Patents

Literature

8889results about How to "Improve welding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

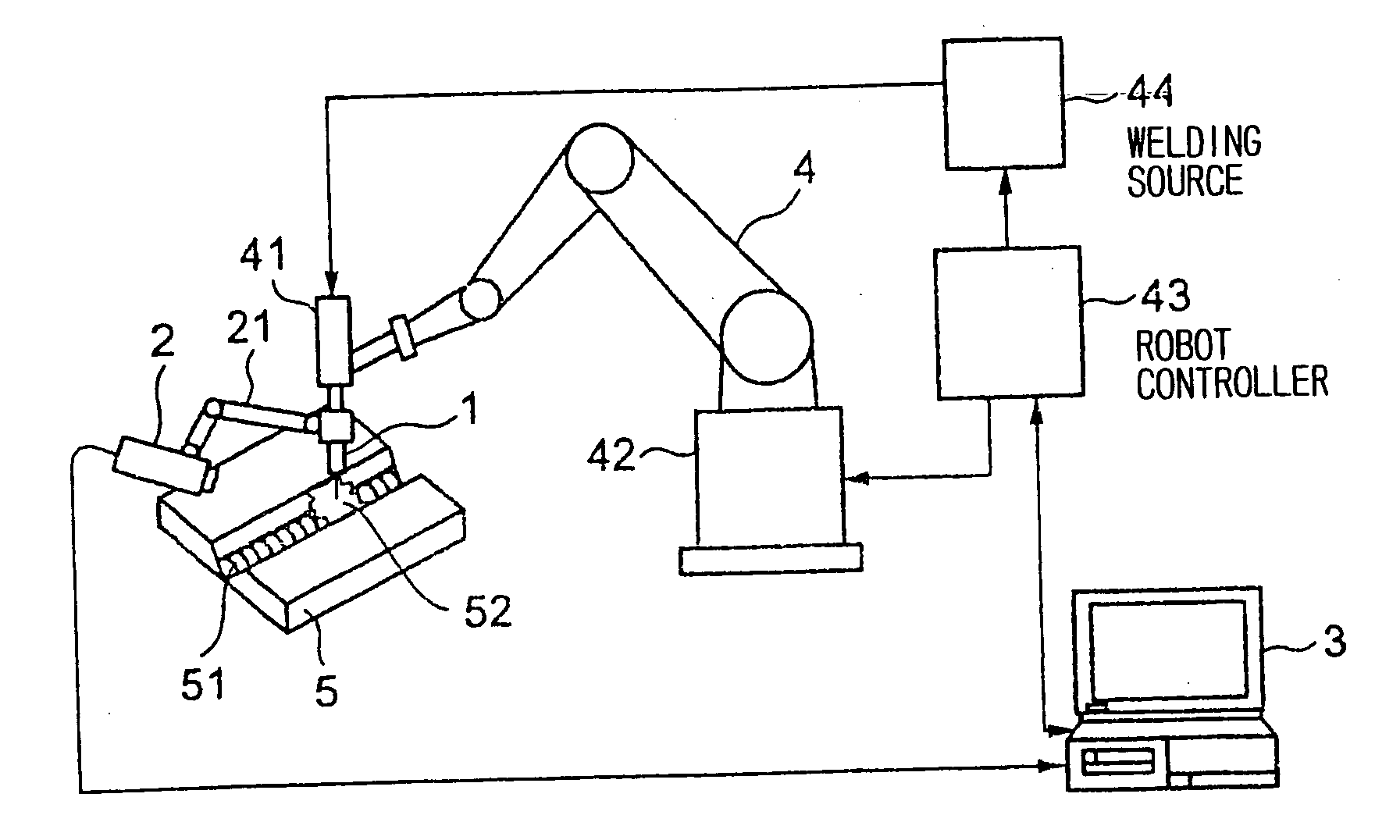

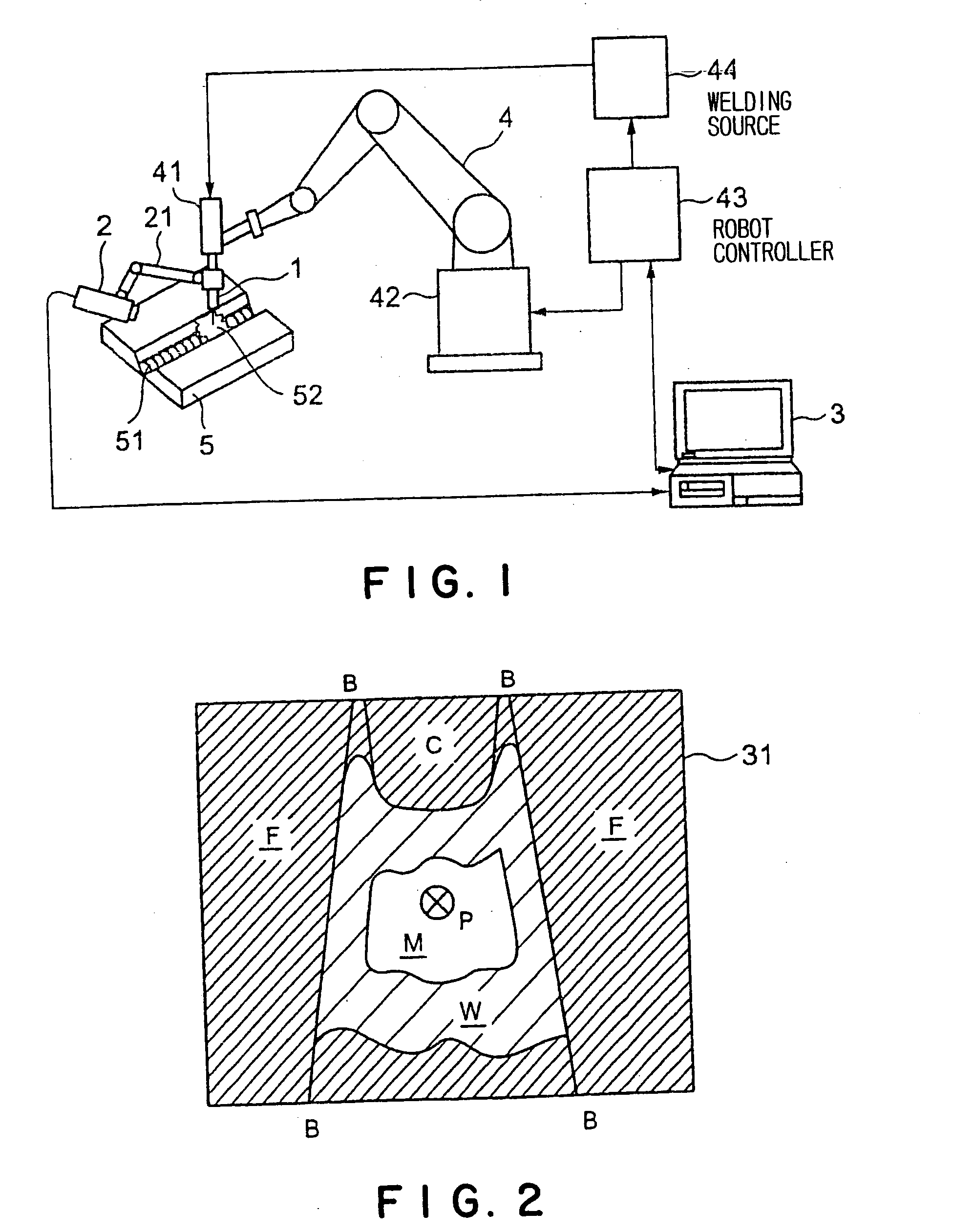

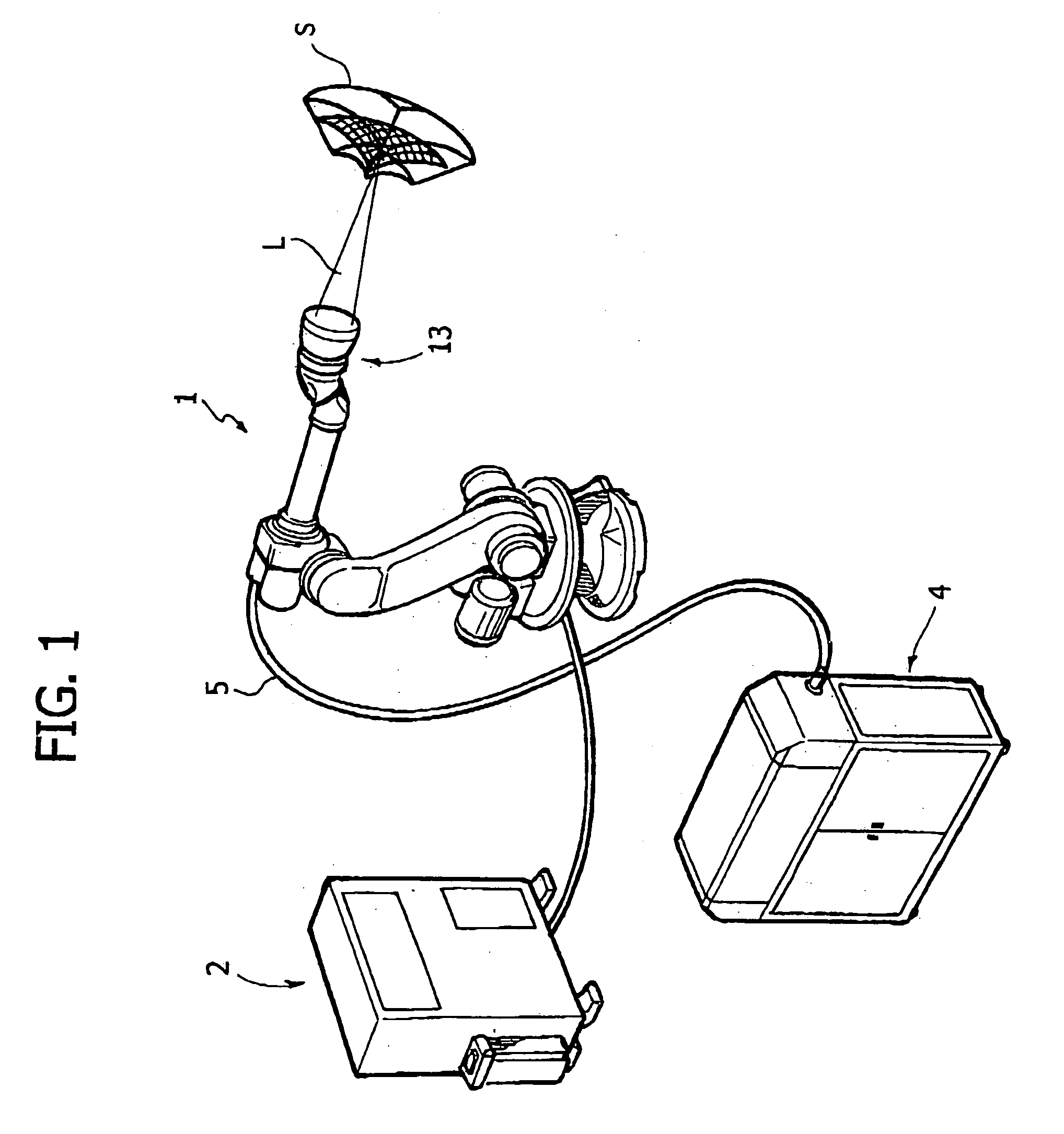

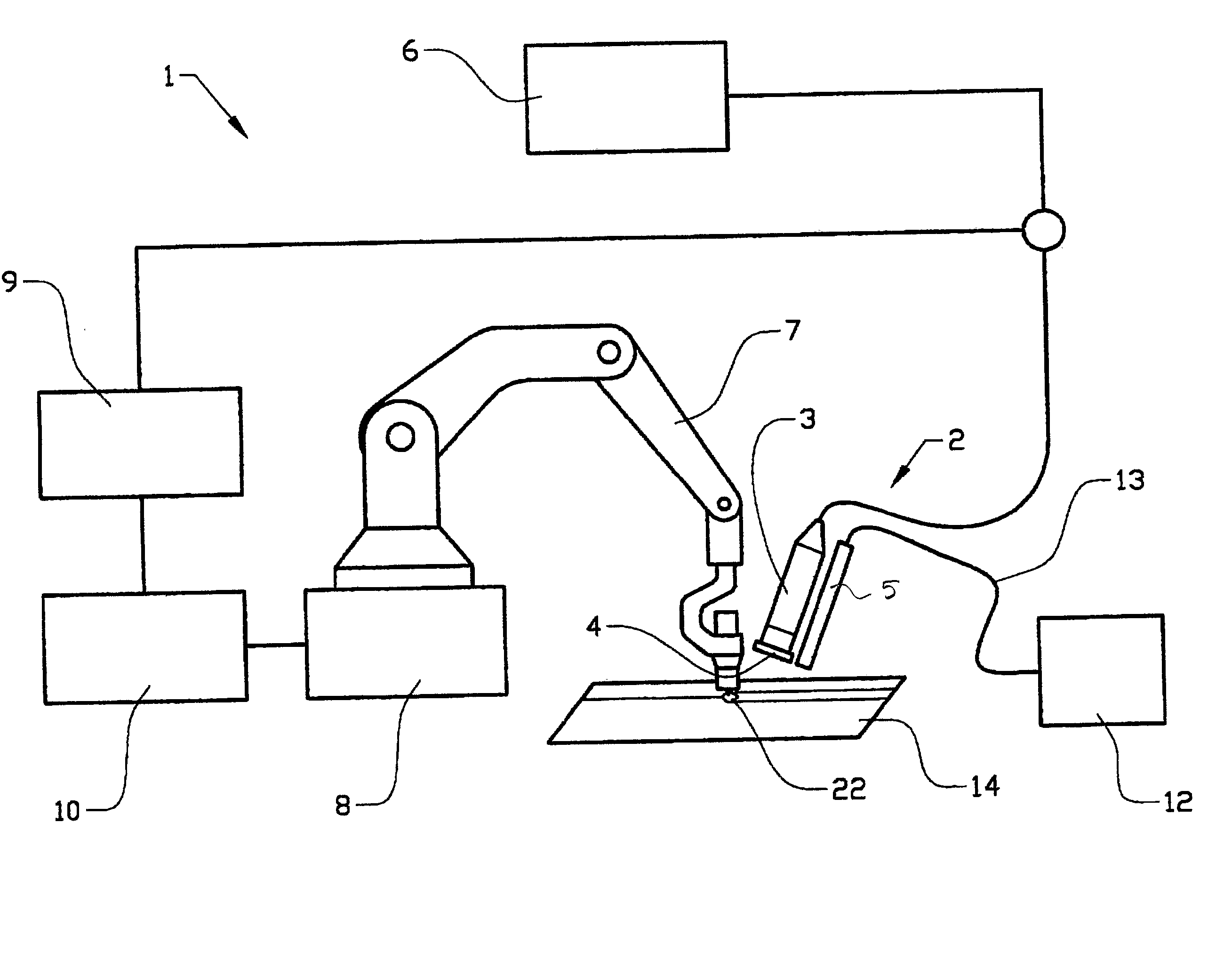

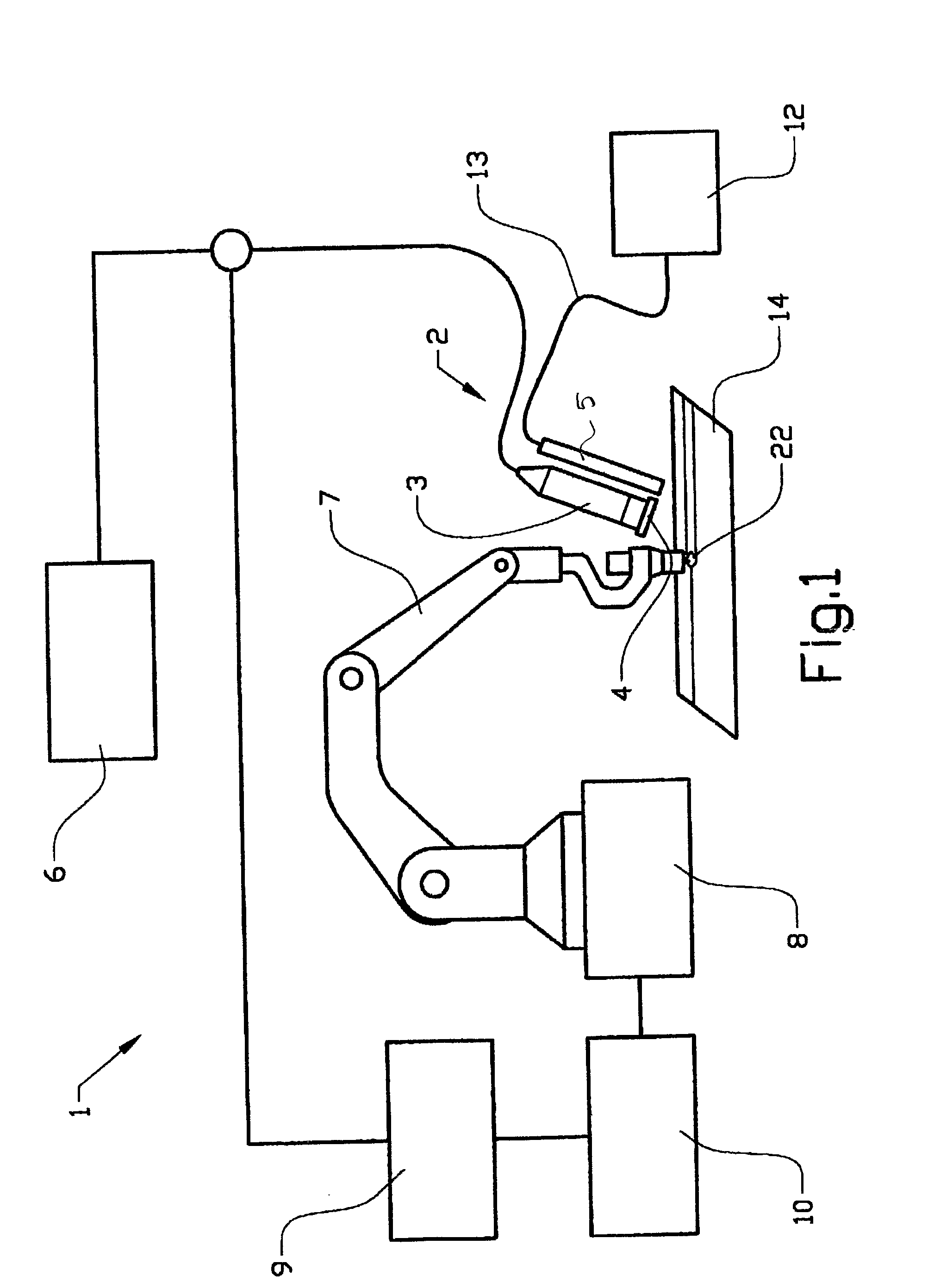

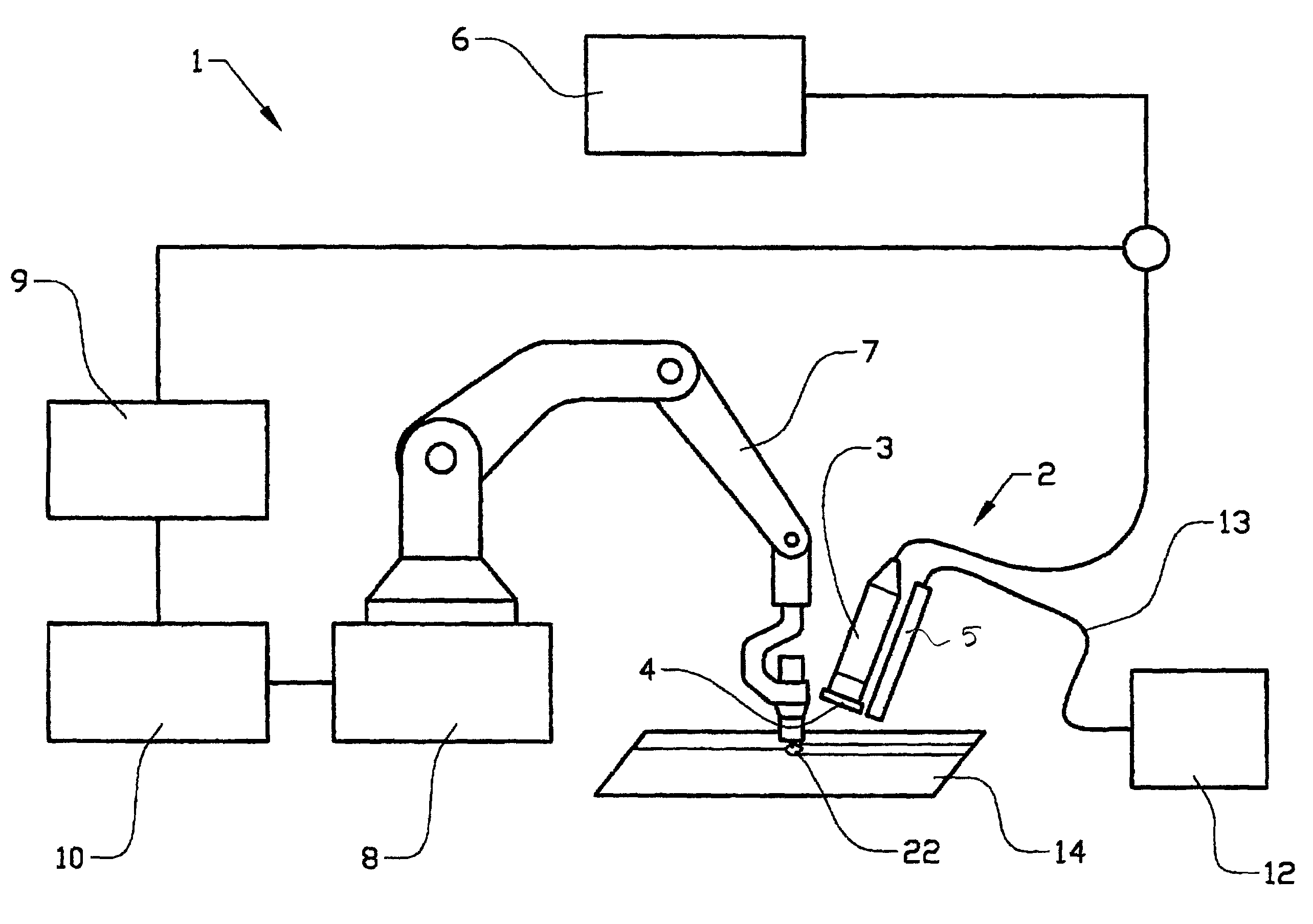

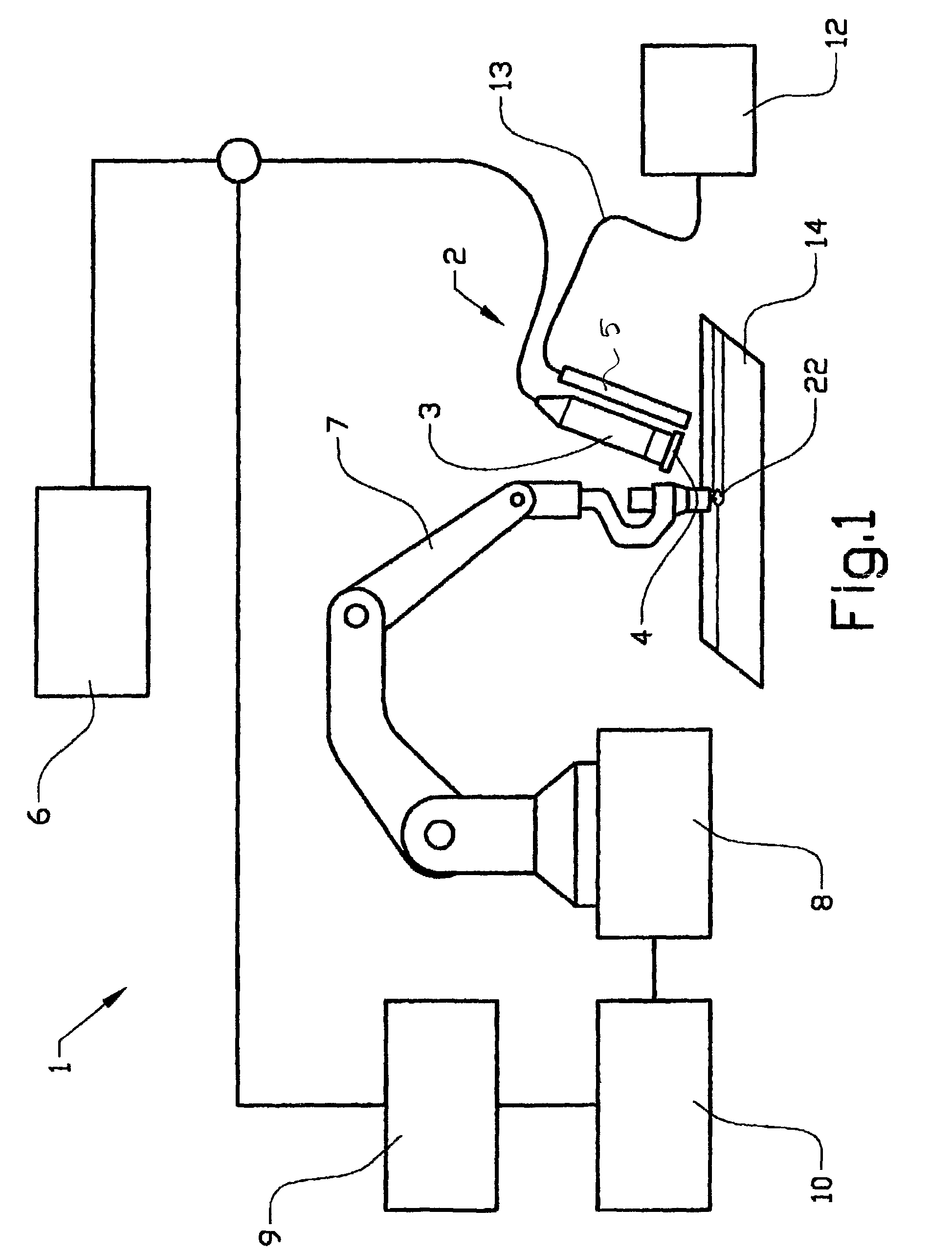

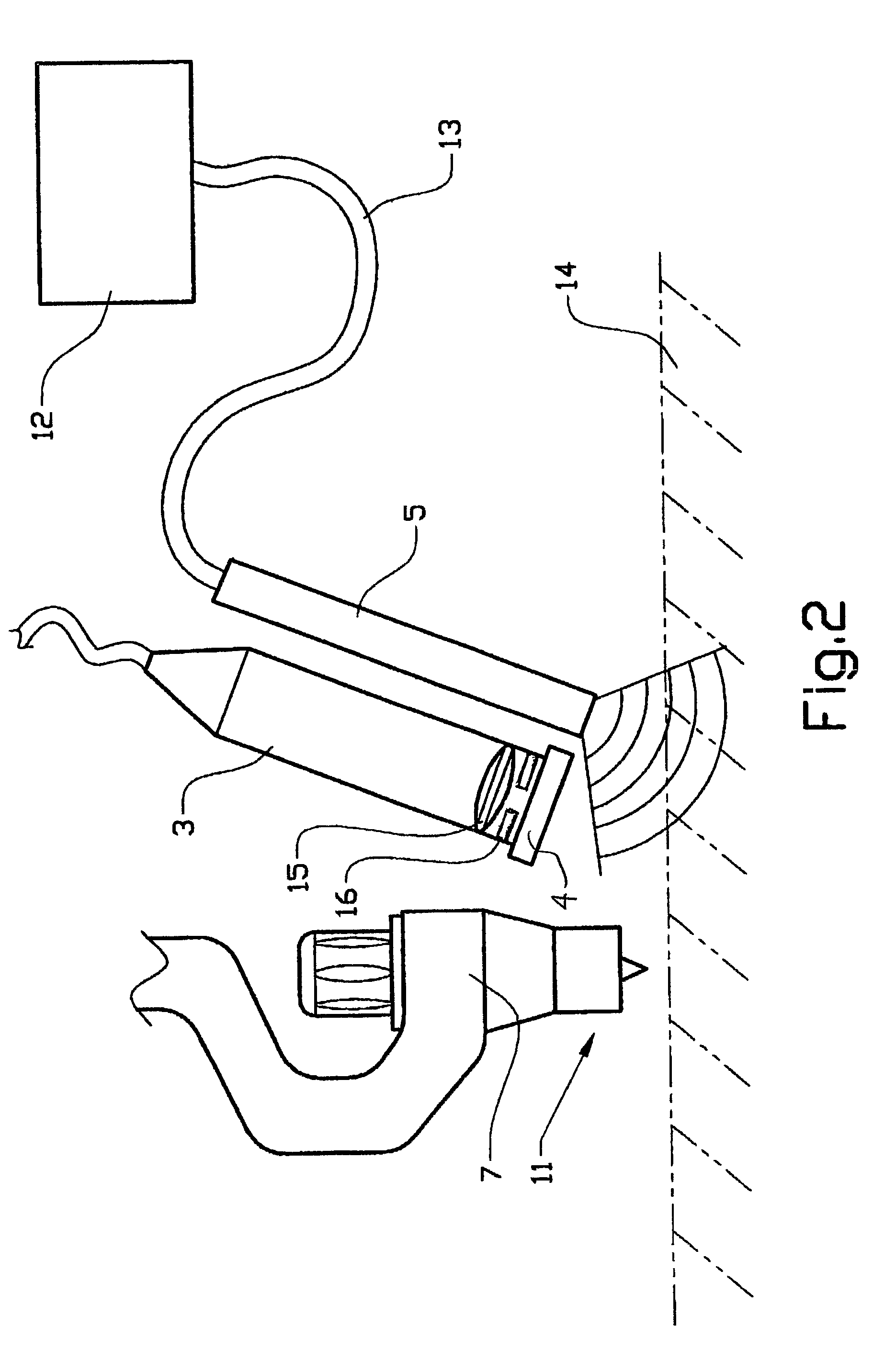

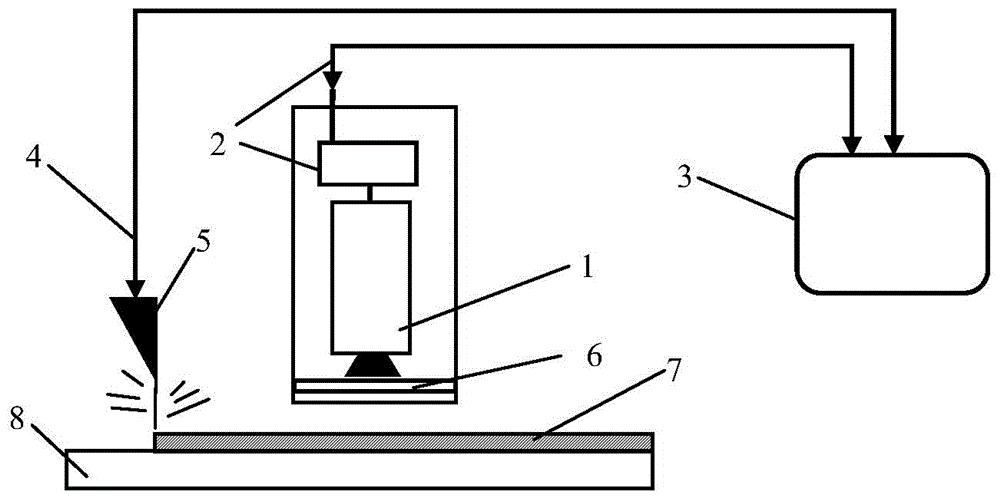

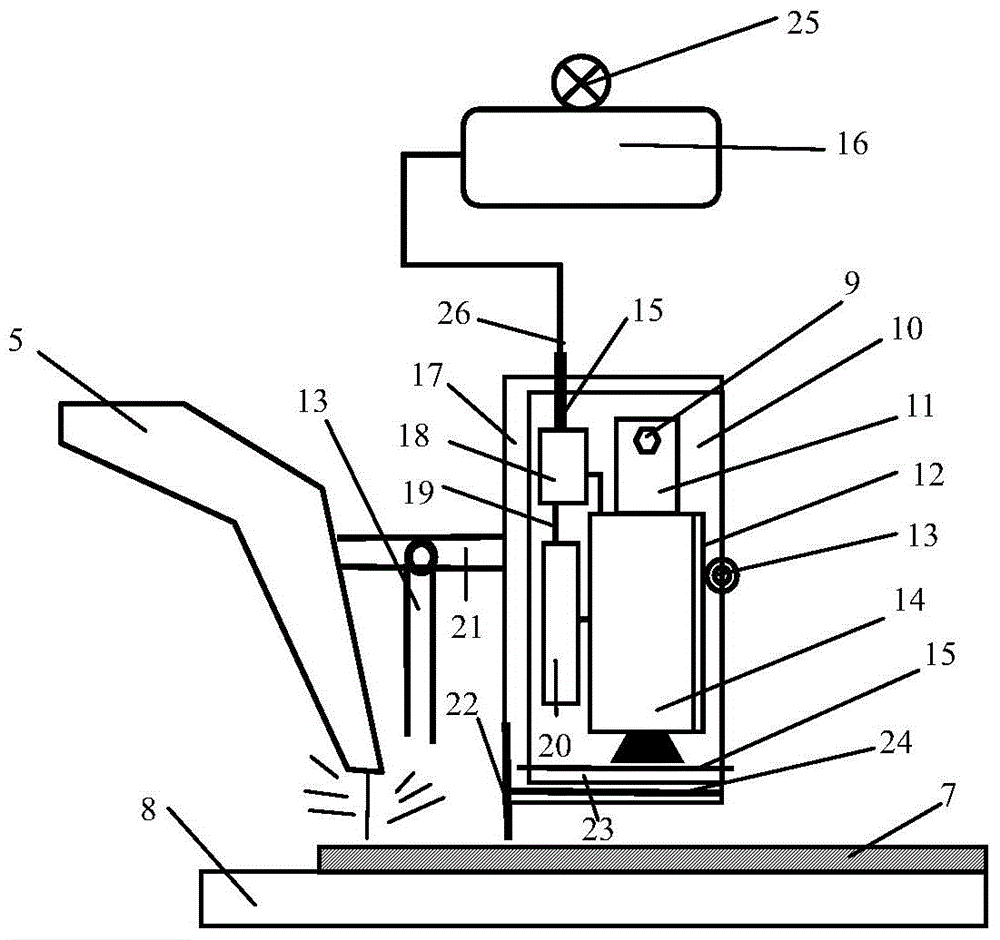

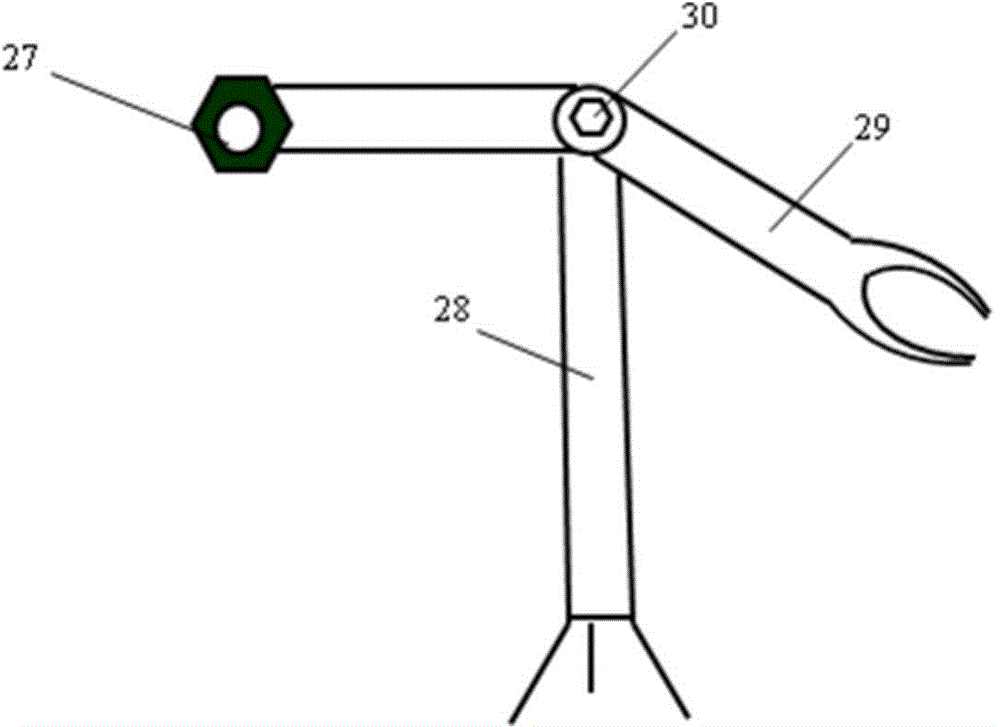

Automatic groove copy welder and welding method

InactiveUS20050103766A1Accurate control operationAccurately carry-outArc welding apparatusEngineeringCcd camera

An automatic groove-tracing welding system is capable of carrying out a welding operation, particularly, a welding operation involving weaving, without requiring monitoring even if conditions of a groove is different from design conditions of the groove. An image processor 3 receives an image signal representing an image of a weld zone 52 including the tip of a welding wire from a camera head 2 provided with a CCD camera, processes the image of the weld zone 52 to determine the position of a groove, calculates the positional relation of the groove with a welding torch 1, and sends a position correction for correcting the position of the welding torch 1 so that the welding path of the tip of the welding torch 1 may coincide with a predetermined middle part in the groove to a robot controller 43 for controlling a welding robot. When the automatic groove-tracing welding system performs a welding operation involving weaving, the image processor 3 receives a weaving phase signal representing phases of weaving from the robot controller 43, calculates the positional relation between the groove and the welding torch on the basis of the phase of weaving, and sends a weaving width correction signal to the robot controller 43.

Owner:KAWASAKI HEAVY IND LTD

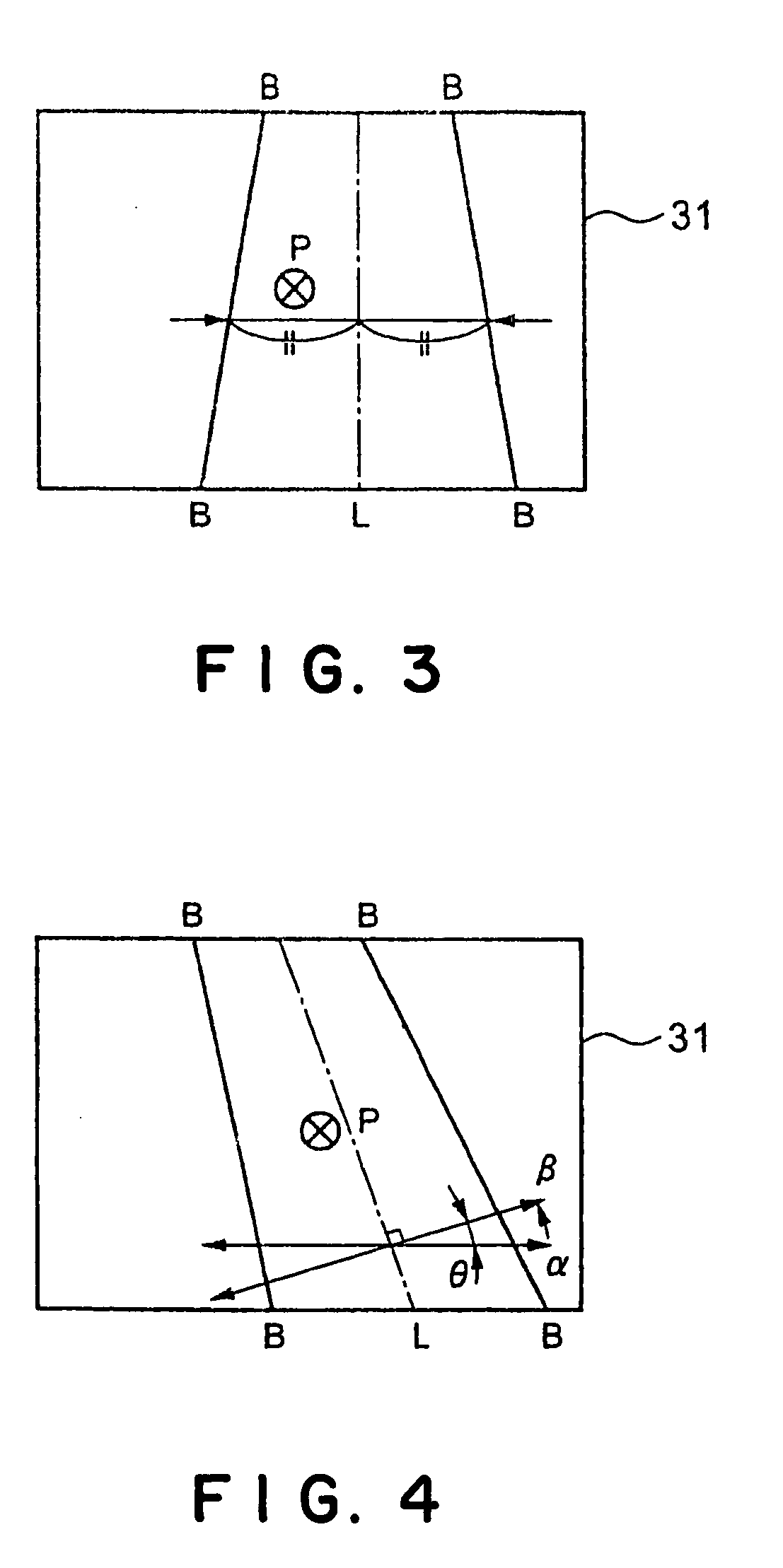

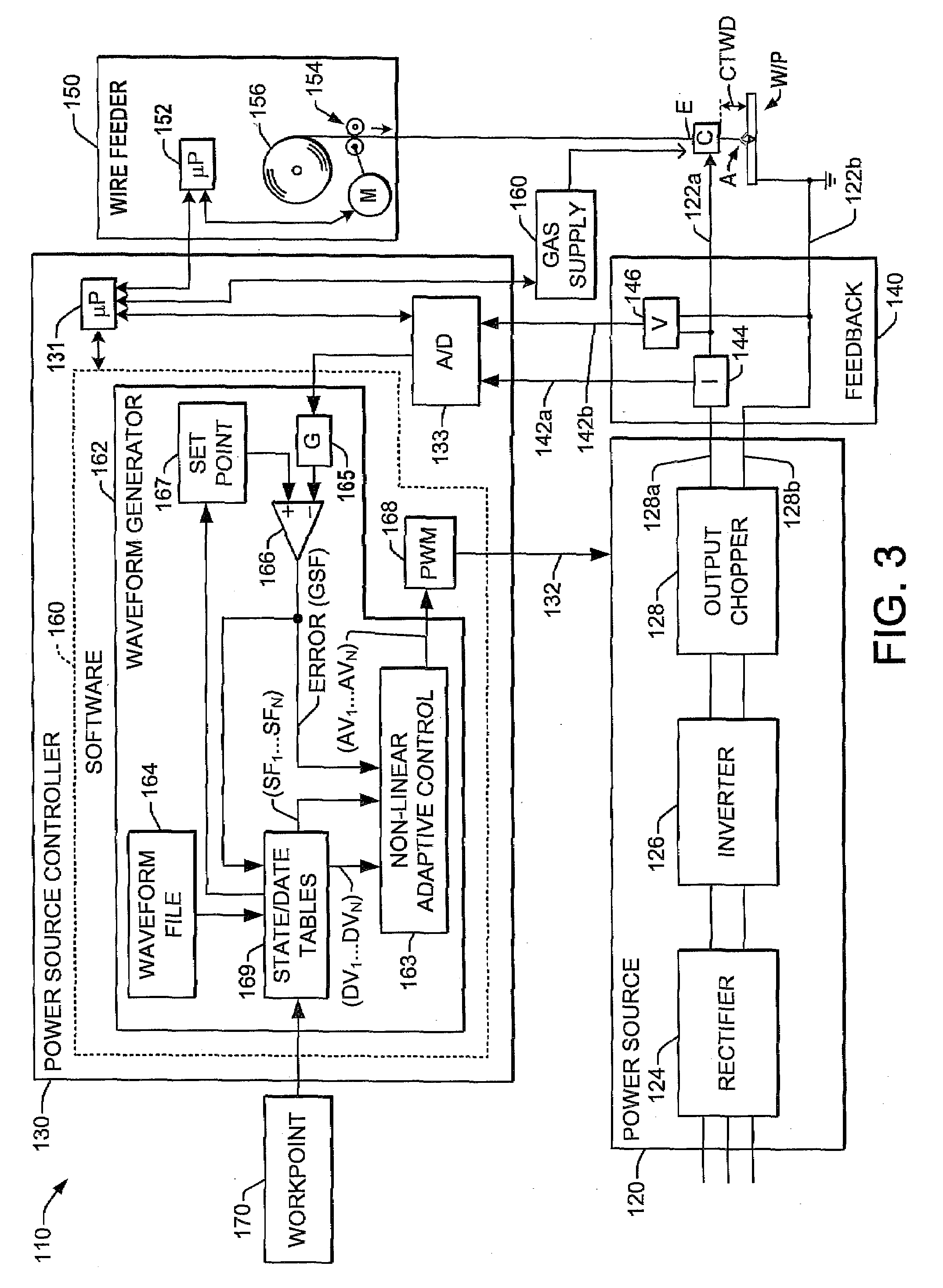

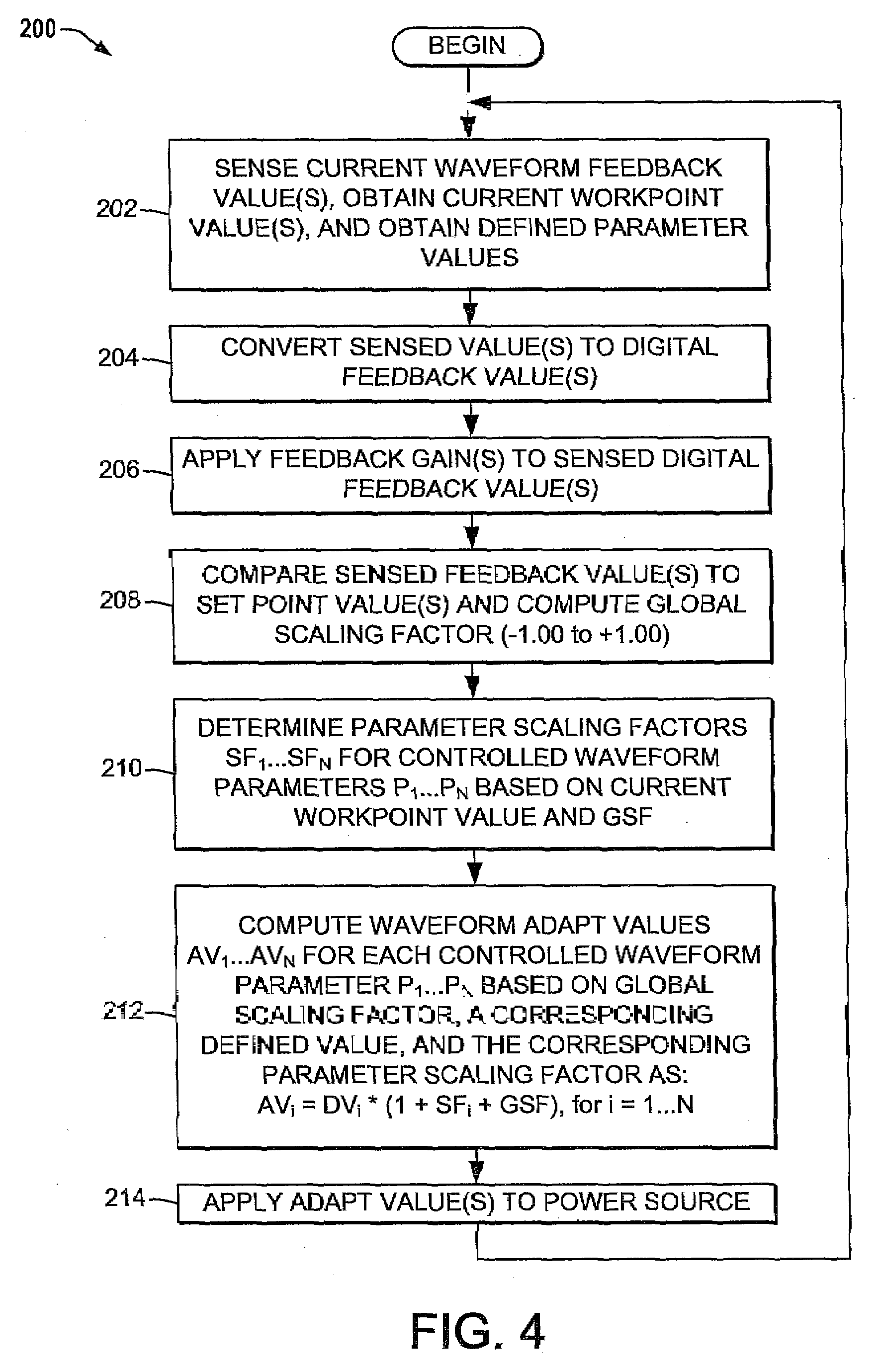

Non-linear adaptive control system and method for welding

InactiveUS20080078812A1Improve croppingEasy to controlProgramme controlCooking-vessel materialsControl systemNonlinear adaptive control

Nonlinear adaptive welders and power source controls are provided along with welding methods method for regulating a welding process, in which one or more welding waveform parameters are adapted in nonlinear fashion based on measured welding process feedback information.

Owner:LINCOLN GLOBAL INC

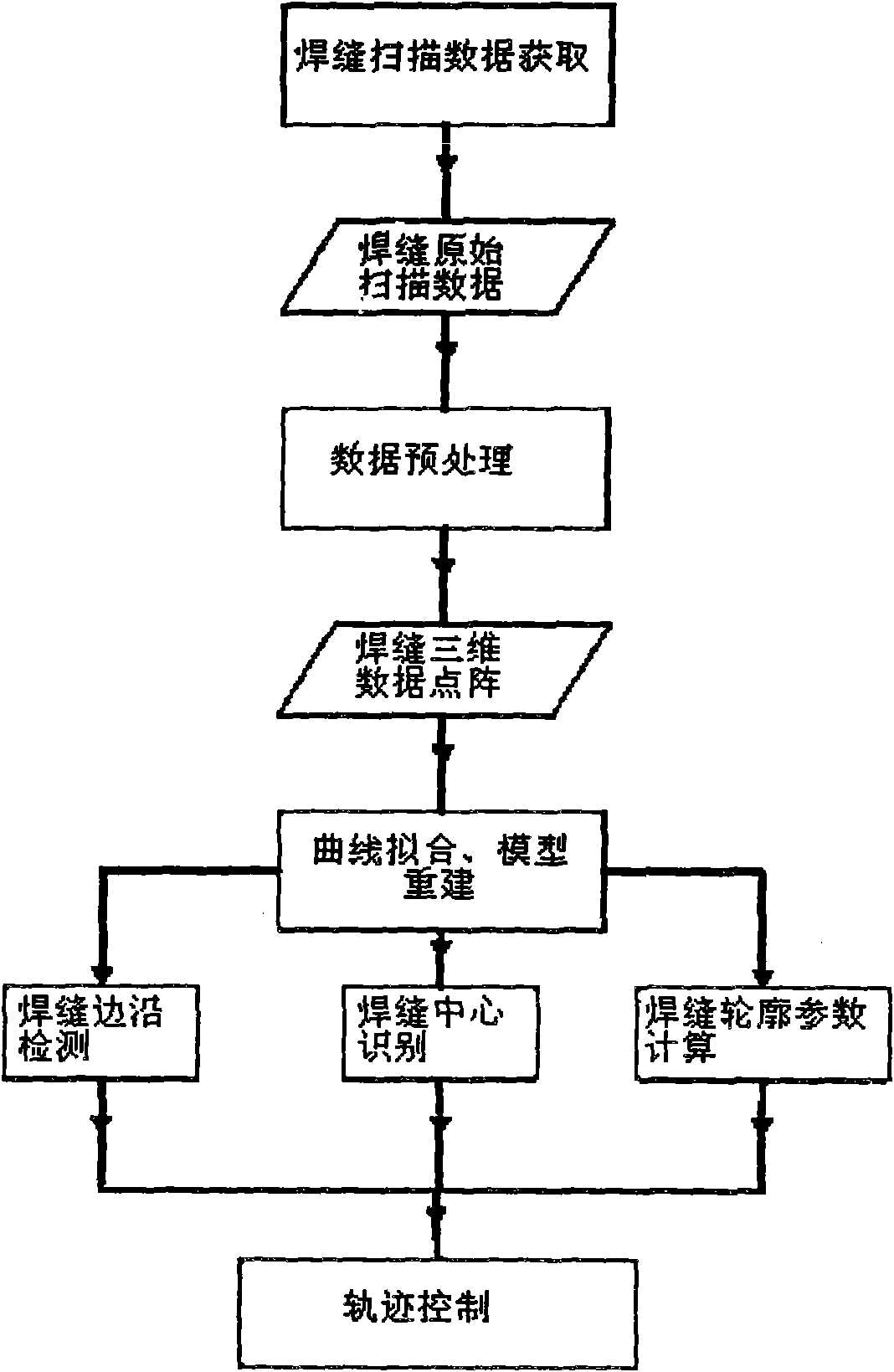

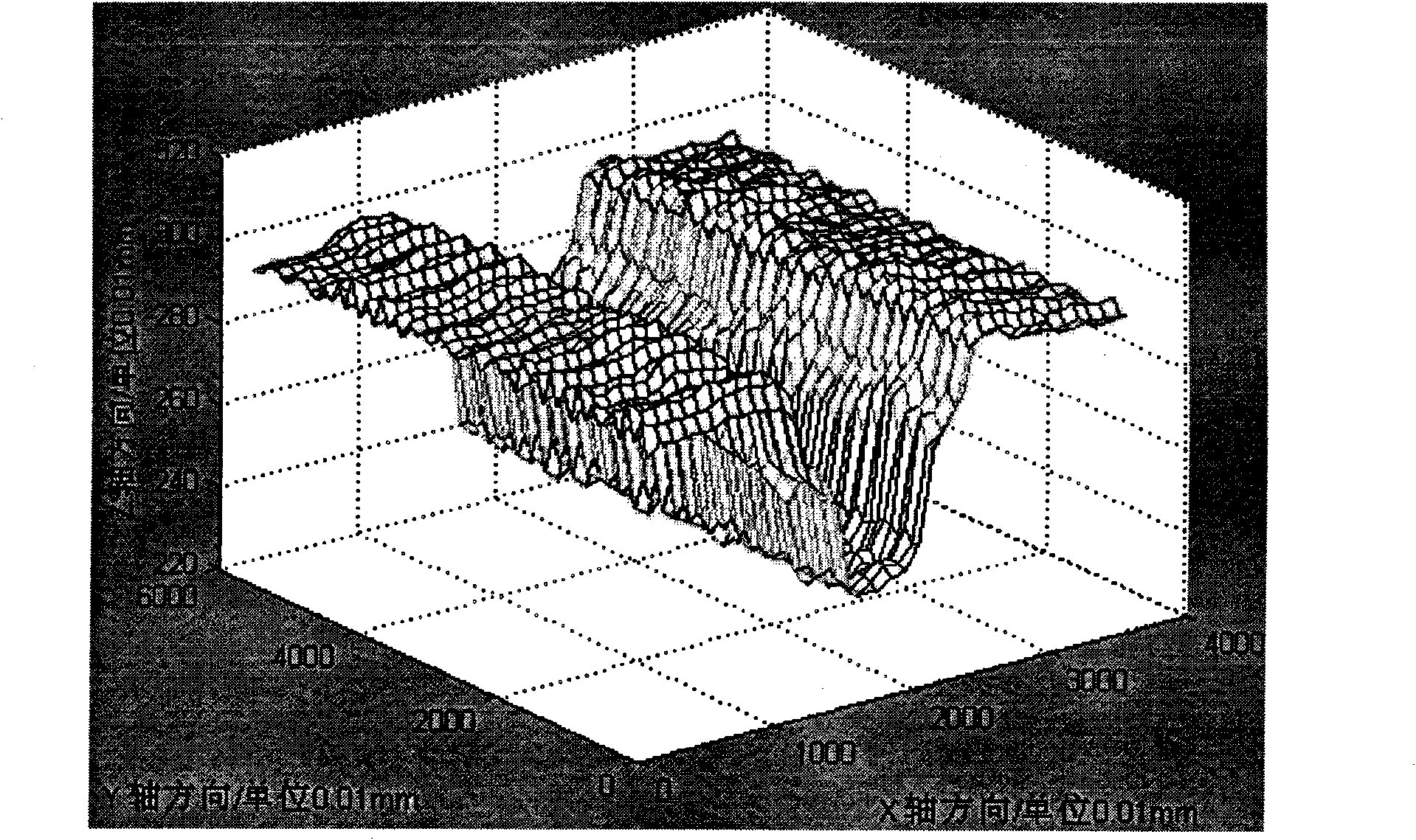

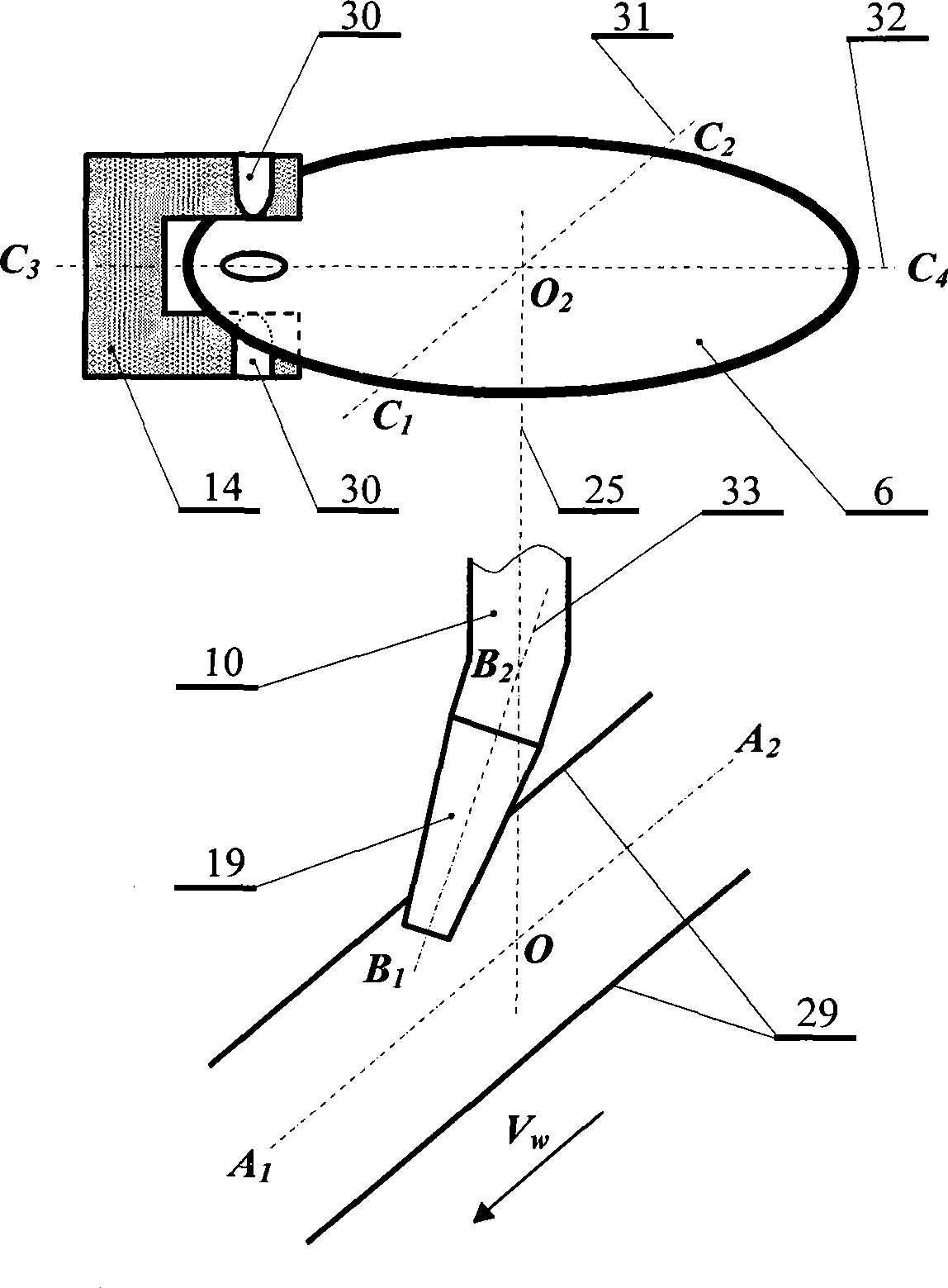

Welding track detection and control method of plate butt weld based on laser ranging

InactiveCN101559512ATo achieve the purpose of seam trackingTo achieve the purpose of trackingArc welding apparatusNumerical controlLaser rangingField tests

The invention relates to a welding track detection and control method of plate butt weld based on laser ranging, including the following steps: A. track detection is carried out; B. track identification and extraction are carried out; C. track control is carried out; D. the relative position relation between a welding gun and a welding seam is adjusted at last by performing mechanism actions. In the invention, the information of welding seam profile is obtained by transverse scanning of a laser sensor, and welding seam is rebuilt after effective wave filtering treatment to realize three-dimensional detection of the welding seam; simultaneously, the welding track curve is obtained by fit while detecting welding seam by using dynamic B spline fit algorithm, and the track control is carried out in combination with constant speed B spline track interpolation algorithm, thereby fundamentally solving the problem of track detection and control in automatic welding of plate butt weld. By using the method in the invention, the field test welding has welding profile identification precision of 0.15mm and welding track identification precision of 0.2mm, and the welding speed is more than four times of common manual welding.

Owner:SHANDONG UNIV

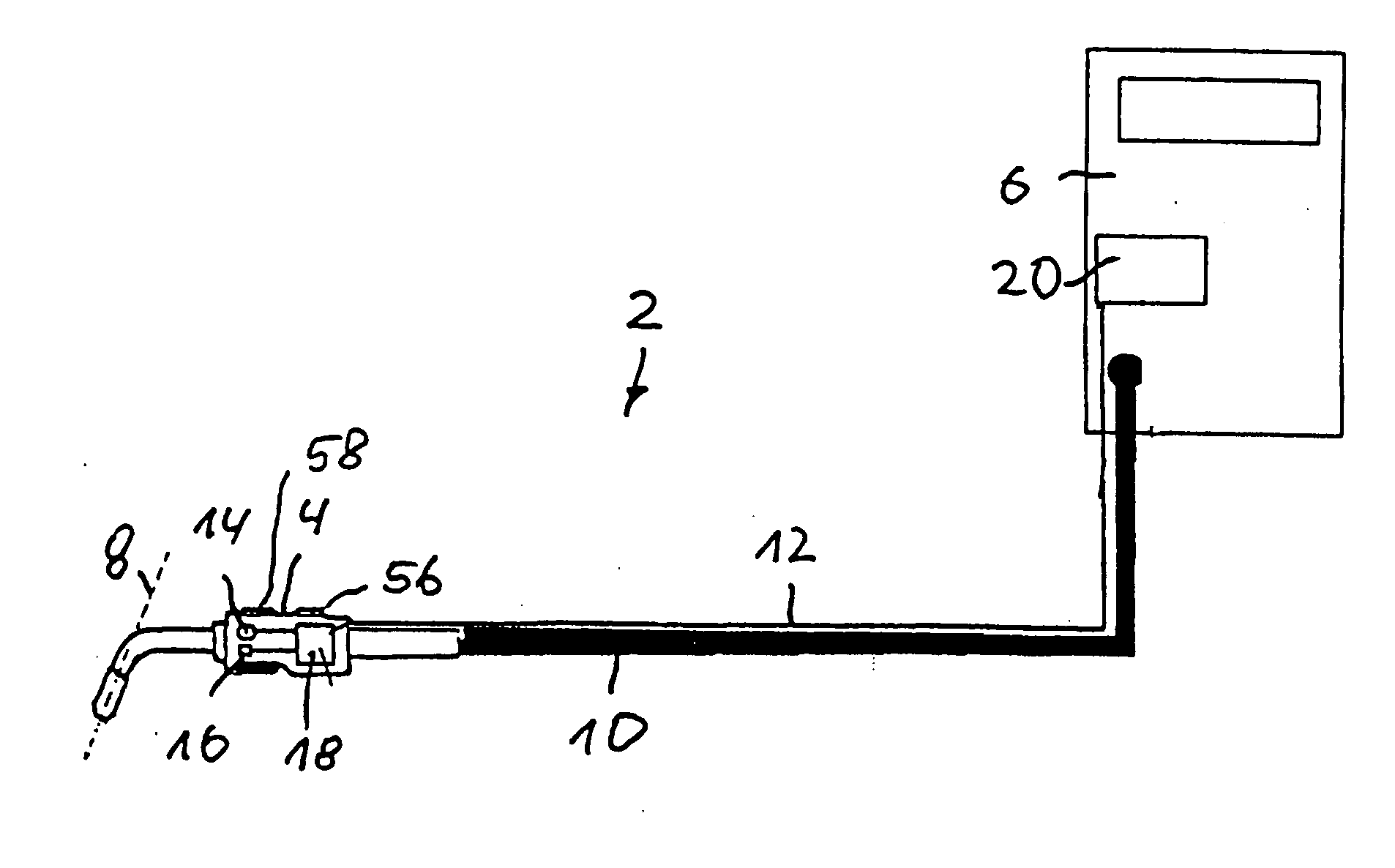

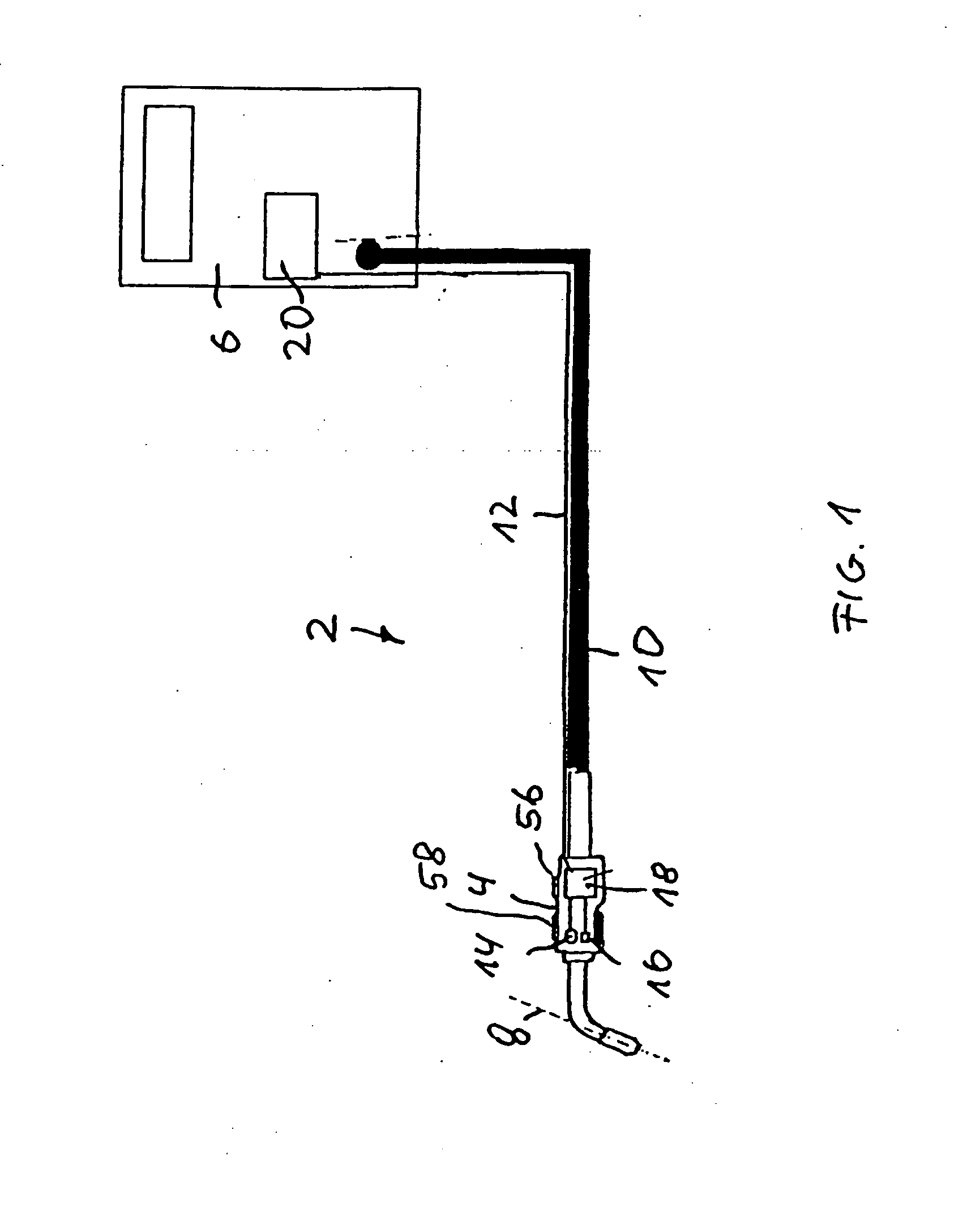

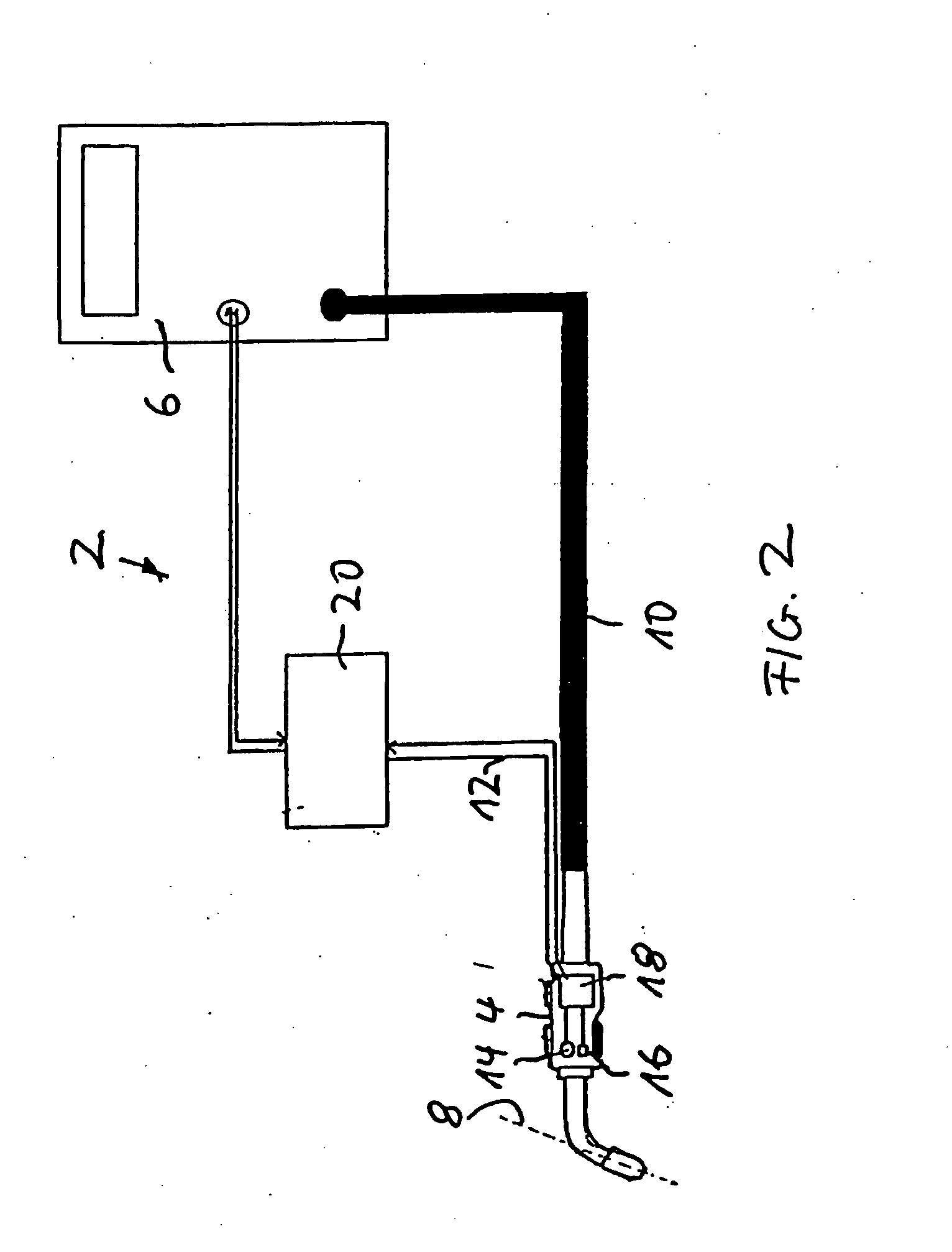

Device for carrying out a joint, separation, or suface treatment process, particularly a welding process

InactiveUS20070187378A1Easy and comfortable to operateImprove welding qualityWelding/cutting auxillary devicesArc welding apparatusEngineeringSoldering process

Owner:DRITTE PATENTPORTFOLIO BET GMBH & CO KG

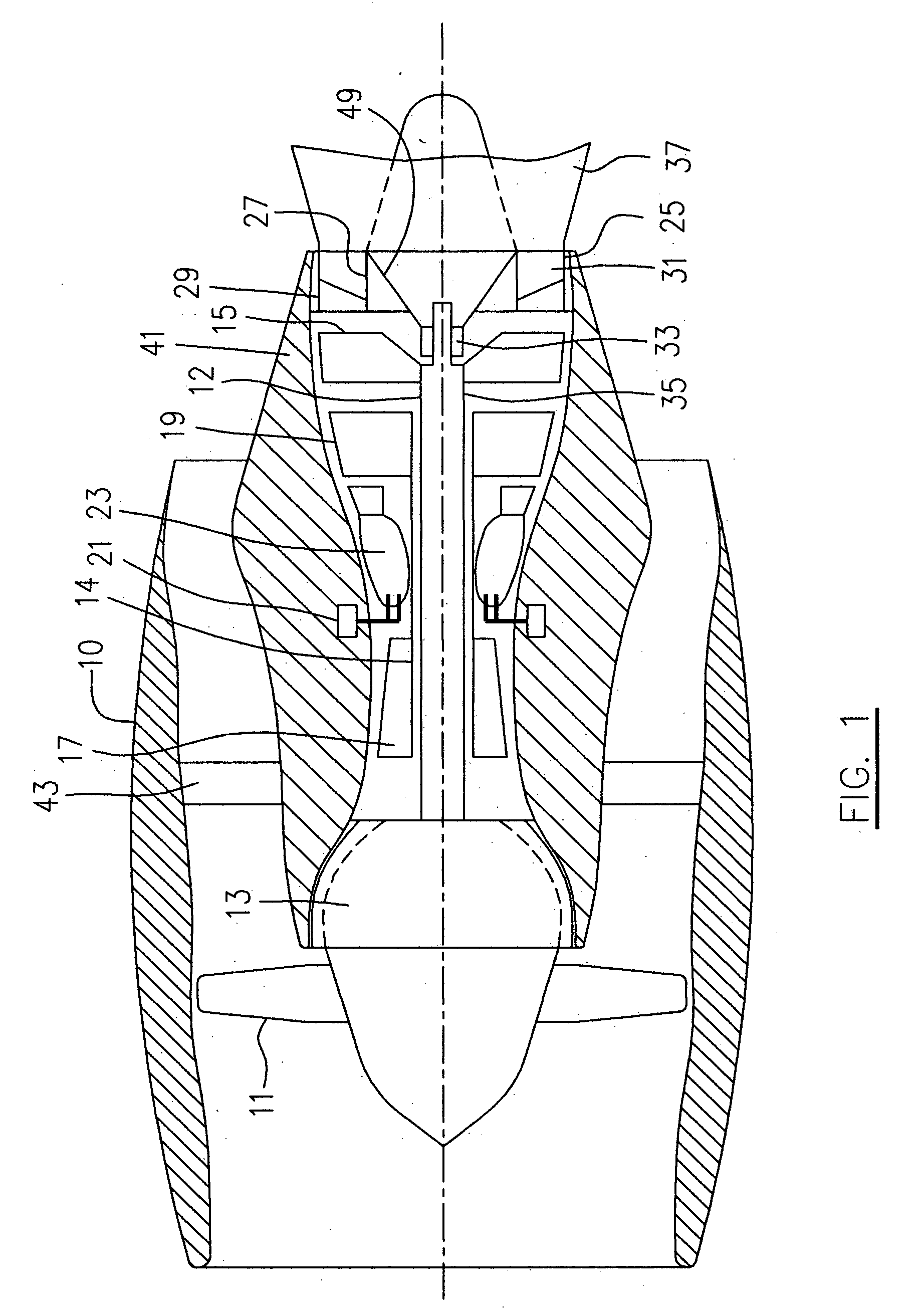

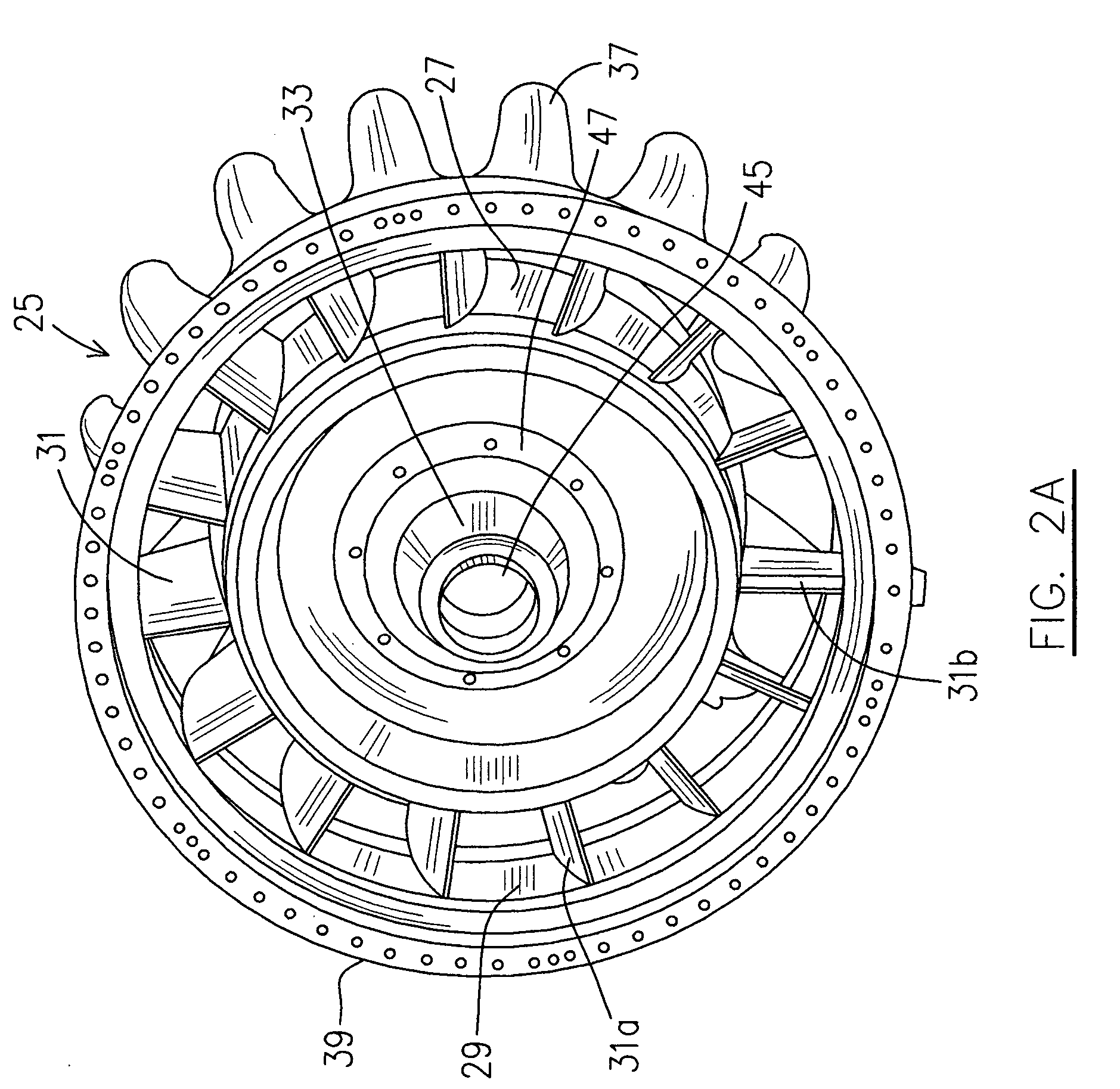

Turbine exhaust case and method of making

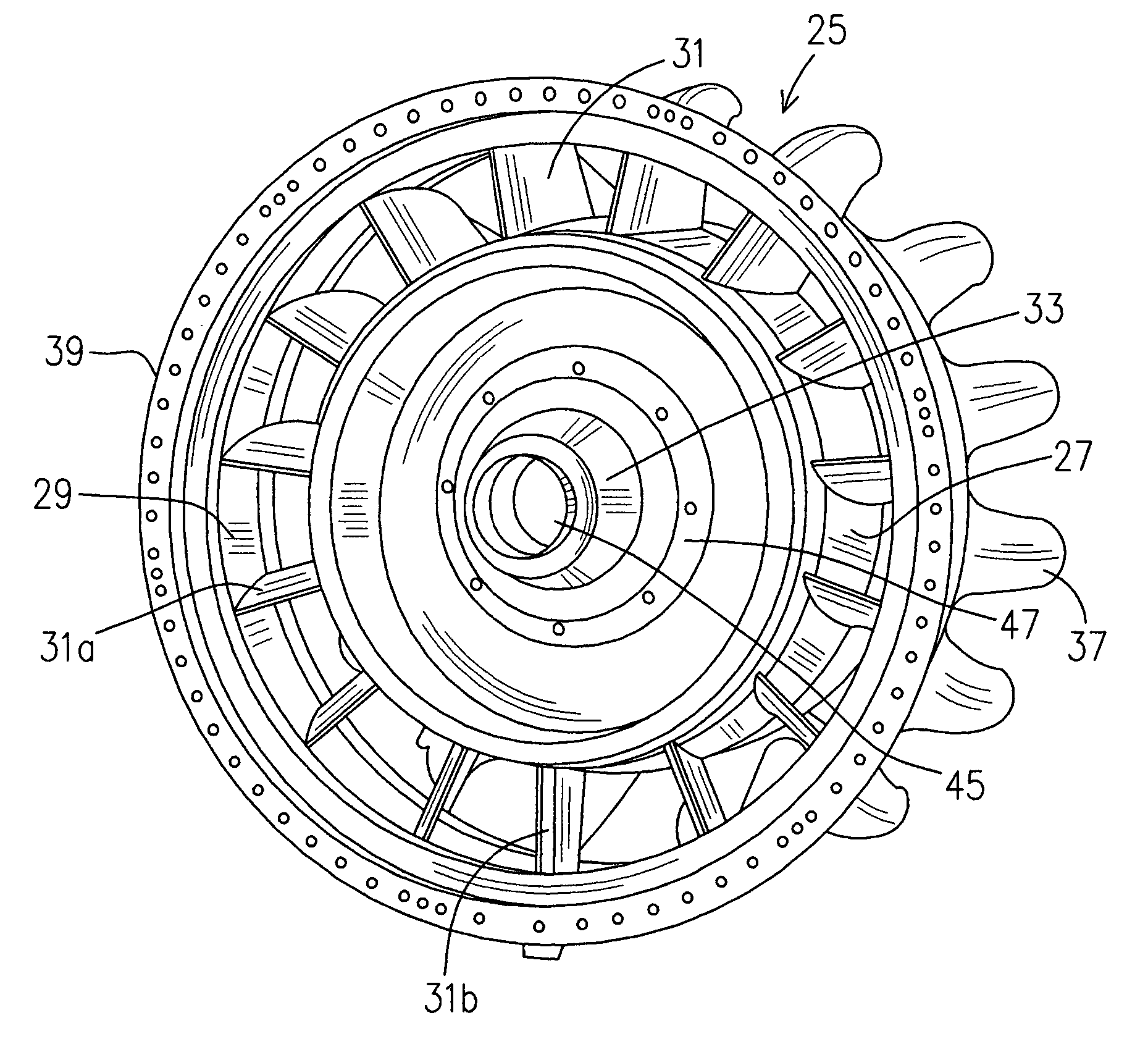

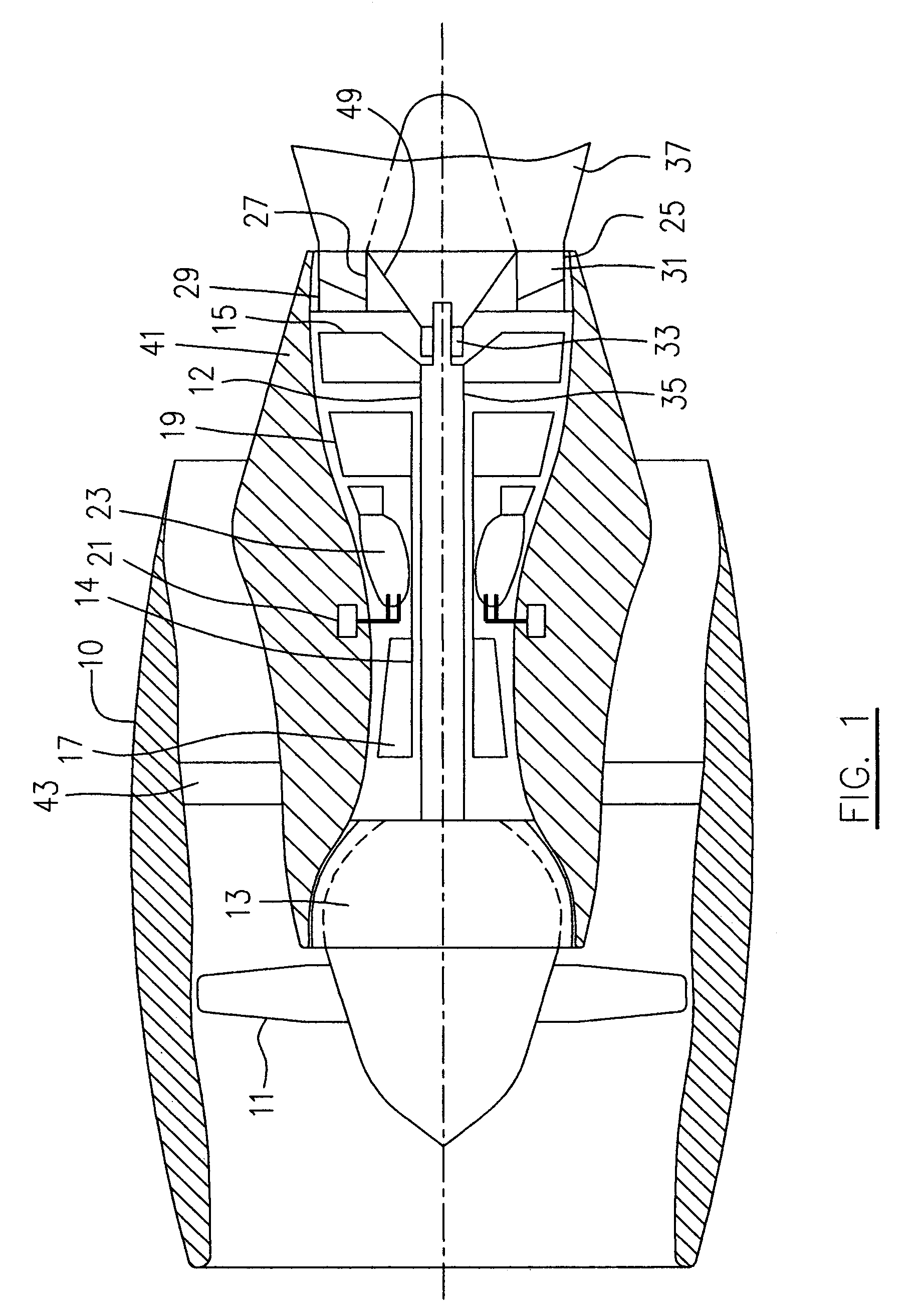

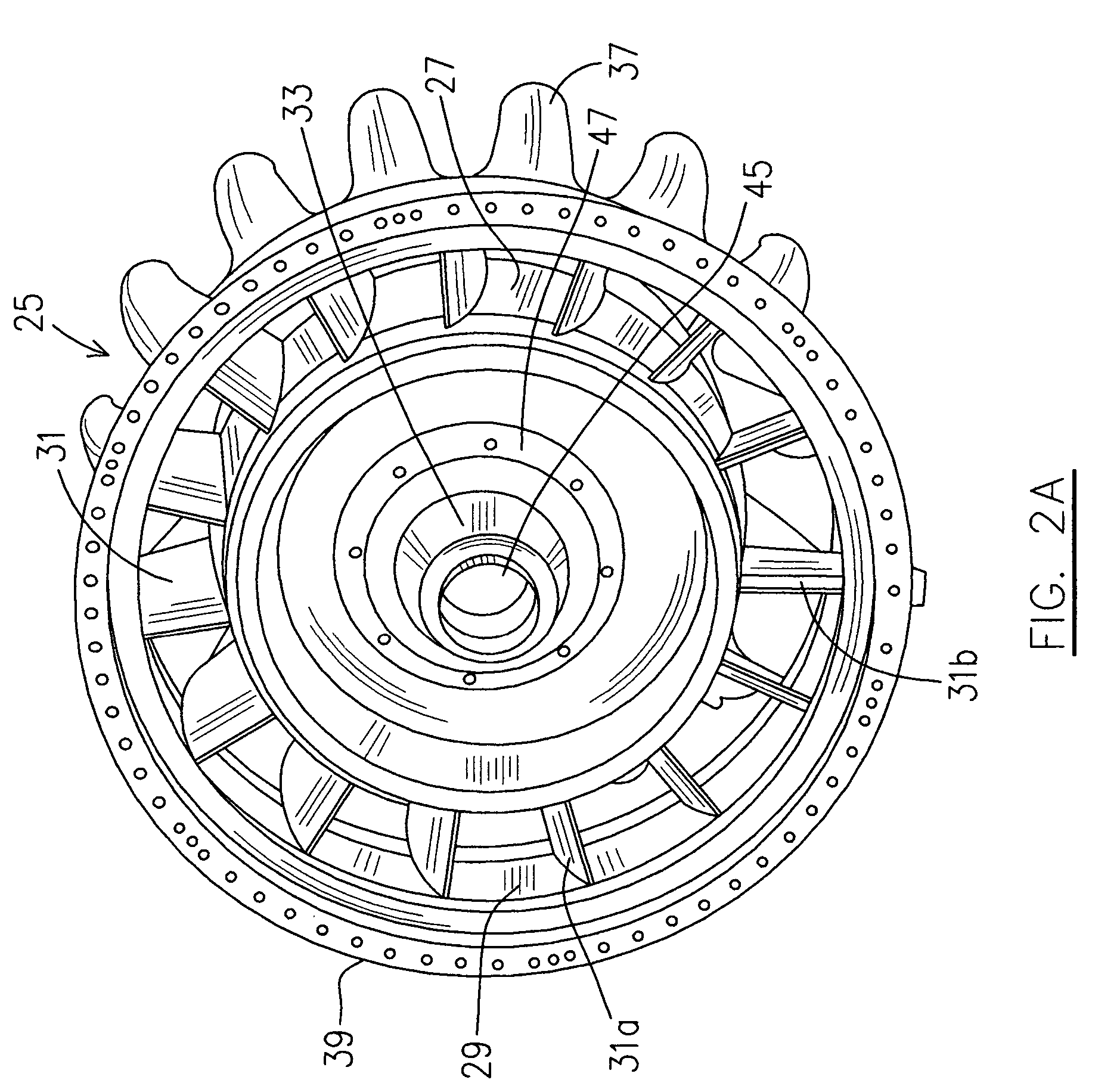

A structural turbine exhaust case of a gas turbine engine, comprises inner and outer case portions; a bearing housing connected to the inner case portion for supporting a main spool of the gas turbine engine; and a plurality of airfoils extending between the inner and outer case portions, airfoils structurally connecting the inner case portion to the outer case portion.

Owner:PRATT & WHITNEY CANADA CORP

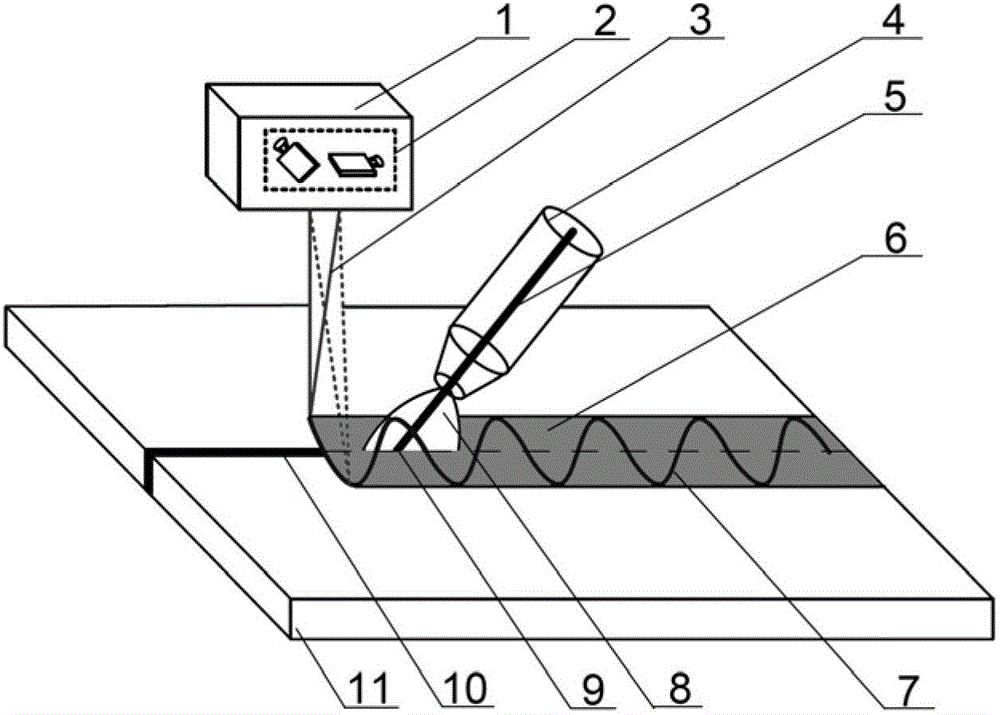

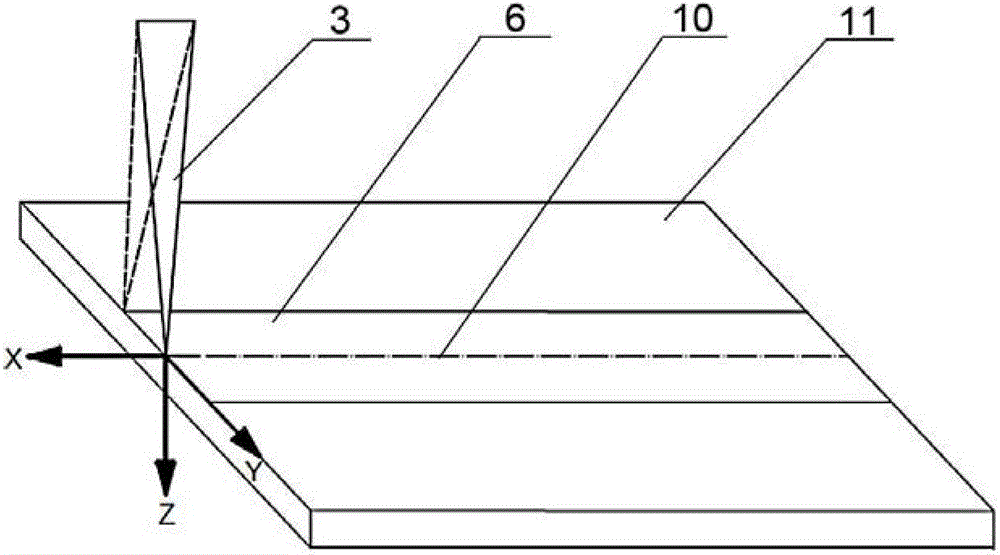

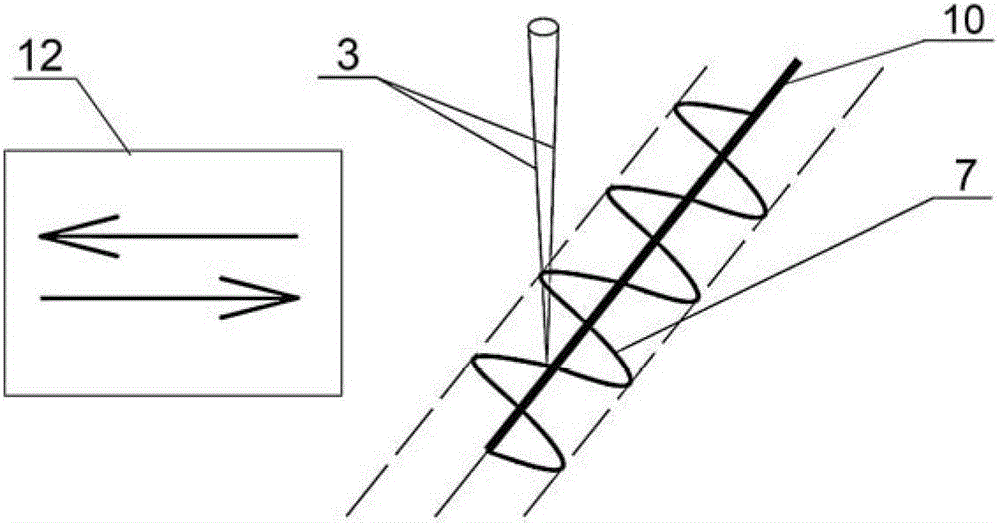

Oscillatory scanning laser beam-electric arc hybrid welding method and system

ActiveCN103056533AImprove featuresImprove welding qualityLaser beam welding apparatusPorosityLaser scanning

The invention discloses an oscillatory scanning laser beam-electric arc hybrid welding method and system. Laser beams and electric arc move together along an abutted seam in large range space, simultaneously the laser beams surround acting points of the electric arc to perform oscillatory scanning movement in a local small area, and an actual welding track is a curve formed by overlying two types of movements. As for an optimal range of laser beam oscillatory scanning displacement, the range in the direction of an X axis is minus 2mm to 3mm, the range in the direction of an Y axis is minus 5mm to 5mm, the range in the direction of a Z axis is minus 2mm to 2mm, and the oscillation frequency is in a range from 20Hz to 500Hz. According to the method and the system, an enhanced technical effect is achieved by the aid of interaction of a laser beam oscillatory scanning effect and a laser-electric arc synergistic effect, and the welding quality is improved. Compared with existing laser-electric arc hybrid welding and laser scanning welding methods and systems, the method and the system have the advantages that higher weld porosity inhibiting capability is achieved, and the weld strength is improved by 10% to 50%.

Owner:武汉飞能达激光技术有限公司

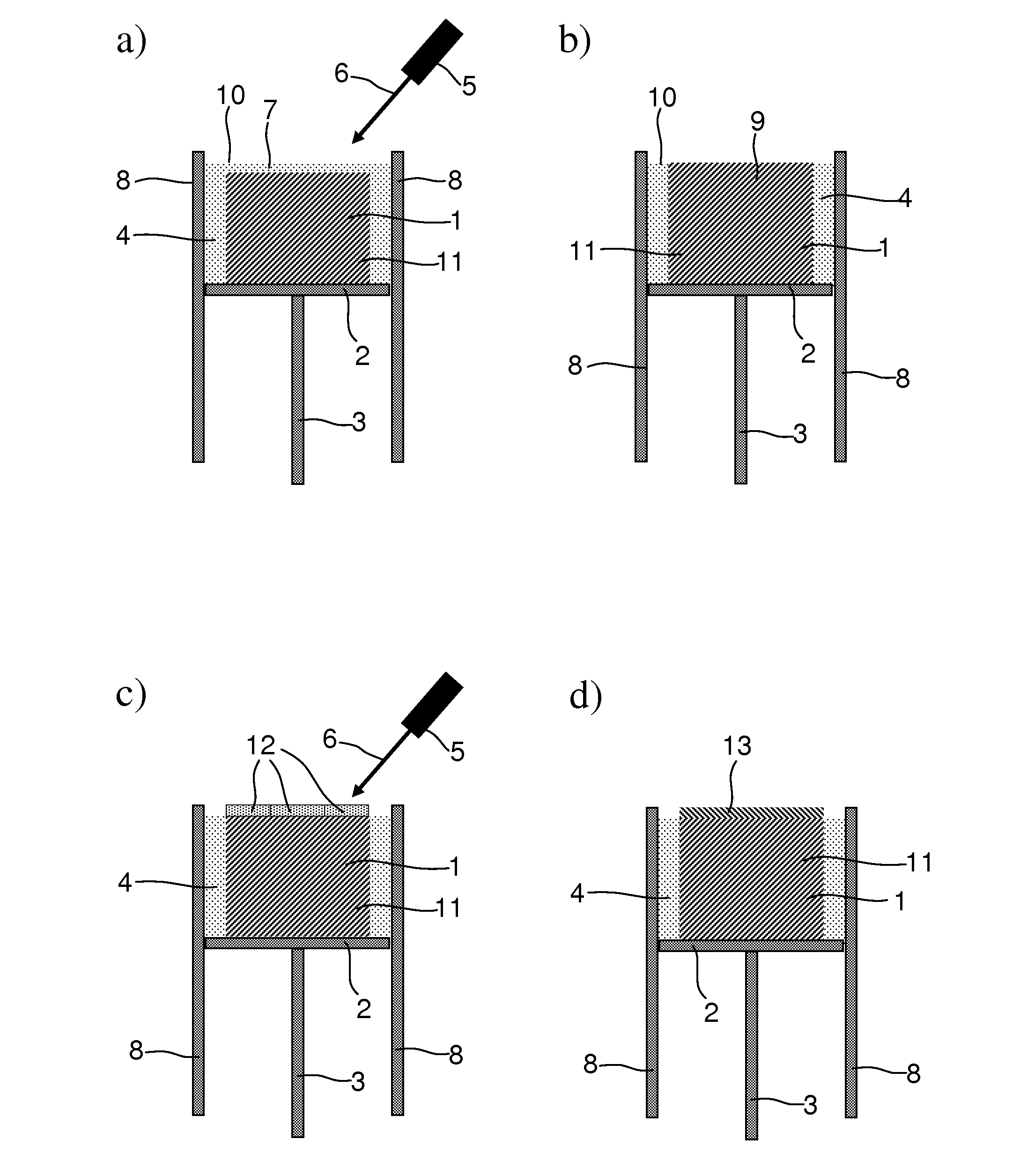

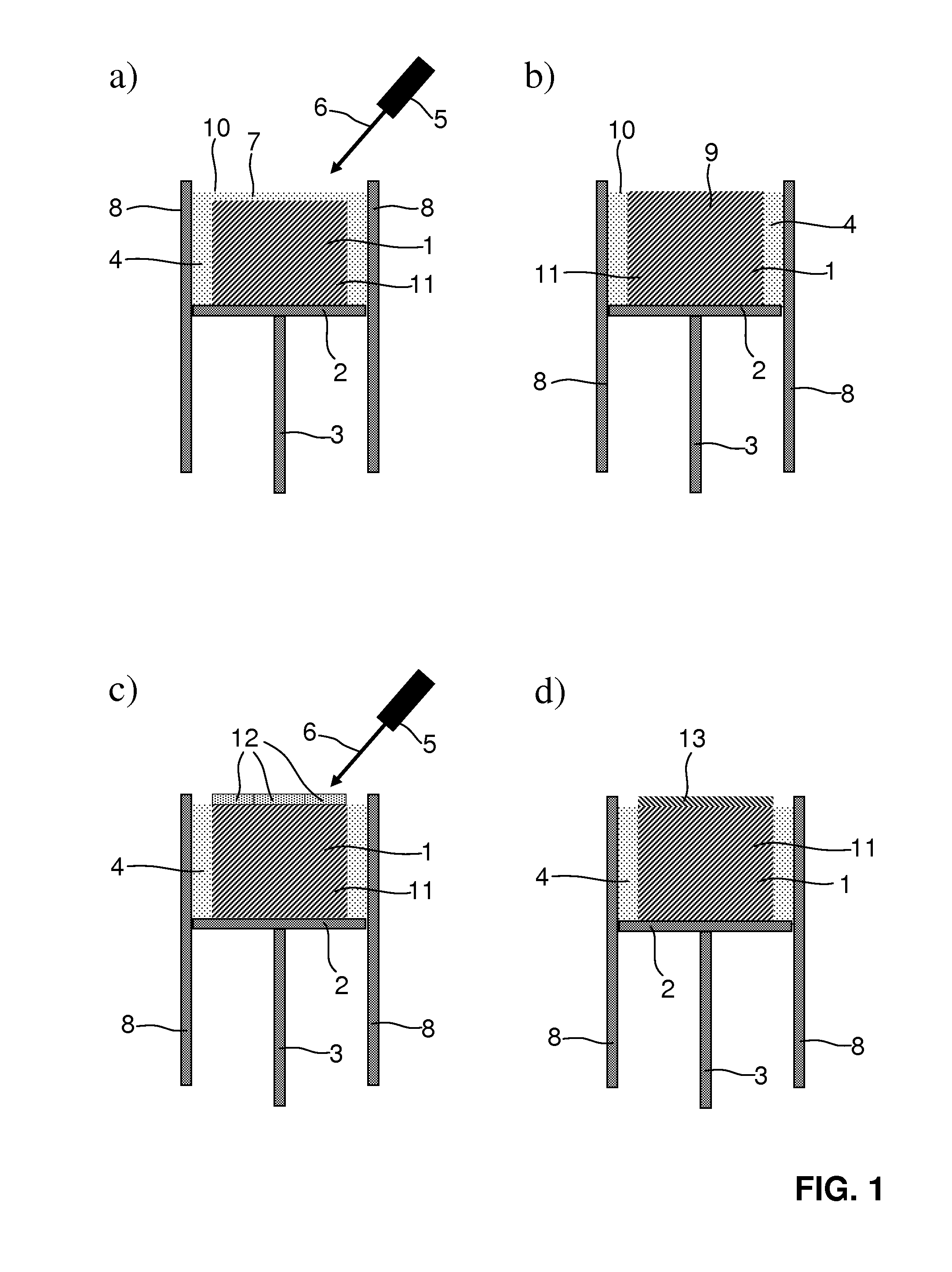

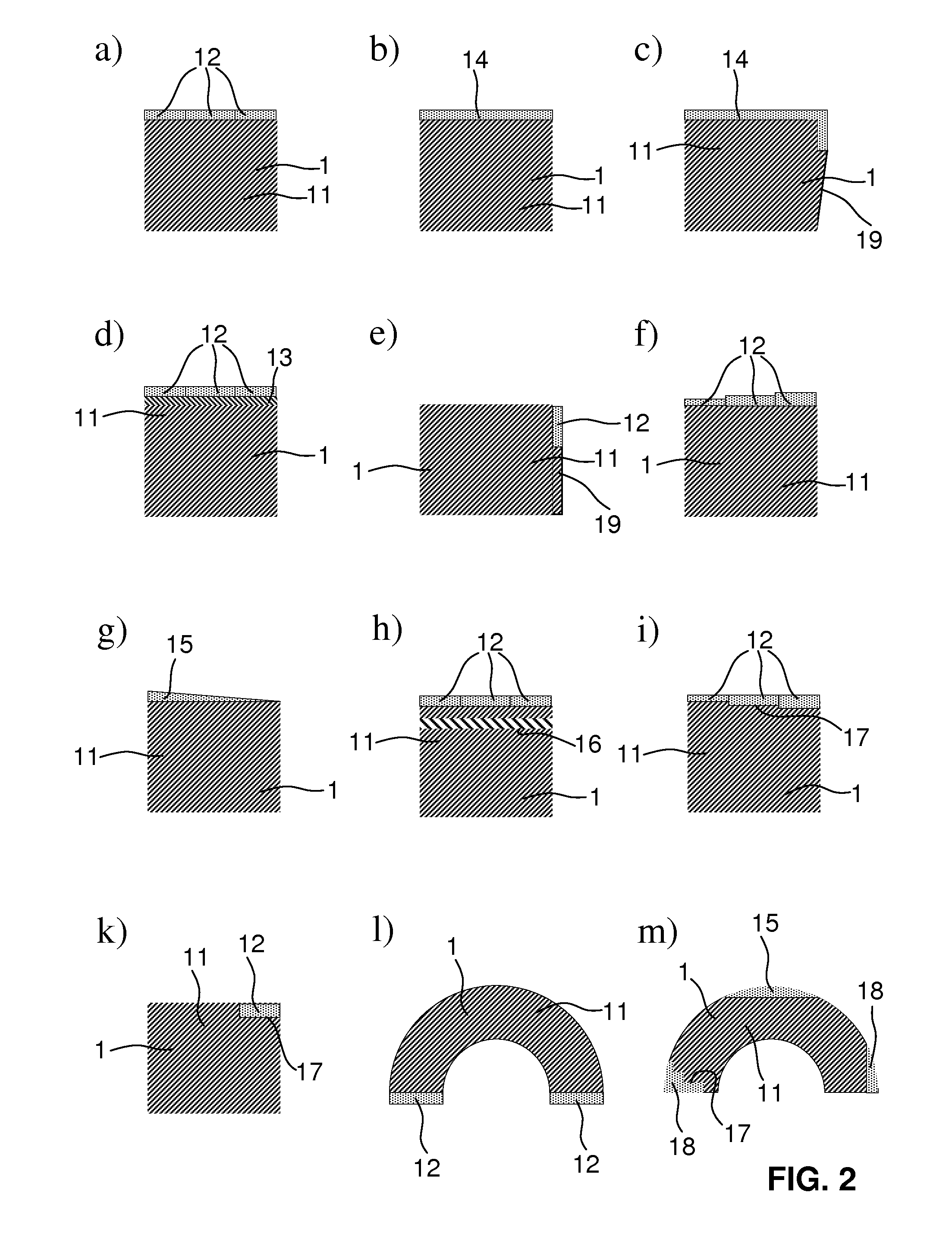

Method of applying multiple materials with selective laser melting on a 3D article

InactiveUS20110106290A1Increase weld ability/brazeabilityEasy to optimizeTurbinesAdditive manufacturingMulti materialSelective laser melting

In a method for manufacturing an article (1), particularly a prototype of a product or component, a tool prototype or spare part, by using selected laser melting, for the application onto the article (1) of a layer (13) or portion of a second metallic material, which is different from the material of the first metallic powder (4), a tape (12), sheet (14), foil or three-dimensional pre-form (18) of a second material is applied to the article (1) and is heated by a focused laser or electron beam (6) to a specified temperature such that the tape (12), sheet (14), foil or pre-form, respectively, are made molten by the electron laser beam (6), wherein the focused beam (6) is applied to a given area corresponding to a selected cross-sectional area of the model of the article (1) under formation of a new layer or part made of second material integral with the article (1).

Owner:ANSALDO ENERGIA IP UK LTD

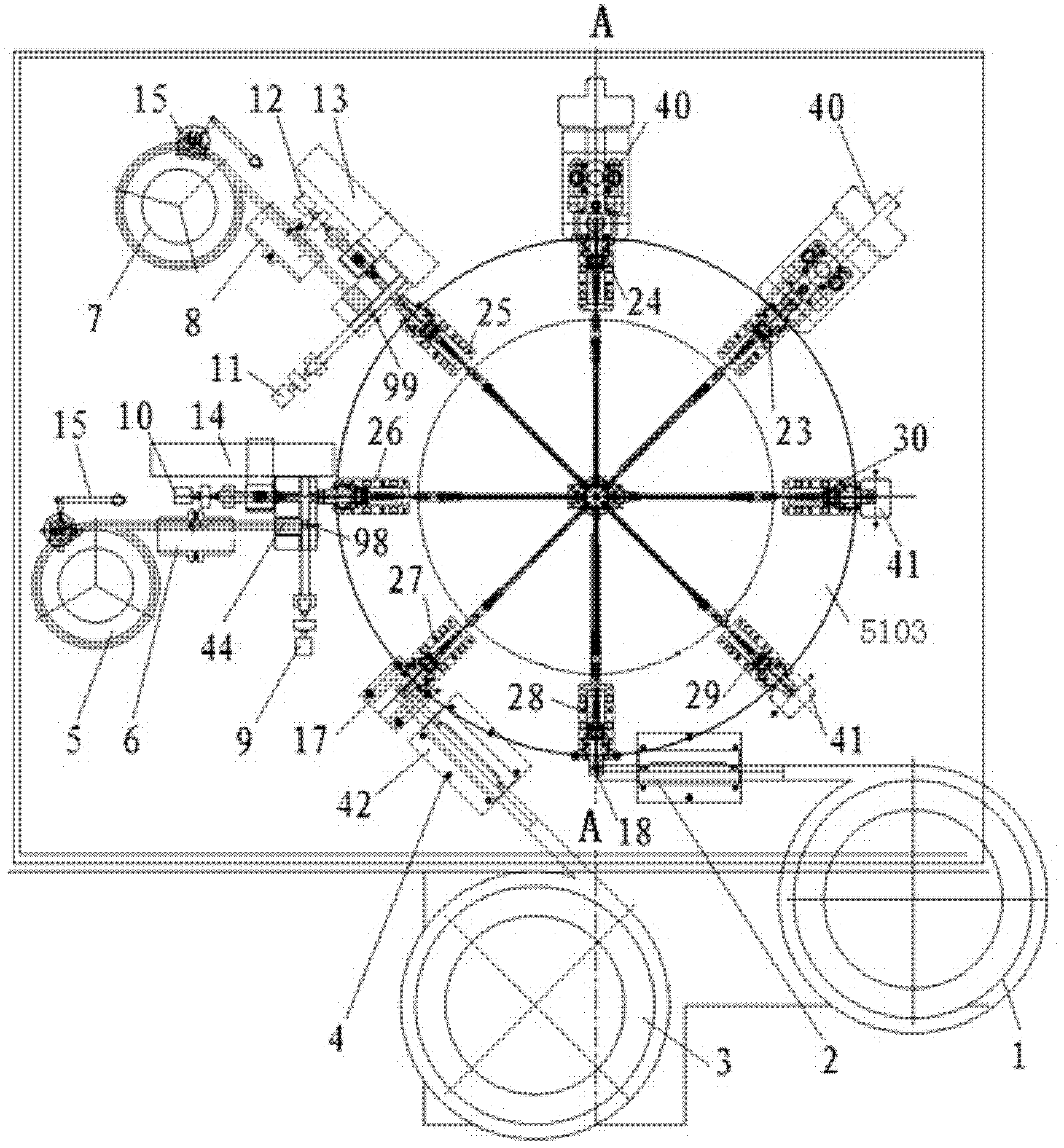

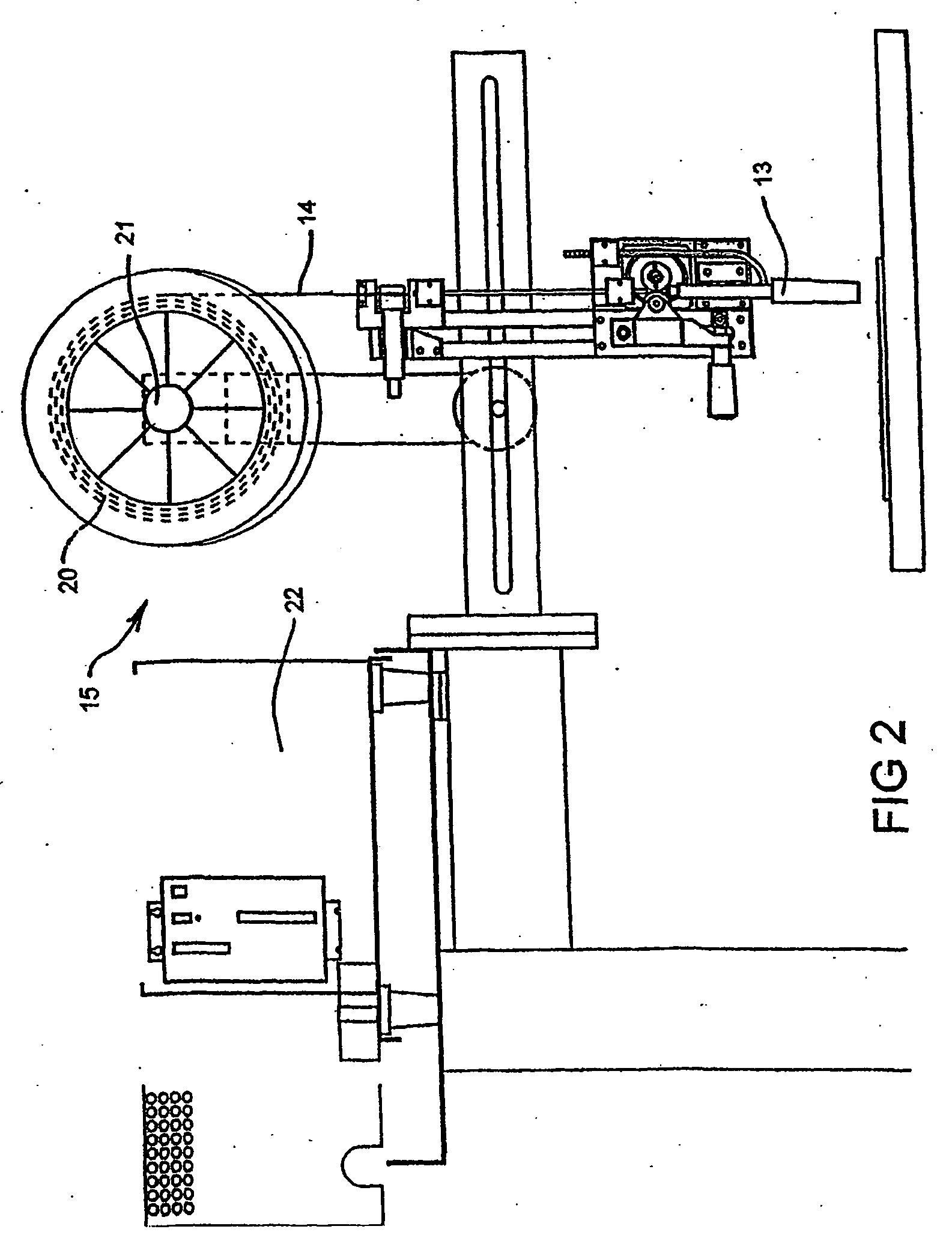

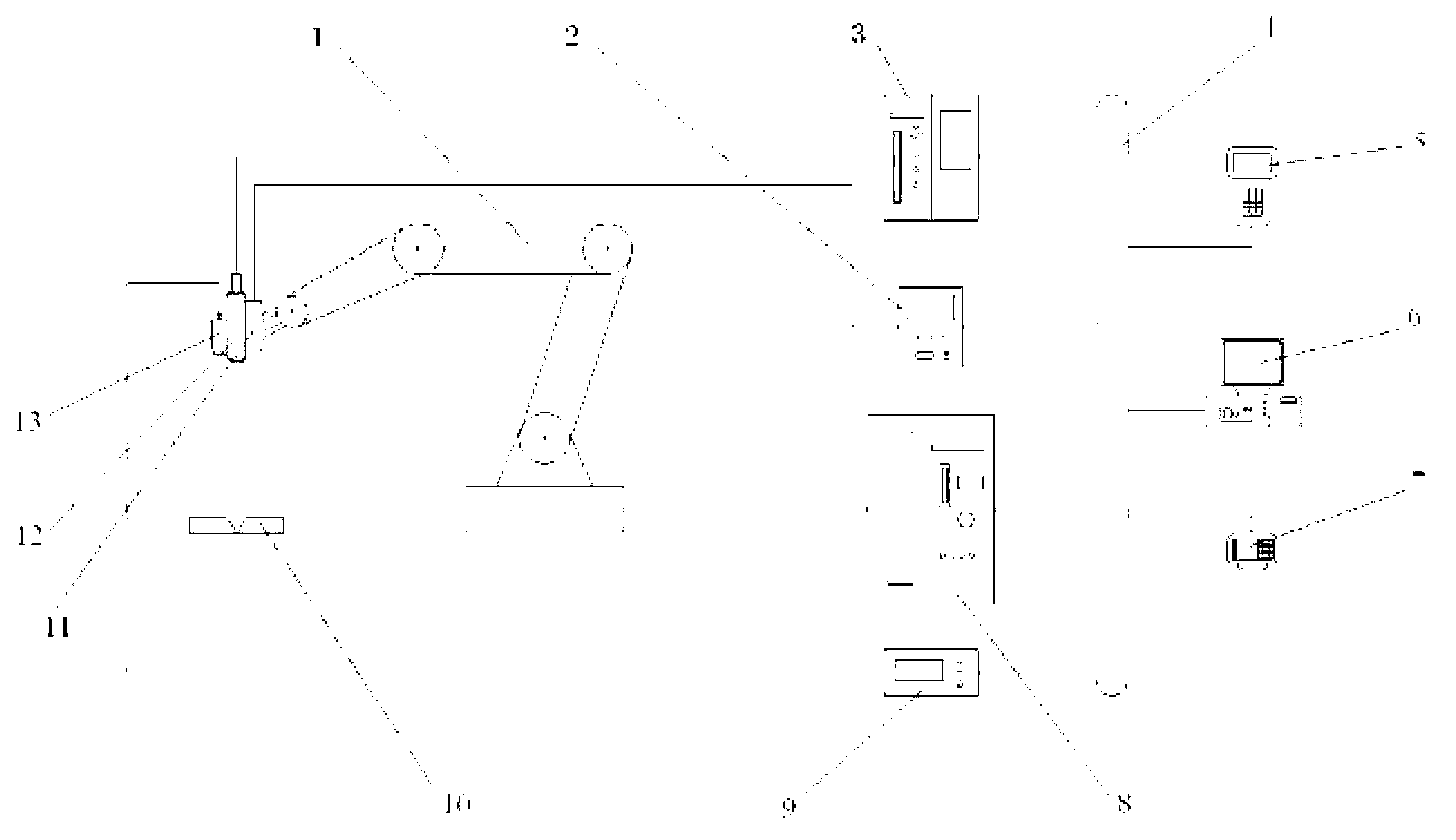

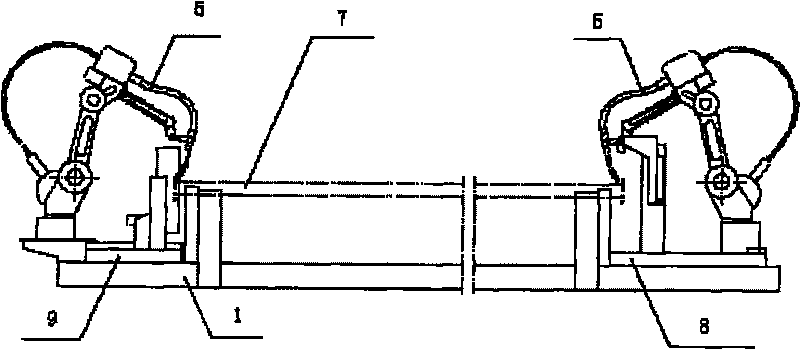

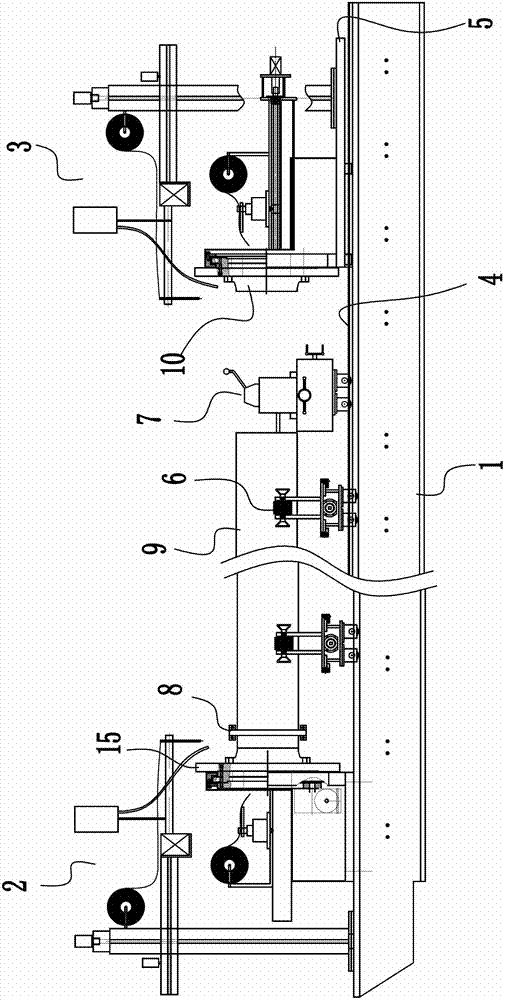

Full-automatic multi-station welding system

ActiveCN102528353AAchieve separationAchieve storageWelding/cutting auxillary devicesAuxillary welding devicesManipulatorContactor

The invention discloses a full-automatic multi-station welding system which mainly comprises a rotary table and driving device, contact bridge storage and feeding devices, contactor feeding and conveying devices, welding machine heads and a discharge component, wherein the rotary table and driving device is internally and externally divided in the shape of a ring in the such way of equal and concentric eight parts and four stations, and the positions are set to be an even number according to the welding positions of welded pieces; eight mechanical arm assemblies are uniformly distributed in the circumferential direction on the upper surface of an outer rotary table; two contact bridge storage and feeding devices, two contactor feeding and conveying devices, two welding machine heads and two discharge devices are correspondingly arranged in sequence on the outer side of eight positions; each contact bridge storage and feeding device is engaged with a lower mechanical arm in the present position; each contactor feeding and conveying device comprises a device for identifying front / back faces and sorting during contactor feeding, a solder dropping device and a contactor cross-pushing device. The full-automatic multi-position welding system achieves synchronization of fully automatically welding, assembling and forming multiple sets of equipment in multiple positions at the same time.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

Method and device for laser welding

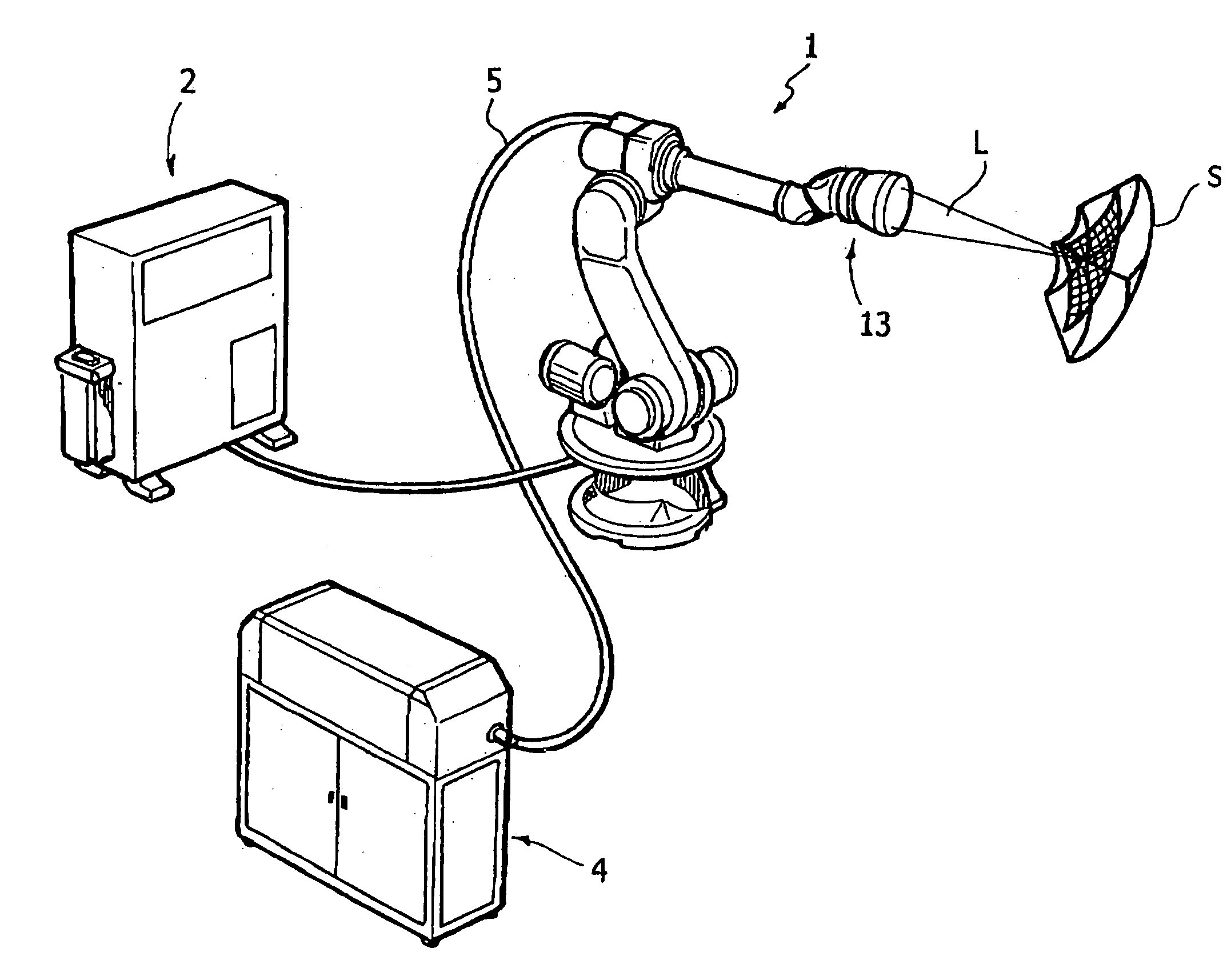

ActiveUS20050150876A1Improve welding qualityShorten production timeLaser detailsSpecial data processing applicationsClassical mechanicsManipulator

A plurality of stretches of laser weld are executed on a structure to be welded by means of a device for focusing and orientation of the laser beam, which is associated to a component element of a manipulator robot. The focusing head is kept in the proximity of, but not closely adjacent to, the different areas to be welded and can consequently follow a simplified path, whilst the device for orientation of the laser beam aims the latter on the different areas of the structure to be welded, so that the speed of travel of the laser beam spot along the longitudinal direction of the weld stretch is independent from the speed of travel of the robot end element.

Owner:COMAU SPA

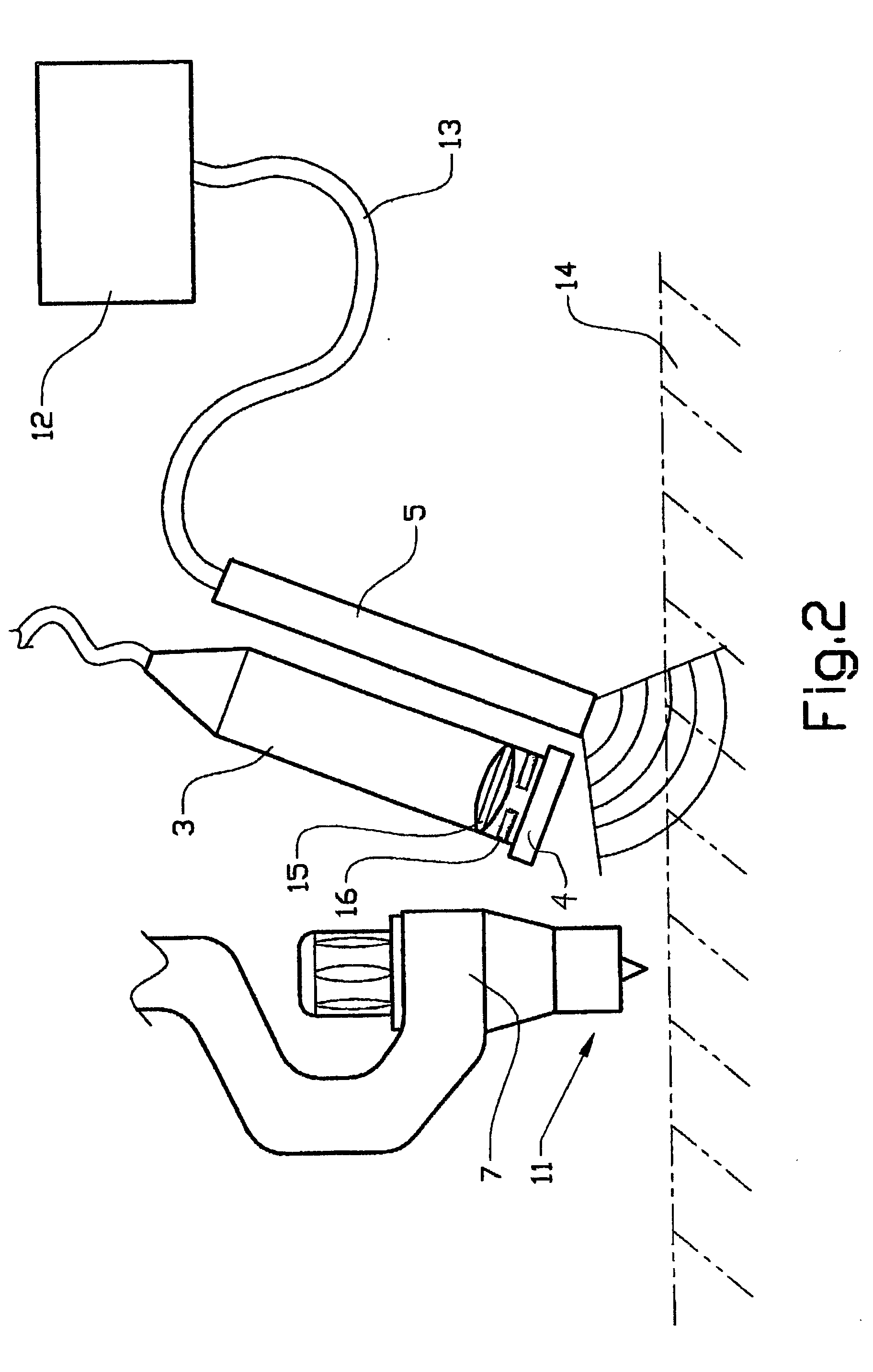

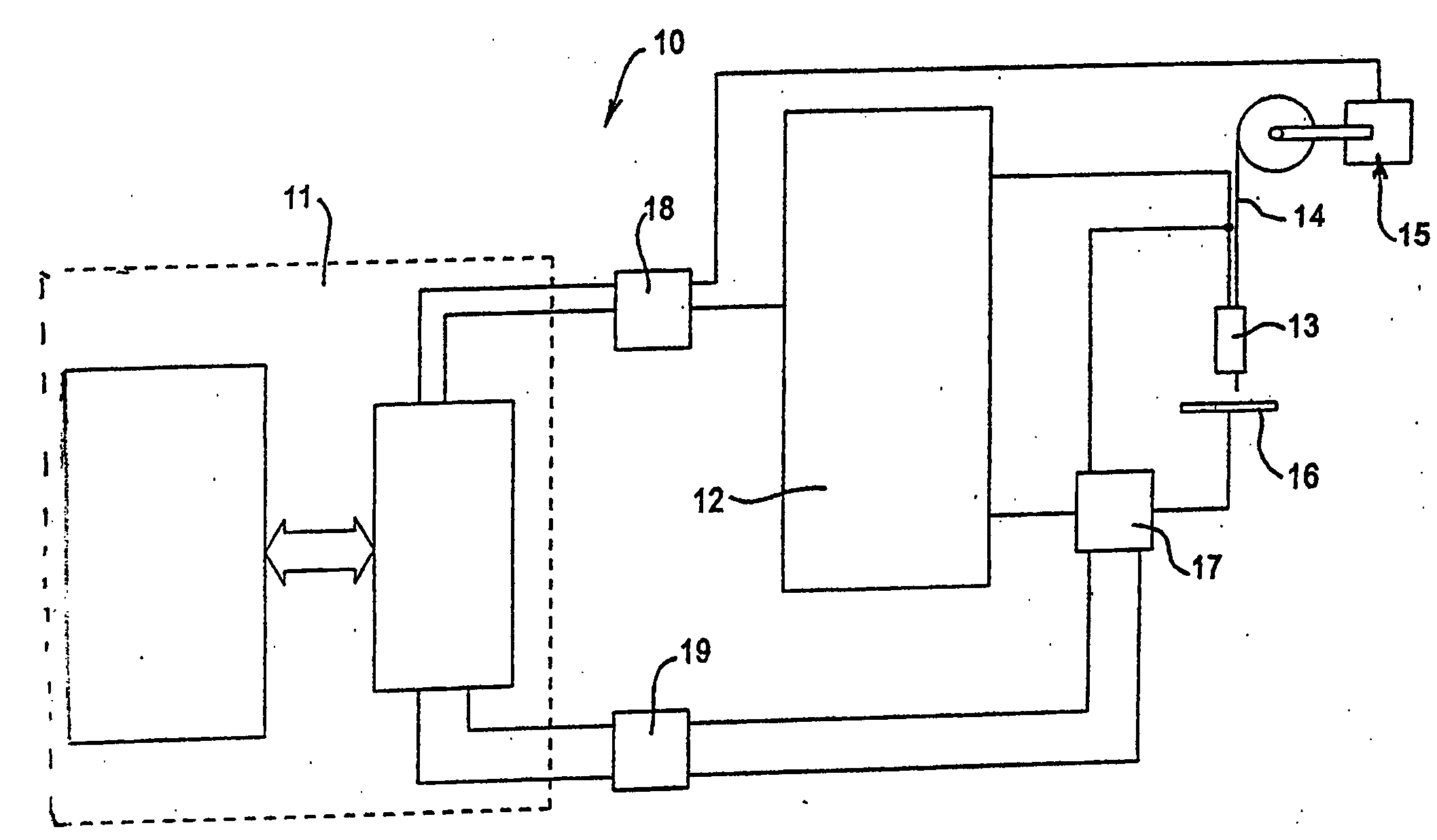

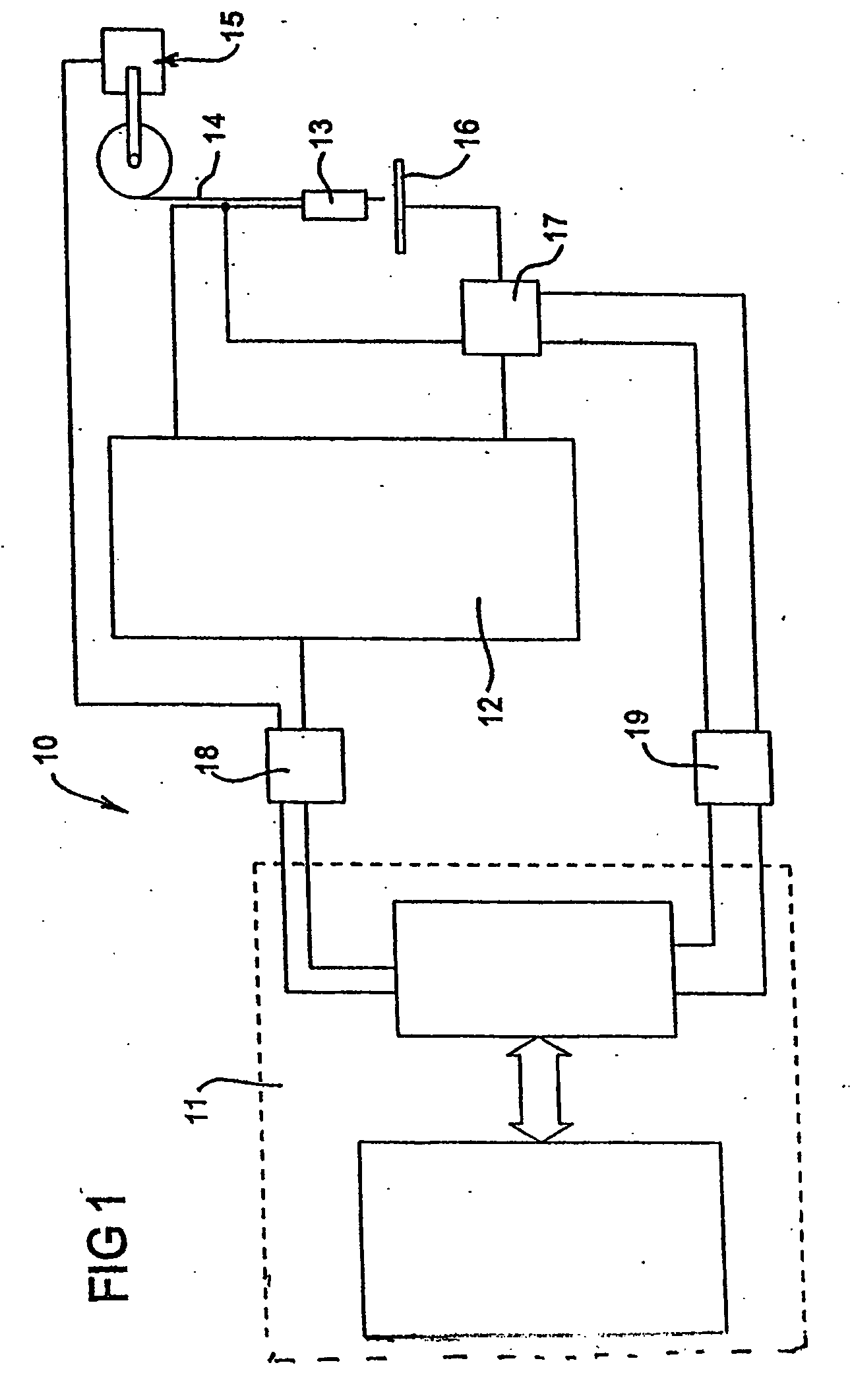

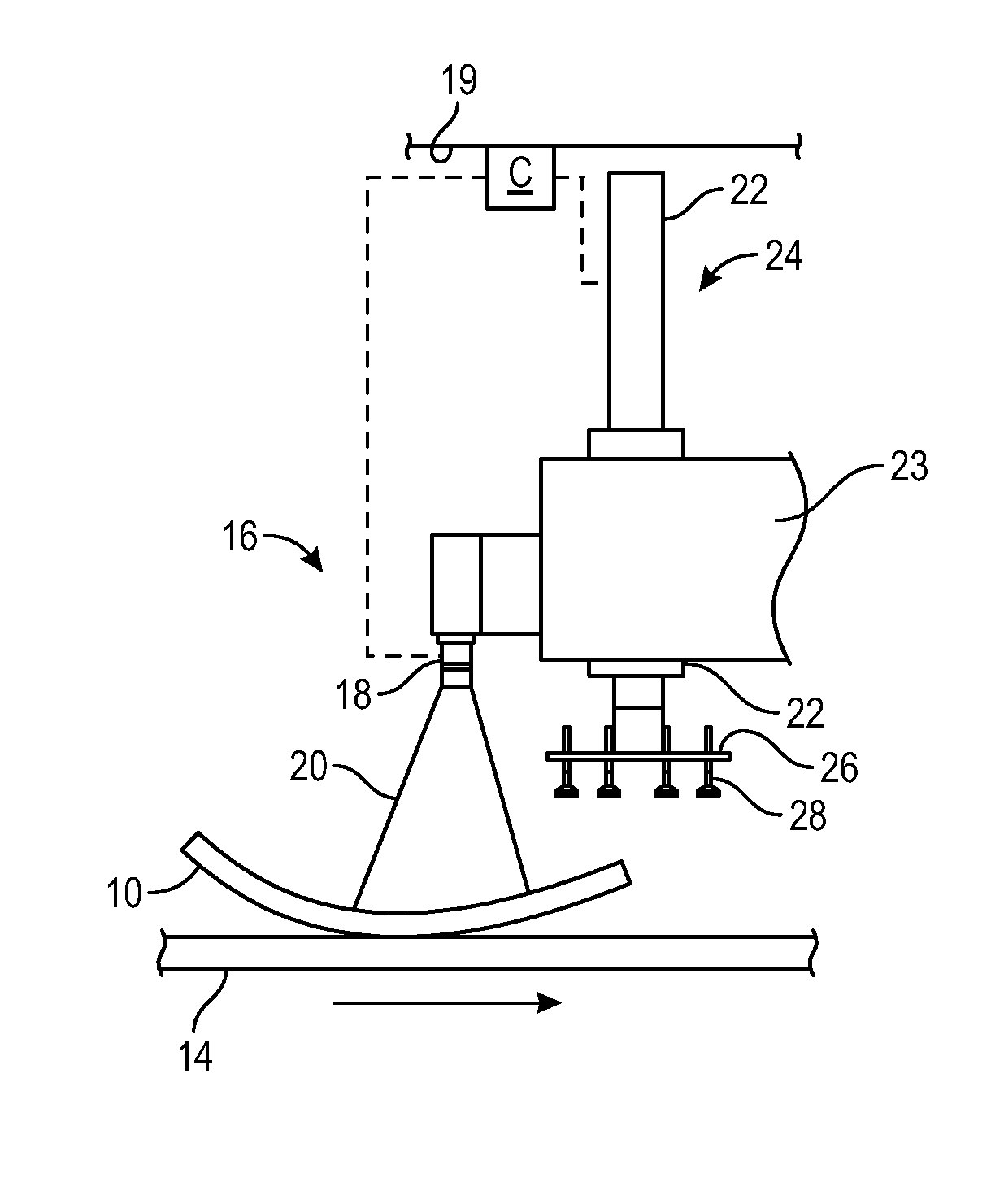

Device and method for monitoring a welding area and an arrangement and a method for controlling a welding operation

InactiveUS20050029326A1Great amount of detailed information and precisionImprove welding qualityAutomatic control devicesPrecision positioning equipmentBand-pass filterUltraviolet

Method and device (2) for monitoring a welding area of an object (14) in connection with welding, which device includes arrangements (3) for reproduction of the welding area, at least one filter (4) arranged in front of or in the reproduction arrangement (3), and an illumination arrangement (5) of the welding area with ultraviolet radiation. The filter (4) consists of a band-pass filter which is adapted for filtering around a wavelength within the ultraviolet wavelength range.

Owner:GKN AEROSPACE SWEDEN AB

Control method and system for metal arc welding

ActiveUS20060138115A1Reduce time takeQuality improvementArc welding apparatusElectric arcEngineering

A method of controlling an arc welding system during a welding process is disclosed. The welding process has a plurality of welding cycles in which a consumable electrode is advanced towards a workpiece. The method includes dynamically regulating a rate of advancement and instantaneous melt rate of the electrode during each welding cycle in response to predetermined events occurring during the welding process. The melt rate may be coordinated with the rate of advancement of the electrode to provide a wide range of stable deposition rates with a shielding gas such as CO2. An arc welding system for carrying out the method is also disclosed.

Owner:UNIV OF WOLLONGONG

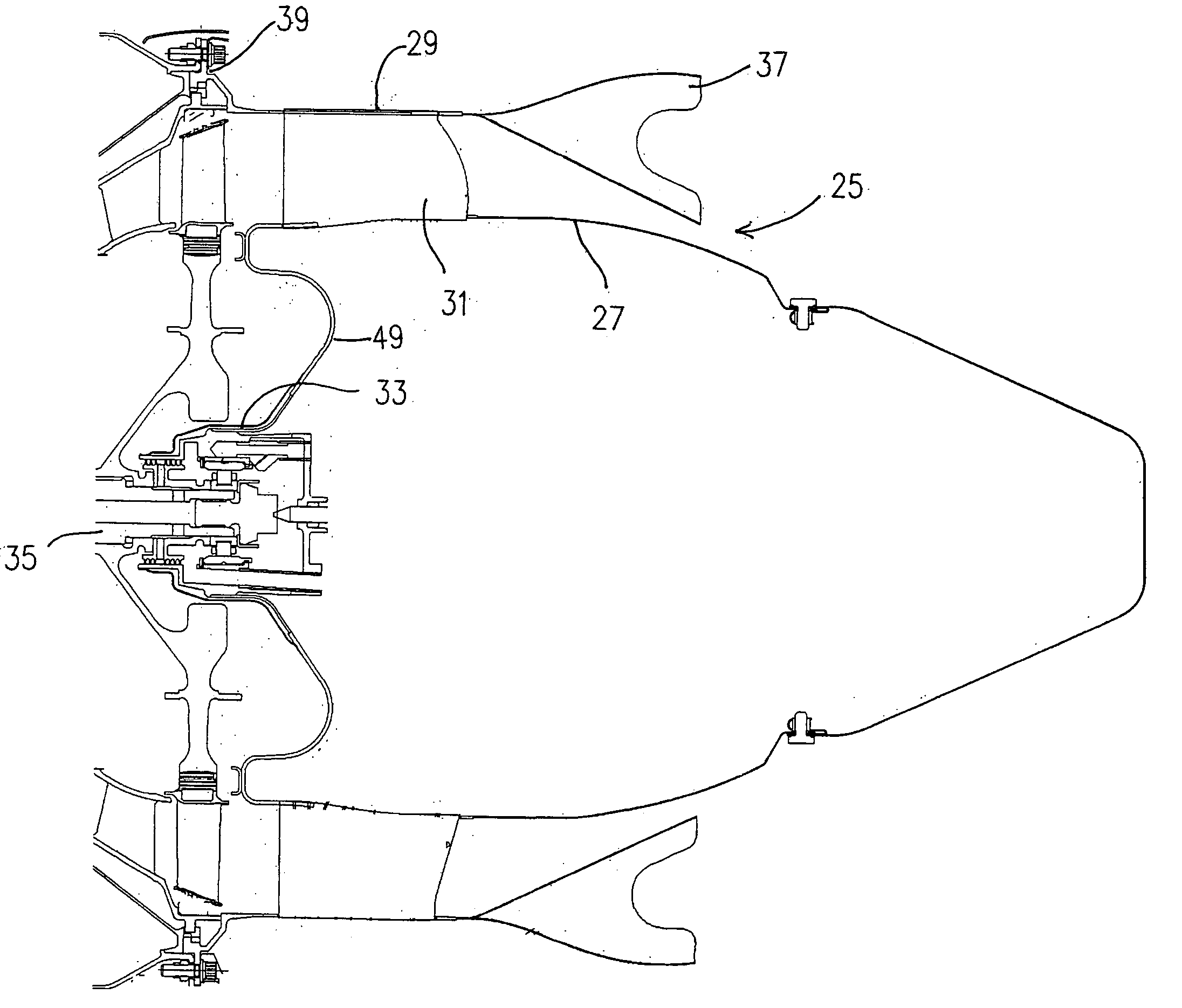

Turbine exhaust case and method of making

A structural turbine exhaust case of a gas turbine engine, comprises inner and outer case portions; a bearing housing connected to the inner case portion for supporting a main spool of the gas turbine engine; and a plurality of airfoils extending between the inner and outer case portions, airfoils structurally connecting the inner case portion to the outer case portion.

Owner:PRATT & WHITNEY CANADA CORP

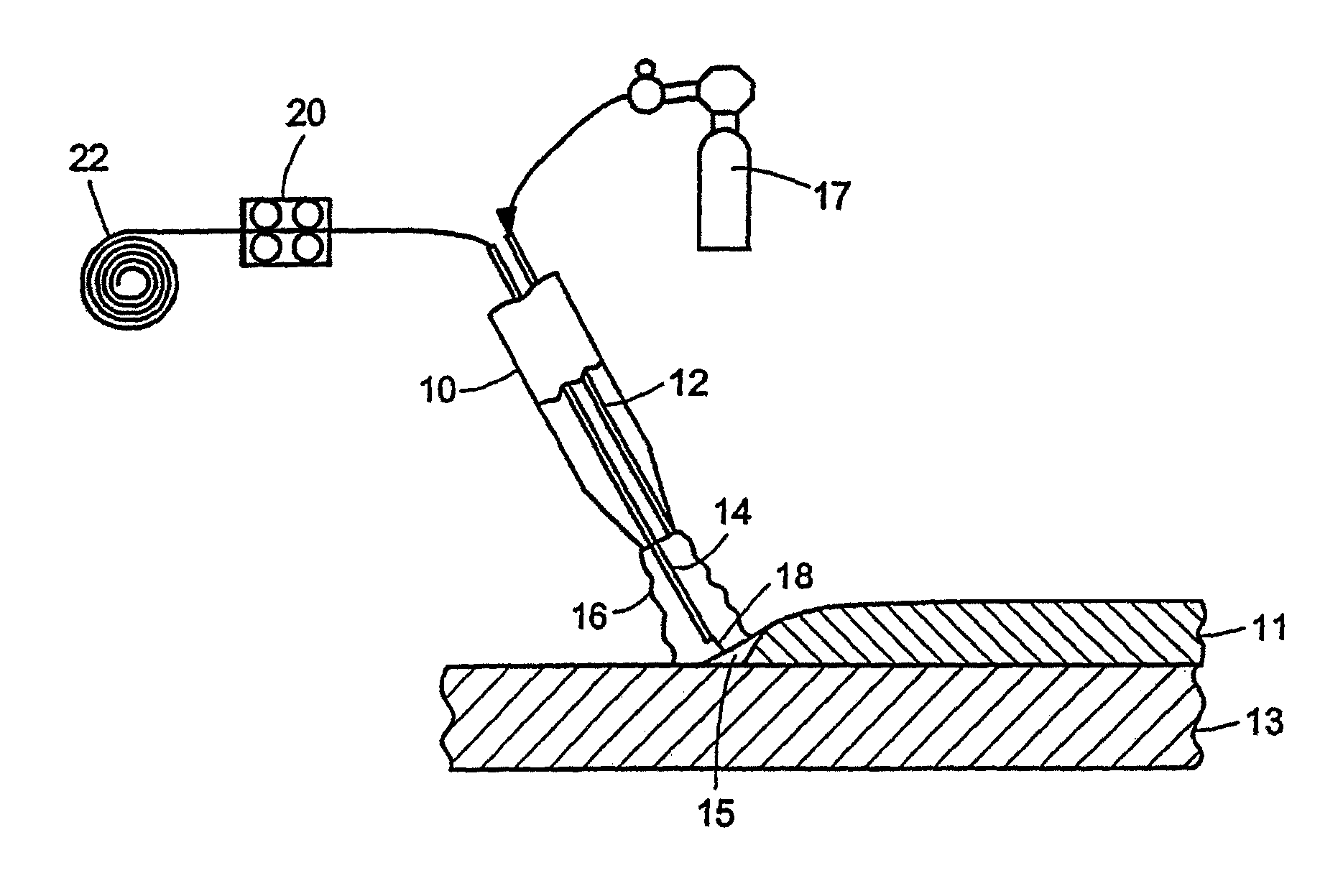

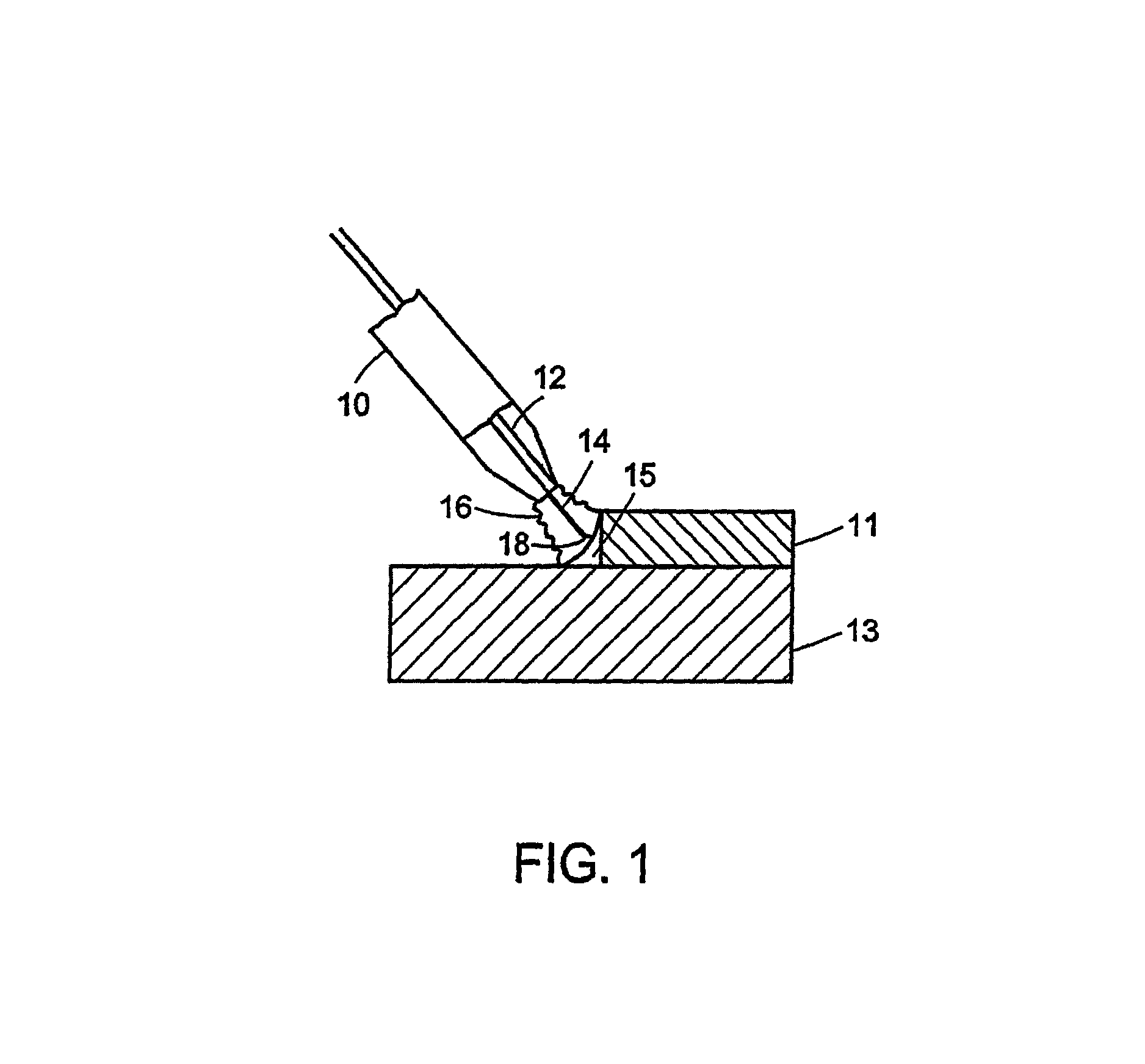

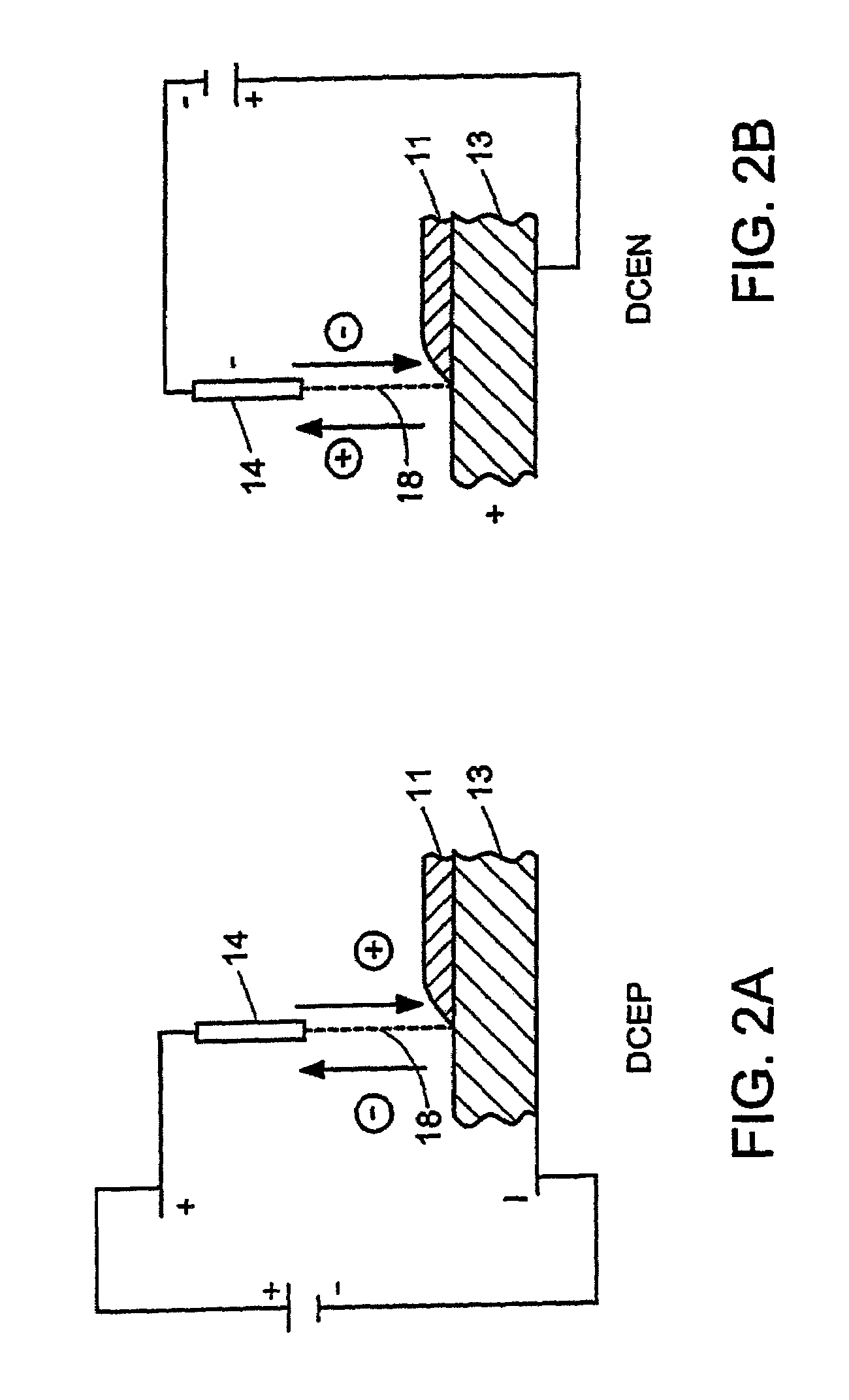

Straight polarity metal cored wires

InactiveUS7087860B2Increase deposition rateImprove welding qualityArc welding apparatusWelding/cutting media/materialsManganeseGraphite

A core composition of a metal-cored wire comprising a combination of graphite and potassium compounds has been proven to stabilize the arc in a straight polarity welding configuration. In particular, adding a combination of graphite and potassium manganese titanate (K2MnTiO4) and potassium sulfate (K2SO4) in the preferred combination of graphite and potassium compounds from the range of about 0.3% to about 5.0% wt resulted in a greatly stabilized arc, reduced spatter and reduced warpage while maintaining high deposition rates of the DCEN welding process

Owner:HOBART BROS

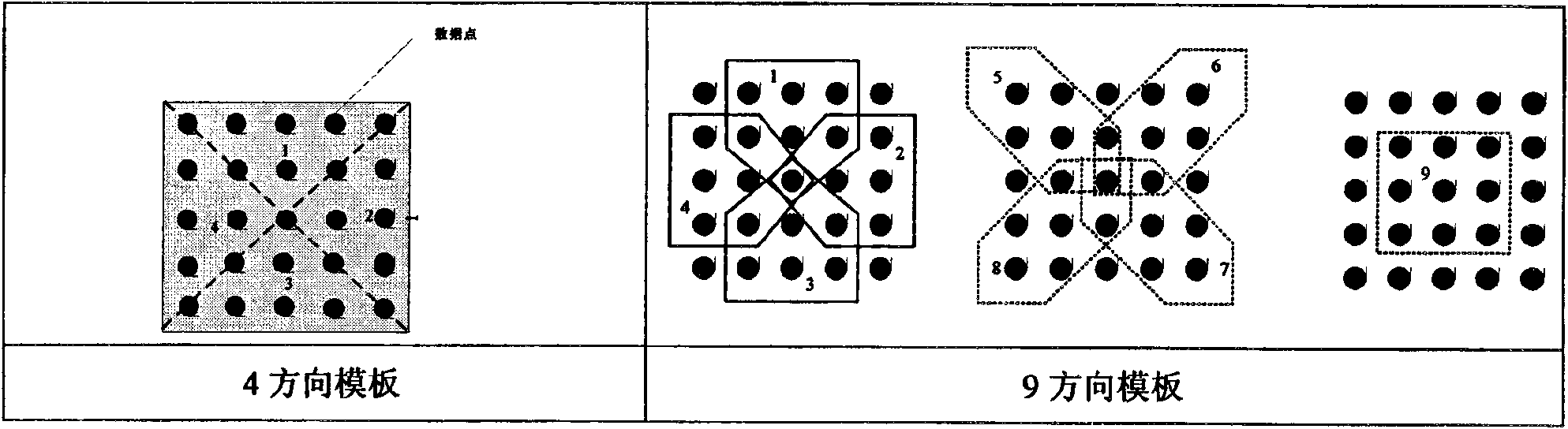

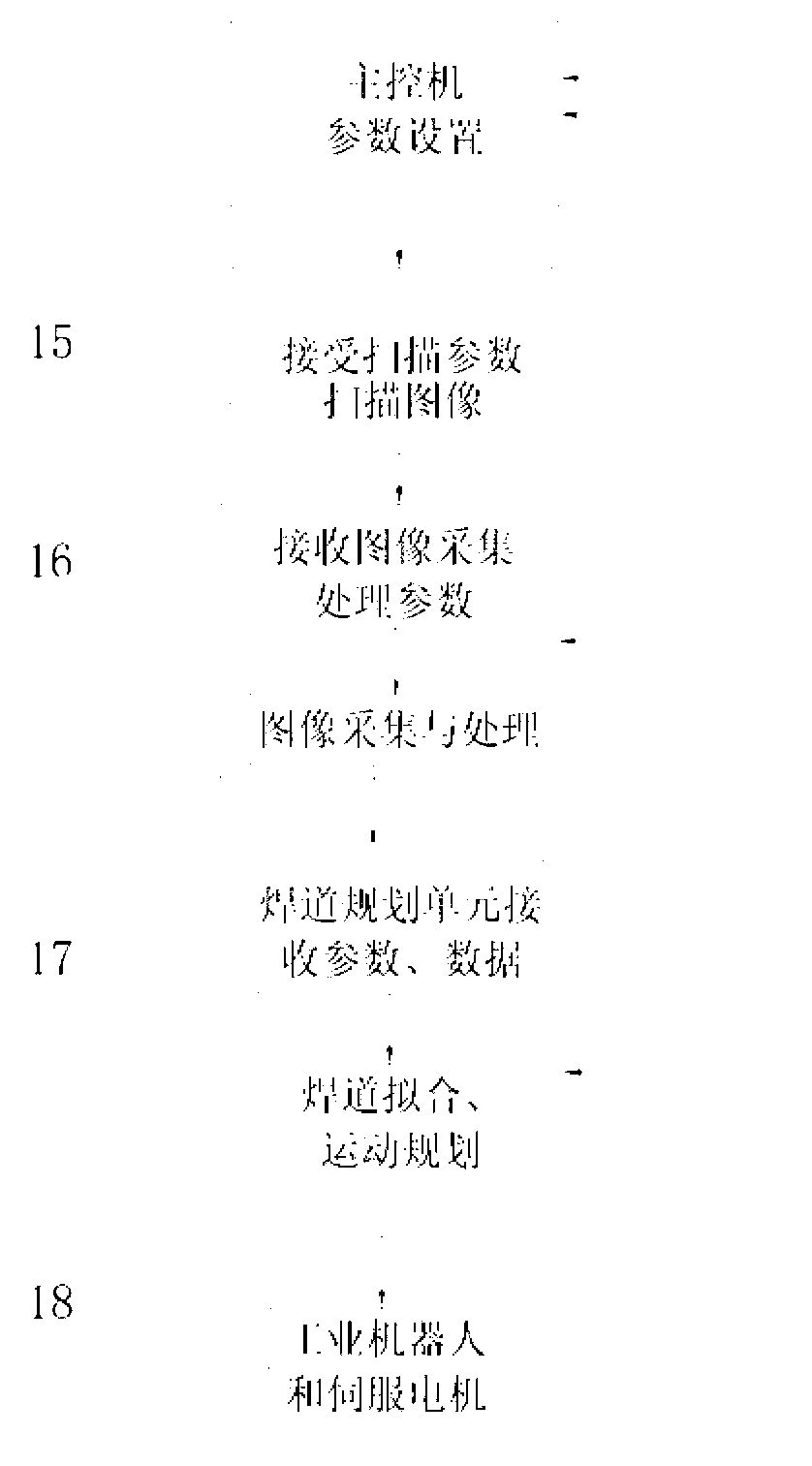

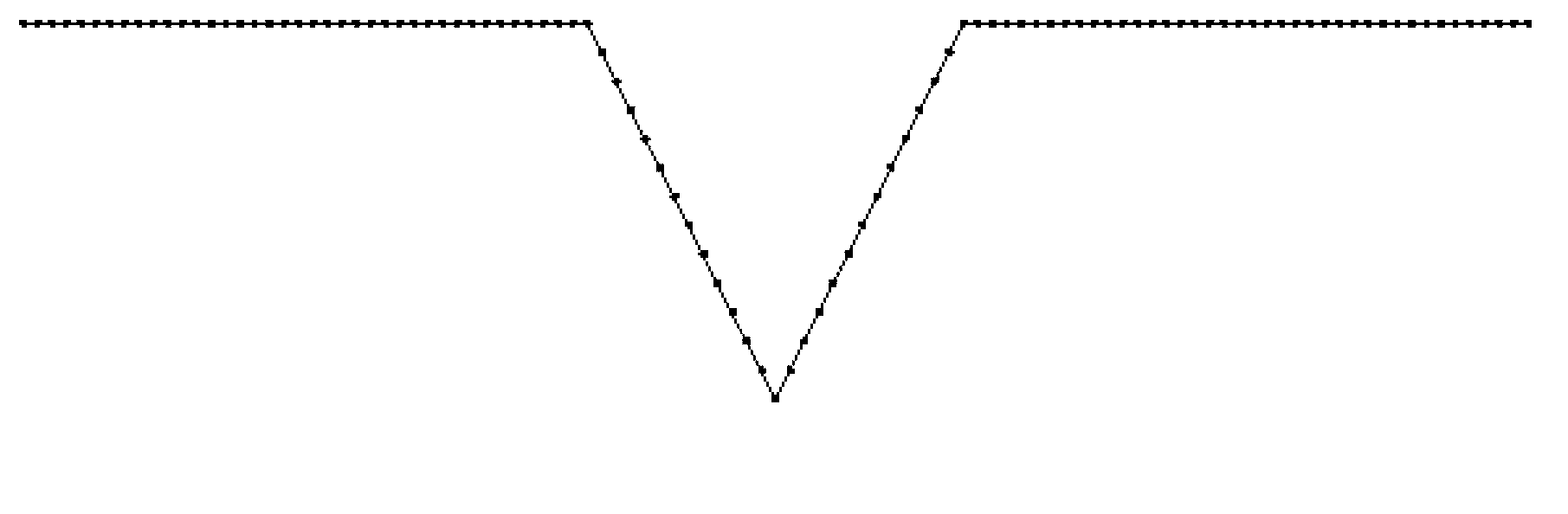

Scanning type laser vision sensing-based narrow-gap deep-groove automatic laser multilayer welding method for thick plate

InactiveCN102699534AImprove portabilityIncrease flexibilityLaser beam welding apparatusThick plateImaging algorithm

The invention discloses a scanning type laser vision sensing-based narrow-gap deep-groove automatic laser multilayer welding method for a thick plate, relates to a welding method, and aims to solve the problems that the conventional structured light vision sensing-based welding method can only be used for a simple shallow-groove laser weld seam tracking task and that when the conventional structured light vision sensing-based welding method is used for the narrow-gap deep-groove weld seam welding of the thick plate, a covering phenomenon is easily produced, the groove identification accuracy is lower, only real-time weld seam alignment calibration can be realized and narrow-gap deep-groove laser multilayer welding bead planning and welding cannot be realized. The method specifically comprises the following steps of: 1, selecting a groove form; 2, scanning a groove section image of a thick plate workpiece to be welded by using an image scanning unit; 3, processing the acquired groove section image by using an image algorithm to obtain weld seam image data; 4, performing fitting calculation; and 5, finishing the welding of welding beads layer by layer. The method is used for the deep-groove weld seam welding of the thick plate.

Owner:HARBIN INST OF TECH

Device and method for monitoring a welding area and an arrangement and a method for controlling a welding operation

InactiveUS7766213B2Great amount of detailed information and precisionImprove welding qualityAutomatic control devicesPrecision positioning equipmentBand-pass filterUltraviolet radiation

Method and device (2) for monitoring a welding area of an object (14) in connection with welding, which device includes arrangements (3) for reproduction of the welding area, at least one filter (4) arranged in front of or in the reproduction arrangement (3), and an illumination arrangement (5) of the welding area with ultraviolet radiation. The filter (4) consists of a band-pass filter which is adapted for filtering around a wavelength within the ultraviolet wavelength range.

Owner:GKN AEROSPACE SWEDEN AB

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

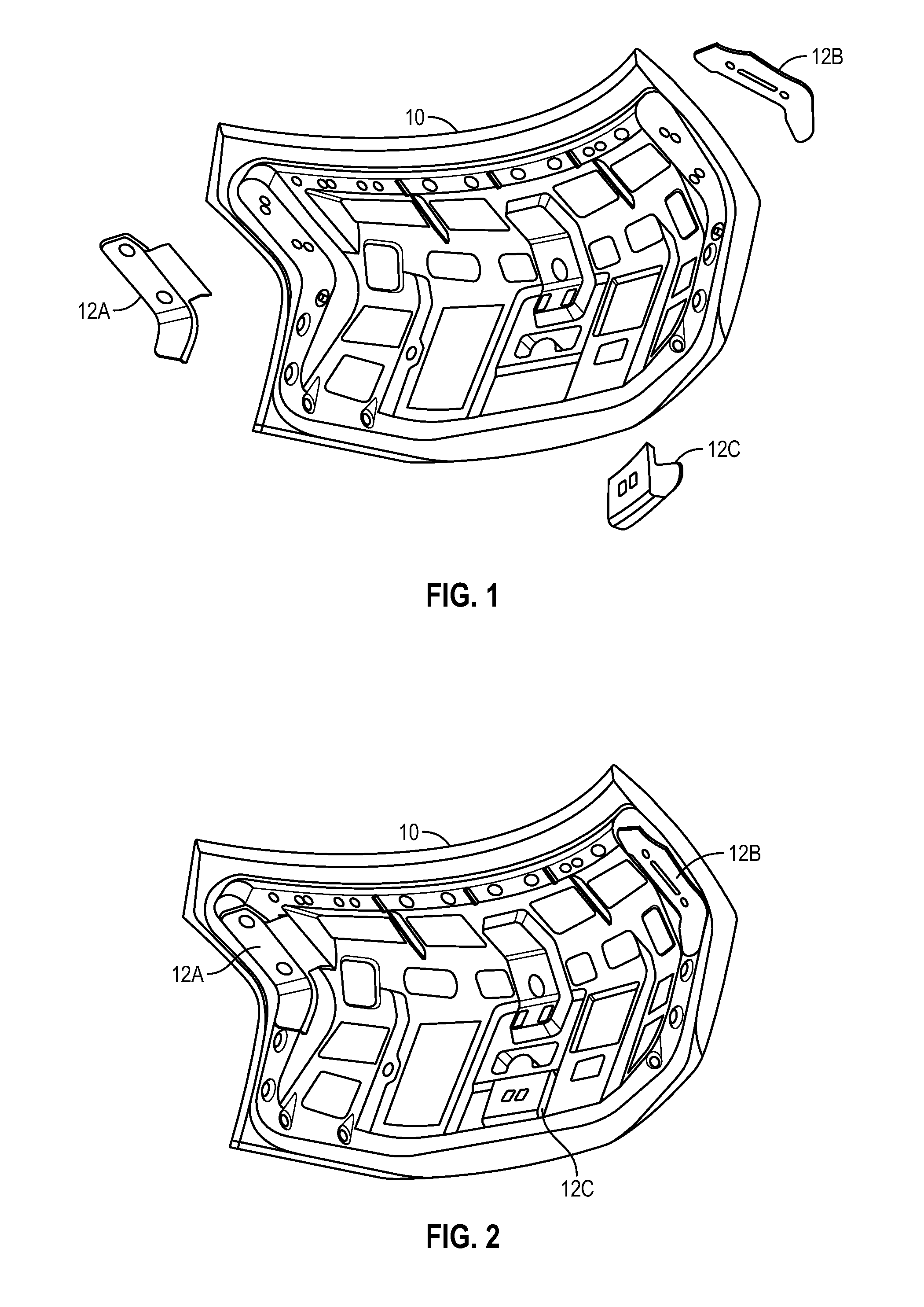

System and method for fixtureless component location in assembling components

InactiveUS20150336271A1Quality improvementReduce porosityProgramme-controlled manipulatorAdhesive processesRobotic systemsEngineering

A system for assembling a first component and a second component comprises a support operatively supporting the first component without any fixtures, a vision system configured to view the supported first component and the second component and determine the locations thereof, a robotic system configured to move and position the second component relative to the first component, and a controller operatively connected to the vision system and to the robotic system and operable to control the robotic system to position the second component relative to the first component based on the locations determined by the vision system. Various methods of assembling the first component and the second component are provided to create a process joint prior to creation of a structural joint in a subsequent assembly operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

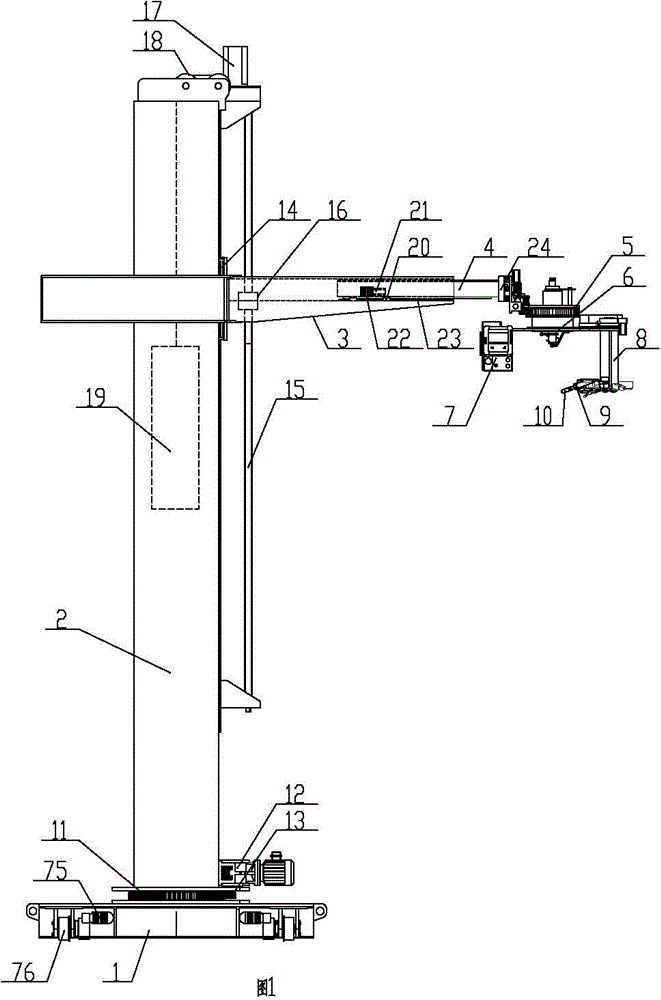

Multifunctional single-cantilever cutting and welding integrated machine

InactiveCN104308333AAvoid frequent movementReduce the number of card positioningWelding/cutting auxillary devicesAuxillary welding devicesFillet weldEngineering

The invention relates to the technical field of automated cutting and welding, and discloses a multifunctional single-cantilever cutting and welding integrated machine. The integrated machine comprises a machine frame base, a machine frame stand column, a stand column rotary device, a vertical lifting device, a machine frame transverse arm, a left-right translation device, a telescopic arm, a front-rear transverse moving device and a multi-joint machine head, wherein the machine frame stand column is mounted on the machine frame base through the stand column rotary device, and the machine frame transverse arm is mounted at the upper part of the machine frame stand column through the vertical lifting device. The integrated machine is reasonable and compact in structure and convenient to use; the welding of longitudinal, circumferential and fillet weld seams, cutting of an intersecting line hole and automatic welding of a saddle-shaped weld seam between a barrel body and a connecting pipe can be finished in a relatively fixed station through the stand column rotary device, the vertical lifting device, the left-right translation device, the front-rear transverse moving device and the multi-joint machine head, the frequent motion of a workpiece can be avoided, the clamping and positioning frequency of the workpiece is greatly reduced, the welding efficiency and quality are remarkably improved, and the labor intensity of welding workers is reduced.

Owner:新疆威奥科技股份有限公司

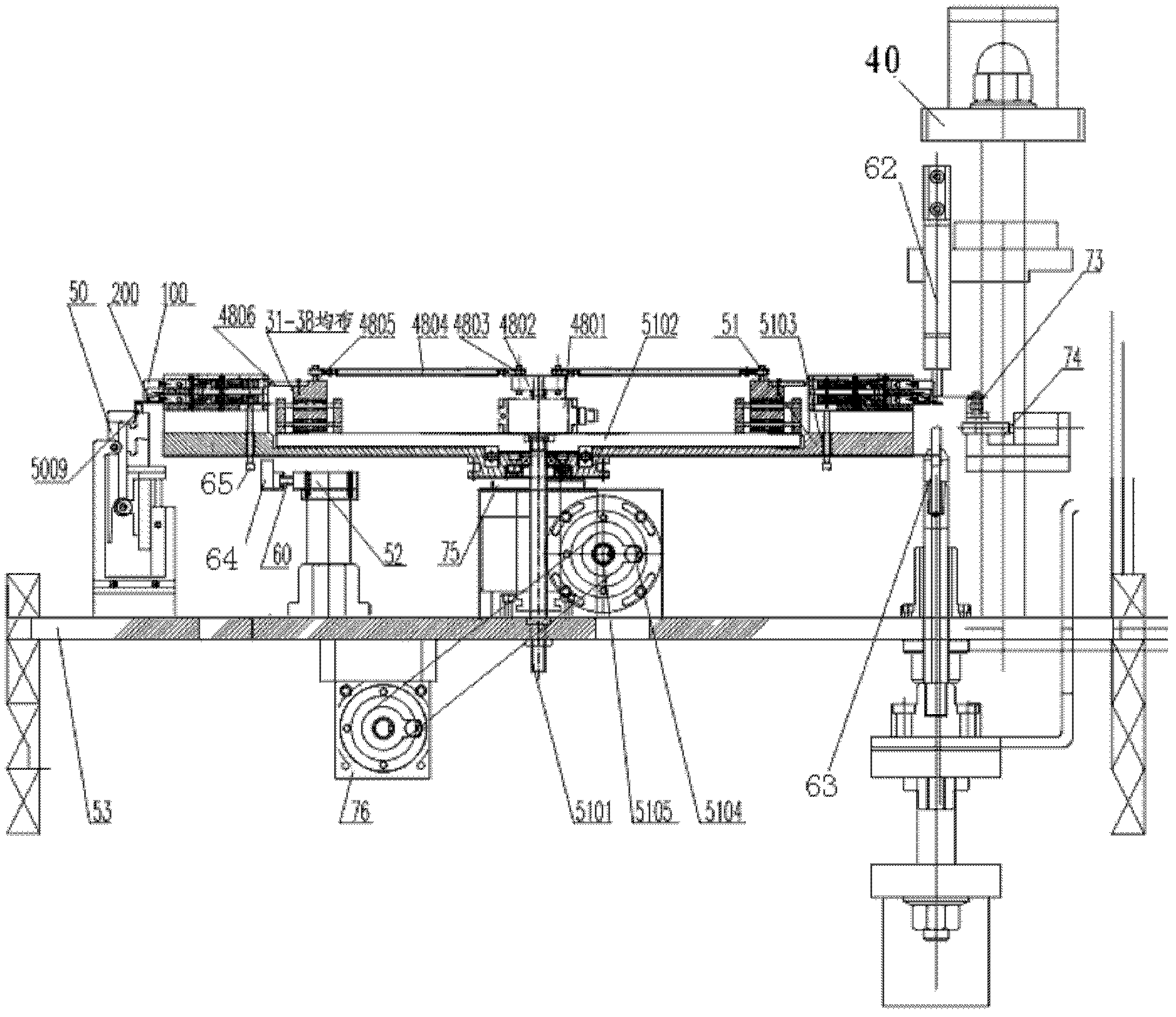

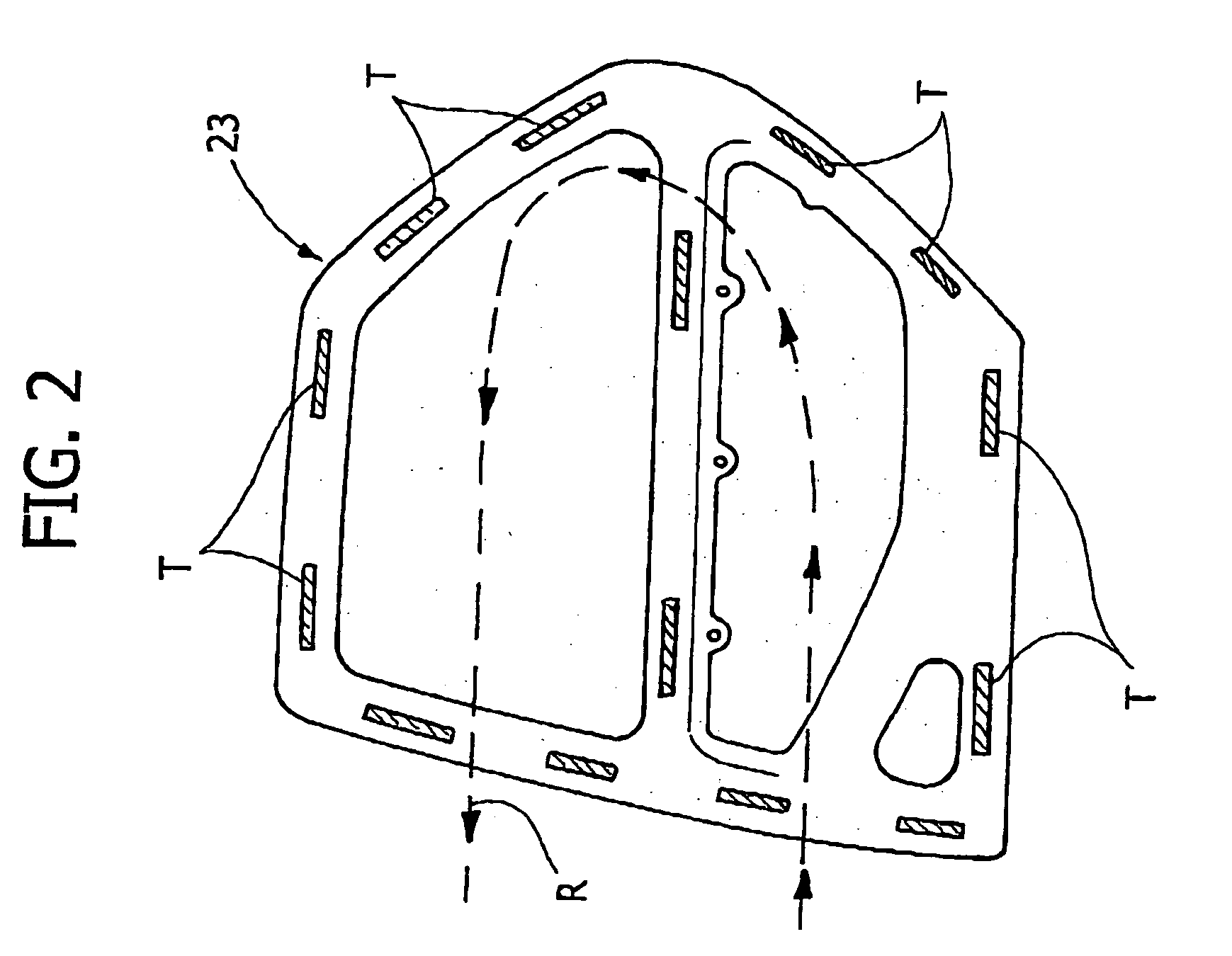

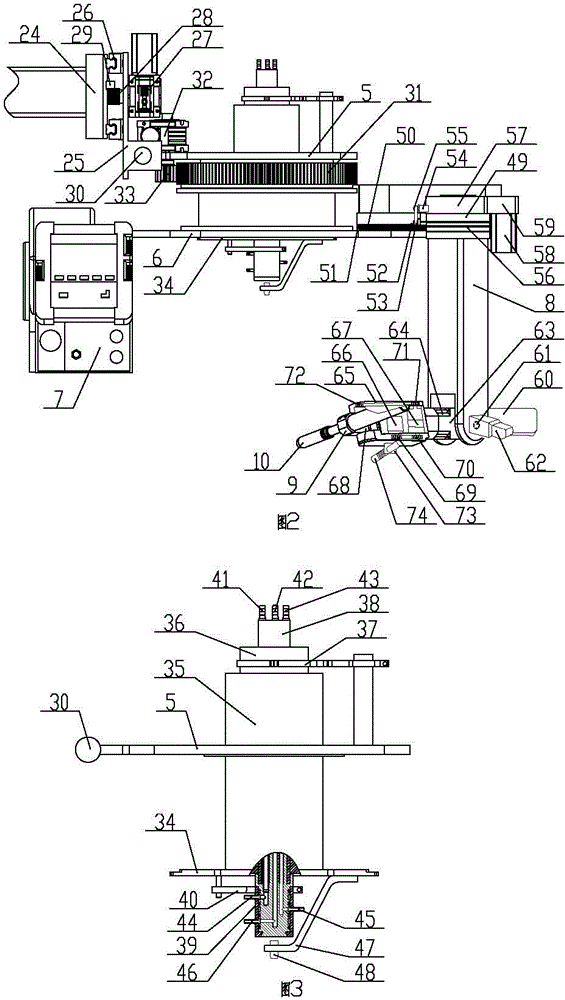

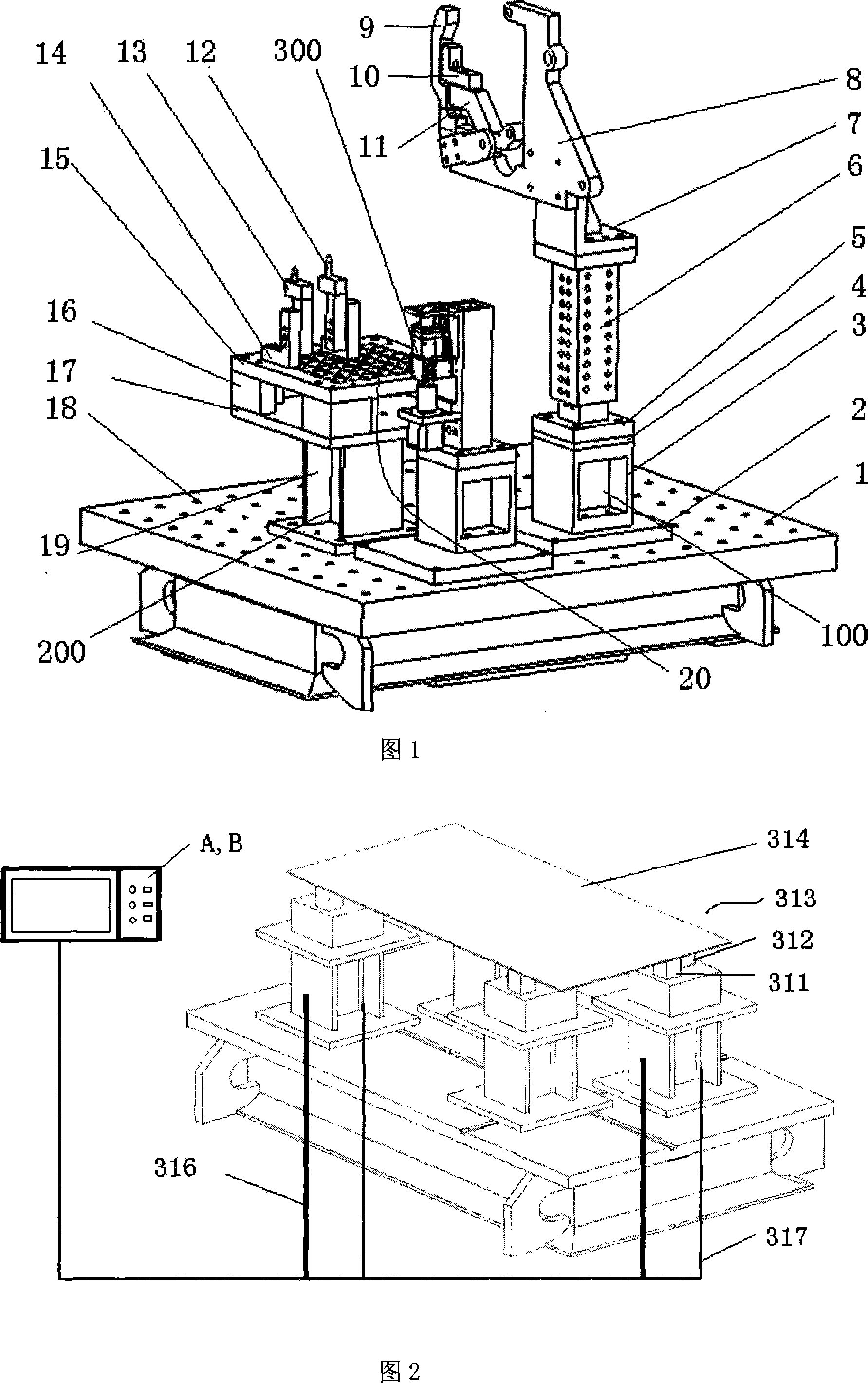

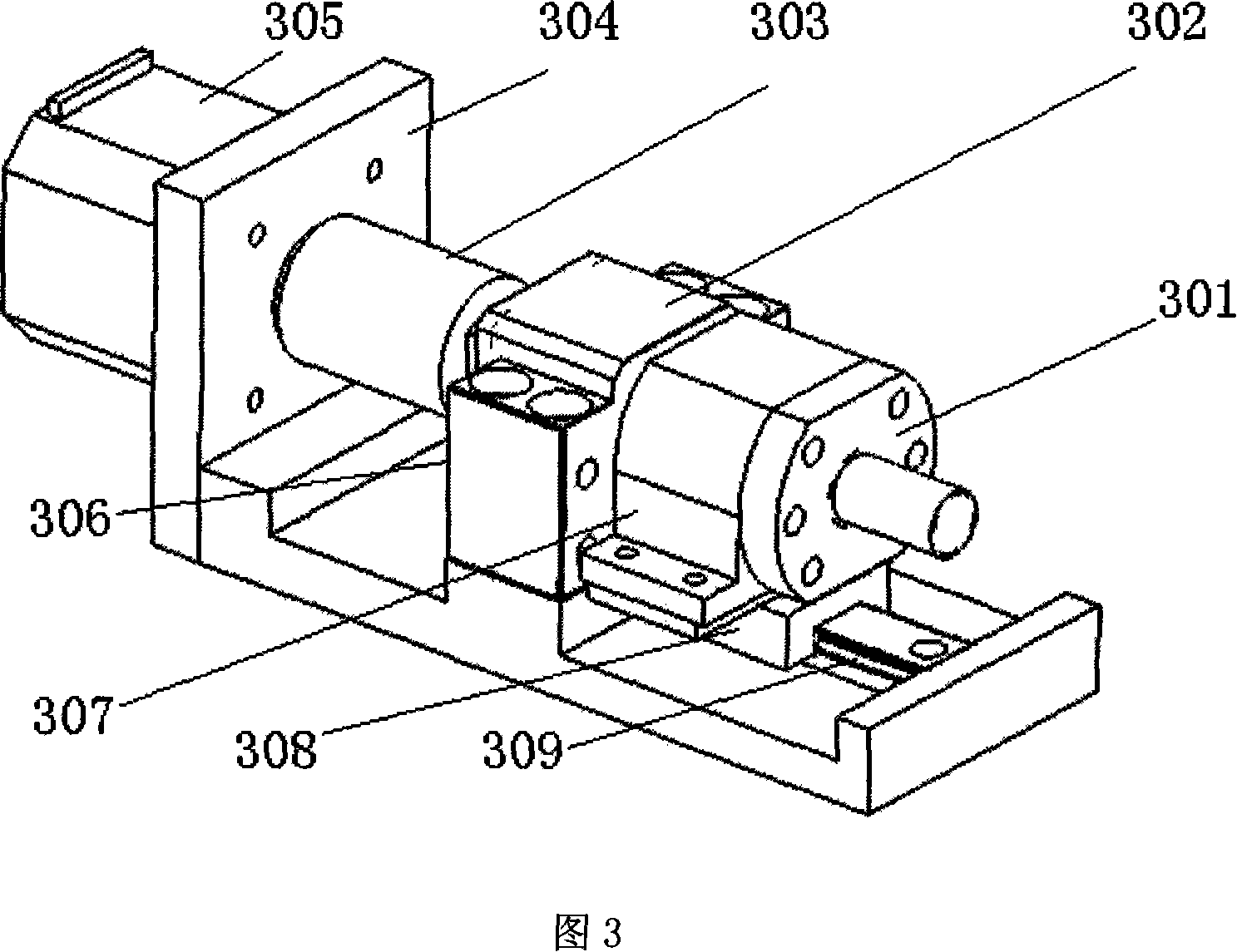

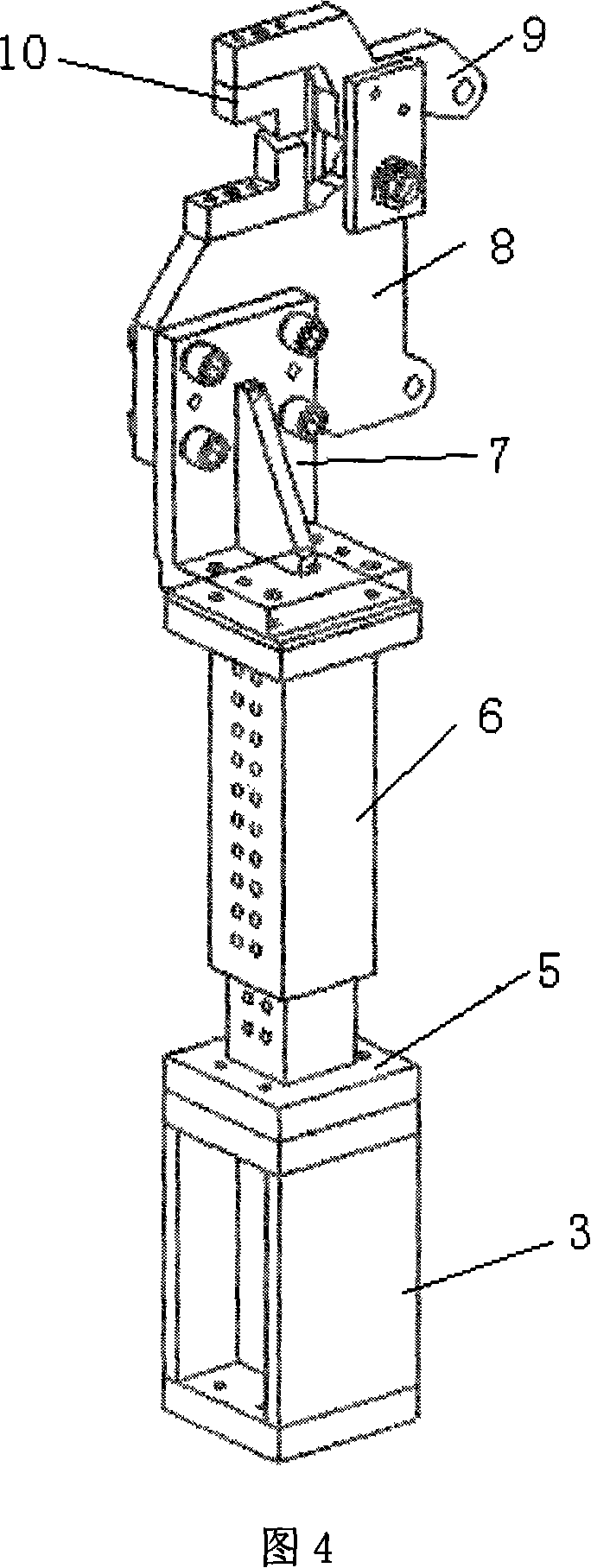

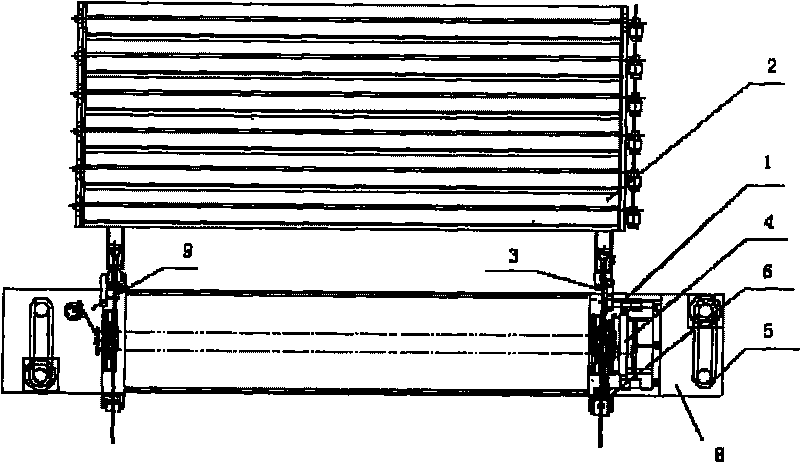

Modular self-adaptive regulation clamp to weld car and its regulating method

InactiveCN101104233AEasy to connectImprove flexibilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSelf adaptive

The invention relates to a modularizing self-adaptation adjusting clamp used in the automobile welding, comprising a based station(1), a clamping mechanism(100) fixed on the based station(1) , an independent principal positioning mechanism(200), and an online real-time detecting and self-adaptation adjusting device(300). The online real-time detecting and self-adaptation adjusting device (300) is composed of a stepping motor (305), a slider (308), a straight-line guiding rail (309) and a transmission device. The transmission device, which is driven by the stepping motor (305), pushes a pushing rod (301) and the slider to slide along the straight-line guiding rail (309). The invention is more flexible and is convenient for the connection and combination of every component by means of modularized, standardized and serialized clamp elements, can be adapted to various work within a certain range and type, can effectively reduce the manufacturing cost, effectively controls the precision of the key points of workpieces and improves the welding quality and efficiency.

Owner:DONGHUA UNIV

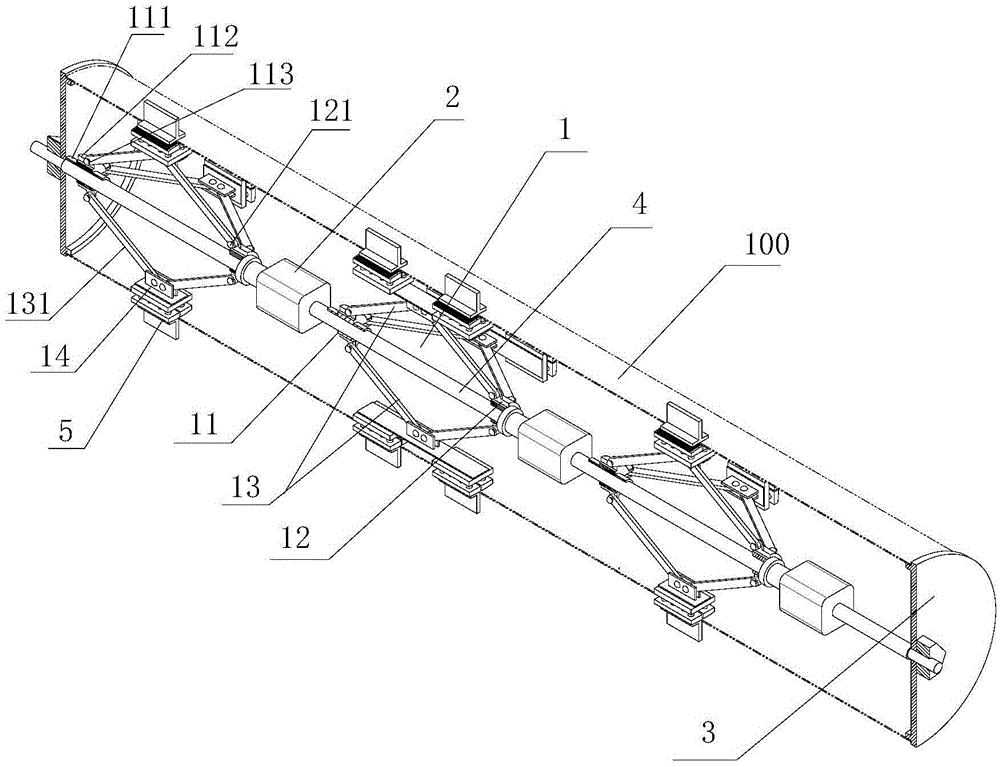

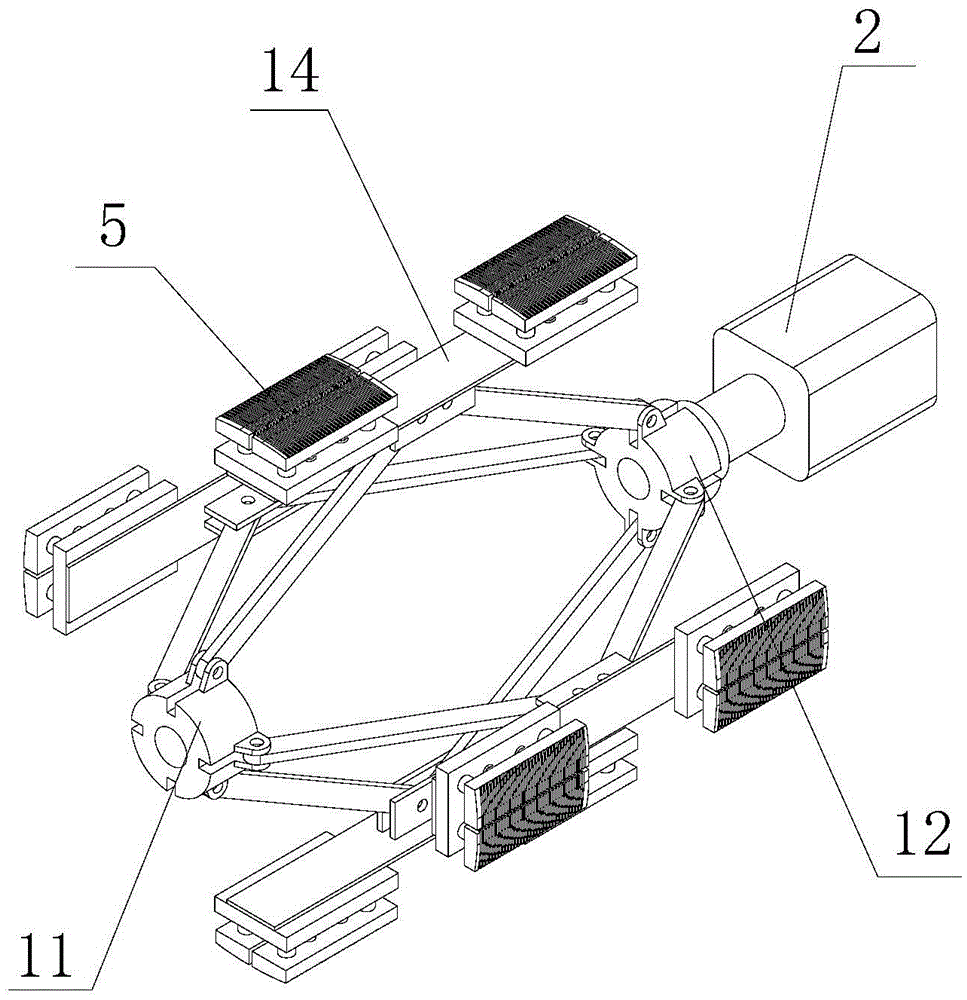

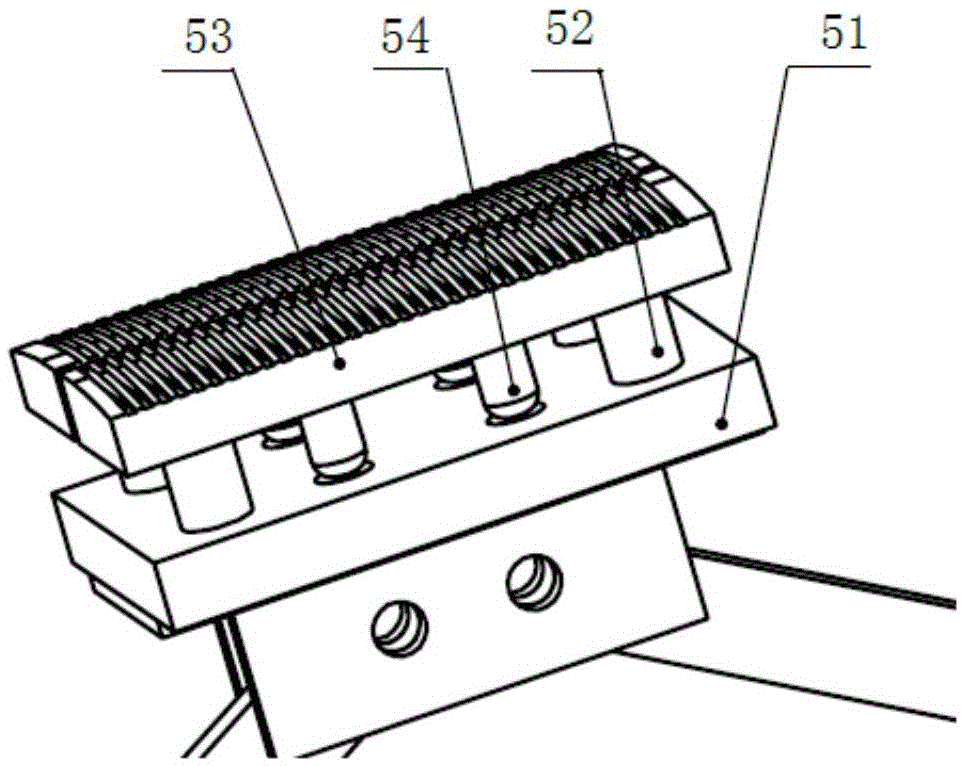

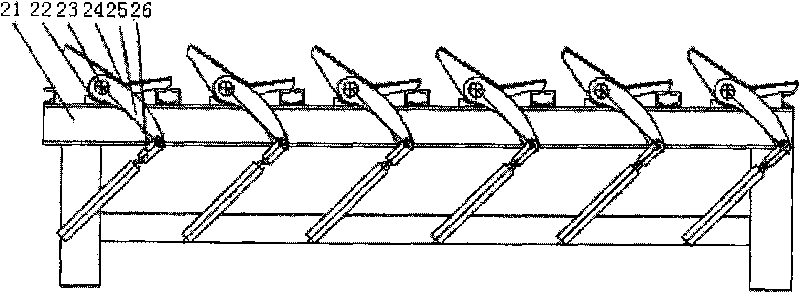

Rhombic internal support clamp for round pipe welding

ActiveCN105598631ASolve protection problemsImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesDiagonalThermal deformation

The invention discloses a rhombic internal support clamp for round pipe welding. The rhombic internal support clamp comprises at least one rhombic internal support unit, push cylinders corresponding to the rhombic internal support units one to one, two end covers, a main shaft and a plurality of pressing back-blowing modules, wherein the main shaft is arranged at the center of a round pipe, and both ends of the main shaft are respectively fixed in the centers of the two end covers; each push cylinder is fixedly arranged on the main shaft; each rhombic internal support unit comprises a positioning ring, a movable ring and at least one rhombic supporting frame; the positioning rings fixedly sleeve the main shaft; the movable rings sleeve the main shaft and can move back and forth along the main shaft along with the pushing of the corresponding push cylinders; one pair of diagonals of each rhombic supporting frame is respectively hinged to the corresponding positioning ring and the corresponding movable ring, and the other pair of diagonals of each rhombic supporting frame is respectively hinged to two supporting platforms; at least one pressing back-blowing module is fixed on each supporting platform. According to the rhombic internal support clamp, the internal protection problem for pipe welding is solved, the quality of welds is improved, and thermal deformation is relieved.

Owner:SHANGHAI PURUIMA INTELLIGENT TECH CO LTD

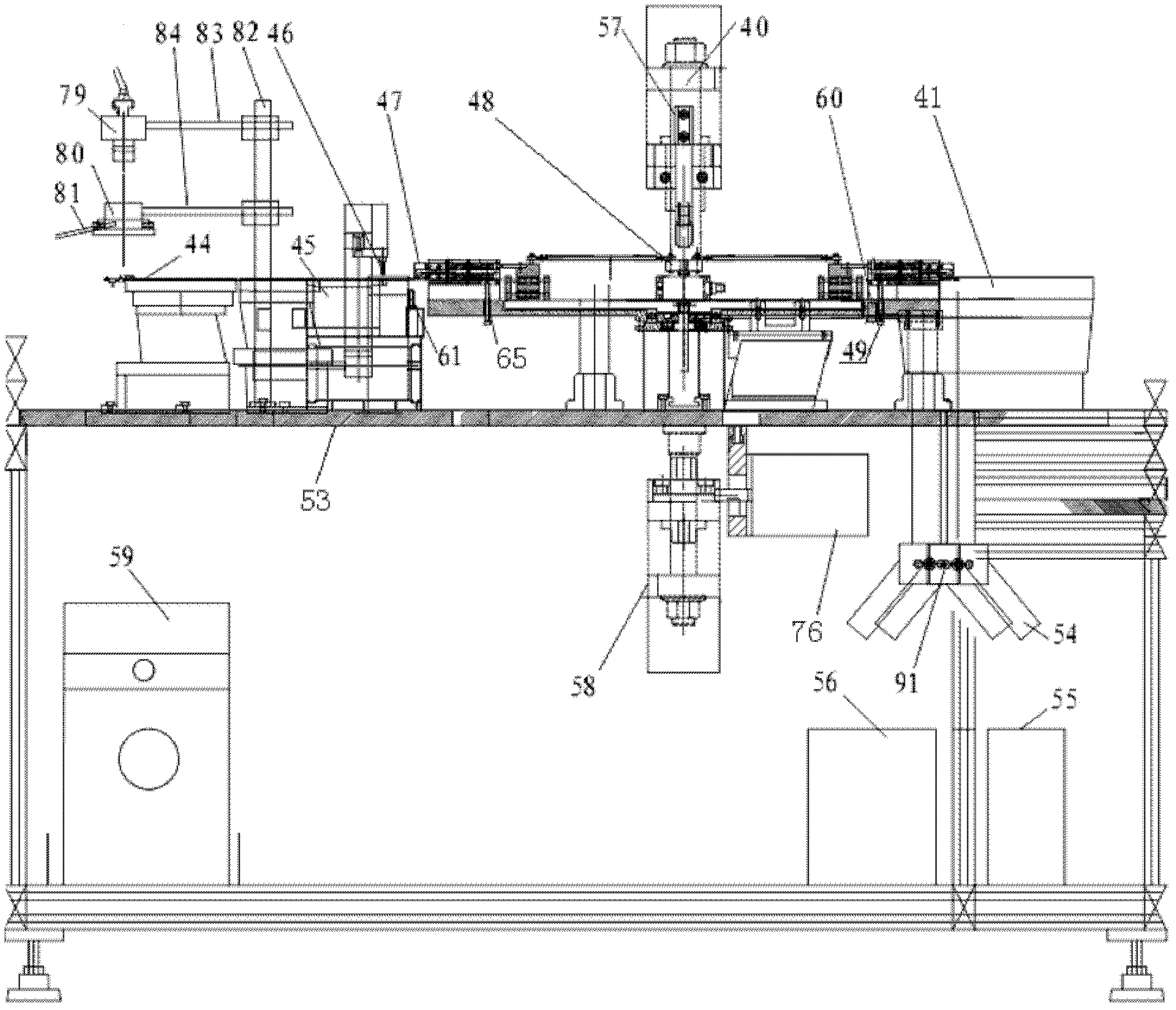

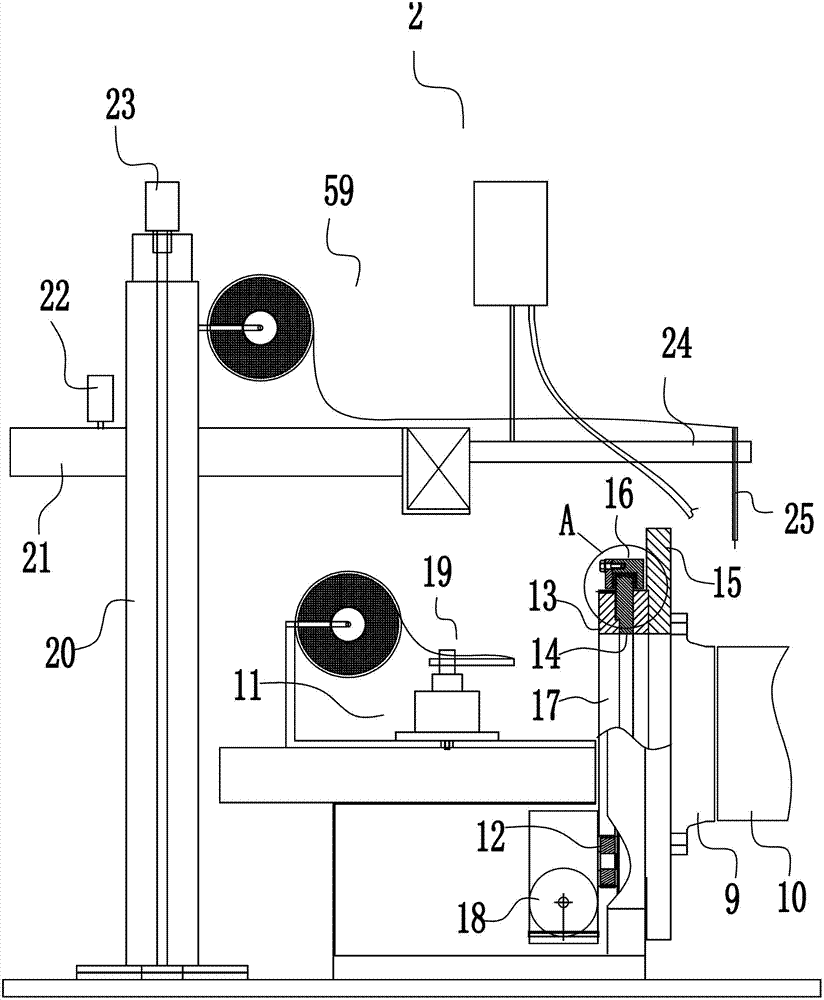

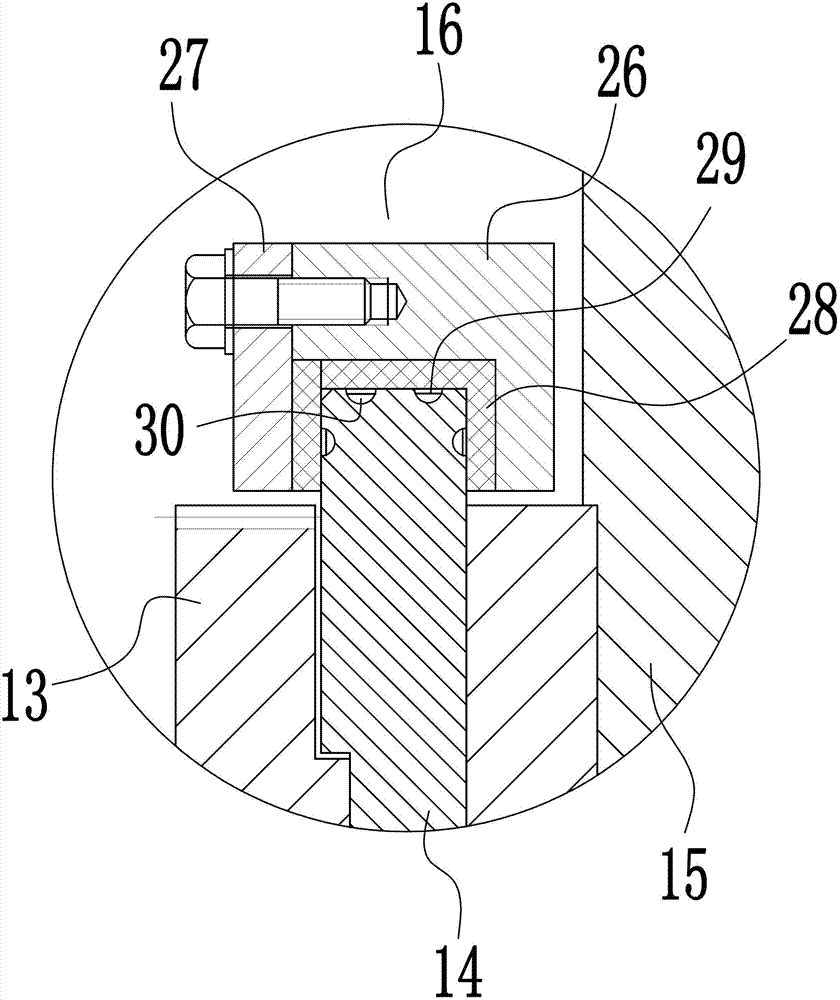

Pipe-flange automatic welding equipment

ActiveCN101733593AReduce labor intensityIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyWorking environment

The invention discloses pipe-flange automatic welding equipment, which comprises a machine frame. The pipe-flange automatic welding equipment is characterized in that the machine frame is provided with a rack conveyor and also provided with a feeding positioning device, a clamping rotating device, a discharging device and a welding device. In the invention, the conventional welding processing mode which is operated manually and performs production discretely is converted into the automatic welding production mode which runs in a continuous production line, so the production efficiency and the welding quality of the product are improved, the working environment is improved, the labor intensity of workers is reduced and the level of ship-manufacturing technology can be improved.

Owner:上海中船临港船舶装备有限公司 +1

Method for welding thin steel plate

InactiveCN101745718AAvoid deformationShort production cycleArc welding apparatusSteel platesSheet steel

The invention discloses a method for welding a thin steel plate. The method is characterized by comprising the following steps: preparing before welding, namely flattening the plate before assembly to flatten the surface of the plate; flattening a profile before assembly; and machining edge-board blanking by adopting an edge planer or cutting the blanking by plasma to ensure uniform assembly clearance. During arc welding of the jointed plate, the assembly clearance is less than 0.5 millimeters; the misalignment edge e of the plate edge is less than 0.15t, and the nonuniform or out-of-tolerance local clearance is polished or cut to be smooth without deformation due to the adoption of oxy-acetylene cutting, wherein the t is less than or equal to 8 millimeters; the three parts of positioned welding and welding are reasonably designed, so the welding of the thin steel plate has a complete system; therefore, the method can effectively prevent the thin steel plate of a ship deck from deforming during welding, and achieves the targets of short production period and good thin plate welding quality.

Owner:浙江东海岸船业有限公司

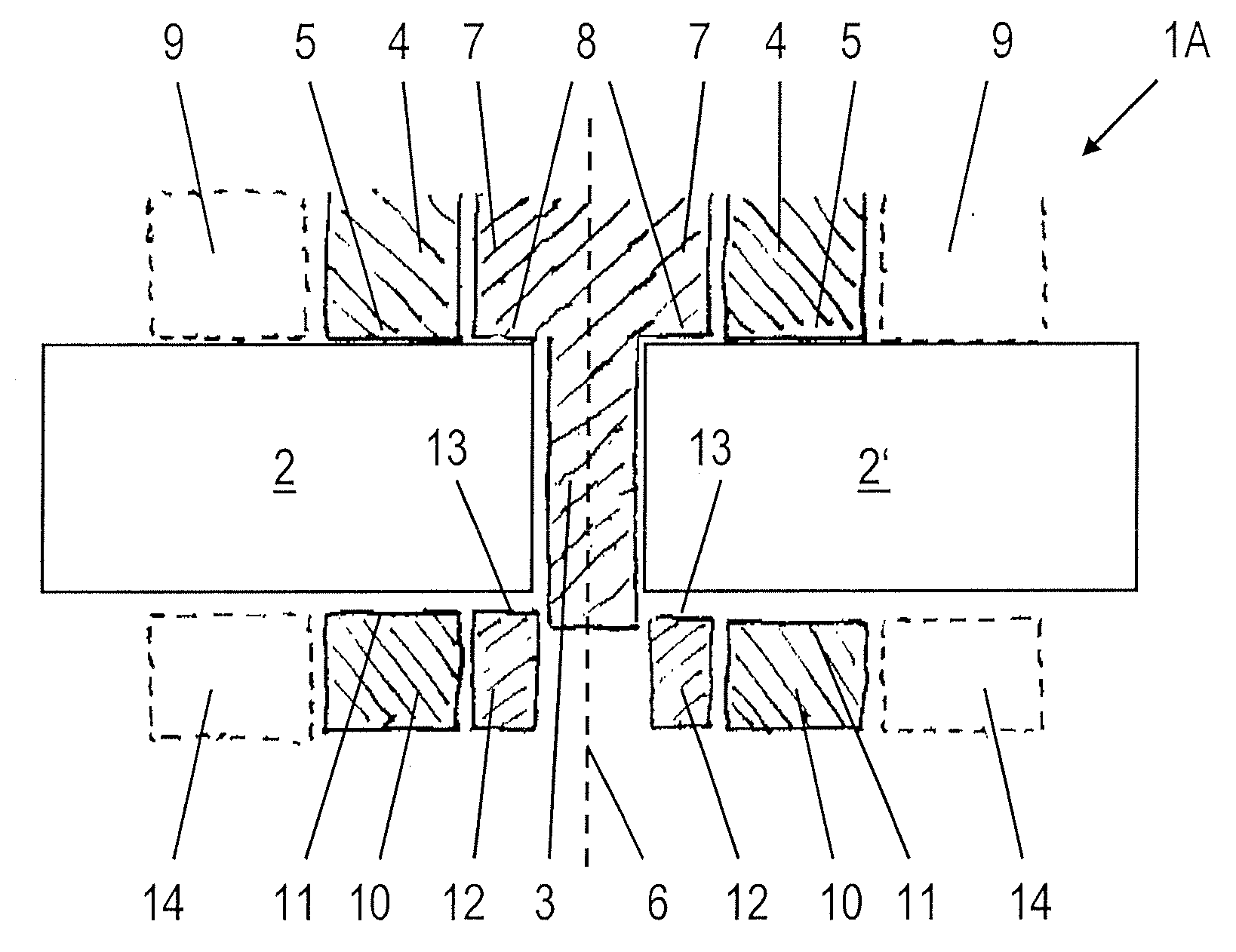

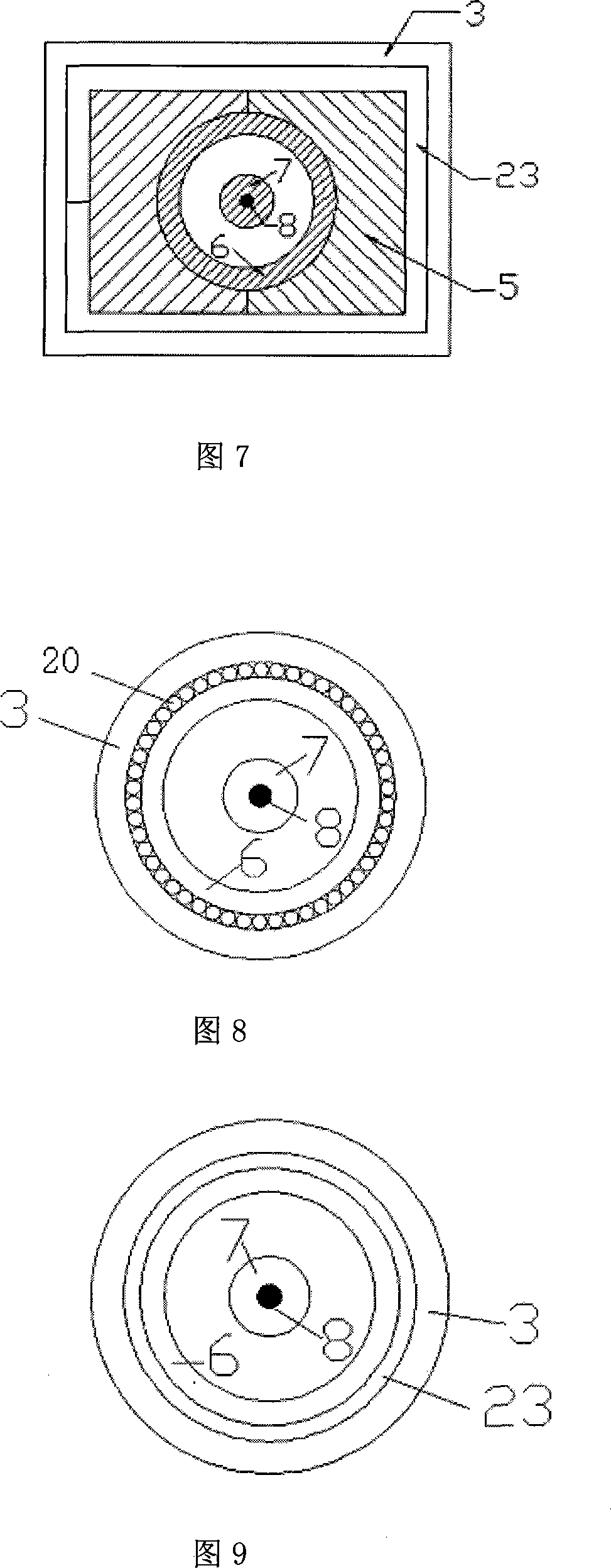

Friction stir welding appparatus

InactiveUS20060289604A1Small sizeMuch successWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

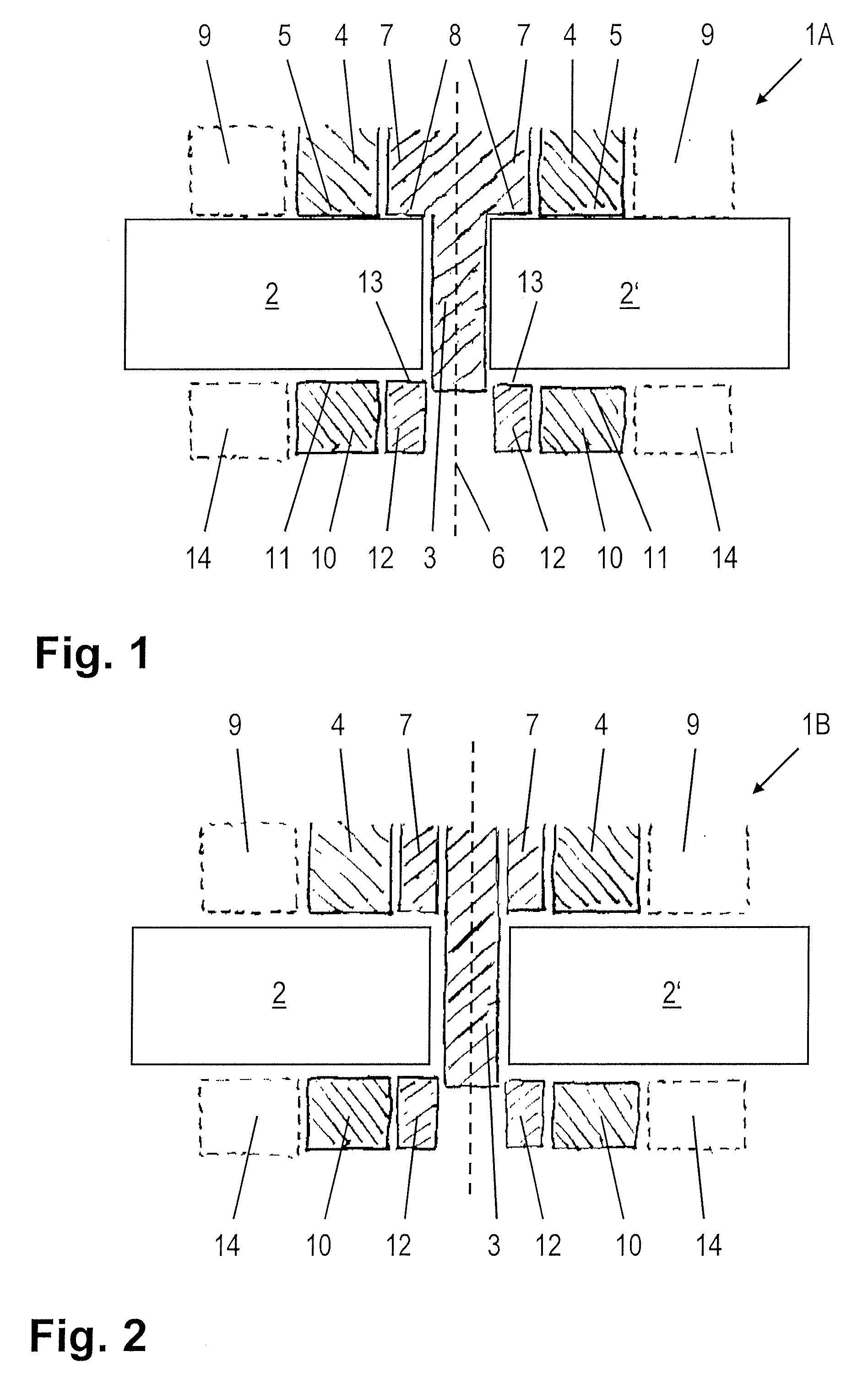

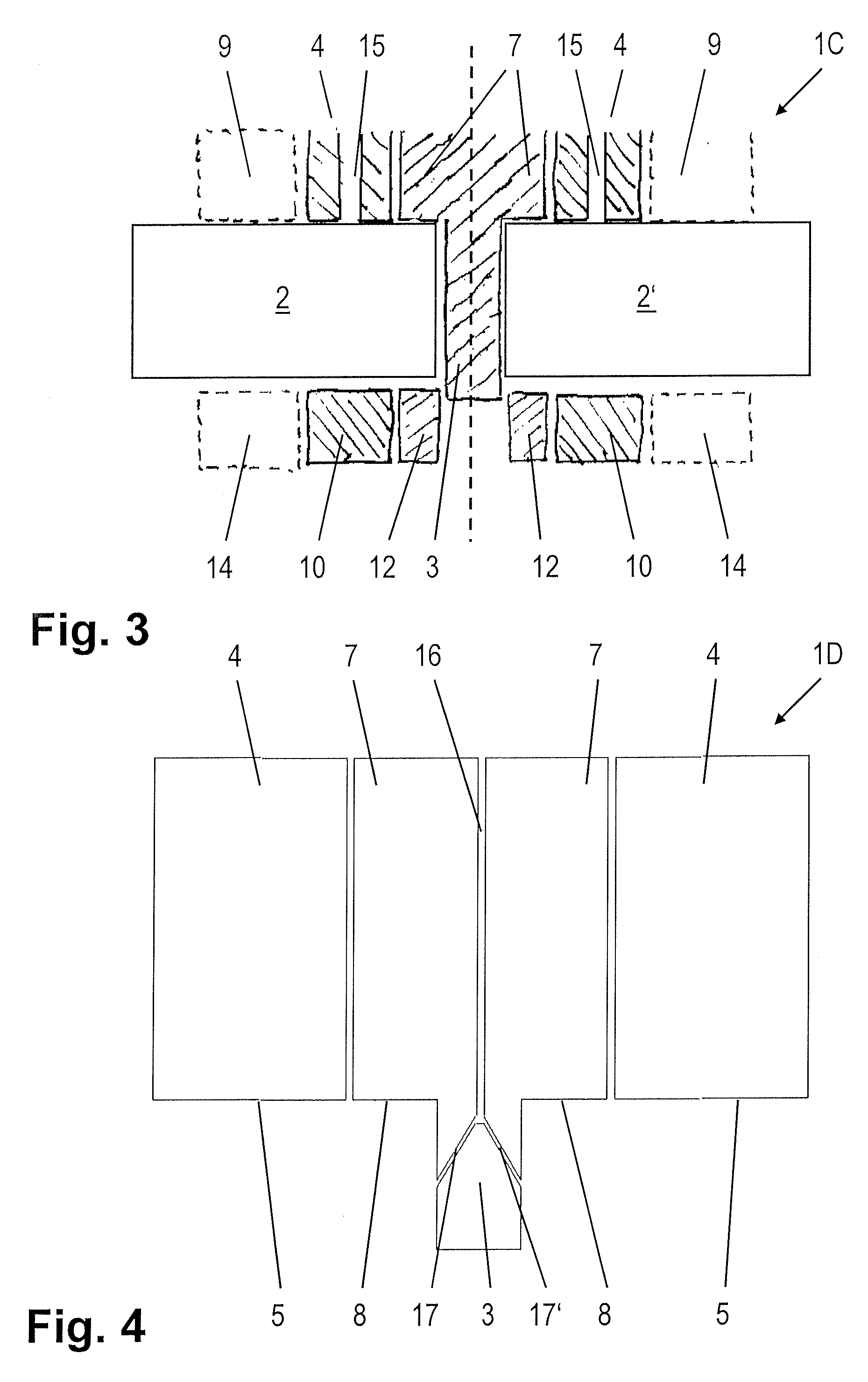

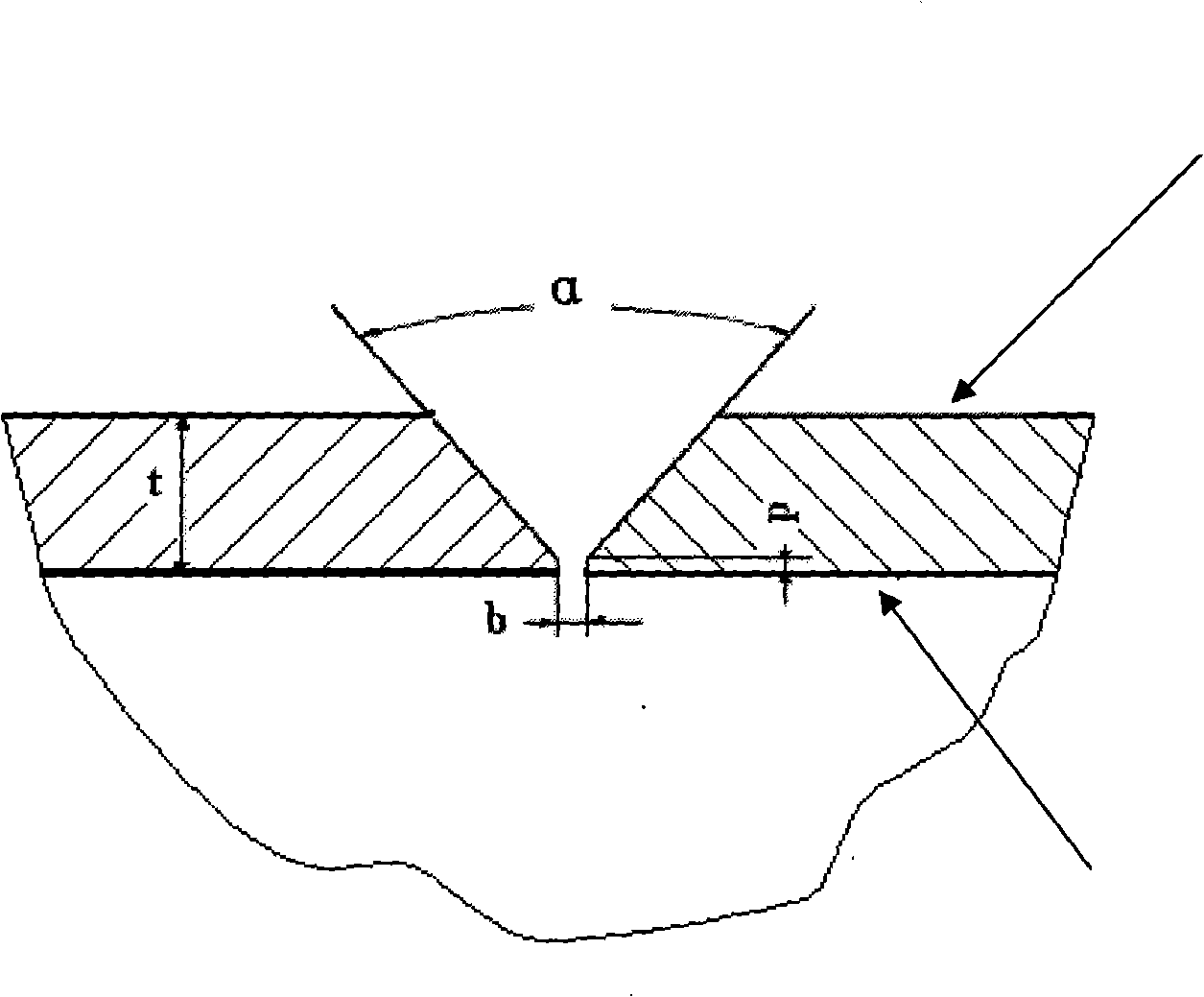

The invention illustrates and describes an apparatus for friction stir welding, having a pin (3) and a first friction surface segment (4), the pin (3) and the first friction surface segment (4) being rotationally driven about an axis of rotation (6), and the first friction surface segment (4) having a first friction surface (5) for resting on a workpiece (2). The object of providing a friction stir welding apparatus which can be used to better set the energy which is introduced into the workpiece by way of the friction between pin and friction surface, on the one hand, and workpiece, on the other hand, is achieved by virtue of the fact that a first inner segment (7) is provided, having a first inner friction surface (8) for resting on a workpiece (2, 2′), that the first inner segment (7) surrounds the pin (3), that the first friction surface segment (4) surrounds the first inner segment (7), and that the first friction surface segment (4) is rotationally driven independently of the first inner segment (7).

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

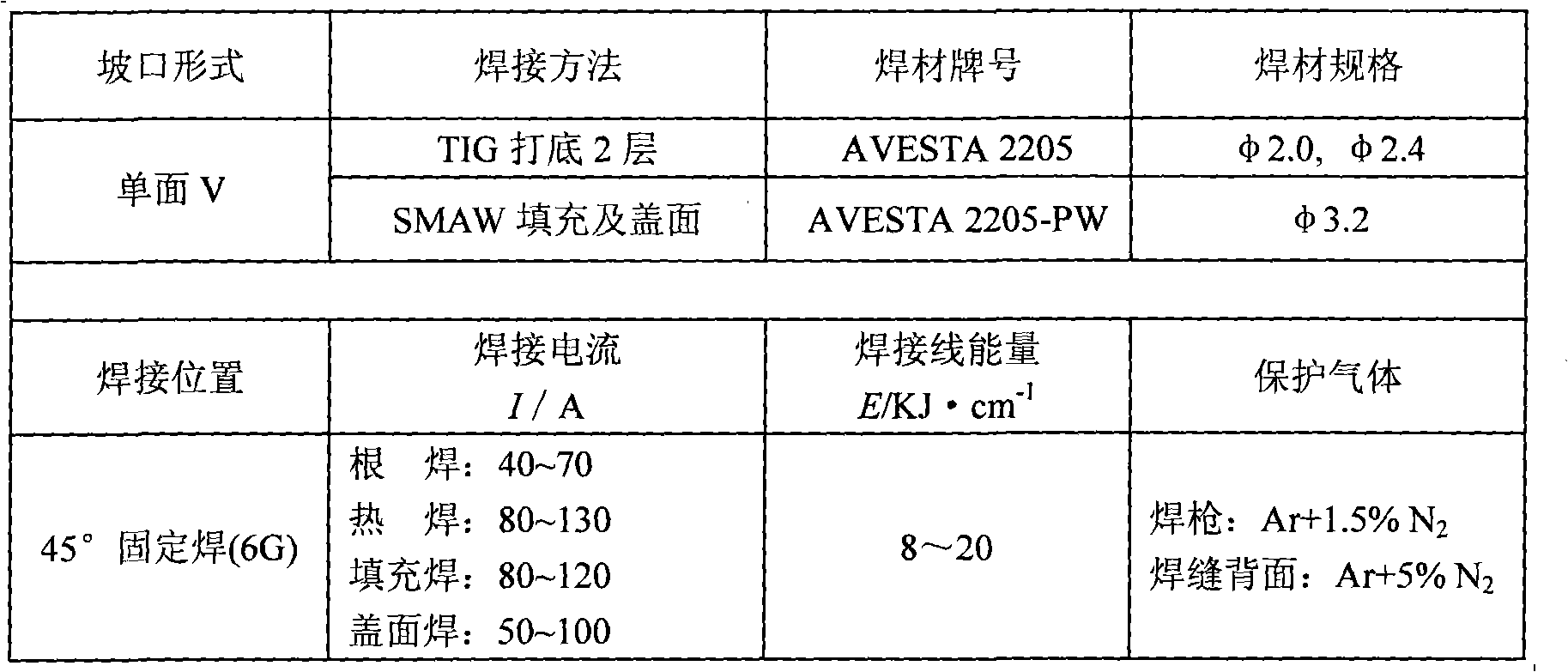

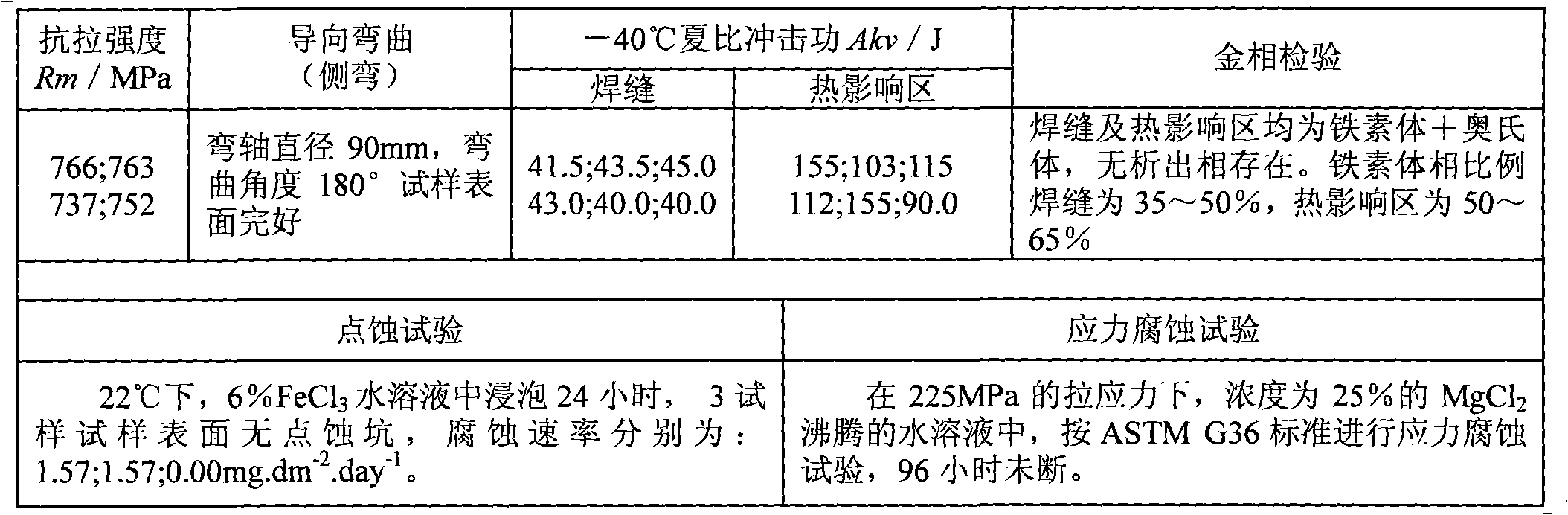

22Cr duplex phase stainless tube welding method

InactiveCN101288918AImprove tensile propertiesImprove low temperature impact toughnessWelding/cutting media/materialsWelding/soldering/cutting articlesMicrostructurePitting corrosion

The invention relates to a welding method of 22Cr duplex stainless steel corrosion resistant alloy pipe, which adopts a gas mixture of 99.995 percent pure Ar and 98 to 99 percent Ar plus 2 percent N2 or a gas mixture of 90 to 95 percent of N2 plus 5 to 10 percent H2 to weld the two laterals within the range equal to or more than 100mm inside the pipe; back welding, fill welding and cap welding are implemented when the oxygen content is equal to or less than 50ppm; the welding and filling metal deposit includes the following components according to the weight percentage: C is equal to or less than 0.04, Cr is 22.0 to 23.5, Ni is 8.5 to 10.5, Mo is 3.0 to 3.5, Mn is 0.5 to 2.0, Si is equal to or less than 0.9, P is equal to or less than 0.04, S is equal to or less than 0.03, N is 0.15 to 0.20 and Cu is equal to or less than 0.75. A balanced austenitic-ferritic microstructure is obtained with good joint tensility and low-temperature shock toughness, as well as good corrosion performances of anti-pitting corrosion of chloride, stress corrosion and simulated environment medium corrosion resistance.

Owner:CNPC TUBULAR GOODS RES INST

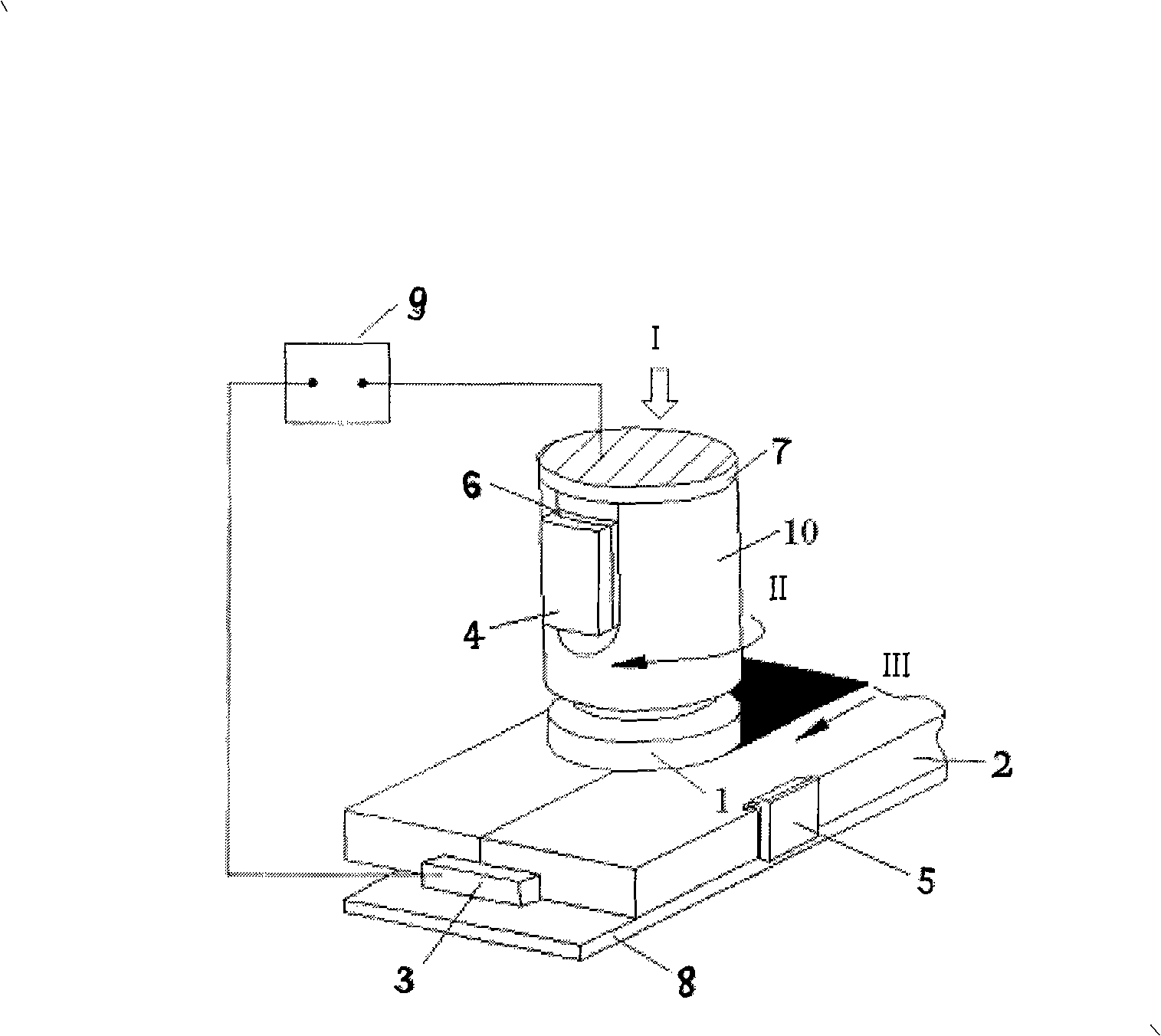

Electric conduction-stirring friction composite heat power supply welding method and equipment

ActiveCN101323054AOvercoming a lack of energy inputBreak through limitationsResistance welding apparatusNon-electric welding apparatusEngineeringWeld seam

The invention discloses a conducting-stirring friction hybrid heat source welding method and a piece of equipment, wherein, in stirring friction welding, a stir head and a workpiece are simultaneously insulated from the main body of a welding machine, the clamp of a fixed workpiece and a worktable, current is galvanized in the weld seam direction of the workpiece, the current and the weld seam through which the current flows produce resistance heat with the contact resistance of a friction stirring welding area, and the resistance heat together with stirring friction heat forms the hybrid heat source of the stirring friction welding. The method and the equipment of the invention have the following remarkable effects: 1. the limitation of the stirring friction welding on welding materials is broken through, leading the stirring friction welding to be used for welding such structural materials as black ferrous metals, superalloy, and the like; 2. the service life of the stir head can be improved; and 3. welding speed and welding quality can be further improved, thus improving the mechanical property of a welding joint. The method and the equipment of the invention can be used for the stirring friction welding, the preheating before welding, and the postweld heat treatment of such structural materials as carbon steel, stainless steel, and superalloy, etc.

Owner:罗键

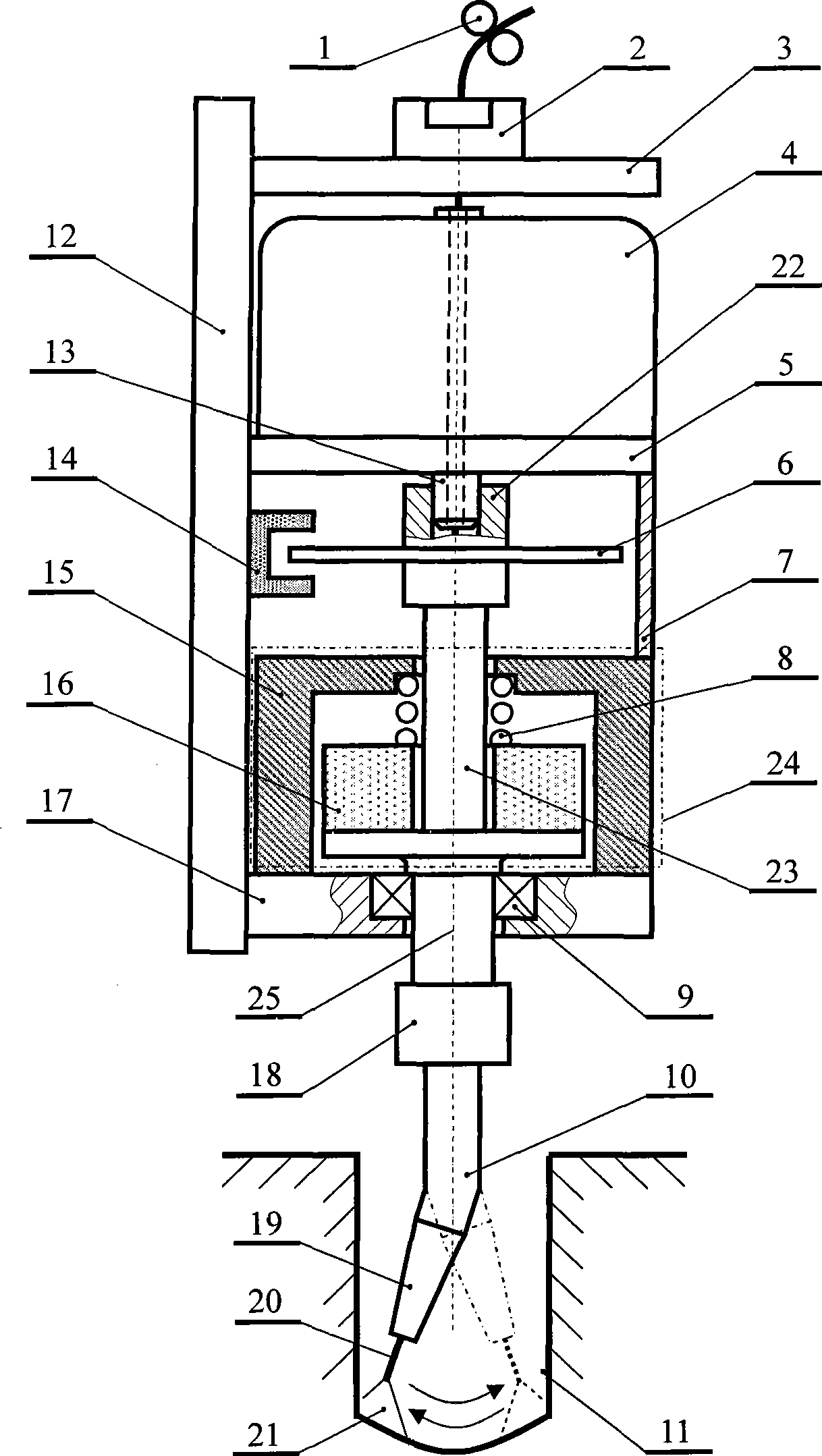

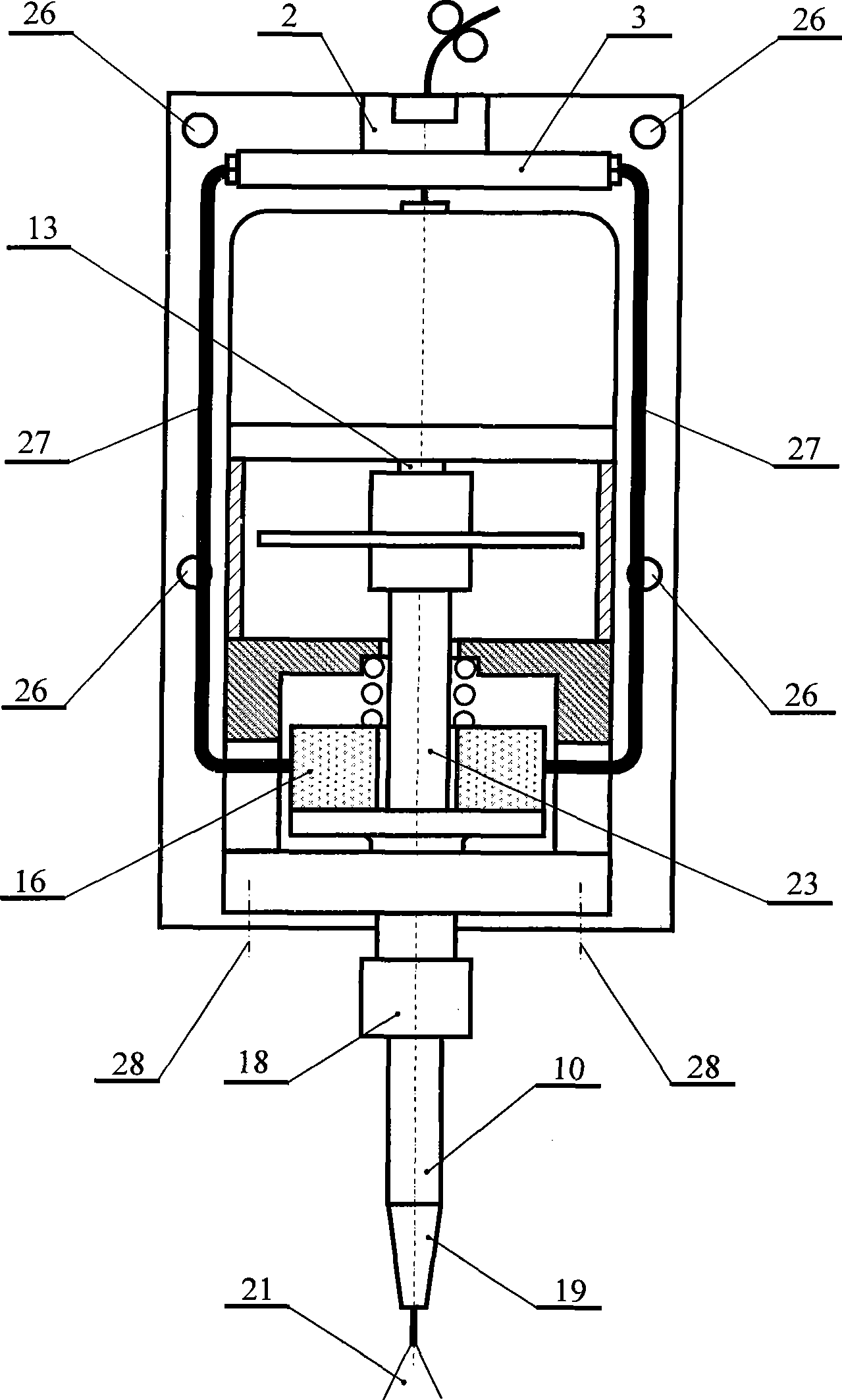

Method for welding rocking arc narrow clearance melting electrode with gas protection and welding torch

InactiveCN101412143AMeet the needs of different welding processes for weldsReduce drive powerElectrode supporting devicesCouplingEngineering

The invention discloses a rocking arc narrow gap consumable electrode gas shielded welding method and a welding torch. The method comprises the following steps: a connecting cable is fixed on an electric brush mechanism and a coupling head; a hollow shaft motor is connected with a straight conducting rod through a shaft joint; a welding wire passes through a center hole of a cable coupling head, and penetrates out a center hole of a current contact nozzle; the lower end of the straight conducting rod is fixed with a connecting piece; and one end of a minor bend conducting rod is connected with the straight conducting rod through the connecting piece, while the other end of the minor bend conducting rod is connected with the current contact nozzle. The hollow shaft motor directly drives the straight conducting rod and the minor bend conducting rod capable of extending into a divided edge of a workpiece to make reciprocating rotation around the central axial line of the welding torch, thereby driving electric arc of the end of the welding wire send from the center hole of the current contact nozzle to make arc rocking in the divided edge of the workpiece so as to realize rocking arc narrow gap welding. The welding torch has the advantages of simple and compact structure, low implementation cost, high reliability of operation, strong practicality, and can adapt requirement of welding process for mean position and spatial position with different welding seams. The welding wire has strong rocking regulation, good directivity of the electric arc, and high welding quality.

Owner:JIANGSU UNIV OF SCI & TECH

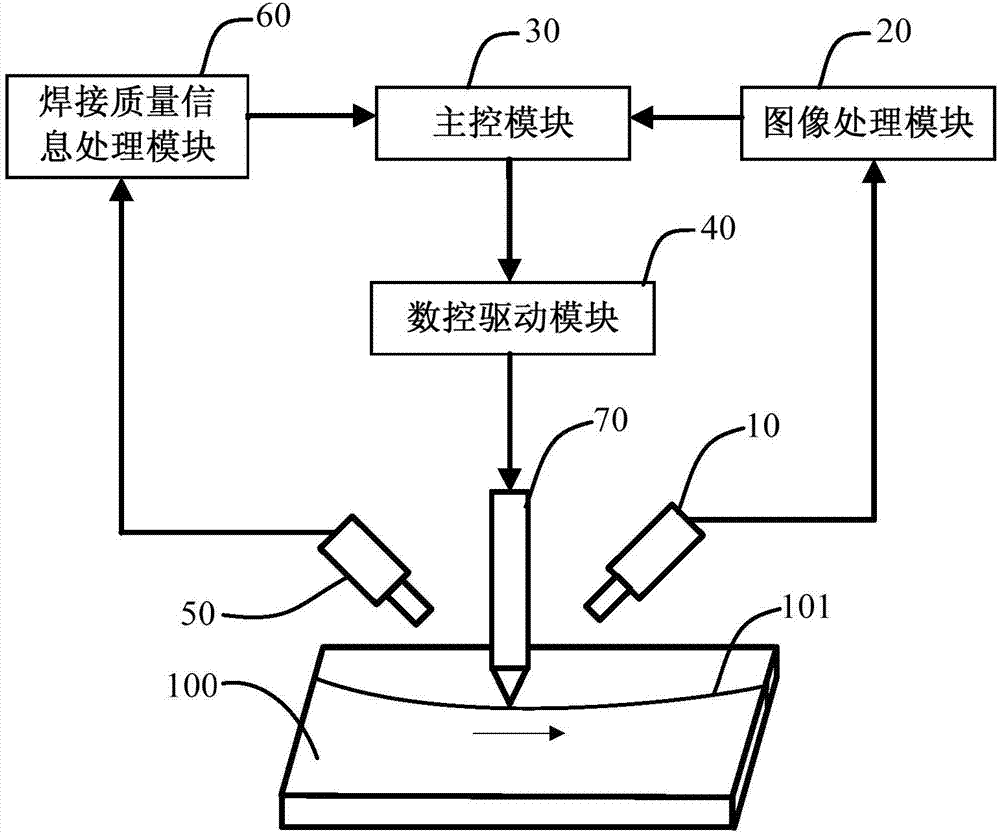

Welding seam tracking system and method of laser welding machine

ActiveCN103753015AImprove the level ofThe workload is reduced or even ignoredLaser beam welding apparatusNumerical controlSimulation

The invention discloses a welding seam tracking system of a laser welding machine. A CCD (Charge Coupled Device) visual sensor is used for converting collected light signals into image data which is output in a serial mode according to the time sequence to obtain a welding seam path image; an image processing module is used for preprocessing the welding seam path image, calculating the actual welding seam path width and tracking direction and combining with the obtained workpiece height through detection to output actual welding track data; a main control module is used for processing the actual welding track data and sending out a control instruction according to the processing result; a numerical control driving module is used for executing the control instruction of the main control module to drive a lase welding head, adjusting the position of the laser welding head and controlling the welding action of the welding head. According to the welding seam tracking system and method of the laser welding machine, the automatic laser welding is achieved, the deviation is small, the accuracy is high, the welding quality is good, and the like.

Owner:SHENZHEN GDLASER TECH CO LTD

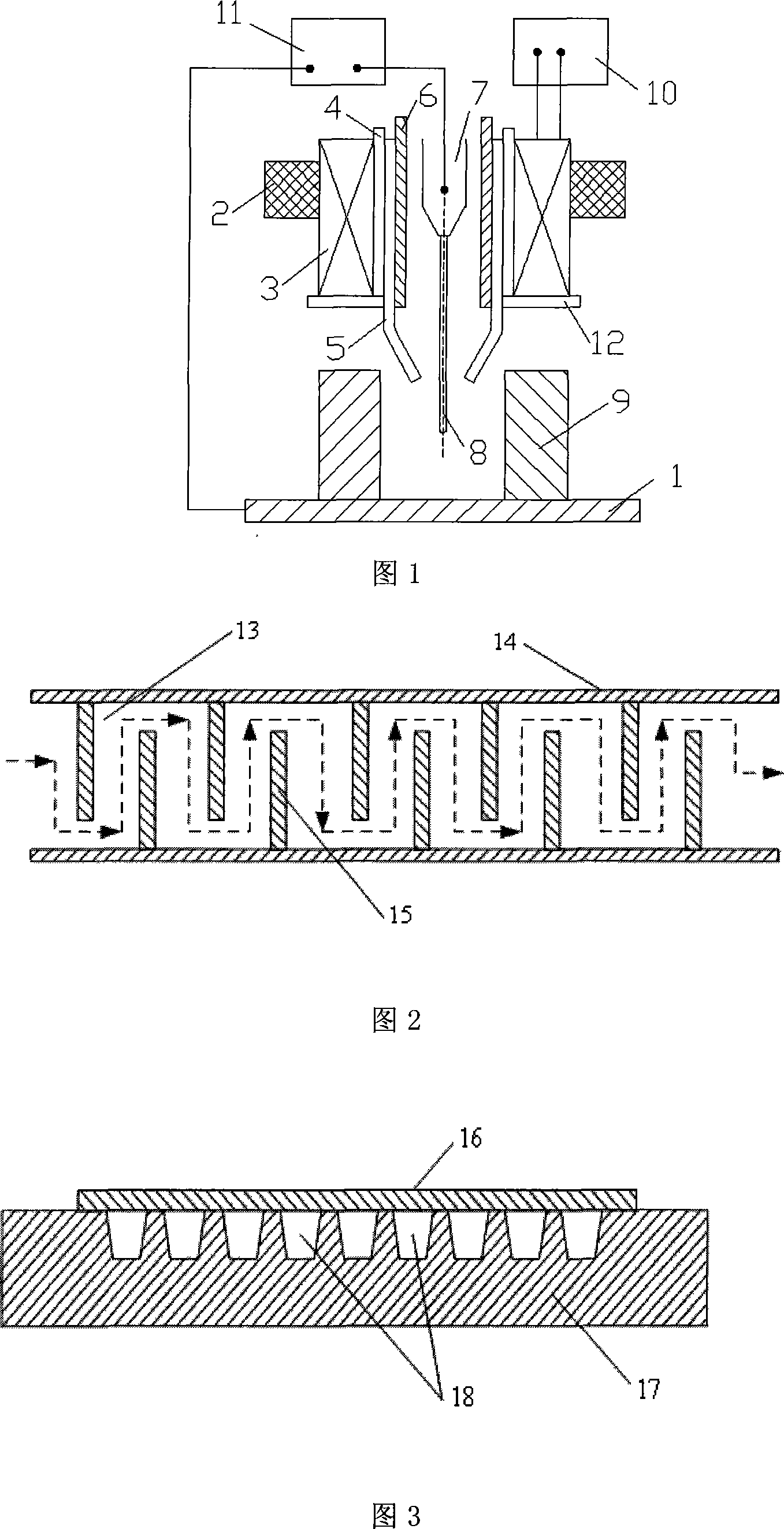

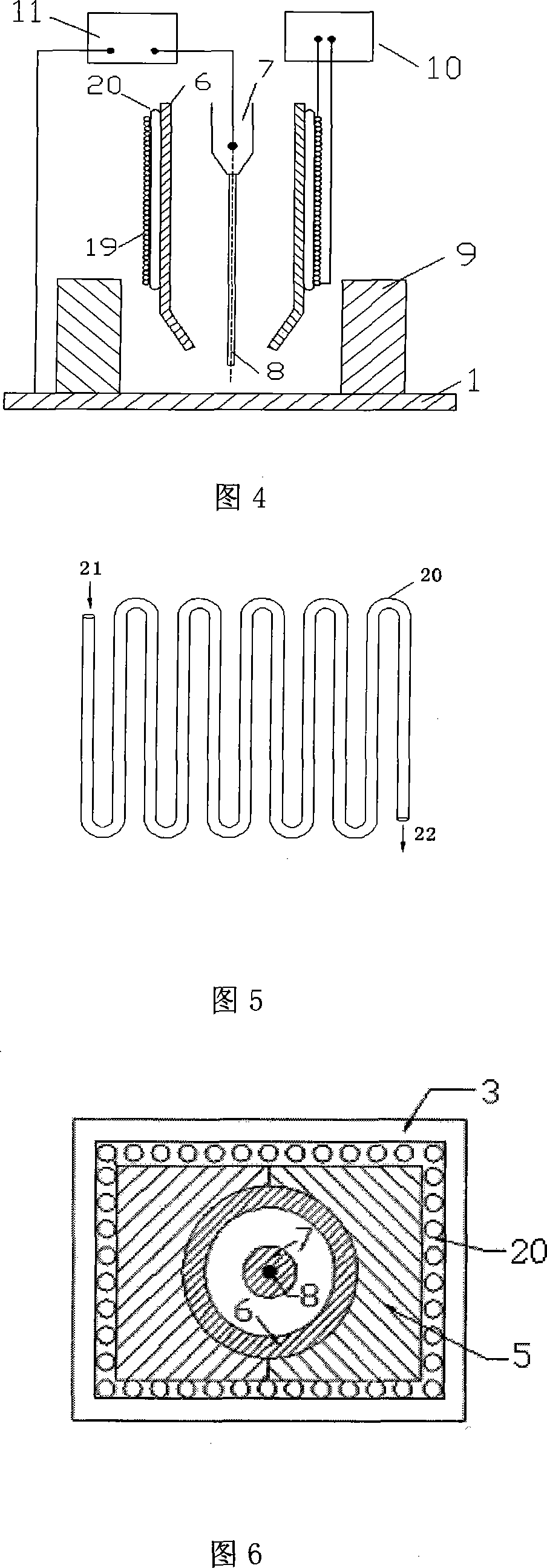

Moderate and high strength large-thickness component electromagnetic controlling narrow gap or ultra-narrow gap pulse efflux molten electrode gas-shield welding method and equipment

InactiveCN101143401AOvercoming arcingImprove crystallizationTransformers/inductances coolingWelding/cutting media/materialsElectric arcEngineering

The invention relates to a gas shielded welding method and device of a narrow gap or a super-narrow gap impulse jet current consumable electrode controlled by electromagnetic of the heavy section part with middle and high strength. The invention uses a magnetic coil (3) to provide excitation current processed by an excitation source, which can generate an extra magnetic field. Under the conditions of narrow gap or super-narrow gap, high feed rate, fused drop spray transfer and impulse welding current, the process of the gas shielded welding of the rotating jet current consumable electrode with high-melting frequency pulse that is controlled by the electromagnetic for the heavy section part with middle and high strength can be realized. The device of the invention comprises the excitation source, excitation equipment, auxiliary equipment and a water cooling system. The excitation equipment is the magnetic coil (3) with or without a conducting core (5). The excitation equipment is fixed on a welding burner (6), which is positioned above a work piece (9). The excitation current provided by the excitation source (10) produces stationary or time-varying electromagnetic mixing magnetic field that has the combination control over the processes of arc welding, wire burn-off, drop transfer, melting bath flow and welding line coagulation, which finally forms the welding line of good quality.

Owner:CHONGQING UNIV

Integrated steel pipe and flange splicing and machining machine and machining process thereof

InactiveCN102729045ALarge amount of welding depositionImprove welding speed and qualityArc welding apparatusOther manufacturing equipments/toolsSteel tubeMachining process

The invention discloses an integrated steel pipe and flange splicing and machining machine and a machining process thereof and aims to provide an integrated steel pipe and flange splicing and machining machine which can improve the manufacturing precision and the production efficiency and reduce the labor intensity and is high in steel pipe and flange welding quality and a machining process of the machine. The integrated steel pipe and flange splicing and machining machine comprises a working platform, and a supporting bracket which is arranged on the working platform and is used for supporting a steel pipe, wherein one end of the working platform is provided with a first welding device; a first guide rail which extends to the other end of the working platform is arranged on the top of the working platform; a first mounting plate is arranged on the first guide rail in a sliding mode; a second welding device is arranged on the first mounting plate; and flange fixing templates are arranged on the first welding device and the second welding device. The machining process comprises the following steps of: lifting the steel pipe to the supporting bracket, and fixing the flange to a flange fixing template; and welding annular gaps of the inner and outer side faces of the steel pipe and the flange through the first welding device and the second welding device.

Owner:戴刚平

Welding quality analysis device based on infrared vision and analysis method thereof

InactiveCN104977305ALower regenerationIncrease the level of automationWelding/cutting auxillary devicesOptically investigating flaws/contaminationMelting tankVision processing

The invention discloses a welding quality analysis device based on infrared vision and an analysis method thereof. The analysis device comprises an infrared vision collecting system that is adjustably and fixedly connected to a welding facility, a vision processing system, in which welding defect intelligent recognition algorithm is embedded, and a feed control system, which can evaluate the welding quality, give an alarm, and adjust the parameters of the welding facility. The analysis method comprises the following steps: (1) collecting the infrared vision information of a molten pool or an area near a molten pool in real time through infrared sensing; (2) processing the infrared vision information by the welding defect intelligent recognition algorithm so as to obtain the weld seam positions and welding defect characteristics; (3) evaluating the welding quality in real time, and controlling the welding facility and giving an alarm aiming at different welding defects. According to the provided intelligent analysis device and intelligent analysis method, the welding process can be monitored in real time, the welding defects can be recognized, the welding seam position can be traced, the welding quality can be evaluated, the welding loss can be reduced, and the finished product yield rate can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com