Patents

Literature

2116 results about "Biocatalysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biocatalysis (/ˌbaɪoʊkəˈtælɪsɪs/) refers to the use of living (biological) systems or their parts to speed up (catalyze) chemical reactions. In biocatalytic processes, natural catalysts, such as enzymes, perform chemical transformations on organic compounds. Both enzymes that have been more or less isolated and enzymes still residing inside living cells are employed for this task.. The modern usage of biotechnologically produced and possibly modified enzymes for organic synthesis is termed chemoenzymatic synthesis; the reactions performed are chemoenzymatic reactions.

Microsensors for glucose and insulin monitoring

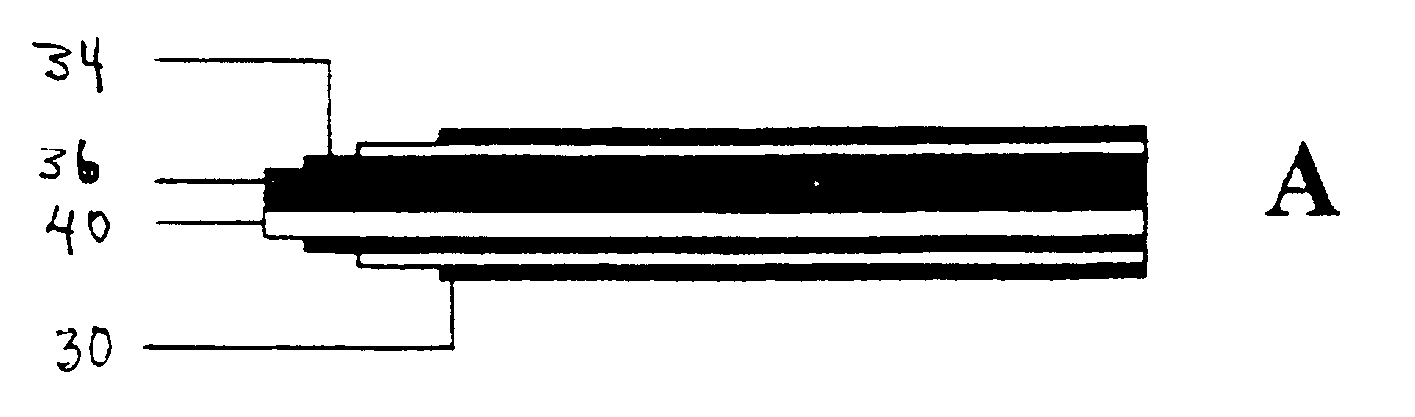

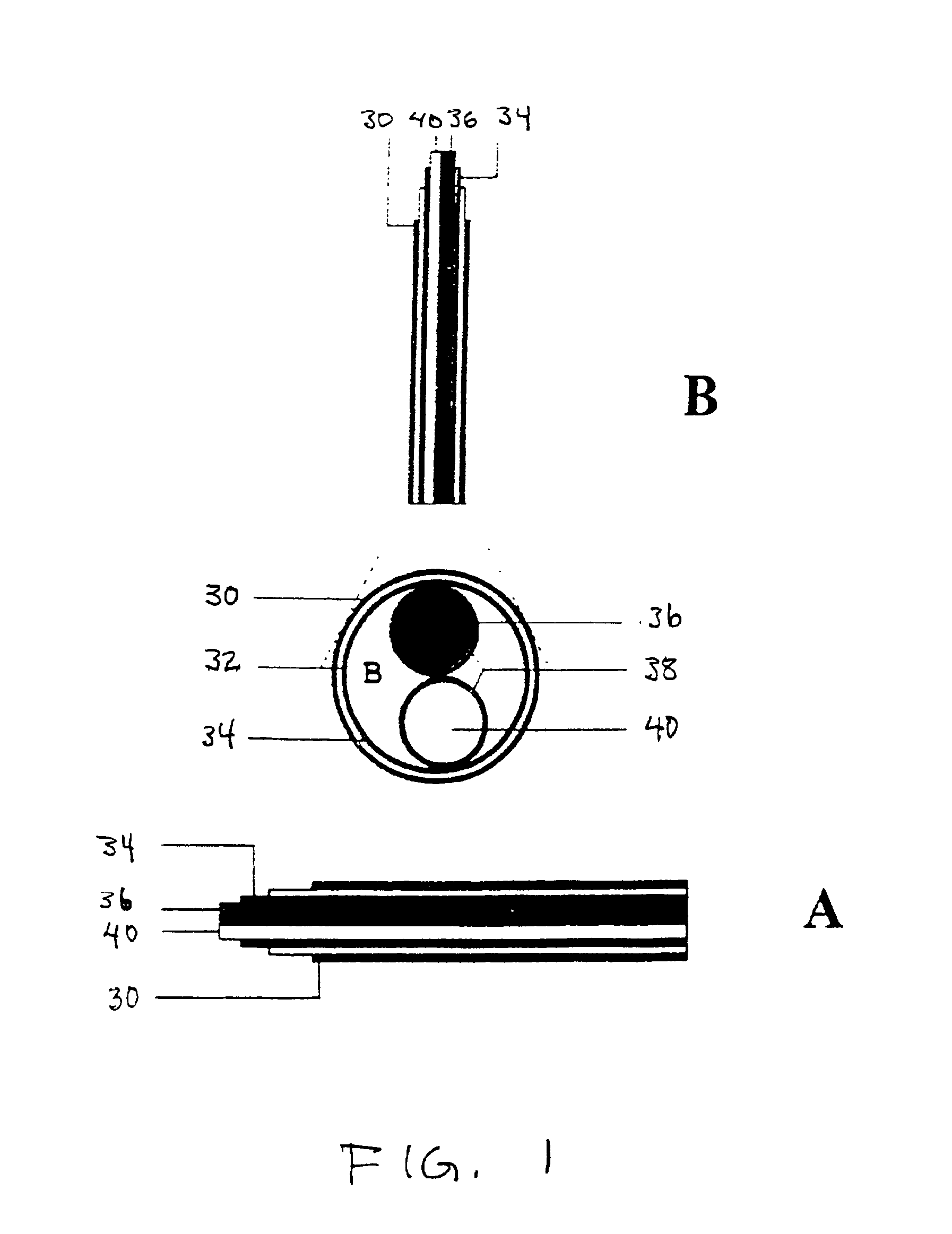

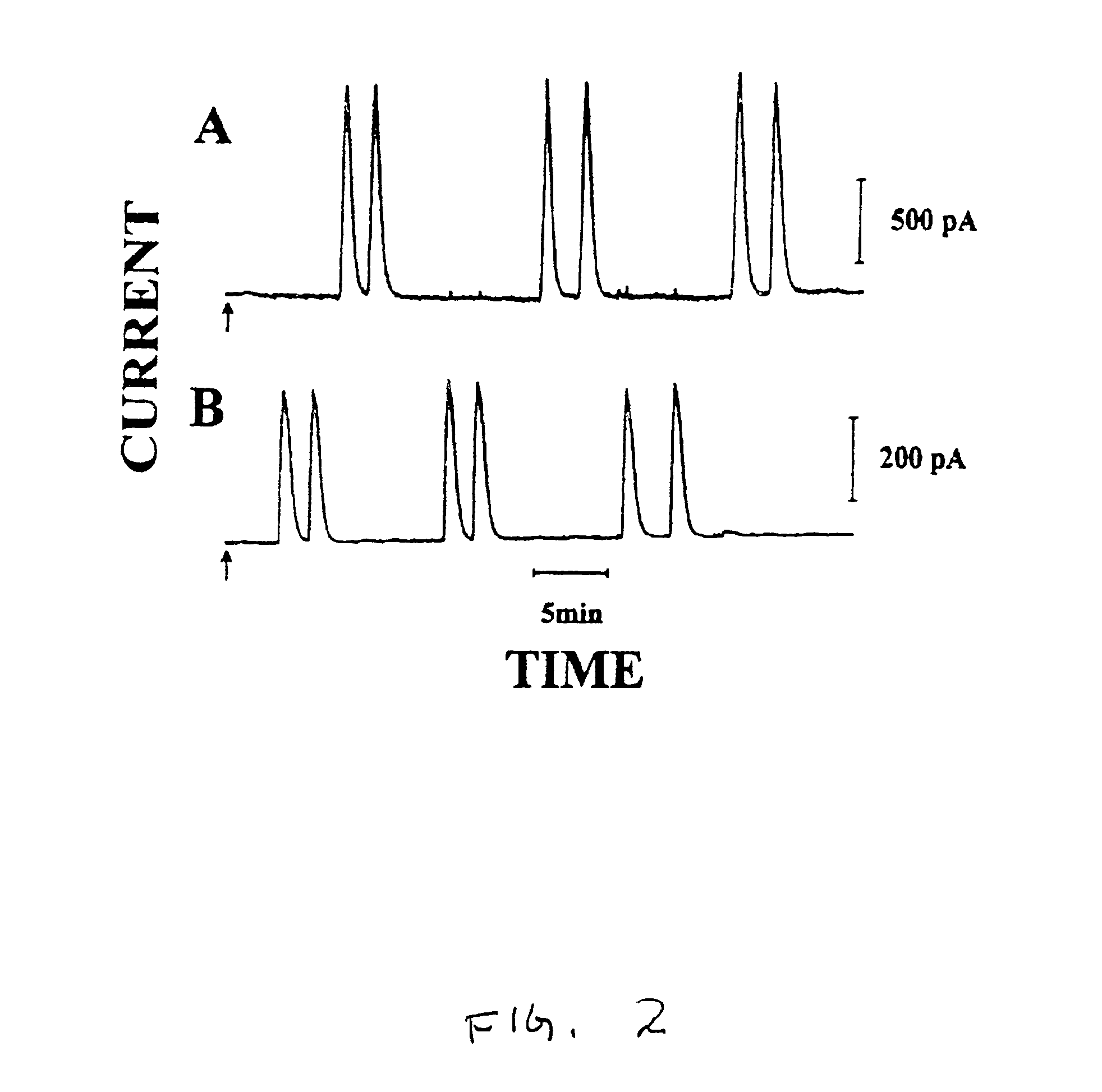

InactiveUS6893552B1Simultaneous measurementLacking and neededImmobilised enzymesBioreactor/fermenter combinationsOxidative enzymeD-Glucose

A dual sensor for the simultaneous amperometric monitoring of glucose and insulin, wherein the glucose probe is based on the biocatalytic action of glucose oxidase, and the insulin probe is based on the electrocatalytic activity of metal oxide. Further provided is an oxidase enzyme composite electrode with an internal oxygen-rich binder. The present invention also optionally includes metallizing components within the carbon paste to eliminate signals from interfering compounds. The present invention includes embodiments for both in vitro and in vivo uses.

Owner:ARROWHEAD CENT

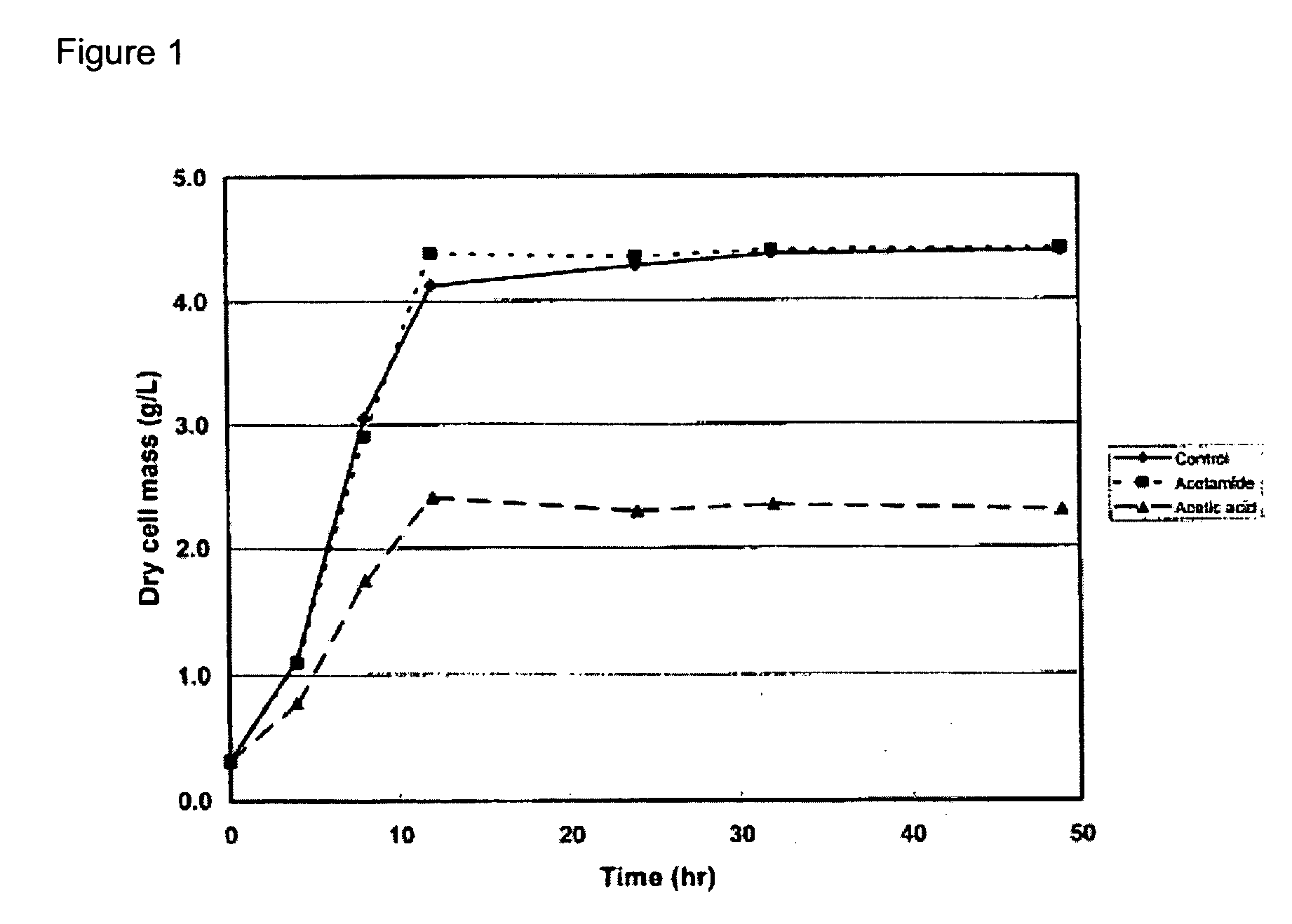

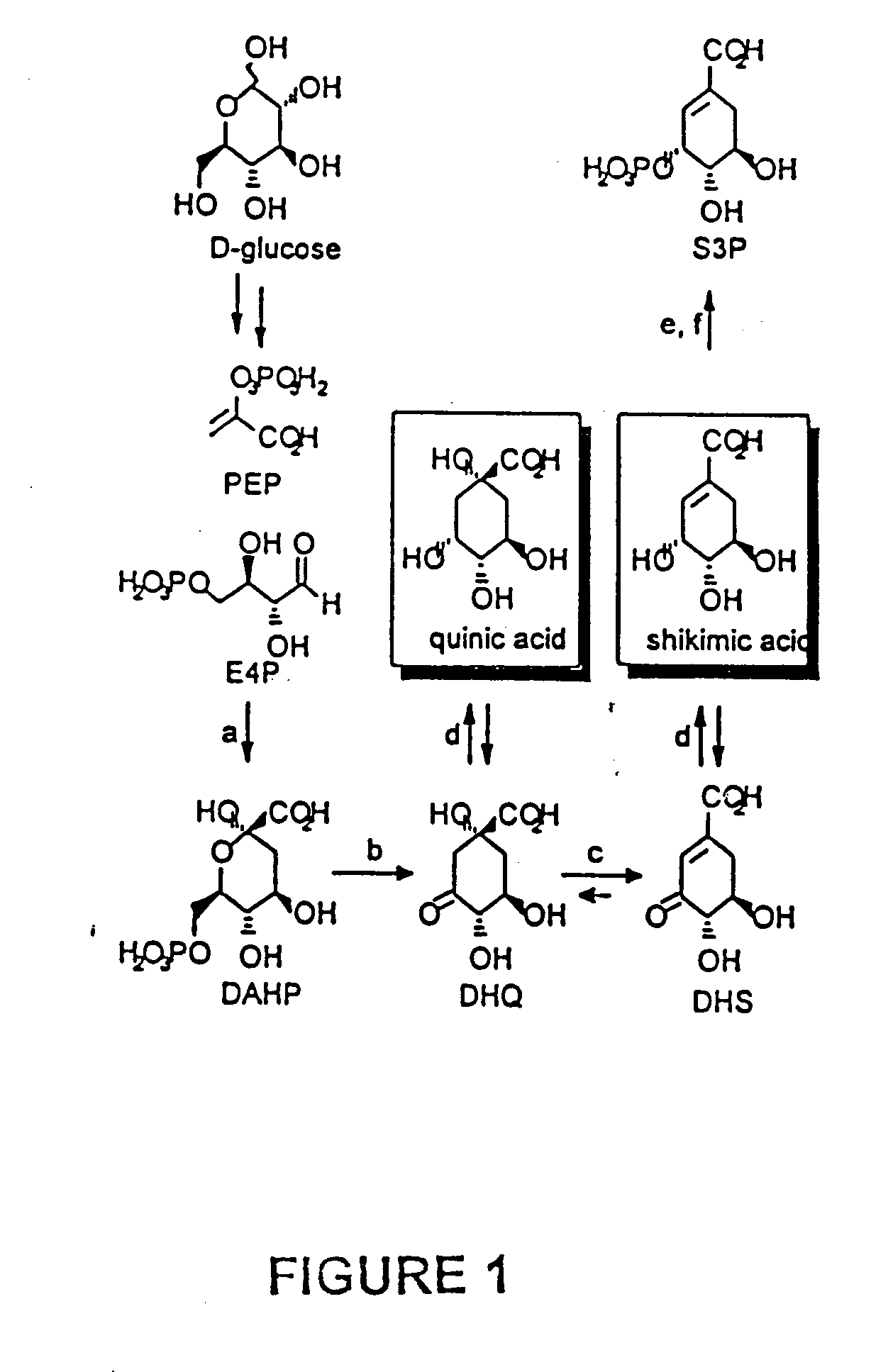

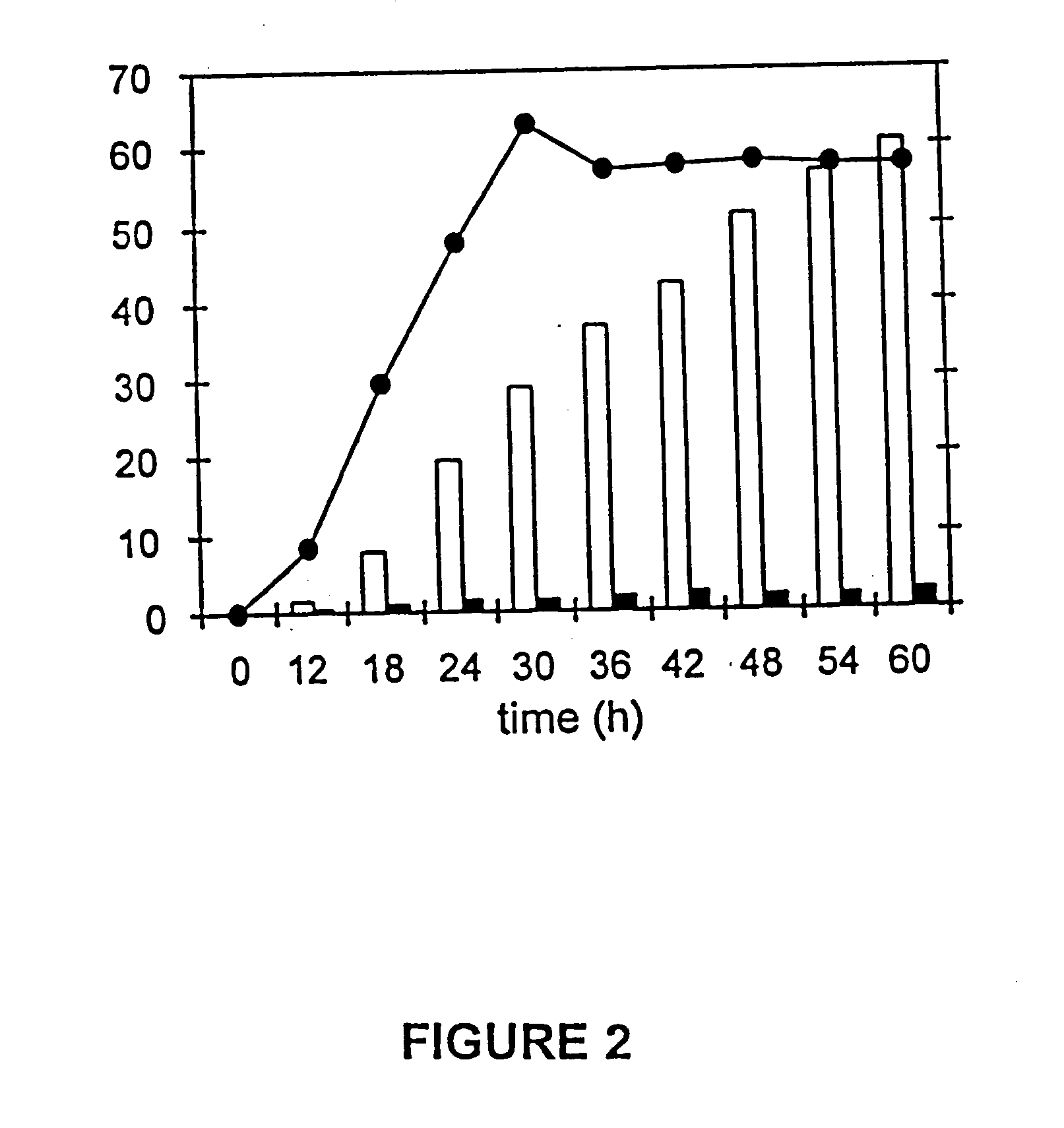

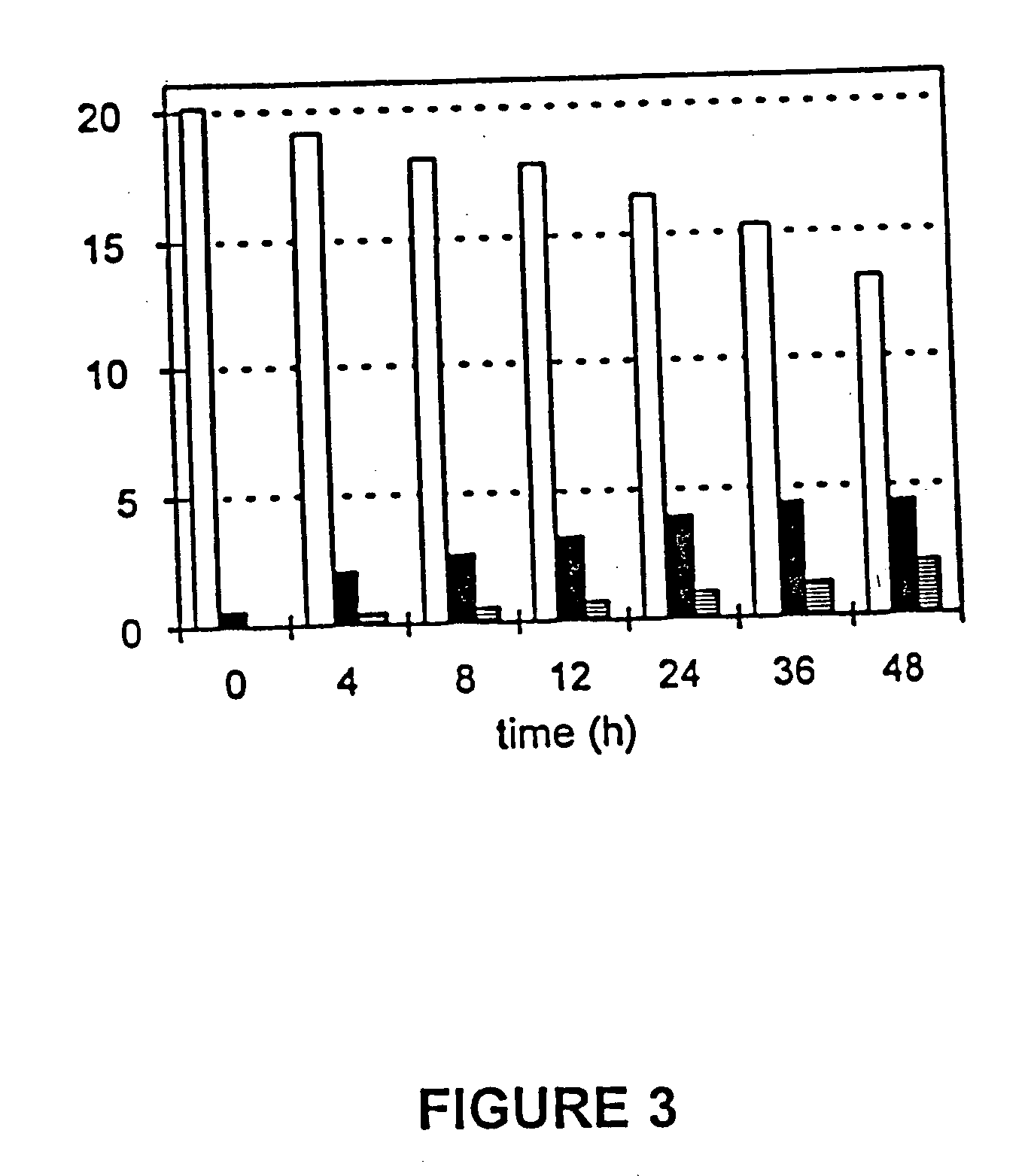

Biocatalytic synthesis of quinic acid and conversion to hydroquinone

A bioengineered synthesis scheme for the production of quinic acid from a carbon source is provided. Methods of producing quinic acid from a carbon source based on the synthesis scheme as well as conversion of quinic acid to hydroquinone are also provided.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

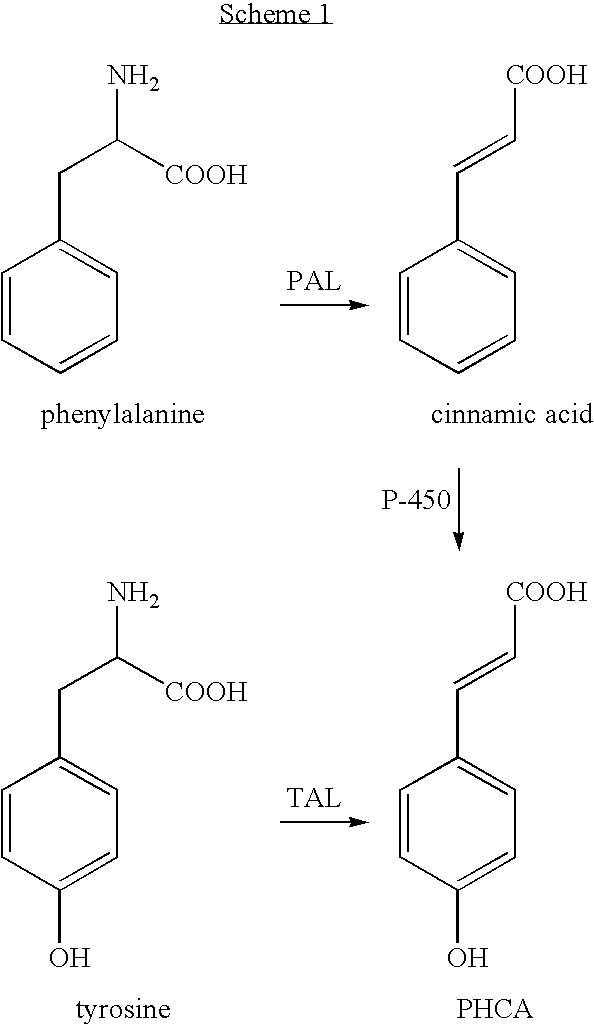

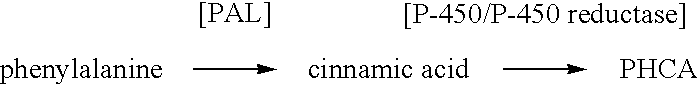

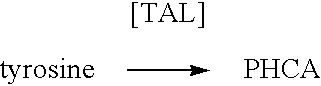

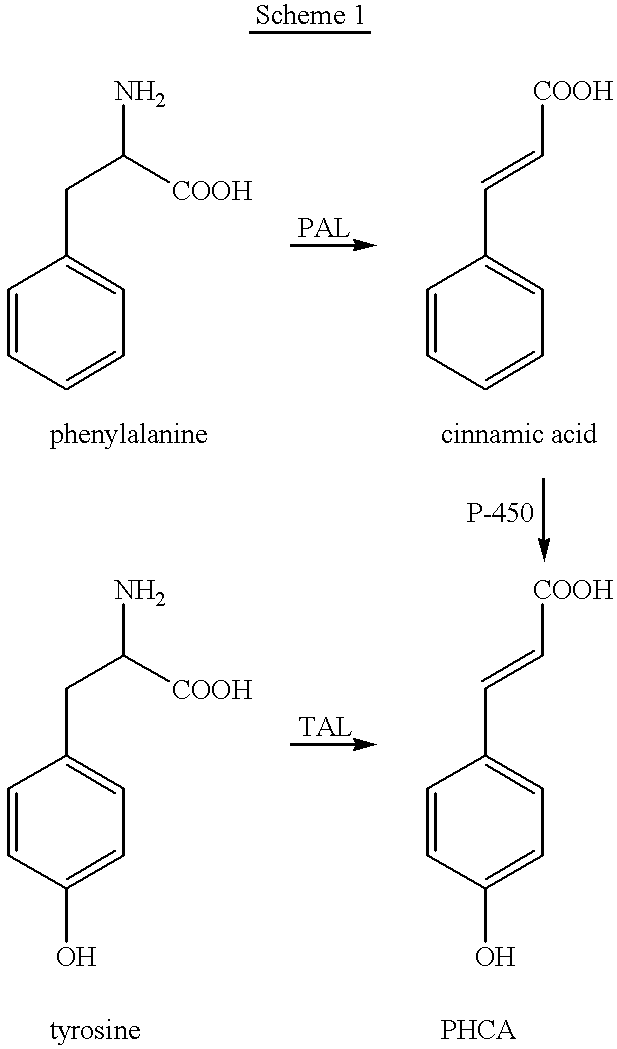

Bioproduction of para-hydroxycinnamic acid

InactiveUS6368837B1Increased substrate specificityEnhanced TAL activityMicroorganism based processesOxidoreductasesEscherichia coliTyrosine

Owner:DUPONT US HLDG LLC

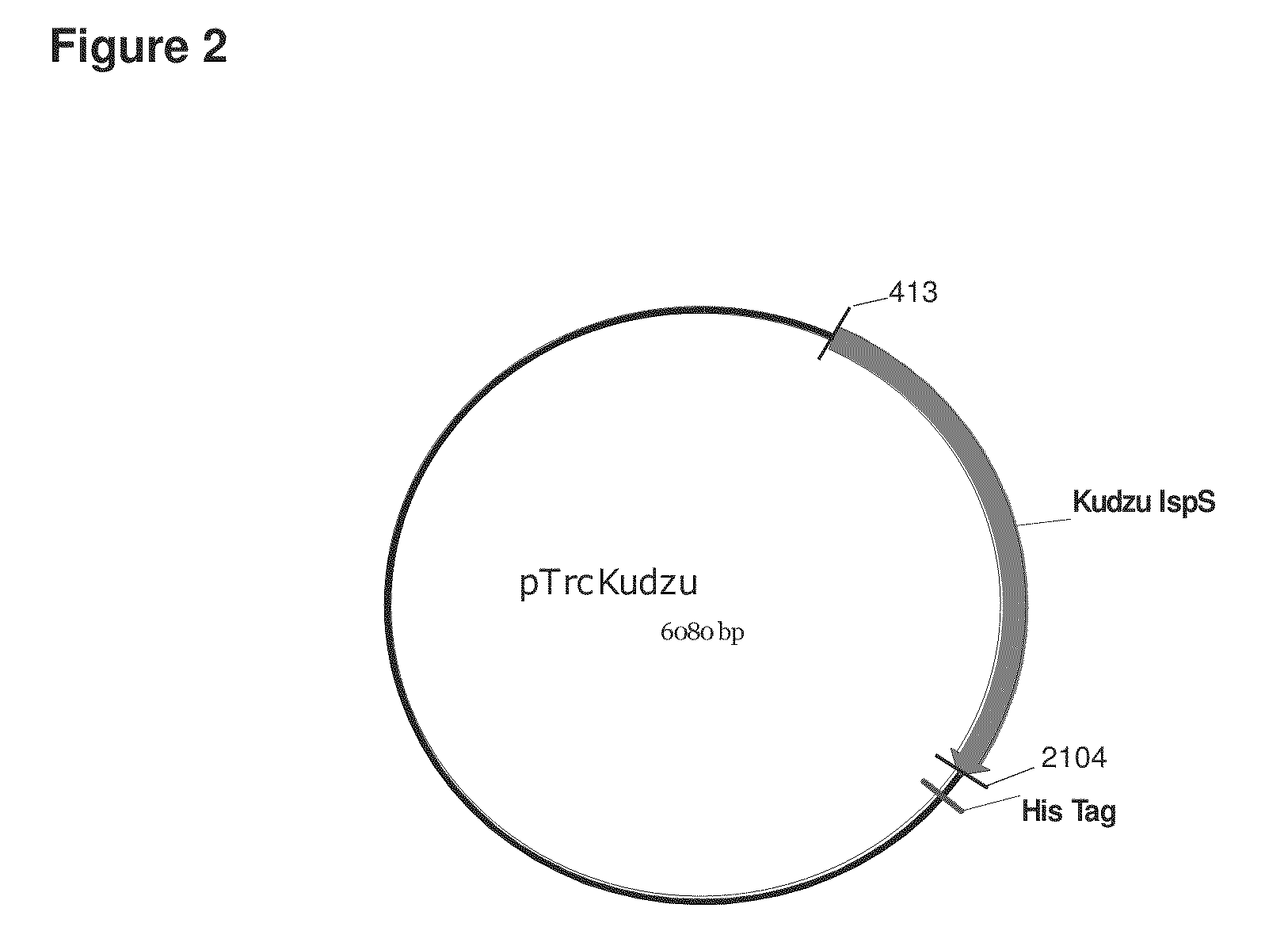

Conversion of prenyl derivatives to isoprene

InactiveUS20100113846A1HydrolasesHydrocarbon from oxygen organic compoundsPetrochemicalCultured cell

The present invention provides methods for producing derivatives from cultured cells. In addition, the present invention provides methods for conversion of prenyl deerivatives, obtained from biological or petrochemical sources, to isoprene by employing chemical or biological catalysts. The present invention also provides compositions that include the cultured cells or isoprene or prenyl derivatives produced there from.

Owner:THE GOODYEAR TIRE & RUBBER CO

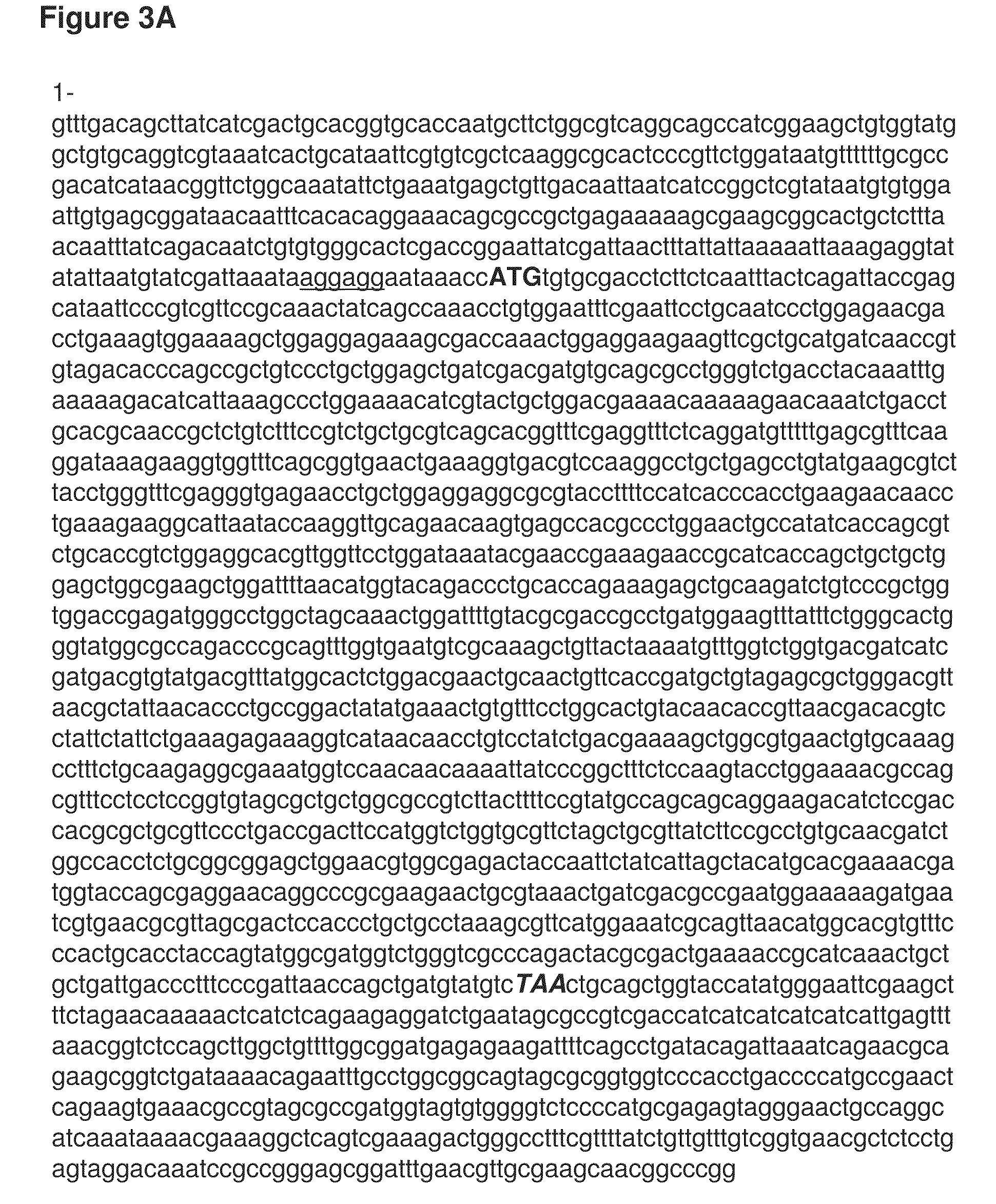

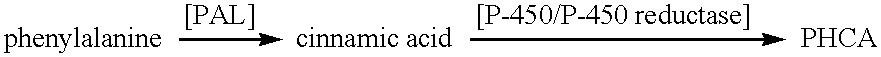

Bioproduction of para-hydroxycinnamic acid

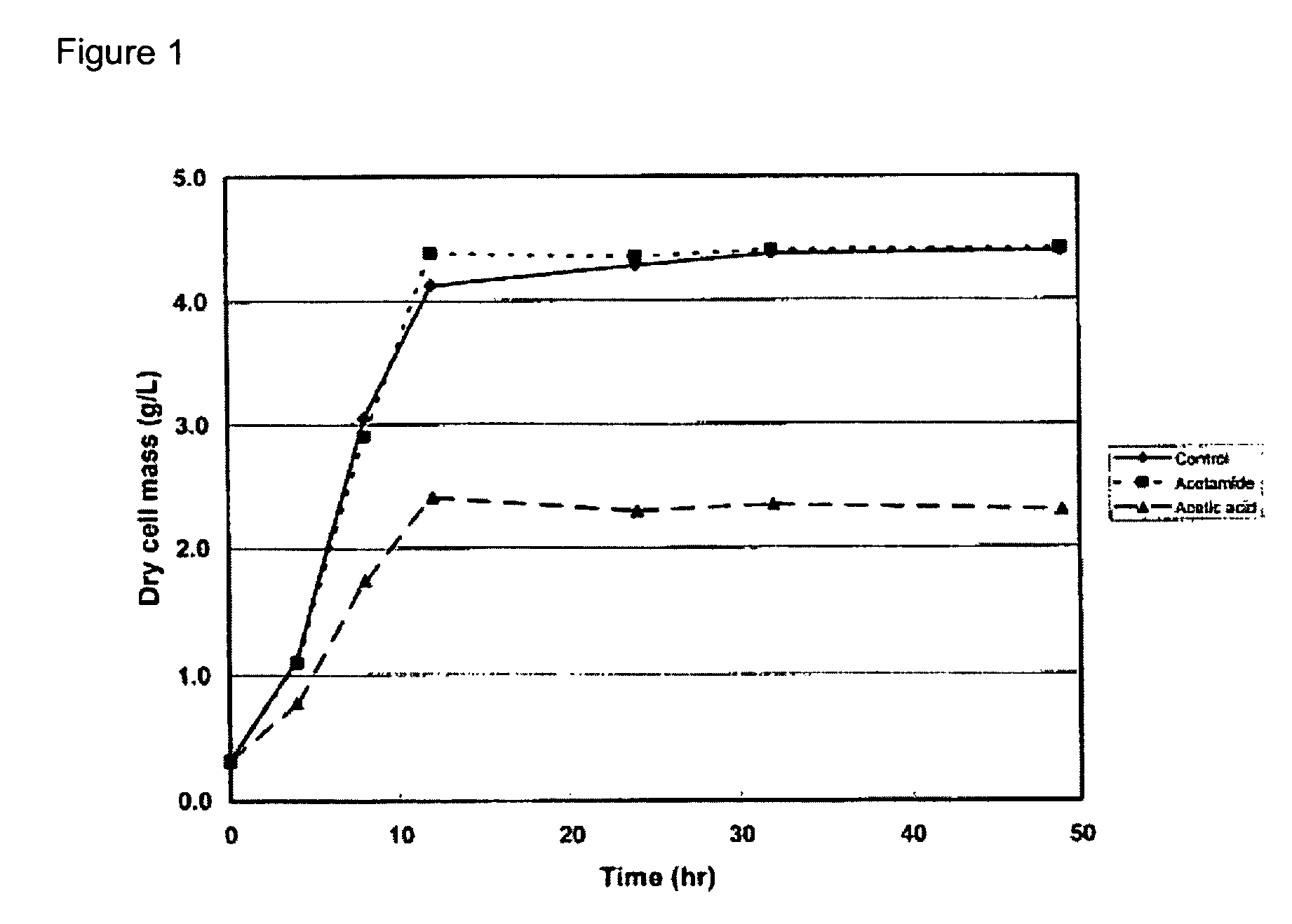

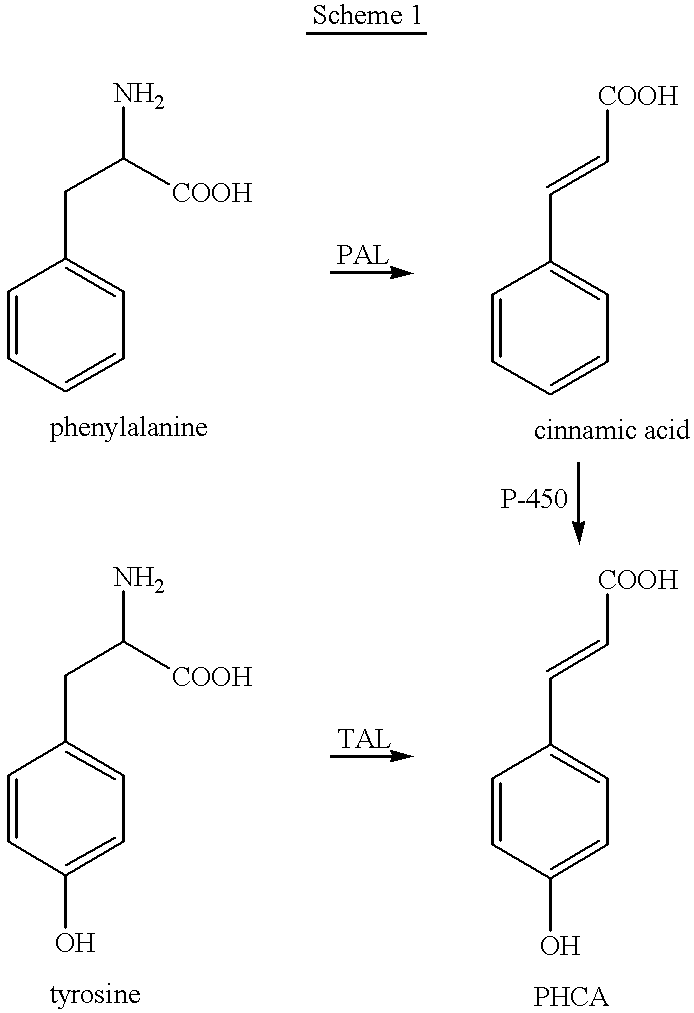

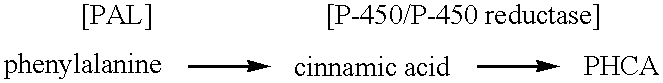

The present invention provides several methods for biological production of para-hydroxycinnamic acid (PHCA). The invention is also directed to the discovery of new fungi and bacteria that possess the ability to convert cinnamate to PHCA. The invention relates to developing of a new biocatalyst for conversion of glucose to PHCA by incorporation of the wild type PAL from the yeast Rhodotorula glutinis into E. coli underlining the ability of the wildtype PAL to convert tyrosine to PHCA. The invention is also directed to developing a new biocatalyst for conversion of glucose to PHCA by incorporation of the wildtype PAL from the yeast Rhodotorula glutinis plus the plant cytochrome P-450 and the cytochrome P-450 reductase into E. coli. In yet another embodiment, the present invention provides for the developing of a new biocatalyst through mutagenesis of the wild type yeast PAL which possesses enhanced tyrosine ammonia-lyase (TAL) activity.

Owner:GATENBY ANTHONY A +4

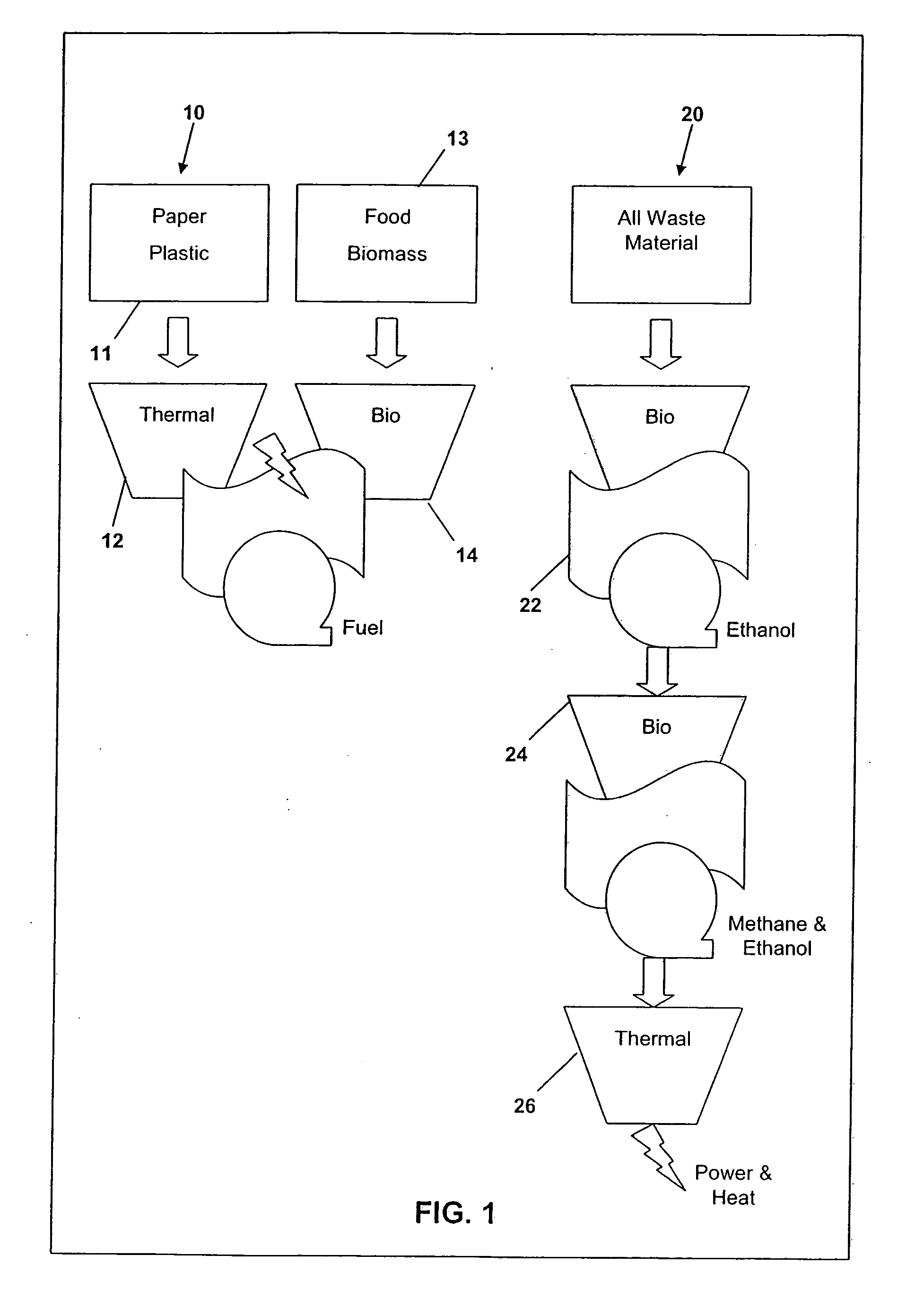

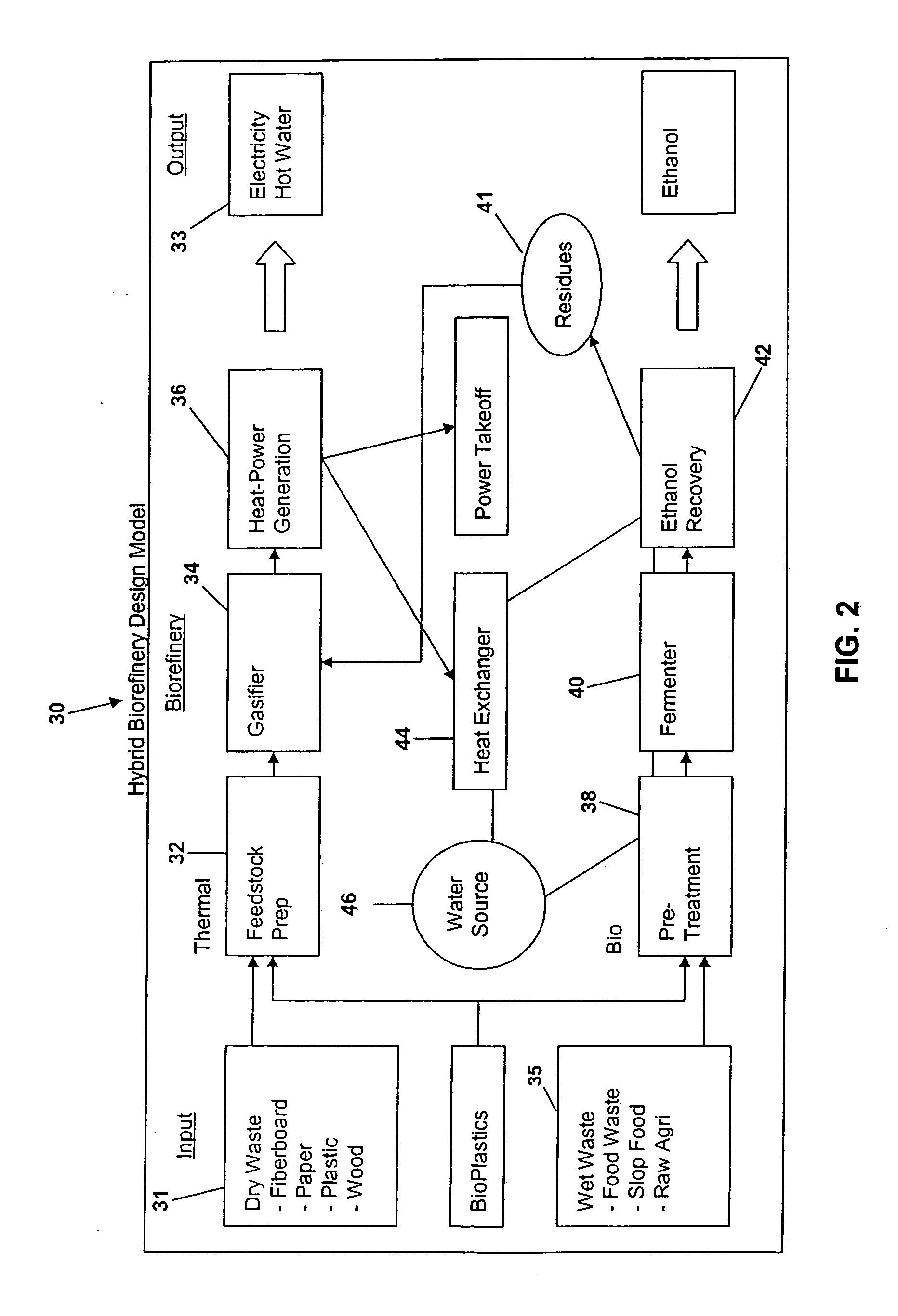

Integrated thermochemical and biocatalytic energy production system

InactiveUS20070117195A1Readily susceptibleEnergy costBioreactor/fermenter combinationsBiological substance pretreatmentsDistillationWaste stream

A method and apparatus for treating organic wastes is provided. Organic wastes are separated into high and low moisture content organic waste streams. The low moisture content organic waste stream is subjected to a gasification process and generates a producer gas. The high moisture content organic waste is subjected to a fermentation process and produces a mixture of ethanol and water. Waste heat from the gasification process is subjected to a distillation column. Vapors recovered from the distillation column are mixed in a hydrous vapor form with the producer gas and produce fuel that can be used as an energy source.

Owner:PURDUE RES FOUND INC

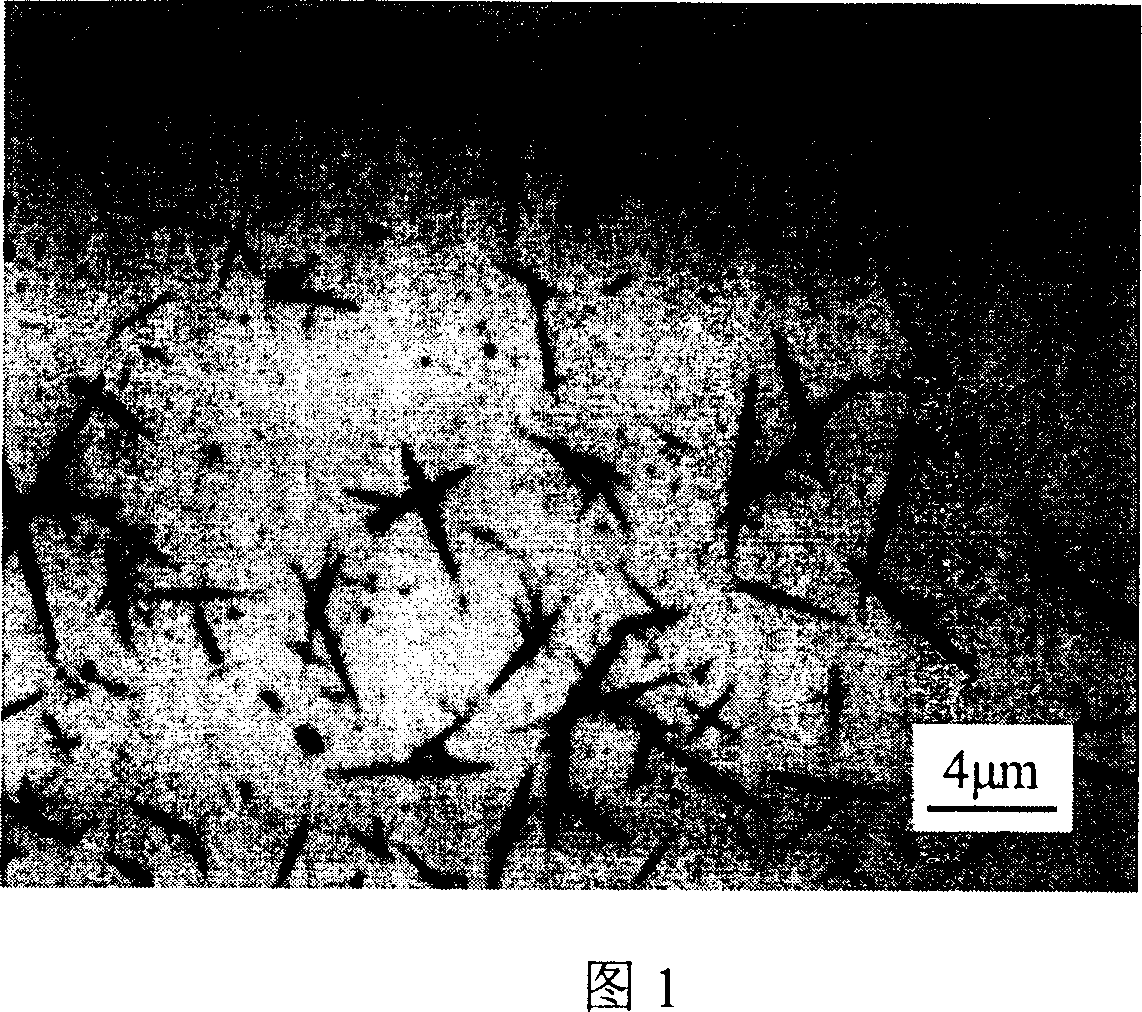

Filter material, method for the production thereof, a filter and filtering method

ActiveUS20080164214A1High propertyLow hydrodynamic resistanceOther chemical processesLayered productsFiberRetention efficiency

The invention concerns the production of filter materials for the purification and disinfection of water, water solutions and other liquids, as well as for sterilizing filtration of injections and other solutions, for concentration of biomolecules in physiological liquids, concentration and extraction of viruses, preparation of apyrogenic water, in biocatalytic diaphragm reactors. The invention solves the problems of a new filter material production, characterized by high sorption properties, high retention efficiency of submicron electronegative particles, microorganisms, submicron non-polar particles and chemical contaminations, and, at the same time, characterized by low hydrodynamic resistance. A base of filter material is the nonwoven organic synthetic polymeric fabric, modified by the aluminum hydroxide particles, fixed to the surface of base fibers for improvement of its sorption properties and for making it positively charged. A method of filter material production comprises: applying the modifying composition onto the fibrous base in the form of organic nonwoven synthetic polymeric fabric, wherein said modifying composition comprises the particles of the aluminum-based material, hydrolysis thereof results to formation and fixation of the aluminum hydroxide particles to the base fibers. A method of fluid filtration is carried out using the filter material as a non-woven organic synthetic polymeric fabric, to the fibers of which the aluminum hydroxide particles are fixed.

Owner:INST OF STRENGTH PHYSICS & MATERIALS SCIENC

Application of bio-enzyme catalysis in residual sludge treatment

A bio-enzyme consists of pectinase, protease, lipase, cellulose, catalase and amylase; the application of bio-enzyme catalysis in residual sludge treatment is that: the residual sludge is treated by utilizing the high-efficiency biocatalysis of the bio-enzyme, odor molecules in the sludge are decomposed and deodorized through enzyme technology, pathogenic bacteria, ova and larvae are killed by utilizing an acid environment formed by inorganic acid generated by the sludge and a high temperature environment in the fermentation process, heavy metal ions in the sludge are stabilized by utilizing the chelation of the bio-enzyme, and the sludge is catalyzed by the enzyme, so that the sludge and water are quickly separated, a large amount of supernate is discharged, the sludge volume is reduced, and the sludge in inland river is reduced and is subjected to innocent treatment; meanwhile, through the bio-enzyme catalysis, long-chain molecules in the sludge are converted into short-chain molecules, polysaccharide and cellulose are converted into protein and amino acid, nutritional components of organic fertilizers are remained, the fertilizer efficiency is improved and the fermentation period can be shortened.

Owner:孙祥章

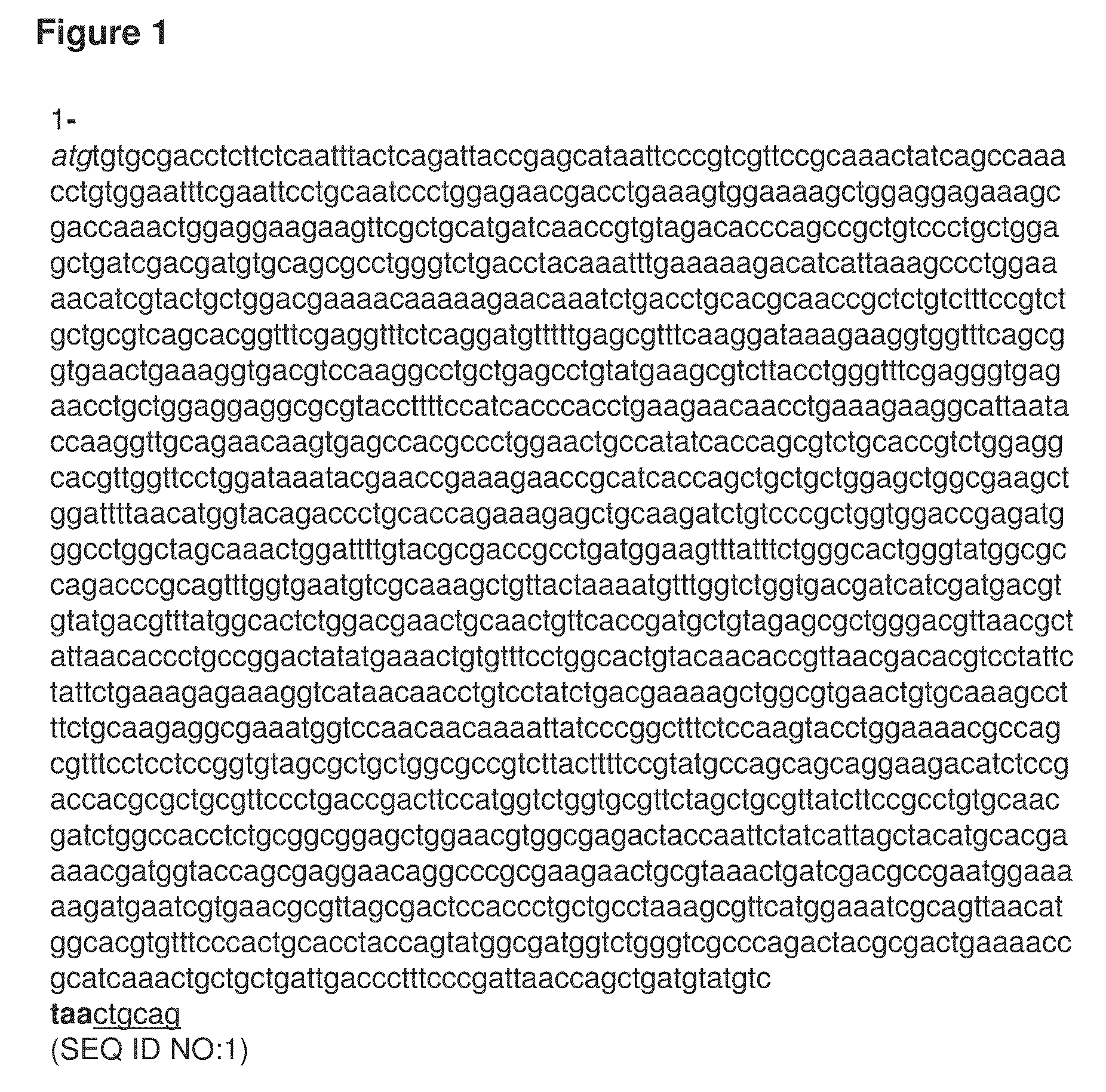

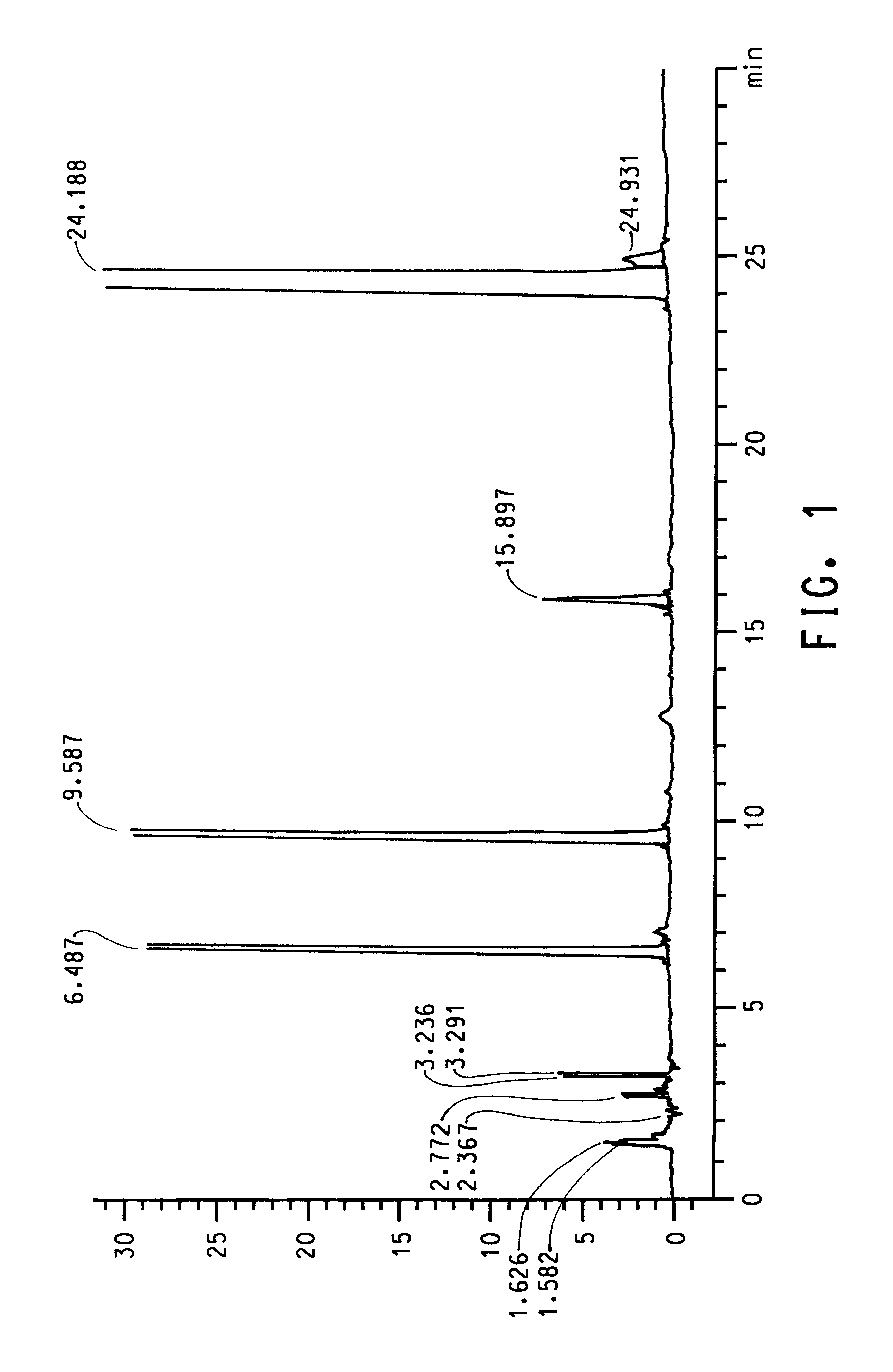

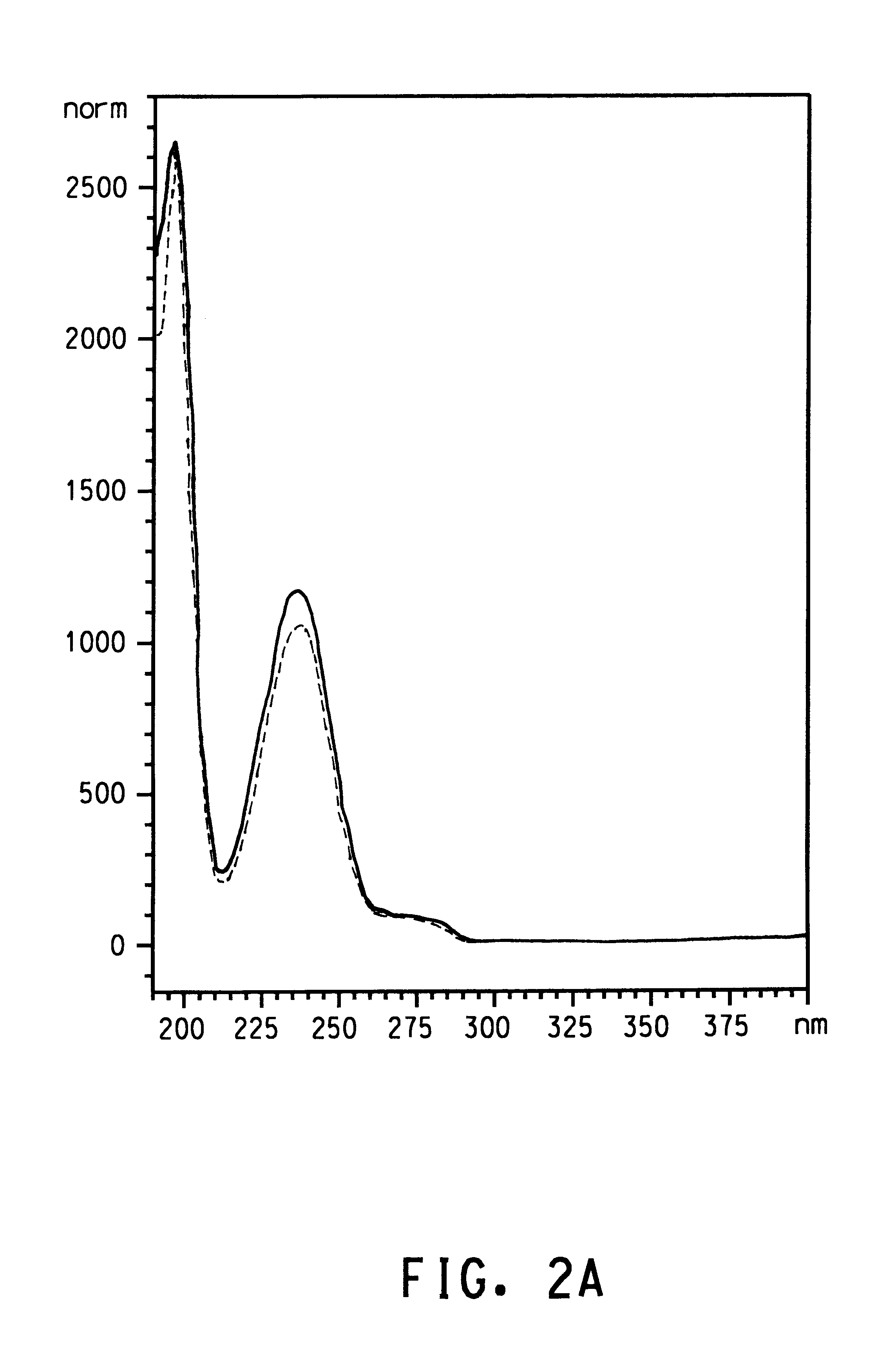

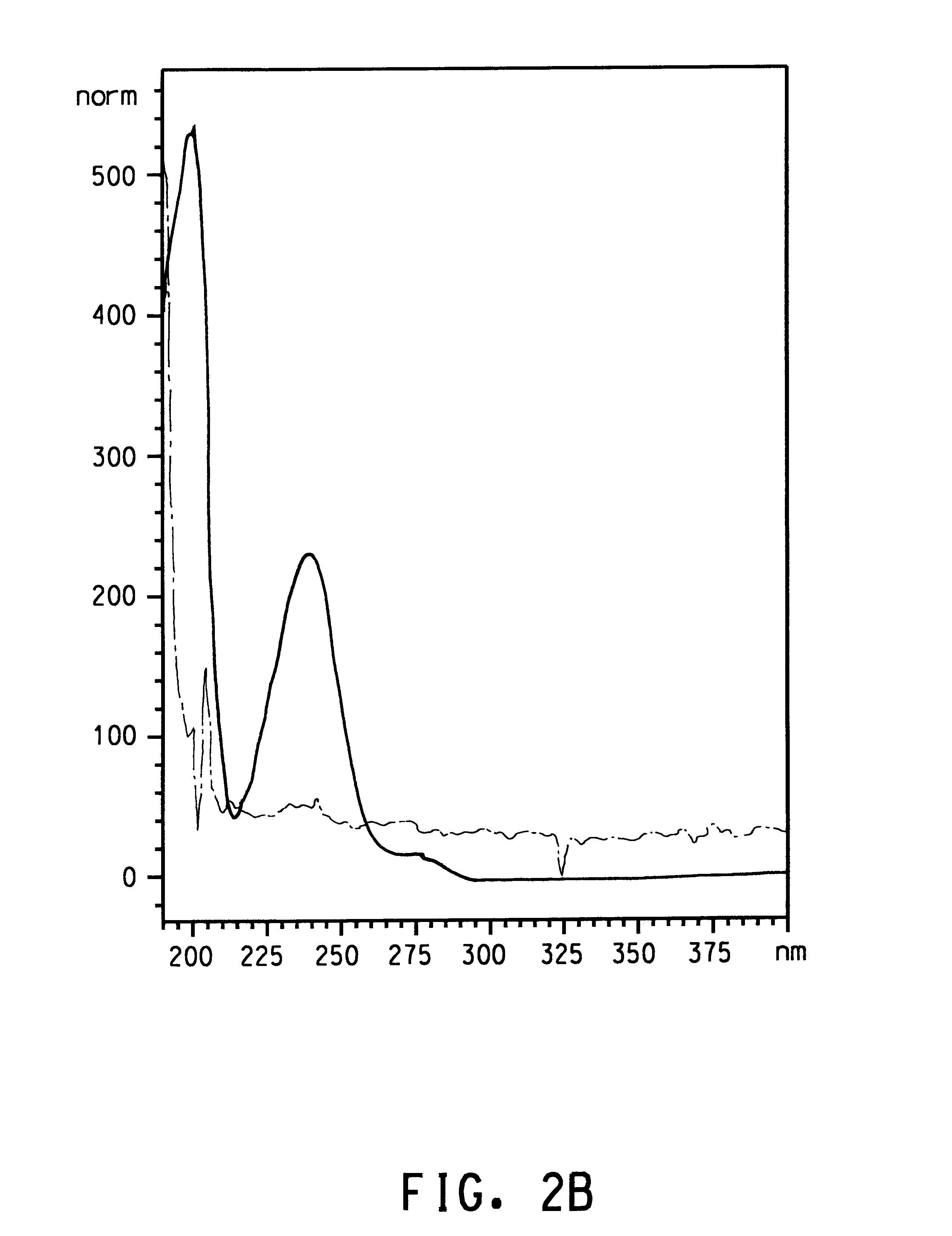

Polynucleotide encoding a mutant Rhodotorula glutinis tyrosine ammonia lyase polypeptide

The present invention provides several methods for biological production of para-hydroxycinnamic acid (PHCA). The invention is also directed to the discovery of new fungi and bacteria that possess the ability to convert cinnamate to PHCA. The invention relates to developing of a new biocatalyst for conversion of glucose to PHCA by incorporation of the wild type PAL from the yeast Rhodotorula glutinis into E. coli underlining the ability of the wildtype PAL to convert tyrosine to PHCA. The invention is also directed to developing a new biocatalyst for conversion of glucose to PHCA by incorporation of the wildtype PAL from the yeast Rhodotorula glutinis plus the plant cytochrome P-450 and the cytochrome P-450 reductase into E. coli. In yet another embodiment, the present invention provides for the developing of a new biocatalyst through mutagenesis of the wild type yeast PAL which possesses enhanced tyrosine ammonia-lyase (TAL) activity.

Owner:EI DU PONT DE NEMOURS & CO

Microorganism fermentation grease and method for preparing organism diesel oil from the same

InactiveCN1923960AAbundant raw materialsLow costBiofuelsLiquid hydrocarbon mixture productionOil and greaseYeast

The invention discloses a biological diesel preparing method of fat fermented by microbe in the biological energy and biological catalytic technological domain, which comprises the following steps: grafting yeast microbe in the fat-producing bacterial culture medium; centrifuging; separating; extracting to obtain the fat; esterifying under catalyst to obtain biological diesel and glycerine as by-product.

Owner:TSINGHUA UNIV

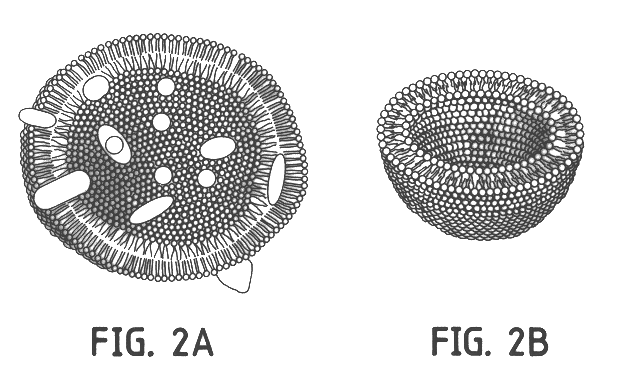

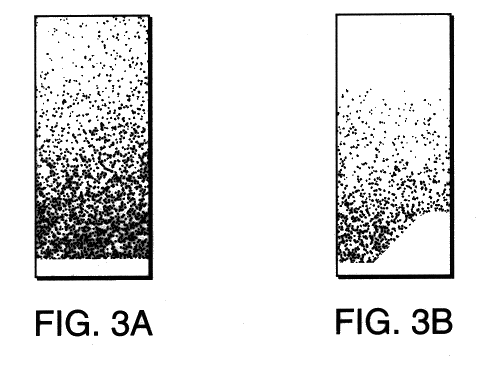

Direct colorimetric detection of biocatalysts

InactiveUS6468759B1Rapid optical signalFast response timeMaterial nanotechnologyColor measuring devicesAnalyteColor changes

The present invention relates to methods and compositions for the direct detection of membrane conformational changes through the detection of color changes in biopolymeric materials. In particular, the present invention allows for the direct colorimetric detection of membrane modifying reactions and analytes responsible for such modifications and for the screening of reaction inhibitors.

Owner:RGT UNIV OF CALIFORNIA

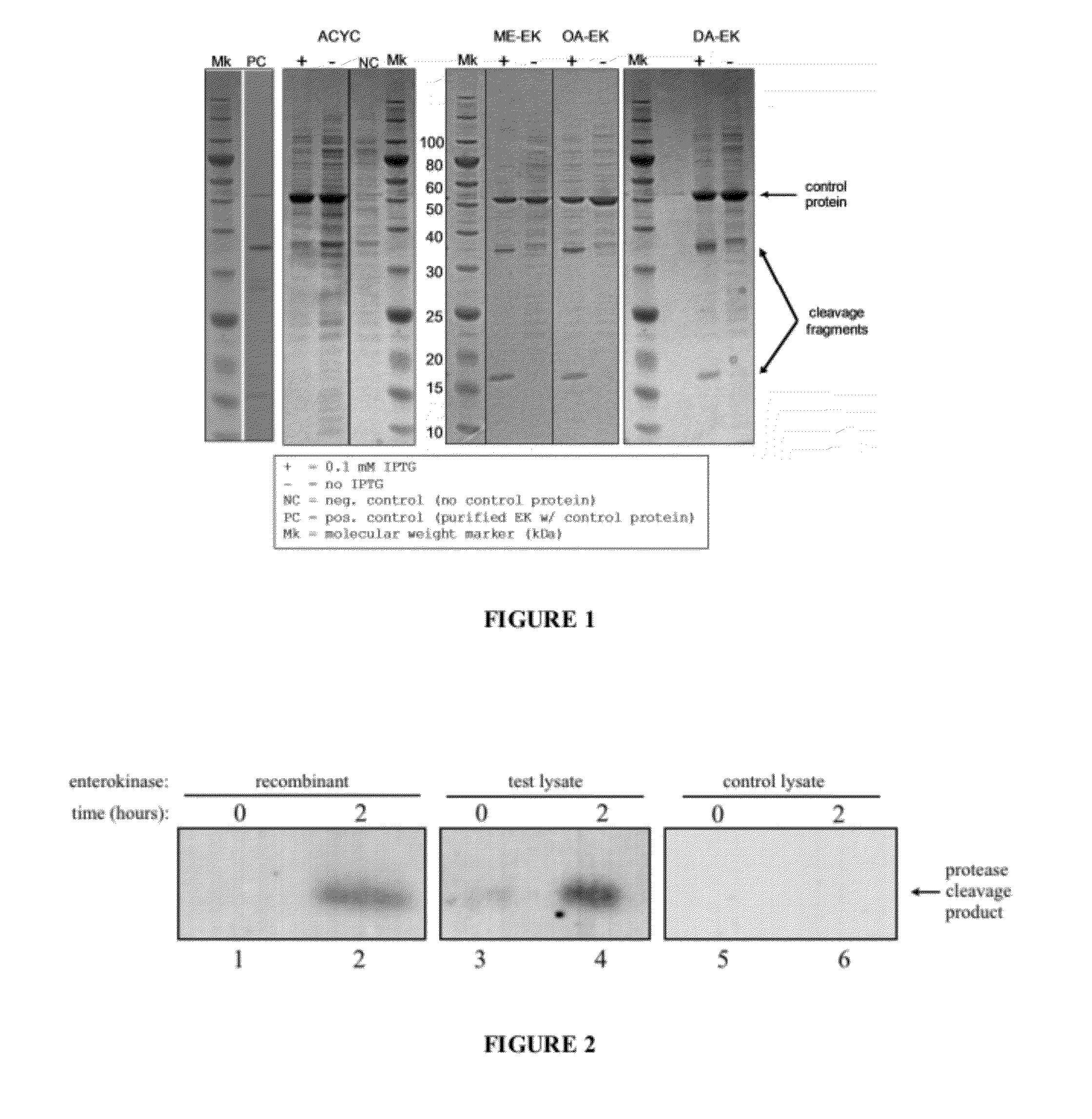

Methods for control of flux in metabolic pathways through protease manipulation

The embodiments described herein pertain to cells, and methods for preparing cells, that can be used as biocatalysts by altering enzymes that compete for a substrate or product of a pathway of interest such that the targeted enzyme is sensitive to a site-specific protease, which protease is expressed but relocated in the cell to a site where it is not in contact with the targeted enzyme in the intact cell. Upon cell lysis, the protease contacts the target enzyme, which is then inactivated by protease cleavage.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

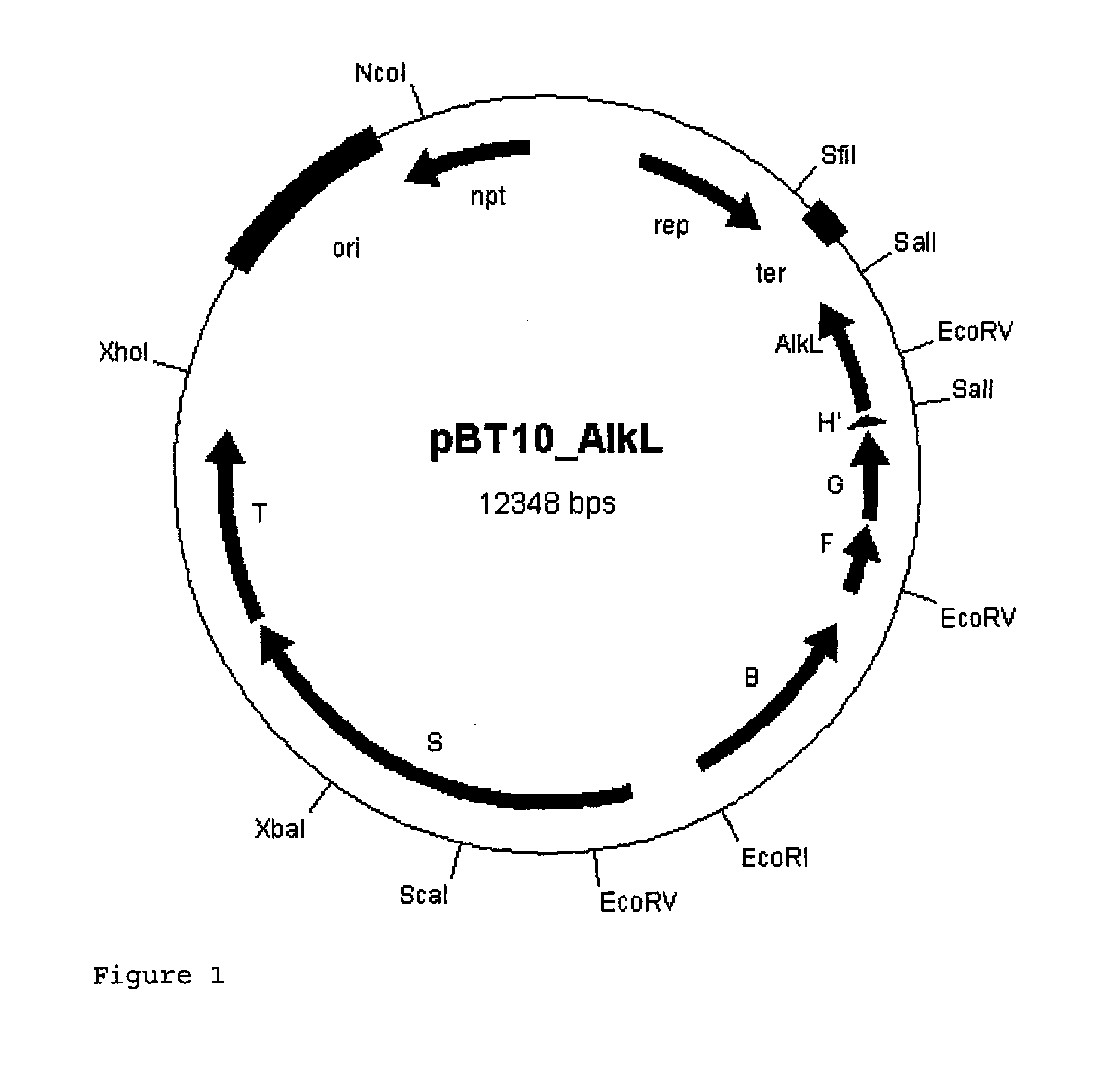

Biocatalytic oxidation process with alkl gene product

ActiveUS20130052700A1Increase synthesisHigh expressionBacteriaUnicellular algaeSimple Organic CompoundsMicroorganism

The invention provides a biocatalytic process for oxidation of organic compounds with the aid of an alkL gene product, and microorganisms used in this process.

Owner:EVONIK OPERATIONS GMBH

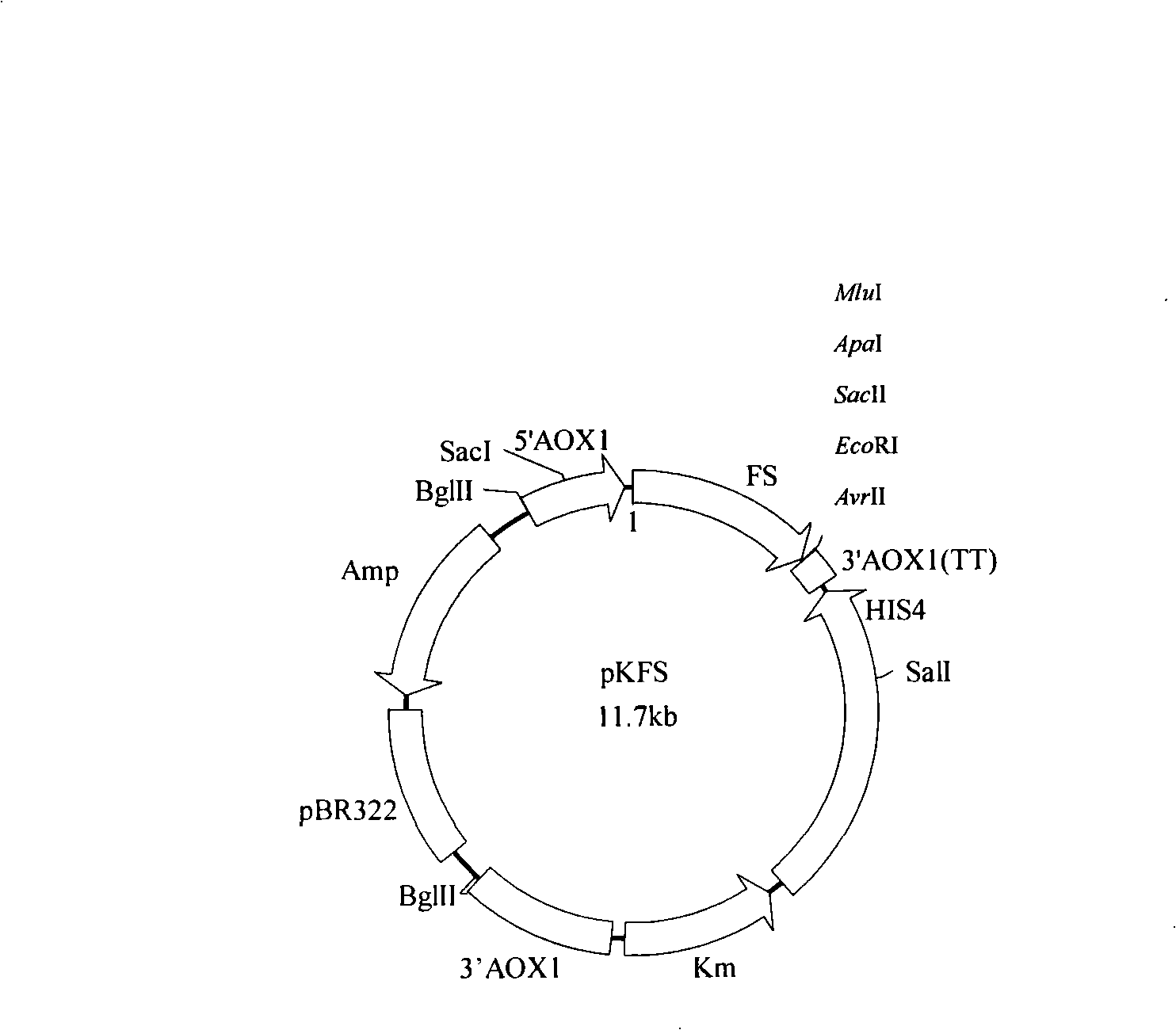

Process for synthesizing ethyl caproate by yeast display lipase synthesis

InactiveCN101285078AImprove operational stabilityHigh biosecurityFungiHydrolasesBiotechnologySurface display

The invention discloses a method for synthesizing ethyl caproate under the catalysis of yeast display lipase. The method comprises two steps, namely the production of full cellular zymin and the synthesis of ethyl caproate. The method comprises the following: a step of cloning the lipase gene into the Pichia yeast surface display vector pKFS to construct the Pichia yeast surface display expression vector pKFS-lipase which is transformed into the host bacteria of Pichia yeast through linearization, a yeast genetic engineering bacteria capable of displaying active pheron on the surface of the Pichia yeast being obtained through screening, and the engineering bacteria being fermented in a rocking bottle to obtain a thallus which is used to make the full cellular zymin after 24 hours of vacuum freeze drying; and then a step of adopting caproic acid and alcohol as raw material which is esterified at the action of the biocatalyst of yeast full cellular zymin with the lipase displayed on the surface to obtain the ethyl caproate product. The method is capable of collecting thalli centrifugally for reuse after the reaction with short reaction time, high yield and good operational stability, thereby greatly reducing production costs.

Owner:SOUTH CHINA UNIV OF TECH

High-efficiency purifier of biological enzyme

InactiveCN101306867AImprove biological activityRealize the combinationBiological water/sewage treatmentTreatment effectWater quality

The invention provides a biological enzyme high-efficiency water purifier. The raw materials of the water purifier by weight portion comprise the following compositions: 24 to 52 potions of biological enzyme, 10 to 20 potions of microorganism, 0 to 4 potions of plant extract additive, and 40 to 63 potions of water or 28 to 53 potions of filler. The water purifier is a biological preparation for treating pollution sources that the prior pollution treatment technologies fail to treat through a biocatalysis technology with a biodegradation function, can greatly get rid of odor, quickly degrade liquid pollutants, reduce the volume of solid matters, and quickly purify polluted substances, has good treatment effect, greatly reduces running cost of wastewater treatment, ensures that purified water quality is more stable, is energy saving and high efficient in treating pollution, is suitable for the treatment of various sewage, has no side effect, and has remarkable economic benefit and environmental benefit.

Owner:江苏晨翔环境科技股份有限公司

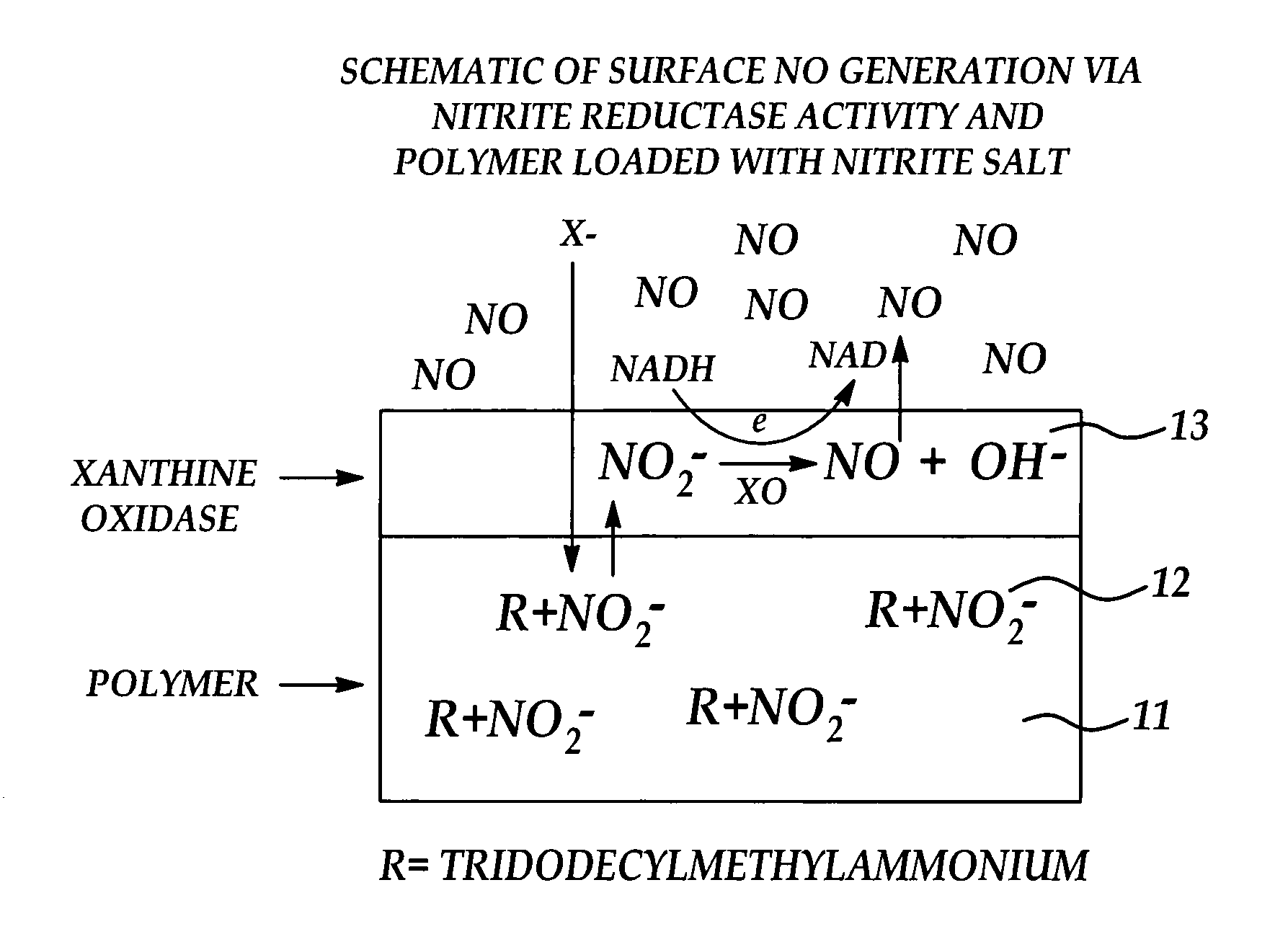

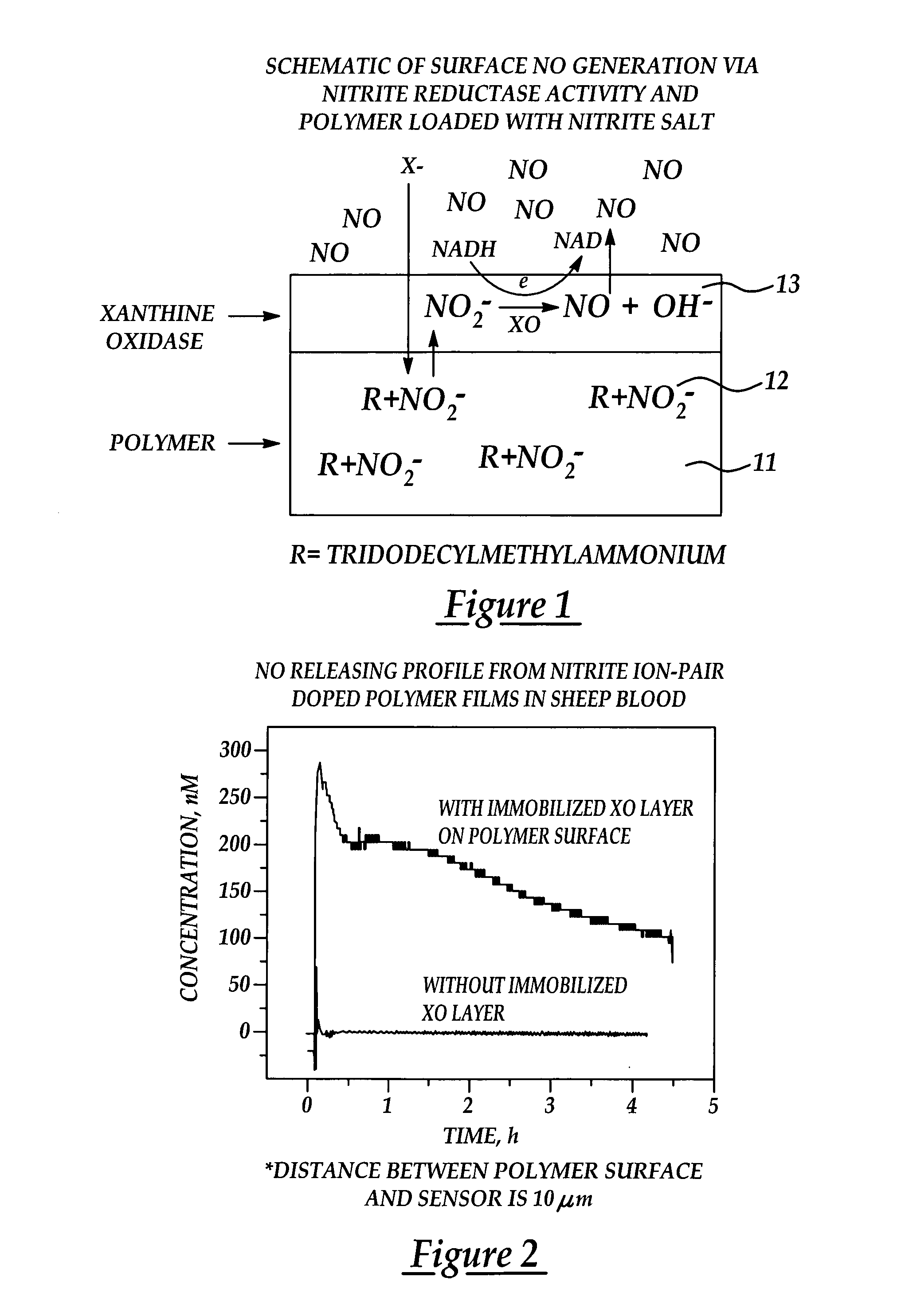

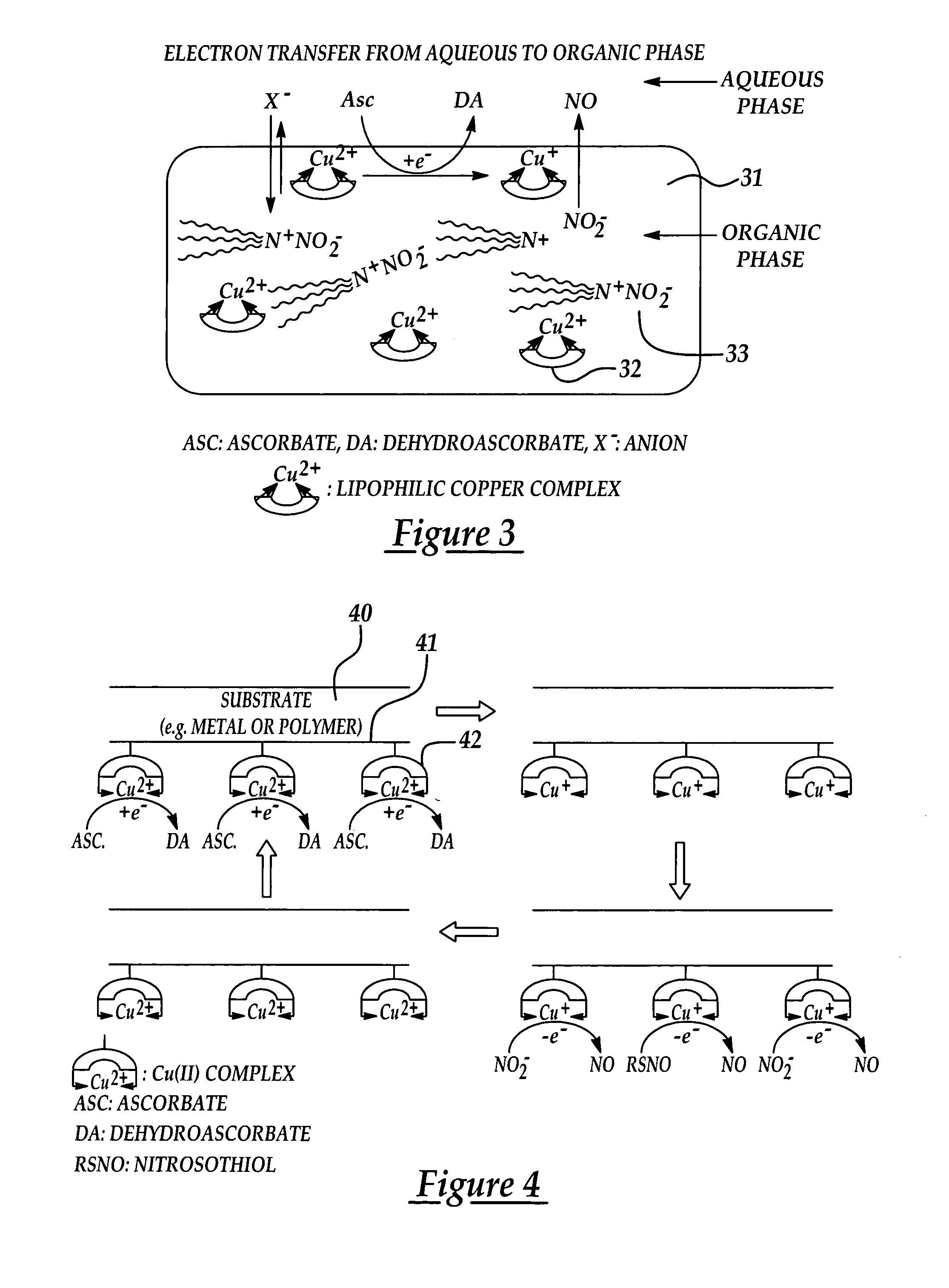

Material containing metal ion ligand complex producing nitric oxide in contact with blood

InactiveUS7128904B2Good biocompatibilityPeptide/protein ingredientsOther blood circulation devicesPolymer thin filmsNitric oxide

Biocompatible materials that have the ability to release nitric oxide (NO) in situ at the surface-blood interface when in contact with blood. The materials which may be polymers (e.g., polyurethane, poly(vinyl chloride), silicone rubbers), metals, such as stainless steel, carbon, and the like are provided with biocatalysts or biomimetic catalysts on their surface that have nitrite, nitrate, and / or nitrosothiol-reducing capability. Illustratively, the catalysts are adsorbed or immobilized at the surface of the material. The catalysts can act on endogenous nitrite, nitrate, or nitrosothiols within the blood creating a local increase in the NO levels at the surface of the material. An illustrative enzymatic biocatalyst is mammalian xanthine oxidase. In another illustrative embodiment, a biomimetic catalyst is a copper (Cu(II)-ligand complex, e.g. dibenzo[e,k]-2,3,8,9-tetraphenyl-1,4,7,10-tetraaza-cyclododeca-1,3,7,9-tetraene. In some cases, lipophilic salts of nitrite / nitrate (e.g., tridodecylmethylammonium nitrite (TDMA+NO2− / NO3−)) or certain salts of nitrosothiols can be doped within a polymer material, or an underlying polymeric film, to create a reservoir of nitrite or nitrosothiol that continuously leaks into the immobilized catalytic layer. Adequate levels of endogenous reducing equivalents are present within blood to provide catalytically-generated surface levels of NO that are above the threshold reportedly required to prevent platelet adhesion or activation.

Owner:RGT UNIV OF MICHIGAN

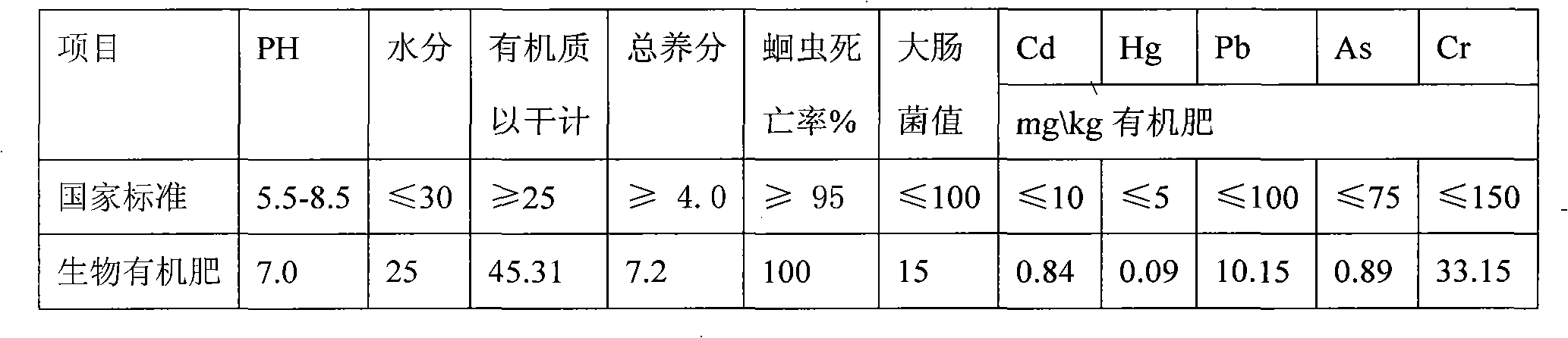

Microorganism and enzyme powder composite biological agent for microbial organic fertilizer

ActiveCN101786911AImprove decomposition effectSpeed up fermentationBio-organic fraction processingClimate change adaptationBiotechnologyNoxious weed

The invention discloses a microorganism and enzyme powder composite biological agent for a microbial organic fertilizer, which consists of 25 percent of various microbial agents, 23 percent of various bio-enzyme preparations, 30 to 35 percent of microbial nutrition agent, 5 percent of mordenite, 8 percent of dolomite, 3 percent of potassium fulvic acid, and the balance of water. The invention provides the microorganism and enzyme composite biological agent for promoting the high-quality and high-yield production of the microbial organic fertilizer, which is formed by compounding purely natural microorganism and enzyme, and integrates the advantages of the microbial agents and the enzyme preparation, and has the biocatalyst and biological degradation function; when used in a compost, the microorganism and enzyme composite biological agent accelerates the degradation speed of organic matters, makes the temperature of the composting materials rise in a short time (24 hours), eliminates the situations such as strong smelling and mosquitoes and flies breeding, and the like caused in the composting process of the biological organic raw materials, reduces the emission of massive pollution gases, and kills the noxious weeds, pathogenic bacteria and ova in the raw materials, and improves the content of organic matters of the composting product; improves the insect resistance capability of crops, and improves the soil degradation problems caused by the fertilizer.

Owner:北京微邦生物工程有限公司

Microbial production of terephthalic acid and isophthalic acid

This invention relates to a biocatalytic process to produce terephthalic acid and isophthalic acid from p-xylene and m-xylene, respectively. Terephthalic acid has been prepared by oxidizing p-xylene with bacteria belonging to the genus Burkholderia. Conversion of p-xylene into terephthalic acid is accomplished by a single bacterial strain that produces all of the requisite enzymes. In addition, this invention relates to the preparation of isophthalic acid from a mixture of m- and p-xylene.

Owner:EI DU PONT DE NEMOURS & CO

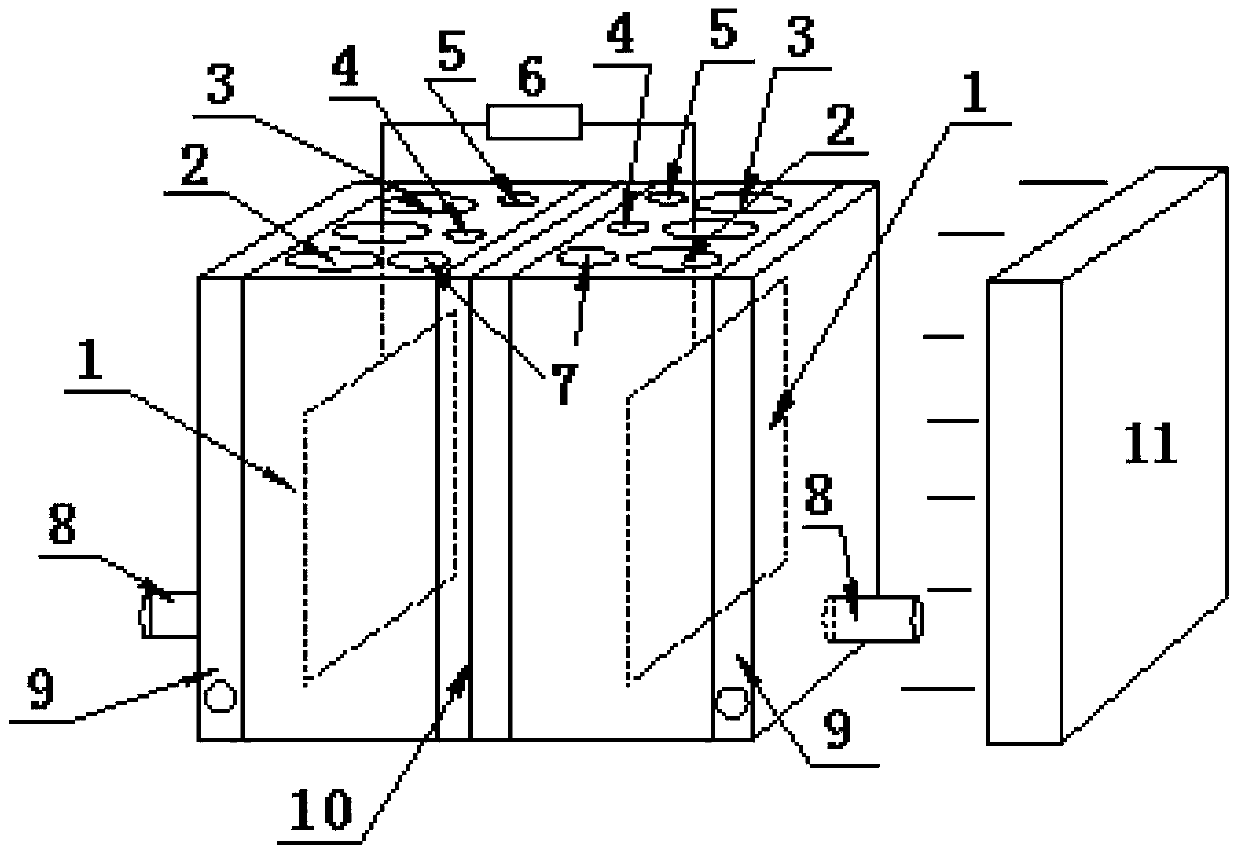

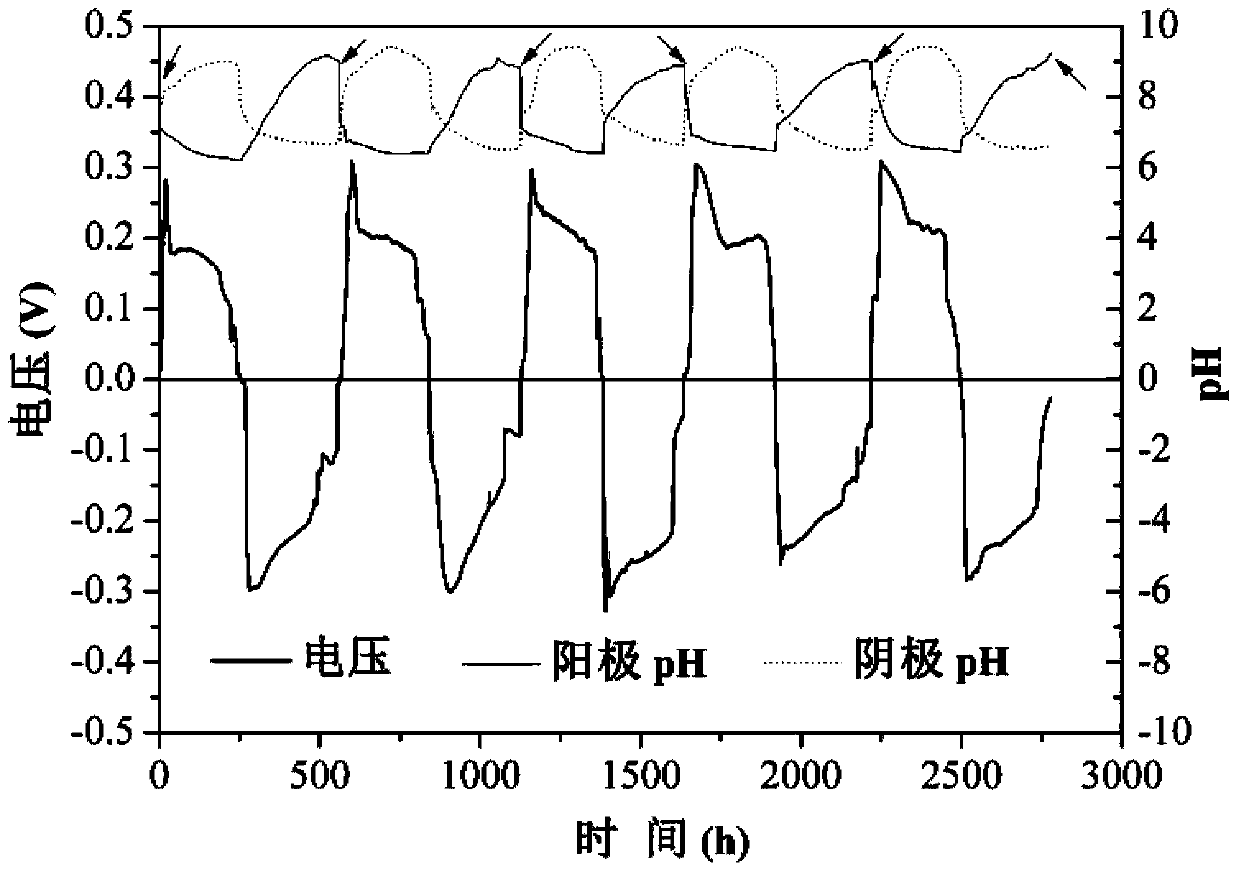

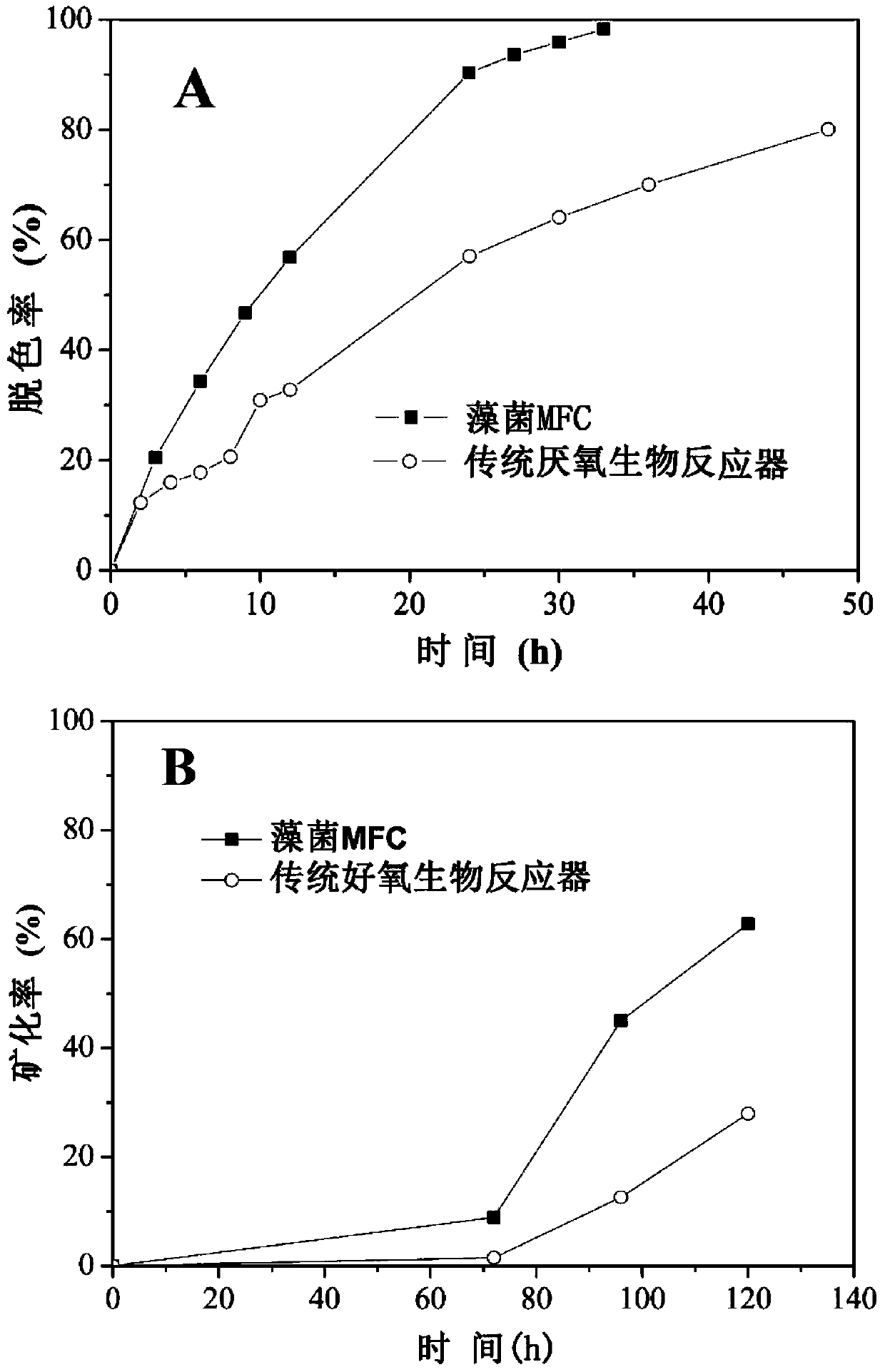

Phycomycetes microbial fuel cell and preparation method and application of phycomycetes microbial fuel cell

ActiveCN103427102AReduce physiological toxicityEfficient power generationCell electrodesFinal product manufactureEngineeringCathode

The invention belongs to the technical field of biological fuel cells, and discloses a phycomycetes microbial fuel cell and a preparation method and application of the phycomycetes microbial fuel cell. The phycomycetes microbial fuel cell comprises an anode chamber, a cathode chamber, a transverse diaphragm, an anode, a cathode and an outer circuit, wherein phycomycetes, a culture solution and a carbon source are respectively installed in the anode chamber and the cathode chamber. In the operation process of the phycomycetes microbial fuel cell, operation is conducted by repeatedly converting the electrodes; in the whole operation process, with the help of synergistic effects of the phycomycetes, the effect that azo dye pollutants are degraded efficiently is achieved; the electrodes are alternately used for degrading the azo dye pollutants, therefore, the physiologically toxic effect on current-producing bacteria by the azo dye pollutants is eliminated, and continuous efficient current generation is realized; the phycomycetes is adopted as a biocatalyst for both the anode and the cathode, no metal catalyst is used for modification, no exogenous artificial mediator is added, aeration is not needed, therefore, the construction and operation cost of the microbial fuel cell is lowered, the sustainability of the microbial fuel cell is enhanced, and industrial amplified production of the microbial fuel cell can be conducted beneficially.

Owner:SOUTH CHINA UNIV OF TECH

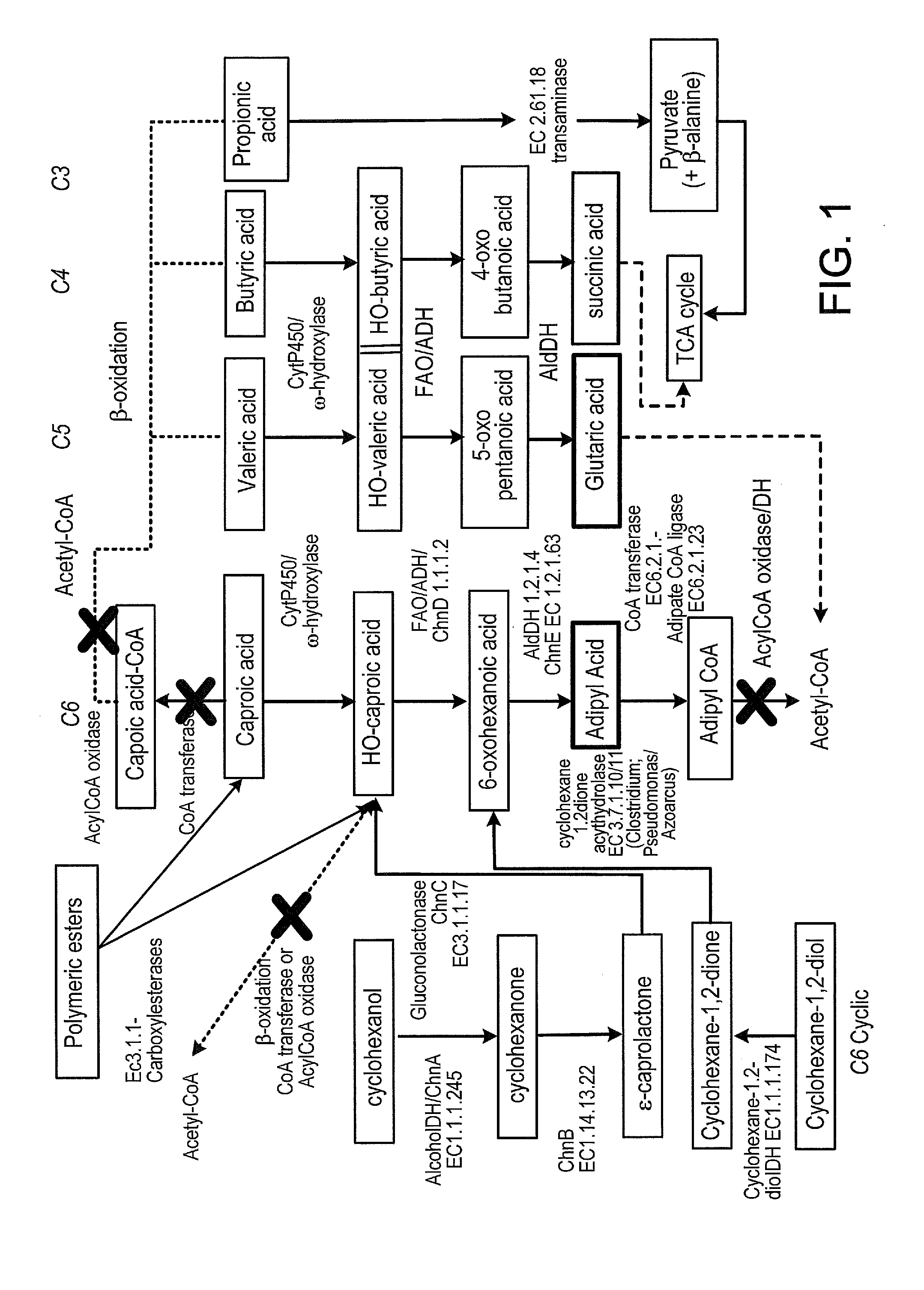

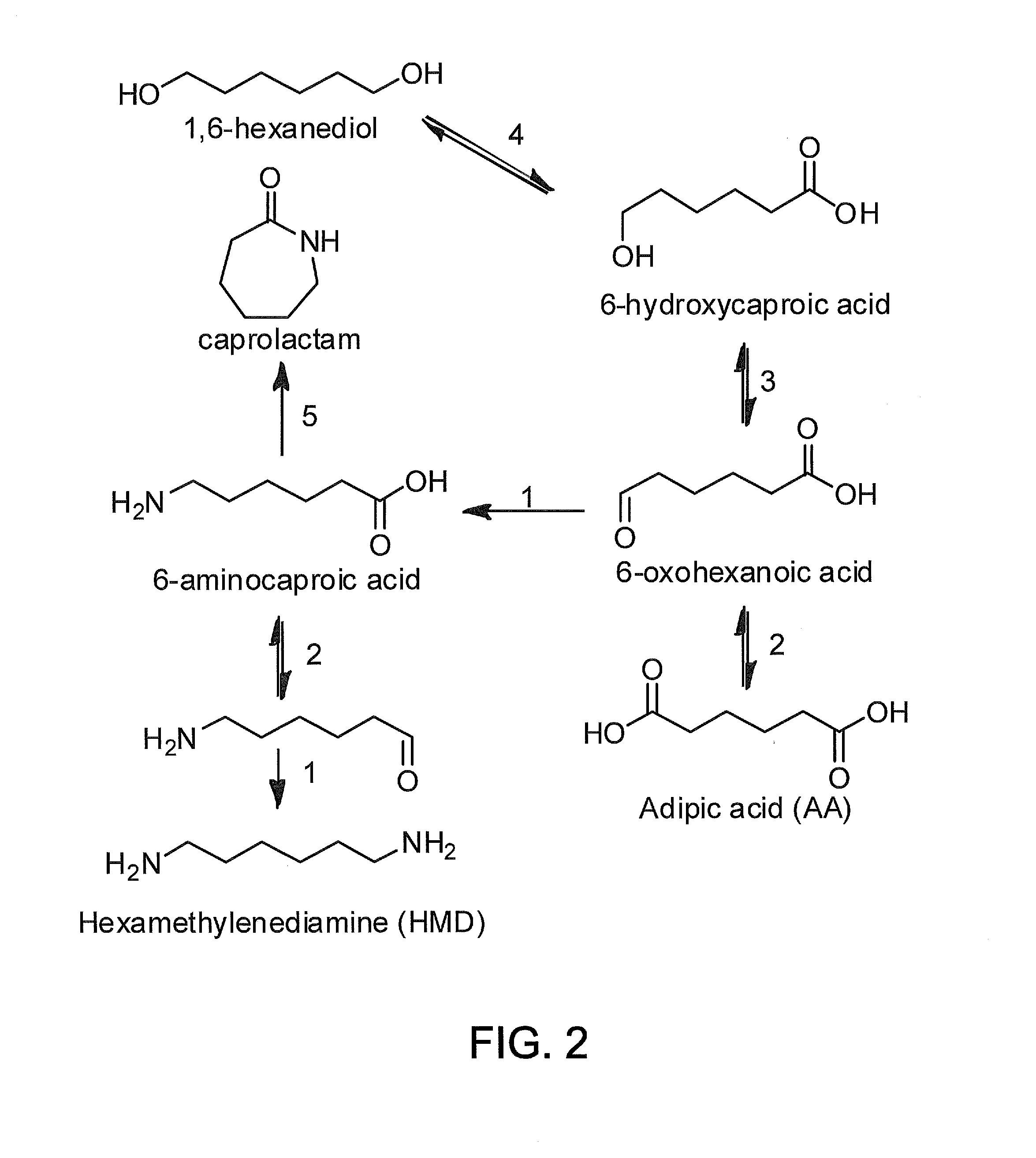

Methods of producing carboxylic acids

The invention relates to methods for enriching monomer content in a cycloalkane oxidation process mixed organic waste stream. In particular, the methods involve combining a biocatalyst with a mixed organic waste stream from a cycloalkane oxidation process, and enzymatically converting dimeric and / or oligomeric components of said waste stream into monomeric components. The methods may enrich the content of diacids, adipic acid, and / or other α,ω-difunctional C6 alkanes in the mixed organic waste stream. Additionally, the treated mixed organic waste streams may have improved burning efficiency.

Owner:INV NYLON CHEM AMERICAS LLC

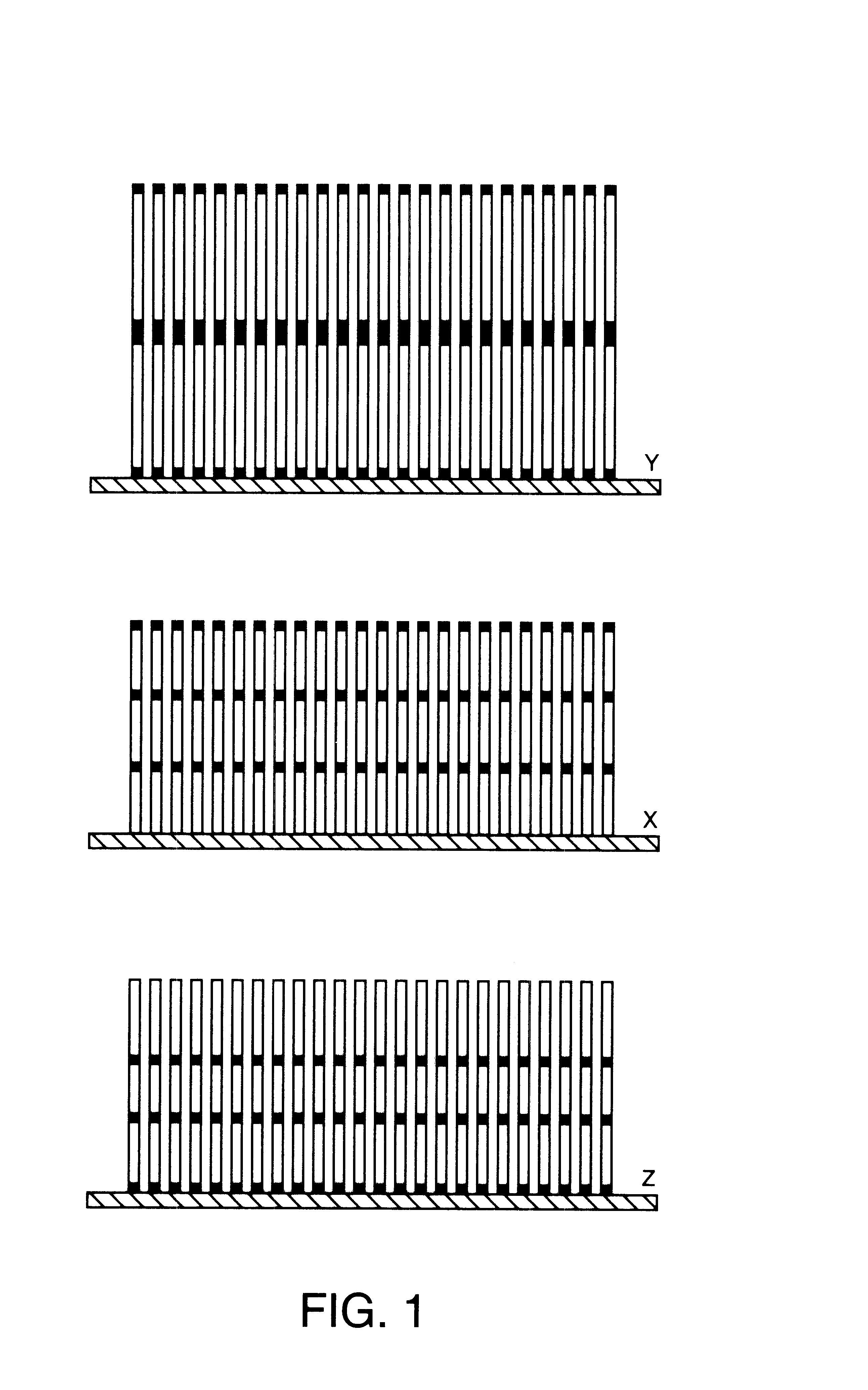

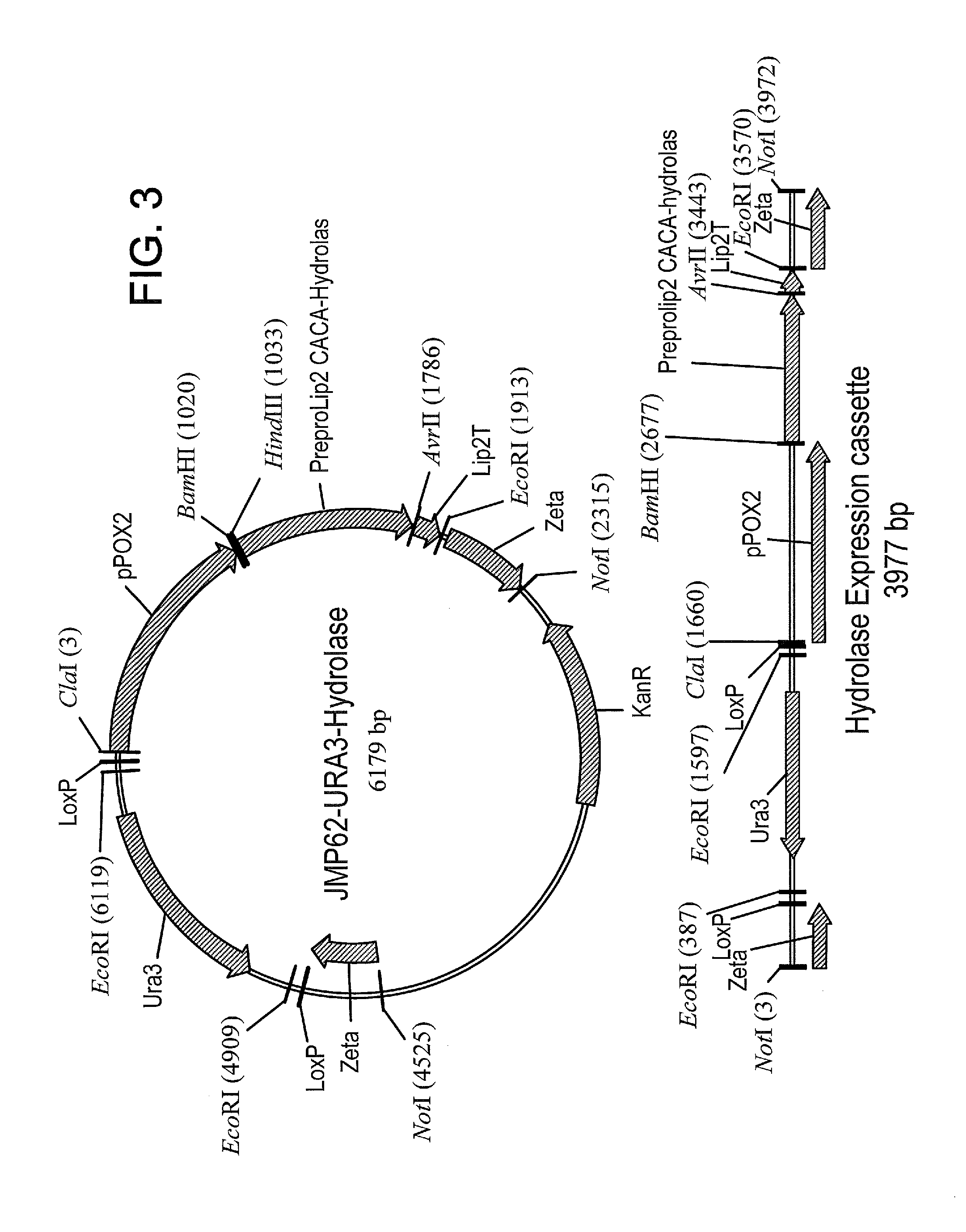

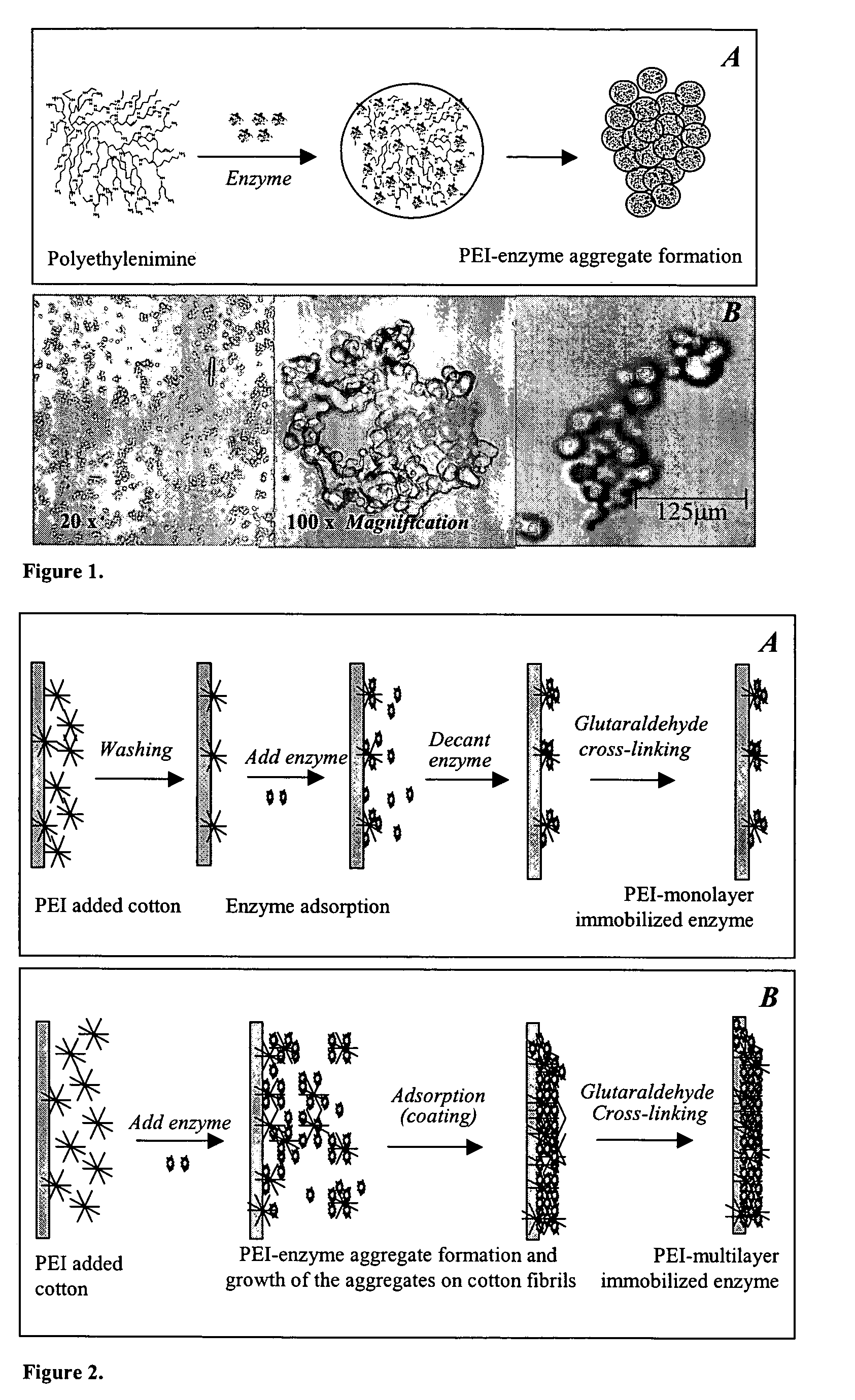

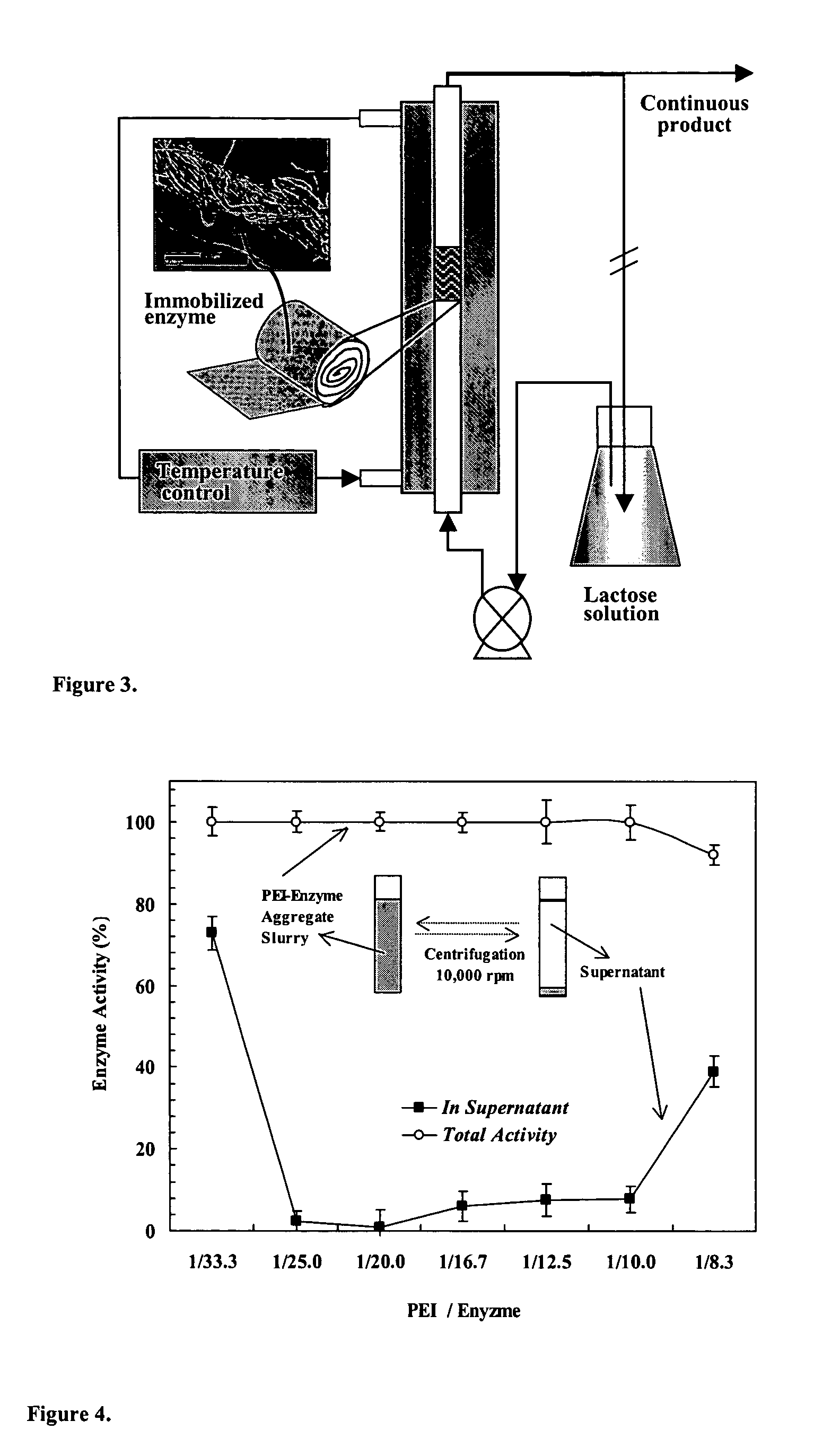

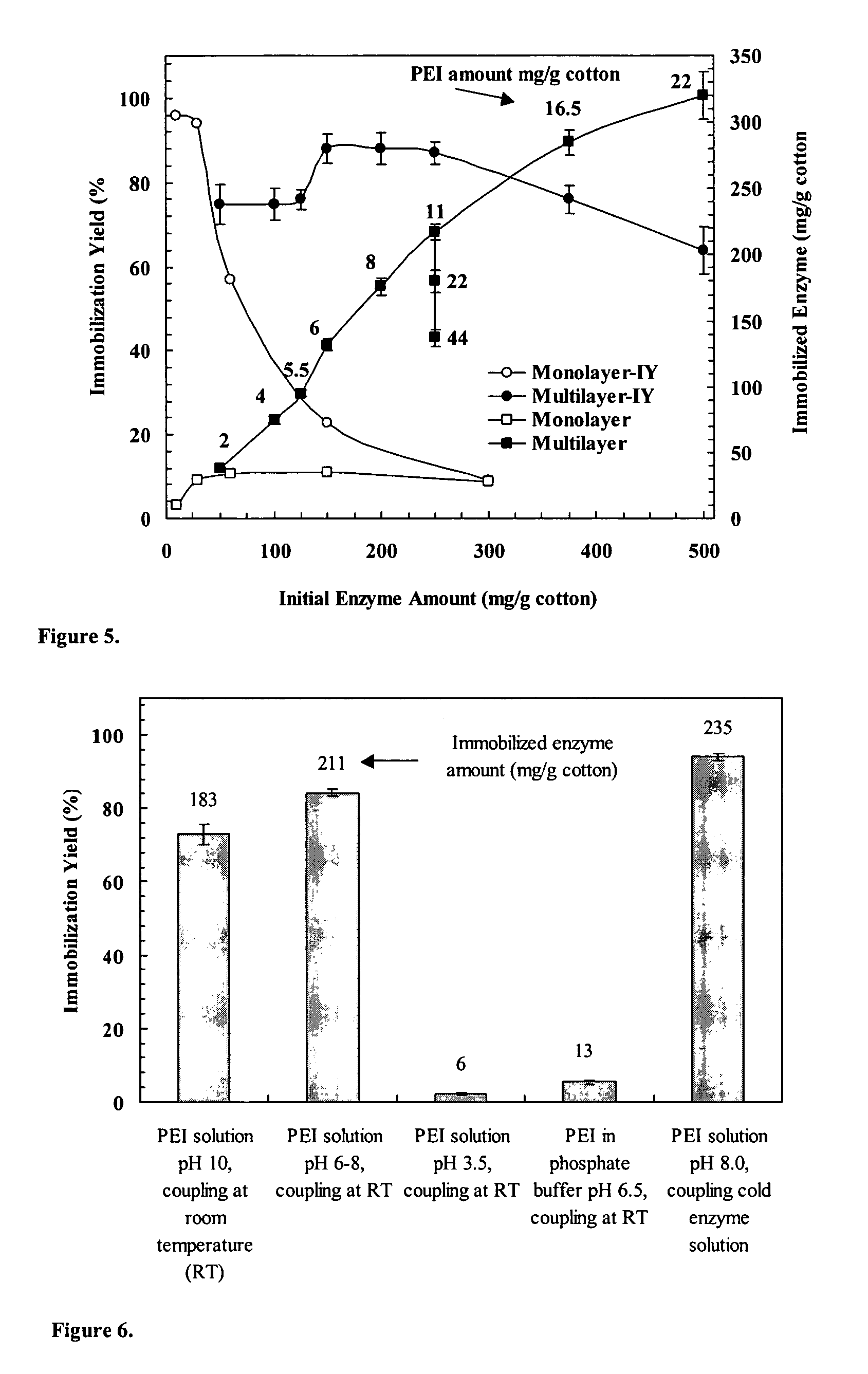

Immobilization of enzyme on a fibrous matrix

ActiveUS7166451B1The process is simple and clearHigh enzyme loadingOn/in organic carrierFermentationFiberCross-link

A multilayer enzyme immobilization process is provided comprising adsorbing a polyethyleneimine (PEI) solution in a fibrous matrix, and adding an enzyme to the fibrous matrix, which comprises a plurality of fibrils. The process further comprises forming at least two layers of PEI-enzyme aggregates on the fibrils, and cross-linking the multilayer PEI-enzyme aggregates. The process can further comprise washing the fibrils containing the cross-linked PEI-enzyme aggregates with distilled water and acetic acid buffer subsequent to cross-linking. However, the PEI-containing matrix is not washed prior to the addition of enzyme. The enzyme can be β-galactosidase and the fibrous matrix can be cotton cloth. The multilayer immobilized enzyme can be employed in a biocatalyst reactor for production of galacto-oligosaccharides from lactose and the hydrolysis of lactose to glucose and galactose.

Owner:THE OHIO STATE UNIV RES FOUND

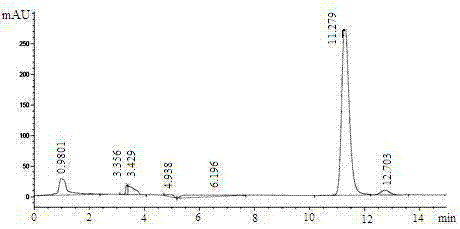

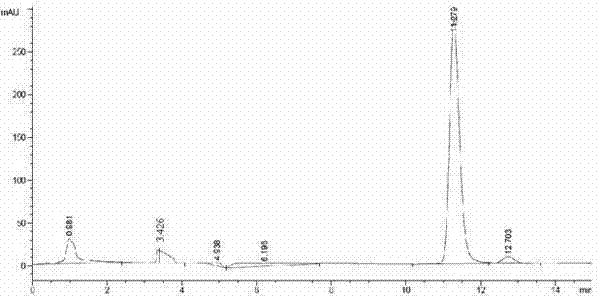

Method for preparing (S)-(4-chlorphenyl)-(pyridine-2-yl)-methanol by utilizing microbial catalysis

ActiveCN102559520AHigh excessLess side effectsFungiMicroorganism based processesPhosphateReaction temperature

The invention relates to a method for preparing (S)-(4-chlorphenyl)-(pyridine-2-yl)-methanol by utilizing microbial catalysis, and belongs to the technical field of biological catalysis. According to the method, 4-chlorphenyl-(pyridine-2-yl)-ketone is subjected to asymmetrical reduction by utilizing kluyveromycessp (CCTCCM 2011385) whole cells to synthesize the (S)-(4-chlorphenyl)-(pyridine-2-yl)-methanol. The method comprises the following steps of: sieving a microbe which has high-stereoselectivity carbonyl reductase activity on a prochiral ketone substrate, determining a series of conditions of asymmetrical reduction reaction, such as reaction temperature, pH, the concentration of cells, the concentration of the substrate and reaction time and additives (including various secondary solvents, polyethyleneglycol (PEG), phosphates and the like), wherein the enantiomer excess value and yield of the (S)-(4-chlorphenyl)-(pyridine-2-yl)-methanol serving as a product can reach 86.7 percent e.e and 92.1. The product is separated and extracted initially by silicagel column chromatography, so that the purity of the separated product is 99.2 percent, and the extraction yield is 56.7 percent.

Owner:JIANGNAN UNIV

Immobilized enzyme biological catalyst, preparation method and application

InactiveCN101058824AReduce dosageImprove distributionImmobilised enzymesChemical industryDielectricPotassium

The invention relates to an immobilized enzyme biocatalyst and the manufacturing method and application. The immobilized enzyme biocatalyst regards tubular hollow silica dioxide dielectric hole material as a carrier external surface, inner surface and micropore in the wall of which are fixed biological enzyme molecule. The method includes physical adsorption cast investment or chemical coupling / crosslinking method; the biocatalyst is provided with good enzyme dispersibility and high carrying quantity, high recovery ratio of enzymatic activity, low enzyme flow rate. The invention can fix penicillin acylating enzyme, glucose oxidase, peroxidase, cytase and so on, which also can be used for removing sugar in protein, removing sugar in total egg, removing oxygen in food , microbiological sensing device, antibiosis and disinfection reaction, wherein immobilized penicillin acylating enzyme biocatalyst can be used to hydrolyze penicillin potassium and manufacture 6-APA.

Owner:BEIJING UNIV OF CHEM TECH

Process for liquid/solid separation of lignocellulosic biomass hydrolysate fermentation broth

InactiveUS20120178976A1Efficient liquid/solid separationReduce resistanceOrganic compound preparationBiofuelsCelluloseHydrolysate

When lignocellulosic biomass hydrolysate is included in fermentation medium, the broth resulting from biocatalyst production is complex with low filterability. A heat treatment was found to increase filterability, allowing efficient separation of a liquid fraction from a solid fraction, which is further processed for water recycle and syrup production.

Owner:SUSTAINABLE TECH CORP

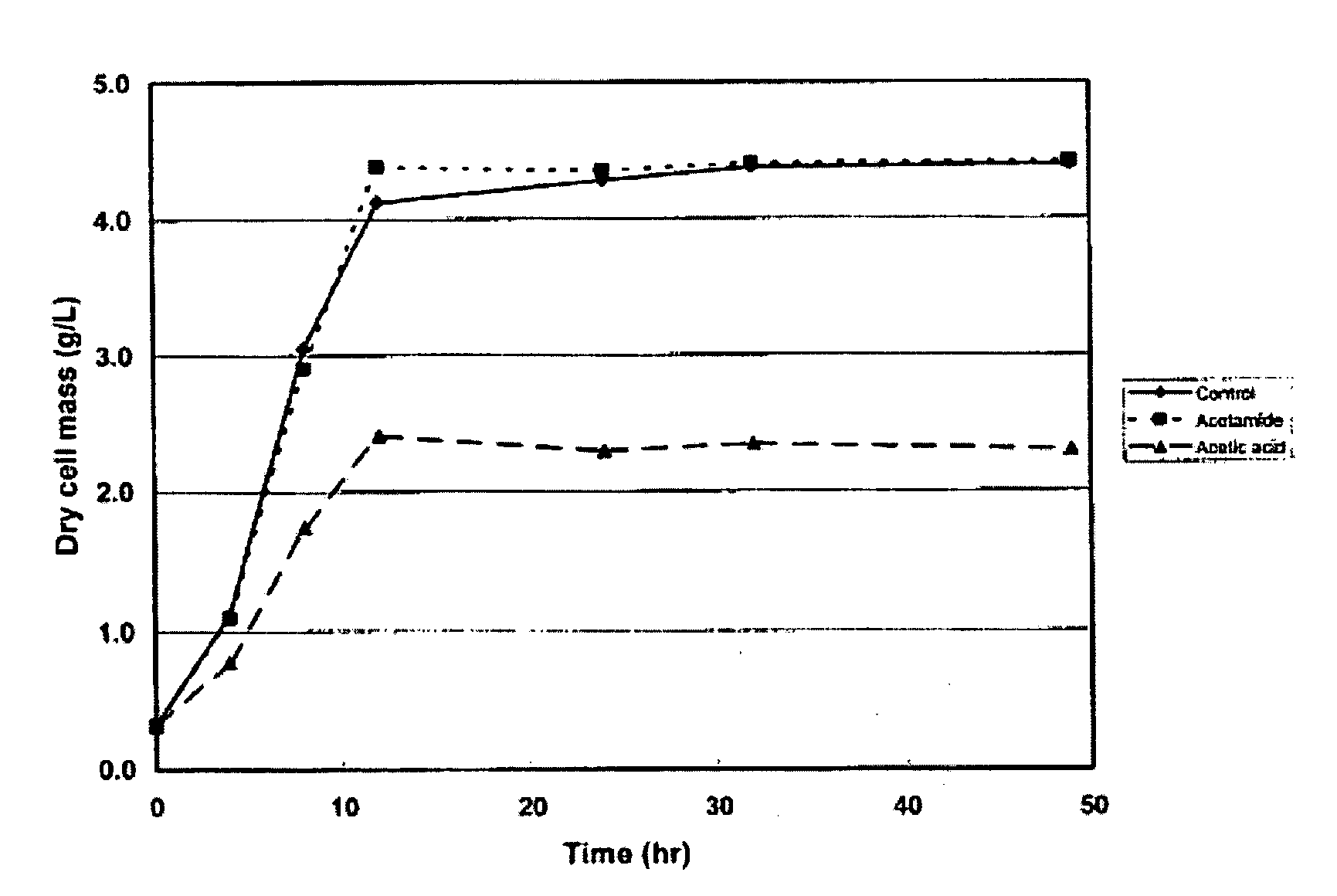

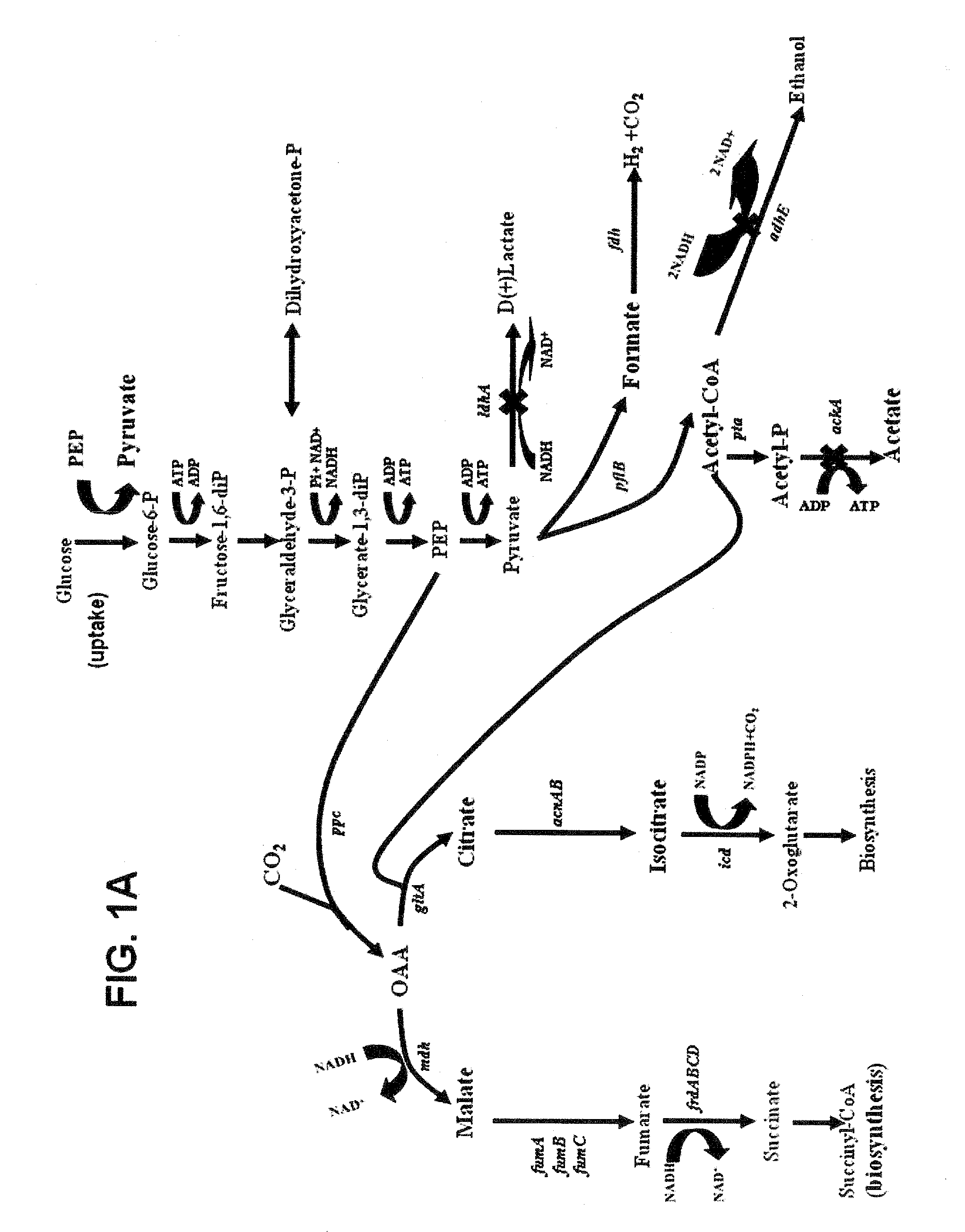

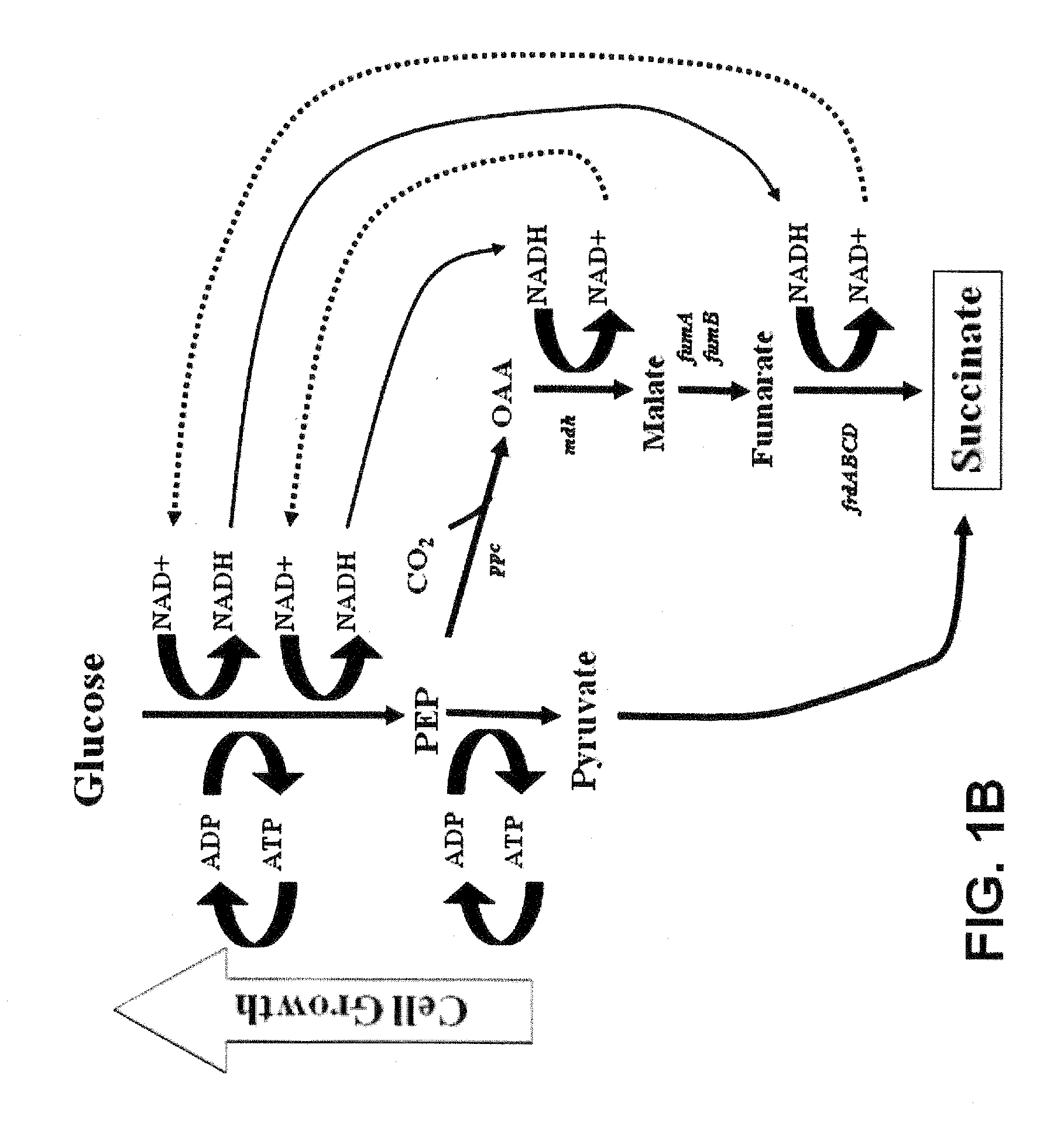

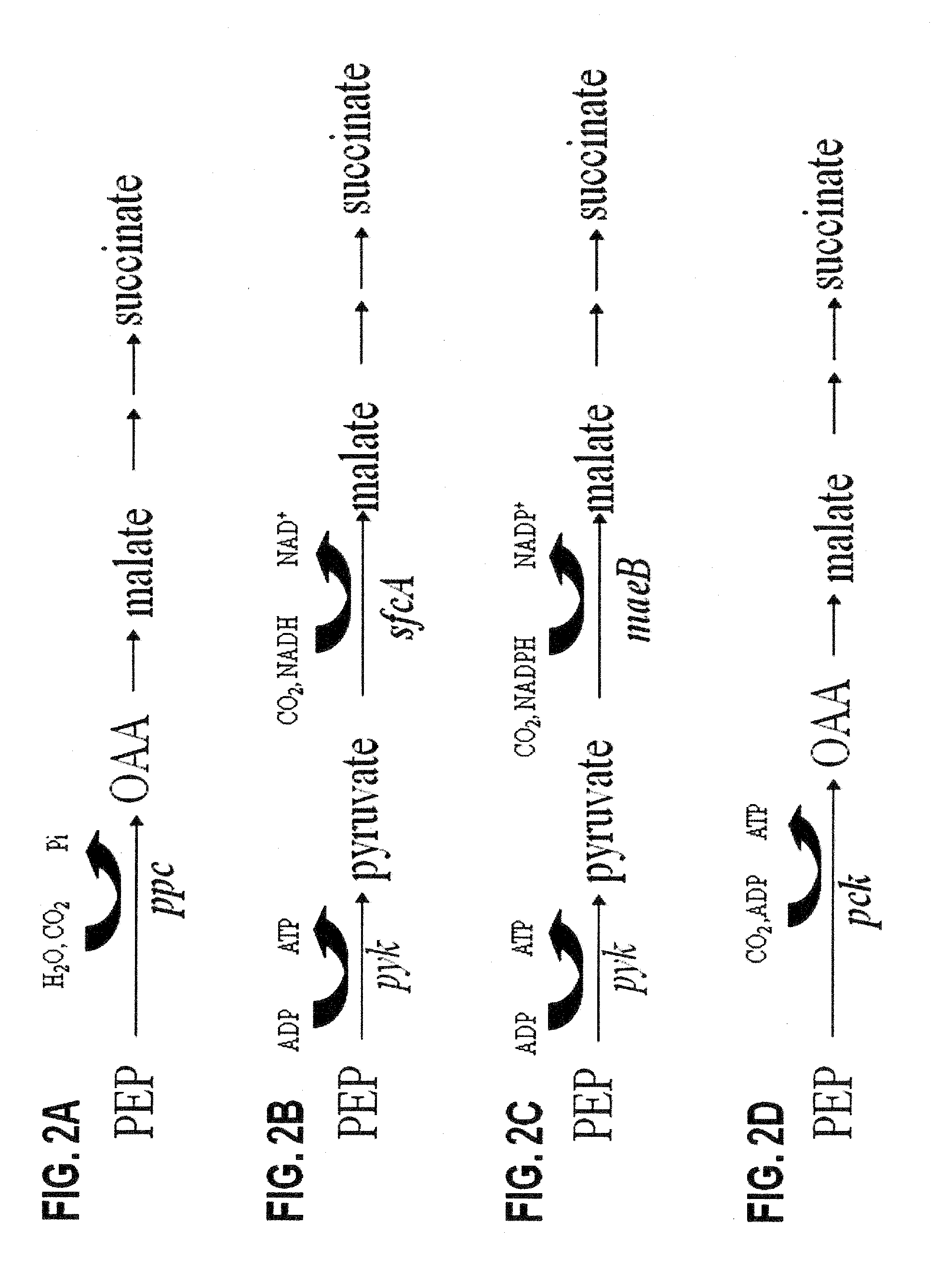

Engineering the pathway for succinate production

InactiveUS20120058530A1Increase overall carbon flowHigh expressionVectorsBacteriaMannheimiaPh control

This invention relates to the biocatalysts for the efficient production of succinic acid and / or other products from renewable biological feedstocks. The biocatalysts have a very high efficiency for the growth-coupled production of succinic acid and / or other products from carbohydrate feed stocks as a result of both genetic manipulations and metabolic evolution. More specifically, certain biocatalysts of the present invention produce succinic acid at high titers and yield in mineral salts media during simple pH-controlled, batch fermentation without the addition of any exogenous genetic material. The genetic manipulations of the present invention are concerned with the energy-conserving strategies coupled with the elimination of alternative routes for NADH oxidation other than the routes for succinic acid production. The biocatalysts contain glucose-repressed gluconeogenic phosphoenol pyruvate carboxykinase (pck) depressed by genetic modifications and a genetically-inactivated phosphotransferase system. In terms of succinic acid production efficiency, the biocatalysts of the present invention are functionally equivalent to succinate producing rumen bacteria such as Actinobacillus succinogens and Mannheimia succiniproducens with one difference that the biocatalysts are able to achieve this high level of succinic acid production in a minimal salt medium with carbohydrate source as opposed to the requirement for a rich media for succinic acid production by rumen bacteria.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

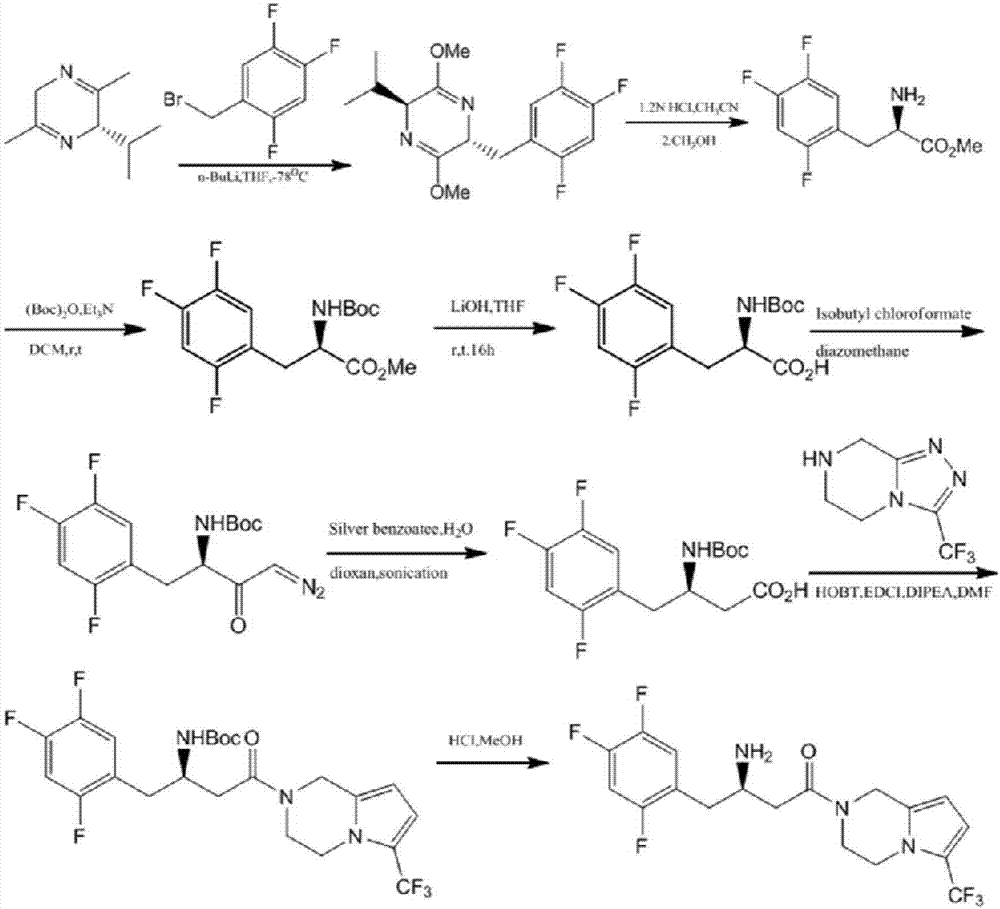

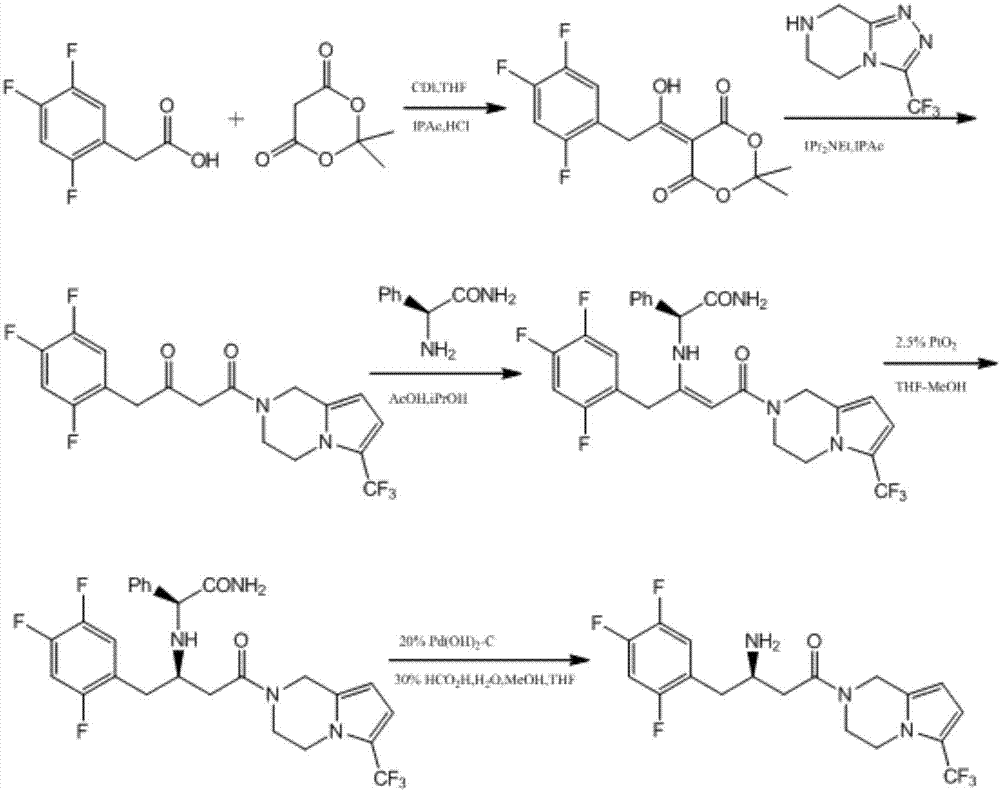

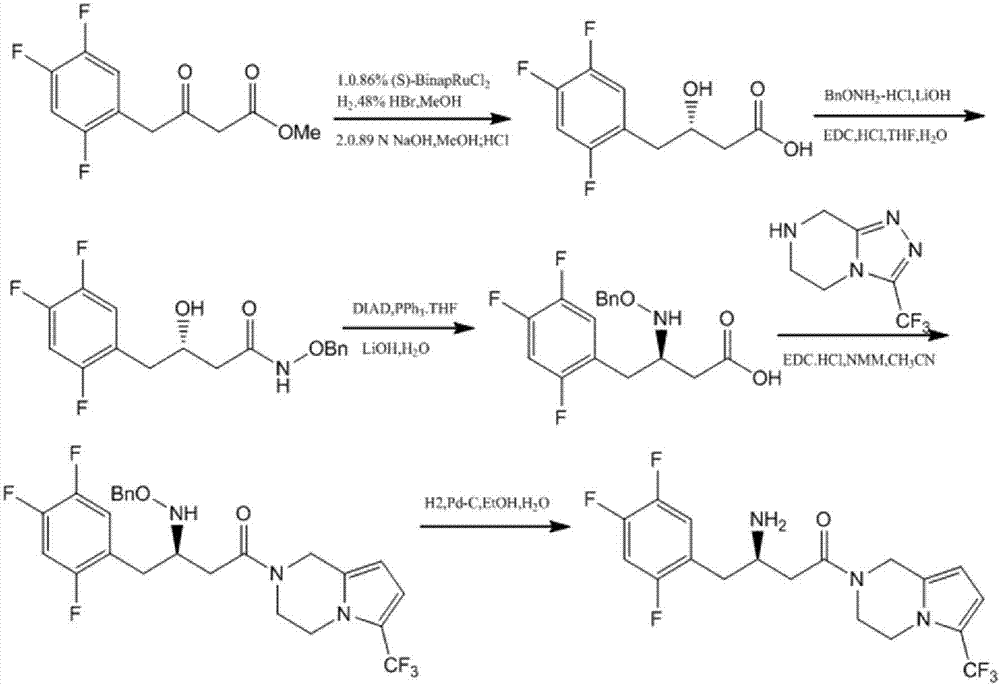

Aminotransferase, mutant and application to Sitagliptin preparation

The invention discloses aminotransferase, a mutant and application to Sitagliptin preparation. According to the application, wet thalli obtained by performing fermentation culture on recombinant escherichia coli containing aminotransferase encoding genes are used as biocatalysts; Sitagliptin precursor ketone is used as a substrate; dimethyl sulfoxide is used as a latent solvent; phosphopyridoxal is used as a coenzyme; isopropylamine is used as an auxiliary substrate; a trolamine buffer solution with the pH being 8 to 9 is used as a reaction medium; a reaction system is formed; the biocatalytic reaction is performed under the conditions of the temperature being 30 to 45 DEG C and the stirring speed being 100 to 250 r / min; after the reaction is completed, the reaction liquid is separated and purified; the Sitagliptin is obtained. The aminotransferase and the mutant are used as biocatalysts; the latent carbonyl compound of Sitagliptin precursor ketone is directly used as the substrate; meanwhile, biocatalytic reaction is performed by using isopropylamine as the auxiliary substrate and using the pyridoxal phosphate as the coenzyme; the separation and purification is performed; Sitagliptin with high optical purity is prepared. The method has the advantages that the total yield is 76 percent; the product e.e. value reaches 99 percent.

Owner:ZHEJIANG UNIV OF TECH +2

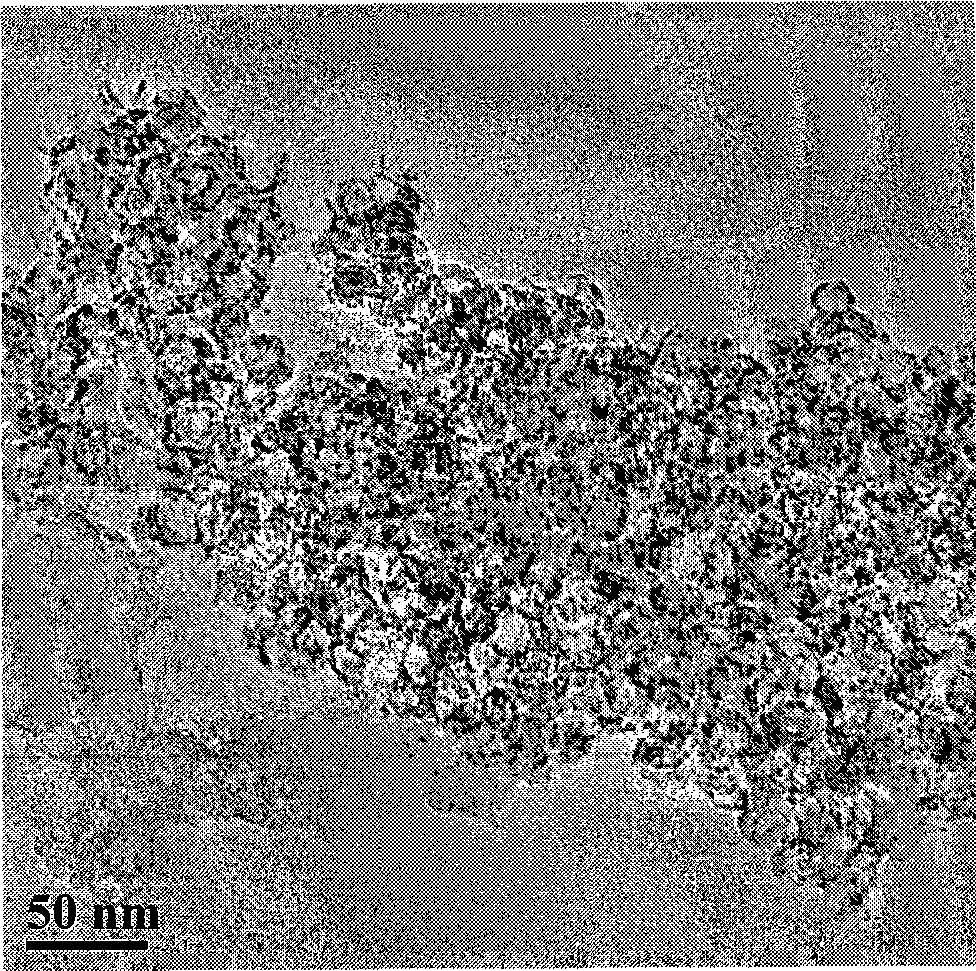

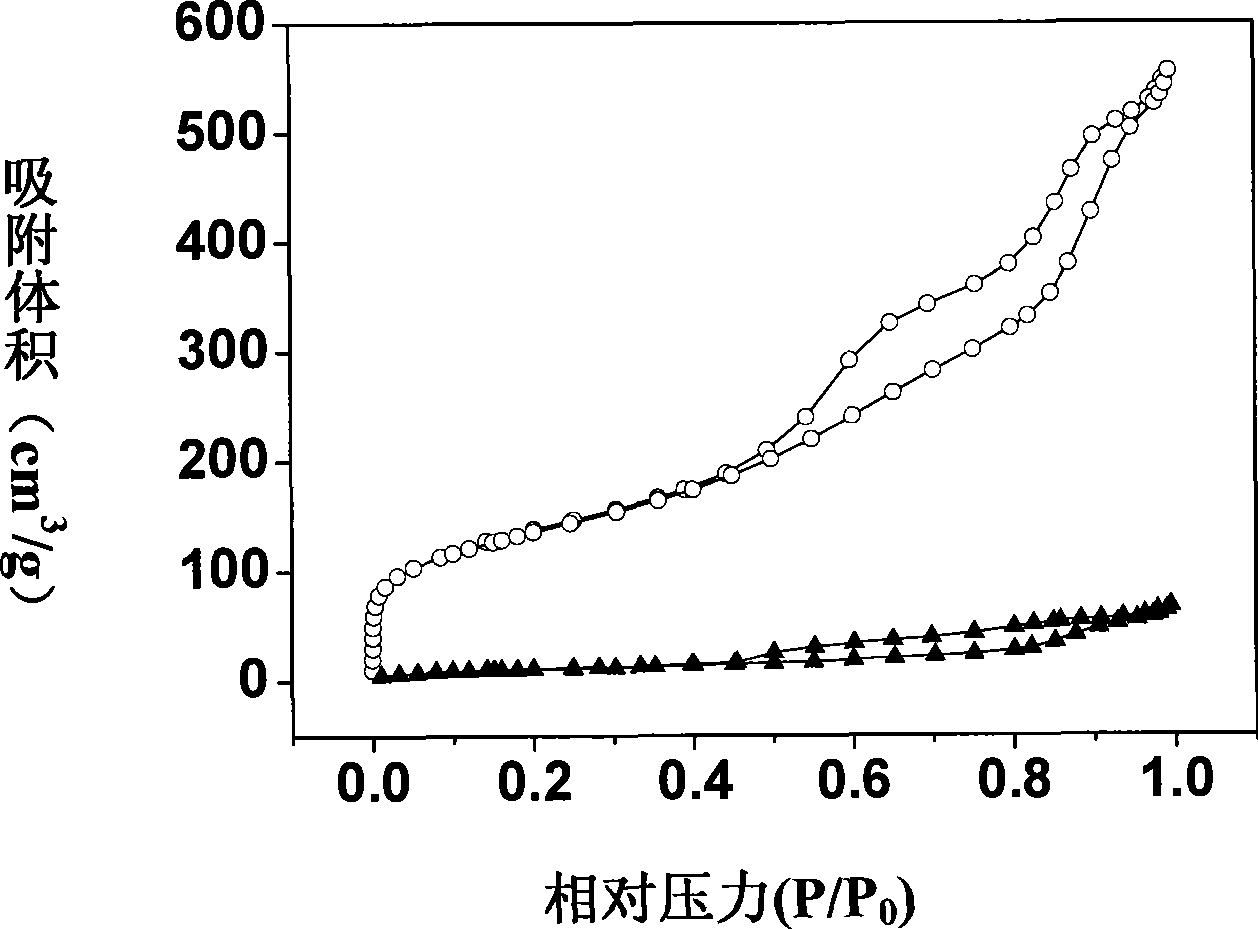

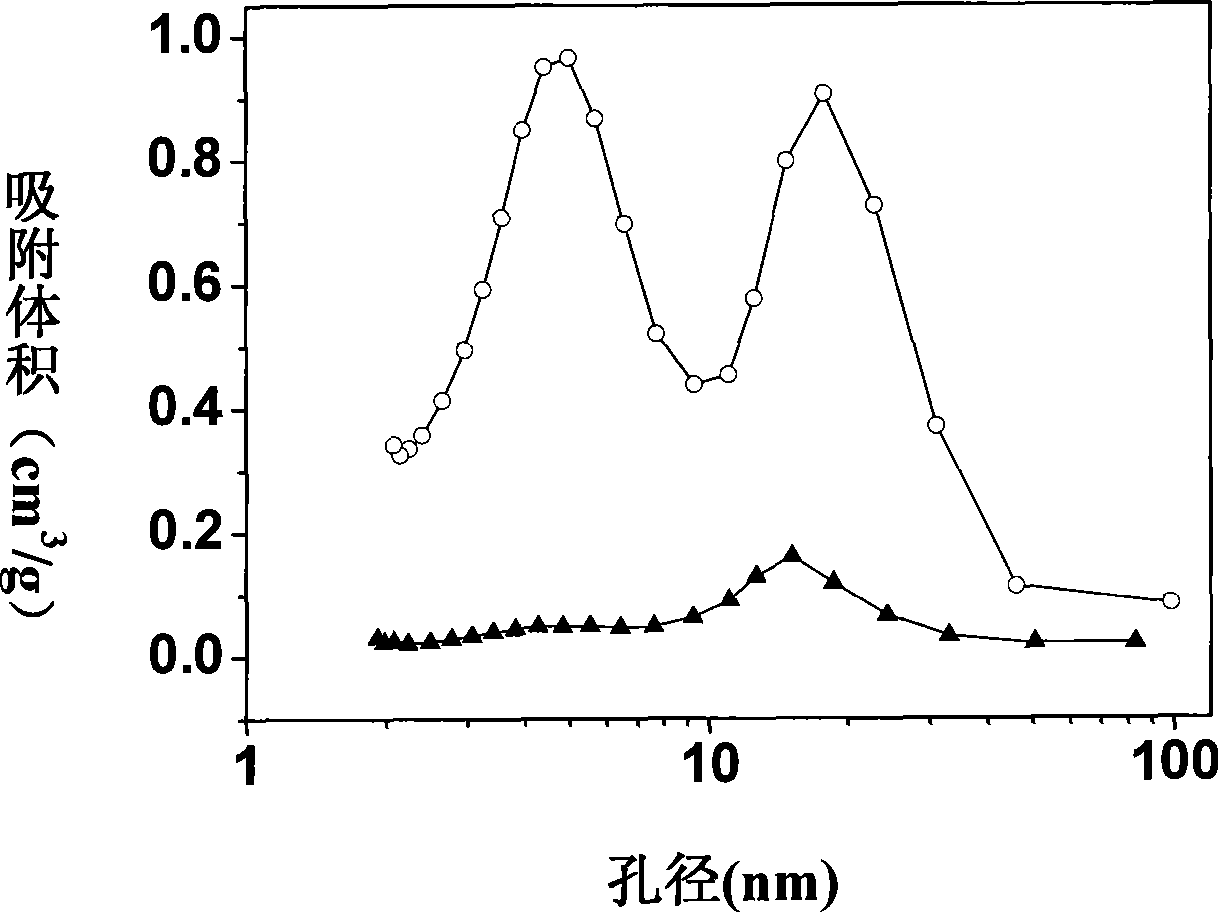

Mesoporous carbon immobilized enzyme biological sensing material doped with nitrogen and preparing method thereof

InactiveCN101435792AConducive to loadKeep aliveMaterial analysis by electric/magnetic meansEthylenediamineBiocompatibility Testing

The invention relates to a nitrogen-doped mesoporous carbon immobilized enzyme biosensing material and a preparation method thereof, which belongs to the field of biocatalysis and biosensing. Mesoporous carbon is prepared by taking mesoporous silica as a template and ethylenediamine, acrylonitrile or tripolycyanamide as a carbon-nitrogen source, and then nitric acid is used to modify the surface of the mesoporous carbon to obtain hydrophilically modified nitrogen-doped mesoporous carbon. The material has high specific surface area, large pore volume, large aperture and good biocompatibility, and also has good water and thermal stability and electric conductivity at the same time. The activity of enzyme molecules mobilized by taking the material as a carrier is well maintained. The biosensing based on nitrogen-doped mesoporous carbon immobilized enzyme has quick response time, wide linear range, high sensitivity, and low detection limit. In addition, a preparation process for the immobilized enzyme biosensing material is simple and controllable, and has the advantages of mild conditions, easily-obtained raw materials, and conventional equipment.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

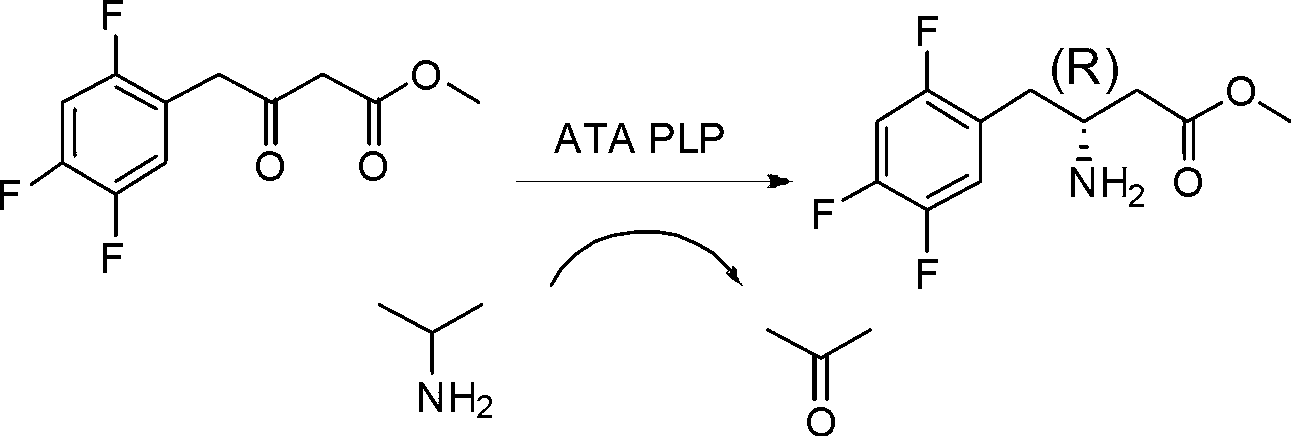

Biological preparation method of 3-amino-4-(2,4,5-trifluorophenyl)methyl butyrate

InactiveCN103014081AReduce energy consumptionEasy to operateTransferasesFermentationAminopheraseSolvent

The invention relates to a biological preparation method of 3-amino-4-(2,4,5-trifluorophenyl)methyl butyrate. According to the biological preparation method, 3-carbonyl-4-(2,4,5-trifluorophenyl)methyl butyrate is used as a substrate; under the condition that a biocatalyst, a cofactor, an amino donor and a cosolvent exist, the substrate performs the reaction to generate a target product 3-amino-4-(2,4,5-trifluorophenyl)methyl butyrate; the biocatalyst is recombination aminopherase; and the reaction is carried out in water-phase buffer solution with the pH of 6.0 to 9.0. The biological preparation method realizes that 3-carbonyl-4-(2,4,5-trifluorophenyl)methyl butyrate is converted into 3-amino-4-(2,4,5-trifluorophenyl)methyl butyrate by adopting the recombination aminopherase for the first time; compared with a conventional chemical method, the biological preparation method has low energy consumption, is simple and convenient to operate, generates a small number of by-products; and moreover, the product has high optical activity.

Owner:ENZYMEWORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com