Patents

Literature

49results about How to "Potential for industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel N-acetylneuraminic acid-producing escherichia coli engineering bacteria as well as construction method and application thereof

ActiveCN103602627AEnhanced rate-limiting enzyme gene expressionPrevent backflowBacteriaMicroorganism based processesEscherichia coliPhosphate

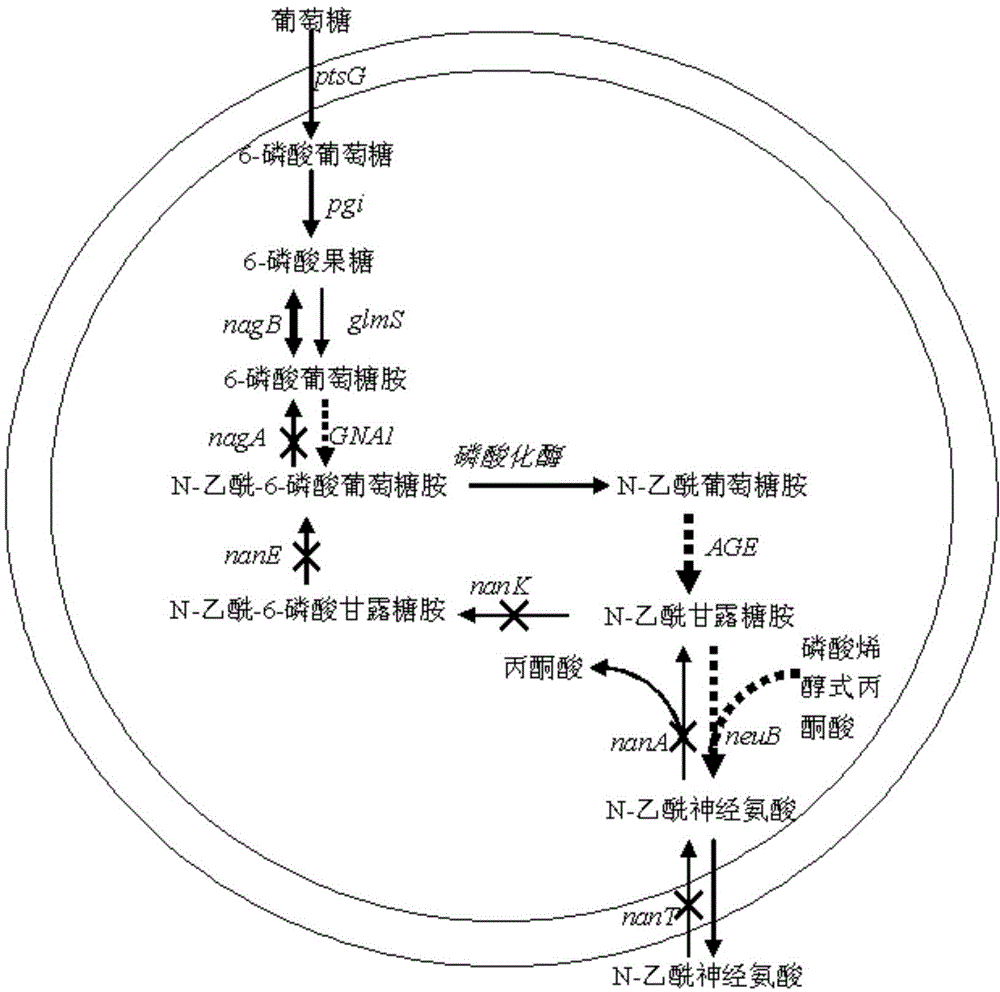

The invention discloses novel N-acetylneuraminic acid-producing escherichia coli engineering bacteria as well as a construction method and application thereof. The engineering bacterial is constructed by introducing an encoded 6-glucosamine phosphate acetylase gene, an N-acetyl glucosamine-2-isomerase gene and an N-acetylneuraminic acid synthetase gene into escherichia coli to express, carrying out strengthened expression on 6-glucosamine phosphate deaminase gene contained in the escherichia coli per se and knocking off genes, for decomposing and utilizing enzyme in metabolic pathways, of the N-acetylneuraminic acid in the engineering bacteria. The engineering bacteria disclosed by the invention can be used for fermentation culture to synthesize the N-acetylneuraminic acid by using glucose or glycerinum as a substrate.

Owner:武汉中科光谷绿色生物技术有限公司

Adsorptive catalyst and preparation method and application thereof as well as air purification device, and air purification method and application thereof

ActiveCN104941571AGood catalytic purification effectSimple processDispersed particle filtrationOther chemical processesPorous channelActive component

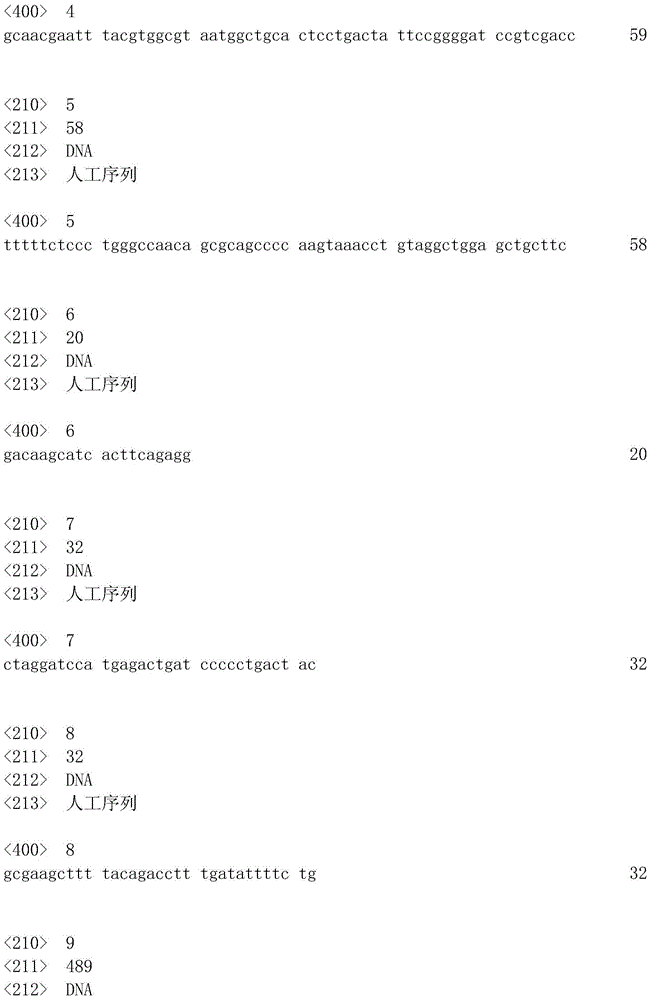

The invention relates to the field of air purification, and particularly provides an adsorptive catalyst, and a preparation method and application thereof. The adsorptive catalyst comprises a structured carrier and a coating distributed on the inner surface and / or outer surface of the structured carrier; the total weight of the coating is standard, and the coating comprises 50-95% by weight of hydrophobic silica and 5-50% by weight of catalytically active components capable of oxidizing gaseous pollutants. The invention further provides an air purification device, and an air purification method and application thereof. The adsorptive catalyst provided by the invention can enhance the adsorption and diffusion processes of the gaseous pollutants, especially non-polar gaseous pollutants, in porous channels of the adsorptive catalyst to realize an excellent catalytic purification effect, and is particularly suitable for catalytic purification reactions under high-moisture and high-humidity working conditions. The preparation method is simple in process and low in cost and has the industrial production potential.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

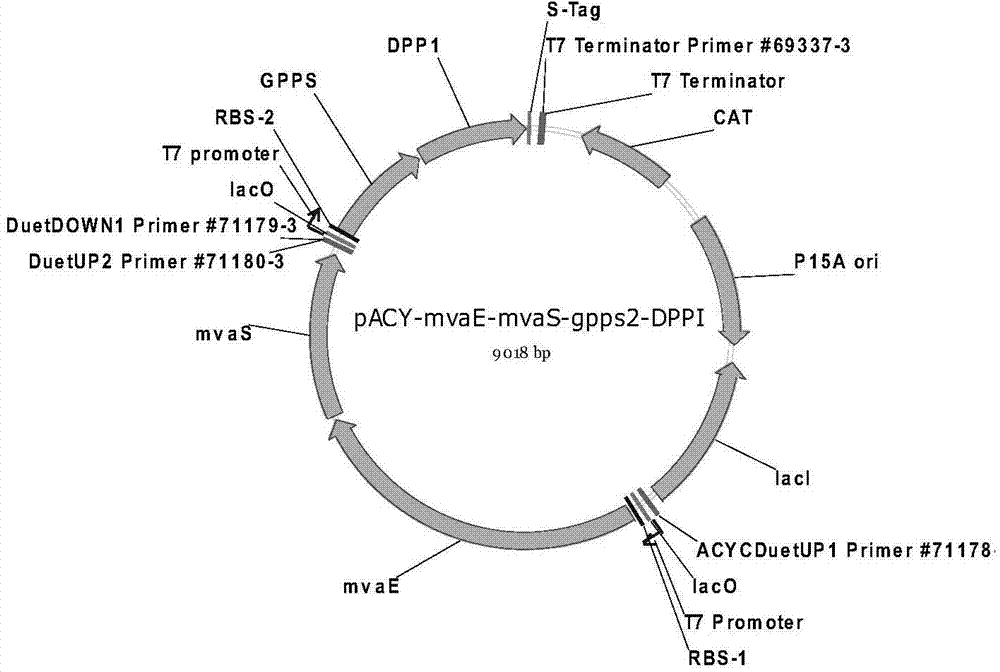

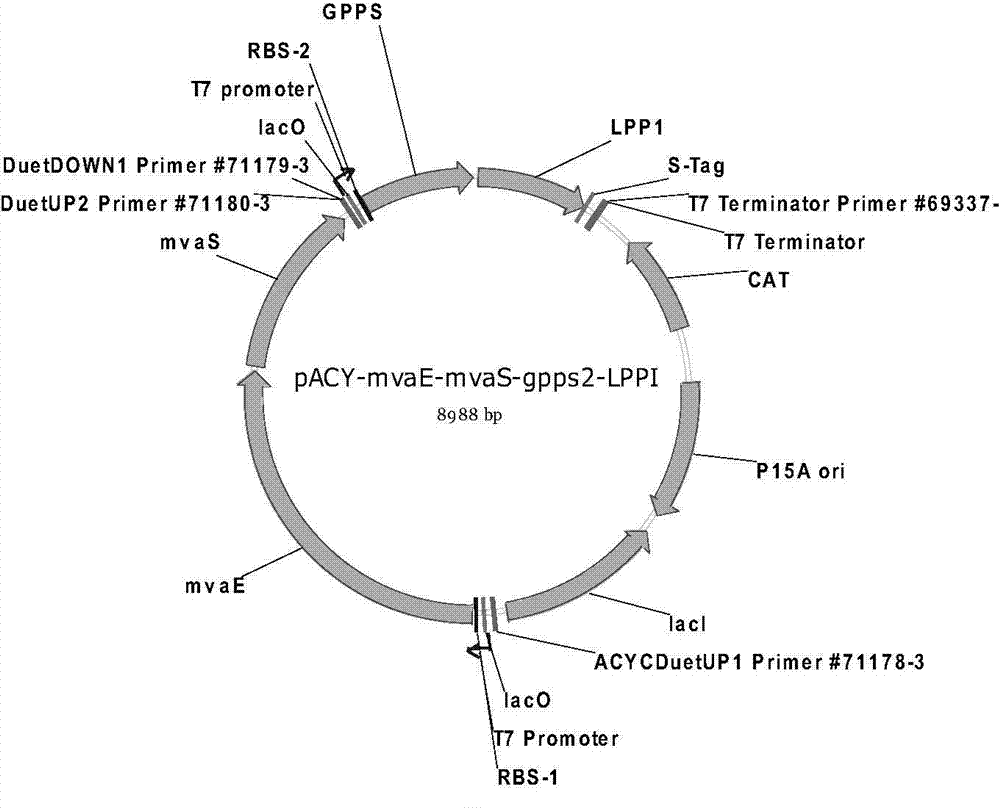

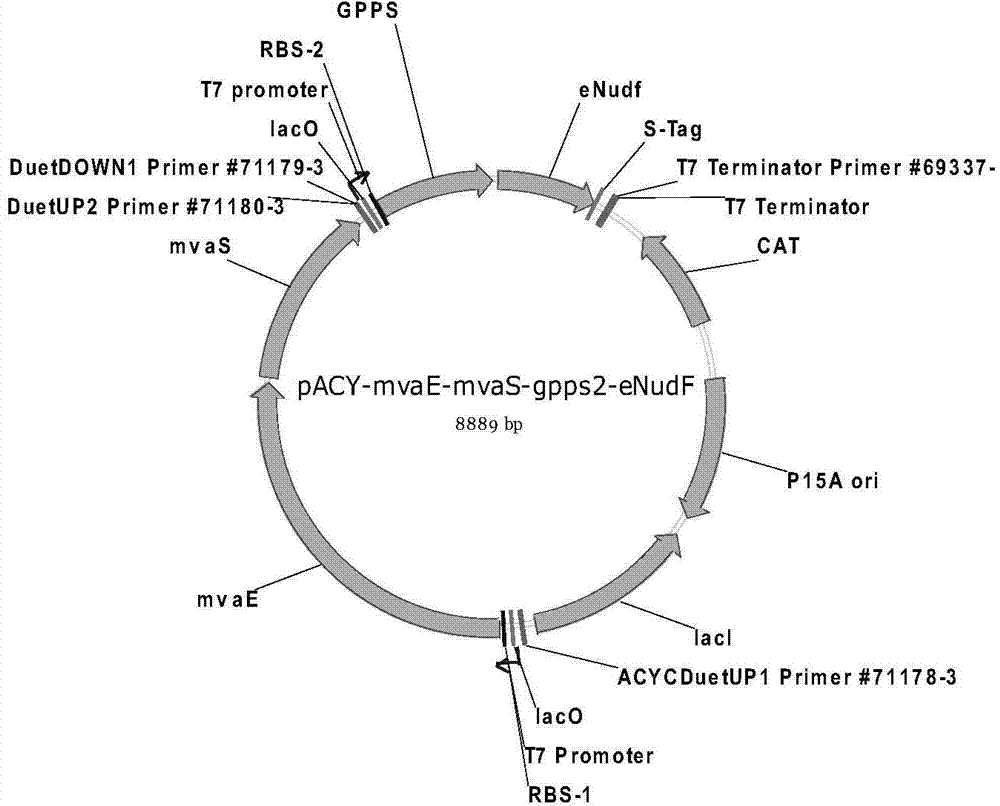

Genetically engineered bacterium co-generating geraniol and nerol and construction method and application thereof

ActiveCN103898037AFast growthShort fermentation cycleBacteriaMicroorganism based processesEscherichia coliGenetically engineered

The invention discloses a genetically engineered bacterium co-generating geraniol and nerol and a construction method and an application thereof, and belongs to the technical field of generic field. According to the genetically engineered bacterium disclosed by the invention, acetyl coenzyme A acyltransferase / hydroxymethyl glutaryl coenzyme A reductase, 3-hydroxyl-3-methyl glutaryl coenzyme A synthase, mevalonic acid kinase, mevalonic acid-5-phosphokinase, mevalonic acid-5-diphosphonic acid decarboxylase, isopentenylpyrophosphate isomerase, geranyl diphosphonic acid synthetase and geraniol synthetase or phosphatase are expressed. The metabolic pathways of geraniol and nerol synthesized in escherichia coli are successfully constructed by genetic engineering means, and glucose is biologically converted into geraniol and nerol.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

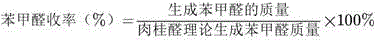

Preparation method of natural benzaldehyde by ozone collaborative heterogeneous catalysis of cinnamaldehyde or cinnamon oil

ActiveCN105601481AIncrease profitGood choicePreparation by ozonolysisMetal/metal-oxides/metal-hydroxide catalystsDistillationBenzaldehyde

The invention discloses a preparation method of natural benzaldehyde by ozone collaborative heterogeneous catalysis of cinnamaldehyde or cinnamon oil. The method is as below: adding 0.5%-10% of aNiO, BaO, MgO, La2O3, SnO2 binary or ternary oxide component catalyst into a raw material cinnamic aldehyde or cinnamon oil, introducing ozone in a bubble reactor under conditions of atmospheric pressure temperature of -10 to 30 DEG C and flow rate of 0.1-5 g / L, and reacting at low temperature for 1-8 h to obtain a benzaldehyde crude product; and finally, using a molecular distillation apparatus to obtain high-purity natural benzaldehyde. The invention has the advantages of simple process, convenient operation, no toxicity or harm of the catalyst, environment-friendliness; the cinnamaldehyde is fully utilized; and the benzaldehyde has good selectivity, high yield, and natural degree intact.

Owner:广西庚源香料有限责任公司

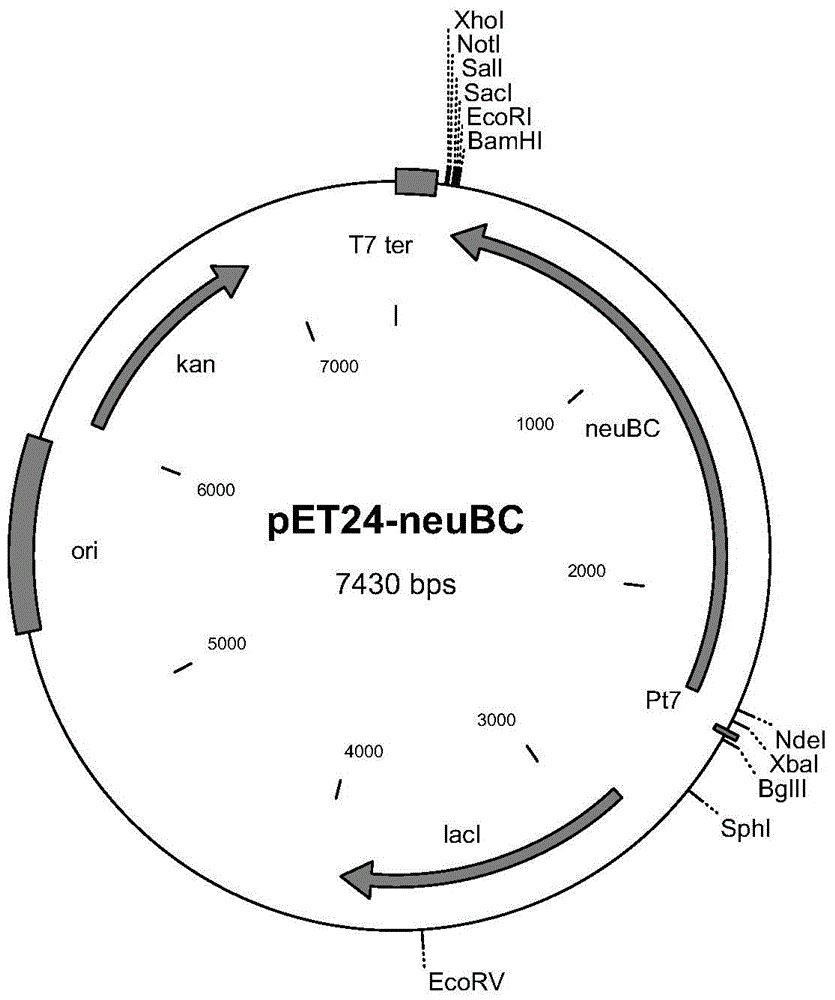

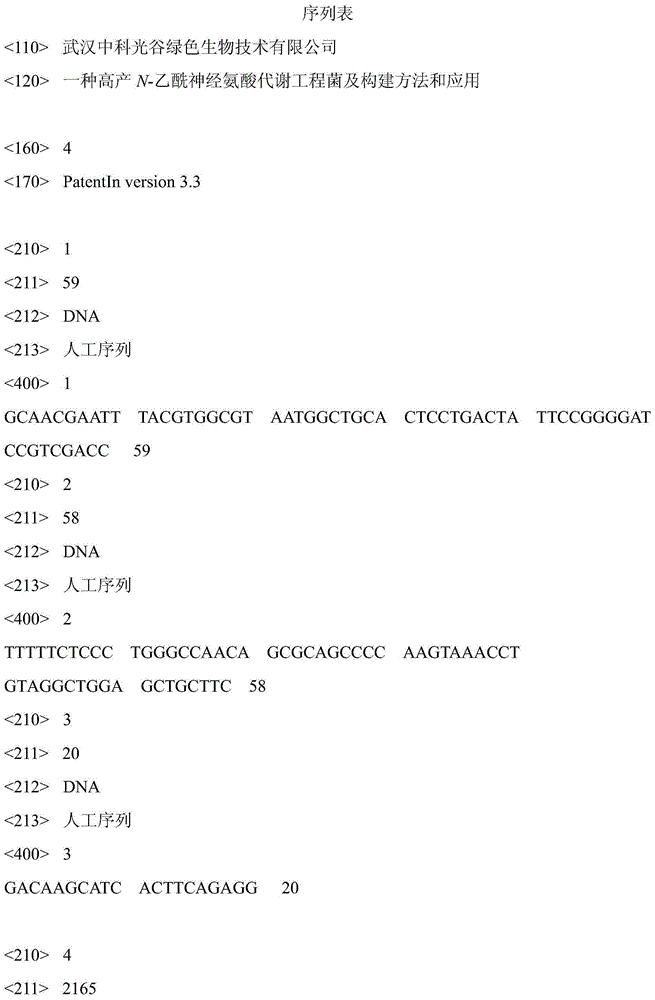

High-yield N-acetylneuraminic acid metabolic engineering bacterium and construction method and application

InactiveCN104988108AHigh synthesis efficiencyAvoid consumptionBacteriaMicroorganism based processesEscherichia coliGlycerol

The invention discloses a high-yield N-acetylneuraminic acid metabolic engineering bacterium and a construction method and application. According to the engineering bacterium, the activity of coded UDP-N-acetylglucosamine epimerase and N-acetylneuraminic acid synthetase gene enzyme is enhanced by expressing the two enzymes in Escherichia coli through a T7 strong promoter, and the recombinant Escherichia coli is constructed by removing genes of an N-acetylneuraminic acid decomposition pathway enzyme in the Escherichia coli; and a constructed engineered strain utilizes glucose or glycerinum as a substrate for fermentation cultivation to generate N-acetylneuraminic acid. The engineering bacterium utilizes glucose or glycerinum for synthesizing the N-acetylneuraminic acid, so that the fermentation level is high, the accumulated by-products are few, and the engineering bacterium has the industrial potential.

Owner:武汉中科光谷绿色生物技术有限公司

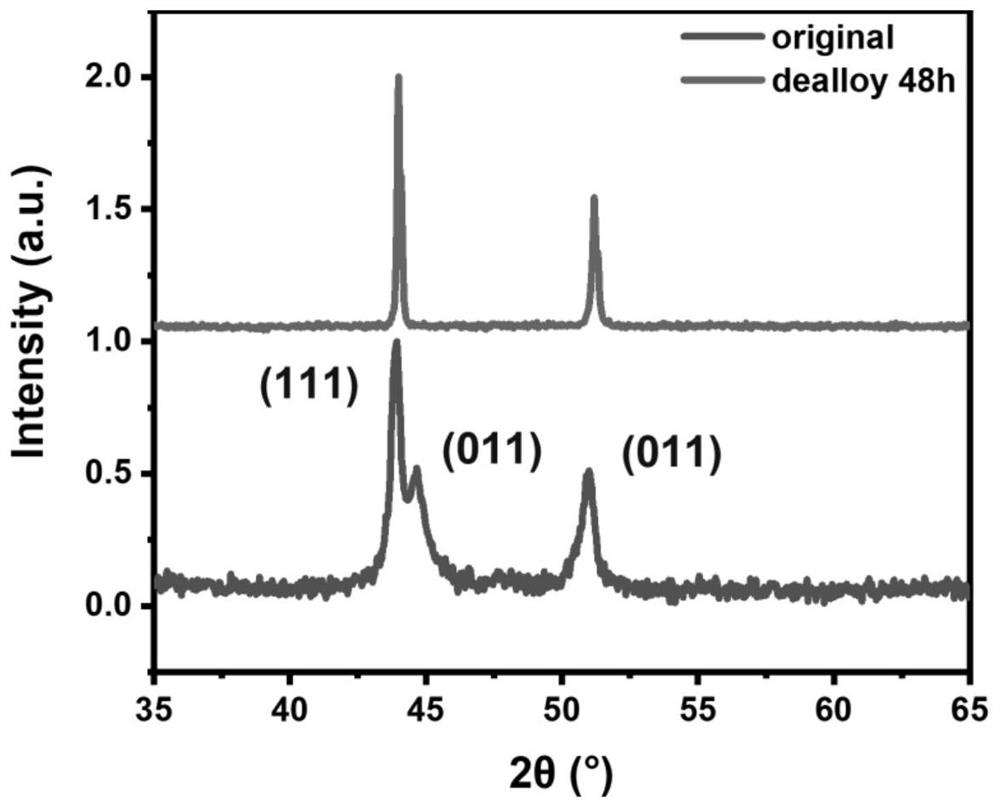

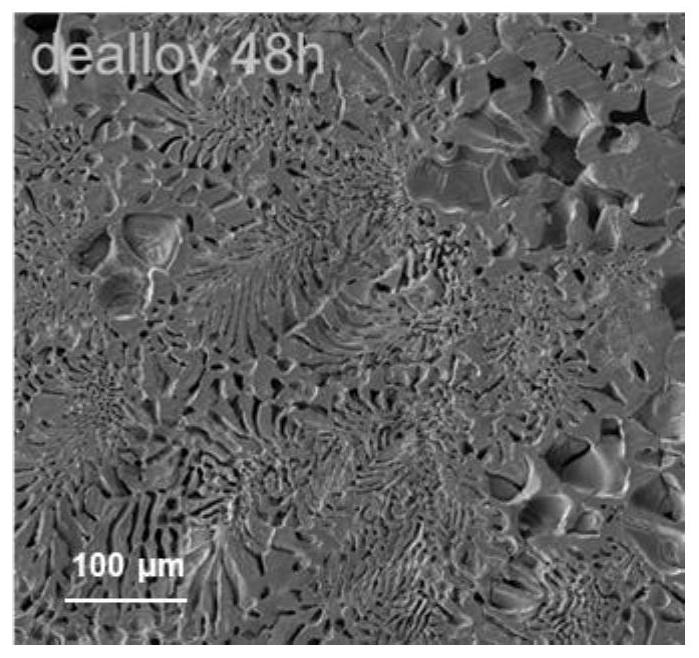

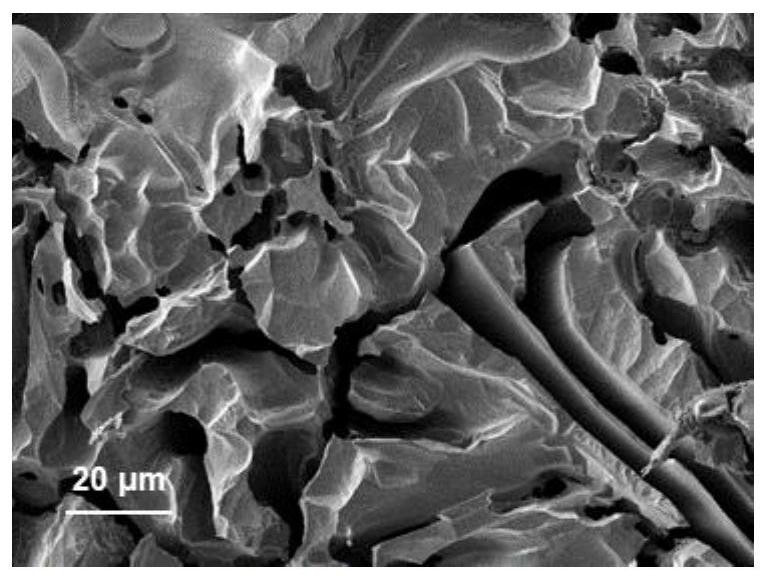

Porous high-entropy alloy self-supporting electrode for electrolyzing water and preparation method thereof

ActiveCN112725818AExcellent decomposabilityLow costNon-noble metal oxide coatingsHigh entropy alloysSurface oxidation

The invention discloses a porous high-entropy alloy self-supporting electrode for electrolyzing water and a preparation method thereof. The preparation method comprises the following steps: smelting, mixing and melting nickel powder, cobalt powder, chromium powder, iron powder, aluminum powder and tungsten powder, and conducting cooling to form a high-entropy alloy with an eutectic structure; cutting the high-entropy alloy into an alloy sheet, and conducting polishing to remove surface oxide skins; then carrying out dealloying treatment; and after dealloying treatment is completed, taking out the alloy sheet and carrying out ultrasonic treatment so as to obtain the self-supporting electrode. The invention provides a simple, efficient and controllable dealloying means for treating the high-entropy alloy sheet to obtain the sheet-shaped high-entropy alloy self-supporting catalytic electrode with a multi-scale pore structure, and the sheet-shaped high-entropy alloy self-supporting catalytic electrode is proved to have excellent electro-catalytic hydrogen evolution / oxygen evolution reaction activity and stability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

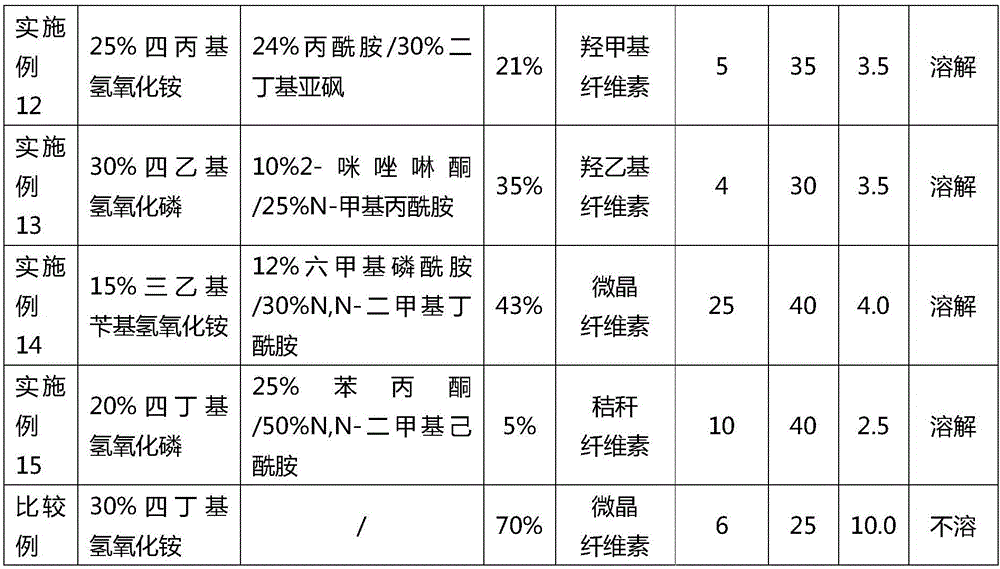

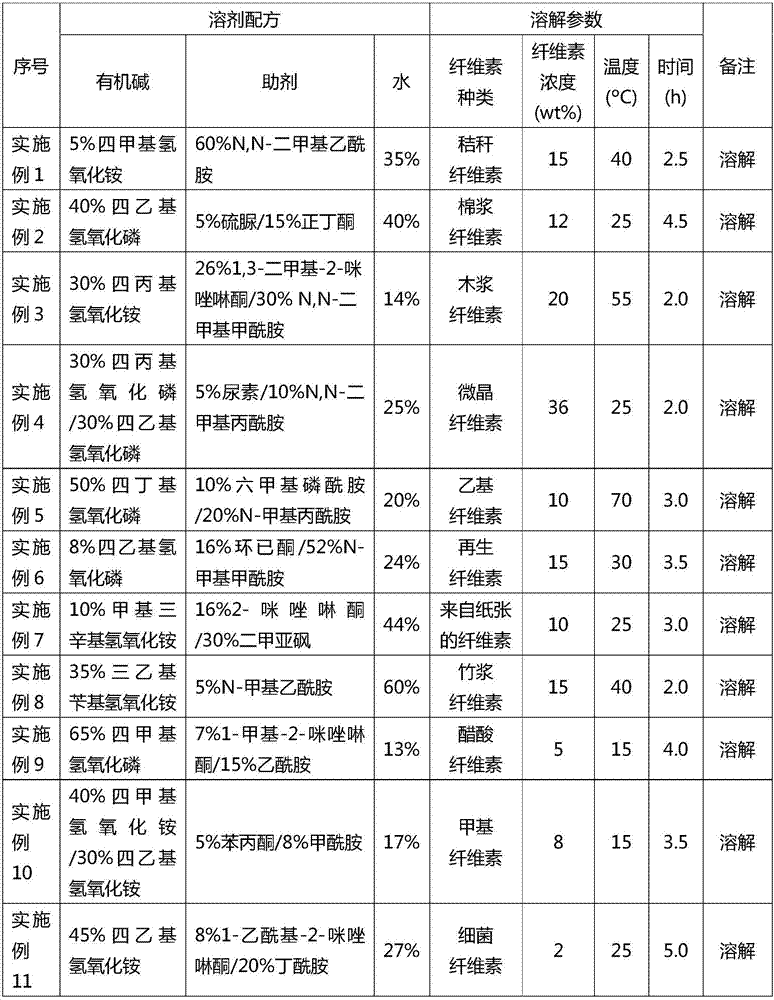

Method for preparing cellulose solution

The invention discloses a method for preparing a cellulose solution.According to the basic technical principle of the method, the wetting property of a solvent on natural cellulose crystals is improved with the amphipathicity of the cellulose solvent so that dissolution of cellulose can be promoted.Based on the principle, the invention provides a room-temperature mild dissolution technical method for cellulose.The method has the advantages that the technology is simple, room-temperature dissolution is achieved, and the method is environmentally friendly and not sensitive to the moisture content of a system.The cellulose solvent is prepared from, by weight, 5-70% of organic base, 2-90% of an assistant and 1-65% of water.Cellulose and the cellulose solvent are blended to form a blend, stirring is carried out until complete dissolution, and the target cellulose solution is obtained.The cellulose solution prepared with the method is used for manufacturing regenerated cellulose membranes or regenerated cellulose fibers or cellulose-base composites.

Owner:SOUTHWEST JIAOTONG UNIV

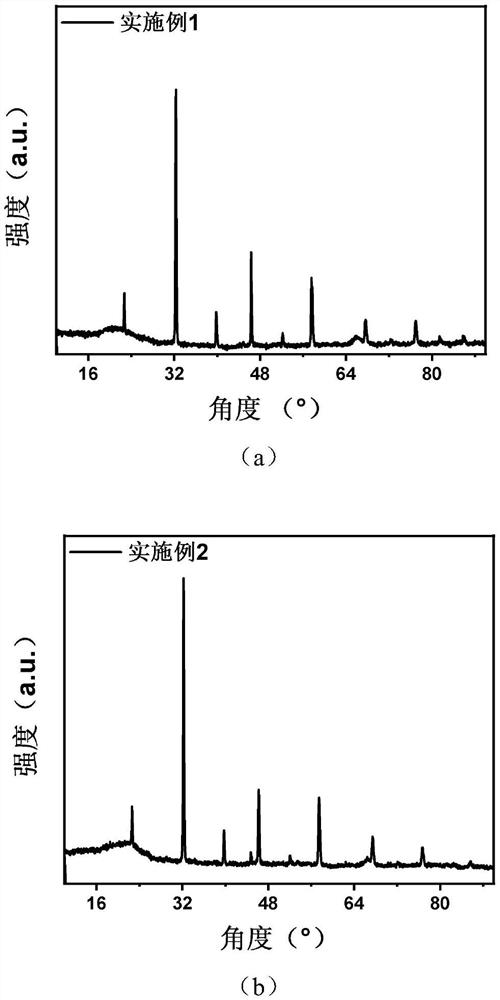

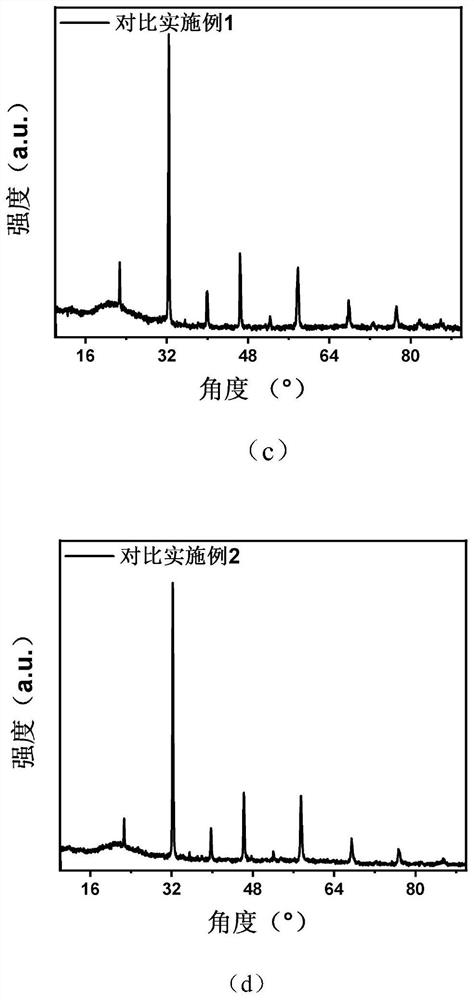

Method for producing sodalite pure phase with shale ash

InactiveCN101492167ALow costRich sourcesSolid waste disposalCrystalline aluminosilicate zeolitesMolecular sieveThermal treatment

The invention discloses a method for preparing a sodalite pure phase by taking oil shale ash as a raw material, and belongs to the field of production and preparation of inorganic functional materials. The method is characterized by comprising the following steps: firstly determining contents of SiO2 and Al2O3 in the oil shale ash raw material, sieving the oil shale ash by a sieve, and drying the oil shale ash in an oven; after drying, evenly mixing the oil shale ash with NaOH and deionized water, and stirring the mixture electromagnetically at normal temperature, wherein the proportion of a reaction raw material formulation is as follows: the proportion of H2O to Na2O is equal to 5.0-7.8, and the proportion of the Na2O to the SiO2 is equal to 2.5-7.0; transferring the materials into a reaction kettle, and crystallizing the materials at constant temperature; and finally, filtering, washing and drying the product to obtain the sodalite pure phase. The method has the advantages of preparing a sodalite molecular sieve pure phase from the low-cost raw material oil shale ash. The pretreatment for the oil shale ash is simple, has no redundant heat treatment and acid treatment, and saves energy; and the preparation flow has no alkali fusing process, simple process, easy operation, and friendly environment.

Owner:DALIAN UNIV OF TECH

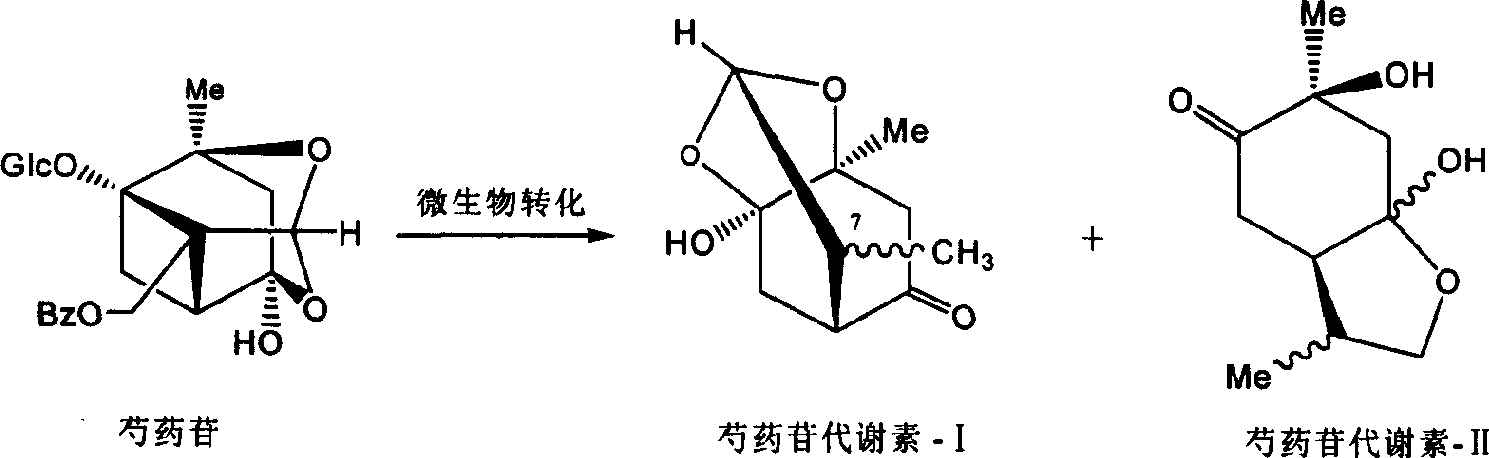

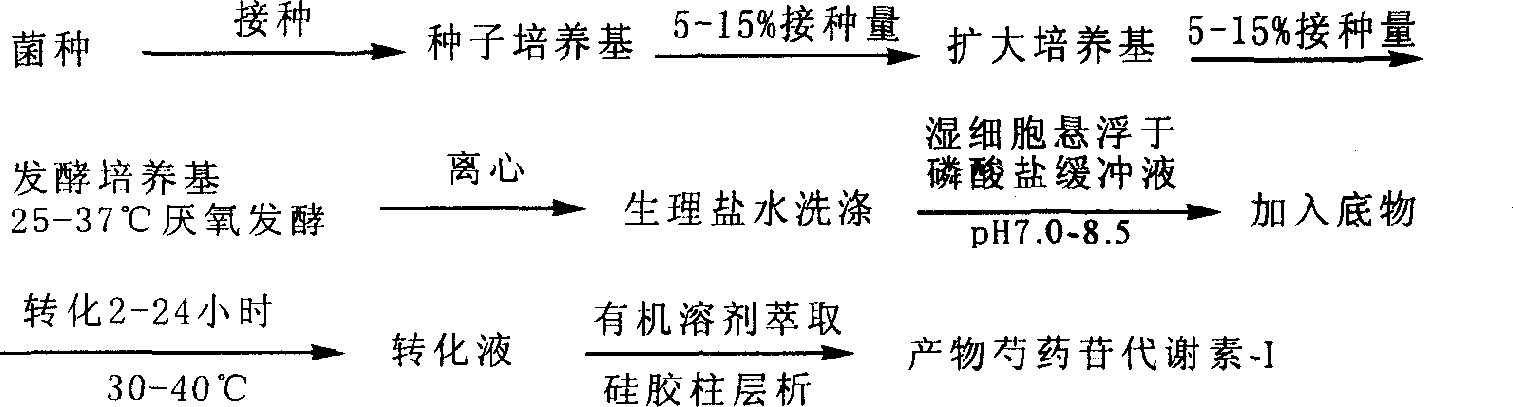

Method for producing paeonin metabolite-I by short lactobacillin fermentation

InactiveCN101074447AEasy to operateThe separation method is matureOrganic active ingredientsAntipyreticMetabolitePhosphate

A method for producing paeonoside metabolic hormone-I by fermenting short Lactobacillus is carried out by inducing L.brevis AS 1.12 into culture medium with tomato juice 200g / L, protein peptone 7.5g / L, yeast paste 7.5g / L, glucose 10g / L, Tween-80 0.3 ml / L and pH=7.0-8.5, anaerobic culturing at 25-37 degree for 12-24 hrs, centrifugal collecting bacterial cells, washing by normal saline, centrifuging, dispersing obtained cells into buffer liquid of 0.05M phosphate, adding into substrate paeonoside or its analogs hydroxy-paeonoside or methyl-paeonoside or benzoyl-paeonoside or mixture of paeonoside and its analogs, converting at 30-40 degree for 2-24 hrs, extracting by ethyl acetate, drying concentrated extract to obtain concrete, chromatographying by silica-gel column to obtain final product. It's simple, cheap, efficient, fast and controllable and has friendly environment. It can be used for anti-inflammatory, stress ulcer, analgesic and antispasmodic, ecstatic coronary blood vessel, myocardial ischemia and platelet aggregation-inhibition.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

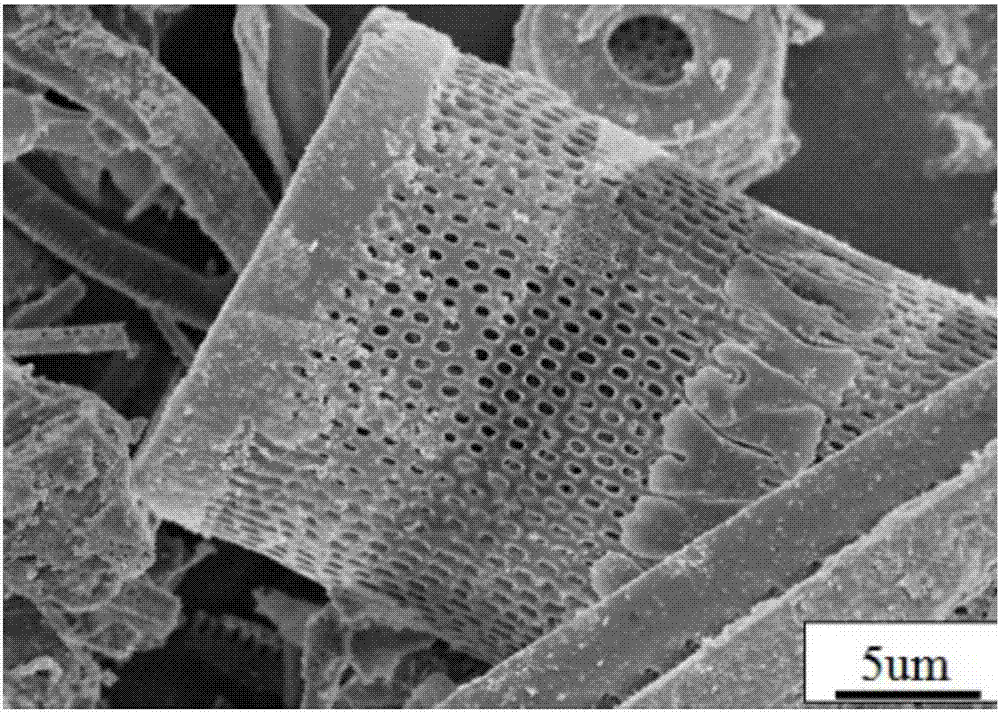

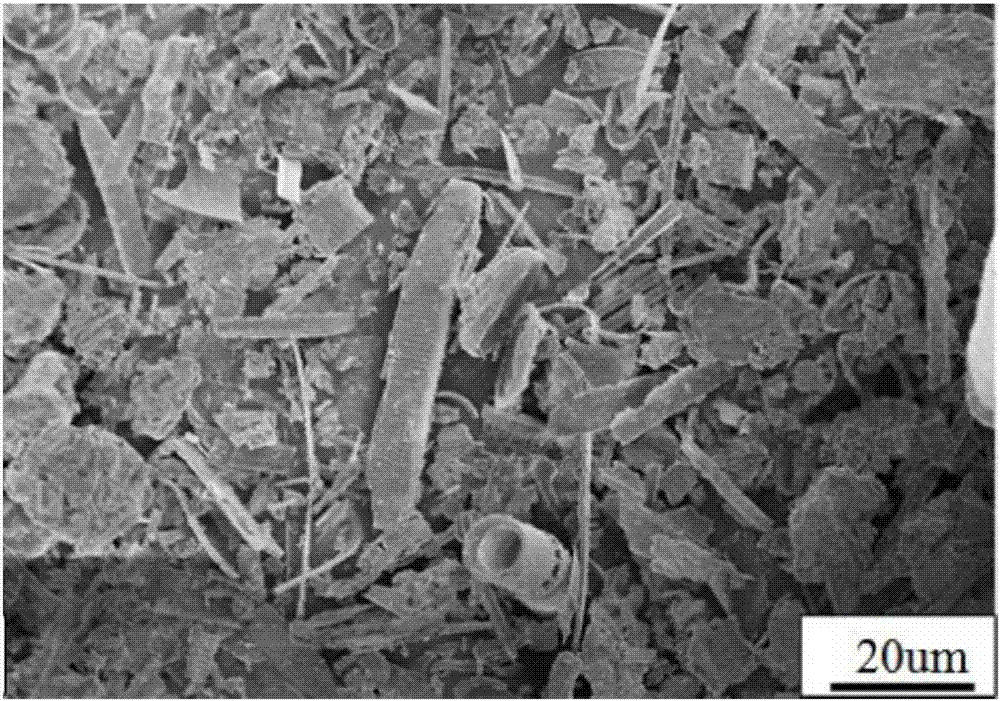

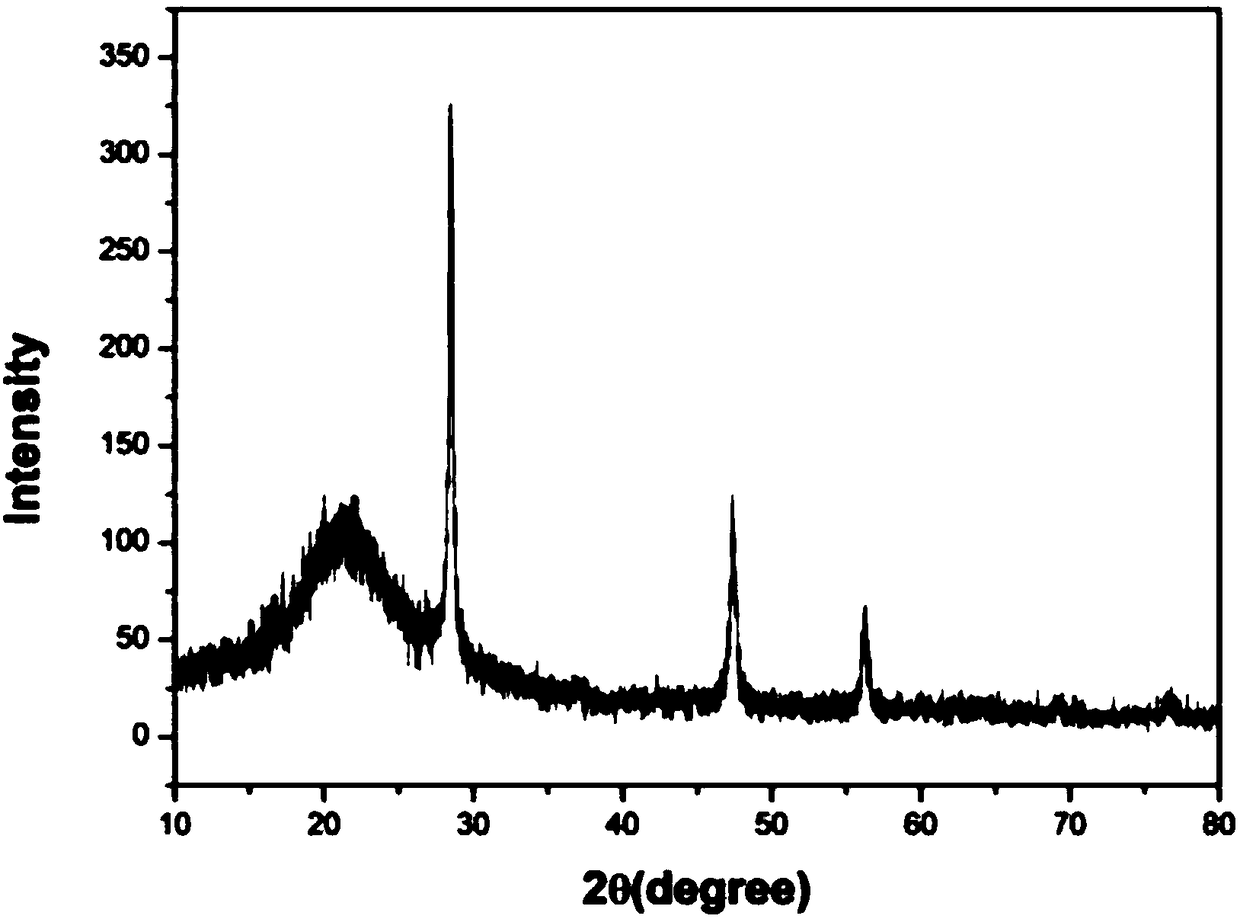

Method for preparing mordenite by using diatomite

InactiveCN103787364ARich sourcesThe pre-processing process is simpleChemical industryMordenite aluminosilicate zeoliteMordenitePre treatment

The invention discloses a method for preparing mordenite by using diatomite and belongs to the field of production and preparation of inorganic functional materials. The method is characterized by comprising the following steps of: firstly determining the content of SiO2 and Al2O3 in a diatomite raw material, screening through a screen, and then drying in a drying box; uniformly mixing the dried diatomite raw material with deionized water and water glass, wherein the proportion of reaction raw materials in the formula is as follows: H2O / Na2O=8-11, Na2O / SiO2=0.05-0.30, SiO2 / Al2O3=12-16; transferringthe material into a reaction kettle, and crystallizing at constant temperature; finally filtering, washing and drying the product to obtain the mordenite. According to the method disclosed by the invention, mordenite is prepared from the low-cost raw material diatomite; few diatomite pretreatment steps are carried out; and the energy source is saved through use of direct hydrothermal method synthesis. The preparation process has the advantages of simple process, easy operation and environmental friendliness.

Owner:DALIAN UNIV OF TECH

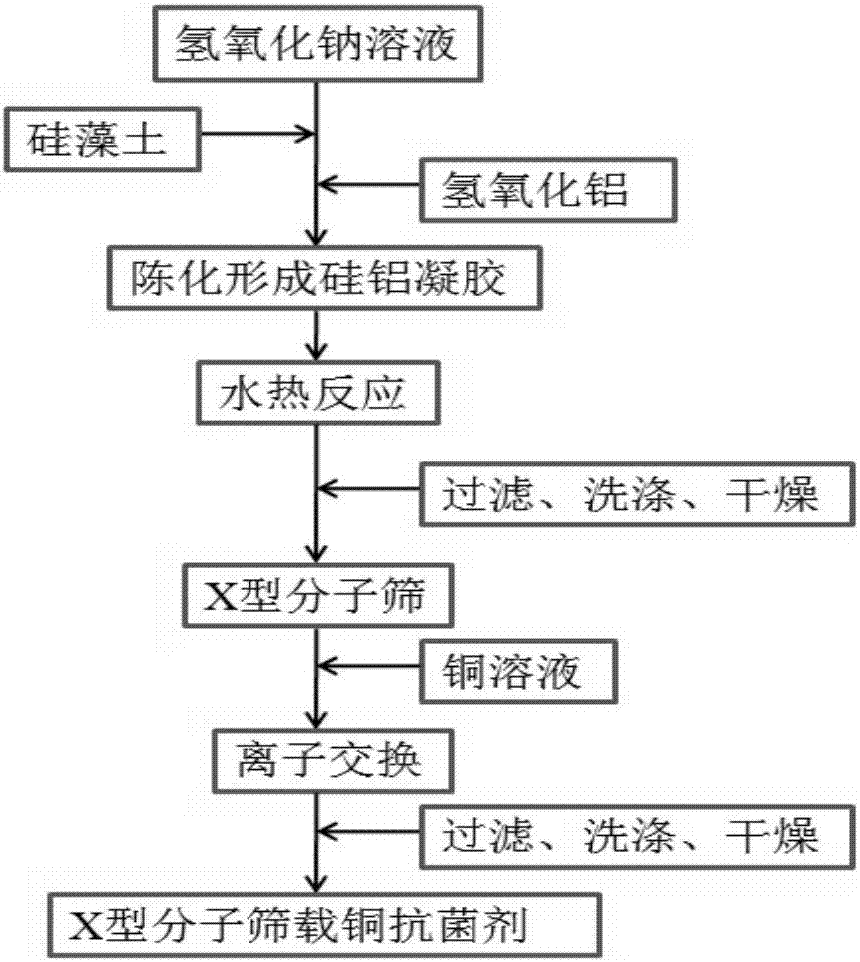

Feed antibacterial agent containing copper-carrying X-type molecular sieve and preparation method of feed antibacterial agent

InactiveCN107879358ARich reservesThe pre-processing process is simpleAccessory food factorsFaujasite aluminosilicate zeoliteMolecular sieveIon exchange

The invention provides a feed antibacterial agent containing a copper-carrying X-type molecular sieve and a preparation method of the feed antibacterial agent. Aiming at the defects of the traditionalmethod for preparing the X-type molecular sieve material at present, the invention provides a method for synthesizing the X-type molecular sieve from diatomite as a silicon source and part of aluminum source with a hydrothermal method; a copper-carrying molecular sieve antibacterial material is further prepared from the X-type molecular sieve as a carrier with an ion exchange method, and accordingly, antibiotics in feed are replaced. Harm of the antibiotics to people and animals is greatly reduced. The antibacterial agent has obvious advantages in preparation cost, product performance, process flow, environmental friendliness, cost performance and the like; the raw materials are from natural minerals, thereby being richly sourced and low in cost; the synthesis process is green and environmentally friendly, the equipment requirement is low, the product performance is high, and industrial production potential is achieved.

Owner:博智农贸易(深圳)有限公司

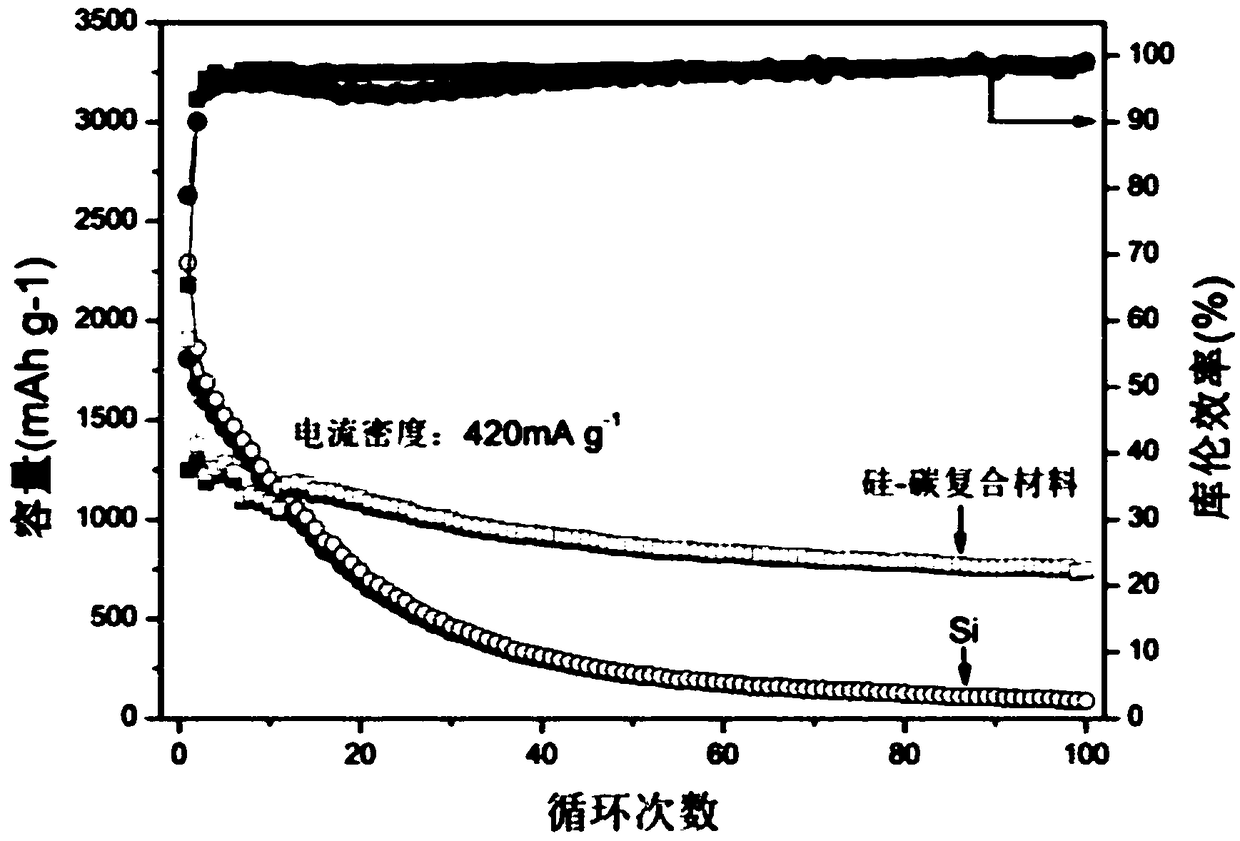

Method for preparing lithium ion battery silicon-carbon composite negative electrode material by taking konjac flour as carbon source

ActiveCN108565431ASimple preparation conditionsMild experimental conditionsSecondary cellsNegative electrodesCarbon compositesLithium-ion battery

The invention discloses a method for preparing a lithium ion battery silicon-carbon composite negative electrode material by taking konjac flour as a carbon source, and belongs to the technical fieldof an energy new material. The method comprises the following steps: ultrasonically dispersing the konjac flour into water to form a gel-like material, adding silicon powder into the gel-like materialby a magnetic stirrer, stirring for 2 to 12 hours, drying, placing a sample into a tubular furnace, performing heat preservation at 200 to 400 DEG C for 1 to 4 hours in the atmosphere of inert gas, heating to 500 to 900 DEG C, performing heat preservation for 1 to 8 hours, cooling to room temperature, and grinding uniformly to obtain the silicon-carbon composite negative electrode material. The method is simple in process and mild in experiment condition; and the prepared silicon-carbon composite negative electrode material has high specific capacity and high cycling performance and is suitable for large-scale production.

Owner:CHINA UNIV OF MINING & TECH

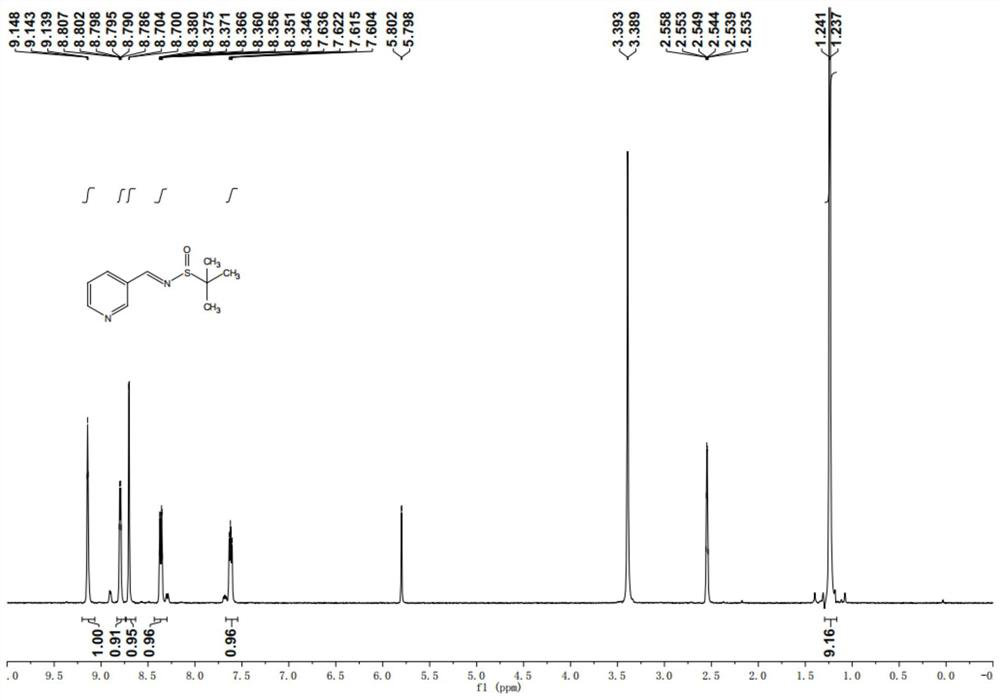

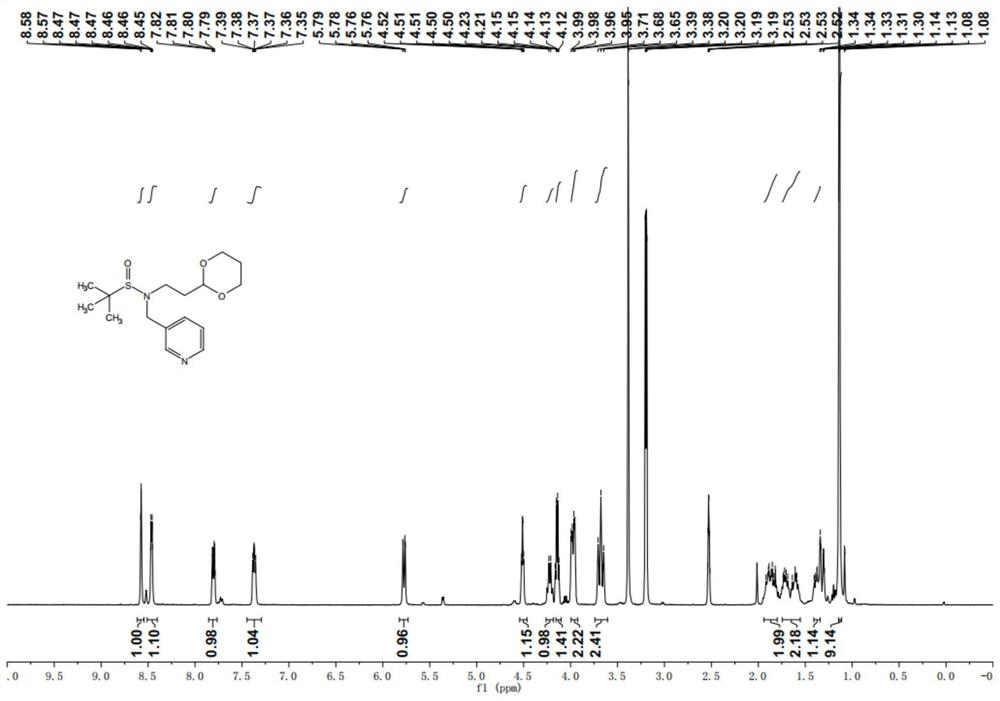

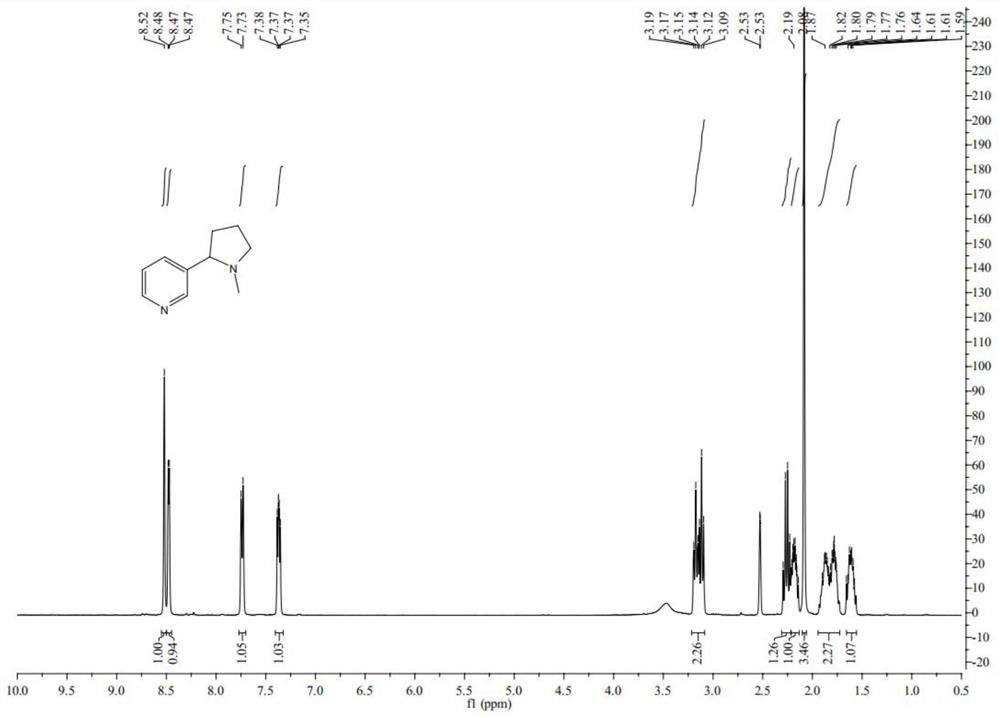

Preparation method of nicotine and intermediate thereof

ActiveCN112876461AReduce manufacturing costEasy to operateOrganic chemistryOrganic chemistryMedicinal chemistry

The invention relates to a preparation method of nicotine and an intermediate thereof, wherein the intermediate has a structure as shown in a formula (II), X1, X2 and X3 are respectively and independently CR2R3, R1 is a C1-6 alkyl group, and R2 and R3 are each independently H or a C1-6 alkyl group. According to the invention, the preparation method of the nicotine and the intermediate thereof has the advantages of simple operation, mild reaction conditions, easily available raw materials, and high conversion rate, can effectively reduce the production cost of the nicotine, and has the potential of industrial production, and each reaction can be directly post-fed through simple post-treatment basically.

Owner:上海零诺生物科技有限公司

A kind of method that clay prepares nax type zeolite molecular sieve pure phase

InactiveCN103738978BReduce consumptionImprove gelation performanceOther chemical processesFaujasite aluminosilicate zeoliteSodium aluminateWaste material

The invention belongs to a method for preparing a zeolite molecular sieve and relates to a method for preparing a NaX-type zeolite molecular sieve pure phase by using clay. The method comprises the following steps: stirring and mixing clinker prepared by mixing and calcining clay and sodium carbonate with sodium metaaluminate and water into colloid, crystallizing, filtering, washing and filtering to obtain the NaX-type zeolite molecular sieve pure phase. The filtered mother solution is recycled and serves as one part of the raw material. The mother solution is recycled, so that the synthetic cost is reduced, waste discharge is avoided, and the environment is not polluted. The method has obvious advantages in aspects of preparation cost, product performance, process flow, environment friendliness and economic profits, and the raw material source is rich, the cost is low, the synthesis simple and convenient, the equipment requirement is low, the product performance is high and the industrial production potential is high.

Owner:DALIAN BEIDI SCI & TECH

Preparation method of silicon oxide nanosheet composite ternary positive electrode material for lithium battery

InactiveCN112421035AImprove structural stabilityThe preparation process is simple and controllableMaterial nanotechnologySecondary cellsMANGANESE ACETATENano silicon

The invention provides a preparation method of a silicon oxide nanosheet composite ternary positive electrode material for a lithium battery. The preparation method comprises the following steps: adding silicon-lithium alloy (Li13Si4) powder into absolute ethyl alcohol and isopropanol to prepare a silicon-lithium alloy dispersion liquid; then conducting slow stirring and reacting in an ice-water bath to obtain a nano-silicon wafer dispersion liquid; then mixing and stirring the nano-silicon wafer dispersion liquid with nickel acetate, cobalt acetate, manganese acetate and deionized water, thenadjusting a pH value, and carrying out rotary evaporation on the solvent to obtain silicon nanosheet / NCM precursor slurry; and finally, conducting sintering under an oxygen-enriched condition to obtain the positive electrode material for the lithium battery. According to the method provided by the invention, silicon nanosheets are formed by delithiation of the silicon-lithium alloy, then the silicon nanosheets are loaded with NCM to form a uniform layered structure, and the uniform layered structure is oxidized to support positive electrode particles as a framework, so the layered structure can be inhibited from being converted into a spinel structure in circulation and sintering processes, and the structural stability of the positive electrode material is remarkably improved; and the method is simple and controllable in preparation procedures and has industrial production potential.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Method for preparing NaX-type zeolite molecular sieve pure phase by using clay

InactiveCN103738978AReduce consumptionImprove gelation performanceFaujasite aluminosilicate zeoliteSodium aluminateEngineering

The invention belongs to a method for preparing a zeolite molecular sieve and relates to a method for preparing a NaX-type zeolite molecular sieve pure phase by using clay. The method comprises the following steps: stirring and mixing clinker prepared by mixing and calcining clay and sodium carbonate with sodium metaaluminate and water into colloid, crystallizing, filtering, washing and filtering to obtain the NaX-type zeolite molecular sieve pure phase. The filtered mother solution is recycled and serves as one part of the raw material. The mother solution is recycled, so that the synthetic cost is reduced, waste discharge is avoided, and the environment is not polluted. The method has obvious advantages in aspects of preparation cost, product performance, process flow, environment friendliness and economic profits, and the raw material source is rich, the cost is low, the synthesis simple and convenient, the equipment requirement is low, the product performance is high and the industrial production potential is high.

Owner:DALIAN BEIDI SCI & TECH

Modification method for collector electrode material of electrolytic cell for water-electrolytic hydrogen making, and application

InactiveCN105803482AAvoid corrosionIncreased durabilityHeat inorganic powder coatingElectrodesHydrogenNitrate

The invention discloses a modification method for a collector electrode material of an electrolytic cell for water-electrolytic hydrogen making. The method includes the following steps that nitrate, an iridium compound and a solvent are fully mixed to form a solution; a pre-treated collector electrode material of the electrolytic cell for water-electrolytic hydrogen making is soaked in the solution, then dried, calcined, cooled, washed and dried, and a modified collector electrode material of the electrolytic cell for water-electrolytic hydrogen making is obtained, or the steps that the nitrate, the iridium compound and the solvent are fully mixed, subjected to ball-milling, dried and sieved to obtain a mixture, the pre-treated collector electrode material of the electrolytic cell for water-electrolytic hydrogen making is uniformly covered with the mixture, then calcined, cooled, washed and dried, and the modified collector electrode material of the electrolytic cell for water-electrolytic hydrogen making is obtained. The modified collector electrode material, prepared by the method, of the electrolytic cell for water-electrolytic hydrogen making serves as an anode electrode of the electrolytic cell, the electric potential is obviously lowered in the electrolytic process, and the activation impedance and ohmic impedance of the electrolytic cell are obviously reduced.

Owner:TONGJI UNIV

Method for preparing creatine in catalyzed mode

InactiveCN105254538APromote full conversionShort reaction timeOrganic chemistryOrganic compound preparationPhase-transfer catalystSolubility

The invention relates to a method for preparing creatine in a catalyzed mode. According to the method, S-methyl isothiourea sulfate and potassium sarcosinate are adopted as raw materials and are further prepared into creatine, utilization of highly-toxic ammonia cyanide is avoided, and production safety is effectively ensured. Meanwhile, a phase transfer catalyst is added in the reaction process, the reaction is carried out in an alcohol / water system, dissolvability of the materials can be guaranteed, and the sufficient conversion of the materials can be promoted under the action of the catalyst. The method in the technical scheme has the advantages of being environmentally friendly, high in yield and short in reaction time and has a wide industrialization prospect.

Owner:王晓伟

Preparation method for preparing medium-low pressure composite dielectric film-containing formed foil by surface self-assembly method

ActiveCN111768974AIncrease depositionIncrease specific volumeCapacitor dielectric layersElectrolytic capacitor manufactureDielectricAdipic acid

The invention discloses a preparation method for preparing a medium-low pressure composite dielectric film-containing formed foil by a surface self-assembly method. According to the method, low-pressure corrosion foil serves as a raw material, and surface modification is conducted on the aluminum foil through a soaking method. The preparation method comprises the following steps: sequentially soaking a corrosion foil in a solution taking 5-10mmol / L of gamma-mercaptopropyltrimethoxysilane and cyclohexane as solvents for 5 hours, a solution taking CH3COOH / H2O2(Vol) as a ratio of 5: 1 for 1 hour,and 0.3-0.8 mol / L of Ti gel for 5-10 hours; and carrying out heat treatment at 500 DEG C for 5 minutes after airing; carrying out anodic oxidation on the aluminum foil, preparing a formation solutionby taking ammonium adipate and ammonium citrate as solutes, and carrying out six-stage gradient formation on the modified aluminum foil according to the conditions that the current density is 0.1-0.3A / cm < 2 > and the voltage is 12-141 V; and sequentially carrying out intermediate treatment, re-formation, heat treatment and post-treatment on the aluminum foil to finally obtain the high-specific-volume intermediate-low-pressure composite dielectric film-containing formed foil. The method has the advantages that the process is simple, and the operation is convenient. The deposition amount of TiO2 on the surface of the aluminum foil is large, and the prepared aluminum foil is high in specific volume.

Owner:GUANGXI UNIV

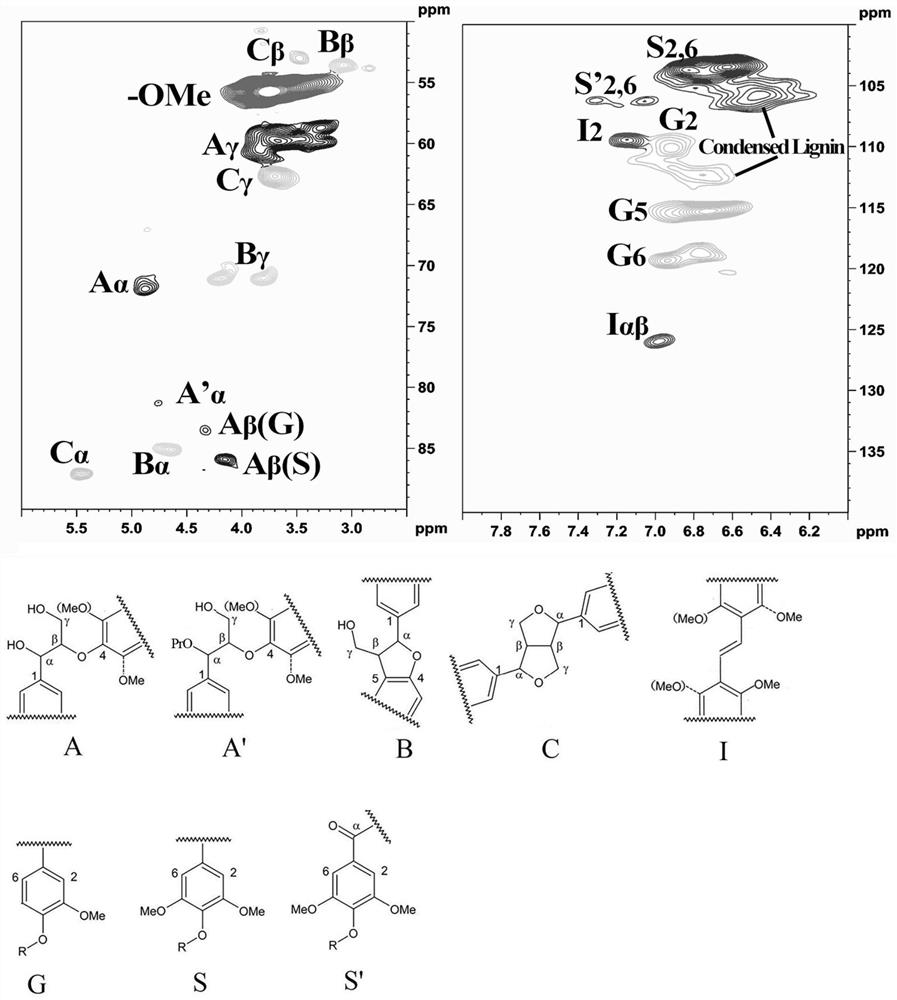

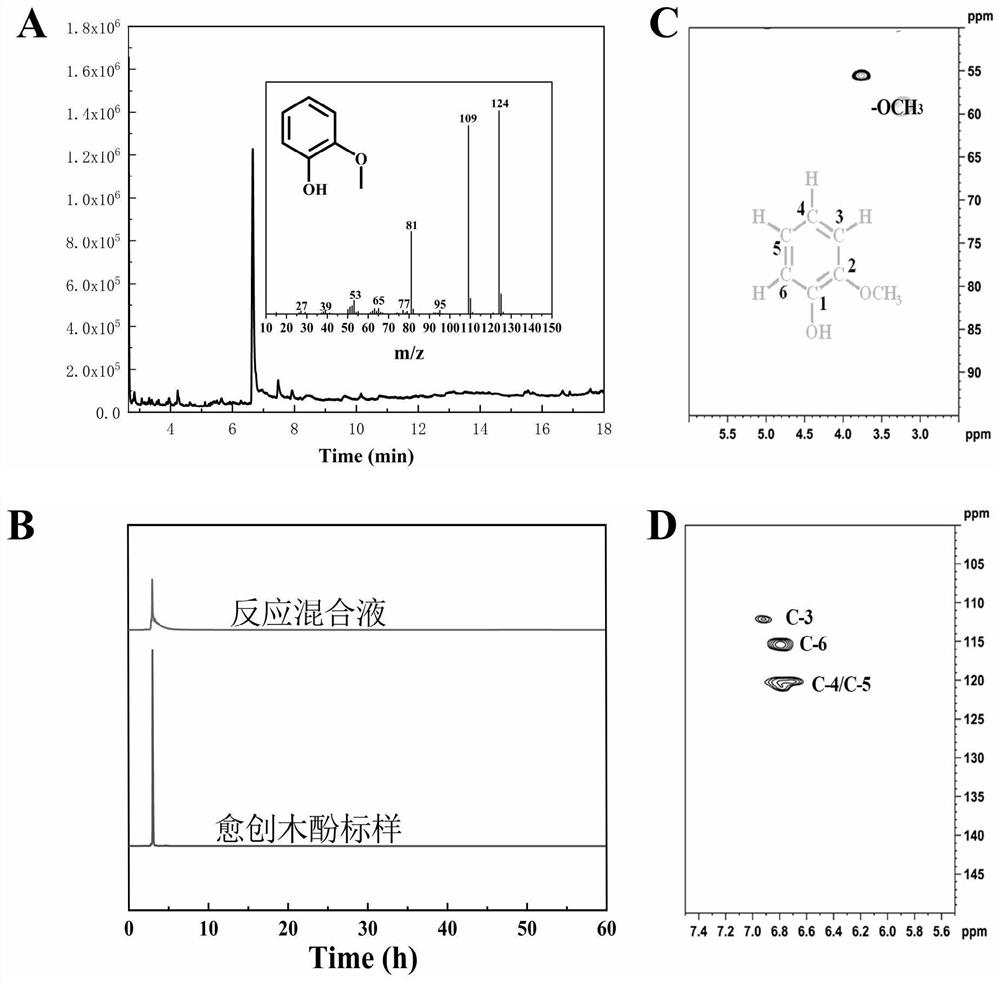

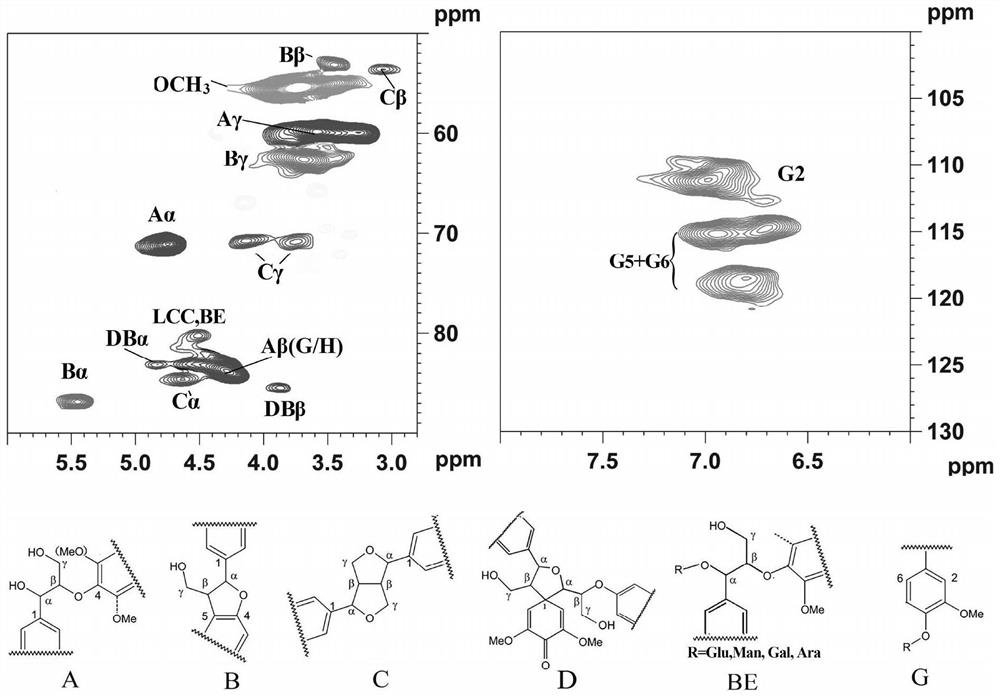

Method for preparing guaiacol by catalyzing efficient conversion of lignin through Lewis acid

ActiveCN113105314AHigh yieldCatalytic conversion method is simpleOrganic compound preparationEther preparationChemical industryLiquid product

The invention discloses a method for catalyzing conversion of lignin into guaiacol as a single chemical by lewis acid. According to the method, the lignin is catalyzed to be converted into the guaiacol in an inert atmosphere with lewis acid as a catalyst, and the guaiacol is the only liquid product. The lewis acid comprises at least one of iron trifluoromethanesulfonate, ytterbium trifluoromethanesulfonate and lanthanum trifluoromethanesulfonate. According to the method, the catalytic system is simple in composition and green, the liquid product yield is high, only guaiacol is a liquid product, and other residues are solids. The invention provides a new way for preparing the guaiacol, provides a new method for preparing high value-added platform molecules, especially important chemicals from a traditional fossil resource route, for oriented conversion of lignin, and also provides a new thought for resource utilization of lignin. The method is a green and sustainable lignin carbon resource catalytic conversion strategy, and the dependence of chemical industry on fossil resources can be reduced.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of medium-low pressure formed foil containing composite dielectric film

ActiveCN111710528AHigh withstand voltageGood hydration resistanceCapacitor dielectric layersElectrolytic capacitor manufactureHydration reactionDielectric

The invention discloses a preparation method of a medium-low pressure formed foil containing a composite dielectric film. According to the method, a low-pressure corrosion foil is used as a raw material, and the corrosion foil is put into Ti-containing sol through a soaking method, so that the surface of the aluminum foil contains the Ti-containing sol. Anodic oxidation is carried out on the pretreated aluminum foil, and the specific operations comprise six-stage formation, intermediate treatment, re-formation, heat treatment and post-treatment. The formation liquid is prepared from ammonium adipate, sodium citrate and deionized water, and the intermediate treatment liquid is prepared from phosphoric acid, citric acid and deionized water. The post-treatment liquid is prepared from ammoniumdihydrogen phosphate, ammonium dihydrogen citrate and deionized water. The preparation method is simple in process and convenient to operate, and the prepared aluminum foil is higher in specific volume and higher in hydration resistance.

Owner:GUANGXI UNIV

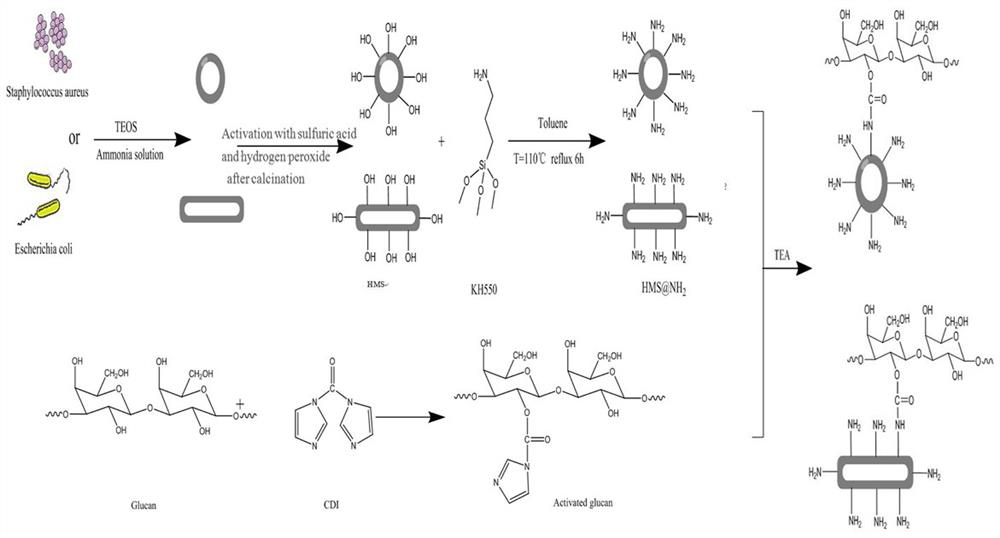

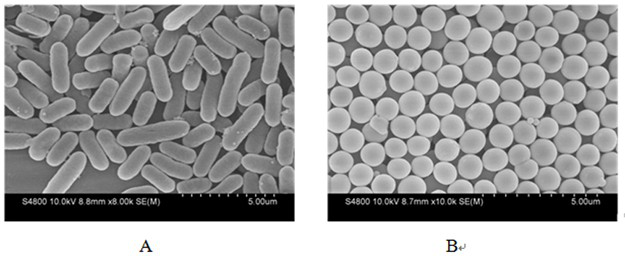

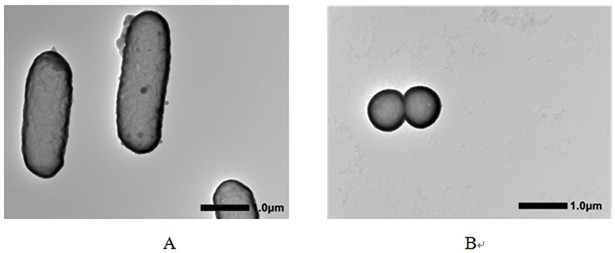

A biomimetic hollow silica composite particle modified by β-1,3-d-glucan and its application

ActiveCN108653727BEasy to passSustained releaseInorganic non-active ingredientsAntibody medical ingredientsFreund's adjuvantPharmaceutical drug

Owner:SUN YAT SEN UNIV

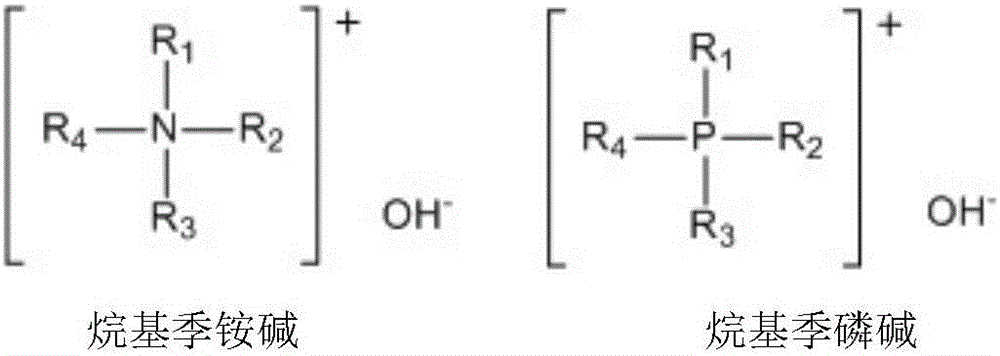

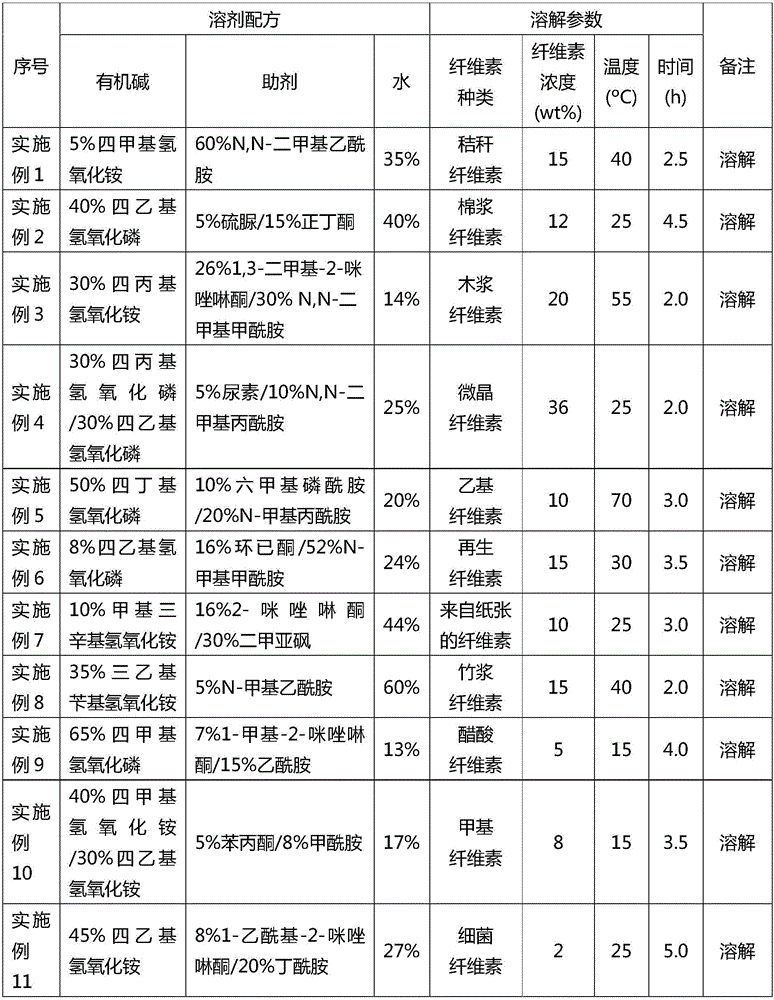

A kind of method for preparing cellulose solution

The invention discloses a method for preparing a cellulose solution. The basic technical principle is to improve the wettability of the solvent to natural cellulose crystals by regulating the amphiphilic properties of the cellulose solvent, thereby promoting the dissolution of the cellulose. Based on this principle, the room temperature temperature and dissolution technology method of cellulose was proposed. The method has the advantages of simple process, dissolution at room temperature, environmental friendliness and insensitivity to the water content of the system. The cellulose solvent adopts the following composition: organic base accounts for 5-70% of the total weight of the solvent, additives account for 2-90% of the total weight of the solution, and water accounts for 1-65% of the total weight of the solvent. The cellulose is blended with the cellulose solvent to form a blend, and stirred until completely dissolved to obtain the target cellulose solution. The cellulose solution prepared by the method of the present invention is used for manufacturing regenerated cellulose film, regenerated cellulose fiber or cellulose-based composite material.

Owner:SOUTHWEST JIAOTONG UNIV

A preparation method for preparing medium and low pressure composite medium-containing film into foil by surface self-assembly method

ActiveCN111768974BIncrease depositionIncrease specific volumeCapacitor dielectric layersElectrolytic capacitor manufactureComposite mediaDielectric membrane

The invention discloses a preparation method for preparing medium-low pressure compound medium-containing film forming foil by surface self-assembly method. In the method, the low-pressure corroded foil is used as a raw material, and the surface of the aluminum foil is modified by a soaking method. Soak the corroded foil in the solution of 5~10mmol / L γ-mercaptopropyltrimethoxysilane and cyclohexane as solvent for 5 h, CH 3 COOH / H 2 o 2 (Vol)=5:1 solution for 1 h, 0.3~0.8mol / L Ti gel soaked for 5~10 h. Heat treatment at 500°C for 5 min after drying. After that, the aluminum foil is anodized, and ammonium adipate and ammonium citrate are used as solutes to prepare a chemical solution, according to the current density of 0.1~0.3A / cm 2 , and the voltage ranged from 12 V to 141 V to perform six-level gradient formation on the modified aluminum foil. The aluminum foil is then subjected to intermediate treatment, re-formation, heat treatment, and post-treatment operations in sequence, and finally a high specific volume medium-low pressure compound dielectric film-containing foil is obtained. The advantages of the present invention are: simple process, convenient operation; TiO 2 The amount of deposition on the surface of the aluminum foil is large, and the specific volume of the aluminum foil made is high.

Owner:GUANGXI UNIV

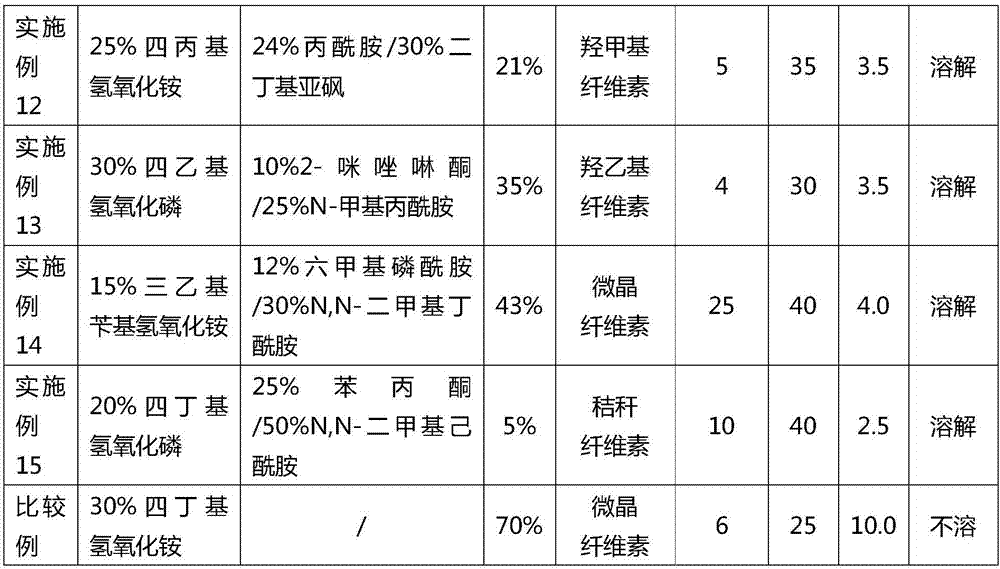

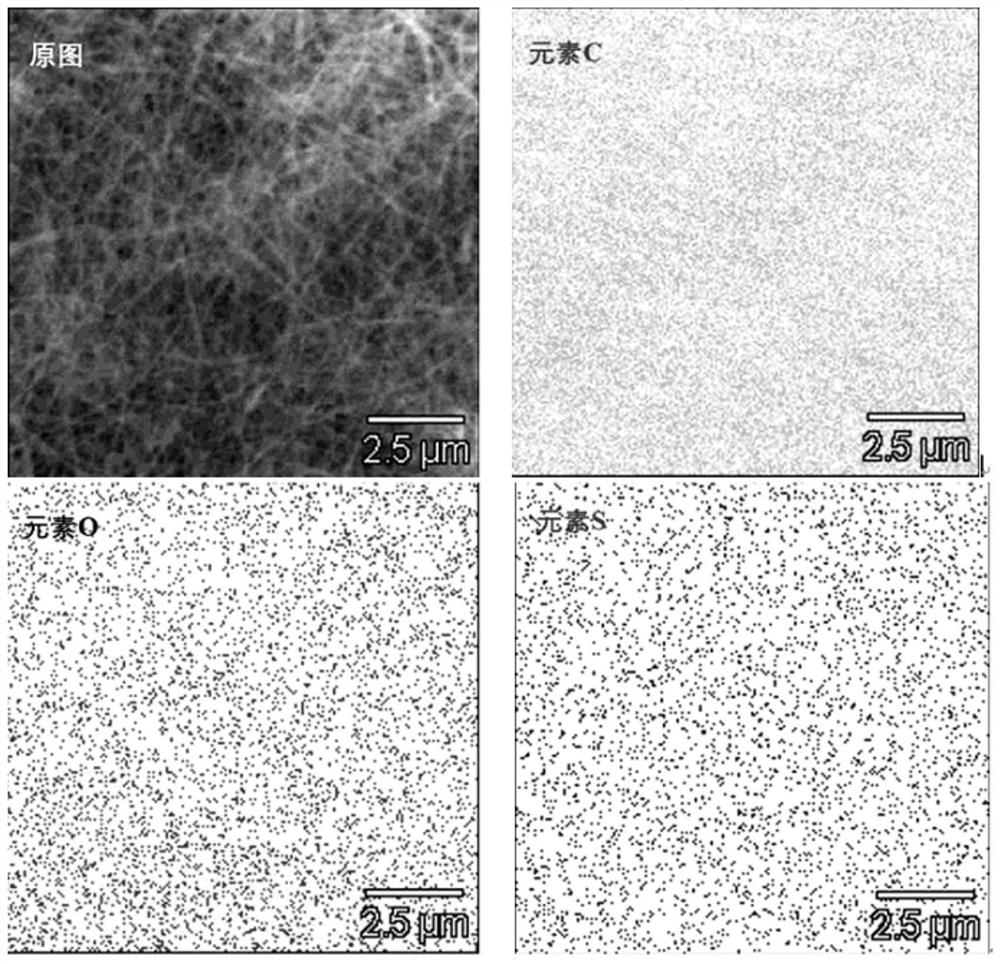

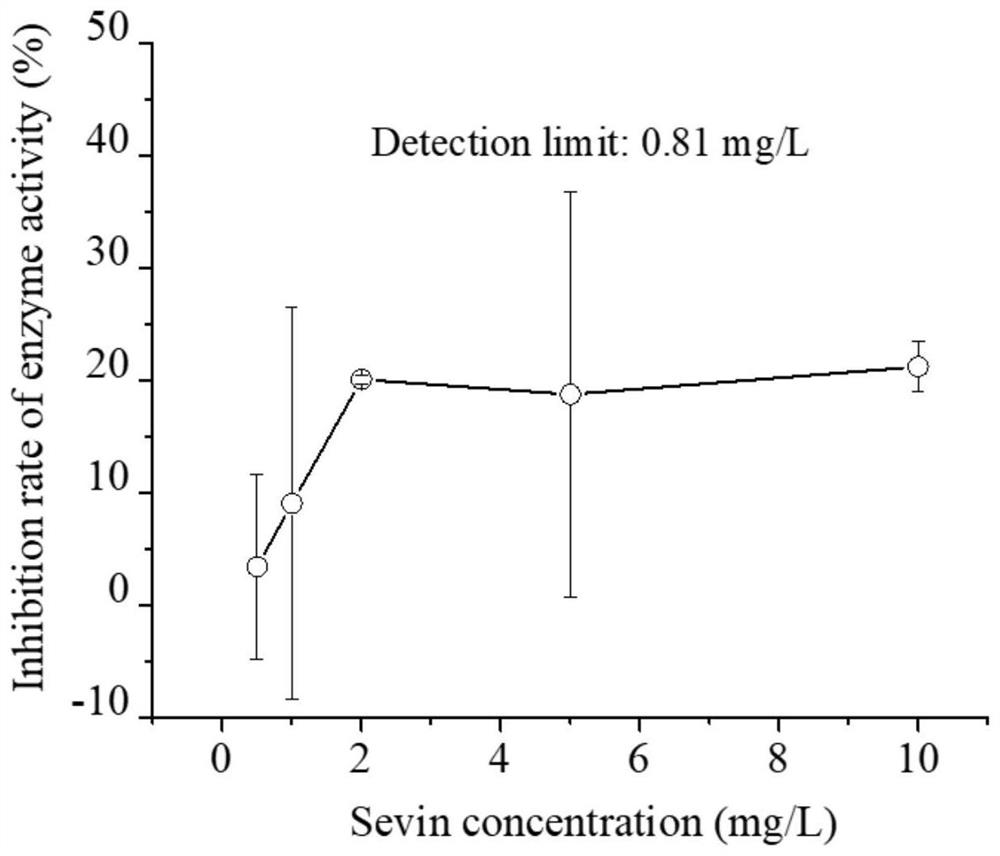

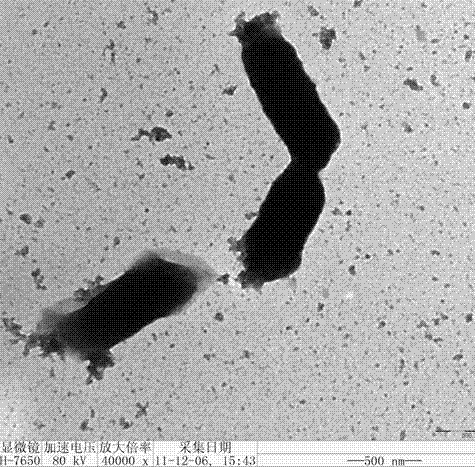

Preparation method of pulullan-animal esterase composite nanofiber

PendingCN113355315AImmobilizationSimple processHydrolasesFilament/thread formingBiotechnologyComposite nanofibers

The invention discloses a preparation method of pulullan-animal esterase composite nanofiber. The method comprises the following steps of: extracting and purifying animal liver to prepare an animal esterase solution, then uniformly mixing the animal esterase solution with a pulullan solution to obtain a pulullan-animal esterase electrostatic spinning solution, and finally performing electrostatic spinning to prepare the pulullan-animal esterase composite nanofiber. The average diameter of the pulullan-animal esterase composite nanofiber is 70.39-108.79nm, animal esterase is uniformly distributed on the surface of the nanofiber, and the lower limit of detection on pesticide carbaryl is 0.81-1.10mg / L. The preparation method disclosed by the invention realizes immobilization of a nano material of the animal esterase, and has the advantages of simple process, low cost, environmental friendliness and the like.

Owner:YANGZHOU UNIV

A kind of preparation method of medium and low pressure forming foil containing composite dielectric film

ActiveCN111710528BHigh withstand voltageGood hydration resistanceCapacitor dielectric layersElectrolytic capacitor manufactureDielectricHydration reaction

The invention discloses a preparation method for low-pressure forming foil of a film containing a composite medium. In the method, low-pressure corroded foil is used as a raw material, and the corroded foil is put into Ti-containing sol through a soaking method, so that the surface of the aluminum foil contains Ti sol. The pretreated aluminum foil is anodized, and the specific operations include: six-stage chemical formation, intermediate treatment, re-formation, heat treatment, and post-treatment. The chemical conversion solution is prepared from ammonium adipate, sodium citrate and deionized water, and the intermediate treatment solution is prepared from phosphoric acid, citric acid and deionized water. The post-treatment solution is prepared by adding ammonium dihydrogen phosphate, ammonium dihydrogen citrate and deionized water. The invention has simple process and convenient operation, and the produced aluminum foil has higher specific volume and stronger hydration resistance.

Owner:GUANGXI UNIV

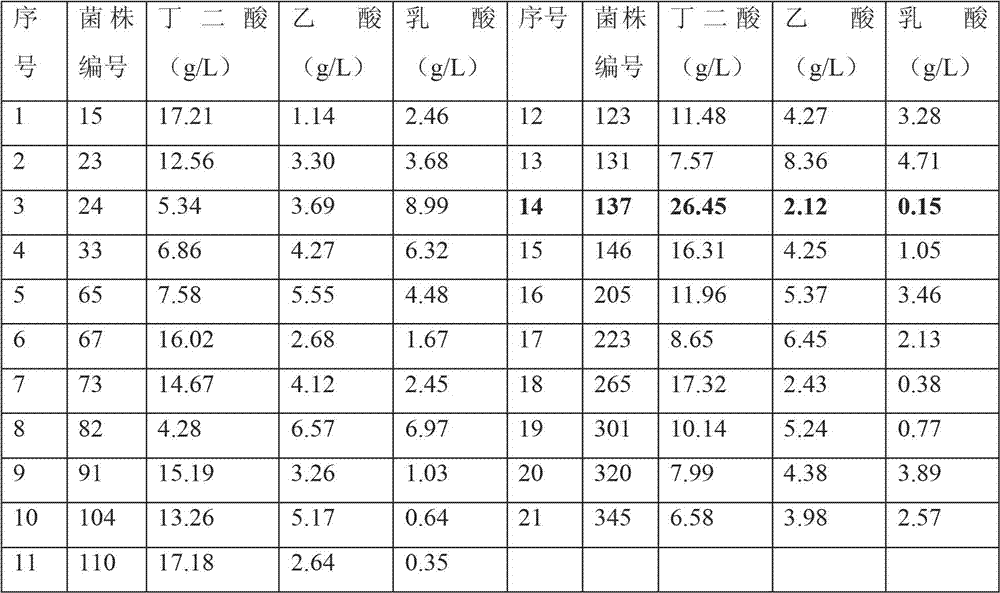

Actinobacillus succinate producing strain and method for its screening and fermentative production of succinic acid

InactiveCN102851224BWith industrial productionPotential for industrial productionProductsBacteriaMicrobiologyActinobacillus succinogenes

The invention discloses an actinobacillus succinogenes GXAS-137, and a method for producing succinic acid by screening and fermentation of the strain; the strain is obtained by enrichment and screening from a cattle rumen; the method comprises the following steps: inoculating the actinobacillus succinogenes strains in a seed medium, culturing for 24-36 hours in an anaerobic incubator or a common incubator at 30-38 DEG C in a static manner, inoculating into a fermentation medium with an inoculation amount of 1-10%, adjusting the pH to 6.0-7.0, and performing fermentation at 30-38 DEG C for 24-120 hours to obtain succinic acid. Fermentation research is performed with different raw materials and in different media; the succinic acid yield is up to 70 g / L; and the method has potential for industrial production.

Owner:GUANGXI ACAD OF SCI

Preparation method and application of perovskite oxide catalyst containing alloy particles

ActiveCN112680740AImprove electronic conductivityImprove electrocatalytic performanceElectrodesPtru catalystMixed gas

The invention relates to a preparation method of a perovskite oxide catalyst containing alloy particles, and the method comprises the following steps: S1, mixing raw materials and a solvent, and carrying out ball milling to obtain a mixture A, wherein the raw materials comprise Co3O4, La2O3, SrCO3 and Fe2O3; S2, roasting the mixture A to obtain a sample B; S3, roasting the sample B in mixed gas of reducing gas and inert gas to obtain a product. Through an electrochemical test, the product obtained by the preparation method of the perovskite oxide catalyst containing the alloy particles can be used as an electrocatalyst, and the overpotential required by hydrogen production by water decomposition can be remarkably reduced, so the electrocatalytic performance is improved, the energy waste is reduced, and the energy utilization rate is improved.

Owner:WUYI UNIV

Method for producing sodalite pure phase with shale ash

InactiveCN101492167BLow costRich sourcesSolid waste disposalCrystalline aluminosilicate zeolitesMolecular sieveThermal treatment

The invention discloses a method for preparing a sodalite pure phase by taking oil shale ash as a raw material, and belongs to the field of production and preparation of inorganic functional materials. The method is characterized by comprising the following steps: firstly determining contents of SiO2 and Al2O3 in the oil shale ash raw material, sieving the oil shale ash by a sieve, and drying theoil shale ash in an oven; after drying, evenly mixing the oil shale ash with NaOH and deionized water, and stirring the mixture electromagnetically at normal temperature, wherein the proportion of a reaction raw material formulation is as follows: the proportion of H2O to Na2O is equal to 5.0-7.8, and the proportion of the Na2O to the SiO2 is equal to 2.5-7.0; transferring the materials into a reaction kettle, and crystallizing the materials at constant temperature; and finally, filtering, washing and drying the product to obtain the sodalite pure phase. The method has the advantages of preparing a sodalite molecular sieve pure phase from the low-cost raw material oil shale ash. The pretreatment for the oil shale ash is simple, has no redundant heat treatment and acid treatment, and savesenergy; and the preparation flow has no alkali fusing process, simple process, easy operation, and friendly environment.

Owner:DALIAN UNIV OF TECH

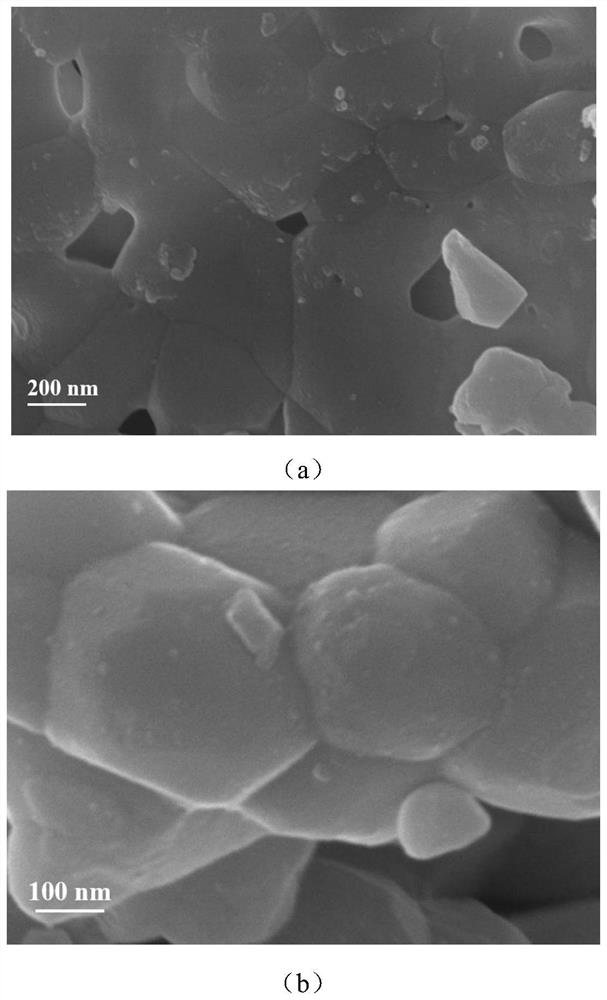

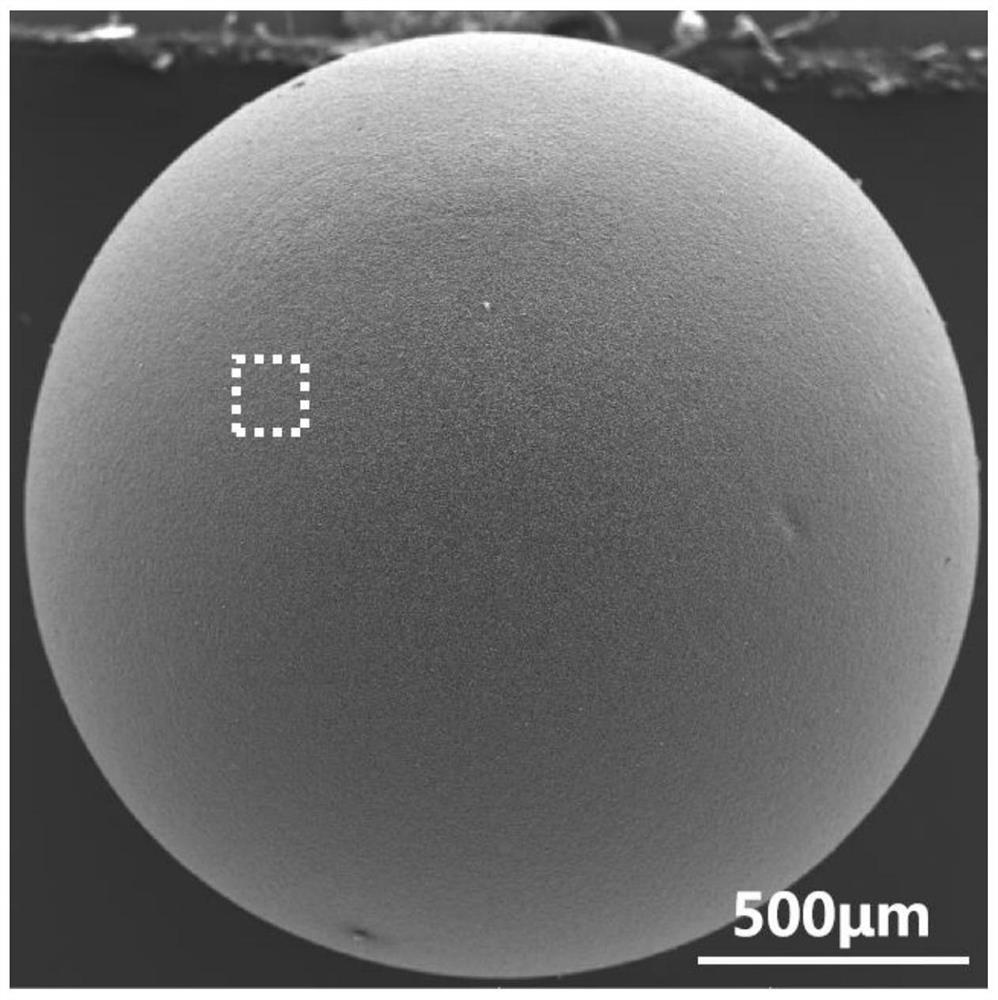

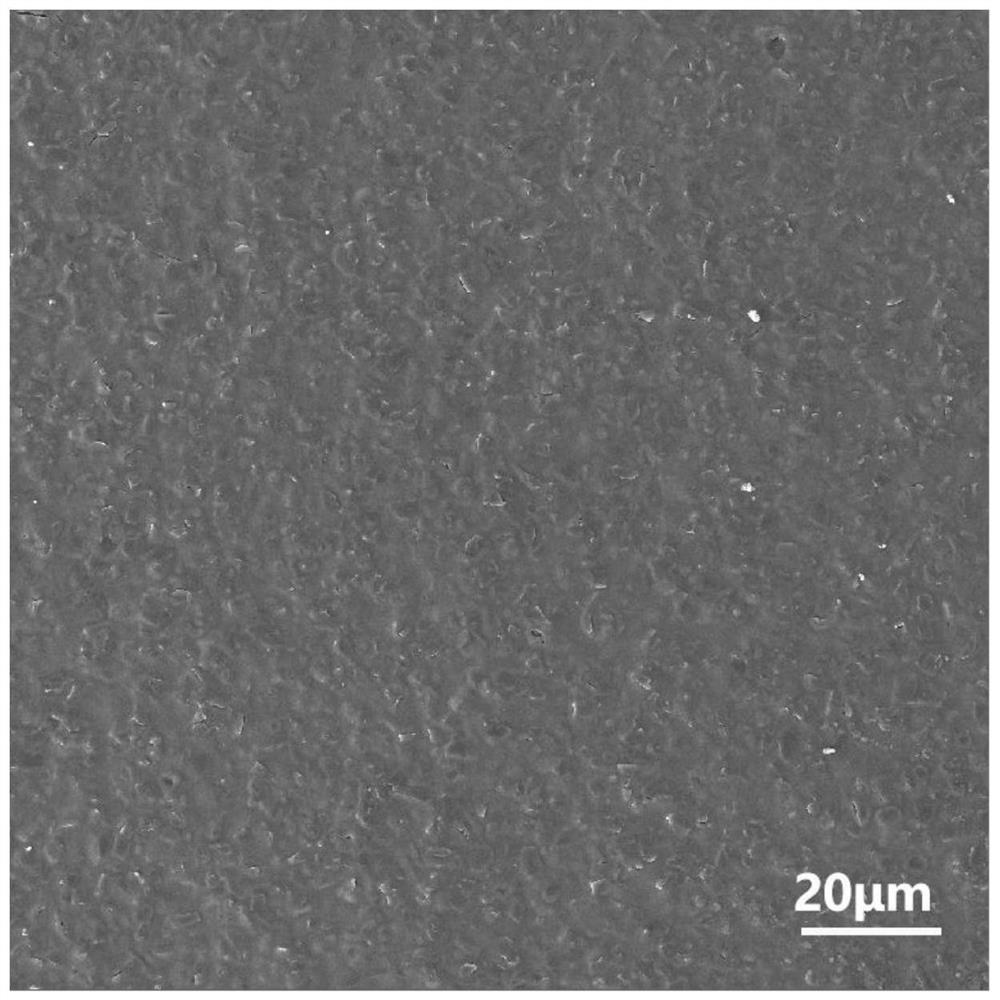

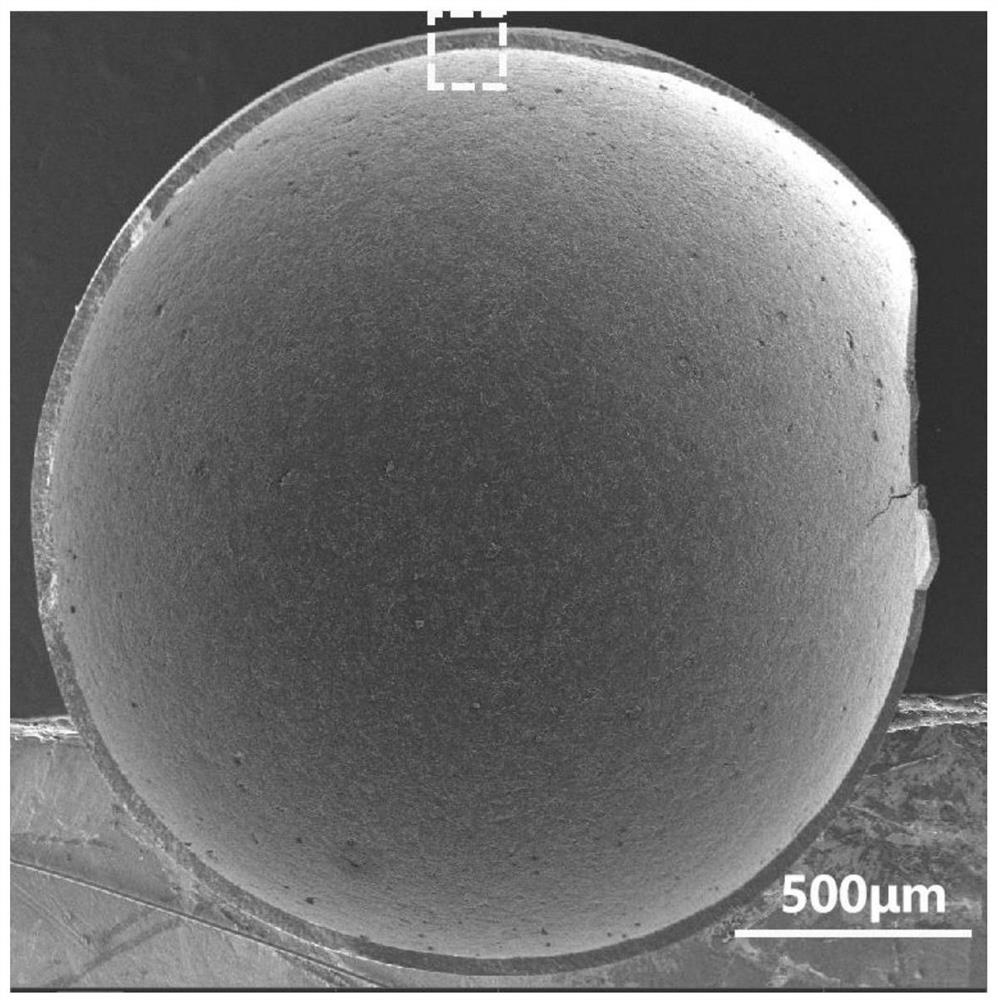

A kind of boron carbide/silicon carbide ceramic hollow microsphere and preparation method thereof

The invention discloses a boron carbide / silicon carbide ceramic hollow microsphere and a preparation method thereof. The preparation method utilizes a vinyl silane coupling agent to modify boron carbide, and then grafts PCS to B 4 on C‑V, then B 4 C-PCS is prepared into a slurry, and the polymer ball is used as a template to prepare a slurry coating ball, and finally the slurry on the polymer ball is cured in an air atmosphere, and then heat-treated in an air atmosphere to remove polymerization. Object spherical template, and finally fired at high temperature in an inert atmosphere to obtain boron carbide / silicon carbide ceramic hollow microspheres. The preparation method provided by the present invention can adjust the diameter of boron carbide / silicon carbide ceramic hollow microspheres by selecting polymer spheres with different diameters, and realize a wide range of diameter control, and the wall thickness of ceramic hollow microspheres can be changed by changing the slurry coating. The thickness of the wall can be adjusted in a wide range by adjusting the number of coating times. The preparation method is simple, convenient, fast and efficient, and the raw materials are cheap and easy to obtain, which has the potential for industrial production.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com