Patents

Literature

36 results about "Adipic acid dimethyl ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

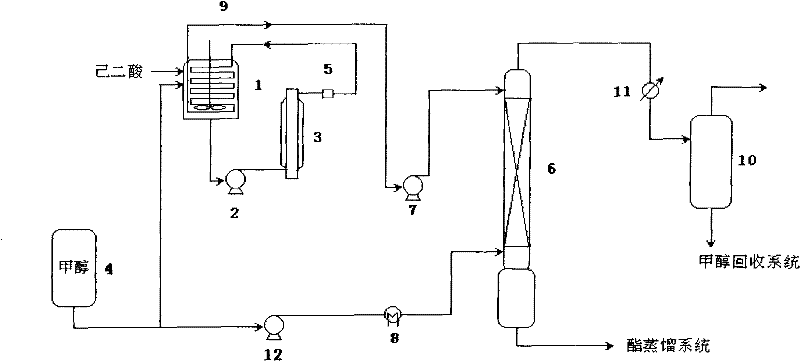

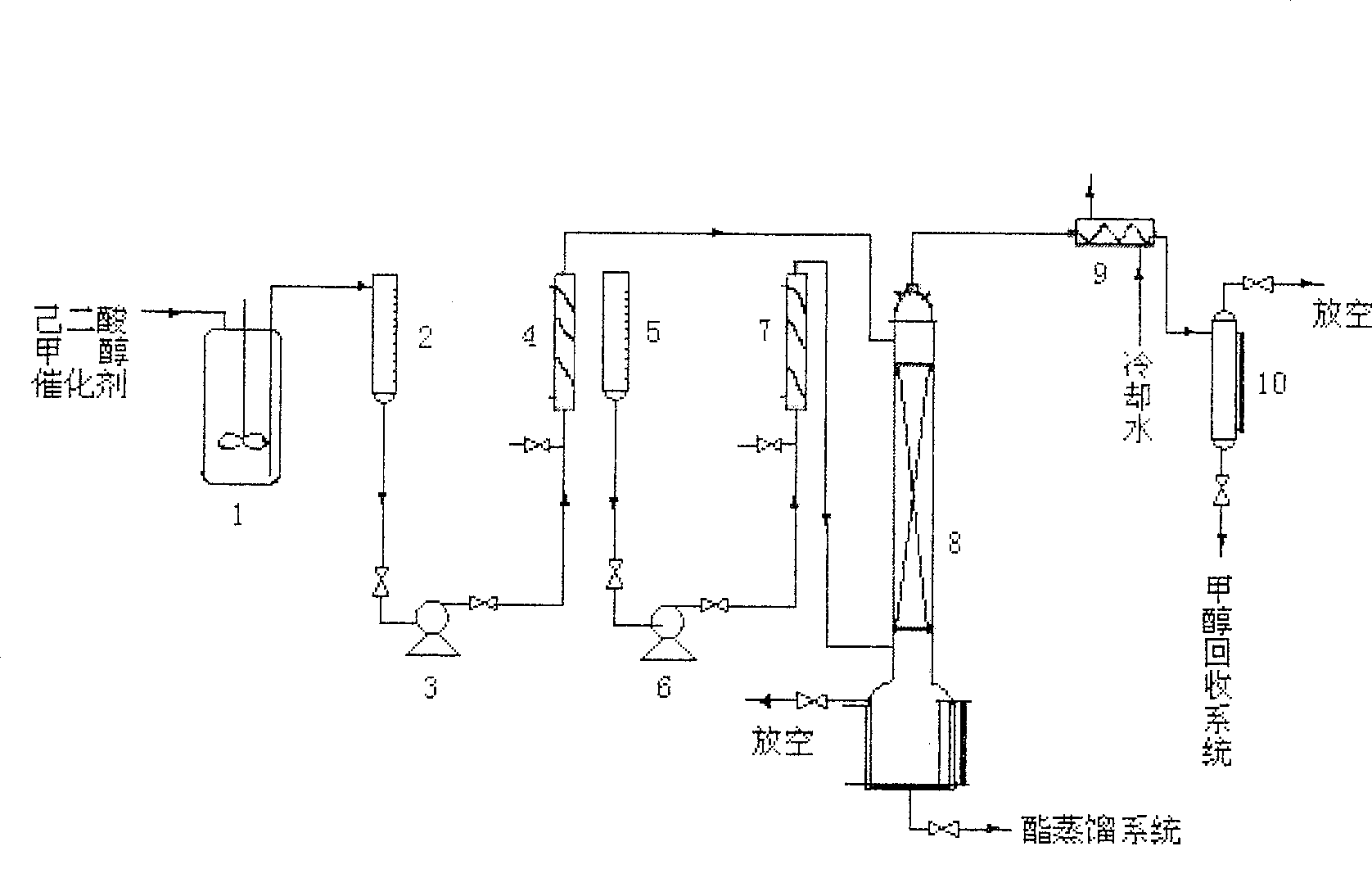

Method and equipment for continuous esterification production of adipic acid dimethyl ester

ActiveCN101134725ABreak down the esterification rateImprove the conversion rate of esterificationOrganic compound preparationCarboxylic acid esters preparationAdipic acid dimethyl esterReaction temperature

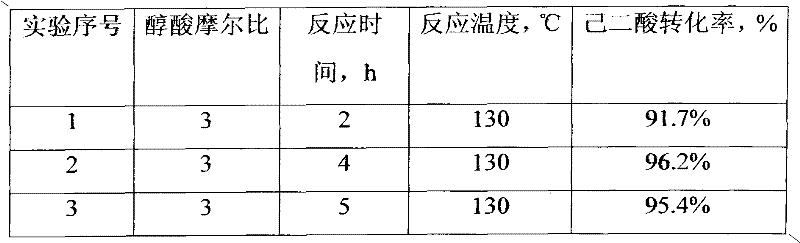

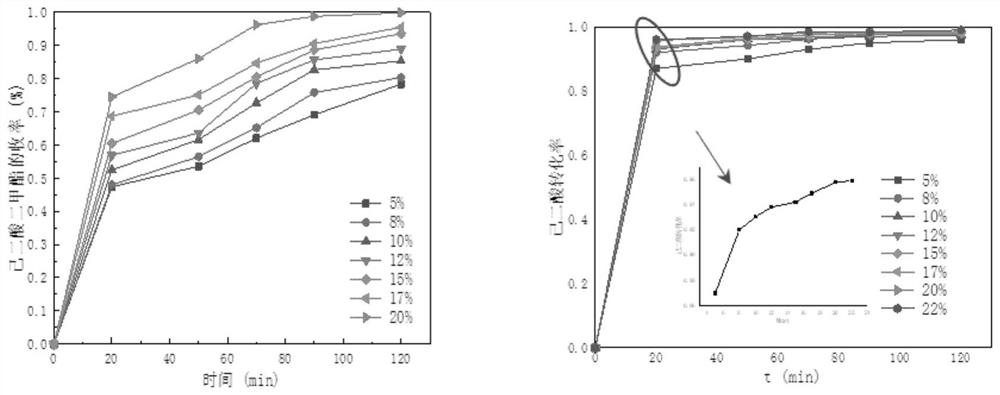

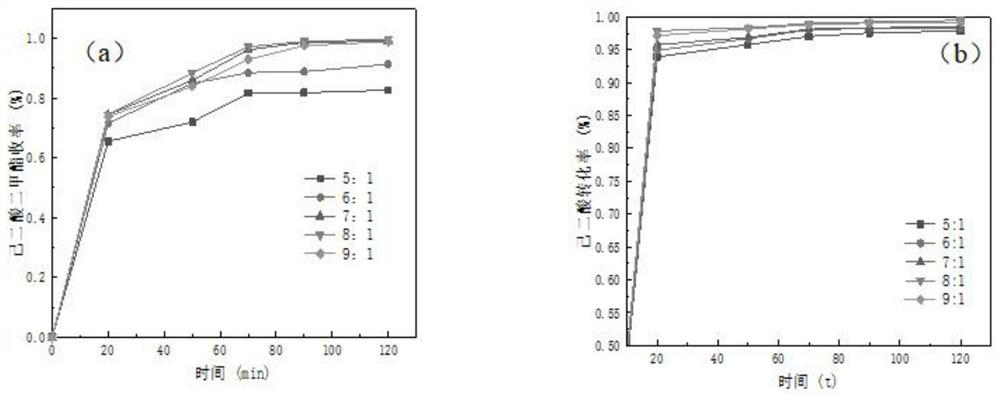

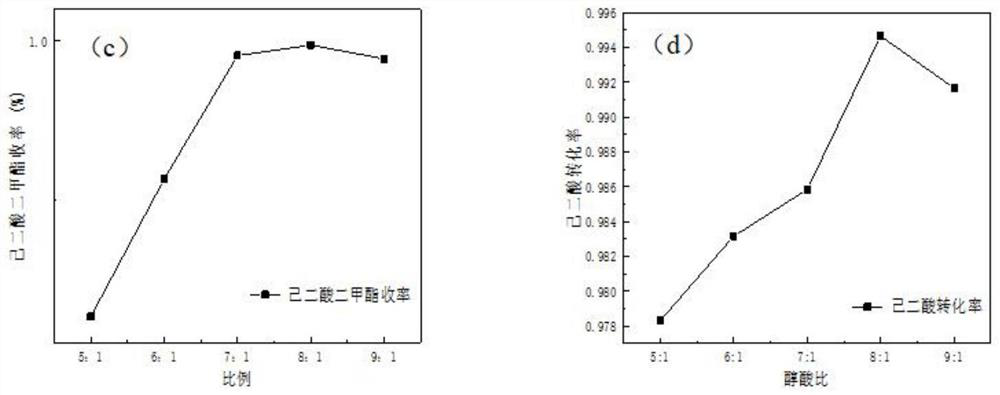

The present invention relates to continuous esterification process and apparatus for producing dimethyl adipate in the presence of solid acid catalyst. The process includes the following steps: setting solid acid catalyst, adipic acid and methanol into pre-esterifying kettle; heating to 50-100 deg.c to react at normal pressure to obtain lean ester; feeding the supernatant with lean ester to the upper part of one continuous esterifying tower and methanol vapor to its lower part for countrecurrent reaction in the catalyst section at the temperature of 70-150 deg.c, liquid space velocity of 0.1-0.7 kg / kg.hr and methanol space velocity of 0.1-1.0 kg / kg.hr; rectifying the resultant at operation pressure of 0-0.01 MPa to obtain dimethyl adipate. The present invention has adipic acid converting rate up to 99 % and dimethyl adipate purity up to 99.8 %.

Owner:PETROCHINA CO LTD

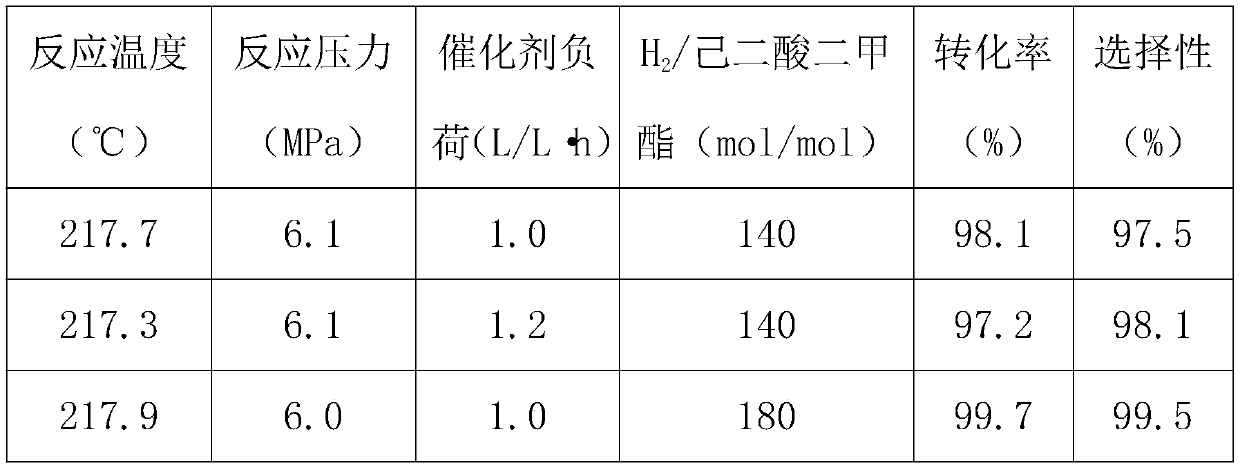

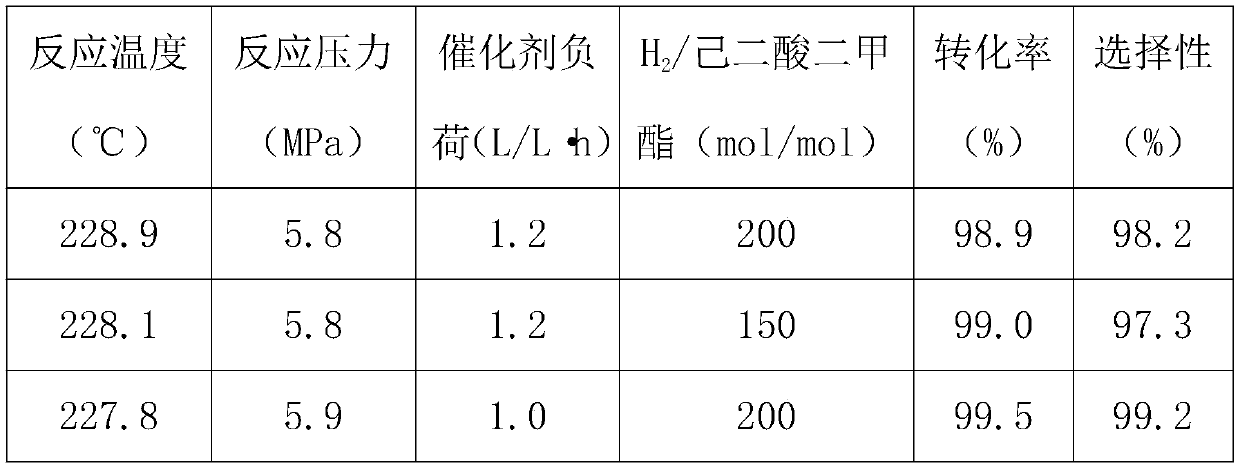

Method for preparing 1,6-hexandiol by hydrogenation of 1,6-adipic acid dimethyl ester

InactiveCN101113128AReduce production processEasy loadingOrganic compound preparationHydroxy compound preparationPolymer scienceAdipic acid dimethyl ester

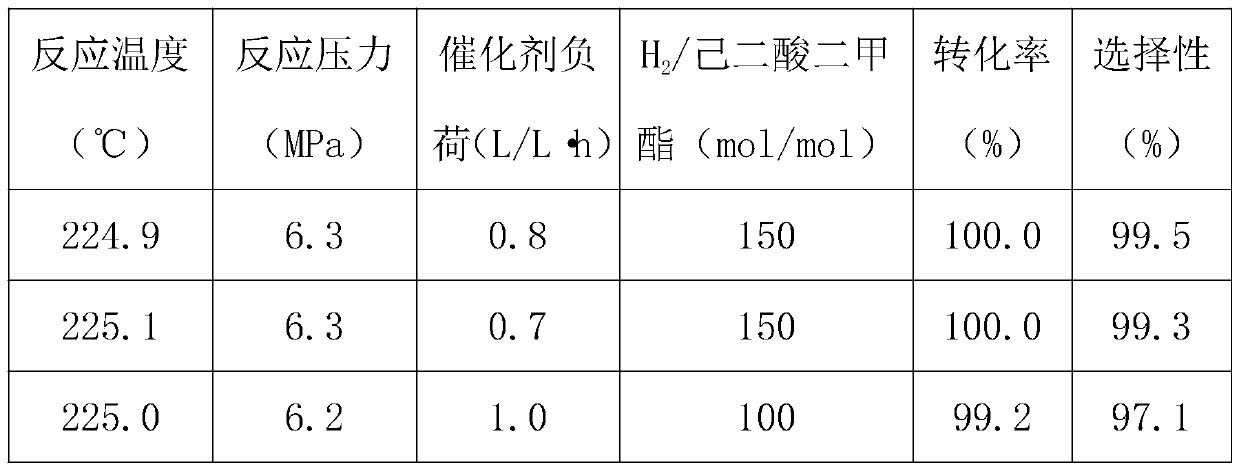

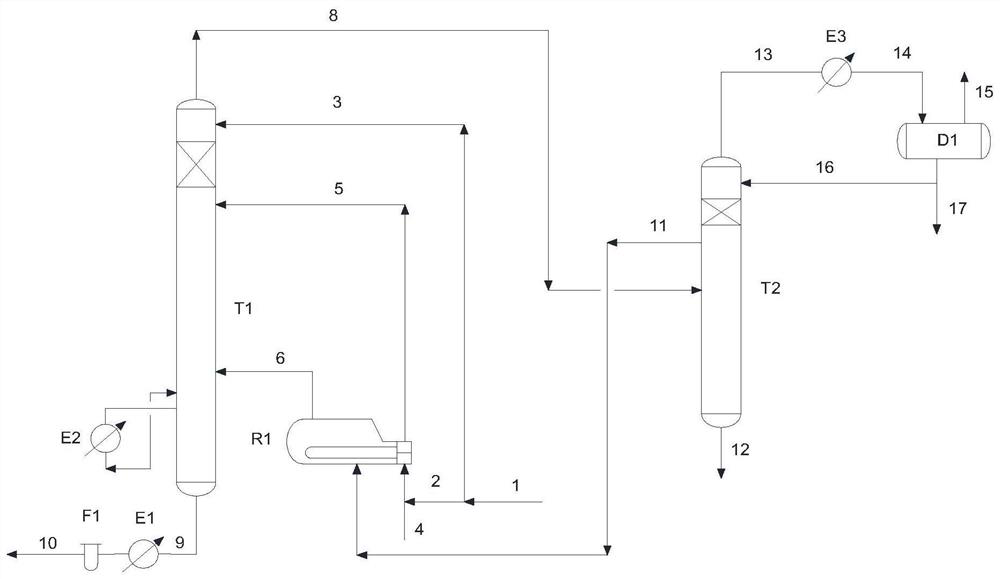

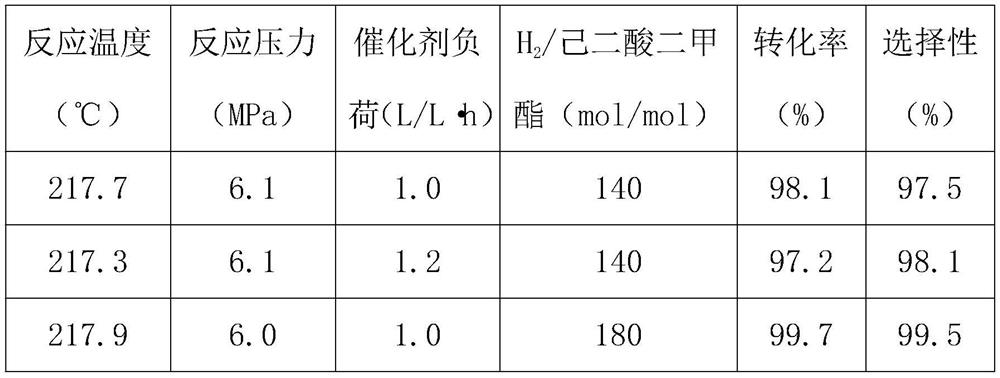

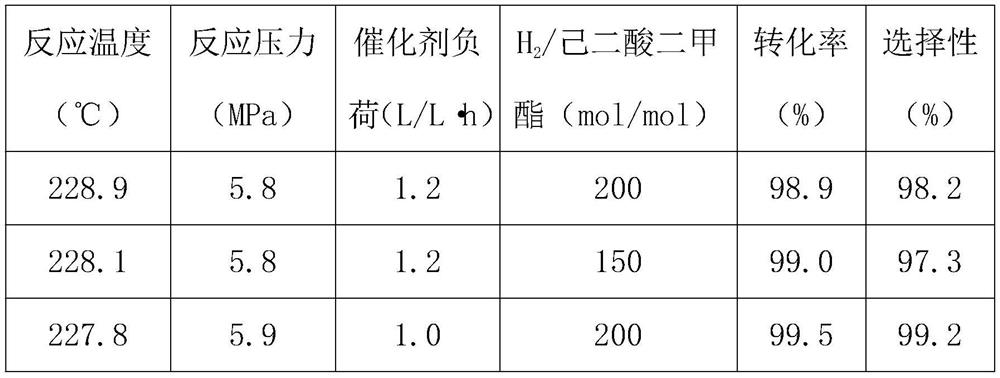

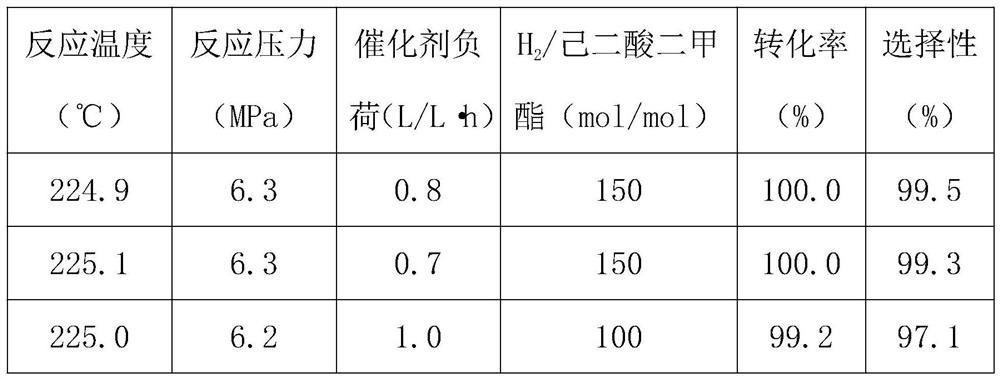

The invention relates to a hydrogenated preparation method of 1, 6-hexanediol by 1, 6 dimethylene adipate. The raw material of 1, 6-hexanediol is injected to a mixer and mixed with hydrogen and the mole proportion of the hydrogen and the 1, 6-hexanediol is 50-150 : 1; the mixed materials put in a reactor is hydrogenated after being contacted with catalyst; the loading of the catalyst is 0.1-0.5 kg ester / H.kg, the bedding temperature is 150-300 DEG C while the reacting pressure is 4-7MPa; mixed reacting matters enters gas and liquid separator after going through a heat exchanger and a condenser and then 1, 6 dimethylene adipate is obtained. The weight proportion of each component of the catalyst is that: 25-60 percent copper oxide, 25-60 percent zinc oxide and 10-30 percent aluminum oxide. The invention adopts comparatively low ratio of hydrogen and ester under comparatively low temperature and pressure, realizes the hydrogenated preparation method of 1, 6-hexanediol by 1, 6 dimethylene adipate with a transforming rate of the 1, 6 dimethylene adipate above 99 percent and option of the 1, 6-hexanediol above 96 percent.

Owner:PETROCHINA CO LTD

Method for producing 1,6-dimethyl adipate

ActiveCN102311342AOvercome CorrosivityOvercoming pollutionOrganic compound preparationCarboxylic acid esters preparationAdipic acid dimethyl esterEsterification reaction

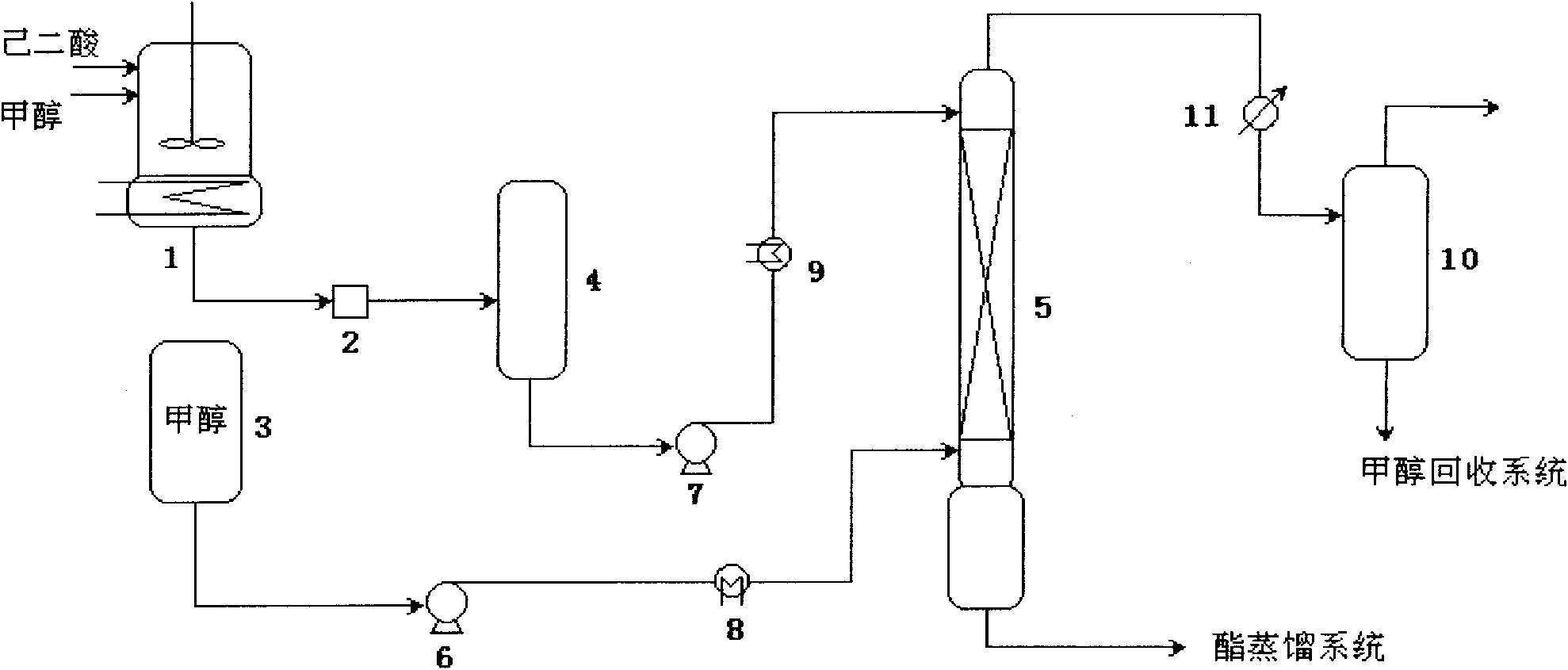

The invention discloses a method for producing 1,6-dimethyl adipate. The method comprises the following steps of: (1) mixing adipic acid and methanol without adding a catalyst, and performing pre-esterification reaction at the temperature of 80 and 200 DEG C under the gage pressure of between 0.05 and 3 MPa; and (2) conveying materials which are subjected to the pre-esterification reaction to the upper part of a continuous catalytic rectifying tower, and gasifying the dried methanol, conveying to the lower part of the catalytic rectifying tower, allowing the materials which are subjected to the pre-esterification reaction to contact methanol steam in a reverse flow mode in the catalytic rectifying tower and performing esterification reaction further. By the method, the problems of equipment corrosion and pollution which are caused by the utilization of a sulfuric acid catalyst in the conventional process are solved, and the defects of complex processes, large consumption level of the catalyst and the like which are caused by the adoption of two-step or multi-step catalytic esterification are overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing dimethyl adipate by continuous esterification

ActiveCN102442905AImprove conversion rateReduce reaction loadOrganic compound preparationCarboxylic acid esters preparationAdipic acid dimethyl esterEsterification reaction

The invention discloses a method for preparing dimethyl adipate by continuous esterification, comprising the steps of (1) pre-esterifying mixture of adipic acid and methanol in a tubular reactor with an inner component on the catalyst-free condition, wherein the temperature is 90-180 degrees centigrade and the pressure is 0.05-3 MPa; (2), sending the pre-esterified product to upper part of a continuous catalytic rectifying tower; enabling the dried methanol to enter the lower part of the catalytic rectifying tower after being vaporized; enabling the pre-esterified material to contact the methanol steam in the catalytic rectifying tower in a counter-current manner; and further performing esterifying. The method overcomes the problems that the traditional process has device corrosion and pollution problem caused by the sulphuric acid catalyst, and has no continuous pre-esterification and large catalyst consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing 1,6-hexylene glycol through dimethyl adipate gas-phase hydrogenation

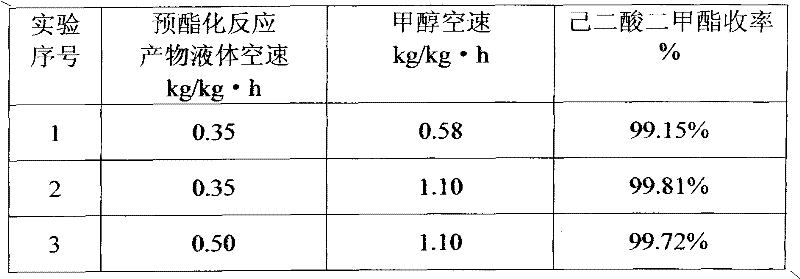

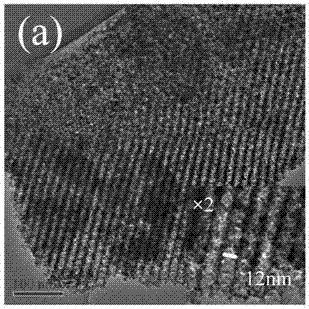

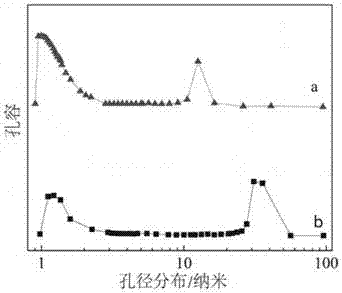

ActiveCN107118076AImprove conversion rateHigh selectivityMolecular sieve catalystsOrganic compound preparationDispersityGas phase

The invention provides a method for preparing 1,6-hexylene glycol through dimethyl adipate gas-phase hydrogenation. The method comprises the following steps: by taking a hierarchical pore SiO2 molecular sieve as a carrier, loading a copper-based catalyst, mixing gasified dimethyl adipate with hydrogen, putting the mixture into a fixed bed reactor for reaction under a certain condition, a 1,6-hexylene glycol-containing liquid phase product is obtained. According to the method provided by the invention, by taking the SiO2 molecular sieve with ordered meso pores and micro pores as the carrier, the dispersity of copper serving as an active component is substantially promoted, and the number of effective active sites of the catalyst is increased; moreover, due to the adoption of an ammonia distillation method, the copper is loaded on the mesoporous silicon oxide molecular sieve, so that high dispersion of the catalyst is realized; furthermore, the ordered meso pores of the hierarchical pore SiO2 molecular sieve is retained, and the catalysis capacity is improved.

Owner:TIANJIN UNIV

Method and equipment for continuous esterification production of adipic acid dimethyl ester

ActiveCN100537511CBreak down the esterification rateImprove the conversion rate of esterificationOrganic compound preparationCarboxylic acid esters preparationPtru catalystAdipic acid dimethyl ester

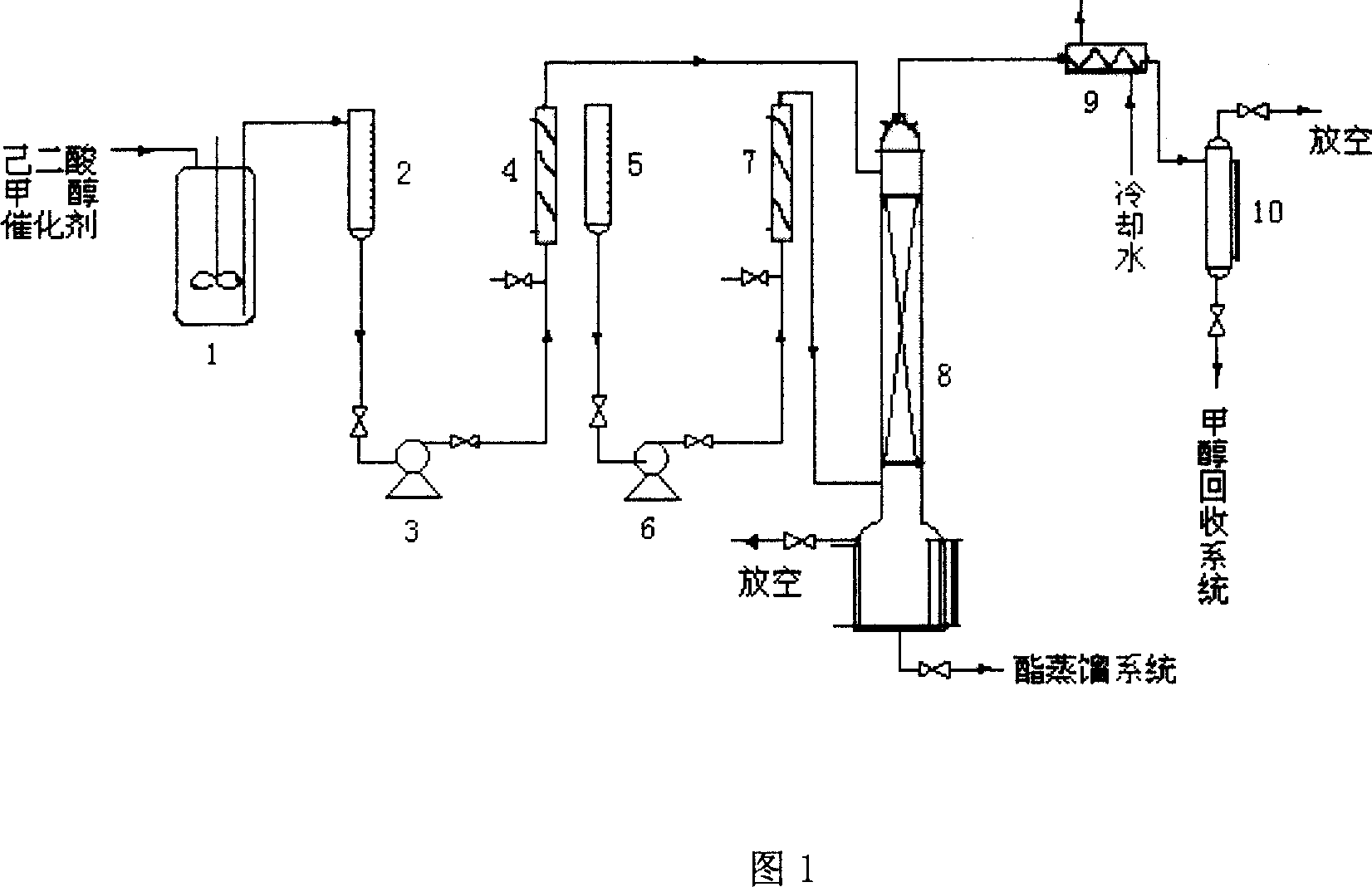

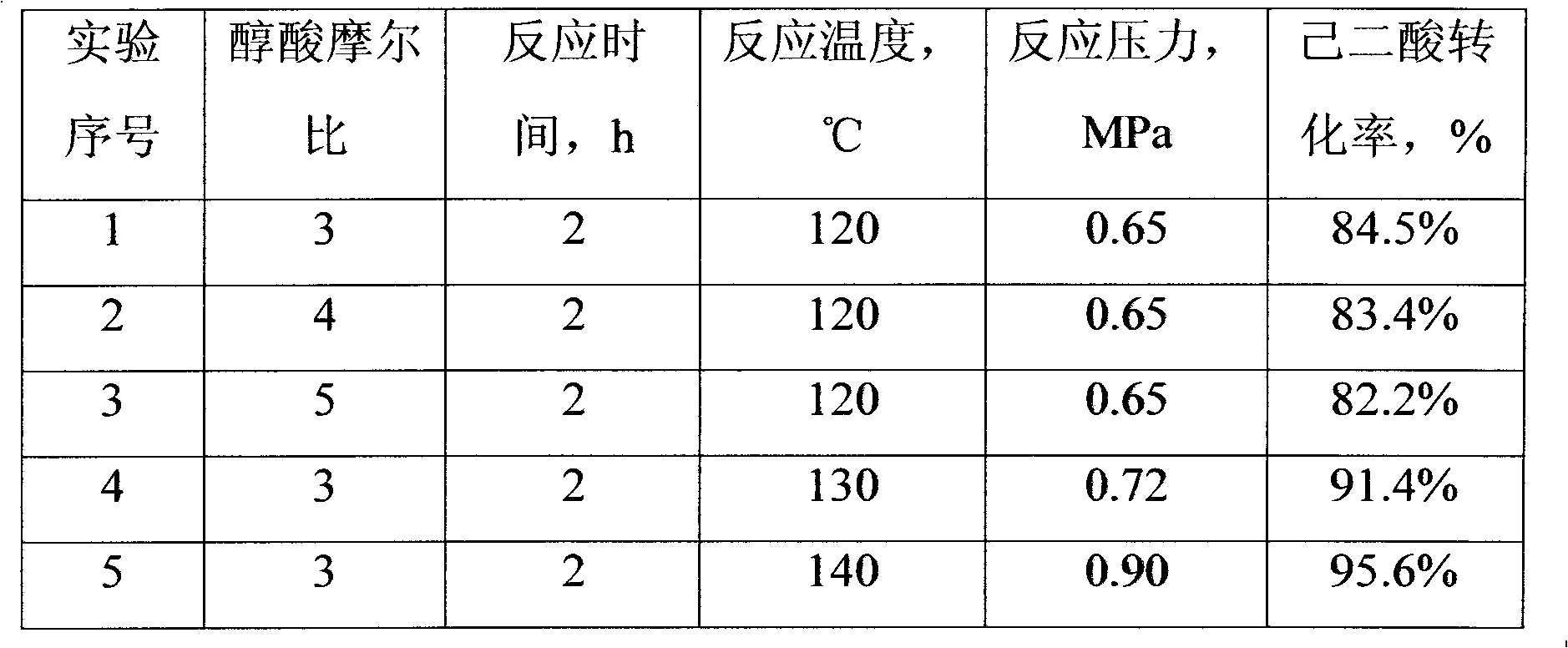

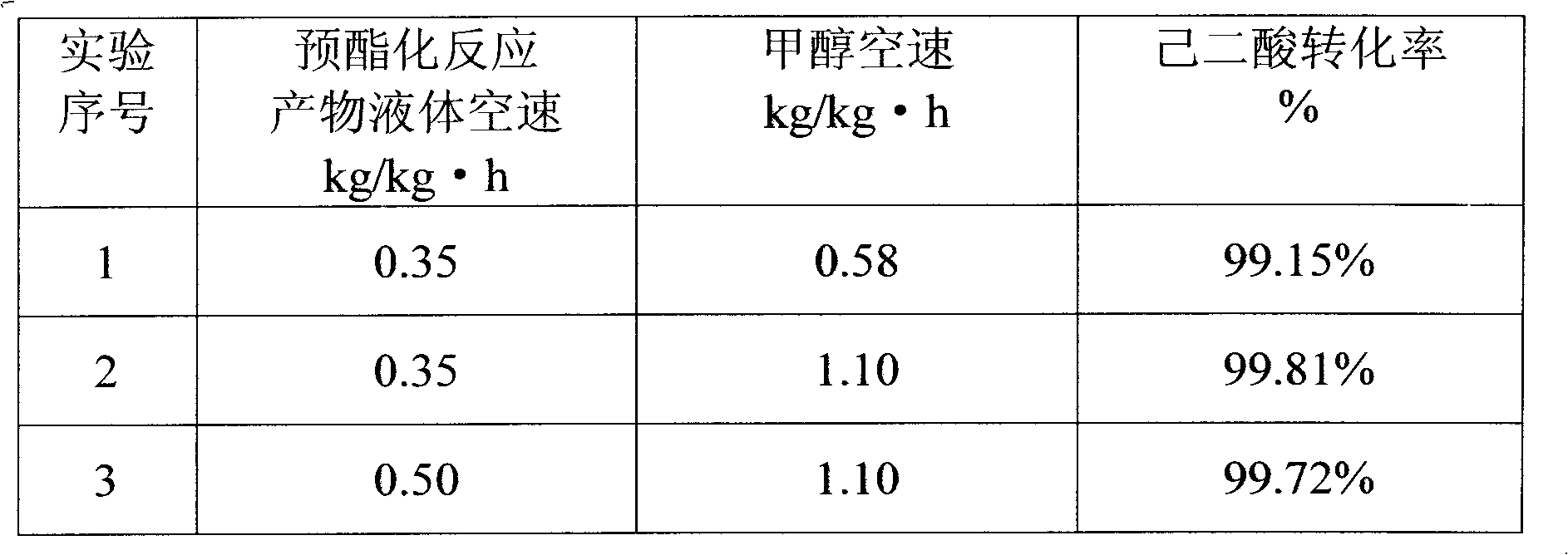

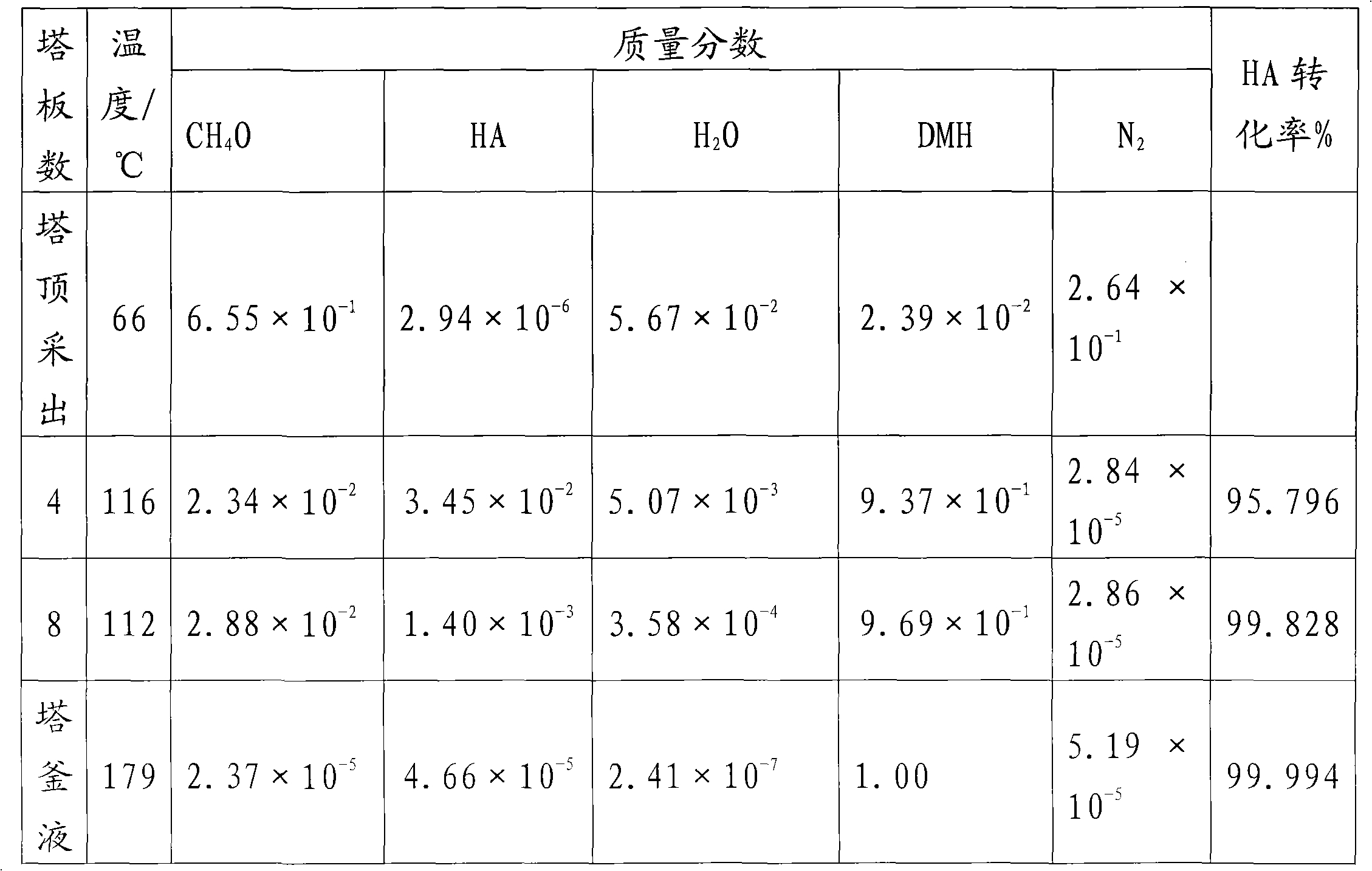

The present invention relates to a method and equipment for producing dimethyl adipate through continuous esterification. A solid acid catalyst, adipic acid and methanol are added to a pre-esterification kettle; the pre-esterification reaction kettle is heated at a temperature of 50-100°C , react under normal pressure to obtain lean ester, the addition amount of solid acid catalyst is 1-10% of the mass of adipic acid, the molar ratio of methanol to adipic acid is 1-10, the solid acid catalyst is a strong acid type cation exchange resin; The supernatant liquid of the ester is sent to the upper part of the continuous esterification tower, and the methanol vaporized into steam enters the lower part of the continuous esterification tower, so that the two do a countercurrent reaction in the catalyst section of the continuous esterification tower, and the reaction temperature is 70 ~ 150°C, the liquid space velocity is 0.1-0.7Kg / Kg h, the methanol space velocity is 0.1-1.0Kg / Kg h; the obtained reactant is obtained by rectification to obtain dimethyl adipate, and the operating pressure is 0~ 0.01MPa; the conversion rate of adipic acid is 99%.

Owner:PETROCHINA CO LTD

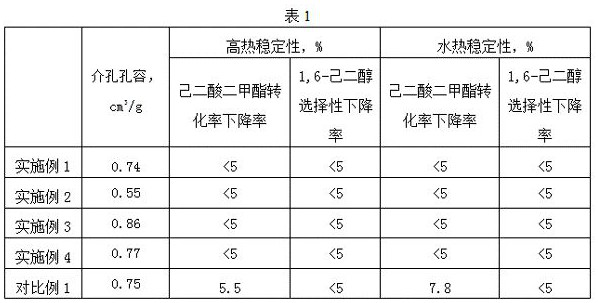

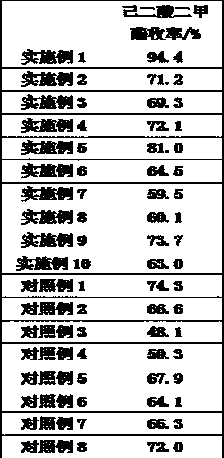

Catalyst for preparing 1, 6-hexanediol by hydrogenating dimethyl adipate, and preparation method and application thereof

ActiveCN111659375AIncrease loading capacityGood dispersionOrganic compound preparationHydroxy compound preparationIridiumPtru catalyst

The invention discloses a catalyst for preparing 1, 6-hexanediol through hydrogenating dimethyl adipate. The catalyst is composed of a carrier and an active component dispersedly loaded on the carrier, wherein the active component is composed of a first active component and a second active component, the first active component is ruthenium and / or iridium, and the second active component is copperchromite; the carrier is a lanthanum doped SiO2 / ZrO2 carrier; and the carrier is of a mesoporous structure, and the pore size of the carrier is 10-50 nm. The catalyst provided by the invention not only has the advantages of high dimethyl adipate conversion rate and strong 1, 6-hexanediol selectivity, but also has the excellent performances of large specific surface area, high active component loading capacity, stable performance and long service life. The invention further discloses a preparation method and application of the catalyst for preparing 1, 6-hexanediol through hydrogenating dimethyl adipate.

Owner:TANGSHAN ZHONGRONG TECH CO LTD

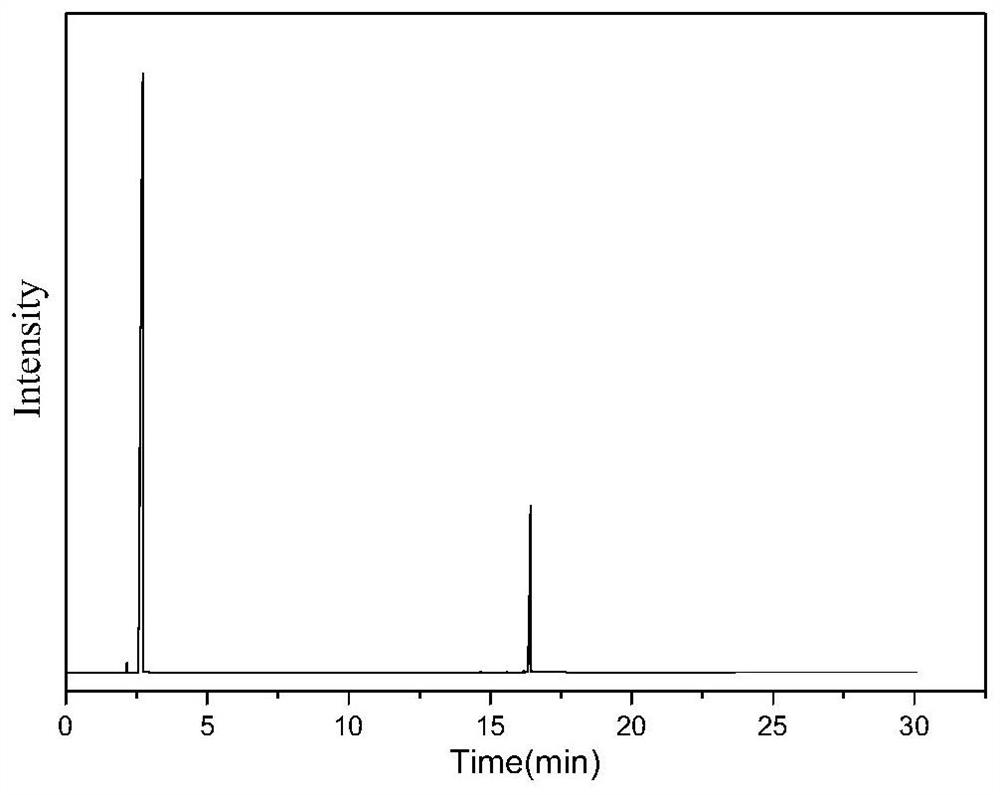

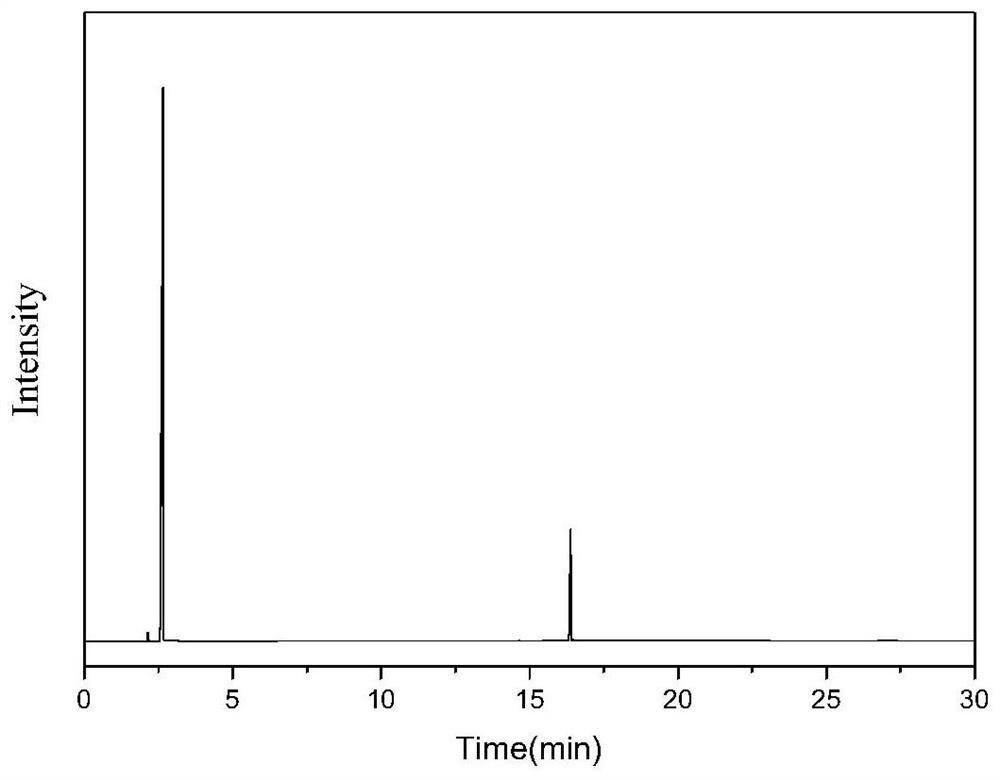

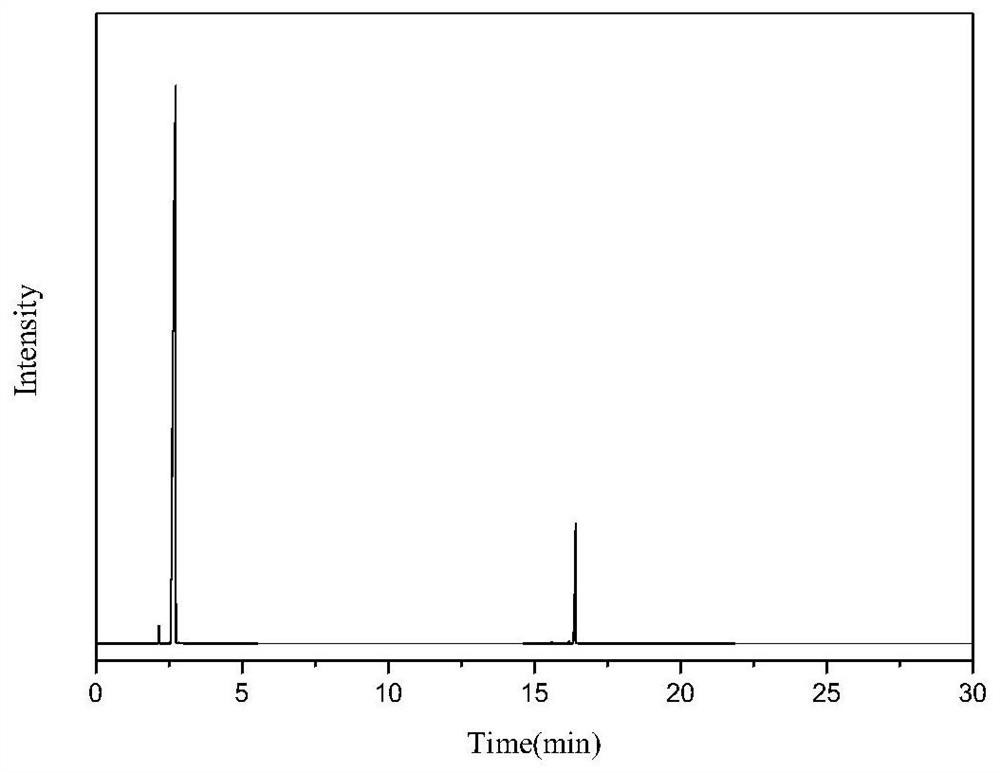

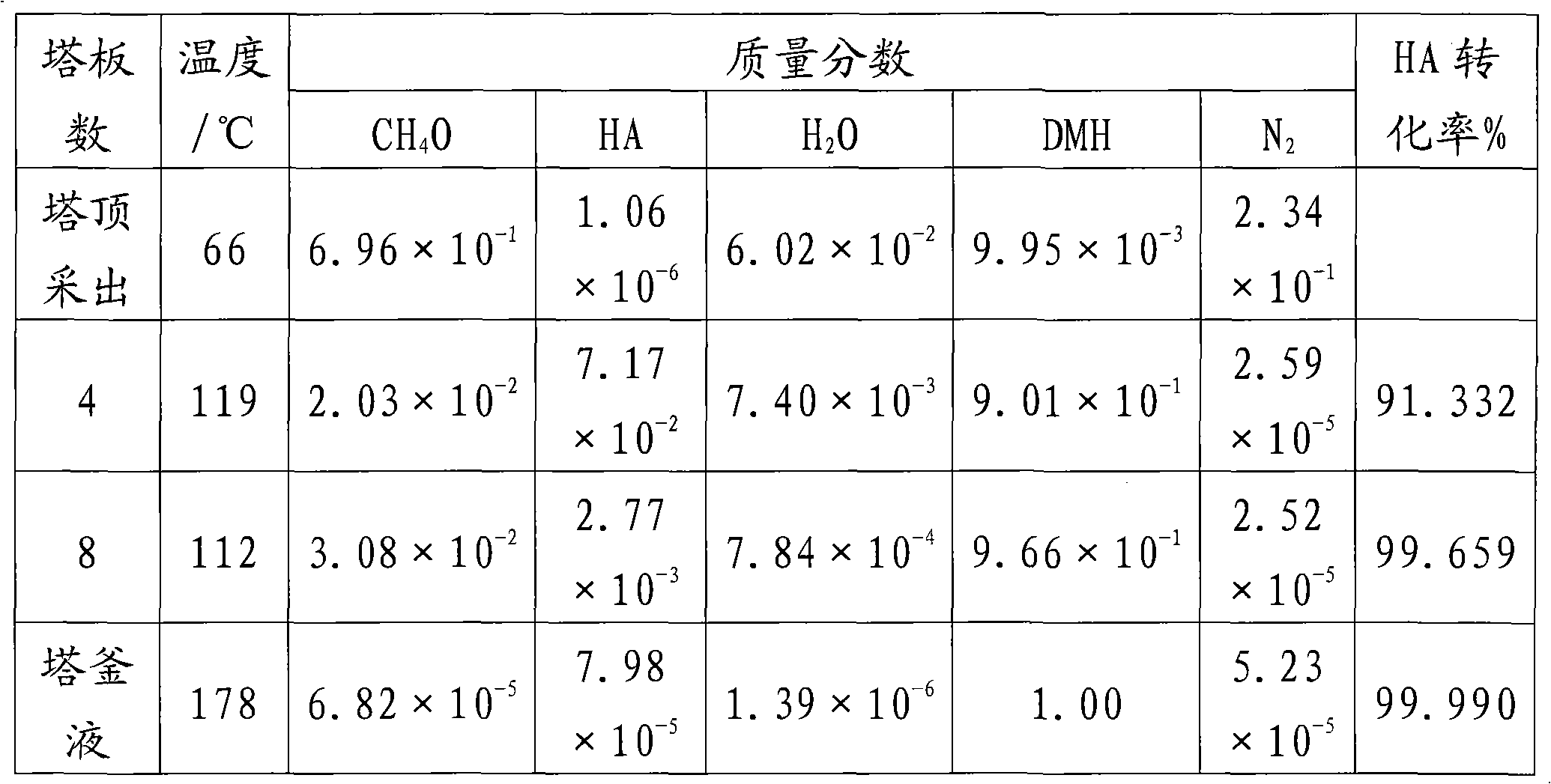

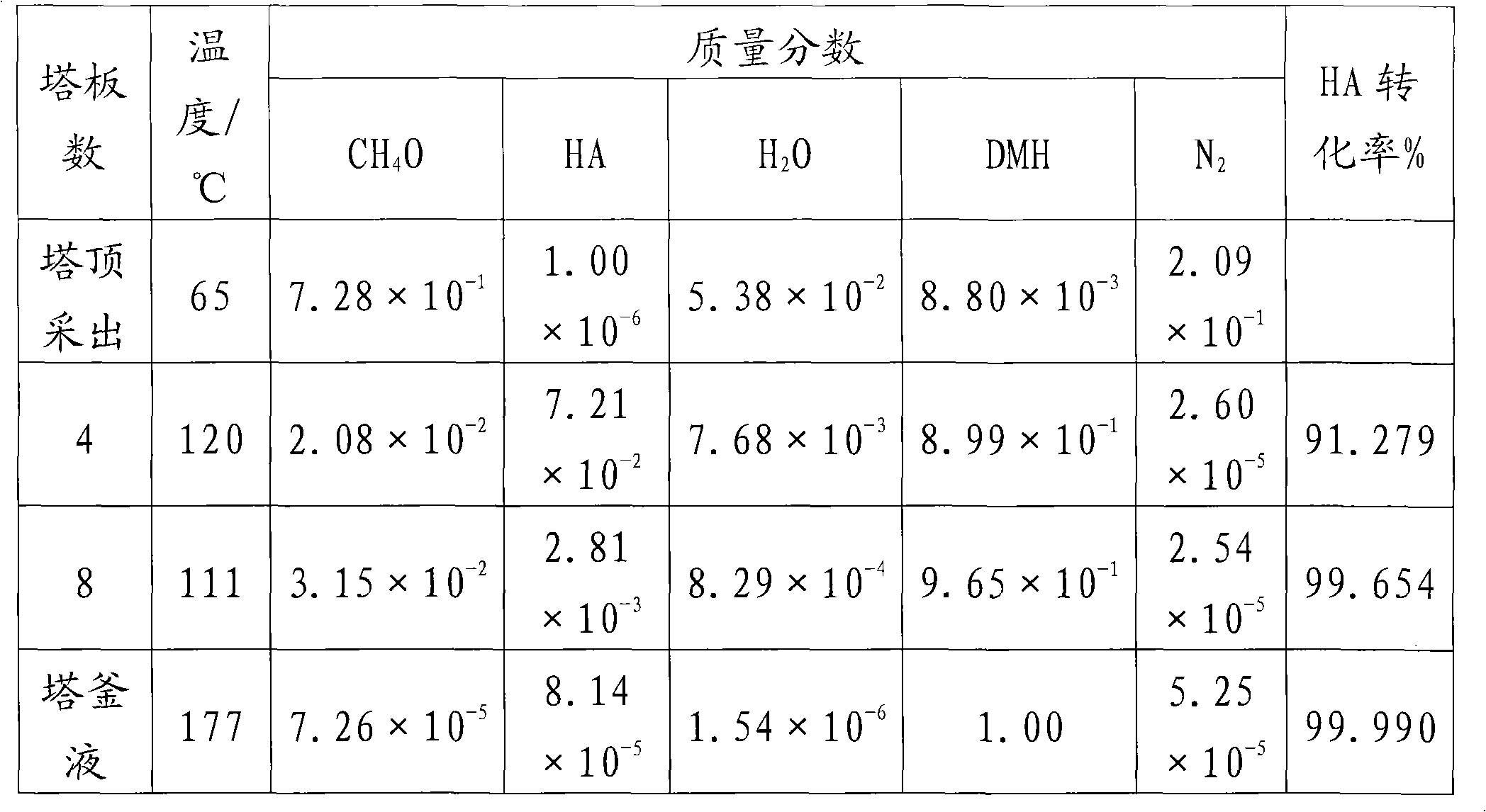

Method for preparing high-purity adipic acid dimethyl ester by catalytic gas stripping coupling technology

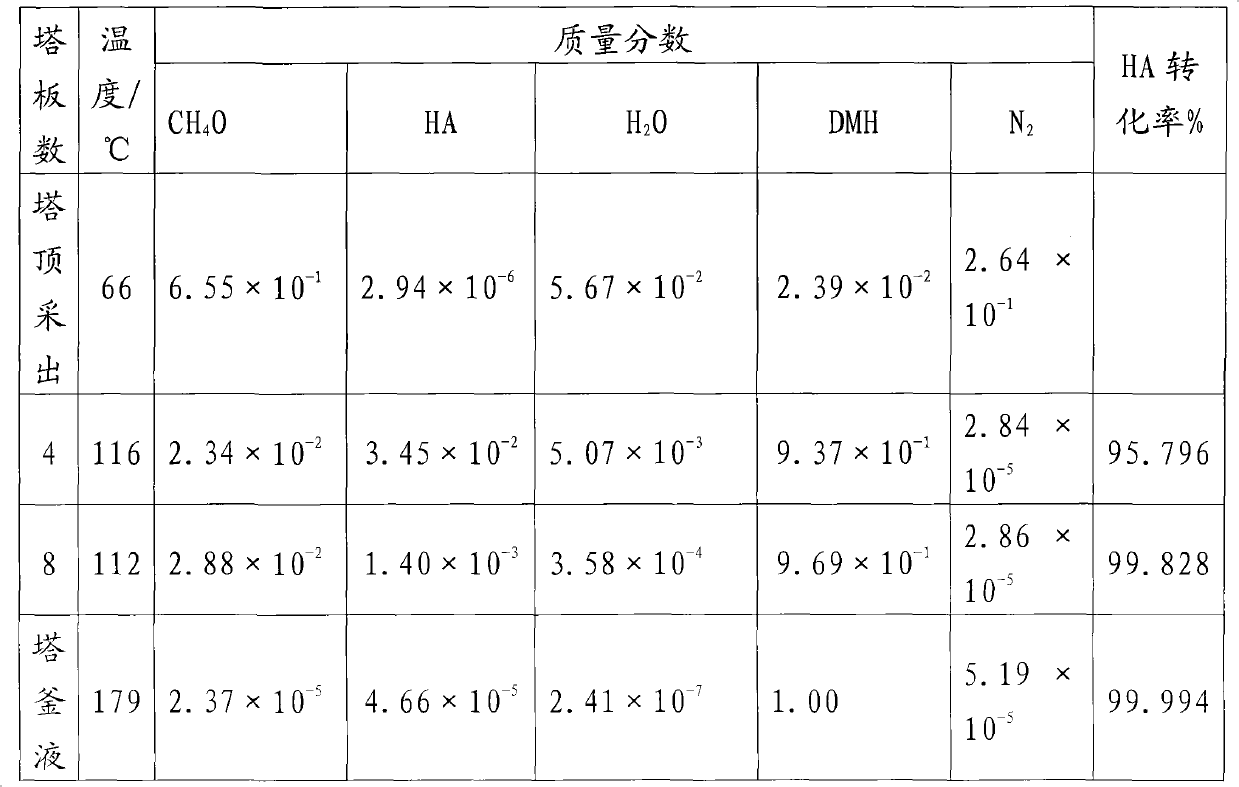

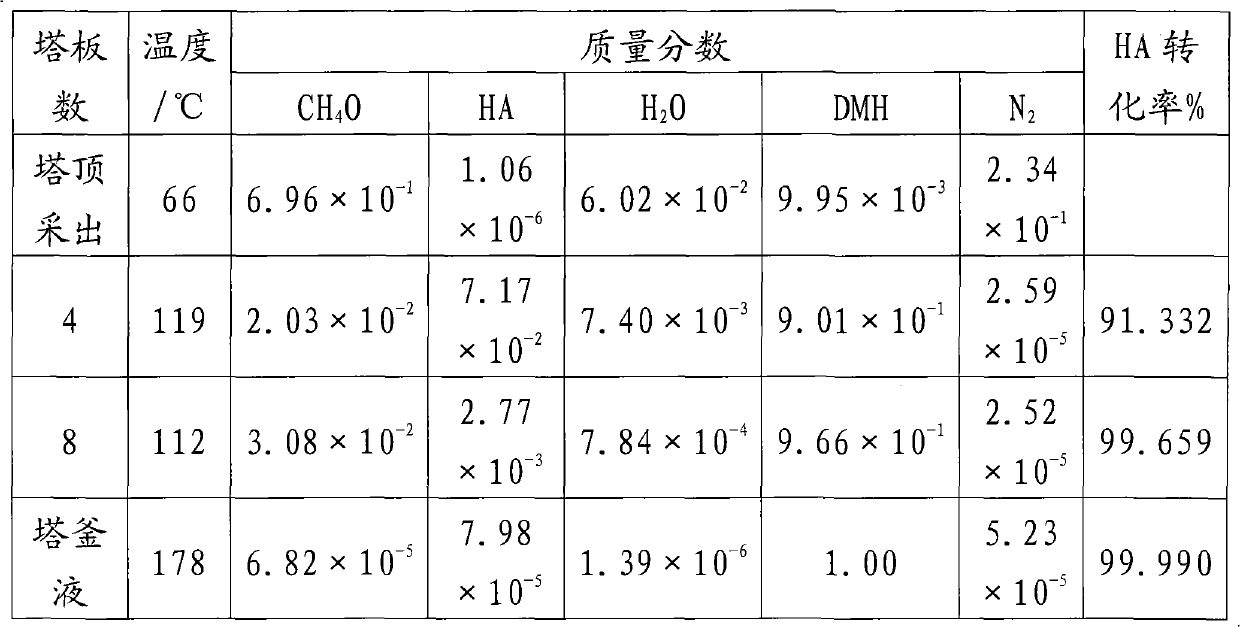

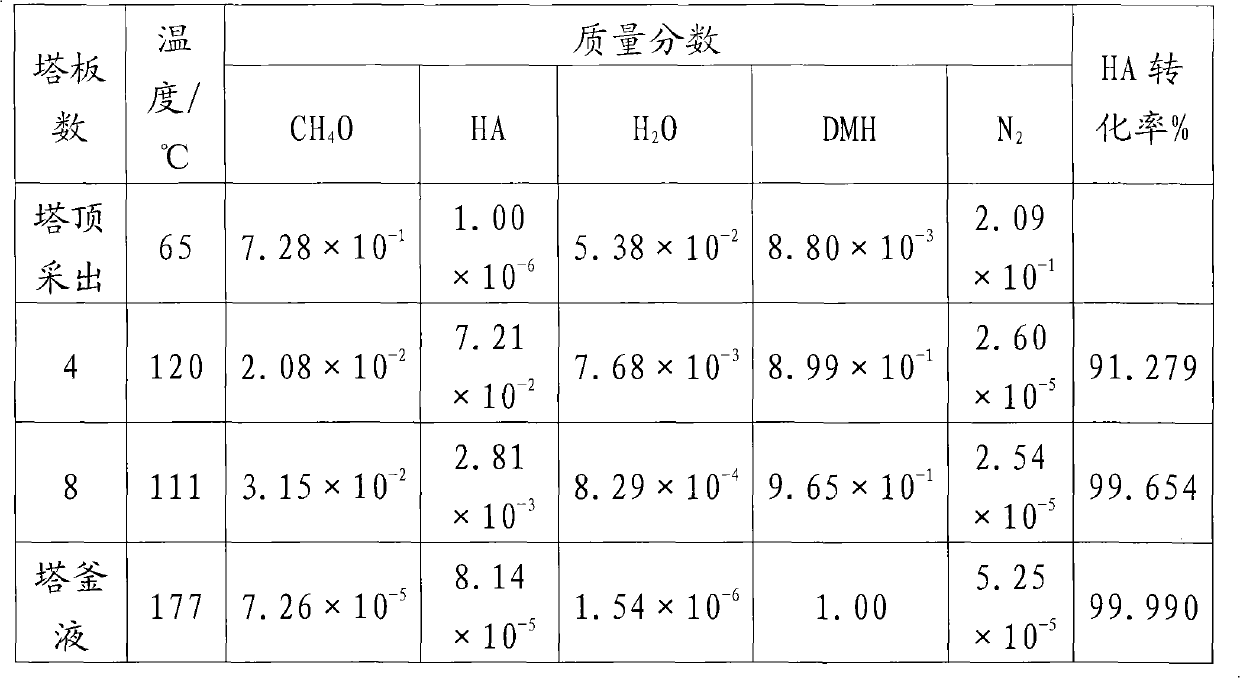

ActiveCN101768077ALow costEasy to useOrganic compound preparationCarboxylic acid esters preparationAdipic acid dimethyl esterGas phase

The invention discloses a method for preparing high-purity adipic acid dimethyl ester by catalytic gas stripping coupling technology. The method comprises the following steps: carrying out countercurrent contact on adipic-acid-containing liquid phase, methanol gas and inert gas in a gas stripping tower and carrying out reaction to generate water which is gas-stripped to the gas phase and recovered from the top of the gas stripping tower; obtaining high-purity adipic acid dimethyl ester from the tower bottom. The method of the invention features simple process, high purity of produced adipic acid dimethyl ester, no need of further refining and direct application as raw material for preparing 1,6-hexanediol.

Owner:WANHUA CHEM GRP CO LTD +1

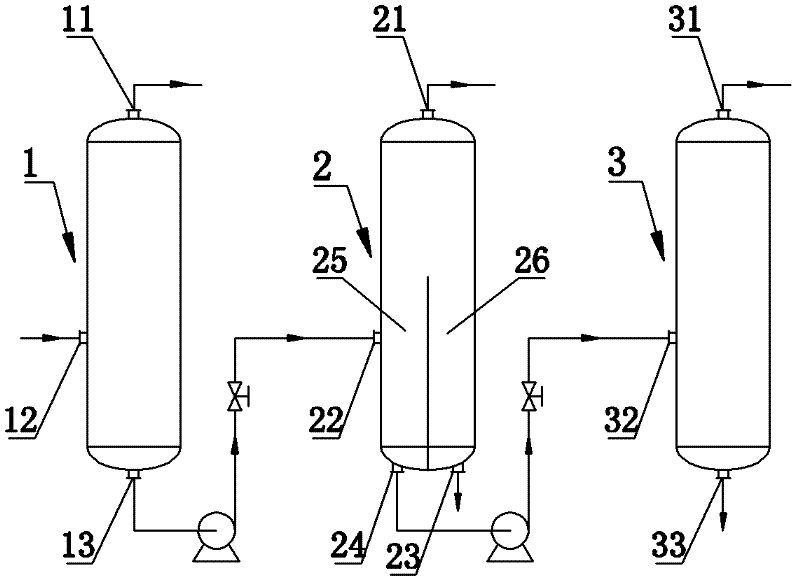

Method for purifying diacid dimethyl esters by plate distillation separation

ActiveCN102432460AReduce consumptionSimple processOrganic compound preparationCarboxylic acid esters preparationGlutaric acidButanedioic acid

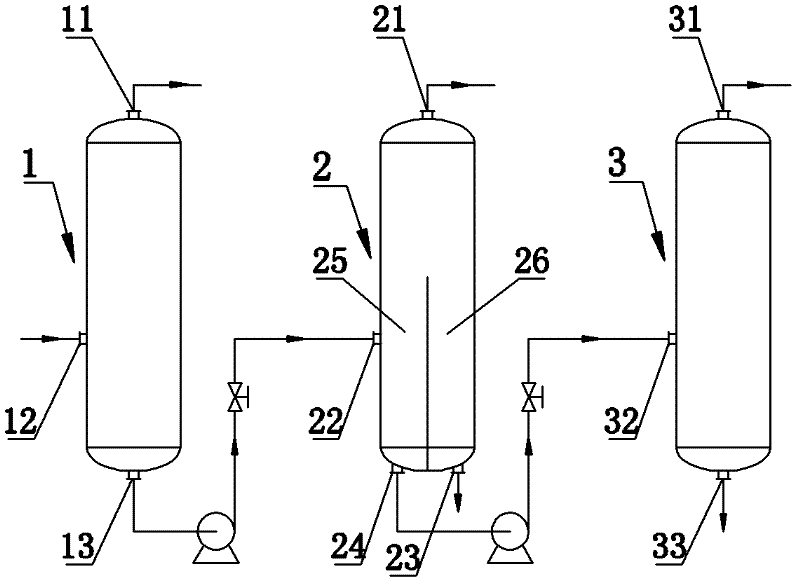

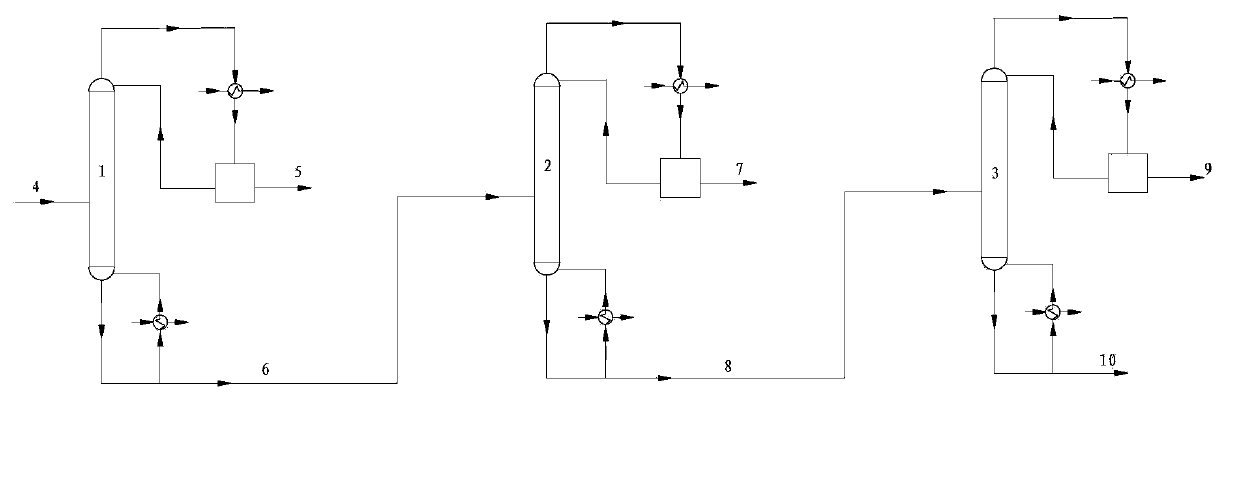

The invention discloses a method for purifying diacid dimethyl esters by plate distillation separation. The distillation separation is successively finished in three series-wound distillation towers. The bottom of a second distillation tower is vertically provided with a separator plate, which divides the bottom cavity into a first tower chamber and a second tower chamber. A material inlet of the second distillation tower is positioned below the top of the separator plate. The method provided by the invention comprises the following steps of: mixing a raw material with diacid dimethyl esters, allowing the mixture to enter into the first distillation tower, separating a light component out from the top of first distillation tower, allowing the material at the tower bottom to enter into the second distillation tower, separating 1,4-succinic acid dimethyl ester out from the top of the distillation tower, separating 1,5-dimethyl glutarate out from the bottom of the second tower chamber of the second distillation tower, allowing the material at the tower bottom of the first tower chamber of the second distillation tower to enter into the third distillation tower, separating 1,6-adipic acid dimethyl ester out from the top of the third distillation tower, and discharging a heavier component in the raw material from the tower bottom. Starting with the first distillation tower, the temperature of the distillation towers successively rises and the pressure successively reduces.

Owner:WEIFANG YUANLI CHEM

A method for preparing 1-amino-2-cyanocyclopentene

ActiveCN109608360BOrganic compound preparationPreparation by ammonia-carboxylic acid reactionCyclopentenePtru catalyst

The invention provides a method for preparing 1-amino-2-cyanocyclopentene, the method uses dimethyl adipate and ammonia as raw materials to carry out gas-phase ammonolysis reaction, and the catalyst is selected as a solid acid catalyst; A mixture containing 1-amino-2-cyanocyclopentene and adiponitrile was prepared by high-temperature gas-phase ammoniation, and then pure 1-amino-2-cyanocyclopentene was obtained by vacuum distillation and recrystallization techniques. The method has easy-to-obtain raw materials, is simple and easy to implement, has high product purity, and can realize mass preparation of target products.

Owner:CHINA TIANCHEN ENG

Method for separating mixed diacid dimethyl ester

InactiveCN103965043AIncrease profitImprove separation efficiencyOrganic compound preparationCarboxylic acid esters preparationRefluxAdipic acid dimethyl ester

The invention discloses a method for separating mixed diacid dimethyl ester. Mixed diacid dimethyl ester successively passes through a rectification tower 1, a rectification tower 2 and a rectification tower 3; dimethyl succinate is separated from the top of the rectification tower 1, dimethyl glutarate is separated from the top of the rectification tower 2, and dimethyl adipate is separated from the top of the rectification tower 3; the reflux ratio of the rectification tower 1, the rectification tower 2 or the rectification tower 3 is 0.5 to 3.0; the mixed diacid dimethyl ester is a product of esterification of methanol and mixed diacid by-produced in production of adipic acid, and comprises 10 to 30 wt% of dimethyl succinate, 40 to 60 wt% of dimethyl glutarate and 20 to 40 wt% of dimethyl adipate. With the method, the recovery rate and purity of dimethyl succinate, dimethyl glutarate and dimethyl adipate are more than 95 wt% and no less than 98%, respectively. According to the invention, a rectification apparatus is divided into the three rectification towers, each rectification tower is provided with 5 to 30 tower plates, the reflux ratio is controlled to be 0.5 to 3, energy consumption is low, the utilization rate of resources is high, and the advantages of easy realization of industrialization and low energy consumption are obtained.

Owner:CHINA PETROLEUM & CHEM CORP

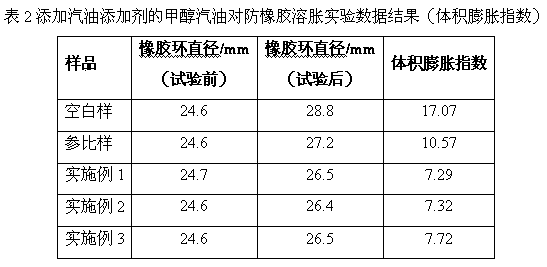

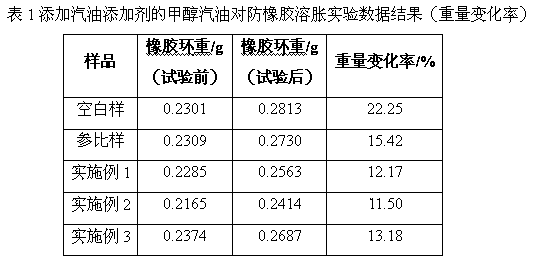

Beta-hydroxyalkylamide curing agent preparation method

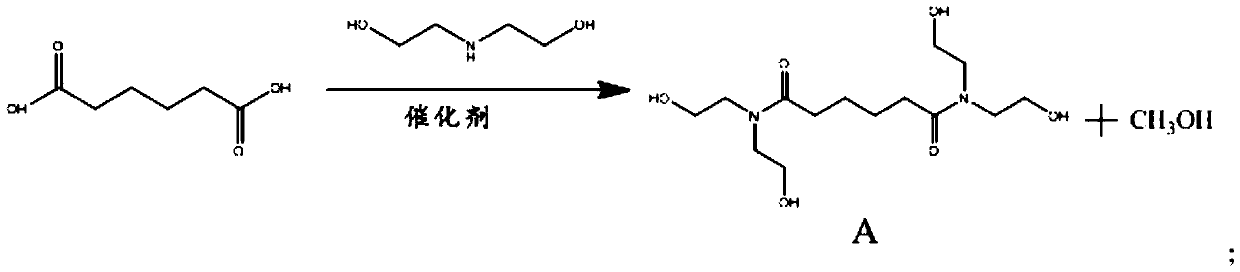

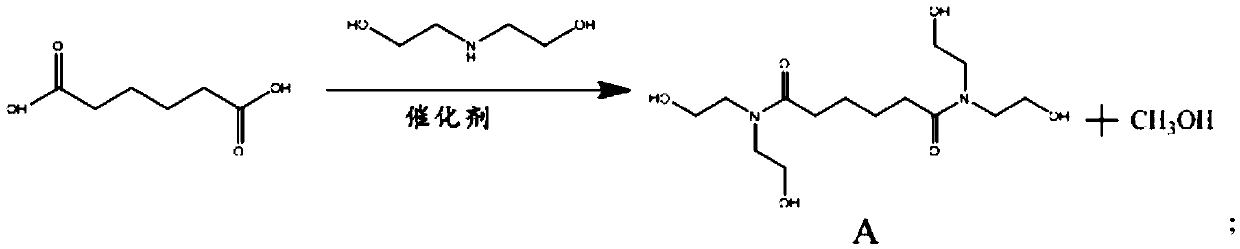

PendingCN110642742AHigh yieldPreparation Process GreenOrganic compound preparationCarboxylic acid amides preparationPtru catalystAdipic acid dimethyl ester

The invention discloses a beta-hydroxyalkylamide curing agent preparation method, which comprises: (1) mixing dimethyl adipate or diethyl adipate and diethanol amine, adding a catalyst, heating, and carrying out pressure reducing distillation to remove volatile components to obtain a tetrahydroxyethyl adipamide solution, i.e., a product A, wherein the reaction equation formula is defined in the specification; and (2) curing the product A, breaking, and drying to obtain a white powder solid, ie., the qualified tetrahydroxyethyl adipamide (beta-hydroxyalkylamide). The method of the invention hasadvantages of high yield, no generation of wastewater, waste liquid and waste solid during preparation, environmental protection, less equipment investment and simple operation.

Owner:甘肃青宇新材料有限公司

Method for preparing N,N,N',N'-tetra(beta-hydroxypropyl) adipamide

PendingCN113698314AHigh viscosityImprove solubilityOrganic compound preparationCarboxylic acid amide separation/purificationPolymer sciencePtru catalyst

The invention discloses a method for preparing N,N,N',N'-tetra(beta-hydroxypropyl) adipamide, which comprises the following steps: (1) adding excessive diisopropanolamine and a basic catalyst into a reaction kettle, and then dropwise adding dimethyl adipate to prepare a crude product of N,N,N',N'-tetra(beta-hydroxypropyl) adipamide; (2) lowering the temperature in the reaction kettle to a set temperature, dropwise adding or adding neutralizing acid into the reaction kettle in batches under a vacuum condition so as to neutralize the excessive diisopropanolamine, and dehydrating at the same time; (3) after the neutralization is finished, adding a solvent into the reaction kettle, stirring and crystallizing, then filtering, and separating out diisopropanolamine sulfate, and subjecting the filtrate to distillation to separate the solvent so as to obtain the N,N,N',N'-tetra(beta-hydroxypropyl) adipamide product with high purity. According to the method, the unreacted diisopropanolamine raw material is separated by utilizing the high-amine ester, so that the preparation process is simple in flow and low in energy consumption, and the separated diisopropanolamine salt can be recycled as an industrial raw material.

Owner:南京安科迩环保新材料有限公司

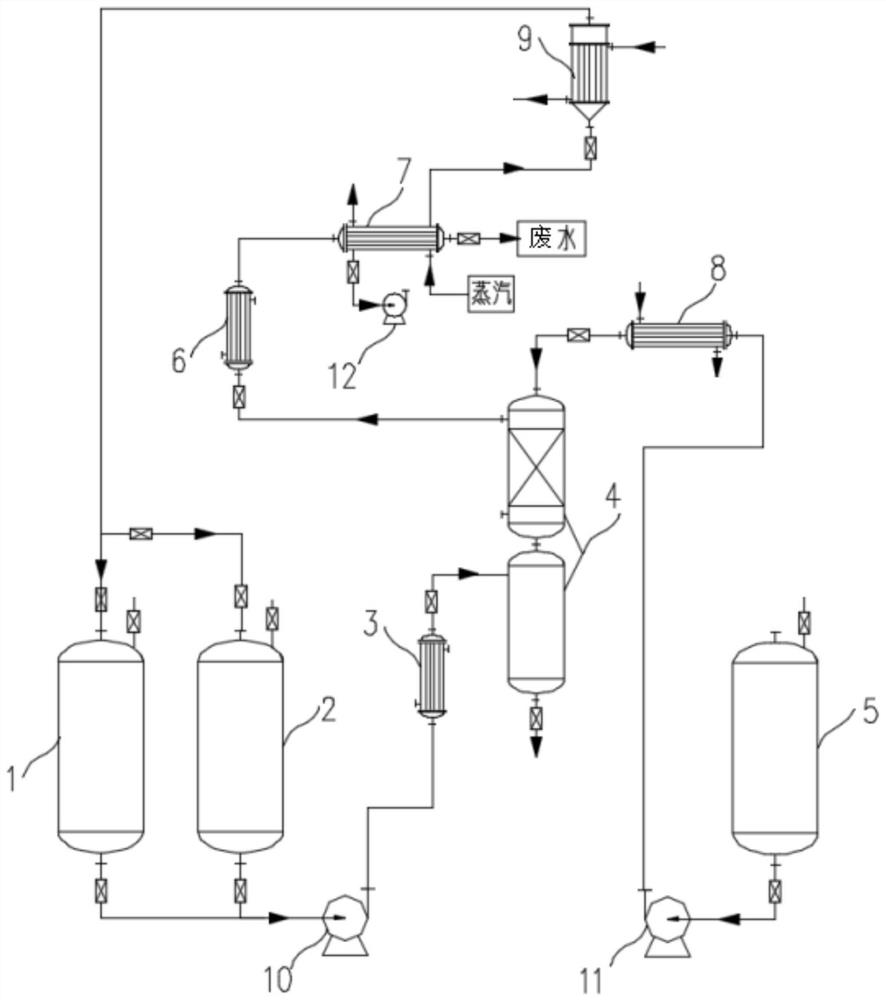

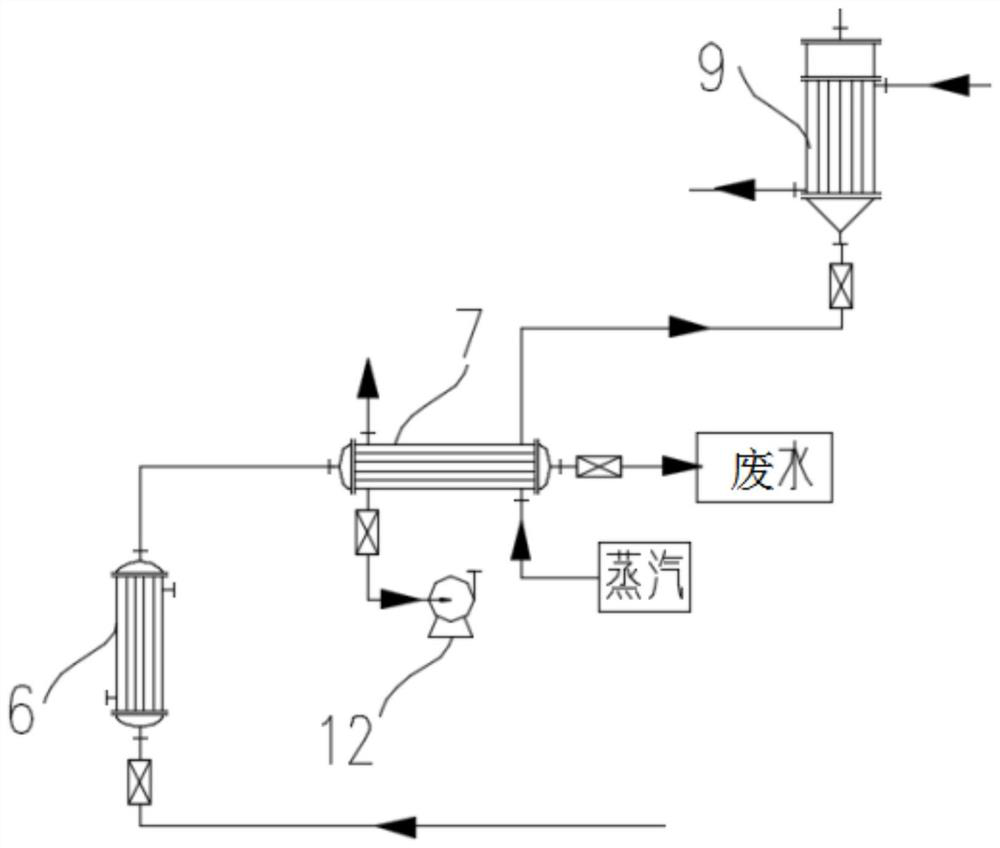

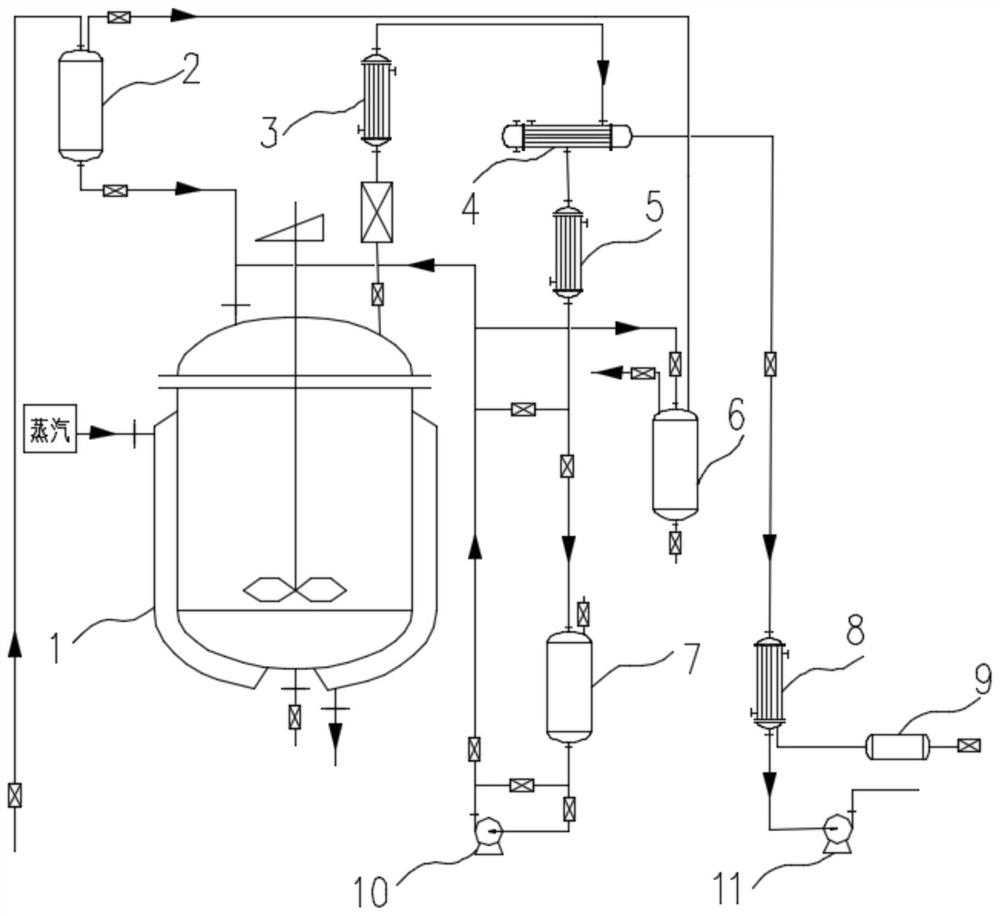

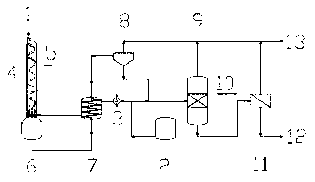

Continuous esterification reaction system, production method of dimethyl adipate and application

PendingCN114177852ASolve the problem of energy consumptionSolve the costOrganic compound preparationDispersed particle separationAdipic acid dimethyl esterProcess engineering

The invention relates to the technical field of chemical processes, and particularly discloses a continuous esterification reaction system and a production method and application of dimethyl adipate, a continuous methanol separation system comprises a continuous esterification tower and a methanol raw material tank, the methanol raw material tank is used for storing methanol, the end of the esterification tower is communicated with a material tank used for storing pre-esterification liquid, and the material tank is communicated with the esterification tower. The stored pre-esterification liquid can be conveyed into the esterification tower and is subjected to esterification reaction with methanol, the esterification tower is connected with a methanol preheater, and the output end of the methanol preheater is connected with a membrane dryer; according to the invention, unreacted methanol and generated water in the esterification tower are heated and evaporated out through the methanol preheater, and then are filtered and separated through the membrane dryer, so that water is removed, and the residual methanol flows back to the methanol raw material tank and can be continuously conveyed into the esterification tower for esterification reaction; the problems that an existing continuous esterification method for producing dimethyl adipate is high in energy consumption and production cost is increased are solved.

Owner:岳阳职业技术学院

A kind of synthetic method of adipic acid dihydrazide

The invention discloses a method for synthesizing adipic dihydrazide. The method uses dimethyl adipate, acetonazine and water as raw materials, adds a catalyst to the system at a certain temperature, and reacts for a certain period of time. The reaction product is subjected to distillation, crystallization, washing and drying to obtain a white solid, which is the target product adipic acid dihydrazide. The synthesis route of the method is simple, the product yield is high; the by-products and impurities produced are less, the post-treatment process is simple, and the purity of the product is high; there is no "three wastes" in the synthesis process, which is green and environmentally friendly, and the cost of raw materials is low, which is suitable for industrial production .

Owner:JIANGSU LINGYUN PHARMA

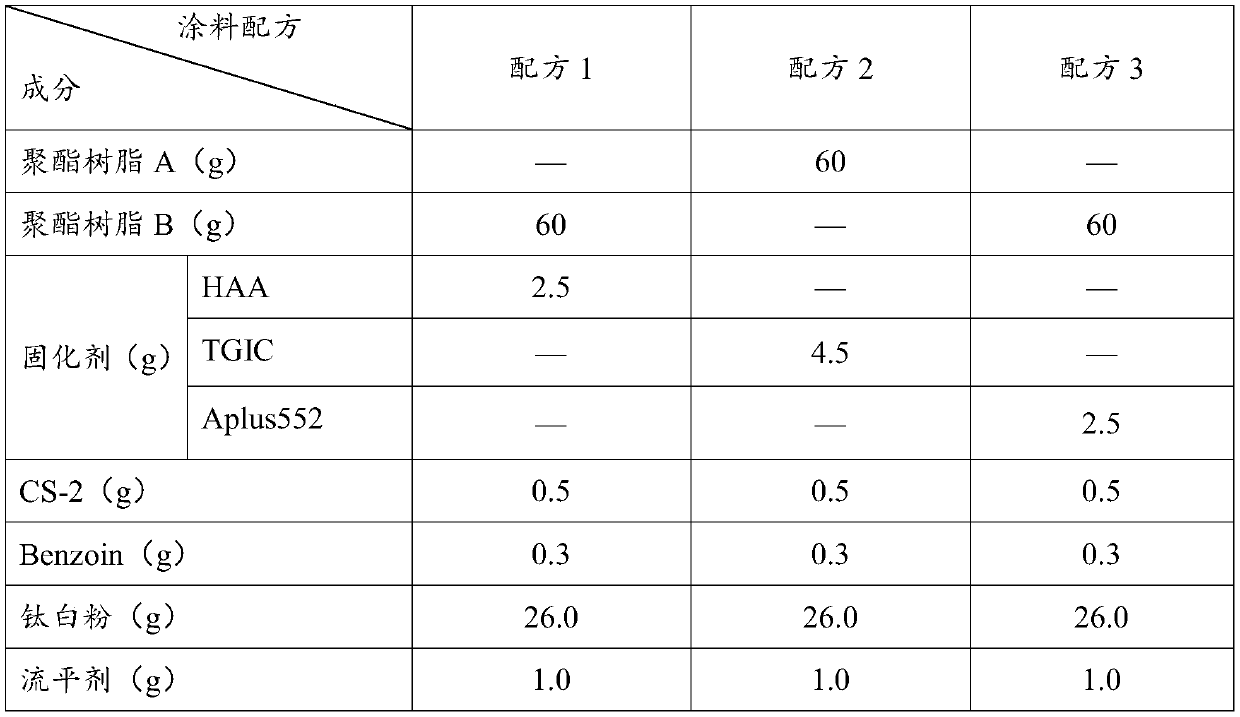

Preparation method of mixed adipic acid alcohol amide curing agent

InactiveCN111073367AReduce pollutionEasy to separate and purifyPowdery paintsPolyester coatingsPtru catalystAdipic acid dimethyl ester

The invention provides a preparation method of a mixed adipic acid alcohol amide curing agent, and the method comprises the following steps: mixing diethanolamine, ethanolamine and a composite catalyst, and dropwisely adding dimethyl adipate; after the reaction is finished, adding a mixed solvent, then adding a decolorizing agent for decolorizing, and filtering out the decolorizing agent and the composite catalyst; cooling the obtained organic phase, crystallizing, and finally filtering to obtain the mixed adipic acid alcohol amide curing agent. According to the invention, the dimethyl adipate, the diethanolamine and the ethanolamine are used as raw materials to synthesize mixed adipic acid alcohol amide; by adopting the mixed catalyst, the separation and purification process is simple, the reaction time is short, the product yield is high and can reach more than 95%, the product purity is high, the energy consumption is reduced, the environmental pollution is small, the cost is low, and the method is an ideal process for realizing industrial preparation.

Owner:JIANGSU XINLU CHEM NEW MATERIAL

Environment-friendly wave-absorbing coating and preparation method thereof

ActiveCN109627832BEasy to useExtended service lifePolyurea/polyurethane coatingsRadiation-absorbing paintsGlutaric acidButanedioic acid

An environment-friendly wave-absorbing coating and a preparation method thereof belong to the field of wave-absorbing materials. The environmentally friendly wave-absorbing coating includes the following raw materials in mass percentage: 7-73% matrix resin, 9-63% wave-absorbing agent, 4-26% solvent, 0.5-2% dispersant, 0.4-1% anti-sedimentation agent and 1‑12% curing agent; wherein, the solvent is selected from dimethyl carbonate, tert-butyl acetate, dimethyl adipate, dimethyl glutarate, dimethyl succinate, propylene glycol diacetic acid At least one of ester, propylene glycol methyl ether acetate. The environmentally friendly wave-absorbing coating provided by the invention does not contain solvents such as benzenes and ketones that are highly toxic and harmful and have carcinogenic risks, and is environmentally friendly, low-toxic, low-harm and non-polluting, and the cured coating has very Good mechanical properties and absorbing properties. The invention also provides a preparation method of the above environment-friendly wave-absorbing coating.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

Method for preparing high-purity adipic acid dimethyl ester by catalytic gas stripping coupling technology

ActiveCN101768077BHigh purityNo emissionsOrganic compound preparationCarboxylic acid esters preparationAdipic acid dimethyl esterFluid phase

Owner:WANHUA CHEM GRP CO LTD +1

Catalyst for ester hydrogenation, and preparation method and application thereof

ActiveCN110227470AHigh selectivityHydrogenation reaction pressure is lowOrganic compound preparationHydroxy compound preparationHydrogenation reactionSpace velocity

The invention belongs to the technical field of catalyst preparation, and concretely relates to a noble metal-free catalyst for ester hydrogenation, and a preparation method thereof. The catalyst canbe well applied to hydrogenation of dimethyl adipate to prepare 1,6-hexanediol. The catalyst has the advantages of low hydrogenation reaction pressure, high space velocity, few side reactions, high selectivity of an ester hydrogenation product, high yield of the product, easiness in achieving continuous production, and no device corrosion when applied to the catalytic hydrogenation of dialkyl adipate to prepare 1,6-hexanediol.

Owner:ZHENGZHOU UNIV

Method for producing dimethyl adipate

ActiveCN109748790BImprove conversion rateReduce dosageOrganic compound preparationCarboxylic acid esters preparationAdipic acid dimethyl esterFluid phase

The object of the present invention is to provide the method for producing dimethyl adipate, the method comprises: (1) the adipic acid of fresh methyl alcohol and melting adds primary esterification reactor; (2) primary esterification reactor tube pass The output material enters the upper part of the reaction section of the esterification rectification tower, and the vaporized methanol enters the lower part of the reaction section. The product containing dimethyl adipate is extracted from the bottom of the tower, and the top gas containing dimethyl ether is extracted from the top of the tower without cooling. (3) The non-condensable gas containing dimethyl ether and the liquid phase containing light components are extracted from the top of the methanol recovery tower, and the side line liquid phase is extracted to recover methanol, which is recycled to a The first-grade esterification reactor is used as the heat removal medium, and the heavy components containing water are extracted from the tower; (4) Fresh methanol is used as the reflux liquid of the rectification tower for the esterification reaction, and esters are absorbed from the ascending gas phase at the same time. The method has the advantages of small floor area, high reaction conversion rate, low unit consumption, high product purity and low energy consumption, and can be used for industrial production of dimethyl adipate.

Owner:CHINA PETROLEUM & CHEM CORP +1

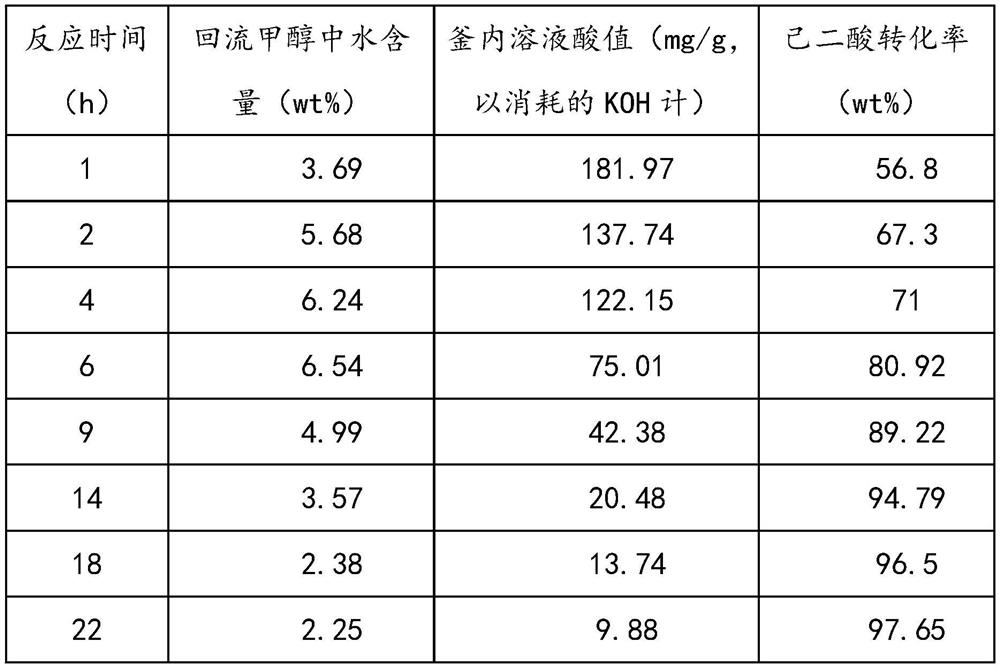

Environmentally-friendly synthesis method of dimethyl adipate

InactiveCN109438231AHigh yieldGuaranteed yieldOrganic compound preparationCarboxylic acid esters preparationAdipic acid dimethyl esterSynthesis methods

The invention discloses a synthesis method of dimethyl adipate. The dimethyl adipate is prepared from methanol and adipic acid which serve as main raw materials by adopting a metal solid-phase catalyst prepared by dual-metal salt coprecipitation. Compared with traditional strong acid catalysts such as sulfuric acid or methylbenzenesulfonic acid, the catalyst can be repeatedly used after being recycled and avoids corrosion of equipment and production of the three types of wastes.

Owner:XUZHOU NORMAL UNIVERSITY

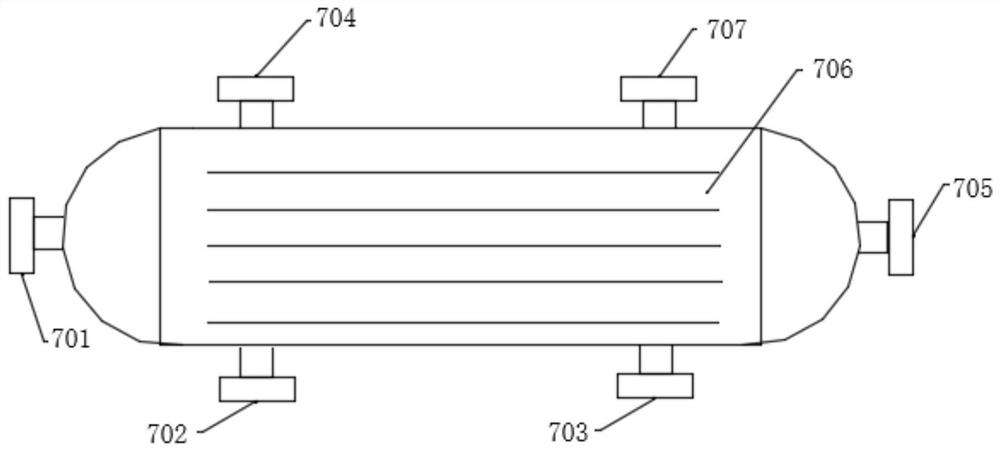

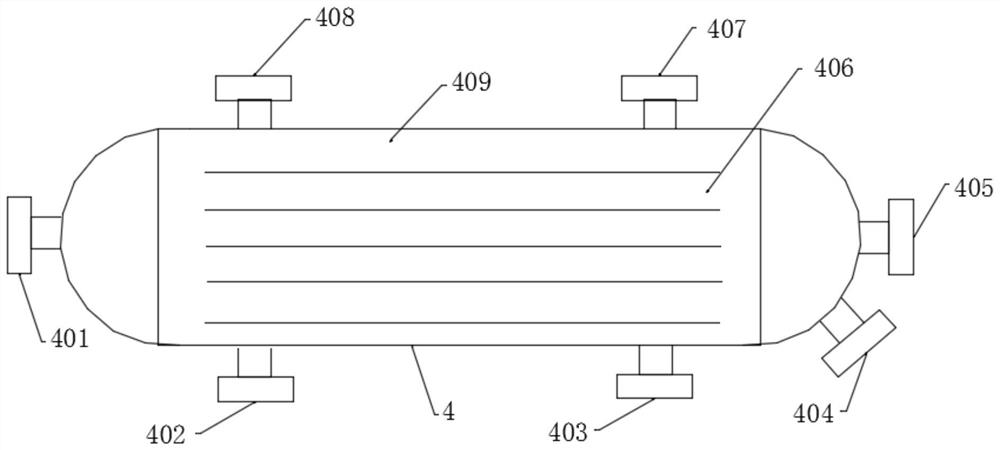

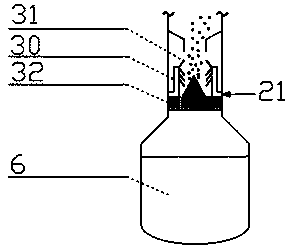

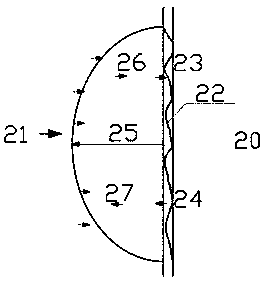

Membrane dryer, intermittent esterification reaction system and dimethyl adipate preparation method

PendingCN114160055ASolve the problem of conversion rateOrganic compound preparationCarboxylic acid esters preparationAdipic acid dimethyl esterEsterification reaction

The invention relates to the field of chemical engineering, and particularly discloses a membrane dryer, an intermittent esterification reaction system and a dimethyl adipate preparation method.The membrane dryer comprises a shell and a first cavity, a ceramic membrane tube is arranged in the first cavity, a second cavity is formed in the ceramic membrane tube, a second steam inlet is formed in the outer side of the shell, and a second steam outlet is formed in the outer side of the shell; the ceramic membrane tube is used for conveying a gaseous material to be dried to the first cavity, so that only water molecules are conveyed to the second cavity under the filtration of the ceramic membrane tube; a negative pressure environment is provided for the second cavity, a to-be-dried gaseous material is conveyed into the first cavity through a second steam inlet, only water molecules in the to-be-dried gaseous material are conveyed into the second cavity through filtration of the ceramic membrane tube under the driving of negative pressure power, and then the to-be-dried gaseous material is conveyed out of the membrane dryer. The method can be used for continuing to participate in dimethyl adipate synthesis reaction, and solves the problem that the conversion rate of adipic acid is influenced by water generated in the esterification process in the existing dimethyl adipate production method.

Owner:岳阳职业技术学院

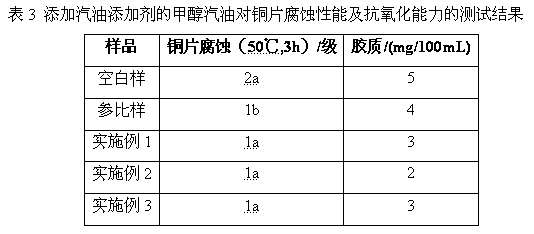

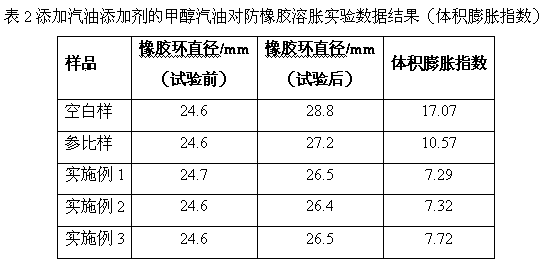

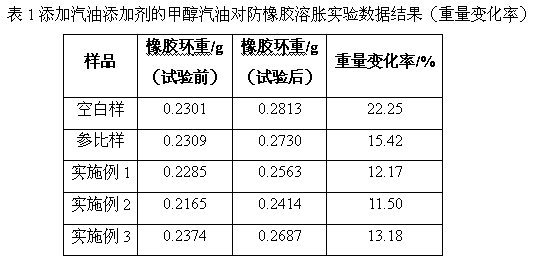

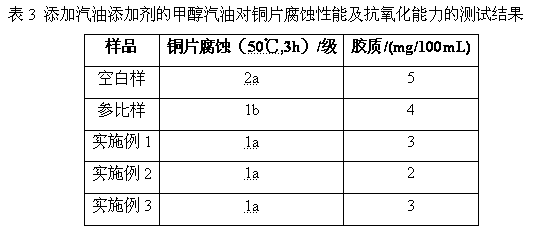

Alcohol-based gasoline additive as well as preparation method and application thereof

ActiveCN103695054BAnti-swellImprove antioxidant capacityLiquid carbonaceous fuelsFuel additivesOil additiveEngineering

Owner:XIAN JIAHONG PETROCHEM TECH

Method for producing dimethyl adipate from adipic acid

ActiveCN111320543AStable reaction temperatureThe pre-esterification reaction went smoothlyOrganic compound preparationChemical industryPolymer scienceAdipic acid dimethyl ester

The invention discloses a method for producing dimethyl adipate by continuous esterification of adipic acid. The method comprises the following steps: feeding adipic acid particles into a pre-esterification reactor in a solid form, contacting methanol steam with adipic acid in the pre-esterification reactor to carry out reactions, introducing generated materials into a double-esterification reactor, carrying out reactions, and separating the double-esterification product to obtain dimethyl adipate. The method overcomes the problems that the existing adipic acid cannot be continuously fed, thepre-esterification is discontinuous, and the pre-esterification product is unstable in composition.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of dimethyl adipate and lignin carbon-based solid acid catalyst

PendingCN114369025AReduce energy consumptionSave resourcesPhysical/chemical process catalystsOrganic compound preparationAdipic acid dimethyl esterPtru catalyst

The invention provides a preparation method of dimethyl adipate and a lignin carbon-based solid acid catalyst, reaction raw materials for preparing the dimethyl adipate comprise methanol, adipic acid and the lignin carbon-based solid acid catalyst, in an esterification reaction of the dimethyl adipate, the yield of the dimethyl adipate can reach 98%, the conversion rate of the adipic acid can reach 99%, and the yield of the lignin carbon-based solid acid catalyst can reach 98%. And compared with other solid acid catalysts, the lignin carbon-based solid acid catalyst has a more excellent effect of catalyzing the reaction, and can reach a higher esterification level within a shorter time and at a lower temperature, thereby greatly reducing the energy consumption and saving the resources.

Owner:HEBEI UNIV OF TECH

Alcohol-based gasoline additive as well as preparation method and application thereof

ActiveCN103695054AAnti-swellAnti-corrosionLiquid carbonaceous fuelsFuel additivesOil additiveAdipate

The invention discloses an alcohol-based gasoline additive which comprises the following components by weight: 1-3 parts of dimethyl adipate, 0.2-1.5 parts of amyl dicyclohexyl phenol, 0.5-2 parts of oleic acid, 0.005-0.1 part of pentadecafluorooctanoic acid and 0.02-0.15 part of polyisobutene succinimide. The alcohol-based gasoline additive has remarkable effects of preventing rubber swelling and corrosion, can be used for improving the oxidation resistance of alcohol-based gasoline, and has a good industrial application prospect.

Owner:XIAN JIAHONG PETROCHEM TECH

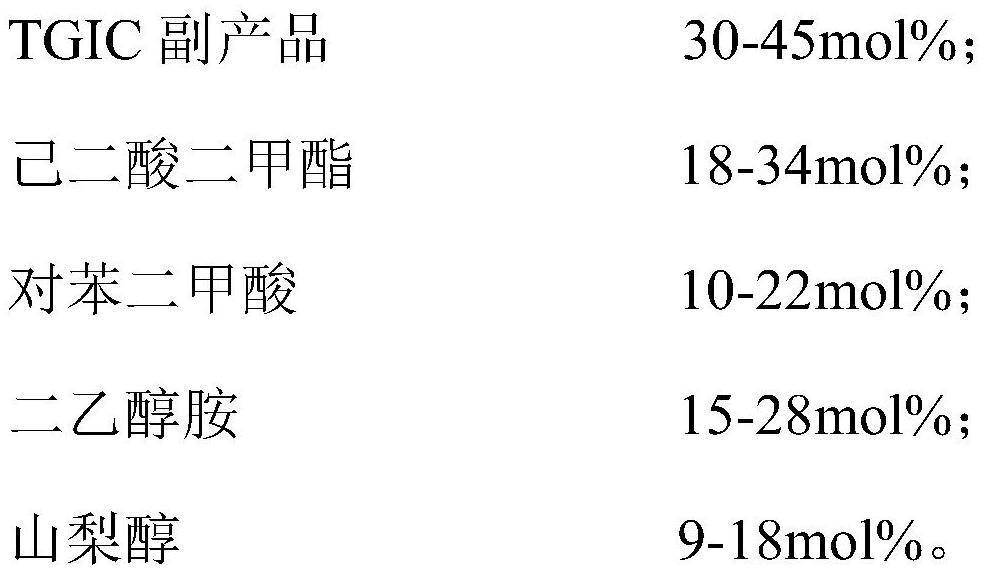

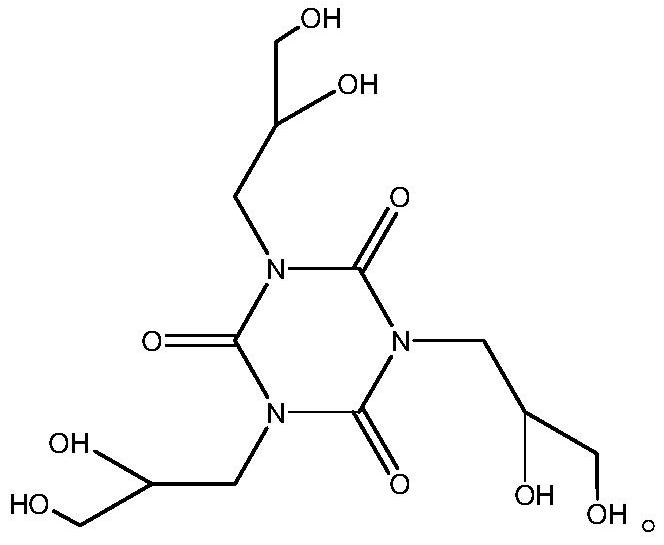

A kind of hydroxyl polyester resin prepared based on Tgic by-product and preparation method

ActiveCN110204702BImprove liquidityHigh heat resistancePolyurea/polyurethane coatingsPowdery paintsPolymer scienceAdipic acid dimethyl ester

Owner:HUANGSHAN HUAHUI TECH

Preparation method and application of bottle-grade bio-based 2, 5-furandicarboxylic acid-based copolyester

The invention discloses a preparation method of bottle-grade bio-based 2, 5-furandicarboxylic acid-based copolyester, and relates to the technical field of polyester preparation. The preparation method comprises the following preparation steps: (1) adding sorbitol, dimethyl adipate and an ionic liquid catalyst into a reactor for transesterification to prepare a reaction solution; (2) adding 2, 5-furandicarboxylate, aliphatic diol, a catalyst, a stabilizer and an antioxidant into a reactor for a primary ester exchange reaction, and then adding the reaction liquid for a secondary ester exchangereaction to prepare an esterification liquid; (3) carrying out a pre-polycondensation reaction on the esterification liquid to obtain a prepolymer; (4) carrying out final polycondensation reaction onthe prepolymer to obtain bottle-grade bio-based 2, 5-furandicarboxylic acid-based copolyester. The dimethyl adipate and sorbitol esterification oligomer is used as a crosslinking center, and a micro-crosslinking structure is constructed in the molecular chain so that the final polycondensation time is greatly shortened, the molecular weight of the copolyester is improved, and the performance of the copolyester is improved.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

A kind of anti-yellowing type β-hydroxyalkylamide curing agent and its preparation method and application

ActiveCN109535024BHigh purityReduce alkalinityOrganic compound preparationCarboxylic acid amides preparationPtru catalystAdipic acid dimethyl ester

The invention belongs to the technical field of powder coating curing agents, in particular to a yellowing-resistant β-hydroxyalkylamide curing agent, and further discloses its preparation method and its application for preparing powder coatings. The anti-yellowing type β-hydroxyalkylamide curing agent of the present invention uses diethanolamine and dimethyl adipate conventionally used in the prior art as raw materials, and is a loaded solid superbase catalyst prepared by means of high-temperature loading and calcination processes Na / NaOH / Al 2 o 3 Made by amidation reaction, the obtained β-hydroxyalkylamide curing agent product has high purity, the alkalinity of the catalyst hardly remains in the product, the final product has a low alkalinity, almost neutral, and the product is durable Excellent yellowing properties.

Owner:HUANGSHAN HUAHUI TECH

Catalyst for hydrogenation of ester, preparation method and application thereof

ActiveCN110227470BHigh selectivityHydrogenation reaction pressure is lowOrganic compound preparationHydroxy compound preparationPtru catalystAdipic acid dimethyl ester

The invention belongs to the technical field of catalyst preparation, and in particular relates to a catalyst for hydrogenation of esters containing no precious metals and a preparation method thereof. The catalyst can be well applied to the hydrogenation of dimethyl adipate to prepare 1,6-hexane diol. When it is applied to the catalytic hydrogenation of dialkyl adipate to prepare 1,6-hexanediol, the hydrogenation reaction pressure is low, the space velocity is high, and side reactions are few, the selectivity of ester hydrogenation products is high, and the product yield is high. High efficiency, easy to achieve continuous production and no corrosion to equipment and many other advantages.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com