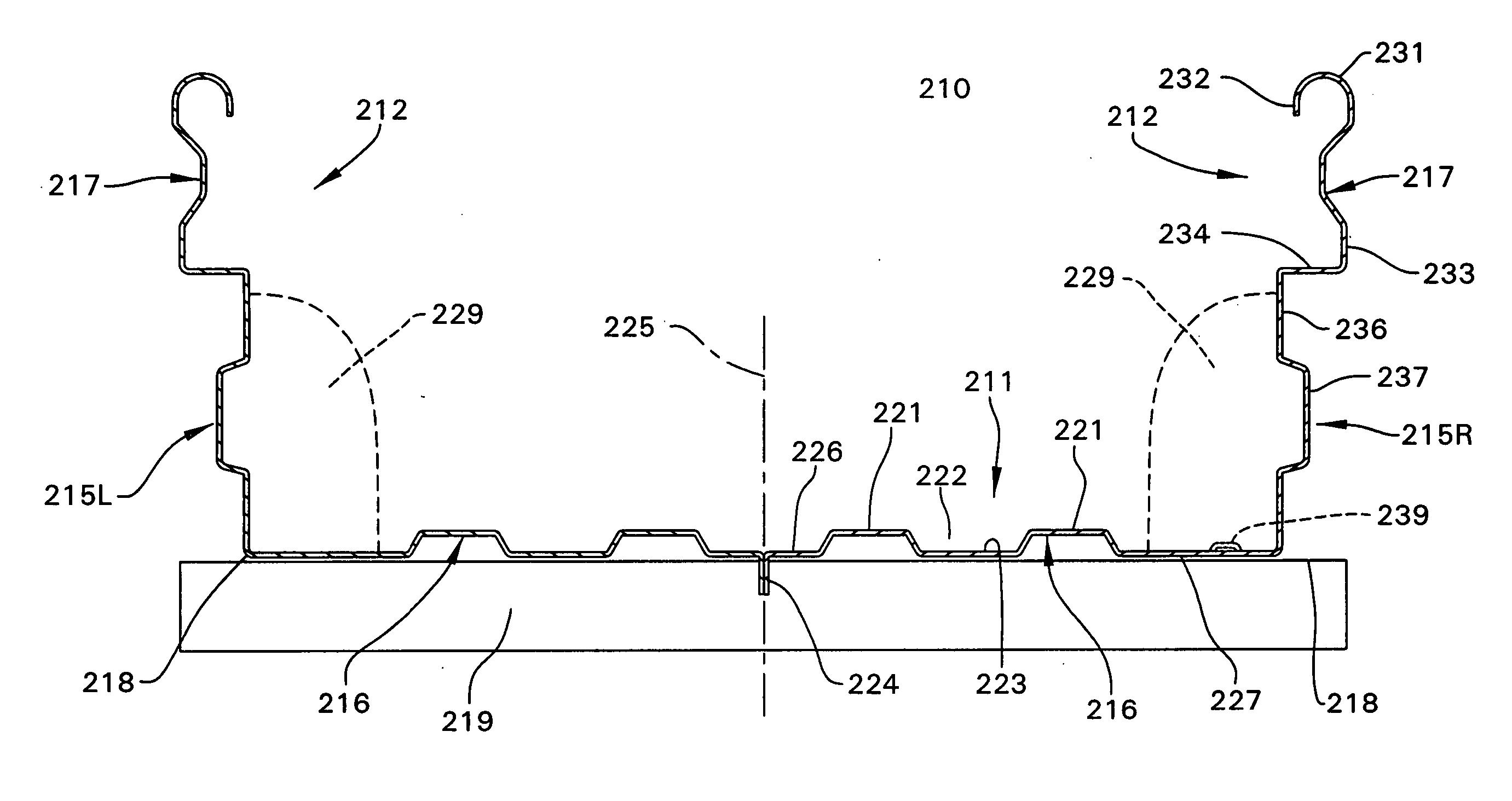

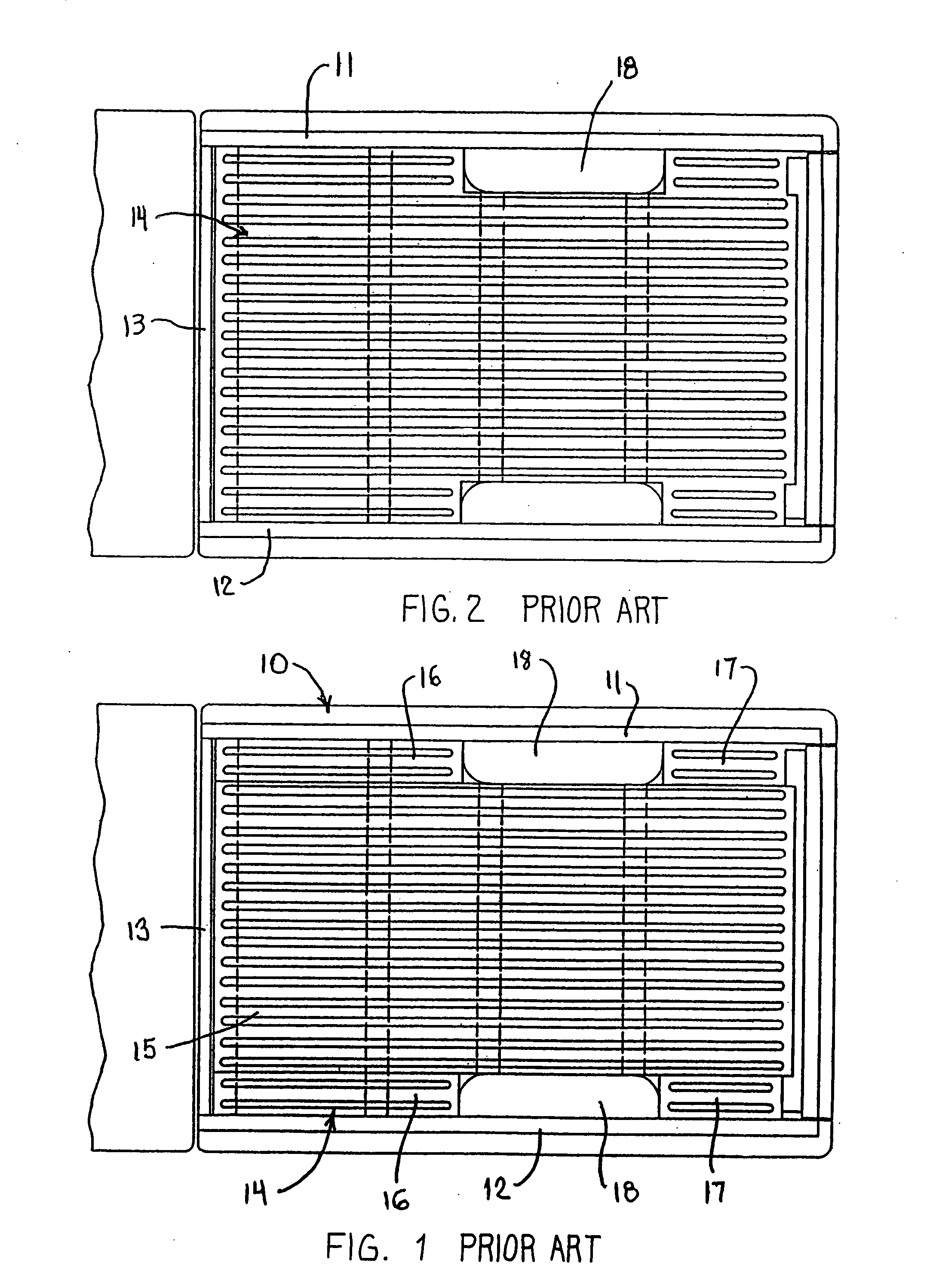

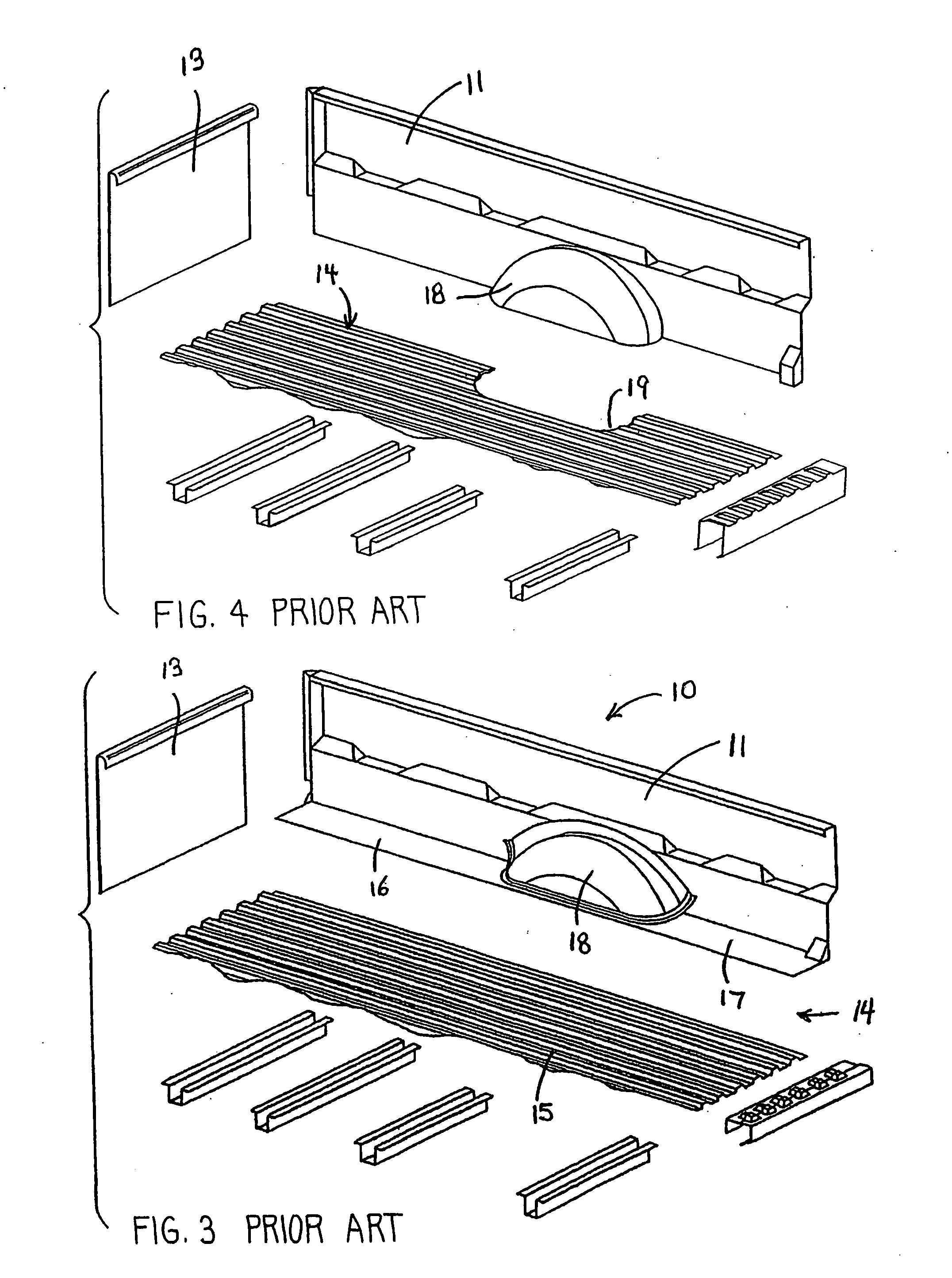

Roll-formed panels for vehicle box assembly

An improved vehicle box assembly with an upright front or side panel defined by a monolithic one-piece roll-formed steel sheet member having a desired three-dimensional configuration. The sheet steel member is roll-formed in the lengthwise direction thereof. The panel has a channel, preferably a closed tubular channel on the front panel, roll-formed along one edge of the sheet steel during forming of the panel. The closed tubular edge rail is preferably closed by a seam weld which extends lengthwise therealong and is performed in line with the roll-forming operation. The roll-formed panel is preferably provided with a flat shelf deformed horizontally to extend lengthwise along the panel downwardly from the top rail.

Owner:PULLMAN IND

Two-piece side and floor panel arrangement for box assembly

An improved vehicle box assembly with an upright front or side panel defined by a monolithic one-piece roll-formed steel sheet member having a desired three-dimensional configuration. The sheet steel member is roll-formed in the lengthwise direction thereof. The panel has a channel, preferably a closed tubular channel on the front panel, roll-formed along one edge of the sheet steel during forming of the panel. The closed tubular edge rail is preferably closed by a seam weld which extends lengthwise therealong and is performed in line with the roll-forming operation. The roll-formed panel is preferably provided with a flat shelf deformed horizontally to extend lengthwise along the panel downwardly from the top rail.

Owner:PULLMAN IND

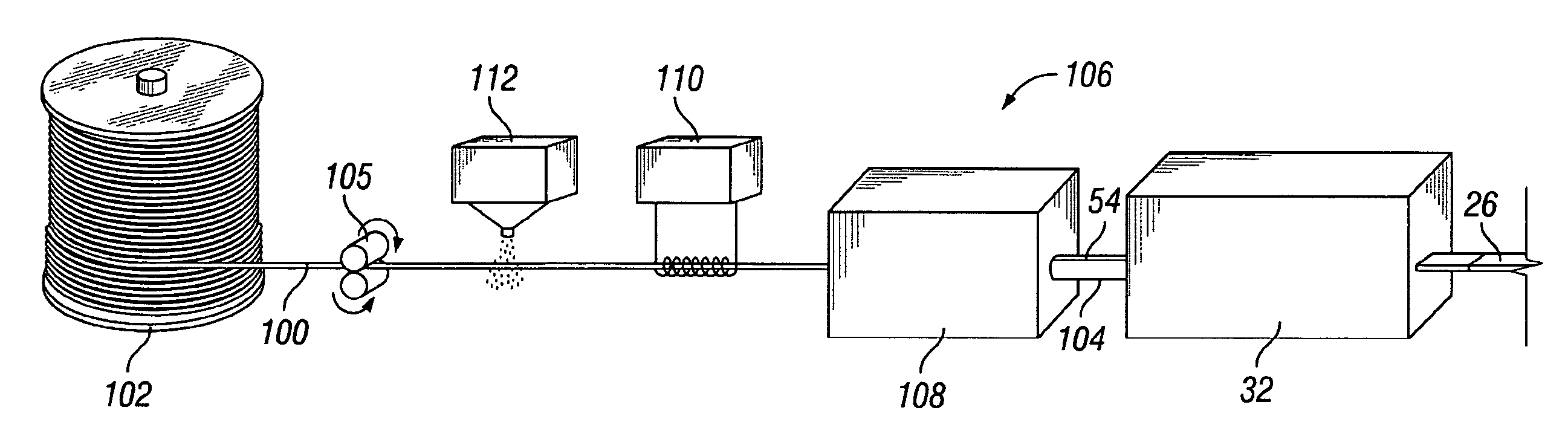

Hot reduced coil tubing

InactiveUS20060157539A1Quality improvementImprove reliabilityWelding apparatusMetallurgyCoiled tubing

Continuous coil tubing made from shorter lengths of flat metal strip which are spliced end-to-end and formed into tubular form and seam welded and thereafter introduced into a forging or hot reduction process. Finished coil tubing is withdrawn from the process at a different rate than flat metal strip is fed into the process. Welds made to the flat metal strip blend into and substantially disappear from the finished coil tubing.

Owner:DUBOIS JON D

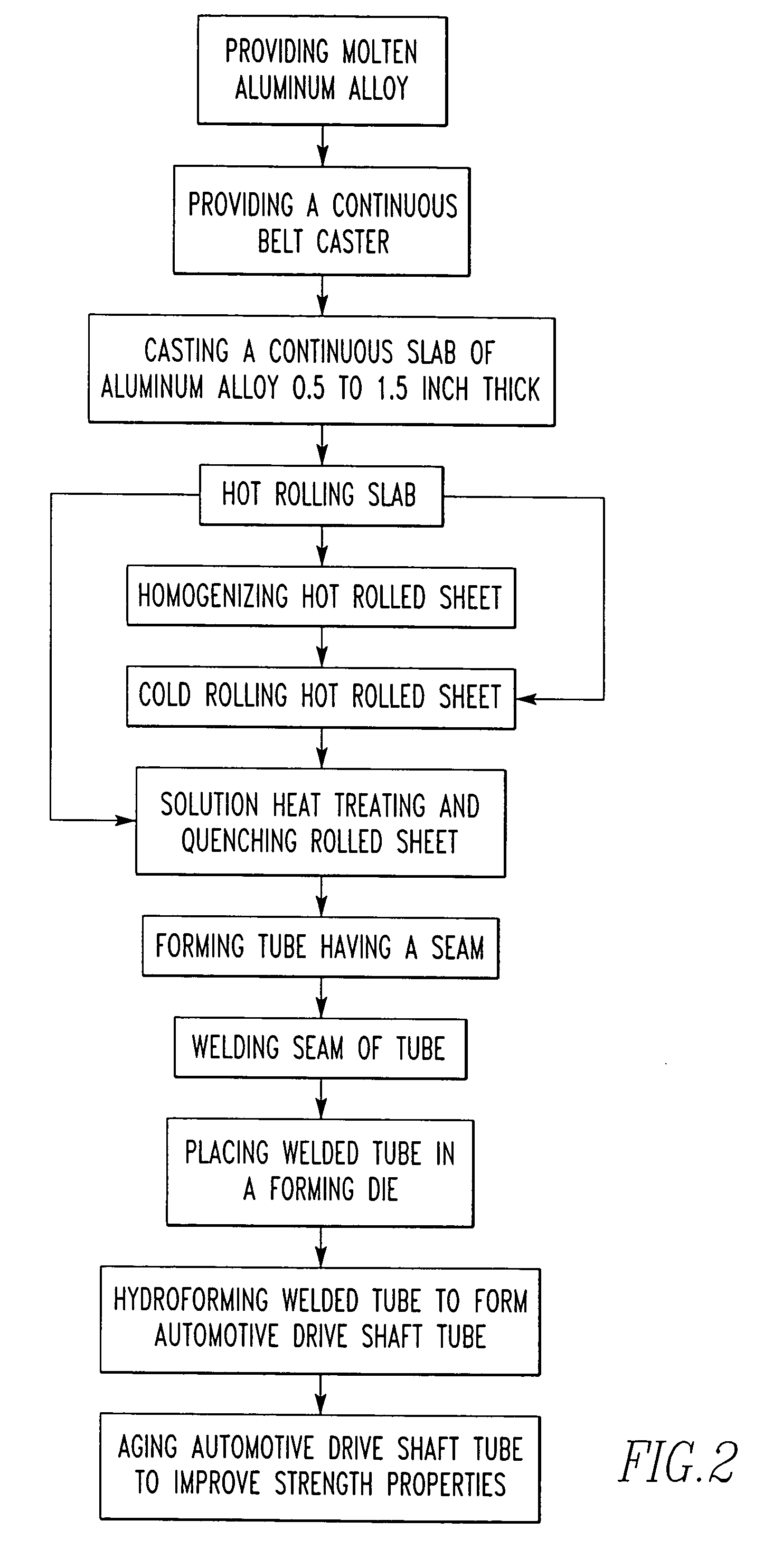

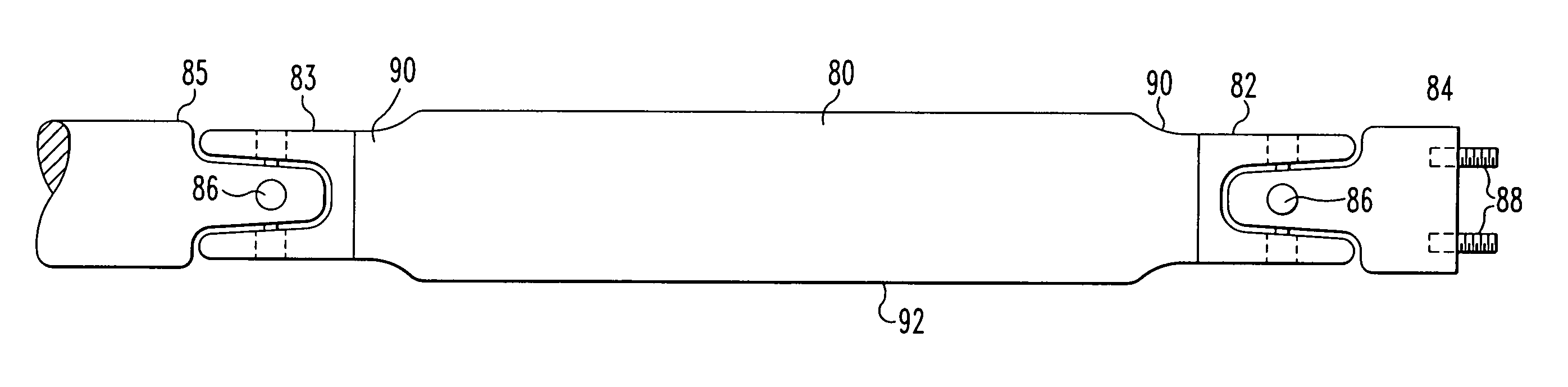

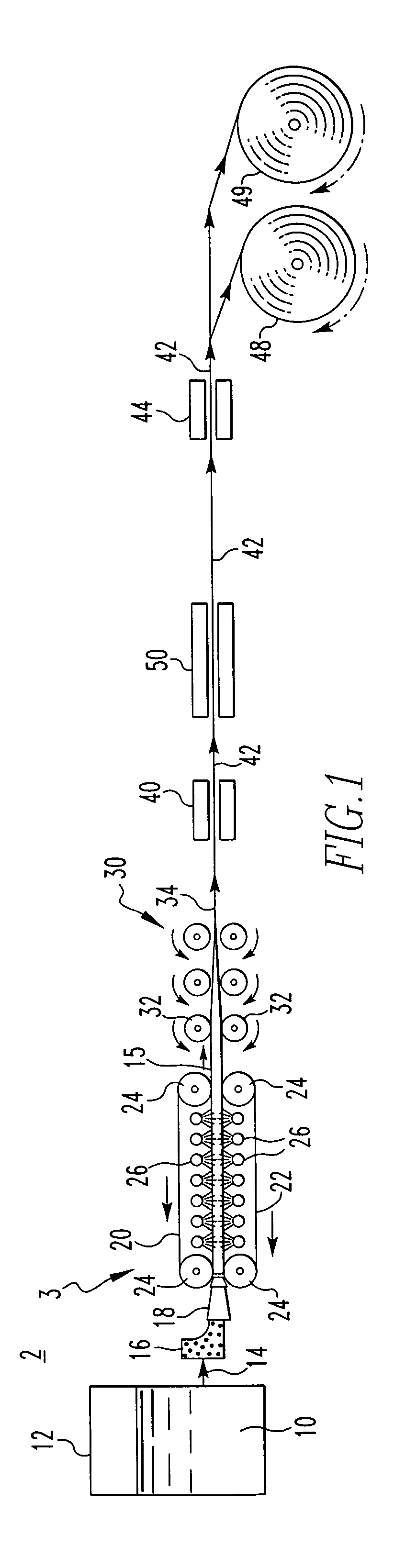

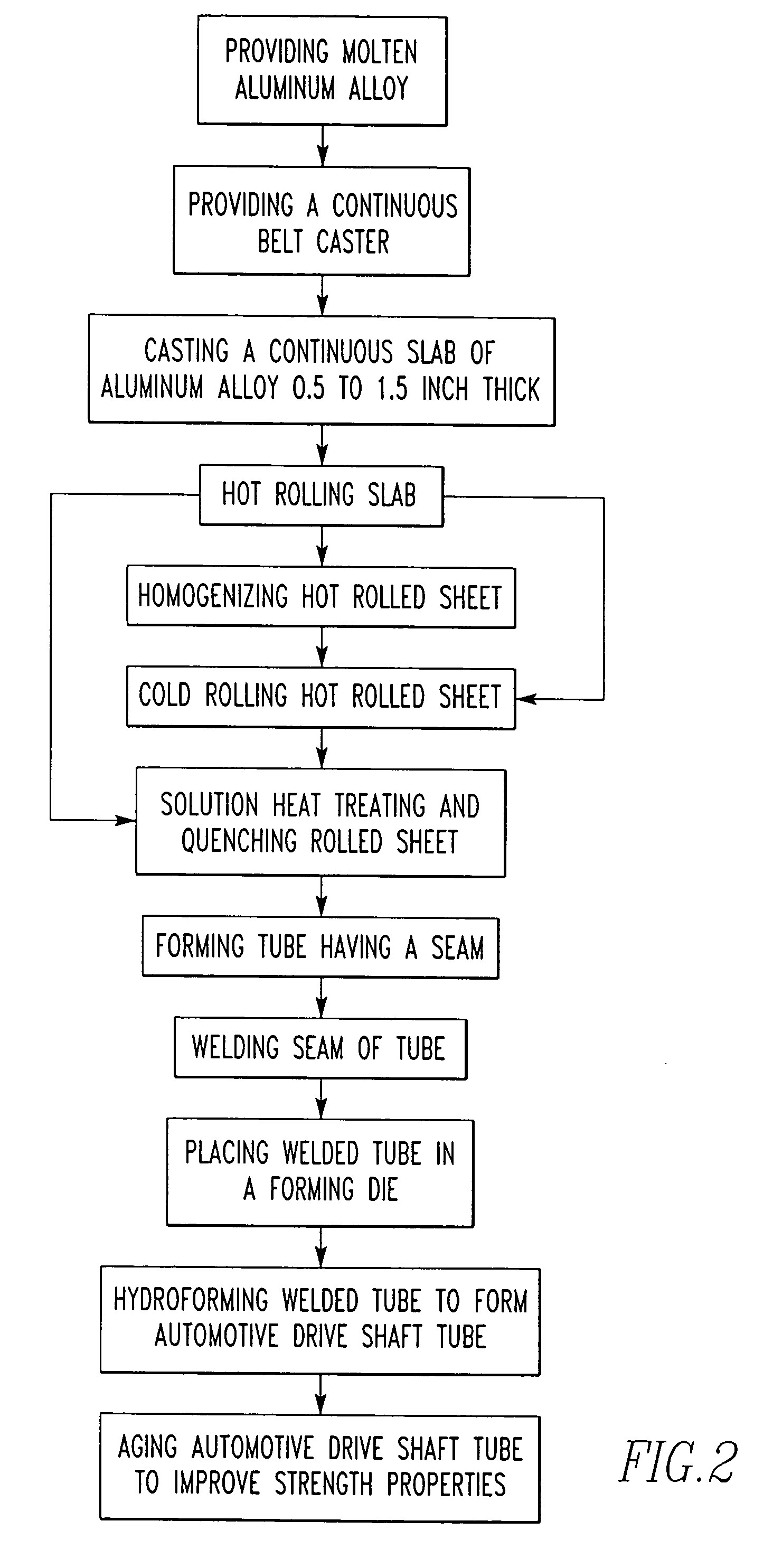

Aluminum automotive drive shaft

InactiveUS20050086784A1Improve strength propertiesMetal rolling stand detailsShaftsDrive shaftSeam welding

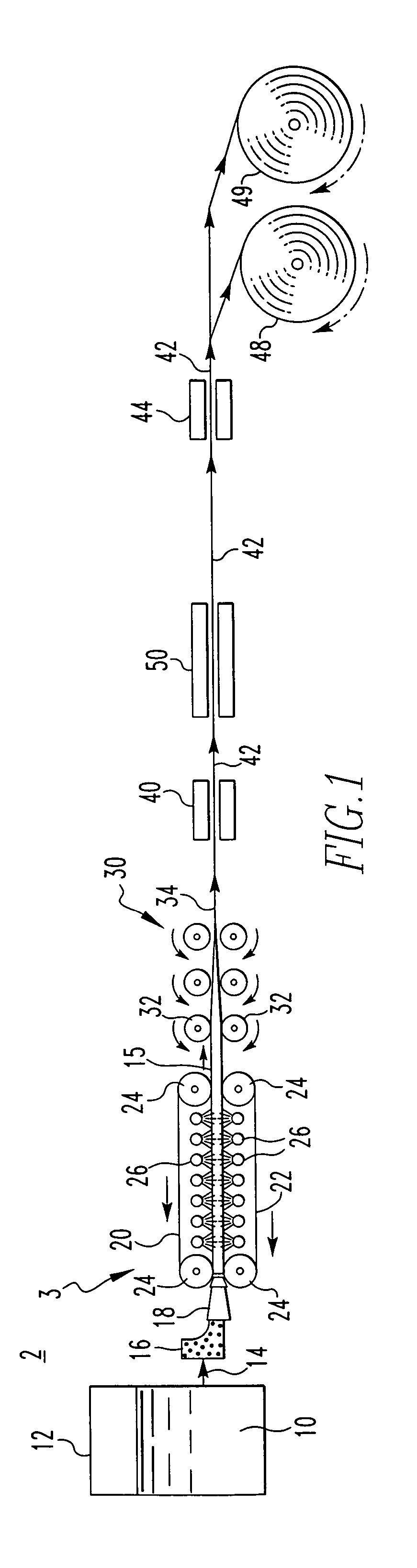

Disclosed is a method for producing aluminum drive shafts from molten aluminum alloy using a continuous caster to cast the alloy into a slab. The method comprises providing a molten aluminum alloy consisting essentially of 0.2 to 0.8 wt. % Si, 0.05 to 0.4 wt. % Cu, 0.45 to 1.2 wt. % Mg, 0.04 to 0.35 wt. % Cr, 0.7 wt. % max. Fe, 0.15 wt. % max. Mn, 0.25 wt. % max. Zn, 0.15 wt. % max. Ti, the remainder aluminum, incidental elements and impurities and providing a continuous caster such as a belt caster for continuously casting the molten aluminum alloy. The molten aluminum alloy is cast into a slab which is rolled into a sheet product. After solution heat treatment, the sheet product is formed into a tube having a seam which is welded to provide a seam welded tube. The seam welded tube is placed in a forming die and hydroformed to form the drive shaft.

Owner:COMMONWEALTH INDS

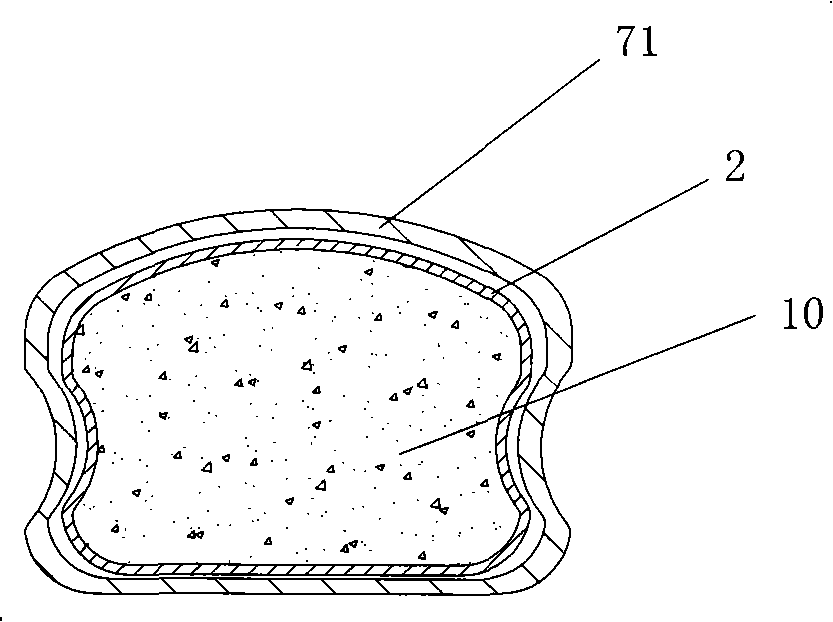

T/R assembly integrated air tightness packaging structure resistant to overload

ActiveCN103824816AAll-in-one packagingMiniaturizationAntenna supports/mountingsSemiconductor/solid-state device detailsMicrowaveMiniaturization

The invention discloses a T / R assembly integrated air tightness packaging structure resistant to overload. The T / R assembly integrated air tightness packaging structure resistant to overload comprises a cylindrical shell, a groove used for containing an antenna is formed in one end of the shell, the other end of the shell is provided with a cavity used for containing a signal processing unit, and the cavity is sealed by a cover board. An installation hole used for installing a microwave insulator is reserved in the portion, clamped between the groove and the cavity, of the shell and the microwave insulator is arranged in the installation hole through eutectic welding. Wires on the two sides of the microwave insulator are connected with the antenna and a signal processing unit substrate respectively. According to the T / R assembly integrated air tightness packaging structure resistant to overload, miniaturization and integration of a radio frequency / microwave T / R assembly are achieved. The microwave insulator is sintered on the metal shell in a gold-tin eutectic welding mode and matched with parallel seam welding (or laser welding) air tightness packaging, the sealing performance of a cavity of the signal processing unit can be guaranteed, and the reliability of the assembly can be improved. Transmission between the sending / receiving antenna and the signal processing unit is conducted through the microwave insulator, the transmission distance is shortened, and the microwave characteristic of a circuit is improved.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Aluminum automotive drive shaft

InactiveUS6959476B2Improve strength propertiesMetal rolling stand detailsShaftsDrive shaftSeam welding

A method for producing aluminum drive shafts from molten aluminum alloy using a continuous caster to cast the alloy into a slab. The method comprises providing a molten aluminum alloy consisting essentially of 0.2 to 0.8 wt. % Si, 0.05 to 0.4 wt. % Cu, 0.45 to 1.2 wt. % Mg, 0.04 to 0.35 wt. % Cr, 0.7 wt. % max. Fe, 0.15 wt. % max. Mn, 0.25 wt. % max. Zn, 0.15 wt. % max. Ti, the remainder aluminum, incidental elements and impurities and providing a continuous caster such as a belt caster for continuously casting the molten aluminum alloy. The molten aluminum alloy is cast into a slab which is rolled into a sheet product. After solution heat treatment, the sheet product is formed into a tube having a seam which is welded to provide a seam welded tube. The seam welded tube is placed in a forming die and hydroformed to form the drive shaft.

Owner:COMMONWEALTH INDS

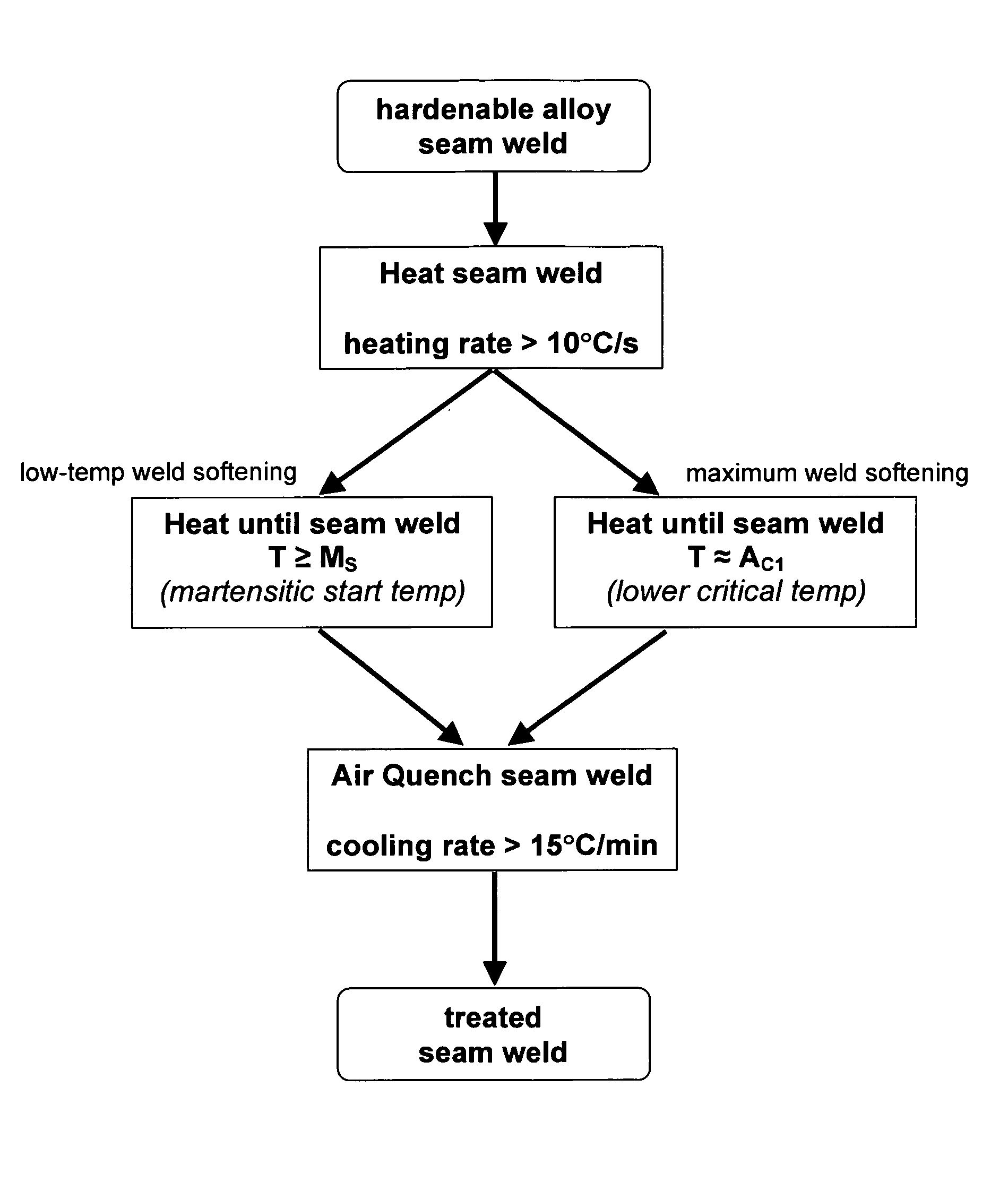

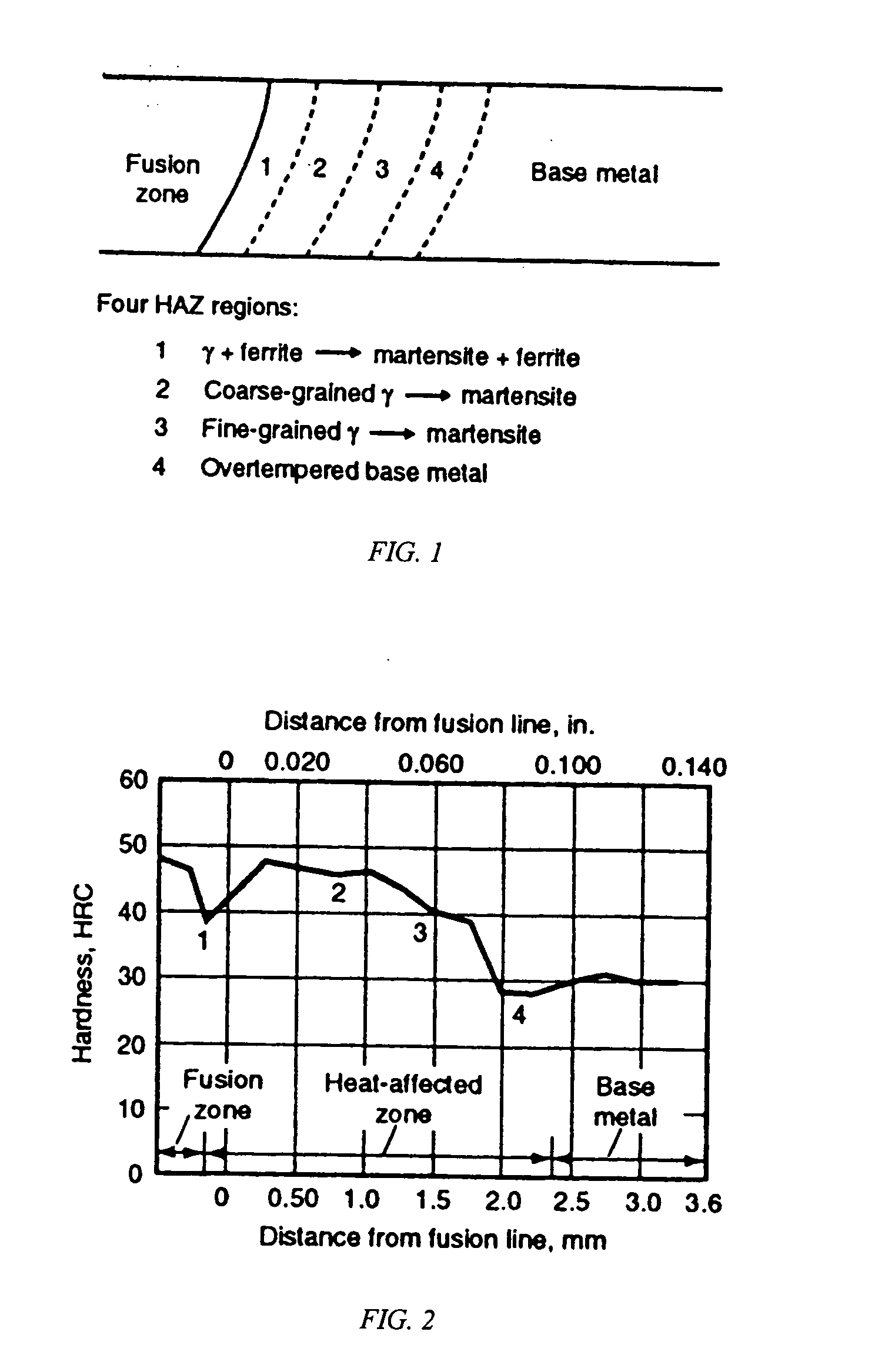

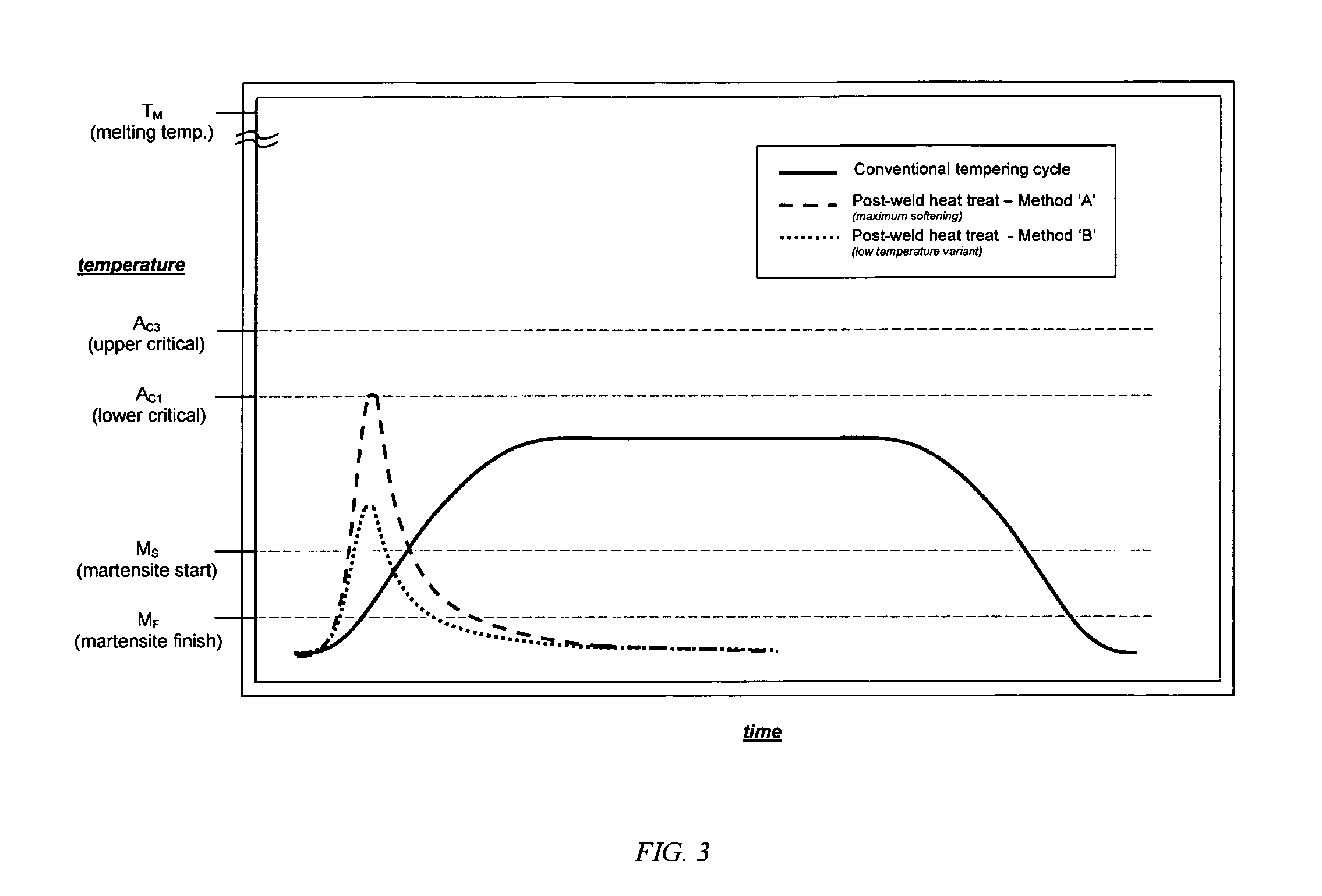

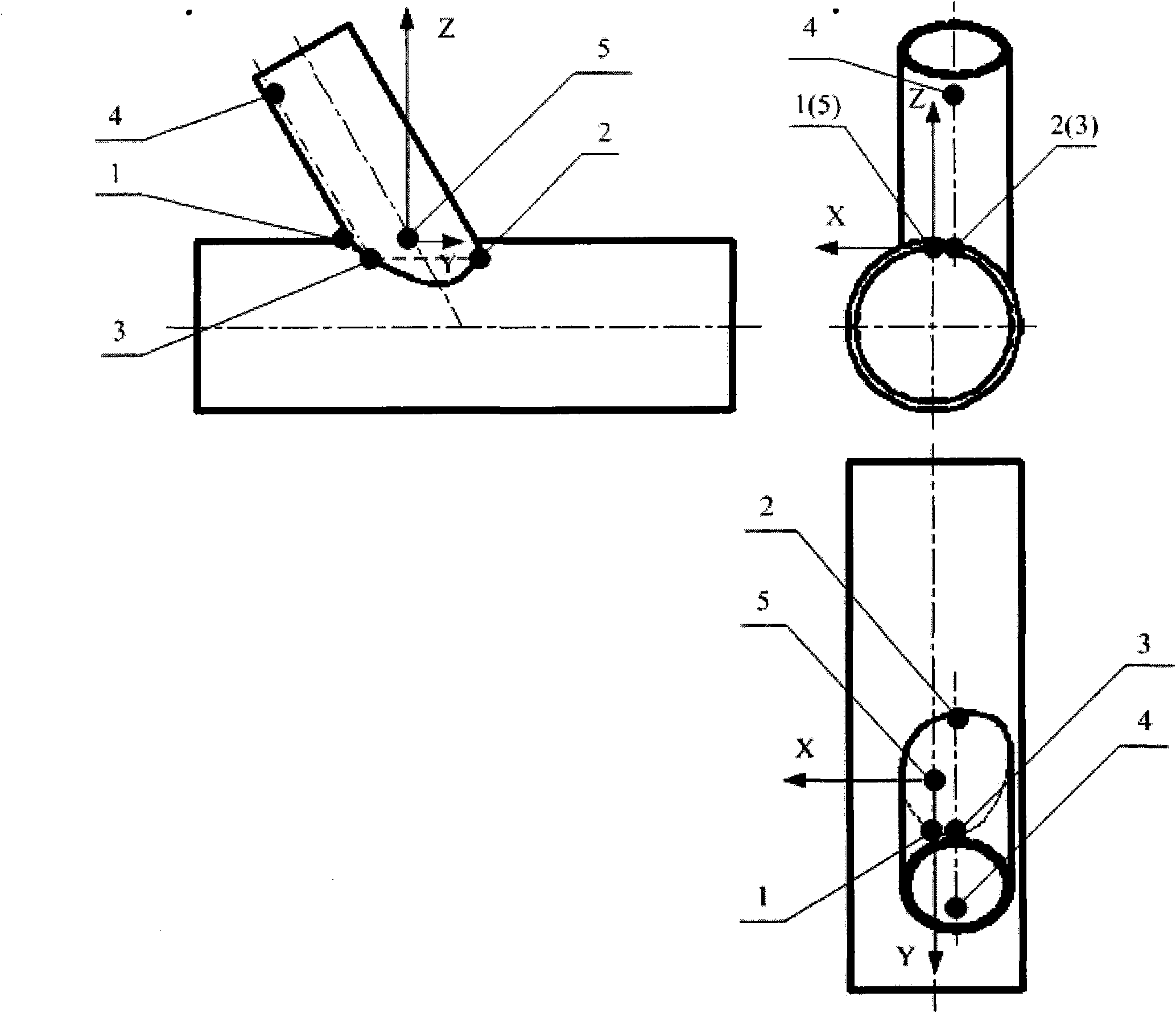

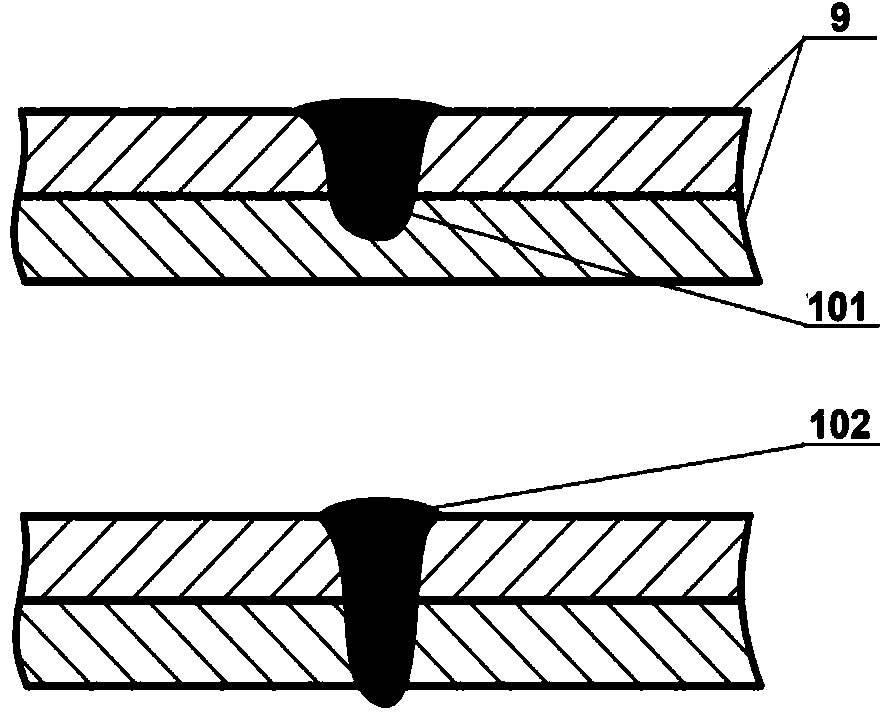

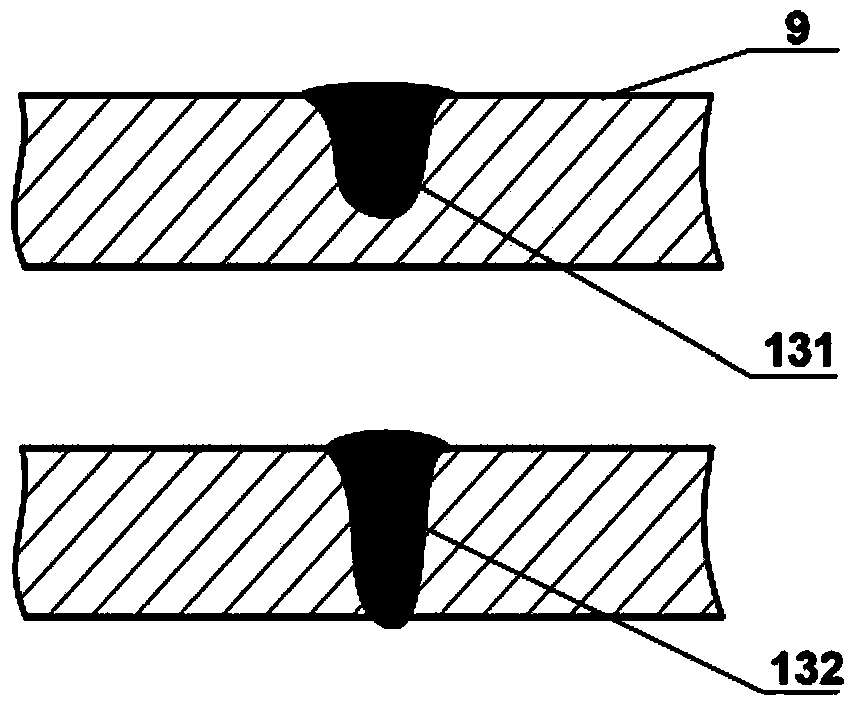

Method for improving the performance of seam-welded joints using post-weld heat treatment

InactiveUS20080115863A1Simple methodImprove mechanical propertiesIncreasing energy efficiencyFurnace typesHardnessAlloy

The present invention provides a method for heat-treating seam-welded constructions of hardenable steel and ferrous alloys with reduced weld-zone hardness and improved weld-zone ductility and toughness. This method consists of heating the seam weld rapidly with a secondary heat source to a temperature greater than the martensitic start temperature but not greater than the lower critical temperature, followed by immediately allowing the seam weld to air-cool. The rapid tempering of this invention is particularly suited to the production of high strength hardenable alloy seam-welded pipe and tubing and other structures.

Owner:CODD DANIEL SHAWN

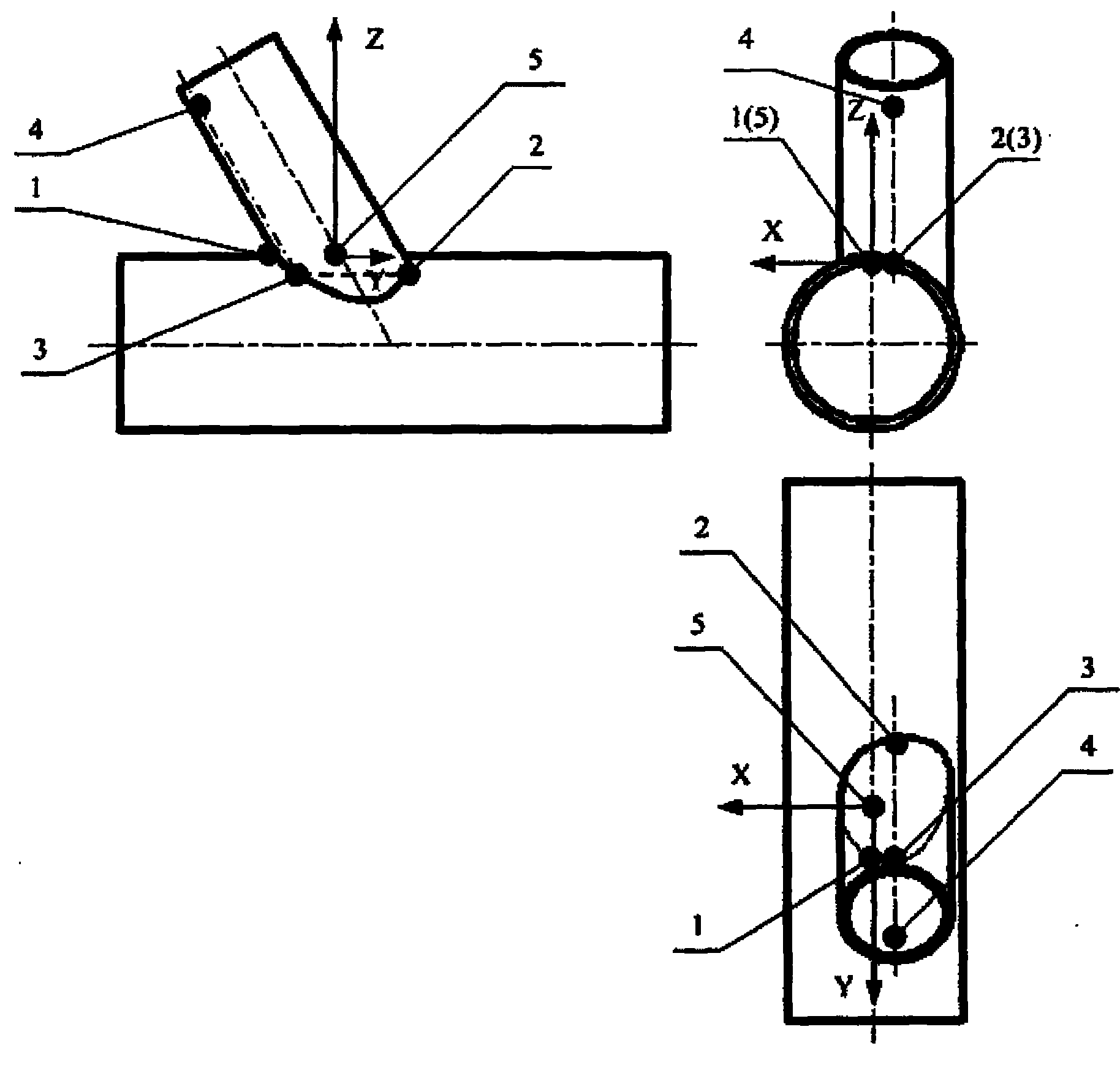

Universal arc welding robot teaching method regarding cylinder intersection welding seam

InactiveCN102069267ALess number of teaching pointsImprove teaching efficiencyArc welding apparatusEngineeringWeld seam

The invention relates to a universal arc welding robot teaching method regarding a cylinder intersection welding seam. The method is suitable for four kinds of cylinder intersection welding seams, namely central vertical crossing, central inclined crossing, eccentric vertical crossing and eccentric inclined crossing. The method is characterized in that a pose transformation matrix of a workpiece coordinate system relative to a robot-based coordinate system is established and calibration of a cylinder intersection welding seam workpiece coordinate system is realized by operating a robot to teach four characteristic points on a cylinder intersection welding seam workpiece on line; a cylinder intersection discrete point coordinate and a corresponding welding gun pose under the robot-based coordinate system are generated through the corresponding interpolation algorithm, so that generation of a cylinder intersection welding seam track and welding gun pose fitting are realized. The method has the following advantages: the arc welding robot only needs to teach four characteristic points in a cylinder intersection welding seam welding task; the teaching efficiency is high, the track interpolation accuracy is high and the adaptability is strong; and the working efficiency and the welding quality of the arc welding robot for welding the cylinder intersection can be greatly improved.

Owner:HANGZHOU KAIERDA ELECTRIC WELDING MACHINE

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

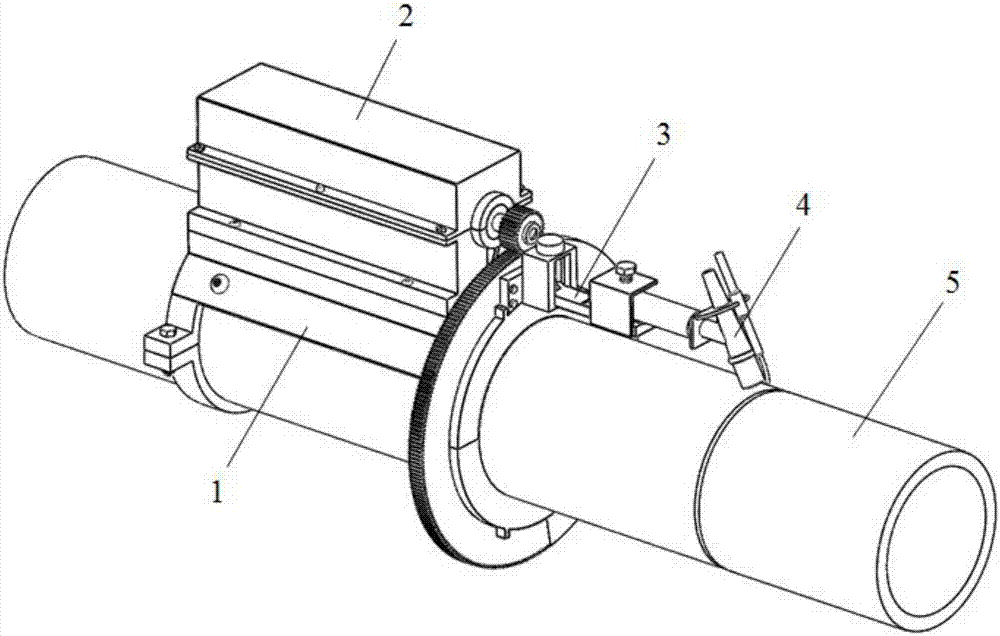

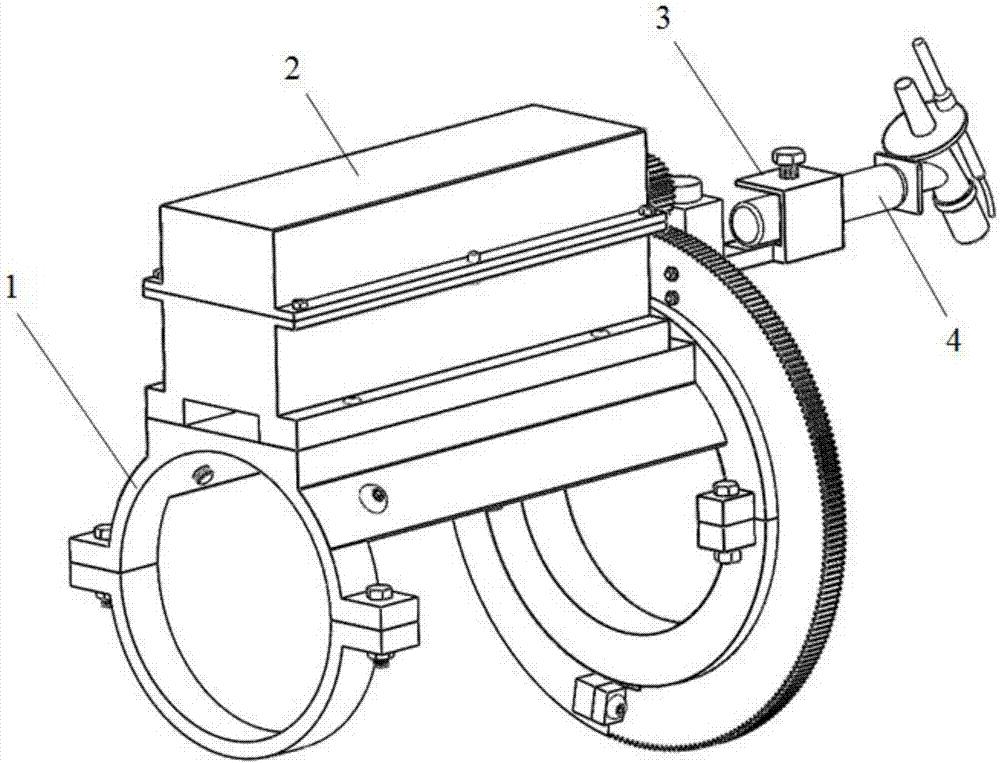

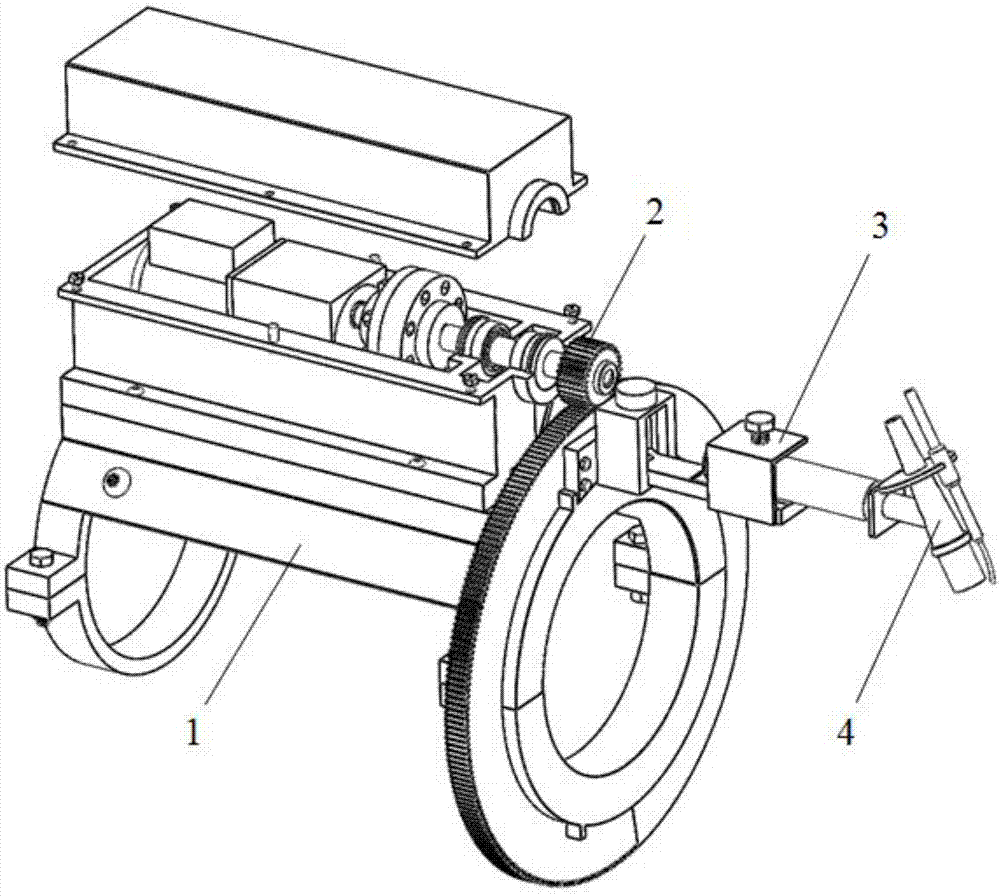

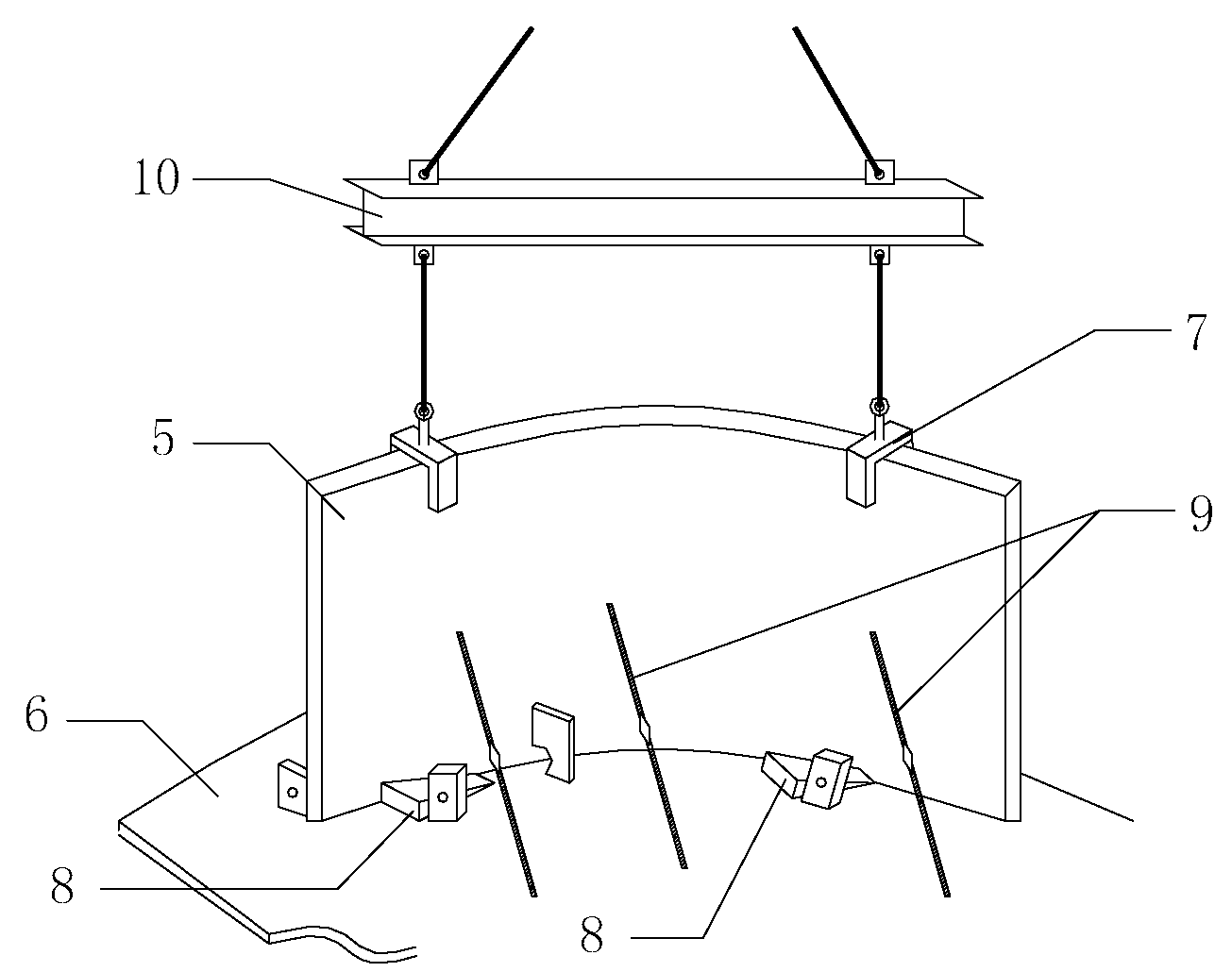

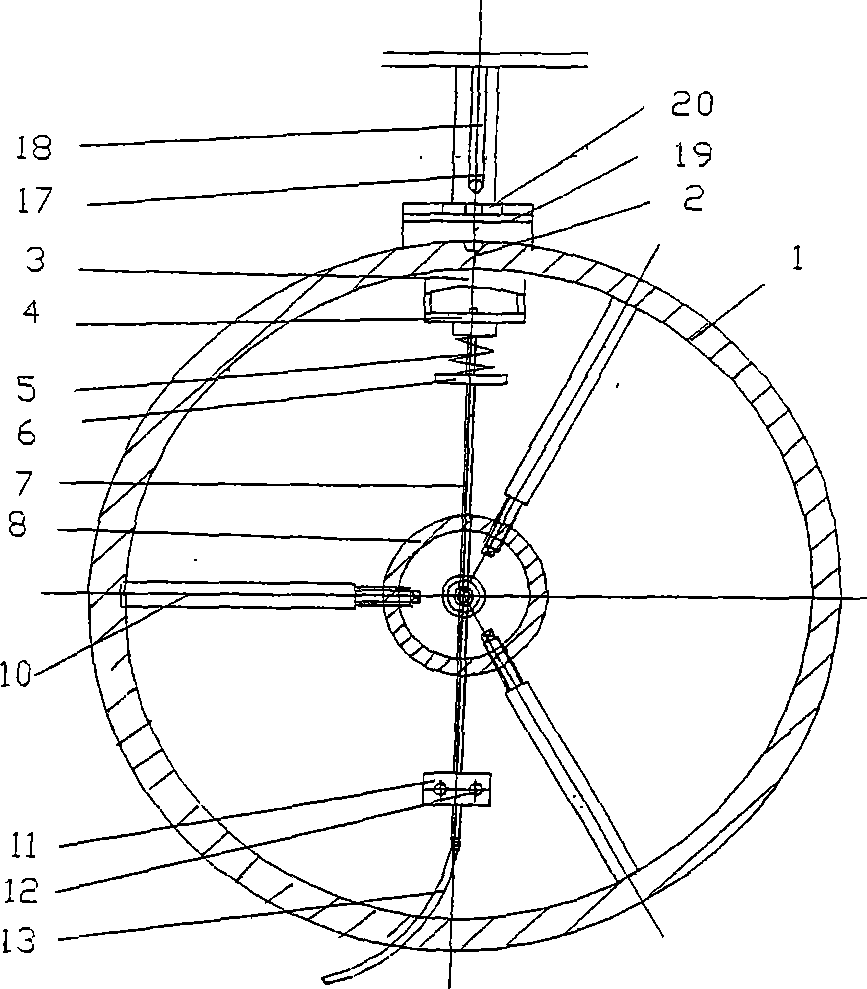

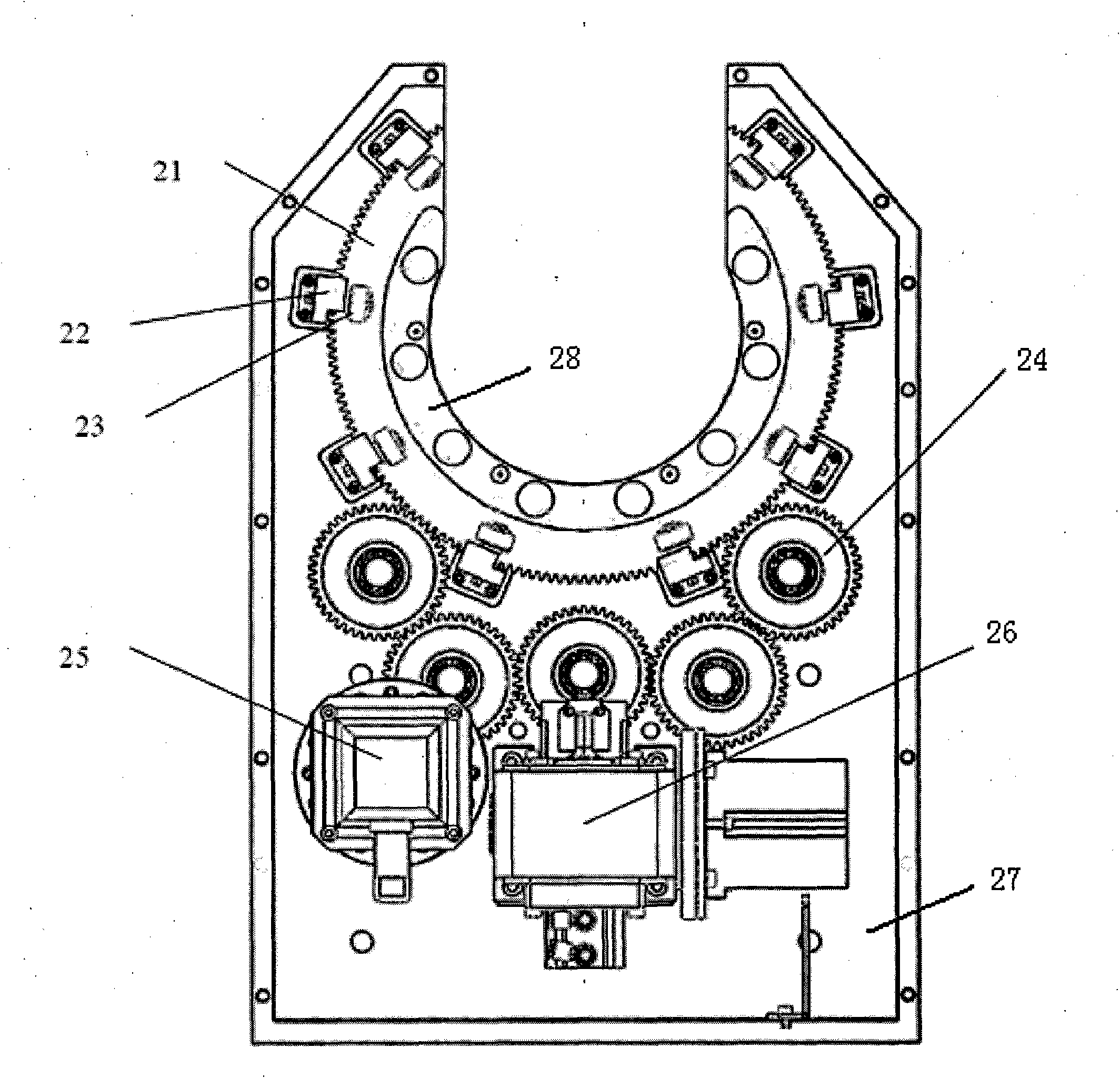

Automatic petroleum pipeline circular seam welding device

ActiveCN107414367ACompact structureReduce volumeWelding/cutting auxillary devicesAuxillary welding devicesControl systemContact type

The invention relates to a welding device, in particular to an automatic petroleum pipeline circular seam welding device. The automatic petroleum pipeline circular seam welding device comprises a pipeline clamping system, a power and control system, a welding gun clamping system and a welding gun. The pipeline clamping system is installed on a petroleum pipeline, the power and control system is installed on the pipeline clamping system, the welding gun clamping system is installed on the power and control system, and the welding gun is installed on the welding gun clamping system. The automatic petroleum pipeline circular seam welding device is directly installed on the petroleum pipeline in need of welding, the welding gun is driven to act through gear transmission so as to complete the circular seam welding process. The automatic petroleum pipeline circular seam welding device has the advantages of being simple and compact in structure, small in size, low in cost and high in automated degree. Welding can be stopped automatically through a contact type travel switch when a half circle is welded, the welding process is divided into two steps and completed through welding of the two half circles, and thus welding quality is improved. Spiral transmission is adopted for the welding gun clamping system to adjust the position of the welding gun, the distance between the welding gun and the petroleum pipeline can be adjusted precisely, and the welding quality of a circular seam is further improved.

Owner:XUZHOU XINLONG PIPE IND CO LTD

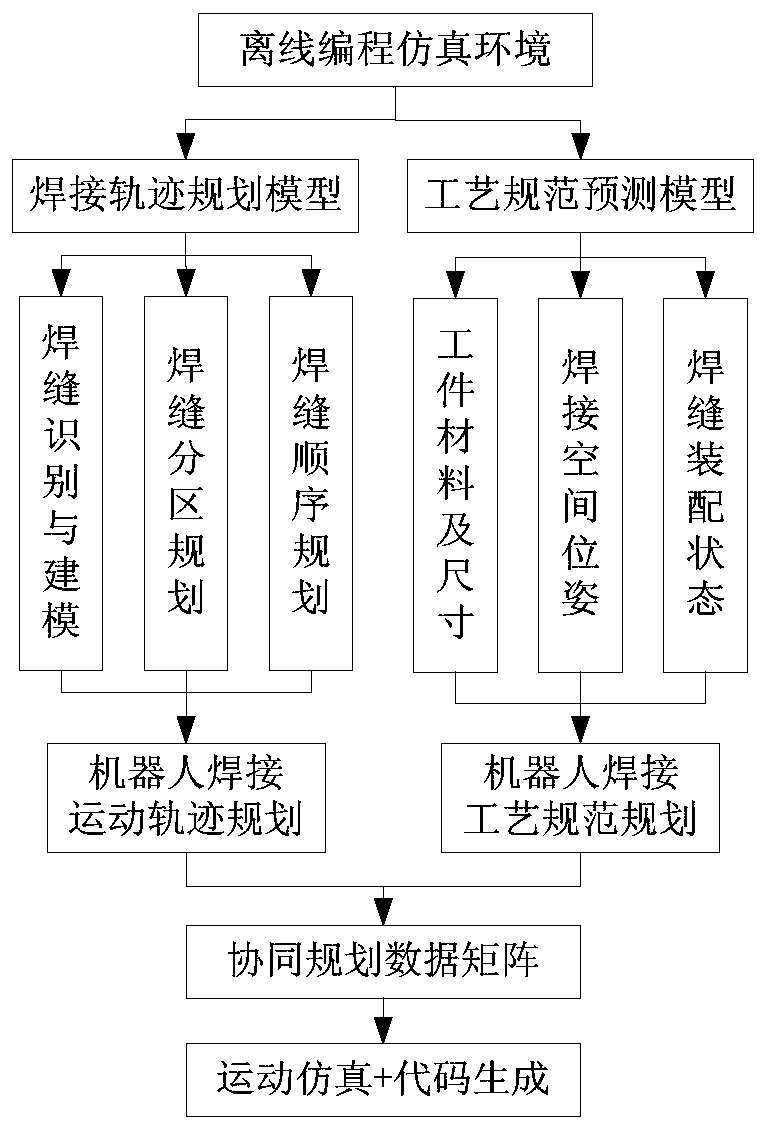

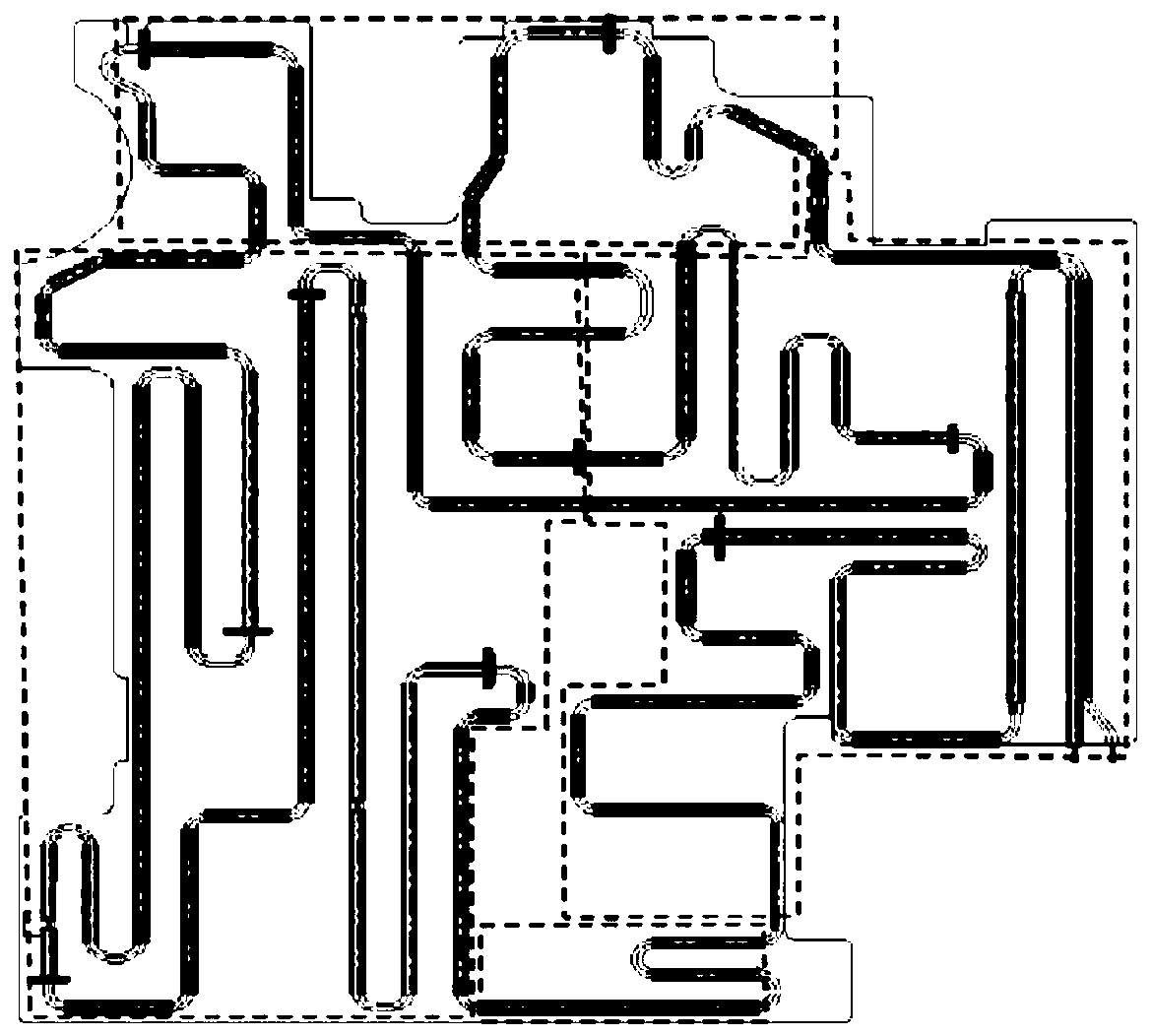

Collaborative planning method of complicated space curve welding seam motion track and welding technology

ActiveCN111230869AImplement sequence planningWeld adaptationProgramme-controlled manipulatorWelding/cutting auxillary devicesControl engineeringWeld seam

The invention relates to a collaborative planning method of a complicated space curve welding seam motion track and the welding technology. The collaborative planning method comprises the following steps: 1, extracting a complicated product welding seam outline; 2, carrying out zoning planing on the three-dimensional outline of the welding seam; 3, planning the welding seam welding sequence of each area; 4, carrying out motion simulation and multi-robot synergic movement simulation on a formed robot motion track; 5, planning the welding technological parameters; and 6, carrying out data distribution and execution. The collaborative planning method is innovatively used in the automatic welding field of complicated space curve welding seams, realizes intelligent partition of the space curvewelding seam and the sequence planning of the welding seam, carries out self-adaption collaborative planning on the motion track and technology of a pose-variable and curvature-variable welding seam robot and realizes collaborative intelligent planning of the motion track and technology of the space curve welding seam robot.

Owner:BEIJING SATELLITE MFG FACTORY

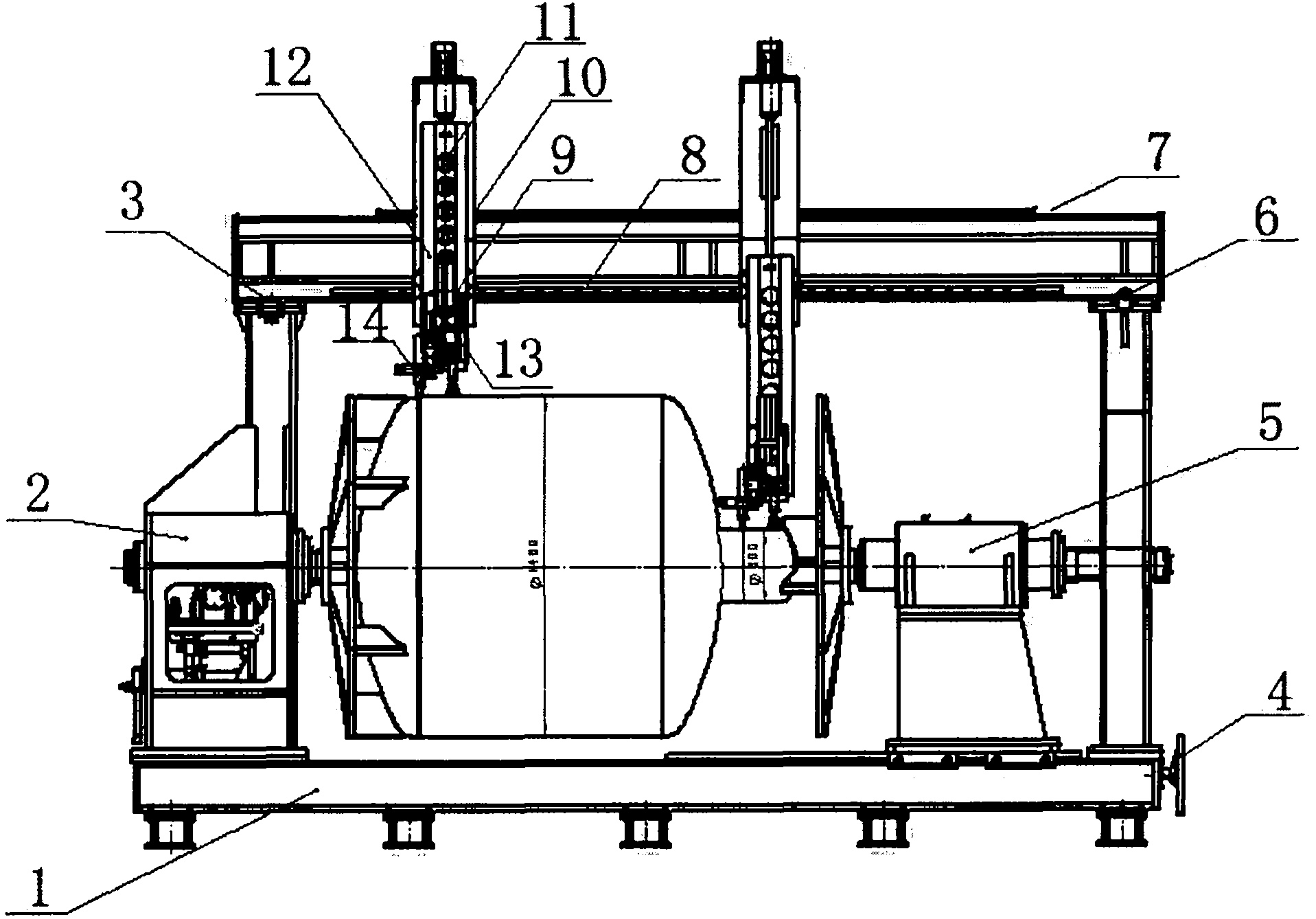

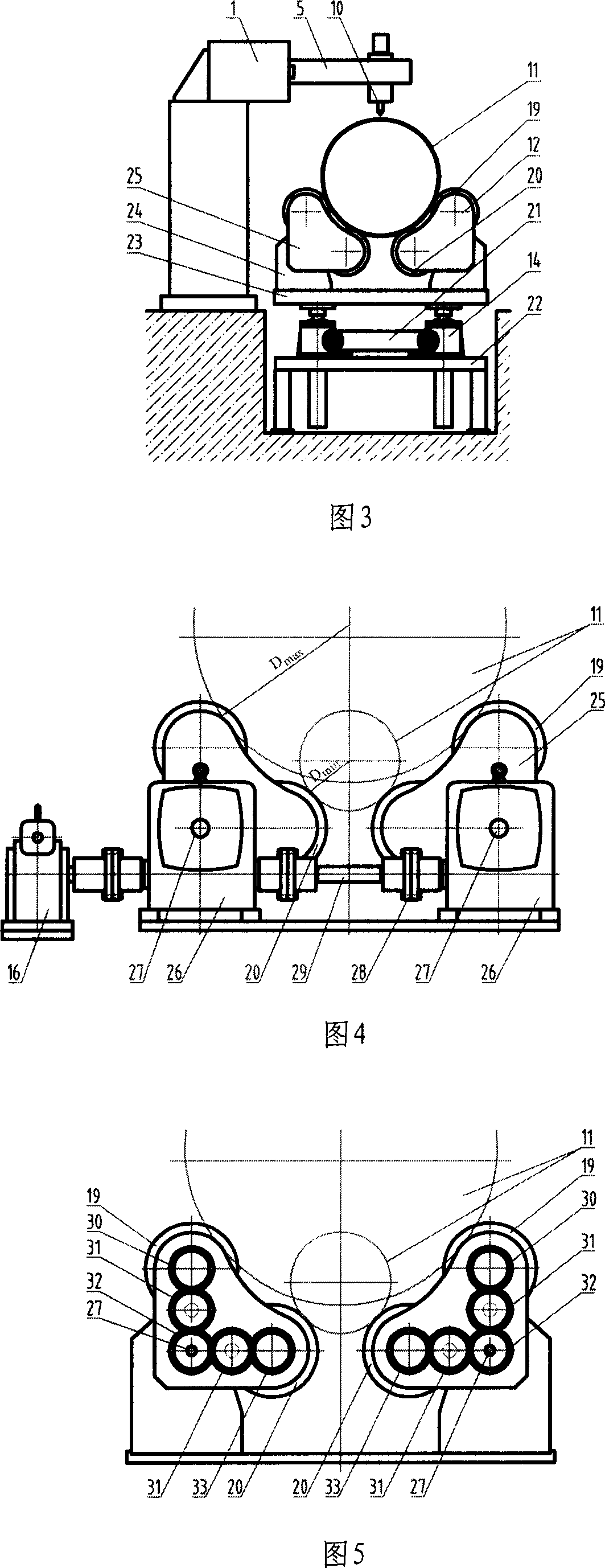

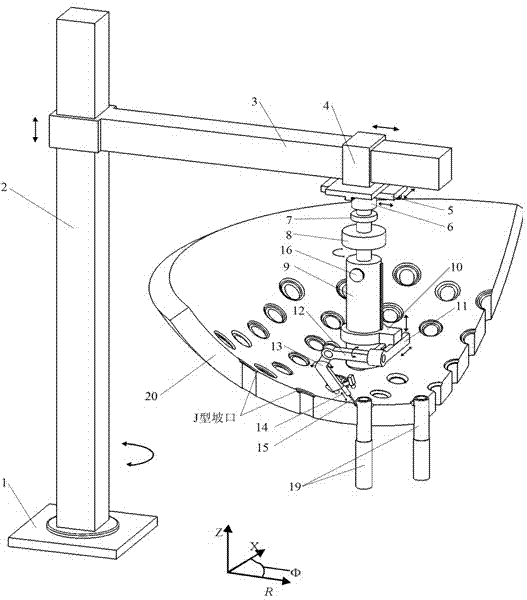

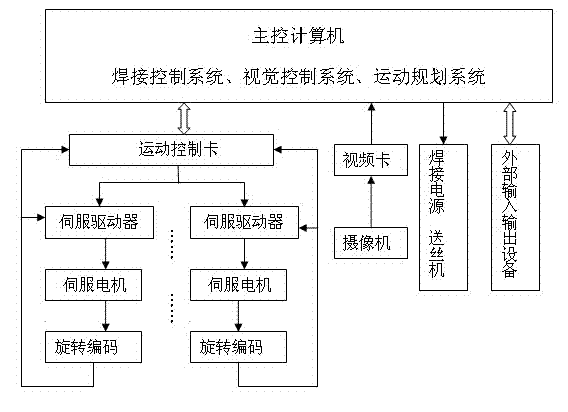

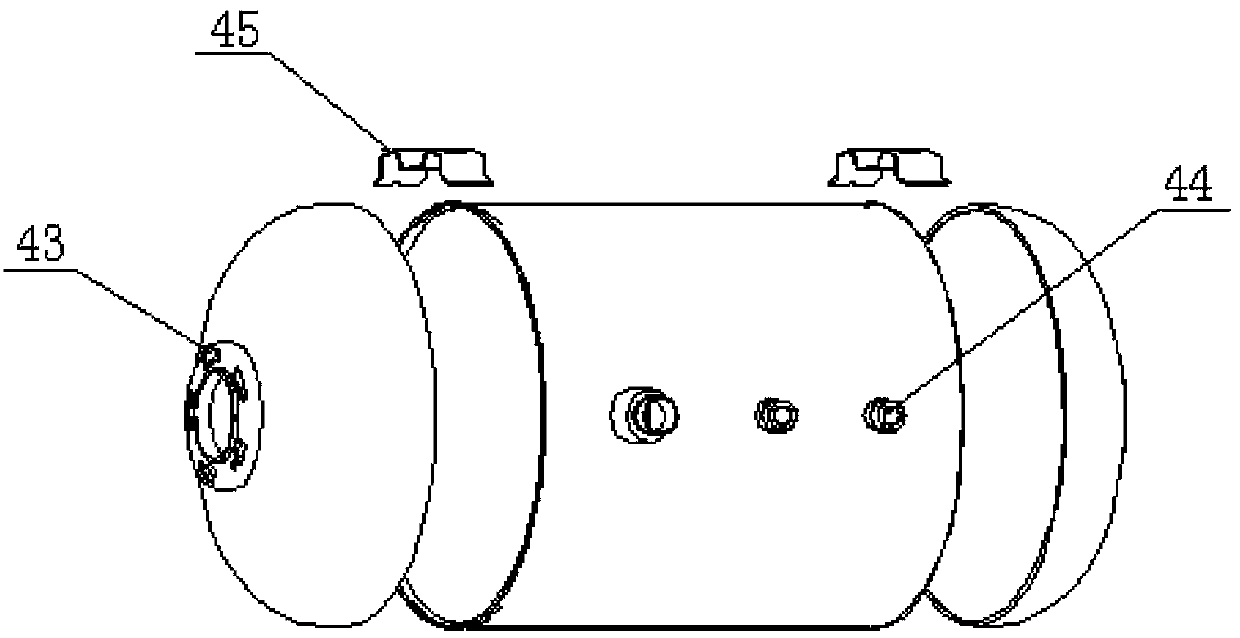

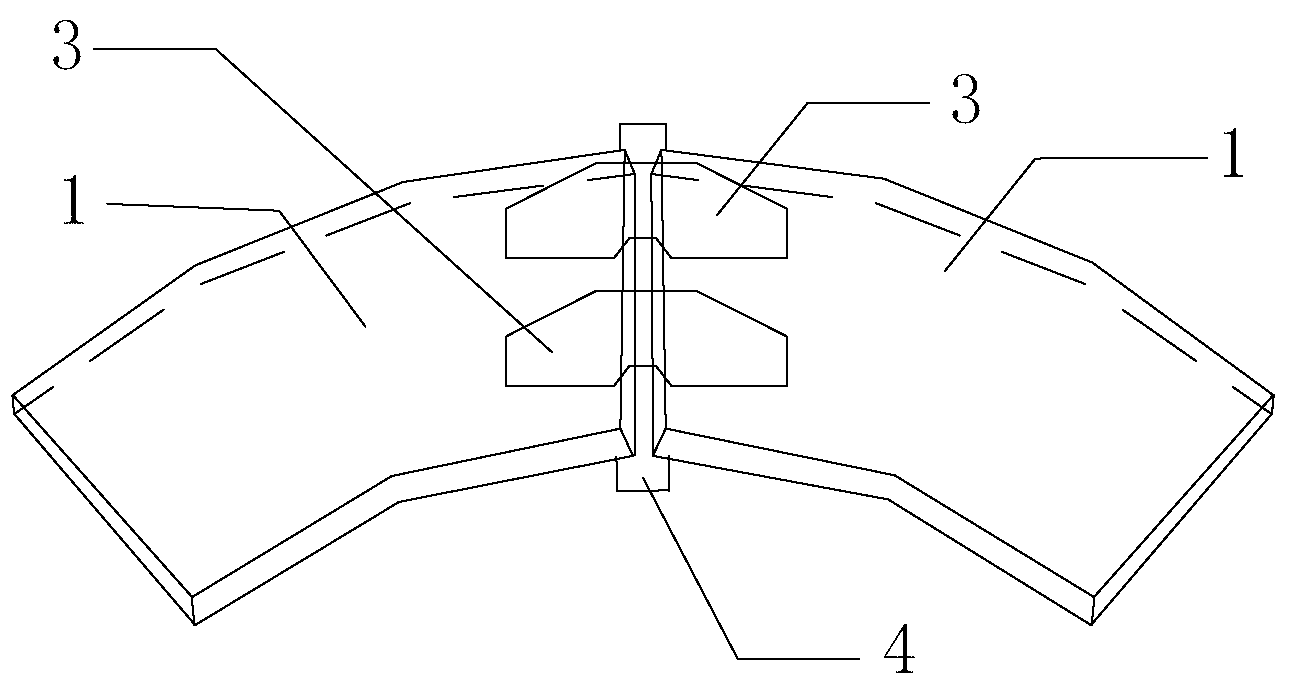

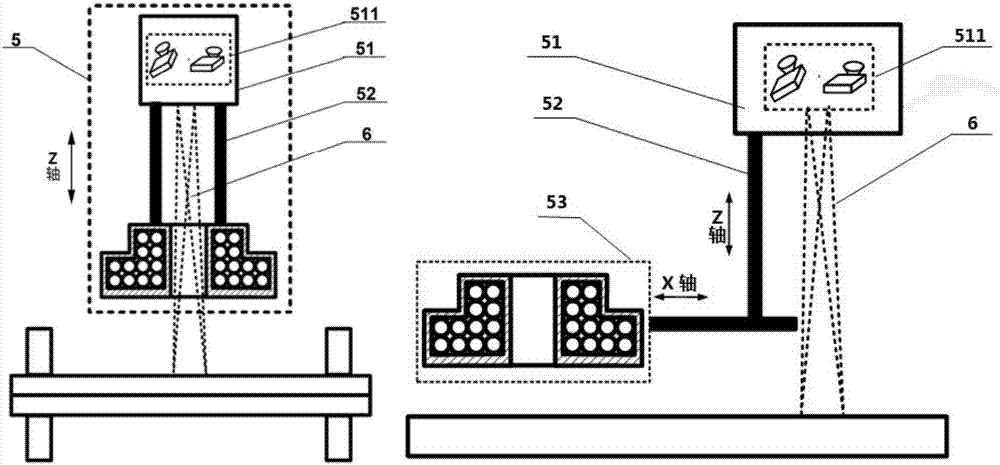

Circular seam welding robot device

ActiveCN102049638AWith visual functionFacilitates motion controlProgramme-controlled manipulatorWelding/cutting auxillary devicesMachineVision sensor

The invention discloses a robot device for the circular seam welding of large spherical crown workpieces and pipes. A robot main body comprises a machine head and a machine frame. The machine head consists of a cross sliding table mechanism, a six-freedom-degree motion system, a sliding ring system and a welding gun. The machine frame consists of a fixed base, upright columns, a cross beam and a slider. The machine frame of the robot makes large range motion and moves the robot main body to a position to be welded, the accuracy of micro motion is compensated by the cross sliding table mechanism of the machine head, and six-freedom-degree circular seam welding is realized. Welding process is monitored by a visual sensing technology, and a video camera fits a laser generator and serves as an optical visual sensor for laser structures. Another video camera fits the welding gun, serves as a visual sensor for a welding pool, and carries out real-time visual detection for the welding process. The robot device is particularly suitable for accurate locating motion required for welding large spherical crown workpieces and pipes, and can finish specific track welding in narrow space and control welding hot deformation.

Owner:TIANJIN YANGTIAN TECH CO LTD

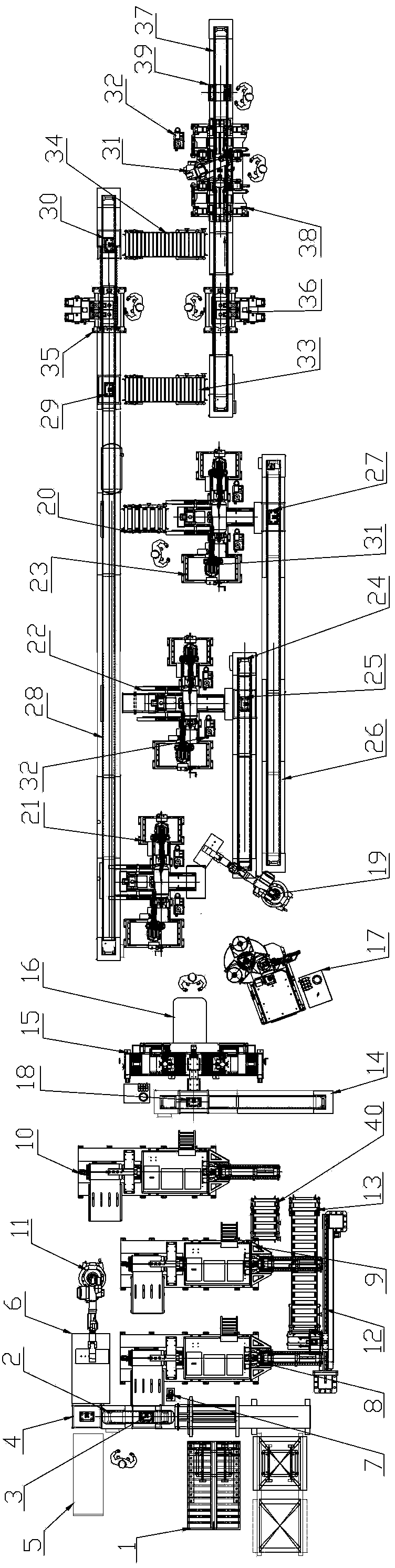

Semi-automatic liner welding production line

ActiveCN103962843AReasonable layoutStable deliveryOther manufacturing equipments/toolsWelding apparatusProduction lineSemi automatic

The invention provides a semi-automatic liner welding production line. The semi-automatic liner welding production line comprises a sheet metal edge-coiling mechanism, a straight seam welding plant, an end cover girth welding device, a water inlet / outlet pipe welding device, and a technologic rack welding device, wherein the devices are connected by conveyor chains; the sheet metal edge-coiling mechanism is an edge coiling machine; the straight seam welding plant is a working station for finishing straight seam welding of the edge rolling liner, and comprises three ion tunnel straight seam welders; the girth welding device comprises three-station assembly machine and three horizontal type girth robot workstations; the water inlet / outlet pipe welding device is a magnesium rod water pipe welder; the technologic rack welding device is a robot rack welder. The semi-automatic liner welding production line disclosed by the invention, compared to the prior art, is reasonable in layout, can reduce the occupied area of the production equipment by 60%, the labor by 260%, and improve the production efficiency by nearly 3 times.

Owner:HUNAN JINGYI AUTOMATION

Method for laser welding of metal

A method of welding at least two metal sheets protected by a zinc coating that has a low vaporizing temperature. The metal sheets are placed on top of each other and a head of a welding machine is passed over the sheets. The head of the welding machine is configured such that a laser is positioned in front of a GMAW welding or MIG brazing device. The laser cuts a channel into the metal sheets in order to allow the protective zinc coating to vaporize and escape. The GMAW welder or MIG brazing device then follows the laser and deposits a material that fills the channel to weld the two pieces together.

Owner:METALSA SA DE CV

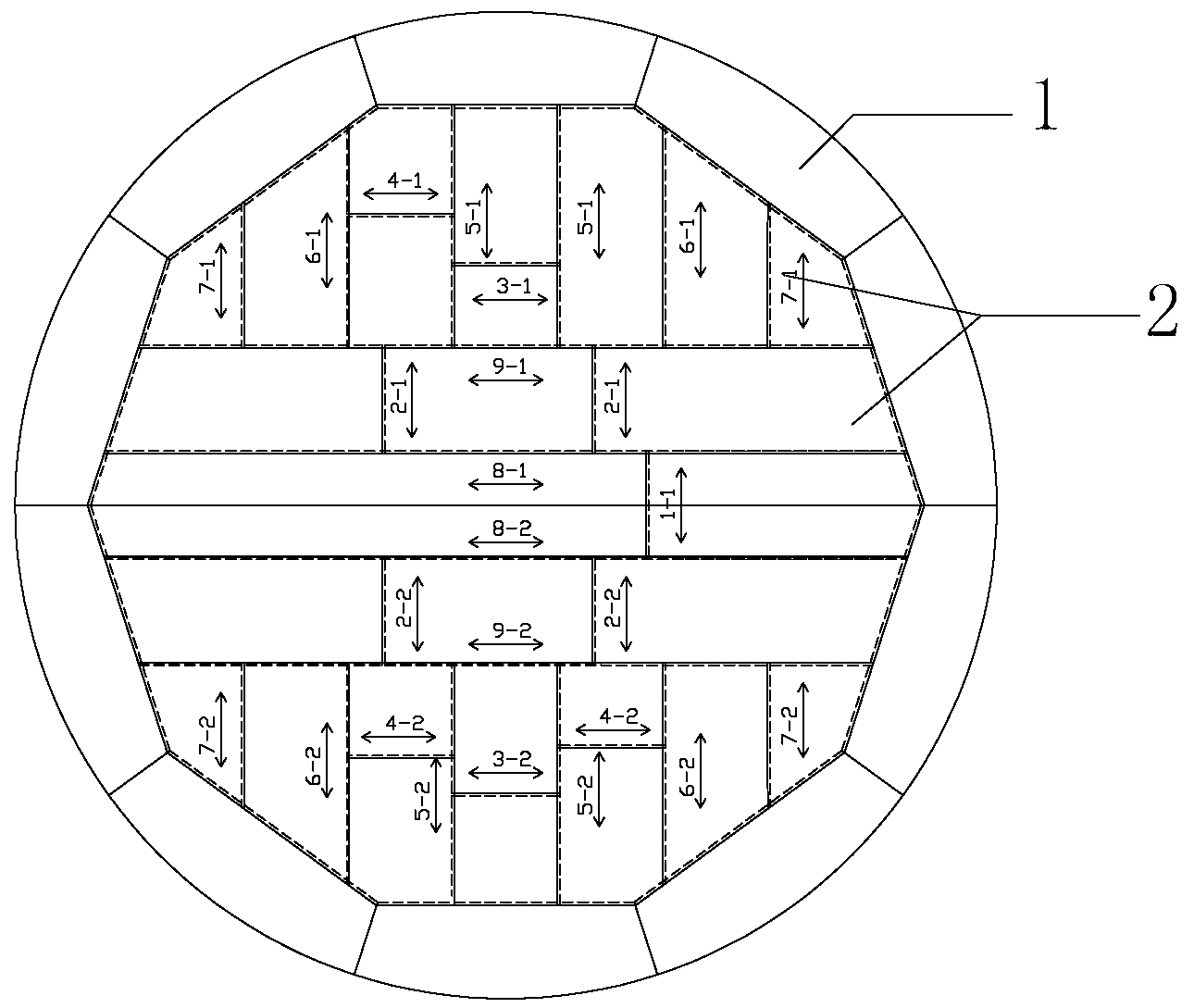

Tank fabricating and welding method

ActiveCN102848087AControl welding deformationAdvantages of making welding methodsWelding apparatusStructural engineeringSeam welding

The invention discloses a tank fabricating and welding method, which is characterized by comprising the following steps of: a. fabricating and welding a tank soleplate, wherein the step comprises: (1) paving the soleplate, and (2) welding the soleplate; and b. fabricating and welding a tank wall board, wherein the step comprises: (1) paving the wall board, and (2) welding the wall board, and the step of welding the wall board comprises: 1) temporarily not welding 300mm of the lower edge of a longitudinal weld and welding the lower edge together with a circular seam after being paired with a next sine wall board; 2) when welding the circular seam, enabling welders to be uniformly distributed on the surrounding of the tank and welded in the same direction; 3) selecting the setting distance of an anti-deformation fixture according to the thickness of the wall board before welding the circular seam, the distance of the fixture of the wall board with delta equal to 6mm being 300mm; and 4) selecting an even number of welders when welding the wall board, the levels of the welders being close, and welding with the same vertical seam and circular seam welding parameters. The tank fabricating and welding method disclosed by the invention has the advantages of simple and convenient operation, strong maneuverability and the capability of effectively controlling the welding deformation of the tank.

Owner:MCC5 GROUP CORP SHANGHAI

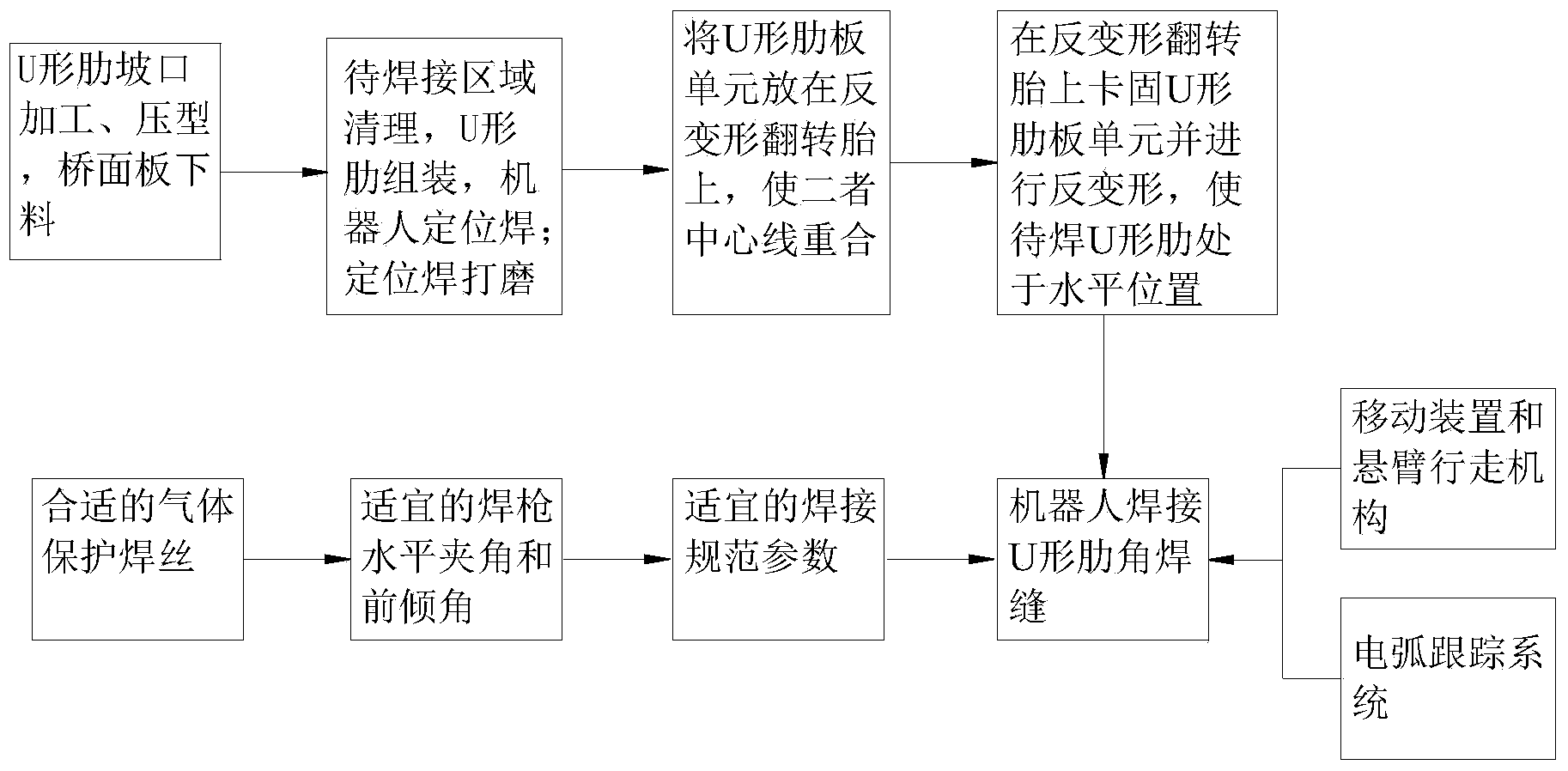

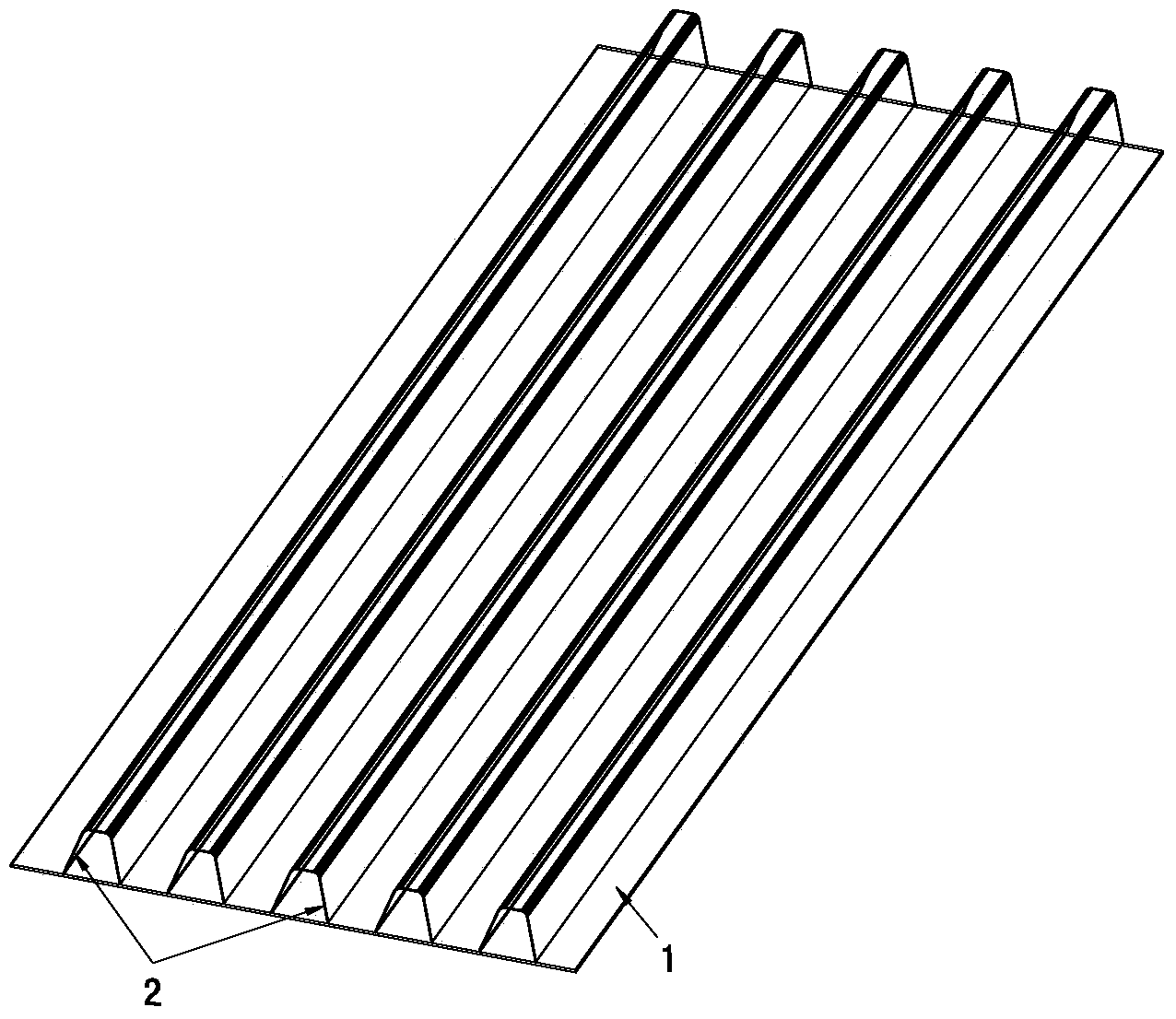

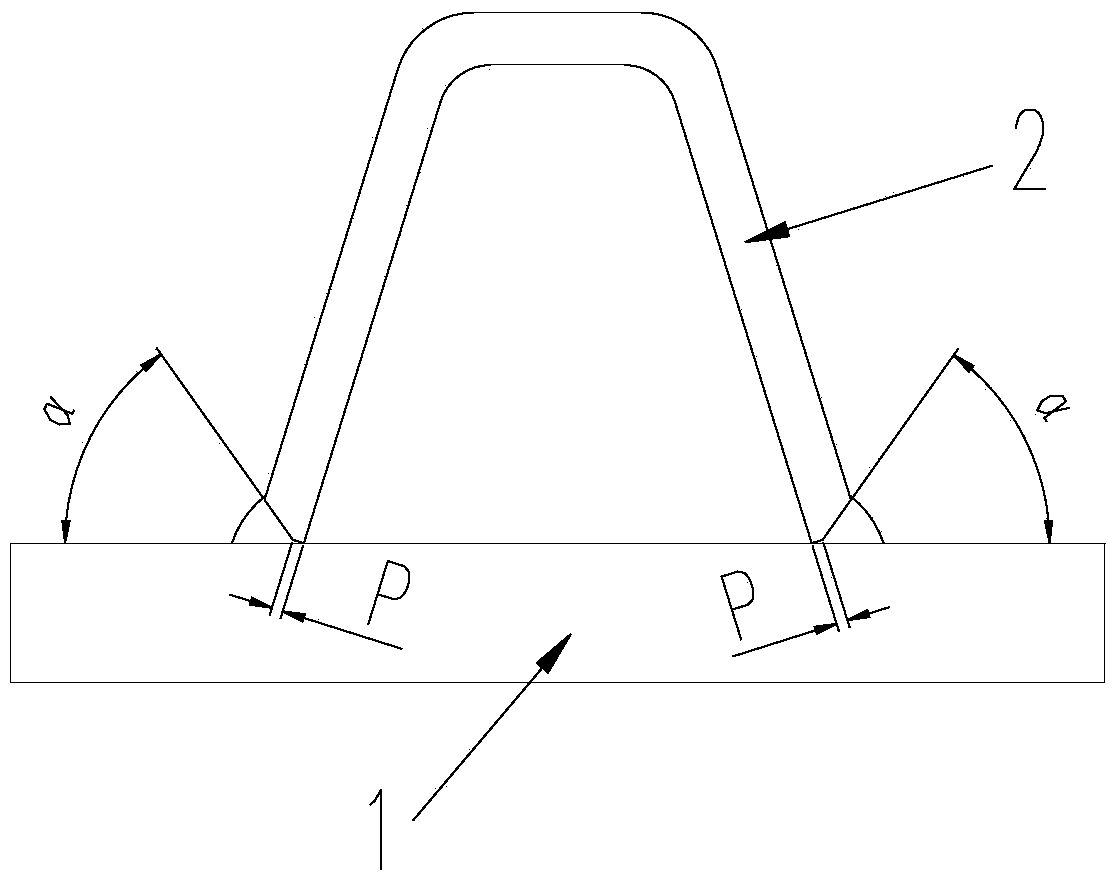

Flat position single-seam symmetrical welding method for orthotropic plate U-shaped rib corner welding seam robot

ActiveCN103862142AAnti-morph implementationImprove assembly accuracyWelding/cutting auxillary devicesArc welding apparatusBridge deckWeld seam

The invention relates to a flat position single-seam symmetrical welding method for an orthotropic plate U-shaped rib corner welding seam robot. The method comprises the following steps that A, U-shaped rib groove processing, compression and bridge deck plate blanking are carried out for obtaining a U-shaped rib plate unit through assembly; B, the U-shaped rib plate unit is horizontally placed on a reverse deformation turning moulding bed, and the position of the U-shaped rib plate unit is regulated so that the center line of the U-shaped rib plate unit is coincident with the center line of the turning moulding bed; C, the U-shaped rib plate unit is clamped and fixed, in addition, reverse deformation is carried out, the turning angle of the reverse deformation turning moulding bed is regulated so that a U-shaped rib to be welded is positioned in the horizontal position, and in addition, an angle scale is used for detection; D, the welding program and the welding specification parameters are input into a robot automatic welding system so that two welding hands arranged on a robot cantilever respectively and simultaneously carry out flat position single-seam welding on the angle welding seams of the two sides of the U-shaped rib. The method provided by the invention has the advantages that the U-shaped rib is assembled on the platform, the assembling precision is high, and a gap between the U-shaped rib and a bridge deck plate can be enabled to be within 0.5mm. The robot automatic welding hand has the electric arc tracking function, the change of the welding current and the electric arc voltage is sensed through swinging in the welding process, and the small deviation of a weld pass is corrected.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

Shell circumferential-seam welding method using plasma welding

ActiveCN101456098AOvercoming the inability to align the weld bead instantlyOvercoming protectivePlasma welding apparatusDomestic vesselsShielding gasAlloy

The invention discloses a method for welding circular seams of a vessel by plasma welding. A laser head (18) for aiming at a weld bead is arranged on a plasma welder head, an upper large protective cover (19) is arranged on the front side of a welding seam, and a lower large protective cover (4) is arranged on the back side of the welding seam, wherein the upper large protective cover is arranged on a plasma welding torch at the front side of the weld bead, and the lower large protective cover is arranged on a tool capable of automatically aiming at the welding position in vessel cylinder; and the welding seam adopts a novel Y-shaped groove beveled edge to finish the welding for the circular welding seam of the vessel cylinder automatically and continuously. The method is applied to the welding the circular welding seam of the vessel cylinder made of zirconium, nickel, titanium, stainless steel and alloys, and composite plate materials, and has the remarkable advantages of good welding quality, high welding efficiency, and protective gas conservation, and the reduction of the labor intensity of operators.

Owner:云南大为化工装备制造有限公司

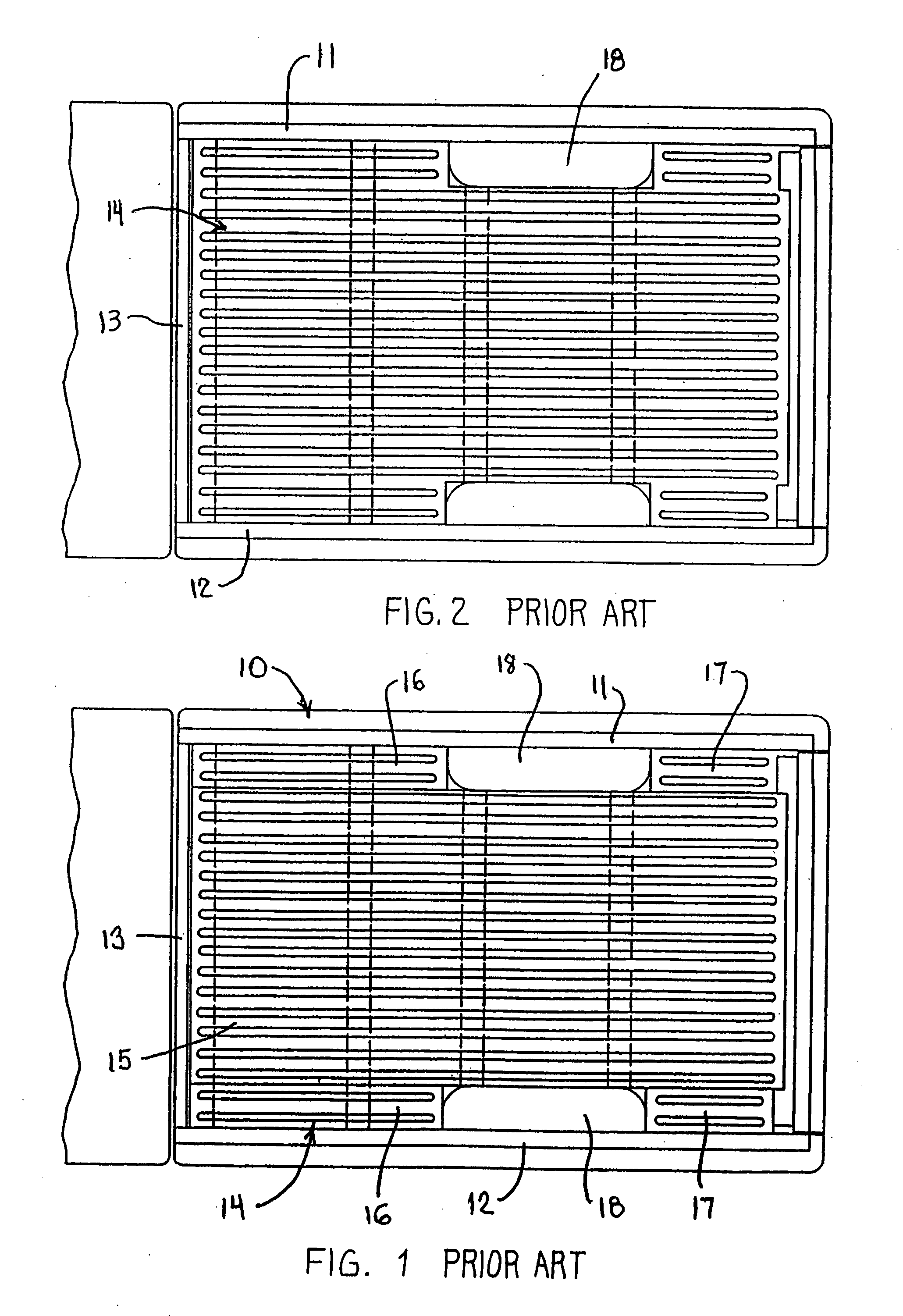

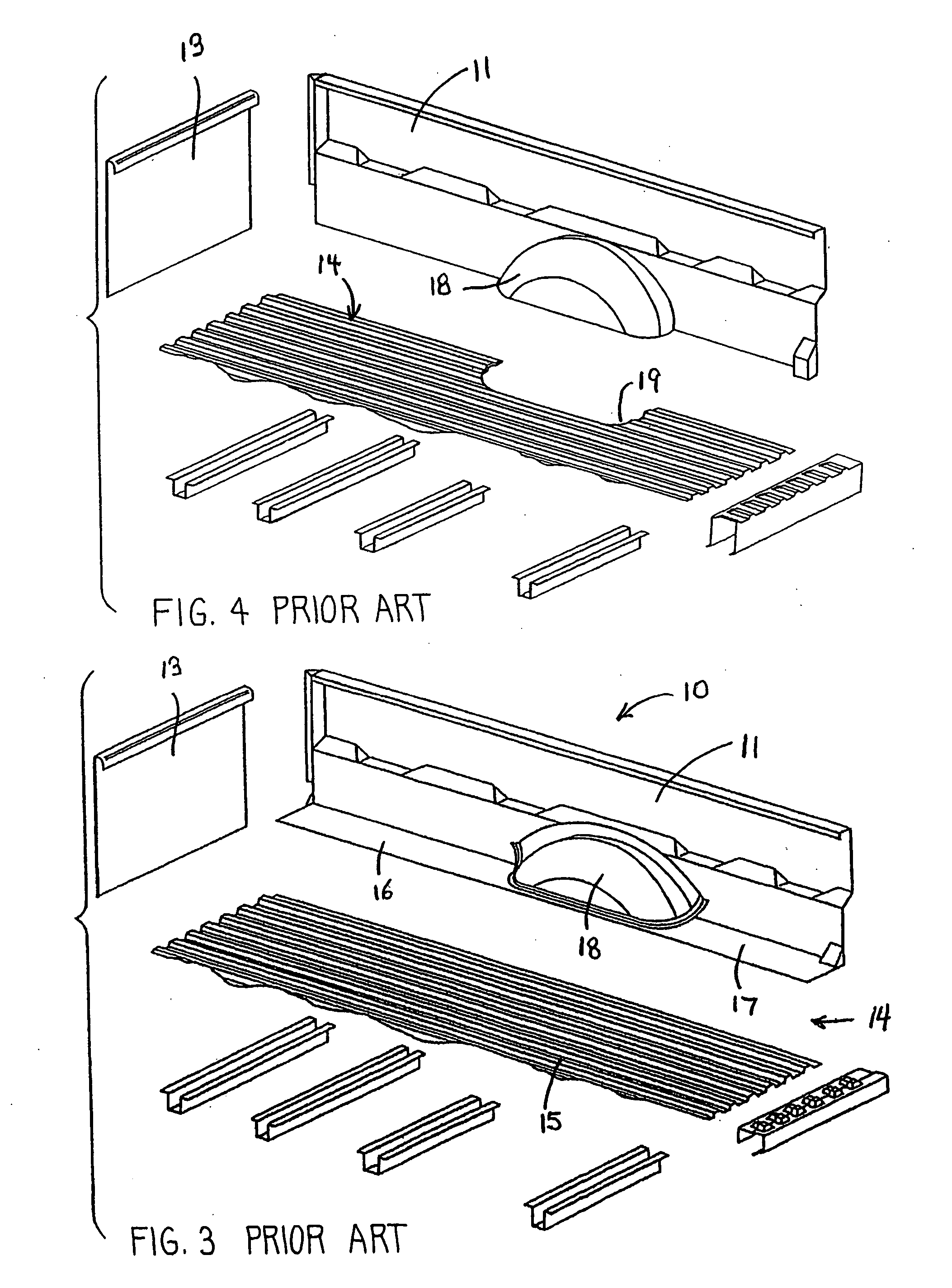

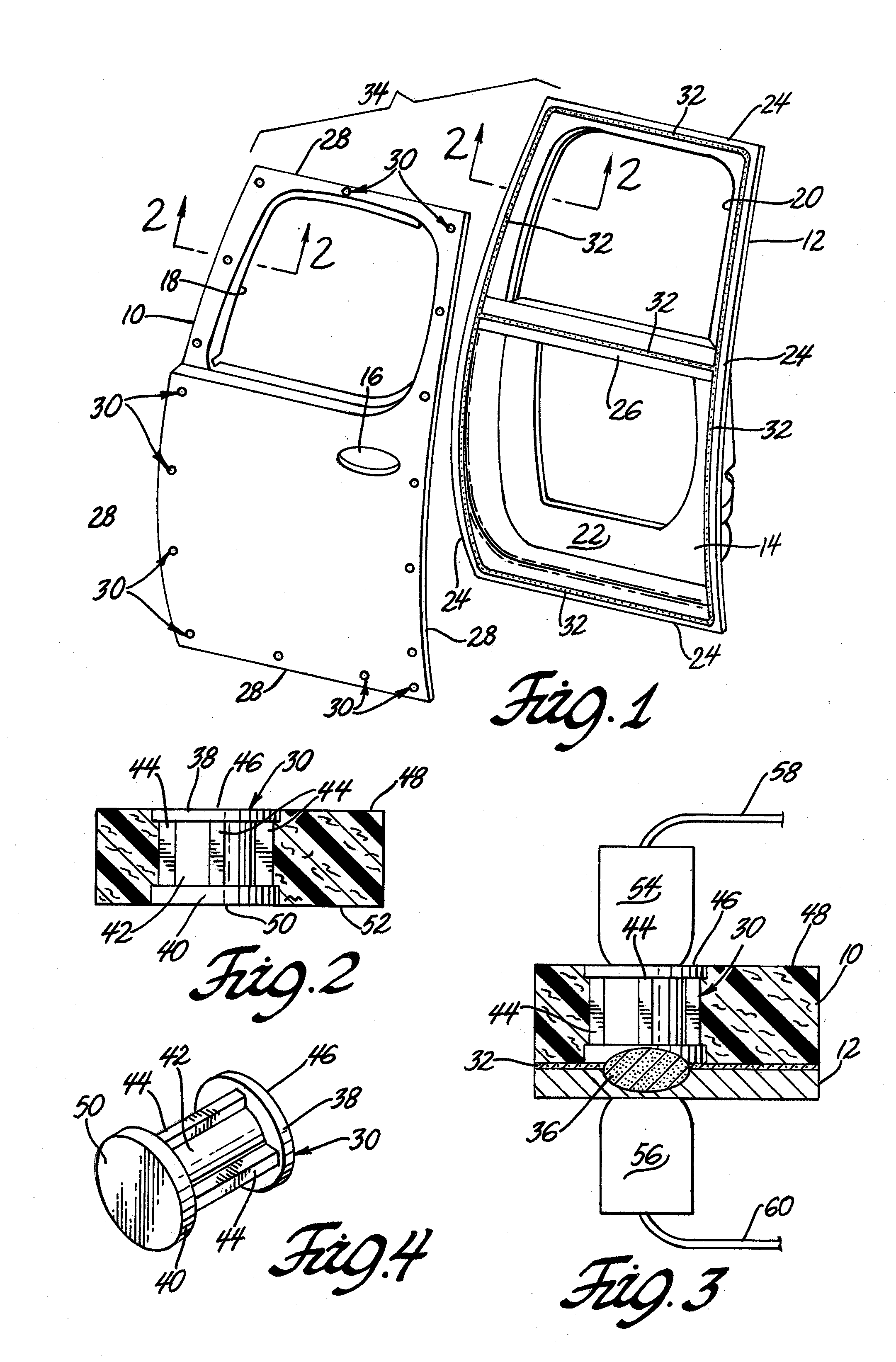

Welding polymeric panels to metal surfaces

InactiveUS20090065484A1Sufficient cross-sectional areaEasy to placeArc welding apparatusVehicle componentsEngineeringSpot welding

A joining portion of a polymeric component, such as a vehicle door panel, may be welded (for example, a spot weld) to a metal component, such as a mating vehicle panel, using a molded-in-place metallic welding insert. The welding insert is shaped to provide welding surfaces at both surfaces of the joining portion of the plastic component and to conduct a welding current between the surfaces. When the workpieces are assembled for welding, opposing spot welding electrodes bear against the outer surfaces of the metal part and the metal insert in the plastic part. A spot welding operation produces a weld nugget between the facing surface of the metal part and the metal insert anchored in the plastic part. Continuous seam welds or a series of stitch seam welds may be made using suitably shaped welding inserts.

Owner:GM GLOBAL TECH OPERATIONS LLC

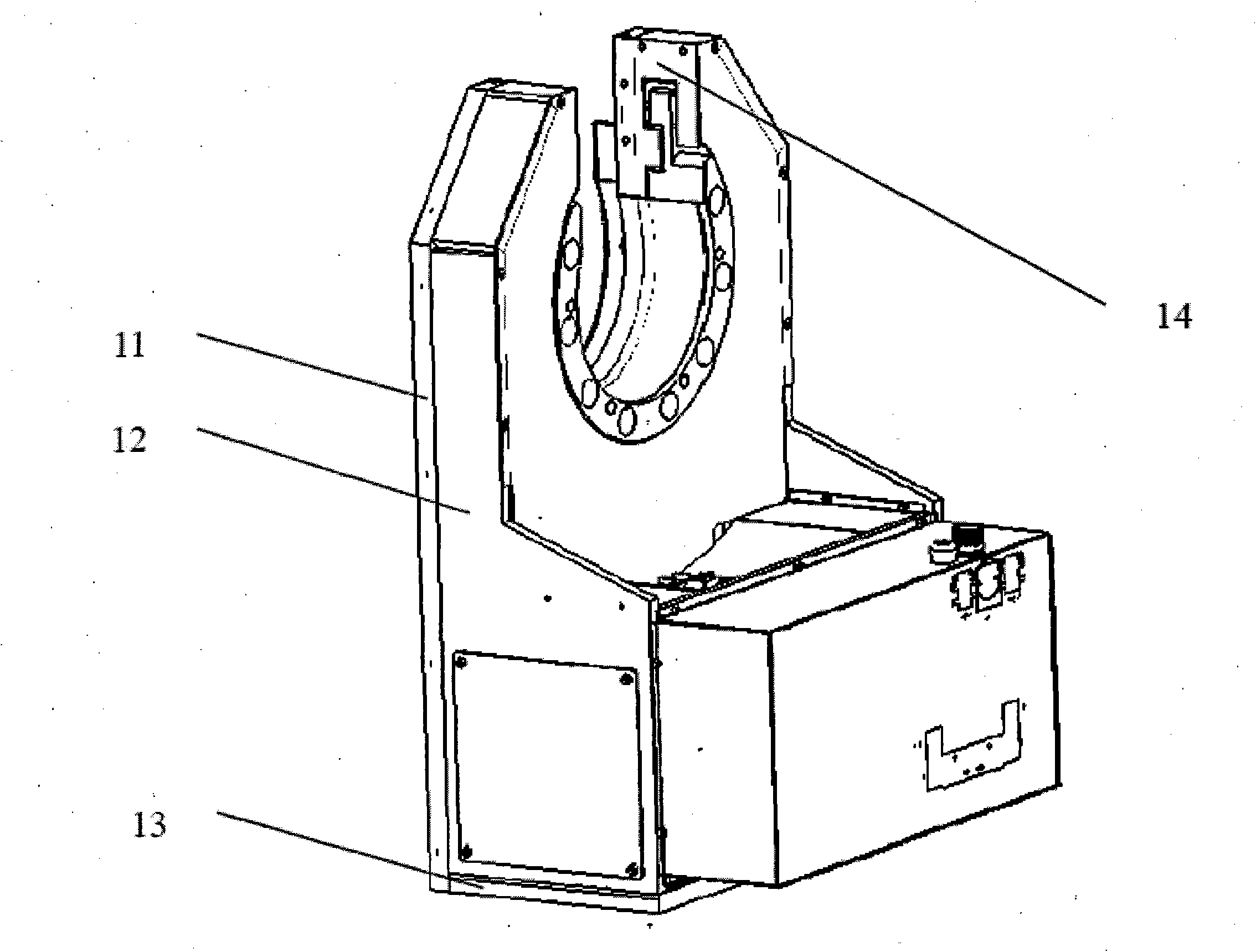

Automatic circular seam welding pipe tongs

ActiveCN101885130ASelf-centering is easy to operateReduce setup timeWelding/cutting auxillary devicesAuxillary welding devicesProcess equipmentDrive shaft

The invention discloses automatic circular seam welding pipe tongs and relates to processing equipment for automatically welding circular seams of elbows / flanges, belonging to the technical field of welding processing equipment. The welding pipe tongs are characterized in that the main body of a driving and rotating mechanism is a bracket with a U-shaped groove, and one side of the bracket is connected and fixed with a U-shaped base box body, while the other side is provided with a rotary gear ring, a supporting seat, a roller bearing, a transition gear, a drive device and a jacking drive, wherein a driving shaft of the drive device is connected with the transition gear, the transition gear is externally engaged with the rotary gear ring, and the rotary gear ring is supported by the supporting seat and the roller bearing which are distributed along the circumference of the rotary gear ring; and a self-centered positioning and clamping mechanism is arranged in the rotary gear ring. Thewelding tool can clamp and rotate an elbow / flange to be welded and realize manual welding and ensures that circular welding seams of elbows / flange inner corners / outer corners can be automatically welded, thereby the labor intensity of workers is reduced, the clamping number of times is reduced, and the welding quality and efficiency are improved.

Owner:KUSN HUAHENG ENG TECH CENT

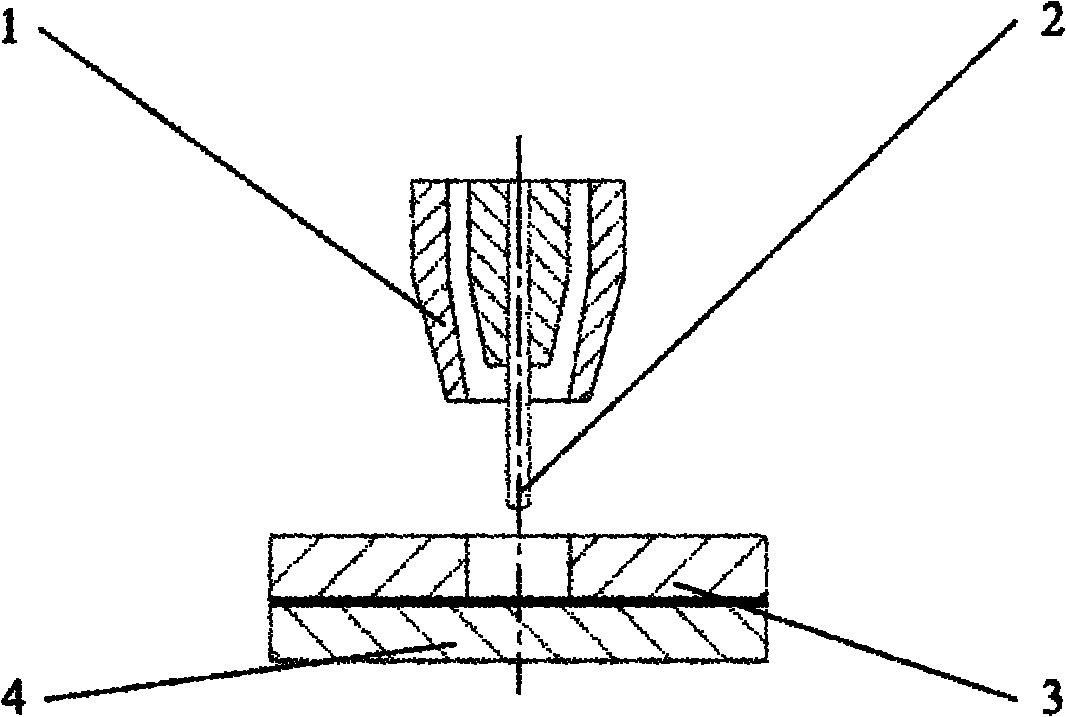

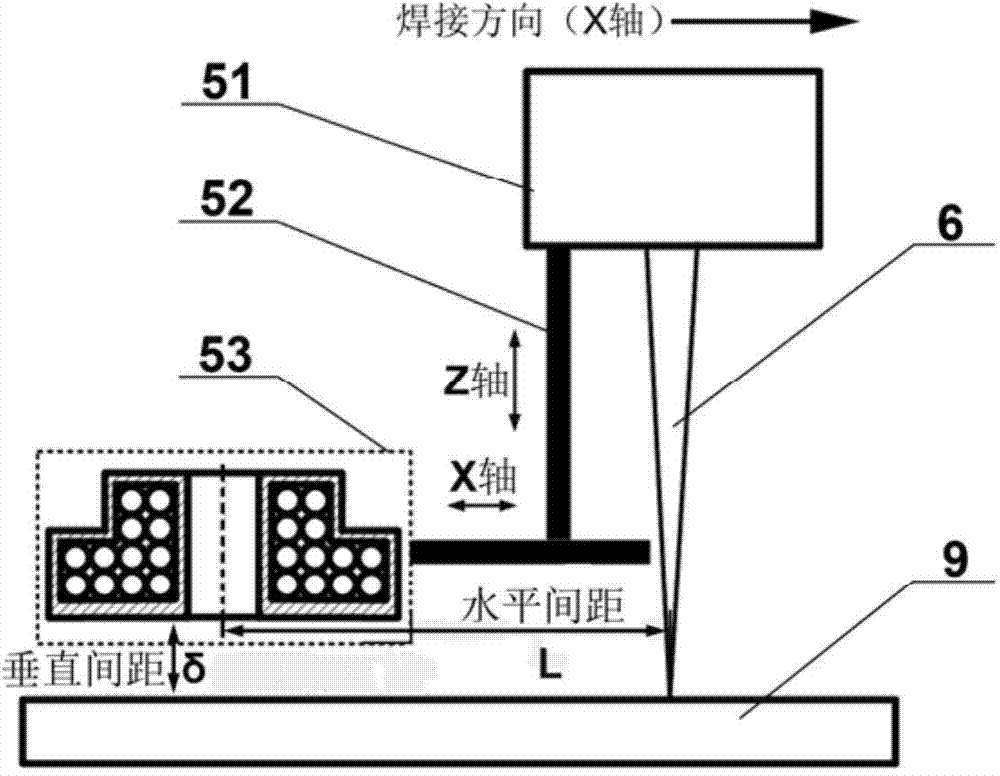

Pulsed high magnetic field auxiliary laser welding method and device

ActiveCN103769746AImprove fatigue strengthSmall structural deformationLaser beam welding apparatusStructural deformationStress concentration

The invention discloses a pulsed high magnetic field auxiliary laser welding method and device. The method and device can be applied to laser spot welding and seam welding. According to the method, in the overall welding process, laser beams are emitted to a workpiece to form a welding connector, a high pulsed magnetic field is exerted to the welding connector which is just solidified and the surrounding area, the pulsed magnetic field generates pressure stress on the surface of the workpiece to enable the connector area to have plastic deformation, residual stress is released to lower the degree of stress concentration and the degree of structural deformation of the welding connector, and the fatigue strength of the welding connector is improved. The device comprises a laser, a pulsed magnetic field generator, a numerical control system, an optical transmission system and a laser pulsed magnetic field composite processing head. The processing head is used for integrating the laser beams and the high pulsed magnetic field, and regulating the perpendicular distance between an electromagnetic conversion device and the surface of the workpiece and the horizontal distance between the electromagnetic conversion device and the laser beams. By means of the pulsed high magnetic field auxiliary laser welding method and device, structural deformation can be lowered, welding quality and processing efficiency are improved, and the processing effect which is superior to that of an existing laser welding process is achieved.

Owner:武汉飞能达激光技术有限公司

Jet printing type steel guard rail

ActiveCN101265694AImprove structural strengthAvoid deformationTraffic signalsRoad signsVertical barEngineering

The invention discloses a spraying type steel barrier, which comprises columns, upper cross bars, lower cross bars and vertical bars. The main bodies of the columns, the upper cross bars, the lower cross bars and the vertical bars are all integrated style steel works. The columns are made from the galvanized steel strip, made into steel pipe of a certain shape and sprayed with plastic or paint; the upper cross bars, the lower cross bars and the vertical bars are integrated parts which the upper cross bars, the lower cross bars and the vertical bars are respectively made from the galvanized steel strip, steel pipes of a certain shape are made through extrusion forming of the steel pipe stock mould, seam welding of the high frequency induction welder and extrusion forming of the steel pipe shaping mould and the integrated parts are formed by placing the vertical bars between the upper cross bars and the lower cross bars, welding and fixing, and at last spraying plastic or paint on the exterior surface of the integrated parts. The spraying type steel barrier has the advantages of high structural strength, deformation resistance, beautiful and clean barrier surface, rustiness resistance, easy cleaning, greatly reduced maintenance cost, both the beautiful appearance of the PVC plastic steel barrier and the high strength of the assembly type barrier.

Owner:JIANGSU AIKEQING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com