Patents

Literature

1424 results about "Frictional coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coefficient of friction. The coefficient of friction is the ratio of the frictional force to the force acting perpendicular to the two surfaces in contact. This force is usually gravitational.

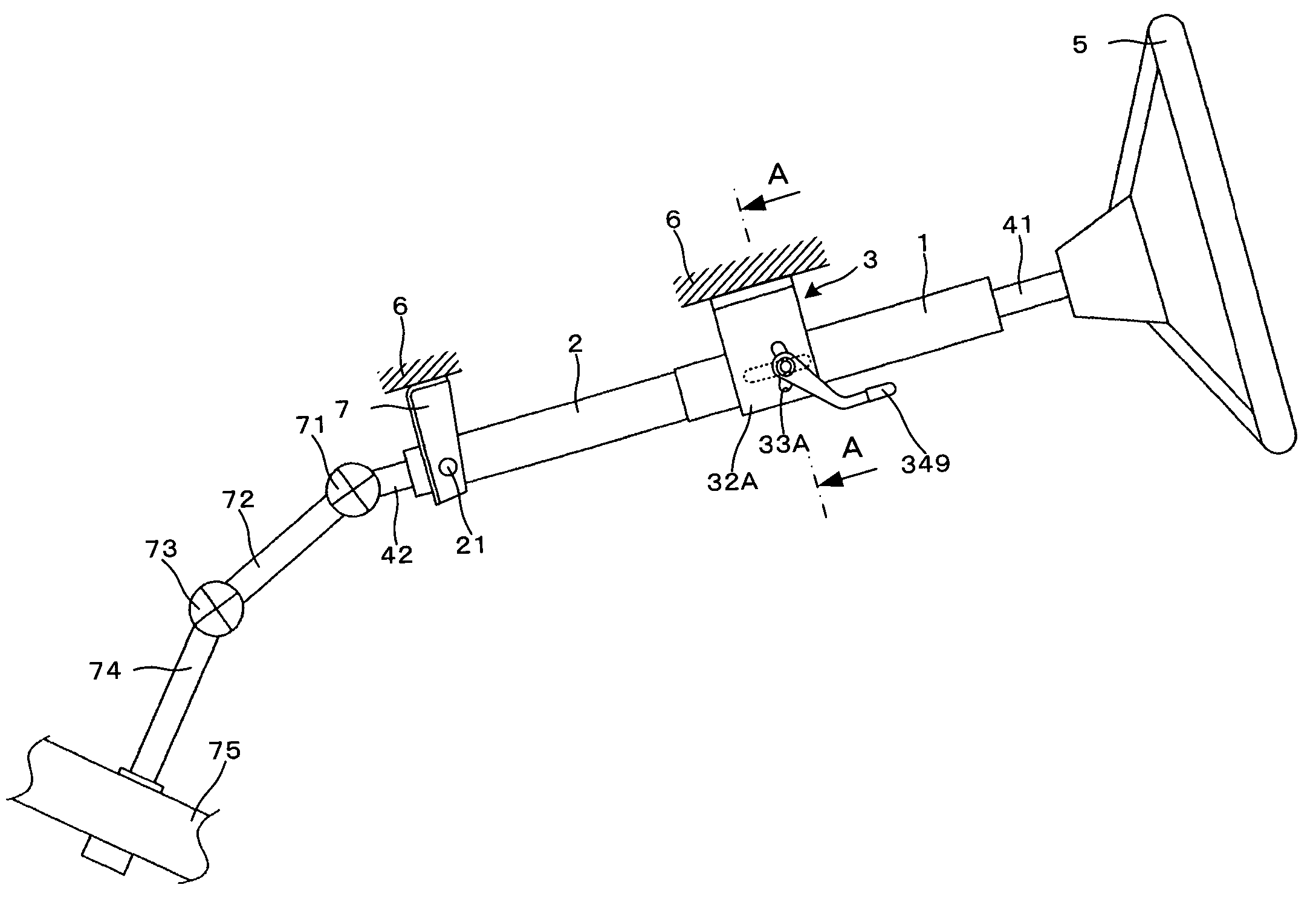

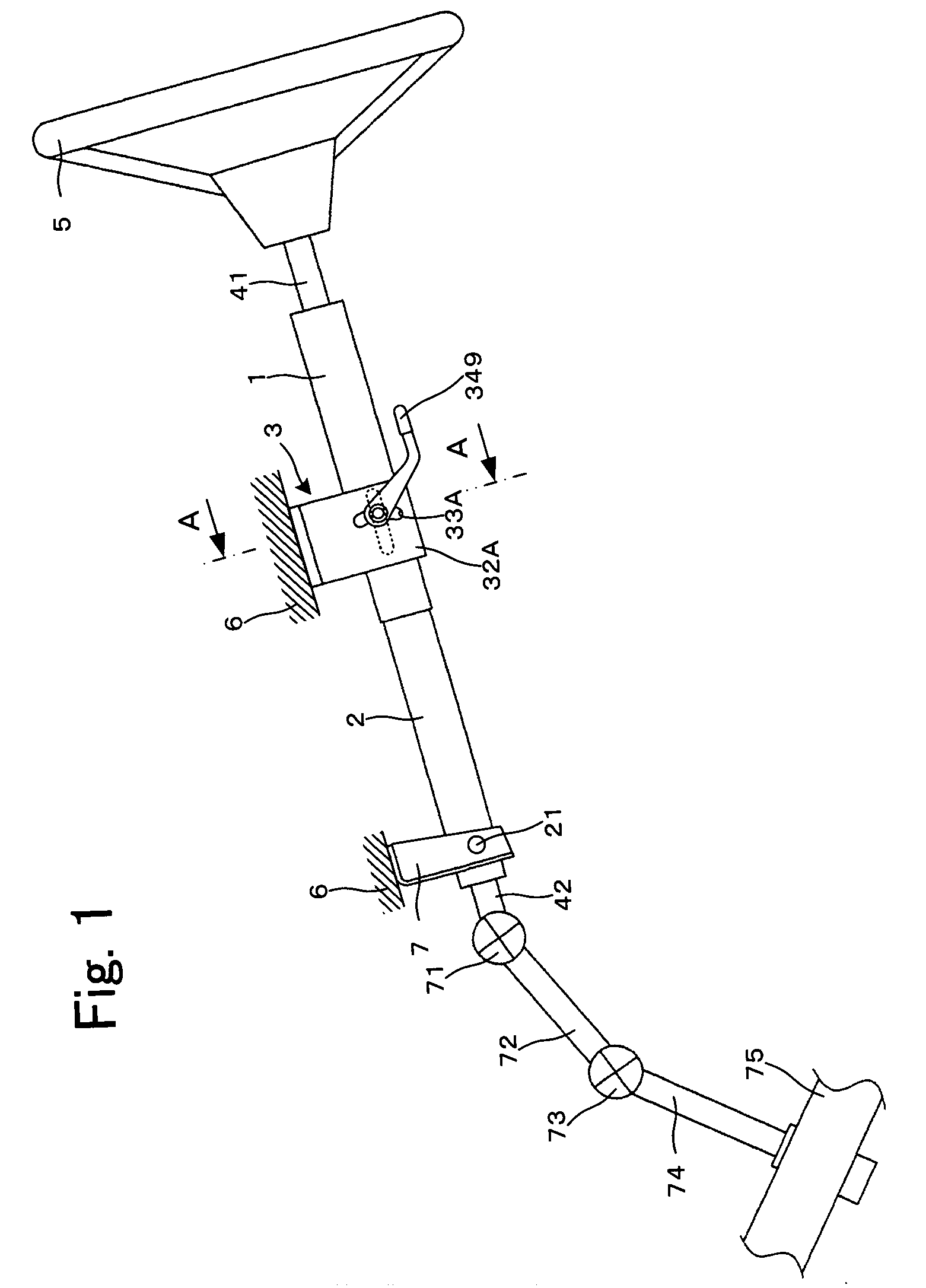

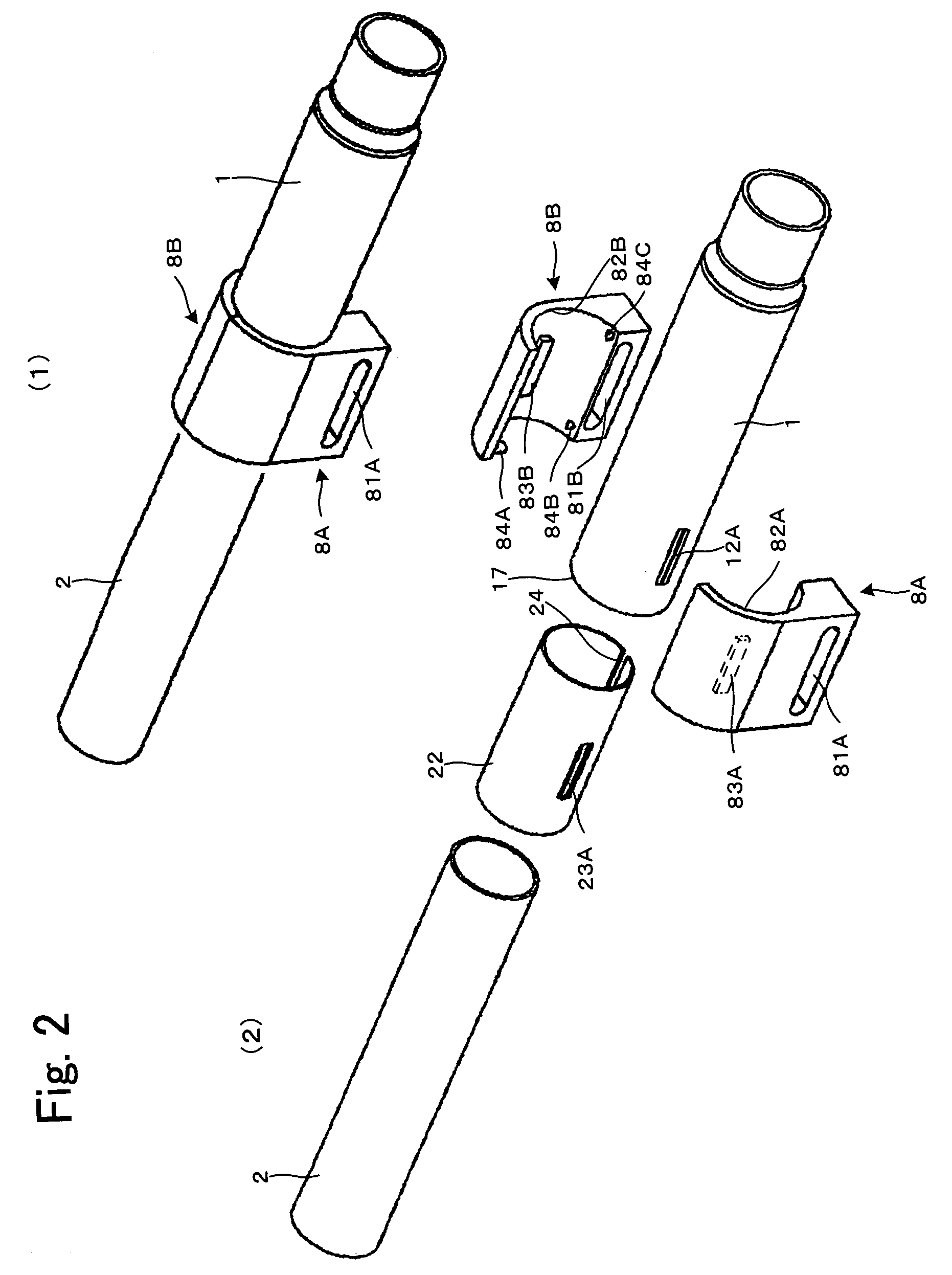

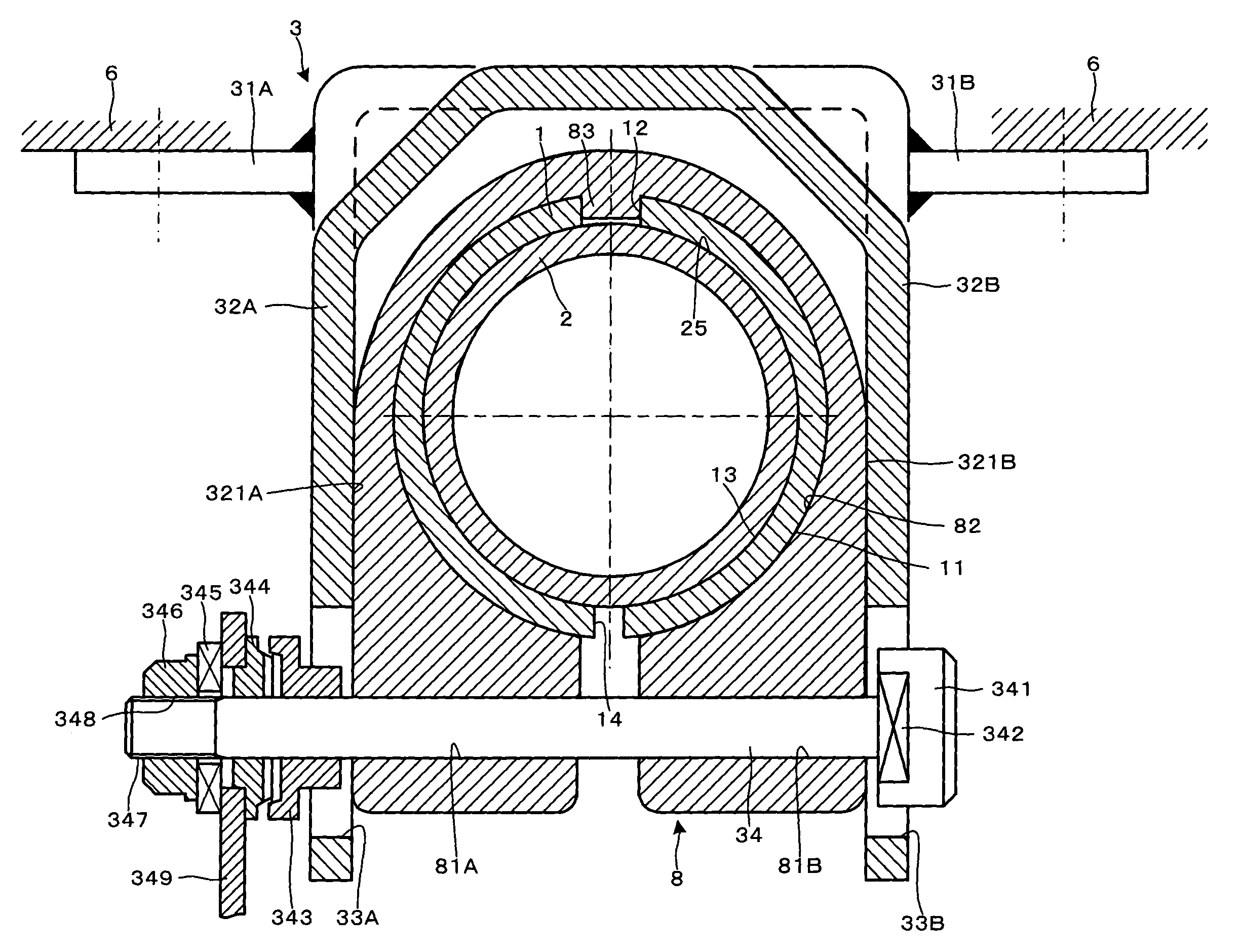

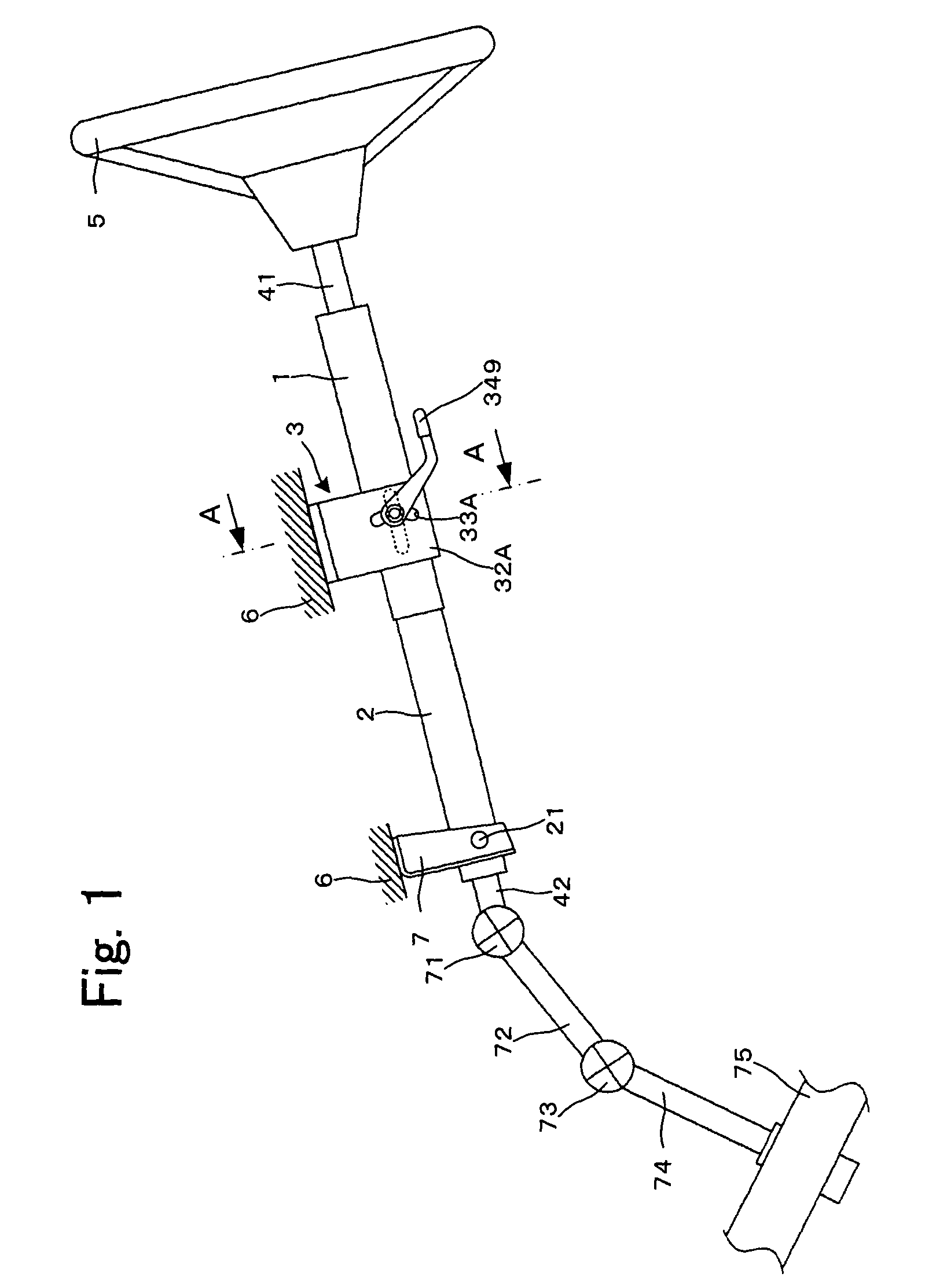

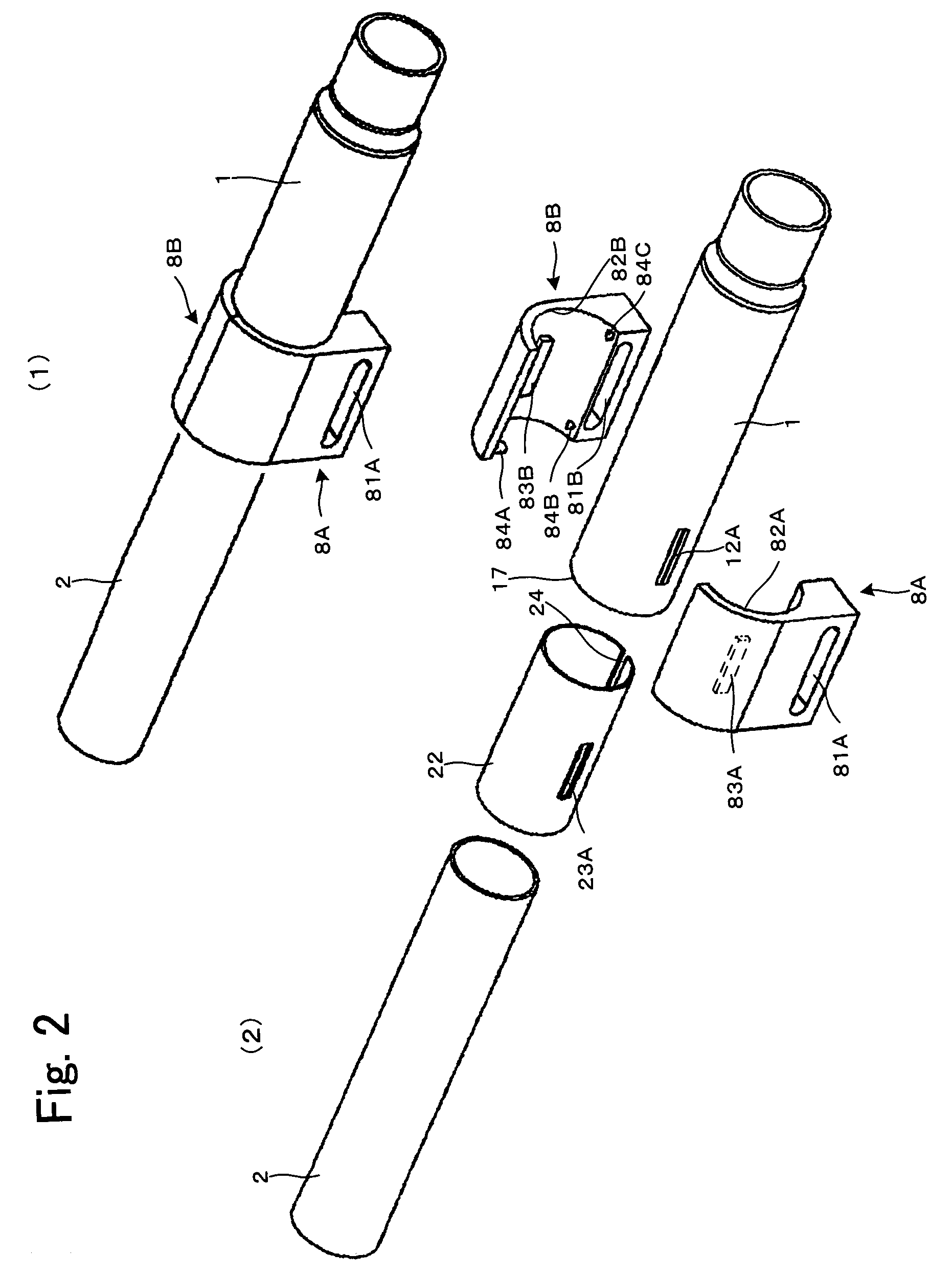

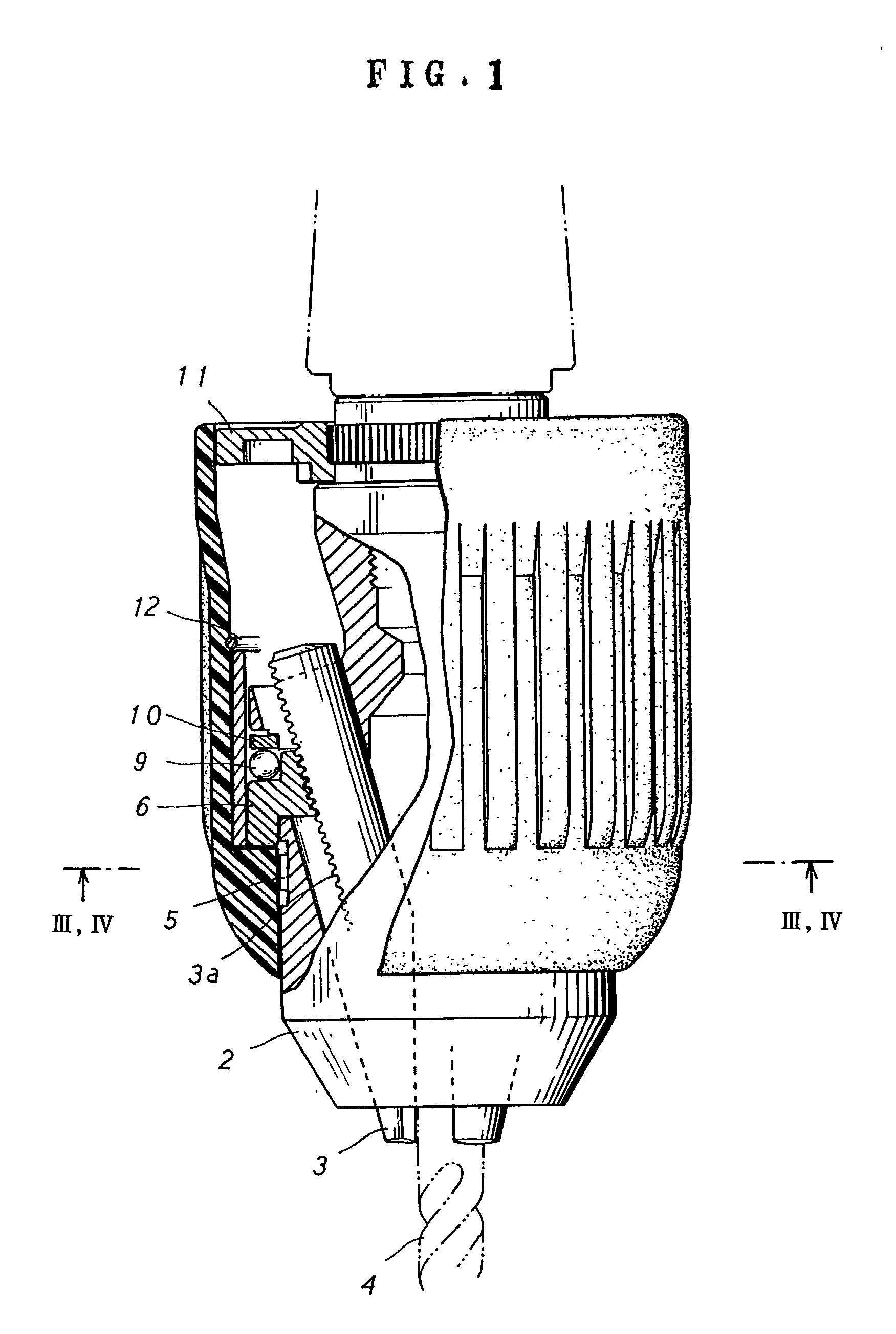

Steering column device

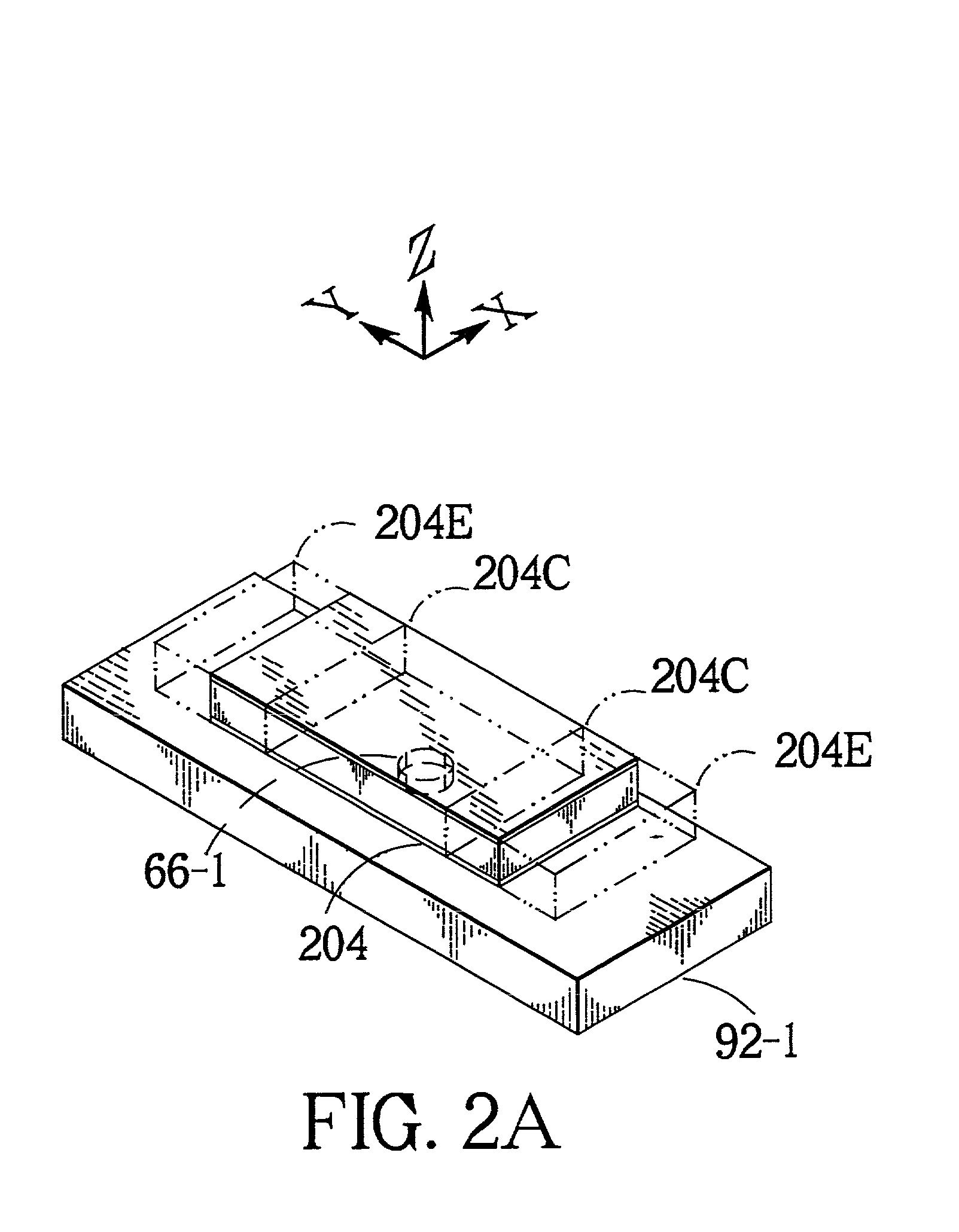

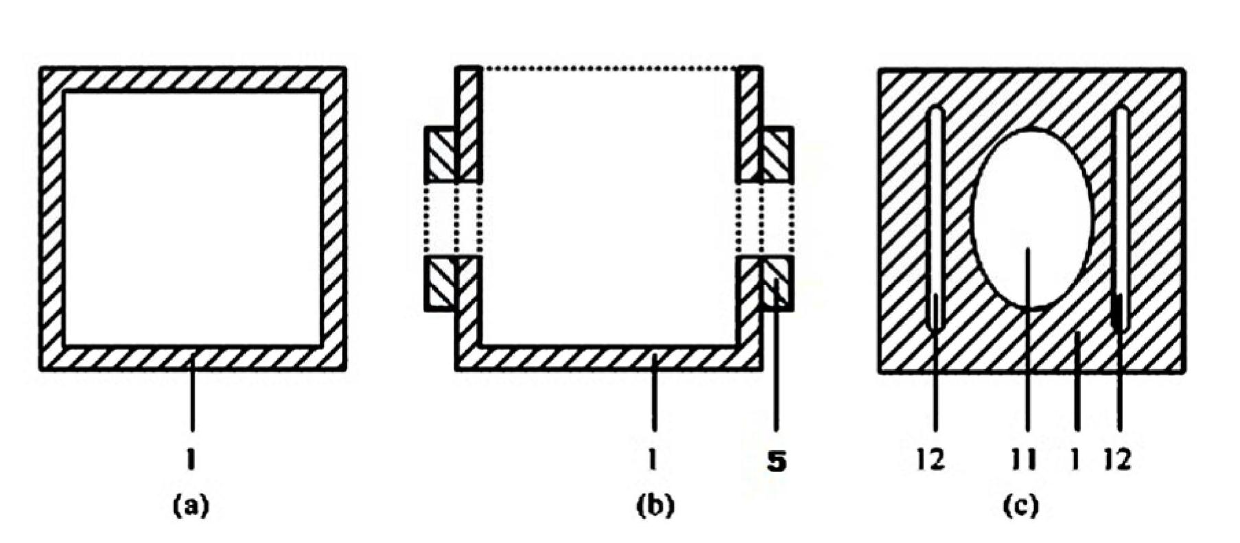

InactiveUS20060028010A1Simple configurationReduce manufacturing costSteering columnsSteering columnFrictional coefficient

A structure of the steering column device for clamping the outer column to the inner column is simple and its manufacturing cost is reduced. The outer column 1 and the bushing are stopped against rotation to the clamp members and at the same time when the outer column is adjusted in its telescopic position in respect to the inner column, the outer column, clamp members and bushing can be integrally and axially slid. Since the bushing having a low frictional coefficient is present between the inner circumference of the outer column and the outer circumference of the inner column, the outer column can be moved with a light force in respect to the inner column.

Owner:NSK LTD

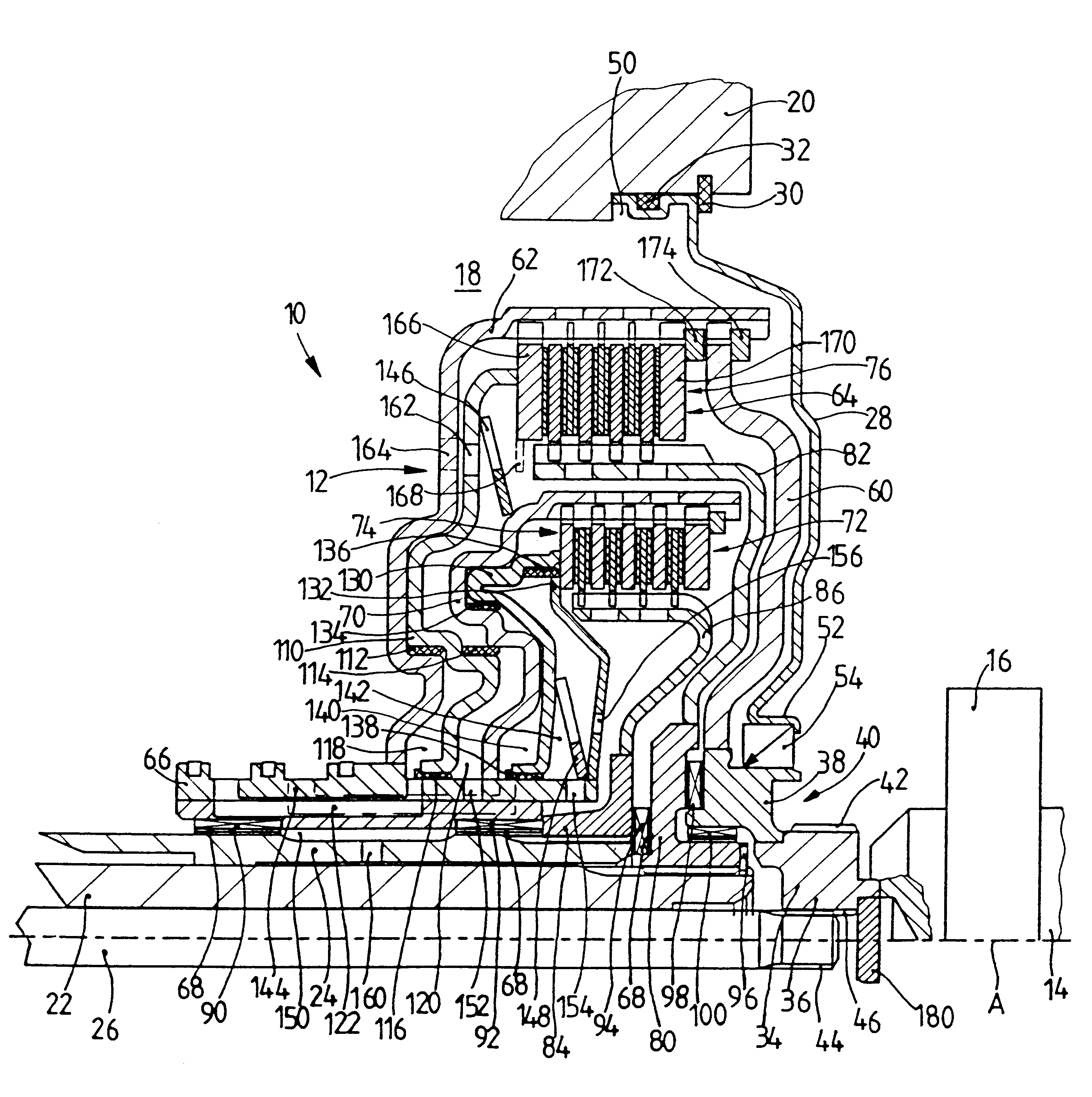

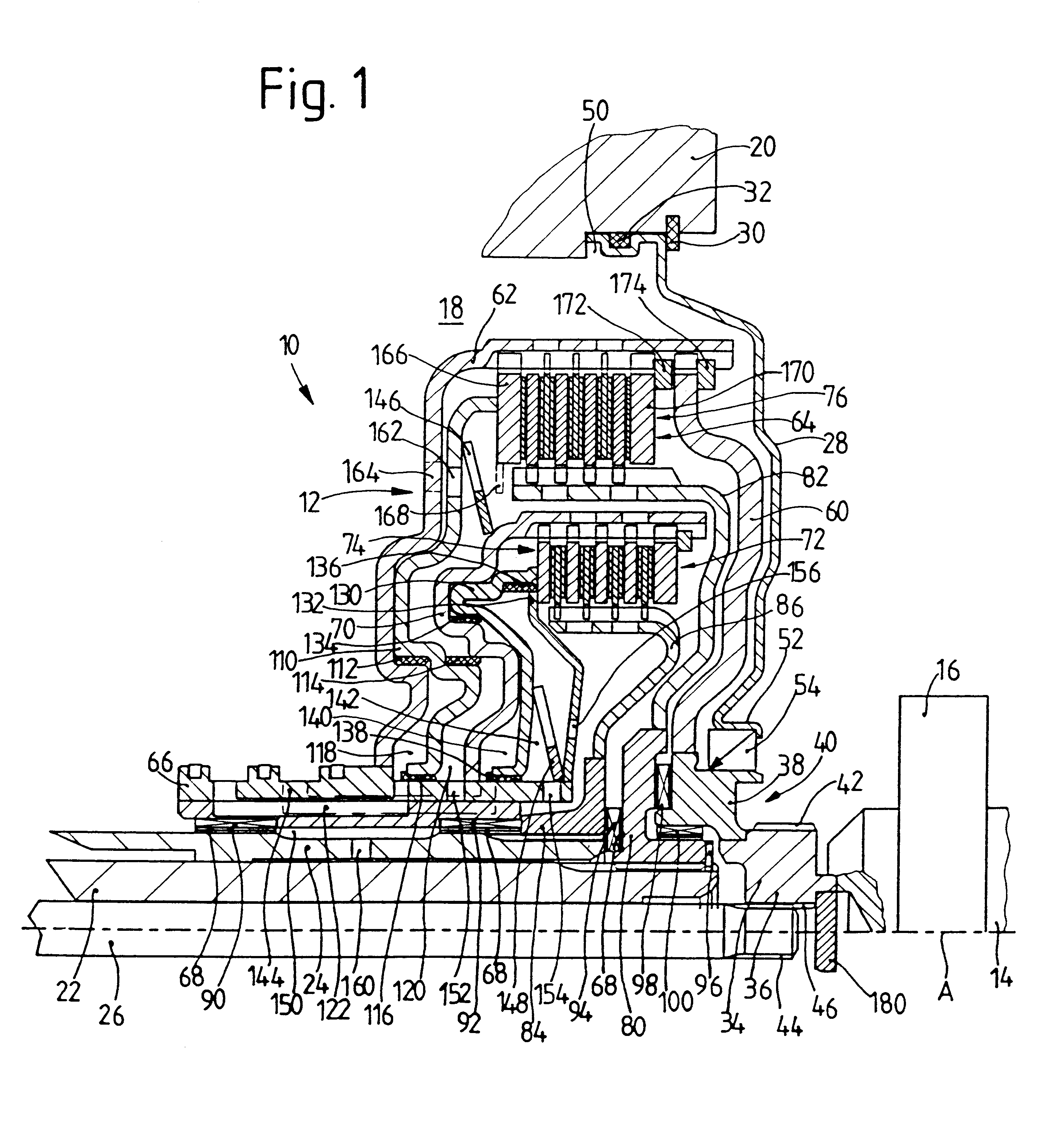

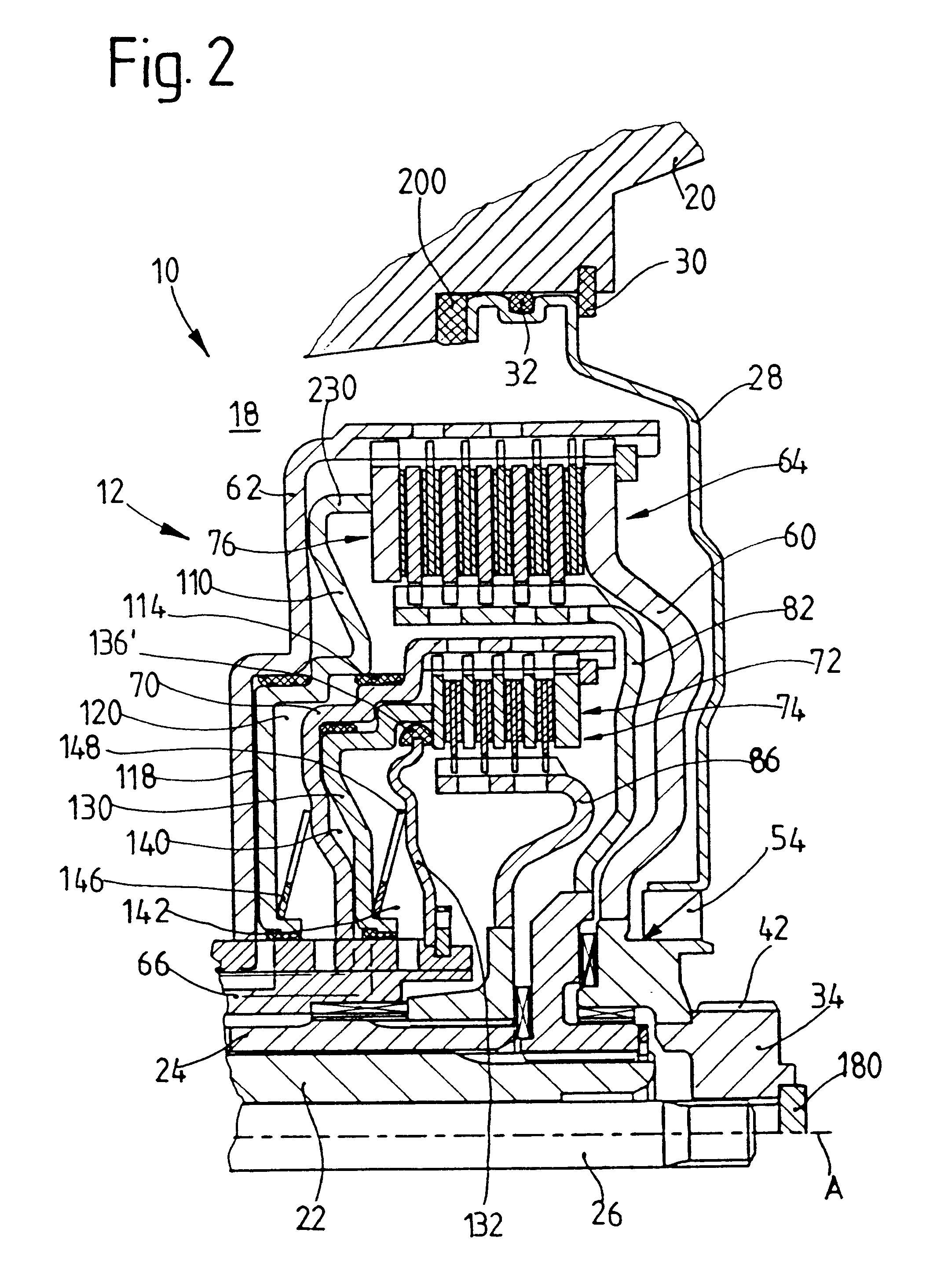

Multiple-clutch device

InactiveUS6523657B1Large massLarge heat capacityRoad transportFluid actuated clutchesMobile vehicleDrivetrain

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that plates in a plate stack of a clutch arrangement constructed as a plate clutch arrangement which have at least one friction facing can be brought into frictional engagement with plates having no friction facing, wherein at least one of the plates not having a friction facing is thicker in axial direction than friction facing carrying elements of adjacent plates having at least one friction facing. Alternatively or in addition, it is suggested that at least one plate which has at least one friction facing of sintered material and at least one plate which has at least one friction facing made of another friction facing material are provided in the plate stack, wherein the other friction facing material has a progressive frictional coefficient curve (dlambd / dDELTAN) in relation to a slip speed (DELTAN).

Owner:ZF FRIEDRICHSHAFEN AG +1

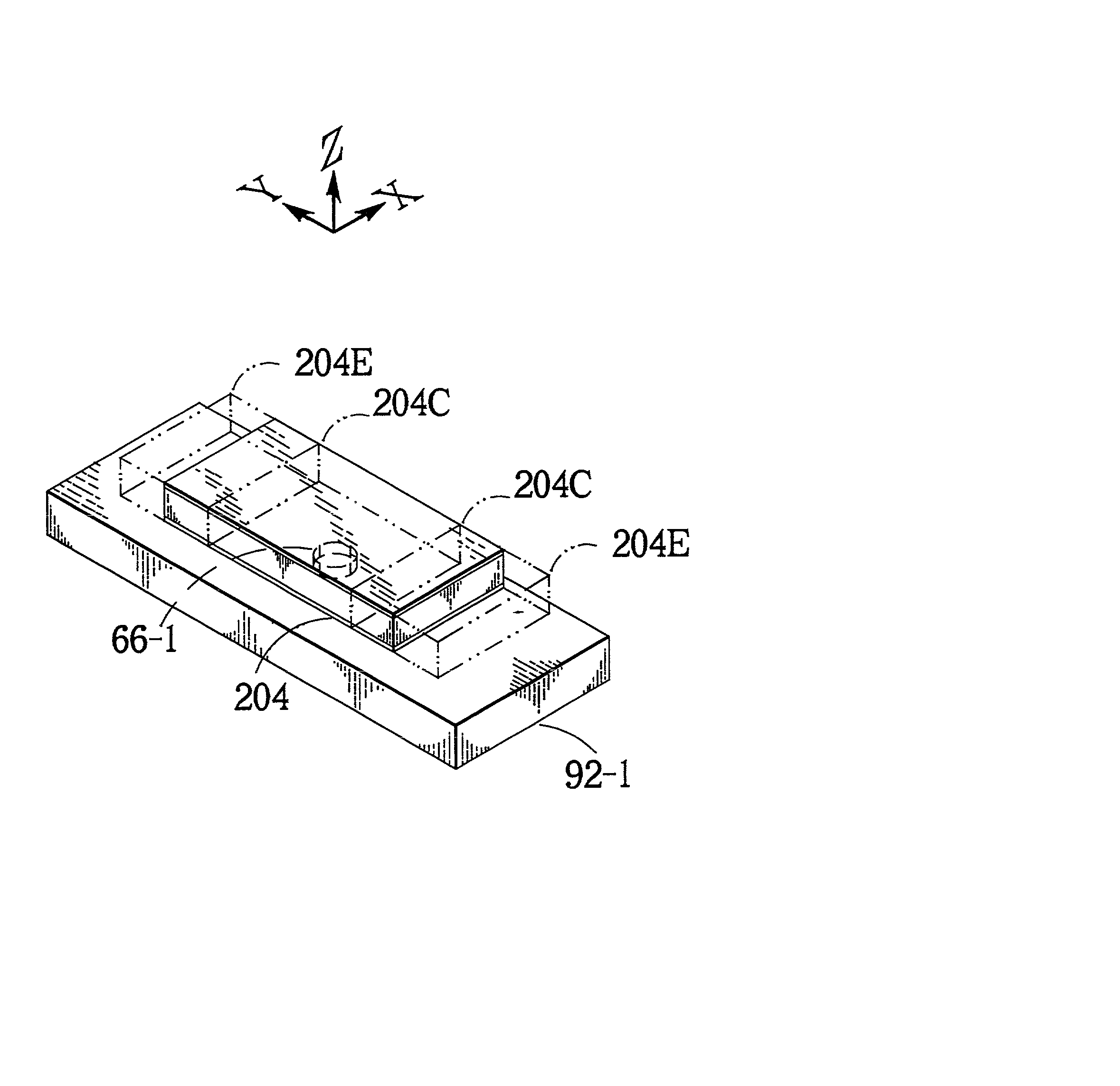

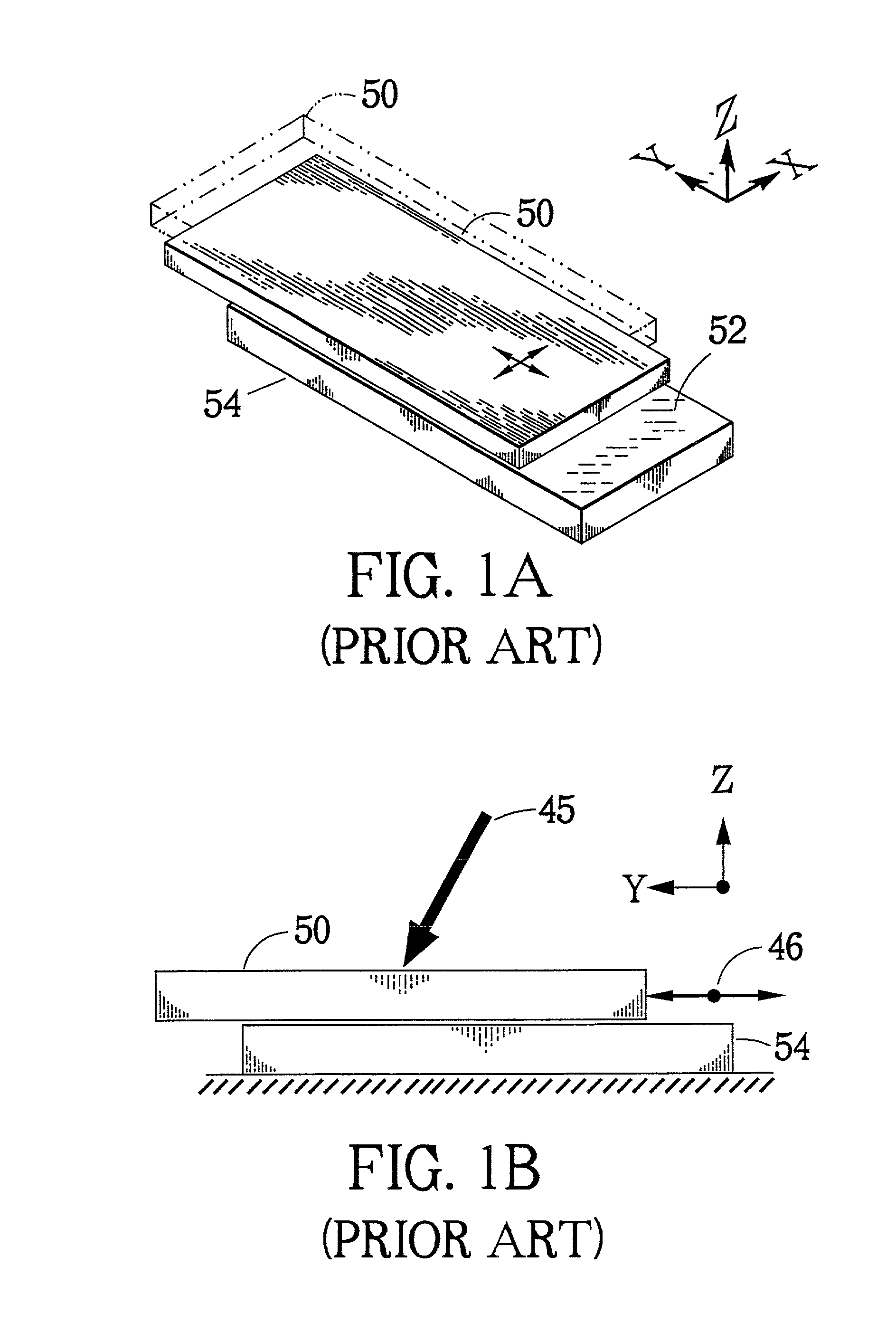

Smart Sonic bearings for frictional force reduction and switching

InactiveUS20020126922A1High compression stiffnessReduce sensitivityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesFriction reductionStatic friction

An ultrastiff precision sonic bearing assembly and method thereof for controlling an effective coefficient of friction between two elements in slidable contact configured along an interface under a force sufficient to maintain contact and having static friction therebetween, by inducing a repetitive motion in one of the elements parallel to the interface thereby altering the effective coefficient of friction therebetween. The bearing assembly also provides for additional and independent electronic control over the average thickness thereof and senses the force thereon to allow the bearing assembly stiffness to be altered.

Owner:GRQ INSTR

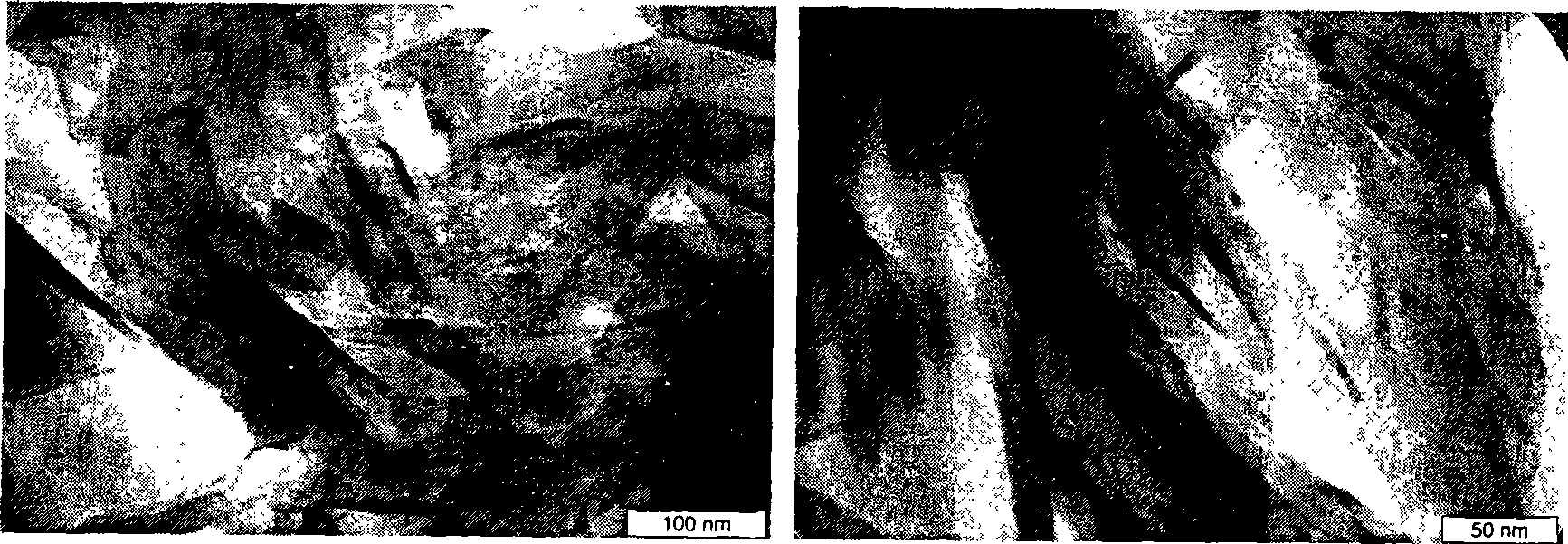

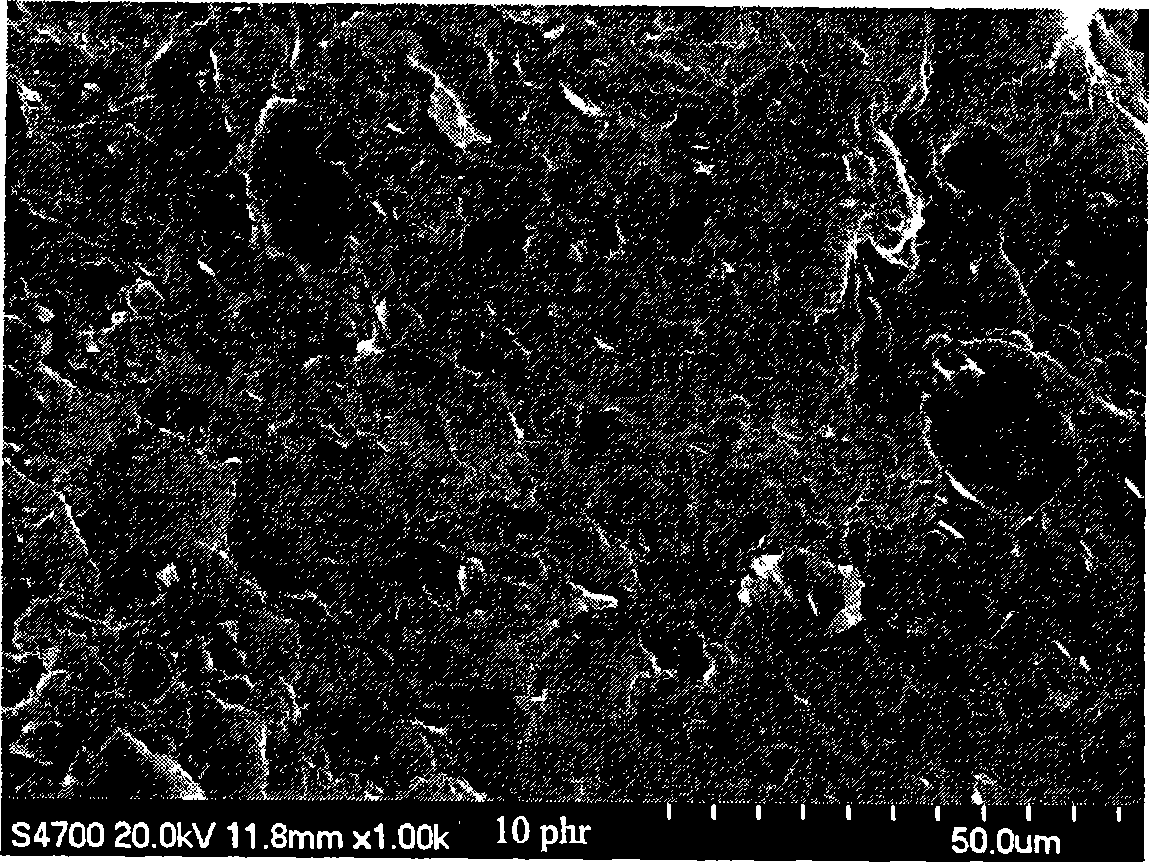

Preparation of wear resistant rubber composite material

InactiveCN101463149AImprove mechanical propertiesImprove recycling efficiencyOrganic solventPolymer science

The invention relates to a preparation method of a graphite-modified abrasive resistant rubber composite material. The method comprises the following steps: soaking expandable graphite with laminar crystal layer structure in water or an organic solvent containing a surfactant; preparing a suspension system of nano flaky graphite by stirring and ultrasonic treatment; mixing the suspension system with rubber latex or rubber solution, and then adding a flocculant for breaking latex and flocculating or adding a poor solvent for precipitation; and drying flocculate or precipitate, mixing and vulcanizing to obtain the graphite / rubber composite material. The latex (solution) blending process is introduced into preparation of the graphite / rubber nano-composite material to realize homogeneous dispersion of the graphite in a rubber matrix compound system by a nanoscale size, to cause good strengthening effect and prepare the rubber composite material with excellent mechanical property, low frictional coefficient and high abrasive resistance.

Owner:BEIJING UNIV OF CHEM TECH

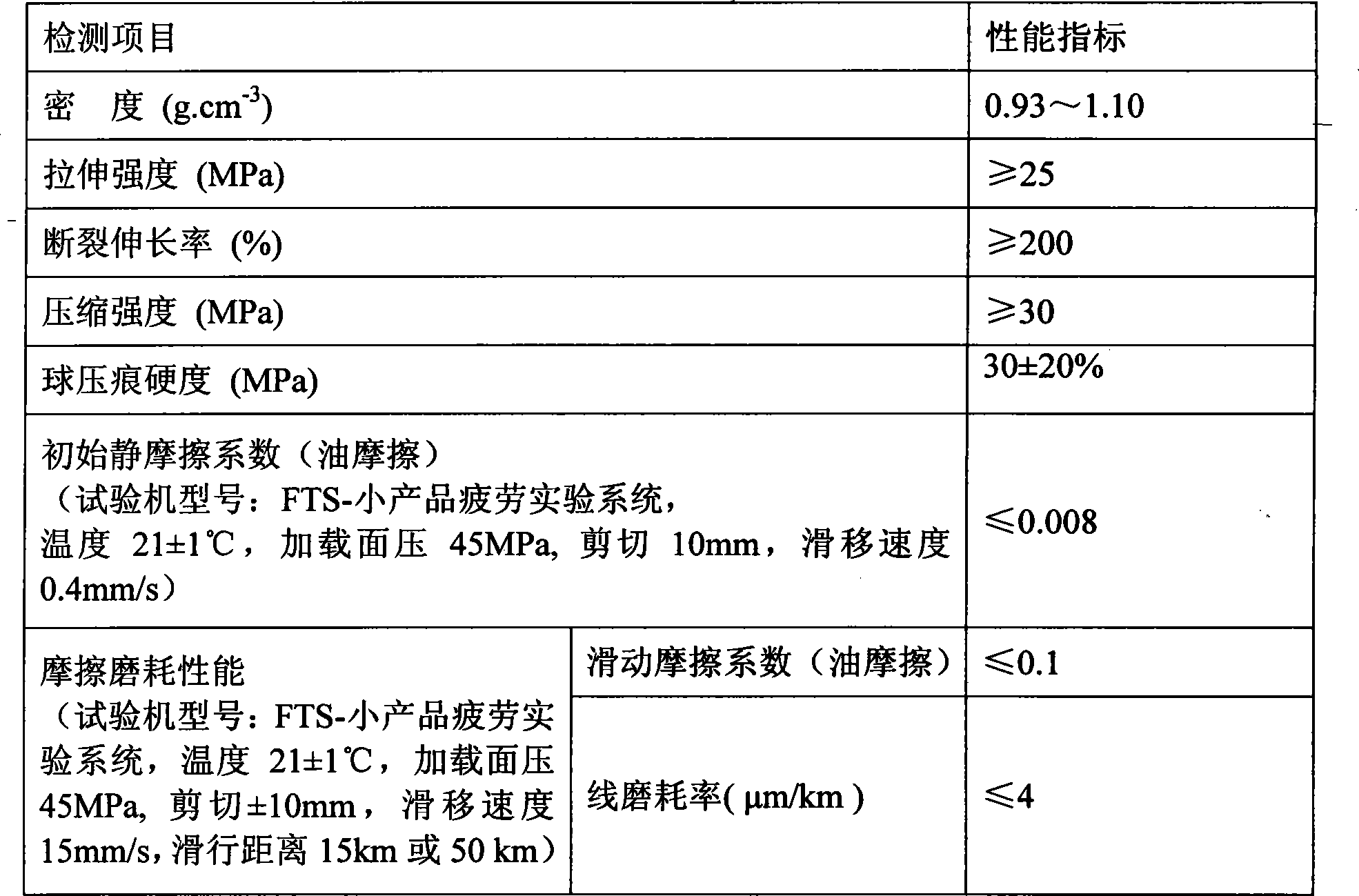

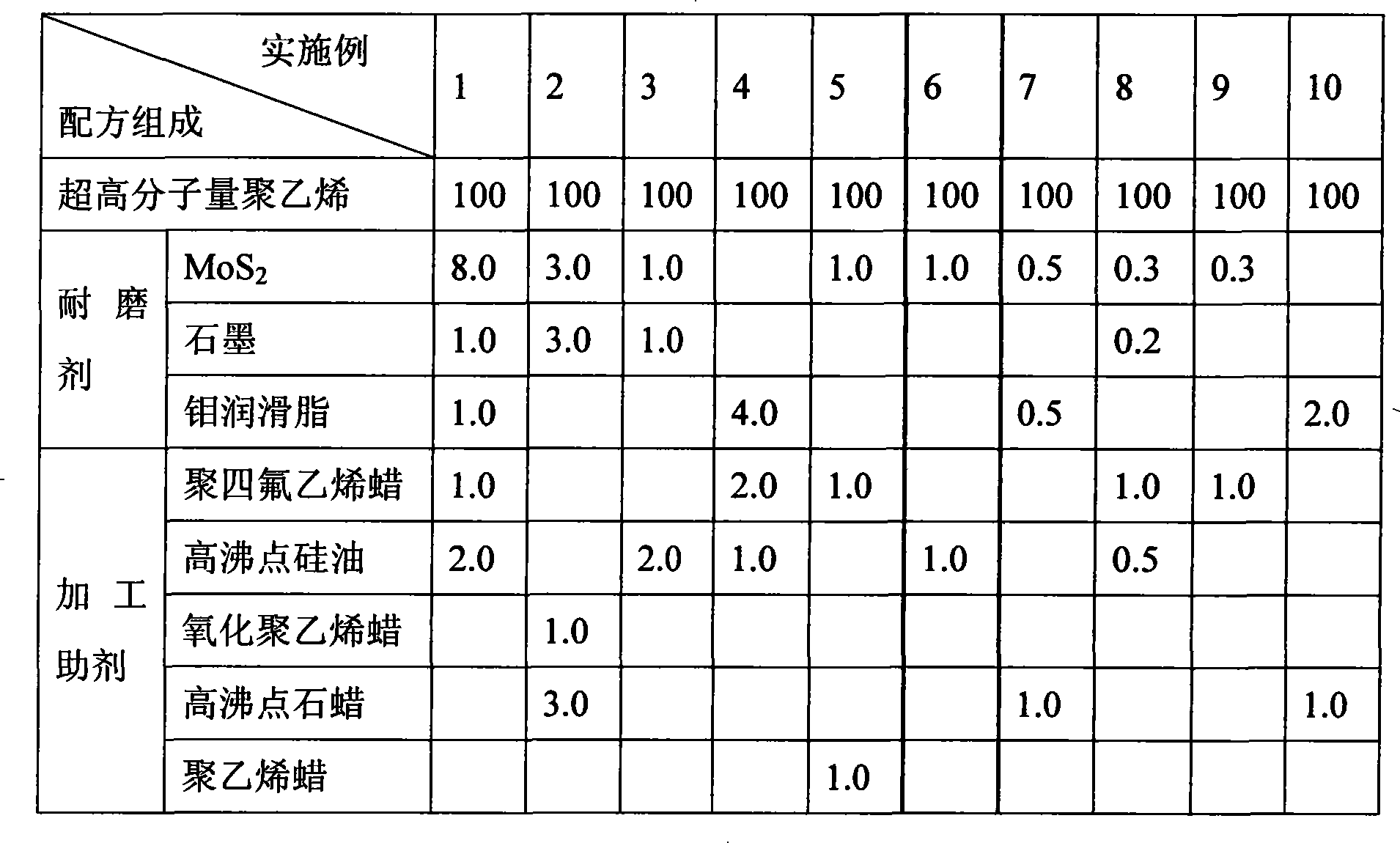

Super-high molecular weight polyethylene low frictional coefficient wearable composite material and its preparation and use

InactiveCN101240092AImprove performanceExcellent formulaBridge structural detailsParaffin waxProcedure Agents

Ultra high molecular weight polyethylene composite with low molar mass and high friction resistance, preparation and application thereof. Raw materials of 100 parts by weight of ultra high molecular weight polyethylene, 0.1-10 parts by weight of wear-resisting agent, 0.1-5.0 parts by weight of processing aid is prepared into highly friction resistant composite by mixing, chill-pressing, heating to melt, compression molding, cooling for shaping and cutting. The mentioned utra high molecular weight polyethylene has a matrix molecular weight of greater than 6 millionl. The mentioned wear-resisting agent is MoS2 surface treated by coupling agent, black lead, lubricating grease of molybdenum, copper powder, or mixture of more than two of them. The mentioned processing agent is organic silicon oil with high boiling point, polytetrafluroethylene, oxidized polyethylene wax, olefin or polyethylene wax with high boiling point, or mixture of more than two of them.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Steering column device

InactiveUS7726691B2Simple configurationReduce manufacturing costSteering columnsSteering columnFrictional coefficient

A structure of the steering column device for clamping the outer column to the inner column is simple and its manufacturing cost is reduced. The outer column 1 and the bushing are stopped against rotation to the clamp members and at the same time when the outer column is adjusted in its telescopic position in respect to the inner column, the outer column, clamp members and bushing can be integrally and axially slid. Since the bushing having a low frictional coefficient is present between the inner circumference of the outer column and the outer circumference of the inner column, the outer column can be moved with a light force in respect to the inner column.

Owner:NSK LTD

Composite wear-resisting shoe sole

A composite wear-resisting shoe sole is prepared from, by weight, 60-100 parts of natural rubber, 10-50 parts of styrene butadiene rubber, 5-20 parts of polar rubber, 10-60 parts of modified white carbon black, 1-10 parts of zinc oxide, 1-4 parts of accelerant, 0.1-0.5 part of antioxidant, 2.5-4.5 parts of active agent, 5-20 parts of filler and 1-10 parts of sulfur .The filler is tetrapod-like zinc oxide whiskers .According to the composite wear-resisting shoe sole, the natural rubber and a small amount of polar rubber are jointly used as main rubber materials, the white carbon black subjected to toluene diisocyanate graft modification is added to serve as a reinforcing material, the tetrapod-like zinc oxide whiskers of a highly regular structure are used as a filling frame, the accelerant, the composite antioxidant and the active agent are added in sequence, and the composite wear-resisting shoe sole with high slippery resistance and tear strength and a remarkably improved frictional coefficient is prepared.

Owner:宁波市富罗迷鞋业有限公司

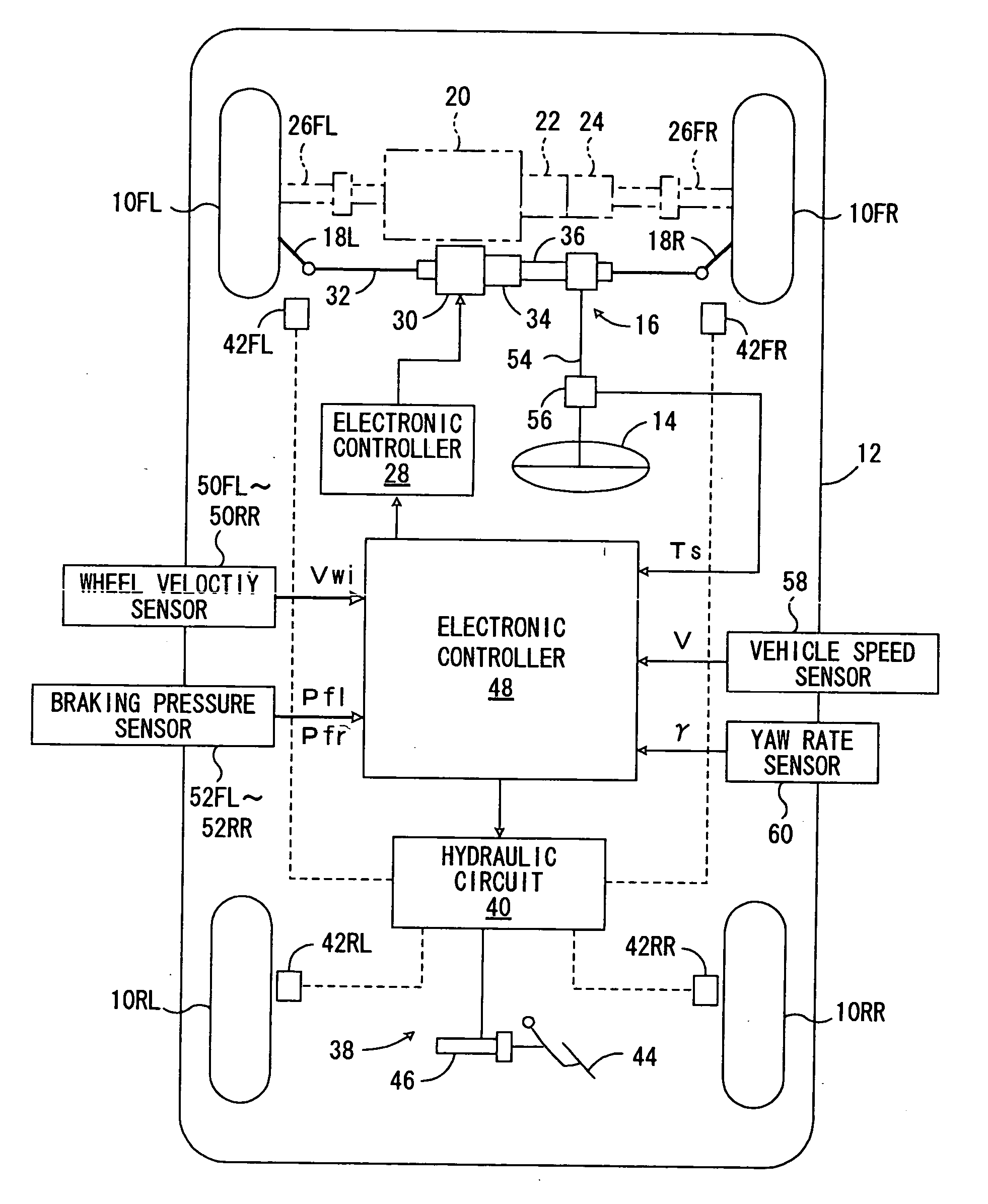

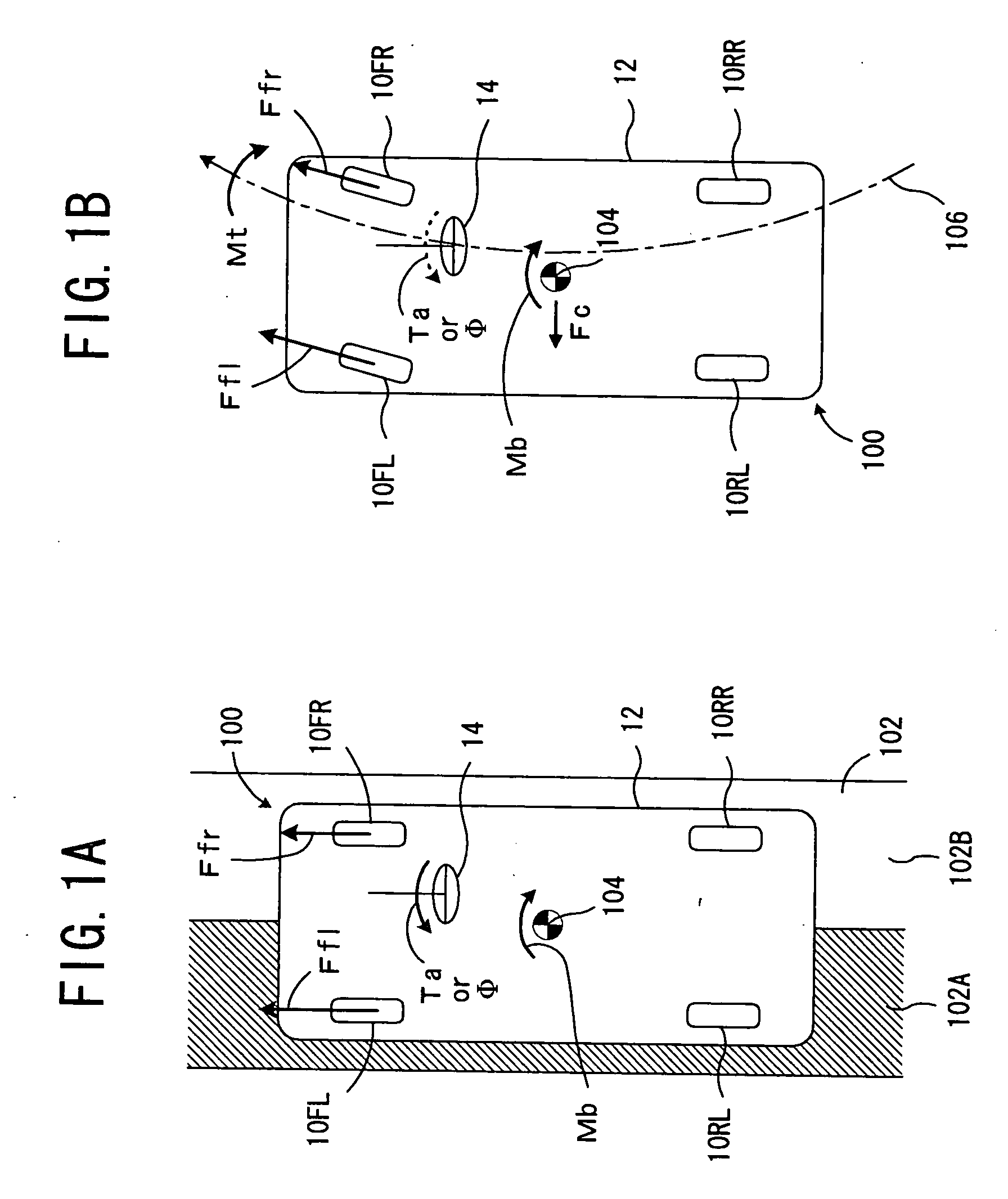

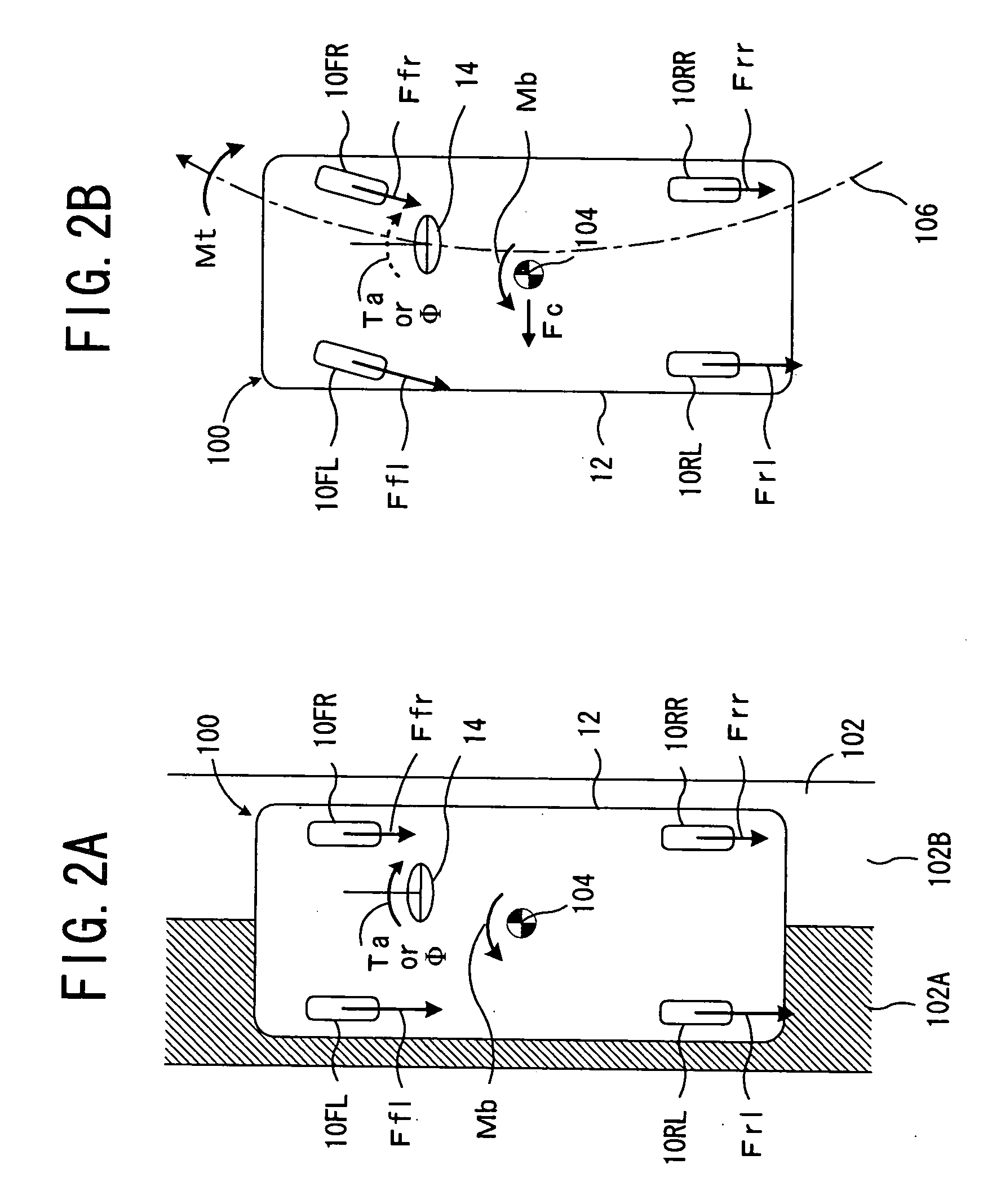

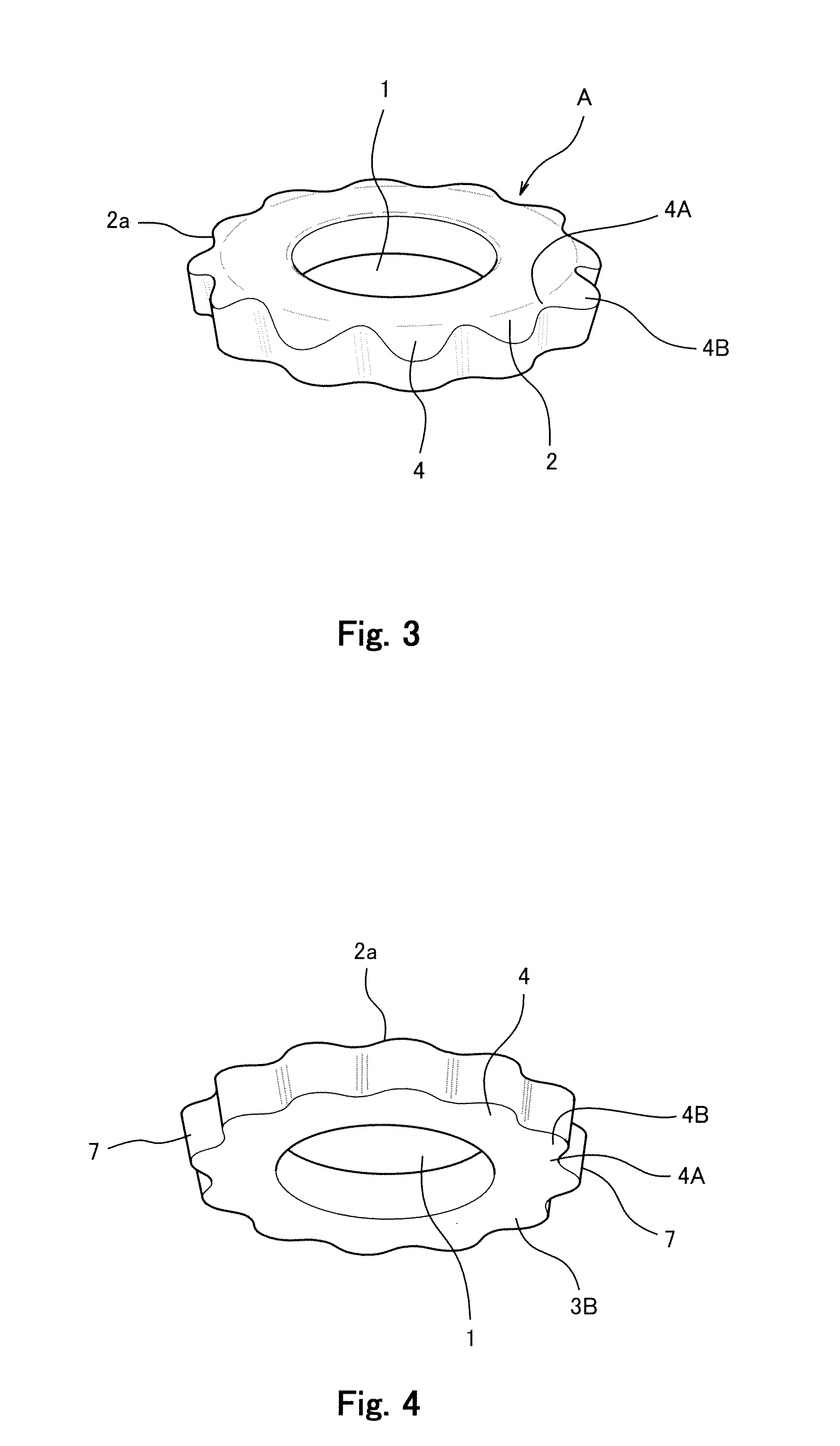

Vehicle steering control device

InactiveUS20040099469A1Restricting undesirableRestricting unexpected modificationHand manipulated computer devicesBrake system interactionsSteering angleFrictional coefficient

A new and novel device for controlling a steering characteristic of a vehicle such as automobile so as to enhance an effect of suppressing a change in a behavior of the vehicle body due to a difference between driving and braking forces on the left and right wheels is characterized in that the device makes an amount of controlling the steering characteristic smaller as an index indicating an amount of a shift of vertical loads between the left and right wheels is increased. The steering characteristic is modified through controlling steering assist torque or a steering angle of the steered wheels. The steering assist by the steering control device is fully effective when the vehicle is running on a straight road having surfaces of different frictional coefficients while less effective on a curved road having a uniform frictional surface, preventing undesirable and unexpected modification of the steering characteristic during turning of the vehicle.

Owner:TOYOTA JIDOSHA KK

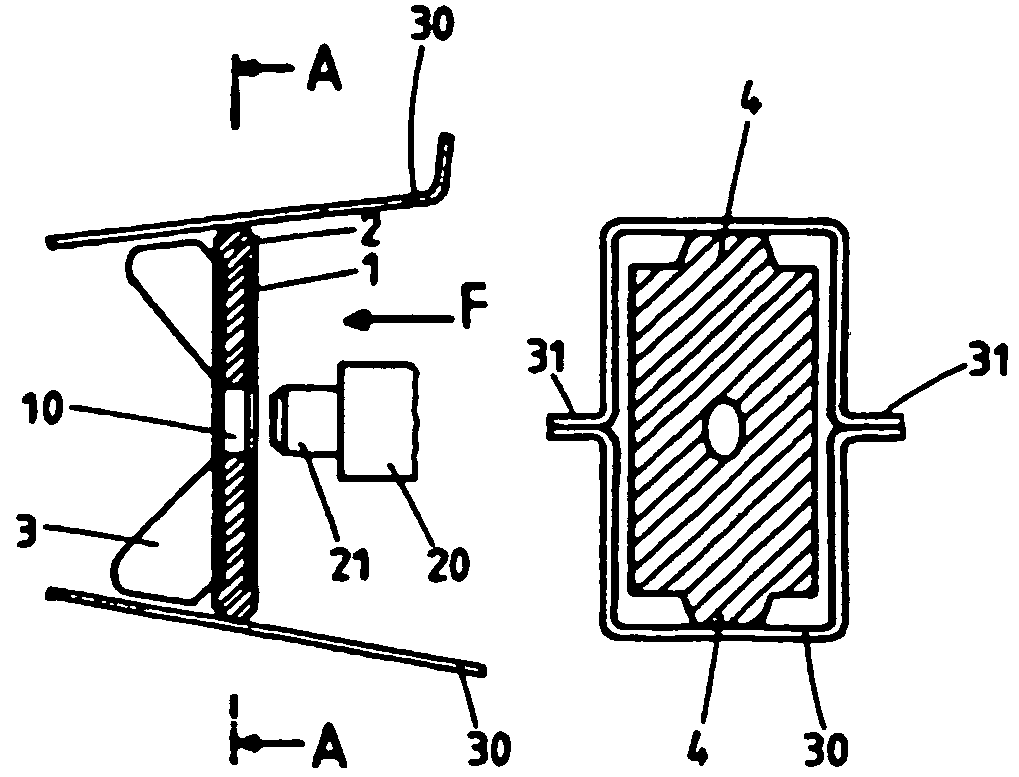

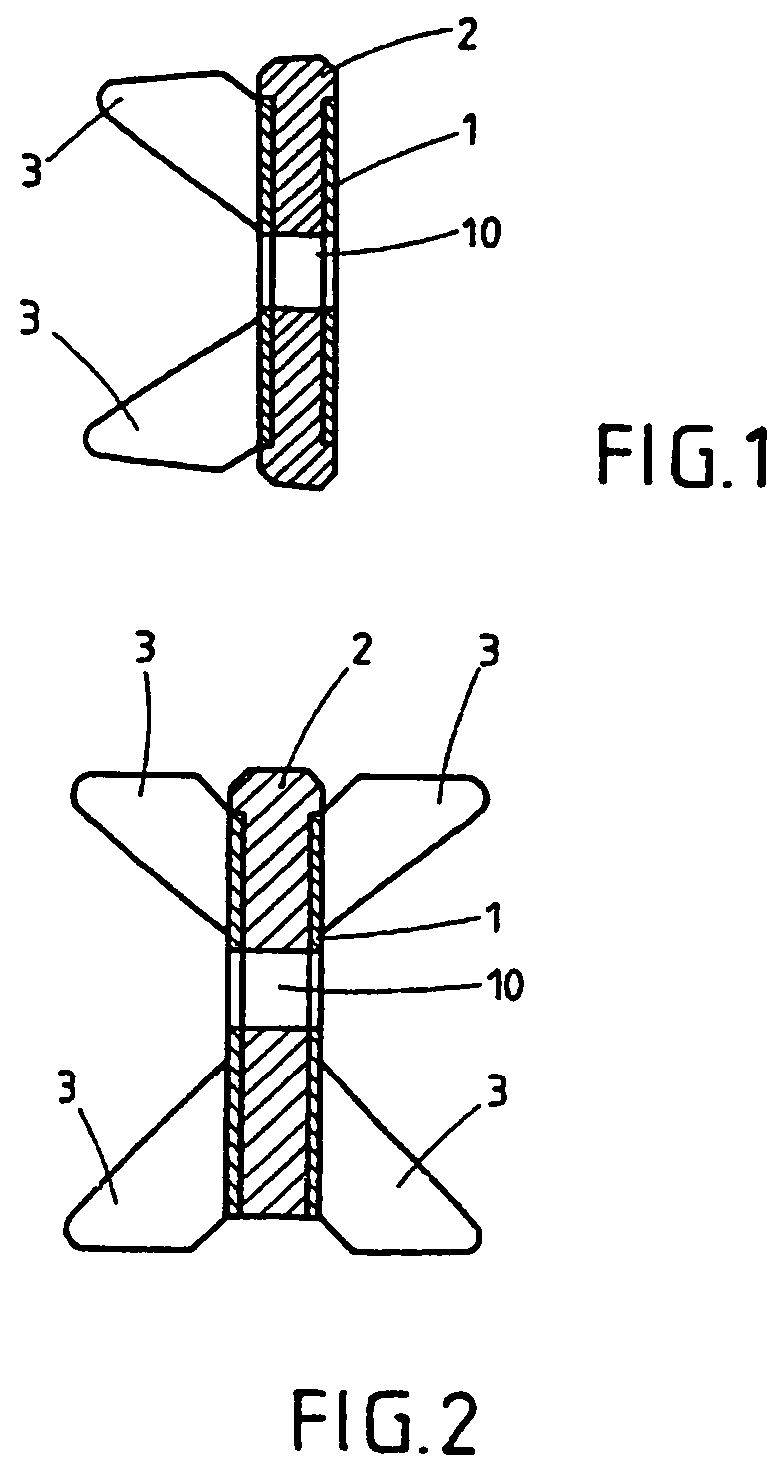

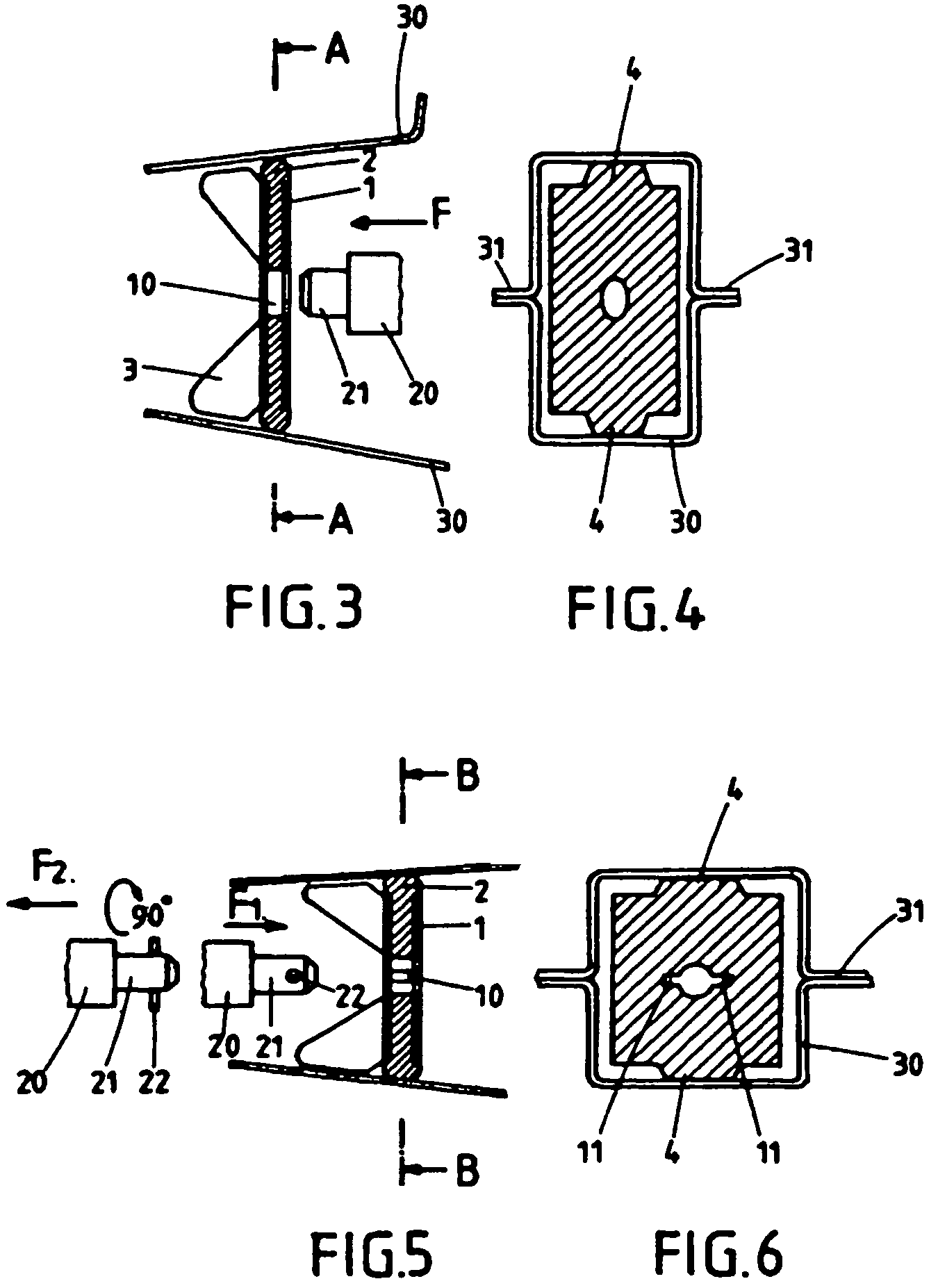

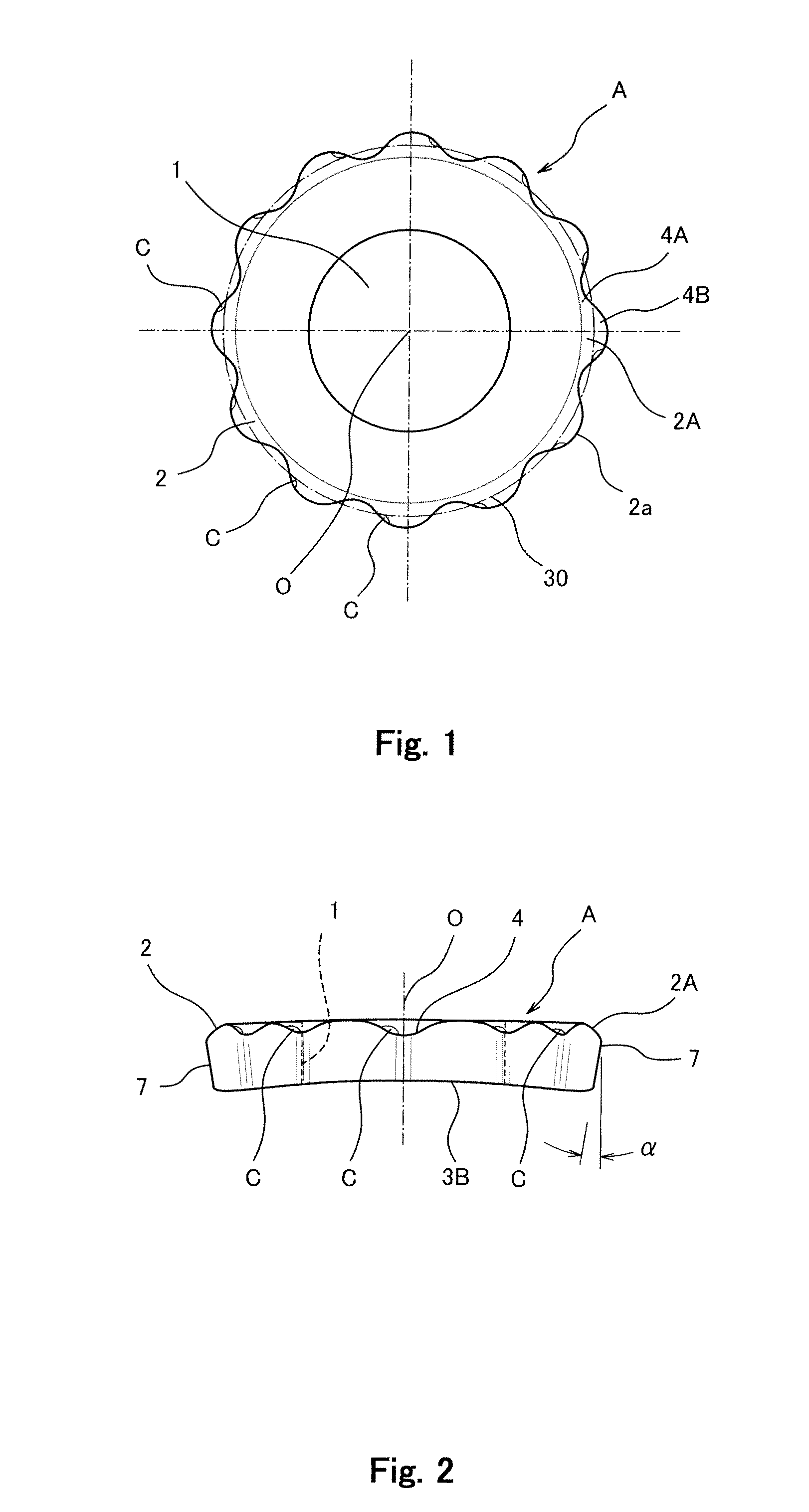

Process and components for fixing bulkhead parts

A molding is described, the outer edge region of which comprises a thermally expandable material that has a high coefficient of friction in relation to metal or plastic. In its inner region this molding has an aperture and / or recess for receiving a mounting aid. The molding is suitable as a sealing and acoustically active bulkhead part and with the aid of friction forces can be fixed mechanically in the cavity of structural components without these components having to exhibit bores, apertures or other devices for fixing the bulkhead part.

Owner:HENKEL KGAA

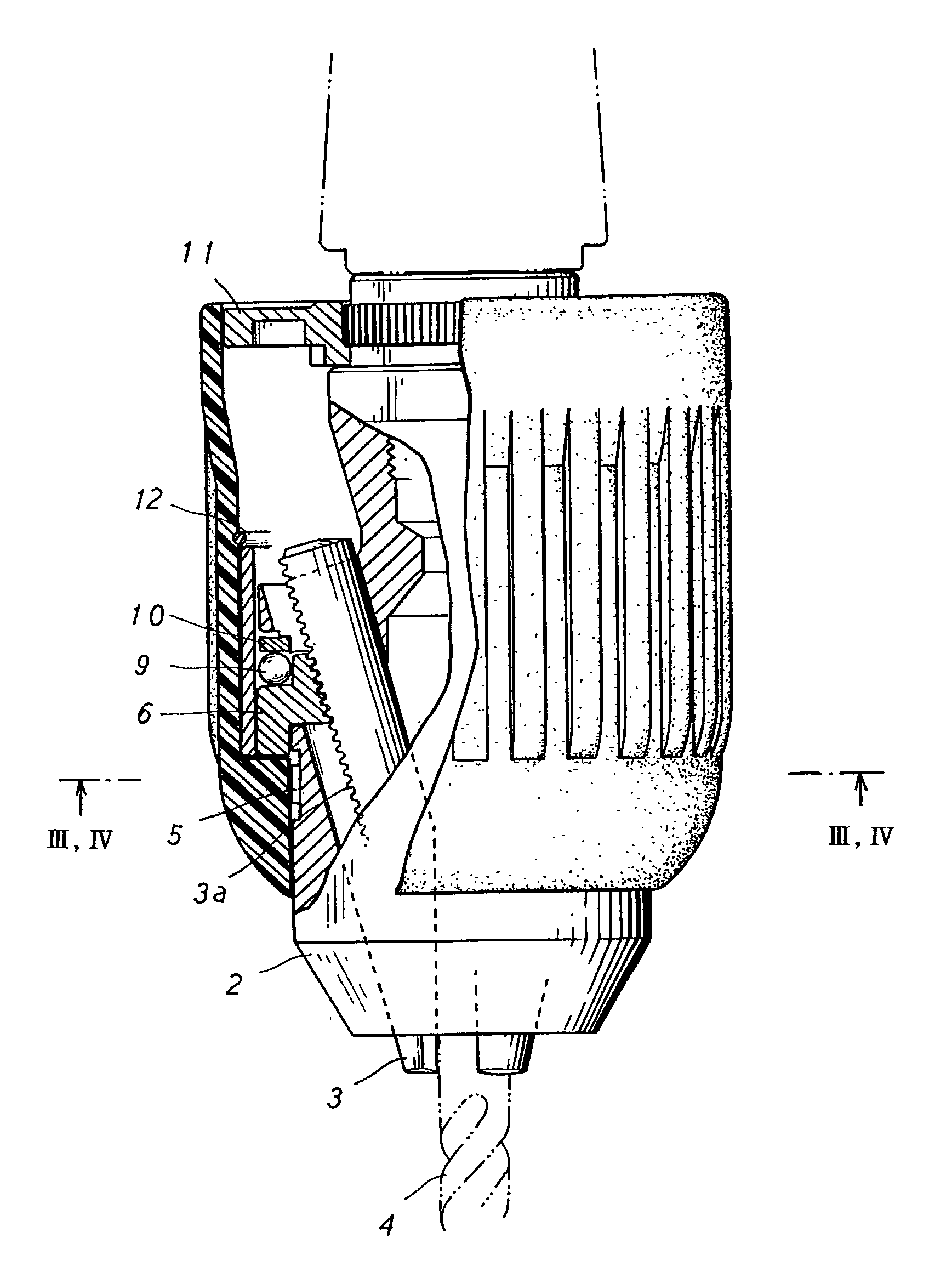

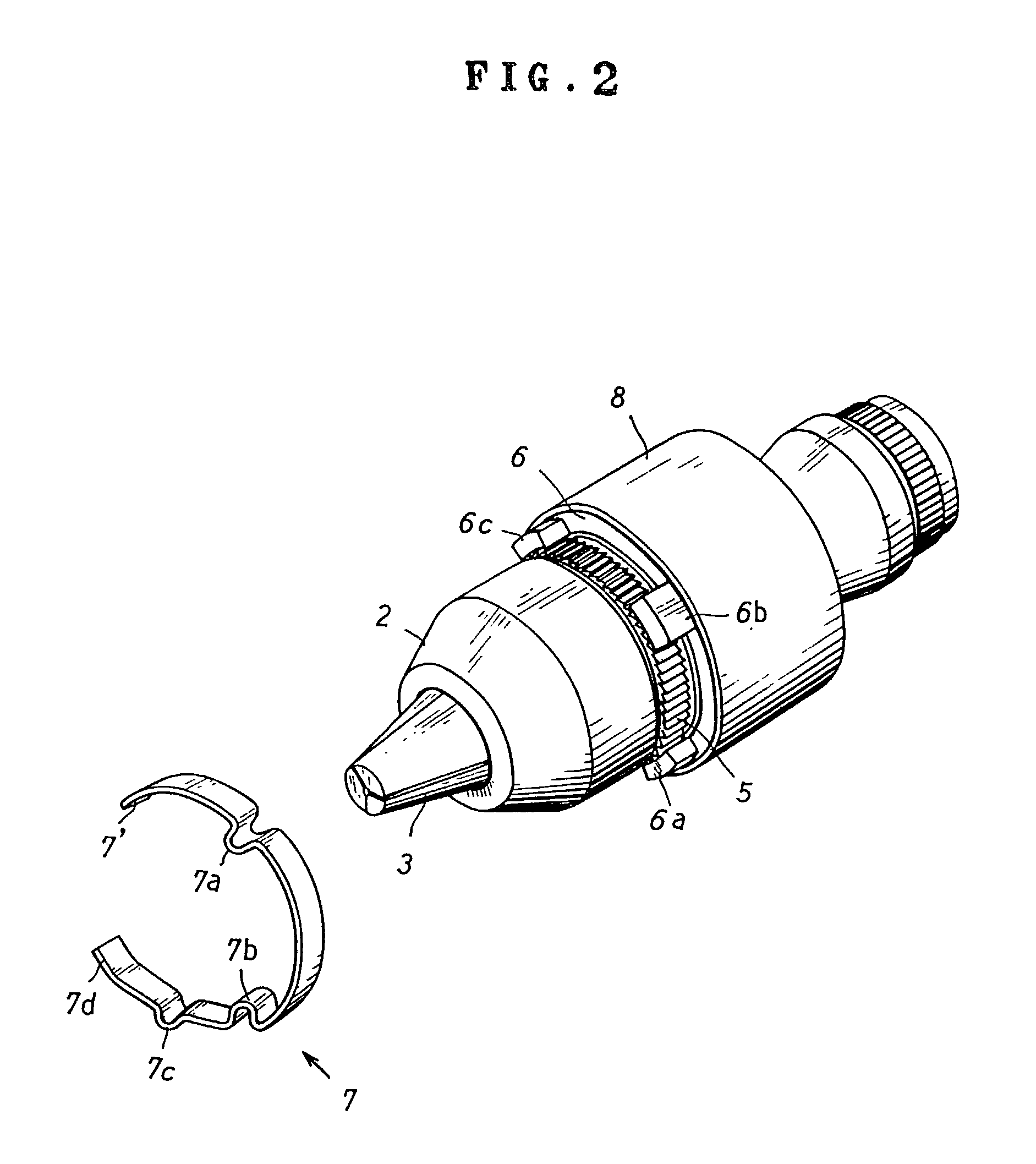

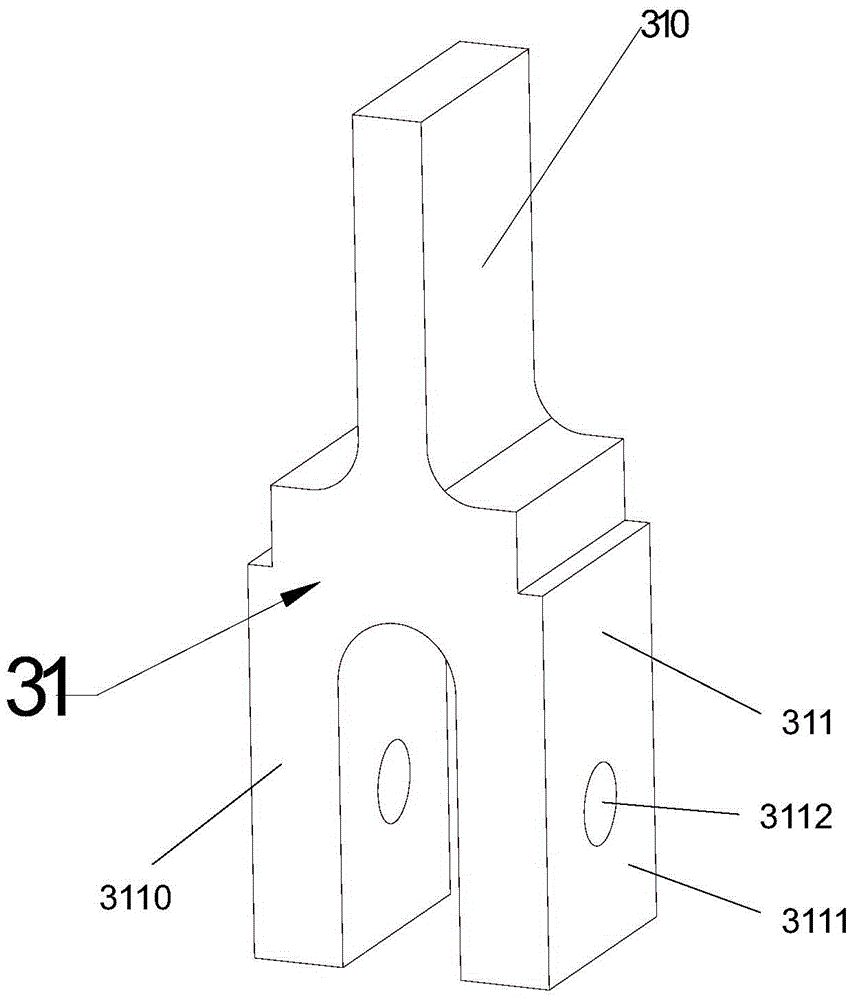

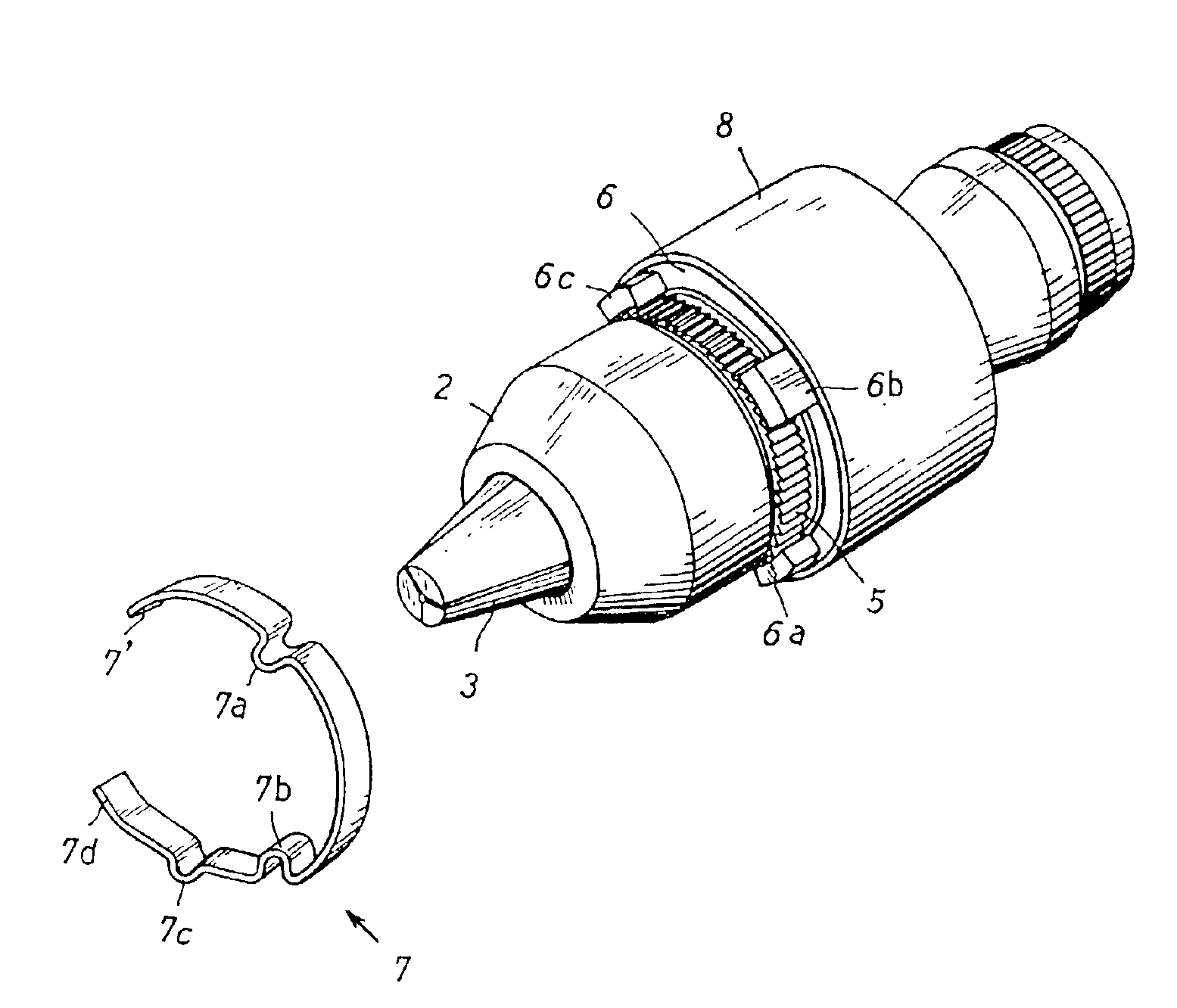

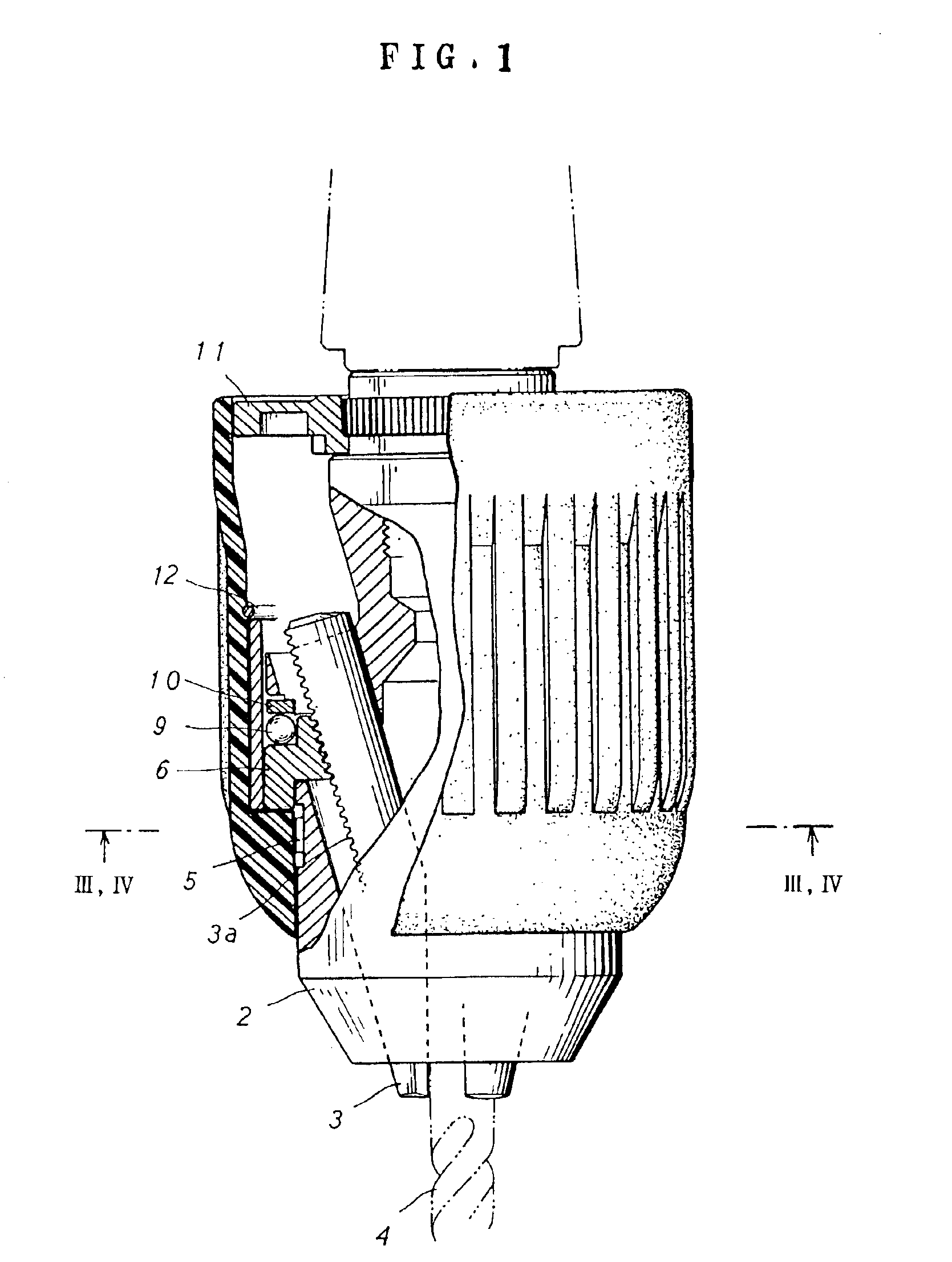

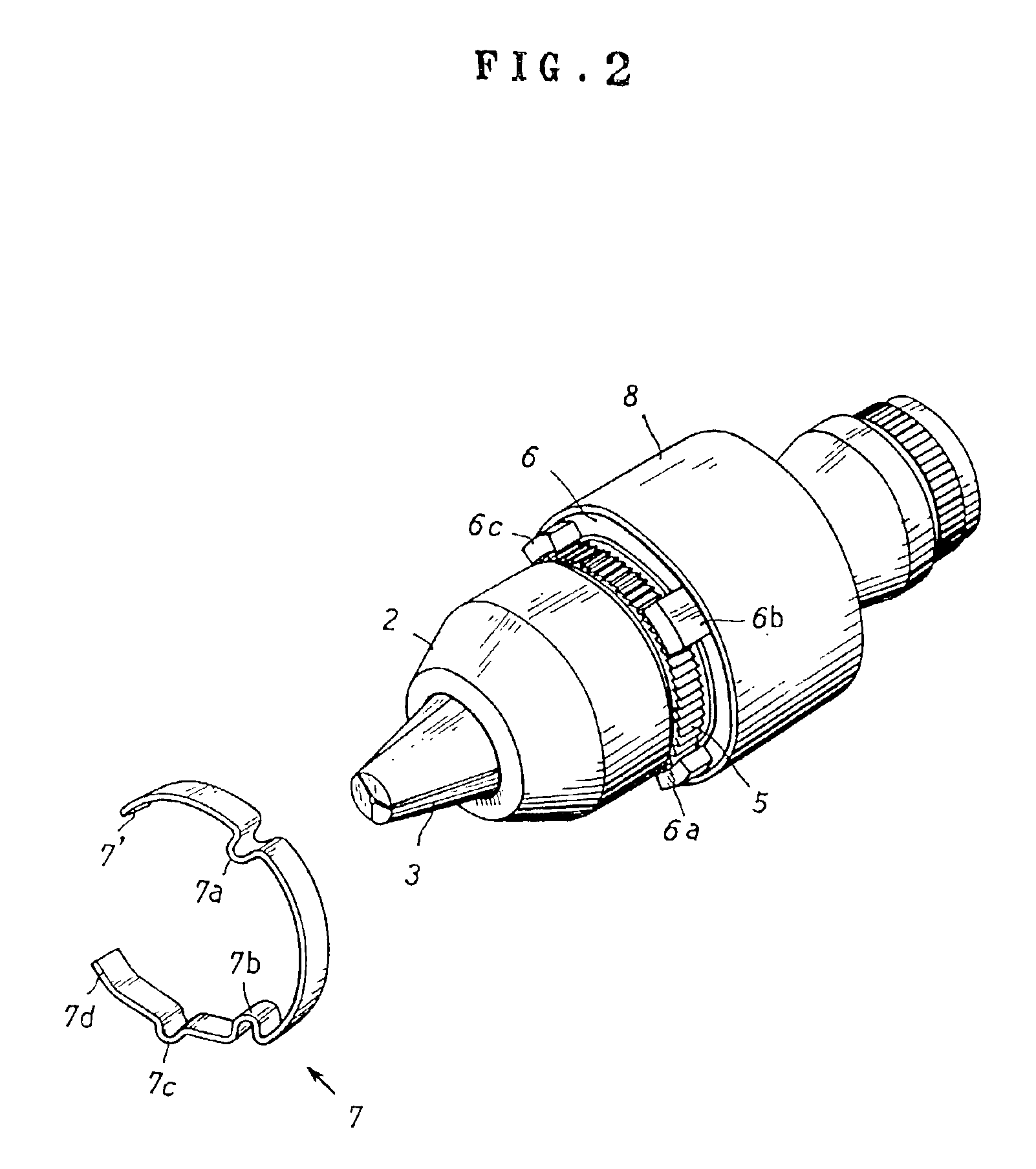

Chuck device

InactiveUS20030141676A1Reduce coefficient of frictionEasy to moveSleeve/socket jointsAnodisationFrictional coefficientEngineering

To provide a chuck device for preventing the loosening of the fastening condition, a plurality of claws inserted into a hole provided at an end of a body are opened, closed and slid by the rotation of a rotary sleeve and a tool is clamped by means of the claws. A coating that is hard and has a low frictional coefficient as much as possible is applied to an inner surface of the hole.

Owner:YUKIWA SEIKO

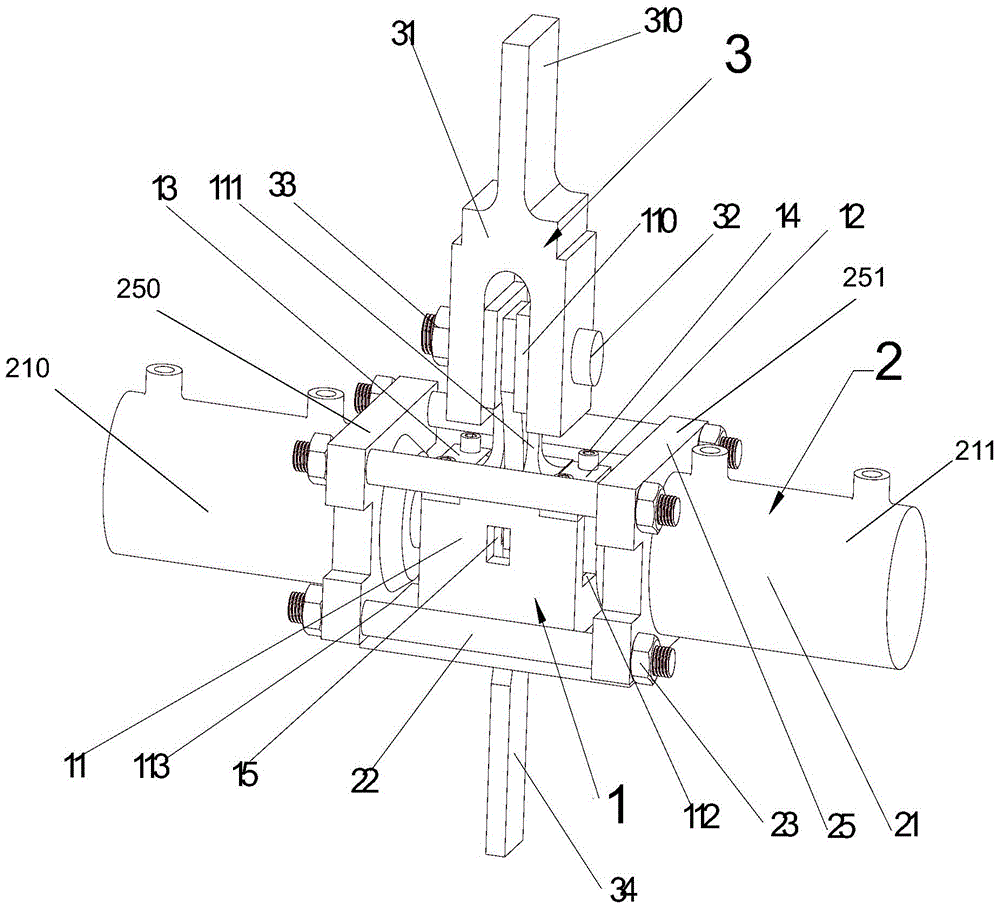

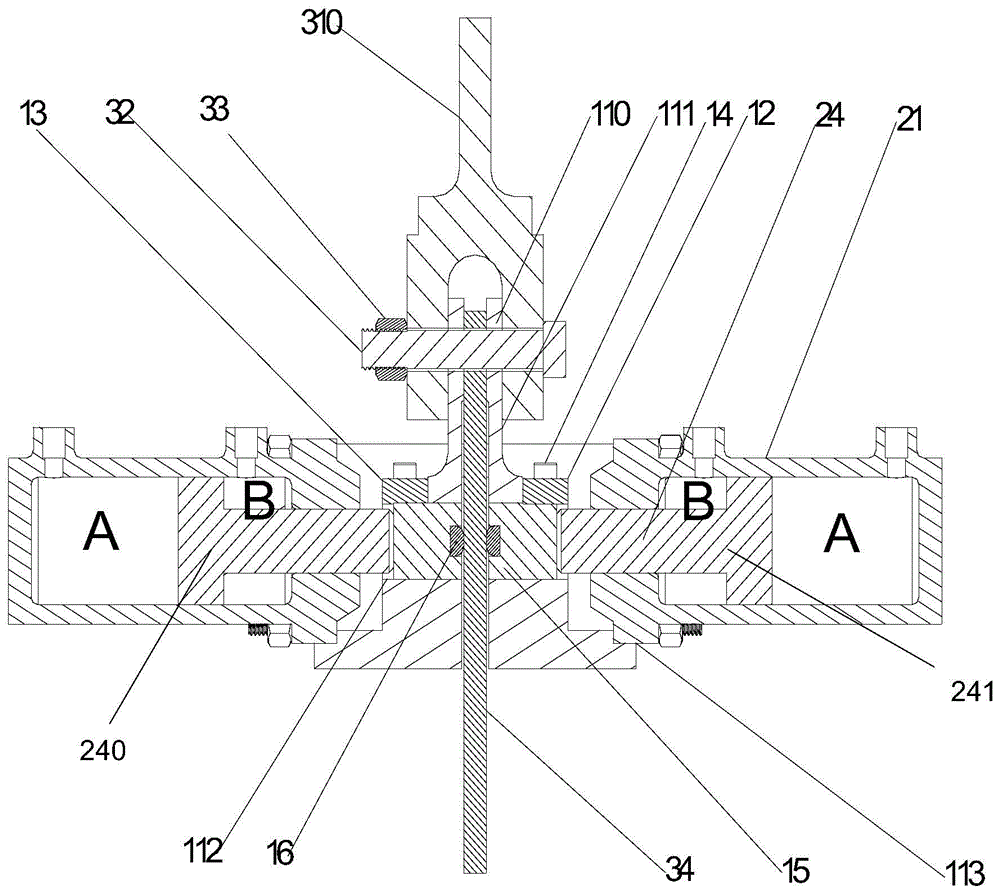

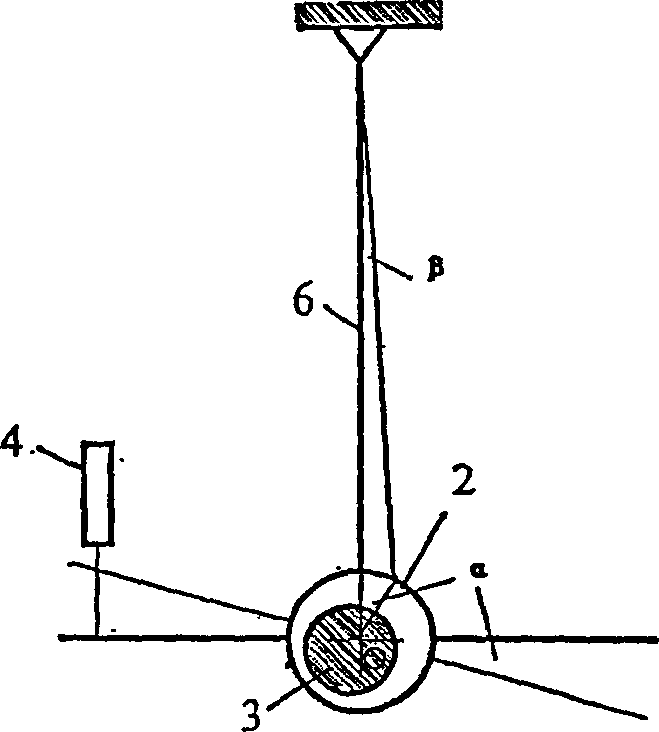

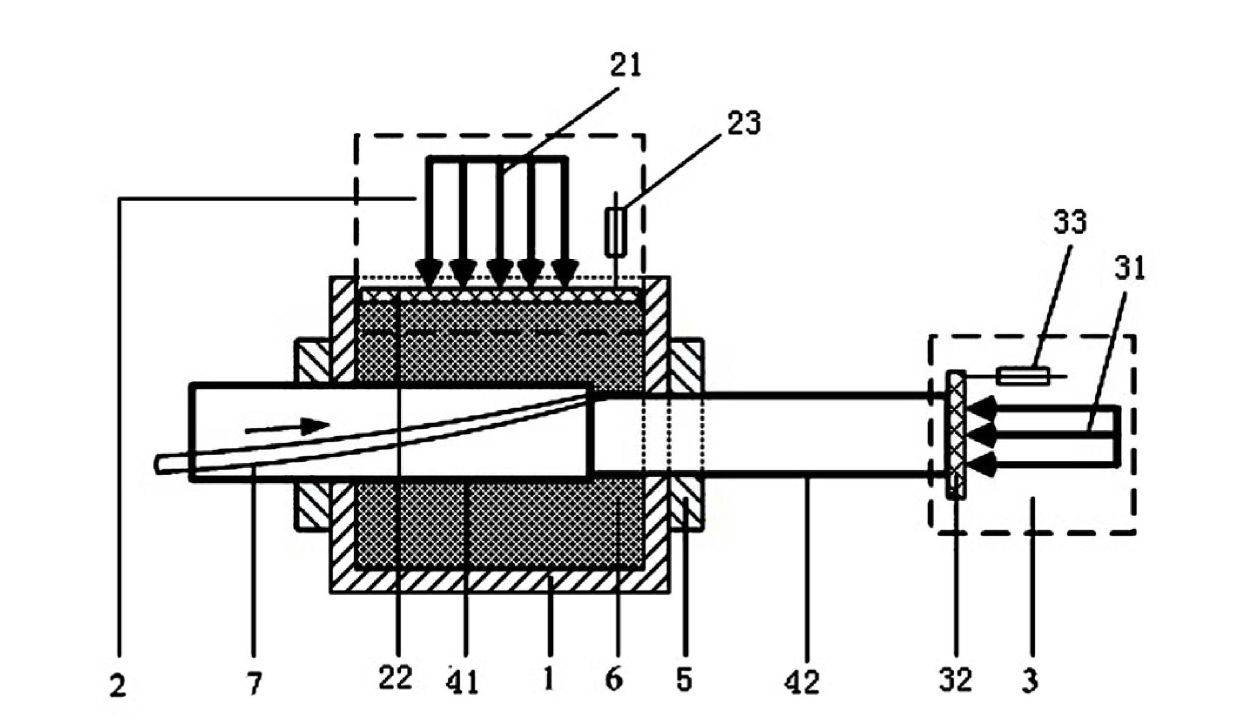

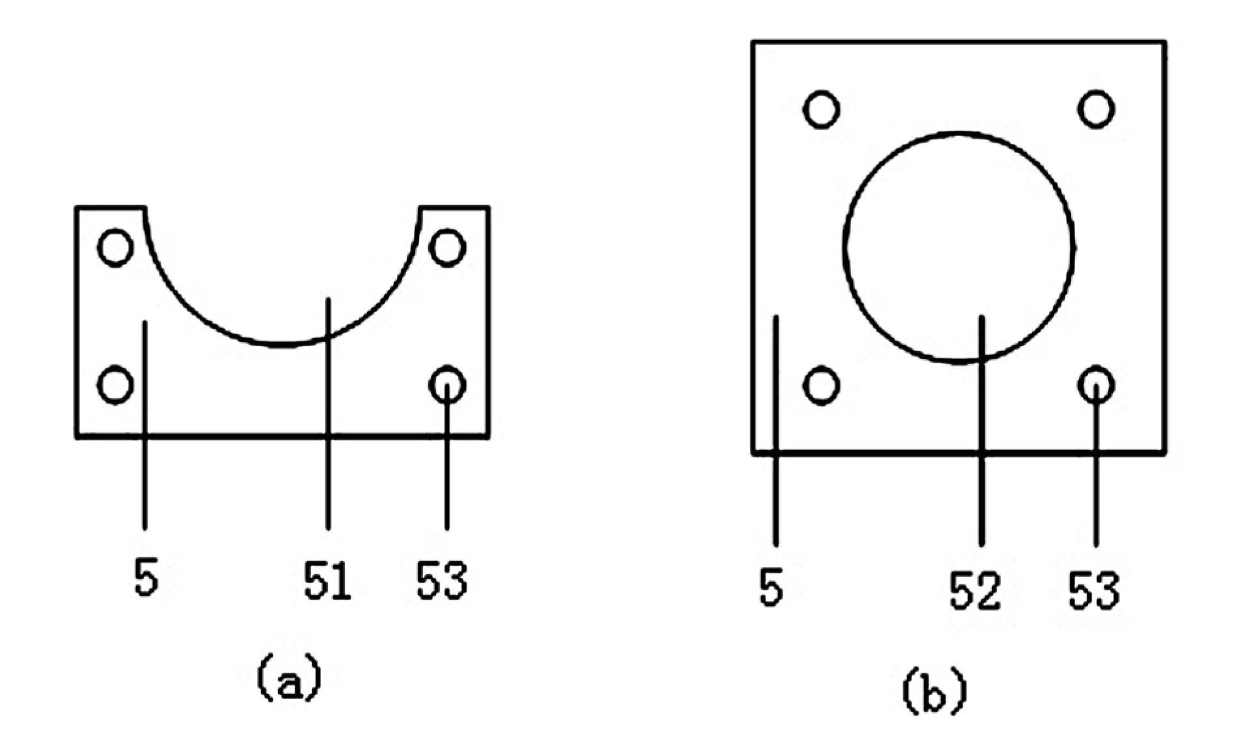

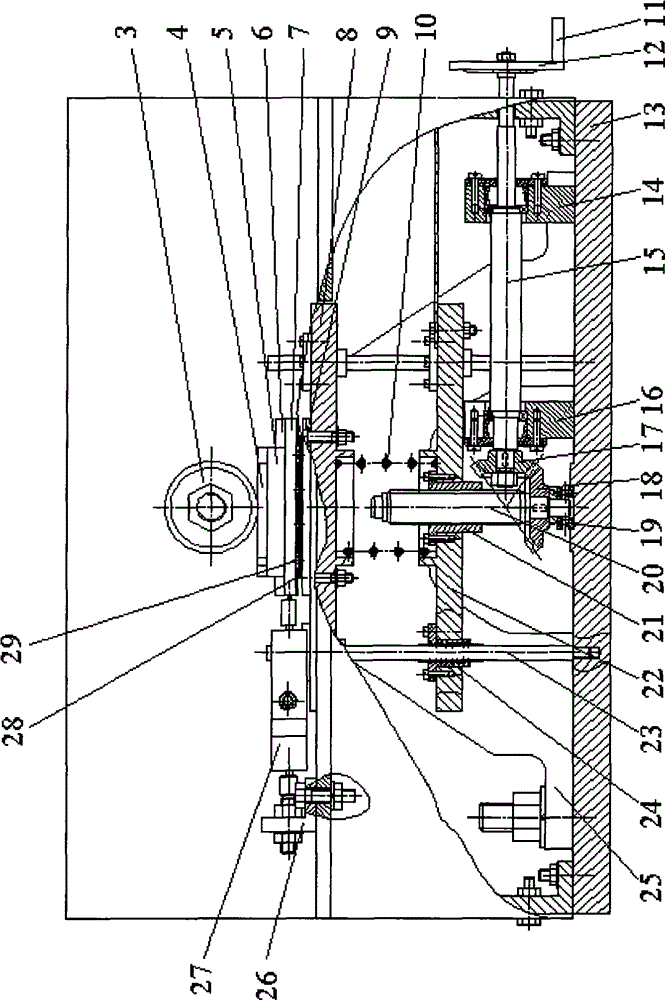

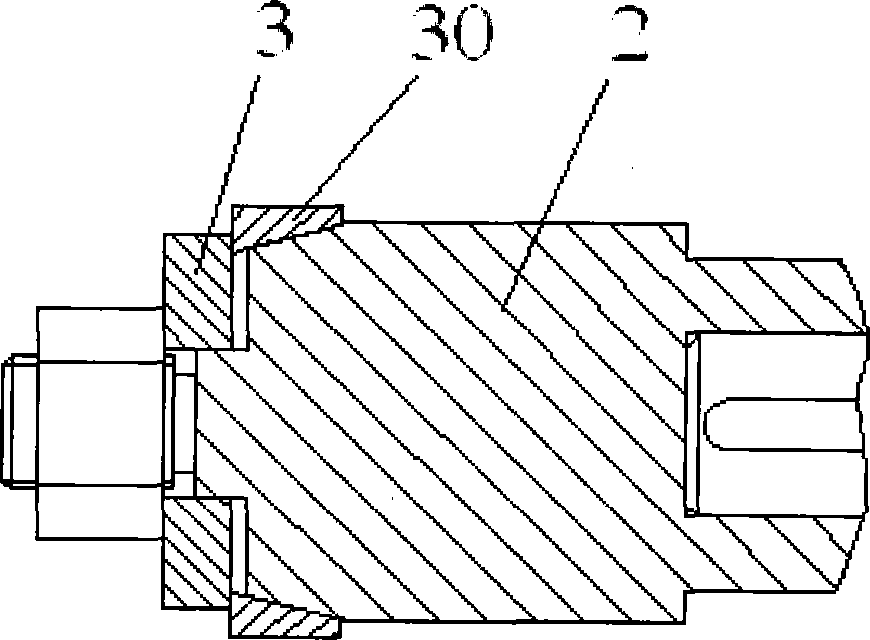

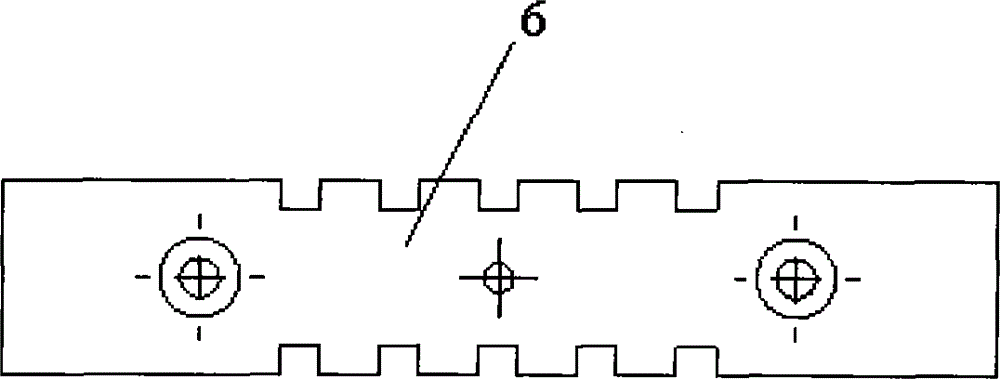

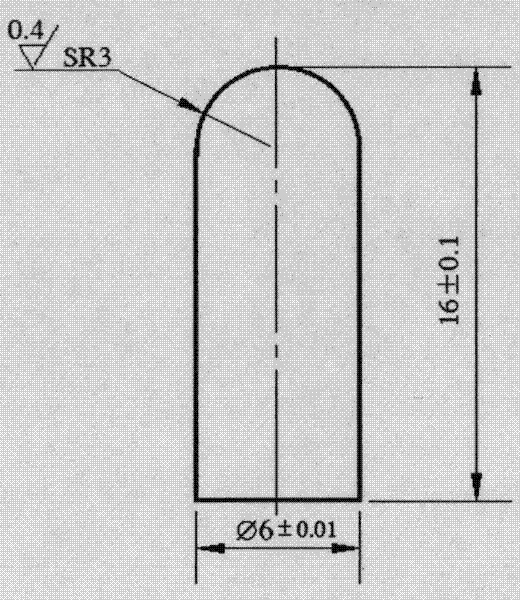

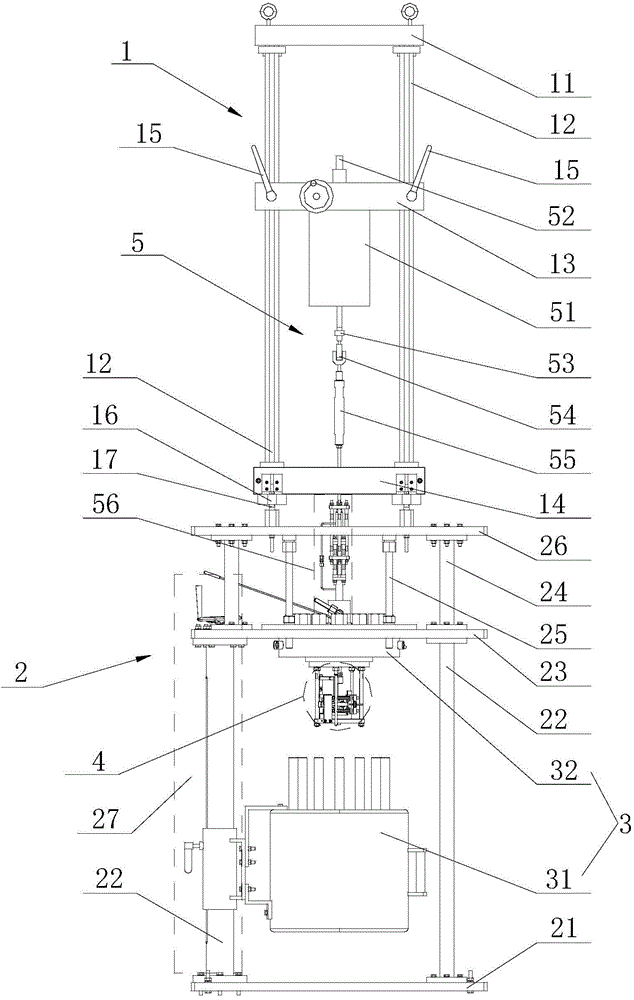

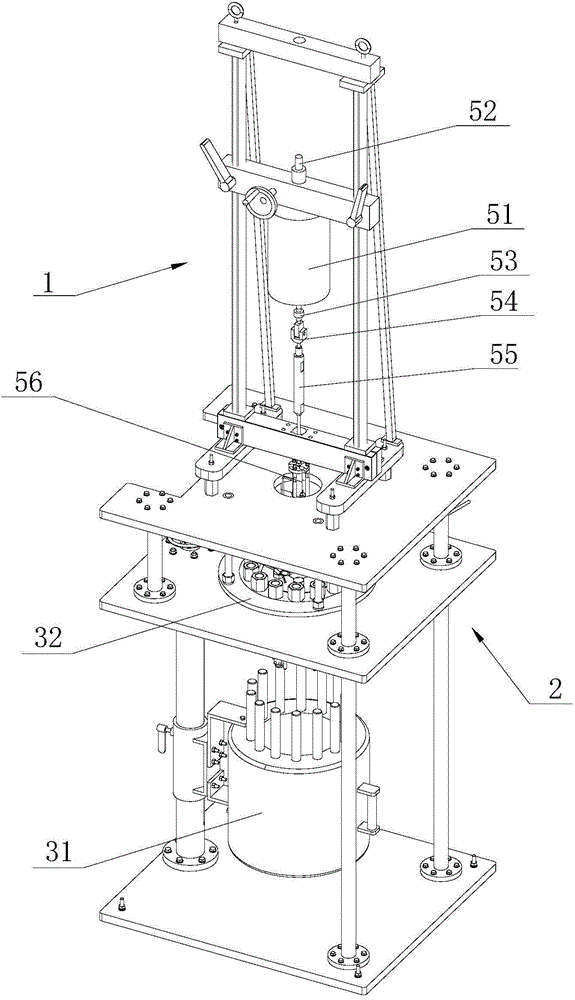

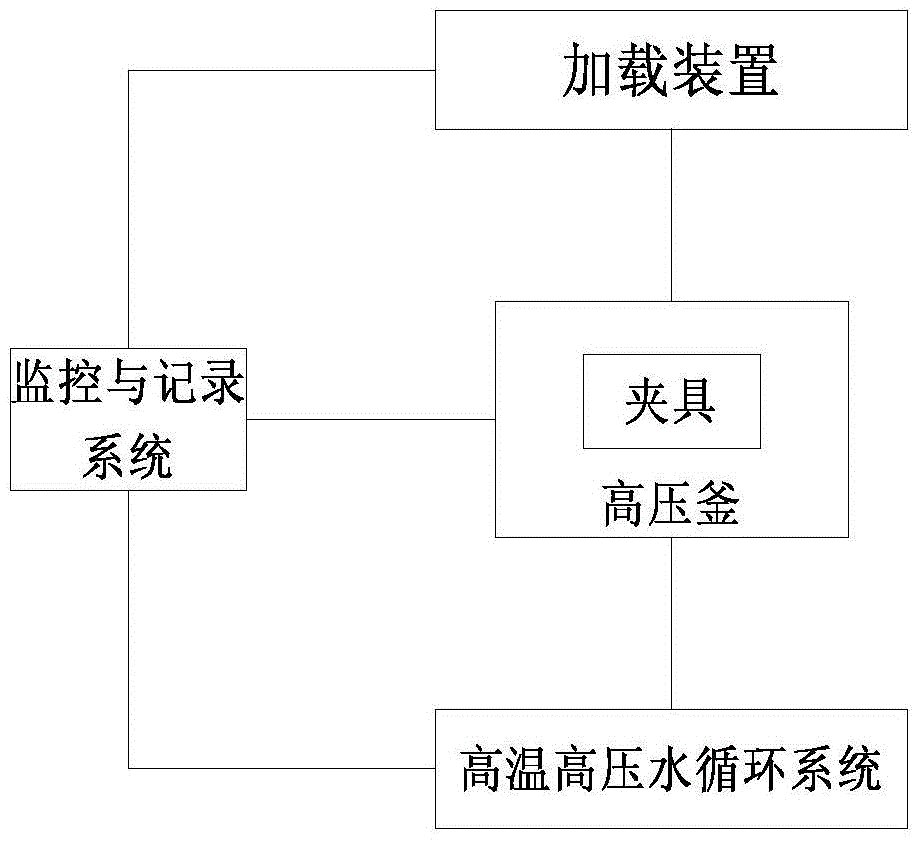

Test device for dynamically measuring fretting pair frictional coefficient during fretting fatigue process and test method

ActiveCN105043976AReduce testing costsAvoid local stress concentrationsUsing mechanical meansMaterial analysisHydraulic cylinderFrictional coefficient

The invention provides a test device for dynamically measuring fretting pair frictional coefficient during the fretting fatigue process. A frictional coefficient measurement component realizes the fretting working condition and dynamically measures the frictional coefficient of a fretting pair formed by the cooperation of a fretting section and a fretting pad of a test piece during the fretting fatigue process; a normal force loading component realizes load applying in the horizontal direction; an upper-end fixing component realizes the fixing of the test piece and a clamp body; the horizontal direction loading in the fretting fatigue test is realized by adopting a hydraulic system; the loading system adopts a closed force system frame structure; the piston rods of hydraulic cylinders pushes the fretting pad to clamp a sliding block to move in a sliding groove in the clamp body; the frictional coefficient measurement component is fixed on the upper-end fixing component through a pin bolt; in the vertical direction, except the own gravity and the gravity of the hydraulic cylinder, the frictional coefficient measurement component only receives the frictional force produced due to fretting action between the test piece and the fretting pad; by adhering a strain piece to the working section of the clamp body and calibrating, dynamic monitoring of the frictional coefficient of the fretting pair during the fretting fatigue test process is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

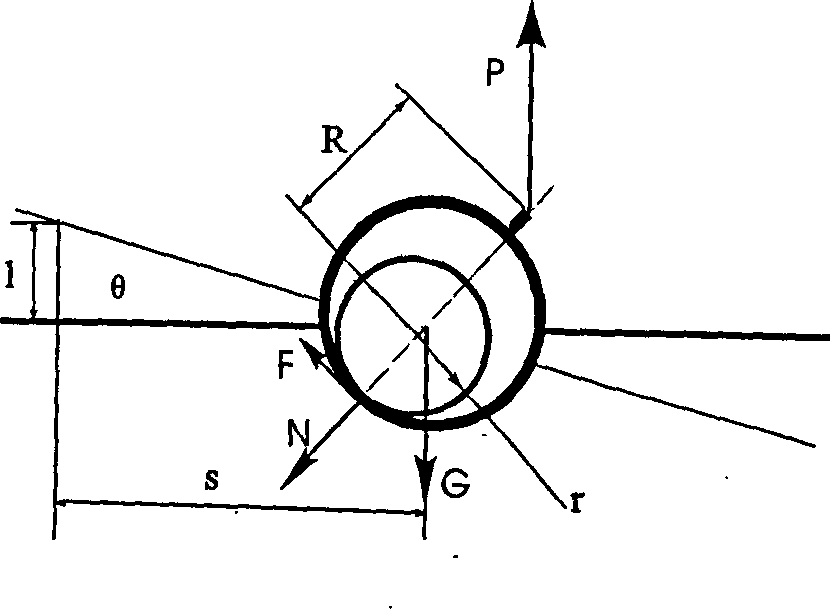

Method and device for measuring friction force of bearing under tiny load

InactiveCN1687728AAccurate measurementStudy opening and closing characteristicsWork measurementTorque measurementPull forceRolling-element bearing

The invention discloses the bearing micro-load friction measuring method and the equipment. The measuring frame comprises the extruding arm, the measuring dial, the loading bolt, the measured bearing and the baffle. Equip the measured bearing in the hole of the measuring dial; add the force on the measuring frame from the top by the upward force and realize the micro-load measuring through the gravity of the measuring frame paralleled floating above the spin axis. The angle produced by the parallel of the friction and the pull force of the deviation is amplified into the vertical displacement of the extruding arm end. The non-contacting sensor realizes the precise measurement of the friction and the frictions coefficients of the sliding bearing and rolling bearing.

Owner:ZHEJIANG UNIV

Indoor simulation experiment system for pipe-jacking grouting drag reduction

InactiveCN102636430ASimple structureEasy to operateUsing mechanical meansMaterial analysisFrictional coefficientGround system

The invention discloses an indoor simulation experiment system for pipe-jacking grouting drag reduction, which comprises an experiment box. An opening and a vertical loading test system are arranged on the experiment box; obround holes are arranged on two opposite sides of the experiment box; a horizontal loading test system is arranged on the one side of the experiment box; the experiment box is internally filled with a soil sample; a pipe to be tested penetrates through the experiment box via the obround holes on the two sides of the experiment box. The experiment system also comprises a grouting system and a grouting pipe connected with the grounding system; the pipe to be tested is formed by a front pipe segment and a rear pipe segment that are connected with each other; and the diameter of the front pipe segment is larger than that of the rear pipe segment; at least one grouting hole is configured on the wall of the pipe to be tested; and a slurry outlet end of the grouting pipe extends in the pipe to be tested and is connected with the grouting holes. According to the invention, the experiment test can simulate pipe-jacking process in soil layers; mixed slurry is injected to surrounding soil during the jacking process to test frictional resistance and frictional coefficient during the pipe-jacking process under different slurry proportions and different grouting pressures, so that the grouting pressure and the grouting proportion suitable for pipe-jacking in the soil layers can be obtained comprehensively and accurately.

Owner:SHANGHAI JIAO TONG UNIV

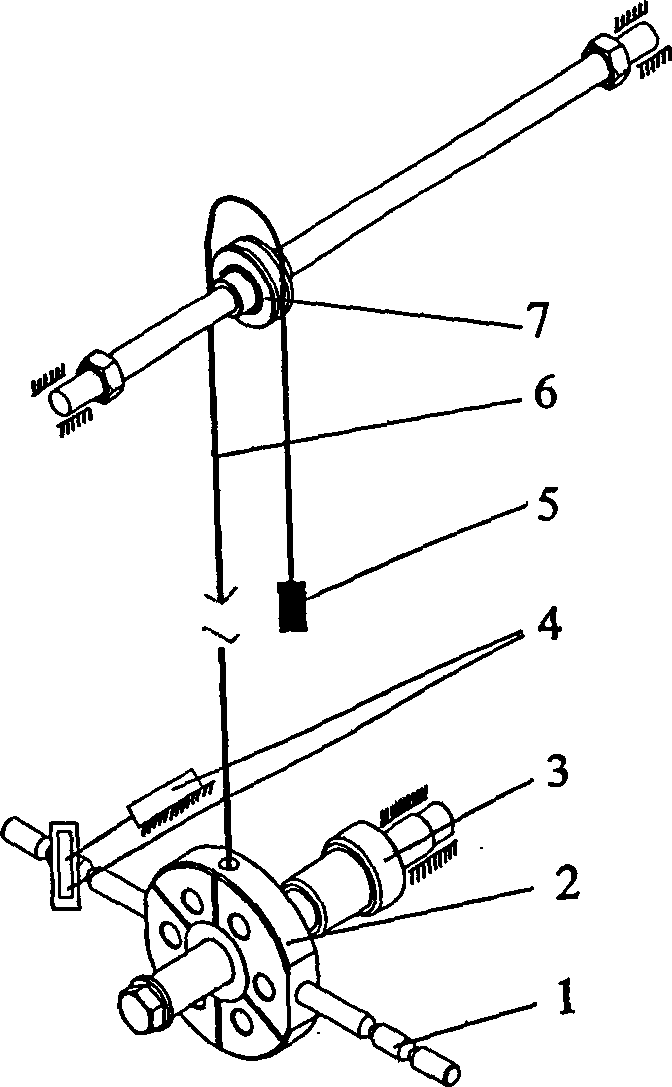

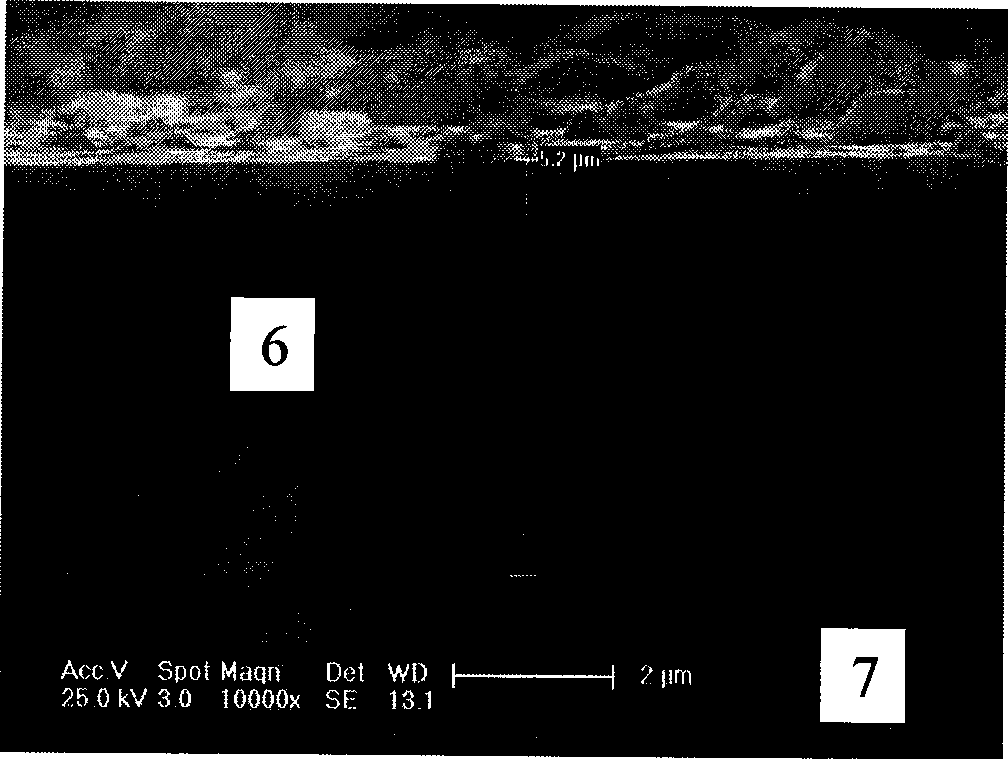

PVD nano composite ceramic coating screw and method for manufacturing same

InactiveCN101518935ASolve pollutionIncreased microhardnessLayered productsVacuum evaporation coatingCarbon filmDiamond-like carbon

The invention provides a PVD nano composite ceramic coating screw. A screw substrate (7) is coated with a coating (6) consisting of a bonding layer, a primary wear-resistance layer and a lubricating layer sequentially. The method for manufacturing the screw comprises the following steps: firstly, depositing a 50 to 100 nanometer thick transitional metal bonding layer at an air pressure of 0.1 Pa; secondly, depositing a 2 to 5 micrometer thick composite ceramic layer as the primary wear-resistance layer at a temperature of between 350 and 400 DEG C, a voltage of between -50 and -200 volts and an air pressure of 0.2 to 1Pa; and finally, depositing a 1 to 3 micrometer transitional metal doped diamond carbon film layer as the lubricating layer at a temperature of between 100 and 150 DEG C, a voltage of between -50 and -150 volts and an air pressure of 0.1 to 0.5Pa. Compared with the prior art, the screw has the advantages of having lubricating performance, along with high hardness (more than 40GPa Hv hardness) and excellent wear resistance (friction coefficient about 0.1). The method is free from pollution and the coating has strong adhesive force.

Owner:舟山市汉邦机械科技有限公司

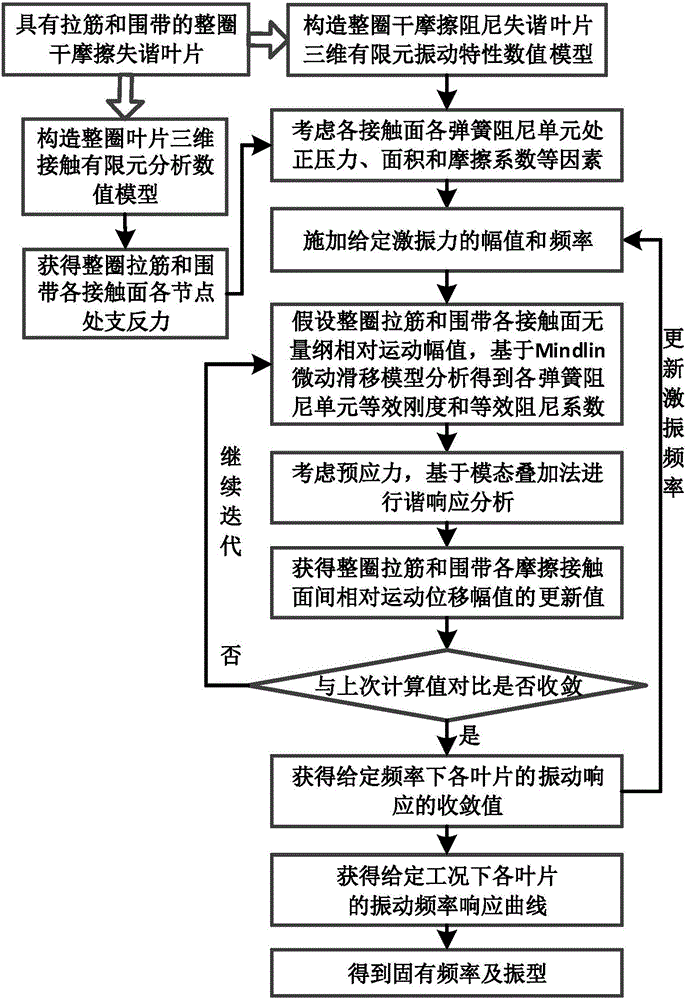

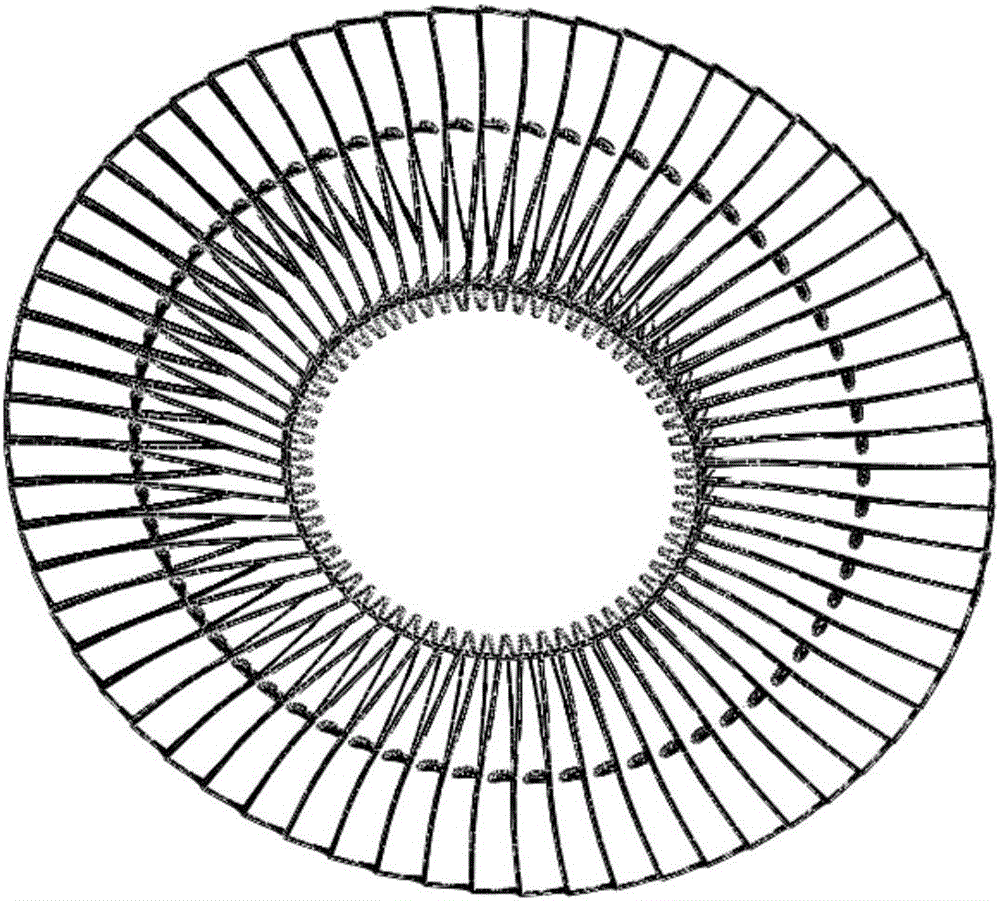

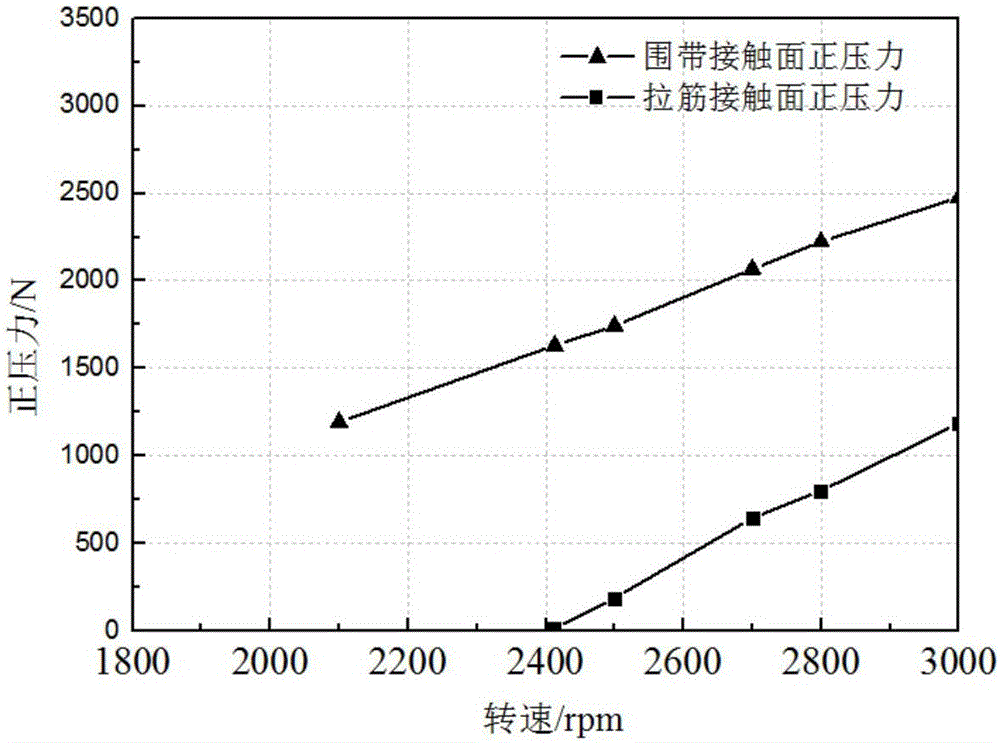

Vibration analysis method for dry frictional damping mistuned blades with tendons and shroud bands

ActiveCN106528982AHigh precisionShort analysis timeGeometric CADDesign optimisation/simulationVibration amplitudeFrictional coefficient

The invention discloses a vibration analysis method for dry frictional damping mistuned blades with tendons and shroud bands. The method comprises the steps of for actual mistuned states of the blades of a steam turbine, performing three-dimensional contact finite element analysis firstly to obtain support reactions of nodes of contact surfaces of the tendons and the shroud bands of the entire circle of the blades; secondly establishing a contact surface relationship by adopting spring damping units, considering positive pressures, areas and frictional coefficients at the spring damping units, and building a dry frictional damping mistuned vibration analysis model based on a Mindlin micro-sliding friction model and a harmonic balance method; thirdly considering a pre-stress and adopting harmonic response analysis for obtaining convergency values of vibration responses of the blades through iterative solving; and through cyclic calculation, obtaining vibration amplitude response curves of the dry frictional mistuned blades, and performing further extraction to obtain an inherent frequency and a vibration mode. The method is of important significance for dry frictional damping mistuned analysis of the blades and improvement of mistuned bladed disk vibration.

Owner:XI AN JIAOTONG UNIV

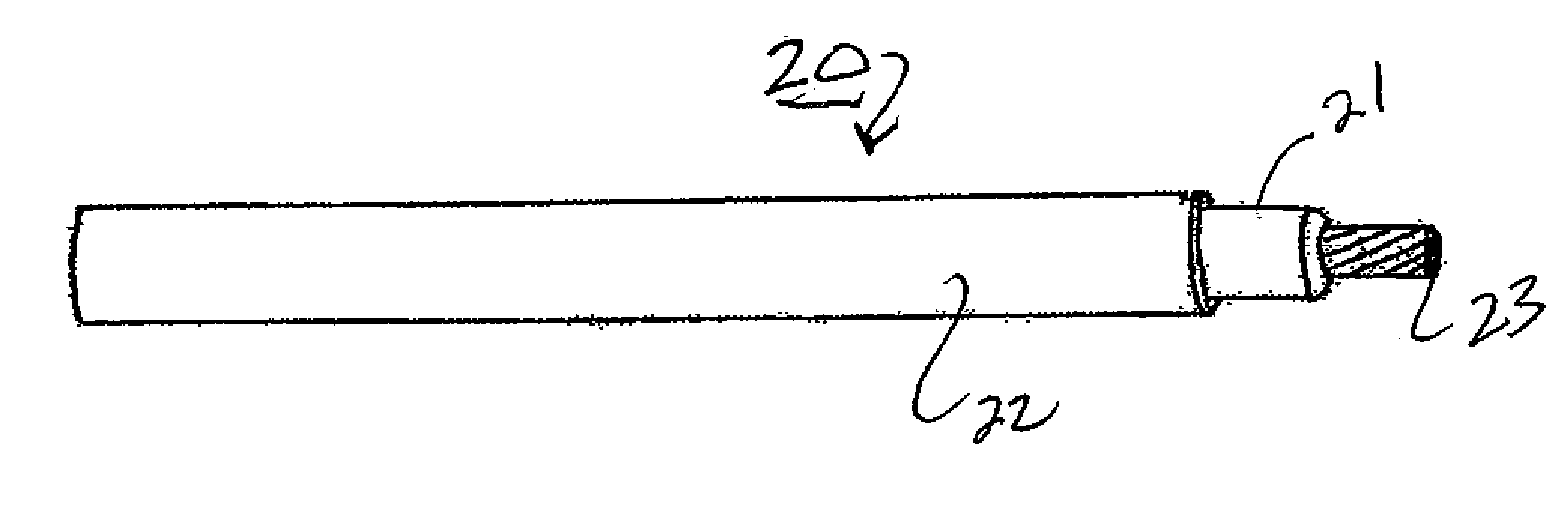

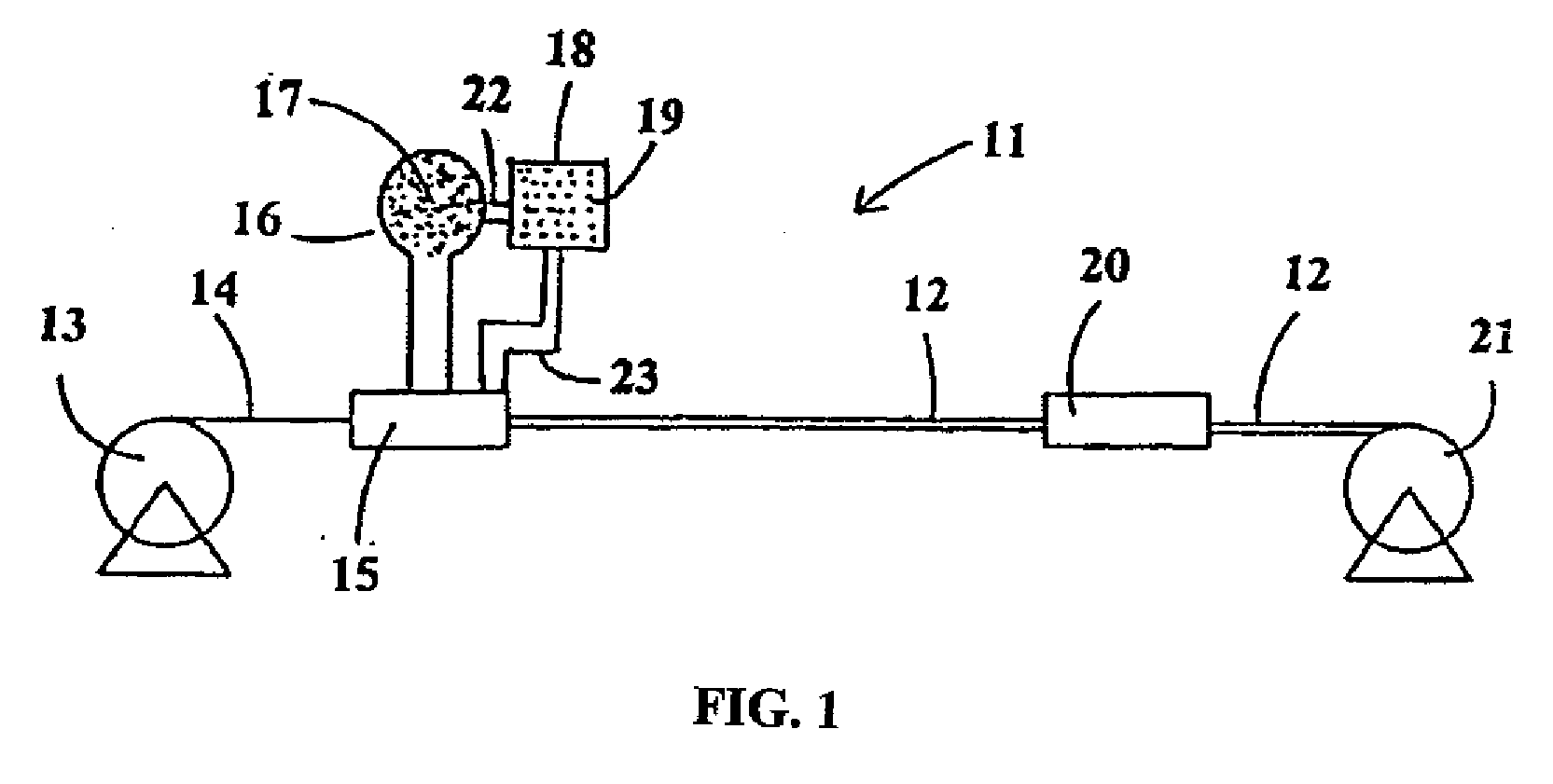

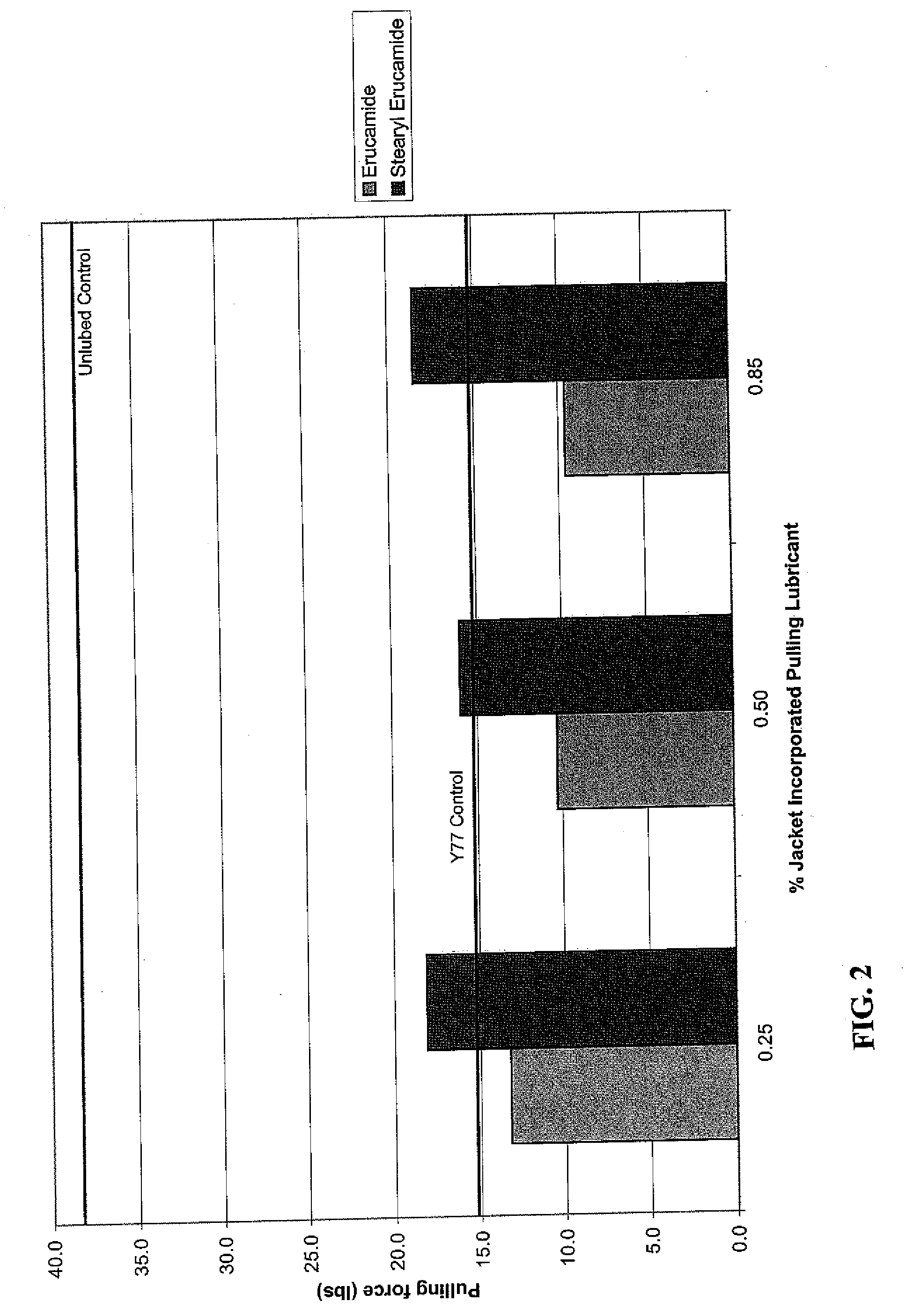

Electrical cable having a surface with a reduced coefficient of friction

InactiveUS20070243761A1Reduce coefficient of frictionMinimizing required installation pulling forceLiquid organic insulatorsSecuring/insulating coupling contact membersElectrical conductorFrictional coefficient

Owner:SOUTHWIRE CO LLC

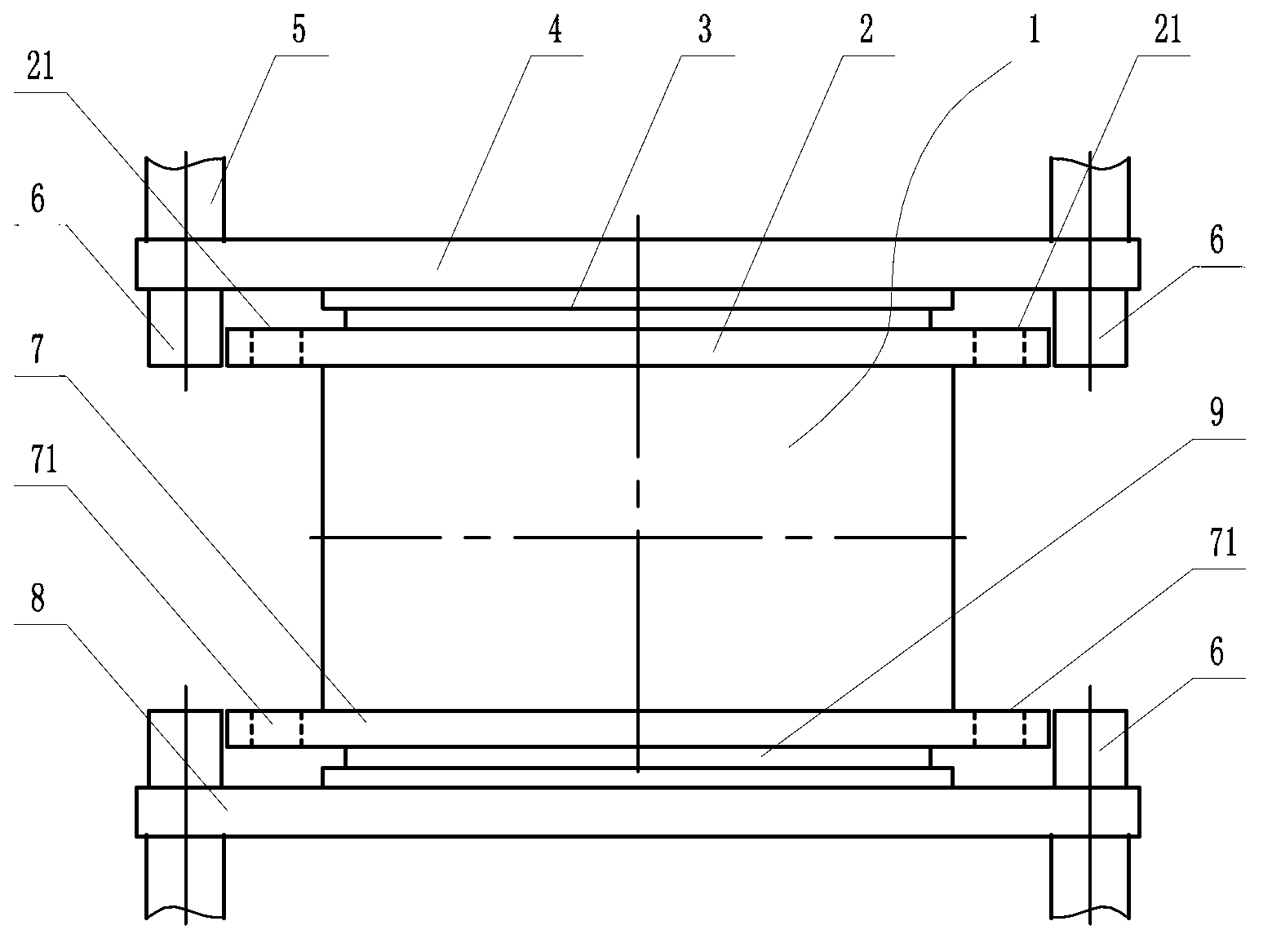

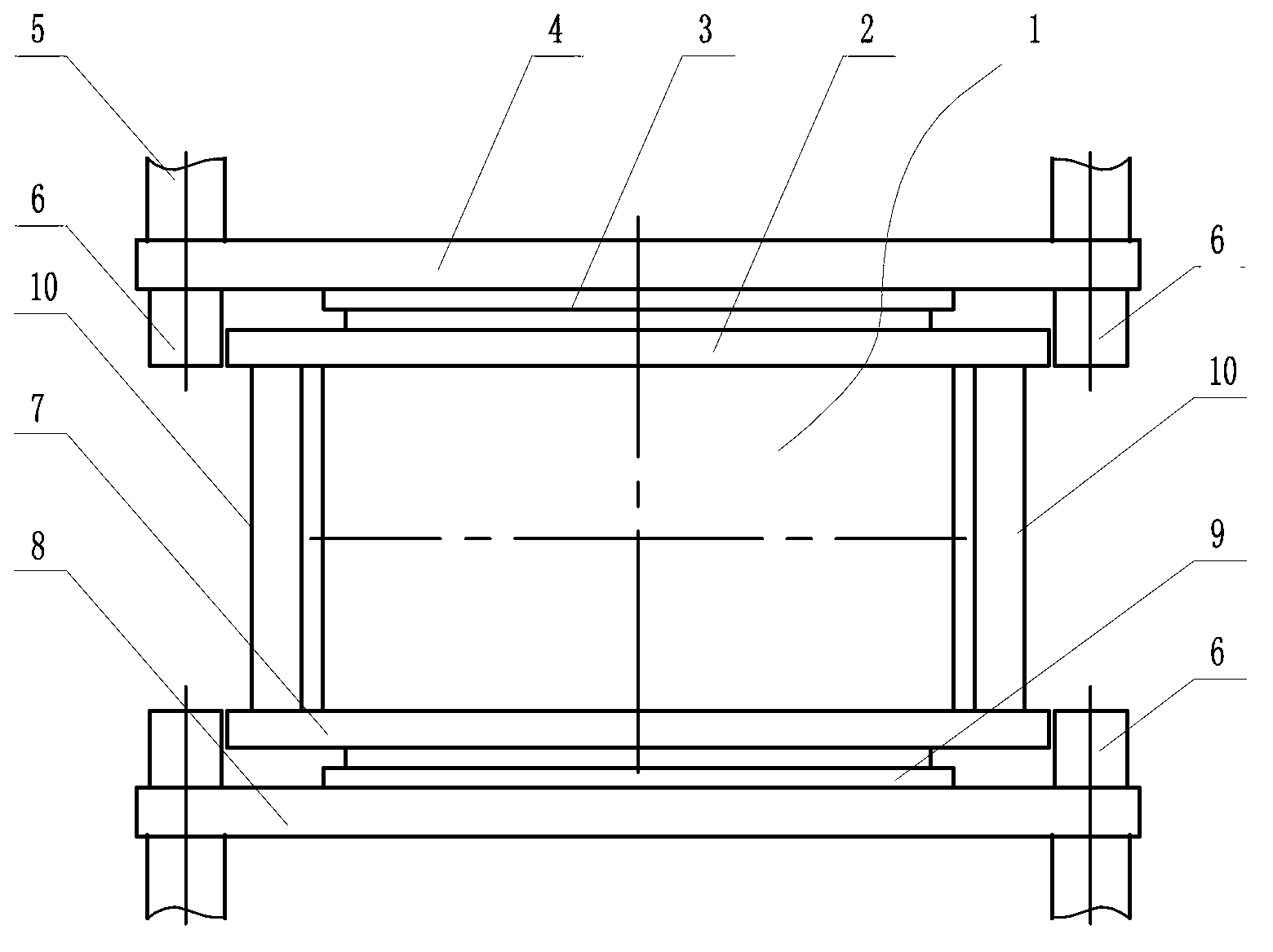

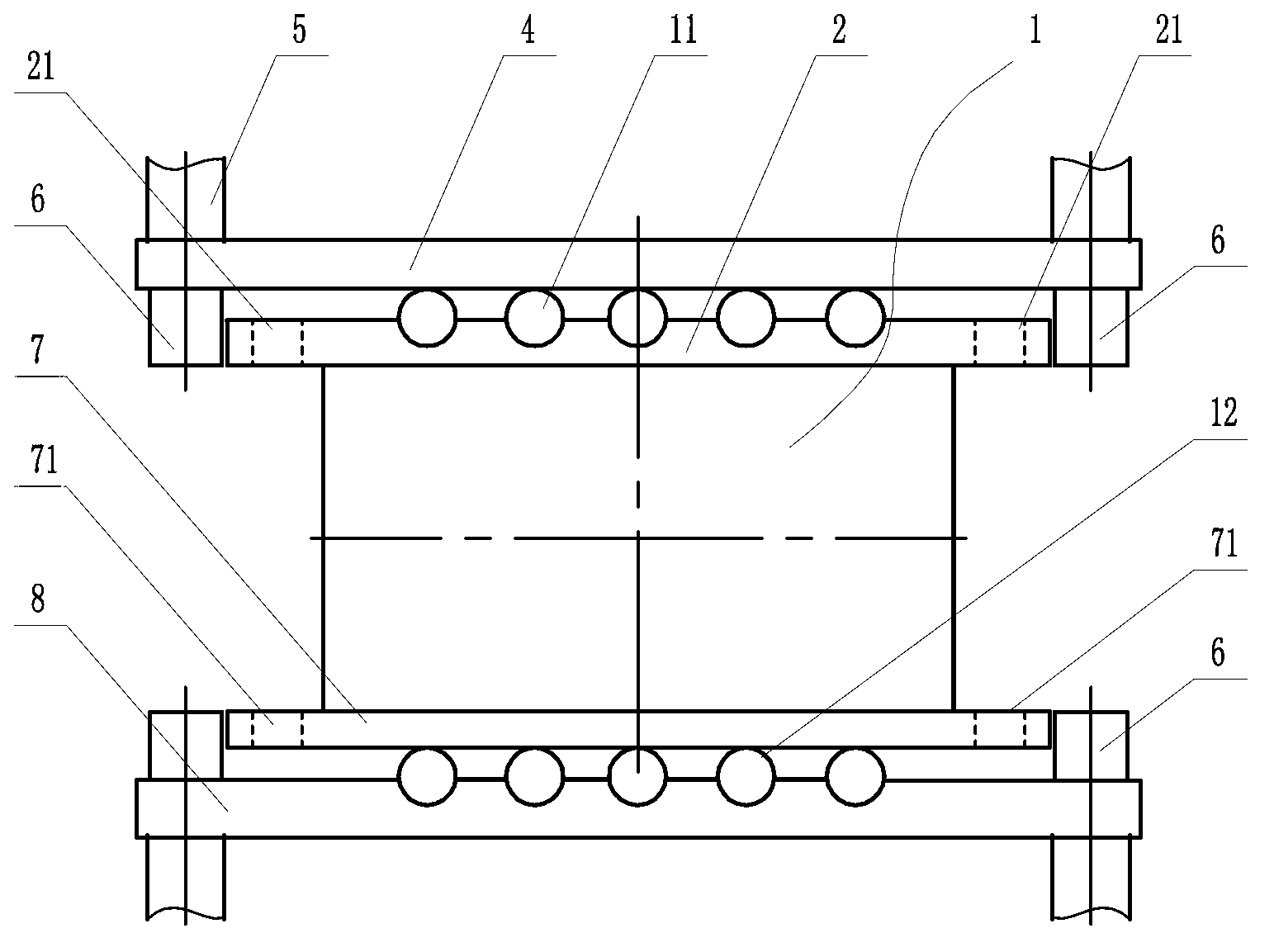

Novel seismic mitigation and absorption support and changing method thereof

ActiveCN103215890AEasy to useReduce coefficient of frictionBuilding repairsBridge structural detailsFrictional coefficientClassical mechanics

The invention relates to a novel seismic mitigation and absorption support comprising a support body, an upper connection steel plate and a lower connection steel plate, wherein the upper connection steel plate and the lower connection steel plate are arranged at the upper / lower part of the support body, the support body is connected with the upper / lower connection steel plate through a sliding mechanism or a rolling mechanism in a sliding manner, the upper / lower side surface of the upper / lower connection steel plate is provided with a sleeve and an anchoring bolt, and the lower / upper side surface of the upper / lower connection steel plate is provided with a limiting stop block for limiting the horizontal sliding of the support body; and a connecting mechanism for mounting a pull rod is arranged on the circumferences of an upper steel plate and a lower steel plate of the support body. According to the novel seismic mitigation and absorption support disclosed by the invention, the friction coefficient of the support body and the upper / lower connection steel plate is small so that the removal and the change are easy; due to the limitation of the limiting stop block, the support body does not generate the horizontal sliding during regular use and does not interfere the shearing deformation of rubber in the support as well; and a change method of the support is simple, convenient and safe in operation, is not limited by the site condition, does not need to use large-scale jacking devices, has a short change periodand high efficiency and is low in cost.

Owner:柳州东方工程橡胶制品有限公司

Two-way stretched polyester thin-film of capacitor and its production

InactiveCN1897178AHigh dielectric strengthImprove thermal stabilityFixed capacitor dielectricPolyesterFrictional coefficient

A biaxially oriented polyester film with high dielectric intensity in thin type can be used on capacitor and it has features as surface resistance being greater than 1x1014, relative dielectric constant being greater than 2.8, DC dielectric intensity being greater than 450 and frictional coefficient being less than 0.60. Its preparing method includes using proper additives and polyester pellets as raw material, utilizing special polyester film production device and applying biaxially oriented polyester film process to prepare said biaxially oriented polyester film.

Owner:SHANGHAI ZIDONG FILM MATERIAL CO LTD

Diamond-like carbon film for sliding parts and method for production thereof

ActiveUS20090186206A1Increased durabilityReduce coefficient of frictionLayered productsVacuum evaporation coatingCarbon filmDiamond-like carbon

A diamond-like carbon film for sliding parts which is applied to the sliding surface of sliding parts, the diamond-like carbon film including at least two layers, one being a lower layer of diamond-like carbon (referred to as DLC hereinafter) and the other being an upper layer of DLC placed thereon, wherein the lower layer has a hardness no lower than 20 GPa and no higher than 45 GPa, a Young's modulus no lower than 250 GPa and no higher than 450 GPa, and a thickness no smaller than 0.2 μm and no larger than 4.0 μm, and the upper layer has a hardness no lower than 5 GPa and lower than 20 GPa, a Young's modulus no lower than 60 GPa and no higher than 240 GPa, and a thickness no smaller than 1.0 μm and no larger than 10 μm. The diamond-like carbon film has both good durability and low frictional coefficient.

Owner:KOBE STEEL LTD

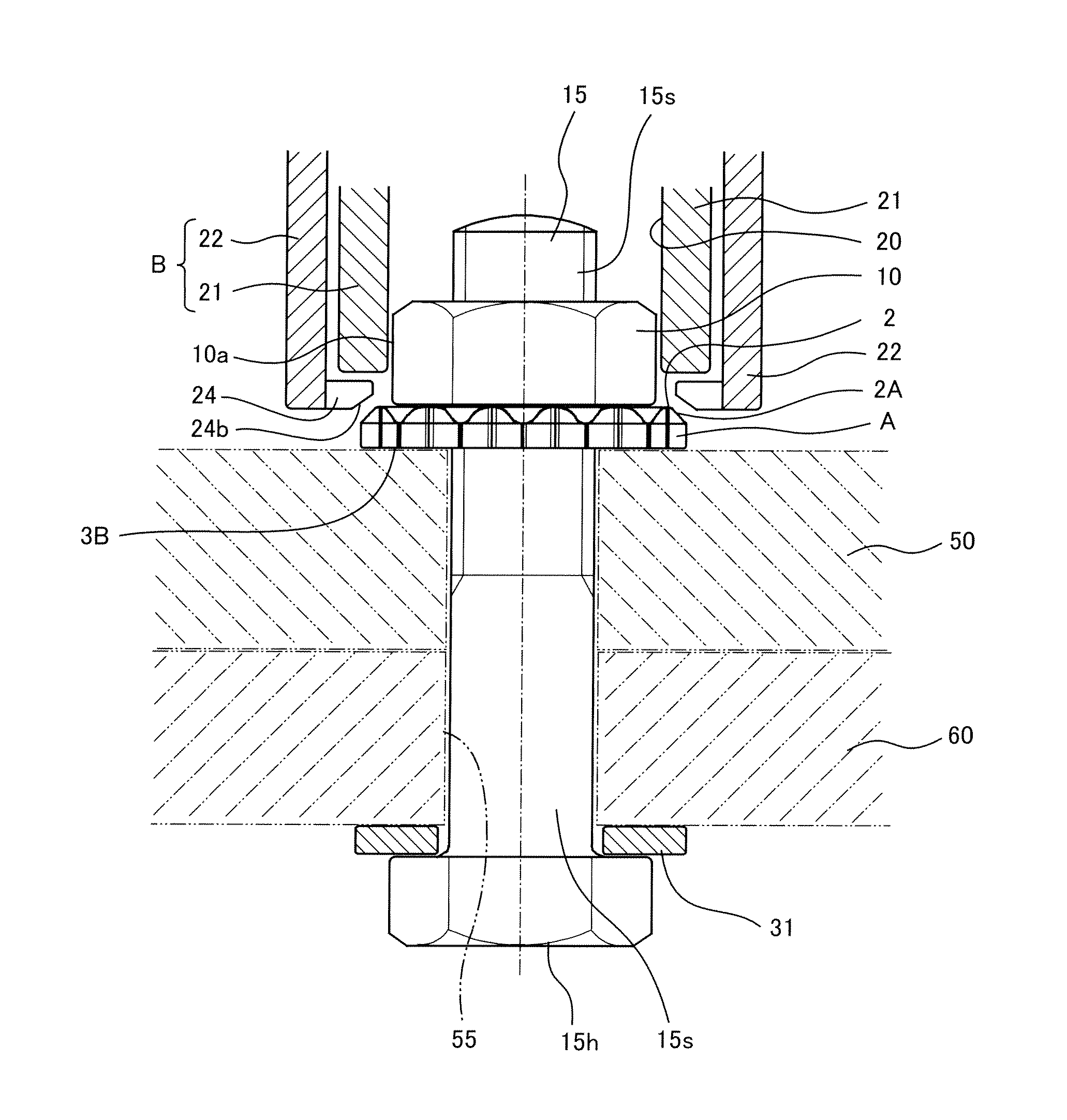

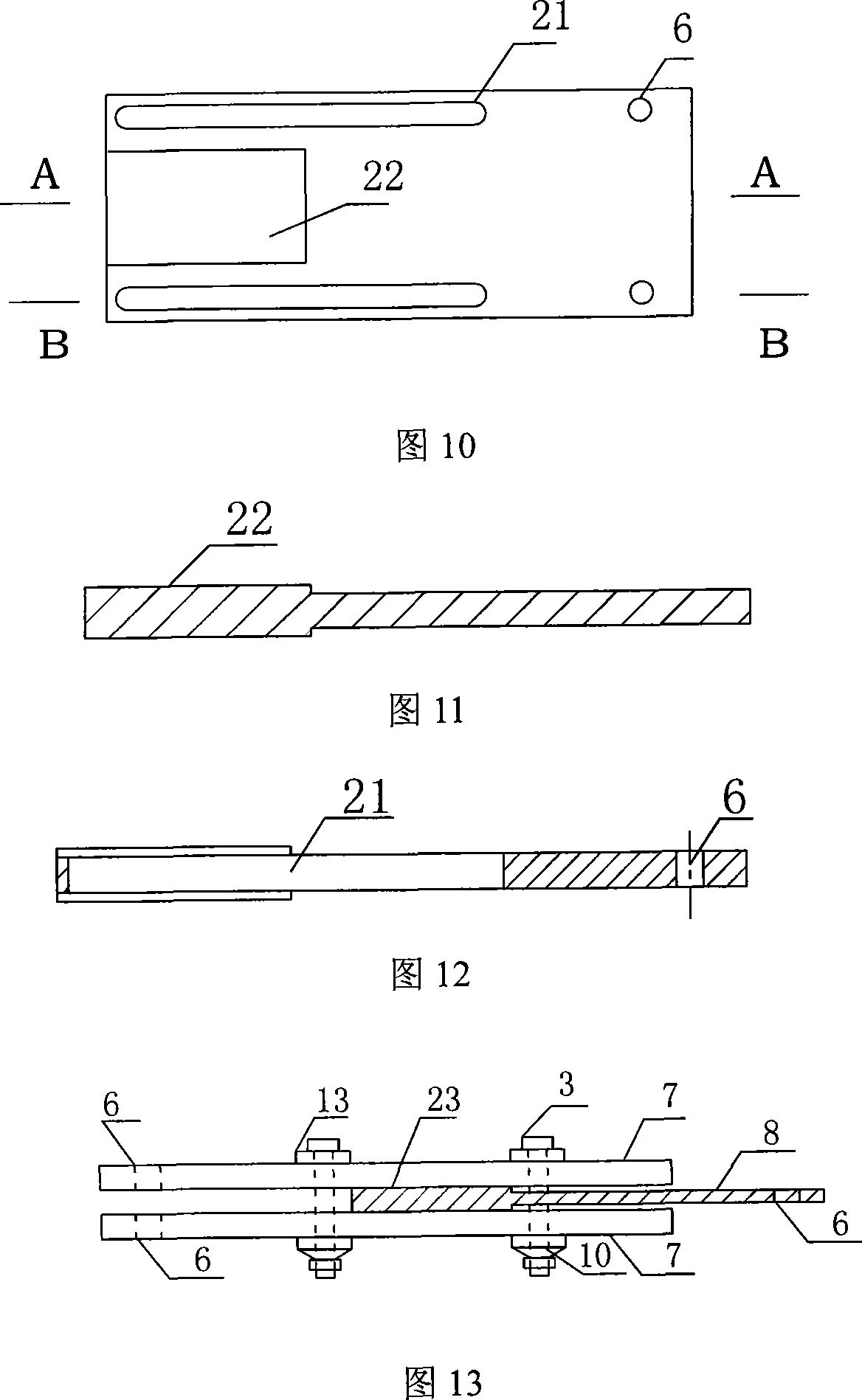

Fastening sockets, washers and fasteners used with the washers and the fastening sockets

A fastening socket B includes an inner socket portion including engaging means for engaging a nut or the like, and an outer socket portion for engaging a washer A with an outer edge portion 2, which includes a tapered surface and engaging teeth. The tapered surface is gradually inclined outwardly and toward a bottom surface of the outer edge portion. The inner socket portion 21 and the outer socket portion 22 are coupled together with a mechanism so as to be rotated in opposite directions. The outer socket portion is provided with engaging claws for engaging the engaging teeth, and a tapered bottom end surface of each of the claws 24 is gradually inclined radially inwardly and toward a base end side. A surface of a bolt head that is brought into contact with a surface of objects is provided with frictional coefficient increasing treatment.

Owner:YUNITAITO

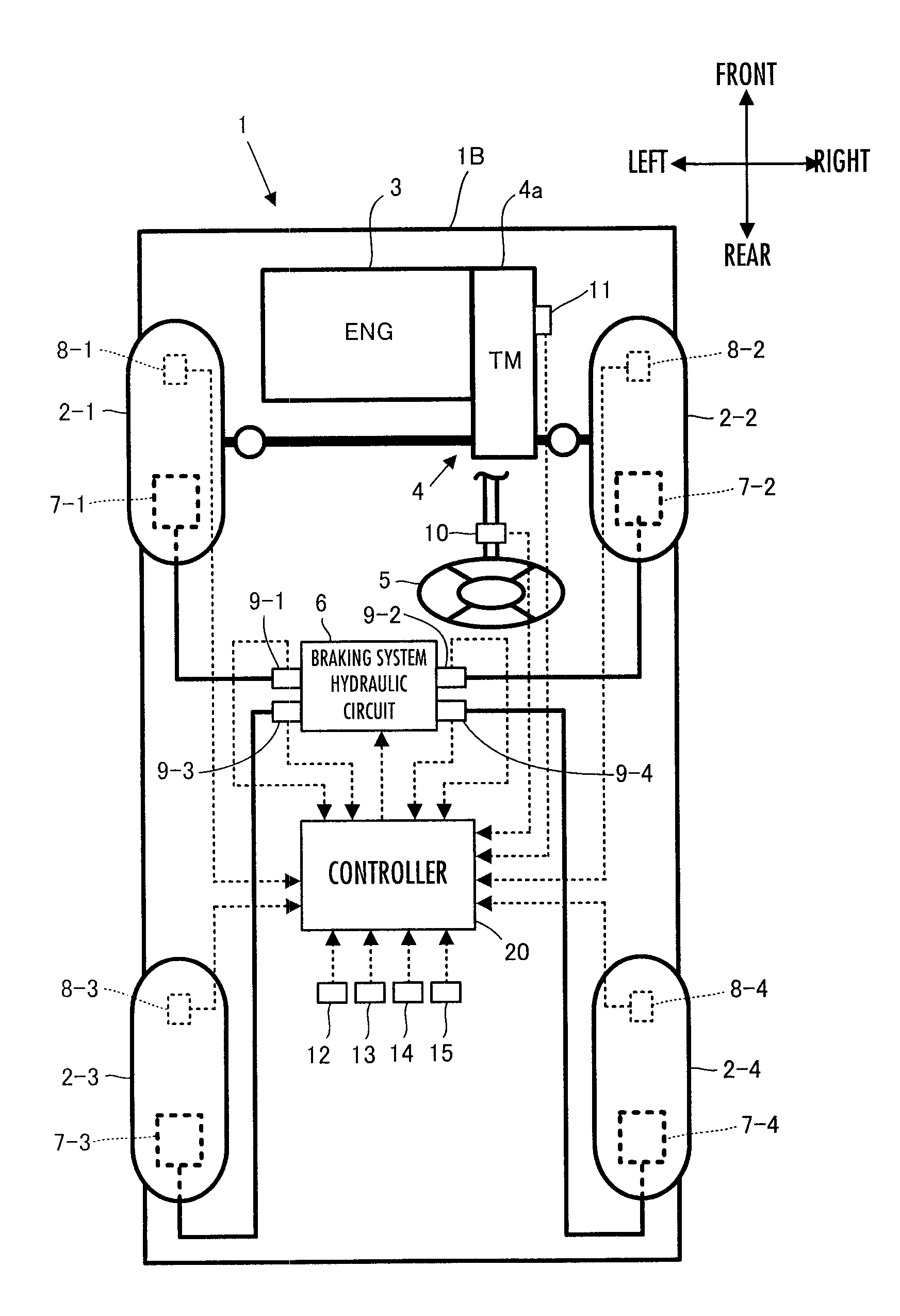

Road surface frictional coefficient estimating apparatus

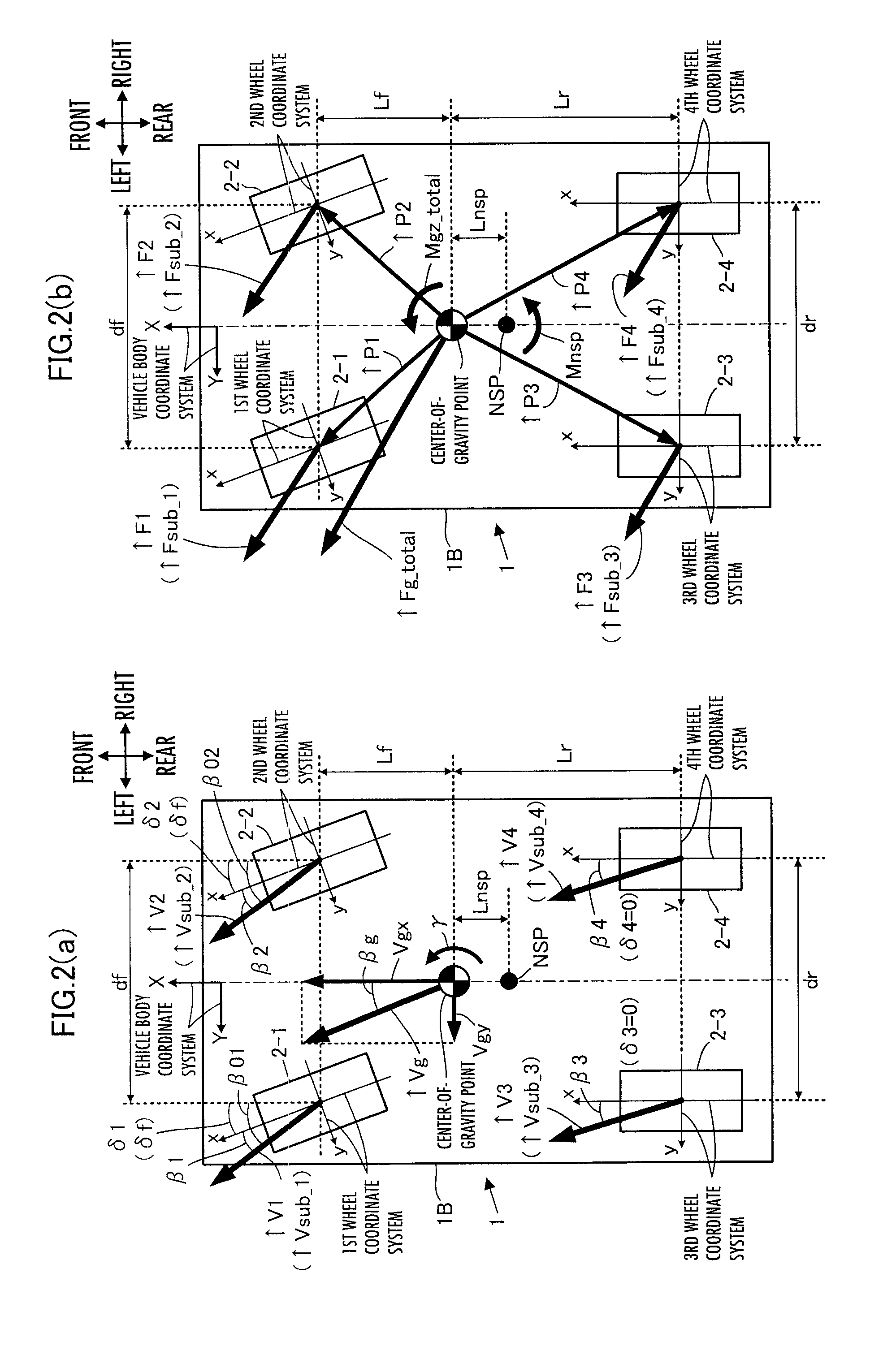

ActiveUS20100211256A1Correction coefficientImprove robustnessVehicle testingRegistering/indicating working of vehiclesFrictional coefficientEngineering

A road surface frictional coefficient estimating apparatus has a device for determining a first estimated value of a yaw moment Mnsp_estm generated at an NSP of a vehicle due to the resultant force of road surface reaction forces acting on each wheel by using, for example, a frictional coefficient estimated value that has been determined, and a device for determining a second estimated value of a yaw moment Mnsp_sens generated at the NSP from the observed value of motional state amounts defining an inertial force moment at the NSP. The increasing / decreasing manipulated variable of the frictional coefficient estimated value is sequentially determined on an error (Mnsp_sens−Mnsp_estm) such that the error is converged to zero, and the road surface frictional coefficient is updated on the basis of the increasing / decreasing manipulated variable.

Owner:HONDA MOTOR CO LTD

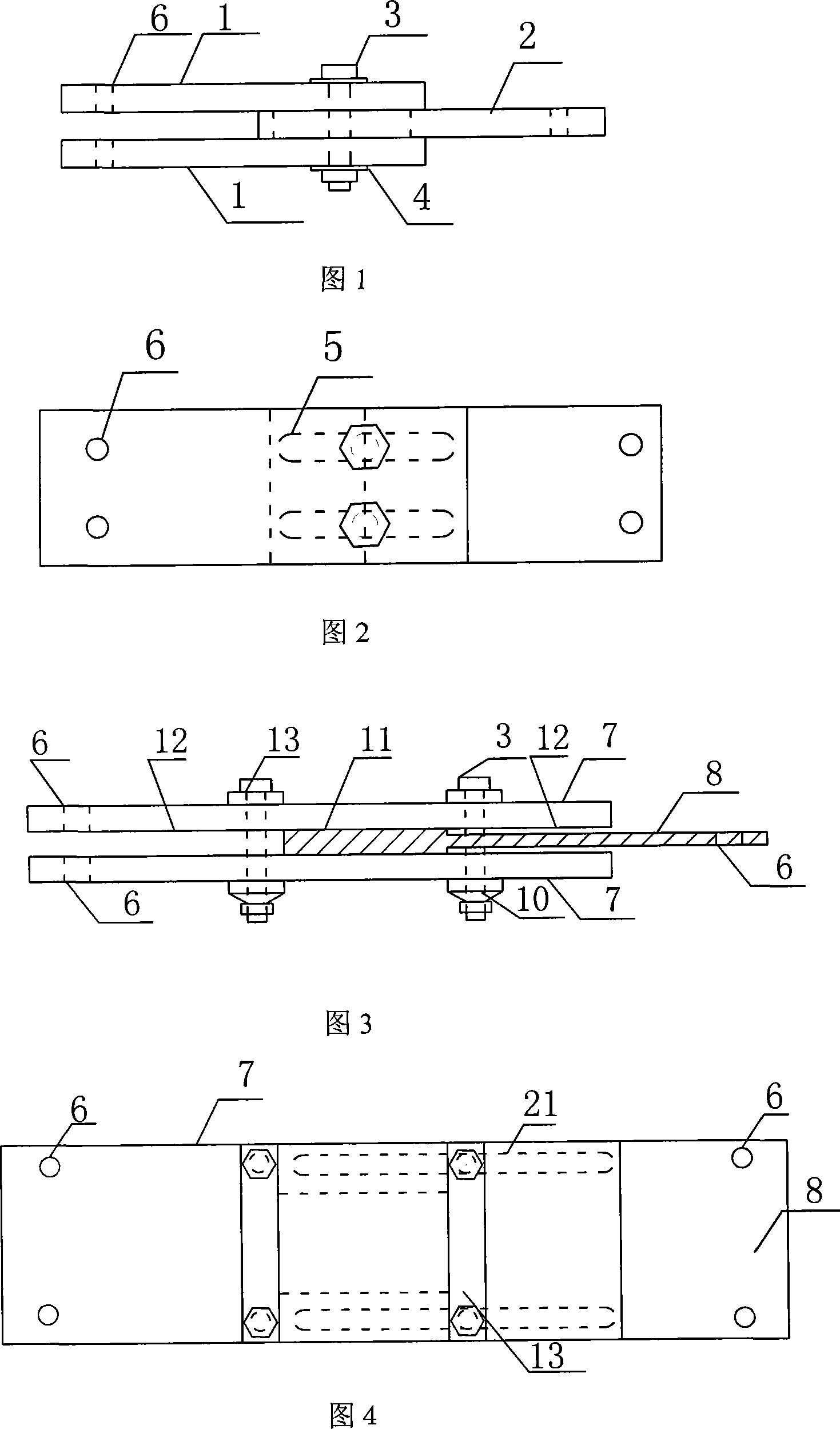

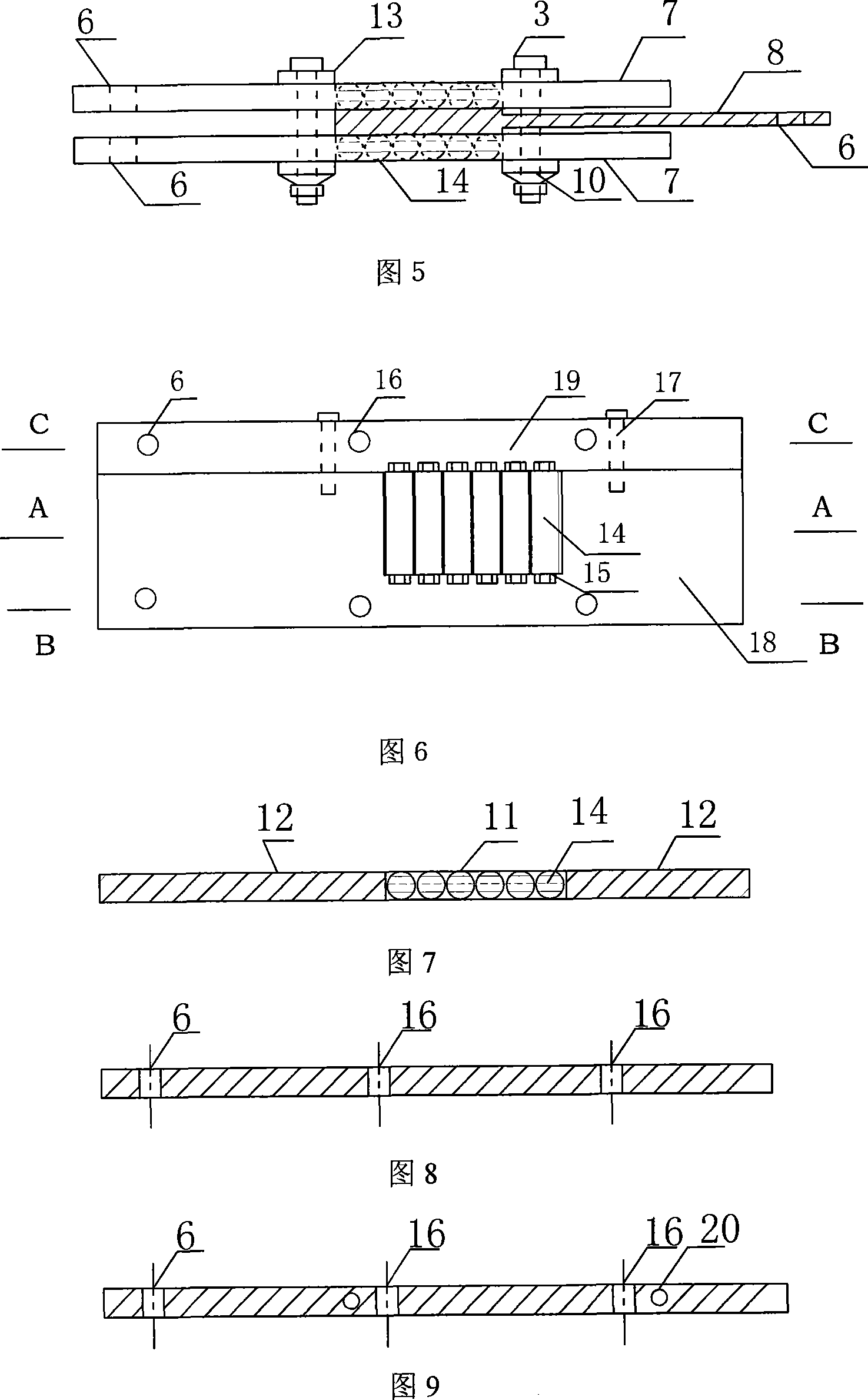

Plate-type friction-changing damper

InactiveCN101216087ADoes not affect natural vibration characteristicsNo additional stiffnessFriction dampersShock proofingFrictional coefficientShock resistance

The invention relates to a plate type variable friction damper, which is primarily used in the field of wind resistance and shock resistance of structures and equipments. The invention makes use of the variation of the friction factor of a friction surface to provide a linear damping variable friction damping device. The plate-type variable friction damper primarily consists of two cover boards, a sliding panel, a pre-tightening bolt, a disk spring and a packing strip. The friction surface of the cover board is divided into three equal parts; the friction factor between the middle friction surface and the friction surface of the sliding panel is smaller than the friction factors between the friction surfaces of the two parts on both sides and the friction surface of the sliding panel. The plate-type variable friction damper avoids the defects of high cost, being maintained intricately and oil leakiness of the traditional linear damping device, such as the oil damper, and overwhelms the problem that the constant friction damper can not keep the same control under different loads. The invention has simple structure, and is produced easily with low cost. The invention is applicable for both large structures and small structures and equipments, and is suitable to be promoted and used in the field of shock resistance of structures and equipments.

Owner:BEIJING UNIV OF TECH

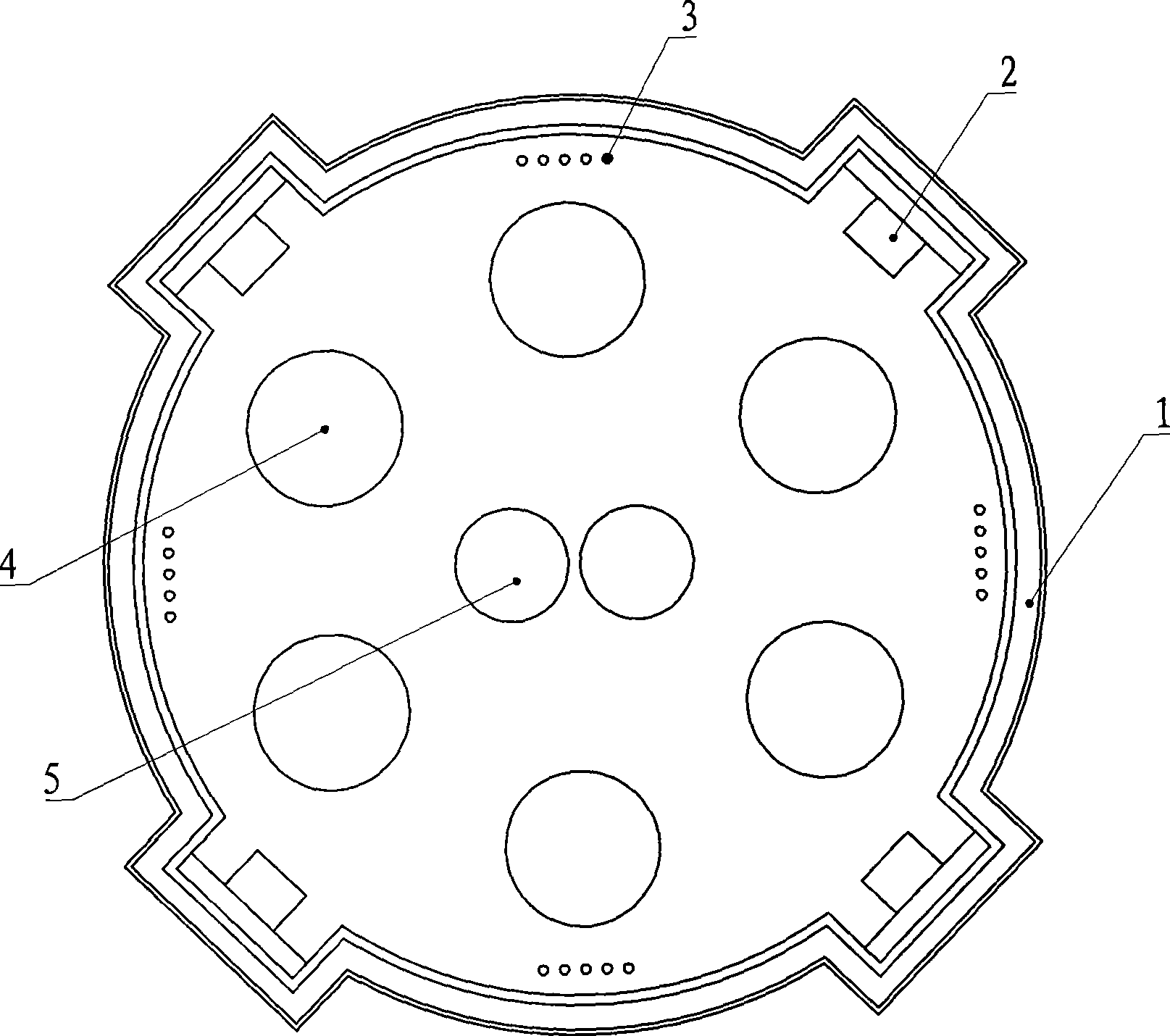

Desk type annular block abrasion and wear tester

InactiveCN103604710AReduce frictionHigh precisionUsing mechanical meansInvestigating abrasion/wear resistanceFrictional coefficientElectric machinery

The invention discloses a desk type annular block abrasion and wear tester. The tester comprises a driving part, a testing part, a measuring part, and a loading part; the motor of the driving part is fixed on a motor support, a test ring is directly driven to rotate by the motor shaft; the test ring in the testing part is arranged on a sleeve which is connected to the motor shaft, a test block is tightly clamped with wedges in a bottom seat clamp which can be arranged in a plurality of positions; the measuring part is composed of a temperature sensor and a force measuring sensor; the loading part is manually operated, a bevel wheel drives a screw rod to push a spring support plate, and then the spring pushes a workbench move upward so as to tightly press the test ring to the test block. The desk type annular block abrasion and wear tester can effectively measure the test piece temperature, frictional force, and change of frictional coefficient under different loads.

Owner:HEFEI UNIV OF TECH

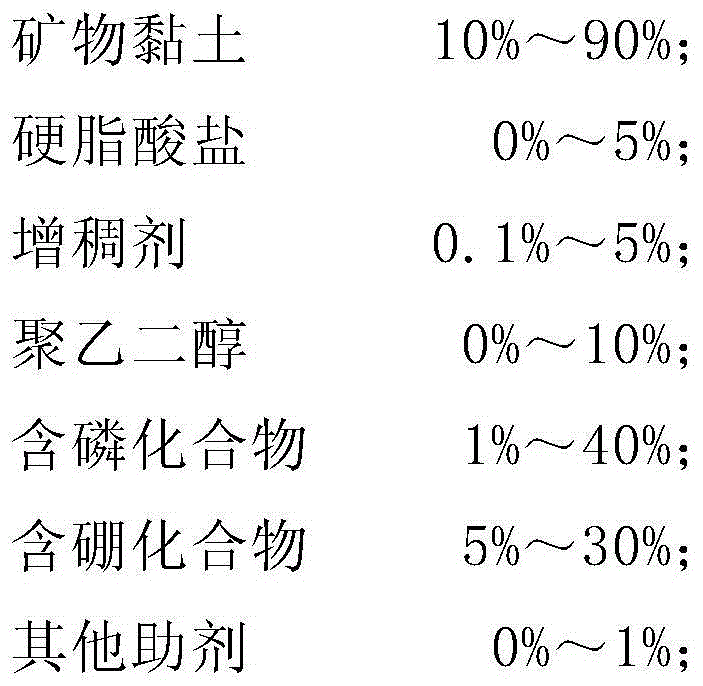

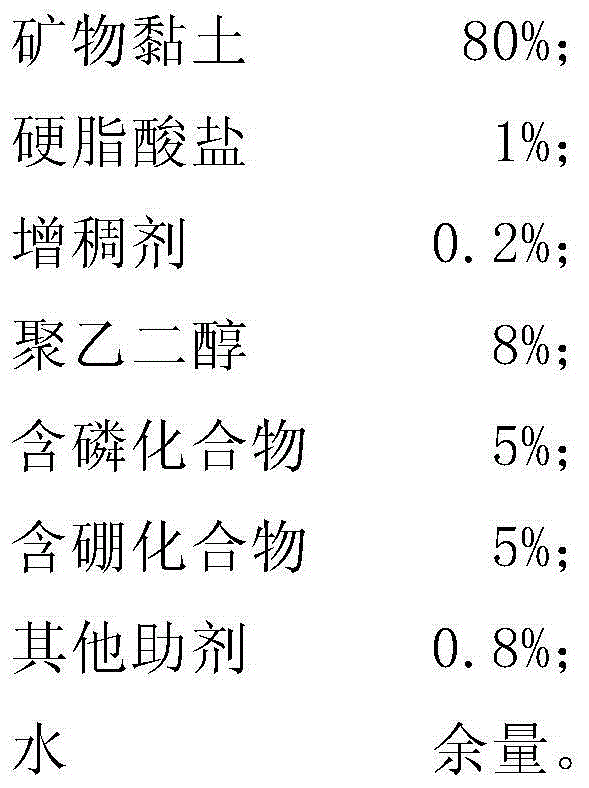

Water-based clay lubricant

ActiveCN104694240AEvenly dispersedDifficult to sprayLubricant compositionFrictional coefficientGraphite

The invention discloses a water-based clay lubricant, and aims at solving the problems of difficult cleaning, easy smoking, large pollution, easy conducting and danger of the existing water-based graphite lubricant and solving the problem of high frictional coefficients of the graphite lubricant. The water-based clay lubricant is characterized by being prepared from the following raw materials in percentage by weight: 10 to 90% of mineral clay, 0 to 5% of stearate, 0.1 to 5% of a thickening agent, 0 to 10% of polyethylene glycol, 1 to 40% of a phosphorous-containing compound, 5 to 30% of a boron-containing compound, 0 to 1% of other additives, and the balance of water. The water-based clay lubricant is an environmentally friendly water-based clay lubricant which is uniform to disperse, easy to spray, resistant to high temperature, good in lubricating effect, easy to clean, and free of pollution.

Owner:HUNAN JINHUA SCI & TECH GRP

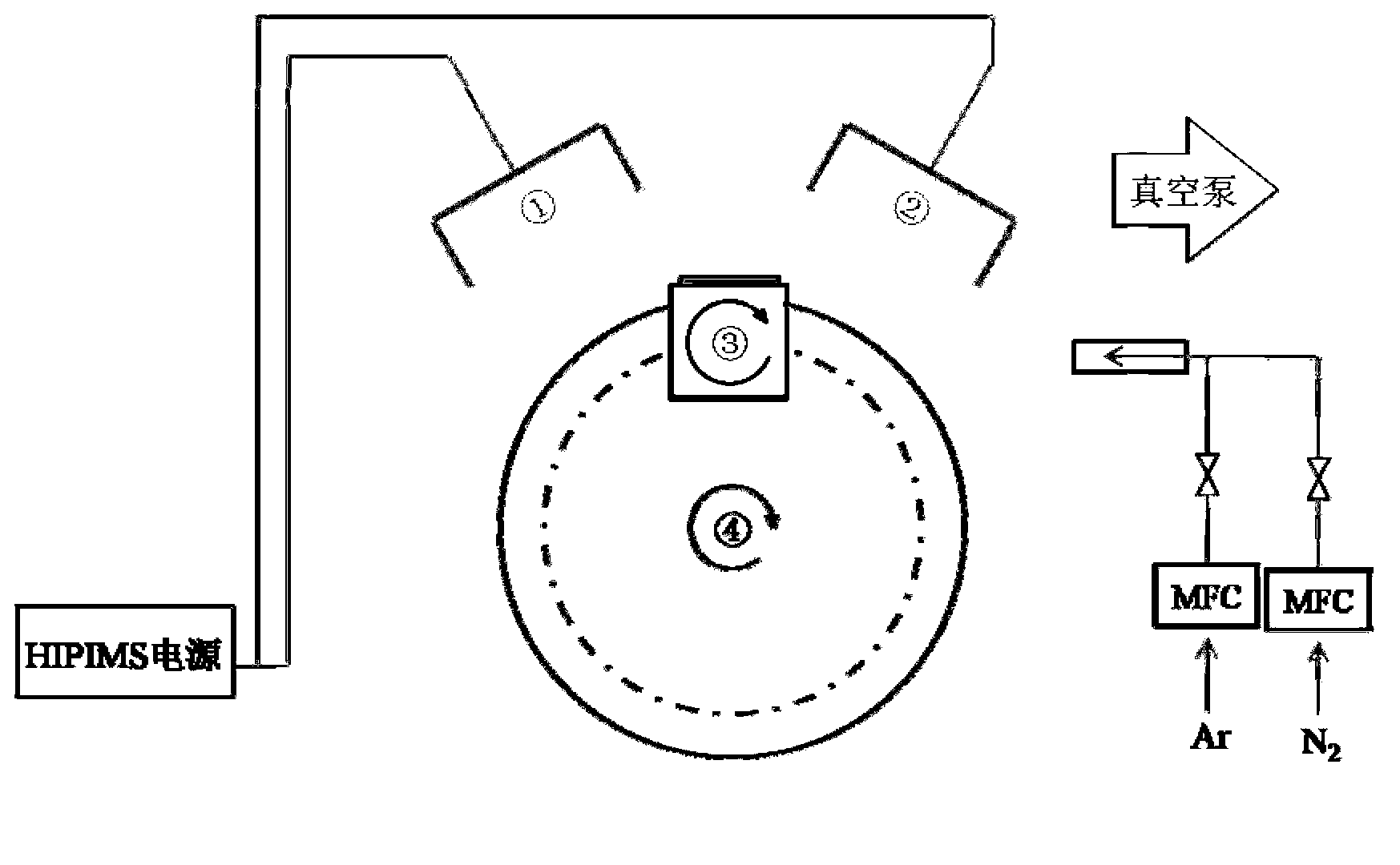

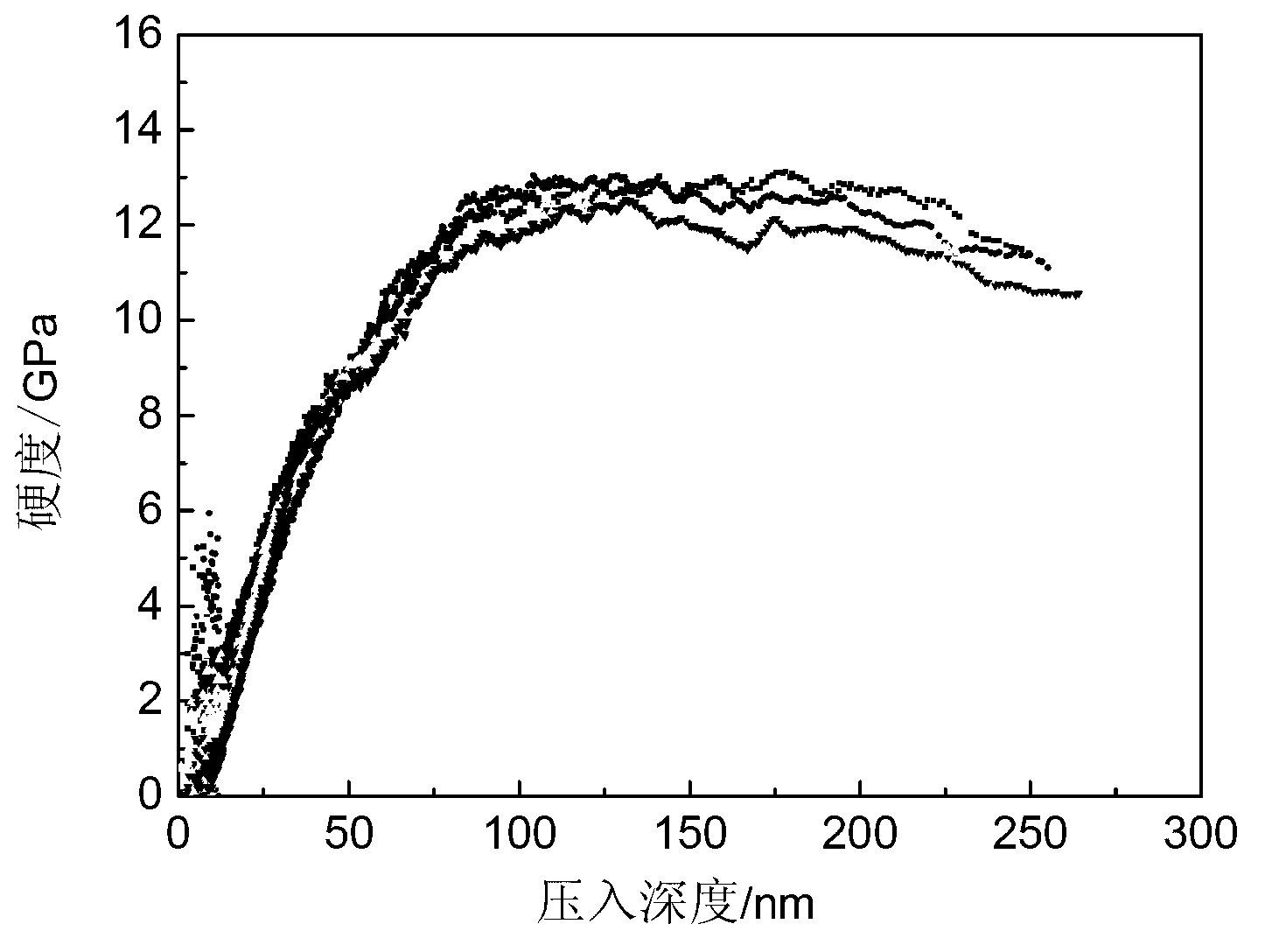

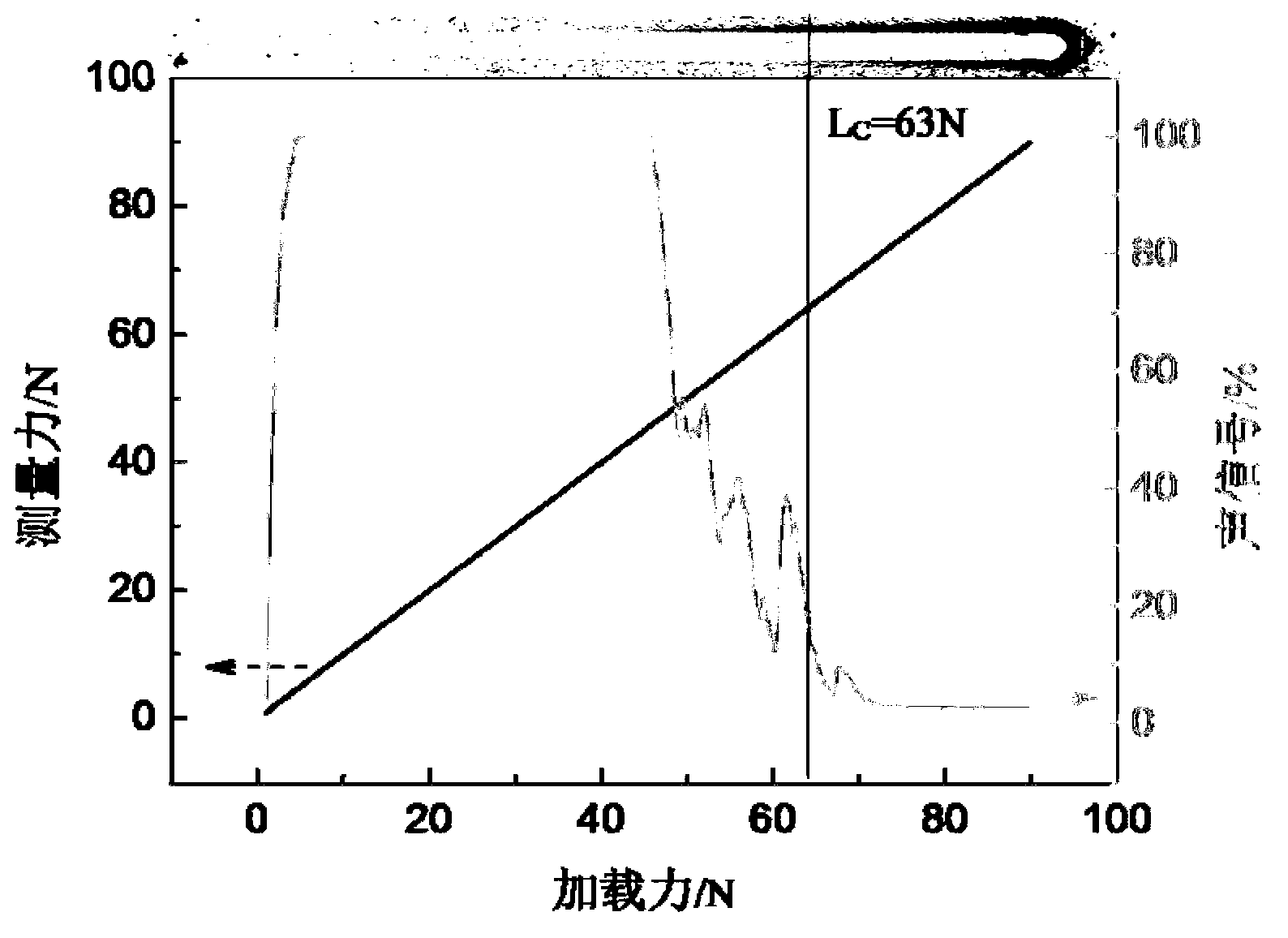

Preparation method of MoS2 composite thin film with high hardness and loss abrasion on surface of substrate

ActiveCN103060765AFast sputtering rateIncrease ionization rateVacuum evaporation coatingSputtering coatingComposite filmCritical load

The invention discloses a preparation method of a MoS2 composite thin film with high hardness and loss abrasion on a surface of a substrate. The method comprises the following step: sequentially depositing a metal Ti priming coat, a TiN transitional layer and a Ti / MoS2 composite thin film on the surface of the substrate by using a high power pulse magnetron sputtering technology combined with optimized process conditions to obtain the MoS2 composite thin film which is strong in film binding force and high hardness and has low frictional coefficient and wear rate in various frictional environments. The nano hardness of the composite thin film is over 11GPa, the critical load value is over 60N, and the frictional coefficients in room-temperature air with relative humidity of 30%, 50% and 70%, an N2 atmosphere and a hydraulic oil environment are below 0.055. Therefore, the substrate is effectively protected in frictional reduction, and the composite thin film has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

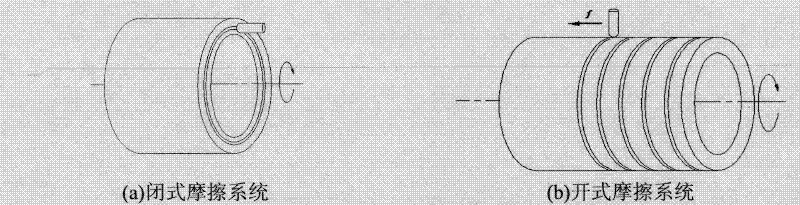

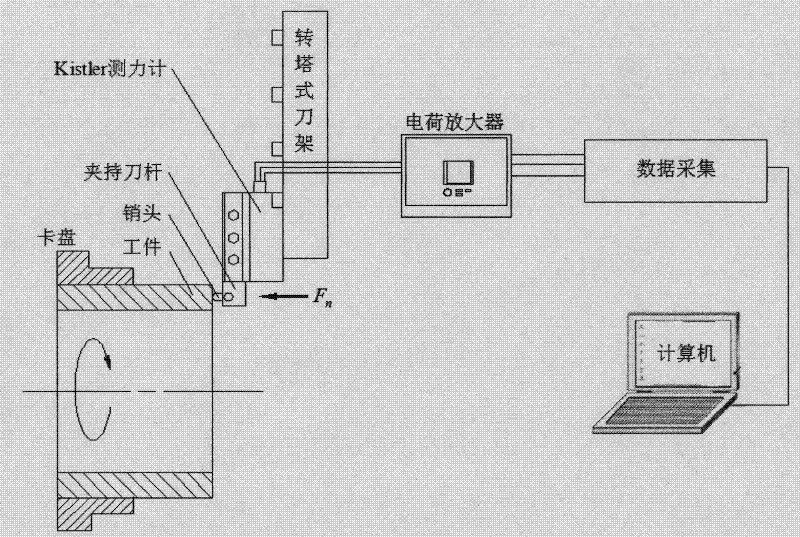

Method for testing cutting and bonding friction characteristics with point-contact opened-closed type pin-disc friction system

The invention relates to a method for testing cutting and bonding friction characteristics with a point-contact opened-closed type pin-disc friction system which is structured by a friction test platform transformed by a lathe. Aiming at the research requirements on the cutting friction problem and through the design of a pin-disc structure and the combination of lathe space motion trail, an opened-closed type system can be structured, and the cutting friction under an extreme working condition can be simulated; and an acting force of a contact interface can be measured by utilizing a Kistler piezoelectric force meter, a tangential force component caused by material elasticplastic deformation can be removed by combining a finite element simulation method, and thus a bonding friction factor can be obtained. The method disclosed by the invention is mainly used for testing and analyzing the friction characteristic of cutters in the cutting process. A main body of equipment is common equipment in a manufacturing laboratory, and has the advantages of good rigidity, simple structure, easy implementation and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

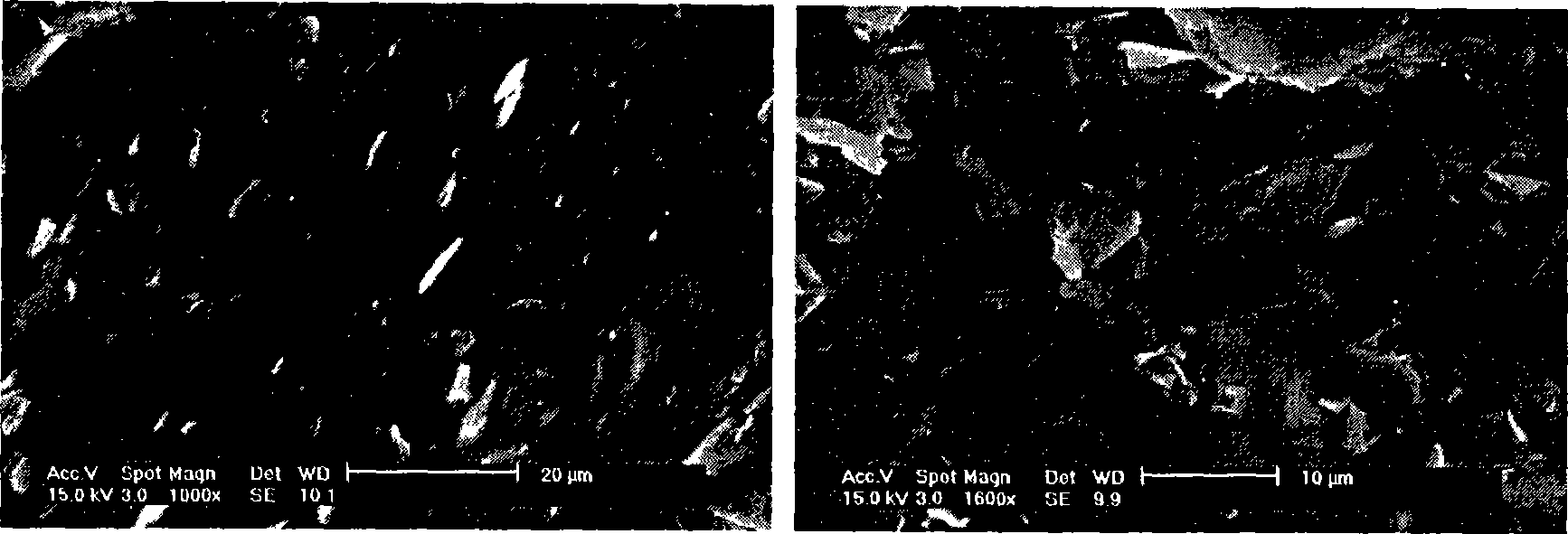

Titanium base whisker reinforced polyether ether ketone wearable composite material and its preparation method

The invention relates to polyether ether-ketone wear-resisting compound material which is strengthened by titanium base crystal as well as preparative method. The mentioned titanium base crystal has a diameter of 0.5-3.0 mum, length-diameter ratio of 5-50 and its surface reshaped. The ingredient of the compound material includes titanium base crystal, polytef and PEEK, it's shaped by hot mould pressing or pouring so it has very good strength, and abradability. Compared to the carbon fiber strengthened polyether ether-ketone of the same content, the abradability of the invention has been increased by 10 times, the frictional coefficient has been decreased by 30% and the temperature of the friction surface has been lowered by half. The invention has very good alkali resistance, so it is adaptable to be the ware and wear-resisting material in lye; it's also applicable to special conditions such as high temperature, vacuum, radiation and causticity; it can be widely used as piston link, filling, sliding piece and valve piece, the service life of the material in the invention has been greatly prolonged.

Owner:NANJING UNIV OF TECH

Fretting wear testing machine in high temperature and high pressure water or steam environment

ActiveCN104914042APayloadEffective displacement loadingUsing mechanical meansMaterial analysisFrictional coefficientEngineering

The invention discloses a fretting wear testing machine in a high temperature and high pressure water or steam environment, wherein two workpieces for testing are clamped by arranging fixtures and placed in an autoclave which is positioned in the high temperature and high pressure water or steam environment by a high temperature and high pressure water circulating system, vibration excitation effect is applied to the testing workpieces in the autoclave by a loading device, and thereby the fretting wear test in high temperature and high pressure water or steam environment can be performed. The testing machine can simulate infinitesimal displacement amplitude and high vibration frequency fretting wear test under the primary and secondary loop temperature, pressure and hydrochemistry condition of nuclear power plant; the testing machine can perform slip wear test or impact wear test, and the friction coefficient and the wear coefficient between the friction pair can be obtained by measurement; the components of the testing machine are reasonably distributed, thus ensuring that the load and displacement loading of the testing machine is effective and reliable; the load control and measurement accuracy is high, and the friction force between the friction pair can be quantificationally obtained.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Chuck device

InactiveUS6902171B2Reduce coefficient of frictionEasy to moveAnodisationSleeve/socket jointsFrictional coefficientEngineering

Owner:YUKIWA SEIKO

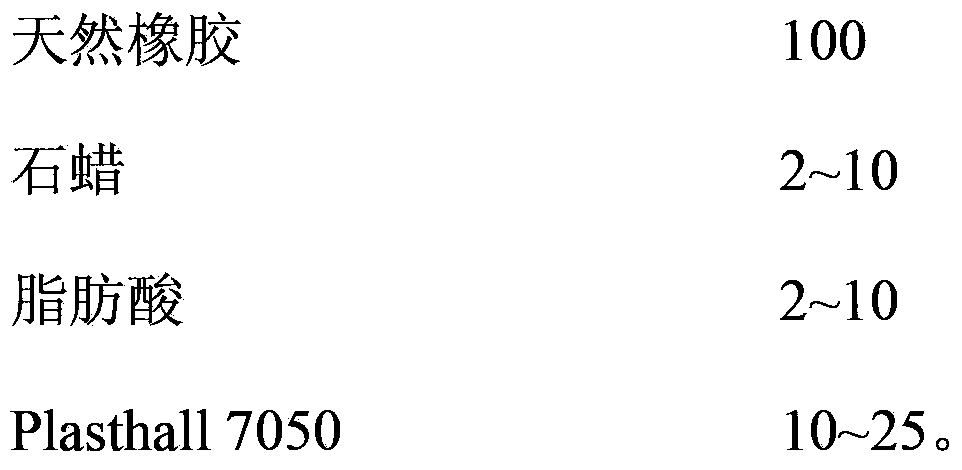

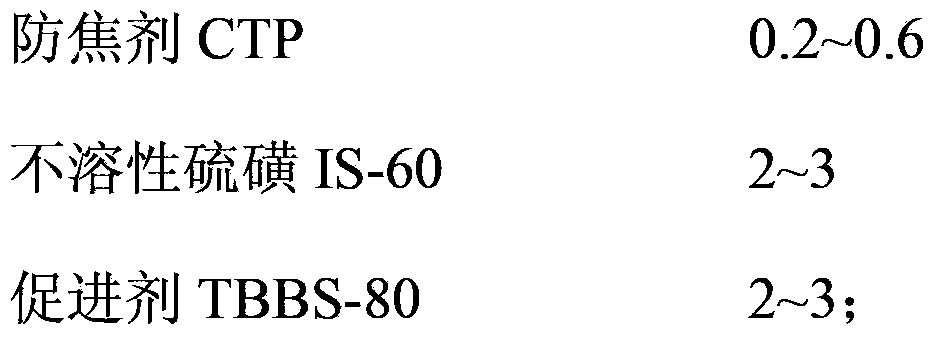

Stabilizer bar bushing and preparation method thereof

The invention relates to a stabilizer bar bushing. The stabilizer bar bushing is prepared by adopting injection molding and performing high-temperature and high-pressure vulcanization. The main raw materials comprise natural rubber, a Plasthall7050 plasticizer, fatty acid, paraffin, sulfur, carbon black and the like. The stabilizer bar bushing provided by the invention has the advantages of good high-temperature and low temperature resistance, small permanent deformation, low frictional coefficient, good abrasion resistance, long service life and the like, and particularly, when an oil product in the stabilizer bar bushing is separated to the surface of a product, the surface frictional coefficient of the product can be reduced, and the friction noise between the rubber and a metal bar is eliminated.

Owner:ANHUI ZHONGDING SEALING PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com