Patents

Literature

1324 results about "Color effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

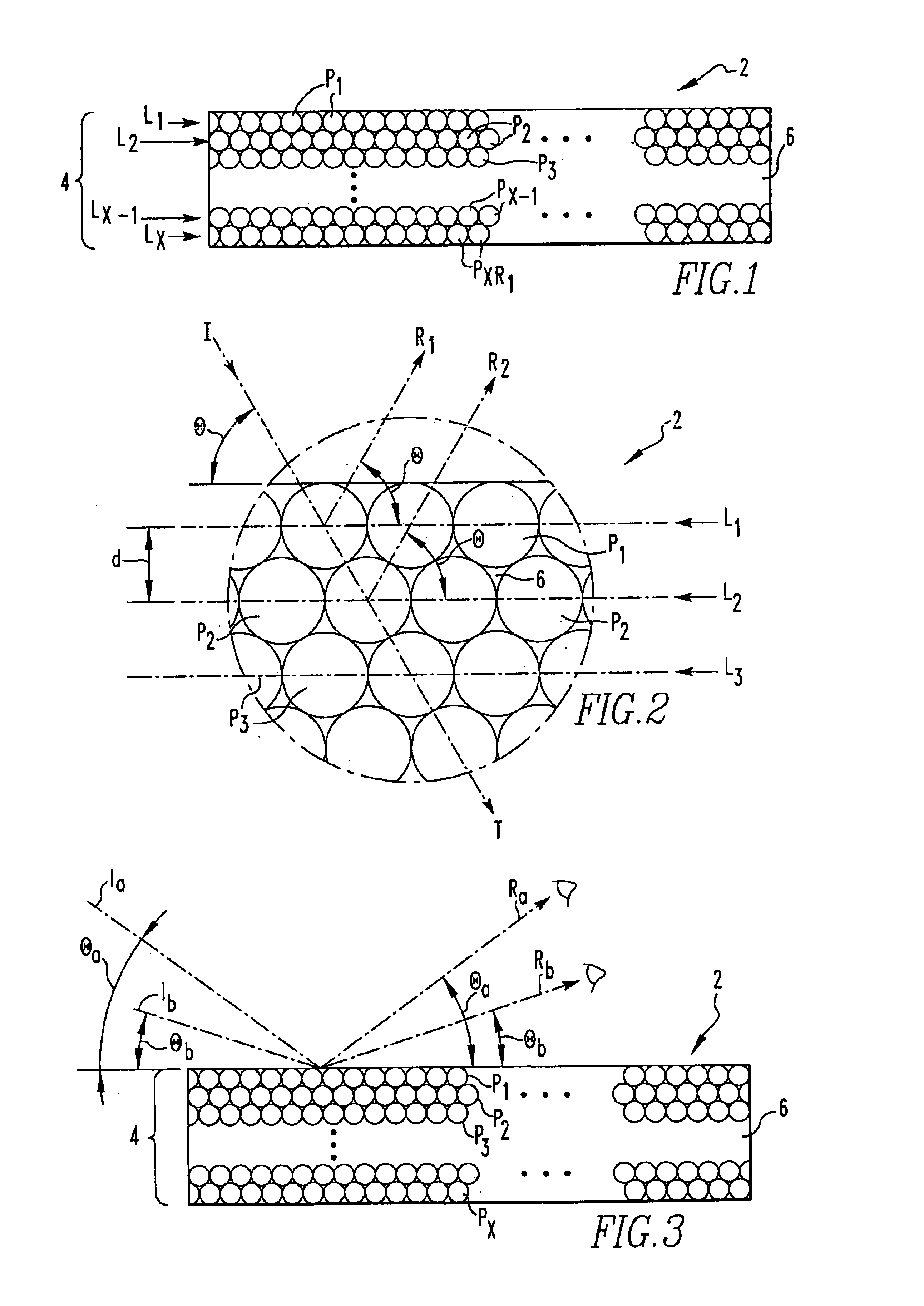

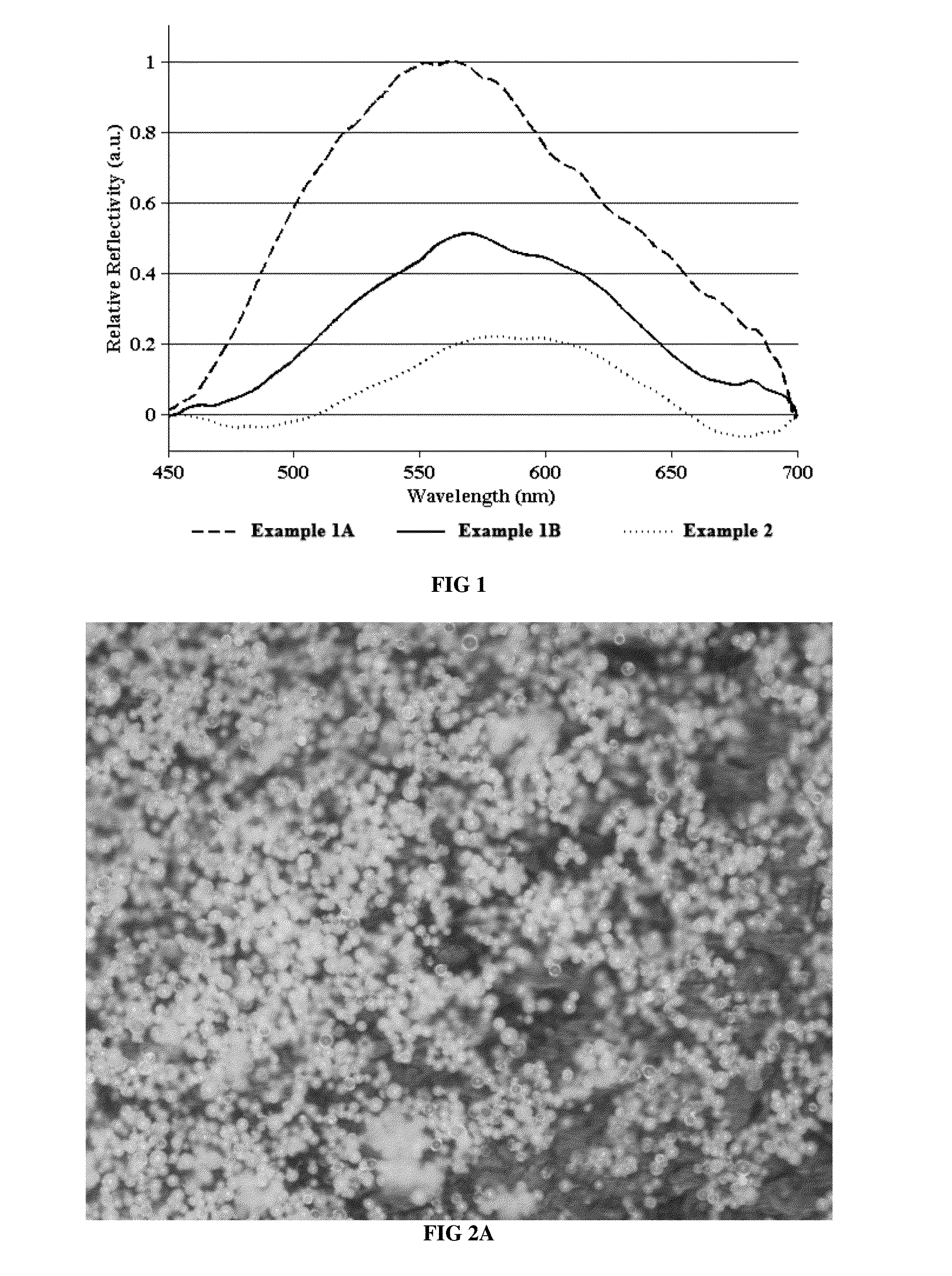

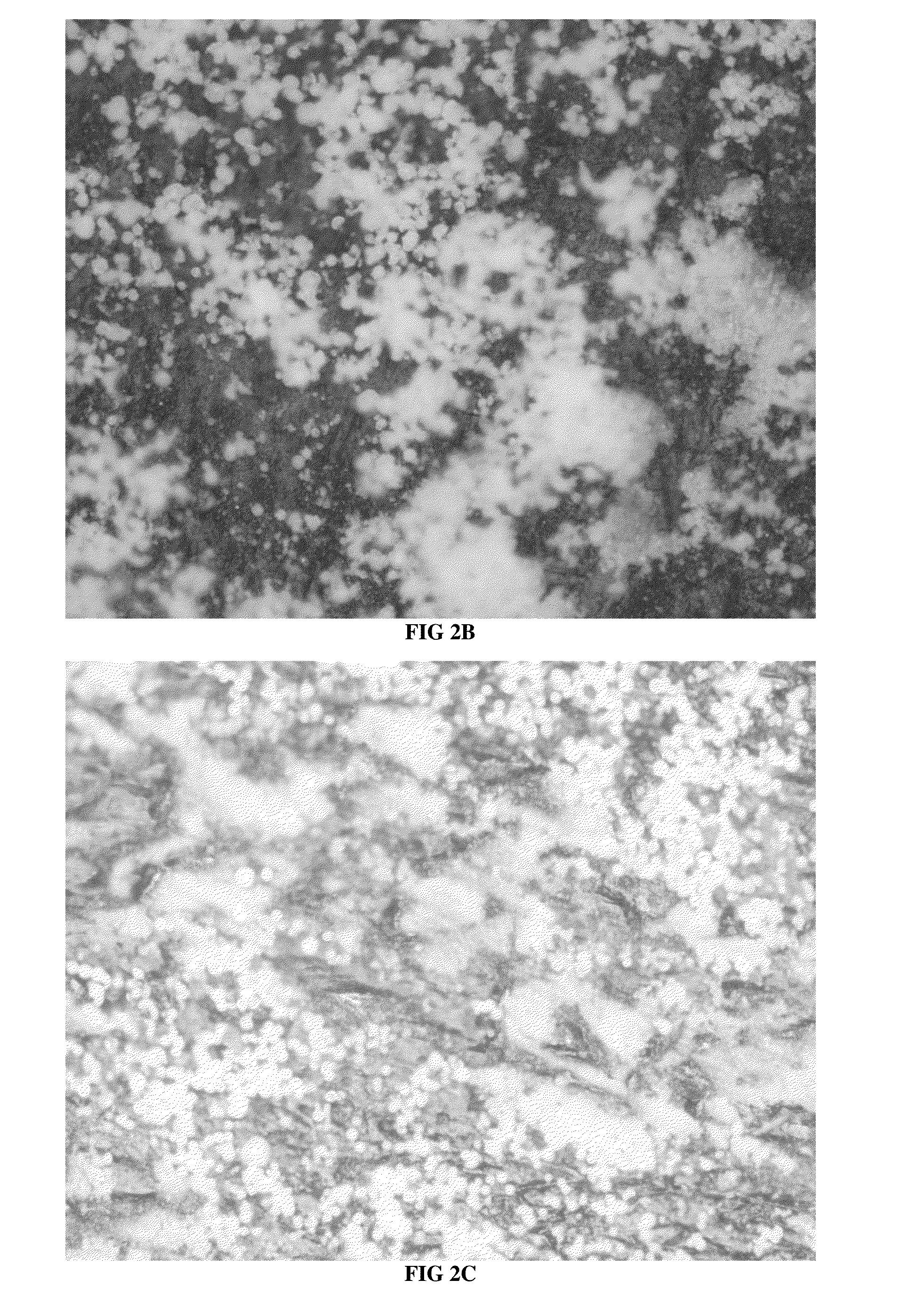

Color effect compositions

A coating composition comprising a resinous binder and a color effect colorant in particulate form. The colorant includes an ordered periodic array of particles held in a polymer wherein a difference in refractive index between the polymer and the particles is at least about 0.01. The colorant reflects visible light according to Bragg's law to yield a goniochromatic effect to the coating composition.

Owner:PPG IND OHIO INC

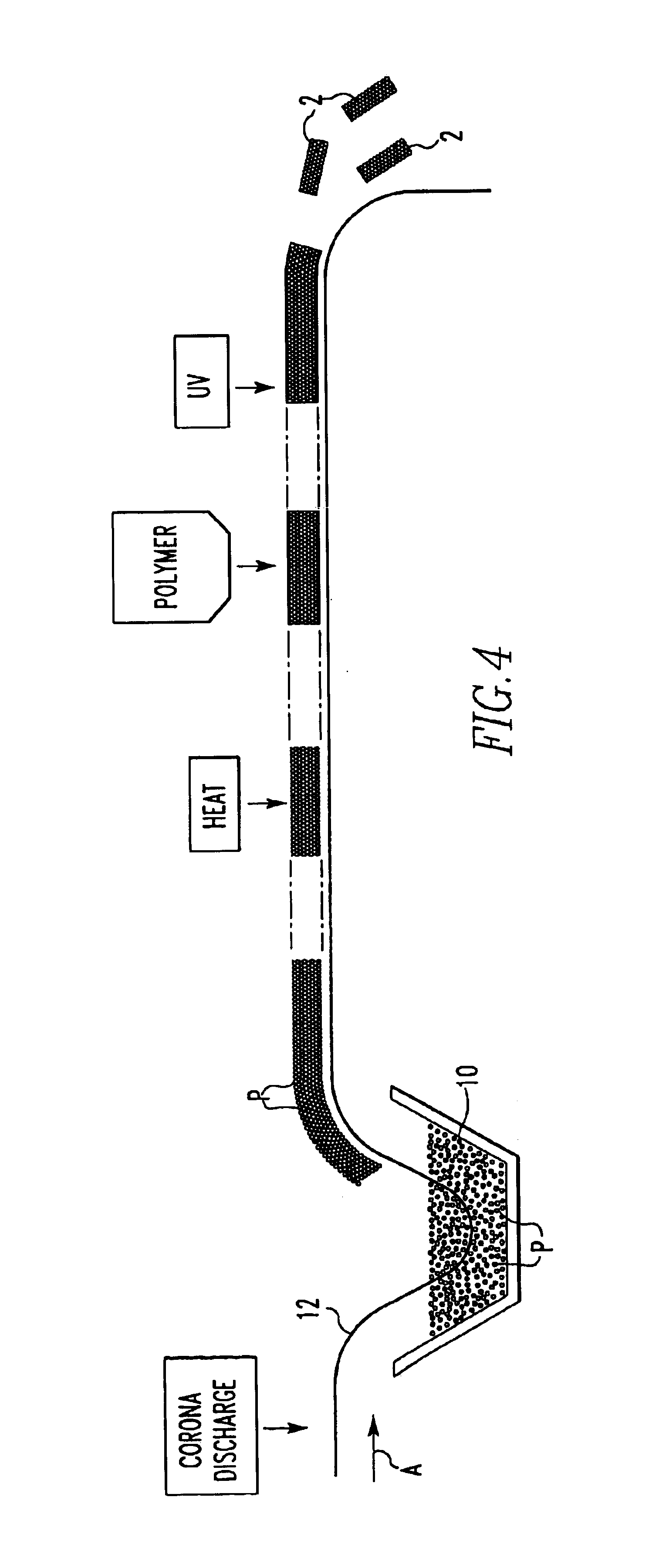

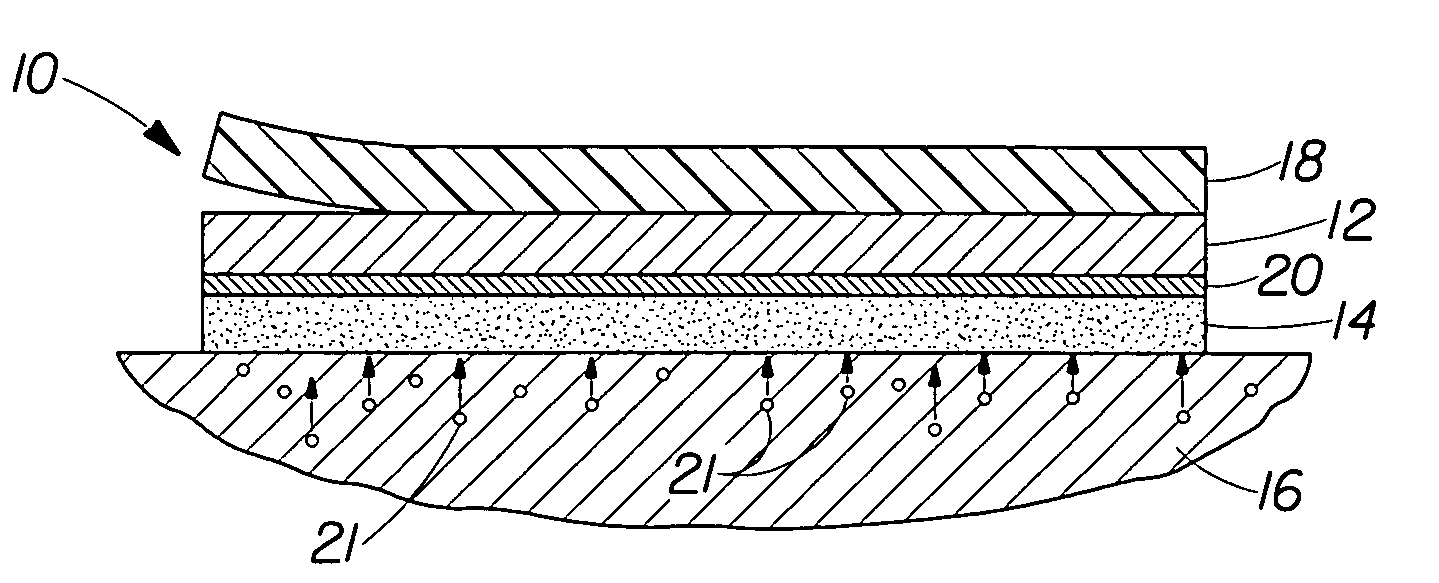

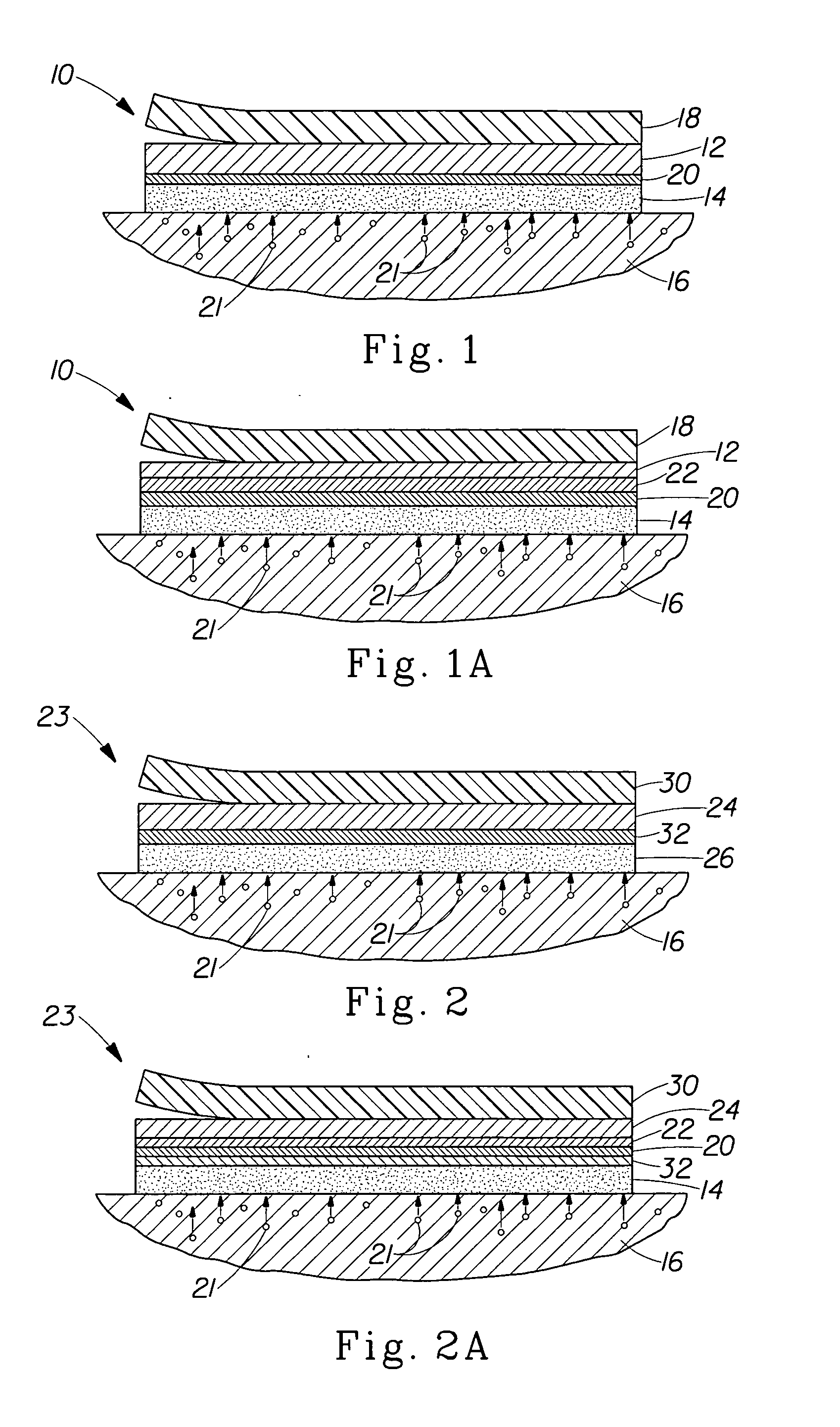

Absorbent articles with color effects

Owner:THE PROCTER & GAMBLE COMPANY

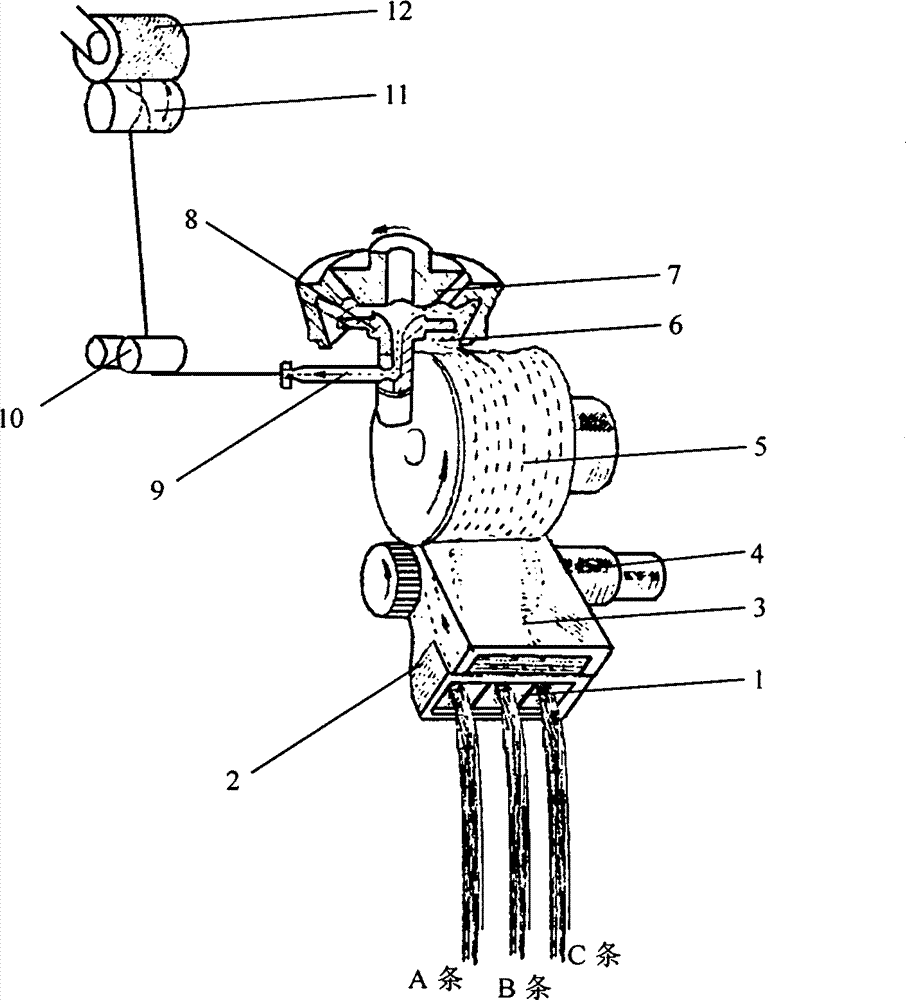

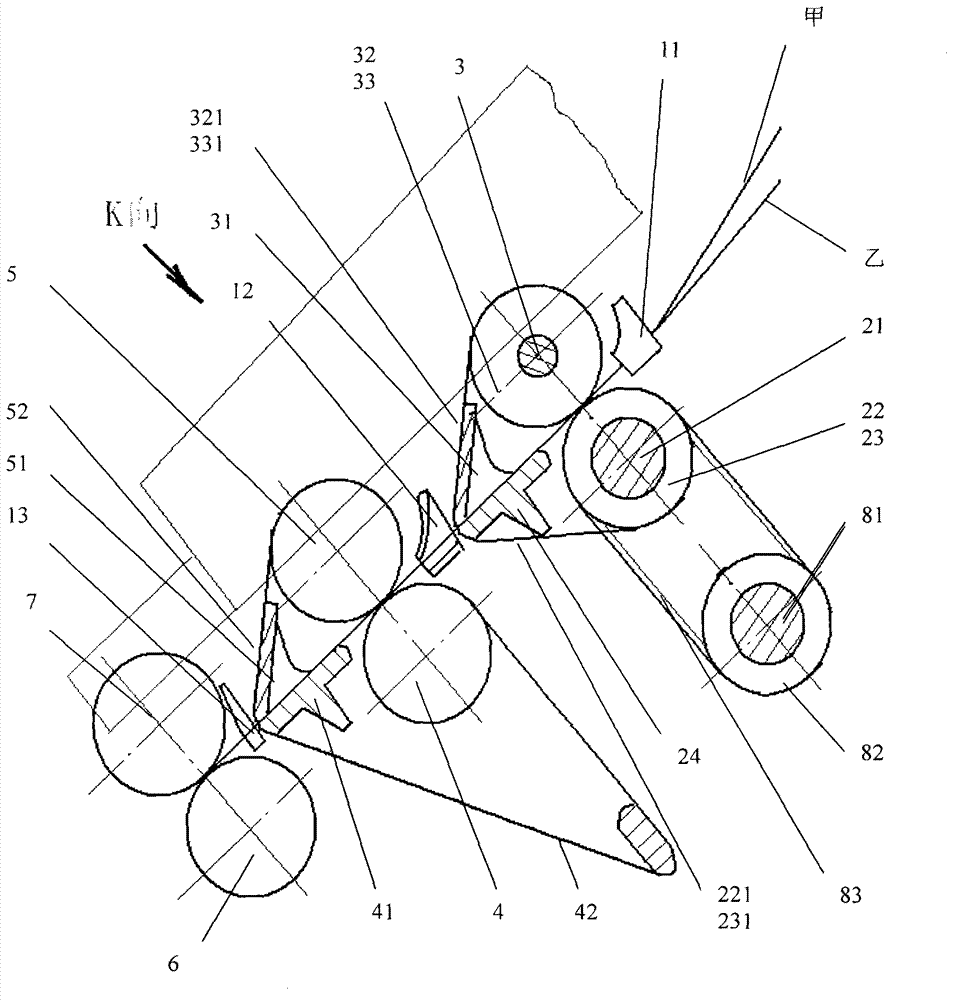

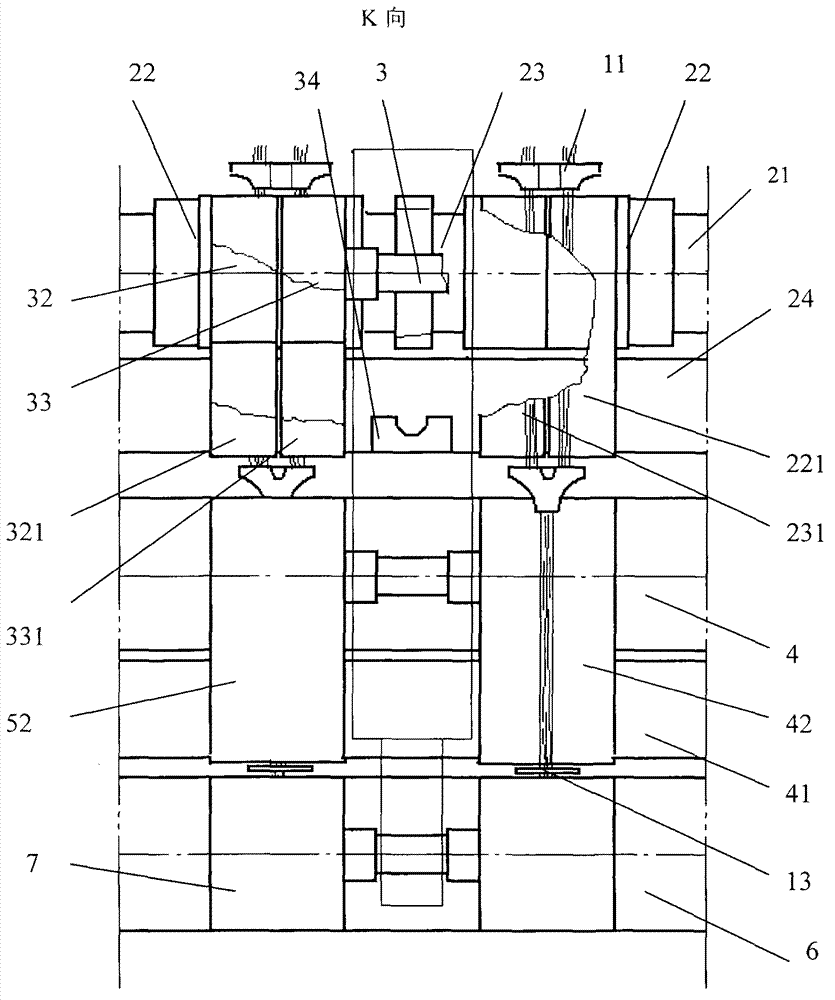

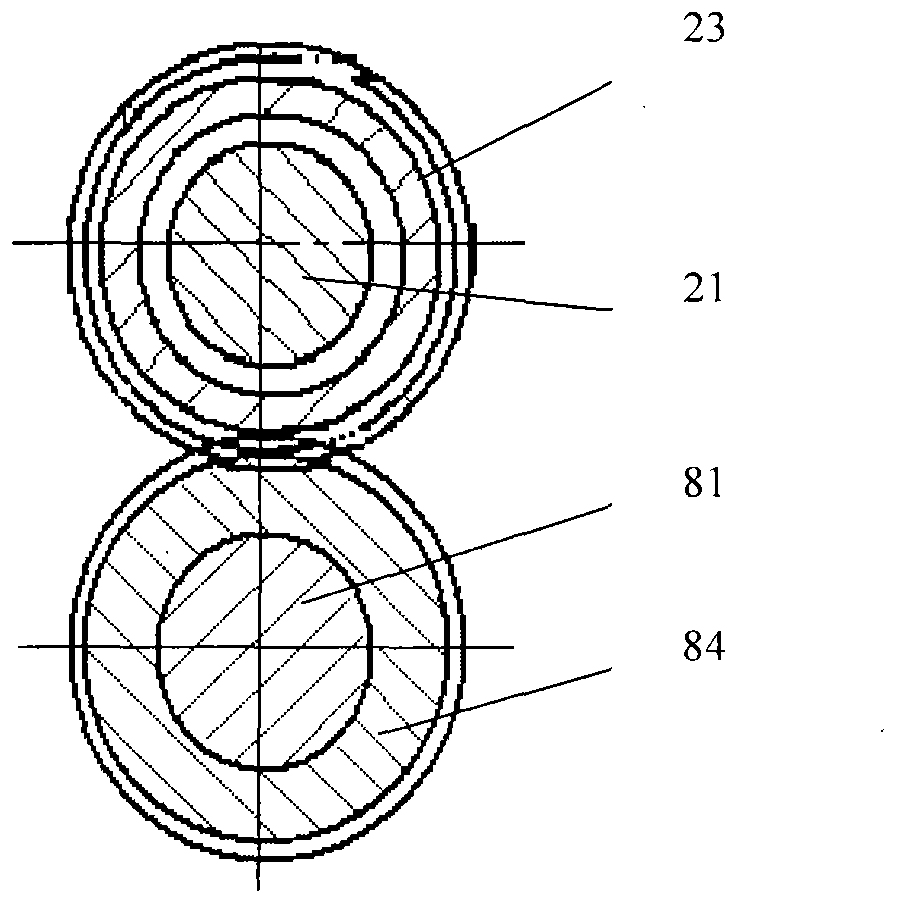

Rotor spinning melange yarn forming method and device and product

The invention discloses a rotor spinning melange yarn forming method and device and product. On a rotor spinning machine, two or more fiber strips enter a feeding mechanism through a striping gate and a horn mouth, the feeding mechanism contains at least two independently controlled feeding rollers and can control the independent feeding of at least two fiber strips, different fiber strips are of different colors, or of different color combinations, or of different fiber components, the feeding speed of each fiber strip is controllable, the feeding can be conducted at different time sections, and the feeding speeds of all the fiber strips are independently changeable or simultaneously changeable; through the implement of continuous constant-speed feeding or segmentation variable speed feeding of different fiber strips, continuous constant feeding or segmentation variable feeding of the fiber strips is controlled; the fed fiber strips break away from a combing roller, are transferred to a delivery pipe, and then enter a spinning cup depending on the centrifugal force of the combing roller and the action of added air flow after the opening and carding actions of the combing roller; single fibers of different components are mixed, condensed and twisted in the spinning cup to form rotor spinning melange yarn blended by monochrome or polychromatic fiber, or with segmentation color effect, uniform linear density or changing linear density.

Owner:JIAXING UNIV

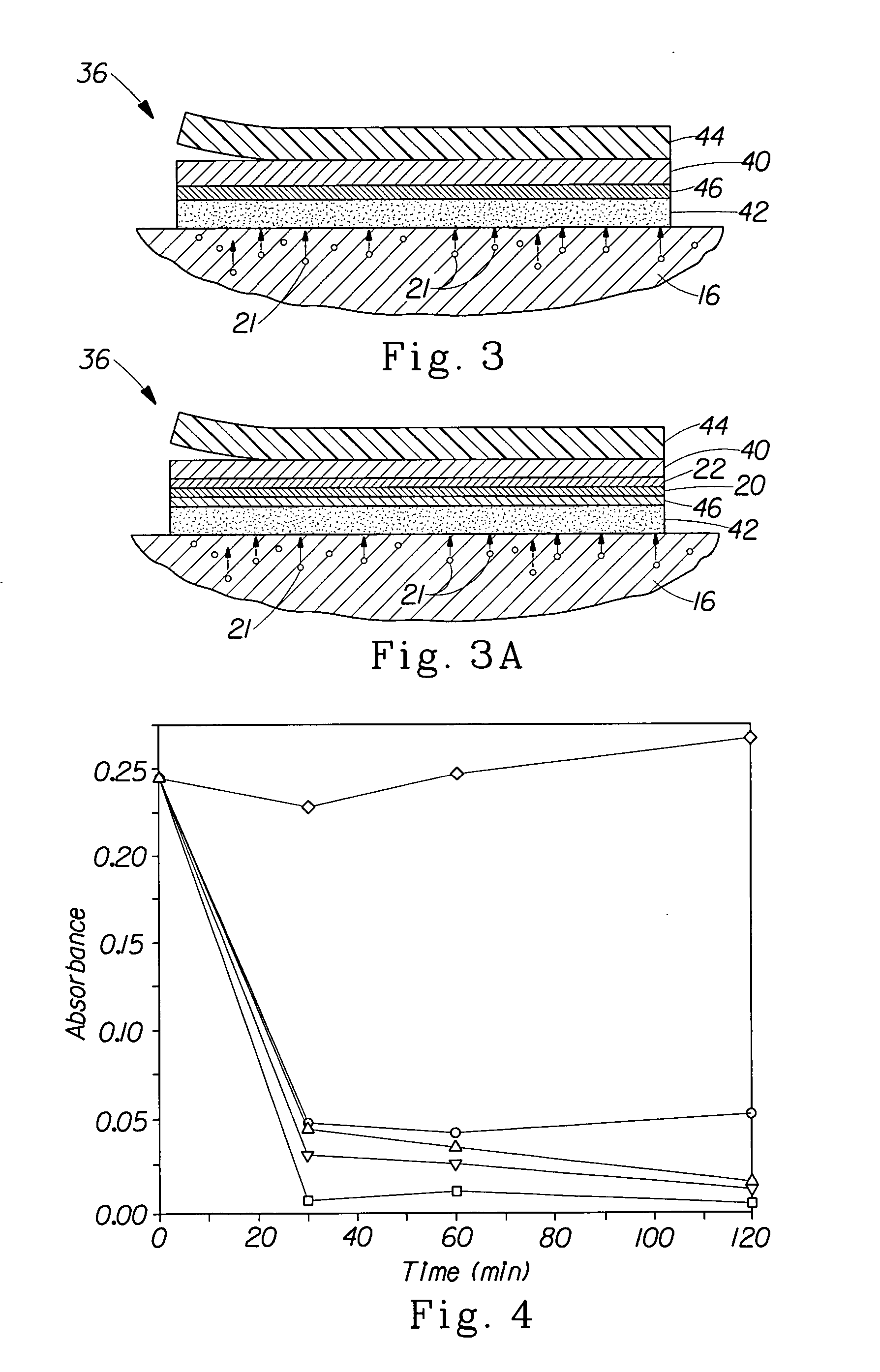

Discoloration-resistant articles for applying color on surfaces and methods of reducing discoloration in articles for applying color on surfaces

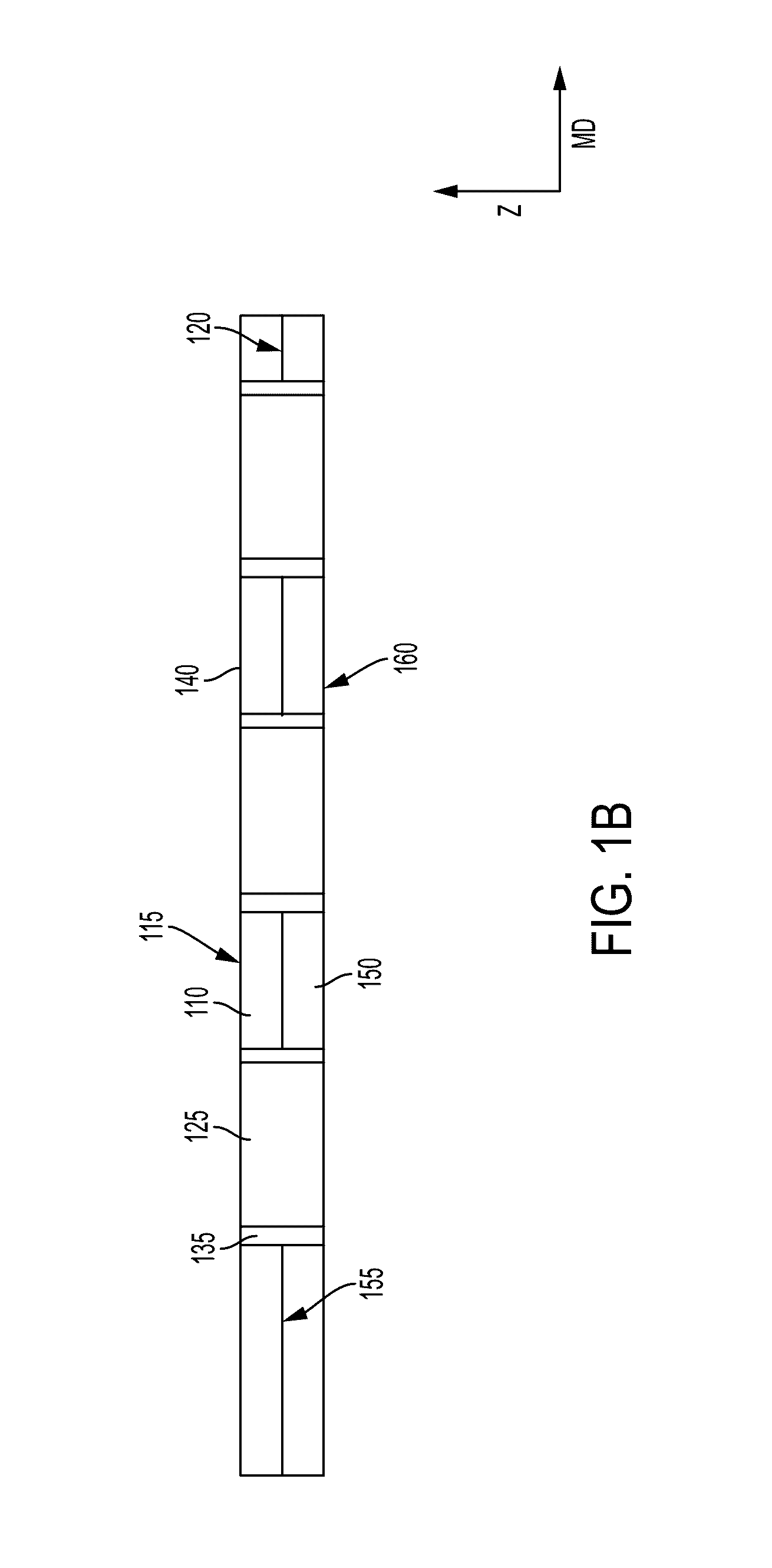

InactiveUS20060046028A1Reduce transferPreventing and reducing discolorationDecorative surface effectsTraffic signalsColor effectEngineering

Layered articles for applying color on a surface including a sheet of visually-perceivable color effects, a bonding agent capable of bonding the sheet to the surface, and a releasable liner removably attached to the sheet. The article further includes a substance, agent or barrier that prevents or, at the least, reduces the transfer of an extraneous agent from the surface to a location in the layered article that would affect the visually-perceivable color effect conveyed by the sheet.

Owner:THE PROCTER & GAMBLE COMPANY +1

Ultra thin graphics and methods

InactiveUS20060246266A1Reduce shipping costsQuality improvementDecorative surface effectsDuplicating/marking methodsColor effectGraphics

A transferable image for water-slidable application to surfaces is provided comprising a water-absorbing Porous Backing Sheet; a water-soluble Resin Coating coated on the water-absorbing Porous Backing Sheet; a base layer on the water-soluble Resin Coating; and a plurality of ink layers on the base layer, at least one of the ink layers being translucent or transparent and applied in overlapping fashion in a manner to provide a color effect. In preferred embodiments, a transfer premask is provided wherein the transfer premask is substantially no wider than about 0.25 inches than the perimeter of the image shape.

Owner:MODERNISTIC

Extrusion grade aesthetical resin possessing metal color effect and its preparation method

The invention relates to an extrusion grade aesthetical resin possessing metal color effect and its preparation method, which comprises the following ingredients by weight content: 100 parts of matrix resin, 0.1-3.0 parts of metal pigment, 0.1-3.0 parts of pearlescent pigment, 0.1-3.0 parts of molecular sieve adsorbent, 0.1-3.0 parts of lubricant and 0.1-1.0 parts of anti-oxidant. The method comprises the following steps: stirring and mixing the above raw materials in a high speed mixer, sending in a double screw extruder, under the conveying, shearing and mixing of a screw, fusing the raw materials, compositing, extruding, bracing, cooling, cutting into granule to obtain the extrusion grade aesthetical resin possessing the metal color effect. Compared with prior art, the extrusion surface effect of the extrusion grade aesthetical resin possessing metal color effect is close to metal spray paint effect, thereby the energy saving and environmental protection scheme without spraying can be realized, the aesthetical resin possessing metal color effect enables large market potential in the fields of automobile, household electrical appliance, consumer electronics and the like which possess high appearance requirement.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

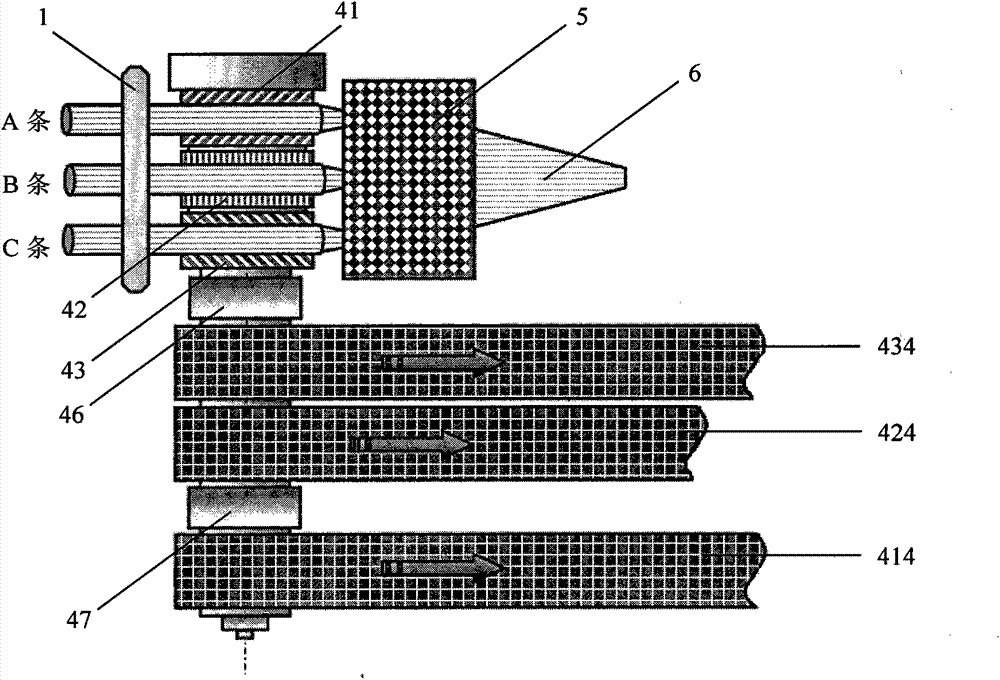

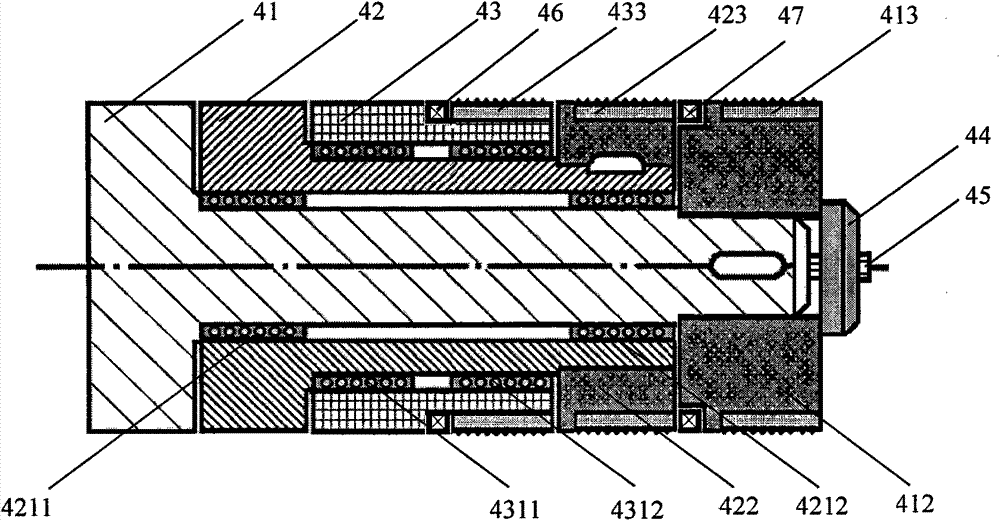

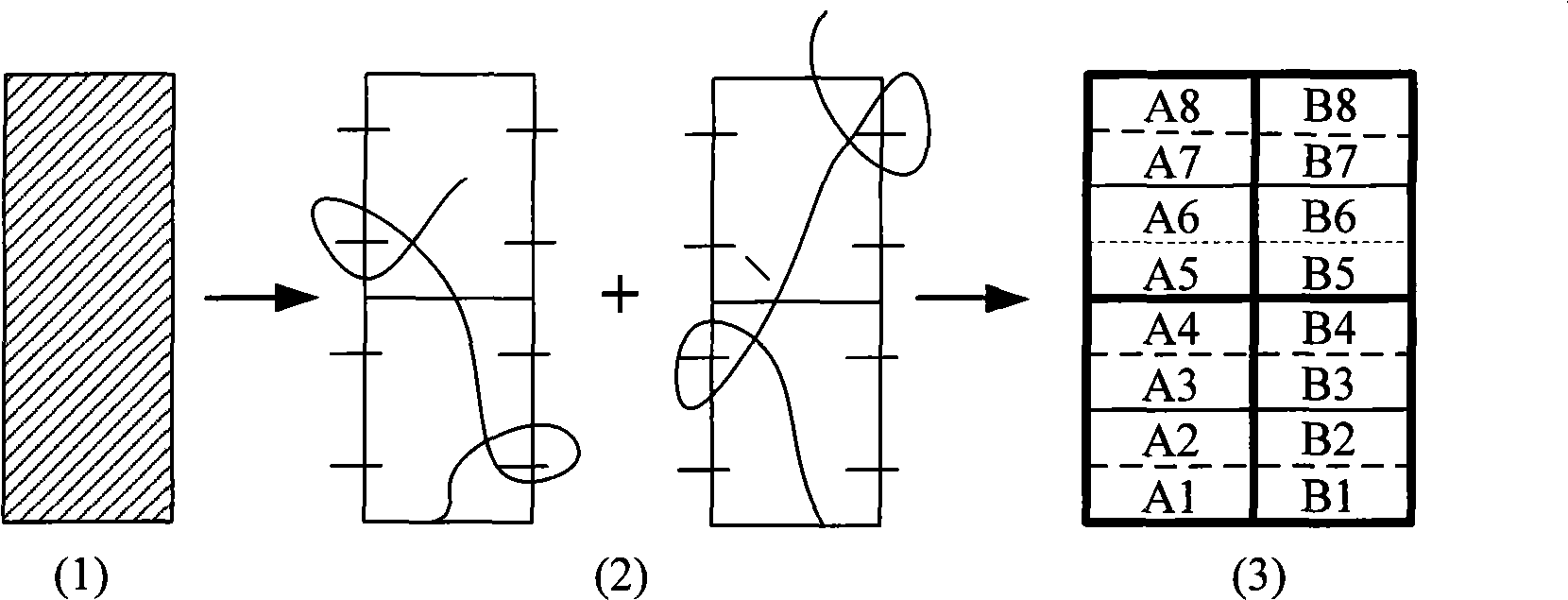

Method for spinning section-color yarns and drafting mechanism for spinning

The invention discloses a method for spinning section-color yarns and a drafting mechanism for spinning. At the rear drafting area of the drafting mechanism, leather rings are used for guiding and controlling yarns, namely a group of upper leather rings and a group of lower leather rings are used for controlling two groups of fiber fringes respectively, so for the rear drafting area of the drafting mechanism, the capacity of controlling free fibers is improved, when the drafting ratio at the rear area is changed greatly in sections, the stability of drafting of each sectional process is kept, and evenness and a sectional color effect of section-color resultant yarns are ensured. In the respect of product process design, the drafting ratio of the rear area is increased, and the transition length of the two groups of fibers between every two sections is shortened.

Owner:陈伟雄

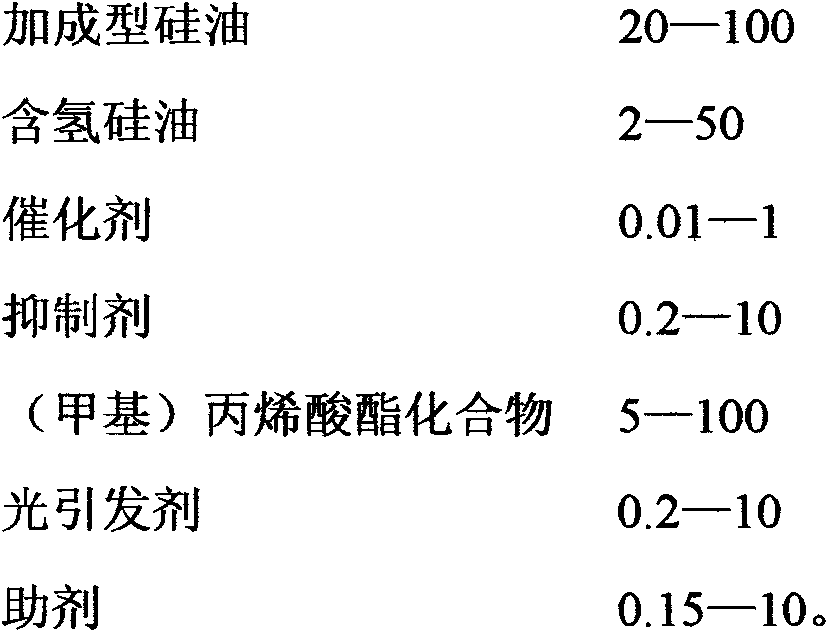

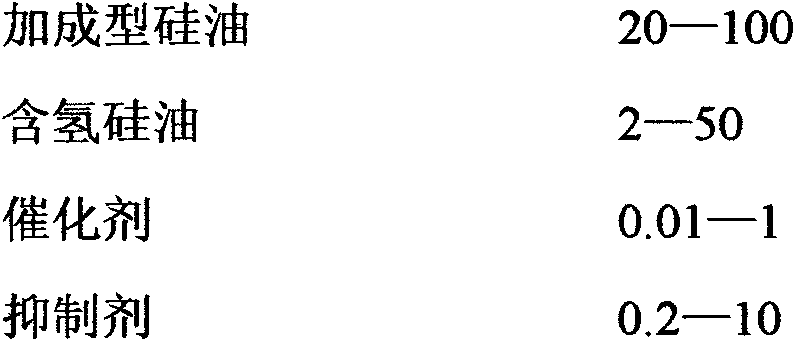

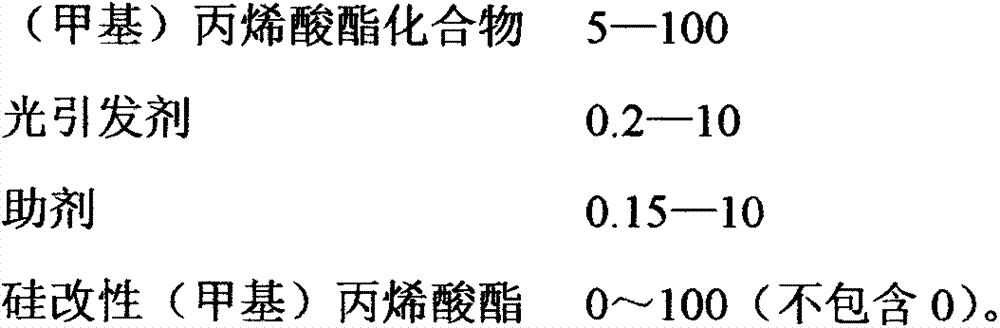

Dual-curing composition

The invention discloses a dual-curing composition which comprises addition type silicone oil, hydrogen-containing silicone oil, an inhibitor, a catalyst, a (methyl) acrylic ester compound, a light initiator and an auxiliary, and selectively comprises silicon modified (methyl) acrylic ester, a filler, a reinforced silica resin and a solvent. Due to adoption of the composition disclosed by the invention, dual-curing of heating and ultraviolet light can be conveniently achieved, materials of different properties such as rubber and plastics can be prepared, and materials with different physical characteristics and different color effects can be prepared.

Owner:甘春丽 +1

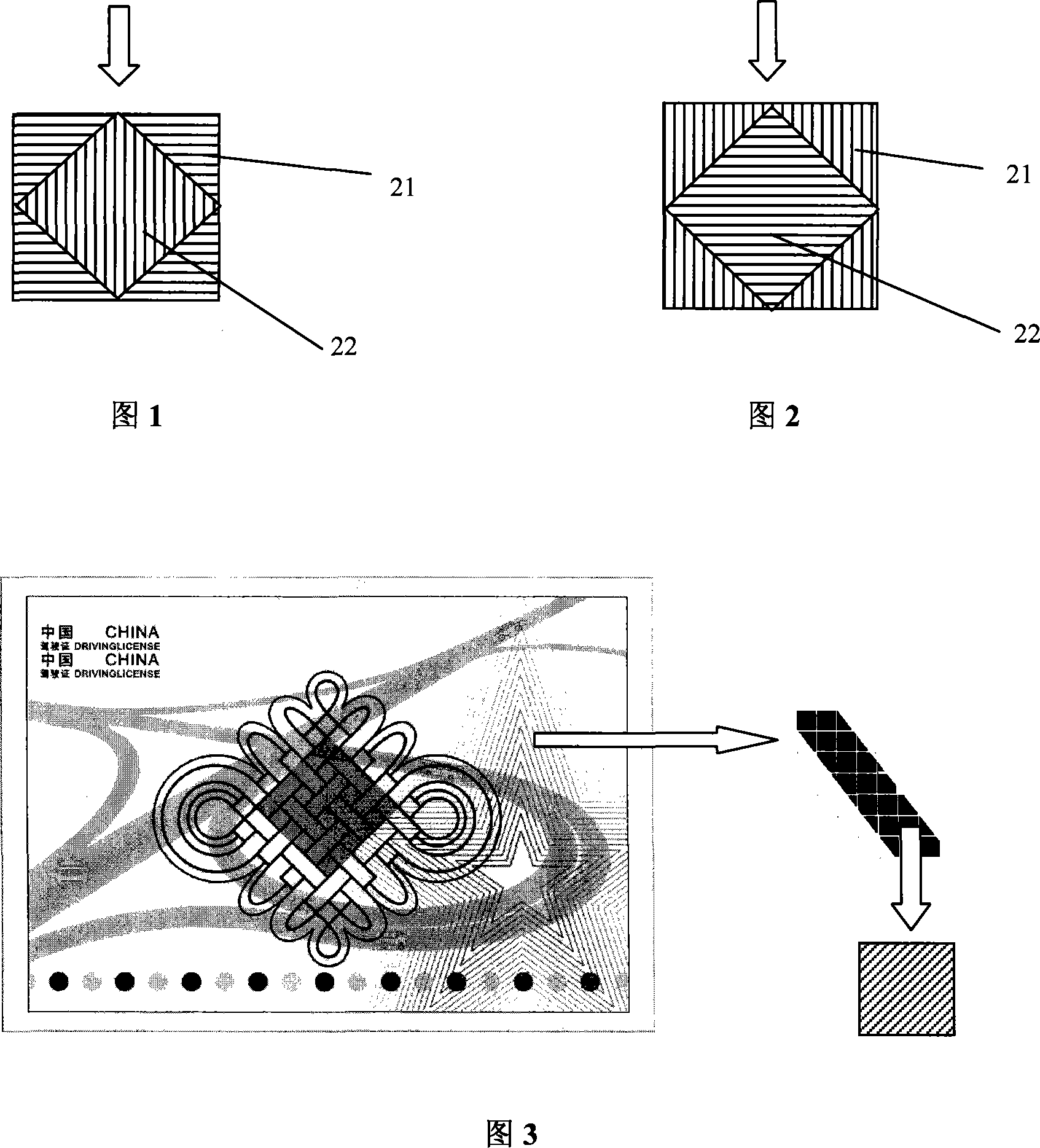

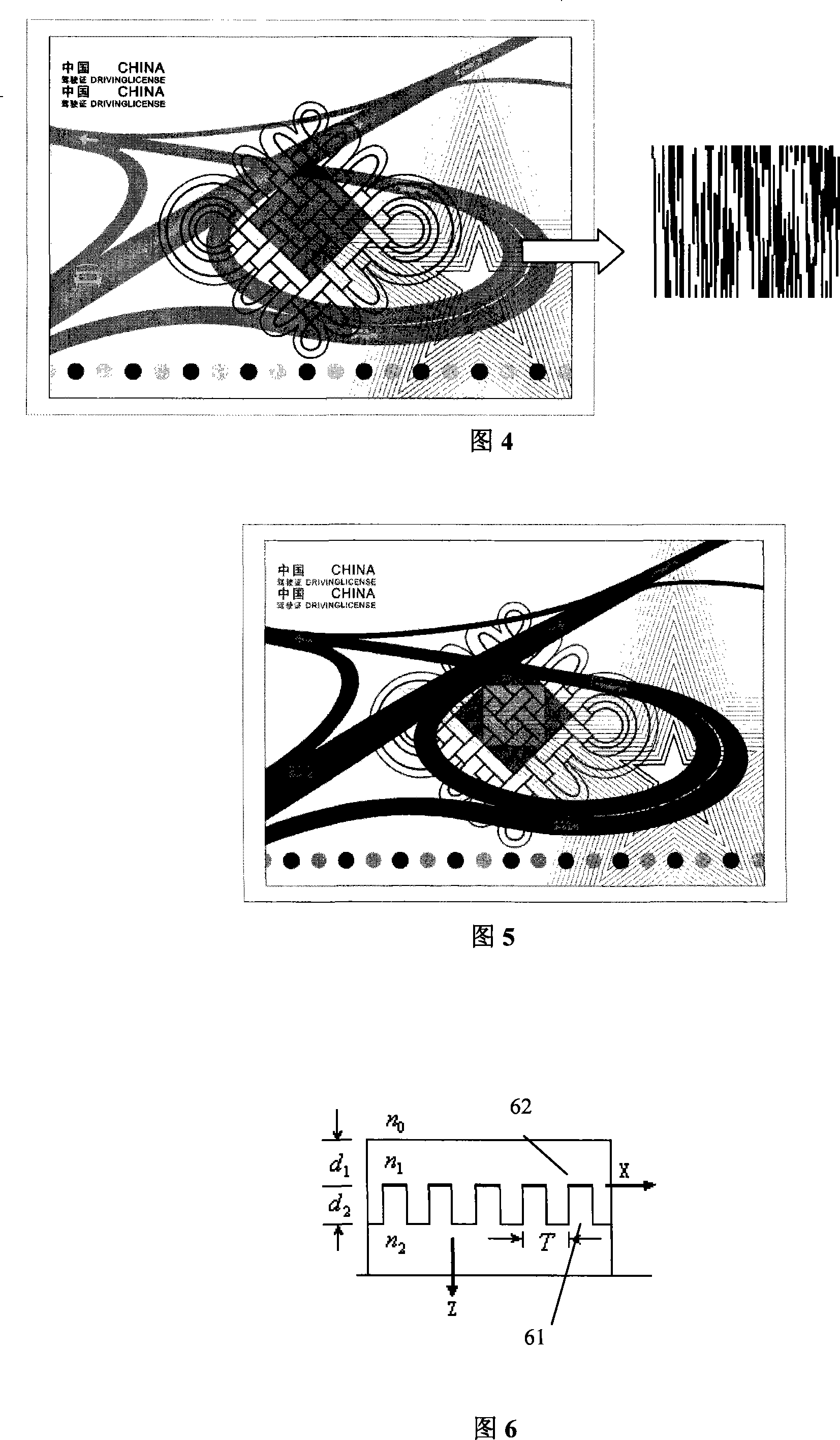

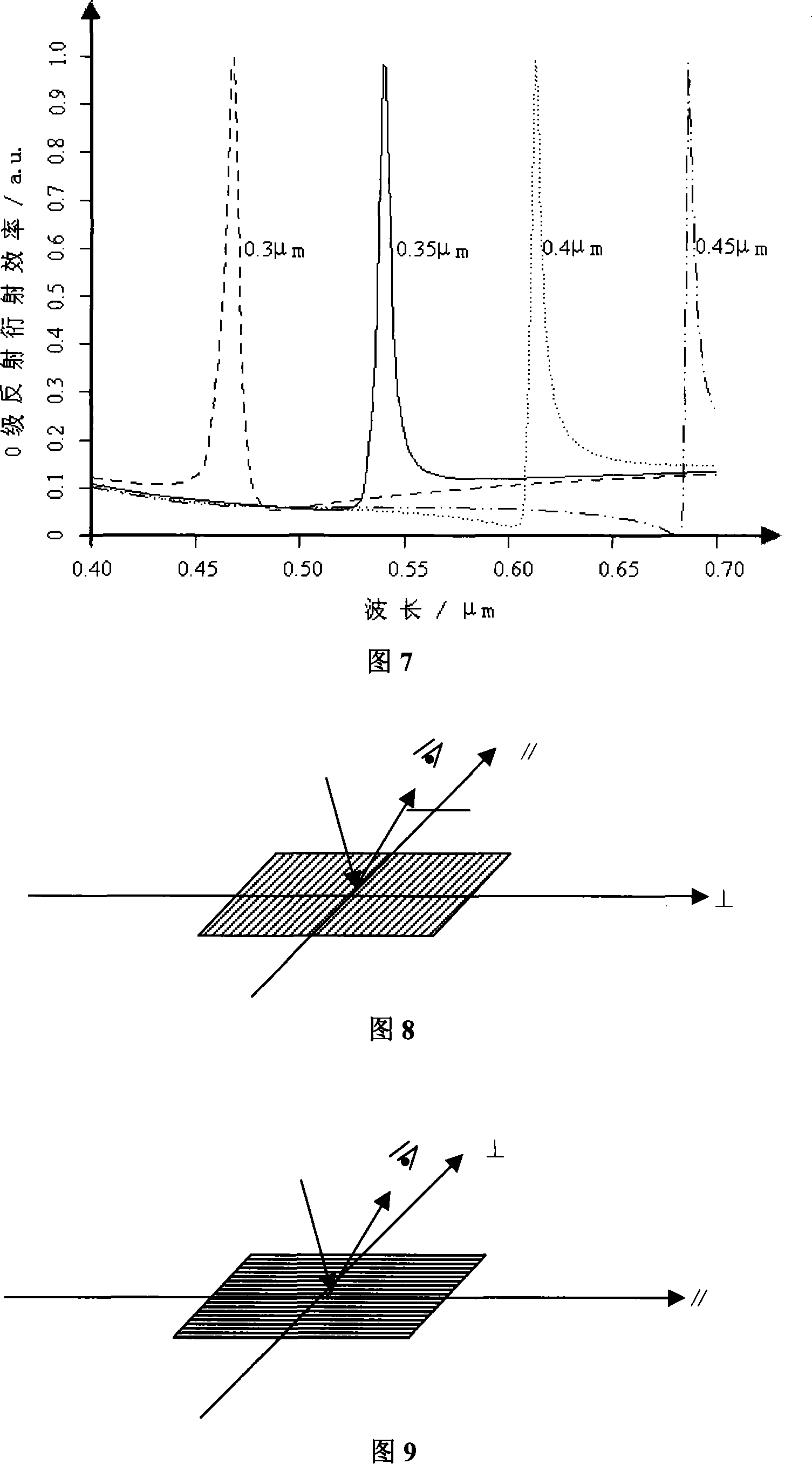

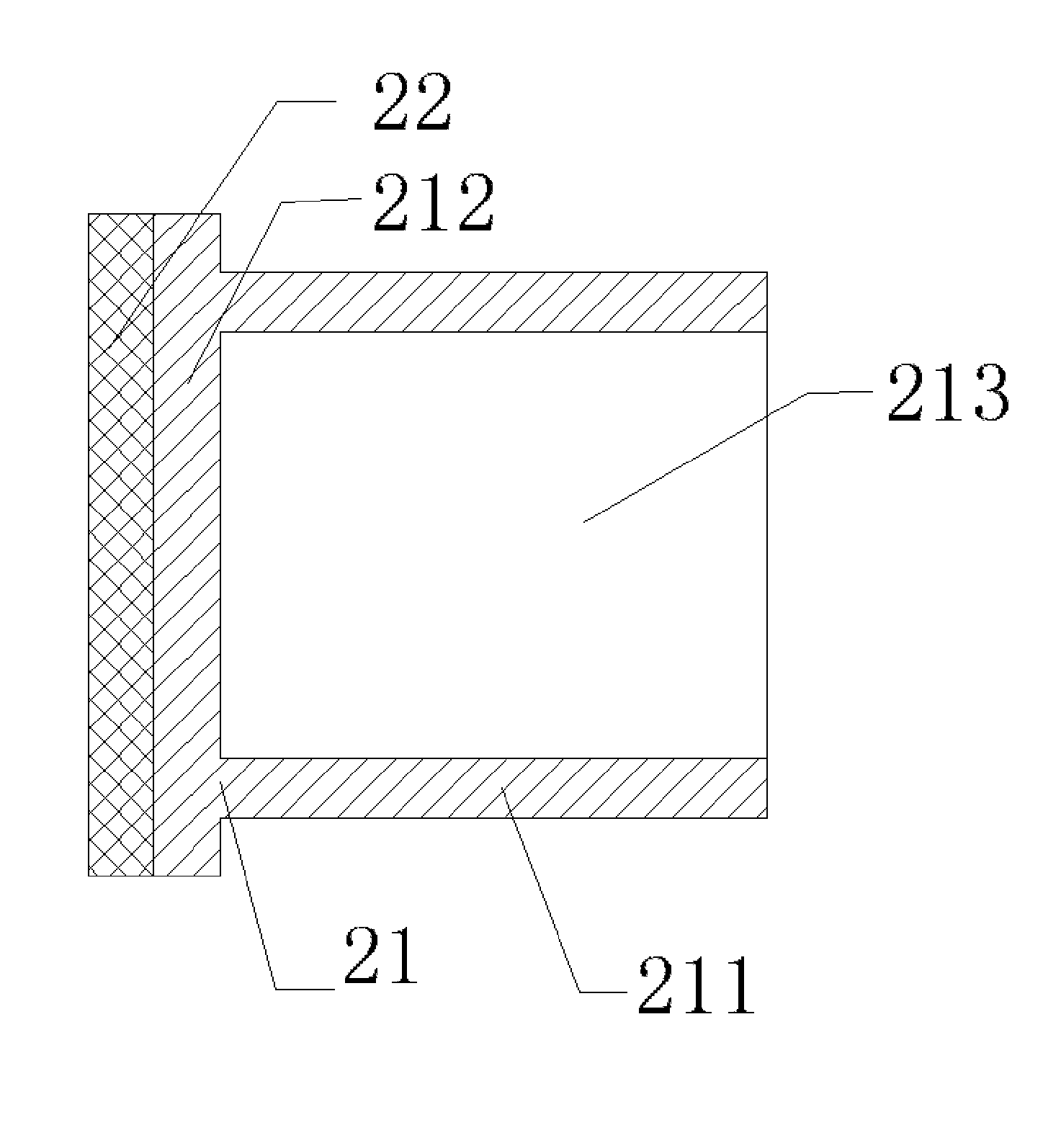

False proof structure for driving license and its identifying method

ActiveCN101161482AWith dynamic effectProminent visual featuresOther printing matterLight effect designsColor effectBody shape

The invention discloses an anti-counterfeiting structure for driving card. The marked pattern composed of microstructure is set on the plastic packaged film of the card. The said marked pattern comprises at least three pattern area. A first pattern area is composed of sub-wavelength structure raster of orientated orthogonal structure and the double vision channel forms single color effect. A second pattern area is composed of light spot with body shape of square. The light spot shape of the pattern edge is determined by the outer outline of the pattern, with gliding property. The interference fringes are set in the light point. A third pattern area is composed of bar speckle microstructure, with oriented achromatization effect for white light reflection. The vision character of pattern is notable, easy to recognize in public places and conveniently and quickly distinguish the card. At the same time, the structure data is computed using rigid coupled wave. The said microstructure is produced using electron beam or laser interference optical lithography, and the means is advanced and the difficulty of technique is high with high safety.

Owner:TRAFFIC MANAGEMENT RES INST OF THE MIN OF PUBLIC SECURITY +1

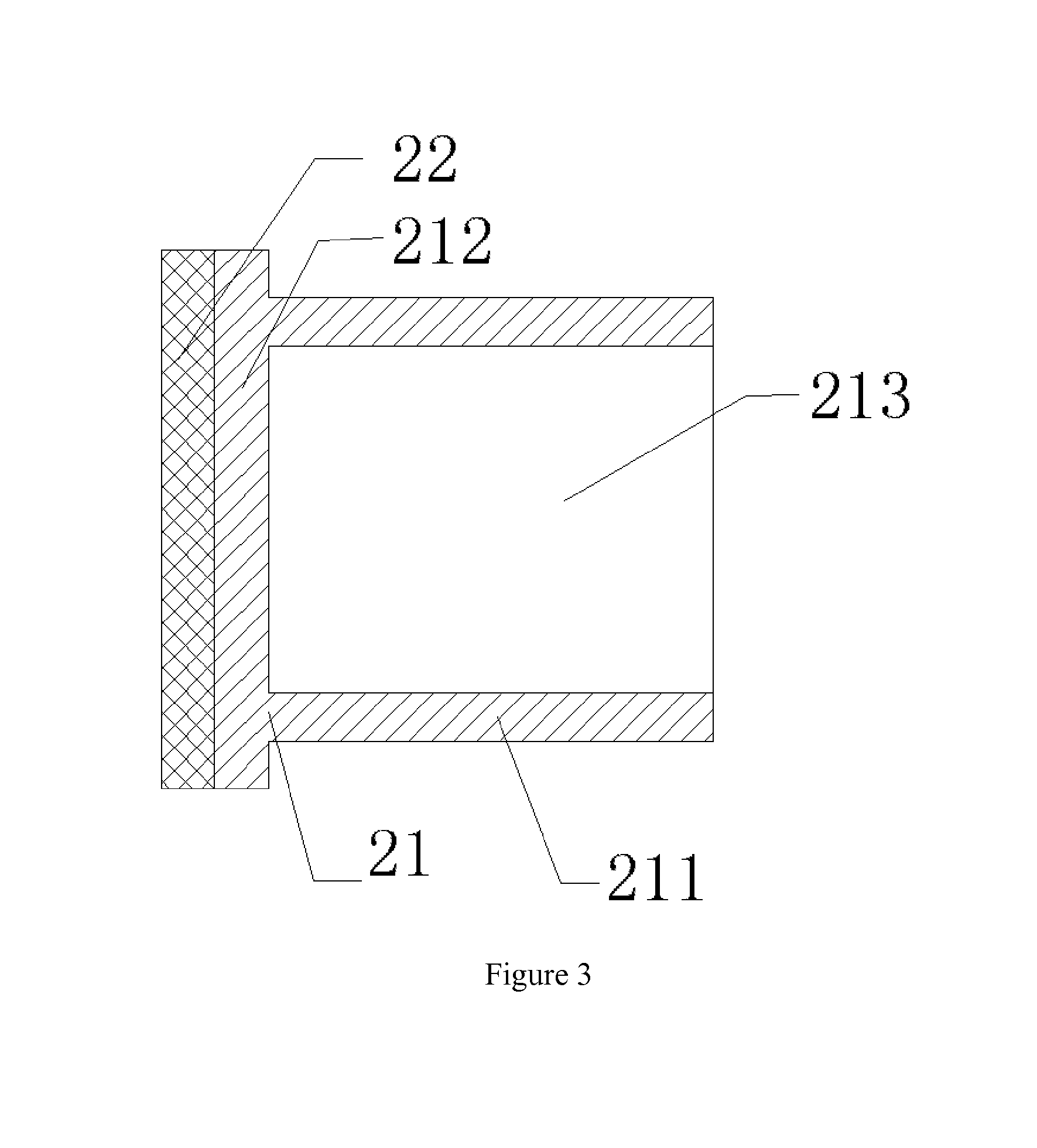

Lamp cover and electronic cigarette using the same

InactiveUS20140290673A1Meet the requirementsSimple structureLighting support devicesTobacco pipesColor effectEngineering

Owner:KIMREE HI TECH

Colorful transparent polished-glazed brick and production method thereof

The invention discloses a colorful transparent polished-glazed brick and a production method thereof. The production method for the colorful transparent polished-glazed brick comprises the following steps: enameling a dried ceramic blank, spreading one or more glazes in different colors and with different burning temperature and different refractive indexes on the brick blank, and performing calcining and profiling soft polishing treatment to obtain the brick. According to the colorful transparent polished-glazed brick and the production method thereof, the layering effects and transition of the surface of the colorful transparent polished-glazed brick are closer to those of a natural stone, and the grade of the product is improved to a certain extent; original color effects can be achieved without adding a coloring material, so that process complexity is reduced, the labor intensity of a worker is reduced, and the production efficiency is favorably improved, and the colorful transparent polished-glazed brick and the production method thereof are suitable for popularization and application.

Owner:GUANGDONG JIA MEI CERAMIC

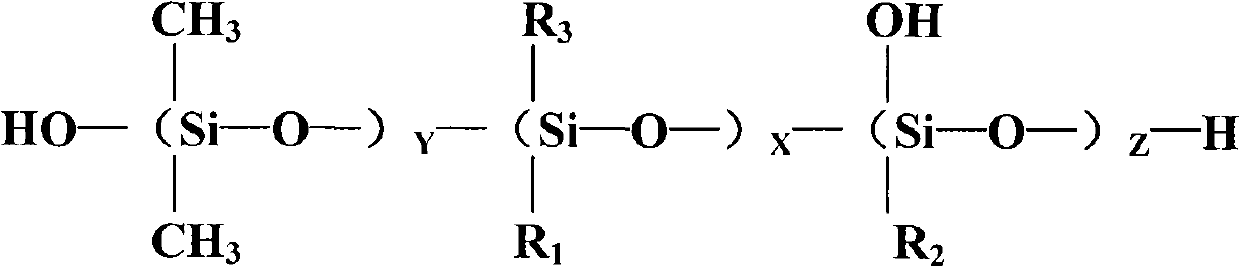

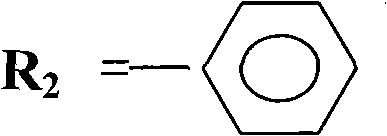

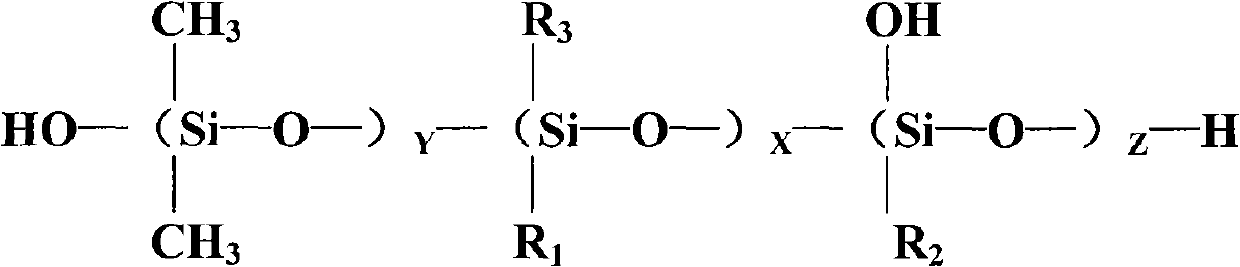

Darkening and coloring finishing agent of dyed cotton fabrics and preparation method thereof

The invention relates to a darkening and coloring finishing agent of dyed cotton fabrics and a preparation method thereof. The darkening and coloring finishing agent of the dyed cotton fabrics is prepared by mixing an organic polysiloxane emulsion and methyl hydrogen-contained silicone oil shown in structural formulas in a ratio of 100 to 5-10, wherein R1=-CH2CH2CH2NH2 and / or -CH2CH2CH2NHCH2CH2NH2 and / or -CH2CH2CH2NHCH2CH2NHCH2CH2NH2, R3=-OH and / or -CH3, X=4-6000, Y=1-100 and Z=1-100. The invention has favorable darkening and coloring effects on the dyed cotton fabrics; and the treated dyed cotton fabrics have soft and smooth hand feeling and good washability without remaining substances harmful to human bodies.

Owner:江苏卓特知识产权服务有限公司

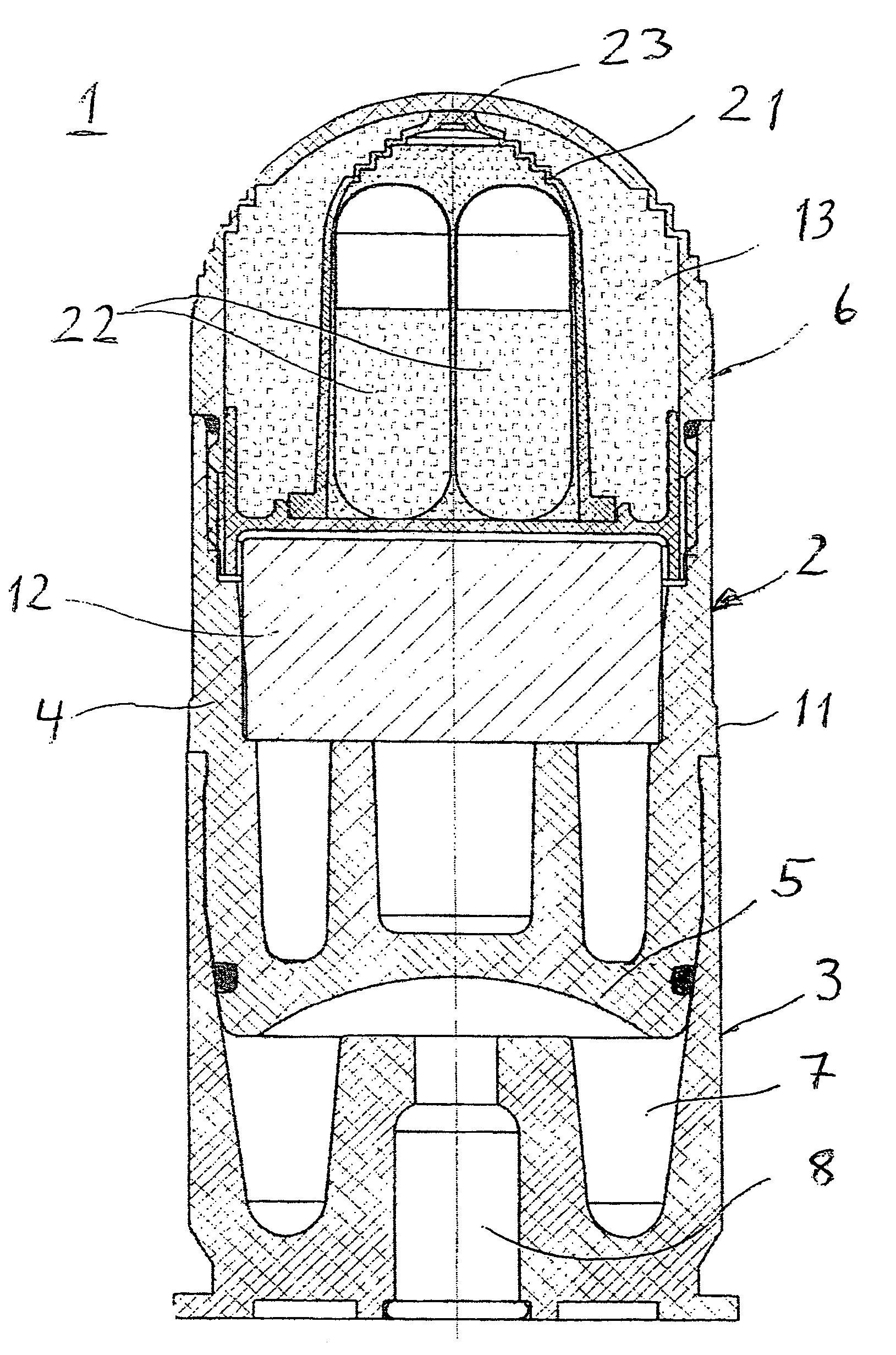

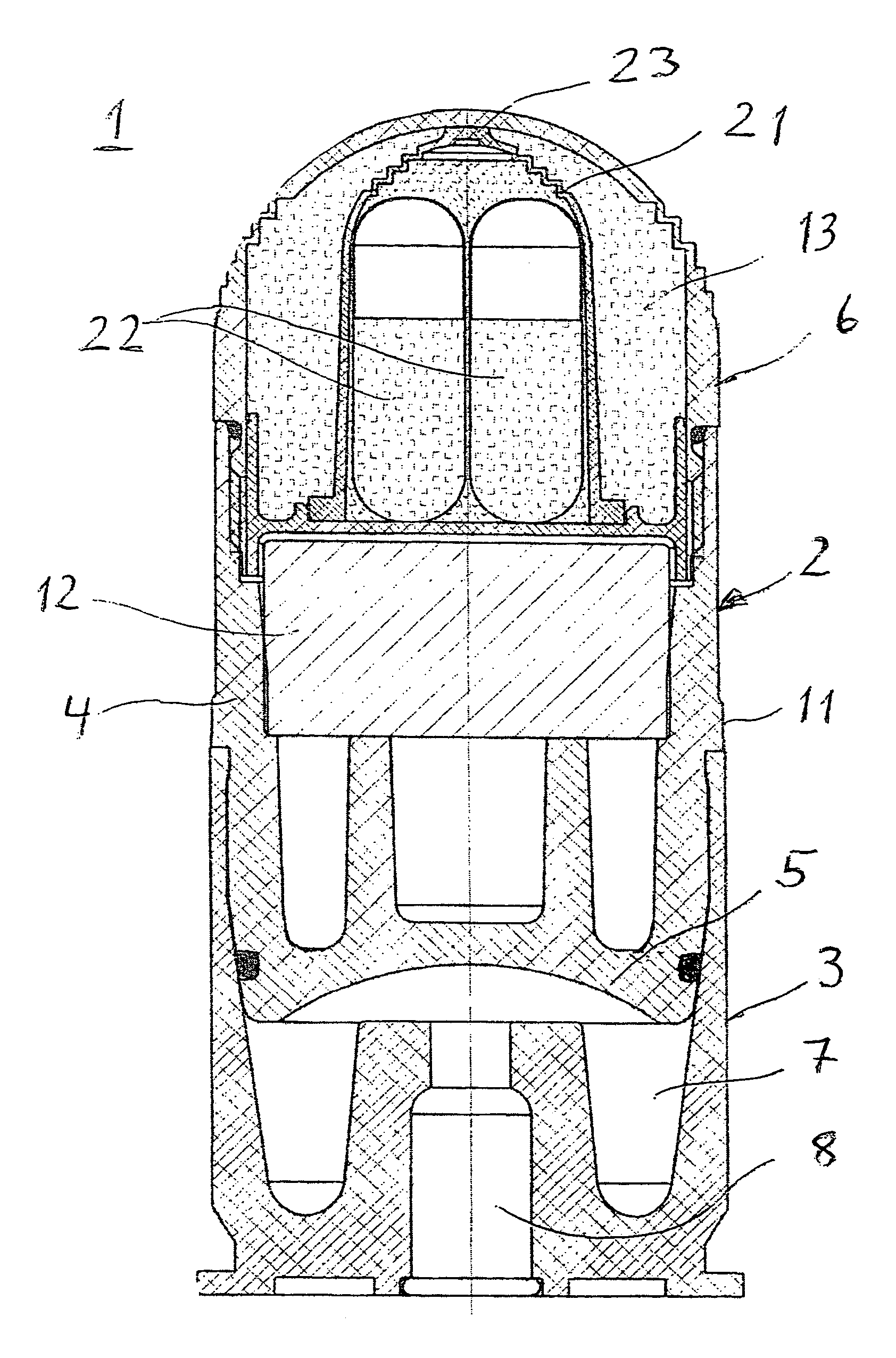

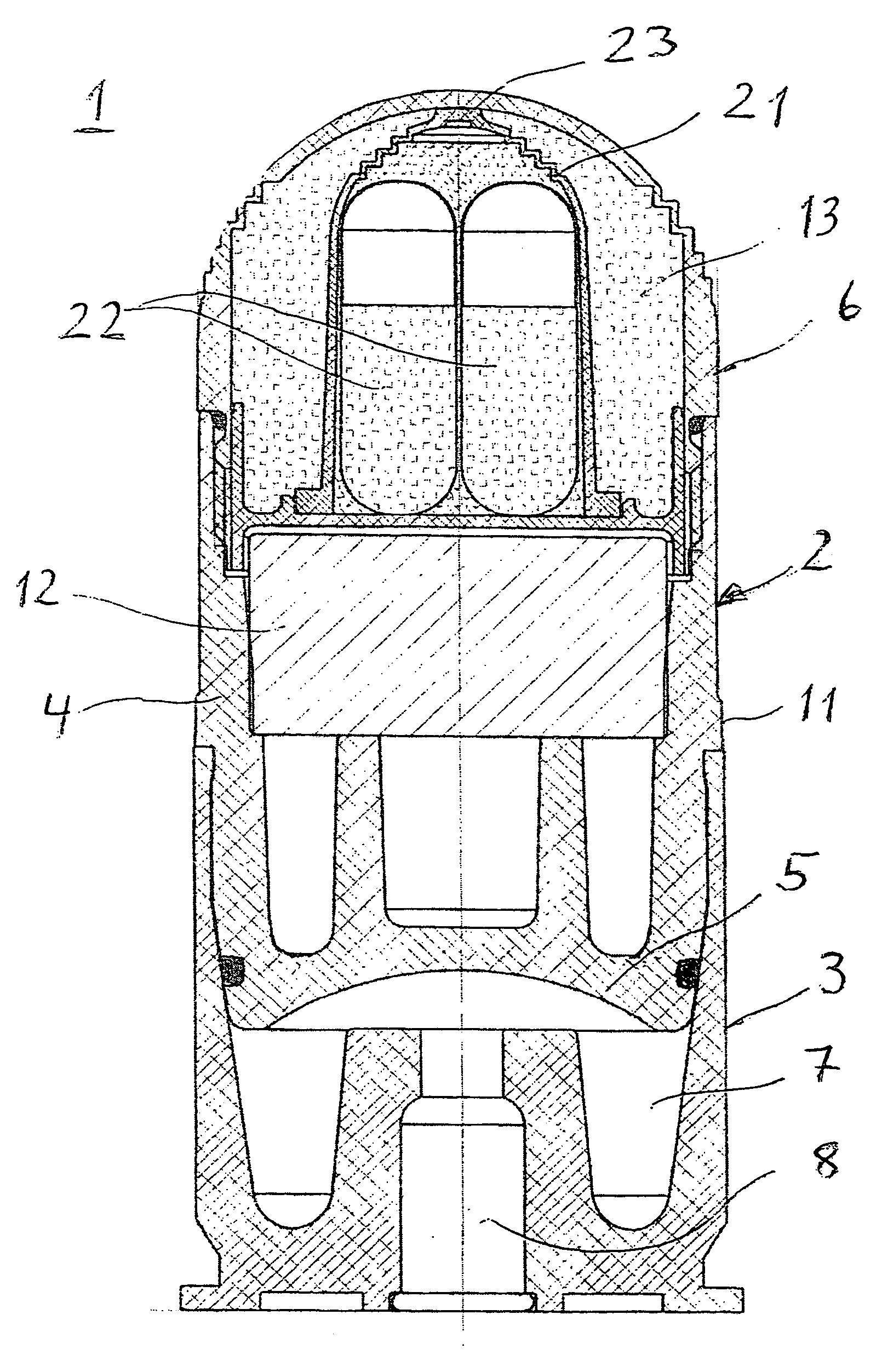

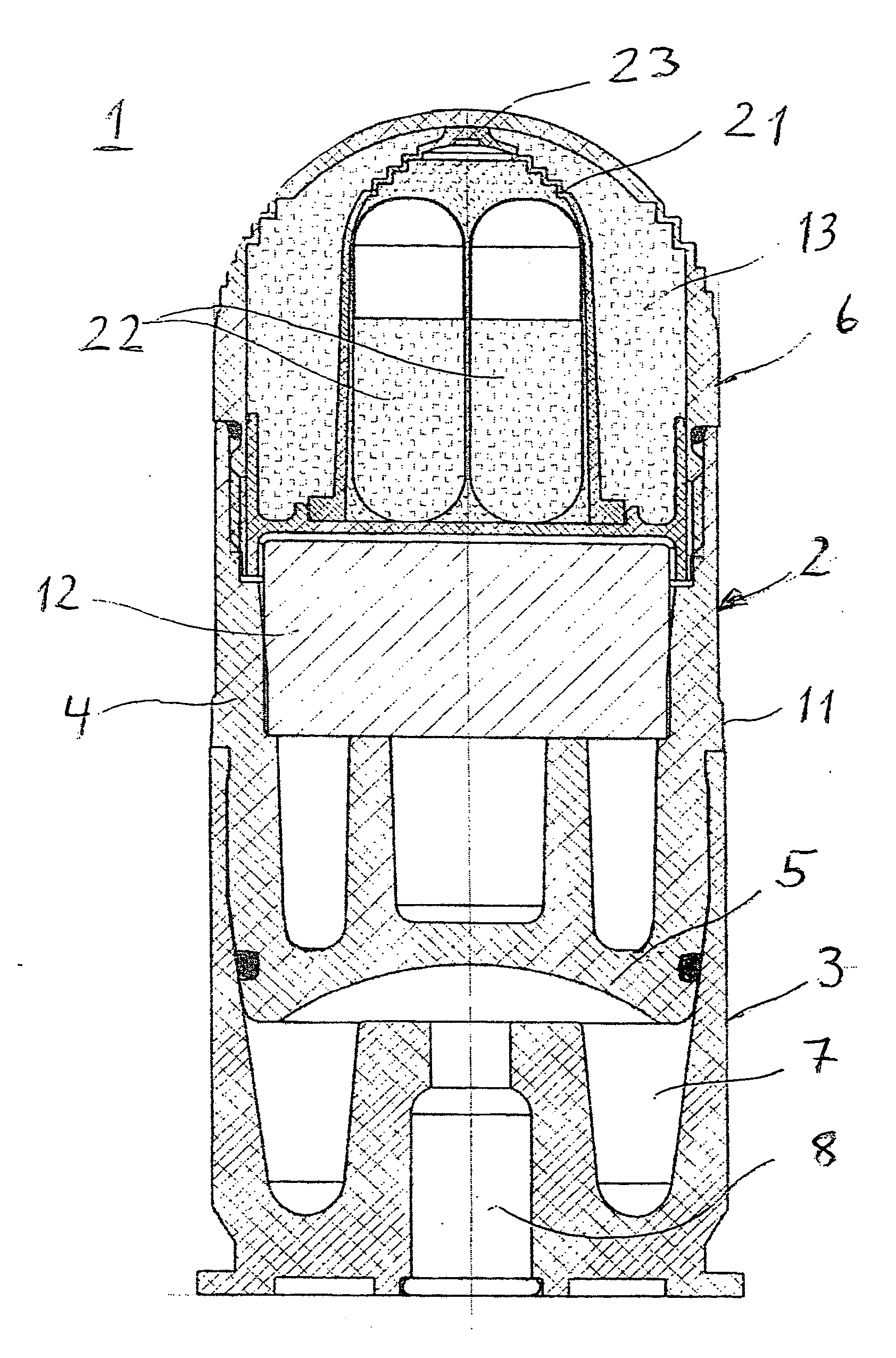

Projectile with means for marking its strike point

ActiveUS7475638B2Good colorClearly visibleAmmunition projectilesTraining ammunitionColor effectEngineering

A training projectile includes at its head a hollow arched cavity or cap that defines a hollow cavity within the head of the training projectile, and that bursts when the projectile strikes a target. Into this cavity are placed a first chemically-inactive marking material and a second chemically-active marking material, whereby both marking materials are released upon bursting of the arched cavity. The first marking material creates, for example, a color effect by means of a colored powder; the second marking material produces a light effect by means of, for example, materials that interact to produce chemo-luminescence.

Owner:NICO PYROTECHNIK HANNS JUERGEN DIEDRICHS GMBH & CO KG

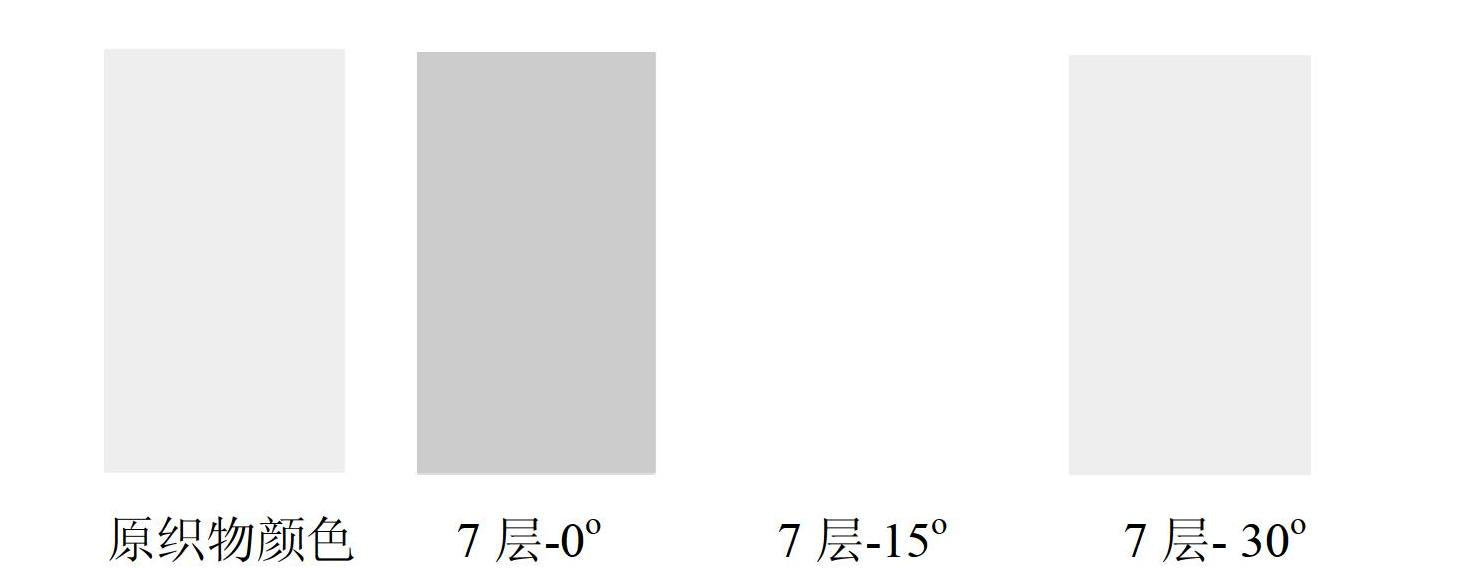

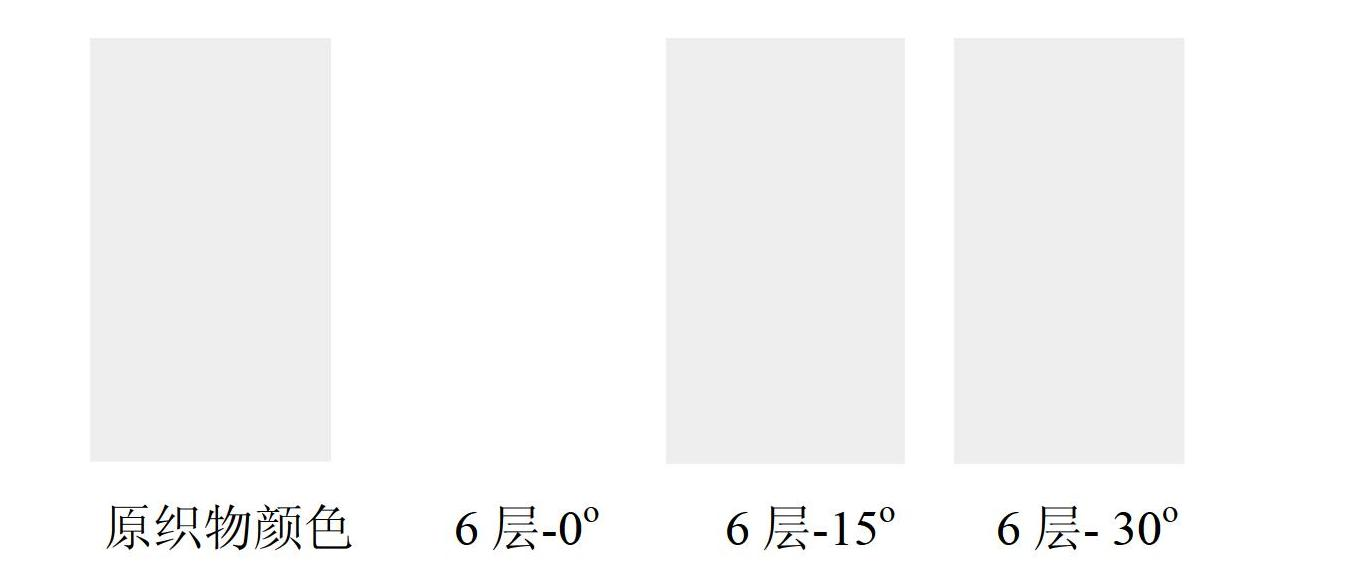

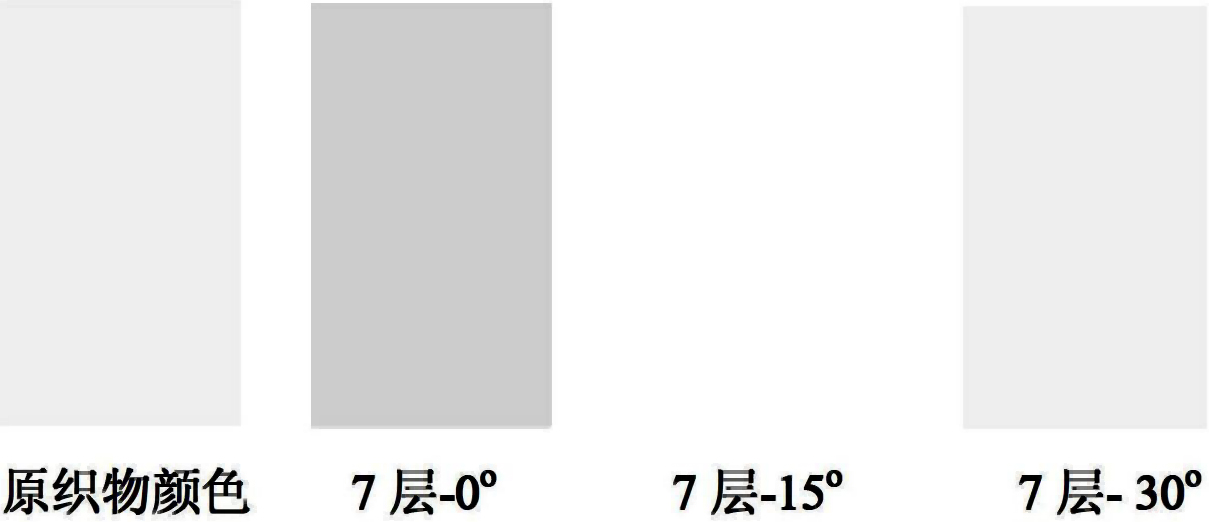

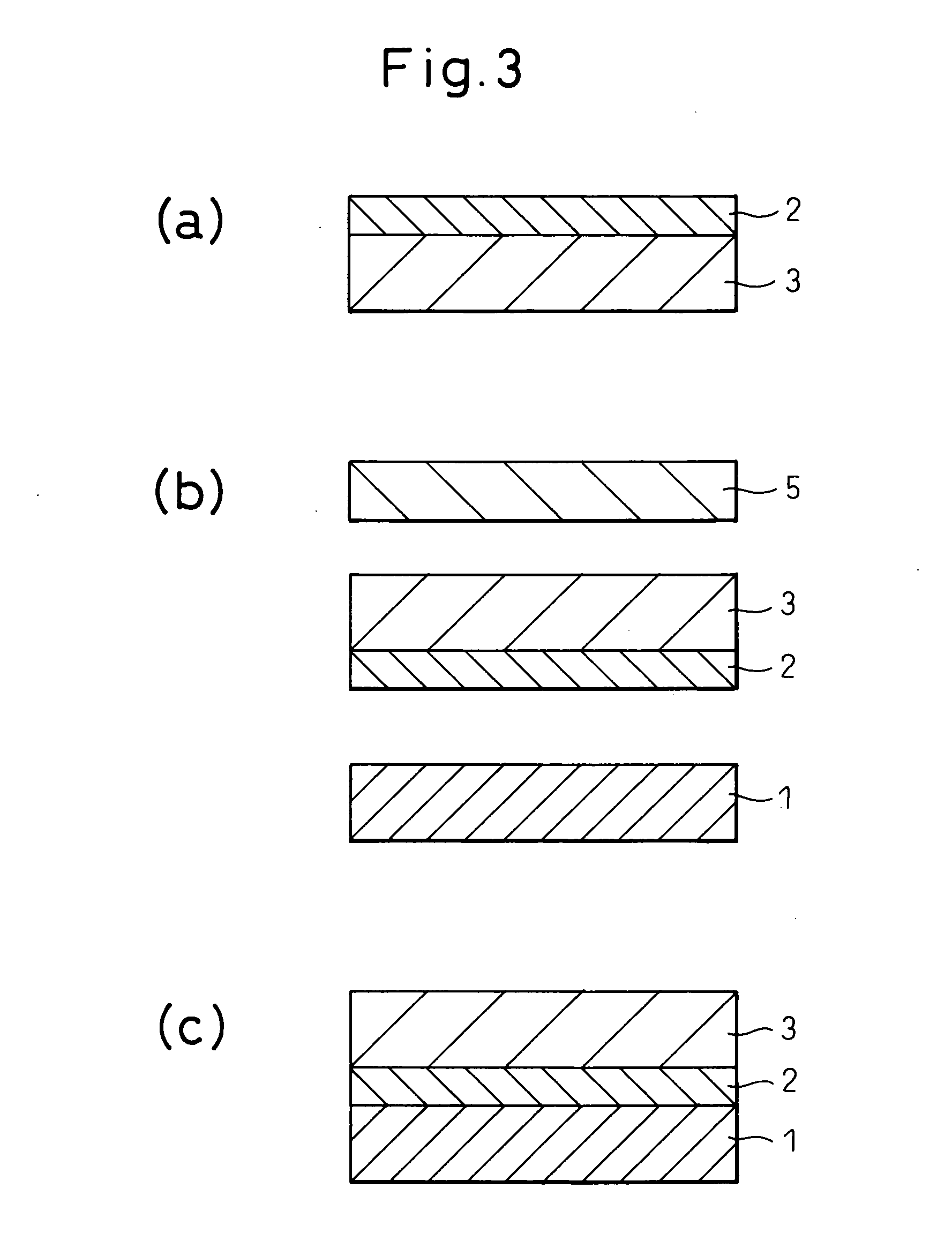

Method for preparing one-dimensional photonic crystal film on fabric surface to realize structural color

The invention relates to a method for preparing a one-dimensional photonic crystal film on the fabric surface to realize a structural color. The method comprises preparation of titanium sol and silica sol and alternate forming of a titanium dioxide film layer and a silicon dioxide film layer on the fabric surface. The structural color can be formed on the fabric surface by adopting the method. The results show that variation of the surface color of the fabric treated by the method can be observed from different angles and the structural color effect is generated. The synthetic method and required production equipment are simple, are easy to realize industrial production and have great reference significance in reducing the environmental pollution of the dyeing industry. The prepared fabric dispenses with any dye to realize the structural color and has excellent optical property and good application prospect.

Owner:DONGHUA UNIV

Projectile with means for marking its strike point

ActiveUS20070119329A1Large distributionGood colorAmmunition projectilesTraining ammunitionColor effectEngineering

A training projectile includes at its head a hollow arched cavity or cap that defines a hollow cavity within the head of the training projectile, and that bursts when the projectile strikes a target. Into this cavity are placed a first chemically-inactive marking material and a second chemically-active marking material, whereby both marking materials are released upon bursting of the arched cavity. The first marking material creates, for example, a color effect by means of a colored powder; the second marking material produces a light effect by means of, for example, materials that interact to produce chemo-luminescence.

Owner:NICO PYROTECHNIK HANNS JUERGEN DIEDRICHS GMBH & CO KG

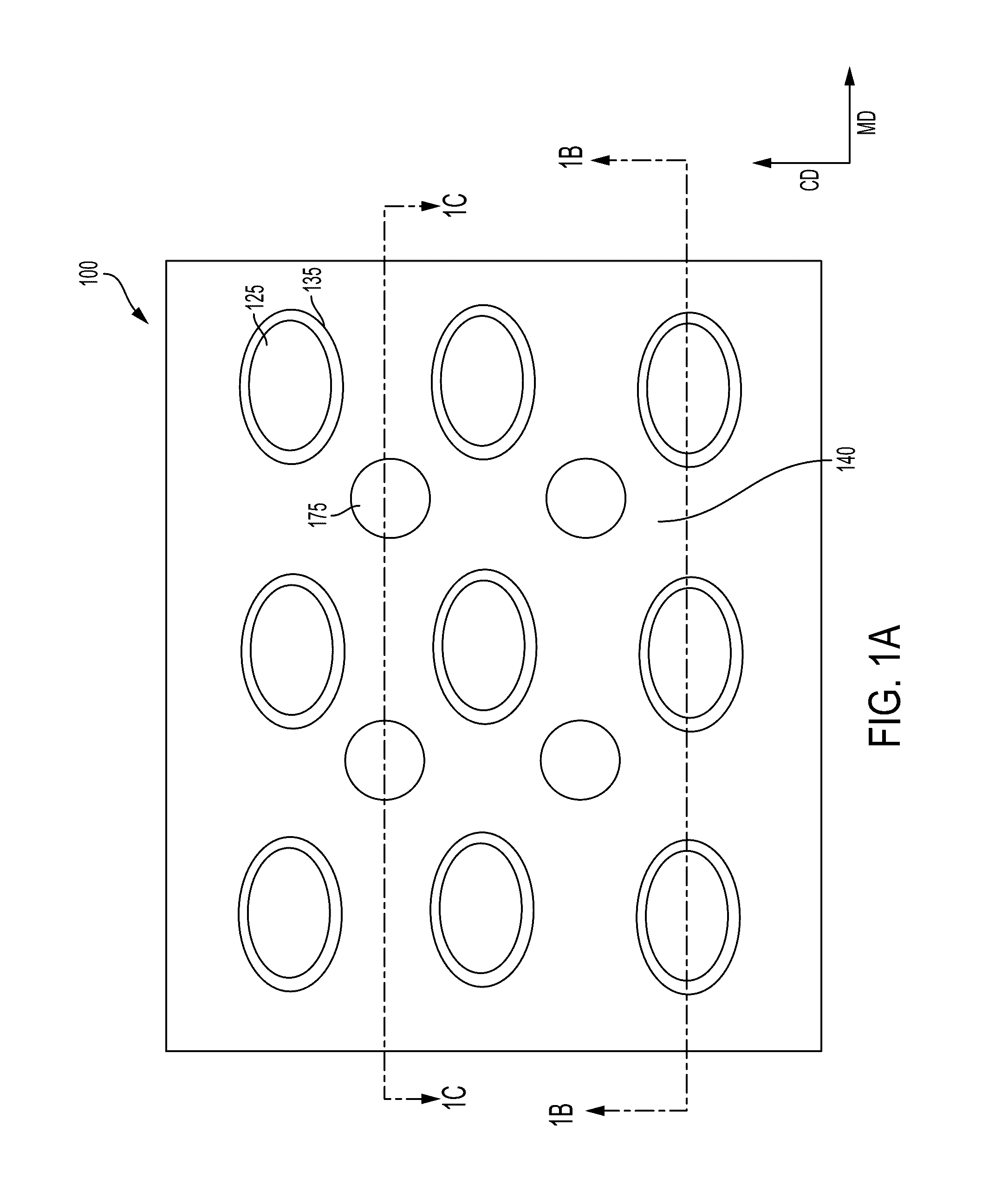

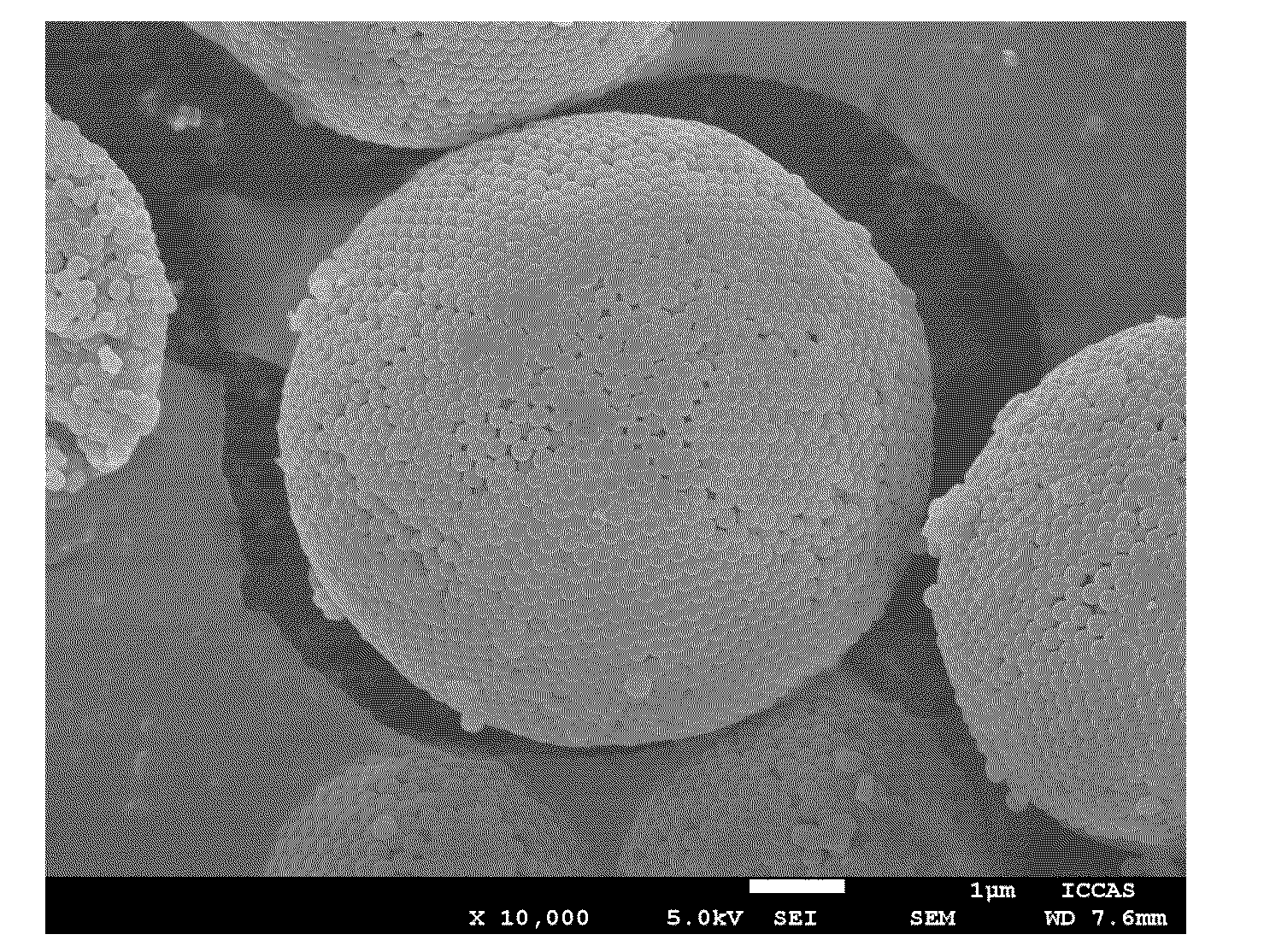

Photonic Crystal Microsphere

ActiveUS20160170091A1Pure colorMass productionFrom gel stateCosmetic preparationsColor effectPhotonic crystal

Owner:THE PROCTER & GAMBLE COMPANY +1

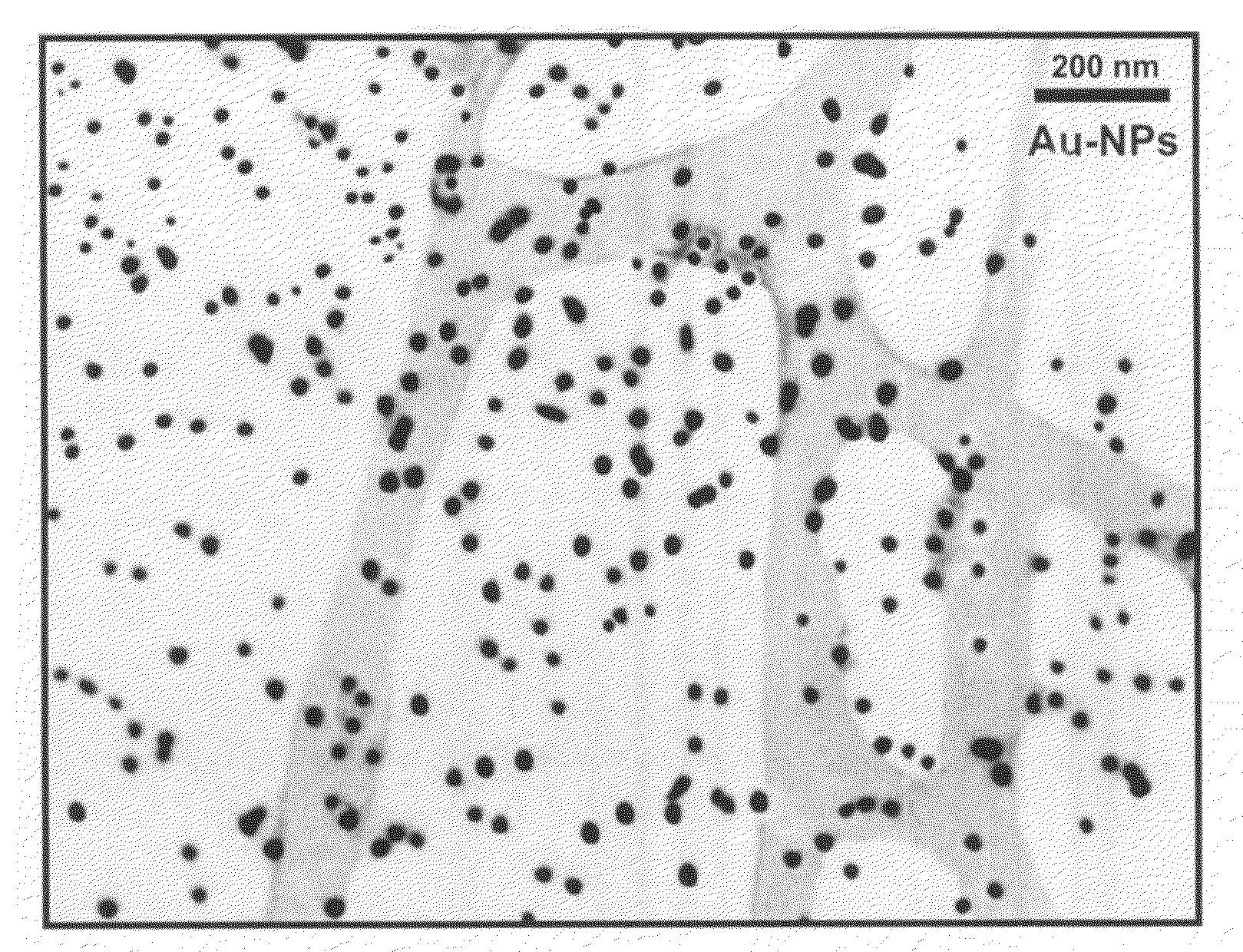

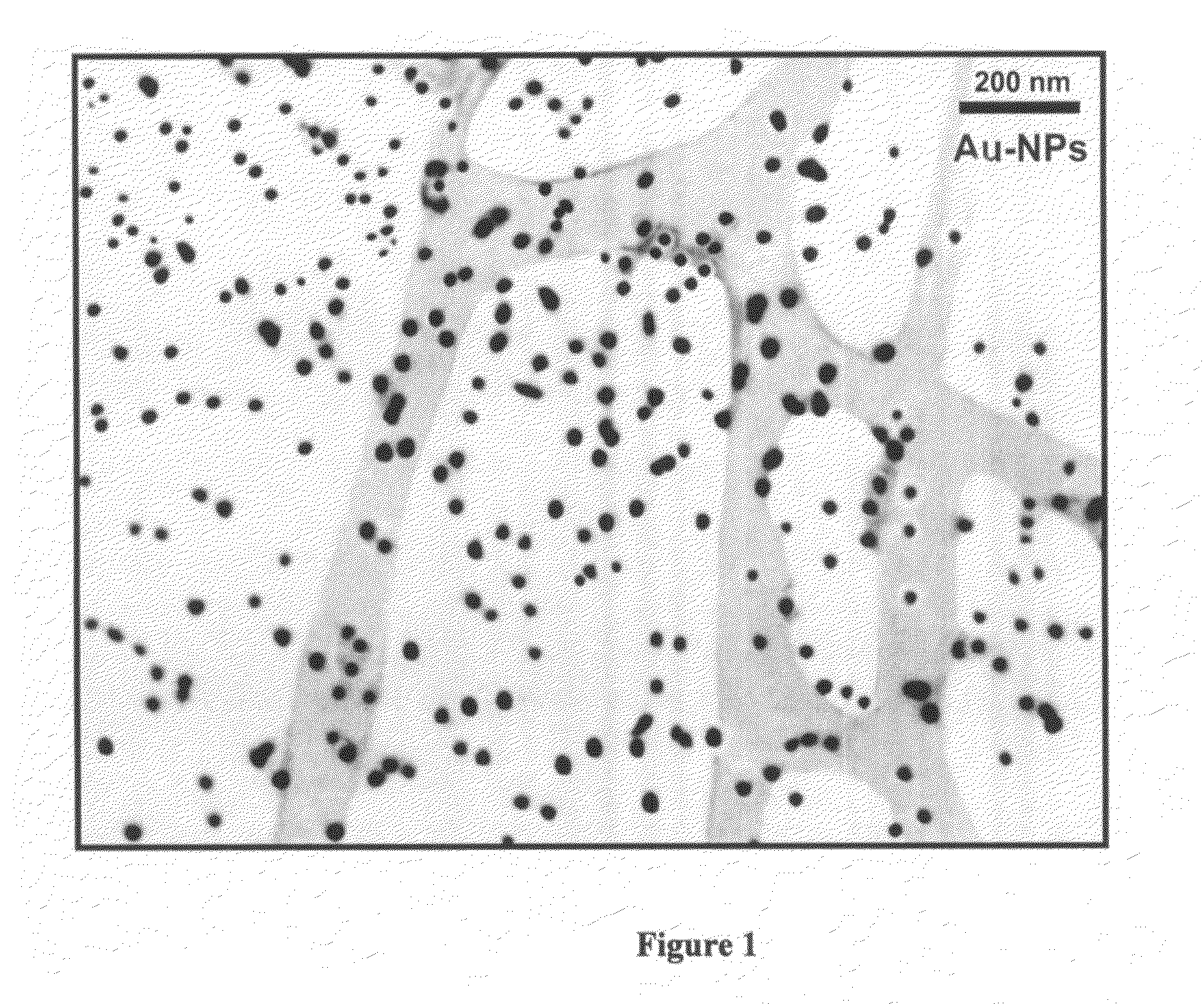

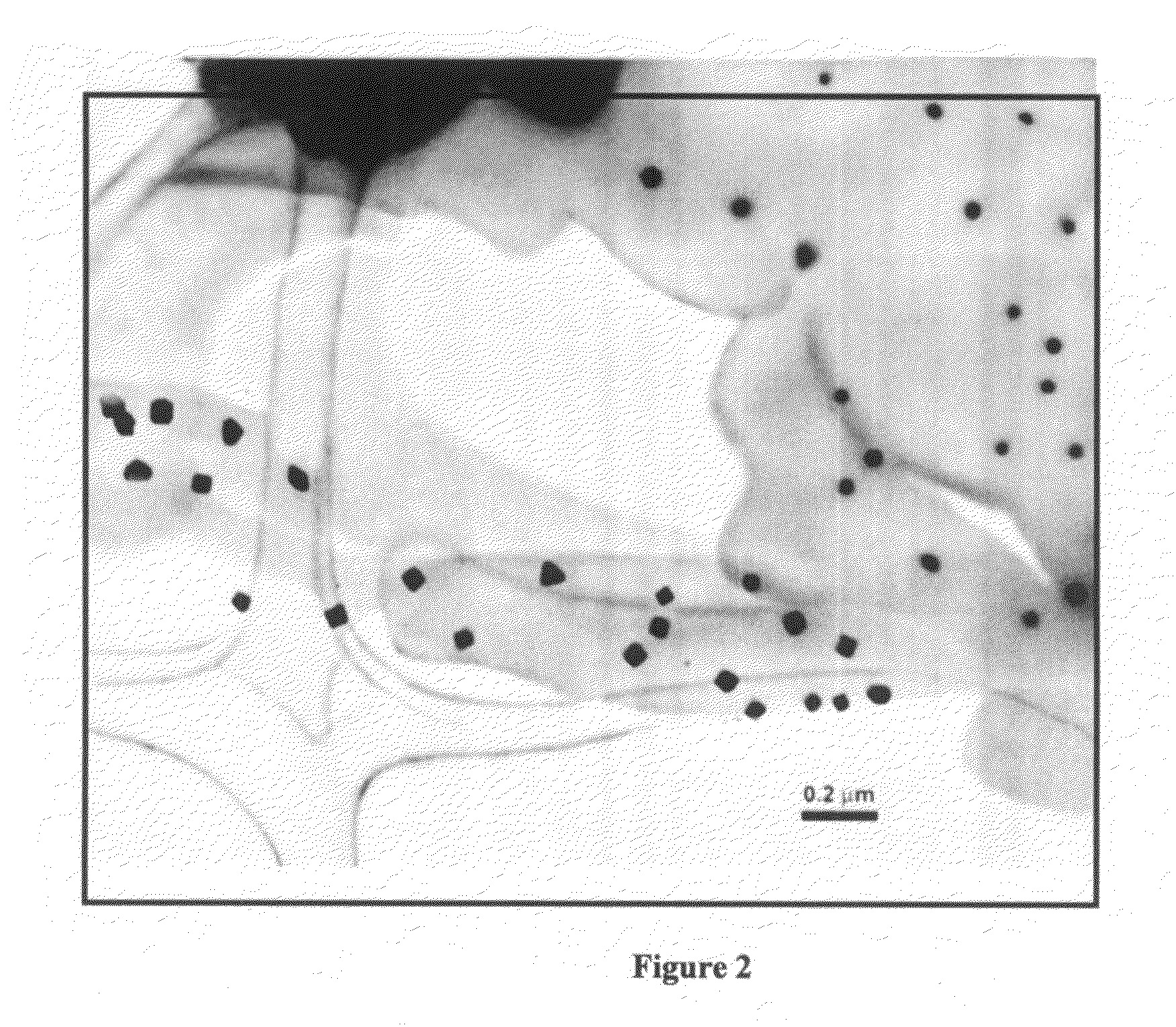

In-situ nanoparticle formation in polymer clearcoats

Methods and compositions for forming a transparent clear coat characterized by a desired property, such as a color effect, resistance to UV light-induced degradation and / or scratch resistance, on a substrate are detailed according to embodiments of the present invention. Particular compositions and methods for producing a transparent clear coat layer include nanoparticles formed in-situ during curing of a transparent clear coat. Curable clear coat compositions are described according to embodiments of the present invention which include one or more substantially dissolved nanoparticle precursors.

Owner:UNIVERSITY OF KENTUCKY

Film coating material and preparation method thereof

ActiveCN101628492AColorfulStrong metal textureVacuum evaporation coatingSputtering coatingColor effectBinding force

The invention provides a film coating material. The material comprises a transparent substrate and a film layer coated on the transparent substrate, wherein the film layer consists of an oxide film layer and a metal film layer, the oxide film layer is positioned between the transparent substrate and the metal film layer, and both the oxide film layer and the metal film layer are single layers. The invention also provides a preparation method for the film coating material. According to the film coating material provided by the invention, the film layer is simple and only consists of the oxide film layer and the metal film layer, and various color effects can be obtained through different matches of the oxide film layer and the metal film layer, so the film coating material has gorgeous color, strong metal texture and good binding force. And the preparation method for the film coating material has simple process so as to have high production efficiency.

Owner:BYD CO LTD

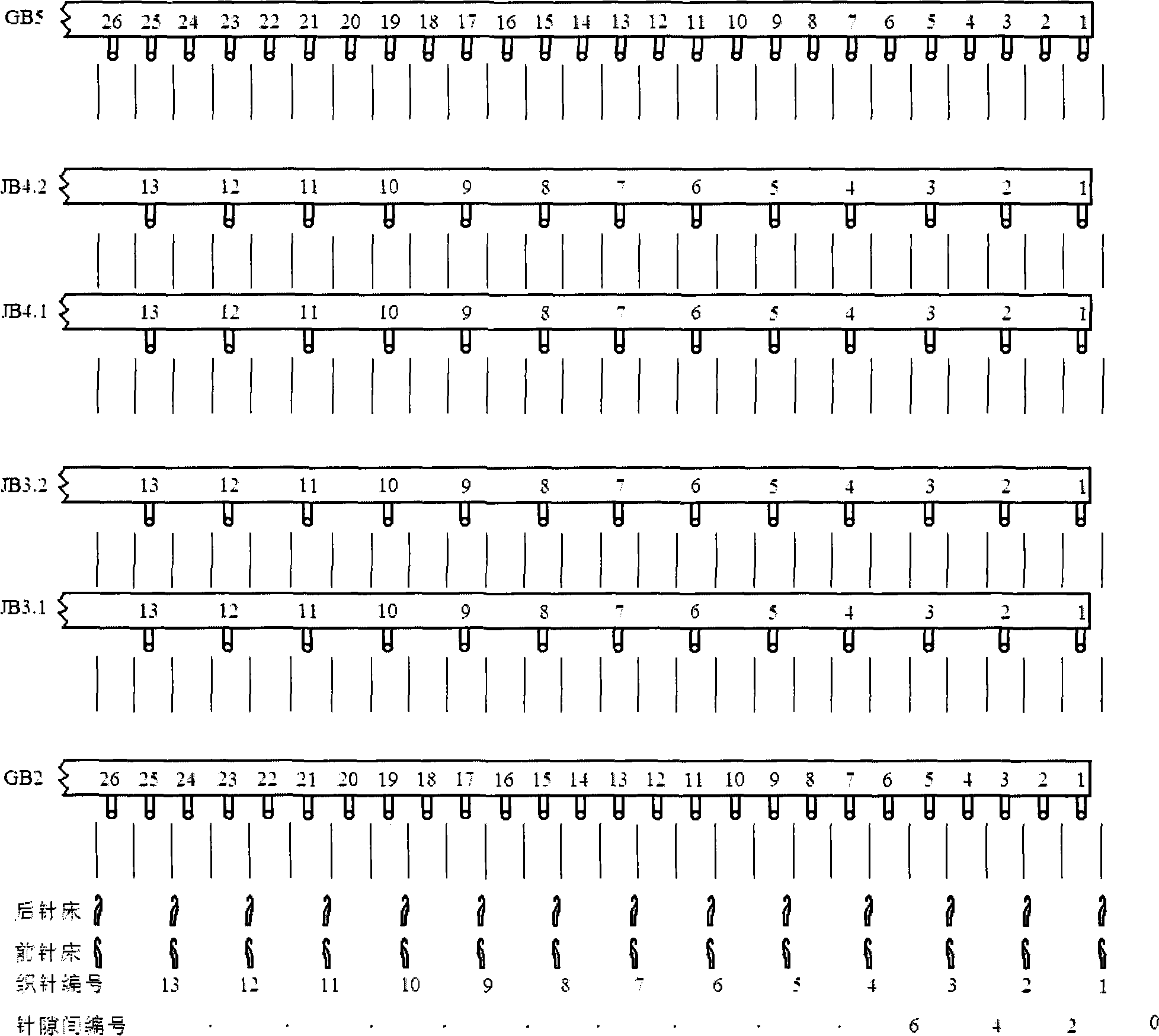

A warp knitting method for double-color jacquard seamless fabric

The invention discloses a warp knitting method for double-color jacquard seamless fabric. The concrete process is as follows: first, determining basic knitting process; each of front and back needle bed uses one ground guide bar for knitting base cloth and two jacquard guide bar for knitting main jacquard pattern and connection tissue for front and back sheet; second, determining overlap of main pattern formed by jacquard comb and corresponding motion information of jacquard needle, combines corresponding basic motion information of jacquard needle; finally, determining overlap of edge of front and back sheets and motion information of jacquard needle by adopting superposition method. The invention adopts special machine configuration and specific process, knits double-color seamless fabric, completes warp knitting jacquard seamless fabric with concurrent structural effect and color effect. The seamless fabric of the inventive method has a solid pattern and outstanding layers, rich color, variable structural effect, massive thickness, thereby largely promoting market competitive force of seamless fabric.

Owner:JIANGNAN UNIV

Method for processing plastic surface

The invention provides a method for processing a plastic surface; comprising the following steps: providing a plastic base body, wherein the surface of the plastic base body is previously provided with a rough area; spraying a priming paint layer on the surface of the plastic base body; forming a vacuum plating film layer on the surface of the priming paint layer; spraying a transparent middle paint layer on the surface of the vacuum plating film layer; and spraying a transparent finish paint layer on the surface of the middle paint layer. By the method for processing the plastic surface, theplastic surface t can not only achieve bright metal appearance but also can show obvious bright and matte double-color effect.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

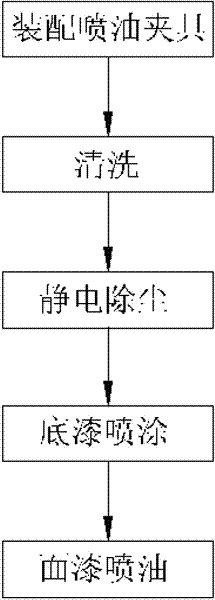

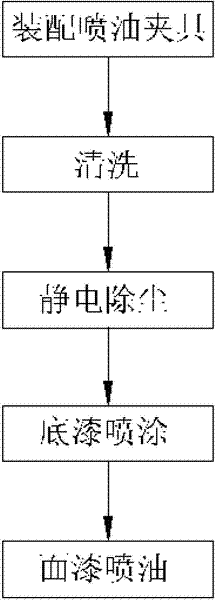

Process for spraying plastic parts of mobile phone and mobile phone shell made by adopting process

InactiveCN102671844AReduce consumptionImprove drop resistancePretreated surfacesCoatingsColor effectEngineering

The invention discloses a process for spraying plastic parts of a mobile phone. The process comprises the following steps of (1) assembly of an oil injection clamp; (2) cleaning; (3) electrostatic dust collection; (4) spraying of primer; and (5) oil injection on finishing paint. The invention also discloses a mobile phone shell made by adopting the process. The process is easy to operate, the primer of a corresponding color is selected according to the required color effect, the spraying frequency is lowered, the consumption of the pigments is reduced, and the production efficiency is improved, the production cost is lowered; and due to the adoption of the steps of cleaning and electrostatic dust collection, the adhesive force of the primer and the finishing paint is improved, the spraying effect is effectively improved, and the product quality is guaranteed. The mobile phone shell has a reasonable structure; due to the combination of the primer and the finishing paint, the primer is used for showing the required color effect, the finishing paint is used for improving the crash resistance and the wear resistance of the mobile phone shell, and the service life is prolonged. The spraying process is simple, low in cost and convenient to produce, and large-area popularization and application are facilitated.

Owner:DONGGUAN XUTONGDA MOLD PLASTIC +2

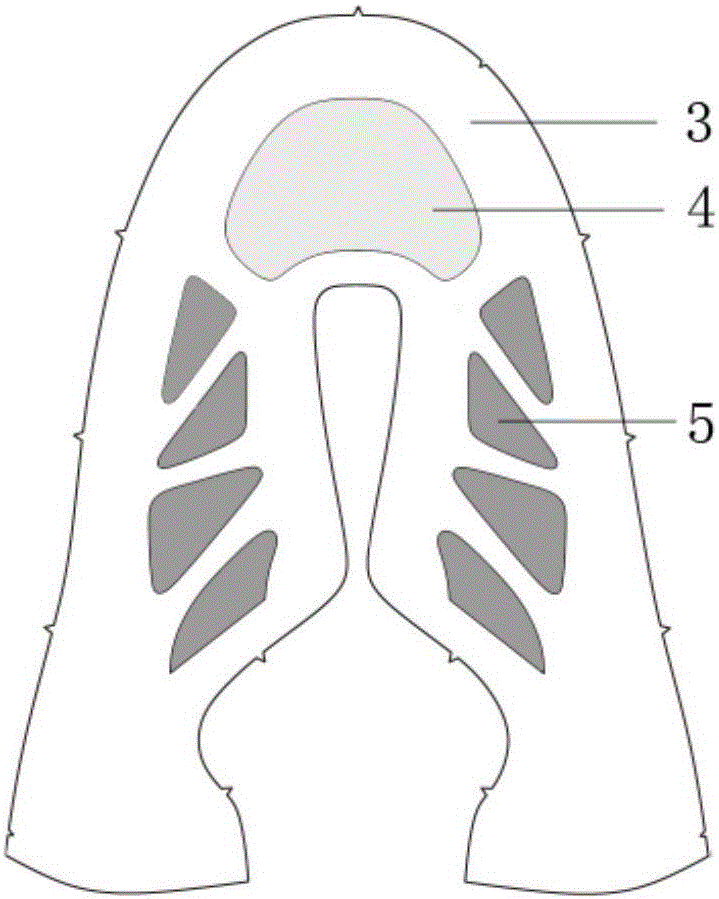

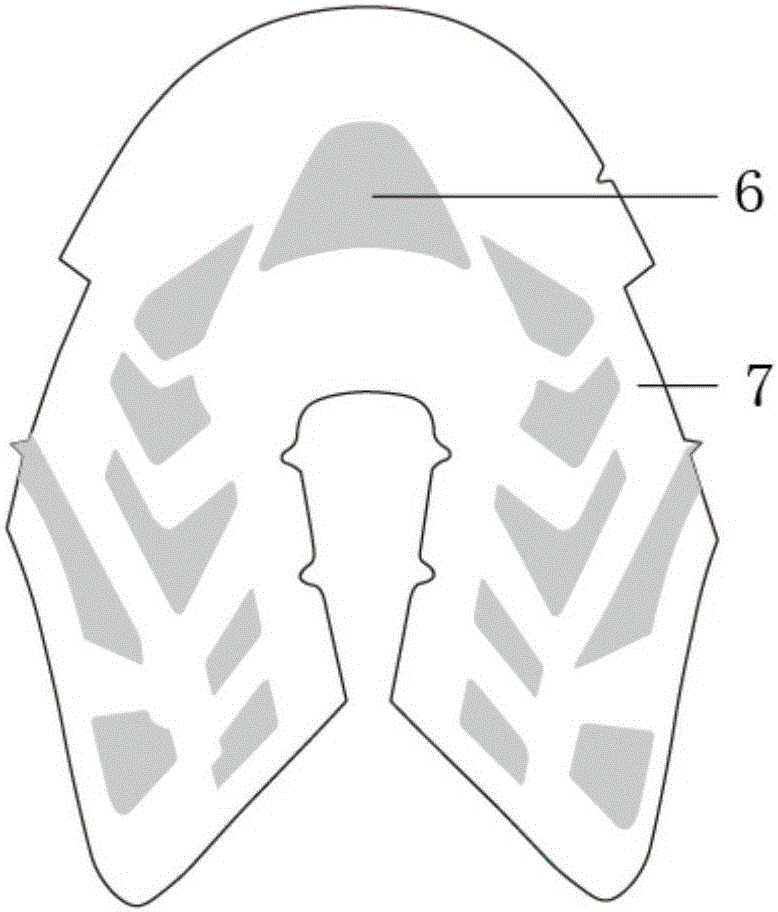

Wear-resistant and non-slip ceramic tile and preparation method thereof

The invention discloses a wear-resistant and non-slip ceramic tile. A mixed glaze layer of wear-resistant and non-slip particles and engobe is applied to the surface of a moulded ceramic tile base clay blank, wherein the mixed glaze layer of the wear-resistant and non-slip particles and the engobe is prepared from a mixed glaze slurry consisting of an engobe glaze slurry and high-temperature wear-resistant and non-slip particles. The invention further discloses a preparation method of the wear-resistant and non-slip ceramic tile. In the wear-resistant and non-slip ceramic tile, the wear-resistant and non-slip dry particles are inlaid into the engobe glaze layer and are positioned below a ceramic tile pattern decoration layer, so that the particle components and the transparency of the wear-resistant and non-slip dry particles do not affect the color effect of a product pattern, and the wear-resistant and non-slip dry particles are unlikely to be worn or scraped off during actual use; the particle size of the wear-resistant and non-slip dry particles is relatively large, so that the surface of a product achieves a better non-slip and anti-fouling effect.

Owner:JIANGXI HEMEI CERAMICS +1

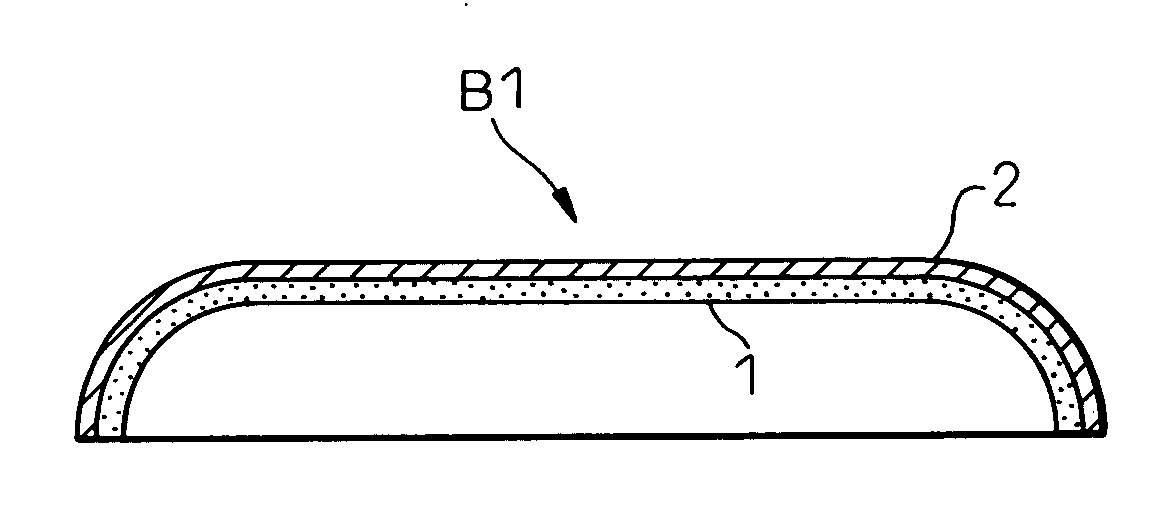

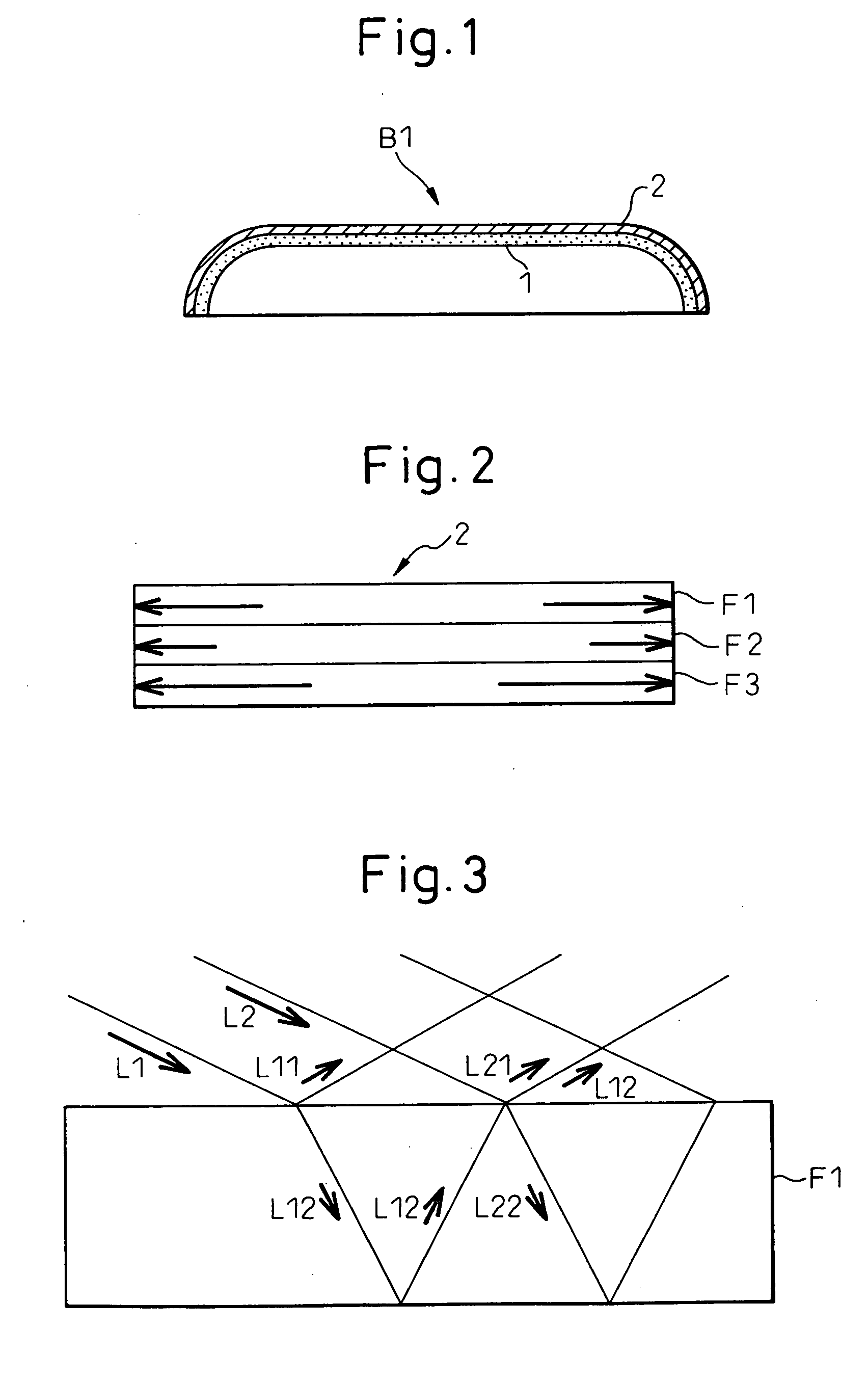

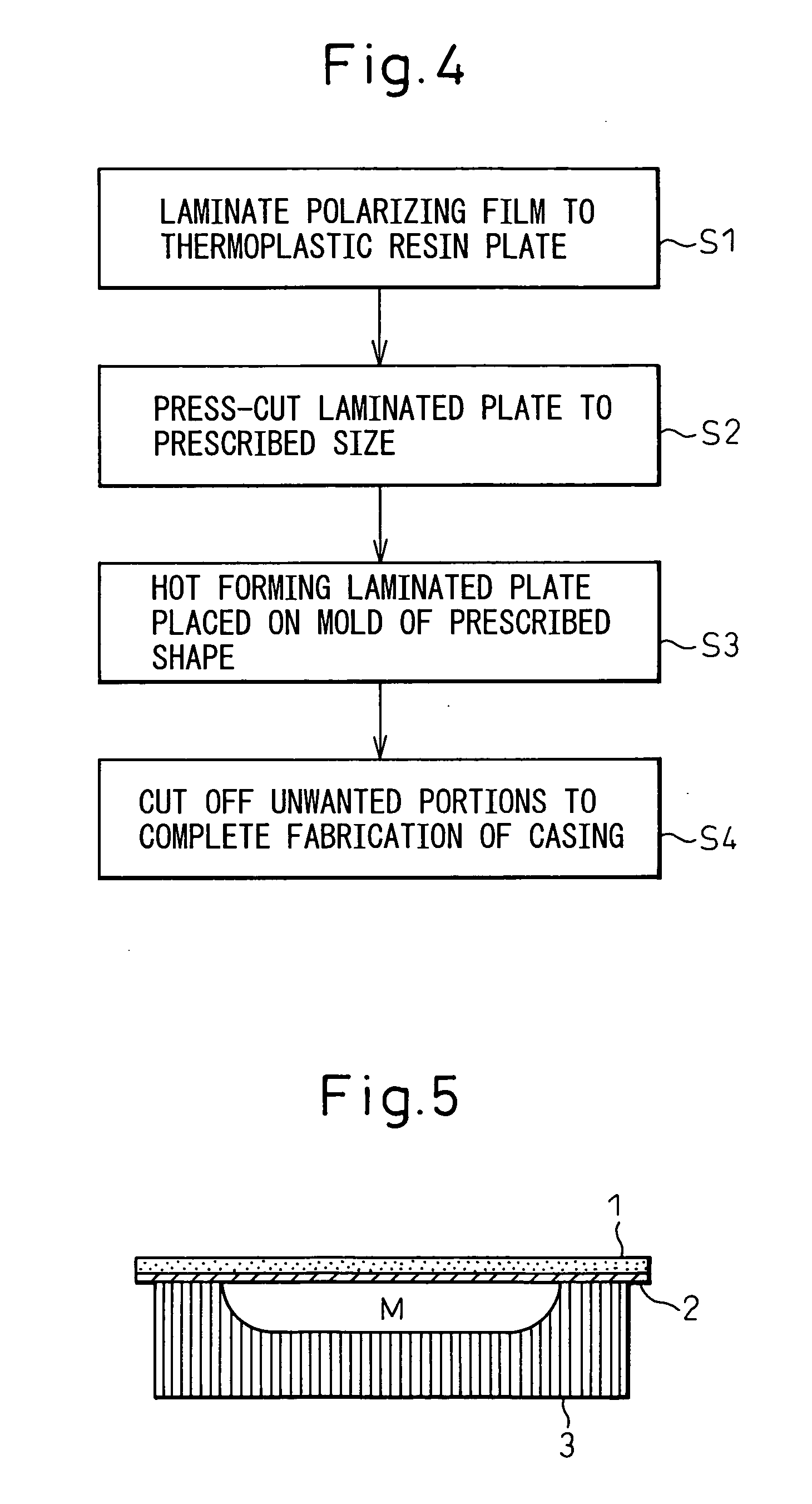

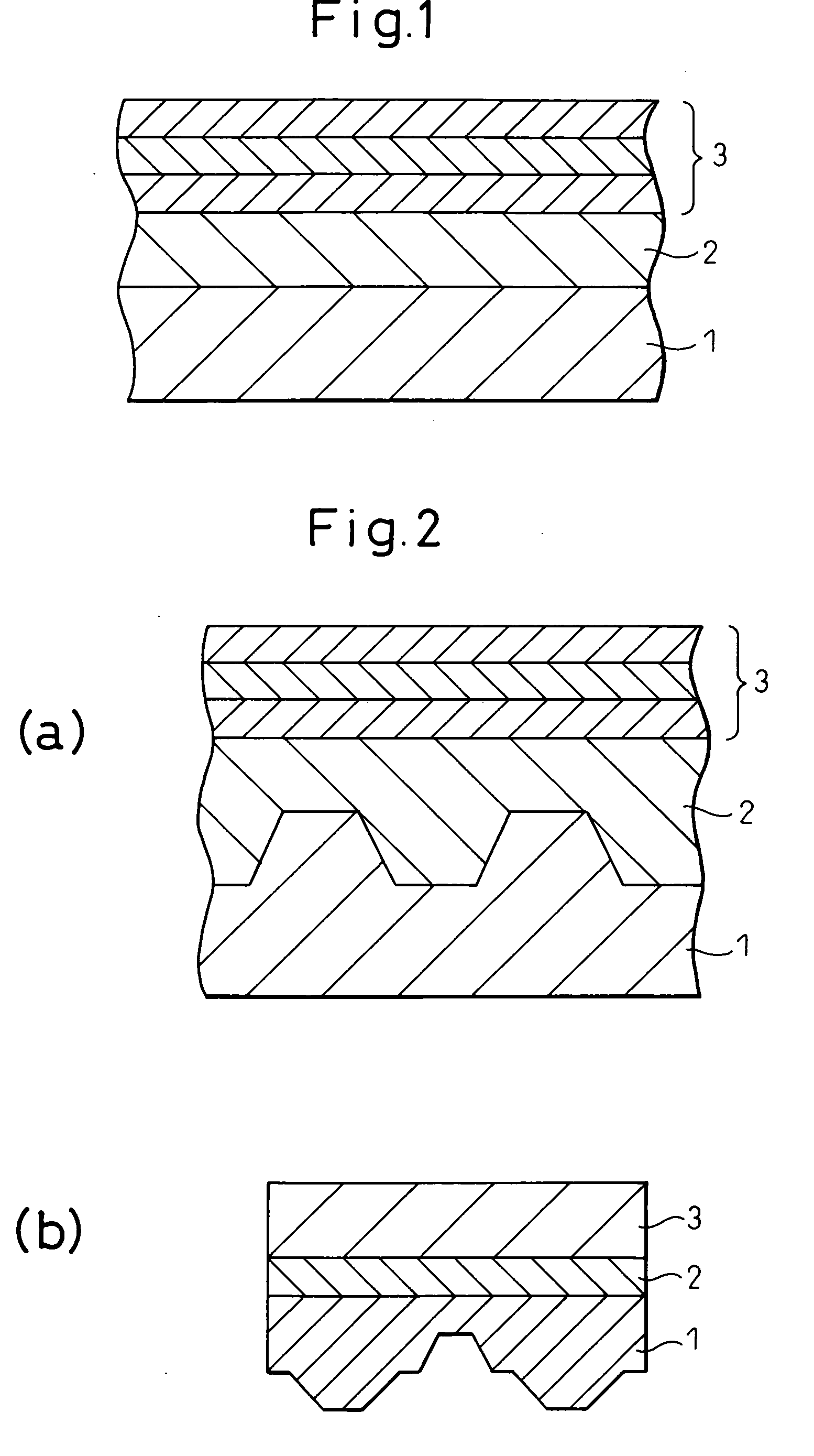

Casing formed from thermoplastic resin and method for fabricating the casing

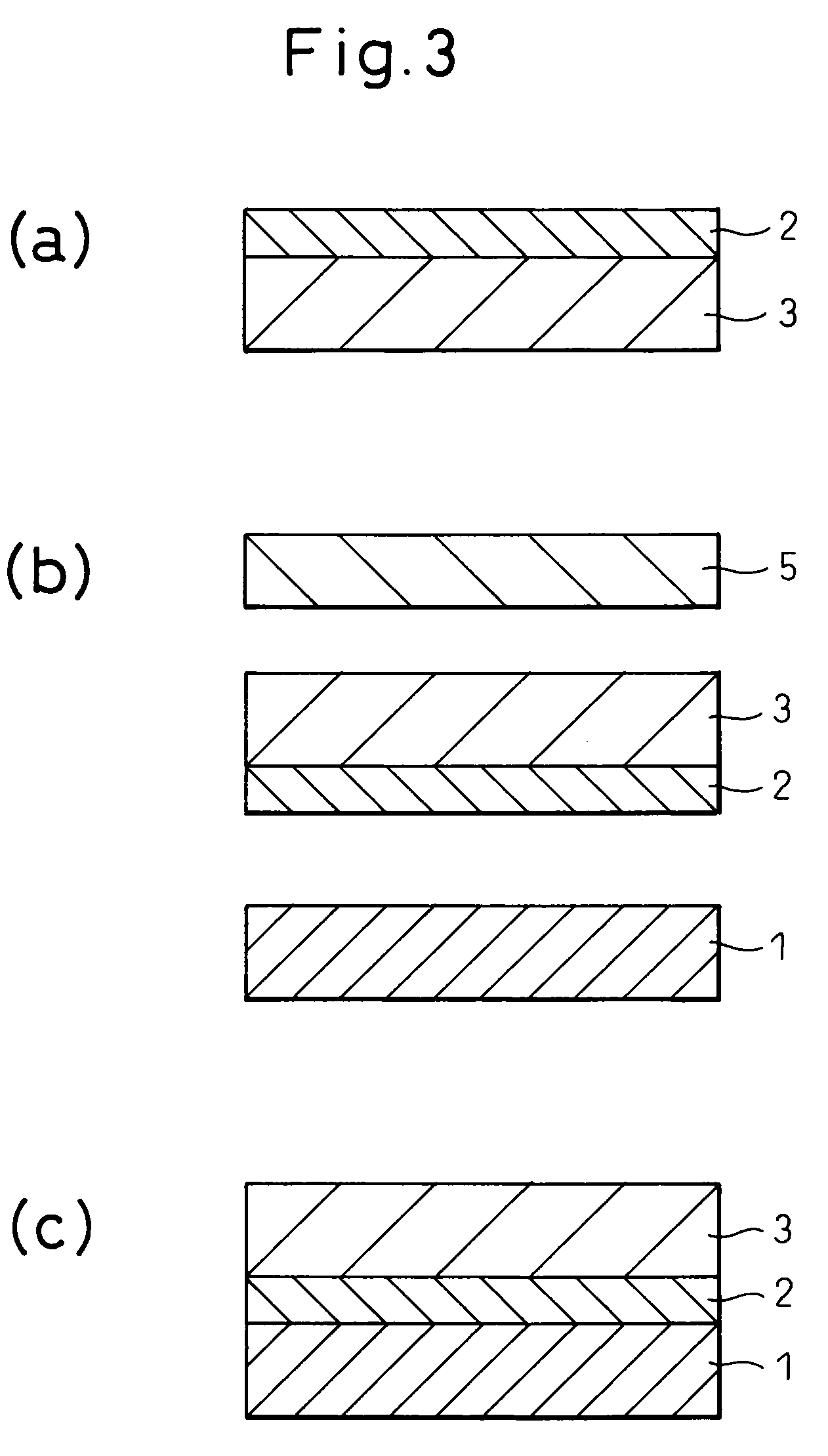

InactiveUS20070102110A1Prevent uneven colorEfficient use ofLamination ancillary operationsSynthetic resin layered productsColor effectEngineering

The present invention relates to decoration techniques for providing smoothly changing iridescent color effects or glittering luster effects to resin casings. A thermoplastic resin casing having a protruding shape is fabricated by hot forming with a laminated plate made up of a thermoplastic resin plate and a polarizing film using a vacuum forming, an air-pressure forming, or a press forming technique. Alternatively, after forming a polarizing film in a mold having a prescribed shape, a thermoplastic resin is injected for molding, to produce a thermoplastic resin casing to which the polarizing film is firmly adhered. According to these fabrication methods, the polarizing film can be attached, without creases, over the entire surface of the casing.

Owner:FUJITSU COMPONENENT LTD

Solid wood bending technological method for curve-shaped structural member of redwood furniture

ActiveCN104802247AImprove the level of production technologyHigh strengthWood compressionWood treatment detailsSolid woodColor effect

The invention discloses a solid wood bending technological method for a curve-shaped structural member of redwood furniture. The solid wood bending technological method comprises the following steps: (1) wood type selection and lumber processing; (2) boiling or steaming for thermal treatment for softening; (3) longitudinal compression; (4) die bending forming; (5) drying sizing; (6) aging for life nourishing; (7) later processing and bending to manufacture the curve-shaped structural member of the redwood furniture. The solid wood bending technological method has the advantages that the generally conventional lineation sawing processing method can be replaced; a redwood type solid wood lumber can be directly bent into a curve-shaped part; the production technological level for the curve-shaped part of the redwood furniture can be increased, and the production technological steps can be simplified; the utilization rate of redwood type woods can be increased, the intensity of the curve-shaped part is enhanced, and the texture and color effect and the paint decoration quality on the surface of a product are guaranteed.

Owner:ZHONGSHAN TAIXING FURNITURE CO LTD

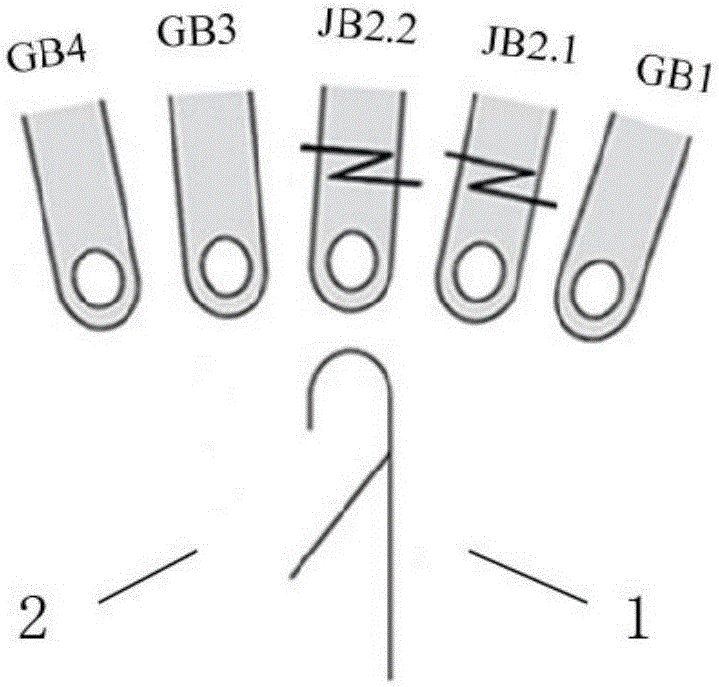

Warp knitting machine for producing single layer structure three-dimensional jacquard weave vamp, and production method thereof

InactiveCN106048877AJacquard effect is clearImprove the three-dimensional effectFlat warp knitting machinesColor effectPolyester

The invention discloses a warp knitting machine for producing single layer structure three-dimensional jacquard weave vamp, and a production method thereof. The production method includes: designing a vamp sample according the design demands of all the parameters; performing designing through CAD software, converting the design data into a machine file which can be read by the warp knitting machine, and inputting the machine file into the warp knitting machine; arranging jacquard combs in the center of the machine, and arranging ground combs at two sides of the jacquard combs; allowing guide bars to knit after threading, wherein each jacquard combs knit three stitches to form a loop stitch, the ground combs knit one stitch to form a weft-insertion or a warp chain stitch; allowing the jacquard combs to perform co-directional or reverse yarn laying, and correspondingly allowing the ground combs to take part in knitting; performing finishing to obtain single layer structure three-dimensional jacquard weave vamps. The obtained single layer structure three-dimensional jacquard weave vamps are clear in l jacquard weave effect, and is high in stereoscopic impression of patterns; the single layer jacquard weave vamps adopt polyamide polyester as a raw material to achieve a dual-color effect, and can be composited with three-layer structure or single-layer structure plain net fabric to achieve a richer color effect in later; and the single layer structure three-dimensional jacquard weave vamps are excellent in stiffness and wear-resisting property, can achieve a good reliability after composited with the other fabrics.

Owner:JIANGNAN UNIV

Mixed dry granules, dry granular glazed decorative ceramic tile with color crystal effect and preparation method

The invention provides mixed dry granules, a dry granular glazed decorative ceramic tile with a color crystal effect and a preparation method. The mixed dry granules include color dry granules and transparent dry granules, a softening temperature of the color dry granules is 987-1035 DEG C, and a softening temperature of the transparent dry granules is 1130-1175 DEG C. By combination of the low-temperature color dry granules and the low-temperature transparent dry granules, the mixed dry granules applied to dry granular ceramic tiles are fired and melted to form a color effect, ceramic products decorated according to the process are not limited to antiqued products, and types of products are enriched. The color dry granules are partially wrapped in the transparent dry granules in a meltingprocess of the color dry granules and the transparent dry granules, so that a color portion of a designed pattern of the obtained ceramic tile is bright and transparent, and the crystal effect can beachieved.

Owner:MONALISA GRP CO LTD

Decorative casing and manufacturing method thereof

InactiveUS8153270B2Improve the decorative effectReduce in quantityOptical articlesRecord information storageColor effectEngineering

The invention concerns a decorative casing fabricated by bonding a film having a polarizing characteristic to the surface of the casing body via an adhesive layer, and an object of the invention is to provide the casing with enhanced decorativeness by designing the adhesive layer so as to render various color effects in addition to the effect rendered by the polarizing characteristic. The polarizing film is bonded to the surface of the casing body via the adhesive layer containing a special-effect material having a color effect. According to the present invention, by directly bonding the polarizing film to the casing via the adhesive layer that produces a desired color effect, other effects such as color hue can be conferred in the film bonding step, and thus a casing having an excellent decorative effect can be manufactured by a simple process without increasing the number of process steps.

Owner:FUJITSU COMPONENENT LTD

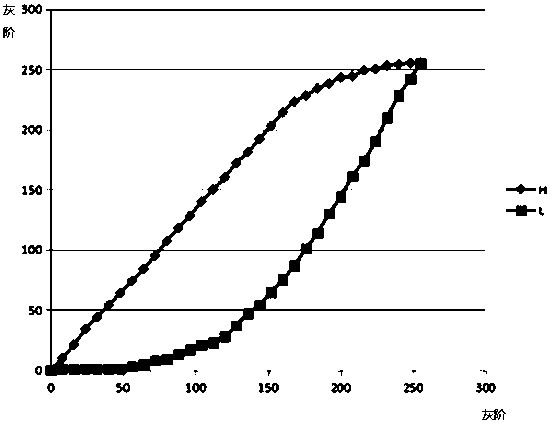

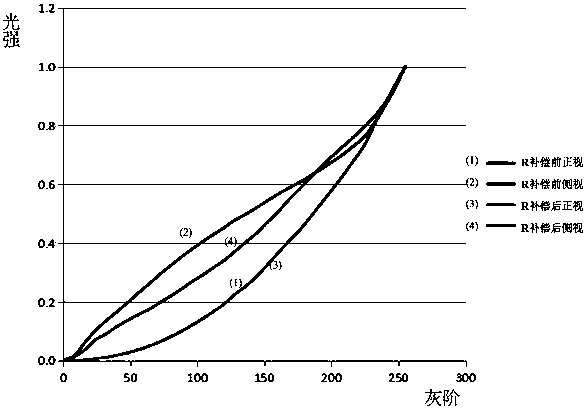

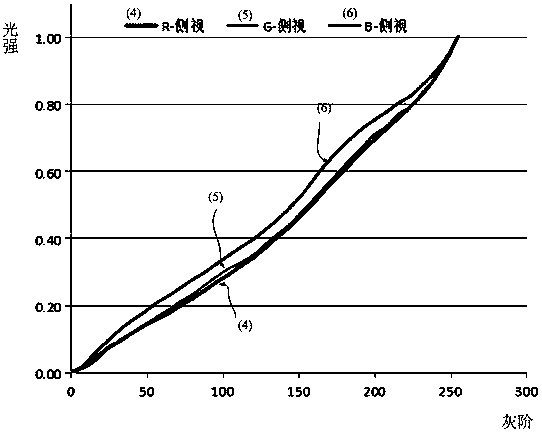

Method and device for compensative adjustment of pixel data and liquid crystal display panel

ActiveCN108133692AReduce graininessReduce the differenceStatic indicating devicesColor effectLiquid-crystal display

An embodiment of the invention discloses a method for compensative adjustment of pixel data. The method includes a step 1 of receiving pixel original gray scale data of a to-be-displayed image; a step2 of querying a first compensation table for each pixel original gray scale data so as acquire a first gray scale value and a second gray scale value corresponding to each sub pixel original gray scale data; a step 3 of querying a second compensation table so as to acquire a first adjustment value and a second adjustment value corresponding to each sub pixel original gray scale data in the pixels; a step 4 of performing adjustment on the first gray scale value of each sub pixels in the pixels with the first adjustment value so as to acquire a first gray scale value of said sub pixel subjectedto adjustment; performing adjustment on the second gray scale value with the second adjustment value so as to acquire a second gray scale value of said sub pixel subjected to adjustment; a step 5 ofdisplaying the first gray scale value and the second gray scale value subjected to adjustment of each sub pixel of each pixel. The invention also discloses a corresponding device and a liquid crystaldisplay panel. By applying the invention, the screen view angle can be enlarged, pixel granular sensation can be reduced and side view color effect can be improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

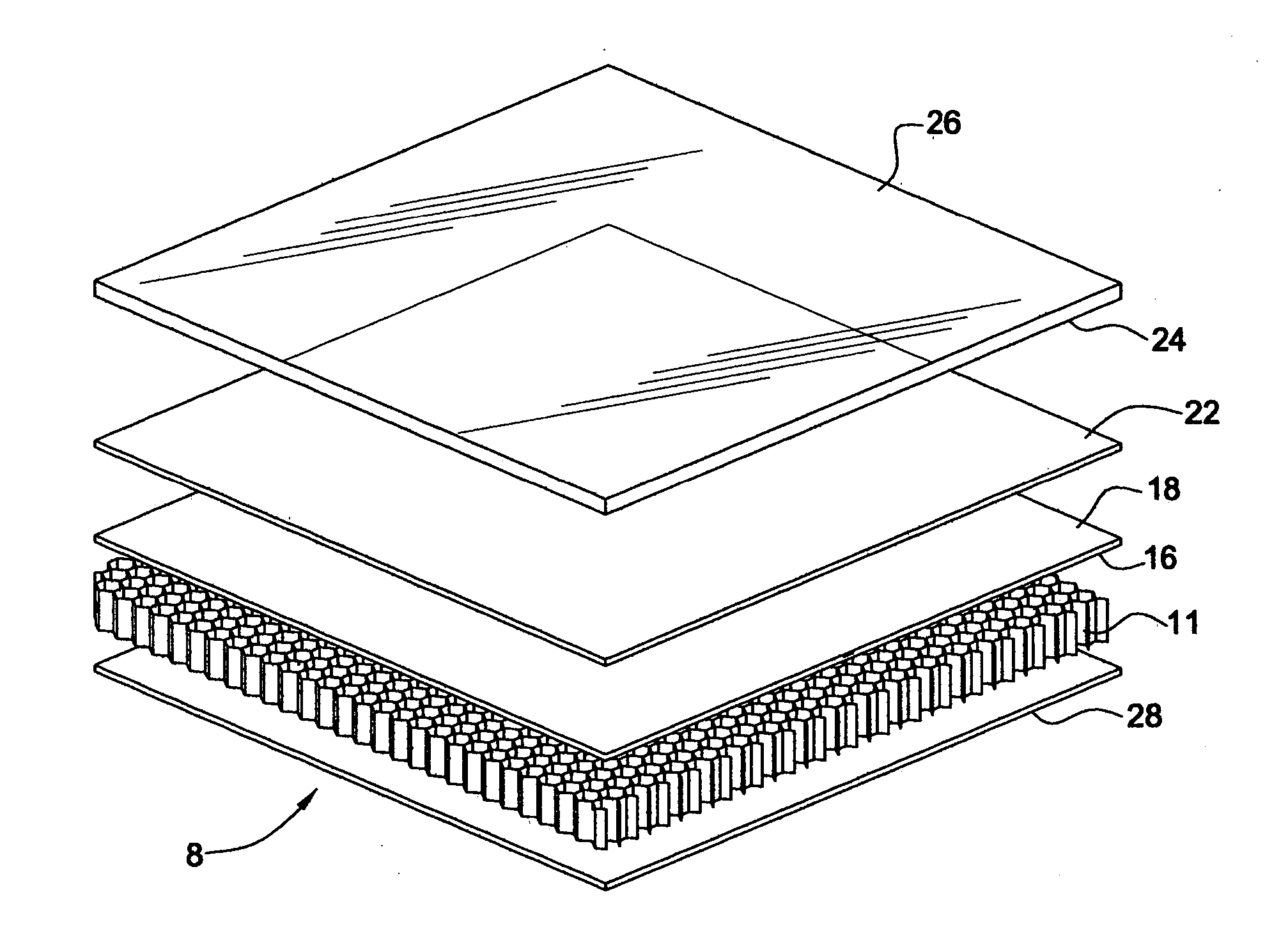

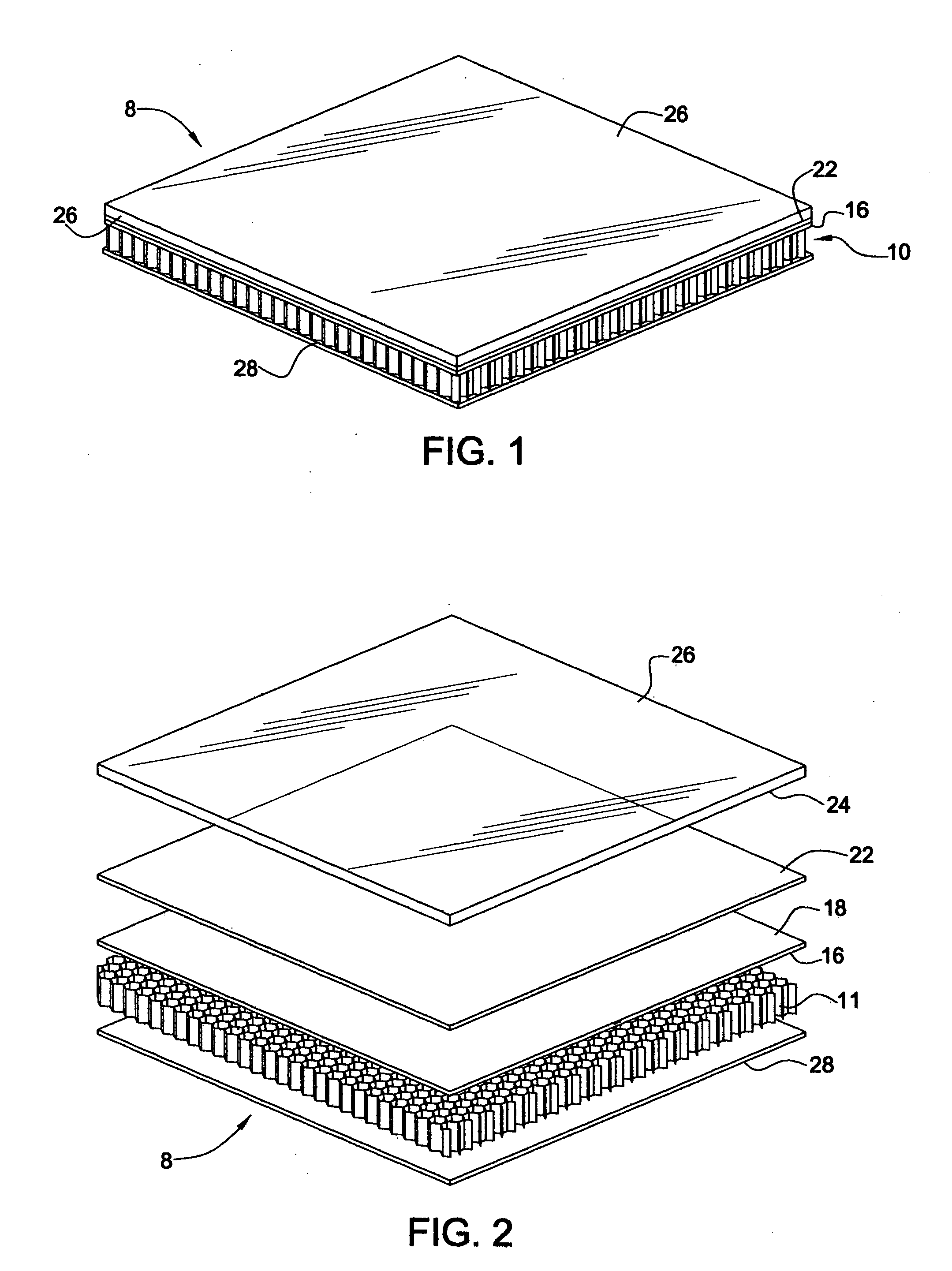

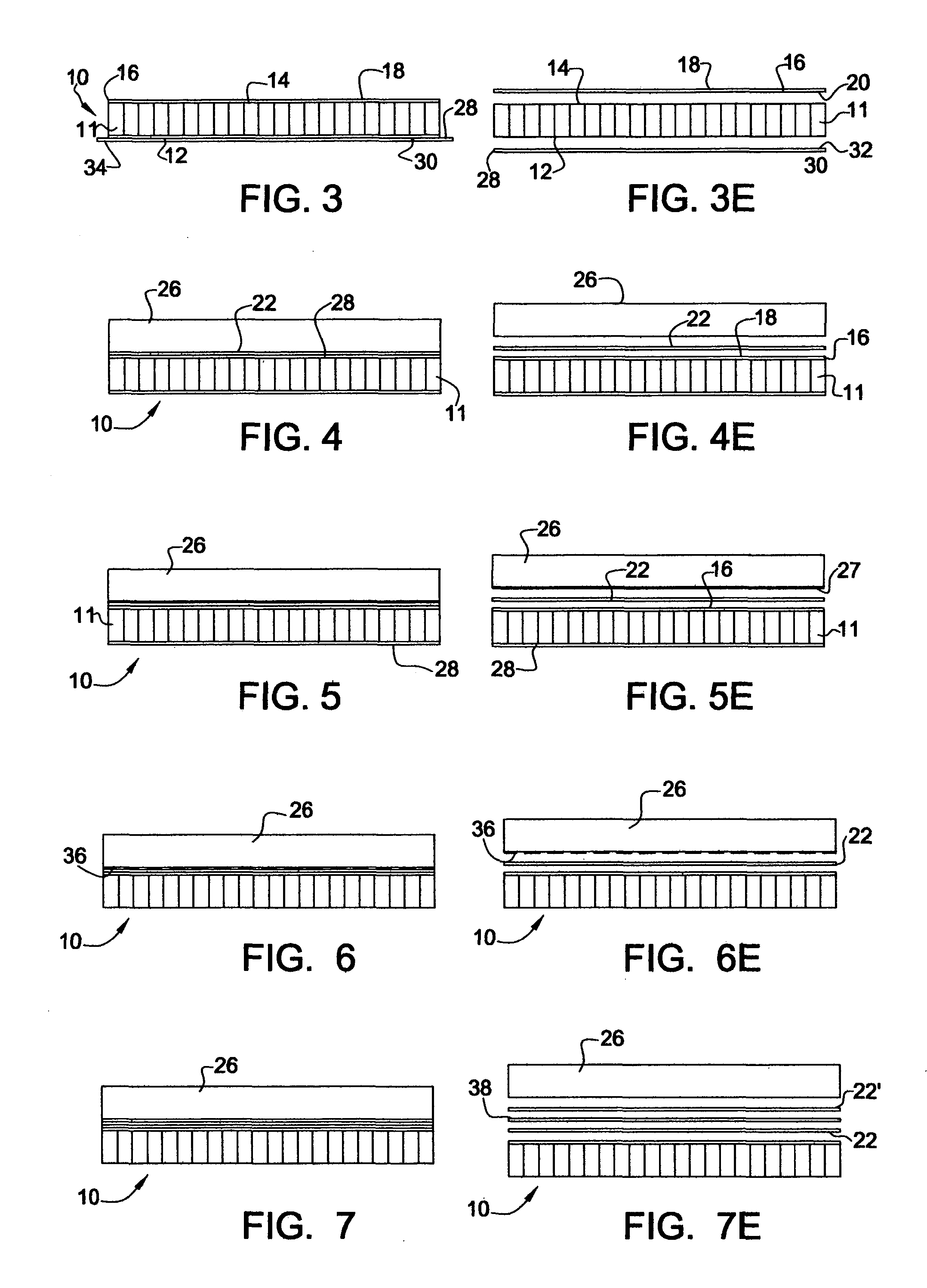

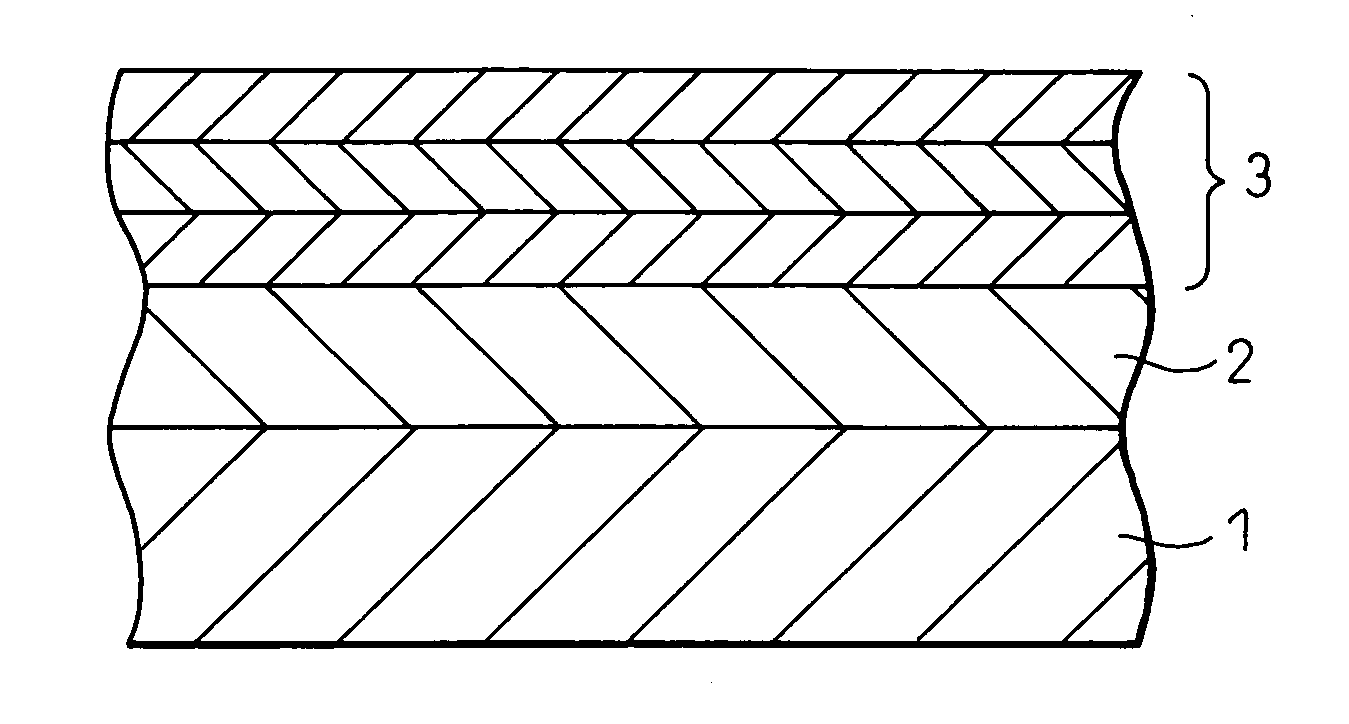

Single panel glass structural panel and method of making same

InactiveUS20050003148A1Improve rigidityHigh strengthGlass/slag layered productsThin material handlingColor effectGlass fiber

A window-type structural panel has a glass outer panel bonded to a core panel consisting of an aluminum honeycomb core having outer and inner skin surfaces of resin impregnated fiberglass having substantially the same coefficient of thermal expansion as the aluminum honeycomb core. Design and color effects are imparted to the glass panel by film sheets, printing on adhesive layers, physical insertion of wire, cloth or other solid materials bonded in position by heat and pressure to form a uniform rigid structure of great strength and a light weight.

Owner:CUNNINGHAM BETH KAY EKLAND +1

Decorative casing and manufacturing method thereof

InactiveUS20090068404A1Improve the decorative effectReduce in quantityOptical articlesRecord information storageColor effectEngineering

The invention concerns a decorative casing fabricated by bonding a film having a polarizing characteristic to the surface of the casing body via an adhesive layer, and an object of the invention is to provide the casing with enhanced decorativeness by designing the adhesive layer so as to render various color effects in addition to the effect rendered by the polarizing characteristic. The polarizing film is bonded to the surface of the casing body via the adhesive layer containing a special-effect material having a color effect. According to the present invention, by directly bonding the polarizing film to the casing via the adhesive layer that produces a desired color effect, other effects such as color hue can be conferred in the film bonding step, and thus a casing having an excellent decorative effect can be manufactured by a simple process without increasing the number of process steps.

Owner:FUJITSU COMPONENENT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com