Patents

Literature

211results about How to "High foaming rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water thin type expanding steel structure fire-resisting paint and its preparation method

The present invention relates to a water thin expanding steel structure fire-resisting coating material and its preparation method. Said ivnention adopts a self-synthesized high melting temp. acrylate emulsion as main film-forming substance, adding proper quantity of chlorometaemulsion to raise fibre resistance of film-forming substance self-body, and on the basis of convertional ammonium polyphosphate fire-resistant adjuvant an expandable graphite as foaming material is added so as to form the invented fire-resisting coating material. Said invention can greatly raise forming rate to coating layer, the thickness of foamed layer can be up to 30-50 times that of original coating layer, and its fire-resisting limit can be up to 75 min (thickness of coating layer is 3 mm).

Owner:TONGJI UNIV

Whipped cream powder, preparation method and application

ActiveCN103039631AHigh foaming rateImprove plasticityEdible oils/fats production/working-upSodium CaseinateAnticaking agent

The invention relates to a preparation method of whipped cream powder. The method comprises the following steps that (1) vegetable fat and an emulsifying agent are mixed uniformly to form mixed liquid 5; white granulated sugar, sodium caseinate, whey protein and milk powder are mixed with water to form mixed liquid 1; the mixed liquid 1 is mixed with glucose syrup to form mixed liquid 3; a water retention stabilizer and a thickener are mixed with the water to form mixed liquid 2; the mixed liquid 2 is mixed with the mixed liquid 3 to form mixed liquid 4; the mixed liquid 5 is mixed with the mixed liquid 4 to form oil-water mixed pulp; the oil-water mixed pulp is stirred, sheared and emulsified to form uniform light-milk yellow pulp; (2) the pulps obtained in Step (1) are homogenized to form homogenized pulp; and (3) the homogenized pulp is pasteurized and subjected to spray drying; an anticaking agent is added to powder obtained through the spray drying, and mixed uniformly to form the whipped cream powder. The whipped cream powder can serve as a principal raw material of preparation of decorative cakes, mousse cakes and puffs.

Owner:无锡超科食品有限公司

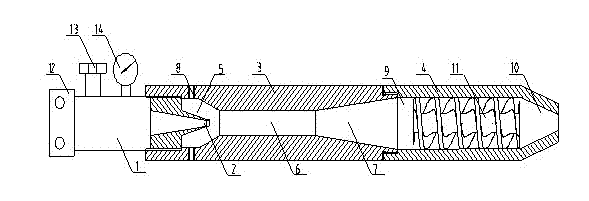

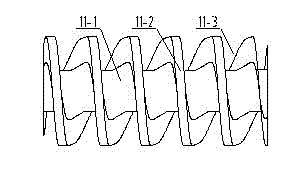

Self-absorption air type cyclone foaming device for dust removal of coal mine

The invention discloses a self-absorption air type cyclone foaming device for dust removal of coal mine. The device mainly comprises a foaming liquid supply pipe, a jet flow nozzle, an air suction mixing barrel body and a foaming barrel body, wherein the foaming liquid supply pipe is connected with the jet flow nozzle; an air suction chamber, an air and liquid mixing chamber and a diffusion foaming chamber are sequentially arranged inside the air suction mixing barrel body; the jet flow nozzle is connected to the air suction chamber; an air suction hole is formed in the air suction chamber; and a cyclone foaming chamber and a foam flow-out chamber are sequentially arranged inside the foaming barrel body. Foaming liquid with set pressure is sprayed at high speed through the jet flow nozzle to form turbulent jet flow; under the suction of the turbulent jet flow, air in the environment can automatically enter the air suction chamber through the air suction hole and is brought into the air and liquid mixing chamber from the air suction chamber to perform energy transmission and mass transmission; the accelerated and compressed air is crushed into air bubbles by liquid drops in the diffusion foaming chamber; and the preliminarily foamed flow is fully foamed in the cyclone foaming chamber. The self-absorption air type cyclone foaming device is simple in structure, convenient to operate, high in foaming rate, low in energy consumption, safe, reliable and low in running and maintenance cost.

Owner:CHINA UNIV OF MINING & TECH

Production method of polyurethane insole material

InactiveCN101864164AHigh foaming rateReduce weightInsolesDomestic articlesFoaming agentSURFACTANT BLEND

The invention relates to a production method of a polyurethane insole material, which comprises the steps of putting raw material into a thermostatic chamber with the temperature of 7-35 DEG C and standing still for 5-8 hours; applying a release agent in a mould used for preparing polyurethane, and maintaining the temperature of the mould at 45-48 DEG C; pouring polyalcohol composite into a mixing tank, adding a catalyst, a surfactant, an antimicrobial agent, a foaming agent, color paste and an opening agent and stirring for 120-150 seconds, and then adding isocyanate and stirring for 10-20 seconds; pouring the stirred mixture into the mould within 5 seconds, blowing away crafters by a blower gun, and then covering and locking the mould; and demoulding for material outlet after 35-45 minutes, and then cutting into slices according to the required size of the insole. Compared with the original mould closing pouring mode, the surface of each insole prepared in the production method of the polyurethane insole material can not generate a layer of airtight skin, and has higher foaming rate, lighter weight and obviously improved air permeability.

Owner:DONGGUAN CHENGGUAN SPORT PROD TECH CO LTD

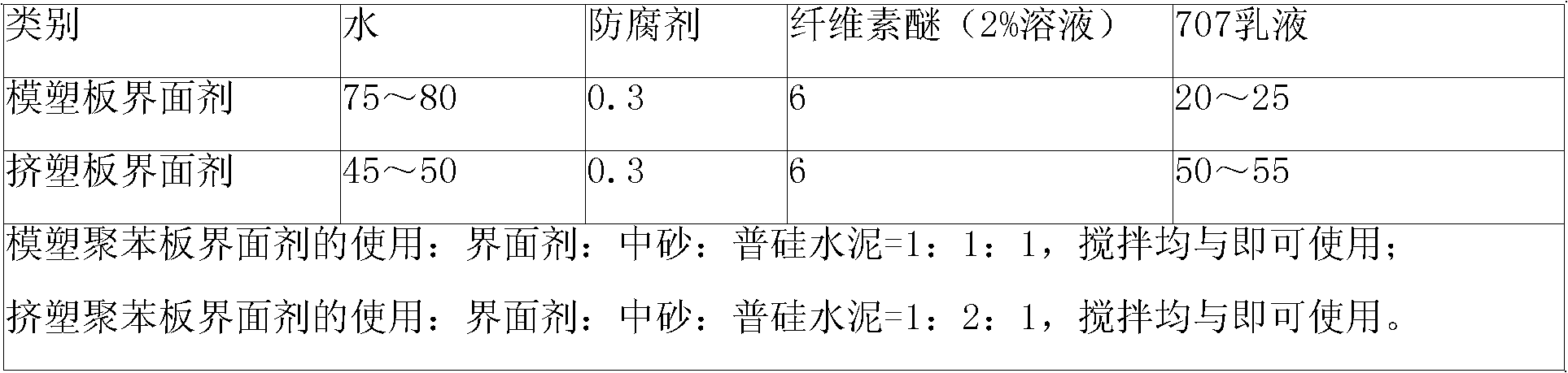

Fireproof interface agent for polystyrene foam heat insulation material and preparation method thereof

InactiveCN101787236AImprove flame retardant performanceImprove combustion effectFireproof paintsConjugated diene hydrocarbon coatingsFiberPolystyrene

The invention discloses a fireproof interface agent for a polystyrene foam heat insulation material and a preparation method thereof. The fireproof interface agent is compounded by components A and B, wherein the mass ratio of the components A to B is 1: 1.2 to 1.4. The fireproof interface agent comprises the following raw materials in percentage by mass: the component A: 40 to 50 percent of butyl benzene emulsion, 35 to 40 percent of water glass, 1 to 3 percent of water glass stabilizing agent, 3.4 to 8 percent of ammonium polyphosphate fireproof aid, 10 to 15 percent of stable thickening agent and 0.2 to 0.4 percent of preservative; and the component B: 25 to 30 percent of water, 0.2 to 0.4 percent of preservative, 3 to 5 percent of antimonous oxide, 7 to 11 percent of chlorinated paraffin, 15 to 20 percent of fireproof paper fiber pulp, 3 to 5 percent of mica, 15 to 20 percent of aluminum hydroxide, 20 to 25 percent of fly ash, 0.5 to 1 percent of expanded perlite and the like. The fireproof interface agent has good flame-retardant property, and can greatly improve the combustion performance of the polystyrene foam heat insulation material.

Owner:北京振利节能环保科技股份有限公司

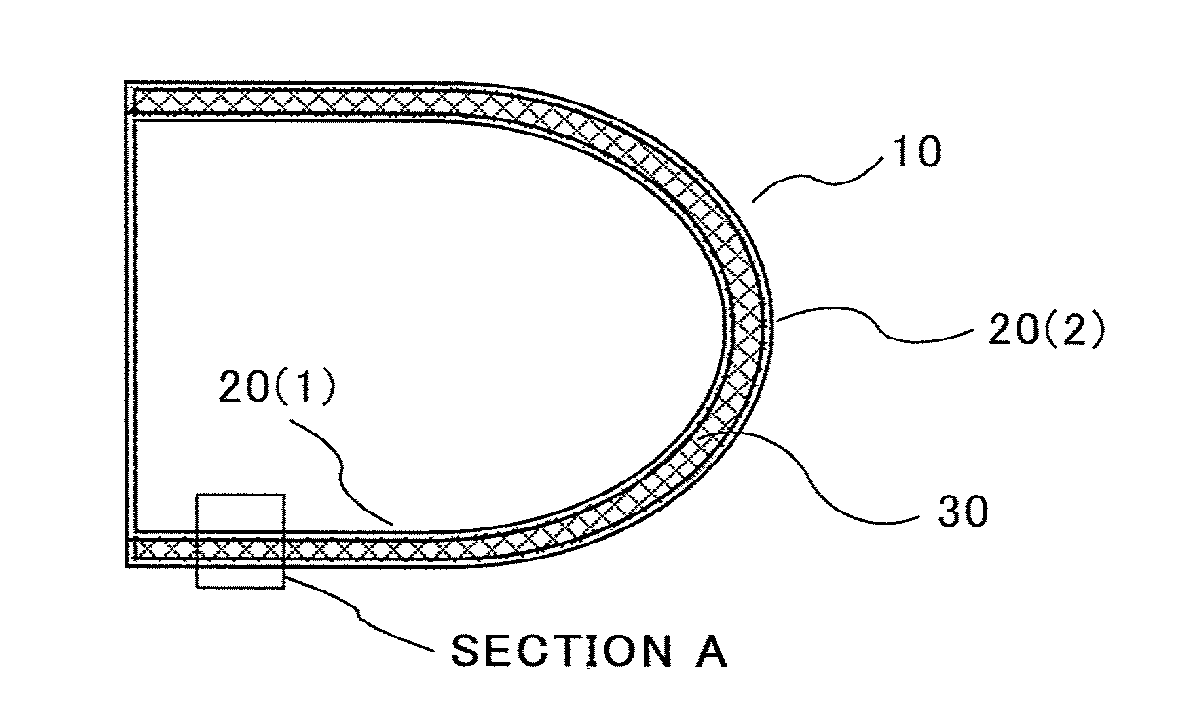

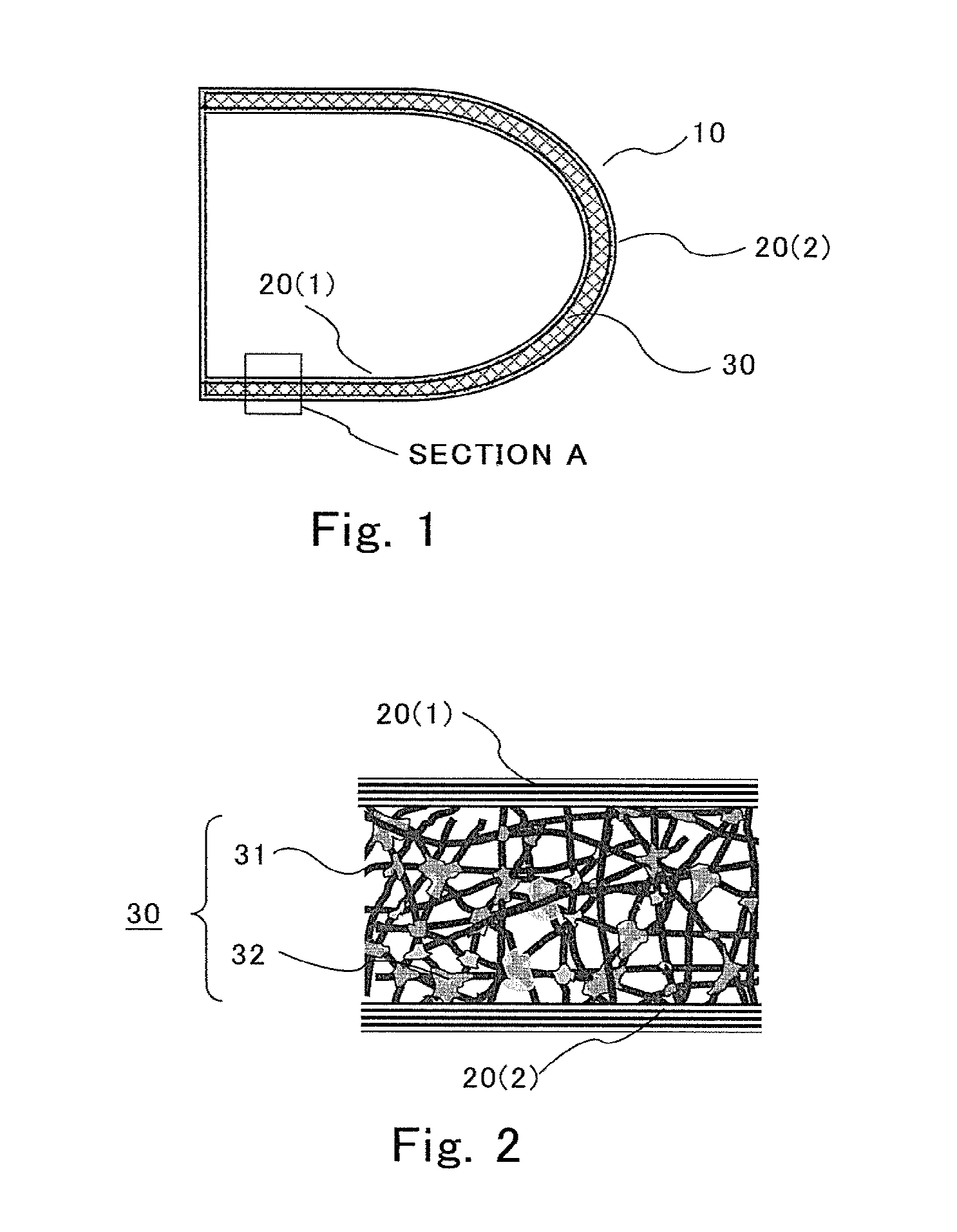

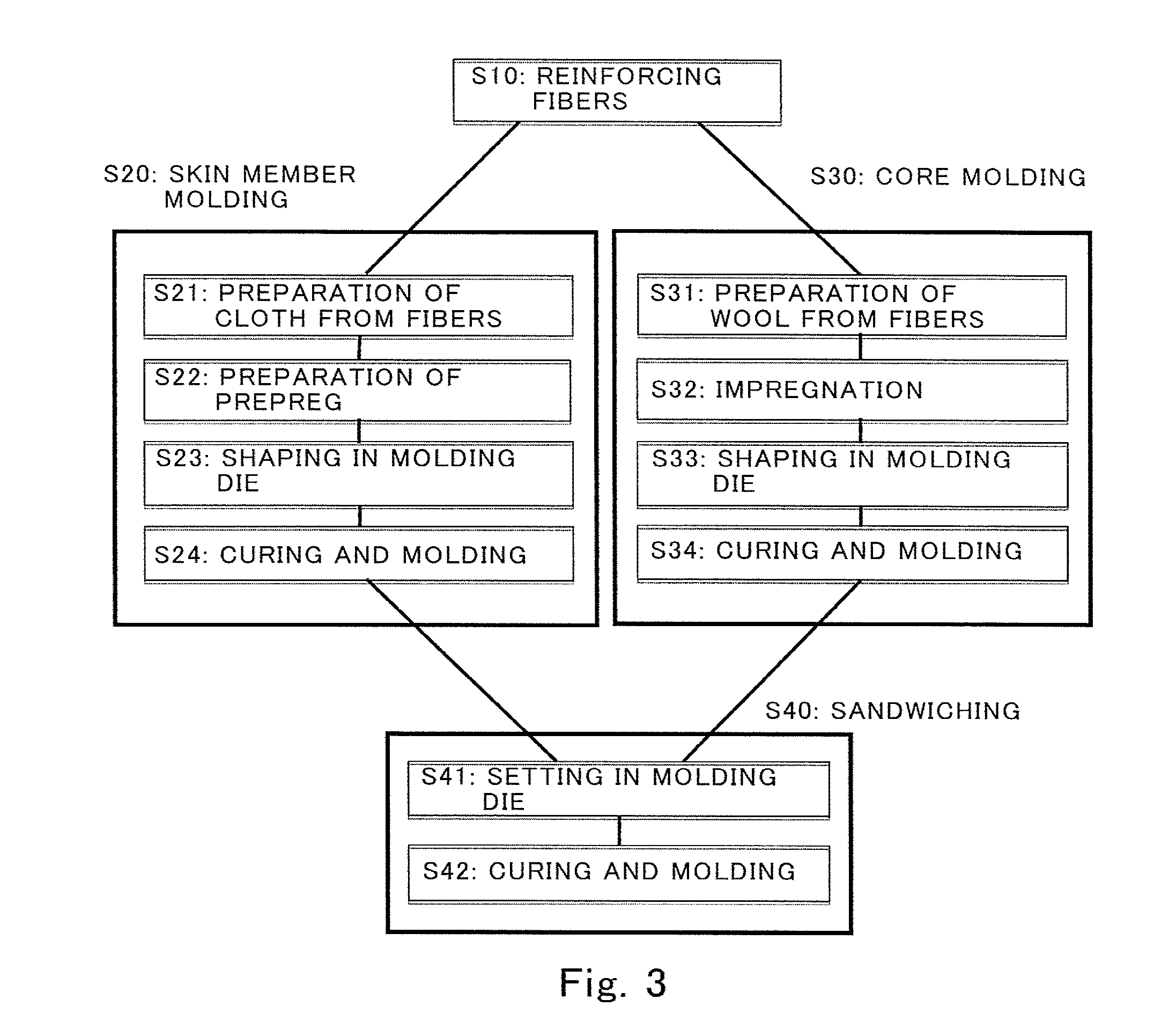

Flight vehicle radome and method for producing flight vehicle radome

InactiveUS20160233578A1Excellent mechanical propertiesExcellent transmissivity to radio waveAntenna adaptation in movable bodiesRadiating element housingsRadio equipmentFlight vehicle

A flight vehicle radome according to the present invention has a shape that covers radio equipment installed in a flight vehicle. The flight vehicle radome is formed of a sandwich panel structure in which a core member (30) resulting from foaming and compositing of a heat-resistant resin (32) and insulating reinforcing fibers (31) is sandwiched between skin members (20) made of a fiber reinforced material being a composite of quartz cloth (20) and a heat-resistant resin (22).

Owner:MITSUBISHI ELECTRIC CORP

Foamed resin composition and wire/cable using the same

A foamed resin composition includes a polyolefin-based resin, and a ring opening polymer of norbornene or a copolymer of norbornene and ethylene or a mixture thereof. The ring opening polymer of norbornene or the copolymer of norbornene and ethylene or the mixture thereof is used as a foam nucleating agent in the foamed resin composition.

Owner:HITACHI CABLE

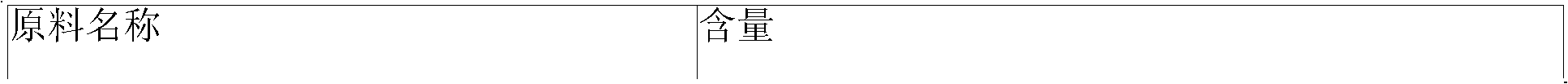

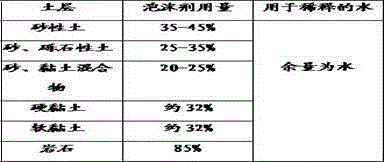

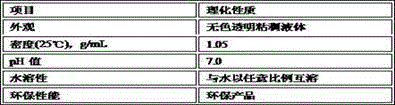

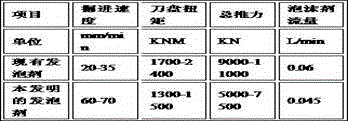

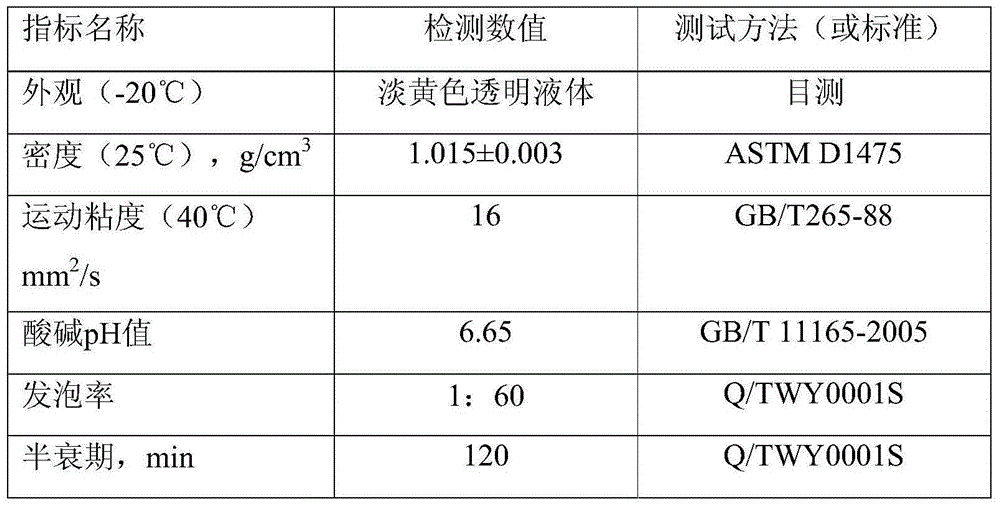

Earth pressure balance shield foaming agent

ActiveCN104946263AImprove plasticityImprove liquidityBuilding constructionsOrganic fertilisersBetaineCocamidopropyl betaine

The invention relates to an earth pressure balance shield foaming agent and a preparation technology thereof. The earth pressure balance shield foaming agent is prepared from 4-15% by weight of sodium dodecyl sulfate, 1-10% by weight of cetyltrimethylammonium chloride, 2-8% by weight of cocamidopropyl betaine, 1-5% by weight of dodecyldimethylamine oxide, 0.1-0.5% by weight of disodium ethylene diamine tetraacetate, 0.1-2.0% by weight of a tackifier and the balance water. The earth pressure balance shield foaming agent has a simple formula and high effects, and utilizes cetyltrimethylammonium chloride with excellent permeability, flexibility, emulsification effects and sterilization performances as a cationic surfactant which can be mixed with other surfactants. The earth pressure balance shield foaming agent is environmentally friendly, has excellent permeability and lubricity and can effectively improve excavated soil fluidity and watertightness.

Owner:XIAMEN NORNS TECH

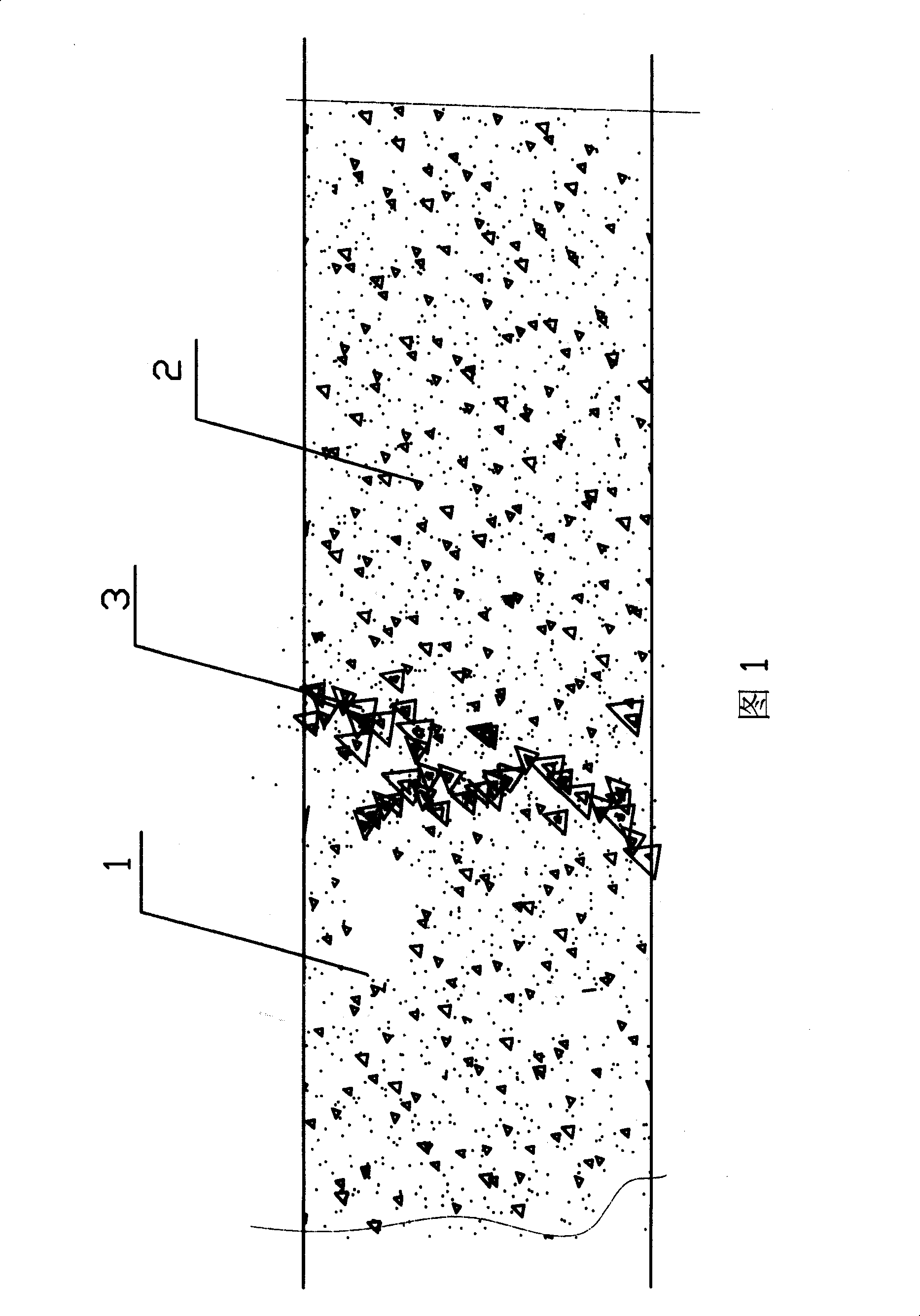

Water permeating pipeline, film or container for agricultural irrigation, manufacturing method and uses thereof

InactiveCN101233818ANo barriersIrrigate evenlyWatering devicesSpray nozzlesAgricultural irrigationAgricultural engineering

The invention relates to a seepage pipe, film or vessel for agricultural irrigation and a making method and application thereof. People first use water permeability of pottery clay to sinter permeation irrigation pipes of pottery clay, and then uses a rubber foam technique to manufacture permeation irrigation pipes of rubber, and some people apply a laser perforating method on plastic pipes to produce porous permeation irrigation pipes of plastic. Due to high cost, inconvenient application or blockage often happening during application, the pipes of the types are not popularized or widely applied. The product of the invention comprises a plasticization forming matrix material (1), an inert filler(2) with melting point higher than plasticizing temperature which is added in the plasticization forming matrix material and is wrapped over by a release agent, and a bent seepage channel (3) which bypasses the inert filler and is formed by dissolving the release agent in the matrix material, wherein, The weight ratio between the inert filler and the plasticization forming matrix material is 5-30 : 100 and the weight ratio between the inert filler and the release agent is 100 : 5-10. The product is applied as pipe, film or vessel for agricultural irrigation.

Owner:SHENZHEN MOISTUBE IRRIGATION TECH

Method for foaming polymer microspheres with two-component or multi-component foaming agent under low pressure

The invention relates to a method for foaming polymer microspheres with two-component or multi-component foaming agent under a low pressure and a foamed material obtained by the method. The polymer microspheres are comprised of a polymer serving as shells and foaming agent serving as a nuclear, wherein the polymer shells may be formed by the polymerization of a polymerizable monomer and a crosslinking agent; and the foaming agent consists of two or more components between which the boiling point difference is 10 to 100 DEG C, preferably 20 to 90 DEG C and more preferably 30 to 80 DEG C. When the outside pressure is less than a standard atmosphere, preferably 0.5 to 0.8 standard atmosphere, and the temperature is 100 to 180 DEG C, preferably 110 to 170 DEG C and more preferably 120 to 160 DEG C, the polymer microspheres begin to foam to form foamed material of which the foaming expansion ratio is no less than 20 times.

Owner:FUDAN UNIV +1

Polylactic acid-starch foaming material and preparation method thereof

The invention discloses a polylactic-starch epispastic material and preparing method, which comprises the following steps: melting the polylactic and starch; mixing up with sparkle to form foam article with water resisting property and high frothing percentage. The invention can reduce the retrogradation of the polylactic, which improves the frothing percentage of the polylactic-starch.

Owner:SOUTH CHINA AGRI UNIV

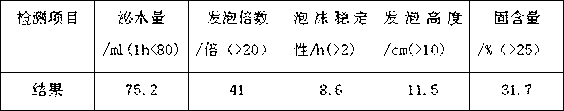

Modified soy protein foaming agent for concrete

The invention discloses a modified soy protein foaming agent for concrete. The foaming agent consists of the following raw materials, by weight: 10-15 parts of a modified soy protein powder, 1-5 parts of hexadecyl trimethyl ammonium bromide, 1-5 parts of sodium dodecyl benzene sulfonate, 1-3 parts of rhamnolipid, 1-5 parts of Arabia gum, 1-5 parts of carrageenan, 0.1-1 part of hydrogen peroxide, 0.05-0.2 part of protease solution and 100-150 parts of water. The modified soy protein foaming agent for concrete provided by the invention can effectively improve the foaming capacity, foam stability, concrete compatibility, and various performances of the foam concrete, and provide technical support for preparation of novel wall material. The invention has advantages of simple product preparation process, low production cost, simple foaming process, high foaming rate of the foaming agent and good foam stability.

Owner:安徽艾柯泡塑股份有限公司

Foam generating device used for dust fall

ActiveCN104533501AImprove stabilityPlay a role in dust suppressionTransportation and packagingDust removalMouth shapeDust fall

The invention discloses a foam generating device used for dust fall. The foam generating device comprises an air inlet main pipe, one end of the air inlet main pipe is communicated with a foaming shell through a Venturi diffusion mechanism, the other end of the foaming shell is communicated with a foam output pipe, a longitudinal hollow air supply rod is arranged in the foaming shell, the air supply rod is sequentially provided with rotary power blades and a net type swirler, the air supply rod is provided with multiple air supply rod air outlet pipes which are evenly distributed in the circumferential direction of the air supply rod, an air supply rod air outlet is formed in the end, close to the foam output pipe, of the air supply rod and is of a horn mouth shape, the air supply rod air outlet corresponds to the foam output pipe, and an air supply rod air inlet pipe is arranged on the air supply rod and is communicated with the air supply rod air outlet and the air supply rod air outlet pipes. Foaming is performed on a foam dedusting agent solution three times, the foaming rate is greatly increased, and operation stability of the foam generating device is improved.

Owner:SHANDONG UNIV OF SCI & TECH

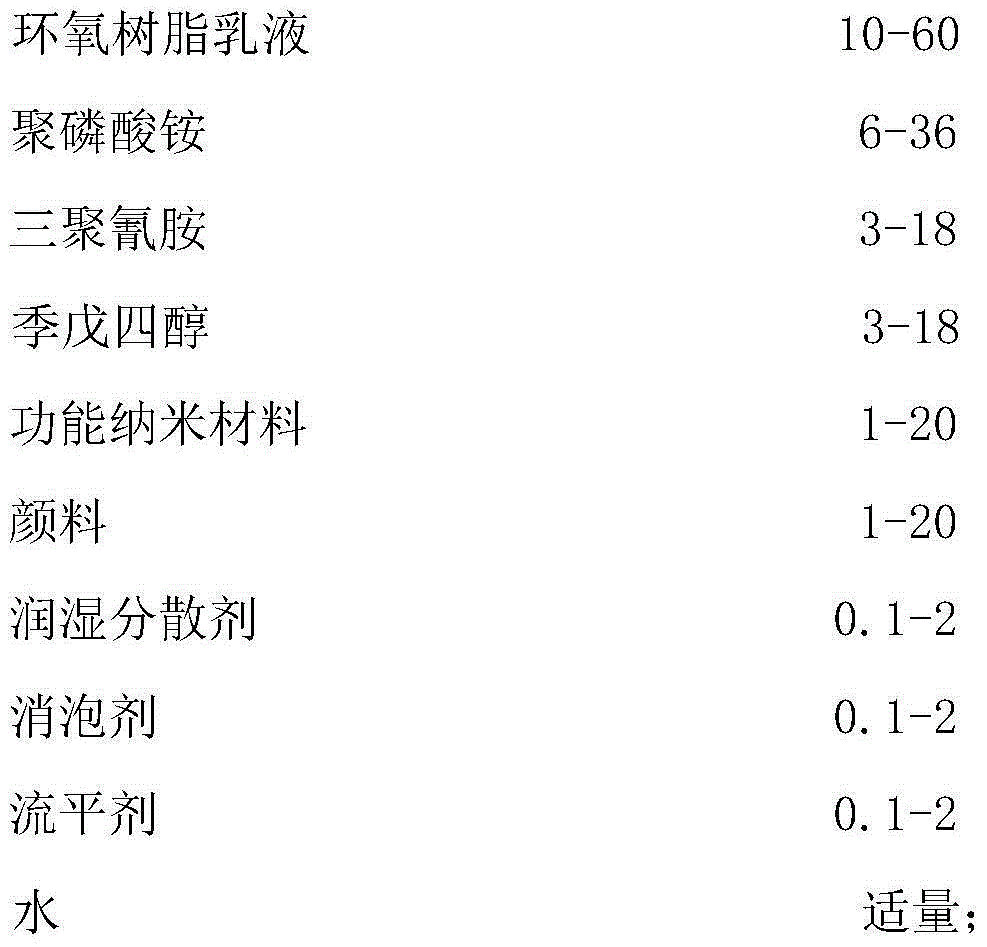

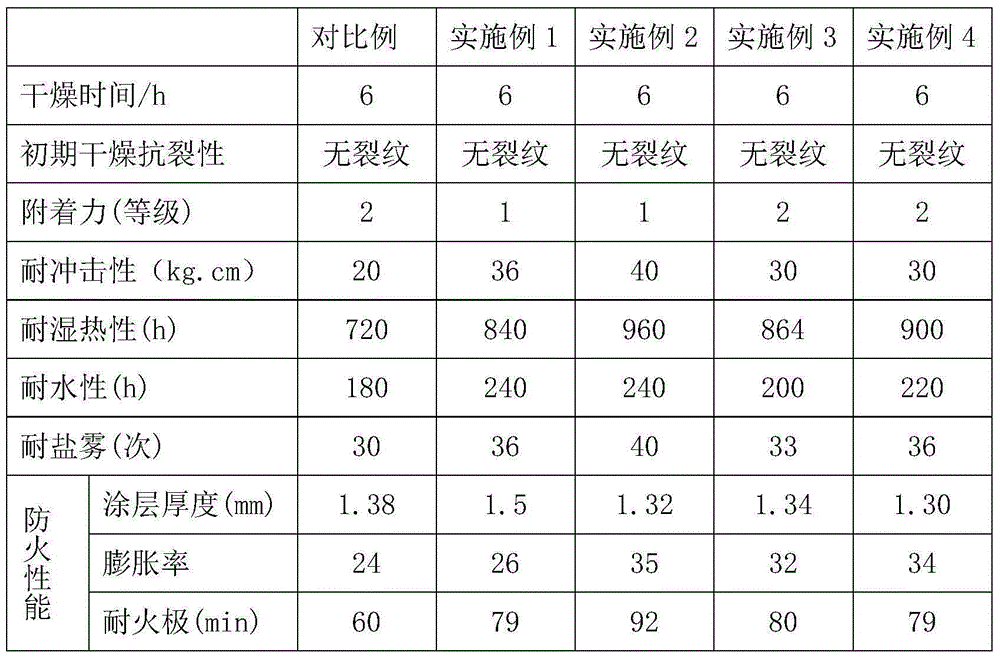

Water-based epoxy multifunctional steel structure paint and preparation method thereof

InactiveCN105111886AImprove water resistanceImprove fire protection timelinessFireproof paintsAnti-corrosive paintsWater basedEpoxy

The invention relates to a water-based epoxy multifunctional steel structure paint and a preparation method thereof. The water-based epoxy multifunctional steel structure paint is composed of a component A and a component B. The component A comprises a water-based epoxy emulsion, ammonium polyphosphate, pentaerythritol, melamine, a pigment and filler, a functional nano material, a water-based defoaming agent, a water-based wetting and dispersing agent and the like. The component B is a modified amine curing agent. The preparation method comprises the following steps: (1) premixing the ammonium polyphosphate, pentaerythritol, melamine, pigment and functional nano material; (2) gradually adding the mixture obtained in the step (1) into a water solution containing the defoaming agent and wetting and dispersing agent, uniformly dispersing the materials by stirring, adding the epoxy resin emulsion, and dispersing by stirring to obtain the component A of the water-based epoxy multifunctional steel structure paint; and (3) adding the component B and defoaming agent into the component A, stirring uniformly and screening. The water-based epoxy multifunctional steel structure paint has the advantages of excellent fire and flame retardancy, simple preparation method and environment friendliness, and can be widely used for coating various steel structures.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Fireproof and anti-corrosion bifunctional ultra-thin steel structure coating and preparation method thereof

InactiveCN102241925AHigh foaming rateImprove fire resistanceFireproof paintsChloropene polymer coatingsAdhesiveAcrylic resin

The invention discloses a fireproof and anti-corrosion bifunctional ultra-thin steel structure coating and a preparation method thereof. The fireproof and anti-corrosion bifunctional ultra-thin steel structure coating is prepared from the following raw materials by weight percentage: 1-30% of chloroprene rubber adhesive, 1-30% of melamine, 1-20% of pentaerythritol, 1-30% of pigment and filler, 1-50% of 1000# solvent gasoline,1-20% of ammonium polyphosphate, 1-15% of chlorinated paraffin solution with a chlorine content of 70%, 1-10 % of acrylic resin, 0.1-5% of amino resin, 1-10% of raw vermiculite, 1-10% of charring aid, 0.1-5% zinc borate and 0.1-10% of auxiliary agent. The fireproof and anti-corrosion bifunctional ultra-thin steel structure coating has the advantages of greatly improved maximum flexibility, fire resistance limit, binding strength and fire resistance time, good flame retardance, corrosion resistance, water resistance and weather resistance and low cost; and more importantly, the coating is safe and environmentally-friendly, and the coating layer formed by the coating is light and thin, thus truly embodying the fireproof and anti-corrosion dual functions and ultrathin characteristic.

Owner:浙江川科防保材料发展有限公司

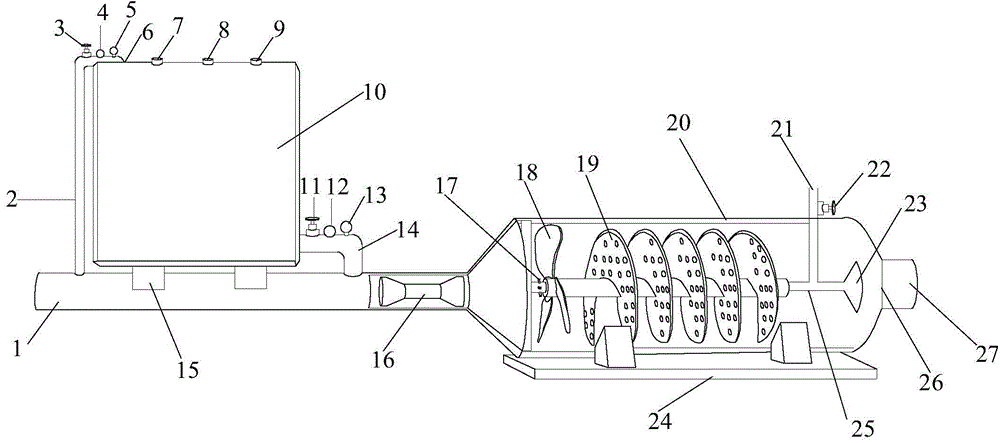

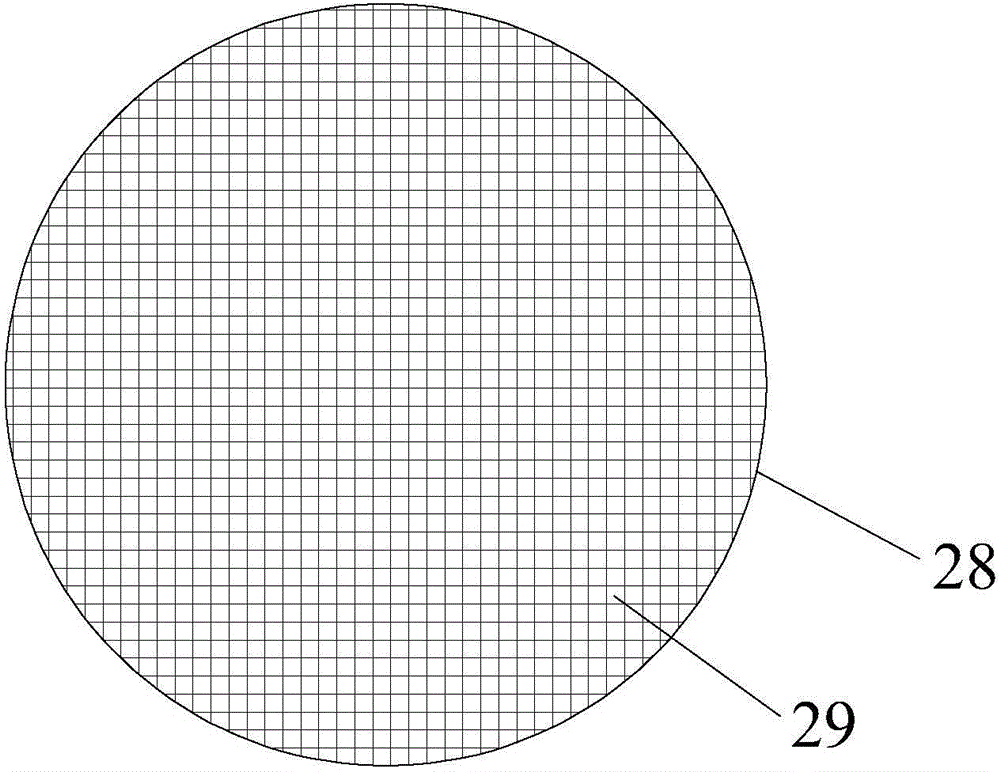

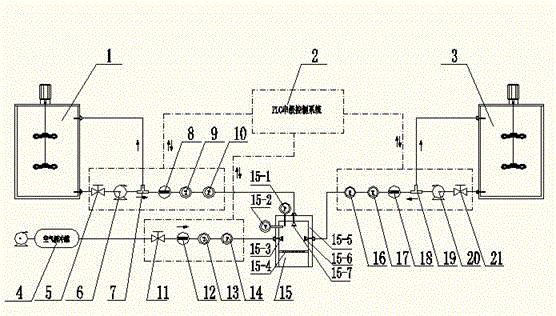

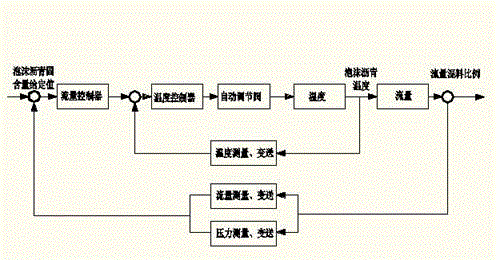

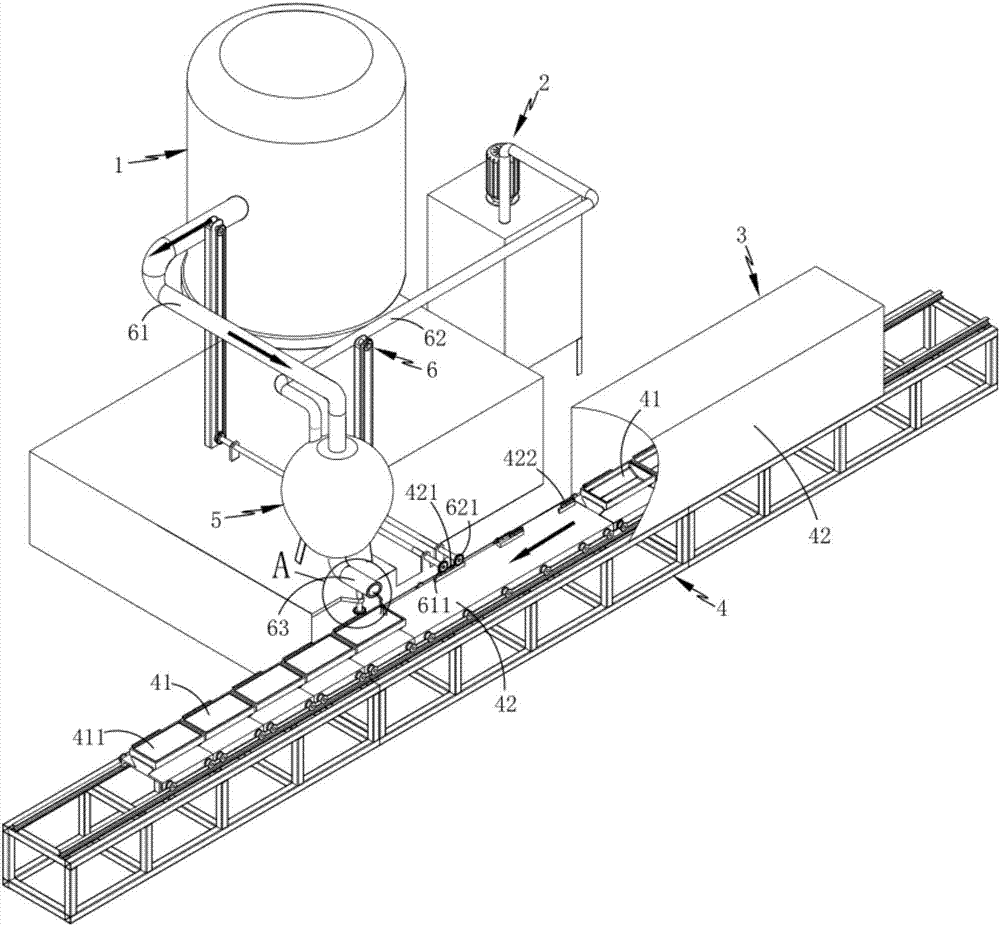

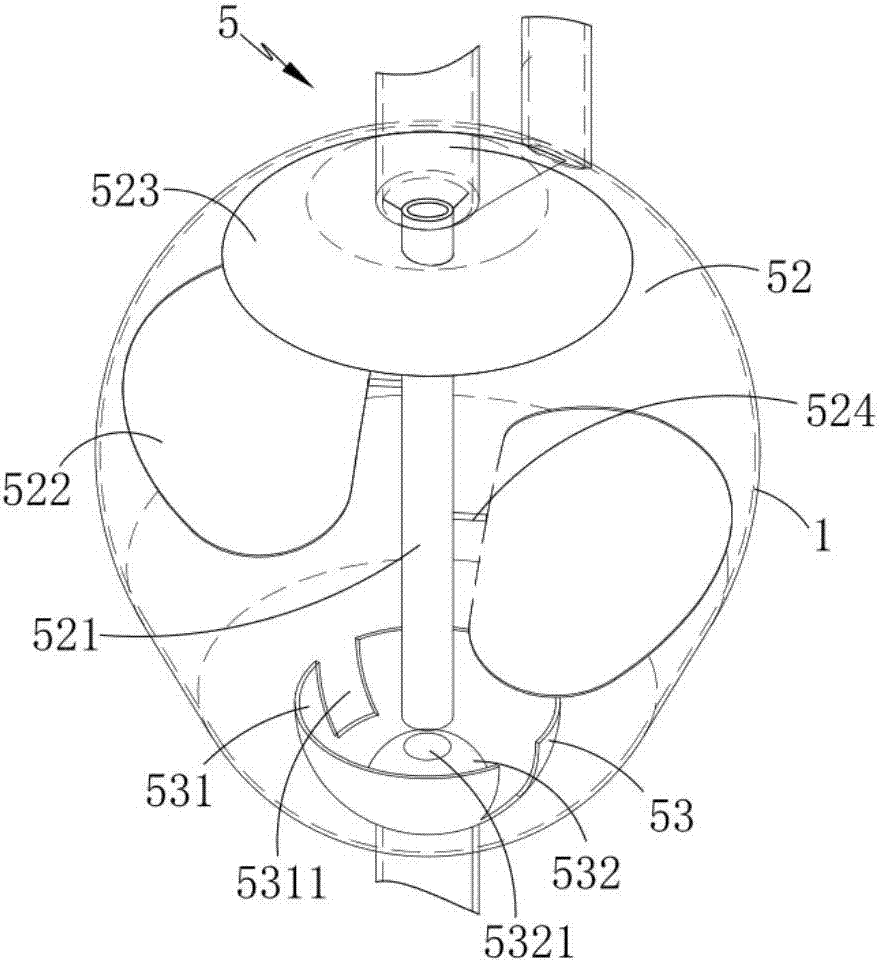

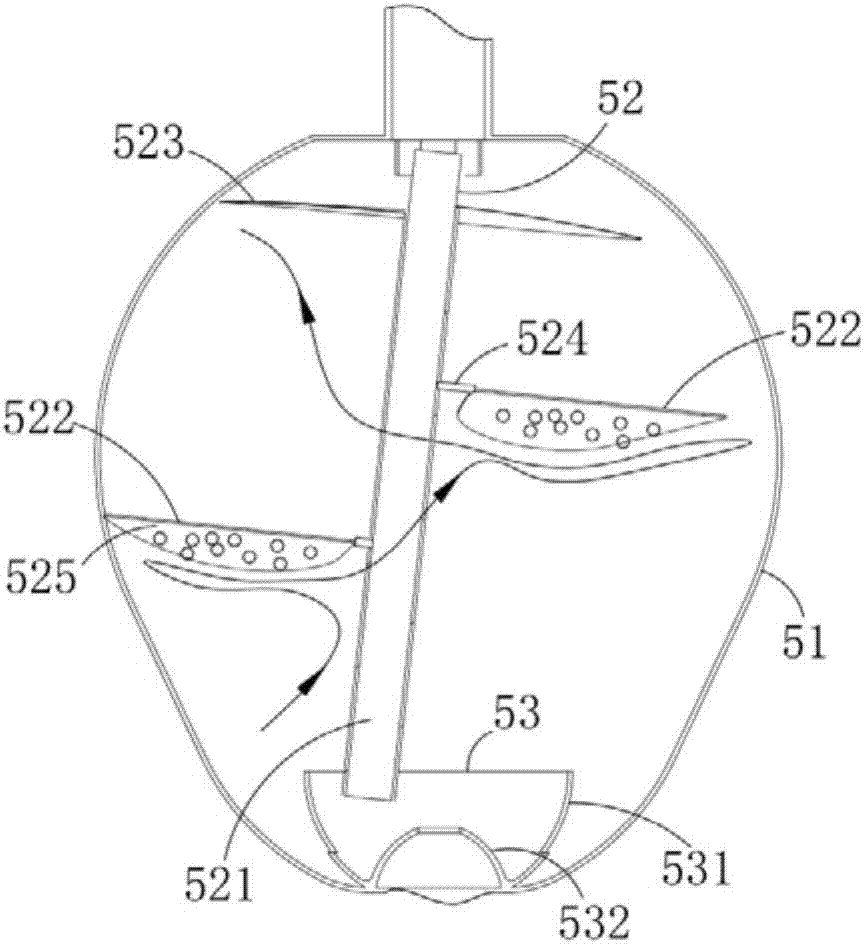

Foam asphalt production device and automatic production method

The invention discloses a foam asphalt production device and an automatic production method. The device comprises a hot asphalt tank, a water tank, an air compressor, a hot asphalt feeding device, a water feeding device, an air feeding device, a foam asphalt generator and a PLC control system. Hot asphalt, water, and air are mixed in the foam asphalt generator to generate foam asphalt, and the foamed asphalt is homogenized by the foam asphalt generator. The hot asphalt, water, and air feeding devices respectively transfer the hot asphalt, water, and air into the foam asphalt generator from the hot asphalt tank, the water tank, and the air compressor. The PLC control system sends the measured temperature, flow, and pressure signals of hot asphalt, water, and air to a PLC controller to perform control calculation, then carries out cascade-stage control adjustment on the flow, temperature, and pressure of hot asphalt, water and air according to the foaming degree of foam asphalt, and thus achieves the automatic production of foam asphalt.

Owner:UNIV OF JINAN

High-temperature-resistant and heat-insulating room-temperature-vulcanized organic silicon foaming sealant and preparation method thereof

The embodiment of the invention relates to the technical field of organosilicone sealants, in particular to a high-temperature-resistant and heat-insulating room-temperature-vulcanized organosiliconefoaming sealant and a preparation method thereof. The room-temperature vulcanized organic silicon foaming sealant provided by the invention comprises a component A and a component B. The sealant is stable and fine in foam structure, uniform and controllable in size, good in elasticity, low in thermal conductivity, good in high-temperature resistance, high in initial decomposition temperature and good in flame retardance. According to the preparation method of the room-temperature-vulcanized organic silicon foaming sealant, a chemical foaming process is adopted, so that the controllability of the reaction process is high, the operation process is simple, the cross-linking rate and the foaming rate can be regulated and controlled, and the cell structure is easier to control.

Owner:BEIJING UNIV OF CHEM TECH

Acid-resistant shield foaming agent

ActiveCN106433679AHigh foaming rateEvenly distributedBuilding constructionsOrganic fertilisersFoaming agentBetaine

The invention discloses an earth pressure balance type shield foaming agent. The foaming agent comprises the following components by weight percent: 2.5-10.0% of fatty alcohol polyoxyethylene ether (AEO-9), 2.0-8.0% of alkyl glucoside (APG), 2-6.5% of dodecyl betaine, 1.0-3.0% of polyethylene glycol (PEG4000), 2-4.5% of ammonium sulfate and 32.0-90.5% of water. Through the earth pressure balance type shield foaming agent disclosed by the invention, high-rate foaming can be realized even in an acid condition, and the generated foam is fine while the stabilization time is long; and the product can perfectly meet the requirements of modified acid residue soil in a tunneling process of an earth pressure balance shield machine.

Owner:DALIAN RES & DESIGN INST OF CHEM IND +1

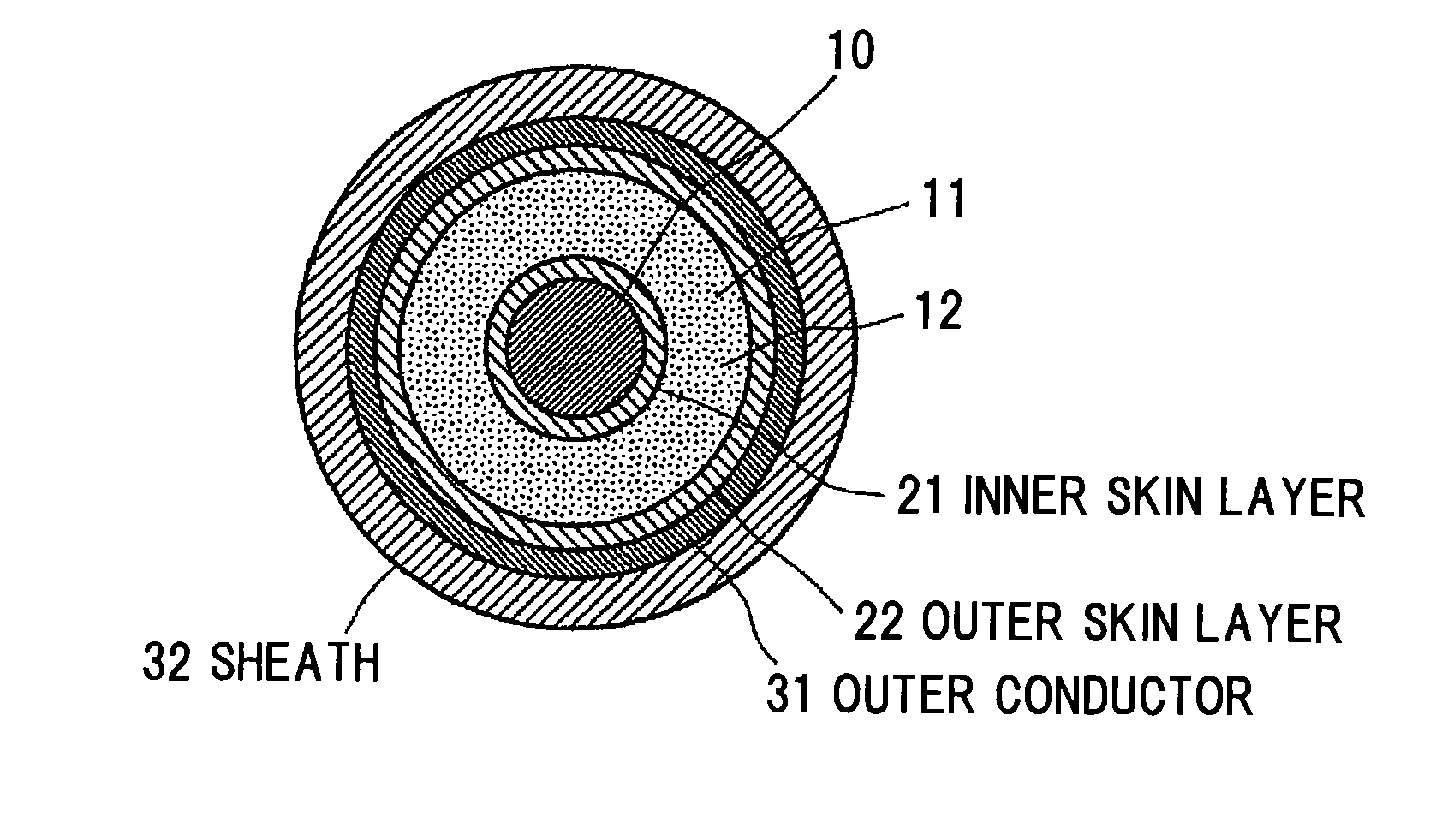

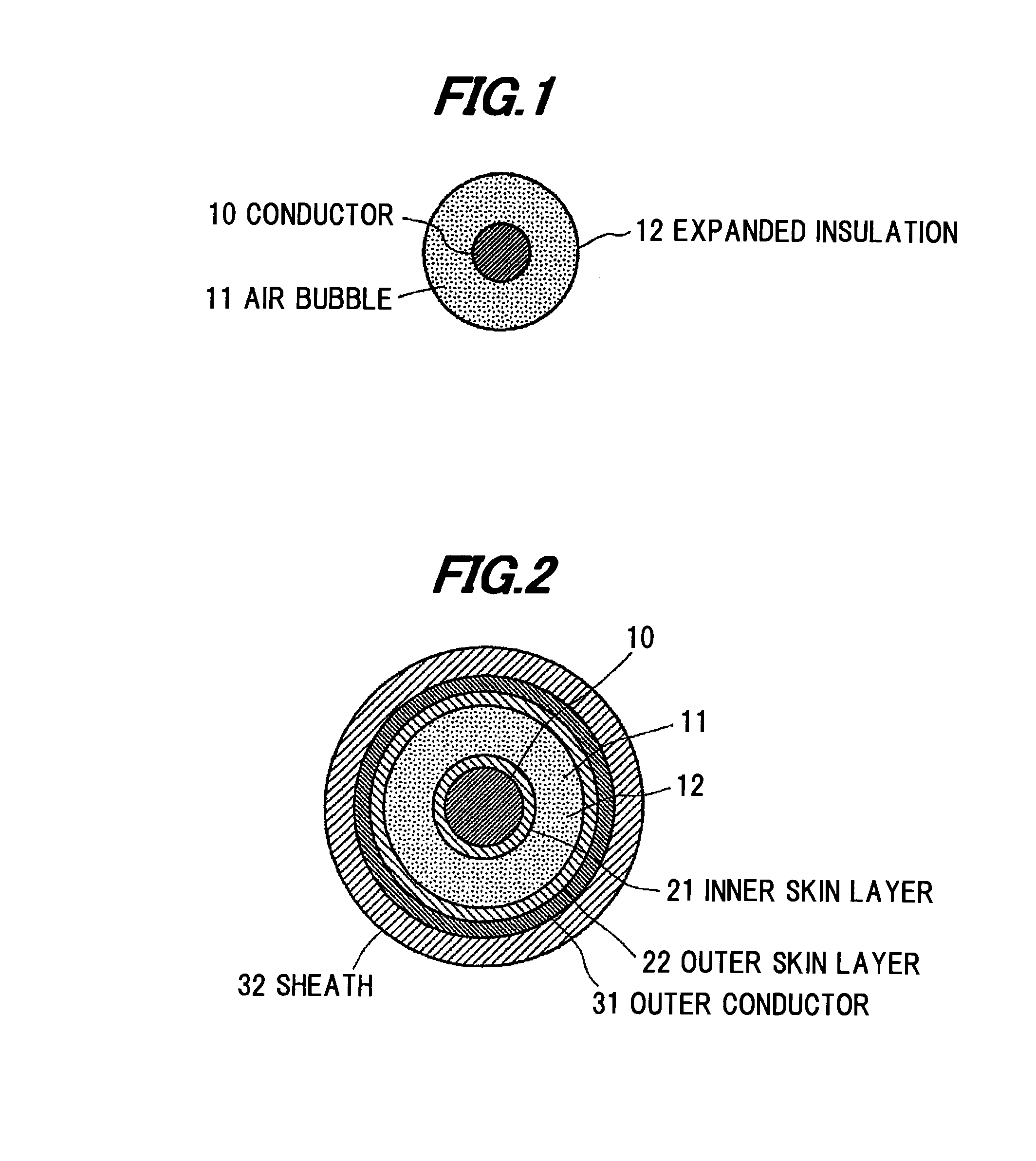

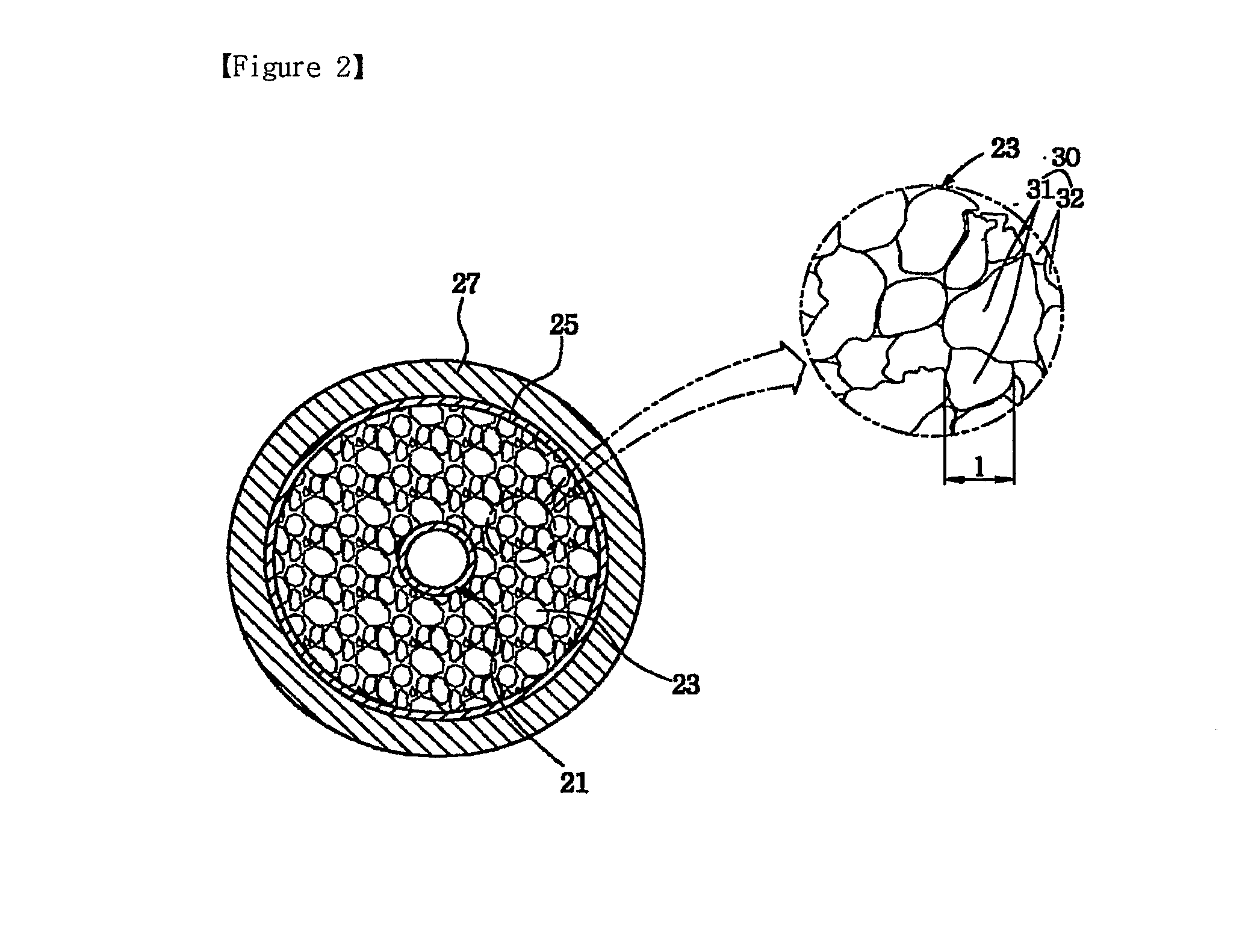

Highly foamed coaxial cable

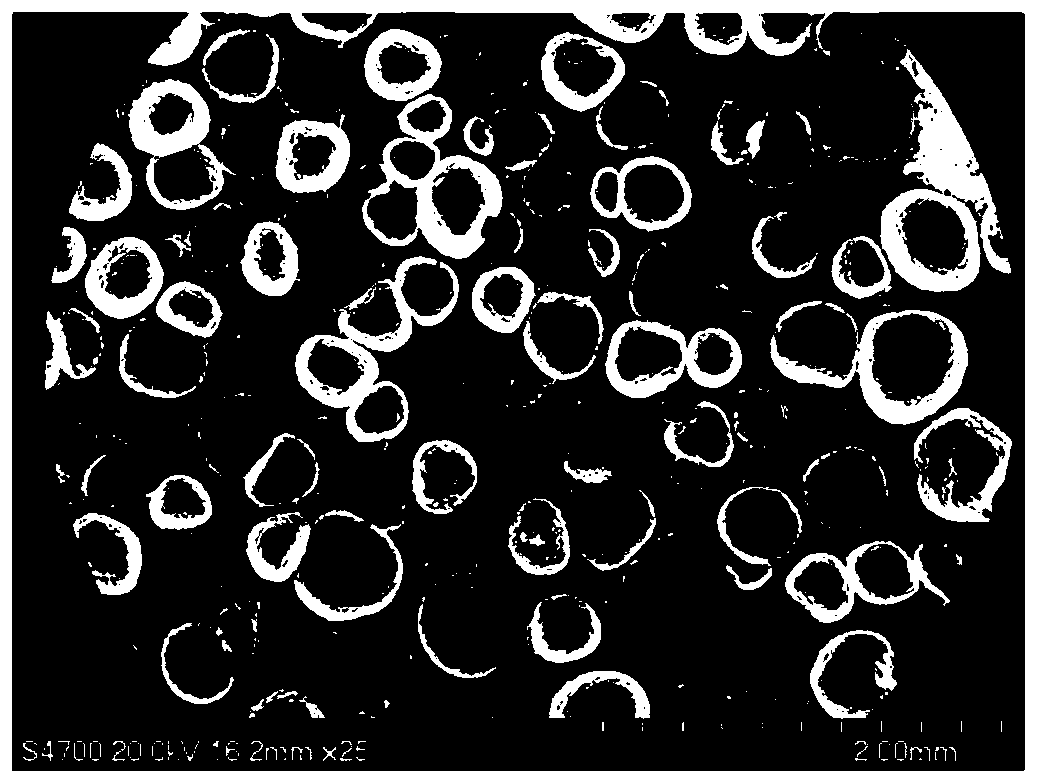

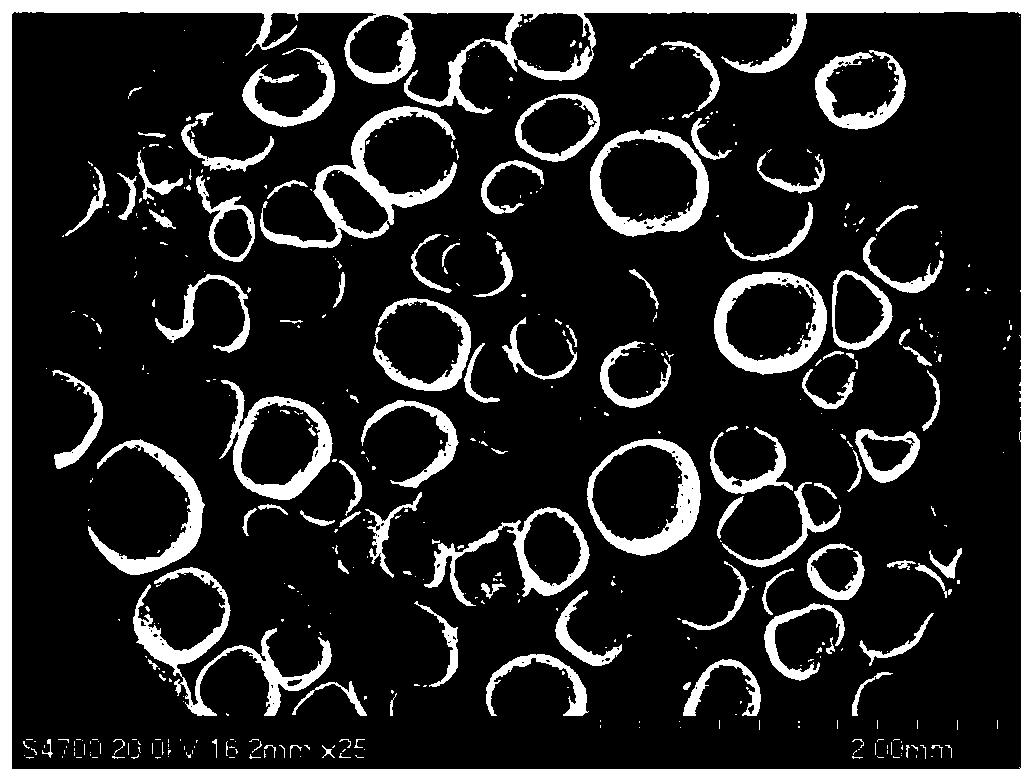

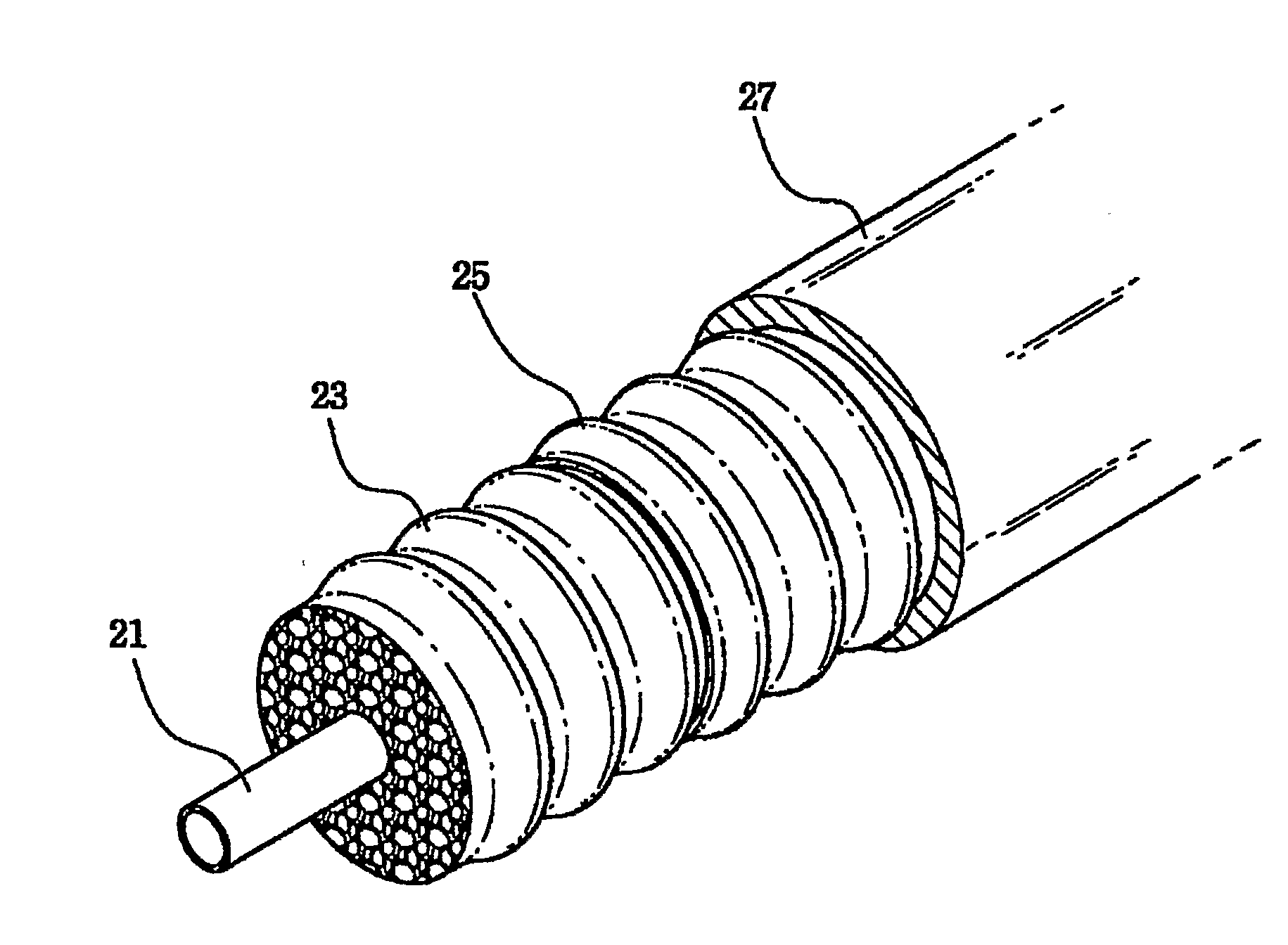

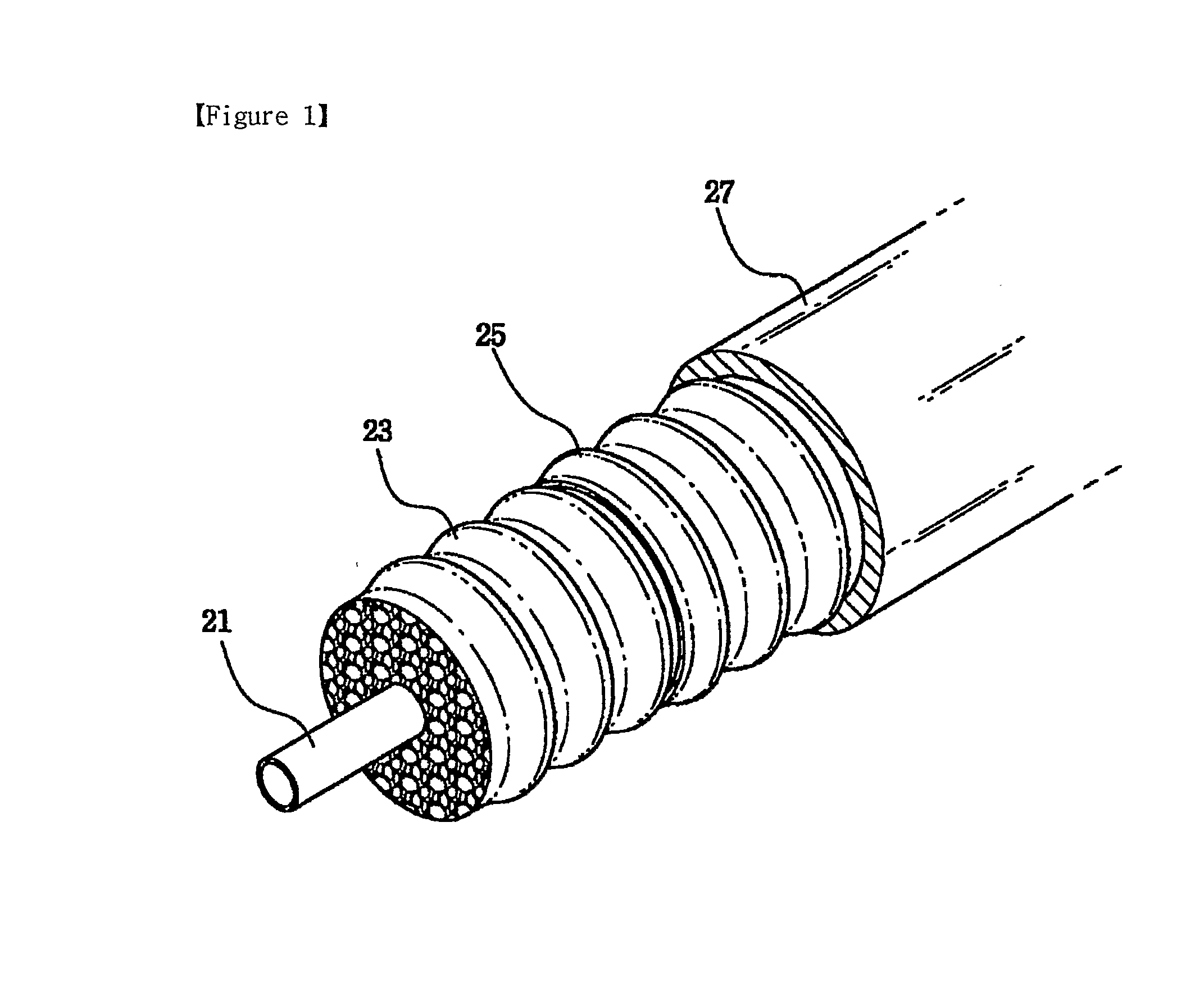

ActiveUS20100212935A1Low foam densityHigh foaming rateCable conductor constructionCable insulation constructionElectrical conductorCoaxial cable

A highly foamed coaxial cable comprising, an inner conductor disposed in the cable, and a foamed insulator comprising porous cells and surrounding the inner conductor, and an outer conductor surrounding said insulator, and a sheath surrounding said outer conductor, and in said insulator, the total area of macro cell which has a diameter of at least 300 / M is larger than the total area of micro cell which has a diameter smaller than 300 / M at cross section of cable.

Owner:LG CABLE LTD (KR)

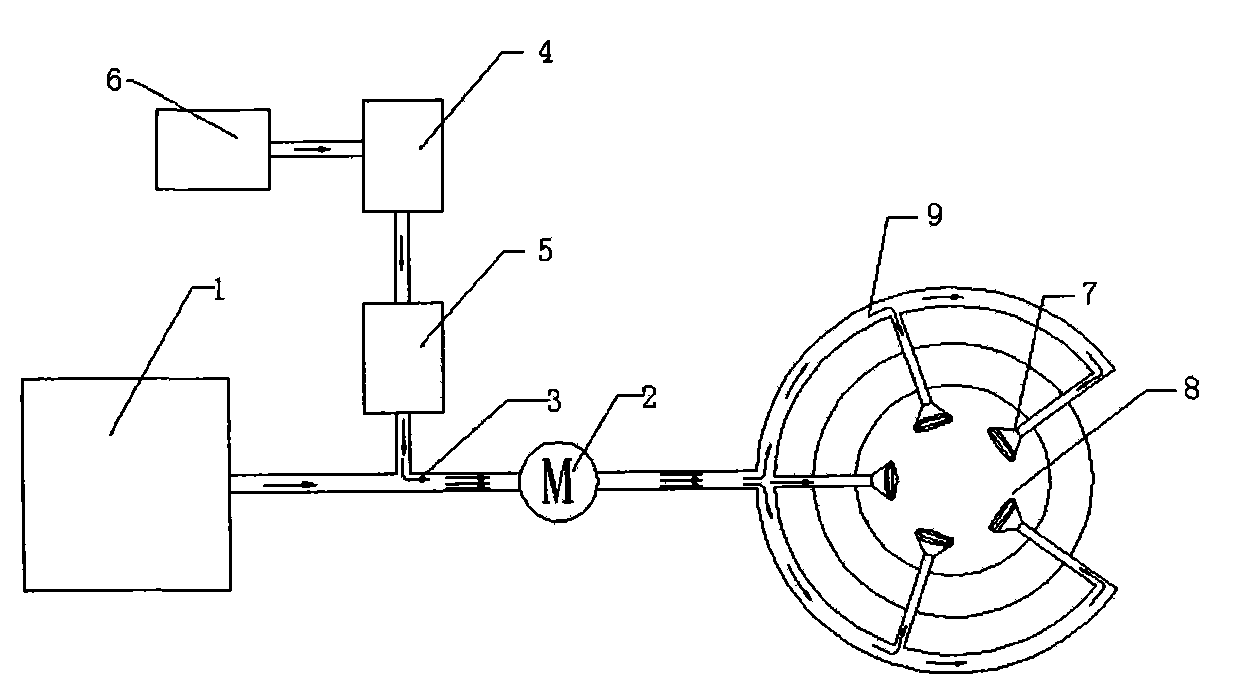

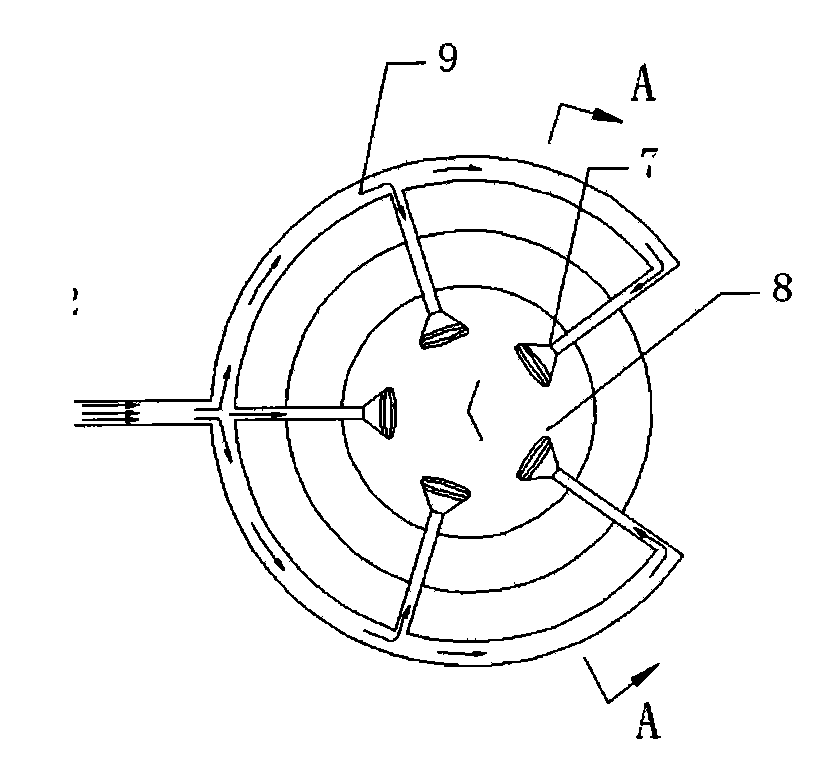

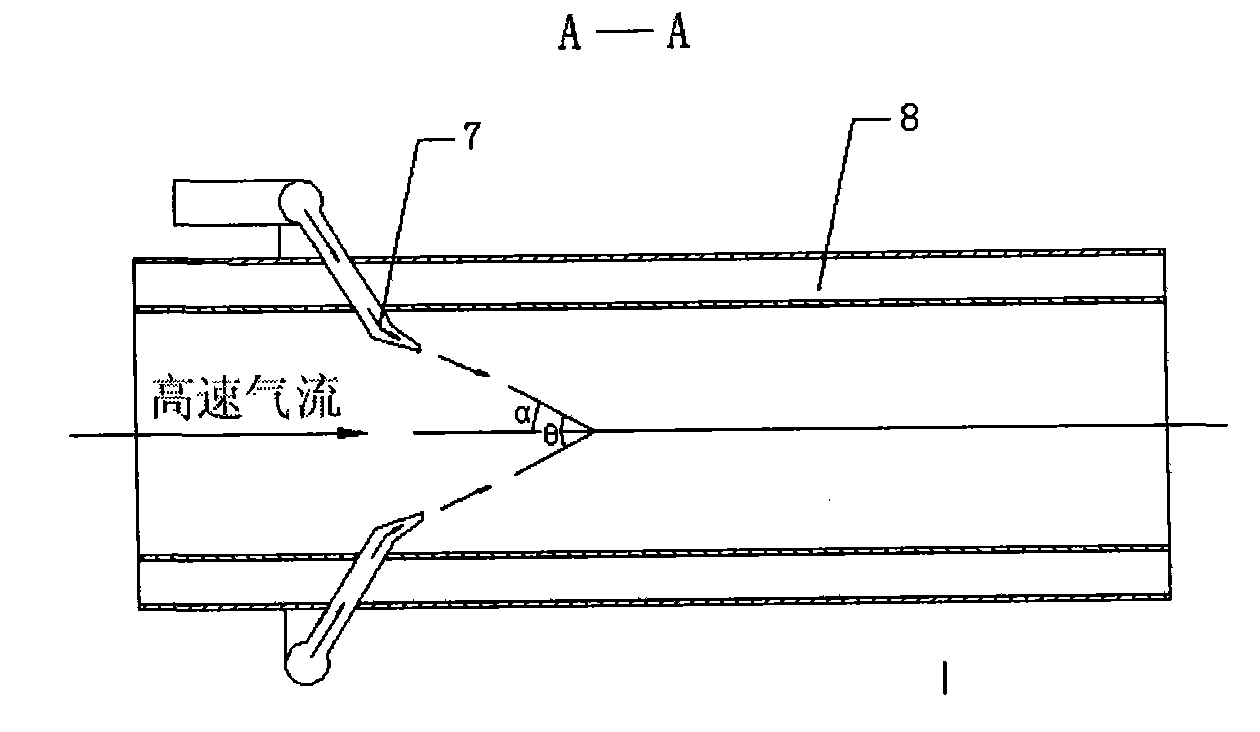

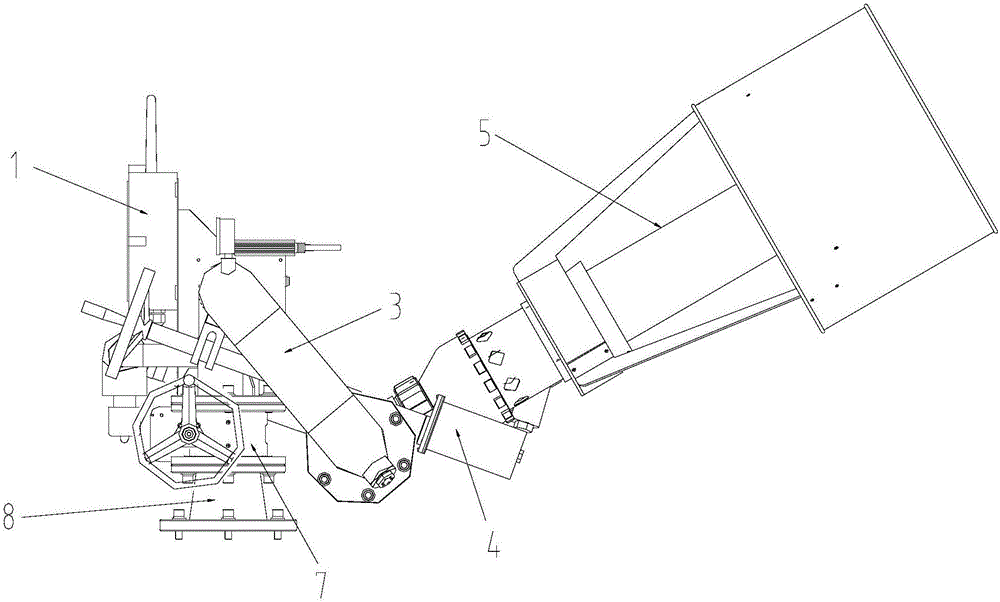

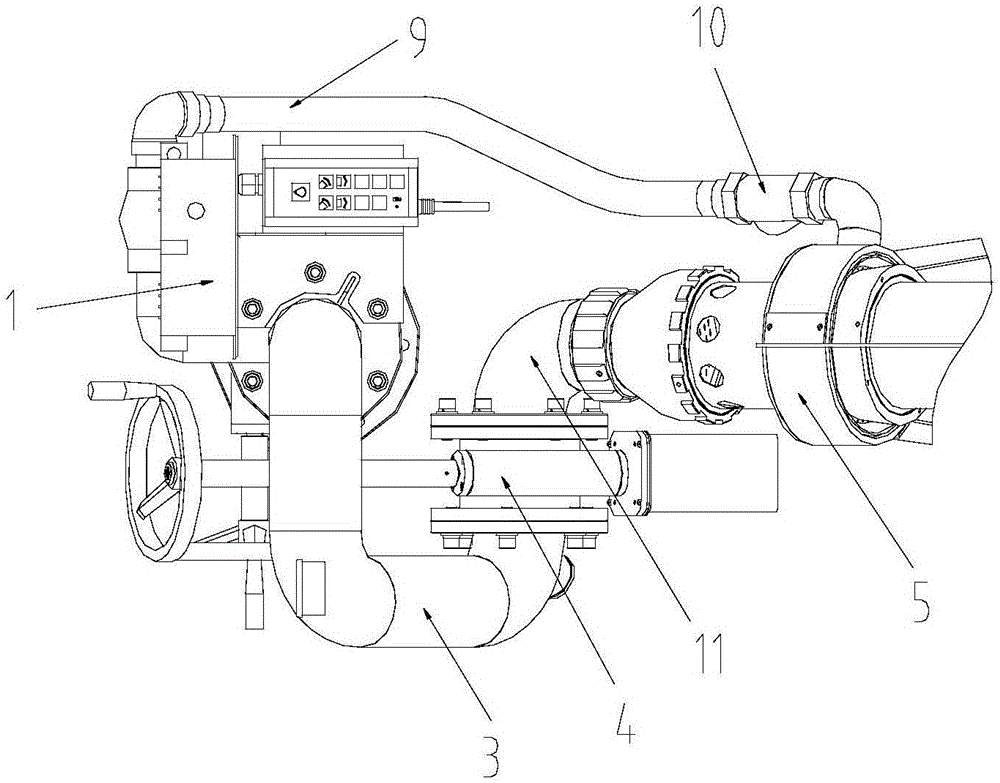

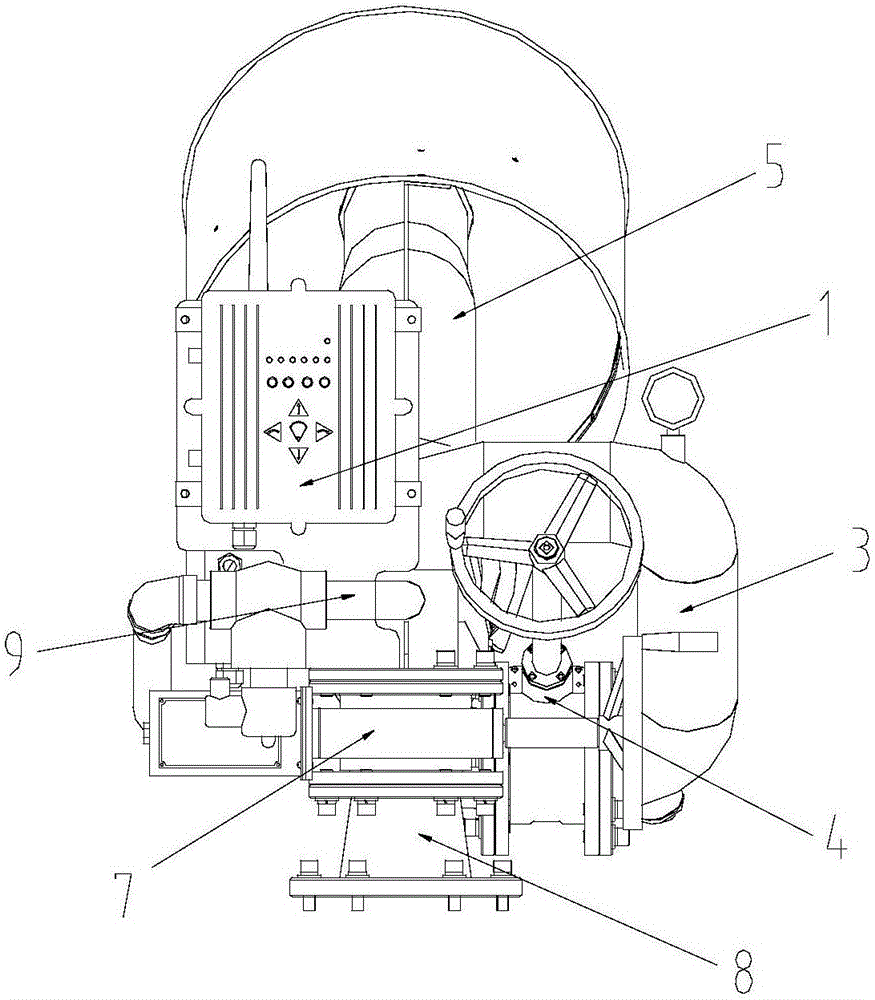

Method and device for generating foam in high-speed gas jet

ActiveCN102029030AImprove fire extinguishing efficiencyHigh foaming rateFire rescueLiquid waterTruck

The invention discloses a method and a device for generating foam in high-speed gas jet. The method comprises the following steps of: jetting foam extinguishing fluid to form liquid film jet, impacting a liquid film by using high-speed airflow to tear the liquid film, mixing the torn liquid film and gas to generate foam beads so as to form foam jet which does not contain flowable liquid water. A turbojet fire fighting truck has the function of jetting a foam extinguishing agent, and extinguishing efficiency is greatly improved; when a foam jetting button is not pressed, the turbojet fire fighting truck jets gas-water mist jet to disperse toxic fume in a fire scene, control fire, cool the fire scene and rescue people in the fire scene; and when the foam jetting button is pressed, the turbojet fire fighting truck jets gas-foam jet to quickly extinguish large oil gas fire and prevent oil gas from reburing, so that the turbojet fire fighting truck with the jet power of thousands of kilowatts becomes truly large fire fighting equipment.

Owner:JIANGSU KAWEI SPECIAL PURPOSE VEHICLE MFG

Foaming agent for low temperature-resistant soil pressure balance shield, and preparation method and application of foaming agent

The invention discloses a foaming agent for a low temperature-resistant soil pressure balance shield, and a preparation method and the application of the foaming agent. The foaming agent is prepared from formulation components in percent by weight: 2 to 4 percent of alpha-olefin sulfonate, 4 to 10 percent of fatty alcohol-polyoxyethylene ether alkyl sulfate, 1 to 2 percent of coco fatty acid diethanol amide, 0.5 to 1 percent of cocamidopropyl betaine, 0.5 to 2 percent of polyethylene glycol, 0.1 to 0.5 percent of glycerol, 0.05 to 0.3 percent of lauryl alcohol, 0.1 to 0.5 percent of sodium chloride, 0.05 to 0.15 percent of 5-chloro-2-methyl-4-isothiazolin-3-one, 0.05 to 0.2 percent of citric acid and the balance of 79.35 to 91.65 percent of water. The foaming agent disclosed by the invention is used for construction under minus 20 DEG C, is particularly suitable for winter construction and is used for improving a soil body of which a construction soil layer is fine sand, medium-coarse sand and / or sandy gravel, the transparency of the foaming agent used for shield construction under a low-temperature condition in winter is ensured, so that a high foaming rate of the foaming agent is ensured, the foam stability is high, and an adverse effect brought to the construction as the foaming agent changes along with the temperature is reduced.

Owner:北京铁五院工程机械有限公司 +1

Medium-low-power composite fire fighting foam monitor

The invention relates to the technical field of fire extinguishing, in particular to a medium-low-power composite fire fighting foam monitor. The medium-low-power composite fire fighting foam monitor comprises a base, worm gear boxes and a control device and is characterized in that the upper portion of the base is connected with one end of the horizontal worm gear box through a flange, the other end of the horizontal worm gear box is connected with one end of a middle bent pipe through a flange, and the other end of the middle bent pipe is connected with one end of the pitching worm gear box; and the other end of the pitching worm gear box is connected with a composite foam spray device through an upper bent pipe, and one side of the middle bent pipe is connected with the composite foam spray device through a hose. Compared with the prior art, according to the medium-low-power composite fire fighting foam monitor, the structure of the composite foam spray device of the medium-low-power composite fire fighting foam monitor is improved, the performance of an original low-power foam monitor is maintained, and medium-power foam with the high foaming rate can be brought to the long-distance range.

Owner:上海务进消防安全设备有限公司 +1

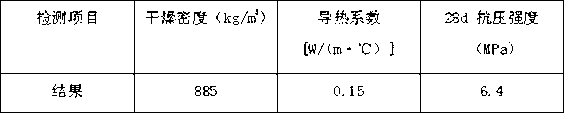

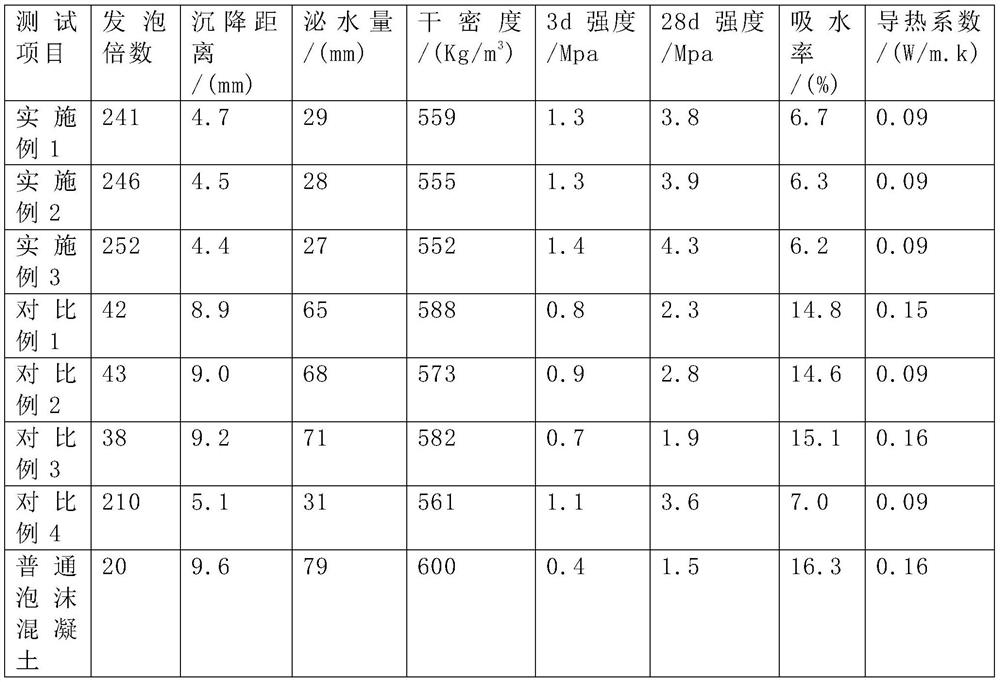

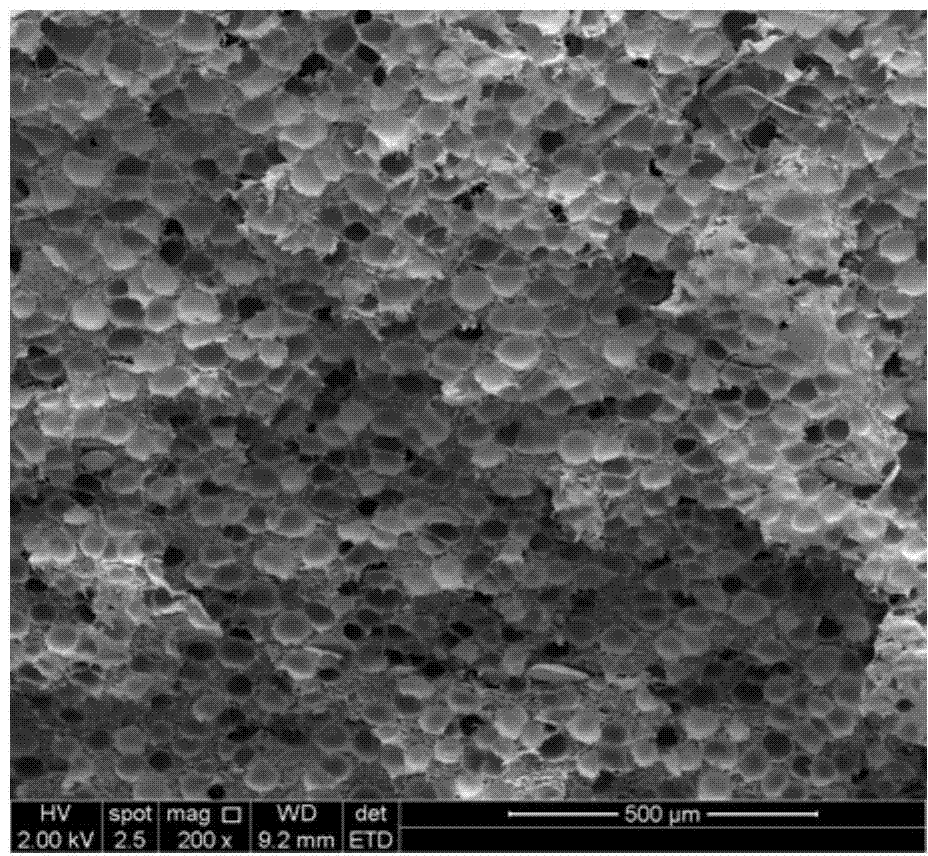

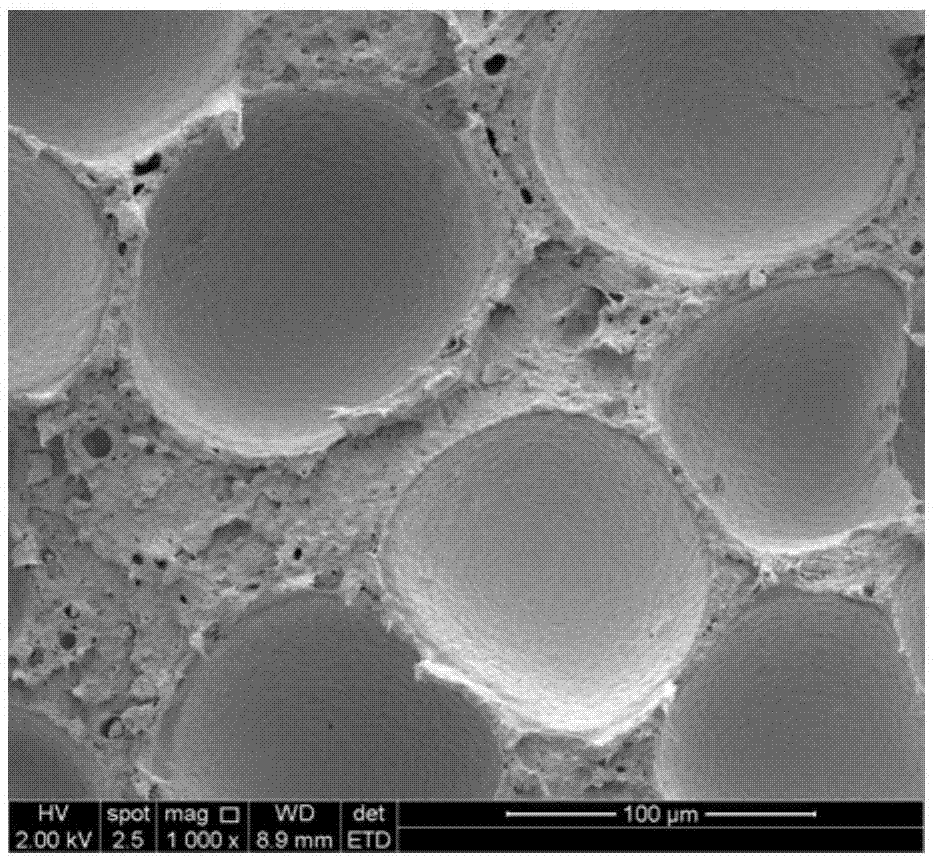

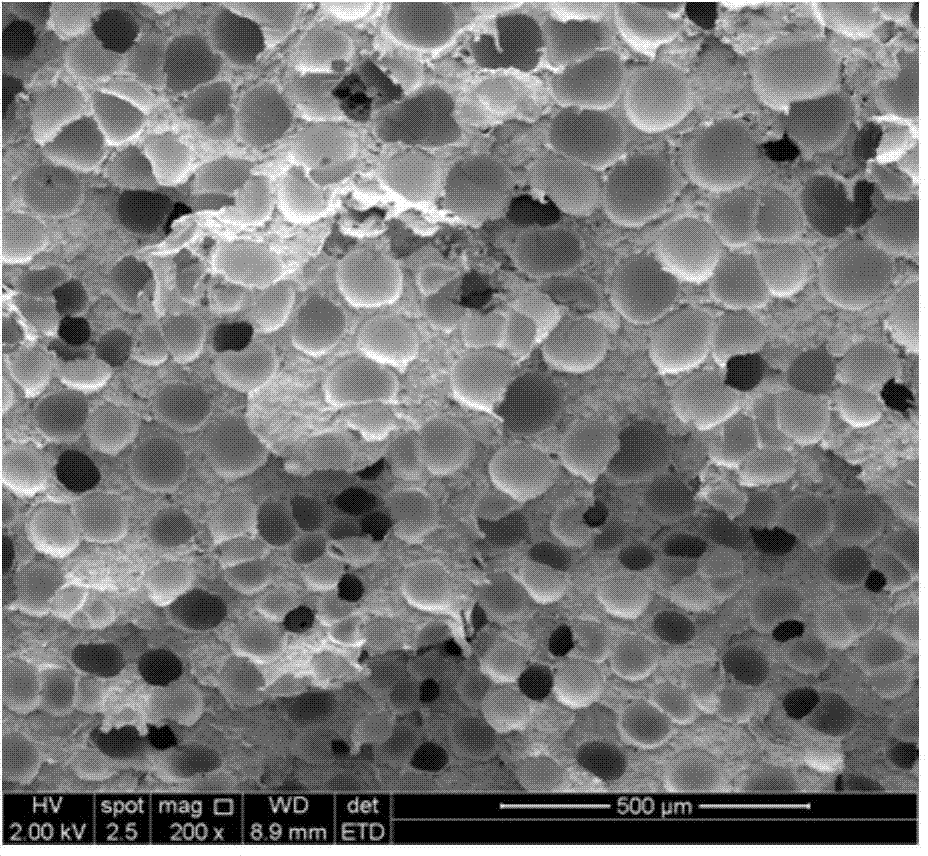

Foam concrete based on high-stability foaming agent and preparation method of foam concrete

ActiveCN112279675ALarge specific surface areaLow densityCeramicwareMethacrylate methylFerriferrous Oxide

The invention discloses foam concrete based on a high-stability foaming agent and a preparation method of the foam concrete. The preparation method comprises the steps of firstly, constructing a halloysite aerogel three-dimensional network on halloysite through methyl methacrylate and graphene oxide, then loading ferroferric oxide on the halloysite aerogel, and grafting a large number of double-ion groups on the halloysite to obtain modified halloysite; putting the nano particles into the modified auxiliary liquid for reaction to obtain modified nano particles; and mixing the modified nanoparticles and the modified halloysite, and adding the mixture into an anionic surfactant for further reaction. The prepared modified foaming agent has high foaming capacity and foam stabilizing performance; and the concrete block prepared by mixing the modified foaming agent, the cement slurry and the low-hardness tap water has the characteristics of light weight, high compressive strength and good heat-insulating property, and is very practical.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for recycling retired car polyolefin plastic parts and components by virtue of chemical foaming

InactiveCN104262779AAvoid resource waste and environmental pollutionReduce energy consumptionPolyolefinEngineering

The invention provides a method for recycling retired car polyolefin plastic parts and components by virtue of chemical foaming, and relates to a method for preparing a micro-cellular foaming material by recycling the retired car polyolefin plastic parts and components by virtue of chemical foaming. According to the method provided by the invention, an injection molding micro-cellular foaming technique is applied to the field of car plastic recycling, the defects of the prior art can be overcome, the difficult problem of recycling scraped car plastic can be solved, the resource recycling of car polyolefin plastic can be achieved, and the environmental pollution can be reduced; an obtained product is low in energy consumption and high in additional value; and the method has wide application prospects.

Owner:WUHAN UNIV OF TECH

Inorganic fireproof material and preparation method thereof

The invention discloses an inorganic fireproof material and a preparation method thereof, and belongs to the field of fireproof materials. A coating of the fireproof material mainly comprises alumina sol as a film forming matter, diatomite as filler and some trace auxiliaries, wherein the alumina sol is a water-based inorganic binder and has the characteristics of no toxity, high temperature resistance, high binding force, environmental protection and the like; the diatomite has porous heat insulation and can obviously prolong duration of fire resistance; the performances of the coating such as adhesive force and duration of fire resistance can be obviously enhanced by adjusting the percentage composition and the thickness of the coating. The raw materials used are all low in cost, and are non-toxic and harmless inorganic materials; the coating is expanded and foamed during the heated process to form a loosened porous expansion layer with an extremely good heat insulation effect, and meanwhile hazardous gas is not generated; the duration of fire resistance is over 60 minutes; the coating can be coated on various modern buildings with wood structures and steel structures, and can be applied to the field of fireproof coatings well.

Owner:KUNMING UNIV OF SCI & TECH

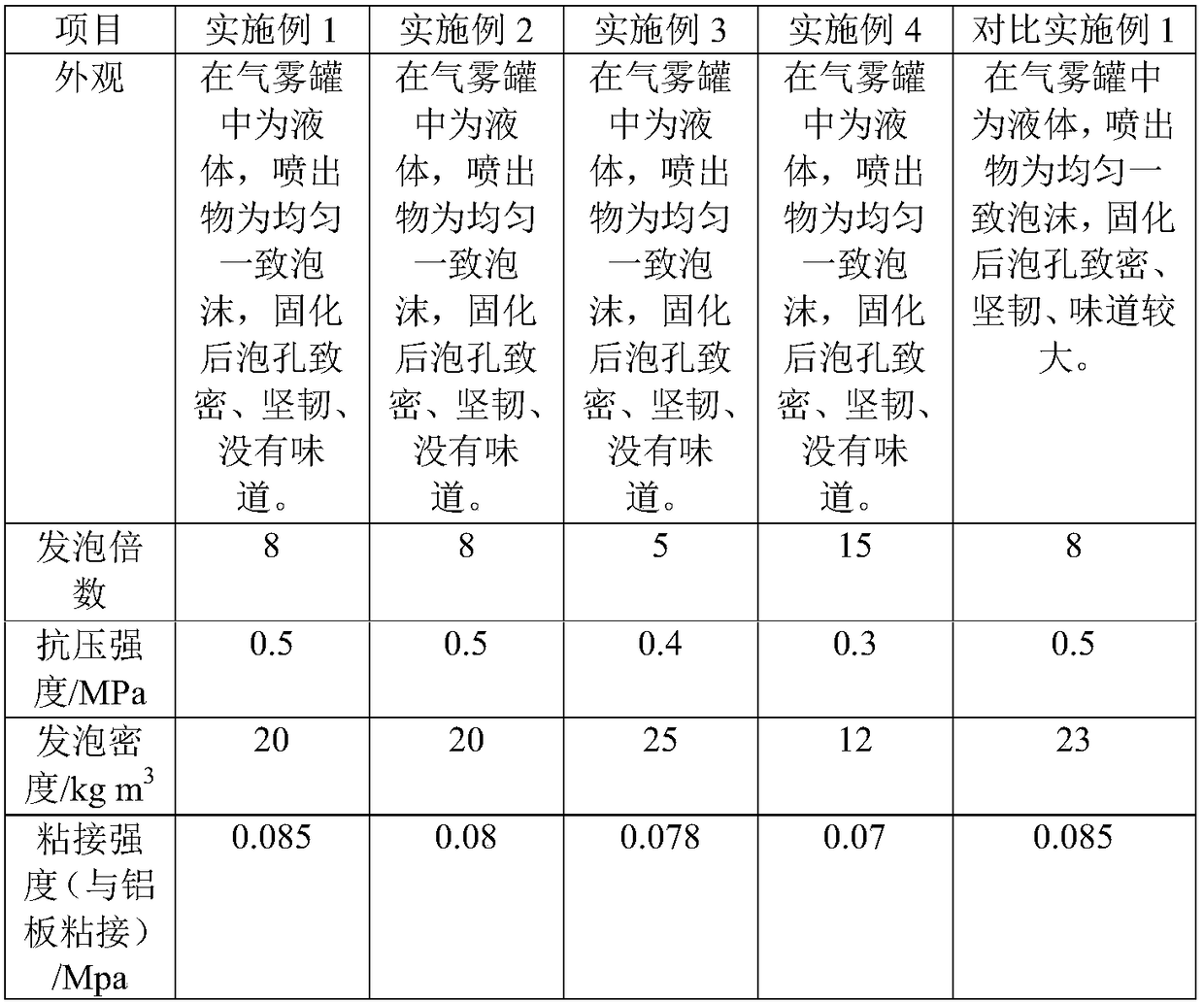

Single-component polyurethane foam rubber and preparation method thereof

InactiveCN108219097ADense cellsHigh foaming rateNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses single-component polyurethane foam rubber and a preparation method thereof. The single-component polyurethane foam rubber is prepared from the following components in parts bymass: 30 to 100 parts of polyether polyol and / or polyester polyol, 0.5 to 5 parts of a crosslinking agent, 1 to 15 parts of an opening agent, 0.5 to 10 parts of gas-phase white carbon black, 1 to 3 parts of a foam stabilizer, 0.2 to 5 parts of a catalyst, 1 to 10 parts of supercritical fluid and 30 to 150 parts of polyisocyanate. According to the single-component polyurethane foam rubber and the preparation method thereof, a supercritical foaming technology and a single-component polyurethane foaming technology are integrated. The supercritical fluid of the single-component polyurethane foam rubber is used as a brand-new environmentally-friendly adhesive, so that the prepared single-component polyurethane foam rubber has dual advantages of foam hole compactness and high foaming rate, and is inevitably widely applied to occasions with requirements for high intensity.

Owner:SHANGHAI DONGDA CHEM

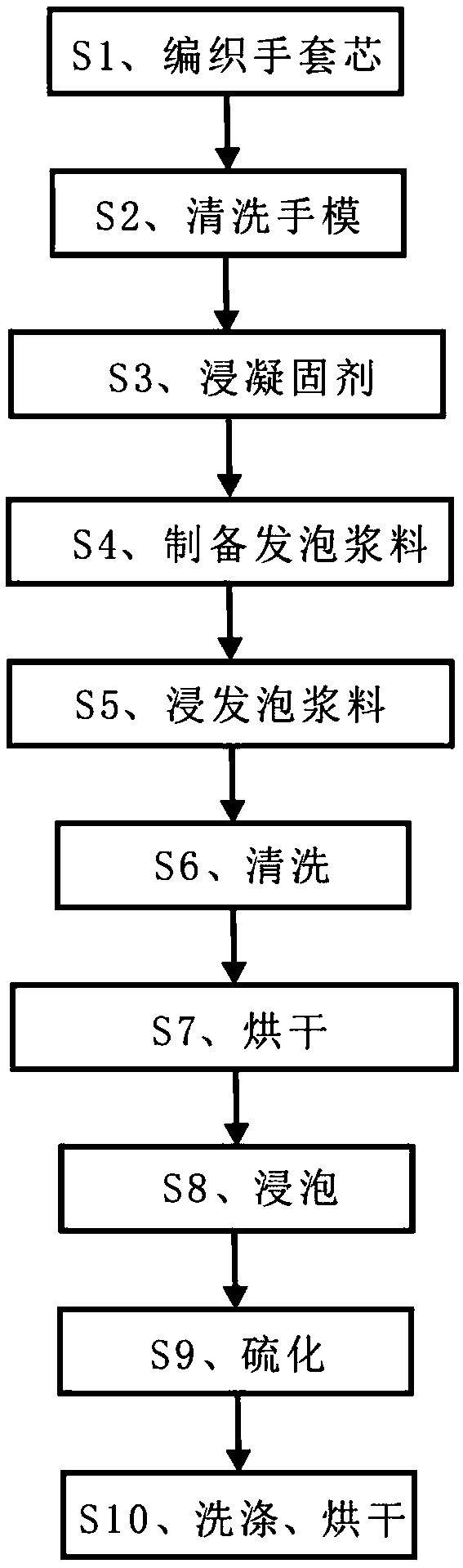

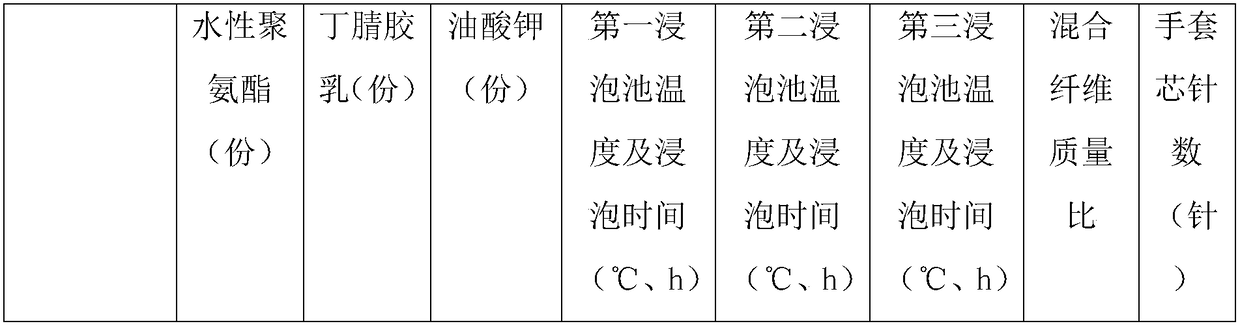

Foaming glove and production method thereof

InactiveCN109457489AImprove wear resistanceIncrease frictionGlovesTextiles and paperFoaming agentPolymer science

The invention discloses a foaming glove and a production method thereof, and belongs to the technical field of labor protection gloves. The production method includes the steps: S1 glove core weaving;S2 hand mold cleaning; S3 coagulator soaking; S4 forming slurry preparation: sufficiently mixing and stirring waterborne polyurethane, nitrile latex, foaming agents and thickening agents to obtain forming slurry; S5 forming slurry soaking; S6 cleaning; S7 drying; S8 soaking; S9 vulcanization; S10 washing and drying. According to the glove produced by the production method, residual solvents on the glove are omitted, the performance of the prepared glove far exceeds national standards and European standards, the rubber surface of the glove is fine, smooth and soft and has excellent elasticity,toughness, abrasion resistance and tearing resistance, friction force of the palm surface of the glove can be improved when the glove is used, and the glove is resistant to abrasion and skid, flexible to use and comfortable in hand feeling.

Owner:NANTONG JIADELI SAFETY PROD CO LTD

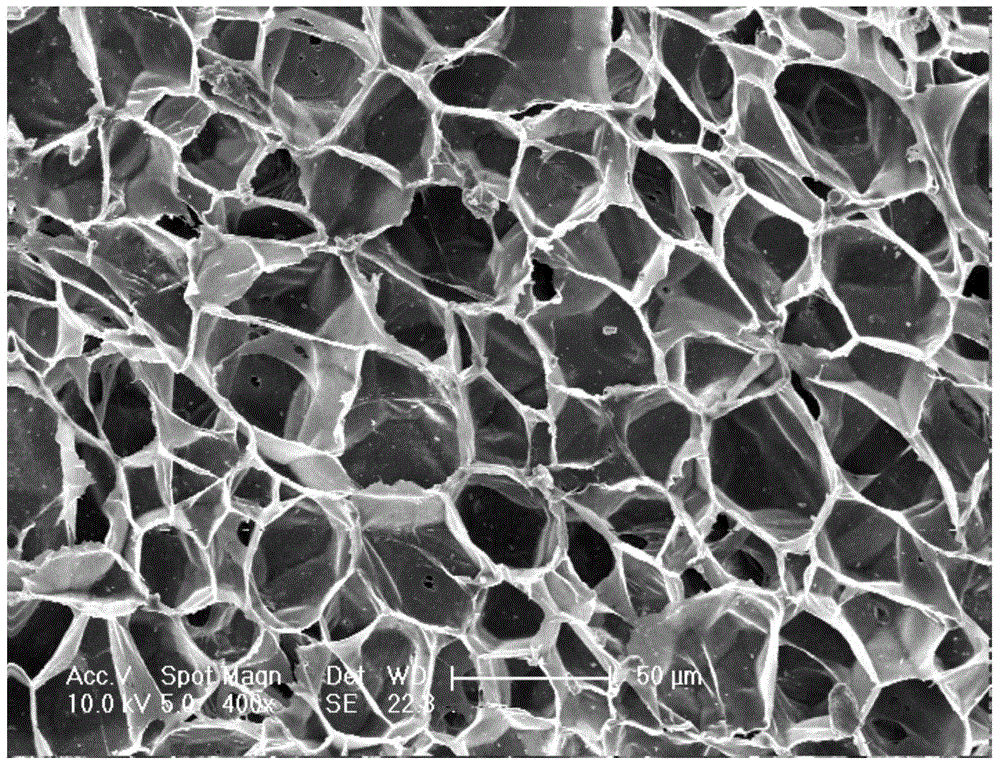

Production system for continuously manufacturing foamed aluminum through gas foaming method

The invention relates to a production system for continuously manufacturing foamed aluminum through a gas foaming method. The production system for continuously manufacturing the foamed aluminum through the gas foaming method comprises a heat preservation bin, a nitrogen supply station and a preheating chamber and further comprises a conveying mechanism, a foaming mechanism and a control mechanism, wherein the conveying mechanism linearly conveys a mold group arranged on the upper side of the conveying mechanism and a connecting assembly used for controlling output of the heat preservation bin and the gas supply station, the foaming mechanism is used for secondary foaming of molten aluminum, and the control mechanism is used for controlling all steps to be operated in order. In the secondary foaming process of the molten aluminum, the staying time of gas in the molten aluminum is prolonged, so that the foaming rate is improved, the loss of nitrogen is reduced, the foaming period is shortened, and therefore the production efficiency is improved; in the operation process of the conveying mechanism, all the steps are controlled to operate in order according to the movement displacement of the conveying mechanism, and the automatic production process of the foamed aluminum ingots is formed. The production system for continuously manufacturing the foamed aluminum through the gas foaming method has the advantages of being simple in structure, high in foaming efficiency, uniform in foaming, controllable in quality, efficient in production and environmentally friendly and saving energy.

Owner:陈明海

Carbon dioxide-epoxypropane copolymer foam plastic and preparation method thereof

The invention provides a carbon dioxide-epoxypropane copolymer foam plastic which is prepared from a carbon dioxide-epoxypropane copolymer and a flexibilizer, wherein the mass ratio of the carbon dioxide-epoxypropane copolymer to the flexibilizer is 100:(50-200). The invention provides a preparation method of the carbon dioxide-epoxypropane copolymer foam plastic; the preparation method comprises the following steps: (1) mixing the carbon dioxide-epoxypropane copolymer with the flexibilizer, and granulating to obtain plastic particles; and (2) putting the plastic particles into a carbon dioxide environment of 3MPa-8MPa, and depressurizing at a speed of 5MPa / s-20MPa / s after carbon dioxide is absorbed by the plastic particles to obtain the carbon dioxide-epoxypropane copolymer foam plastic. The carbon dioxide-epoxypropane copolymer foam plastic has relatively good resilience while being biodegradable.

Owner:中科应化(长春)科技有限公司

Method for preparing foam glass with high foaming rate by utilizing lead-free high-barium abandoned lamp tube

InactiveCN106630649AHigh foaming rateUniform pore sizeGlass shaping apparatusCalcium carbonateBall mill

The invention discloses a method for preparing foam glass with a high foaming rate by utilizing a lead-free high-barium abandoned lamp tube and belongs to the field of foam glass. The method comprises the following steps: carrying out ball milling on the lead-free high-barium abandoned lamp tube to form a glass powder raw material; feeding foaming agents, namely manganese dioxide and calcium carbonate, a fluxing agent, namely sodium fluorosilicate, and a stabilizer, namely sodium phosphate into a ball mill to be subjected to ball milling; feeding mixture obtained through ball milling into a high-temperature-resistant mould, preheating for 15-20 minutes at the temperature of 400-430 DEG C, then heating up to 800-820 DEG C, and carrying out heat preservation for 20-30 minutes; then cooling to 500-550 DEG C, annealing, and carrying out heat preservation for 35-40 minutes; and finally carrying out furnace cooling to room temperature. The prepared foam glass is uniform in pore diameter, closed pores are formed mainly, the average pore diameter reaches about 4.2mm, the density is 0.58g / cm<3>, the compressive strength is 3.78MPa, the performance is excellent, and the application standard of the foam glass can be met.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com