Program-controlled side-moving oil cylinder peripheral seam welding machine

A side-moving, welding machine technology, used in welding equipment, welding equipment, welding accessories, etc., can solve the problems of low welding tensile strength, uneven welding seam width, pits, etc., and achieve a high degree of automation and welding. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

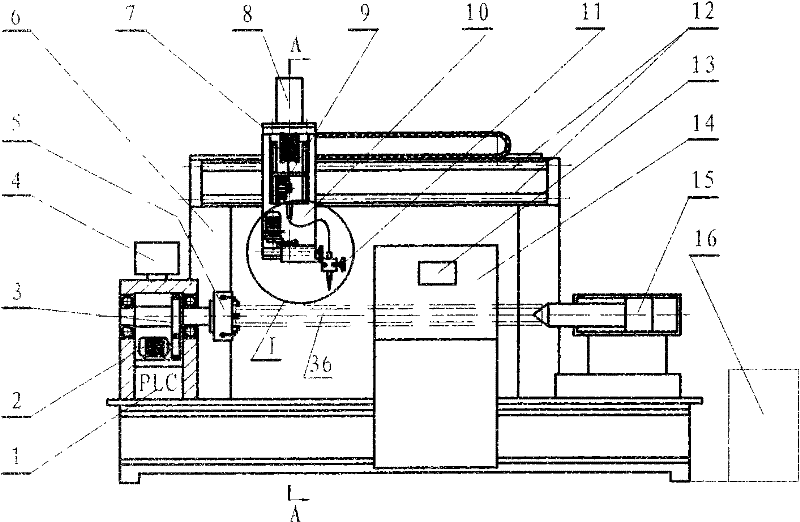

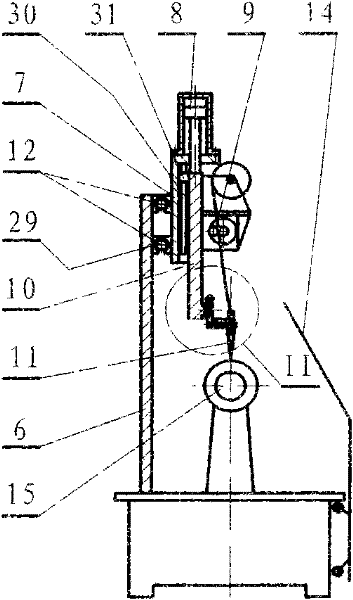

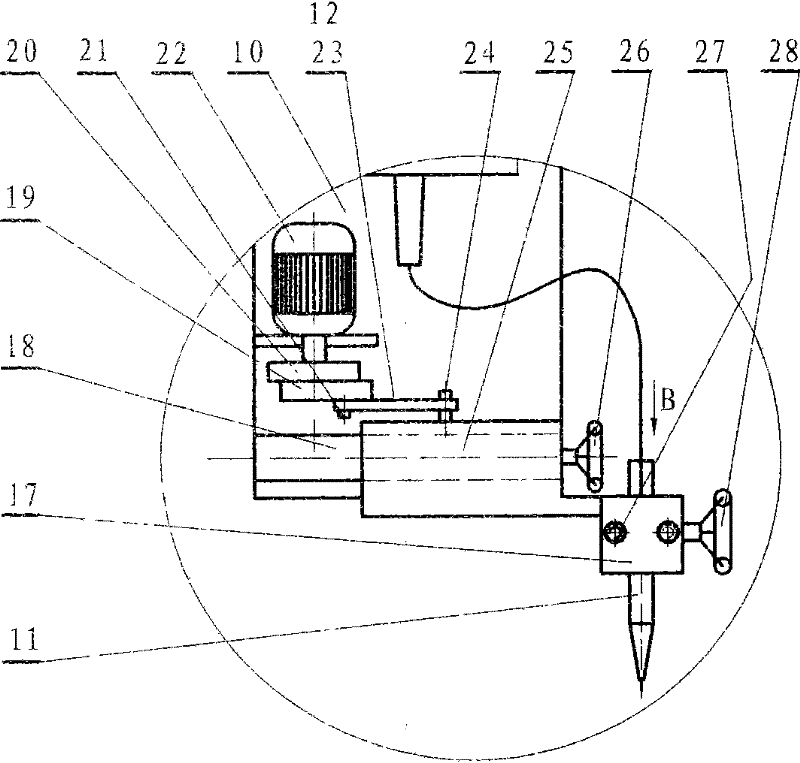

[0012] As attached figure 1 As shown, the welding voltage, current and air pressure control of each layer of the workpiece 36 to be welded are preset by the encoder, the number of welding turns, the automatic lifting of the welding gun 11 between layers, and the circumferential welding speed of the workpiece 36 to be welded driven by the frequency conversion motor 3; 22 drives the swing speed of the welding torch 13 swing device; the lifting cylinder 8 drives the automatic, manual and semi-automatic of the welding torch 11 up and down; the automatic, manual and semi-automatic data programs of the pneumatic tailstock 15 tightening and loosening and input in the PLC programmable controller 1 in. Clamp the workpiece 36 to be welded on the three-jaw chuck 5 and click on the tightening program of the pneumatic tailstock 15 in the touch screen 4, so that the axis of the workpiece 36 to be welded is placed on the axis of the three-jaw chuck 5 and the pneumatic tailstock 15 Heart conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com