Patents

Literature

132 results about "Actinobacillus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Actinobacillus is a genus of Gram-negative, nonmotile and non-spore-forming, oval to rod-shaped bacteria occurring as parasites or pathogens in mammals, birds, and reptiles. It is a member of the Pasteurellaceae family. The bacteria are facultatively aerobic or anaerobic, capable of fermenting carbohydrates (without production of gas), and of reducing nitrates. The genomic DNA contains between 40 and 47 mol % guanine plus cytosine.

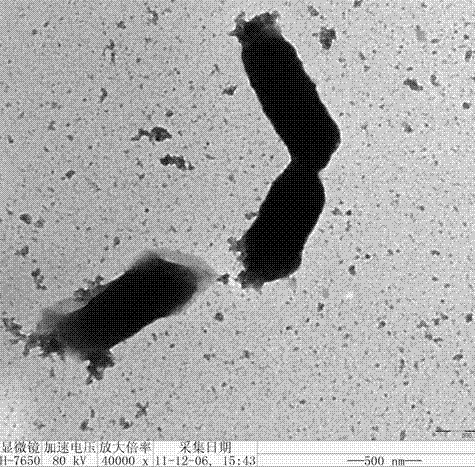

Bacterial speices and method for producing succinic acid by microbial fermentation

InactiveCN1814747AEfficient accumulationAlleviate resource constraintsBacteriaFermentationMicroorganismButanedioic acid

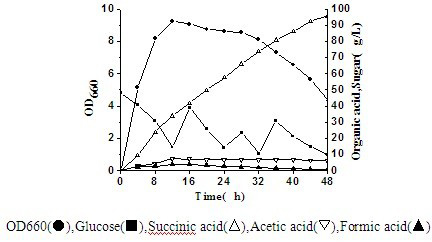

This invention relates to a method for producing succinic acid type culture by animalcule fermentation, especially relating to an animalcule actinobacillus succinogenes SW0580 generating succinic acid by a fermentated sugariness raw material, its preservation number: CGMCC No. 1593 and a method for utilizing said animalcule fermentation to produce succinic acid, in which, said animalcule is the actinobacillus succinogenes separated from the rumen tested and 10-50g / L succinic acid can be produced by anaerobic fermentating 20-100g / L sugariness raw materials.

Owner:JIANGNAN UNIV

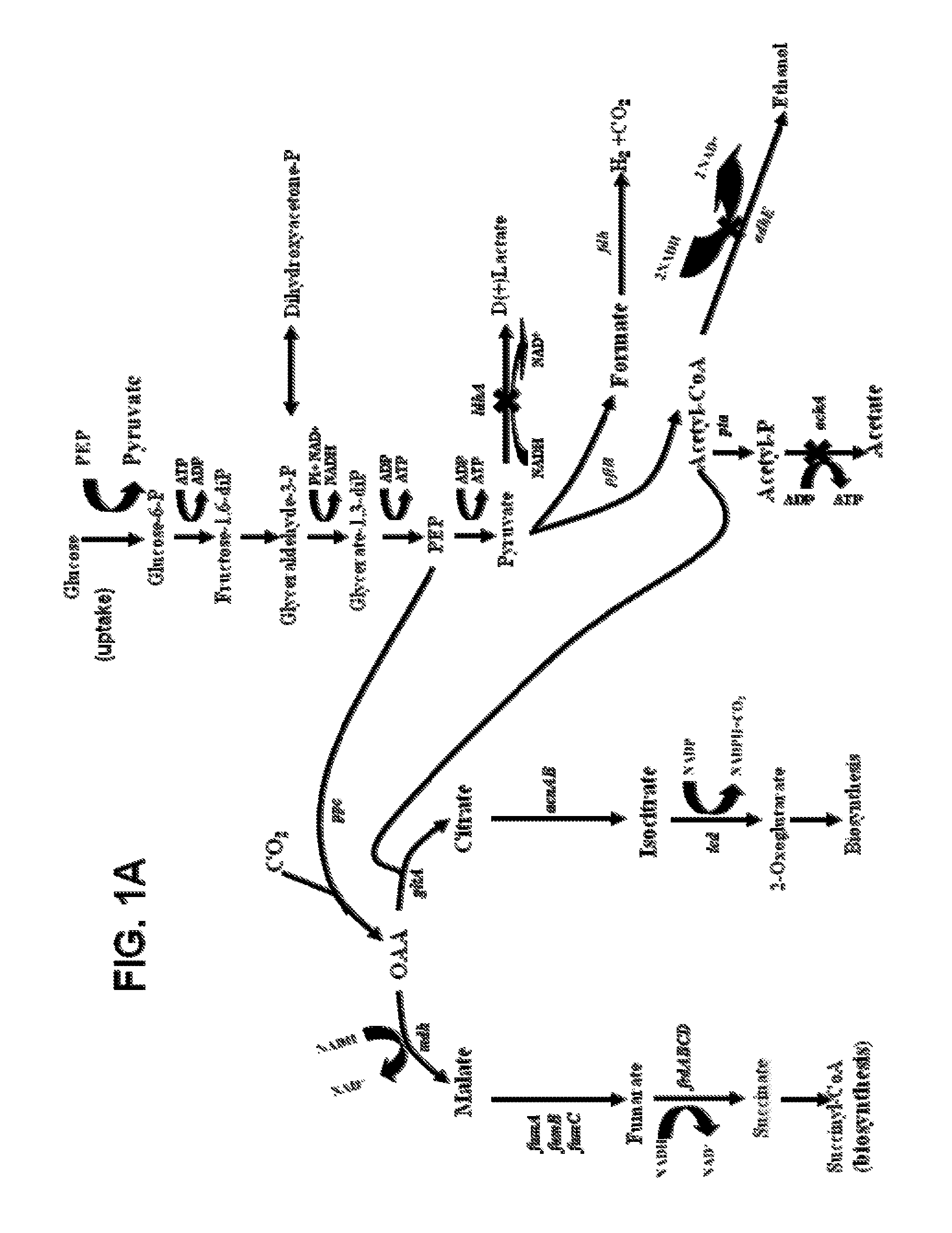

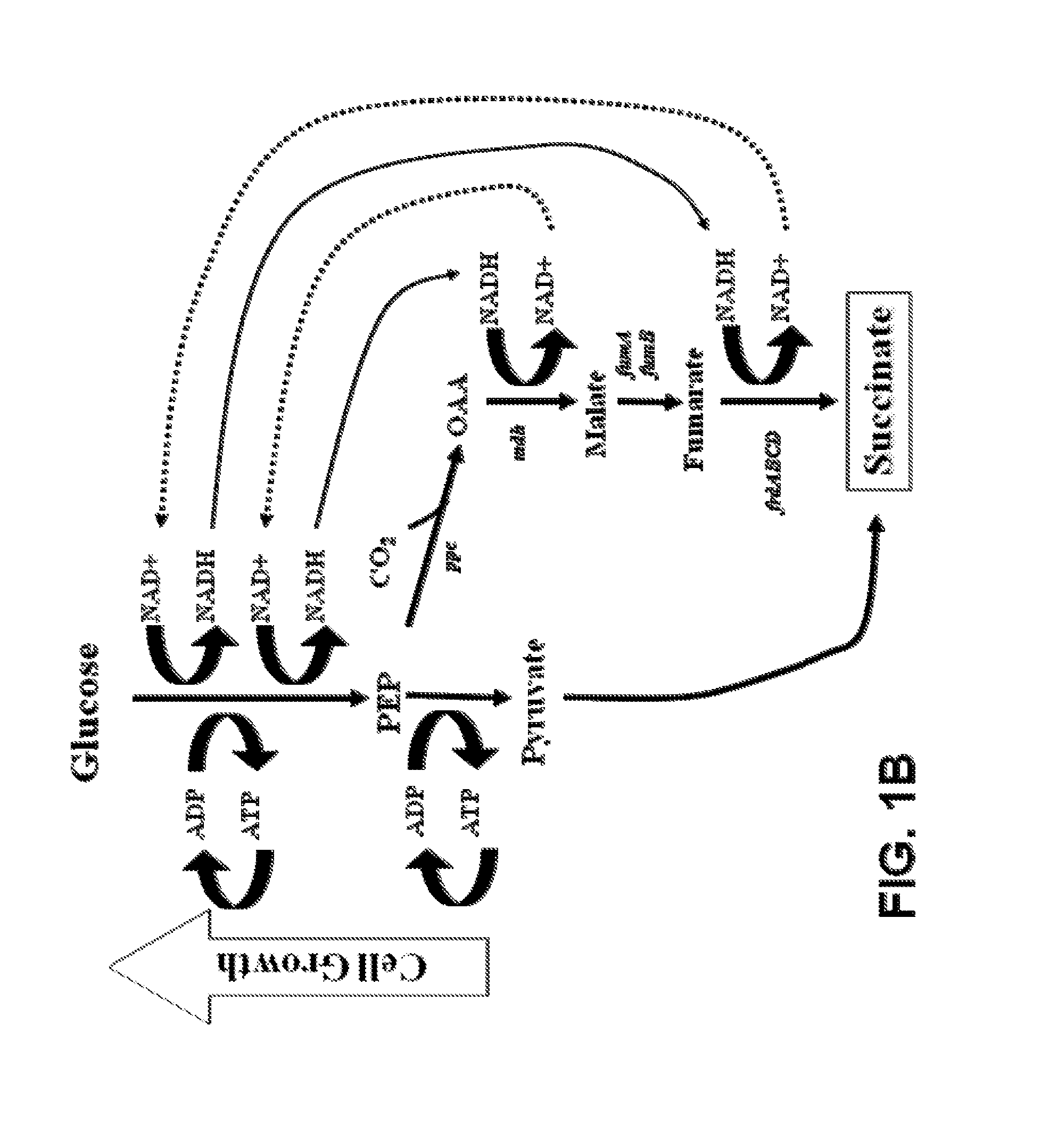

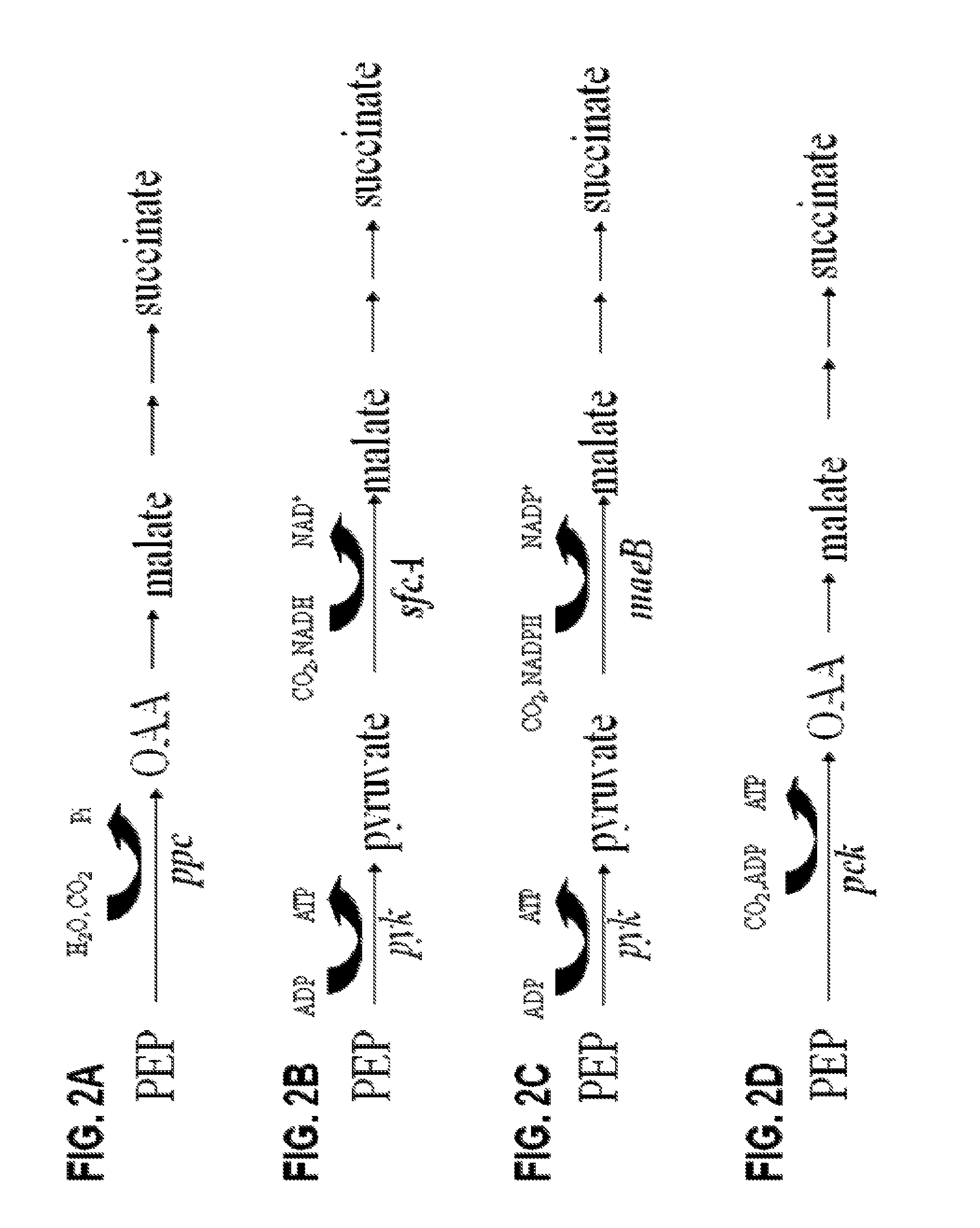

Engineering the pathway for succinate production

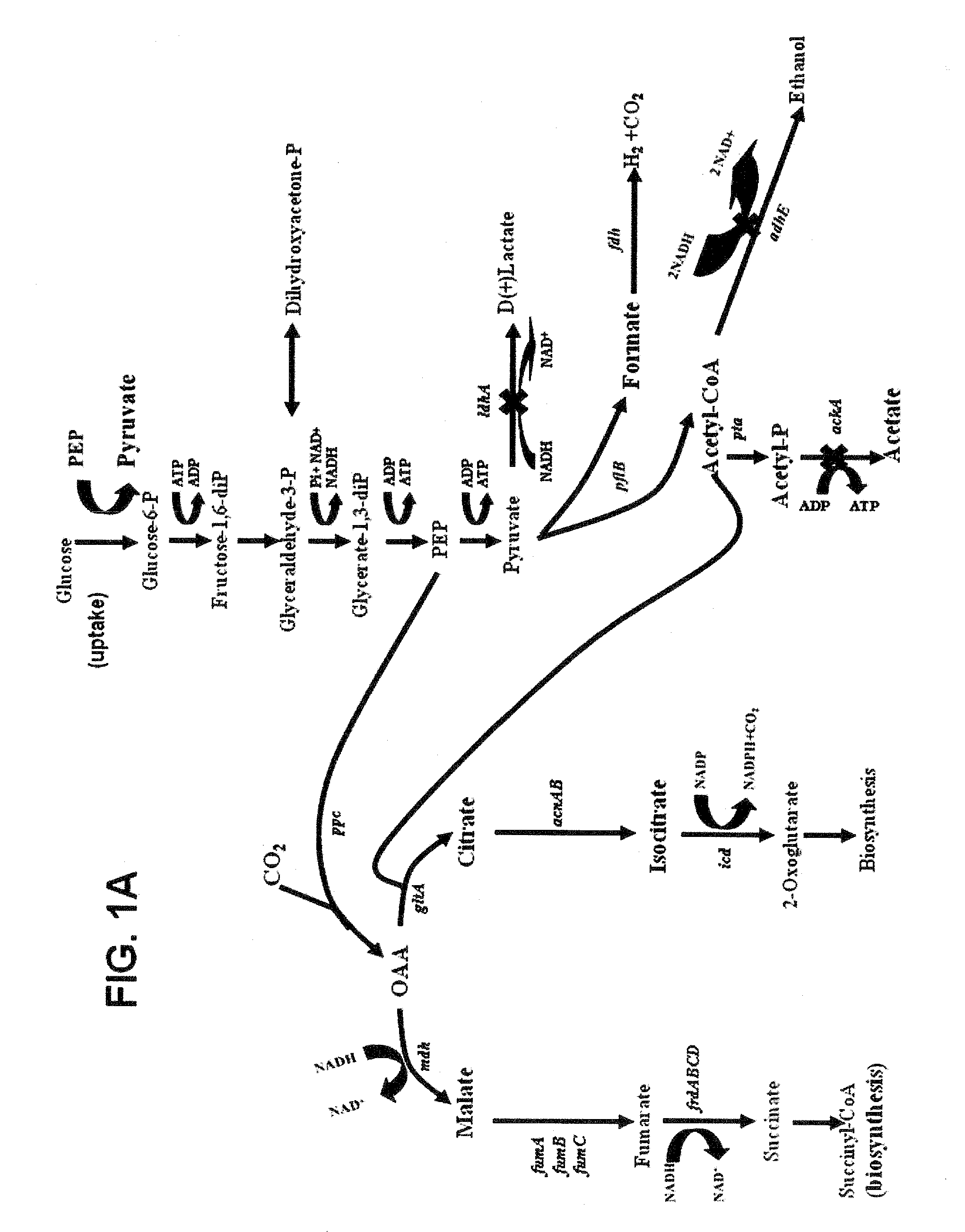

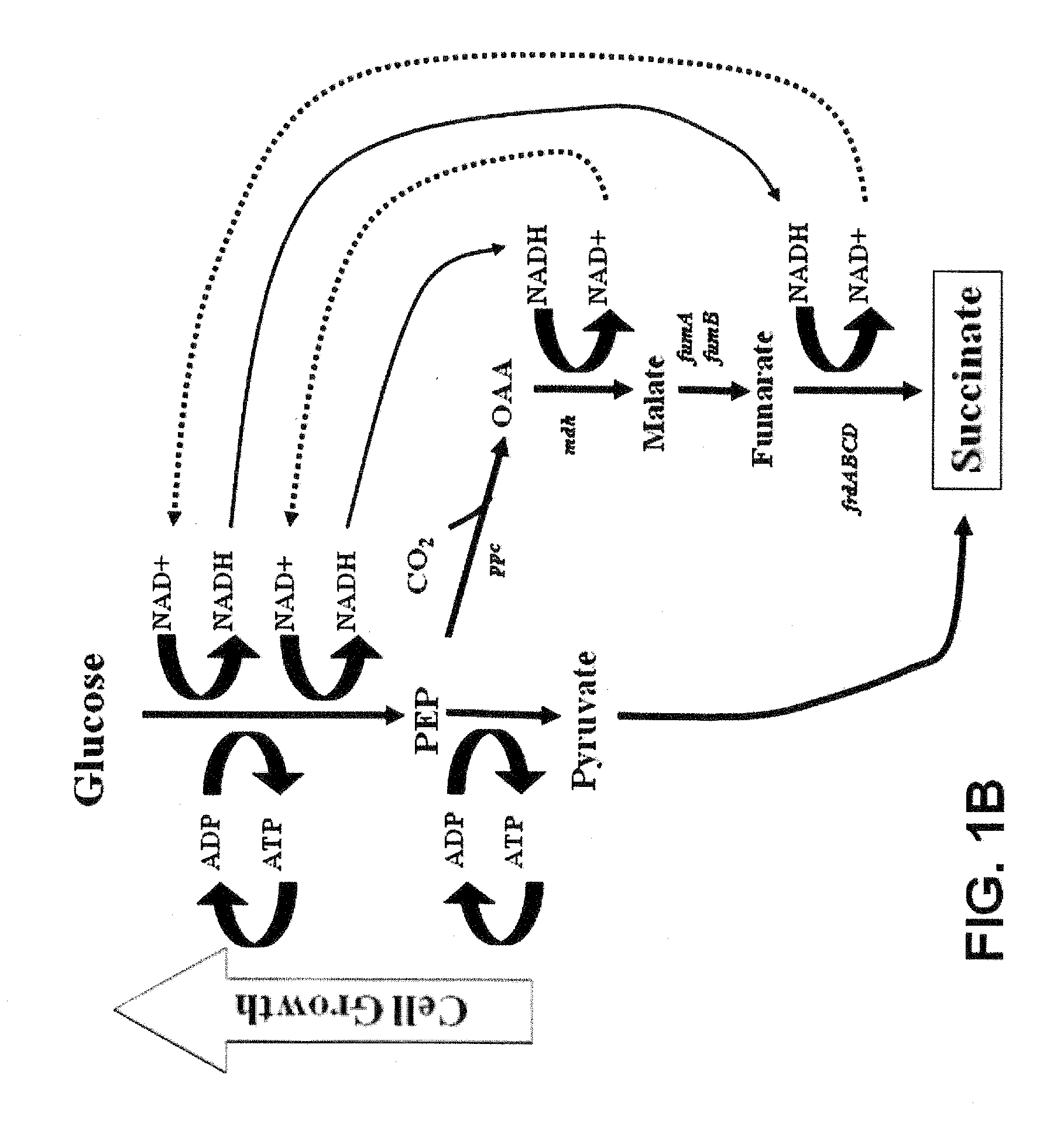

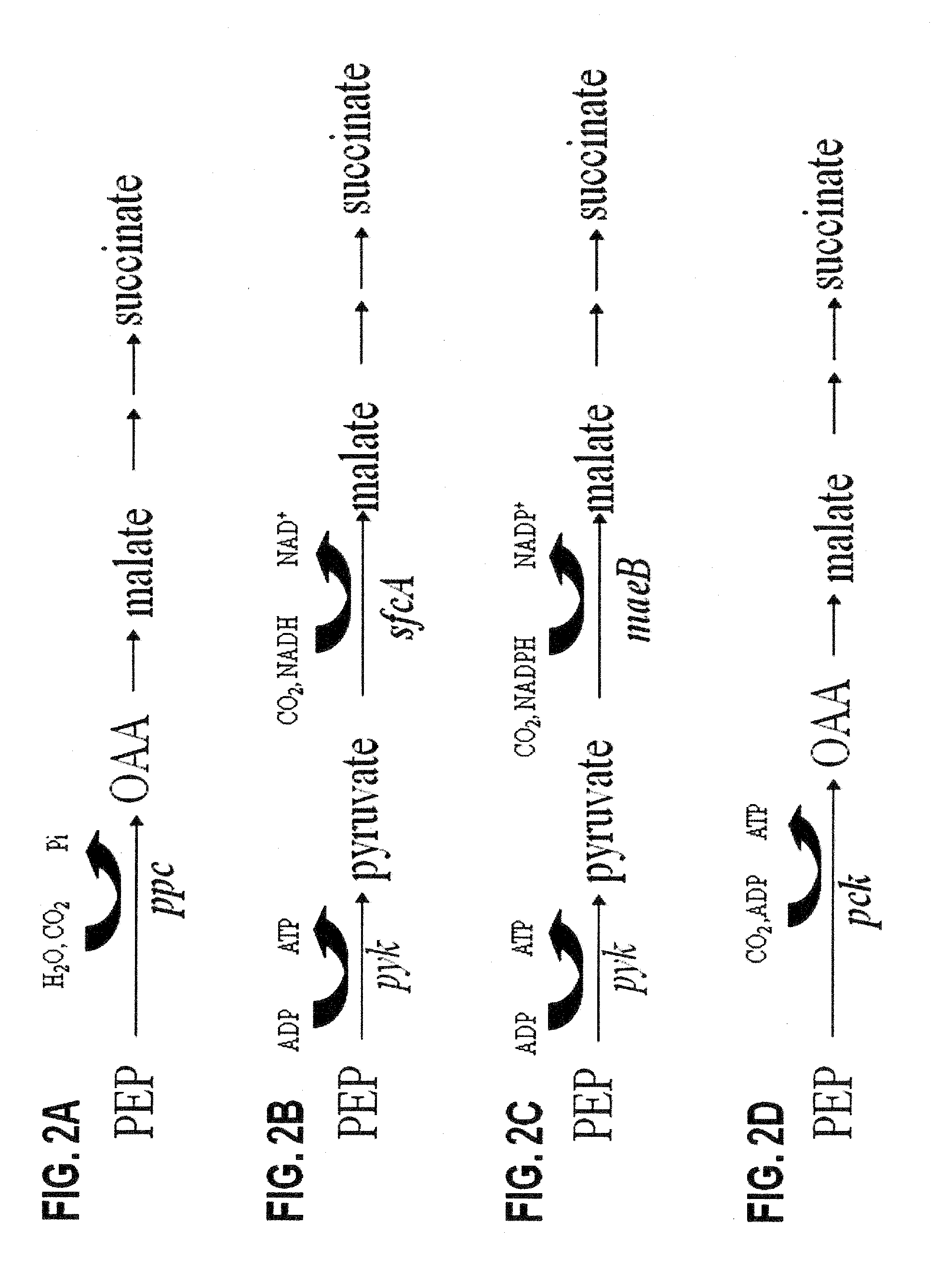

InactiveUS20120058530A1Increase overall carbon flowHigh expressionVectorsBacteriaMannheimiaPh control

This invention relates to the biocatalysts for the efficient production of succinic acid and / or other products from renewable biological feedstocks. The biocatalysts have a very high efficiency for the growth-coupled production of succinic acid and / or other products from carbohydrate feed stocks as a result of both genetic manipulations and metabolic evolution. More specifically, certain biocatalysts of the present invention produce succinic acid at high titers and yield in mineral salts media during simple pH-controlled, batch fermentation without the addition of any exogenous genetic material. The genetic manipulations of the present invention are concerned with the energy-conserving strategies coupled with the elimination of alternative routes for NADH oxidation other than the routes for succinic acid production. The biocatalysts contain glucose-repressed gluconeogenic phosphoenol pyruvate carboxykinase (pck) depressed by genetic modifications and a genetically-inactivated phosphotransferase system. In terms of succinic acid production efficiency, the biocatalysts of the present invention are functionally equivalent to succinate producing rumen bacteria such as Actinobacillus succinogens and Mannheimia succiniproducens with one difference that the biocatalysts are able to achieve this high level of succinic acid production in a minimal salt medium with carbohydrate source as opposed to the requirement for a rich media for succinic acid production by rumen bacteria.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

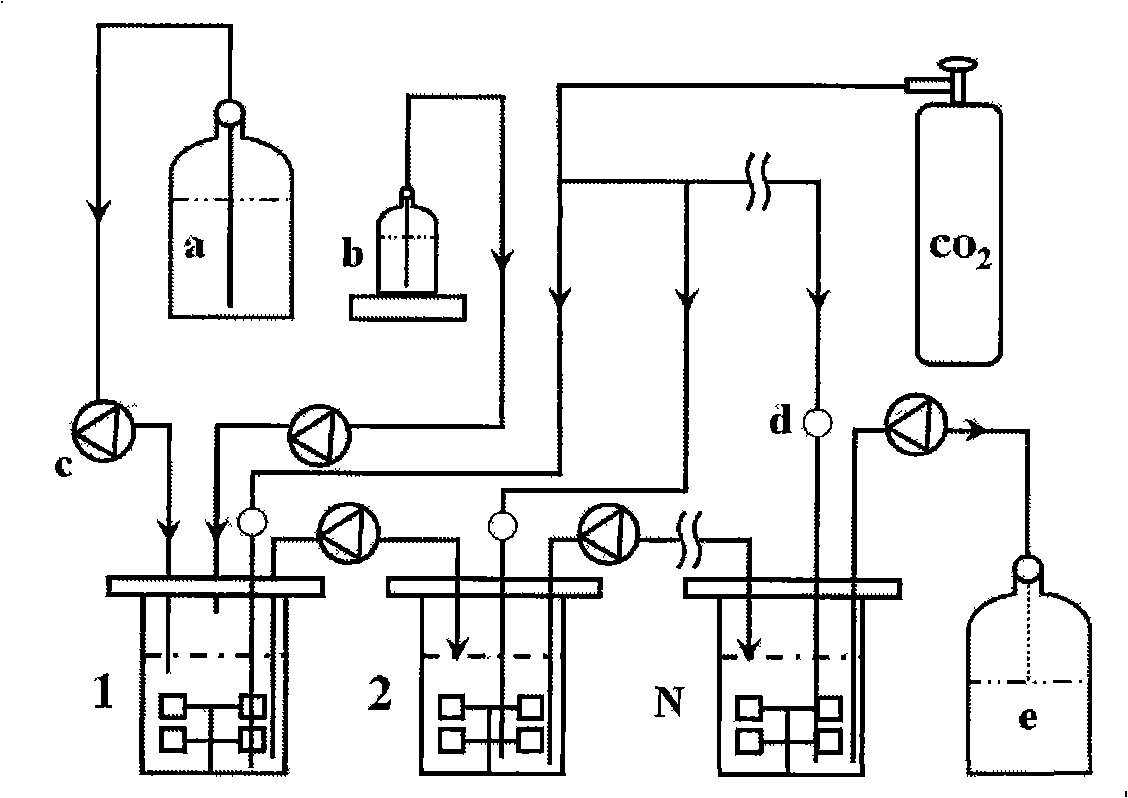

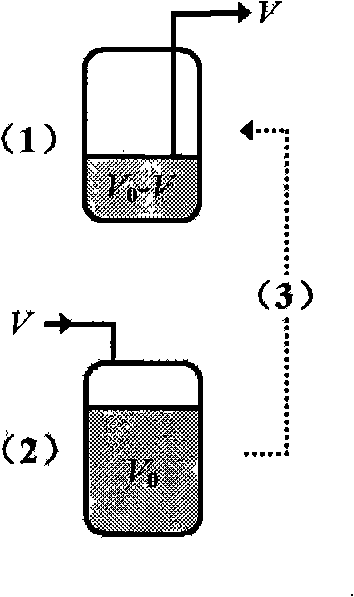

Method for producing amber acid by continuous fermentation or semi-continuous fermentation

InactiveCN101302546AIncrease production intensityLess investmentBacteriaMicroorganism based processesBatch fermentationSweet sorghum

The invention discloses a method for producing butane diacid through continuous fermentation or semi-continuous fermentation, which belongs to the bioengineering technical field. The invention provides application of Actinobacillus succinogenes in the method for continuously or semi-continuously preparing the butane diacid by utilizing carbohydrate raw materials such as cane molasses, corn starch syrup, Jerusalem artichoke hydrolysis syrup, sweet sorghum straw syrup, and lignocellulose hydrolysis syrup and so on. The method utilizes multi-step continuous fermentation or two-step semi-continuous fermentation, which can improve germ concentration and cell activity and can obtain high butane diacid output and high butane diacid production intensity; the method is easy to realize automatic and continuous operation; compared with batch fermentation, the method can save non-fermentation time such as repeated tank cleaning, sterilization and so on, so the production efficiency can be greatly improved; the semi-continuous fermentation for producing the butane diacid is easier to control fermentation parameters than the continuous fermentation, has high sugar utilization rate, target product yield and target product output, has simple and easy equipment and operation, and is suitable for industrialized production.

Owner:JIANGNAN UNIV

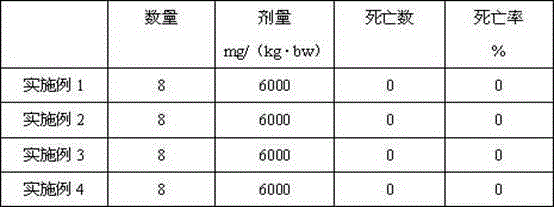

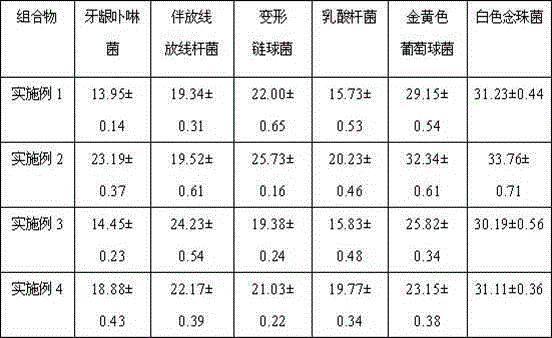

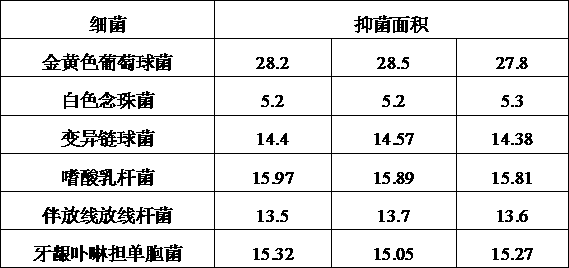

Oral antibacterial composition containing nisin and polylysine and preparation method thereof

InactiveCN105326656AImprove the bactericidal effectNo adverse reactionAntibacterial agentsCosmetic preparationsSide effectPorphyromonas gingivalis

The invention provides an oral antibacterial composition containing nisin and polylysine. According to the composition, the growth of oral pathogenic bacteria such as porphyromonas gingivalis, actinobacillus actinomycetemcomitans, streptococcus mutans, lactic acid bacillus, staphylococcus aureus and candida albicans can be effectively inhibited, and tooth decay, gingivitis, periodontitis, ozostomia and the like can be prevented; the composition can be prepared into toothpaste, mouth wash, refreshing and tasting chips and chewing gum which are used for preventing and treating oral diseases. Meanwhile, the invention provides a preparation method of the compositions such as the toothpaste, the mouth wash, the refreshing and tasting chips and the chewing gum. The oral antibacterial composition prepared through the method can prevent and treat various oral diseases and has no toxic and side effect and allergy or stimulation phenomenon on a human body.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

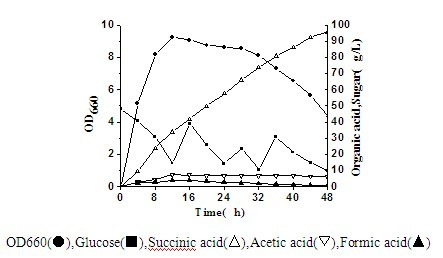

Method for producing succinic acid by fermenting straw raw material

InactiveCN101215582AMitigate utilization issuesInsufficient reliefBacteriaMicroorganism based processesChemical synthesisSuccinic acid

A method for using straw raw materials to ferment and produce succinic acid belongs to the technical field of biological engineering. The invention takes straws as raw materials and obtains hydrolysis straw syrup of hexose and pentose through hydrolysis treatment, and then succinic acid actinobacillus CGMCC 1593 is used to ferment and produce the succinic acid in culture medium of the hydrolysis straw syrup which contains reducing sugar. The microorganism CGMCC 1593 of the invention which is obtained through screening from paunches is fed-batched and anaerobically fermentted for 48 hours in a 5L-25L fermenter under the anaerobical circumstance whose pH is kept within 5.5-7.5. The concentration of total reducing sugar which is invested is 68.6-70.9g / L, the concentration of the succinic acid which is produced is 49.5-52.1g / L, the yield of the succinic acid to consumption suger is 80.0%-81.2%( the availability ratio of the sugar is 87.3-93.6%), and the production intensity is 1.03-1.09g / (L h). The invention has the prominent advantages that the raw materials of agricultural wastes straws are utilized to ferment and produce the succinic acid, the method is a producing method which uses renewable raw materials and is environmental friendly, and the problem of petrifaction resources tension of chemosynthesis succinic acid can be alleviated.

Owner:JIANGNAN UNIV

Compositions for the treatment of cancer, and methods for testing and using the same

ActiveUS20090075883A1Rapidly and effectively determinedHigh activityPeptide/protein ingredientsDisease diagnosisBacteroidesProtein isolate

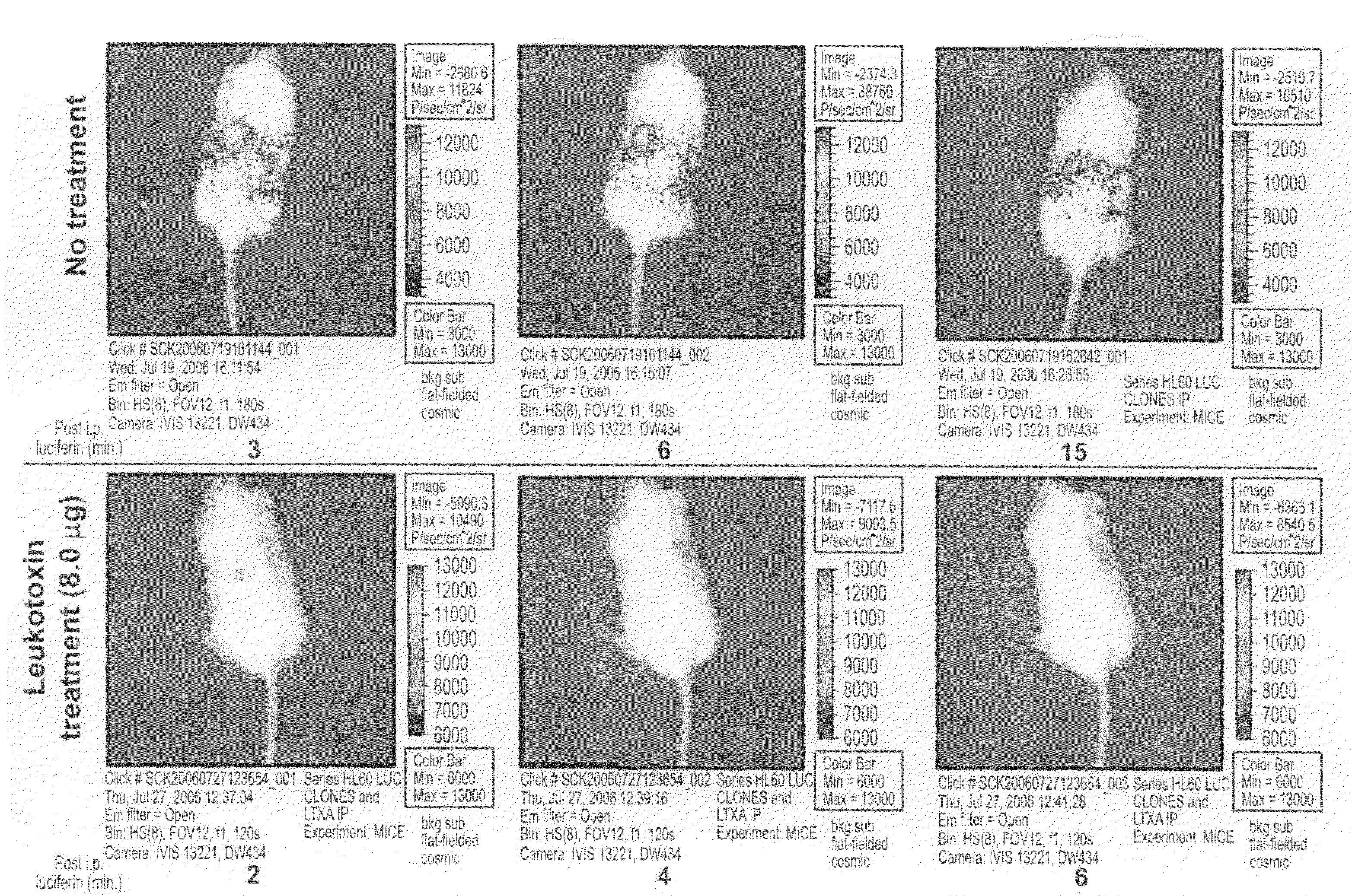

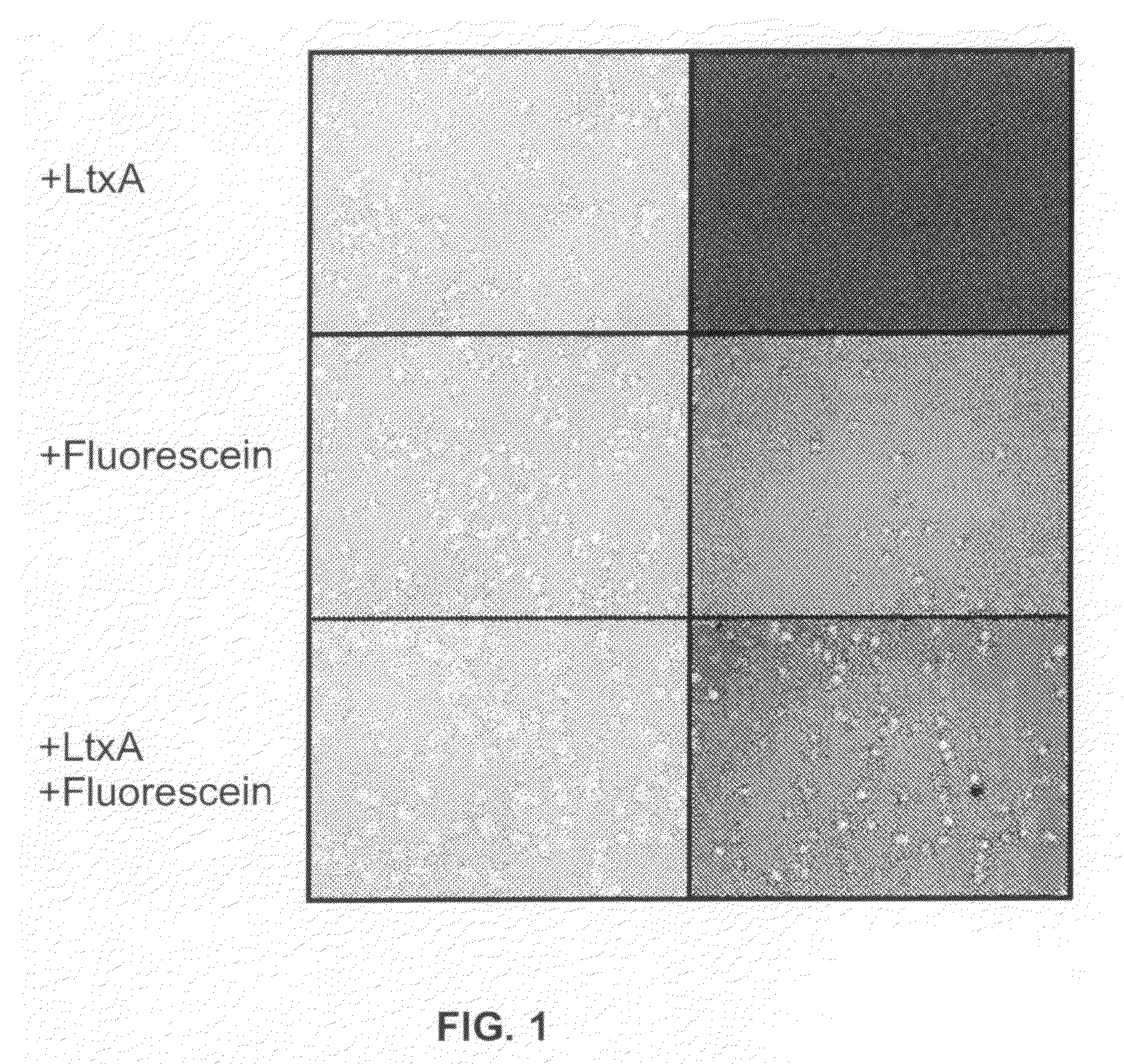

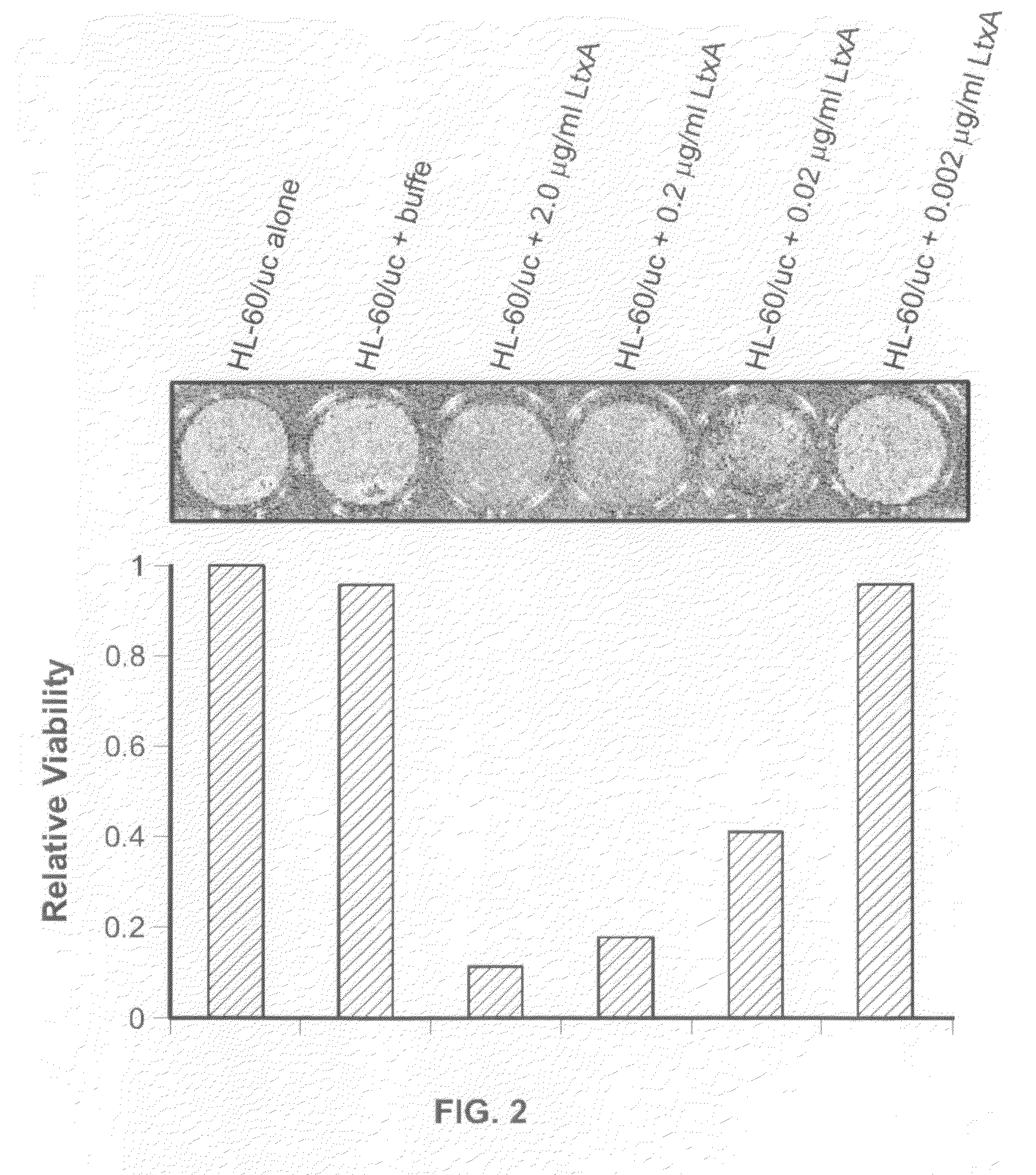

A composition comprising leukotoxin proteins isolated from a bacterium is provided. In this composition, greater than 85% of the leukotoxin proteins are chemically modified at a basic amino acid residue, and the proteins induce cell death in myeloid leukocytes, while remaining substantially non-toxic to lymphoid leukocytes, lymphocytes, and red blood cells. Also provided is a method of selectively inducing cell death in myeloid leukocytes. The method comprises contacting the myeloid leukocytes with a composition comprising leukotoxin proteins. These leukotoxin proteins may be isolated from the NJ4500 strain of Actinobacillus actinomycetemcomitans. A method of purifying leukotoxin protein from the NJ4500 strain of Actinobacillus actinomycetemcomitans is also provided, as well as an assay that allows for the rapid determination of the activity of a given drug against leukemic cells either taken from a patient or derived from a cell line. The assay is performed in the presence of whole blood or serum.

Owner:RUTGERS THE STATE UNIV

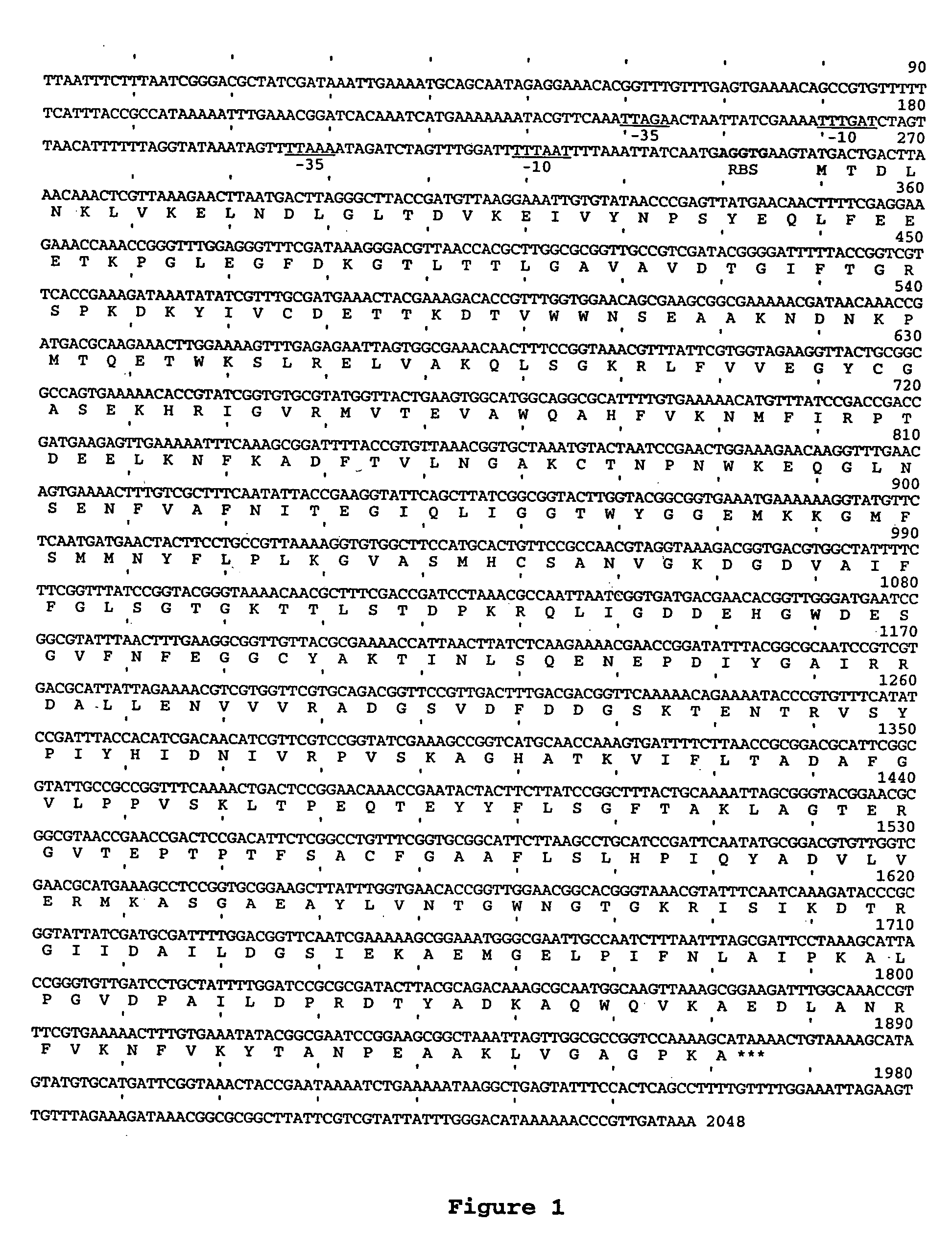

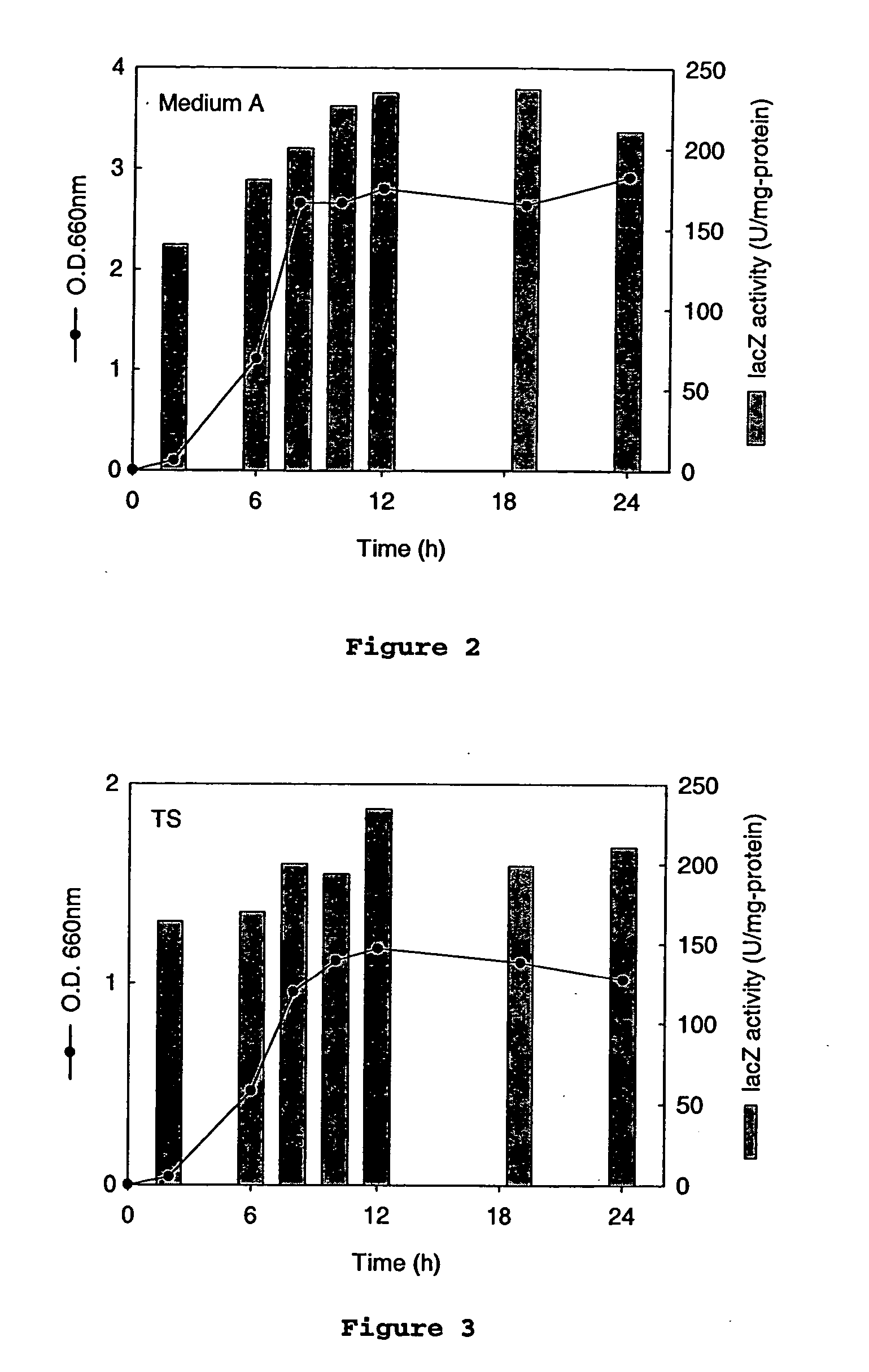

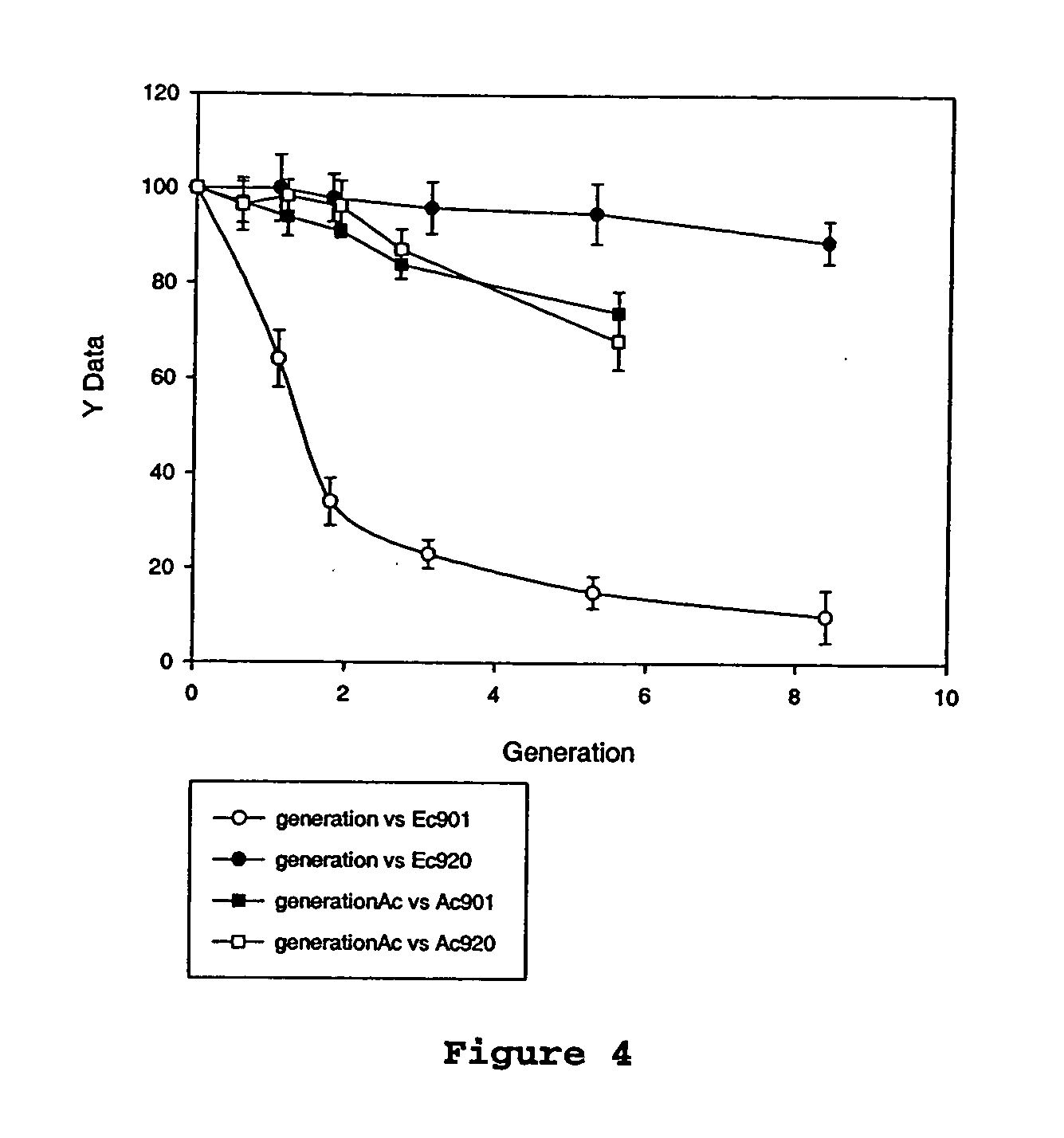

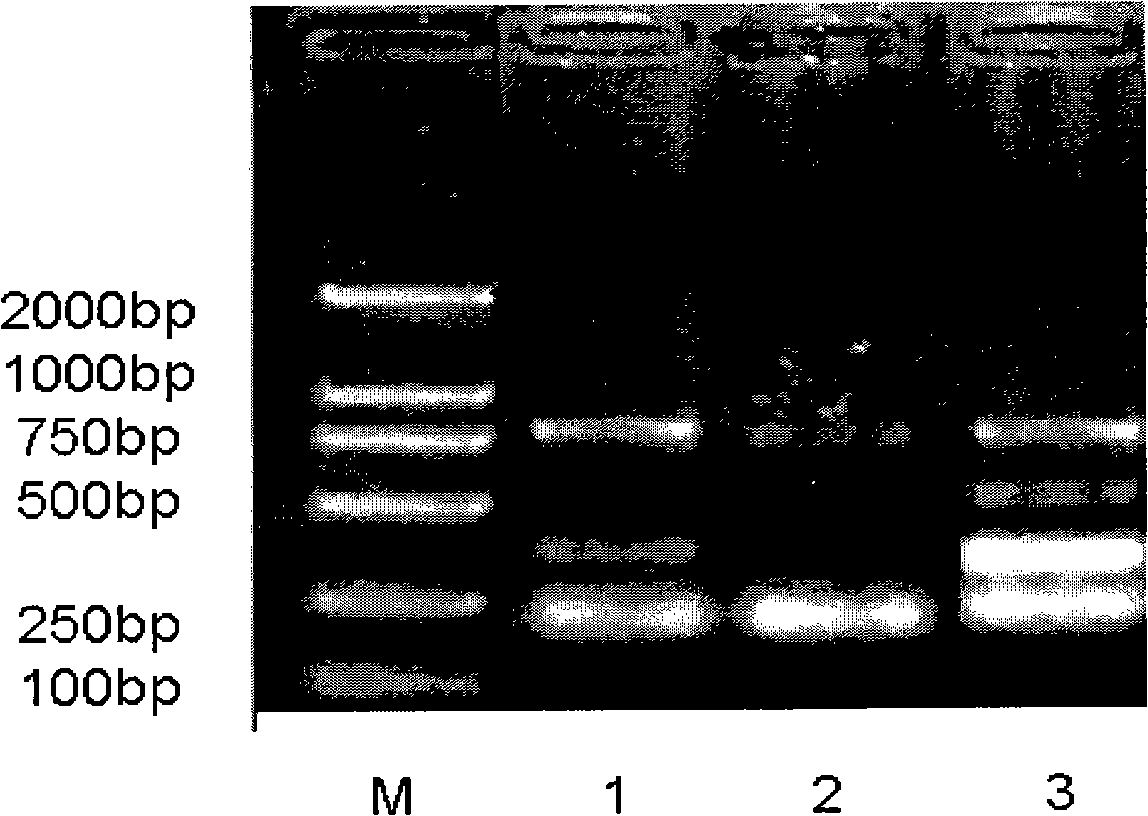

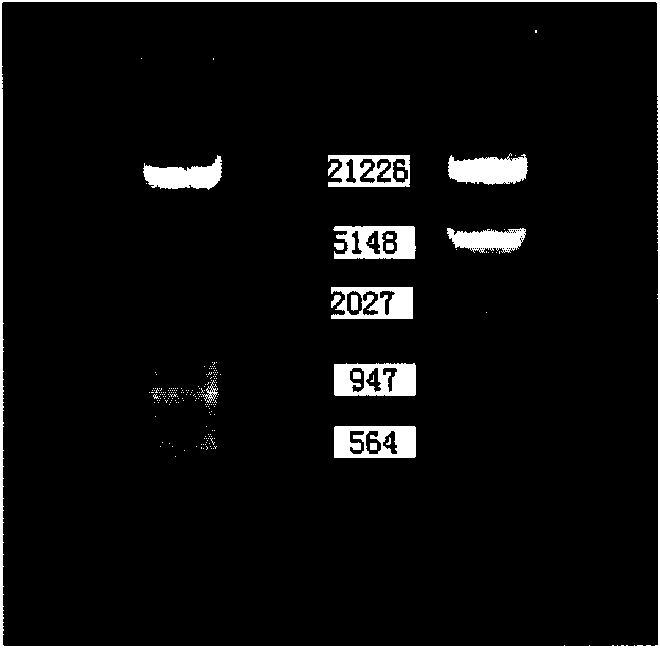

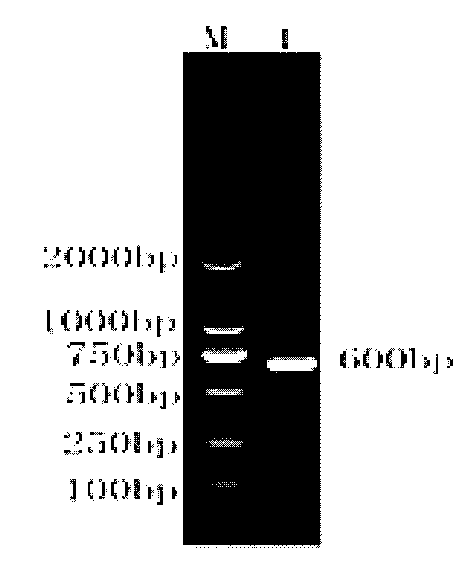

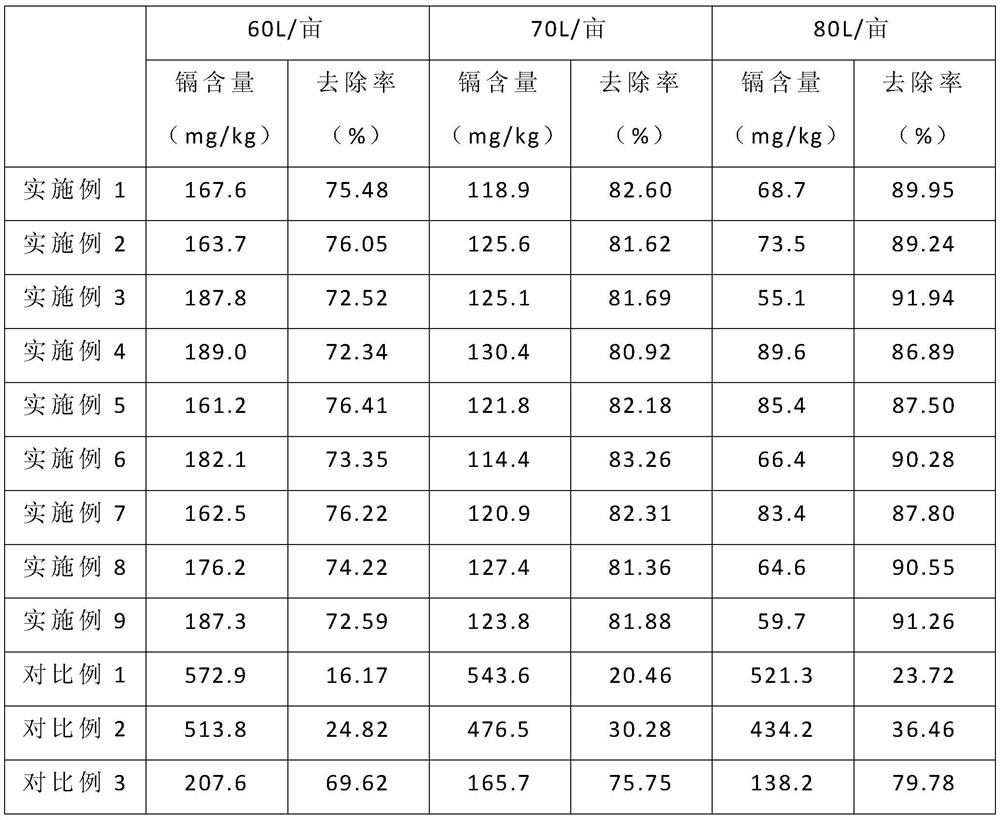

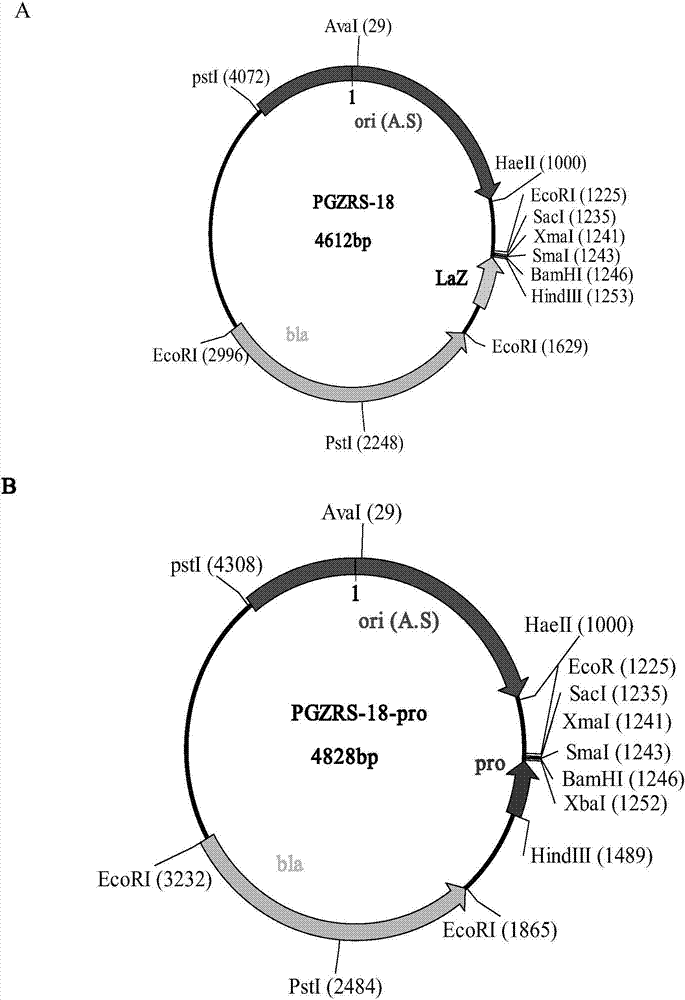

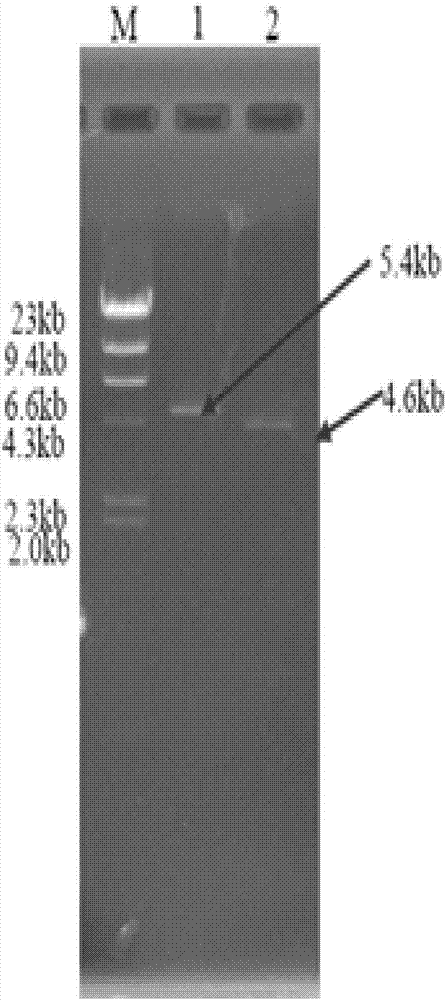

Actinobacillus succinogenes shuttle vector and methods of use

An Actinobacillus succinogenes plasmid vector which provides a means to overexpress proteins in A. succinogenes. The plasmid can be transformed efficiently by electroporation, and replicates in a stable manner in A. succinogenes. The plasmid comprises at least one marker gene, operably linked to a first promoter functional in Actinobacillus succinogenes, an origin of replication functional in Actinobacillus succinogenes, a second promoter isolated from Actinobacillus succinogenes, and a cloning site downstream from the second promoter. Plasmids pLGZ901, pLGZ920, pLGZ921, and pLGZ922 are disclosed. The pckA gene polypeptide sequence and nucleic acid sequence of Actinobacillus succinogenes, including the promoter and ribosome binding site, is disclosed. Furthermore, a method for producing a recombinant Actinobacillus succinogenes is described, including a method of transformation. Additionally, a recombinant Actinobacillus succinogenes is disclosed and a method for producing succinate utilizing this recombinant Actinobacillus succinogenes is described.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

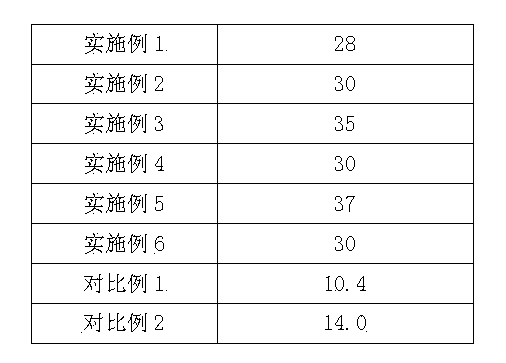

Method for restructuring/breeding Actinobacillus succinogenes strain, and method for producing succinic acid by fermenting Actinobacillus succinogenes strain

InactiveCN101531972AImproved sodium toleranceImprove fermentation characteristicsBacteriaMutant preparationGenome shufflingX-ray

The invention relates to an Actinobacillus succinogenes strain CGMCC 2653 (namely F3-10) with better sodium-ion tolerance and acid-producing performance, a method for breeding the strain and a method for producing succinic acid by fermenting the strain. Actinobacillus succinogenes CGMCC 1593 is taken as an original strain and then subjected to X-ray mutation, ultraviolet mutation, diethyl sulfate (EMS) chemical mutation and nitrosoguanidine (NTG) chemical mutation respectively; three strains X-8, UV-17 and SE-6 with improved fermentative acid-producing performance and particularly improved sodium-ion tolerance, as well as a high-yield strain SF-9 with fluoroacetate resistance, are obtained by screening the obtained product; and a genome restructuring method is used for breeding the strains so as to obtain the strain F3-10 with high yield, sodium tolerance and fluoroacetate resistance. The strain F3-10 takes sugarcane molasses as raw material, adopts Na2CO3 to control fermentation pH, and performs fed-batch fermentation in a 5L fermenter, and produces 53.96 grams of succinic acid per liter in 48 hours; the yield of consumed sugar is 89.2 percent; the utilization rate of sugar is 94.0 percent; and the ratio of succinic acid to heteroacid is 6.58:1. Therefore, the strain F3-10 is remarkably improved as compared with the original strain CGMCC 1593.

Owner:JIANGNAN UNIV

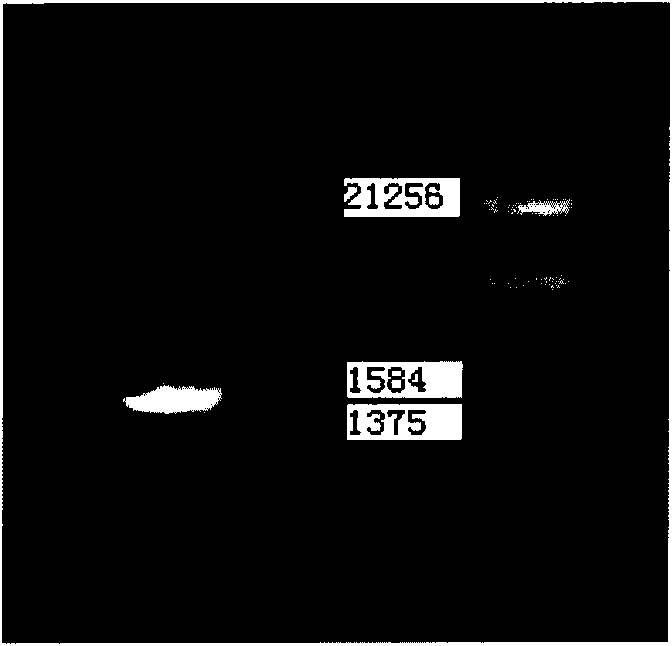

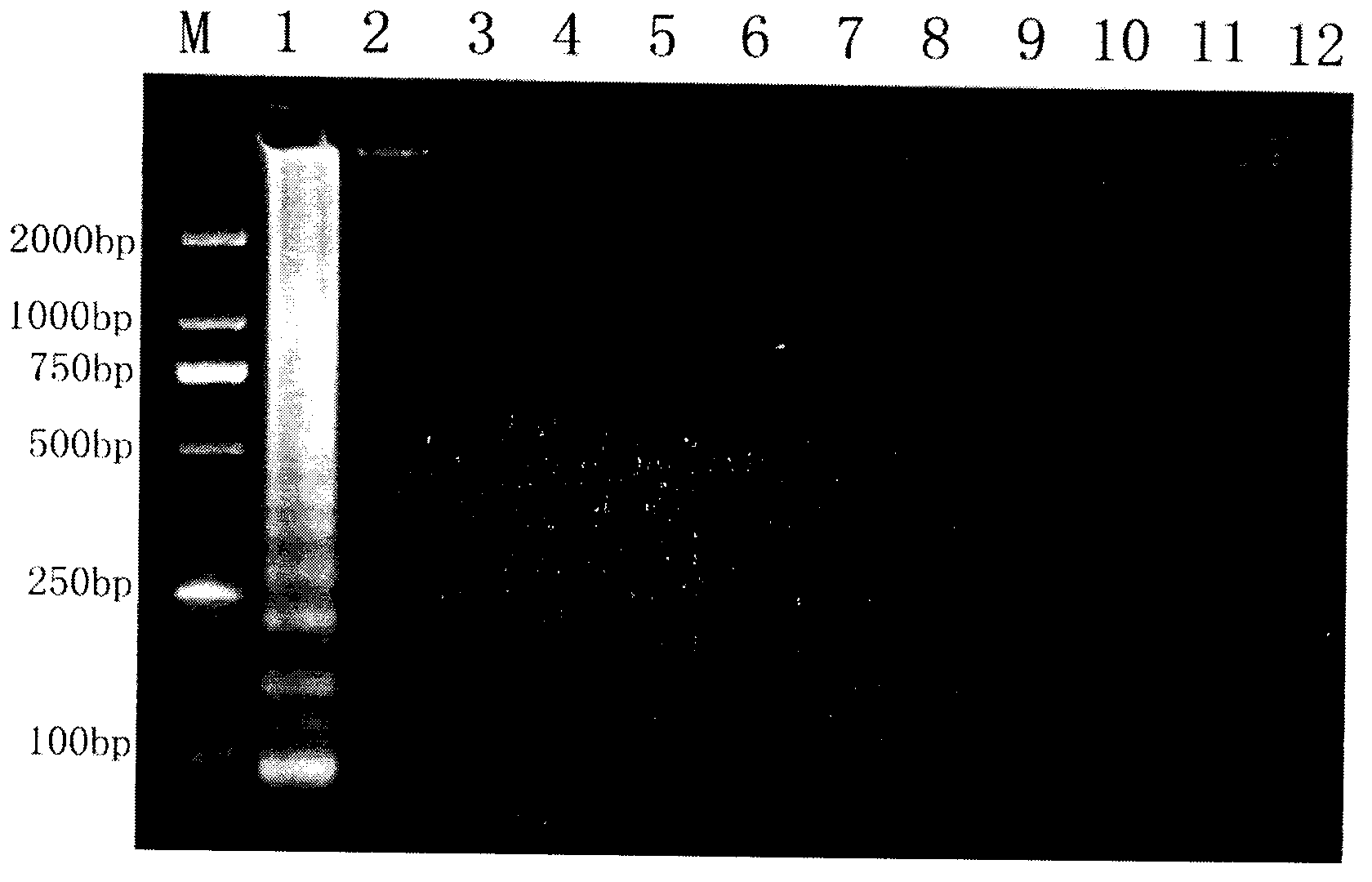

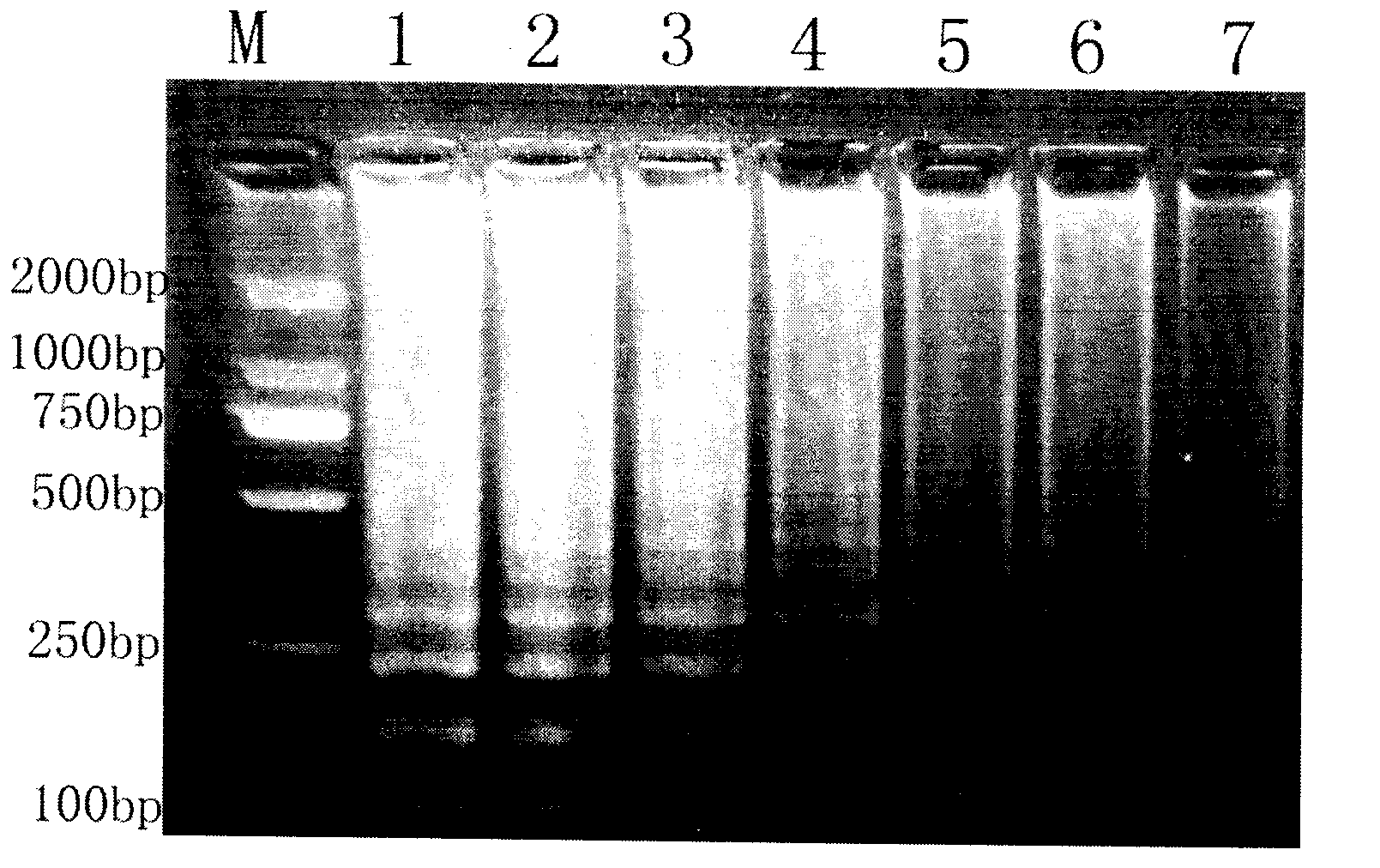

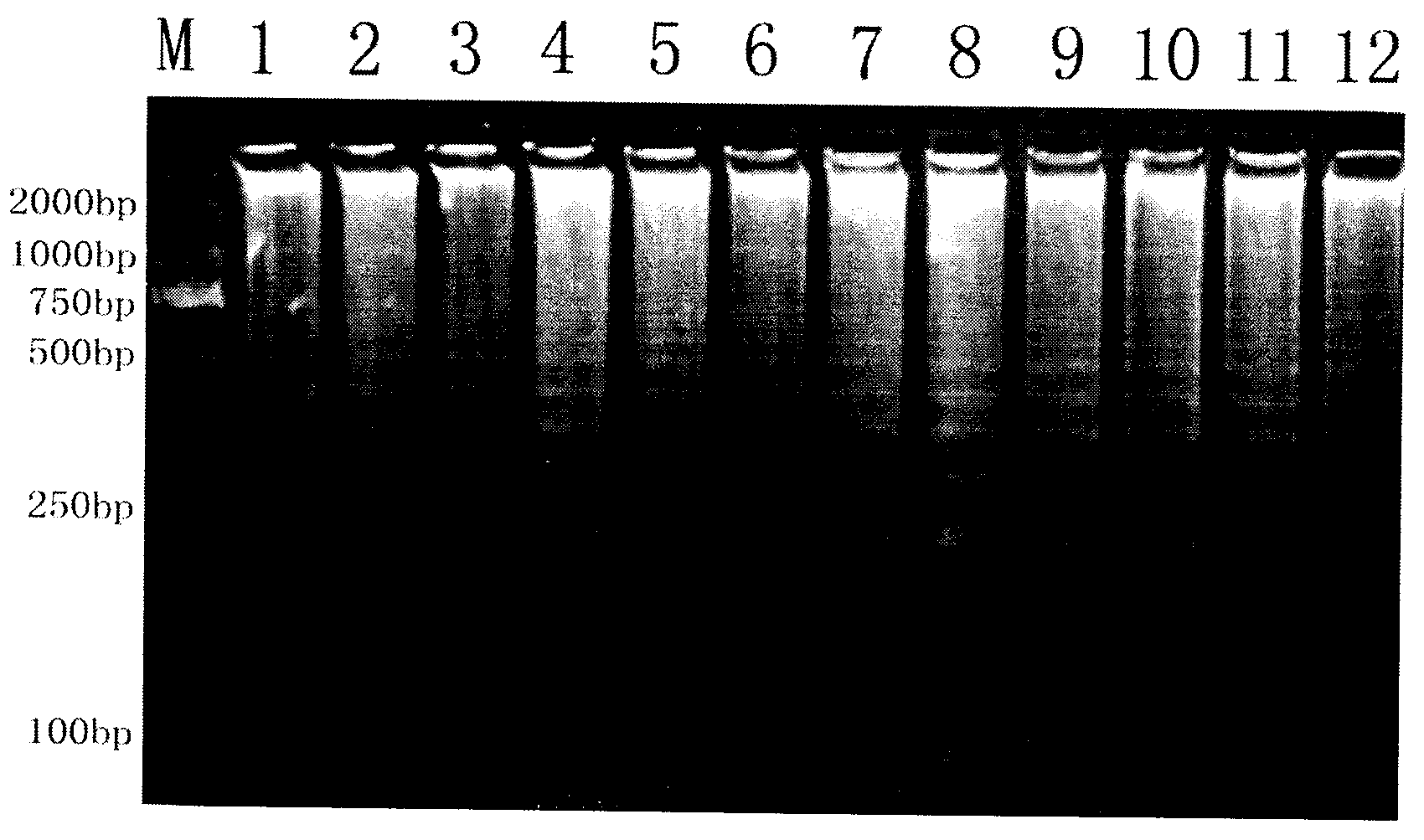

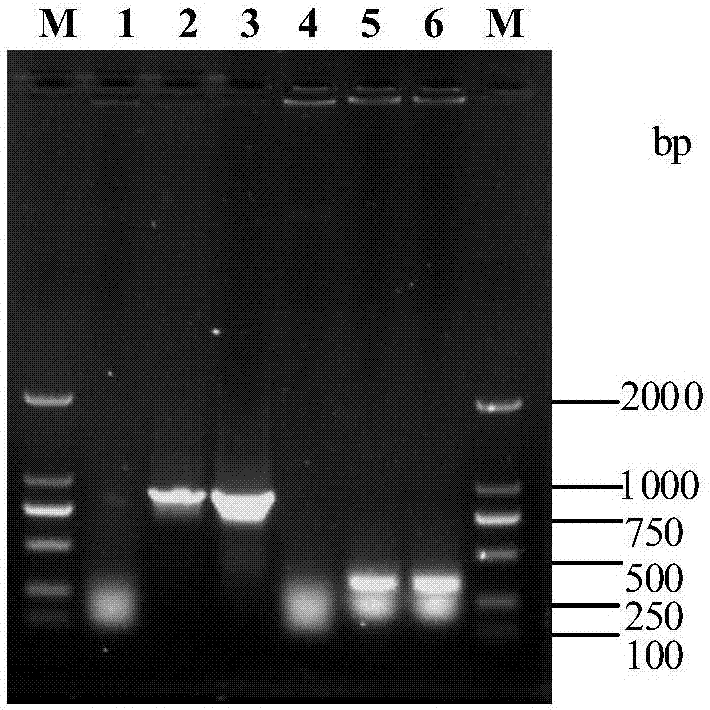

Multiple PCR fast detecting method for oral cavity pathogen

InactiveCN101270381ASame reaction conditionsSensitive methodMicrobiological testing/measurementPorphyromonas gingivalisElectrophoresis

The invention relates to a multiple PCR rapid detection method of common pathogen in mouth such as Actinobacillus actinomycetemcomitans, Bacterides forsythus, F. nucleatum and Porphyromones gingivalis and belongs to the field of molecular biology technology. The invention utilizes the multiple PCR to increase specific gene of Actinobacillus actinomycetemcomitans, Bacterides forsythus, F. nucleatum and Porphyromones gingivalis in mouth and utilizes electrophoresis to detect the specific gene. By designing the primers of Actinobacillus actinomycetemcomitans, Bacterides forsythus, F. nucleatum and Porphyromones gingivalis, the multiple PCR rapid detection method has the advantages of the uniform reaction condition, the sensitivity and the strong specificity of the method, the simultaneous detection and identification of the four bacteria in the specimen, accurate judgment of infection of different bacteria and greatly promoting the detection speed and the detection efficiency.

Owner:肖水清

Actinobacillus and method for producing succinic acid

InactiveCN101845407AIncrease productionMeet the needs of fermentation productionBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobiologySuccinic acid fermentation

The invention provides actinobacillus and a method for producing succinic acid. The Actinobacillus succinogenes CGMCC2560 for producing the succinic acid by fermenting saccharine materials can produce the succinic acid through fermentation, or joint production is performed through succinic acid fermentation and cellulosic ethanol fermentation. Under the anaerobic condition of introducing CO2 and / or N2 and in the environment that pH is maintained 5.5-7.5, 10-110g / L of succinic acid can be produced from 10-100g / L of saccharine materials by anaerobic fermentation. In the joint production method, CO2 generated in the cellulosic ethanol fermentation process is used for the fermentation production of the succinic acid so as to improve the yield of the succinic acid and the cellulosic ethanol and realize zero emission of the CO2. In the joint production, the yield of the succinic acid can reach 92g / L, and the yield of the cellulosic ethanol reaches 108g / L.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

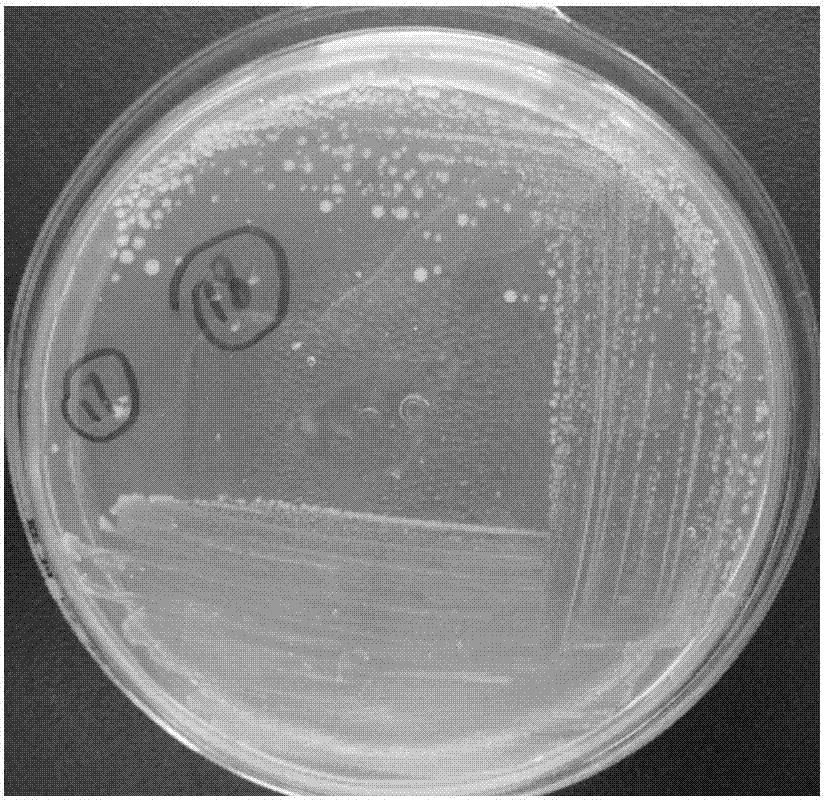

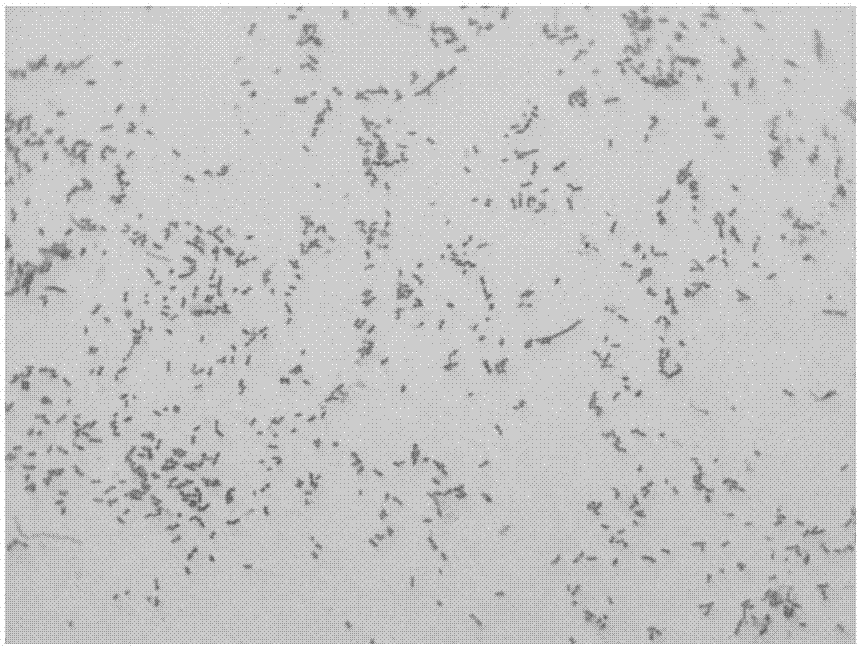

Actinobacillus succinogenes strain and method for producing succinic acid by screening and fermentation of same

InactiveCN102851224APotential for industrial productionSolve the problem of resource shortage and environmental pollutionProductsBacteriaBiotechnologyButanedioic acid

The invention discloses an actinobacillus succinogenes GXAS-137, and a method for producing succinic acid by screening and fermentation of the strain; the strain is obtained by enrichment and screening from a cattle rumen; the method comprises the following steps: inoculating the actinobacillus succinogenes strains in a seed medium, culturing for 24-36 hours in an anaerobic incubator or a common incubator at 30-38 DEG C in a static manner, inoculating into a fermentation medium with an inoculation amount of 1-10%, adjusting the pH to 6.0-7.0, and performing fermentation at 30-38 DEG C for 24-120 hours to obtain succinic acid. Fermentation research is performed with different raw materials and in different media; the succinic acid yield is up to 70 g / L; and the method has potential for industrial production.

Owner:GUANGXI ACAD OF SCI

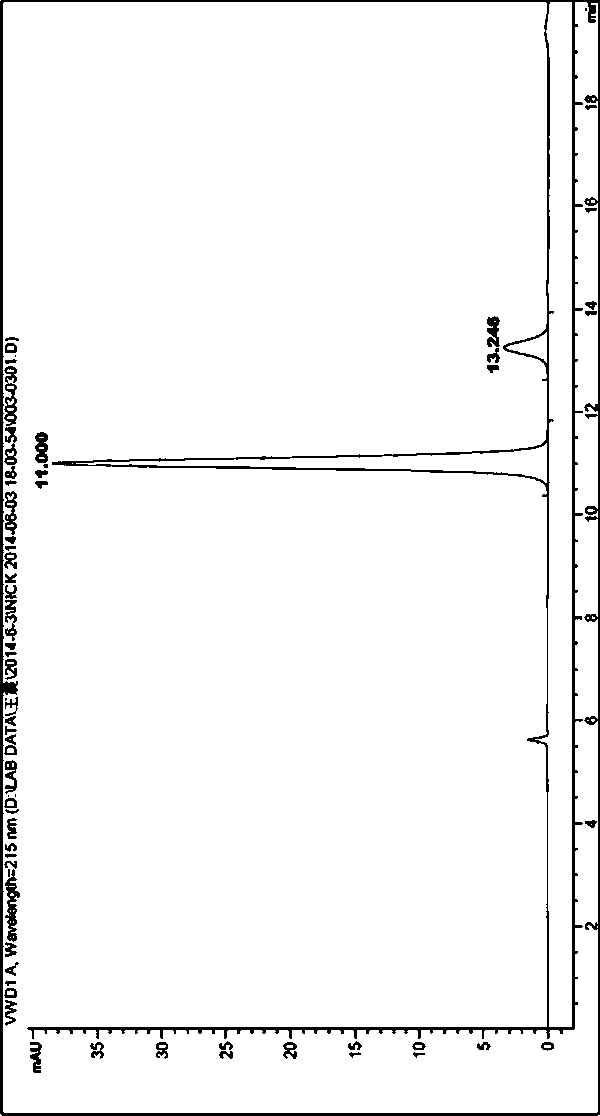

Actinobacillus succinogenes capable of producing succinic acid

ActiveCN102533622AReduce manufacturing costIncrease production intensityBacteriaMutant preparationSaccharic acidD-Glucaric Acid

The invention discloses actinobacillus succionogenes capable of producing succinic acid with high yield and a method for screening and producing the succinic acid by a fermentation method. The actinobacillus succinogenes takes CGMCC1593 as the original strain and is obtained by blending a plurality of turns of protoplast in a progressive way through a method of '96-pore plate culture, HPLC concentration detection and then anaerobic bottle re-screening'. The actinobacillus succinogenes has already been preserved on February 26, 2012 in China Center for Type Culture Collection with the preservation number CCTCCNO: M2012036. The actinobacillus succinogenes adopts fed-batch culture in a 5 to 15 L fermentation tank, 95.6 g / L succinic acid is produced in 48 hours, the production intensity is 1.99 g / (L.h), and the saccharic acid transformation rate is 0.71 g / g. Compared with other bacterial strains at home and abroad, the actinobacillus succinogenes has the advantages of high yield and lowerproduction cost.

Owner:JIANGNAN UNIV

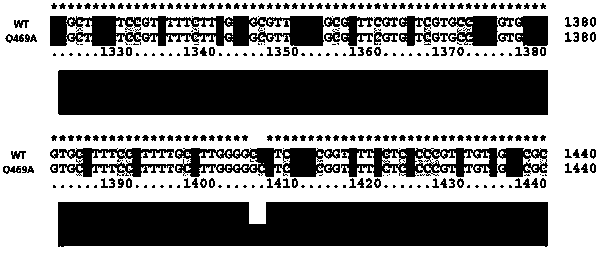

ApNGT gene of actinobacillus pleuropneumoniae and application of ApNGT gene

InactiveCN105505959ABasement efficiency improvementHigh stereoselectivityTransferasesPeptide preparation methodsEscherichia coliActinobacillus pleuropneumoniae

The invention relates to specificity mutation and application of nucleotide at the 1405th bit and the 1406th bit of the ApNGT gene (NCBI:ACCESSION A3N2T3) of actinobacillus pleuropneumoniae. The nucleotide is the nucleotide shown in SEQ ID NO:1 or the nucleotide shown in SEQ ID NO:2. ApNGT is glycosylation transferase coming from actinobacillus pleuropneumoniae, can recognize the N-X-S / T sequence in polypeptide or protein, and can transfer Glucose (Glc) to an Asn residue from an activated donor UDP-Glc. After mutated ApNGT is expressed in actinobacillus pleuropneumoniae, the glycosylation efficiency at the polypeptide level is improved by 160 or more times compared with wild ApNGT, great convenience is provided for galactosylated modification of polypeptide and protein type biological products. Stability of mutated ApNGT is good, and ApNGT can be used as a tool enzyme, can be easily produced in a commercialized mode and has wide application prospects.

Owner:NANKAI UNIV

Actinobacillus pleuropneumoniae LAMP kit and application method thereof

InactiveCN102925548AEasy to operateStrong specificityMicrobiological testing/measurementMicroorganism based processesWater bathsBetaine

The invention discloses a LAMP kit used for detecting actinobacillus pleuropneumoniae, and an application method thereof. The kit comprises 50mul of 8U / mul BstDNA polymerase, 125mul of a BstDNA polymerase buffer solution, 100mul of 0.1mol / l MgSO4, 100mul of 12.5mmol / l betaine, 100mul of 17.5mmol / l dNTP, and primers. As a result of multiple times of tests of practice, with the kit, trace amount of various serotypes of actinobacillus pleuropneumoniae can be detected specifically, sensitively, fast, and highly efficiently in a 63-64 DEG C constant-temperature water-bath pot. The method does not need complicated instrument and large amounts of professional skills, such that an urgent need currently of actinobacillus pleuropneumoniae field detection can be satisfied. The kit and the method can be used in field detections of import and export quarantine, food sanitation departments, animal husbandry farms, and the like. The kit and the method are especially suitable to be used by grassroots veterinary workers for carrying out wild and real-time detections of actinobacillus pleuropneumoniae.

Owner:SICHUAN AGRI UNIV +1

PCR diagnostic kit for porcine infectious pleuropneumonia

InactiveCN101724709AThe test result is accurateThe detection method is simpleMicrobiological testing/measurementMicroorganism based processesPositive controlTE buffer

The invention discloses a PCR diagnostic kit for porcine infectious pleuropneumonia, which comprises 400mu L of proteinase K with the concentration of 20mg / mL, 1000mu L of cracking solution, 1500mu L of TE buffer solution, 250mu L of PCR enzyme, 170mu L of ultra-pure water, 50mu L of MarkerDL2000, 40mu L of primer P1 and primer P2 which are mixed in the same volume and have the same concentration of 20mu M, 20mu L of negative control and 20mu L of positive control. By optimizing the PCR reaction conditions, the invention develops a PCR kit for detecting the actinobacillus of the porcine infectious pleuropneumonia; and by comparing the PCR detection result with the negative control and the positive control, detection conclusions can be obtained, thereby achieving the aim of quickly detecting whether a sample has porcine infectious pleuropneumonia or not. The invention has accurate detection result, quick and sensitive detection process, simple detection mode and good using effect.

Owner:GUIZHOU INST OF ANIMAL HUSBANDRY & VETERINARY

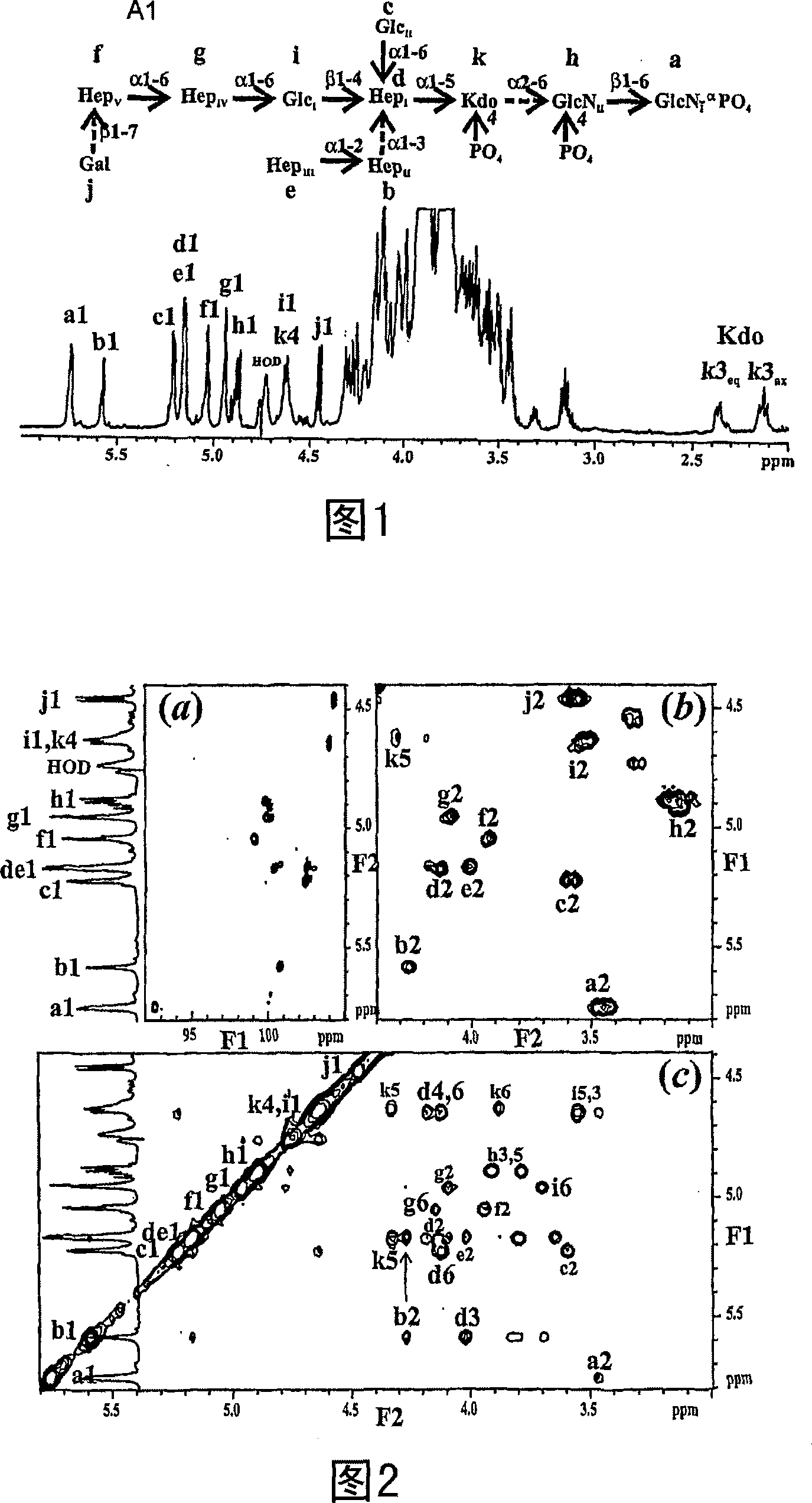

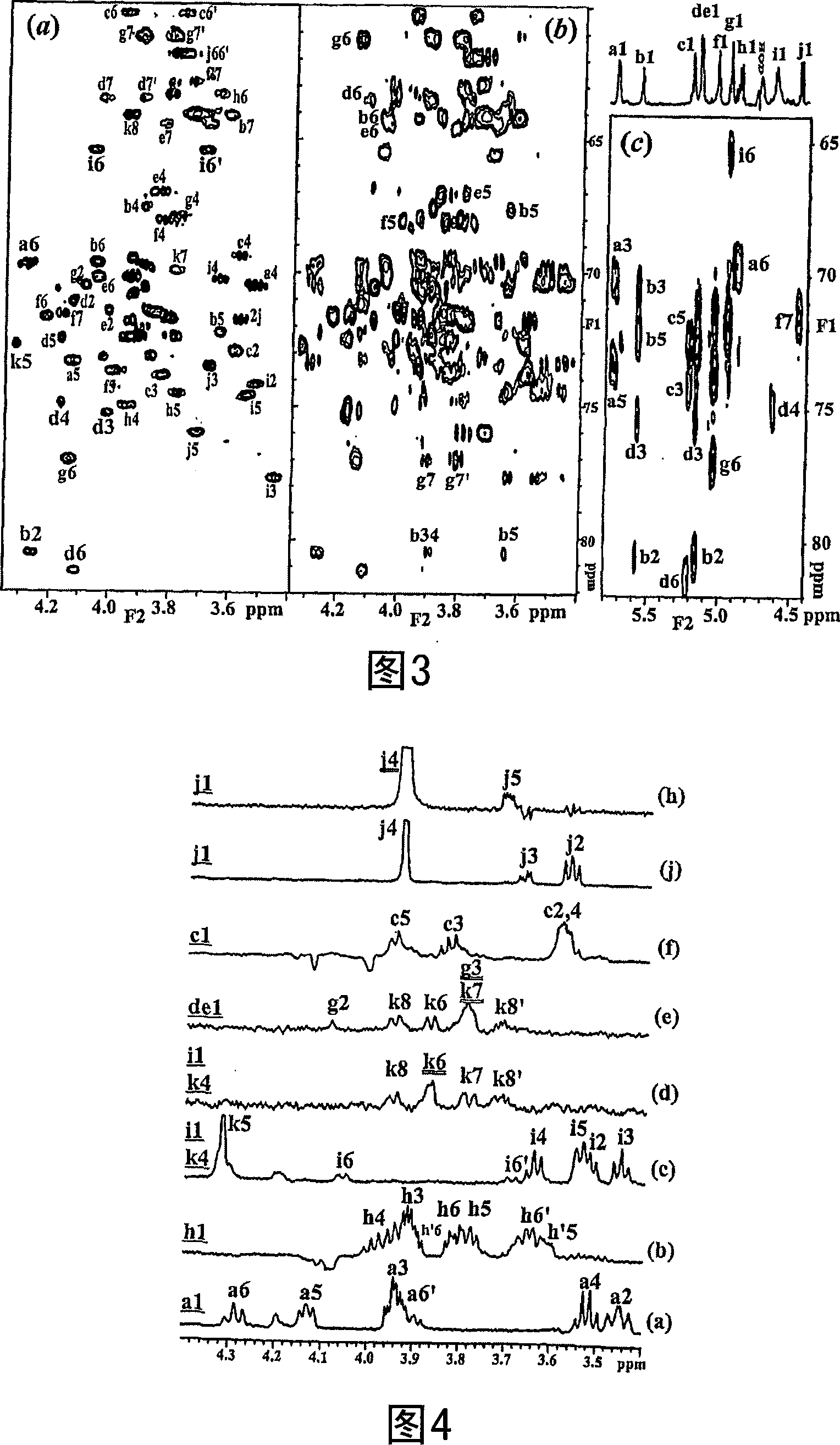

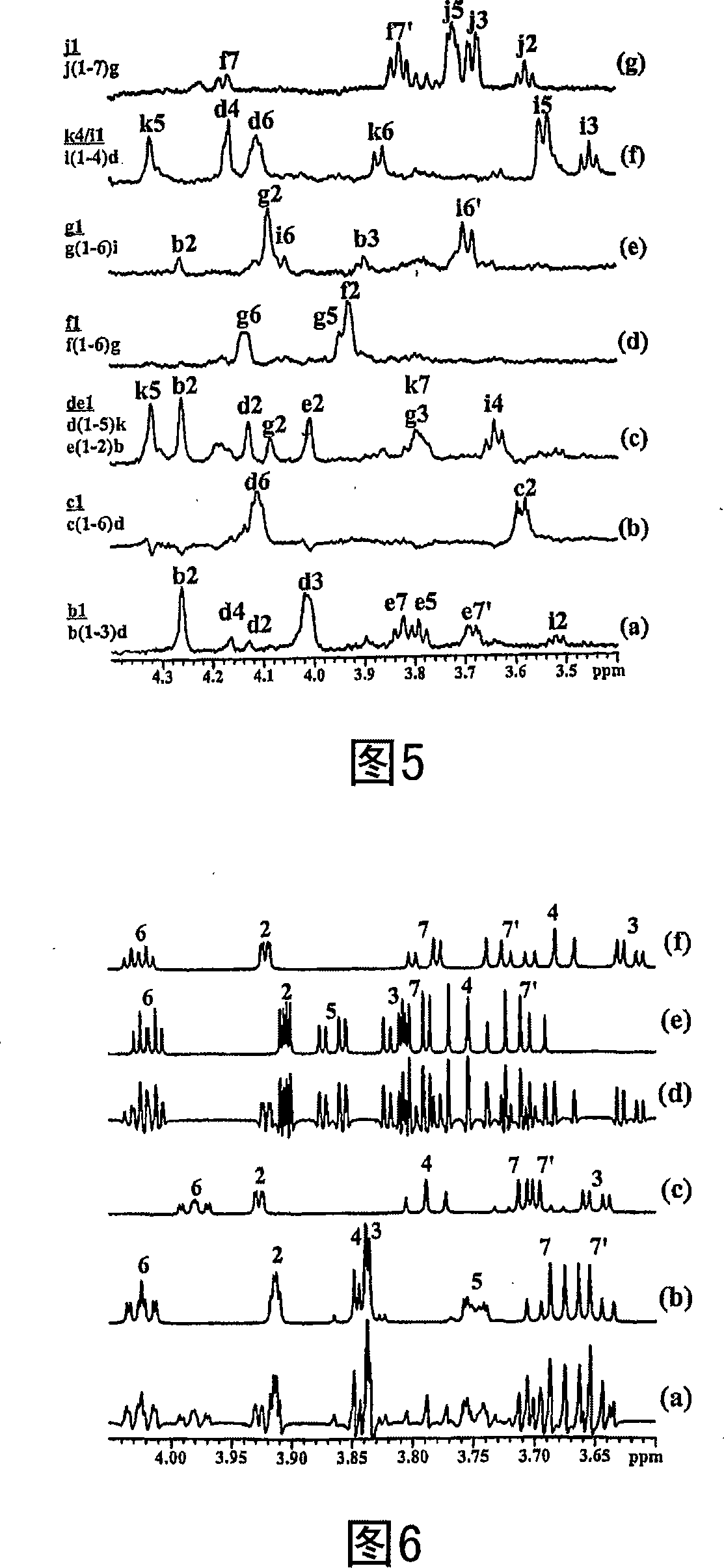

Conserved inner core lipopolysaccharide epitopes as multi-species vaccine candidates

InactiveCN101014698AEsterified saccharide compoundsAntibacterial agentsDiseaseMANNHEIMIA HAEMOLYTICA

A conserved inner-core oligosaccharide epitope expressed on the lipopolysaccharide (LPS) of a range of disease causing pathogenic bacterial isolates, including Actinobacillus pleuropneumoniae (Ap), Mannheimia haemolytica (Mh) and Pasteurella multocida (Pm), is disclosed. Construction of a mutant bacterial strain exclusively expressing the conserved inner core OS epitope as a terminally exposed structure has allowed the identification, production and isolation of an inner core LPS which is common to all three organisms. Further provided are associated vaccines, antibodies raised against the conserved LPS inner core and glycoconjugates comprising the LPS inner core linked to an immunogenic carrier.

Owner:NAT RES COUNCIL OF CANADA

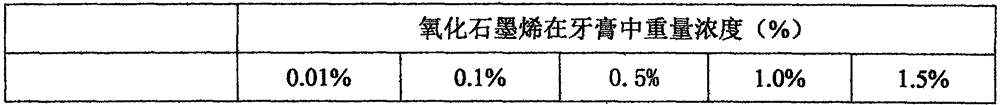

Novel toothpaste with graphene oxide and preparation method thereof

InactiveCN105395372AGood antibacterial effectLarge specific surface areaAntibacterial agentsCosmetic preparationsEscherichia coliToothpaste

The invention discloses novel toothpaste with graphene oxide and a preparation method thereof, and belongs to the technical field of daily chemical products. The toothpaste is technically characterized by being prepared from 0.01-1.5% of graphene oxide, 0.1-0.85% of ionic liquid and the balance additives, wherein the additives comprise an abrasive agent, a wetting agent, a surfactant, a binding agent, a stabilizing agent, spice, a sweetening agent and water. The graphene oxide is applied in toothpaste components for the first time, and the application range of the graphene oxide in daily chemical products is expanded again. The toothpaste with the graphene oxide has the strong bacteriostasis effect on staphylococcus aureus, escherichia coli, porphyromonas gingivalis, prevotella intermedia and actinobacillus actinomycetemcomitan.

Owner:张建刚

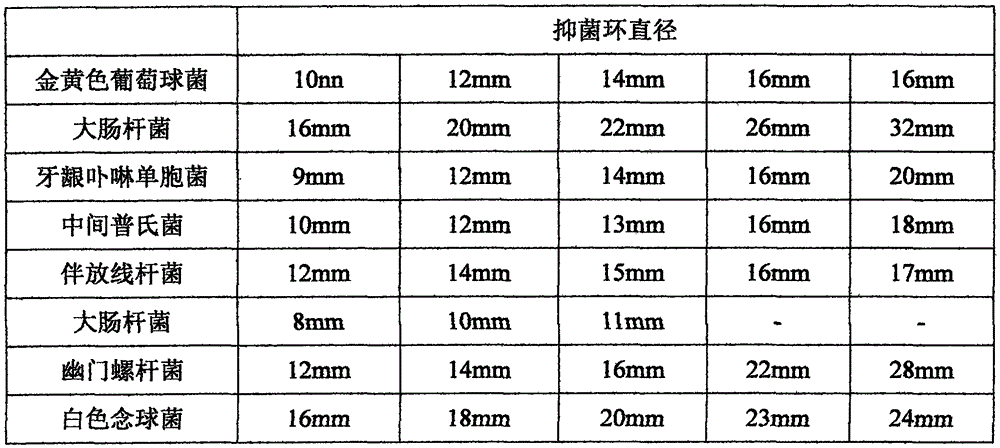

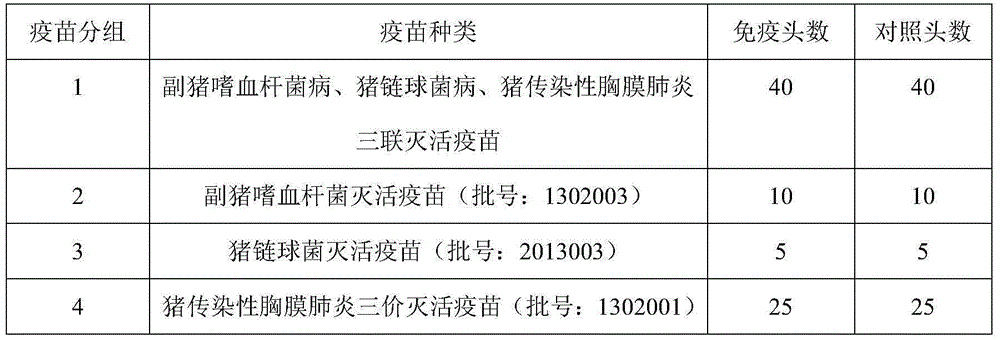

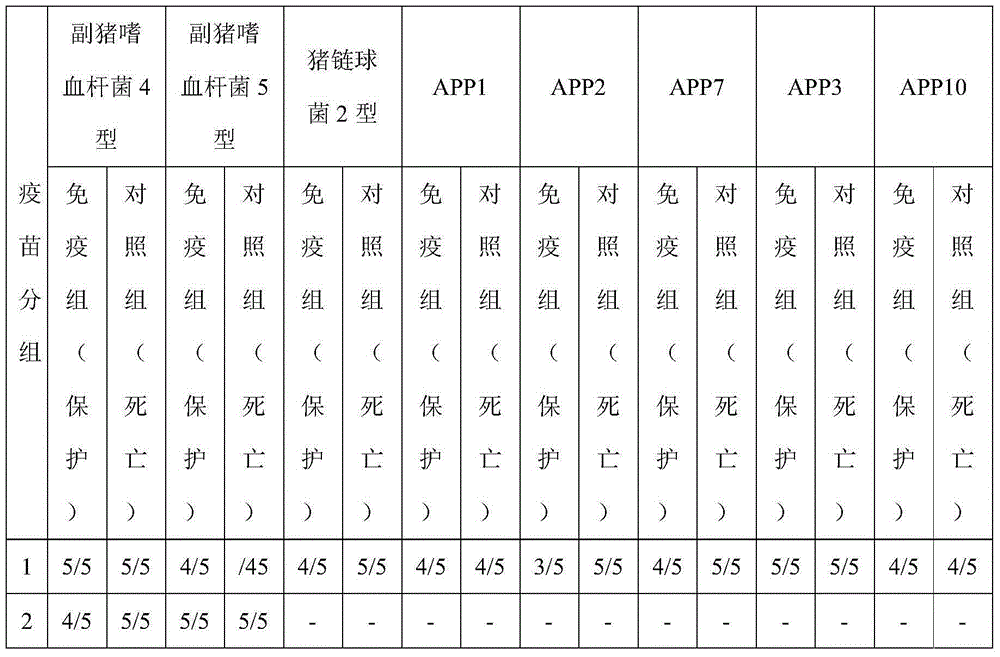

Preparation method of triple inactivated vaccine for pigs

InactiveCN104998256AImprove immunityHighlight immune functionAntibacterial agentsBacterial antigen ingredientsAntigenProtective antigen

The invention provides a preparation method of a triple inactivated vaccine for pigs. The method determines an antigen composition with excellent immunization effects by selection of the antigen. The prepared polyvalent vaccine has outstanding immunization effects. The prepared vaccine contains a PCP immunization protective antigen exotoxin (Aps), has cross immunization protection effects better than those of a whole cell inactivated vaccine, greatly reduces side reaction, and can simultaneously prevent haemophilus parasuis, swine streptococcosis and actinobacillus pleuropneumonia by combined immunization with inactivated haemophilus parasuis and streptococcus suis. Compared with haemophilus parasuis and streptococcus suis inactivated vaccines sold on the market, the triple inactivated vaccine has the same corresponding pathogen immune protection force. Compared with the actinobacillus pleuropneumonia inactivated vaccine sold on the market, the triple inactivated vaccine has a cross immunization protecting force on diseased pigs with different serotypes and realizes multiple protection purposes.

Owner:TIANJIN RINGPU BIO TECH

Engineering the pathway for succinate production

This invention relates to the biocatalysts for the efficient production of succinic acid and / or other products from renewable biological feedstocks. The biocatalysts have a very high efficiency for the growth-coupled production of succinic acid and / or other products from carbohydrate feed stocks as a result of both genetic manipulations and metabolic evolution. More specifically, certain biocatalysts of the present invention produce succinic acid at high titers and yield in mineral salts media during simple pH-controlled, batch fermentation without the addition of any exogenous genetic material. The genetic manipulations of the present invention are concerned with the energy-conserving strategies coupled with the elimination of alternative routes for NADH oxidation other than the routes for succinic acid production. The biocatalysts contain glucose-repressed gluconeogenic phosphoenol pyruvate carboxykinase (pck) derepressed by genetic modifications and a genetically-inactivated phosphotransferase system. In terms of succinic acid production efficiency, the biocatalysts of the present invention are functionally equivalent to succinate producing rumen bacteria such as Actinobacillus succinogens and Mannheimia succiniproducens with one difference that the biocatalysts are able to achieve this high level of succinic acid production in a minimal salt medium with carbohydrate source as opposed to the requirement for a rich media for succinic acid production by rumen bacteria.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

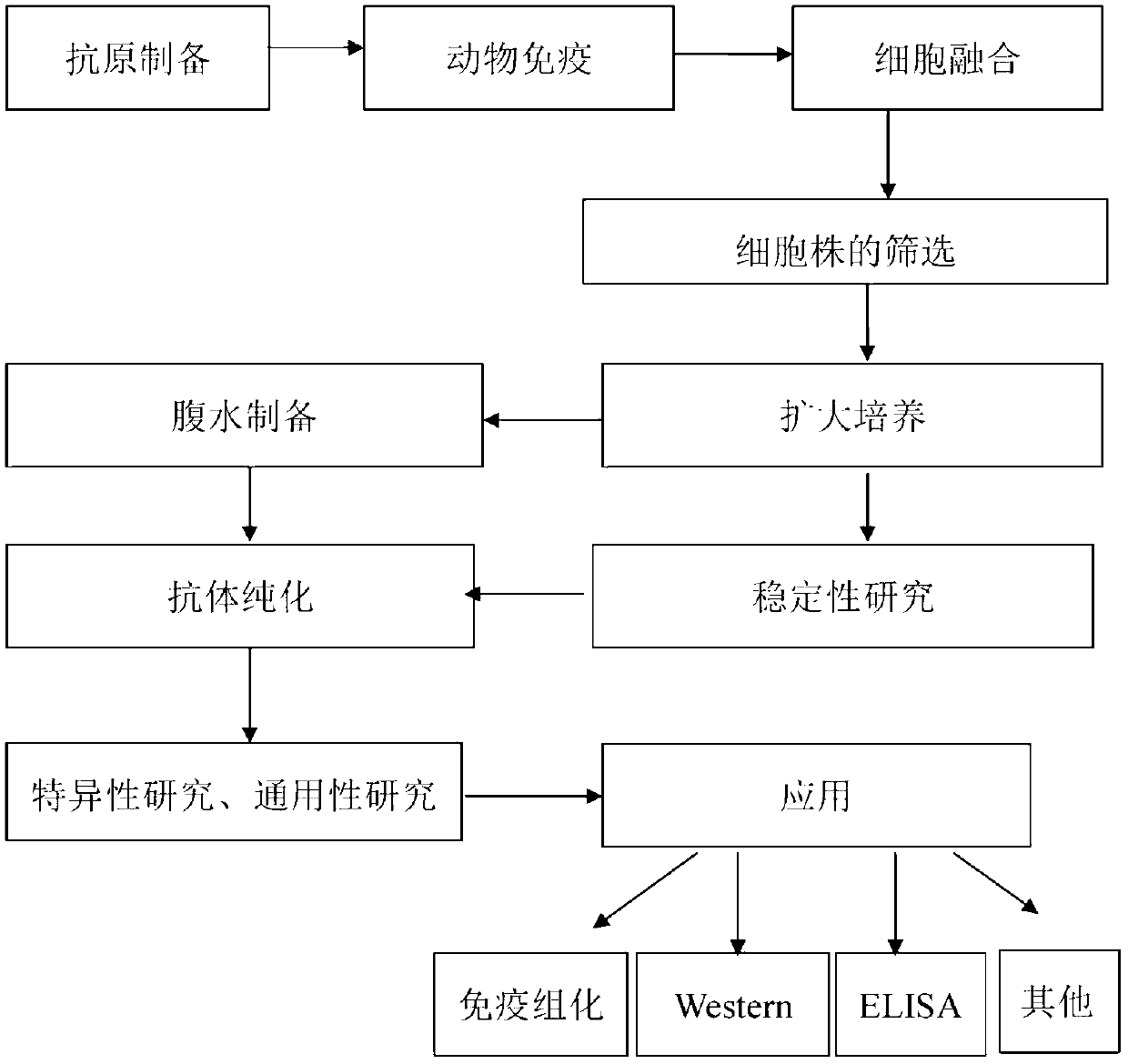

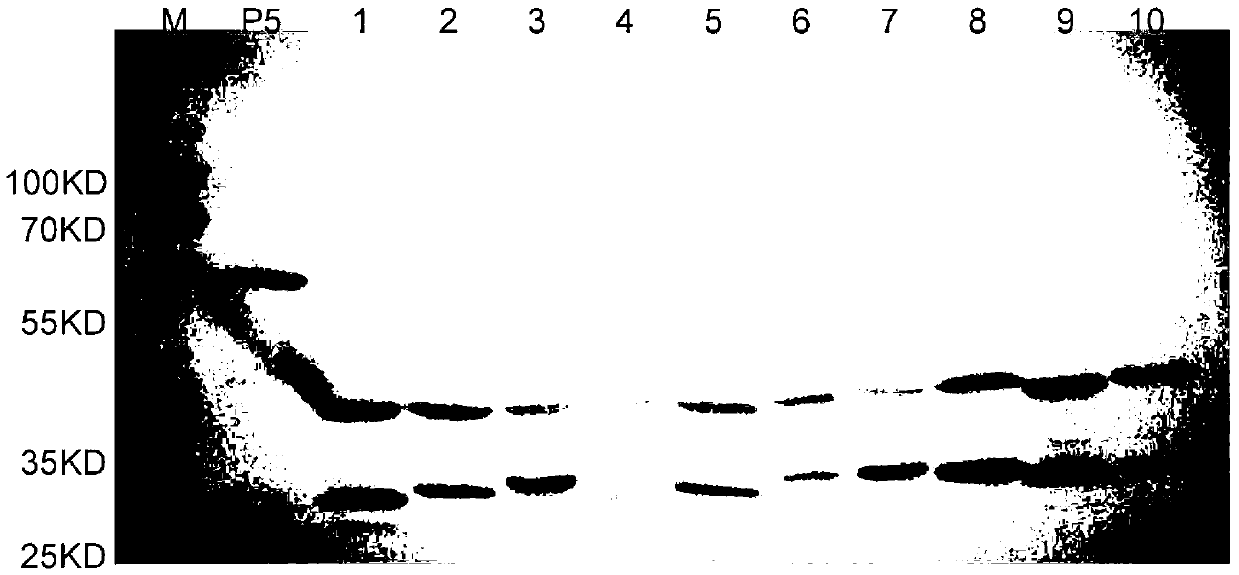

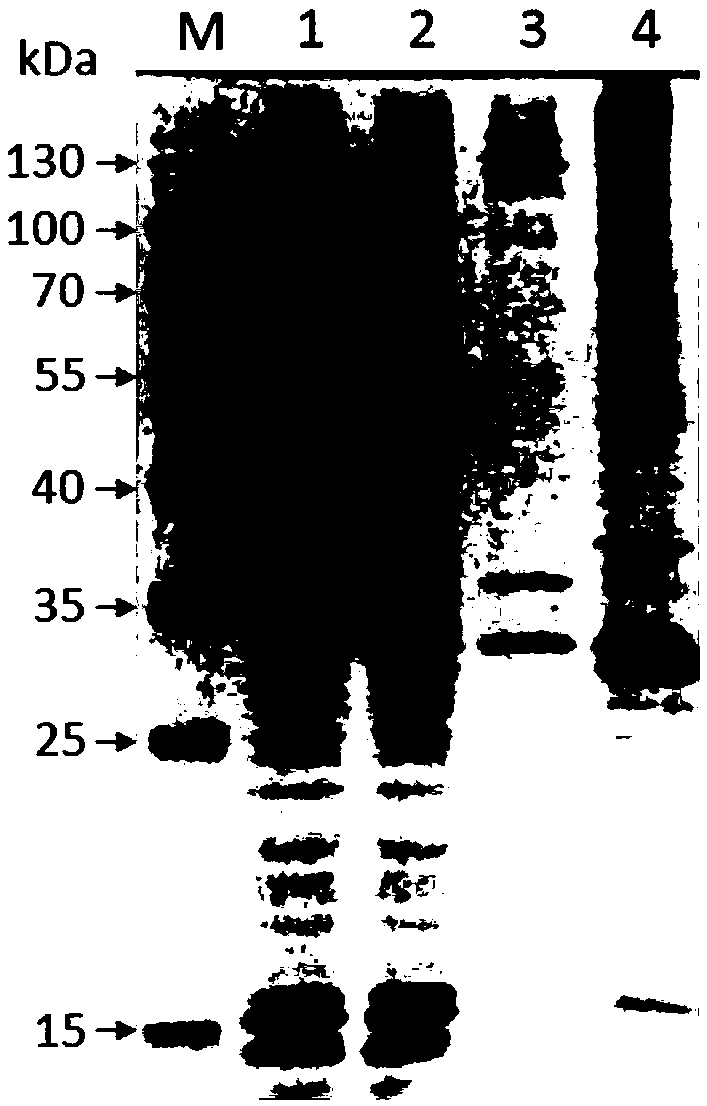

Haemophilus parasuis outer membrane protein P5 (OMP5) resistant monoclonal antibody, hybridoma cell strain and application

InactiveCN102876635ANo cross reactionStrong specificityImmunoglobulins against bacteriaMicroorganism based processesEscherichia coliBordetella

The invention discloses a haemophilus parasuis outer membrane protein P5 (OMP5) resistant monoclonal antibody, a hybridoma cell strain and an application. The hybridoma cell strain is preserved in the China center for type culture collection (CCTCC), and the preservation serial number is CCTCCC2012135. The monoclonal antibody prepared by the hybridoma cell strain is good in specificity, high in valence, high in generality, free from cross reaction with swine Escherichia coli, swine pasteurella, swine pleuropneumonia actinobacillus, streptococcus suis and swine bordetella bacilli, capable of detecting haemophilus parasuis with different serotypes and widely applicable to etiology diagnosis, serology detection and immunology detection and prevention of haemophilus parasuis diseases, and the enzyme-linked immuno sorbent assay (ELISA) antibody valence can reach 1:204800 after purification.

Owner:广东省农业科学院兽医研究所

Mouthwash capable of effectively inhibiting bacteria and preparation method

PendingCN110522675AAntibacterial agentsCosmetic preparationsSodium bicarbonatePorphyromonas gingivalis

The invention discloses mouthwash capable of effectively inhibiting bacteria and a preparation method thereof. The mouthwash is composed of an antibacterial biological extract, sodium bicarbonate, biologically refined glycerin, peppermint oil, lauryl sodium sulfate, a freshener WS-23, an anti-caking agent, a sweetening agent and a mouthwash matrix. Wherein the antibacterial biological extract is natamycin, nisin and phenyllactic acid; natamycin, nisin and phenyllactic acid are weighed, natamycin, nisin and phenyllactic acid are added into purified water, stirring is carried out through a reaction kettle until natamycin, nisin and phenyllactic acid are dissolved, and other components can be added, stirring at a high speed is carried out until all substances are dissolved, and finally packaging is carried out after sterile filling. The mouthwash disclosed by the invention contains natamycin, nisin and phenyllactic acid, the mouthwash can effectively kill and inhibit G<+> and G<->bacteriasuch as porphyromonas gingivalis, actinobacillus actinomycetemcomitan, Fusobacterium, streptococcus mutans and the like in the oral cavity, has a decomposition effect on plaque biofilms generated byflora, can decompose dental plaque while protecting beneficial bacteria, and has the tooth cleaning effect while sterilizing and removing the plaque.

Owner:伟日(山东)生物科技有限公司

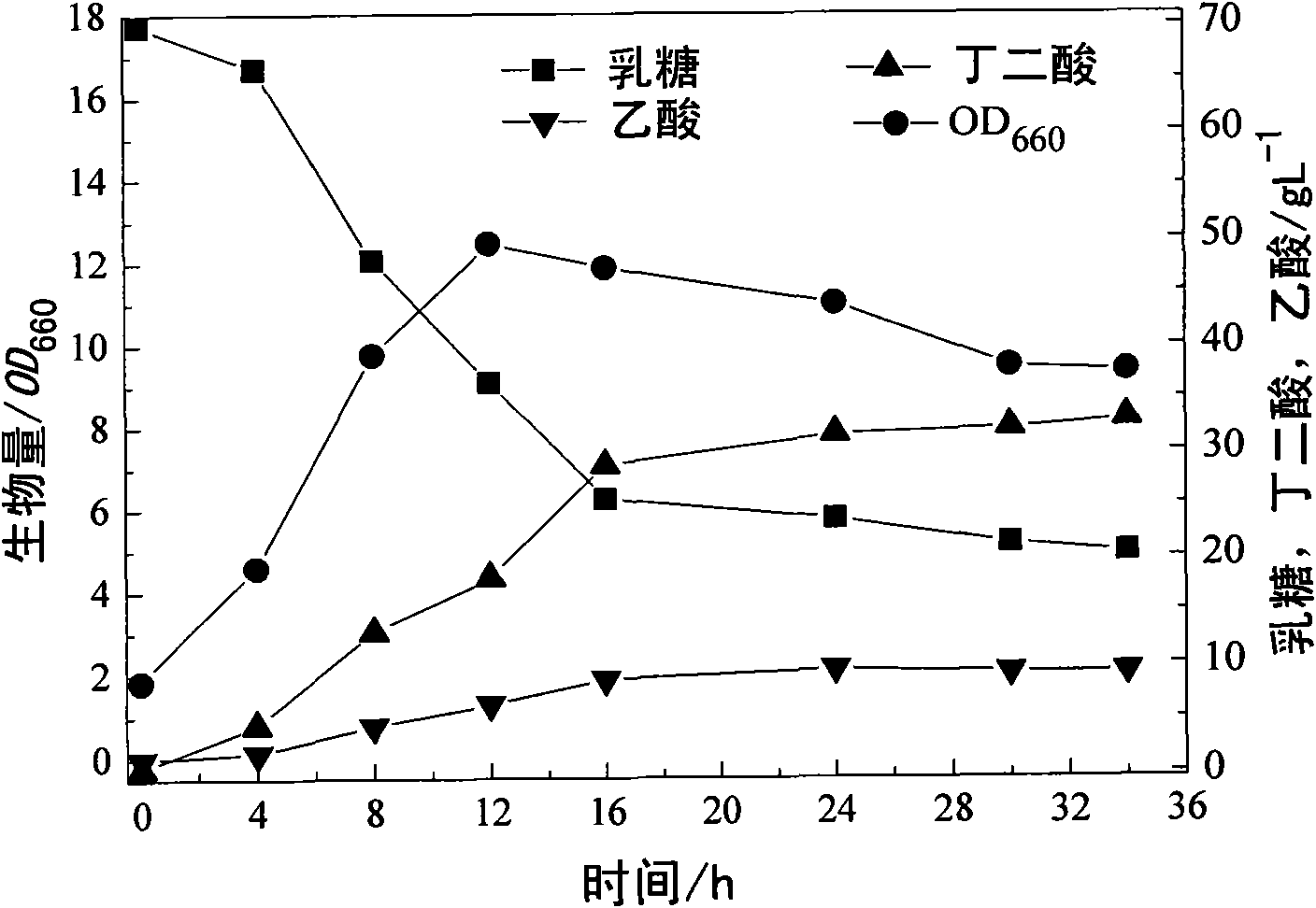

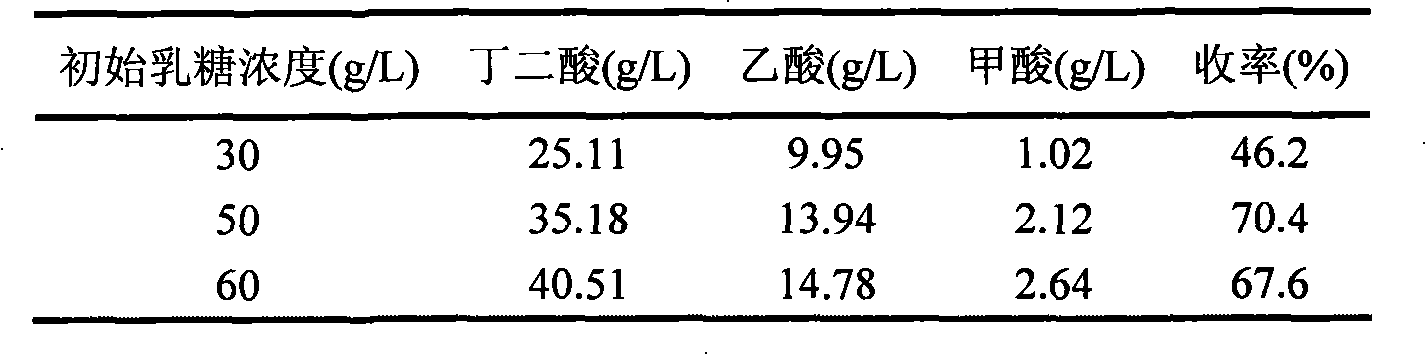

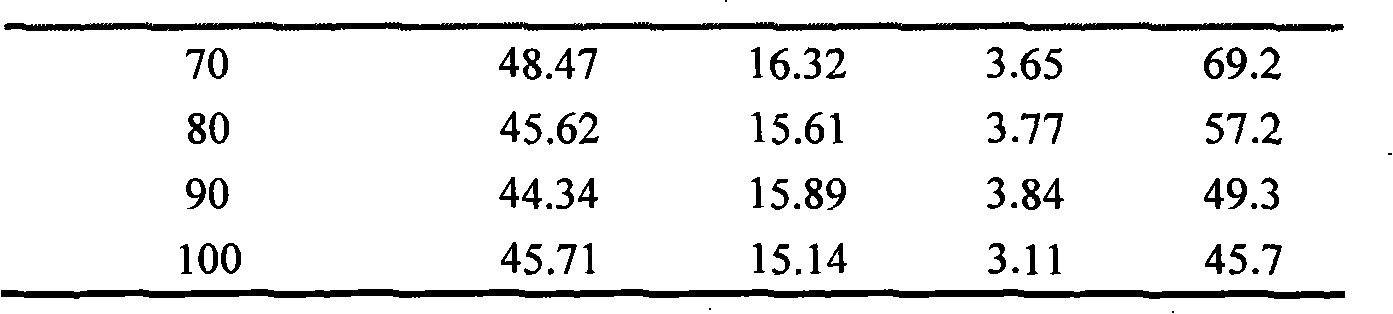

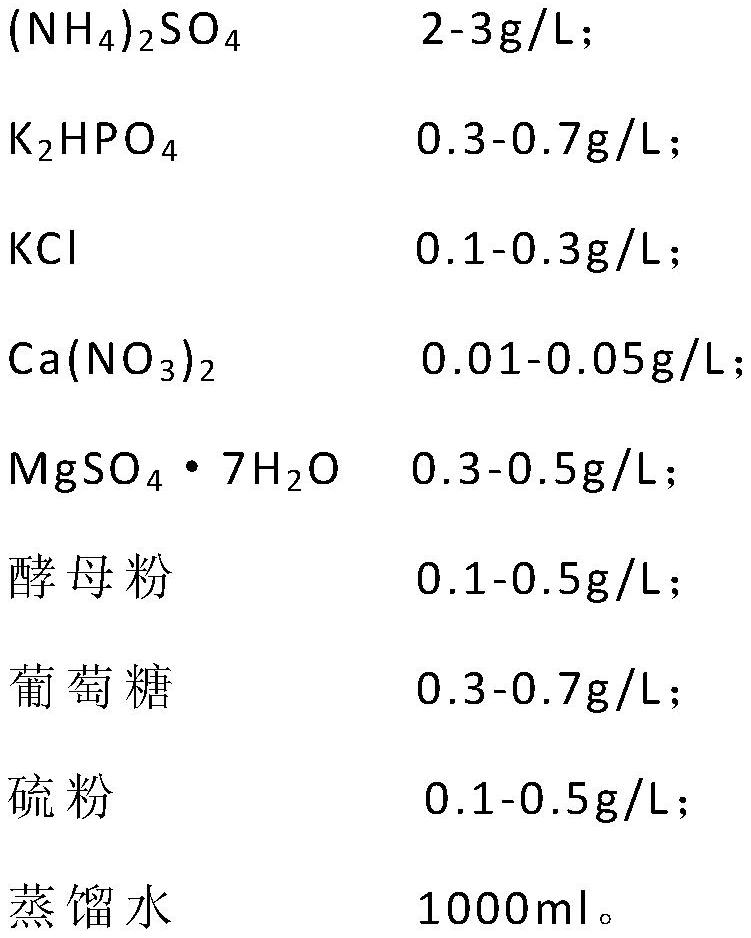

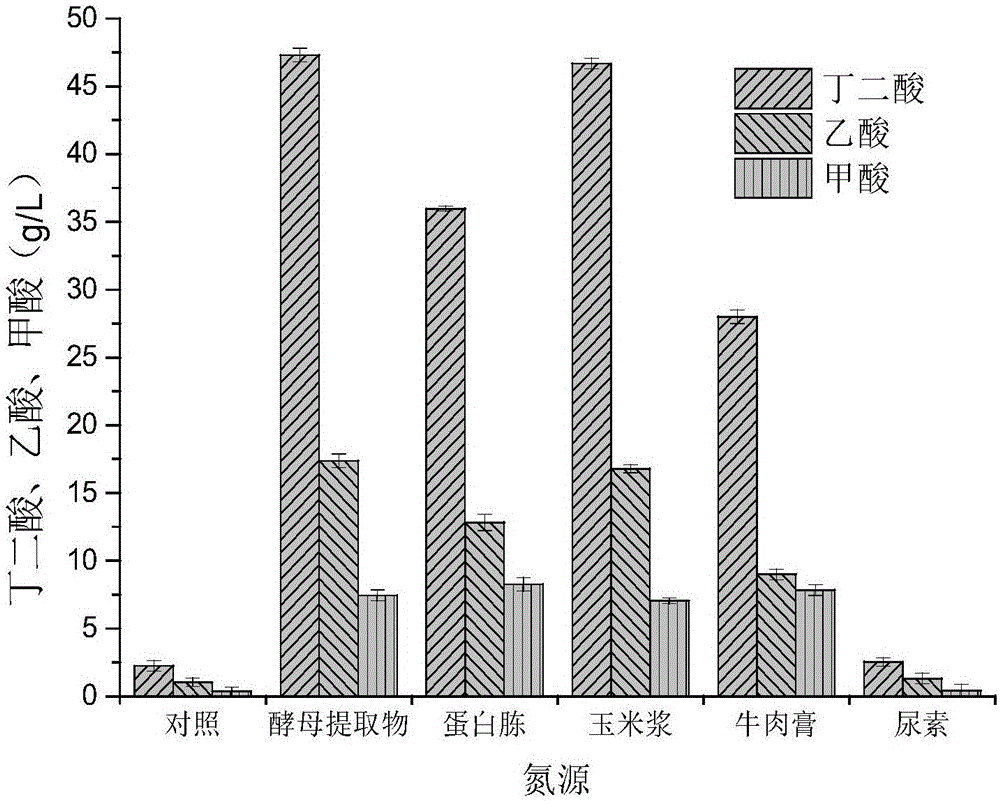

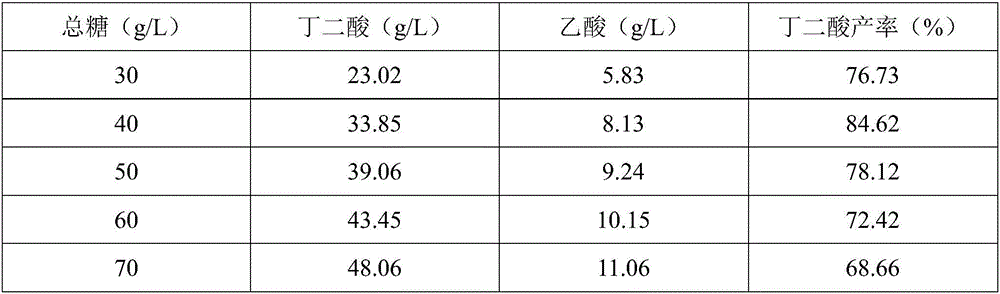

Fermentation production method of succinic acid with whey

InactiveCN101857888AIncrease concentrationSuitable for industrial productionMicroorganism based processesFermentationChemical synthesisRumen

The invention relates to a fermentation production method of succinic acid with whey, which adopts the technical scheme that: actinobacillus succinogenes NJ113 is put in a culture medium of whey containing 30-100g / L of lactose to produce succinic acid by fermentation. The invention utilizes actinobacillus succinogenes selected from rumen which is suitable for fermenting whey raw material to produce the succinic acid, so that the consumption of a nitrogen source can be effectively reduced, the product concentration is up to 47.51g / L, and the yield is up to 67.9%; and the actinobacillus succinogenes is very suitable for industrial production of the succinic acid in low cost. The invention has outstanding advantages that: cheap whey raw material is utilized to produce the succinic acid by fermentation, and the whey as an cheap crude raw material can substitute glucose to be used as a carbon source to produce the succinic acid by fermentation; the method is a production method utilizing renewable raw materials, can alleviate the shortages of petroleum resources for chemical synthesis of the succinic acid, and is environmentally friendly; and the whey contains the nitrogen source and other nutrients which can be utilized by microorganisms, thereby obviously reducing the fermented culture medium components.

Owner:NANJING UNIV OF TECH

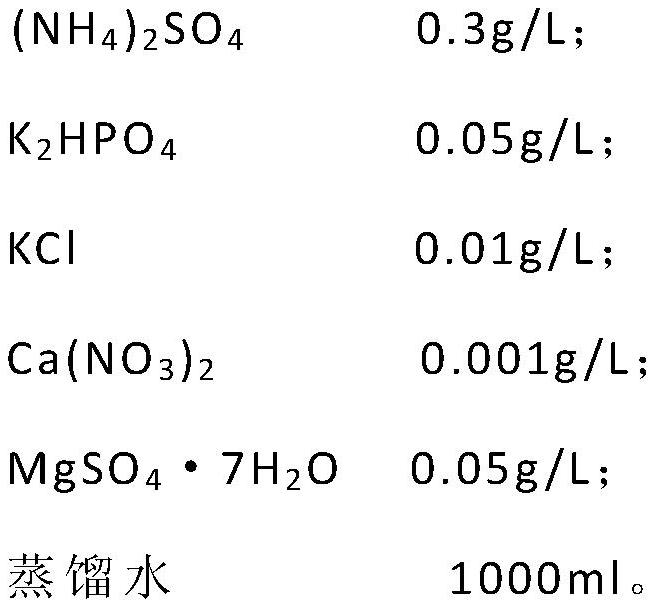

Complex microbial agent for efficiently converting heavy metal chromium in soil as well as preparation method and application thereof

PendingCN113265362AGood synergyImprove adaptabilityBacteriaContaminated soil reclamationThiobacillus ferrooxidansMicrobial agent

The invention belongs to the technical field of soil remediation, and particularly relates to a complex microbial agent for efficiently converting heavy metal chromium in soil as well as a preparation method and application thereof. The complex microbial agent is obtained by mixing and carrying out enrichment culture on the following two florae: a flora A consisting of bacillus, pediococcus acidilactici, clostridium coriolis, actinobacillus succinogenes and bacillus aceticus; a flora B consisting of acidophilic iron bacteria, thiobacillus ferrooxidans, acid-thiobacillus thiooxidans, sulfur-oxidizing acid-thiobacillus thiooxidans, sulfur-oxidizing bacteria and acidophilic thiobacillus ferrooxidans. After the complex microbial agent is used for treating the chromium-contaminated soil, the chromium removal rate can reach 91% or above. The complex microbial agent is formed by culturing and mixing a plurality of strains, and the strains have a good synergistic effect and do not generate antagonism; after compounding, the adaptability to heavy metals can be improved, so that the survival and removal effects of the soil in heavy metal contaminated soil are improved. The microbial agent is simple in preparation and application method, short in culture period and treatment period and low in cost, prevents secondary pollution, and has a wide application prospect.

Owner:CENT SOUTH UNIV +2

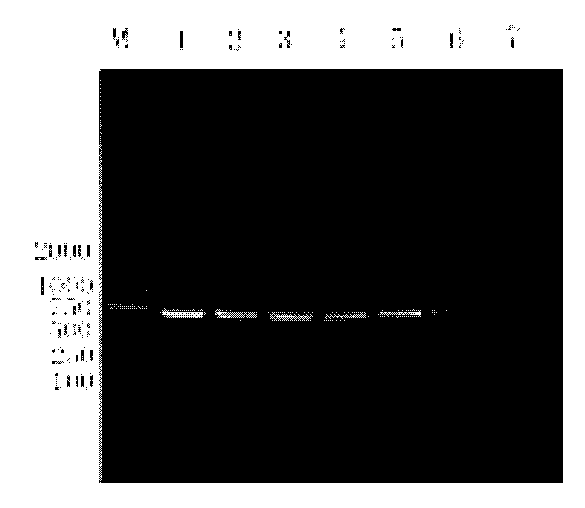

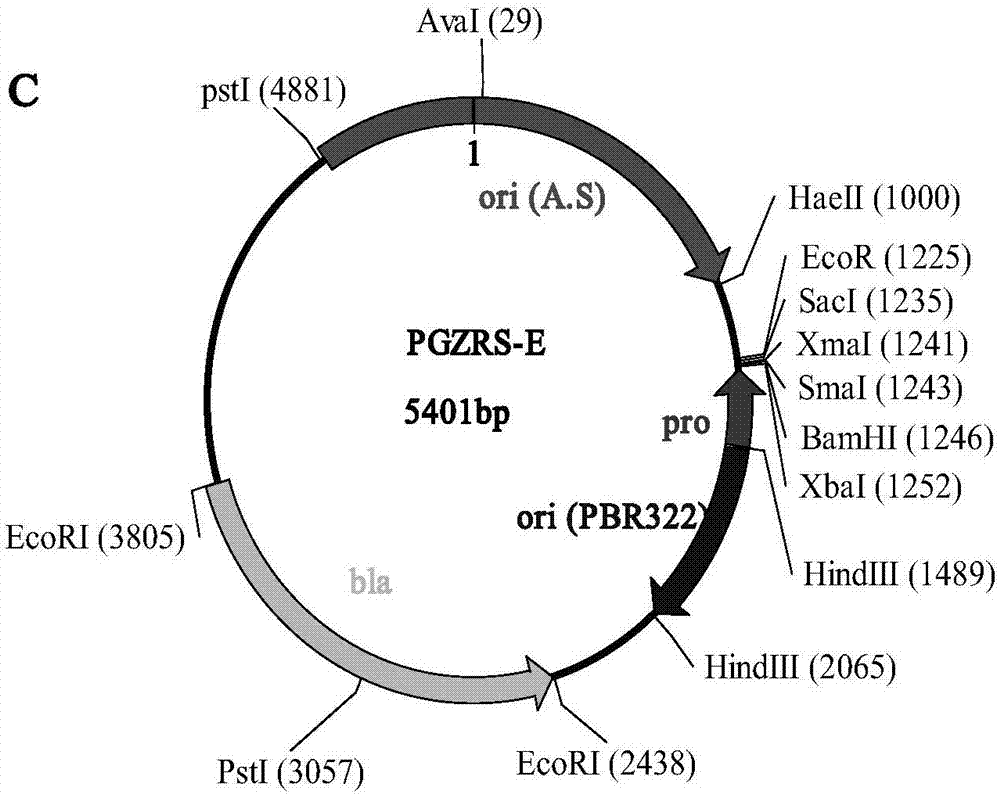

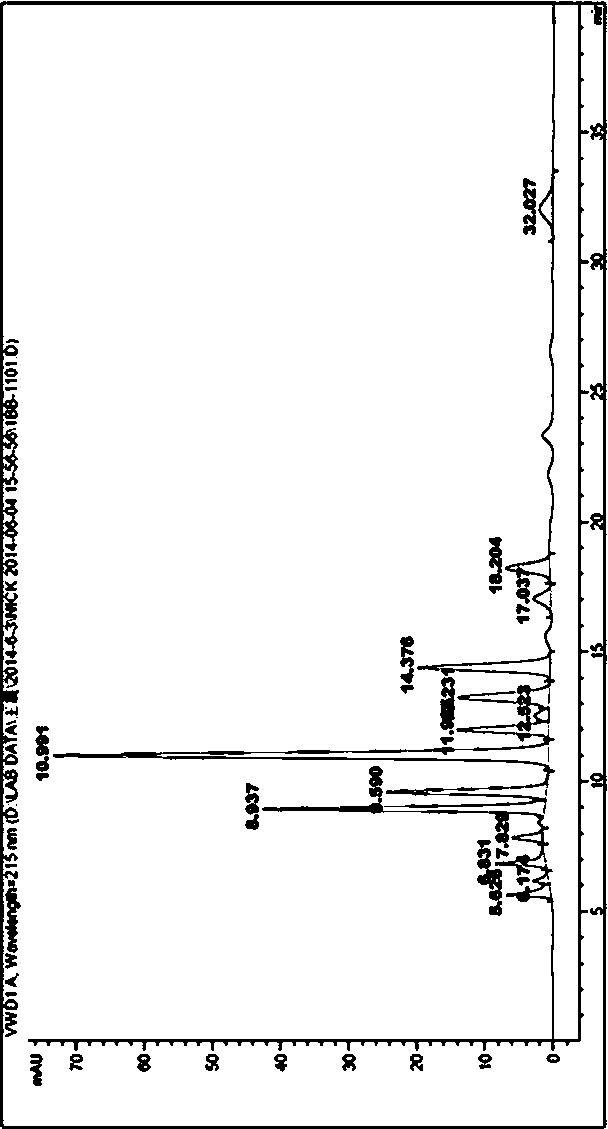

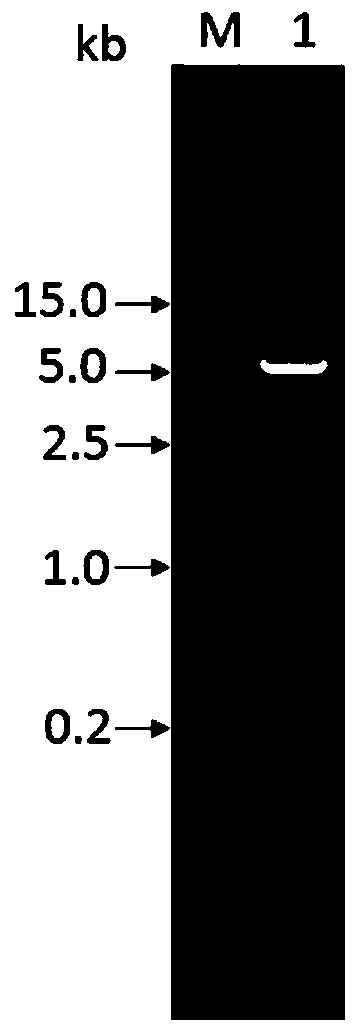

Actinobacillus succinogenes PZ improving yield of succinic acid, and construction method and application thereof

ActiveCN106995794AIncrease productionHigh activityBacteriaTransferasesMicrobiologyRate limiting enzyme

The invention provides an actinobacillus succinogenes PZ improving yield of succinic acid, and a construction method thereof. The construction method comprises the steps of constructing an expression carrier, constructing recombinant plasmid and constructing the actinobacillus succinogenes PZ. The actinobacillus succinogenes starting strain is connected in series with and expressed excessively by gene pepck of a key rate-limiting enzyme, PEPCK, for generating succinic acid by using the actinobacillus succinogenes, and gene zwf of G6PDH improving the restoring force level in a body, so as to acquire the actinobacillus succinogenes PZ. The actinobacillus succinogenes PZ can improve the yield of succinic acid, and has the potential of industrial production application.

Owner:GUANGXI ACAD OF SCI

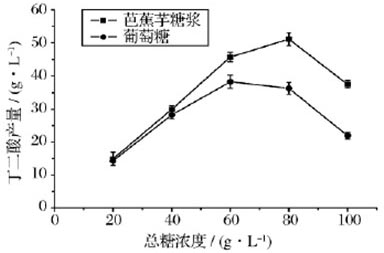

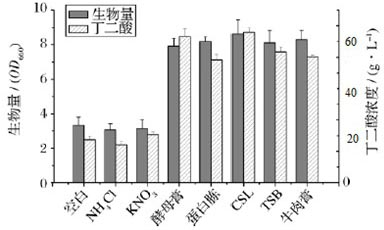

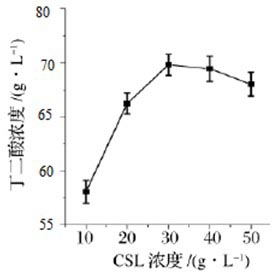

Method for producing succinic acid by utilizing fermentation of actinobacillus succinogenes

The invention provides a method for producing succinic acid by utilizing fermentation of actinobacillus succinogenes. The method includes taking canna edulis ker syrup as a main material, producing the succinic acid by using the fermentation of actinobacillus succinogenes CICC11014, determining the optical fermentation medium for bacterial strains through research for medium of bacterial strains; and fermenting the medium after optimization, wherein the medium comprises 89.66g / L of canna edulis ker syrup (by total suger), 38.55g / L of CSL, 2.23g / L of Na2HPO4*12(H2O), 2.23g / L of KH2PO4*3(H2O),60g / L of MgCO3, and 6.5 of the pH; and performing moist heat sterilization at a temperature of 115 DEG C for 20 minutes. The conversion rate of sugar can be improved through fermentation under the optical medium condition, so that the yield of the succinic acid can reach 70g / L.

Owner:苏州百趣食品有限公司

Infectious actinobacillus pleuropneumoniae and application thereof

ActiveCN107201326AHigh proliferative titerStrong pathogenicityAntibacterial agentsBacteriaDiseaseBacteroides

The invention discloses an infectious actinobacillus pleuropneumoniae and application thereof. The infectious actinobacillus pleuropneumoniae is an actinobacillus pleuropneumoniae HNAPP1 with a preservation number of CGMCC NO:13333 and preserved on November 22, 2016 in the China General Microbiological Culture Collection Center (3#, 1# Yard, West Beichen road, Chaoyang District, Beijing). The strain HNAPP1 provided by the invention is separated from a heart of an acute-death fattening pig with typical dyspnea, no other bacteria grow but only the infectious actinobacillus pleuropneumoniae grows during separation on a TSA solid culture medium, and the proliferation titer in a TSB liquid culture medium is high and reaches 109 CFU / mL or above. The strain HNAPP1 in the invention has strong pathogenicity for nursery pigs to cause diseases and death to the nursery pigs, and has high immunogenicity.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY MEDICINE HENAN ACAD OF AGRI SCI

Strain and method for producing succinic acid by fermenting xylose mother liquor

ActiveCN106801026AEfficient resource utilizationSave foodBacteriaMicroorganism based processesHigh concentrationProduction rate

The invention discloses a strain and a method for producing succinic acid by fermenting xylose mother liquor. The strain is actinobacillus succinogenes PZ, and has a preservation number of CCTCC (China Center For Type Culture Collection) No: M2016396. The actinobacillus succinogenes can be used for producing the succinic acid by fermenting the high-concentration xylose mother liquor; the maximum yield of the succinic acid can reach 95g / L, and the maximum production rate of the succinic acid is 85%. The method provided by the invention is low in cost, high in yield and simple in technology, realizes the efficient resource utilization of the xylose mother liquor, and has great significance on resource optimization and environmental protection.

Owner:GUANGXI ACAD OF SCI

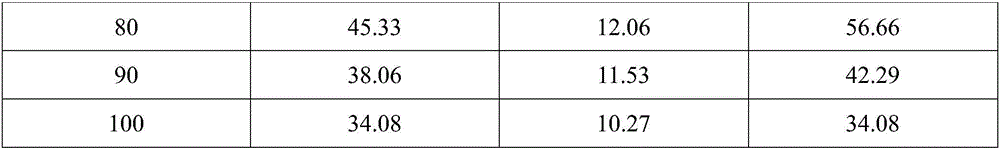

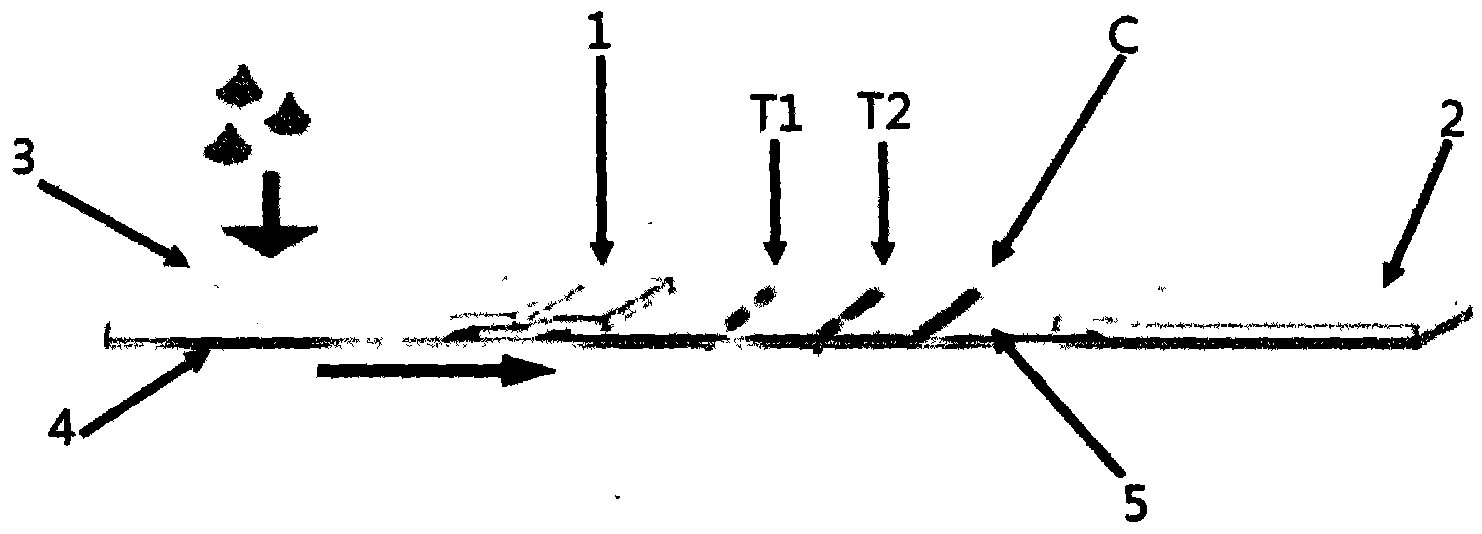

Preparation method of test strip for rapidly diagnosing porcine contagious pleuropneumonia actinobacillus

InactiveCN103777018AQuick checkStrong specificityBiological material analysisMonoclonal antibodyQuality control

The invention discloses a preparation method of a test strip for rapidly diagnosing hematoxin ApxI arranged outside porcine contagious pleuropneumonia actinobacillus, and relates to the technical field of rapid biological detection. The test strip comprises an analyzing film (5) and a gold-labelled antibody combining pad (1), wherein a detection line 1 (T1) and a detection line 2 (T2) are made from an actinobacillus-resisting exotoxin ApxI / ApxIV monoclonal antibody arranged on the analyzing film (5), a quality control line (C) is made from a goat anti rabbit IgG, and the gold-labelled antibody combining pad (1) is a fusion protein anti rabbit polyclonal antibody of p380-ApxI-ApxIV. The preparation method provided by the invention solves the problems that the inspection speed is slow, the sensitivity is low, the operation is complicated and the like in the prior art.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

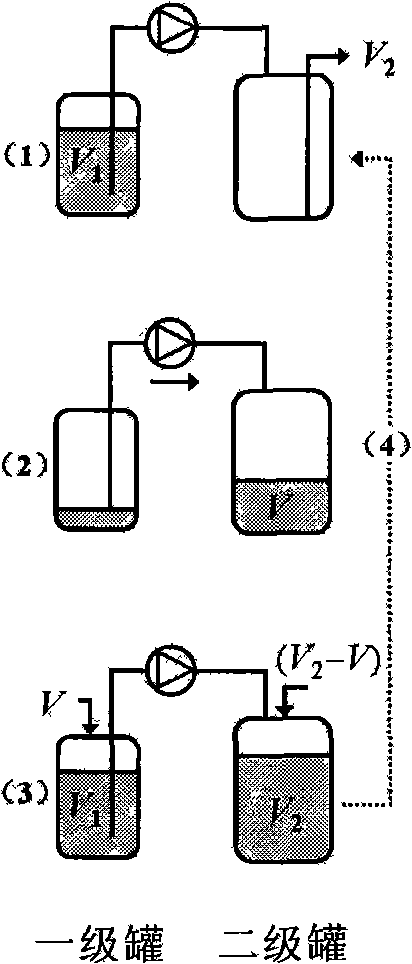

Method for producing succinic acid by multistage continuous fermentation

InactiveCN104372037AIncrease productionSimple methodMicroorganism based processesFermentationBiotechnologyContinuous fermentation

The invention relates to a method for producing succinic acid by multistage continuous fermentation, which comprises the following steps: 1. preparing a seed culture medium, an initial fermentation culture medium, a carbon source supplementation tank culture solution and a culture medium supplementation tank culture solution; 2. sterilizing the cascade fermentation tank set, carbon source supplementation tank, culture medium supplementation tank, seed culture medium, initial fermentation culture medium, carbon source supplementation tank culture solution, culture medium supplementation tank culture solution and serum bottle; 3. taking the sterilized serum bottle, inoculating the sterilized seed culture medium, introducing CO2, inoculating the Actinobacillus succinogenes NJ113-producing oscillating table, and culturing to obtain a fermentation strain; and 4. carrying out multistage continuous fermentation. The production method is simple, has the advantage of high yield and purity of succinic acid, and thus, is suitable for industrialized production.

Owner:NANJING TECH UNIV

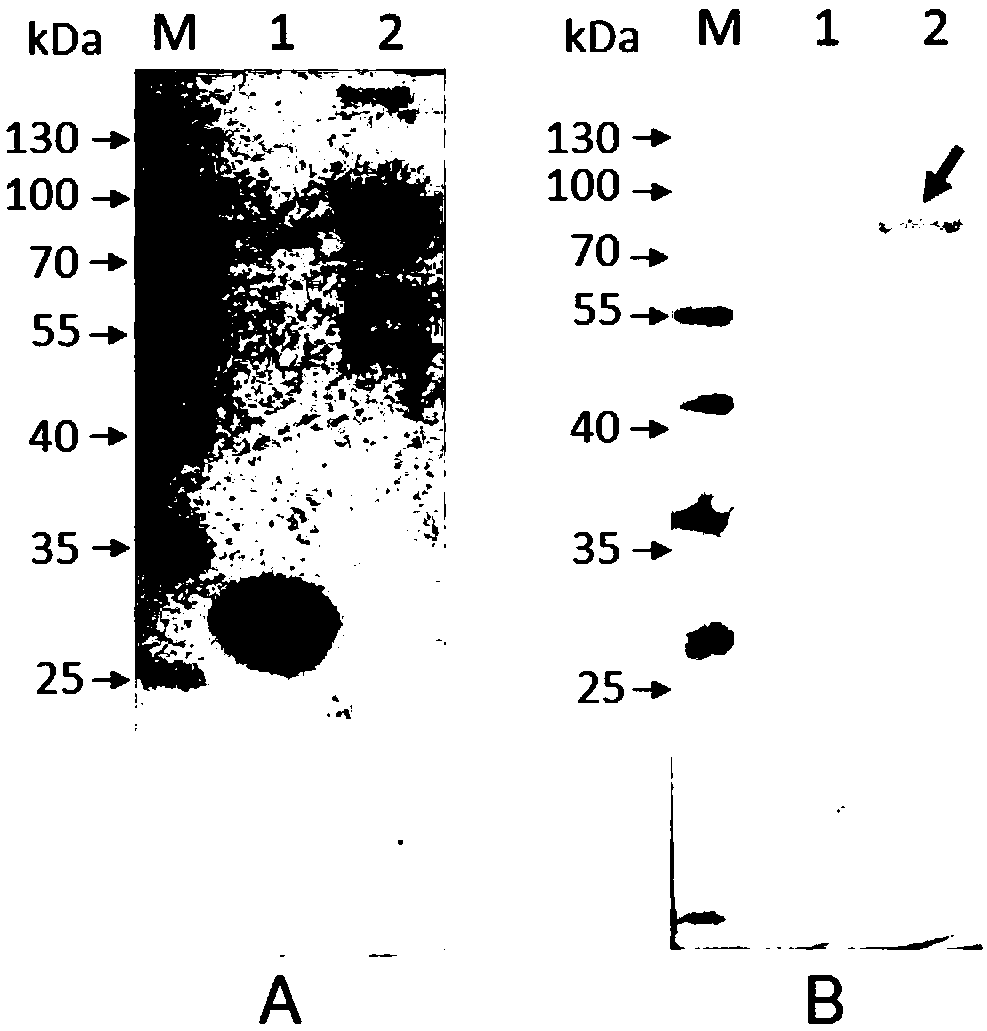

Immunoprotective antigen protein APJL_1380 for actinobacillus pleuropneumoniae and application thereof

ActiveCN108794584AImproving immunogenicityImprove protectionAntibacterial agentsBacterial antigen ingredientsProtective antigenActinobacillus pleuropneumoniae antibody

The invention discloses immunoprotective antigen protein APJL_1380 for actinobacillus pleuropneumoniae and application thereof. An amino acid sequence of the immunoprotective antigen protein for the actinobacillus pleuropneumoniae is shown in SEQ ID NO.1. The immunoprotective antigen protein consists of 273 amino acids, and the matured polypeptide part has amino acids at the 25th to 582nd sites; anucleotide sequence for coding the immunoprotective antigen protein is shown in SEQ ID NO.2. The immunoprotective antigen protein has the advantages that the immunogenicity is good, and the immunoprotective function is strong; the immunoprotective antigen protein can be applied to preparation of kits for detecting actinobacillus pleuropneumoniae antibodies, preparation of swine pleuropneumoniae sub-unit vaccines, and preparation of medicines for preventing diseases caused by the actinobacillus pleuropneumoniae; a novel material is provided for the preparation of the swine pleuropneumoniae sub-unit vaccines, and the important meaning is realized in the preventing and treatment of the swine pleuropneumoniae.

Owner:HUAZHONG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com