Warp knitting machine for producing single layer structure three-dimensional jacquard weave vamp, and production method thereof

A single-layer structure, jacquard shoe upper technology, applied in the field of textile textiles, can solve the problems of easy collapse of monofilament, affecting comfort, low production efficiency, etc., and achieve strong three-dimensional effect of pattern, excellent wear resistance and rich color effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A production method of a warp knitting machine for producing a three-dimensional jacquard shoe upper fabric with a single-layer structure, the steps of which are:

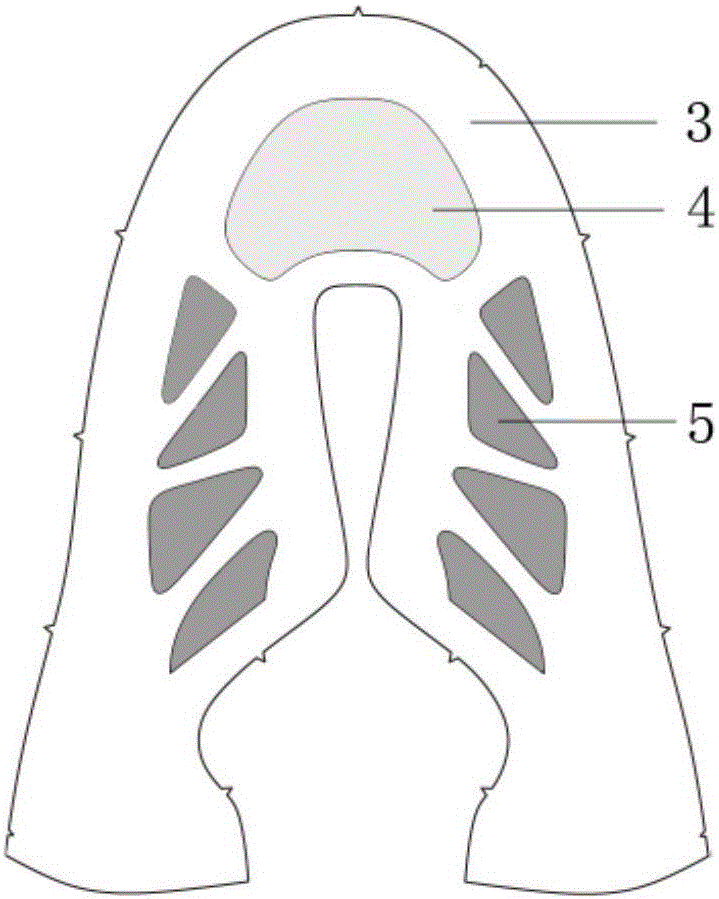

[0031] (1) if figure 2 As shown, according to the size of the shoe, the characteristic requirements of the human foot, the type of the upper and the design requirements of the upper pattern, design the upper model and the schematic diagram of the structure of the upper model;

[0032] (2) Through CAD software, fill in the jacquard pattern according to the outline drawing of the shoe upper model, and figure 2 Area 3 is filled with thick weave, area 4 is filled with mesh weave, and area 5 is filled with thin weave, and then we design the weave structure and machine parameters and other process parameters, and finally convert it into a single-needle bed sheet Jarascher warp knitting machine readable Take the machine file and input it into the single-needle bed sheet jacquard Rachel warp knitting machine whos...

Embodiment 2

[0041] A production method of a warp knitting machine for producing a three-dimensional jacquard shoe upper fabric with a single-layer structure, the steps of which are:

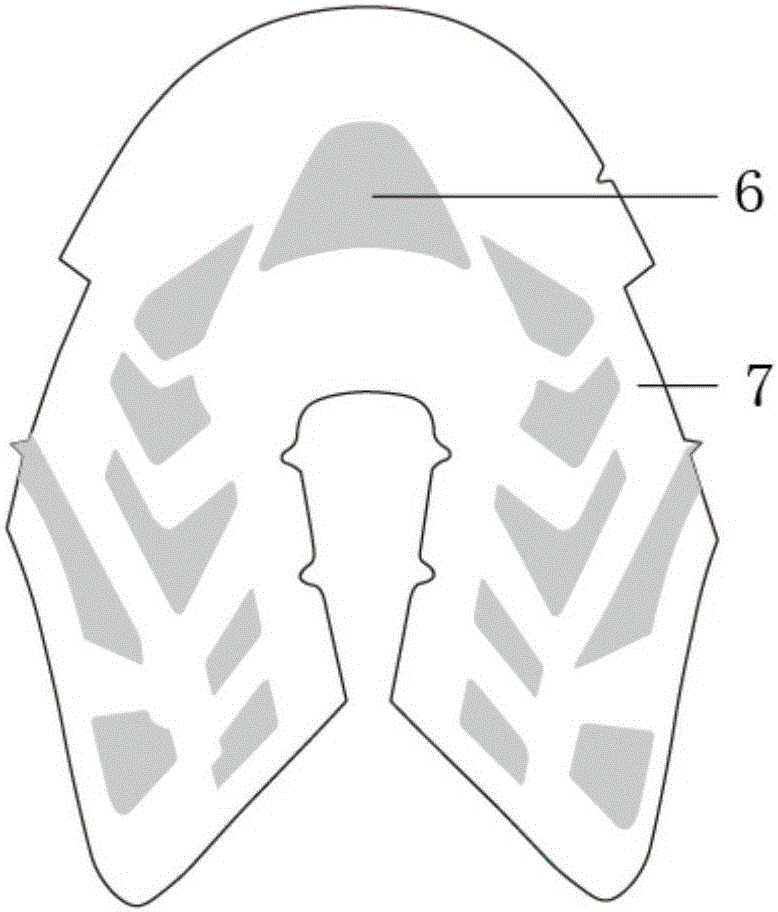

[0042] (1) if image 3 As shown, according to the size of the shoe, the characteristic requirements of the human foot, the type of the upper and the design requirements of the upper pattern, design the upper model and the schematic diagram of the structure of the upper model;

[0043] (2) Through CAD software, fill in the jacquard pattern according to the outline drawing of the shoe upper model, and image 3 Area 6 is filled with mesh weave, area 7 is filled with plain weave, and then the weave structure and machine parameters are designed, and finally it is converted into a machine file that can be read by a single-needle bed sheet jacquard Raschel warp knitting machine, and input Single-needle bed sheet jacquard kraschel machines, gauge E22;

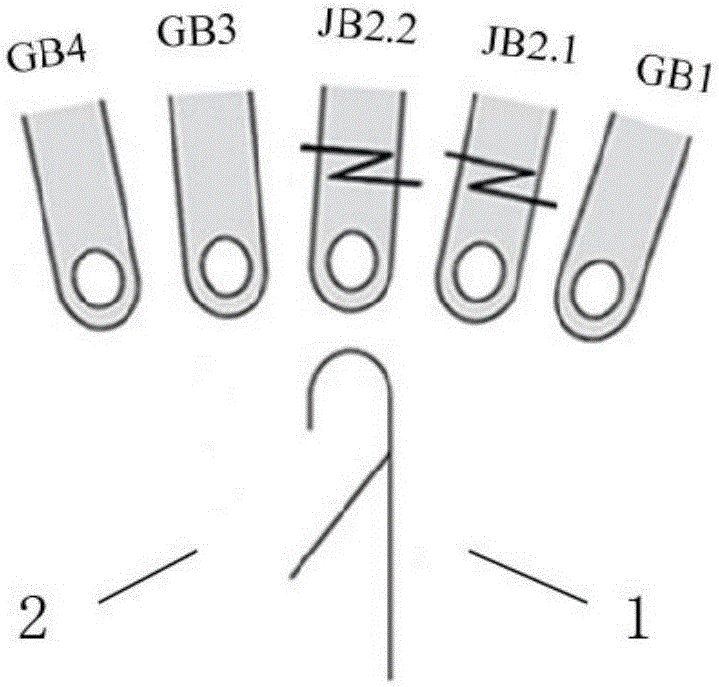

[0044] (3) if figure 1 As shown, the bar configuration relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com