Patents

Literature

209results about How to "High strength properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

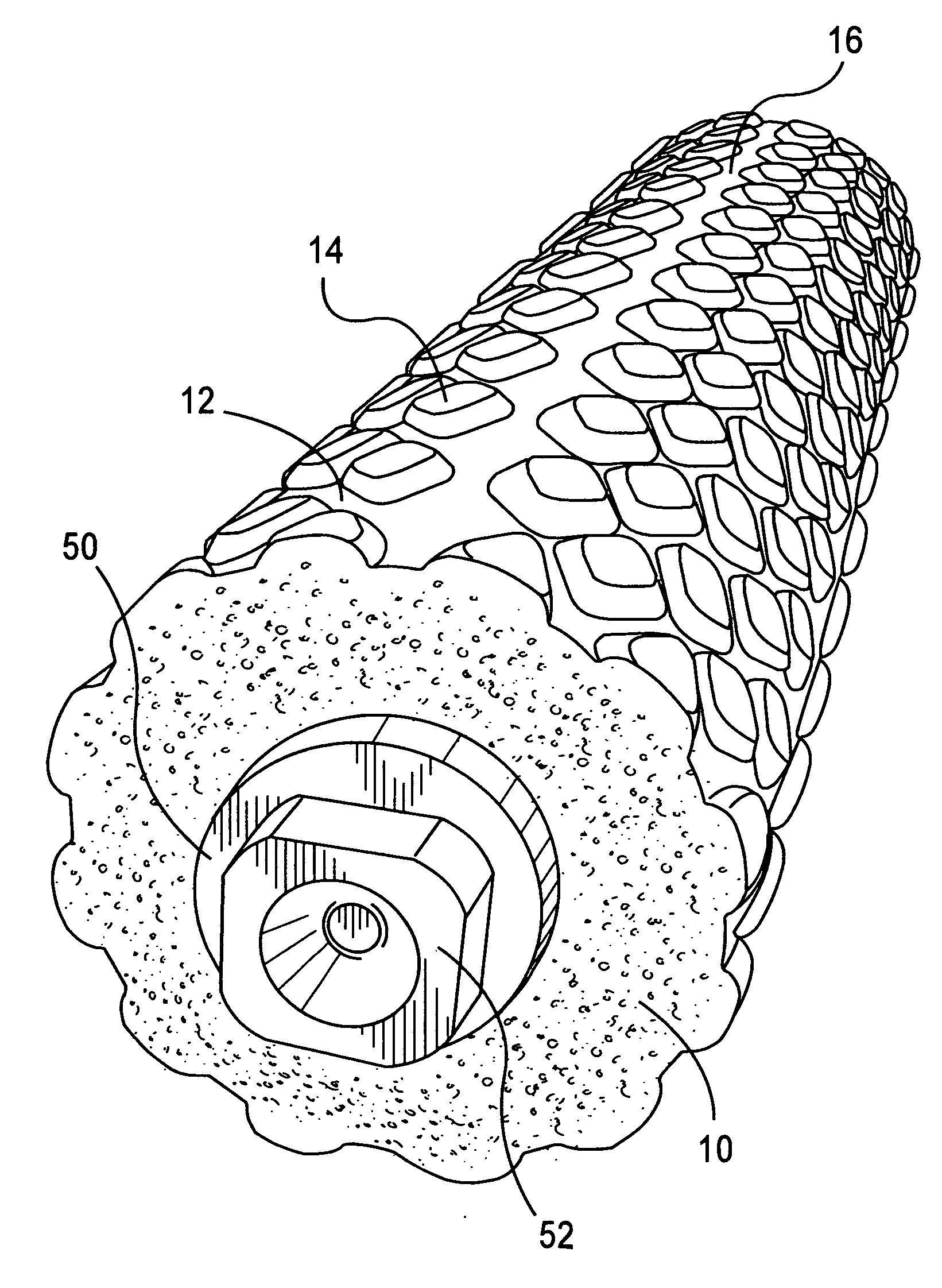

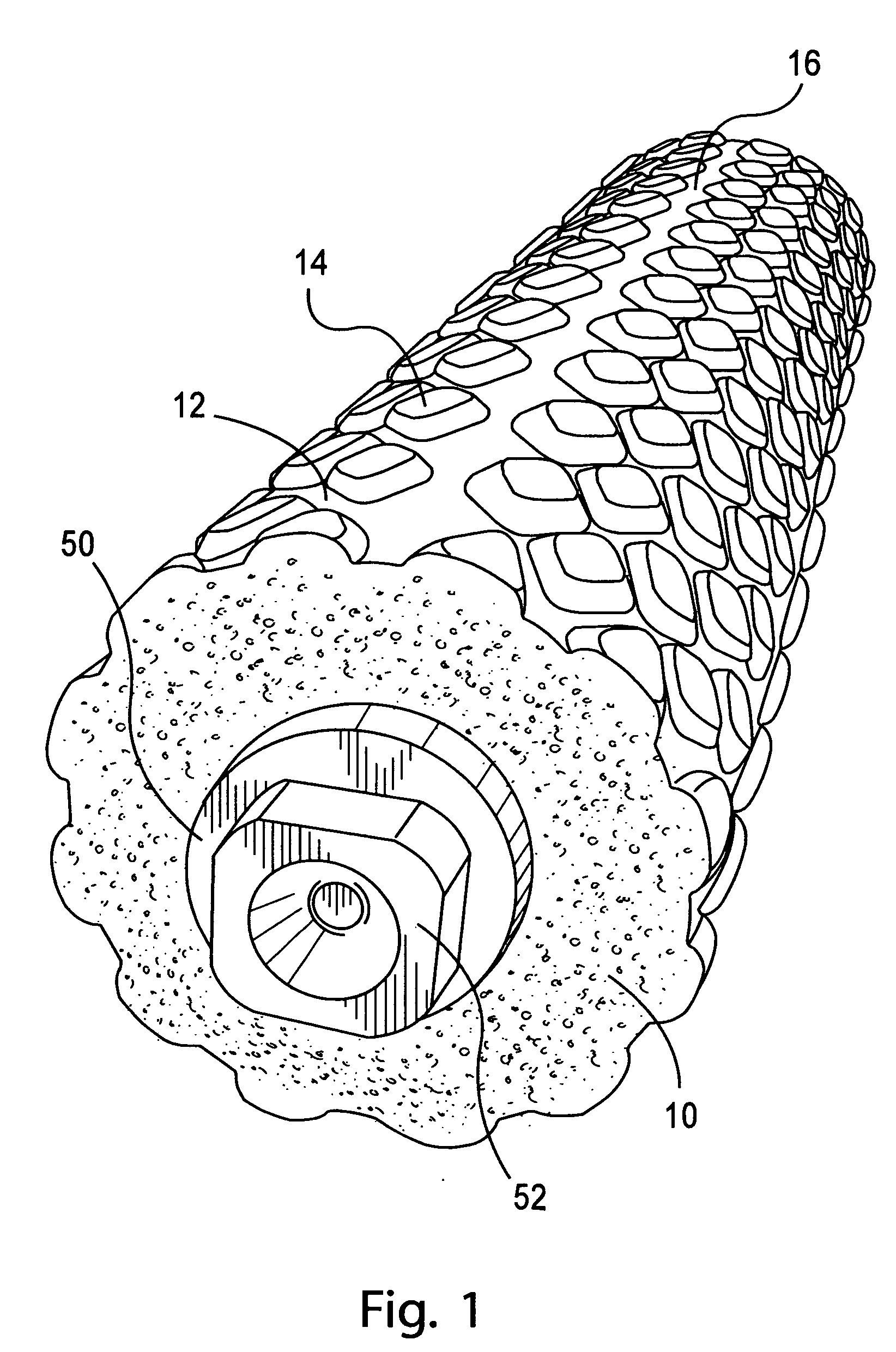

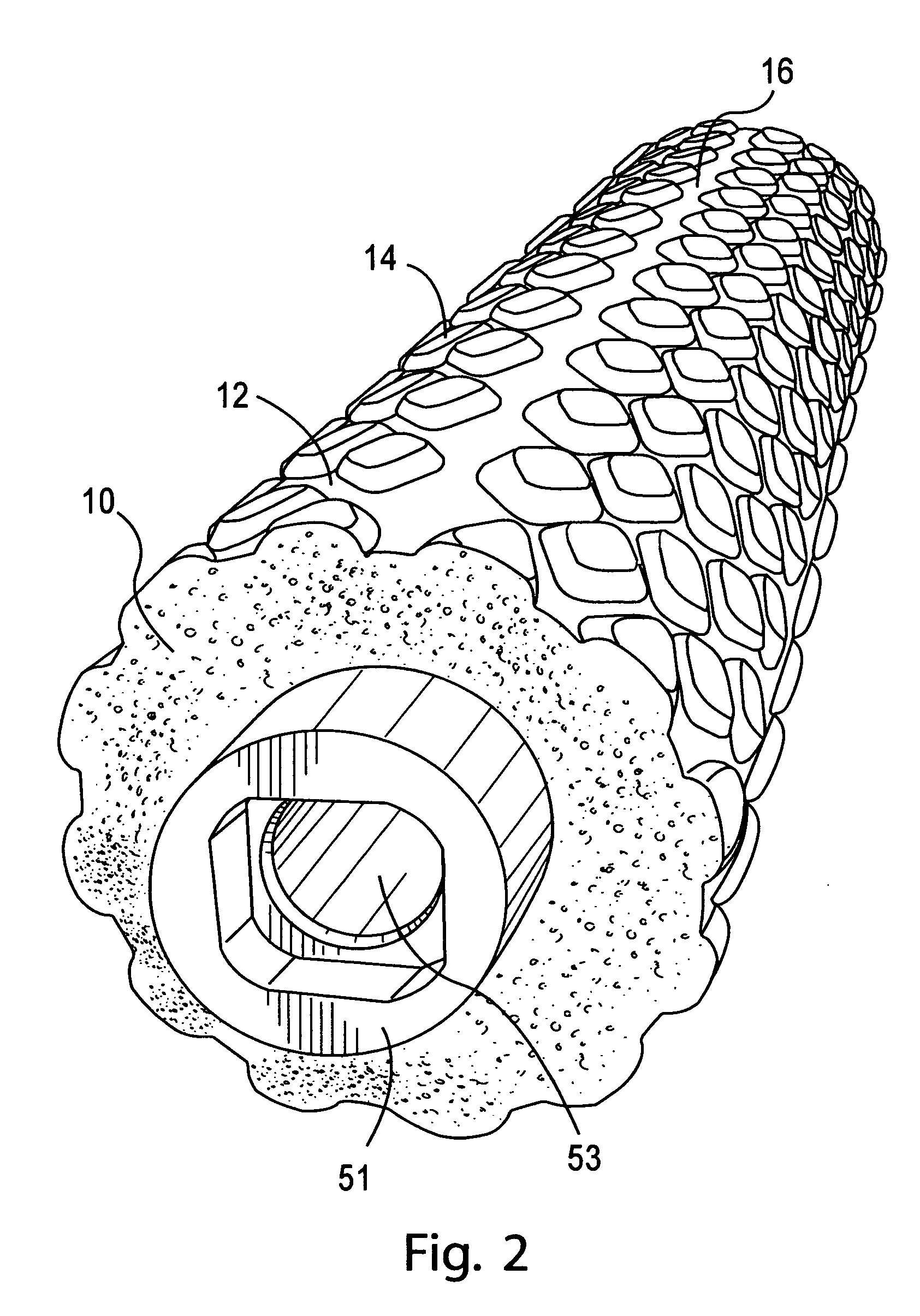

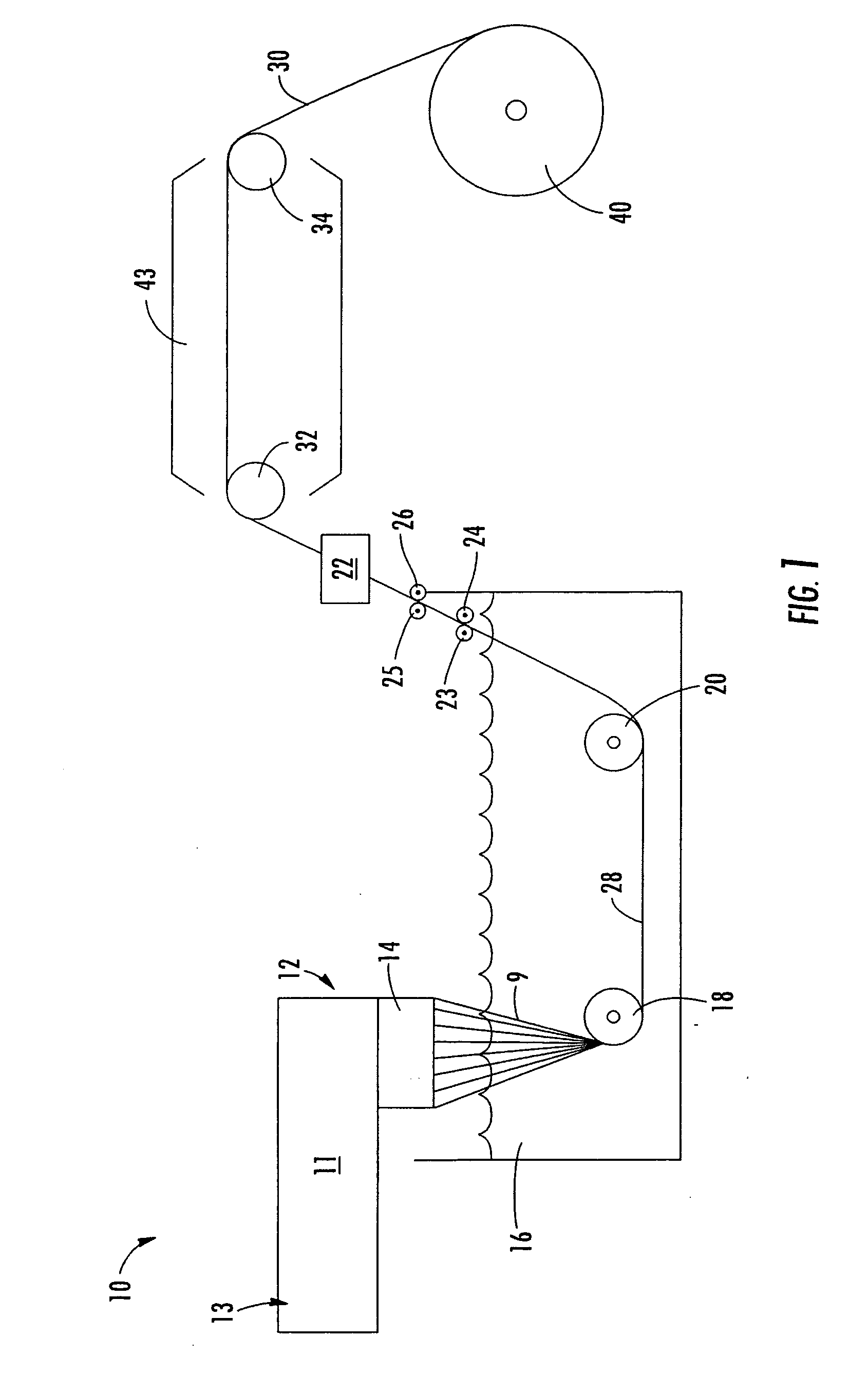

Manufacture of polyolefin fishing line

InactiveUS6148597AReduce resistanceReduce wearAgriculture tools and machinesFilament/thread formingYarnPolyolefin

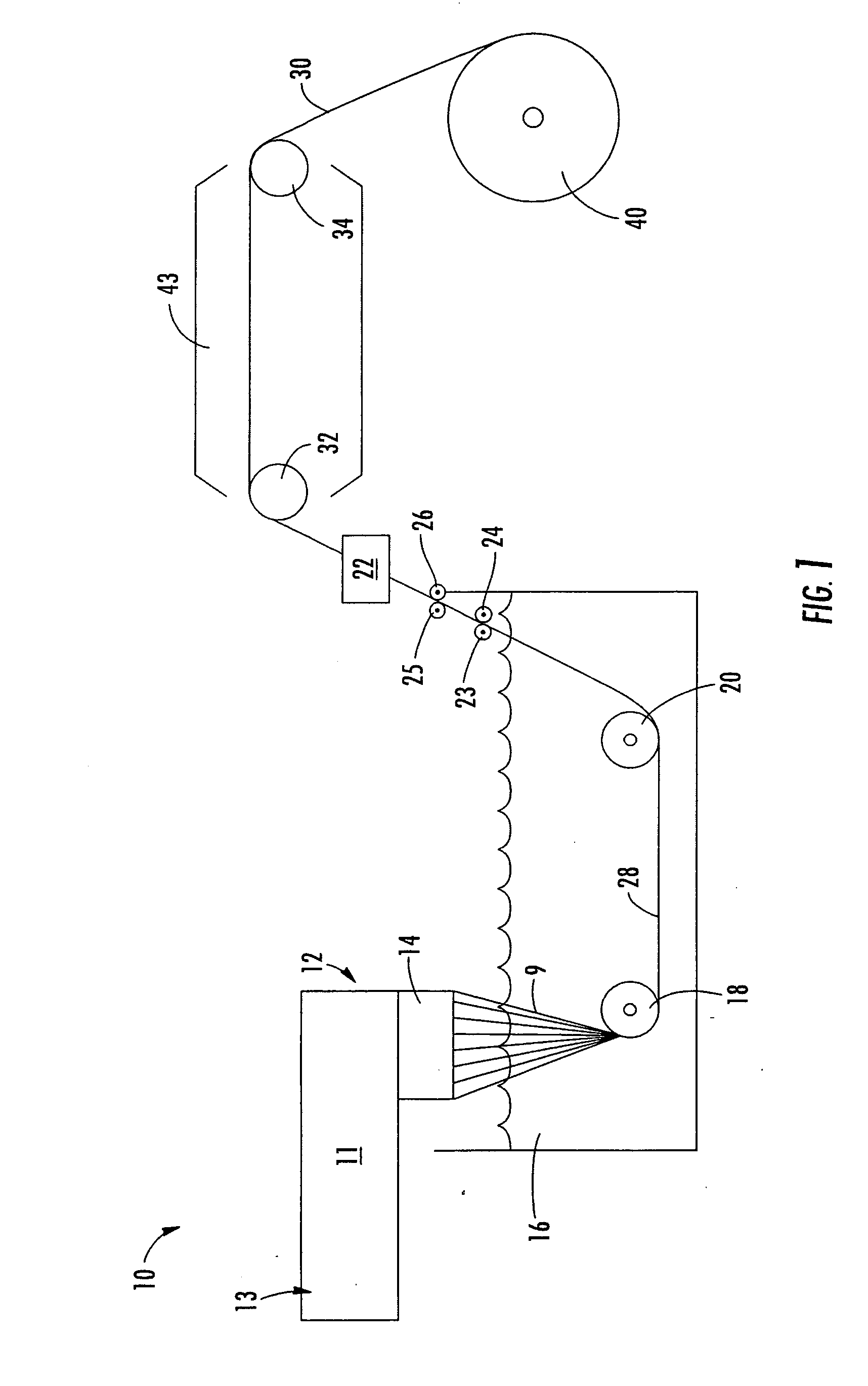

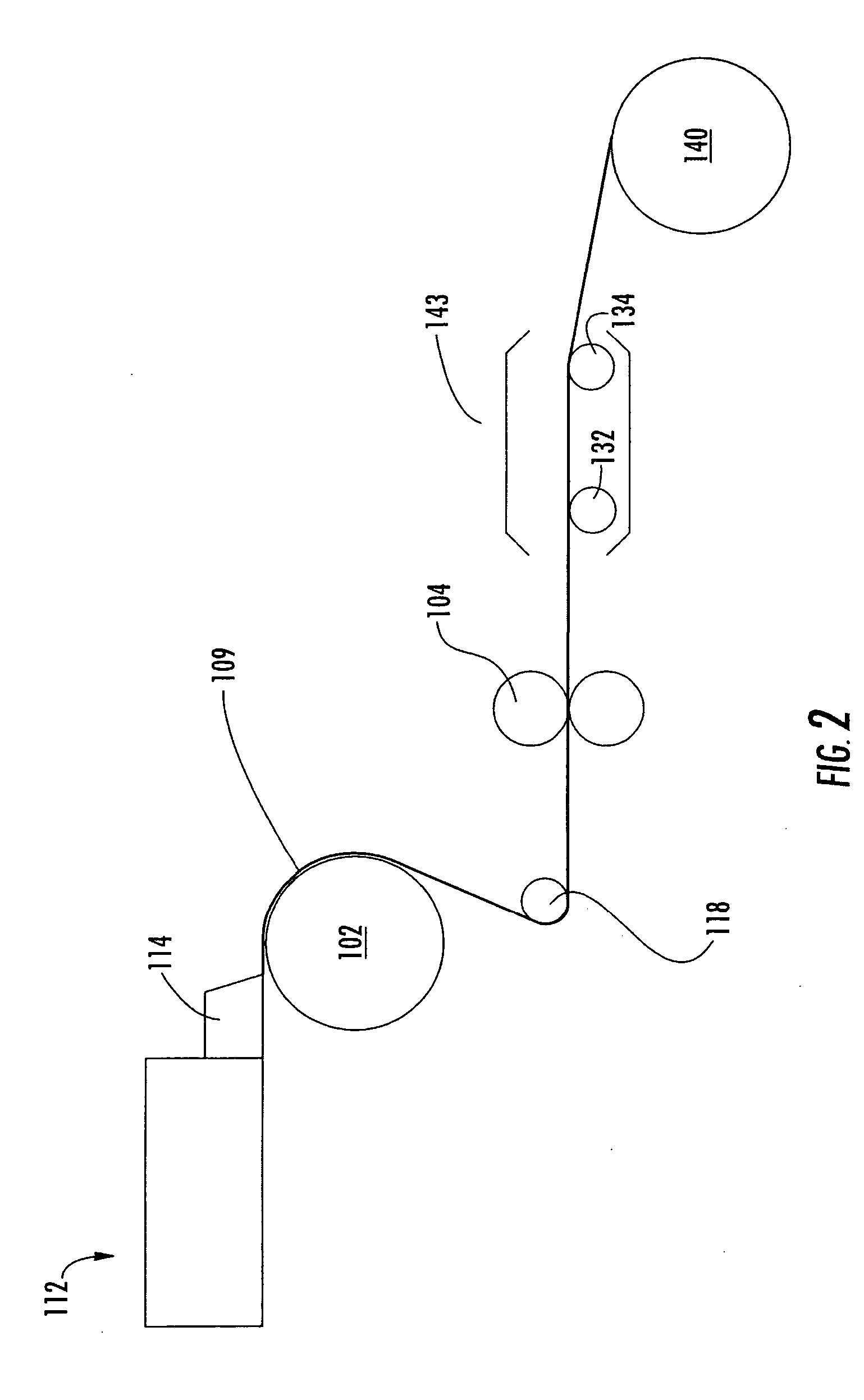

Yarns and fishing lines are made by a process that includes the step of exposing an opaque yarn made from ultrahigh molecular weight, gel spun polyolefin filaments to a temperature within the melting point range of the filaments for a time sufficient to at least partially fuse the contact surfaces of adjacent filaments. For ultrahigh molecular weight, gel spun polyethylene, this temperature is preferably within the range from about 150 DEG -157 DEG C. The surface fusion between and among filaments imparts desirable handling characteristics to the ultrahigh molecular weight, gel spun polyolefin yarns and fishing lines that are similar to those of a conventional monofilaments. Preferably, the temperature, residence time, and stretching ratio at the selected temperature are chosen to provide a fishing line exhibiting a tensile modulus within the range from about 230 g / d to about 780 g / d with a tenacity of at least 15 g / d.

Owner:PURE FISHING

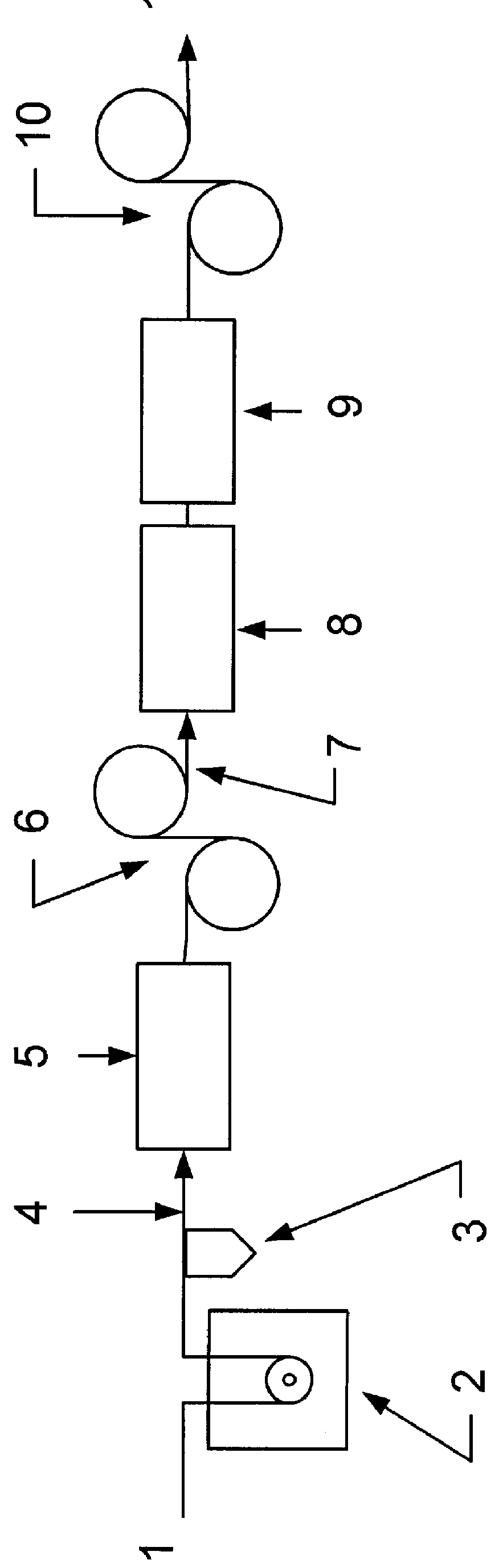

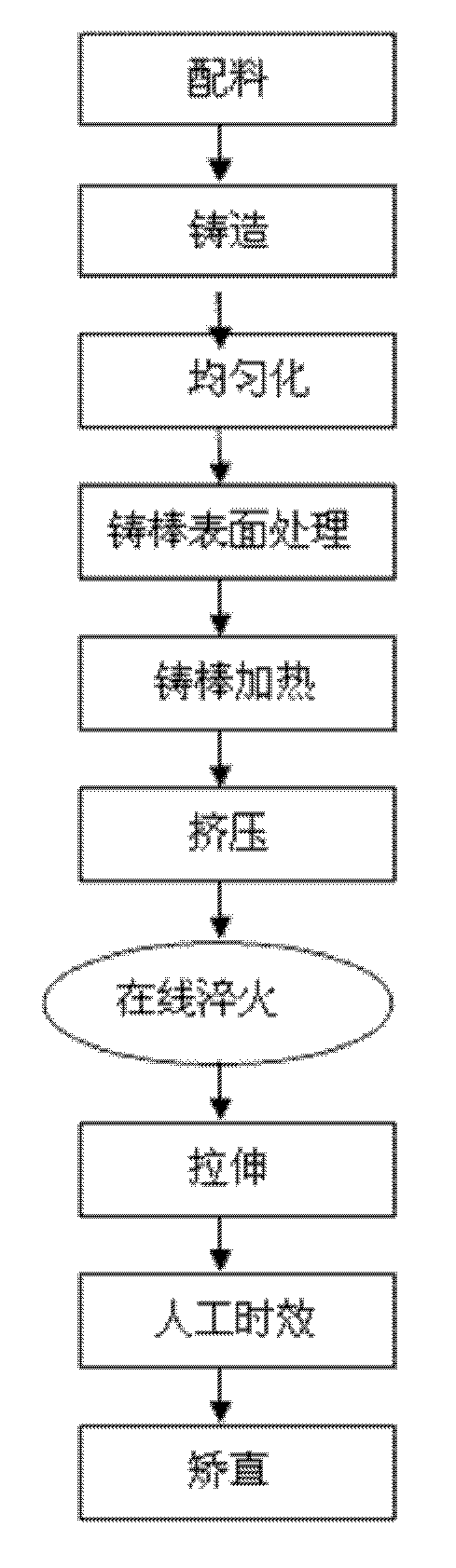

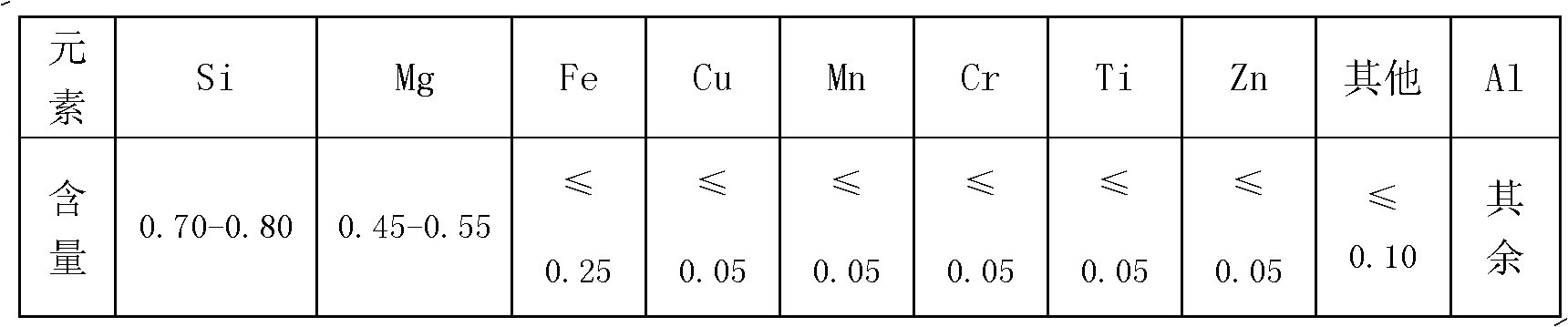

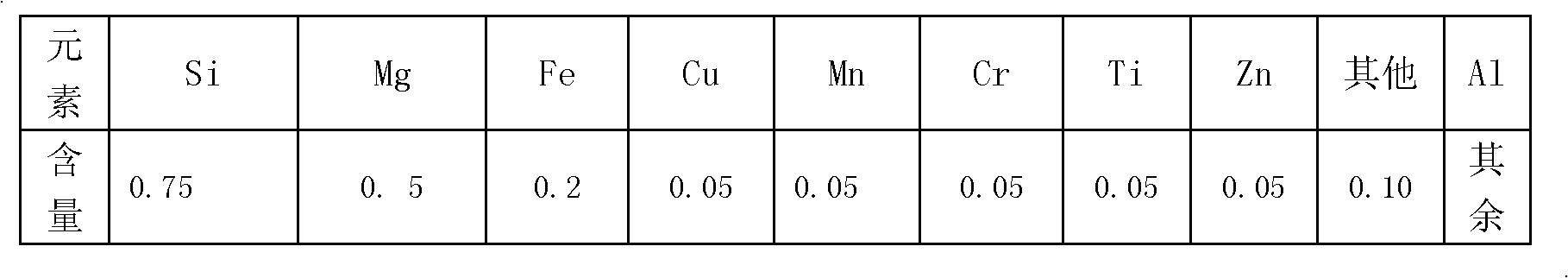

Extruding processing technology of aluminium alloy tubing with large diameter

InactiveCN102492877AReduce residual stressHigh strength propertiesExtrusion control devicesFailure rateHigh energy

The invention discloses an extruding processing technology of an aluminium alloy tubing with large diameter. The method comprises steps of a. proportioning, b. casting, c. uniformization, d. surface treatment on casting rod, e. casting rod heating, f. extrution, g. on-line quenching, h. stretching, i. artificial aging and j. straightening, etc. Strict control on each parameter can solve problems of extruding production of tubing with large diameter, eliminate disadvantages of long production period, low production efficiency, high energy consumption, huge environmental pollution and expensiveauxiliary equipment of rolling and drawing, save cost, simplify arrangement of auxiliary equipment and further reduce failure rate of an apparatus. The energy consumption of the present invention is merely 1 / 4 that of rolling and drawing, and water consumption is 1 / 8 that of a steam jet pump set; therefore, the invention brings obvious economic effects.

Owner:CHINA ZHONGWANG

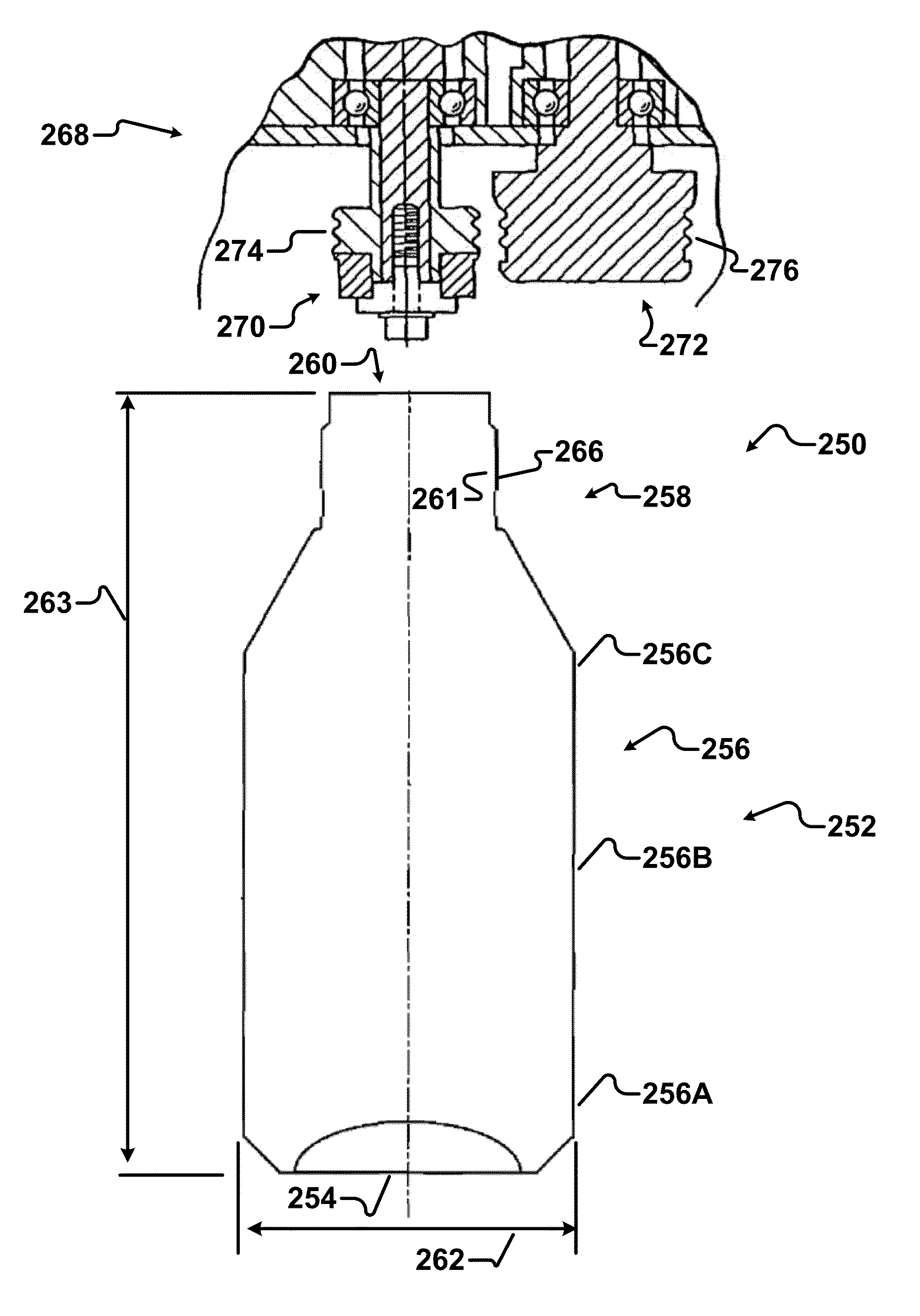

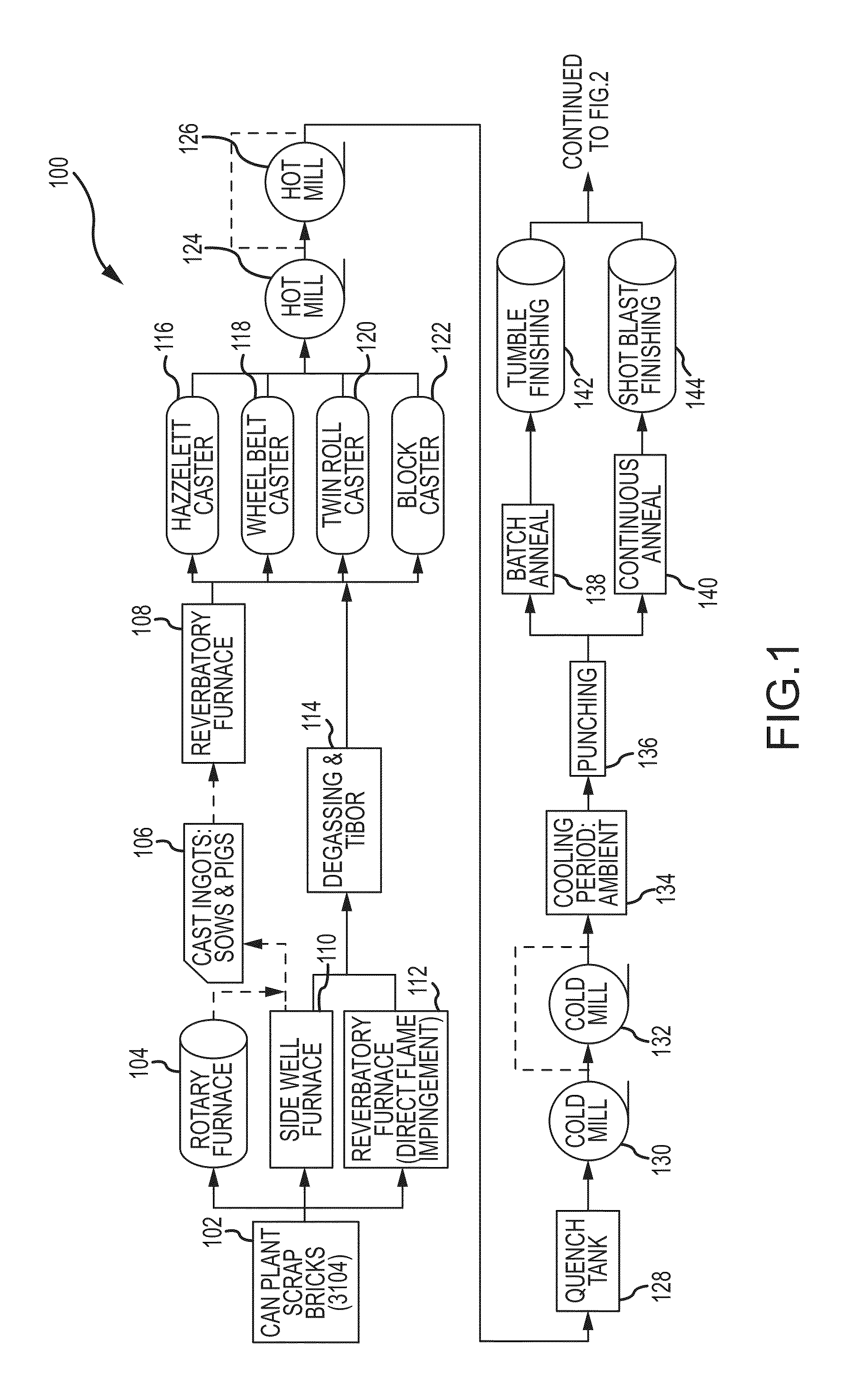

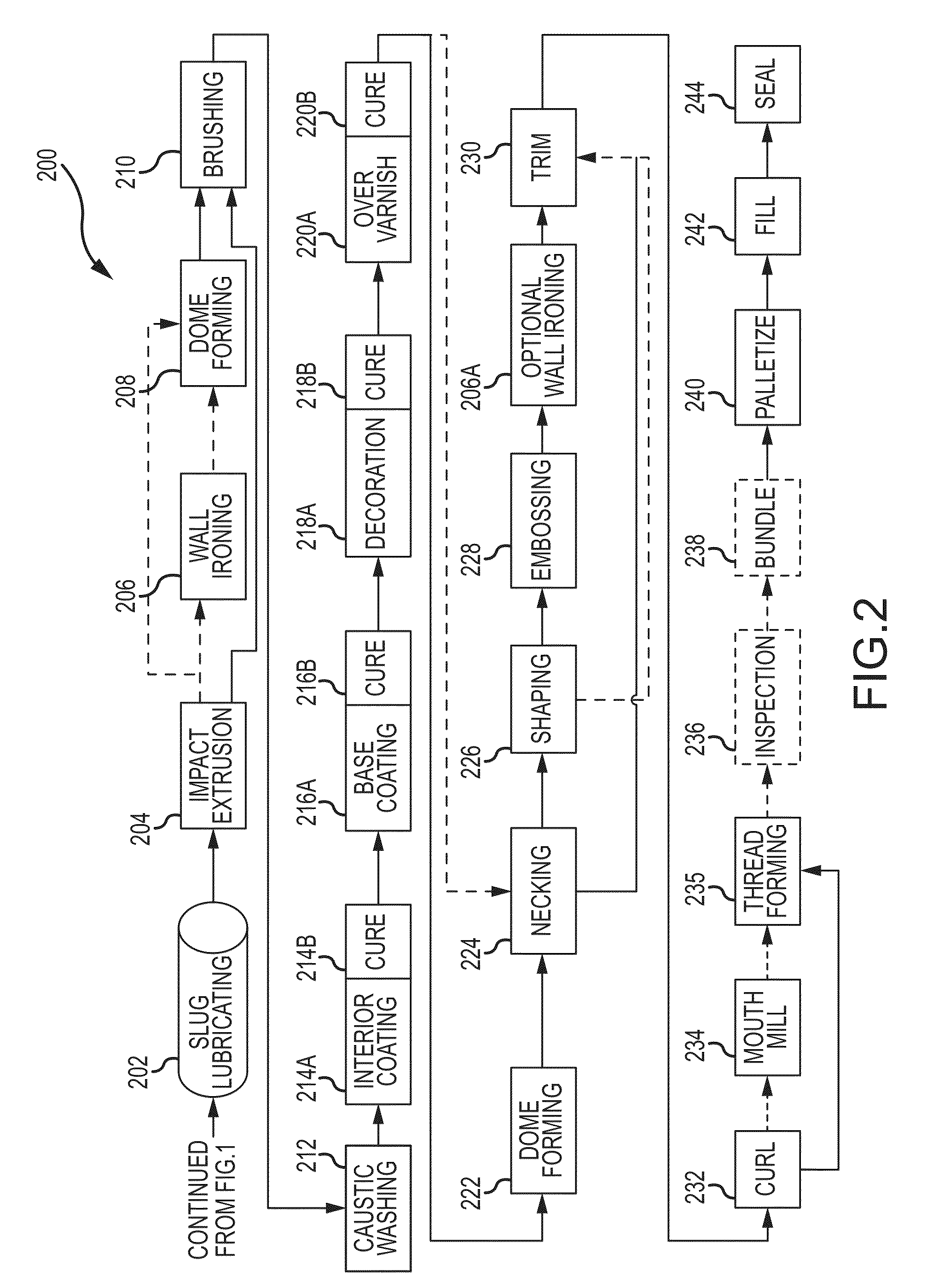

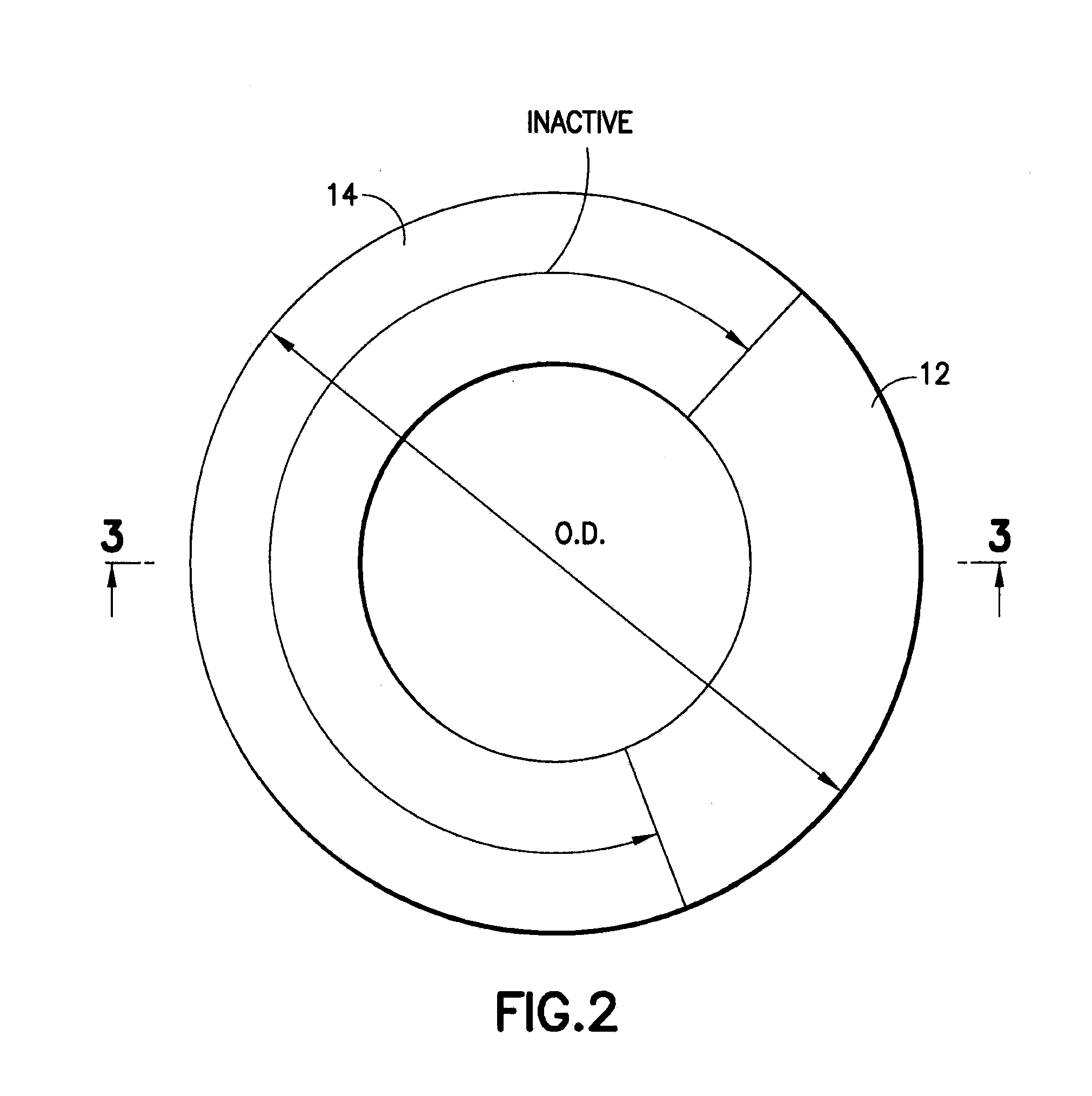

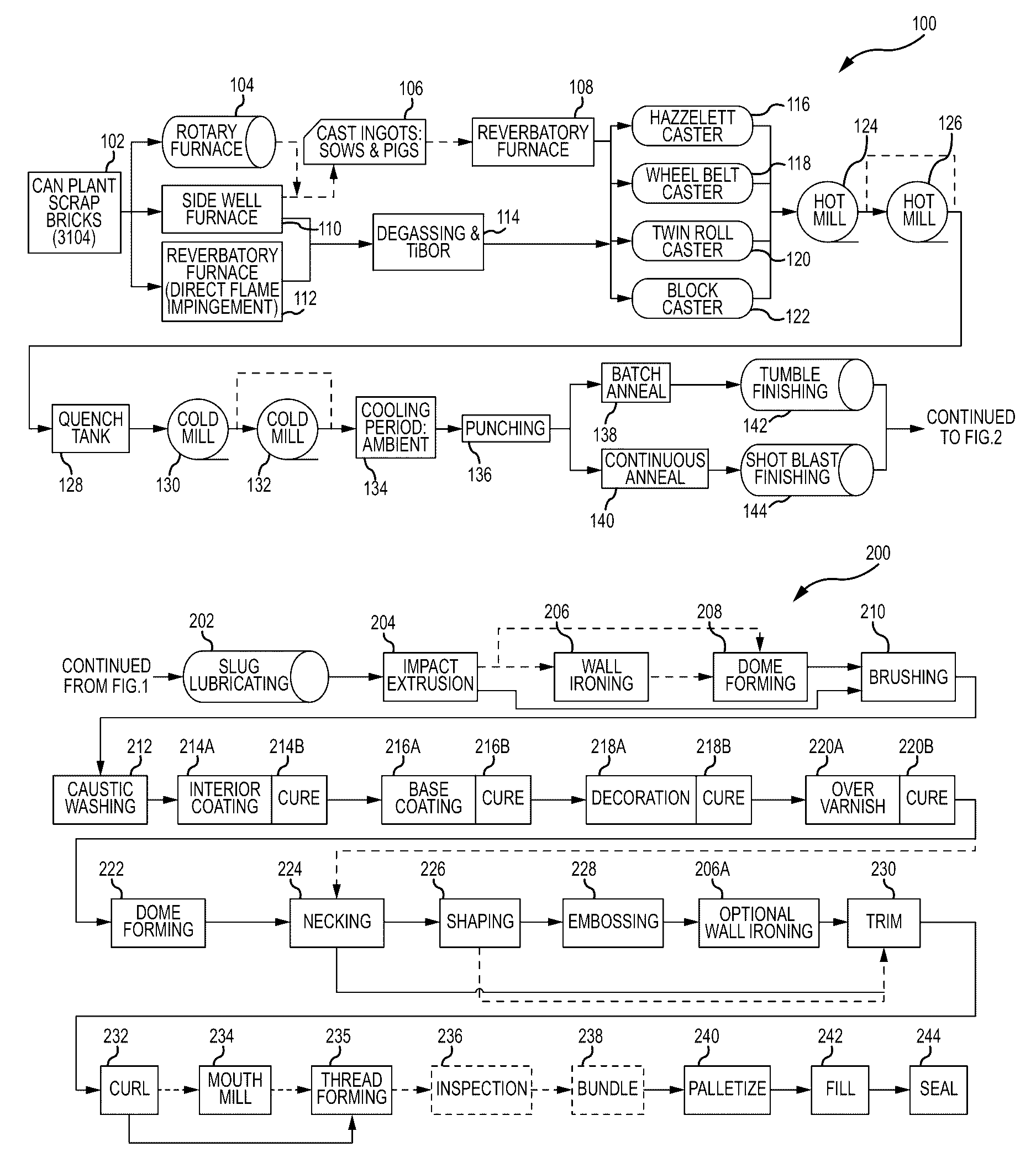

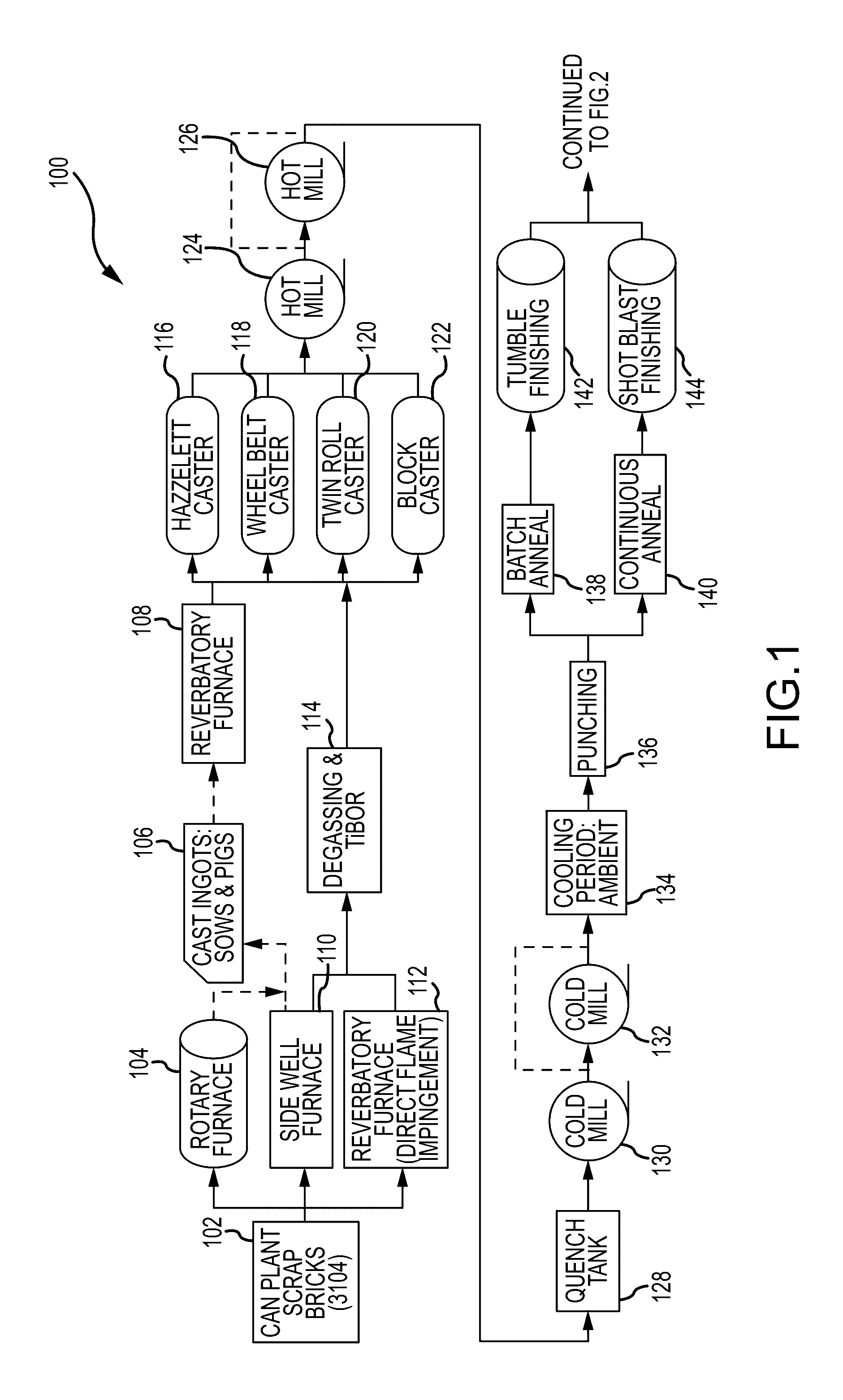

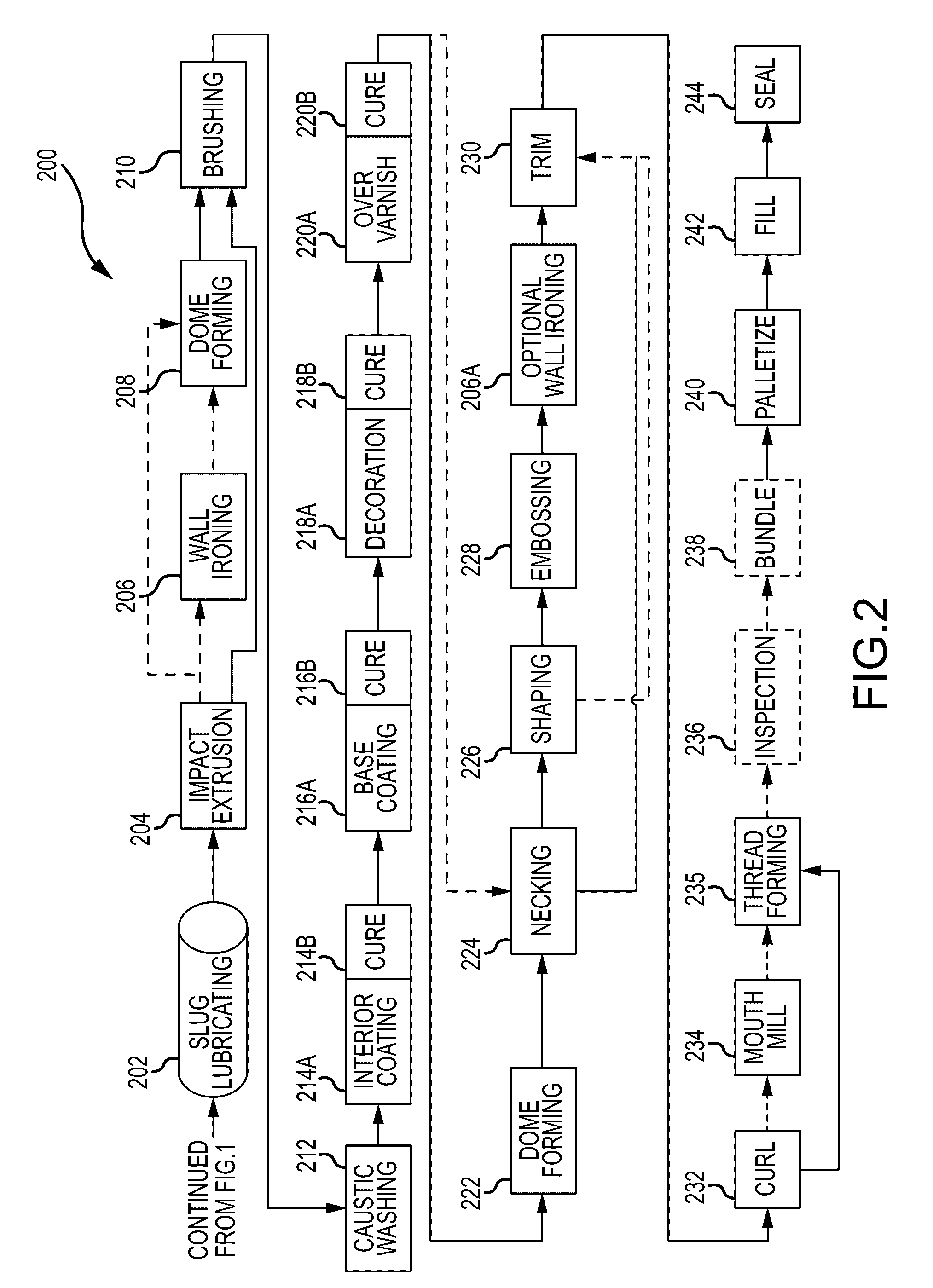

Aluminum impact extruded bottle with threaded neck made from recycled aluminum and enhanced alloys

ActiveUS20140298641A1High mechanical strengthLow costMetal rolling stand detailsClosure capsBottleUltimate tensile strength

The present invention relates generally to forming a threaded neck in a metal bottle manufactured by a process known as impact extrusion. More specifically, the present invention relates to methods, apparatus and alloy compositions used in the impact extrusion manufacturing of containers and other articles with sufficient strength characteristics to allow threading the container necks to receive a threaded closure on the threaded neck.

Owner:BALL CORP

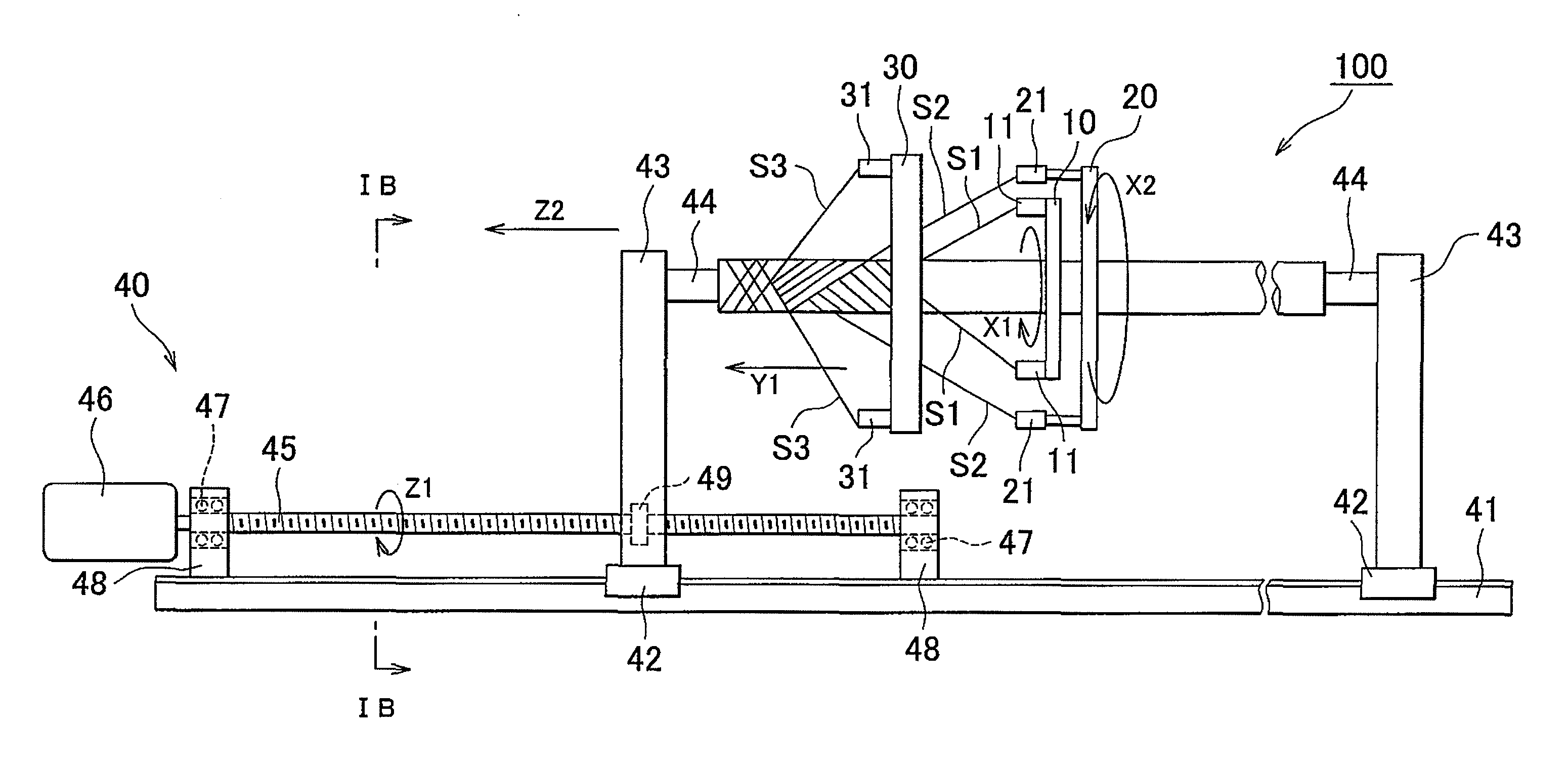

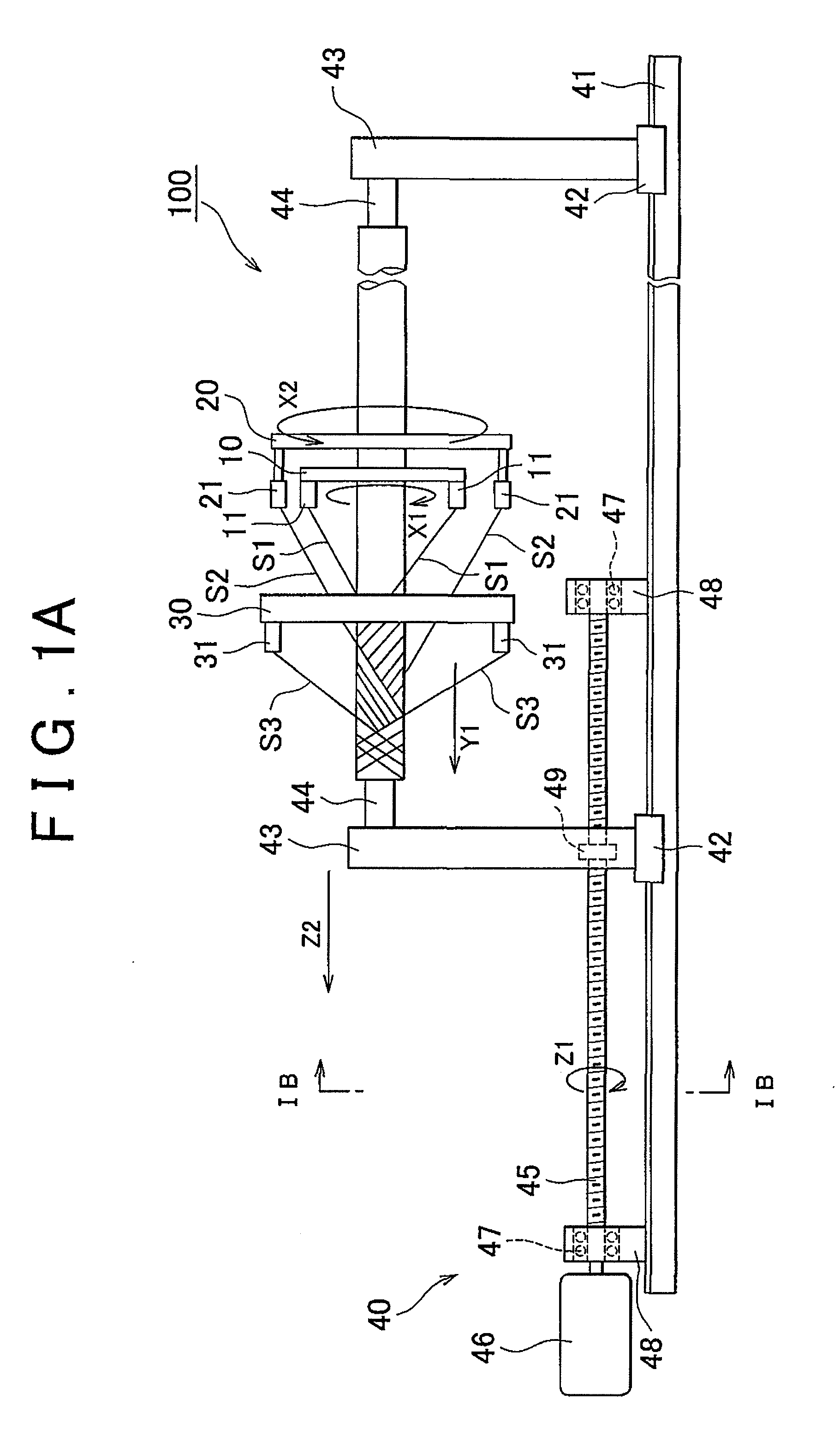

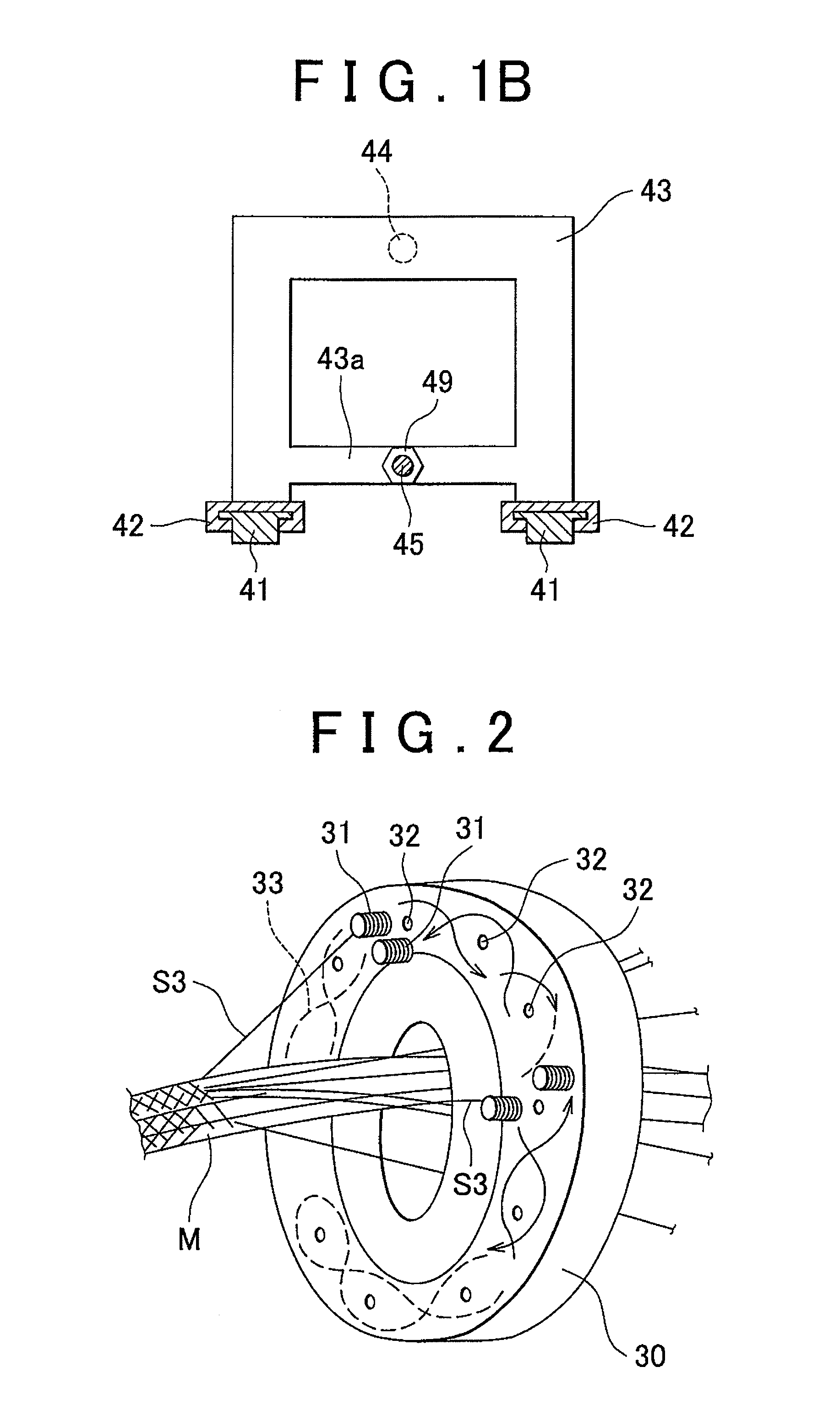

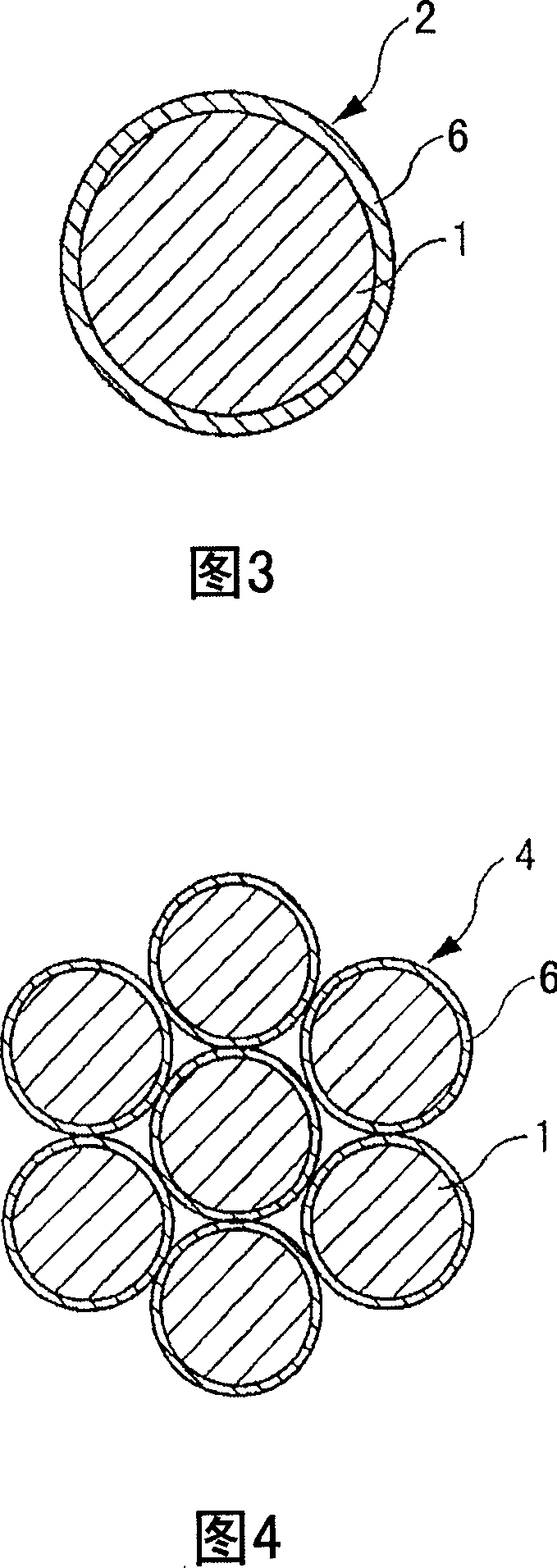

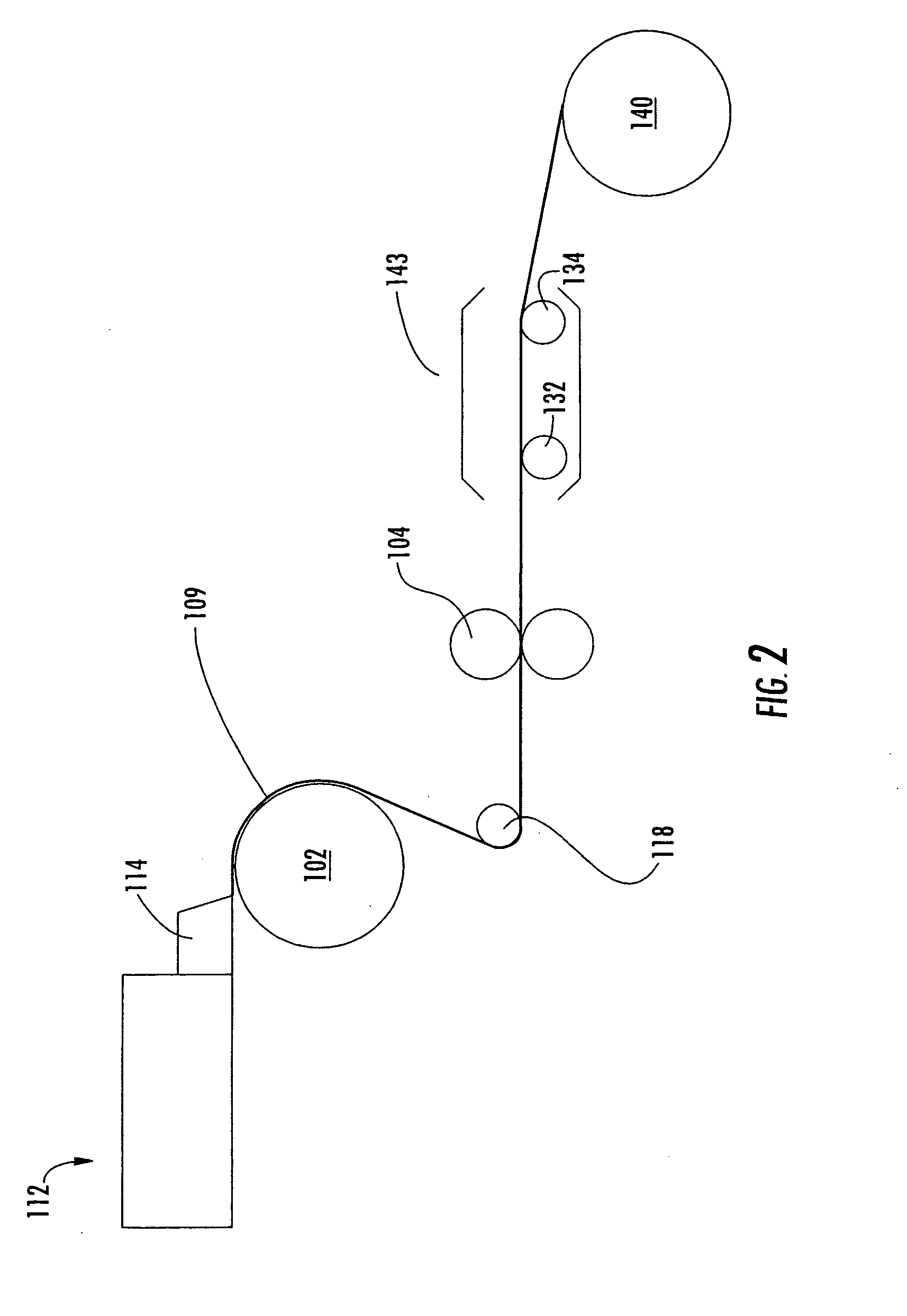

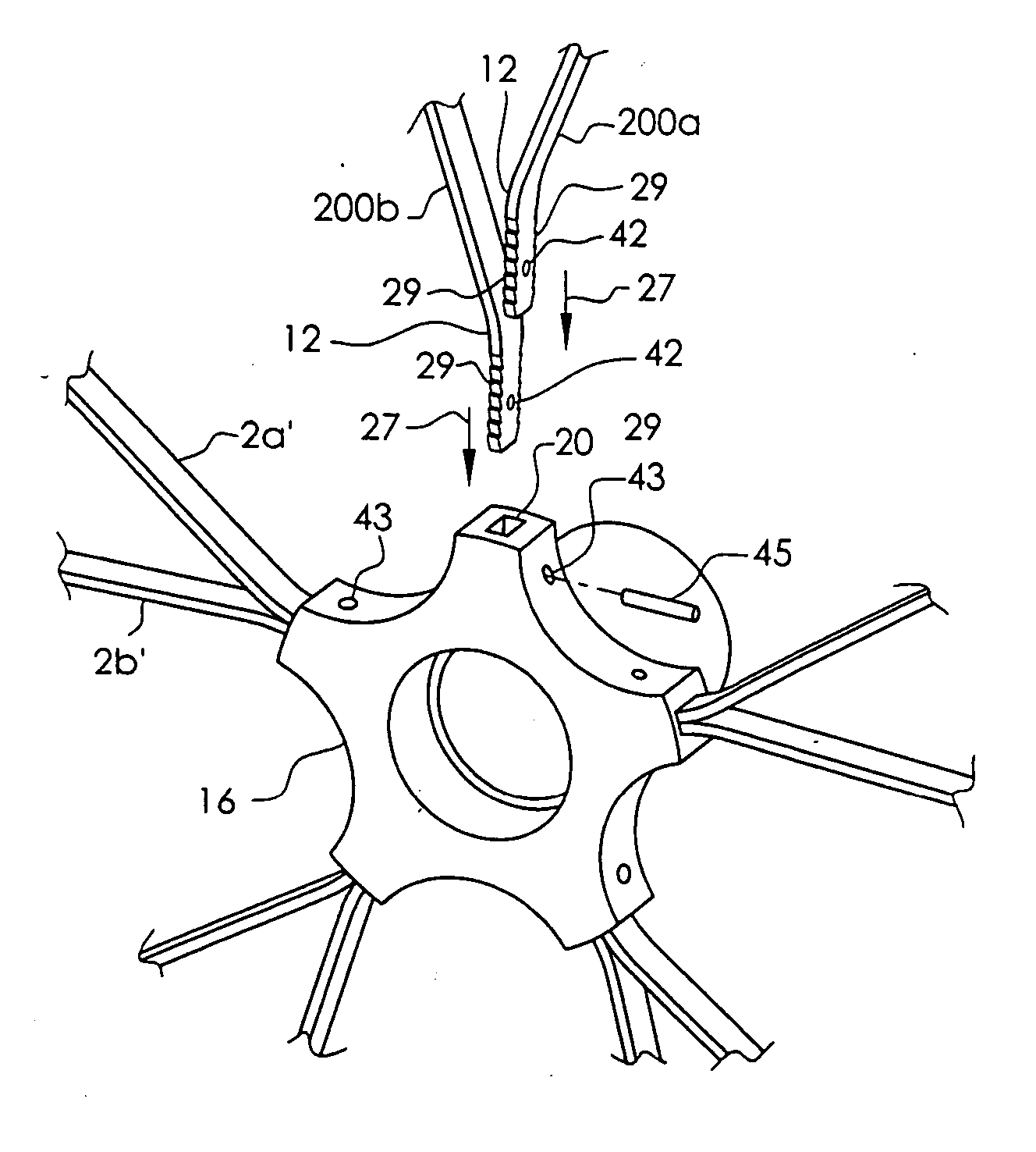

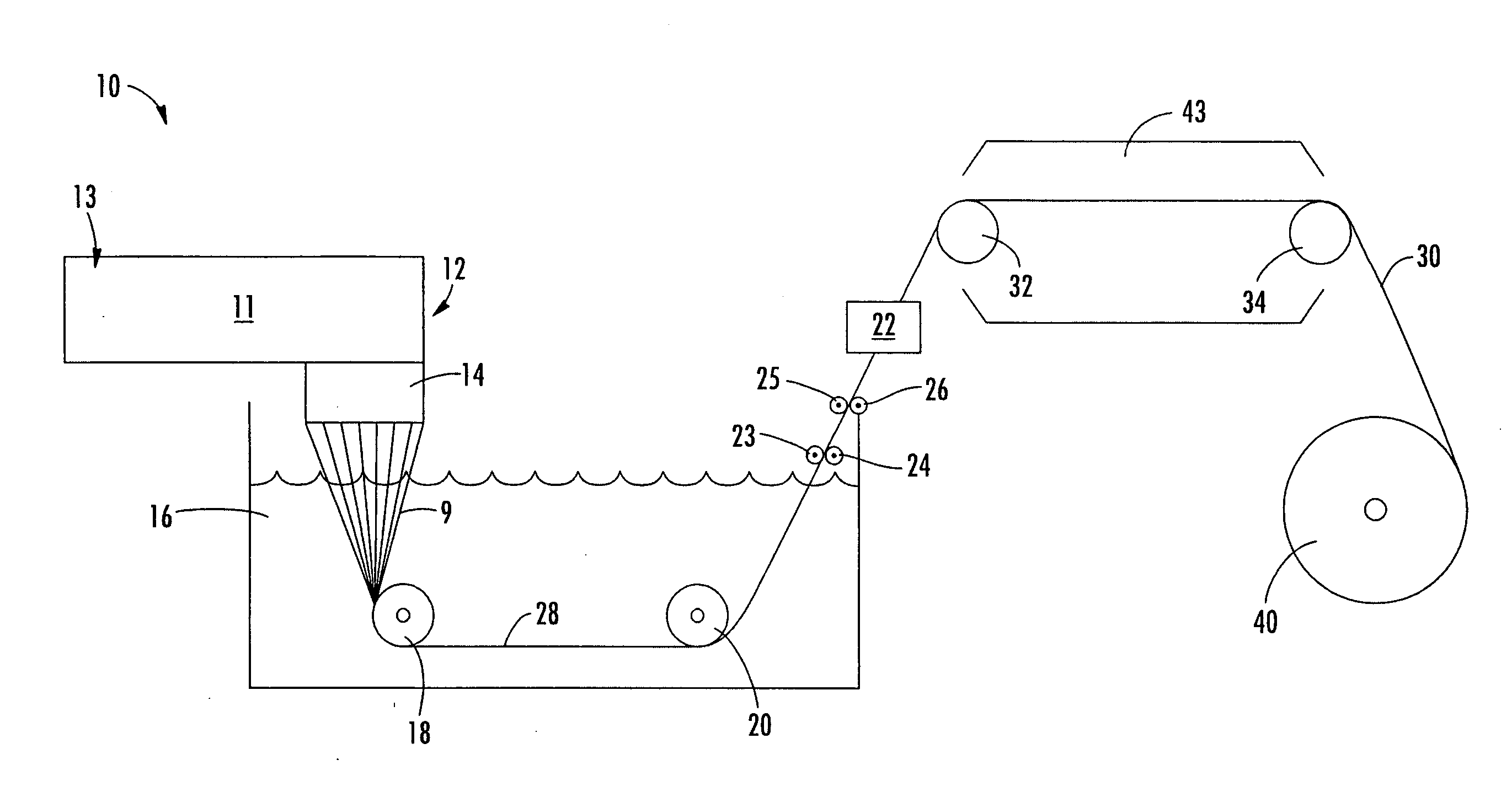

Yarn layer forming apparatus, yarn layer forming method, and method of manufacturing fiber-reinforced member

A yarn layer forming apparatus includes: an annular braider that supplies braider yarn; an annular first supply device that supplies first yarn; an annular second supply device that supplies second yarn; and an actuating device that moves a mandrel. At least one of the first supply device and the second supply device is rotatable. A layer structure of yarn layers is formed on a peripheral surface of the mandrel. The layer structure of yarn layers includes at least yarn arrangement layers formed respectively by the first and second supply devices and a woven layer formed by the braider.

Owner:TOYOTA JIDOSHA KK +1

Composite wear-resisting shoe sole

A composite wear-resisting shoe sole is prepared from, by weight, 60-100 parts of natural rubber, 10-50 parts of styrene butadiene rubber, 5-20 parts of polar rubber, 10-60 parts of modified white carbon black, 1-10 parts of zinc oxide, 1-4 parts of accelerant, 0.1-0.5 part of antioxidant, 2.5-4.5 parts of active agent, 5-20 parts of filler and 1-10 parts of sulfur .The filler is tetrapod-like zinc oxide whiskers .According to the composite wear-resisting shoe sole, the natural rubber and a small amount of polar rubber are jointly used as main rubber materials, the white carbon black subjected to toluene diisocyanate graft modification is added to serve as a reinforcing material, the tetrapod-like zinc oxide whiskers of a highly regular structure are used as a filling frame, the accelerant, the composite antioxidant and the active agent are added in sequence, and the composite wear-resisting shoe sole with high slippery resistance and tear strength and a remarkably improved frictional coefficient is prepared.

Owner:宁波市富罗迷鞋业有限公司

Extra-fine copper alloy wire, extra-fine copper alloy twisted wire, coaxial cable, multi-core cable and manufacturing method thereof

ActiveCN1988055AImprove heat resistanceHigh strength propertiesCoaxial cables/analogue cablesSingle bars/rods/wires/strips conductorsMulticore cableElectrical conductor

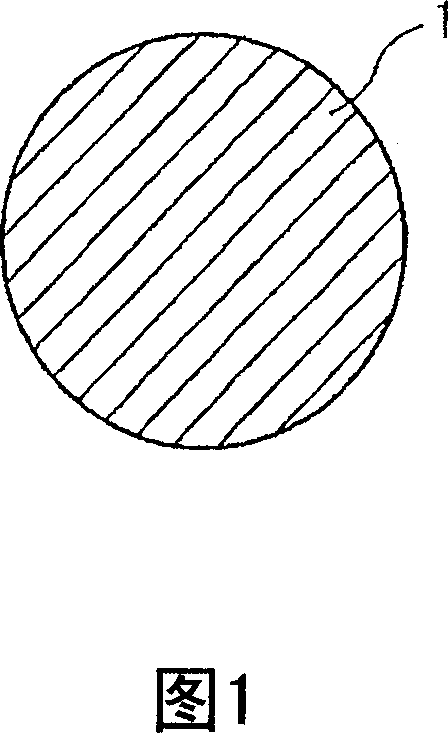

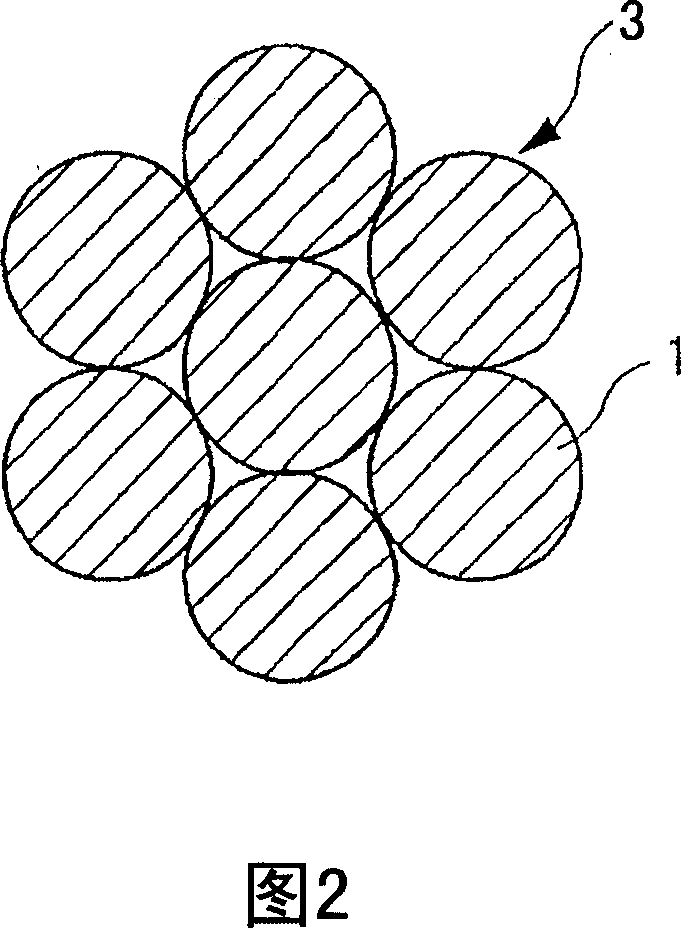

The object of the invention is to provide an extra-fine copper alloy wire, an extra-fine copper alloy twisted wire, an extra-fine insulated wire, a coaxial cable having high intensity, low resistance and high heat tolerance, their manufacturing method and a multicore cable thereof. The extra-fine copper alloy wire has 1 to 3 weight % of silver in the copper, a wire diameter less than 0.025 mm, and a tensile strength of more than 850 MPa, an electrical conductivity of more than 85% IACS after heat treatment; the coaxial cable (20A) is configured that, an inner conductor is formed by an extra-fine copper alloy twisted wire (3) twisted from seven extra-fine copper alloy wires (1), the inner conductor is then peripherally envelopped with a solid insulator (5a) to form an extra-fine insulated wire (10), a plurality of conductor wires (13) are winding in a screw shape on the periphery of the extra-fine insulated wire along a length direction of the extra-fine insulated wire to form an outer conductor (15), thereafter, the outer conductor is envenlopped with a protection layer (17).

Owner:HITACHI CABLE

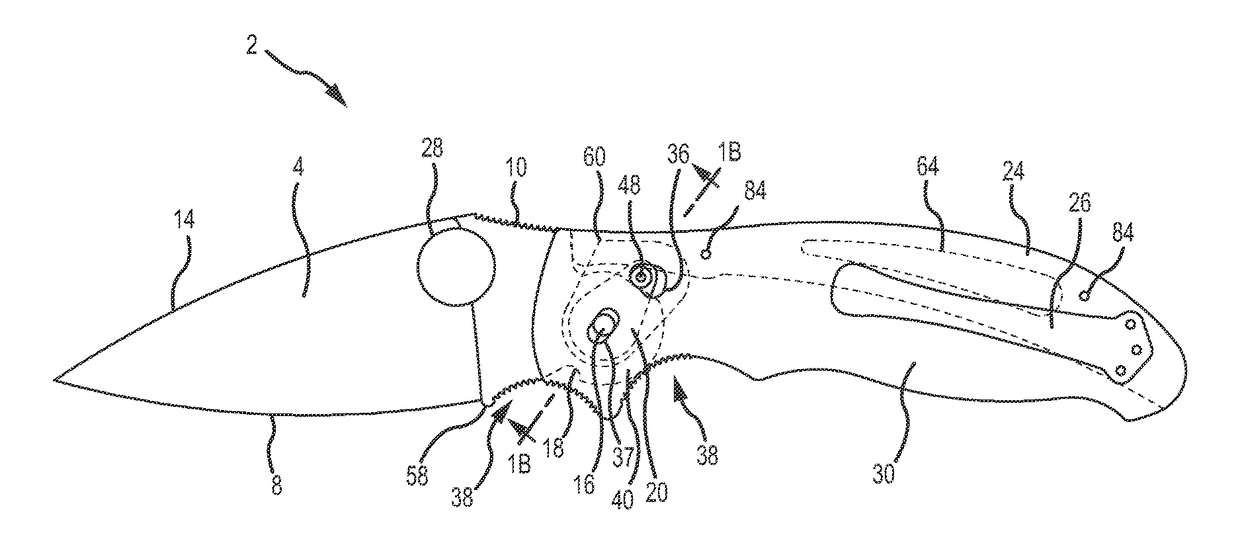

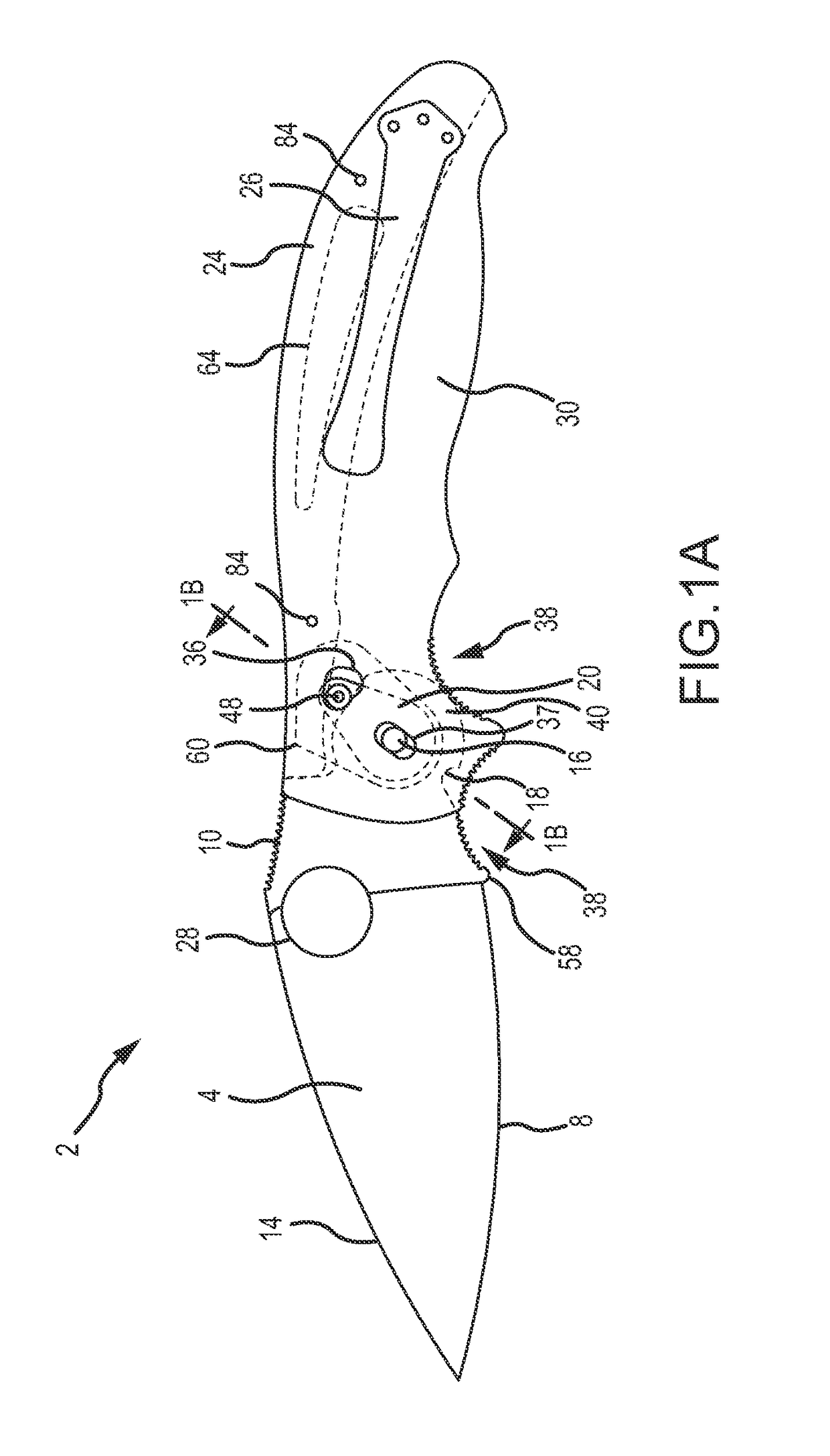

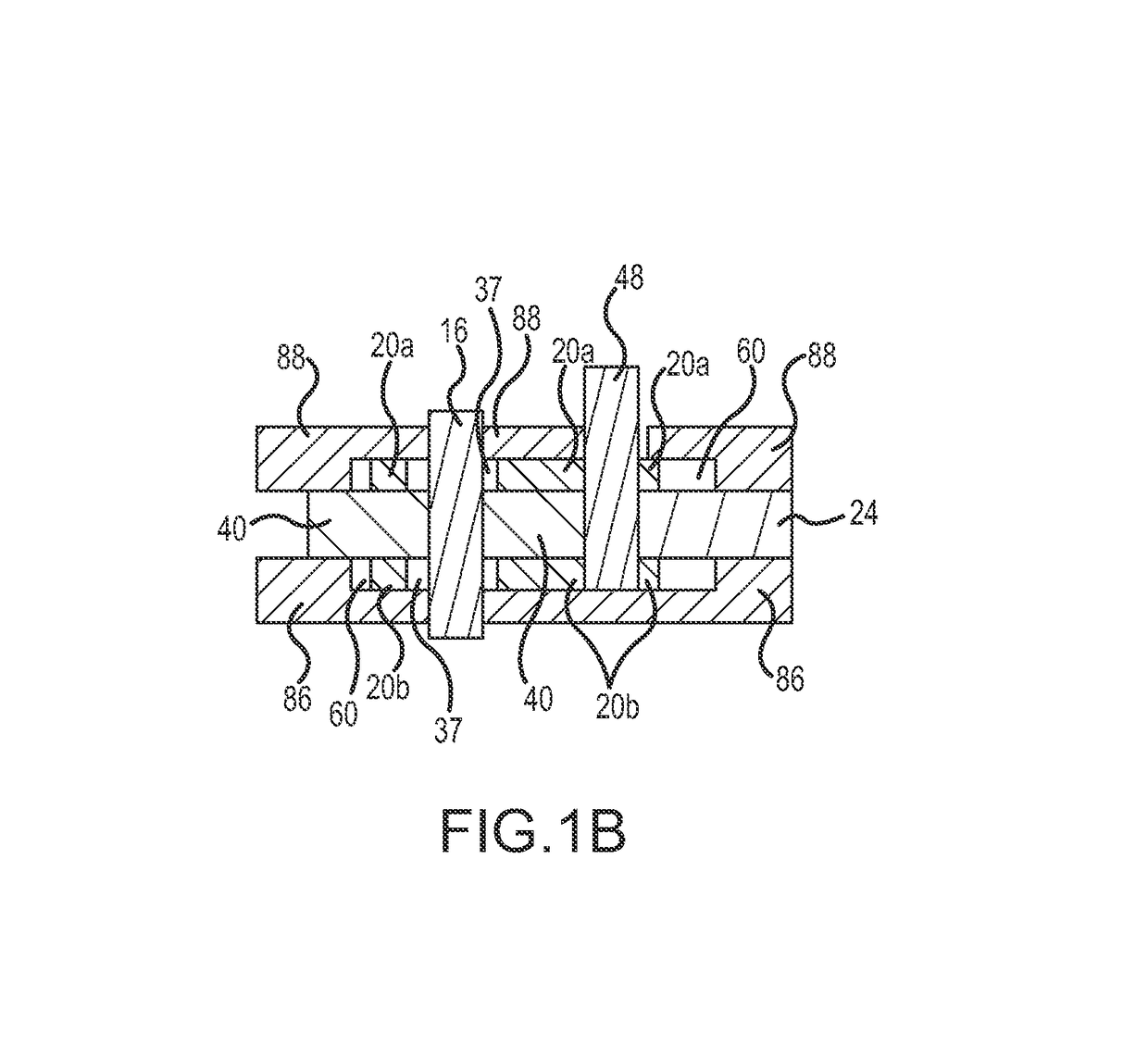

Rotational wedge locking mechanism for a folding knife

ActiveUS9943970B2High strength propertiesIncreased durabilityMetal working apparatusLocking mechanismEngineering

A locking mechanism for a folding knife is provided. More specifically, the locking mechanism is a rotational wedge locking mechanism that maintains the folding knife's blade in an extended position and prevents the blade from inadvertently closing when the knife is in use in the extended position. The rotational wedge locking mechanism also impedes the folding knife from inadvertently opening when the blade is in a closed position of storage. The rotational wedge locking mechanism generally comprises a lock pin, a means for moving the lock pin, and a biasing member, which work in conjunction with the tang of the blade and the back spacer to securely retain the folding knife in an open or closed position.

Owner:SPYDERCO

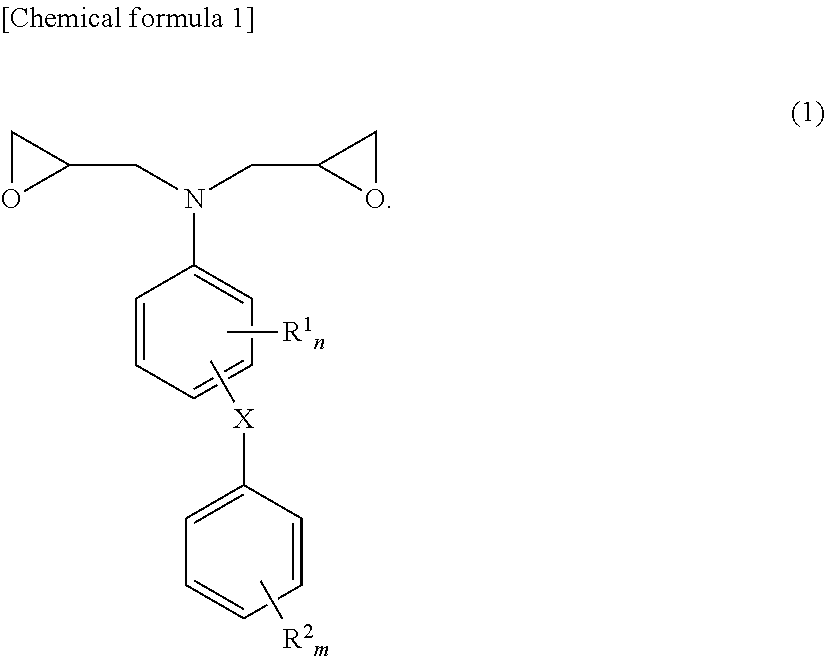

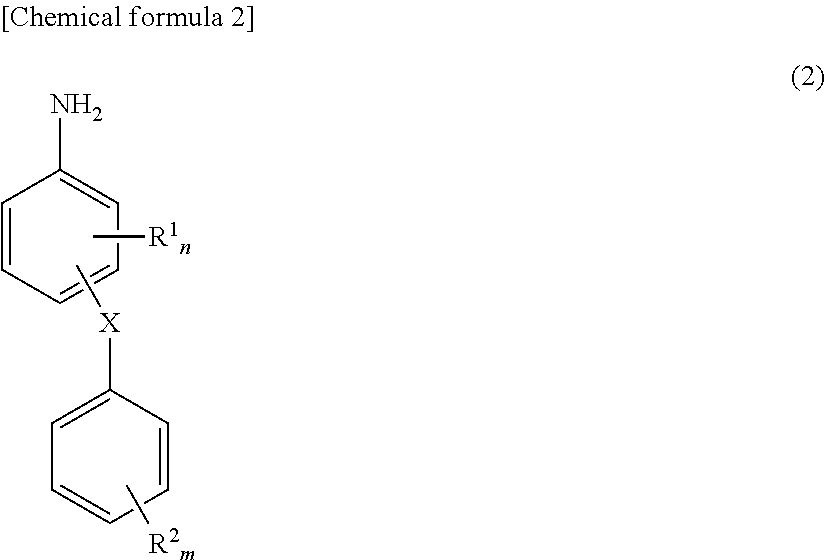

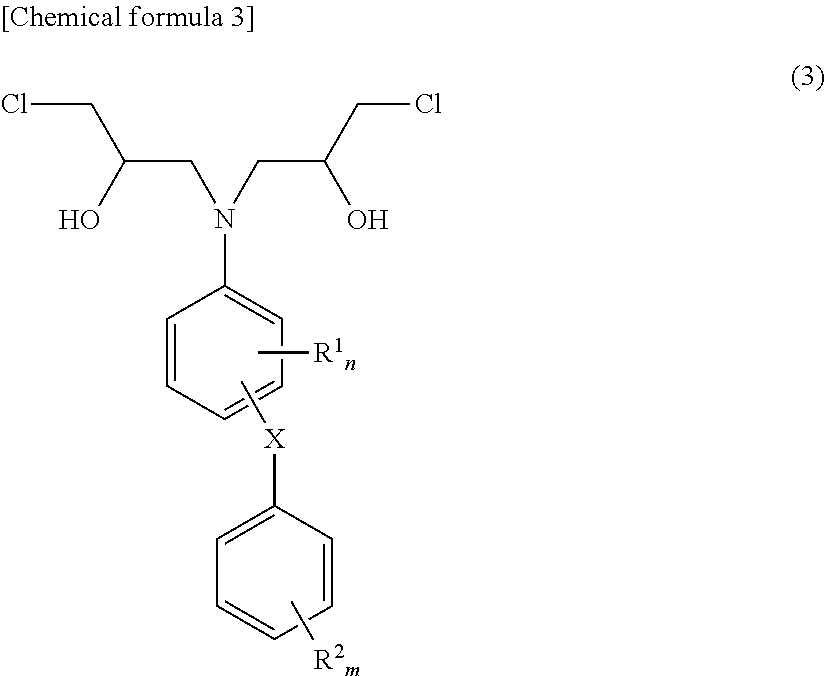

Epoxy resin composition for fiber-reinforced composite material, prepreg, and fiber-reinforced composite material

InactiveUS20130202873A1Excellent heat resistance and strength characteristicHigh reliabilitySynthetic resin layered productsCeramic layered productsFiber-reinforced compositeGlycylxylidide

Provided are a fiber-reinforced composite material excellent in heat resistance and strength properties, an epoxy resin composition to obtain the fiber-reinforced composite material, and a prepreg obtained by using the epoxy resin composition. Further provided are a fiber-reinforced composite material having less volatile matters during the curing time, and having excellent heat resistance and strength properties, an epoxy resin composition to obtain the fiber-reinforced composite material, and a prepreg obtained by using the epoxy resin composition. Provided are: an epoxy resin composition for a fiber-reinforced composite material, comprising an amine type epoxy resin [A], an aromatic amine curing agent [B], and a block copolymer [C] having a reactive group capable of reacting with an epoxy resin; a prepreg obtained by impregnating a reinforced fiber with the epoxy resin composition; and a fiber-reinforced composite material obtained by curing the prepreg. Further provided are: an epoxy resin composition comprising an epoxy resin [A] having two or more of four- or more-membered ring structures, and having either one of a glycidyl amino group directly bonded to the ring structure or a glycidyl ether group directly bonded to the ring structure, epoxy resin [B] having three or more of functional groups, a curing agent [C], and an elastomer component [D]; a prepreg obtained by impregnating a reinforced fiber with the epoxy resin composition; and a fiber-reinforced composite material obtained by curing the prepreg.

Owner:TORAY IND INC

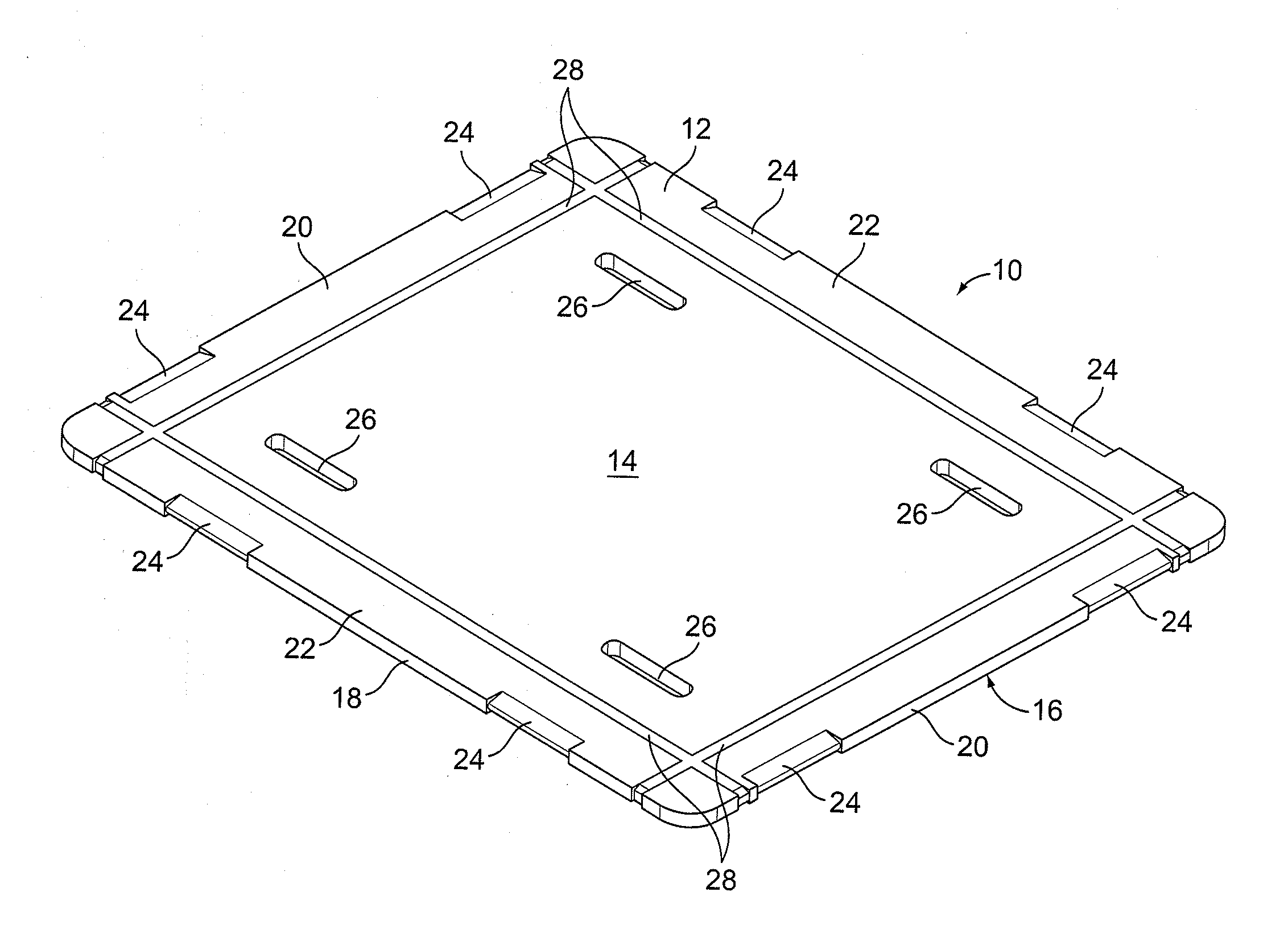

Rigid Urethane Self-Skinning Foam Top Frame, Pallet Support Board, and Pallet

ActiveUS20120111238A1High strength propertiesEasy to handleSledgesCellulosic plastic layered productsEngineeringPallet

Owner:ORBIS CORP

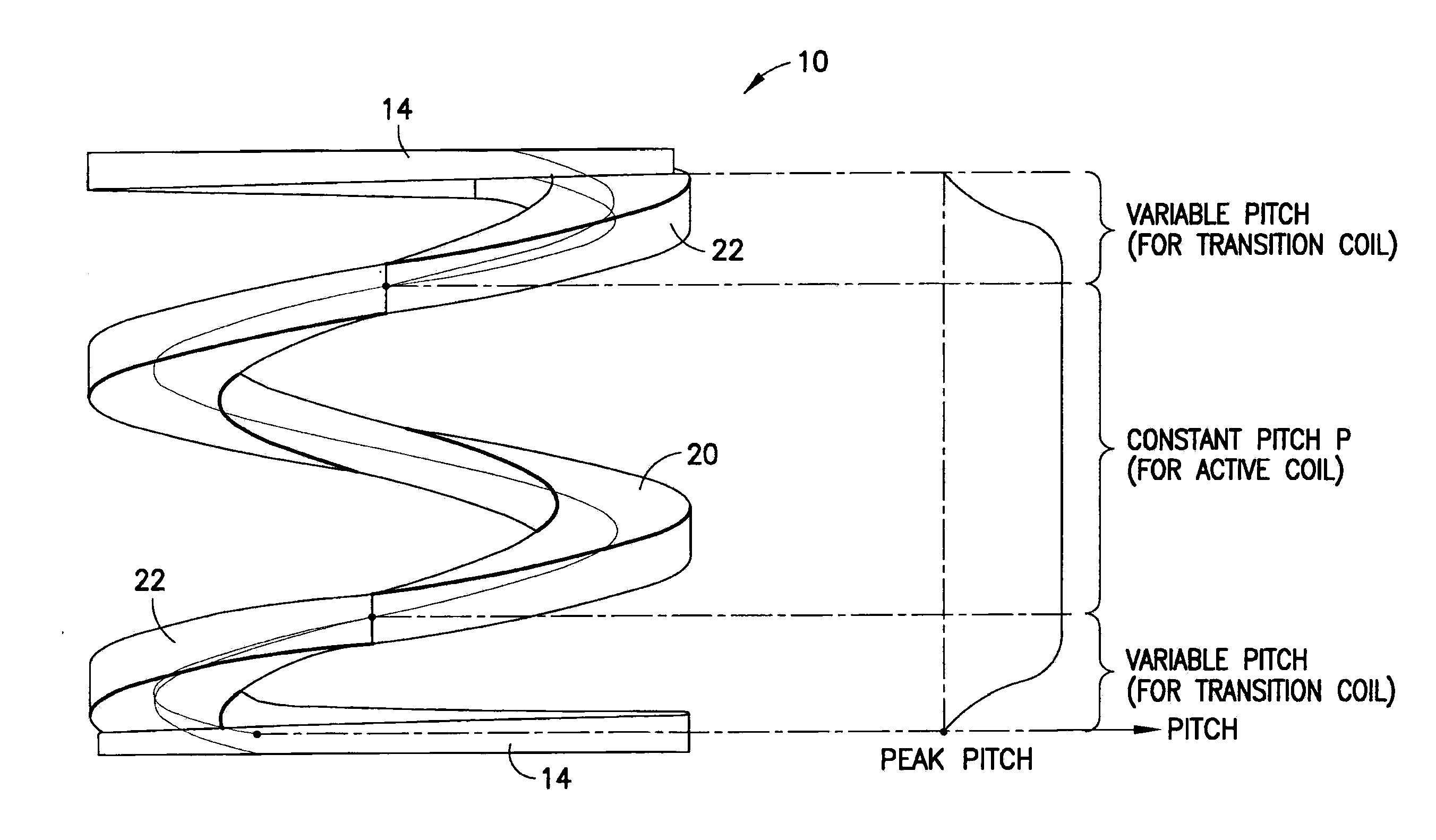

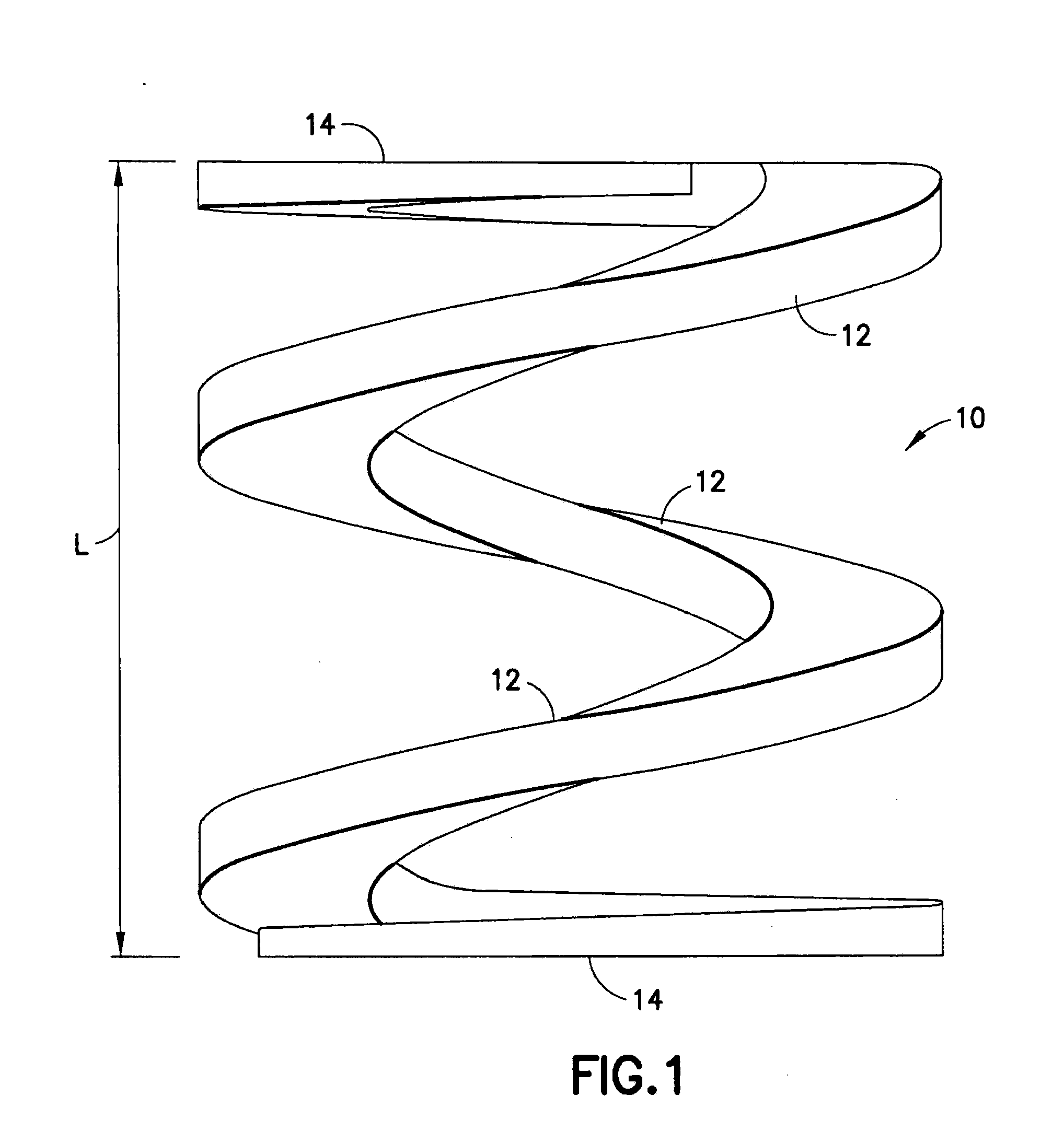

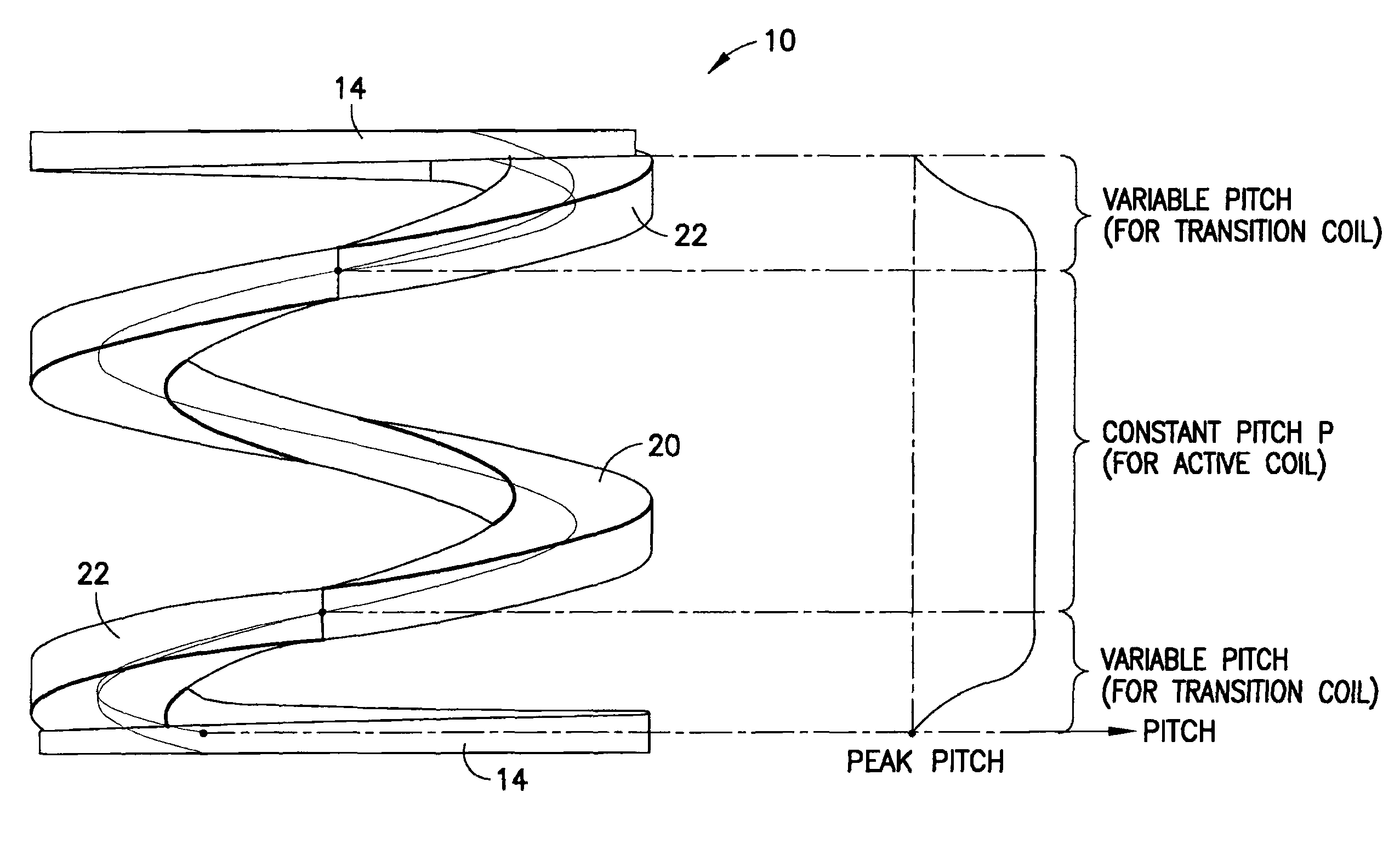

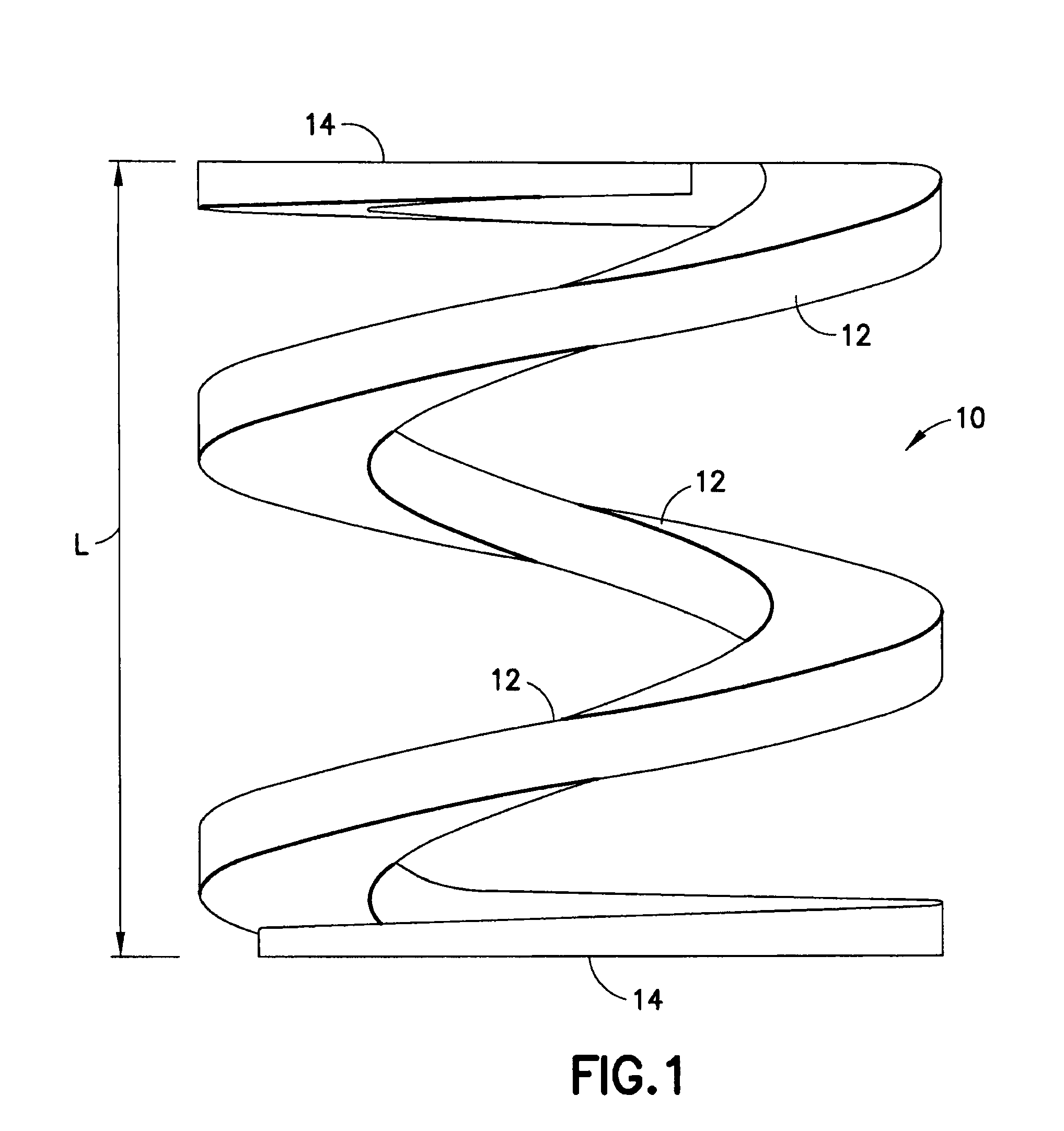

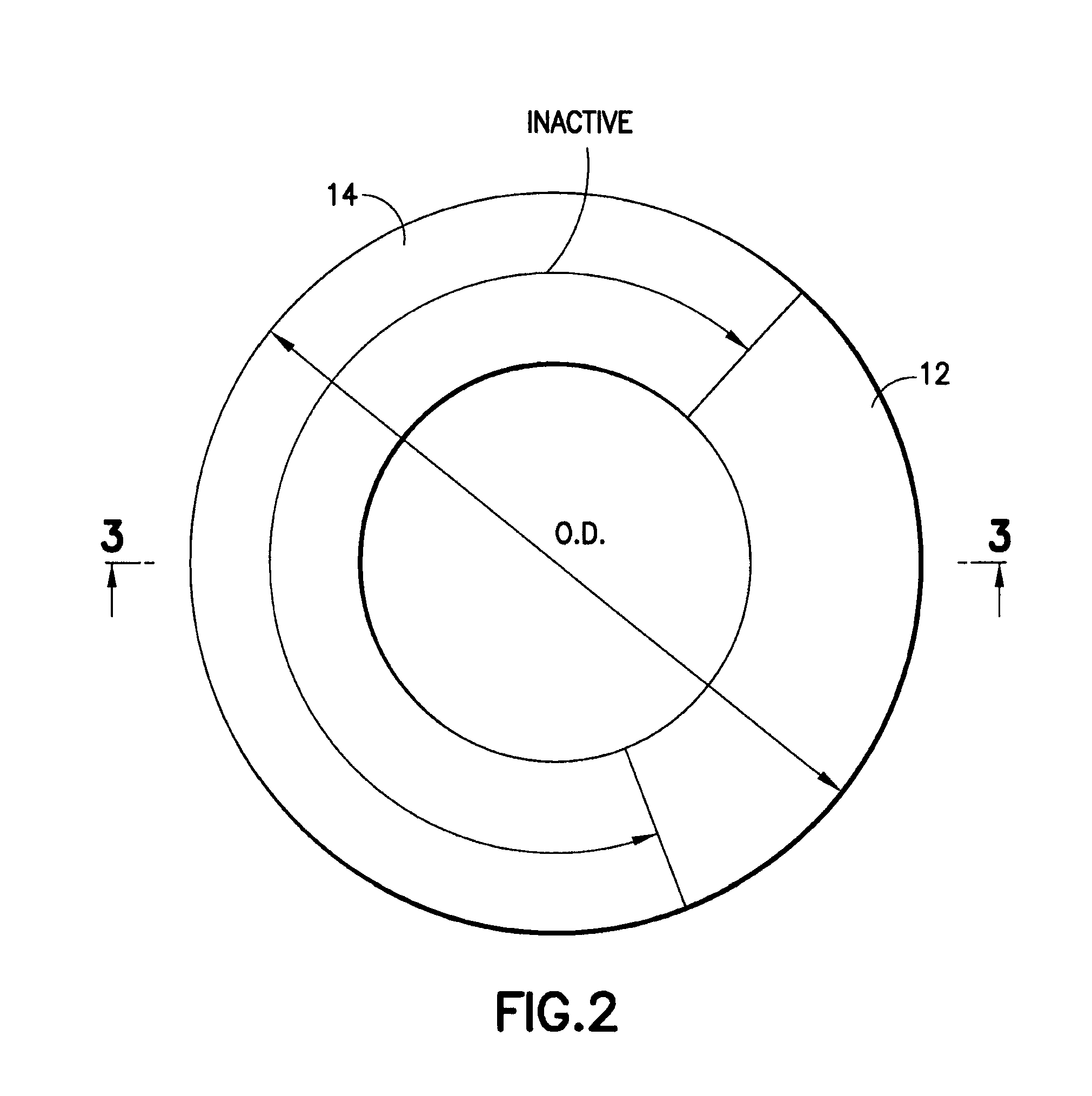

Plastic Spring And Method And Apparatus For Making The Same

ActiveUS20110169205A1Affect performanceReduce materialMouldsScrew-threads articlesEngineeringCoil spring

This invention provides a helical spring formed of plastic material, comprising a pair of end coils situated at respective ends of said helical spring; at least one full pitch active coil between said pair of end coils; a pair of transition coils, each transition coil interconnecting an end of a respective end coil to an end of a respective proximate full pitch active coil, and having a varying pitch.

Owner:LEE SPRING

Aluminum impact extruded bottle with threaded neck made from recycled aluminum and enhanced alloys

The present invention relates generally to forming a threaded neck in a metal bottle manufactured by a process known as impact extrusion. More specifically, the present invention relates to methods, apparatus and alloy compositions used in the impact extrusion manufacturing of containers and other articles with sufficient strength characteristics to allow threading the container necks to receive a threaded closure on the threaded neck.

Owner:BALL CORP

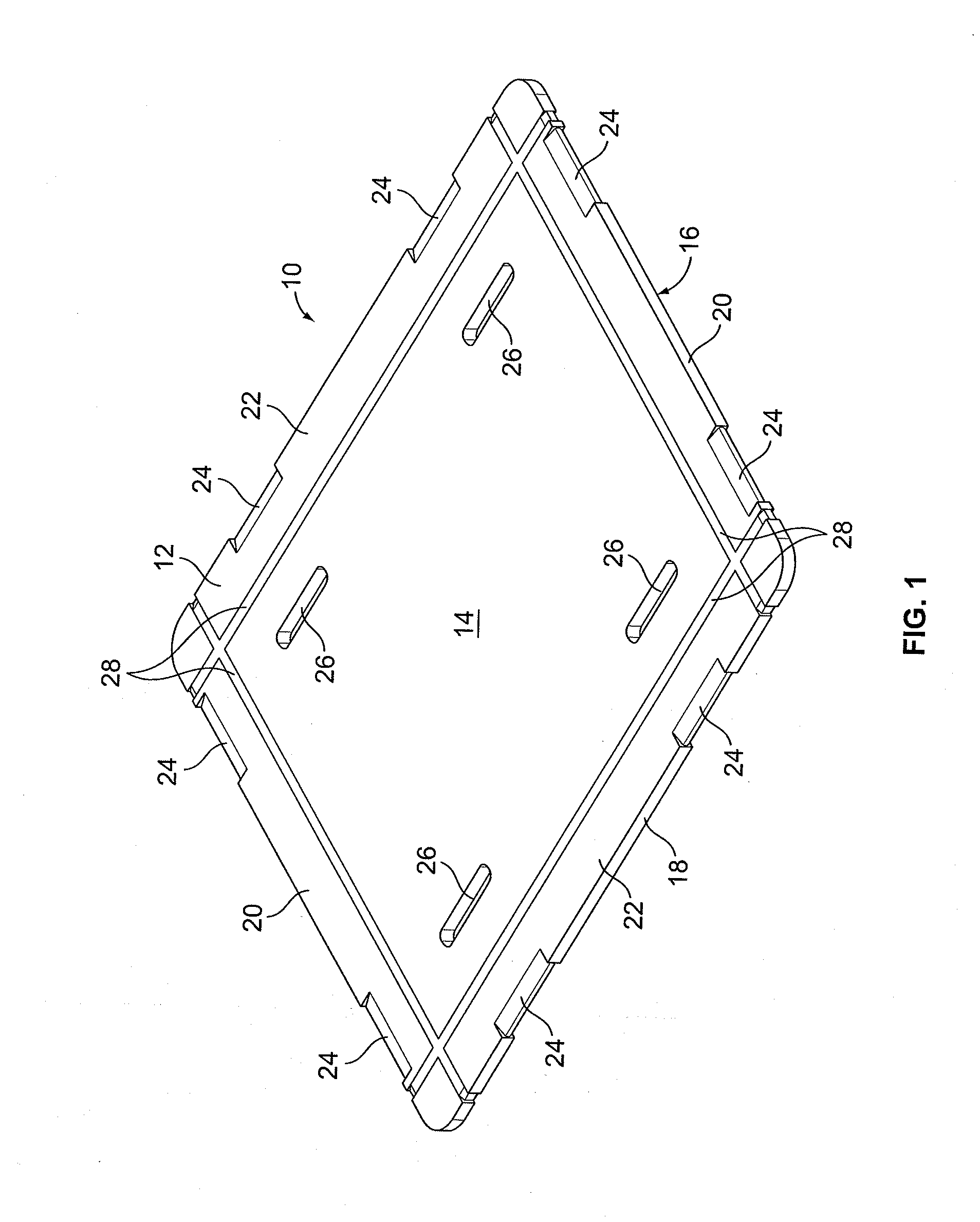

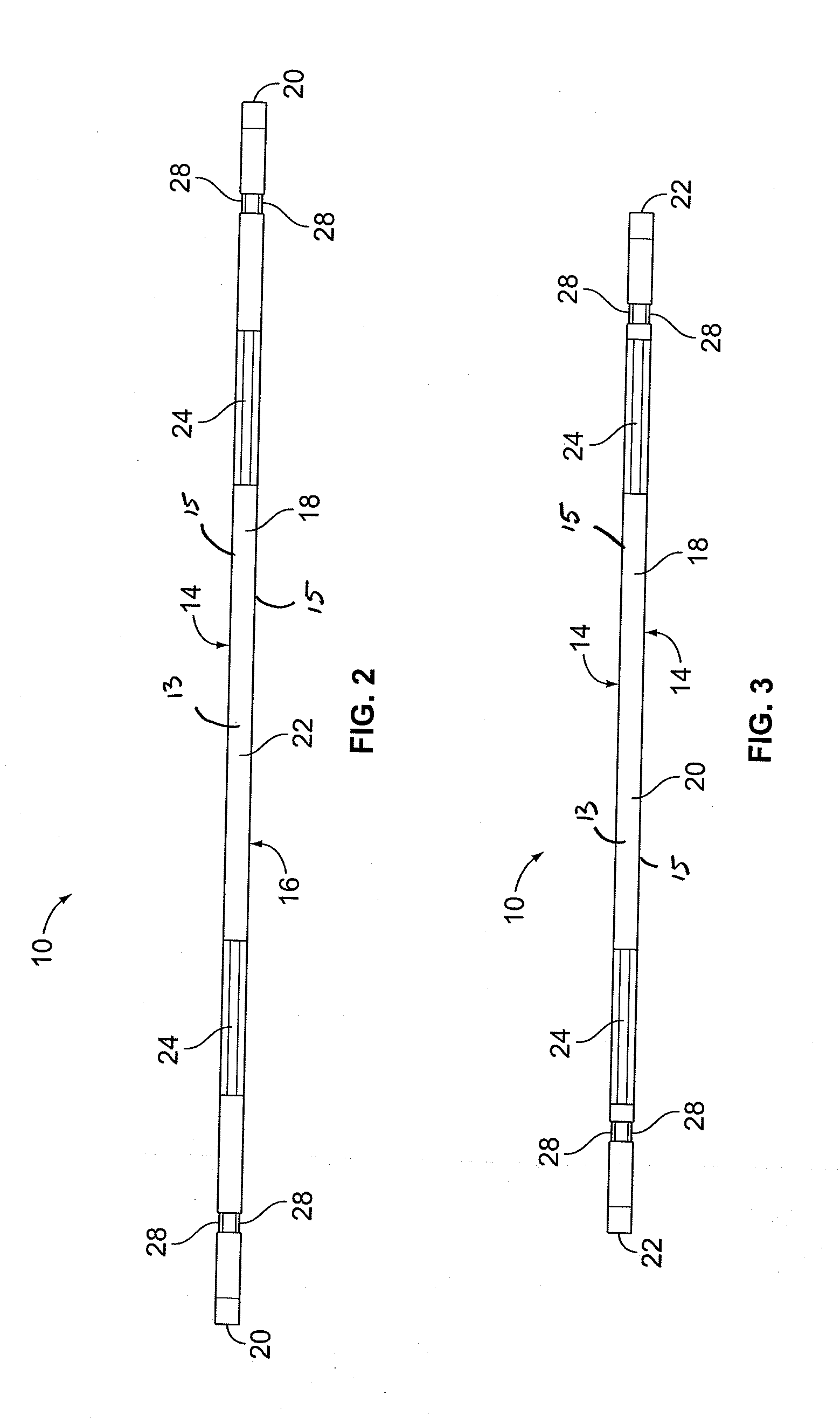

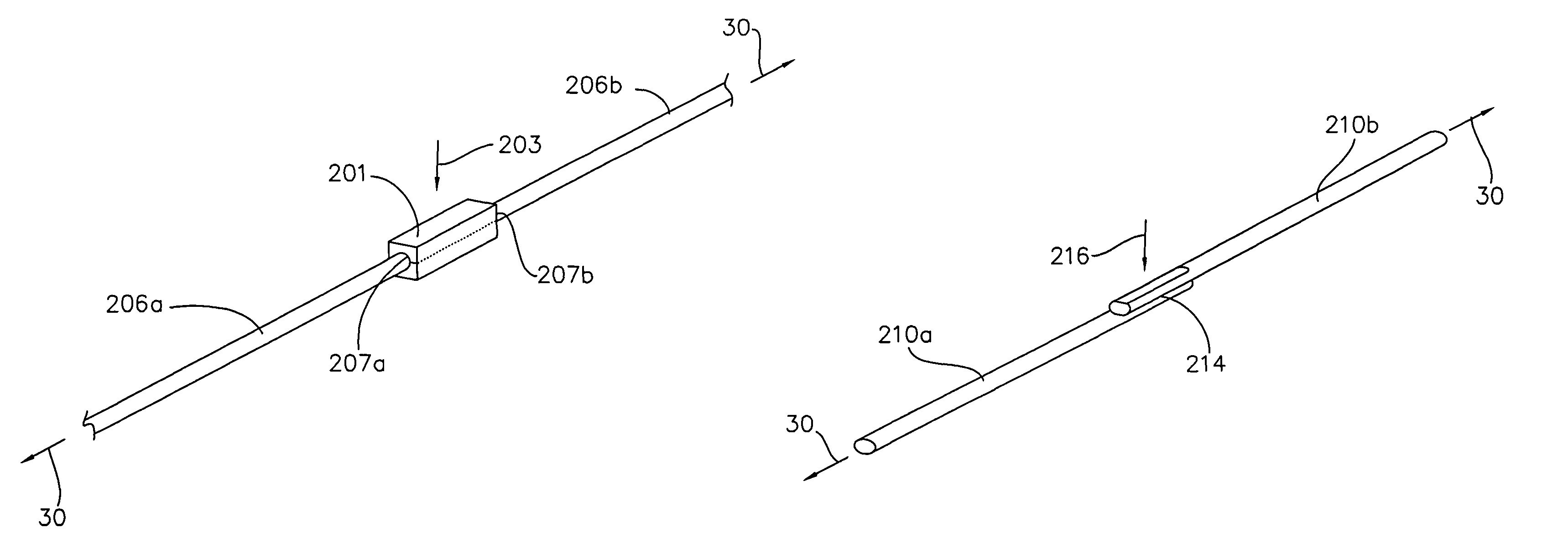

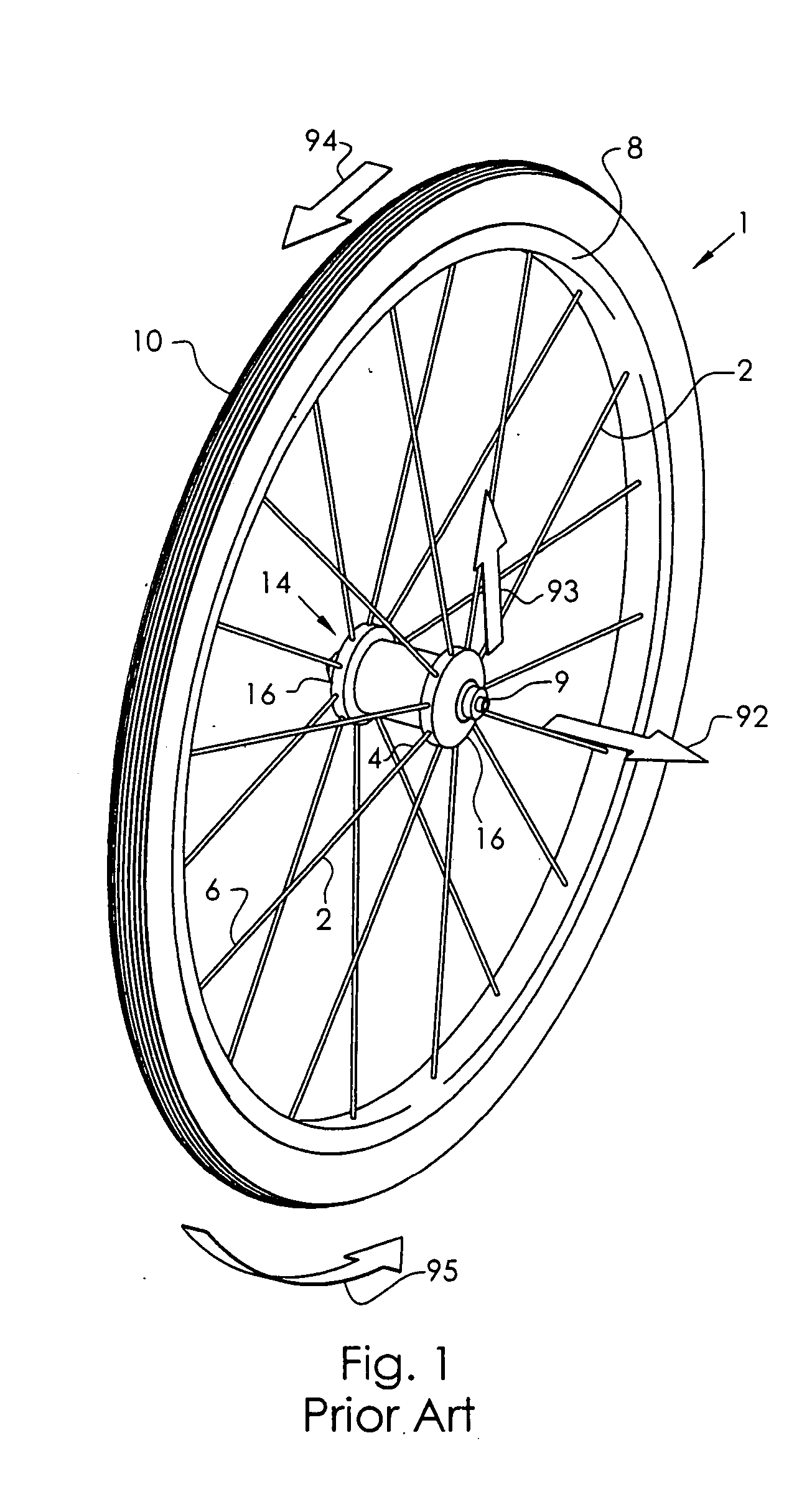

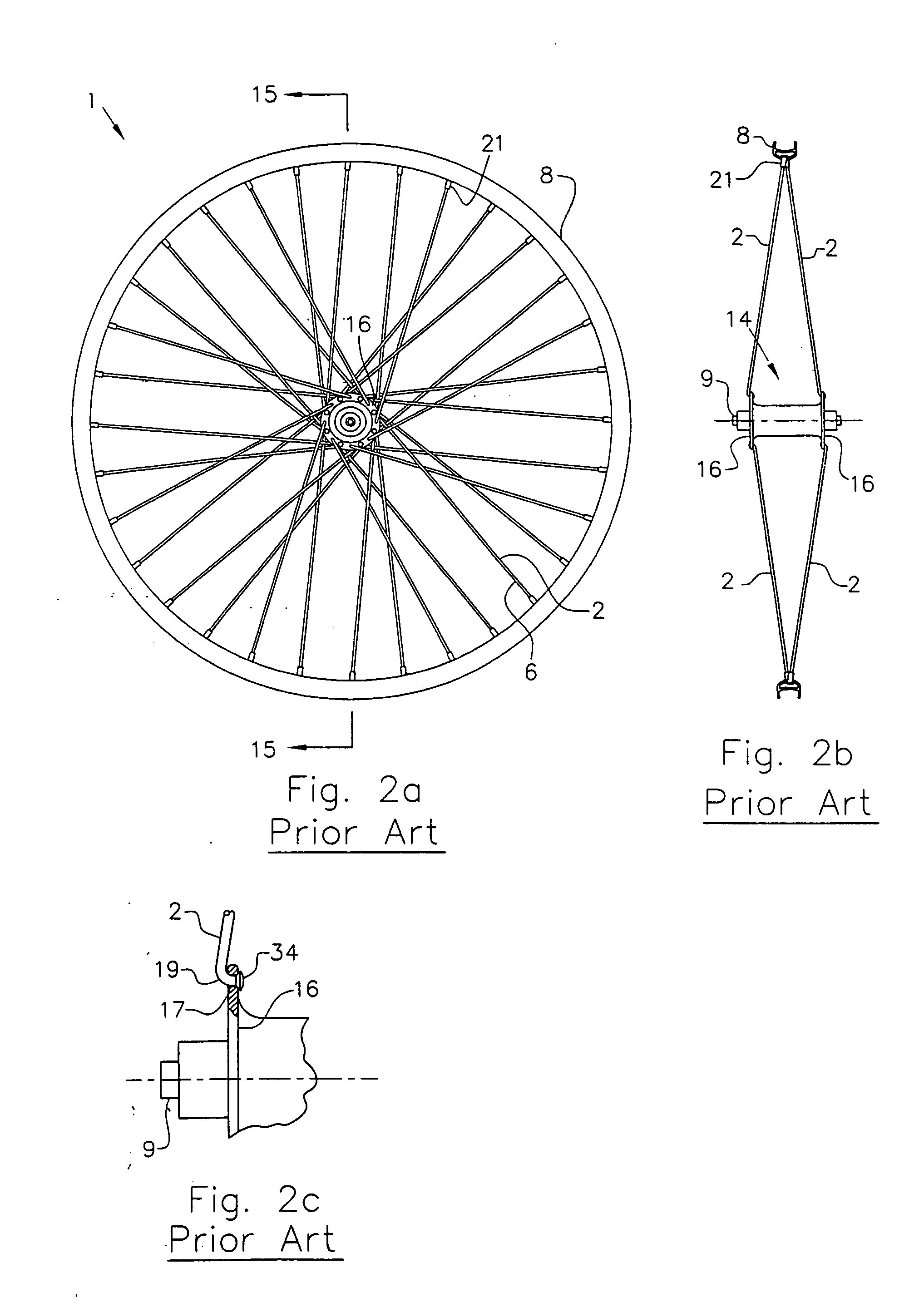

Connecting system for tensile elements such as spokes

ActiveUS7784878B2Lower performance requirementsLow costRimsRopes and cables for vehicles/pulleyEngineeringSpoke

A tensile connector assembly comprising a longitudinal tensile element having a longitudinal axis, an end portion and a cross-section, a connecting element connected to the longitudinal tensile element, and a bracing element connected to the longitudinal tensile element. With a tensile axis of applied tensile load along said longitudinal tensile element. Where the longitudinal tensile element is anchored to the bracing element and the connecting element is connected to the longitudinal tensile element via a welded connection at a welded interface. Where the connections permit the longitudinal tensile element to support said tensile load along the tensile axis.

Owner:SCHLANGER RAPHAEL

Method for manufacturing the one body abutment of an implant

The invention discloses a method for manufacturing the one body abutment of an implant. Particularly, the method of manufacturing an abutment of an artificial tooth, includes an implant fixture installed in a jaw bone and a crown defining a contour thereof. The abutment is fixed to the implant fixture to connect the implant fixture to the crown. A three-dimensional image of an oral cavity of a patient is generated on a computer by 3D scanning of a dental plate of plaster. A virtual tooth is designed using the image of the oral cavity, in consideration of a row of teeth in a region from which a tooth is missing, the height of adjacent teeth and alignment with an upper or lower tooth. The shape of the abutment is designed according to the shape of the designed virtual tooth. Data on the designed abutment are transmitted to a precision machine. The designed abutment is cut using the precision machine to have a one body structure.

Owner:金正韩

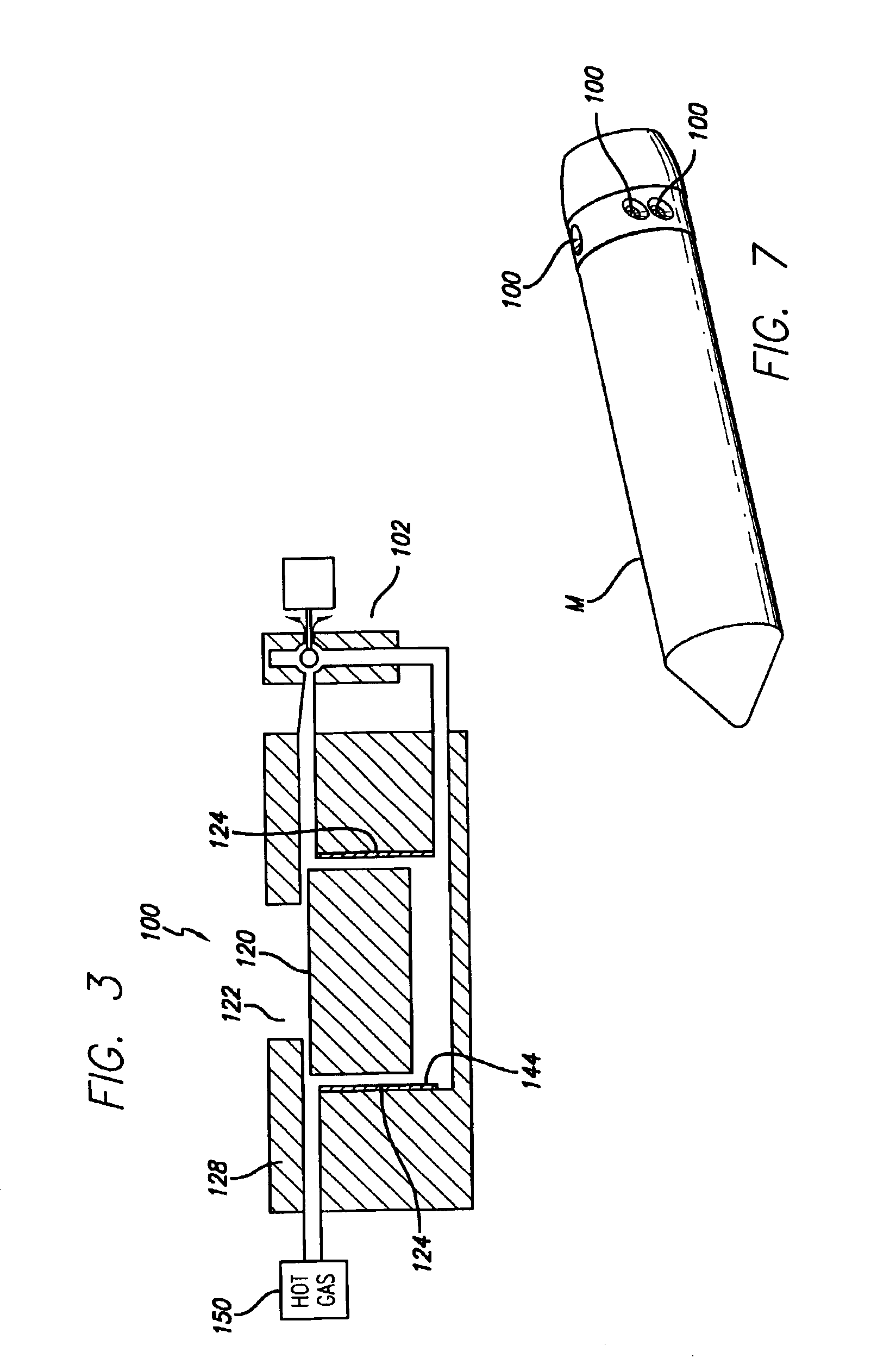

Missile thrust system and valve with refractory piston cylinder

InactiveUS6895991B2Good and more predictably directed and controlledHigh strength propertiesPipe supportsRocket engine plantsRheniumGas passing

An improved pneumatic valve and a missile with an improved thrust directional valve. In one embodiment, a refractory material lining for a pneumatic valve enables better valve operation and better valve performance. A thin-wall cylindrical sleeve of rhenium or other suitable refractory metal is located inside a cylinder. A valve piston may then travel within the refractory sleeve with greater reliability and better operation. The refractory sleeve cylinder lining can be subject to high temperatures at a rapid rate and remain operational. Under such a hostile environmental, including corrosive / erosive environments created by the passage of hot propellant gasses, the refractory cylinder sleeve has a more reliable operational life and is lighter in weight than conventional valves made entirely of refractory metals.

Owner:HONEYWELL INT INC

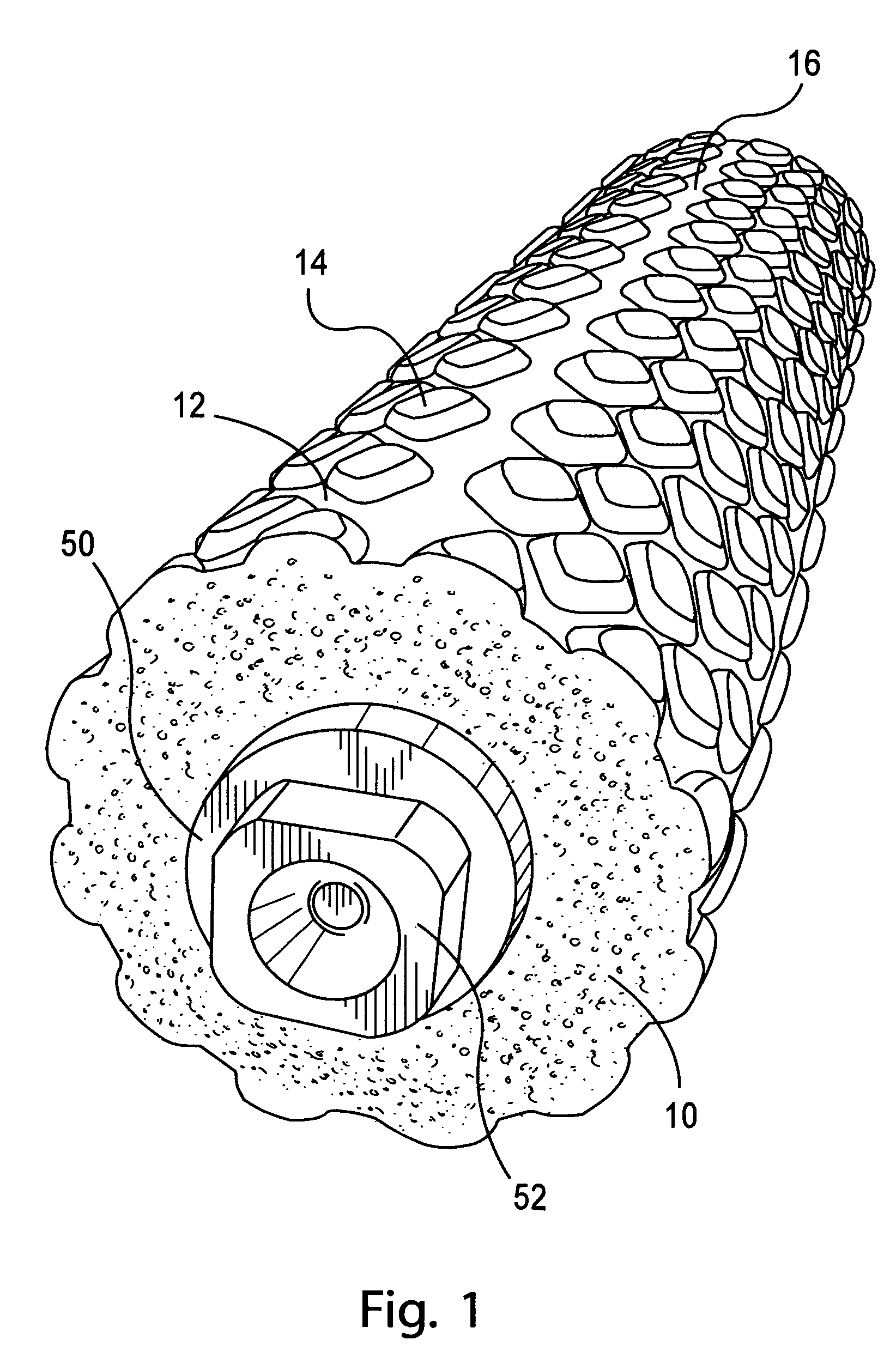

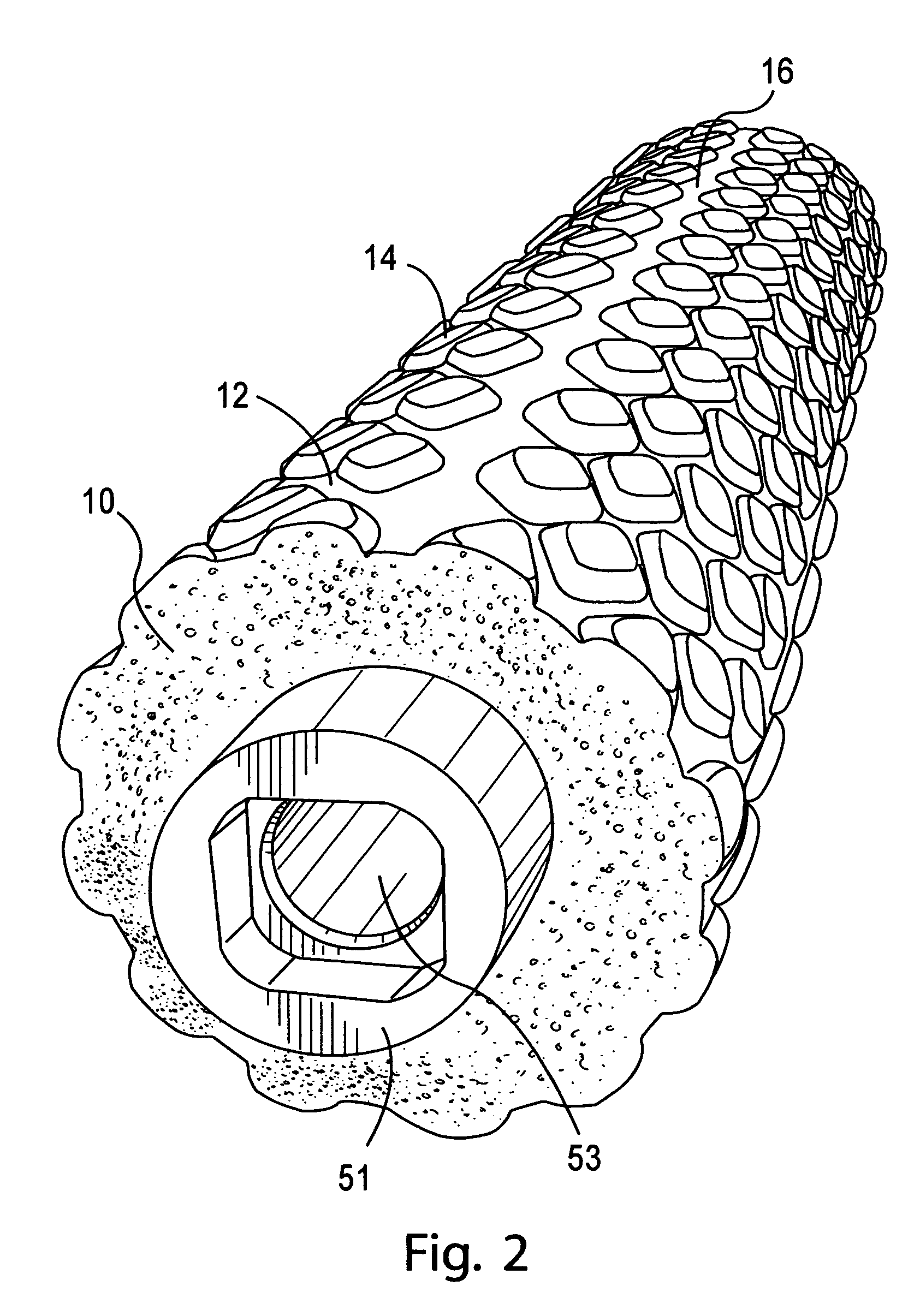

Foam Composition roller brush with embedded mandrel

InactiveUS20080141475A1Improve suppression propertiesUniform small pore sizeLiquid processingReconditioning/cleaning record carriersEngineeringMechanical engineering

The invention is directed toward a chemical mechanical polishing / planarizing (CMP) brush with an embedded mandrel. PVA foam injected into the substantially hollow mandrel expands through apertures in the mandrel to fill a mold in the desired shape of the brush with the foam in the mandrel being integral with the outer foam covering the brush.

Owner:HYDROFERA

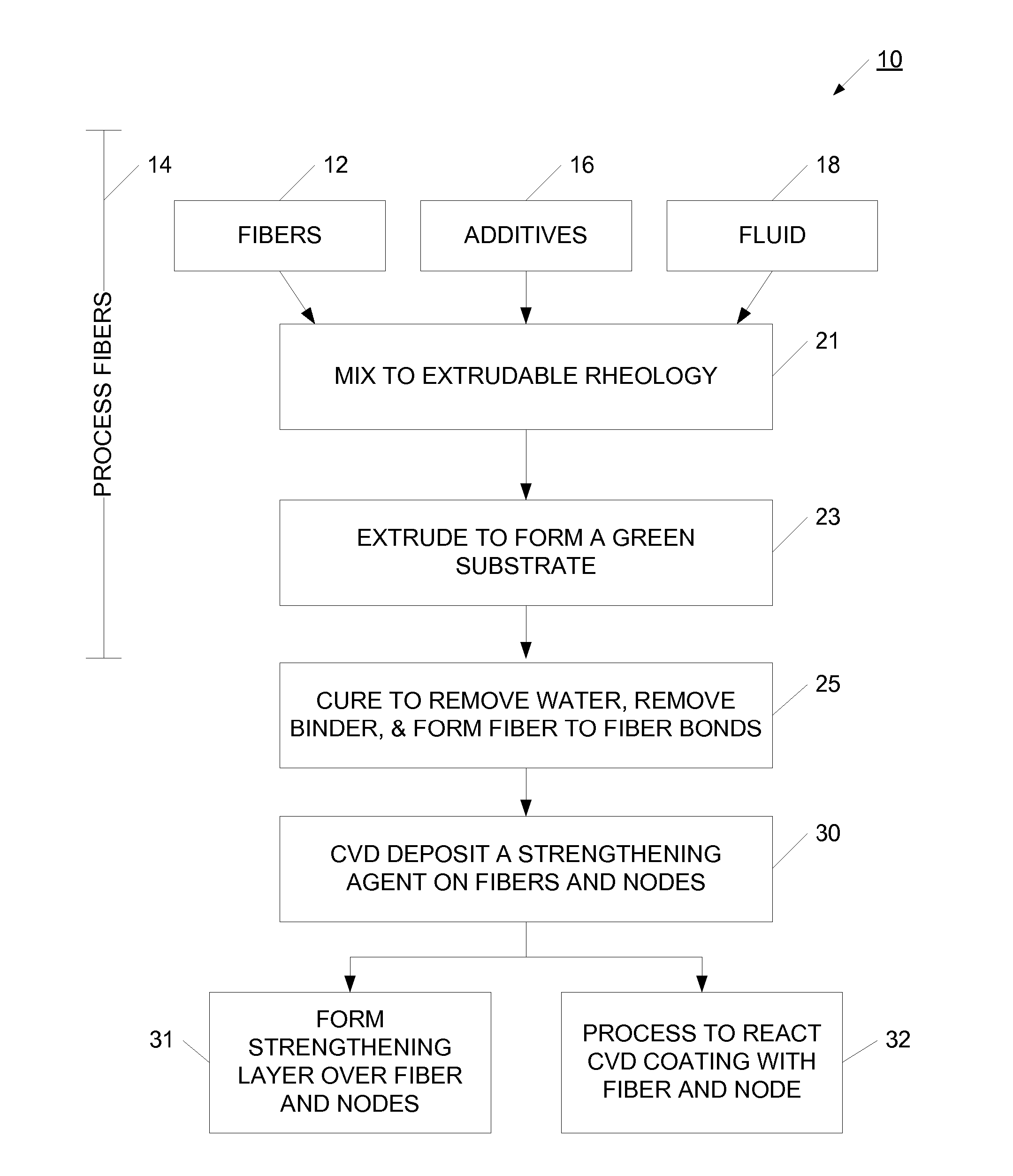

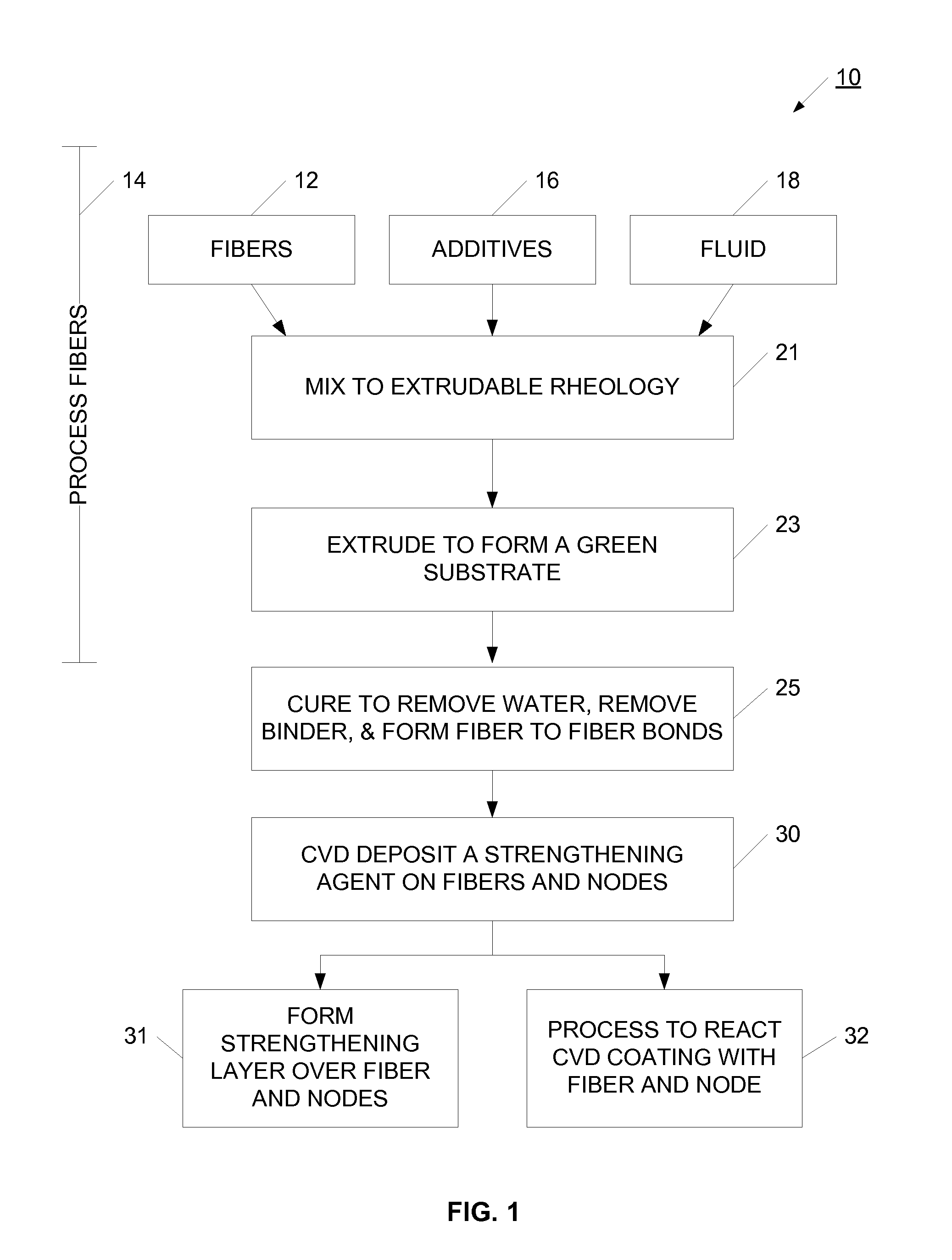

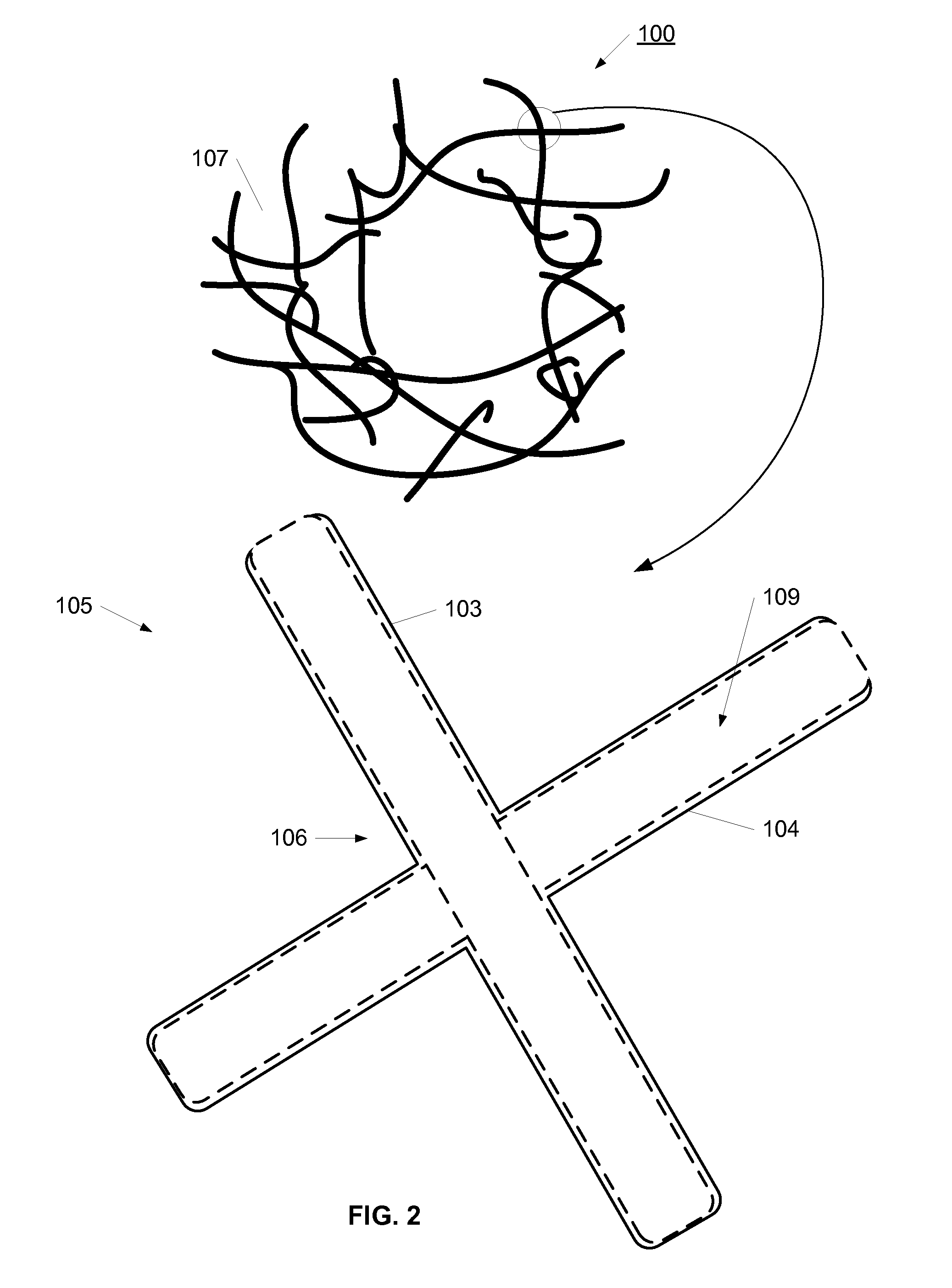

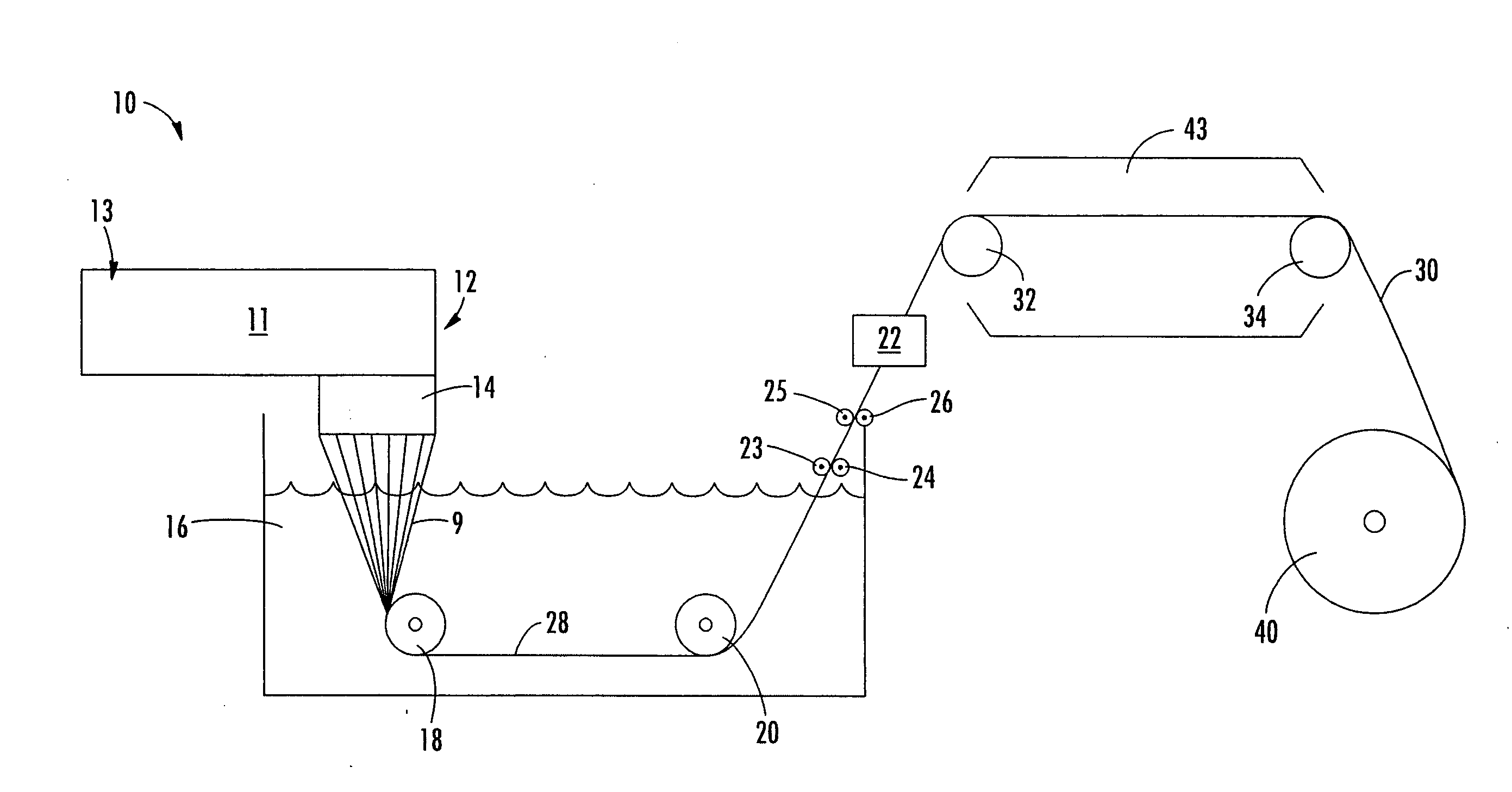

Method and apparatus for strengthening a porous substrate

InactiveUS20070141255A1High porosityHigh strength propertiesLaminationLamination apparatusFiberPorous substrate

A process is provided for strengthening a porous substrate. The process includes providing a substrate having intersecting fibers, where the intersecting fibers cooperate in the final substrate product to form an open pore network. Pathways are opened into the fibrous substrate structure, which enable a flow of gas into the or through the substrate. The substrate is positioned in a CVD (chemical vapor deposition) station, and one or more layers of a strengthening agent is deposited. The deposited layer or layers form a strong coating around fibers and fiber intersections to provide additional strength to the substrate. The strengthened substrate may then be used in wide variety of applications and fields. Advantageously, the disclosed fiber strengthening process produces a substrate having high porosity and higher strength characteristics as compared to a non-strengthened substrate.

Owner:GE02 TECH INC

Low dielectric composite materials including high modulus polyolefin fibers

ActiveUS20070290942A1High bonding strengthPromote strong bond formationSynthetic resin layered productsHigh frequency circuit adaptationsGlass fiberCarbon fibers

Disclosed are composite laminates that can exhibit high strength and / or low dielectric loss and can also be lightweight. The laminates include layers formed of high modulus polyolefin fiber. The fibers can be woven or knit to form a fabric or can be included in a nonwoven fabric that can be one or more layers of the composite structures. The layers including the high modulus polyolefin fibers can include other fibers, such as fiberglass. The composites can also include layers of other materials, for instance layers formed of polyaramids, fiberglass, or carbon fiber wovens or nonwovens. The composites can advantageously be utilized in low loss dielectric applications, such as in forming circuit board substrates, or in applications beneficially combining strength with low weight, such as automobile and boat materials.

Owner:QUANTUM MATERIALS LLC

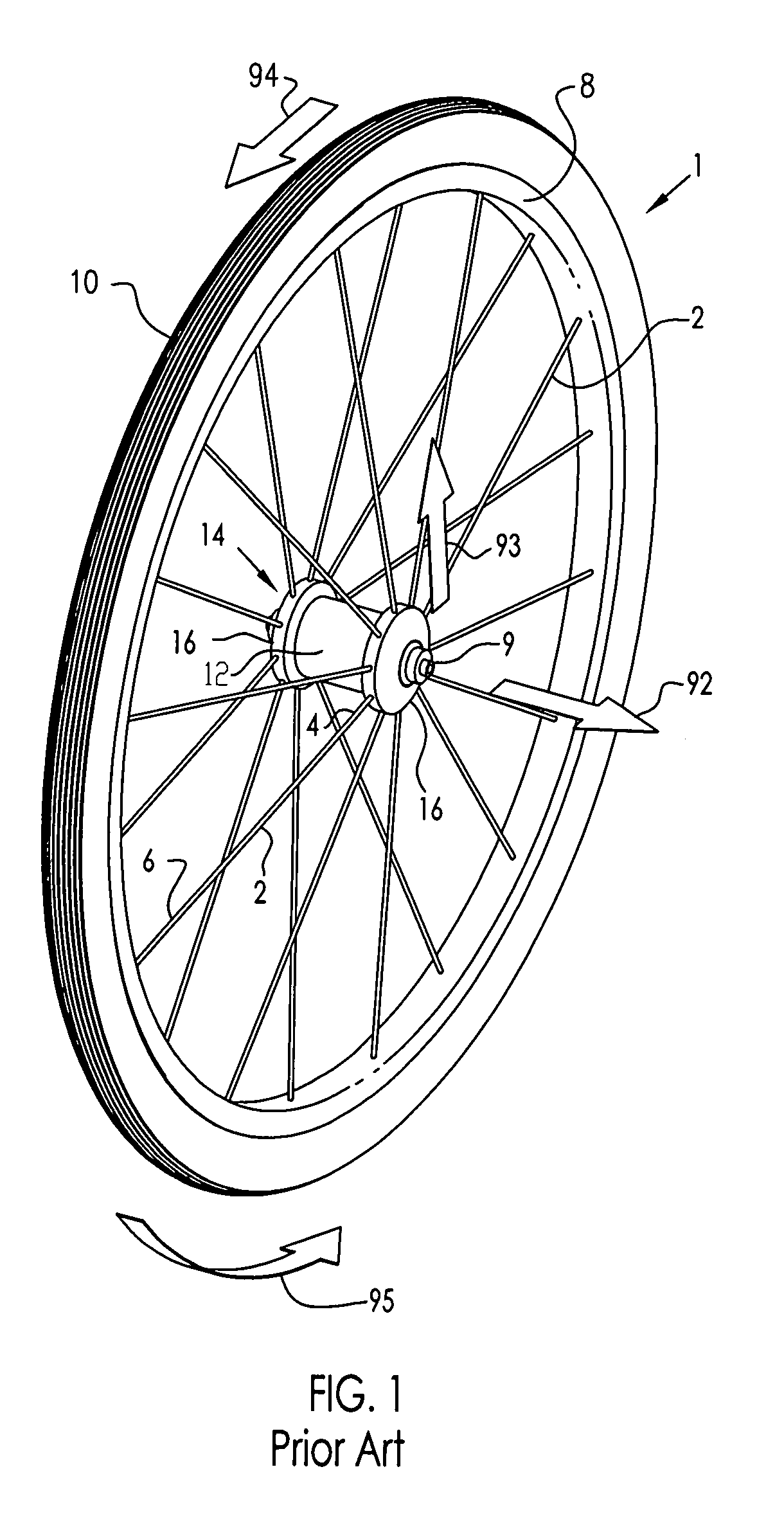

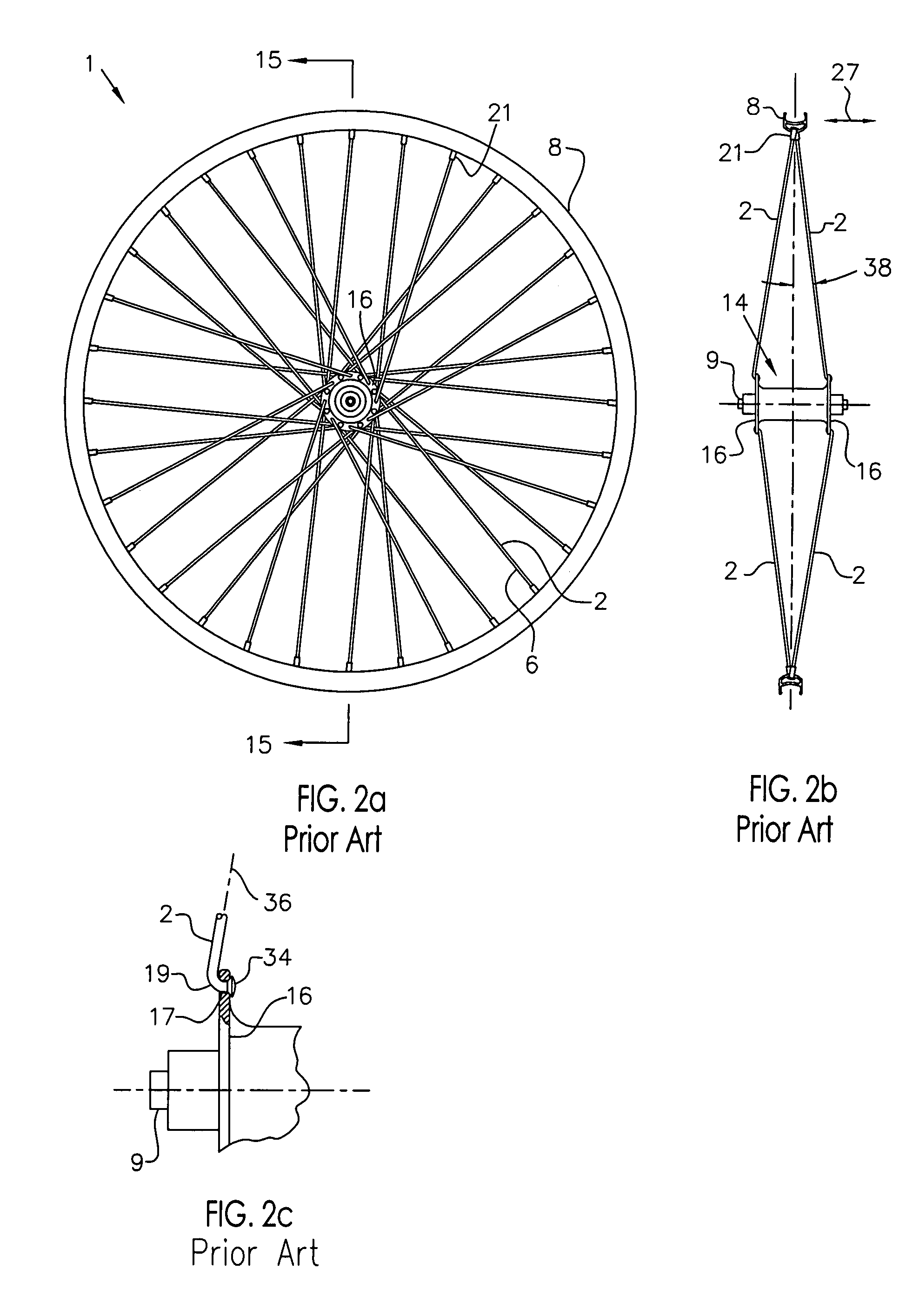

Vehicle wheel including spoke attachment

The vehicle wheel includes an outer rim hoop with means for holding a tire, a plurality of spoke portions, and a central hub assembly. The central hub assembly includes an axle assembly and a hub shell that is rotatable about the axle. The hub shell includes at least two axially spaced outer flanges for attachment with the spokes. The spokes are connected at their outer ends to the rim hoop and at their inner ends to their respective outer flange. Firm attachment between the spoke and the outer flange is achieved by engaging of a portion of the spoke with a cavity formed within at least one of the rim and the outer flange. Also disclosed are attachment arrangements that include an intermediate connection member to facilitate attachment between the spoke and the cavity.

Owner:SCHLANGER RAPHAEL

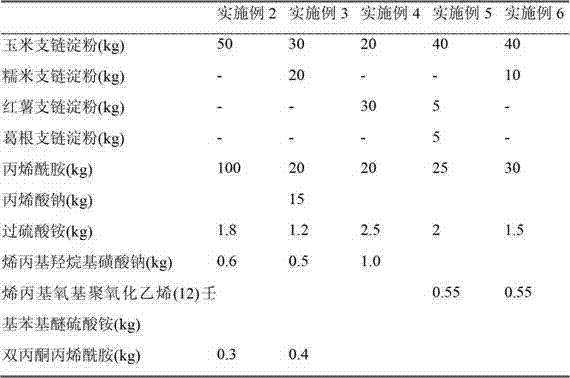

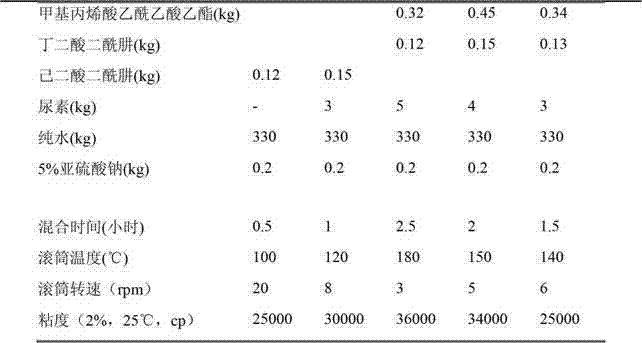

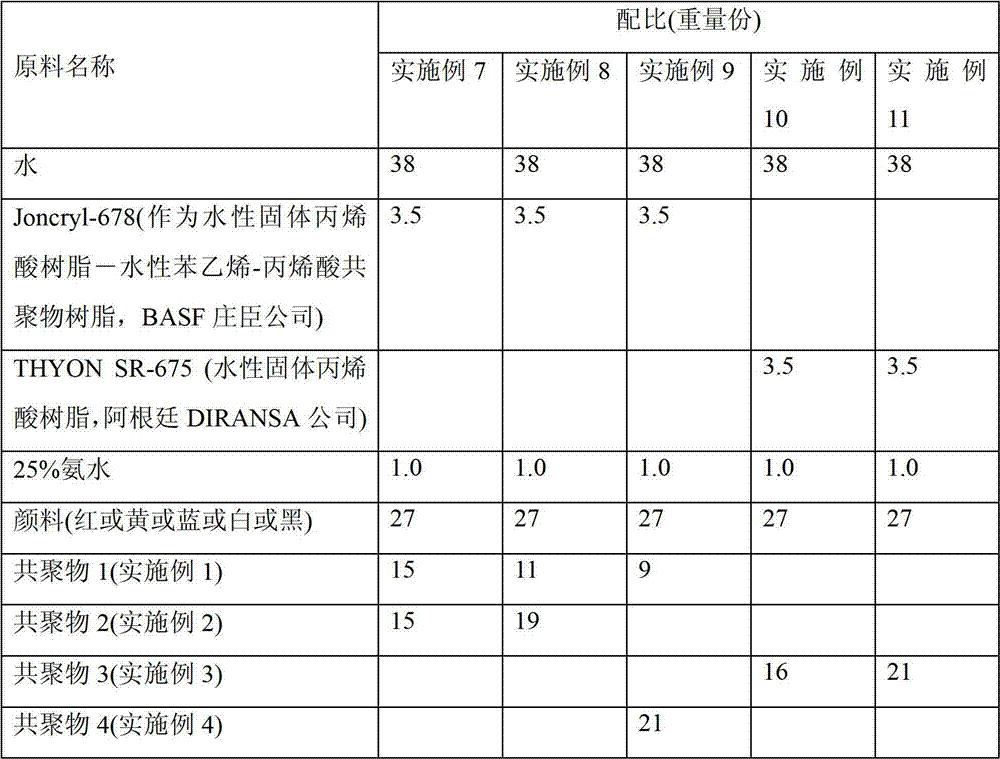

Manufacturing method of high branching degree acrylamide graft copolymer taking amylopectin as framework

InactiveCN102875742AStable and better water retentionStable and better temperature resistanceInksCross-linkWater based

The invention relates to a manufacturing method of high branching degree acrylamide graft copolymer taking amylopectin as the framework. The manufacturing method comprises the following steps: A) carrying out free radical grafting reaction with amylopectin, water-soluble vinyl monomers (such as acrylamide), optional carbamide and optional reaction type surfactant; and B) adding cross-linking monomer and cross-linking agent that can react with the cross-linking monomer to carry out modification reaction for obtaining wet slurry, then dry up the slurry optionally, so that high branching degree and slightly cross-linked water-soluble graft polymer (or copolymer) is prepared. At 25 DEG C, the rotary viscosity the aqueous solution of which the concentration is 2wt% is generally within the range of 2000 to 70,000 mPa.s, wherein the aqueous solution is made of water. The graft polymer is used as biomedical material, water absorbing material, water-based ink coating, polymer additives, separation film material or photosensitive material.

Owner:广州睿宜精测环保科技有限公司

Conductive materials

ActiveUS7663076B2High strength propertiesConsider flexibilityHeater elementsHeating element shapesElectrical connectionConductive materials

The invention relates to conductive materials particularly to serve as a heater. Heating means formed by or with electrically conductive materials are known and particularly effective for its flexibility is that sold under the British, Community and US Registered Trade Mark INDITHERM. Conductive rails are used to provide electrical connection to a source of power that need to have a commensurate flexibility, and the object of the invention is to ensure the maintenance of power to the full length of the conductive rail. This objective, is met by a construction comprising spaced first rails for the supply and return of electrical power, the said rails having a flexibility compatible with the semi-conductive material, and there being a supplementary rail attached to each first rail along the length thereof, the supplementary rails being flexible and having strength characteristics greater than those of the first rails.

Owner:INSPIRATION HEALTHCARE GRP PLC

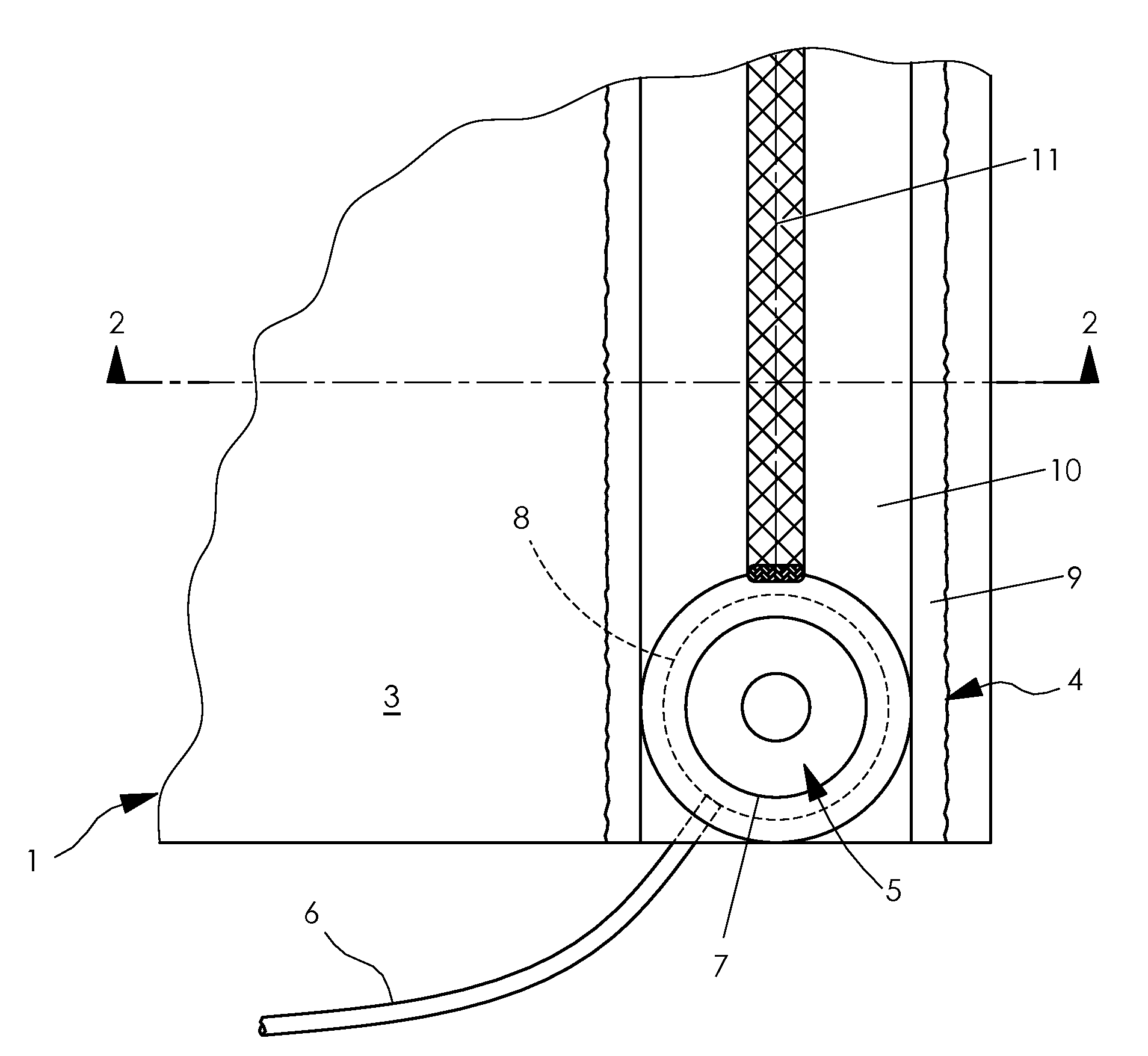

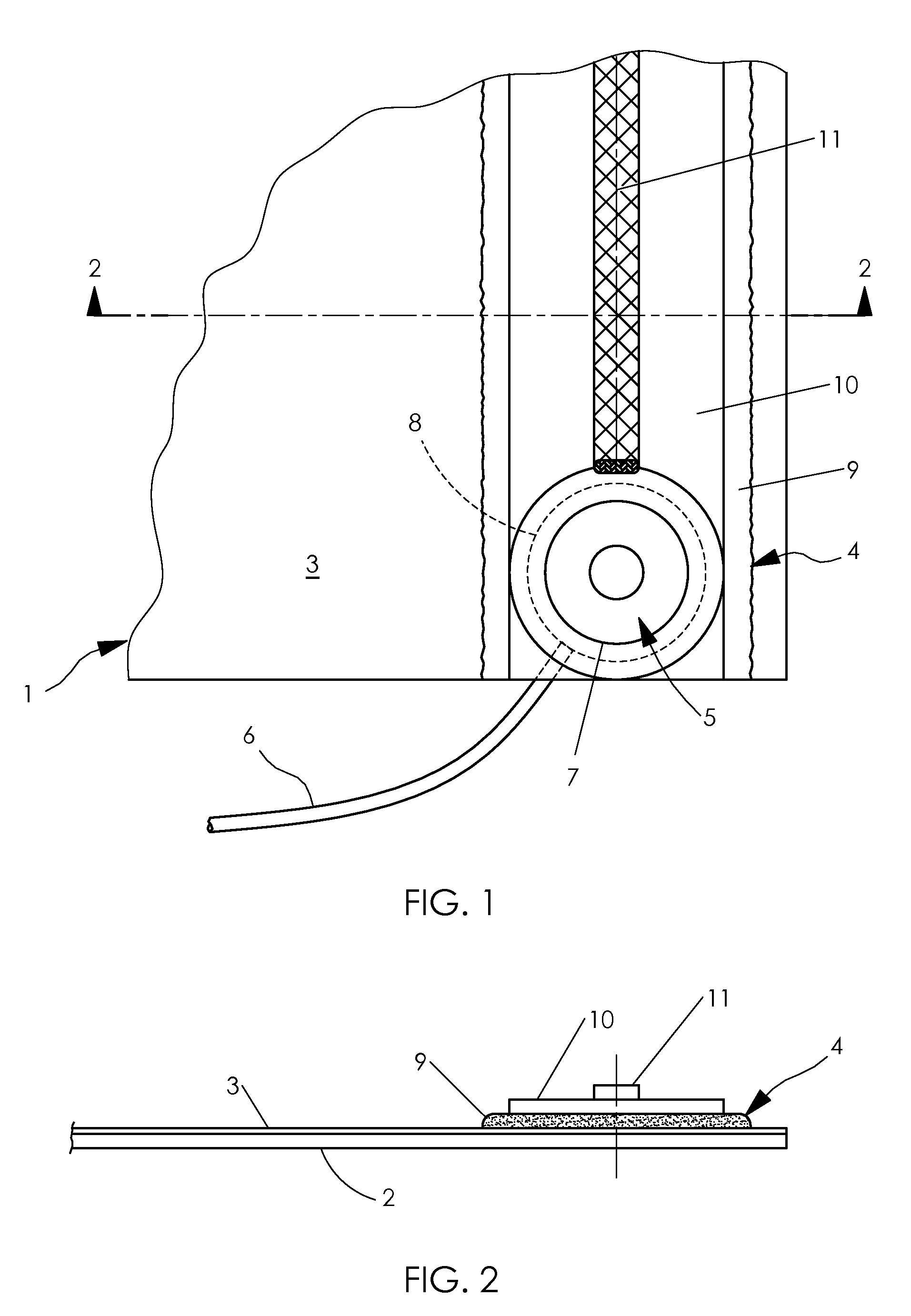

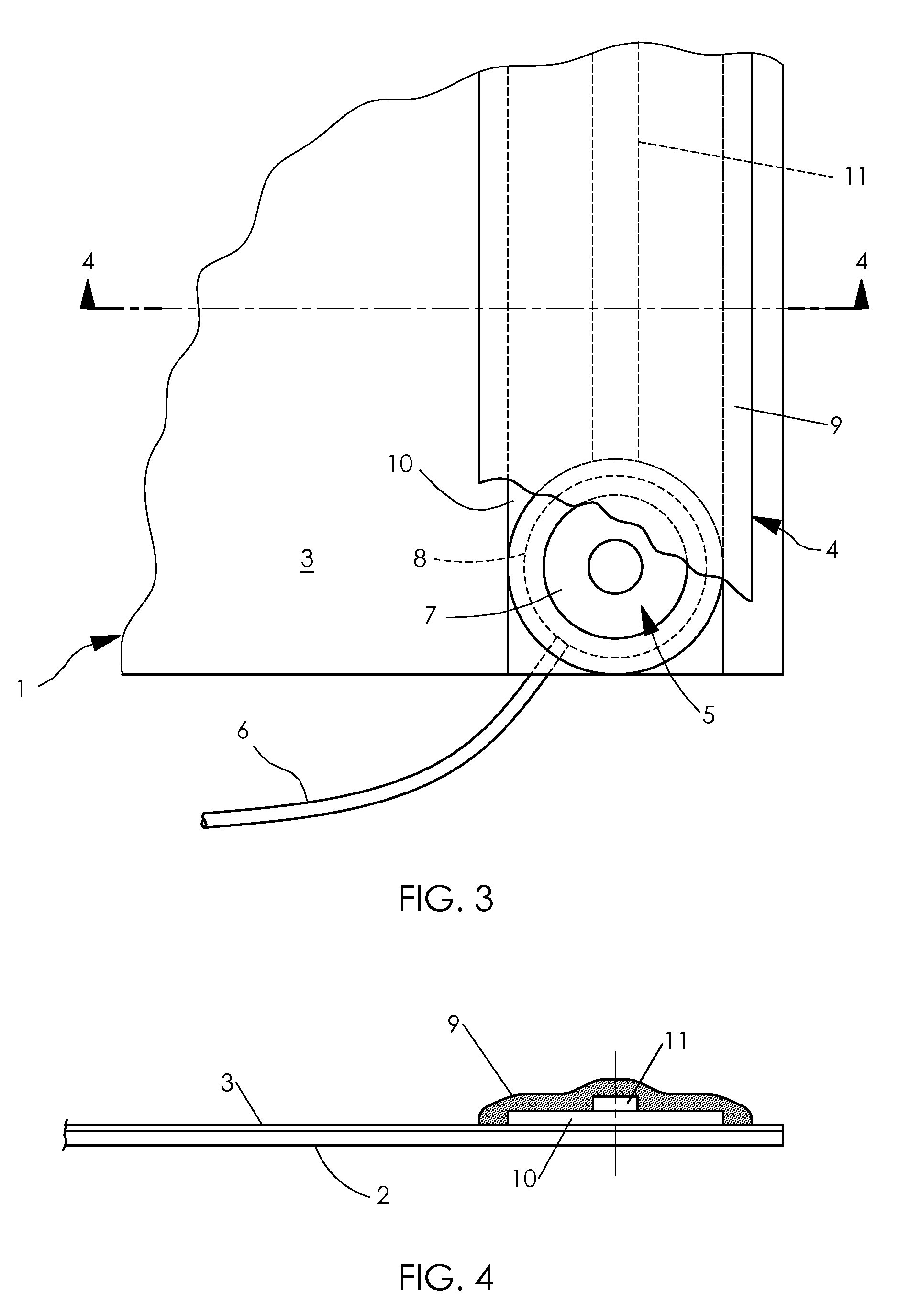

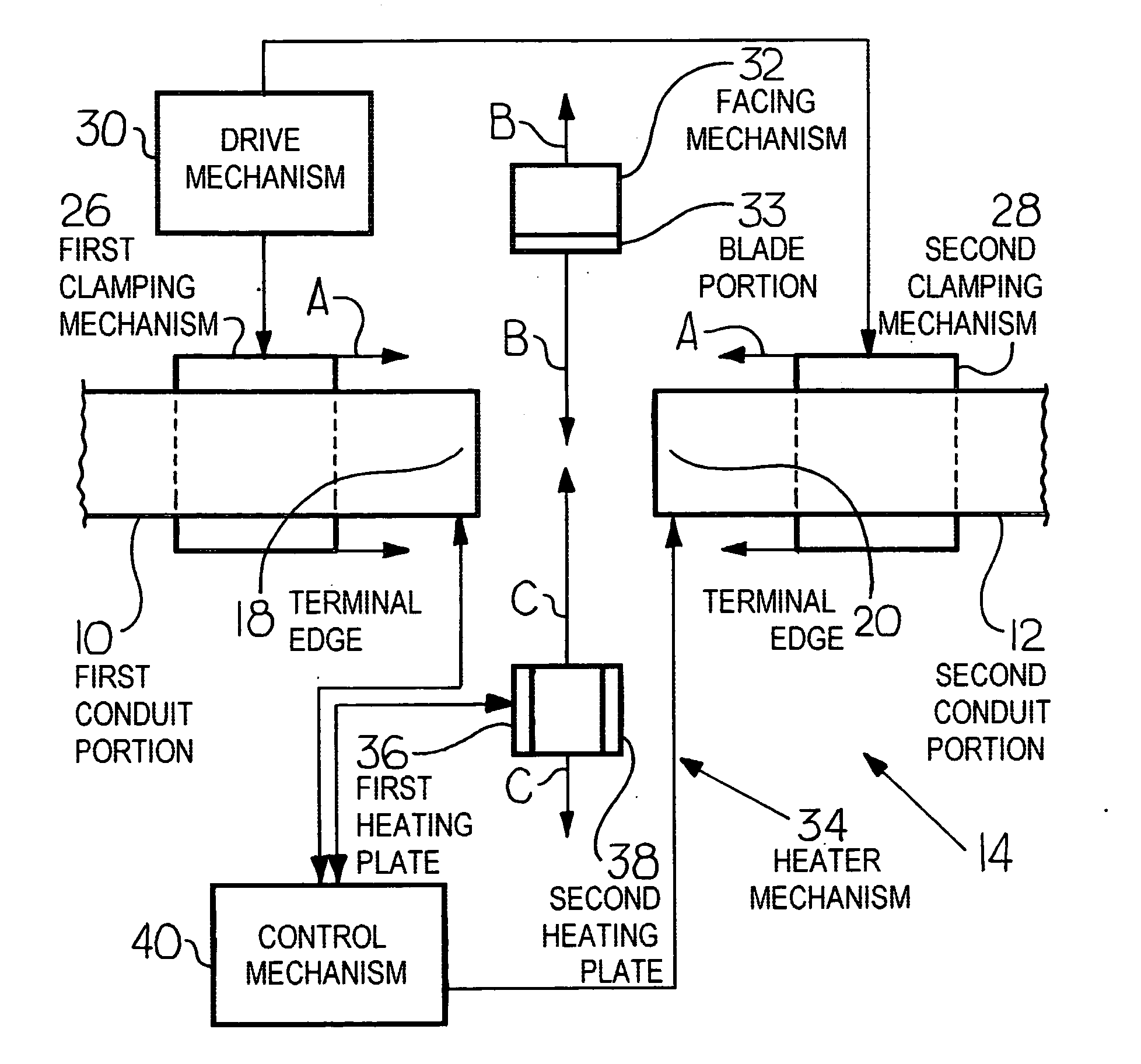

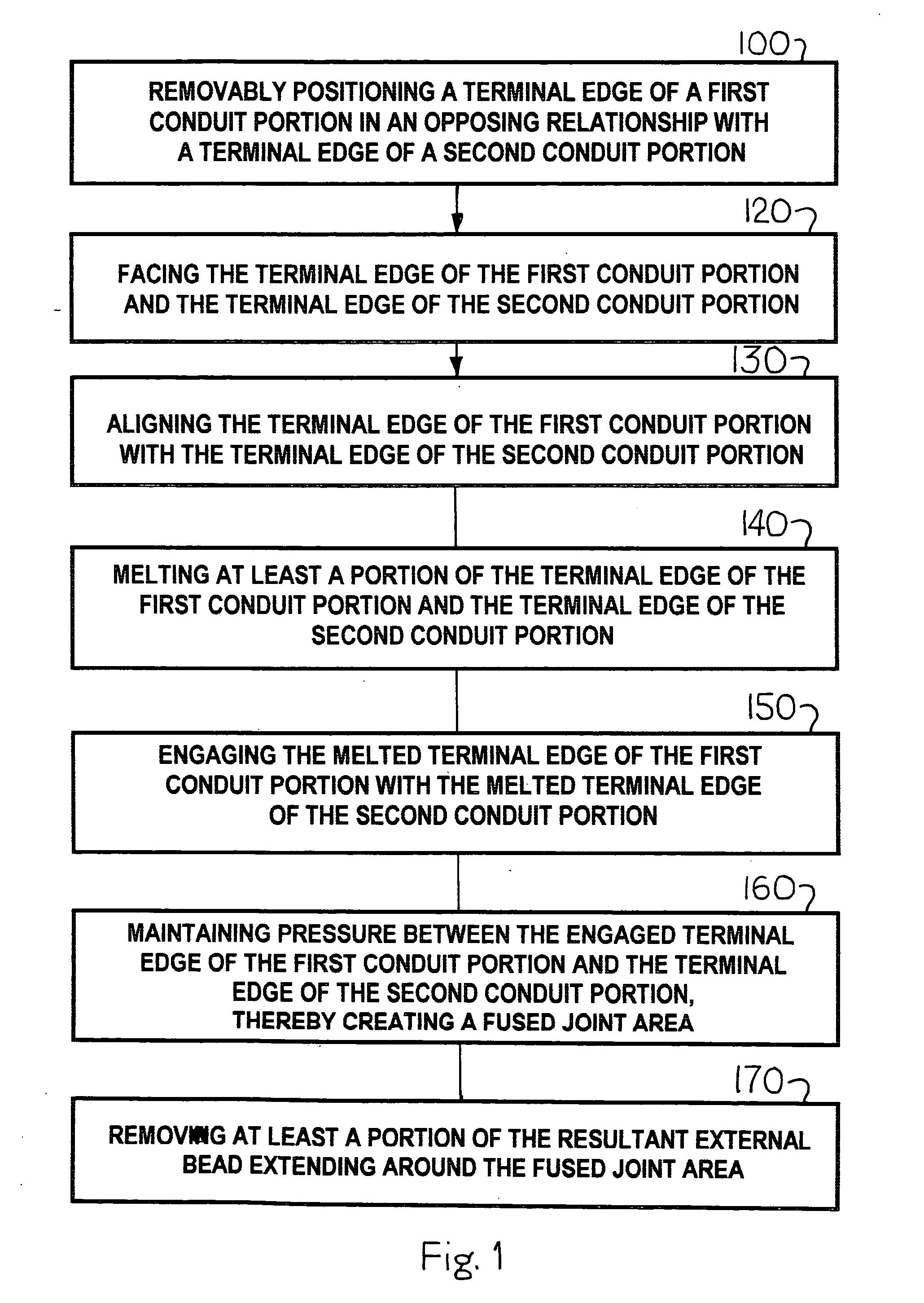

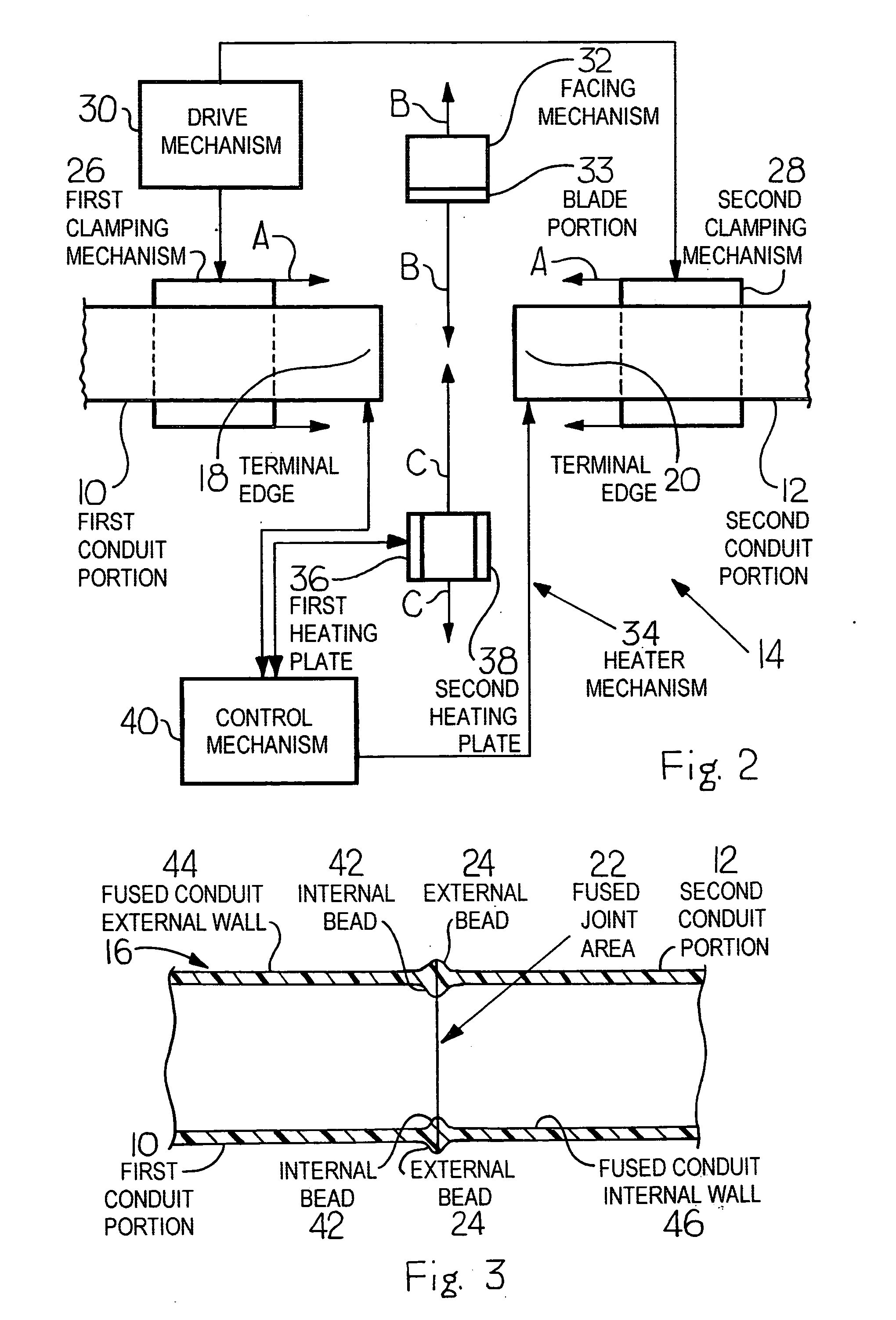

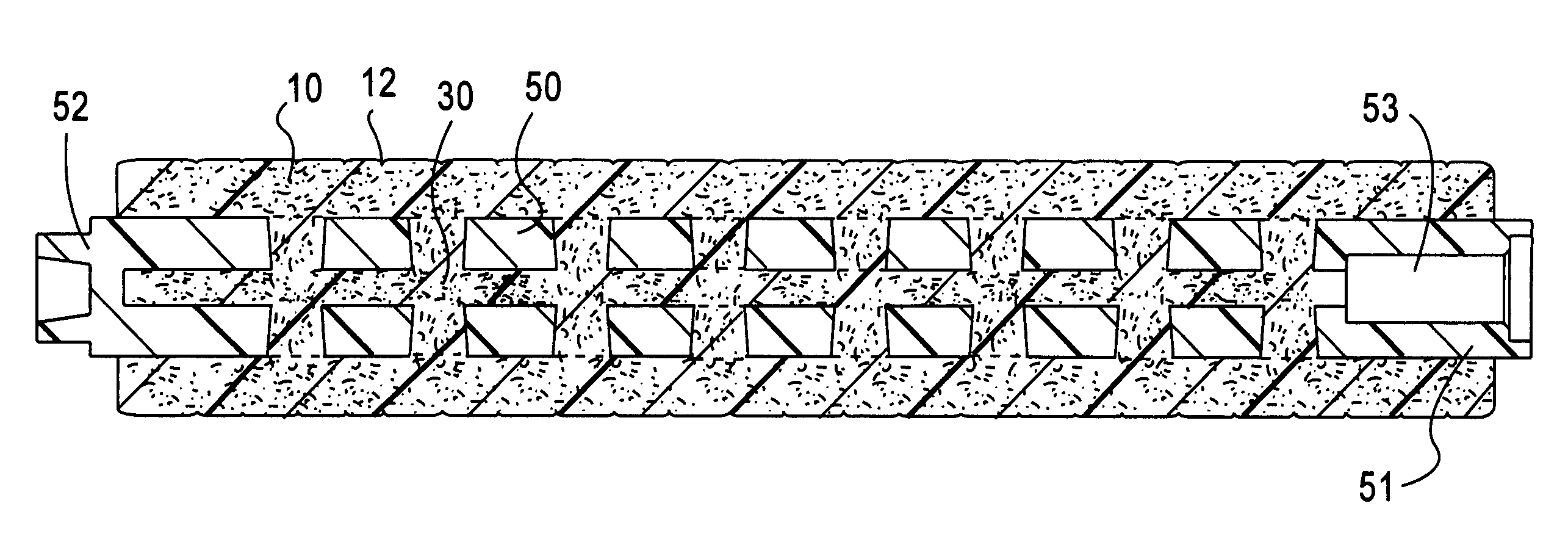

Fusion process for conduit

ActiveUS20060071365A1High strength propertiesEasy to useLamination ancillary operationsControlling laminationEngineeringMechanical engineering

Owner:UNDERGROUND SOLUTIONS INC

Foam composition roller brush with embedded mandrel

InactiveUS7955693B2Improve suppression propertiesUniform small pore sizeLiquid processingReconditioning/cleaning record carriersMechanical engineeringEngineering

Owner:HYDROFERA

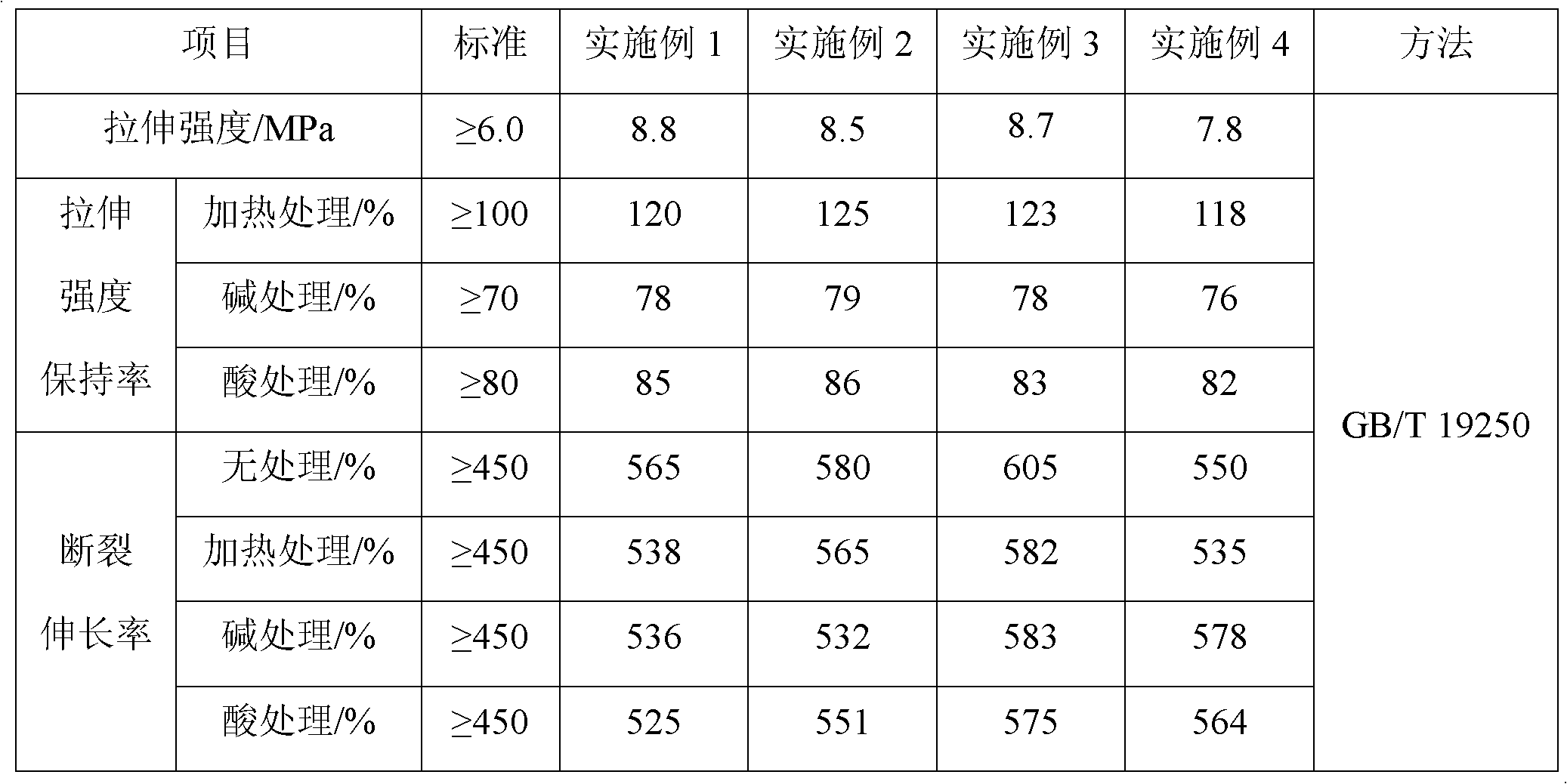

Asphalt-based reactive polyurethane coating, as well as preparation method and application thereof

InactiveCN102604520AAvoid pollutionGood storage stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsAntioxidantPlasticizer

The invention provides an asphalt-based reactive polyurethane coating which is obtained by performing reaction on (1) polyisocyanate monomers or a (1') NCO-terminated polyurethane prepolymer and (2) asphalt in the presence of polylol B and a catalyst, as well as optional additives, namely a chain extender D, a water removing agent, an antioxidant, a defoaming agent, a filling material, a solvent, a ductility increasing agent and a plasticizer. The reactive asphalt-based polyurethane coating provided by the invention has the advantages of simple and environment-friendly processing technology, stable product performance and low cost. The coating (or a coat) provided by the invention has higher strength property, the tensile strength is 7-9MPa, the retention rate of the tensile strength after heating treatment is 115-130% (compared with that before heating treatment), and the elongation at break is 550-620%.

Owner:WANHUA CHEM GRP CO LTD +1

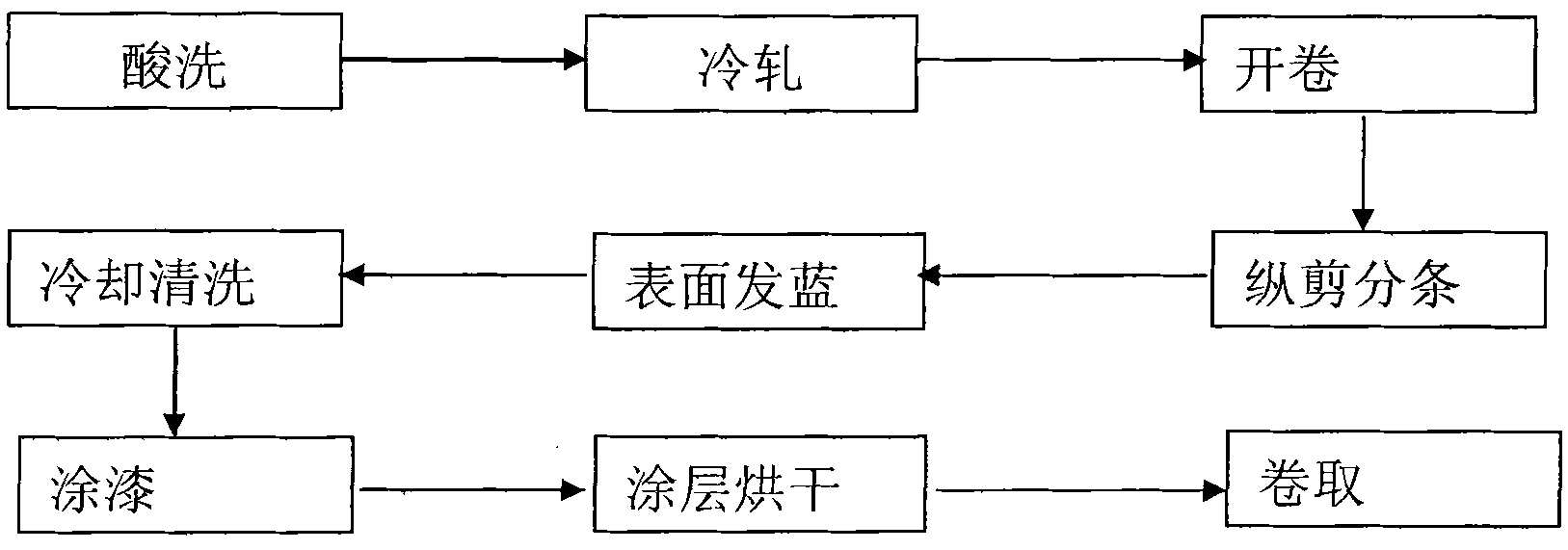

Medium-strength packaging steel strip and production method thereof

ActiveCN101886217ALow plastic indexReduce manufacturing costLiquid surface applicatorsSolid state diffusion coatingSteel beltCoating

The invention relates to a steel strip, in particular to a medium-strength packaging steel strip and a production method thereof. The medium-strength packaging steel strip comprises the following components in percentage by weight: 0.05 to 0.10 percent of C, 0.10 to 0.15 percent of Si, 1.00 to 1.55 percent of Mn, less than or equal to 0.05 percent of P, less than or equal to 0.050 percent of S and the balance of Fe. The production method of the medium-strength packaging steel strip comprises the following steps: a) cold-rolled roll unrolling; b) steel strip longitudinal cutting and stripping; c) surface blueing; d) cooling and washing; e) painting; f), drying coatings; and g) rolling. The medium-strength packaging steel strip solves the technical problem that the packaging steel strip produced by using a cold-rolled roll with a carbon content of less than 0.10 percent has a tensile strength which cannot be kept over 800MPa stably and a breakage elongation of more than 6 percent.

Owner:上海宝钢新材料技术有限公司

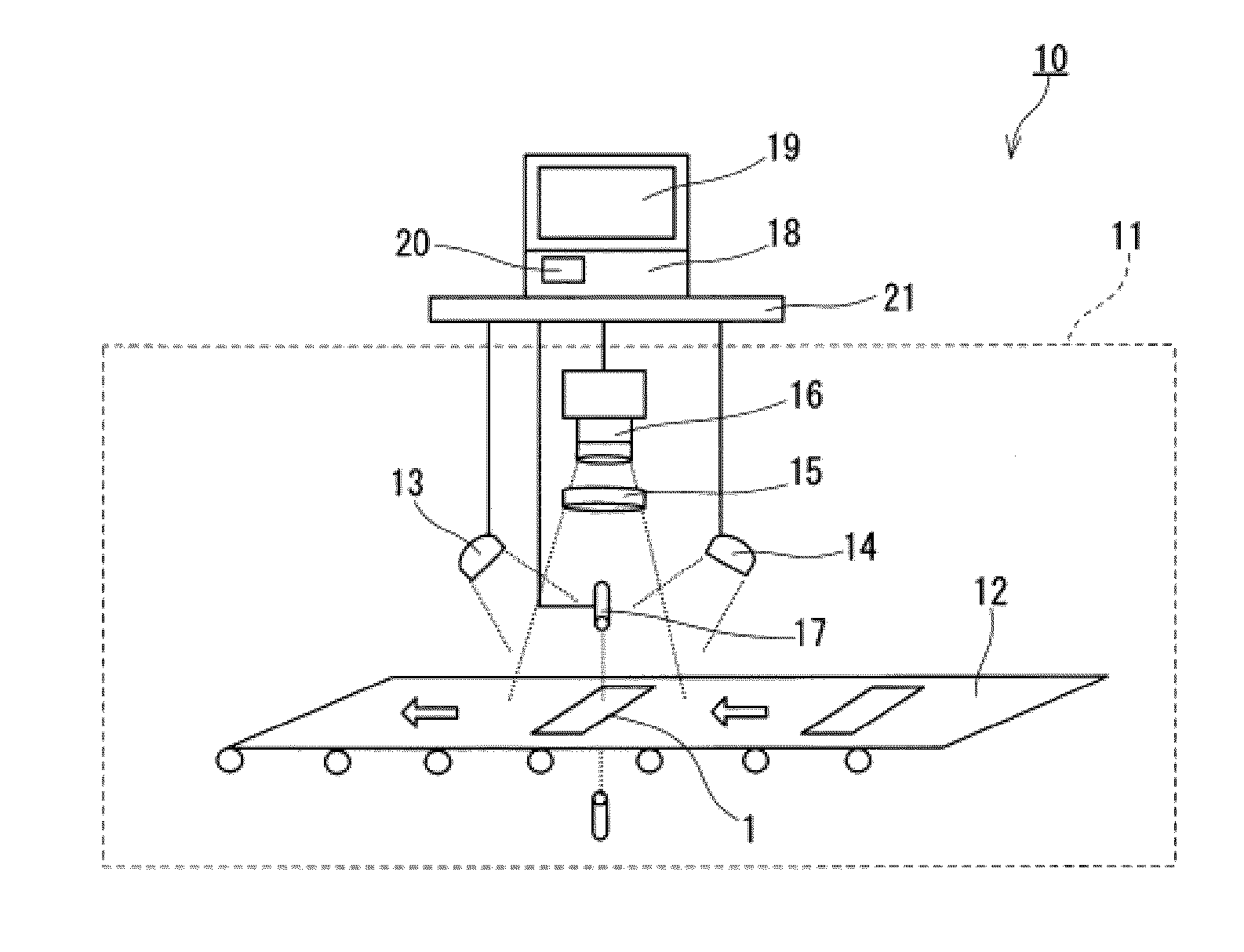

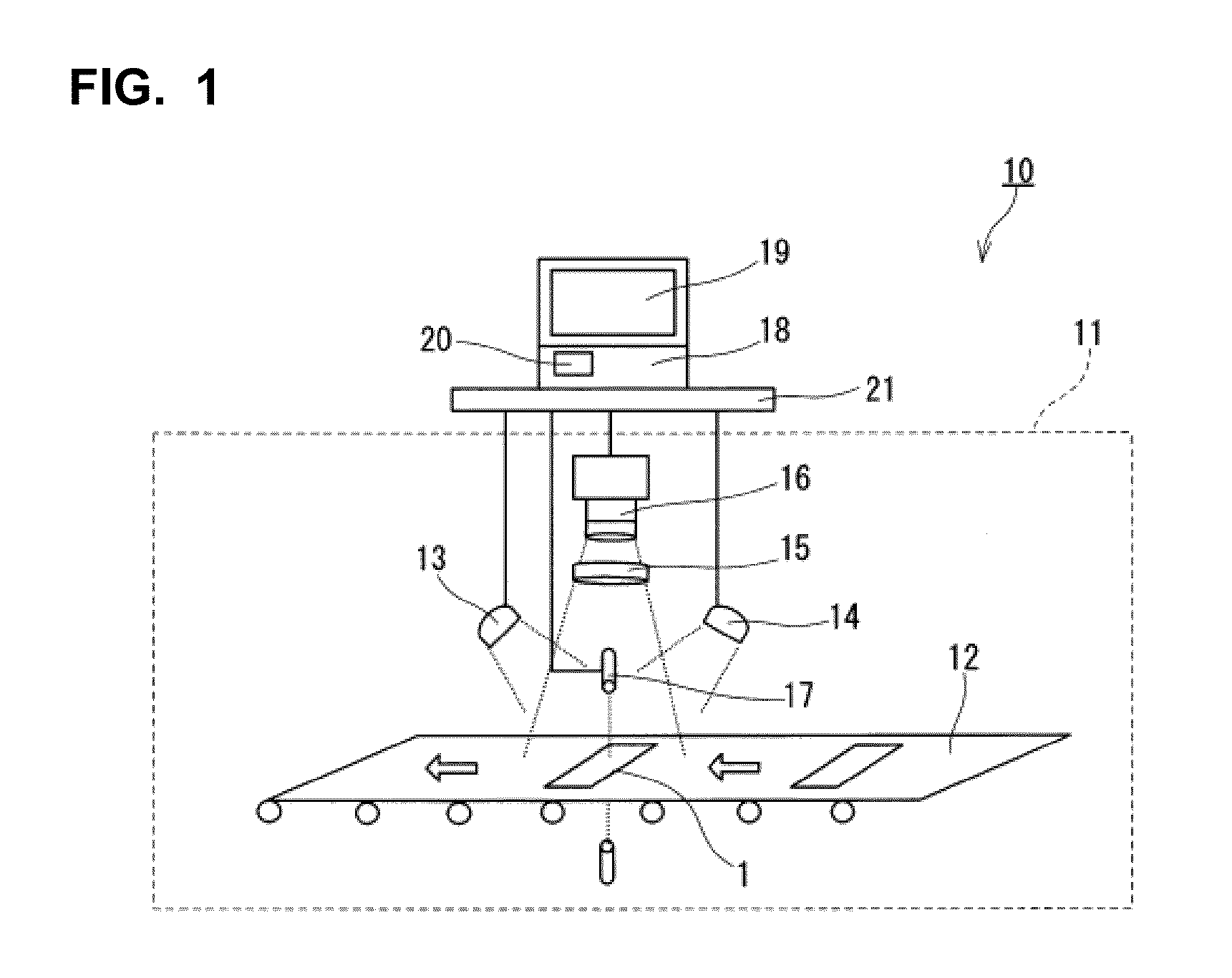

Electrolyte sheet for solid oxide fuel cell, unit cell for solid oxide fuel cell and solid oxide fuel cell equipped with same, method for testing electrolyte sheet for solid oxide fuel cell, and method for manufacturing electrolyte sheet for solid oxide fuel cell

ActiveUS20140017579A1Reduce harmImprove reliabilityFinal product manufactureLuminescent dosimetersFuel cellsFluorescence

In an electrolyte sheet for a solid oxide fuel cell according to the present invention, the number of flaws on at least one of surfaces of the sheet detected by a fluorescent penetrant inspection is 30 points or less in each of sections obtained by dividing the sheet into the sections each measuring 30 mm or less on a side. A unit cell for a solid oxide fuel cell according to the present invention comprises a fuel electrode, an air electrode, and the electrolyte sheet for a solid oxide fuel cell according to the present invention, which is disposed between the fuel electrode and the air electrode. A solid oxide fuel cell of the present invention includes the unit cell for a solid oxide fuel cell according to the present invention.

Owner:NIPPON SHOKUBAI CO LTD

Methods of forming composite materials including high modulus polyolefin fibers

InactiveUS20070039683A1High bonding strengthPromote strong bond formationLamination ancillary operationsAdhesive processes with surface pretreatmentGlass fiberCarbon fibers

Disclosed are composite laminates that can exhibit high strength and / or low dielectric loss and can also be lightweight. The laminates include layers formed of high modulus polyolefin fiber. The fibers can be woven or knit to form a fabric or can be included in a nonwoven fabric that can be one or more layers of the composite structures. The layers including the high modulus polyolefin fibers can include other fibers, such as fiberglass. The composites can also include layers of other materials, for instance layers formed of polyaramids, fiberglass, or carbon fiber wovens or nonwovens. The composites can advantageously be utilized in low loss dielectric applications, such as in forming circuit board substrates, or in applications beneficially combining strength with low weight, such as automobile and boat materials.

Owner:INNEGRITY LLC

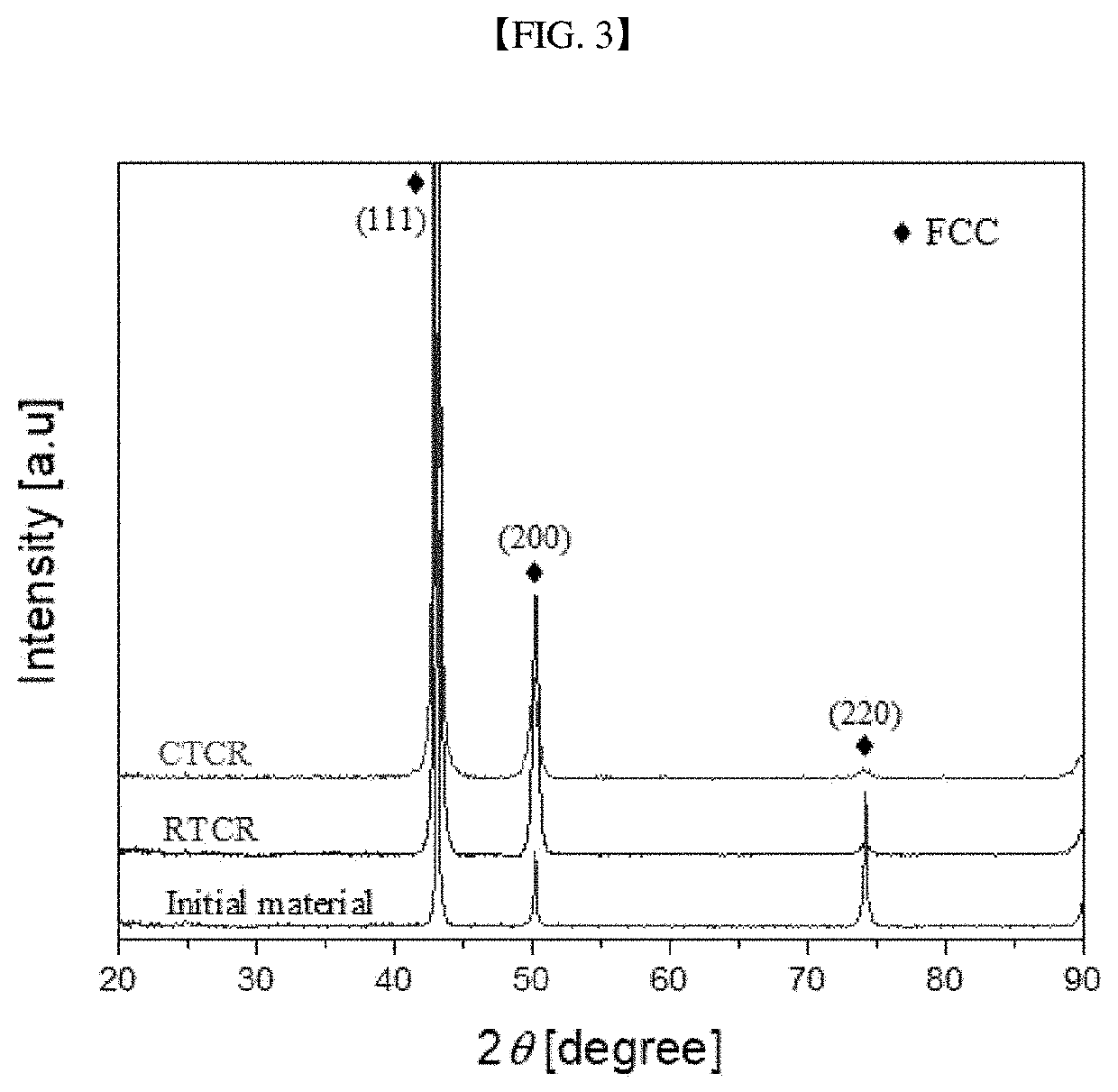

High-entropy alloy, and method for producing the same

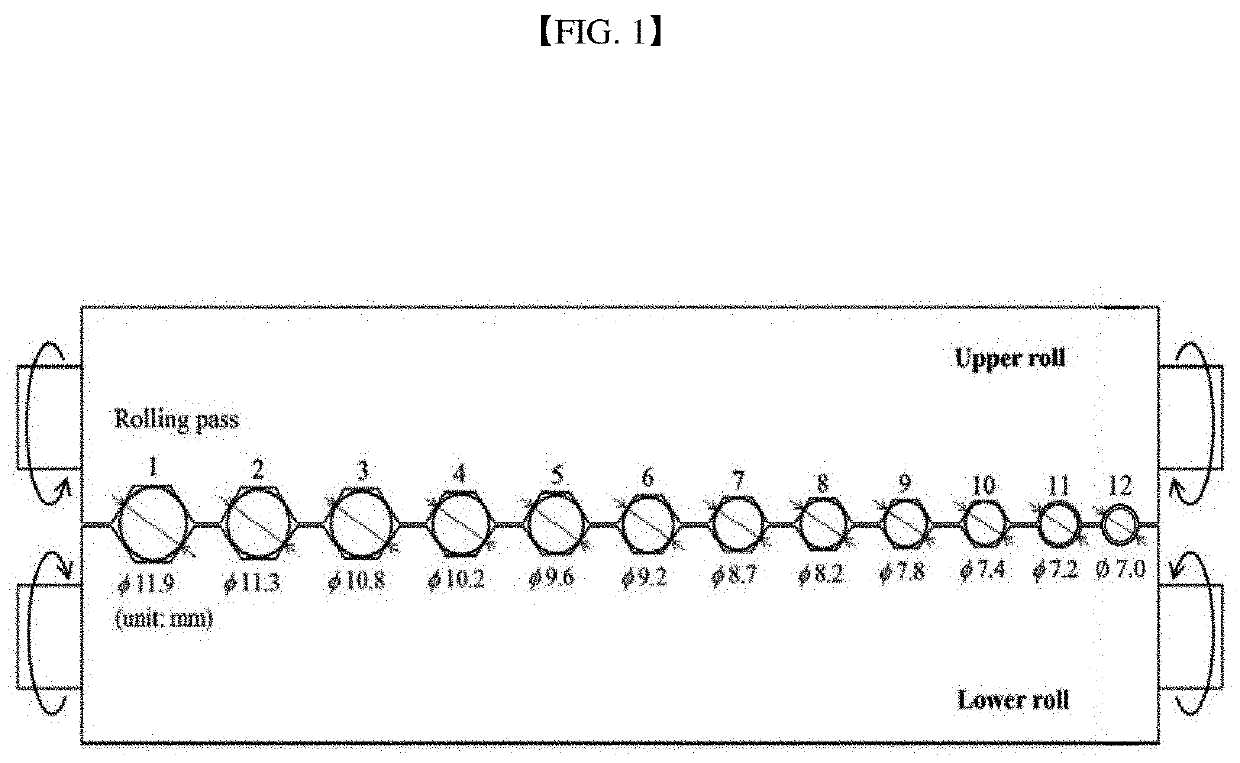

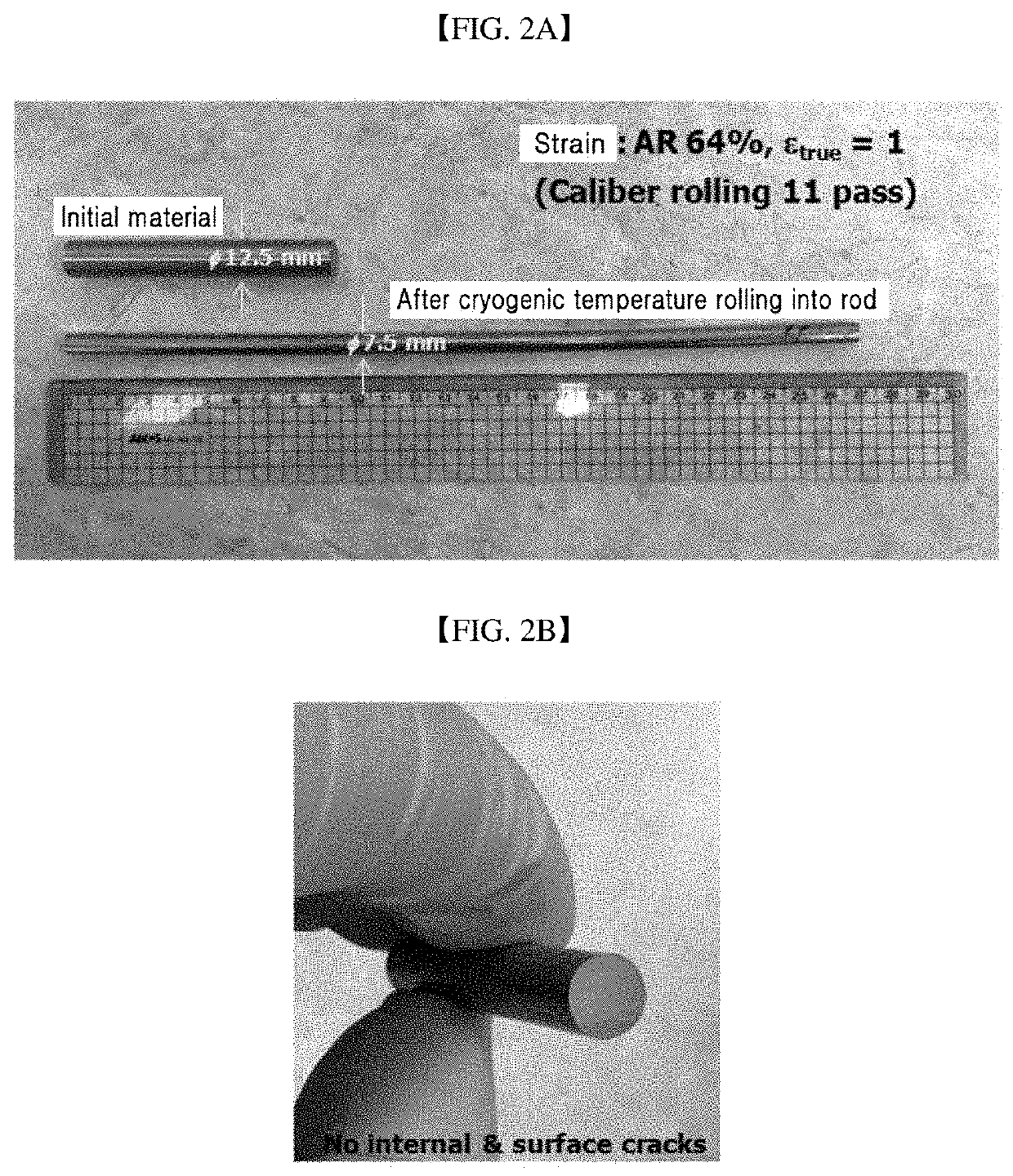

ActiveUS20200392613A1Effective segmentationImprove refinementMetal rolling arrangementsHigh entropy alloysUltimate tensile strength

A high-entropy alloy having ultra-high strength and high hydrogen embrittlement resistance due to formation of a microstructure at a low strain may be produced without a severe plastic deformation.A method for producing the high-entropy alloy includes (a) annealing and homogenizing an initial alloy material at 1000 to 1200° C. for 1 to 24 hours; and (b) rolling the annealed and homogenized initial alloy material into a rod, at a cryogenic temperature of −100 to −200° C. while pressing the initial alloy material in multi-axial directions at a strain of 0.4 to 1.2, thereby to produce the high-entropy alloy having intersecting twins as a microstructure, and secondary fine twins formed in the intersecting twins, wherein the initial alloy material contains Co of 5 to 35%, Cr of 5 to 35%, Fe of 5 to 35%, Mn of 5 to 35%, and Ni of 5 to 35%, based on weight %.

Owner:KOREA INST OF MATERIALS SCI

Plastic spring and method and apparatus for making the same

ActiveUS8939438B2High strength propertiesFacilitated releaseMouldsScrew-threads articlesPlastic materialsCoil spring

This invention provides a helical spring formed of plastic material, comprising a pair of end coils situated at respective ends of said helical spring; at least one full pitch active coil between said pair of end coils; a pair of transition coils, each transition coil interconnecting an end of a respective end coil to an end of a respective proximate full pitch active coil, and having a varying pitch.

Owner:LEE SPRING

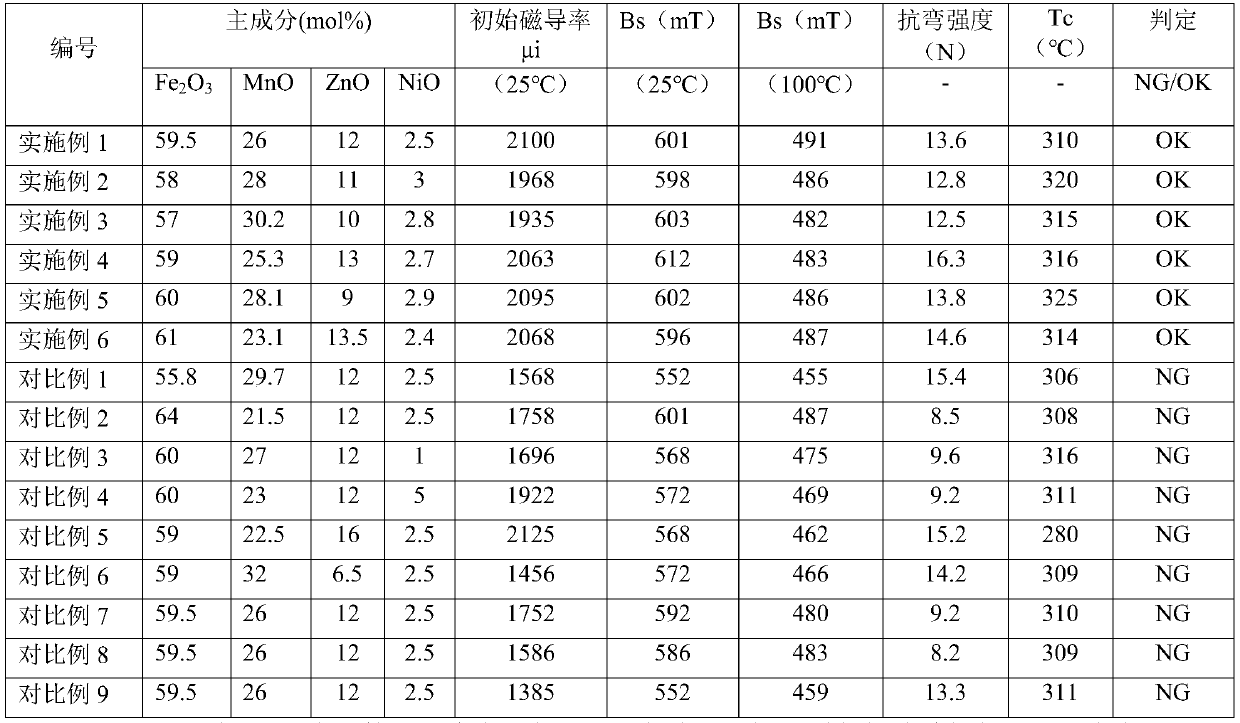

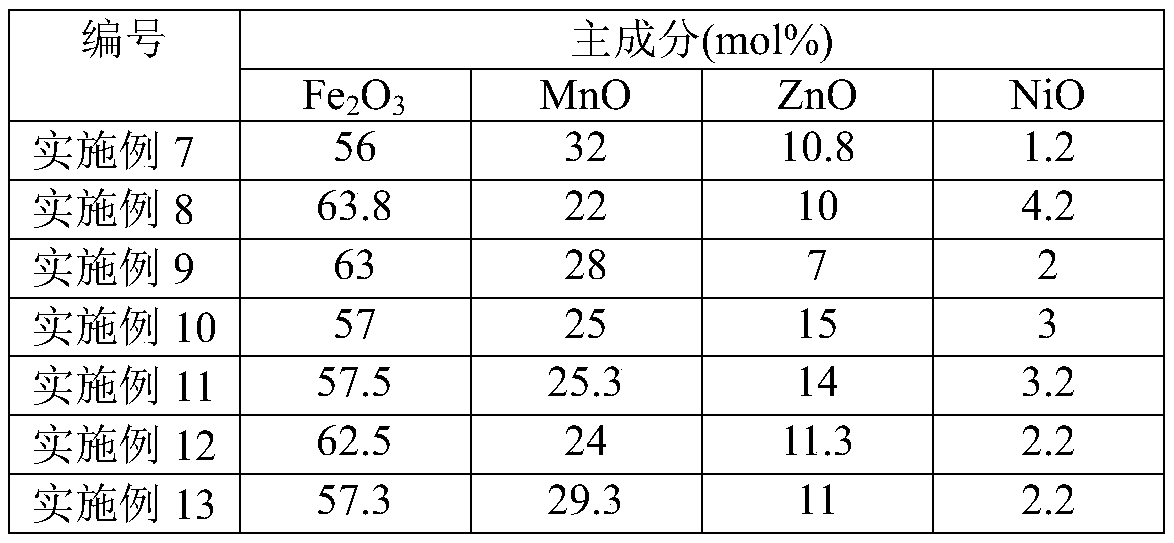

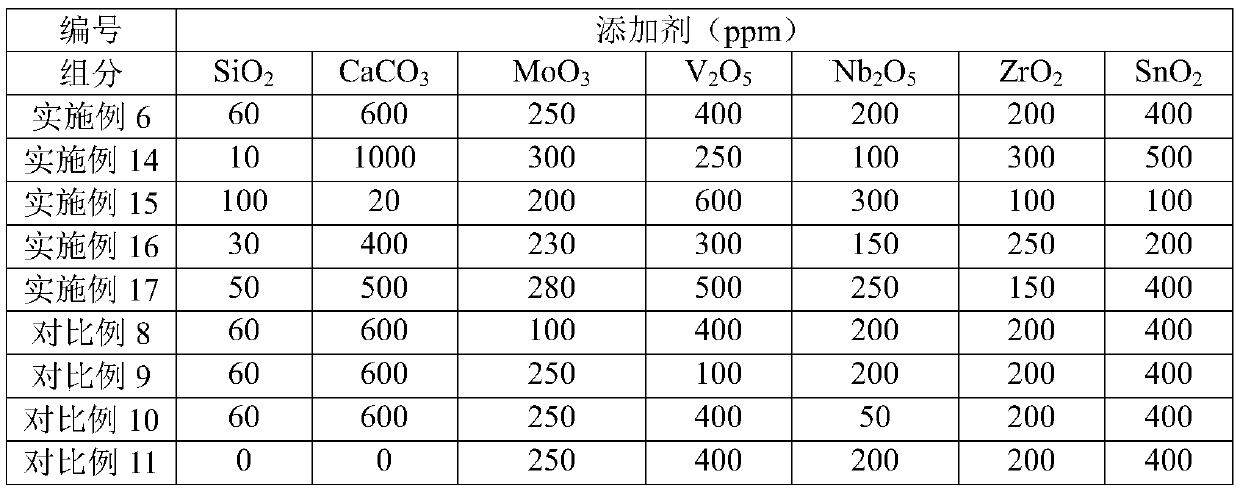

High-Bs high-strength manganese-zinc ferrite material and preparation method thereof

The invention relates to the technical field of magnetic materials, and provides a high-Bs high-strength manganese-zinc ferrite material in order to solve the problems that a traditional manganese-zinc ferrite material is low in magnetic strength, high in magnetic conductivity and low in Curie temperature after loading current. The material is composed of a main component and additives; the main component comprises, by mole percent, 56-63.8% of Fe2O3, 22-32% of MnO, 7-15% of ZnO and 1.2-4.2% of NiO; according to the total quantity of the main component, the additives comprise 10-100 ppm SiO2,200-1000 ppm CaCO3, 200-300 ppm MoO3, 250-600 ppm V2O5, 100-300 ppm Nb2O5, 100-300 ppm ZrO2 and 100-500 ppm SnO2. In the formula of the MnZn ferrite material, an iron-rich formula with the molar ratioof Fe2O3 higher than 55% is designed so that high-Bs can be greatly improved, and the superposition performance of the high-Bs can be further improved. Through synergistic interaction and mutual effects of the additives, the grain growth is uniform, the mechanical strength can be improved, the grain resistivity can be increased, and the loss of the MnZn ferrite material can be reduced.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

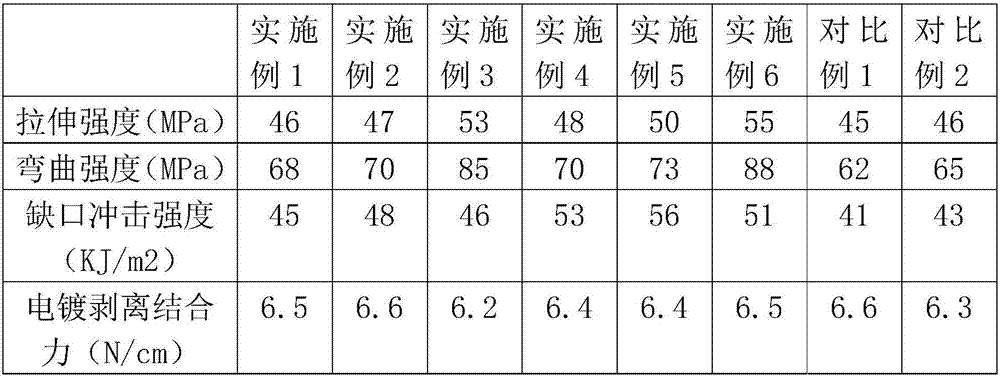

High-strength electroplating PC/ABS alloy material and preparation method thereof

The invention discloses a high-strength electroplating PC / ABS alloy material and a preparation method thereof. The high-strength electroplating PC / ABS alloy material is prepared by comprising the following raw materials in parts by weight: 40-60 parts of PC, 40-60 parts of ABS, 5-10 parts of ABS-g-MAH compatilizer, 1-5 parts of GMA toughening agent, 0.5-1 part of nano calcium carbonate, 0.2-0.5 part of antioxidant 168, and 0.2-0.5 part of lubricant. By adding GMA toughening agent, and nano calcium carbonate in preparation of the PC / ABS alloy material, the modified PC / ABS alloy has higher tensile strength and bending strength, and the PC / ABS alloy material has excellent rigidity; the impact strength of the electroplating PC / ABS alloy material can be improved synergistically by the GMA toughening agent and ABS-g-MAH compatilizer, and the electroplating PC / ABS alloy material has impact toughness of excellent rigidity; and the electroplating PC / ABS alloy material added with GMA toughening agent and nano calcium carbonate does not influence the electroplating performance, and is especially applicable to automobile outer door electroplating handles and inner door electroplating clasping hands and other products which are frequently subjected to drawing force.

Owner:南京跃贝新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com