Patents

Literature

1413results about How to "Improve stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

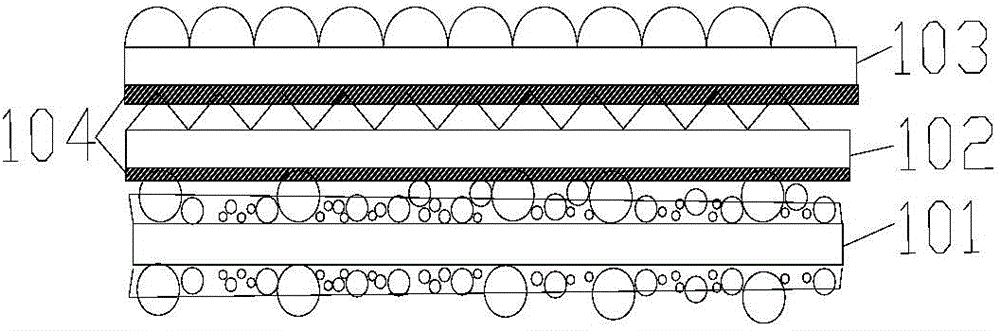

White reflective polyester film and preparation method thereof

ActiveCN104608446AHigh reflectivity and stiffnessHigh tensile strengthSynthetic resin layered productsTotal thicknessReflectivity

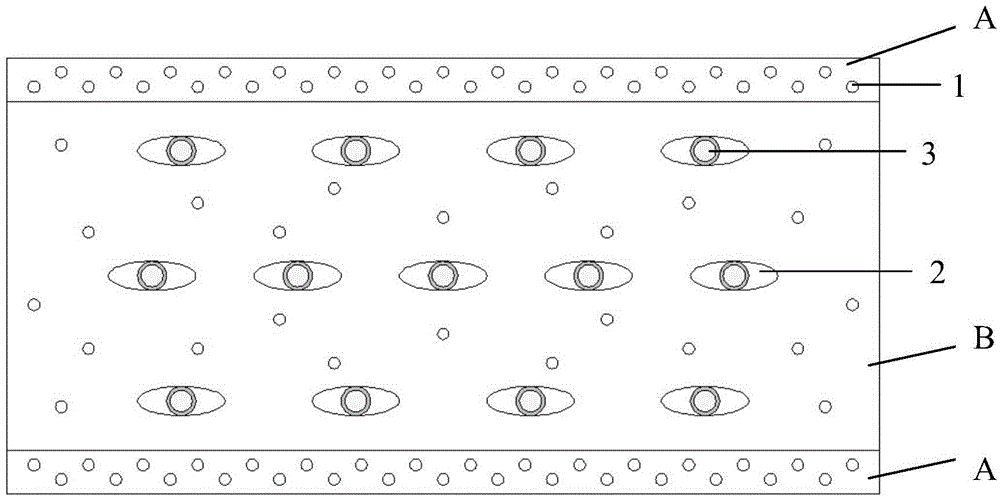

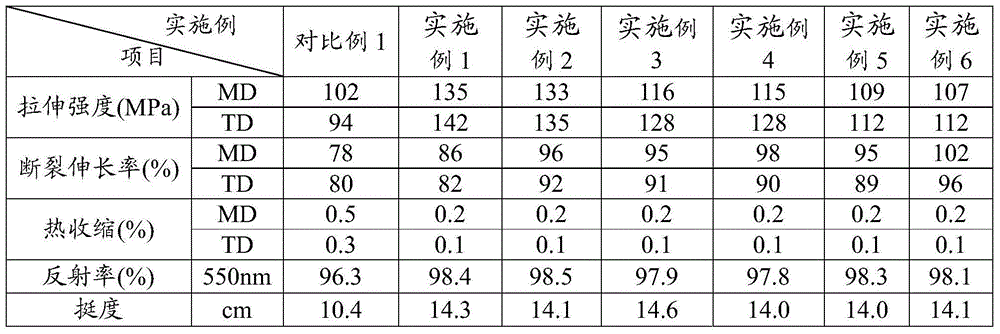

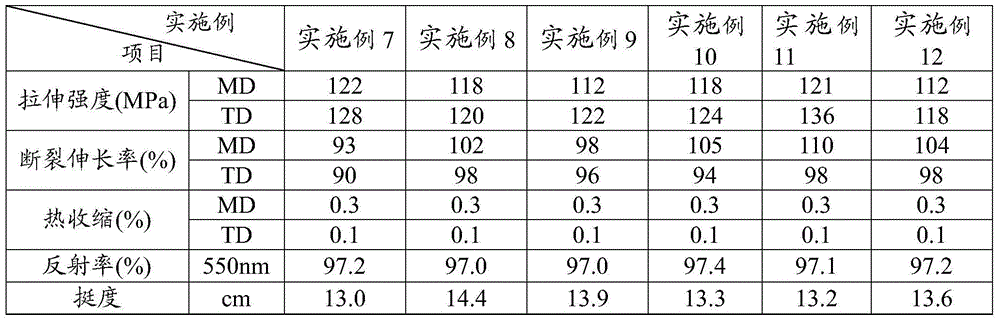

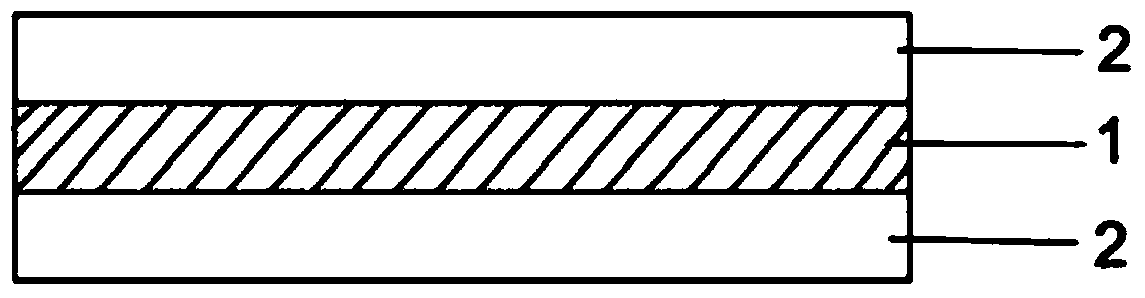

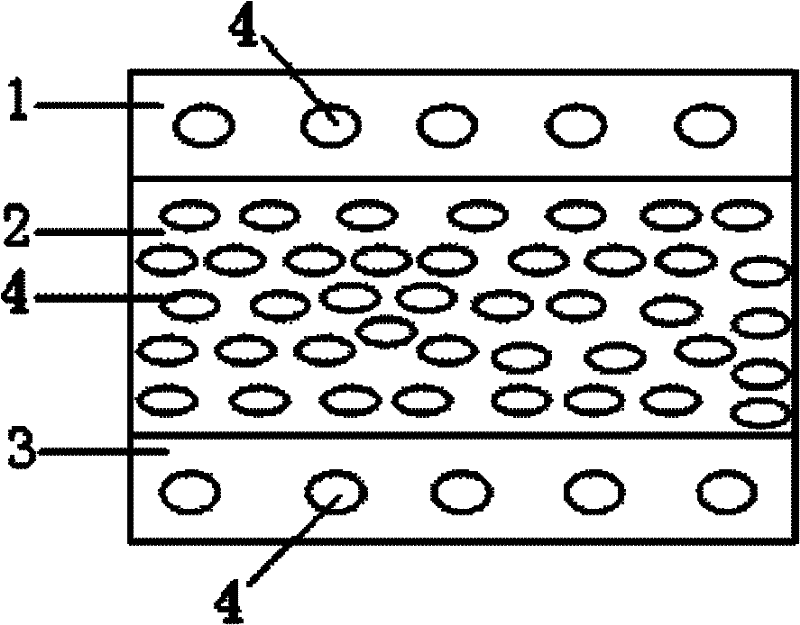

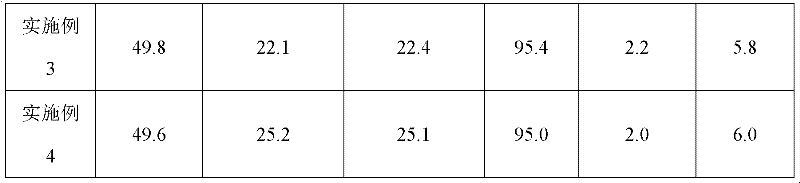

The invention relates to a white reflective film, and provides a white reflective polyester film and a preparation method thereof in order to improve the reflectivity and stiffness of the conventional white reflective film. The film adopts an A-B-A three-layer structure, wherein the A-layer structure accounts for 4%-15% of the total thickness, and the B layer accounts for 70%-92% of the total thickness; the A layer comprises 50%-99.9% of polyester resin and 0.1%-50% of inorganic particles; the B layer comprises the polyester resin, the inorganic particles, incompatible resin, toughened resin, a chain extender, a nucleating agent and a dispersing agent; oval cell structures are arranged in the B layer, round resin particles are arranged in cells and adopt core-shell structures, the diameter of each core is 0.01-1 mu m, and the thickness of each shell is 0.01-0.1 mu m; and the thickness of the film is 50-350 mu m. The film has excellent reflectivity and stiffness.

Owner:NINGBO CHANGYANG TECH

Fiber mat, preparation method and core material for vacuum thermal insulation plate

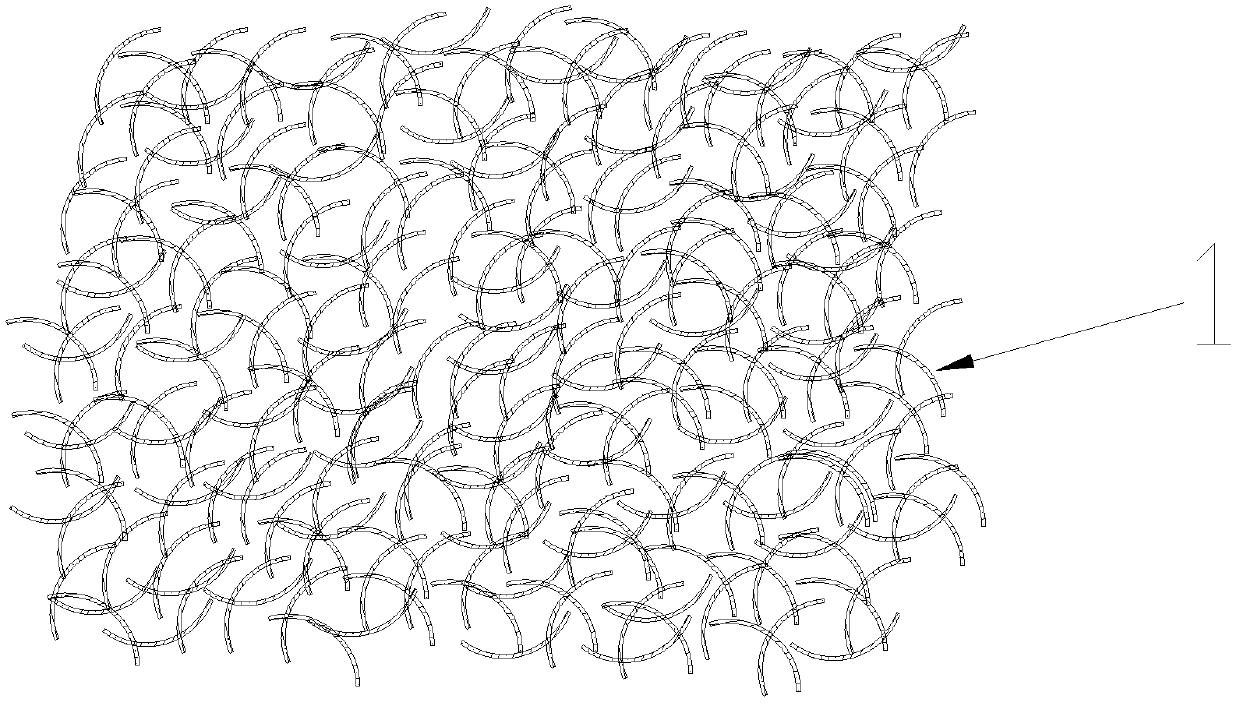

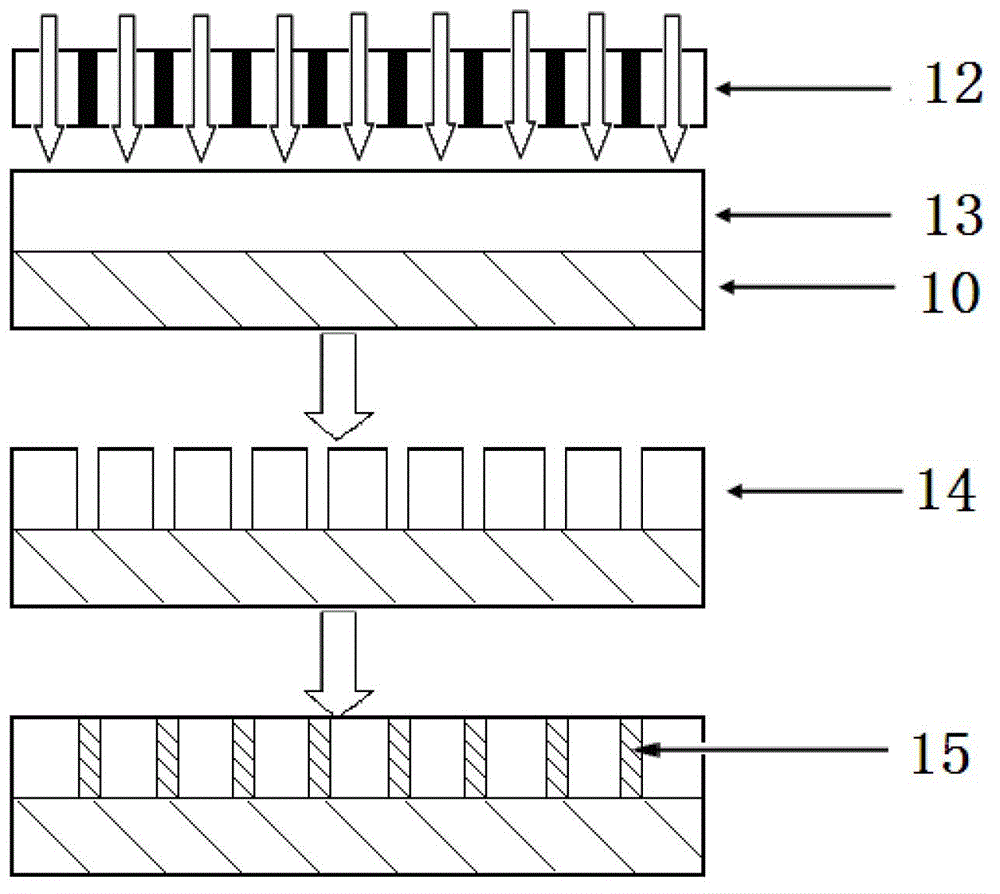

InactiveCN103306048ALow thermal conductivityHigh strengthFibreboardGlass/slag layered productsGlass fiberPunching

The invention discloses a fiber mat, comprising 50-100 (weight ratio accounting for the dried fiber mat and the same below) glass fiber and chopped strands, and one or more of 0.1-30 inorganic fibers, 0.1-30 natural fibers, 0.1-30 synthetic fibers, 0.1-30 manmade fibers and an anti-radiation material besides the glass fibers and the chopped strands. The fiber mat is prepared by a needle punching method, a spun lacing method, a thermal rolling method, a wet type paper-manufacturing acid process, a wet type paper-manufacturing thickener method, a wet type paper-manufacturing gel method and the like. According to the preparation method for the fiber mat disclosed by the invention, the conductive thermal coefficient of a vacuum thermal insulation plate made of the fiber mat achieves 25-65% under the premise of adopting the same production mode, and a more superexcellent thermal insulation effect is obtained.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

Welding device and method for avoiding high-nitrogen steel welding air holes and improving connector strength

ActiveCN105772944AImprove toughnessImprove stabilityWelding/soldering/cutting articlesLaser beam welding apparatusMagnetEngineering

The invention discloses a welding device and method for avoiding high-nitrogen steel welding air holes and improving connector strength, and belongs to the technical field of welding. Two welded workpieces are fixed to a first workpiece supporting plate and a second workpiece supporting plate in a butt joint manner. A welded workpiece connector gap is formed between the two welded workpieces. A groove is formed in the front faces of the welded workpieces and the position of the welded workpiece connector gap. The pipe wall of a first water passing copper pipe and the pipe wall of a second water passing copper pipe are closely attached to the two sides of the groove. Magnet exciting coils are arranged on the back faces of the welded workpieces, a laser beam vertically irradiates the front faces of the welded workpieces, a welding gun is arranged on the front faces of the welded workpieces, and the laser beam, the welded workpiece connector gap and the magnet exciting coils are coaxial. The problems that in the high-nitrogen steel welding process in the prior art, gas is prone to being generated, nitride, carbide and carbonitride are likely to be separated out, and the grain of a weld line is thick are solved, accordingly, the mechanical performance of a high-nitrogen steel welding connector is improved, and the tenacity of a welding heat affected zone is improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

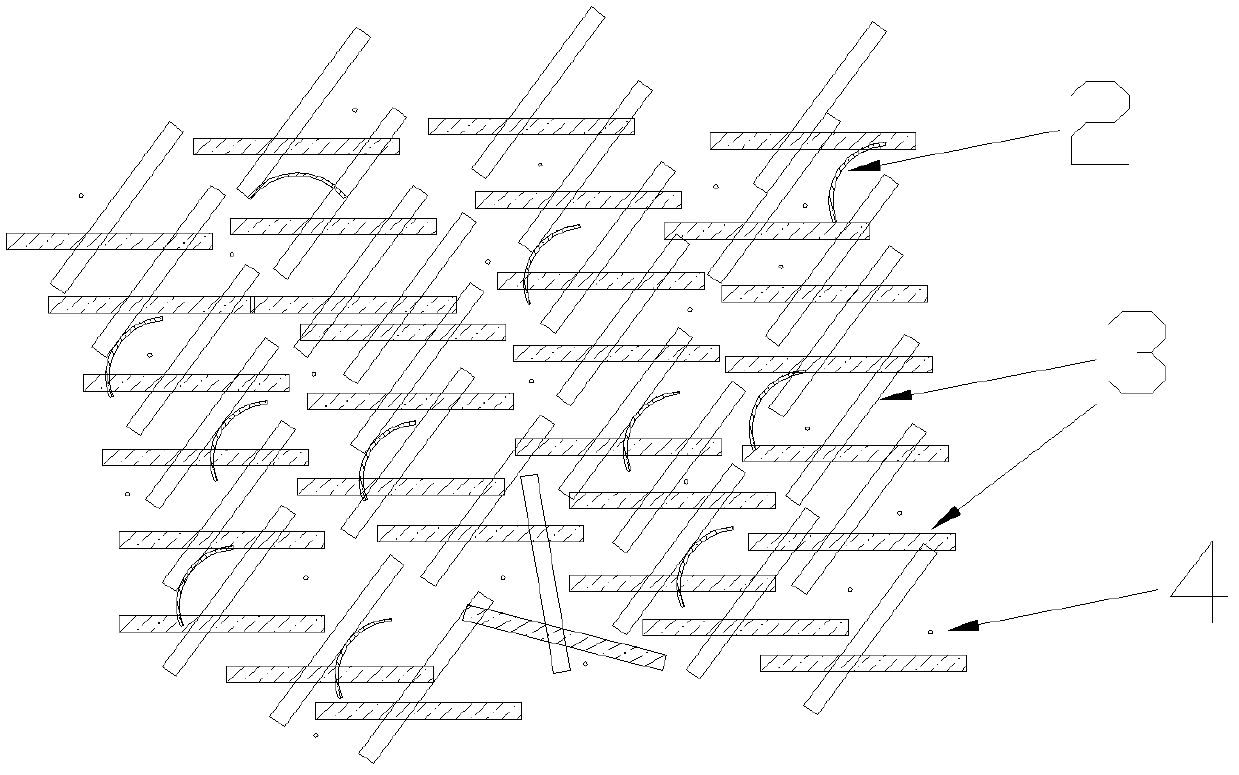

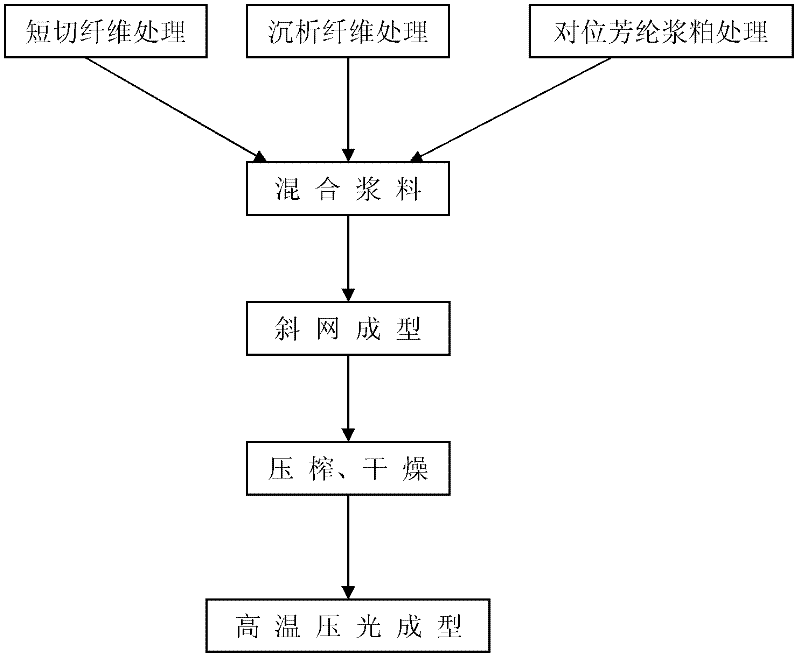

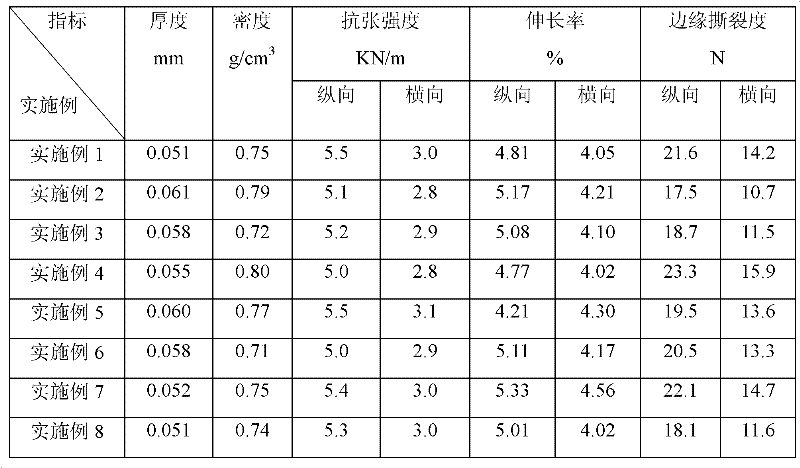

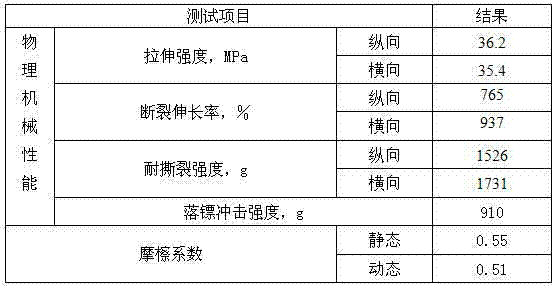

Preparation method of pure p-aramid paper

InactiveCN102517976AImprove interface affinityHigh tensile strengthSynthetic cellulose/non-cellulose material pulp/paperHigh stiffnessHigh density

The invention relates to a preparation method of pure p-aramid paper. The preparation method of the pure p-aramid paper comprises the following steps of 1, respectively preparing p-aramid chopped fiber pulp, p-aramid fibrid pulp and p-aramid pulp, and mixing the p-aramid chopped fiber pulp, the p-aramid fibrid pulp and the p-aramid pulp, 2, approaching flows of the mixed pulp onto a net for molding, 3, carrying out squeezing and drying, and 4, carrying out high-temperature press-polish molding. The preparation method of the pure p-aramid paper has the advantages that p-aramid fibrids are utilized as bonding materials of the pure p-aramid paper so that interface affinity of fibers is improved and fiber paper mechanical properties of tensile strength, tearing strength and wear resistance are improved; p-aramid pulp has a high specific surface area so that a hydrogen bond binding capacity of fibers is improved and the pure p-aramid paper having high density, high stiffness and high strength is obtained; and in a preparation process, concentrated sulfuric acid is not needed so that the problems of equipment corrosion and dilute sulphuric acid recovery complexity are solved.

Owner:YANTAI METASTAR SPECIAL PAPER +1

Barrier heat sealing type biaxial tensile composite thin film and preparation method thereof

InactiveCN102501511ASimple production processLow costSynthetic resin layered productsLinear low-density polyethyleneLow-density polyethylene

The invention discloses a barrier heat sealing type biaxial tensile composite thin film and a preparation method thereof. The thin film comprises two surface layers, and at least a barrier layer, wherein the surface layer and the barrier layer are connected through bonding layers. The thin film is characterized in that the two surface layers comprise the following components, by weight, 90-99% of metallocene linear low density polyethylene resin with a characteristic of bimodal molecular weight distribution, 0-5% of an antistatic agent, 0-5% of an anti-adhering agent, 0-5% of a smoothing agent, and 0-5% of an antioxidant; the barrier layer is a barrier polymer, and the bonding layer is a high strength and high temperature resistance adhesive. The preparation method adopts a multi-layer co-extruding successive biaxial tensile process or a multi-layer co-extruding simultaneous biaxial tensile process. The composite thin film has excellent gas and moisture barrier property, and the mechanical properties of the thin film are further improved. The thin film has characteristics of high tensile strength, low temperature high heat sealing strength, and high puncture resistance strength.

Owner:FSPG HI TECH

Method for preparing fiber wallboard through wet process

InactiveCN101638874ALarge stockWide variety of sourcesWater-repelling agents additionPaper/cardboardFiberHigh intensity

The invention discloses a method for preparing a fiber wallboard through a wet process. The method comprises the following steps: 1) pulping: mixing non-wood type natural plant fiber pulp with gramineous plant pulp according to a dry weight ratio of 1:0-1.5 and adding water into the raw materials to dilute the pulp; 2) storing the pulp: placing the obtained mixture pulp into a pulp storage pond and adding water for dilution; 3) carrying out suction filter and formation: inputting the pulp obtained from the previous step into a die cavity for cold-pressing, dehydration and formation so as to obtain a wet blank; and 4) carrying out hot-pressing formation and drying; transferring the wet blank into a hot-pressing mould for hot pressing, removing water generated during the hot pressing, and obtaining the fiber wallboard. The fiber wallboard obtained by using the method has the characteristics of environment-friendliness and high strength.

Owner:陈集双

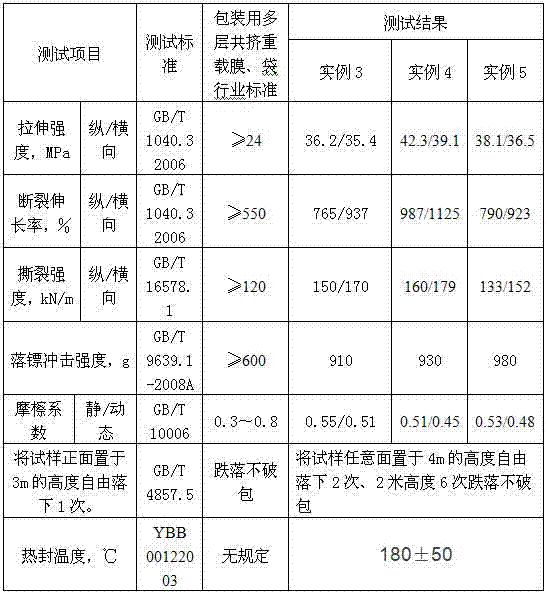

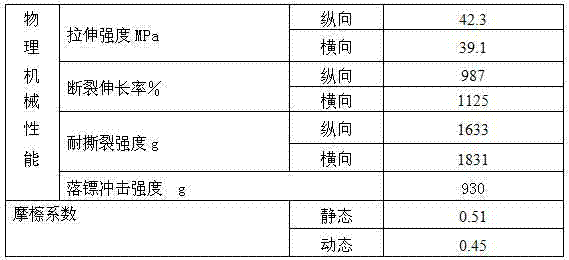

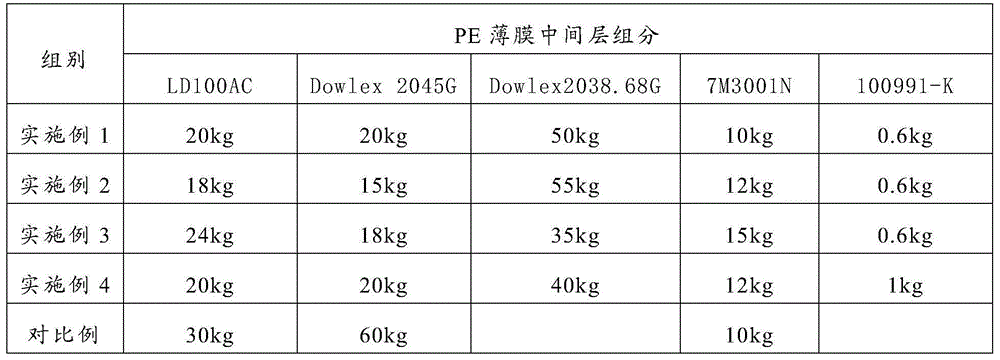

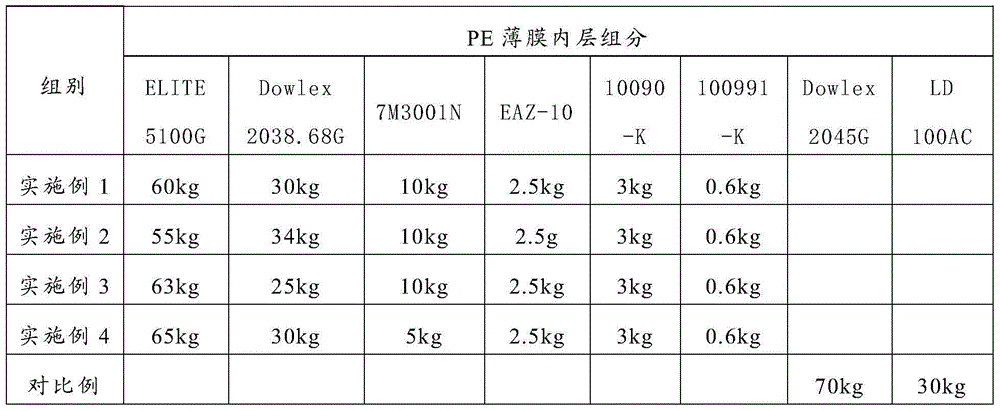

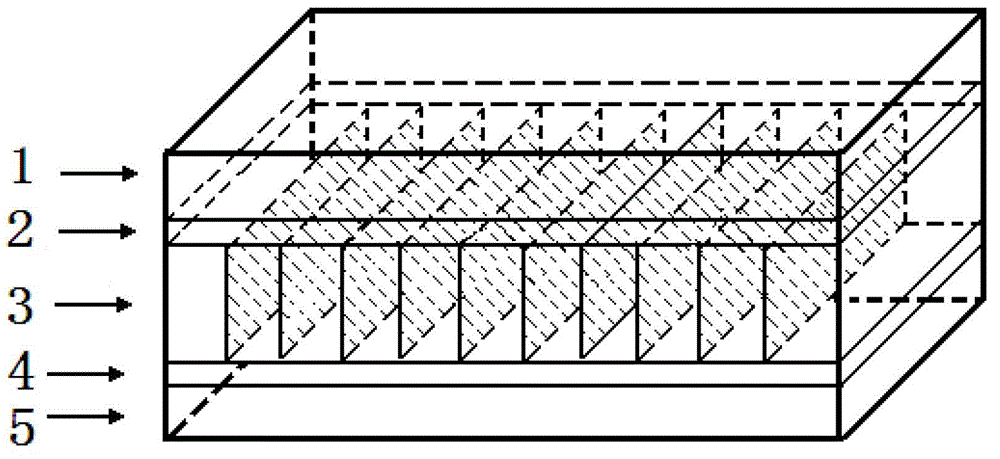

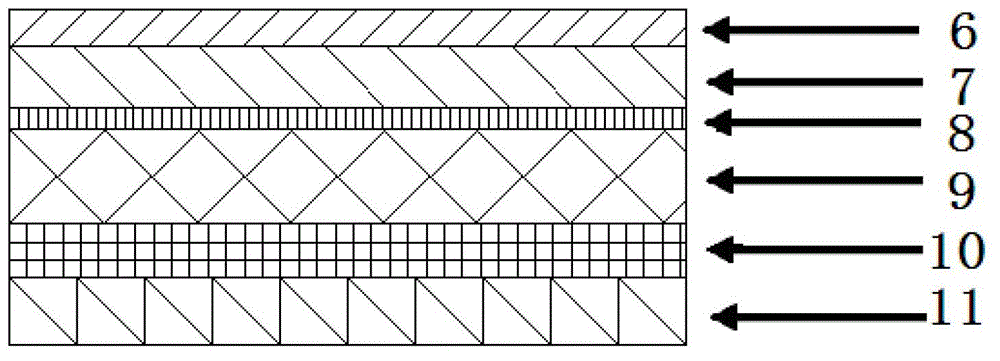

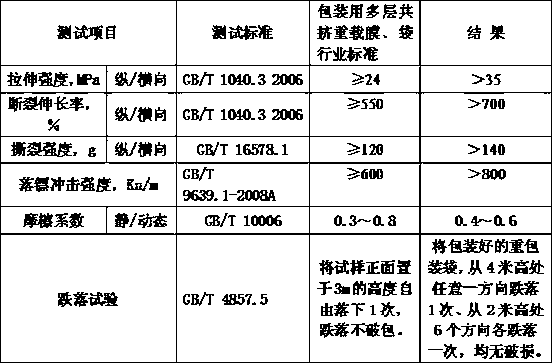

Three-layer coextrusion heavy packaging membrane and fabrication method thereof

The invention relates to the technical field of heavy packaging membranes, in particular to a three-layer coextrusion heavy packaging membrane and a fabrication method thereof. An inner layer of the three-layer coextrusion heavy packaging membrane contains LLDPE (linear low density polyethylene) and m-LLDPE (metallocene-linear low density polyethylene); a middle layer thereof contains m-LLDPE, LLDPE, MDPE (medium density polyethylene), EVA (ethylene-vinyl acetate) and a color masterbatch; and an outer layer thereof contains LLDPE, LDPE (low density polyethylene) and m-LLDPE. The fabrication method of the three-layer coextrusion heavy packaging membrane adopts the proportioning, and a product is fabricated on a certain technological condition. Compared with the prior art, the membrane has the characteristics that the membrane is excellent in mechanical property and good in deflexion; a skin-friction coefficient of the membrane is moderate; and a heat-seal window can reach 180 minus / plus 50 DEG C. The membrane can fully meet the requirement of normal use of downstream packaging, is particularly suitable for high-speed FFS (form-fill-seal) packaging, and has a good economic benefit and a social benefit.

Owner:GUANGDONG SUNION CHEM & PLASTIC

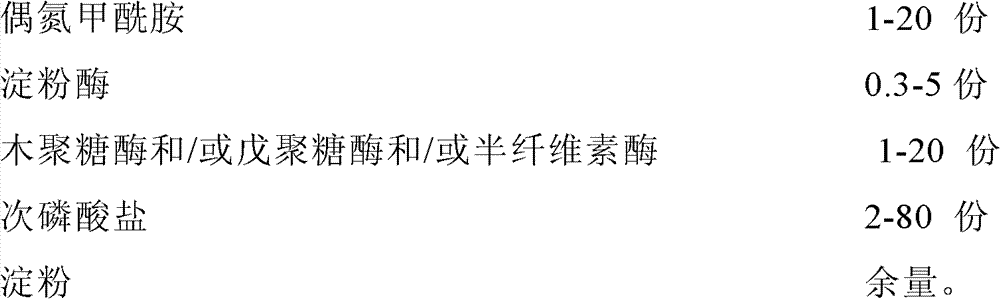

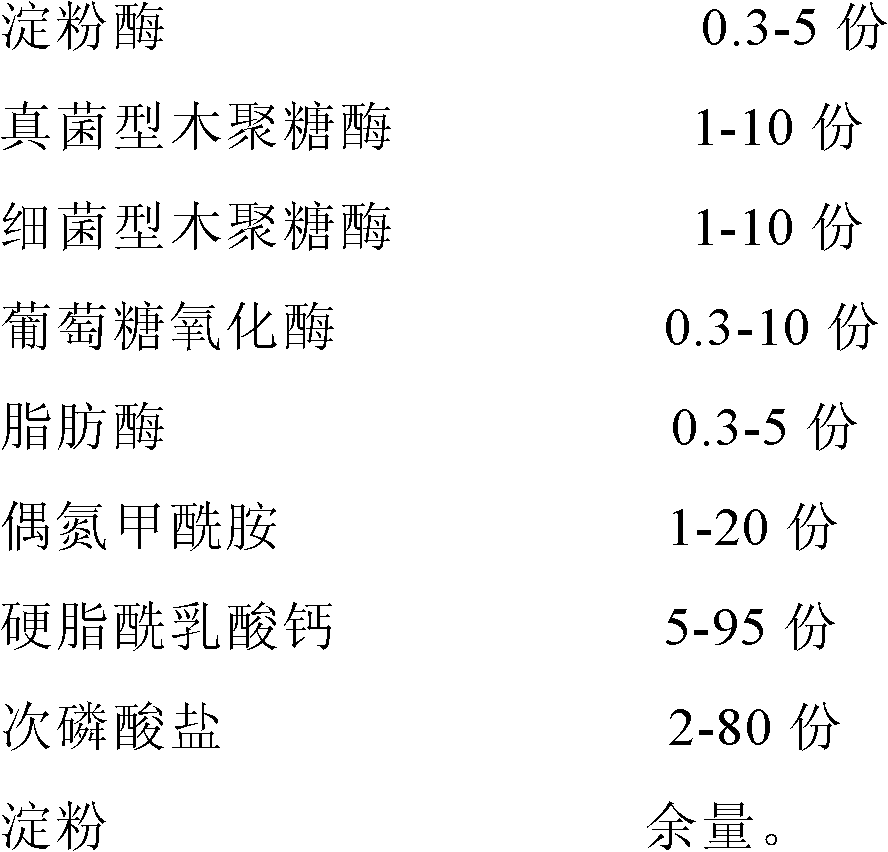

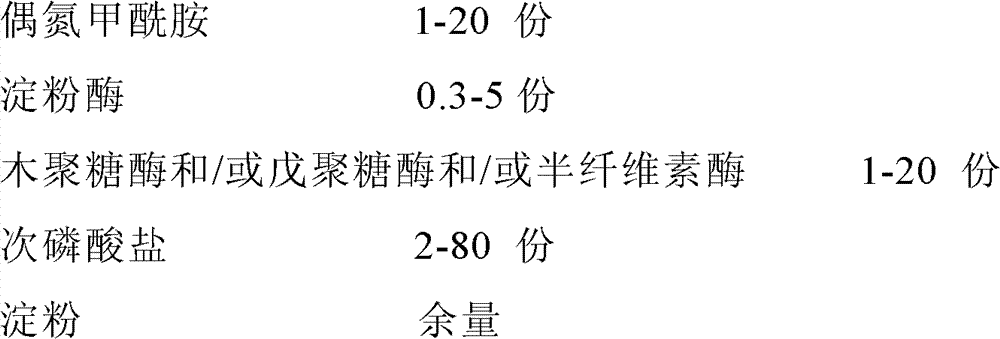

Flour improver or flour product improver

ActiveCN102763697AImprove finenessIncrease bread volumeDough treatmentConfectioneryMatrix strengthFermentation

The invention discloses a flour improver or flour product improver, wherein the flour improver or flour product improver contains hypophosphite. The invention also discloses flour or flour products containing the flour improver or flour product improver provided by the invention. Compared with the flour improver or flour product improver containing no hypophosphite, the gluten matrix strength of dough using the improver provided by the invention is high, the gluten quality is improved obviously, the gas holdup property is good; in the later operation period, the dough turns to be dry and comfortable, elastic and resistant to last fermentation; produced bread is large in size and expands quickly in an oven, the stiffness is high, the texture is delicate, and both the taste and the softness are improved obviously.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Whipped cream powder, preparation method and application

ActiveCN103039631AHigh foaming rateImprove plasticityEdible oils/fats production/working-upSodium CaseinateAnticaking agent

The invention relates to a preparation method of whipped cream powder. The method comprises the following steps that (1) vegetable fat and an emulsifying agent are mixed uniformly to form mixed liquid 5; white granulated sugar, sodium caseinate, whey protein and milk powder are mixed with water to form mixed liquid 1; the mixed liquid 1 is mixed with glucose syrup to form mixed liquid 3; a water retention stabilizer and a thickener are mixed with the water to form mixed liquid 2; the mixed liquid 2 is mixed with the mixed liquid 3 to form mixed liquid 4; the mixed liquid 5 is mixed with the mixed liquid 4 to form oil-water mixed pulp; the oil-water mixed pulp is stirred, sheared and emulsified to form uniform light-milk yellow pulp; (2) the pulps obtained in Step (1) are homogenized to form homogenized pulp; and (3) the homogenized pulp is pasteurized and subjected to spray drying; an anticaking agent is added to powder obtained through the spray drying, and mixed uniformly to form the whipped cream powder. The whipped cream powder can serve as a principal raw material of preparation of decorative cakes, mousse cakes and puffs.

Owner:无锡超科食品有限公司

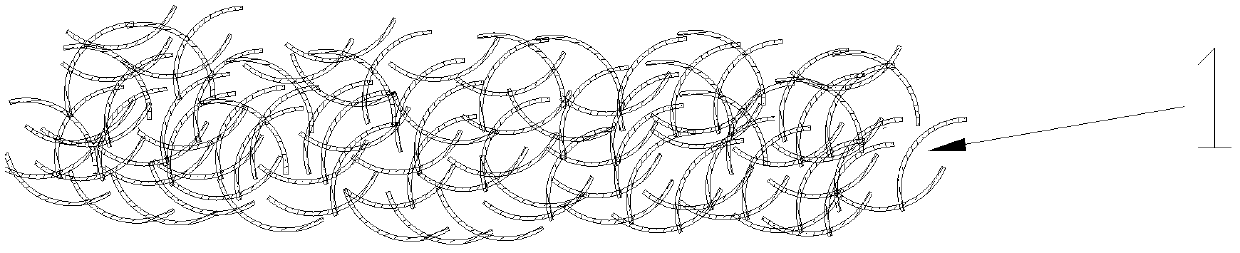

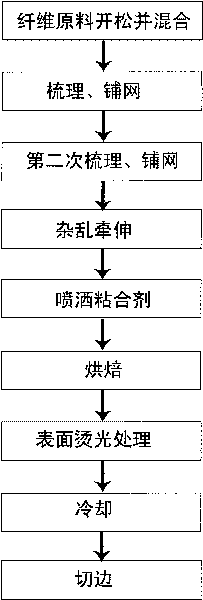

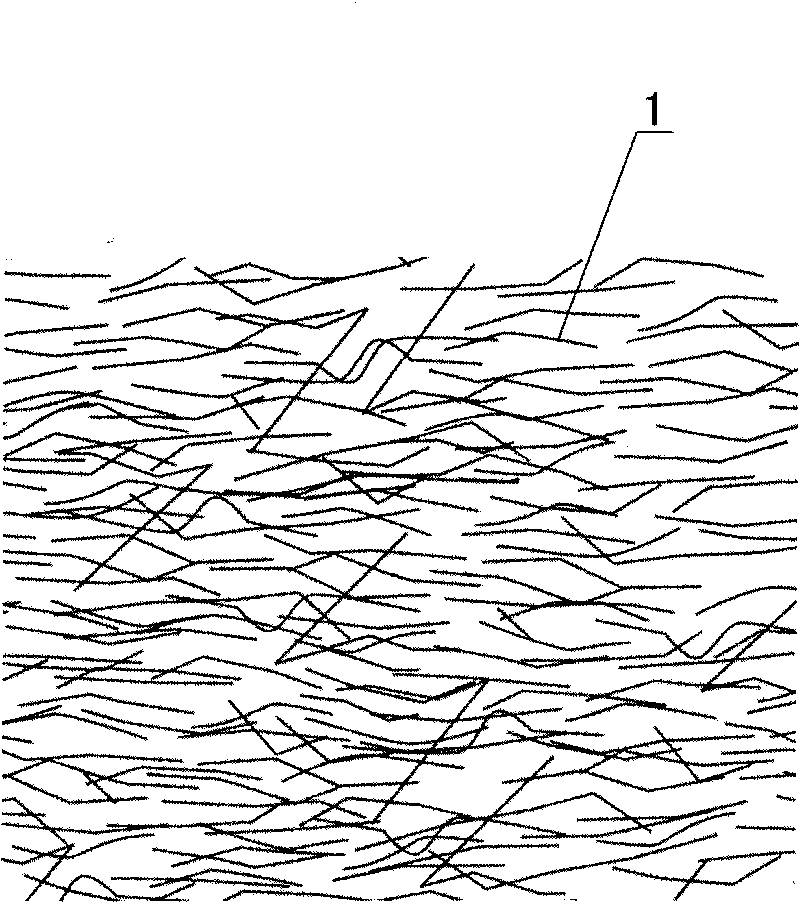

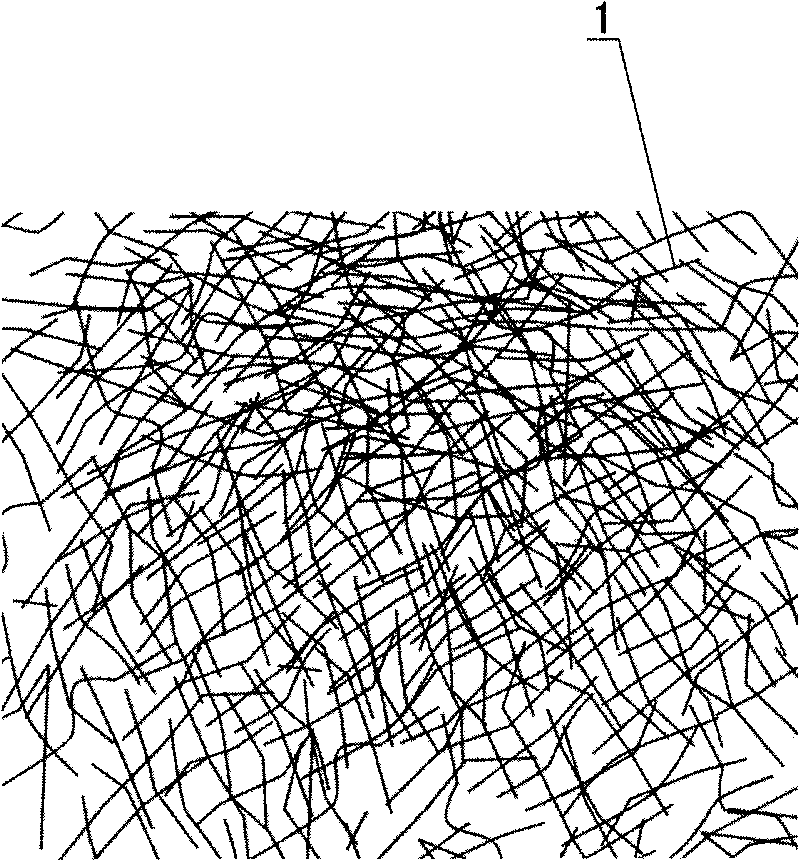

Insulation flocculus and manufacture method thereof

InactiveCN101718024AReduce conductionReduce convectionNon-woven fabricsAdhesivesCross ventilationRaw material

The invention relates to insulation flocculus which is made by 20-80 percent by weight of superfine denier fiber, 10-70 percent by weight of fine denier fiber, 5-30 wt% of tacky fiber and 0-5 wt% of bond. The insulation flocculus is made by adopting the following steps of: loosening and mixing the fiber raw materials; carding and lapping to form a fiber web; carrying out disorder traction on the fiber web to enable the fiber web to form a solid meshy across structure; spraying the bond on the two faces of the fiber web; heating and baking the fiber web to enable the tacky fiber to bond the fiber around and to solidify the bond. In the invention, due to the adoption of the superfine denier fiber and the fine denier fiber, heat conduction can be effectively reduced, cross ventilation in the space can be prevented or reduced, and the insulation property of the insulation flocculus is improved. In addition, due to the adoption of the tacky fiber and the bond, the fill power and the compression resilience of the insulation flocculus can be improved, and the fill power and the compression resilience of the insulation flocculus are higher through disorder traction.

Owner:汕头市奥山服饰有限公司

Thermoplasticity environmentally-friendly stone paper and preparation method

InactiveCN101871182AGood thermoplastic processabilityImprove stiffnessPaper/cardboardInorganic compound additionButyl acrylateLubrication

The invention discloses a thermoplasticity environmentally-friendly stone paper and a preparation method. The thermoplasticity environmentally-friendly stone paper comprises the following components in parts by weight: 80-90 parts of inorganic mineral powder, 3-5 parts of surface active ingredient, 2-3 parts of polymer monomer, 0.01-0.05 part of initiator and 5-15 parts of lubrication accessory ingredient, wherein the inorganic mineral powder is at least one of various inorganic mineral powders, such as wollastonite of which the grain diameter is 5-10 mu m, bentonite and the like; the surface active ingredient comprises at least one of anion surface active ingredient comprising inorganic acid ester; and the polymer monomer is one of methyl methacrylate, methyl acrylate, butyl acrylate and styrene. The thermoplasticity environmentally-friendly stone paper contains 90% of inorganic mineral powder, has favoarble thermoplasticity processing performance and can use the thermoplasticity processing equipment to carry out quick blow molding or calendaring and drawing shaping; and paper has obvious vertical and horizontal orientation, good deflection and strong rigidity, and appearance texture more approaches the traditional paper. The thermoplasticity environmentally-friendly stone paper is a novel environmentally-friendly paper.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

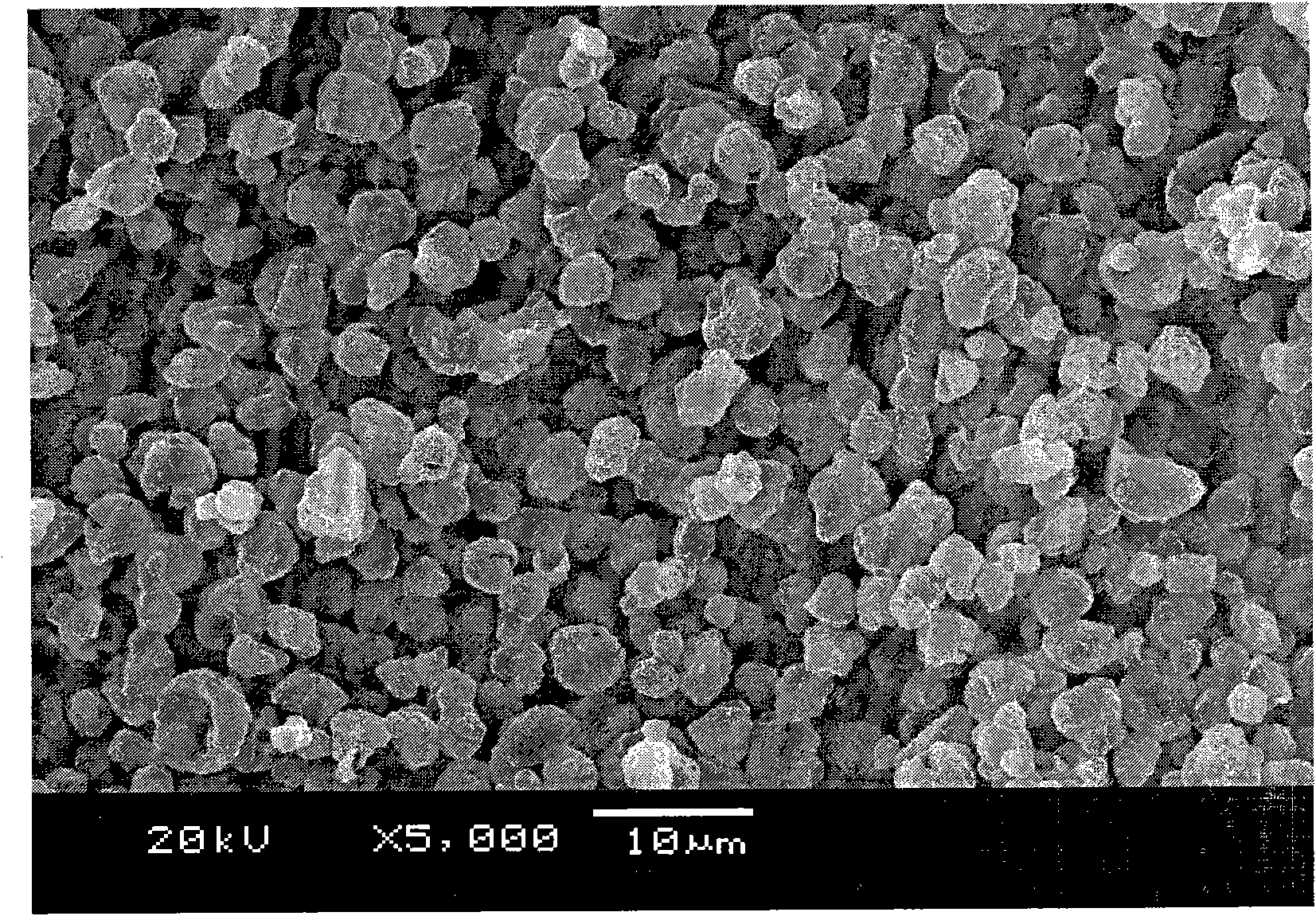

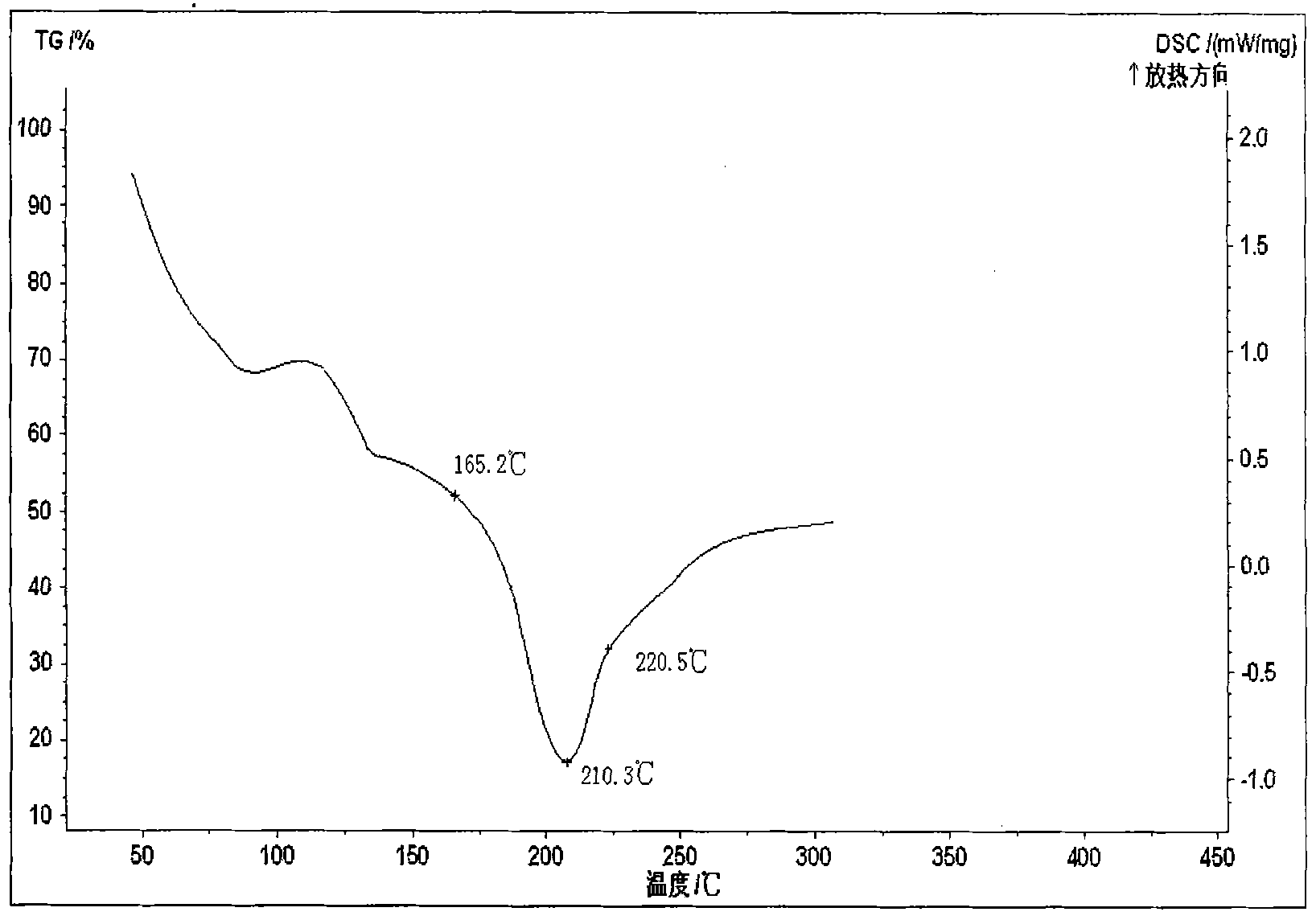

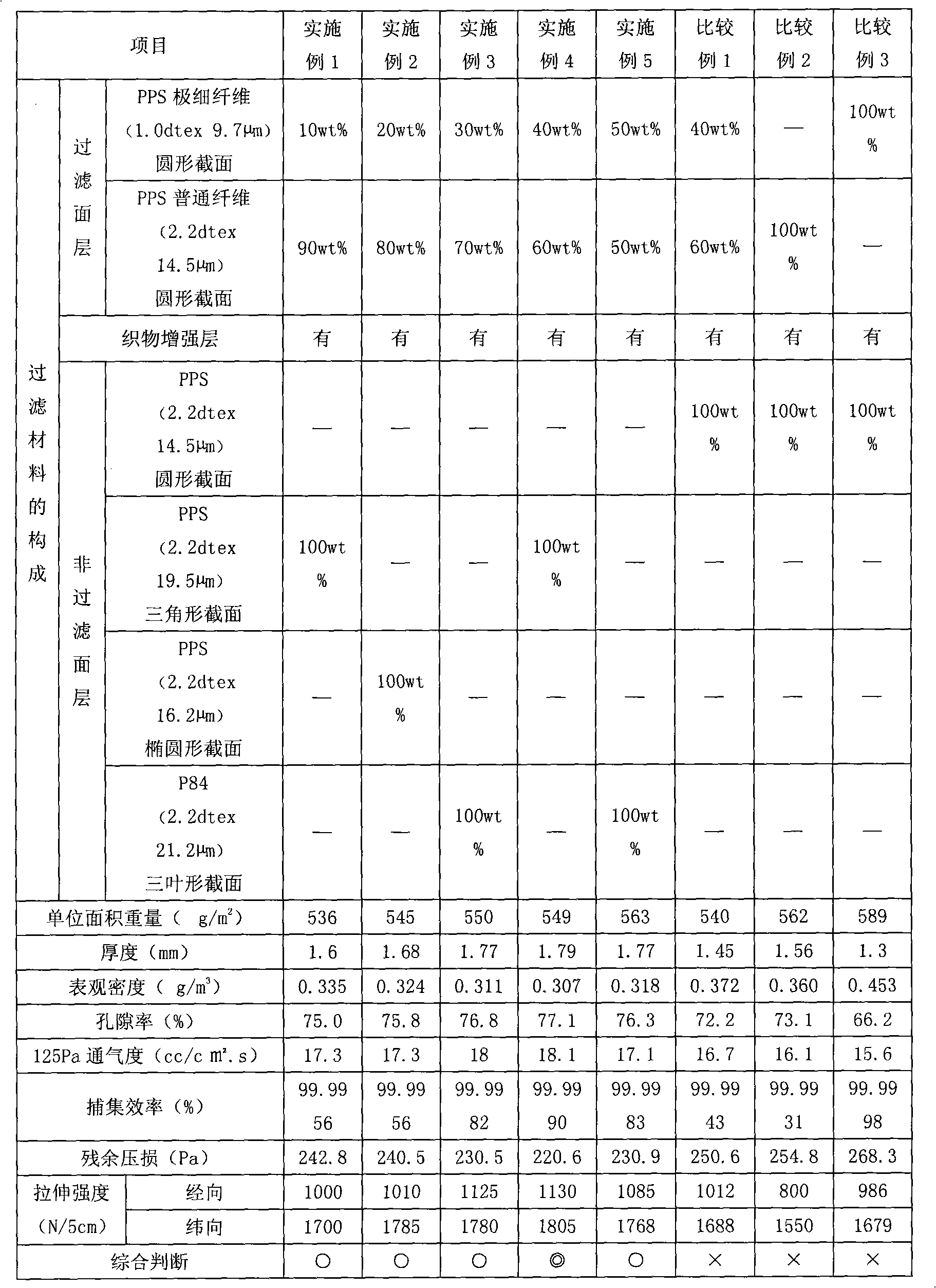

Filtering material and application thereof

InactiveCN102335533AAvoid damageExtended service lifeDispersed particle filtrationLayered productsFiberSurface layer

The invention discloses a filtering material and its application. The filtering material comprises a three-layer structure of a filtering surface layer, a non-filtering surface layer, and an intermediate fabric enhancement layer, wherein, the filtering surface layer is a fibrous mesh comprising 10-90 wt% of heat resistant fibers with the average diameter of below 10 mum and 10-90 wt% of heat resistant fibers with the average diameter of 10-20 mum, the non-filtering surface layer is a fibrous mesh comprising deformed section heat resistant fibers with the average diameter of 10-200 mum, and the intermediate fabric enhancement layer is a fibrous mesh comprising heat resistant fibers. The filtering material disclosed herein has good filtering performance, high mechanical strength, little loss of pressure, and long cycle time, and can improve the service life of the filtering material.

Owner:TORAY IND INC

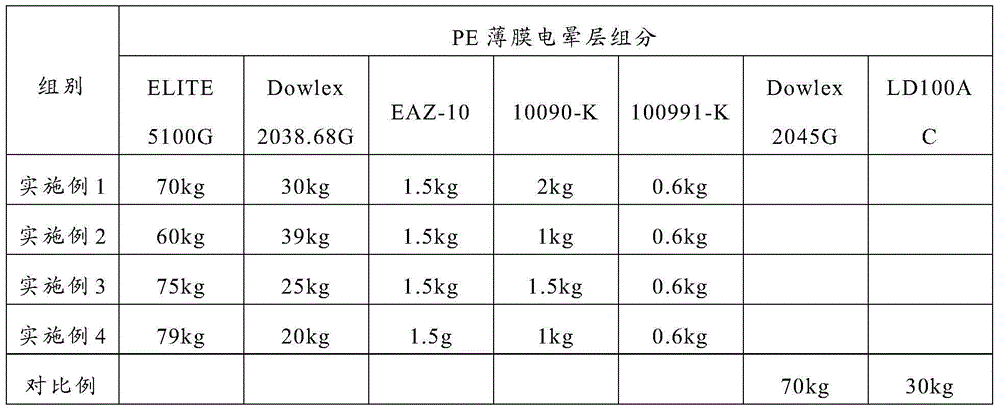

PE film and preparation method thereof

ActiveCN104476889AImprove stiffnessGood flexibilitySynthetic resin layered productsFlat articlesPliabilityMedium-density polyethylene

The invention provides a PE film which is formed by co-extruding a corona layer, a middle layer and an inner layer. The corona layer comprises metallocene linear low density polyethylene resin and medium density polyethylene resin. The middle layer comprises low density polyethylene resin, linear low density polyethylene resin and medium density polyethylene resin. The inner layer comprises metallocene linear low density polyethylene resin and medium density polyethylene resin. The corona layer and the inner layer each comprises the high-proportion metallocene linear low density polyethylene resin, so that the PE film has good heat sealing performance, and the medium density polyethylene resin added in the corona layer, the middle layer and the inner layer enable the film to have good stiffness and flexibility, and the PE film is suitable for package of hygienic products.

Owner:永新股份(黄山)包装有限公司

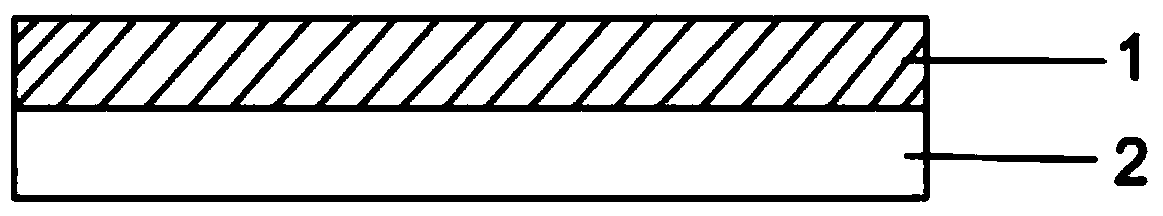

Nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film

ActiveCN102717549AExcellent scratch resistanceInnovative materials and treatmentsSynthetic resin layered productsFingerprintIn situ polymerization

The invention discloses a nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film, which comprises an organic silica gel layer, a peep-proof polarization film, a bonding agent layer, a PET (Polyester) film layer and an anti-glare fingerprint-resistant nano coating from inside to outside. The anti-glare fingerprint-resistant nano coating takes silicon-fluorine polymers as a substrate, and is prepared by forming a layer of silicon dioxide or calcium carbonate with nano microbumps on the surface of a PET film in a in-situ polymerization manner; the peep-proof polarization film comprises a plurality of strip-shaped photoresists that are arranged in parallel, the cross section of each strip-shaped photoresist is square, and a non-transparent interlayer is arranged on the strip-shaped photoresist; and the interval of the photoresist is half of the thickness of the photoresist. The surface hardness of the nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film is greater than 4H, and the fingerprint-resistant performance of the nano-sized anti-glare peep-proof fingerprint-resistant screen protecting film obviously surpasses the commercial conventional merchandises; the peep-proof polarization film adopts photoresist solidification and non-transparent matter filling technologies, and has greater innovations in material and processing method; in addition, a PC (polycarbonate) film is replaced by the PET film with the effects of tough texture, good stiffness, high transparency and low price, so that the quality is ensured, and the cost is lowered at the same time.

Owner:SHANGHAI BENPU TECH DEV

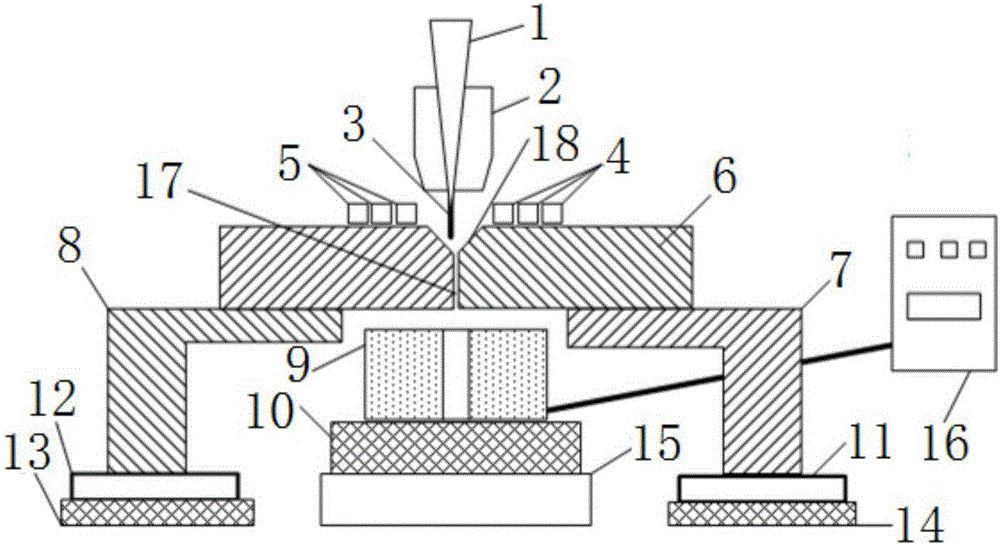

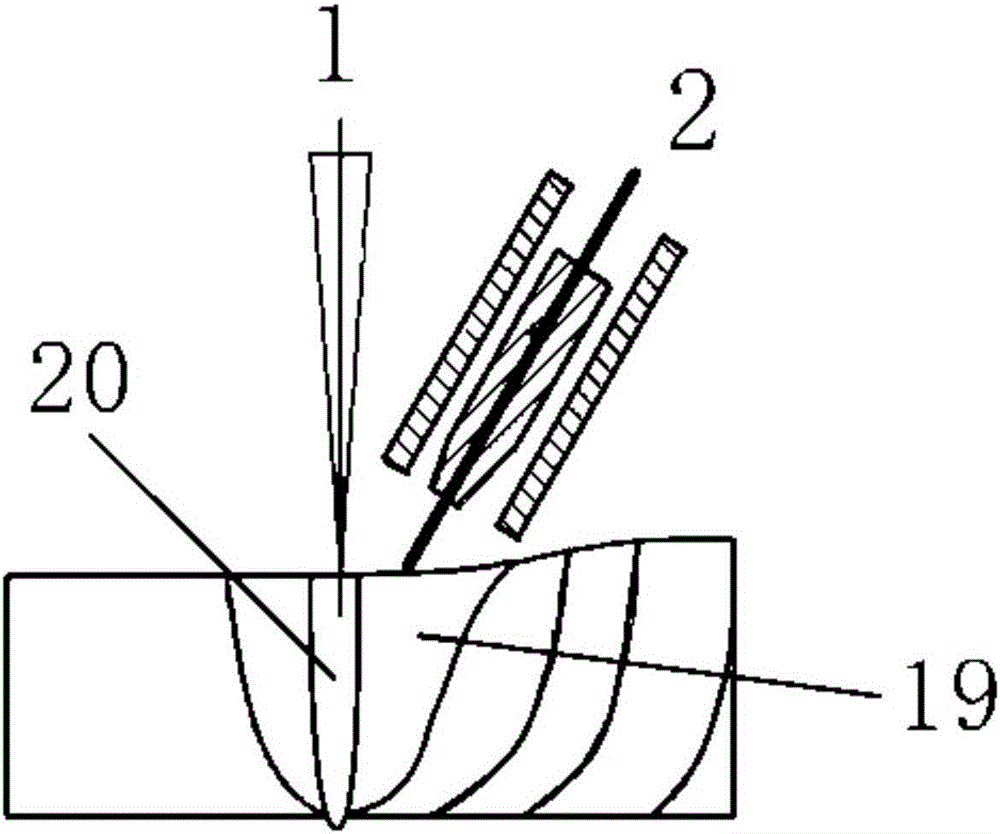

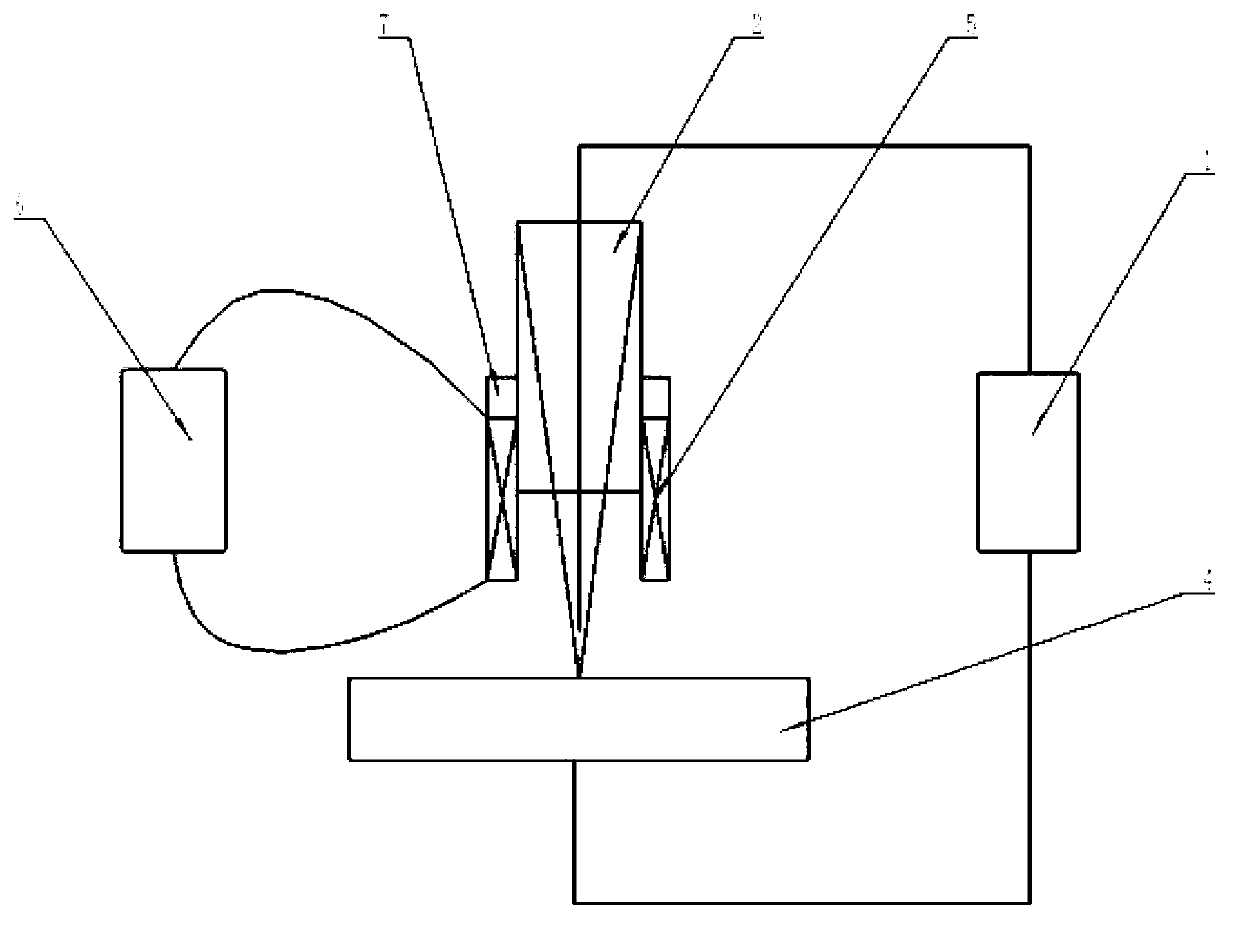

Laser tungsten inert gas (TIG) arc coaxial hybrid welding method with additional high frequency magnetic field and device

InactiveCN103128423AImprove stabilityImprove impact performanceArc welding apparatusLaser beam welding apparatusShielding gasEngineering

The invention relates to a laser TIG arc coaxial hybrid welding method with an additional high frequency magnetic field and a device. The method includes firstly connecting positive and negative poles of a TIG welding machine to a workpiece and a tungsten electrode respectively, then connecting an exciting power output end to a field coil, connecting the field coil with a laser TIG composite welding head through a composite welding head connecting device, and determining a welding running path; and opening an exciting power supply to supply power for the field coil; opening shielding gas for welding and observing the weld seam formation condition. The method and the device have the advantages that the arc pneumatic pressure and the arc current density are effectively improved, so that the arc heat distribution is concentrated, the arc radius is compressed, the arc energy density and the arc stiffness are further improved, the stability of the welding arc in a laser arc composite welding process is improved, the coaxial composite degree of the laser and the arc during laser TIG arc composite coaxial welding is quite facilitated, and wide markets and application prospects are provided.

Owner:鞍山煜宸科技有限公司

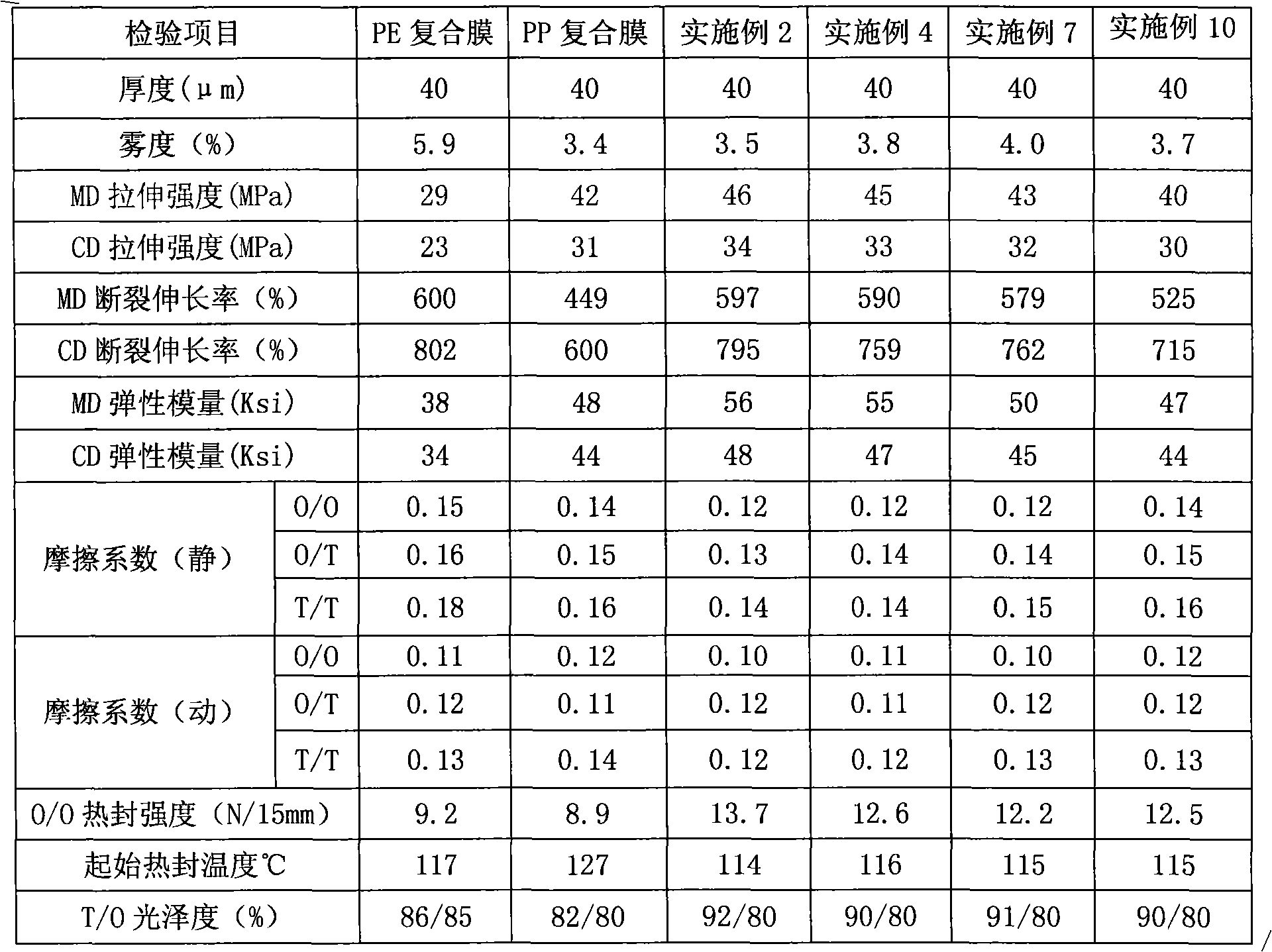

Multifunctional casting polyolefine firmness-increasing film

InactiveCN101659142ALower surface resistance valueProduce anti-static effect of plastic filmFlexible coversWrappersCompound aPolyolefin

The invention relates to a multifunctional casting polyolefine firmness-increasing film which is formed by compounding a heat sealing layer, a core layer and a corona layer. The corona layer or the heat sealing layer mainly comprises the following components in portions by weight: 100 portions of polyethylene resin, 10-60 portions of compatilizer, 0.1-0.5 portion of anti-blocking agent and 0.1-0.5portion of slipping agent; and the core layer mainly comprises the following components in portions by weight: 100 portions of polypropylene resin and 0.1-1.1 portions of nucleating agent. The multifunctional casting polyolefine firmness-increasing film has the characteristics of low temperature, favorable heat sealing performance, high firmness, high elastic modulus and the like, not only combines the advantages of polyethylene and polypropylene films, but also overcomes the defects of polyethylene or polypropylene composite films, is widely applied for packing facial tissues, foods and other products, and is particularly suitable for quick and automatic package of products.

Owner:湖北慧狮塑业股份有限公司

Composite filter material for heat-setting-free pleated filter cartridge and processing method of composite filter material

InactiveCN103908837AGood mechanical foldabilityImprove stiffnessSynthetic resin layered productsFiltration separationGlass fiberPolymer science

The invention discloses a composite filter material for a heat-setting-free pleated filter cartridge and a processing method of the composite filter material. The composite filter material is prepared by taking paper made of plant fibers, synthetic fibers and glass fibers as a base material, and compounding the base material and a polypropylene (PP) or polytetrafluoroethylene (PTFE) synthetic fiber filter film by adopting hot melt adhesive, liquid glue or an ultrasonic composite method. The paper made of the plant fibers, synthetic fiber materials and glass fibers serves as the base material, and the prepared material is a novel composite filter material which is low in airflow resistance, high in tensile strength, diversified in varieties, convenient to fold, wide in application range and excellent in overall performance.

Owner:重庆造纸工业研究设计院有限责任公司

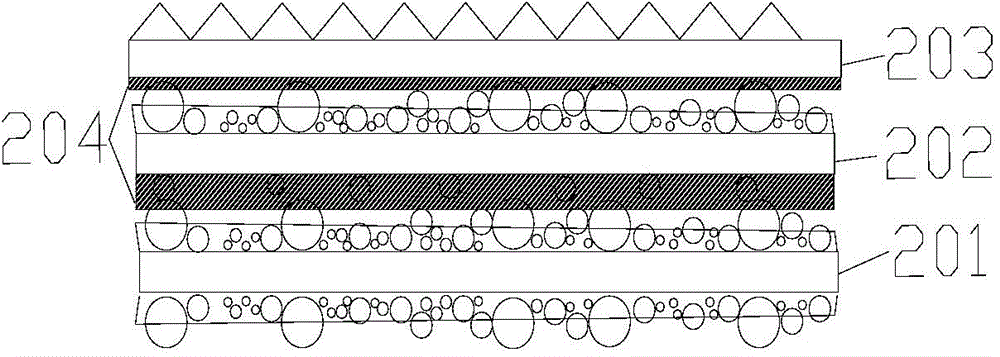

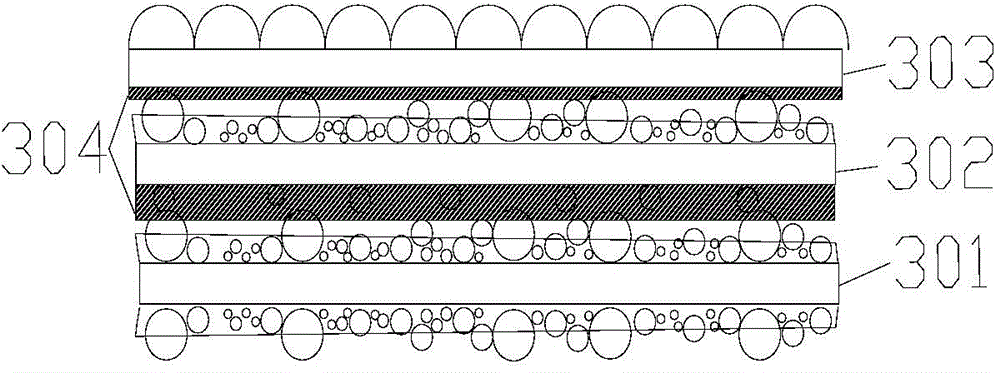

High-reflection and high-stiffness light reflecting film

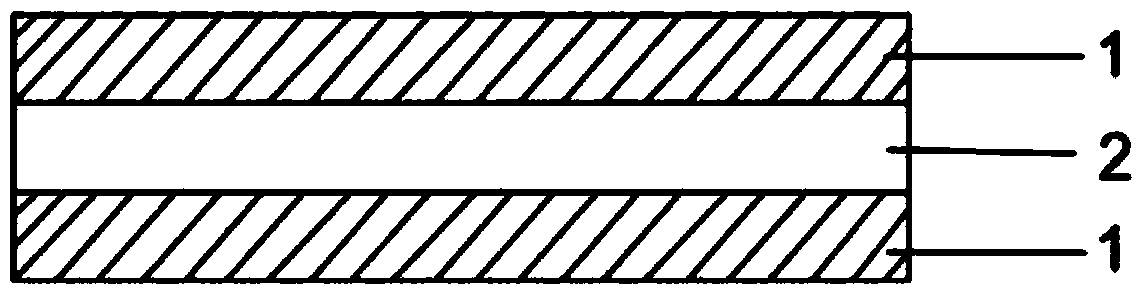

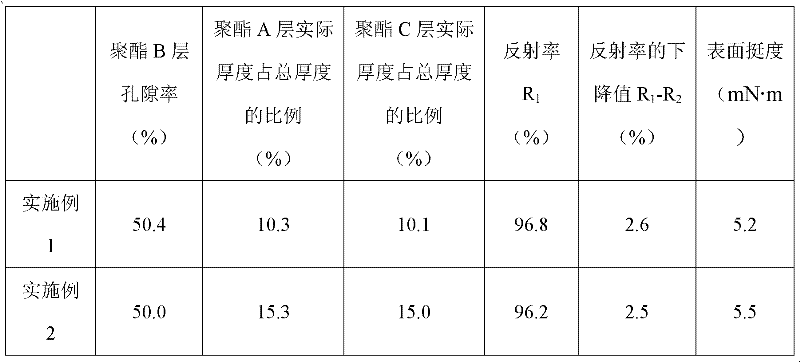

The invention discloses a high-reflection and high-stiffness light reflecting film which comprises a pore-containing polyester layer B, wherein at least one polyester layer A and at least one polyester layer C are also respectively arranged at two sides of the polyester layer B, and the porosity of the polyester layer B is 50-80%; pores are arranged at inner parts of both the polyester layer A and the polyester layer C, and the porosities of the polyester layer A and the polyester layer C are respectively 5-20%; and the thicknesses of the polyester layer A and the polyester layer C are respectively 10-25% of the total thickness of the reflecting film. In the invention, high stiffness is obtained while high reflection of the reflecting film is realized through adjusting the pore content and the thickness of respective structural layers of the reflecting film, and the high stiffness and the high reflection are beneficial to using and processing in the later period. In the invention, as the high stiffness is obtained while high reflection of the reflecting film is realized, scratches and crease loss of the reflecting film in the processing process are reduced, the processing yield of the reflecting film is increased, the assembly difficulty of a backlight source is reduced, and the production efficiency is increased; and the invention is suitable for a reflecting film.

Owner:WUHAN KINGBULL ECONOMIC DEV

Embedded digitization controlled tube-plate all-position automatic welding inverter

InactiveCN101391336AGood consistencyGuaranteed arc stability and stiffnessArc welding apparatusDc-ac conversion without reversalThree-phaseHigh frequency

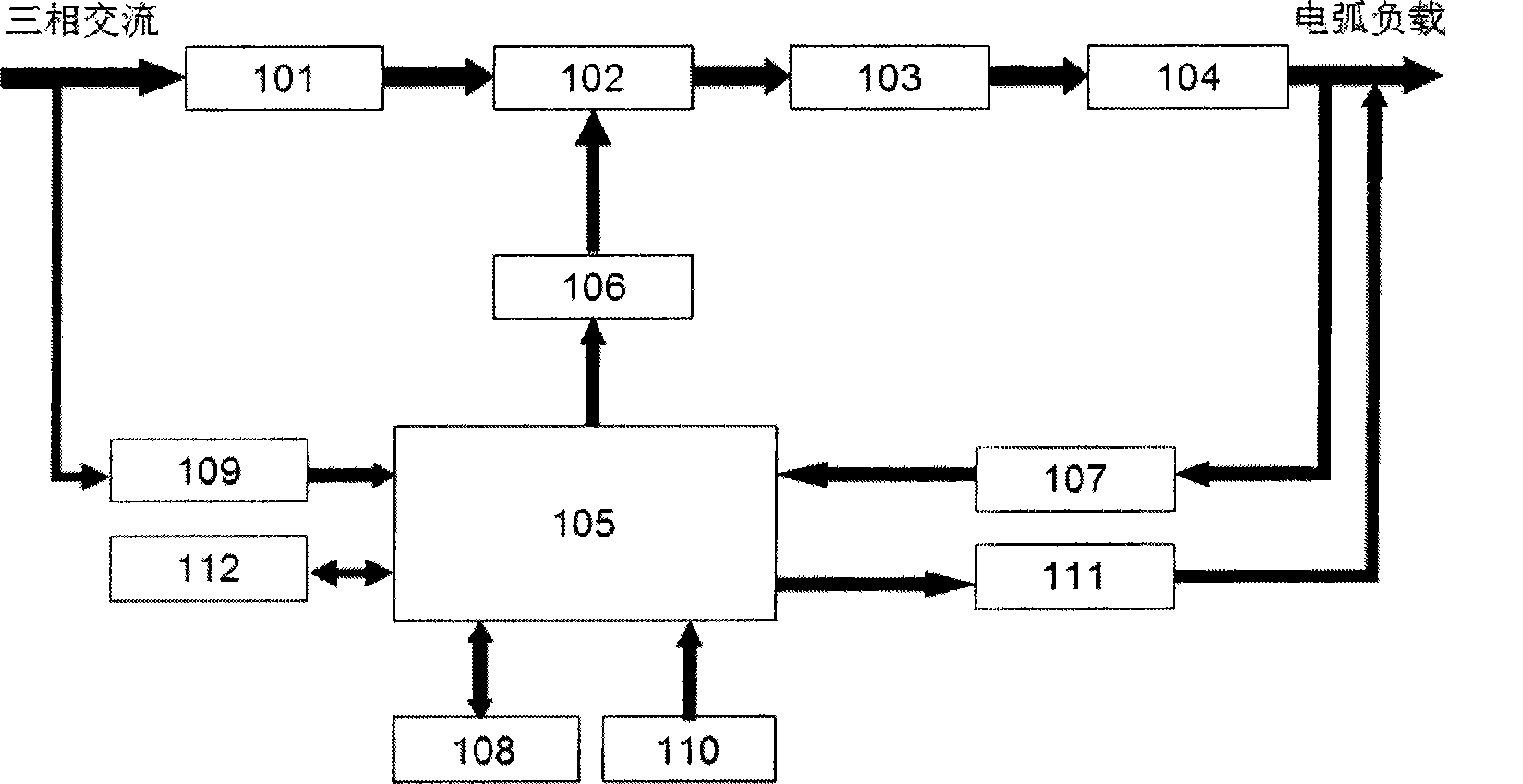

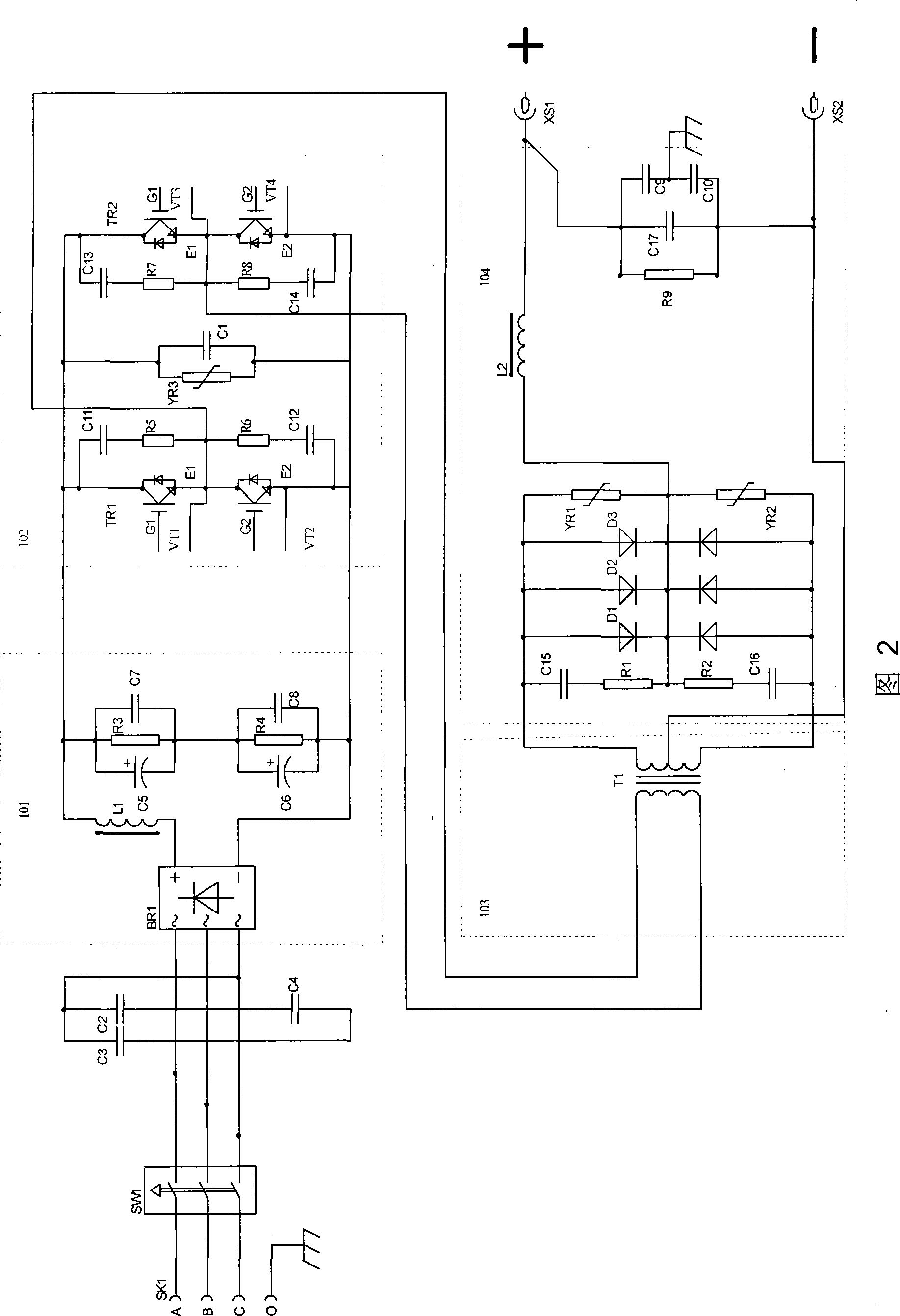

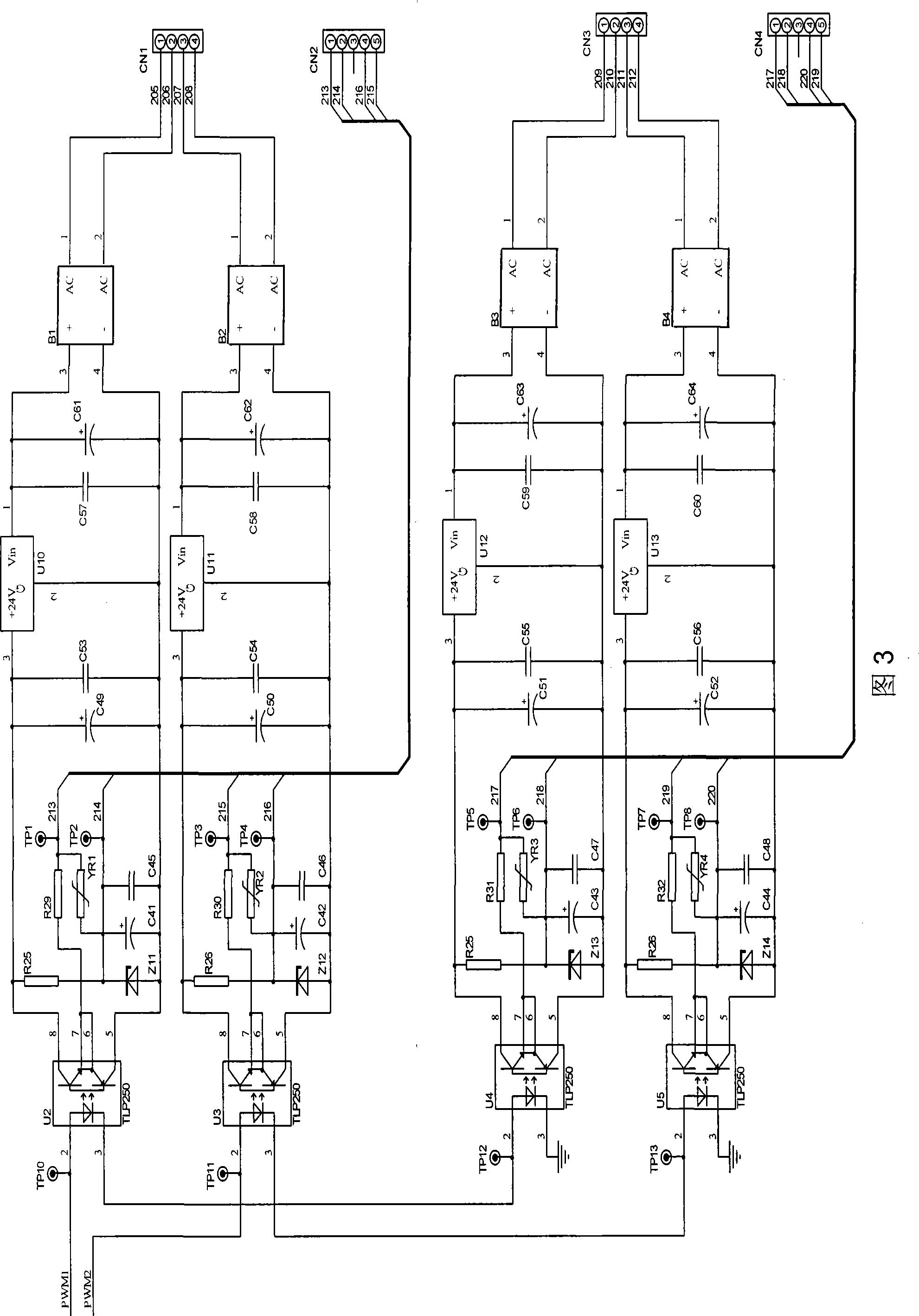

The invention is an embedded digital control inverter power source used in tube and plate overall position automatic welding, which comprises a main circuit, a control circuit and a high frequency arc-ignition circuit. The main circuit comprises a rectifying wave filter module, a high frequency inverter module, a power voltage-transforming module and a rectifying smooth module which are connected sequentially. The rectifying wave filter module is connected with a three-phase alternating current (AC) input power, and the rectifying smooth module is connected with a load. The control circuit includes an over-voltage and under-voltage protective testing module, a voltage and current sample testing and feedback module, an ARM microprocessor and a high frequency drive module. The over-voltage and under-voltage protective testing module is respectively connected with the three-phase AC input power and the ARM microprocessor. The voltage and current sample testing and feedback module is respectively connected with the ARM microprocessor and the load. The ARM microprocessor is also connected with the high frequency drive module and the high frequency arc-ignition circuit. The high frequency drive module is also connected with the high frequency inverter module, and the high frequency arc-ignition circuit is also connected with the load. The invention can realize the overall digital control of the tube and plate automatic welding inverter power source.

Owner:GUANGDONG POWER ENG +1

Multi-function composite optical membrane capable of replacing diffusion plate and manufacturing method thereof, and display screen

The invention relates to an optical film, especially to a multi-function composite optical membrane capable of replacing a diffusion plate and a manufacturing method thereof, and a display screen, thereby reducing the cost of the large-size backlight template and improving a yield and an optical effect. The multi-function composite optical membrane is composed of a lower layer, a middle layer, and an upper layer; and a diffusion membrane is arranged at the lower layer, a diffusion membrane or prism membrane is arranged at the middle layer, and a diffusion membrane, prism membrane or micro lens membrane is arranged at the upper layer; the lower layer, the middle layer, and the upper layer are combined together by adhesives; the top surface of the lower layer is combined with the middle layer and the top surface of the middle layer is combined with the upper layer. The composite optical membrane can replace the diffusion plate or other optical membrane plates in the large-size backlight module group, thereby saving the cost and improving the yield.

Owner:NINGBO JIANGBEI EXCITON NEW MATERIAL TECH CO LTD

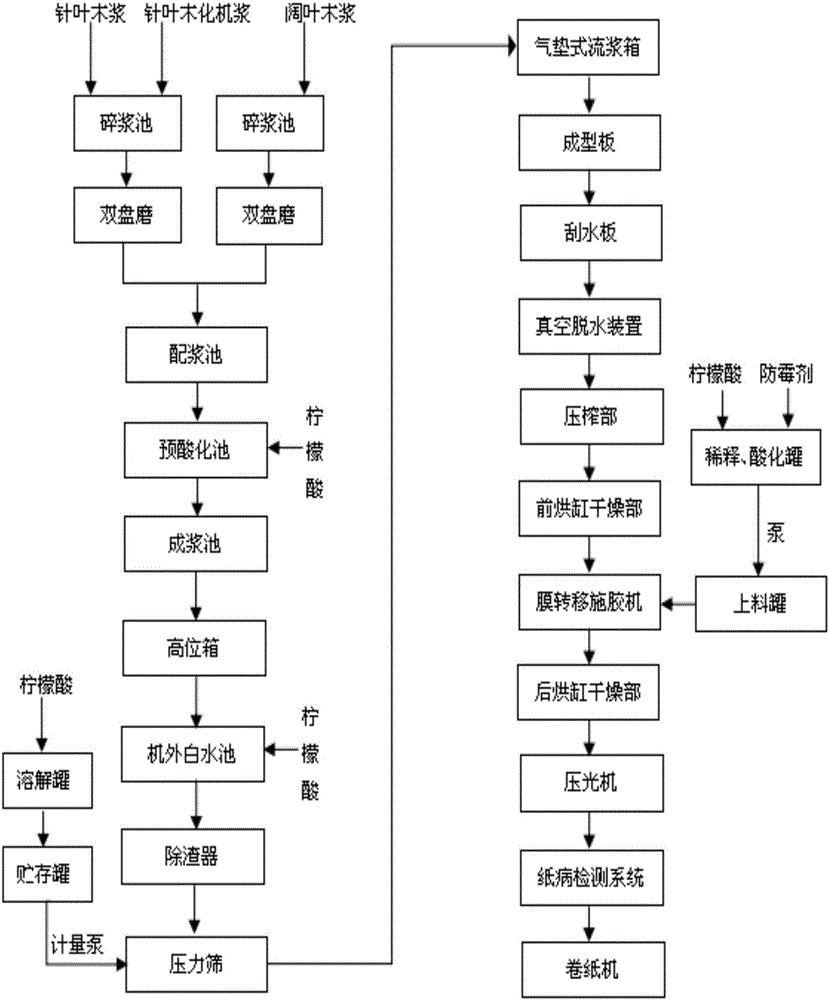

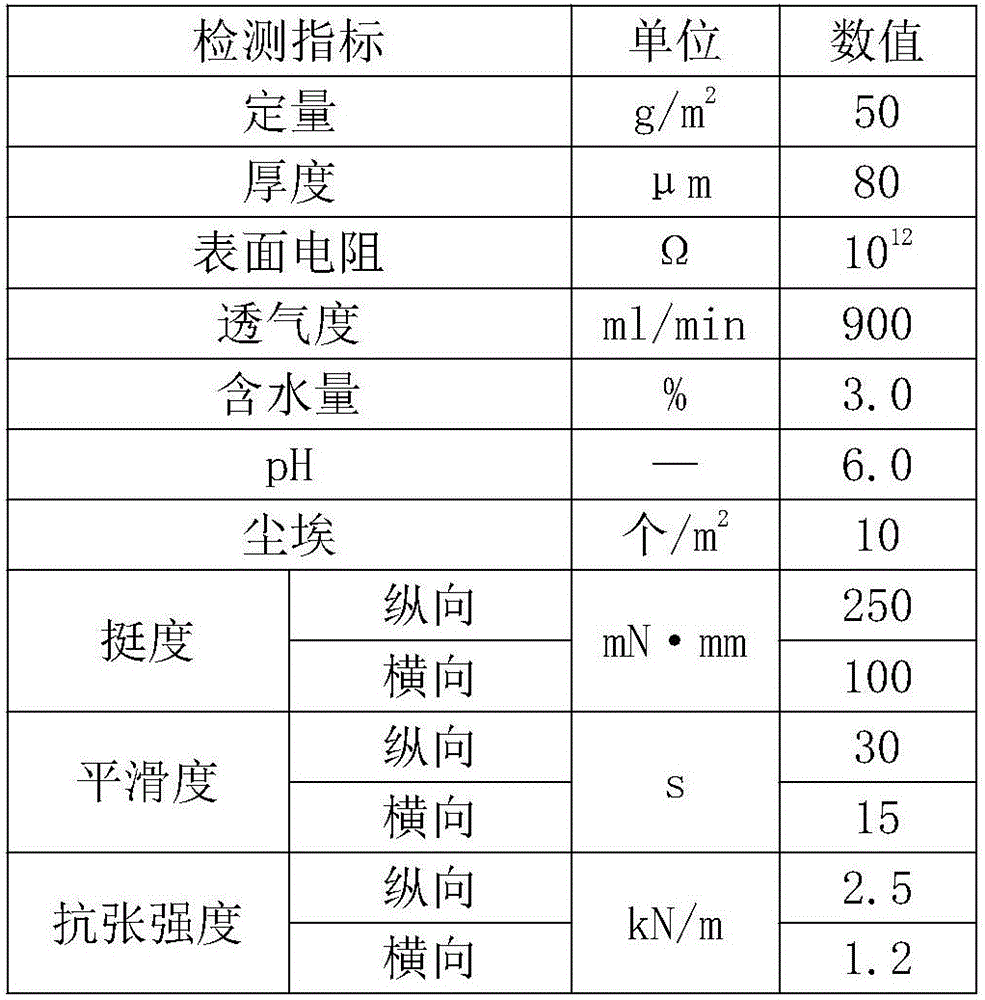

Mildew-proof and anti-bacterium liquid crystal electronic glass partition paper and production technology thereof

The invention discloses mildew-proof and anti-bacterium liquid crystal electronic glass partition paper and a production technology thereof. Pulp of the partition paper comprises 50% to 70% of original coniferous wood pulp, 10% to 30% of original hardwood pulp and 10% to 20% of coniferous wood chemithermomechanical pulp, wherein the coniferous wood pulp and the coniferous wood chemithermomechanical pulp are pulped in a mixed mode, and the beating degree is 25 degreeSR to 30 degreeSR; the hardwood pulp is independently pulped, the beating degree is 20 degreeSR to 25 degreeSR, the fixed quantity is 30 g / m<2> to 60 g / m<2>, the pH value is 4.5 to 6.5, the moisture content is 1.0% to 4.0%, the surface resistance is larger than or equal to 1,010 omega, and air permeability is larger than or equal to 500 ml / min. The faintly-acid mildew-proof and anti-bacterium liquid crystal electronic glass partition and packaging paper high in stiffness, mechanical strength and air permeability is prepared in combination with various measures, and the paper has the certain separation and protection effects in the storage process and the transportation process of electronic glass, and meanwhile has the mildew-proof function and the moistureproof function.

Owner:YINGGE PULPING & PAPER MAKING LUOHE CITY

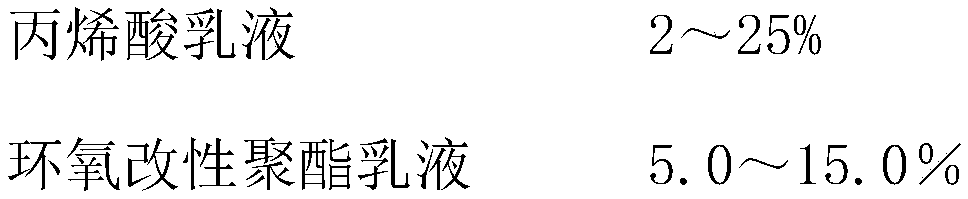

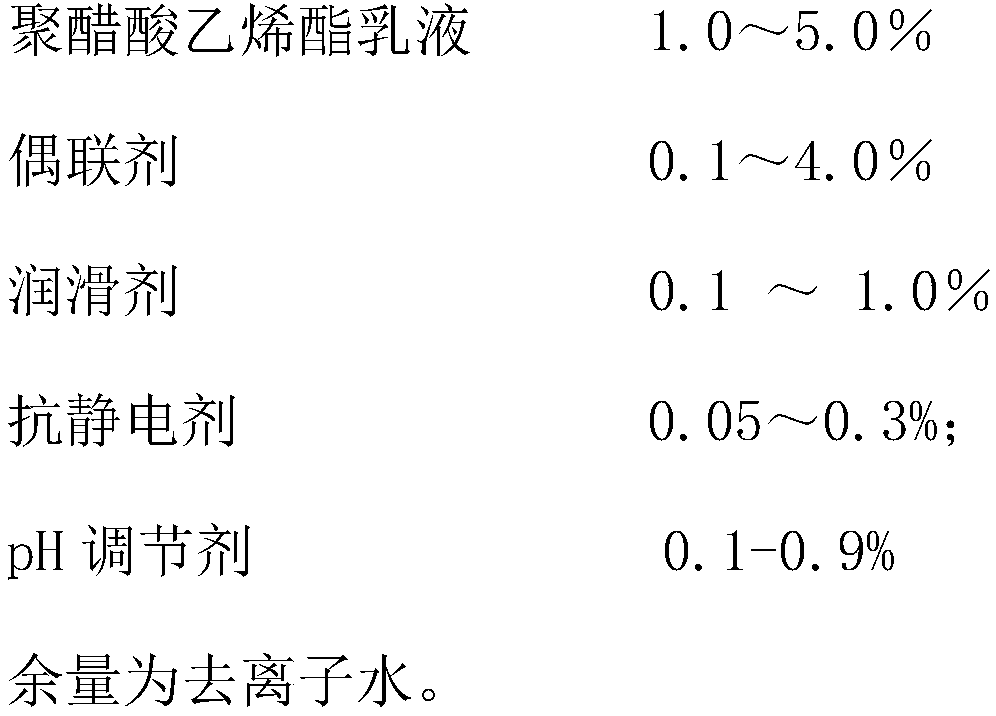

Impregnating compound for enhancing polypropylene plastic-glass fiber chopped yarn

The invention relates to an impregnating compound for enhancing polypropylene plastic-glass fiber chopped yarn. The impregnating compound is prepared from components in percentage by total mass of theimpregnating compound as follows: 3%-22% of an acrylic emulsion, 5.0%-15.0% of epoxy modified polyester emulsion, 1.0%-5.0% of a polyvinyl acetate emulsion, 0.1%-1.0% of a lubricating agent, 0.05%-0.3% of an antistatic agent, 0.1%-0.9% of a pH regulator and the balance of deionized water. Compared with the prior art, the provided impregnating compound can have a good compatibility with polypropylene plastic resin, the plasticity and stiffness of the glass fiber are enhanced, and the impregnating compound has small static electricity and adjustable hardness, can be compatible with multiple resin, is high in resin permeation speed and good in bondability with resin and endows a composite with excellent mechanical properties.

Owner:SHANDONG FIBERGLASS GRP

Method for producing high strength thermal-insulating paper

The invention discloses a method for producing high strength thermal-insulating paper, comprising the following steps of: a, mixing long glass fiber, softwood pulp and polyvinylalcohol PVA water solution, pulping, filtering and drying to obtain fiber paper substrate; b, soaking the paper substrate into siliceous sol having coagulant, gelling, performing supercritical CO2 drying to obtain the thermal-insulating paper substrate compounded with nano-silicon dioxide aerogel powder; and c, soaking the thermal-insulating paper substrate into the polyvinylalcohol PVA water solution, heating, pressurizing and drying to obtain the high strength thermal-insulating paper. The method can effectively improve the thermal-insulating performance and strength of the paper; the produced product is high in deflection, good in thermostability, excellent in high-temperature resistance performance, good in heat preservation performance and the like.

Owner:沈阳临德陶瓷研发有限公司

Method for preparing rose calcium carbonate from low-grade limestone

InactiveCN102502749AFull flowImprove mass transfer efficiencyCalcium/strontium/barium carbonatesChemical industryPorosityHigh surface

The invention discloses a method for preparing rose calcium carbonate from low-grade limestone, which comprises the following steps: 1) proportionally calcining low-grade limestone and blind coal to prepare calcium oxide; 2) screening under vibrations to remove coal ash and lime powder, thereby obtaining lumpy lime; 3) adding water to slake the lumpy lime, removing impurities by hydrocyclone and vibration screening to obtain fine emulsion slurry, adding a whitener, and aging to obtain the Ca(OH)2 prime slurry; 4) after regulating the temperature and concentration of the Ca(OH)2 prime slurry, adding a crystal form control agent, carrying out bubbling carbonation reaction, and adding a dispersant; when the pH value of the slurry is lower than or equal to 7, stopping carbonation to obtain a cured slurry; and 5) after the cured slurry is thickened, dehydrating to obtain the rose calcium carbonate. Compared with common light calcium carbonate, the rose calcium carbonate disclosed by the invention has the advantages of higher crystal completeness, high surface porosity, high light scattering coefficient and stronger covering power; and the invention is applicable to the industries of paper making, rubber, plastics and paint.

Owner:福建省万旗非金属材料有限公司

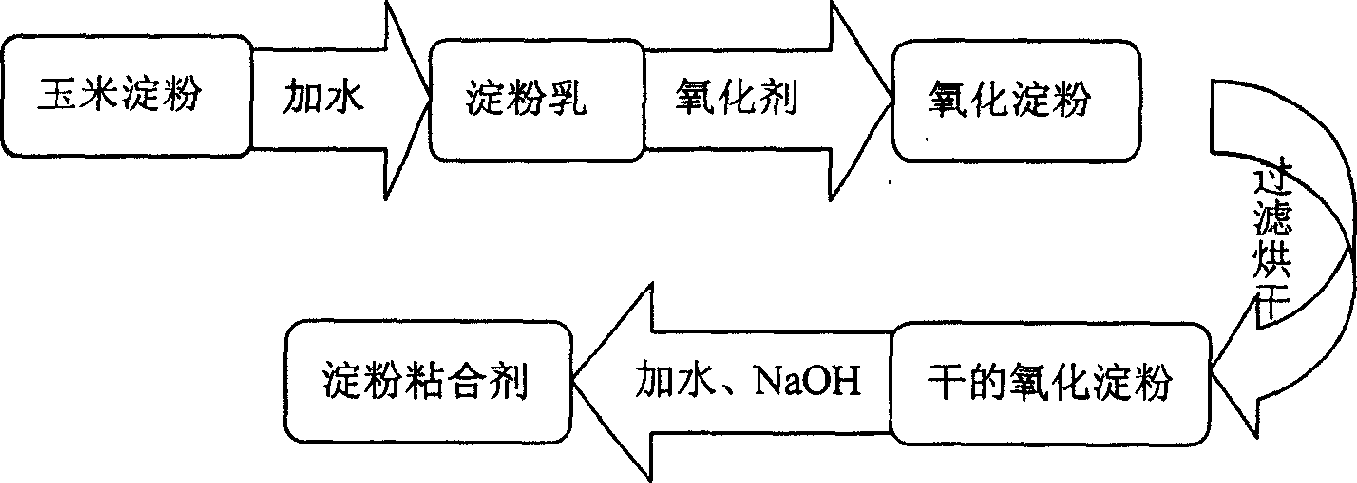

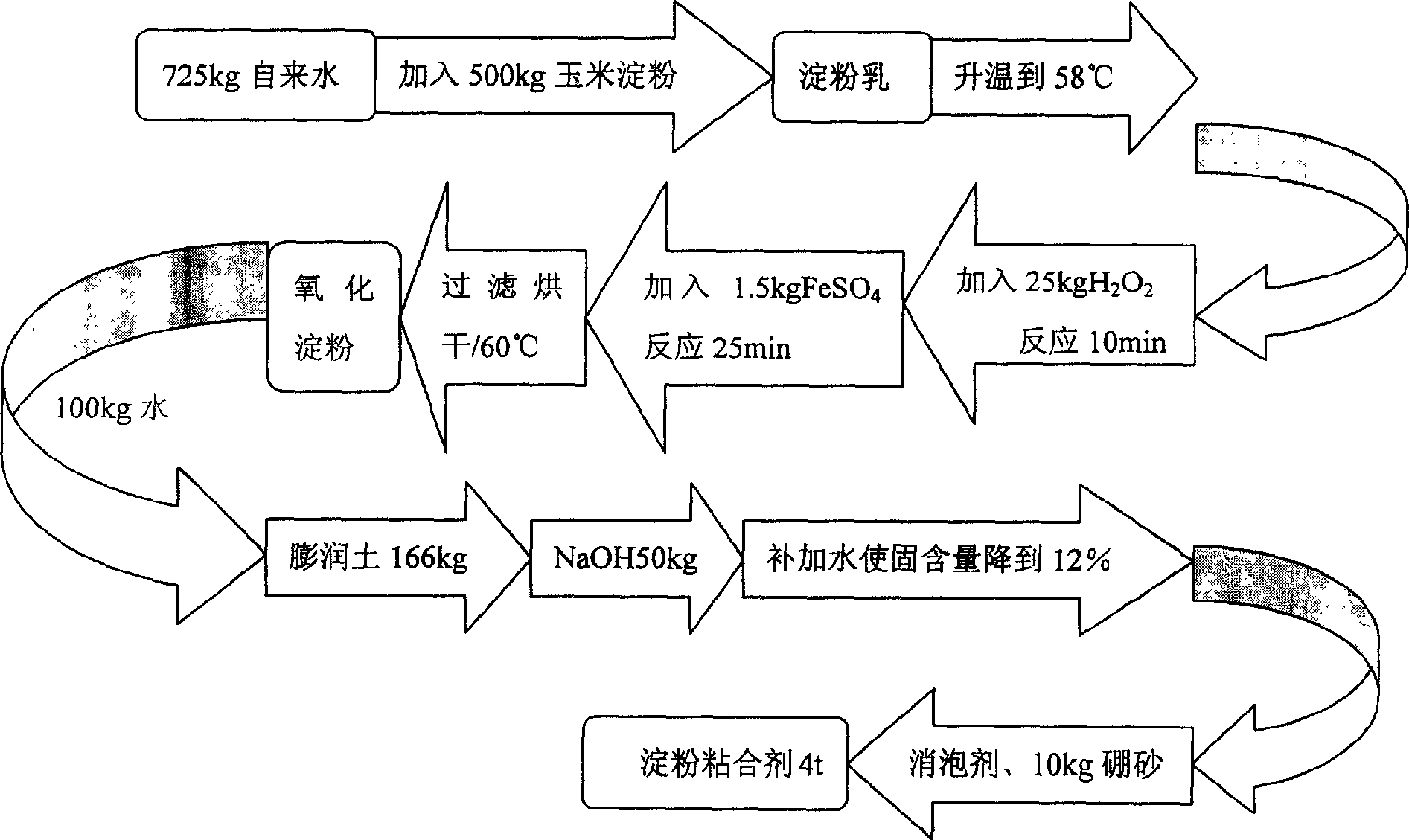

Method for preparing rapid-dry corn starch adhesive

InactiveCN1528849AHigh bonding strengthFast bond strengthStarch adhesivesSodium BentonitePolymer science

The invention discloses a manufacturing method for dry core starch adhesives, the method uses new catalyst Fe2+, reduces the use quantity of oxidant to 5%A, reduces the reaction time to 30 minutes, and produces a kind of cheap and high adhesives starch adhesives. The method adds in modified bentonite or natrium group bentonite whose weight is 30% of dried starch as the fillers before adding in NaOH, it enhances the drying speed greatly. The adhesives can be dried quickly, it doesn't counter tide, high rigidity. The cost is reduced greatly, the dry speed is enhabced greatly.

Owner:XI AN JIAOTONG UNIV

Method for preparing high-strength cured filter paper

ActiveCN102953295AImprove air permeabilityGood stiffnessPaper coatingFiltration separationBursting strengthPapermaking

The invention relates to a method for preparing high-strength cured filter paper. The method comprises the following steps: (1) taking the following components in percentage by weight: 30-35% of softwood pulp, 45-55% of mercerization wood pulp and 15-20% of bleached hardwood pulp; and repulping and grinding to obtain mixed paper pulp size; (2) papermaking and molding to obtain body paper, and drying the body paper; (3) curing agent preparation: selecting phenolic resin and formaldehyde as a curing agent; and preparing the curing agent according to the proportion of 1-1.5% of paper pulp size; (4) coating the synthesized curing agent on the surface of the body paper; heating to precure the raw materials of the curing agent step by step, wherein the coating amount of the curing agent is 40-55g / m<2>; and (5) cured filter paper drying: drying the body paper coated with the curing agent through a drying tunnel or a drying oven, wherein the drying temperature is 120-135 DEG C, and the drying time is 15-30 seconds. The high-strength cured filter paper prepared by the method provided by the invention has higher air permeability, and simultaneously has better stiffness and waterproof effect; the bursting strength of the high-strength cured filter paper after being cured is improved; and the service life is prolonged.

Owner:杭州特种纸业有限公司

Preparation method of non-woven fabric for shoe linings

InactiveCN105019143AEasy extractionIncrease relative volatilityInsolesNon-woven fabricsActivated charcoal powderAfter treatment

The invention relates to the field of preparation of non-woven fabrics for shoe linings and discloses a preparation method of non-woven fabric for shoe linings. The preparation method comprises following steps of: (1) taking and adding natural perfume to water, adding sea-foam stone powder to a solution, allowing mixed liquor to stand and obtaining sea-foam stone powder loaded with natural perfume by centrifugal and drying treatment; (2) additionally taking activated charcoal powder, aluminum chloride, polyoxyethylene, carboxymethylcellulose, dispersants, silane coupling agents and sea-foam stone powder loaded with natural perfume in order to obtain a mixture; (3) fusing isotatic polypropylene slices and the mixture and performing spinning, drawing, web-forming and hot-rolling operation in order to obtain base cloth of the non-woven fabric; (4) utilizing finishing liquor to process one of surfaces of the base cloth of the non-woven fabric and performing roll-pressing operation on the base cloth after treatment; (5) drying the base cloth of the non-woven fabric subjected to roll-pressing operation and thus obtaining the non-woven fabric for shoe linings. The preparation method of non-woven fabric for shoes is good in deodorization function and breathability and high in hardness so that the shape of a vamp can be kept for a long time.

Owner:LANXI YIMING WEAVING

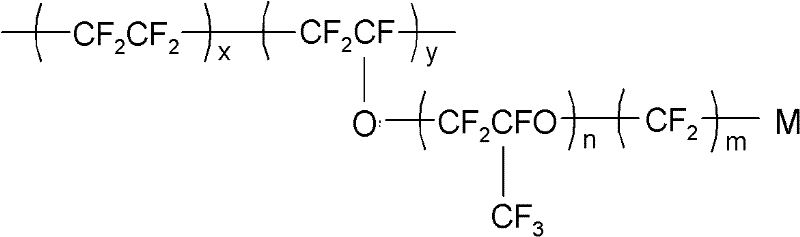

Ion exchange membrane with high current efficiency, and preparation method and application thereof

ActiveCN102336043AHigh mechanical strengthImprove current efficiencyCellsSynthetic resin layered productsCarboxylic acidIon-exchange resin

The invention relates to an ion exchange membrane with high current efficiency, and a preparation method thereof, and application of the ion exchange membrane to preparation of caustic soda in a chlor-alkali tank, and belongs to a compound membrane for producing alkali metal hydroxides and chlorine simultaneously in an ion membrane electrolytic tank. The ion exchange membrane with high current efficiency is characterized by being formed by compounding three layers of perfluorinated ion exchange resin base membranes and a reinforcing material; the three layers of perfluorinated ion exchange resin base membranes are sequentially a high-exchange-capacity sulfonic acid layer, a low-exchange-capacity sulfonic acid layer and a high-exchange-capacity carboxylic acid layer; and the reinforcing material is compounded on one side near the high-exchange-capacity sulfonic acid layer. The invention provides the ion exchange membrane which is high in current efficiency, mechanical strength and chemical stability, suitable for high and low alkali liquor concentration, and low in cost; the preparation method is simple; and in an electrolytic process, the electrolytic tank always keeps high current efficiency and low tank pressure; and products hydroxides have few impurities and are high in purity.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

A form-fill- seal (FFS) single layer heavy-duty film and a preparation method thereof

ActiveCN103059402AHigh tensile strengthHigh impact strengthLinear low-density polyethyleneLow-density polyethylene

The present invention relates to the technical field of packaging film, and concretely relates to a form-fill- seal (FFS) single layer heavy-duty film and a preparation method thereof. The single layer heavy-duty film is composed of 30-50% of metallocene linear low density polyethylene, 5-20% of an ethylene-vinyl acetate copolymer, 5-20% of ultra low density polyethylene, 20-50% of linear low density polyethylene, and 3-5% of masterbatch, and is obtained via blending in a single screw extruder, and processes of extrusion molding via a machine head, traction, cooling, winding, and printing. Compared with the prior art, the single layer heavy-duty film of the present invention optimizes product formulation, has good tensile strength, impact strength and tear strength; in the preparation process, a gradual cooling mode is adopted, so the resulting product is more stable in performance; and aids are not added in the raw materials, so the product is low in cost and has a good market prospect.

Owner:GUANGDONG SUNION CHEM & PLASTIC

High-strength and high-toughness composite silver solder ring for in-situ synthesis of soldering flux

ActiveCN105127618AHigh activityStrong ability to remove filmWelding/cutting media/materialsSoldering mediaPotassium borohydridePotassium fluoride

The invention discloses a high-strength and high-toughness composite silver solder ring for in-situ synthesis of soldering flux. The high-strength and high-toughness composite silver solder ring comprises a silver solder ring body of a hollow structure. The silver solder ring body is formed by winding composite silver solder formed by a silver solder pipe and a flux core with which the silver solder pipe is filled. The flux core is prepared from boron micro-powder, sodium borohydride or potassium borohydride, potassium fluoborate, boric anhydride or boric acid, potassium fluoride or sodium fluoride or lithium fluoride, potassium bifluoride and potassium fluoroaluminate according to a certain proportion. The purpose of in-situ synthesis of the soldering flux through the boron micro-powder in the flux core and metal elements in the silver solder pipe is achieved, so that the content of the flux core is reduced, and when the content of the flux core is low, the solder still achieves good brazing manufacturability; meanwhile, due to the fact that the wall thickness of the solder pipe is increased, good toughness and high stiffness are achieved, the processing performance of the solder is greatly improved, the minimum diameter can be reduced to 0.8 mm, the solder can be easily wound into the solder ring with the intermediate diameter below 6 mm, and application and popularization of the automatic brazing process are facilitated.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com