Patents

Literature

384results about How to "Increase ionization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

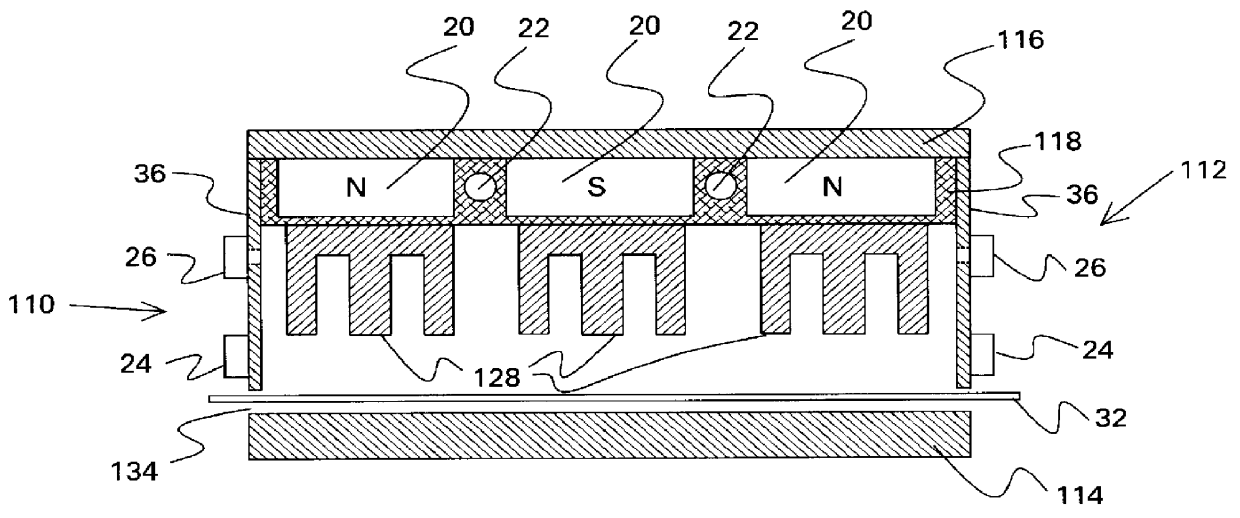

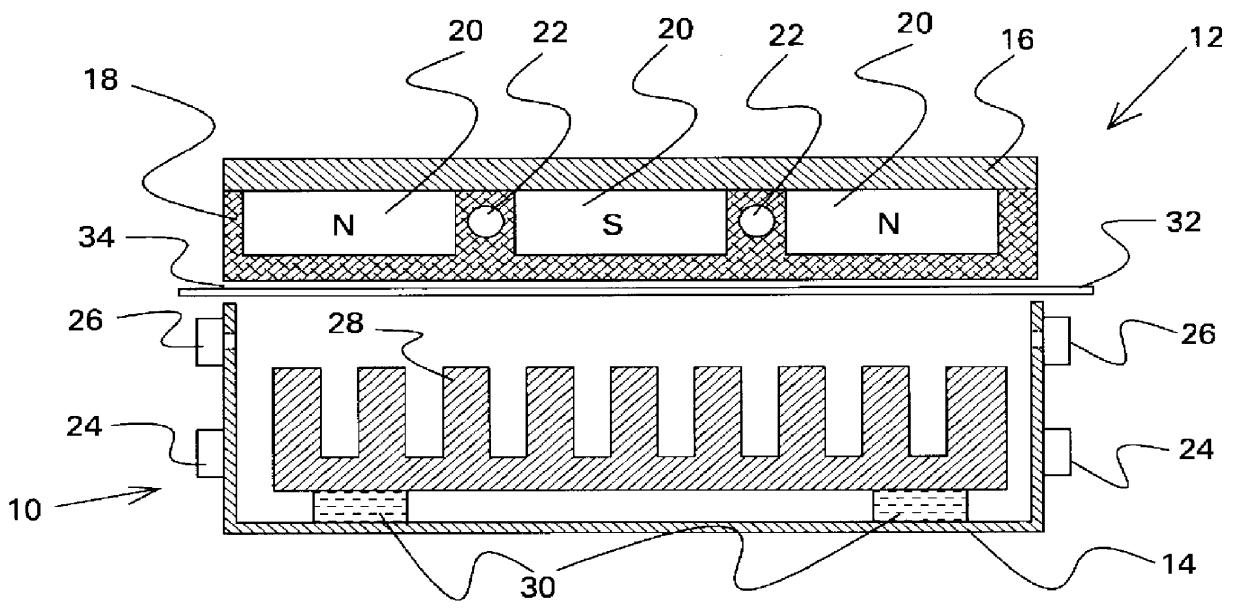

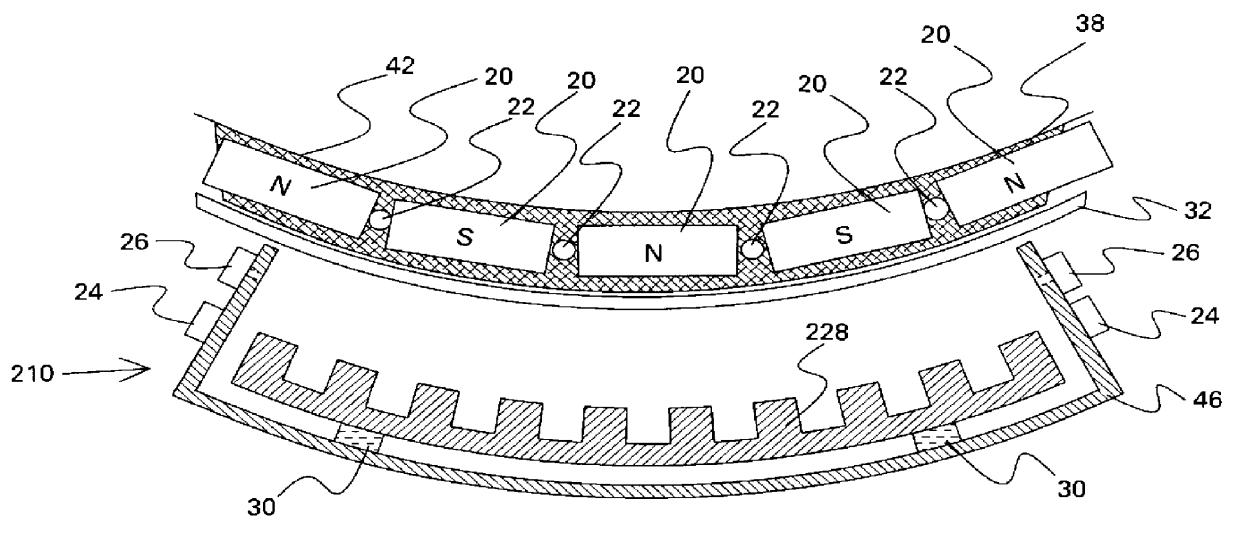

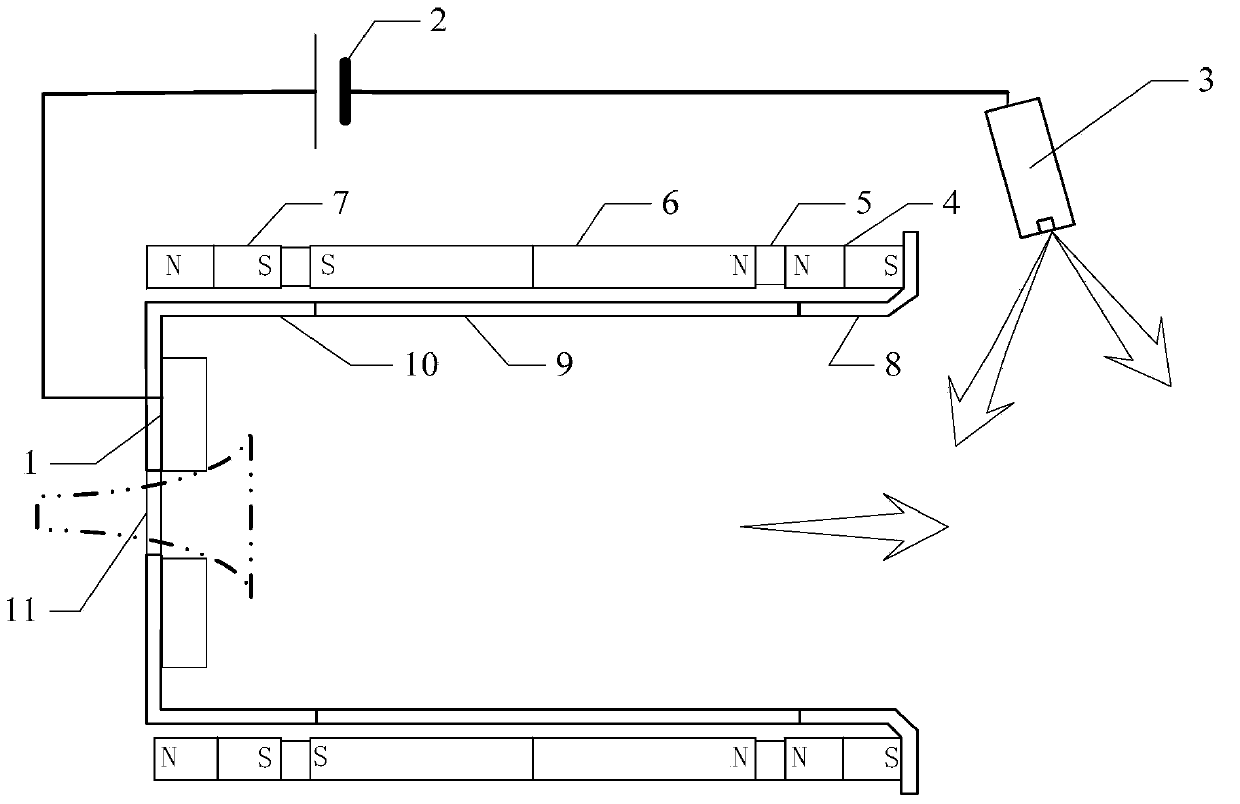

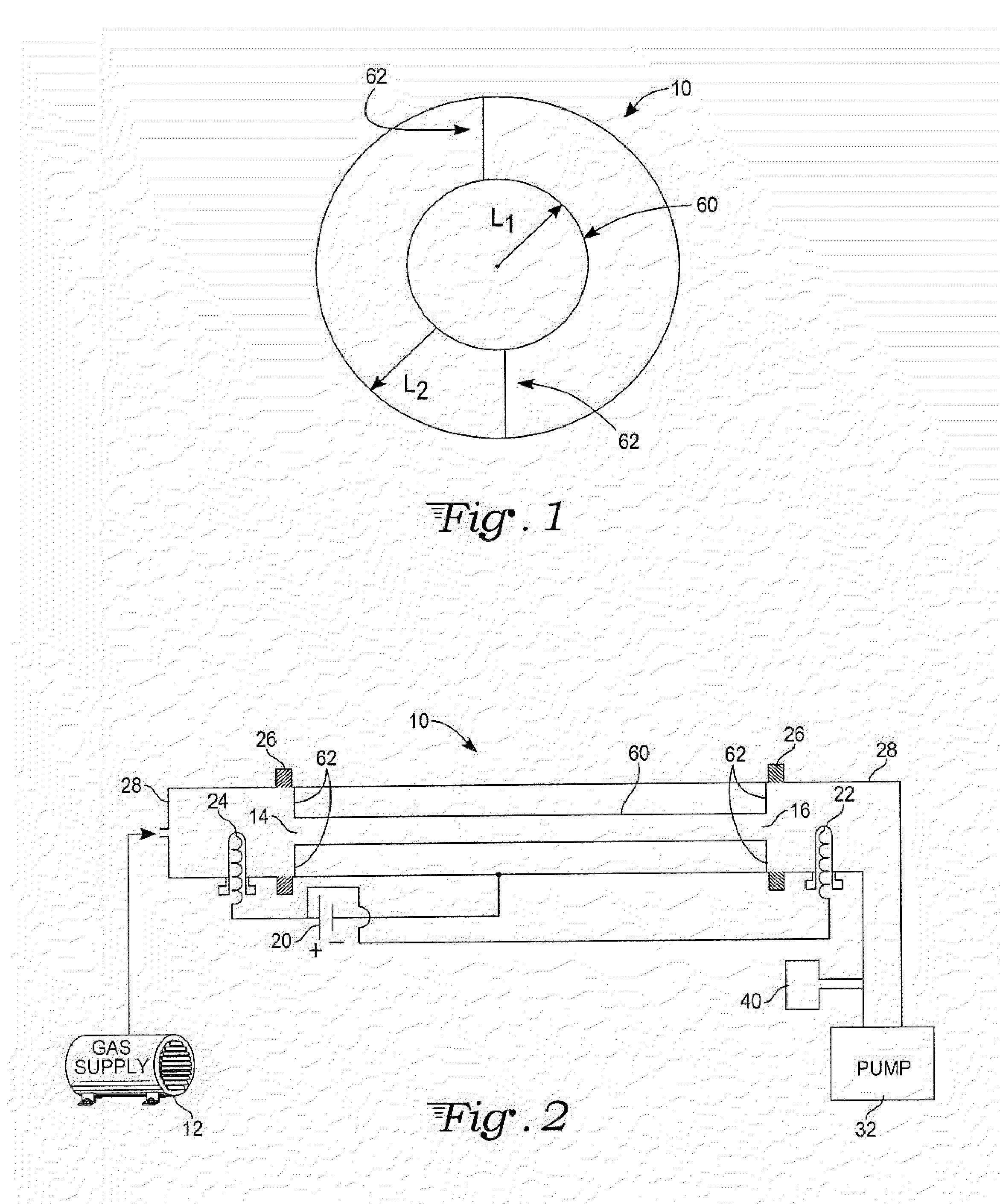

Apparatus for plasma treatment of moving webs

InactiveUS6066826AEasy to useHigh strengthElectric discharge tubesArc welding apparatusEngineeringPlasma treatment

Apparatus and process for plasma treatment of moving webs, or films, are disclosed. The apparatus includes magnets and multiple hollow cathodes, which, in the presence of a plasma, magnetically focuses and thereby intensifies the plasma to one side of the film surface. The moving web is positioned either between the hollow cathodes and the magnets or in front of the hollow cathodes and the magnets. The plasma treatment functionalizes the film surface.

Owner:ASTEN GROUP

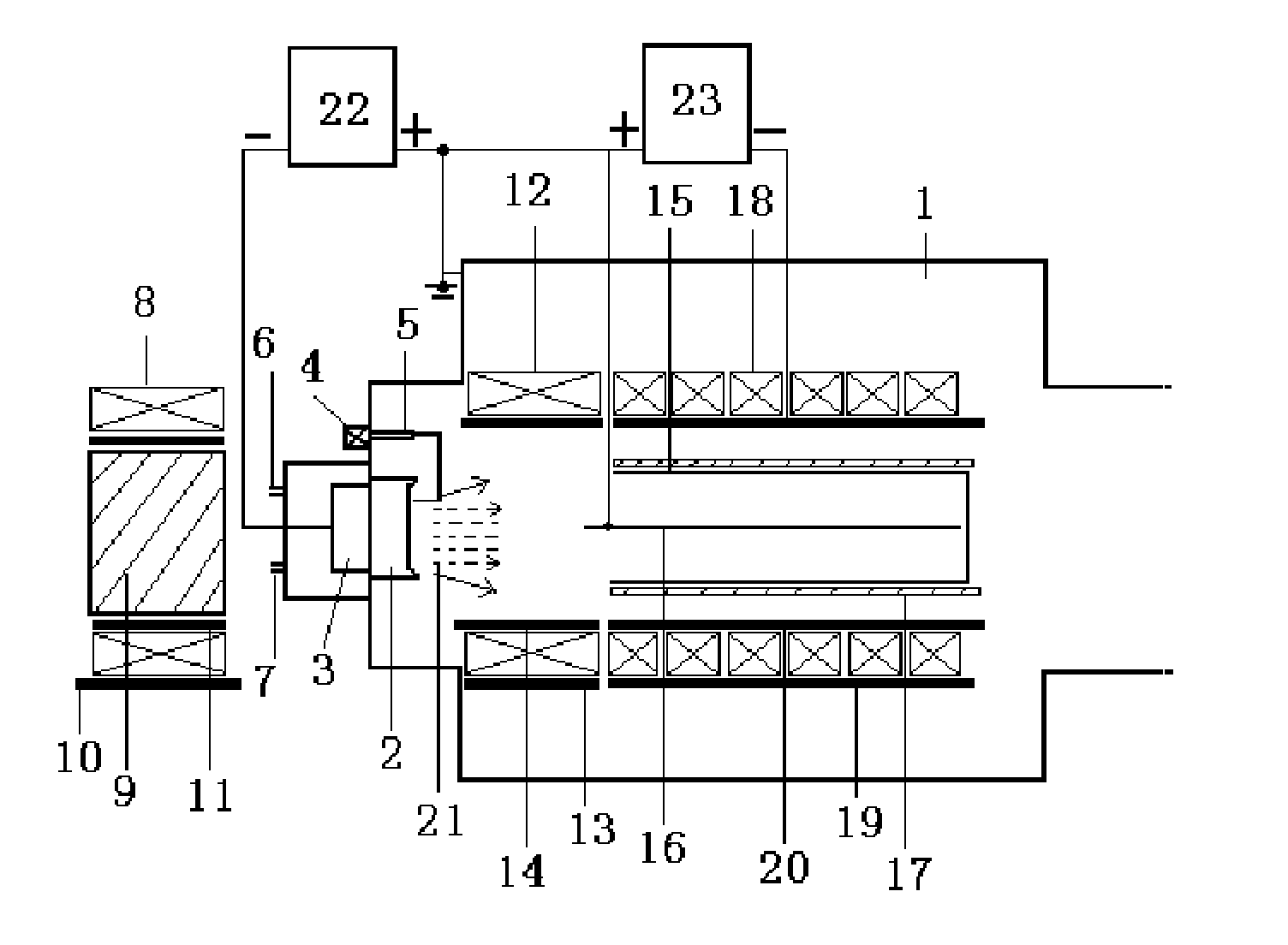

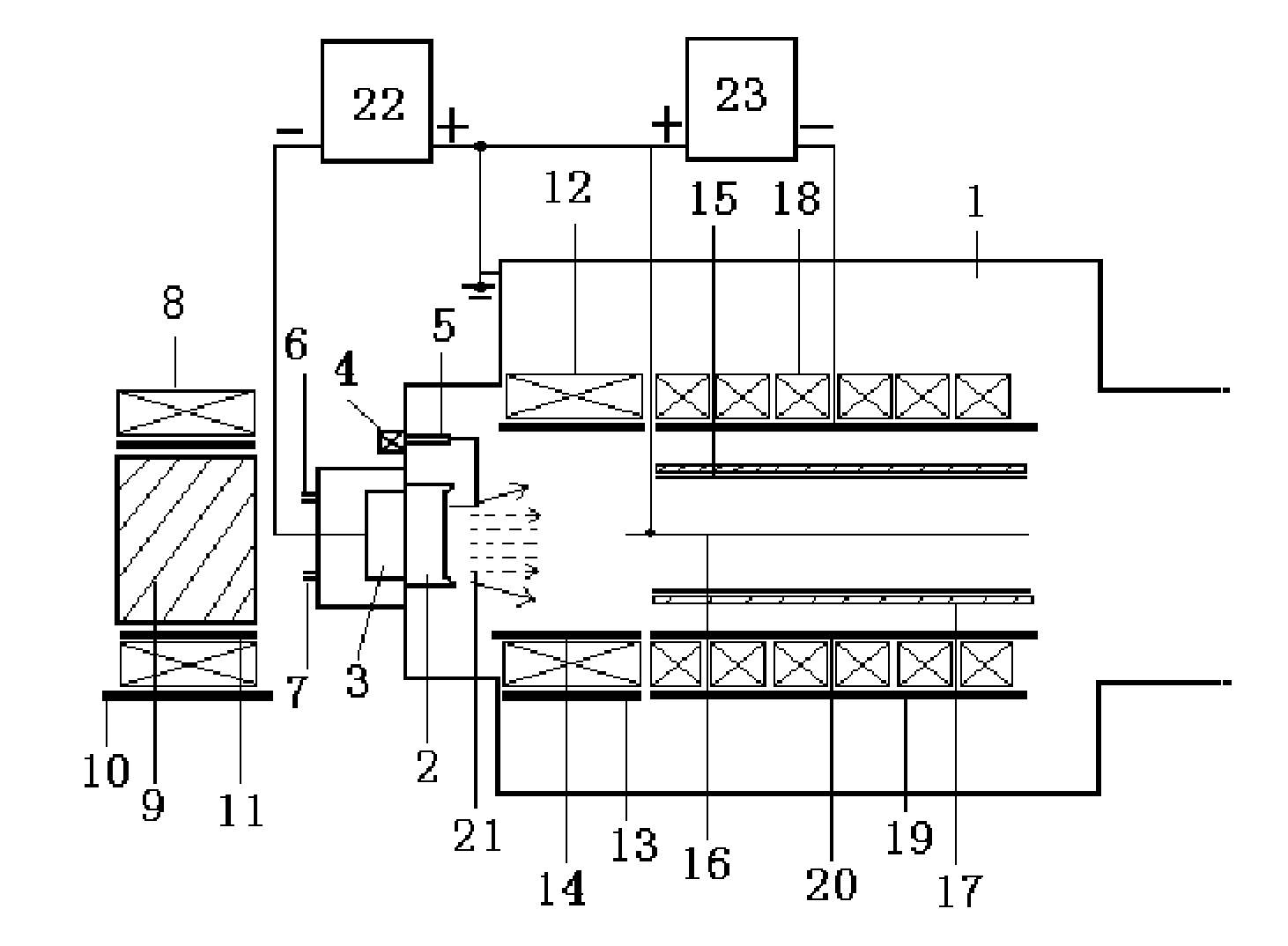

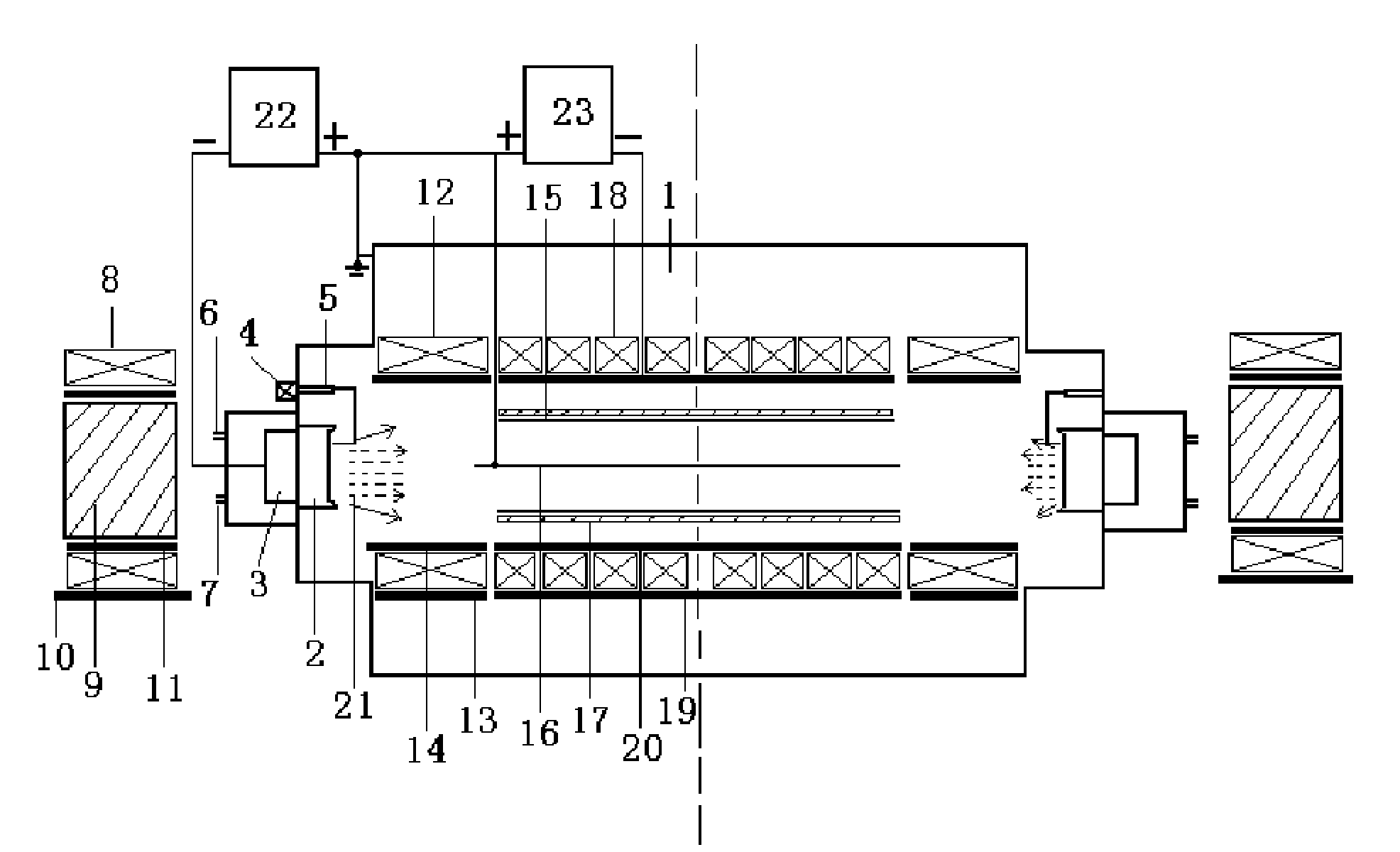

Multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method

ActiveCN103276362ALow ionization rateLow pulse duty cycle to generate high ionization rateVacuum evaporation coatingSputtering coatingPlasmaMagnetic filtration

The invention relates to a multi-stage magnetic field straight pipe magnetic filtration and pulsed bias compounded electrical arc ion plating method, and belongs to the technical field of material surface treatments. In the prior art, plasma transmission efficiency is low and pulsed bias can not completely remove large particles due to applying of magnetic filtration on an arc source. A purpose of the present invention is to solve problems in the prior art. The method comprises: 1, connecting a workpiece to a pulsed bias power supply, connecting an electrical arc ion plating target source to a target power supply, and connecting a multi-stage magnetic field straight pipe magnetic filtration device in front of the target source; 2, carrying out thin film deposition, wherein work gas is introduced until achieving 0.01-10 Pa when a pressure in a vacuum chamber is less than 10<-2> Pa, the pulsed bias power supply is opened, a pulsed bias amplitude value, frequency and a duty ratio are adjusted, the target power supply is opened, plasma is generated, the multi-stage magnetic field straight pipe magnetic filtration device is opened, removal of large particles and efficient transmission of the plasma in the magnetic filtration device are achieved, process parameters are adjusted, and a thin film with no large particle defect is rapidly produced; and 3, adopting a single-stage magnetic field to combine direct current / pulsed bias to obtain a thin film with a certain thickness.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

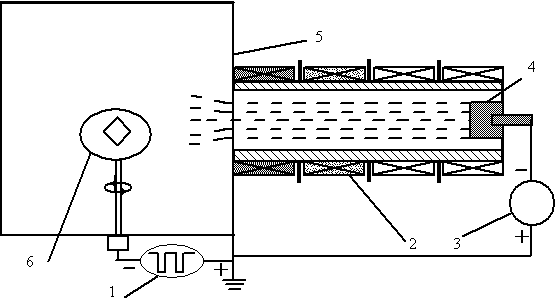

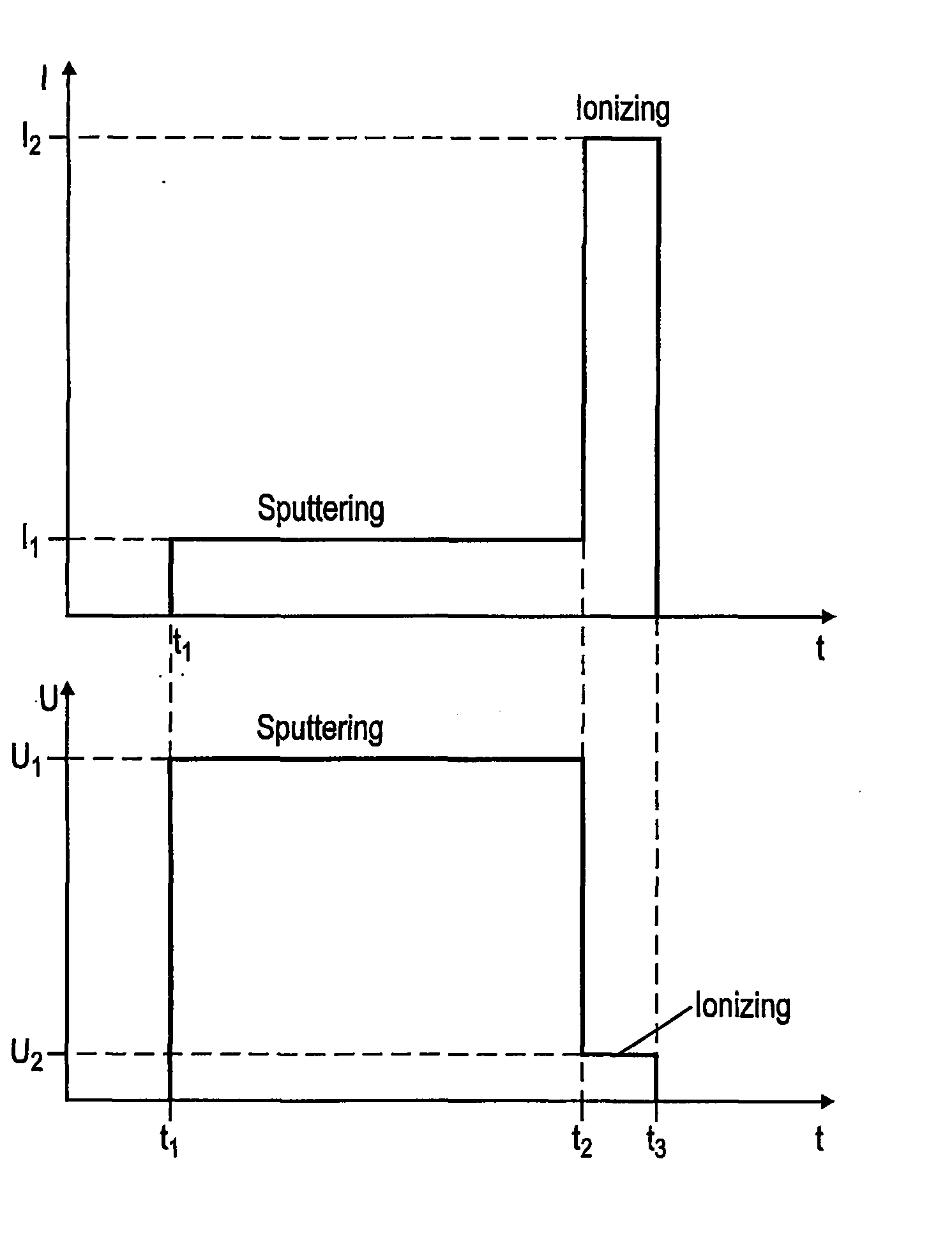

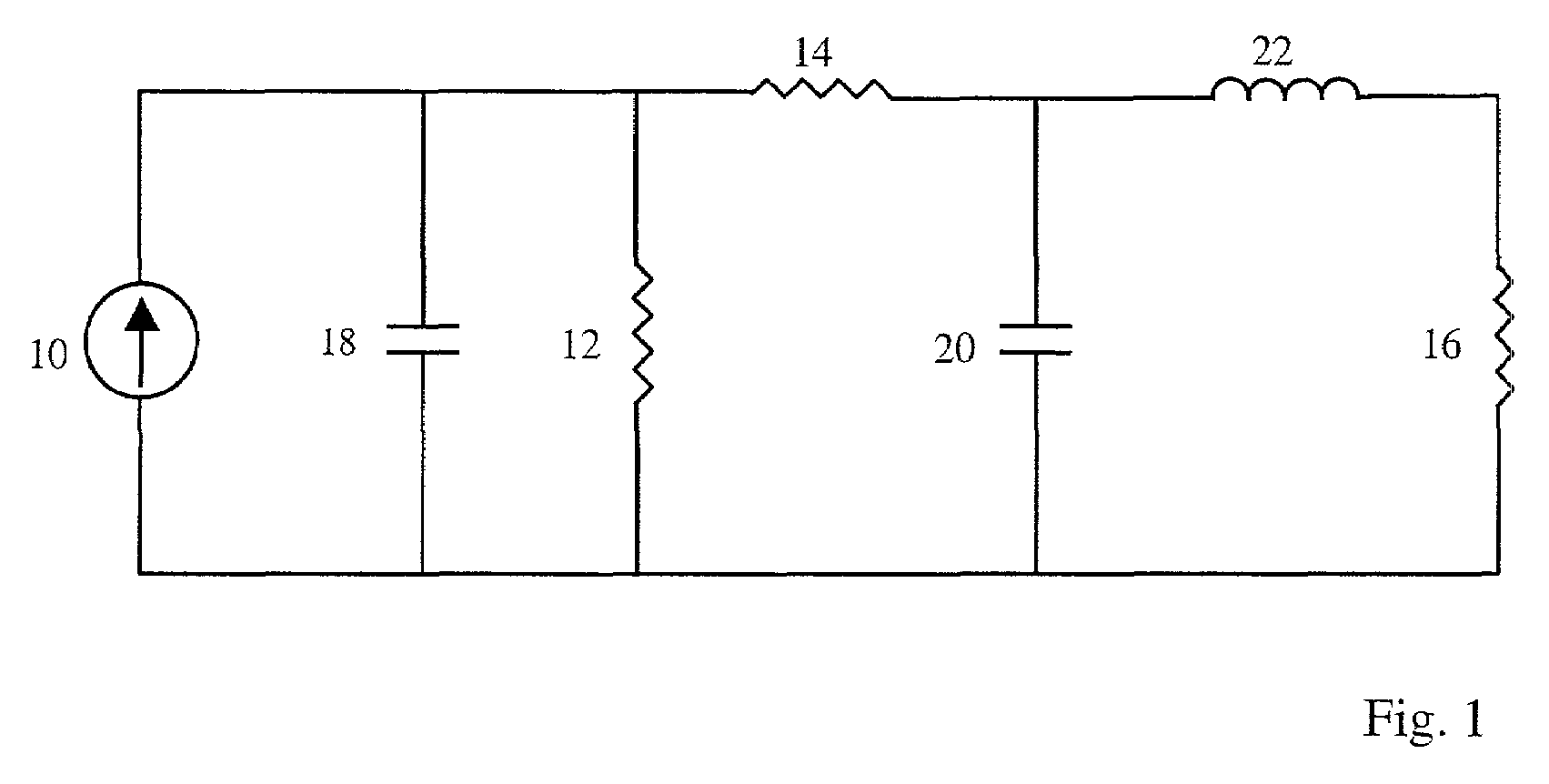

Method and apparatus for plasma generation

ActiveUS20050092596A1Improved plasma confinement propertyIncrease currentElectric discharge tubesVacuum evaporation coatingElectric dischargePlasma flow

In a simple method and device for producing plasma flows of a metal and / or a gas electric discharges are periodically produced between the anode and a metal magnetron sputtering cathode in crossed electric and magnetic fields in a chamber having a low pressure of a gas. The discharges are produced so that each discharge comprises a first period with a low electrical current passing between the anode and cathode for producing a metal vapor by magnetron sputtering, and a second period with a high electrical current passing between the anode and cathode for producing an ionization of gas and the produced metal vapor. Instead of the first period a constant current discharge can be used. Intensive gas or metal plasma flows can be produced without forming contracted arc discharges. The selfsputtering phenomenon can be used.

Owner:CEMECON +1

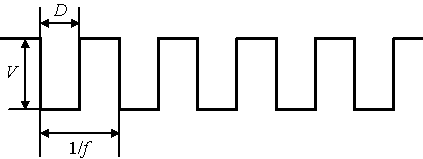

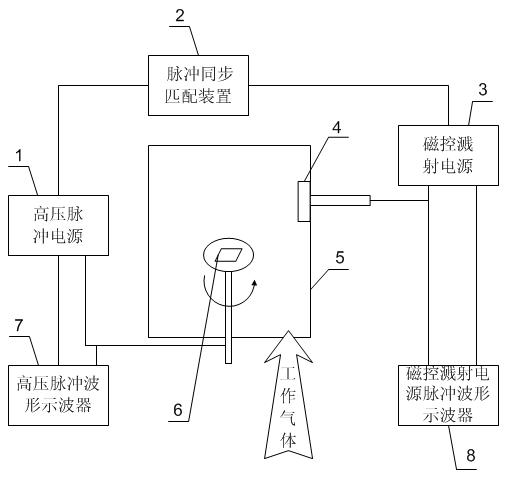

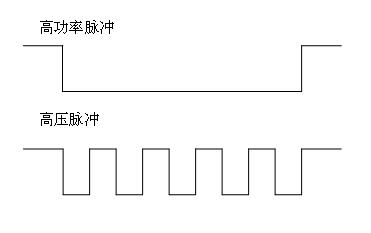

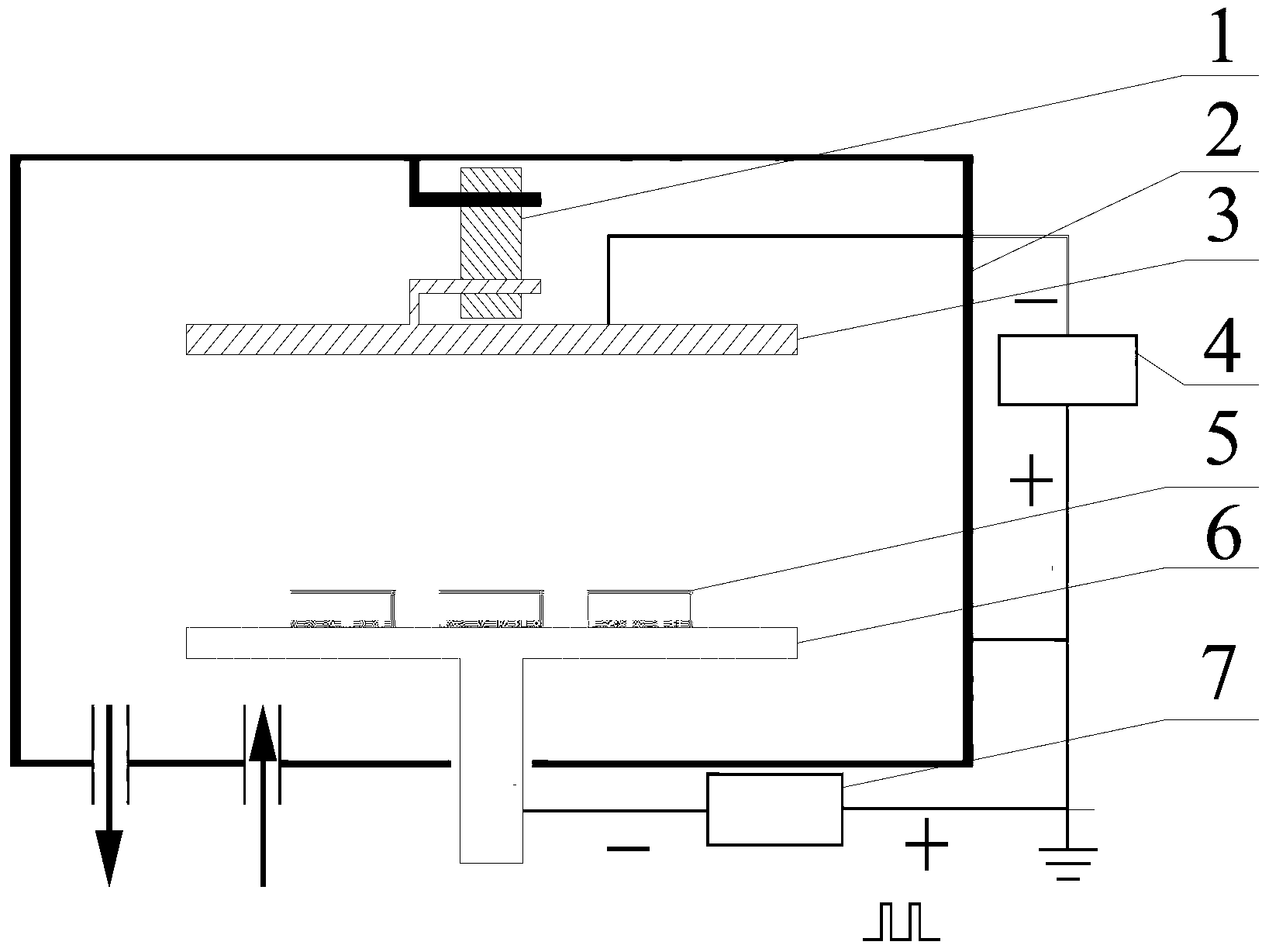

Ion implantation and deposit method of high-power composite pulse by magnetic control sputtering

ActiveCN101838795AIncrease ionization rateHigh bonding strengthVacuum evaporation coatingSputtering coatingPhase differenceHigh pressure

The invention discloses an ion implantation and deposit method of high-power composite pulse by magnetic control sputtering, which belongs to the field of material surface treatment technology and solves the problems of large particles and low film deposit efficiency in an adopted method in which negative high voltage pulse is applied to a workpiece. The method disclosed by the invention comprises the steps of: 1. placing the workpiece on a sample platform in a vacuum chamber, connecting the workpiece with a high-voltage pulse power supply, and connecting a magnetic control sputtering target source with a magnetic control sputtering power supply; and 2. implanting and depositing: when the vacuum degree in the vacuum chamber is lower than 10-2Pa, introducing working gas until the vacuum degree in the vacuum chamber reaching 0.011-10 Pa, starting up the high-voltage pulse power supply, adjusting the voltage value of output pulse of the high-voltage pulse power supply to 0.5-100kV, adjusting the pulse frequency to 0-1000Hz, adjusting the pulse width to 0-500 microseconds, starting up the magnetic control power supply, adjusting required process parameters by direct-current luminance pre-ionization, and controlling the voltage phase difference of the two power supplies to be -1000-1000 microseconds to perform the ion implantation and deposit.

Owner:HARBIN INST OF TECH

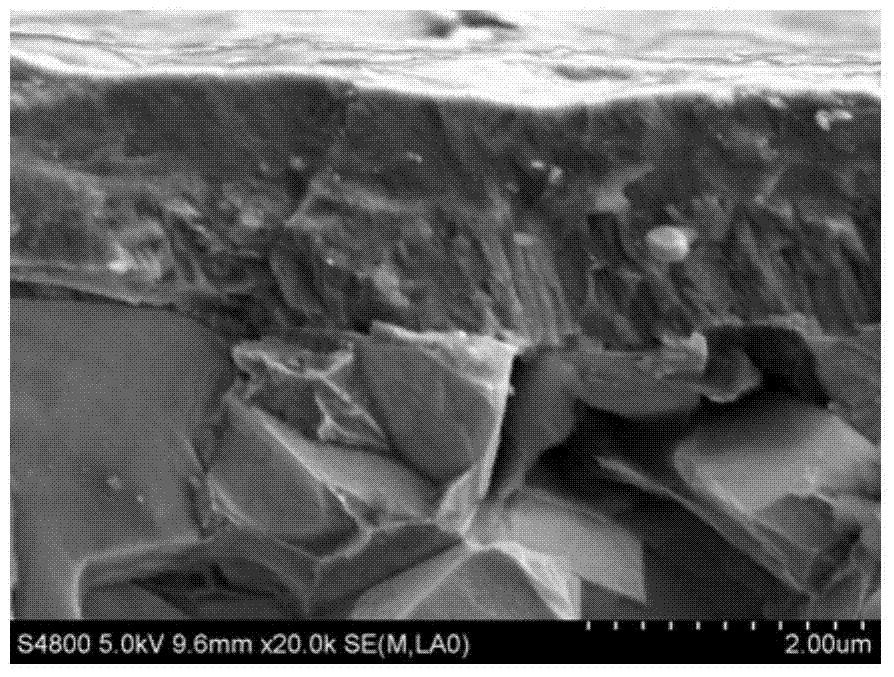

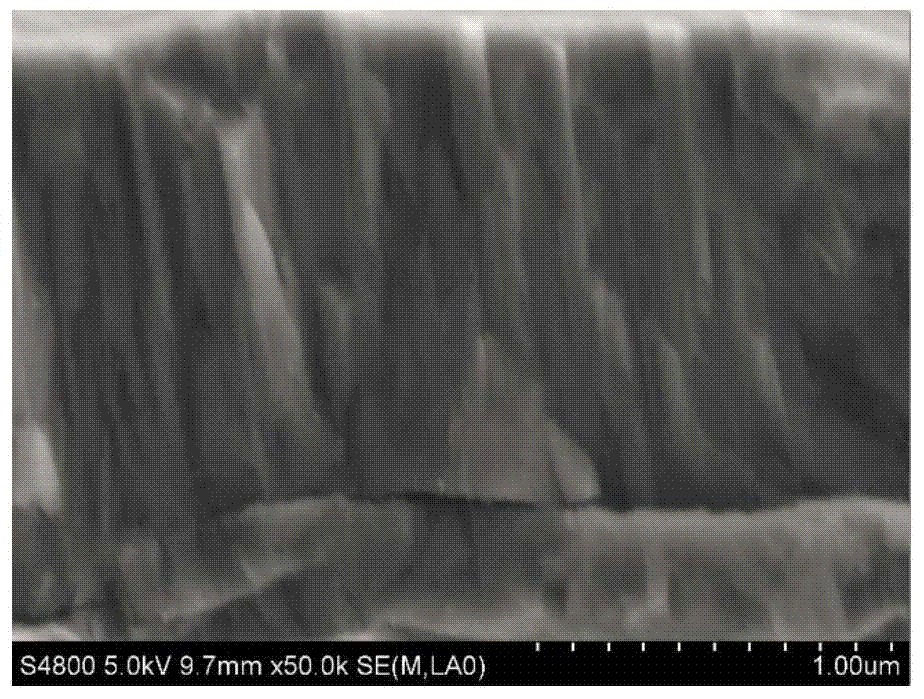

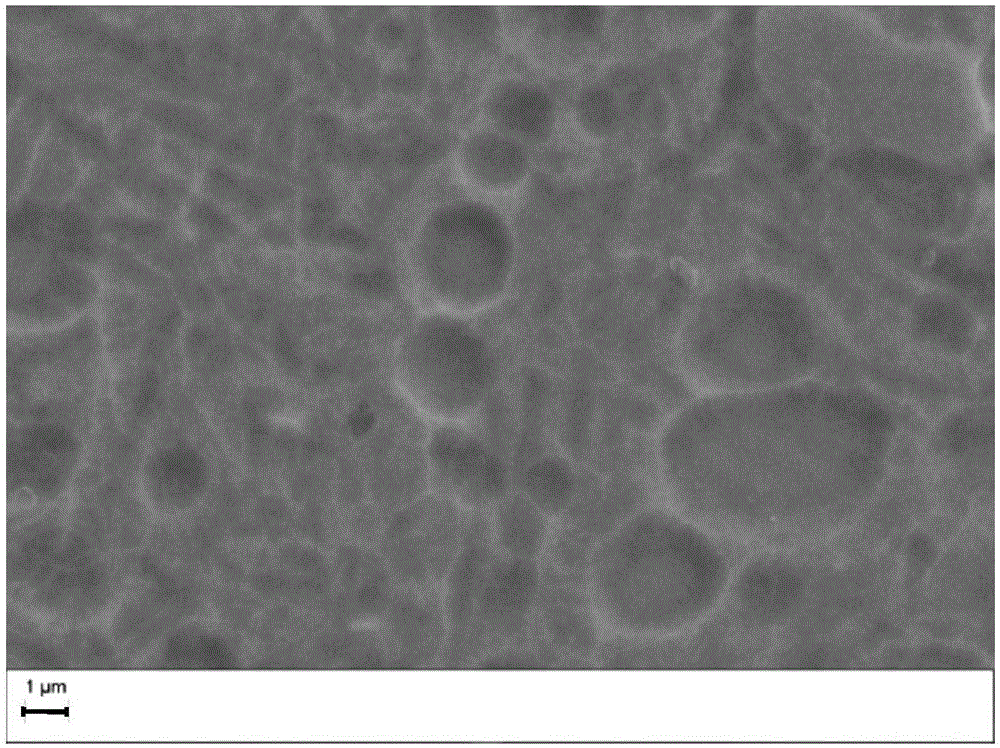

TiAlN/TiAlCN multilayer coating of substrate surface and preparing method thereof

ActiveCN102011090AMitigate defectsAlleviate dislocationVacuum evaporation coatingSputtering coatingSputteringHardness

The present invention discloses a TiAlN / TiAlCN multilayer coating of substrate surface and preparing method thereof, wherein a transitional layer is between a substrate and a TiAlN / TiAlCN multilayer coating; the multilayer coating is formed by alternating periodic arrangement of TiAlN films and TiAlCN films; in a period, the thickness sum of the TiAlN films and the TiAlCN films is 1-20 nano; the percentage by weight of C atom in the TiAlCN films is 0.1-5%. The multilayer coating of the present invention has the advantages of high hardness, low internal stress and high tenacity; the cutting efficiency and corrosion resistance of the substrate can be improved, and the service life of the substrate can be prolonged. In the present invention, the multilayer coating is deposited by high power pulse magnetron sputtering technique; the problems that cathode arc ion plating and depositing speed is too fast to prepare a nano epitaxial film and that target poisoning is caused during the procedure for preparing films by DC magnetron sputtering are solved; the nano modulation period is controlled via adjusting the autorotation and revolution speeds of the substrate and adjusting the quantity of targets.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

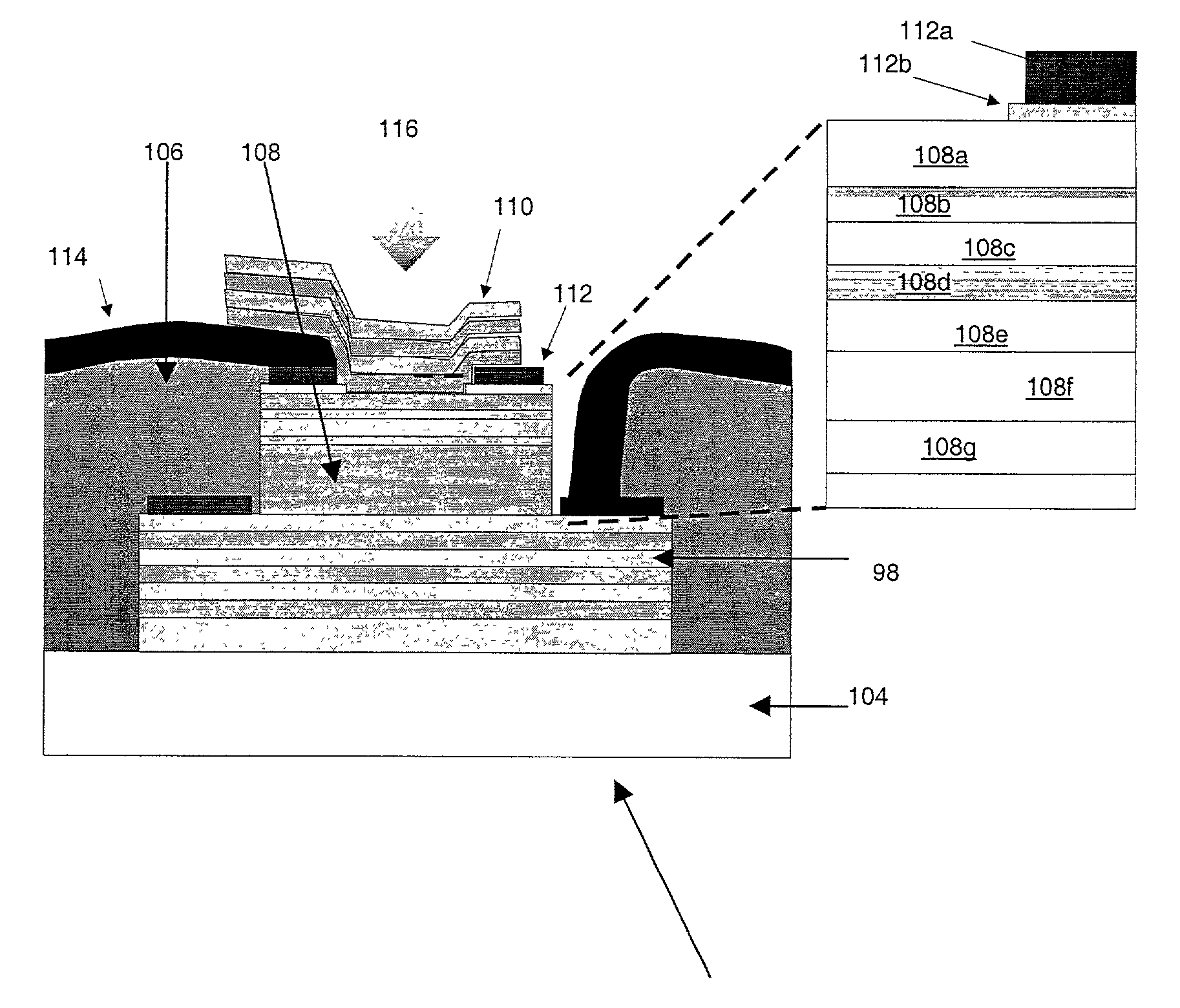

Avalanche photodiodes with an impact-ionization-engineered multiplication region

InactiveUS7045833B2Reduction in avalanche noiseDecreasing multiplication region thicknessSolid-state devicesSemiconductor/solid-state device manufacturingCharge carrierElectron avalanche

An avalanche photodiode including a multiplication layer is provided. The multiplication layer may include a well region and a barrier region. The well region may include a material having a higher carrier ionization probability than a material used to form the barrier region.

Owner:INTELLECTUAL VENTURES HLDG 40

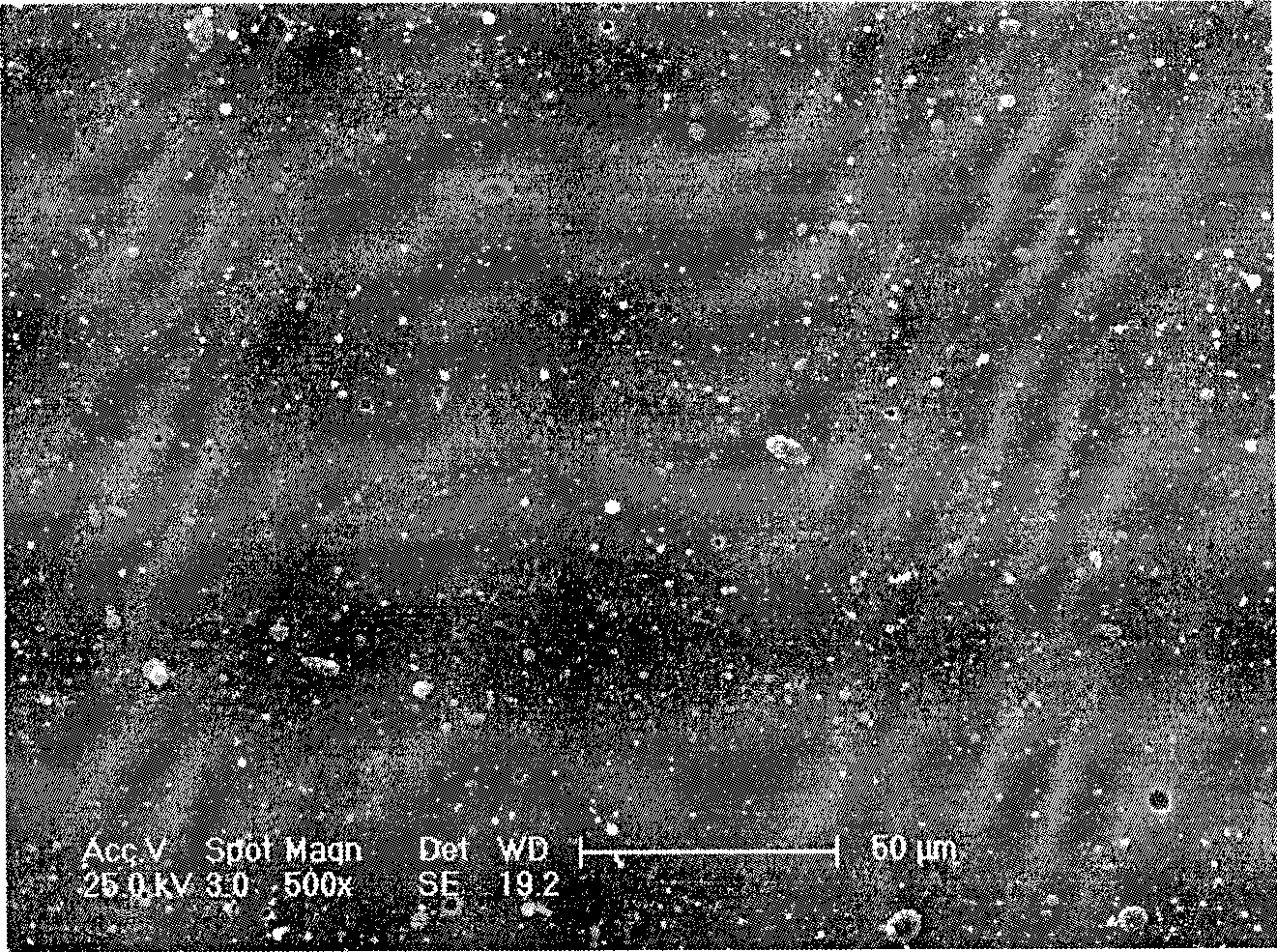

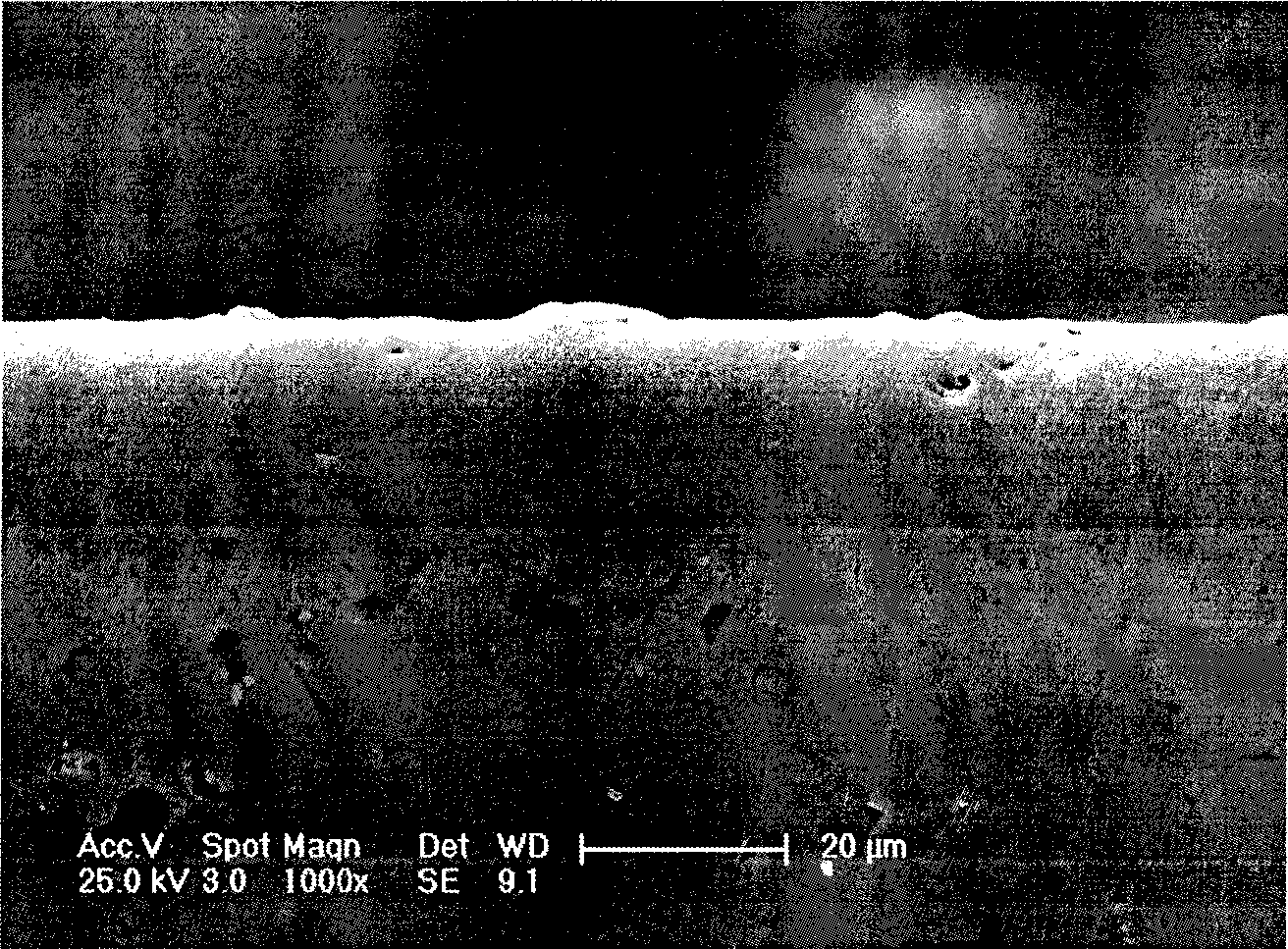

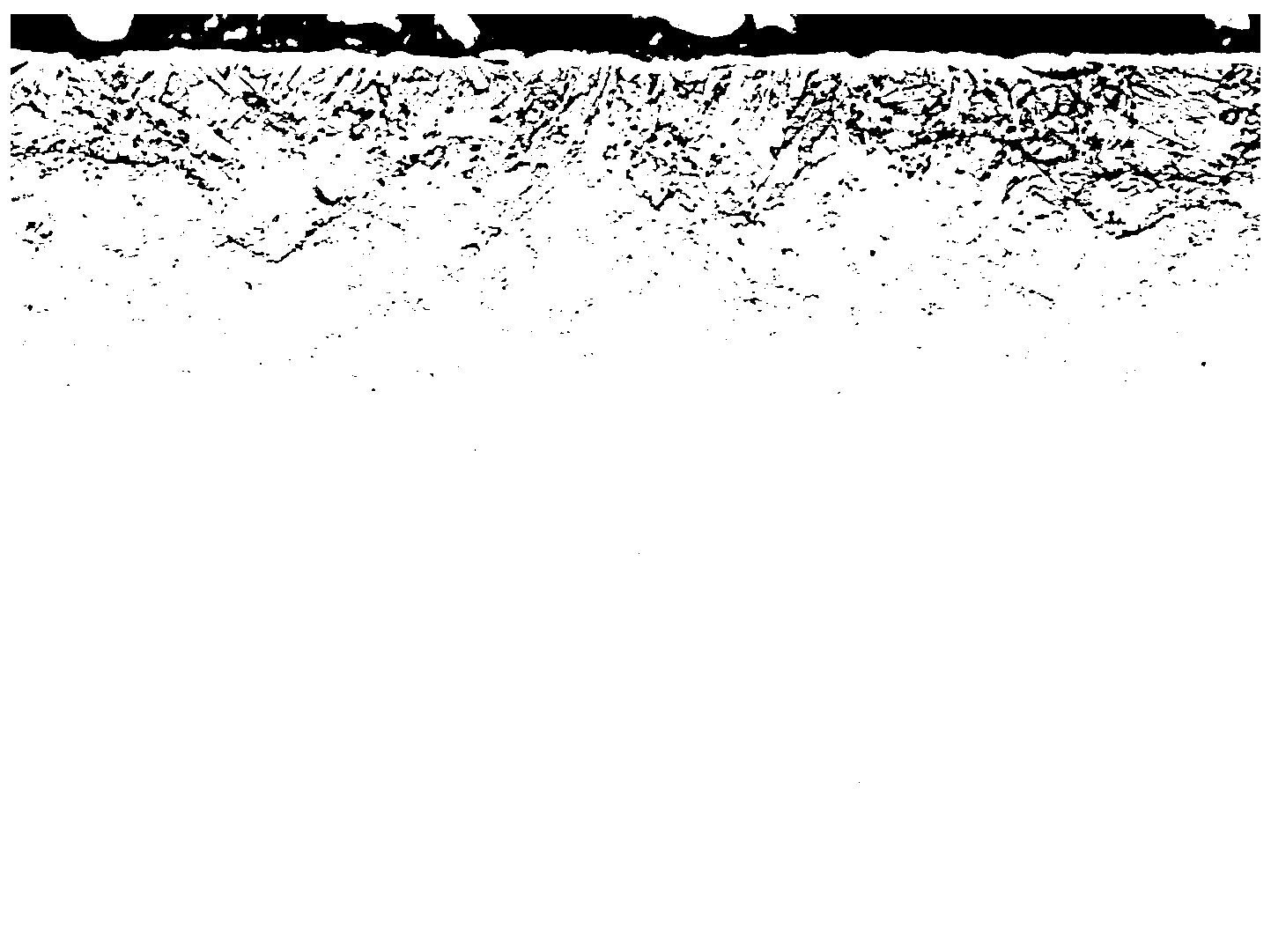

Ni Co Cr Al Y Si B coating layer capable of resisting thermal corrosion and its preparation method

InactiveCN1536033AExcellent thermal corrosion resistanceCorrosion weight gain is smallCoatingsHigh resistanceIon deposition

The present invention relates to coating technology, in the concrete, it discloses a NICoCrAlYSiB hot corrosion resisting high-temp. protection coating and its preparation method. Its element content composition includes: Co 28-35 wt%, Cr 17-23 wt%, Al 5-12 wt%, Y 0.1-0.6 wt%, Si 0.9-1.1 wt%, B 0.02-0.04 wt% and the rest is Ni. Said invention adopts electric arc ion deposition technique to prepare said protection coating, and as compared with existent technology said invented protection coating has highest resistance to hot corrosion and high temp. oxidative property, and its preparation process is low in cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Cr/CrN/(Ti, Al, Si, Cr)N composite hard coating and preparation method thereof

InactiveCN103789723AIncrease ionization rateImprove bindingVacuum evaporation coatingSputtering coatingIntermediate frequencyAlloy

The invention discloses a preparation method of a Cr / CrN / (Ti, Al, Si, Cr)N composite hard coating. The preparation method comprises the steps of pretreatment, heating, plasma cleaning, Cr adhesion layer preparation, CrN transition layer preparation, (Ti, Al, Si, Cr)N anti-wearing layer preparation and the like. As a plasma enhanced intermediate frequency reaction magnetron sputtering technology is adopted in the preparation method provided by the invention, the ionization rate of a target material is substantially increased, so that the surface nano-hardness of the prepared composite hard coating can reach above 34 GPa, and the membrane base bonding force grade of the hard coating is HF1-HF2 of German Standard VDI3198. Therefore, the preparation method is suitable for preparation of the coating for high-speed dry-type cutting stainless steel, iron-based high-temperature alloy, high-strength constructional steel and anti-wearing cast steel cutters. The coating is simple in process and suitable for industrial production.

Owner:SICHUAN UNIV

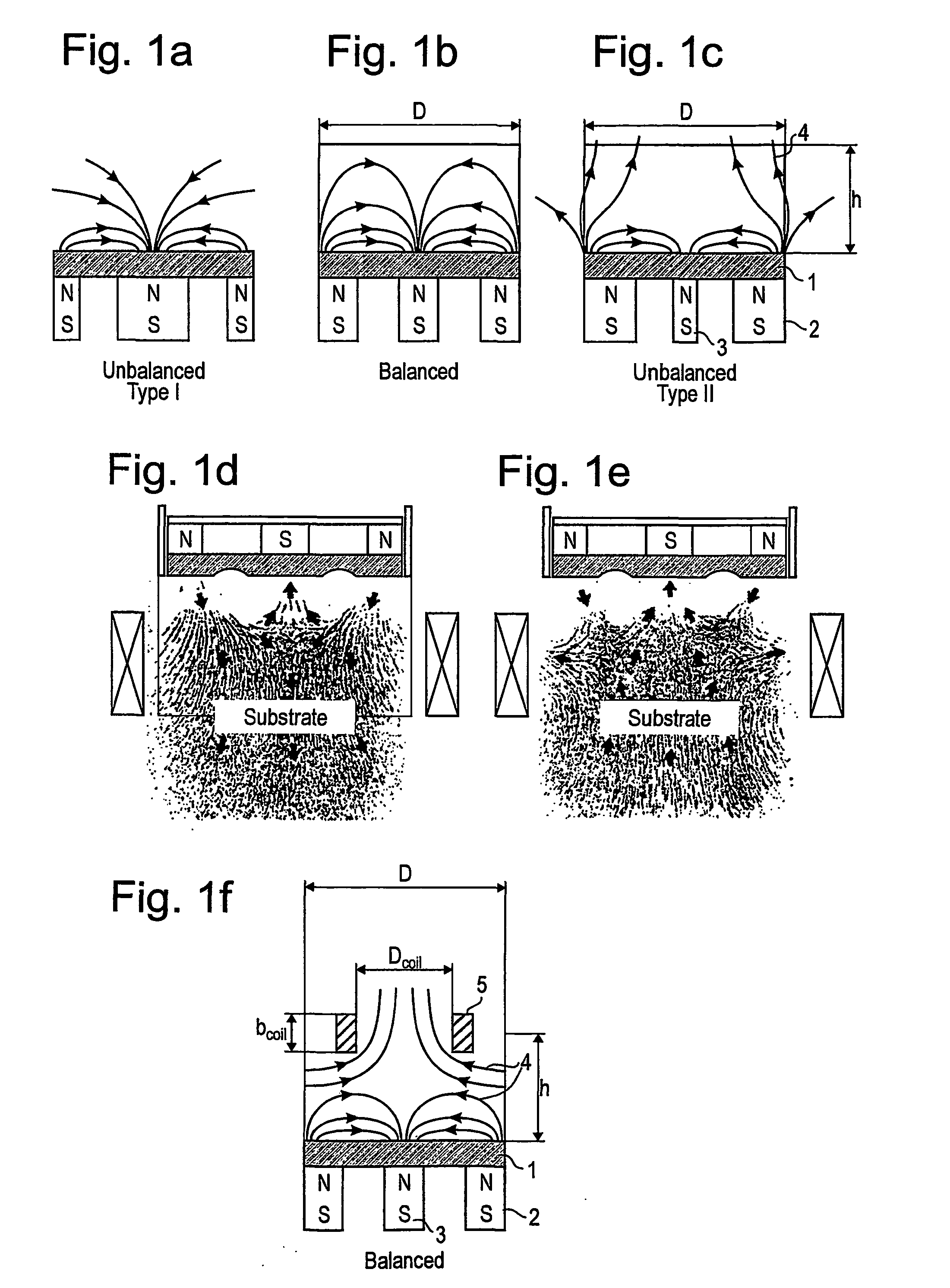

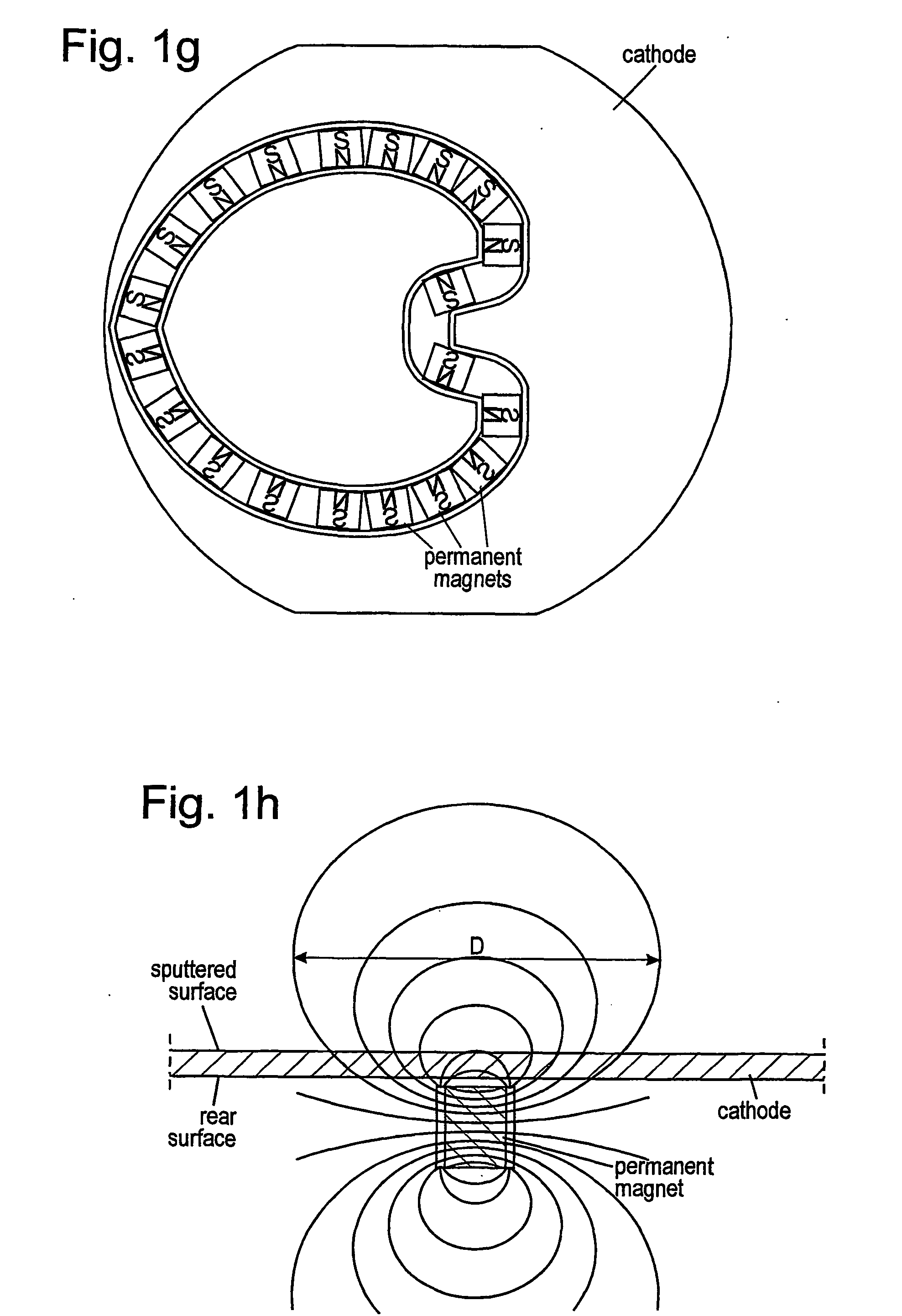

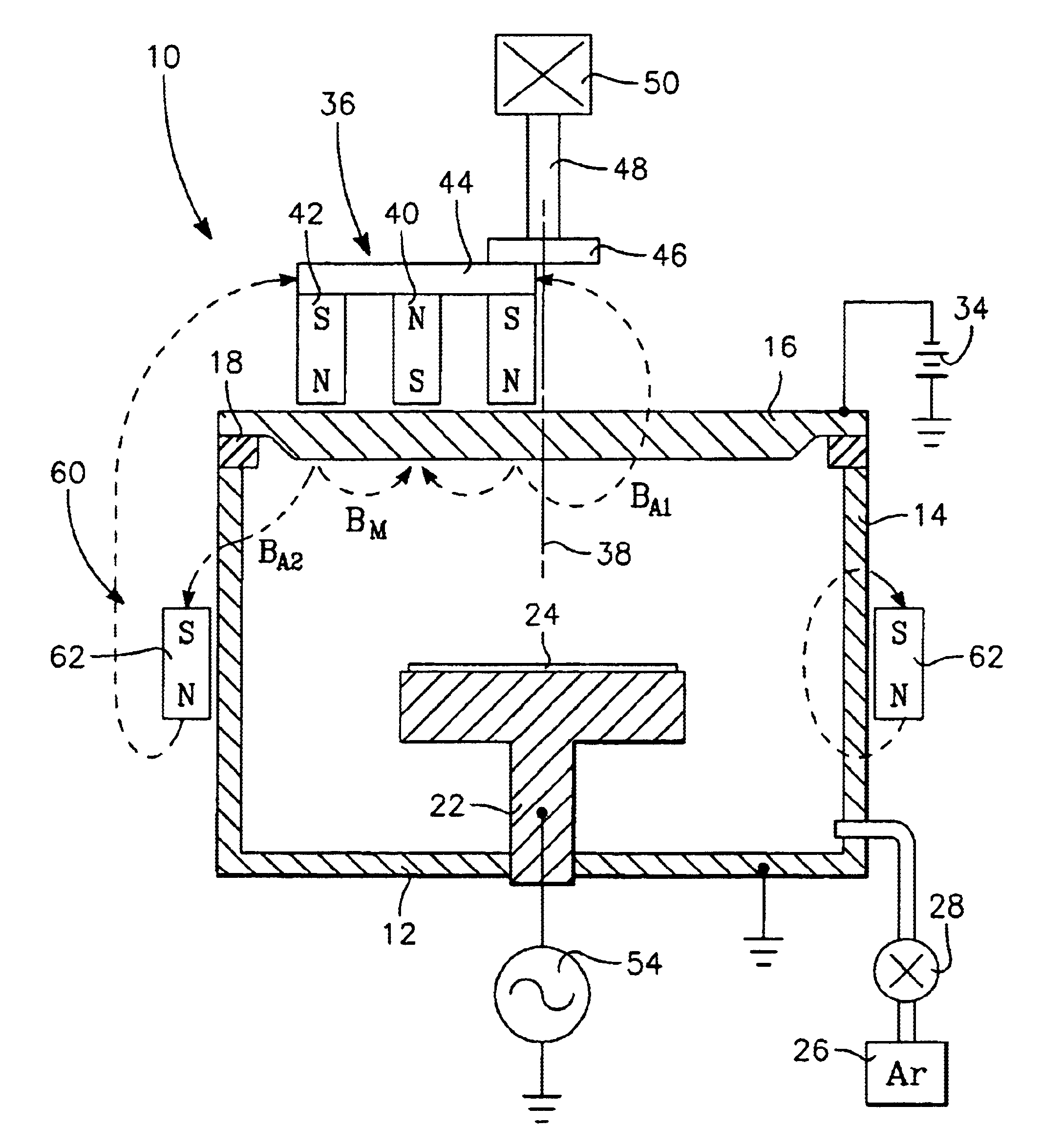

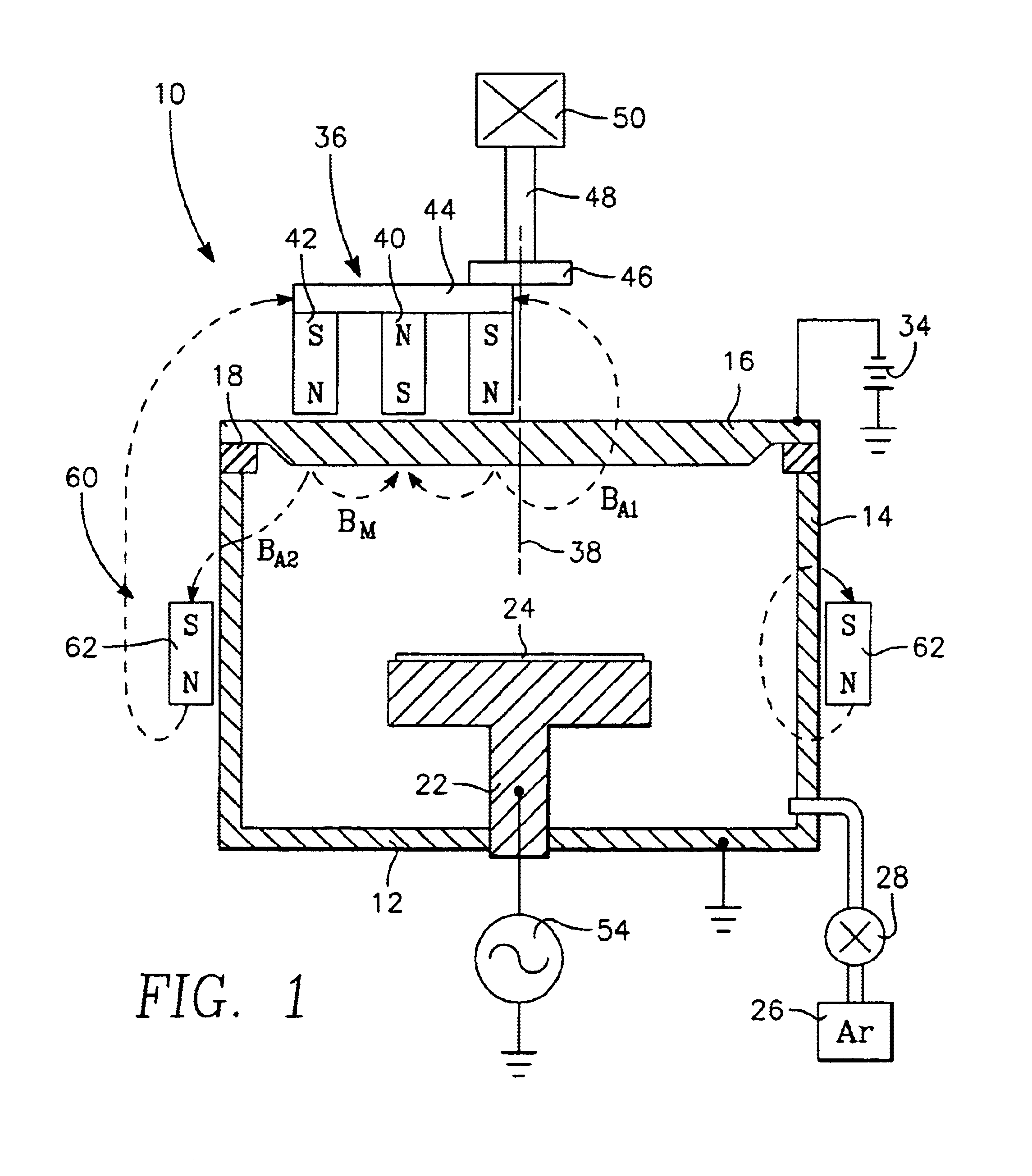

Auxiliary magnet array in conjunction with magnetron sputtering

InactiveUS6875321B2High densityIncrease ionization rateCellsElectric discharge tubesPhysicsElectromagnet

An array of auxiliary magnets is disclosed that is positioned along sidewalls of a magnetron sputter reactor on a side towards the wafer from the target. The magnetron preferably is a small, strong one having a stronger outer pole of a first magnetic polarity surrounding a weaker outer pole of a second magnetic polarity and rotates about the central axis of the chamber. The auxiliary magnets preferably have the first magnetic polarity to draw the unbalanced magnetic field component toward the wafer. The auxiliary magnets may be either permanent magnets or electromagnets.

Owner:APPLIED MATERIALS INC

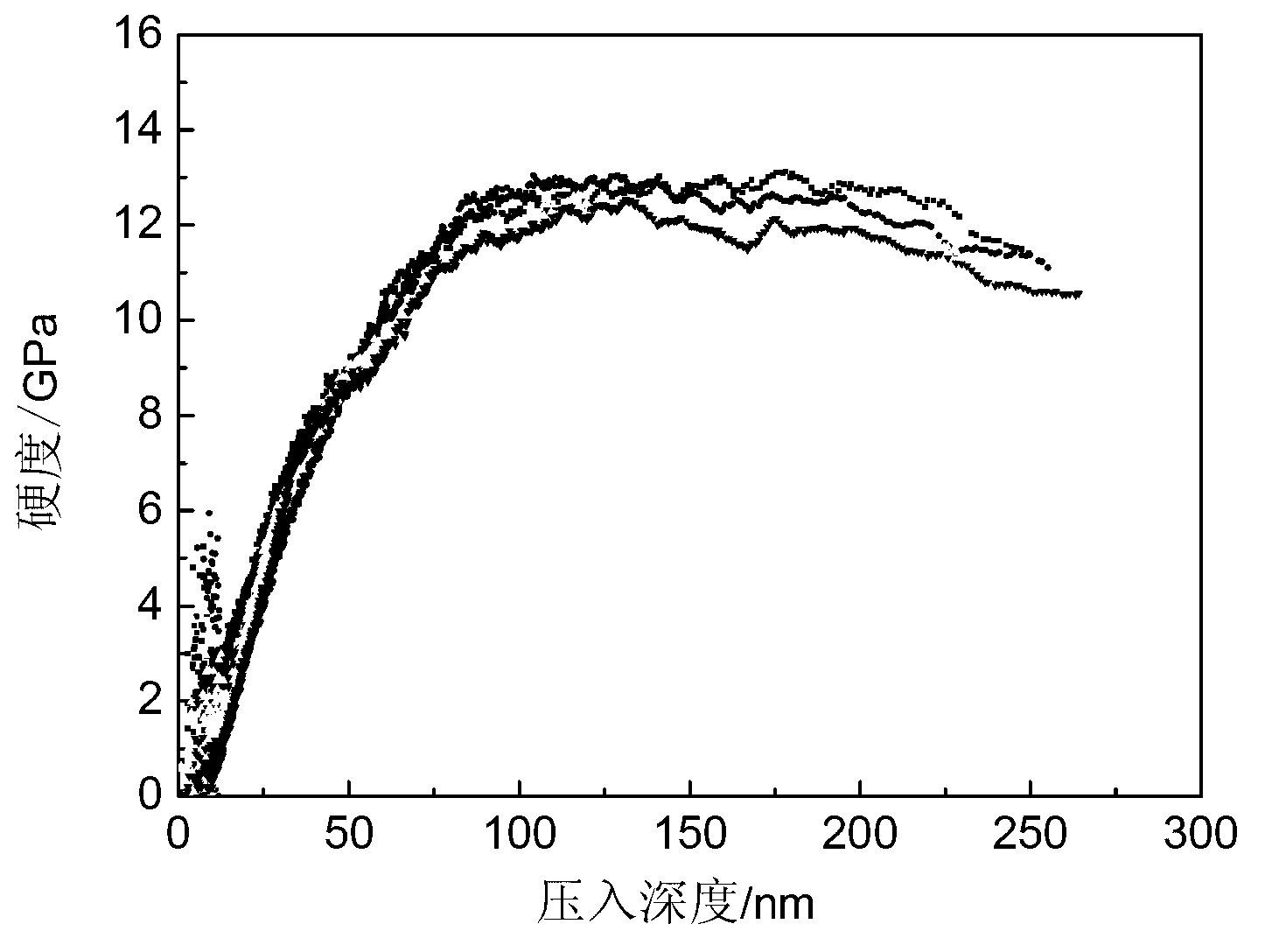

Preparation method of MoS2 composite thin film with high hardness and loss abrasion on surface of substrate

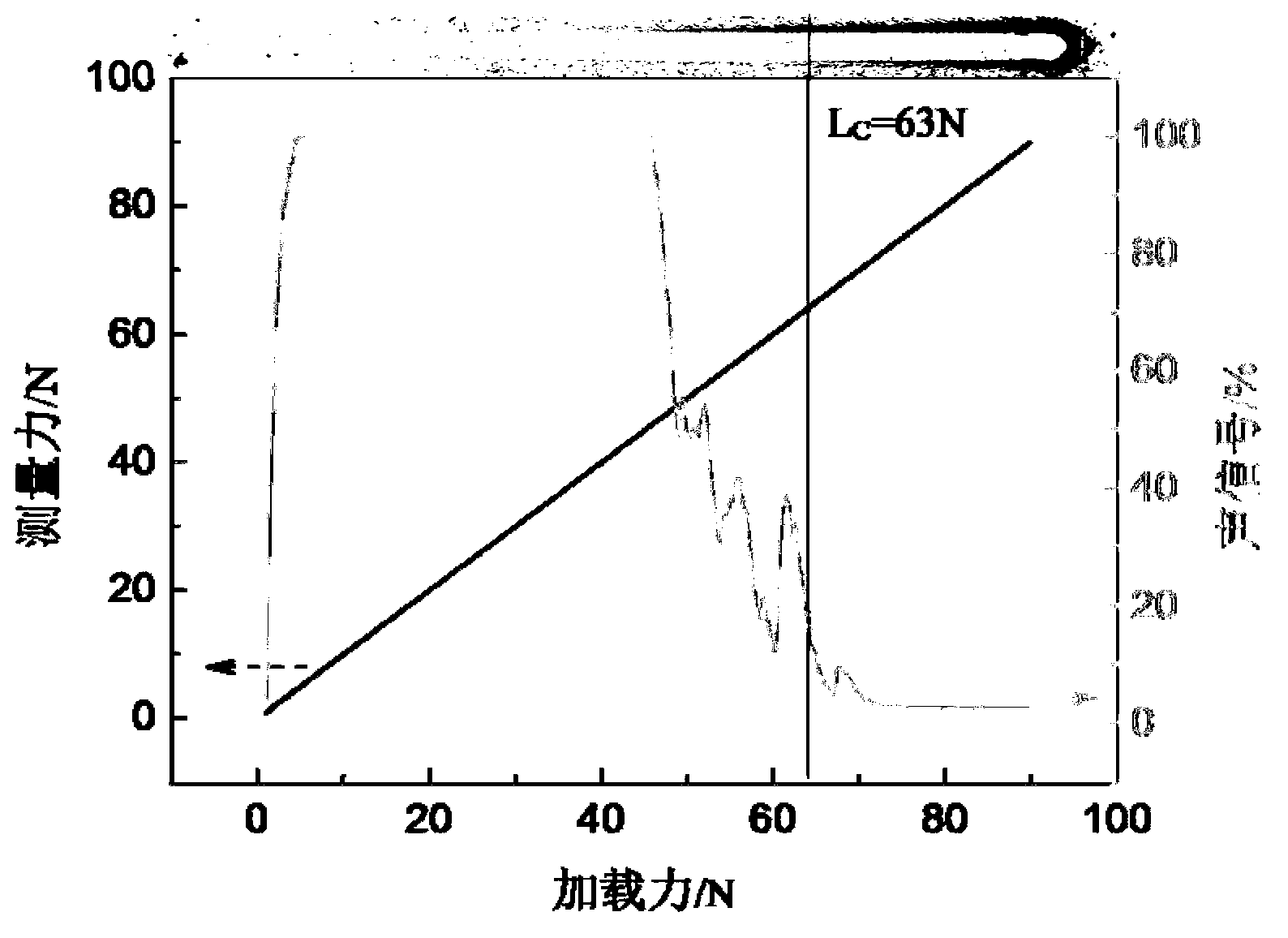

ActiveCN103060765AFast sputtering rateIncrease ionization rateVacuum evaporation coatingSputtering coatingComposite filmCritical load

The invention discloses a preparation method of a MoS2 composite thin film with high hardness and loss abrasion on a surface of a substrate. The method comprises the following step: sequentially depositing a metal Ti priming coat, a TiN transitional layer and a Ti / MoS2 composite thin film on the surface of the substrate by using a high power pulse magnetron sputtering technology combined with optimized process conditions to obtain the MoS2 composite thin film which is strong in film binding force and high hardness and has low frictional coefficient and wear rate in various frictional environments. The nano hardness of the composite thin film is over 11GPa, the critical load value is over 60N, and the frictional coefficients in room-temperature air with relative humidity of 30%, 50% and 70%, an N2 atmosphere and a hydraulic oil environment are below 0.055. Therefore, the substrate is effectively protected in frictional reduction, and the composite thin film has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

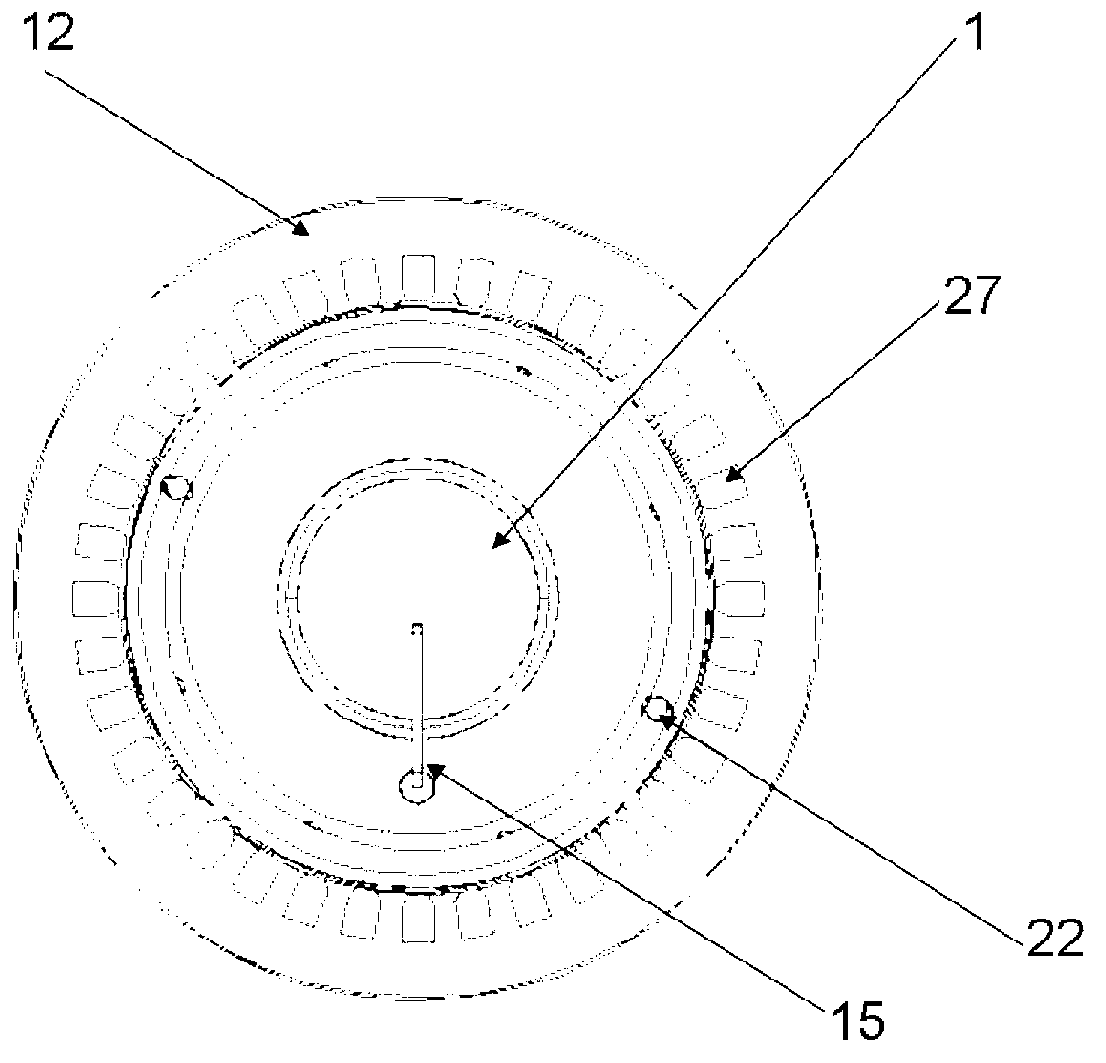

Non-balance magnetron sputtering thin film deposition apparatus for cusped magnetic field confined ICP reinforced ionization

InactiveCN101476110AIncrease ionization rateHigh degree of ionizationVacuum evaporation coatingSputtering coatingSputteringVolumetric Mass Density

The invention relates to a non-equilibrium magnetron sputtering film depositing device of a cusped magnetic field for restricting ICP enhancing ionization which belongs to the plasm film depositing technique field. The device has characteristic that a main body of the device is a non-equilibrium magnetic control; ICP enhance ionization discharge is added between the non-equilibrium magnetic control sputter target for increasing ionization degree of the magnetic control sputter product; three rings annular permanent magnets are added under the non-equilibrium magnetic control sputter target and is closed with the non-equilibrium magnetic control sputter magnetic field for generating a close magnetic field distribution along a discharge chamber wall which can restrict discharge plasm efficiently, increase ionization degree of the magnetic control sputter product and improve uniformity of discharge plasm space distribution. The device has advantages that the device can prepare a film with high quality based on improving density and space distribution uniformity of the non-equilibrium magnetic control sputter discharge plasm.

Owner:DALIAN UNIV OF TECH

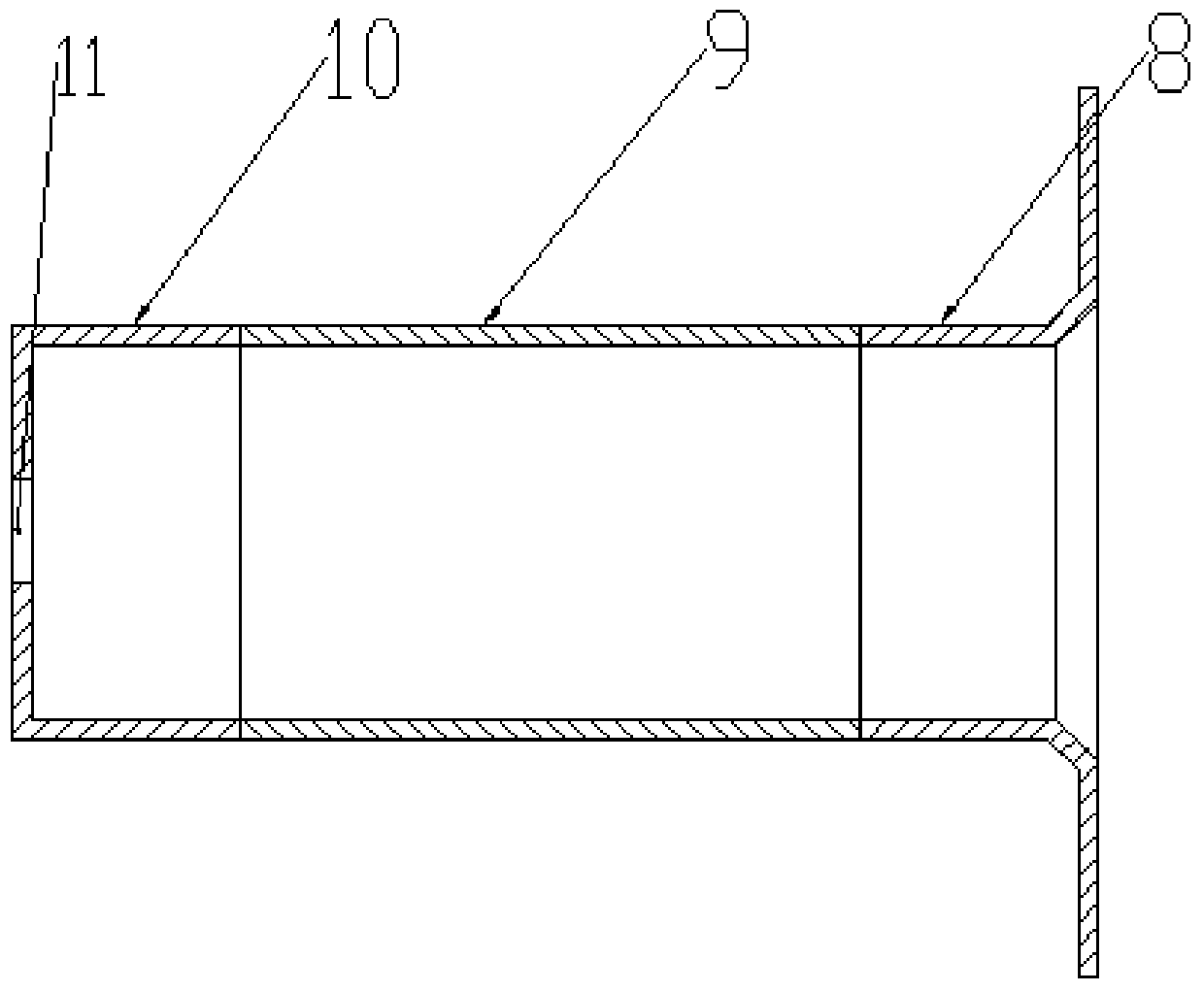

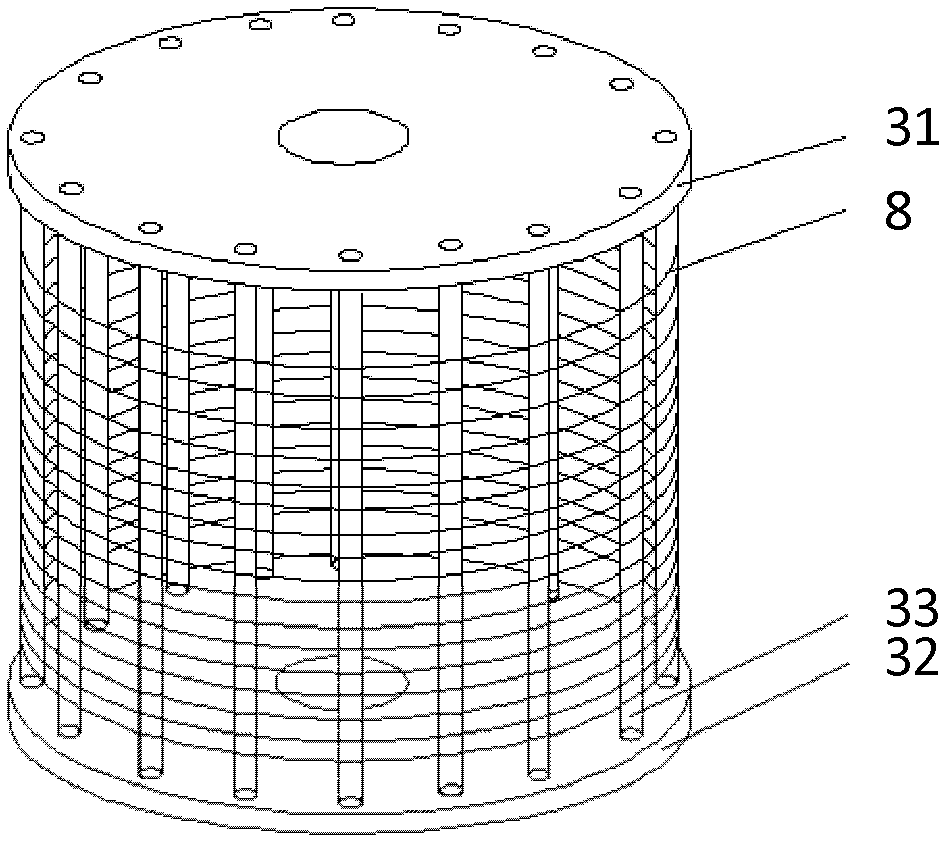

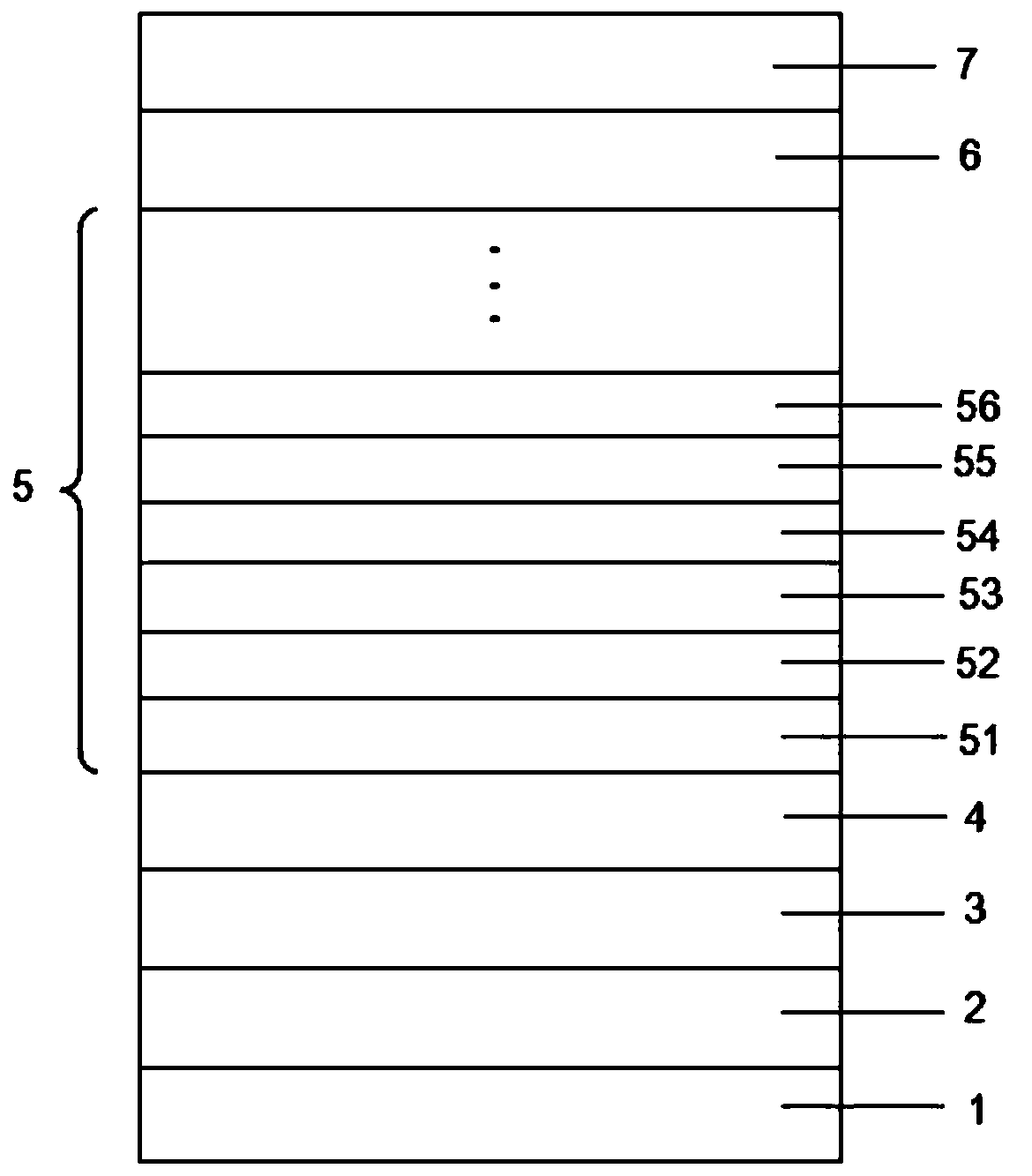

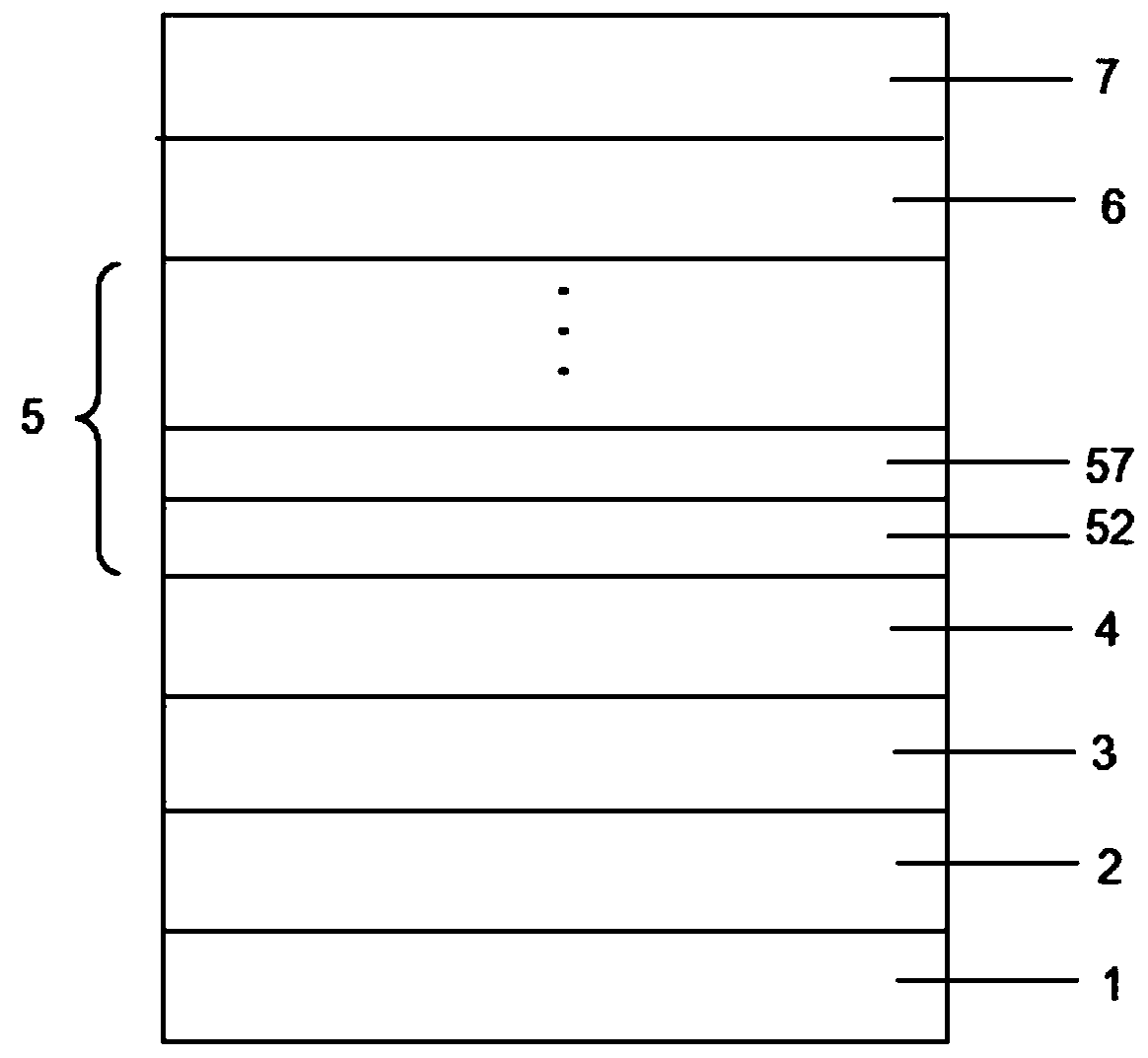

Multistage cusped magnetic field plasma thruster segmented ceramic channel

ActiveCN103775297AReduce plume divergence angleSmall plume divergence angleMachines/enginesUsing plasmaElectron temperatureDivergence angle

The invention discloses a multistage cusped magnetic field plasma thruster segmented ceramic channel, relates to the field of plasma thrusting, and aims to solve the problems of plume concussion of an outlet area of a multistage cusped magnetic field plasma thruster, large plume divergence angle, over-high wall temperature of a ceramic channel and low ionization rate. The front section of the ceramic channel is of a baffle structure, so that corrosion of the front end face of the thruster caused by electrons is decreased, the front section of the ceramic channel and an outlet permanent magnet form a magnet loop with a certain shielding function, the magnetic field intensity of the outlet plume area is reduced, the electrons more easily enter the channel to perform ionization, potential drop is concentrated in an outlet magnetic interface, the plume divergence angle is decreased, boron nitride ceramics of a middle section has a low secondary electron emission coefficient, the electron temperature and the ionization rate are high, heat insulation ceramics close to a rear section of an anodic area reduce anodic heat absorbed by the channel, the anodic heat is conducted and dissipated by the aid of an anodic bottom surface, heat dissipation of the permanent magnet is decreased, and demagnetization of the permanent magnet due to high temperature is avoided. The multistage cusped magnetic field plasma thruster segmented ceramic channel is applicable to the field of plasma thrusting.

Owner:HARBIN INST OF TECH

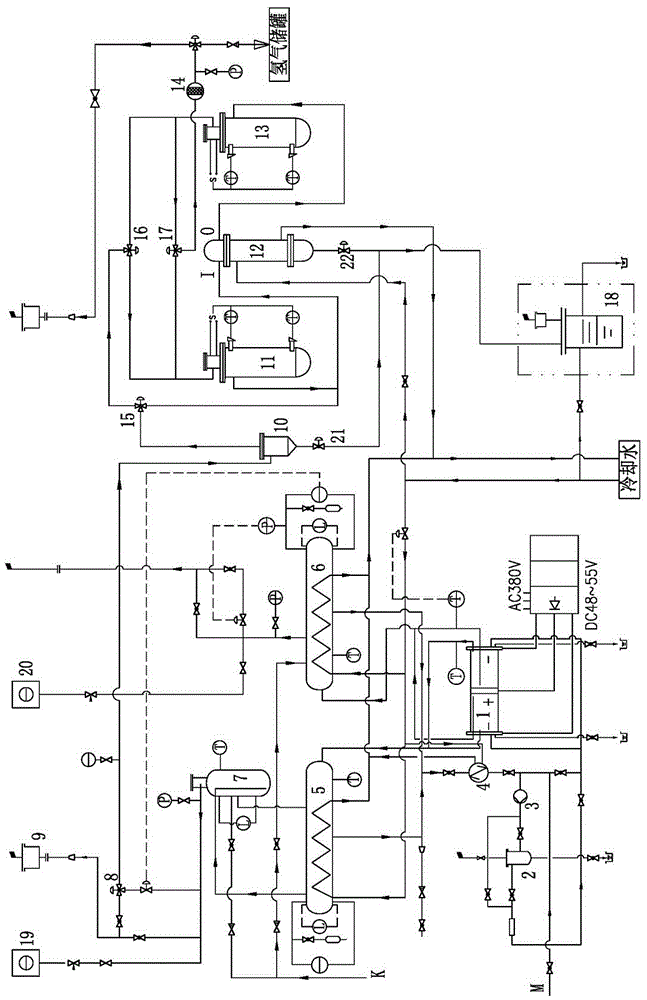

Alkaline solution electrolytic hydrogen production device and hydrogen production method

ActiveCN106119885AIncrease ionization rateSpeed up electrolysisCellsDispersed particle separationGas phaseOxygen

The invention discloses an alkaline solution electrolytic hydrogen production device in the field of hydrogen production devices. The alkaline solution electrolytic hydrogen production device comprises a direct current power supply, an electrolytic cell, a hydrogen separator and an oxygen separator, wherein the bottom of the electrolytic cell is provided with an alkaline solution inlet; the upper part of an anode zone of the electrolytic cell communicates with a circulating liquid inlet of the oxygen separator, and a gas phase outlet at the top of the oxygen separator communicates with the atmosphere through a valve; the upper part of a cathode zone of the electrolytic cell communicates with a circulating liquid inlet of the hydrogen separator, a gas phase outlet at the top of the hydrogen separator is connected to a hydrogen washing device, and the hydrogen washing device communicates with an inlet of a gas-water separator through a three-way valve I; circulating liquid outlets at the bottoms of the hydrogen separator and the oxygen separator communicate with the alkaline solution inlet sequentially via an alkaline solution cooler, an alkaline solution circulating pump and an alkaline solution filter; and a gas outlet of the gas-water separator is connected to a hydrogen storing tank through a three-way valve II and a drying system. A KOH or NaOH solution with a 25-30% mass concentration is used as an electrolyte. The device can safely produce hydrogen and is high in hydrogen producing efficiency, low in equipment investment and great in production continuity.

Owner:YANGZHOU CHUNGDEAN HYDROGEN EQUIP

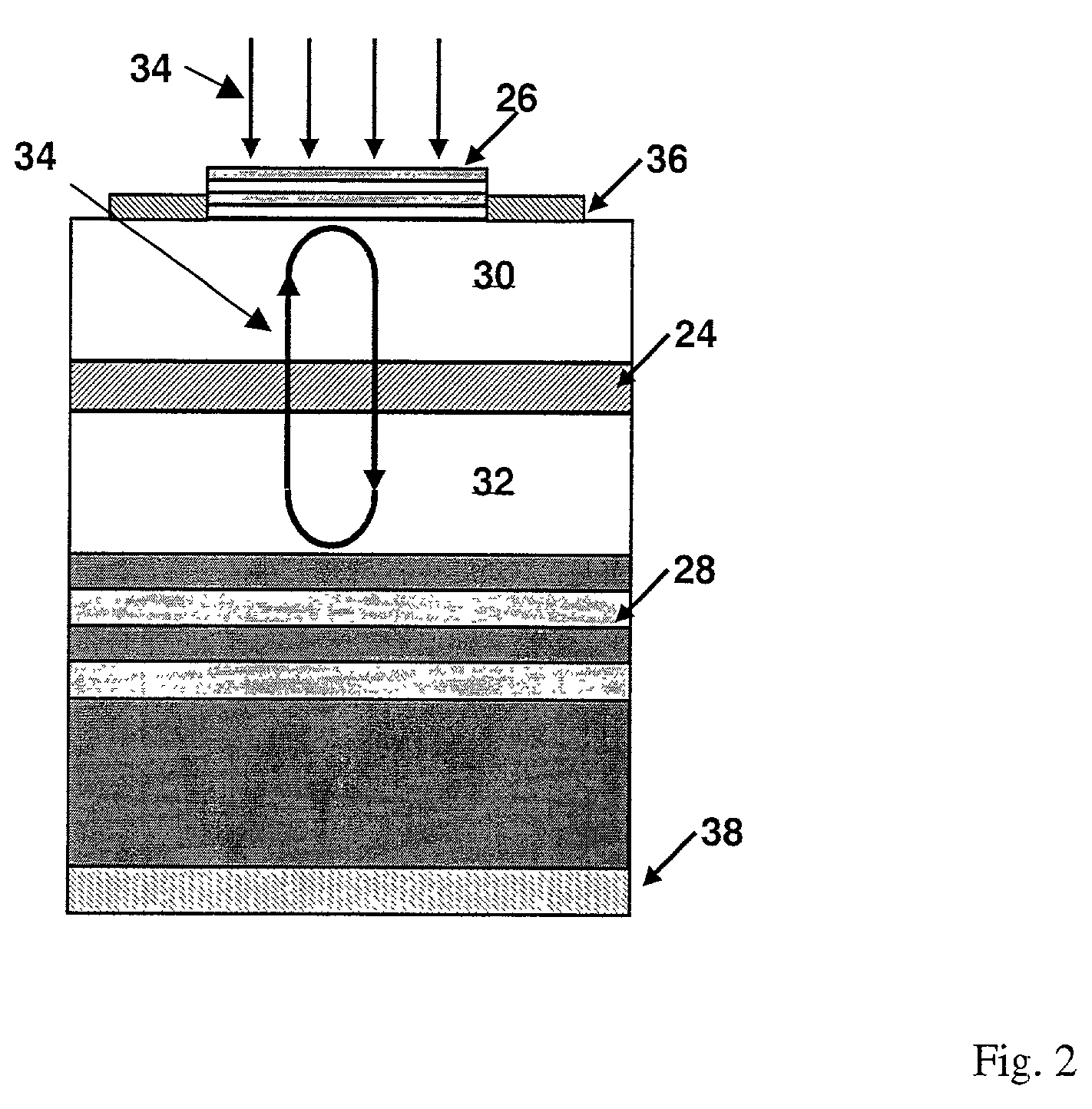

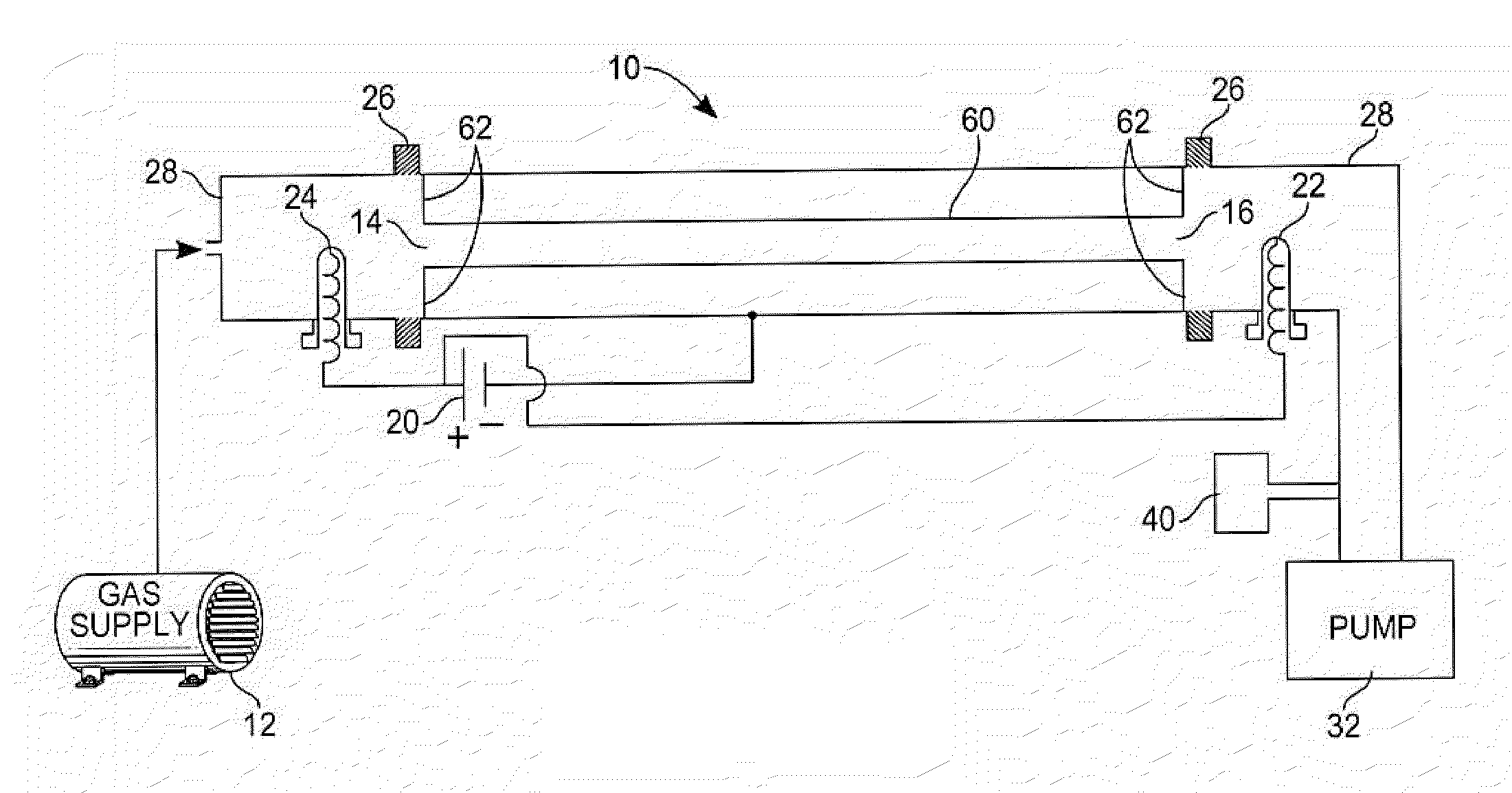

Method of coating inner and outer surfaces of pipes for thermal solar and other applications

ActiveUS20090311443A1Increase ionization rateReduce quality problemsSolar heating energyLiquid surface applicatorsMetallurgyMetal

In accordance with one embodiment of the invention, a workpiece having a smaller cross sectional dimension (e.g., diameter) is centered within a workpiece having a larger cross sectional dimension, with the workpieces being electrically connected. In this embodiment, surfaces of the two workpieces can be coated simultaneously, either with the same coating material or different coating materials. In another embodiment, holes are located along the length of an internal metal tube which functions as a gas distribution injector and anode holder. A ceramic liner may be placed inside the internal metal tube, with a conductive wire within the ceramic liner. The internal metal tube may be biased as a cathode, while the internal wire is biased as an anode. The hollow cathode effect is applied in all spaces directly adjacent to the surface or surfaces being coated. In some applications, different surfaces being coated are biased at different voltages.

Owner:AGM CONTAINER CONTROLS

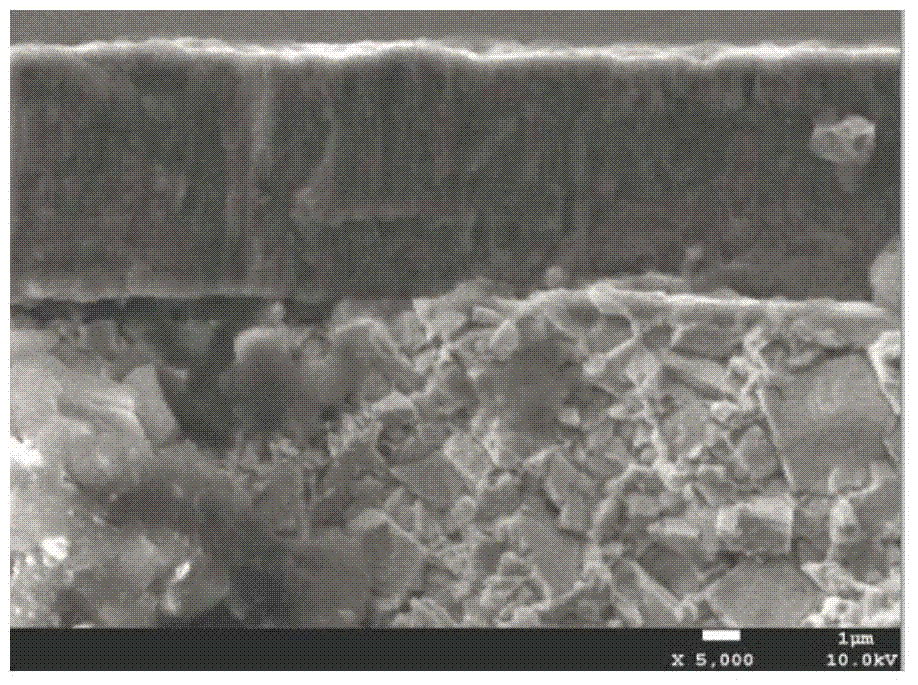

PVD chromium based ceramic composite coating piston ring and method for producing the same

InactiveCN101430004AOvercome the hardnessOvercome uniformity issuesPiston ringsVacuum evaporation coatingCeramic compositePiston ring

The invention discloses a PVD chromium base ceramic composite coating piston ring and a preparation method thereof, and the piston ring is manufactured by plating a chromium base ceramic composite coating on a basal body of the piston ring which is treated by nitriding by adopting high power electric arc discharge method; the chromium base ceramic composite coating is composed of a bonding layer, a main wearing layer and an anti-attrition layer, wherein, the bonding layer is binded with the basal body of the piston ring in a metallurgical way, the main wearing layer is arranged on the bonding layer, and the anti-attrition layer is positioned on the surface of the main wearing layer; the bonding layer is Cr, the main wearing layer is a Cr / CrN multilayer coating formed by the Cr and the CrN which are alternately arranged, and the anti-attrition layer is a Cr / Cr2O3 multilayer coating formed by the Cr and the Cr2O3 that are alternately arranged. The coating structure has reasonable design, and the manufactured coating has good cementing property, high hardness and good lubricating property. Furthermore, the method used for manufacturing the piston ring has no pollution in the preparation process, and overcomes the serious problem of environmental pollution of the conventional electrodeposited chromium; as the manufactured coating has better abrasion resistant and corrosion resistant performance compared with the electrodeposited chromium, the service life of the piston ring is greatly prolonged.

Owner:WUHAN UNIV

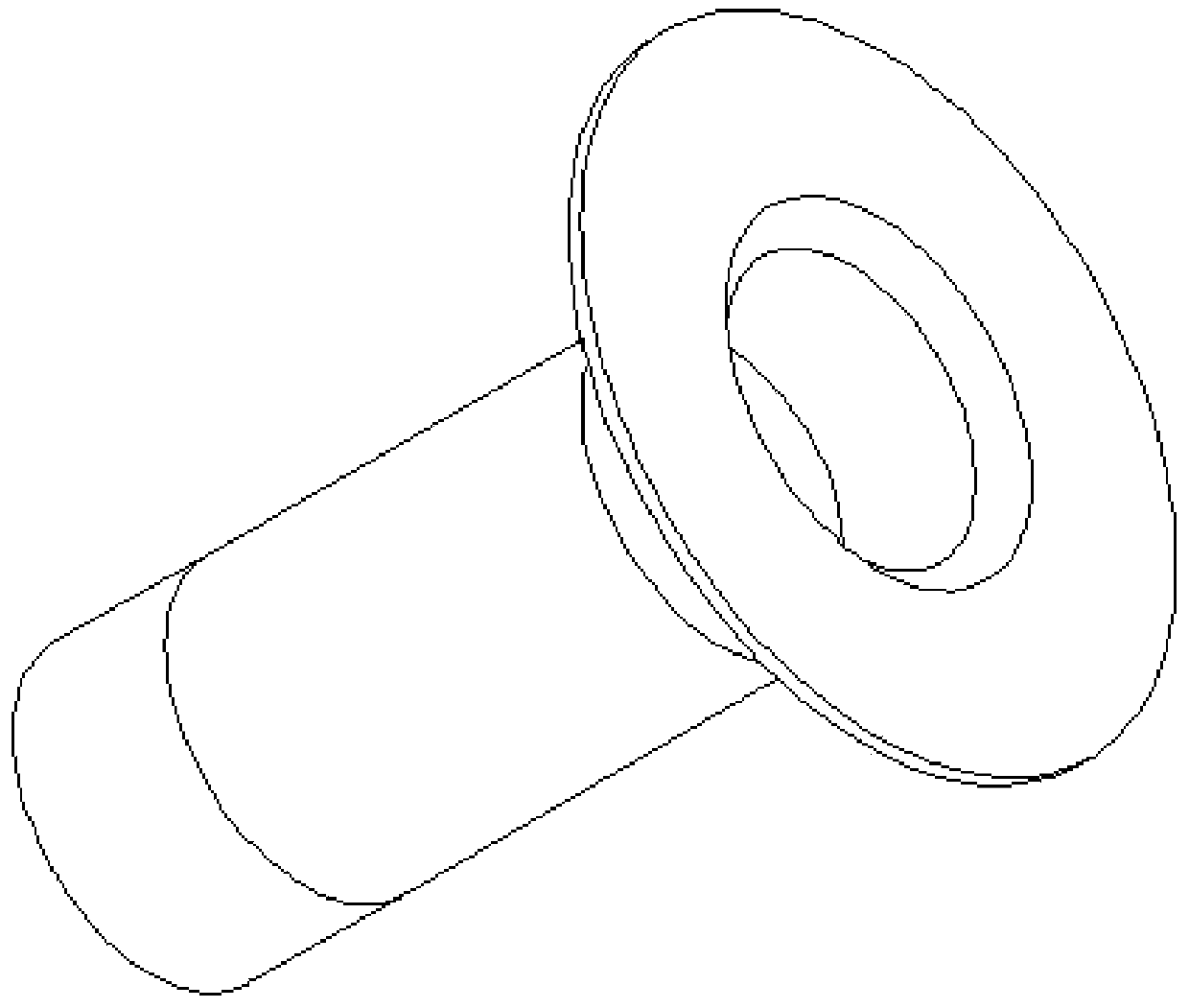

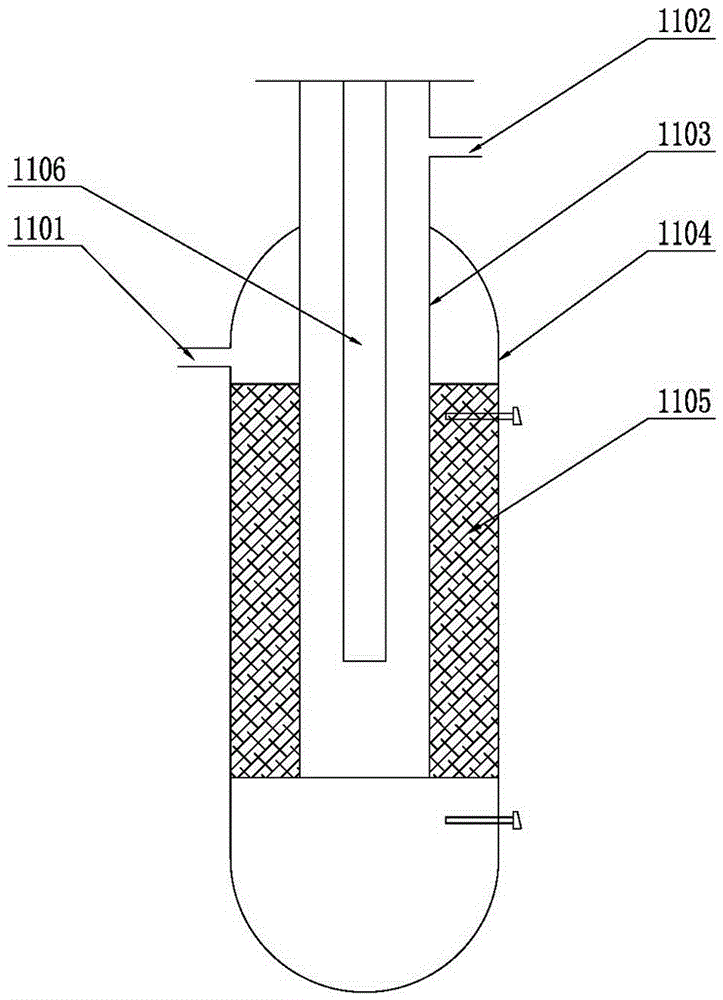

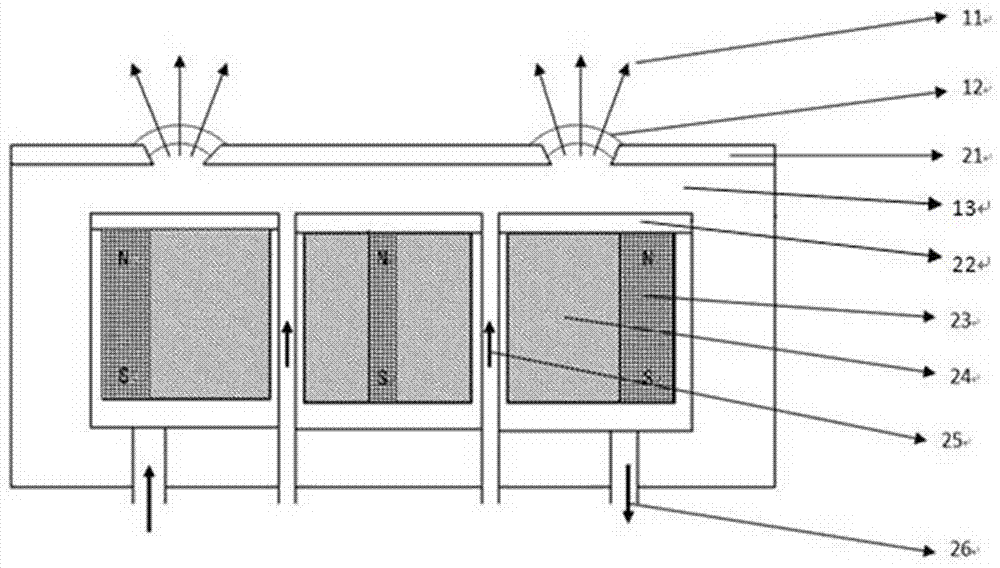

Hollow anode for plasma thruster of cusped magnetic field

InactiveCN104675650AImprove anode lifeImprove efficiencyMachines/enginesUsing plasmaIonizationNuclear magnetic resonance

The invention provides a hollow anode for a plasma thruster of a cusped magnetic field, and relates to a plasma thruster of a cusped magnetic field. By the hollow anode for the plasma thruster of the cusped magnetic field, the problems that a permanent magnet is demagnetized and the service life of a thrust is shortened due to the fact that an anode of the existing thruster of a cusped magnetic field is over hot are solved. The ionization rate of the thruster is increased, and the performance of the thruster is further improved. The hollow anode for the plasma thruster of the cusped magnetic field comprises a gas distributor, a buffering cavity and a ceramic sleeve, wherein a gas supply piece comprises a guide tube and a cavity; and the gas distributor comprises the gas supply piece and a distributor bottom plate. The hollow anode for the plasma thruster of the cusped magnetic field is used in the field of plasma thrusters of the cusped magnetic field.

Owner:HARBIN INST OF TECH

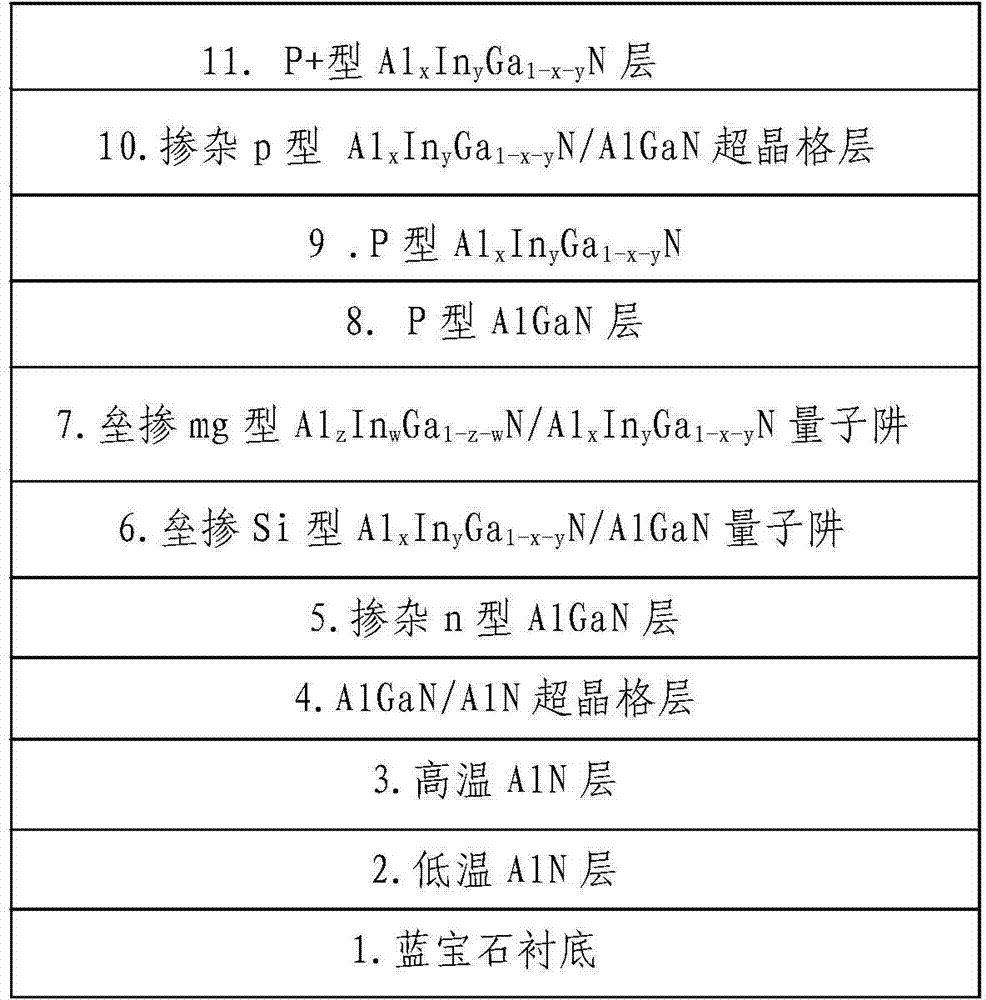

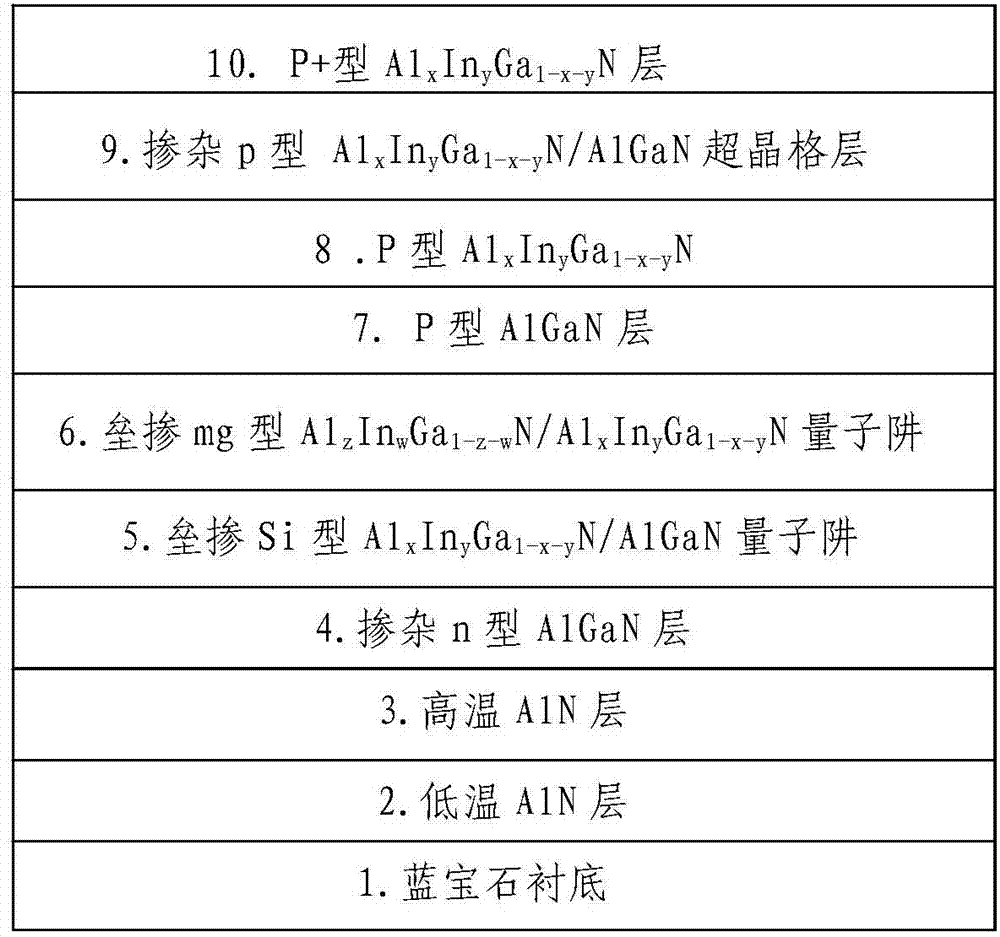

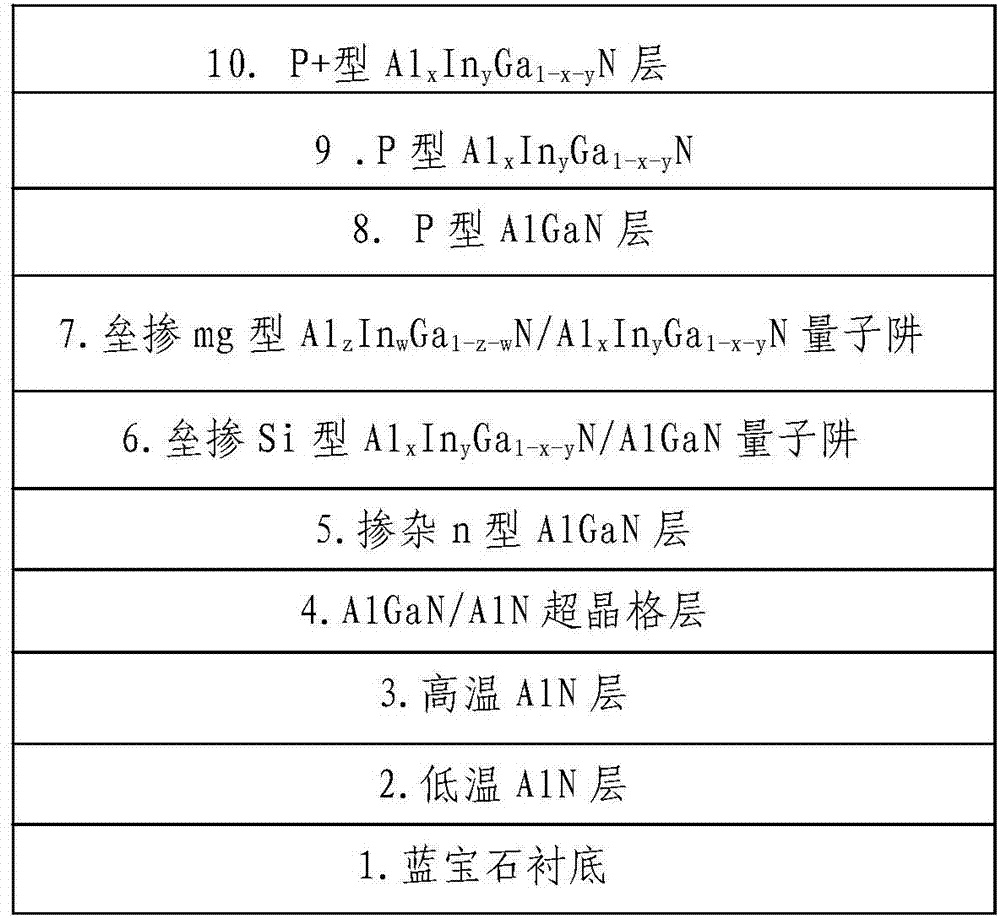

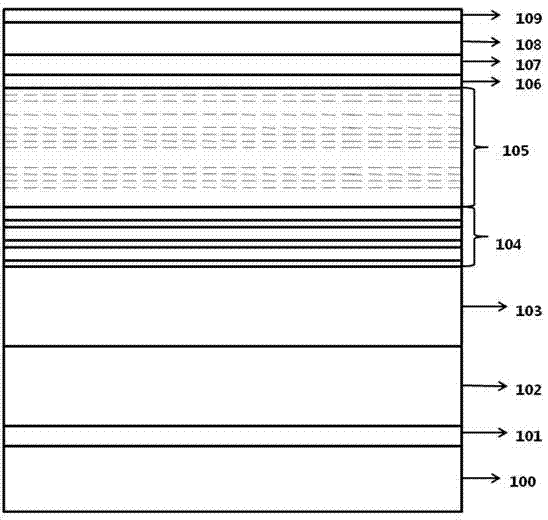

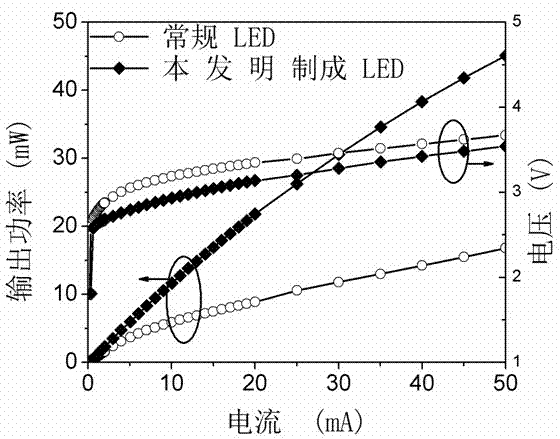

Method for epitaxial growth of ultraviolet LED with high luminous efficacy

The invention provides a new method for epitaxial growth of an ultraviolet LED. By the adoption of the method for epitaxial growth of the ultraviolet LED, the growth difficulty can be greatly lowered, and the radiant power of the ultraviolet LED is greatly increased. An AlGaN / AlxInyGa1-x-y layer is grown for a plurality of periods, wherein x, y, z and w meet the following requirements for x

Owner:西安利科光电科技有限公司

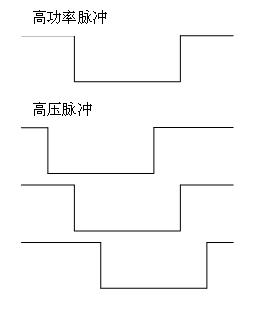

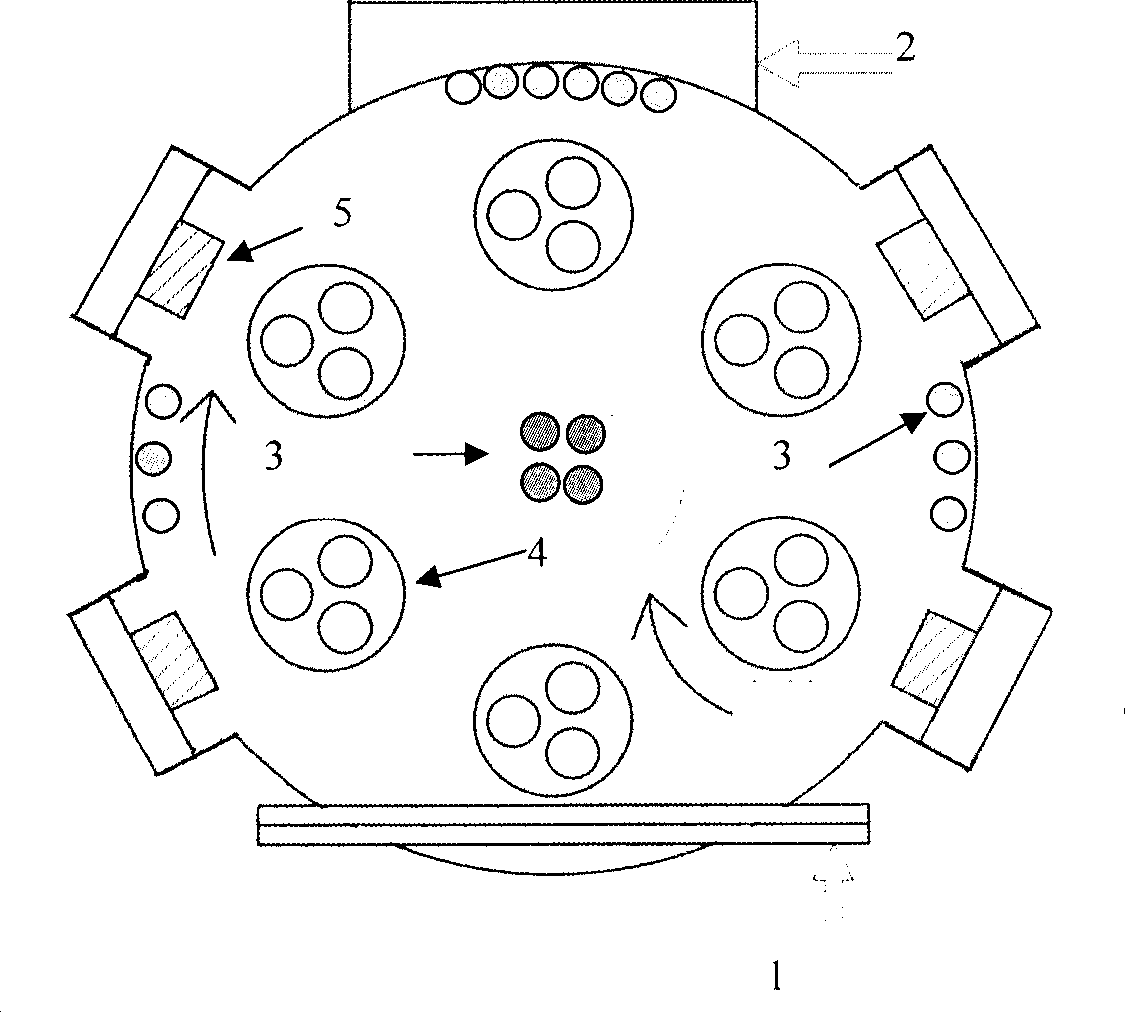

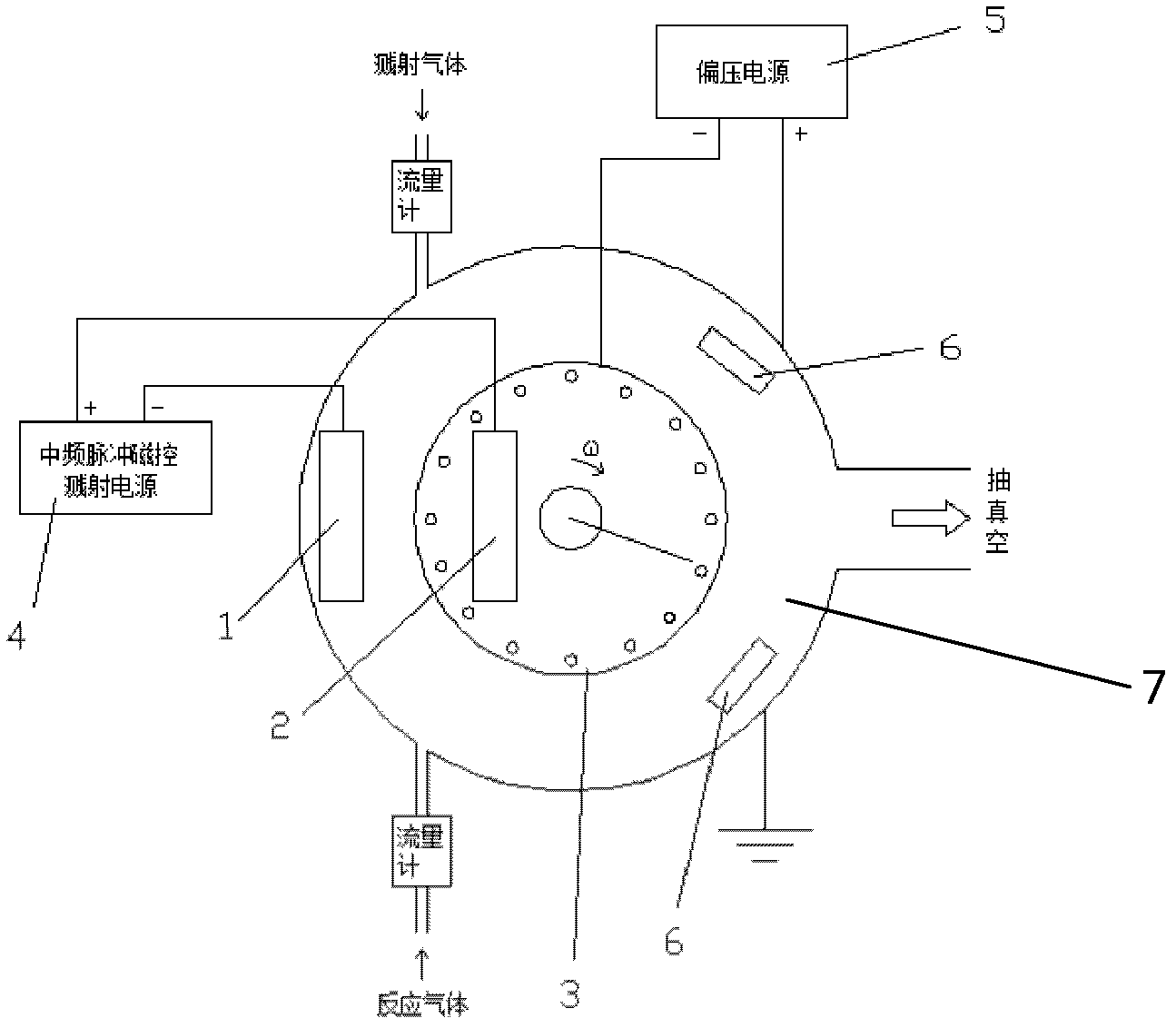

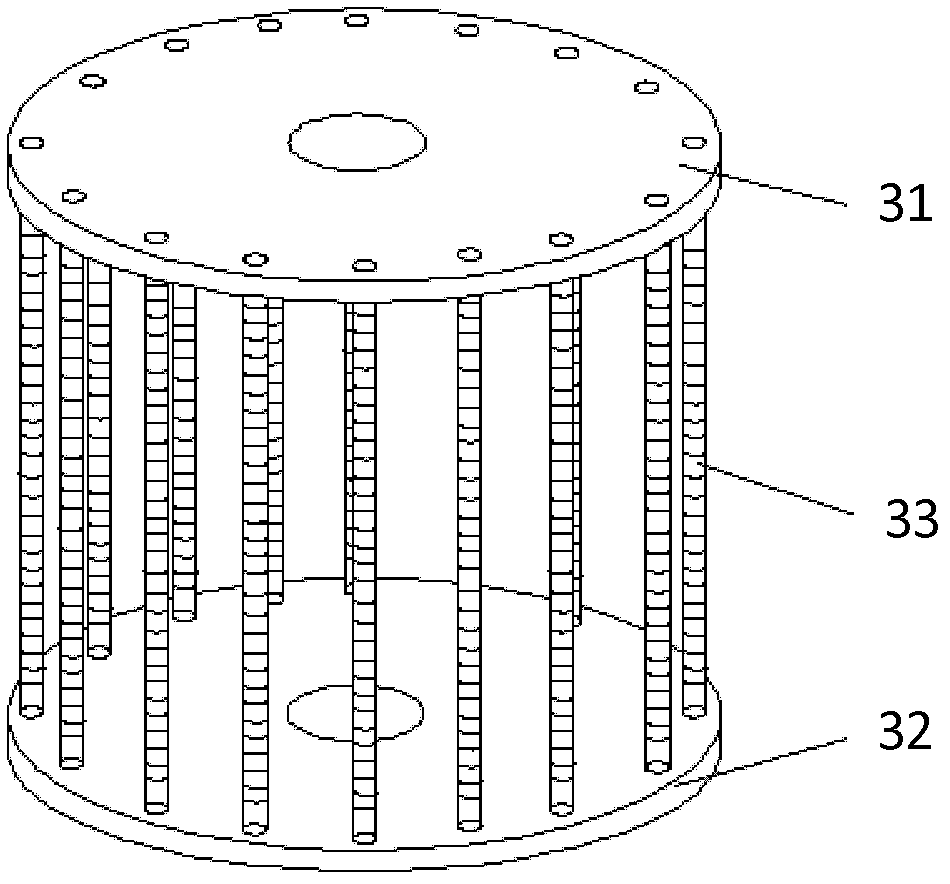

Device and method for depositing film on SiC fiber surface

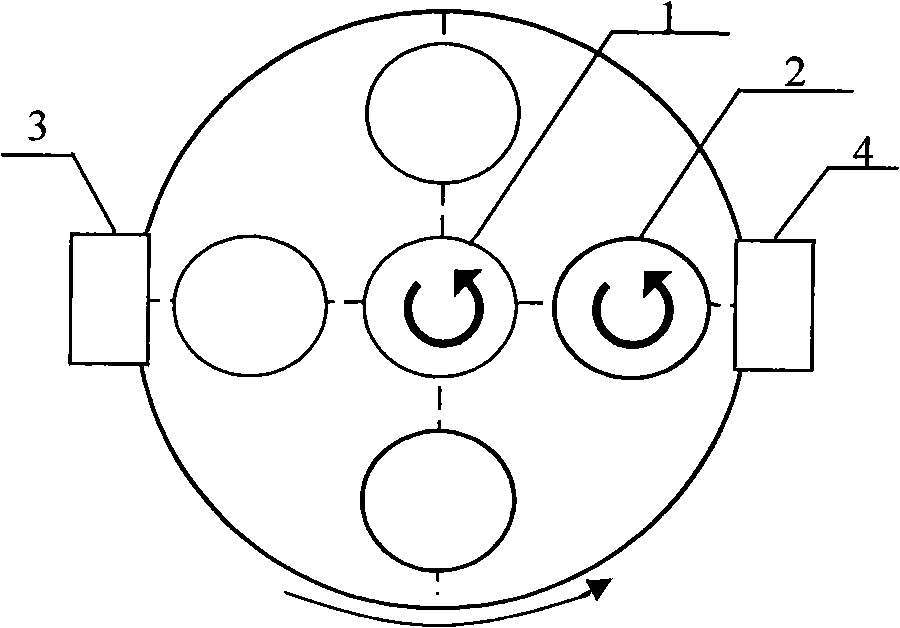

InactiveCN102251224AUniform thicknessPrevent escapeVacuum evaporation coatingSputtering coatingIntermediate frequencySputter deposition

The invention relates to vacuum coating magnetron sputtering deposition technology, and particularly a device and a method for depositing a film on a SiC fiber surface; on one hand, a film with a uniform thickness is deposited on a continuous SiC fiber surface; on the other hand, the problem of target material poisoning of compound film deposition is solved, and the continuity and stability of the deposition process is realized. The device is provided with a target material I, a target material II, a workpiece rotating shelf, an intermediate-frequency pulsed magnetron sputtering power supply, a magnetron sputtering vacuum chamber; the workpiece rotating shelf is disposed in the magnetron sputtering vacuum chamber; the target material I and the target material II are facingly disposed inside and outside the workpiece rotating shelf in the magnetron sputtering vacuum chamber; a cathode of the intermediate-frequency pulsed magnetron sputtering power supply is connected to the target material I; and an anode of the intermediate-frequency pulsed magnetron sputtering power supply is connected to the target material II. According to the invention, the gas flow, the reaction gas types, the sputtering time and the like in the vacuum chamber of the magnetron sputtering device are adjusted so as to realize the deposition of metals or compound films with different types and different thicknesses on a continuous SiC fiber surface, and to realize the surface modification of the SiC fiber.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

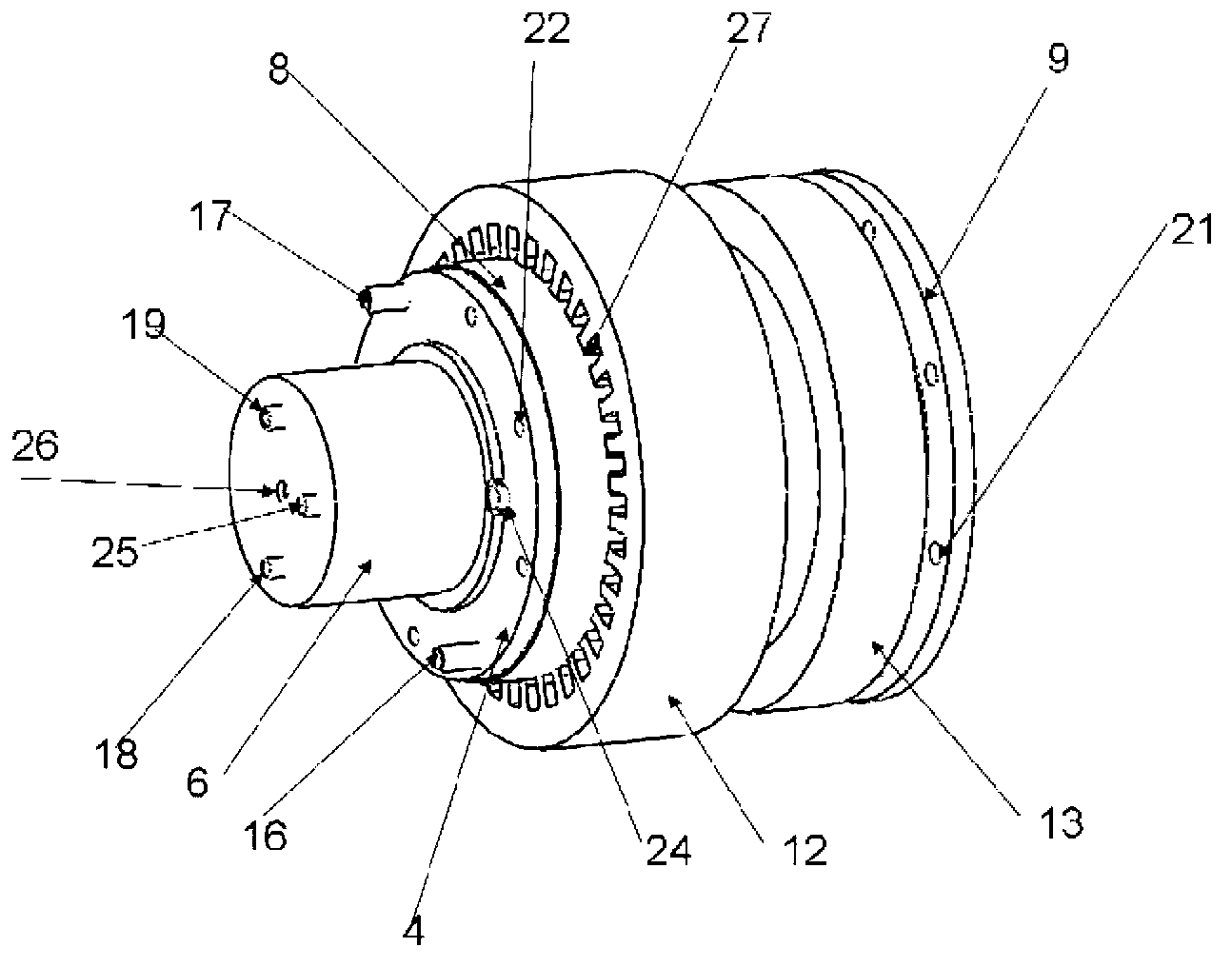

Compact and efficient cold cathode arc source of quasi diffusion arc

ActiveCN102936717AFast movementShort stayVacuum evaporation coatingSputtering coatingPhysicsSource structure

The invention relates to the technical field of preparation of films and coatings, particularly to a compact and efficient cold cathode arc source of a quasi diffusion arc. The cold cathode arc source is composed of an arc source head and a control magnetic field group, wherein the arc source head comprises a target, a target base, a target base shielding cover, a target base plate, an arc striking device and a permanent magnet device; the control magnetic field group comprises a flange sleeve, a flange sleeve insulating bush, a dipolar radial rotating magnetic filed generating device, an axial focusing guiding magnetic field generating device, a coaxial focusing magnetic field magnetic yoke and a flange sleeve shielding cover; and the arc source head is connected with the bottom of the flange sleeve through the target base plate to form a whole arc source structure, and connected with a finance through a flange arranged in front of the flange sleeve. Arc spots are distributed on the whole target surface under the comprehensive action of a certain magnetic field intensity and rotary frequency, the power density of the arc spots is reduced, the quasi diffusion arc state is achieved, launch of large grains is reduced, simultaneously, purified high-density plasmas are extracted through the axial focusing guiding magnetic field, and the transmission efficiency is improved.

Owner:WENZHOU POLYTECHNIC

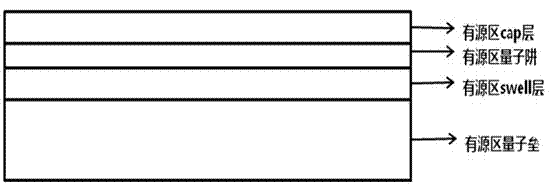

Green nitride light-emitting diode (LED) epitaxial wafer and growth method thereof

InactiveCN102969417AEase the separationPromote excitationSemiconductor devicesLuminous fluxLight-emitting diode

The invention relates to a green nitride LED epitaxial wafer and a growth method thereof, and belongs to the technical field of semiconductor photo-electricity. The method is characterized in that an InGaN material layer with a low content of In components is grown between a quantum barrier and a quantum well in each quantum well active area when a plurality of quantum well active areas are grown; a quantum barrier is grown on a cap layer in a last quantum well active area, a hole injection layer is grown on the quantum well, and a p-AlGaN electronic blocking layer is grown on the hole injection layer. According to the green nitride LED epitaxial wafer and the growth method thereof, the process is reasonable, and the production is facilitated; LED chips are manufactured through a standard chip process, so that the internal quantum efficiency is improved, and the hole injection efficiency is improved greatly; and manufactured chips are high in luminous flux after being packaged, the inverse antistatic capacity reaches more than ten thousand volts, the electricity is not leaked under 8-volt inverse voltage measurement, and the working voltage is smaller than 3.1 volts under a 15 mA forward current.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

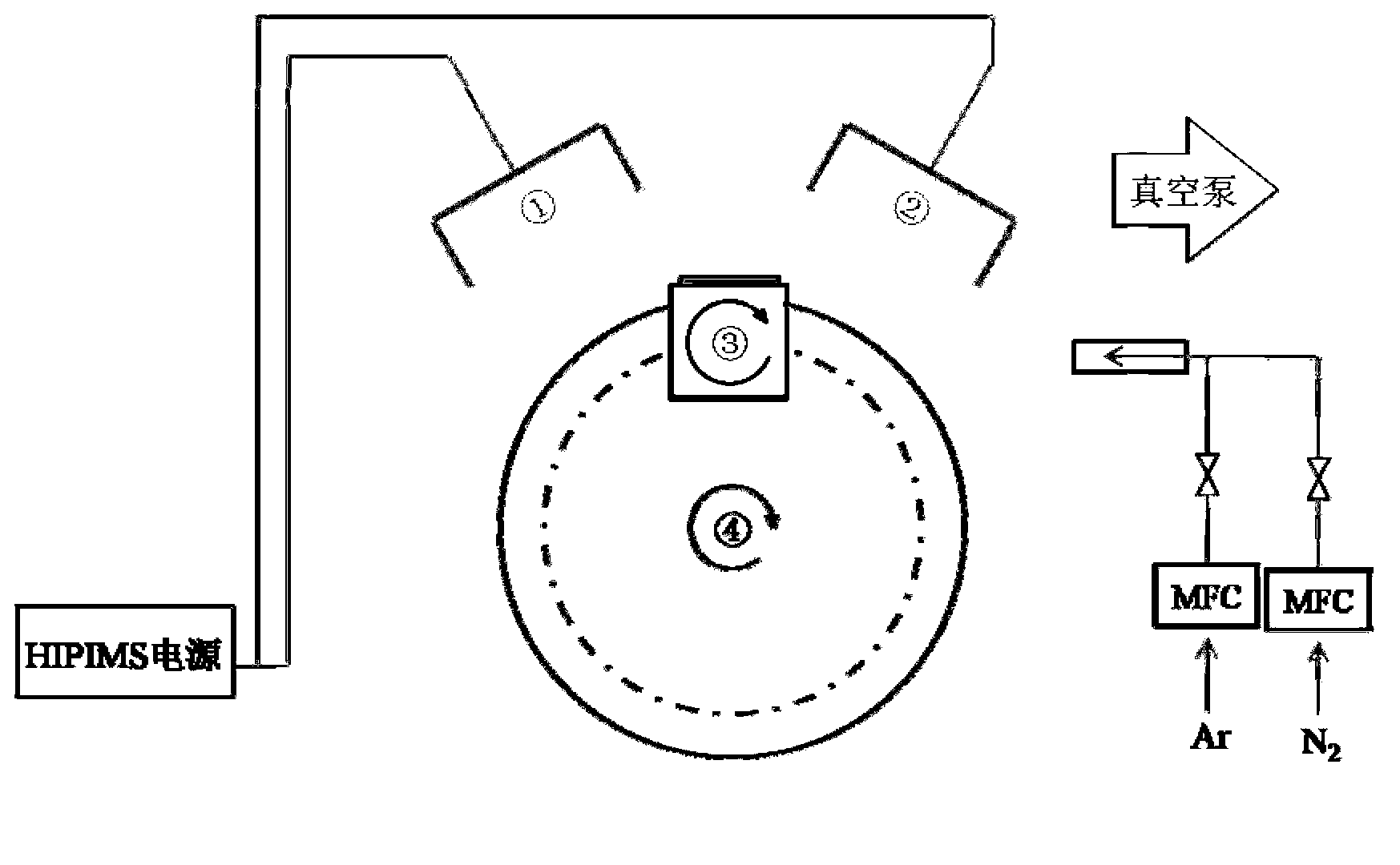

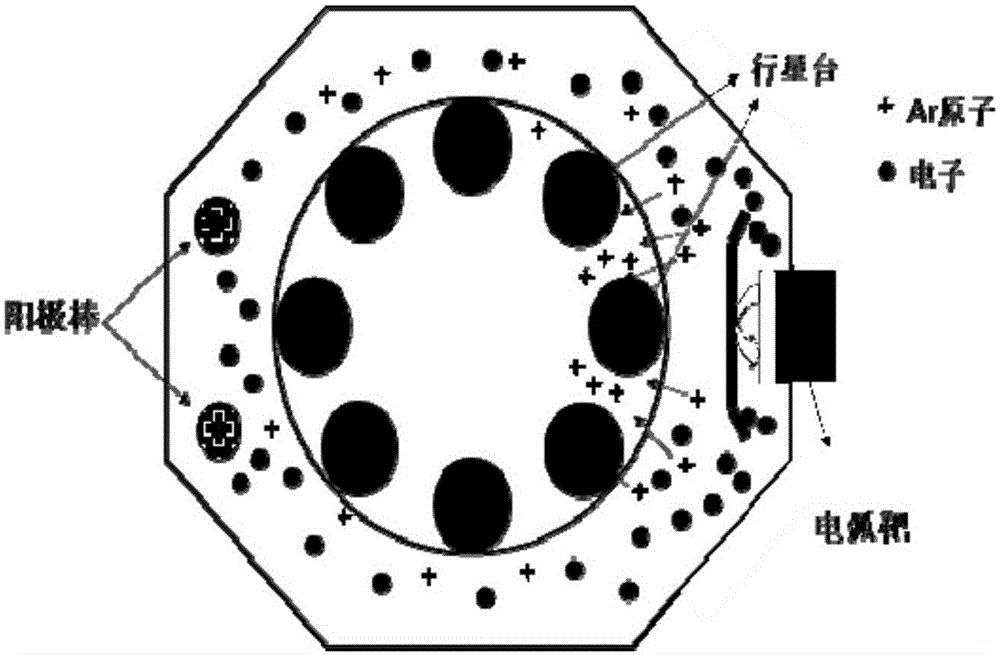

Method for depositing film through high ionization rate high power pulse magnetron sputtering

ActiveCN105154838AImprove bindingEfficient preionizationVacuum evaporation coatingSputtering coatingBack biasFilm material

The invention discloses a method for depositing a film through high ionization rate high power pulse magnetron sputtering, relates to the technical field of film materials, and mainly solves the problems that the existing target is low in ionization rate, the plasma is nonuniform and the film uniformity is poor. The method comprises the following steps: I, cleaning a chamber, and fixing a test sample on a planet platform; II, placing the planet platform in the sealed chamber, vacuumizing the chamber, and removing moisture on the test sample and absorbed air; III, applying back bias voltage on the test sample, and feeding high-purity Ar; IV, feeding Ar and N2 in the chamber, and applying impulse voltage on a sputtering target for surface coating; V, adopting a stepping motor to control the motion track of the planet platform so as to control film coating; VI, taking the test sample out when the temperature in the vacuum chamber is reduced to the room temperature. According to the invention, target magnetic field control during film preparation and target voltage applying form during film coating are changed, so that the film thickness and density are easy to control, and the binding force and the uniformity are high.

Owner:SOUTH CHINA UNIV OF TECH

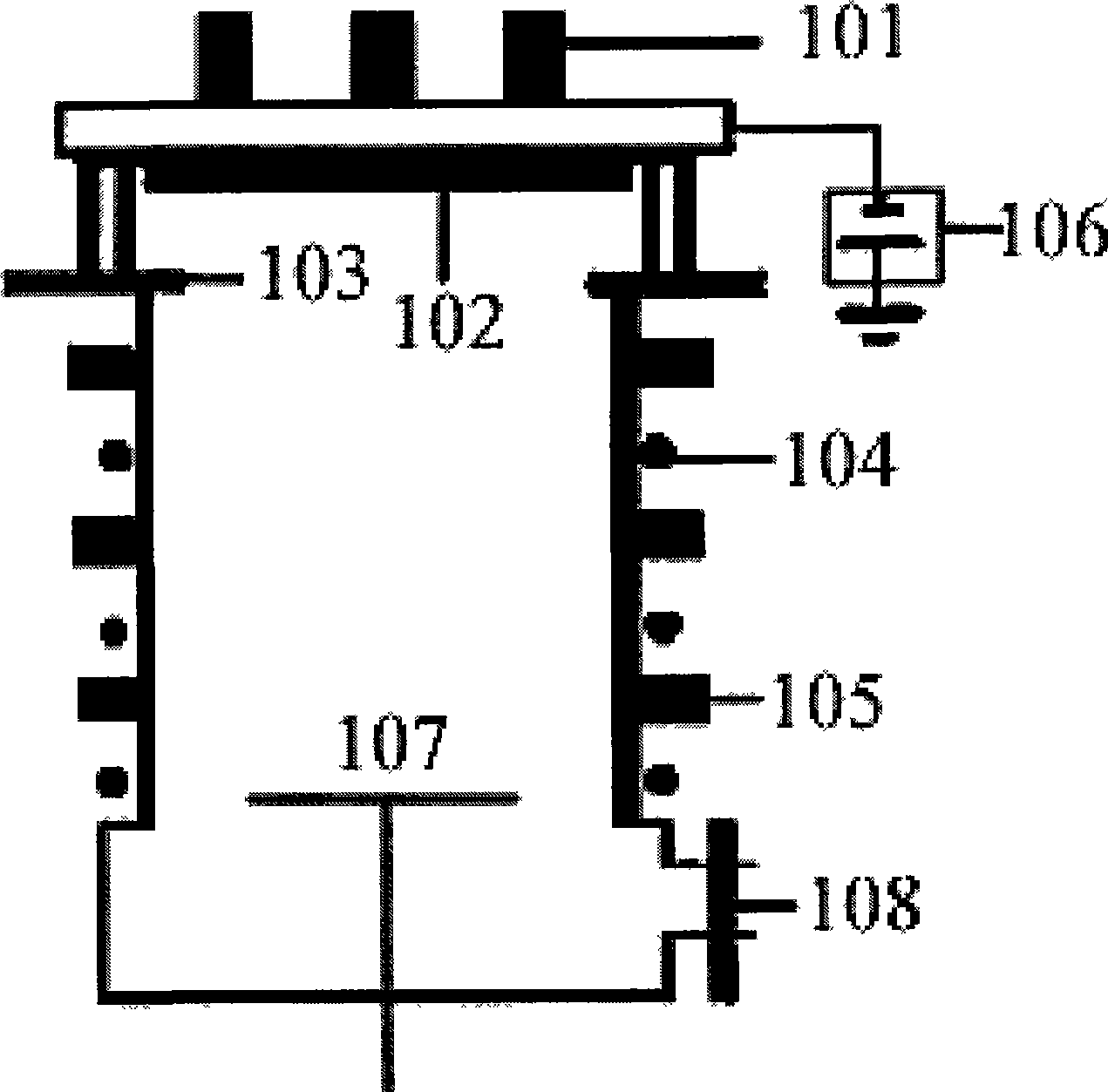

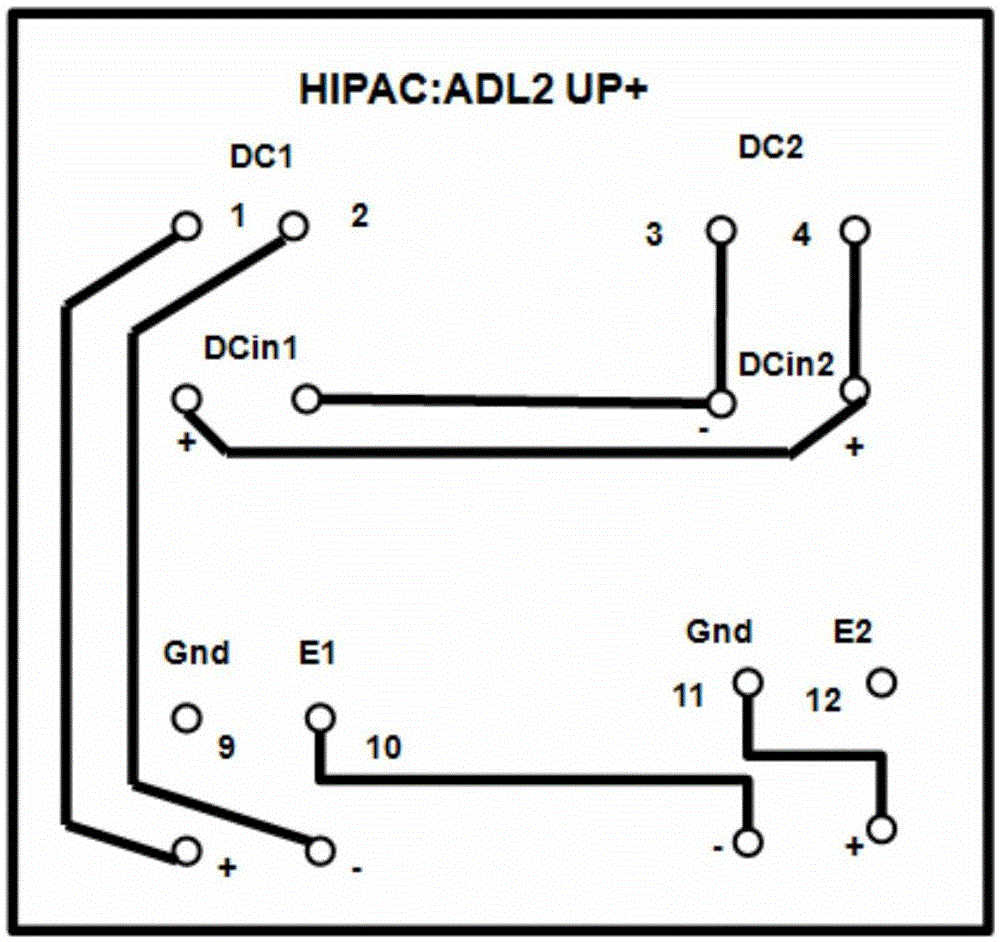

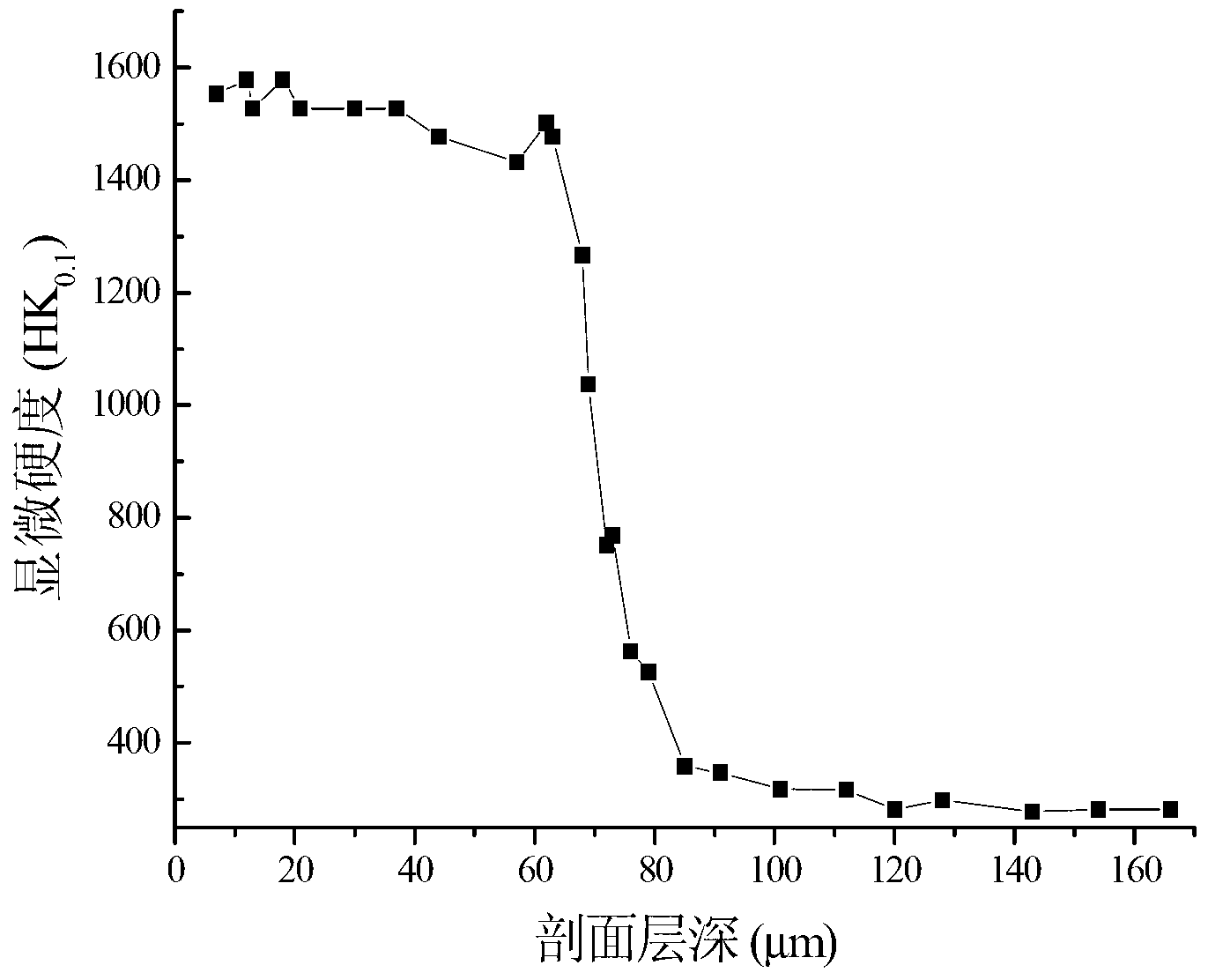

Low-temperature and low-pressure ion nitriding method and device for stainless steel workpiece

InactiveCN103305786AIncrease ionization rateRealize nitriding treatmentSolid state diffusion coatingPulse power supplyVacuum chamber

The invention discloses a low-temperature and low-pressure ion nitriding method and a low-temperature and low-pressure ion nitriding device for a stainless steel workpiece. A nitriding vacuum chamber of the low-temperature and low-pressure ion nitriding device for the stainless steel workpiece can be vacuumized to keep constant air pressure; nitrided stainless steel can be placed on a sample platform; a negative electrode of a pulse power supply is connected with the sample platform; a negative electrode of a direct current power supply is connected with an auxiliary cathode titanium plate; the auxiliary cathode titanium plate is suspended in the nitriding vacuum chamber through an insulating ceramic suspension rod; the nitrided stainless steel is placed on the sample platform; and an appropriate distance is formed between the auxiliary cathode titanium plate and the nitrided stainless steel. In the nitriding process, the stainless steel workpiece subjected to low-temperature and low-pressure ion nitriding is obtained by controlling process parameters. According to the method and the device, the corrosion resistance, abrasion resistance and fatigue resistance of stainless steel are improved, and the nitriding surface of the obtained stainless steel workpiece is clean and bright.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

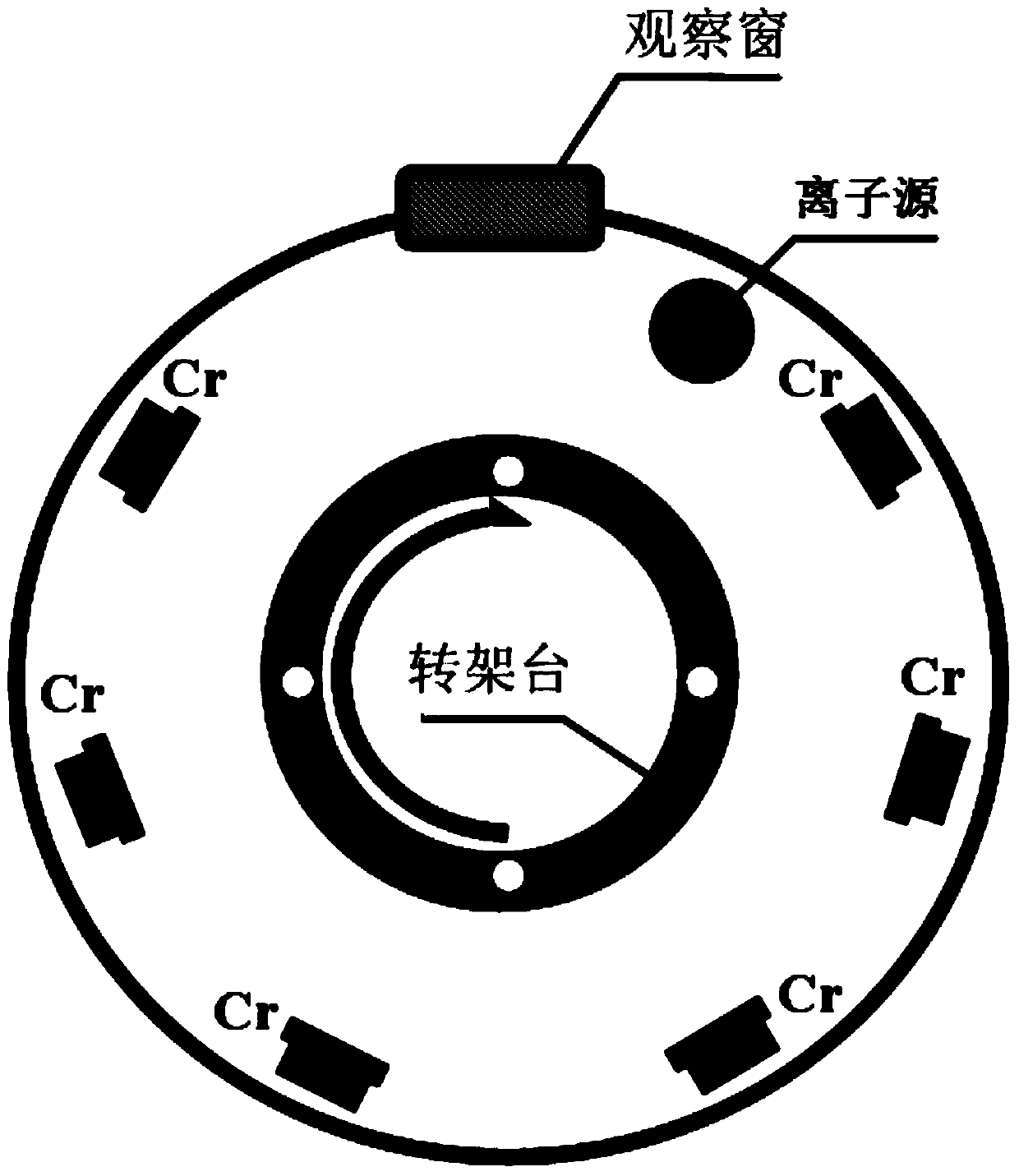

Preparation method of decorating protective coating for CrNx-based component gradient transition

ActiveCN103741108AUniform appearance and colorImprove bindingVacuum evaporation coatingSputtering coatingIonizationTriple layer

The invention discloses a preparation method of a decorating protective coating for CrNx-based component gradient transition. The method comprises the following steps: adopting three pairs of plane Cr targets as sources of a corresponding Cr element; uniformly installing the three pairs of plane Cr targets on the inner wall of ion source-enhanced magnetron sputtering ion plating equipment; controlling the sputtering rate of three pairs of plane Cr targets by adjusting the current of a medium-frequency pulse power supply; adopting an anode layer gas ion source to improve the ionization rate of the gas and the energy of reaction particles; adopting high-purity Ar as a target sputtering gas; adopting high-purity N2 as a reaction gas; ionizing and combining with Cr particles sputtered from the target after passing through an anode layer gas ion source; depositing and forming a Cr base layer / a CrNx-based gradient transition layer / a CrN outer layer in a triple-layer structure on the surface of the sample. The coating is smooth and compact in surface, the microhardness is Hv800, the film-substrate adhesion achieves 80N, the dry friction coefficient of the CrNx-based coating is 0.35 when the friction pair is Al2O3 balls, and the corrosion resistance of a neutral salt spray test exceeds 672 hours.

Owner:晨光真空技术(东莞)有限公司

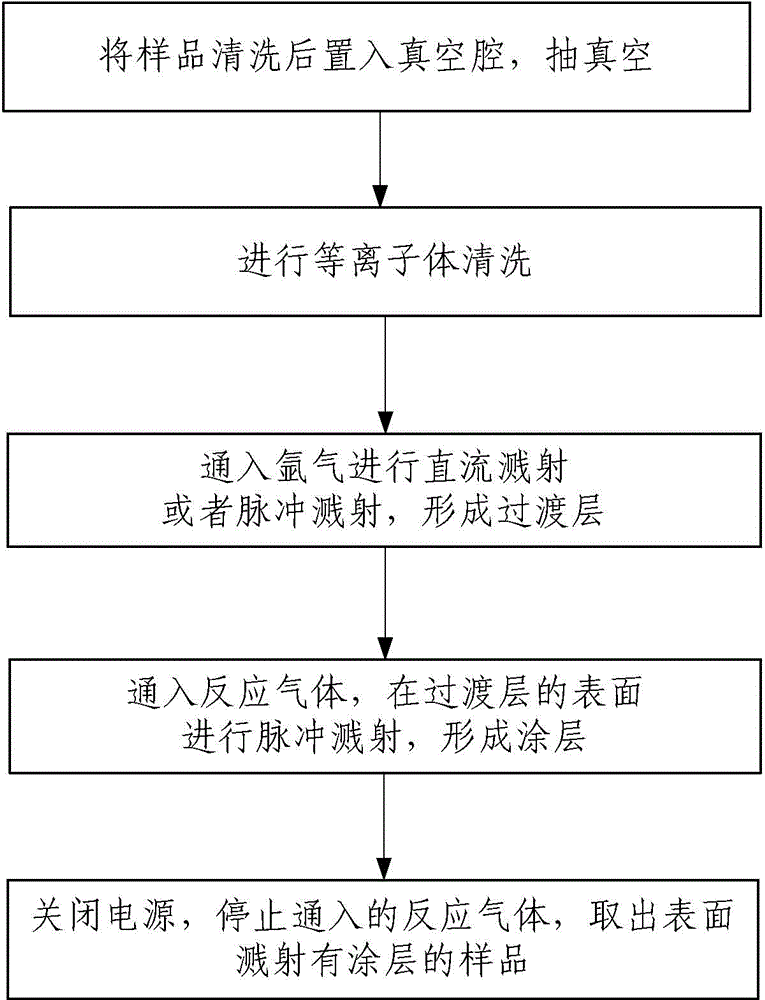

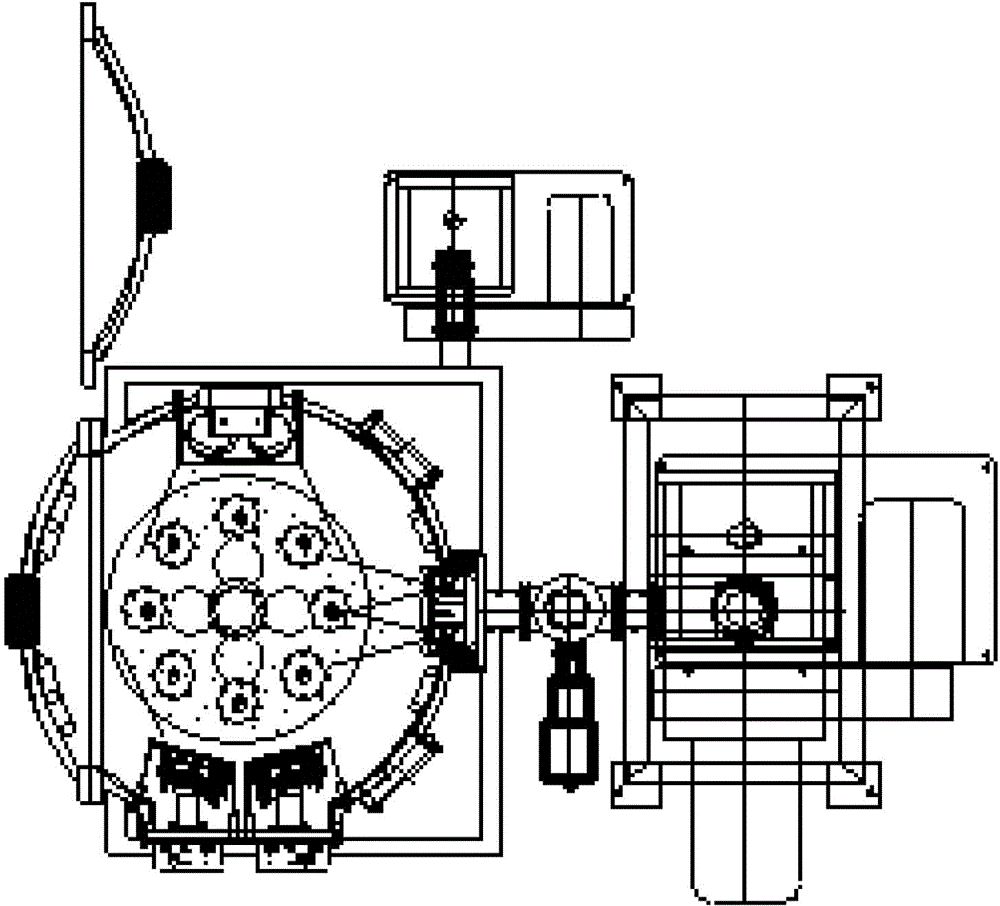

High-energy pulse-type magnetron sputtering method and magnetron sputtering device

InactiveCN103938166AIncrease ionization rateHigh densityVacuum evaporation coatingSputtering coatingHigh energyVacuum chamber

The invention provides a high-energy pulse-type magnetron sputtering method and a magnetron sputtering device. The method includes: cleaning a sample, putting the sample into a vacuum chamber and vacuumizing the vacuum chamber; feeding argon to perform plasma cleaning for the sample; feeding argon as a sputtering gas and performing direct current sputtering or pulse sputtering on the surface of the sample to form a transition layer; feeding a reaction gas and performing pulse sputtering on the surface of the transition layer to form a coating; and closing a sputtering cathode, stopping feeding of the reaction gas, and taking out the sample the surface of which is sputtered with the coating. Compared with traditional magnetron sputtering technologies, the gas participating in the reaction and the ionization rate of the target material particles are increased, thus largely improving the density, uniformity, and other properties of the formed film, eliminating the heating effect in manufacturing processes of a thick coating, and reducing the internal stress for forming the film. The magnetron sputtering method adjusts the color through a method of adjusting the gas flow rate, and a pulse waveform adjusting method of the magnetron sputtering method is more accurate and wider in scope than traditional methods.

Owner:HONG KONG PRODUCTIVITY COUNCIL +1

LED epitaxial growth method for improving radiation recombination efficiency

PendingCN111223764AImprove luminous efficiencyIncrease hole concentrationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingElectron blocking layerMultiple quantum

The invention discloses an LED epitaxial growth method for improving radiation recombination efficiency. The method sequentially comprises the steps of processing a substrate, growing a low-temperature buffer layer GaN, growing an undoped GaN layer, growing a Si-doped N-type GaN layer, growing a multi-quantum well layer, growing an AlGaN electron blocking layer, growing a Mg-doped P-type GaN layerand cooling, wherein the step of growing the multi-quantum well layer sequentially comprises the sub-steps of growing an InGaN transition layer, growing an InGaN well layer, growing a doped gradientSiN layer, growing a doped gradient MgN layer, growing a GaN barrier layer doped with Mg in a linear gradient mode and growing an InAlN layer. According to the method, the problems of low quantum wellgrowth quality and low quantum well radiation recombination efficiency in the existing LED epitaxial growth method are solved, so that the luminous efficiency of the LED is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

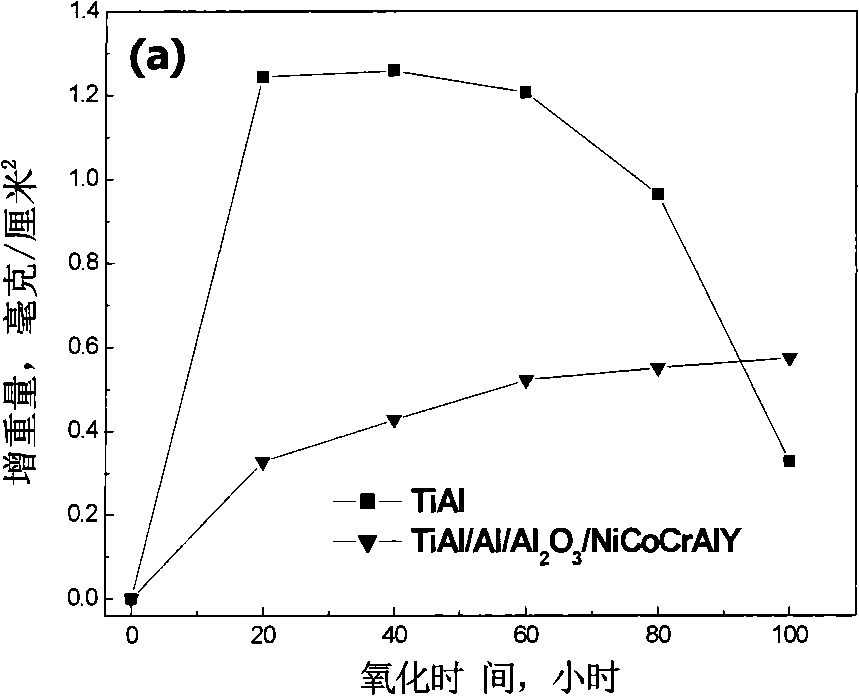

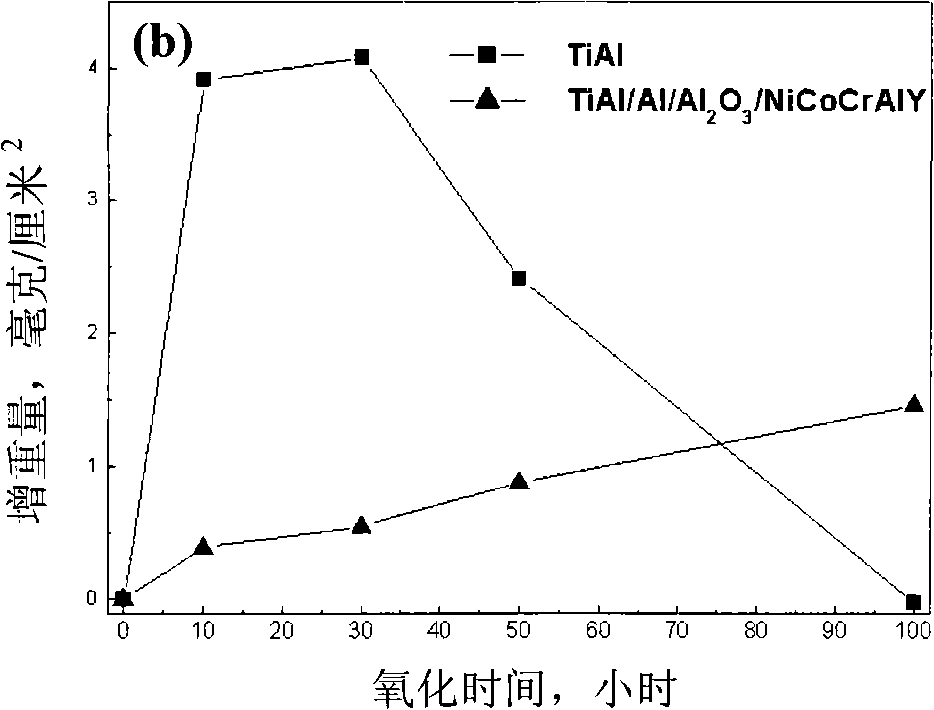

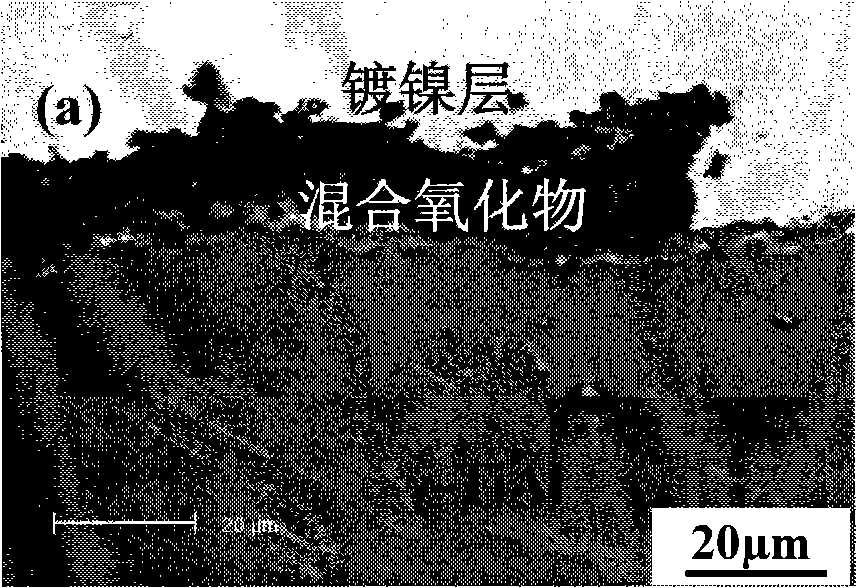

Aluminum/aluminum oxide/Ni-base superalloy composite coating for titanium-aluminum alloy and preparation method thereof

InactiveCN101310969AImprove high temperature stabilityBlocking interdiffusionVacuum evaporation coatingSputtering coatingSuperalloyIon plating

The invention relates to the coating technique, in particular to an Al / Al2O3 / MCrAlY composite coating used in Ti-Al alloy and a preparation method thereof, which aims at improving the high-temperature oxidation resistance of the Ti-Al alloy, guaranteeing the serviceability of the Ti-Al alloy in the high-temperature environment and solving the problem of non-matching between the MCrAlY coating and the Ti-Al alloy and is used for the high-temperature protection of the Ti-Al alloy. The composite coating comprises an Al / Al2O3 diffusion impervious layer and an MCrAlY alloy protective coating which are deposited on a substrate of the alloy in sequence; the thickness ratio among an Al film, an Al2O3 film and the MCrAlY protective coating is (1 to 5): (1 to 5): (20 to 50); in the MCrAlY alloy, M indicates Ni, Co or Ni plus Co. The arc ion plating technique is adopted to deposit the Al / Al2O3 diffusion impervious layer and then the MCrAlY coating on the substrate of the alloy. The composite coating of the invention has good high-temperature oxidation resistance as well as good bonding strength and high-temperature stability and can provide good high-temperature protection to the Ti-Al alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

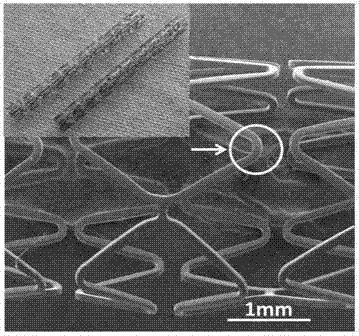

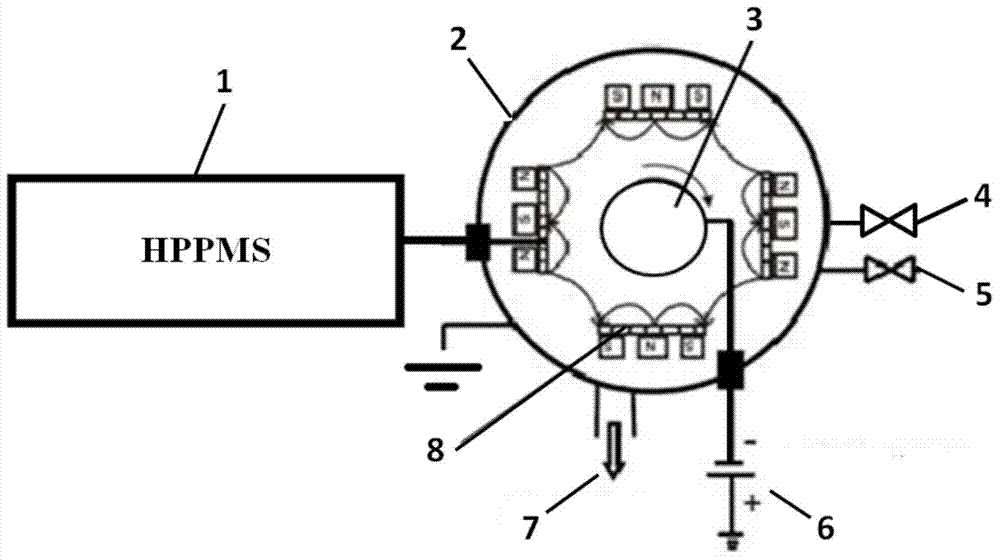

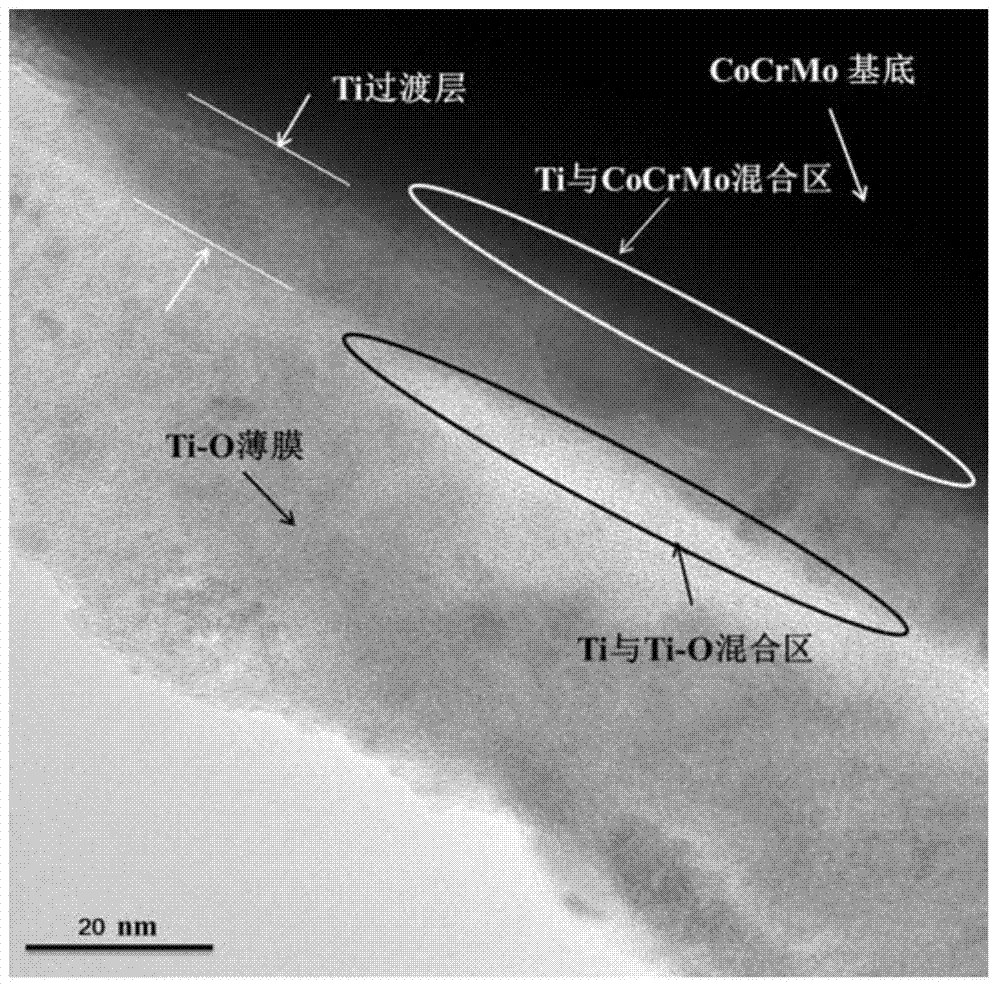

Metal support surface modification method

InactiveCN103924202AIncrease ionization rateHigh densityStentsSurgeryVoltage amplitudeSputter cleaning

The invention relates to a metal support surface modification method and belongs to the technical field of metal surface modification. The method is used for depositing a titanium / titanium oxide film on the surface of a metal support by effectively utilizing high power pulse magnetron sputtering technology. The method includes the following steps: firstly, putting the metal support in a vacuum chamber of high power pulse magnetron sputtering equipment, and vacuumizing the vacuum chamber to 0.5*10<-3> Pa to 2*10<-3>Pa; filling argon into the vacuum chamber, and sputter cleaning the metal support and a target; introducing argon into the vacuum chamber, and preparing a titanium transition layer with high binding force on the surface of the metal support by utilizing the high power pulse magnetron sputtering technology, by means of regulating such parameters as sputtering voltage amplitude, frequency, pulse width, sputtering voltage and matrix bias voltage; finally, introducing argon and oxygen into the vacuum chamber, and preparing a firmly combined titanium oxide film on the surface of the metal support by regulating such parameters as sputtering voltage amplitude, frequency, pulse width, sputtering voltage and matrix bias voltage. The method is mainly applied to surface modification of the metal support.

Owner:SOUTHWEST JIAOTONG UNIV

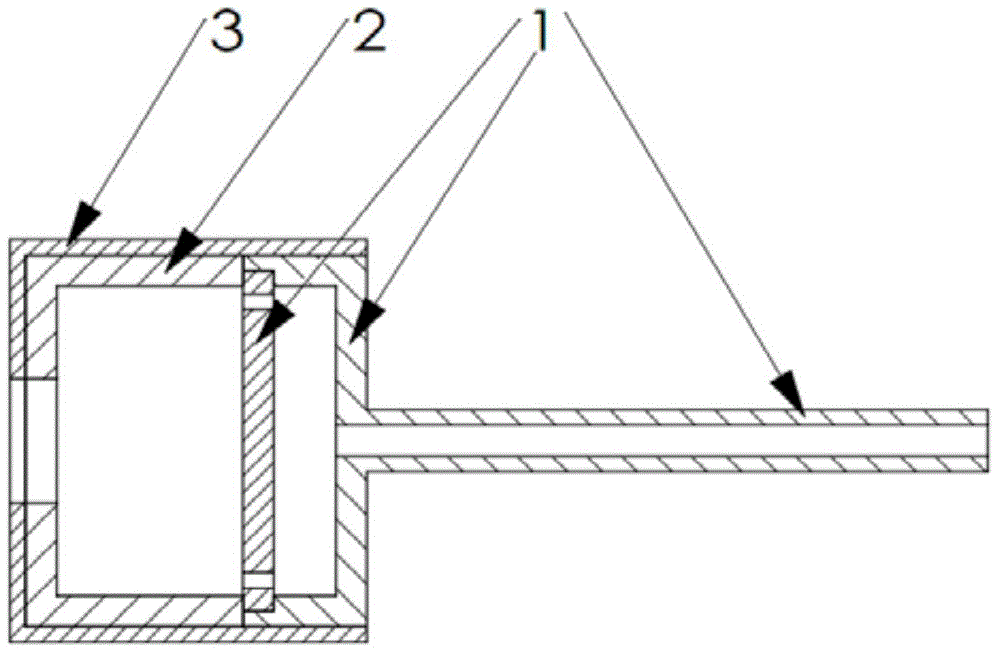

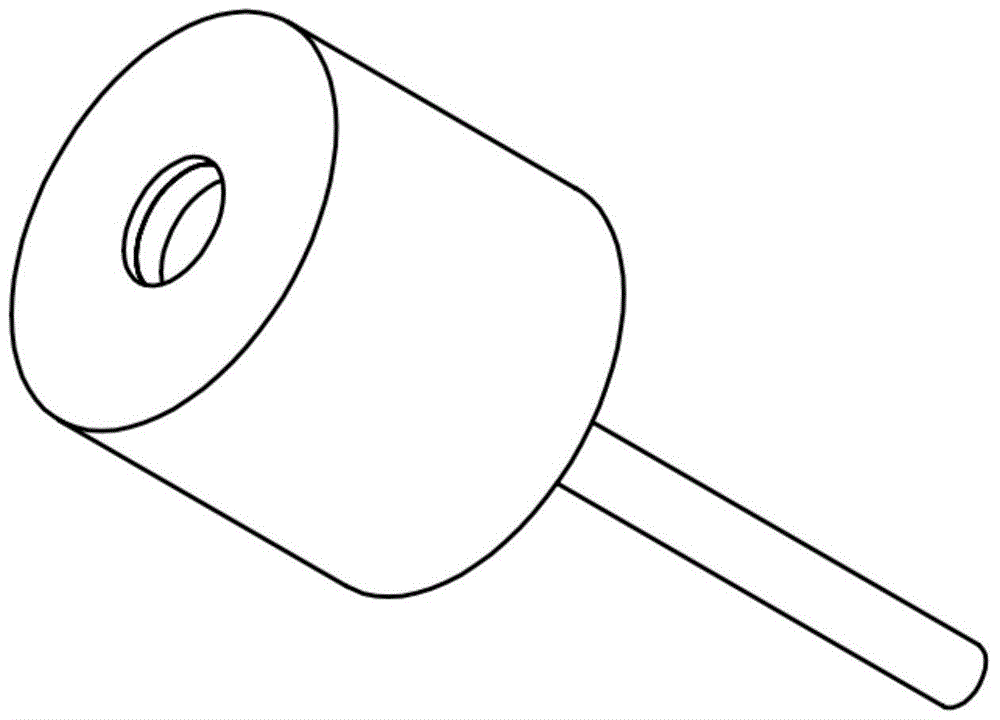

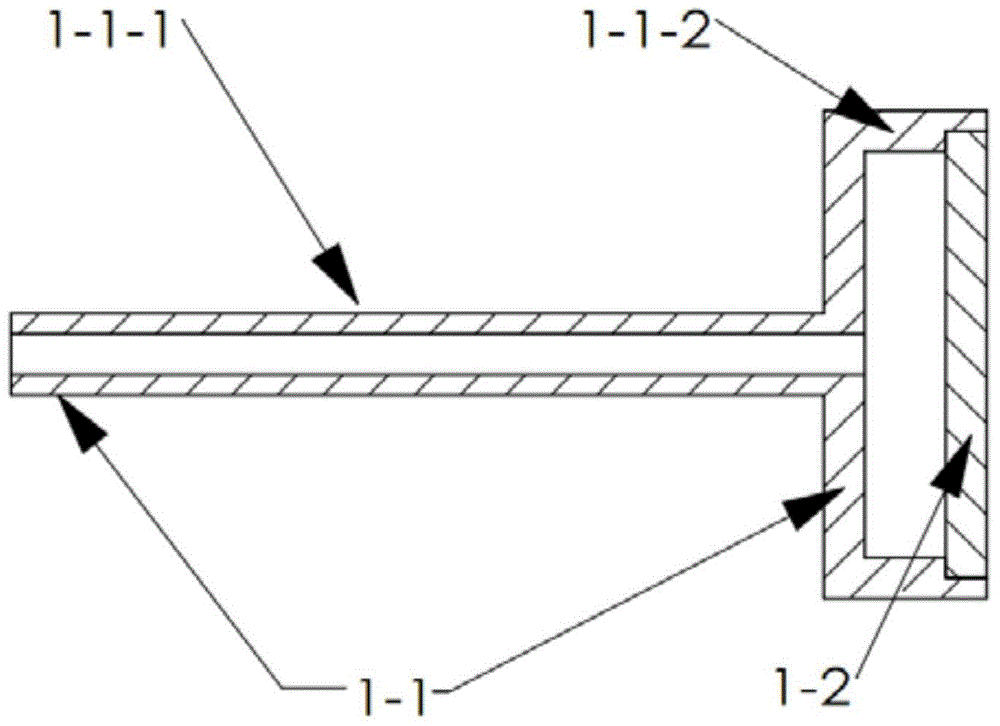

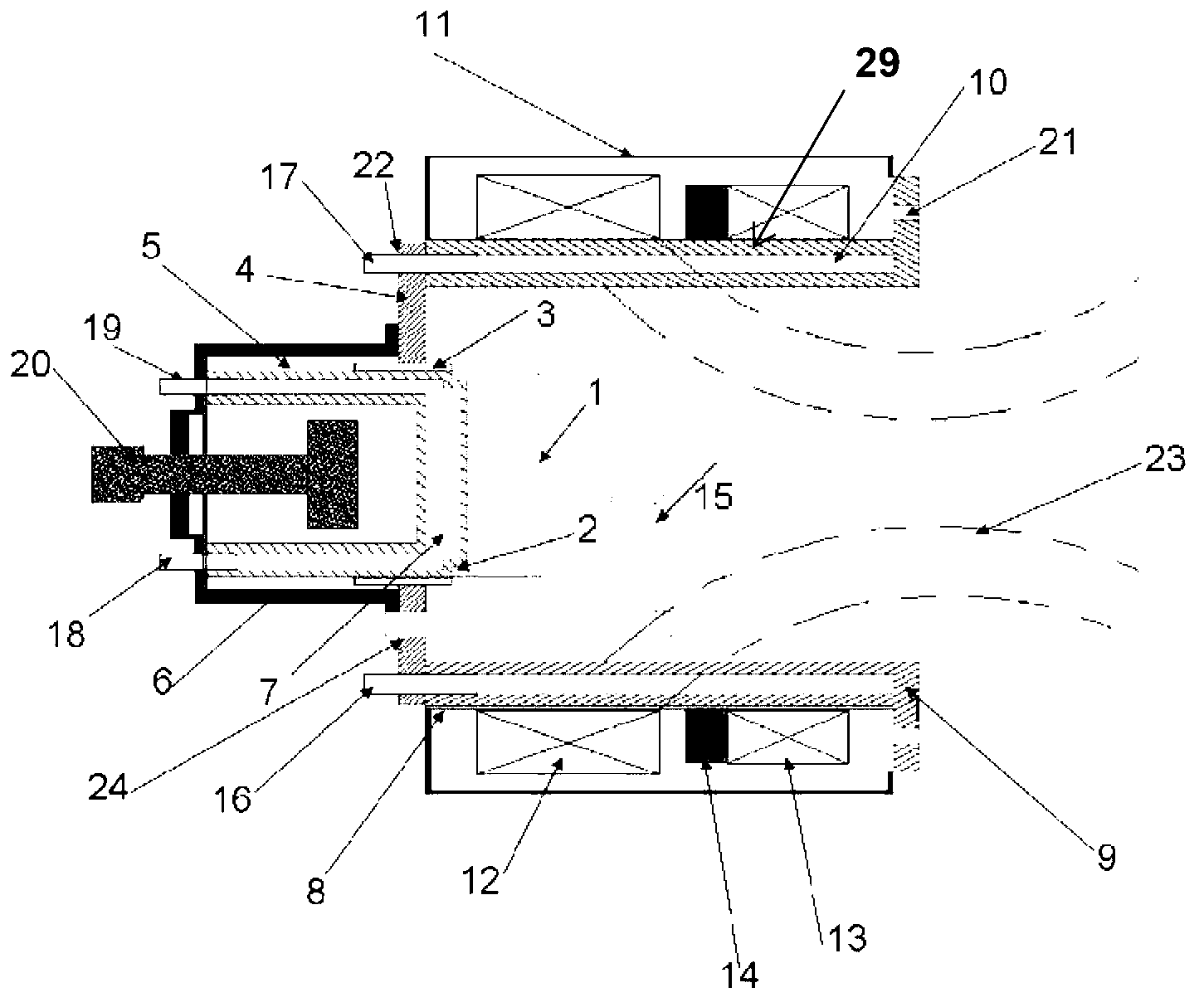

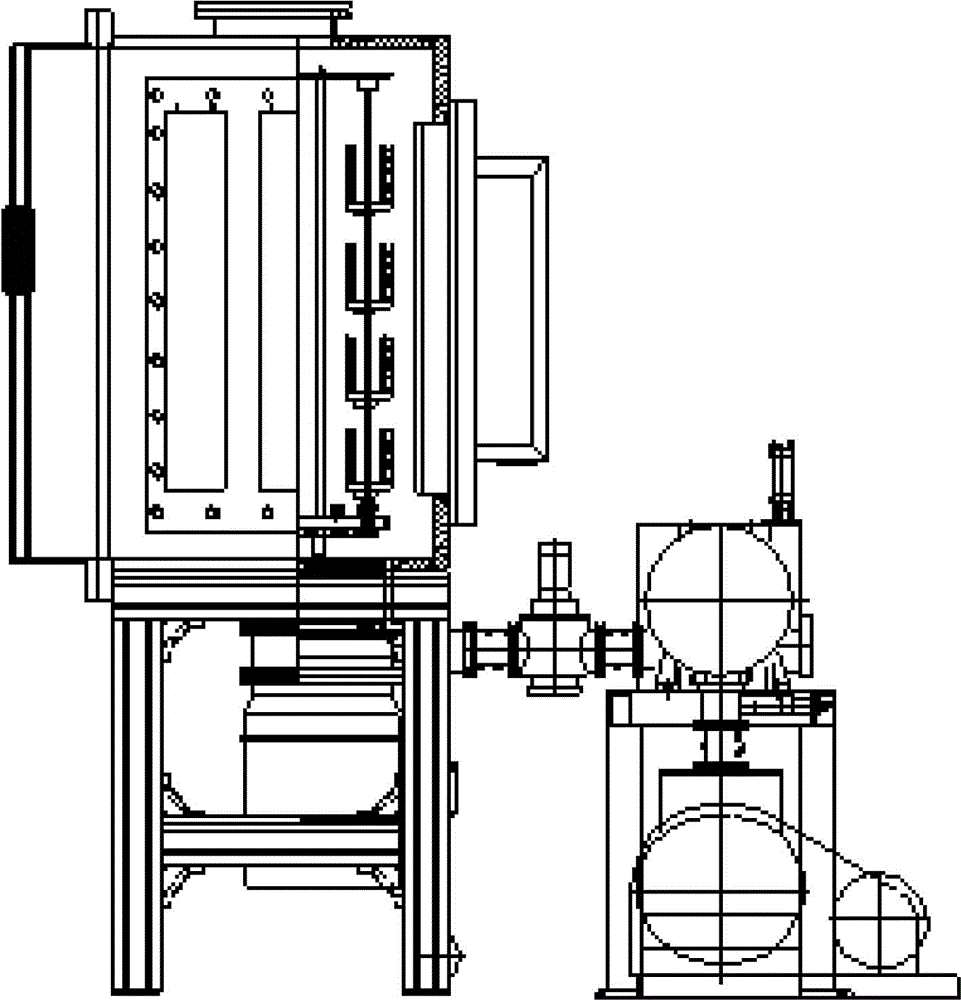

Electric arc ion plating apparatus

InactiveCN102758186ASolving Deposited Thin FilmsSolve the technical problems of coatingVacuum evaporation coatingSputtering coatingVacuum chamberLarge particle

The invention relates to the field of film and coating preparation, and relates to an electric arc ion plating apparatus which is used for depositing a film or a coating on the inner surface of a long pipe or on the inner wall of a deep-hole device. The electric arc ion plating apparatus comprises three sets of magnetic field generation apparatuses. A first magnetic field generation apparatus used for beaming a metal ion flow emitted by a cathode target is arranged outside a vacuum chamber at a position corresponding to the back of the cathode target. A second magnetic field generation apparatus used for beaming the metal ion flow is arranged between the cathode target and a workpiece in the vacuum chamber. A third magnetic field generation apparatus used for diffusing the beamed metal ion flow and for making the metal ions move with a high speed towards the inner surface of the long pipe or the inner wall of the deep-hole device is arranged on the periphery of the workpiece in the vacuum chamber. The electric arc ion plating apparatus also comprises a pulse bias power supply used for further accelerating the metal ions moving towards the inner surface of the long pipe or the inner wall of the deep-hole device. With the apparatus provided by the invention, a technical problem for depositing a film or a coating on the inner surface of the long pipe or the inner wall of the deep-hole device is solved. Film or coating uniformity and quality are ensured, and the content of large particles in the deposited film or coating is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

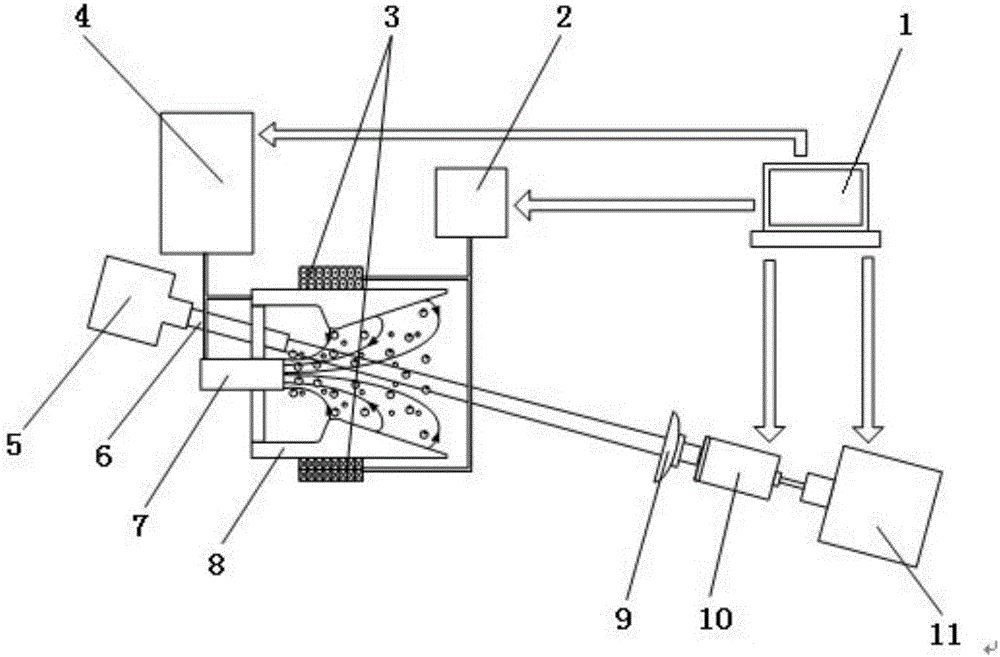

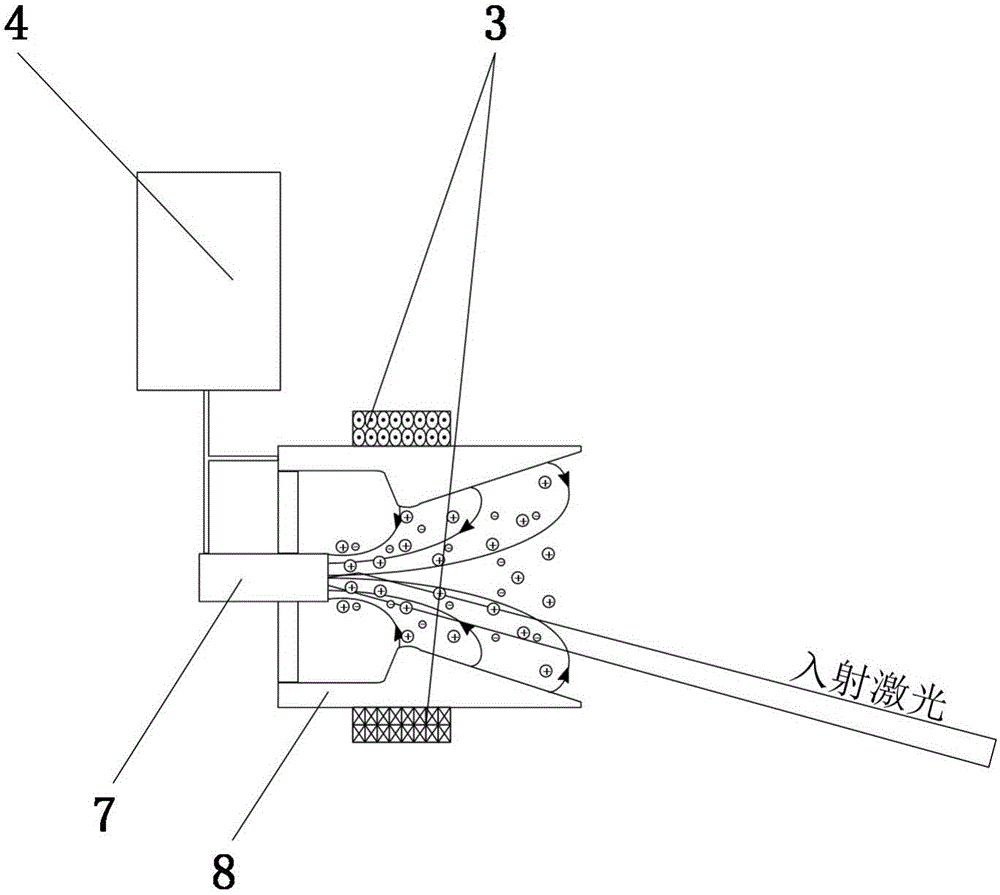

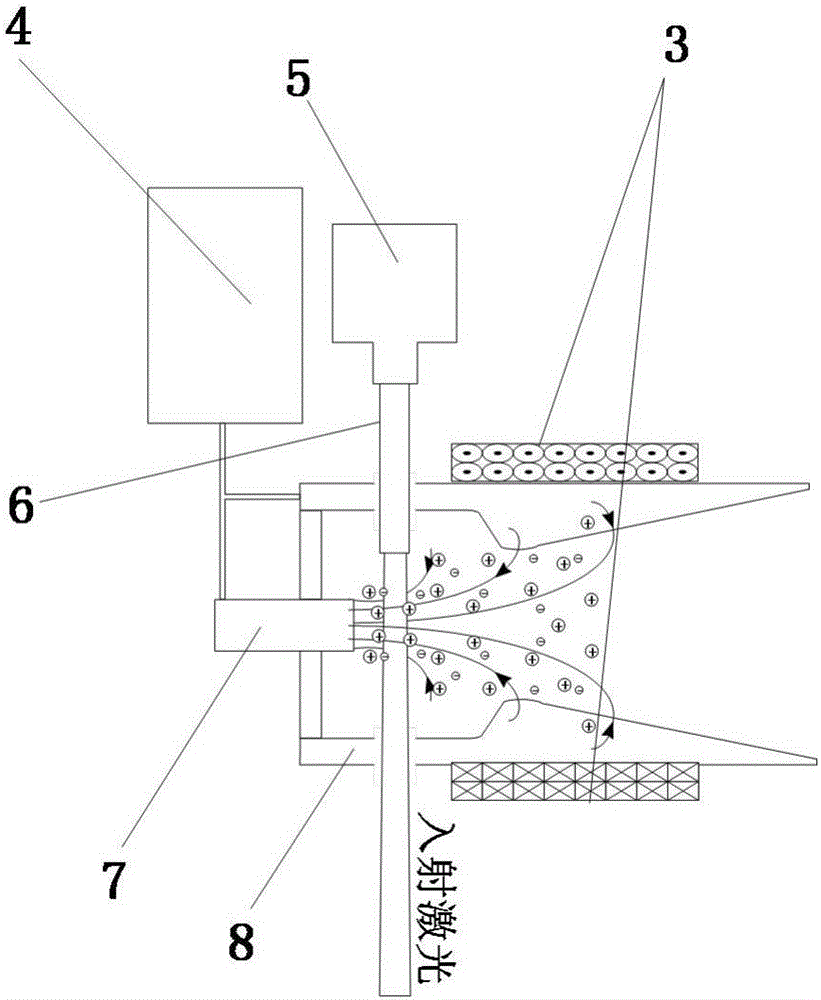

Magnetic plasma thrustor supported through lasers

InactiveCN105781920AReduce quality problemsReduce volumeMachines/enginesUsing plasmaParticulatesEnergy conversion efficiency

The invention provides a magnetic plasma thrustor supported through lasers. The magnetic plasma comprises a thrustor power source for supplying power to all electric equipment in the thrustor; satellite platform electric energy is converted through the thrustor power source to be then supplied to the thrustor; the magnetic plasma thrustor further comprises a working medium supply device, a negative pole, a positive pole and a laser generation mechanism, a discharge channel is formed between the negative pole and the positive pole, the working medium feeding device used for fixing and conveying a working medium is arranged outside the discharge channel, and the working medium is a solid working medium and extends into the discharge channel; and the laser generation mechanism emits laser beams into the discharge channel to conduct ablation on the working medium, the laser beams conduct ablation on the working medium continuously to generate partial ionized gas and particulate matter, and the partial ionized gas and the particulate matter enter the discharge channel. The magnetic plasma thrustor solves the problems that an air supply system is complex, dynamic response is slow, negative pole ablation is serious, and performance reduction is caused by large-current vibration, and the magnetic plasma thrustor which is supported through the lasers and is high in dynamic response, high in working medium using rate and high in energy conversion efficiency is provided for a spacecraft.

Owner:NAT UNIV OF DEFENSE TECH

Plasma chemical vapor deposition and magnetron sputtering or ion plating compounded plating method

InactiveCN107142463AImprove performanceImprove use valueVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

The invention relates to the technical field of new materials and modern surfaces, in particular to a plasma chemical vapor deposition and magnetron sputtering or ion plating compounded plating method. Voltage is applied to the position between a negative pole and a positive pole to enable reaction gases or inert gases to conduct glow discharging, and then plasma composed of electrons and ions is generated. Movement of the electrons is constrained by orthogonal electric field and magnetic field and limited in a certain area to conduct rotation drift movement, the collision probability of the electrons and gas atoms is enhanced, and therefore the ionization rate of the gas is enhanced; and under the combined action of the potential difference between the negative pole and the positive pole and Hall current formed by a crossed electric and magnetic field, the ions are subjected to beam extraction, and deposited on the surface of a base material directly to form a needed thin film. One important use of the compounded surface technology is to be used for preparing a high-quality diamond-like carbon film. The film has excellent performances, so the film is of great use value.

Owner:湖州中科金象科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com