Patents

Literature

248results about How to "Control dwell time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

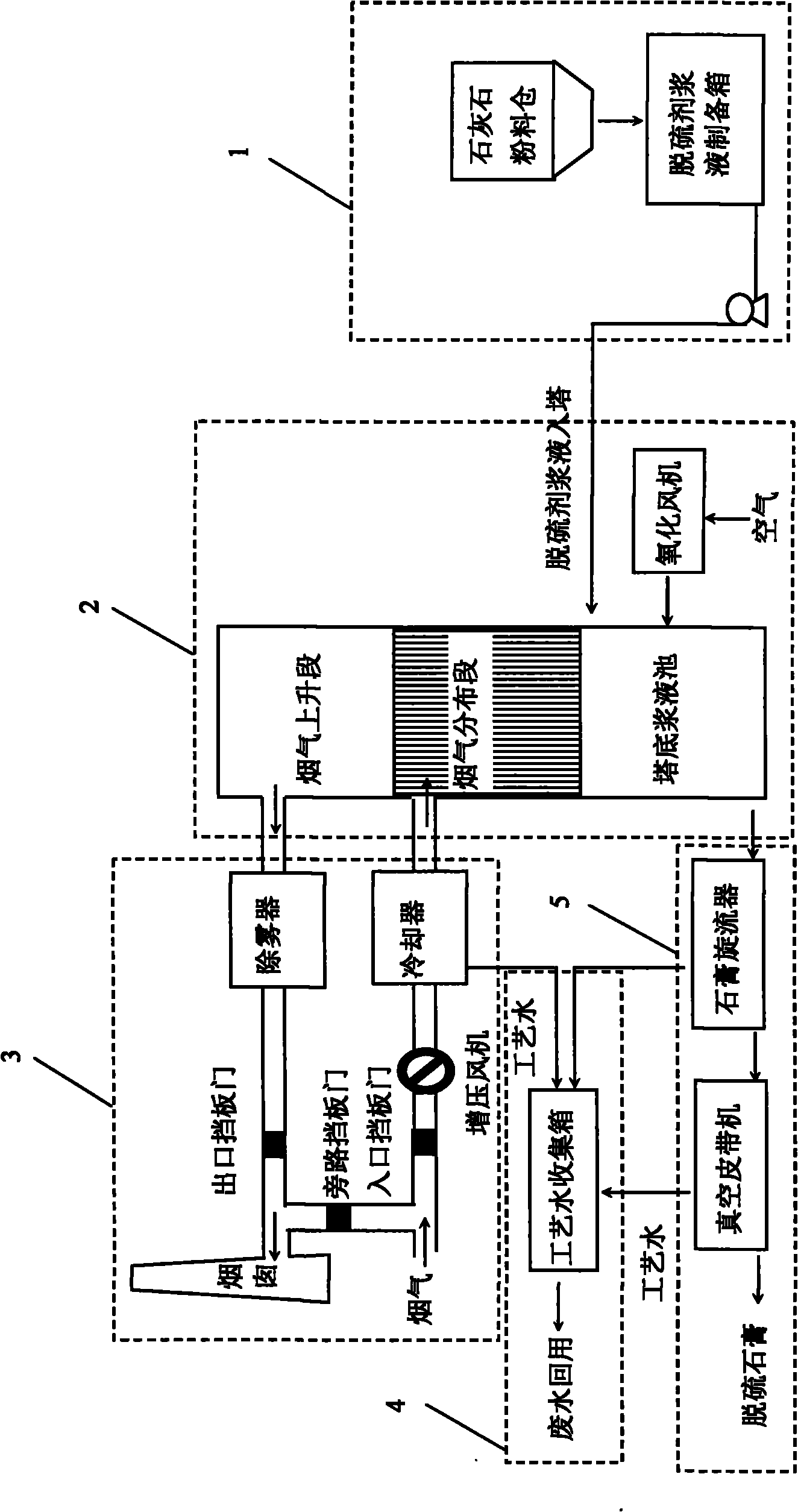

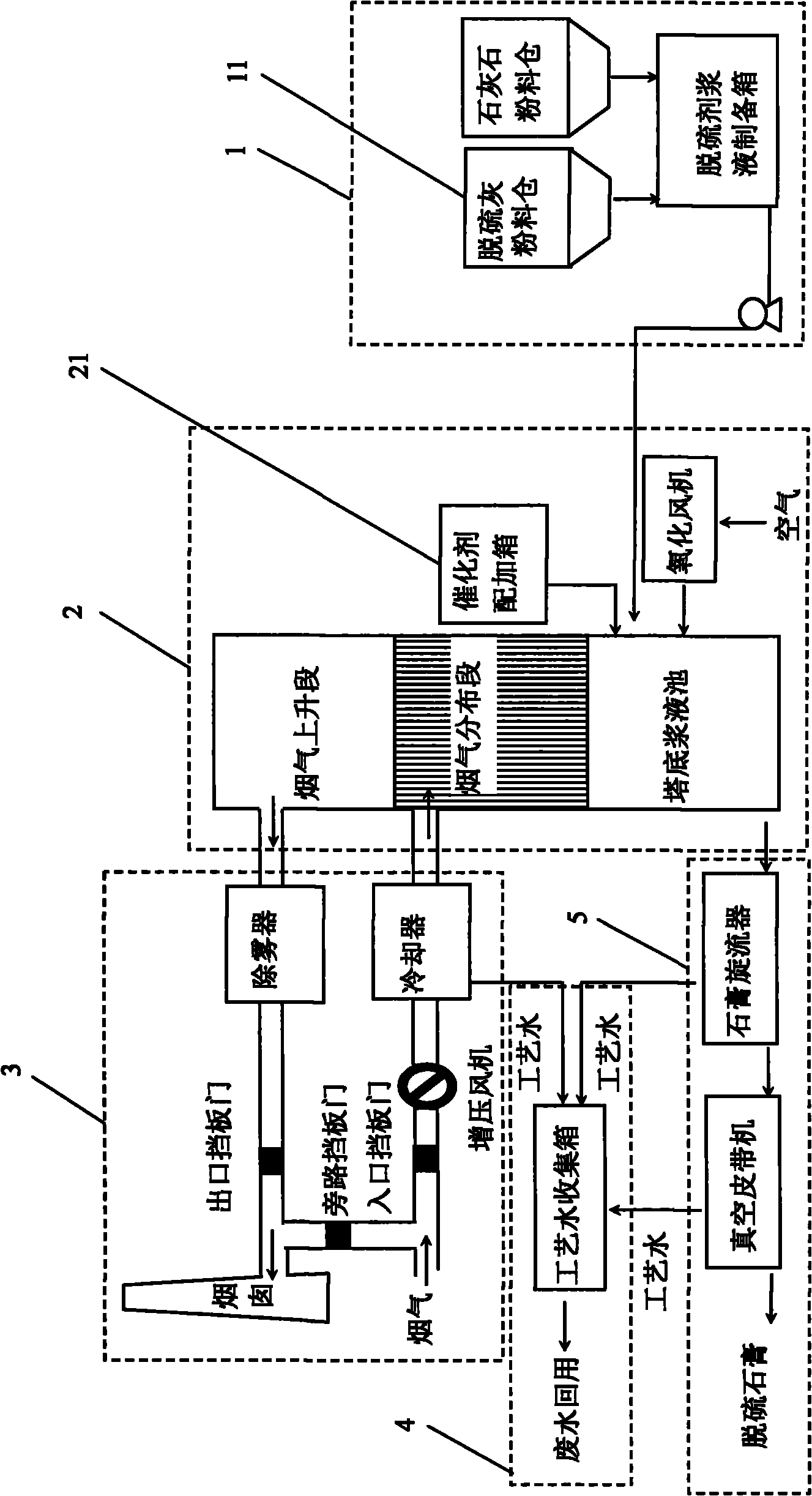

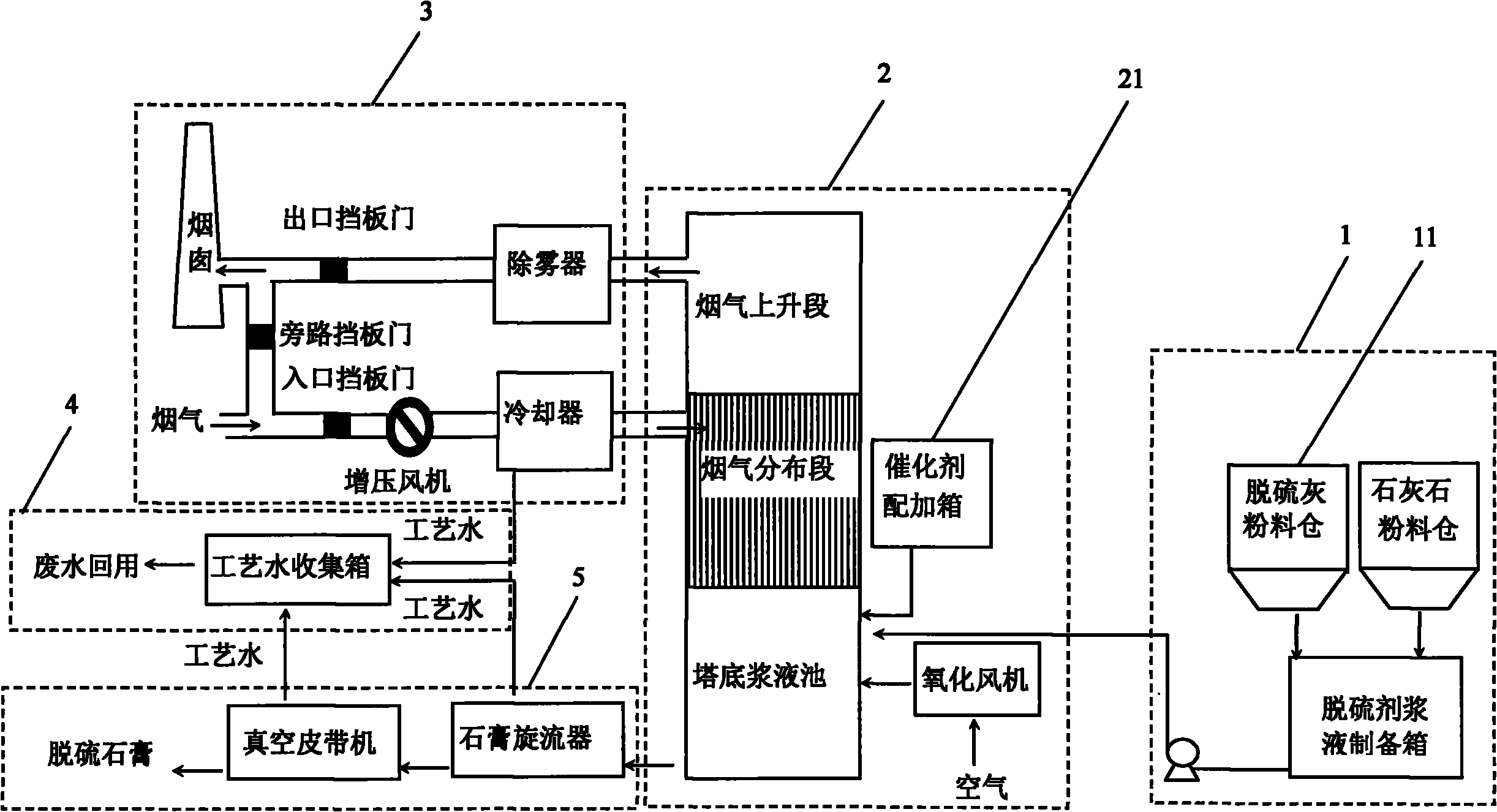

Method for treating desulfurization ash

ActiveCN102000481AEliminate hidden dangersEfficient use ofDispersed particle separationRetention timeProper treatment

The invention discloses a method for treating desulfurization ash. The method comprises the following steps of: mixing the desulfurization ash generated by a dry / semidry desulphurization process and limestone powder, which serve as raw materials of a desulfurizer in a wet flue gas desulfurization process, according to a proportion; uniformly stirring the desulfurizer and pumping the desulfurizer into a slurry pond of an absorption tower; adding a catalyst into the slurry pond; introducing oxidation air into the slurry pond; introducing flue gas into the slurry pond through a flue; reacting the desulfurizer with SO2 in the flue gas under the action of the oxidation air and the catalyst; controlling the pH value of the slurry in the absorption tower, the slurry temperature, the content of solid matters contained in the slurry and the retention time of the desulfurizer in the slurry pond; after the reaction is completed, performing vortex concentration and vacuum filtration to obtain a gypsum by-product; and adding wastewater produced in the process into a process water collection box for recycling. The method is simple, is easy to realize, has remarkable effect, provides a safe and proper treatment way for the dry / semidry desulfurization ash and has good economic and social benefits.

Owner:BAOSHAN IRON & STEEL CO LTD

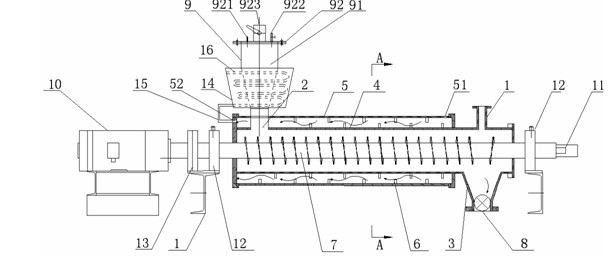

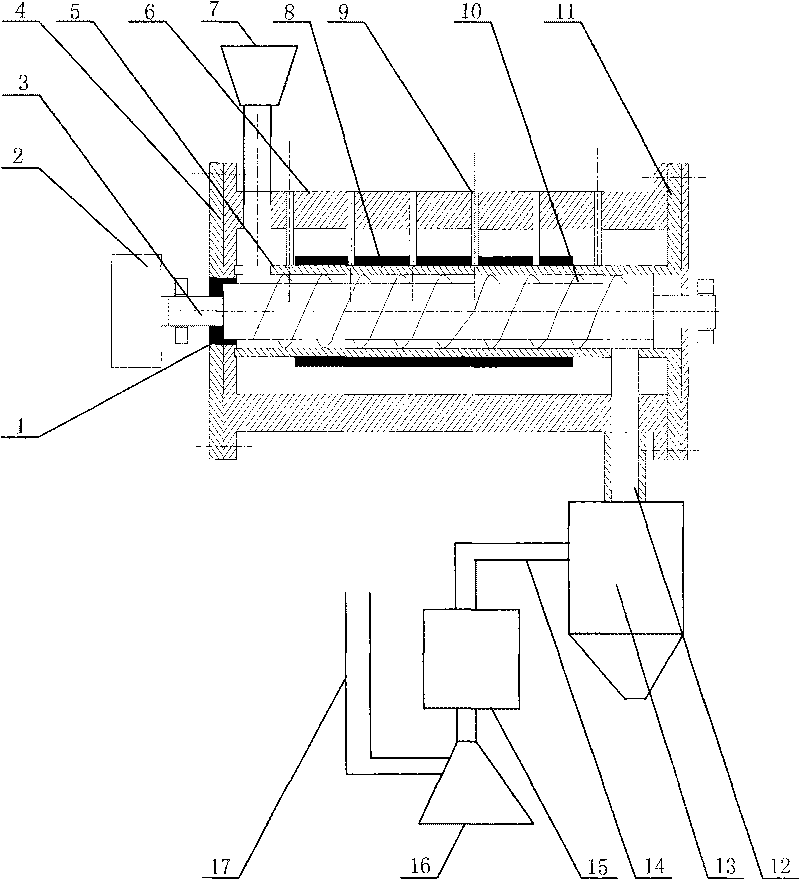

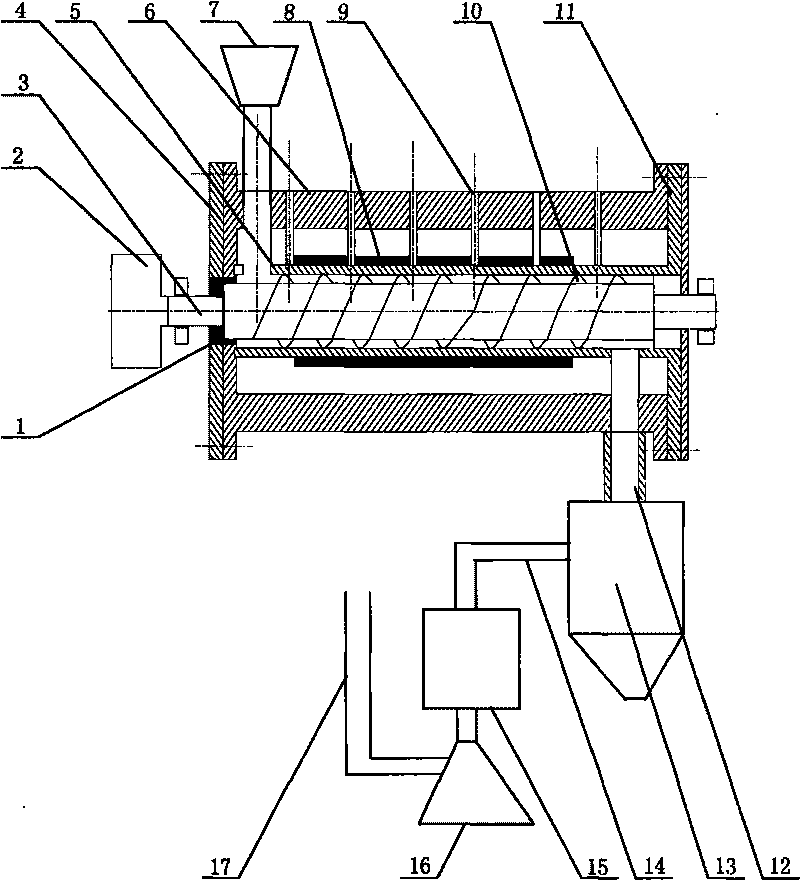

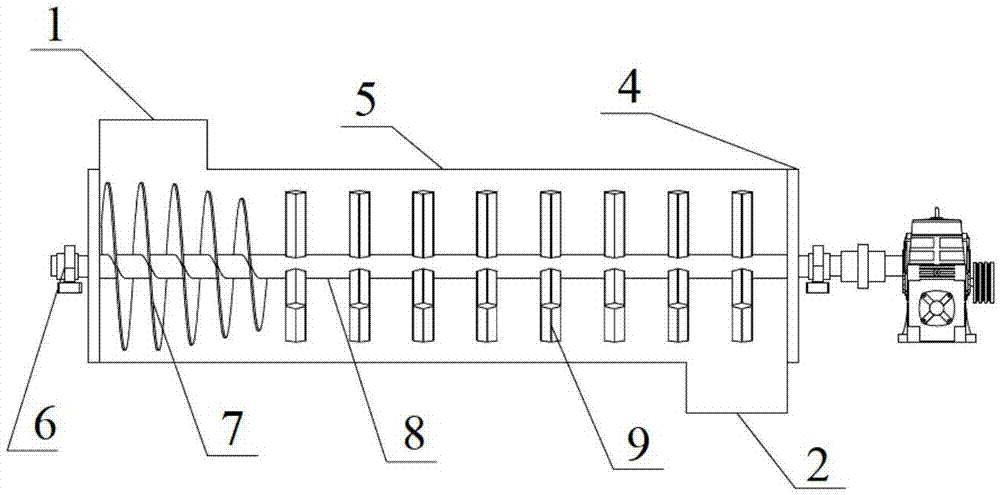

Spiral push type low temperature pyrolysis carbonation furnace

InactiveCN102154019AImprove product qualityQuality improvementBiofuelsEnergy inputElectricityLower grade

The invention discloses a spiral push type low temperature pyrolysis carbonation furnace which comprises a bracket and a furnace body, wherein the furnace body is provided with a feed port and a discharge hole; the furnace body comprises an inner heating cylinder and an outer heating cylinder which are sleeved together; the tail end of the inner heating cylinder penetrates out of the outer heating cylinder; the tail end of the inner heating cylinder is provided with an tail gas outlet; the outer heating cylinder is provided with a high temperature smoke gas inlet and a high temperature smoke gas outlet; a plurality of deflectors are misplaced on the inner wall of the outer heating cylinder and the outer wall of the inner heating cylinder; and a plurality of hollow material transportation screws penetrate through the furnace, and the inside of the furnace body is provided with an electricity or smoke gas heating device. Because a double-layer tube-in-tube structure and a spiral push type pyrolysis carbonation mode are adopted and the tail gas outlet is arranged at the tail end of the inner heating cylinder, the spiral push type low temperature pyrolysis carbonation furnace has the characteristics that raw material adaptability is wide and a structure is simple, tail gas waste heat and low-grade pyrolysis carbonized gas can be fully utilized, thermal efficiency is high, and the like.

Owner:江苏华威龙玖环保科技有限公司

Biomass spiral pyrolysis device and pyrolysis process

InactiveCN101709224AControl dwell timePrevent slippingLiquid hydrocarbon mixture productionCollection systemPropeller

The invention relates to a biomass pyrolysis device and a process thereof. The device comprises a charging system, a spiral pyrolysis reactor and a product collection system, wherein a rotating shaft which is communicated with a variable-frequency motor and provided with a spiral propeller is arranged in center holes on two end covers of a cylinder body of the reactor; the side wall of the cylinder body is provided with a biomass feed pipe and a pyrolysis product outlet pipe; the outlet pipe is vertically extended into a coke collection tank; and the coke collection tank are communicated with a condenser, a bio-oil collection tank and a tail gas discharge pipe in turn through an air outlet pipe on the side wall. The process comprises the following technological processes: firstly, starting an external heating system to ensure that the temperature in a reactor is between 500 and 550 DEG C; secondly, putting biomass granular raw materials into the reactor through an inlet pipe, simultaneously starting the variable-frequency motor, and determining the rotating speed n of the variable-frequency motor according to the set residence time t, and the axial length L and the screw pitch l of the spiral propeller; and finally, starting the pyrolysis product collection system. The biomass pyrolysis device can accurately control the pyrolysis time and control the pyrolysis temperature in a partitioning mode so that the obtained bio-oil components are controllable and are easy to extract chemical products.

Owner:UNIV OF SCI & TECH OF CHINA

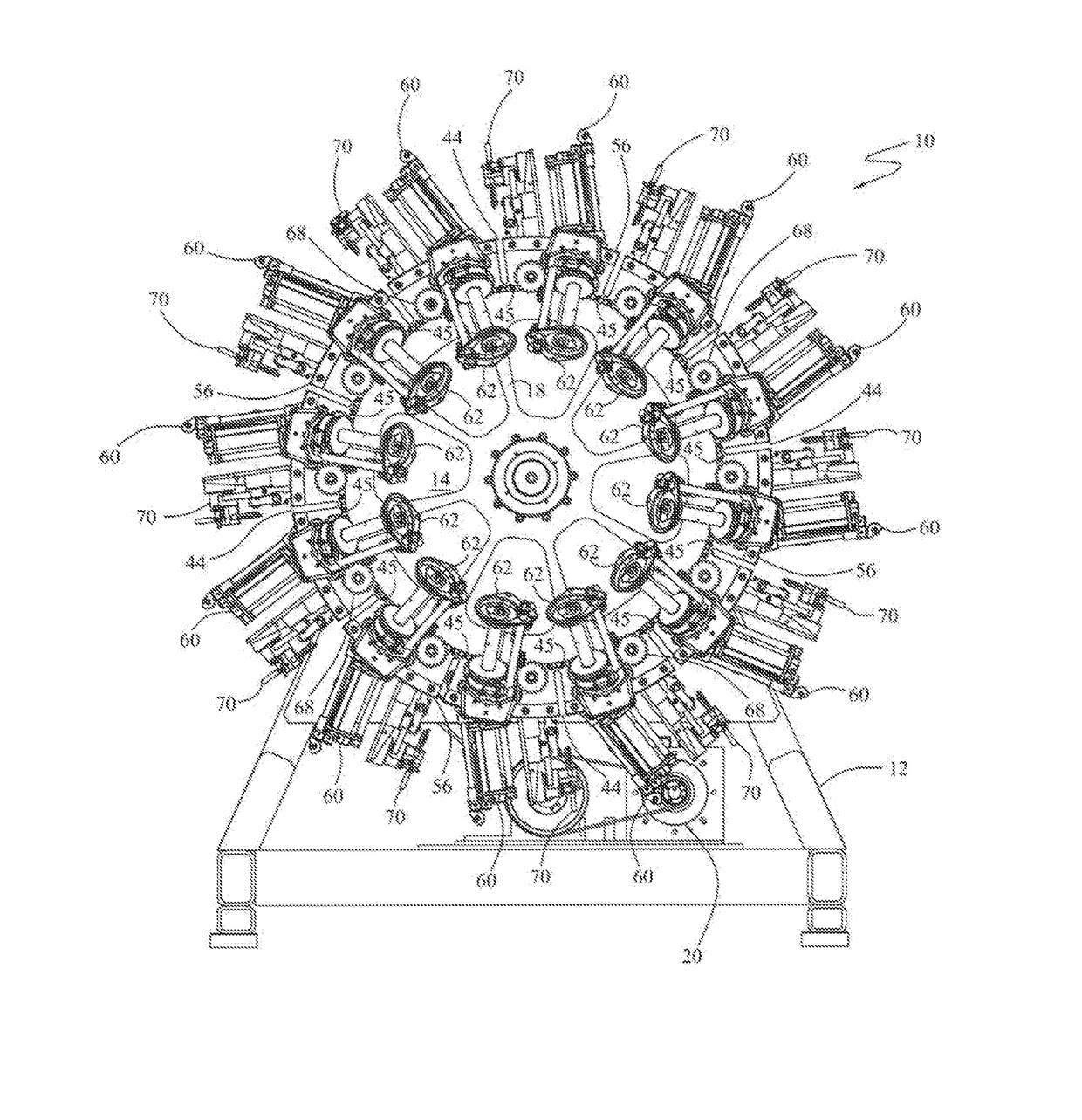

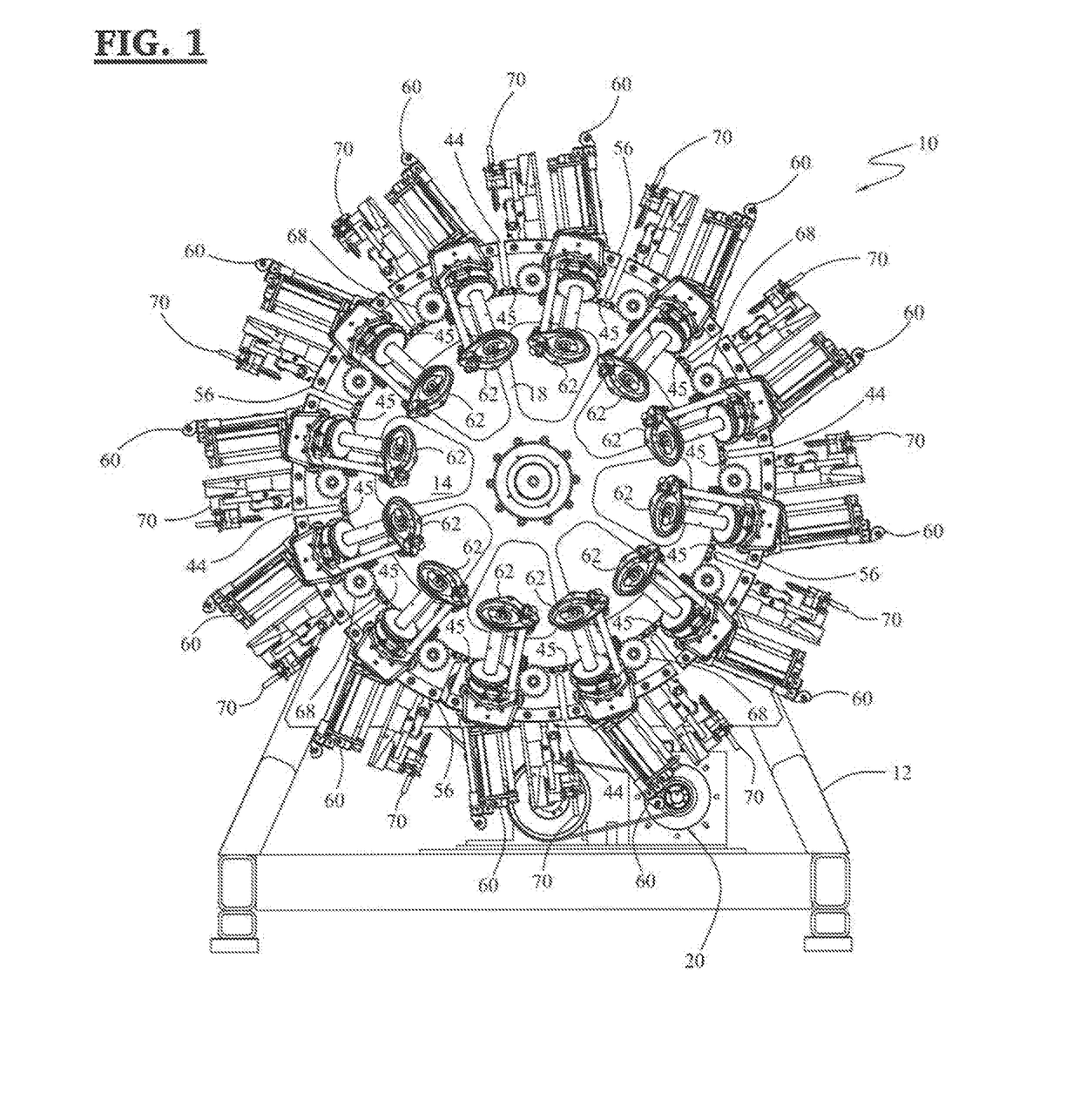

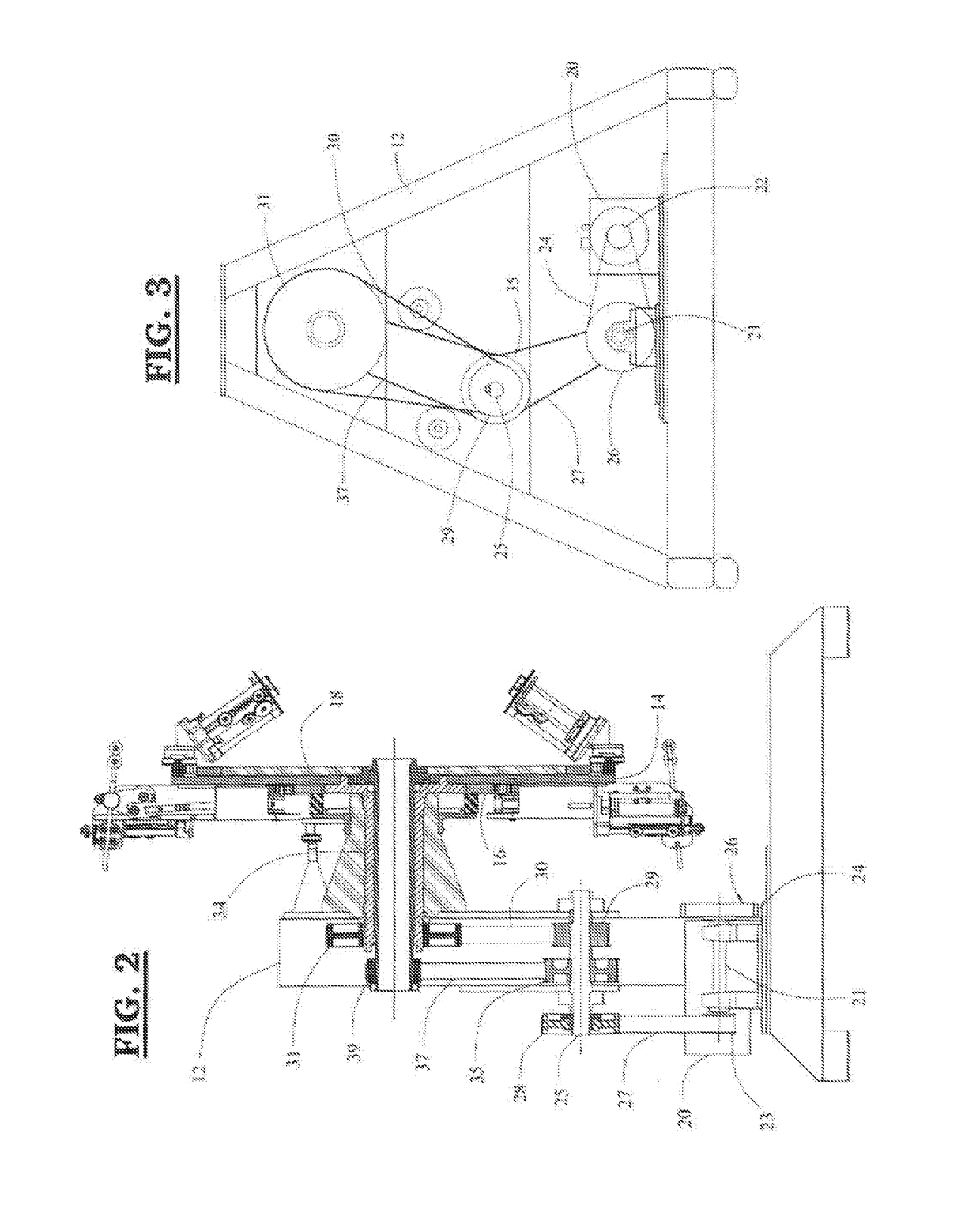

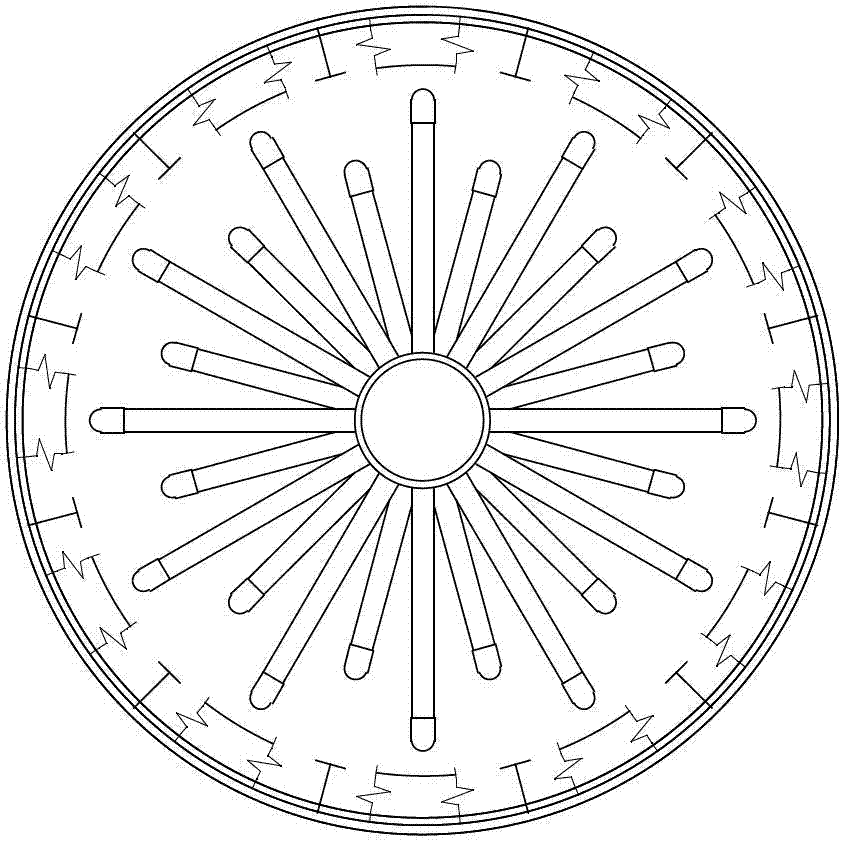

Rotary braiding machine

ActiveUS20170233908A1Faster and efficient braidingOptimization mechanismConnecting rodsBraidActuatorControl theory

In one aspect, various embodiments of the present invention are directed to a rotary braiding machine capable of braiding wire around a cable, hose, mandrel, or other similar item, having an improved actuator arm mechanism that is simpler than those found in conventionally available rotary braiding systems and includes a mechanism for fine-tuning of the dwell timing of the transfer arms. In another aspect, one or more embodiment of the present invention is directed to a method for controlling the dwell timing of a transfer arm in a rotary braiding machine by adjusting the length of the actuator arm mechanism.

Owner:KARG CORP

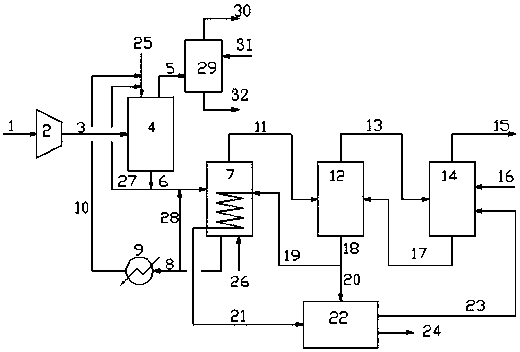

Separation method of olefin hydroformylation reaction liquid-phase discharged material

ActiveCN102826969AControl dwell timePreparation by carbon monoxide reactionGas phaseFormylation reaction

The invention relates to a separation method of an olefin hydroformylation reaction liquid-phase discharged material. The invention belongs to the field of hydroformylation reaction aldehyde preparation. The method comprises the steps that: (1) decompression is carried out upon a C2-C4 olefin hydroformylation liquid-phase discharged material; (2) the decompressed C2-C4 olefin hydroformylation liquid-phase discharged material is subjected to multi-level heating evaporation separation, wherein the pressure after decompression is corresponding to the evaporation temperature, and the evaporation temperature is no higher than 140 DEG C; (3) gas-phase materials obtained in each level of evaporation separation are condensed, such that a liquid-phase aldehyde product is obtained; and (4) a catalyst-containing liquid-phase material obtained through the multi-level evaporation separation is recycled to the reactor. With the technical scheme provided by the invention, the separation of the hydroformylation reaction product and a catalyst solution can be carried out under a relatively low temperature. With leveled evaporation, the retention time of the materials in a hot area in the separation process can be effectively controlled, such that the heat-sensitive rhodium catalyst can be protected.

Owner:CHINA PETROLEUM & CHEM CORP +1

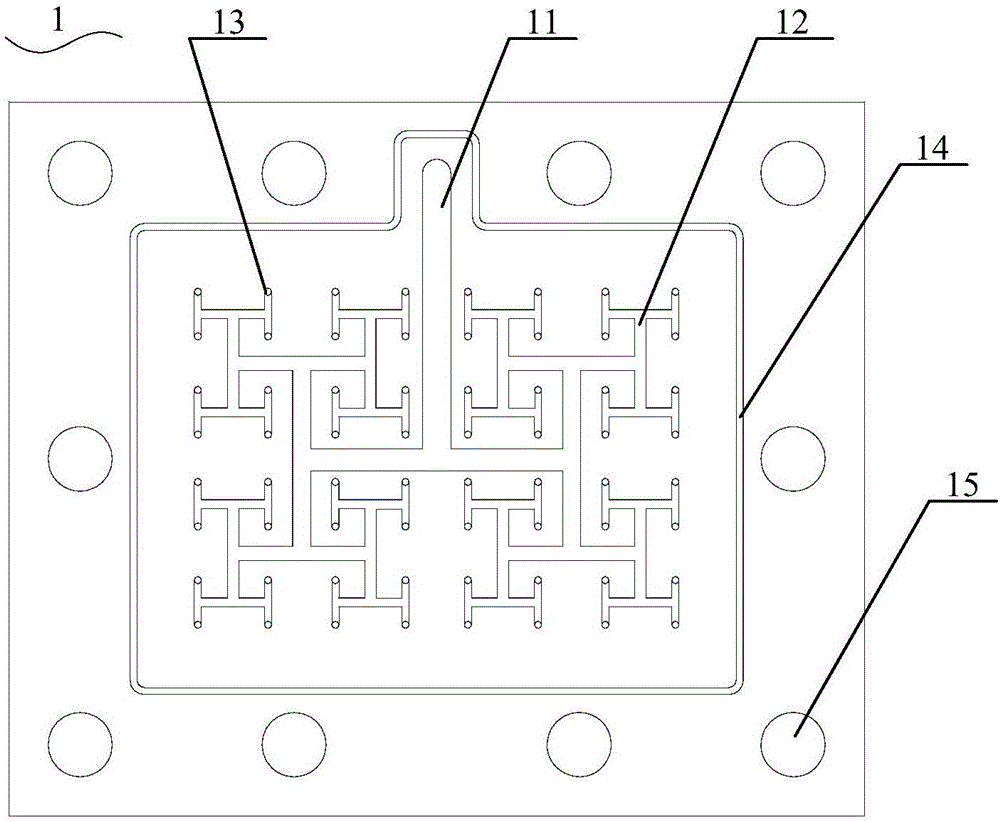

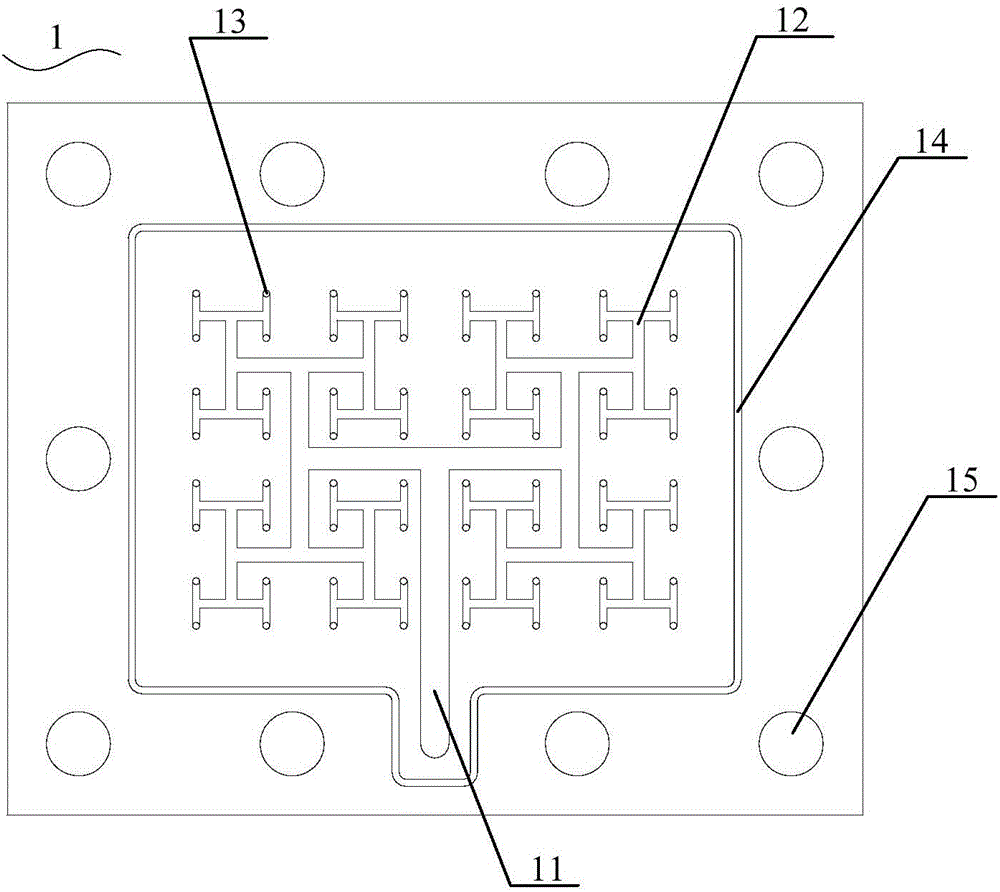

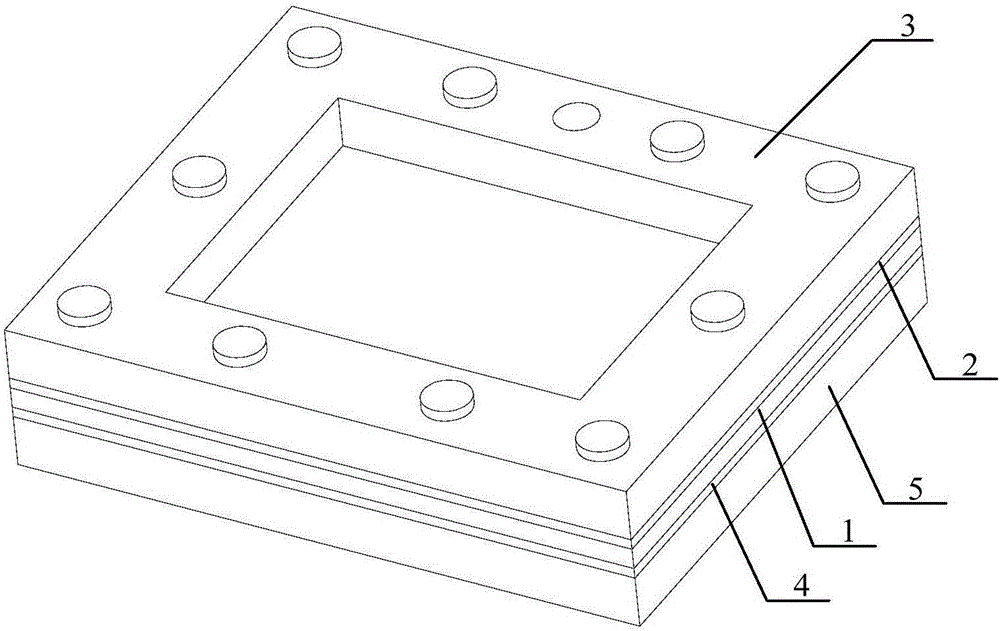

Microchannel plate with fractal structure, photocatalytic reactor and application thereof

InactiveCN106311110AControl flowControl dwell timeChemical/physical/physico-chemical microreactorsEnergy based chemical/physical/physico-chemical processesPhotocatalytic reactionThree-phase

The invention provides a microchannel plate with a fractal structure, a photocatalytic reactor and an application thereof. The microchannel plate with the fractal structure comprises a first surface and a second surface which are opposite; the first surface and the second surface of the microchannel plate with the fractal structure each is provided with a main pipeline microchannel and multistage H-shaped fractal bifurcated microchannels which are connected with one end of the corresponding main pipeline microchannel, and the H-shaped fractal bifurcated microchannels of the first surface of the microchannel plate with the fractal structure communicate with those of the second surface of the microchannel plate with the fractal structure through connecting through holes. According to the microchannel plate with the fractal structure, the photocatalytic reactor and the application thereof, through forming fractal-structured microchannels in the upper and lower surfaces of the microchannel plate with the fractal structure, three phases, i.e., gas, liquid and solid phases can be effectively distributed, heat transfer and mass transfer are strengthened, the problem in collection of reactants of fractal distribution can be effectively solved, meanwhile, the length of the microchannels can be increased, and the control on reaction flux and reactant residence time is better facilitated.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

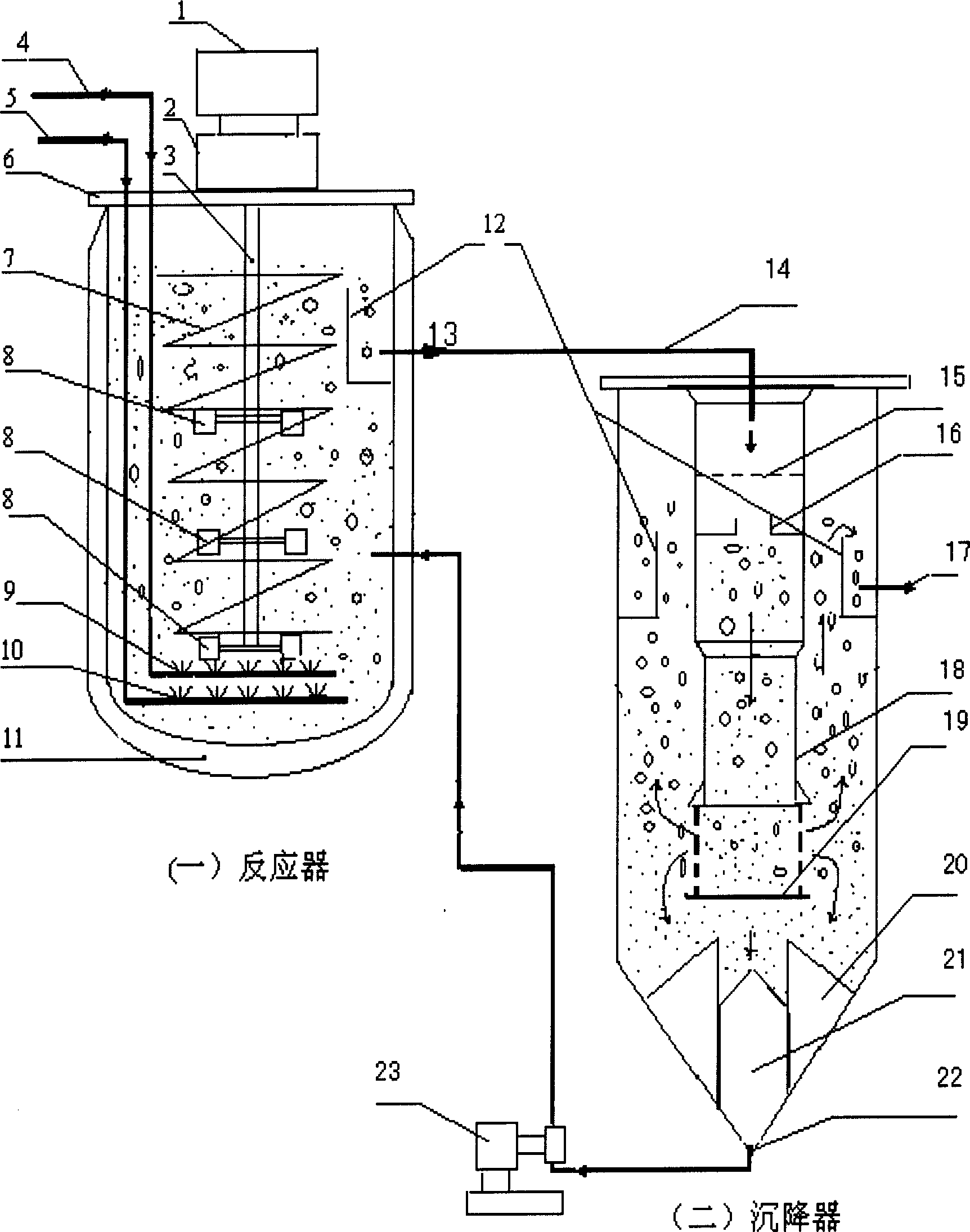

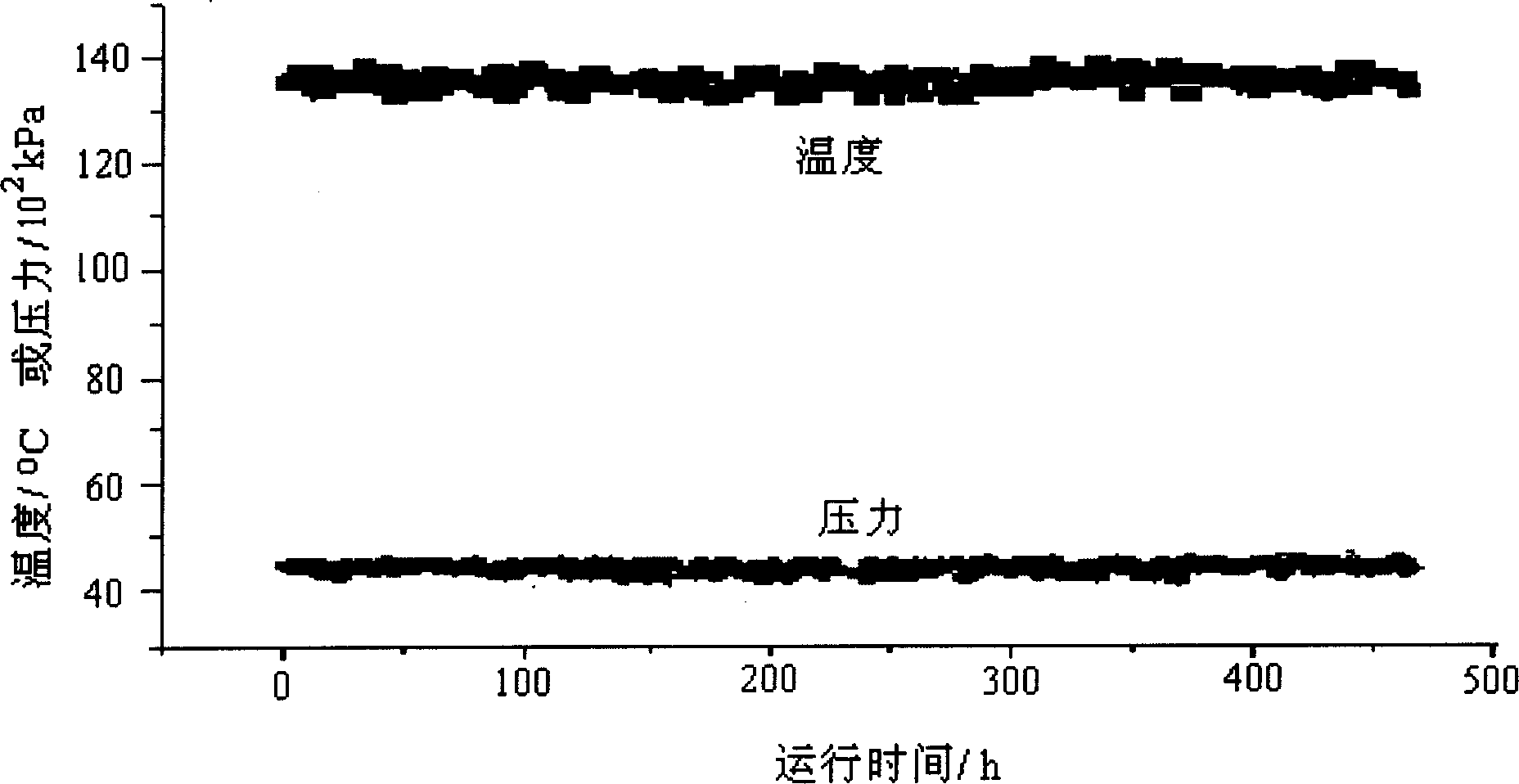

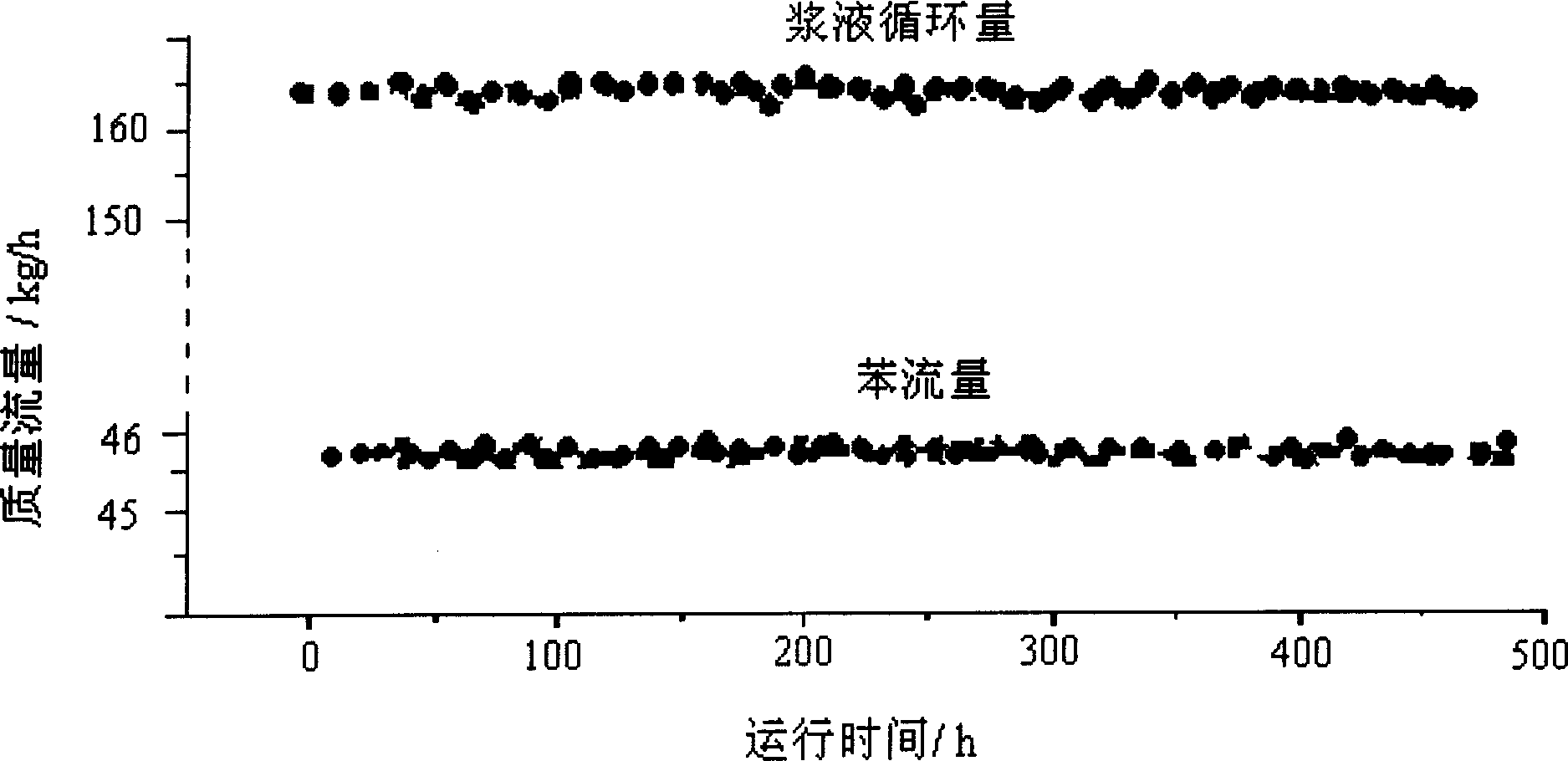

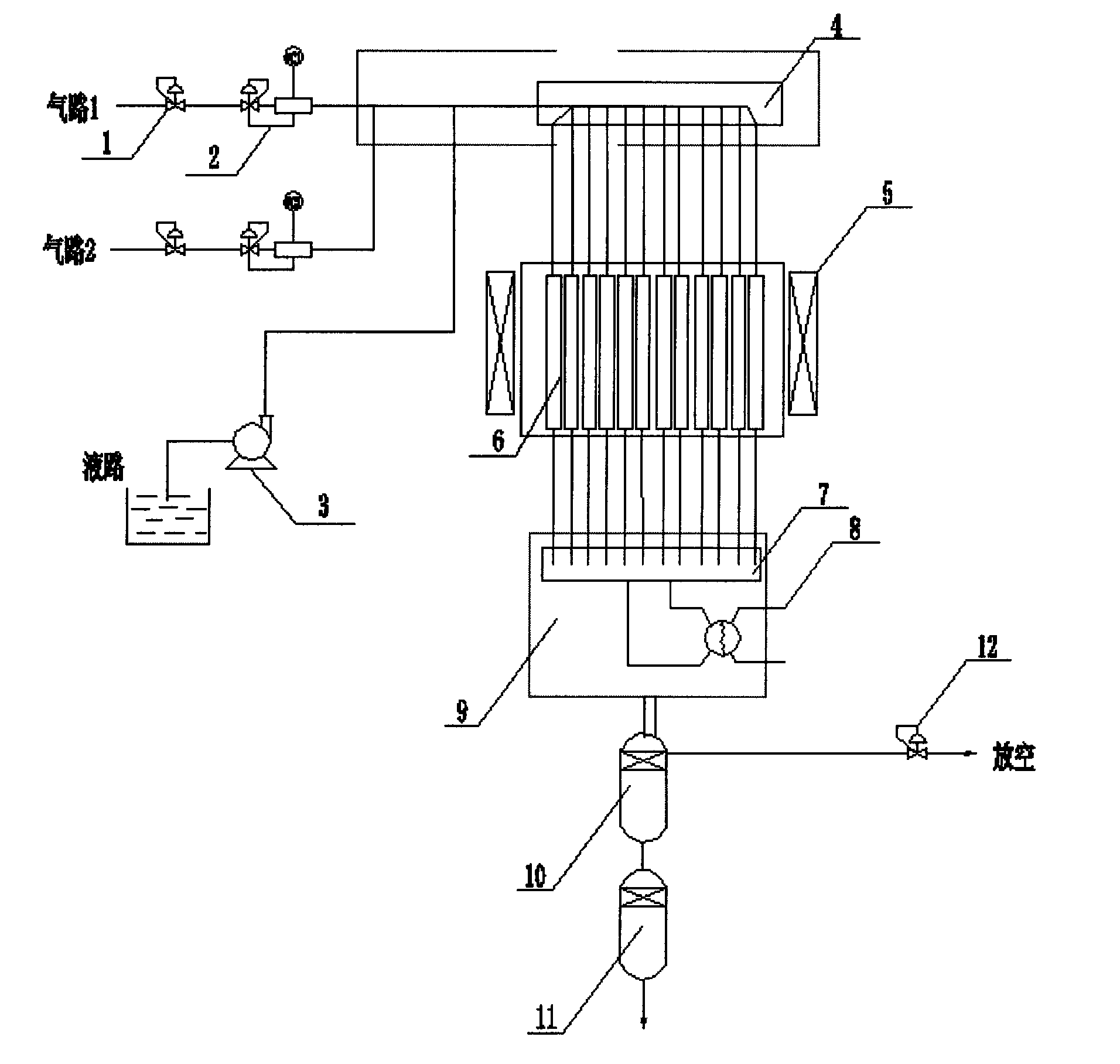

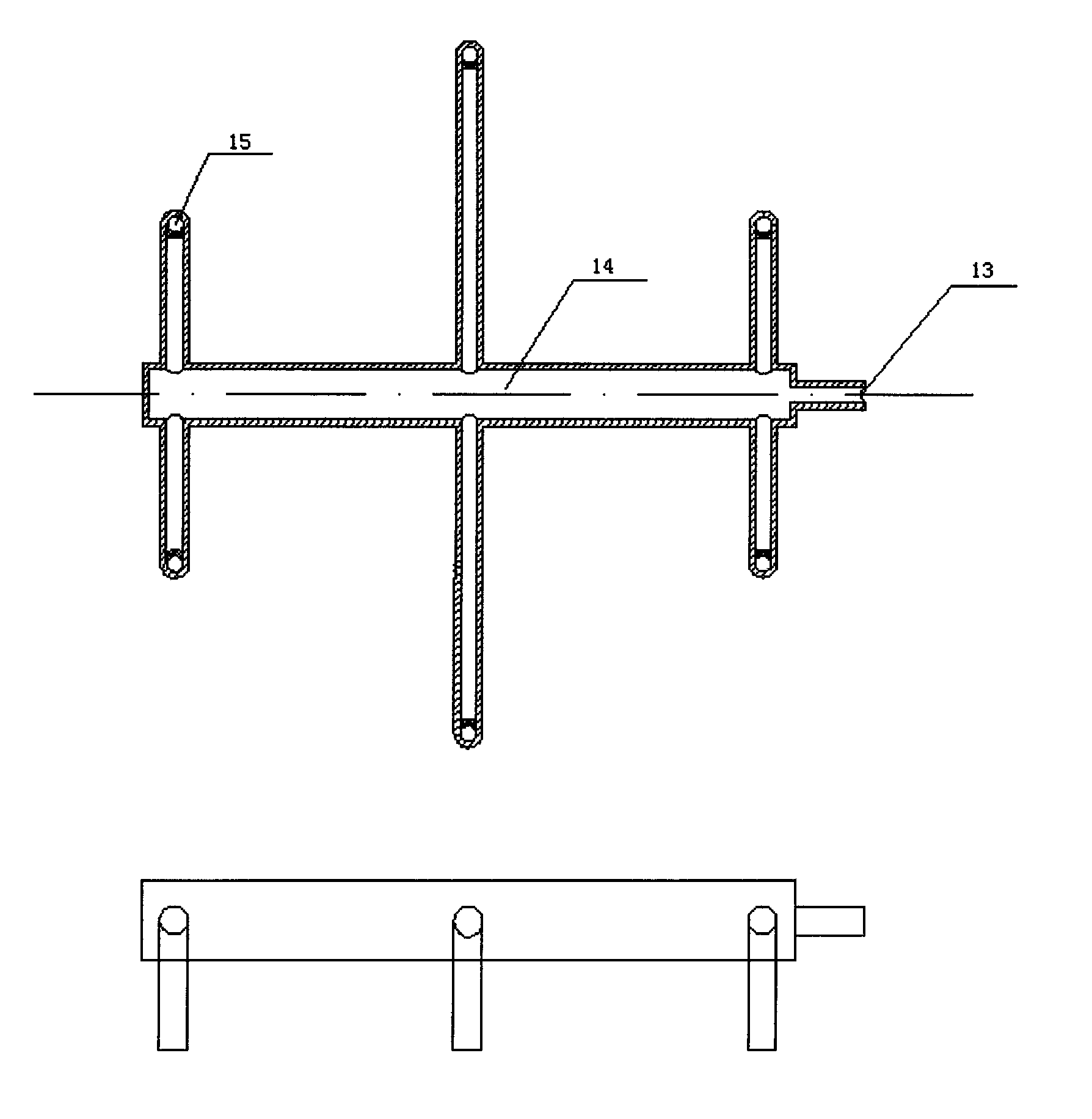

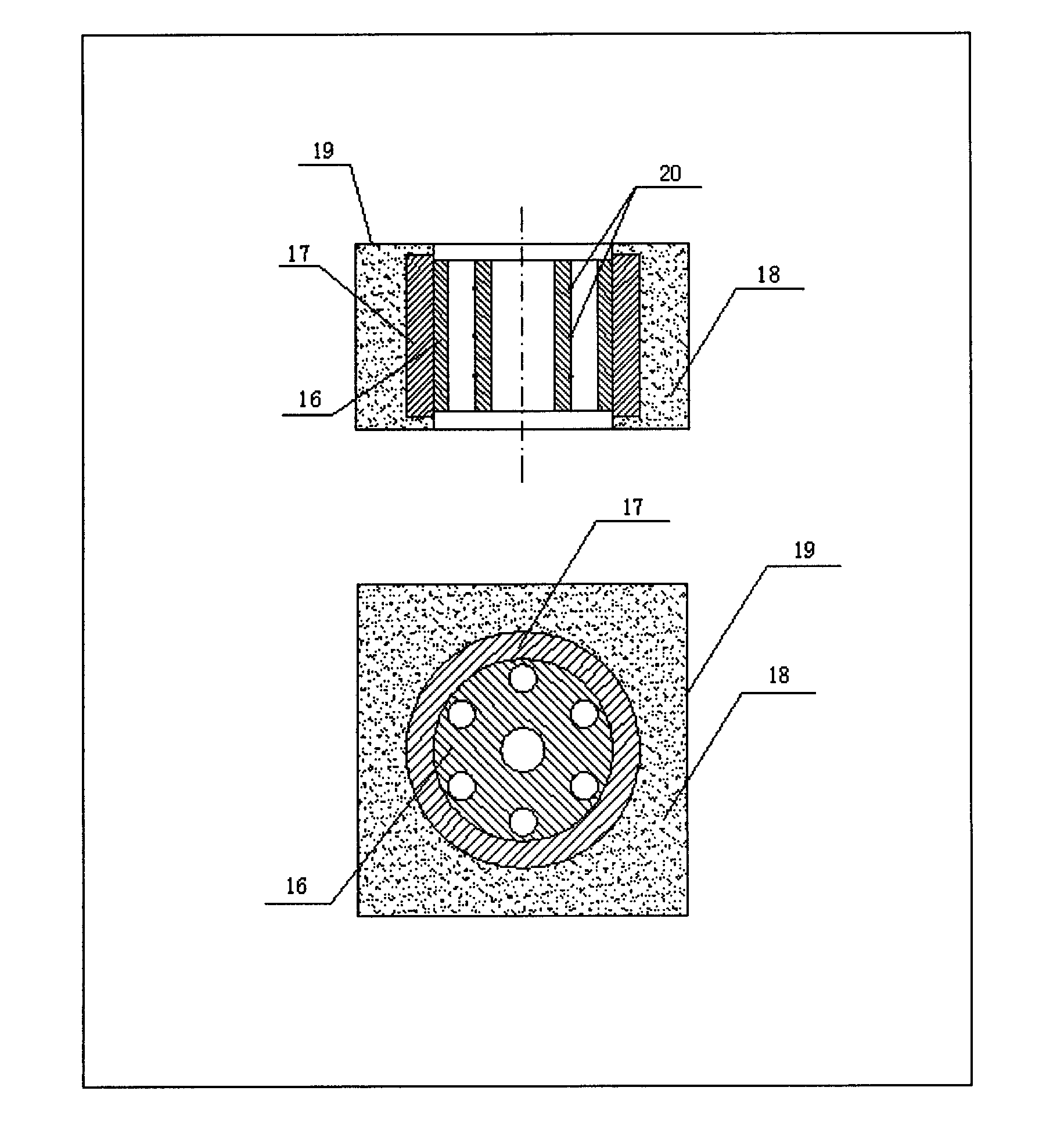

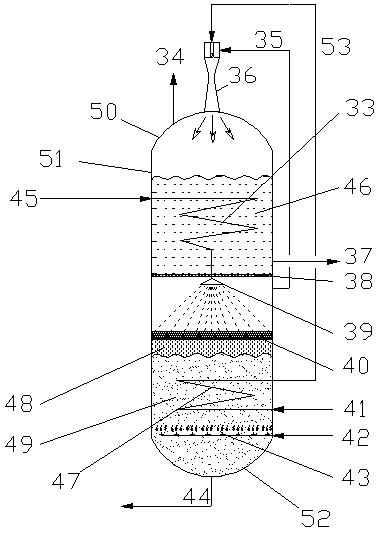

Equipment for producing cyclohexenol through benzene plus hydrogen

An apparatus for preparing cyclohexane from benzene by hydrogenation is composed of a reaction system and a settling separation system. Said reaction system is a high-pressure reactor with heat-exchanging spiral tube, multi-stage stirrer, gas-phase distributor, liquid-phase distributor and overflow dam. Said settling separation system is a diameter-varied separator with grate barrier overflow dam, settling pipe and baffle plate.

Owner:CHINA SHENMA GROUP +1

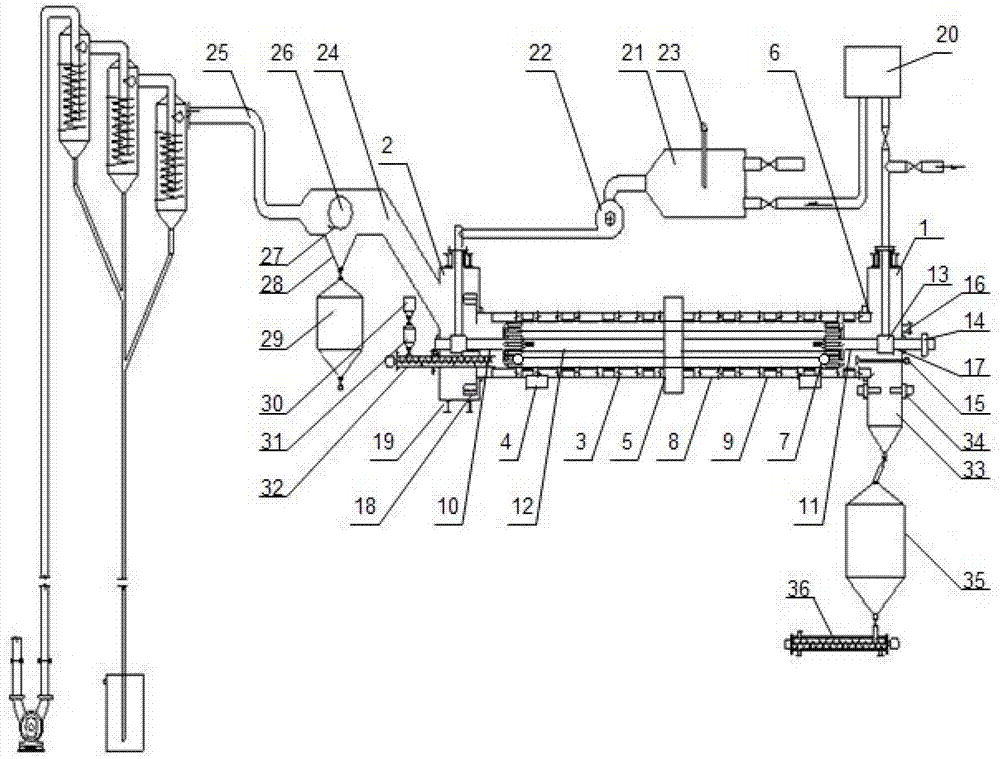

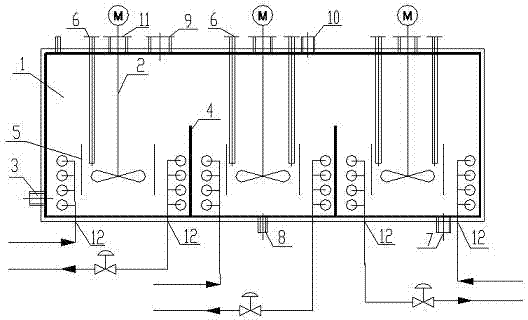

A multi-channel differential reaction device

ActiveCN102266742AImprove efficiencyImprove the level ofComponent separationChemical/physical/physico-chemical processesAutomatic controlGas phase

The invention discloses a multi-channel differential reaction device, and belongs to catalyst analysis and evaluation reaction device. The multi-channel differential reaction device comprises four systems of a gas-liquid charging system of (1)-(3), a multi-channel reactor system of (4)-(6), an automatic control system (7) and an on-line analysis system (8). The multi-channel differential reaction device adopts a high pressure distributor (4) to distribute a raw material into reaction tubes (6) of all channels. Temperatures of the all reaction tubes (6) are controlled unitedly by a heating furnace (5). The multi-channel differential reaction device is provided with the automatic control system (7) and the on-line analysis system (8) and can satisfy that in a reaction process, at any time, reaction products in all channel reaction tubes can be taken out on line simultaneously, are placed respectively in corresponding quantitative rings and are analyzed orderly through use of a gas chromatography. The catalyst analysis and evaluation reaction device can evaluate a catalyst rapidly and also evaluate and screen multiple catalysts simultaneously under a condition thus saves time spent on research and exploitation of a novel catalyst.

Owner:TIANJIN GOLDEN EAGLE TECH

High-throughput preparation device and method for high-silicon aluminum alloy structural gradient material used for packaging

The invention discloses a high-throughput preparation device and method for a high-silicon aluminum alloy structural gradient material used for packaging. The device comprises an upper high-temperature die, outer die moulds, induction coils, a gradient workpiece, cooling water circulating devices, a lower low-temperature die and thermocouples, wherein the upper high-temperature die is used for keeping the inner temperature of the whole die balancing and supplying a certain heat source to atomized powder of the high-silicon aluminum alloy; the outer die moulds are used for positioning two or three kinds of the prepared atomized powder of the gradient high-silicon aluminum alloy; the atomized powder of the high-silicon aluminum alloy is fed based on the sequence that the low-component alloy powder is at the bottom end of each outer die mould, and the high-component aluminum powder is at the top end of each outer die mould; the induction coils can be used as movable induction heating elements for supplying heat to the whole preparation process; the gradient workpiece is used for preparing the gradient material; the cooling water circulating devices can be used for exporting excess heat when the temperature in the preparation process is beyond a set temperature; the temperature of the lower low-temperature die is in contrast to the temperature of the upper high-temperature die, so that temperature gradient can be generated; the thermocouples are used for testing the temperature and controlling the induction heating time, so as to generate the temperature gradient. The alloy prepared by the device and the method is high in density, and the structure is refined, so that the alloy is outstanding in comprehensive performances.

Owner:SUZHOU XINHUILIAN SEMICON TECH CO LTD

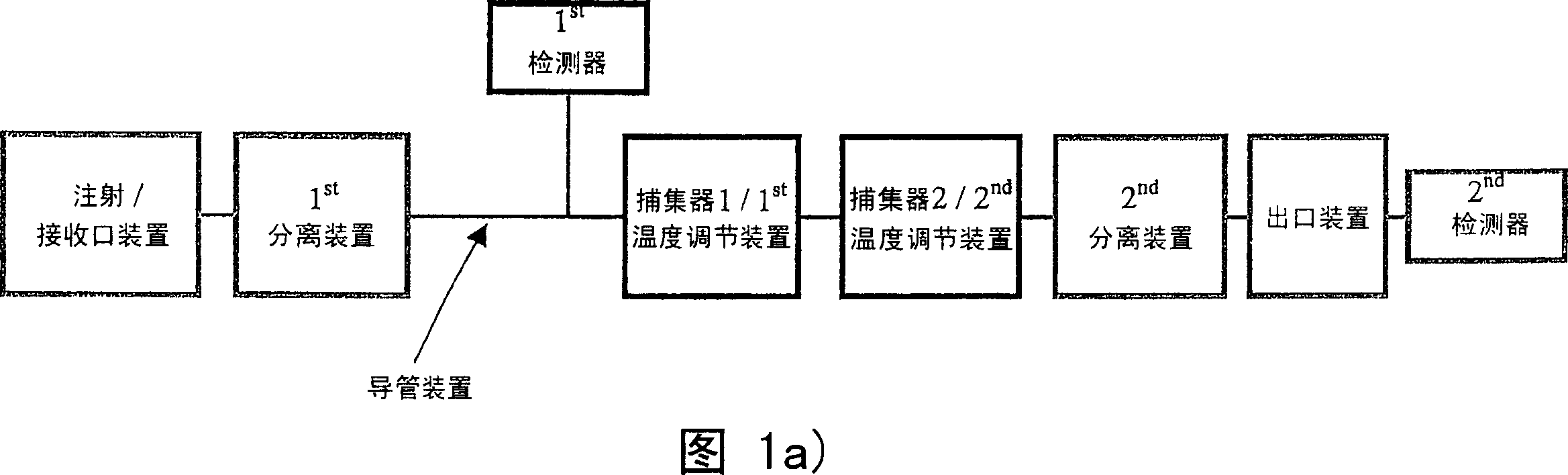

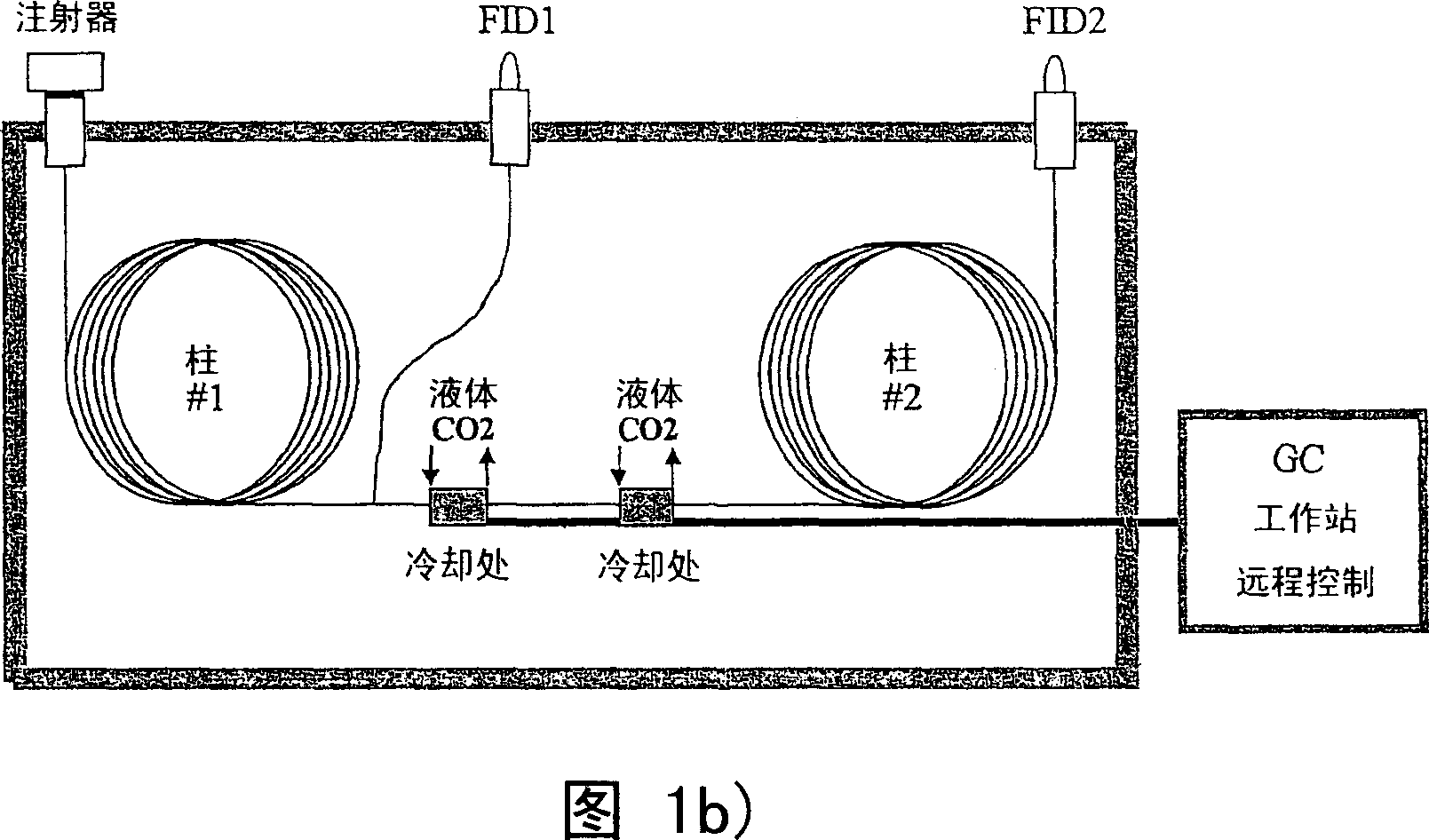

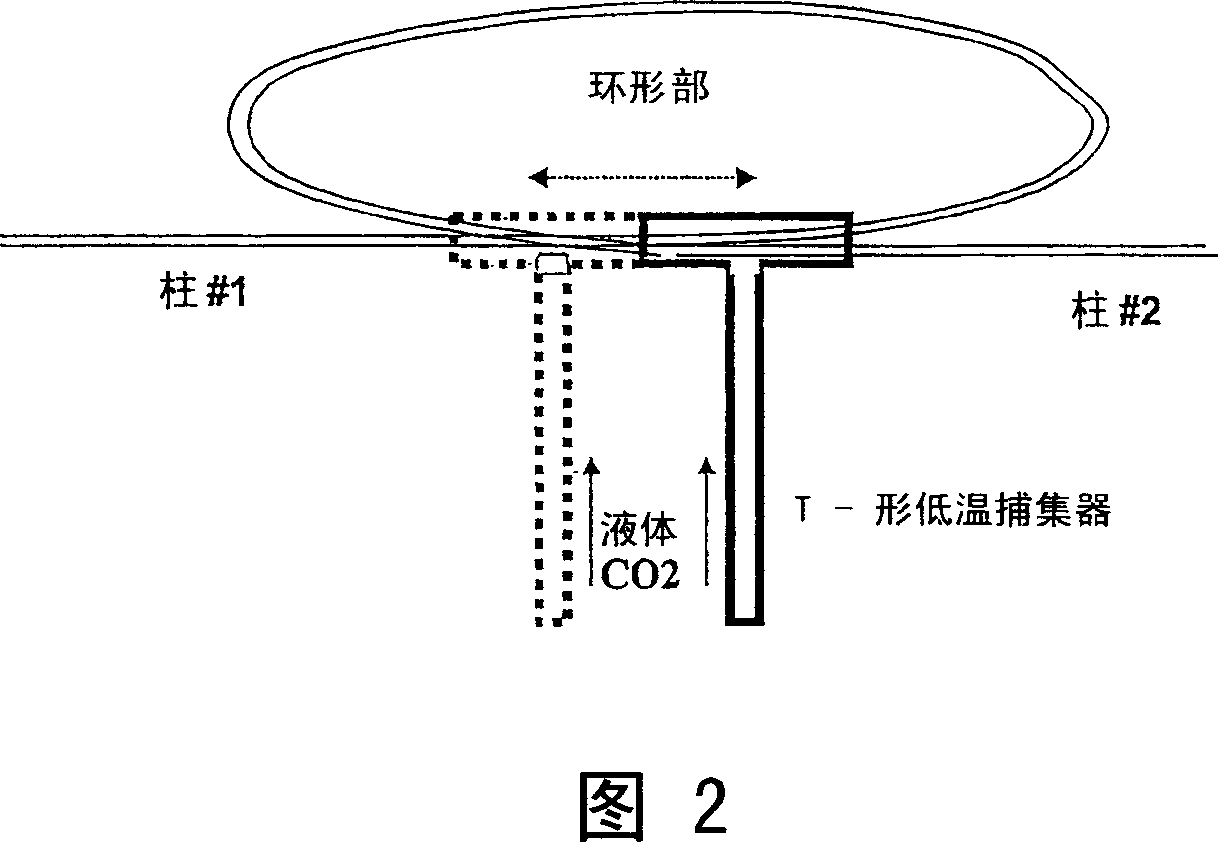

Novel multiple-dimension gas phase chromatographic device and analyte conveying method using multiple cooling wire connections

InactiveCN1954208AControl dwell timeOptimization of separation conditionsComponent separationAnalyteGas phase

The invention provides a MDGC apparatus comprising a cryotrapping means capable of cooling at least twice a portion of a chemical sample and provided with detector means disposed upstream of the cryotrap and allowing identification of the said portion of the chemical sample to control the residence time of the latter in the cryotrapping means.

Owner:FIRMENICH SA

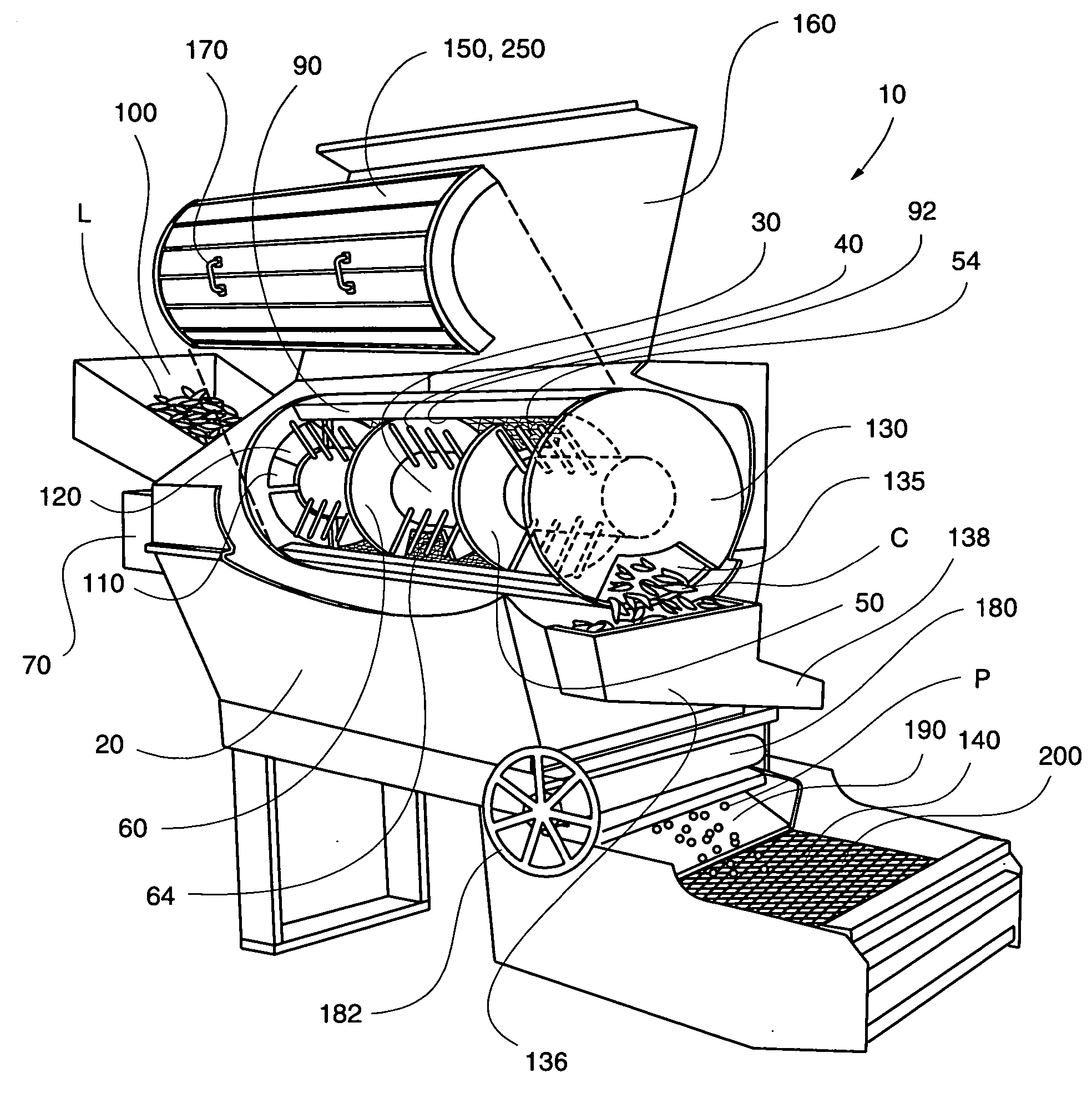

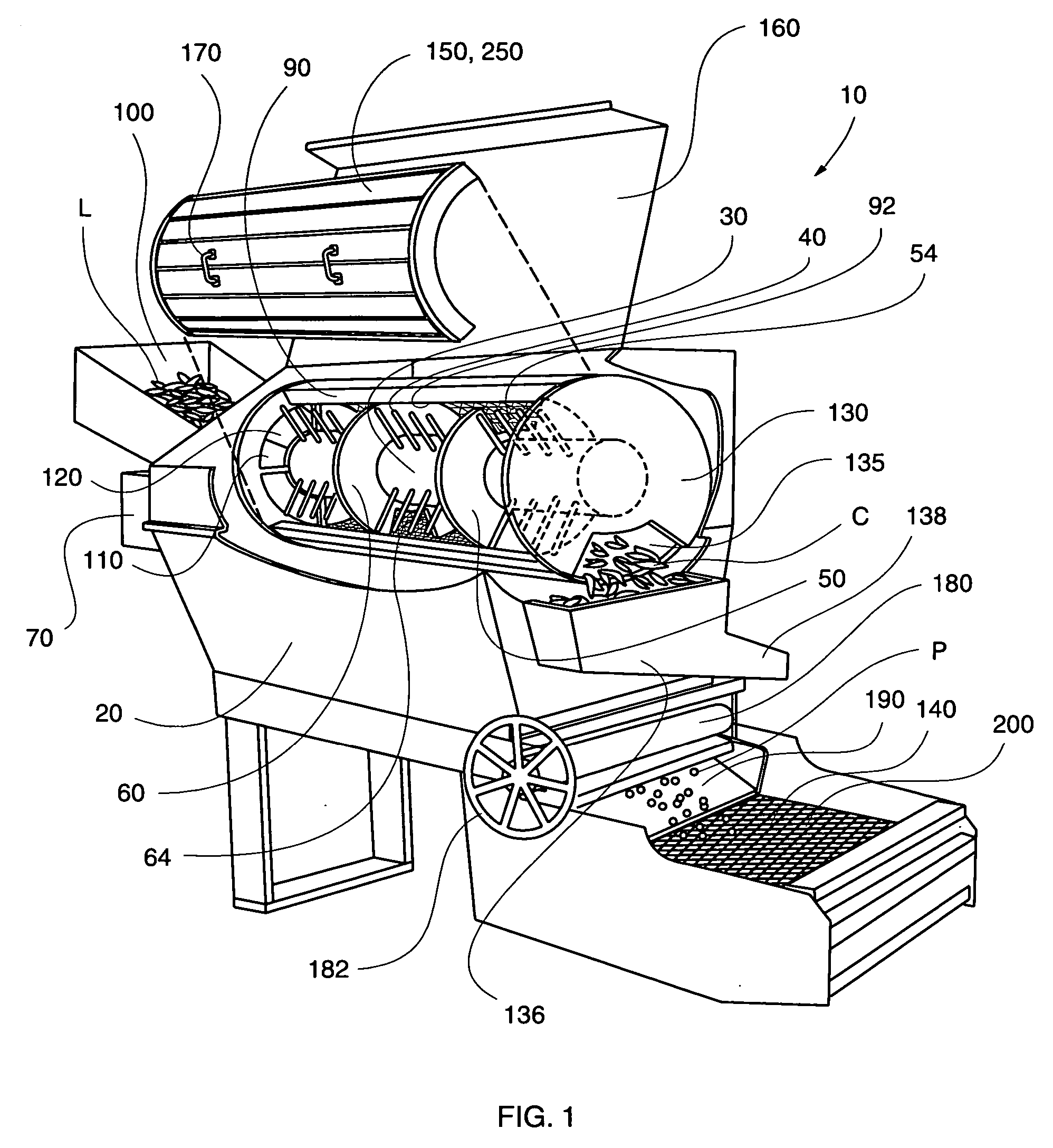

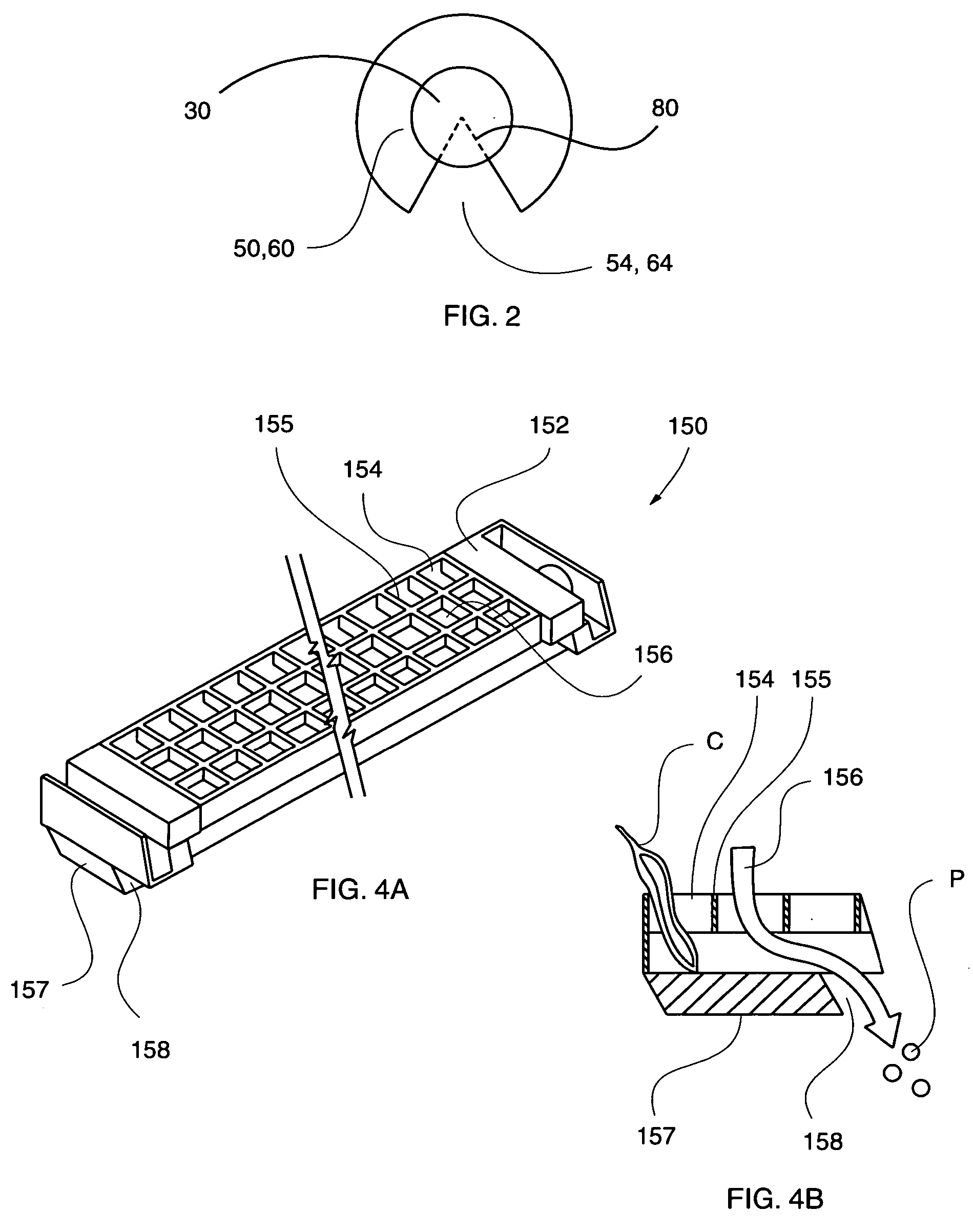

Sheller and method of use thereof

InactiveUS20070004480A1Increase productionQuality improvementGrain huskingGrain polishingMechanical engineeringLegume

Owner:TAYLOR GEORGE

Vacuum rotary kiln and application process thereof

The invention provides a vacuum rotary kiln. A hot air pipe, spiral guide plates and T-shaped lifting boards are mounted in the vacuum rotary kiln; one T-shaped lifting board is mounted between each two spiral guide plates; the hot air pipe comprises a kiln head center main air pipe, a kiln tail center main air pipe and branch air pipes; the branch air pipes are annularly distributed between the kiln head center main air pipe and the kiln tail center main air pipe; the branch air pipe located at the center is communicated with the kiln head center main air pipe and the kiln tail center main air pipe; the both ends of the other branch air pipes are gathered with the kiln head center main air pipe and the kiln tail center main air pipe; and 4-8 fins are respectively welded on the outer wall of the branch air pipe at the center uniformly. A process of roasting refractory gold comprises the steps of preparing sulfuric acid by using SO2 after vacuum dehydration, desulfuration and dearsenification. The vacuum rotary kiln is used for roasting in a metallurgy process, so that heat of mineral itself can be sufficiently used. Thus, the vacuum rotary kiln has the advantages of uniform material heating, less powder dust and high capability.

Owner:伍耀明

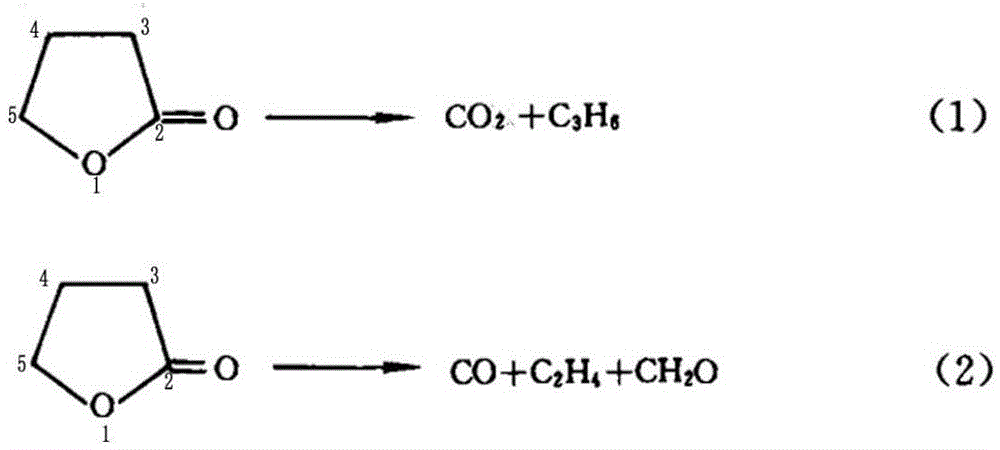

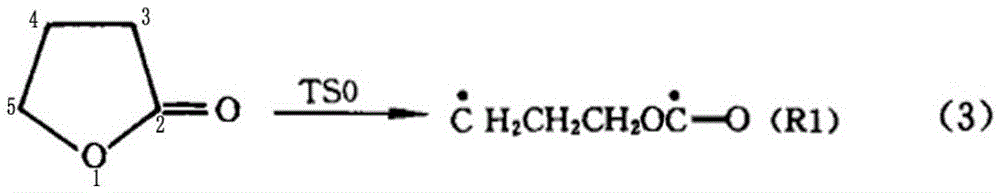

Method for preparing cyclopropyl methyl ketone

ActiveCN105622369AIncrease contact areaNot easy to wearCarbonyl compound separation/purificationPreparation from heterocyclic compoundsOrganic synthesisFixed bed

The invention relates to a method for preparing cyclopropyl methyl ketone, and belongs to the field of organic synthesis. The preparing method includes the following steps that metal halide and an inert solvent are added into a fixed bed reactor, the fixed bed reactor is heated to 185-195 DEG C, and then alpha-acetyl-gamma-butyrolactone is continuously added into the fixed bed reactor, and is subjected to a cleavage reaction; after the reaction is saturated, the alpha-acetyl-gamma-butyrolactone stops to be added, reaction distillation continues to be carried out till no product is distilled out, and a cyclopropyl-methyl-ketone crude product is obtained; the fixed bed reactor is connected with a rectifying tower, the prepared cyclopropyl-methyl-ketone crude product is transferred into the rectifying tower to be subjected to high tower dividing and then subjected to normal pressure rectification, the reflux ratio is adjusted, impurities are separated, and the high-purity cyclopropyl methyl ketone is obtained through distilling. The method is low in production cost, high in production efficiency, product yield and purity, small in by-product number, wastewater amount, waste material number and environment pollution and more suitable for industrial production.

Owner:LINHAI LIANSHENG CHEM

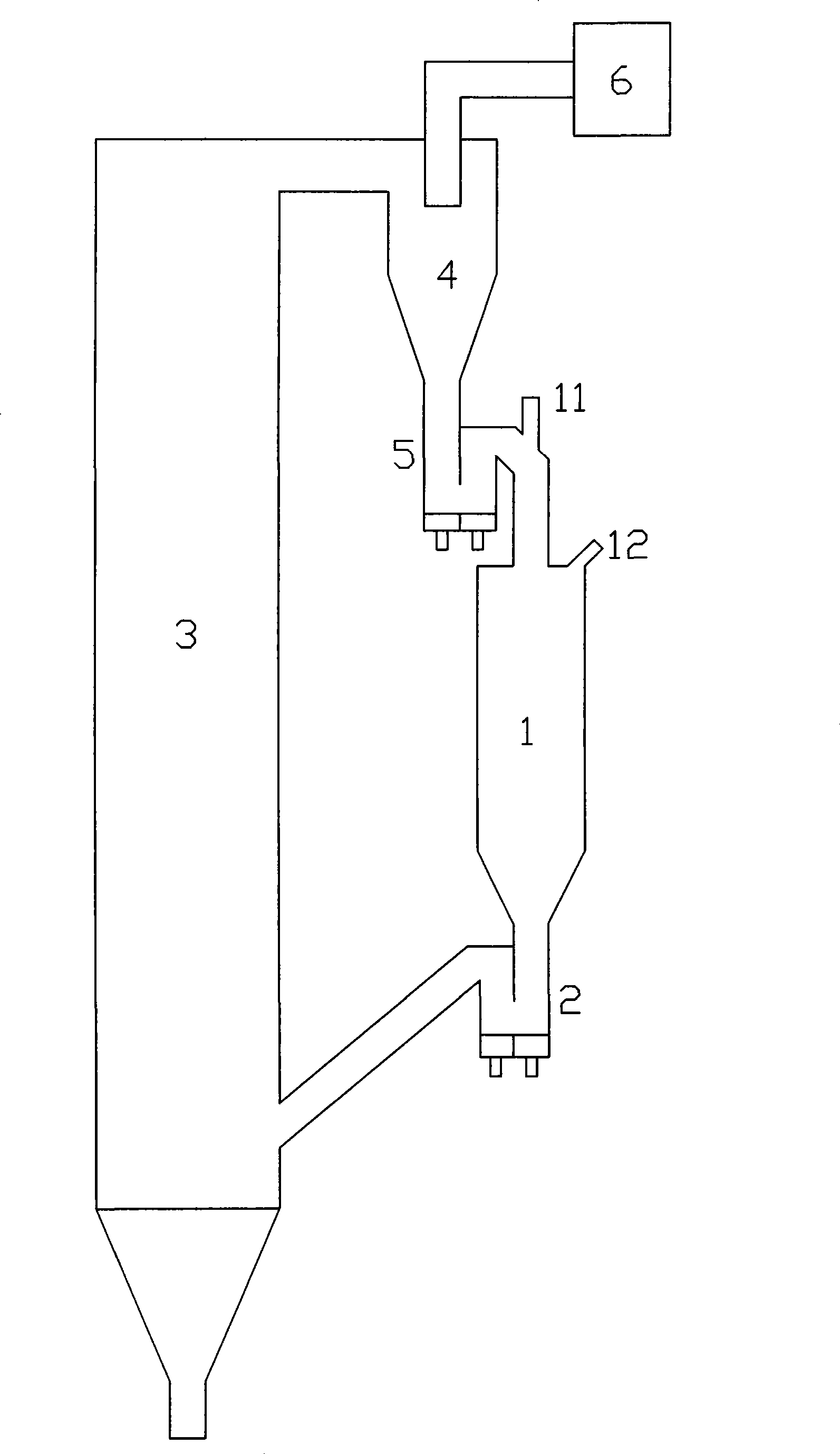

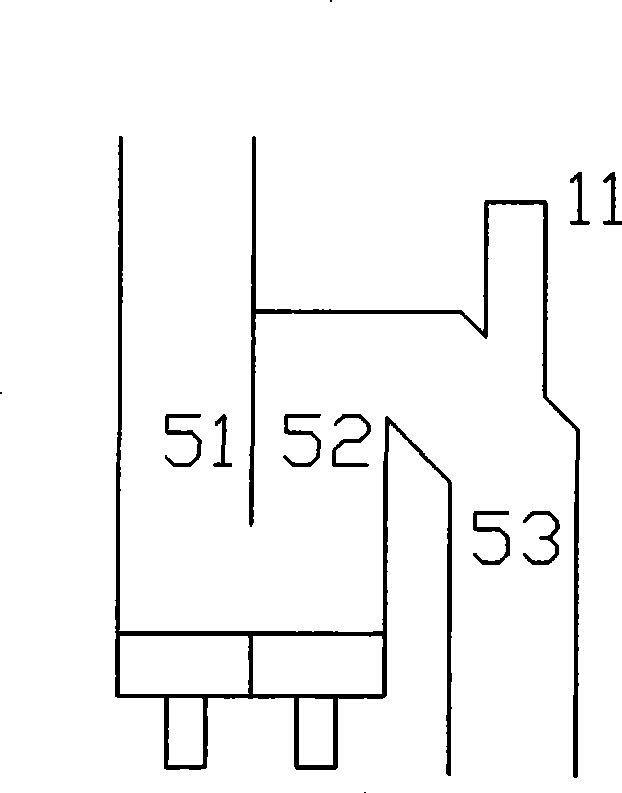

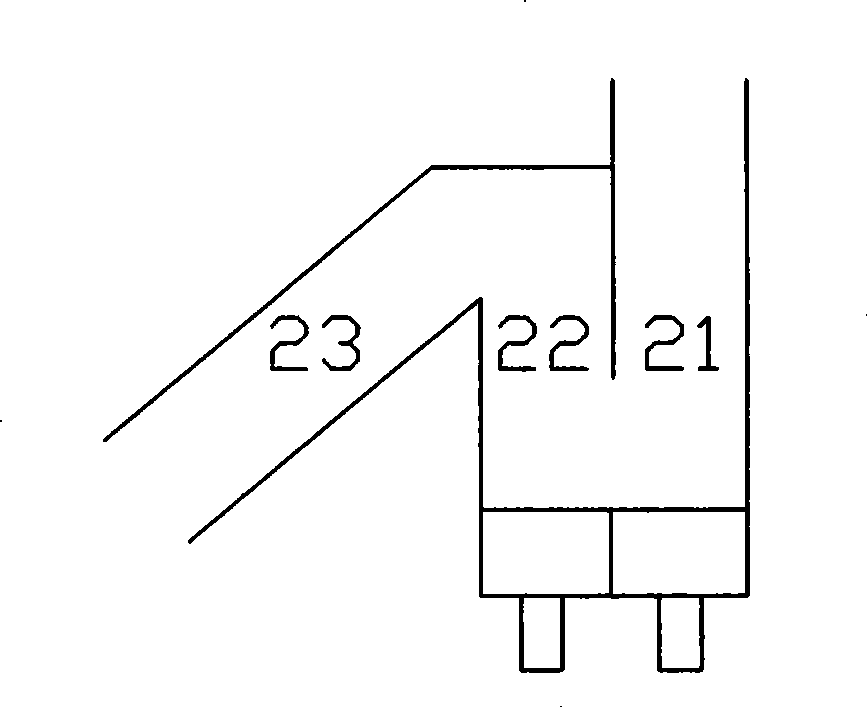

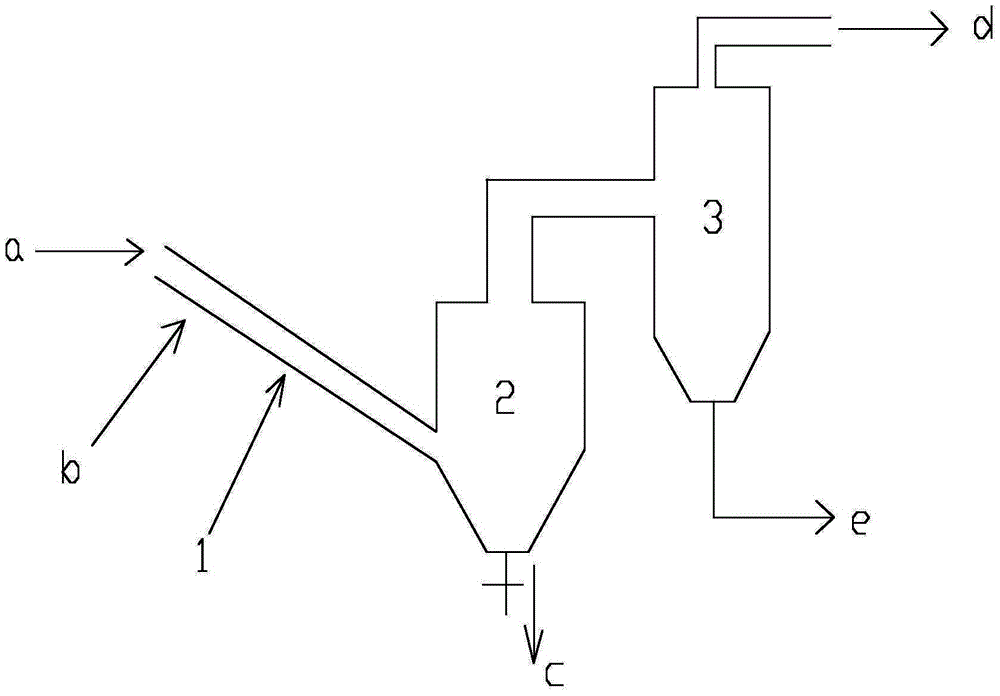

Pyrolysis method and device of low speed bed

ActiveCN101362955AControl dwell timeSimple systemLiquid hydrocarbon mixture productionCombustion chamberAir volume

The invention provides a low velocity bed pyrolysis method and a device; fuel is added from a pyrolysis chamber so as to generate pyrolysis gas and semi-coke; the semi-coke is sent to a combustion chamber so as to be burned; the generated high-temperature material enters the pyrolysis chamber again from top of a material returning device, thus providing heat for the pyrolysis reaction; the combustion chamber is a circular fluidized bed type and the oxygen content of smoke at an outlet is zero; the semi-coke and low-temperature material are exhausted from the pyrolysis chamber and enter the combustion chamber through a pneumatic control valve; the pyrolysis chamber is internally provided with the low velocity bed; the fluidized air quantity of material returning device and the pneumatic control valve is adjusted so as to adjust the material height inside the pyrolysis chamber and the staying time of the material inside the pyrolysis chamber; the quantity of the air which enters the combustion chamber is adjusted so as to adjust the combustion heat exhausting quantity of the fuel, thus adjusting the temperature of the pyrolysis chamber; the pyrolysis chamber runs in a way of the combination of a low speed fluidized bed and a movable bed; the material has long staying time inside the pyrolysis chamber and complete pyrolysis reaction; the method and the device have various control ways of well controlling the temperature of the pyrolysis chamber. The method and the device can be used for coal, biomass and other carbonaceous refuse and alternative fuels, thus generating pyrolysis gas and coal tar.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

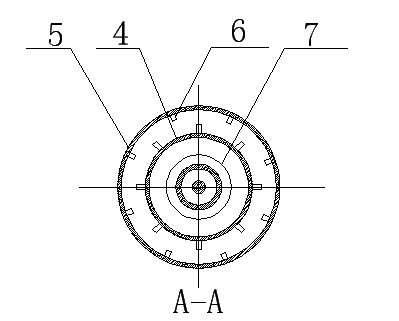

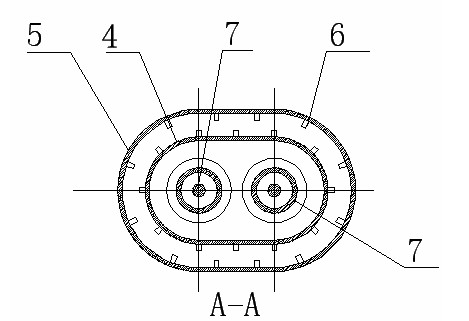

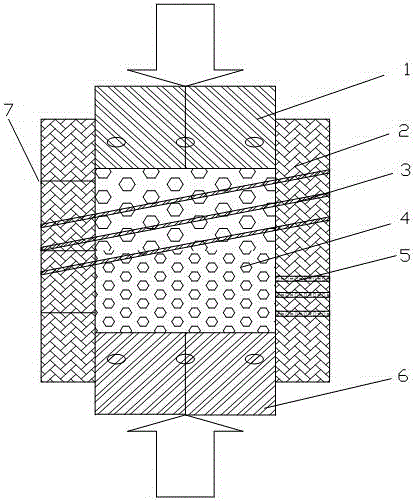

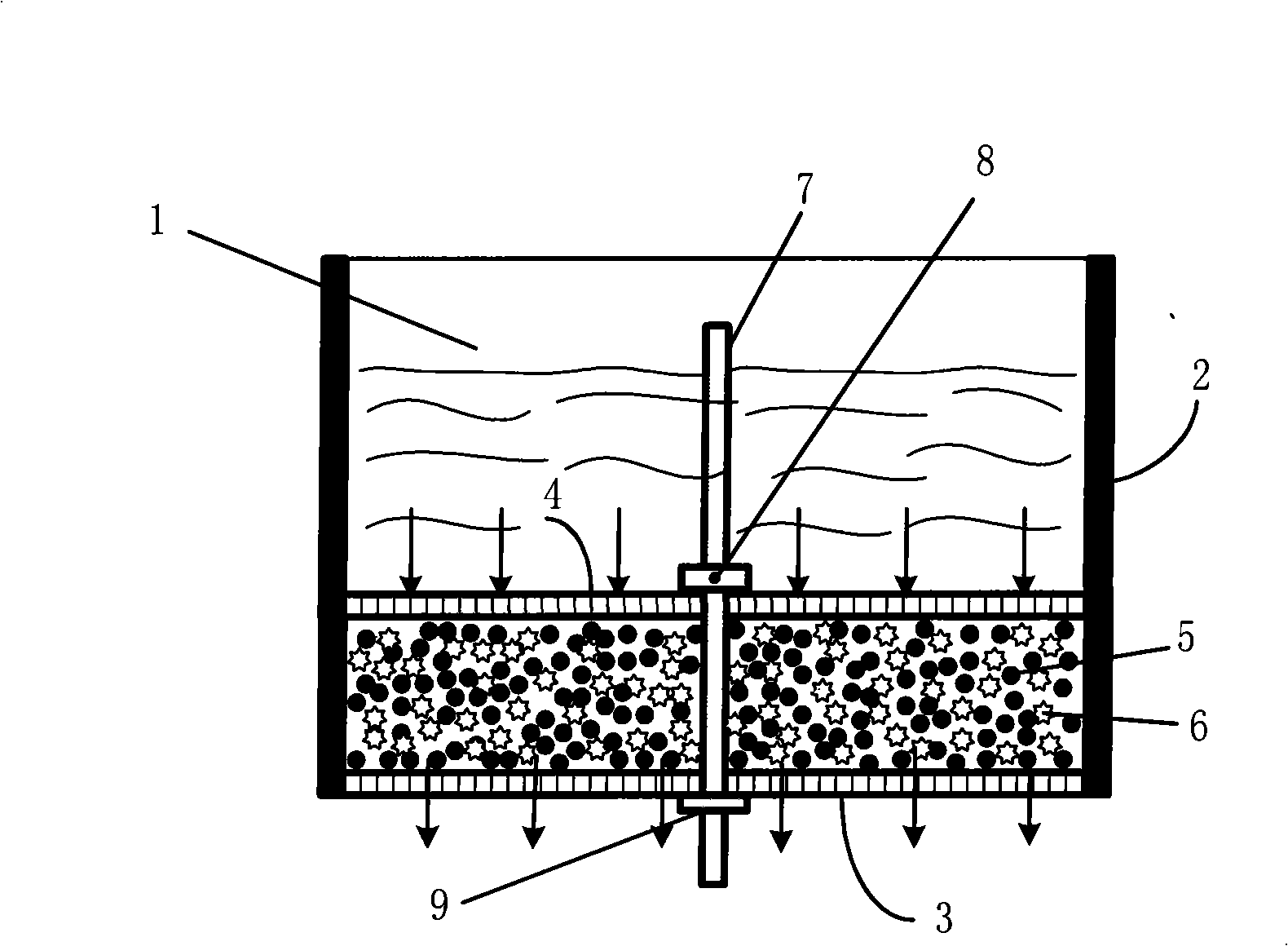

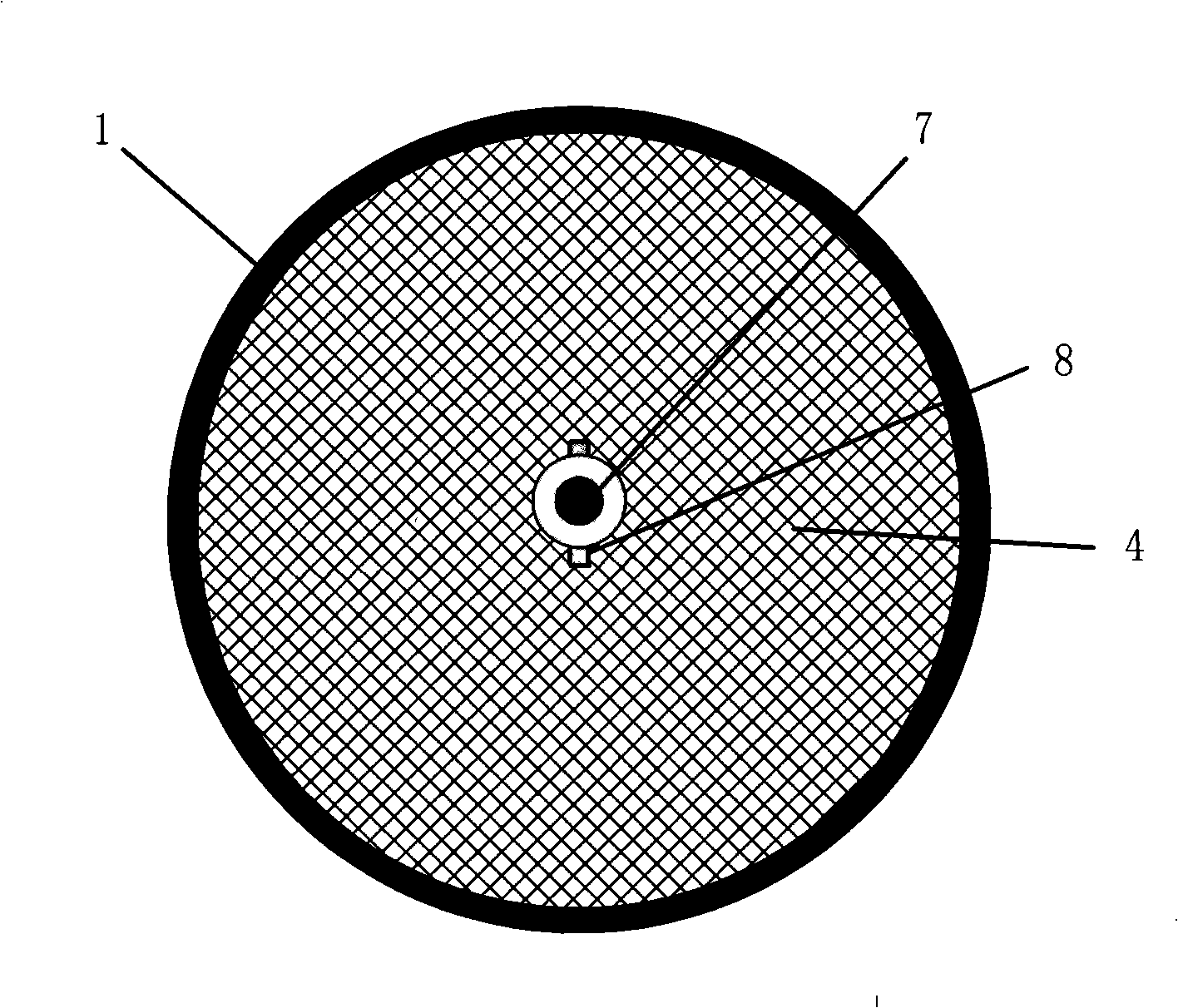

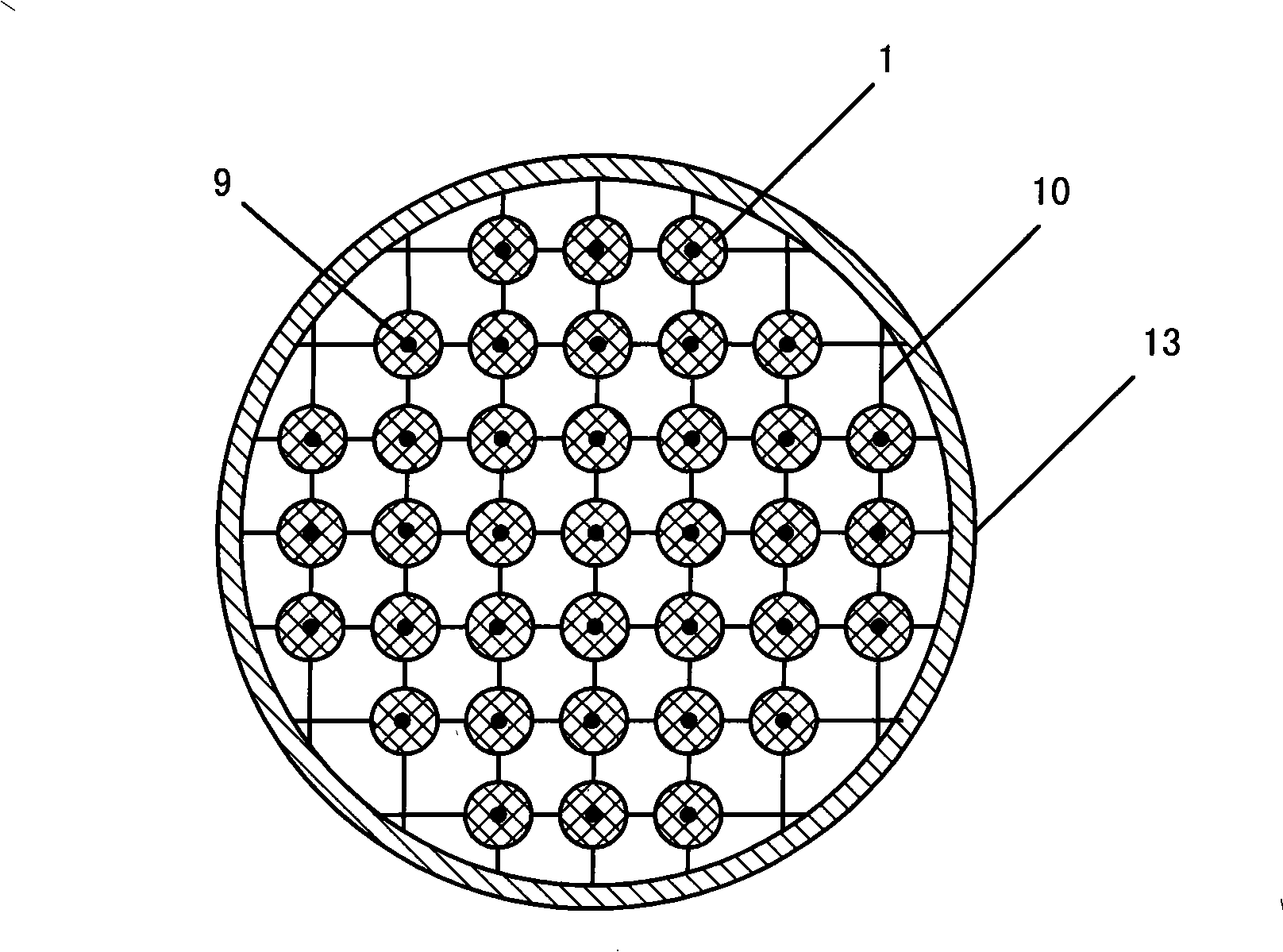

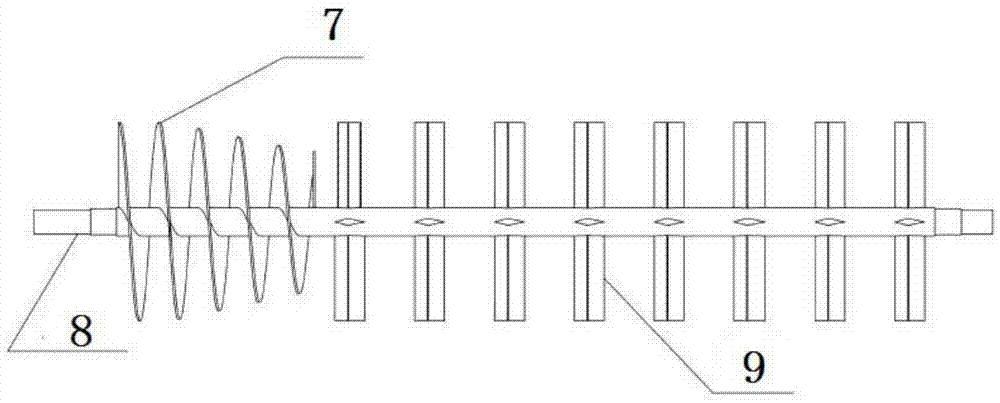

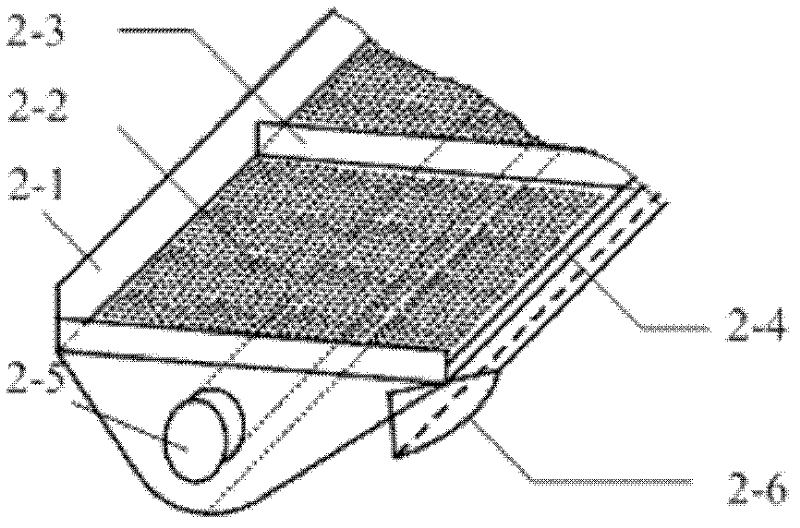

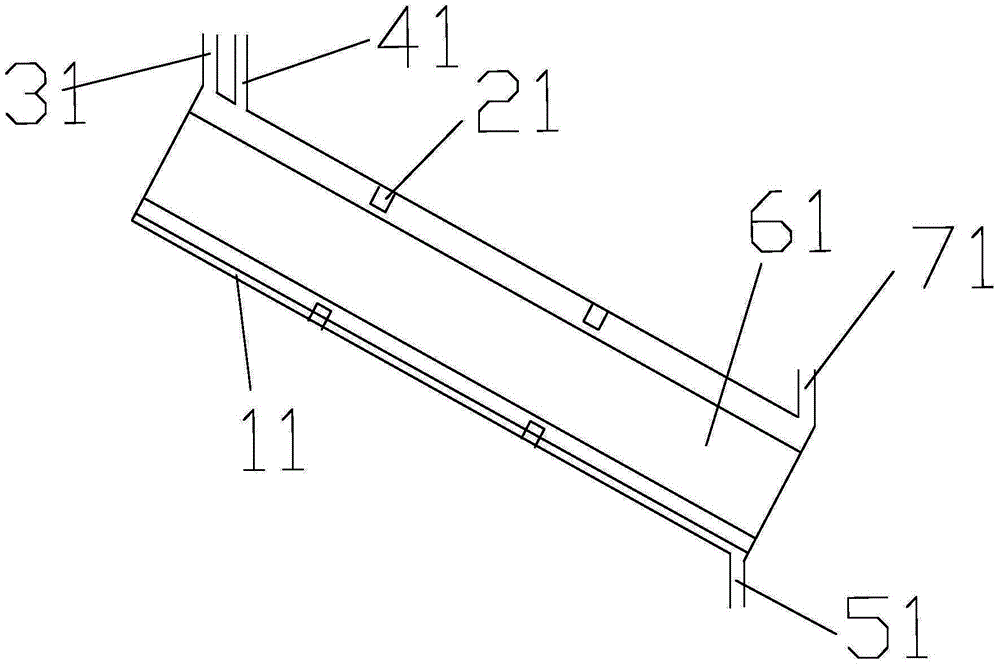

Catalyst distillation column internals for high effective mass transfer

ActiveCN101306256AControl dwell timeFully contactedDistillation separationChemical/physical/physico-chemical processesRetention timeCatalytic distillation

The invention relates to an internal part of a high efficient mass transfer catalytic distillation tower. Wherein, the internal part 1 is composed of a porous container and a filler 5 with catalytic performance therein, the side wall and the lower bottom surface of the container are fixed, at least one longitudinal sliding bar 7 is arranged at the middle part of the lower bottom surface, the upper bottom surface can move up and down along the longitudinal sliding bar and be fixed at an arbitrary height of the sliding bar by a bolt 8, the side wall 2 of the container is not transparent, the upper bottom surface 4 and the lower bottom surface 3 of the container are wire screen plates or porous plates, the internal part is fixed on a grid-shaped support 10 by a nut 9, and the grid-shaped support is fixed on the wall 13 of the catalytic distillation tower. The height of the upper bottom surface of the internal part of the catalytic distillation tower of the invention is lower than the side wall, thereby accumulating liquid with a certain height above a catalyst; reactants are promoted to enter a catalyst bed with the help of the gravity of the liquid, thereby allowing the reactants to be fully contacted with the surface of the catalyst; products are simultaneously impelled to be moved out of the catalyst bed, thereby avoiding the excessive reaction and effectively controlling the retention time of the reactants on the surface of the catalyst.

Owner:TIANJIN UNIV

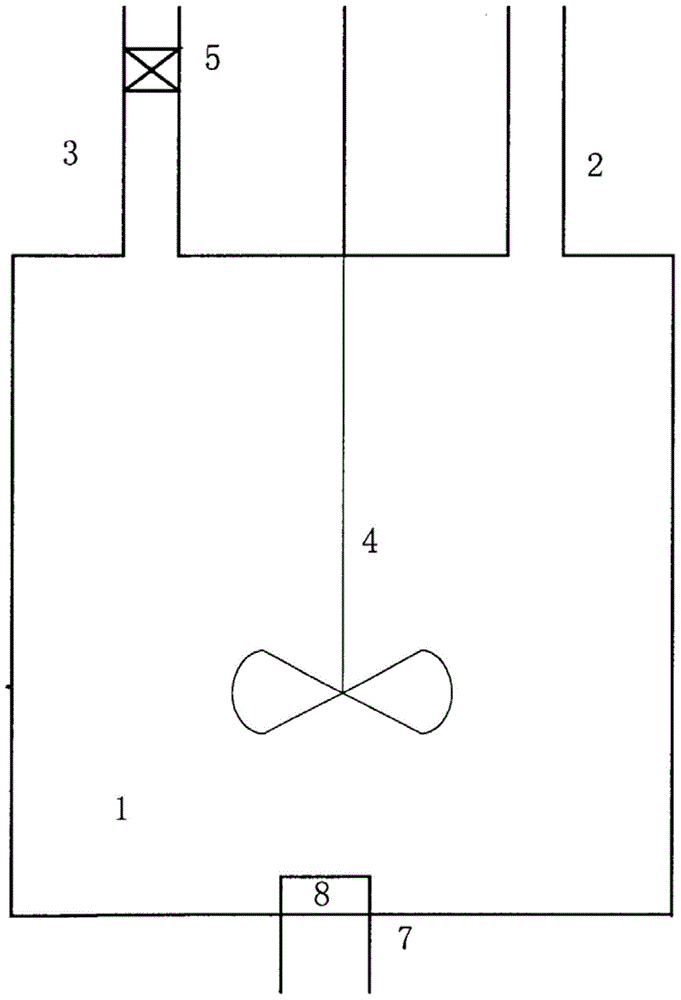

Stirring device capable of realizing cascading fermentation of solid waste and reactor

ActiveCN105436193AReduce mixImprove degradation efficiencySolid waste disposalAxial thrustEngineering

The invention discloses a stirring device capable of realizing cascading fermentation of solid waste and a reactor. The stirring device comprises a center shaft, a conveying screw and a plurality of stirring blades, wherein the conveying screw is used for axially pushing materials, is concentrically fixed on one side of the center shaft and extends from the shaft end to the middle of the shaft in tapered manner; the stirring blades and the conveying screw are coaxially fixed on the other side of the center shaft. The stirring device can be arranged in a barrel to form the reactor used for the solid waste. The layout standard of the stirring blades is that the axial thrust along the center shaft is not generated in the rotation process. Thus, a layered fermentation system can be formed in the reactor. The system can greatly reduce the mixing ratio of new and old materials, effectively control the standing time of solid materials in the reactor, improve the degradation efficiency of output materials, and increase the final product quality.

Owner:ZHEJIANG UNIV

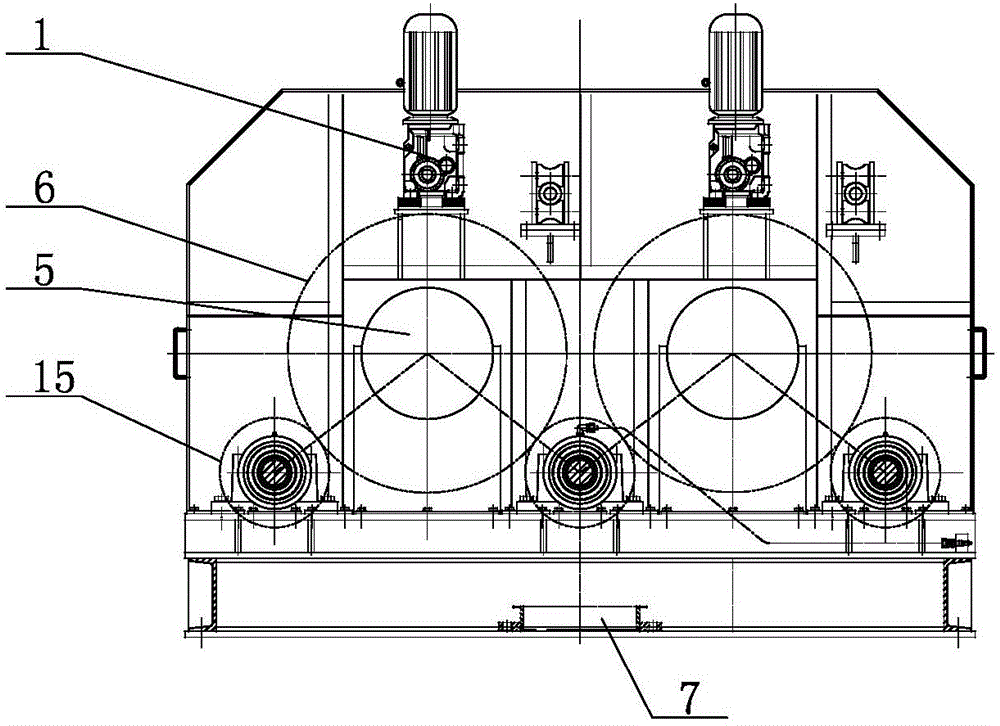

Solid fuel drying equipment

ActiveCN102519230AIncrease contact timeControl dwell timeDrying solid materials with heatDrying gas arrangementsFluidized bedSolid fuel

The invention relates to solid fuel drying equipment, which comprises a drum, a fluidized bed, a fan and a dust removing filter. A bent lifting plate is arranged on the inner wall of the drum, the fluidized bed is mounted in the drum, the fan is connected with the drum, dry air flowing through the fan is filled into the drum via the fluidized bed to realize primary classification for grains falling on the fluidized bed, larger moisture grains are dried on the fluidized bed and in the drum when falling, and smaller fine powdery grains are carried by air to pass through the drum, are dried when carried by the air and are collected by the dust removing filter to be used as dry products. Compared with the prior art, the solid fuel drying equipment has the advantages of simplicity in operation, easiness in control, high drying capacity and the like.

Owner:WISON ENG

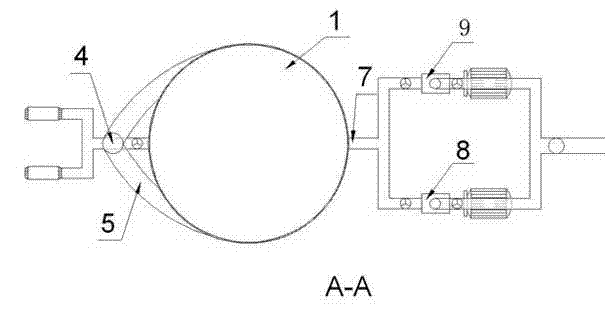

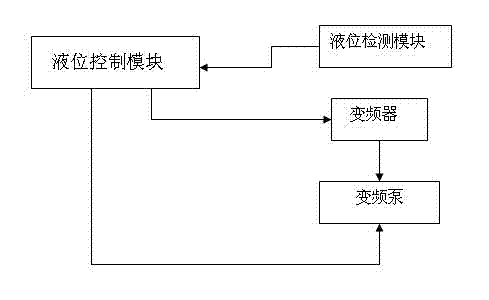

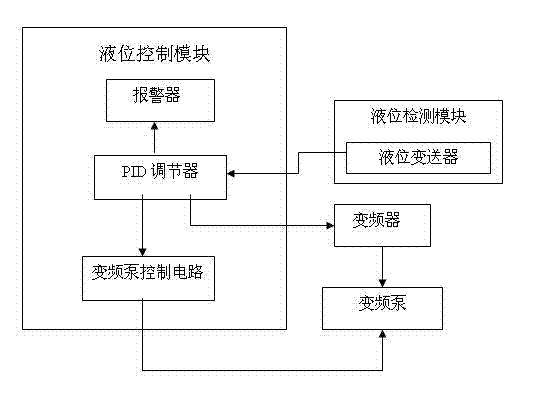

Stoving neutralizing auxiliary reaction tower

InactiveCN103173579AControl dwell timeControl unit controls dwell timePurification by oxidation/reductionPurification using alkaline earth metal compoundsChemical reactionSulfur

The invention aims to provide a stoving neutralizing auxiliary reaction tower. The stoving neutralizing auxiliary reaction tower comprises a cylindrical tank body, a stoving neutralizing reactor, a tube diffuser, a juice outlet pipe, a variable frequency juice outlet pump and a liquid level control device. By using the stoving neutralizing auxiliary reaction tower, the defects of the conventional neutralizing reaction device in a sugar refinery are overcome, and the problem of incomplete chemical reaction of the cane juice subjected to stoving liming is solved. The invention also provides a method for carrying out stoving neutralizing reaction by using the stoving neutralizing auxiliary reaction tower. According to the method, the stoving neutralizing auxiliary reaction tower is reasonably utilized, so that the standing time of the cane juice subjected to stoving liming is greatly increased, the uniformity of the cane juice is improved, the reaction of neutralized juice is more complete, and remarkable effects of improving the syrup purity, reducing the color value of white sugar and turbidity and lowering the sulfur dioxide residues are achieved.

Owner:南宁苏格尔科技有限公司

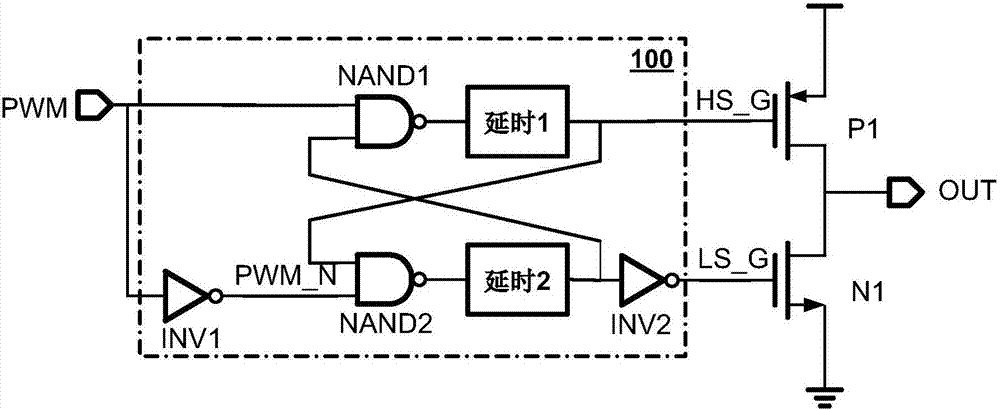

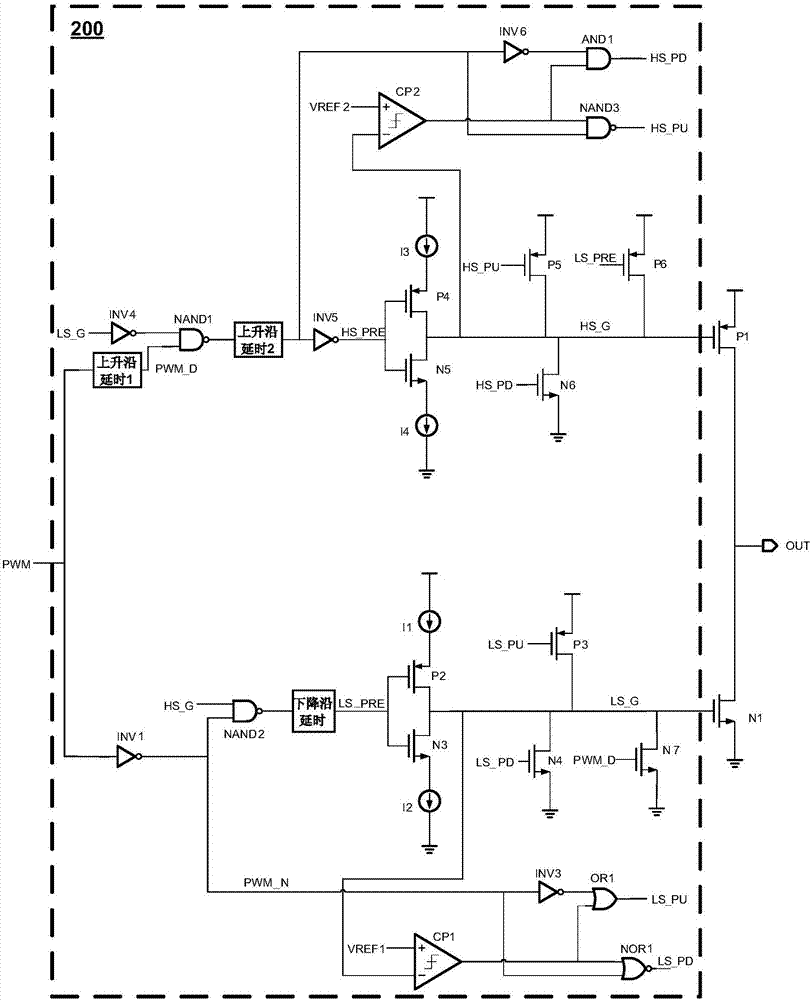

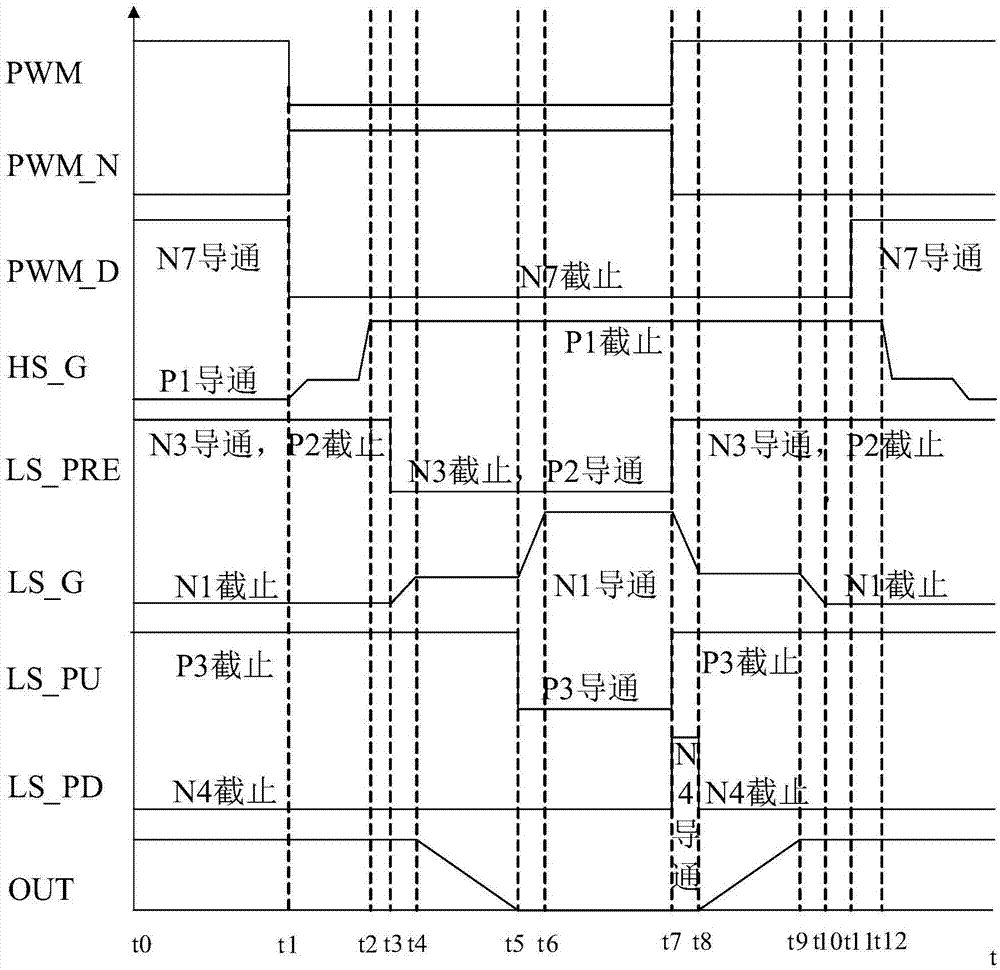

Power tube driving system and method

ActiveCN106954123AControl dwell timeSuppression of radiated electromagnetic interferenceSignal processingTransducer circuitsCharge currentParasitic capacitance

The invention provides a power tube driving system and method. The system comprises a driving circuit part of the lower tube of a power tube and a driving circuit part of the upper tube of the power tube. The driving circuit part of the lower tube of the power tube is configured to control the residence time of the lower tube of the power tube on a Miller platform by controlling the size of the first charging current for charging the stray capacitance of the lower tube of the power tube through a first switching circuit, and / or, control the residence time of the lower tube of the power tube on the Miller platform by controlling the size of the first discharging current for discharging the stray capacitance of the lower tube of the power tube through a second switching circuit. The driving circuit part of the upper tube of the power tube is configured to control the residence time of the upper tube of the power tube on the Miller platform by controlling the size of second discharging current for discharging the stray capacitance of the upper tube of the power tube through a third switching circuit, and / or, control the residence time of the upper tube of the power tube on the Miller platform by controlling the size of second charging current for charging the stray capacitance of the upper tube of the power tube through a fourth switching circuit.

Owner:ON BRIGHT ELECTRONICS SHANGHAI

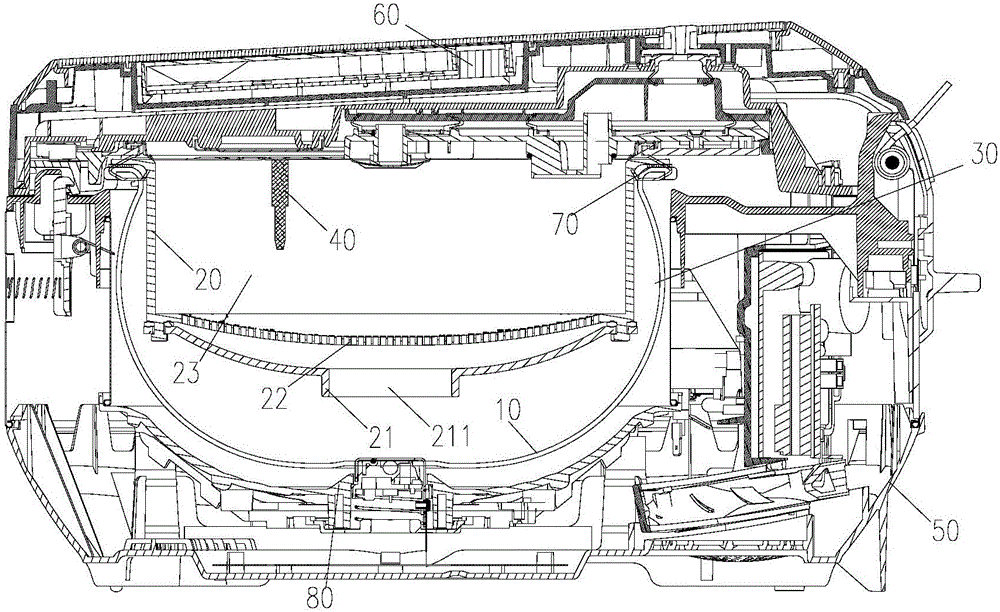

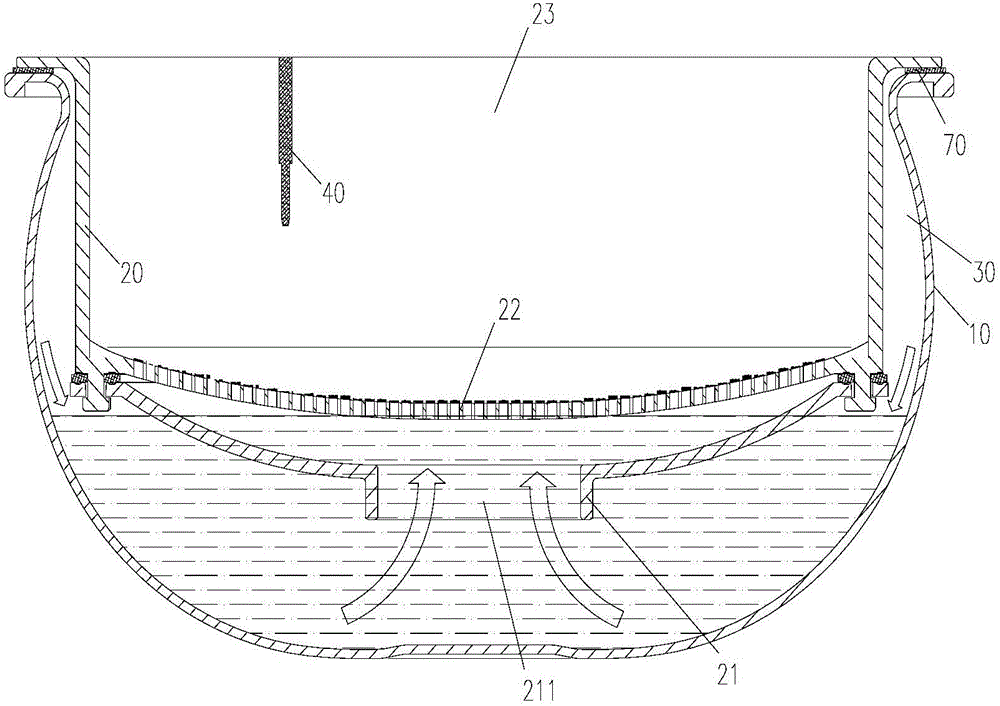

Control method of electric cooking appliance

ActiveCN105996762ATemperature controlControl the number of contactsBoiling over preventionSteam cooking vesselsAutomotive engineeringCooker

The invention provides a control method of an electric cooking appliance. The control method of the electric cooking appliance includes the following steps that a heating element of the electric cooking appliance heats an inner container of the electric cooking appliance, and the electric cooing appliance enters a rice washing process; in the single-pass rice washing process, the heating element of the electric cooking appliance heats the inner container of the electric cooking appliance till an anti-overflow detection part is triggered by water, the heating element stops working with the stop lasting for a first preset time t1 to complete the single-pass rice washing process, and the rice washing process is repeated N1 times; the electric cooking appliance enters a rice steaming process, and the heating element heats the inner container of the electric cooking appliance. By means of the control method of the electric cooking appliance, the GI value of steamed rice can be reduced, the taste of steamed rice can be improved, and the electric cooking appliance can be effectively controlled.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

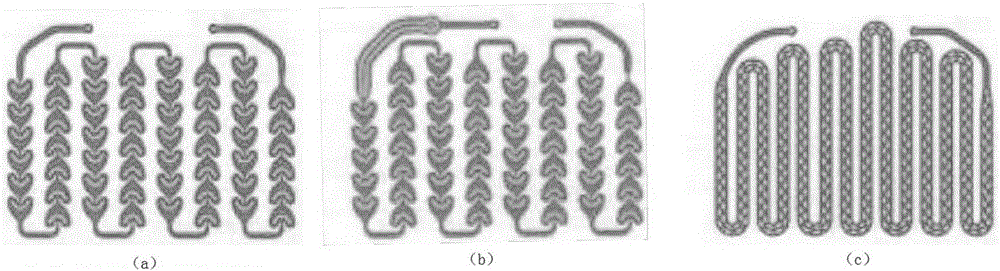

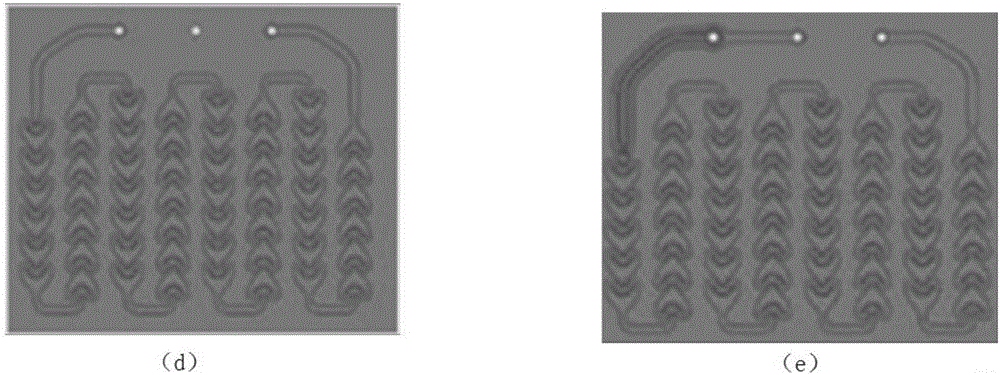

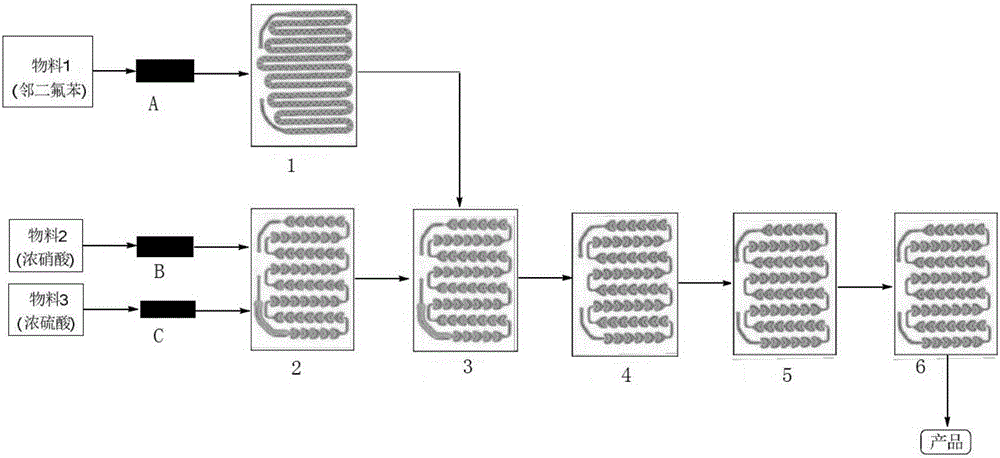

Method for synthesizing 3-fluoro-4-(4-morpholinyl)aniline by using micro-channel reactor

ActiveCN106397358AReduce energy consumptionEfficient mass and heat transferOrganic chemistryAcetic acidHydrogen

The invention provides a method for synthesizing 3-fluoro-4-(4-morpholinyl)aniline by using a micro-channel reactor. The micro-channel reactor comprises a preheating module group composed of one or more parallely-connected preheating modules and a reaction module group composed of one or more tandemly-connected reaction modules, wherein the preheating module group is series connection with the reaction module group. The method comprises the following steps: separately preheating difluorobenzene, concentrated nitric acid and concentrated sulfuric acid, then subjecting the preheated difluorobenzene, concentrated nitric acid and concentrated sulfuric acid to a reaction in the reaction module group and carrying out treatment so as to obtain 3,4-difluoronitrobenzene; dissolving 3,4-difluoronitrobenzene in an organic solvent, adding organic base, dissolving morpholine in the organic solvent, carrying out preheating, allowing the obtained solution to enter the reaction module group for a reaction and carrying out treatment so as to obtain 4-(2-fluoro-4-nitrophenyl)morpholine; and dissolving 4-(2-fluoro-4-nitrophenyl)morpholine in ethyl acetate, adding a catalyst, carrying out preheating, allowing the obtained solution and hydrogen to enter the reaction module group for a reaction and carrying out treatment so as to obtain 3-fluoro-4-(4-morpholinyl)aniline. The method has the advantages of low energy consumption, high yield, high product purity, safety, flexibility, etc.

Owner:HEILONGJIANG XINCHUANG BIOLOGICAL TECH DEV CO LTD

Preparation method of catalytic cracking promoter

ActiveCN104549445AAdequate contact responseControl dwell timeMolecular sieve catalystsBulk chemical productionMolecular sieveGas phase

The invention relates to a preparation method of a catalytic cracking promoter. The method comprises the following steps: preparing a high-silicon ZSM-5 molecular sieve, and mixing and pulping and pelletizing the high-silicon ZSM-5 molecular sieve and a binder and clay, wherein the preparation method of the high-silicon ZSM-5 molecular sieve comprises the following steps: introducing NaZSM-5 molecular sieve crude powder into a gaseous-phase ultra-stable reactor, moving the NaZSM-5 molecular sieve crude powder to a molecular sieve outlet of the gaseous-phase ultra-stable reactor from a molecular sieve inlet of the gaseous-phase ultra-stable reactor under the situation of no carrier gas conveying, and performing contact reaction of the NaZSM-5 molecular sieve crude powder and gaseous phase SiCl4 in the gaseous-phase ultra-stable reactor. According to the preparation method, the ZSM-5 molecular sieve with high silica-alumina ratio can be continuously prepared, and apropylenecatalytic cracking promoter can be further prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

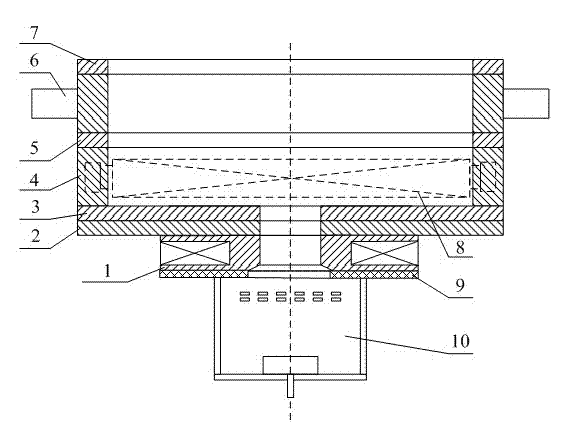

Ion source with ultra-large ion beam divergence angle

InactiveCN102779711ARealize spatial scanningRealize spatial divergence angle controlElectric discharge tubesDivergence angleIon beam-assisted deposition

The invention relates to an ion source used in an optical vacuum coating machine (ion beam auxiliary deposition equipment) or ion beam sputtering and etching equipment, in particular to the ion source with an ultra-large ion beam divergence angle. The technical scheme is that the ion source comprises a gas discharge chamber, wherein an insulating end cover is arranged at one end of the gas discharge chamber; and a focusing magnetic field generating unit and a magnetic field scanning unit are arranged outside the insulating end cover. Through a group of orthogonal magnetic field, the direction of an ion beam led into the magnetic field is controlled, and by setting the voltage change rule of electromagnetic coils in an X direction and a Y direction, space scanning on the ion beam can be realized. Controlling over the space divergence angle of the ion beam can be realized by adjusting the current magnitude of the electromagnetic coils. Compared with the prior art, the ion source has the advantages that 1, the divergence angle of the ion beam output by the ion source can be up to 180 degrees; 2, the divergence angle of the ion beam can be adjusted according to practical needs, and the requirement of different thin film deposition processes can be met; and 3, the uniformity of the flow density of the ion beam is high.

Owner:XIAN TECHNOLOGICAL UNIV

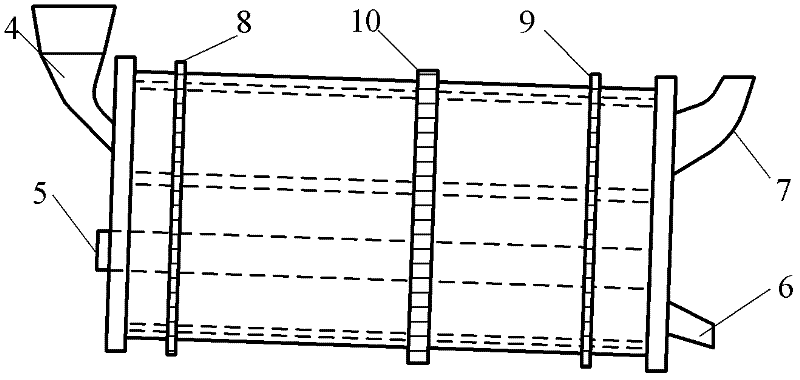

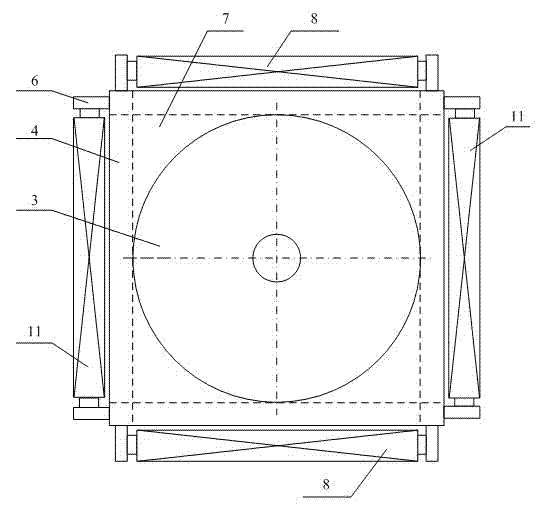

Second esterification reactor in continuous production device of poly (trimethylene terephthalate)

InactiveCN102311541AGuaranteed response timeGuaranteed sequential flowPolyethylene terephthalateRetention time

The invention provides a second esterification reactor in a continuous production device of poly (trimethylene terephthalate) (PTT), comprising a reactor autoclave body, wherein, the reactor autoclave body is horizontal and provided with one or more separator plates inside, the separator plates separate the inner space of the reactor autoclave body into at least two cavities, each cavity has same or different length with other cavity, the bottom of the separator plate is provided with a through hole or a gap for the circulation of the materials, the upper edge of the separator plate is apart from the inner wall of the upper portion of the reactor autoclave body with a spacing, partial or all cavities are correspondingly provided with additive conduits and stirrers, and the reactor autoclave body is provided with a jacket and / or a heating coil. According to the invention, the retention time of the esters in different cavity is controllable, so that the esterification degree is controlled, and by adding various additives in the esters with different esterification degree in different cavity, the product quality is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Treating method and device for carbon dioxide and hydrogen sulfide containing gas

ActiveCN108722148AReasonable useReduce energy consumptionGas treatmentDispersed particle separationProduct gasChemical products

The invention discloses a treating method and device for carbon dioxide and hydrogen sulfide containing gas. The device comprises a hydration reactor, a hydrate decomposing device, an exhaust gas treating device, a first-stage absorbing reactor, a second-stage absorbing reactor and a product tank. The invention further provides a method for treating the carbon dioxide and hydrogen sulfide containing gas through the abovementioned device. With the adoption of the device and the method, NaHS products meeting national quality standard can be produced while acidic gas standardized discharging is realized; the environment treatment and the production process of chemical products are integrated. Compared with the prior art, the method has the advantages that the carbon dioxide and hydrogen sulfide containing gas can be economically and efficiently pretreated; the energy in the technical process can be reasonably utilized, so that the energy consumption is extremely decreased; the whole treatment process is environmentally friendly, reliable, and free of three wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

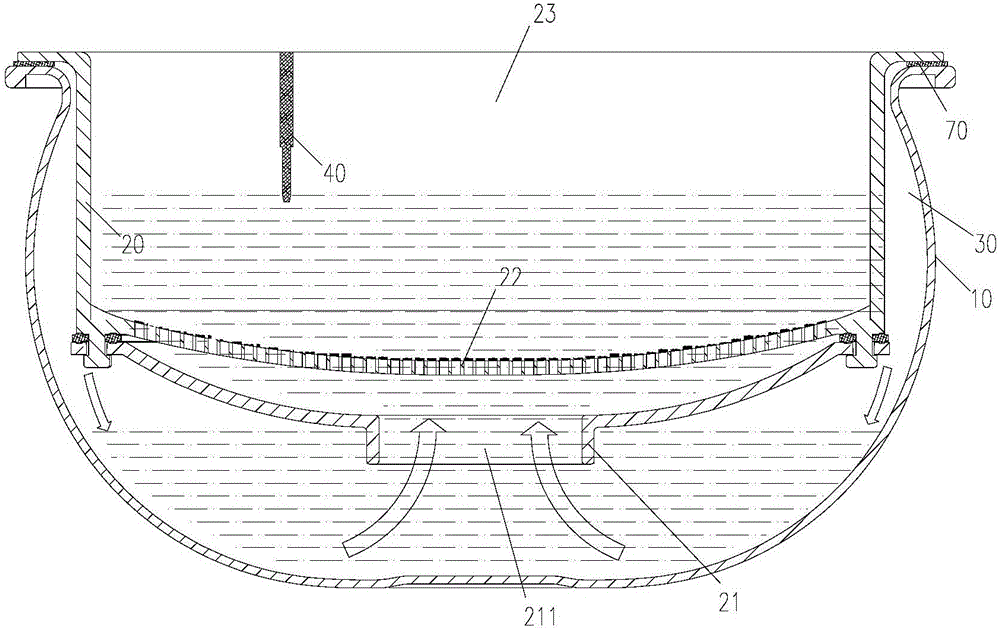

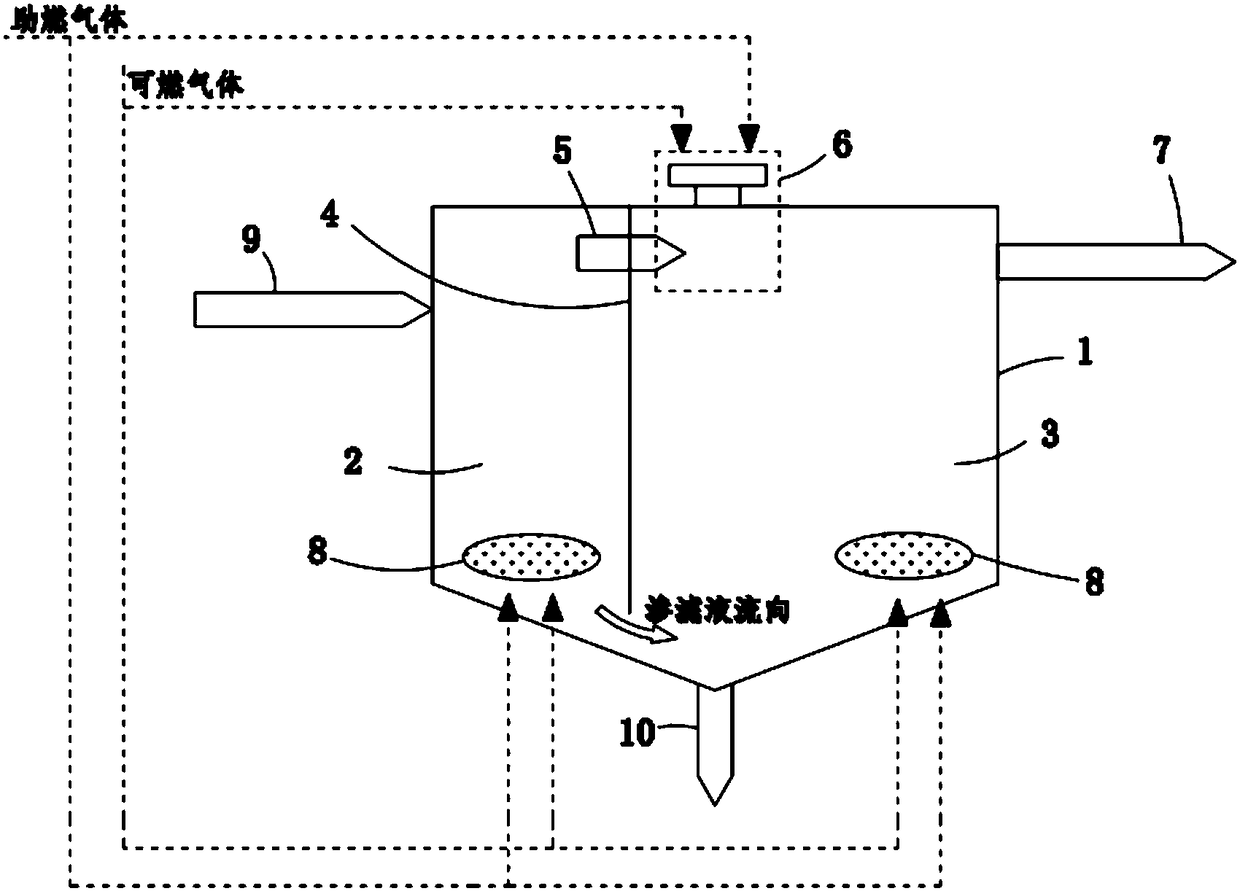

Two-stage immersing, combusting and evaporating integrated device

ActiveCN108249495AAvoid simultaneous evaporationReduce in quantityWater contaminantsEvaporationEvaporatorEvaporation chamber

The invention relates to a two-stage immersing, combusting and evaporating integrated device. The two-stage immersing, combusting and evaporating integrated device comprises an evaporation tank in a single form, wherein two evaporation chambers are formed in the evaporation tank; a treatment fluid can flow from a first evaporation chamber into a second evaporation chamber through a communicated area at the inner bottom of the tank, so that two-stage immersion, combustion and evaporation in one evaporation tank is achieved. The number of evaporators and various gas and liquid conveying pipelines is reduced, the energy is saved, and the floor area and the cost are reduced; moreover, the treatment process is simplified and operation management is facilitated.

Owner:苏州水木湛清环境科技有限公司

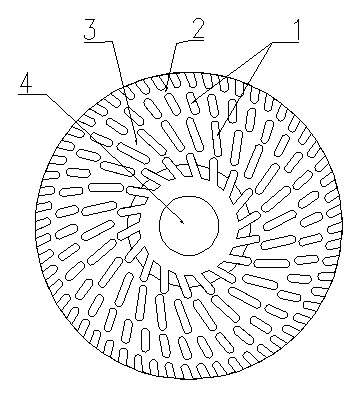

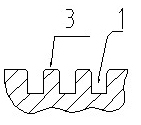

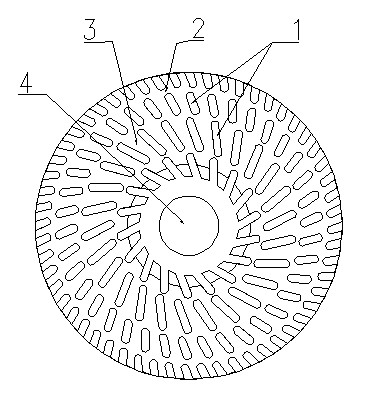

Grinding table of disc grinder for preparing synthetic fiber pulp

ActiveCN102086606AReduce specific edge loadWeaken cut-off functionPulp beating/refining methodsEngineeringResidence time

The invention discloses a grinding table of a disc grinder for preparing synthetic fiber pulp, which comprises a grinding plate, wherein the working surface of the grinding plate is provided with a plurality of grooves; the grooves are distributed in a multiple-layer concentric circle mode around the grinding plate; the grooves are evenly distributed on each layer of the concentric circle; grinding teeth are formed on the grinding plate between every two adjacent grooves on the same circle; and a pulp baffle plate is formed at the gap between any two adjacent layers. The invention can prolongthe the residence time of materials in the disc grinder, weaken the cut-off function of the grinding table, enhance the effects of crushing, kneading and fibrillation on the fibers, and greatly improve the microfibrillation degree of the pulp fibers.

Owner:BLUESTAR CHENGDU NEW MATERIALS

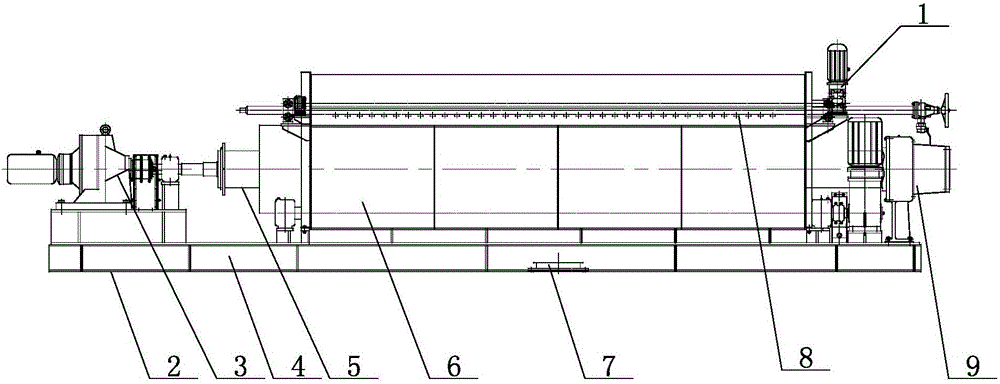

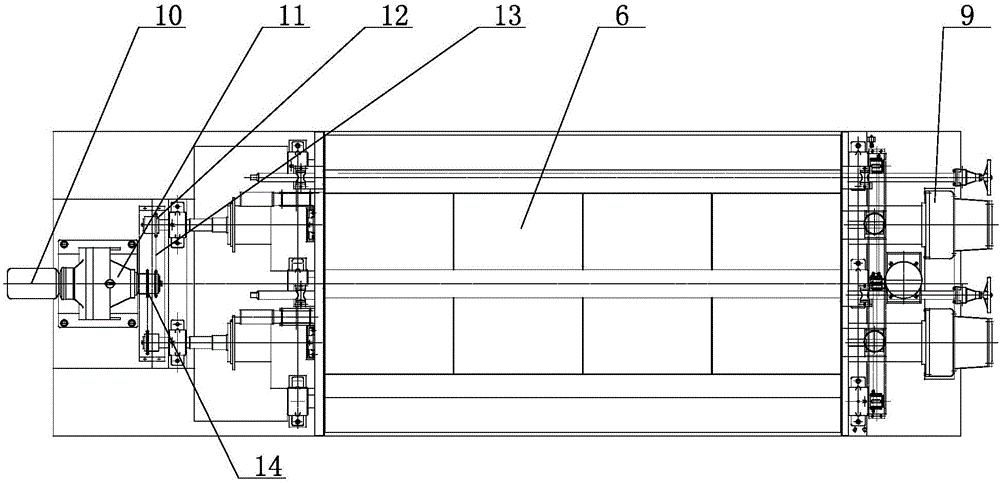

Spiral filtration dehydrator

InactiveCN106334367AControl dwell timeControl dehydration timeSludge treatment by de-watering/drying/thickeningMoving filtering element filtersBristleFiltration

The invention is widely applicable to the technical field of dehydration of paper mill sludge, electroplating sludge, leather sludge, domestic sludge and various types of sludge and particularly relates to a spiral filtration dehydrator. The spiral filtration dehydrator comprises a rack, wherein two spiral shafts are arranged on the rack in parallel, one end of each spiral shaft is connected with a spindle driving device, the two spiral shafts are respectively installed in two filter cartridges, towing wheel shafts are arranged between the outer side walls of the two filter cartridges and the two filter cartridges, one end of each towing wheel shaft is connected with a driving device, two ends of each filter cartridge are respectively a feeding port and a discharging port, the rack is provided with blanking port corresponding to the discharging ports, filtrate outlets are respectively formed in the middle positions, corresponding to the filter cartridges, on the rack, bristle brush roller devices are respectively arranged above the two filter cartridges, and a flushing water device is arranged on one side of the bristle brush roller devices. The spiral filtration dehydrator can decrease flocculant usage amount, adjust spiral and the roller rotation speed according to feeding concentration and control the staying and dehydration time of the sludge in a device. A dehydration effect is good, and material requirements are low. The outlet sludge concentration is adjustable, automatic operation is achieved, and labor intensity is low.

Owner:SHANDONG CHENZHONG MACHINERY

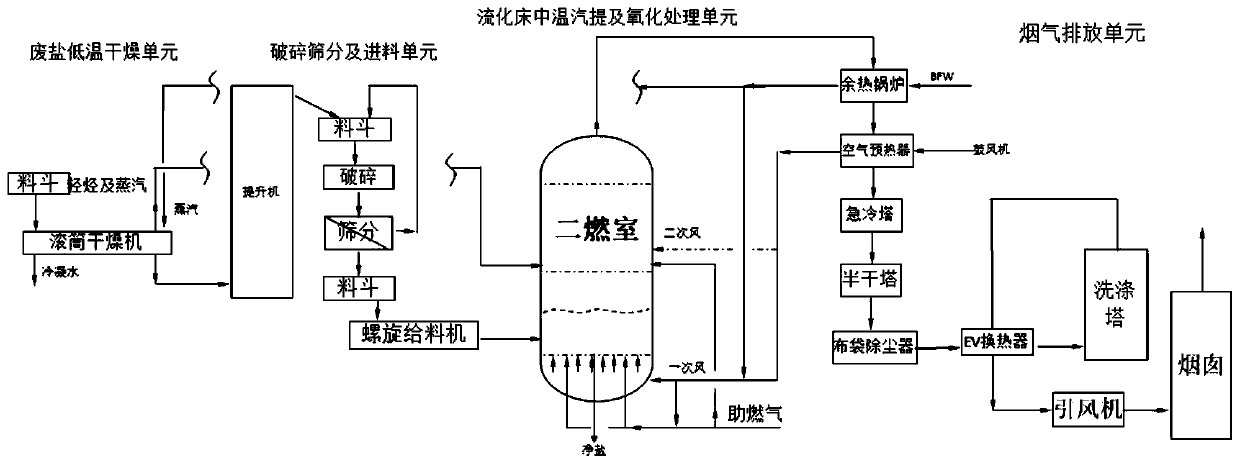

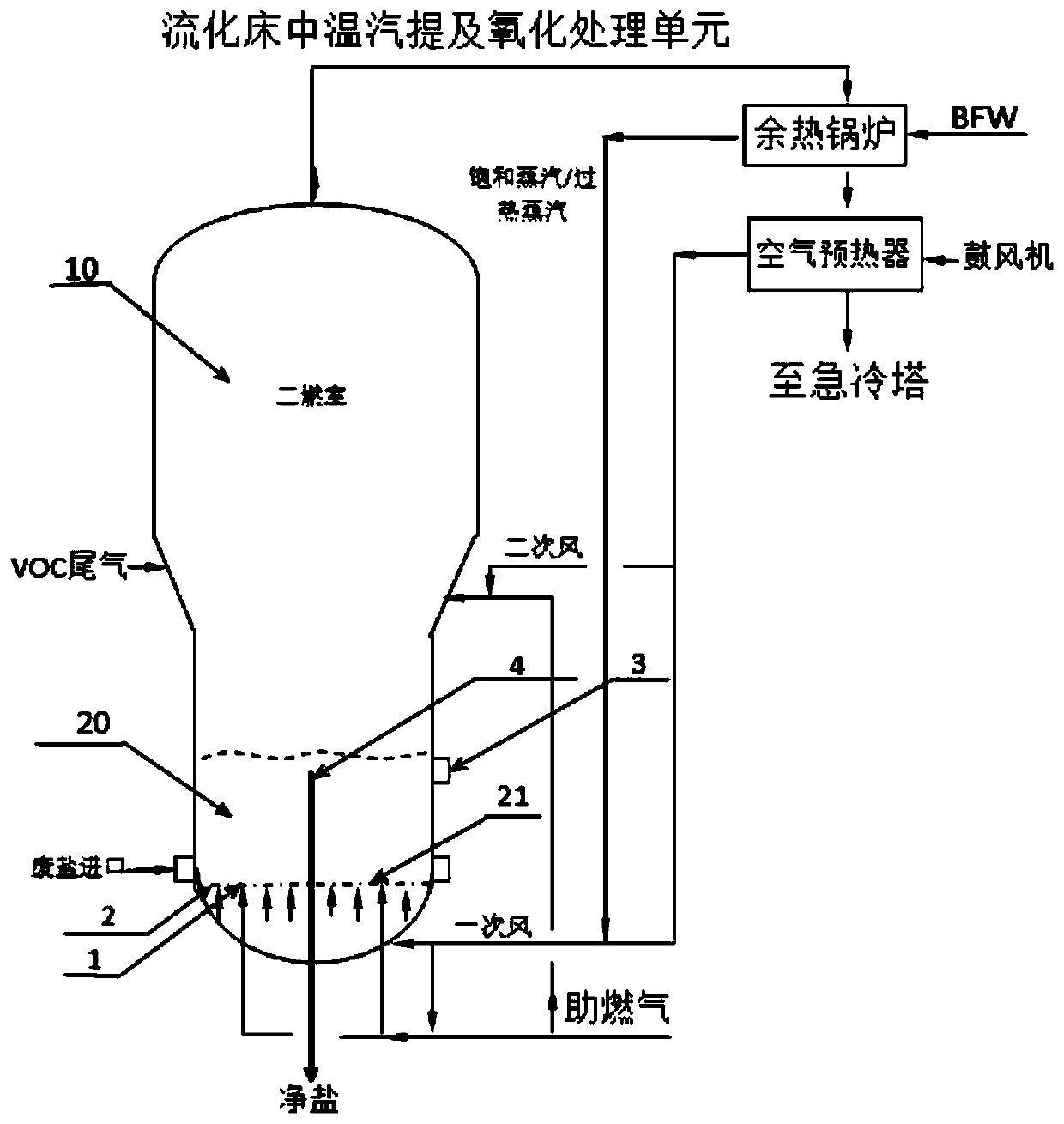

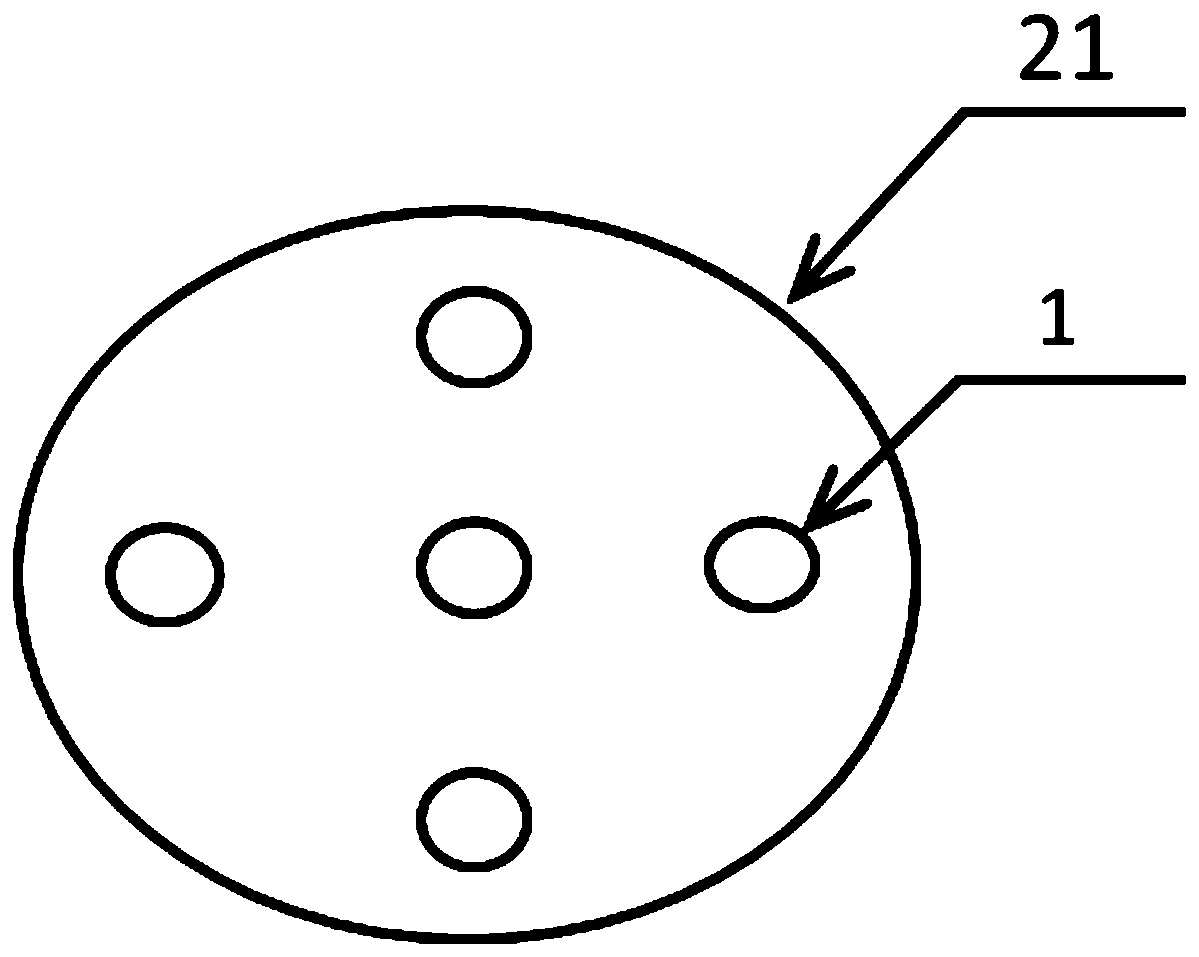

System and method for treating industrial waste salt by fluidized bed

PendingCN111167841AAvoid coking and carbonizationAvoid local overheatingSolid waste disposalCombustion chamberFlue gas

The invention relates to a system and a method for treating industrial waste salt by a fluidized bed, and belongs to an industrial waste salt treatment technology. The system involves a waste salt low-temperature drying unit, a crushing, screening and feeding unit, a fluidized bed medium-temperature steam stripping and oxidation treatment unit and a flue gas emission unit. The method comprises thesteps that the waste salt is dried through a roller dryer and then is crushed into the waste salt particles with proper particle size through a crushing and screening machine; the waste salt particles enter a fluidized bed suspension layer, through steam, combustion-supporting gas and air fluidizing, the waste salt particles turbulently flow and are mixed, and the waste salt particles stay for acertain period of time and then are discharged; and VOC organic matters generated through steam stripping and VOC tail gas generated through drying enter a secondary combustion chamber to be sufficiently combusted, and finally are cooled, purified and discharged. According to the system and the method, the industrial waste salt can be continuously treated on a large scale, the working efficiency is high, and the cost of an enterprise can be greatly saved.

Owner:亚德(上海)环保系统有限公司

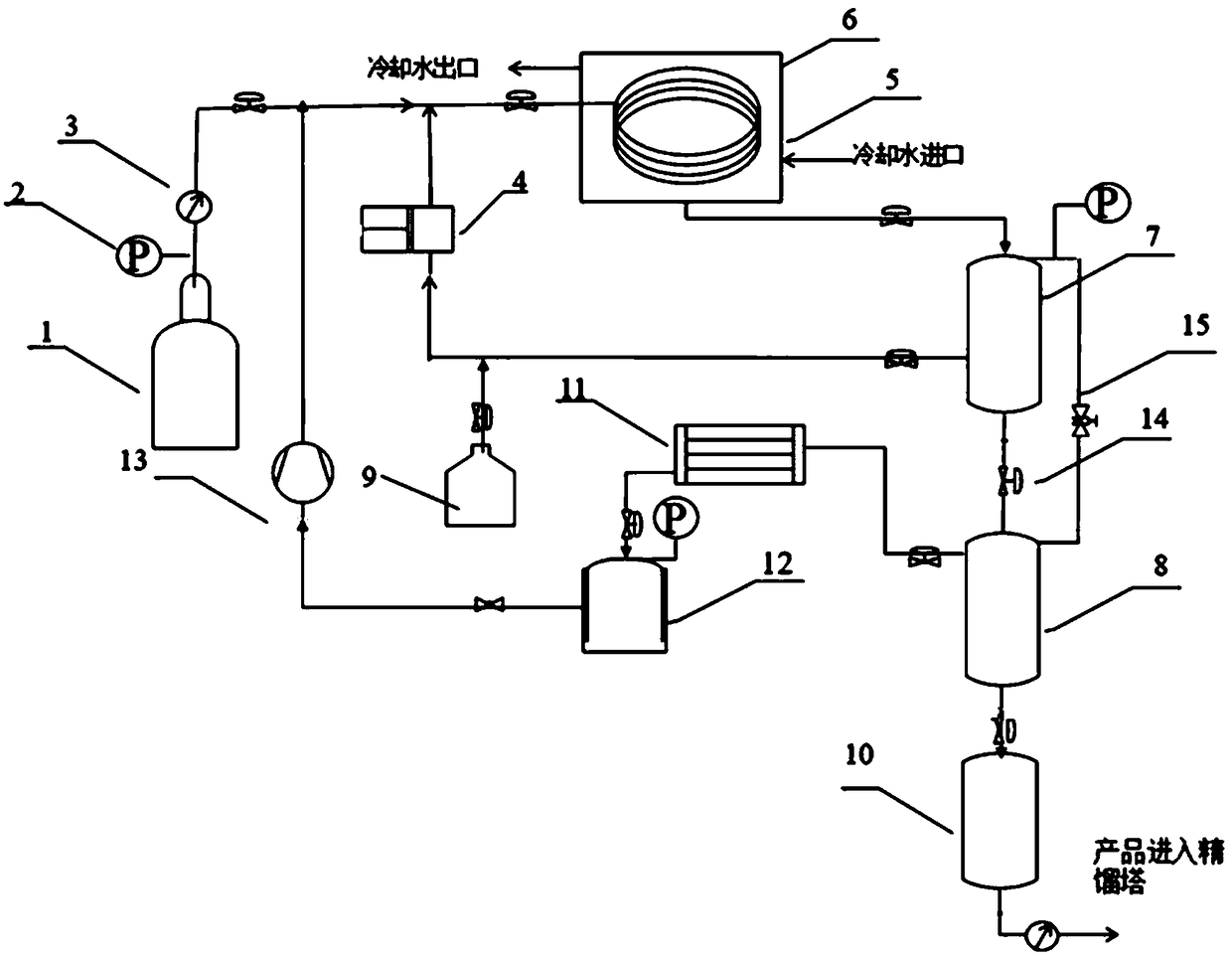

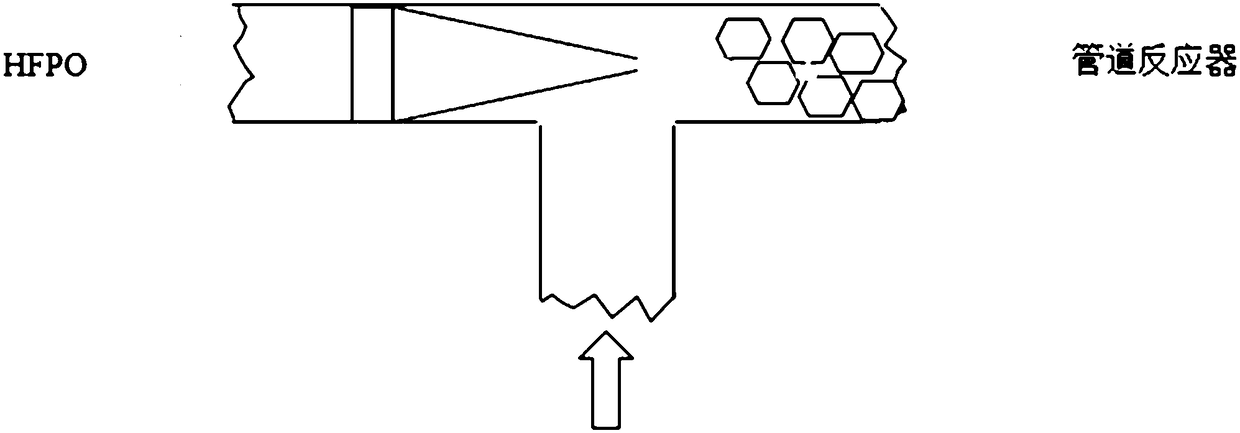

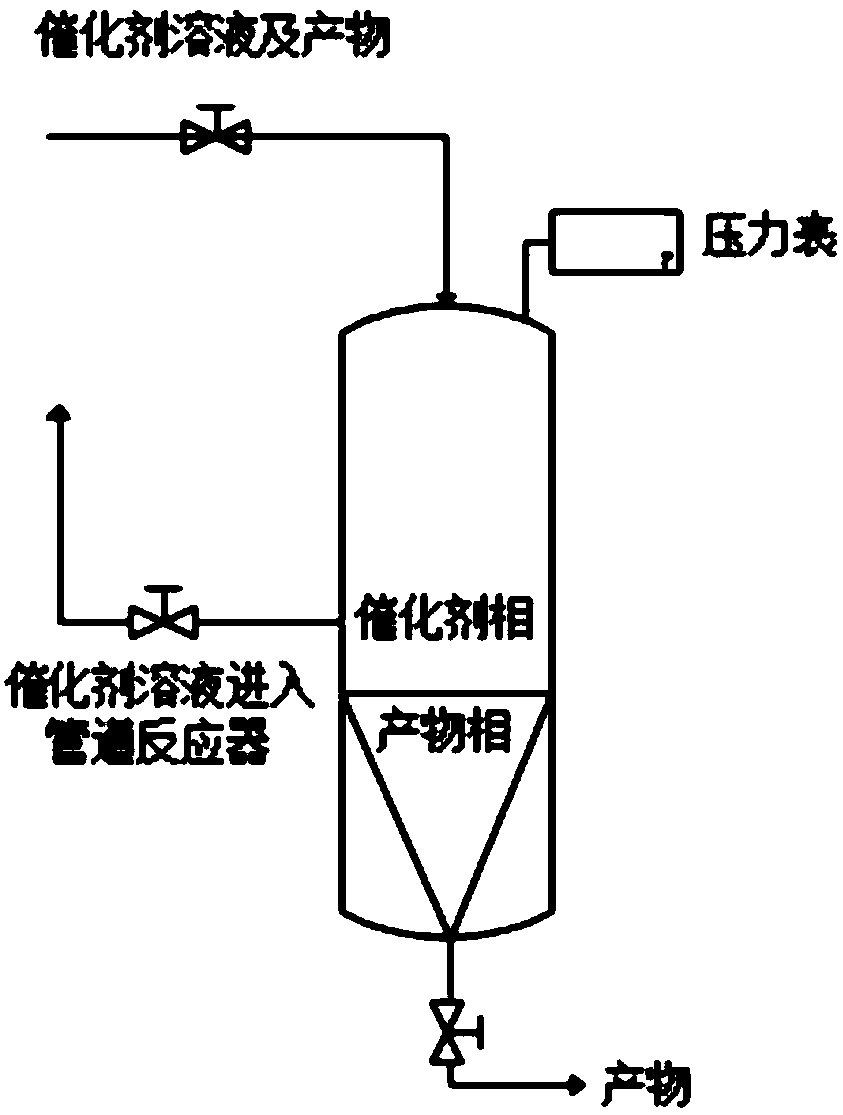

Method and device for preparing hexafluoropropylene oxide oligomer

InactiveCN108752173AAdjust flow rateControl dwell timeEther preparation from oxiranesOligomerHexafluoropropylene oxide

The invention discloses a method and a device for preparing a hexafluoropropylene oxide oligomer. The device comprises a pipeline reactor, a liquid phase separation tank connected with the pipeline reactor, and a gas-liquid separation tank connected with the liquid phase separation tank, the pipeline reactor comprises a spiral pipeline filled with a filler, the spiral pipeline spirally extends vertically, a gas-liquid contact port is arranged at the upper end of the spiral pipeline, a the hexafluoropropylene oxide and catalyst mixed solution enters the pipeline reactor through the gas-liquid contact port, and flows from the upper end to the lower end along the spiral pipeline, a hexafluoropropylene oxide oligomer generated in the pipeline reactor flows into the liquid phase separation tankand realizes layering, a discharge valve is arranged at the outlet of the liquid phase separation tank, and the flow rate is controlled by the discharge valve to make the weight of the product flowing into the gas-liquid separation tank consistent with the weight of the product deposited in the liquid phase separation tank. The method and the device can increase the yield of hexafluoropropylene oxide oligomer.

Owner:ZHEJIANG XINGTENG CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com