Method for synthesis of pentafluoropropionyl fluoride

A technology of pentafluoropropionyl fluoride and hexafluoropropylene oxide, which is applied in the field of synthesis of pentafluoropropionyl fluoride, and can solve problems such as unfavorable large-scale preparation of pentafluoropropionyl fluoride, difficulty in obtaining raw materials, and difficulties in industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

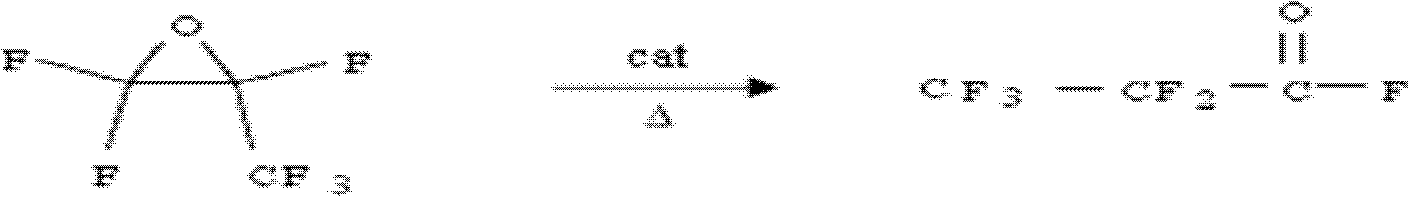

Method used

Image

Examples

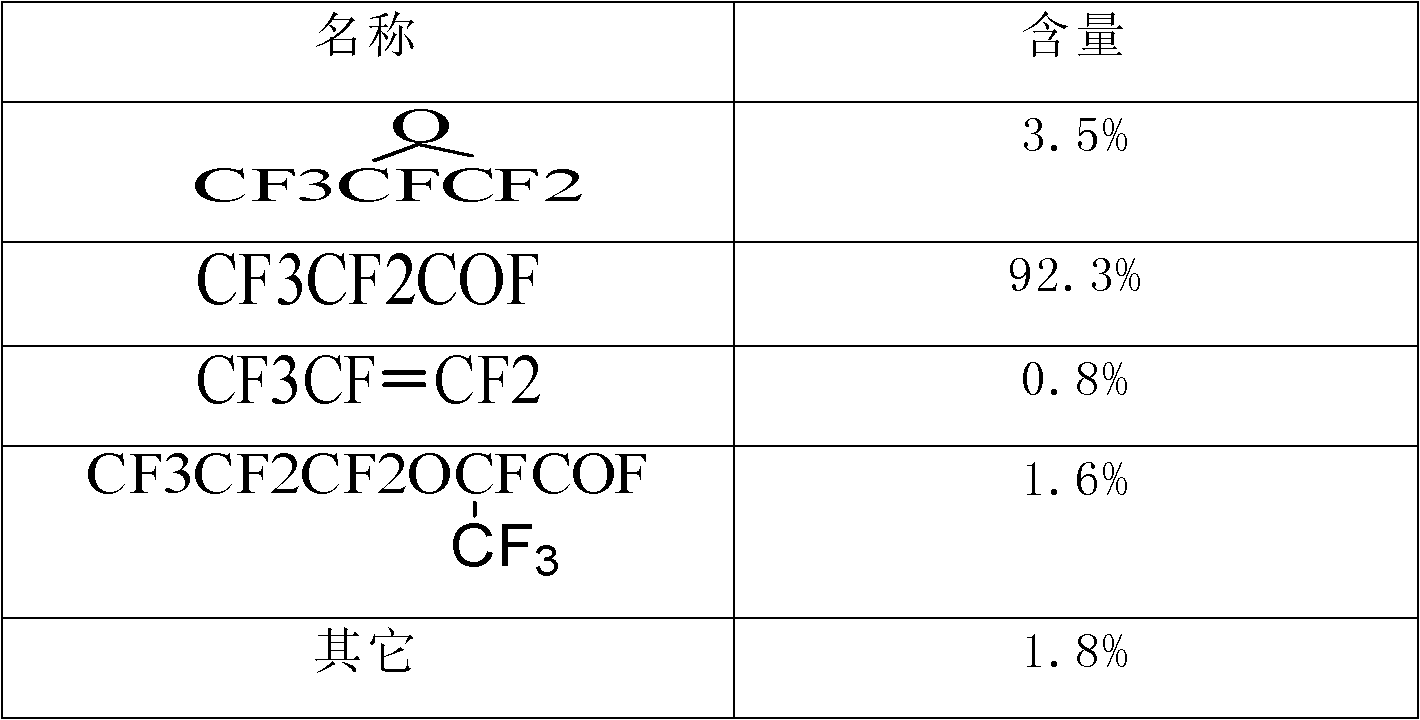

Embodiment 1

[0031] Add 150g of ethylenediamine and 10g of NaF to a pressure reactor with a volume of 0.5L, lined with polytetrafluoroethylene, and a stirrer, then close the reactor, start stirring the reaction, the stirring speed is 300 rpm, and turn on the heating Raise the temperature of the reactor, and control the temperature at 90°C. After the temperature reaches, 200g of raw material hexafluoropropylene oxide is fed into the reactor in batches from the liquid phase tube, and the reaction pressure is maintained at 0.6MPa, and the reaction material is released from the gas phase tube. , condensed and collected to obtain crude product material 175g, gas phase analysis crude product content, wherein CF 3 CF 2 The COF content is 92%, and the product yield is 80.5%.

Embodiment 2

[0033] In a pressure reactor with a volume of 0.5L, lined with polytetrafluoroethylene, and a stirrer, add 180g quinoline and 10gKF, then close the reactor, start stirring the reaction, the stirring speed is 300 rpm, open the reactor Heating to increase the temperature of the reactor, the temperature is controlled at 100°C, after the temperature reaches, 200g of raw material hexafluoropropylene oxide is passed into the reactor in batches from the liquid phase tube, the reaction pressure is maintained at 0.65MPa, and the reaction material is discharged from the gas phase tube Emit, condense and collect to obtain crude product material 186g, gas phase analysis crude product content, wherein CF 3 CF 2 The COF content is 91%, and the product yield is 84.6%.

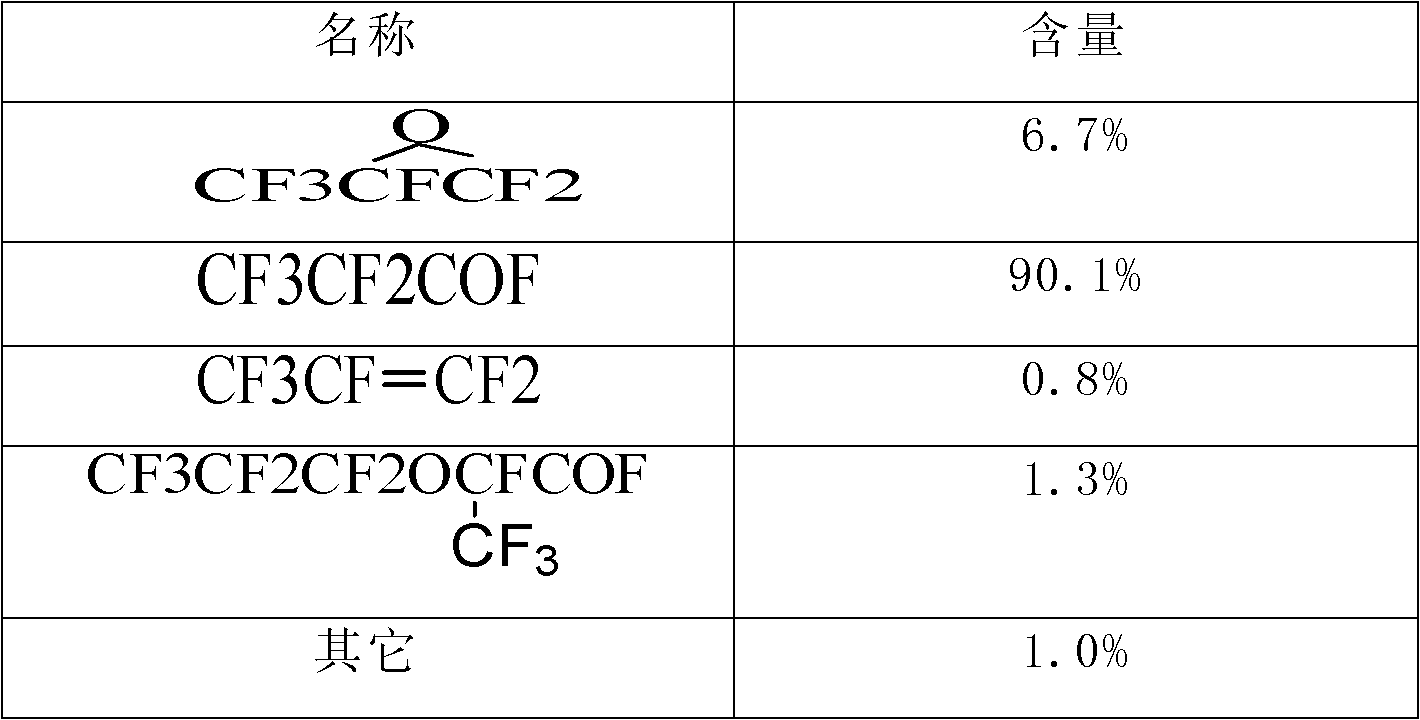

Embodiment 3

[0035]In a pressure reactor with a volume of 0.5L, lined with polytetrafluoroethylene, and a stirrer, add 160g of piperidine and 6g of CsF, then close the reactor, start stirring the reaction, the stirring speed is 300 rpm, open the reactor Heating to increase the temperature of the reactor, the temperature is controlled at 90°C. After the temperature reaches, 210g of raw material hexafluoropropylene oxide is fed into the reactor in batches from the liquid phase tube, and the reaction pressure is maintained at about 0.5MPa. The material is released, condensed and collected to obtain 181g of the crude material, and the crude product content is analyzed by gas phase, wherein CF 3 CF 2 The COF content is 93.5%, and the product yield is 81%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com