Patents

Literature

212 results about "Hexafluoropropylene oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

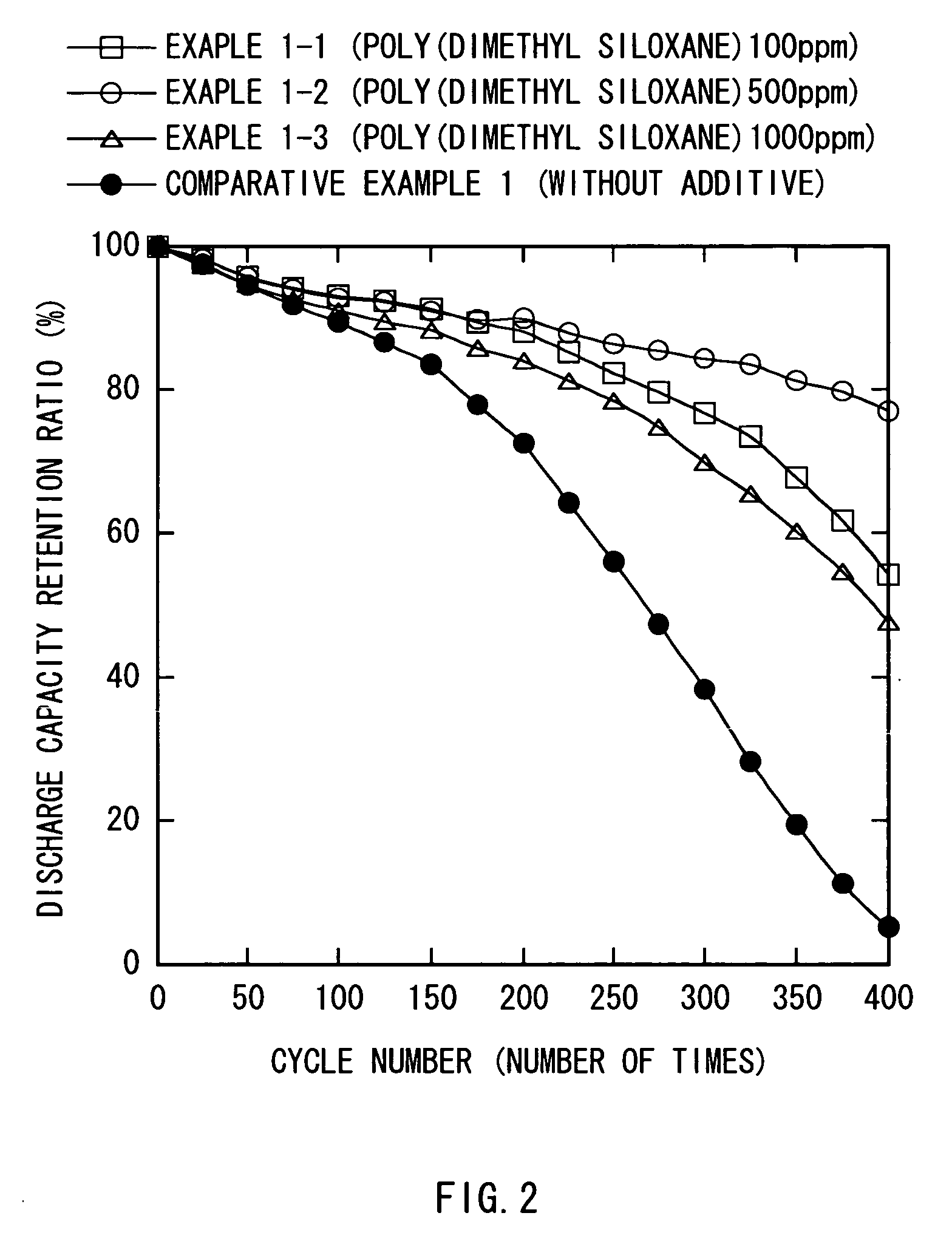

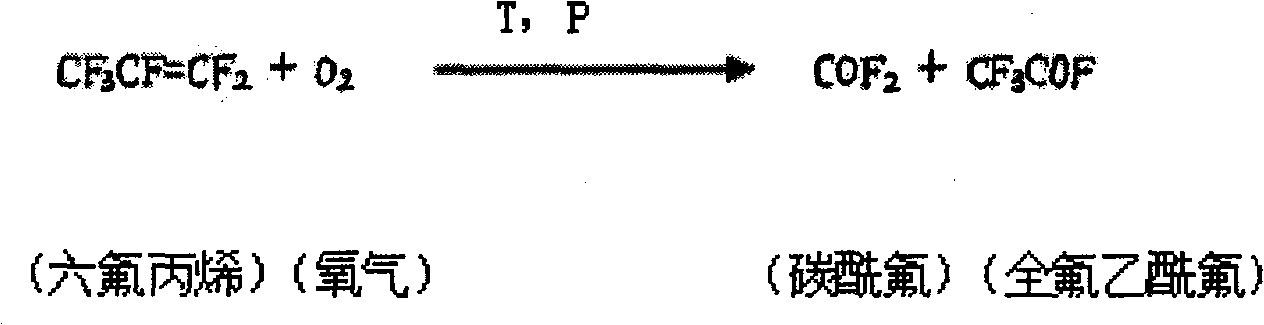

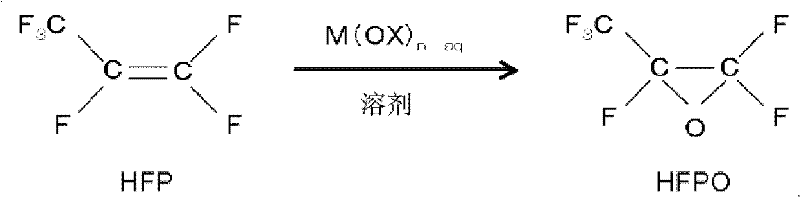

Hexafluoropropylene oxide (HFPO) is an intermediate used in industrial organofluorine chemistry; specifically it is a monomer for fluoropolymers. This colourless gas is the epoxide of hexafluoropropylene, that is fluorinated analog of propylene oxide, HFPO is produced by DuPont and 3M and as a precursor to the lubricant Krytox and related materials. It is generated by oxidation of perfluoropropylene, e.g. with oxygen as well as other oxidants.

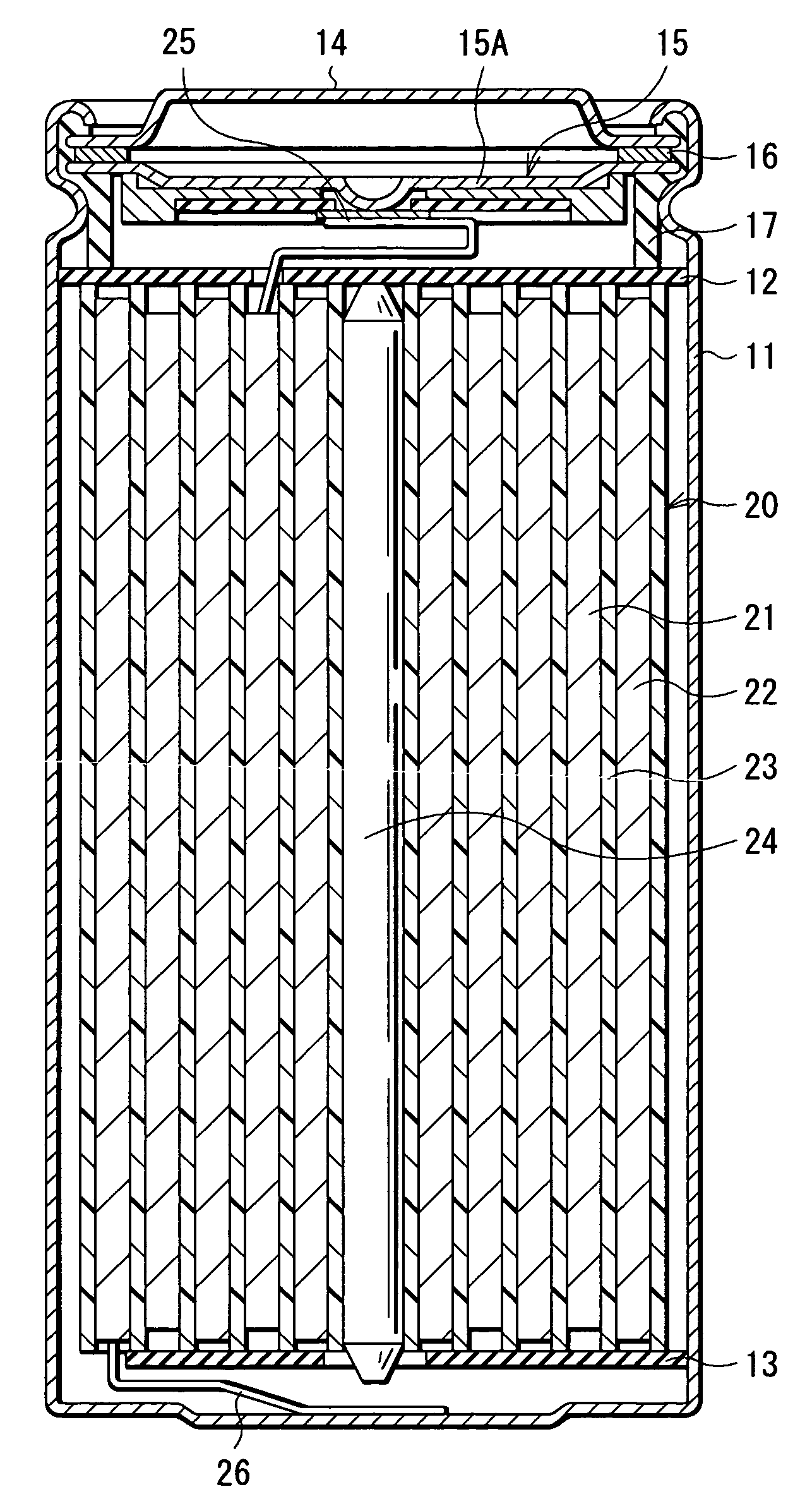

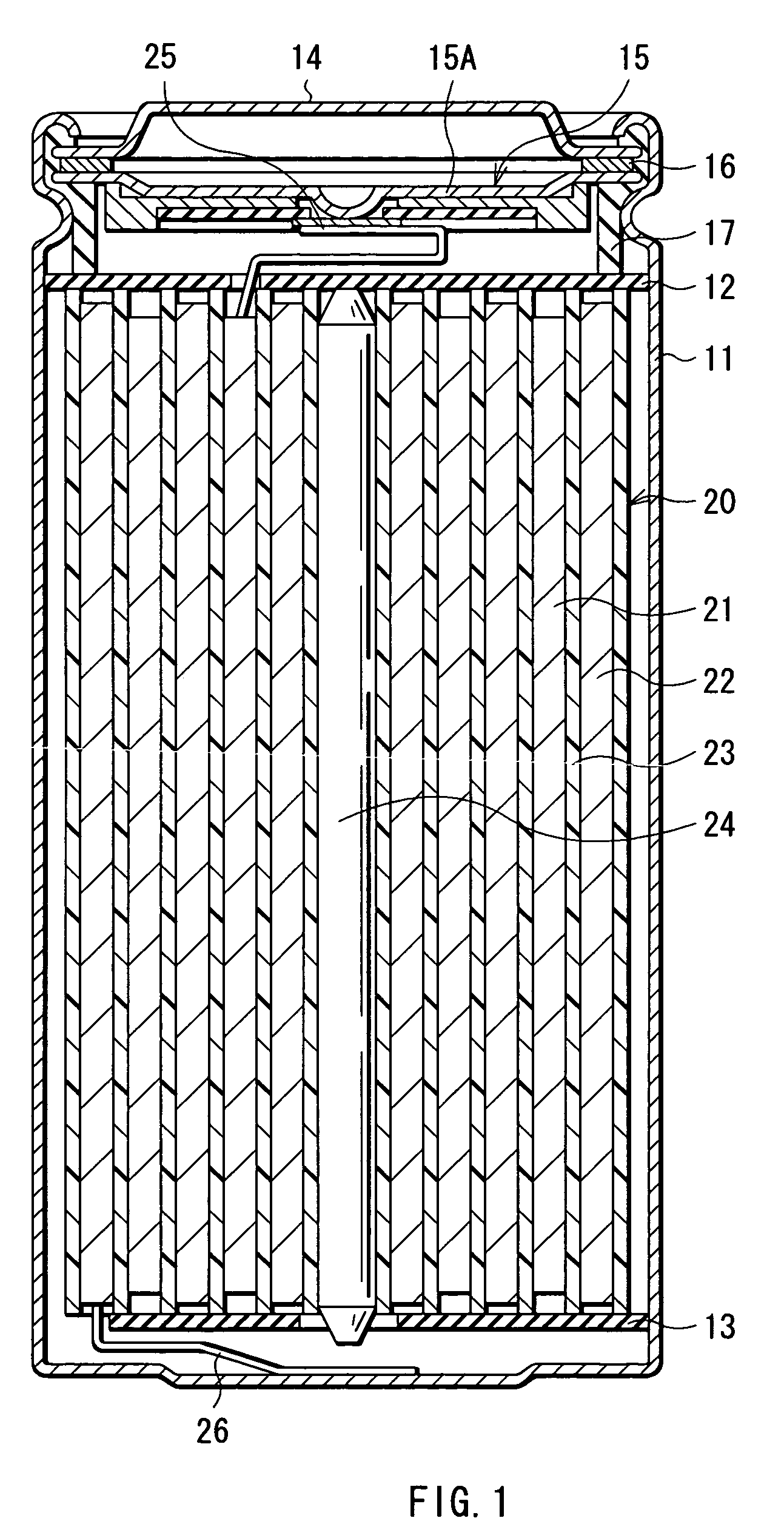

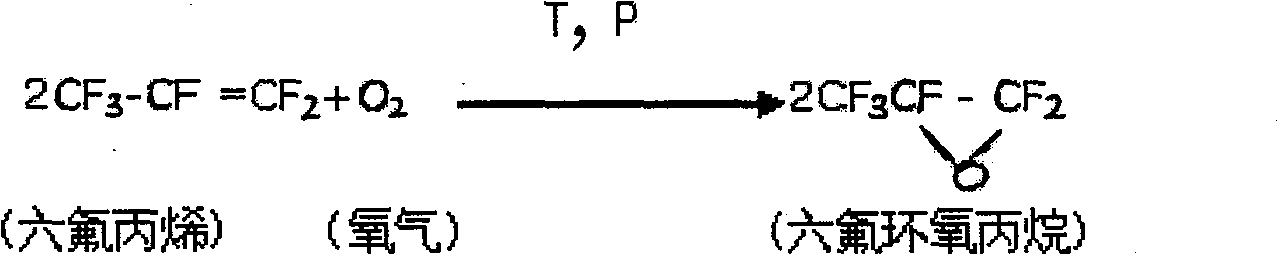

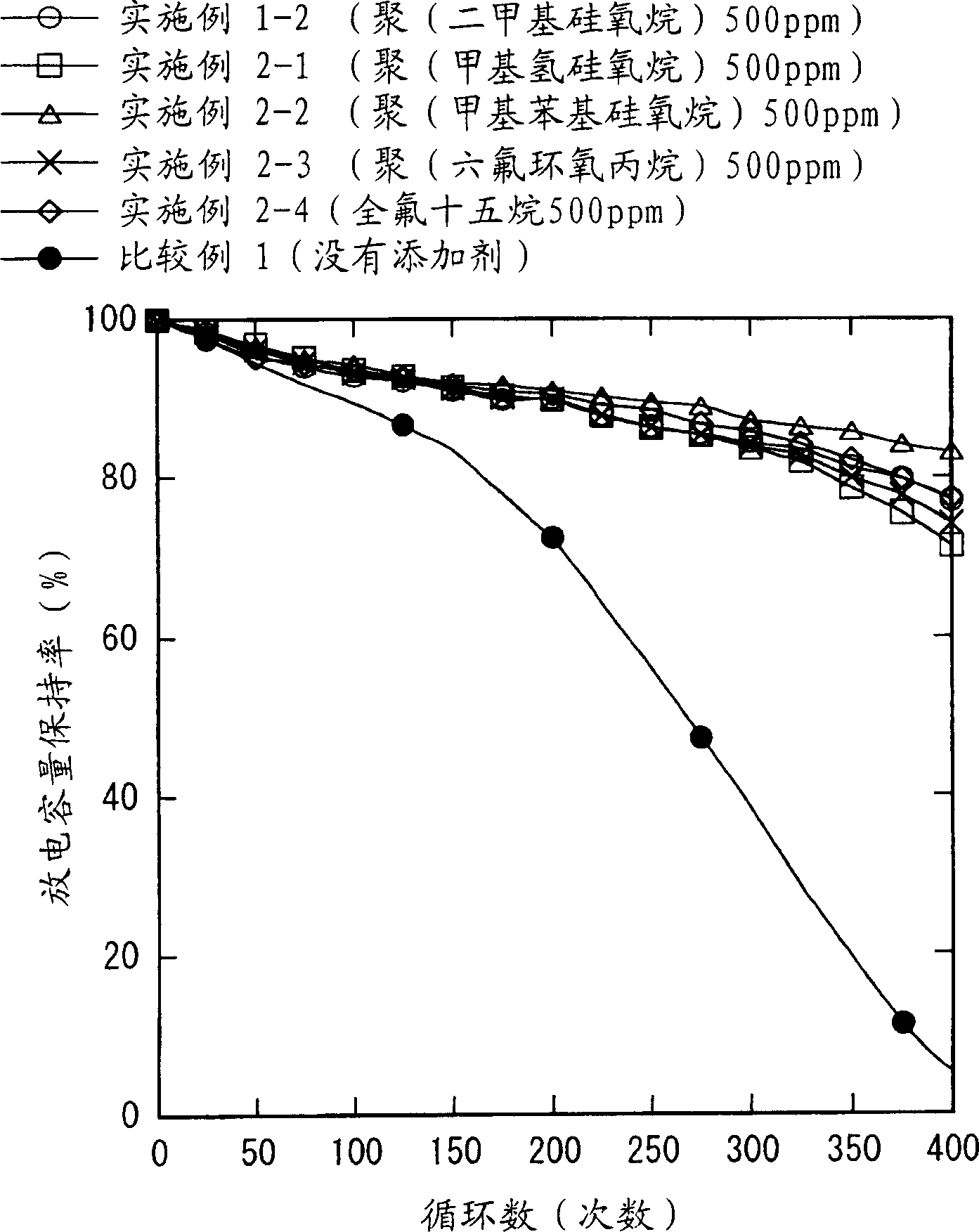

Electrode and battery

InactiveUS20060063073A1Excellent battery characteristicsEfficient coatingFinal product manufactureOrganic electrolyte cellsAlkanePerfluoropolyether

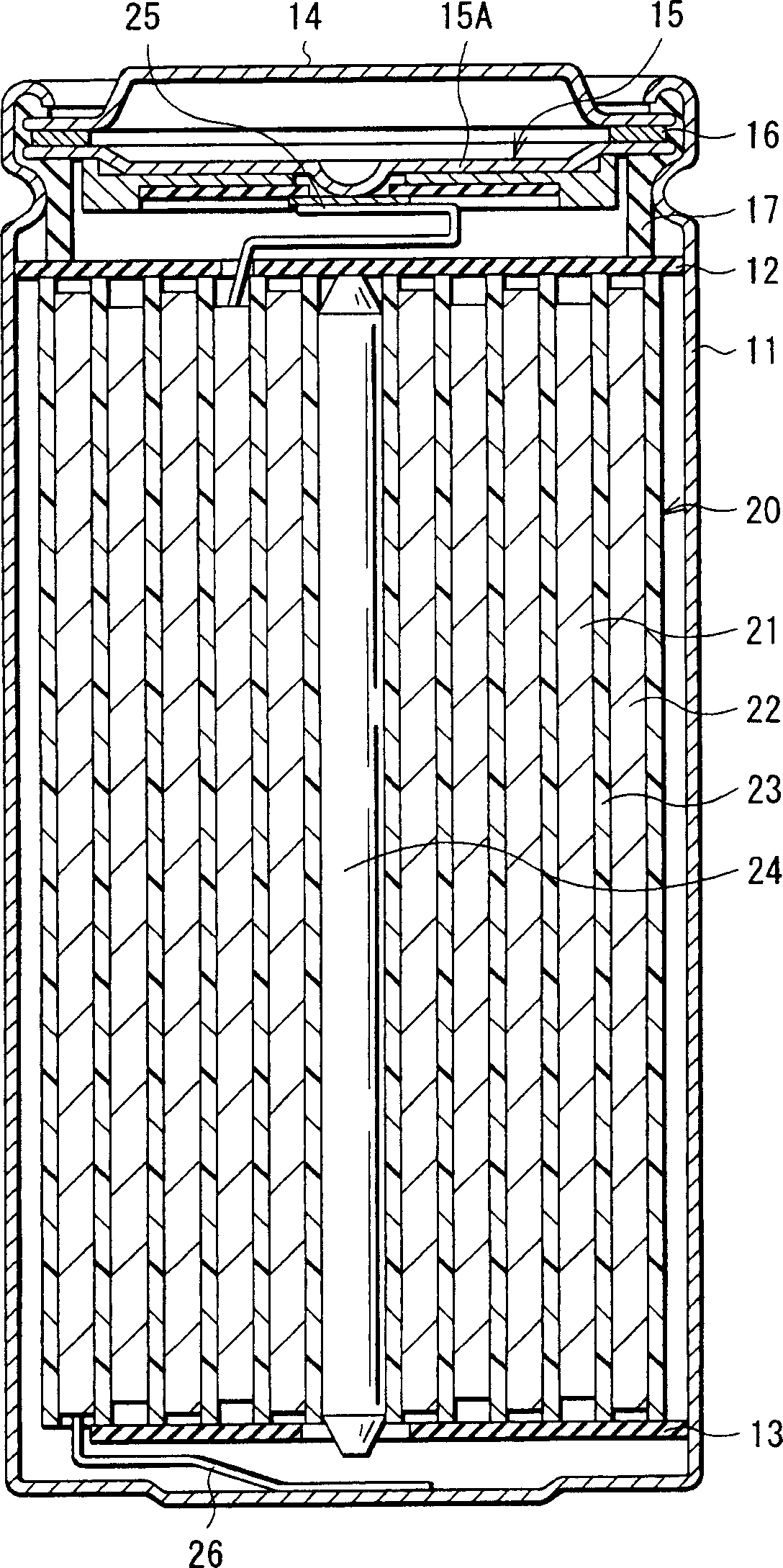

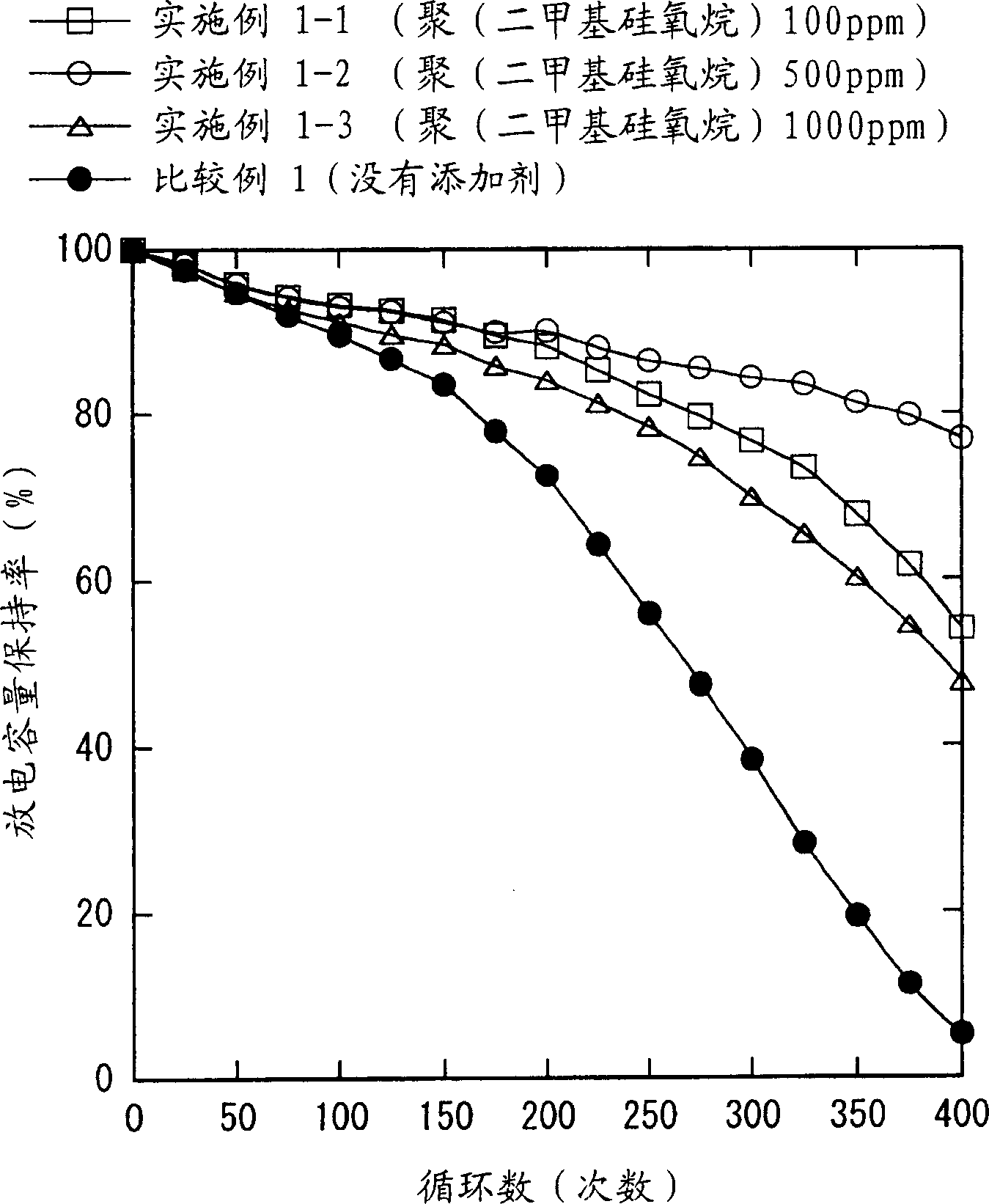

An electrode and a battery coverable of improving cycle characteristics by forming an effective coat are provided. A cathode (21) and an anode (22) are wound with a separator (23) impregnated with an electrolytic solution inbetween. On the surface of the cathode (21) or the anode (22), a coat containing a compound, which has a smaller surface tension than of the electrolytic solution and is insoluble into the electrolytic solution, specifically, a coat containing siloxane such as poly (dimethyl siloxane), poly (methyl hydro siloxane), and poly (methyl phenyl siloxane), or perfluoro polyether such as poly (hexafluoro propylene oxide), or perfluoro alkane such as perfluoro pentadecane is provided. Thereby, without using a great deal of the compound for forming the coat, the coat effective to inhibit decomposition reaction of the electrolytic solution is formed.

Owner:SONY CORP

Fluoroelastomers having low glass transition temperature

Fluoroelastomers are disclosed which have a glass transition temperature less than −10° C. The elastomers contain copolymerized units of a perfluorovinylpolyether that is derived from a trimer or tetramer of hexafluoropropylene oxide.

Owner:DUPONT PERFORMANCE ELASTOMERS L L C

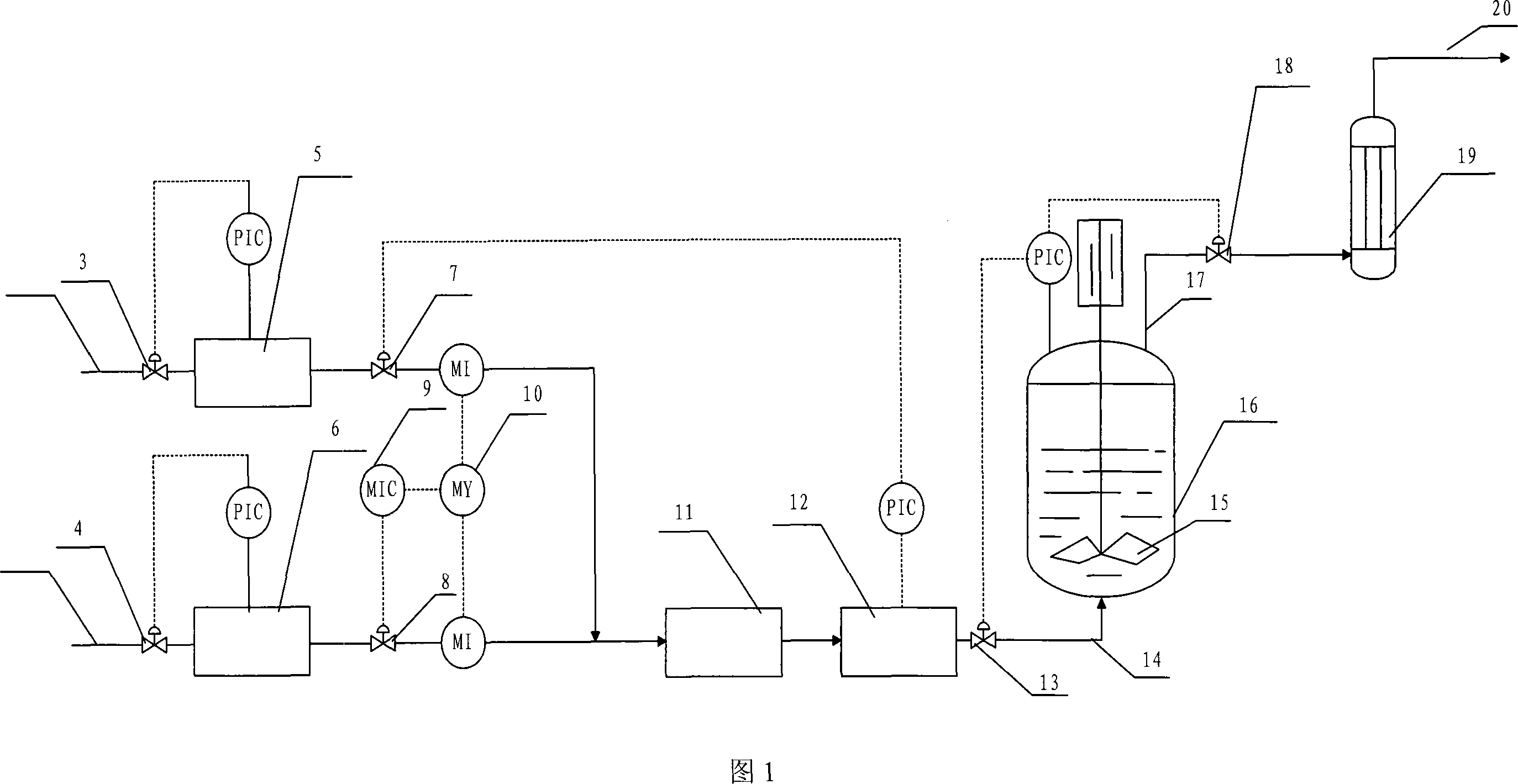

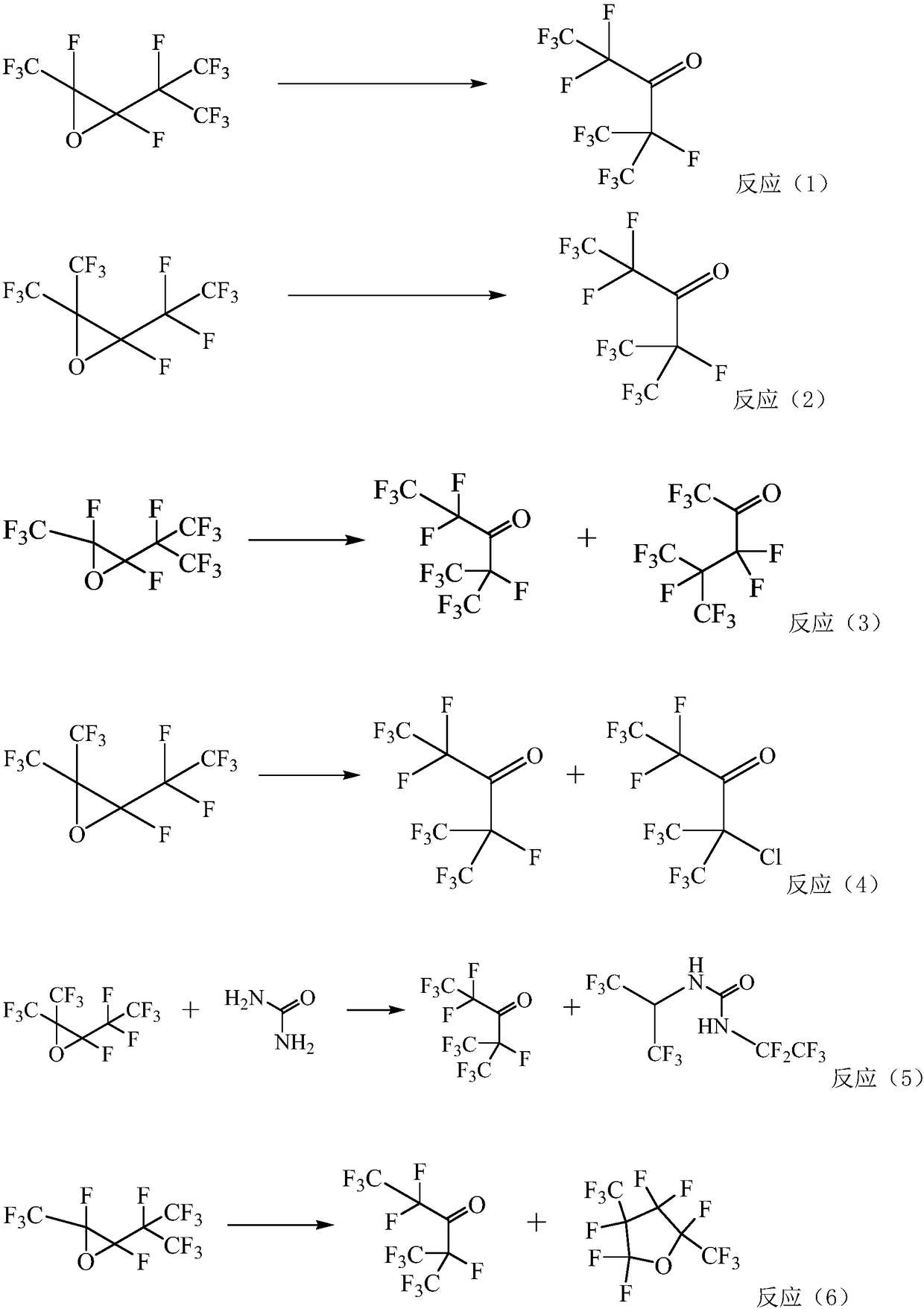

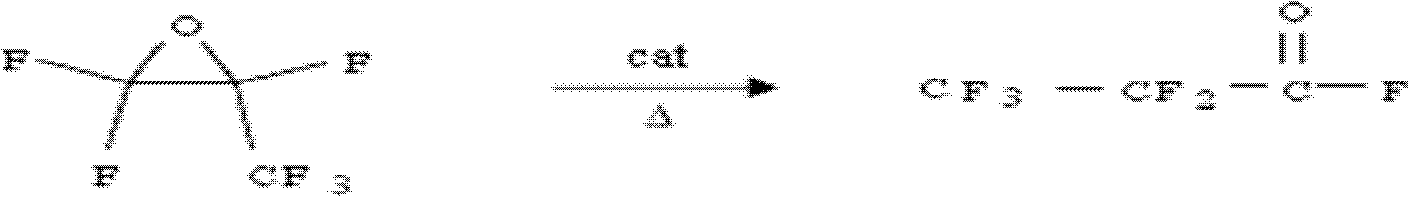

Method for producing hexafluoropropane oxide and coproducing perfluorovinyl ether

ActiveCN101817728ATake advantage ofAvoid pollutionOrganic chemistryOrganic compound preparationHexafluoropropylenePerfluoropolyether

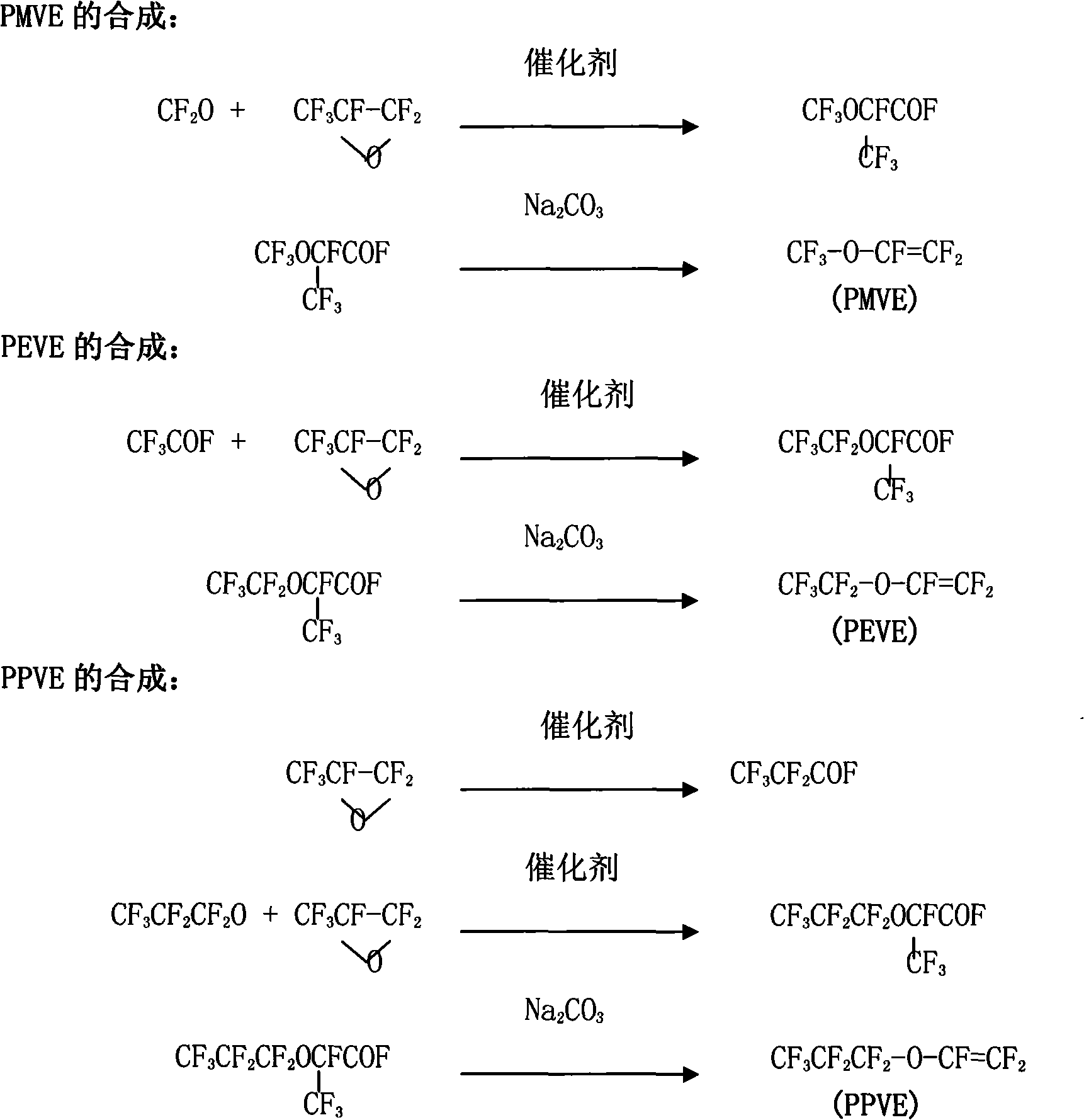

The invention relates to a method for producing hexafluoropropane oxide and coproducing perfluorovinyl ether, which comprises the following steps of: performing reaction of oxidizing hexafluoropropylene to synthesize the hexafluoropropylene oxide to obtain mixed gas, introducing the mixed gas into a coarse fractionating tower, and rectifying and purifying the separated heavy component to obtain hexafluoropropylene oxide; making the separated light component enter a rectifying tower to remove non-condensable gas to obtain mixed gas of fluorophosgene and perfluacetylfluoride, and introducing the hexafluoropropylene oxide for polymerization to obtain a corresponding perfluoroalkylpolyether mixture; in the presence of sodium carbonate, performing cracking reaction at the temperature of between 150 and 300 to obtain a perfluorovinyl ether mixture; and separating by using the rectifying tower to respectively obtain three kinds of perfluorovinyl ether, namely PMVE, PEVE, PPVE. The method fulfills the aim of producing the hexafluoropropane oxide, and fully utilizes a byproduct, namely perfluorovinyl ether with high added-value generated by the reaction, and has the advantages of reasonable process and industrial application.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Electrode and battery

An electrode and battery enabling to improve cycle characteristics owing to formation of an effective coating are disclosed. A positive electrode (21) and a negative electrode (22) are wound while having a separator (23) interposed therebetween. The separator (23) is impregnated with an electrolyte. The surface of the positive electrode (21) or the negative electrode (22) is provided with a coating which contains a compound having a surface tension smaller than that of the electrolyte and insoluble to the electrolyte, specifically a siloxane such as poly(dimethylsiloxane), poly(methylhydrosiloxane) or poly(methylphenylsiloxane), a perfluoropolyether such as poly(hexafluoropropylene oxide), or a perfluoroalkane such as perfluoropentadecane. Consequently, a coating effective for suppressing decomposition reaction of the electrolyte can be formed without using a large amount of the compound which forms the coating.

Owner:SONY CORP

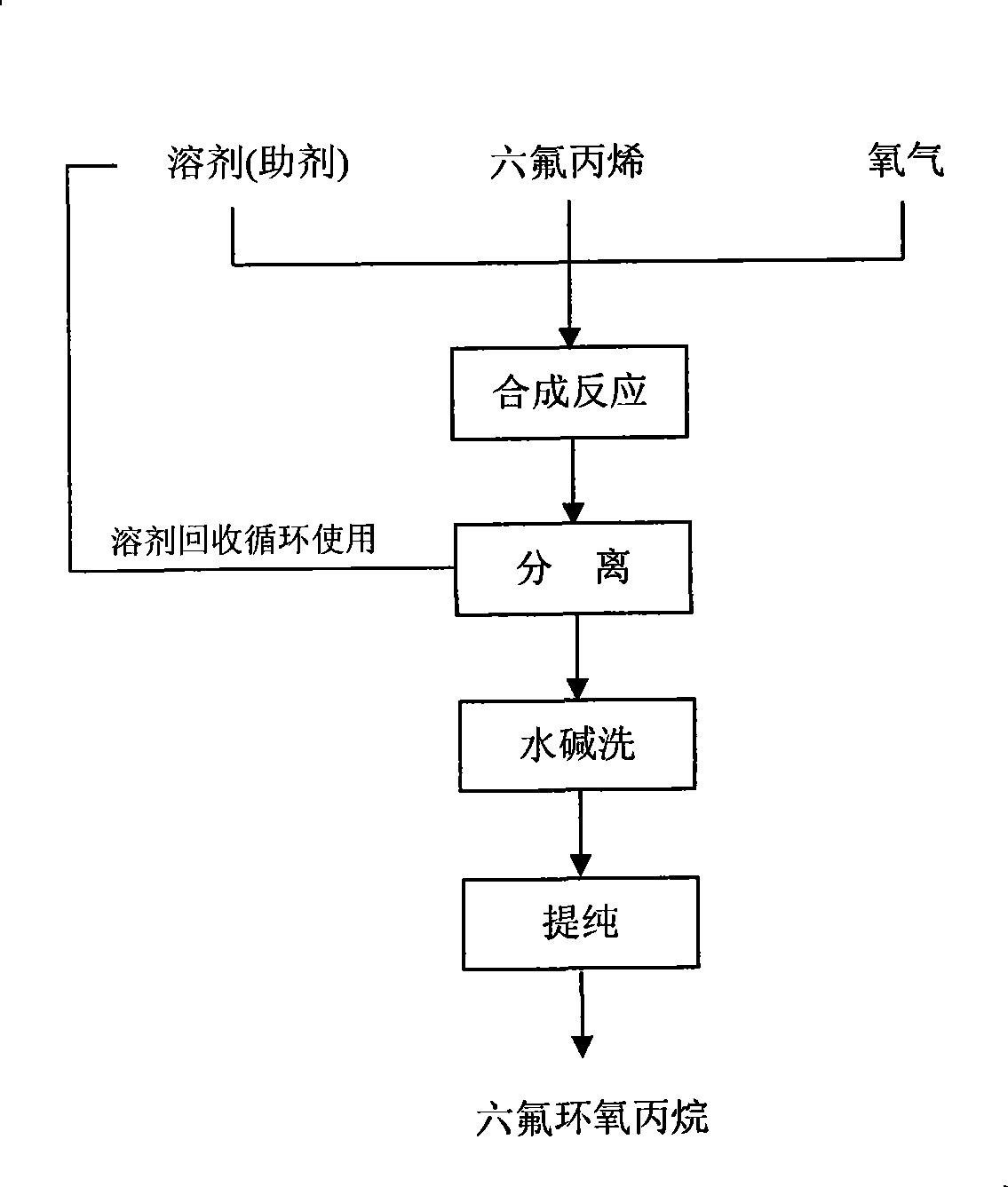

Clean preparation process for hexafluropropylene oxide

ActiveCN1634902ARealize green productionSolve the destructive effectOrganic chemistryBulk chemical productionHexafluoropropyleneAtmospheric ozone

The invention discloses an environmental protection method for preparing hexafluropropylene oxide from hexafluoropropylene by dioxygen liquid phase oxidation method. The method employs at least one supercritical fluid as solvent for replacing the CFCs with destructive effect to atmospheric ozone layer. The supercritical fluid as solvent is used in the invention which can reduce induction period of reaction and prevent the temperature raise in short time at the beginning of reaction.

Owner:SINOCHEM LANTIAN +1

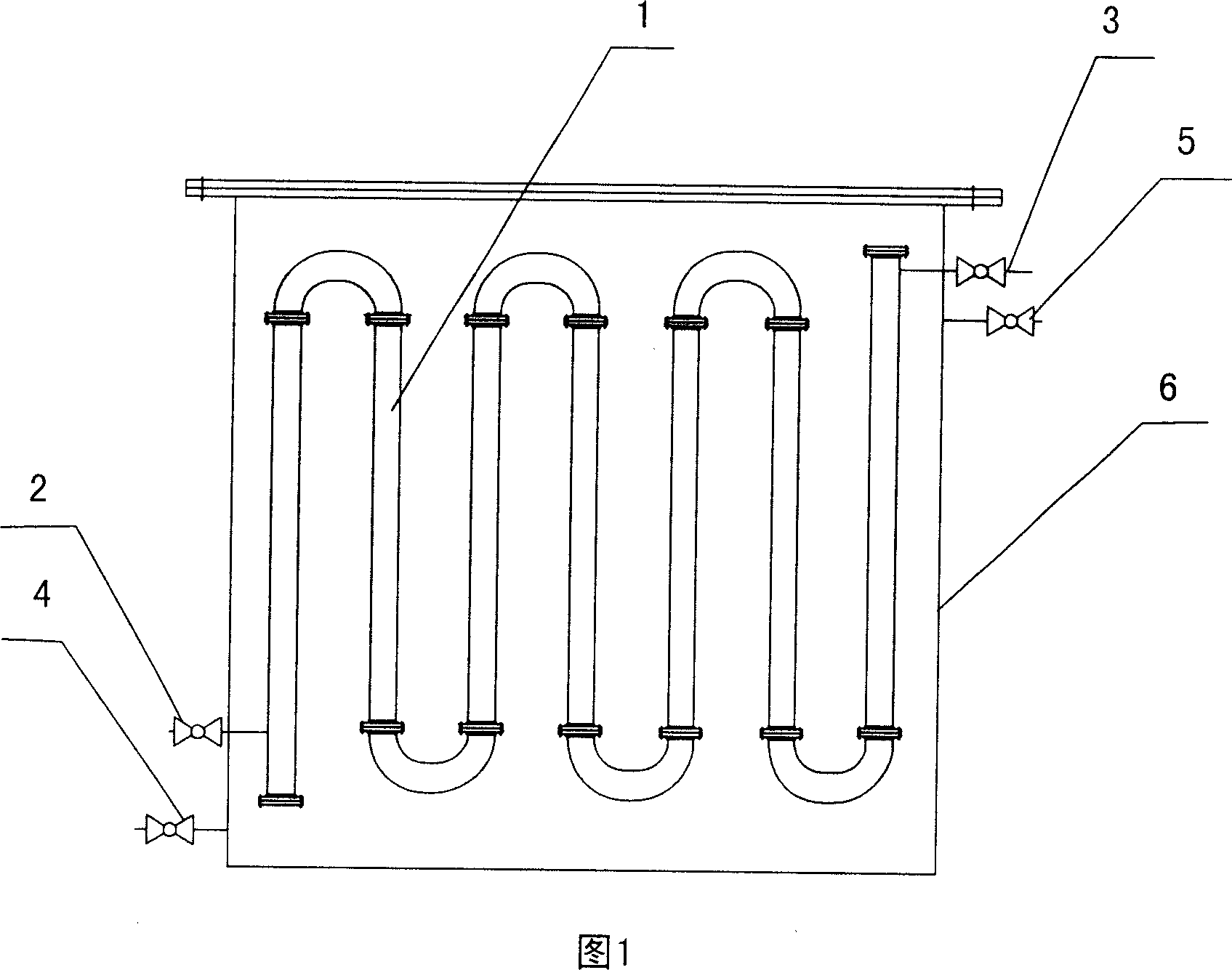

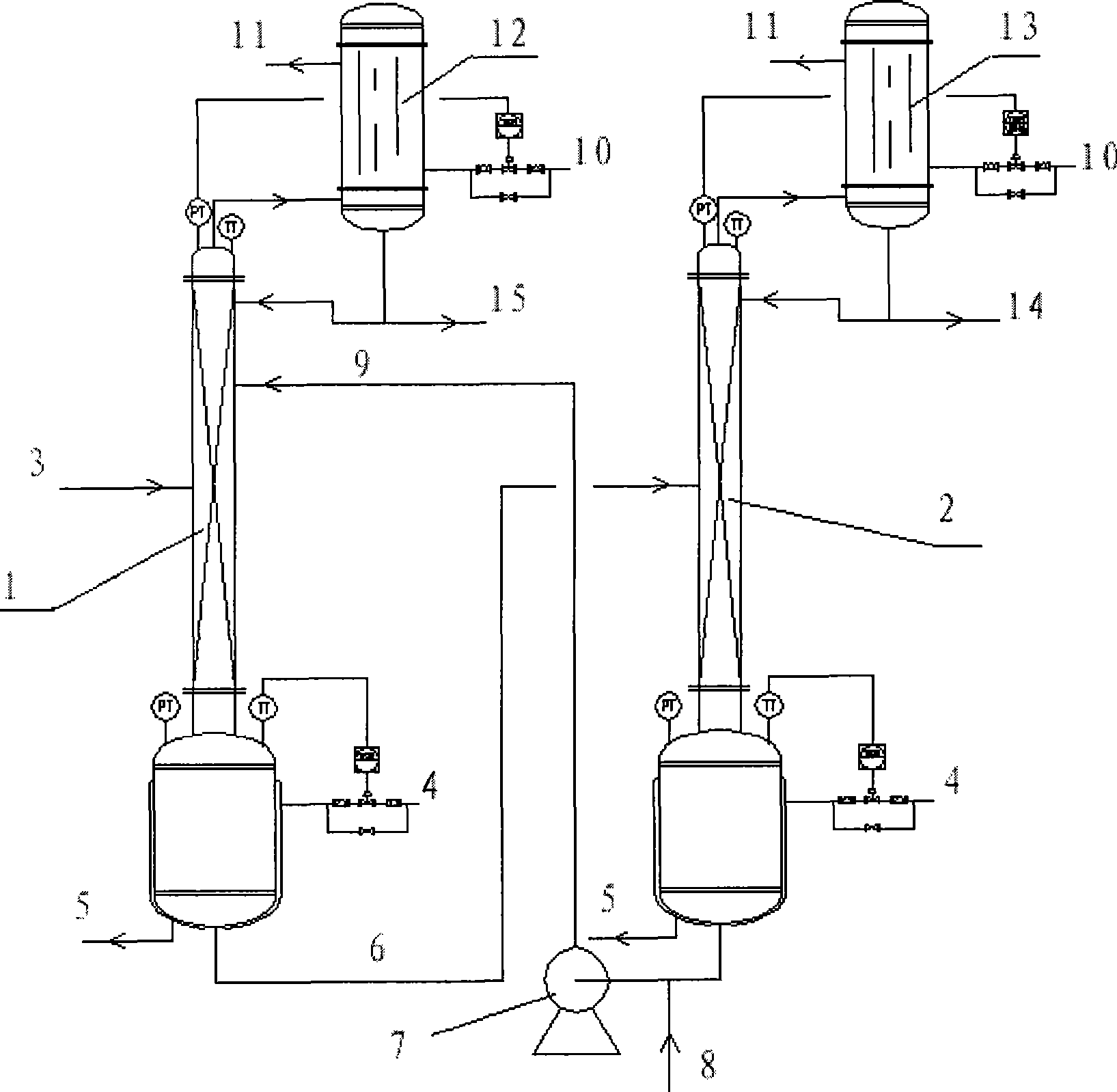

Hexafluoropropyl epoxide continuous production technique

The invention relates to a process for continuous production of hexafluoropropylene oxide. The materials are discharged when the reaction of hexafluoropropylene and oxygen is carried out fully, the hexafluoropropylene gas and the oxygen are mixed by proportion and then are introduced into the solvent in a reactor as a gas mixture, the oxygen and the hexafluoropropylene firstly pass through a solvent layer in the reactor and then are carried out the complete reaction in the solvent, the reactant is accumulated in a gas-phase space in the reactor continuously, the mixed gas containing the reactant in the gas phase can be controlled by pressure regulation, so as to discharge the materials to the outside of the reactor continuously, the discharging gas is condensed and reclaimed the containing solvent in the mixed gas by a condenser, the reactant gas after the condensation is sent to a processing system for further treatment and purification, finally the needed hexafluoropropylene oxide final product is obtained. The process flow is simple, the equipments are fewer, the operation is convenient and the equipment utilization ratio is high.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Photocurable and thermosetting coating composition and article having cured coating of such coating composition

A photocurable and thermosetting coating composition which is solventless and liquid at room temperature is provided. This coating composition provides scratch resistance, crack resistance, smudge resistance, and removability of oil-base felted markers by wiping with the underlying substrate, and this coating composition contains a silicone resin represented by:(R1R2R3SiO1 / 2)a(R4R5SiO2 / 2)b(R6SiO3 / 2)c(SiO4 / 2)d(O1 / 2X)e (1)wherein X is hydrogen atom or an alkyl group; R1 to R6 are respectively at least one monovalent organic group which is a monovalent aliphatic hydrocarbon group or a monovalent aromatic hydrocarbon group optionally substituted with a substituent such as a poly(hexafluoropropylene oxide) structure-containing group; a, b, d, and e are 0 or a positive number; c is a positive number; and a+b+c+d is 1. The silicone resin contains at least one group represented by:CH2═C(R7)COOCH2— (2)wherein R7 is hydrogen atom or methyl group.

Owner:SHIN ETSU CHEM IND CO LTD

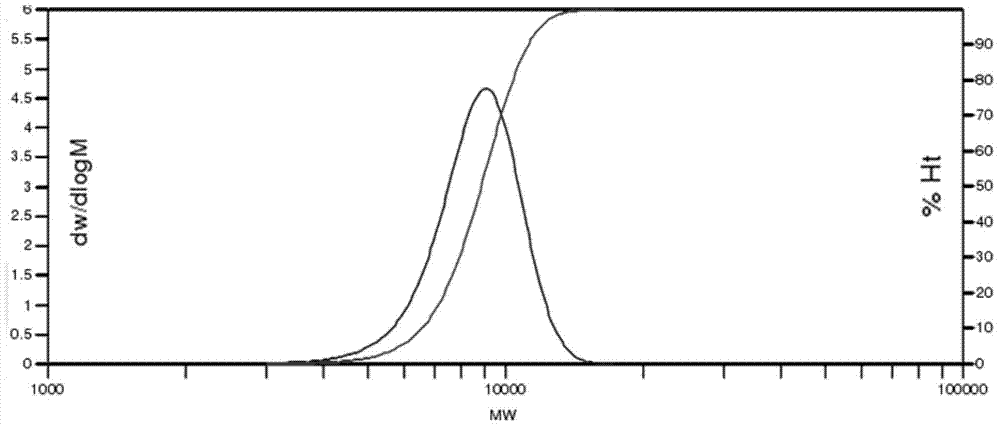

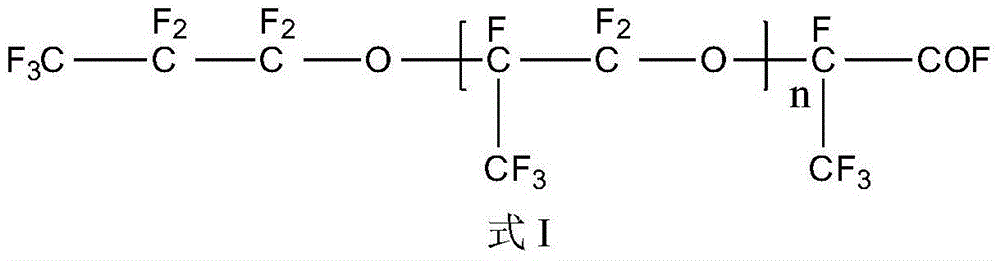

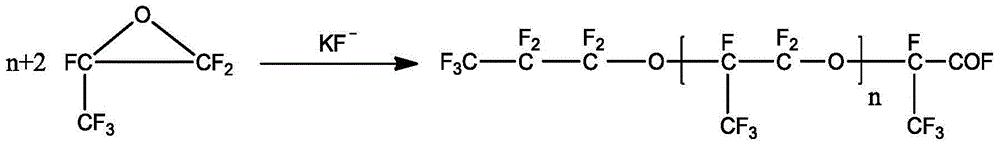

Method for preparing perfluoropolyether with high molecular weight

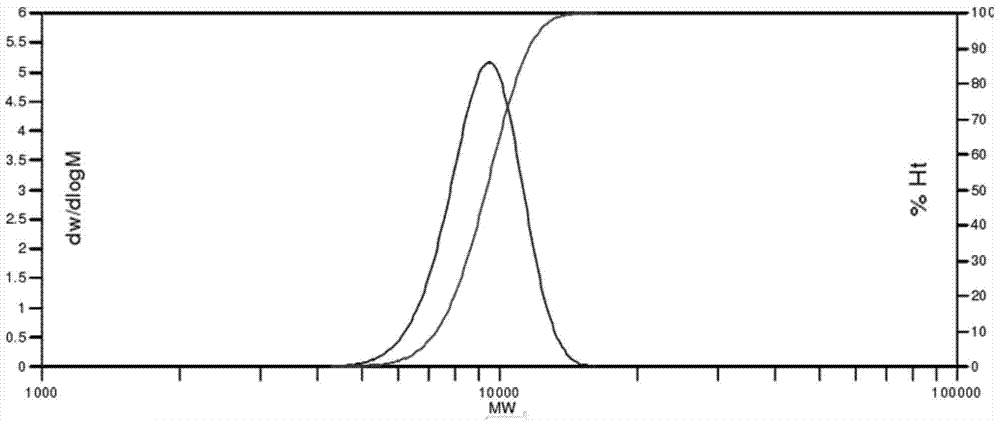

The invention discloses a method for preparing perfluoropolyether with high molecular weight. The method comprises the following steps of: polymerizing in an aprotic solvent by the method for controlling the reaction temperature to control the polymerization degree of hexafluoropropylene oxide under a catalyzing system composed of a phase transfer agent and a water-free alkali metal fluoride; post-processing the obtained polymer to obtain perfluoropolyether with high molecular weight.

Owner:SHANGHAI ICAN CHEM S&T

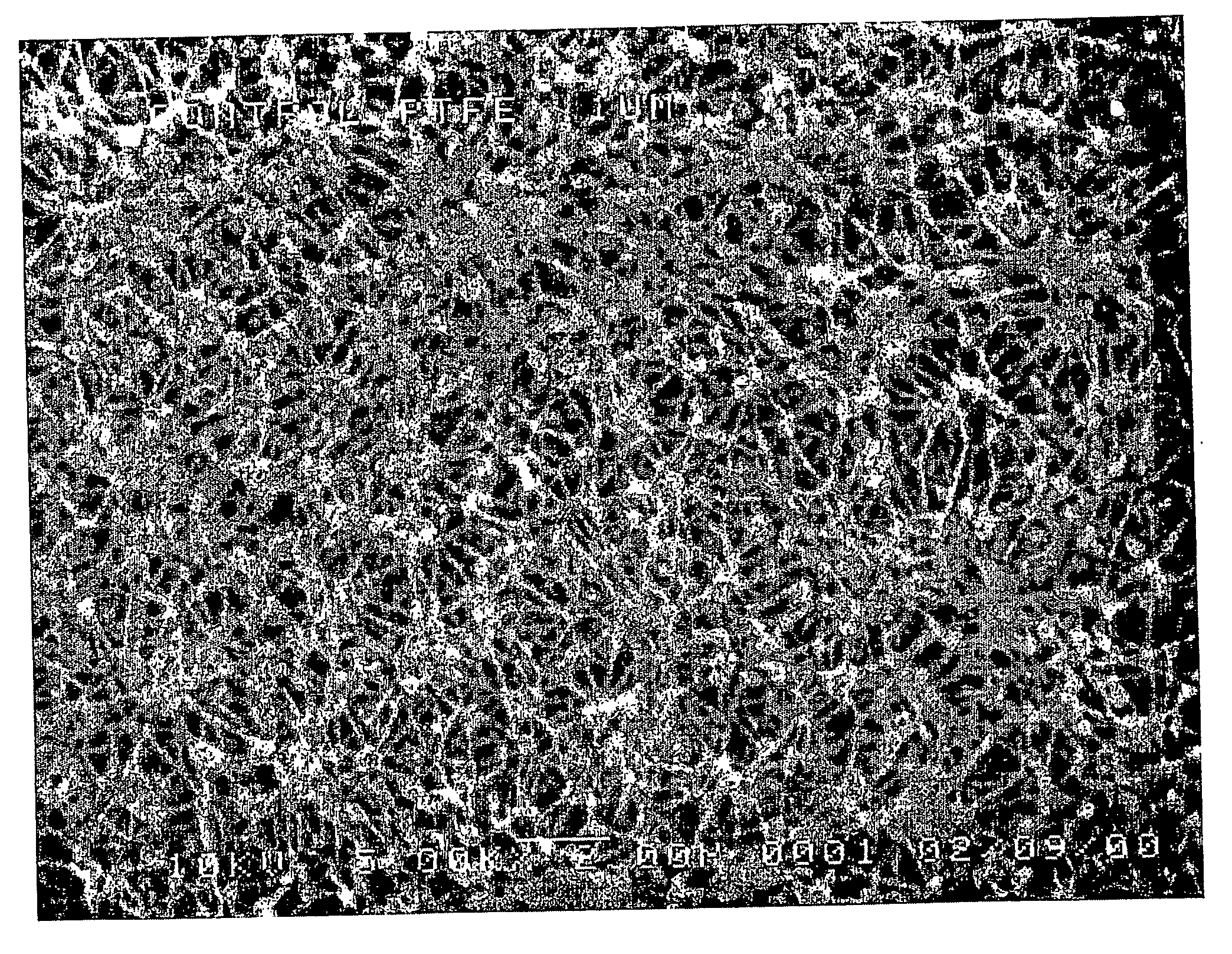

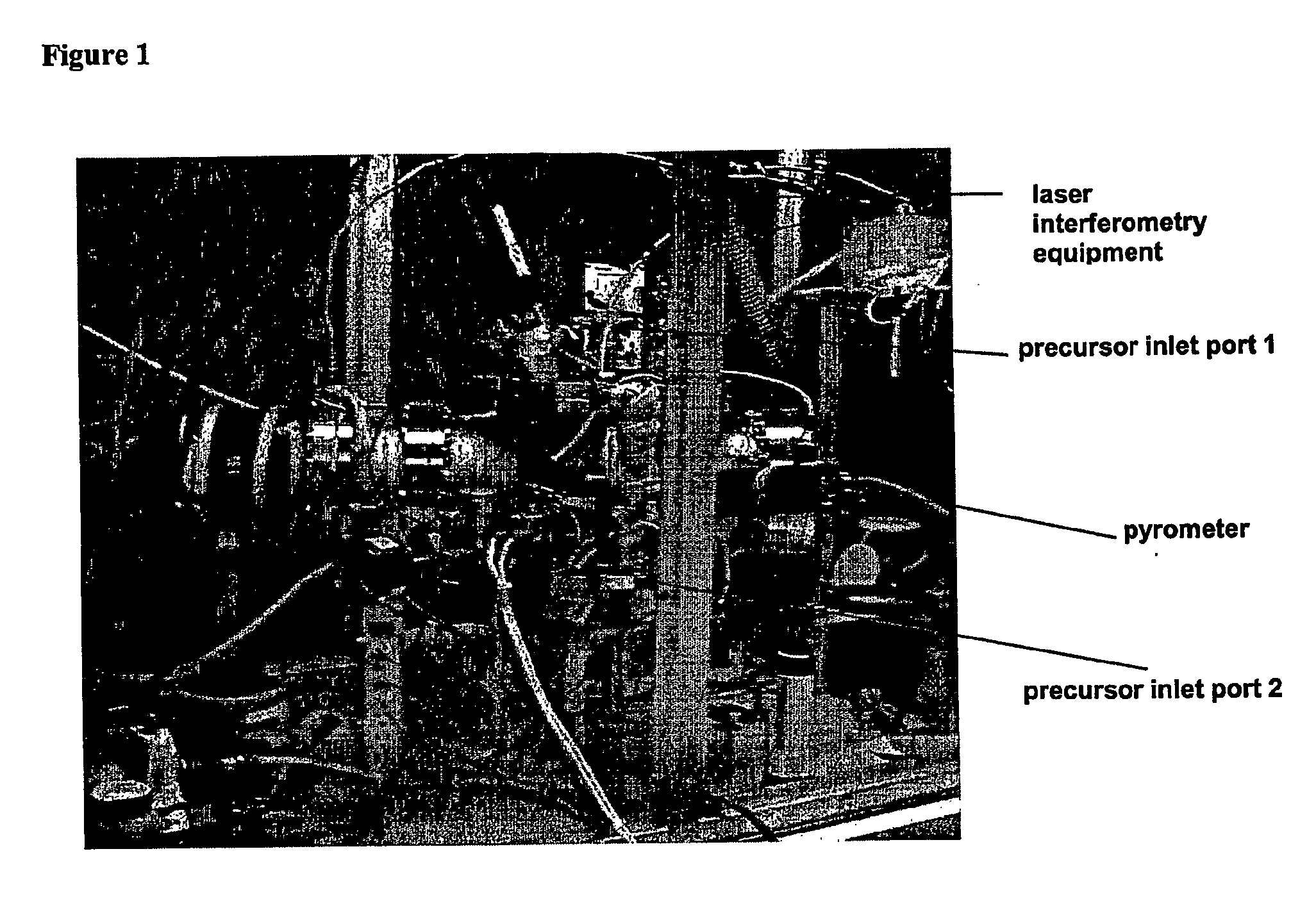

Preparation of asymmetric membranes using hot-filament chemical vapor deposition

InactiveUS20060040053A1Lower overall pressure dropLessMembranesSemi-permeable membranesSpinsVolumetric Mass Density

One aspect of the present invention relates to a method for modifying one side of a PTFE membrane by using HFCVD to deposit a PTFE film on one side of the PTFE membrane. The precursor fluorocarbon gas is preferably hexafluoropropylene oxide, which upon pyrolysis under HFCVD conditions forms reactive CF2 species. The present invention also relates to a modified PTFE membrane having a PTFE film on only one side, wherein the PTFE film has a porosity of greater than about 30% and a dangling bond density of less than about 1018 spins / cm3. The invention further provides a method of filtering a liquid or gas or a mixture of the two, comprising passing the liquid or gas or mixture of the two through the modified PTFE membrane of the present invention.

Owner:MASSACHUSETTS INST OF TECH

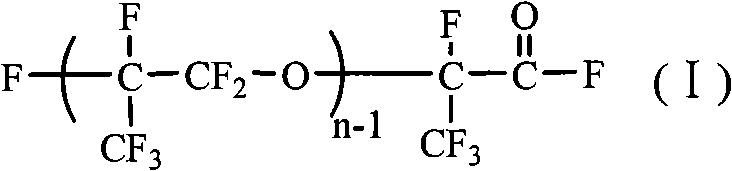

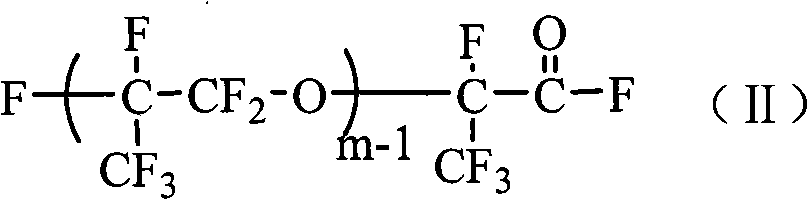

Polymerization of hexafluoropropylene oxide

The present invention provides a process for oligomerization of hexafluoropropylene oxide, the process comprising polymerizing a mixture of hexafluoropropylene oxide and hexafluoropropene in the presence of an aprotic organic solvent using KF as a catalyst.

Owner:3M INNOVATIVE PROPERTIES CO

Synthetic method of epoxy propane hexafluoride

This invention relates to a composing preparation of sexi-fluorine epoxypropane, at the basis of oxygen oxidation method, improve selection of solvent, use two kinds of solvent to compose compound phase, raise contact concentration of raw material, it can add suppressive agent of aromatic compound into liquid phase medium to restrain producing by-product. Compound solvent consists of compound of ethers and alkanes compound, among them compound of ethers is selected from C3H5OCl, C2F5OC4F9, C5F10OC3F7 or C4H9OC3F7,alkanes compound is selected from CCl4, CF2Cl2, CF2HCl, C2F3Cl3 or C7F16.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

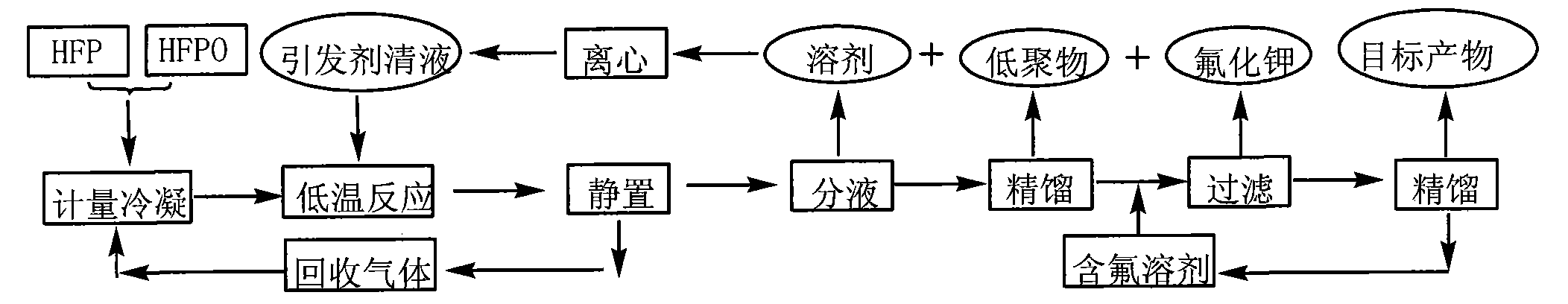

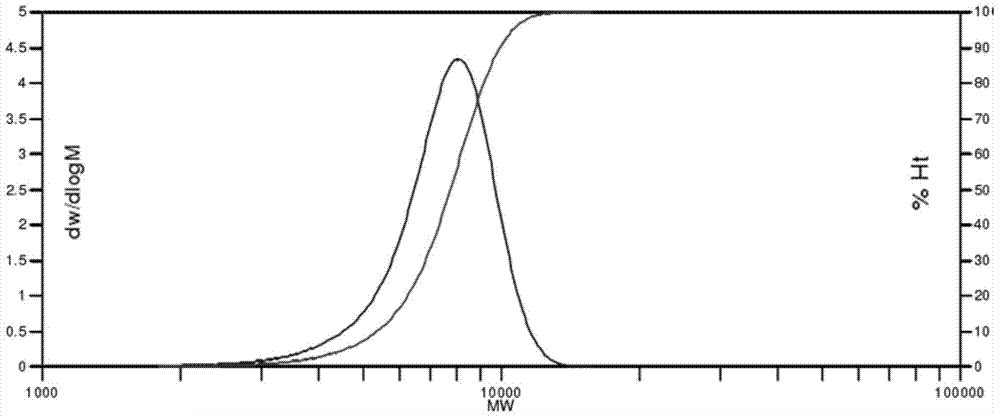

Method for production and post-processing of hexafluoropropylene oxide homopolymer

The invention discloses a method for producing a hexafluoropropylene oxide homopolymer, which comprises the following steps of: reacting potassium fluoride (KF) with a hexafluoropropylene oxide low polymer in a polar non-proton mixed solvent to synthesize an initiating agent, and adding the initiating agent into a reaction kettle at one time; continuously adding a mixed liquid having the temperature lower than the reaction temperature and consisting of hexafluoropropylene oxide (HFPO) and hexafluoropropylene into the reaction kettle, and changing the feeding speed, the reaction temperature and the solvent proportion to synthesize the hexafluoropropylene oxide homopolymer of which the average degree of polymerization is any one from 3 to 50; and reclaiming the potassium fluoride and the solvent respectively through filtration and liquid separation.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Hexafluoroepoxypropane preparation process

This invention discloses a preparation method for hexafluoropropylene oxide (HEP). The said method includes: a) providing solution for HFP in the reaction, and b) heating and charging oxygen, and preparing hexafluoropropylene oxide through molecular oxygen liquid-phase oxidation, wherein the referred reaction medium is selected from alpha-perfluoro-n-butyl-oxa-perfluorocyclopentane, alpha-perfluoro-n-propyl-oxa-perfluorocyclohexane or fluorocarbon cyclic ether mixture. The conversion rate of products can be improved and the reaction time can be shortened by this method.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

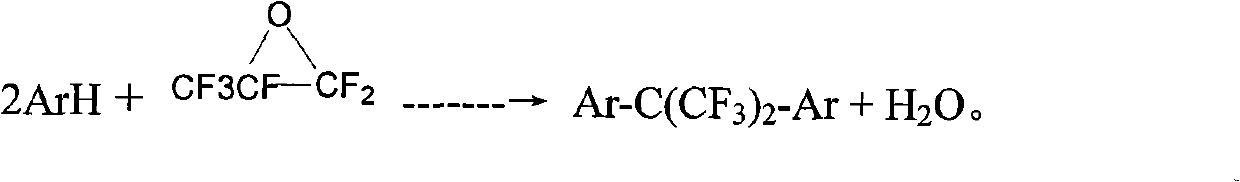

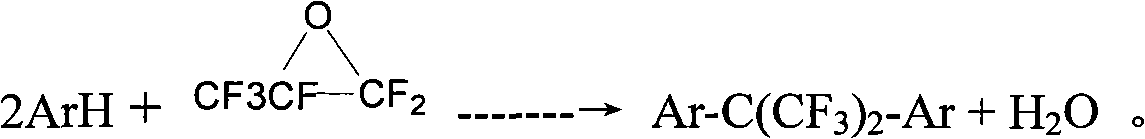

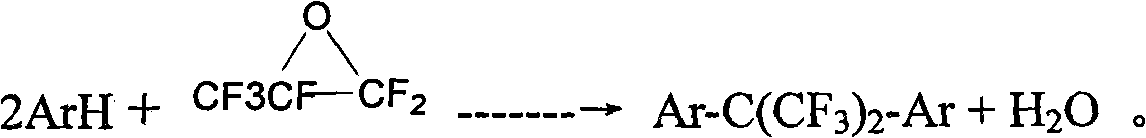

Synthesis method of diaryl hexafluoropropane compound

InactiveCN101851147AReduce synthesisReduce process stepsHalogenated hydrocarbon preparationHydrogen fluorideIsomerization

The invention relates to a synthesis method of a diaryl hexafluoropropane compound, which comprises the following steps that: aromatics with one or more electron repulsive groups are mixed with anhydrous hydrogen fluoride in a reactor, and then hexafluoropropylene oxide is added into the reactor to be mixed and heated; after the reaction, the hydrogen fluoride is removed, the remained product is refined to obtain the diaryl hexafluoropropane compound; with the method, the isomerization of hexafluoropropylene oxide and the concentration reaction of aromatics are integrated into one process stage to be realized, so the process procedure of the synthesis is reduced, and the production cost and side product can be reduced.

Owner:SANMING HEXAFLUO CHEM CO LTD

Solid catalyst and its preparation and method of catalytic preparation epoxy propane hexafluoride

ActiveCN1954911ARealize continuous productionOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalHexafluoropropylene

An Ag-series solid catalyst for preparing hexafluoroepoxy propane from hexapropene and molecular oxygen by gas-phase method in tubular reactor contains Ag (10-50 mass%), alkali (or alkali-earth) metal compound (1-20), and carrier (49-89). It has high output rate and selectivity of product.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

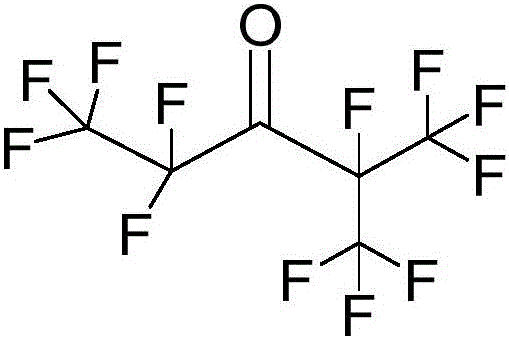

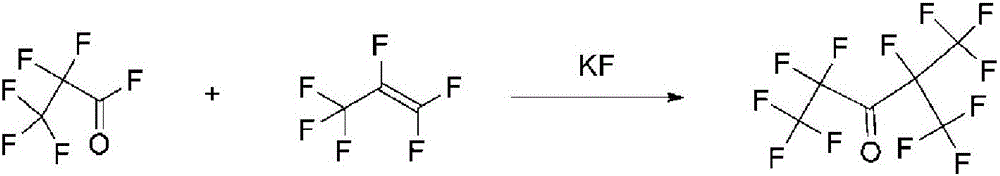

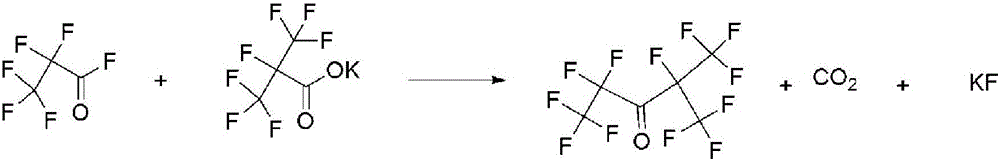

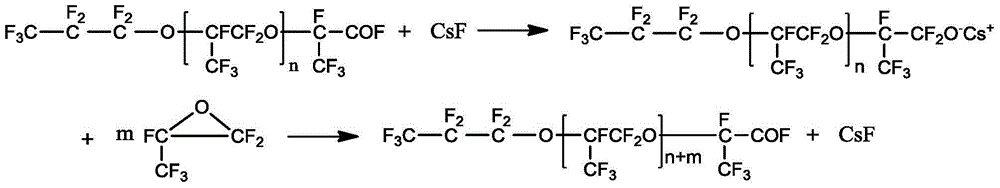

Method of preparing pentafluoroethyl isopropyl ketone

ActiveCN106316809AHigh degree of automationImprove efficiencyPreparation from heterocyclic compoundsOrganic synthesisHexafluoropropylene

The invention relates to the technical field of organic synthesis, in particular to a method of preparing pentafluoroethyl isopropyl ketone. The method includes the steps that hexafluoropropylene oxide and hexafluoropropylene are used as raw materials and react at the temperature of 65-80 DEG C in the presence of a crown ether phase transfer catalyst and fluorine-containing salt to obtain pentafluoroethyl isopropyl ketone. The yield of the product prepared through the method is 88-91%, and the conversion rate of the raw material hexafluoropropylene is up to 100%. The method has the advantages of being easy to operate, low in requirement for equipment, low in cost, high in automation degree and high in equipment use ratio and can meet the requirement for industrial production application.

Owner:航天康达(北京)科技发展有限公司

Synthetic method of perfluoropolyether

The invneiton discloses a synthetic method of perfluoropolyether. The synthetic method comprises the following steps of: reacting a first volume part of purified hexafluoropropylene gas and alkali metal fluoride in an aprotic solvent at 0 DEG C to 50 DEG C to obtain low polymer; cooling the temperature of the obtained low polymer to the range of -40 DEG C to -20 DEG C, and adding a second volume part of purified hexafluoropropylene gas for reaction with the low polymer to obtain perfluoropolyether. According to the synthetic method of perfluoropolyether disclosed by the invention, the synthetic process for feeding materials and controlling temperature in stages is adopted to prepare perfluoropolyether, so that the conversion rate of hexafluoropropylene reaches 99% and above; moreover, the prepared perfluoropolyether has high average molecular weight. Besides, the material hexafluoropropylene gas is purified by using alkali substances and silica gel, so that the used alkali substance and silica gel are low in cost and can be repeatedly used while the material gas reaches the using requirements. Meanwhile, in the process of synthesizing perfluoropolyether, the use of diluents is avoided, so that the process is simple and the cost is lower, therefore, the synthetic method is suitable for industrial application.

Owner:湖南有色郴州氟化学有限公司

Method for preparing hexafluoropropylene oxide oligomer

InactiveCN104513390AEffective control of molecular weightImprove conversion rateProduction effectBiological activation

The invention discloses a method for preparing hexafluoropropylene oxide oligomer. Alkali-metal fluoride salt, aprotic inertia polarity organic solvents, fluorine-containing organic solvents and perfluoro(2-methyl-3-oxahexanoyl)fluoride are used for preparing a homogeneous activation initiator, the homogeneous activation initiator is used for initiating a hexafluoropropylene oxide monomer to have a polymerization reaction, and then the hexafluoropropylene oxide oligomer with a high molecular weight is obtained. Meanwhile, a part of products and related solvents are recycled, and an environment-friendly recycle production effect is achieved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

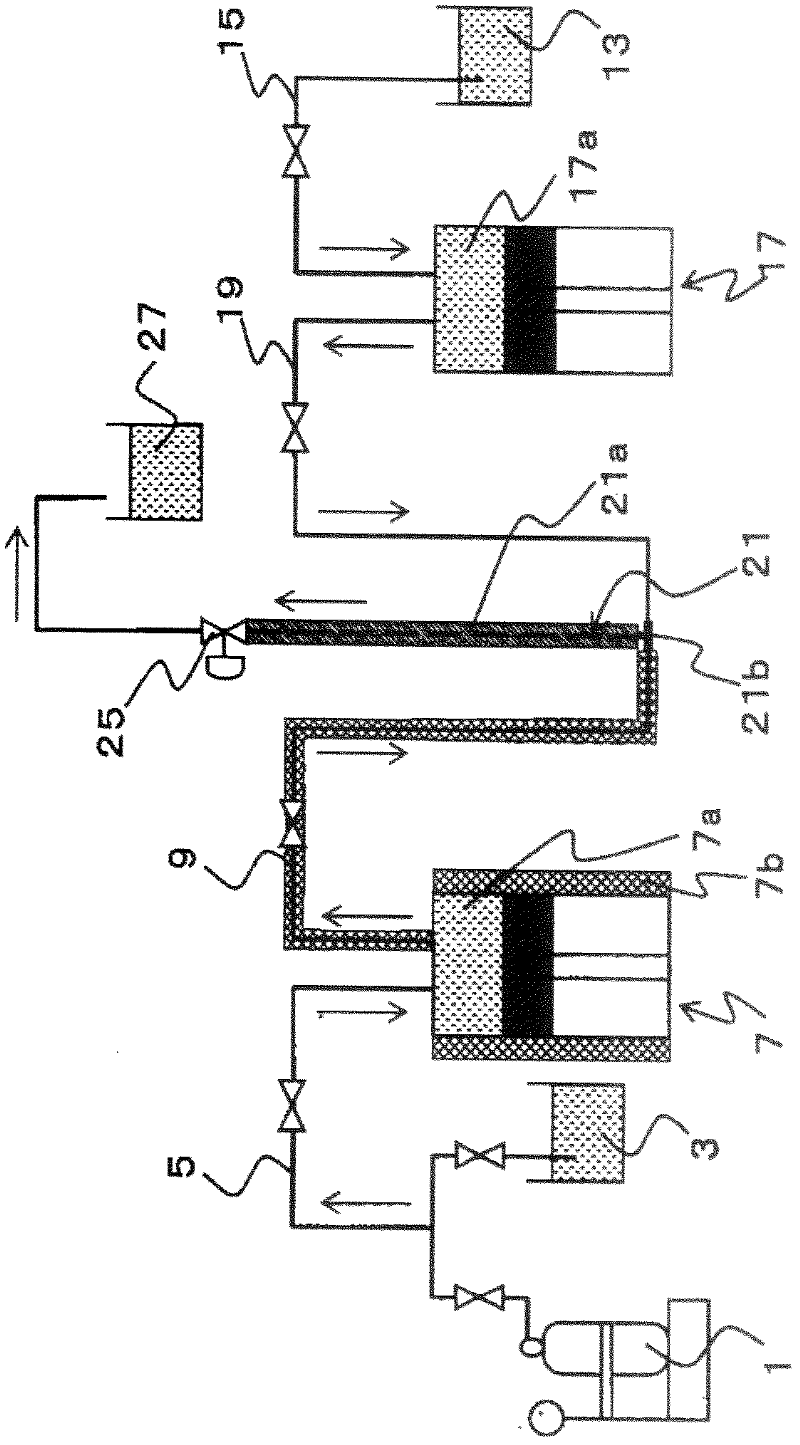

Method for producing hexafluoropropylene oxide

Disclosed is a novel method for producing hexafluoropropylene oxide, wherein a high HFPO selectivity can be achieved without using a phase-transfer catalyst. Specifically, hexafluoropropylene (HFP), a water-soluble and aprotic organic solvent, and an aqueous oxidant solution are brought into contact with each other in a very small space, so that hexafluoropropylene and the oxidant are reacted with each other, thereby obtaining hexafluoropropylene oxide (HFPO).

Owner:DAIKIN IND LTD

Preparation method for hexafluoropropylene oxide homopolymers

The invention discloses a preparation method for hexafluoropropylene oxide homopolymers. Potassium fluoride is employed as a catalyst to trigger ring-opening polymerisation of hexafluoropropylene oxide, a saturated solution of tetraethylene glycol dimethyl ether and fluorine containing solvent of cesium fluoride is added in batches for multiple times, the reaction temperature is lowered gradually from 0 DEG to -40 DEG C, thus reaction activity of tail end groups of hexafluoropropylene oxide homopolymers is kept, hexafluoropropylene oxide monomers are added continuously on this basis, and through control of addition times of hexafluoropropylene oxide and the cesium fluoride solution, hexafluoropropylene oxide homopolymers with an average polymerization degree of 50 can be synthesized. Through control of addition of monomers, hexafluoropropylene oxide homopolymers with an average polymerization degree of 20-50 can be synthesized selectively, and different industrial production requirements are met.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

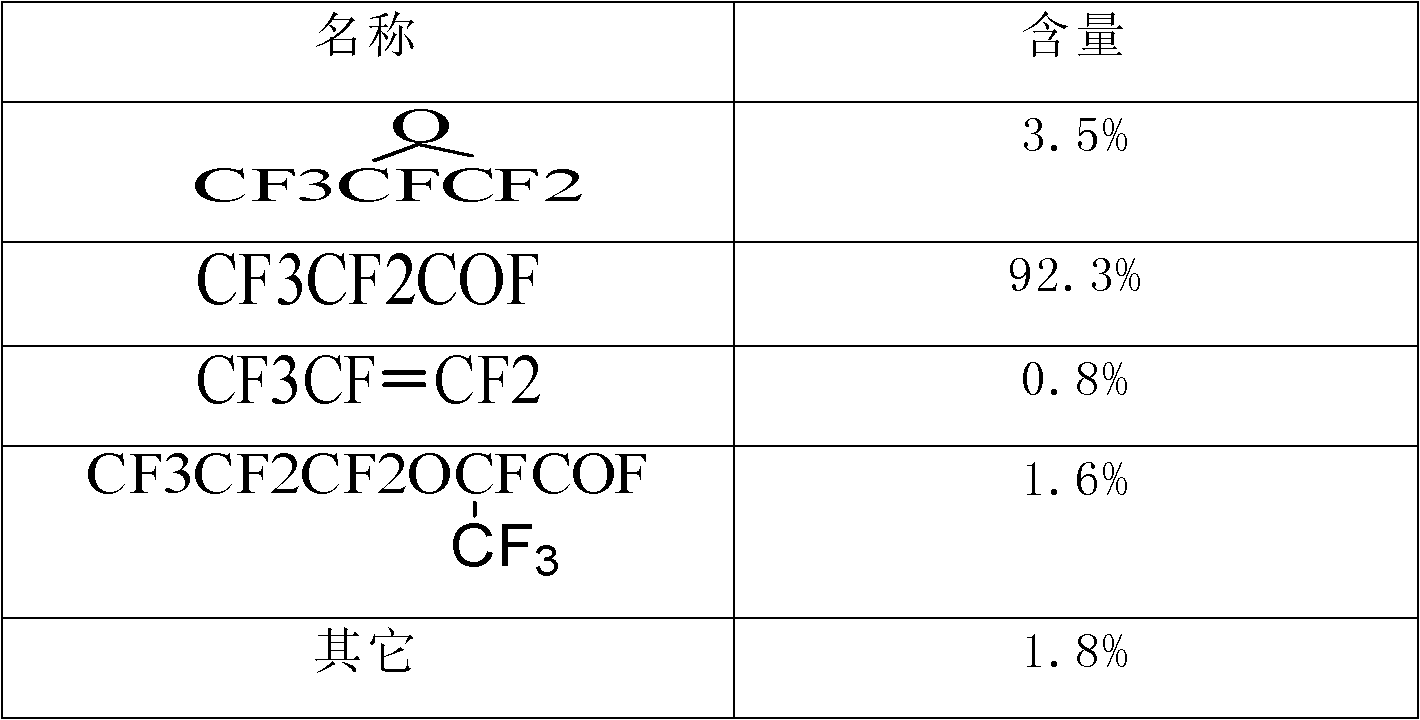

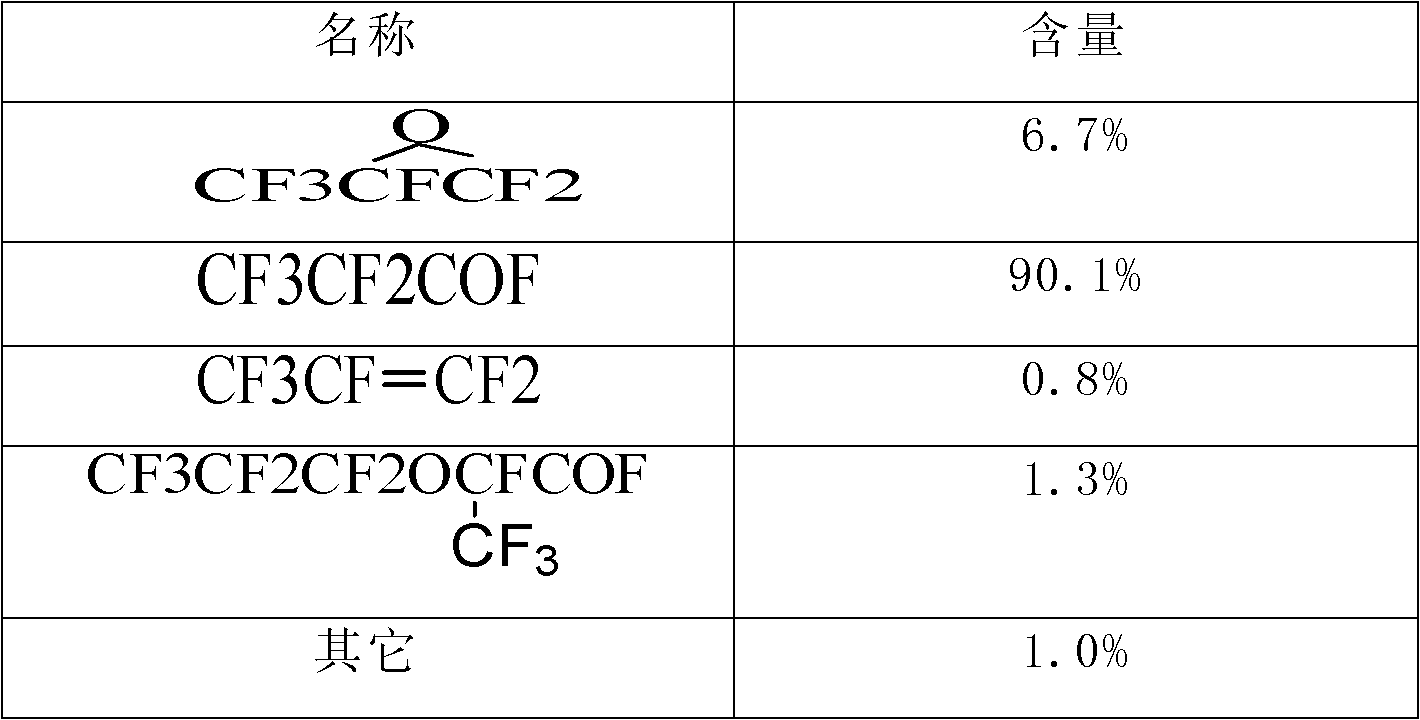

Method for preparing pentafluoride ethyl perfluoro isopropyl ketone through gas phases

ActiveCN108314614ALow priceEasy to produceOrganic compound preparationCarboxylic acid halides preparationPentafluorideCarbonyl fluoride

The invention discloses a method for preparing pentafluoride ethyl perfluoro isopropyl ketone through gas phases. The method is characterized in that under the existence of addition catalysts, hexafluoropropylene and hexafluoropropylene oxide or pentafluoropropionyl fluoride take gas phase addition reaction to obtain the pentafluoride ethyl perfluoro isopropyl ketone, or tetrafluoroethylene and heptafluorobutyl fluoride take gas phase addition reaction to obtain the pentafluoride ethyl perfluoro isopropyl ketone. The method has the advantages that the reaction route is short; in addition, rawmaterials such as the hexafluoropropylene, the tetrafluoroethylene, the hexafluoropropylene oxide and carbonyl fluoride can be easily obtained; the cost is low; the yield of the pentafluoride ethyl perfluoro isopropyl ketone is high; the continuous large-scale industrial production can be realized through the route.

Owner:泉州宇极新材料科技有限公司

Synthetic method of perfluoropropanoyl fluoride and preparation method of catalyst applied to reaction

InactiveCN105541606AImprove conversion rateHigh product purityPhysical/chemical process catalystsPreparation from carboxylic acid halidesIsomerizationChemical reaction

The invention discloses a synthetic method of perfluoropropanoyl fluoride and a preparation method of a catalyst applied to a reaction. The synthetic method is innovatively characterized by comprising the steps that hexafluoropropylene oxide serves as the raw material and is subjected to a isomerization reaction at the proper reaction temperature and under the action of the catalyst, so that perfluoropropionyl chloride is generated. The preparation method of the catalyst is innovatively characterized by comprising the steps of weighing and compounding alkali metal fluoride into a solution with a certain concentration, adding activated carbon, placing mixed liquor into a muffle furnace, and conducting evaporation and sufficient drying till constant weight is reached. According to the preparation method, perfluor epoxypropane serves as the raw material to synthesize the perfluoropropionyl chloride, the hexafluoropropylene oxide is subjected to the isomerization reaction at the specific temperature and under the action of the alkali metal fluoride catalyst with the activated carbon as the carrier, so that the perfluoropropanoyl fluoride is generated, the raw material conversion rate and the product purity are high, the purity of an obtained product can reach 99% and above without being subjected to fractionation, and when the product is made to have a chemical reaction with alcohol, ester with the purity being 98.8% can be obtained.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

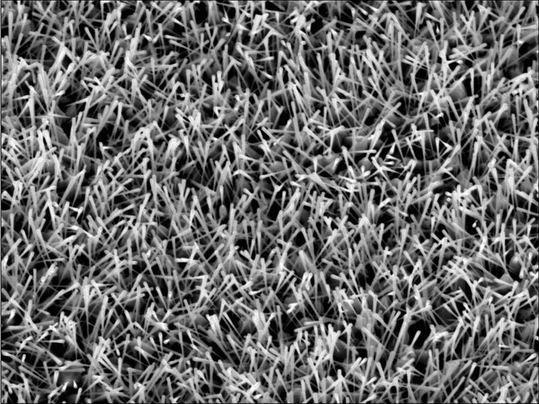

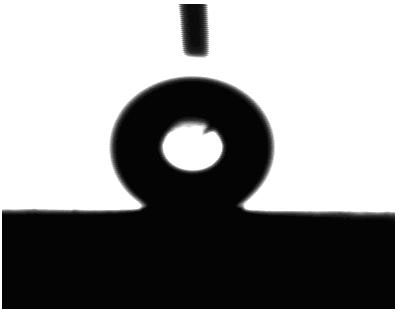

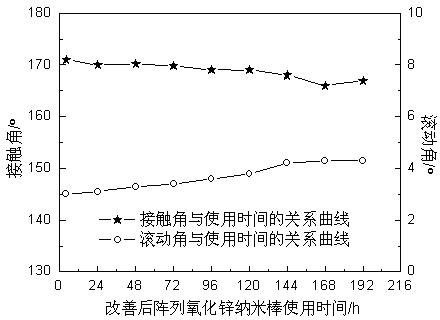

Method of improving hydrophobic stability of nanometer array film

InactiveCN102312226AImprove durabilityChemical vapor deposition coatingHigh energyReaction temperature

The invention discloses a method of improving hydrophobic stability of a nanometer array film. The method comprises the following steps: placing the nanometer array film which has been rinsed in a reaction chamber that is subjected to vacuum-pumping; allowing mixed gas of hexafluoropropylene oxide (HFPO) and sulfonyl-fluorobutane to enter into the vacuum chamber by using an electric field to provide high energy plasma and using hot filament to control reaction temperature, wherein, the ratio of the flow of HFPO to the flow of sulfonyl-fluorobutane is 24:3 to 24:12 sccm; deposing a polytetrafluoroethylene nanometer membrane on the nanometer array film through polymerization. A nanometer array film hydrophobic material treated with the method provided in the invention enables water droplets not to penetrate into gaps in the nanometer array film; according to observation of long-term utilization of the nanometer array film hydrophobic material, a contact angle and a roll angle of the hydrophobic surface of the material do not decrease or increase obviously with utilization time, and therefore, long-term stabilization of hydrophobicity is maintained, and endurance of hydrophobic self-cleaning surfaces is improved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Industrialized manufacturing technique for hexafluoropropylene oxide

The present invention relates to an industrial production process of hexa-fluorine epoxypropane. Hexa-fluorine propylene and oxygen perform liquid-phase oxidation in a reaction solvent, an auxiliary agent is added into the reaction solvent, the volume of the auxiliary agent is 0.3 to 5 percent of the volume of the reaction solvent, the reaction solvent is selected from perfluorocycloalkane; and the auxiliary agent is selected from one of or an arbitrary combination of the following substances: a halogenating alkyl phenylate with a molecular formula C6H5OCnH2nX and alkyl naphthalene with a molecular formula C10+pH8+2p. Because the perfluorocycloalkane and the solvent composed of halogenating alkyl phenylate / alkyl naphthalene are used as media for the reaction for producing the hexa-fluorine epoxypropane, the present invention has the advantages of economy, environmental protection, high conversion, good selectivity, and the like.

Owner:衢州环新氟材料有限公司

Method for synthesis of pentafluoropropionyl fluoride

InactiveCN103145544AImprove corrosion resistanceHigh yieldCarboxylic acid halides preparationArylVinyl ether

The invention discloses a method for synthesis of pentafluoropropionyl fluoride by using hexafluoropropylene oxide as a raw materisl. Under the effect of a catalyst, hexafluoropropylene oxide is subjected to isomerization reaction to synthesize pentafluoropropionyl fluoride. The catalyst comprises a main catalyst and a co-catalyst, wherein the main catalyst is organic amine compounds, five-or six-membered nitrogen-containing heterocycles or six-membered fused ring aromatic compounds; the co-catalyst is an alkali metal fluoride; and the quality ratio of the main catalyst to the co-catalyst is 100:1 to 5:1. The method provided by the invention has the advantages of mild preparation process, simple operations and high yield of synthesized pentafluoropropionyl fluoride. The prepared pentafluoropropionyl fluoride is suitable for preparing fluorine alkyl group-containing vinyl ethers and perfluoro-propionyl peroxides.

Owner:SINOCHEM LANTIAN +1

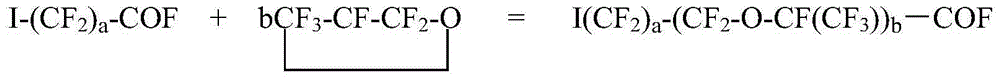

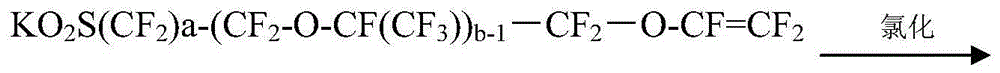

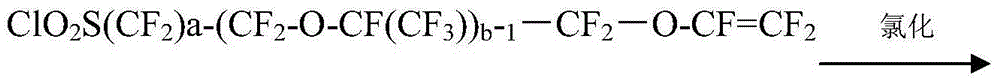

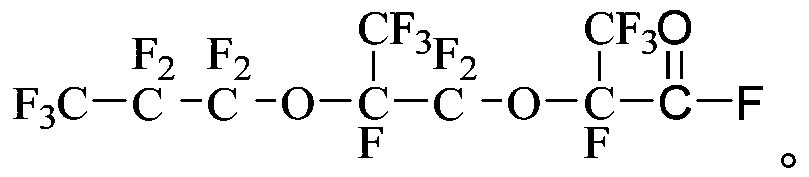

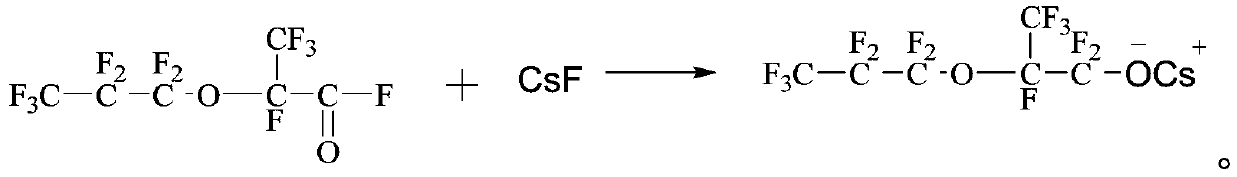

Method for preparing perfluoro alkene ether sulfonyl fluoride compound

The invention relates to a method for preparing a perfluoro alkene ether sulfonyl fluoride compound. The method comprises the following steps: carrying out an addition reaction on perfluoroiodoacetyl fluoride and hexafluoropropylene oxide in a solvent, cracking the obtained material in a solvent to prepare a perfluoroiodo alkene ether monomer, carrying out a mild reaction on the monomer to prepare perfluoro alkene ether sulfite, chlorinating the perfluoro alkene ether sulfite by using a chlorination reagent to obtain perfluoro alkene ether sulfonyl chloride, and carrying out a mild phase transfer catalytic fluorination reaction on the perfluoro alkene ether sulfonyl chloride to prepare a required perfluoro alkene ether sulfonyl chloride monomer with a high yield. A general catalyst and mild reaction conditions are adopted in the whole reaction enforcement process, reaction raw materials involved in the reactions can be prepared by using present technologies or can be purchased in the market, yields of all the reactions under above conditions are high, and a mixture obtained in the invention can be separated by using present technologies, so the target product with the purity of 99% or above, used for polymerizing preparation of perfluorinated ion resin can be obtained.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Method for preparing hexafluoropropylene oxide trimer

ActiveCN110041192AImprove conversion rateHigh selectivityPreparation of metal alcoholatesCarboxylic acid halides preparationHexafluoropropylene oxideFluorine containing

The invention relates to the field of fluorine-containing fine chemistry, in particular to a method for preparing a hexafluoropropylene oxide trimer. Hexafluoropropylene oxide is used as a raw material, hexafluoropropylene oxide dimer alkoxide and fluorinated alkali metal salt are used as composite catalytic initiators, a chain transfer polymerization inhibitor is added, and the hexafluoropropylene oxide trimer is prepared after a reaction. The conversion rate of hexafluoropropylene oxide and the selectivity of the hexafluoropropylene oxide trimer are high in the method, and the operation method is simple, feasible, easy to control industrially and suitable for mass industrial production.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

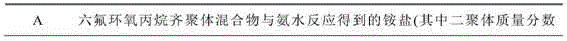

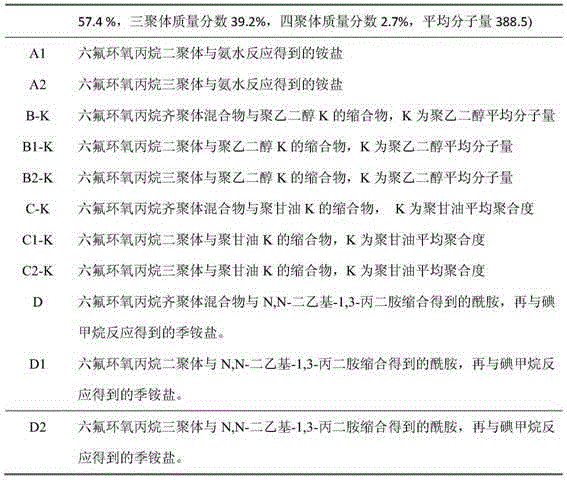

Oil surface spreading agent

ActiveCN103550897APrevent volatilizationInsulate the airFire extinguisherQuaternary ammonium cationHexafluoropropylene oxide

The invention discloses an oil surface spreading agent containing a fluorine containing surfactant, a hydrocarbon surfactant, an additive and water, wherein the fluorine containing surfactant is a combination of an anionic-type fluorine containing surfactant and a non-ionic or a cationic-type fluorine containing surfactant, and the anionic-type fluorine containing surfactant is an ammonium salt of hexafluoropropylene oxide oligomer, the non-ionic fluorine containing surfactant is a condensation product of the hexafluoropropylene oxide oligomer and a polyol polymer or polyoxyethylene polyoxypropylene ether, the cationic-type fluorine containing surfactant is a quaternary ammonium salt obtained by reacting an amide with methyl iodide, wherein the amide is prepared by concentration of the hexafluoropropylene oxide oligomer and a propane diamine compound; and in the oil surface spreading agent, the anionic-type fluorine containing surfactant concentration is 0.01w% ~ 10.0w%, the non-ionic or the cationic-type hydrocarbon surfactant concentration is 0.01w% ~ 5.0w%, the hydrocarbon surfactant concentration is 0.01w% ~ 20.0w% and the additive concentration is 0.00w% ~ 25.0w%.

Owner:菏泽建数智能科技有限公司

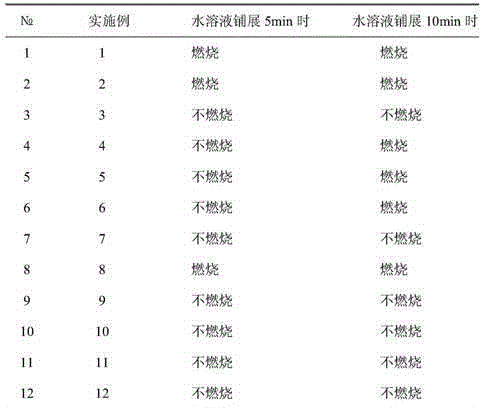

Method for preparing perfluoro olefin ether from compound containing acid-sensing group

ActiveCN101376621AReduce decompositionHigh degree of fluorinationOrganic chemistryOrganic compound preparationDecompositionReaction temperature

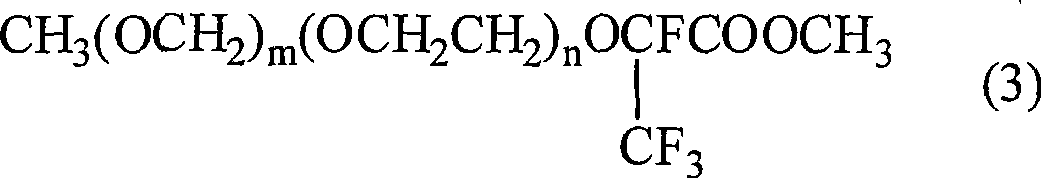

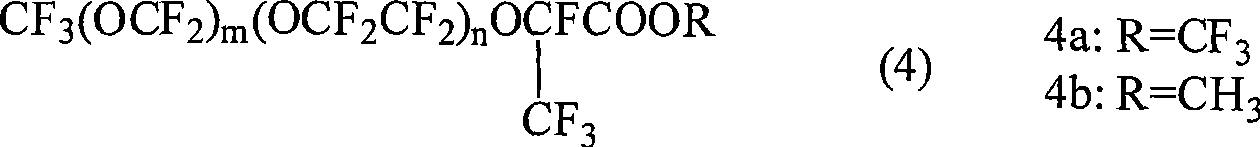

The invention provides a method for preparing perfluoro-olefine ether from an acid-sensitive group-containing compound. The method comprises the following steps: carrying out the reaction between single-substituted glycols compound containing an MOM protecting group (CH3OCH2-) which is sensitive to acid, and hexafluoropropylene oxide; forming a part of fluoro ester through an ester exchange reaction; directly fluorizing the acid-sensitive group-containing compound with fluorine; and subjecting to cracking to obtain the perfluoro-olefine ether. The method is characterized in that the fluorization process adopts the gradual temperature rise method ( minus 20 DEG C to 15 DEG C), and the corresponding reaction temperature condition is applied according to the different requirements for the stability of molecular structures with different fluorization extents in different stages; and in the different temperature stages, sodium fluoride is added intermittently so as to effectively slow down the decomposition of the acid-sensitive group in the raw material in an strong acid environment.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

High pure hexafluoropropylene oxide preparation method using extraction rectification

ActiveCN101455908AReduce volatilityIncrease relative volatilityOrganic chemistryExtractive distillationMass ratioTower

The invention relates to a method for preparing high-purity hexafluoropropylene oxide by extraction and rectification. The method comprises the following steps: selecting epoxy chloropropane as an extracting agent, wherein the mass ratio of the extracting agent to HFPO-HFP mixture feed is controlled between (1-200): 1; introducing the HFPO-HFP mixture into an extraction rectifying tower, spraying the epoxy chloropropane from the tower top, and separating HFPO from the tower top to obtain HFPO with purity over 99 percent; and discharging HFP and the epoxy chloropropane from the bottom of the extraction rectifying tower to be pressed into a reclaiming tower once again, separating the HFP from the top of the reclaiming tower, and discharging the epoxy chloropropane from the bottom of the reclaiming tower to be pumped once again to return a spraying port on the top of the extraction rectifying tower for cycle use. The method selects the epoxy chloropropane as the extracting agent to make relative volatility of the HFPO and the HFP reach 1.5 to 3.7, so that the HFPO and the HFP can be well separated; meanwhile, the number of column plates required for rectification can be reduced, and investment cost can be reduced.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com