Patents

Literature

1339results about "Single bars/rods/wires/strips conductors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

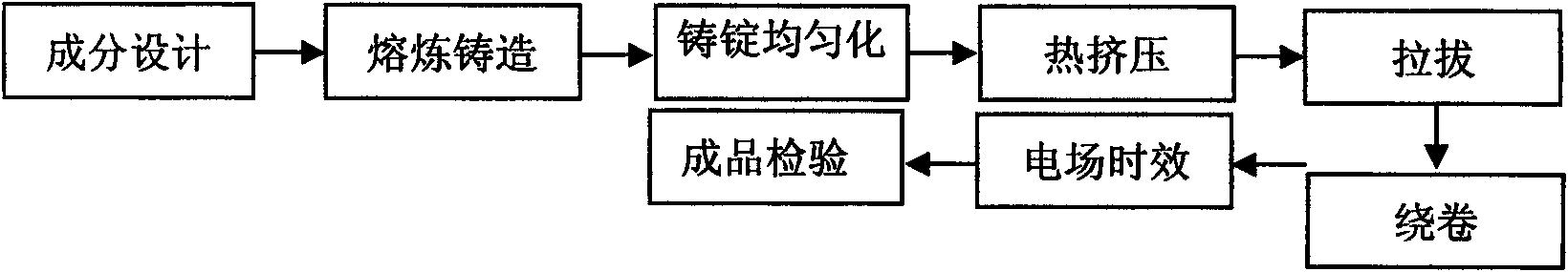

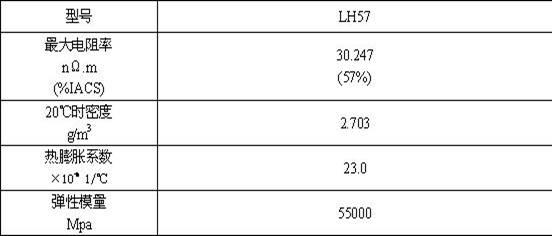

Aluminum alloy lead with lanthanon yttric and preparation method thereof

ActiveCN101587757AImprove conductivityHigh strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare earthTime effect

The invention discloses an aluminum alloy lead with lanthanon yttric and preparation method thereof. The specific component and weight percentage of the invention are Si0.5%-0.7%, Mg0.6%-0.9%, Fe 0.1%-0.2%, Y 0.2%-0.8%, Al residue. The preparation method is following: preparing the elements according to the alloy design to prepare aluminum alloy wire material via melting, casting, homogenization, extrusion and wire drawing, preparing the cables via winding to obtain the aluminum alloy lead with great intensity and conduction via the electric field time effect heat treatment. The aluminum alloy lead with high intensity of the invention adds the lanthanon yttric to purify the melting body and reduce the silicon quantity in the alloy further enhance the conductive rate of the melting on the one hand; on another hand to thin the crystal grain and enhance intensity of the alloy wire; the generatrix intending intensity is 260MPa and the conductive rate can achieve 57% IACS.

Owner:HUNAN XIANGNENG ELECTRIC WORKS

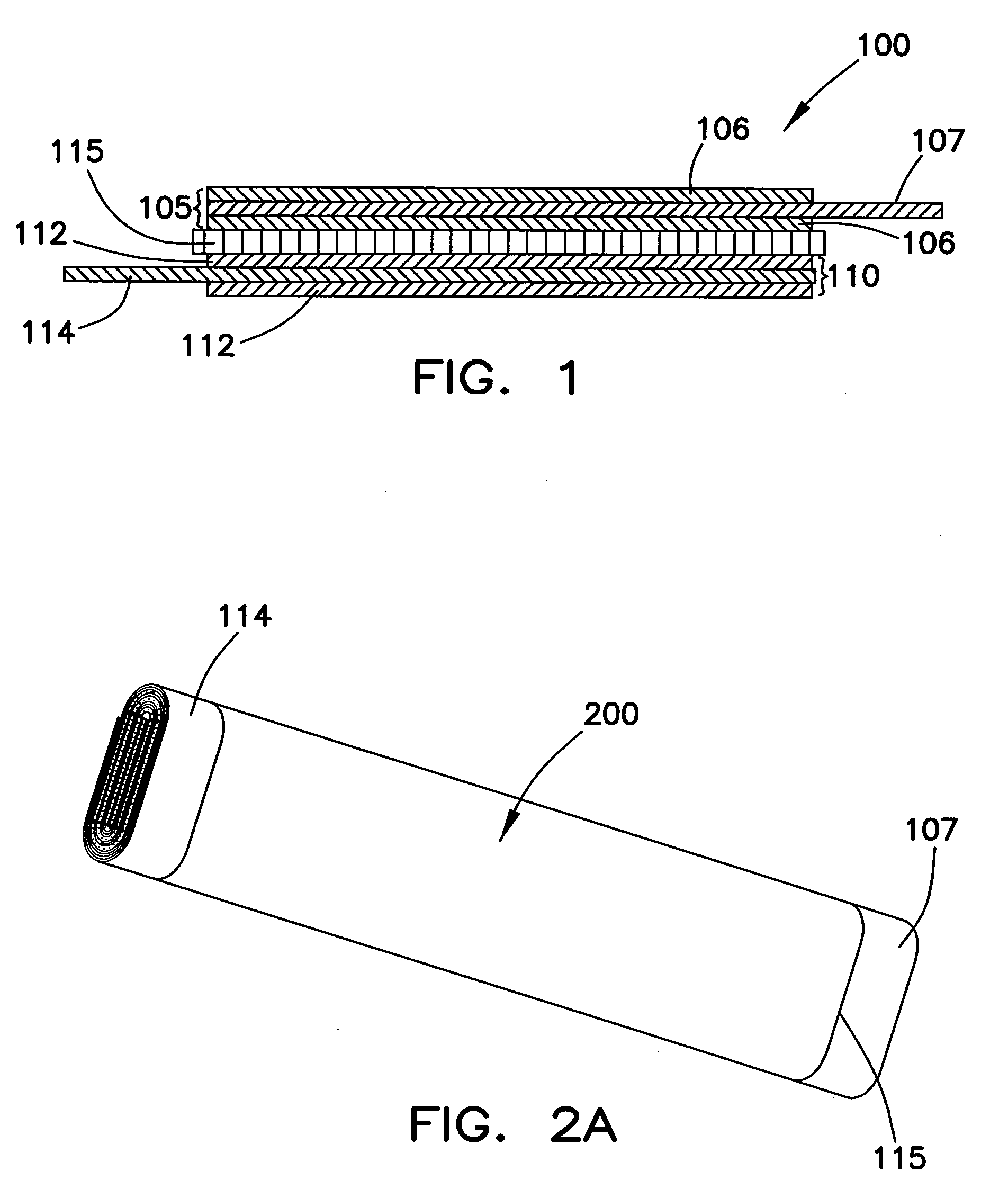

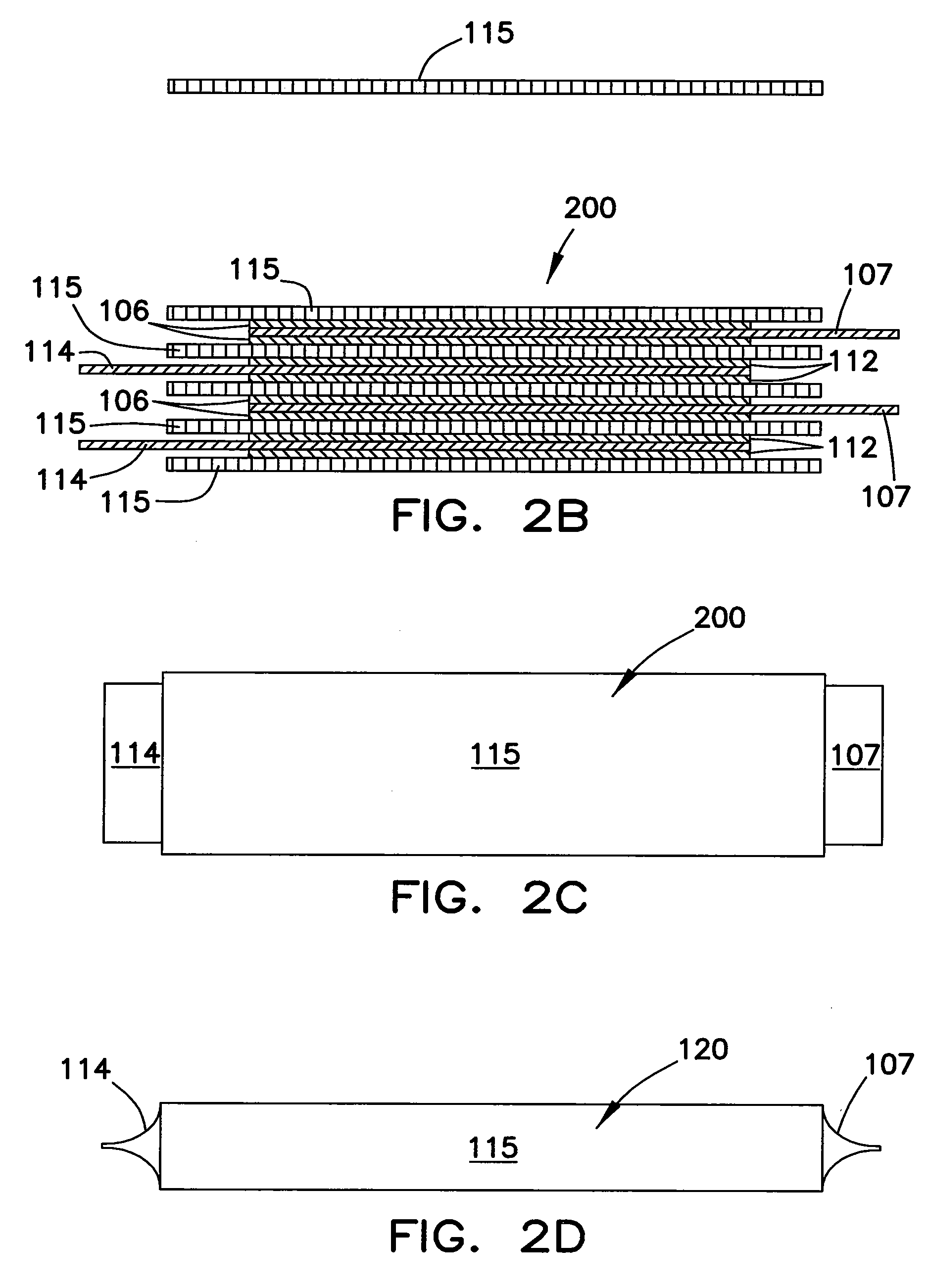

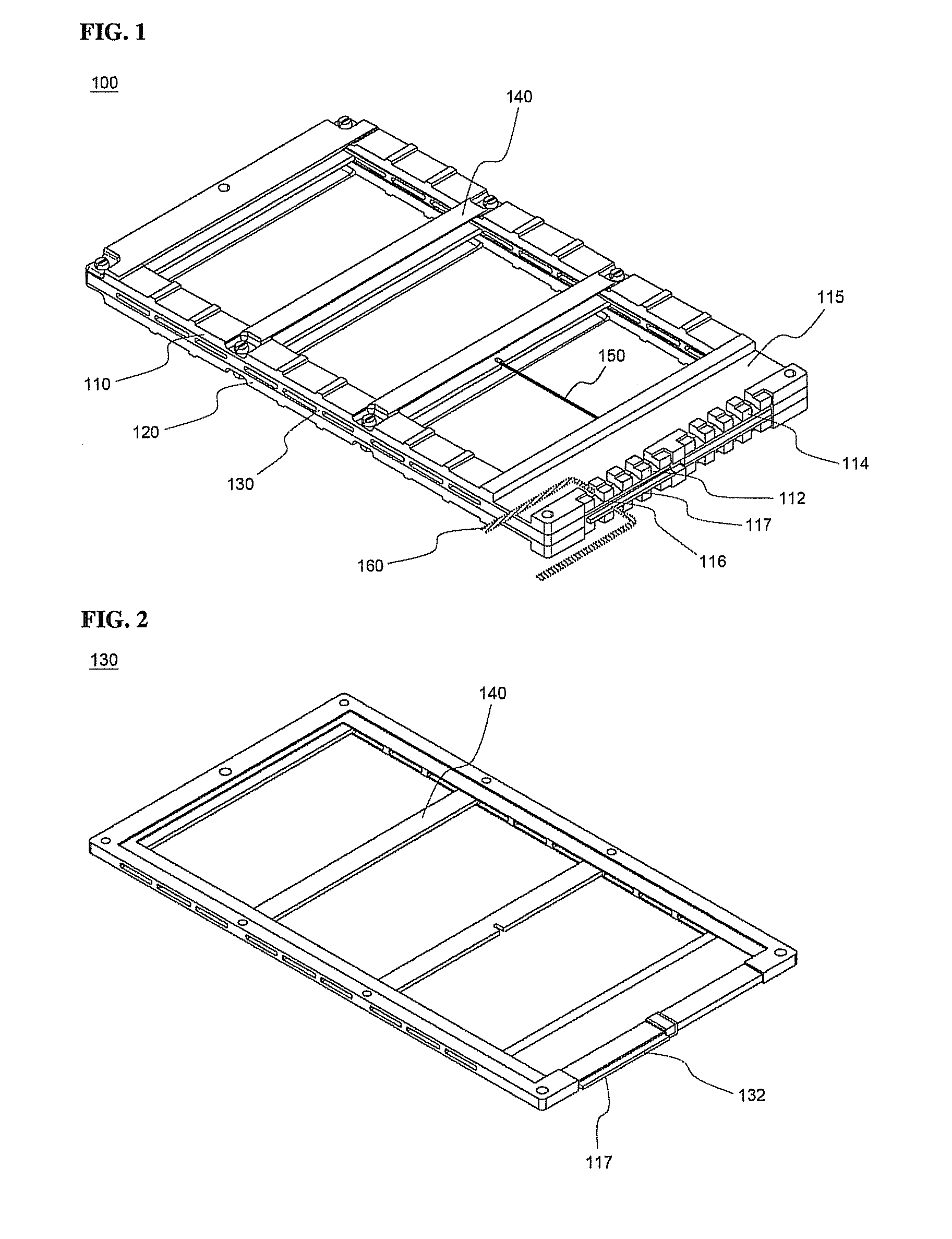

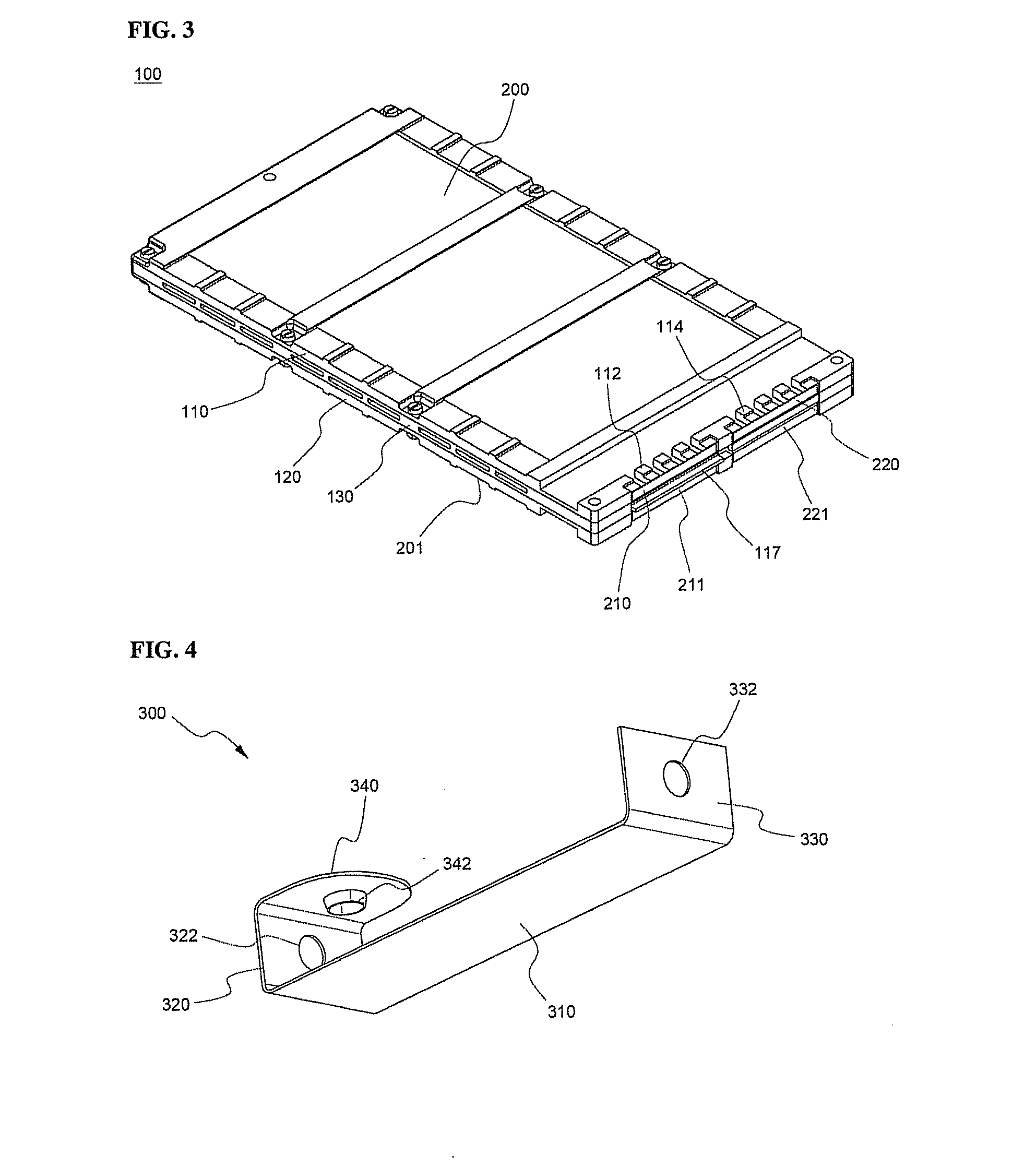

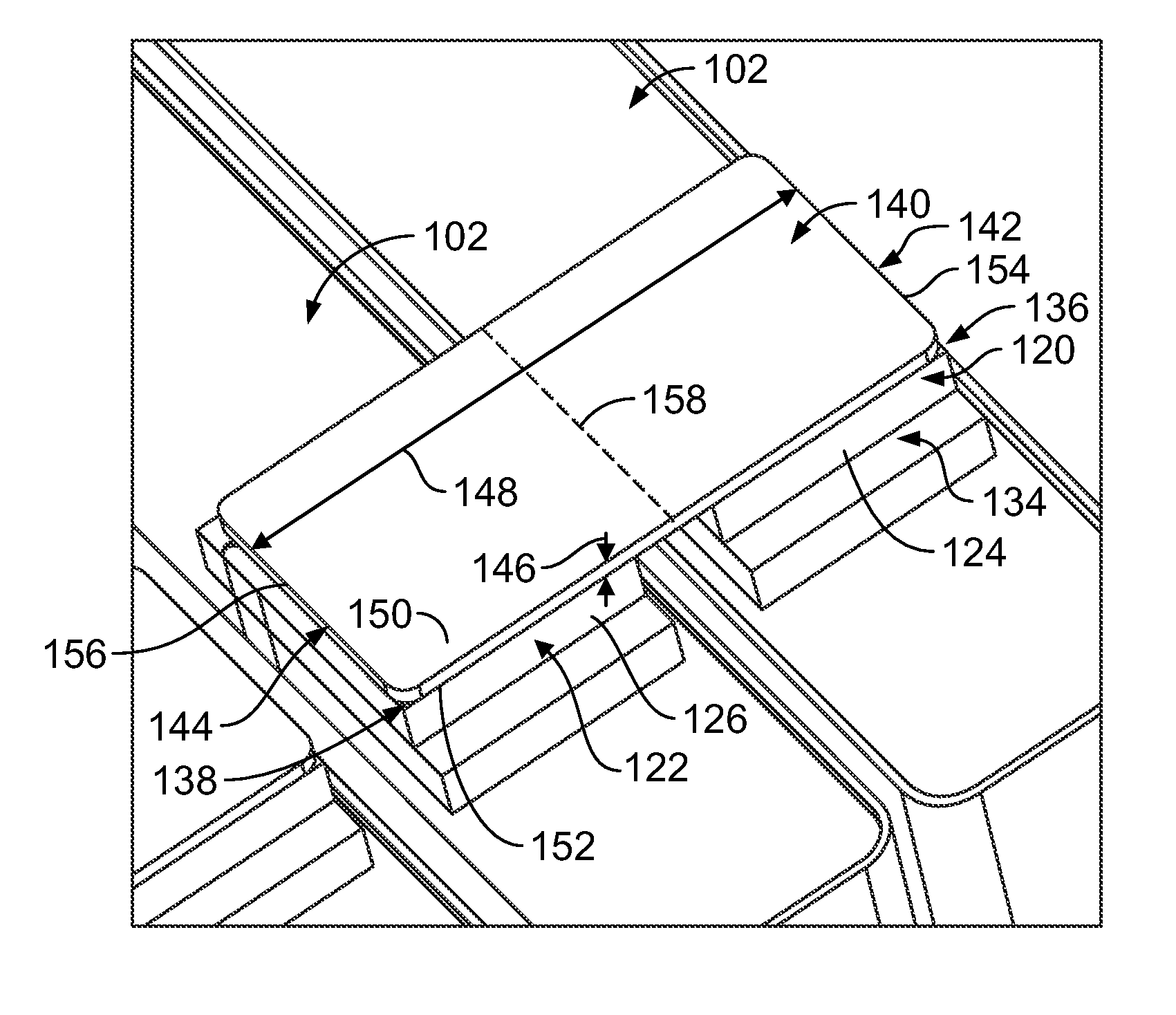

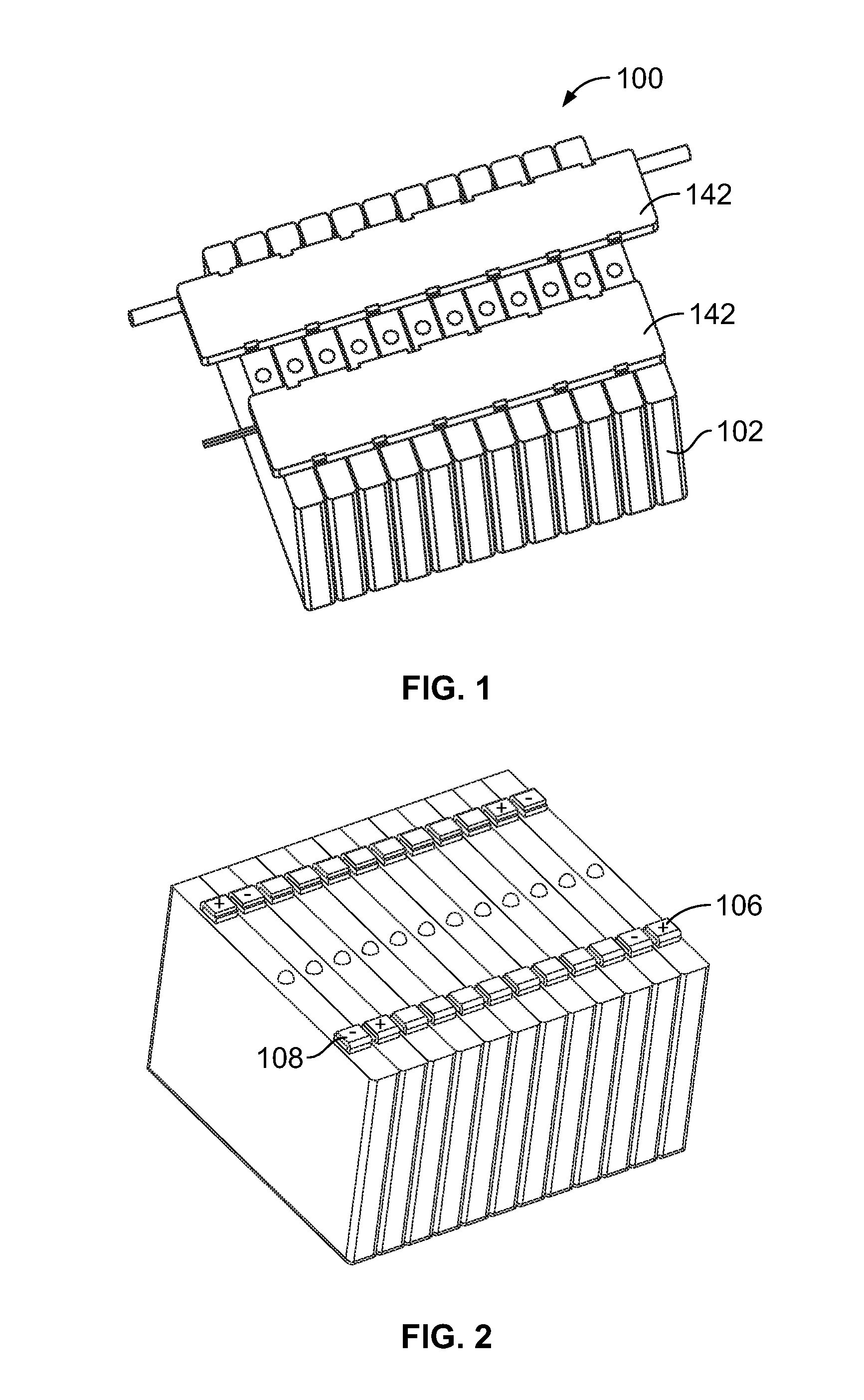

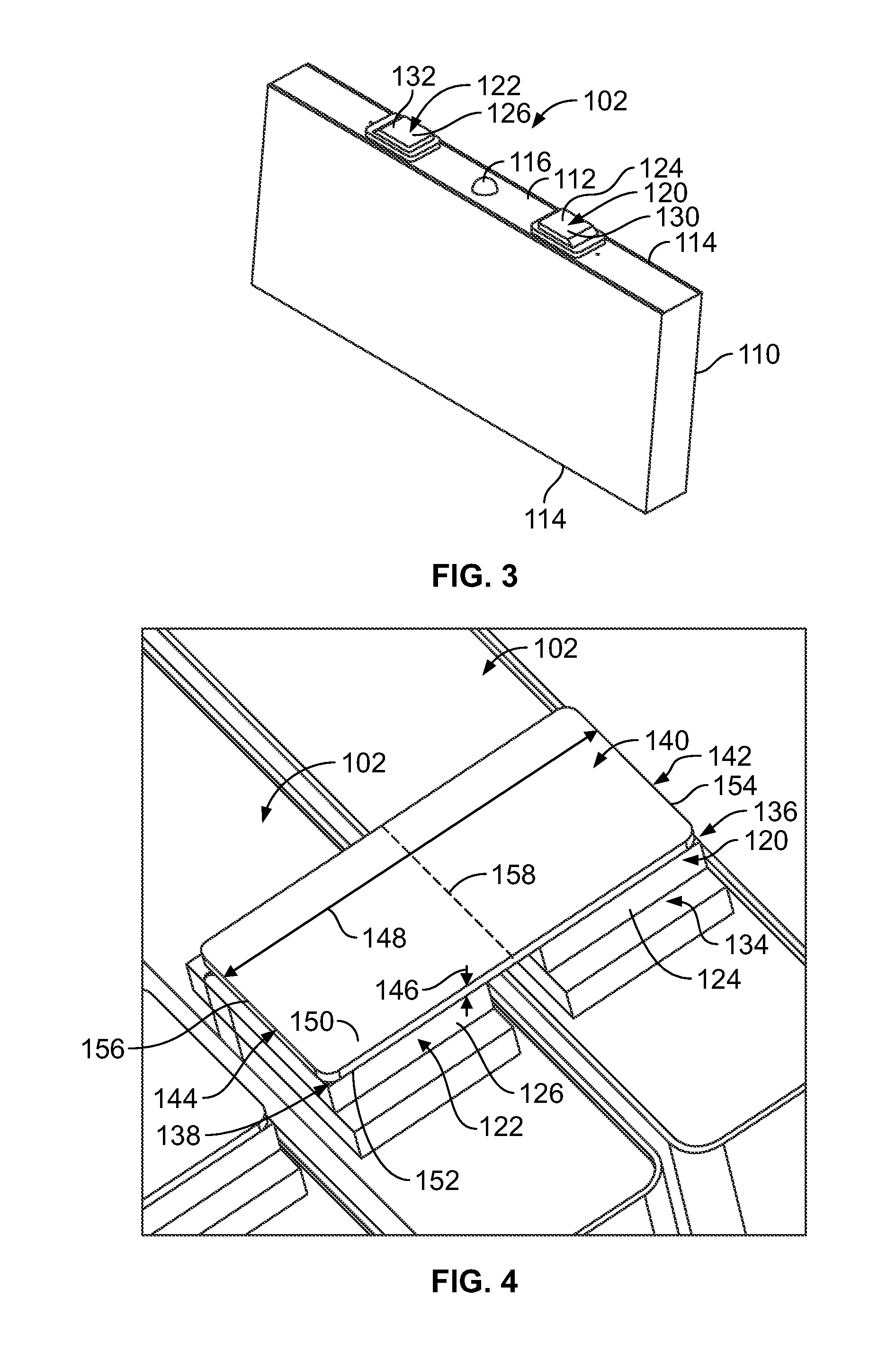

Battery system for a vehicle with severable connections

ActiveUS20090159311A1Primary cell to battery groupingBatteries circuit arrangementsElectricityElectrical connection

A battery system for storing electrical power and supplying electrical power to a vehicle is disclosed. The system includes multiple battery packs, each with a plurality of cells. The cells in each battery pack are electrically connected with one another and the multiple battery packs are also electrically connected with one another to combine the total energy output of the cells of the system. The electrical connections between at least some of the cells include a severable feature, whereby the electrical connection is severed locally at the severable feature in response to an impact force that is in excess of a predetermined magnitude and / or an overcurrent / overtemperature condition.

Owner:BYD CO LTD

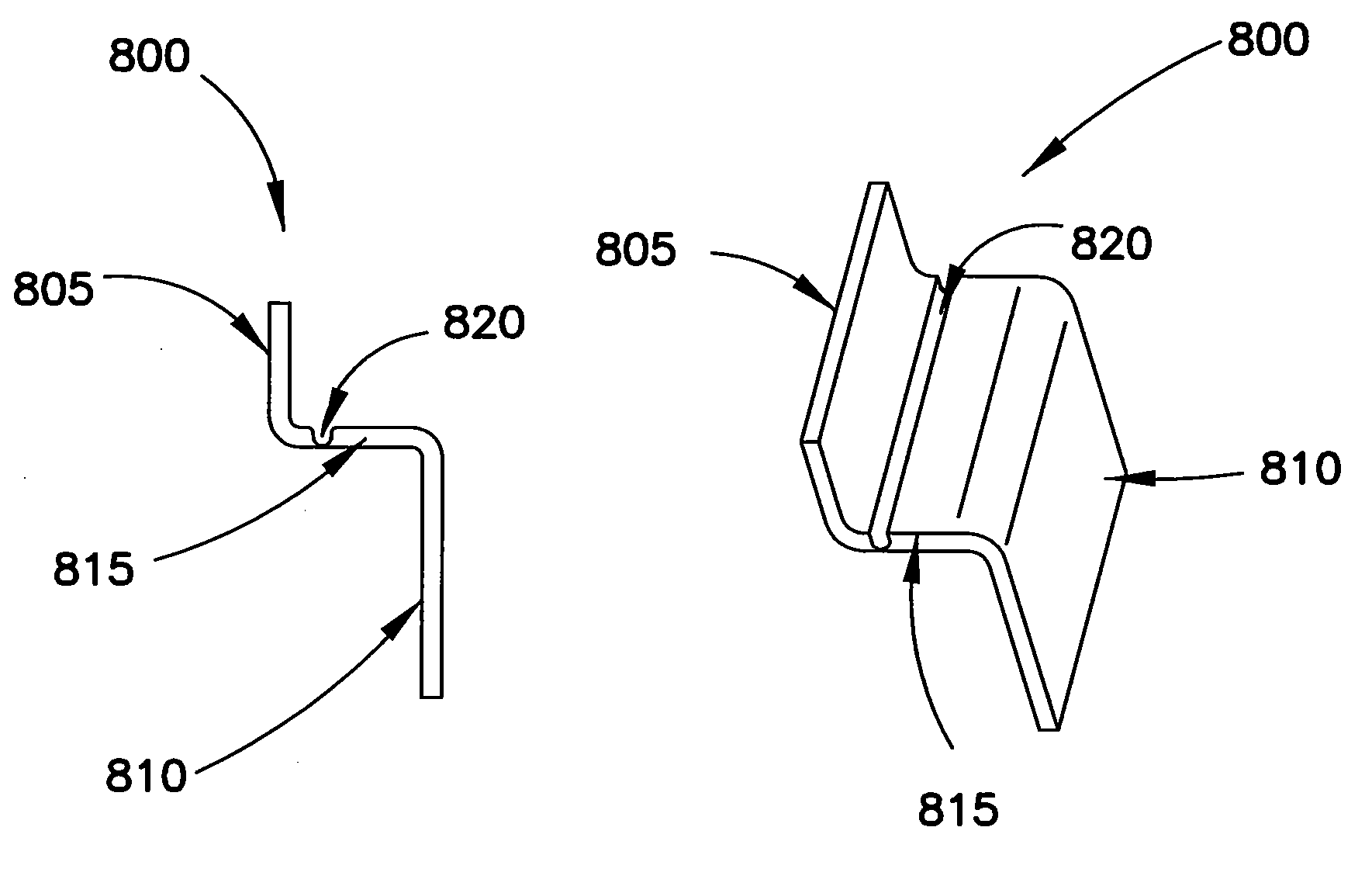

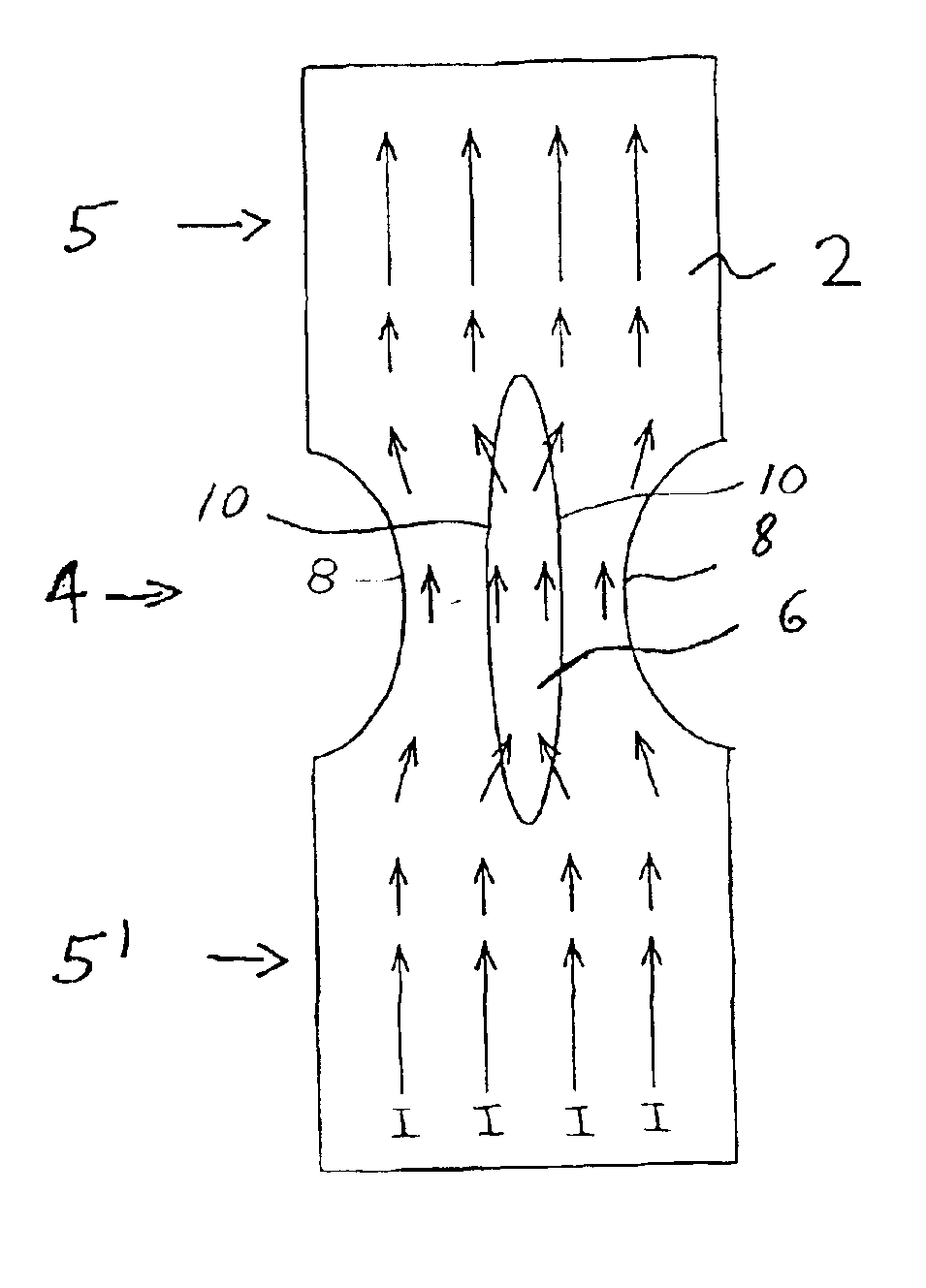

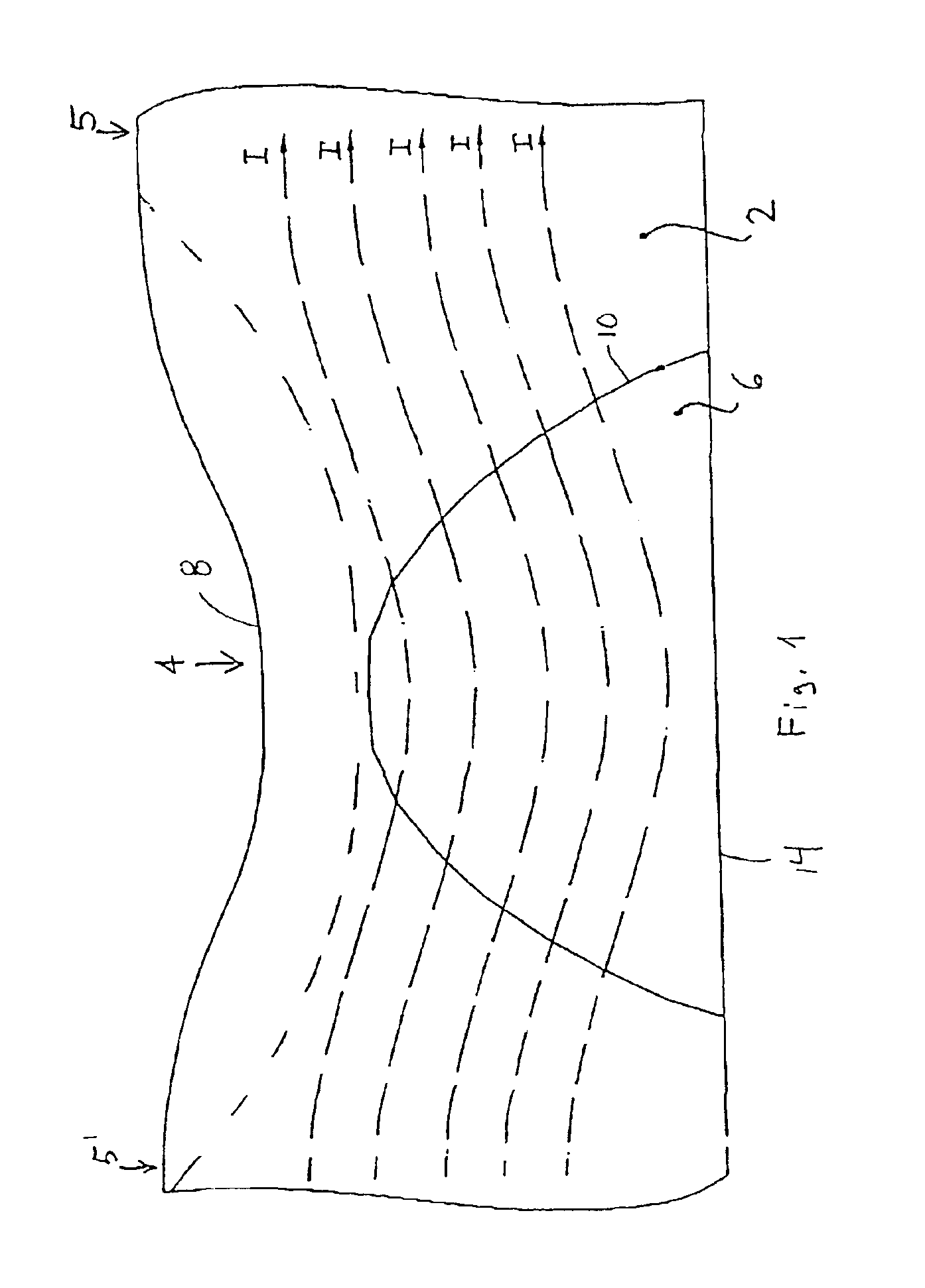

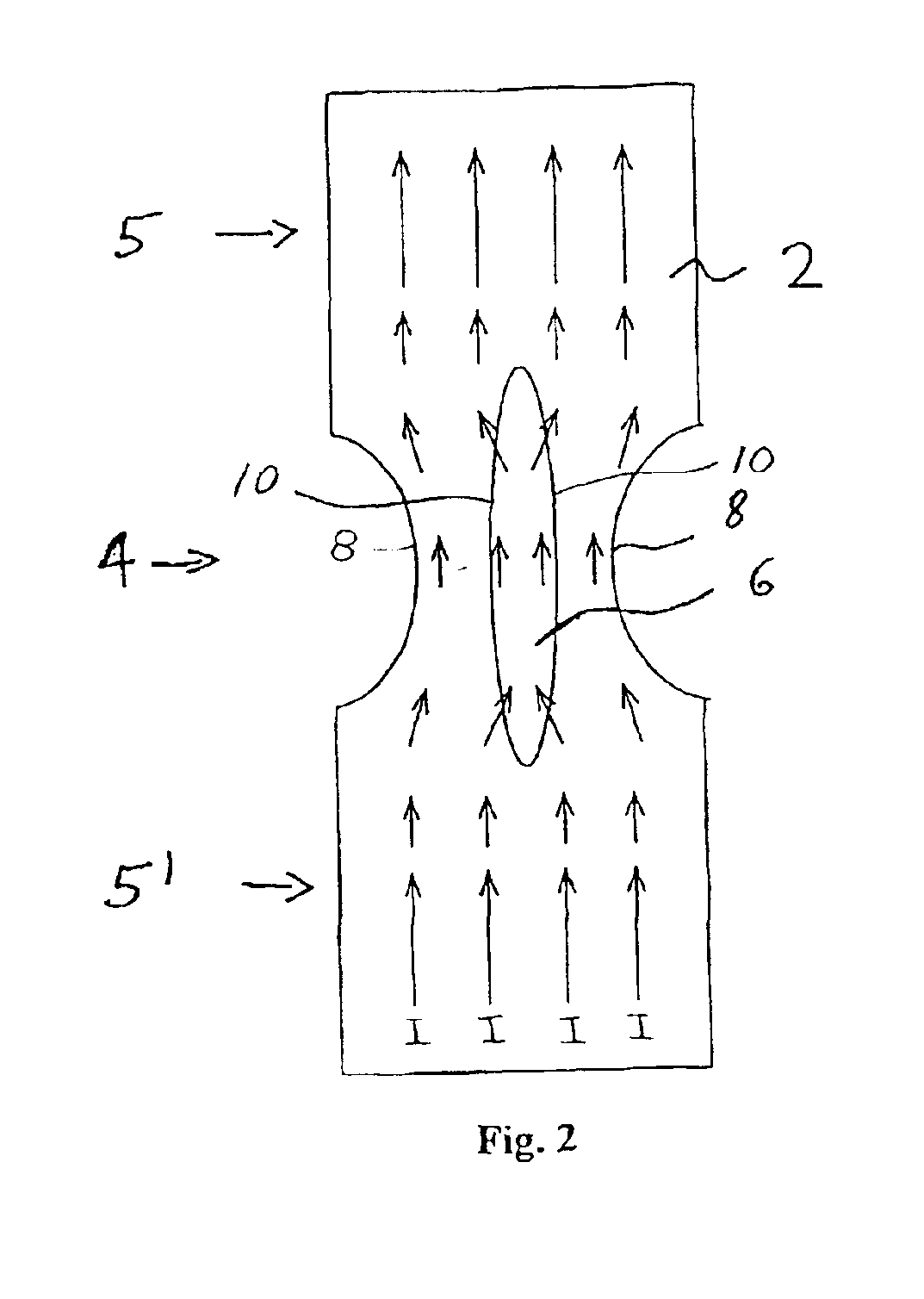

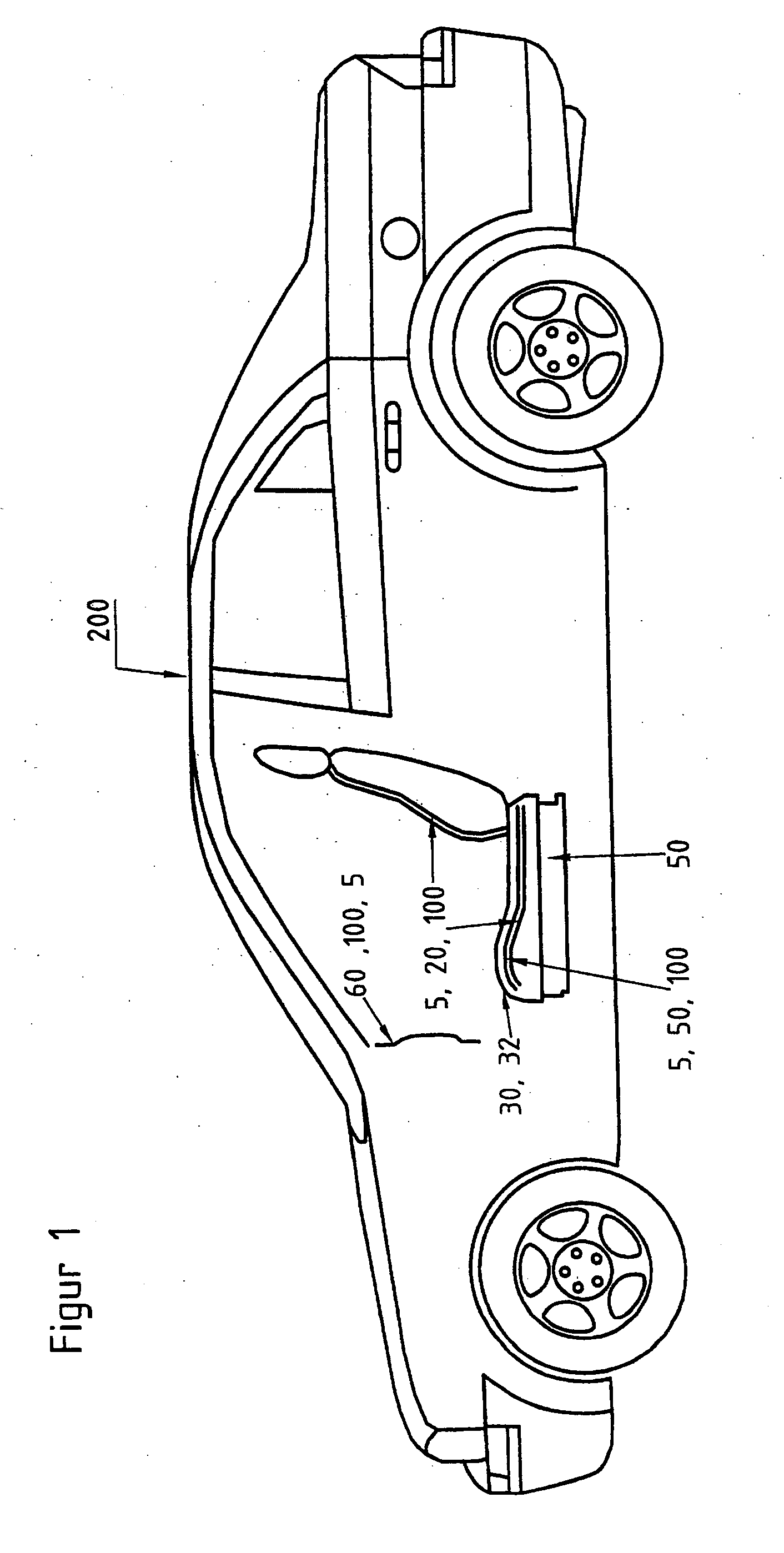

Areal electric conductor comprising a constriction

InactiveUS6872882B2Reduce and eliminate spot in arealPlastic/resin/waxes insulatorsSingle bars/rods/wires/strips conductorsEngineeringConstriction

An electrical conductor including an areal conductor having a constricted current path region along a length thereof is described, in which an accessory conductor bridges the constricted current path region along the length of the areal conductor such that a substantially uniform current density exists throughout the electrical conductor. In this way, current hot spots in the region of the current path constriction are avoided. The constricted current path region may be defined by two lengthwise edges of the areal conductor and the accessory conductor may include two circular or parabolic contours, each opposing and spaced apart from a respective edge of the areal conductor defining the constricted current path region.

Owner:GENTHERM GMBH

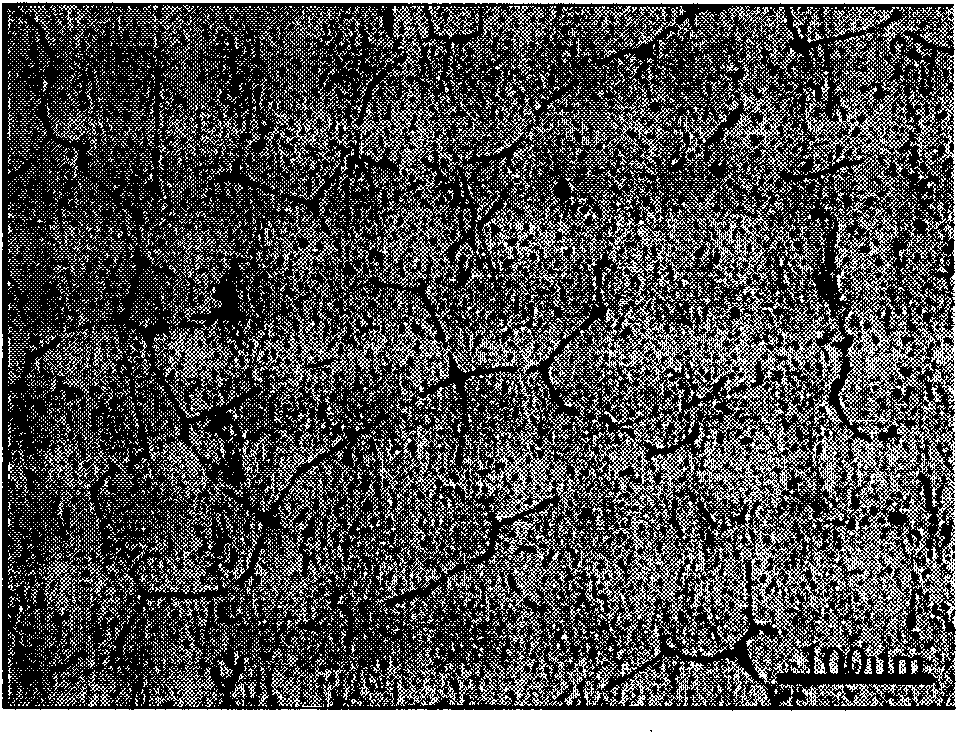

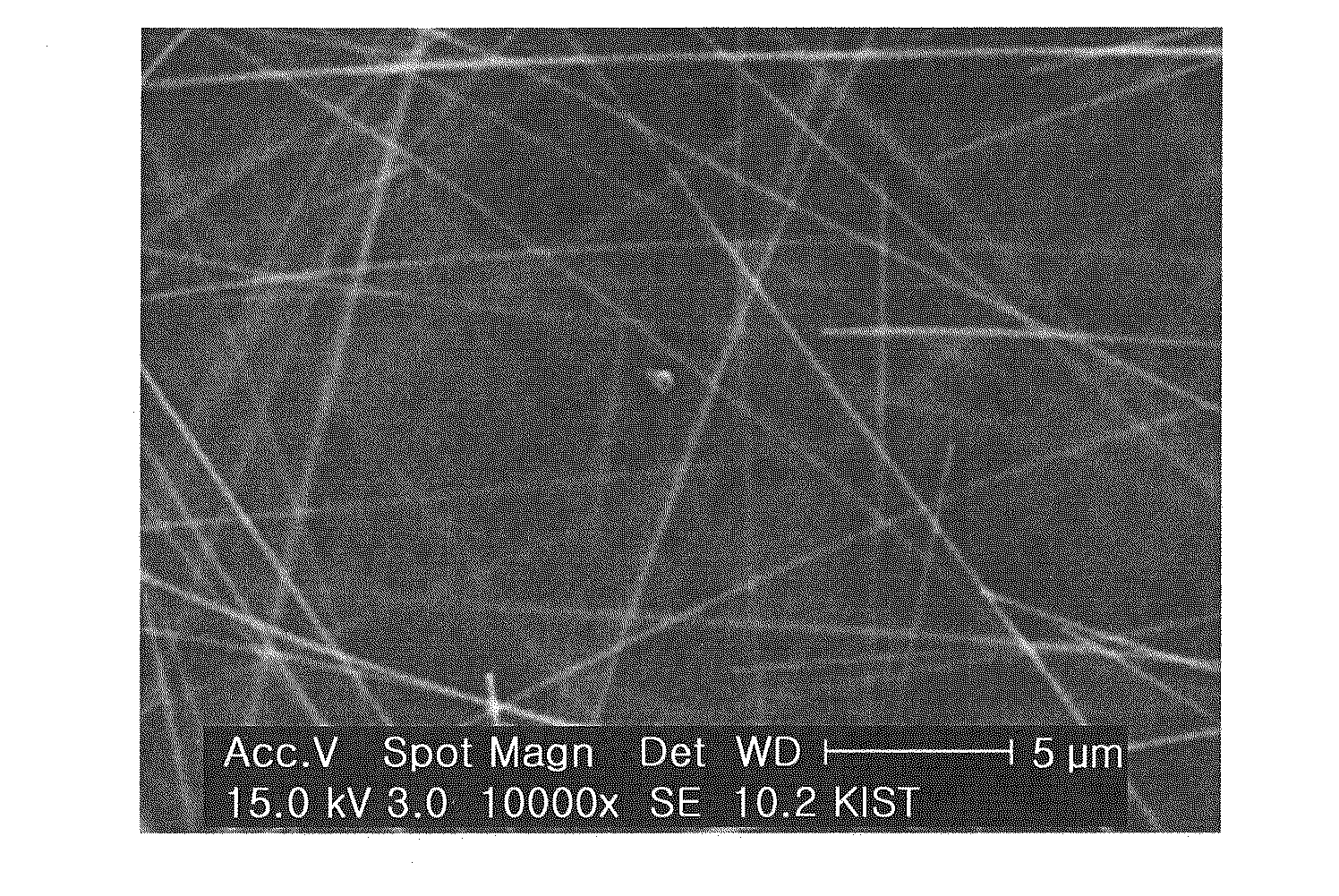

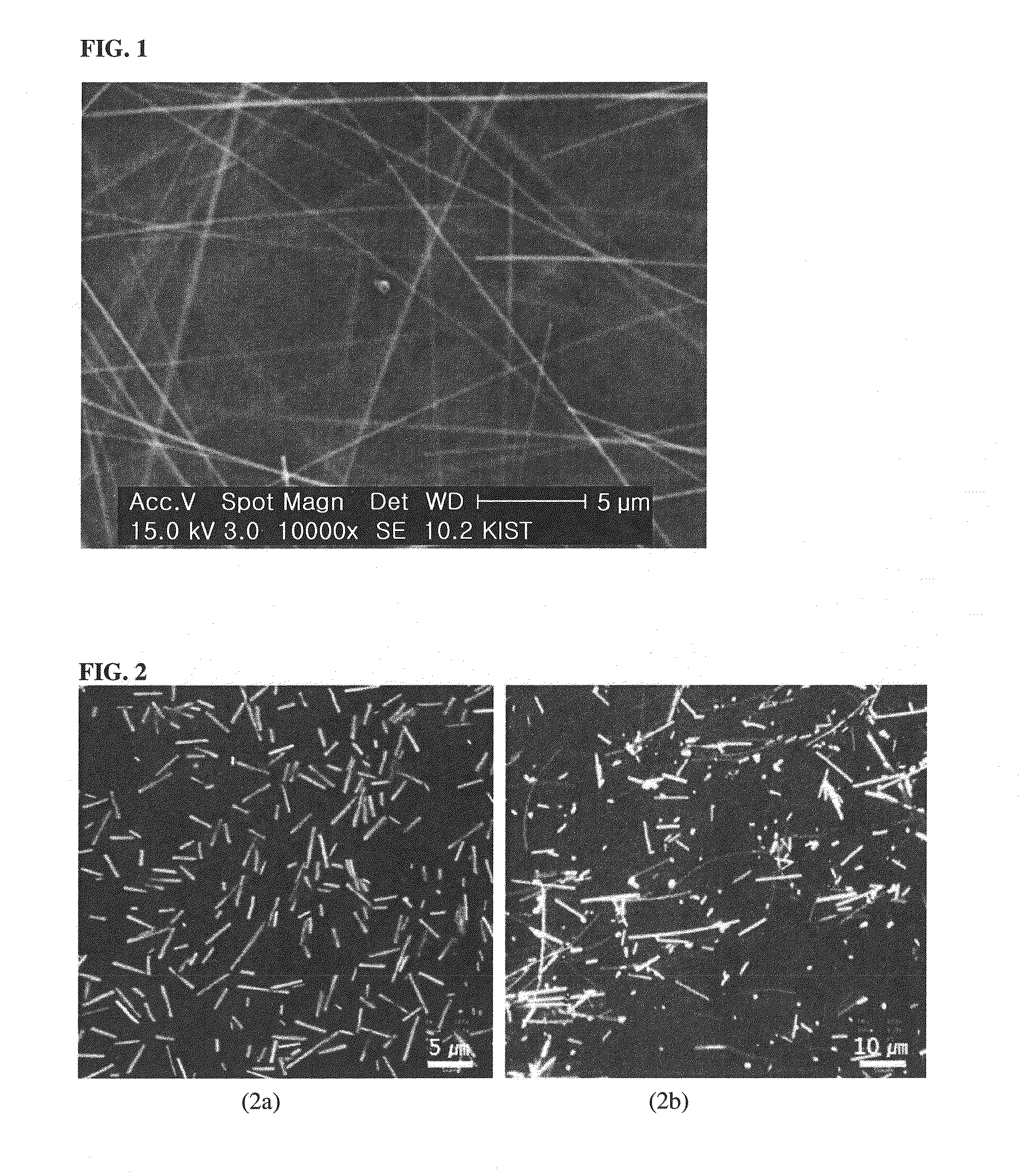

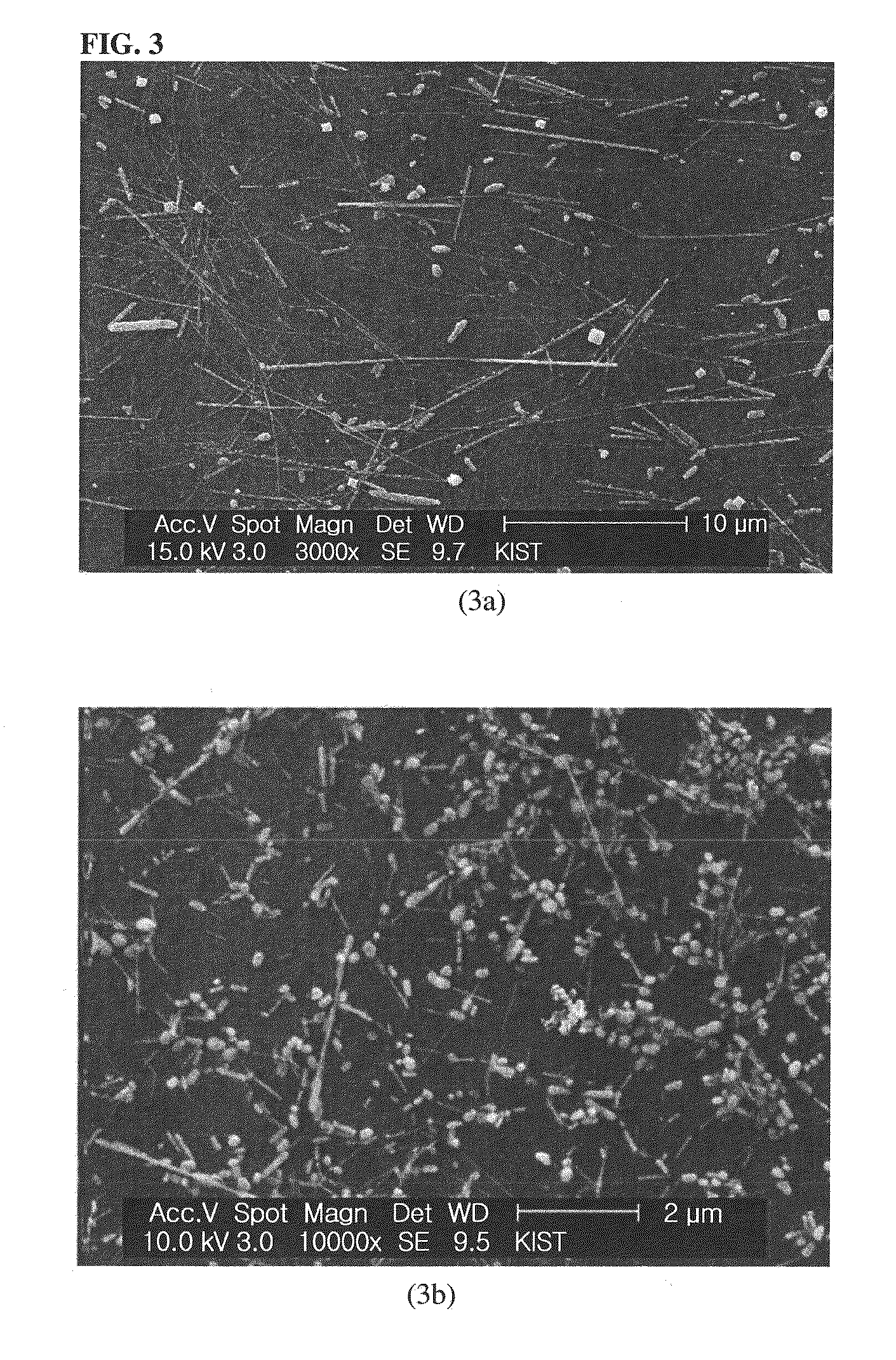

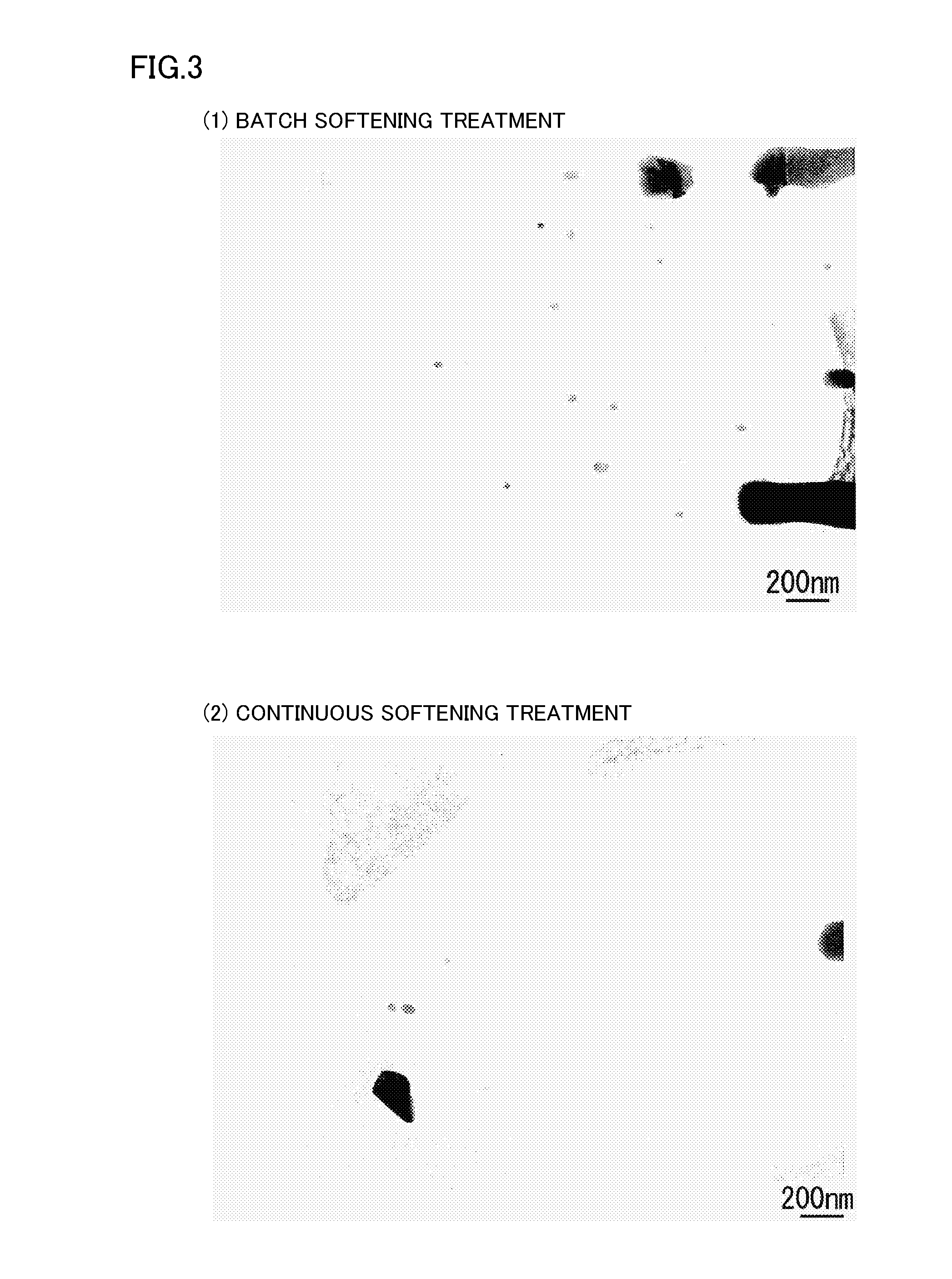

Metal nanowires with high linearity, method for producing the metal nanowires and transparent conductive film including the metal nanowires

ActiveUS20130087363A1Improve linearityExcellent thermalMaterial nanotechnologySingle bars/rods/wires/strips conductorsConductive polymerCarbon nanotube

Metal nanowires with high linearity can be produced using metal salts at a relatively low temperature. A transparent conductive film can be formed using the metal nanowires. Particularly, the transparent conductive film has high transmittance, low sheet resistance, and good thermal, chemical and mechanical stability. The transparent conductive film has a high electrical conductivity due to the high linearity of the metal nanowires. The metal nanowires take up 5% or less of the volume of the transparent conductive film, ensuring high transmittance of the transparent conductive film. Furthermore, the metal nanowires are useful as replacements for existing conductive materials, such as ITO, conductive polymers, carbon nanotubes and graphene. The metal nanowires can be applied to flexible substrates and other various substrates due to their good adhesion and high applicability to the substrates. Moreover, the metal nanowires can find application in various fields, such as displays and solar cell devices.

Owner:KOREA INST OF SCI & TECH

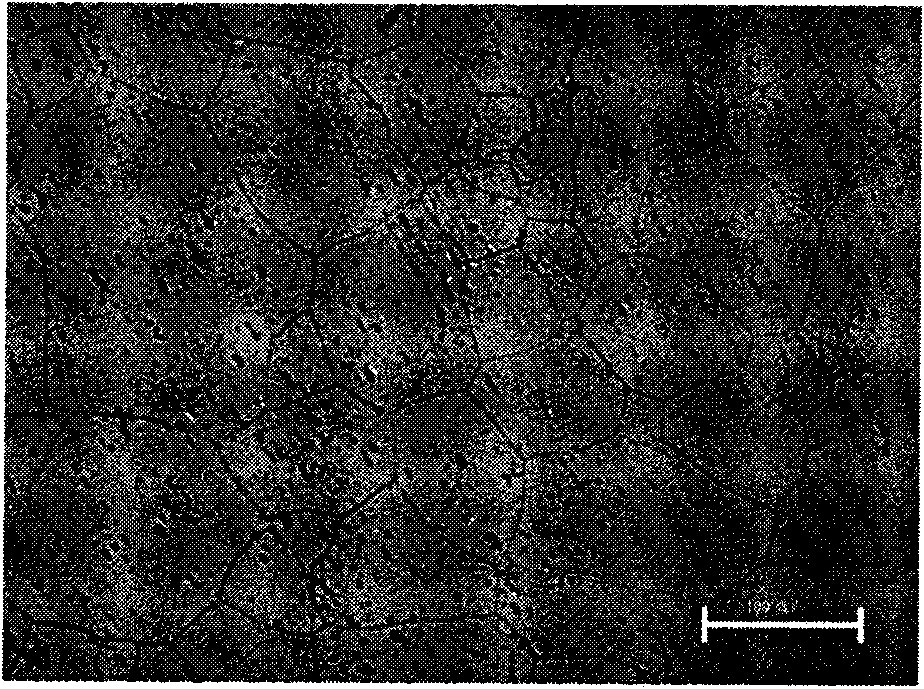

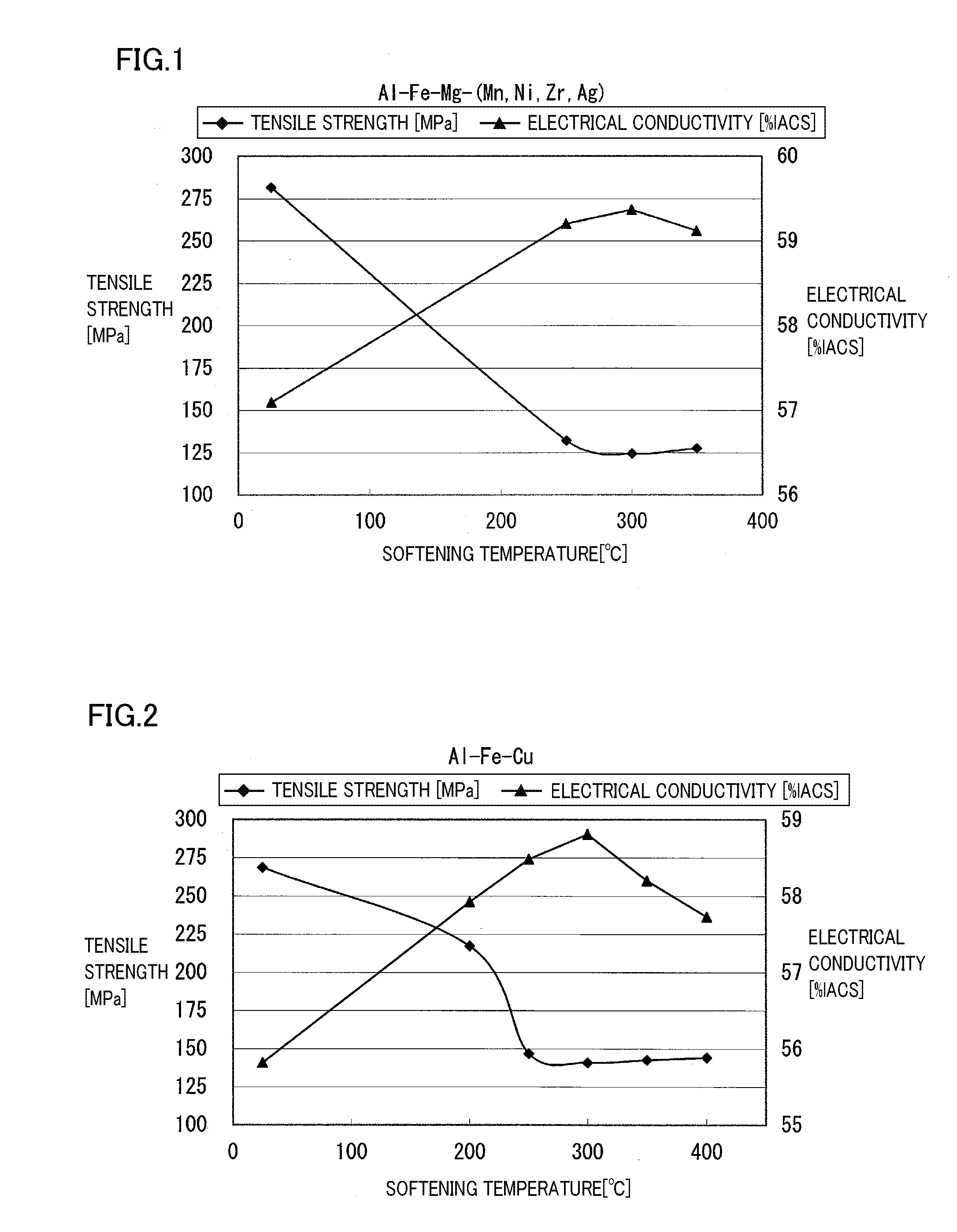

Aluminum alloy wire, and aluminum alloy twisted wire, covered electrical wire and wire harness using the same

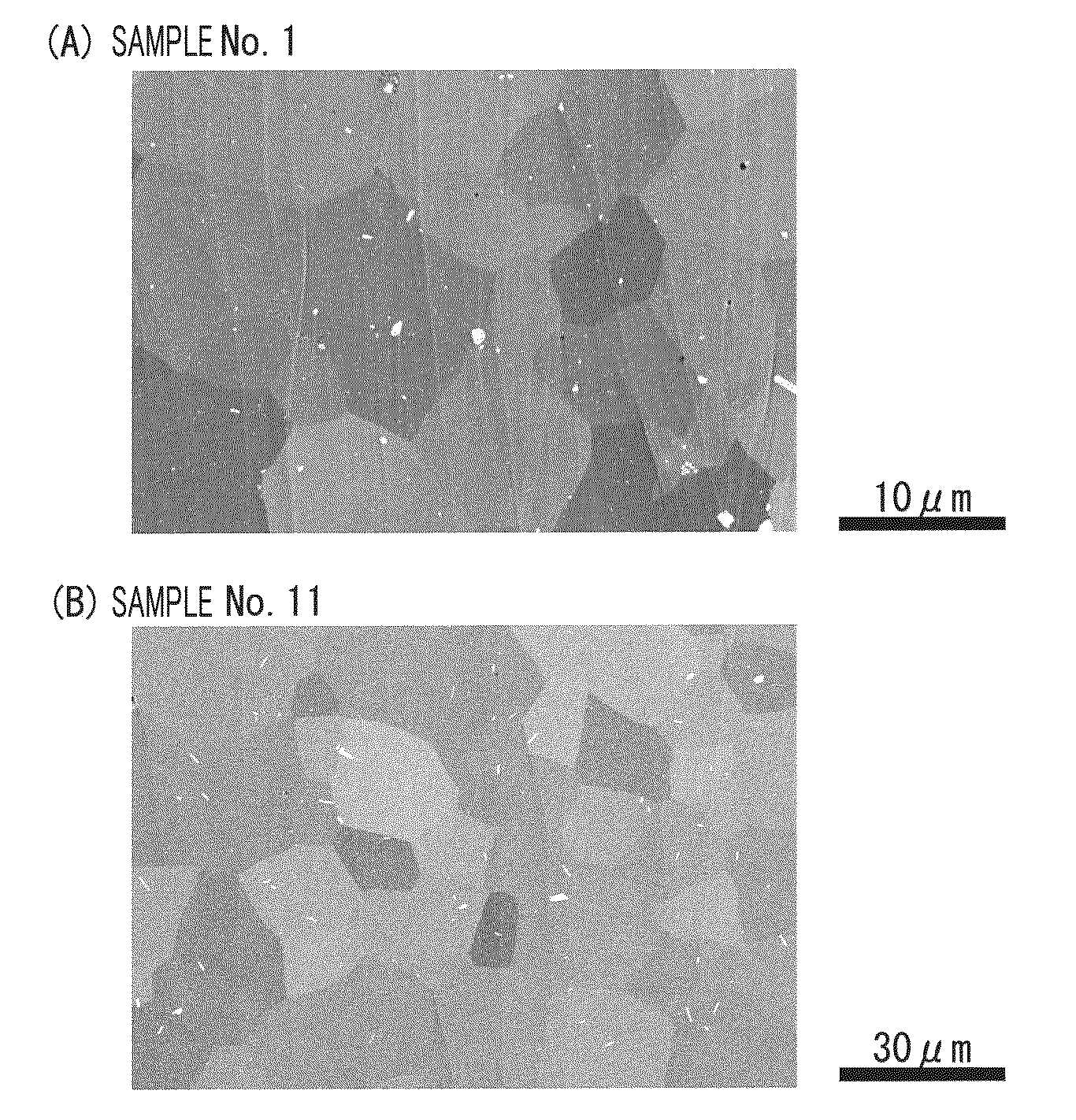

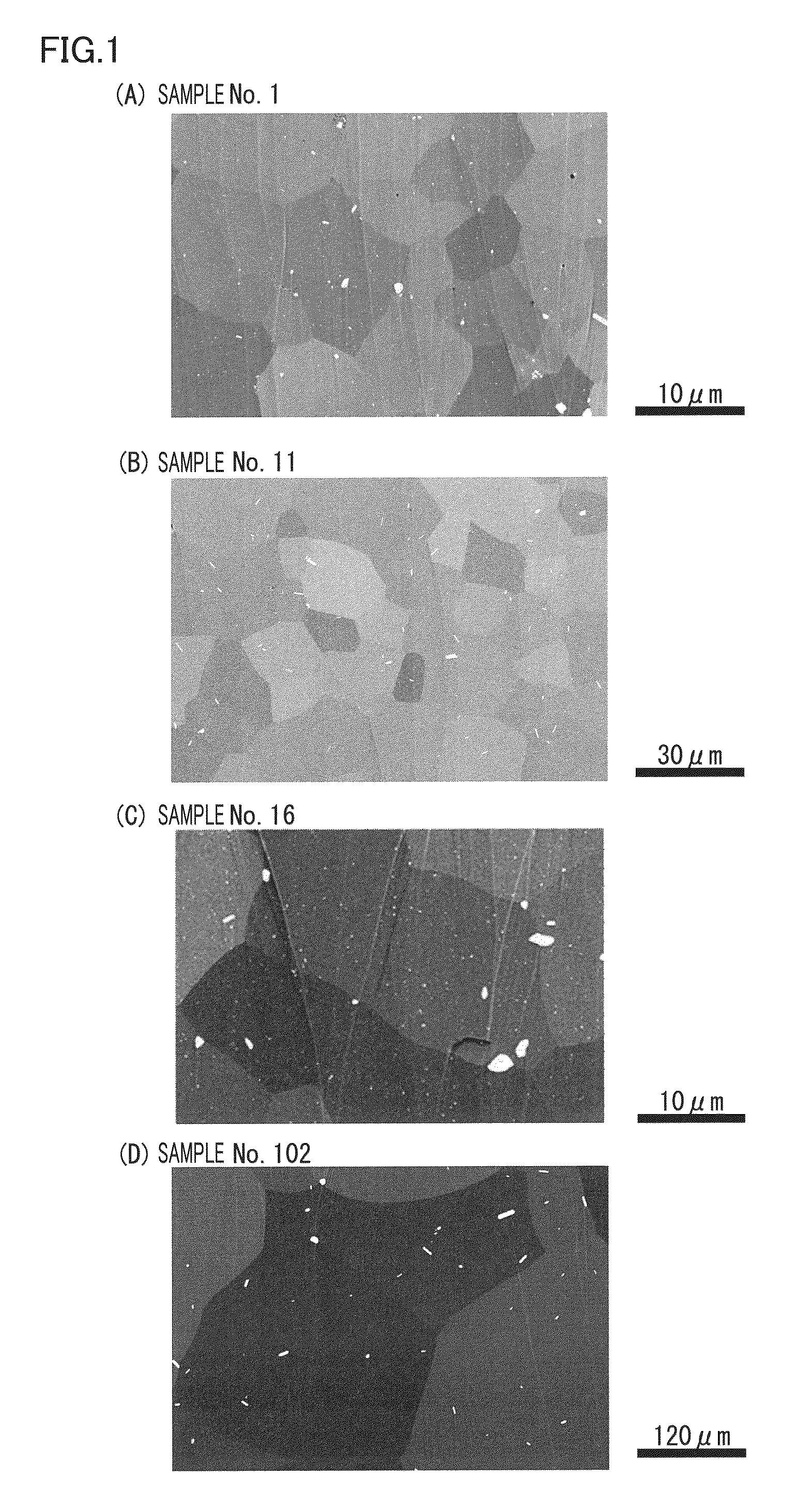

ActiveUS20130264115A1High strengthHigh elongationSingle bars/rods/wires/strips conductorsConductive materialFine structureCable harness

An aluminum (Al) alloy wire, which is an extra fine wire having a wire diameter of 0.5 mm or less, contains, in mass %, Mg at 0.03% to 1.5%, Si at 0.02% to 2.0%, at least one element selected from Cu, Fe, Cr, Mn and Zr at a total of 0.1% to 1.0% and the balance being Al and impurities, and has an electrical conductivity of 40% IACS or more, a tensile strength of 150 MPa or more, and an elongation of 5% or more. By producing the extra fine wire from an Al alloy of a specific composition containing Zr, Mn and other specific elements, though the extra fine wire is extra fine, it has a fine structure with a maximum grain size of 50 μm or less and is superior in elongation.

Owner:SUMITOMO ELECTRIC IND LTD +2

Heat-resistant aluminum-alloy conductor material for cables and manufacture method thereof

InactiveCN101948971AImprove creep resistanceHigh tensile strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare-earth elementElectrical conductor

The invention relates to a heat-resistant aluminum-alloy conductor material for cables and a manufacture method thereof. The aluminum-alloy conductor material is prepared from the following components in percentage by weight: 0.3-1.0 percent of Fe, 0.01-0.3 percent of Cu, 0.01-0.3 percent of Mg, 0.01-0.3 percent of one, two or three of Mg, Ca, Mo and Sb and 0.05-0.8 percent of one or more rear-earth elements of Sc, Y and Er, not larger than 0.1 percent of Si, not larger than 0.15 percent of other impurities and the balance of Al. The aluminum-alloy conductor material has excellent conductivity, tensile performance, flexible performance and excellent heat resistance, can be used as insulated cable cores of wires and cables and is particularly suitable for overhead insulated conductor wire cores.

Owner:绩溪欣意圣厚源电缆有限公司

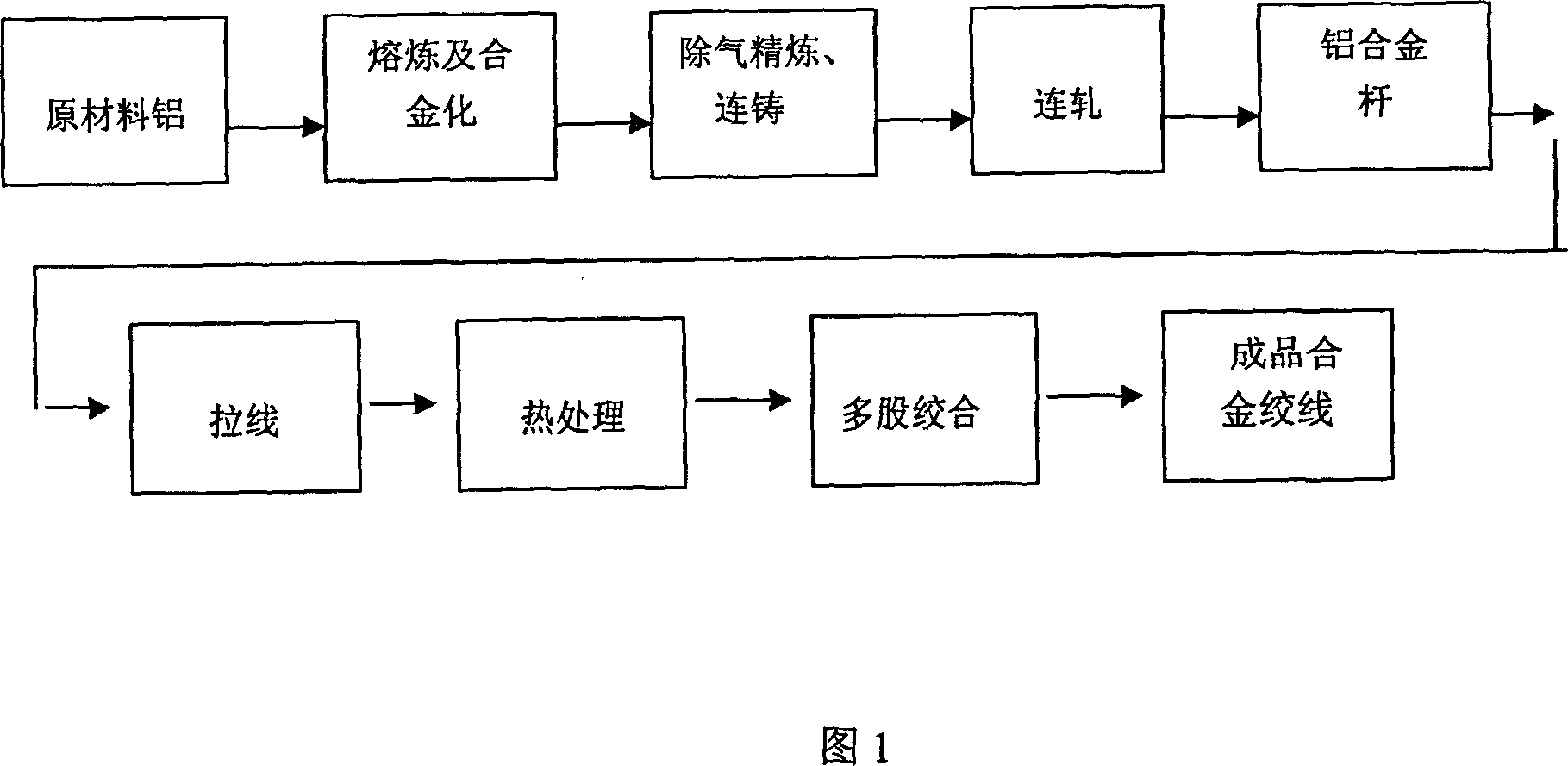

Intermediate-strength aluminum alloy wire and process for manufacturing same

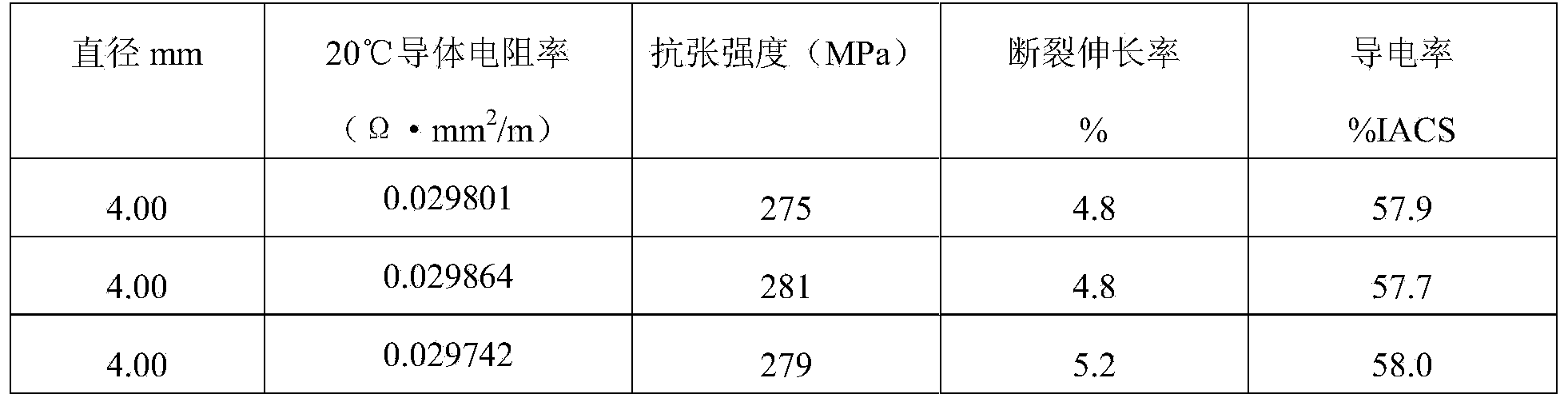

ActiveCN104028961APurify gas impuritiesHigh strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsEddy currentSolid solution

The invention belongs to the field of overhead power transmission technologies, and discloses an intermediate-strength aluminum alloy wire and a process for manufacturing the same. The intermediate-strength aluminum alloy wire is used for an overhead conducting wire. The process includes adjusting components of alloy to a certain extent, and controlling an online deaeration purification system, rolling and an online solid-solution quenching system; performing wire drawing and ageing processing to ultimately obtain the single intermediate-strength aluminum alloy wire. The tensile strength of the single intermediate-strength aluminum alloy wire ranges from 260MPa to 300MPa, the elongation of the single intermediate-strength aluminum alloy wire is higher than or equal to 3.5%, and the single-wire conductivity of the single intermediate-strength aluminum alloy wire is higher than or equal to 57.5% IACS. The intermediate-strength aluminum alloy wire and the process have the advantages that the intermediate-strength aluminum alloy wire manufactured by the aid of the process is high in strength and elongation and good in conductivity, and an intermediate-strength aluminum alloy stranded wire which is formed after a plurality of intermediate-strength aluminum alloy wires are stranded with one another can be used for an overhead power transmission line and is high in tensile weight ratio, so that the running safety of the line can be improved; magnetic hysteresis loss and eddy current loss due to conventional steel-cored aluminum stranded wires can be prevented by the stranded wire which is completely formed after the intermediate-strength aluminum alloy wires are stranded with one another, and electric energy loss of the line can be greatly reduced.

Owner:FAR EAST CABLE +2

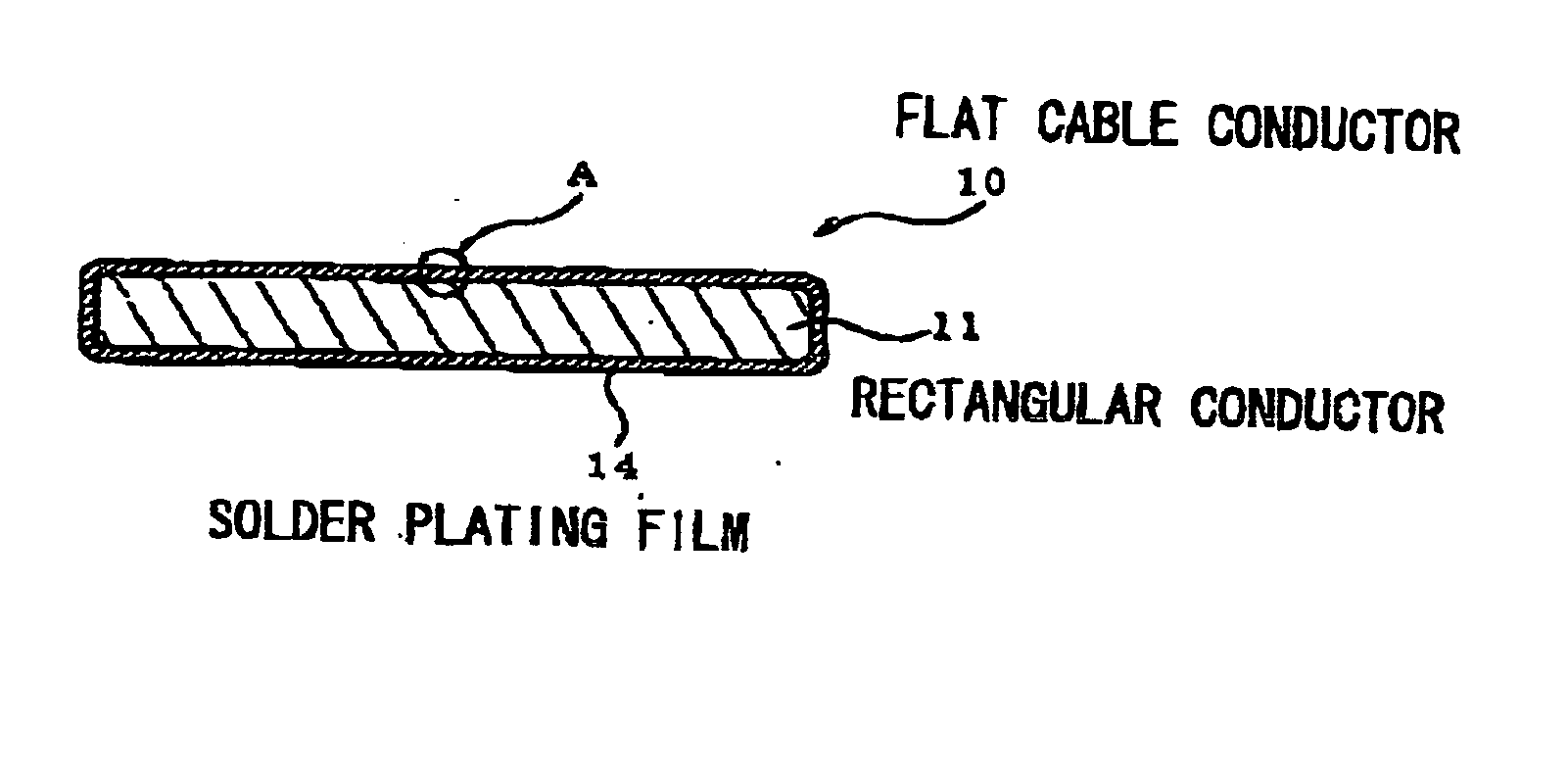

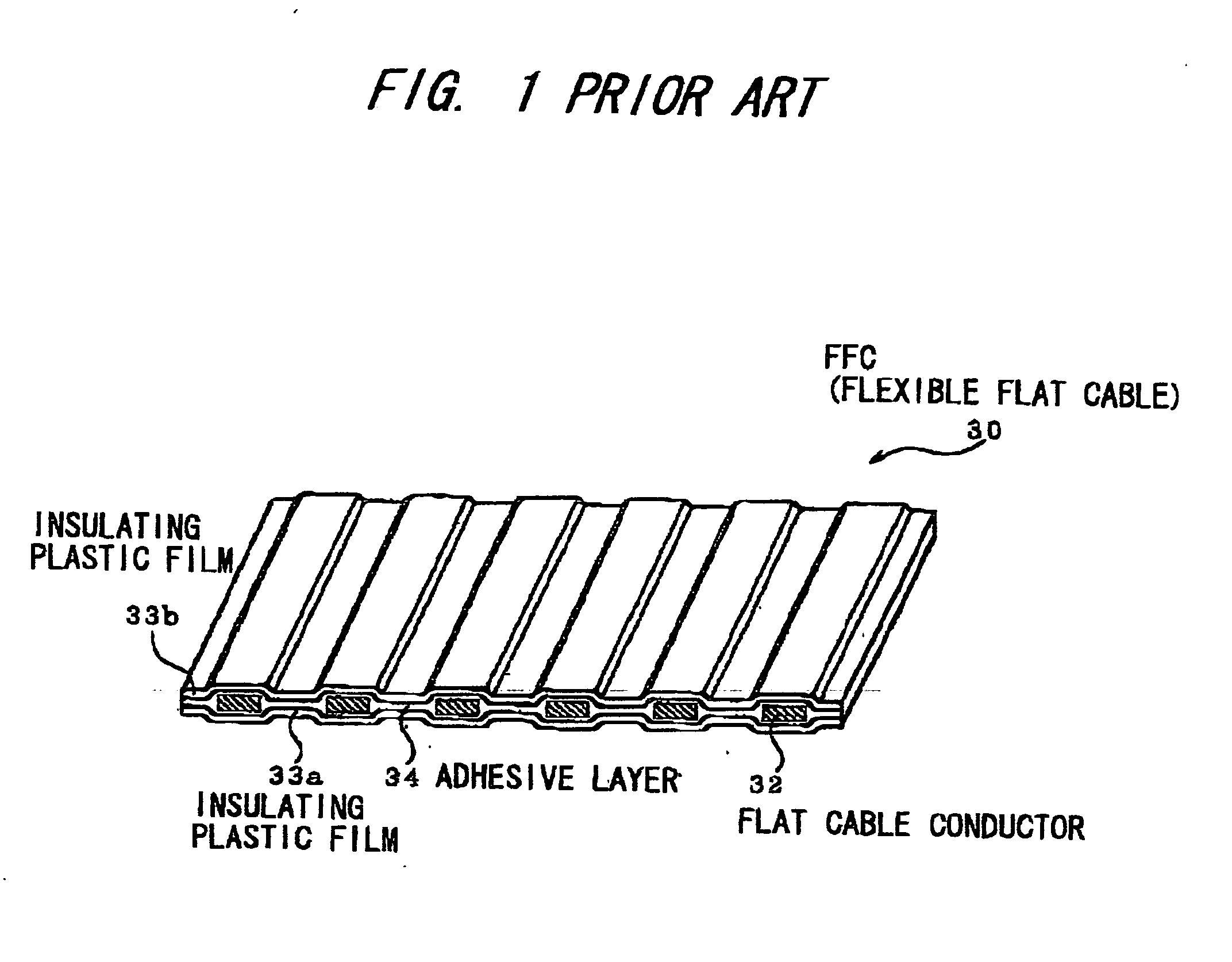

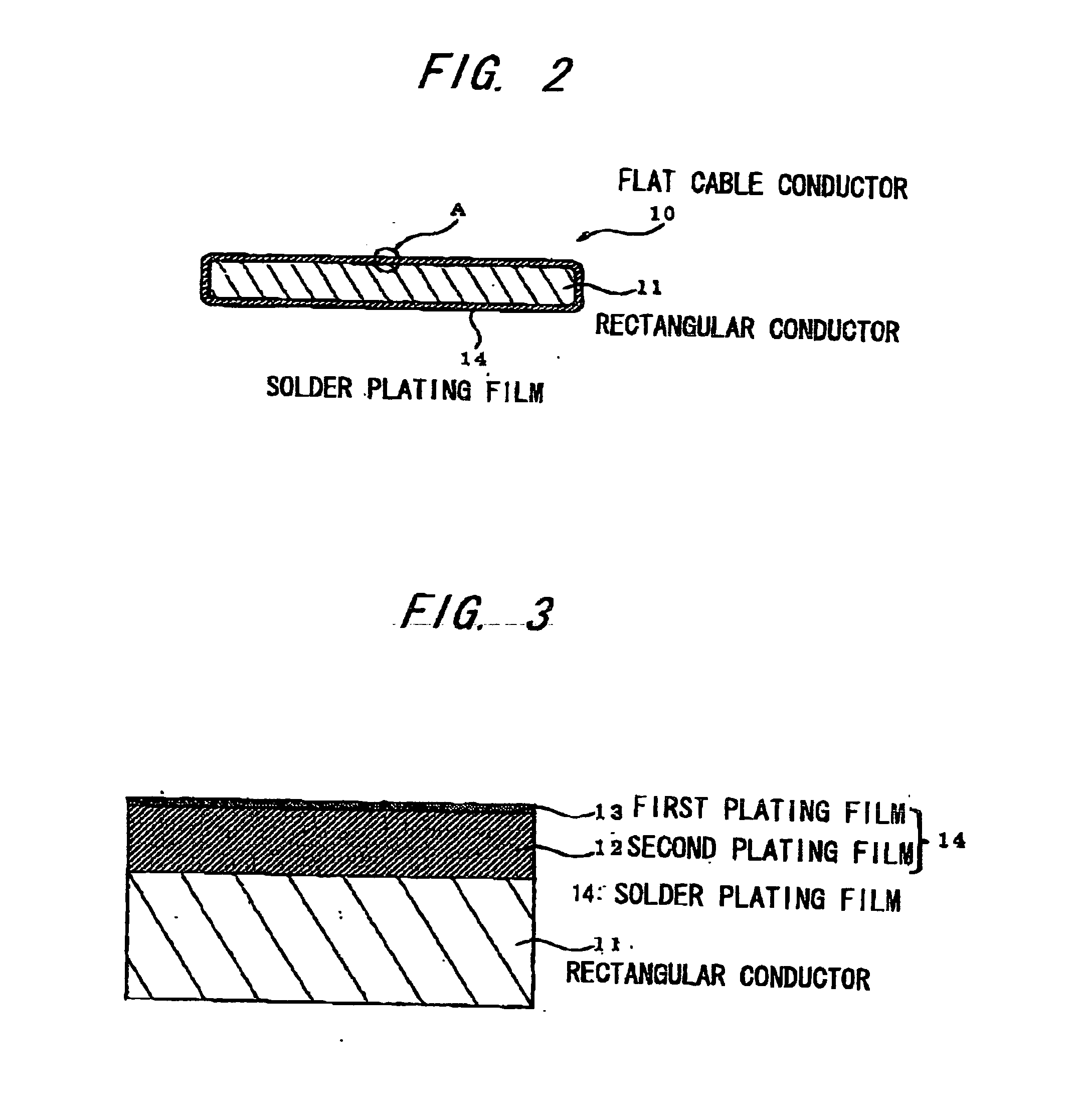

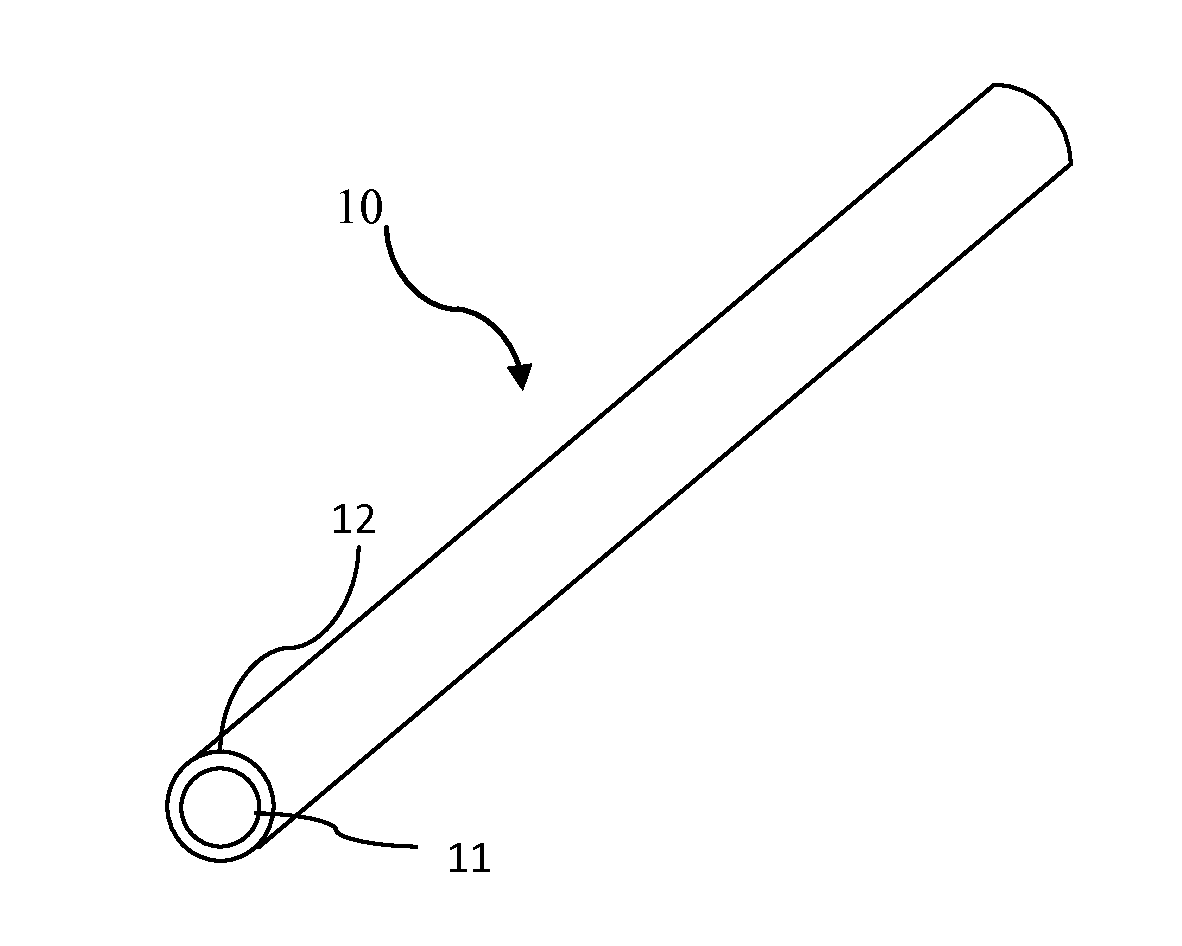

Flat cable conductor, method of making the same and flat cable using the same

ActiveUS20050211461A1Increase manufacturing costHot-dipping/immersion processesInsulating substrate metal adhesion improvementElectrical conductorElectric cables

Owner:HITACHI CABLE

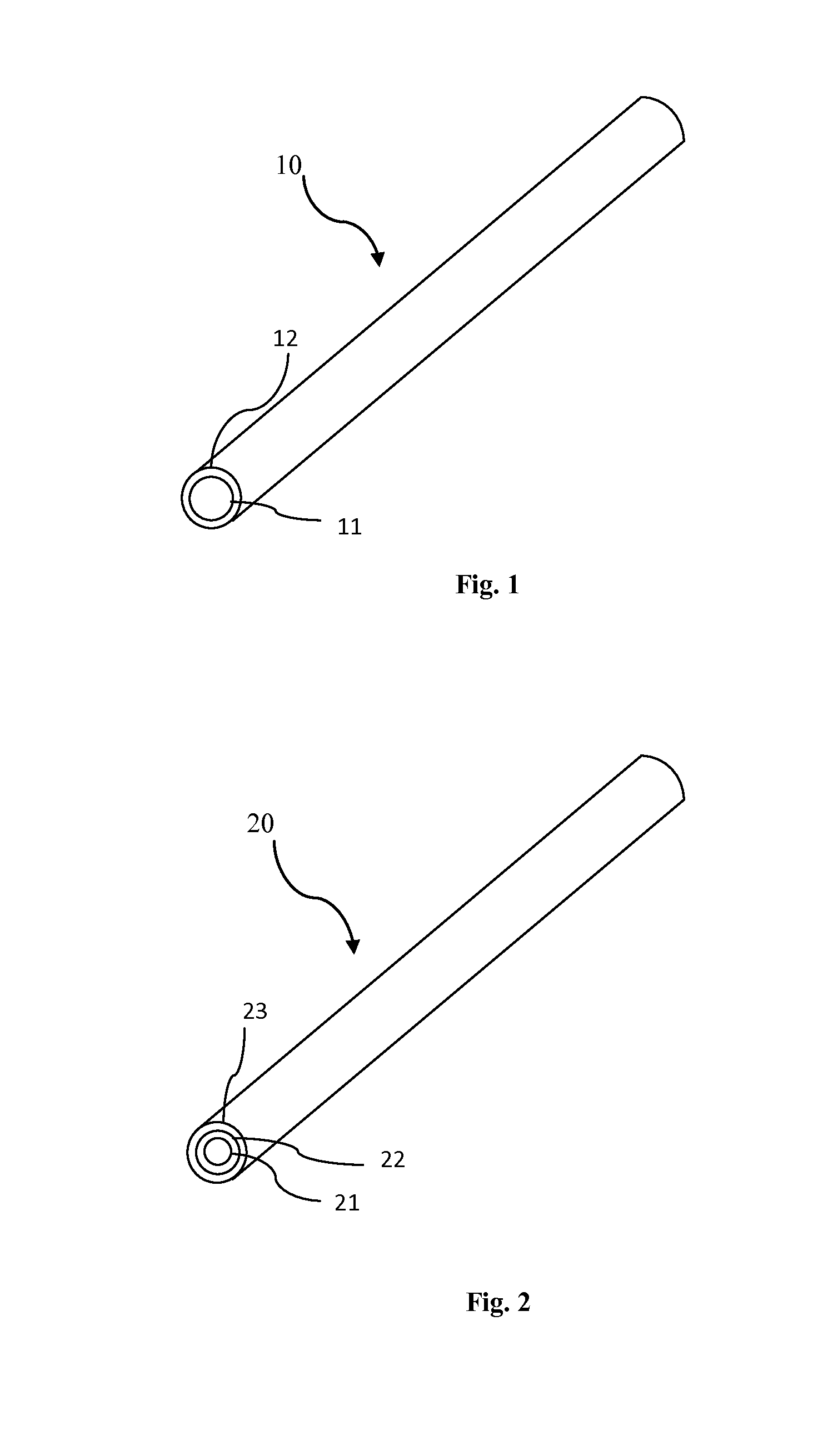

Graphene electrical wire and a method for manufacturing thereof

The present disclosure relates to a graphene electrical wire and a method for manufacturing thereof. In particular, the graphene electrical wire includes a metal core having a shape of fiber, and a graphene layer synthesized on the outer surface of the metal core. Also, the method includes the steps of providing a metal core having a shape of fiber, and synthesizing a graphene layer on the outer surface of the metal core.

Owner:K TECH INC

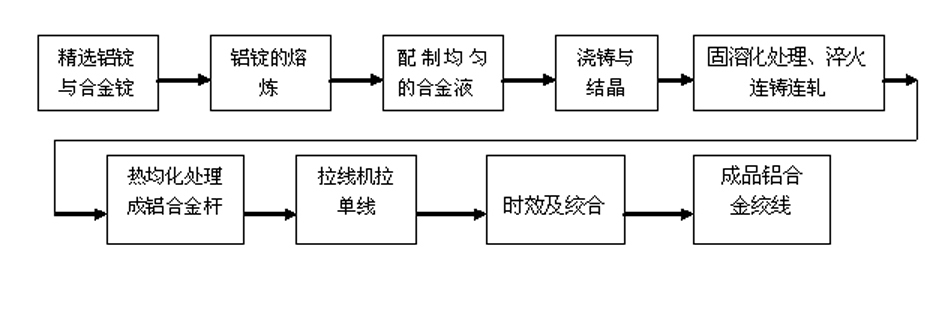

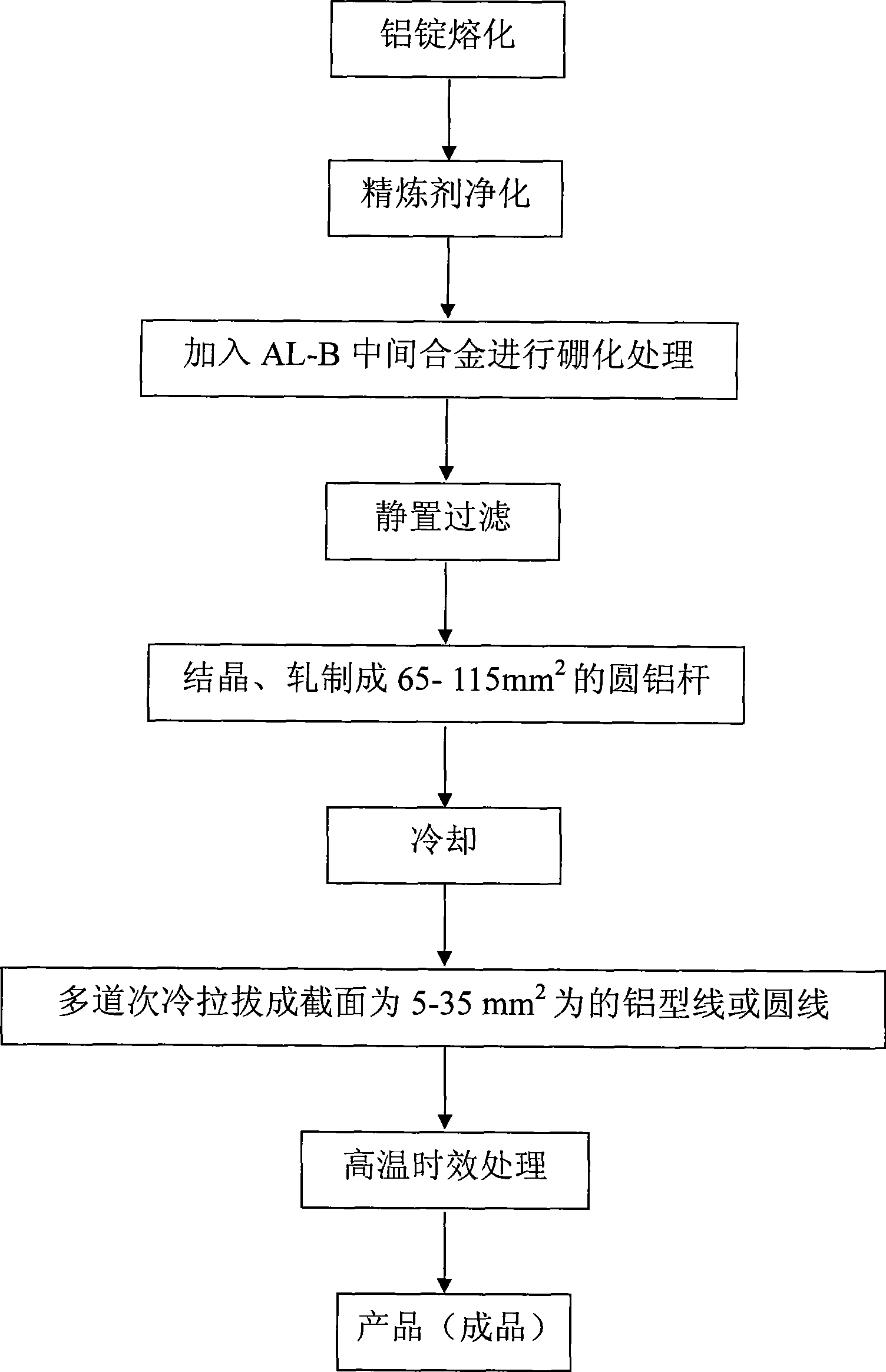

Method for manufacturing moderate intensity aluminium alloy wire with 57% electric conductivity

ActiveCN102041418AQuick checkControl contentSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare earthIngot

The invention provides a method for manufacturing a moderate intensity aluminium alloy wire with 57% electric conductivity, and relates to a method for manufacturing a moderate intensity aluminium alloy wire of which the electric conductivity reaches 57% (IACS), which comprises the following steps of: (1) selecting aluminum matrixes and aluminum moderate alloy ingots; (2) carrying out on-the-spot sample analysis and regulation; placing the selected aluminum ingots into a shaft furnace to be melted to obtain an aluminum liquid; and refining with a refining agent; (3) casting and crystallizing: enabling the aluminium alloy liquid in a tilting holding furnace to pass through a trough, and filtering with a ceramic filter plate, and adding a rear earth to ensure the rear earth content to be 0.05-0.15%; continuously casting in an aluminium alloy continuous casting machine to form the aluminium alloy ingots; and rolling the aluminium alloy ingots to obtain moderate intensity aluminium alloy rods by an aluminium alloy continuous mill; (4) solutionizing and quenching: carrying out homogenizing heat treatment on the aluminium alloy rods; and (5) drawing, ageing and twisting: drawing the aluminium alloy rods treated by the former process into the aluminium alloy wires with the required diameter on an aluminium alloy drawing machine, and twisting the aluminium alloy wires by using a frame-type wire twisting machine to manufacture the moderate intensity aluminium alloy wires with 57% electric conductivity in IACS.

Owner:SHANGHAI ZHONGTIAN ALUMINUM WIRE

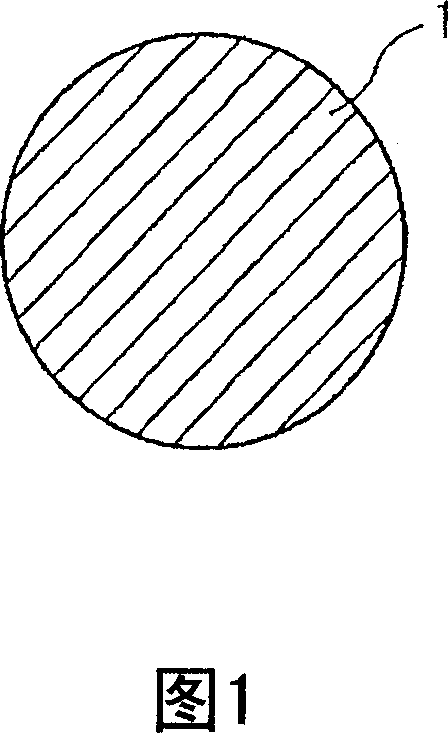

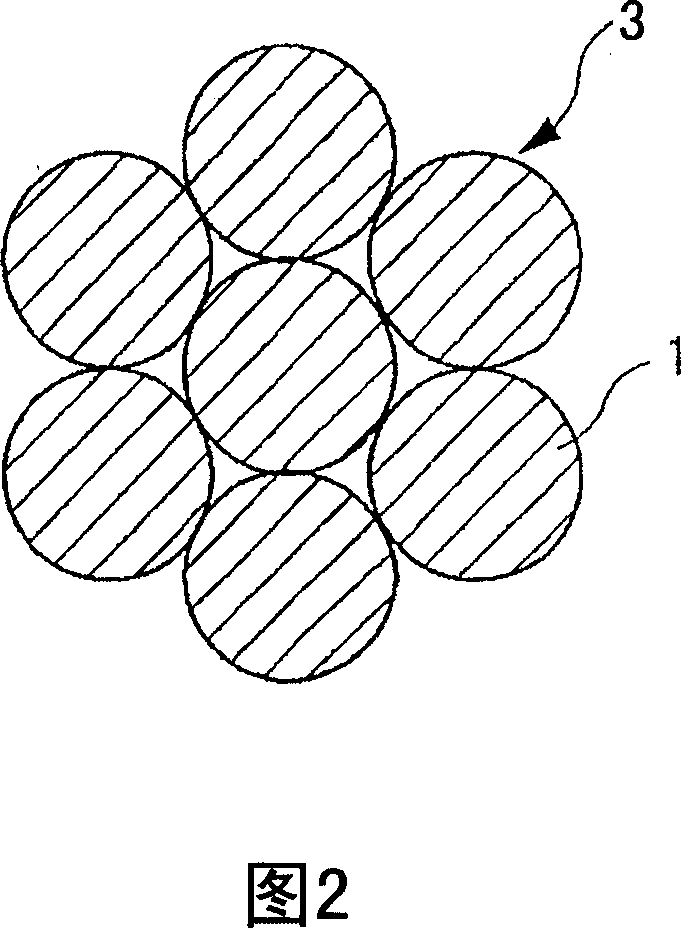

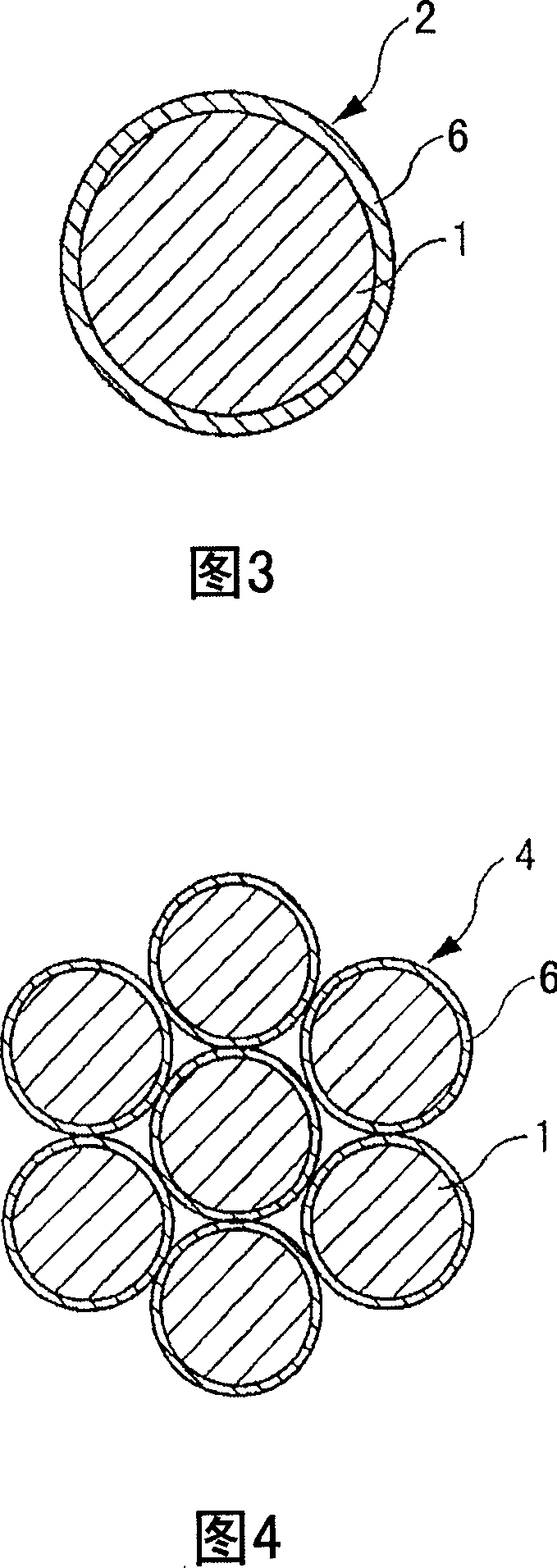

Electrode Wire For Solar Cell

ActiveUS20080169020A1Improve conductivitySingle bars/rods/wires/strips conductorsLayered productsCopperSolar cell

A solar cell electrode wire includes a core material having a volume resistivity of not greater than about 2.3 μΩ·cm and a proof strength in the range of about 19.6 MPa to about 85 MPa, and a hot-dip solder plating layer disposed on a surface of the core material. The core material is preferably an annealed pure copper material having an oxygen content of not higher than about 20 ppm. The core material may be a clad material including an interlayer of aluminum and copper layers disposed on opposite surfaces of the interlayer.

Owner:HITACHI METALS LTD

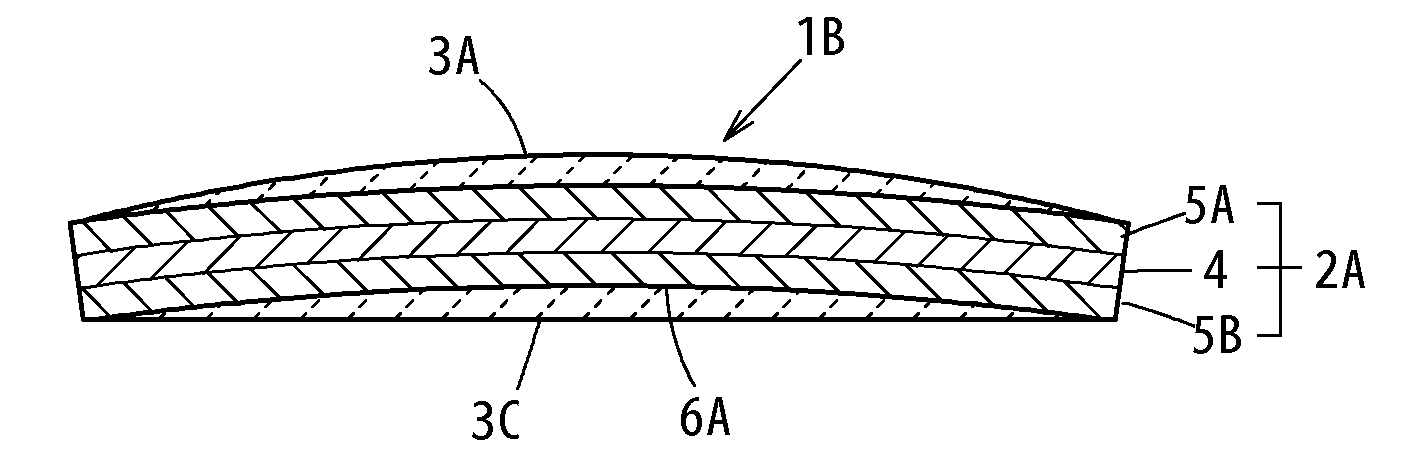

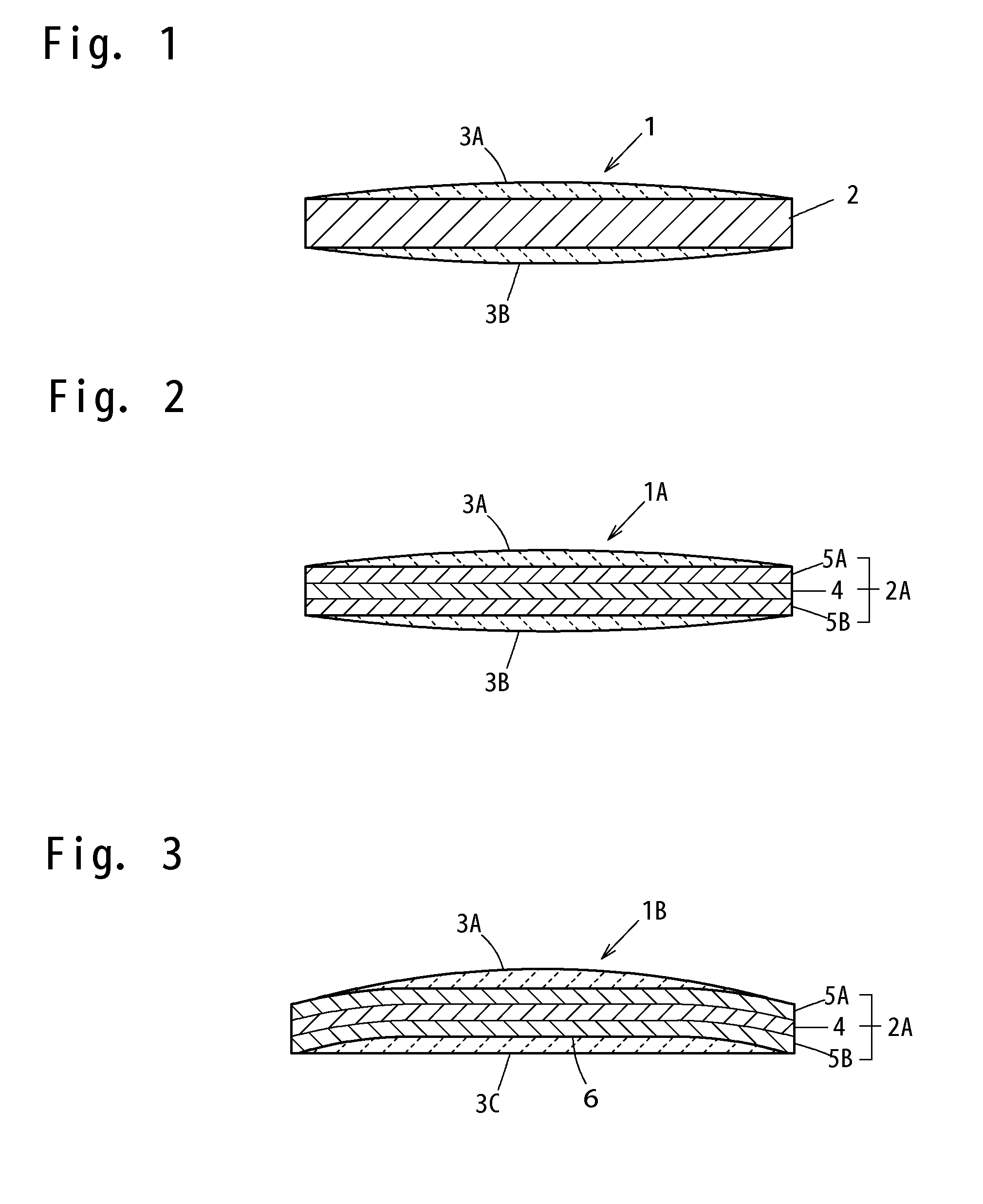

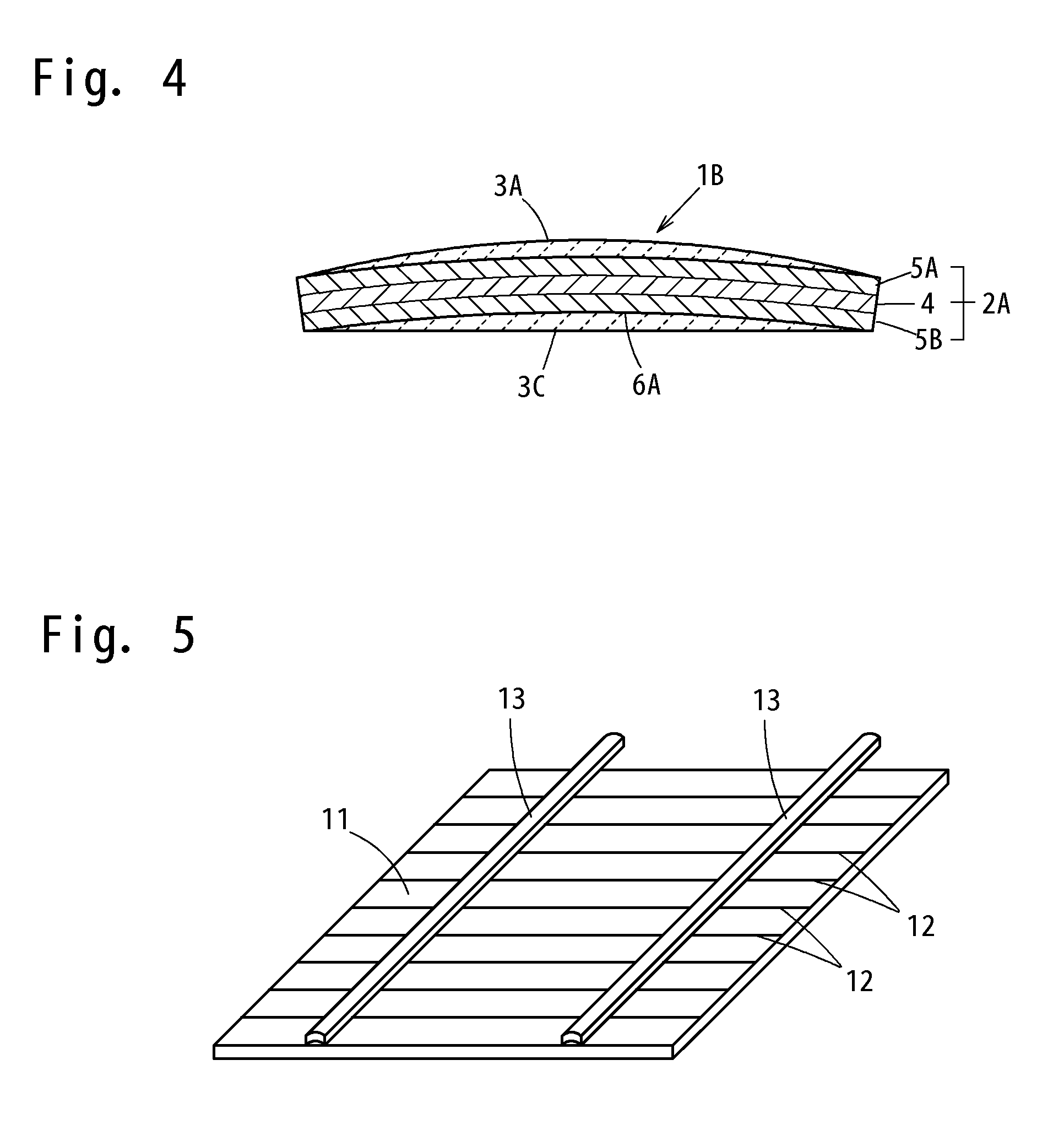

Extra-fine copper alloy wire, extra-fine copper alloy twisted wire, coaxial cable, multi-core cable and manufacturing method thereof

ActiveCN1988055AImprove heat resistanceHigh strength propertiesCoaxial cables/analogue cablesSingle bars/rods/wires/strips conductorsMulticore cableElectrical conductor

The object of the invention is to provide an extra-fine copper alloy wire, an extra-fine copper alloy twisted wire, an extra-fine insulated wire, a coaxial cable having high intensity, low resistance and high heat tolerance, their manufacturing method and a multicore cable thereof. The extra-fine copper alloy wire has 1 to 3 weight % of silver in the copper, a wire diameter less than 0.025 mm, and a tensile strength of more than 850 MPa, an electrical conductivity of more than 85% IACS after heat treatment; the coaxial cable (20A) is configured that, an inner conductor is formed by an extra-fine copper alloy twisted wire (3) twisted from seven extra-fine copper alloy wires (1), the inner conductor is then peripherally envelopped with a solid insulator (5a) to form an extra-fine insulated wire (10), a plurality of conductor wires (13) are winding in a screw shape on the periphery of the extra-fine insulated wire along a length direction of the extra-fine insulated wire to form an outer conductor (15), thereafter, the outer conductor is envenlopped with a protection layer (17).

Owner:HITACHI CABLE

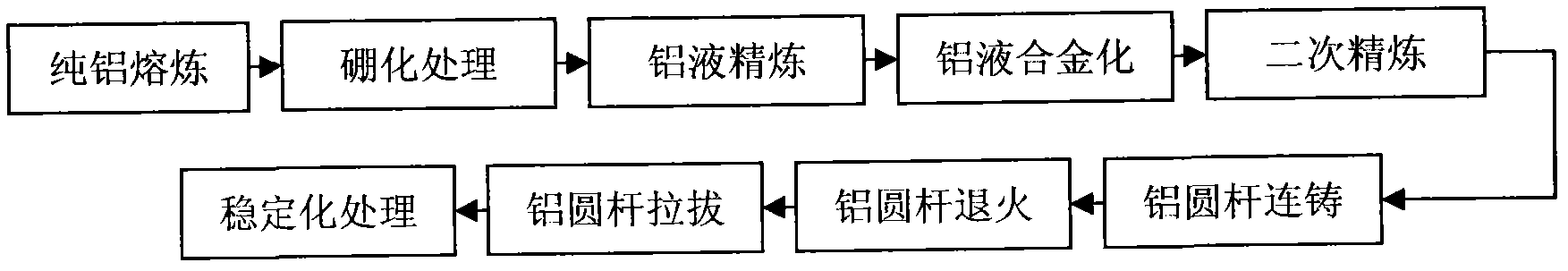

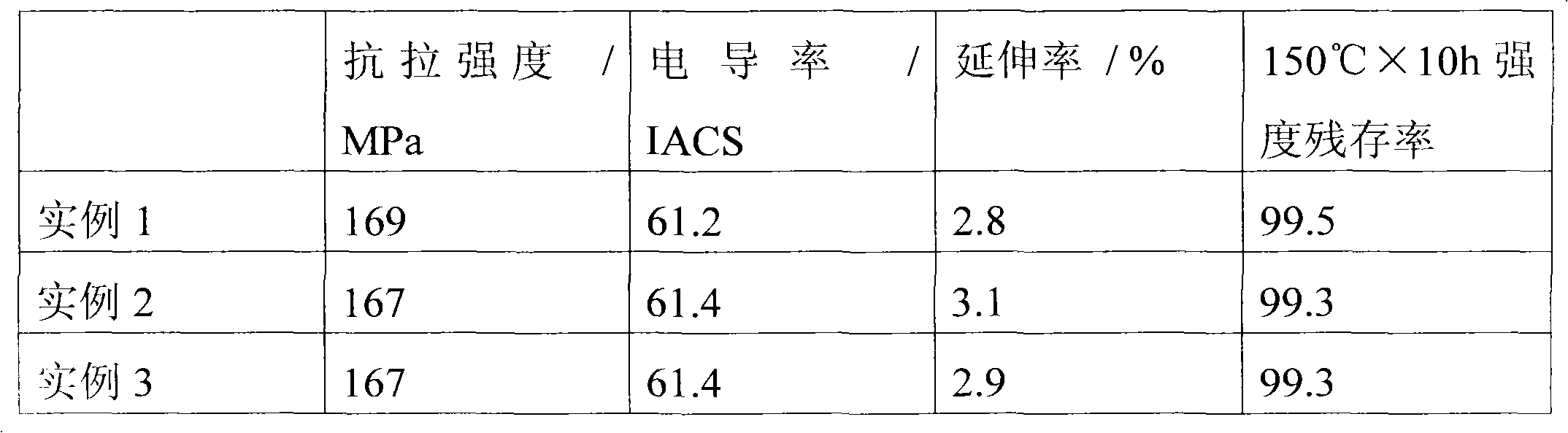

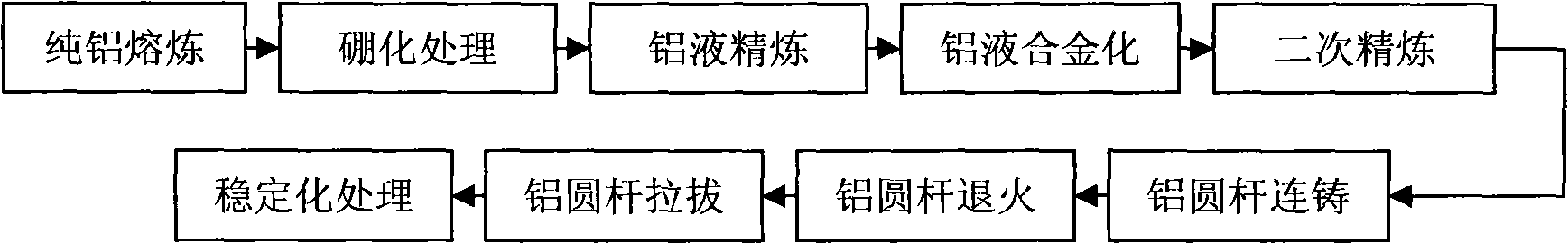

High-conductive heat-resistant aluminium alloy conductor and preparation method thereof

InactiveCN102021444AImprove conductivityHigh strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsChemical compositionHeat resistance

The invention provides a high-conductive heat-resistant aluminium alloy conductor and a preparation method thereof. The aluminium alloy conductor comprises the following chemical components by weight percent: 0.1-0.3% of Zr, 0.02-0.2% of Y, 0.01-0.15% of Sc and the balance of Al and other inevitable impurity elements, wherein the total amount of the other inevitable impurity elements is not more than 0.15%. The aluminium alloy conductor is prepared by the following steps: aluminium ingot fusion, boronizing, refining, alloying, secondary refining, direct water-cooling and continuous casting, annealing, drawing, stabilizing and the like. In the preparation method, the impurity content of the aluminium ingot is strictly controlled by the boronizing and the secondary refining, the conductivity of an aluminium alloyrond bar is ensured; through the stabilization treatment of a single aluminium alloy line, the conductivity of the heat-resistant aluminium alloy conductor is further improved, and the obdurability and twisting performance of the heat-resistant aluminium alloy conductor are regulated, so that the prepared aluminium alloy conductor has the characteristics of high conductivity and heat resistance, thereby meeting the requirements of industry on the performance of the aluminium alloy conductor and especially being suitable for manufacturing high-conductive heat-resistant cables.

Owner:UNIV OF SCI & TECH BEIJING

A copper adulterated aluminum complex flat line and its making method

ActiveCN101236798AImprove performanceEliminate processabilitySingle bars/rods/wires/strips conductorsCable/conductor manufactureCopperAluminum composites

The invention relates to a copper-clad aluminum composite flat wire and a preparation method thereof, relating to bimetal layered composite materials. The copper-clad aluminum composite flat wire is formed by composition of sandwich layer aluminum and clad copper, and the area ratio of the copper clad is 15 percent to 40 percent. The preparation steps are as follows: copper-clad aluminum composite blanks are directly compounded and formed by adoption of horizontal continuous casting; multi-pass groove rolling and / or multi-pass drawing is performed on the copper-clad aluminum blanks as required; the rolling speed of 3 to 60 meters per minute is adopted, and the single-pass relative percent reduction is 20 percent to 40 percent; or the drawing speed of 2 to 30 meters per minute is adopted, and the single-pass section scalage is 10 percent to 25 percent; under the condition of multi-pass processing and that the overall section scalage of the copper-clad aluminum composite materials reaches 75 percent to 95 percent, low-temperature intermediate annealing is performed on the copper-clad aluminum composite materials; the annealing temperature is 200 to 450 DEG C; the annealing time is 0.5 to 2 hours; the blanks after annealing are rolled or drawn further, and the copper-clad aluminum composite flat wire with required section shape and size is prepared. The invention not only can prepare the high performance copper-clad aluminum composite flat wire but also has high production efficiency.

Owner:UNIV OF SCI & TECH BEIJING

Ultra-fine aluminum alloy wire and preparation method thereof

ActiveCN102021442AImprove electrical performanceGood flexibilitySingle bars/rods/wires/strips conductorsMetal/alloy conductorsMisch metalRare earth

The invention discloses a preparation method for an ultra-fine aluminum alloy wire. The aluminum alloy wire comprises the following elements such as Al, Fe, Mg, Cu and Sb, and also comprises 0.1 to 1.2 weight percent of misch metal. The aluminum alloy material has high strength and high stretchability and can be drawn into a 0.1 mm or finer aluminum alloy wires by smelting, line-casting, rolling and drawing; and the aluminum alloy wire can be used for an insulated flexible line, an electrical cable, an electromagnetic line, an electrical equipment line, a vehicle wire, a communication cable line and the like.

Owner:安徽中青欣意铝合金电缆有限公司

Novel bus bar for electric connection and middle and battery module comprising the same

ActiveUS20080199765A1Simplifies electrical connectionsImprove featuresSingle bars/rods/wires/strips conductorsCells structural combinationElectrical resistance and conductanceElectricity

Disclosed herein are a bus bar that simultaneously performs the electrical connection between a plurality of unit cells and the detection of voltage of the unit cells in a battery module having the unit cells mounted therein, wherein the bus bar includes: vertical bent parts formed by bending opposite ends of a strip-shaped bar body in the same direction, respectively, the vertical bent parts being provided with coupling grooves or protrusions; and a horizontal bent part formed by bending one of the vertical bent parts such that the horizontal bent part is parallel with the bar body, and a medium- or large-sized battery module including a plurality of unit cells, wherein the electrical connection between the unit cells and the detection of voltage of the unit cells are simultaneously performed using the bus bar. It is not necessary to use additional connecting members for detecting the voltage of unit cells when the bus bar according to the present invention is used in a battery module or a battery pack. Consequently, the battery module or the battery pack can be manufactured in a compact structure. Also, the electrical connection and the mechanical coupling are easily accomplished in spite of the compact structure. Furthermore, the electrical characteristics, such as electrical resistance at connected regions after the electrical connection, and the mechanical strength against external impacts or vibrations are excellent. In addition, it is possible to prevent occurrence of short circuits, which may be caused by a user or an operator, during a manufacturing process of the battery module or the battery pack or during a maintenance process of the battery module or the battery pack.

Owner:LG ENERGY SOLUTION LTD

High conductivity moderately strong heat-resistant aluminum alloy monofilament and preparation method thereof

ActiveCN103045915ASimple manufacturing processLow costSingle bars/rods/wires/strips conductorsMetal/alloy conductorsHeat resistanceHigh conductivity

The invention relates to the technical field of a power industry electric transmission line overhead conductor. The present invention provides a high conductivity moderately strong heat-resistant aluminum alloy monofilament and a preparation method thereof. The aluminum alloy conductor includes: 0.01-0.1% of Zr, 0.01-0.2% of B, 0.01-0.2% of Si, 0.05-0.3% of Fe, 0.2-0.5% of Mn, 0.01-0.15% of Er and / or 0.01-0.15% of Y, any two or three elements selected from the group consisting of V, Ti and Cr, and the balance being Al and inevitable trace impurities, wherein 0.1-0.15% of V, 0.01-0.05%of Ti, and 0.1-0.15% of Cr are included. The aluminum alloy monofilament prepared by the present invention is high in electrical conductivity, good in heat resistance, and high in tensile strength.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

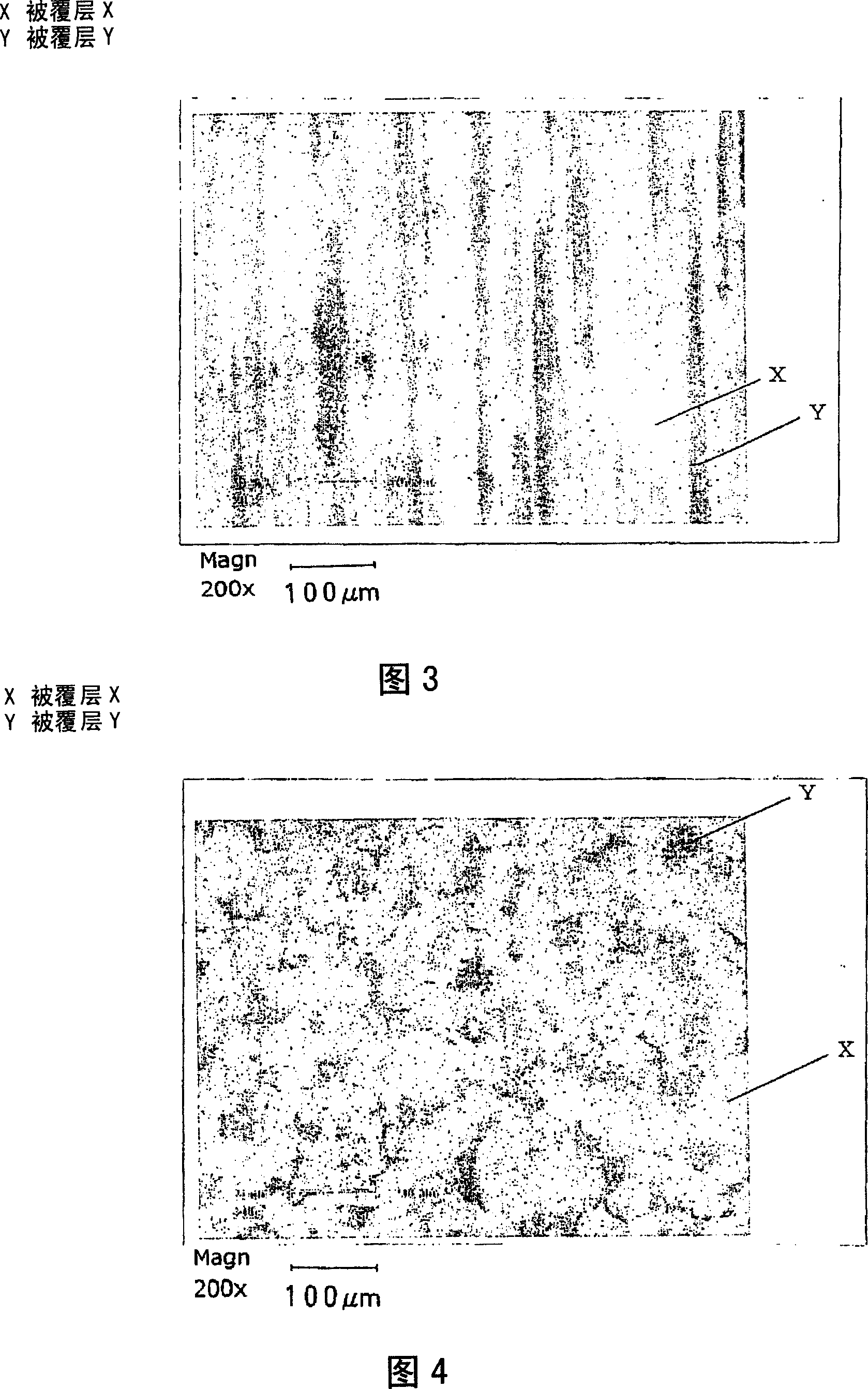

Conductive material for connecting part and method for manufacturing the conductive material

ActiveCN1985333ALower insertion forceImprove reliabilitySingle bars/rods/wires/strips conductorsCoupling contact membersConductive materialsAlloy

In a conductive material, on the surface of a base material composed of a Cu plate strip, a Cu-Sn alloy covering layer, which contains a Cu of 20-70at% and has an average thickness of 0.1-3.0[mu]m, and an Sn covering layer having an average thickness of 0.2-5.0[mu]m are formed in this order, and a part of the Cu-Sn alloy covering layer is exposed from the surface of the Sn covering layer at an exposing area rate of 3-75%. Reflow process is performed to the material surface, and preferably, the arithmetic average roughness Ra at least in one direction is 0.15[mu]m or more, the arithmetic average roughness Ra in all the directions is 3.0[mu]m or less, and the average thickness of the Cu-Sn alloy covering layer is 0.2[mu]m or more. The conductive material is manufactured by forming an Ni plating layer, and further, a Cu plating layer and an Sn plating layer as needed on the roughened base material surface, then by performing reflow process.

Owner:KOBE STEEL LTD

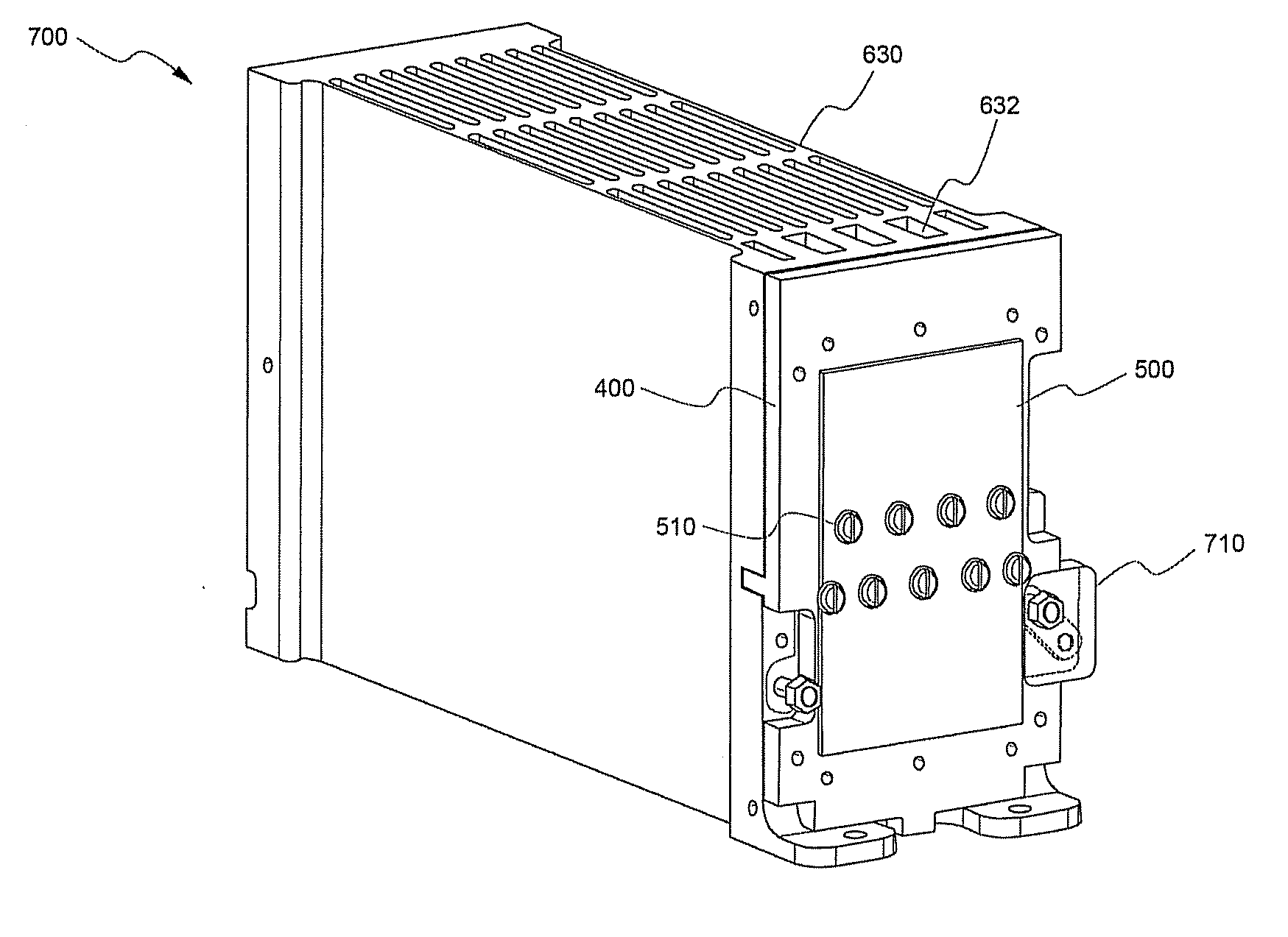

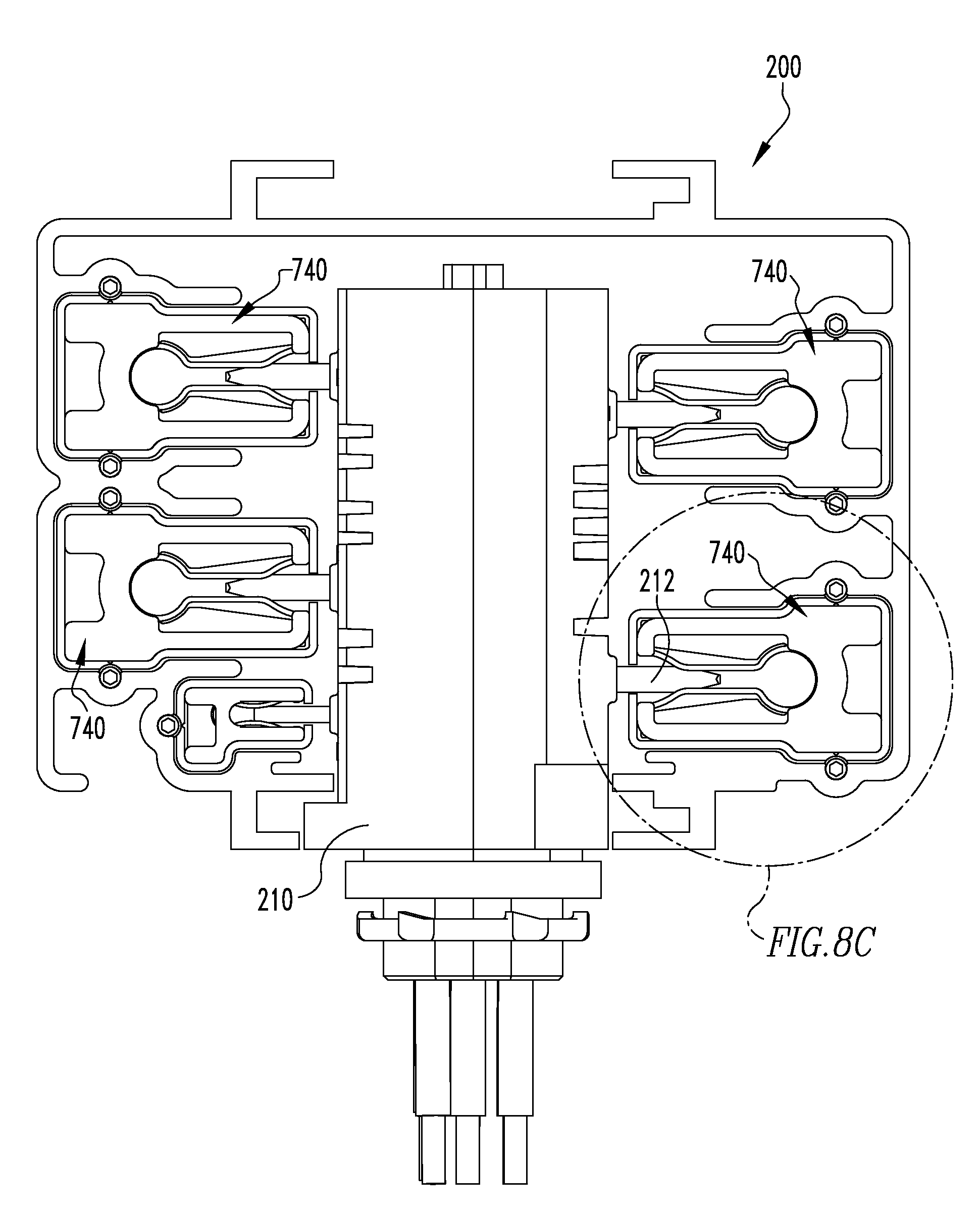

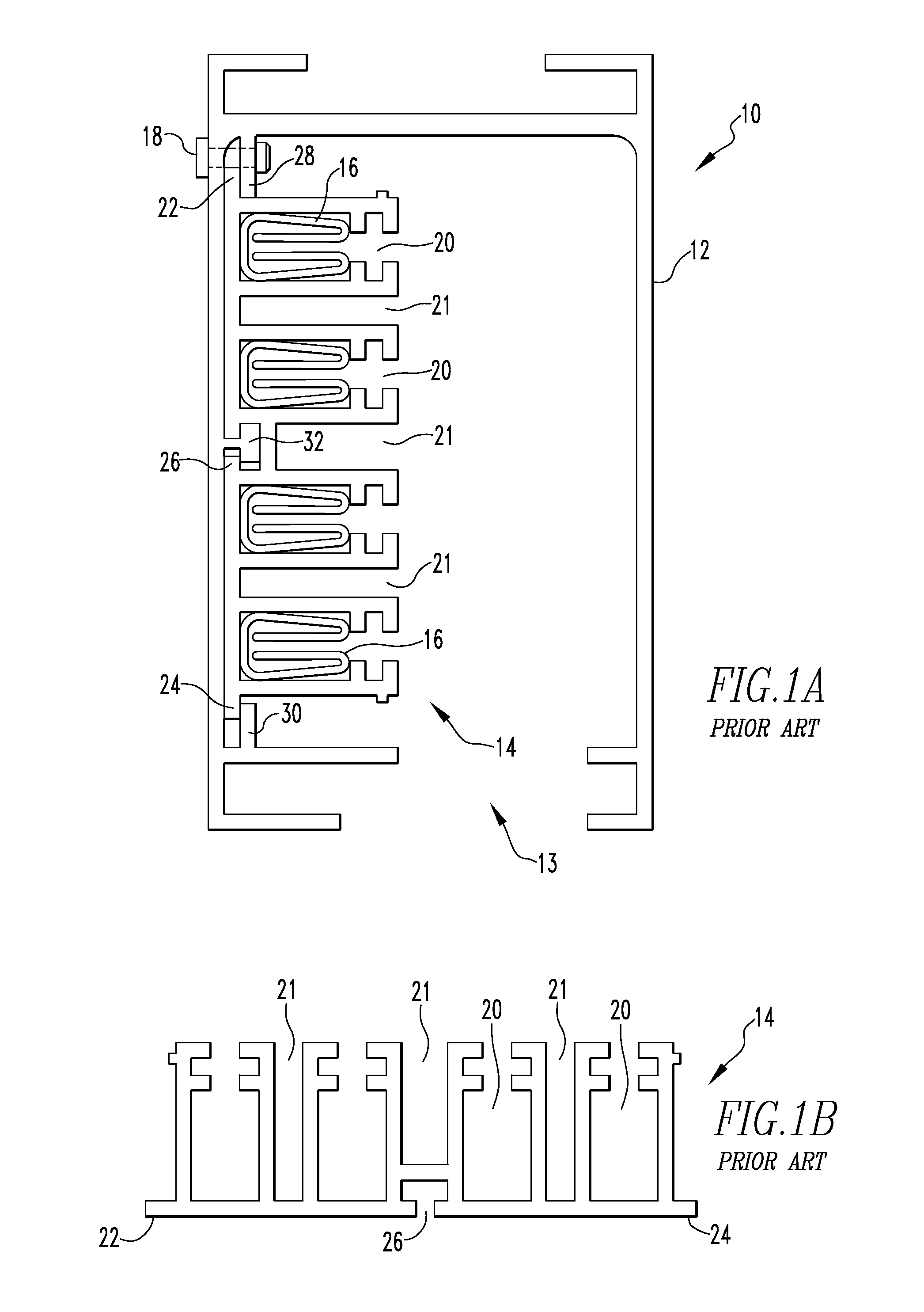

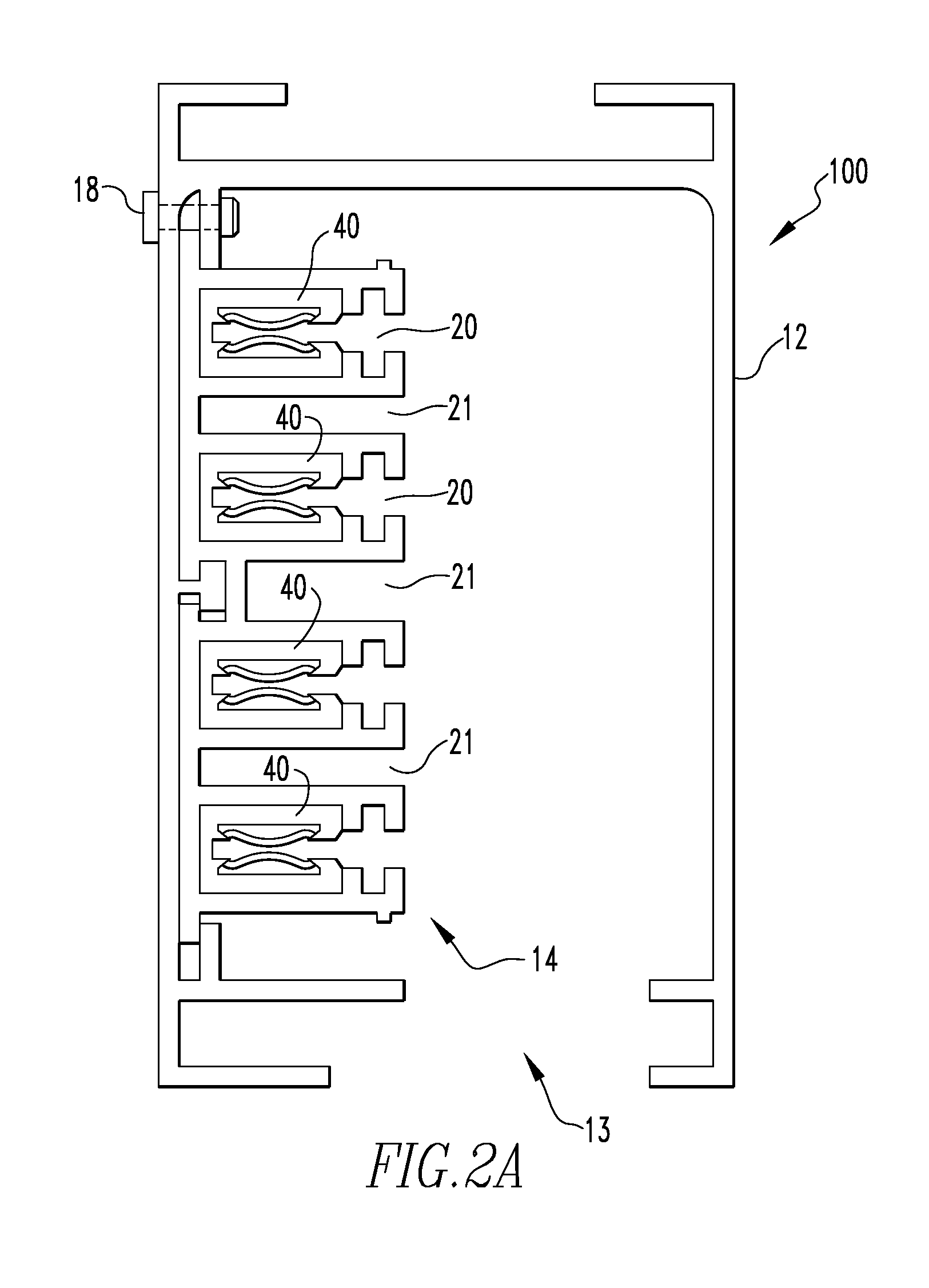

Press-fit busbar and busway employing same

ActiveUS20110261508A1Increase current capacityGood electrical contactCoupling device connectionsBus-bar/wiring layoutsBusbarElectrically conductive

An improved conductive busbar assembly and power distribution track utilizing the improved conductive busbar assembly. The busbar assembly including an inner component adapted to engage a stab member of a plug-in unit and an outer component disposed about, and in contact with, the inner component. The inner and outer components are both formed from an electrically conductive material. The busbar assembly provides greater current-carrying capacity and permits take-off devices to be installed at any point along the busway run.

Owner:UNIVERSAL ELECTRIC

A high-performance cooper-coated aluminum rectangle section compound conductive bus bar and its making technology

ActiveCN101241778AMeet the requirements of multiple specificationsGreat widthSingle bars/rods/wires/strips conductorsMeasuring devicesCopperAluminum composites

The present invention provides a high-performance copper-clad aluminum cross section composite conductive bus-bar and the preparing technique thereof, and the invention relates to a rectangle-cross section bimetal composite material and the preparation thereof. The copper-clad aluminum rectangular cross section composite conductive bus-bar is compounded by the core-part aluminum and the coating layer copper. The area proportion of the coating copper layer is 15to 50 The technique comprises the following procedures: Adopting horizontal continuous casting for directly compounding and forming the copper-clad aluminum composite blank. Commonly flat-roller rolling and finish drawing-pulling the copper-clad aluminum blank according to requirement or rolling with the flat roller provided with a vertical roller, the range of the rolling speed is 3-50m / min, and the single-pass relative reduction is between 15and 40 The speed range of finish drawing-pulling is 1-20m / min and the single-pass cross section scalage is 10%. When the multiple-pass relative reduction is up to 70%, the low-temperature intermediate annealing is executed to the copper-clad aluminum composite conductive bus-bar. The annealing temperature is between 250 and 450 DEG C and the annealing time is between 0.5 and 3h. The annealed composite conductive bus-bar is executed with hole-form rolling or drawing. The invention not only can produce the high-performance copper-clad aluminum cross section composite conductive bus-bar, but also has the advantages of short process flow and high efficiency of the producing method.

Owner:UNIV OF SCI & TECH BEIJING

Bimetal buss bar assembly

ActiveUS20130306353A1Low costSingle bars/rods/wires/strips conductorsCurrent conducting connectionsEngineeringMetal

A bimetal buss bar assembly includes a positive battery cell terminal having a flat pad, a negative battery cell terminal having a flat pad, and a buss bar having a negative end and a positive end. The buss bar is attached to the positive battery cell terminal at the positive end and attached to the negative battery cell terminal at the negative end. At least one of the positive battery cell terminal, negative battery cell terminal, and buss bar have a bimetal interface.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Preparation method of copper covered steel woven wire special for communication cable shielding layer

InactiveCN1913046AWill not disconnectGood flexibilitySingle bars/rods/wires/strips conductorsExtrusion cleaning devicesCopper wireThin wire

This invention relates to a preparation method for special steel woven filaments for communication cable shield layers including rough drawing, plating, mid-drawing, fine-drawing and annealing of copper-wrapped steel filaments with the mechanical performance approaching to copper wires, the extension rate of which reaches to 20% and the tensile strength reaches to that of copper wires, so it will not be broken when used in weaving cable shield layers and the product will not be hard and keep fine flexibility.

Owner:仲庆

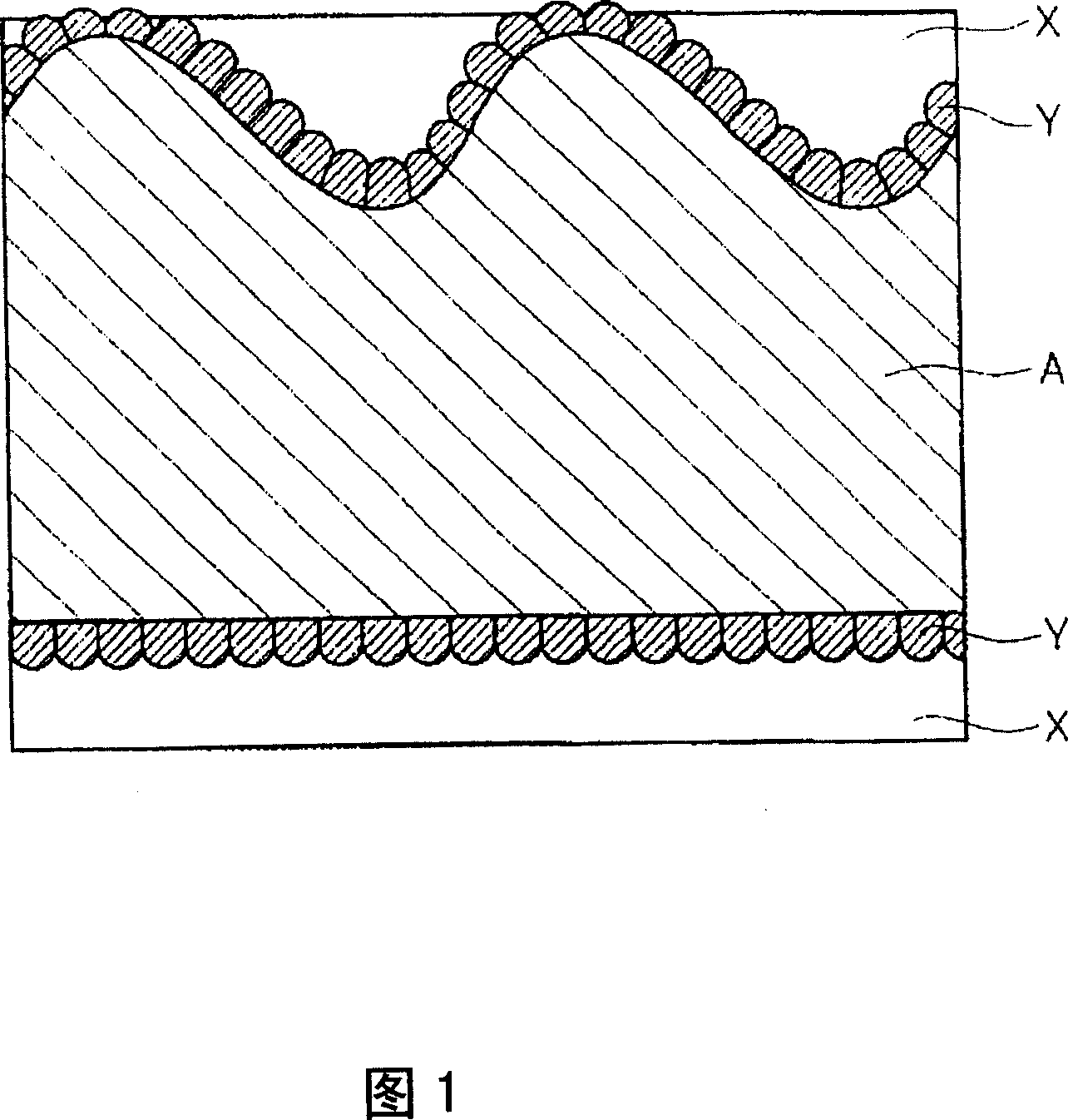

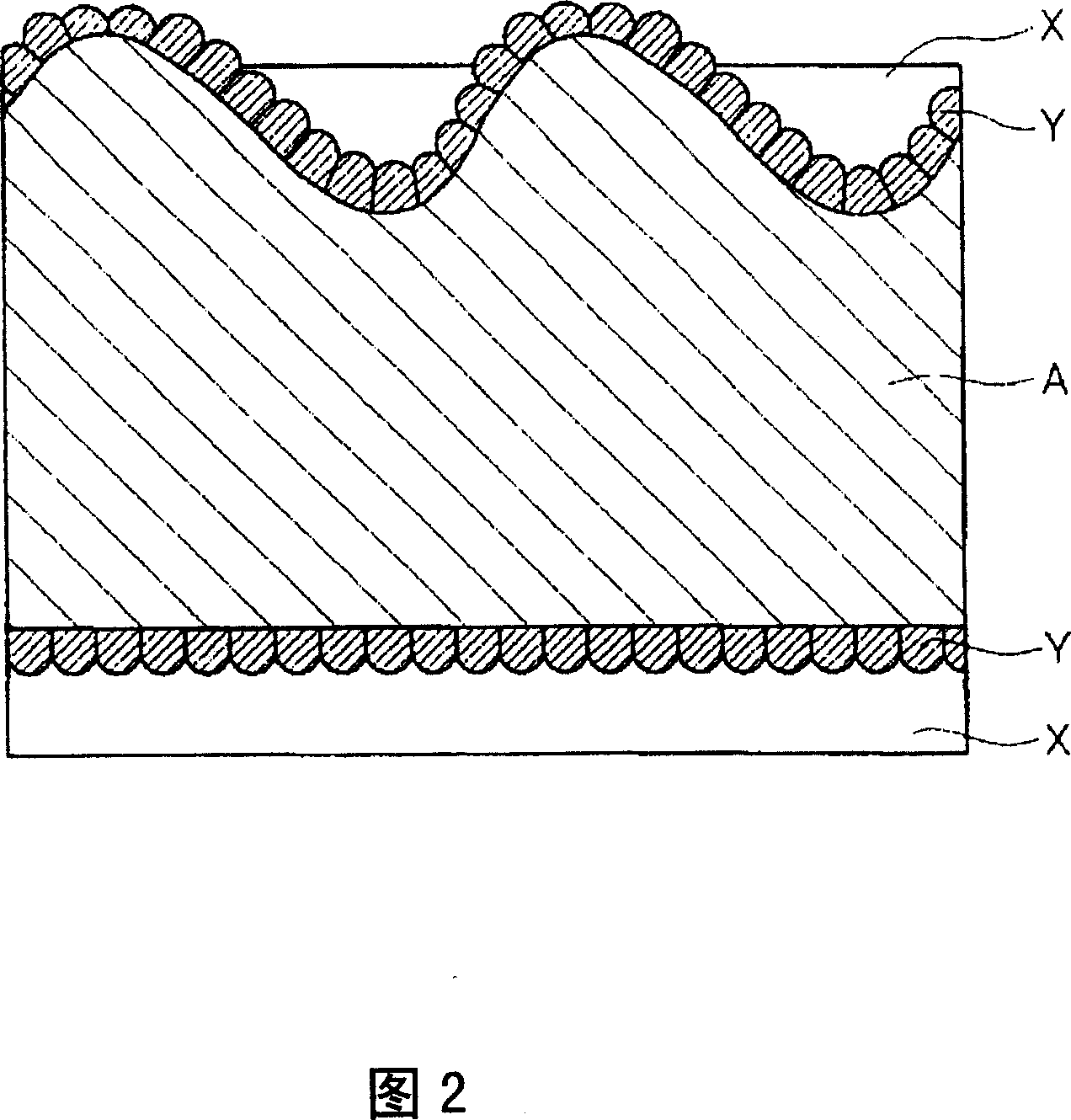

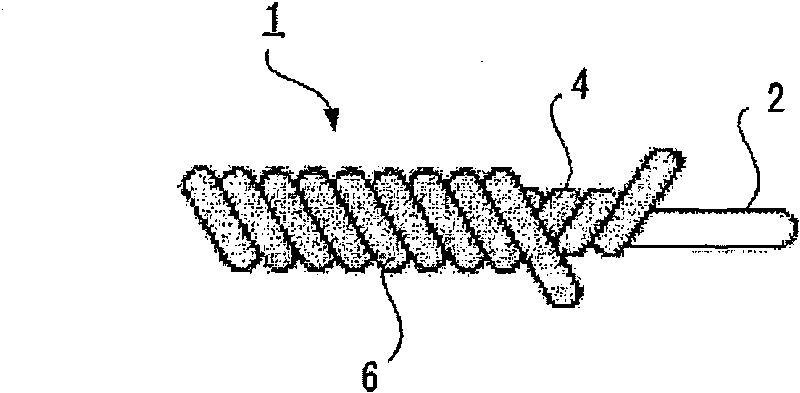

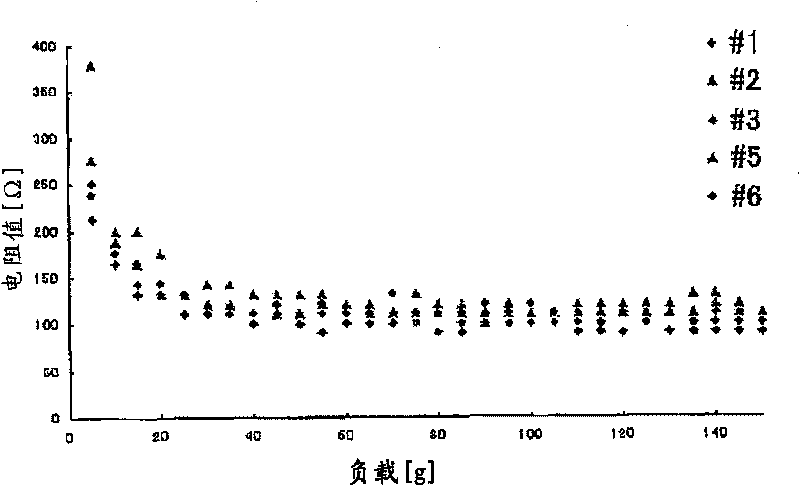

Pressure-sensitive conductive yarn and biological information-measuring garment

InactiveCN101728005ASingle bars/rods/wires/strips conductorsDiagnostic recording/measuringElectrical resistance and conductanceFiber

An object of the present invention is to provide a pressure-sensitive conductive yarn capable of detecting different biological information simultaneously when used as an electrode. A pressure-sensitive conductive yarn comprising a core yarn formed of an elastic yarn around which a winding yarn having conductivity is wound, wherein the winding yarn is a mixed yarn of a conductive fiber and a nonconductive fiber to cause variations in its electrical resistance with elongation or contraction. The invention also provides a biological information-measuring garment.

Owner:THE RITSUMEIKAN TRUST +1

Aluminum alloy wire

ActiveUS20110140517A1Well-balanced strength and toughness and electrical conductivityImprove productivityPlastic/resin/waxes insulatorsElectric devicesToughnessImpurity

An aluminum alloy, an aluminum alloy wire, an aluminum alloy stranded wire, a covered electric wire, and a wire harness that are of high toughness and high electrical conductivity, and a method of manufacturing an aluminum alloy wire are provided. The aluminum alloy wire contains not less than 0.005% and not more than 2.2% by mass of Fe, and a remainder including Al and an impurity. It may further contain not less than 0.005% and not more than 1.0% by mass in total of at least one additive element selected from Mg, Si, Cu, Zn, Ni, Mn, Ag, Cr, and Zr. The Al alloy wire has an electrical conductivity of not less than 58% IACS and an elongation of not less than 10%. The Al alloy wire is manufactured through the successive steps of casting, rolling, wiredrawing, and softening treatment. The softening treatment can be performed to provide an excellent toughness such as elongation and impact resistance and thereby reduce fracture of the electric wire in the vicinity of a terminal portion when the wire harness is installed.

Owner:SUMITOMO ELECTRIC IND LTD +3

High-strength, high-conductivity and heat-resisting aluminum alloy bus and production method thereof

InactiveCN102978490AHigh strengthImprove heat resistanceSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare earthThermal deformation

The invention discloses a high-strength, high-conductivity and heat-resisting aluminum alloy bus and a production method thereof. The high-strength, high-conductivity and heat-resisting aluminum alloy bus comprises the following components in percentage by mass: 0.4-1.1 percent of magnesium (Mg), 0.3-0.9 percent of silicon (Si), 0.85-2.1 percent of copper (Cu), 0.03-0.3 percent of zirconium (Zr), 0.05-0.38 percent of rare earth (La), less than 0.4 percent of Ferrum (Fe), less than 0.01 percent of manganese (Mn) and the balance of aluminum (Al), wherein the ratio of Cu to Mg is 1.9-2.3. The production method comprises the steps of: uniformly annealing a cast ingot obtained through smelting and casting for 10-20h at a temperature of 470-550 DEG C, furnace-cooling; controlling the temperature of the cast ingot to be 480-540 DEG C for thermally deforming, wherein the final temperature of the thermal deformation is not less than 380 DEG C, the total deformation rate of the thermal deformation reaches 80-94 percent; then carrying out cold deformation on a thermally deformed blank at the total deformation rate of 80-90 percent; annealing the deformed product, wherein the annealing temperature is 330-350 DEG C, the insulation time is 2h; carrying out solution treatment for 1-3h at a temperature of 490-525 DEG C; and carrying out artificial ageing treatment for 24-36h at a temperature of 175-200 DEG C.

Owner:BAOTOU JI TAI RARE EARTH ALUMINUM CO LTD

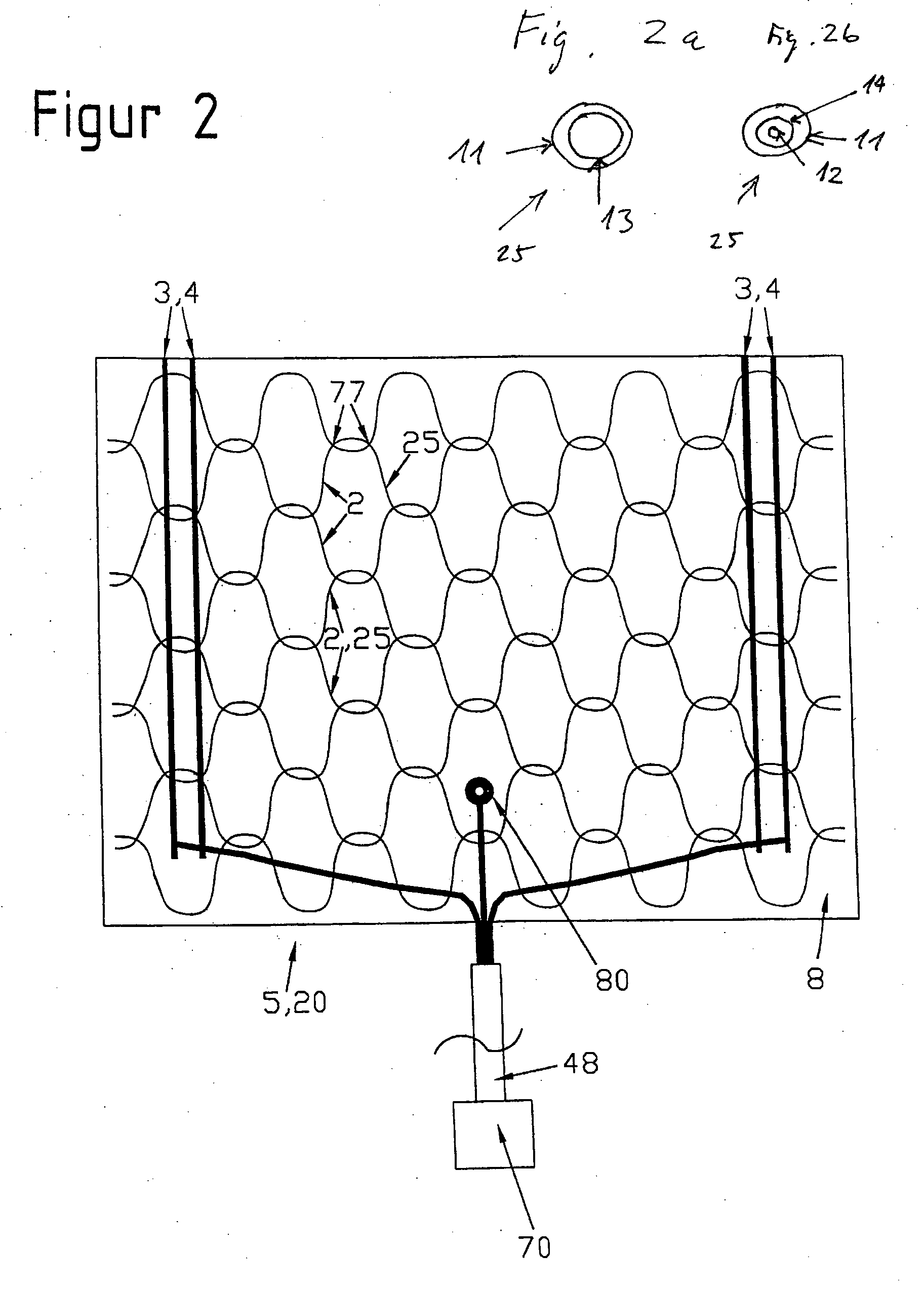

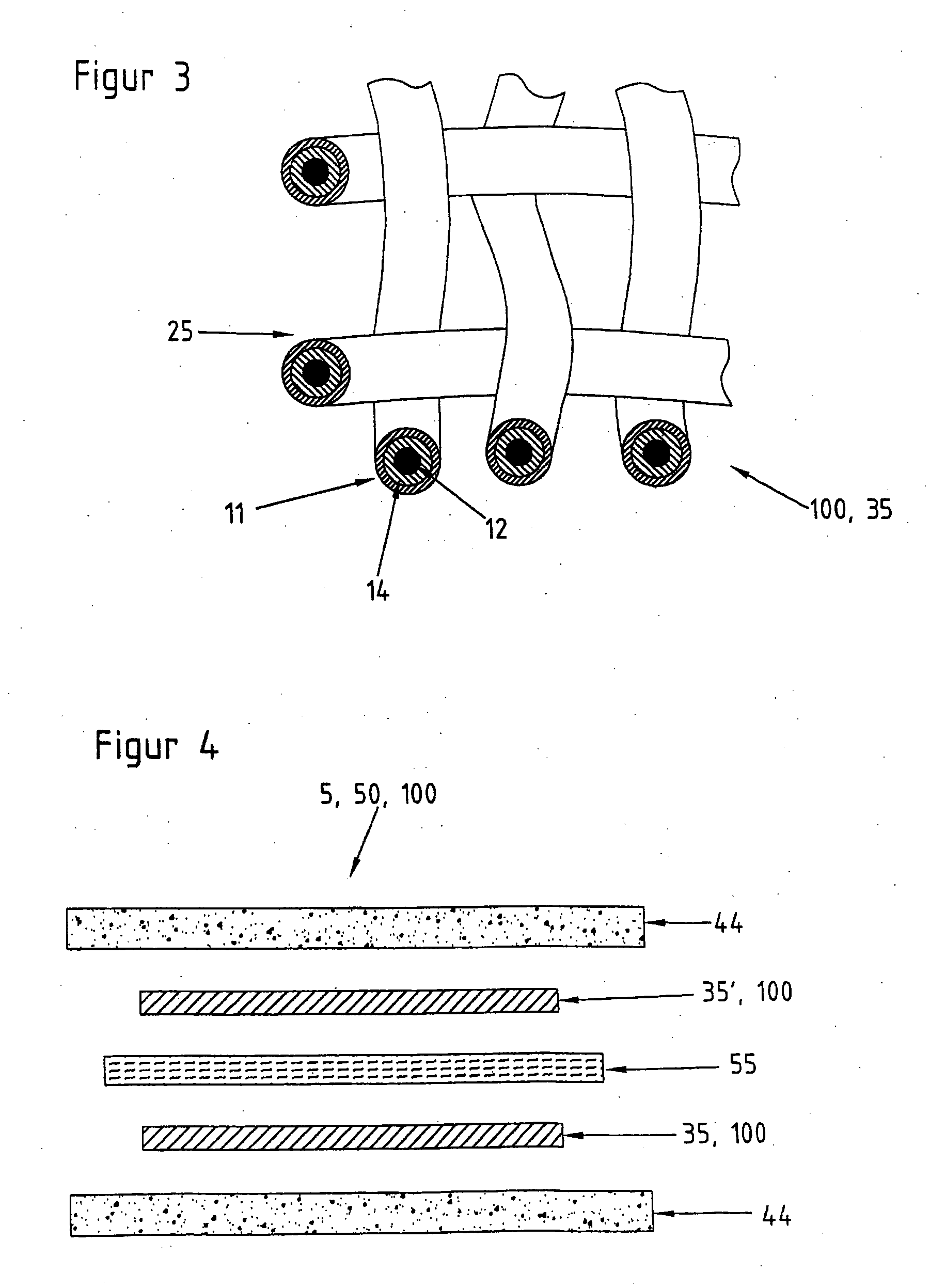

Electric conductor

InactiveUS20100044075A1Single bars/rods/wires/strips conductorsNon-conductive material with dispersed conductive materialConductive materialsEngineering

This invention relates to an electrical conductor (25) which is composed at least partially of an electrically conductive material.According to the invention, at least part of the electrical conductor (25) is provided with a protective layer (11) whose specific electrical conductivity is lower, at least locally, than that of the electrically conductive material of the conductor (25).

Owner:GENTHERM GMBH

High conductivity flexible aluminum wire and manufacturing method thereof

InactiveCN101419849AIncrease working temperatureLow resistivitySingle bars/rods/wires/strips conductorsMetal/alloy conductorsManufacturing technologyMetallurgy

The invention relates to a high conductivity annealed aluminum wire and a manufacturing method thereof, in particular to a conductor material fabrication technique used for overhead conductors of a transmission line. The components of the annealed aluminum wire includes Si having the weight percent being less than or equal to 0.08%; Fe having weight percent being less than or equal to 0.02%; Cu having weight percent being less than or equal to 0.005%; B having weight percent of 0.07-0.15%; and Al having the rest weight percent; the annealed aluminum wire can be used for reducing the consumption of the transmission line, thereby effectively lowering the operating cost.

Owner:WUXI HUANENG ELECTRIC CABLE

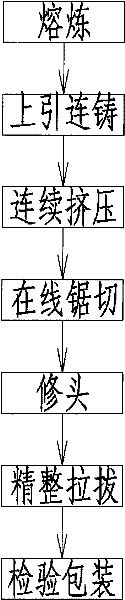

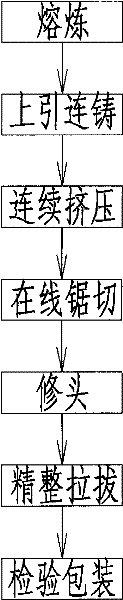

Large-section oxygen-free copper busbar and preparation method thereof

InactiveCN102262924AHigh purityImprove conductivitySingle bars/rods/wires/strips conductorsMetal/alloy conductorsBusbarOxygen content

The invention relates to an oxygen-free copper busbar and a preparation method thereof, in particular to a large-section oxygen-free copper busbar and a preparation method thereof, belonging to the technical field of nonferrous metal processing. The technological process of the present invention is: smelting→upward continuous casting→continuous extrusion→online sawing→head trimming→drawing→inspection and packaging. The invention solves the shortcomings of the traditional process of large-section copper bus bars, provides a production technology with short process flow, high degree of automation, low oxygen content, excellent product quality, environmental protection and pollution-free, and effectively improves the quality and performance of products , has the advantages of high purity, low oxygen content, high electrical conductivity, and excellent surface quality.

Owner:SHANDONG ZHONGJIA NEW MATERIALS

Electroplating preparation method for copper cladded aluminum wire or copper cladded magnesium alloy wire

InactiveCN101187046AAvoid it happening againImprove bindingSingle bars/rods/wires/strips conductorsSuperimposed coating processCopper platingZinc

The invention discloses a process for preparing copper cladding aluminum or copper cladding wire of aluminum magnesium alloy, which utilizes a continuous striking-wire copper plating pipeline of being in series connection with a plurality of lengthening electric plating aluminum-magnesium parts plating groove, sets out line uninterruptedly between adjacent plating grooves, and arranges a transiting water ditch between front groove and rear groove which can avoid wire to contact with air to generate oxide coating when changing the grooves. A problem of burning wire can be resolved by adjusting main plating current to about 300 A before having to shutdown in short time. Simultaneously, the invention employs technique of thickening dip galvanized coating and wiping off zinc cover of the zinc dipping by pickling to overcome the main difficulty of utilizing electric plating method to produce copper cladding aluminum wire or copper cladding wire of aluminum magnesium alloy. Compared with coating method, the invention has the advantages of great binding force between metals, high concentricity of copper layer and core wire, low production cost on producing high tensile strength and high stretch rate production, low reject rate, low product specific gravity and the like, and is a good method for producing copper cladding aluminum wire and copper cladding wire of aluminum magnesium alloy by the electroplating method.

Owner:仲庆

Method for producing heat-resisting high-strength aluminium alloy wire

InactiveCN1941222ASatisfy the requirements of large-scale designSingle bars/rods/wires/strips conductorsCable/conductor manufactureElectricityRare earth

A method for producing high-intensity heat-resistant aluminum alloy line belongs to production technology field of materials applied to electrical engineering. It winnows component and content of alloy and controls technology to produce high-intensity aluminum alloy line. Select zirconium, copper, iron, silicon and rare earth with different percent of weigh and aluminum ingot into stove. The impurity content of aluminum ingot does not exceed 0.02%(besides silicon, iron, copper). Add alloying additive element and whisk, fine, component fast analyzing before entering stove. Put into continuous caster to produce aluminum alloy pole and draw into aluminum alloy line after tempered heat treatment and cooling to get production. In this method, the capability of production is satisfied the overhead designed demand for Three Gorges to serve the construct of transporting electrical power from west to east.

Owner:BEIJING ELECTRIC POWER CONSTR RES INST OF SGCC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com