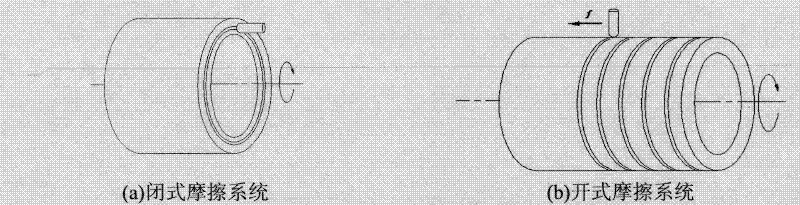

Method for testing cutting and bonding friction characteristics with point-contact opened-closed type pin-disc friction system

A technology of system testing and friction characteristics, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of large contact area and difficulty in reaching the tool stress range, and achieve the effect of ensuring stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

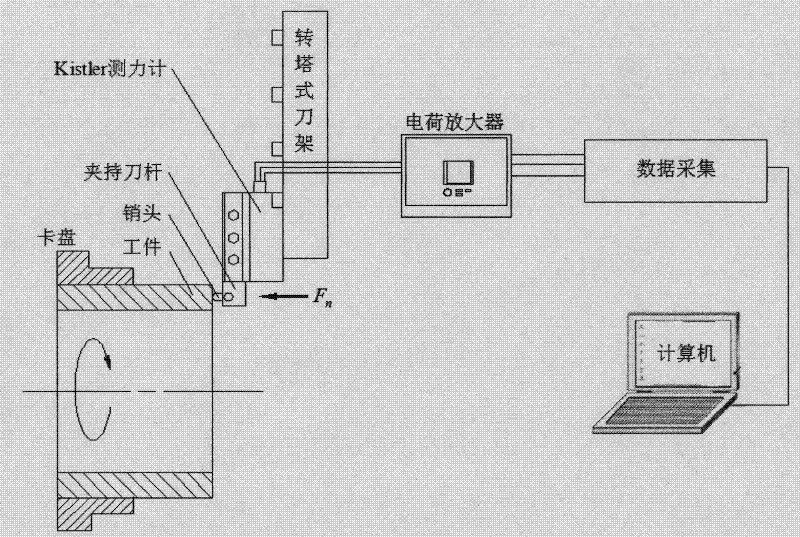

Method used

Image

Examples

Embodiment Construction

[0014] To achieve the above object, the solution of the present invention mainly includes:

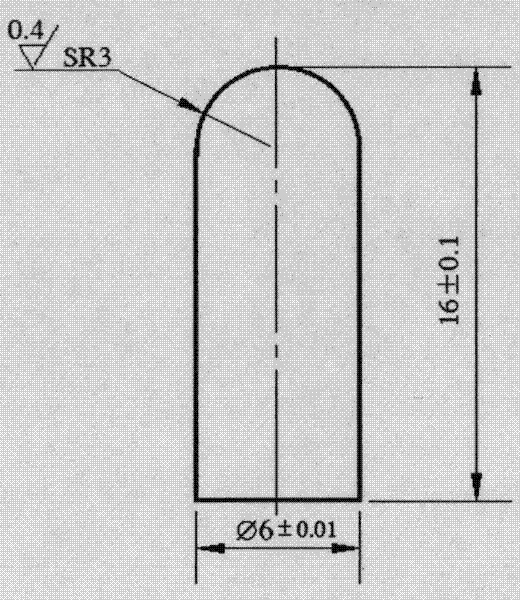

[0015] (1) Since the contact stress of the pin-workpiece friction pair mainly depends on the diameter of the ball stud pin and the applied load, according to the contact stress required for the test and the expected applied load range, the formula R = 6 F ( 1 - μ 1 2 E 1 + 1 - μ 2 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com