Patents

Literature

301results about How to "Increase binding rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Doxy rhodol magnetic microglobule and its making method

InactiveCN1650853AGood magnetic responseHigh killing efficiencyOrganic active ingredientsInorganic non-active ingredientsDocetaxel-PNPOleic Acid Triglyceride

A magnetic microphere of doxytaxol for preventing and treating tumor contains proportionaly magnetic Fe3O4 nanoparticles, alpha 1-acidic glucoprotein, doxytaxol and oleic acid. Its advantage is high target performance. Its preparing process is also disclosed.

Owner:徐玉清 +1

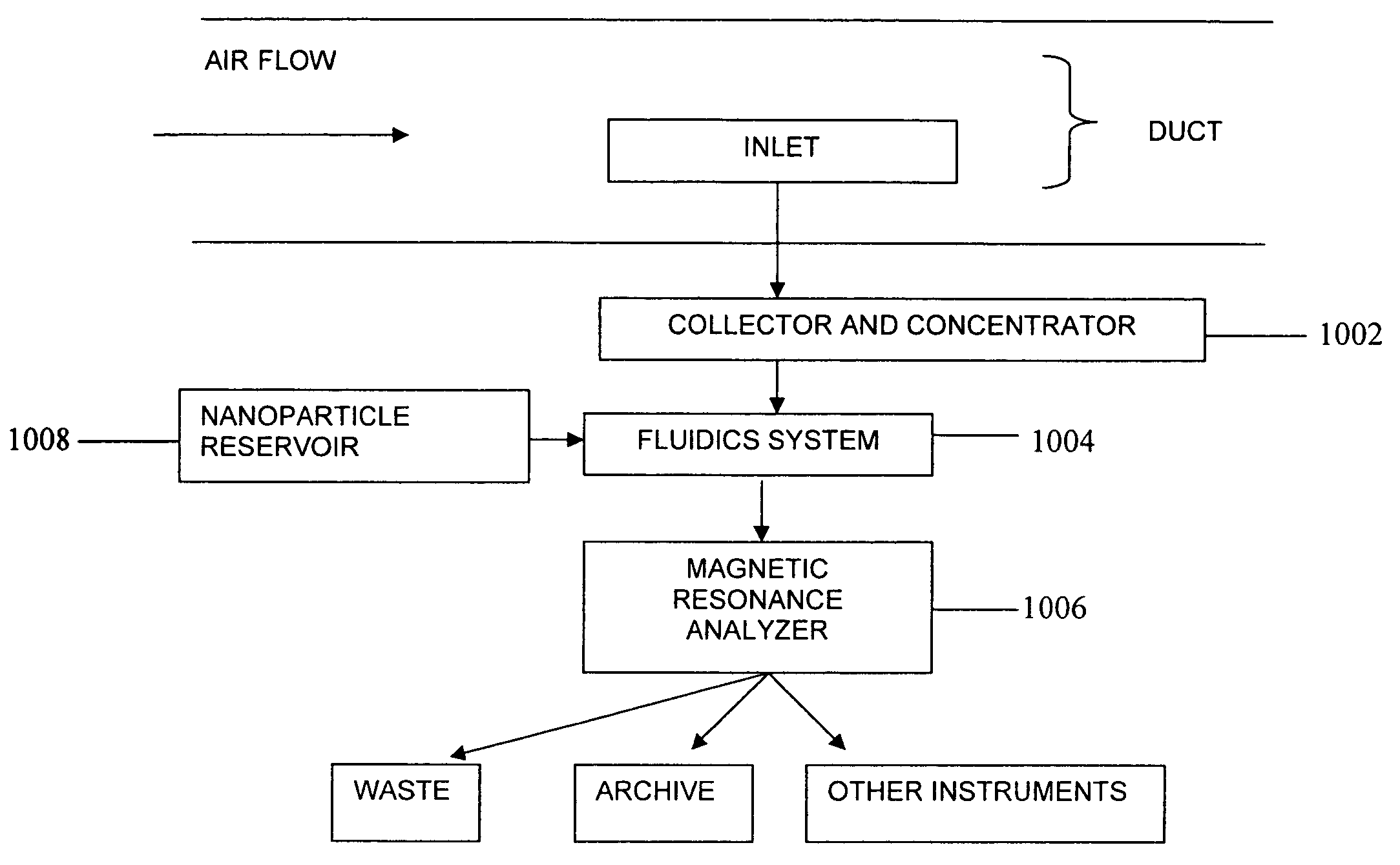

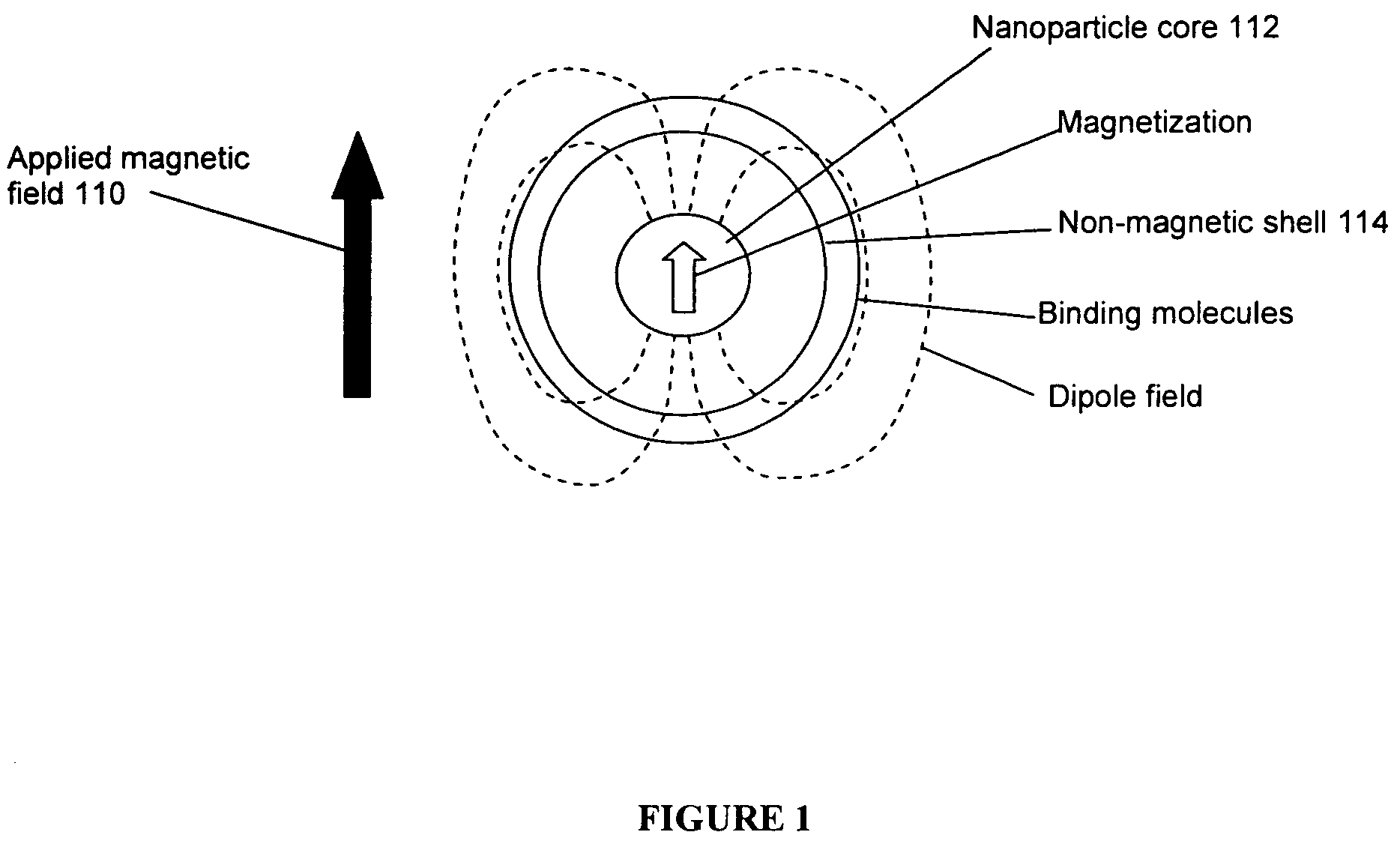

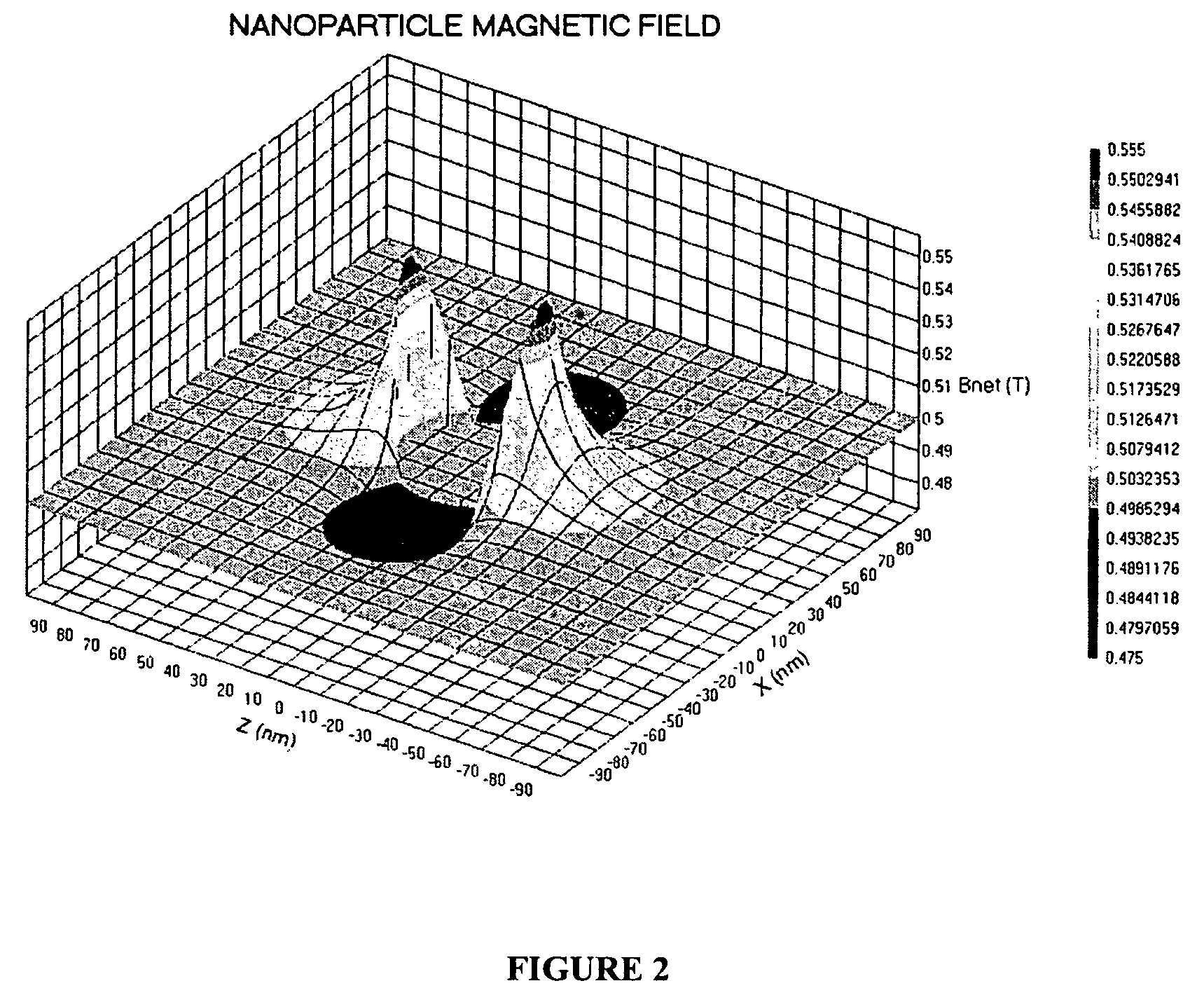

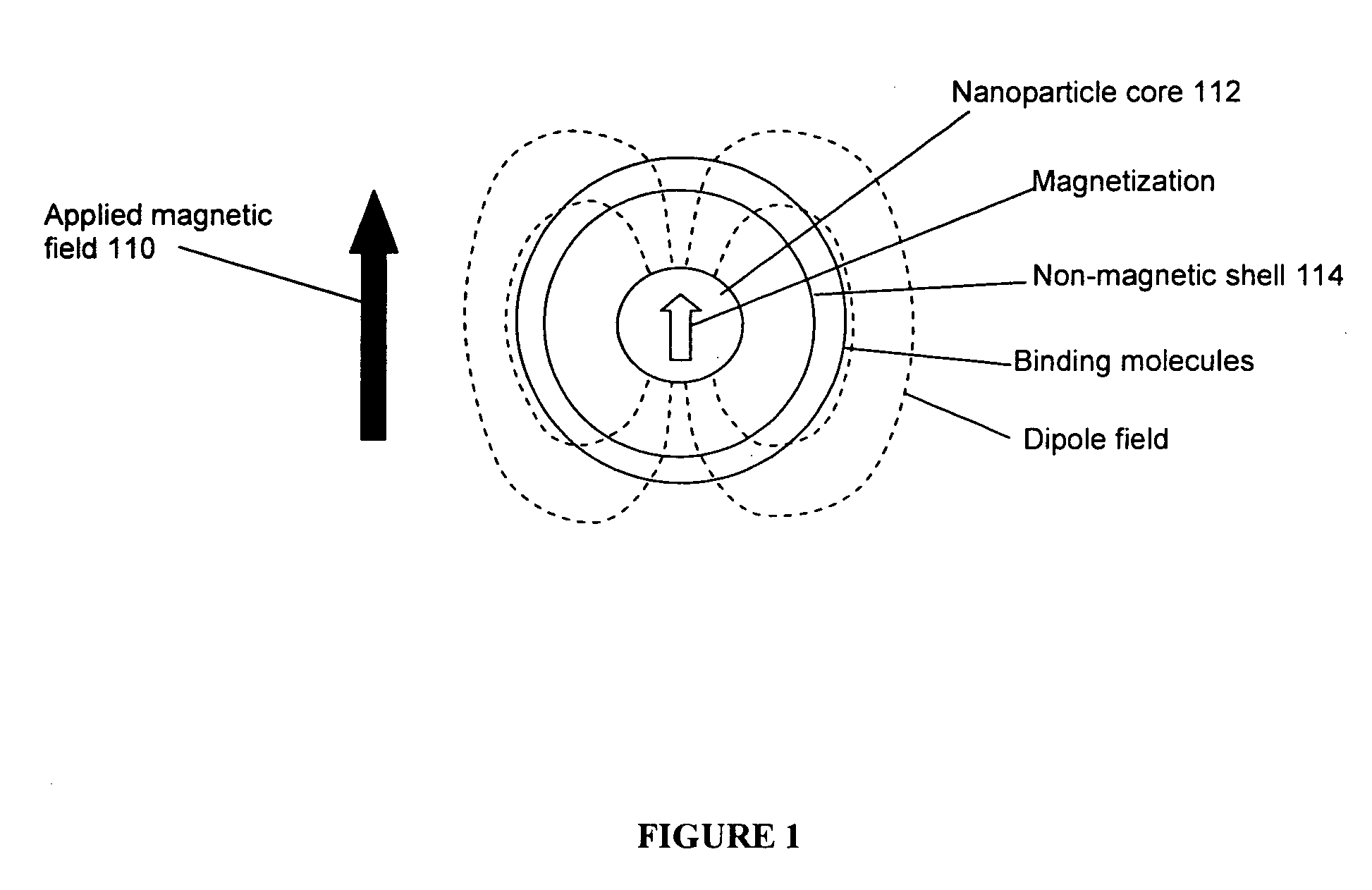

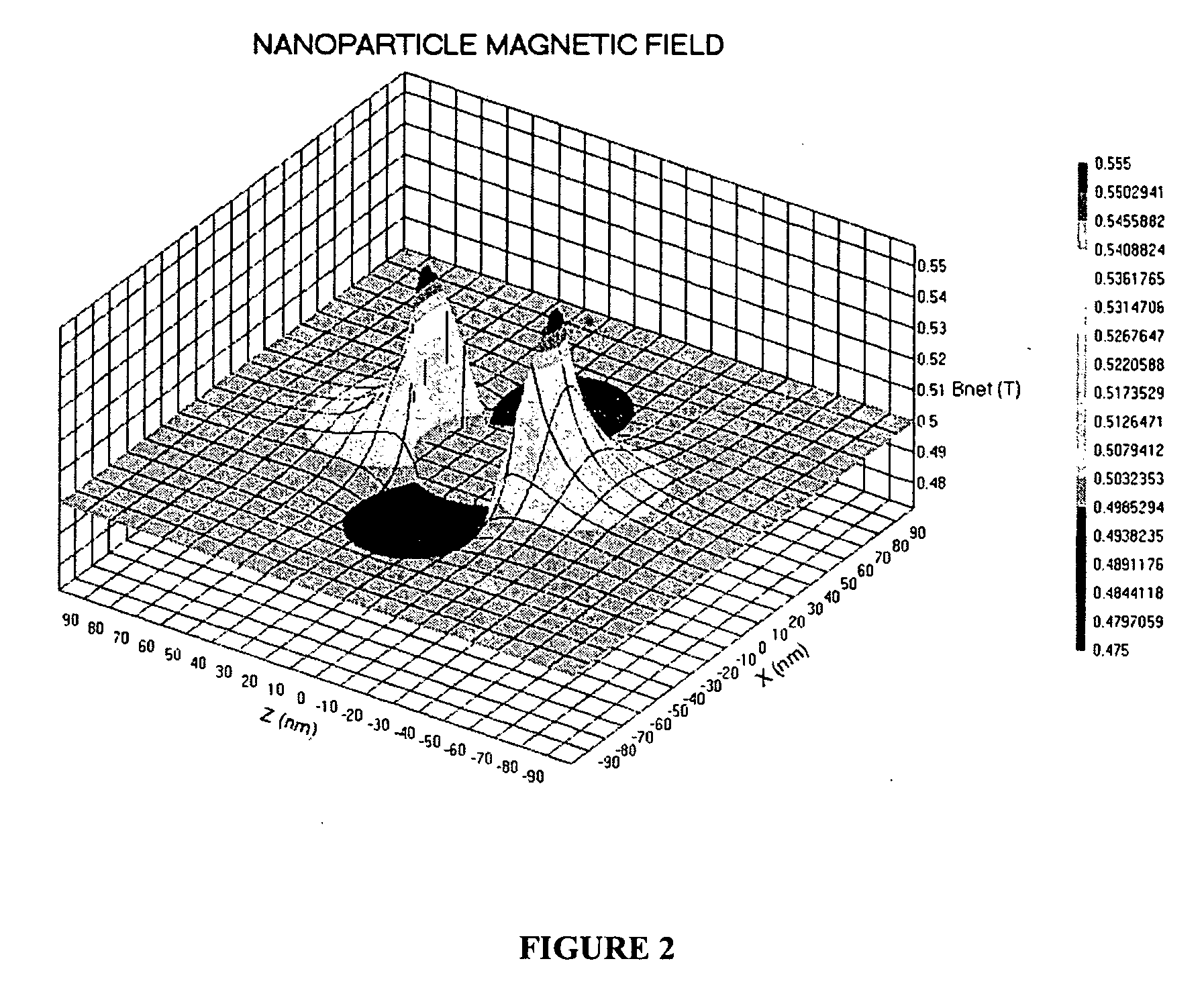

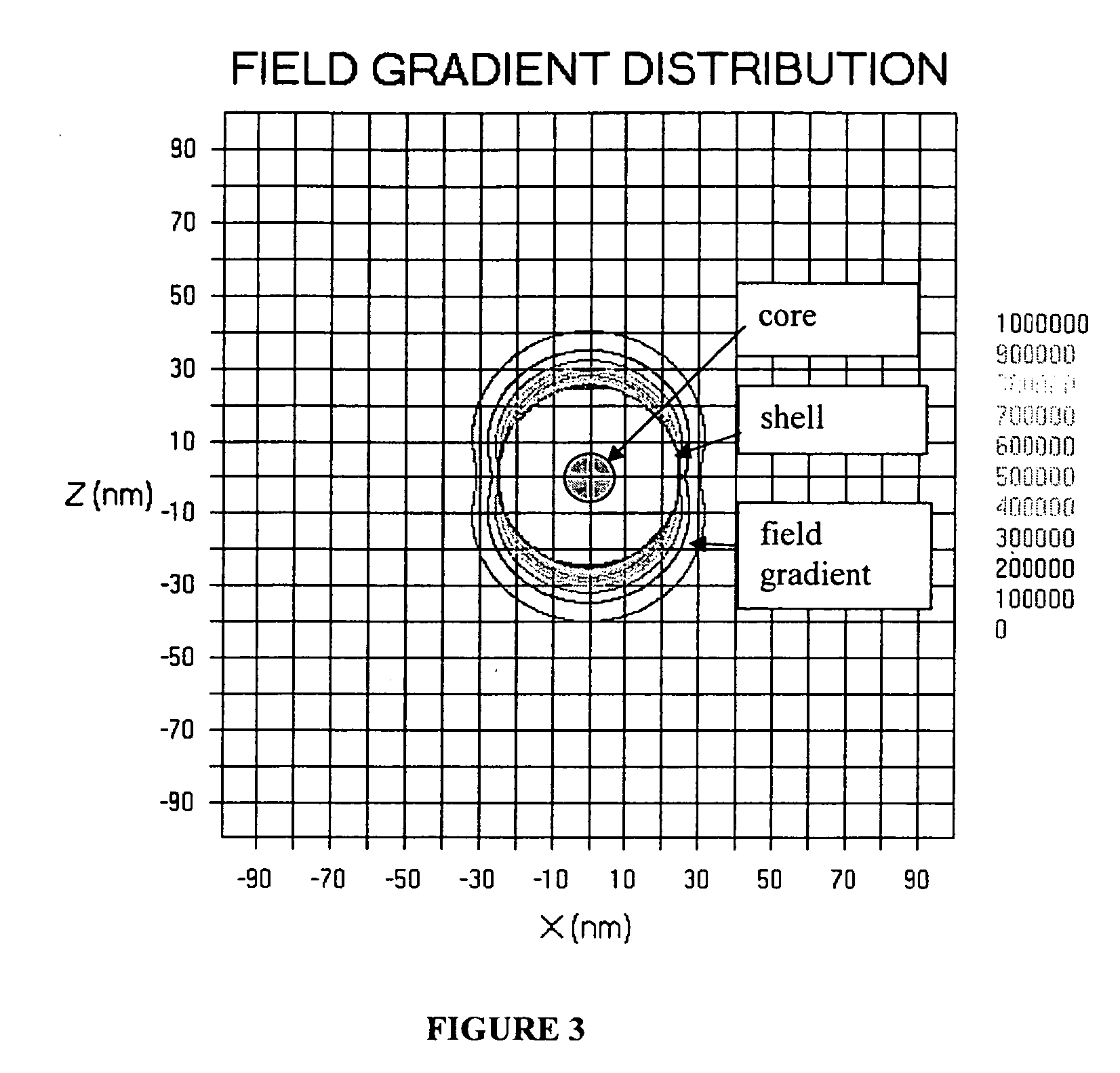

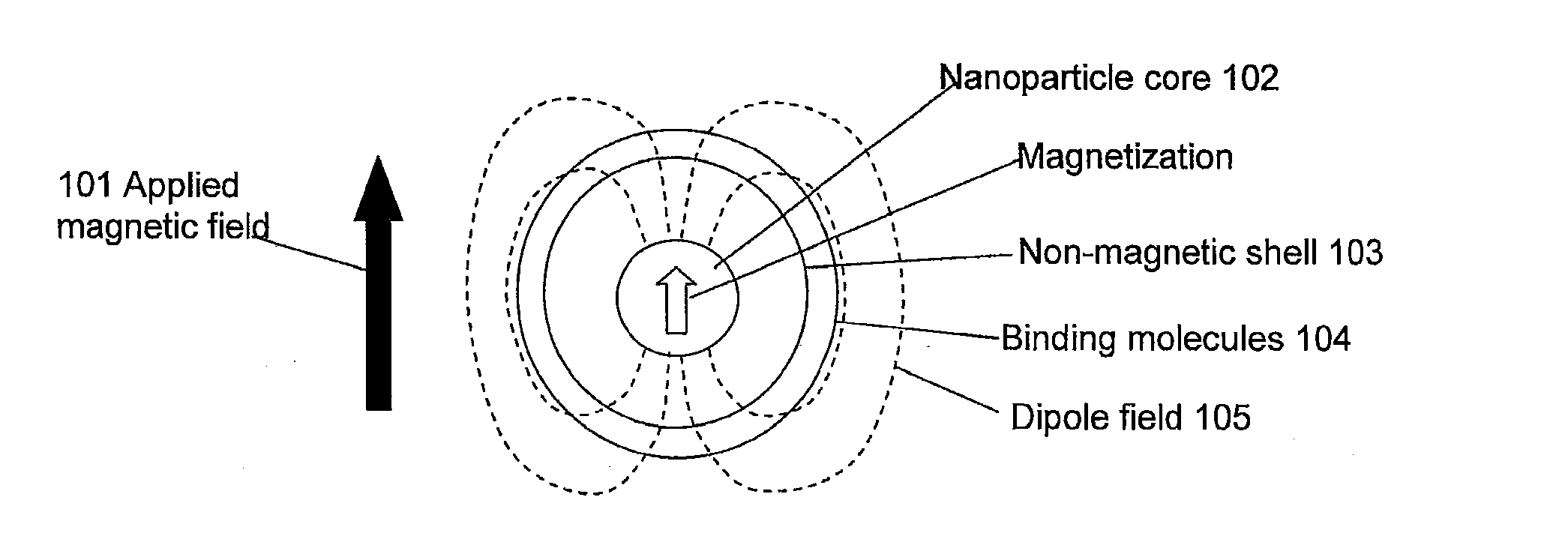

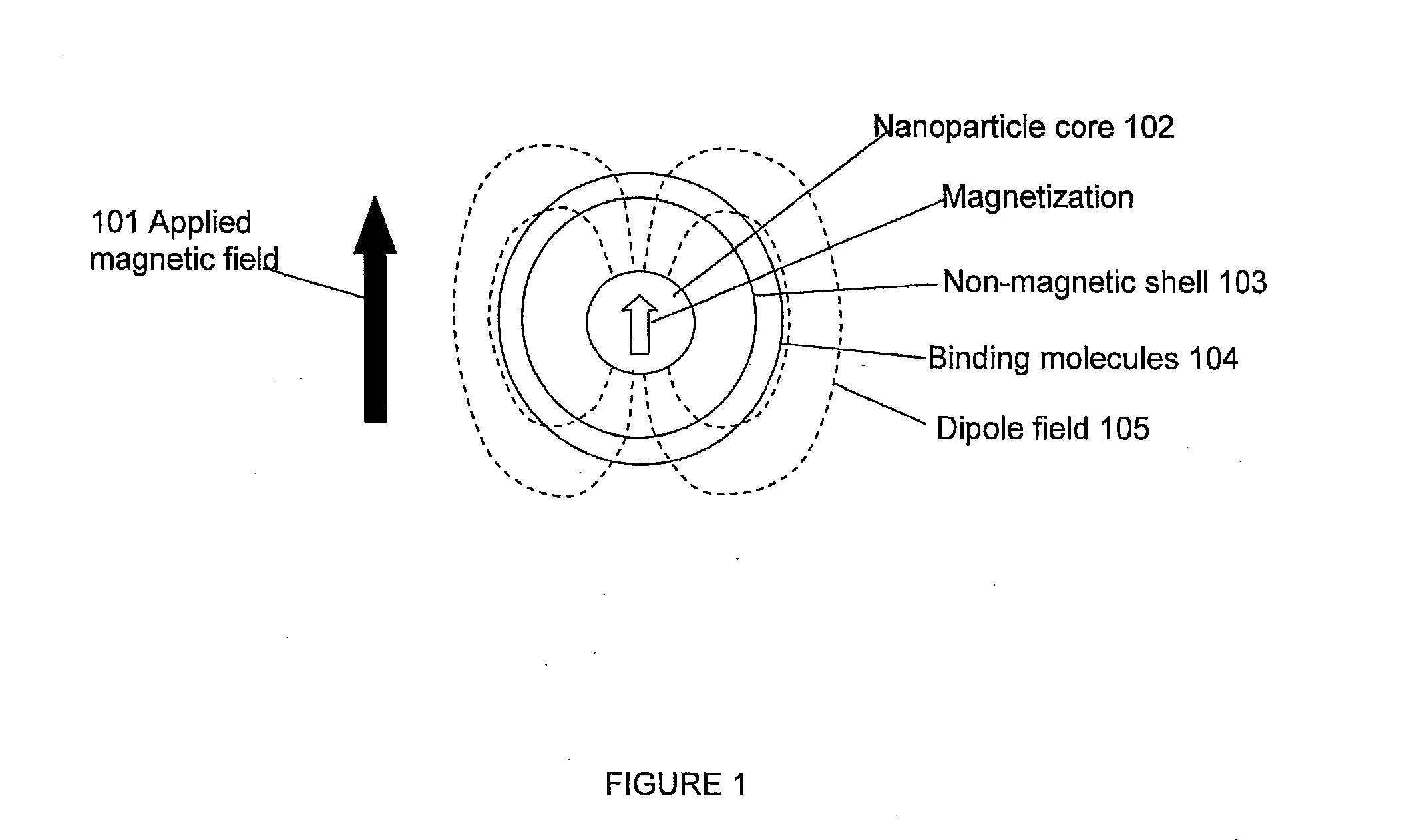

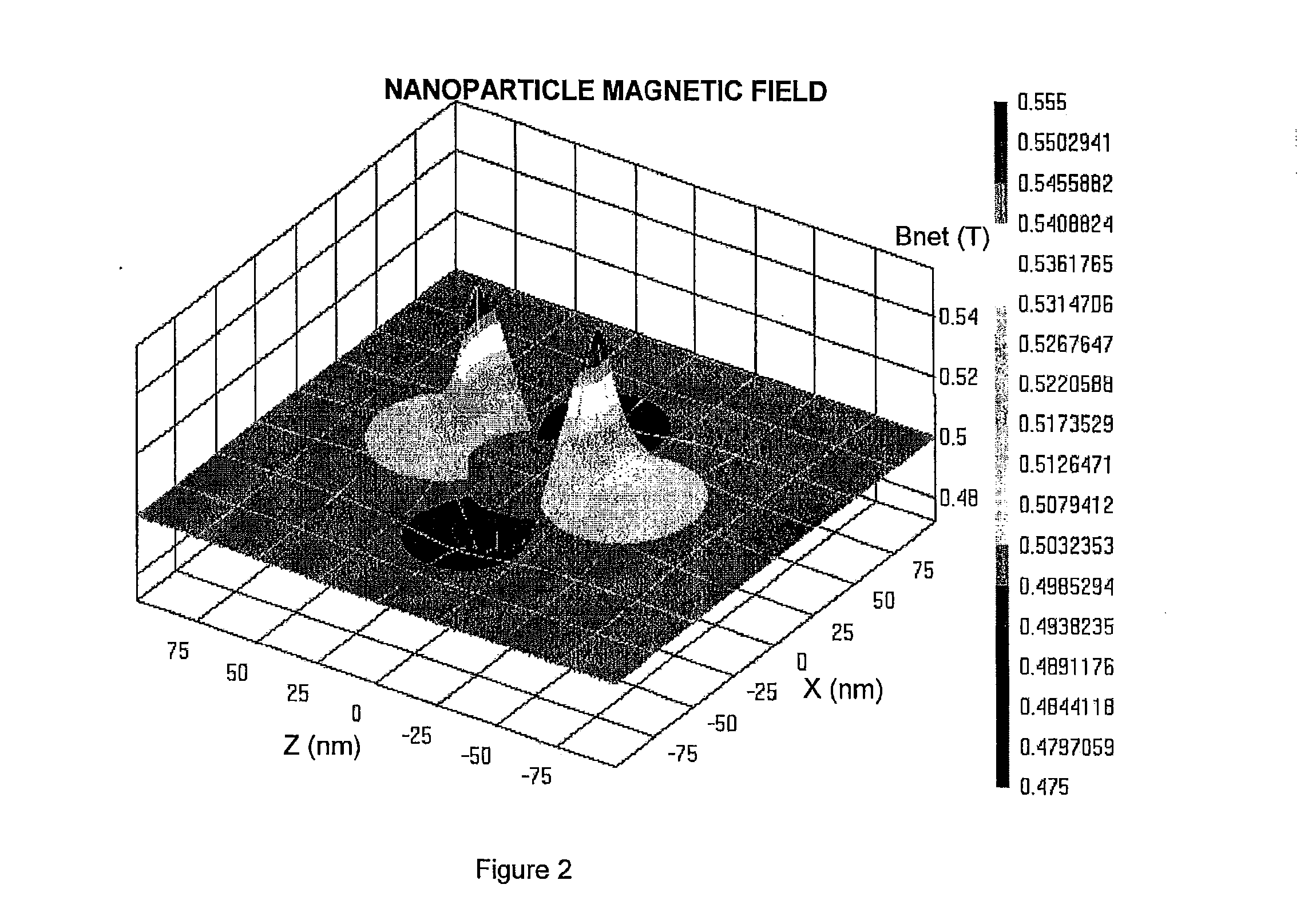

Magnetic resonance system and method to detect and confirm analytes

ActiveUS7781228B2Improve bindingReduce activity timeNanotechMagnetic measurementsResonance measurementProton magnetic resonance

A system and method are provided to detect target analytes based on magnetic resonance measurements. Magnetic structures produce distinct magnetic field regions having a size comparable to the analyte. When the analyte is bound in those regions, magnetic resonance signals from the sample are changed, leading to detection of the analyte.

Owner:MENON BIOSENSORS

Water thin type expanding steel structure fire-resisting paint and its preparation method

The present invention relates to a water thin expanding steel structure fire-resisting coating material and its preparation method. Said ivnention adopts a self-synthesized high melting temp. acrylate emulsion as main film-forming substance, adding proper quantity of chlorometaemulsion to raise fibre resistance of film-forming substance self-body, and on the basis of convertional ammonium polyphosphate fire-resistant adjuvant an expandable graphite as foaming material is added so as to form the invented fire-resisting coating material. Said invention can greatly raise forming rate to coating layer, the thickness of foamed layer can be up to 30-50 times that of original coating layer, and its fire-resisting limit can be up to 75 min (thickness of coating layer is 3 mm).

Owner:TONGJI UNIV

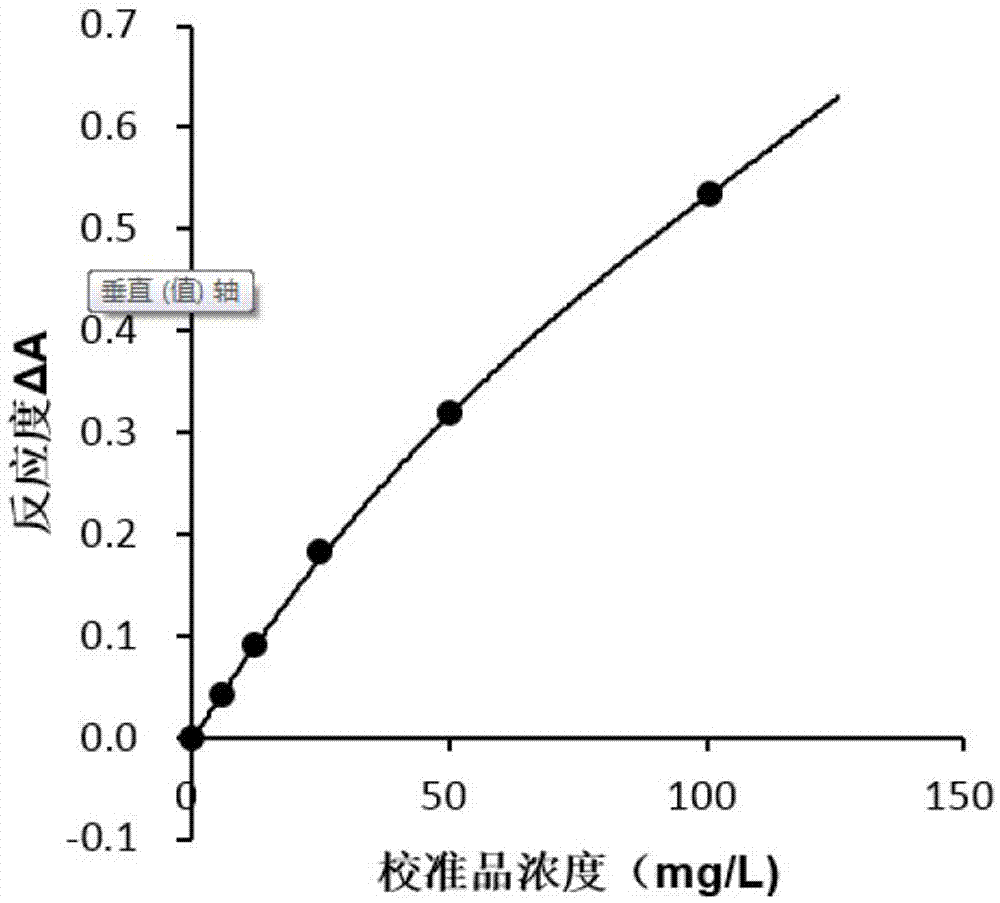

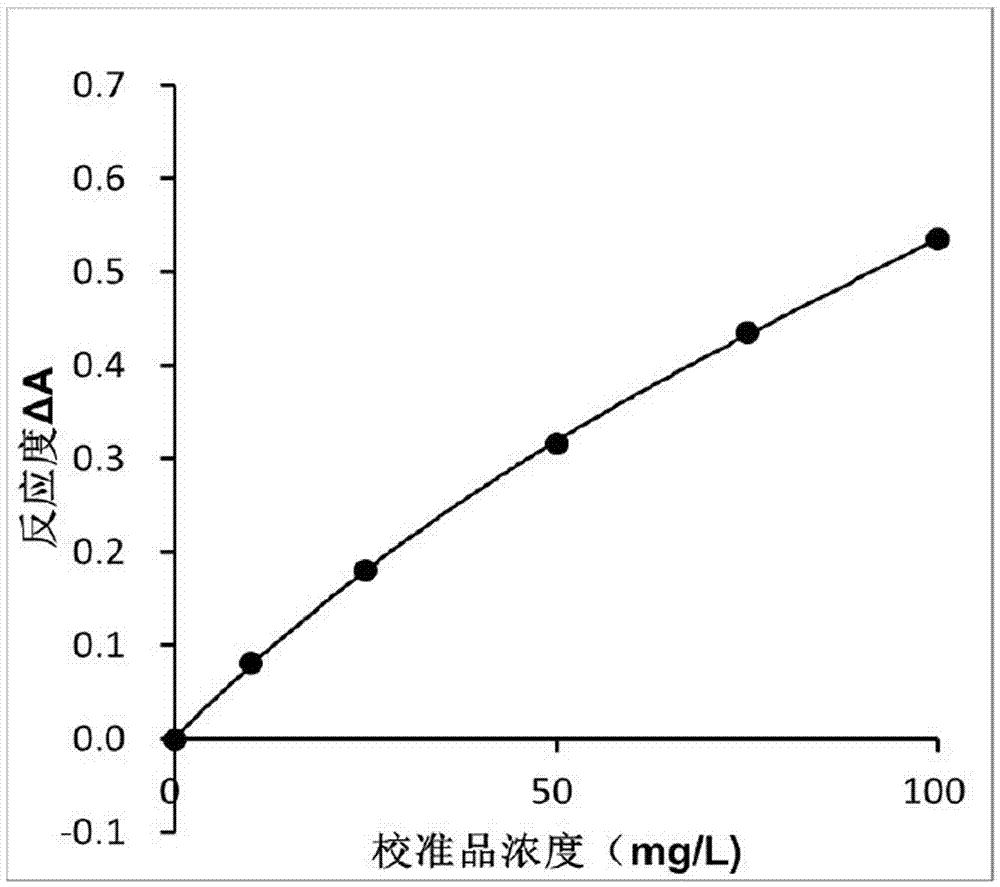

Kit for determining serum amyloid protein A and preparation method thereof

The invention discloses a serum amyloid A assay kit and a preparation method thereof. The kit includes reagent R1 and reagent R2 two-liquid components independent of each other, wherein the reagent R1 component includes buffer solution 1 and reagent R2 Components include buffer 2 and SAA antibody latex beads. The serum amyloid A assay kit of the invention has the advantages of simple operation, rapid response, high sensitivity and good specificity.

Owner:SHENZHEN HUISONG TECH DEV

Magnetic resonance system and method to detect and confirm analytes

ActiveUS20070020701A1Improve detectionEnhance qualityNanotechMagnetic measurementsNuclear magnetic resonanceResonance signal

A system and method are provided to detect target analytes based on magnetic resonance measurements. Magnetic structures produce distinct magnetic field regions having a size comparable to the analyte. When the analyte is bound in those regions, magnetic resonance signals from the sample are changed, leading to detection of the analyte.

Owner:MENON BIOSENSORS

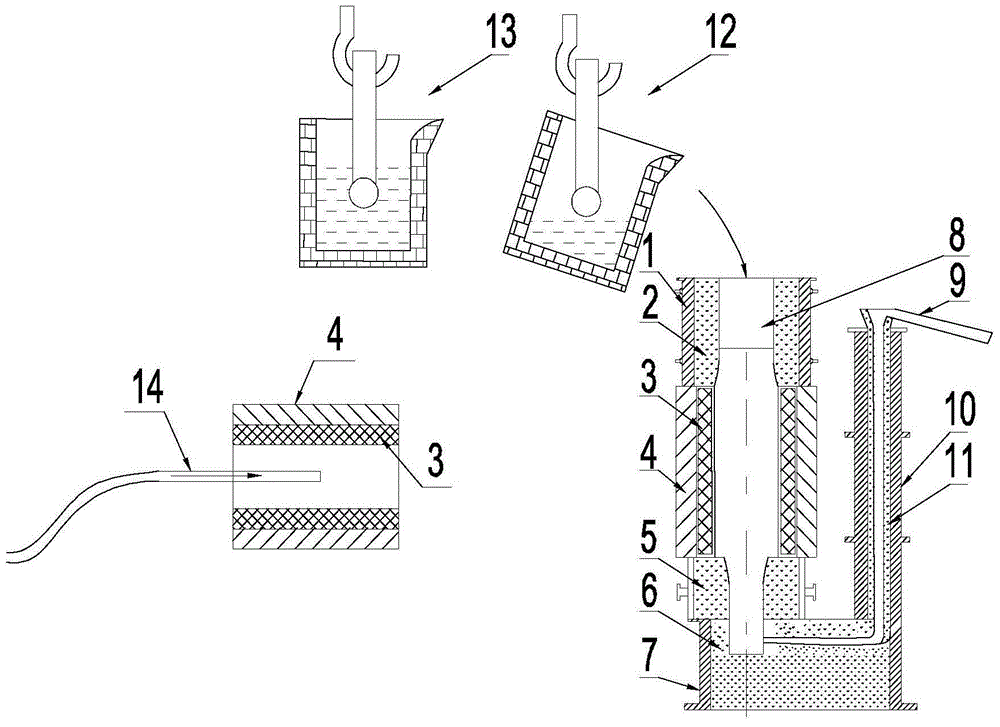

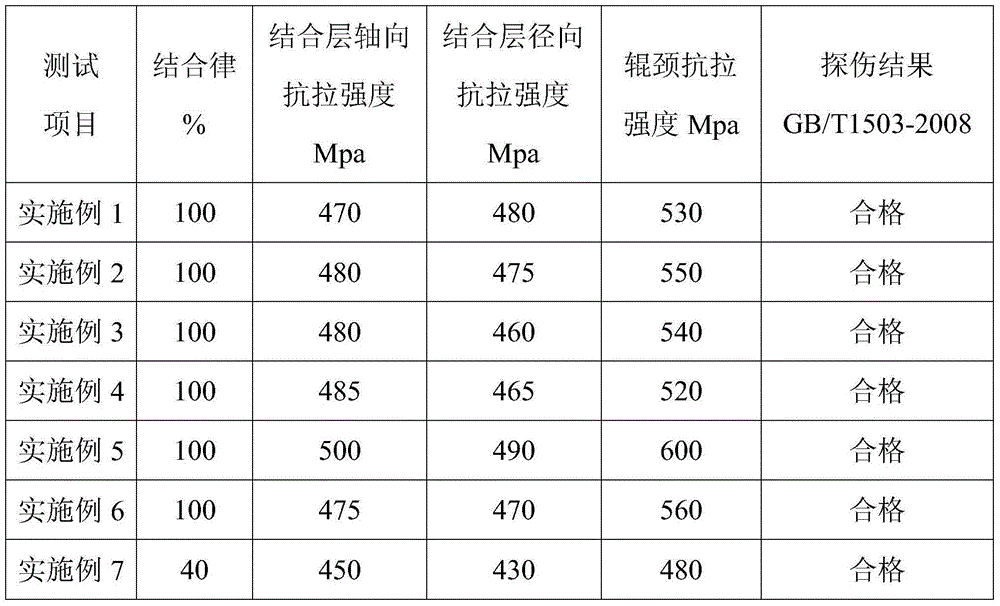

Manufacturing method for high-vanadium high-speed steel composite roll

The invention discloses a manufacturing method for a high-vanadium high-speed steel composite roll suitable for a narrow strip rolling mill. The manufacturing method comprises the steps that an outer layer of a roll body is poured by adopting a centrifugal pouring method, and after the outer layer of the roll body is poured with high-vanadium high-speed liquid steel, inert gas is continuously pumped into a cavity of the outer layer of the roll body; a centrifuge stops rotating when the outer layer temperature of high-vanadium high-speed steel reaches 1220-1280 DEG C, the inert gas is stopped being blown in, and then liquid iron in the core of the roll body is poured through mould closing. According to the manufacturing method for the high-vanadium high-speed steel composite roll, the bonding rate of the high-vanadium high-speed steel of the outer layer and the liquid iron in the core is significantly improved, the binding rate is improved from 40 percent to 100 percent, the bonding strength is improved from about 350 Mpa in the past to about 450 Mpa, and therefore the anti-stripping performance of a roll body bonding layer of the high-vanadium high-speed steel roll is greatly improved; meanwhile, the element amount formed by carbide on the corrosion outer layer of the liquid iron of the core is removed, therefore, roll neck tissues are improved, the tensile strength of the roll neck is improved, and the roll breakage phenomenon in use is effectively and completely eradicated.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

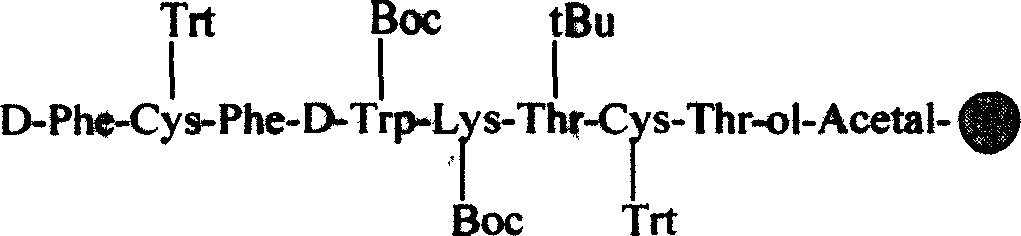

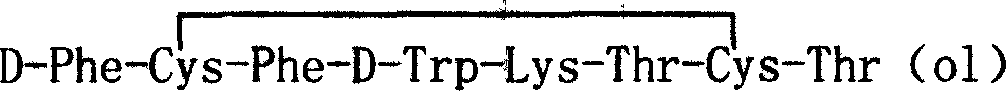

Solid-phase synthesis process of octreotide acetate

ActiveCN1569890AIncrease reaction rateRapid responsePowder deliveryPeptide/protein ingredientsAutoxidationOctreotide acetate

The invention discloses the solid-phase synthesis process of octreotide acetate which consists of, bonding acetal product with macromolecular resin, merging the bonded products with protection amino acid residue in sequence to obtain octapeptide resin, cutting the octapeptide from the resin to obtain aqueous solution, carrying out naturally oxidation in air to obtain Octreotide, charging glacial acetic acid into Octreotide aqueous solution, and freeze-drying.

Owner:SINOPHARM A THINK PHARMA

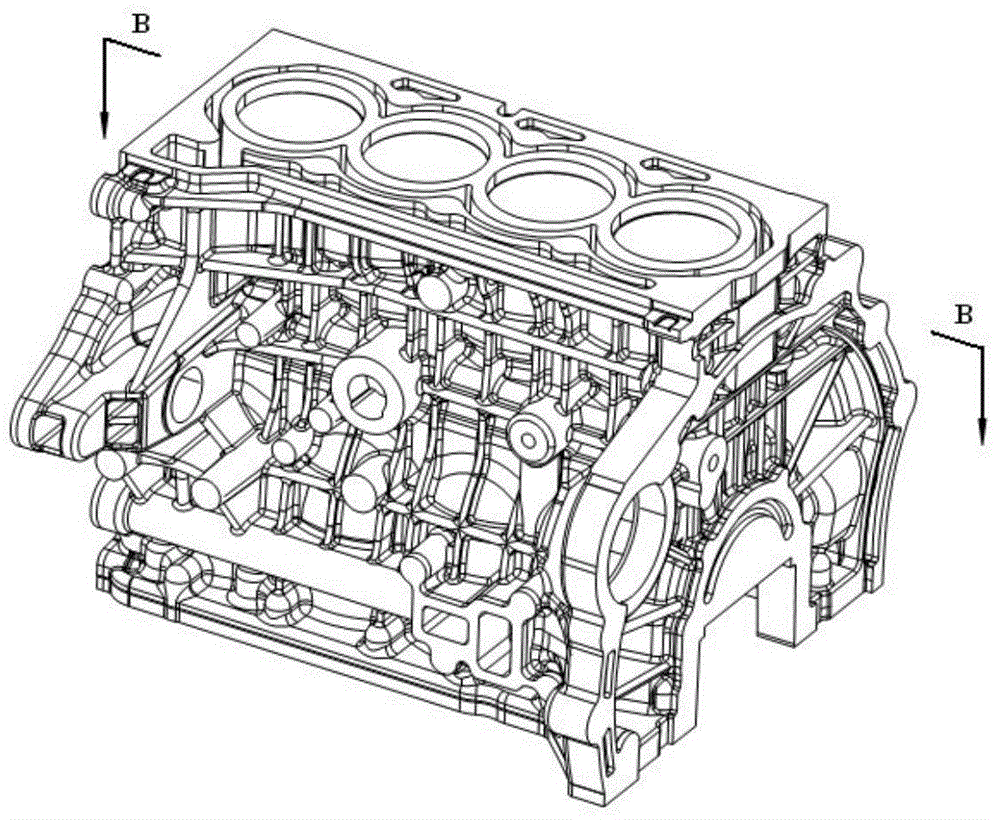

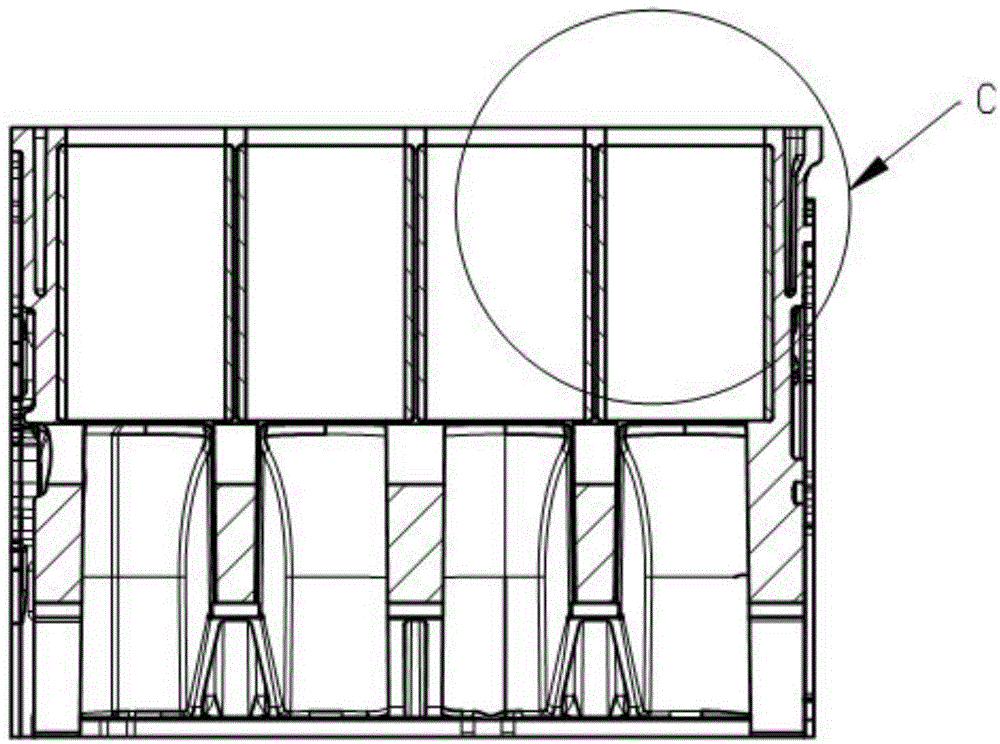

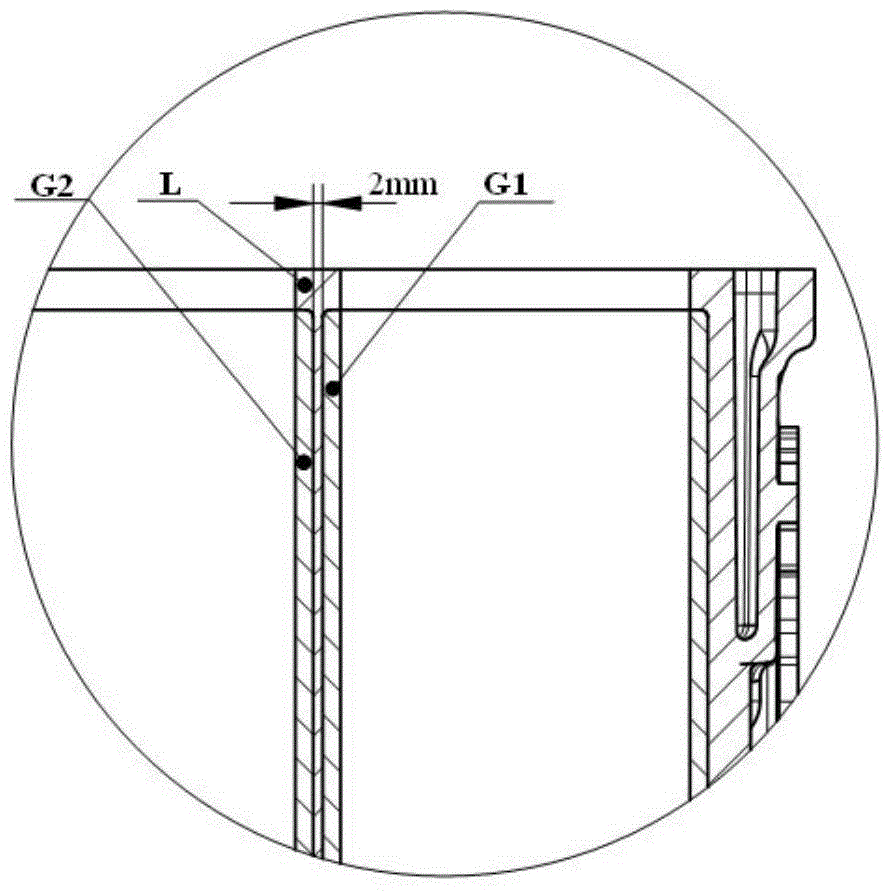

Rapid manufacturing method of aluminum alloy cylinder block casting piece of embedded cylinder sleeve

ActiveCN104550710APromote rapid developmentFast preparationFoundry mouldsFoundry coresManufacturing technologyCylinder block

The invention discloses a rapid manufacturing method of an aluminum alloy cylinder block casting piece of an embedded cylinder sleeve. The rapid manufacturing method comprises the following steps: obtaining 3D data of a to-be-cast aluminum alloy cylinder block of the embedded cylinder sleeve; analyzing the 3D data; determining a process scheme; carrying out parting processing on the 3D data; decomposing and manufacturing a mold core; casting in a manner of mold assembling to obtain a casting piece; cleaning the casting piece; and checking, wherein the design of an aluminum alloy cylinder block mold core of the embedded cylinder is divided into various sand molds and sand mold groups after the 3D data are subjected to parting processing; a left sand mold, a right sand mold, a front sand mold, a rear sand mold, a bottom sand mold, a dead head, a pouring cup and a sprue sand mold are fabricated by adopting a PDM model direct milling technology in the decomposing and fabricating processes of the mold core; and a water sleeve core and a crank case core assembly are fabricated by adopting a PCM patternless casting manufacturing technology. The method has the characteristics of being fast, accurate, efficient and economical, so that the high-quality aluminum alloy cylinder block of the embedded cylinder sleeve for an engine is manufactured; and the method is especially suitable for rapid manufacturing of one-piece, individual, small-batch and complicated products, new product development, and the like.

Owner:GUANGDONG FENGHUA ZHUOLI TECH CO LTD

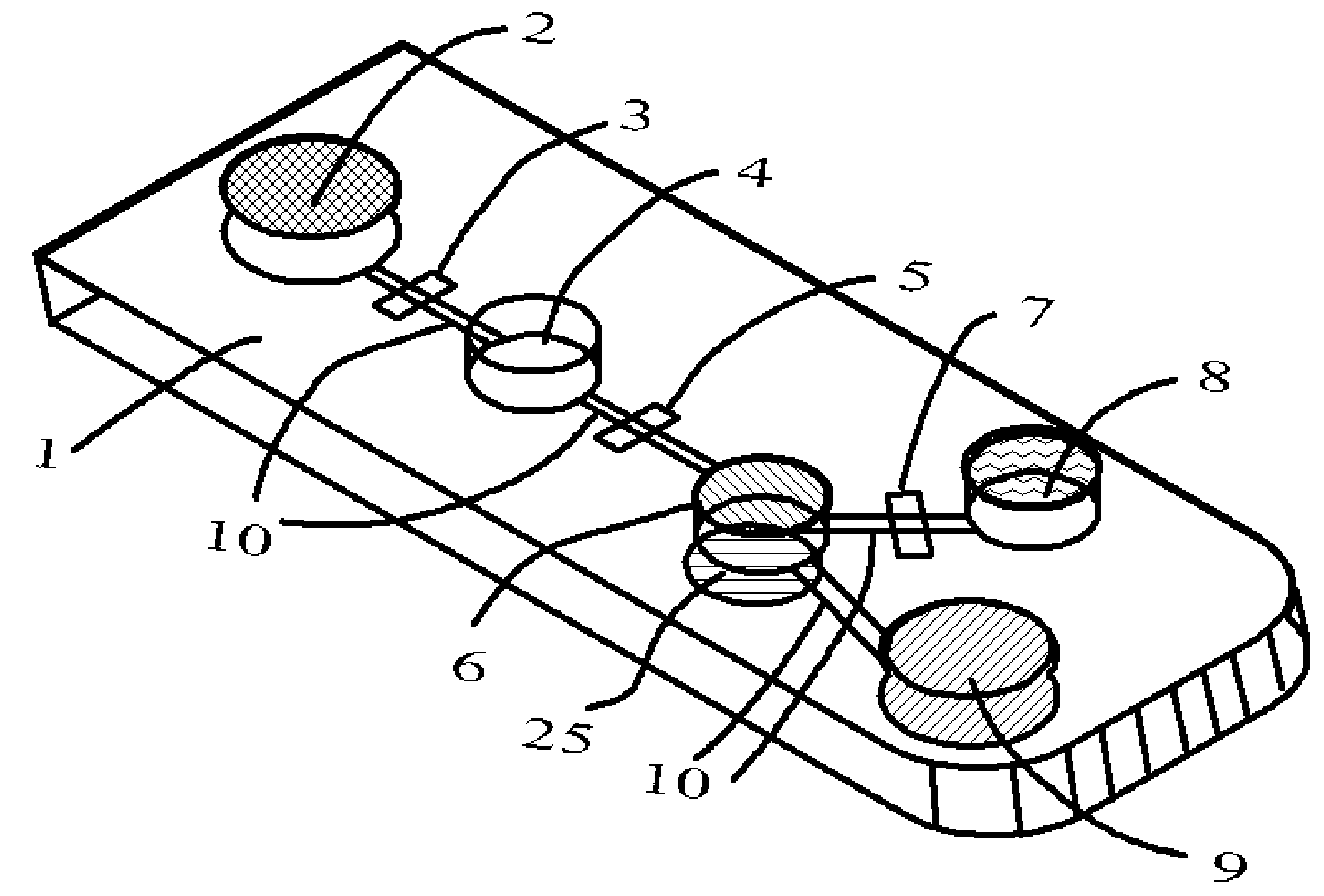

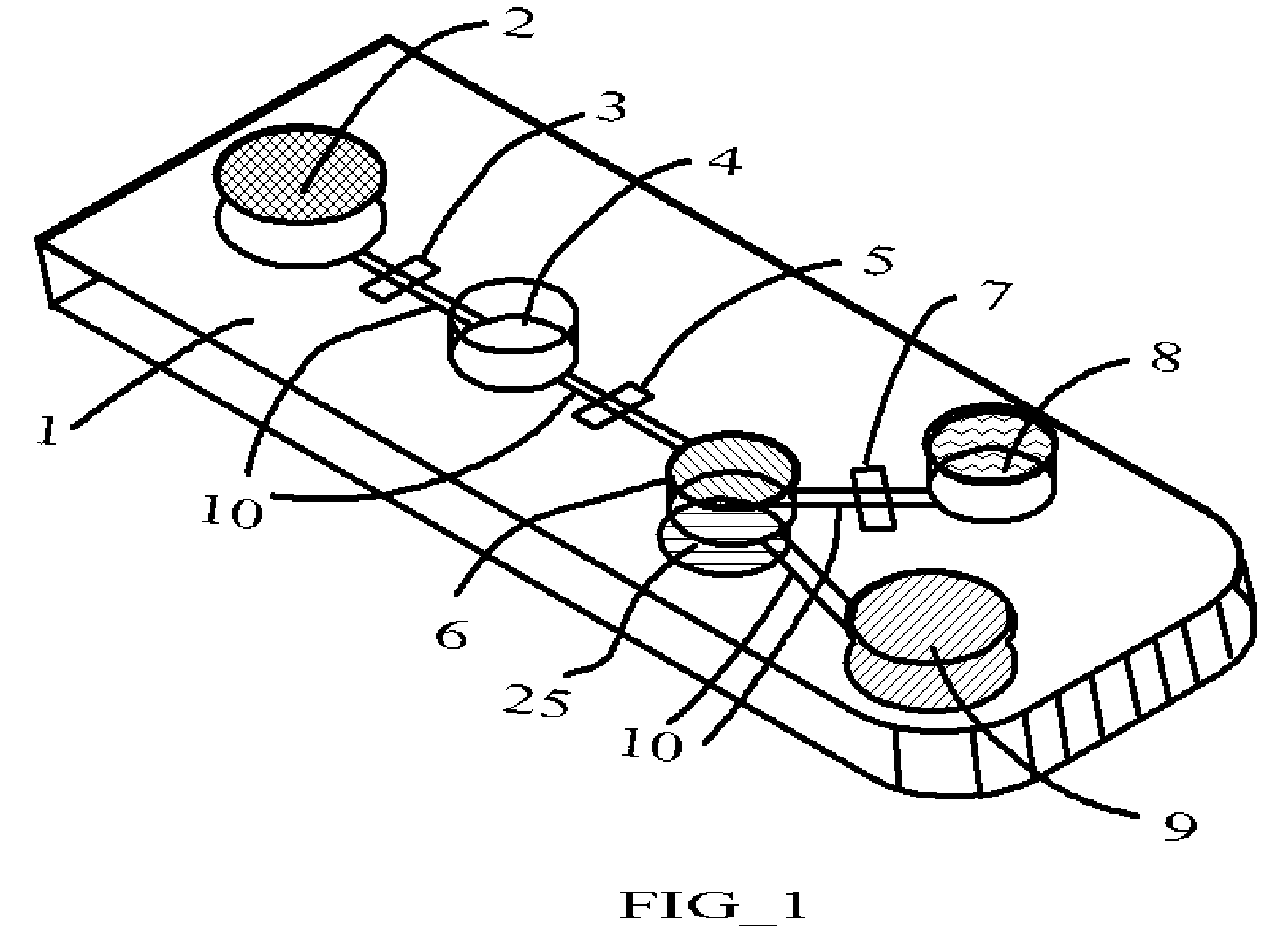

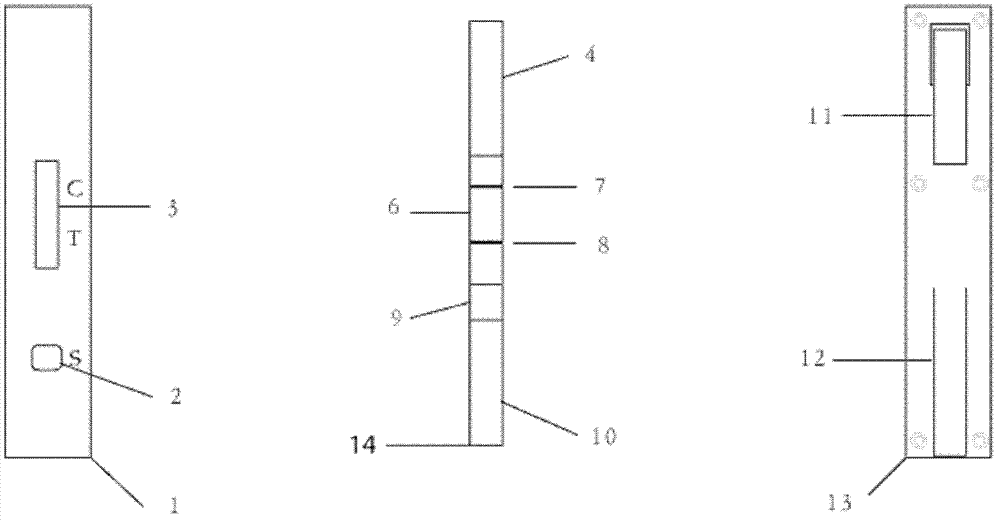

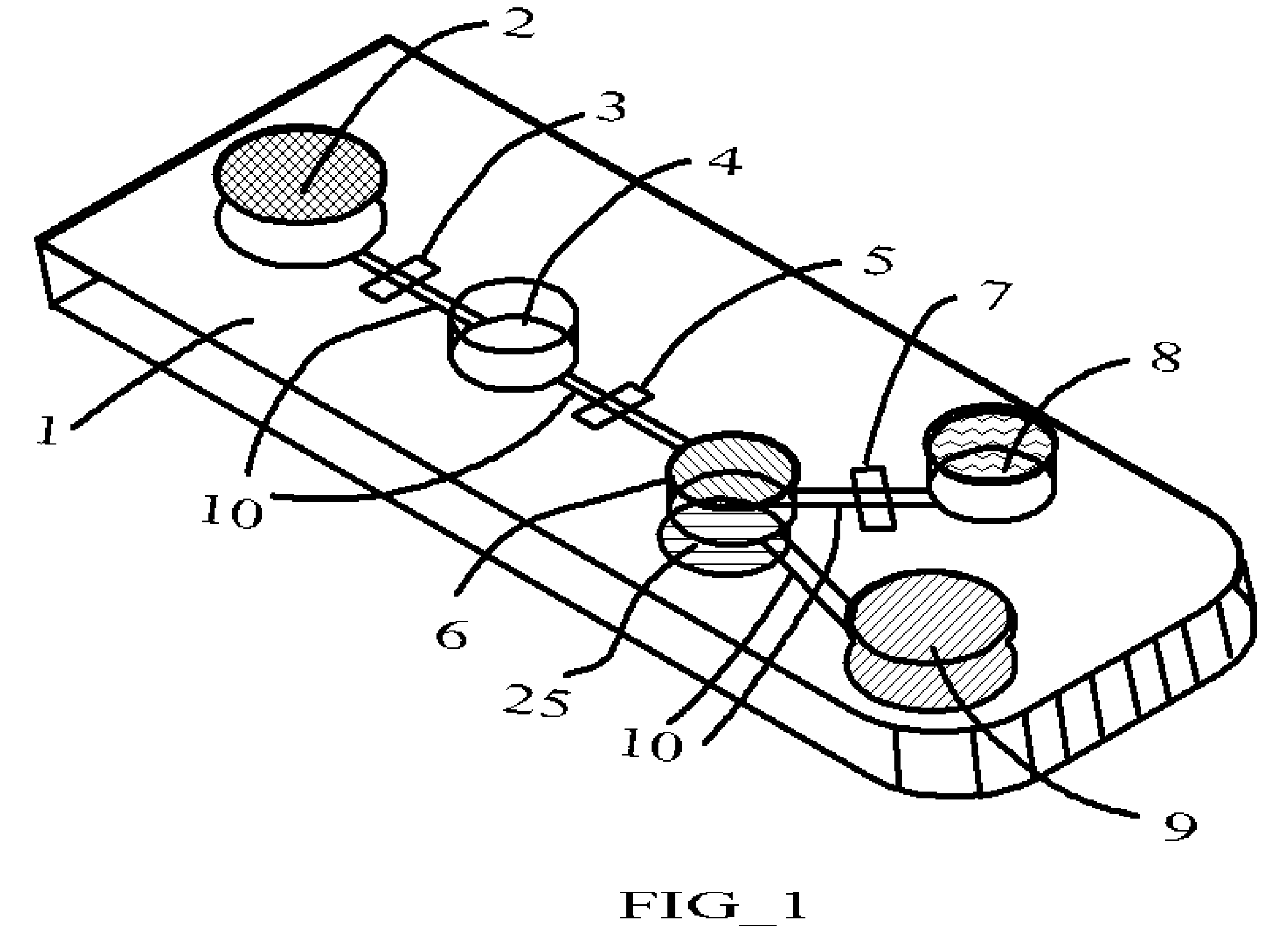

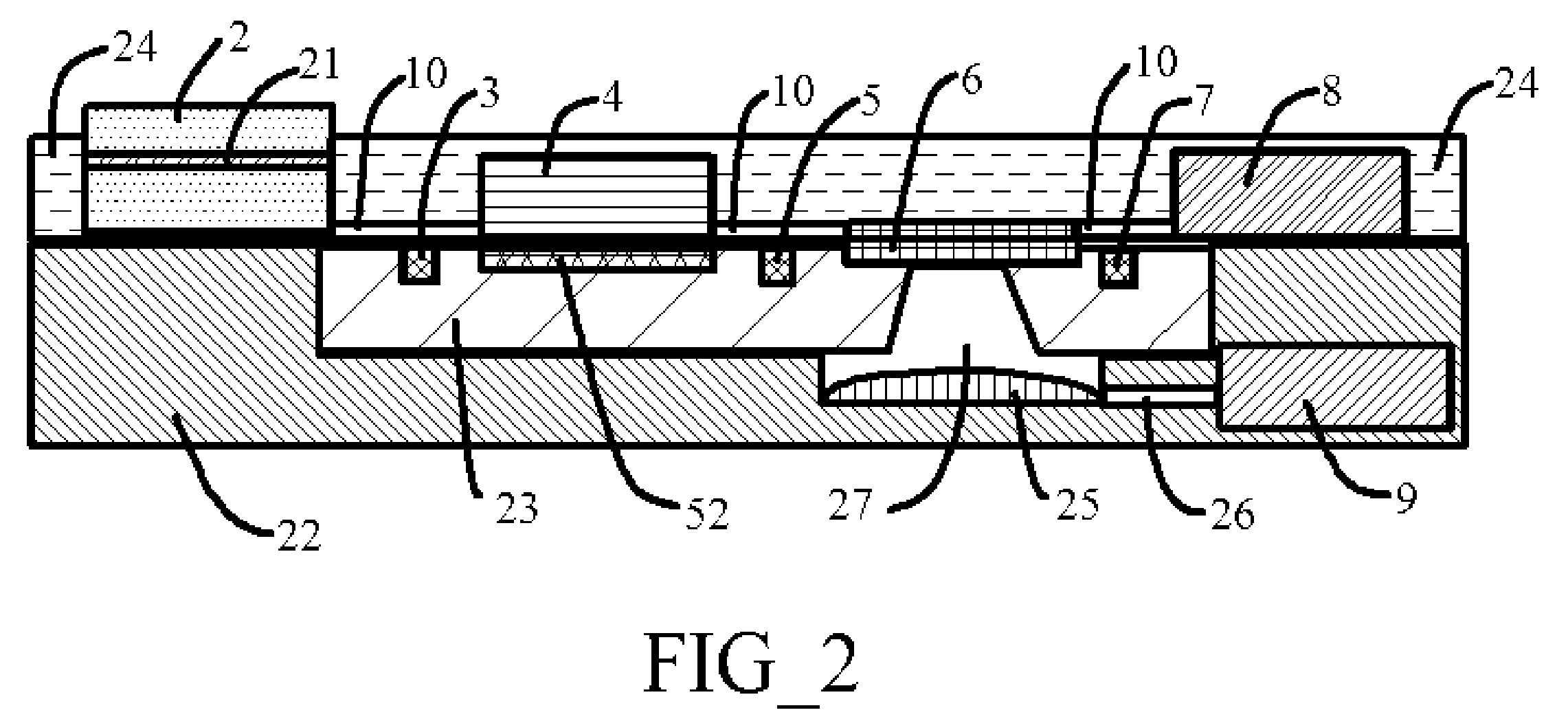

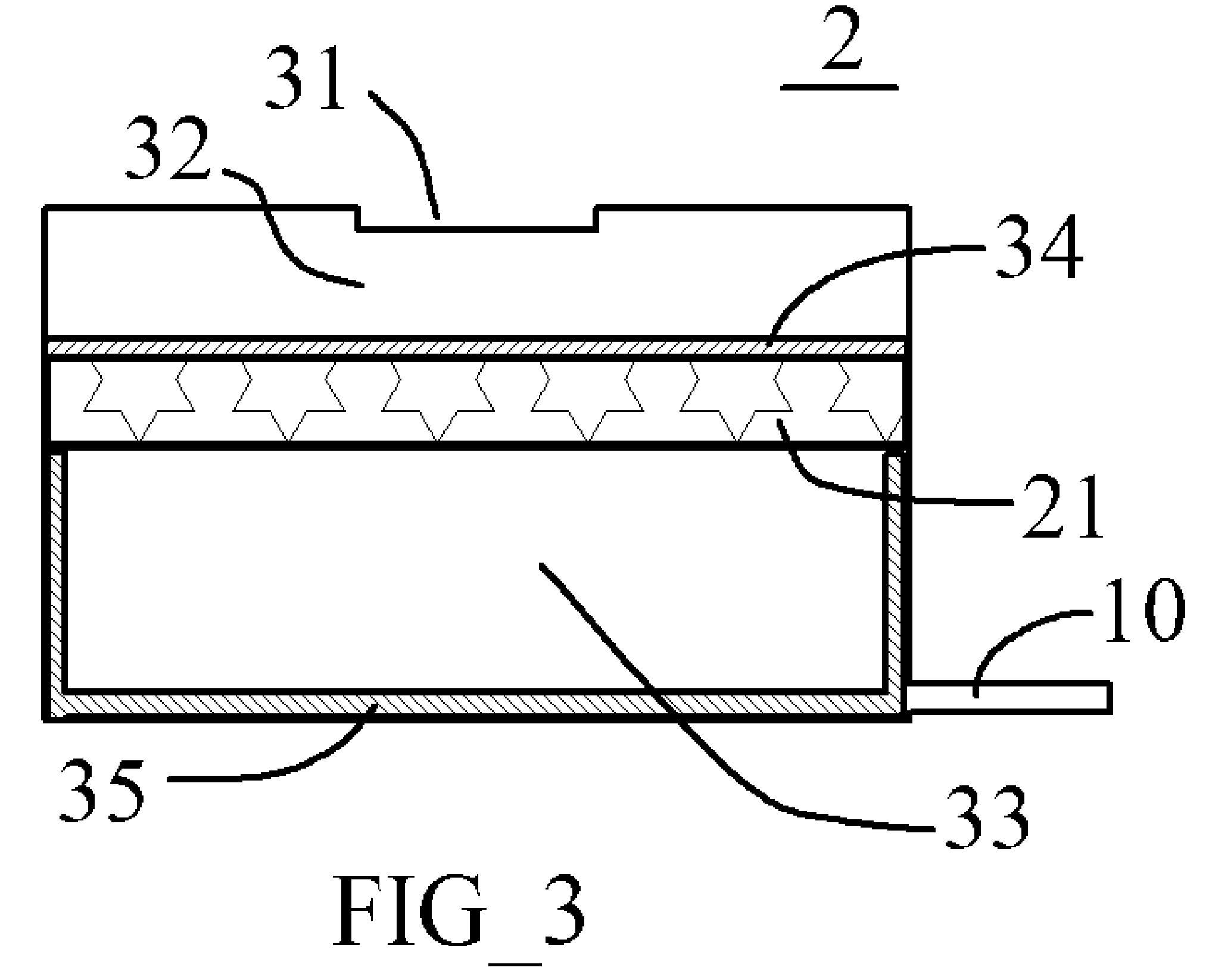

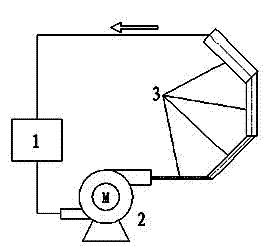

Micromachined Diagnostic Device with Controlled Flow of Fluid and Reaction

ActiveUS20080241962A1Increase binding rateBiological testingParticle suspension analysisAnalyteMicrofluidics

This invention relates to a micromachined microfluidics diagnostic device that comprises one or multiple assaying channels each of which is comprised a sample port, a first valve, a reaction chamber, a second valve, a fluid ejector array, a third valve, a buffer chamber, a capture zone and a waste chamber. Each of these device components are interconnected through microfluidic channels. This invention further relates to the method of operating a micromachined microfluidic diagnostic device. The flow of fluid in the microchannels is regulated through micromachined valves. The reaction of sample analytes with fluorescent tags and detection antibodies in the reaction chamber are enhanced by the micromachined active mixer. By ejecting reaction mixture onto the capture zone through micromachined fluid ejector array, the fluorescent tagged analytes bind with capturing antiodies on capture zone. The fluid ejector array further ejects buffer fluid to wash away unbound fluorescent tags.

Owner:MICROPOINT BIOTECHNOLOGIES CO LTD

Submerged-arc welding repair method after alkali production squeezing roller is worn

ActiveCN104084750AIncrease binding rateImprove wear resistanceArc welding apparatusWelding/cutting media/materialsEngineeringHardness

The invention provides a submerged-arc welding repair method after an alkali production squeezing roller is worn, and belongs to the field of squeezing roller repair and remanufacturing. The method includes the steps that a workpiece is cleaned, a fatigue layer on the roller surface is removed, the size of the repaired part is detected, and the damage part and the abrasion loss are determined; material analysis and hardness detection are conducted on the parent metal of the squeezing roller, and failure analysis and life evaluation are conducted on the workpiece through metallographic detection; relevant parameters of a welding wire and a submerged-arc welding machine are selected according to the detection result and then welding is conducted on the roller surface of the alkali production squeezing roller; mechanical machining is conducted according to requirements; surface colouration flaw detection and overall ultrasonic flaw detection are conducted on the machined workpiece, and roughness of the roller surface is detected. The method has the advantages of being good in wear resistance, high in hardness and strength, and the phenomena of chip off-falling and falling off cannot occur when the method is used.

Owner:河北瑞兆激光再制造技术股份有限公司

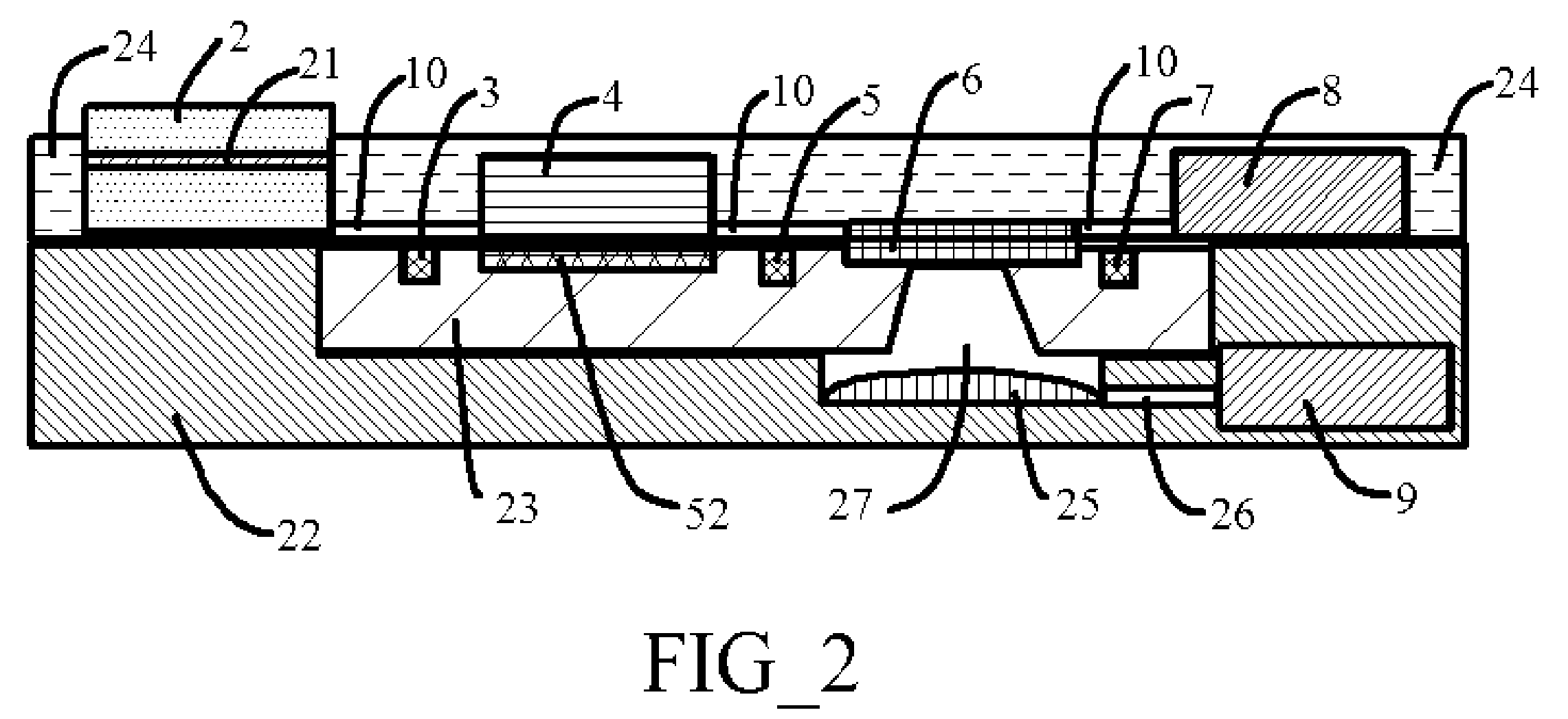

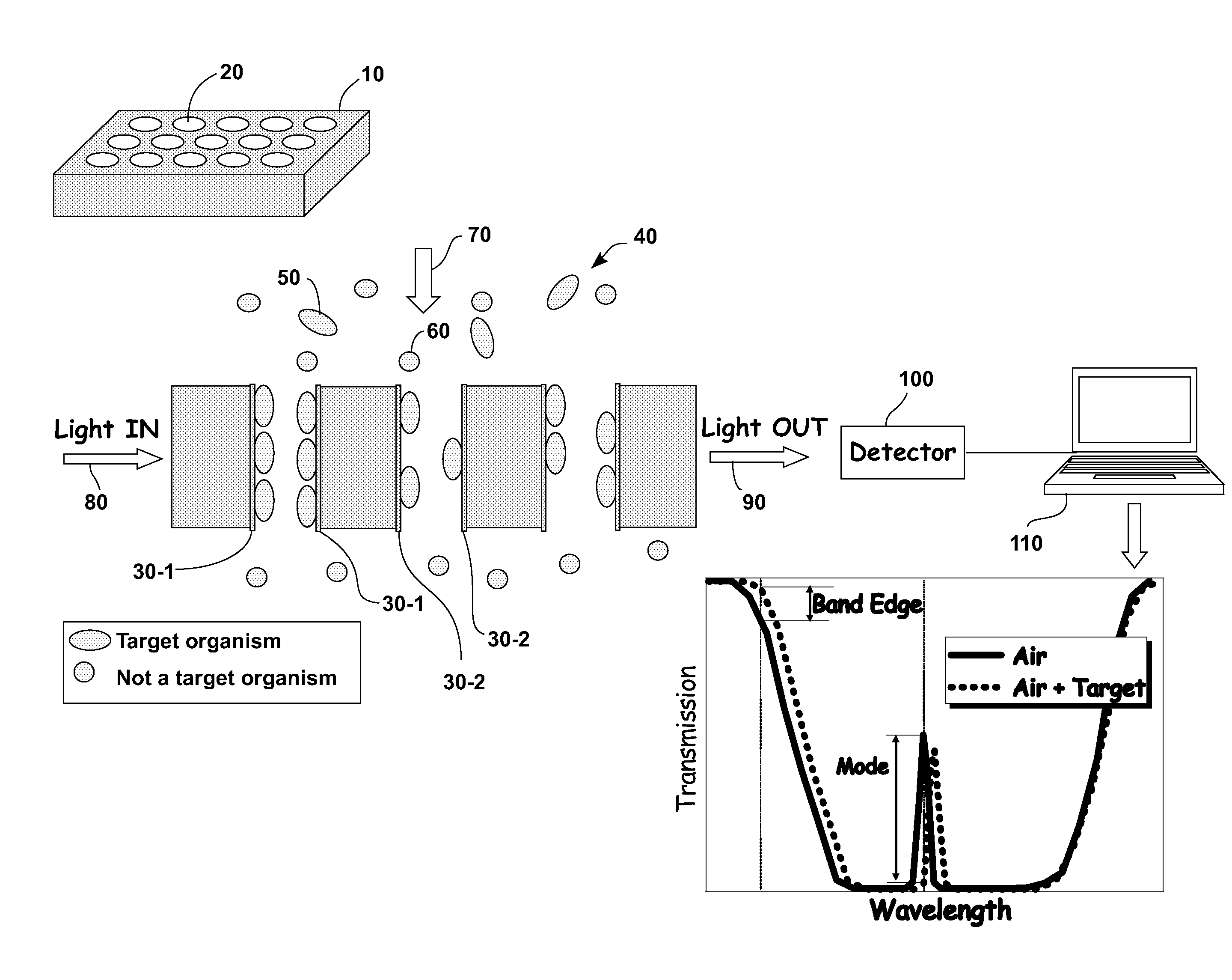

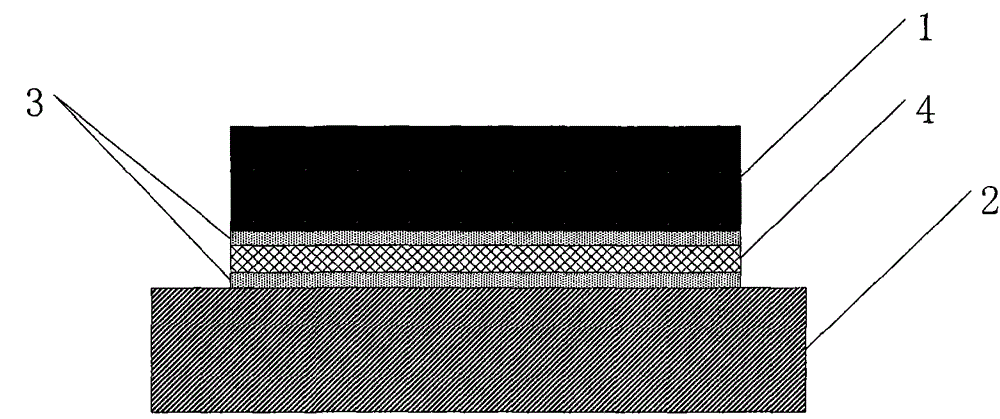

Multiplexed photonic membranes and related detection methods for chemical and/or biological sensing applications

ActiveUS20090244532A1Reduce detection limitIncrease binding rateWavelength-division multiplex systemsMaterial analysis by optical meansMultiplexingSensing applications

Photonic detection systems and methods are shown. A flow through photonic membrane is provided with pores which are distributed along multiple regions. The pores of one region have walls to which a first type of target specific anchor can be attached, while pores of another region have walls to which a second type of target specific anchor can be attached. An additional region of pores without anchors can be provided, so that optical detection occurs differentially. A stack of photonic membranes is also provided. The diameter of the pores of one photonic membrane is larger than the diameter of the pores of another photonic membrane, thus allowing also determination of the size of a target organism flown through the stack of membranes.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Lateral reciprocating immunochromatography method and diagnosis test strip and device based on lateral reciprocating immunochromatography method

ActiveCN102778558AShort reaction timeReduce the probability of bindingMaterial analysisEngineeringBuffer solution

The invention discloses a lateral reciprocating immunochromatography method for detecting biological samples and a diagnosis test strip and a diagnosis device based on the method. The diagnosis device comprises a card bottom, a card cover and a diagnosis test strip, wherein the diagnosis test strip comprises a PVC (Polyvinyl Chloride) plate, and a sample layer, a mark layer, a coated film, a water absorbing layer, a buffer solution sample layer and a water-proof isolating film which are stuck to the PVC plate; the surface of the water absorbing layer is covered with the water-proof isolating film and the sample layer in sequence; the water-proof isolating film is easy to extract; the buffer solution sample layer, the mark layer, the coated film and the water absorbing layer are stuck in sequence along a horizontal extraction direction of the water-proof isolating film; the water absorbing layer and the coated film are not overlapped with each other; and the card cover is respectively provided with a liquid dripping window, an observation window and a sample window at positions corresponding to the buffer solution sample layer, the coated film and the sample layer respectively. The diagnosis device disclosed by the invention is applied to reciprocating immunochromatography, and an antigen or an antibody in a sample undergoes a secondary reaction with antibodies or antigens of T and C lines on the coated film, so that the antigen and antibody reaction time is increased, and the sensitivity is increased by 50-100 times than the conventional unidirectional chromatography test strip.

Owner:广东伊康纳斯生物医药科技股份有限公司

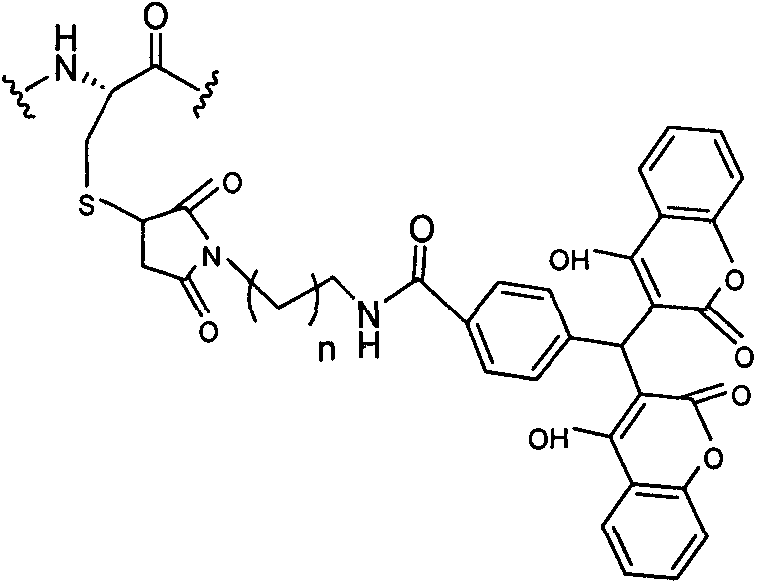

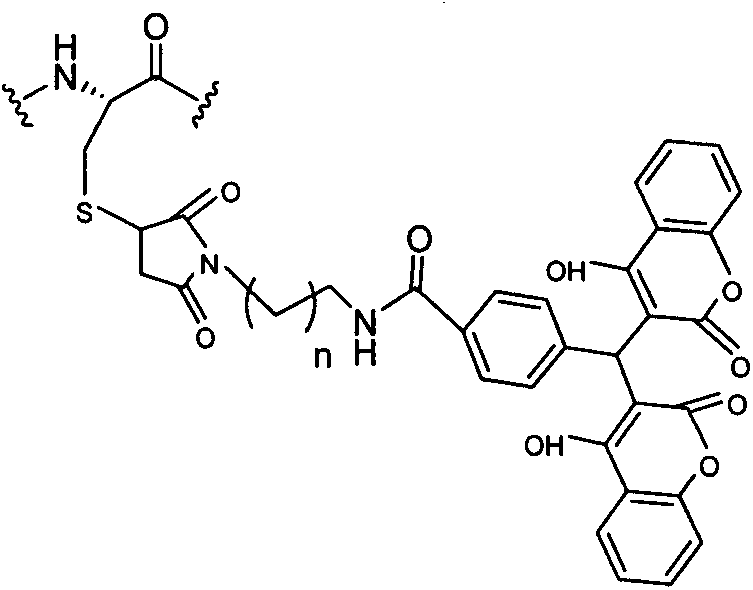

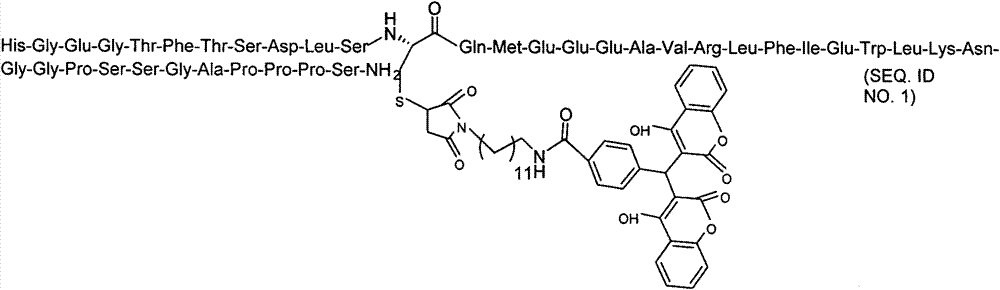

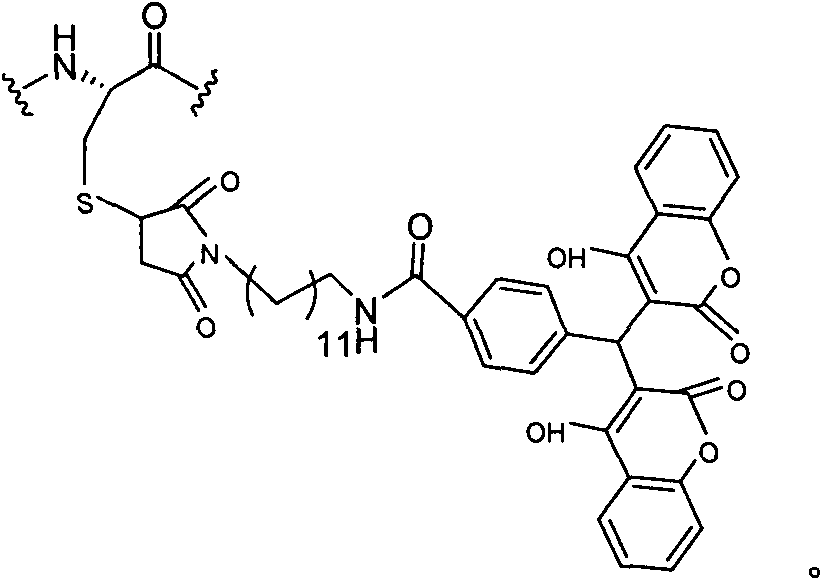

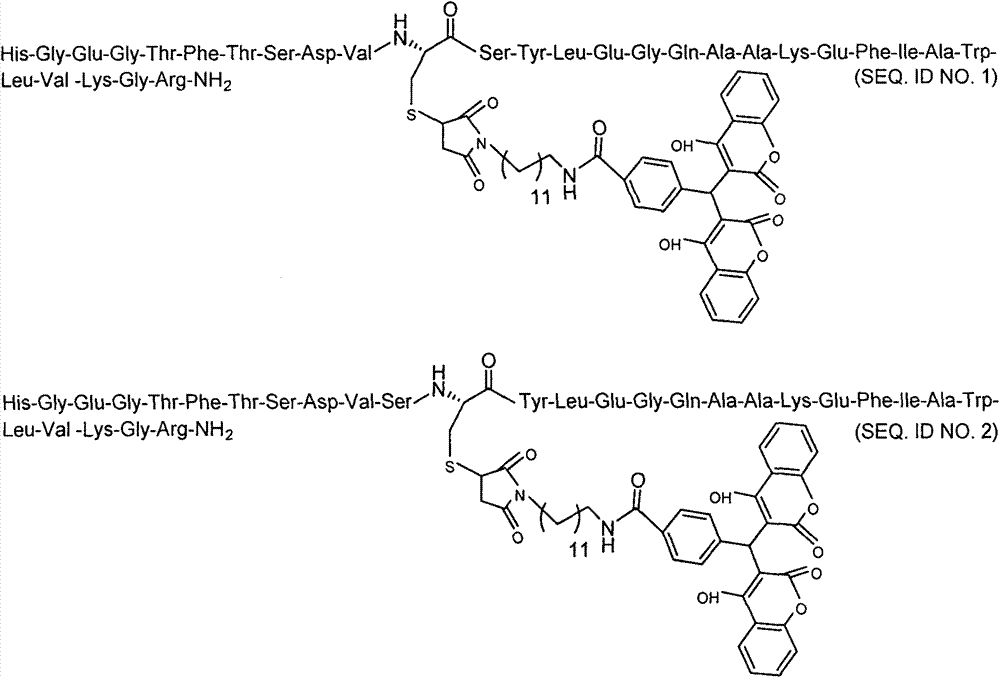

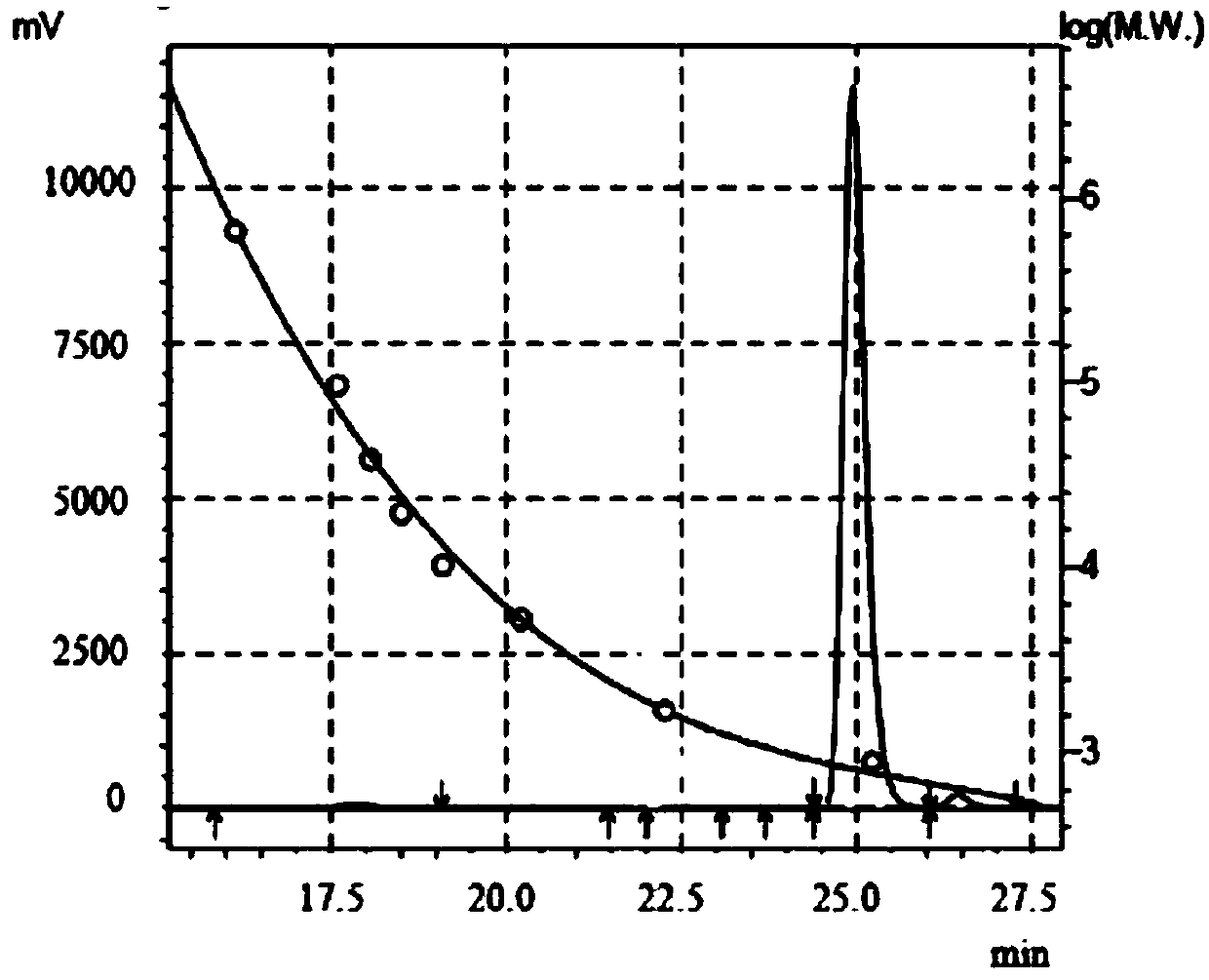

Long-effecting exenatide (Exendin-4) analogue and application thereof

ActiveCN107141348AGood hypoglycemic effectChemically stablePeptide/protein ingredientsMetabolism disorderSynthesis methodsPharmacologic action

The invention relates to a long-effecting exenatide (Exendin-4) analogue and a synthetic method thereof. The Exendin-4 is modified to obtain the Exendin-4 analogue with longer pharmacologic action time, the synthesis of target polypeptide is quickly realized through an orthogonally protection strategy solid-phase synthesis method, and a crude product is purified and freeze-dried to obtain the Exendin-4 analogue.

Owner:CHINA PHARM UNIV

Micromachined diagnostic device with controlled flow of fluid and reaction

This invention relates to a micromachined microfluidics diagnostic device that comprises one or multiple assaying channels each of which is comprised a sample port, a first valve, a reaction chamber, a second valve, a fluid ejector array, a third valve, a buffer chamber, a capture zone and a waste chamber. Each of these device components are interconnected through microfluidic channels. This invention further relates to the method of operating a micromachined microfluidic diagnostic device. The flow of fluid in the microchannels is regulated through micromachined valves. The reaction of sample analytes with fluorescent tags and detection antibodies in the reaction chamber are enhanced by the micromachined active mixer. By ejecting reaction mixture onto the capture zone through micromachined fluid ejector array, the fluorescent tagged analytes bind with capturing antiodies on capture zone. The fluid ejector array further ejects buffer fluid to wash away unbound fluorescent tags.

Owner:MICROPOINT BIOTECHNOLOGIES CO LTD

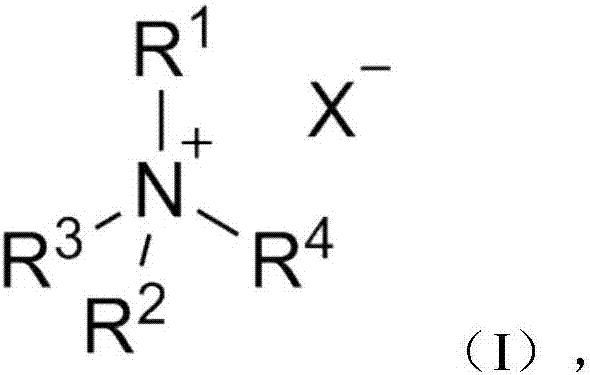

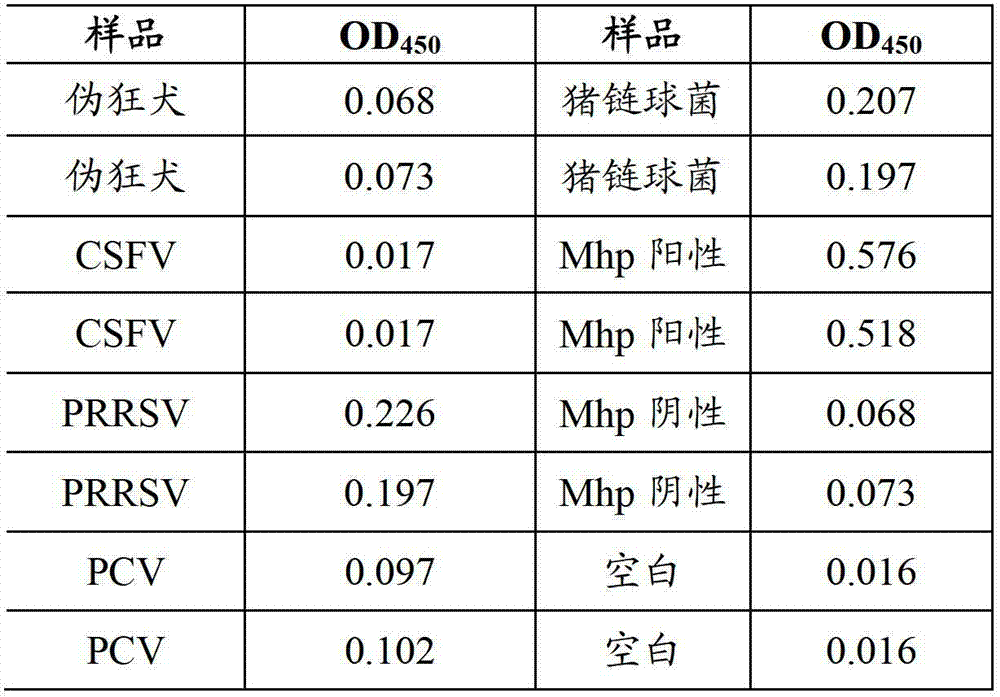

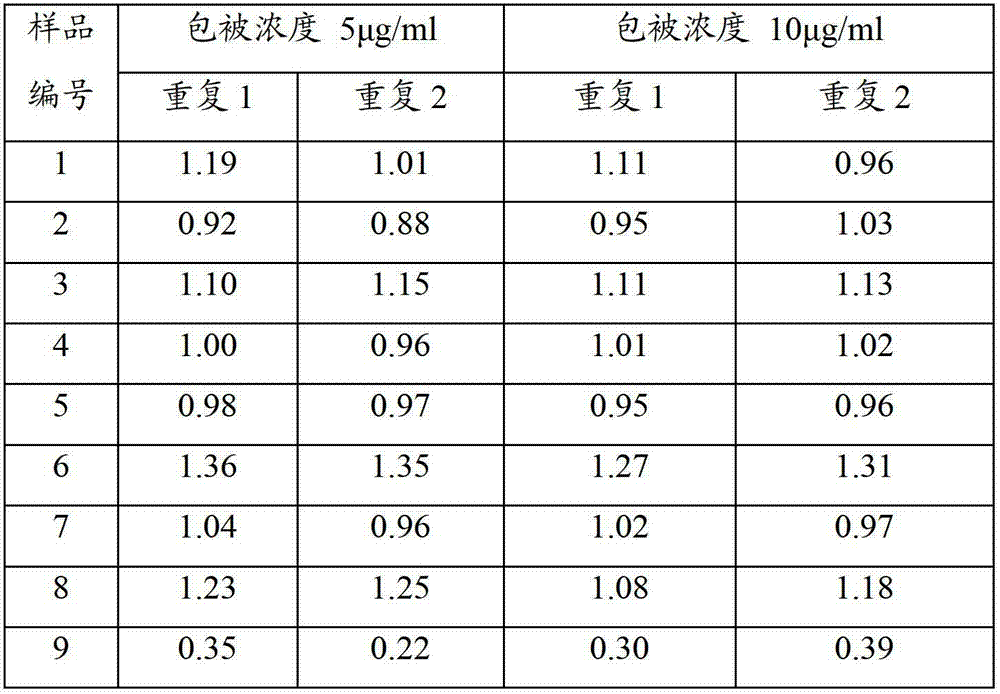

Mycoplasma hyopneumoniae antibody detection kit and manufacture method thereof

ActiveCN102928585AIncrease binding rateHigh detection sensitivityMaterial analysisSorbentImmunologic Surveillance

The invention belongs to the detection field of biotechnology and particularly relates to a mycoplasma hyopneumoniae antibody detection kit and a manufacture method thereof. A solid carrier is wrapped by a link-coupled mycoplasma hyopneumoniae peculiar polypeptide antigen, and the manufactured mycoplasma hyopneumoniae peculiar polypeptide antigen enzyme-linked immuno sorbent assay (ELISA) detection kit is used for clinical detection of mycoplasma hyopneumoniae infection, epidemiological investigation and immunologic surveillance. The non-protein polymer directional link-coupled mycoplasma hyopneumoniae peculiar polypeptide antigen serves as the wrapping solution, the combination efficiency of polypeptide and a target antibody is effectively improved, accordingly, detection sensitivity is remarkably improved, non-singular background value reading is remarkably reduced simultaneously, the specificity is high, and the detection kit has the advantages of being easy to operate, fast in diagnosis, economic and convenient in large-scale detection and the like. The manufacture method is convenient to popularize and has wide application prospect. When the kit is used for detecting samples, the using amount of the wrapping antigen can be reduced to 10ng / ml, so that cost is reduced, and popularization and using are facilitated.

Owner:GUANGDONG HAID ANIMAL HUSBANDRY & VETERINARY RES INST +1

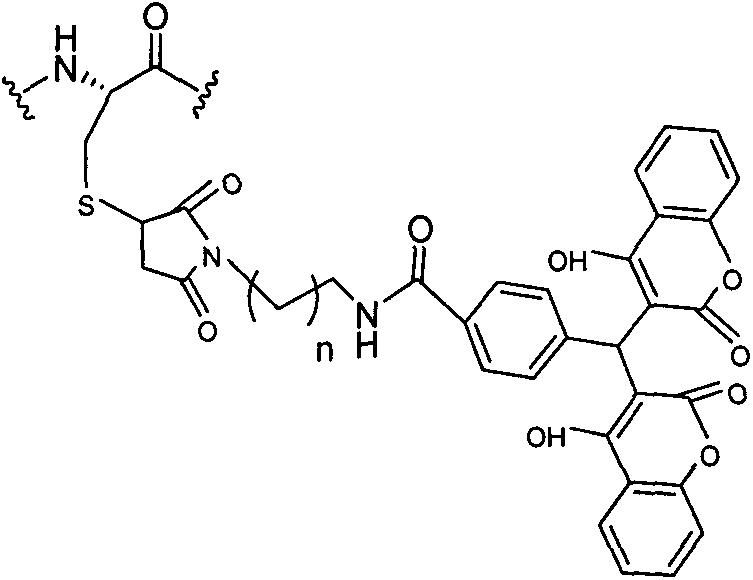

Preparation method and application of MOFs (Metal Organic Frameworks) material-based competitive electrochemical immunosensor

ActiveCN108918627AImprove conductivityIncrease binding rateMaterial electrochemical variablesElectrochemistryMetal-organic framework

The invention relates to preparation and application of a competitive immunosensor, in particular to a competitive immunosensor which takes a composite material of UiO-66 and gold nanoparticles (UiO-66 / Au) as a sensing platform and NH2-MIL-125 as a marker, and belongs to the technical field of novel functional materials and biosensing. The UiO-66 / Au has excellent electrical conductivity and largespecific surface area, so that the electron transfer process can be effectively promoted and the roles of amplifying the current signal and increasing the sensitivity of the sensor are played; and theNH2-MIL-125 synthesized by utilizing an one-pot method has large steric hindrance to ensure that the electron transfer can be hindered and the current signal is reduced, so that the changing value ofthe current signal is increased, the content of a target can be detected by utilizing the change of the electrochemical signal by the sensor; and therefore, the stability and the sensitivity of the immunosensor are significantly increased, the detection range is expanded and the detection limit is reduced.

Owner:UNIV OF JINAN

Copper nanofluid solar cooling liquid and preparation method thereof

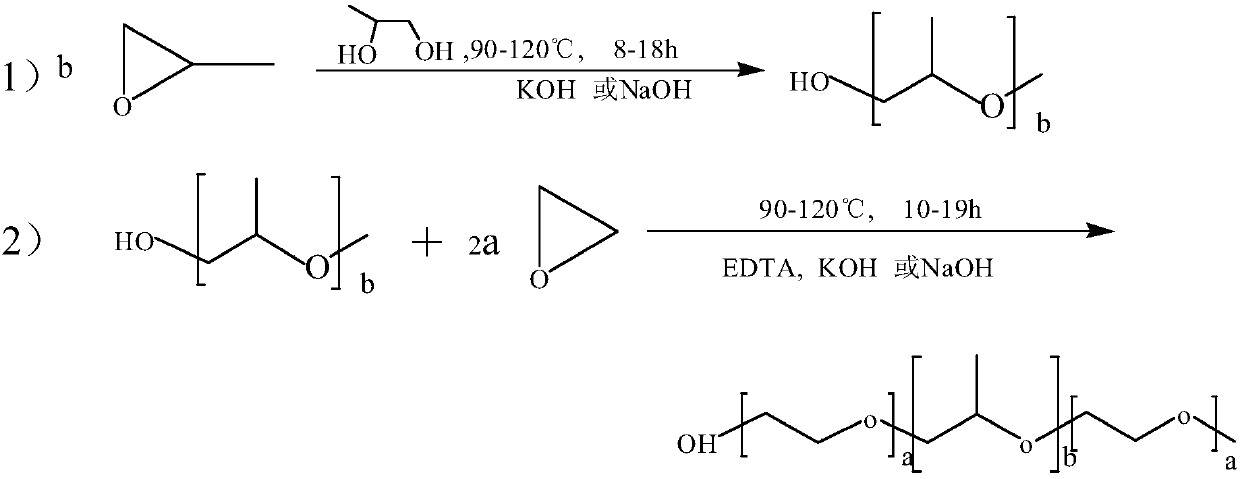

InactiveCN103045181ASolve Oxidation ProblemsDoes not affect thermal conductivityHeat-exchange elementsPhosphatePropanediol

The invention provides a copper nanofluid solar cooling liquid and a preparation method thereof, and belongs to the field of synthesis technologies of inorganic materials. The copper nanofluid solar cooling liquid comprises deionized water, glycol and propylene glycol, nano-copper powder, vinylpyridine, azodiisobutyronitrile, acylamino compound, phosphates and benzotriazole. The preparation method comprises the following steps of: uniformly dispersing the nano-copper powder into alcoholic solution by rapid dispersing; polymerizing on the nanometer copper surface to obtain a monomolecular film; adding a dispersing agent; mixing the obtained alcoholic solution with phosphate aqueous solution; dispersing and mixing at a medium speed again; dispersing by an ultrasonic oscillating instrument; and then homogenizing through a fold-type reducer pipe, so as to obtain the copper nanofluid solar cooling liquid. The prepared copper nanofluid has the characteristics that the thermal conductivity is four times higher than that of the deionized water, the uniformity in dispersing is realized, the stability is excellent, the stability is remained after placing for 2400 hours at the normal state, the freezing point is low, no icing occurs at the temperature of -40 DEG C, the corrosion resistance is excellent, and the copper nanofluid is suitable for an anti-freezing liquid, and the material source is rich; the raw materials are directly sourced, low in price and easy to obtain; low requirement is brought to the running of the equipment; and the massive industrial production can be easily realized.

Owner:济南道生一新能源科技有限公司

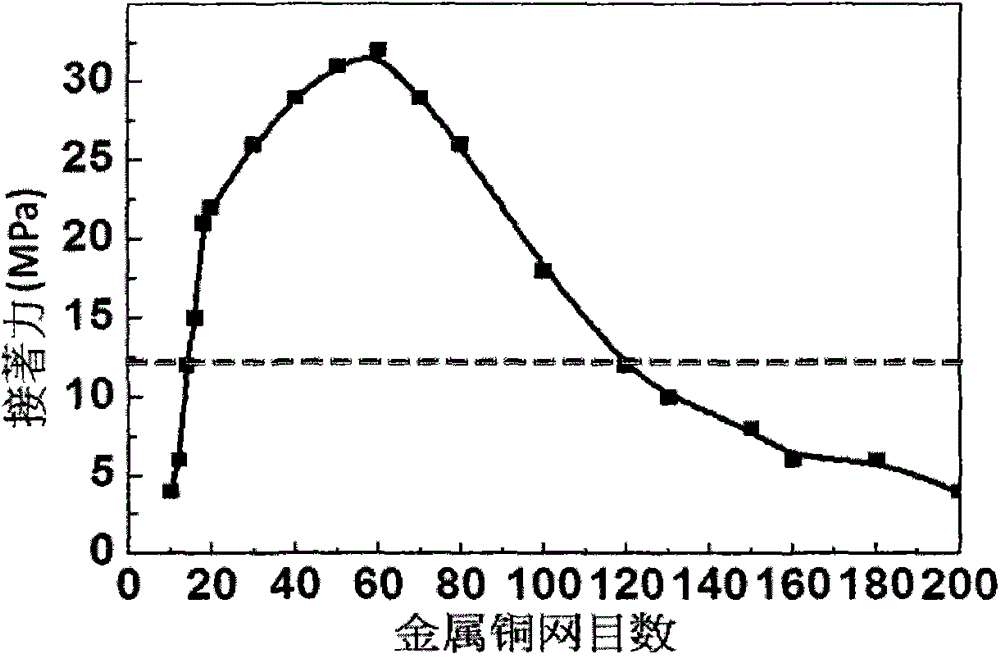

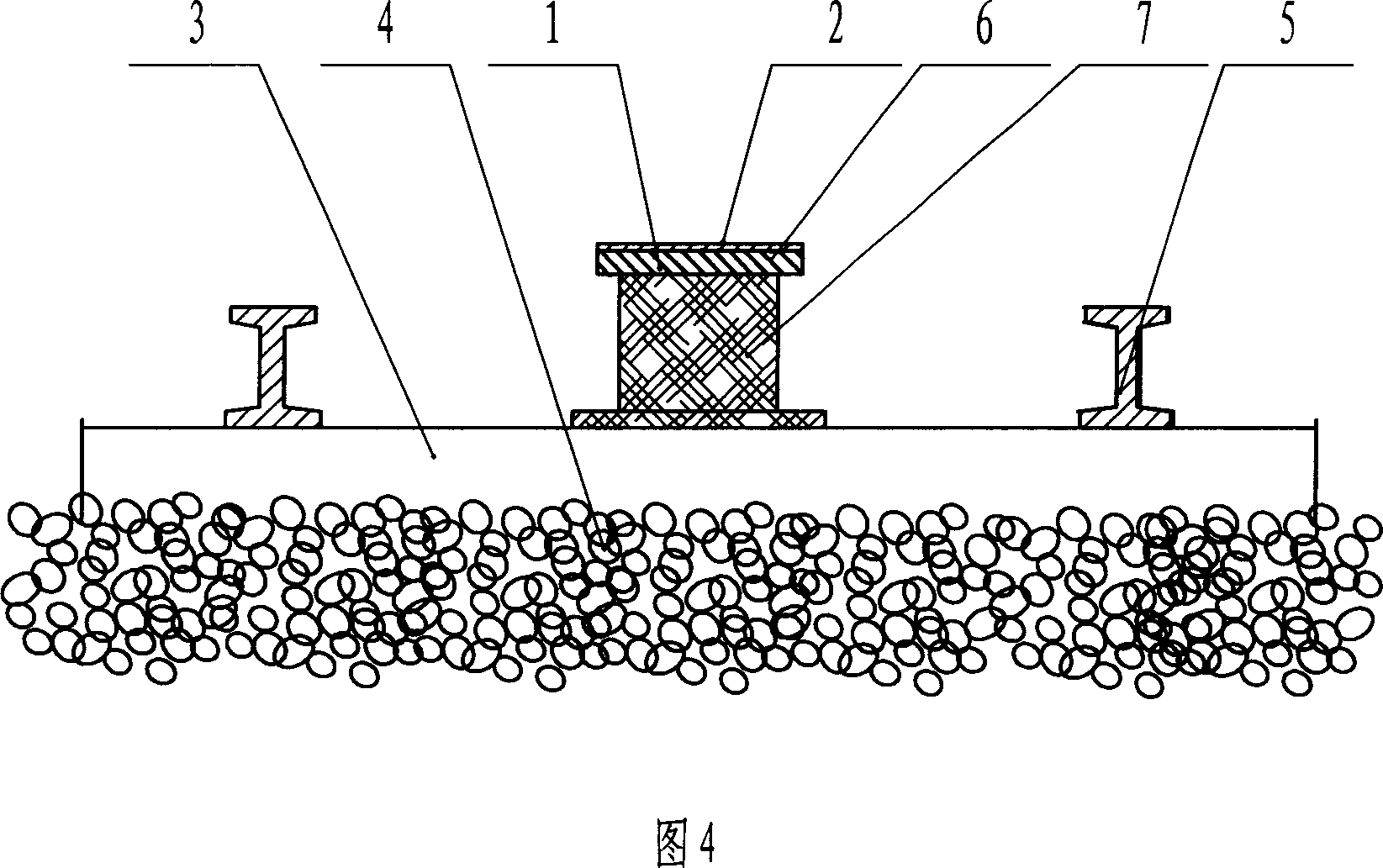

Target material binding method

ActiveCN104928633AIncrease binding rateAvoid off-target hazardsVacuum evaporation coatingSputtering coatingThermal conductivitySieve

The invention discloses a target material binding method; a non-magnetic metal net with the sieve hole size of 20-120 mesh is arranged in a welding layer between a target material and a backing plate, so as to effectively eliminate or splitting large bubbles existing in the welding layer, greatly increase the binding rate of the target material, and effectively avoid target material missing risk caused because the large bubbles are accumulated in the welding layer due to heat in the target material use process; at the same time, the presence of the non-magnetic metal net can also increase the electrical and thermal conductivity and heat resistance of the welding layer, and plays a buffering role and a welding layer thickness controlling role. The method has the advantages of simple process, easy obtained raw material and low cost, and the obtained product has good reliability and has broad application prospects.

Owner:HANERGY MOBILE ENERGY HLDG GRP CO LTD

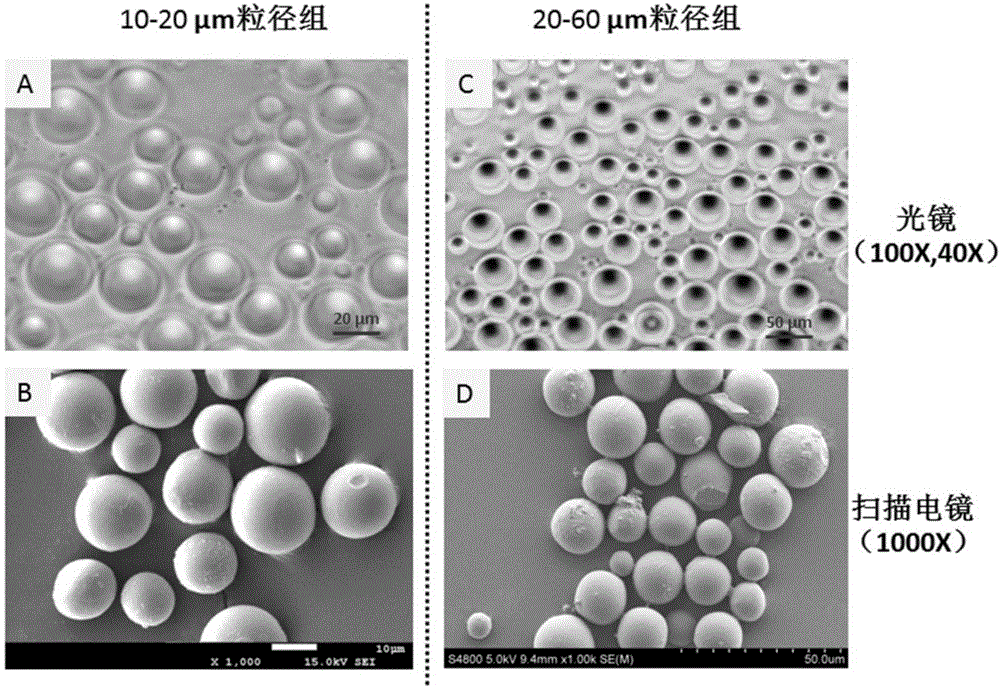

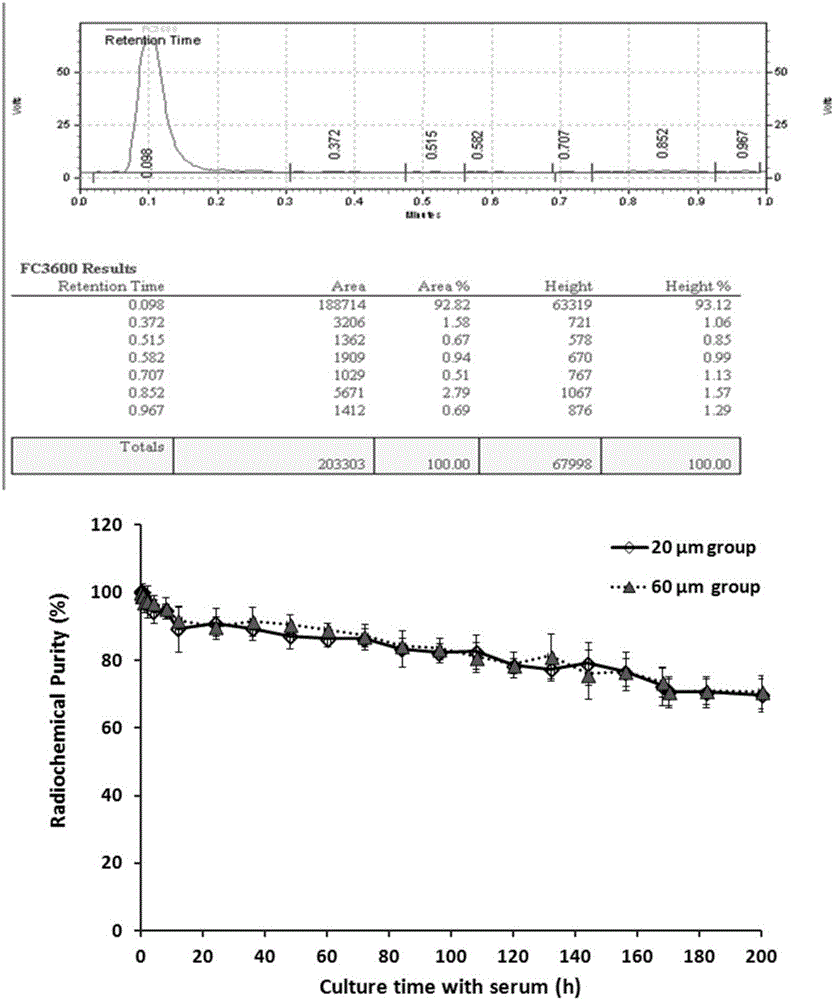

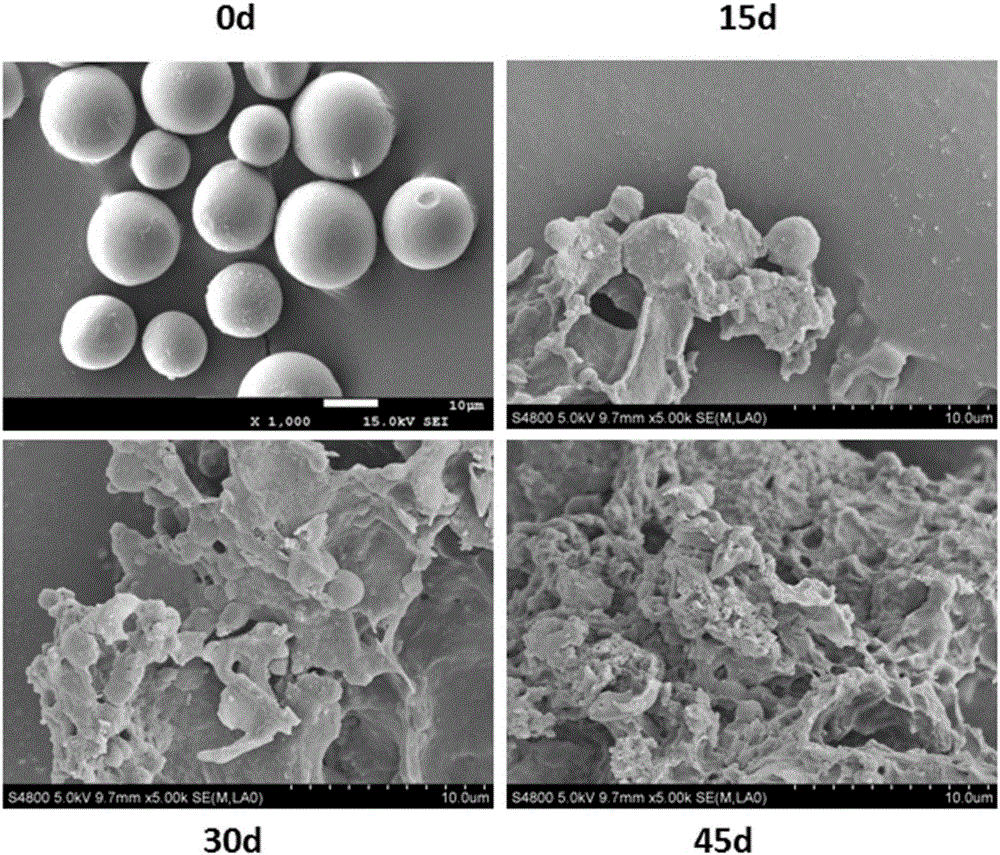

Preparation method and application of radioiodinated biodegradable chitosan-collagen composite microsphere medicine

InactiveCN106344939AGood biocompatibilityStable degradationPowder deliveryRadioactive preparation carriersMicrosphereBiocompatibility Testing

The invention discloses a composite microsphere. The composite microsphere is formed in a way that chitosan and collagen are combined. The invention further discloses a radioactive microsphere for radioactive therapy, and radionuclides are marked on the microsphere. The invention further discloses a preparation method and application of the microsphere. According to the composite microsphere, the preparation method and the application, a biodegradable chitosan-collagen composite microsphere is used as nuclide and a drug carrier, both the chitosan and the collagen have good biocompatibility, are biodegradable and can be stably combined with a plurality of radionuclides and drugs (such as chemotherapy drugs, bioactive macromolecules and the like), and clinical application prospects are good.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

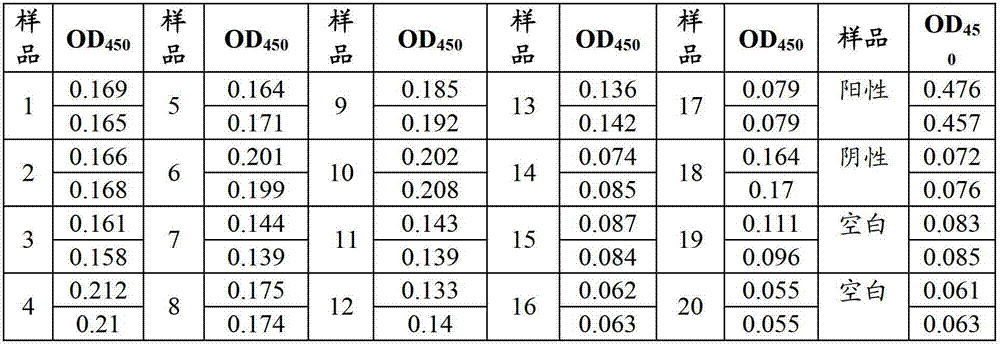

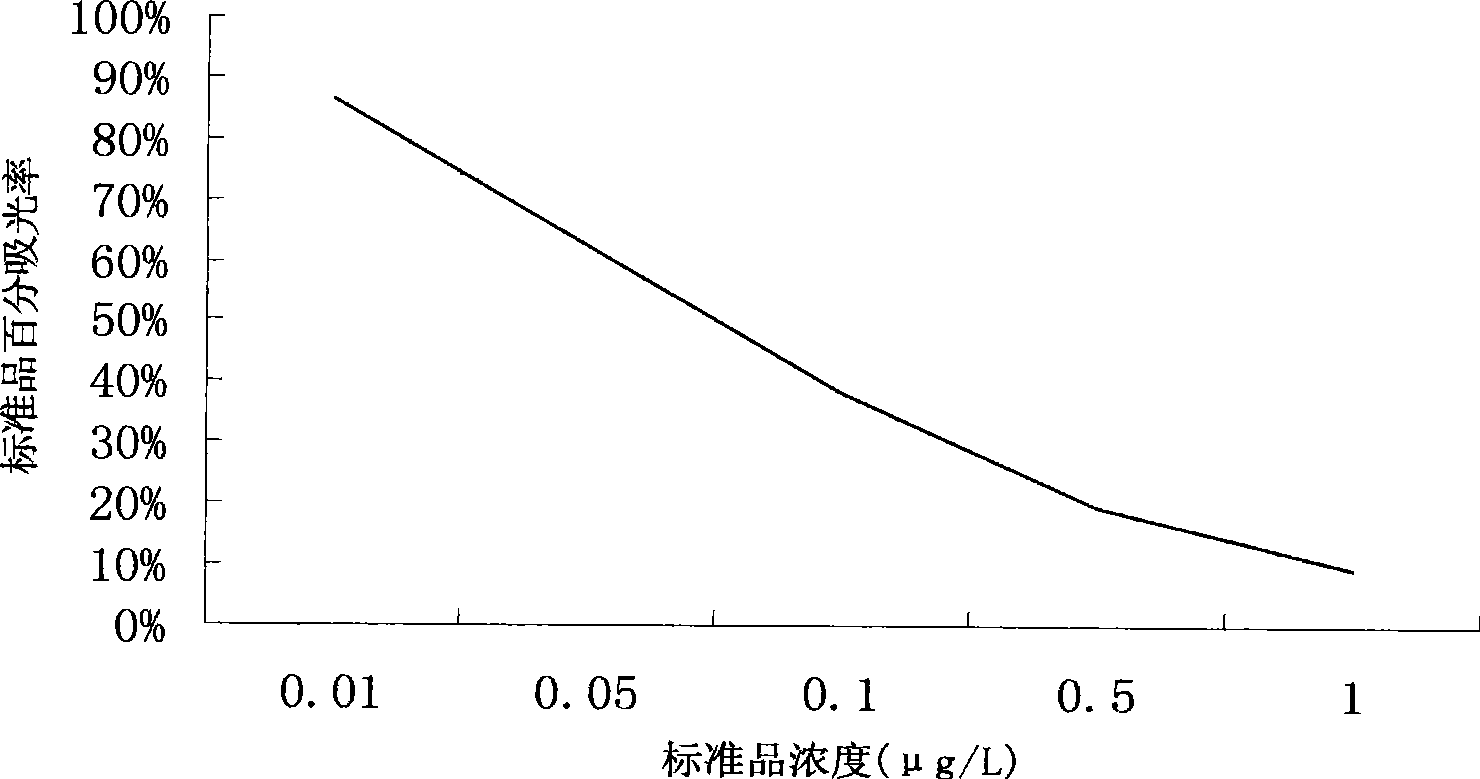

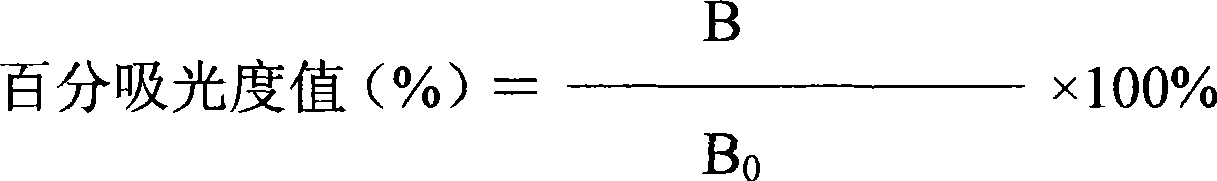

ELISA reagent for detecting malachite green and method

InactiveCN101424686ASimple and fast operationThe pre-processing process is simpleMaterial analysisMalachite greenMalachite green stain

The invention discloses an Elisa agent for detecting malachite green and a method thereof. The Elisa agent comprises a malachite green antigen or antibody coated Elisa plate, an enzyme label, a malachite green specific antibody, a malachite green standard solution, a substrate developing solution, a stop solution, a concentrated cleaning solution, enzyme label diluents and a concentrated combined solution. The Elisa agent is used for the quantitative detection of the content of the malachite green in fishes, shrimps and water samples and has the advantages of high specificity and sensitivity, easy sample pretreatment, short detection time, large sample detection amount, and the like.

Owner:深圳市绿诗源生物技术有限公司

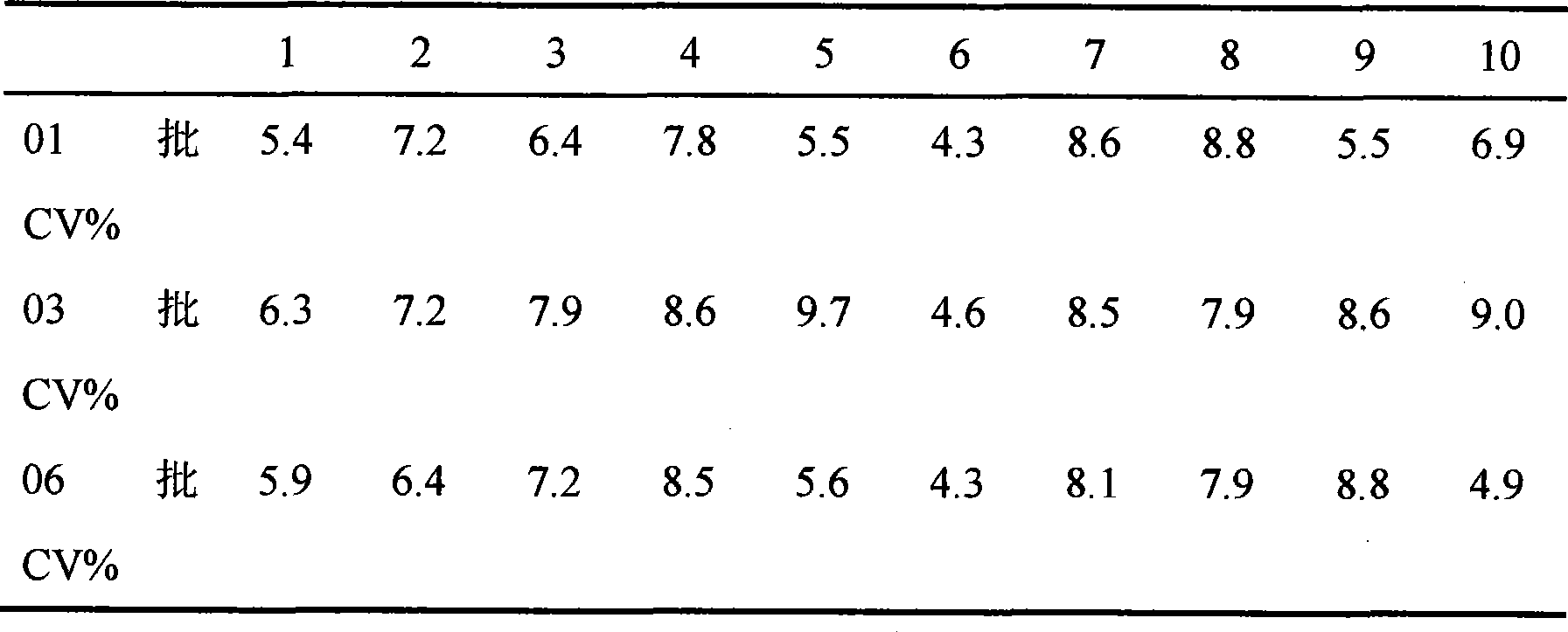

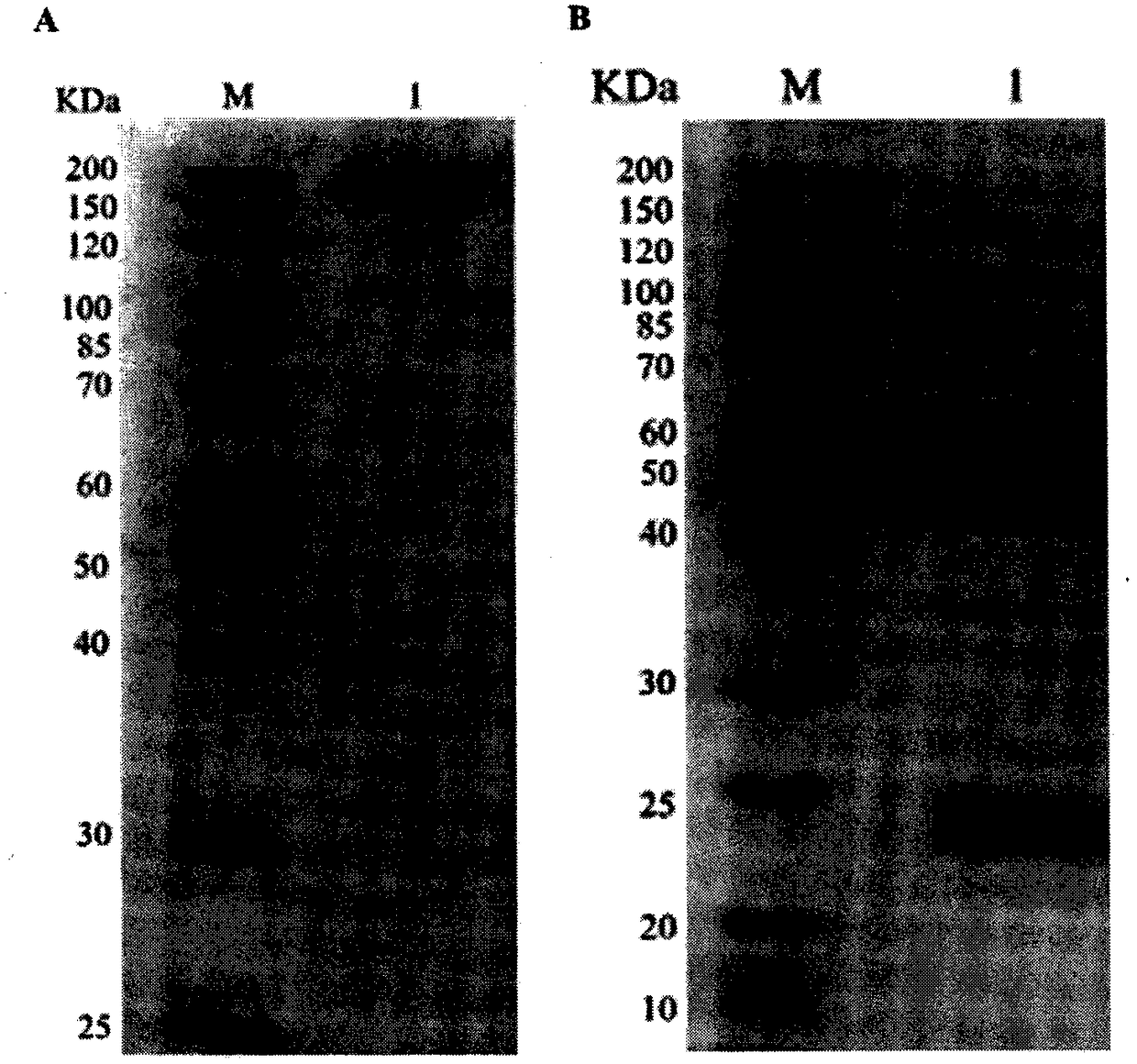

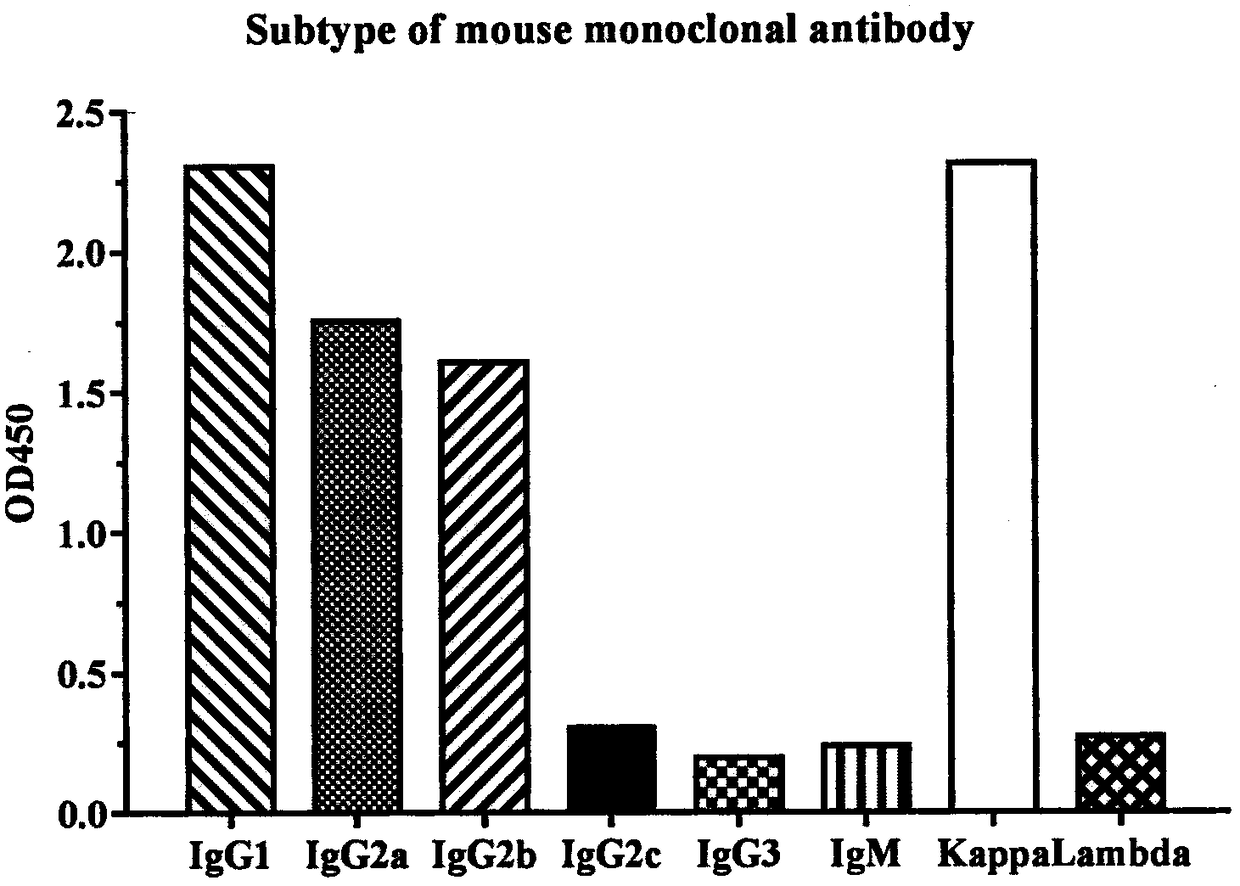

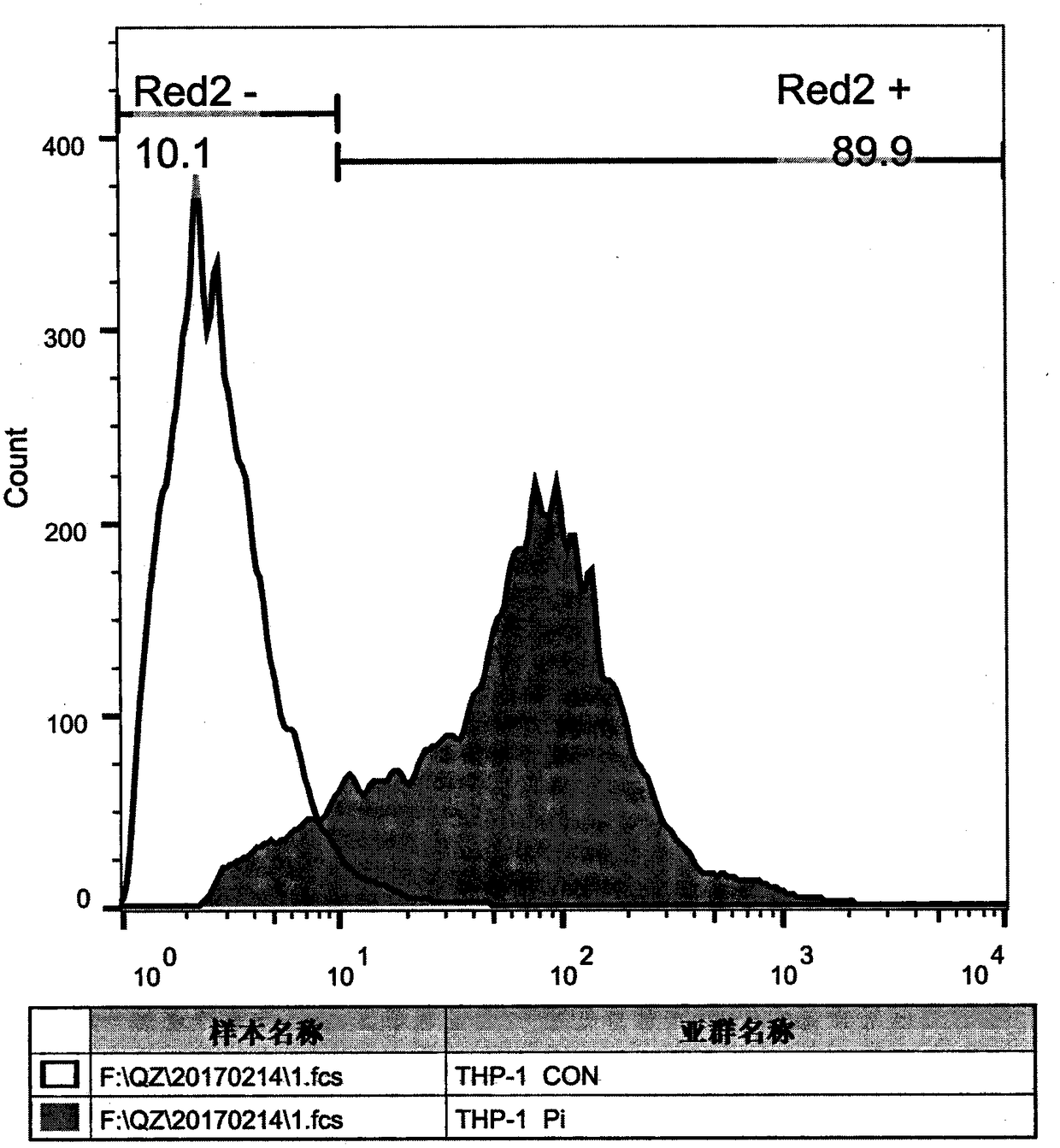

Anti-PD-1 monoclonal antibody and application thereof

ActiveCN108314734AStrong specificityIncrease binding rateImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsNucleotidePD-L1

The invention relates to a novel anti-PD-1 monoclonal antibody and a variable region sequence of the antibody and belongs to the technical field of biology. The novel anti-PD-1 monoclonal antibody takes recombinant human PD-1 protein (rhEPD-1) as an immunogen for immunizing a BAL b / c mouse; spleen cells of the mouse are taken and are fused with myeloma cells sp2 / 0-Ag14 to obtain a hybridoma cell line capable of expressing the anti-PD-1 antibody; the cell line can stably secrete the single monoclonal antibody. According to the novel anti-PD-1 monoclonal antibody, variable region nucleotide andamino acid sequences of an H chain and an L chain of the anti-PD-1 monoclonal antibody are cloned at the same time. The anti-PD-1 monoclonal antibody provided by the invention can be specifically combined with PD-1 and the combination of the PD1 and PD-L1 is blocked; functions of T cells are recovered. The novel anti-PD-1 monoclonal antibody can be used as an immune checkpoint inhibitor and is used for treating cancer and infectious diseases.

Owner:CHINA PHARM UNIV

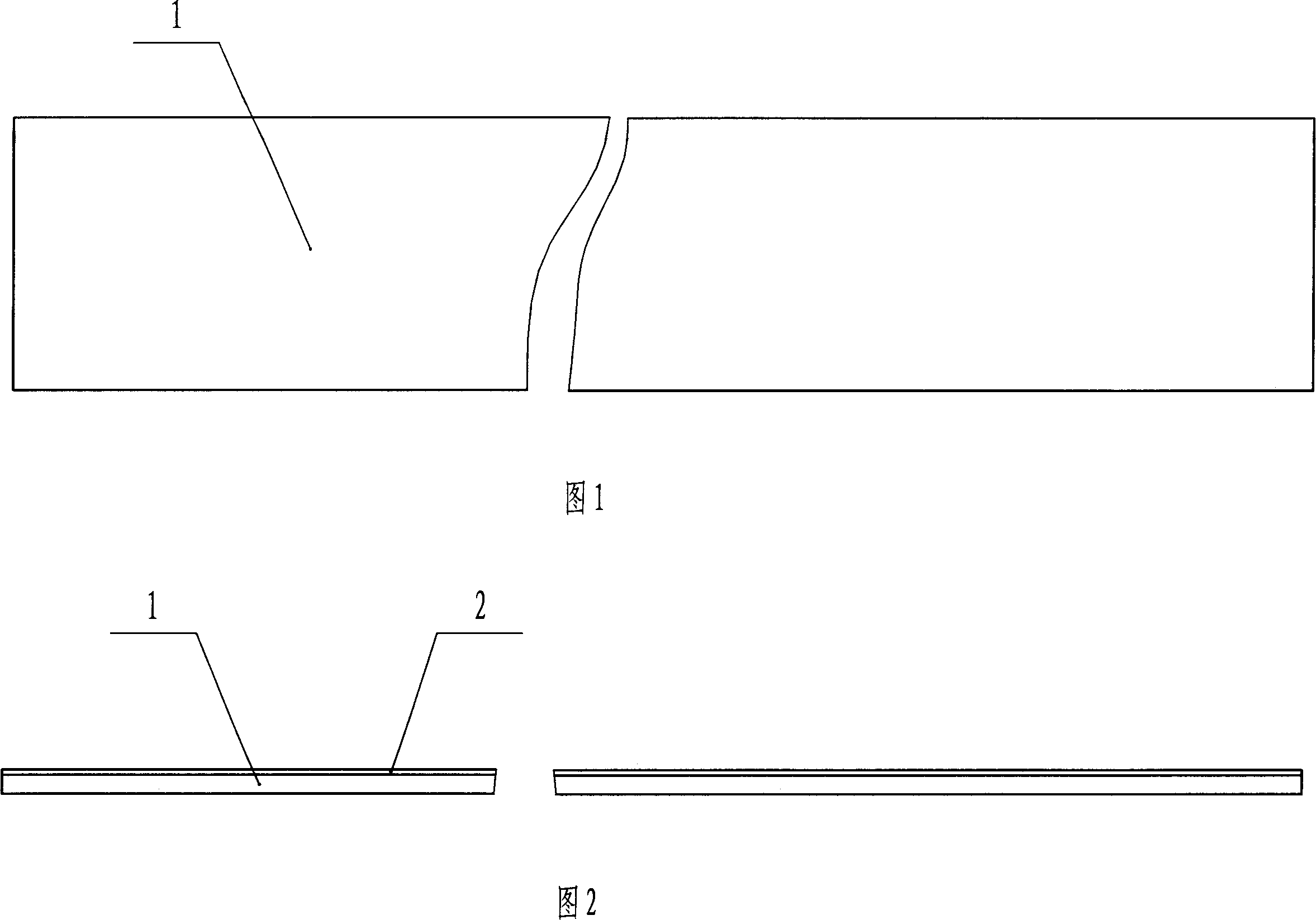

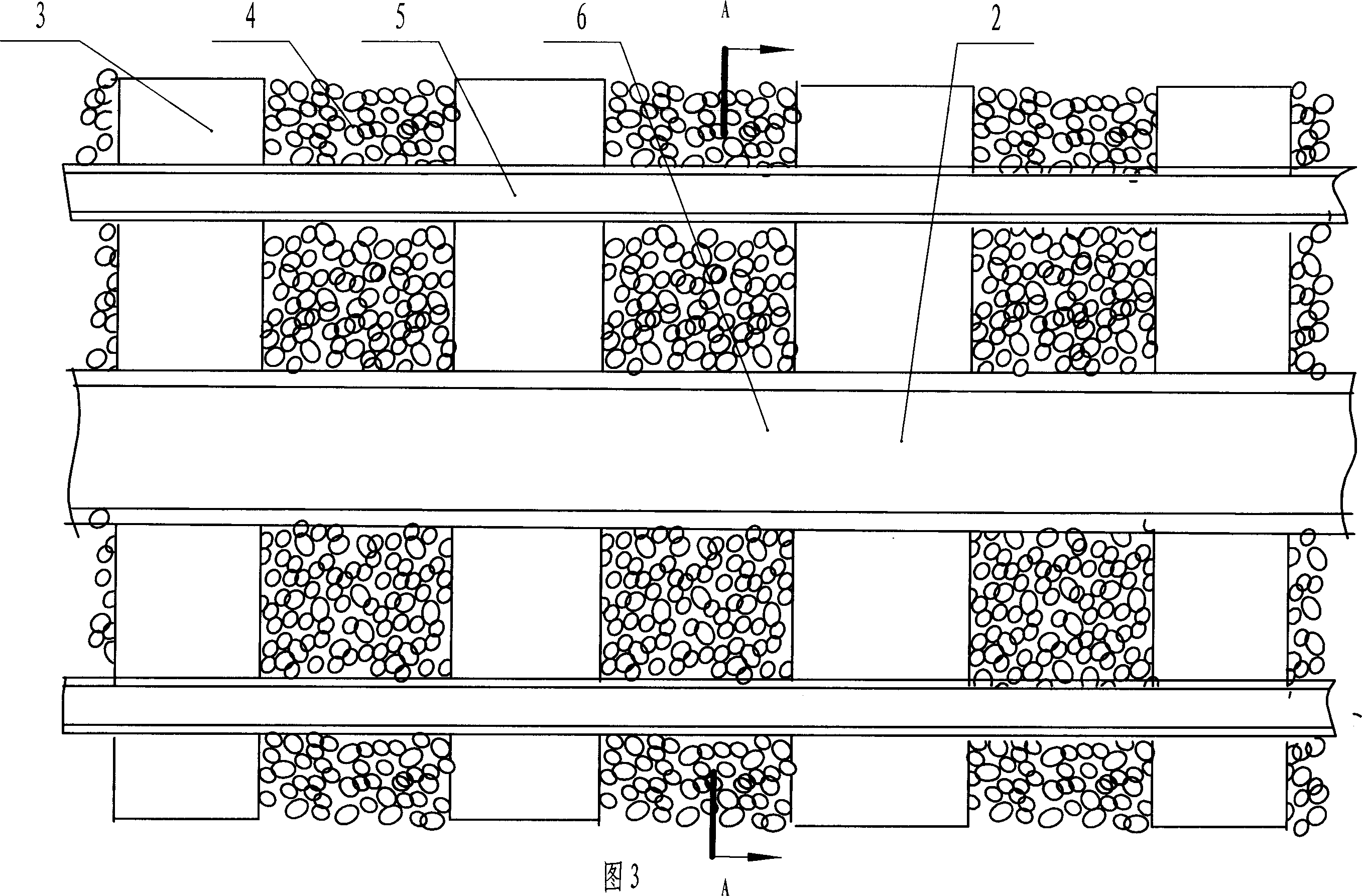

Clad steel plate manufacturing method using explosive welding and application thereof in linear motor

ActiveCN1994650AIncrease binding rateGood effectOther manufacturing equipments/toolsExplosivesSheet steelLinear motor

The invention relates to an explosion welding method of composite steel plate and relative application in linear motor, wherein said method comprises that: 1, matching that: coupling the conductive metal plate with steel plate; 2, abrading surface and coating protective layer that cleaning the face of steel plate that contacts the metal plate and coating protective layer at the explosive contact face; 3, exploding and welding that welding the steel plate with metal plate via explosion; 4, aligning that aligning the composite steel plate on aligning machine; 5, finishing that finishing the concaves on the face caused by explosion. And the inventive composite steel plate can be mounted on the sensitive plate mounting base of subway to form sensitive plate of linear motor rotor. The combine rate of composite steel plate can reach 99. 5%, with low cost.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

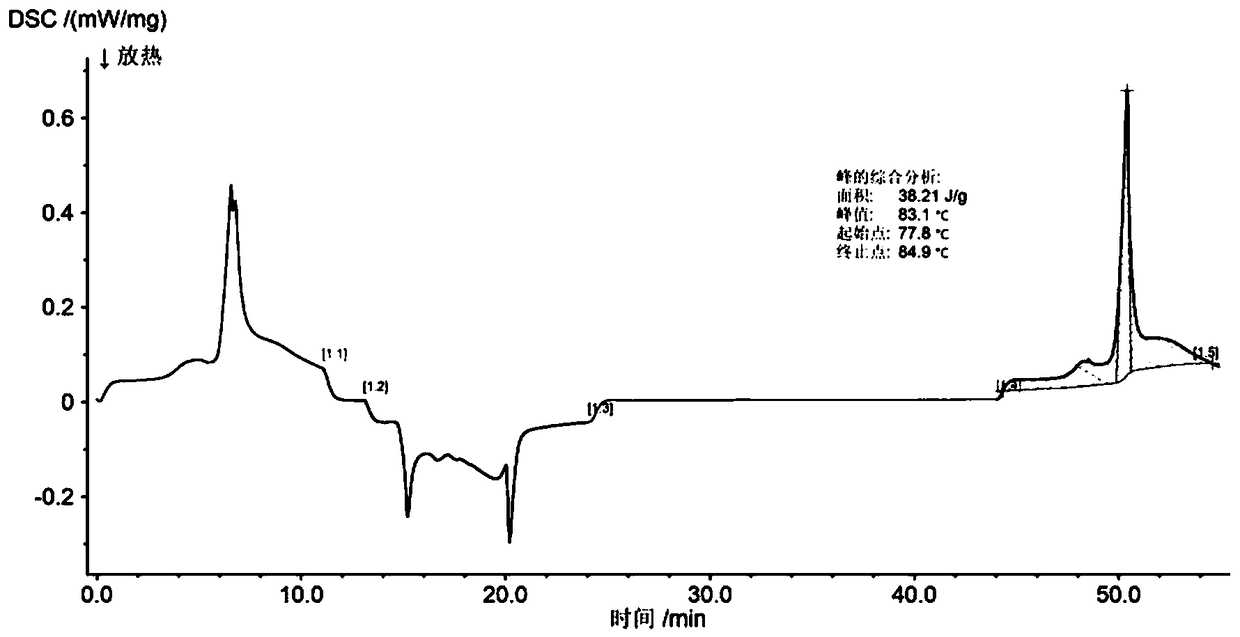

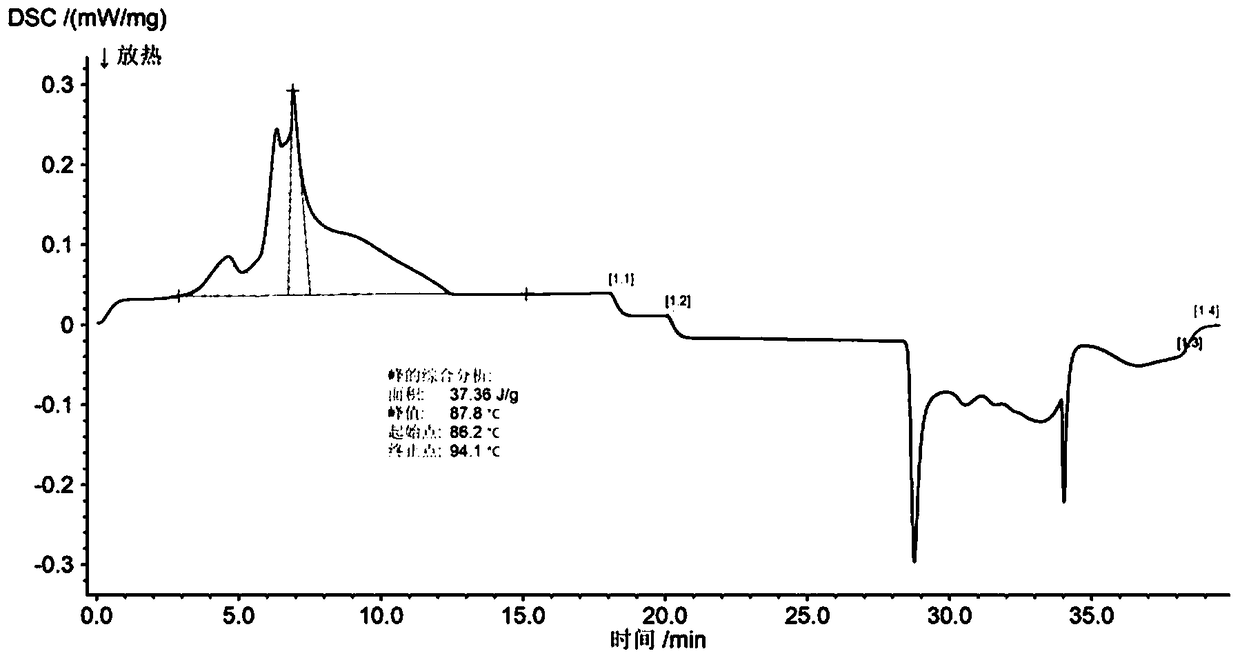

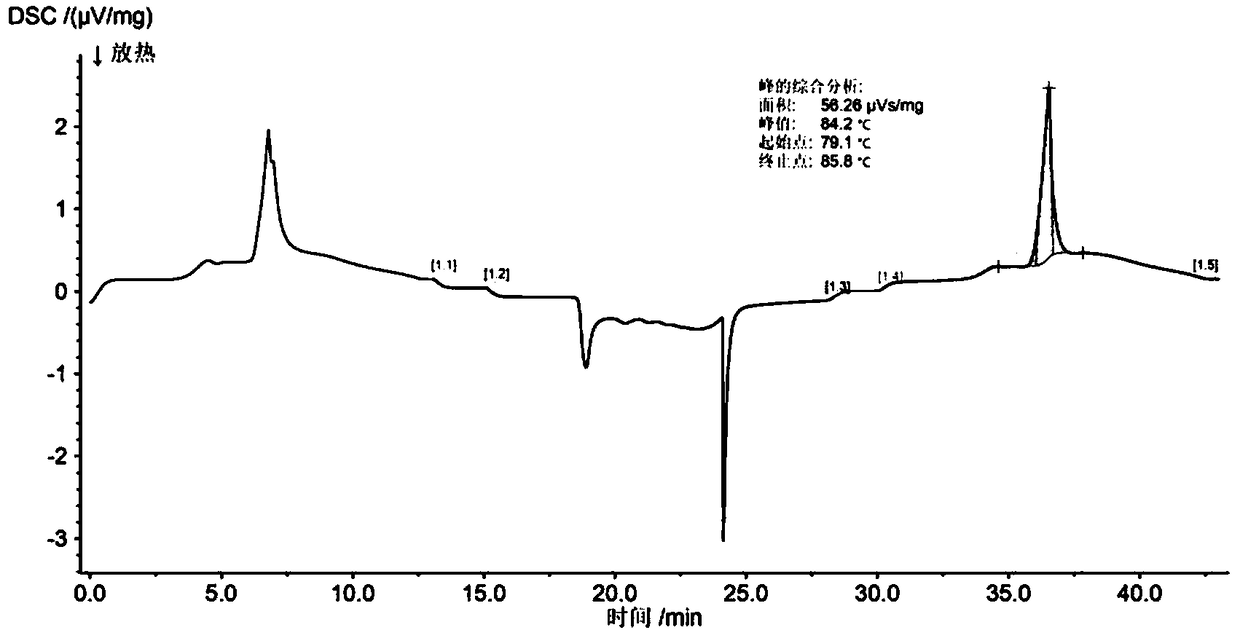

Low-temperature lead-free solder

ActiveCN108971793AEliminate pollution problemsHas thermal fatigue resistanceWelding/cutting media/materialsSoldering mediaEnvironmental resistanceOvervoltage

The invention discloses low-temperature lead-free solder and used for welding electrical contact materials. The low-temperature lead-free solder comprises, by mass percent, 30%-65% of Bi, 15%-50% of Sn and 15%-45% of In. To improve the mechanical performance of the alloy solder and improve the oxidation resistance, the wettability and the like, one or more of microelements including Ag, Zn, Al, Cu, Ga, P and the like is appropriately added. The melting point of the low-temperature solder is controlled within the range of 75 DEG C-100 DEG C, is used for removing damage of welding temperature toa welded object in the welding process and has the advantages that the melting temperature is low, during welding, the binding rate with copper foil is high, the loss tangent value of a capacitor issmall, the partial discharging performance and the overvoltage and large current resistance of the capacitor are improved, the cost is relatively low, no lead exists and the low-temperature lead-freesolder is more environmentally friendly. The low-temperature lead-free solder is especially suitable for welding heat sensitive elements, semiconductor elements with semiconductor manner refrigeratingelements and the like.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

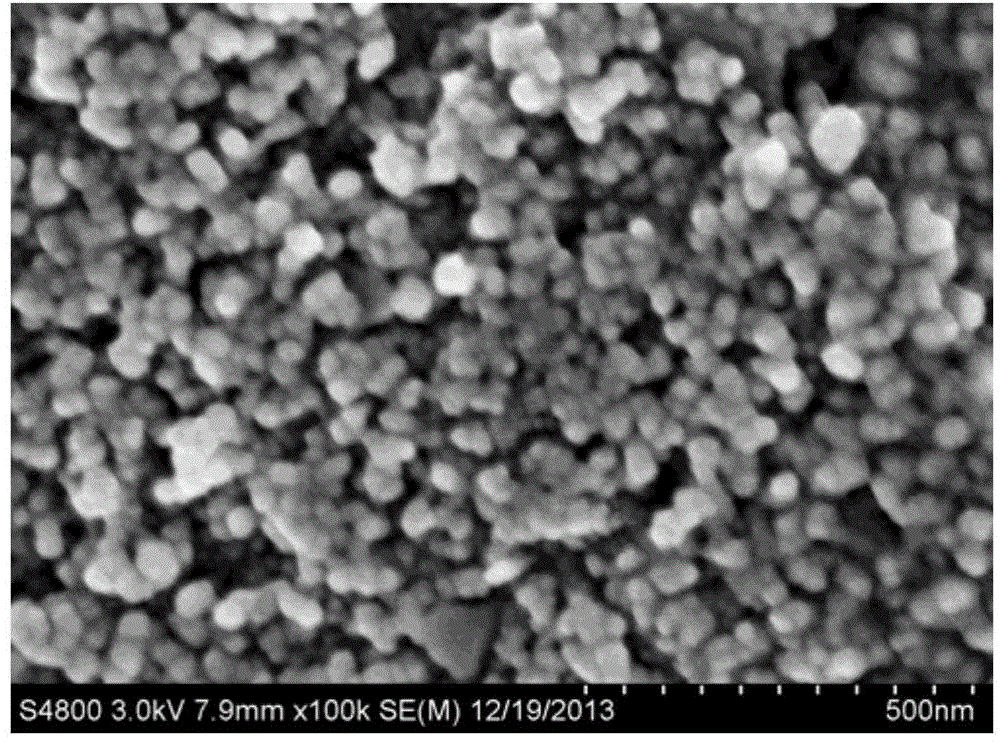

Magnetic resonance system and method to detect and confirm analytes

ActiveUS20130059293A1Improve bindingReduce activity timeNanomagnetismMicrobiological testing/measurementResonance measurementAnalyte

A system and method are provided to detect target analytes based on magnetic resonance measurements. Magnetic structures produce distinct magnetic field regions having a size comparable to the analyte. When the analyte is bound in those regions, magnetic resonance signals from the sample are changed, leading to detection of the analyte.

Owner:MENON BIOSENSORS

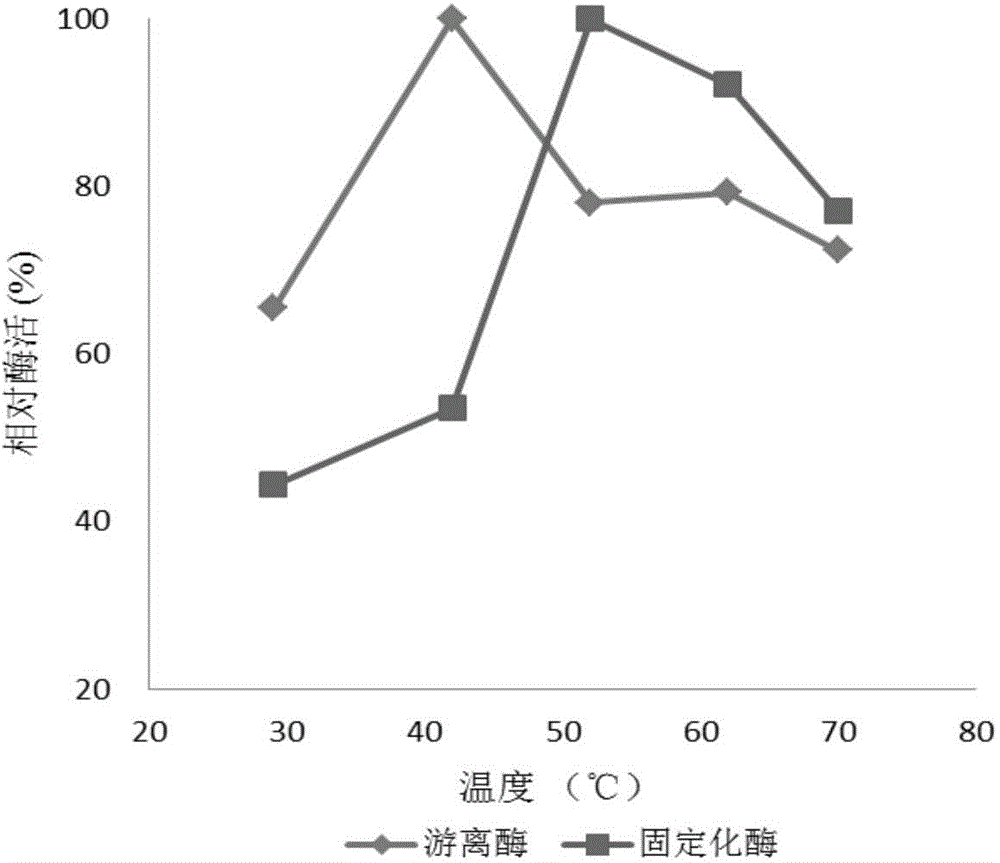

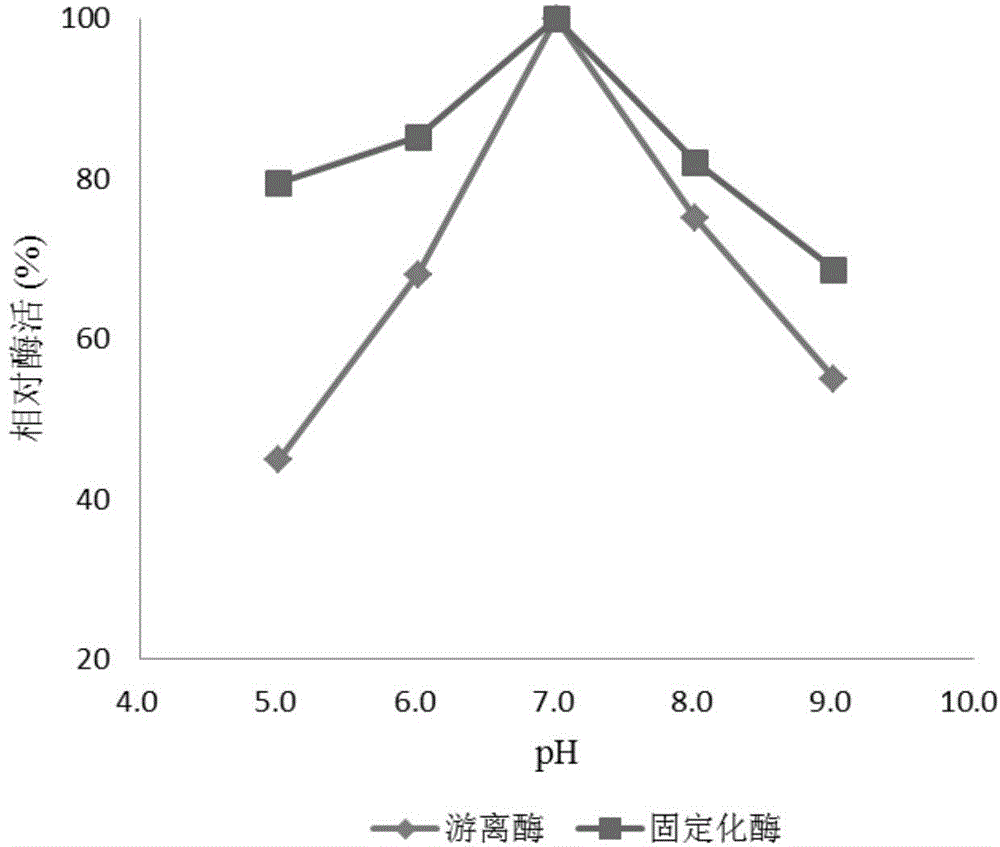

Preparation method of magnetic nanoparticle immobilized amino-acylase as well as product and application of preparation method

InactiveCN104480101AImprove stabilityHigh activityChemical industryFermentationTriethoxysilaneMagnetite Nanoparticles

The invention relates to a preparation method of a magnetic nanoparticle immobilized amino-acylase as well as a product and application of the preparation method, and belongs to the field of nanomaterial preparation technologies and the biocatalysis technologies. The preparation method of the magnetic nanoparticle immobilized amino-acylase comprises the following steps: preparing ferroferric oxide nanoparticles; after ultrasonic dispersion of the ferroferric oxide nanoparticles, reacting the ferroferric oxide nanoparticles with 3-aminopropyltriethoxysilane in the presence of nitrogen, thereby obtaining amino-modified ferroferric oxide nanoparticles; and mixing the amino-modified ferroferric oxide nanoparticles with an amino-acylase solution for reacting, thereby obtaining the magnetic nanoparticle immobilized amino-acylase. The prepared magnetic nanoparticle immobilized amino-acylase is used for resolving theanine. Compared with the prior art, the preparation method of the magnetic nanoparticle immobilized amino-acylase is capable of greatly increasing the optimum catalysis temperature and reutilization efficiency of the amino-acylase on the premise of ensuring the enzyme activity; besides, the product is convenient to recover and can be reutilized; the preparation method is suitable for large-scale industrial production.

Owner:TONGJI UNIV

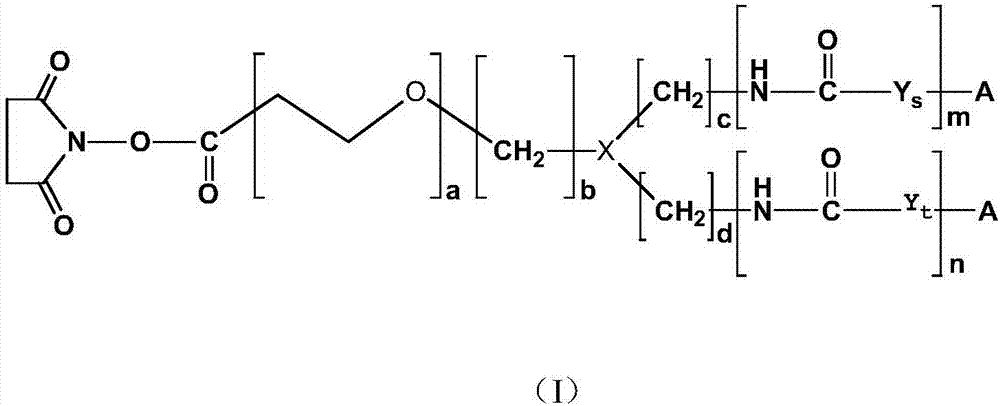

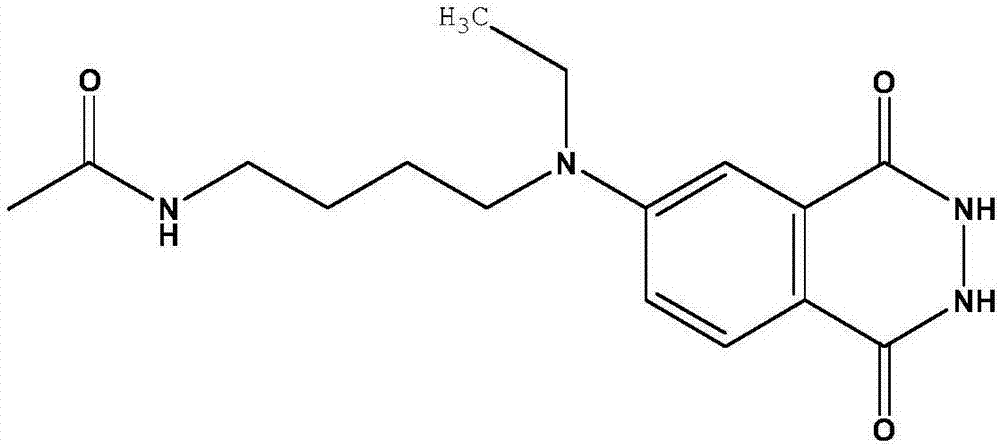

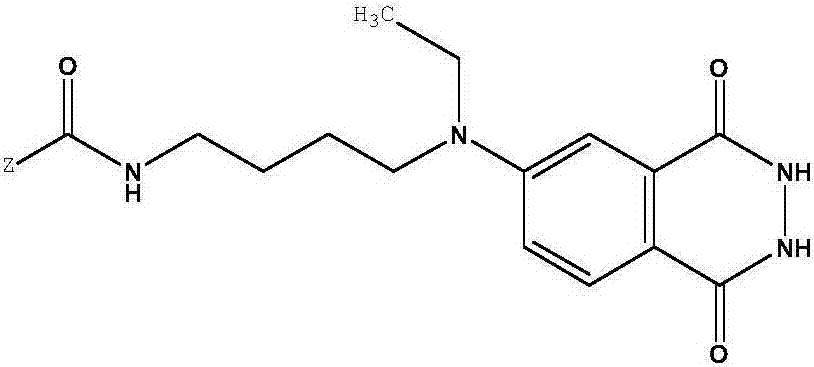

Isoluminol derivative and preparation method and application thereof

ActiveCN107021952AGuaranteed stabilityImprove stabilityOrganic chemistryLuminescent compositionsAntigenLuminous intensity

The invention discloses an enhanced isoluminol derivative with high luminous intensity and a preparation method thereof, and aims to enhance the luminous intensity of an existing luminol-peroxide system, increase the test sensitivity and detection limit, lower the quantity of antibodies or antigens labelled by a luminescent label, and lower the influence of excessive labelling on the antibody or antigen activity. The invention further discloses a chemiluminescent base solution containing the isoluminol derivative, or a chemiluminescent kit containing the antigens or the antibodies labeled by the isoluminol derivative, and a chemiluminescent immunoassay system, and aims to solve the technical problems of low sensitivity and low detection limit when the existing luminol-peroxide system is used for testing. The invention further provides application of the isoluminol derivate to chemiluminescent immune quantitative analyses.

Owner:SHENZHEN NEW INDS BIOMEDICAL ENG

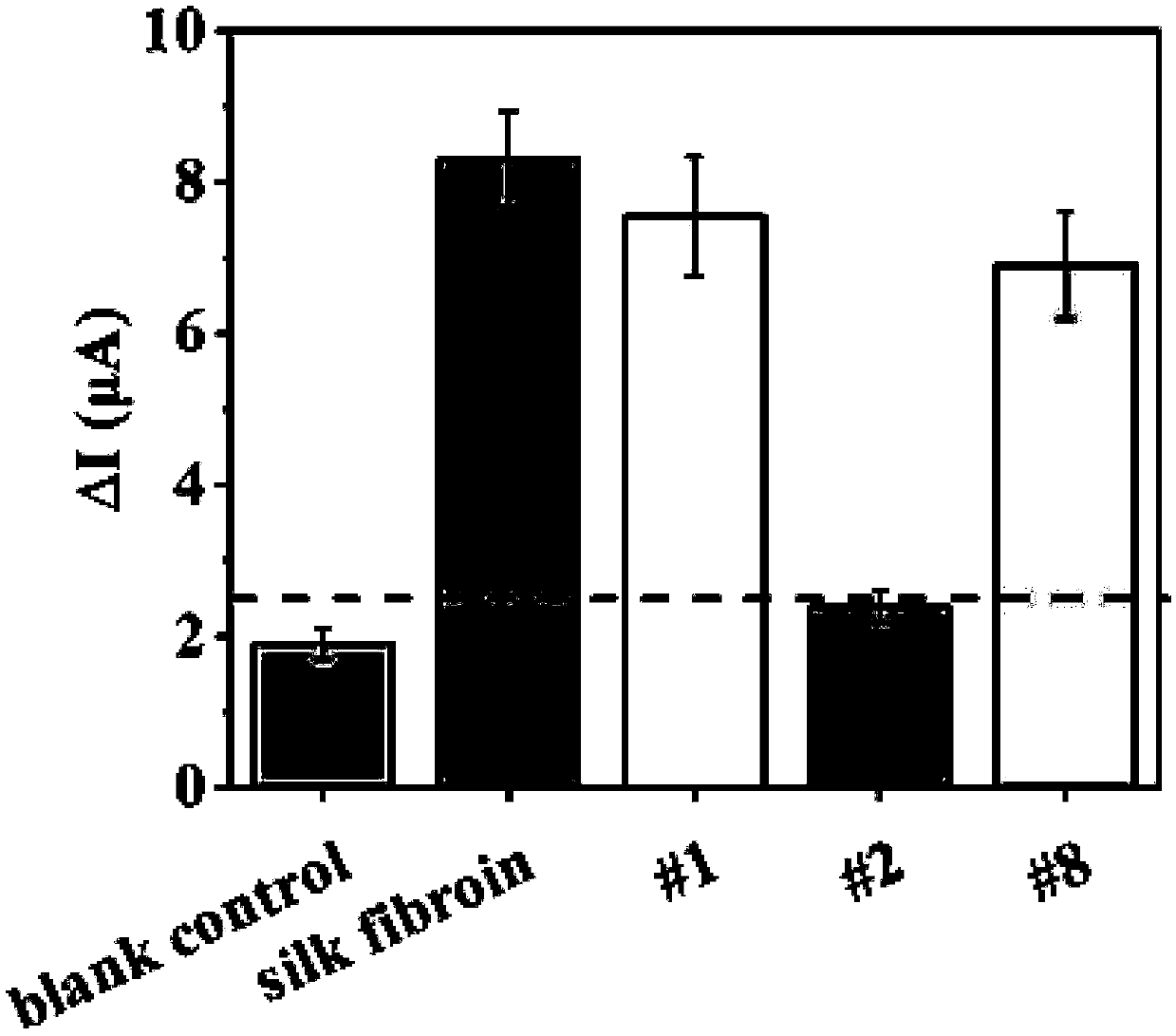

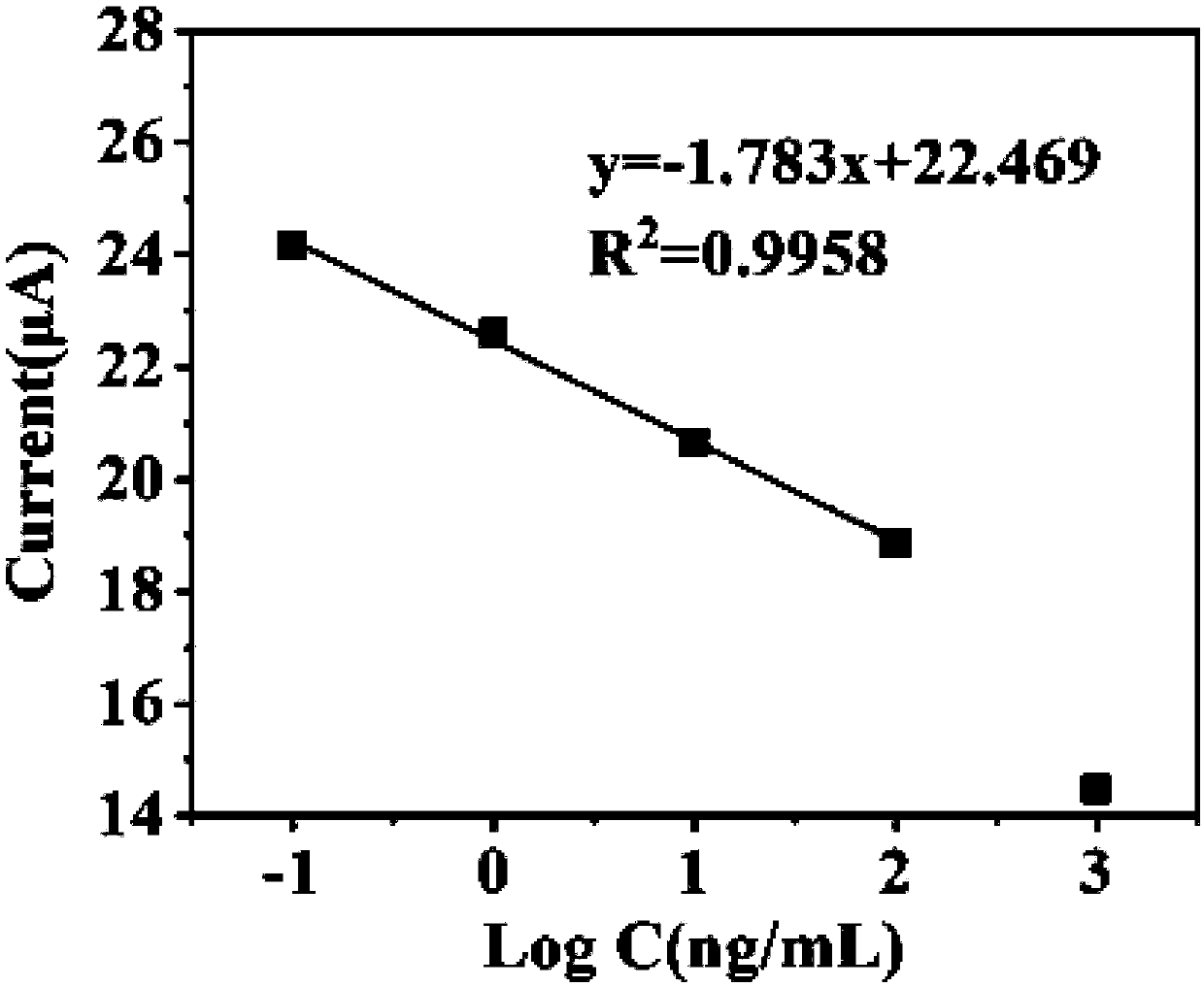

High sensitivity detection method for silk cultural relic

ActiveCN109557154ALarge specific surface areaImprove load effectMaterial electrochemical variablesProtein.monoclonalNanoparticle

The invention relates to the field of cultural relic detection, and discloses a high sensitivity detection method for a silk cultural relic. The method comprises the following steps of: preparing puresilk fibroin powder, and simultaneously extracting the silk fibroin in a cultural sample; sequentially modifying gold nanoparticles, hollow polyacrylic acid-dopamine complex, polymethyl methacrylate-maleic anhydride / 1-octadecene alternating copolymer spherical nanobead, mouse anti-silk fibroin monoclonal antibody on the surface of cleaned glassy carbon electrode by a layer-by-layer self-assemblymethod under the action of NHS / EDC solution; and detecting the silk fibroin solution and the cultural sample solution by using the modified electrode. The high sensitivity detection method for the silk cultural relic has high sensitivity, low detection limit and good reproducibility, and can detect the silk cultural relics with high sensitivity.

Owner:ZHEJIANG SCI-TECH UNIV

Class of long-acting glucagon-like peptide-1 (GLP-1) analog and application thereof

ActiveCN107056928AGood hypoglycemic effectChemically stablePeptide/protein ingredientsMetabolism disorderSynthesis methodsGlucagon-like peptide-1

The invention relates to a class of long-acting glucagon-like peptide-1 (GLP-1) analog and a synthesis method thereof. The GLP-1 analogue with longer pharmacological action time is obtained by modifying GLP-1. The synthesis of target polypeptide is quickly achieved by a orthogonal protection strategy solid phase synthesis method. The crude product is purified and lyophilized to obtain the GLP-1 analog.

Owner:CHINA PHARM UNIV

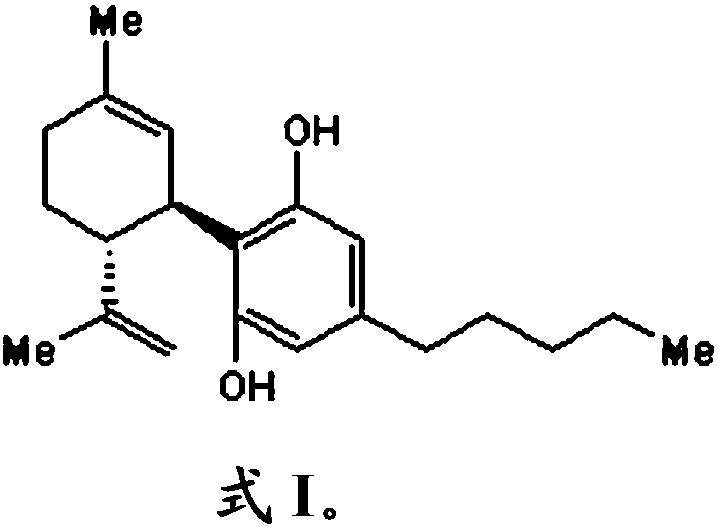

Cannabidiol composition and application thereof

PendingCN110575448AImprove stabilityImprove relative bioavailabilityCosmetic preparationsNervous disorderWater solubleSolubility

The invention relates to cannabidiol compositions and application thereof. Specifically, the invention relates to a cannabidiol composition containing cannabidiol and a surfactant. The composition cansignificantly improve the water solubility of cannabidiol to make cannabidiol to be better applied in the fields of medicine, daily chemical, food, health products and the like.

Owner:YUNNAN HANSU BIO TECH CO LTD

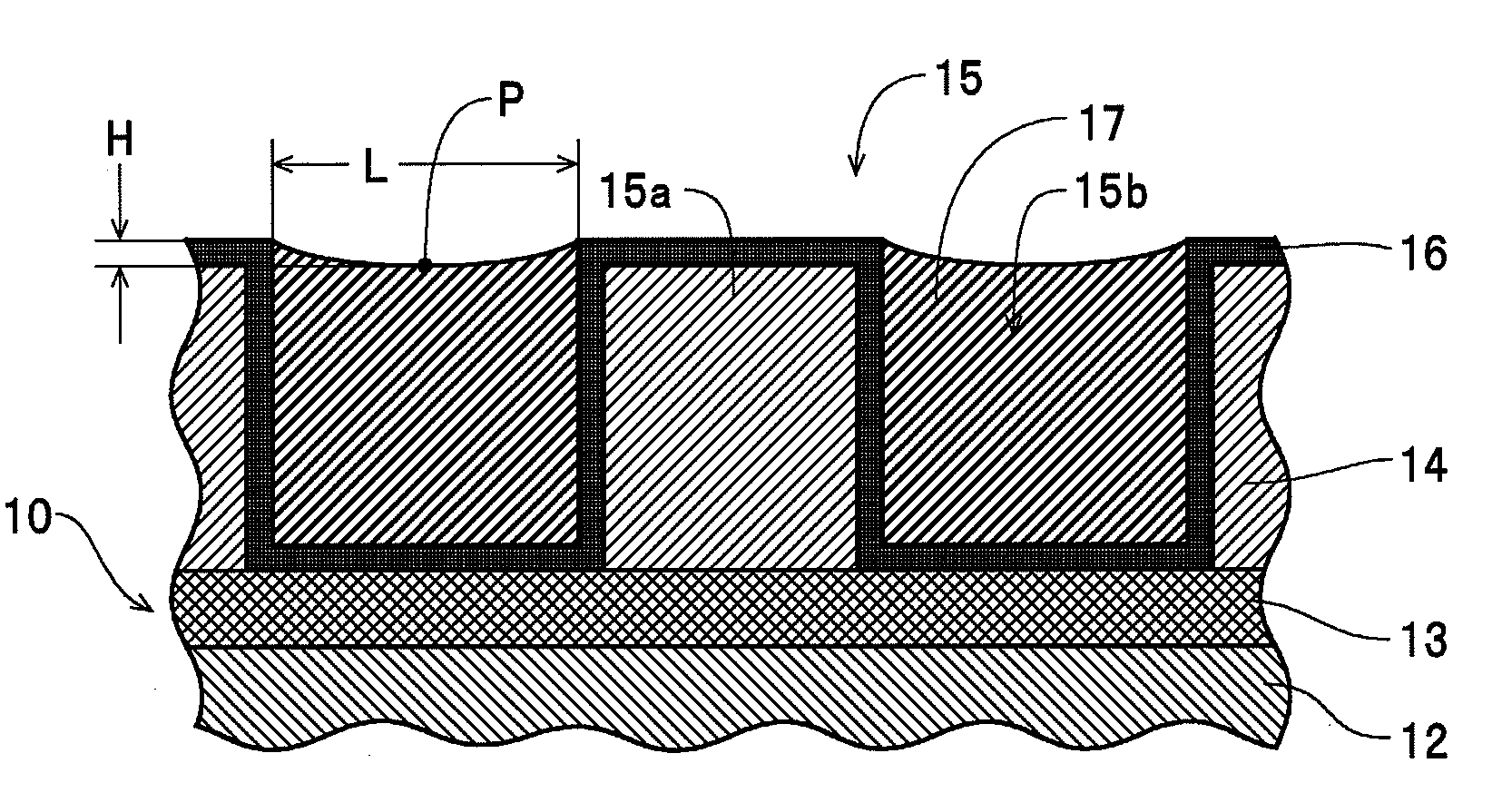

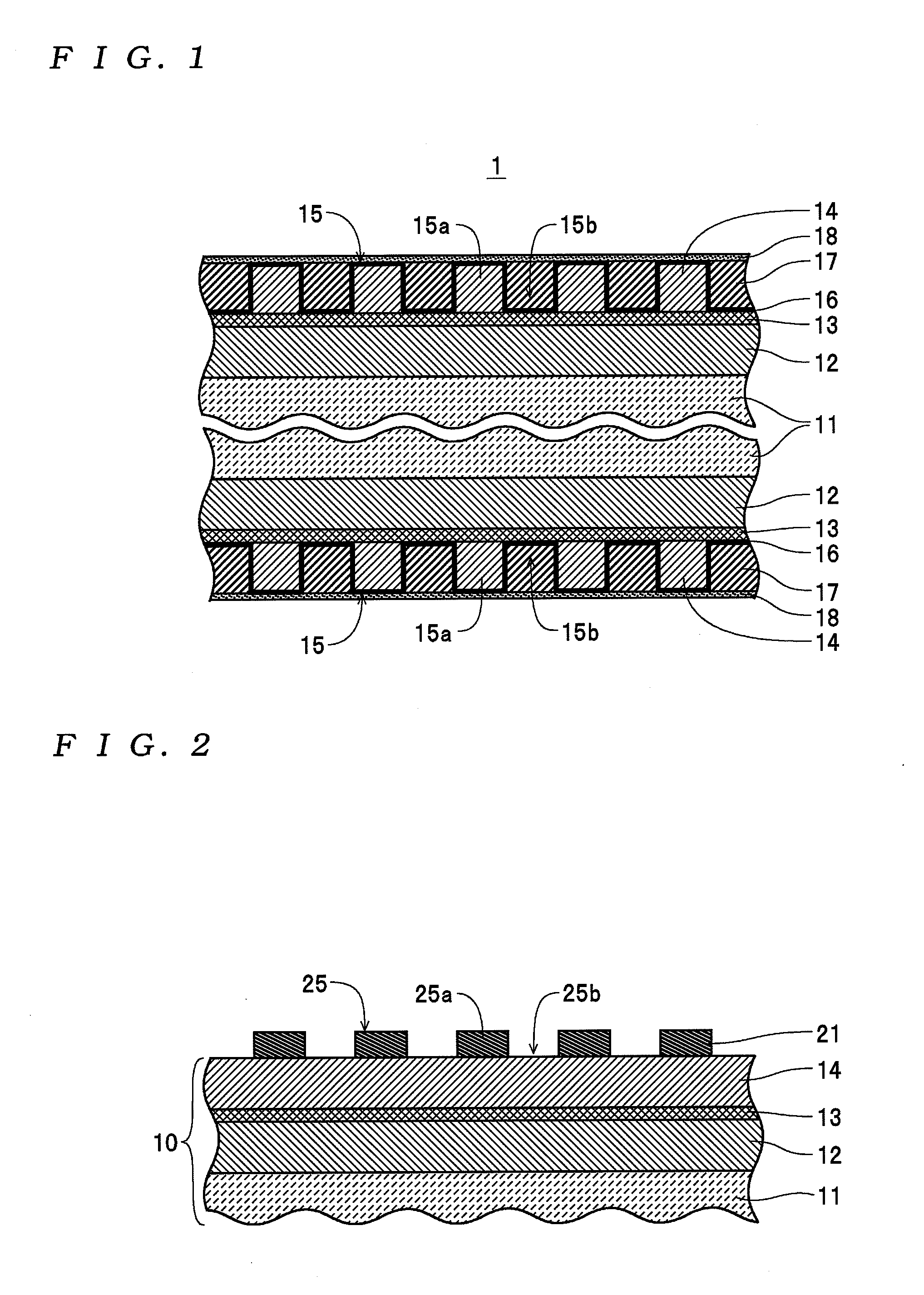

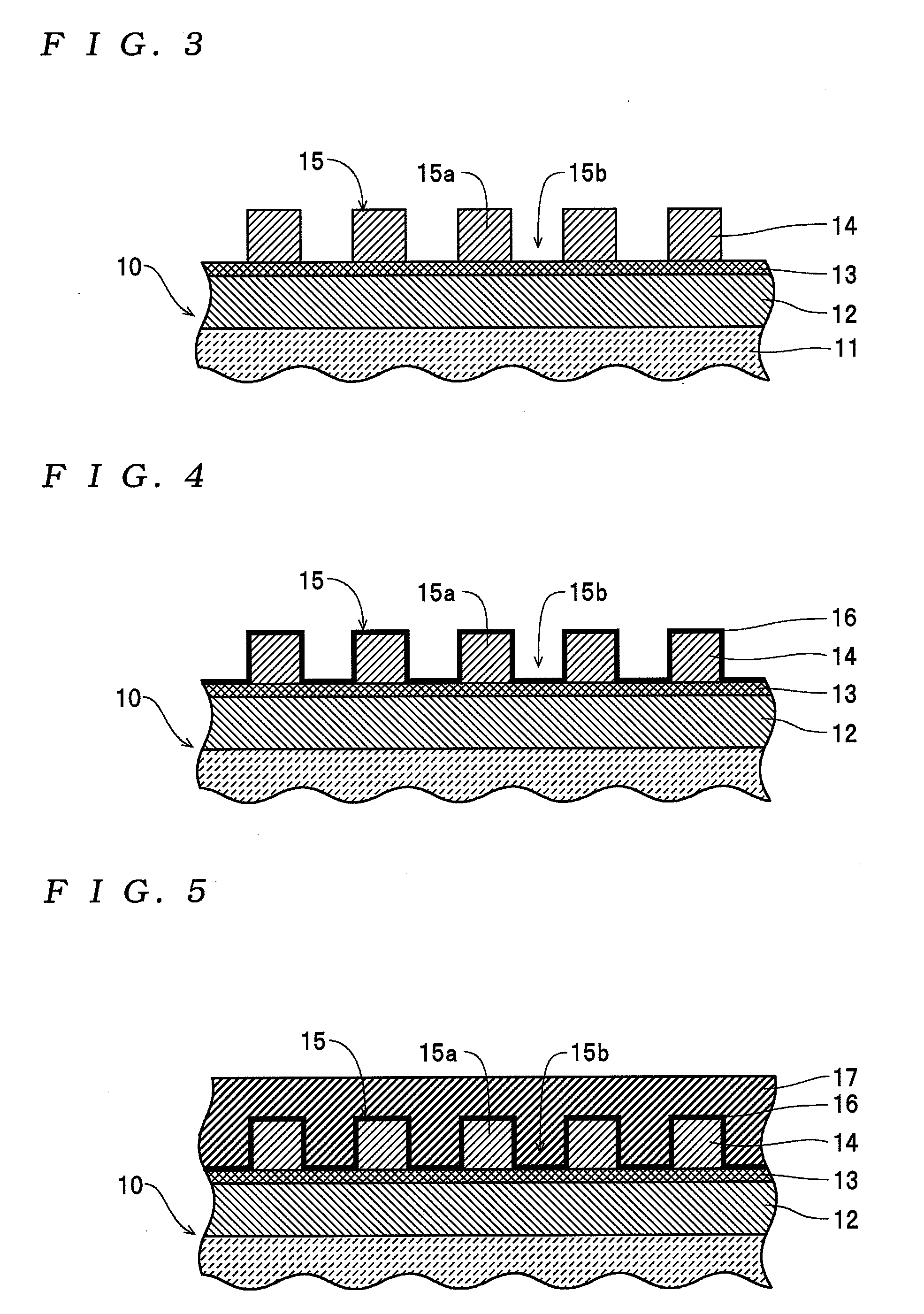

Information medium

InactiveUS20070275270A1Improve protectionReduce the probability of bindingProtective coatings for layersRecord information storageEngineeringRecording layer

An information medium which is capable of maintaining the protection capability by a lubricant for a long term. An information medium has a recording area and a non-recording area disposed on at least one surface of a disk-shaped base plate. The information medium is configured such that a lubricant exists on the one surface of the disk-shaped base plate. The recording area is configured such that a protective film formed of DLC exists above the recording layer. At least a surface-side portion of the non-recording area is formed of a resin material having a higher bonding ratio with respect to the lubricant than that of DLC.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com