Patents

Literature

1463 results about "Distribution uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Distribution uniformity or DU in irrigation is a measure of how uniformly water is applied to the area being watered, expressed as a ratio to avoid confusing it with efficiency. The distribution uniformity is often calculated when performing an irrigation audit. The DU should not be confused with the coefficient of uniformity (CU) which is often preferred for describing the performance of overhead pressurized systems.

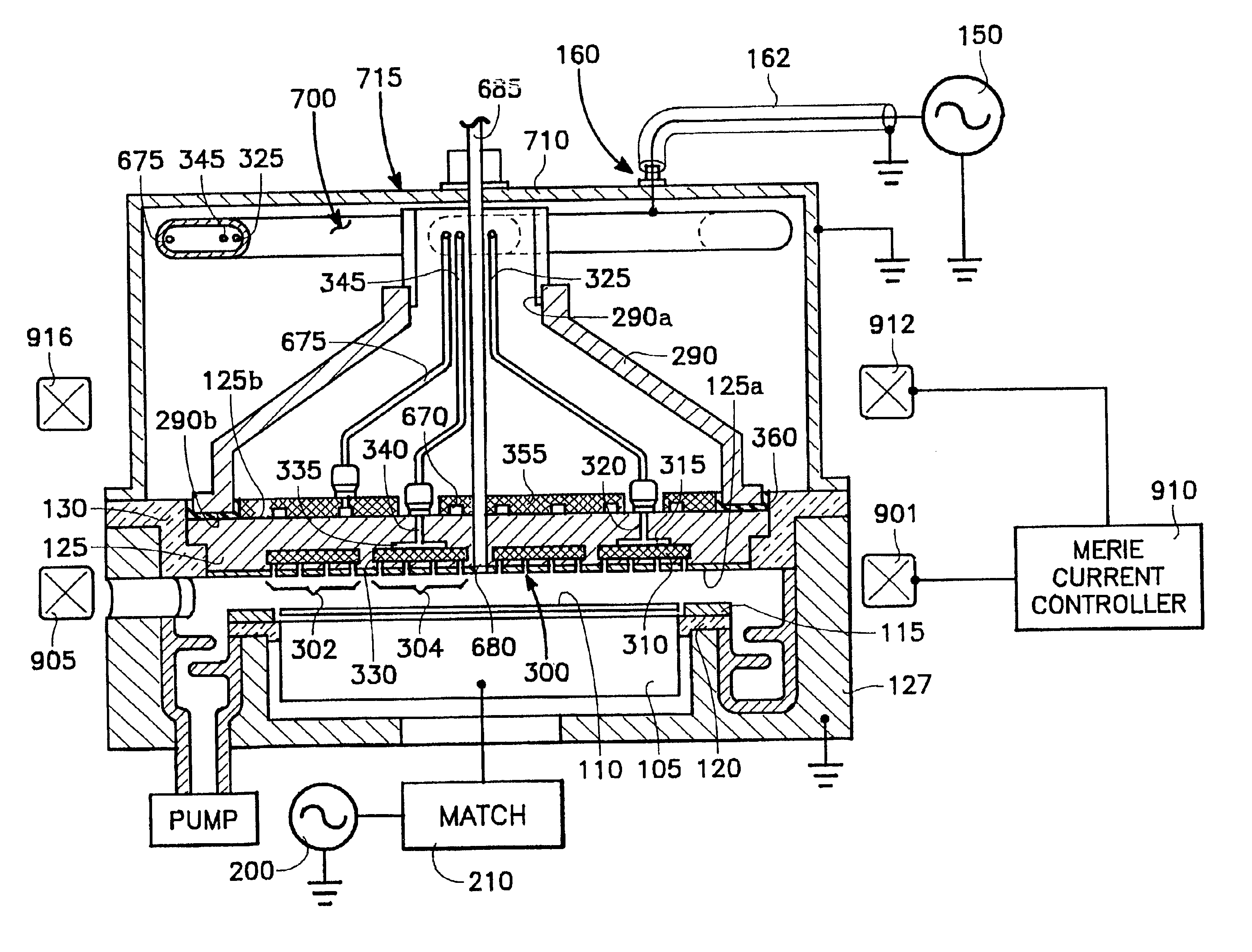

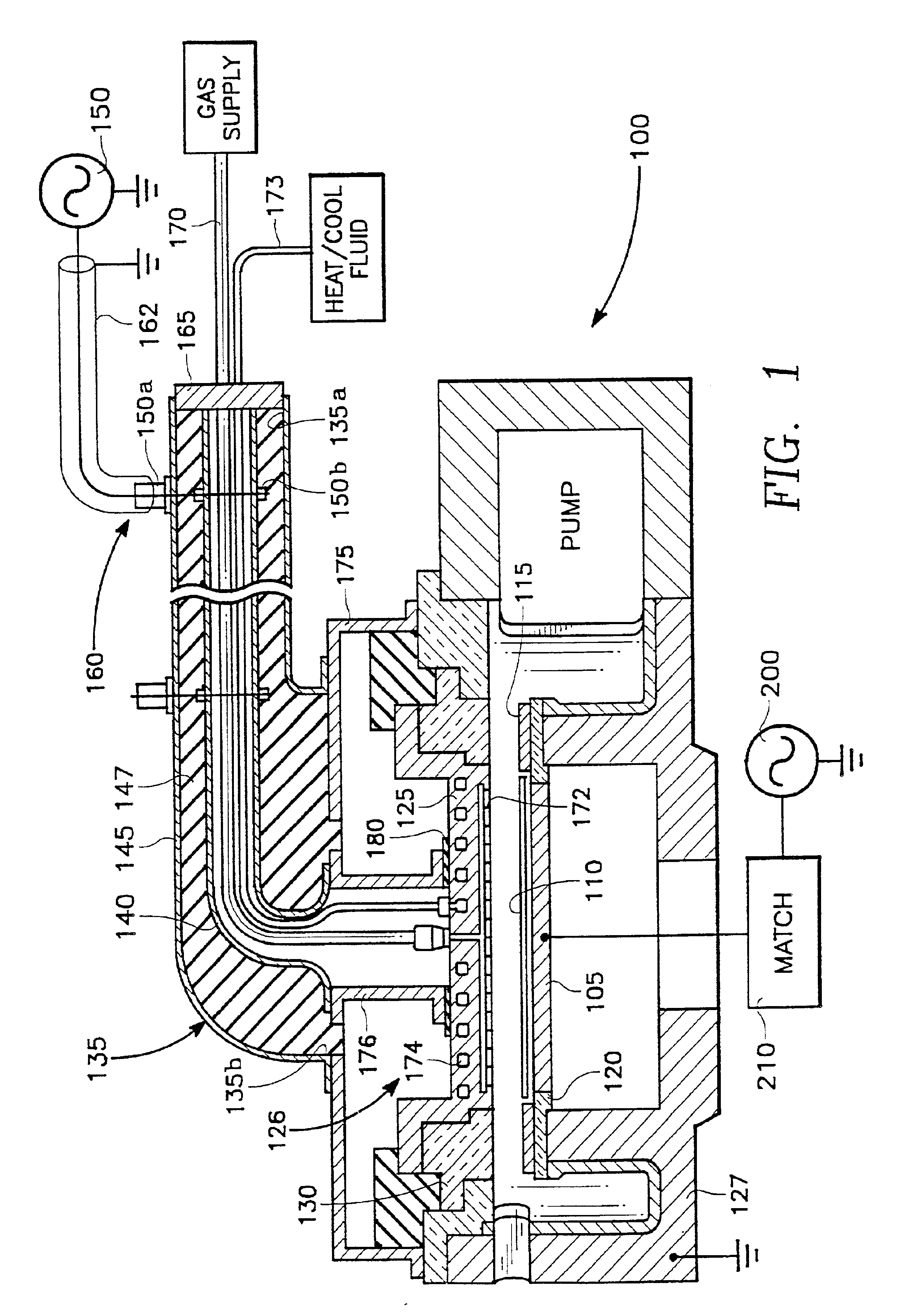

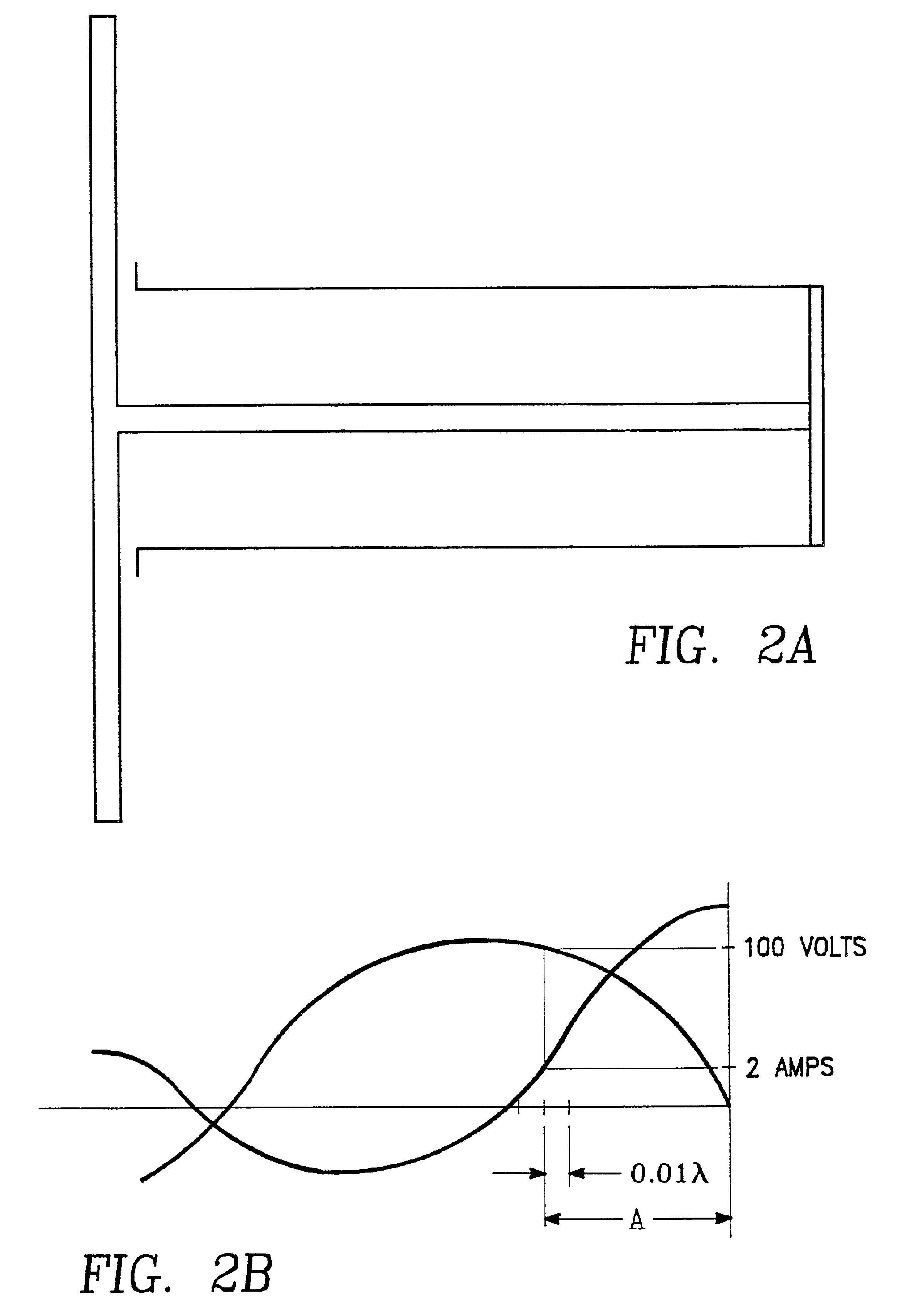

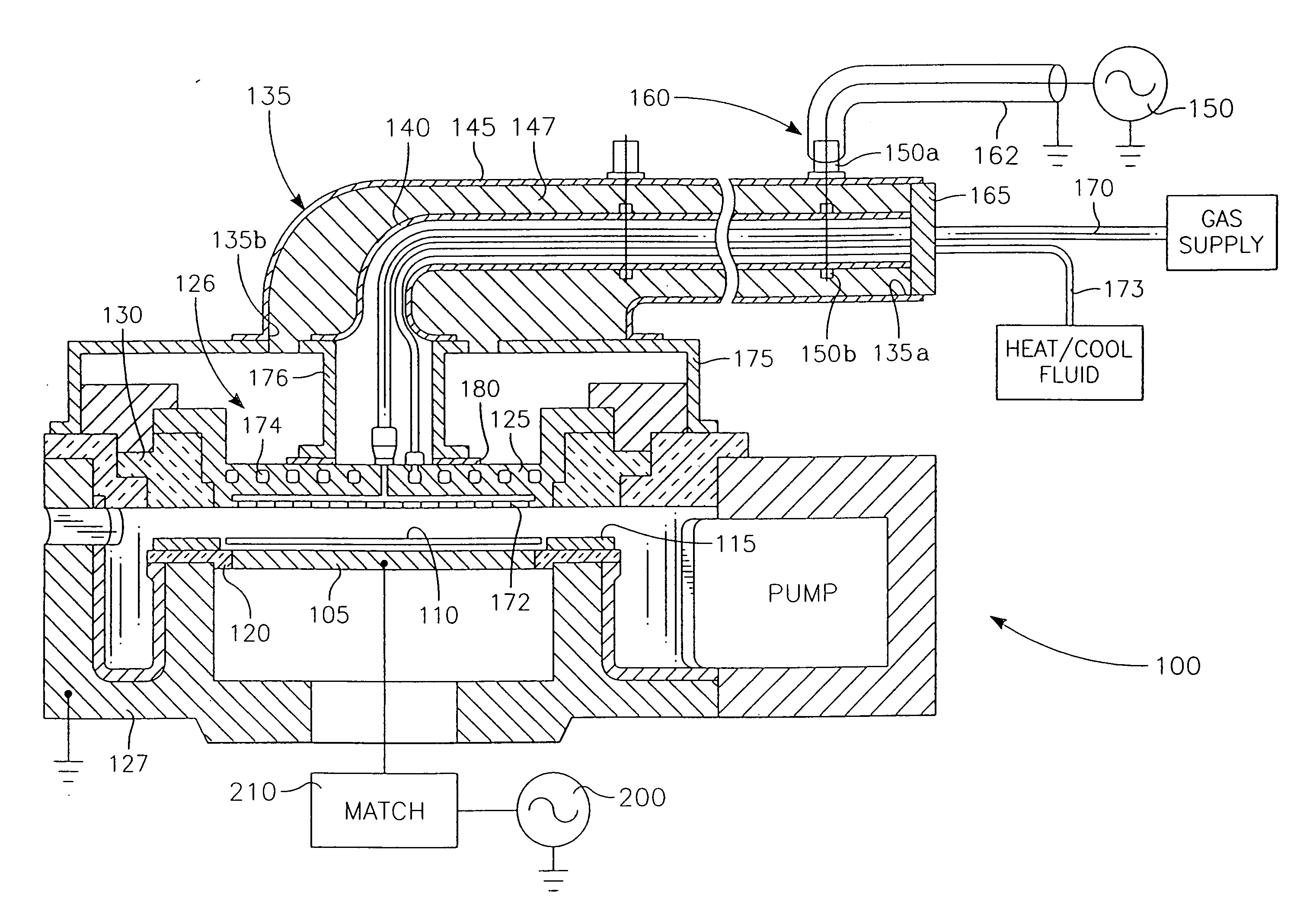

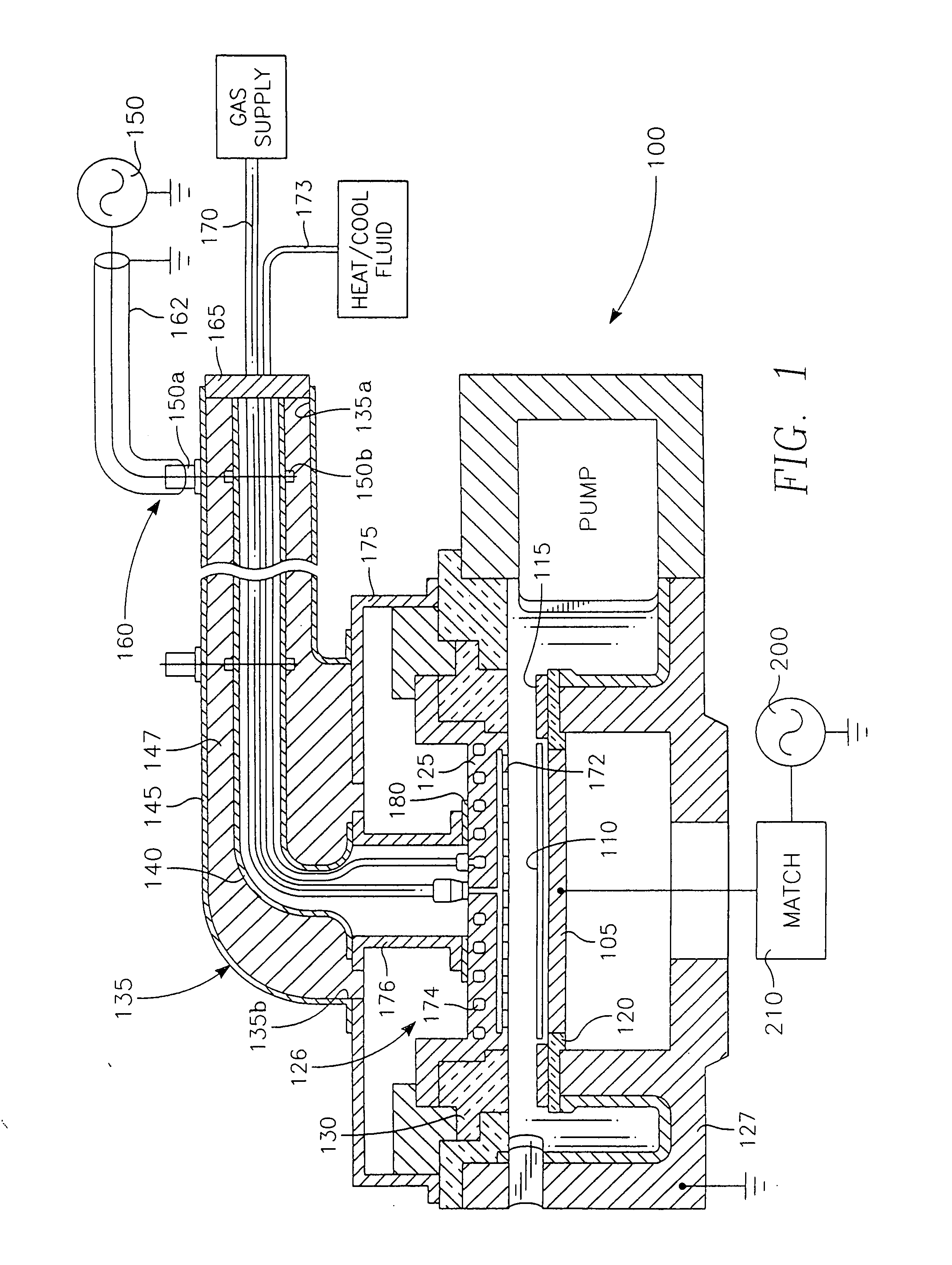

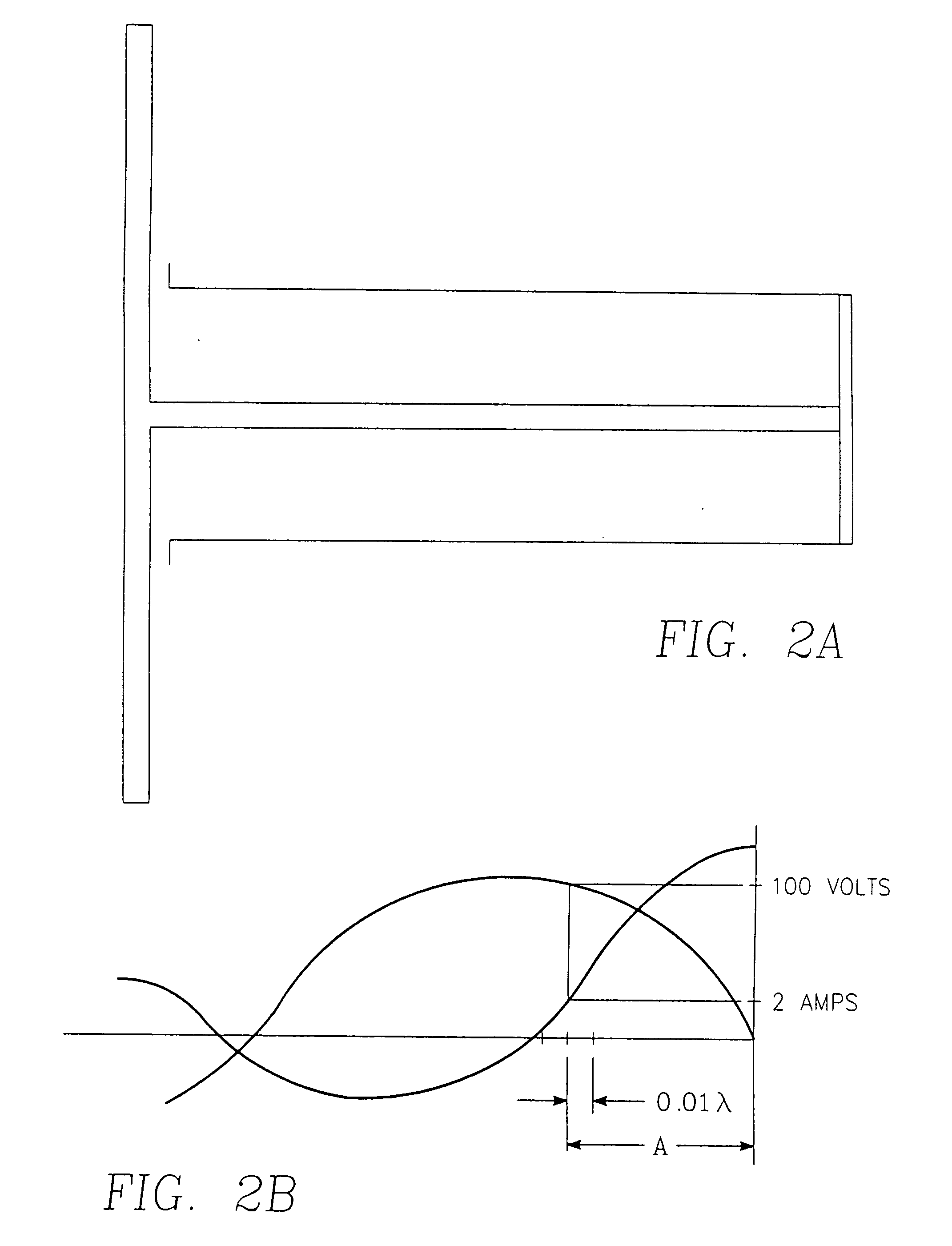

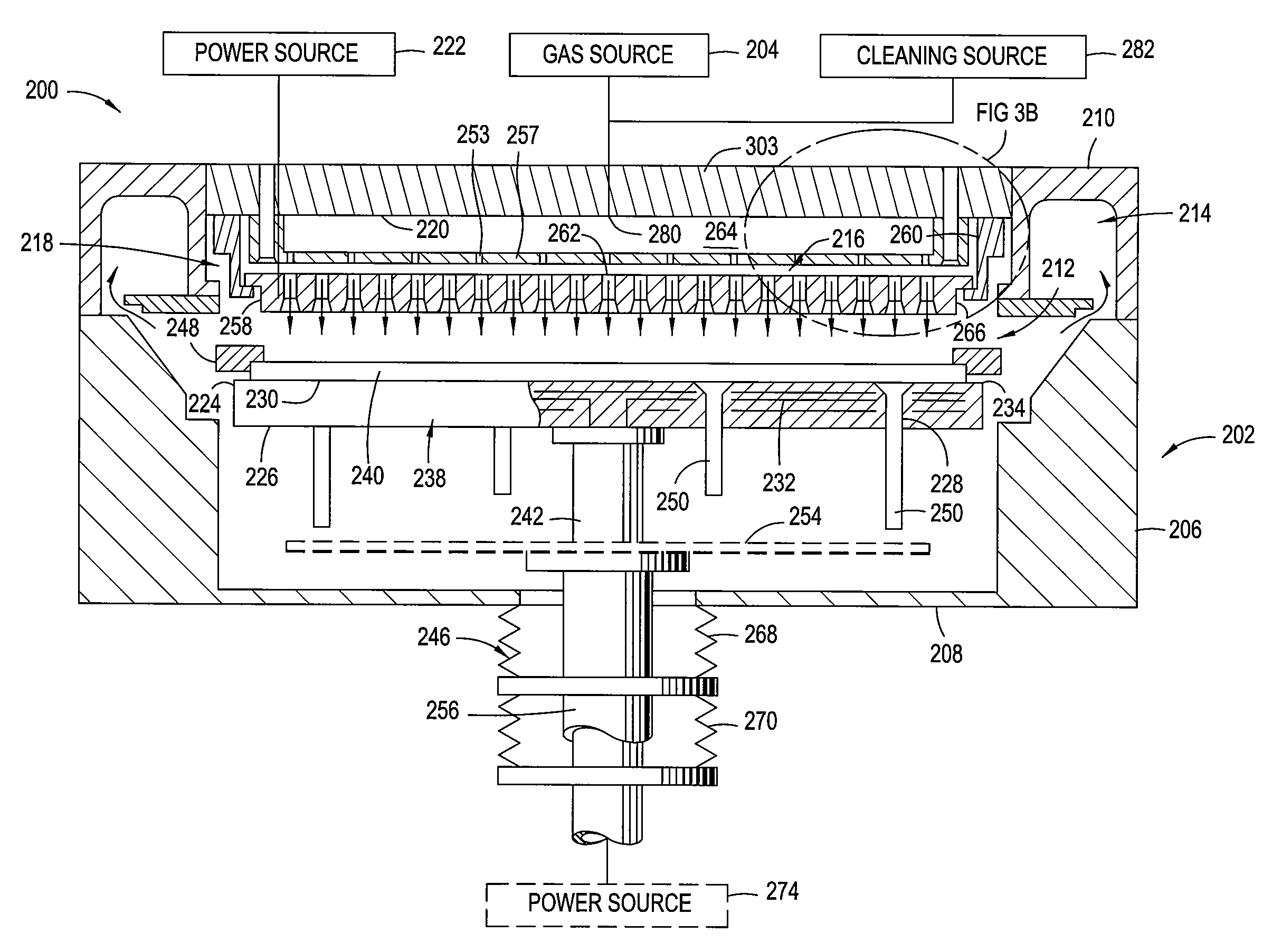

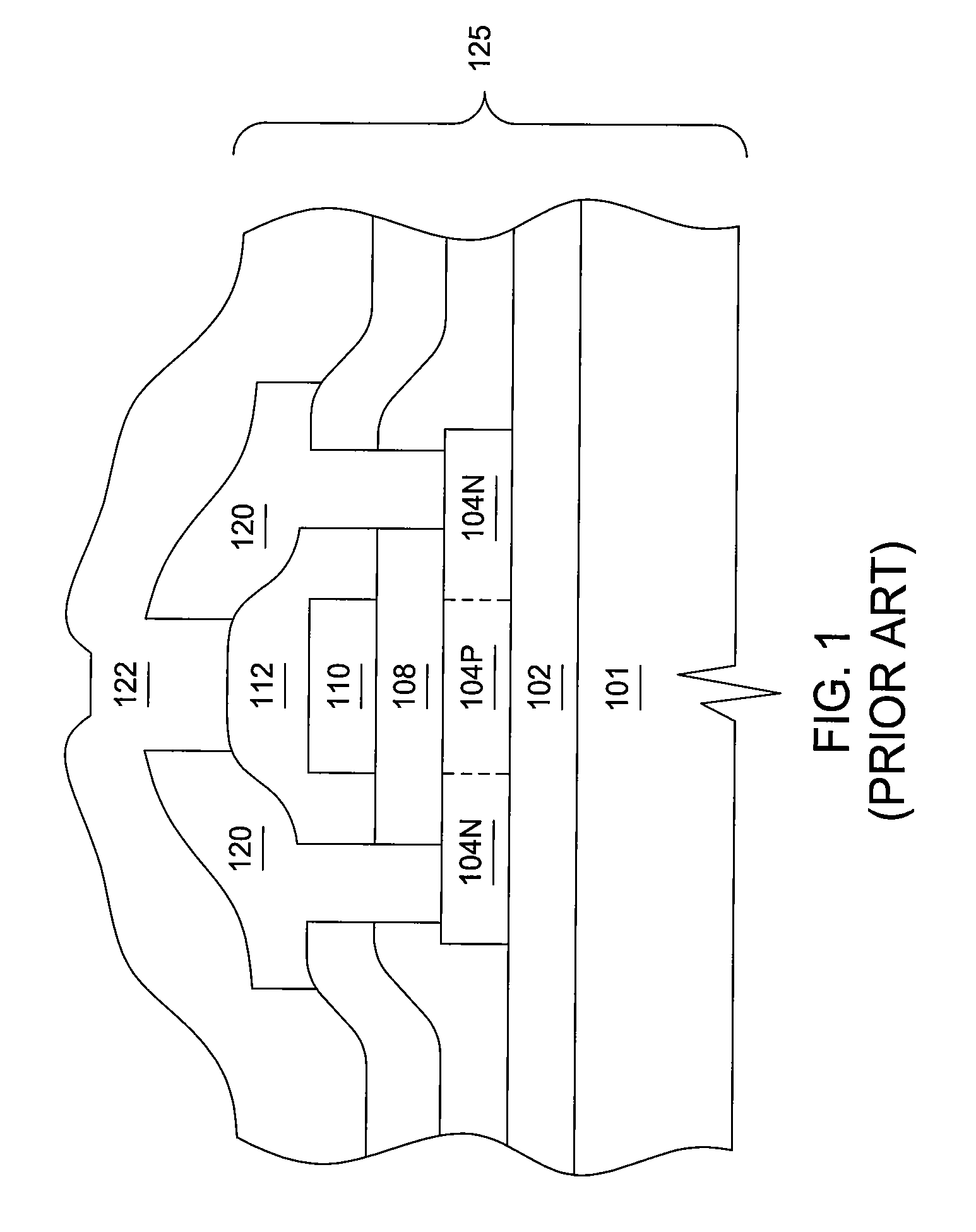

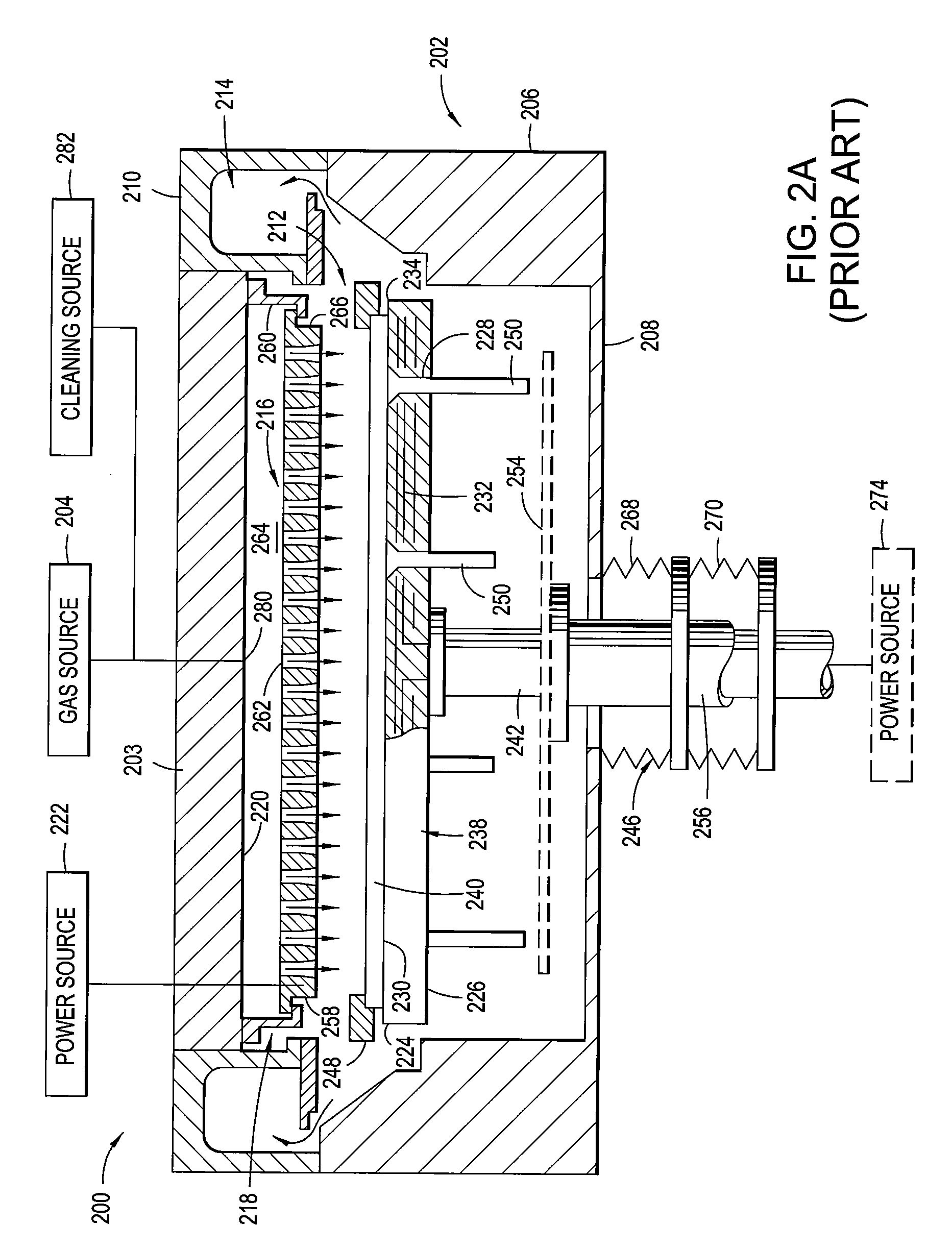

Merie plasma reactor with overhead RF electrode tuned to the plasma with arcing suppression

InactiveUS6894245B2Improve plasma ion density distribution uniformitySufficient capacitanceElectric discharge tubesElectric arc lampsCapacitanceIon density

A plasma reactor for processing a semiconductor workpiece, includes a reactor chamber having a chamber wall and containing a workpiece support for holding the semiconductor support, the electrode comprising a portion of the chamber wall, an RF power generator for supplying power at a frequency of the generator to the overhead electrode and capable of maintaining a plasma within the chamber at a desired plasma ion density level. The overhead electrode has a capacitance such that the overhead electrode and the plasma formed in the chamber at the desired plasma ion density resonate together at an electrode-plasma resonant frequency, the frequency of the generator being at least near the electrode-plasma resonant frequency. The reactor further includes a set of MERIE magnets surrounding the plasma process area overlying the wafer surface that produce a slowly circulating magnetic field which stirs the plasma to improve plasma ion density distribution uniformity.

Owner:APPLIED MATERIALS INC

Catalyzer for catalyzing combustion and its preparing method

InactiveCN1415410AReduced activityAvoid overwritingCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic acidActive component

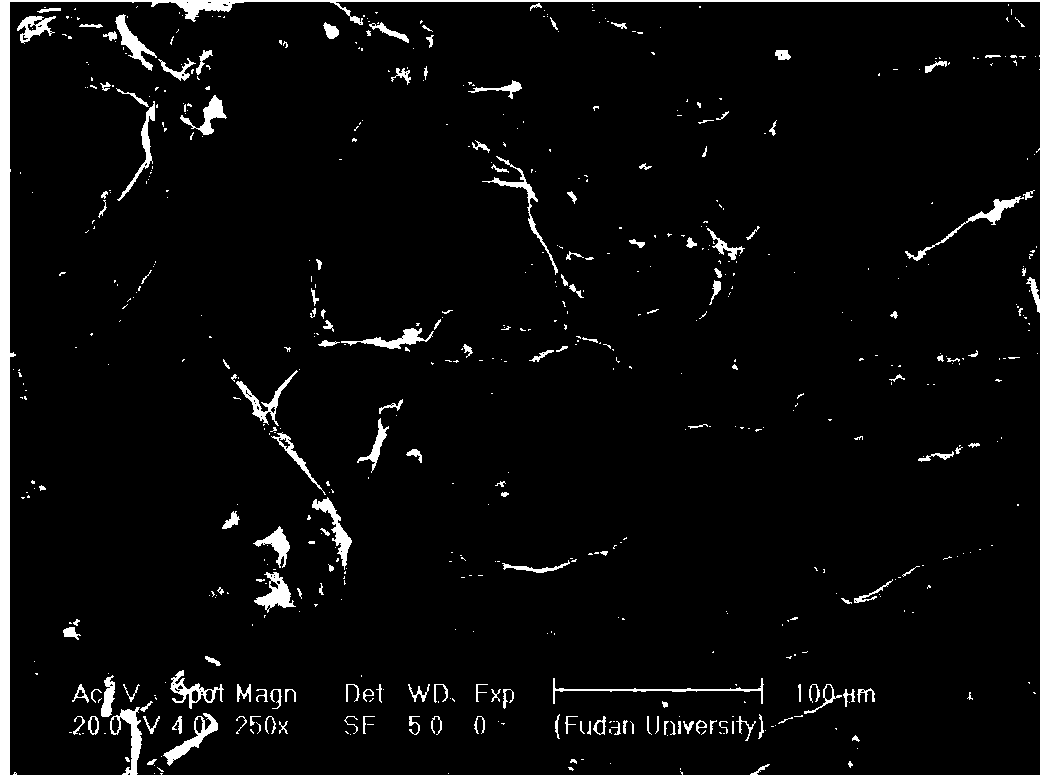

A catalyst for the catalytic combustion of combustible waste gas is prepared by dipping the Pt as active component on the coated layer of cellular ceramics as carrier. The said coated layer contains Al2O3 (20-80 wt.%), TiO2 (10-40 wt.%), CeO2 (5-30 wt.%) and ZrO2 (5-20 wt.%). Its advantages are high utilization rate of Pt, and high distribution uniformity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Molybdenum alloy target preparation method

ActiveCN104439247AImprove distribution uniformityGood alloying performanceVacuum evaporation coatingSputtering coatingMaterials processingOxygen content

The invention belongs to the technical field of material processing, and particularly relates to a molybdenum alloy target preparation method. Alloy powder is formed by molybdenum powder and other metal powder in a mechanical alloying mode, the alloy powder is processed, and a molybdenum alloy target is obtained. The mechanical alloying process is adopted, so that distribution uniformity and alloying performance of the powder raw materials are better; hot isostatic pressing is conducted after cold isostatic pressing, so that the compactness of the molybdenum alloy target is better; through the multi-stage degassing process, the oxygen content of the molybdenum alloy target is lower, and the degassing performance is better.

Owner:SHANDONG HAO XUAN ELECTRONICS CERAMIC MATERIALS

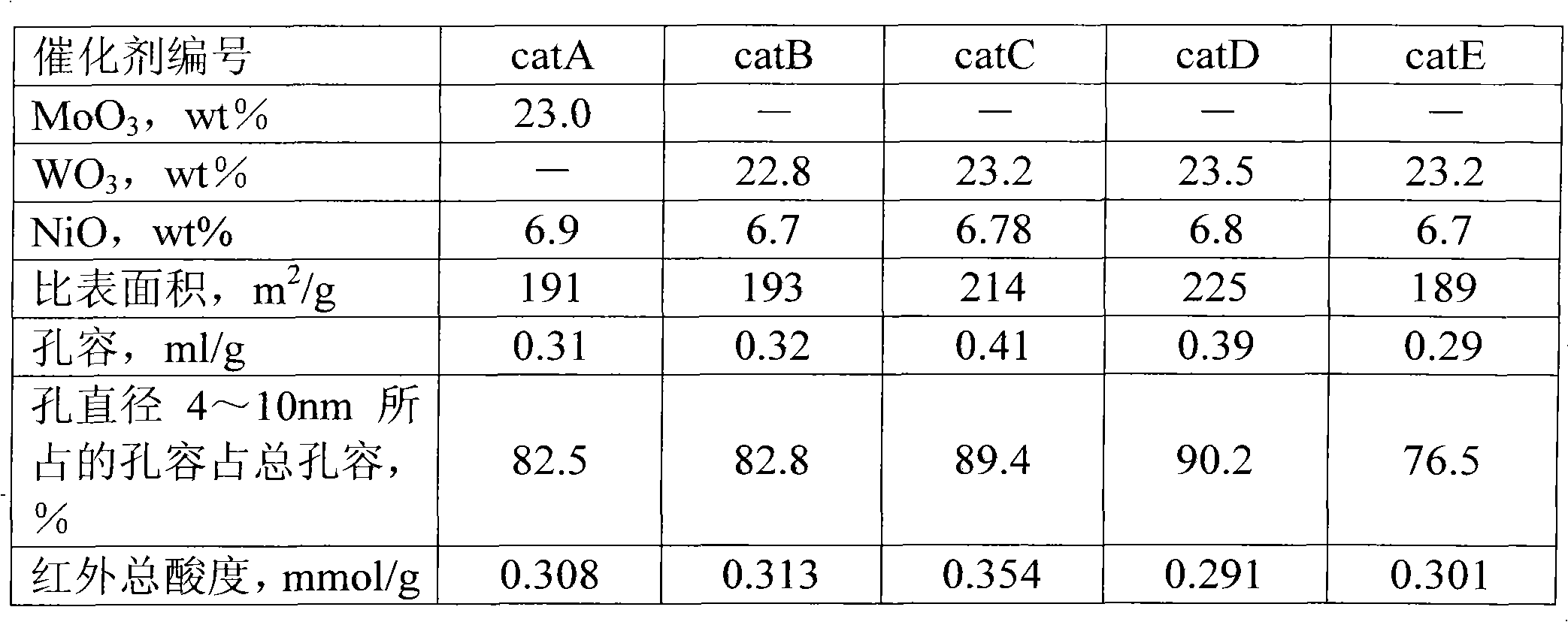

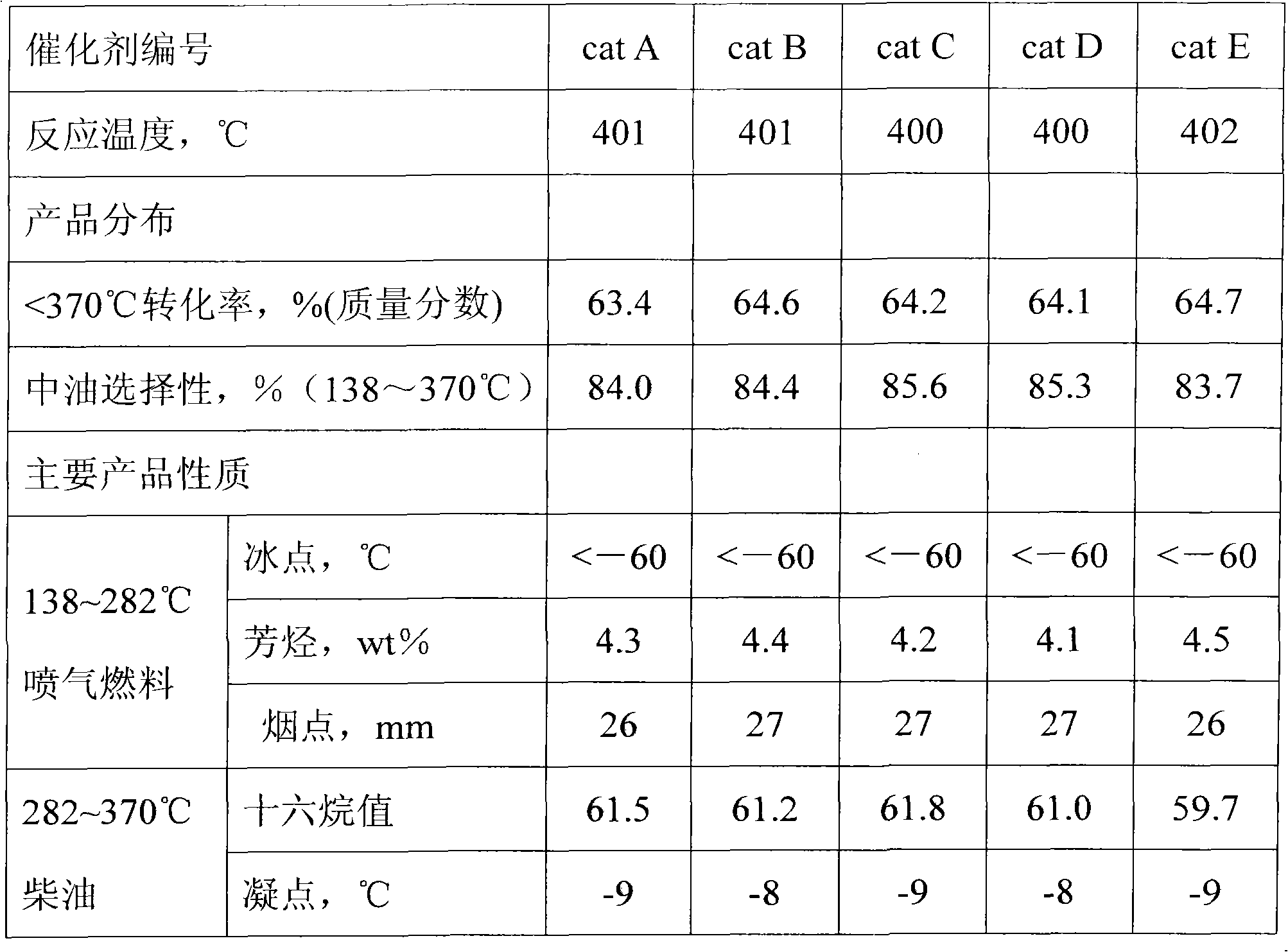

Hydrocracking catalyst and preparation method thereof

ActiveCN102039151AImprove hydrogenation activityHigh selectivityMolecular sieve catalystsCatalyst activation/preparationPore distributionSingle stage

The invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst is prepared by a carbonization method and is amorphous silica aluminum subject to hydro-thermal treatment. The amorphous silica aluminum prepared by the method has the characteristics of large specific surface, large pore volume, centralized pore distribution and appropriate acidity; an enough channel is provided for reactants, the reactants and products are convenient to enter / exit, the active ingredients of the carrier are greatly increased, and the distribution uniformity of the acid centre in the pore channel is improved; and moreover, as a larger space and a specific surface are provided for loading metal, the hydrogenated metal has higher dispersibility, the metal utilization rate is improved, and the catalyst provided by the invention has appropriate cracking activity as well as high hydrogenation activity and medium oil selectivity. The catalyst provided by the invention is particularly suitable for finishing the single-stage hydrocracking process once.

Owner:CHINA PETROLEUM & CHEM CORP +1

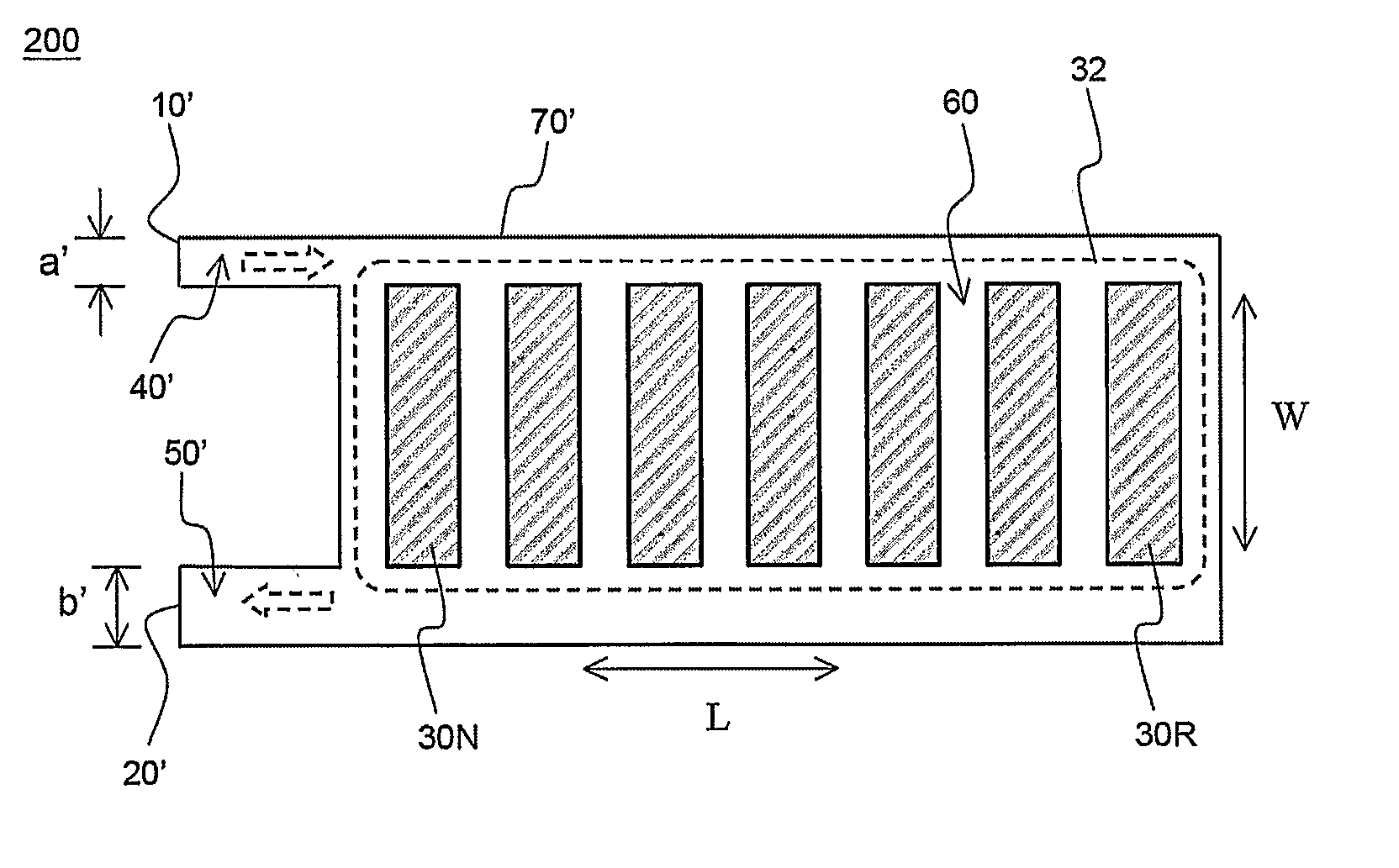

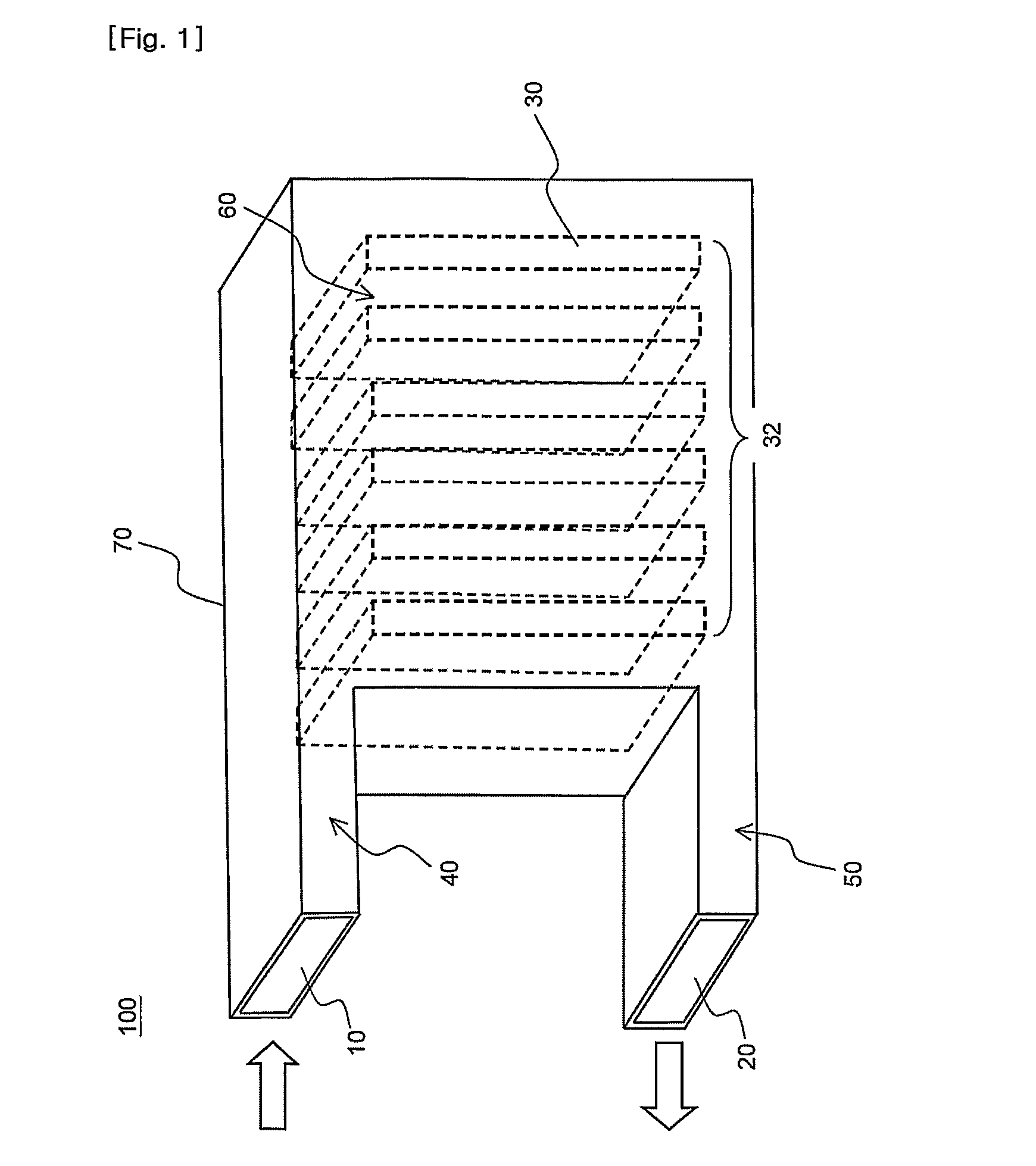

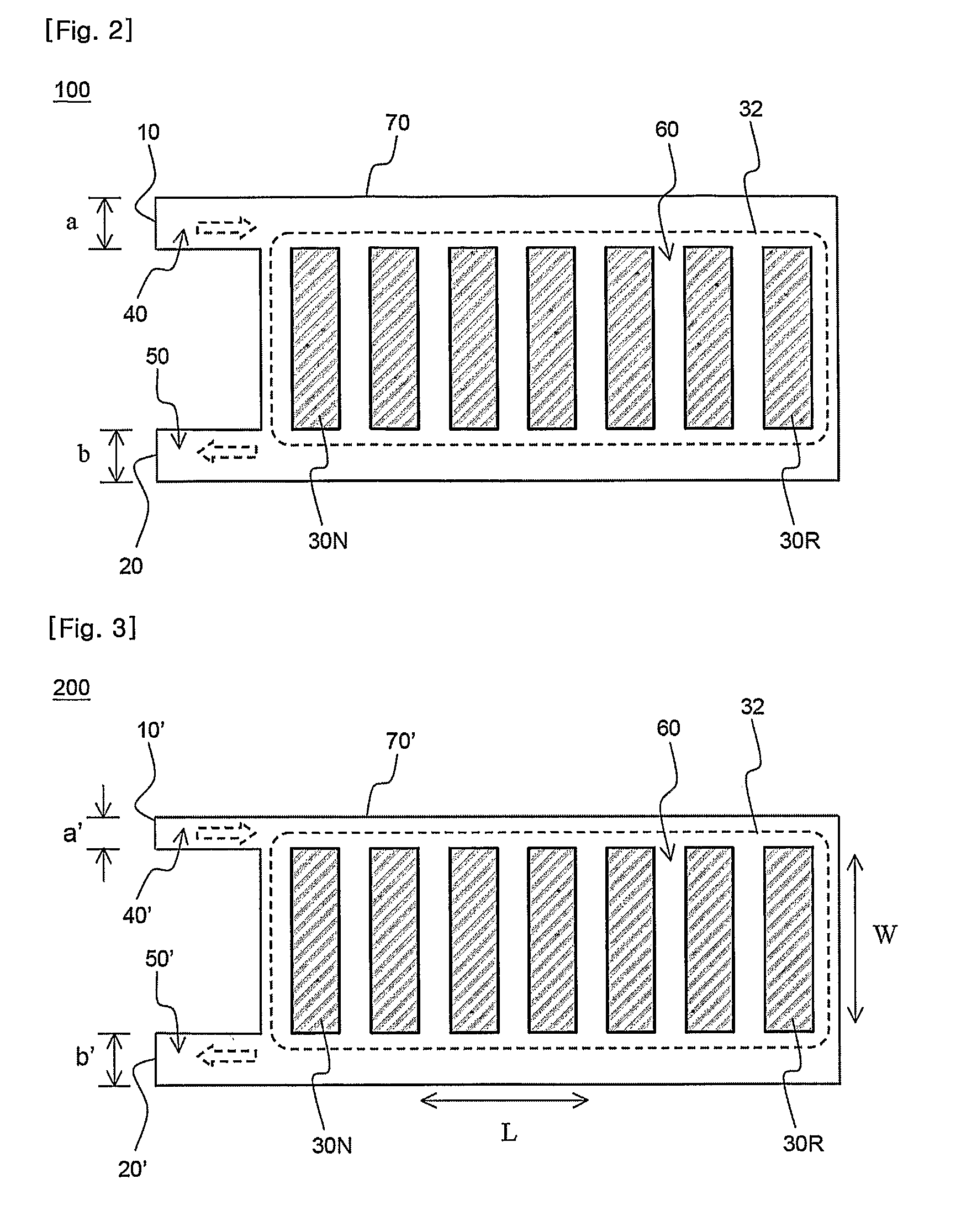

Middle or large-sized battery pack case providing improved distribution uniformity in coolant flux

ActiveUS20100203376A1Increase heightLarge widthCell temperature controlLi-accumulatorsEngineeringBattery cell

Disclosed herein is a middle- or large-sized battery pack case in which a battery module having a plurality of stacked battery cells, which can be charged and discharged, is mounted, wherein the battery pack case is provided with a coolant inlet port and a coolant outlet port, which are disposed such that a coolant for cooling the battery cells can flow from one side to the other side of the battery module in the direction perpendicular to the stacking direction of the battery cells, and the battery pack case is further provided with a flow space (‘inlet duct’) extending from the coolant inlet port to the battery module and another flow space (Outlet duct’) extending from the battery module to the coolant outlet port, the inlet duct having a vertical sectional area less than that of the outlet duct.

Owner:LG ENERGY SOLUTION LTD

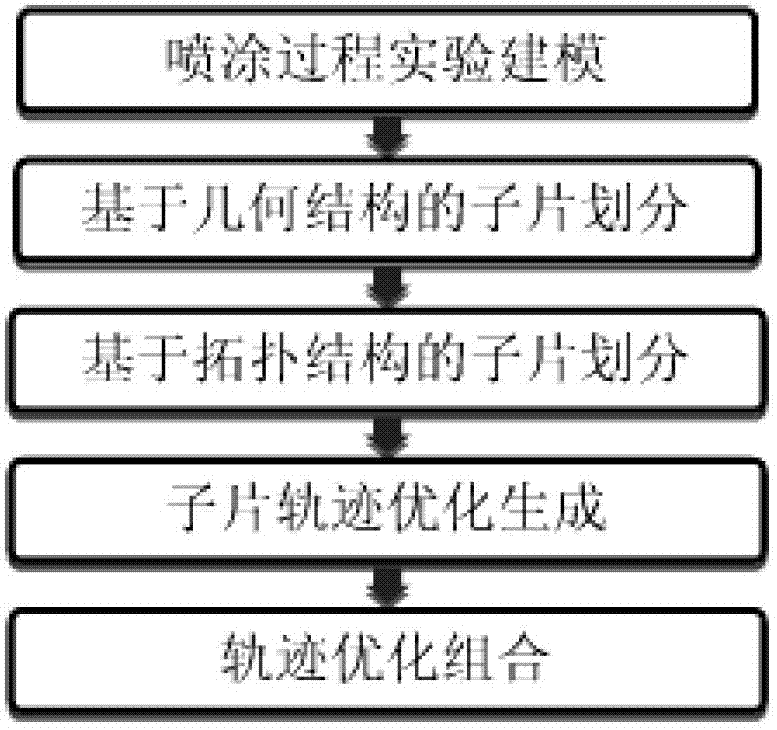

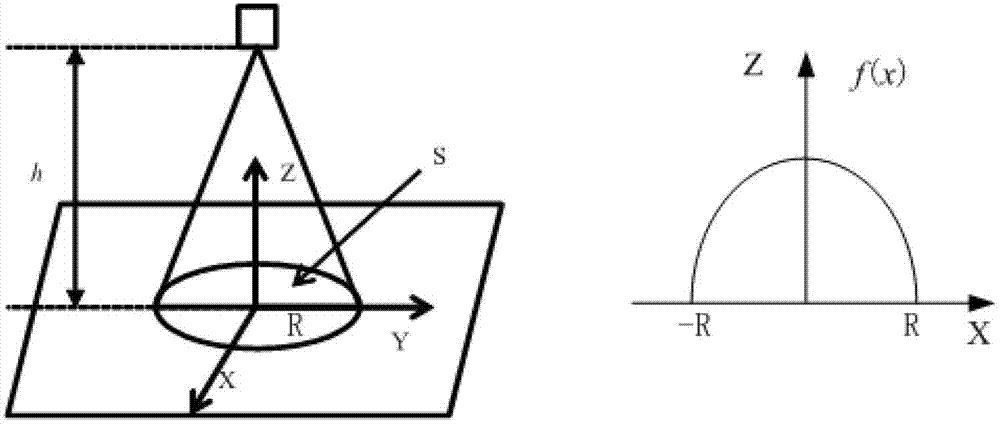

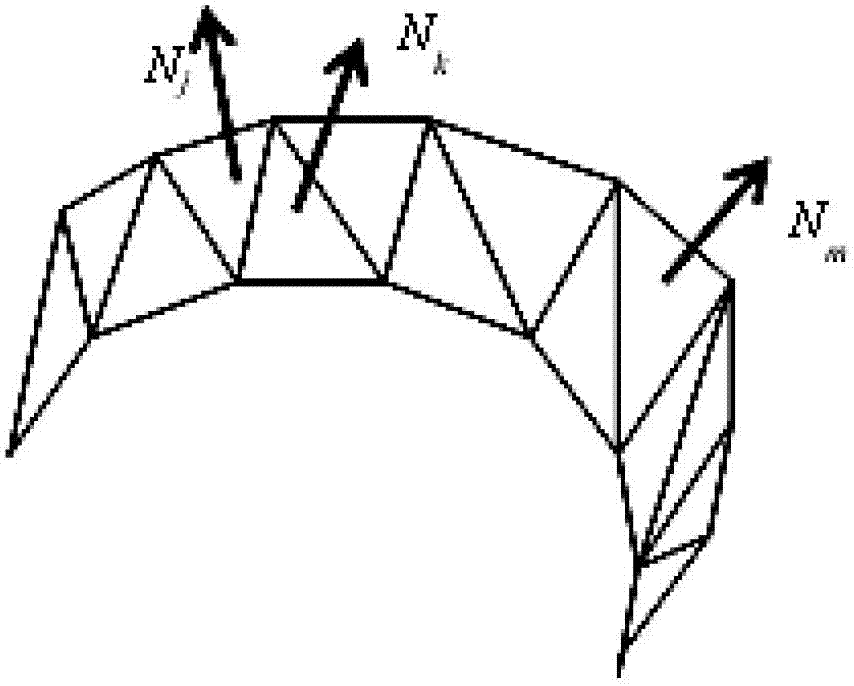

Layered spraying track planning method used for spraying robot

InactiveCN102831306AEfficient sprayingImprove spraying efficiencySpecial data processing applicationsEconomic benefitsTrajectory optimization

The invention discloses a layered spraying track planning method used for a spraying robot. The layered spraying track planning method comprises the steps of: firstly, designing an experiment method to build a model for the spraying process and fitting a coating distribution condition by introducing Gaussian and coating accumulative rate model; then adopting a layered track planning method and dividing a complex curve into a plurality of simple sub-curves by respectively applying a double deviation angle method and a projection method based on geometric and topological characteristics of a work-piece, establishing a corresponding spraying track optimization model and obtaining a travel parameter by adopting a numerical method so as to generate a spraying track in each sub-sheet; and finally, adopting an estimation of distribution algorithm to perform optimized combination on the track of each sub-sheet. The layered spraying track planning method used for the spraying robot, disclosed by the invention, has the advantages of improving the spraying production technology of the spraying robot, realizing track optimized generation of the spraying robot on each complex work-piece surface, improving distribution uniformity under the precondition of satisfying expected thickness of the coating, reducing paint waste, and thereby facilitating to improve production efficiency and economic benefits of the spraying manufacturing industry.

Owner:SOUTHEAST UNIV

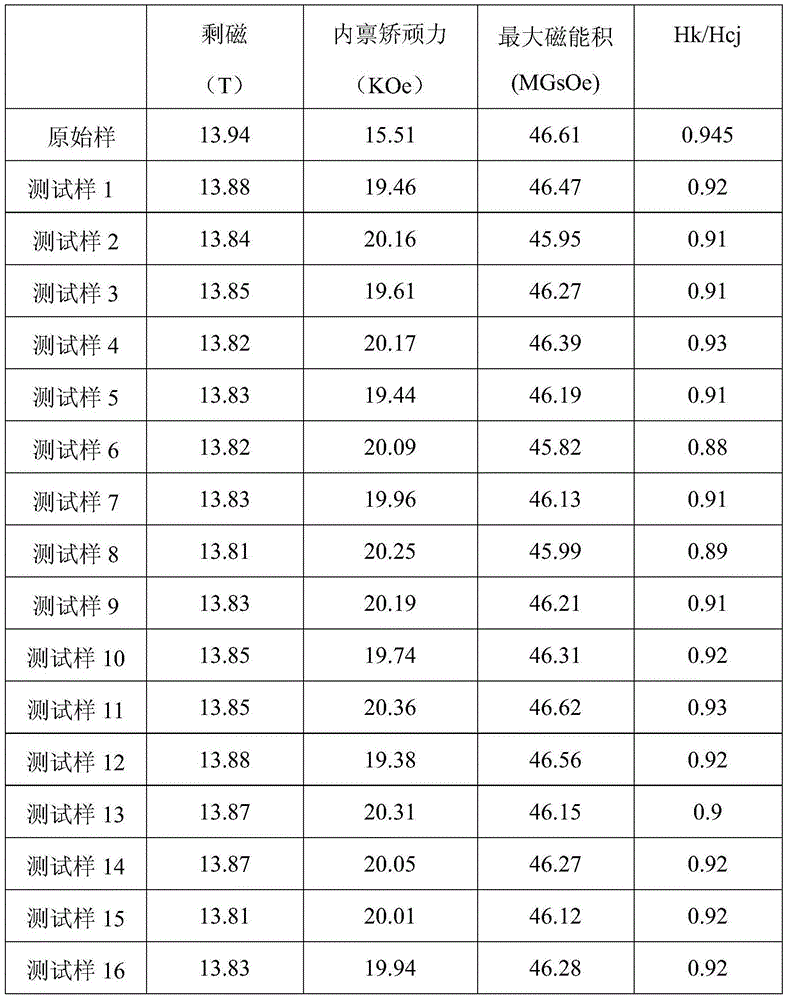

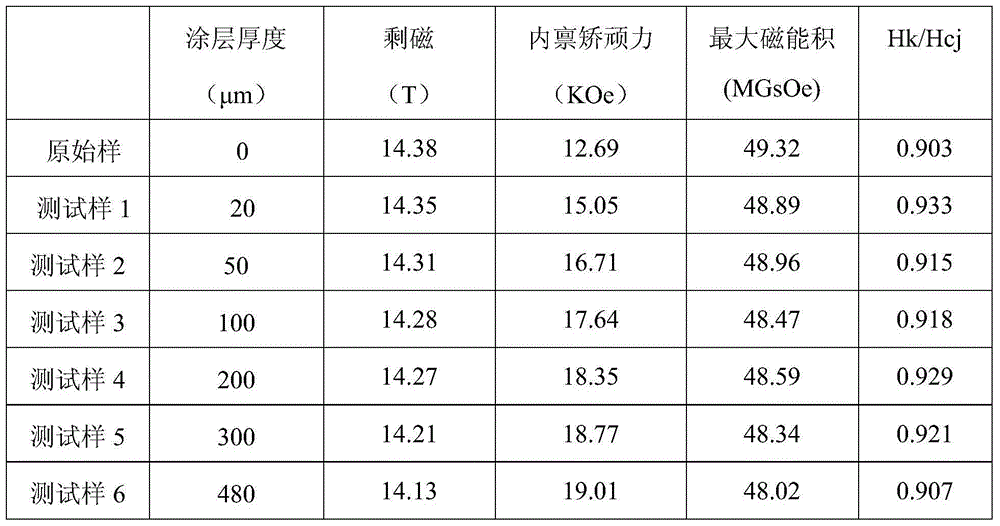

Method for improving the magnetic property of sintered NdFeB flaky magnets

ActiveCN104134528AImprove magnetic propertiesImprove organizationInorganic material magnetismSolid state diffusion coatingRare-earth elementMetallurgy

The invention discloses a method for improving the magnetic property of sintered NdFeB flaky magnets. First, suspension liquid containing heavy rare earth elements and having the viscosity of 0.1 to 500 mpa.s in the conditions of normal temperature and pressure is sprayed onto the surface of a sintered NdFeB flaky magnet uniformly. Second, the sintered NdFeB flaky magnet is dried, and then a coating containing heavy rare earth elements is obtained on the surface of the sintered NdFeB flaky magnet. Finally, the diffusion treatment and the ageing treatment are carried out on the dried sintered NdFeB flaky magnet in the environment of inert gas. The method has the advantages that the spraying technology can be applied to the grain boundary diffusion technique successfully, more specifically, a coating with high distribution uniformity and thickness distribution can be obtained on the surface of sintered NdFeB flaky magnets, and the grain boundary diffusion technology can be applied industrially for improving the magnetic property of sintered NdFeB flaky magnets.

Owner:NINGBO YUNSHENG +2

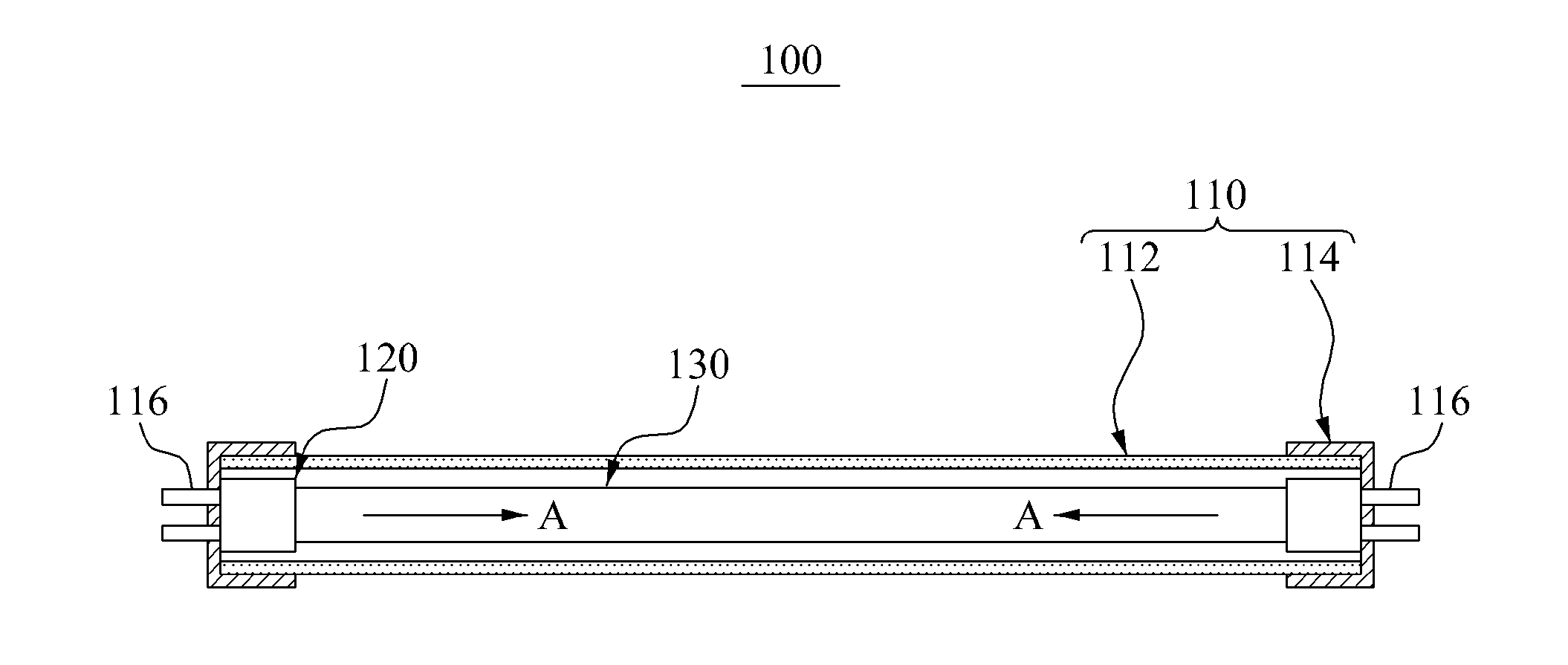

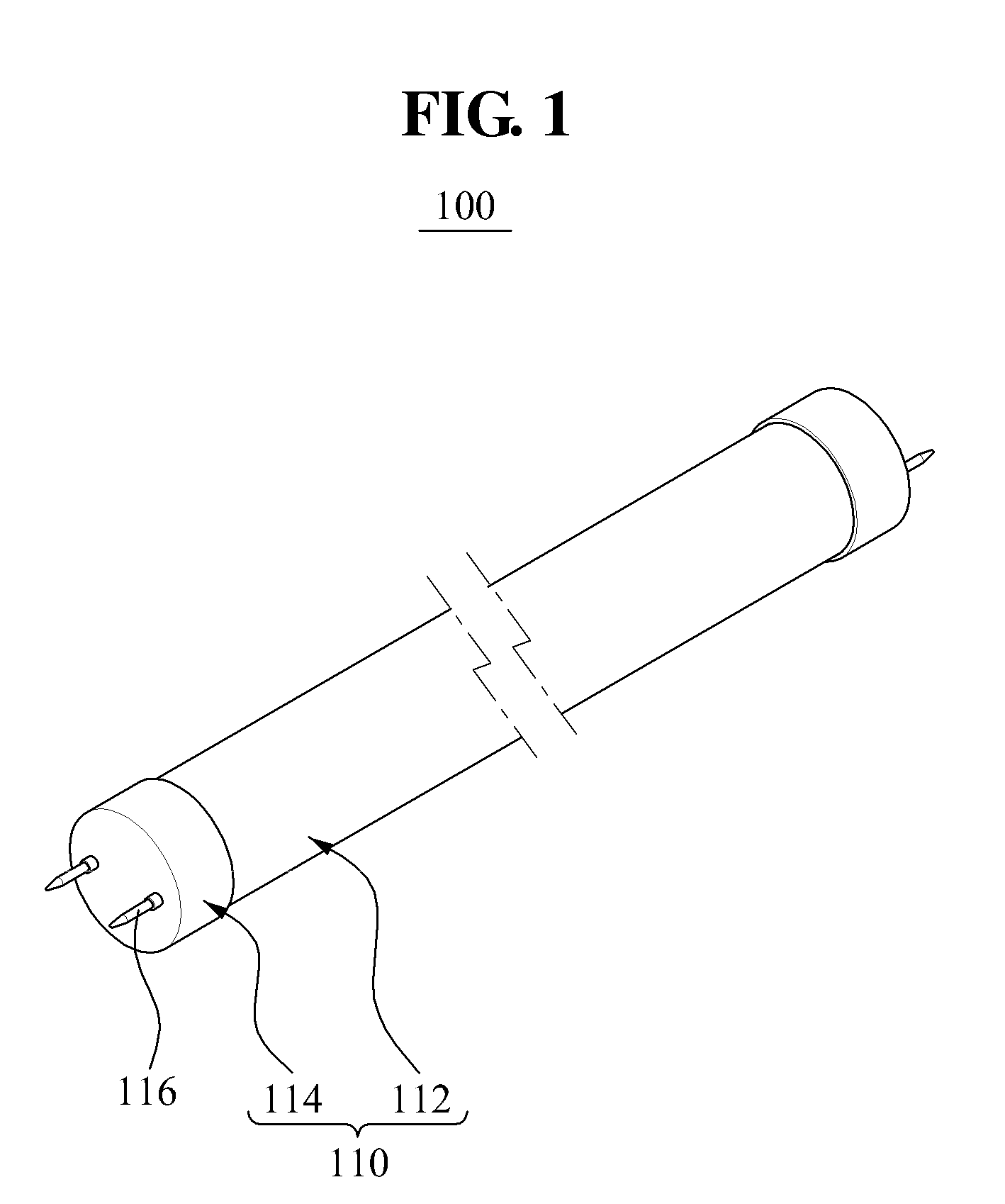

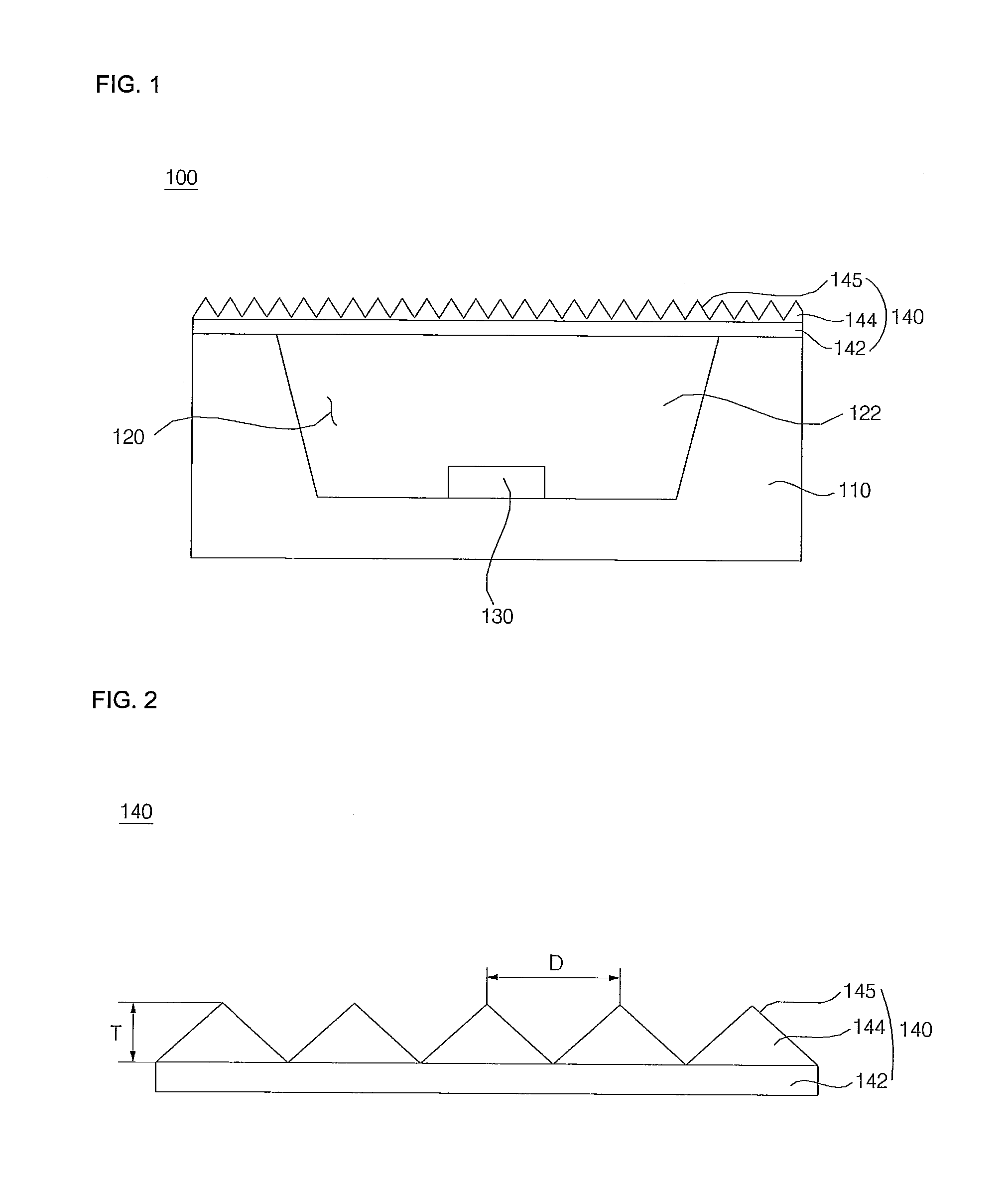

Lighting device

InactiveUS20130170245A1Well representedImprove light uniformityMechanical apparatusFibre light guidesLight guideStraight tube

Owner:SAMSUNG ELECTRONICS CO LTD

Protective agents for wood

InactiveUS6464764B1Effective penetrationLong-term stabilityBiocideNitro compound active ingredientsWater basedAmmonium compounds

Solvent-free coating materials and treating agents used as water-based wood or material protective agents containing emulsifiable binding agents, quaternary ammonium compounds and optional additional active agents. The wood or material protective agents are non-flammable and enable a uniform distribution of the binding agent and the quaternary ammonium compounds in the substrates. As a result, the quaternary ammonium compounds function as a dissolving mediator for the binding agents which are dispersed in water without opacifying effects and are used as a biocide. The agents can additionally absorb water-insoluble organic biocides without impairing the homogeneity or stability of the formulation of the homogeneity of the distribution in the substrate.

Owner:LONZA AG

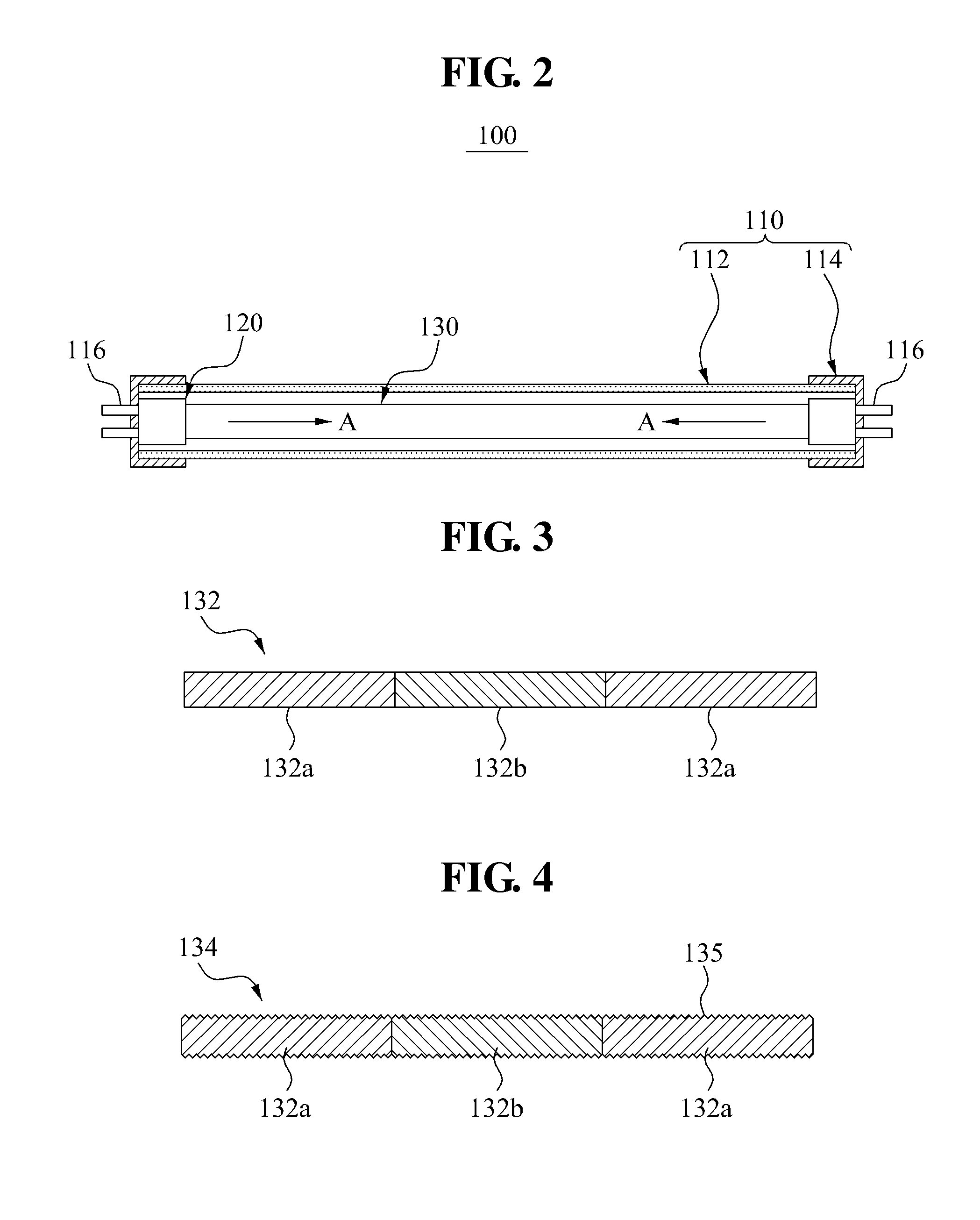

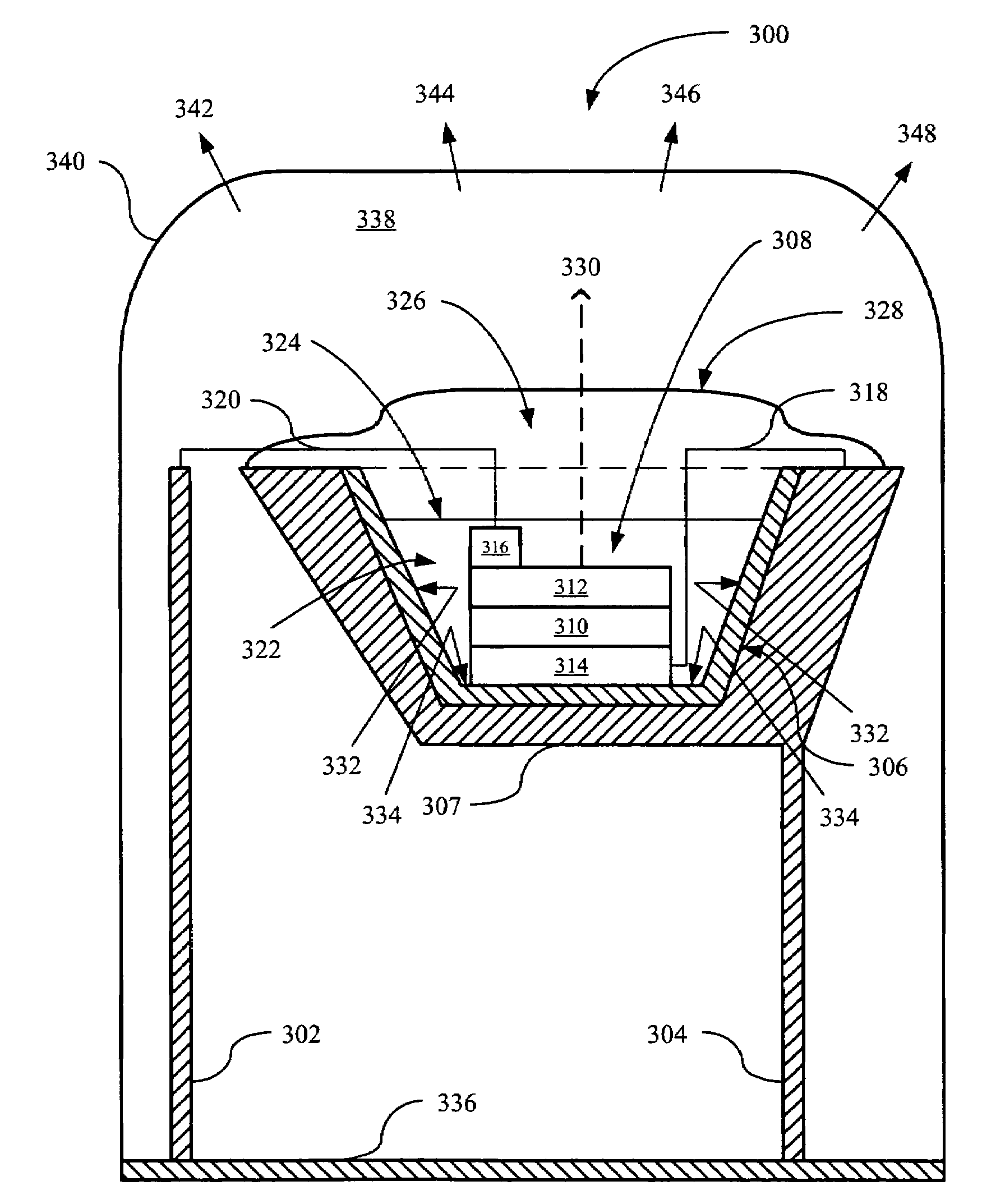

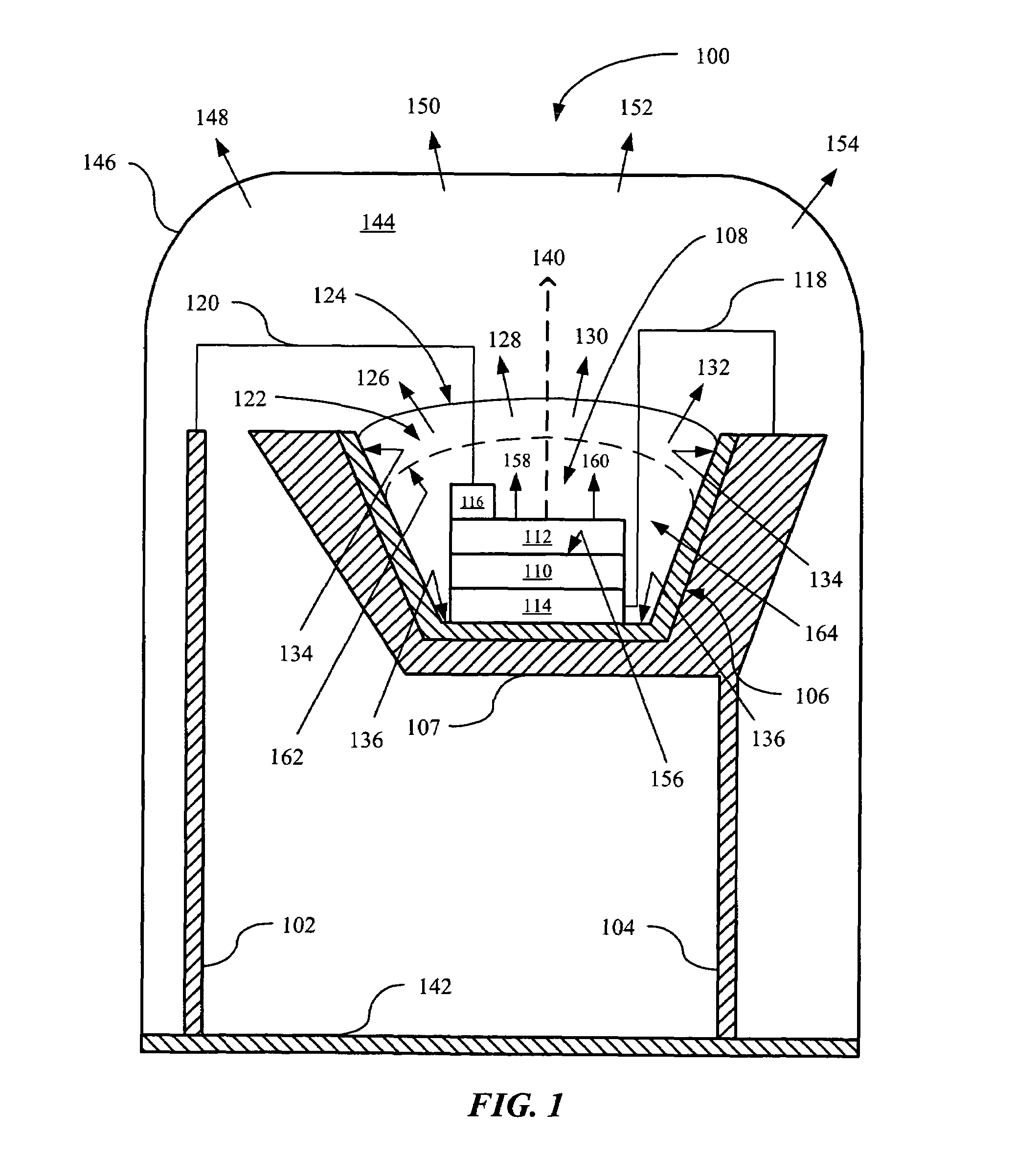

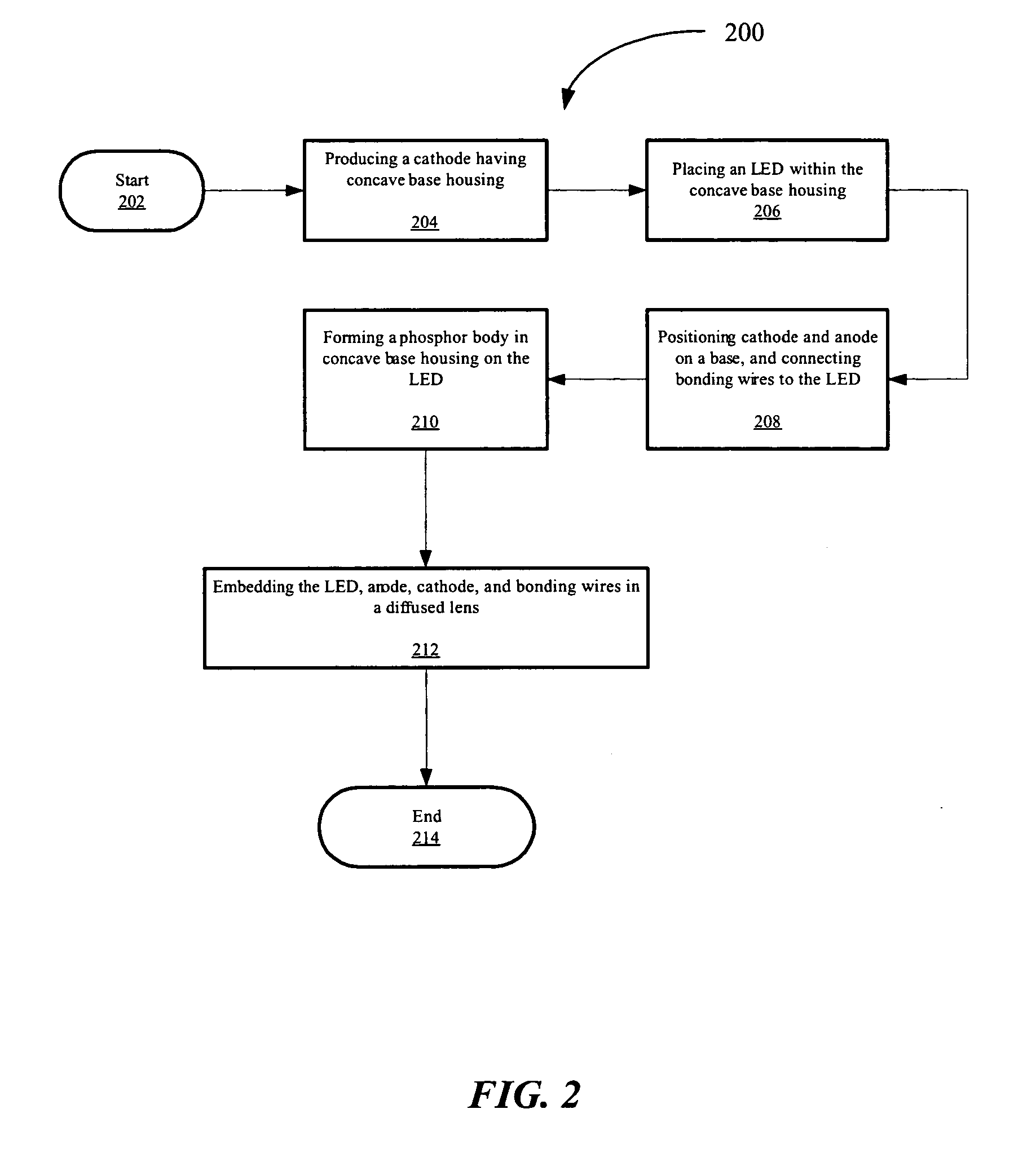

Phosphor-converted LED devices having improved light distribution uniformity

ActiveUS7329907B2Semiconductor/solid-state device detailsSolid-state devicesPhosphorDistribution uniformity

Owner:DOCUMENT SECURITY SYST

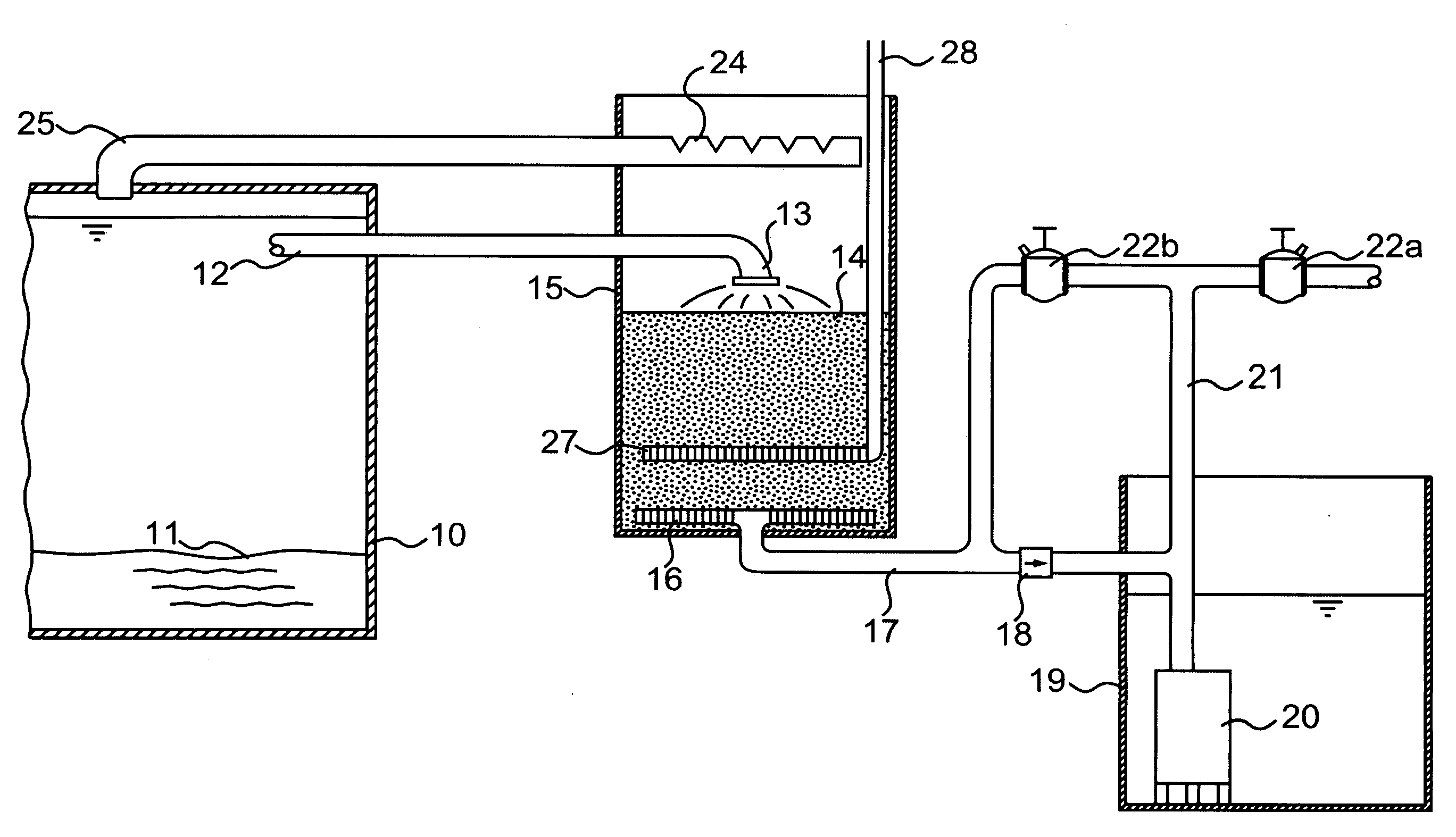

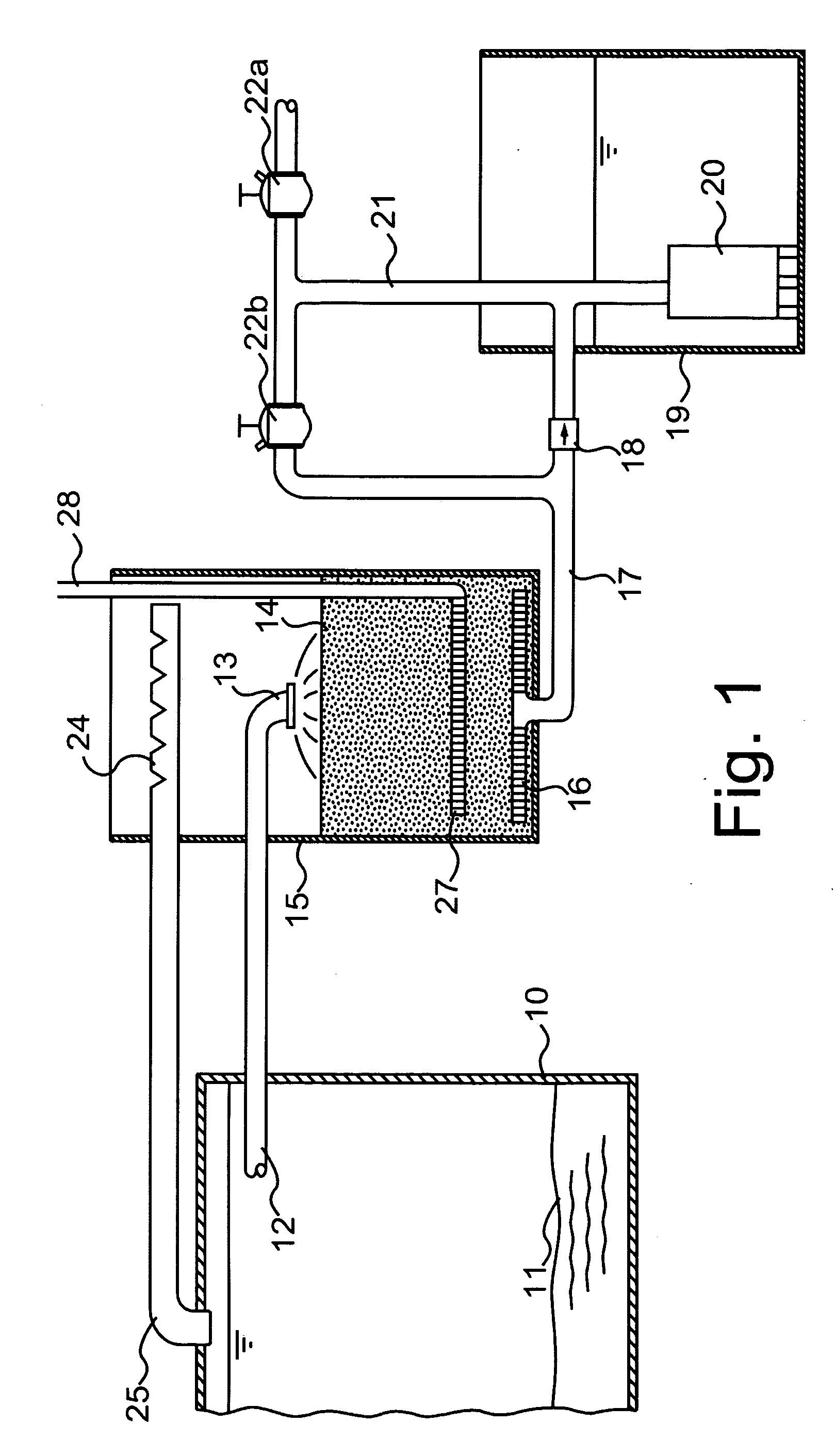

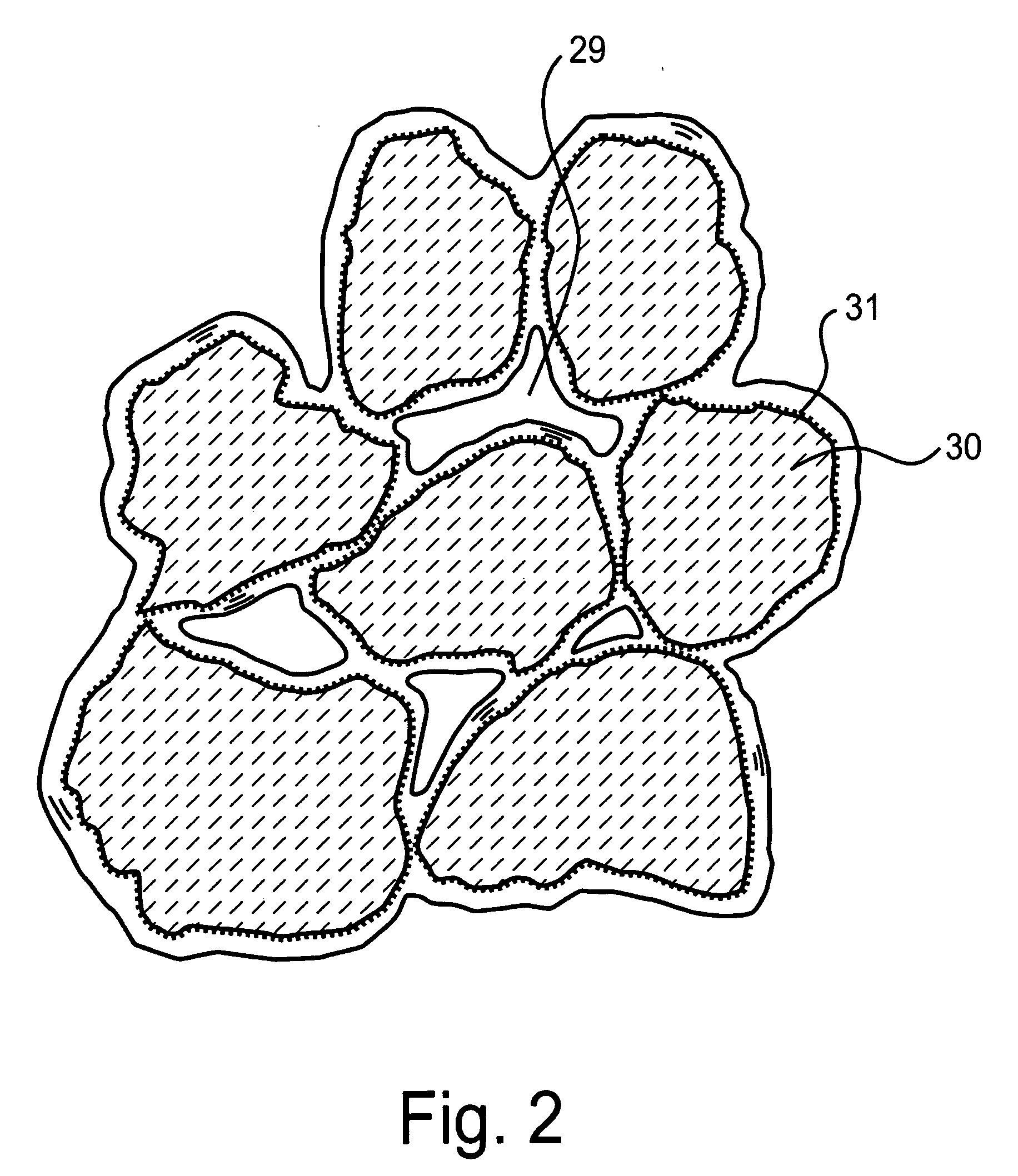

Backwashing unsaturated wastewater filter

ActiveUS20090294356A1Improve uniformityImprove efficiencyTreatment using aerobic processesSpecific water treatment objectivesWater sourceBiofilm growth

A compact high efficiency combined biological and physical unsaturated wastewater treatment filter configured for periodic backwashing is disclosed. The filter utilizes packed media and removes pollutants and pathogens from wastewater and other dirty water sources. The filter comprises a periodic backwashing means to less the chance that biofilm growth will clog the media pores. However, such backwashing still leaves sufficient biofilm attached to the media to maintain a very high level of treatment. In the preferred embodiment, the filter utilizes high frequency dosing to cause pore saturation at or near the surface during dosing and shortly thereafter in order to maximize distribution uniformity and to induce downward airflow into the media. The system provides a number of unexpected benefits; including allowing a very low distribution pressure and providing high oxygen transfer at low energy utilization into the filter media for aerobic biodegradation of pollutants.

Owner:BZAM LLC

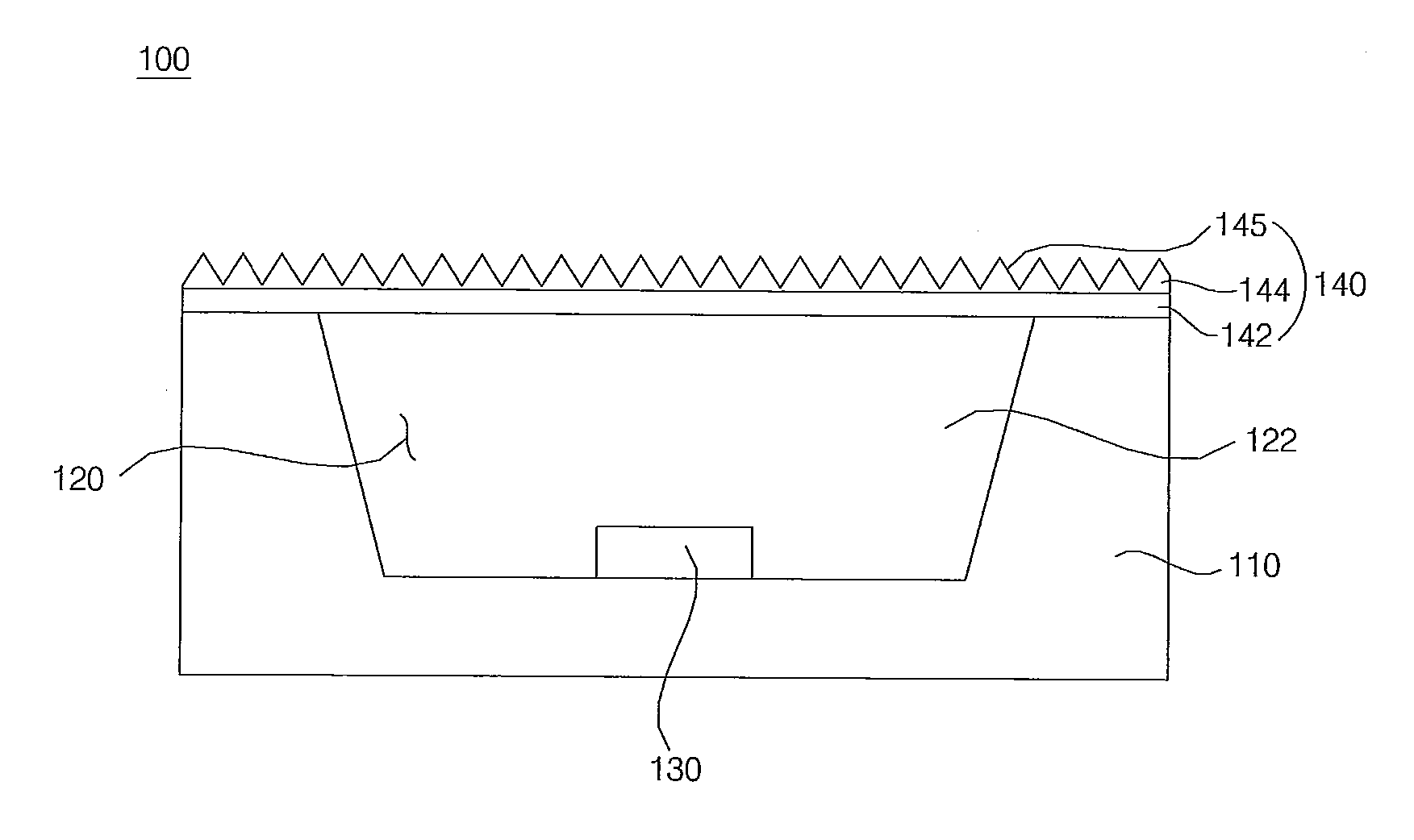

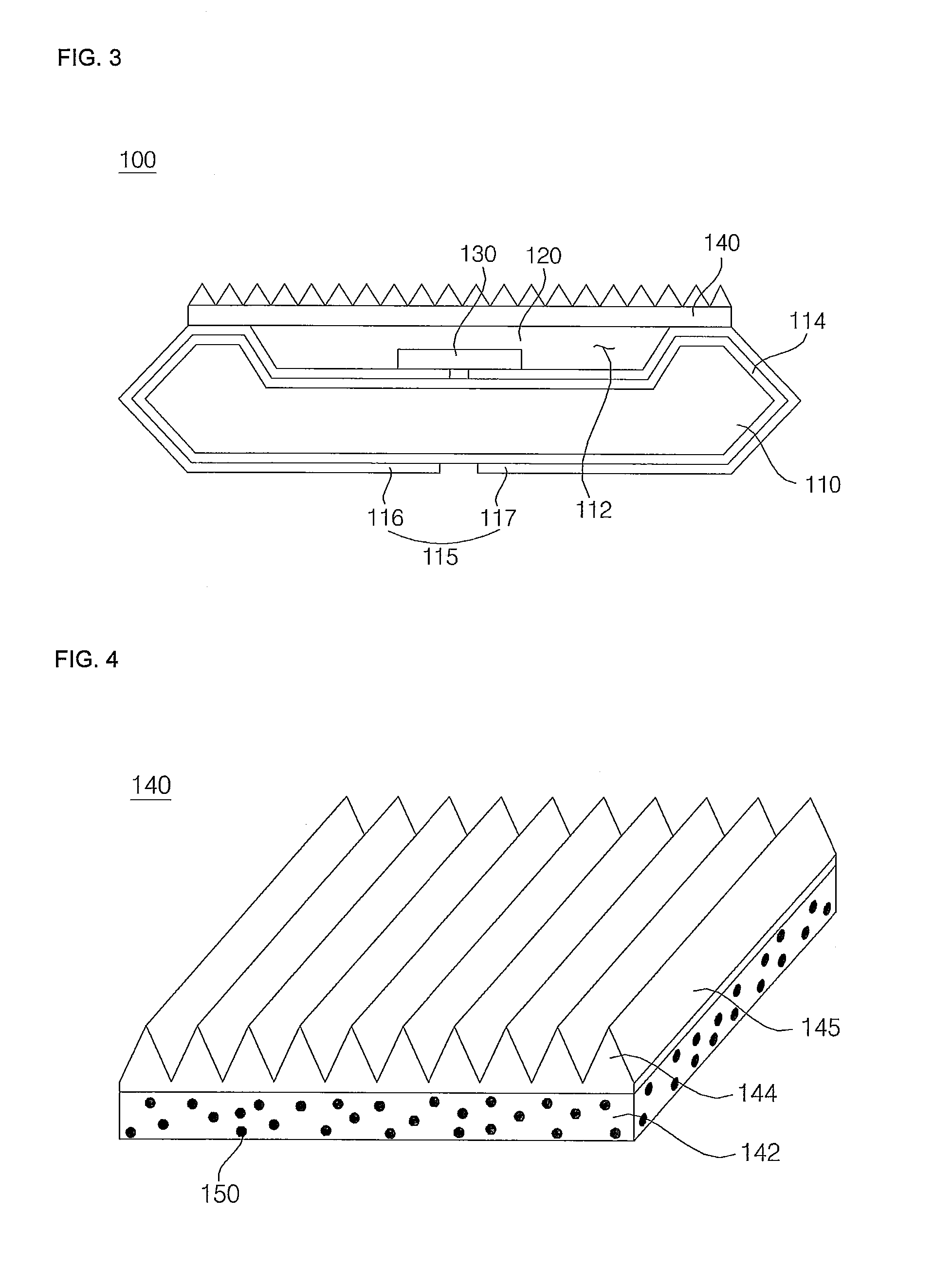

Optical sheet and light emitting device package having the same

ActiveUS20120026720A1Improve lighting efficiencyUniform light distributionPoint-like light sourceDiffusing elementsPrismLight emitting device

A light emitting device package is disclosed. The light emitting device package includes a body having a cavity, a light source mounted in the cavity, and at least one optical sheet located on the body to cover the cavity. The optical sheet includes a first layer and a second layer formed on the first layer, wherein the second layer includes a plurality of linear prism parts. At least one of the first layer and the second layer contains a light diffusive member. The light emitting device package has enhanced light emission efficiency and light distribution uniformity.

Owner:SUZHOU LEKIN SEMICON CO LTD

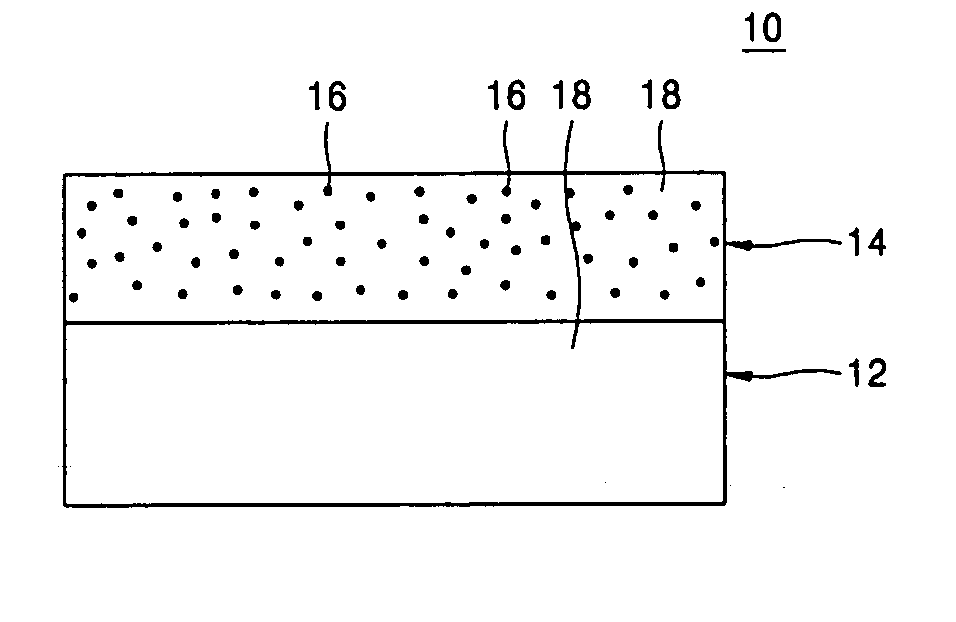

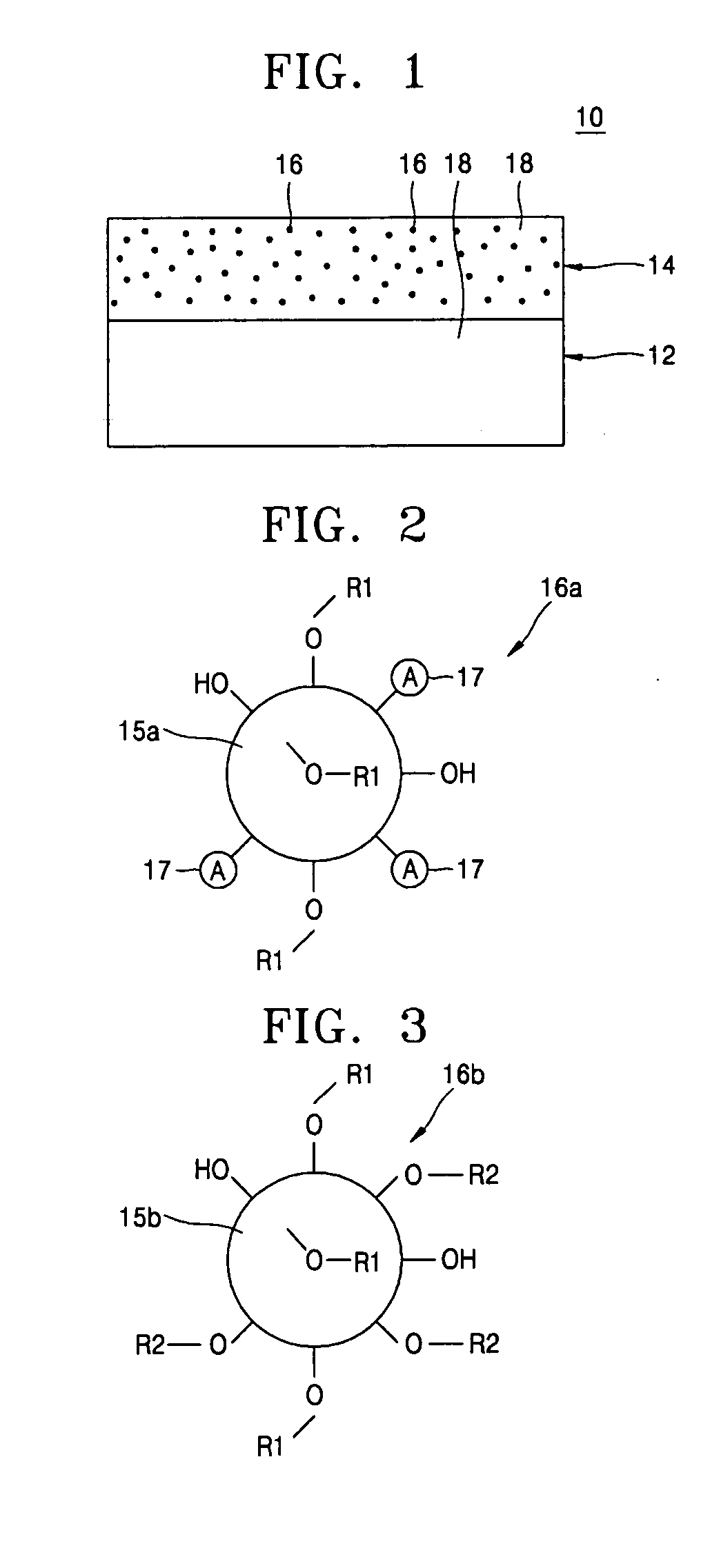

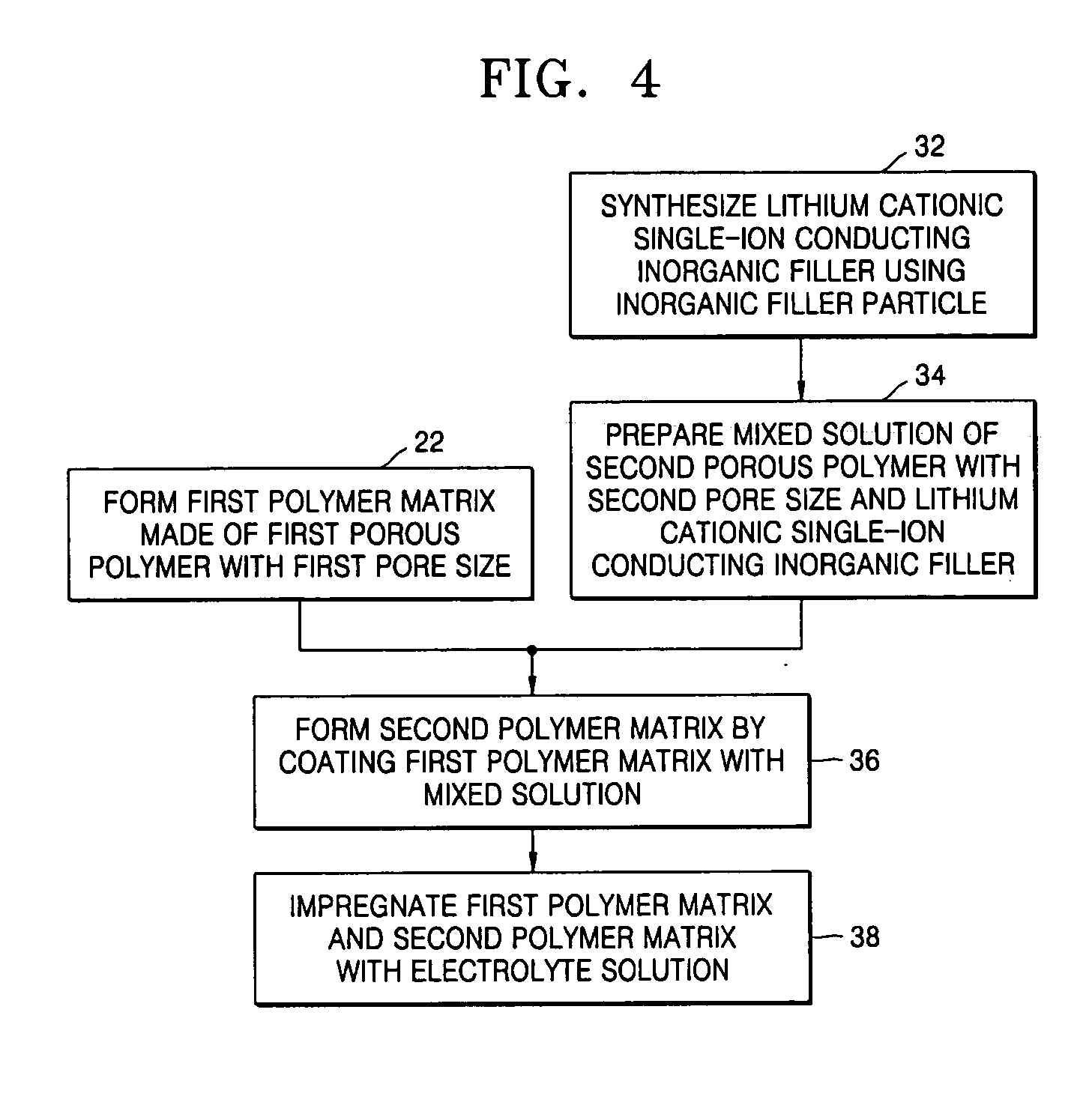

Lithium cationic single-ion conducting inorganic filler-containing composite polymer electrolyte for lithium secondary battery and method of manufacturing the same

ActiveUS20050196677A1High mechanical strengthPrevent increase of inner resistanceNon-metal conductorsSolid electrolytesLithiumPolymer science

Provided are a composite polymer electrolyte for a lithium secondary battery in which a composite polymer matrix multi-layer structure composed of a plurality of polymer matrices with different pore sizes is impregnated with an electrolyte solution, and a method of manufacturing the same. Among the polymer matrices, a microporous polymer matrix with a smaller pore size contains a lithium cationic single-ion conducting inorganic filler, thereby enhancing ionic conductivity, the distribution uniformity of the impregnated electrolyte solution, and maintenance characteristics. The microporous polymer matrix containing the lithium cationic single-ion conducting inorganic filler is coated on a surface of a porous polymer matrix to form the composite polymer matrix multi-layer structure, which is then impregnated with the electrolyte solution, to manufacture the composite polymer electrolyte. The composite polymer electrolyte is used in a unit battery. The composite polymer matrix structure can increase mechanical properties. The introduction of the lithium cationic single-ion conducting inorganic filler can provide excellent ionic conductivity and high rate discharge characteristics.

Owner:ELECTRONICS & TELECOMM RES INST

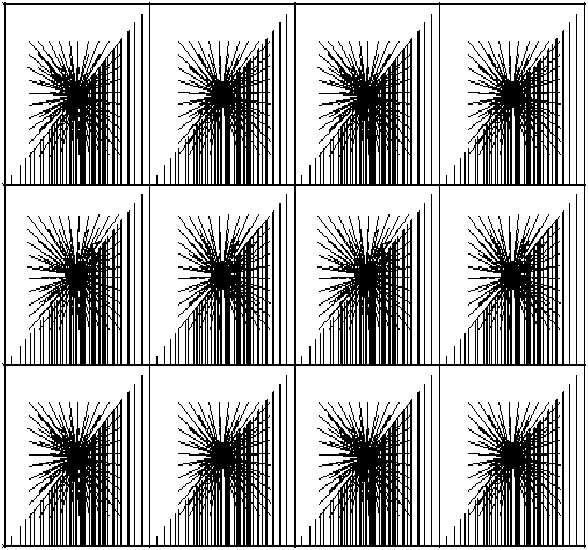

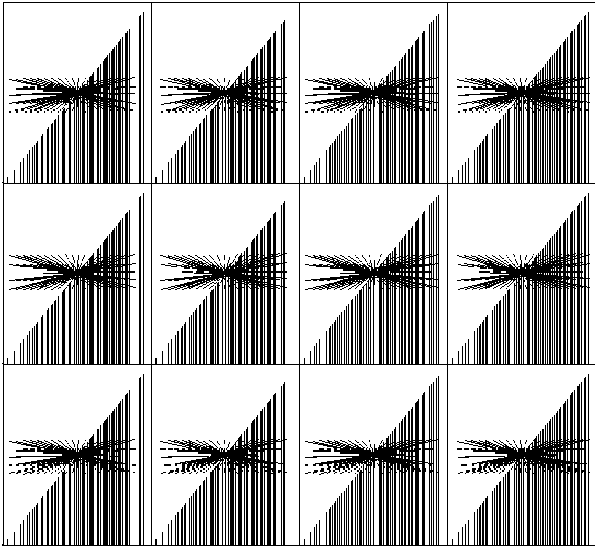

Uniformity analysis method of three-dimensional observation system

The invention provides a uniformity quantitative analysis method of a three-dimensional observation system. The uniformity quantitative analysis method is as follows: by calculating non-uniformity coefficient of coverage time distribution, non-uniformity coefficient of geophone offset distribution, non-uniformity coefficient of azimuth angle distribution and non-uniformity coefficient of geophonecoverage, analyzing the distribution uniformity of coverage time, the geophone offset, the azimuth angle and the geophone coverage of the three-dimensional observation system qualitatively and quantitatively from two levels of a single surface element and a plurality of surface elements, instructing the design of the observation system, and providing basis of judgment for the accuracy of acquisition construction, so that the selection of the three-dimensional observation system can be more scientific, reasonable and objective.

Owner:CHINA PETROCHEMICAL CORP +1

Salt coating liquid and application thereof in reconstituted tobacco

The invention provides salt coating liquid. The salt coating liquid is made with, by weight, 0.5-10% of calcium acetate and 90-99.5% of tobacco sheet coating liquid. After treated by a high-temperature process, the calcium acetate in the salt coating liquid is partially decomposed into calcium carbonate which can convert on the surface of the reconstituted tobacco into a great amount of calcium carbonate particles, so that retention rate and distribution uniformity of the calcium carbonate in the reconstituted tobacco can be significantly improved, specific area is greatly increased, a novel microporous structure is generated, water absorbing and moisture preserving performances of the structure are effectively improved, whiteness and flame retention rate of ash from combustion of the reconstituted tobacco can be improved, bulkiness of the reconstituted tobacco is improved, and thickens of the reconstituted tobacco is increased; in terms of smell absorption, tobacco miscellaneous odors can be decreased, irritation is lowered and comfort is improved. In addition, the undecomposed calcium carbonate is hydratable calcium salt with very high hygroscopic property; good moisture preserving effect and certain mould resistance are provided.

Owner:SHANGHAI TOBACCO GRP CO LTD

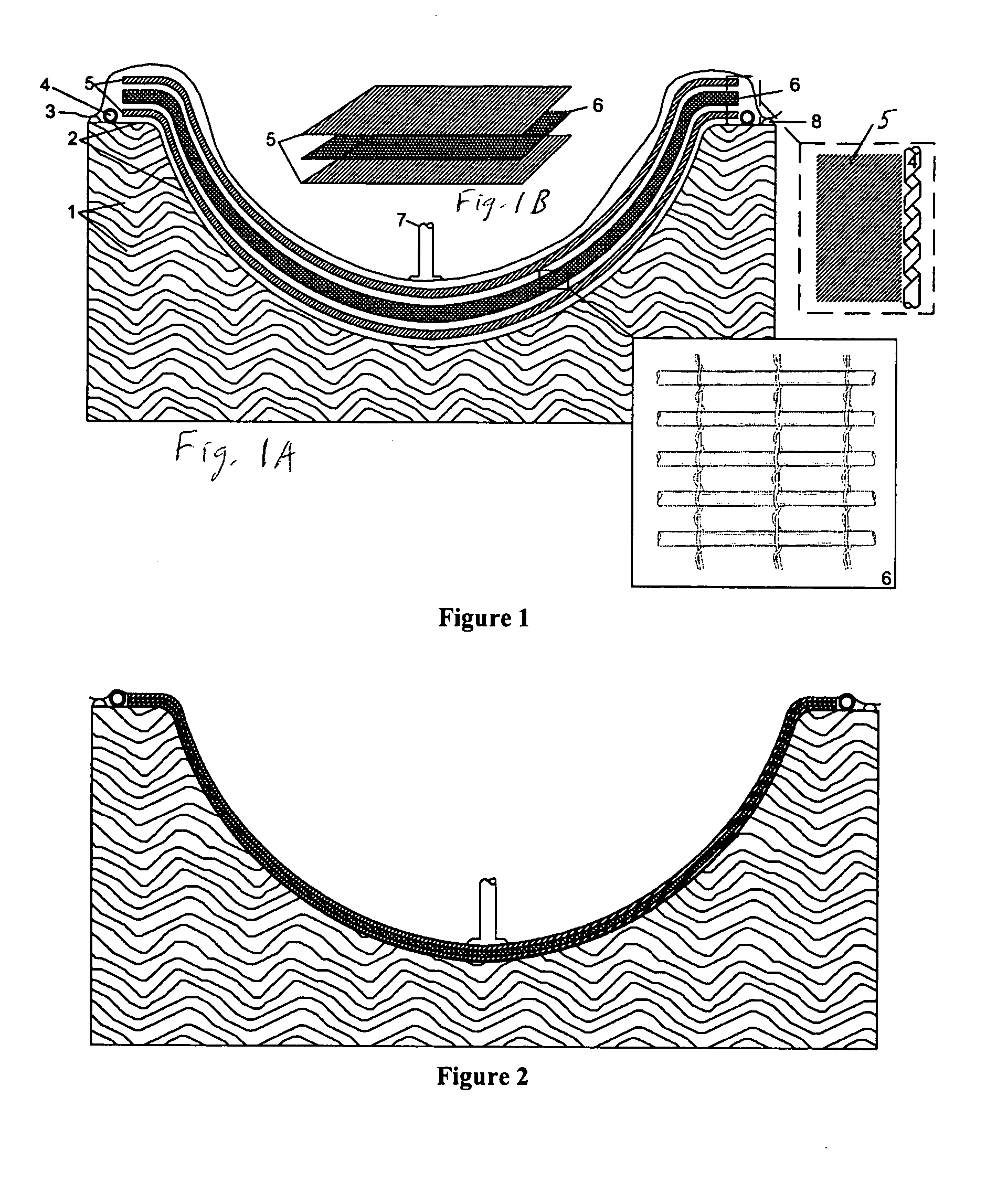

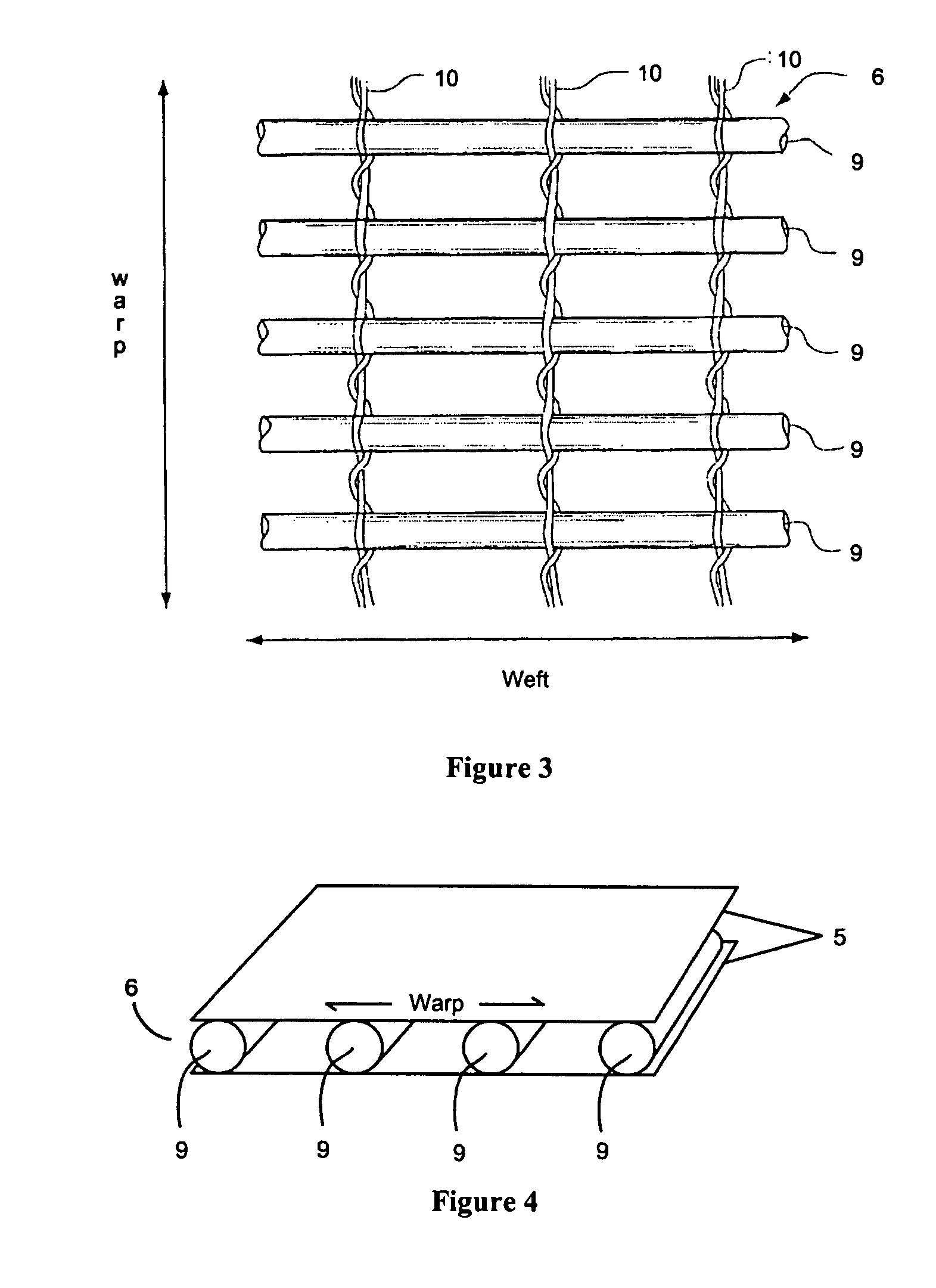

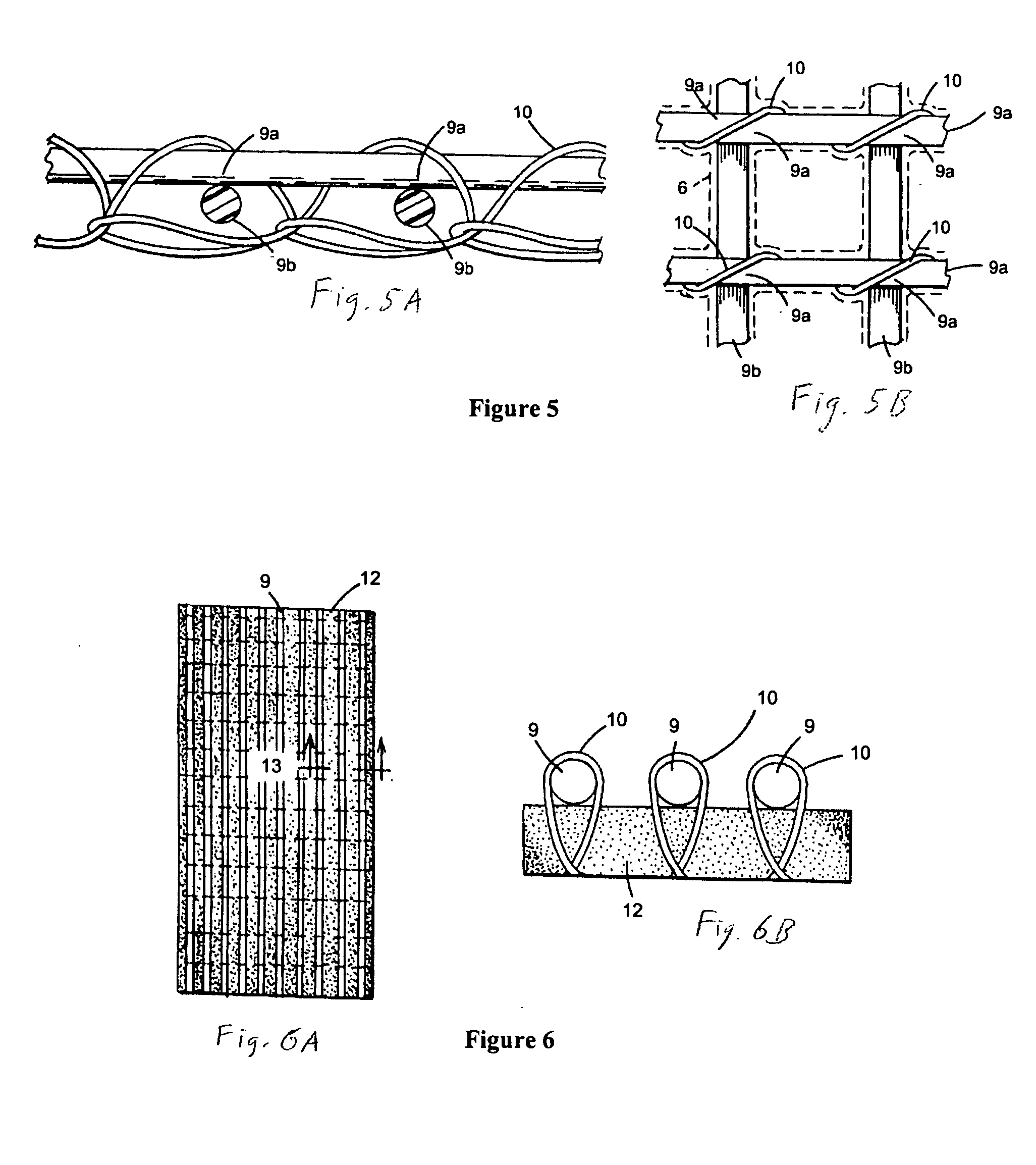

Open grid fabric resin infusion media and reinforcing composite lamina

InactiveUS20050037678A1Increase speedImprove uniformityWeft knittingWarp knittingFiberPolymer science

An open grid fabric resin infusion medium and reinforcing composite lamina used in the manufacture of fiber reinforced polymer resin composites. The use of the open grid fabric as at least one of a composite lamina provides significant improvements in both the resin infusion rate and resin distribution uniformity throughout the laminate.

Owner:VRAC

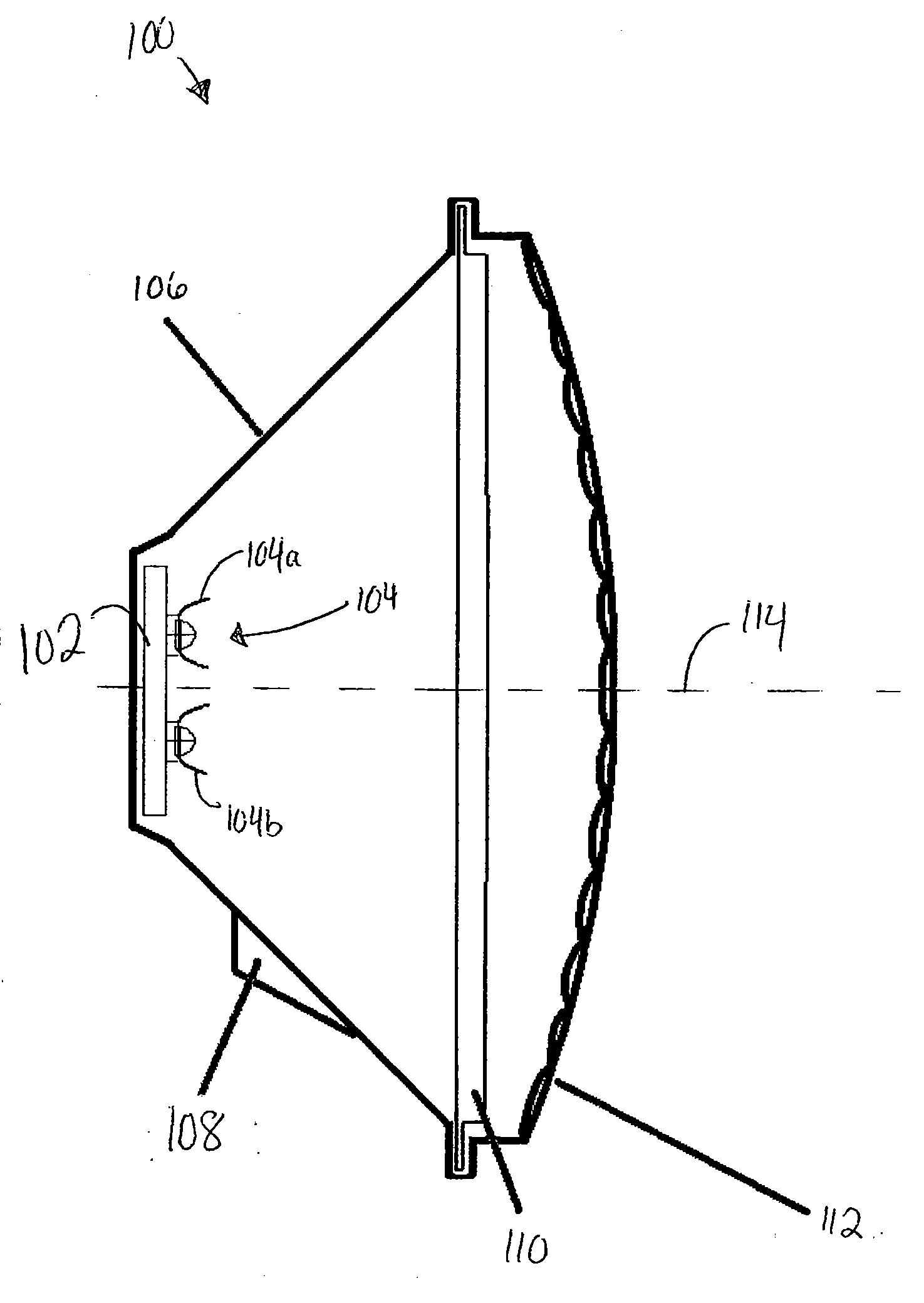

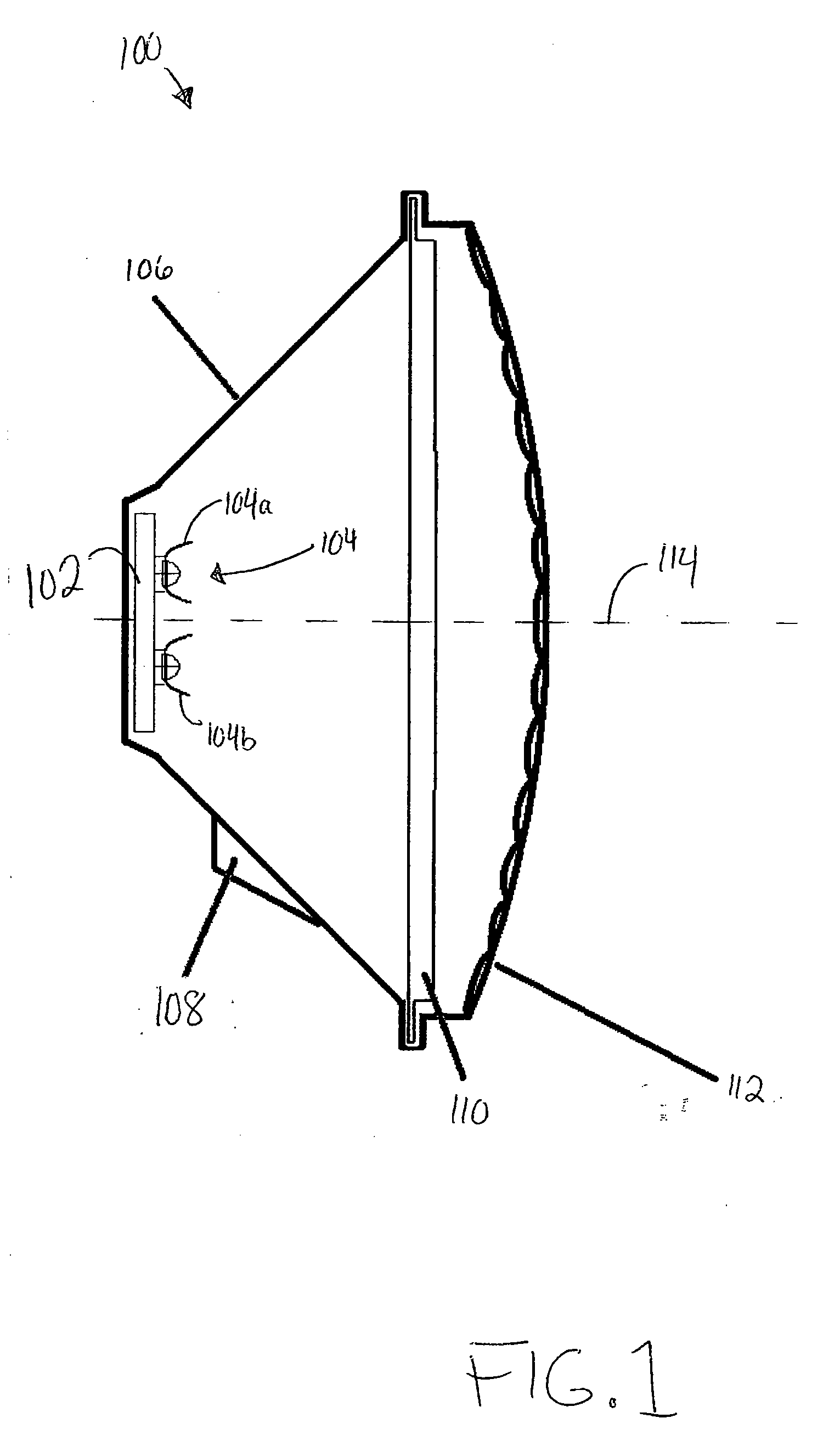

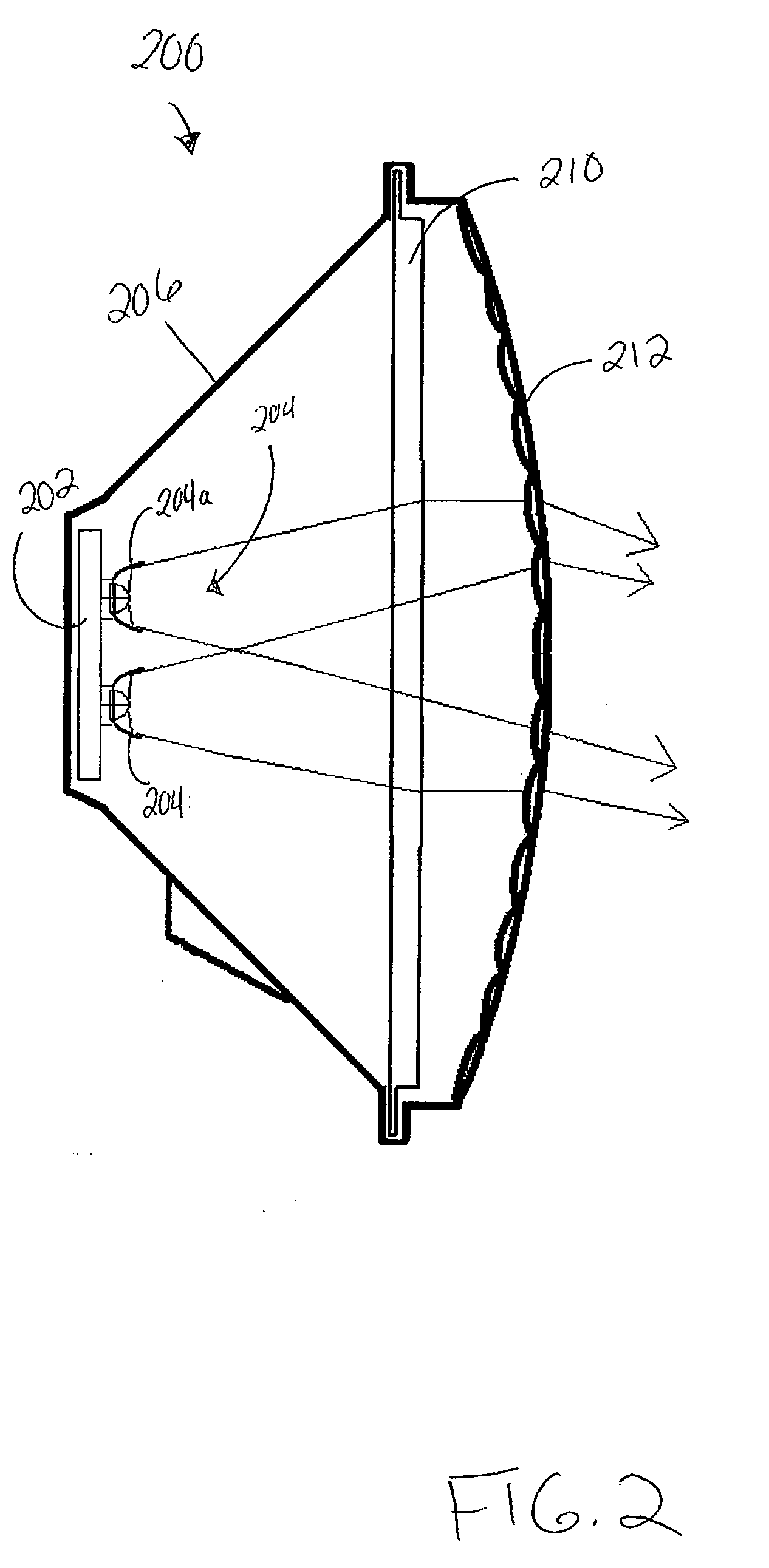

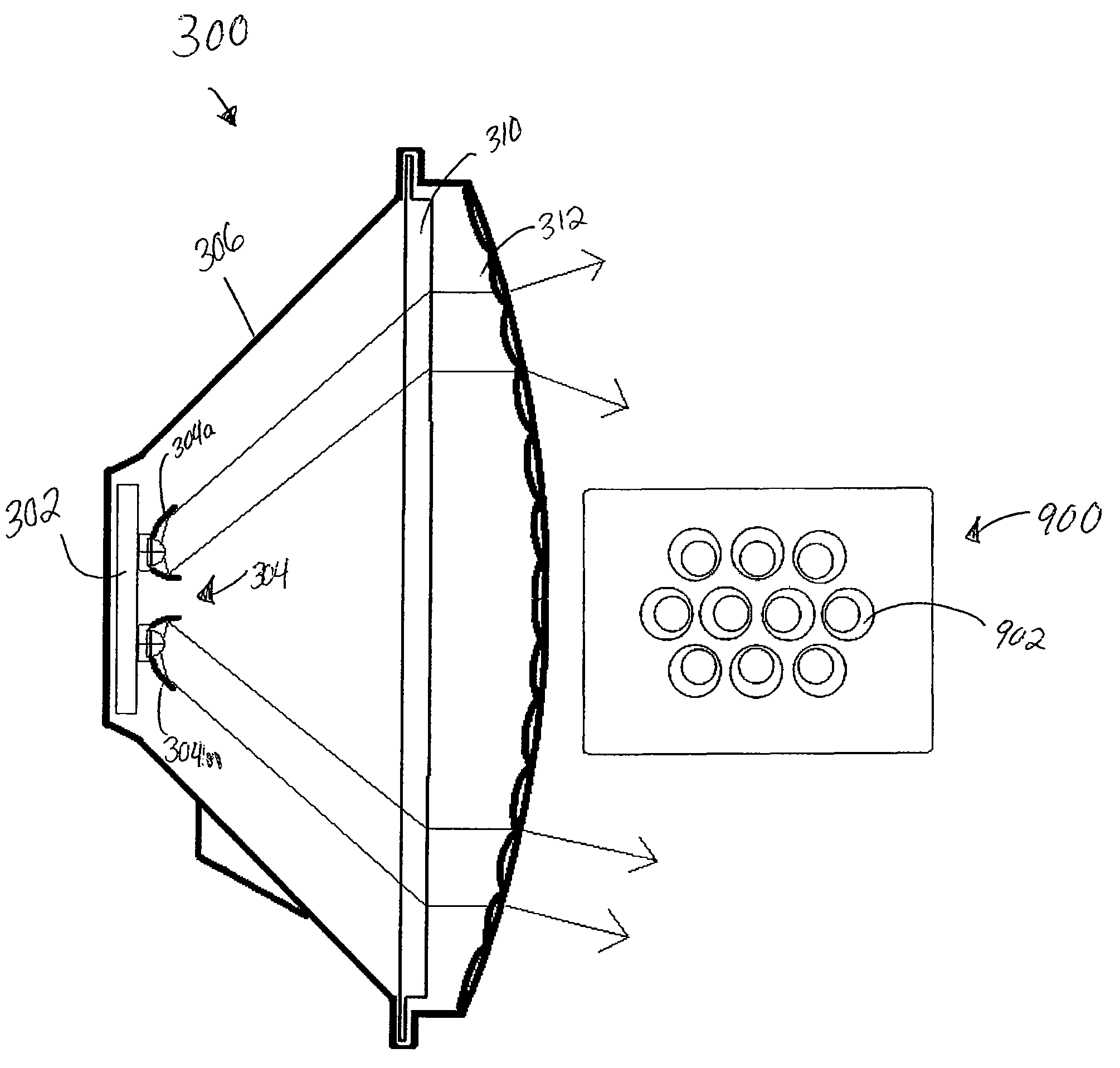

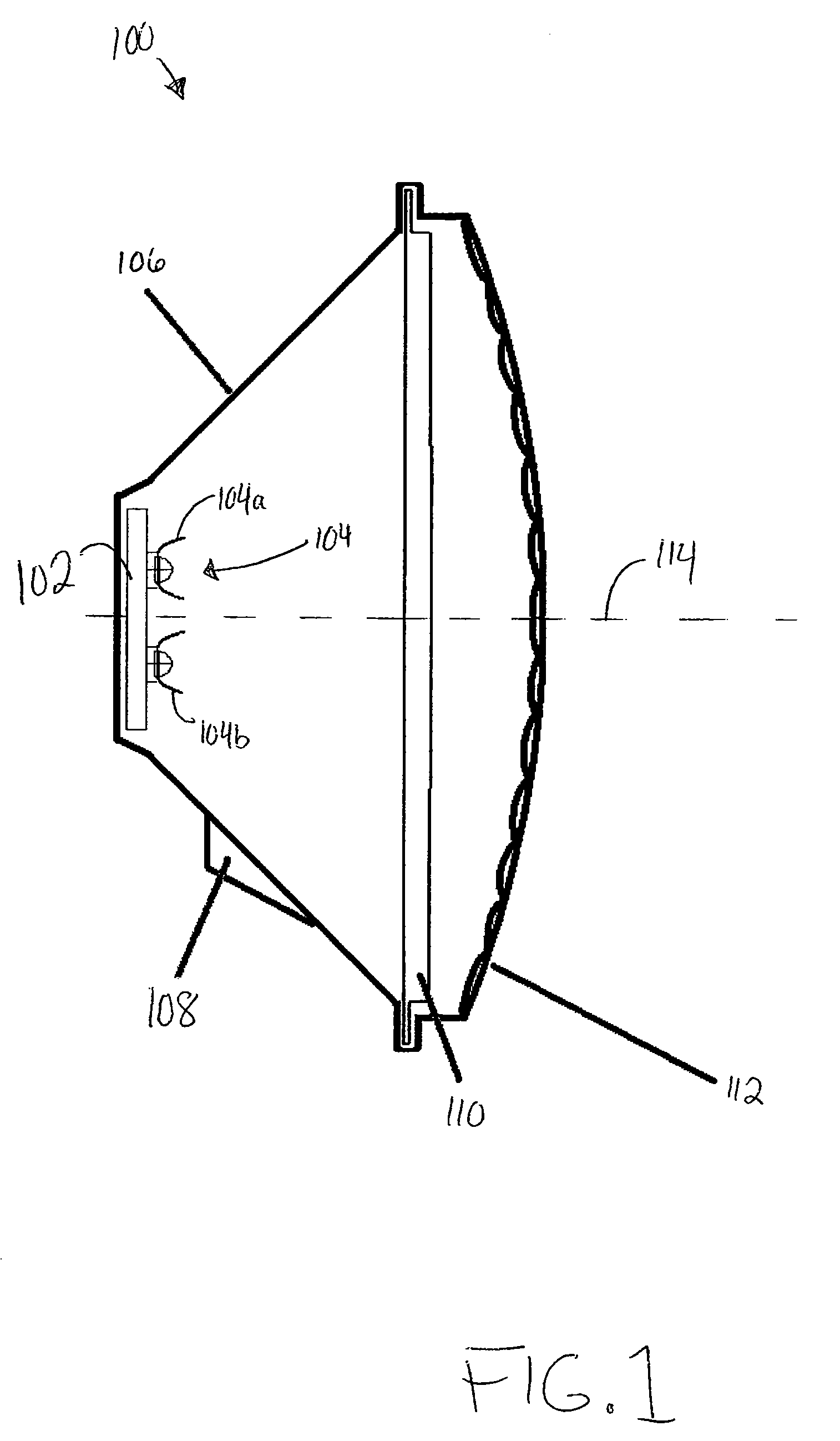

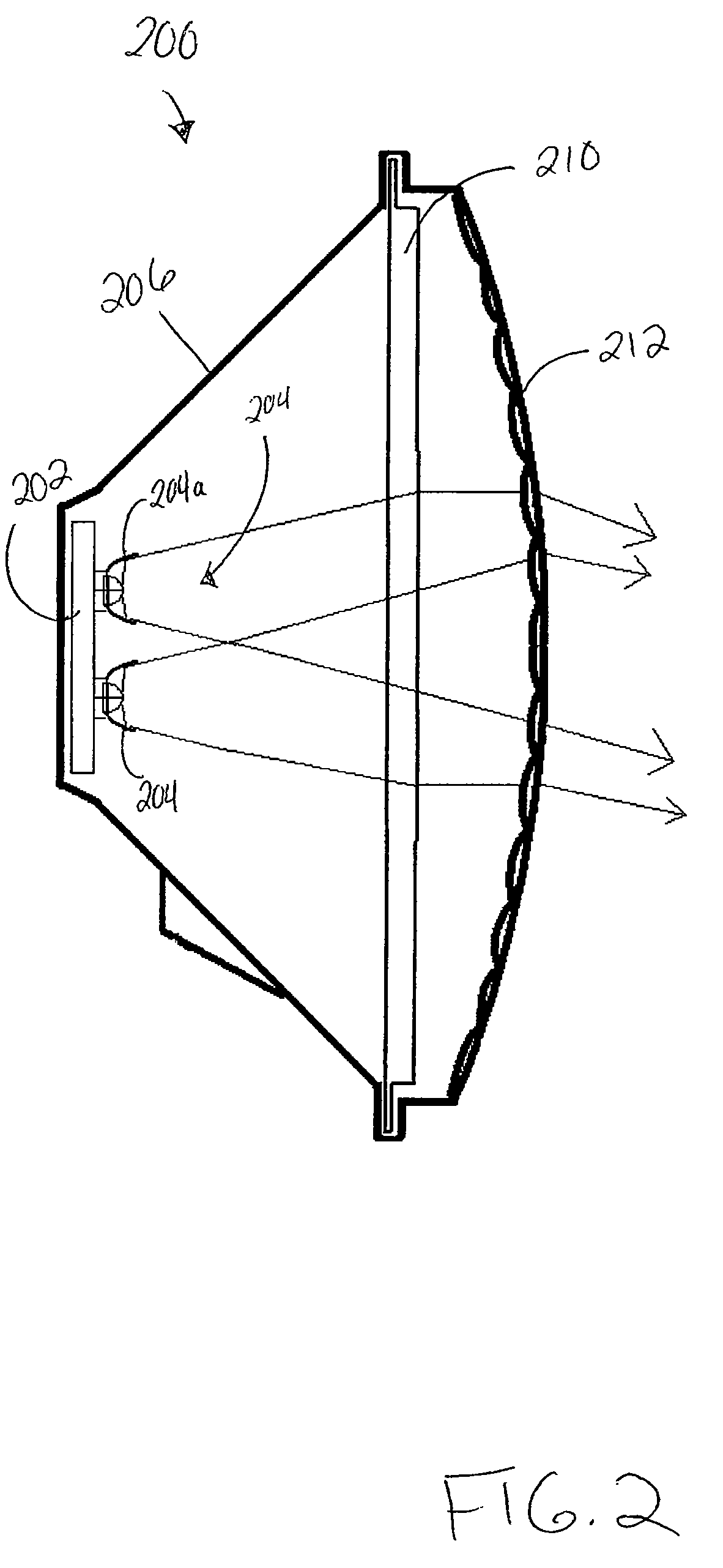

Light emitting diode module with improved light distribution uniformity

ActiveUS20070211473A1Improved light distribution uniformityPoint-like light sourcePavement lightsLight-emitting diodeCup position

In one embodiment, the invention is a light emitting diode module with improved light distribution uniformity. One embodiment of a signal head includes a light emitting diode and a reflector cup positioned to reflect light emitted by the light emitting diode, the reflector cup having a non-symmetrical curvature.

Owner:DIALIGHT CORP

Merie plasma reactor with overhead RF electrode tuned to the plasma with arcing suppression

InactiveUS20050236377A1Increase ion densitySufficient capacitanceElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceIon density

A plasma reactor for processing a semiconductor workpiece, includes a reactor chamber having a chamber wall and containing a workpiece support for holding the semiconductor support, the electrode comprising a portion of the chamber wall, an RF power generator for supplying power at a frequency of the generator to the overhead electrode and capable of maintaining a plasma within the chamber at a desired plasma ion density level. The overhead electrode has a capacitance such that the overhead electrode and the plasma formed in the chamber at the desired plasma ion density resonate together at an electrode-plasma resonant frequency, the frequency of the generator being at least near the electrode-plasma resonant frequency. The reactor further includes a set of MERIE magnets surrounding the plasma process area overlying the wafer surface that produce a slowly circulating magnetic field which stirs the plasma to improve plasma ion density distribution uniformity.

Owner:APPLIED MATERIALS INC

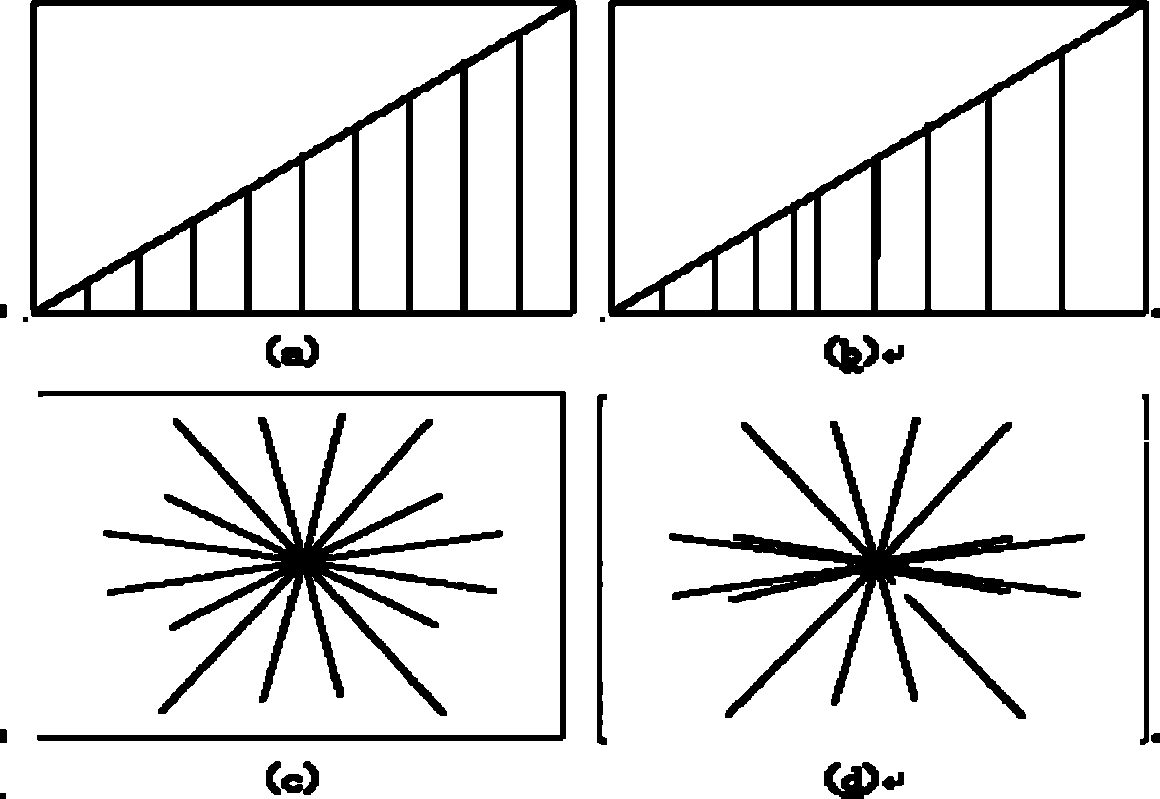

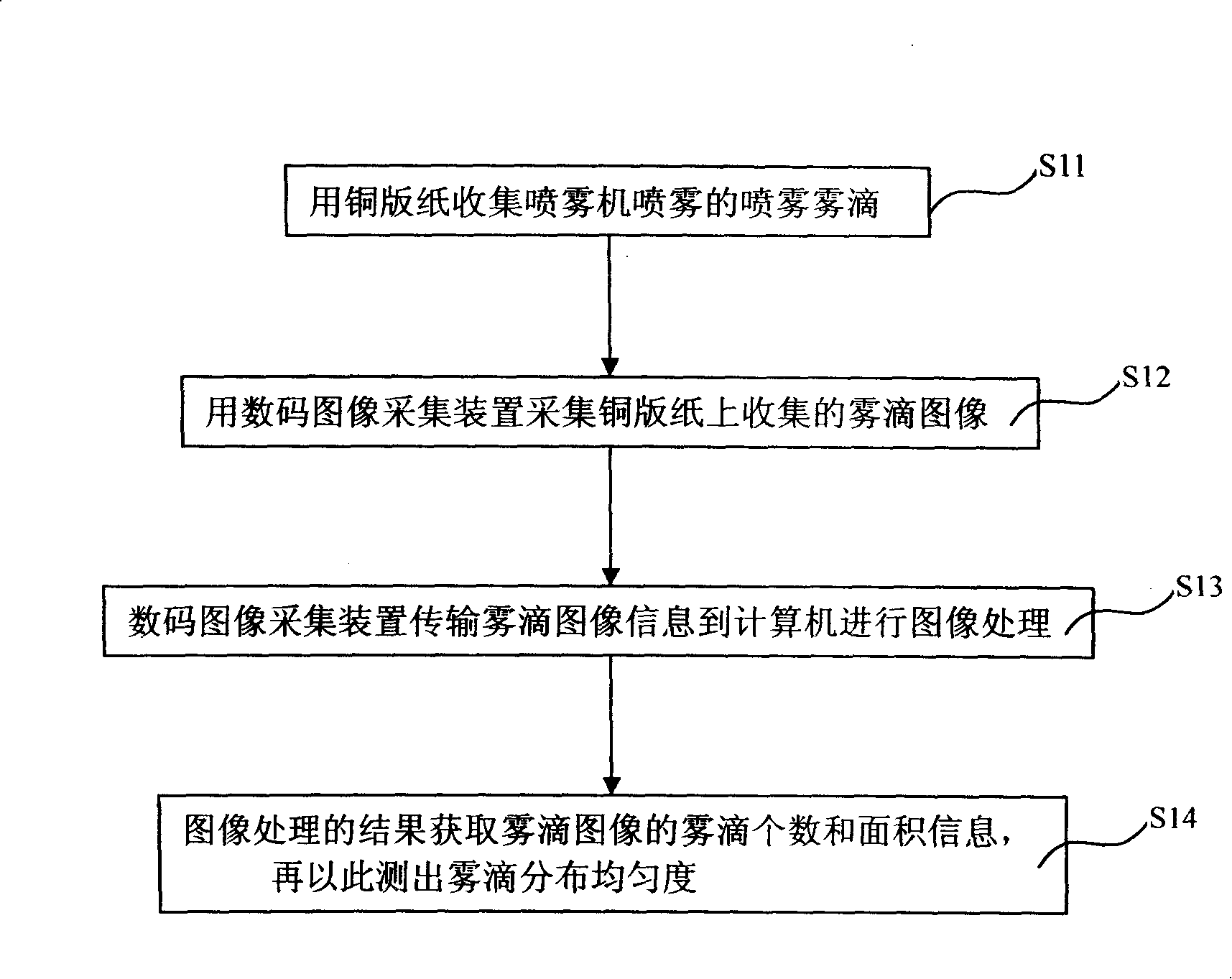

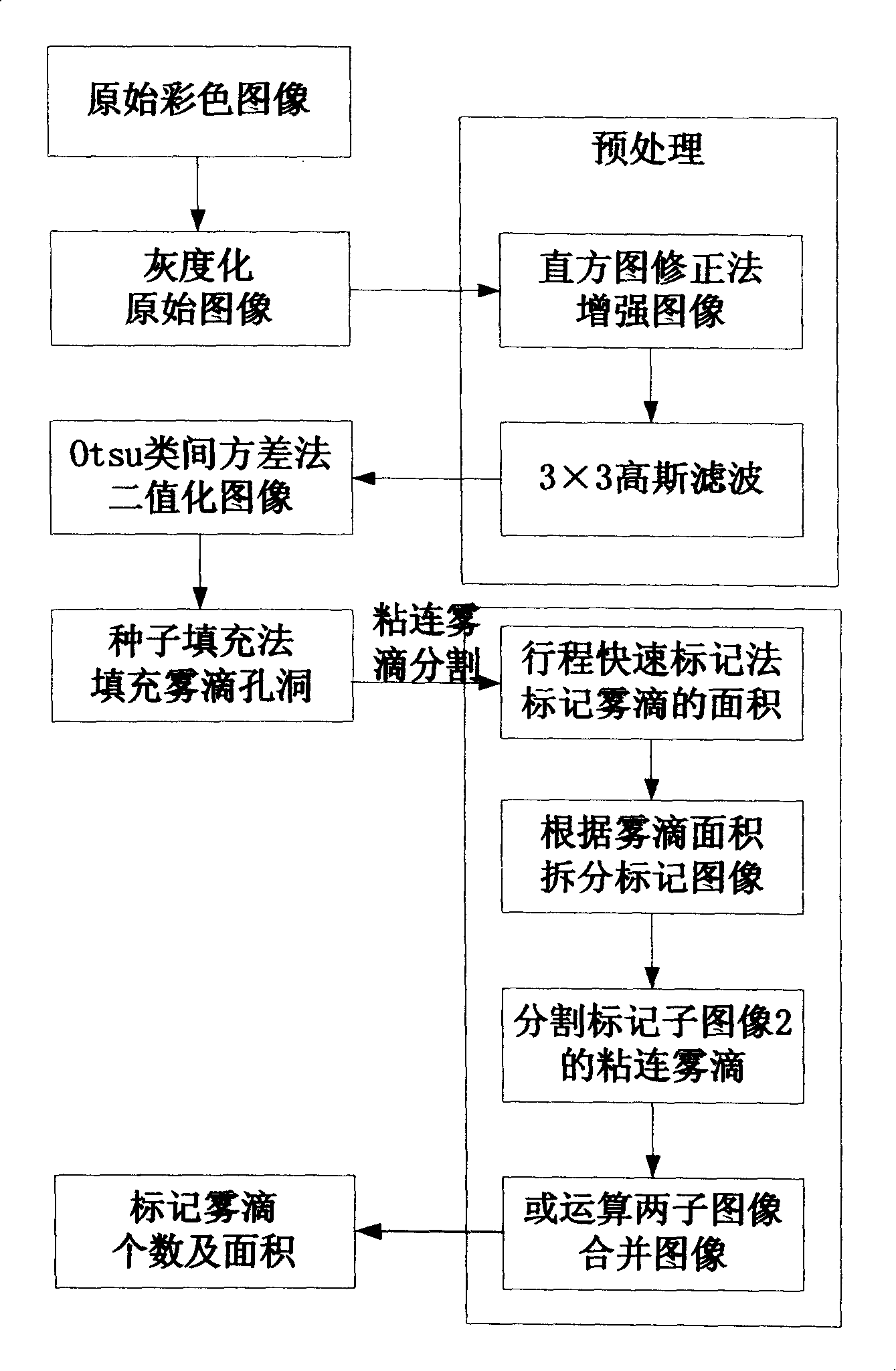

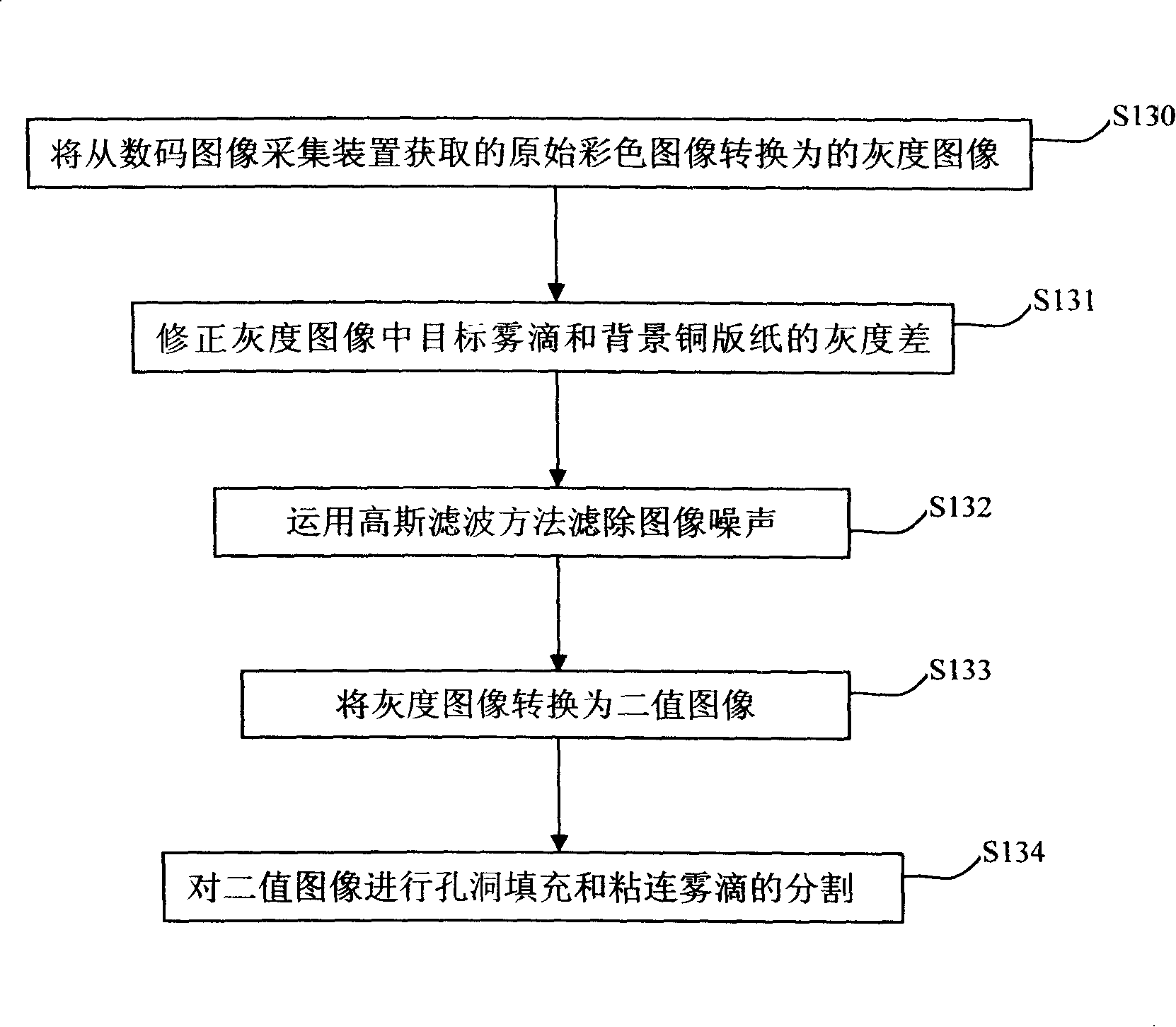

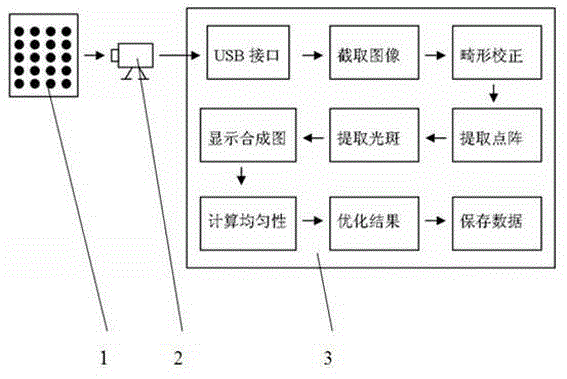

Method for testing droplet distribution consistency degree

ActiveCN101226108AEfficient detectionAutomatic and efficientSurface/boundary effectMaterial analysis by optical meansImaging processingSprayer

The invention discloses a detect method of droplet distribution uniformity, which can detect the droplet uniformity in the spray test of sprayer. The inventive method comprises a spray droplet collecting step for collecting the sprayed droplets of a sprayer, a droplet picture pick-up step for using a digit picture pick-up device to pick up the picture of the collected sprayed droplets, a computer droplet picture information obtaining-processing step that the digit picture pick-up device transmits the droplet picture information to the computer for image processing, and a droplet distribution uniformity information obtaining step for obtaining the droplet number and area information according to the result of the image processing to obtain the droplet distribution uniformity information.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

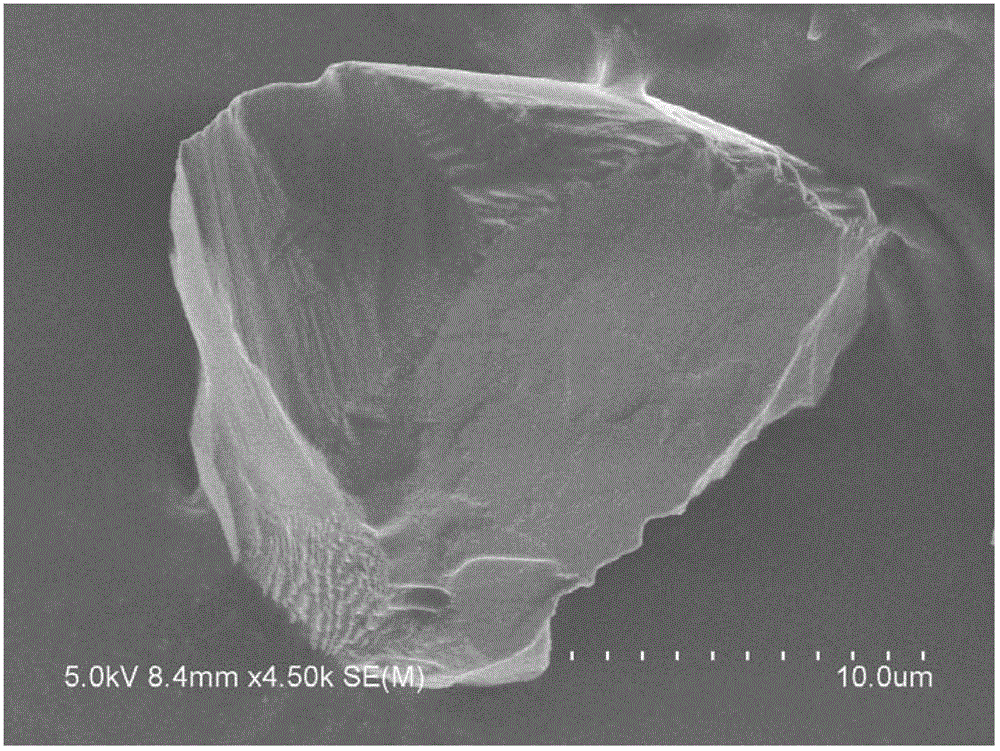

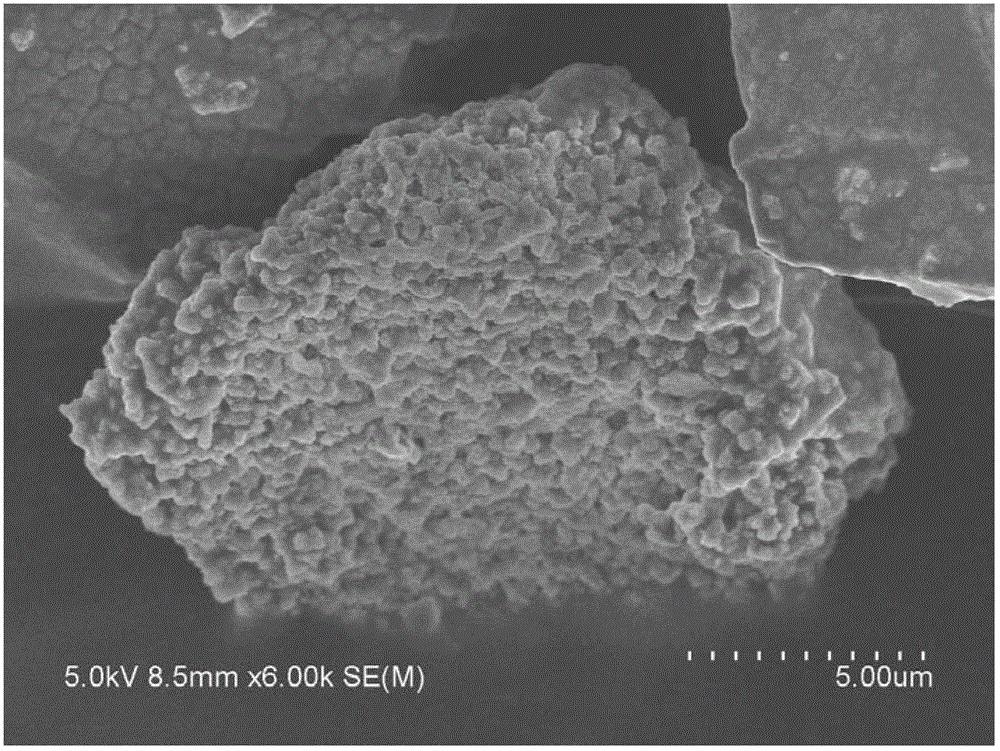

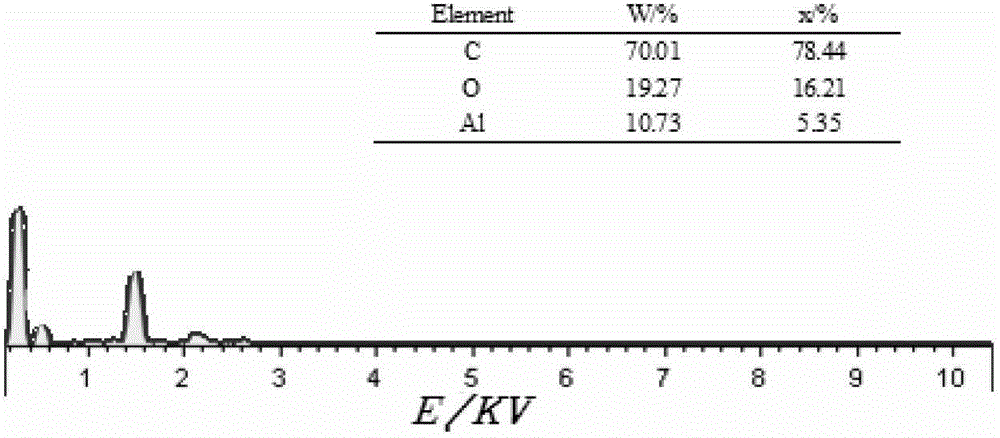

Composite abrasive grain in grain/alumina core-shell structure and preparation method and application of composite abrasive grain

ActiveCN102719220AGood dispersionImprove distribution uniformityOther chemical processesHydrogenCarbide

The invention discloses a composite abrasive grain in a grain / alumina core-shell structure and a preparation method and the application of the composite abrasive grain. An inner core of the composite abrasive grain is selected from diamond, carbide and the like serving as abrasive grains, and an outer shell of the composite abrasive grain is an alumina-coated layer. The preparation method includes: firstly, adding pretreated powder into buffer solution of a certain pH (potential of hydrogen) value, ultrasonically dispersing for 1h, and heating to 50-80 DEG C; secondly, preparing a coating precursor into 0.05-0.4mol / L solution, dripping the solution drop by drop into the buffer solution, violently stirring and keeping the pH value constant; and finally, separating reactants, drying for 24h at 120 DEG C, and performing heat treatment at 300-550 DEG C for more than one hour to obtain the composite abrasive grain in the grain / alumina core-shell structure. Holding power of an abrasive tool base to abrasive grains can be improved to effectively solve the problem of shedding of the abrasive grains, utilization rate of the abrasive grains is increased, the service life of an abrasive tool is prolonged, and uniformity in distribution of the abrasive grains can be remarkably improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

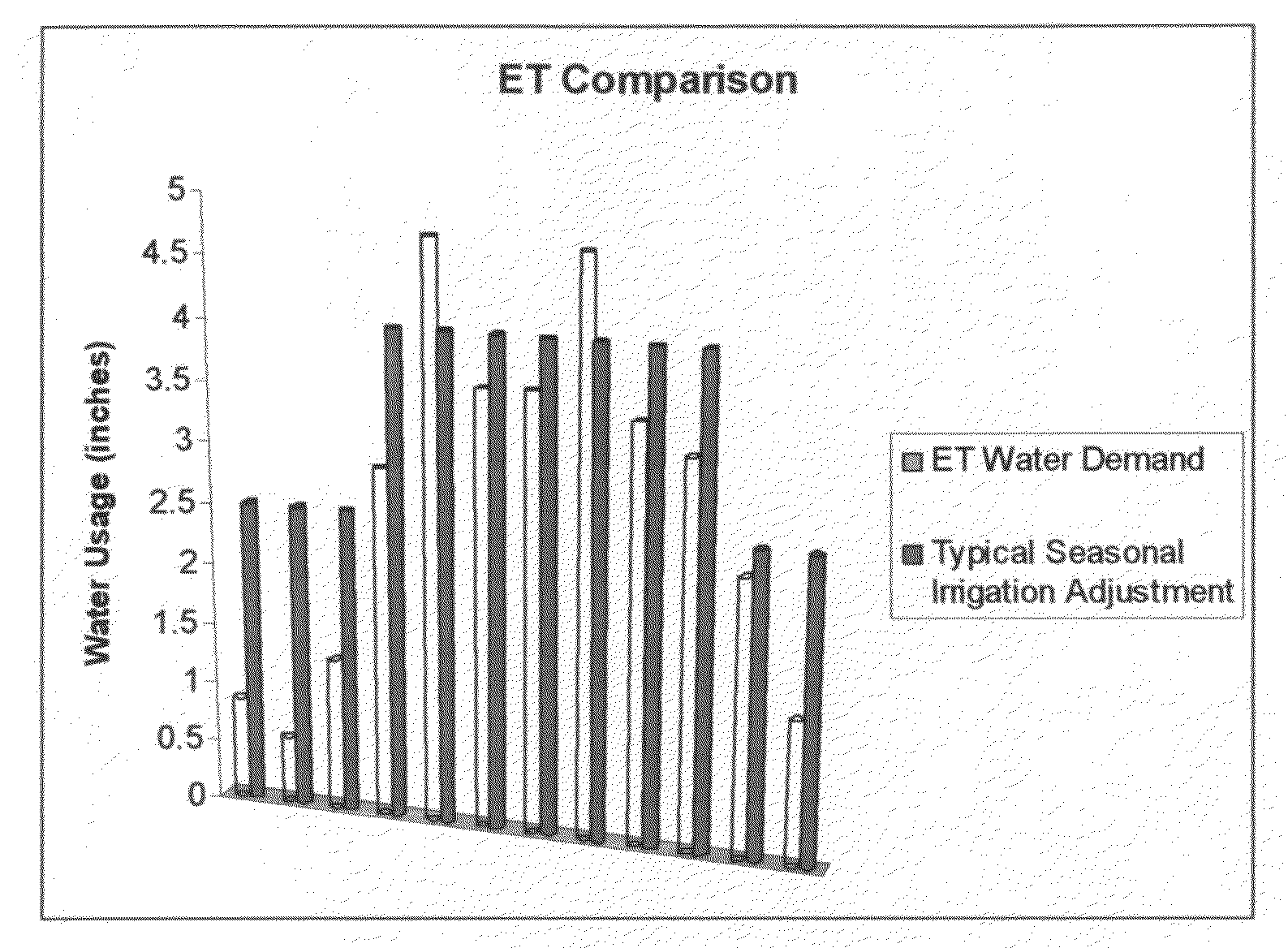

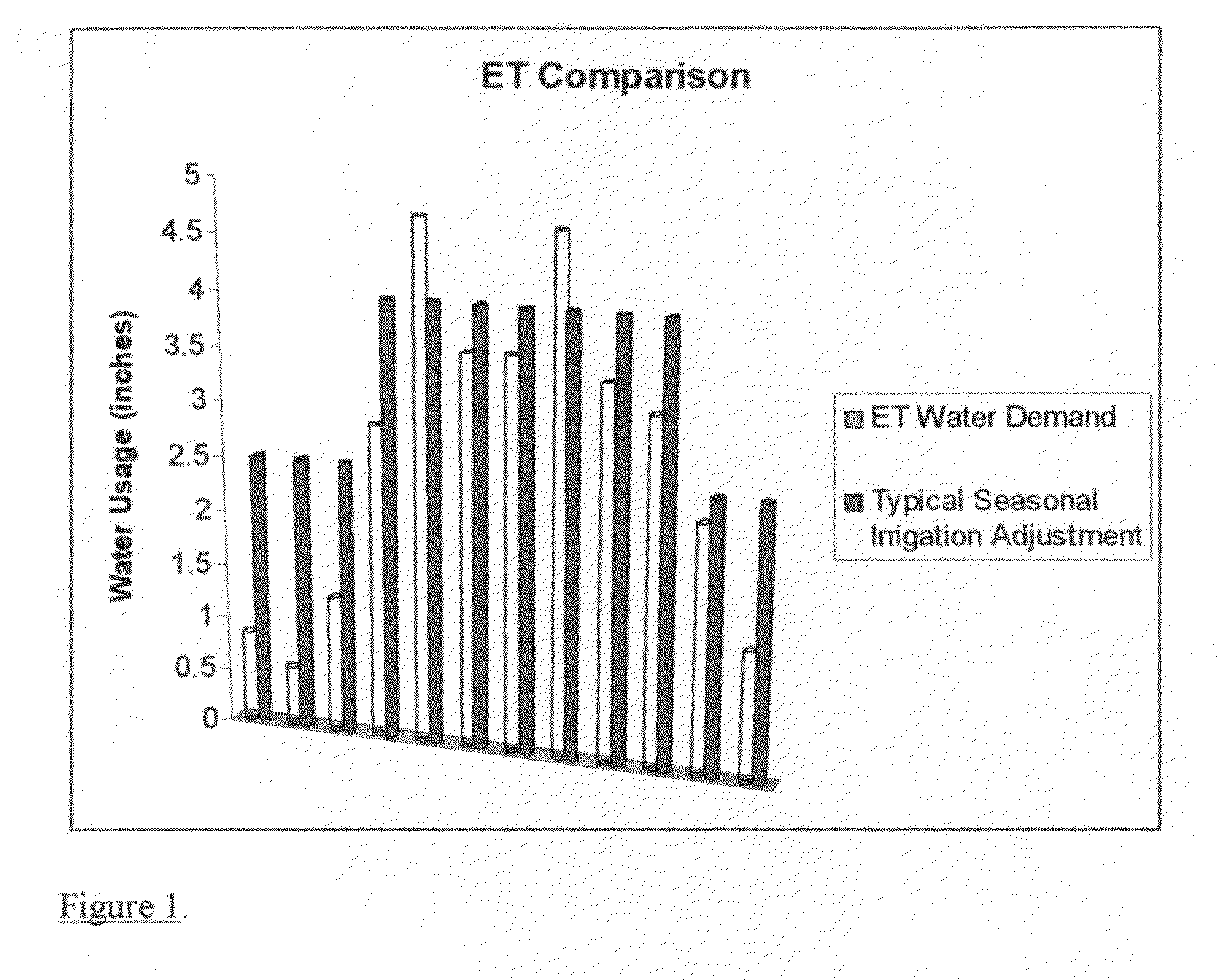

Method of controlling an irrigation system

InactiveUS20090138105A1Easy to understandEliminate excessive use of waterSafety arrangmentsClimate change adaptationRun time settingControl system

The present invention is a method of controlling an irrigation system that minimizes the amount of irrigation water applied with the use of evapotranspiration (ET) to adjust the irrigation controller. By basing the irrigation program on run times which equal a specific amount of water, ET can be used as a percentage to adjust the amount of water applied during an irrigation cycle. By setting a run time to equal 1″ of rainfall ET can be used as a multiplier against the run time to make the correct adjustment to provide required water. By setting the amount of water to be applied to 2″ or any other amount would need an additional multiplier added to make the proper adjustment. Adjustments for landscape coefficient and distribution uniformity would be placed in run time formula based on use of ET set at 1″. The adjusted run time would be the input into the control system.

Owner:CRAWFORD JEFFREY A

High-stability conductive slurry and preparation method thereof

InactiveCN103903675AExtended service lifeExtended shelf lifeNon-conductive material with dispersed conductive materialCable/conductor manufactureMicrometerMembrane switch

The invention discloses a high-stability conductive slurry. The conductive slurry comprises silver powder, a blinder, a stabilizer and a solvent. The silver power can be micrometer silver powder, nanometer silver powder or a combination of the two in any proportions; through adding the stabilizer, the slurry deposition layering phenomenon generated during the preparation, transportation and storage process of the conductive slurry, and the consistency of the conductive slurry, the distribution uniformity and flatness of the a conductive slurry on a base material are ensured; and the stability of the conductive slurry is effectively enhanced, the application and storage life of the conductive slurry is prolonged, and the high-stability conductive slurry and the preparation method are widely applied to conductive slurry fields such as an RFID antenna, a touch screen line, a flexible printed circuit (FPC), a film switch, a solar battery, a printed circuit board and the like.

Owner:北京中科纳通科技有限公司

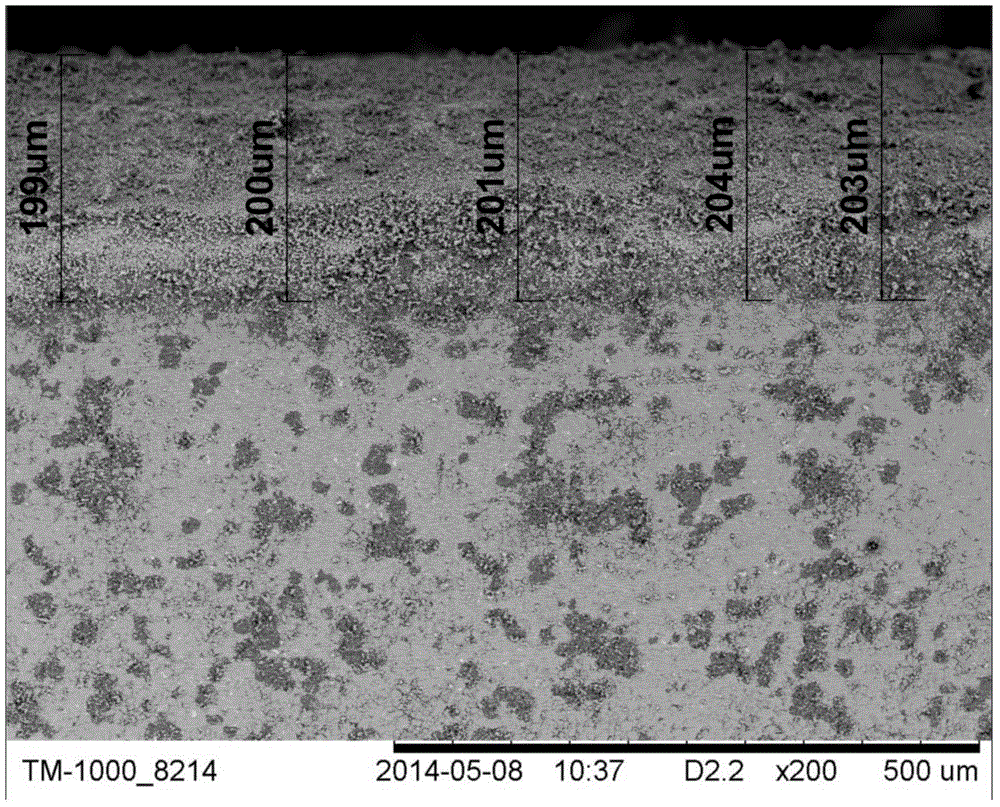

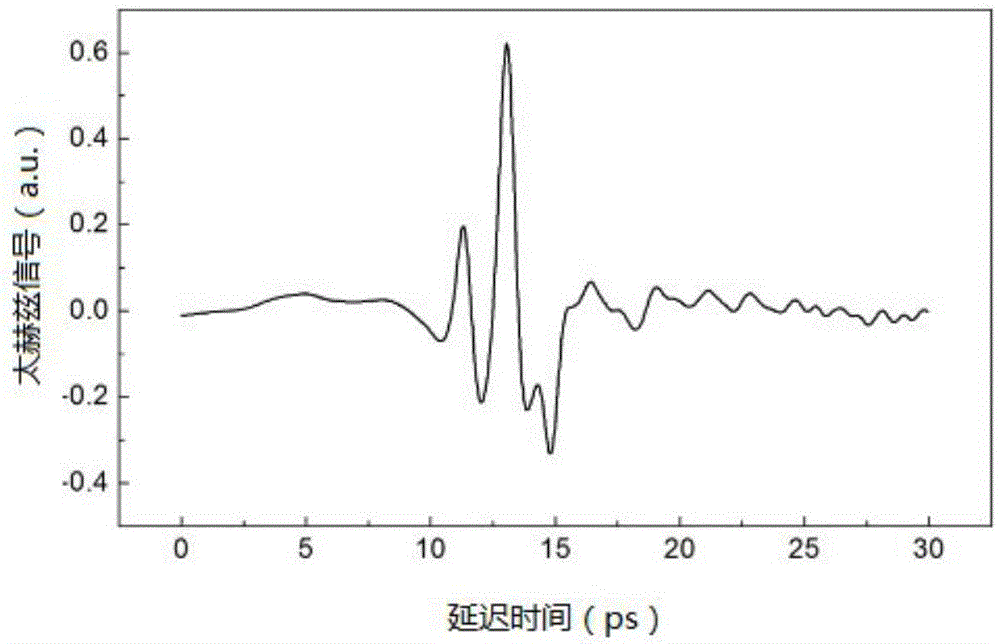

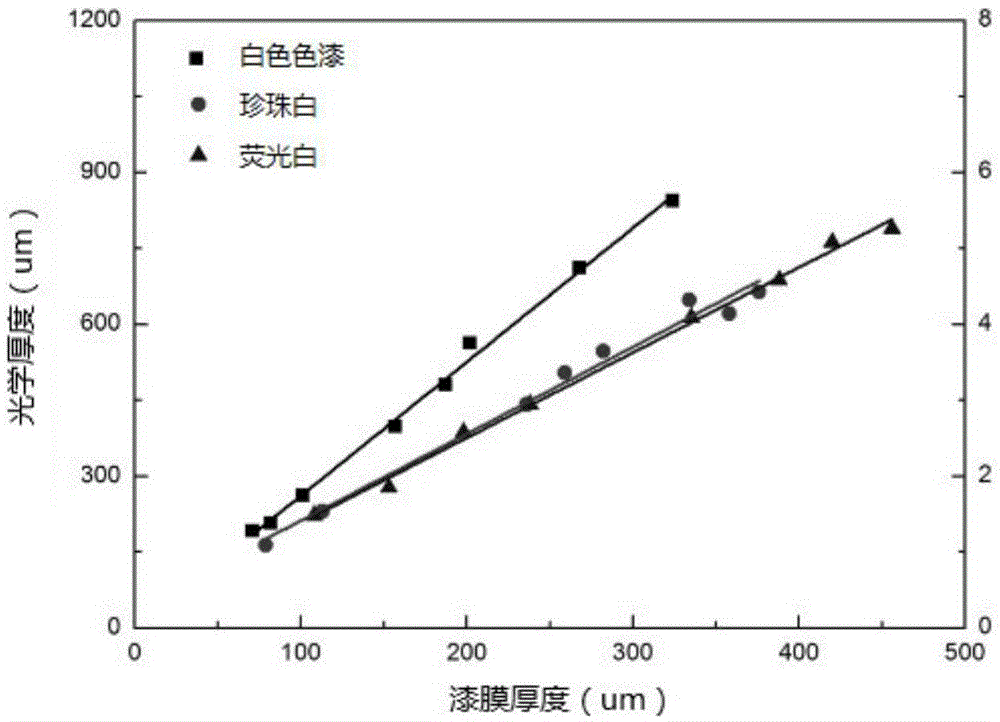

Paint film thickness measuring method based on terahertz pulse spectrum

The invention relates to a paint film thickness measuring method based on terahertz pulse spectrum. The paint film thickness measuring method is characterized in that a paint film thickness measuring model can be established; a terahertz time domain spectrum device is used to measure terahertz pulse spectrum of a sample to be measured, the surface of which is covered by paint; a delay time difference of a reflection peak can be acquired according to the terahertz pulse spectrum; and the paint film thickness of the sample to be measured can be calculated according to the established paint film thickness measuring model. The paint film thickness measuring method based on the terahertz pulse spectrum is advantageous in that the new method can be provided for the paint film thickness measurement; and after the non-contact detection of different measuring points, the single-layer and multi-layer paint film thickness and the distribution uniformity can be detected.

Owner:TIANJIN UNIV

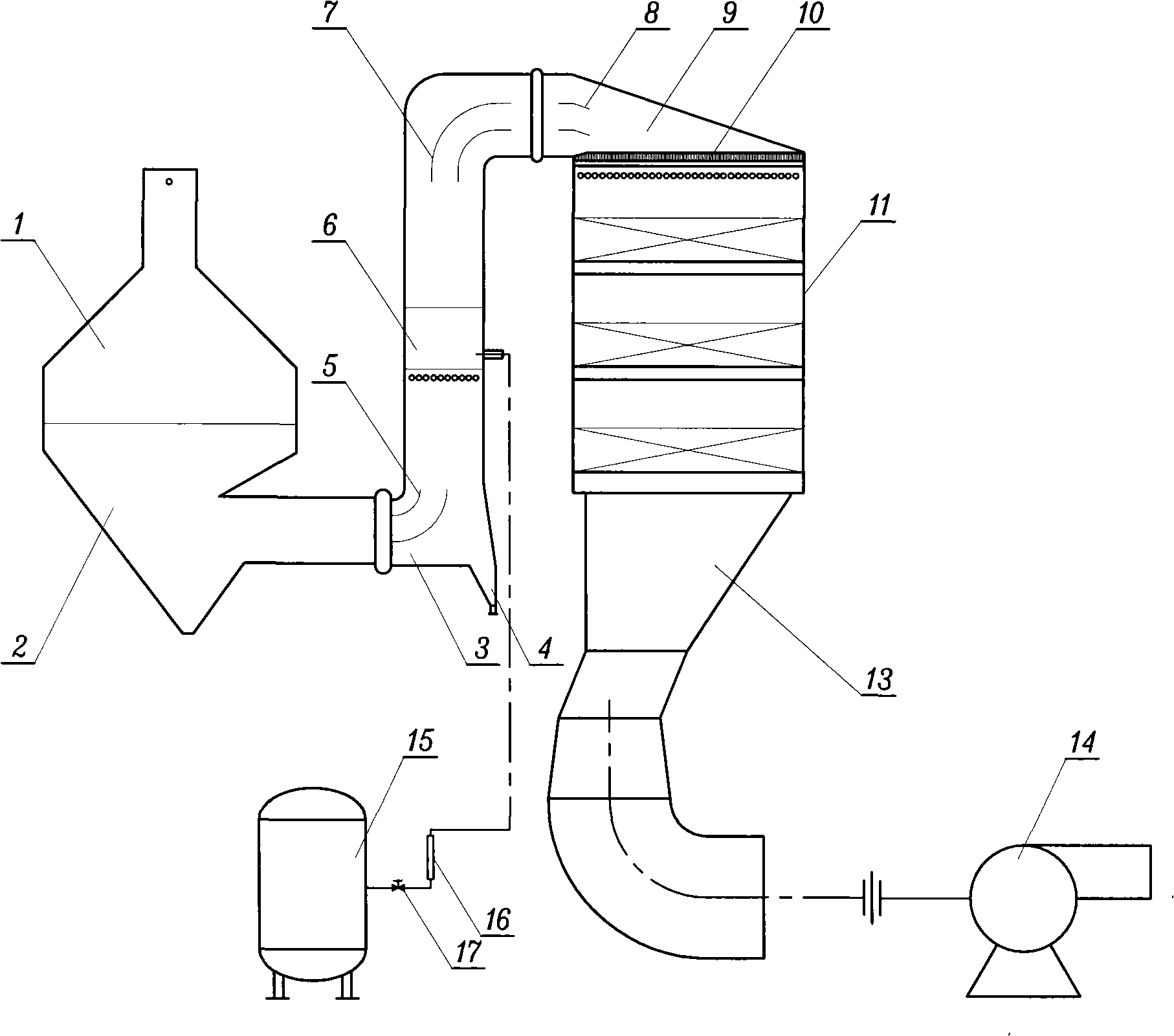

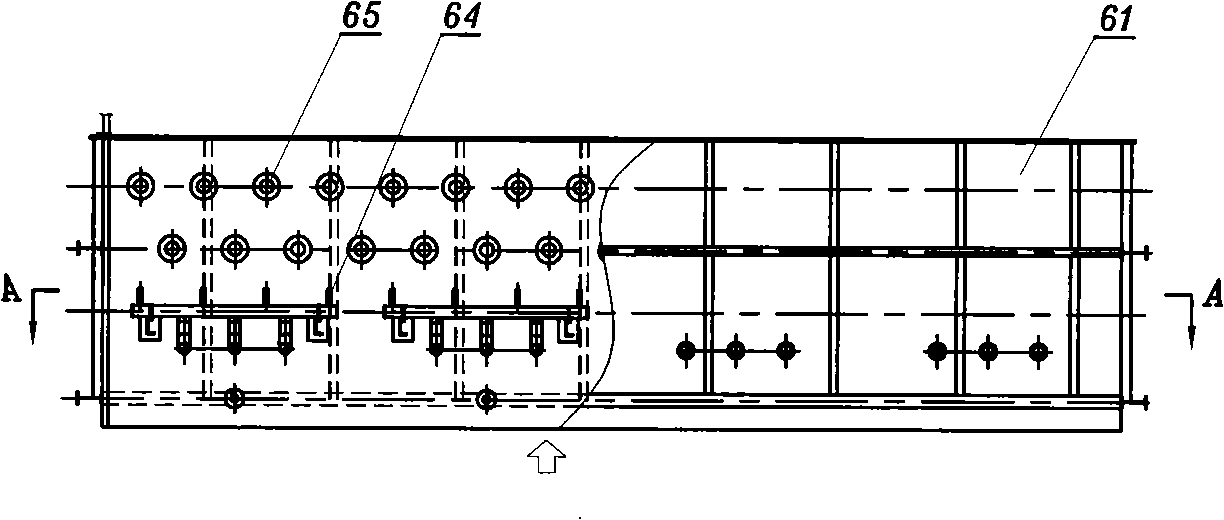

Simulation platform and test method for flow field arrangement structure of flue gas denitration apparatus

The invention discloses a simulating platform of the fume denitration device flow field distributing structure and a testing method. At present the denitration efficiency of the fume denitration device is greatly affected by the fume velocity distributing uniformity and the reducer ammonia gas / nitrogen oxide mixing uniformity. The invention includes an inlet pipe, a coal economizer, an inlet flue, a current stabilizing plate, a reactor, an outlet flue and a blower connected in turn, wherein an ash bucket is arranged at the round of the bottom of the inlet flue, and an air jetting device is arranged on the vertical section of the inlet flue. Guide plates located on the bottom of the top flue are arranged on the round of each flues. A plurality of layers of catalyzer are provided in the reactor, and a plurality of speed measuring holes are arranged at the entrance of the air jetting device and under the current stabilizing plate. The invention builds the simulating platform of the denitration device flow field structure, performs the experiment through the simulating platform, obtains the flow field distributing status of the denitration device, provides reasonable engineering measurement to improve the flow field distributing structure in the denitration system.

Owner:浙江融智能源科技有限公司

Light emitting diode module with improved light distribution uniformity

ActiveUS7810963B2Improved light distribution uniformityPoint-like light sourceLighting support devicesLight-emitting diodeCup position

In one embodiment, the invention is a light emitting diode module with improved light distribution uniformity. One embodiment of a signal head includes a light emitting diode and a reflector cup positioned to reflect light emitted by the light emitting diode, the reflector cup having a non-symmetrical curvature.

Owner:DIALIGHT CORP

Gas distribution uniformity improvement by baffle plate with multi-size holes for large size pecvd systems

InactiveUS20080178807A1Electric discharge tubesChemical vapor deposition coatingEngineeringLarge size

Embodiments of a gas distribution plate for distributing gas in a processing chamber for large area substrates are provided. The embodiments describe a gas distribution plate assembly for a plasma processing chamber having a cover plate comprises a diffuser plate having an upstream side, a downstream side facing a processing region, and a plurality of gas passages formed through the diffuser plate, and a baffle plate, placed between the cover plate of the process chamber and the diffuser plate, having a plurality of holes extending from the upper surface to the lower surface of the baffle plate, wherein the plurality of holes have at least two sizes. The small pinholes of the baffle plate are used to allow sufficient pass-through of gas mixture, while the large holes of the baffle plate are used to improve the process uniformity across the substrate.

Owner:APPLIED MATERIALS INC

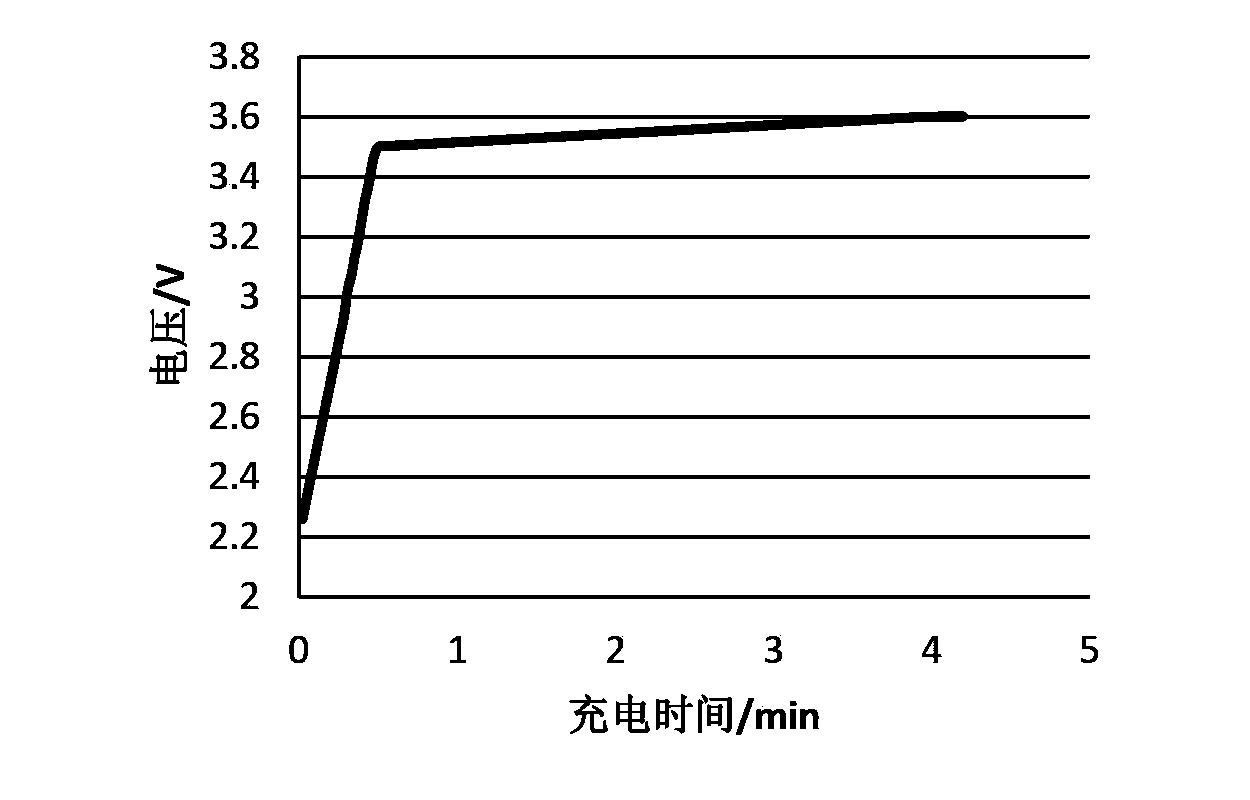

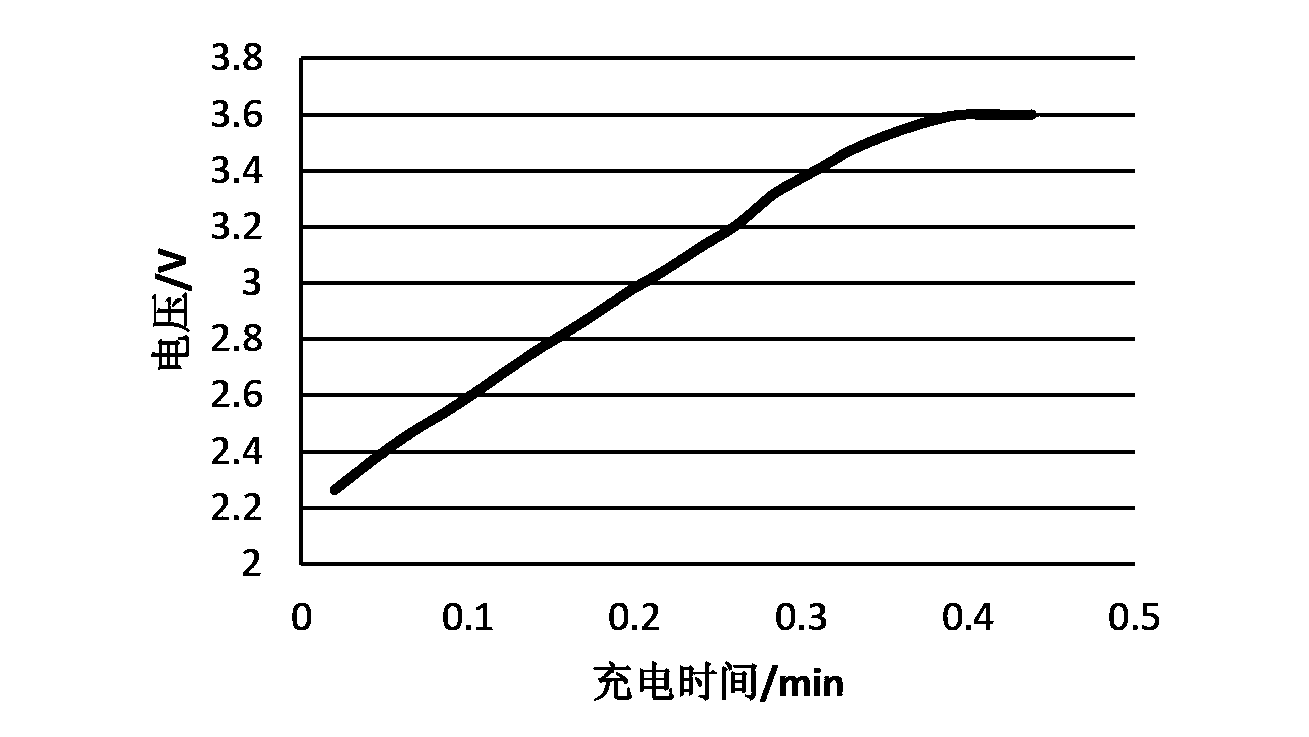

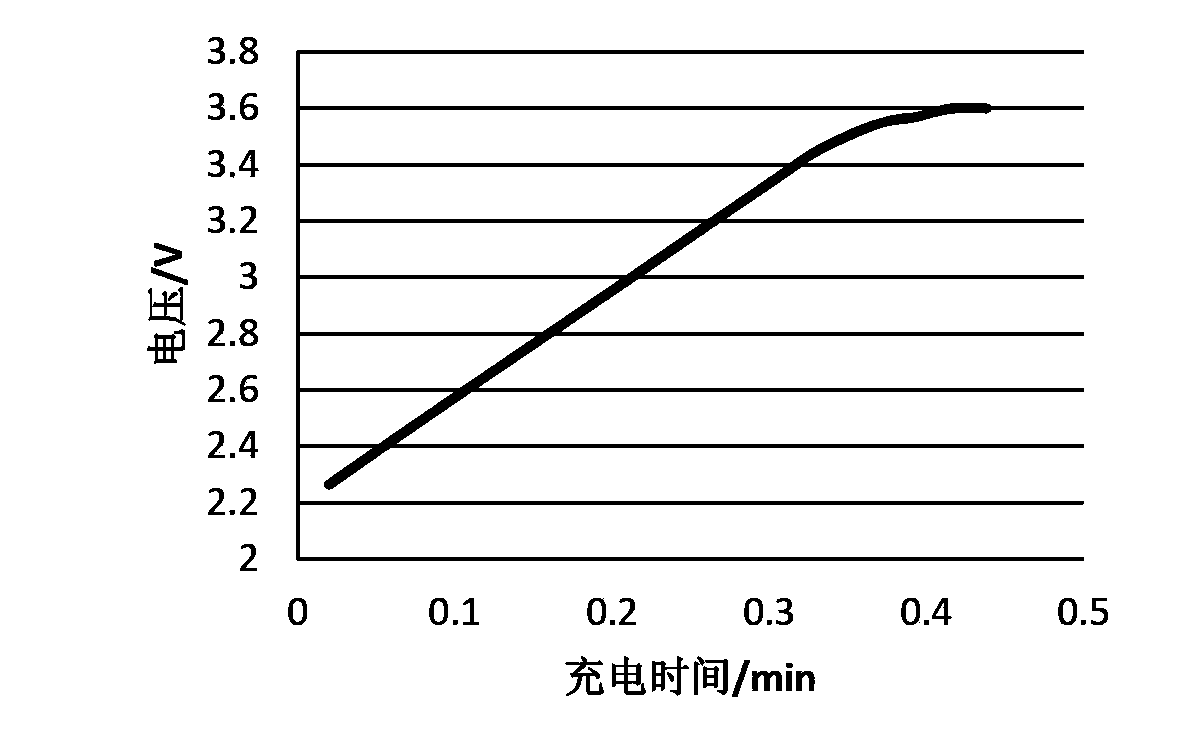

Negative electrode slurry of lithium ion battery, positive electrode of lithium ion battery prepared by slurry and battery

ActiveCN103515607AThe compacted density does not decreaseHigh porosityActive material electrodesSecondary cellsPore distributionHigh energy

The invention provides negative electrode slurry of a lithium ion battery, a positive electrode of the lithium ion battery prepared by using the slurry, and the battery. The negative electrode slurry comprises a negative-electrode active material, a bonding agent, a solvent and a pore-forming agent, wherein the pore-forming agent is selected from one or more in azo-compound and / or sulfonylhydrazine compound. The slurry, the positive electrode and the battery have the advantages that under the condition of guaranteeing no reduction of the compaction density of a negative electrode piece, the porosity of the electrode piece can be increased, the uniformity of pore distribution is increased, the effective area of a liquid phase for conducting lithium ions is improved, the high energy density of the battery is guaranteed, simultaneously the rate capability and the low-temperature performance of the battery are improved and simultaneously the capacity is also improved.

Owner:BYD CO LTD

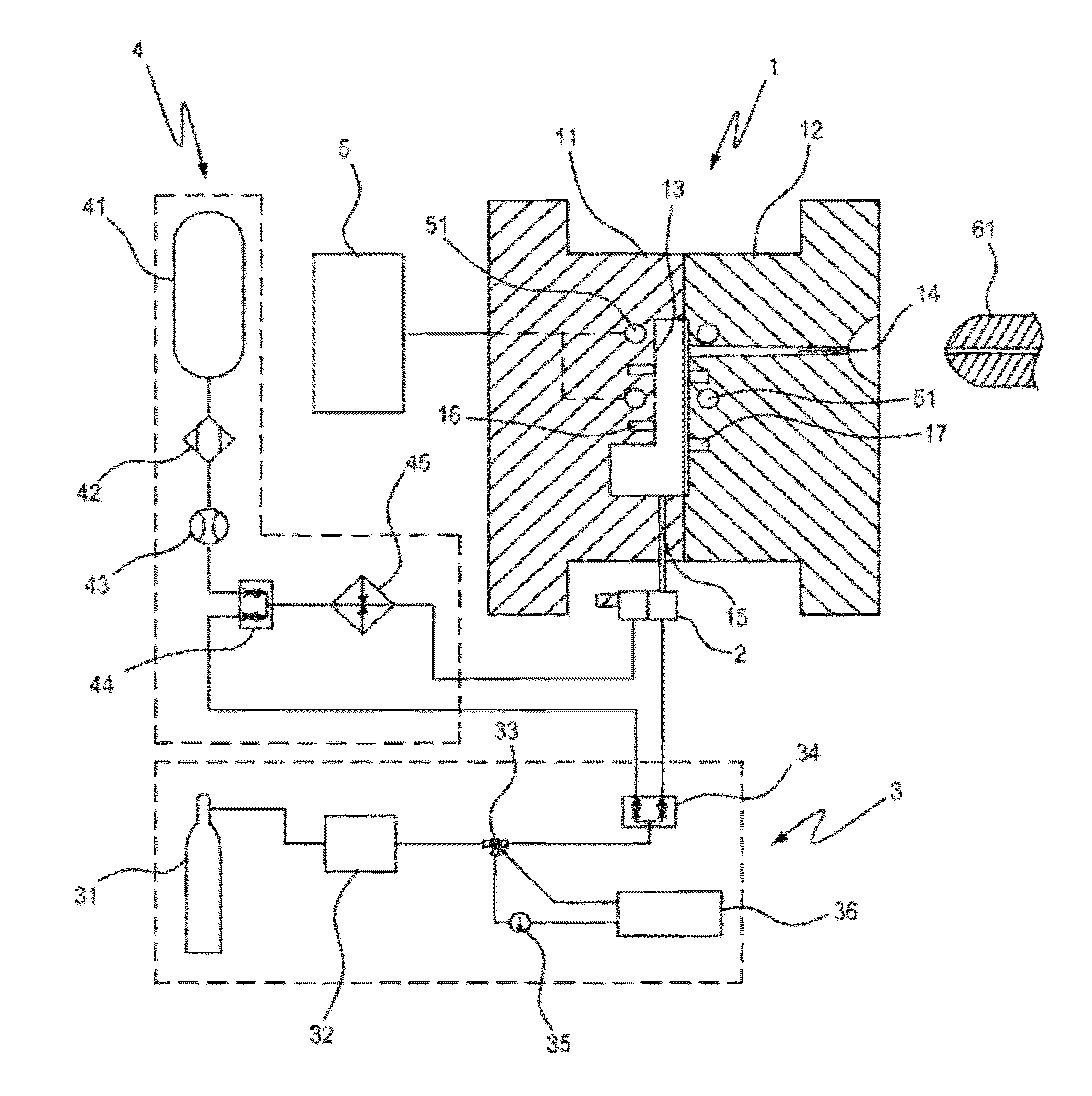

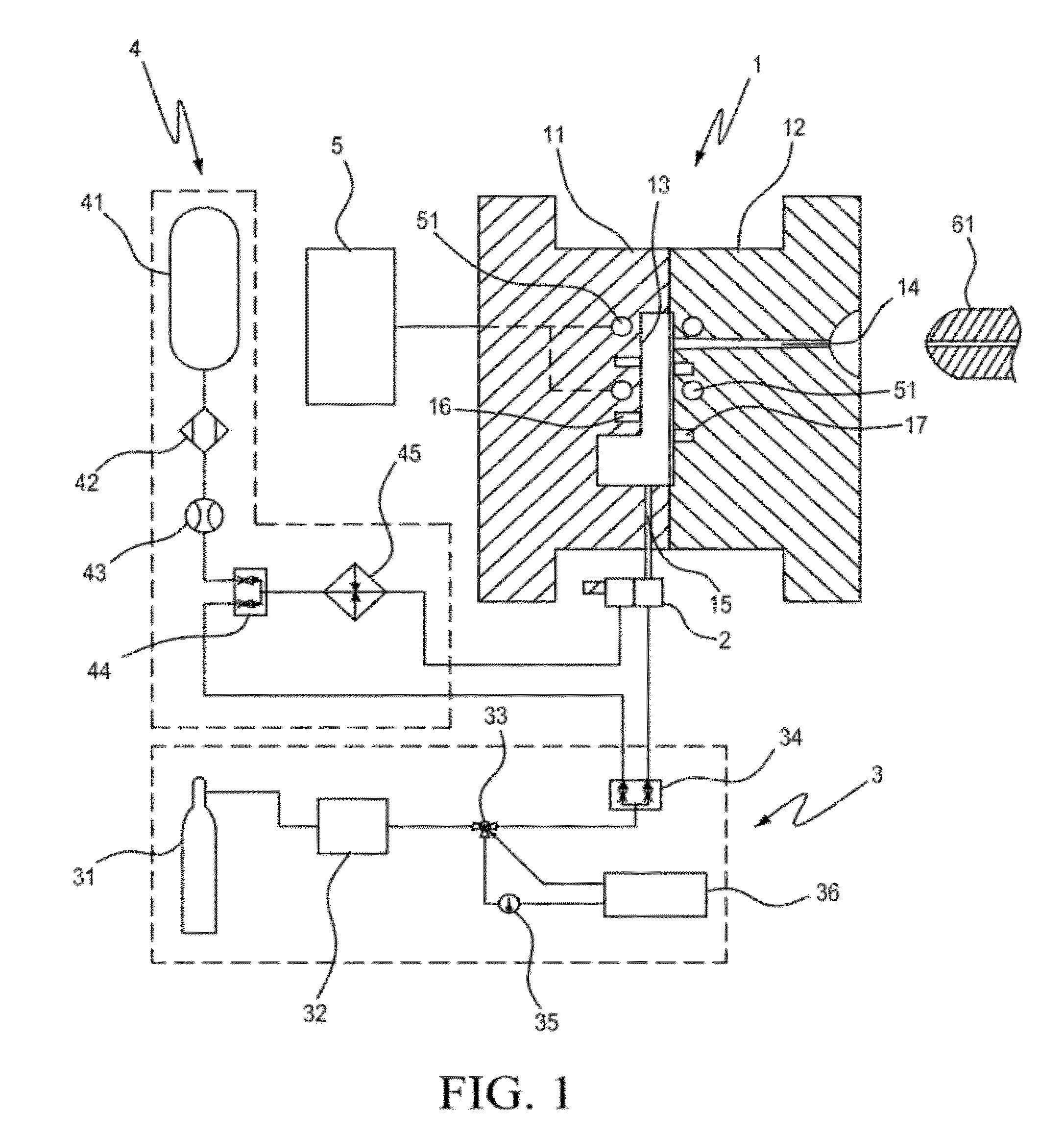

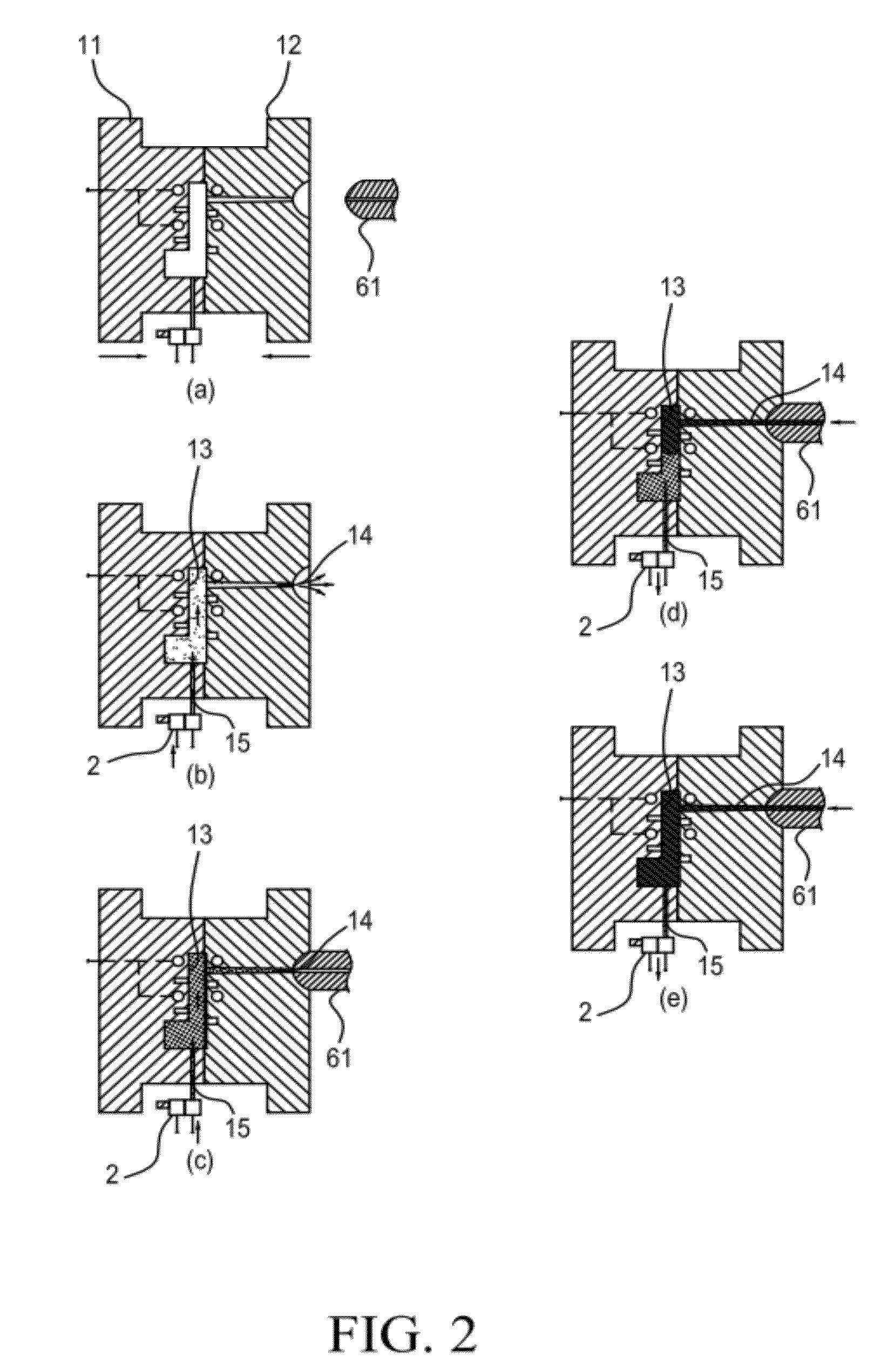

Apparatus for controlling counterpressure and temperature in mold cavity

ActiveUS20120052143A1Improve surface qualityIncrease in sizeConfectionerySweetmeatsTemperature controlProcess engineering

A counterpressure / temperature control apparatus, comprises: a mold, having a runner and an air passage, both coupled to a mold cavity inside the mold; a logic control valve, coupled to the air passage for controlling a high-temperature gas or / and a counterpressure gas to flow in and out the mold cavity; a counterpressure gas supplying device, for supplying the counterpressure gas to the mold cavity through the logic control valve; and a high-temperature gas supplying device, for supplying the high-temperature gas to the mold cavity through the logic control valve; wherein the mold cavity is heated by the high-temperature gas, while subjecting the same to a counterpressure provided from the counterpressure gas supplying device during an injection molding process, and thereby, not only the surface quality of a product resulting from the injection molding process can be improved, but also the size of foams and the distribution evenness thereof are enhanced.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

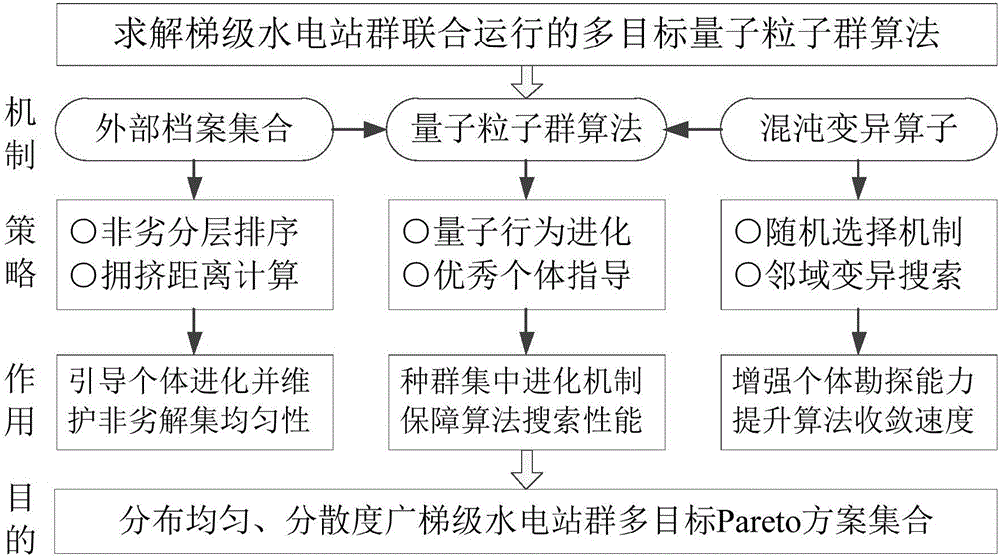

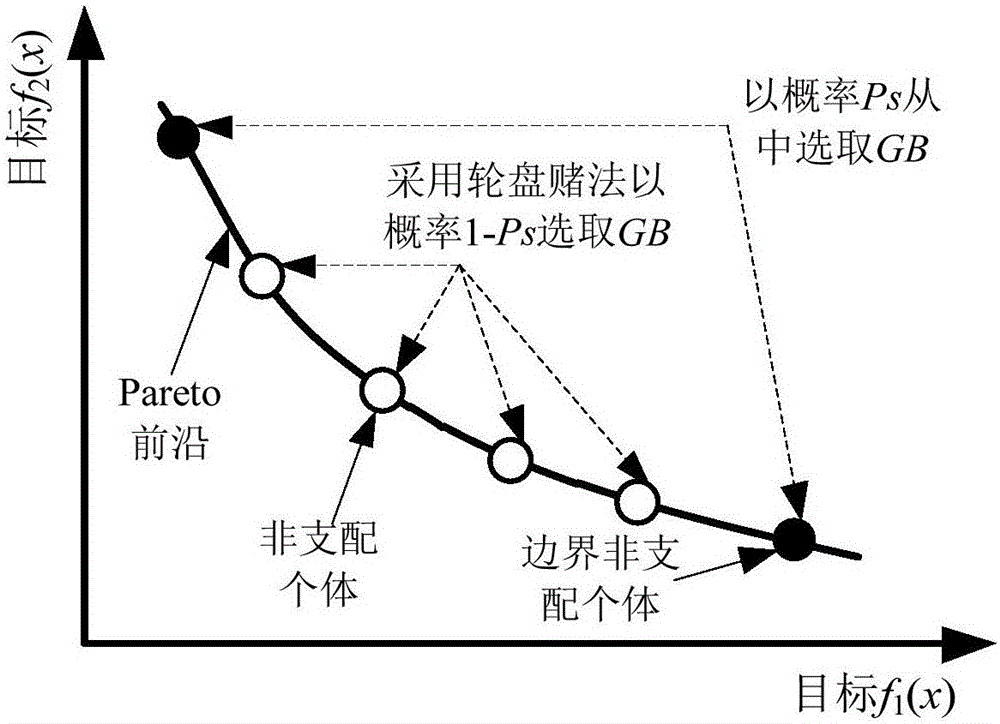

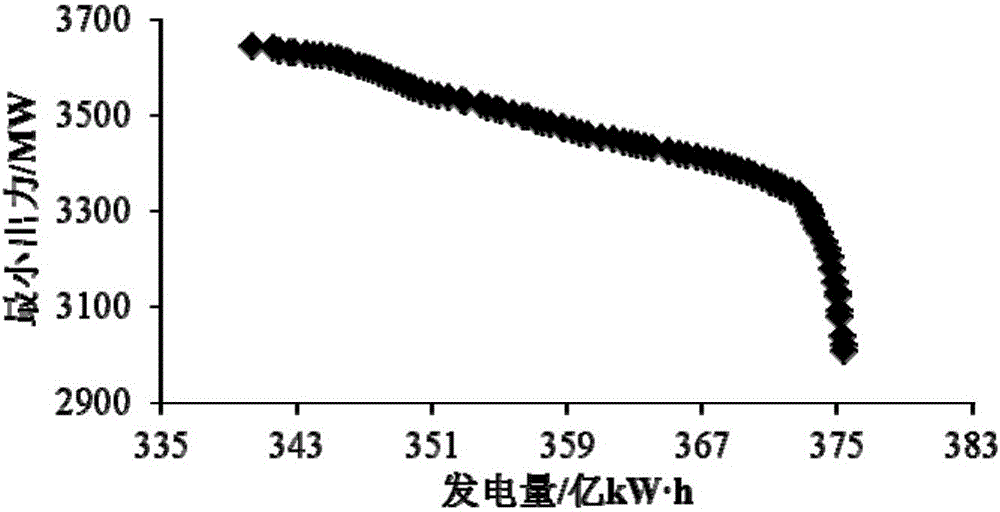

Many-objective optimized scheduling method for combined operation of cascade hydropower stations

InactiveCN106203689AGuaranteed uniformityEnhanced Neighborhood Exploration CapabilitiesForecastingArtificial lifePareto optimalHydropower

The invention discloses a many-objective optimized scheduling method for combined operation of cascade hydropower stations, and aims at solving main problems in engineering application of standard quantum-behaved particle swarm optimization and problems in solving single-objective optimized scheduling. A multi-population evolution strategy is realized by external file set, advantageous individual selection and a chaotic mutation operator strategies, diversity of individuals is ensured, calculation of the method is accelerated, and an approximate Pareto optimal leading edge with sound distribution is obtained. An external file set is introduced to store elite individuals, dynamic update and maintenance of the file set are realized via non-inferior layered ordering and crowd distance, and distribution of the individual is kept uniform; and a chaotic mutation operator is used to carry out local disturbance on a non-control solution, and the neighborhood exploration capability of the individuals is enhanced. According to the invention, the particle swarm optimization is improved, and effectively applied to making the many-objective optimized scheduling scheme of combined operation of the cascade hydropower stations, and a feasible and high efficiency calculating method is provided for many-objective optimized scheduling of the cascade hydropower stations.

Owner:DALIAN UNIV OF TECH

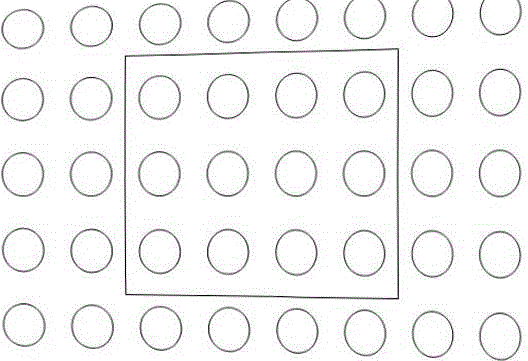

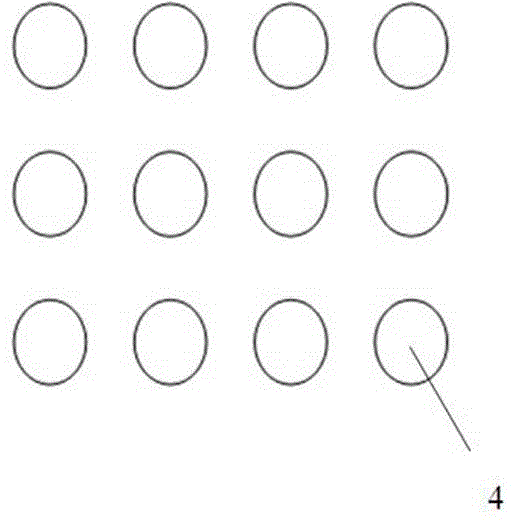

Luminance uniformity test method of dot-matrix light source

InactiveCN104655403ASmall distortionReduce the effects of noiseTesting optical propertiesImaging processingDot matrix

The invention discloses a luminance uniformity test method of a dot-matrix light source, and relates to the technical fields of display, illumination and image processing. According to the luminance uniformity test method, the luminance uniformity is divided into brightness uniformity and distribution uniformity; the luminance uniformity of the dot-matrix light source is evaluated through the brightness uniformity, the distribution uniformity and the sum of the brightness uniformity and the distribution uniformity; in the testing process, image geometric distortion is corrected; the dot-matrix structure is analyzed, and the non-light-emitting area is excluded from the evaluation range. Compared with the existing test method, the luminance uniformity test method is more comprehensive, objective, accurate, effective, direct, simple and convenient.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com