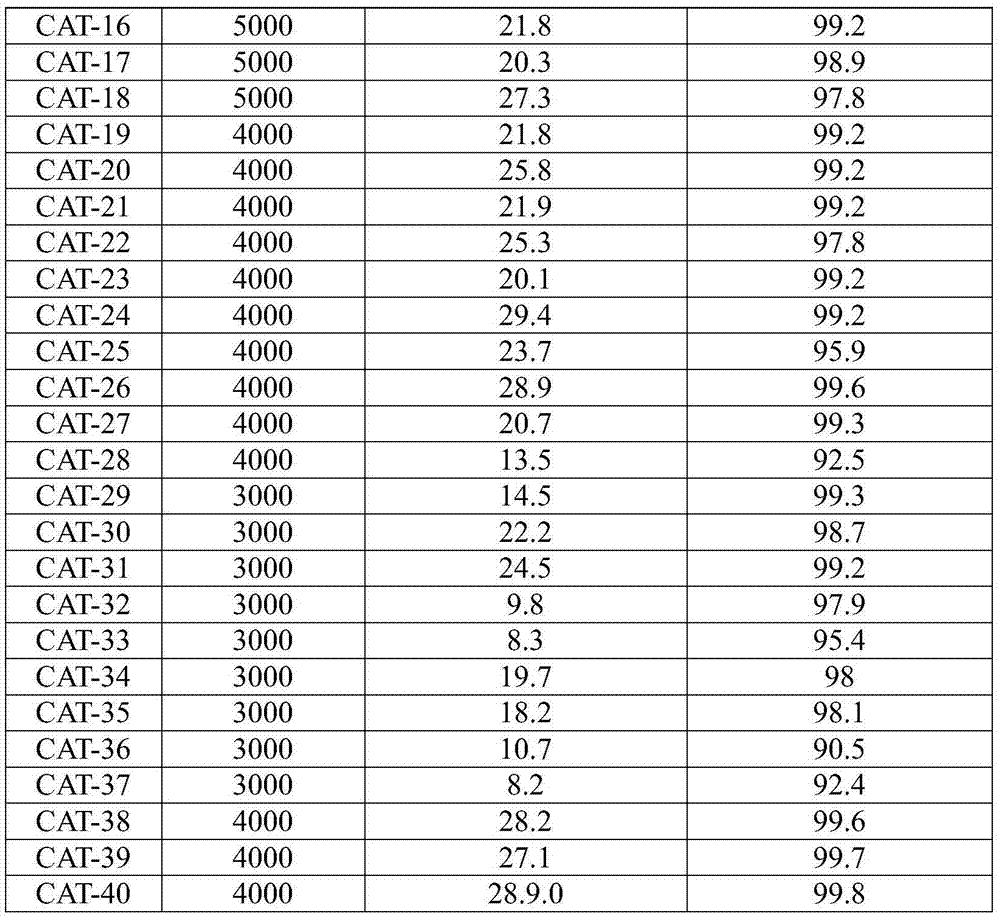

Patents

Literature

124results about How to "Lower regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

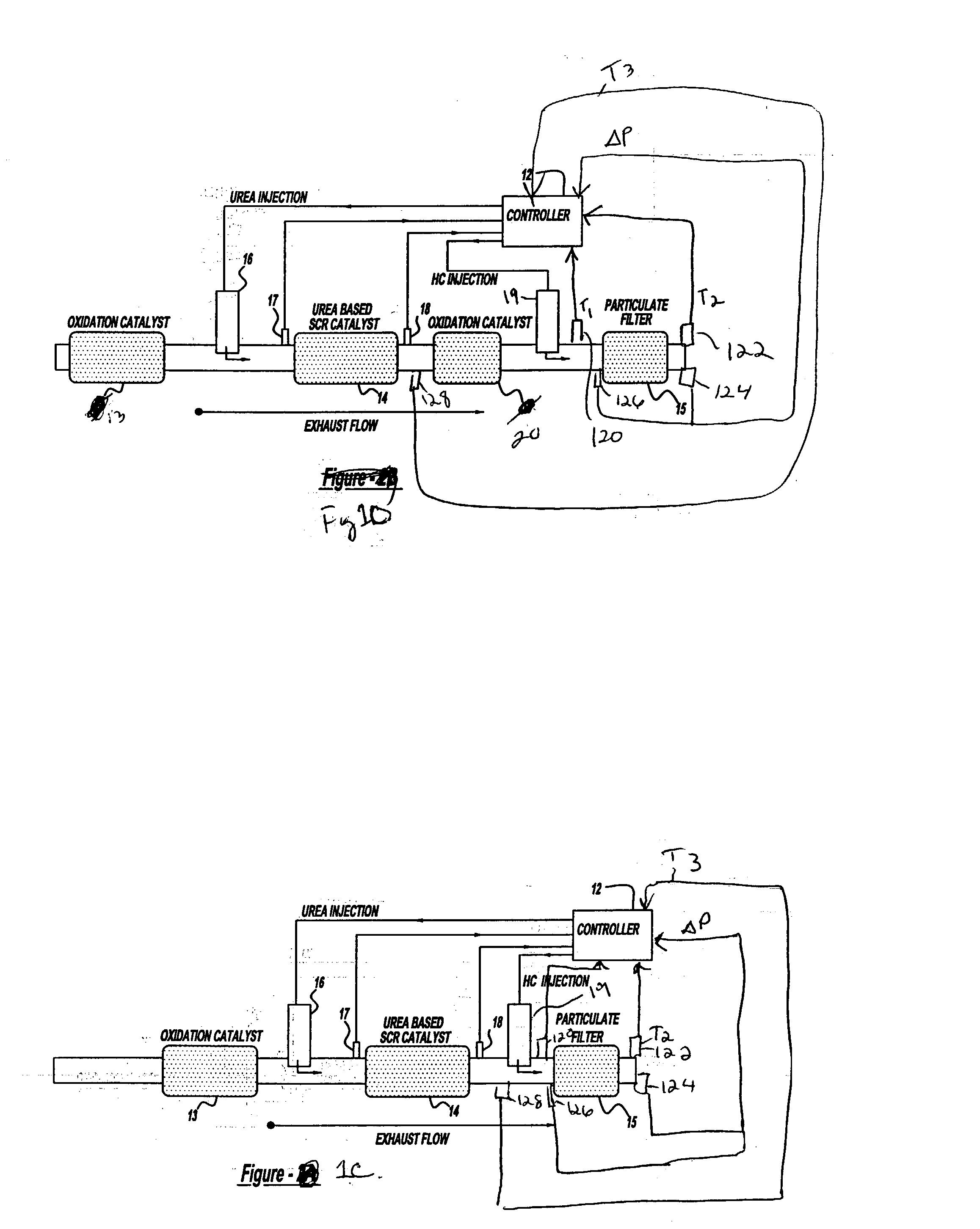

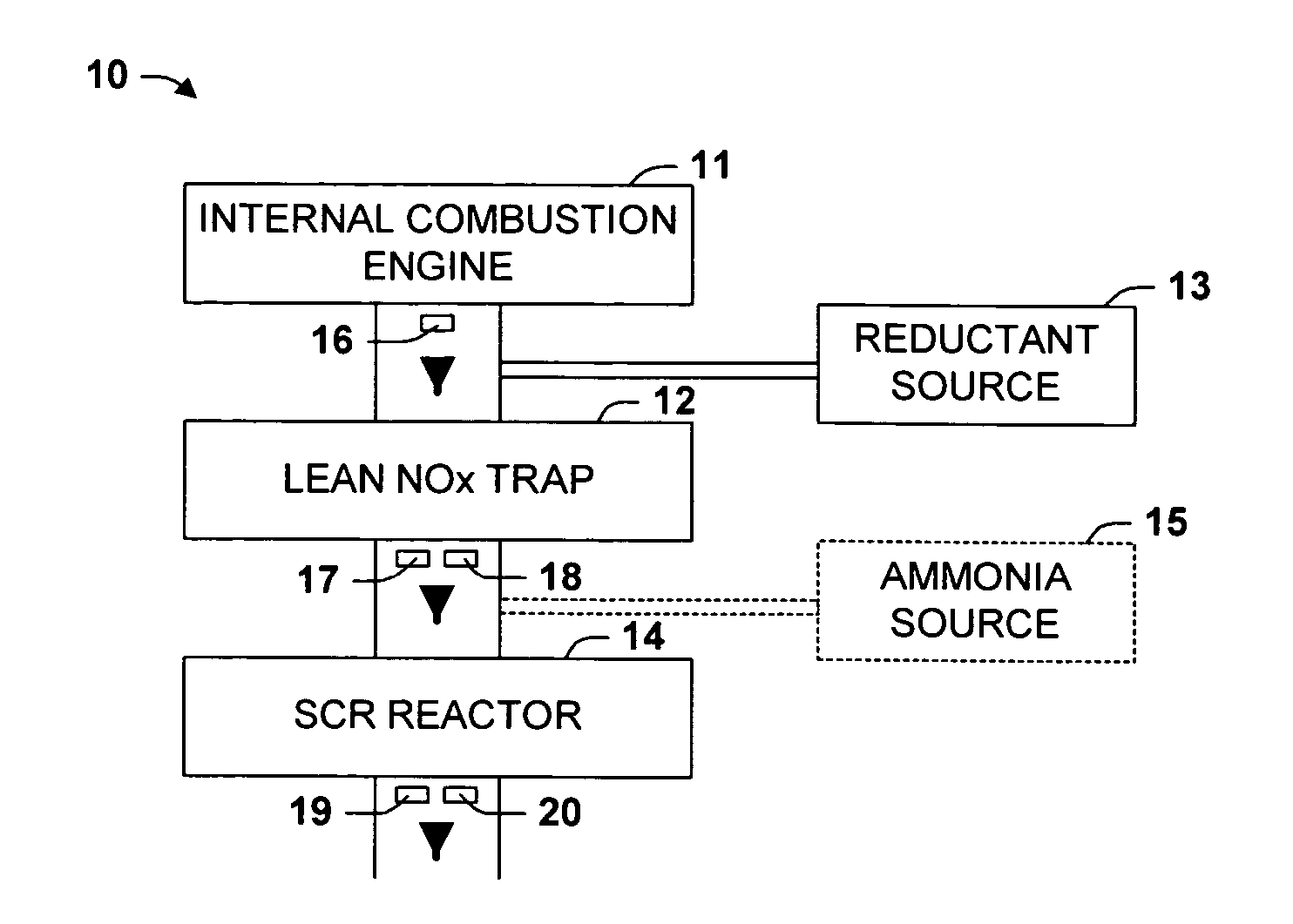

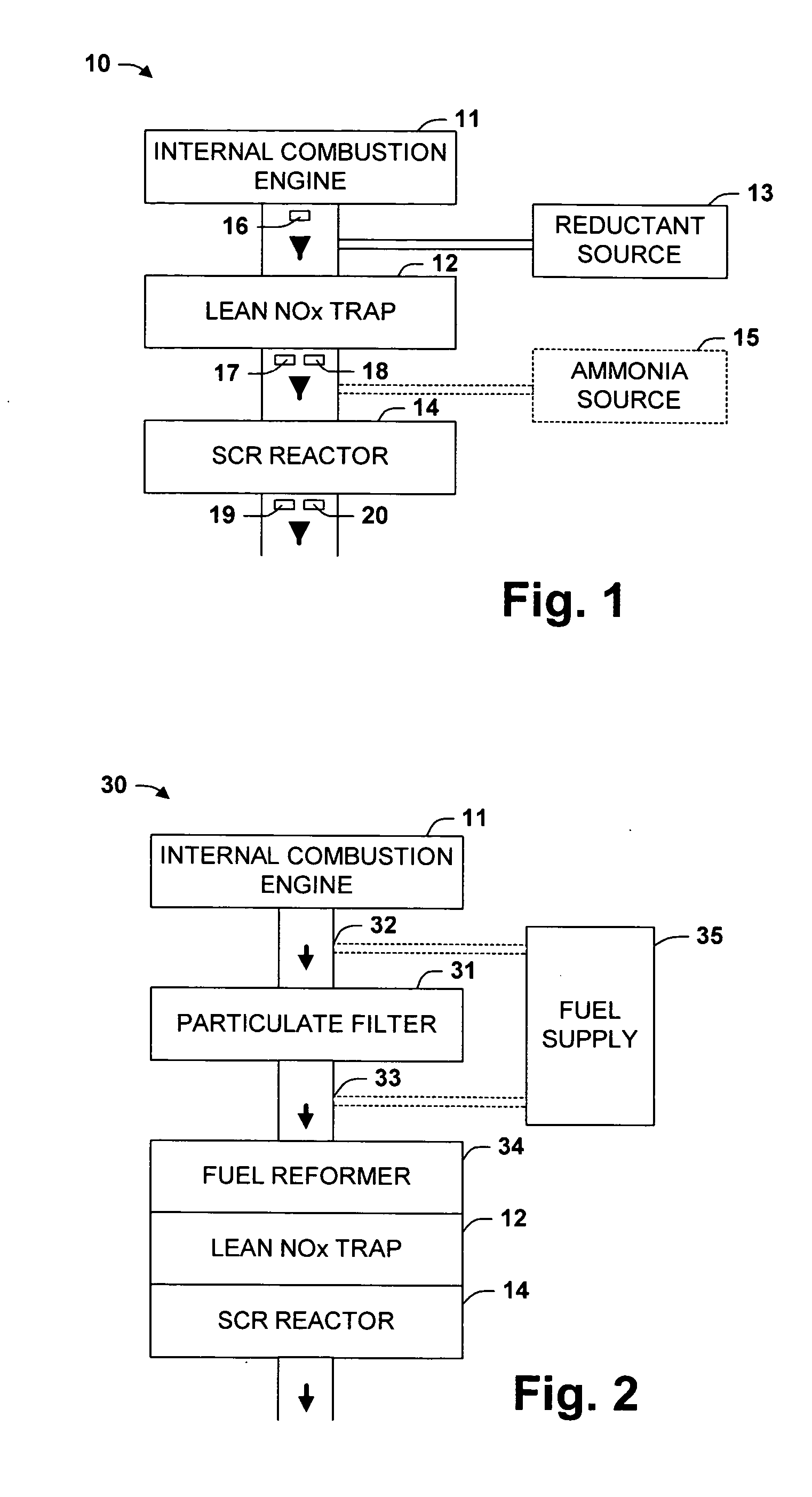

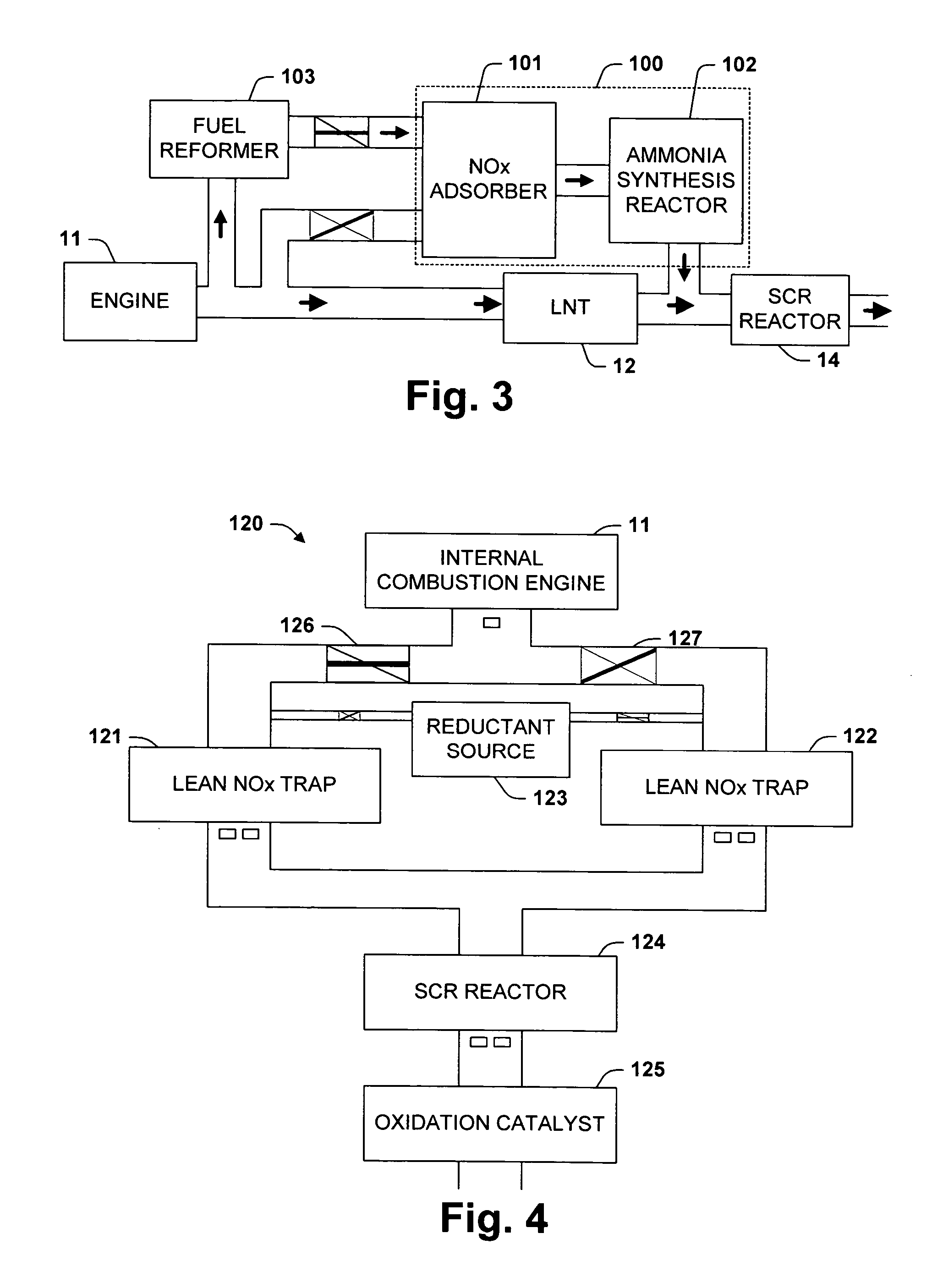

Hybrid catalyst system for exhaust emissions reduction

InactiveUS20060010857A1Improve efficiencySpeed up the conversion processHydrogenGas treatmentExhaust fumesEngineering

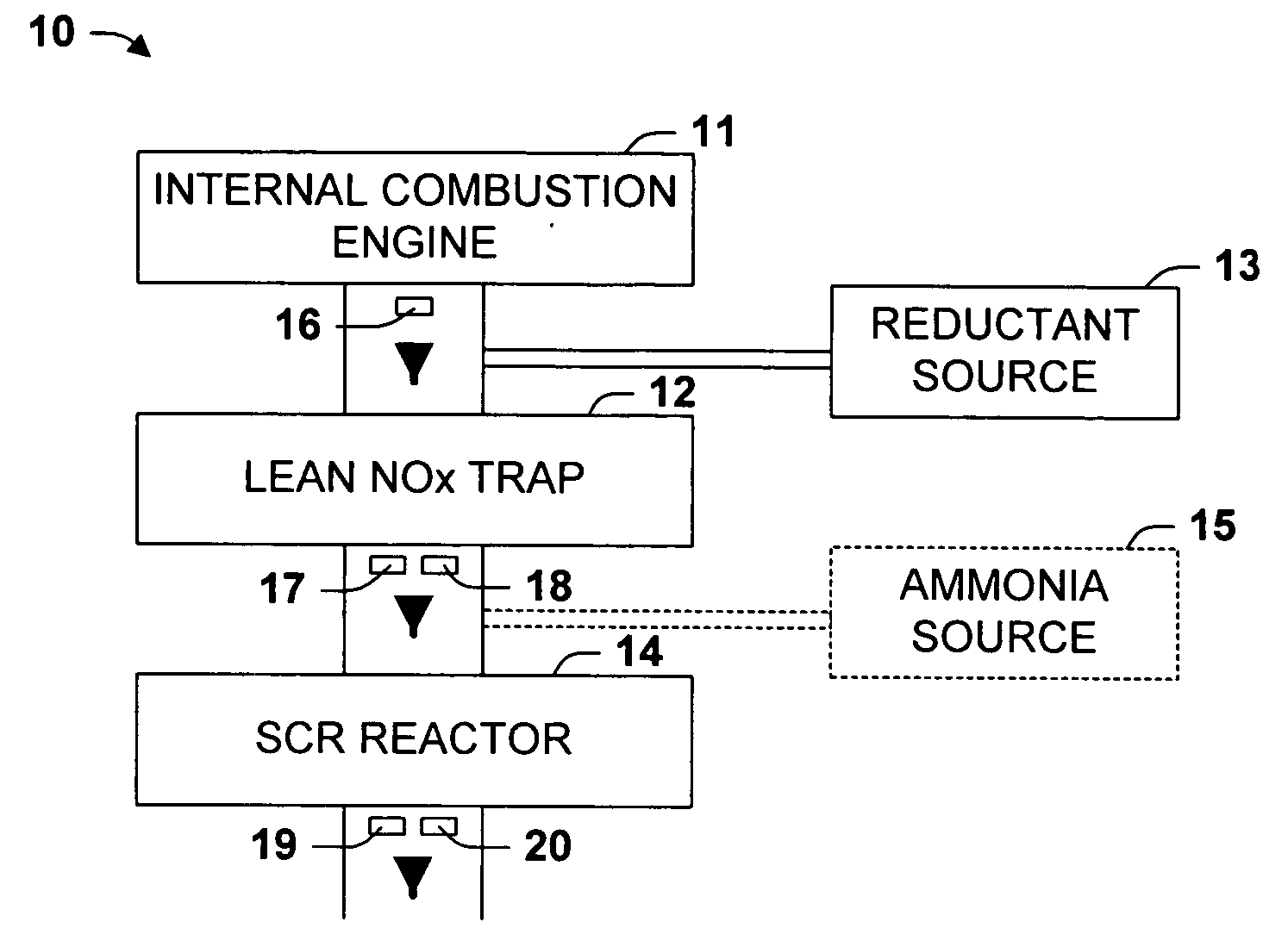

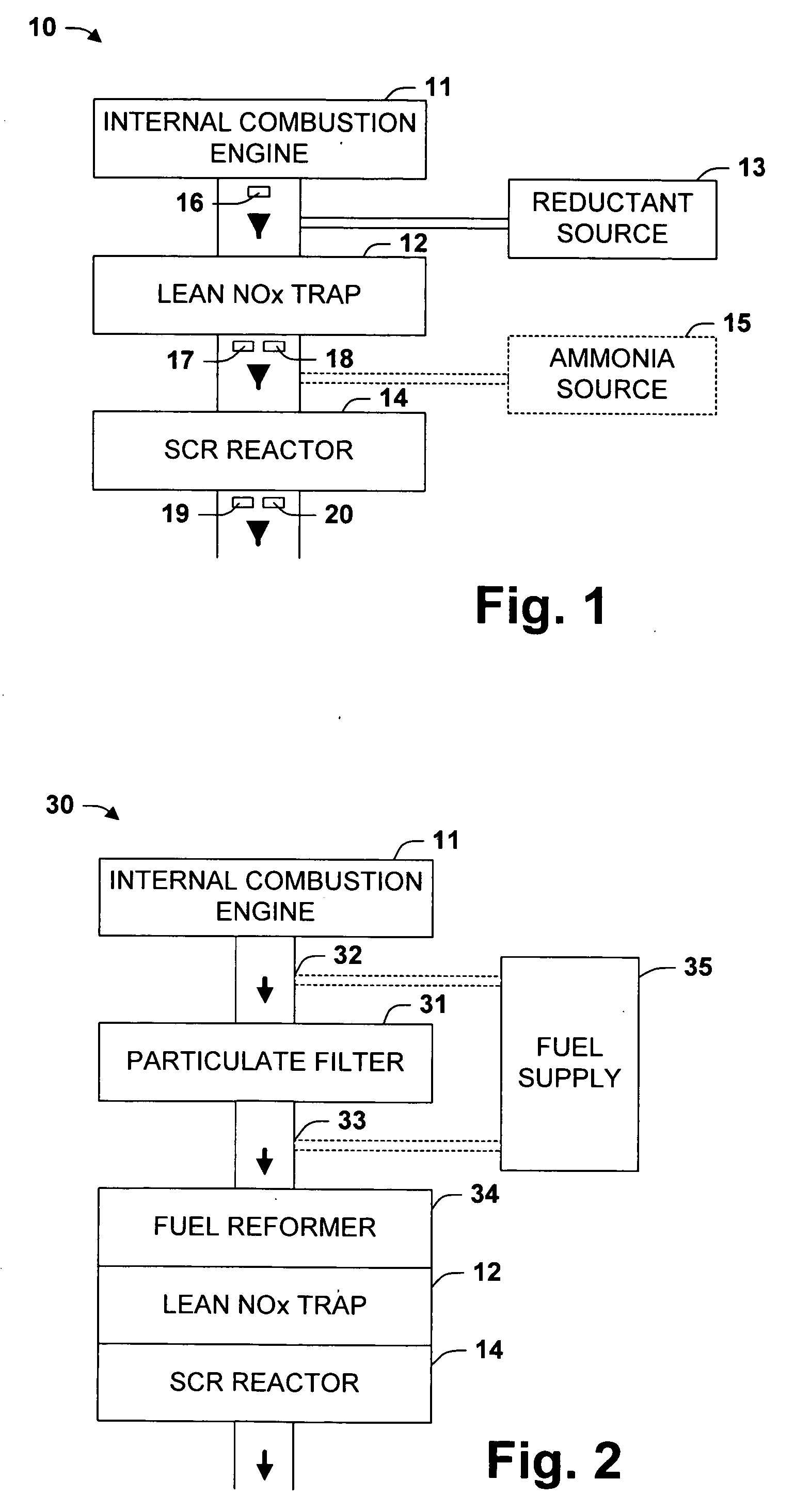

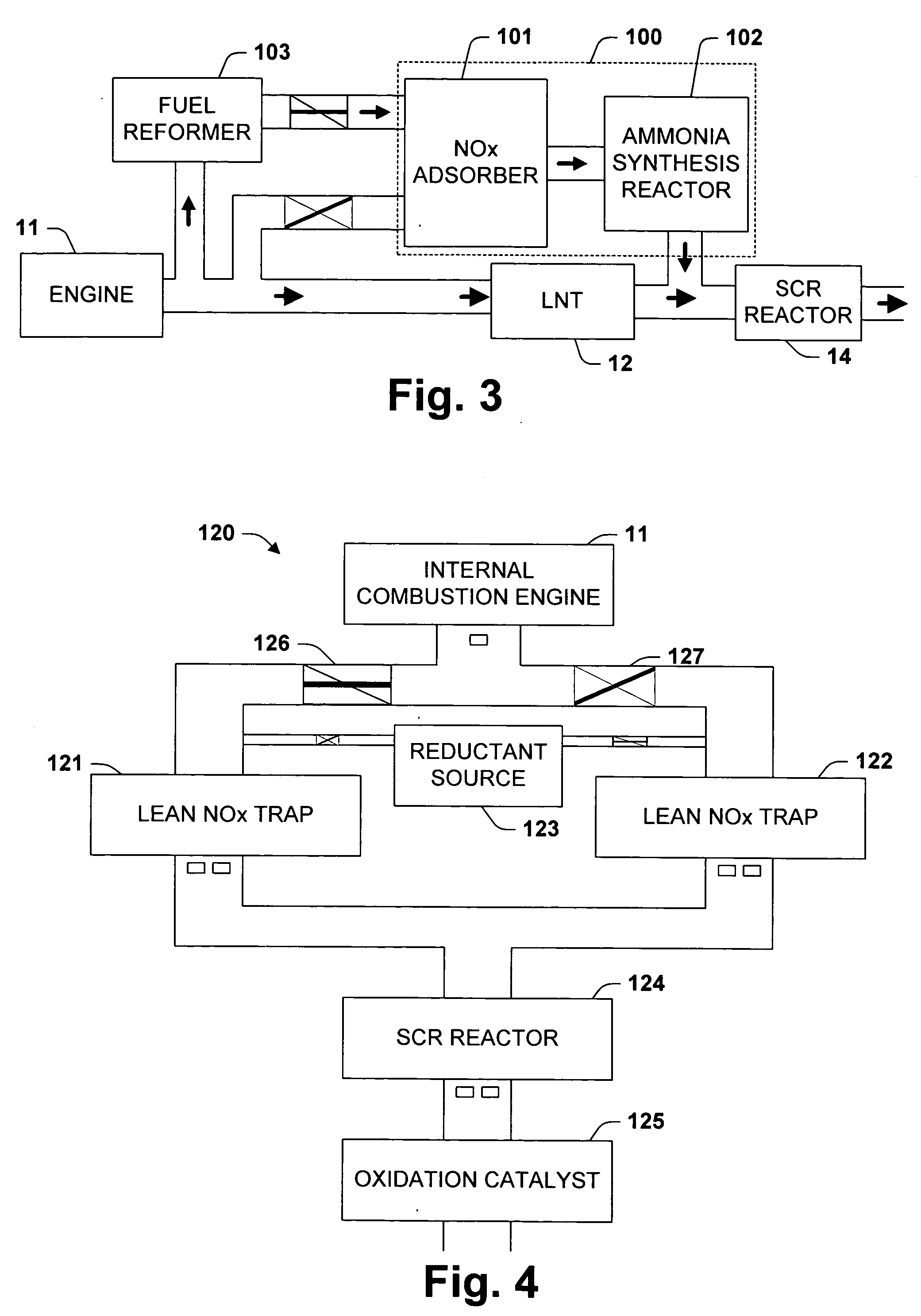

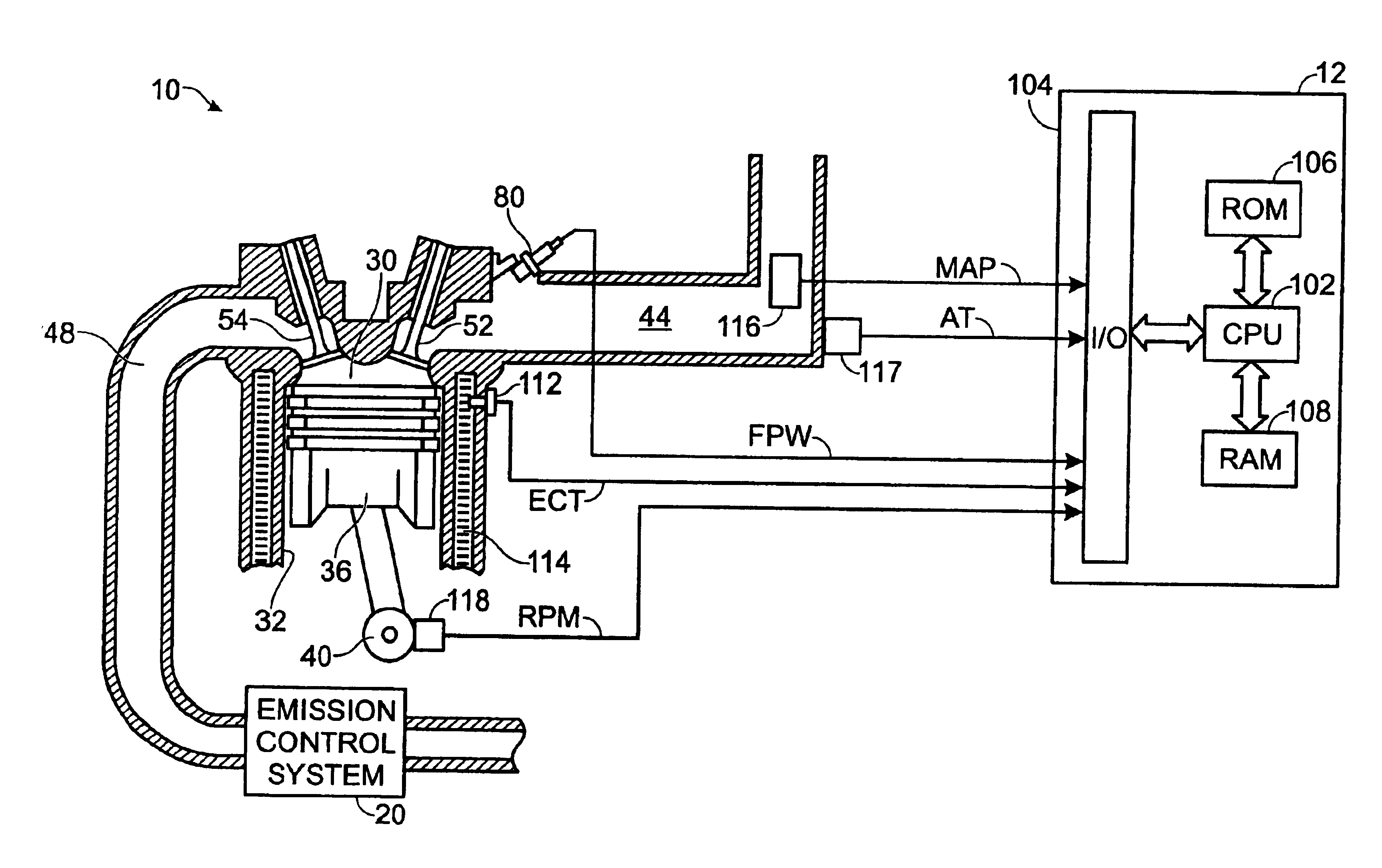

One aspect of the invention relates an exhaust treatment system having an SCR reactor following a NOx adsorber. Syn gas is used to regenerate the NOx adsorber. Another aspect relates to an LNT / SCR provided with an ammonia source separate from the LNT. A further aspect relates to a system comprising first and second LNTs and one or more SCRs downstream of the LNTs. A still further aspect relates to a device comprising first and second NOx adsorbers contained in a single housing. Another aspect relates to coating a surface of a moving part in an exhaust system with an oxidation catalyst to mitigate fouling. Additional aspects of the invention relate to strategies for controlling one or more of the time to initiate a regeneration cycle, the time to terminate a regeneration cycle, and the reductant injection rate during regeneration of LNT / SCR exhaust treatment systems.

Owner:INT ENGINE INTPROP CO LLC

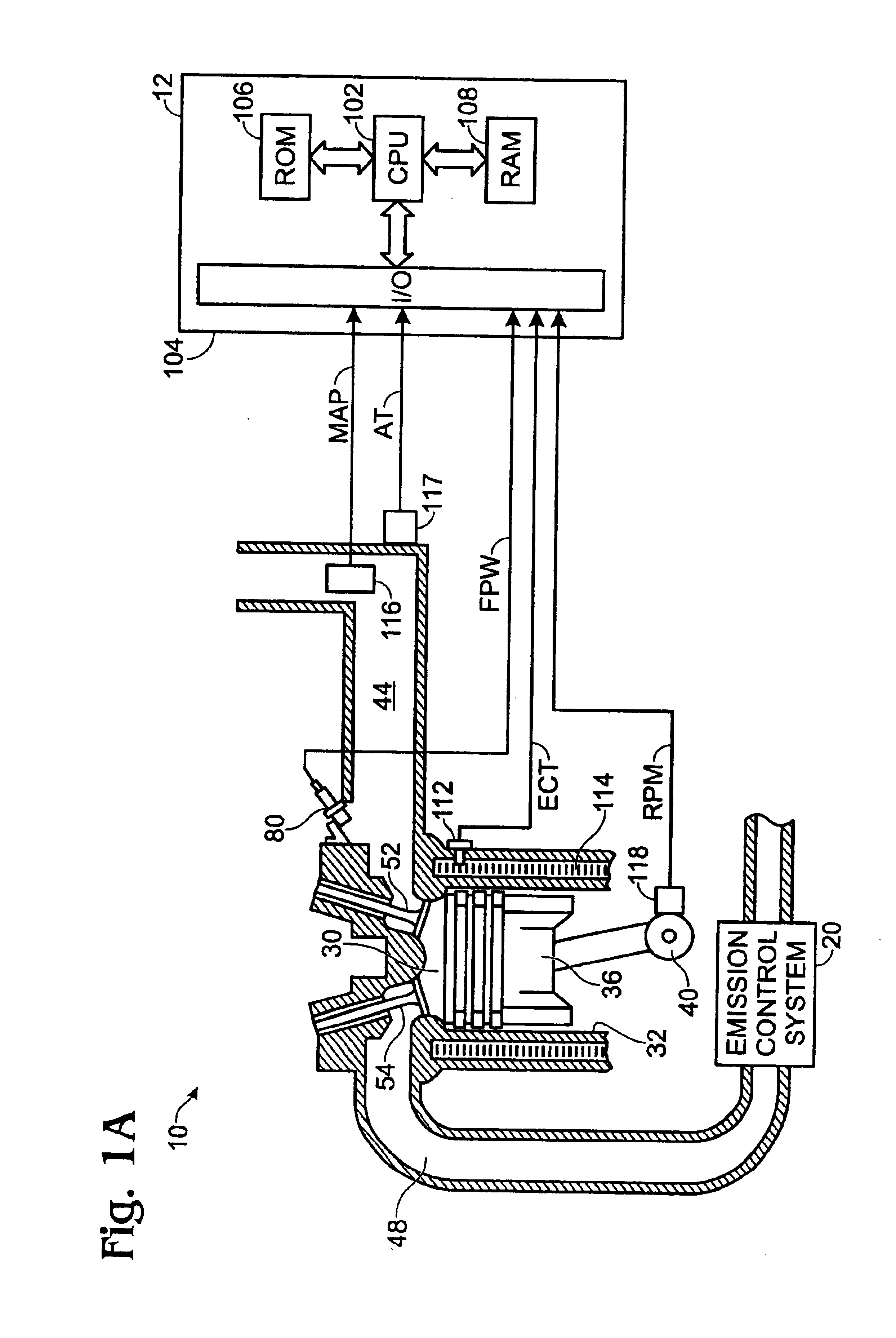

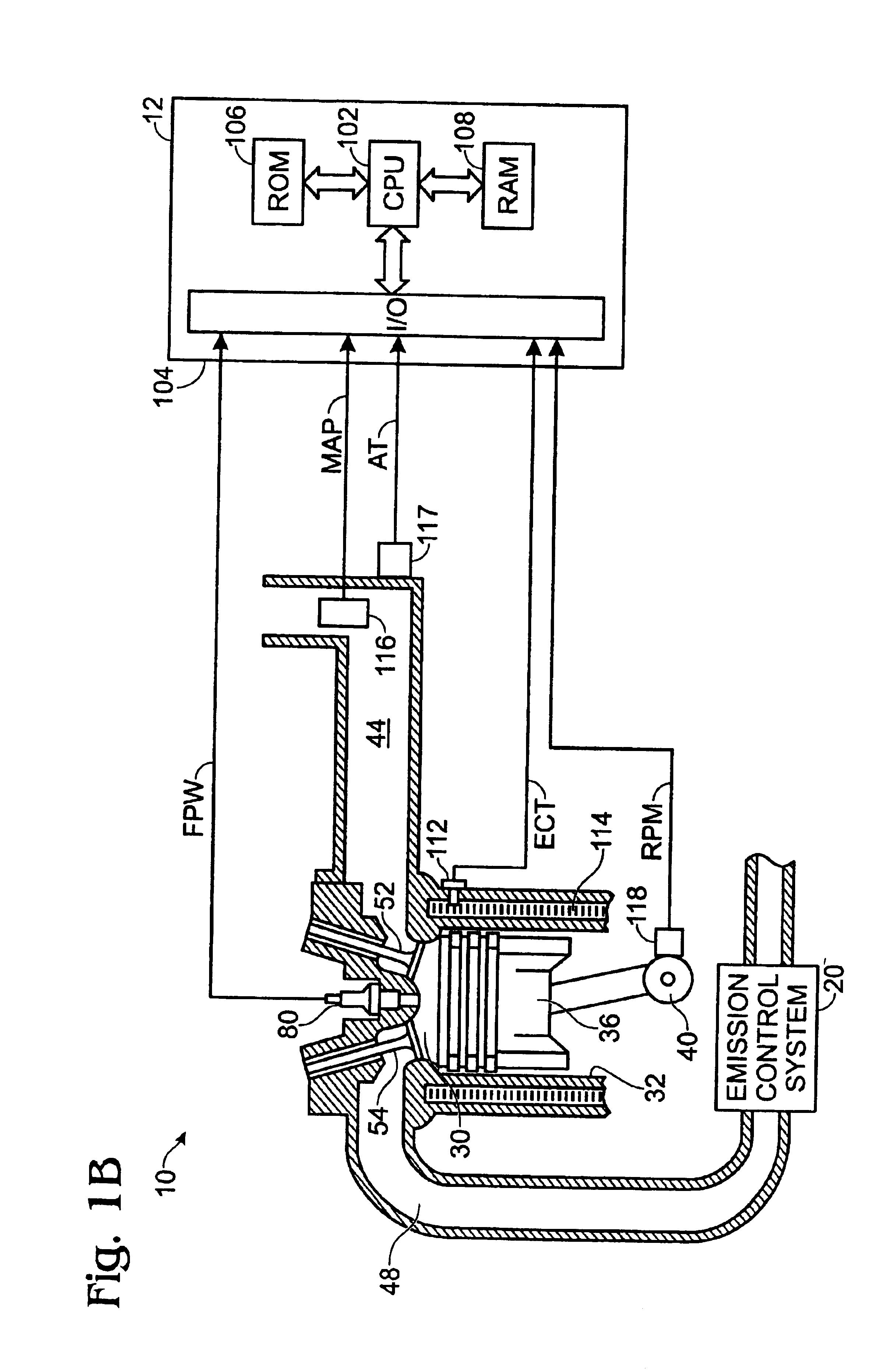

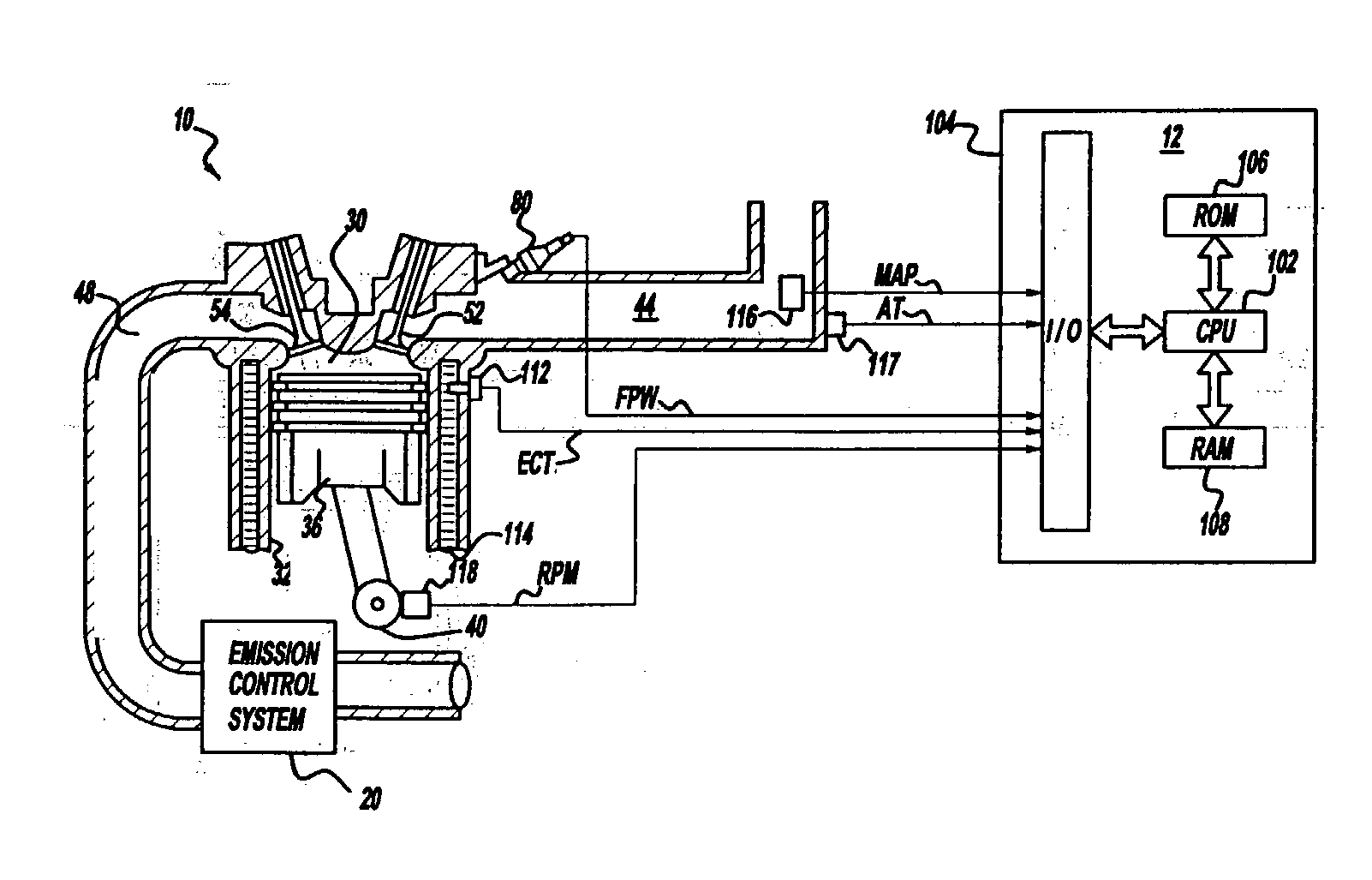

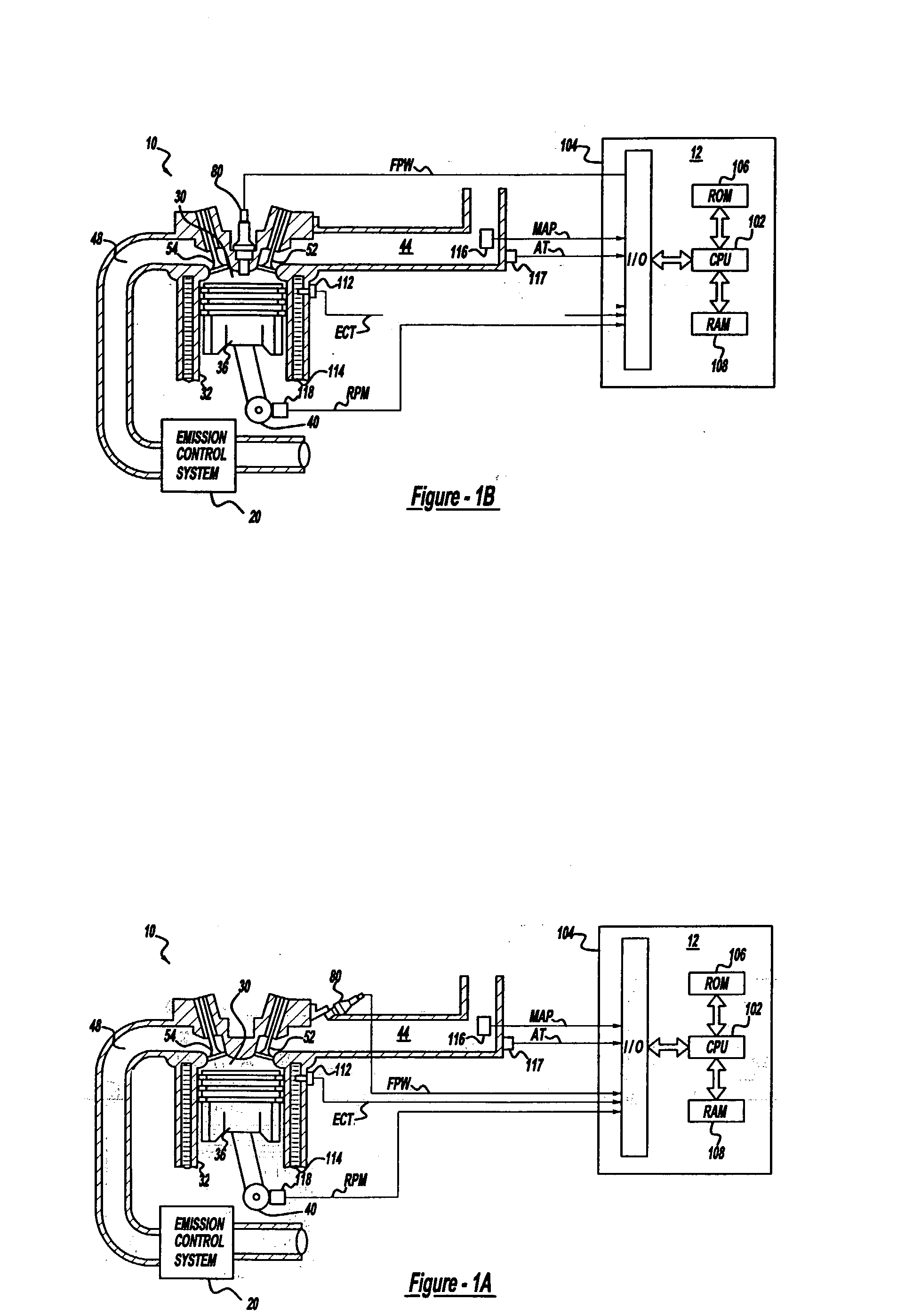

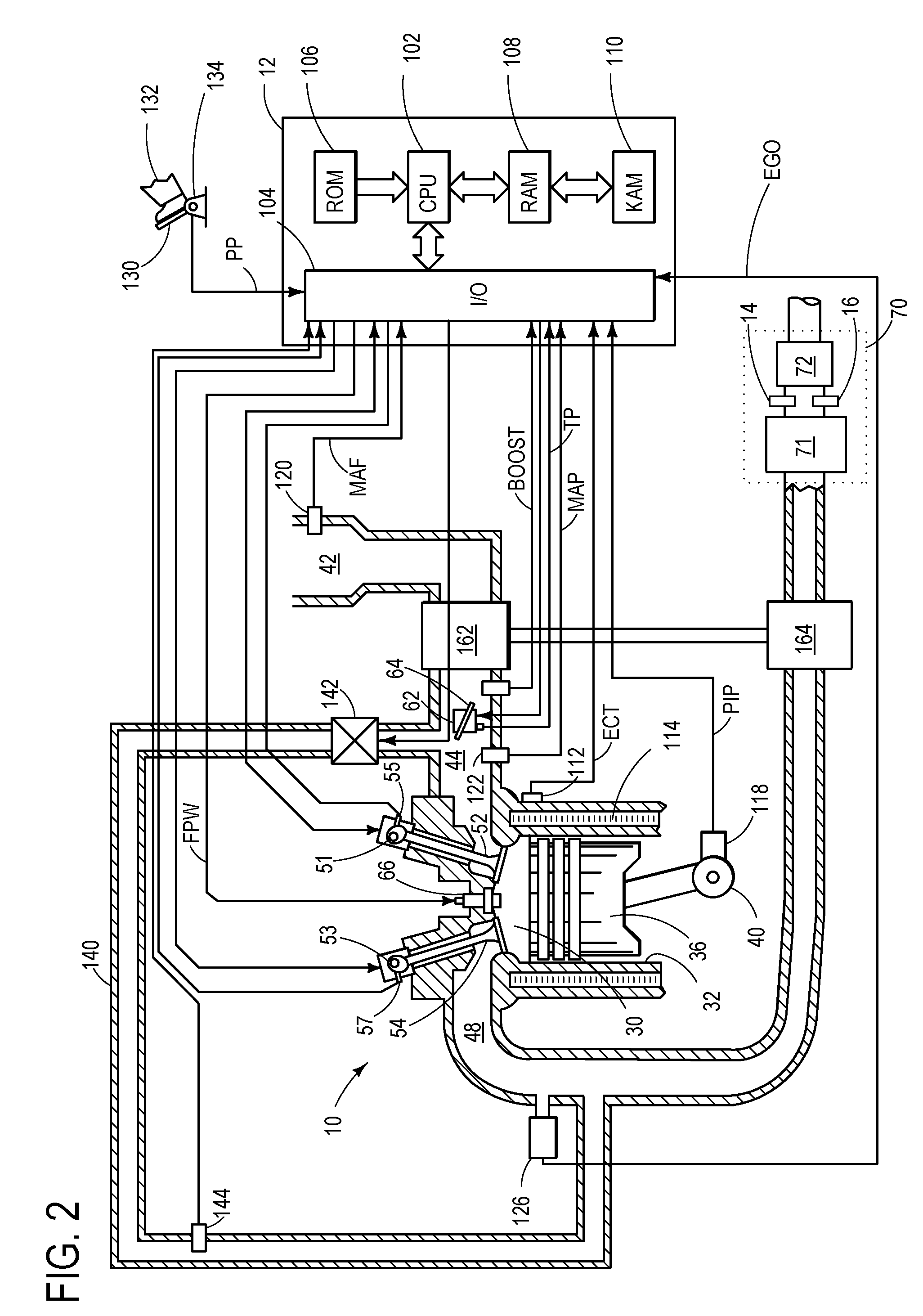

Pressure sensor diagnosis via a computer

InactiveUS6947831B2Reduce stepsLower regenerationAnalogue computers for vehiclesElectrical controlParticulatesDifferential pressure

A method is described for controlling regeneration of a particulate filter based on at least a sensor, such as a differential pressure sensor. Degradation of the sensor is then detected in a variety of ways. One approach takes advantage of the slowly varying flow resistance of the filter compared with the more rapid variations in flow caused by changing engine conditions. Default operation is then taken when a degraded sensor is detected.

Owner:FORD GLOBAL TECH LLC

Pressure sensor diagnosis via a computer

InactiveUS20040200271A1Accelerate emissionsReduce stepsAnalogue computers for vehiclesElectrical controlParticulatesDifferential pressure

A method is described for controlling regeneration of a particulate filter based on at least a sensor, such as a differential pressure sensor. Degradation of the sensor is then detected in a variety of ways. One approach takes advantage of the slowly varying flow resistance of the filter compared with the more rapid variations in flow caused by changing engine conditions. Default operation is then taken when a degraded sensor is detected.

Owner:FORD GLOBAL TECH LLC

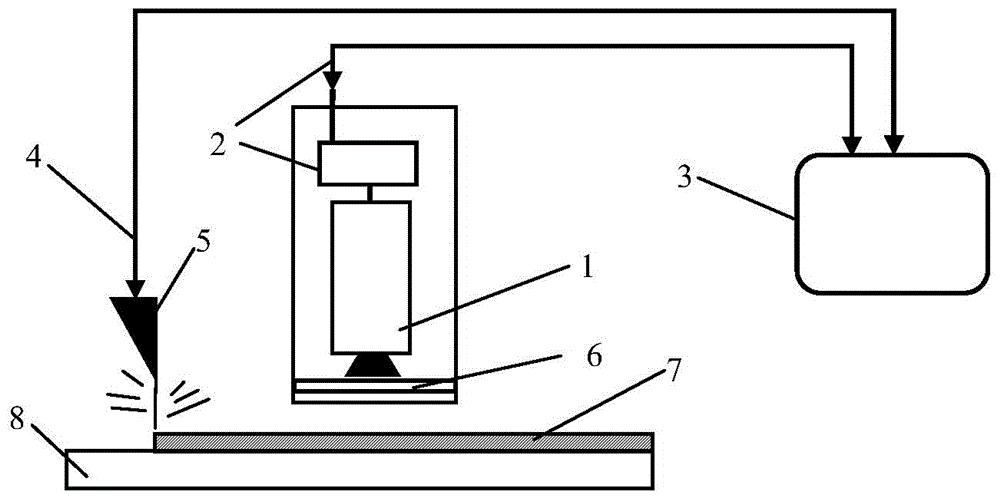

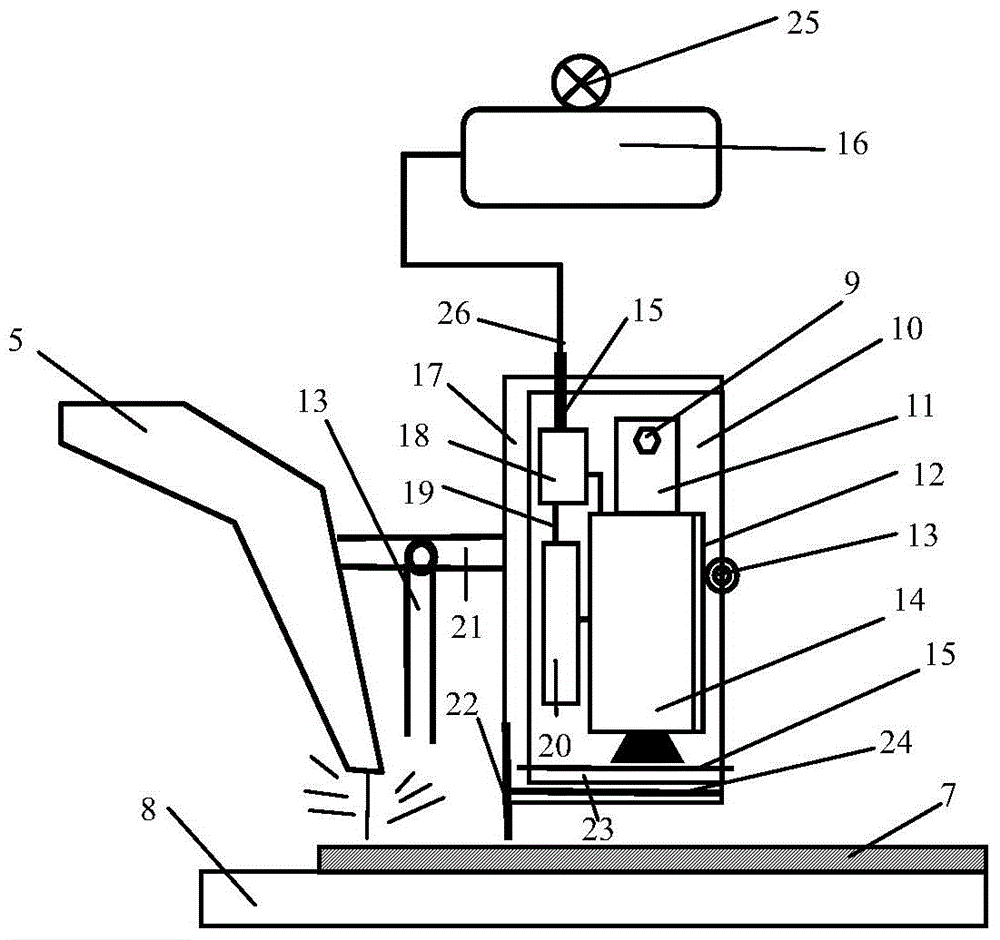

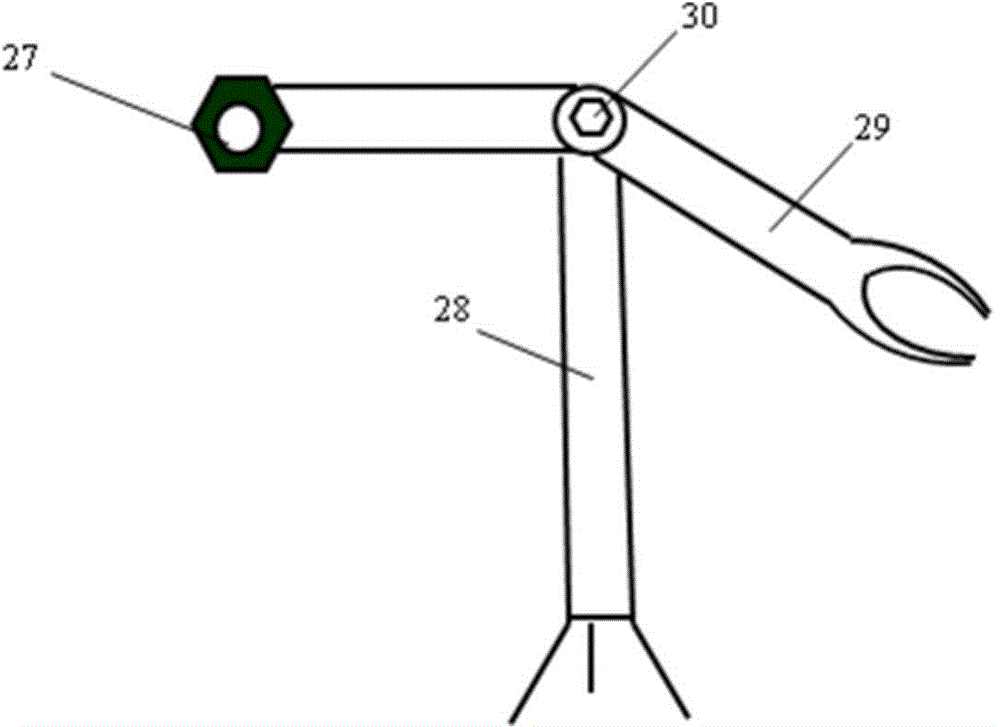

Welding quality analysis device based on infrared vision and analysis method thereof

InactiveCN104977305ALower regenerationIncrease the level of automationWelding/cutting auxillary devicesOptically investigating flaws/contaminationMelting tankVision processing

The invention discloses a welding quality analysis device based on infrared vision and an analysis method thereof. The analysis device comprises an infrared vision collecting system that is adjustably and fixedly connected to a welding facility, a vision processing system, in which welding defect intelligent recognition algorithm is embedded, and a feed control system, which can evaluate the welding quality, give an alarm, and adjust the parameters of the welding facility. The analysis method comprises the following steps: (1) collecting the infrared vision information of a molten pool or an area near a molten pool in real time through infrared sensing; (2) processing the infrared vision information by the welding defect intelligent recognition algorithm so as to obtain the weld seam positions and welding defect characteristics; (3) evaluating the welding quality in real time, and controlling the welding facility and giving an alarm aiming at different welding defects. According to the provided intelligent analysis device and intelligent analysis method, the welding process can be monitored in real time, the welding defects can be recognized, the welding seam position can be traced, the welding quality can be evaluated, the welding loss can be reduced, and the finished product yield rate can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

Hybrid catalyst system for exhaust emissions reduction

InactiveUS20070033928A1Improve efficiencySpeed up the conversion processHydrogenGas treatmentExhaust fumesEngineering

One aspect of the invention relates an exhaust treatment system having an SCR reactor following a NOx adsorber. Syn gas is used to regenerate the NOx adsorber. Another aspect relates to an LNT / SCR provided with an ammonia source separate from the LNT. A further aspect relates to a system comprising first and second LNTs and one or more SCRs downstream of the LNTs. A still further aspect relates to a device comprising first and second NOx adsorbers contained in a single housing. Another aspect relates to coating a surface of a moving part in an exhaust system with an oxidation catalyst to mitigate fouling. Additional aspects of the invention relate to strategies for controlling one or more of the time to initiate a regeneration cycle, the time to terminate a regeneration cycle, and the reductant injection rate during regeneration of LNT / SCR exhaust treatment systems.

Owner:INT ENGINE INTPROP CO LLC

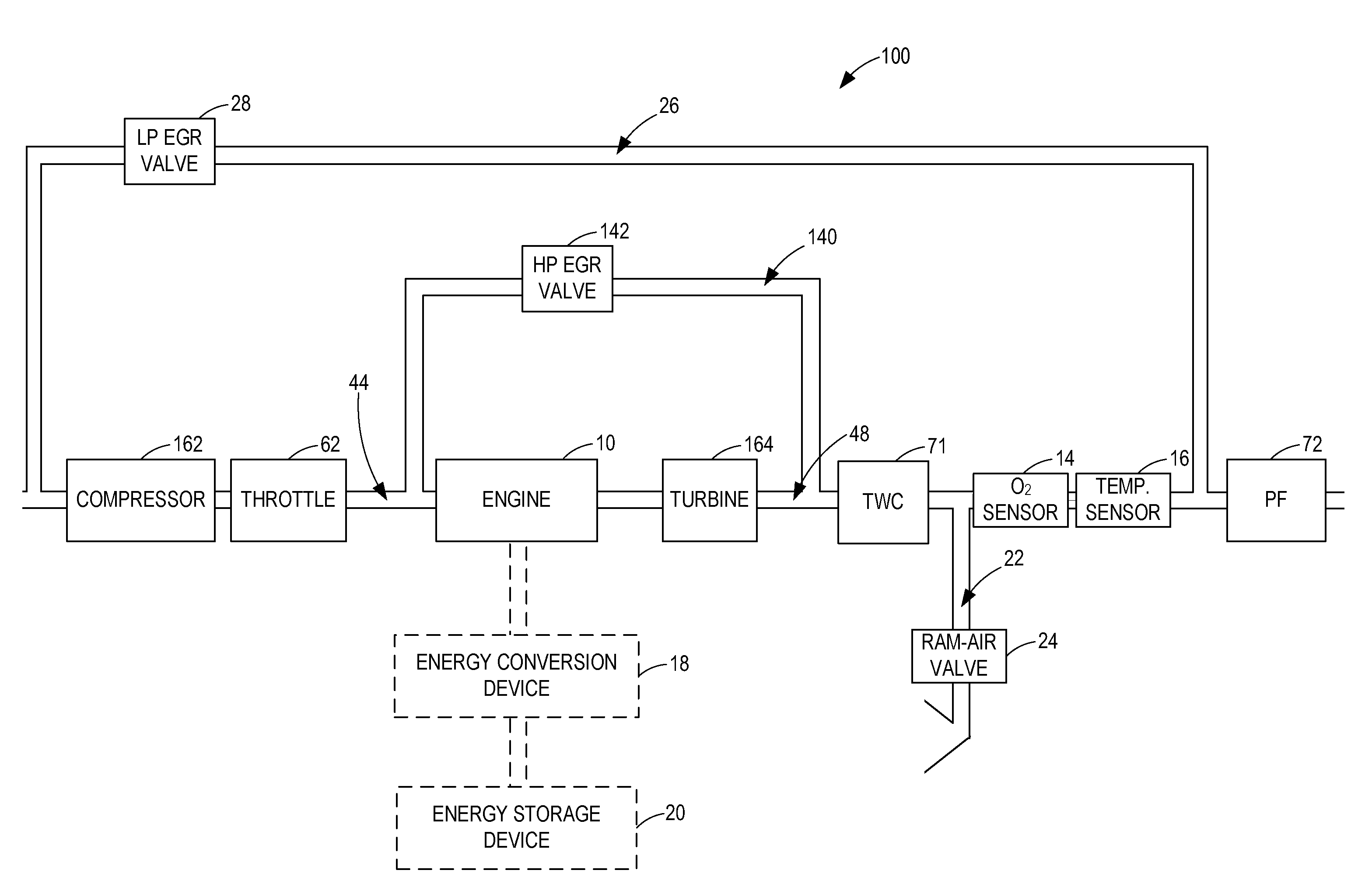

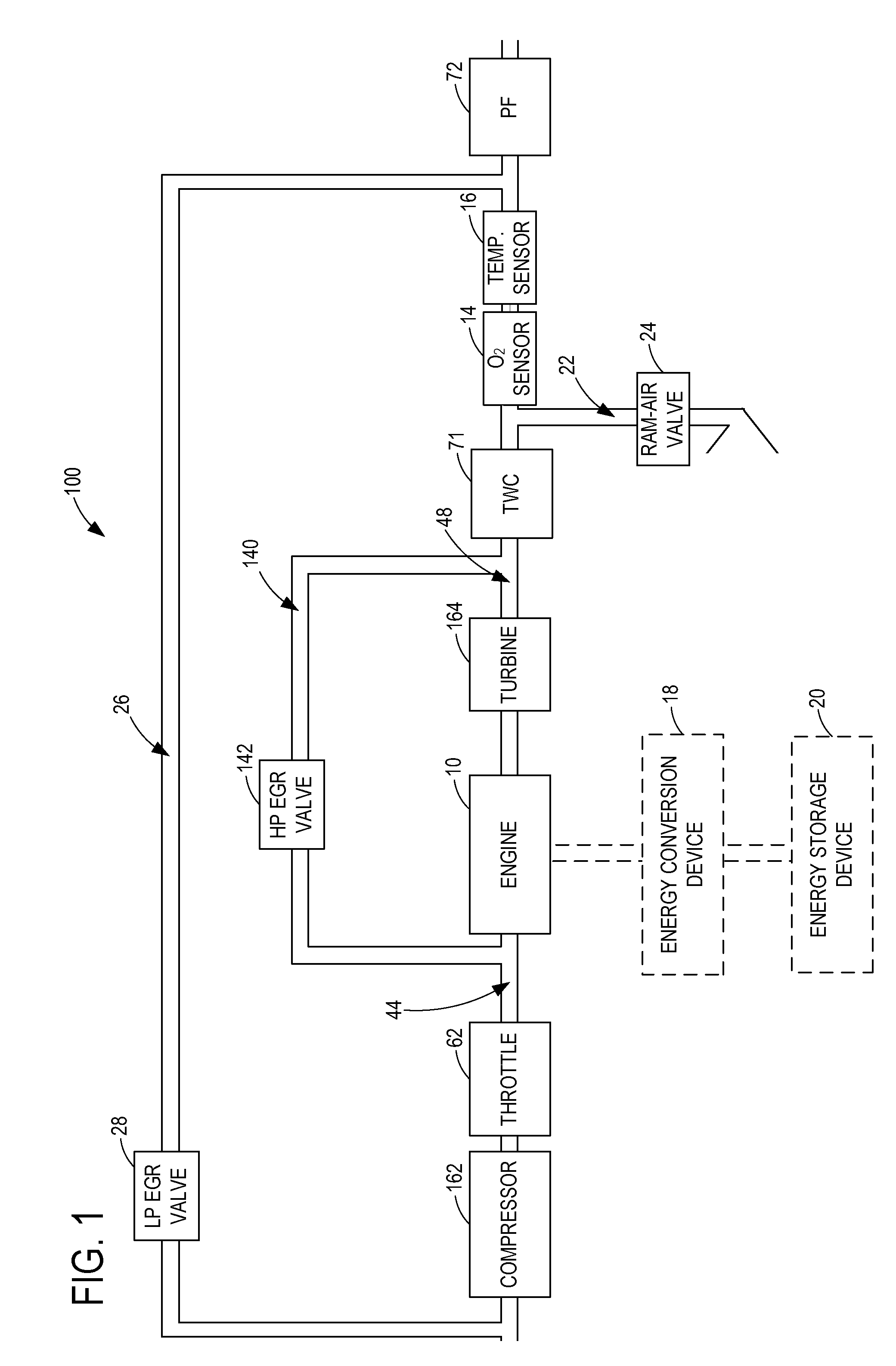

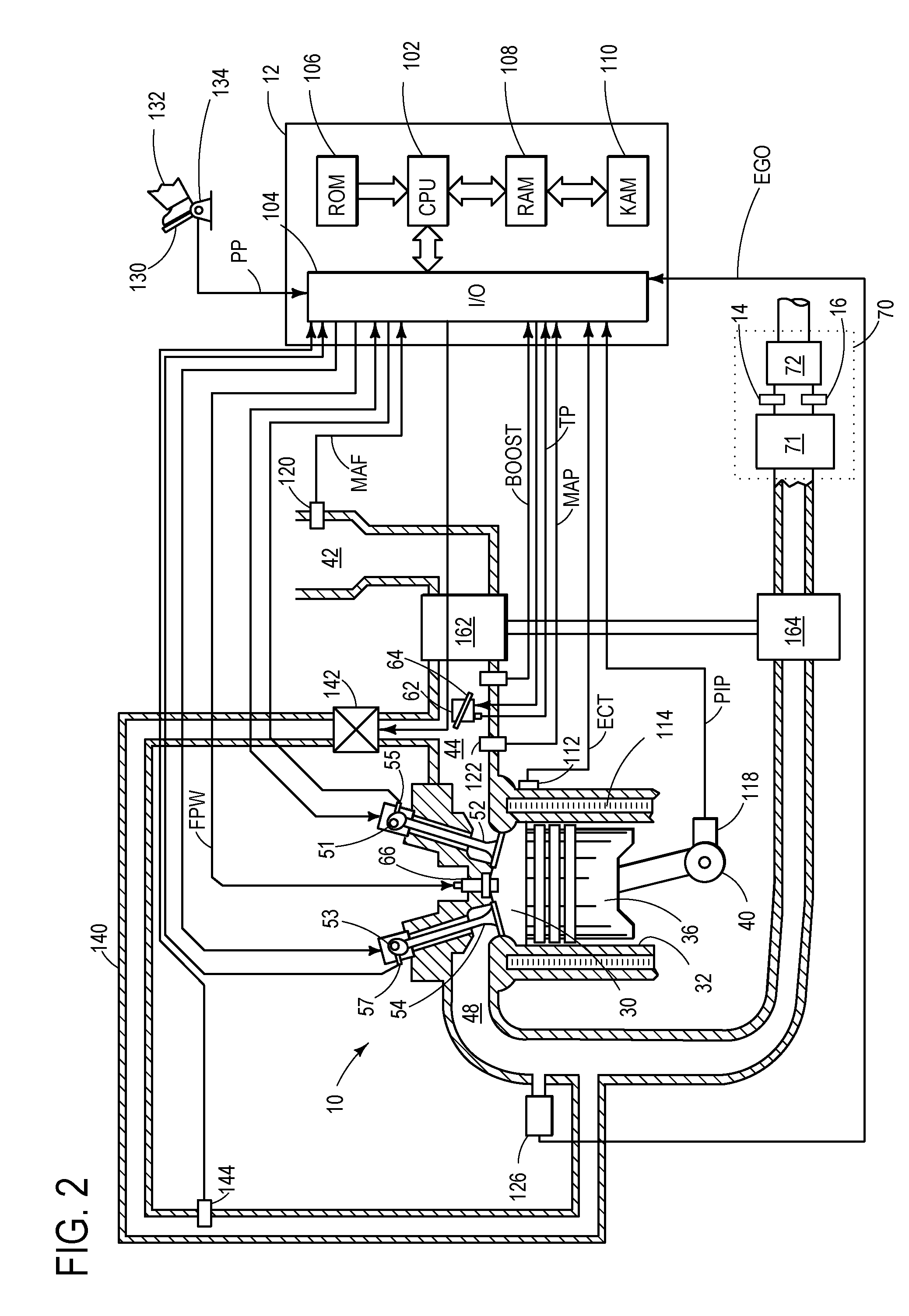

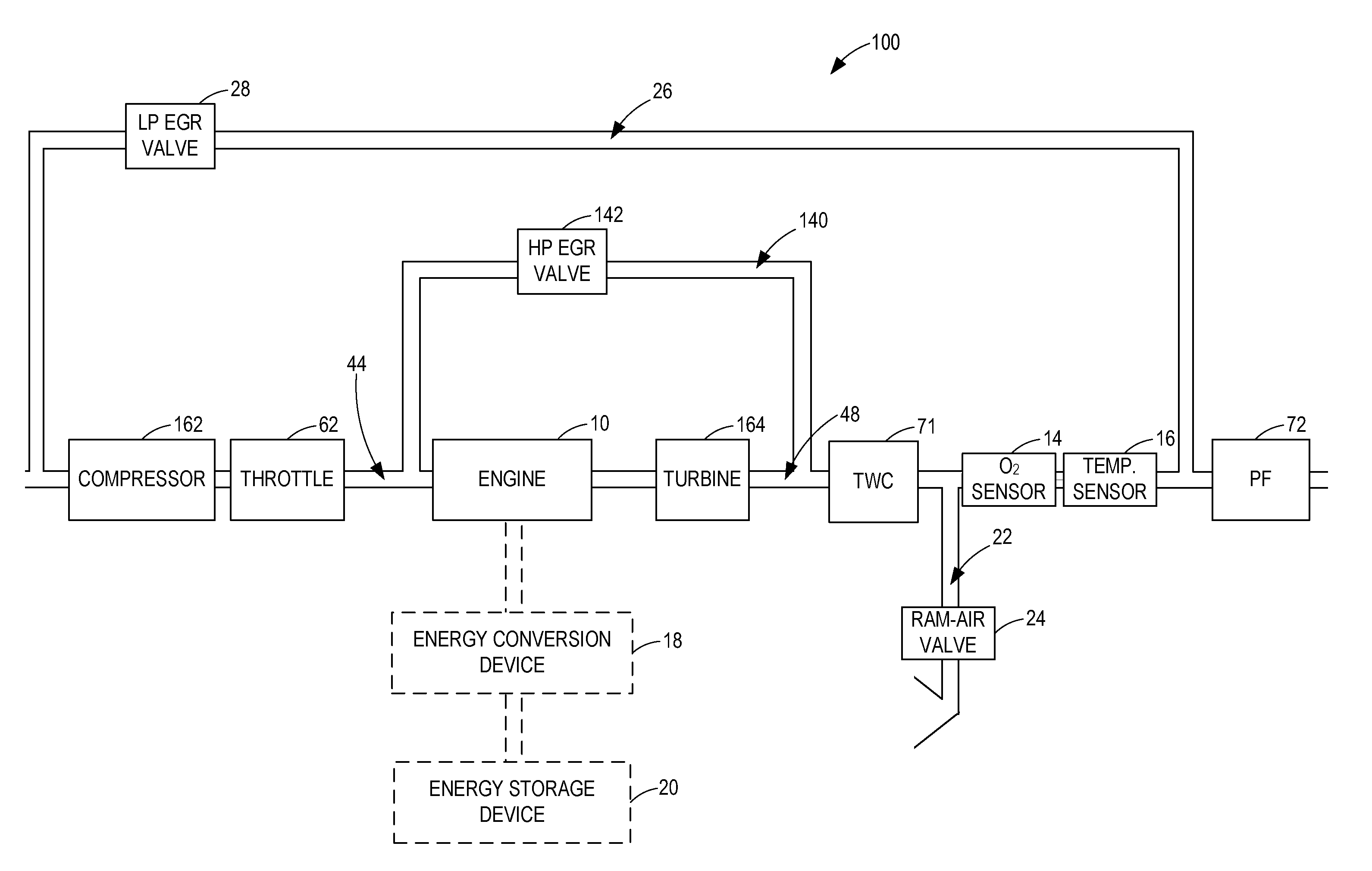

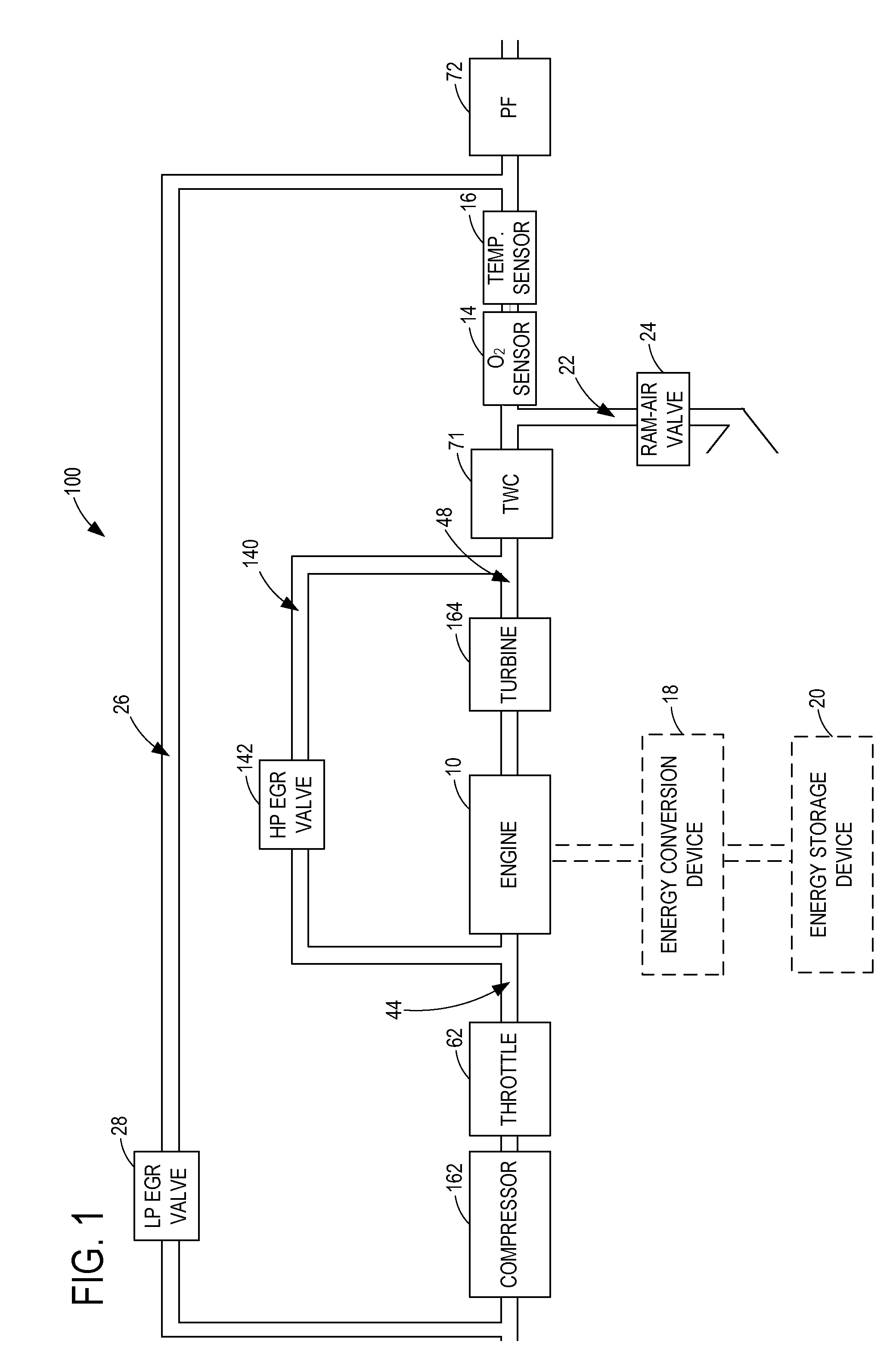

Particulate filter regeneration in an engine

ActiveUS20110072800A1Reduce engine run emissionReduce NOx emissionInternal combustion piston enginesNon-fuel substance addition to fuelAutomotive engineeringMicro particles

Systems and methods for controlling regeneration of a particulate filter downstream of an engine having a plurality of cylinders are provided. One exemplary method includes, during first conditions, spinning down the engine to non-combusting engine rest, and regenerating the particulate filter at least during engine rest. The method also includes, during second conditions, regenerating the particulate filter during combustion of at least one cylinder of the engine.

Owner:FORD GLOBAL TECH LLC

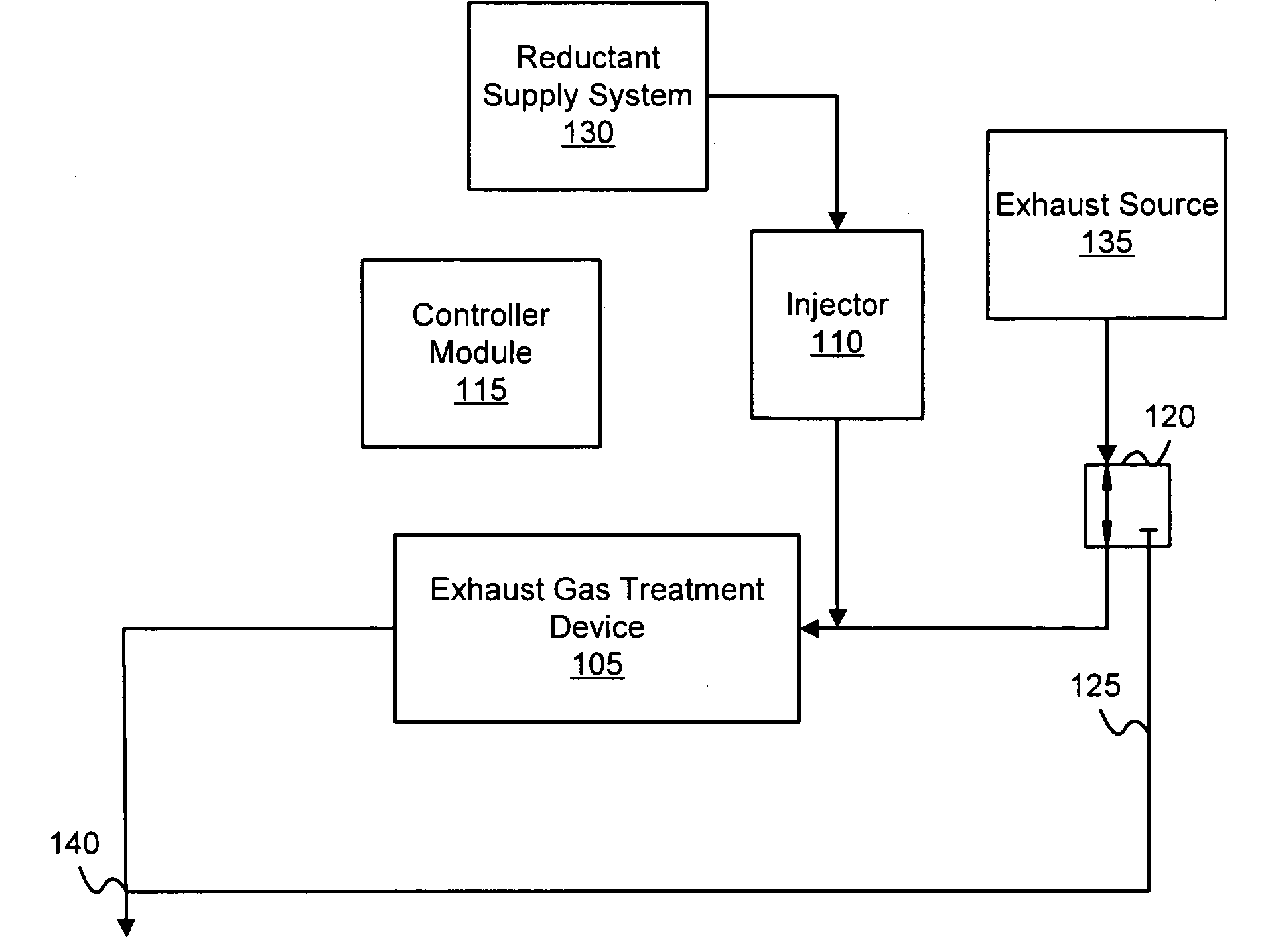

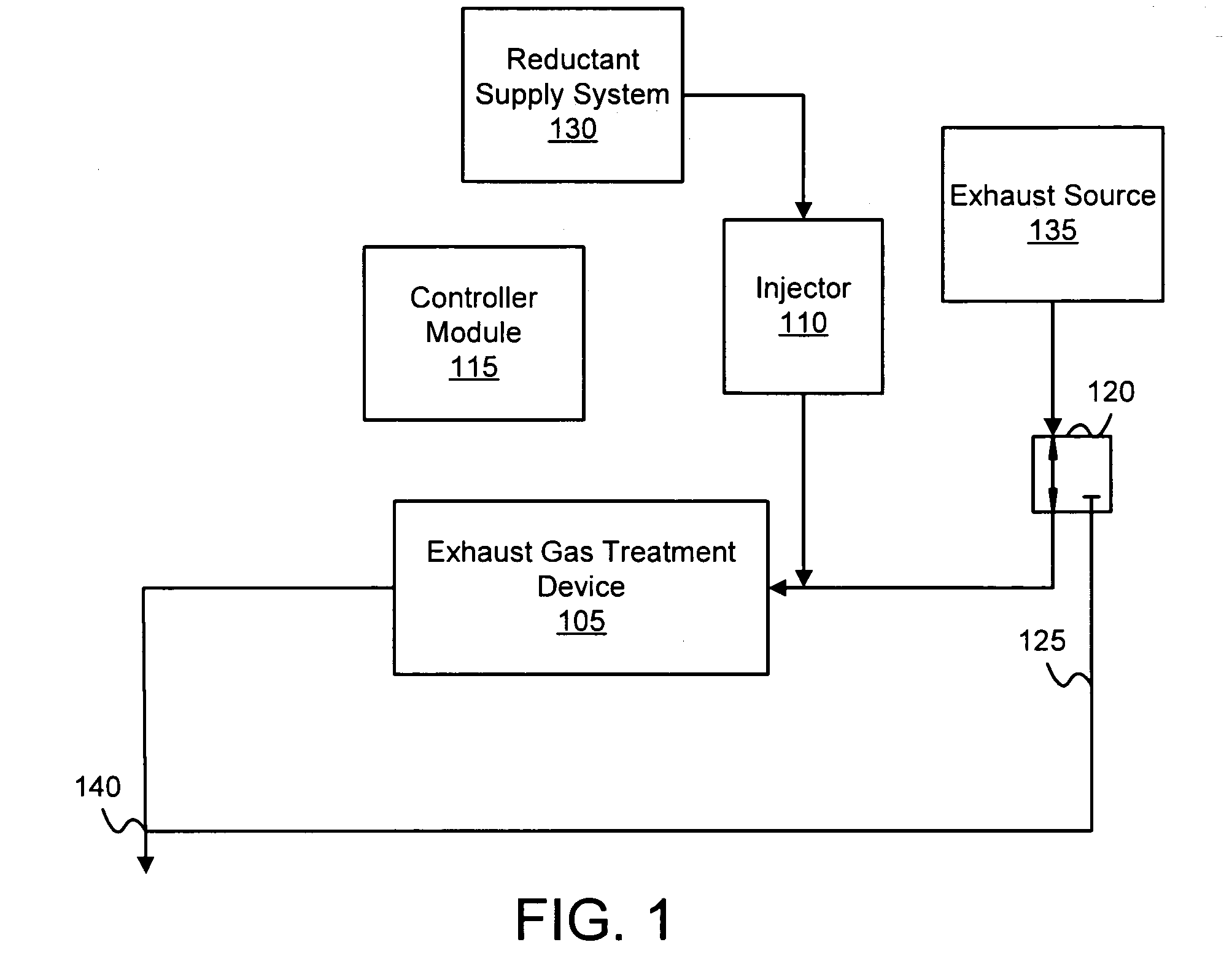

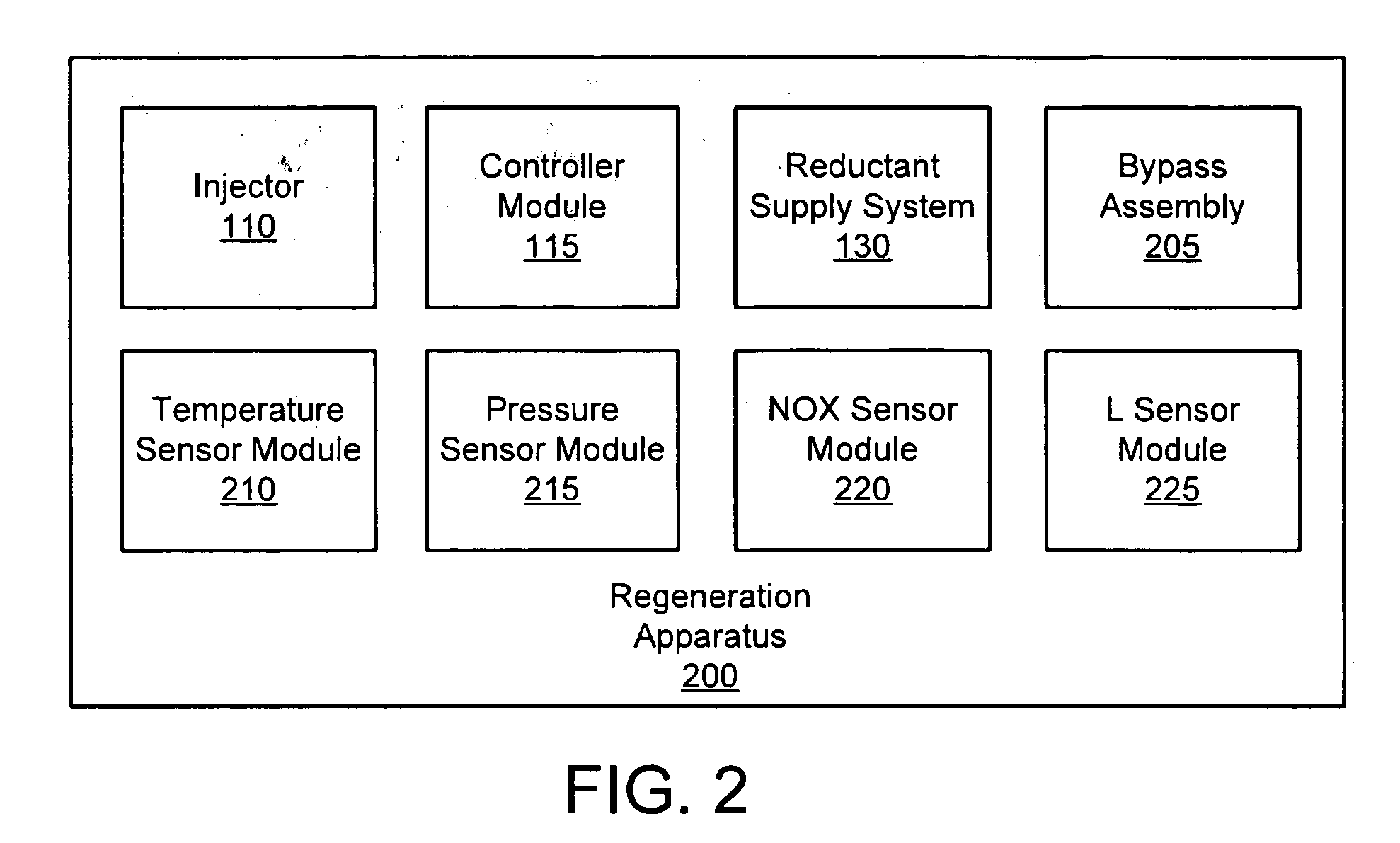

Apparatus, system, and method for regenerating an exhaust gas treatment device

ActiveUS20070220865A1Emission reductionReduce nitrogen oxide emissionsInternal combustion piston enginesExhaust apparatusExhaust fumesEngineering

An apparatus, system, and method are disclosed for regenerating an exhaust gas treatment device. A controller module directs an injector to provide reductant to an exhaust gas treatment device over a plurality of rich intervals during a regeneration cycle. In addition, the controller module directs the injector to reduce the reductant provided to the exhaust gas treatment device over a lean interval between the rich intervals to create a lean environment within the exhaust gas treatment device. In one embodiment, the controller module modifies the reductant provided during each rich interval, the number of rich intervals, the length of the rich intervals, and the length of the lean intervals in response to an exhaust gas state.

Owner:CUMMINS FILTRATION INC

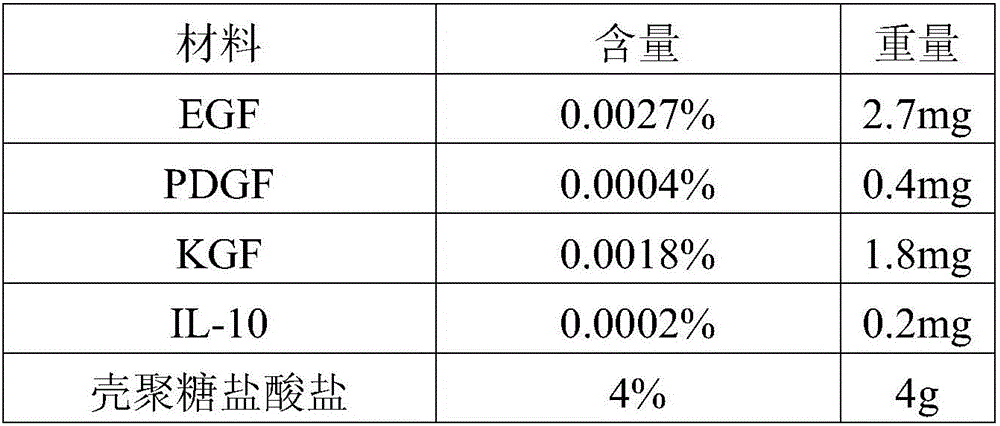

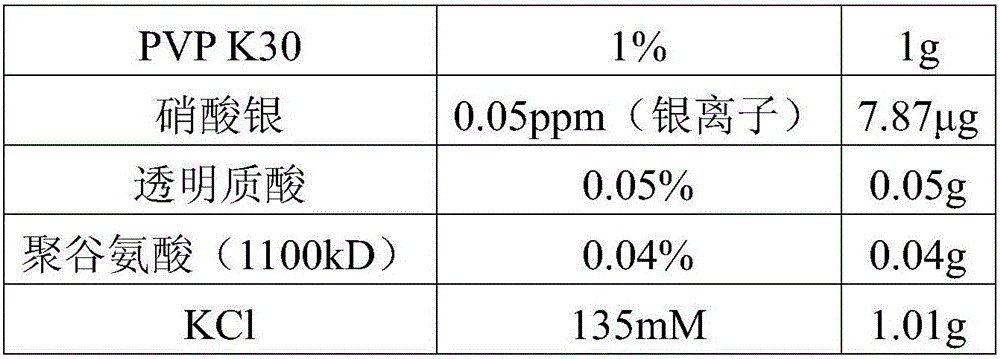

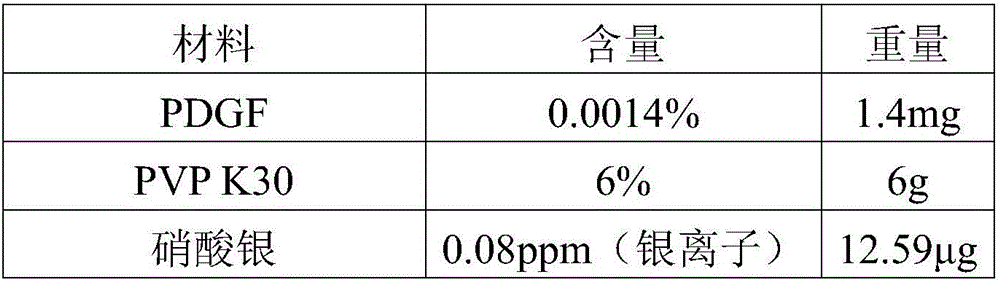

Wound repair liquid and preparation method thereof

InactiveCN106176688ATo promote metabolismPromote repairPeptide/protein ingredientsAerosol deliveryBiocompatibility TestingSolvent

The invention relates to the field of medical dressings / sprays, in particular to wound repair liquid and a preparation method thereof. The wound repair liquid contains cell factors, a film forming material and a solvent. The cell factors are one or more of EGF, PDGF, KGF and 1L-10. The film forming material is chitosan hydrochloride and / or polyvinylpyrrolidone. The solvent is deionized water or distilled water. The wound repair liquid further contains one or more of silver ions, hyaluronic acid and polyglutamic acid. Compared with the prior art, the wound repair liquid is not limited by wounds and the positions where the wounds are located; after the wound repair liquid is sprayed, the film forming speed is high, and no disengagement or breakage is likely to happen; no special smell exists, fewer chemical additives are used, and biocompatibility is good; the spray does not stimulate the wounds or skin, and no allergic reactions or drug resistance is caused; the healing time of the wounds is obviously shortened; after the wounds are healed, film-like matter can be degraded by itself, and formed inflammatory reactions and wound scars are obviously reduced.

Owner:SHENZHEN WATSIN GENETECH

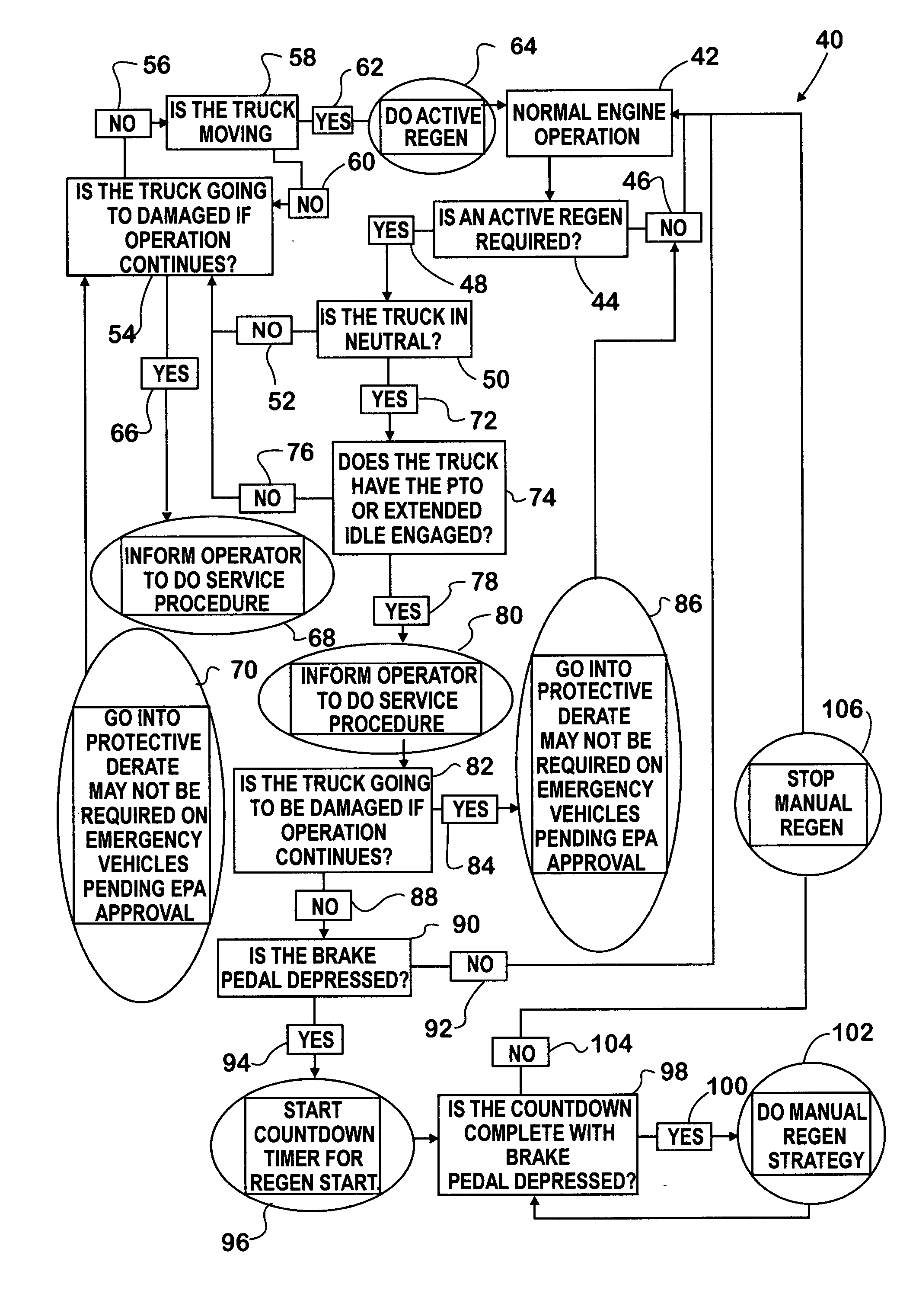

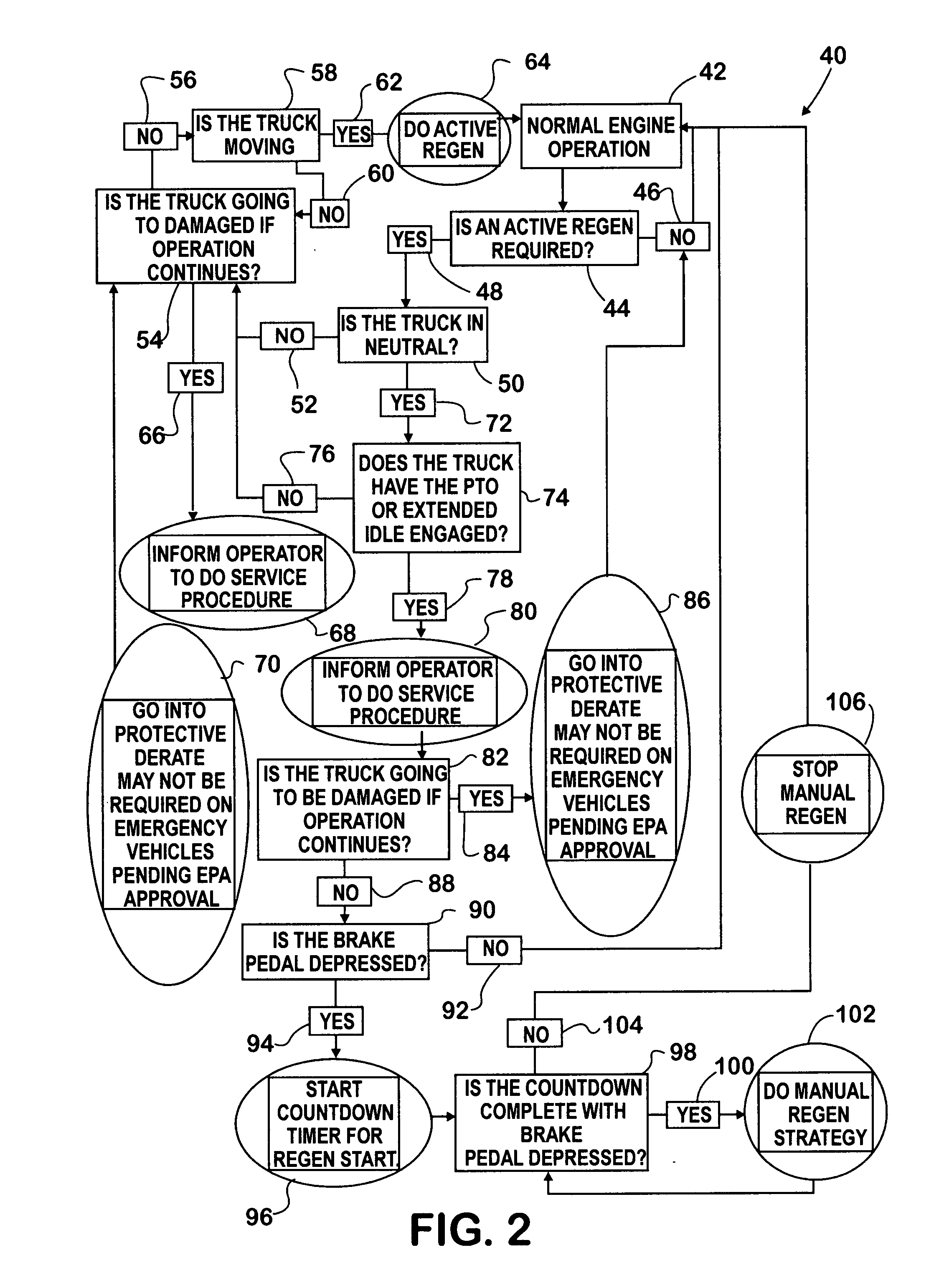

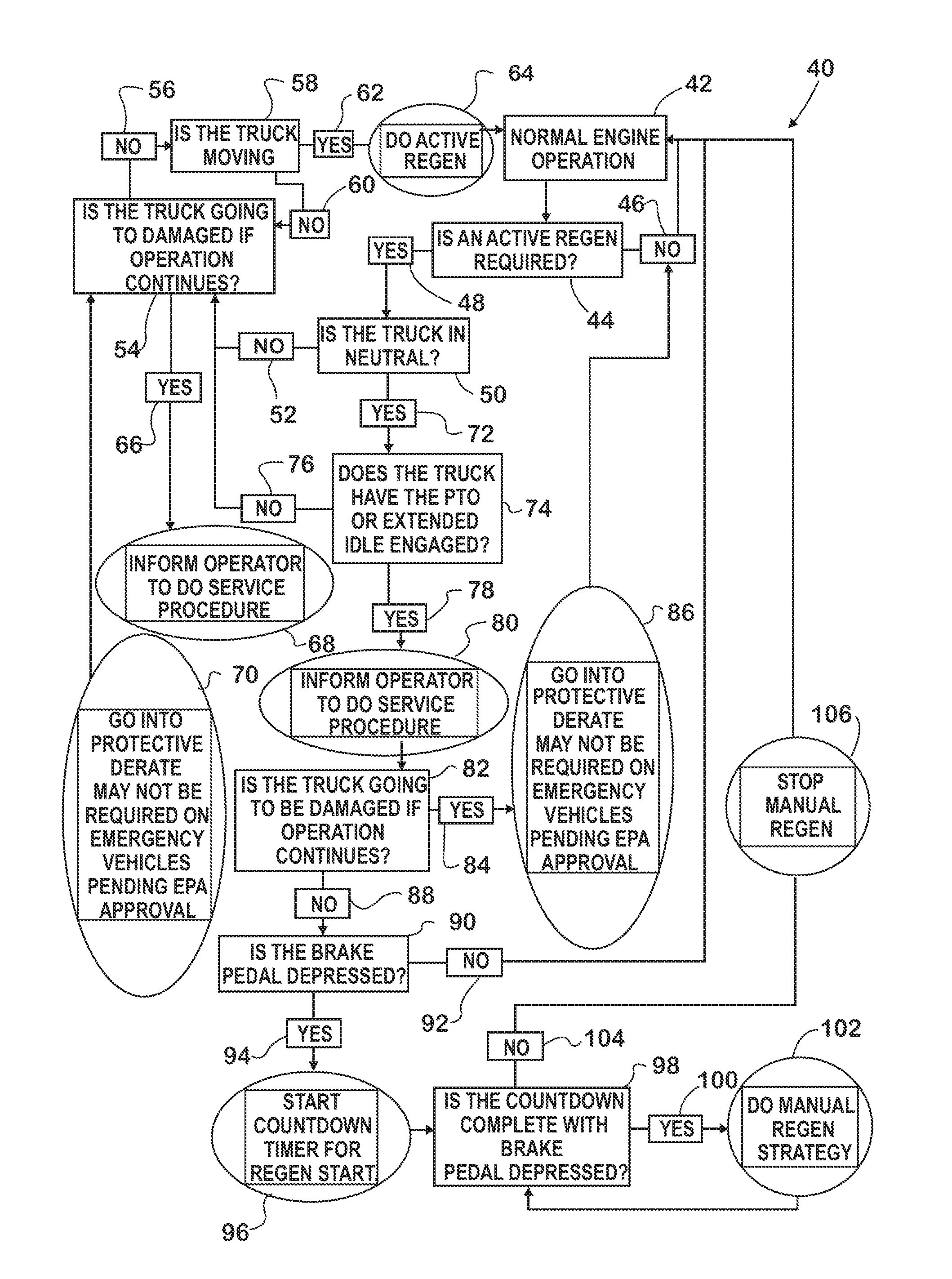

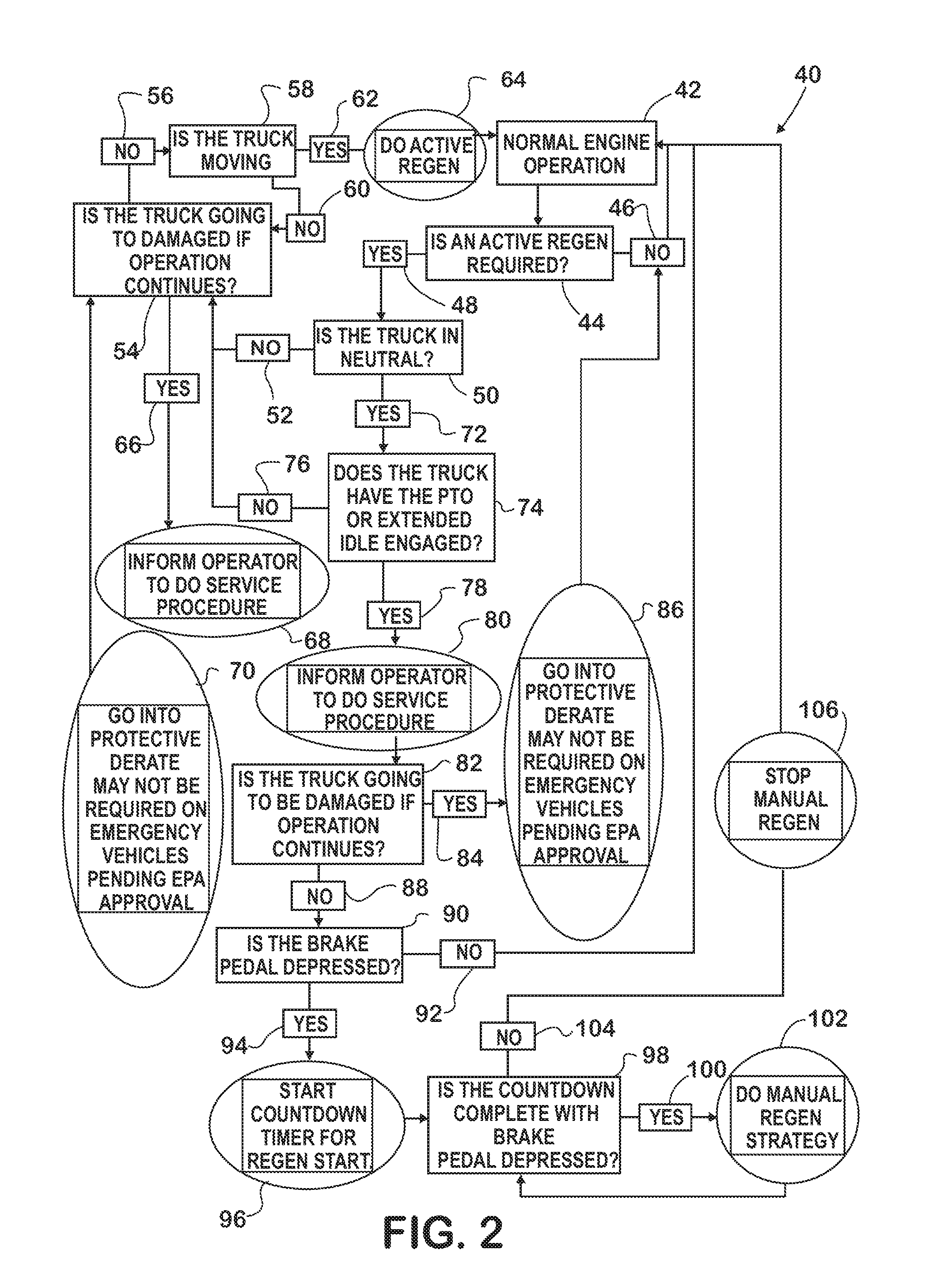

System and method for driver-initiated regeneration of a diesel particulate filter while a motor vehicle is parked

ActiveUS20080093153A1Lower regenerationCertain conditionElectrical controlInternal combustion piston enginesMobile vehicleDiesel particulate filter

A system and method for driver-initiation of regeneration of a diesel particulate filter using a service brake pedal in a motor vehicle to reduce the risk that the vehicle will become unattended during on-going regeneration.

Owner:INT TRUCK INTPROP LLC

Double-treatment cleaning and regenerating method for vanadium-titanium based denitration catalyst

InactiveCN103386313AImprove redox abilityToxic substance reductionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsTitaniumMixed gas

The invention discloses a double-treatment cleaning and regenerating method for a vanadium-titanium based denitration catalyst and aims to solve the technical problem that the regenerating effect of the traditional vanadium-titanium based denitration catalyst is not so good. According to the technical scheme, the double-treatment cleaning and regenerating method comprises the following steps of: introducing air-ozone mixed gas into a catalyst regenerating reactor, and carrying out oxidation treatment to obtain a regenerated vanadium-titanium based denitration catalyst; then, placing the regenerated vanadium-titanium based denitration catalyst into a catalyst activity liquid, dipping the regenerated vanadium-titanium based denitration catalyst for 4-6h, then, taking out the regenerated vanadium-titanium based denitration catalyst, drying the regenerated vanadium-titanium based denitration catalyst in dry air at 50-60 DEG C for 1-3h, and then, repeating the operation once; and then, roasting the regenerated vanadium-titanium based denitration catalyst at the temperature of 160-200 DEG C for 1-3h, and then, roasting the regenerated vanadium-titanium based denitration catalyst at the temperature of 300-400 DEG C for 1-3h to obtain the cleaned and regenerated vanadium-titanium based denitration catalyst. The double-treatment cleaning and regenerating method has the beneficial effects that the denitration ratio of the regenerated vanadium-titanium based denitration catalyst can be up to 87%, so that efficient regeneration is realized, meanwhile, the conversion ratio of SO2 / SO3 is effectively reduced, and the denitration cost is greatly reduced.

Owner:HEBEI MILSON TITANIUM DIOXIDE

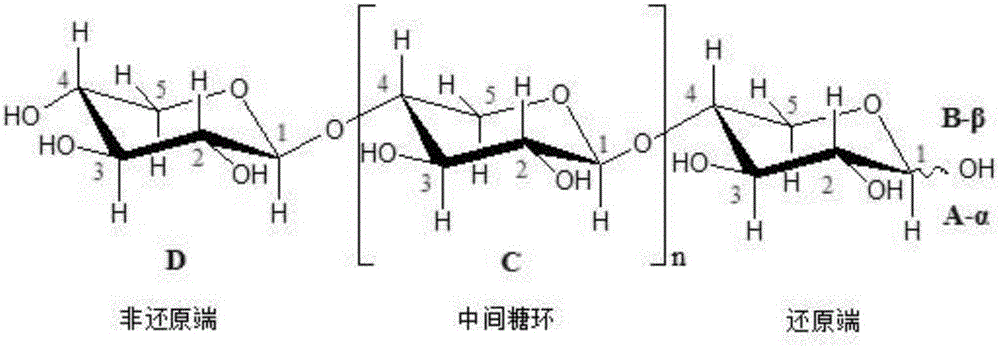

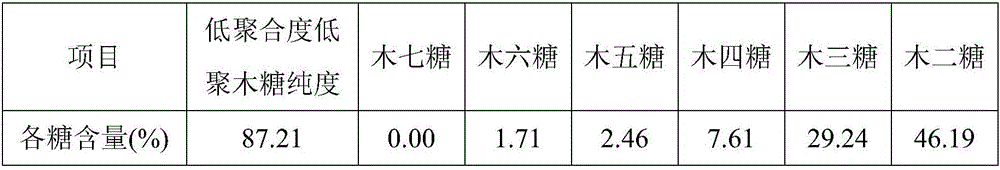

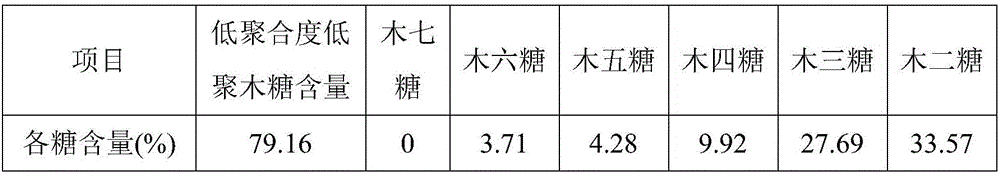

Xylooligosaccharide with low DP (degree of polymerization) as well as preparation method and application of xylooligosaccharide

PendingCN106636256AHigh dissolution ratePromote degradationBacteriaMicroorganism based processesFiberEnzymatic hydrolysis

The invention discloses a preparation method of xylooligosaccharide with low DP (degree of polymerization). The preparation method is characterized by comprising steps as follows: (1) wood fiber biomass is taken as a raw material and subjected to diluted acid / diluted base / hot water pretreatment, a liquid is filtered, a solid phase is treated in a high-temperature degrading or steam explosion pretreatment manner, and the wood fiber biomass is cooled for later use; (2) xylanase is added to a pretreatment solution in step (1) for an enzymatic hydrolysis reaction; (3) an enzymatic hydrolysis solution is treated through enzyme deactivation, purification, concentration and drying, and xylooligosaccharide with low DP is prepared. The DP of finally obtained xylooligosaccharide is low by reasonably optimizing each process step, and xylobiose, xylotriose and xylotetraose are taken as main components, so that the functionality of xylooligosaccharide as a bifidus factor is enhanced. Tests verify that prepared xylooligosaccharide has a good proliferative effect on bifidobacterium animalis and lactobacillus casei. The process is simplified, the product quality is improved, and xylooligosaccharide has good application prospect.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

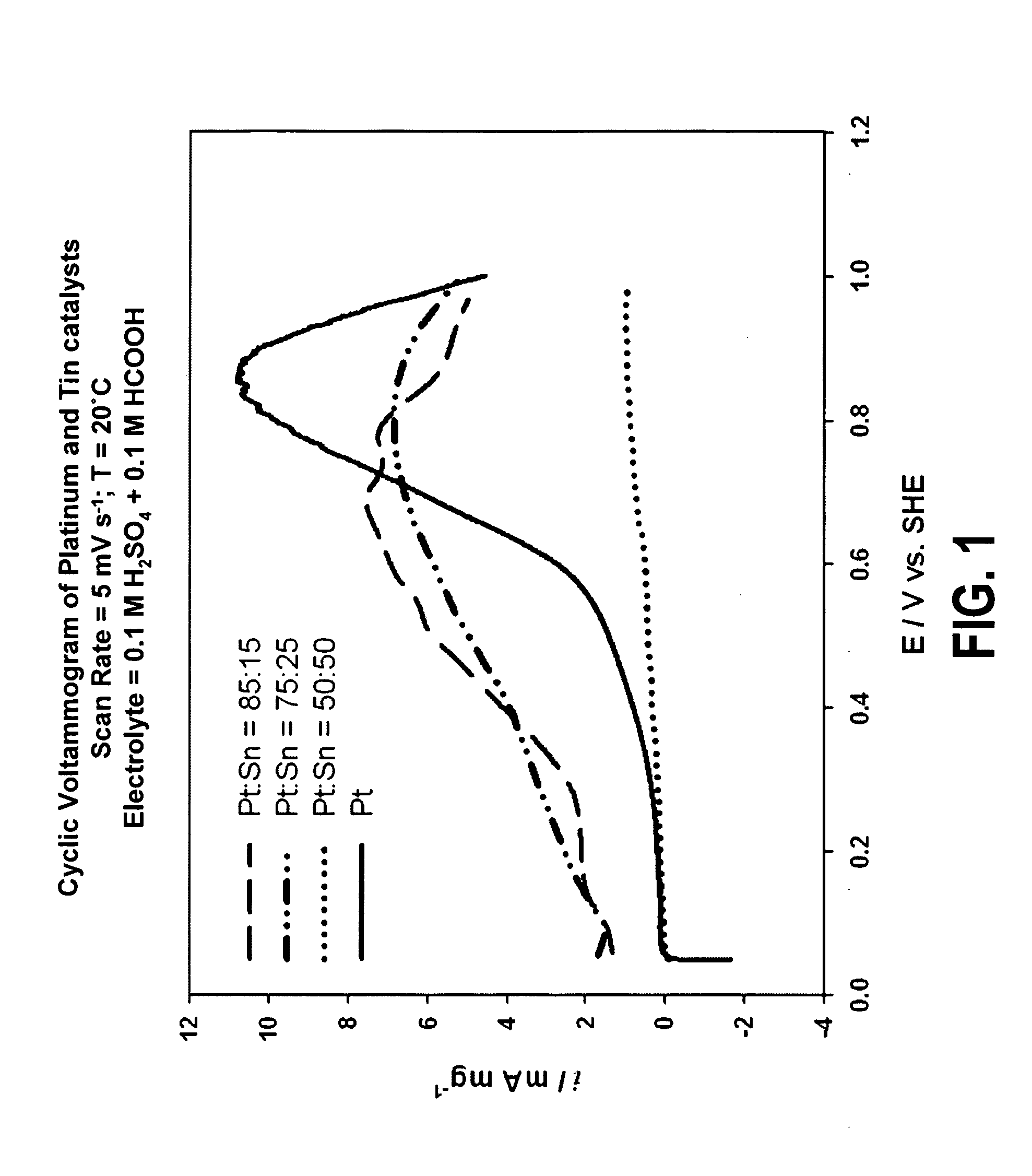

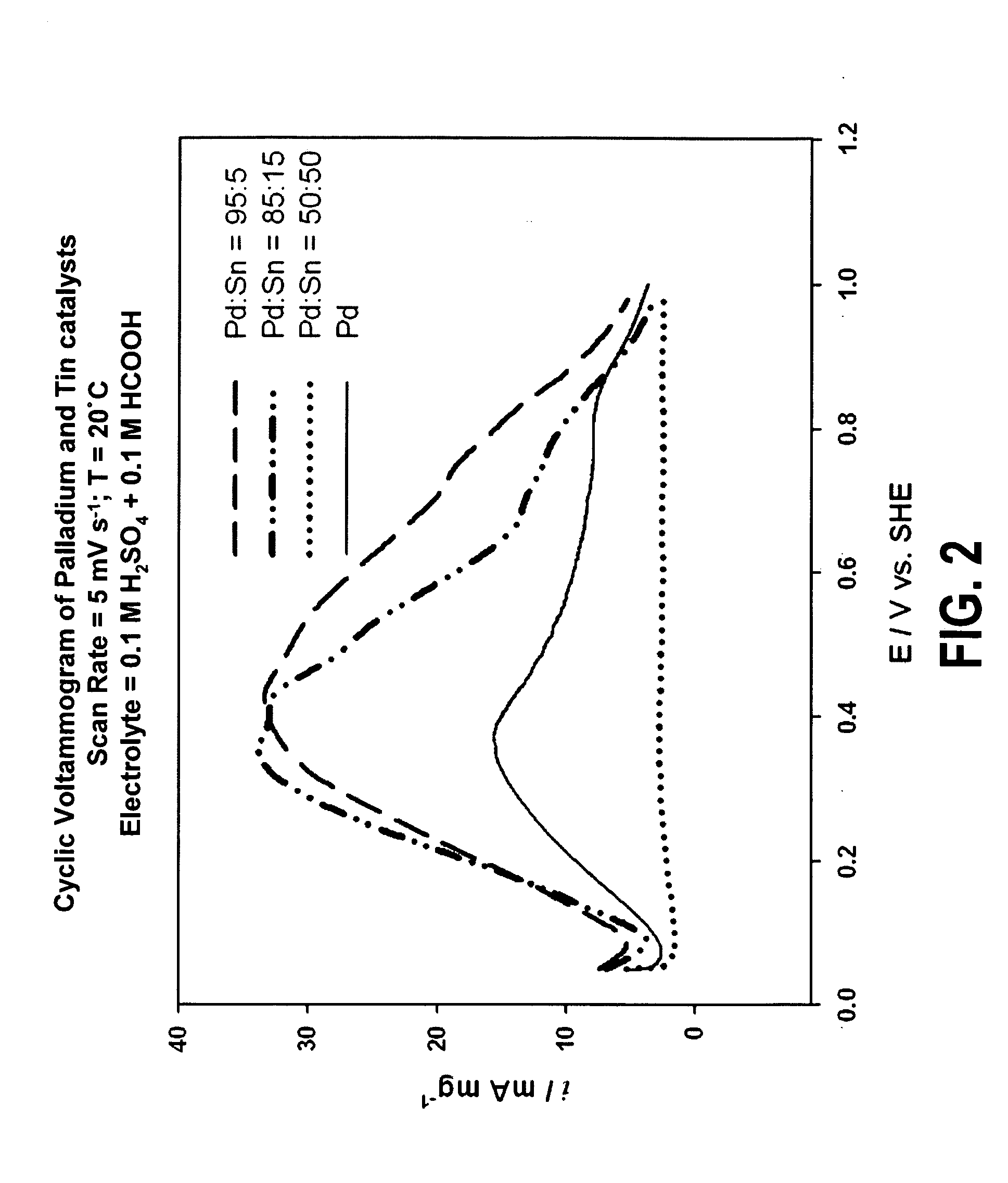

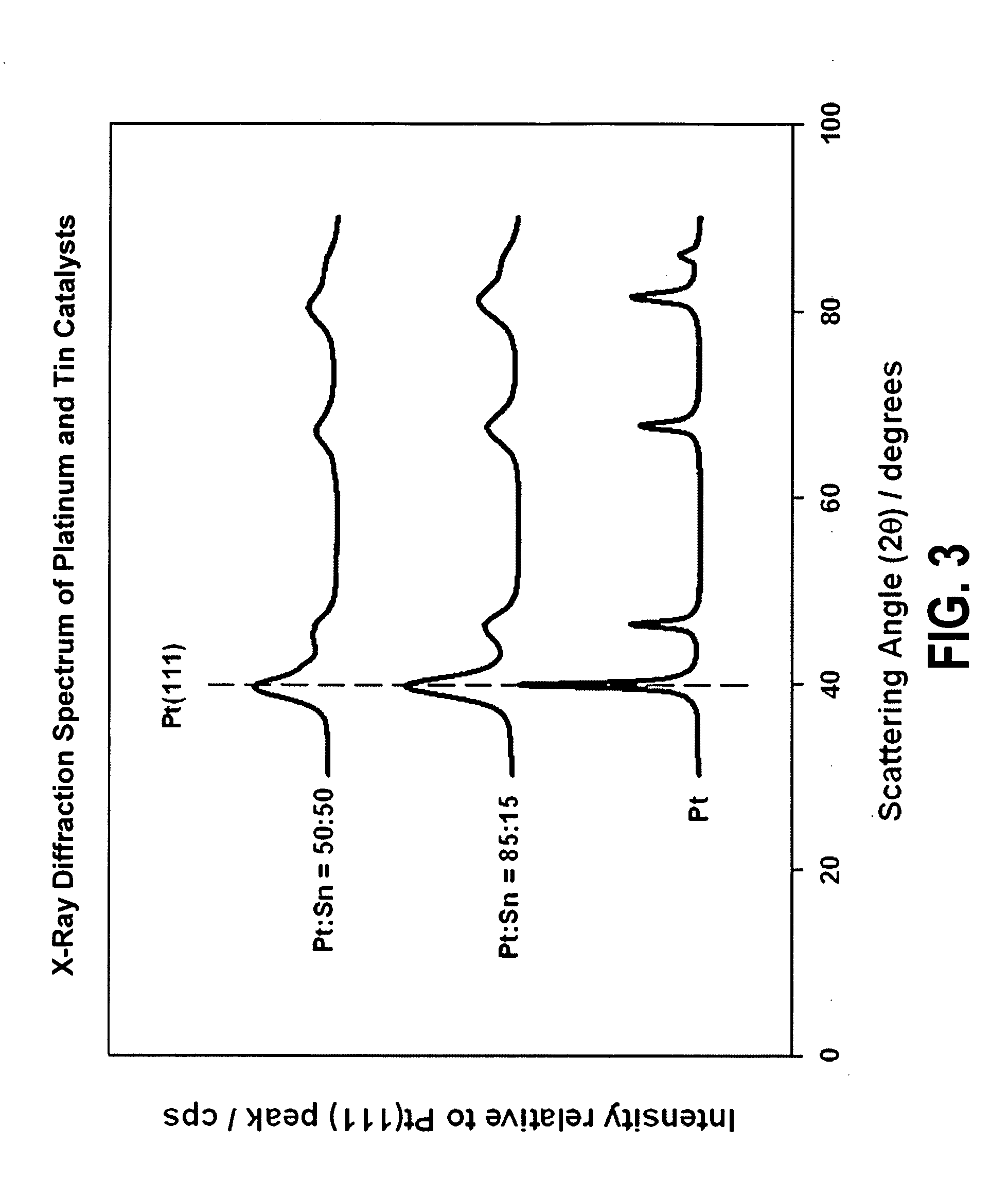

Electrochemical oxidation of formic acid using a noble metal based catalyst with admetals

InactiveUS20080241642A1Limit stabilityHigh activityActive material electrodesFuel cellsFuel cellsRoom temperature

A catalyst formulation for an organic fuel cell includes a noble metal and an admetal. The catalyst formulation can include a noble metal and an admetal in a heterogeneous mixture or a solid solution with up to about 90% degree of alloying. The admetal can encourage the oxidation of catalyst poisons at room temperature and therefore reduces the exhaustion of the fuel cell.

Owner:TEKION

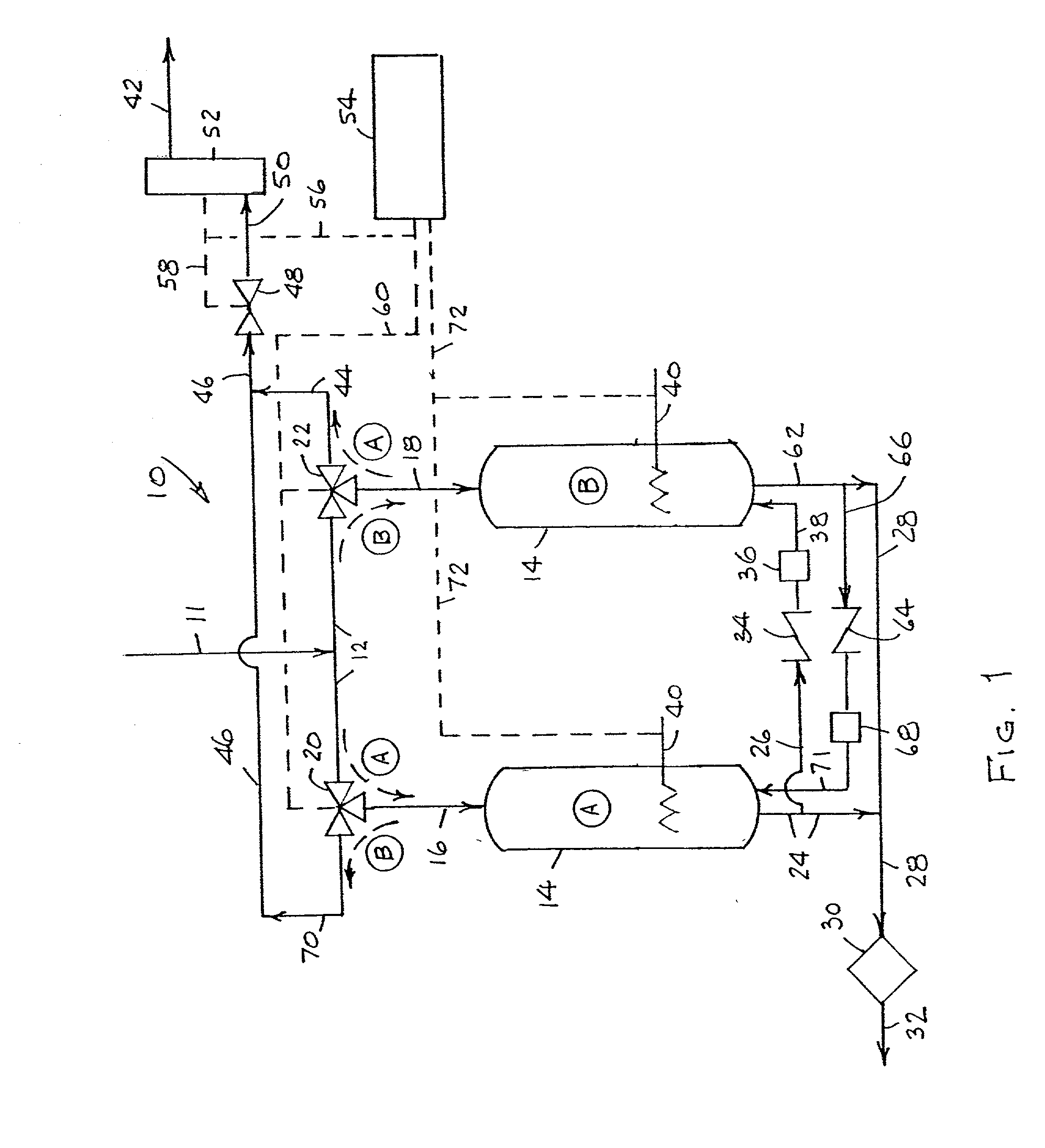

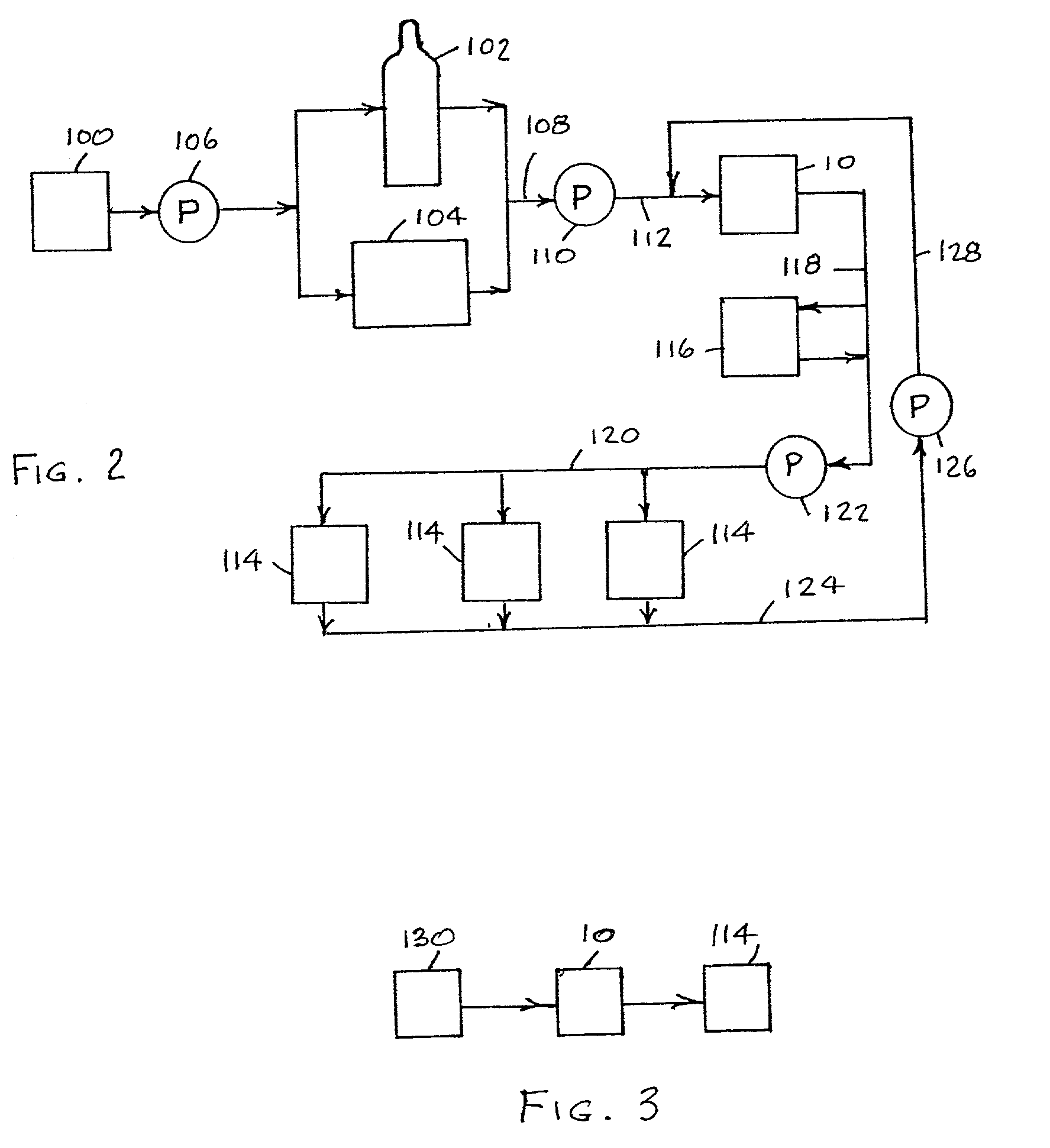

Self-regenerative process for contaminant removal from ammonia

ActiveUS20020128148A1Reduce down timeLess serviceCombination devicesCyanogen compoundsRegenerative processChemistry

A method and apparatus for the decontamination of fluid ammonia are described. Liquid or gaseous ammonia is purified of contaminants by passage through an adsorbent bed, the contaminants accumulating in the bed. A portion of the purified ammonia discharged from the bed is decomposed to hydrogen and nitrogen. The hydrogen is used to regenerate an adsorbent bed which has accumulated sufficient contaminants to reduce its ability to further decontaminate incoming ammonia satisfactorily. Preferably there are a plurality of interconnected adsorbent beds, with some being operated for ammonia decontamination while others are being regenerated, with their operations being reversed as needed to maintain a continual production of decontaminated ammonia from the plurality of beds. Computers or other controllers can be used to control such bed operations and interchanges. Internal production of hydrogen makes the system self-contained and no addition of hydrogen is needed.

Owner:ENTEGRIS INC

PEPSET resin moulding and sand cyclic utilization clean casting technology

ActiveCN103934411AFast and uniform curingLower regenerationFoundry mouldsMould handling/dressing devicesProcess engineeringRaw material

The invention relates to a PEPSET resin moulding and sand cyclic utilization clean casting technology. The technology comprises the following steps: using raw materials to carry out PEPSET resin sand moulding: putting a sand core into a mould cavity, closing the mould cavity by using an automatic mould closer, then casting with molten iron; shaking out the sands after the moulding of product; transferring the old sands into a waste sand regeneration processing system; wherein the regenerated sands can be applied to a cold box core blower to manufacture sand cores, thus the addition amount of new sands is reduced, and the cyclic utilization of old sands is achieved.

Owner:LAIZHOU XINZHONGYAO MACHINERY

System and method for driver-initiated regeneration of a diesel particulate filter while a motor vehicle is parked

ActiveUS7685815B2Lower regenerationCertain conditionElectrical controlInternal combustion piston enginesMobile vehicleDriver/operator

A system and method for driver-initiation of regeneration of a diesel particulate filter using a service brake pedal in a motor vehicle to reduce the risk that the vehicle will become unattended during on-going regeneration.

Owner:INT TRUCK INTPROP LLC

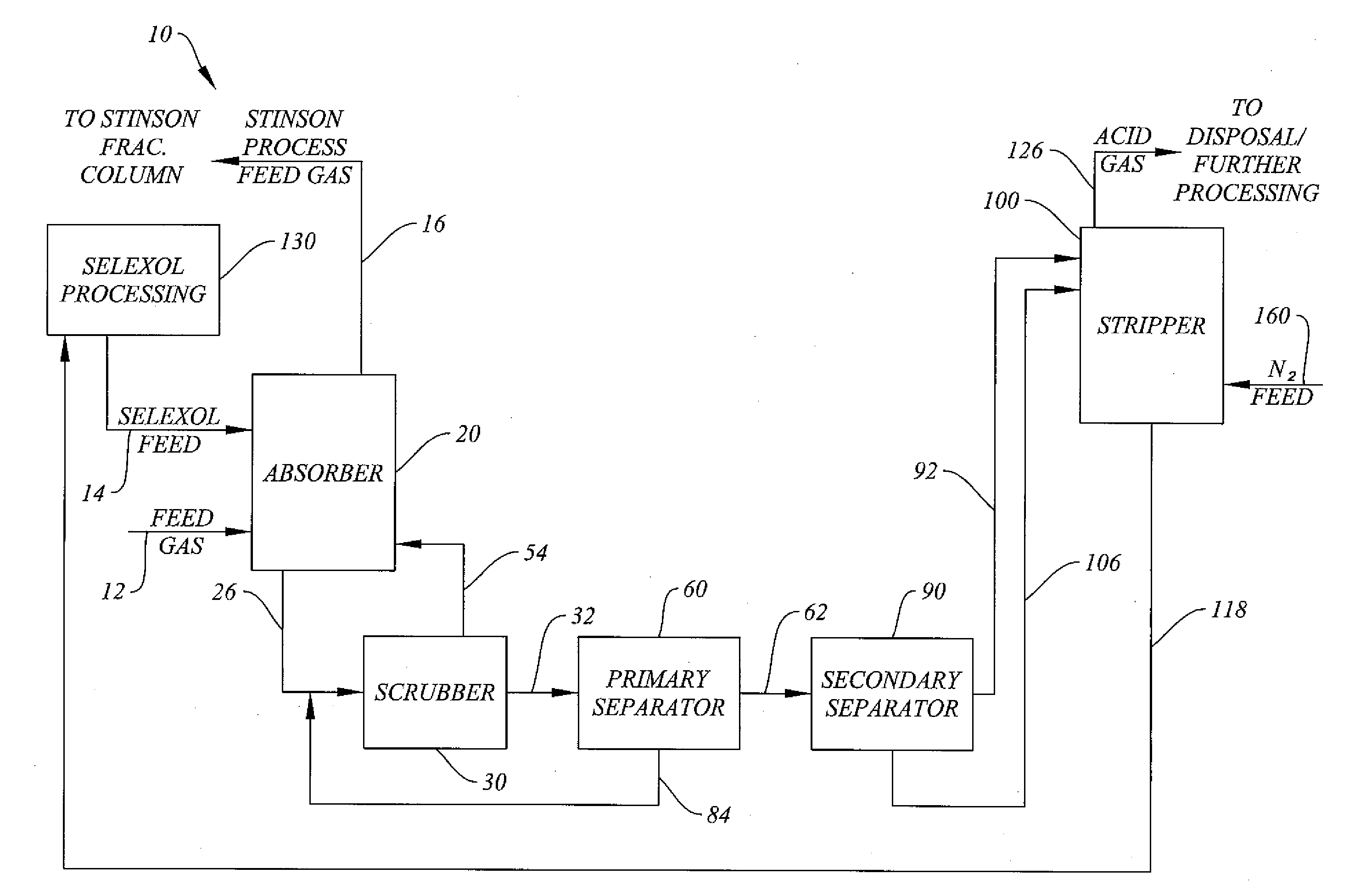

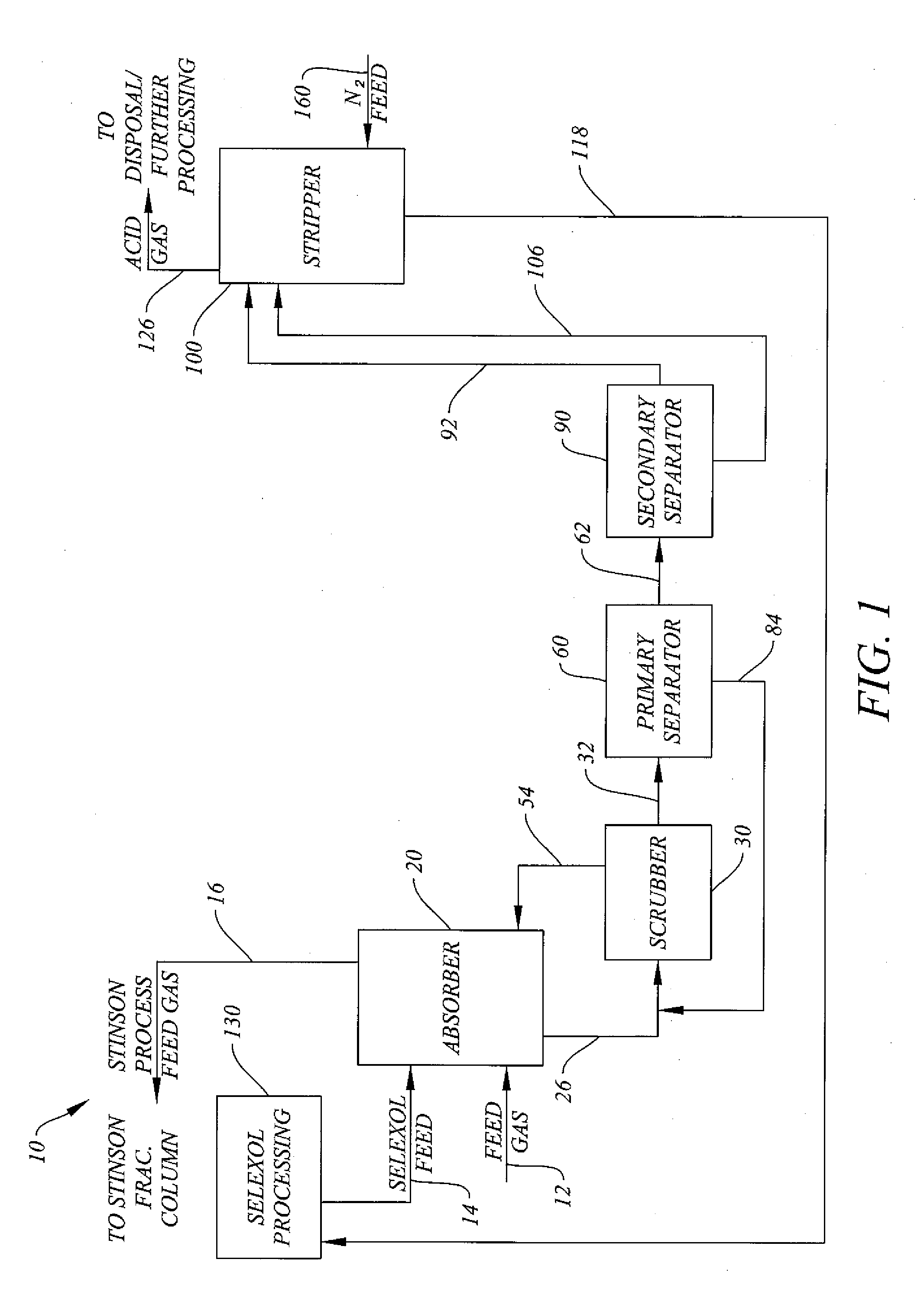

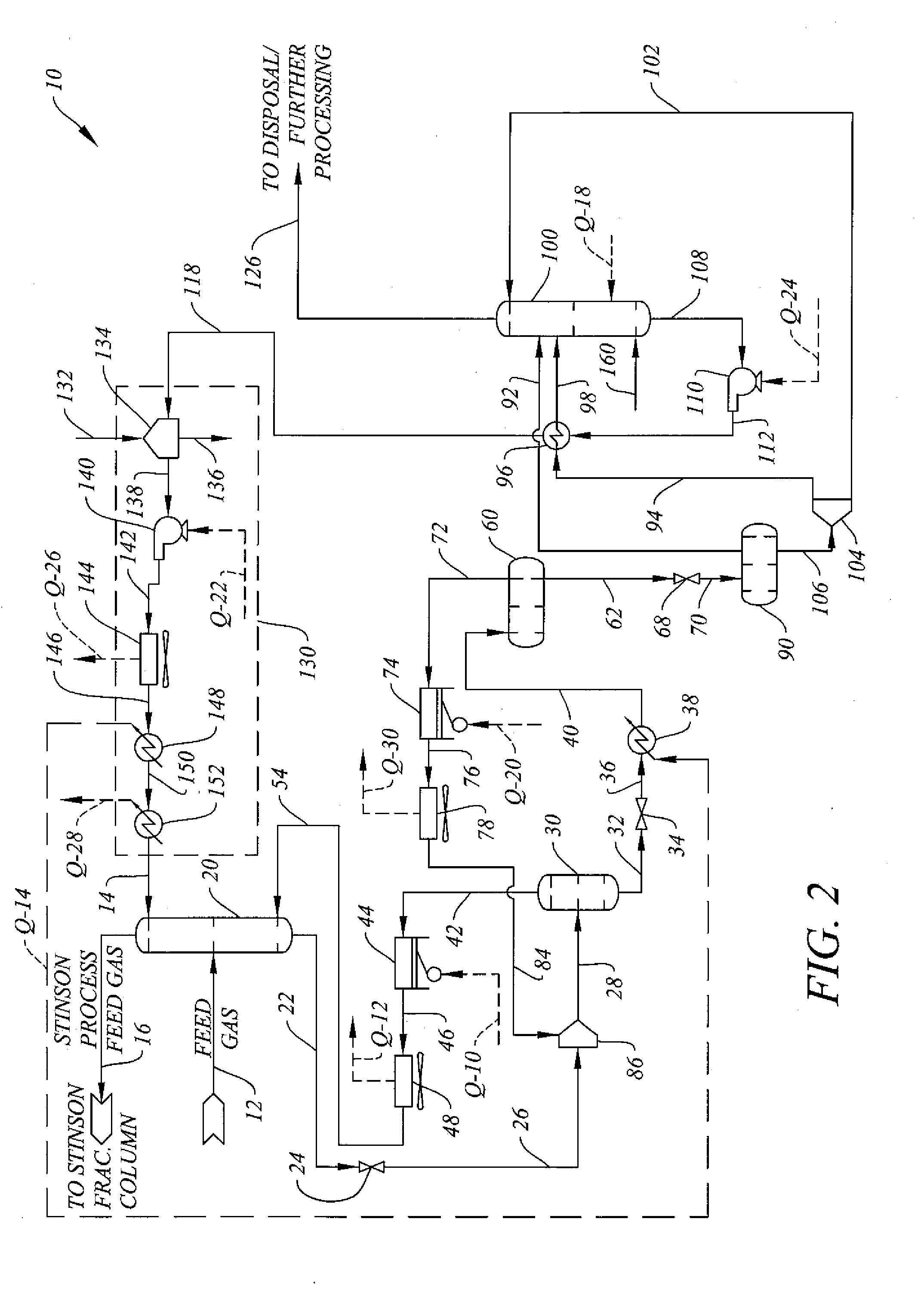

System and Method for H2S Removal Integrated with Stinson Process CO2 Removal

ActiveUS20140275691A1Improve processing efficiencyEfficient removalGas treatmentLiquid degasificationCo2 removalNitrogen

A system and method for efficiently removing hydrogen sulfide from a natural gas feed stream to produce a Stinson Process feed stream and an acid gas stream. A first solvent separates the majority of the carbon dioxide and hydrocarbons from the hydrogen sulfide in the natural gas feed to produce the Stinson feed stream. By removing the majority of the hydrogen sulfide prior to feeding the Stinson Process, a carbon dioxide stream suitable for use in flooding operations may be produced with the Stinson Process. The system and method also increase the concentration of hydrogen sulfide in the acid gas stream, making it suitable for sulfur recovery operations. The system and method are particularly suitable for natural gas feed streams containing 0.5%-20% hydrogen sulfide and at least 20% carbon dioxide. Operation in an anhydrous mode with the addition of nitrogen aids in solvent recovery for recycling.

Owner:BCCK HLDG CO

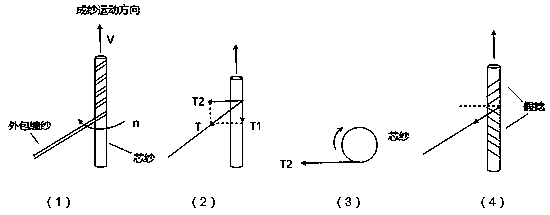

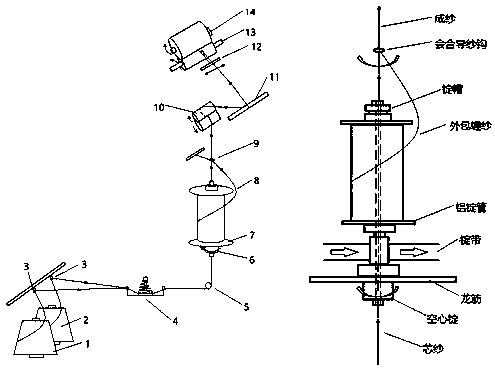

Machining method of wrapped structural flax and polyester filament section color composite yarn and composite yarn

The invention provides a machining method of a wrapped structural flax and polyester filament section color composite yarn and a composite yarn. A section color effect principle of fusing and twistingtwo yarns with different colors, a specific false twisting effect of core yarns when a hollow ingot is subjected to wrap spinning of an externally-wrapped yarn and the core yarns are wound, a twist instability principle of the specific false twisting effect and an uneven distribution principle of a twist on a plucked yarn are comprehensively utilized; by enabling double core yarns to generate anirregular section color effect and adopting the colorless excellent-transparency filament (monofilament or less-number multifilament) externally-wrapped yarn to carry out wrapping consolidation, the flax composite yarn with section color characteristics is obtained. Wrinkle resistance of flax fabric can be effectively improved, yarn hairiness is reduced, hairiness regeneration is reduced, weavability is improved, section color appearance is given to the yarn and the fabric thereof, and the fabric is woven in a dyeing-free and sizing-free mode.

Owner:JIAXING UNIV

Night maintenance mask solution and preparation method thereof

InactiveCN104983646APromote regenerationLower regenerationCosmetic preparationsToilet preparationsIrritationGlycerol

A night maintenance mask solution is made through dipping a liquid in mask paper, and 1000 parts of the liquid are prepared from, by weight, 0.5-3 parts of micro-molecular hyaluronic acid, 1-5 parts of an aloe extract product, 0.7-9 parts of propylene glycol, 5-50 parts of 1,2-butylene glycol, 5-30 parts of glycerin, 20-50 parts of a ginseng extract liquid, 10-50 parts of a licorice root extract liquid, 5-20 parts of rose hydrolat, 1-10 parts of ethyl ascorbic acid, 0.5-5 parts of silk peptides, 0.5-5 parts of argireline peptides, 0.5-5 parts of apple stem cells, and the balance of water. The night maintenance mask solutionis aqueous, can rapidly enter skins, can remove wrinkles, has water supplementation, water retention, restoration, nutrition supplementation, anti-inflammation, bacterium prevention, itch relief and anti-allergy effects in skins, participates in and promotes cell metabolism, relieves skin wrinkles, enhances the skin elasticity, also has the advantages of no irritation to skins and no abnormal sensation, long action time and substantial effect, and is suitable for all skin types.

Owner:GUILIN HONGXU BIOTECH CO LTD

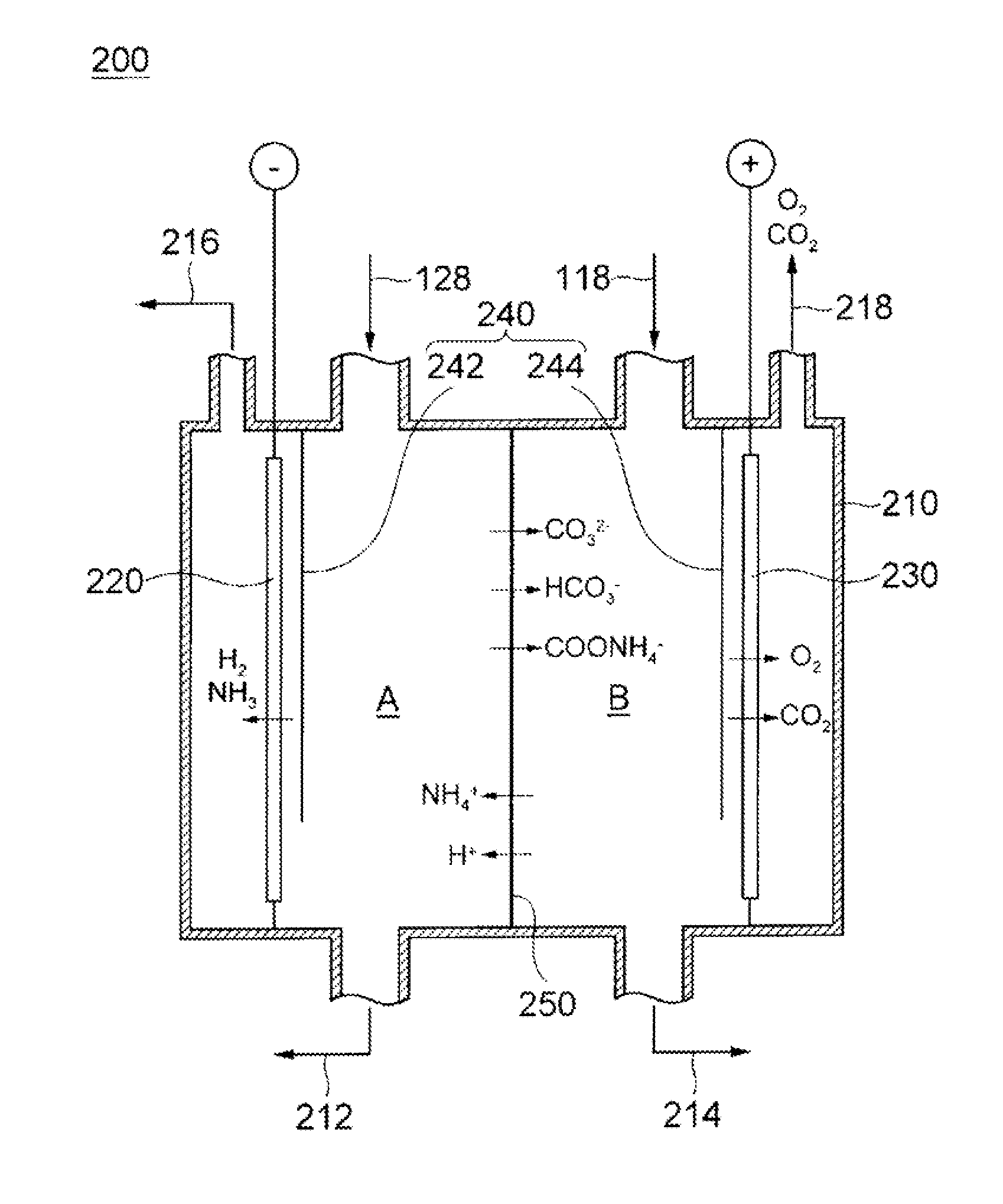

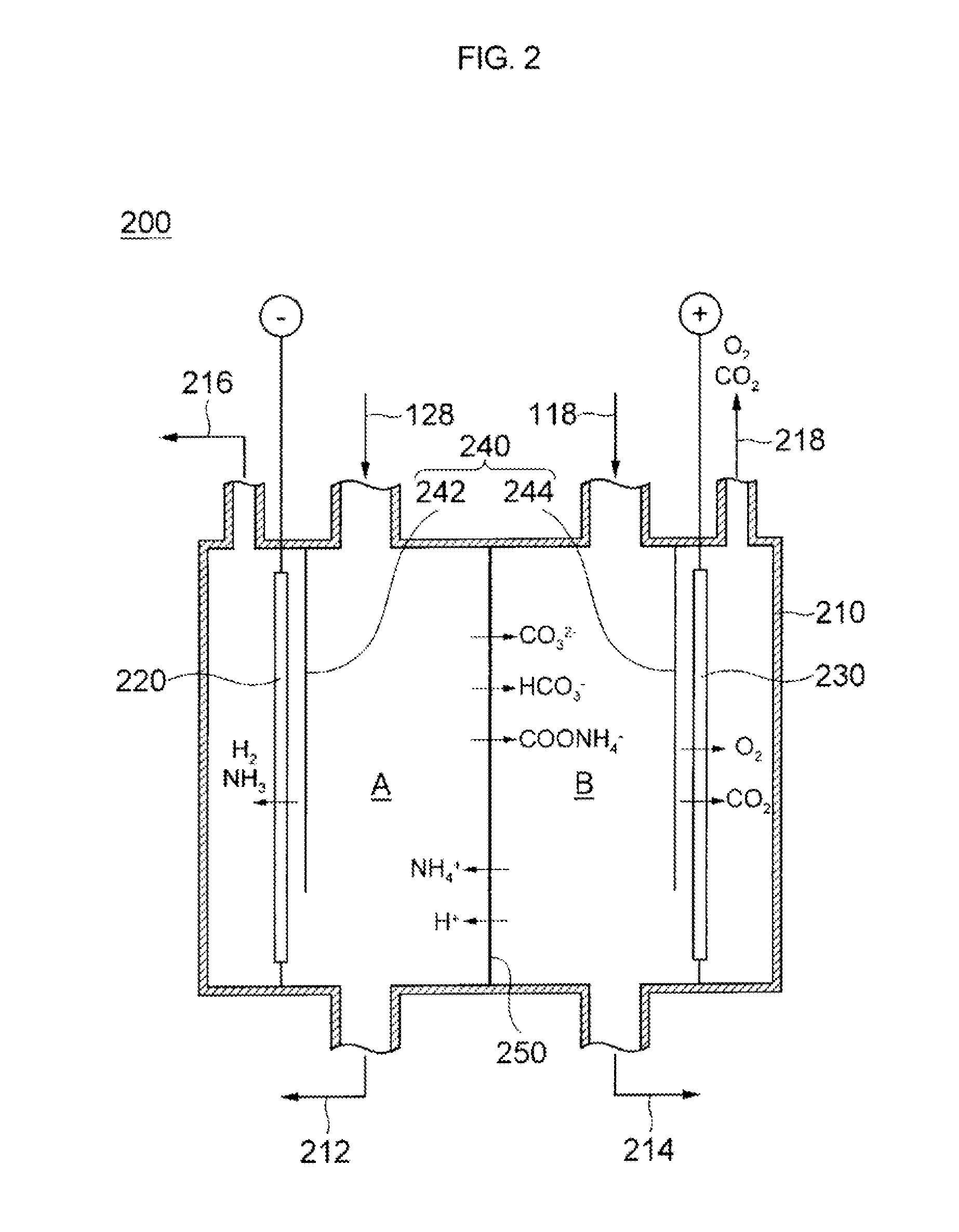

Carbon dioxide isolating device and method

ActiveUS20120240764A1Improve regeneration efficiencyImprove stripping efficiencyGas treatmentDispersed particle separationAbsorption columnIon exchange

An apparatus for separating carbon dioxide is provided. The apparatus includes: an absorption column in which carbon dioxide in off-gas is allowed to react with an absorbent solution so as to strip the carbon dioxide from the off-gas; a regeneration column in which the carbon dioxide is removed from the absorbent solution to regenerate the absorbent solution; and an ion-exchange column including a chamber having a cathode chamber space that receives the absorbent solution from the absorption column and an anode chamber space that receives the absorbent solution from the regeneration column, the ion-exchange column further including a permeable membrane that divides the chamber into the cathode chamber space and the anode chamber space.

Owner:KOREA INST OF ENERGY RES

Cigarettes made from enhanced plant leaves with trace elements and production thereof

InactiveCN1817250AEffective controlMeet the needs of smokingTobacco treatmentBee productsTrace element

A health-care cigarette is prepared from the leaves of aloe, soybean, black bean, sesame, peanut, prickly ash, sun flower and jute, trace elements intensifier, and bee product through slitting said plant leaves, removing stems, drying, steaming, immersing in the mixture of said trace element intensifier and bee product, sealing, fermenting drying and rolling cigarettes.

Owner:成钢

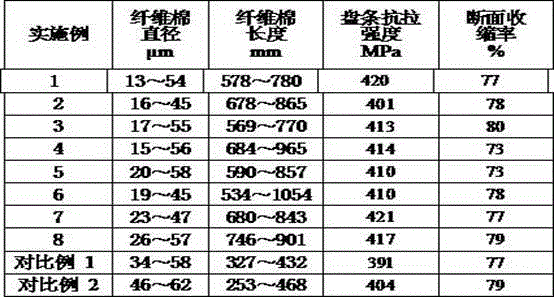

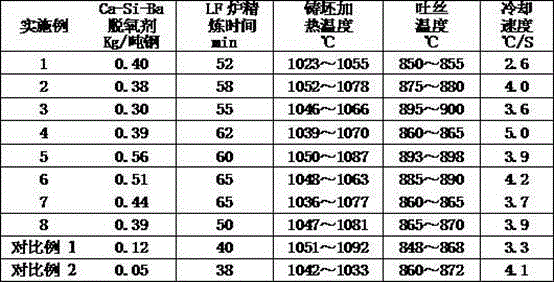

Steel wire rod with a length of greater than or equal to 500 mm used for long-fibered steel wools and production method thereof

The invention discloses a steel wire rod with a length of greater than or equal to 500 mm used for long-fibered steel wools, which comprises the following components in percentage by weight: 0.06-0.10% of C, 0.085-0.24% of Si, 0.85-1.20% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020 % of S, less than or equal to 0.01% of O [T], and less than or equal to 0.005% of Als. The production method comprises the following steps: carrying out molten iron desulphurization and converter melting; conventionally carrying out ladle argon blowing and pre-deoxidation for slag making; carrying out refining in a LF furnace; carrying out continuous casting on the obtained objects so as to obtain blanks; conventionally heating the blanks and carrying out high-speed wire rod rolling; and carrying out conventional delayed cooling on the obtained product and collecting coils for standby. The length of fibers produced by using the method disclosed by the invention is not less than 500 mm, and thinner, the tensile strength of the steel wire rod is not more than 420 MPa, the percentage reduction of area is not less than 70%, and the steel wire rod is soft in handfeel, and no slag drops. The steel wire rod is applicable to the polishing of stone materials and ceramic tiles and the burnishing and cleaning of various high-grade furniture, and extremely easy to degrade; and because the main composition is iron, the steel wire rod after degraded does not pollute the environment.

Owner:武钢集团有限公司

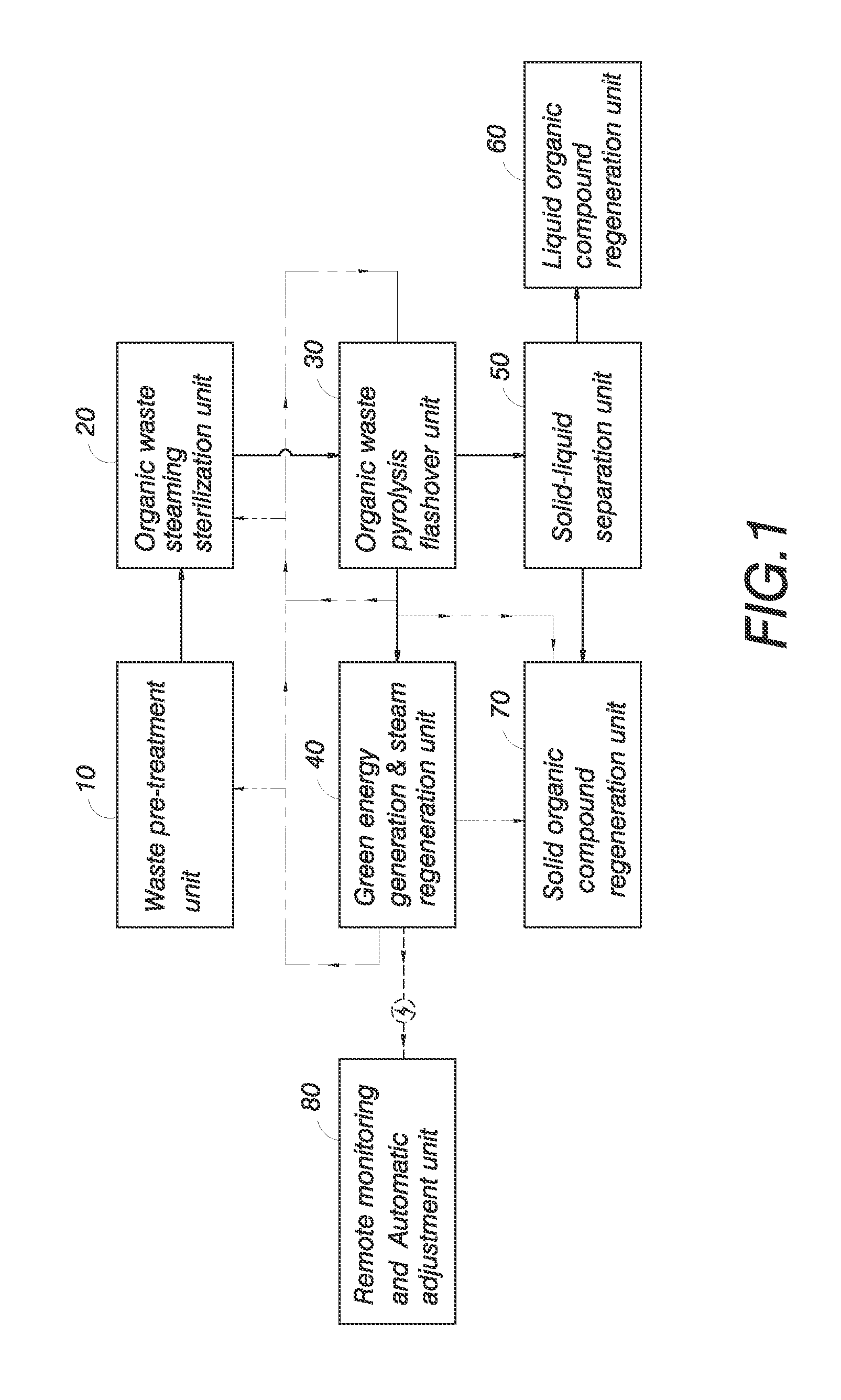

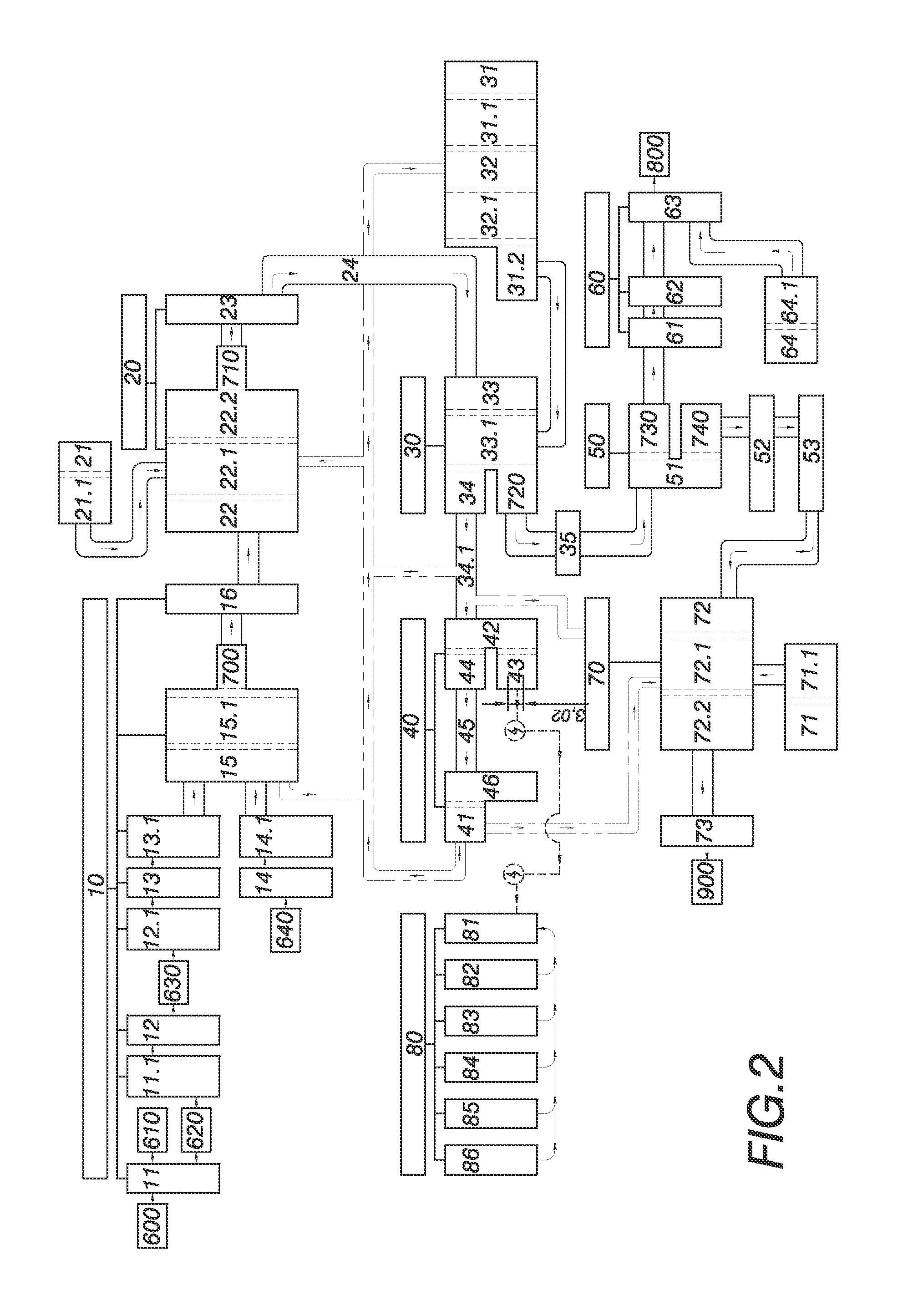

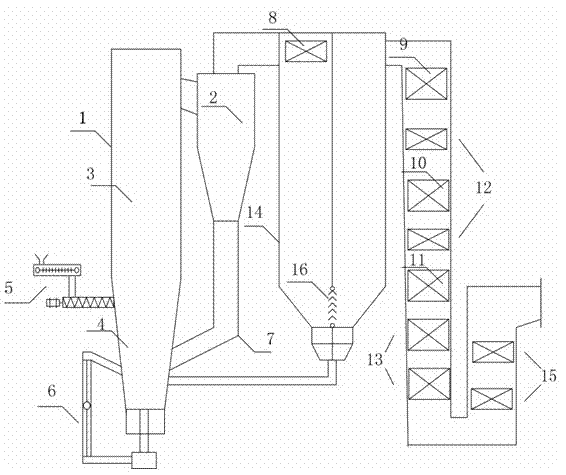

Organic compound pyrolysis flashover energy-saving regeneration treatment system

InactiveUS20140037507A1Save energyLower regenerationLevel controlLiquid hydrocarbon mixture productionSimple Organic CompoundsConservation energy

An organic compound pyrolysis flashover energy-saving regeneration treatment system for remaking organic waste such as family\industrial garbage, sewer mud, agricultural waste and livestock excreta etc. to become liquid and solid regenerated organic compounds by using a waste pre-treatment unit, an organic waste steaming sterilization unit, an organic waste pyrolysis flashover unit, a green energy generation & steam regeneration unit, a solid-liquid organic compound separation unit, a liquid organic compound regeneration unit and a solid organic compound regeneration unit, which compounds are used as organic fertilizer or feed for livestock farming, the system can effectively achieve the objects of recovering resources, purifying environment, saving energy and reducing carbon and regeneration of organic waste for reuse, it further can increase the efficiency of environmental conservation.

Owner:WANG HSIAO LUN

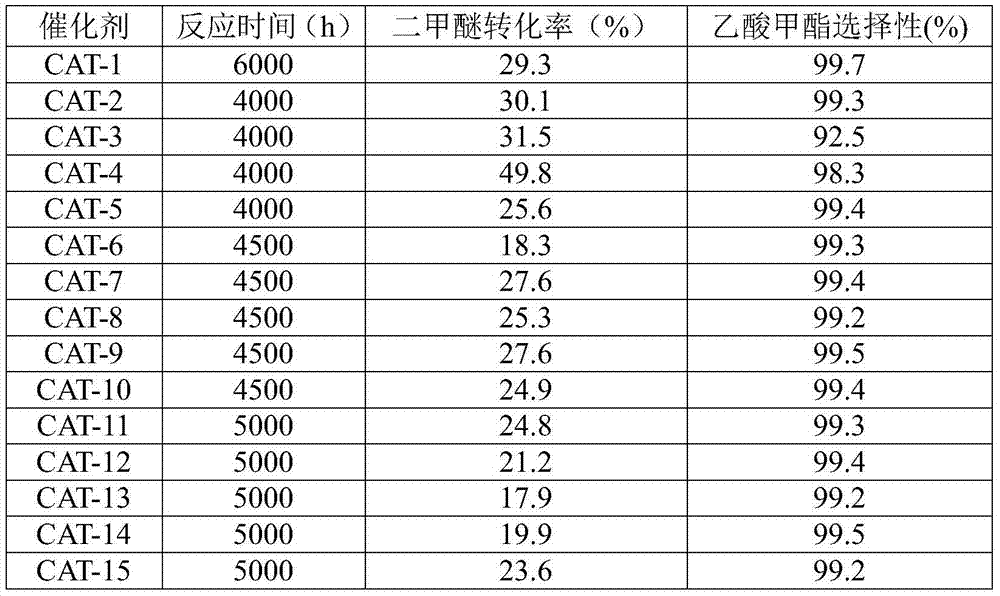

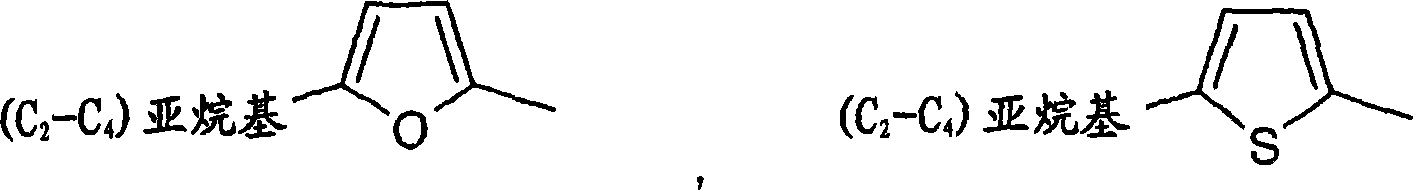

Catalyst for producing methyl acetate as well as preparation method and application of catalyst

ActiveCN106890671ASimple production processLow production costMolecular sieve catalystsCatalyst activation/preparationMolecular sieveMethyl acetate

The invention discloses a catalyst for producing methyl acetate through carbonylation of dimethyl ether. The catalyst is characterized by comprising a modified EMT molecular sieve, wherein the modified EMT molecular sieve is obtained by sequentially processing by virtue of acid and pyridine and / or a pyridine substitute; the pyridine substitute is a compound formed by independently substituting one, two or three of five Hs on a pyridine ring with a substitute selected from F, Cl, Br, I, CH3, CF3, CH3CH2 or NO2. The catalyst has very high stability and methyl acetate selectivity and can still preserve high methyl acetate selectivity after reacting for a long time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Resin carrier solid alkali catalyst and method for synthesizing biological diesel oil with animal vegetable oil

InactiveCN101108338AWide variety of sourcesLow priceOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixture productionBiodieselAqueous solution

The invention discloses a resin load solid alkali catalyst, which comprises a water adsorption resin and alkali, wherein, the mass ration of the water adsorption resin and the alkali is about 1.0 / 0.01 to 1.0 / 15.0. The invention discloses a method of preparing resin load solid alkali catalyst, which comprises that: dissolve, disperse and swell the water adsorption resin in the water, add solid alkali, then dry or dissolve, disperse and swell the water adsorption resin the water solution of alkali then dry; wherein, the ration of the water adsorption resin and alkali is about 1.0 / 0.01 to 1.0 / 15.0 according to the mass ratio. The invention also discloses the use of resin load solid alkali is making as catalyst in animal oil and or plant oil, low level.

Owner:BEIJING UNIV OF CHEM TECH +1

Use of EP2 selective receptor agonists in medical treatment

InactiveCN1859903APromote repairPromote regenerationSenses disorderDigestive systemMetastatic bone tumorCartilage repair

The present invention relates to methods of treating pulmonary hypertension, facilitating joint fusion, facilitating tendon and ligament repair, reducing the occurrence of secondary fracture, treating avascular necrosis, facilitating cartilage repair, facilitating bone healing after limb transplantation, facilitating liver regeneration, facilitating wound healing, reducing the occurrence of gastric ulceration, treating hypertension, facilitating the growth of tooth enamel or finger or toe nails, treating glaucoma, treating ocular hypertension, and repairing damage caused by metastatic bone disease using an EP2 selective receptor agonist.

Owner:PFIZER PRODS ETAT DE CONNECTICUT

Particulate filter regeneration in an engine

ActiveUS8438840B2Lower regenerationEmission reductionNon-fuel substance addition to fuelInternal combustion piston enginesParticulatesCombustion

Systems and methods for controlling regeneration of a particulate filter downstream of an engine having a plurality of cylinders are provided. One exemplary method includes, during first conditions, spinning down the engine to non-combusting engine rest, and regenerating the particulate filter at least during engine rest. The method also includes, during second conditions, regenerating the particulate filter during combustion of at least one cylinder of the engine. By regenerating the particulate filter during engine shutdown and / or engine rest in some conditions, it is possible to reduce engine running regeneration, which can thereby lead to reduced engine running emissions.

Owner:FORD GLOBAL TECH LLC

Chinese medicine for treating burn and frostbite

InactiveCN1569175ALower regenerationPromote regenerationUnknown materialsDermatological disorderMedicinal herbsYolk

The invention provides a Chinese medicine for treating burn and frostbite, which is prepared from Chinese medicinal herbs including alkanna tinctoria, rhubarb horsetails, corktree bark, dried rehmannia root, gypsum, Vaseline, yolk oil, and linseed oil.

Owner:李果

High-temperature air combustion intensifying device and method applicable to low heating value mixed garbage

ActiveCN102878569AIncineration is stable enoughFully stable combustionIncinerator apparatusCombustion chamberSlag

The invention discloses a high-temperature air combustion intensifying device and method applicable to low heating value mixed garbage, wherein a low-temperature preheater is arranged on the rear side of a U-shaped tail part flue; a garbage feeding opening is arranged on the side wall of the lower part of a furnace chamber; the side wall of the upper part of the furnace chamber is connected with the upper part of a cyclone separator; the bottom part of the cyclone separator is connected with the upper end of a back feeder; the lower end of the back feeder is connected with the side wall of the lower part of the furnace chamber; the upper end of the cyclone separator is connected with the upper part of the front side of a U-shaped combustion chamber; the lower end of the U-shaped combustion chamber is connected with the side wall of the lower part of the furnace chamber; the lower end of the furnace chamber is connected with the side wall of the lower part of the furnace chamber through a water-cooled cold slag sorting and back feeding device; and the upper part of the rear side of the U-shaped combustion chamber is connected with the upper part of the front side of the U-shaped tail part flue. The method utilizing the high-temperature air to intensify the low heating value garbage mixed combustion is more suitable for the domestic characteristics that the garbage has complicated components, high moisture and low heating value, has wider fuel application range, and is more sufficient and stable in combustion, the garbage can be purely combusted without the need of coal, the energy consumption is reduced, and the operating economy is improved.

Owner:ZHEJIANG UNIV

Skin-recovering purified essence

InactiveCN106265392AMild ingredientsBalanced Oil-Water RatioCosmetic preparationsToilet preparationsSolventChemistry

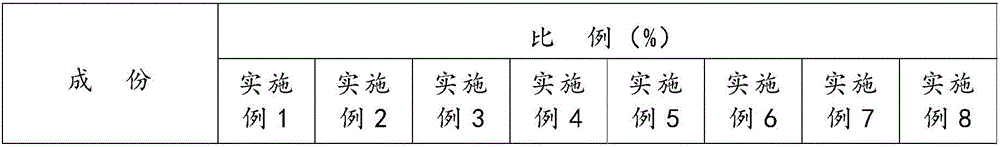

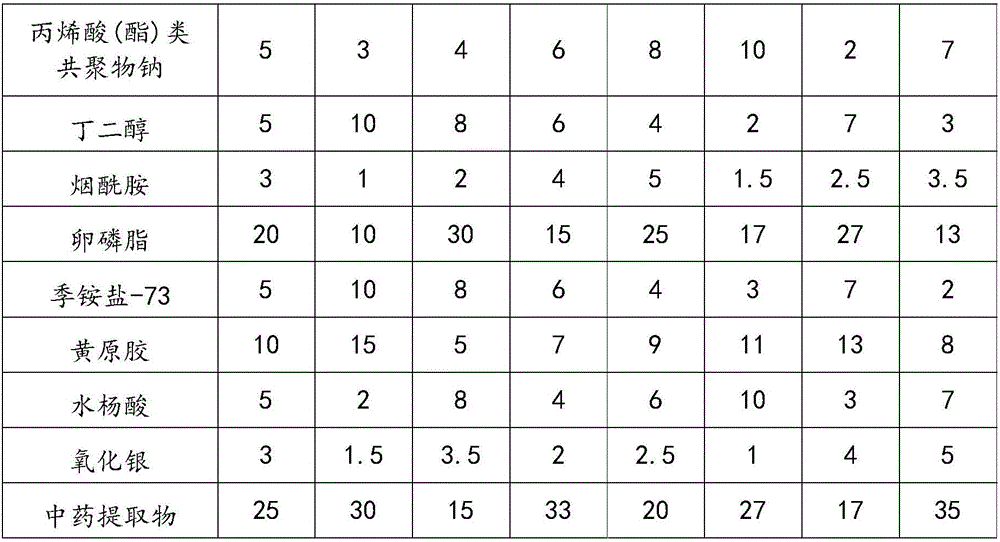

The invention belongs to an acarus killing product in the field of cosmetics and particularly relates to skin-recovering purified essence, which is prepared from the following raw materials in percentage by weight: 1-10% of sodium acrylic acid (ester) copolymer, 1-10% of butanediol, 1-5% of nicotinamide, 10-30% of lecithin, 1-10% of quaternary ammonium salt-73, 5-15% of xanthan gum, 1-10% of salicylic acid, 1-5% of silver oxide, 15-35 % of Chinese herb extracts and the balance of a solvent, wherein deionized water is preferably selected as the solvent; the Chinese herb extracts include flavescent sophora root extracts, cnidium fruit extracts and willow herb extracts. The skin-recovering purified essence is mild and nonirritating in ingredients, can be used for effectively inhibiting and treating poxes and conditioning skin, has favorable efficacies of eliminating poxes, killing acari, diminishing inflammation, reliving pain and itch, promoting tissue regeneration, and caring skin, and is also capable of dredging trichopores, removing residual grease and aged cuticle, balancing oil-water ratio of skin, reducing acne regeneration, restraining acarus growth, promoting skin cell regeneration and promoting fineness and smoothness of skin.

Owner:BEIJING DOUBOSHI ACNE MEDICAL RES INST

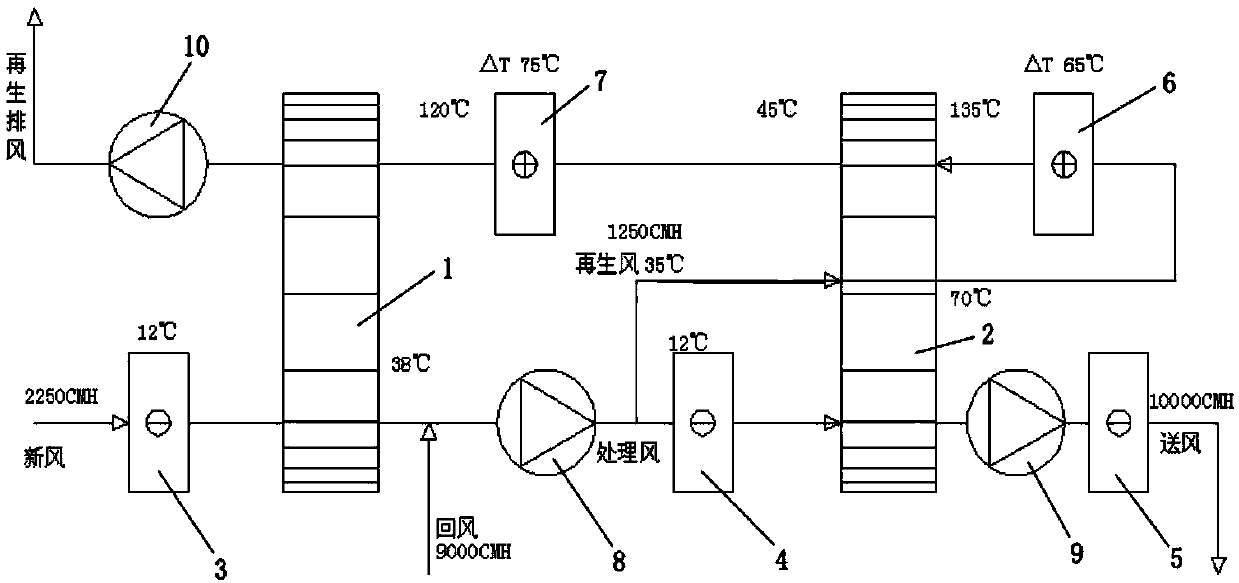

Normal-temperature low-dew-point runner dehumidification unit

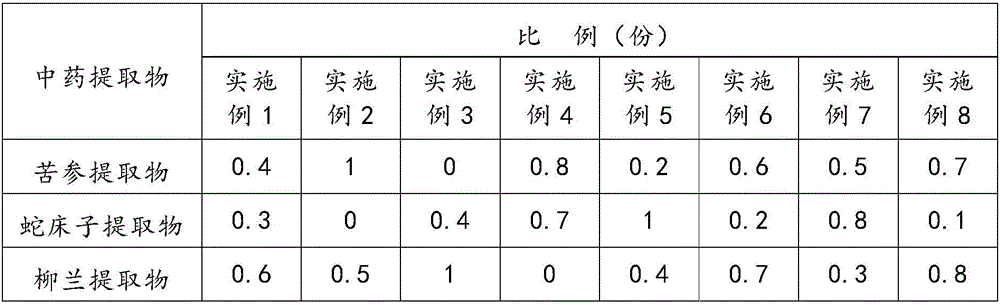

InactiveCN107763760AStable airflowMore adjustable residual pressureLighting and heating apparatusAir conditioning systemsDesorptionRoom temperature

The invention discloses a normal-temperature low-dew-point runner dehumidification unit. The normal-temperature low-dew-point runner dehumidification unit comprises a first-level runner heat exchanger, a second-level runner heat exchanger, a front surface air cooler, a middle surface air cooler, a rear surface air cooler, a first-level regeneration heater and a second-level regeneration heater. Afirst-level treatment moisture absorbing area and a first-level regeneration desorption area are arranged in the first-level runner heat exchanger in a distinguished manner. A second-level treatment moisture absorbing area, a second-level regeneration desorption area and a second-level regeneration cooling area are arranged in the second-level runner heat exchanger in a distinguished manner. Freshair sequentially passes through the front surface air cooler and the first-level treatment moisture absorbing area to mix with return air to be divided into two paths, one path of mixed air sequentially passes through the middle surface air cooler, the second-level treatment moisture absorbing area and the rear surface air cooler to be conveyed to a drying area, and the other path of mixed air sequentially passes through the second-level regeneration cooling area, the first-level regeneration heater, the second-level regeneration desorption area, the second-level regeneration heater and the first-level regeneration desorption area and then is exhausted out of a room. The runner dehumidification unit is stable in airflow, the integral pipeline pressure is balanced, energy saving and consumption reducing are achieved, and the work condition is stable.

Owner:浙江捷峰环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com