Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

A liquid rubber and spray coating technology, which is applied in asphalt coatings, chloroprene homopolymer coatings, coatings, etc., can solve the problems of complex design of the spray gun system, difficult to obtain, and difficult to obtain raw materials, so as to reduce the cost of raw materials. , The effect of advanced formula and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

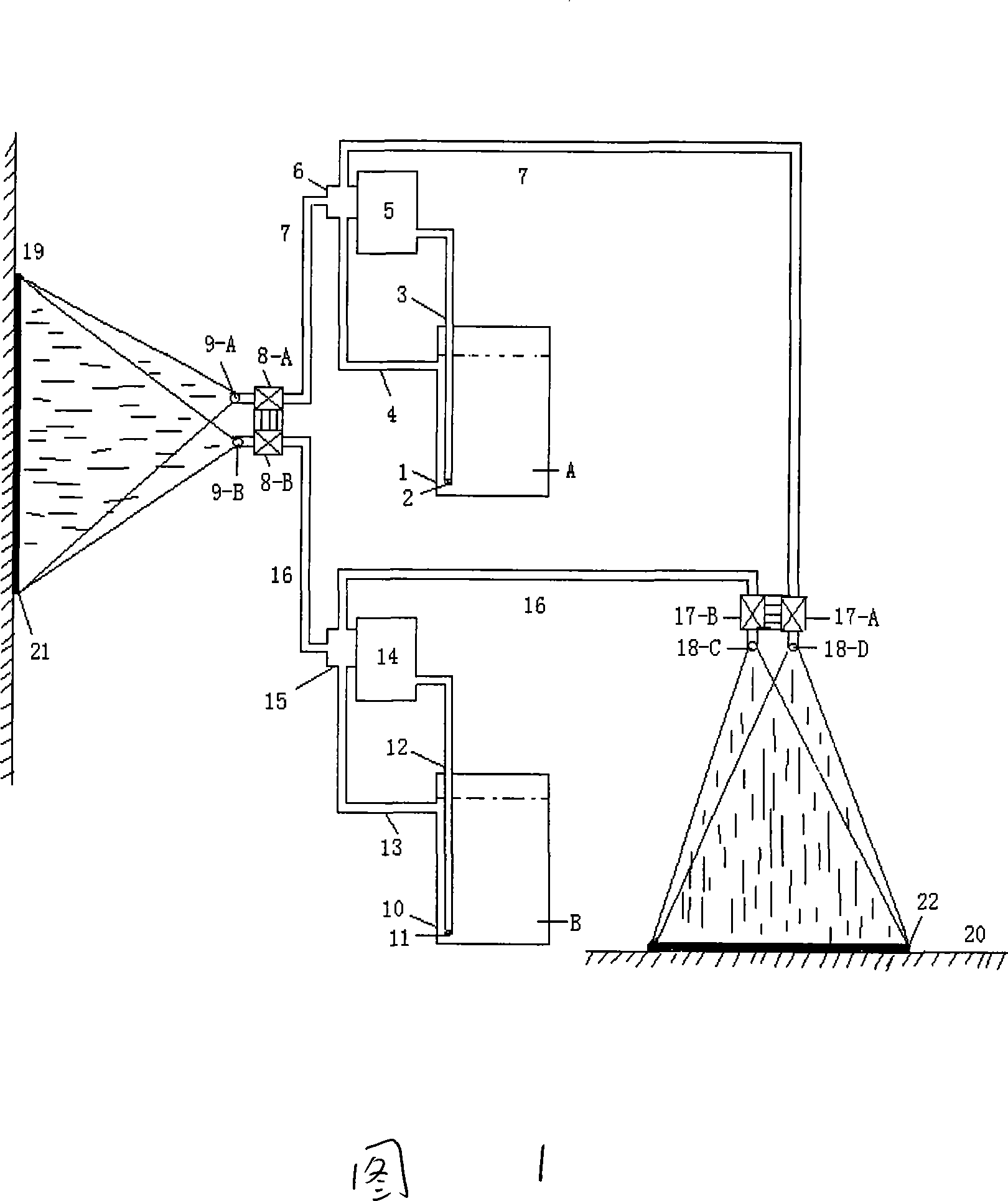

Image

Examples

Embodiment 1

[0033] The preparation and application of embodiment 1, liquid rubber paint

[0034] 1. Process and preparation:

[0035] 1. Process: preparation of component A rubber asphalt emulsion;

[0036] (1) Preparation of natural rubber latex and synthetic rubber latex: the solid content of the purchased rubber latex is lower than 48-65% when necessary and then passed through the low-temperature extraction method to extract the natural rubber anion latex with a solid content greater than 48-65%. and synthetic rubber anionic emulsion, and then put the emulsion into a reaction kettle and heat it up to 20-40°C for later use.

[0037] (2), preparation of asphalt emulsion:

[0038] Add 100 parts by weight of No. 80-120 asphalt to the emulsified asphalt equipment and keep it at 130°C; add 20-45% of water and 3.0-5.0% of anionic surfactant at a temperature of 40-70°C and perform high-speed shearing Stir to prepare anionic emulsified asphalt with a solid content of 50.0-75.0%.

[0039] (3...

Embodiment 2

[0053] Embodiment 2, spraying on the cement-based surface

[0054] Material preparation: Preparation of component A: 100kg of rubber asphalt emulsion, 19.30kg of chloroprene rubber latex to be improved; 45kg of asphalt; 2.0kg of carbon black; 1.0kg of porcelain powder; rosin soap 0.90kg, synthetic fatty acid soap as surfactant 0.80kg, alkyl sulfonate 0.50kg; dispersant TH-904 0.10kg, naphthalene sulfonate formaldehyde condensate 0.30kg, CD-4 0.10kg, water as the balance; obtained component A improved chloroprene A rubber asphalt emulsion with a total solid content of 60.35% of the diene rubber asphalt; the preparation method is the same as in Example 1.

[0055] Component B coagulant is 12% calcium chloride-composite aluminum-iron polymer coagulant (calcium chloride content 94-97%, aluminum-iron polymer metal salt 3-6%), and the preparation method is the same as in Example 1.

[0056] Spraying equipment process method: with embodiment 1;

[0057] Test results: the surface is...

Embodiment 3

[0058] Embodiment 3, spraying on the base surface of wooden board

[0059] Material preparation: A component preparation: 100kg rubber asphalt emulsion, 37.5kg of chloroprene rubber latex; 35.0kg of asphalt; 2.0kg of liquid carbon black; 0.55kg of surfactant rosin soap, 0.5kg of synthetic fatty acid soap, alkylsulfonate salt 0.2kg, alkyl aryl sulfate 0.2kg, α-naphthalenesulfonate alkylsulfonate 0.30kg; dispersant naphthalenesulfonate formaldehyde condensate 0.20kg, CD-4 0.20 water as the balance; A chloroprene rubber asphalt emulsion with a total solid content of 57.9% was obtained, and the preparation method was the same as in Example 1.

[0060] Component B coagulant 6.0% concentration calcium chloride, sodium chloride, composite aluminum-iron polymer polyvalent metal salt coagulant (calcium chloride content 91.0-95.0%, sodium chloride 1.0-3.0%, aluminum-iron polymer metal salt 2.0~6.0%).

[0061] Spraying equipment process method: the design capacity ratio of A and B pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com