Patents

Literature

2093 results about "Acid catalyzed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid catalyzed hydration is a chemical reaction in which water adds to an unsaturated substrate under the influence of an acid catalyst. An example is the hydration of ethene. CH₂=CH₂ + H-OH → H-CH₂-CH₂-OH. The common acid catalysts are sulfuric acid and phosphoric acid.

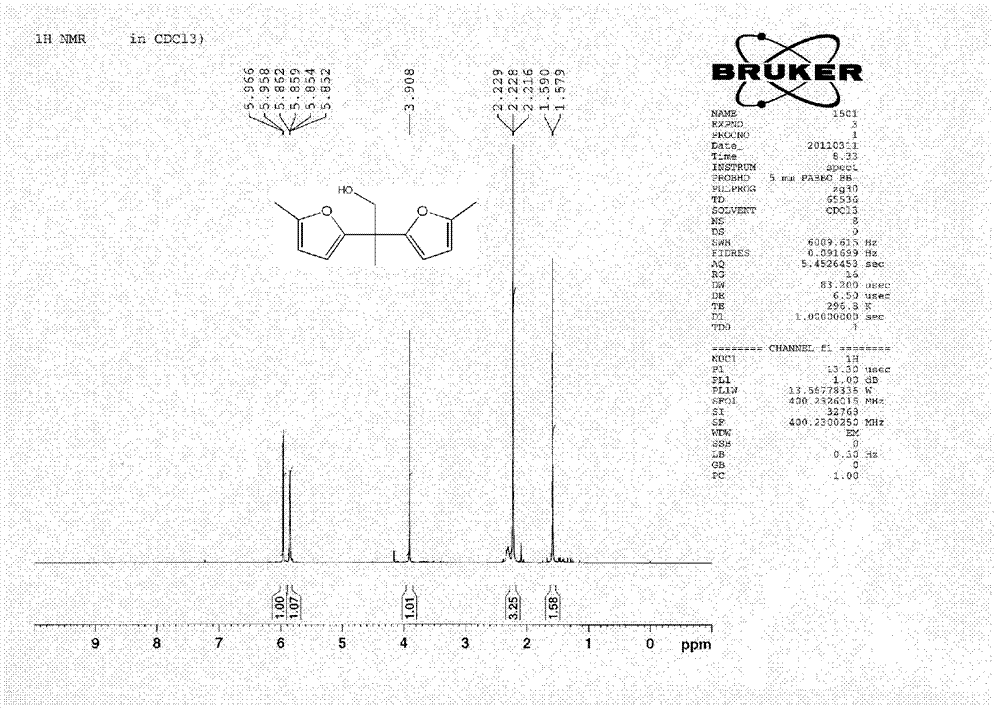

Production of liquid alkanes in the jet fuel range (c8-c15) from biomass-derived carbohydrates

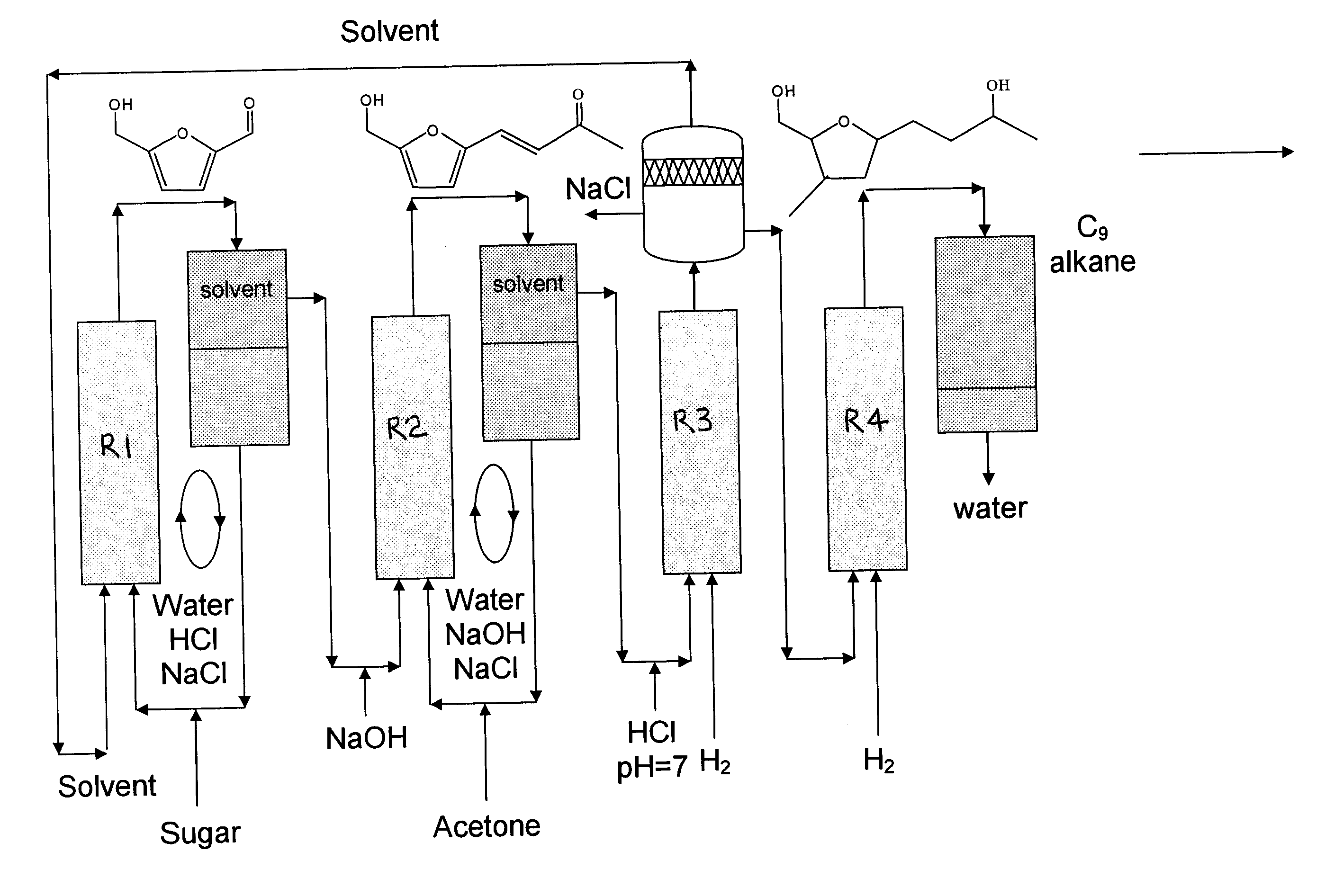

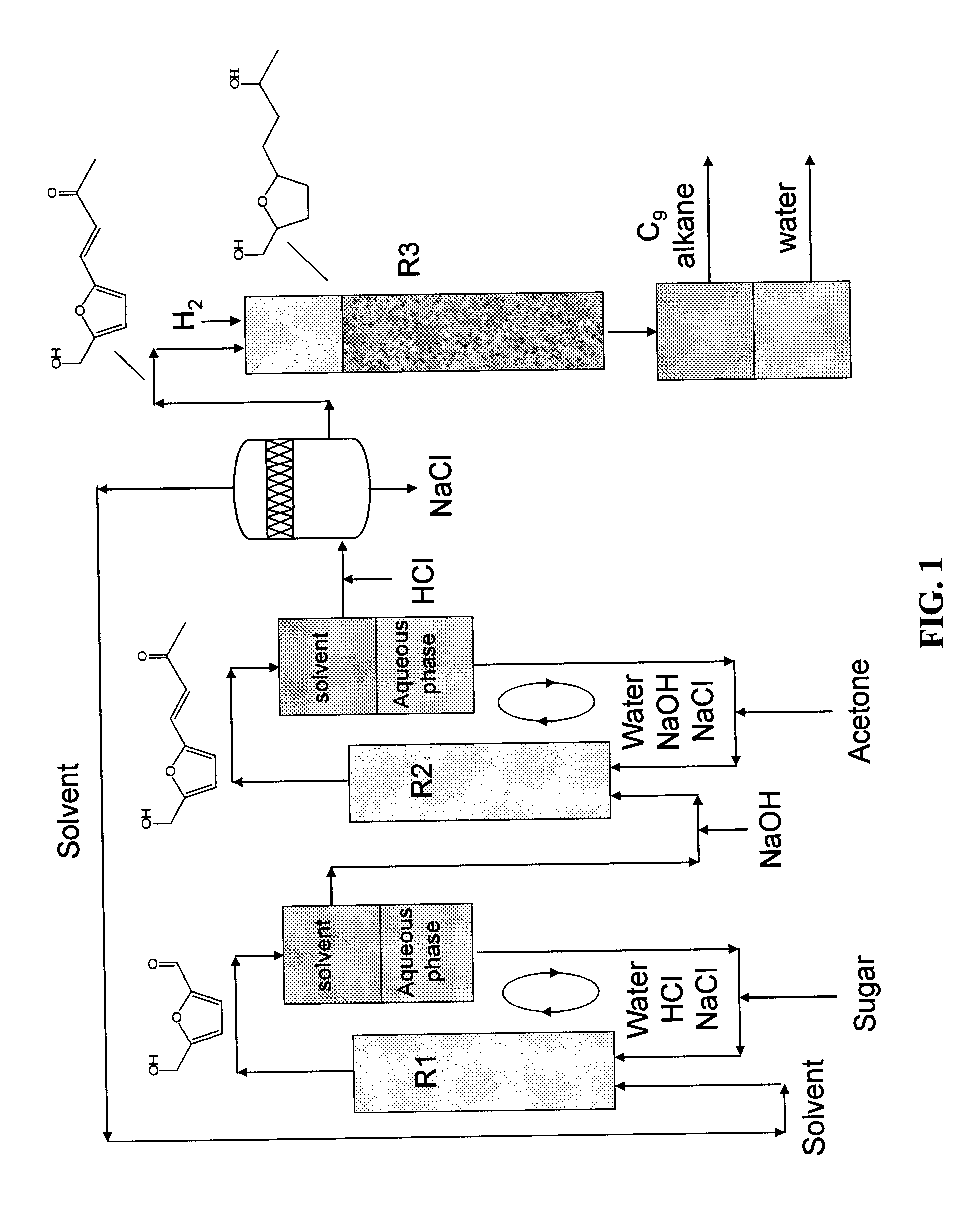

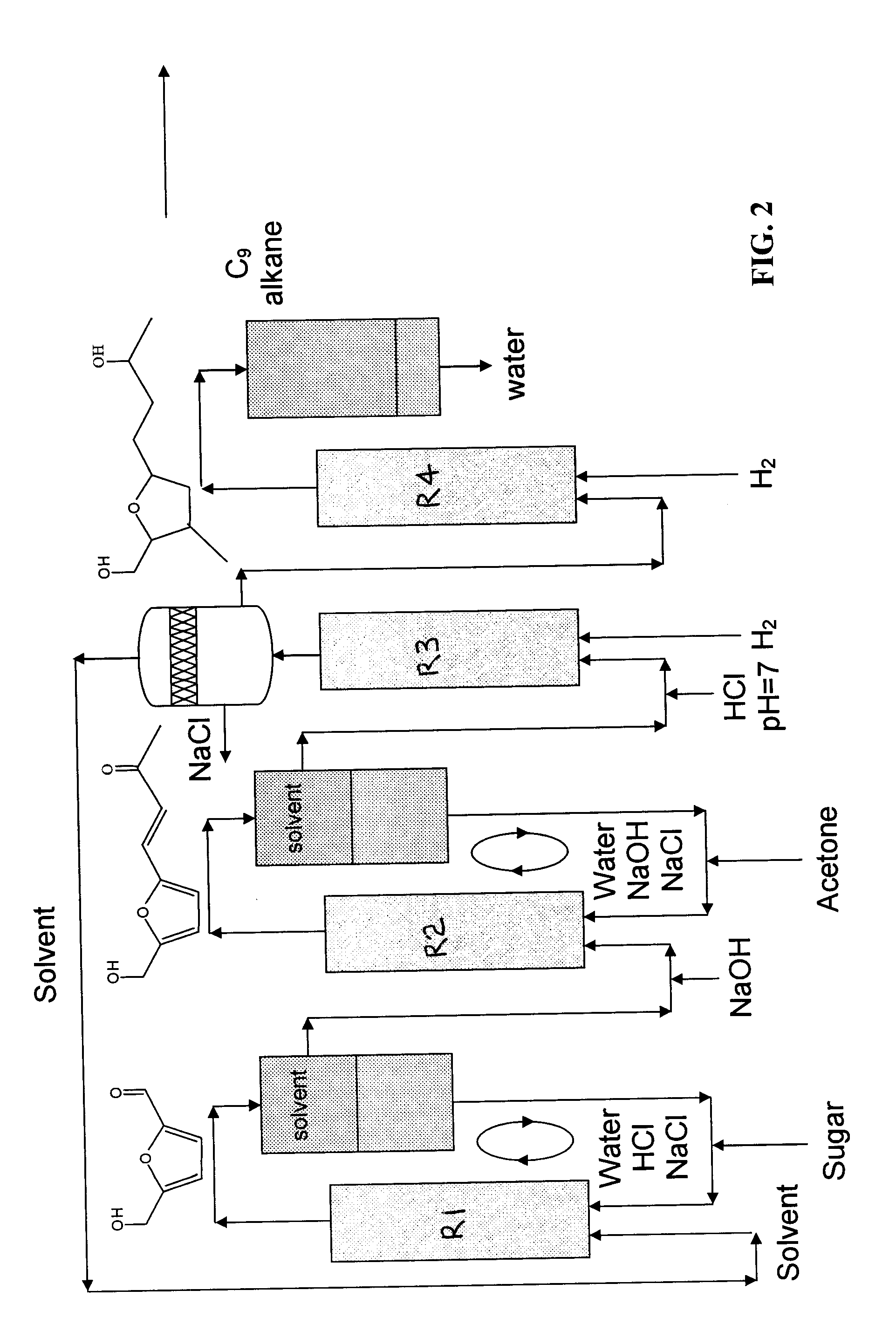

Described is a method for making a composition comprising alkanes. The composition is suitable for use as a liquid transportation fuel in general, and jet fuel in particular. The method includes dehydrating a feedstock solution comprising a carbohydrate, in the presence of an acid catalyst, to yield at least one furan derivative compound, in a reaction vessel containing a biphasic reaction medium: an aqueous reaction solution and a substantially immiscible organic extraction solution. The furan derivative compound is then subjected to a self-aldol condensation reaction or a crossed-aldol condensation reaction with another carbonyl compound to yield a beta-hydroxy carbonyl compound and / or an alpha-beta unsaturated carbonyl compound. The beta-hydroxy carbonyl and / or alpha-beta unsaturated compounds are then hydrogenated to yield a saturated or partially saturated compound, followed by hydrodeoxygenation (e.g., dehydrating and hydrogenating) of the saturated or partially saturated compound to yield a composition of matter comprising alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

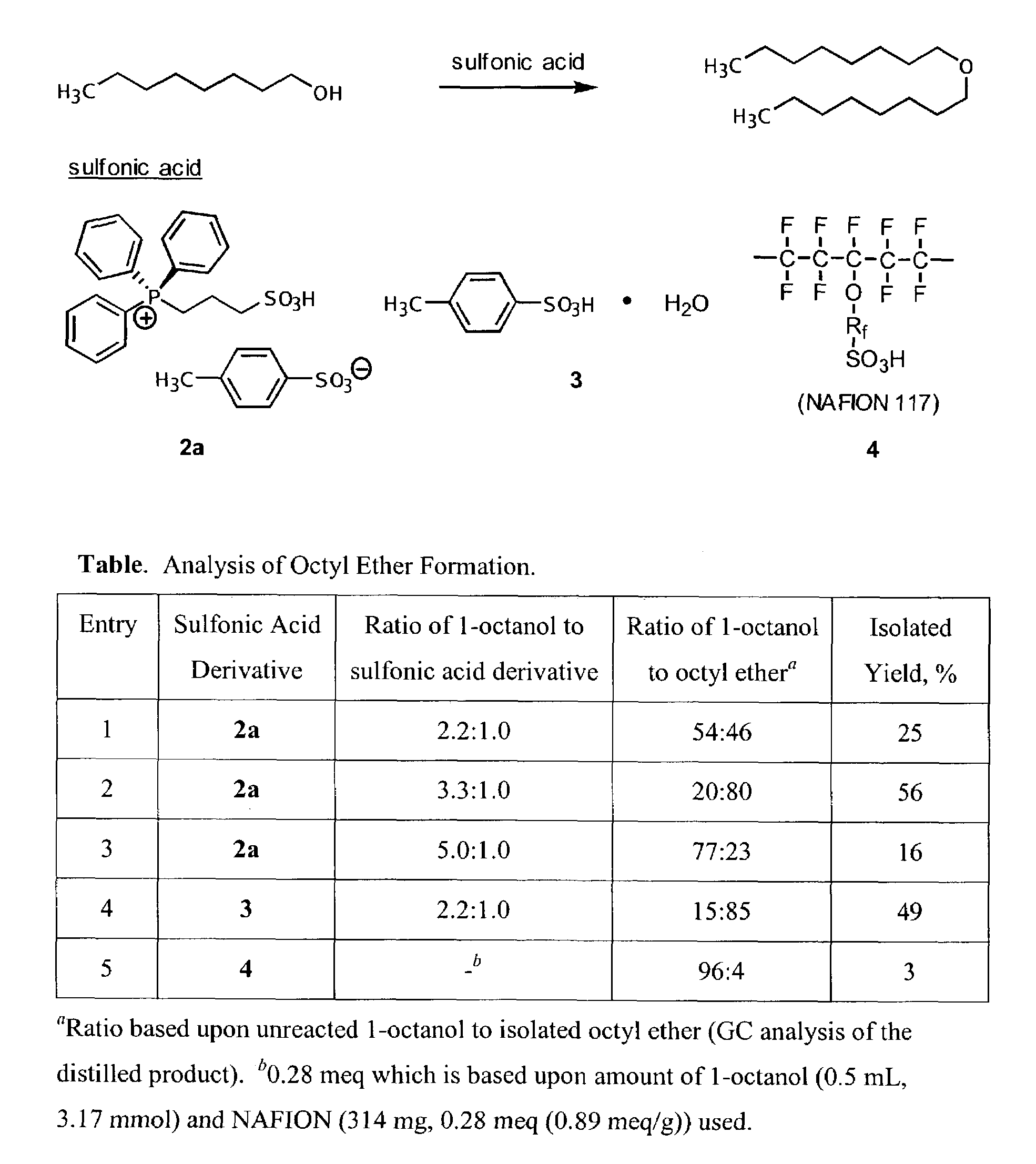

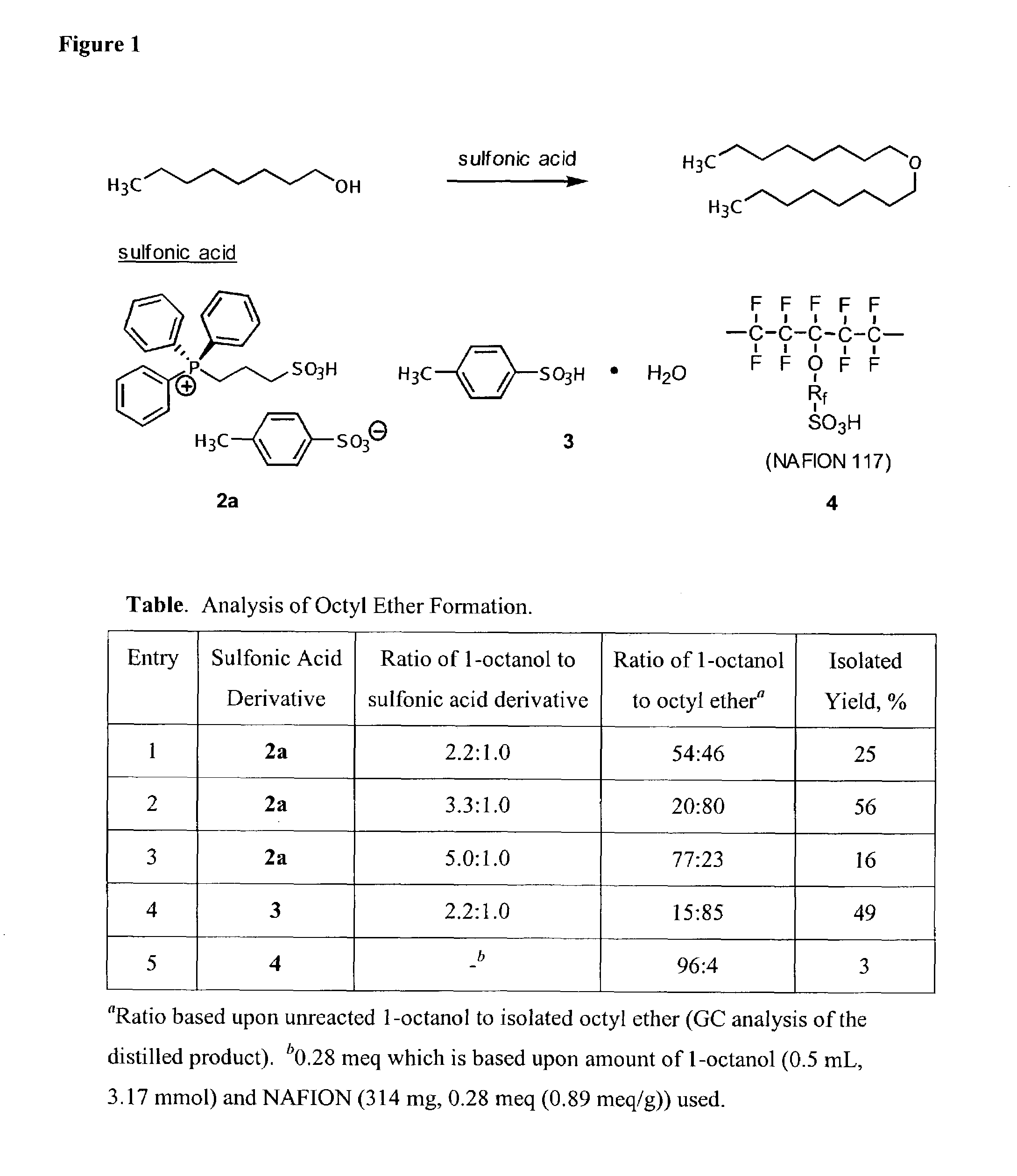

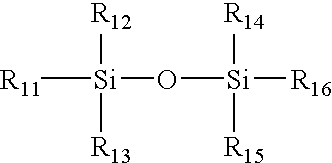

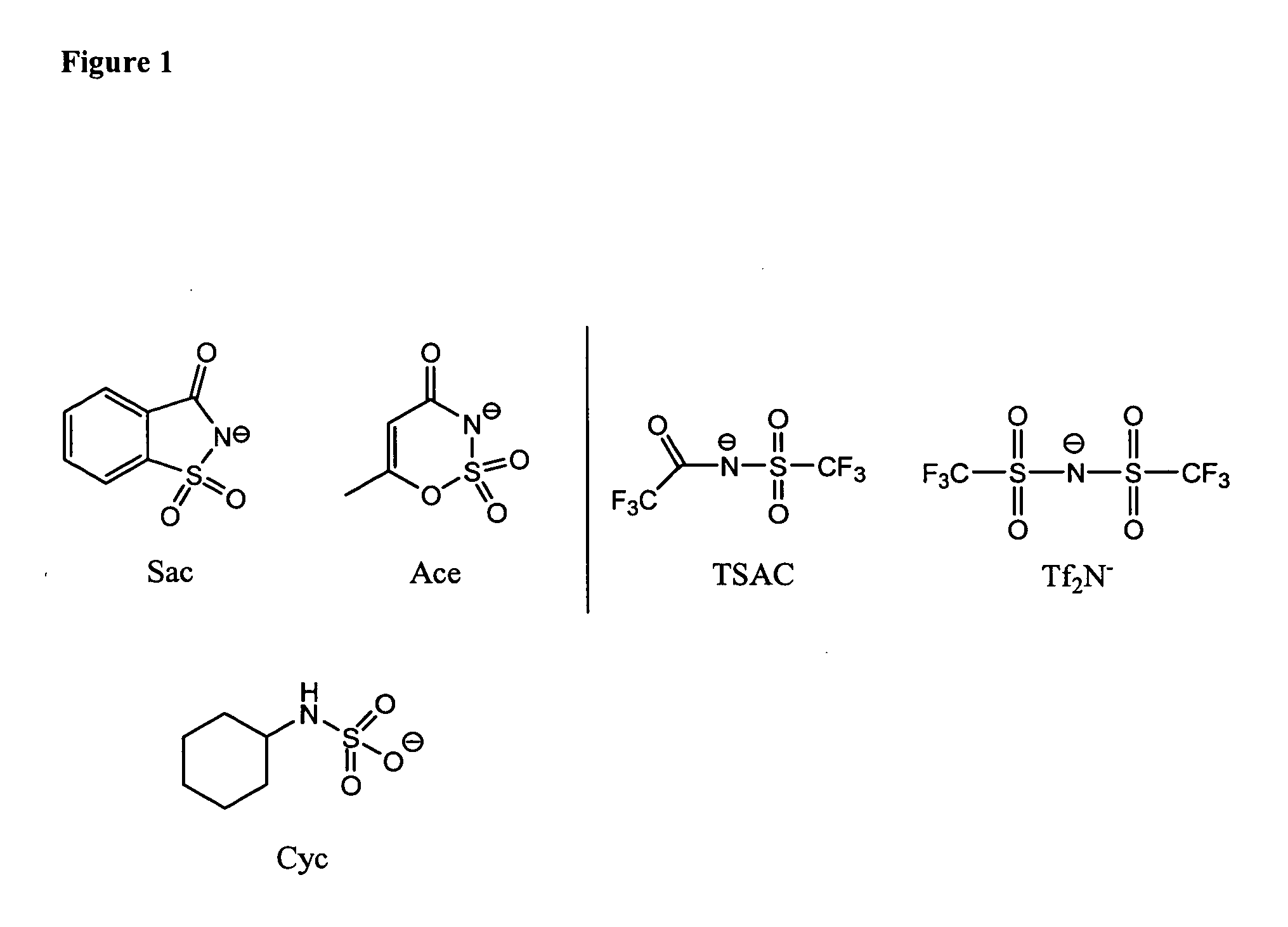

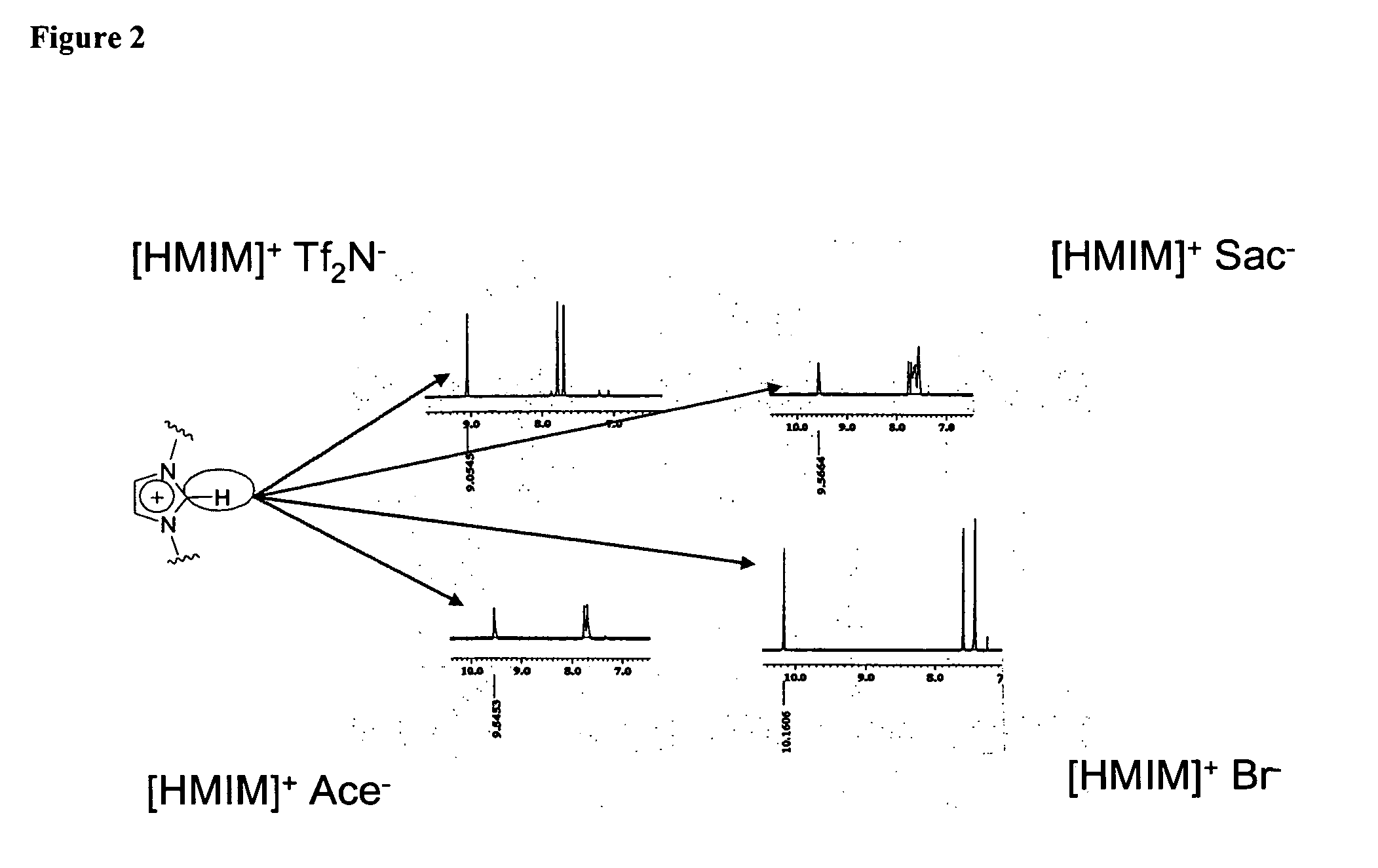

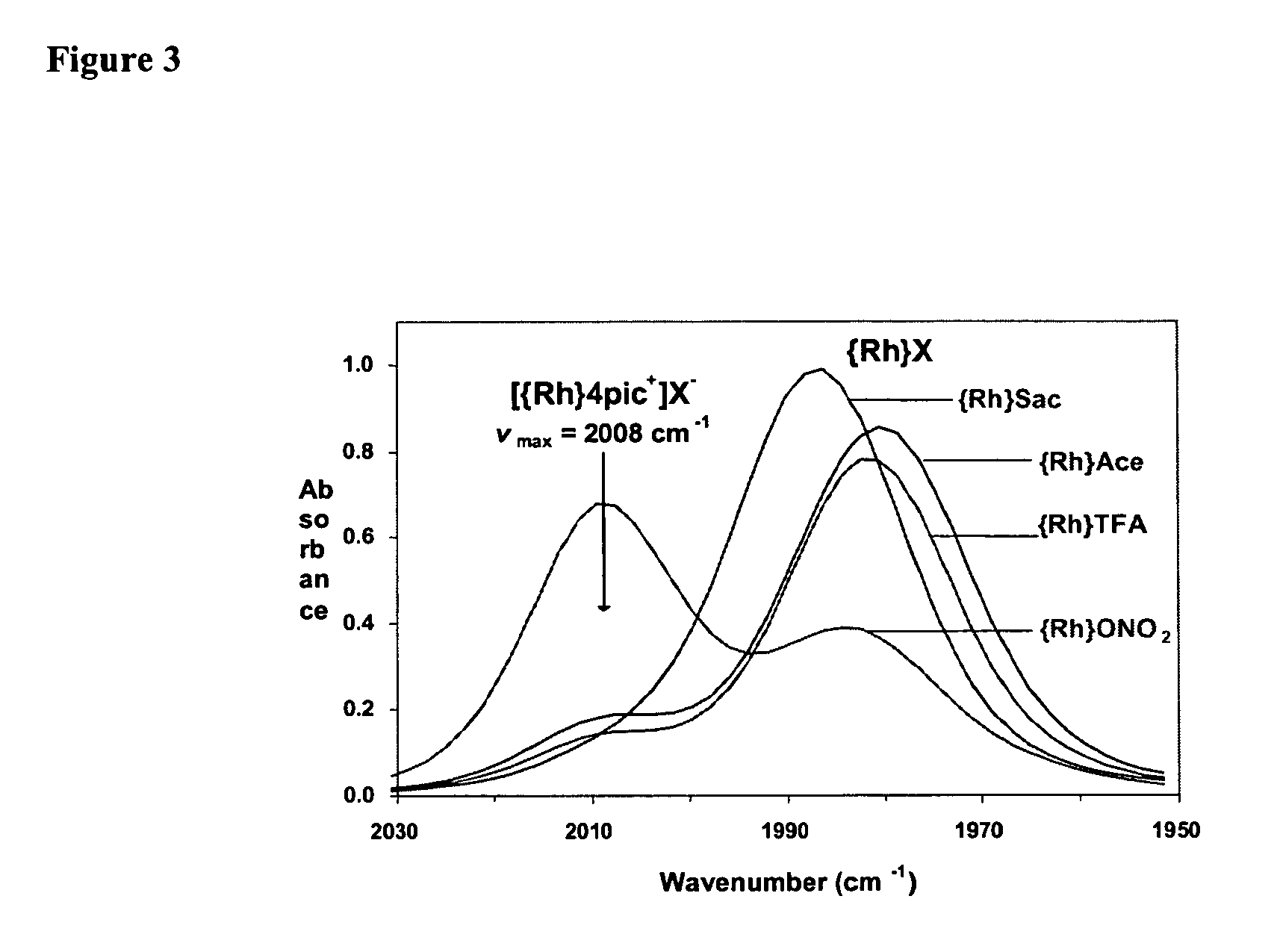

Functionalized ionic liquids, and methods of use thereof

One aspect of the present invention relates to ionic liquids comprising a pendant Bronsted-acidic group, e.g., a sulfonic acid group. Another aspect of the present invention relates to the use of an ionic liquid comprising a pendant Bronsted-acidic group to catalyze a Bronsted-acid-catalyzed chemical reaction. A third aspect of the present invention relates to ionic liquids comprising a pendant nucleophilic group, e.g., an amine. Still another aspect of the present invention relates to the use of an ionic liquid comprising a pendant nucleophilic group to catalyze a nucleophile-assisted chemical reaction. A fifth aspect of the present invention relates to the use of an ionic liquid comprising a pendant nucleophilic group to remove a gaseous impurity, e.g., carbon dioxide, from a gas, e.g., sour natural gas.

Owner:UNIV OF SOUTH ALABAMA

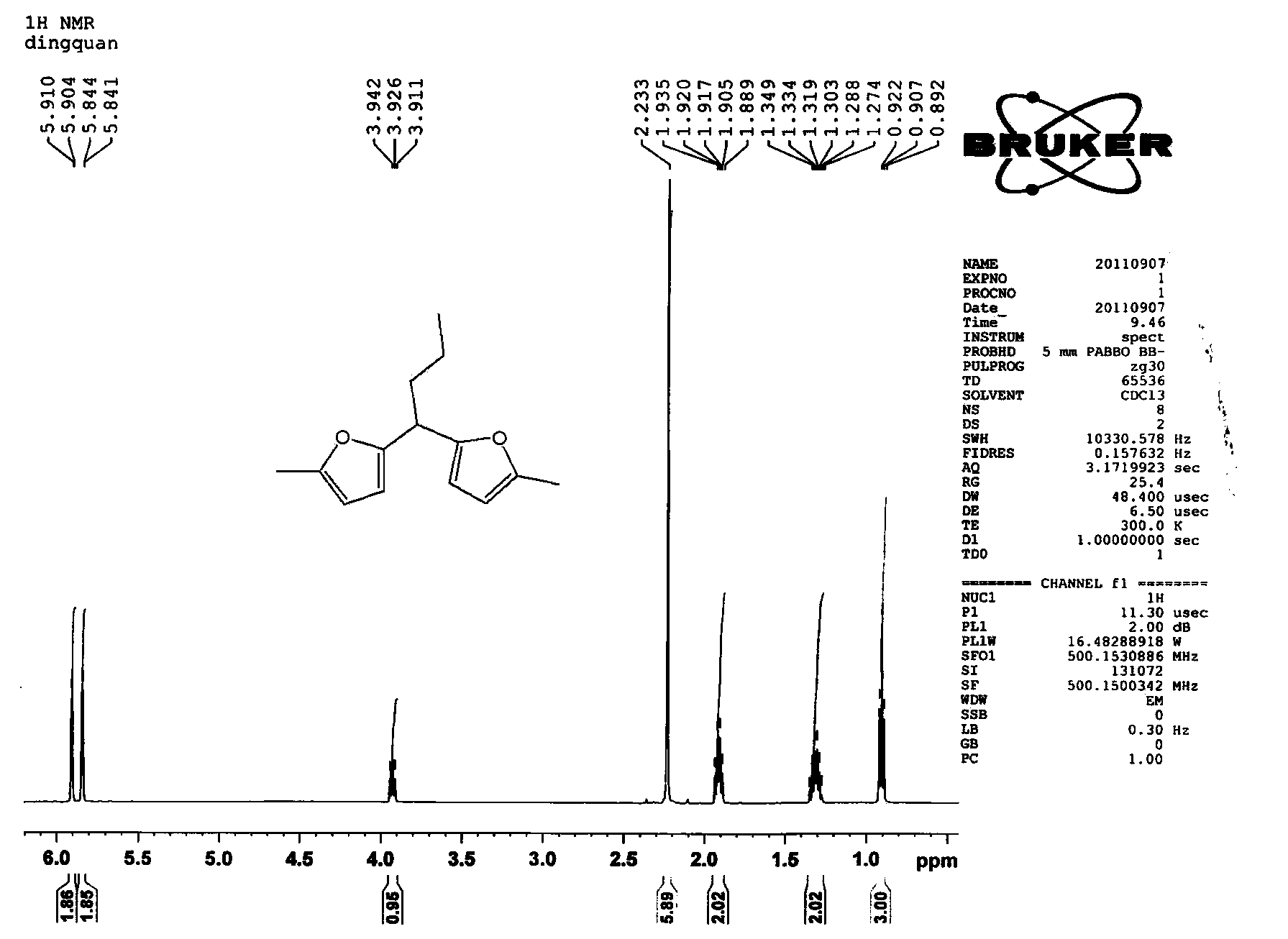

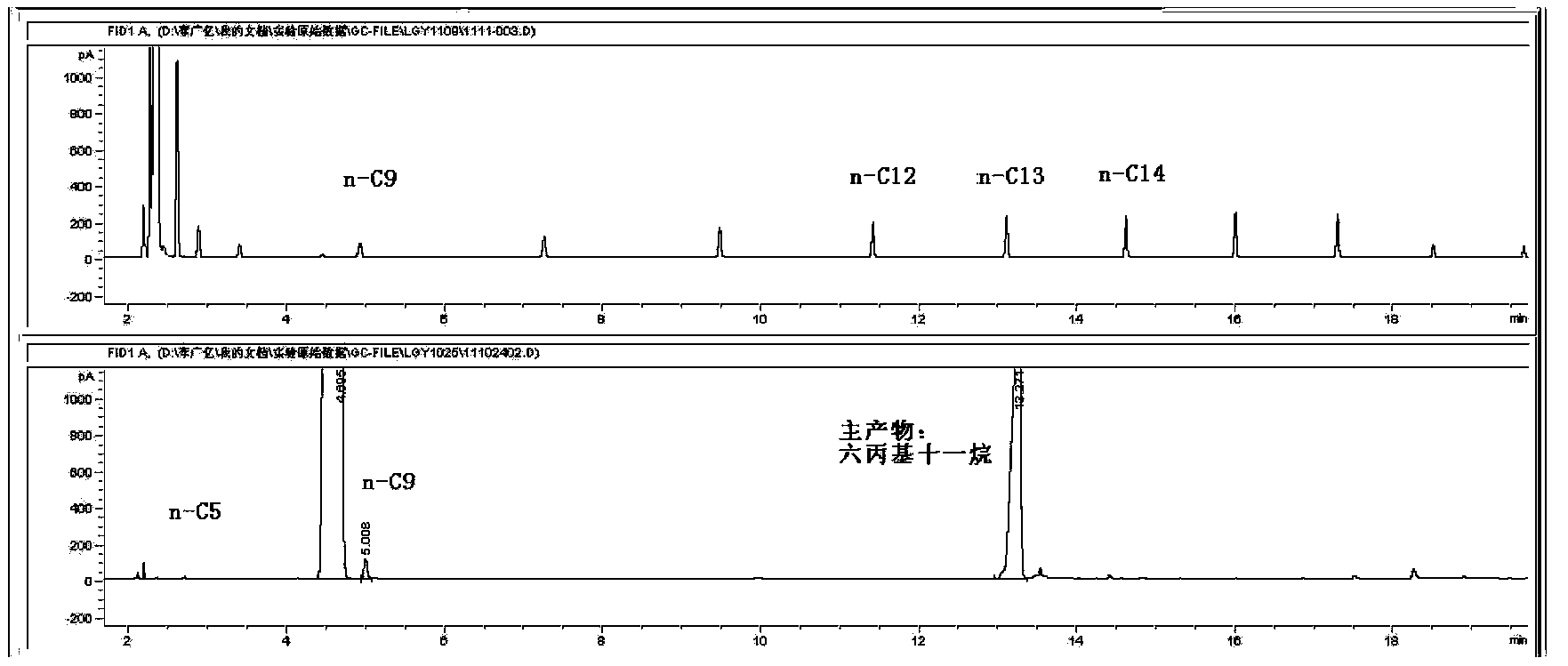

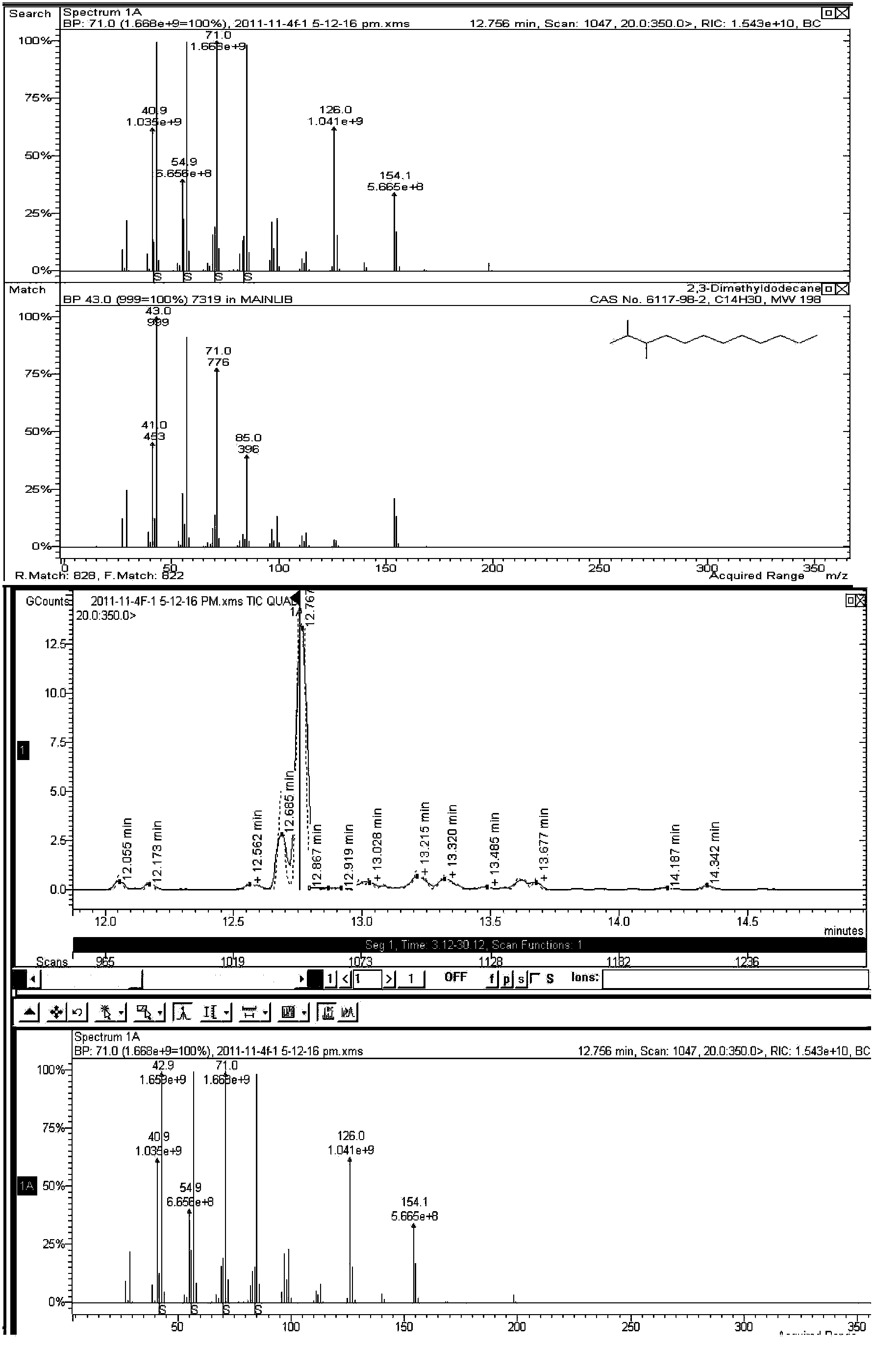

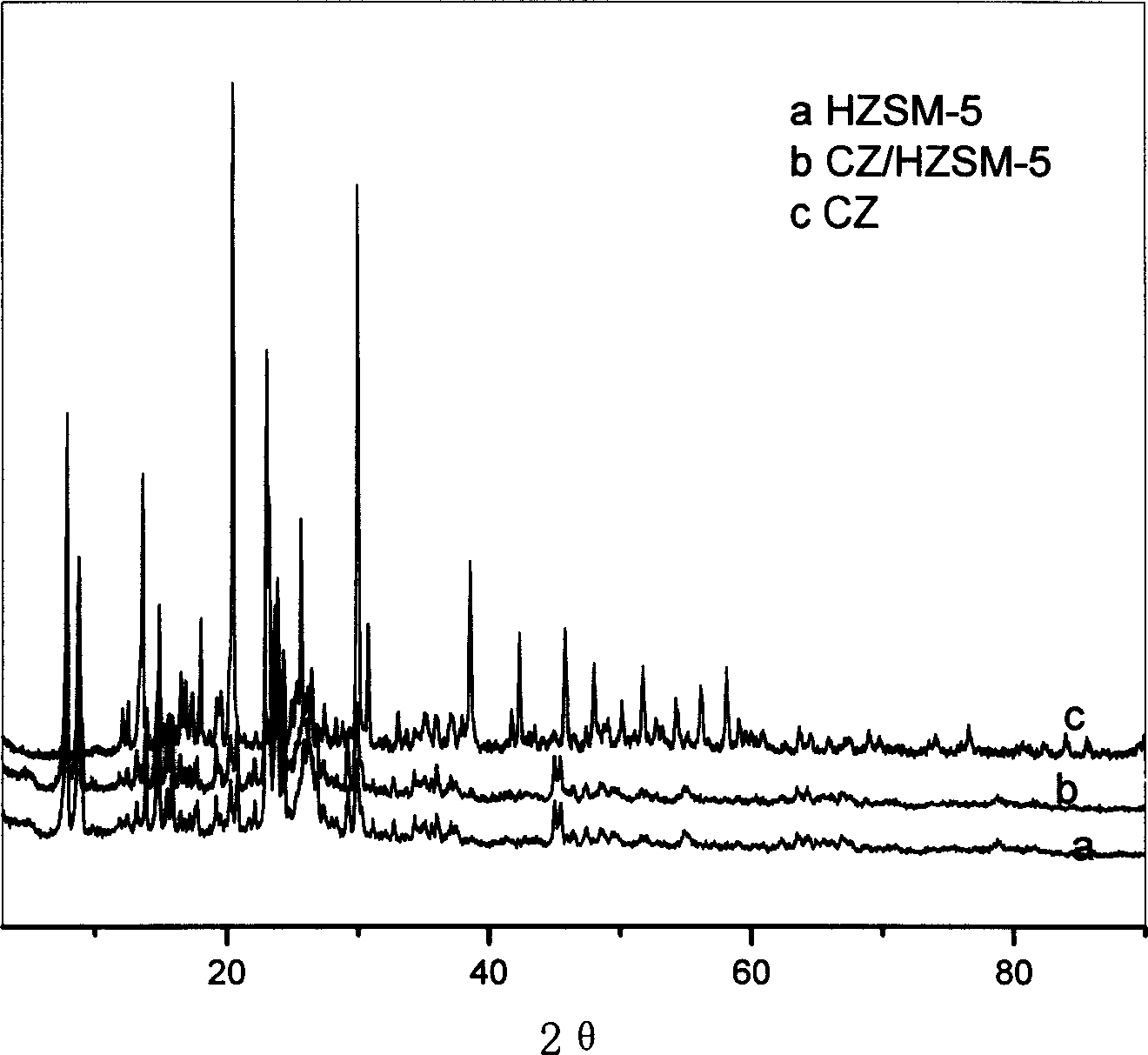

Preparation method of aviation kerosene or diesel

The present invention relates to a novel synthetic route of a liquid chain hydrocarbon fuel totally independent of fossil energy based on a lignocellulose raw material to obtain a platform compound. The method includes three parts: 1) preparing oxygen-containing organic compounds with carbon chain length of 8-16 through the acid-catalyzed alkylation reaction by taking lignocelluloses-based carbonyl-containing platform compounds and furan platform compounds as raw materials on a novel solid catalyst; 2) effectively removing carbon-carbon double bonds and carbon-oxygen double bonds to prepare saturated oxygen-containing organic compounds by hydrogenation of the alkylated product; and 3) conducting hydrodeoxygenation for the hydrogenated alkylation product by using a metal-solid acid bifunctional catalyst to obtain the biomass aviation kerosene or high grade diesel fuel with the carbon chain length of 8-16 and having a high energy density and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

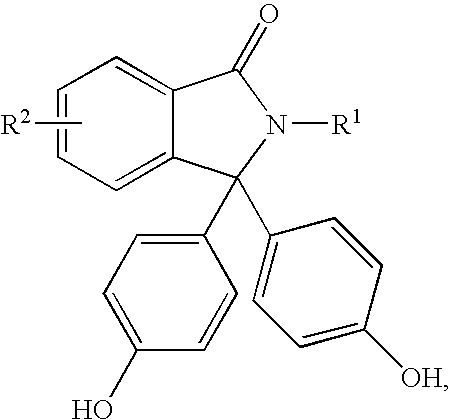

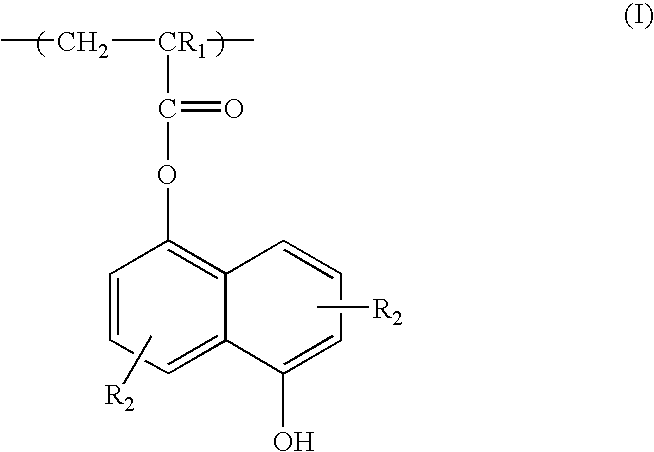

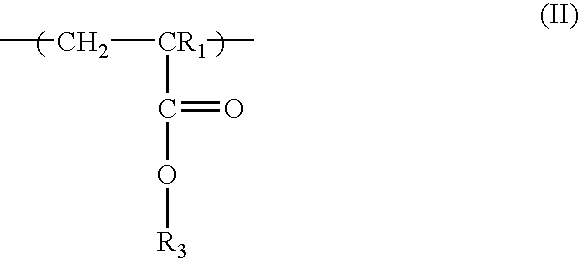

Methods for producing and purifying 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine monomers and polycarbonates derived therefrom

Disclosed herein is a method for producing a 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine. The method comprises forming a reaction mixture comprising at least one substituted or unsubstituted phenolphthalein, at least one substituted or unsubstituted primary hydrocarbyl amine, and an acid catalyst; and heating the reaction mixture to a temperature of less than 180° C. to remove a distillate comprising water and form a crude 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine product; where the 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine has a formula: where R1 is selected from the group consisting of a hydrogen and a hydrocarbyl group, and R2 is selected from the group consisting of a hydrogen, a hydrocarbyl group, and a halogen.

Owner:SHPP GLOBAL TECH BV

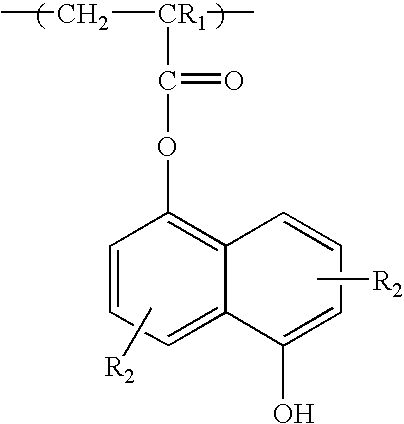

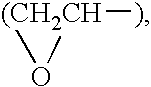

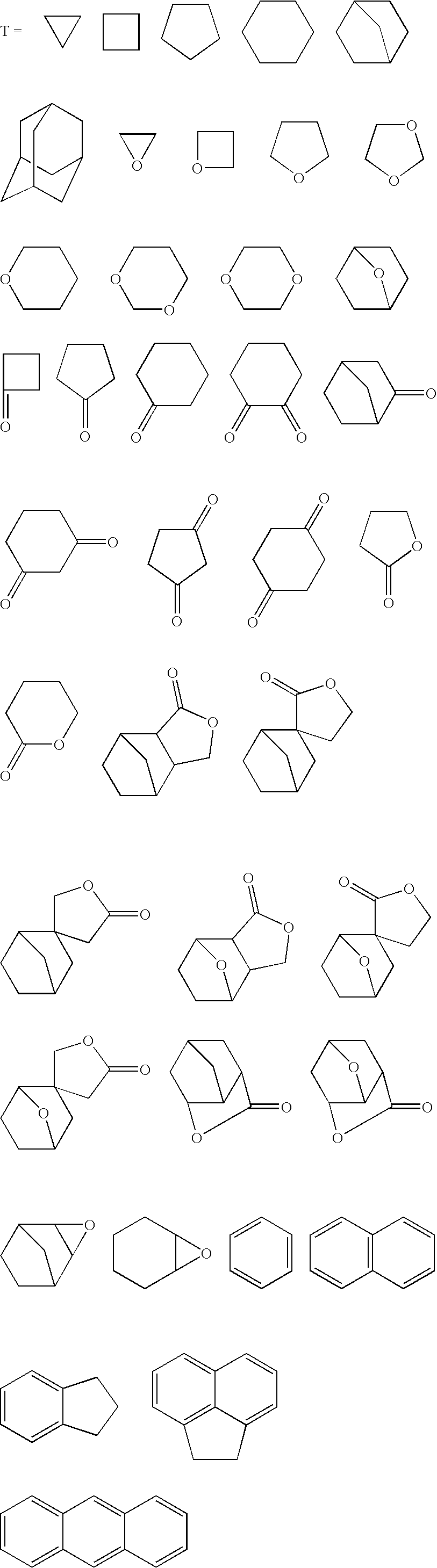

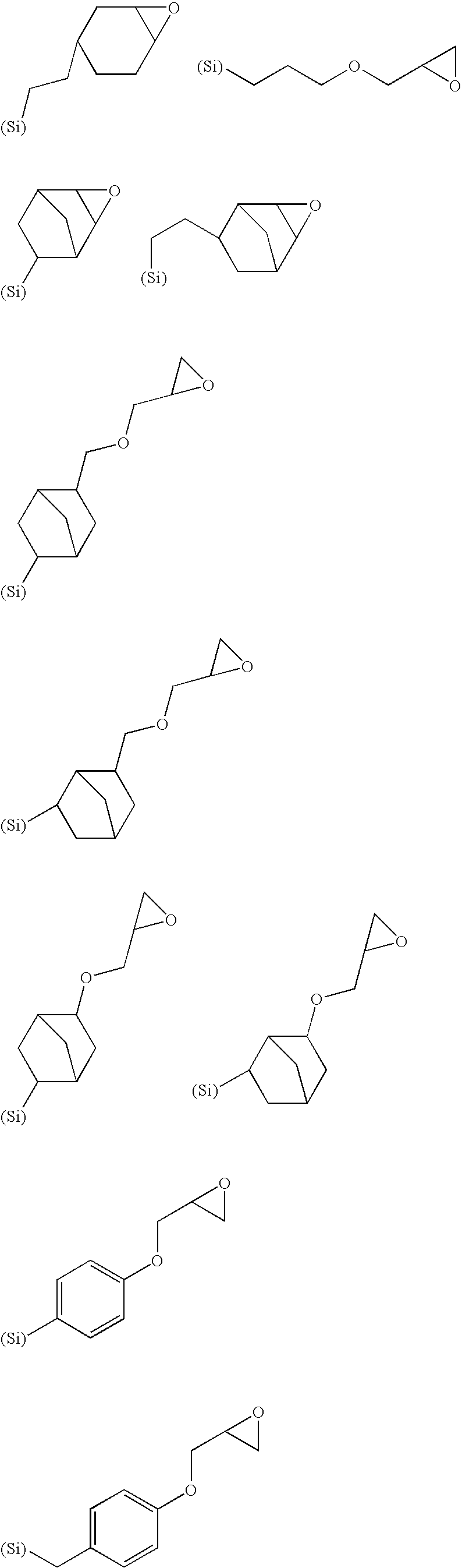

Positive resist containing naphthol functionality

ActiveUS20060105267A1Improve photolithographic effectExcellent etch resistancePhotosensitive material auxillary/base layersPhotosensitive material processingResistMethacrylate

Acid-catalyzed positive resist compositions which are imageable with 193 nm radiation are obtained using a polymer having acrylate / methacrylate monomeric units comprising a naphthol ester group. The resist may optionally contain polymer having acrylate / methacrylate monomeric units with fluorine-containing functional groups. The resists containing the polymer having acrylate / methacrylate monomeric units comprising a naphthol ester group have an improved process window, including improved etch resistance and reduced swelling compared to conventional fluorine-containing 193 nm resist.

Owner:IBM CORP

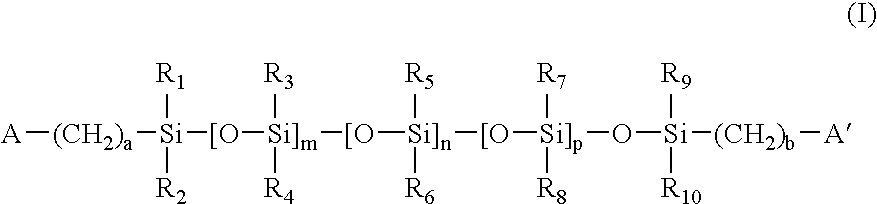

Contact lens materials

InactiveUS6921802B2High oxygen permeabilityLow densityOptical partsOptical elementsSingle vesselTrimethylsilyl

A method for reducing the modulus of polymer silicone hydrogel compositions by employing monomeric polysiloxanes endcapped with trimethylsilyl to reduce the crosslinking density of the hydrogel. The synthesis consists of a single vessel acid catalyzed ring opening polymerization and may be employed to produce copolymers useful as hydrogel contact lens materials.

Owner:BARCLAYS BANK PLC AS SUCCESSOR AGENT

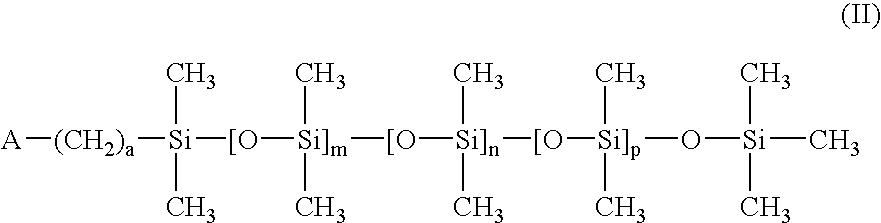

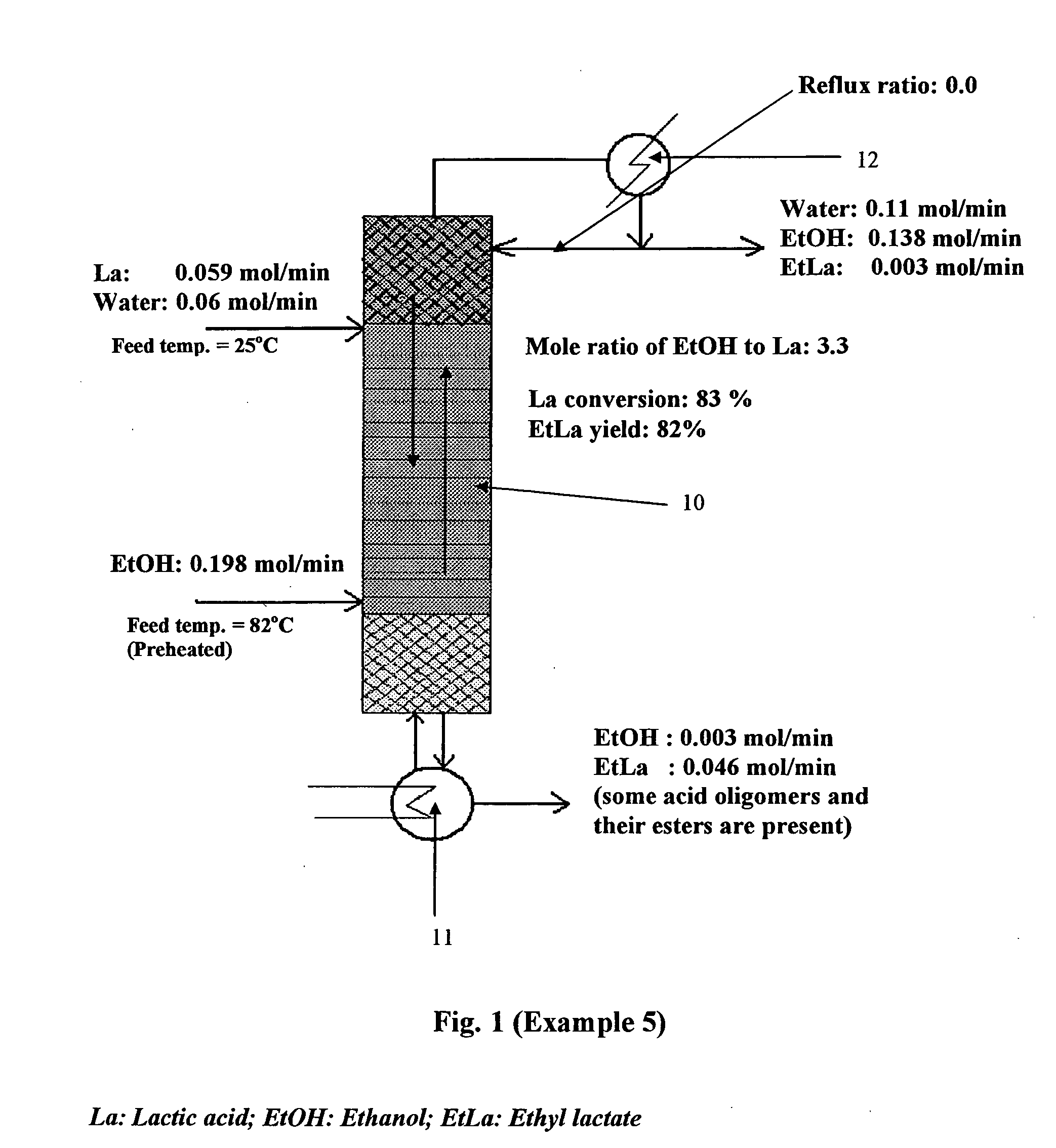

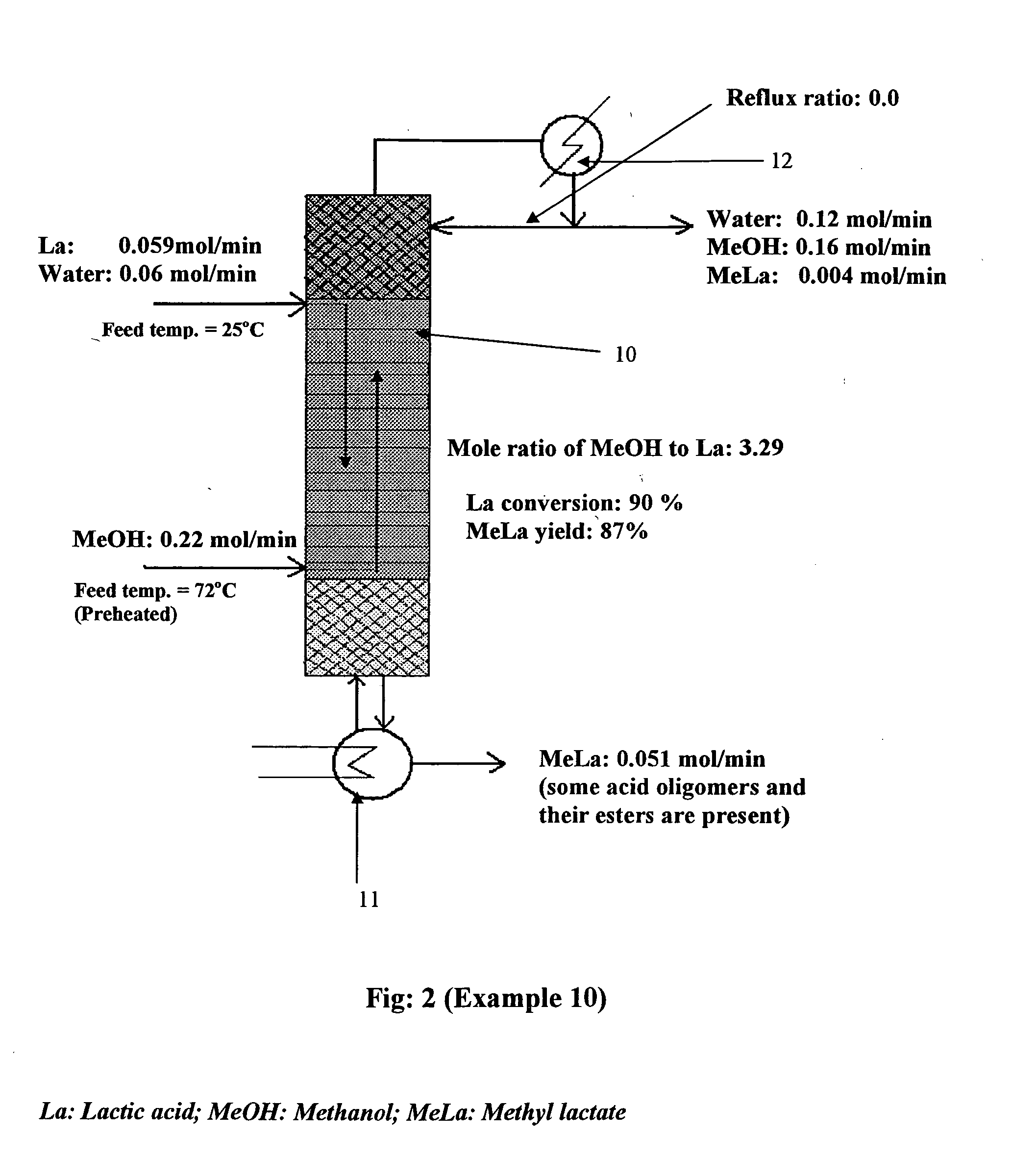

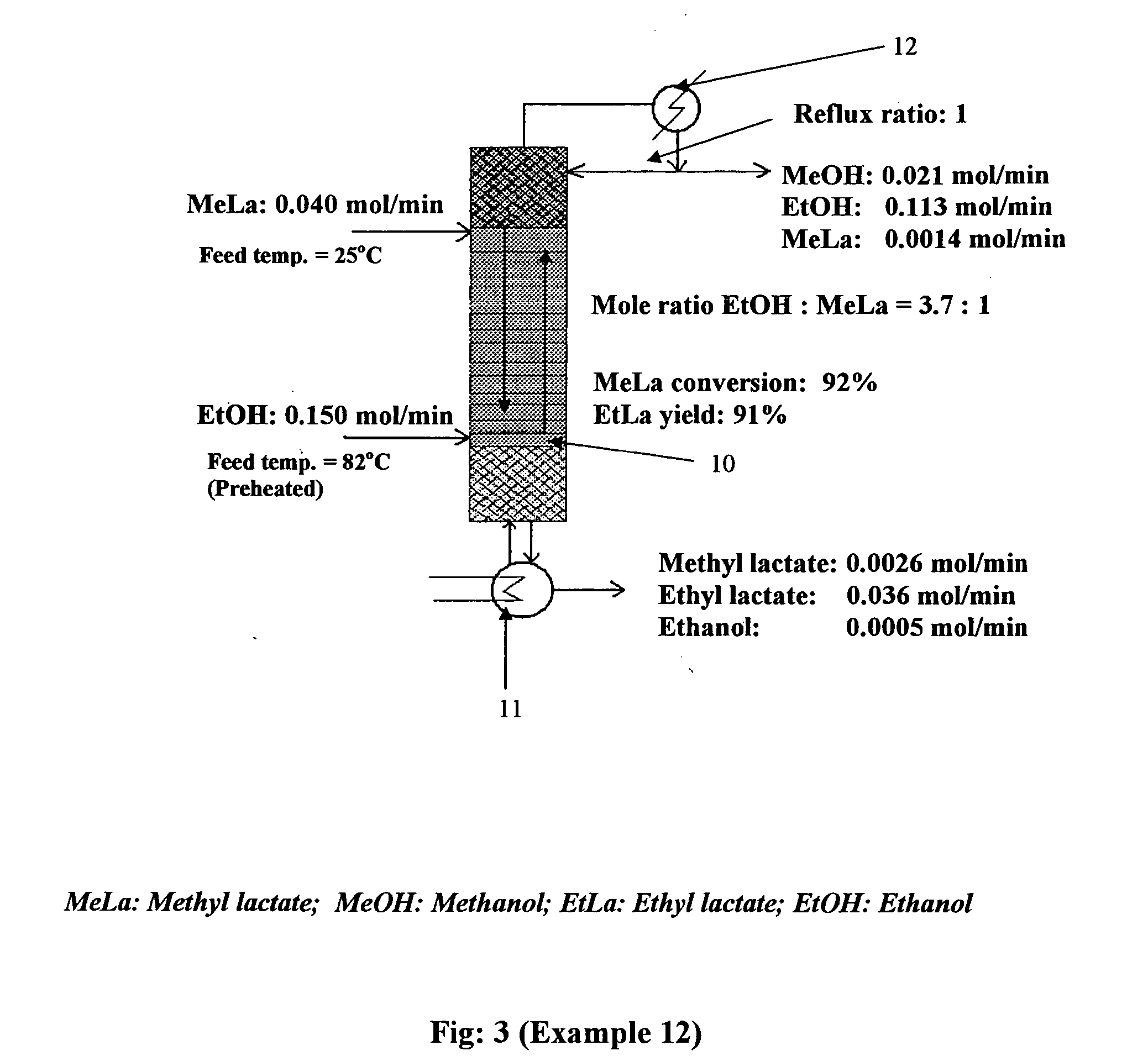

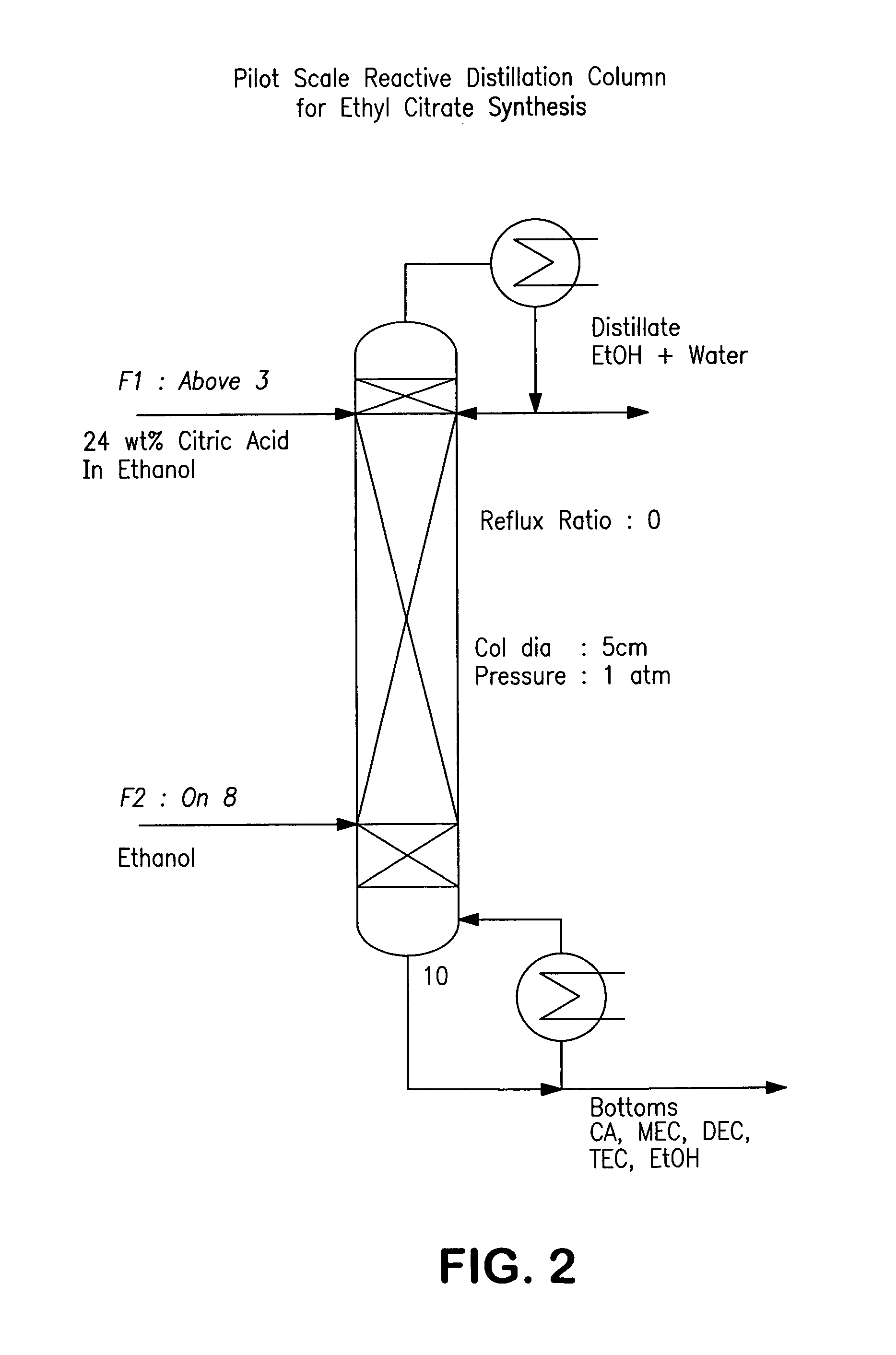

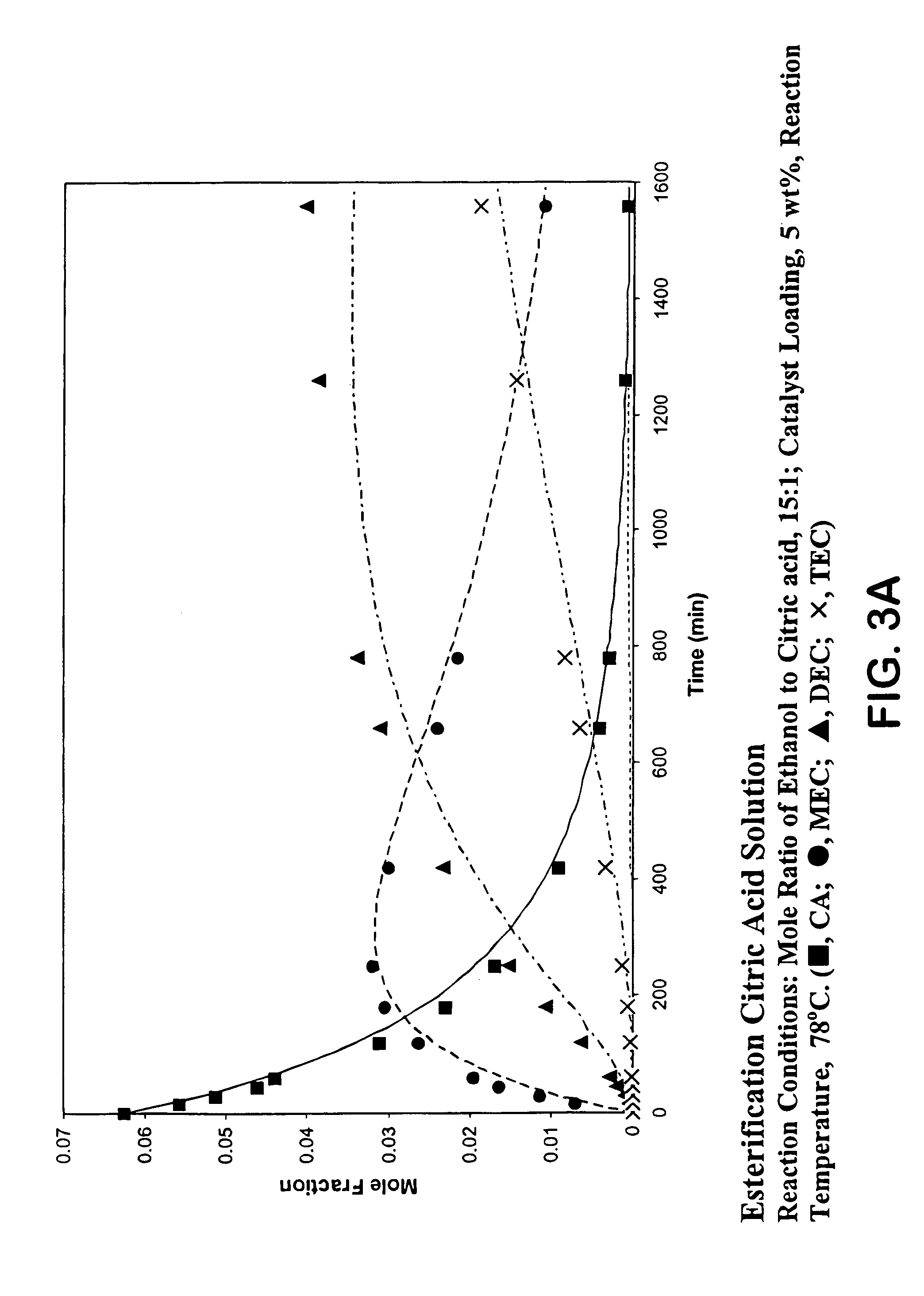

Process for production of organic acid esters

InactiveUS20060014977A1Speed up the processPreparation by ester-hydroxy reactionOrganic compound preparationOrganic acidChemical reaction

A process for producing organic acid esters using continuous countercurrent reactive distillation using acid catalysts in a structured packing in a single column (10) is described. In the reactive distillation an organic acid ester is formed by chemical reaction and can be purified to its final state within the single column. Organic acid esters are produced at relatively low cost, with less waste production, and in a less complicated manner than prior processes. Organic acid ester have uses as solvents, as intermediate chemicals, and in consumer products.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

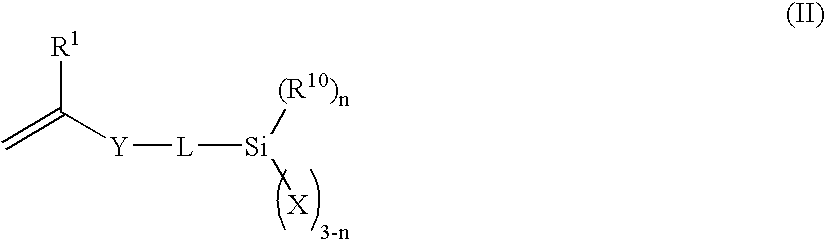

Fine inorganic oxide dispersion, coating composition, optical film, antireflection film, polarizing plate, and image display device

InactiveUS20050154086A1Improve dispersion stabilityImprove visibilityPigment treatment with organosilicon compoundsOrganic solventAlcohol

An inorganic oxide dispersion containing an organic solvent, and inorganic oxide particles surface-treated with at least one of a hydrolyzate and a partial condensate of an organosilane compound represented by formula (I), the inorganic oxide particles being dispersed in the organic solvent: (R10)m—Si(X)4−m (I) as defined herein, the surface treatment of the inorganic oxide particles being carried out in a presence of at least one of: (a) an acid catalyst; and (b) a metal chelate compound having Zr, Ti or Al as a center metal and at least one of an alcohol represented by formula: R3OH in which R3 represents an allyl group having 1 to 10 carbon atoms, and a compound represented by formula: R4COCH2COR5 as defined herein, as a ligand.

Owner:FUJIFILM CORP

Method for preparation of aviation kerosene and diesel oil from biomass derivative

The invention relates to a new liquid chain hydrocarbon fuel synthetic route that acquires a platform chemical compound based on a lignocellulose raw material and is completely independent of fossil energy. The liquid fuel obtained by the method can be used as a substitute of aviation kerosene and diesel oil or as an additive for improving the cetane number and cold hardiness of fuels, thereby reducing the national dependence on imported petroleum in terms of liquid fuels. The method provided in the invention consists of two parts: 1) on a novel solid acid catalyst, an aldehyde group-containing compound (such as formaldehyde, acetaldehyde, propionaldehyde, and butyraldehyde, etc.) and a furan platform compound (such as furan, methyl furan, and hydroxylmethyl furan, etc.) undergo an acid catalyzed alkylation reaction to prepare an oxygen-containing organic compound with a carbon chain length of 8-16; and 2) hydrogenation and hydrodeoxygenation are conducted on an alkylation product to hydrogenate unsaturated bonds and remove the oxygen therein, thus preparing aviation kerosene or high grade diesel oil with a carbon chain length ranging from 8 to 16.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

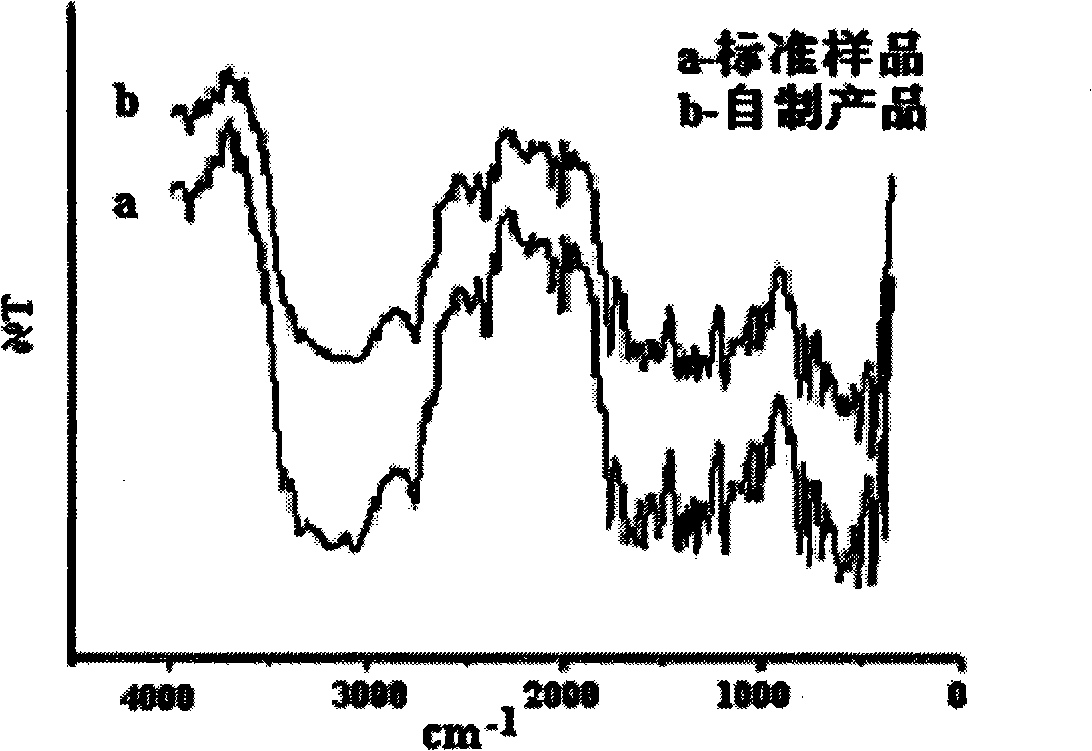

Preparation for hydrophobic solid acid catalyst

InactiveCN1613559AAcidicHydrophobicMolecular sieve catalystsCatalyst activation/preparationHydration reactionAlkyl transfer

A hydrophobic solid, acid catalyst for the acid catalyzing reaction, such as esterifying reaction, alkylation reaction and hydration reaction, is prepared by attaching the inorganic metal salt to the high-hydrophobicity carrier. Its advantages are high catalyst activity and selectivity, high stability, and high hydrophobicity.

Owner:BEIJING UNIV OF CHEM TECH

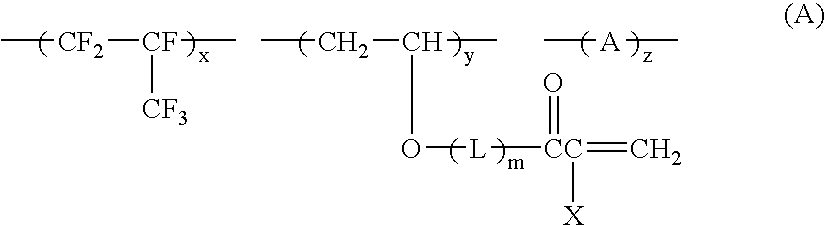

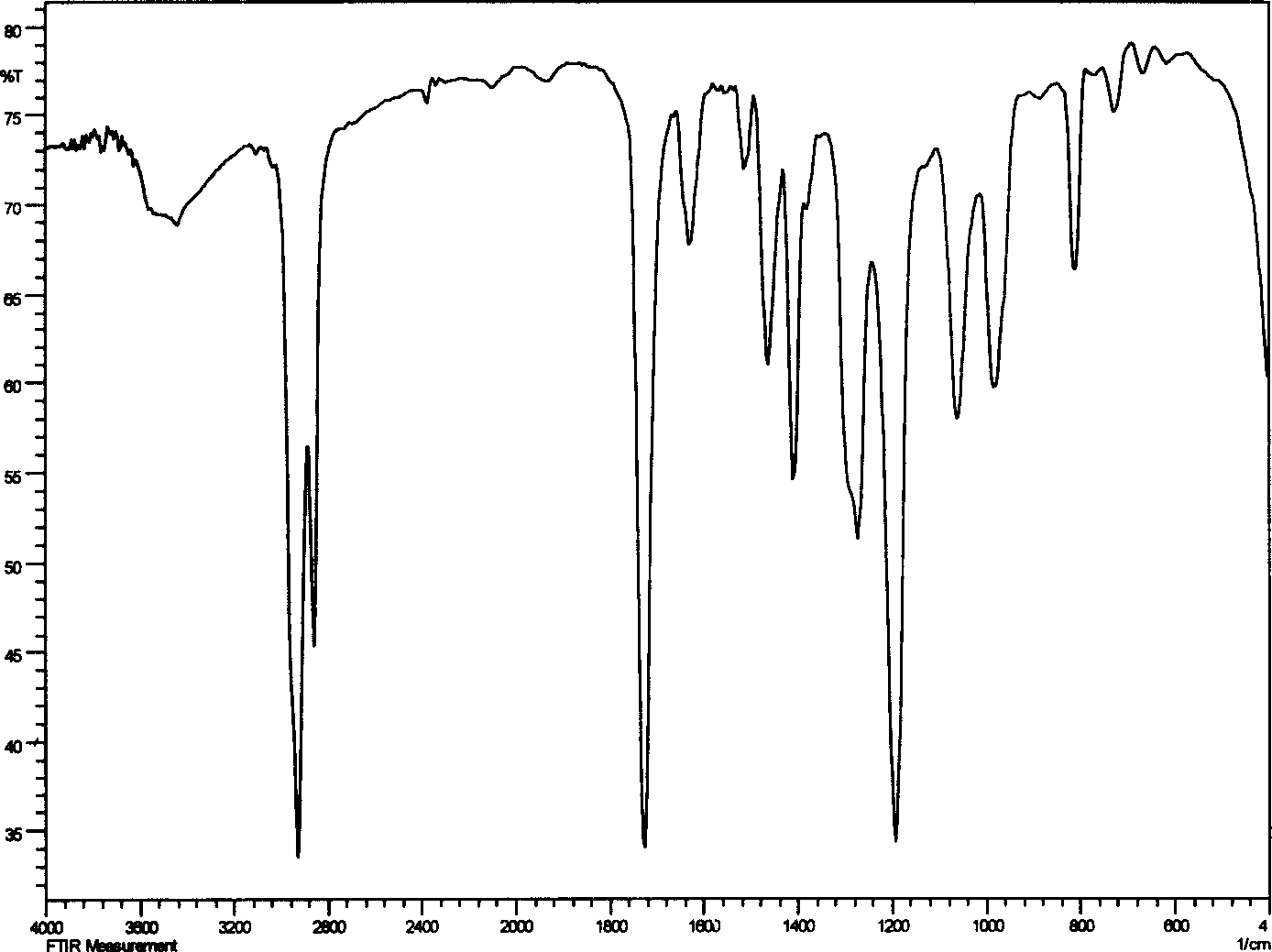

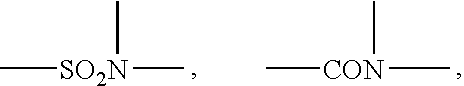

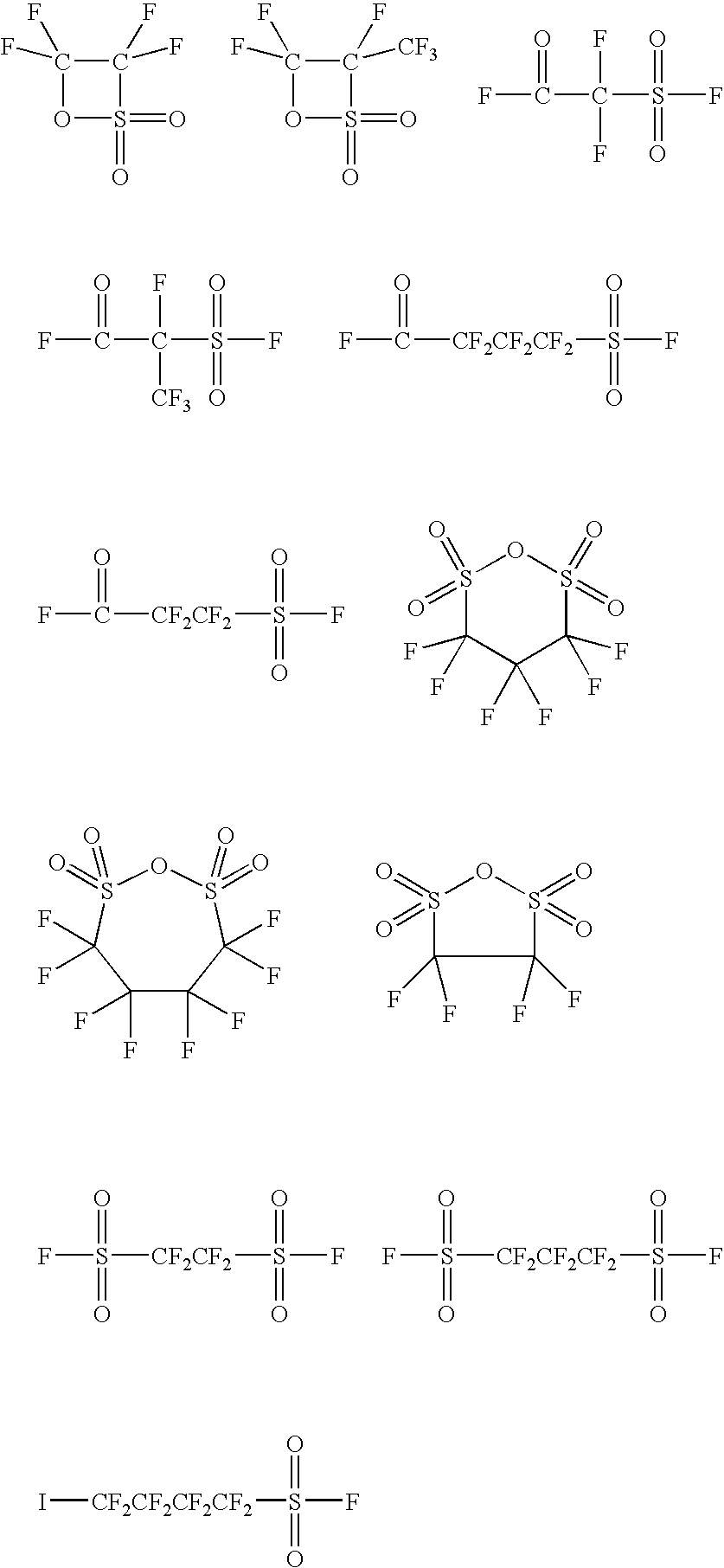

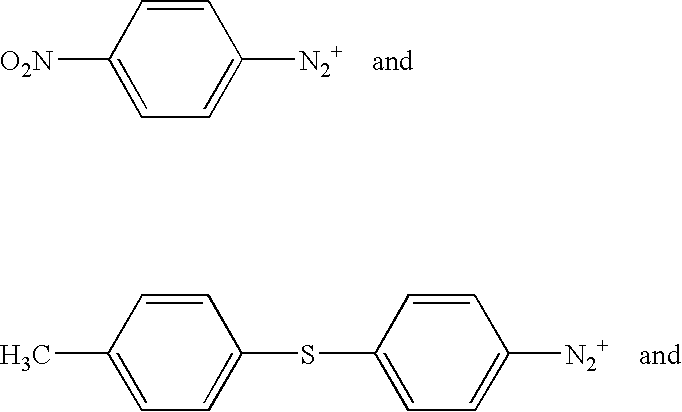

Ionic photoacid generators with segmented hydrocarbon-fluorocarbon sulfonate anions

InactiveUS6841333B2Improve solubilitySolubility in organic compoundsOrganic compound preparationPhotosensitive materialsSolubilityAcid catalyzed

Photoacid generator salts comprising photoactive cationic moieties and segmented, highly fluorinated-hydrocarbon anionic moieties are disclosed which provide high photoacid strength and can be tailored for solubility and polarity. The present invention further relates to photoacid generators as they are used in photoinitiated acid-catalyzed processes for uses such as photoresists for microlithography and photopolymerization.

Owner:3M INNOVATIVE PROPERTIES CO

Preparation method of hydrophobic silica aerogel heat-insulation composite material

ActiveCN104556969AReduce replacement timeReduce the number of replacementsSilicon compoundsFiberPtru catalyst

The invention relates to a preparation method of a hydrophobic silica aerogel heat-insulation composite material. The method comprises steps as follows: (1) preparation of silica sol: siloxane is used as a precursor, an organic solvent, water and an acid catalyst are added, and the silica sol is obtained; (2) preparation of composite gel: a flame retardant and an infrared blocking agent are added to the silica sol, the mixture is evenly mixed, a base catalyst is added, an inorganic fiber product is immersed in the silica sol, and the mixture is left to stand; (3) solvent replacement: the composite gel is replaced by the organic solvent; (4) drying: the composite gel is dried. With the adoption of the method, the process is simple, the production cycle is short, the cost is lower, the equipment requirement is low, reaction conditions are controllable, product performance is excellent, and the prepared silica aerogel composite material has the overall waterproof performance, the extremely low heat conductivity coefficient and the excellent high-temperature heat-insulation performance, can pass an incombustibility test under the condition that the material is ensured to be hydrophobic as a whole and reaches level A1 according to the incombustibility test.

Owner:纳诺科技有限公司

Method for producing pulp and lignin

InactiveUS20040244925A1Pretreatment with acid reacting compoundsPulp bleachingCellulosePtru catalyst

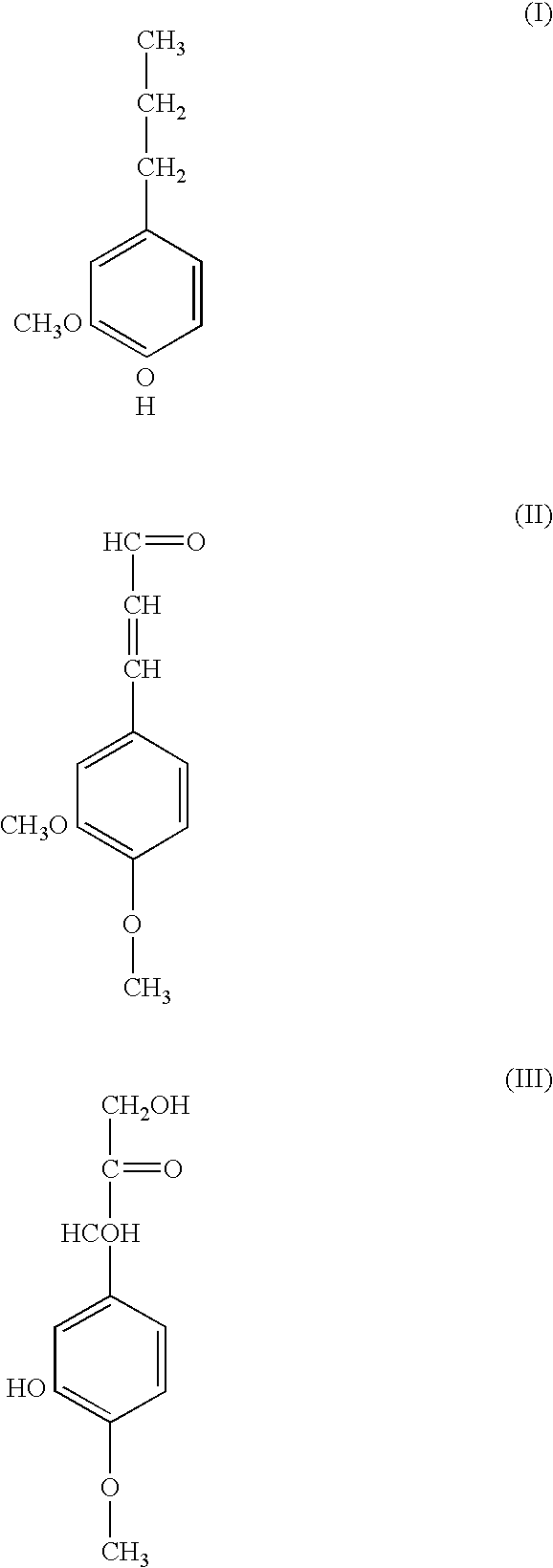

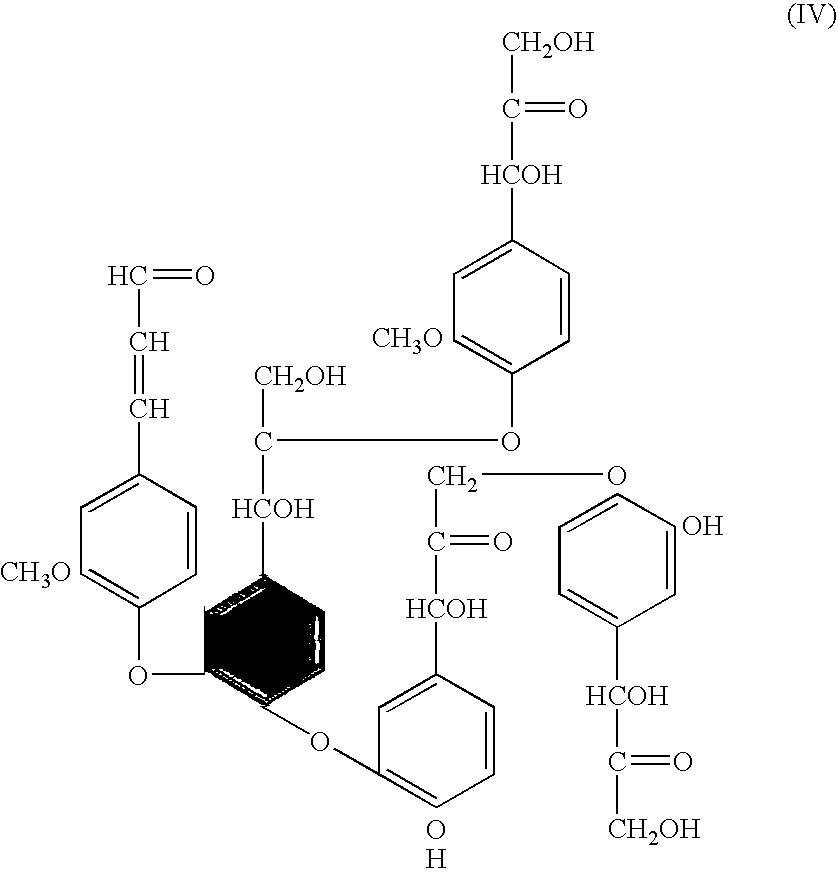

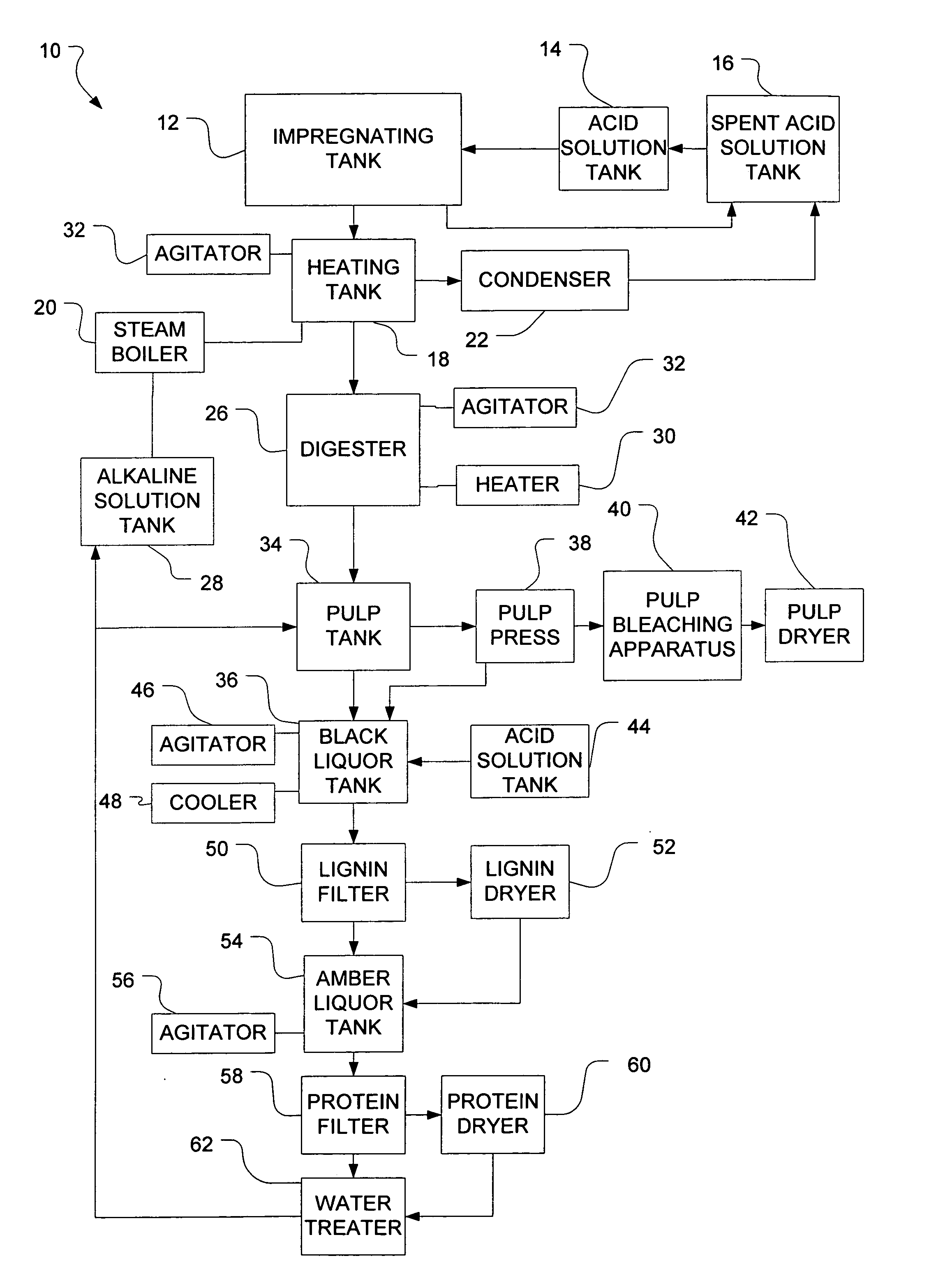

The invention provides for methods for producing pulp (comprising cellulose) and lignin from lignocellulosic material, such as wood chips. The methods involve acid catalyzed hydrolysis. Lignocellulosic material having a relatively high moisture concentration can be used as the starting material. The lignocellulosic material is impregnated with an acid (preferably nitric acid) and heated. During the heating lignin is depolymerized at relatively low temperatures, and the acid catalyst is distilled off. The acid catalyst can be collected and recycled after impregnation and heating. The lignocellulosic material is then digested in an alkaline solution under heat, dissolving the lignin and allowing the pulp to be removed. Acid is added to the black liquor to precipitate the lignin which is then removed. The resultant amber liquor can be further processed into other ancillary products such as alcohols and / or unicellular proteins.

Owner:PACIFIC PULP RESOURCES

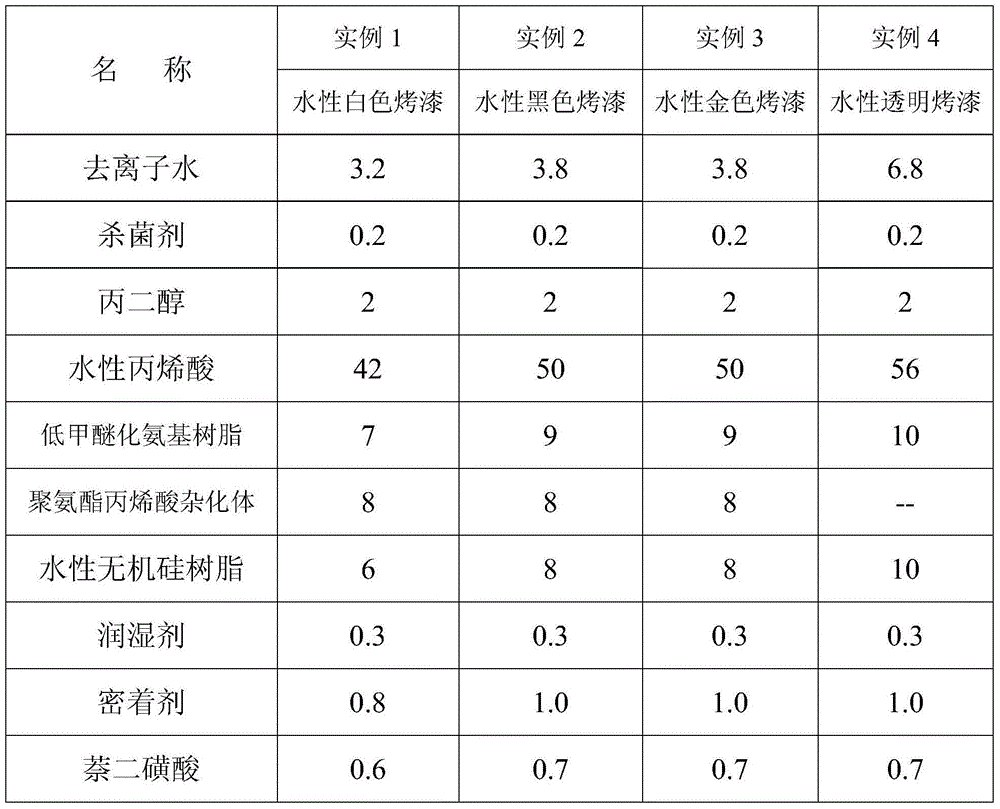

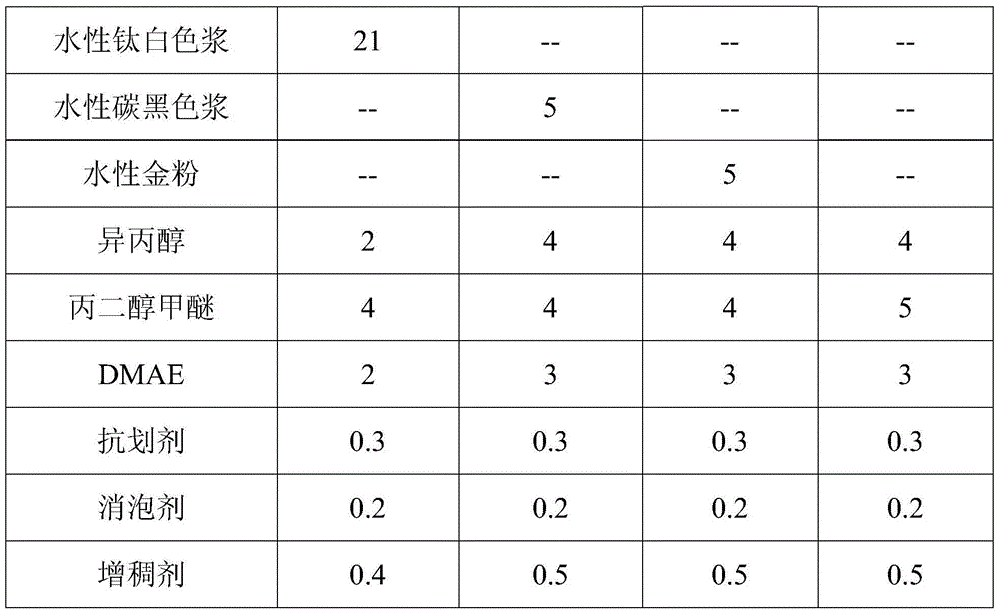

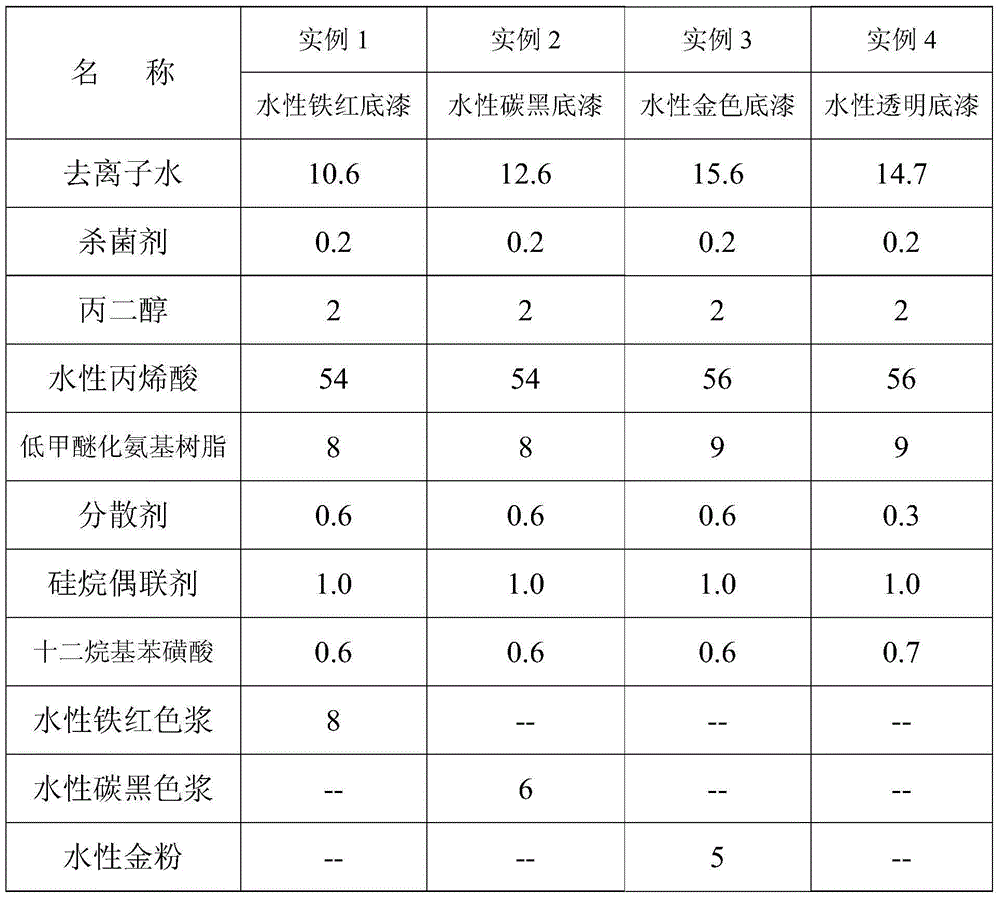

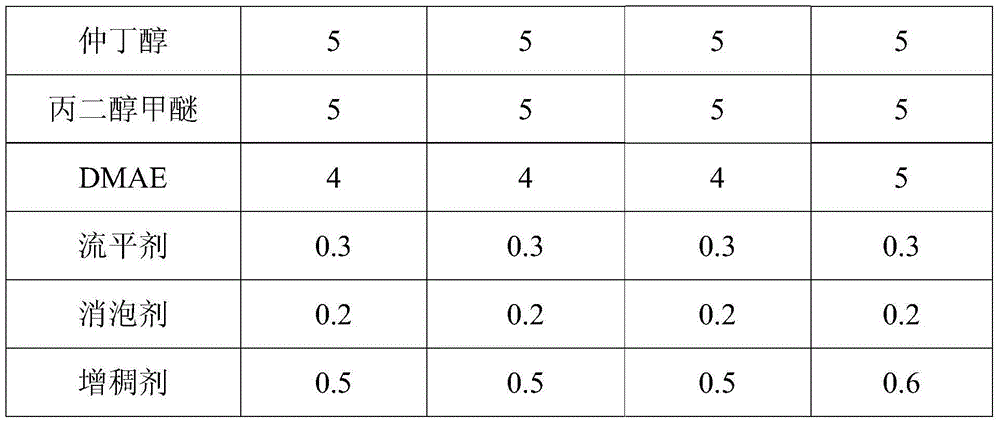

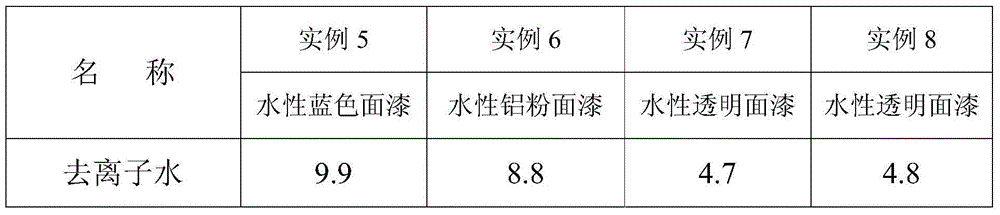

Preparation method for high-hardness water-based glass baking paint

ActiveCN103937354AHigh hardnessNo pollution in the processPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention relates to a preparation method for a high-hardness water-based glass baking paint composed of nano water-based acrylic resin, low-methoxylation amino resin, a water-based polyurethane acrylic hybrid, hardening resin, a colorant, a substrate wetting agent, an adhesive agent, an acid catalyst, a film-forming auxiliary agent, a defoaming agent, an anti-scratch flatting agent, a thickening agent, a bactericide, a pH regulator, a cosolvent and water. The prepared water-based glass baking paint has the advantages of low VOC, no pollution to the environment, no poison and harm to operators, strong coating film adhesive force, good flexibility, high hardness, excellent wear resistance, excellent water resistance, excellent alcohol resistance, excellent salt fog resistance, simple construction, and stable storage. A prepared paint film has the hardness reaching 5 H or more, and has anti-scratch and wear-resistance properties of a ceramic glaze film; a prepared glass product achieves effects of blue and white porcelain, enamel colored glaze porcelain, and white glazed porcelain; and the water-based glass baking paint is widely used for surface protection and decoration of wine bottles, perfume bottles, glass products, lamps, woodware, metals, plastics and other products.

Owner:深圳市莱莉雅环保科技有限公司

Silicon-containing film-forming composition, silicon-containing film, silicon-containing film-bearing substrate, and patterning method

ActiveUS20080026322A1Sufficient etching resistanceImprove accuracyPhotosensitive materialsSemiconductor/solid-state device manufacturingAmmonium compoundsPtru catalyst

A silicon-containing film is formed from a heat curable composition comprising (A-1) a silicon-containing compound obtained by effecting hydrolytic condensation of a hydrolyzable silicon compound in the presence of an acid catalyst and removing the acid catalyst, (A-2) a silicon-containing compound obtained by effecting hydrolytic condensation of a hydrolyzable silicon compound in the presence of a basic catalyst and removing the basic catalyst, (B) a hydroxide or organic acid salt of lithium, sodium, potassium, rubidium or cesium, or a sulfonium, iodonium or ammonium compound, (C) an organic acid, and (D) an organic solvent. The silicon-containing film allows an overlying photoresist film to be patterned effectively.

Owner:SHIN ETSU CHEM IND CO LTD

Production of esters of fatty acids and lower alcohols

InactiveUS20080051599A1Impurity can be harmfulBroad processingFatty acid esterificationFatty acids production/refiningTrans esterificationPtru catalyst

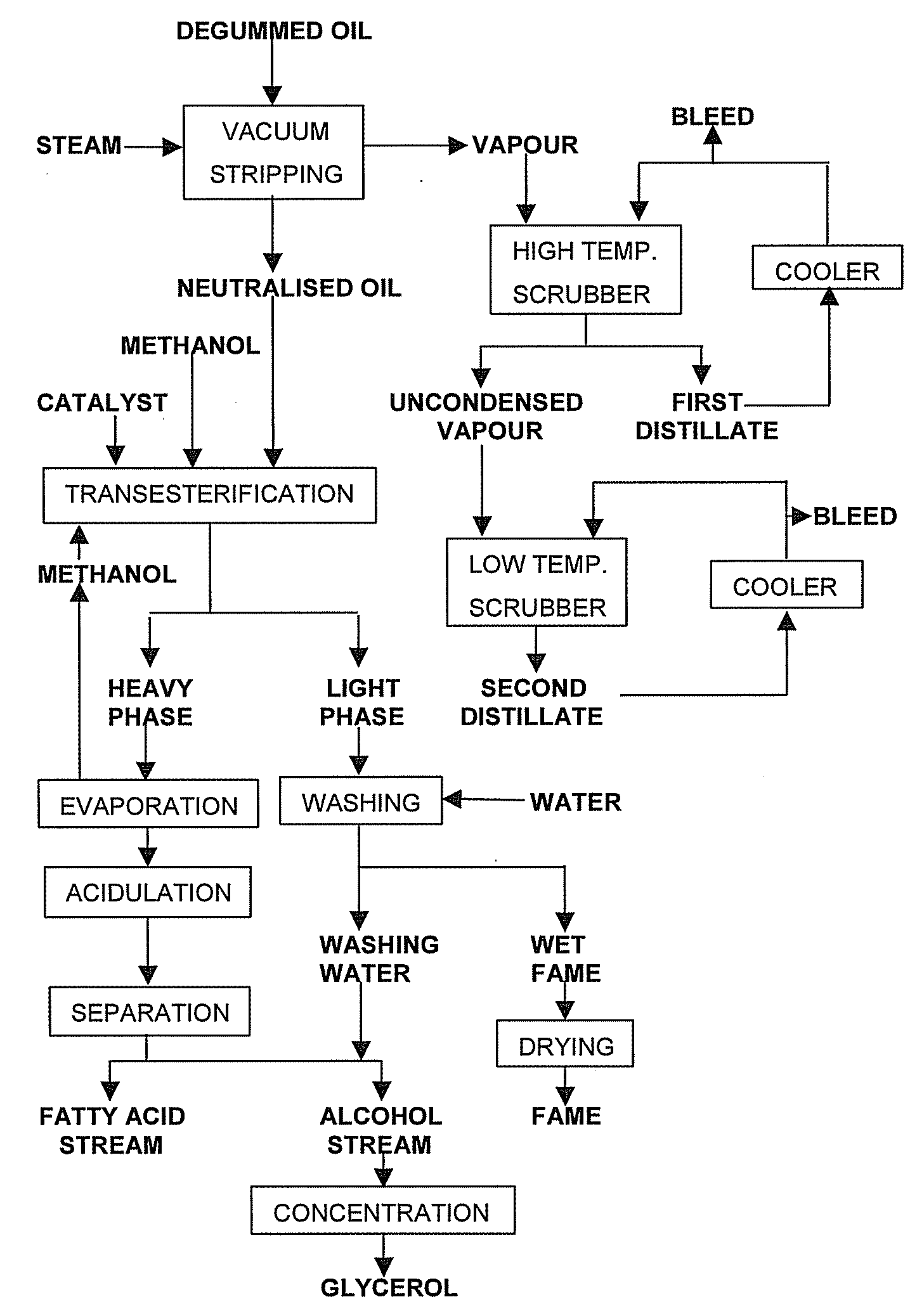

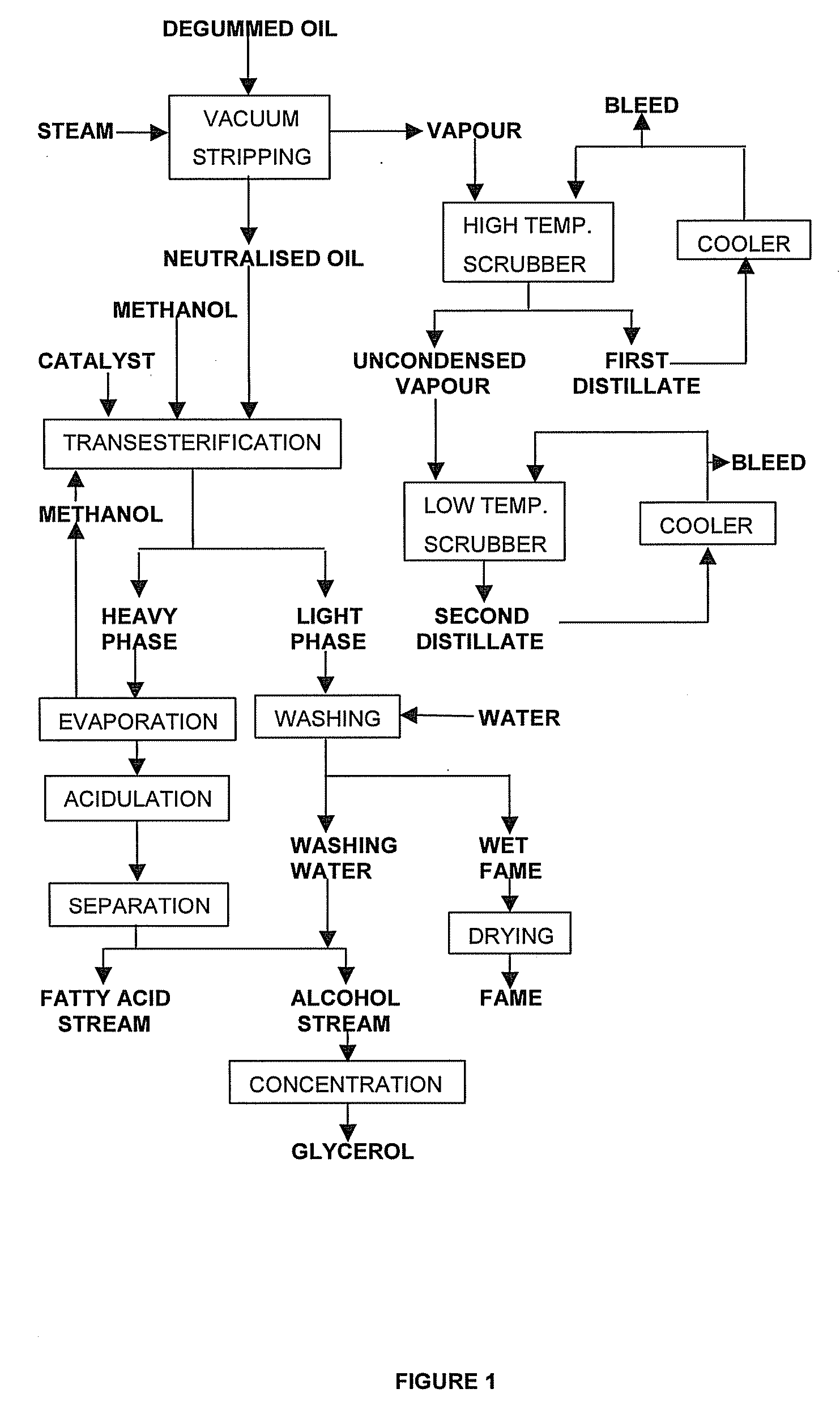

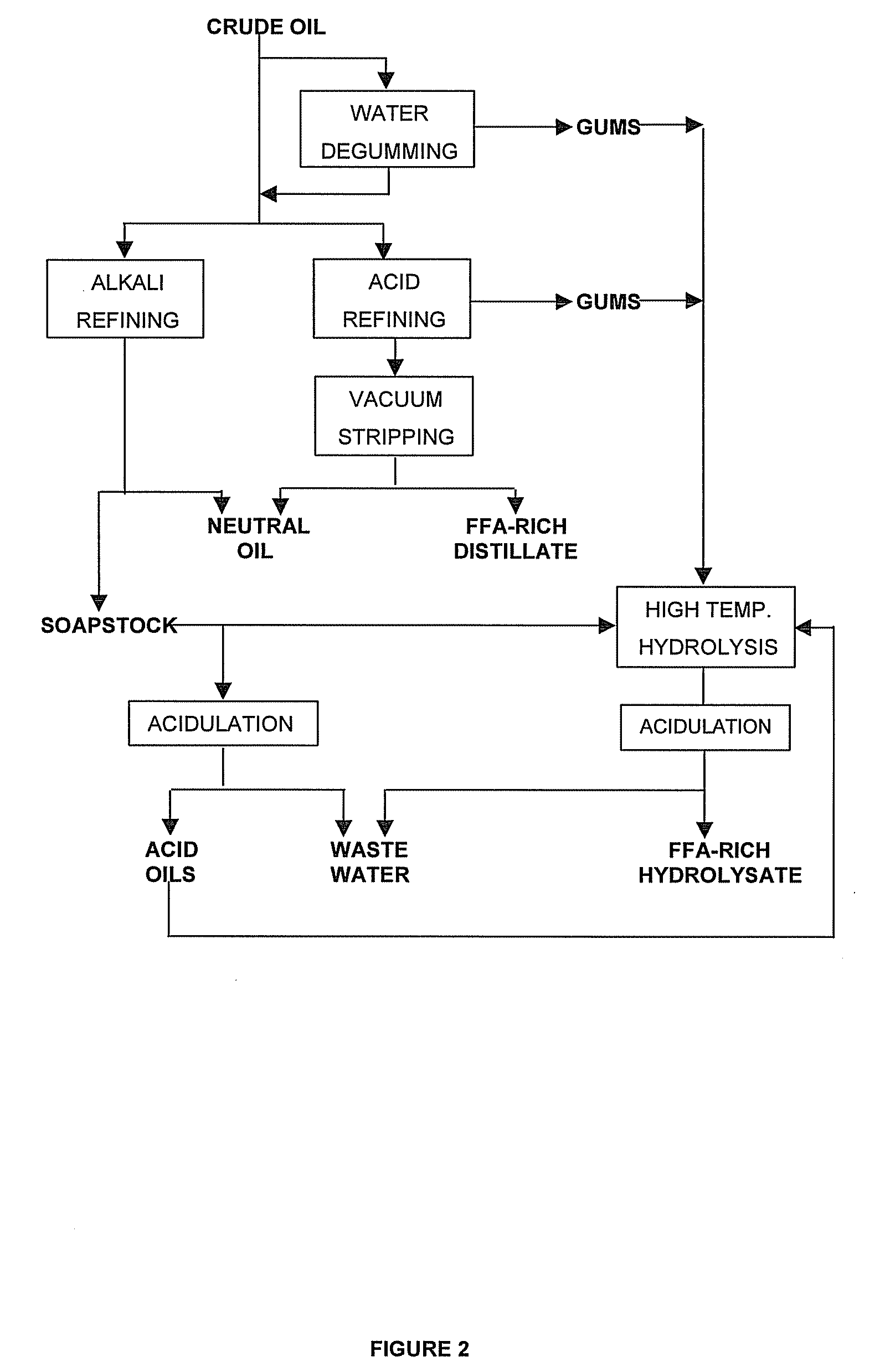

Process for the production of esters of fatty acids and C1-C5 alkyl alcohols comprising the steps of: (a) providing a fatty feed comprising a triglyceride oil or fat, partial glycerides and / or free fatty acids, (b) neutralising said fatty feed by vacuum stripping at a temperature from 200° C. to 280° C., thus providing a vapour stream and a residue, (c) collecting a distillate by scrubbing said vapour stream, (d) transesterifying said residue with a C1-C5 alkyl alcohol while using an alkaline catalyst, (e) separating the transesterification reaction mixture from step (d) into a fraction comprising C1-C5 alkyl esters of fatty acids and an alcoholic fraction (a) wherein at least part of free acids obtained as side products in step (a) and / or (c) and / or (e) are esterifyed with an alcohol using an acid catalyst, the product of this esterification being added to said fatty feed or said residue.

Owner:DESMET BALLESTRA OLEO

Process for reactive esterification distillation

ActiveUS7667068B2Organic compound preparationPreparation by ester-hydroxy reactionOrganic acidChemical reaction

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

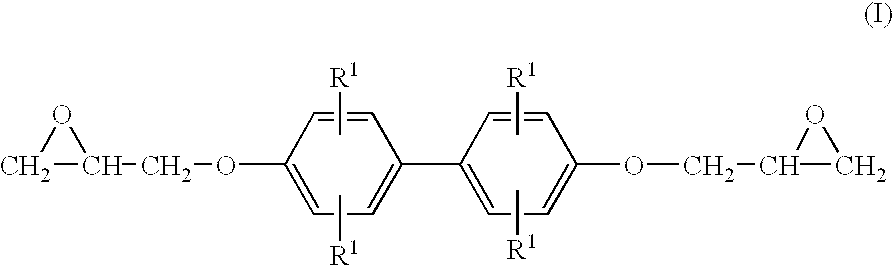

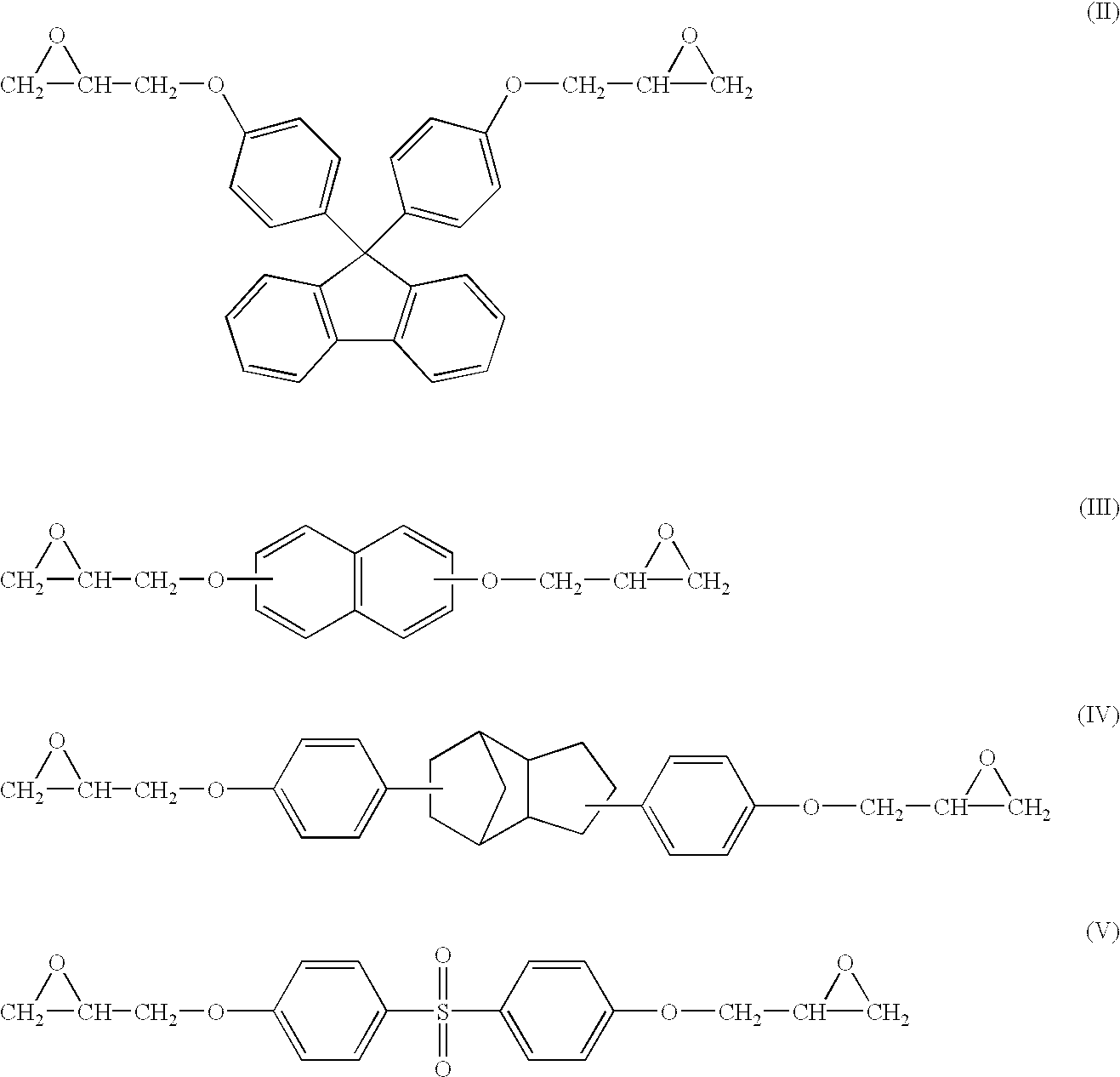

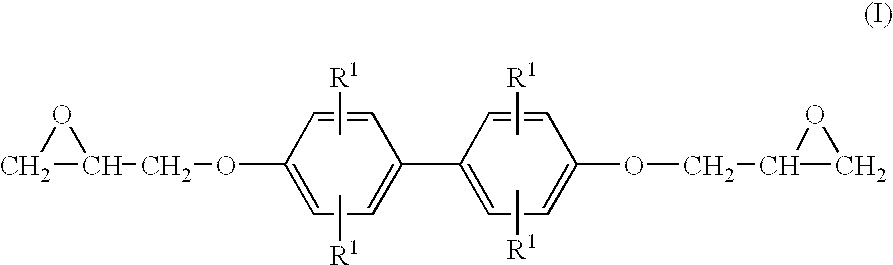

Epoxy resin composition for fibre-reinforced composite material

InactiveUS20030064228A1High viscositySynthetic resin layered productsThin material handlingHeat resistanceFiber-reinforced composite

This invention relates to an epoxy resin composition for a fiber-reinforced composite material, which contains the following constituent components (A), (B) and (C). (A) alicyclic epoxy resin (B) polyamine (C) latent acid catalyst which can dissolve in constituent component (A) or in constituent component (B) This epoxy resin composition is of low viscosity and is suitable for use in the molding of fiber-reinforced composite materials by RTM or the like. More particularly, it is possible to offer an epoxy resin composition for a fiber-reinforced composite material where the cured material obtained by heating has high level heat resistance and strength properties, and which is suitable for use as aircraft components, spacecraft components, artificial satellite components and the like

Owner:TORAY IND INC

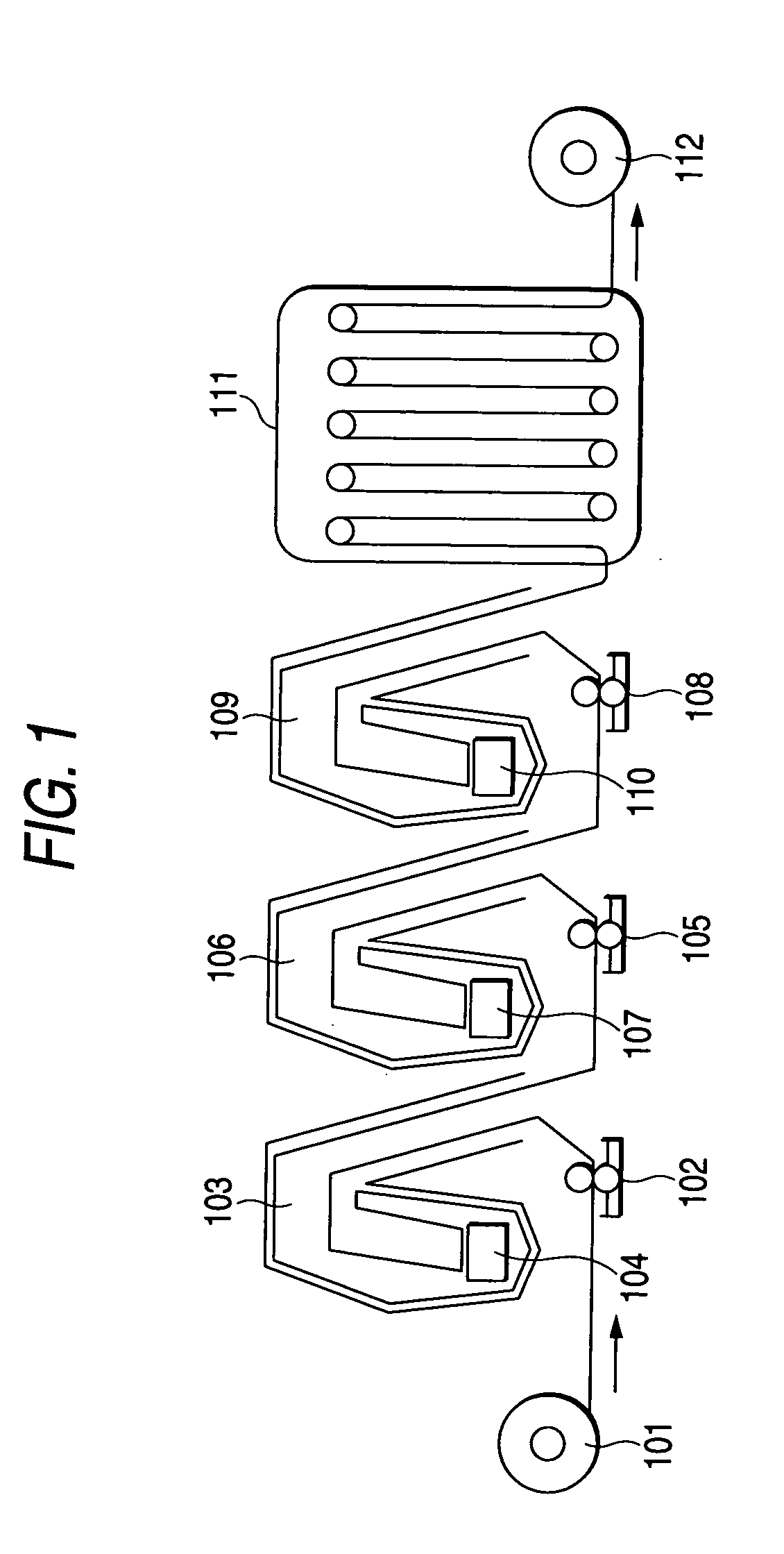

Method for Producing Alpha-Olefin Polymer

ActiveUS20070208151A1Easy to controlHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsPolymer sciencePtru catalyst

The present invention provides a method for producing α-olefin polymer, comprising polymerizing α-olefins in the presence of a halogen atom-containing acid catalyst by use of an aliphatic hydrocarbon having 3-12 carbon atoms, which contains 5 to 95 mass % of α-olefin, as a raw material; removing catalyst residue and halogen-containing compounds by bringing a product in the polymerization step into contact with an aluminum atom-containing inorganic solid treatment agent with or without deactivating the catalyst; and separating the α-olefin polymer. According to this method, the catalyst residue and other halogen-containing compounds can be removed, without relying on aqueous deactivation and separation steps using an alkaline aqueous solution or the like, from a polymerization reaction product obtained by polymerization in the presence of a halogen-containing acid catalyst by use of an α-olefin-containing liquid hydrocarbon as a raw material.

Owner:NIPPON OIL CORP

Manufacture of polytrimethylene ether glycol

InactiveUS7157607B1Increase productionReduce fermentationOrganic compound preparationMixingOrganic solventEther

A process of manufacture of polytrimethylene ether glycol comprising:(a) polycondensing reactant comprising diol selected from the group consisting of 1,3-propanediol, 1,3-propanediol dimer and 1,3-propanediol trimer or mixtures thereof in the presence of acid polycondensation catalyst to form polytrimethylene ether glycol;(b) adding water to the polytrimethylene ether glycol to form an aqueous mixture;(c) heating the aqueous mixture to hydrolyze acid esters formed during the acid catalyzed polycondensation;(d) adding to the hydrolyzed aqueous mixture organic solvent that is miscible with polytrimethylene ether glycol to form (i) organic phase containing the polytrimethylene ether glycol and residual acid polycondensation catalyst from the polycondensing and (ii) aqueous phase;(e) separating the aqueous phase and the organic phase;(f) adding base to the separated organic phase to neutralize the residual acid polycondensation catalyst by forming salts of the residual acid polycondensation catalyst;(g) separating the organic phase into (i) liquid phase comprising the polytrimethylene ether glycol, the organic solvent and any residual water, and (ii) solid phase comprising the salts of the residual acid polycondensation catalyst and the base which is unreacted; and(h) removing the organic solvent and the residual water from the liquid phase to obtain polytrimethylene ether glycol.

Owner:EI DU PONT DE NEMOURS & CO

Methods for producing and purifying 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine monomers and polycarbonates derived therefrom

Disclosed herein is a method for producing a 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine. The method comprises forming a reaction mixture comprising at least one substituted or unsubstituted phenolphthalein compound, at least one substituted or unsubstituted primary hydrocarbyl amine, and an acid catalyst; and heating the reaction mixture to form 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine. An adduct of the 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine is formed either by using an excess of the primary hydrocarbyl amine in the first heating step, or by isolating crude 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine after the heating step and then reacting with a further amount of the primary hydrocarbyl amine. The 2-hydrocarbyl-3,3-bis(4-hydroxyaryl)phthalimidine has a formula:where R1 is selected from the group consisting of a hydrogen and a hydrocarbyl group, and R2 is selected from the group consisting of a hydrogen, a hydrocarbyl group, and a halogen.

Owner:SHPP GLOBAL TECH BV

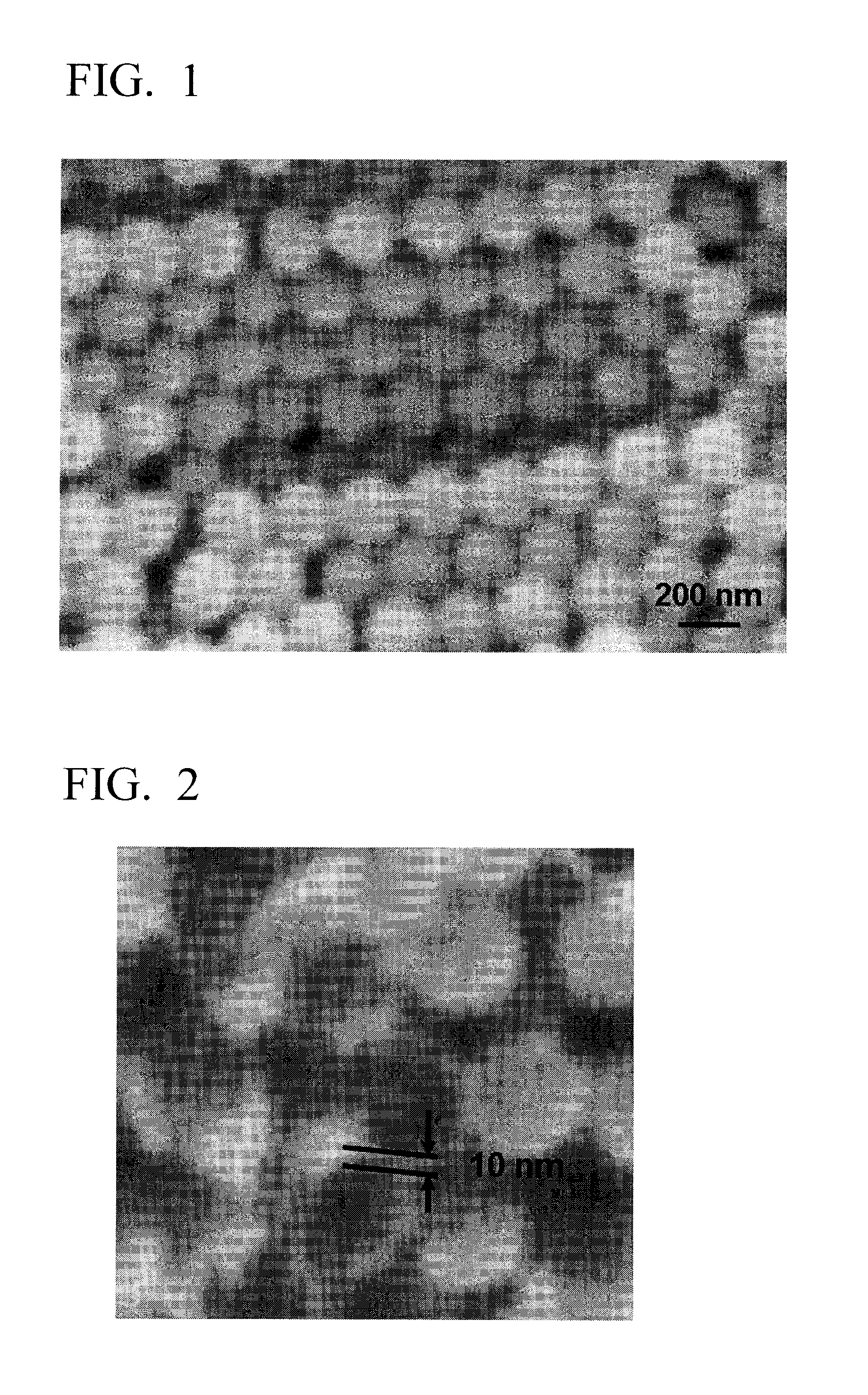

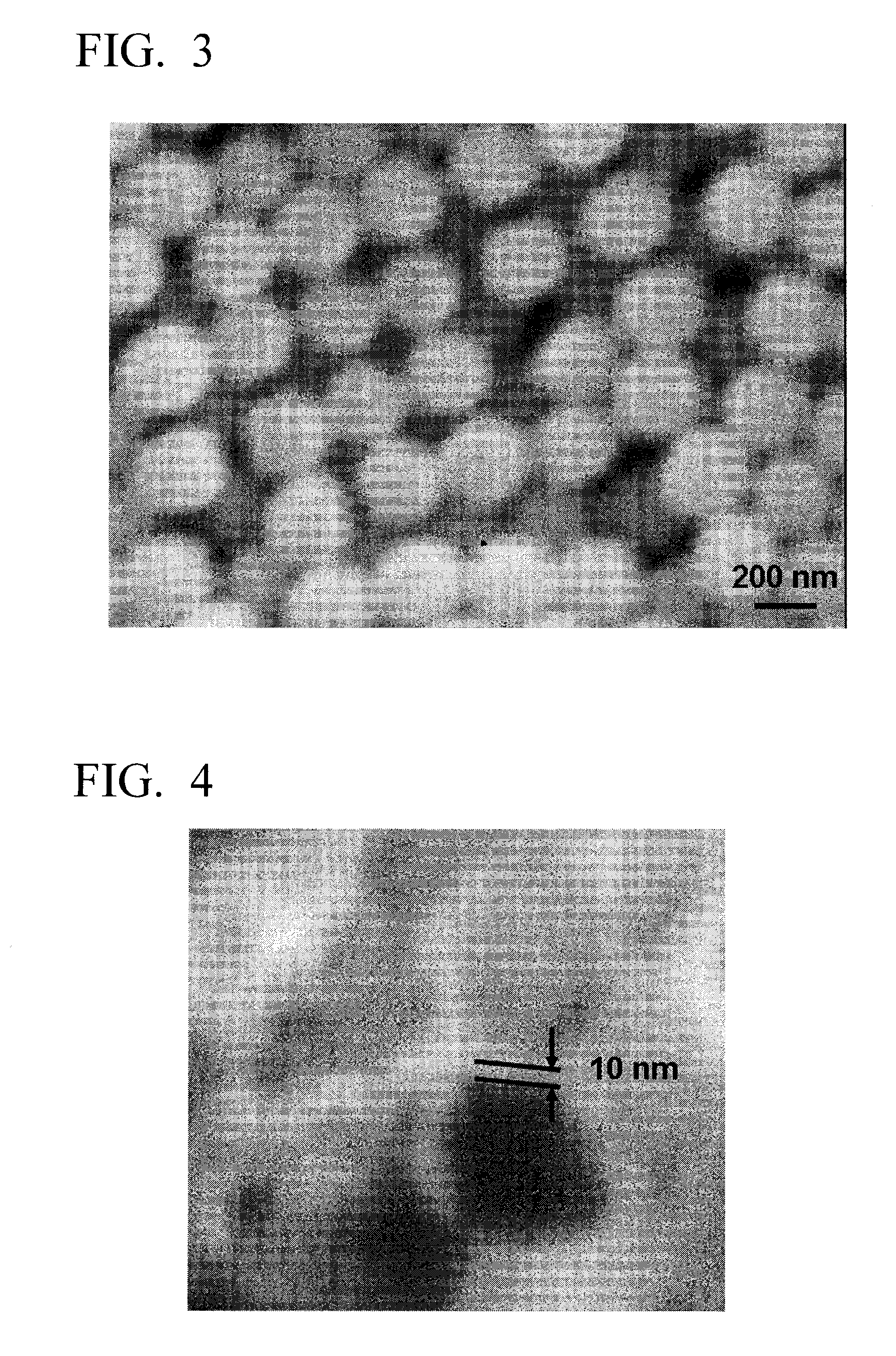

Organic/inorganic composite coating film, structural color film using the same, and preparation methods thereof

InactiveUS20100104810A1Easy to prepareSuitable for useRoof covering using sealantsLayered productsMetal alkoxidePolymer chemistry

An organic / inorganic composite coating film comprising an inorganic material as a matrix and an organic material combined therewith. The coating film has a regular hollow structure therein, and the coating film surface has a rugged pattern with semispherical protrusions. Also provided is a large-area structural color film obtained by burning the composite coating film. The organic / inorganic composite coating film is obtained by applying an aqueous coating composition comprising a metal alkoxide, an aqueous dispersion of monodisperse polymer particles, and an acid catalyst to a substrate and curing the coating composition. Burning the organic / inorganic composite coating film gives the structural color film.

Owner:DAINIPPON INK & CHEM INC +1

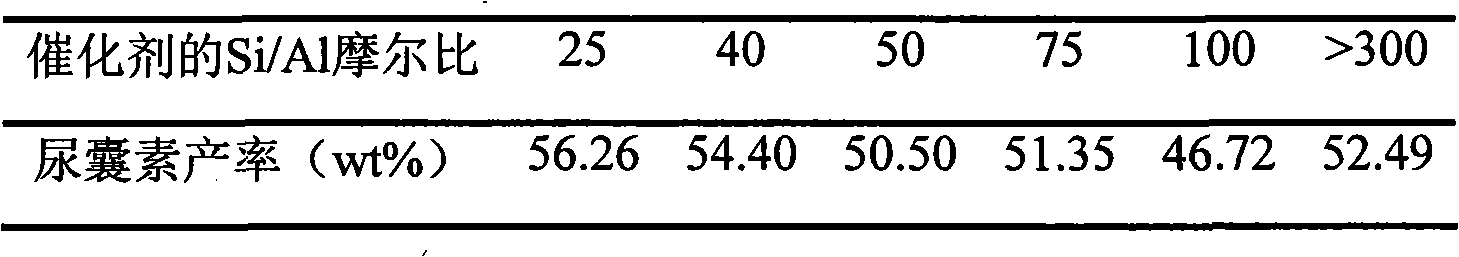

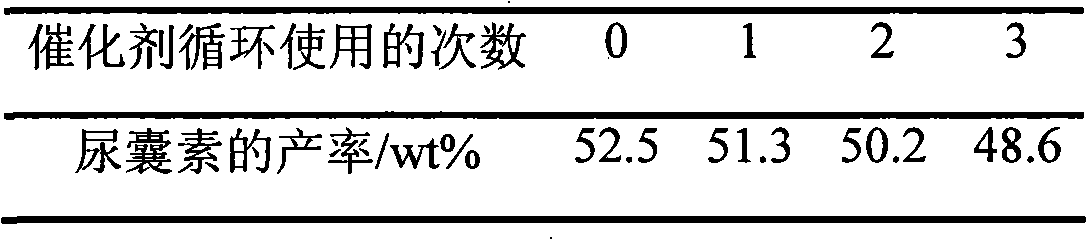

Solid acid catalyst and reaction technique for synthesis of allantoin

InactiveCN101347739AHigh activityImprove stabilityOrganic chemistryMolecular sieve catalystsRare-earth elementSolid acid

The invention relates to a catalyst for synthesis of allantoin by the reaction of glyoxylic acid and urea and a corresponding reaction process. The catalyst is the solid acid catalyst and takes one or the combination of more of oxides and molecular sieves of IVB to VIB elements as a carrier, or a complex which is composed of one or the combination of more of the oxides and the molecular sieves of IVB to VIB elements and one or the combination of more of the oxides of IB, IIB, VIIB, VIIIB and rare earth element as the carrier, and the carrier is carried out the impregnation supporting, the drying and the calcination by using inorganic strong acid or ammonium salt solution thereof for the preparation. The use of the catalyst can synthesize an allantoin product by one-step reaction of the glyoxylic acid and the urea in an atmospheric pressure tank reactor. The catalyst of the invention has the advantages of high activity and stability, recyclable property, no corrosion of the device and environmental pollution, etc. The synthesis reaction process of the allantoin has the advantages of simple process, less using amount of the catalyst, short reaction time and high yield of the allantoin, etc.

Owner:HUNAN UNIV

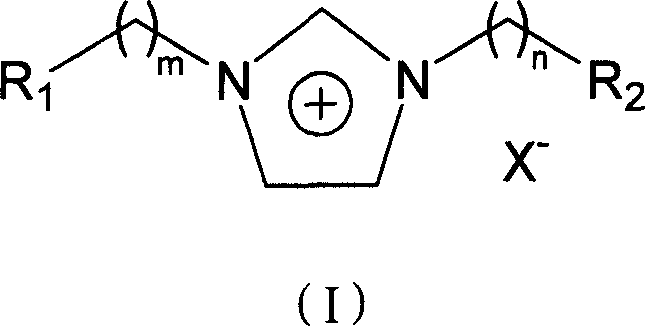

Imidazole two-functionized room temperature inonic liquid and its preparing method

InactiveCN1978433AImprove thermal stabilityExcellent electrochemical propertiesOrganic chemistryHalogenAcid catalysis

This invention relates to a room temperature ionic liquid with dual functional imidazolyl and its preparation. Through reaction of functional imidazole and alkylogen that contains functional group, this ionic liquid first produces dual functional ionic liquid of which anion is halogen anion, then through anion exchange, obtains dual functional ionic liquid that contains different anion. The ionic liquid of this invention has fine heat stability, is stable for water and air, possesses satisfactory electrochemistry character, can be used as electrolyte for electrochemistry research. In orthodox acid catalysis reaction, it not only can be used as catalyst, but also can be used as reaction medium. Meanwhile, it can be used as medium that can separate and extract.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

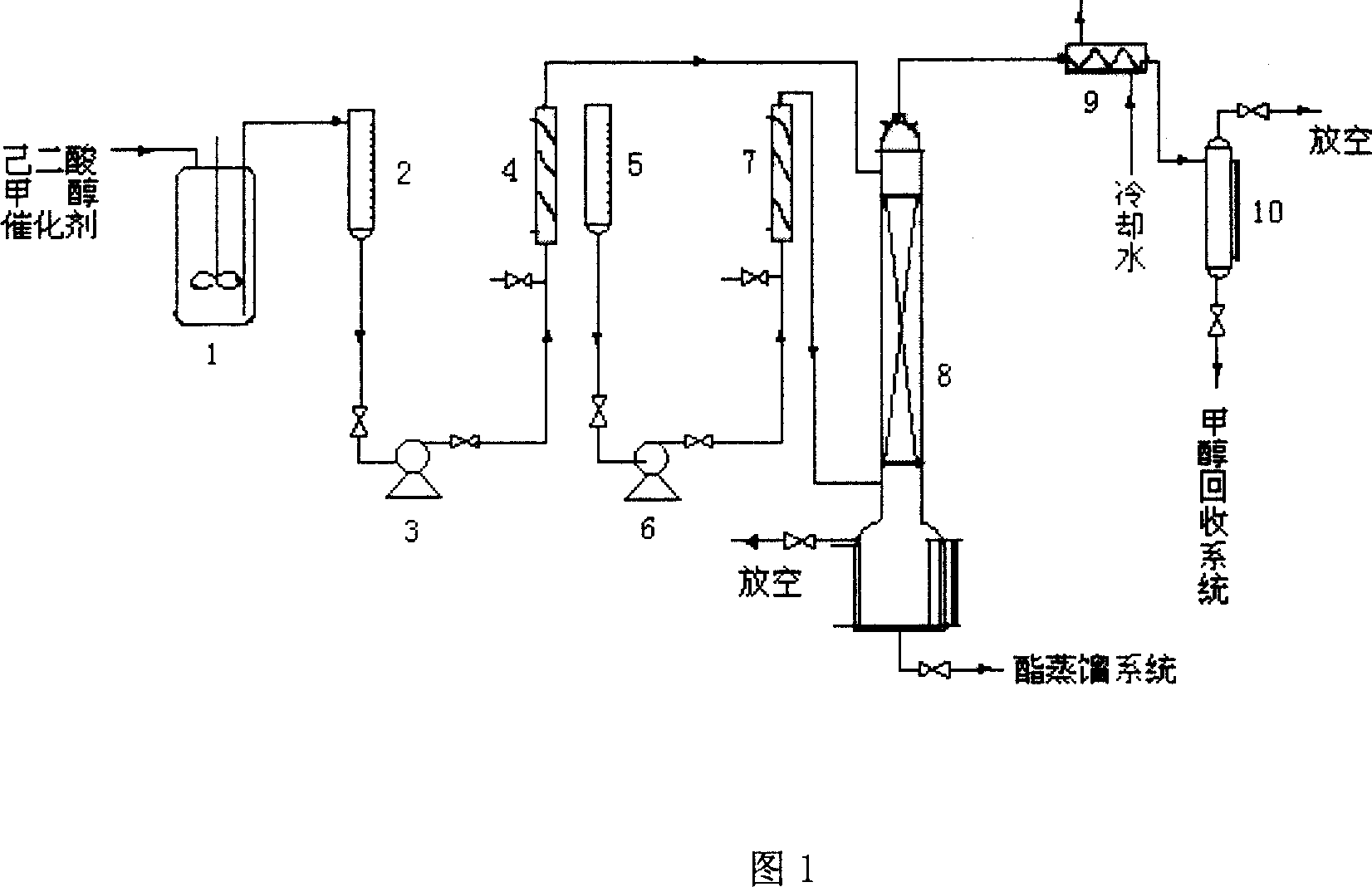

Method and equipment for continuous esterification production of adipic acid dimethyl ester

ActiveCN101134725ABreak down the esterification rateImprove the conversion rate of esterificationOrganic compound preparationCarboxylic acid esters preparationAdipic acid dimethyl esterReaction temperature

The present invention relates to continuous esterification process and apparatus for producing dimethyl adipate in the presence of solid acid catalyst. The process includes the following steps: setting solid acid catalyst, adipic acid and methanol into pre-esterifying kettle; heating to 50-100 deg.c to react at normal pressure to obtain lean ester; feeding the supernatant with lean ester to the upper part of one continuous esterifying tower and methanol vapor to its lower part for countrecurrent reaction in the catalyst section at the temperature of 70-150 deg.c, liquid space velocity of 0.1-0.7 kg / kg.hr and methanol space velocity of 0.1-1.0 kg / kg.hr; rectifying the resultant at operation pressure of 0-0.01 MPa to obtain dimethyl adipate. The present invention has adipic acid converting rate up to 99 % and dimethyl adipate purity up to 99.8 %.

Owner:PETROCHINA CO LTD

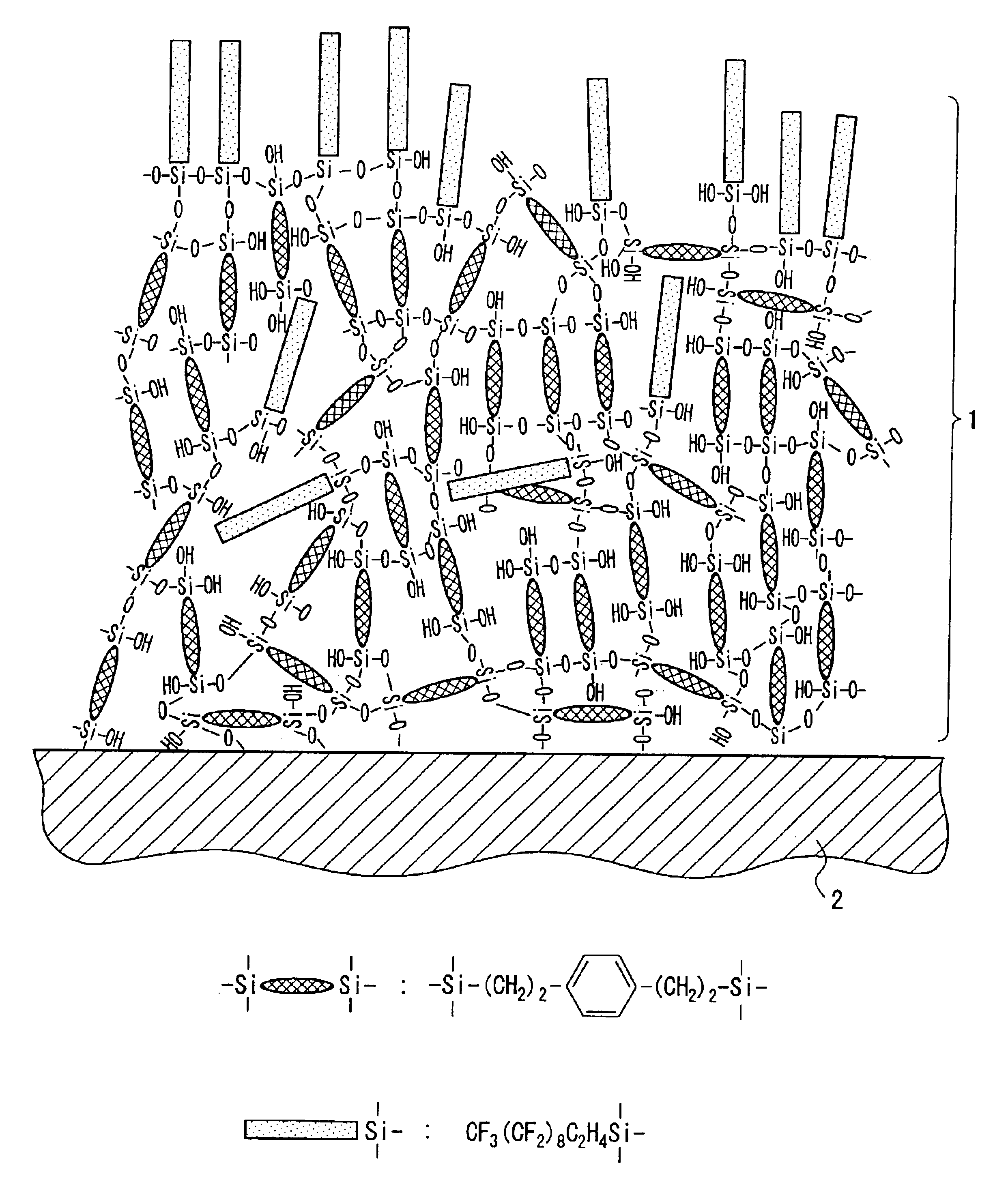

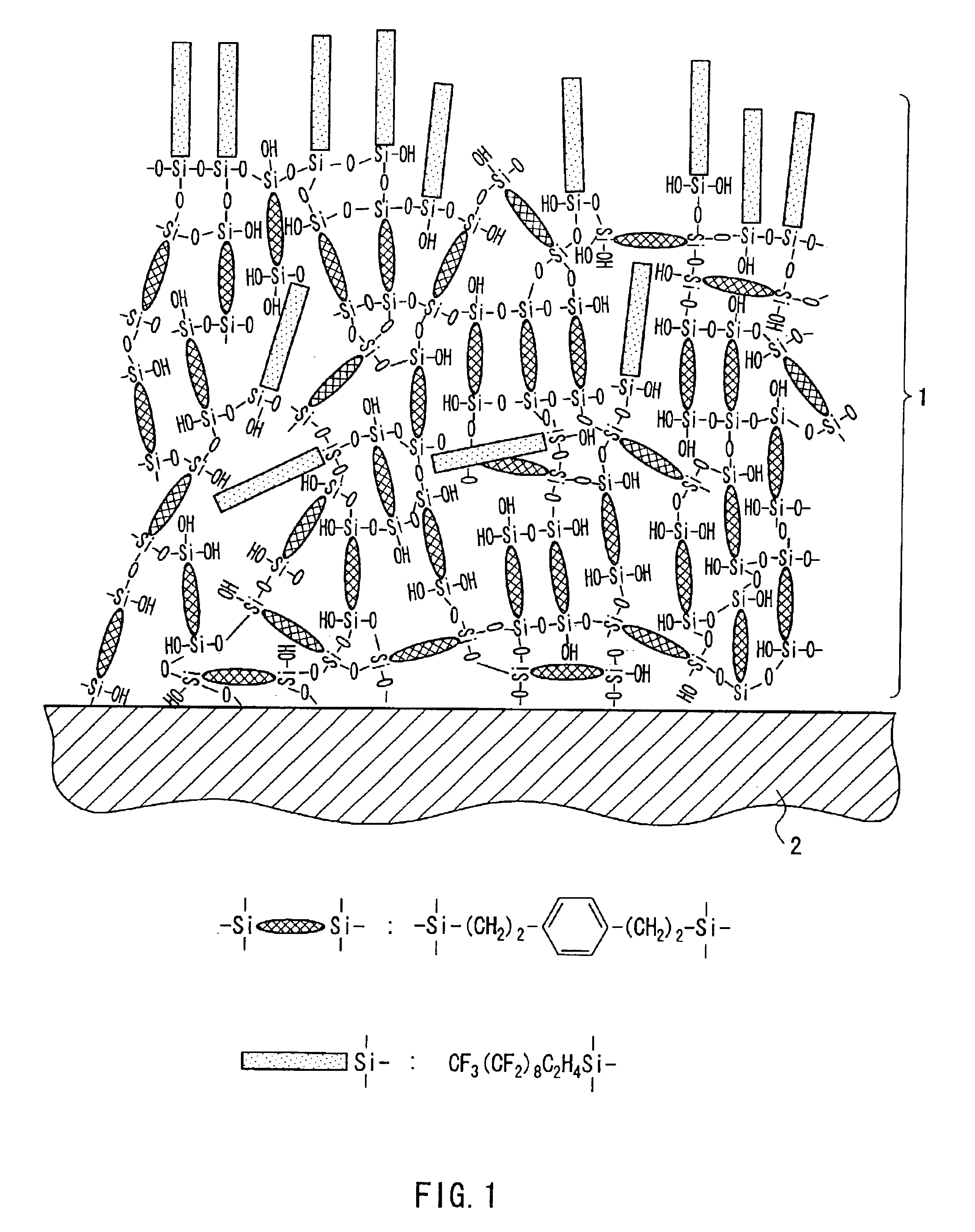

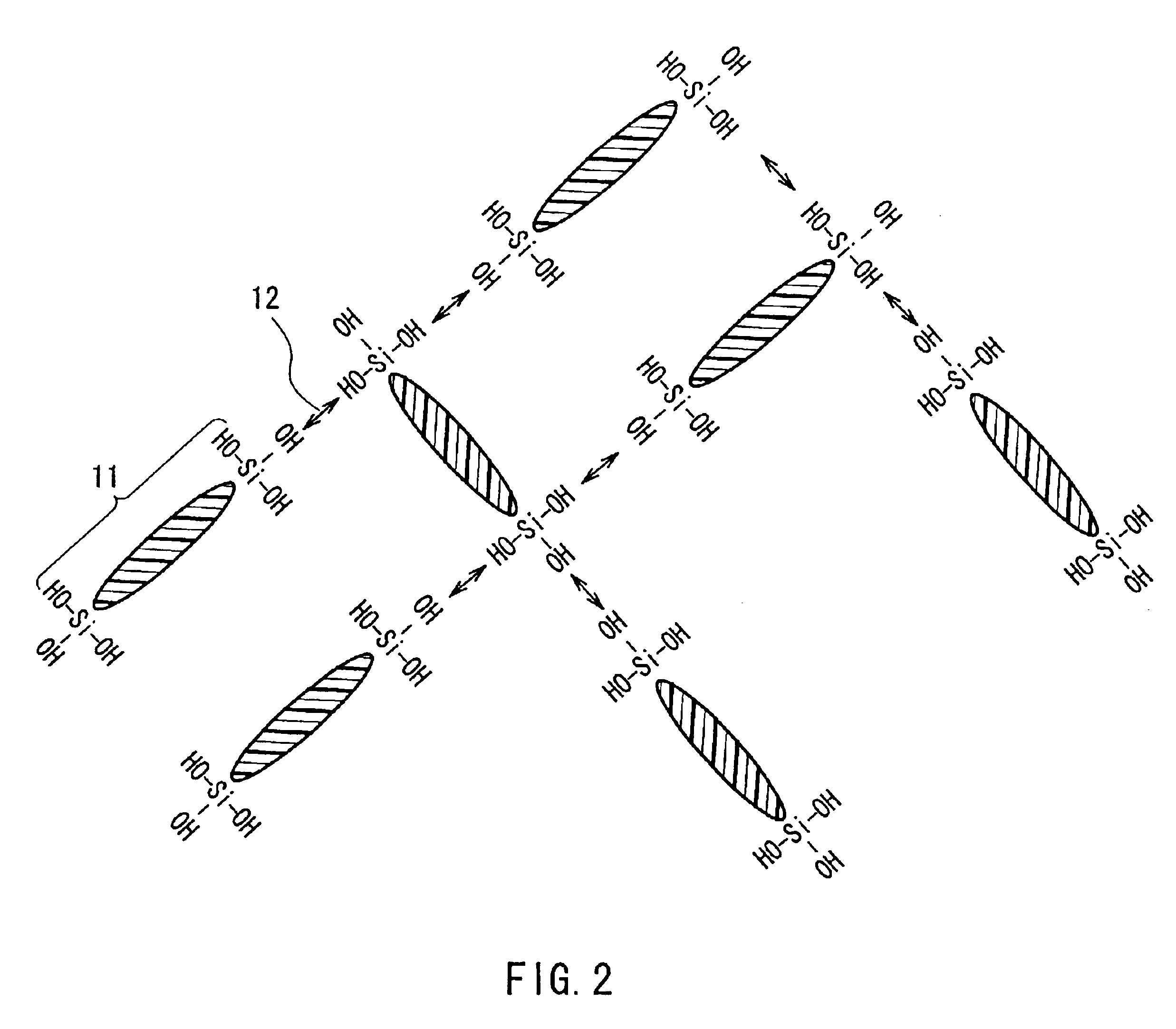

Method for producing water-repellent film

A method for forming a water-repellent film on a solid substrate. The method includes: preparing a mixed solution of a silane coupling agent (A) including reactive functional groups at both ends and a hydrocarbon chain and a benzene ring in the middle part; a silane coupling agent (B) including a fluorocarbon chain at one end and a reactive functional group at another end; and a chemical material including at least an organic solvent, water and acid catalyst; allowing hydrolysis and dehydration polymerization reaction of the silane coupling agents (A) and (B) to proceed; diluting the solution; applying the solution to the substrate and heating the substrate, thereby forming a polymer film of the silane coupling agent (A) and the silane coupling agent (B). Thus, there is provided a method for producing an alkali resistant water-repellent film at low cost.

Owner:PANASONIC CORP

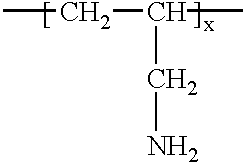

Acid functional polymer dispersants

The present invention is related to novel acid functional pigment dispersing agents. In particular, the invention is directed to novel polymers with acid functional groups for use as pigment dispersants. The novel polymers comprise polymeric amides with free carboxyl functional groups having the structure: wherein PE is a polyester, PA is a polyamine and A is an anhydride. The novel pigment dispersants of the present invention are particularly effective for the dispersion of high color carbon black and organic pigments. The advantages of the novel pigment dispersants over known amine functional polymeric dispersants are several. They do not tend to discolor when exposed to UV light. They do not inhibit acid catalyzed reactions such as melamine crosslinking or react with isocyanate or catalyze the isocyanate / H2O reaction. They are non-toxic or much less toxic to aquatic organisms. The novel dispersants, therefore can be used in acid catalyzed and isocyanate processes without the adverse effects of the prior art amine functional dispersants. Furthermore, the novel dispersants are environmentally safer.

Owner:KING INDUSTRIES INC

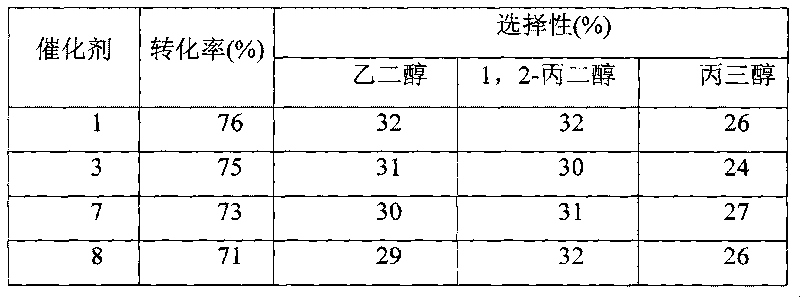

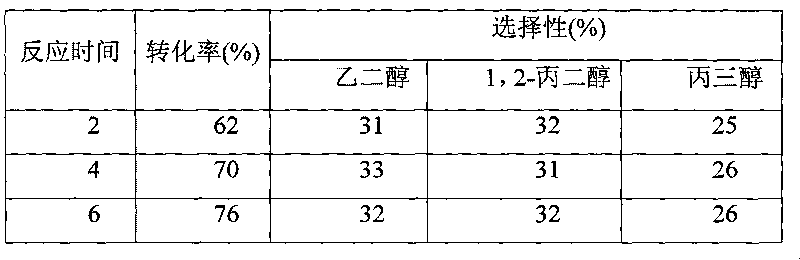

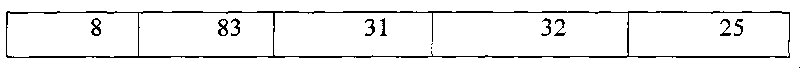

Method for preparing ethylene glycol, propylene glycol and glycerine by carrying out catalytic conversion on corn cobs

ActiveCN101704710ARelieve stressAchieve sustainable useOrganic compound preparationHydroxy compound preparationPolyesterAcid catalyzed

Corn cobs are important biomass resources. For a long time, the corn cobs have low chemical utilization ratio or cannot be utilized sufficiently to cause a great waste of resources. The invention develops a method for preparing ethylene glycol, propylene glycol and glycerine by carrying out catalytic hydrocracking conversion on the corn cobs, wherein the product is an important polyester synthetic chemical raw material. The corn cobs are efficiently converted into low carbon polyol products by the processes of acid-catalyzed hydrolysis, catalytic hydrogenation conversion and cracking. The yield of xylose in the hydrolytic process reaches over 30 percent; the conversion rate in the hydrogenation process reaches over 90 percent; and the selectivity in the hydrogenation process reaches over 90 percent.

Owner:JIANGSU SOPO GRP +1

Anionic-sweetener-based ionic liquids and methods of use thereof

One aspect of the present invention relates to ionic liquids comprising an anionic sweetener. Another aspect of the present invention relates to the use of an ionic liquid of the present invention comprising a pendant Bronsted-acidic group to catalyze a Bronsted-acid-catalyzed chemical reaction. A third aspect of the present invention relates to ionic liquids of the present invention comprising a pendant nucleophilic group, e.g., an amine. Still another aspect of the present invention relates to the use of an ionic liquid of the present invention comprising a pendant nucleophilic group to catalyze a nucleophile-assisted chemical reaction. A fifth aspect of the present invention relates to the use of an ionic liquid of the present invention comprising a pendant nucleophilic group to remove a gaseous impurity, e.g., carbon dioxide, from a gas, e.g., sour natural gas. A sixth aspect of the present invention relates to heat storage media comprising an ionic liquid of the present invention.

Owner:SOUTH ALABAMA UNIV OF

Preparation method of water-based crack paint for glass base material

ActiveCN103937359ANo pollution in the processNon-toxicLiquid surface applicatorsPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention relates to a preparation method of a water-based crack paint for a glass base material. The water-based crack paint is composed of a water-based priming paint and a water-based crack finishing paint; the water-based priming paint is composed of acrylic resin, amino resin, a colorant, a dispersing agent, an adhesion promoter, a film-forming auxiliary agent, an acid catalyst, a functional auxiliary agent and other auxiliary agents; the water-based crack finishing paint is composed of acrylic resin, polyurethane resin, amino resin, a colorant, an acid catalyst, a dispersing agent, a film-forming auxiliary agent, a functional auxiliary agent and other auxiliary agents; the prepared water-based crack paint has low VOC, has no pollution to the environment, is nonhazardous to operators, and has the advantages of excellent coating film performance, strong adhesive force, good flexibility, high hardness, good scratch resistance, excellent water resistance, excellent alcohol resistance, simple construction, and stable storage. A coating film crack is a crystallization product integrated with classical art and a modern decoration style, has a unique three-dimensional aesthetic feeling, is elegant in style, and is quite popular with markets and quite loved by customers. The water-based crack paint is widely used for surface protection and decoration of glass products, woodware, metals, plastics and other products.

Owner:深圳市莱莉雅环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com