Method for producing dimethyl adipate

A kind of technology of dimethyl adipate, adipic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

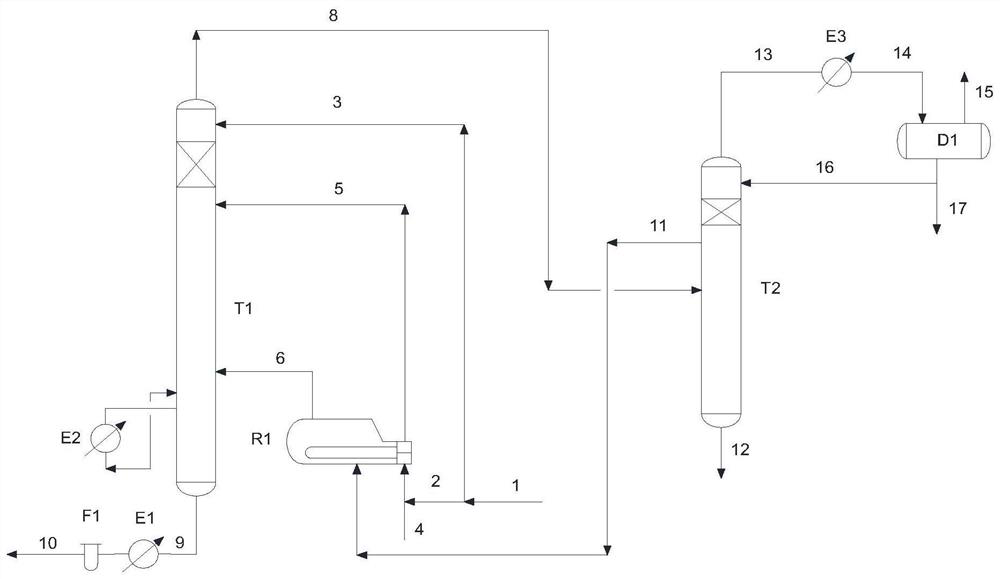

[0037] This implementation reference figure 1 And illustration.

[0038] The reaction pressure of the primary esterification reactor was 0.5 MpAg; the reaction temperature was 100 ° C.

[0039] The molar ratio of methanol and adipic acid in the primary esterification reactor is 3: 1.

[0040] The esterification reaction rectification tower top pressure is 0.04 MpAg; the tower is mainly adipate dimethyl ester, in order to prevent high temperature coking or decomposition, the tower is 175 ° C.

[0041] The emission reactive distillation tower liquid volume is 0.3h -1 .

[0042] The primary esterification reactor residence time was 2 h, and the conversion of adipic acid was 92% in which the dimethyl dimethyl methalate content was 60% in the formula, 40% ethylene adipate, esterified reaction rectification column Hepa diaphrates have purity = 99.50%, and dimethyl acid value of adipate = 0.5 mgKOH / g can be sold directly as a product, and can also produce 1,6-adipanol products.

Embodiment 2

[0044] This implementation reference figure 1 And illustration.

[0045] The reaction pressure of the primary esterification reactor was 0.6 MpAg; the reaction temperature was 100 ° C.

[0046] The molar ratio of methanol and adipic acid in the primary esterification reactor is 3: 1.

[0047] The esterification reaction rectification tower top pressure is 0.04 MpAg; the tower is mainly adipate dimethyl ester, in order to prevent high temperature coking or decomposition, the tower is 175 ° C.

[0048] The esterification reaction rectification tower liquid volume spatial speed is 0.3h -1 .

[0049] The first-order esterification reactor residence time was 2 h, and the conversion of adipic acid was 92% in which the dimethyl meta of adipate was 62%, 38% ethylene adipate, and the esterification reaction rectification column of adipate. The purity of dimethyl adipate is = 99.52%, the dimethyl acid value of adipate = 0.5 mgkoh / g can be sold directly as a product, and can also produce 1...

Embodiment 3

[0051] This implementation reference figure 1 And illustration.

[0052] The reaction pressure of the primary esterification reactor was 0.8 MpAg; the reaction temperature was 120 ° C.

[0053] The molar ratio of methanol and adipic acid in the primary esterification reactor is 4: 1.

[0054] The esterification reaction rectification tower top pressure is 0.06 MpAg; the tower is mainly adipate dimethyl ester, in order to prevent high temperature coking or decomposition, the tower is 182 ° C.

[0055] The esterification reaction rectification tower liquid volume spatial speed is 0.4h -1 .

[0056] The first-order esterification reactor residence time was 4 h, and the conversion of adipic acid was 94% in which the dimethyl methalate content was 68% in the formula of the ester, 32% of hexahalic acid monolide, esterified reaction distillation column The purity of dimethyl adipate is = 99.65%, the dimethyl acid value of adipate = 0.4 mgkoh / g can be directly sold directly, and can als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com