Method for preparing guaiacol by catalyzing efficient conversion of lignin through Lewis acid

A technology of guaiacol and Lewis acid, applied in chemical instruments and methods, preparation of organic compounds, preparation of ethers, etc., can solve the problems of difficulty in improving catalytic conversion of lignin, low reactivity, high heterogeneity, etc. To achieve the effect of easy separation, simple catalytic system and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of eucalyptus organic lignin raw material

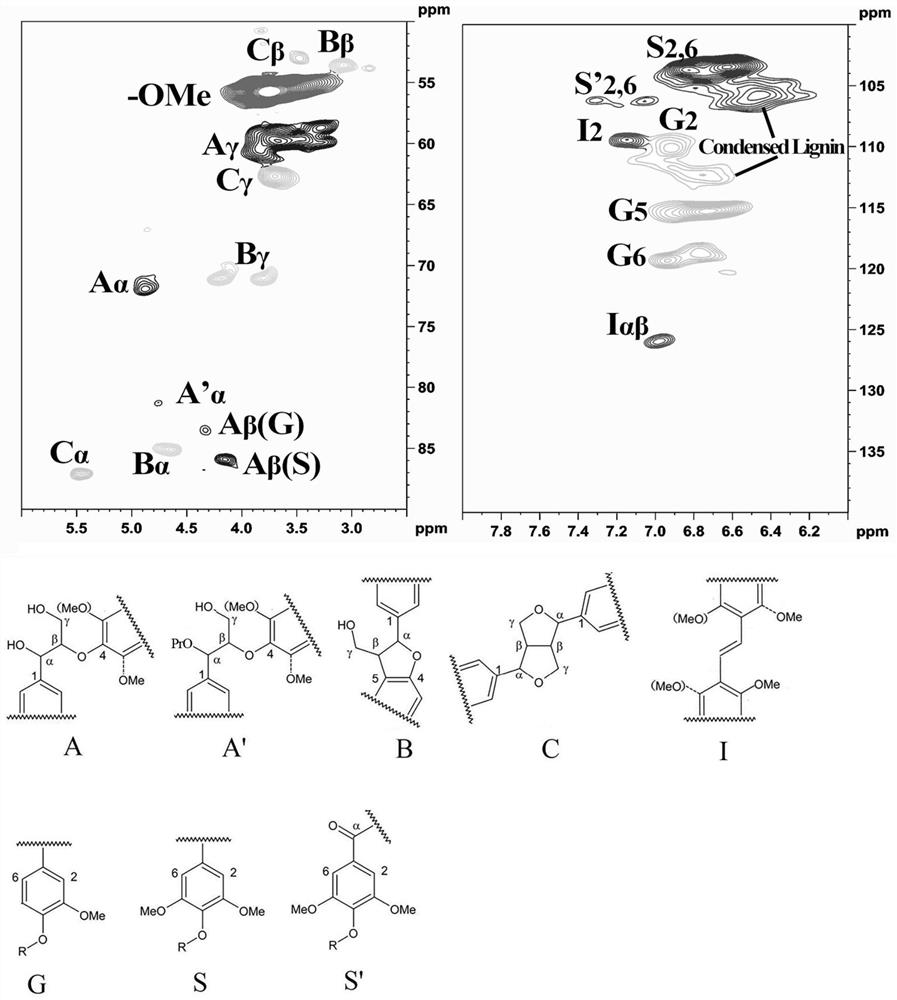

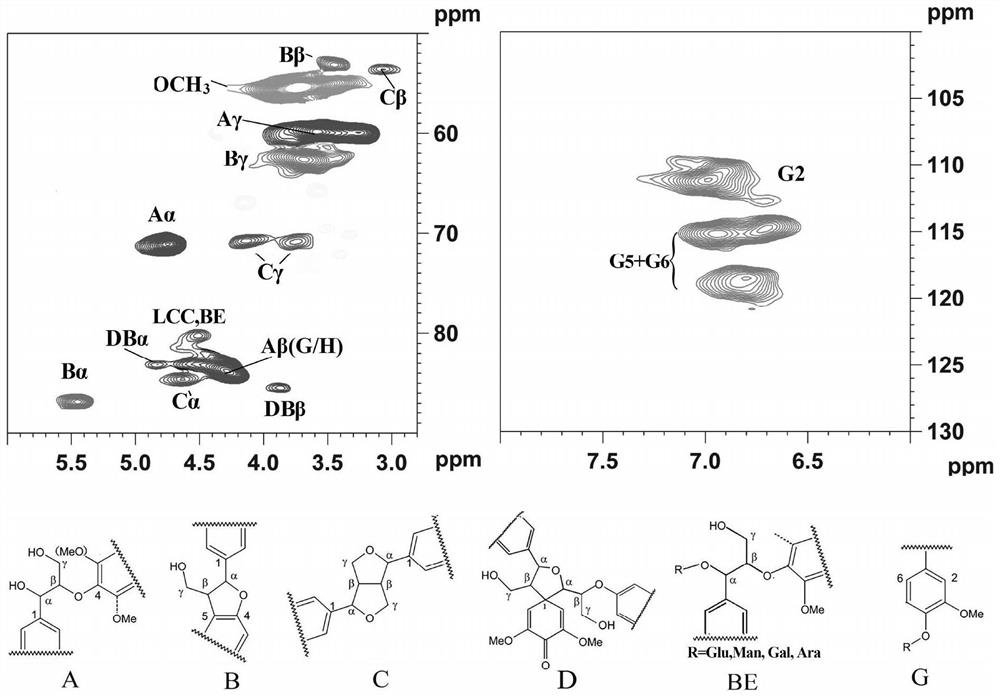

[0025] First, 50g of eucalyptus was placed in a 1000mL acid and alkali resistant reaction kettle containing 500mL of isopropanol aqueous solution (7:3, v / v). Then the reaction kettle was heated to 220° C. and kept at constant temperature for 1 h. Then it was cooled to room temperature, filtered, and the filter residue was washed with 70% isopropanol aqueous solution. The filtrates were combined and concentrated. Then slowly drop the concentrated solution into 10 times the volume of acid water with pH=2, centrifuge the precipitate, and finally freeze-dry to obtain the organic lignin. The two-dimensional NMR spectrum of the Eucalyptus organic lignin extracted and separated by the above method ( figure 1 ) It can be seen that the main constituent unit of the lignin is (A) β-O-4 ether bond structure; (B) resin alcohol structure; (C) phenylcoumarin structure (β-5 and α-O -4 linked); (I) p-hydroxycinnamyl alcohol...

Embodiment 2

[0030] (1) Preparation of eucalyptus organic lignin raw material

[0031] The extraction and separation of eucalyptus organic lignin is the same as in Example 1.

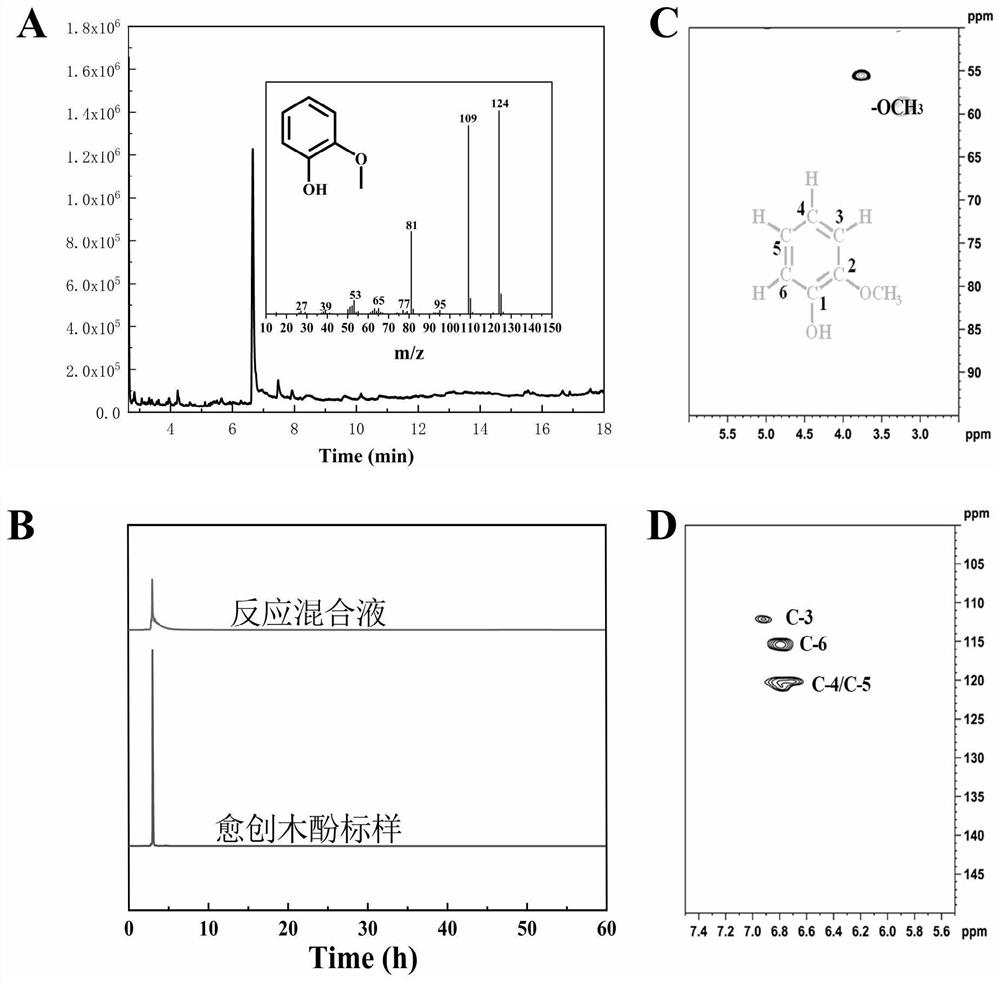

[0032] (2) Lignin conversion to prepare guaiacol reaction

[0033] Add 50 mg of eucalyptus organic lignin, 10 mg of ferric trifluoromethanesulfonate, 4 mL of methanol, and 10 μL of water into a 15 mL Teflon-lined reactor. Then the reaction vessel was sealed, and the air was exhausted and filled with argon to 0.1MPa. The reaction temperature was 270°C and kept for 24h. Cool to room temperature, collect the gas and centrifuge the reaction mixture, use GC-MS, liquid phase and NMR qualitative analysis of the liquid product, use GC to quantitatively analyze the liquid product, and obtain the ratio of the quality of guaiacol to the initial quality of lignin That is its yield.

[0034] (3) After the reaction, the liquid product only contains guaiacol, a lignin degradation monomer, and the yield is 13.5 wt%.

Embodiment 3

[0036] (1) Preparation of eucalyptus organic lignin raw material

[0037] The extraction and separation of eucalyptus organic lignin is the same as in Example 1.

[0038] (2) Lignin conversion to prepare guaiacol reaction

[0039] Add 50 mg of eucalyptus organic lignin, 5 mg of ferric trifluoromethanesulfonate, 4 mL of methanol, and 10 μL of water into a 15 mL Teflon-lined reactor. Then the reaction vessel was sealed, and the air was exhausted and filled with argon to 0.1MPa. The reaction temperature was 270°C and kept for 24h. Cool to room temperature, collect the gas and centrifuge the reaction mixture, use GC-MS, liquid phase and NMR qualitative analysis of the liquid product, use GC to quantitatively analyze the liquid product, and obtain the ratio of the quality of guaiacol to the initial quality of lignin That is its yield.

[0040] (3) After the reaction, the liquid product only contains guaiacol, a lignin degradation monomer, and the yield is 5.3 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com