Patents

Literature

929results about How to "Effective penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

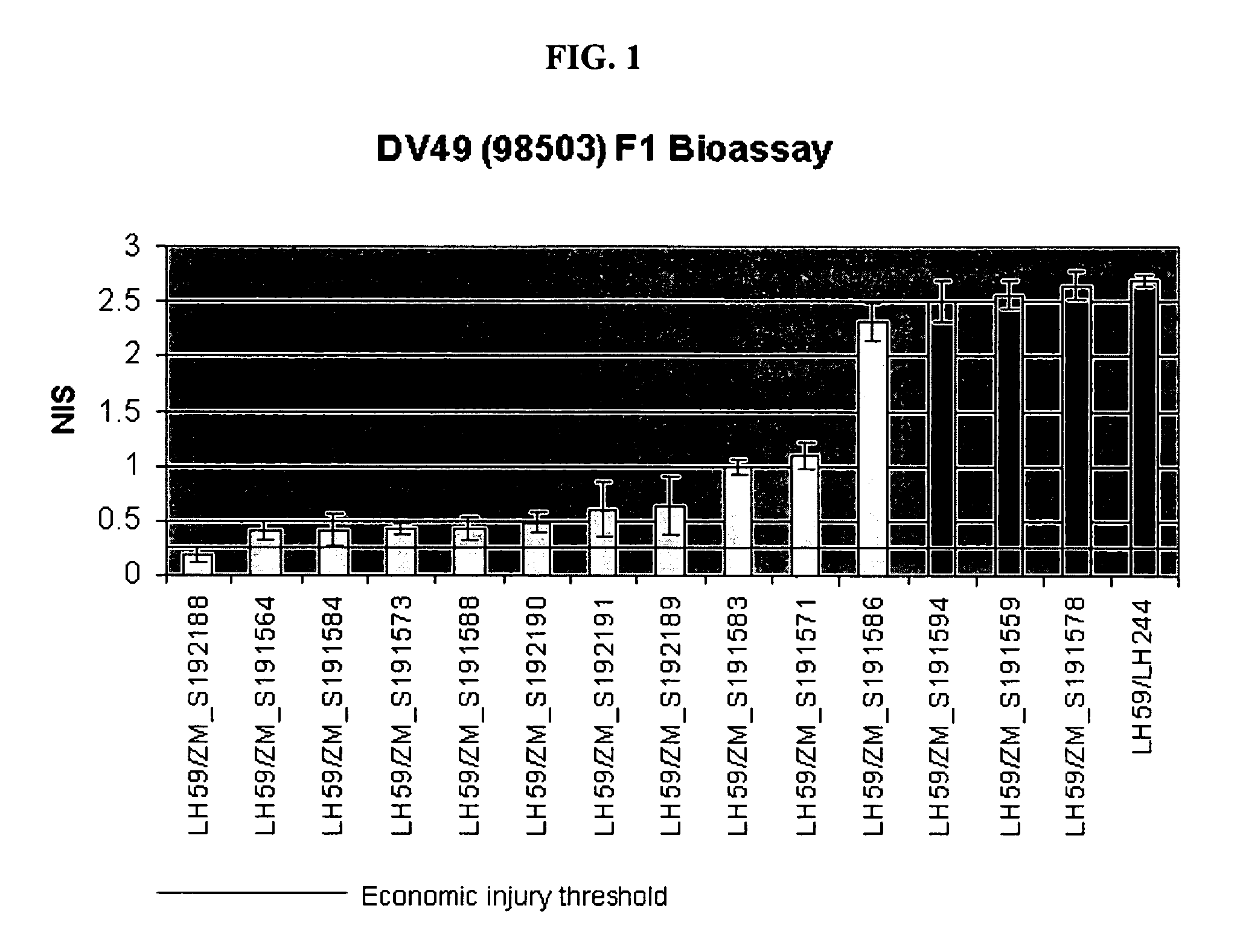

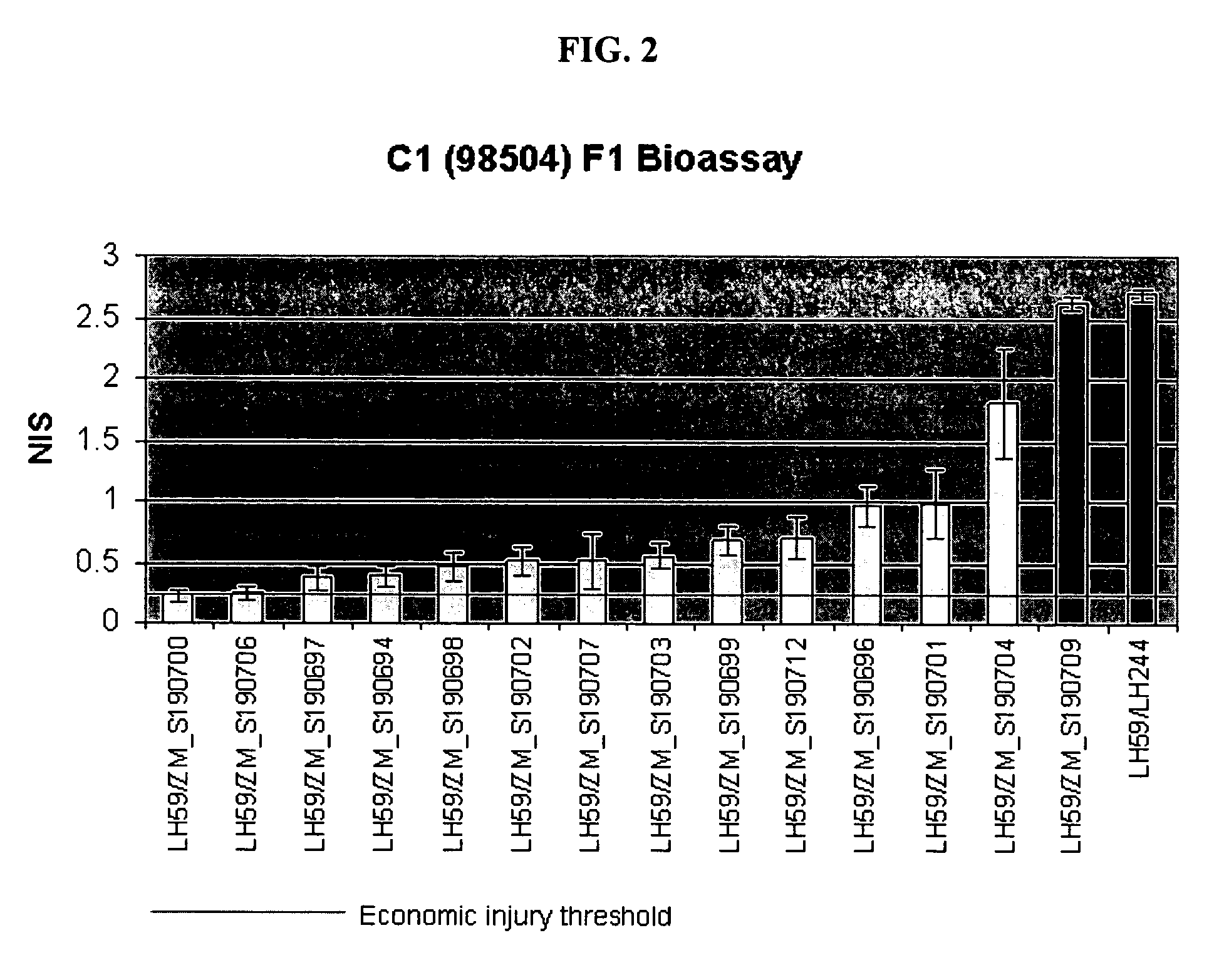

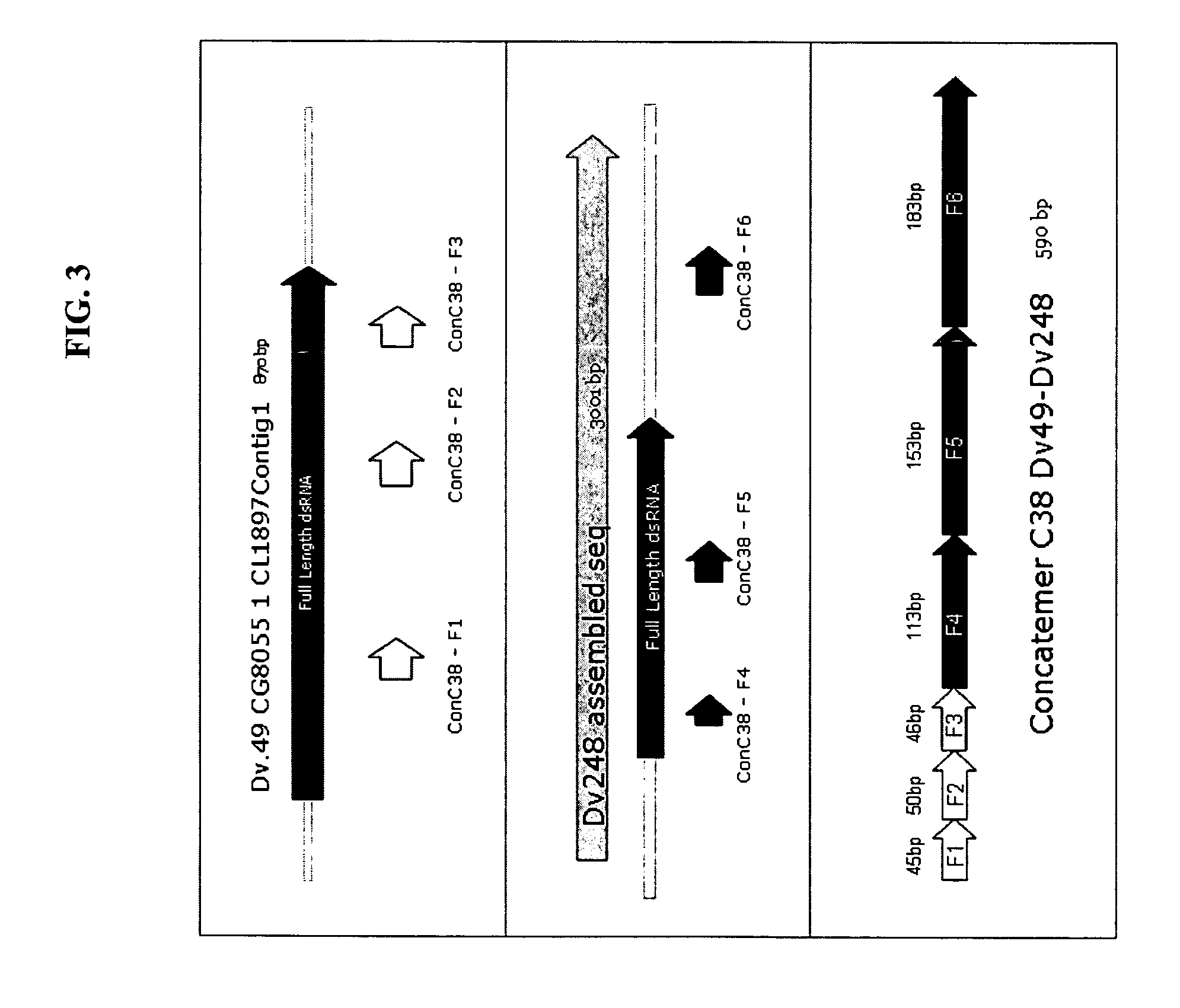

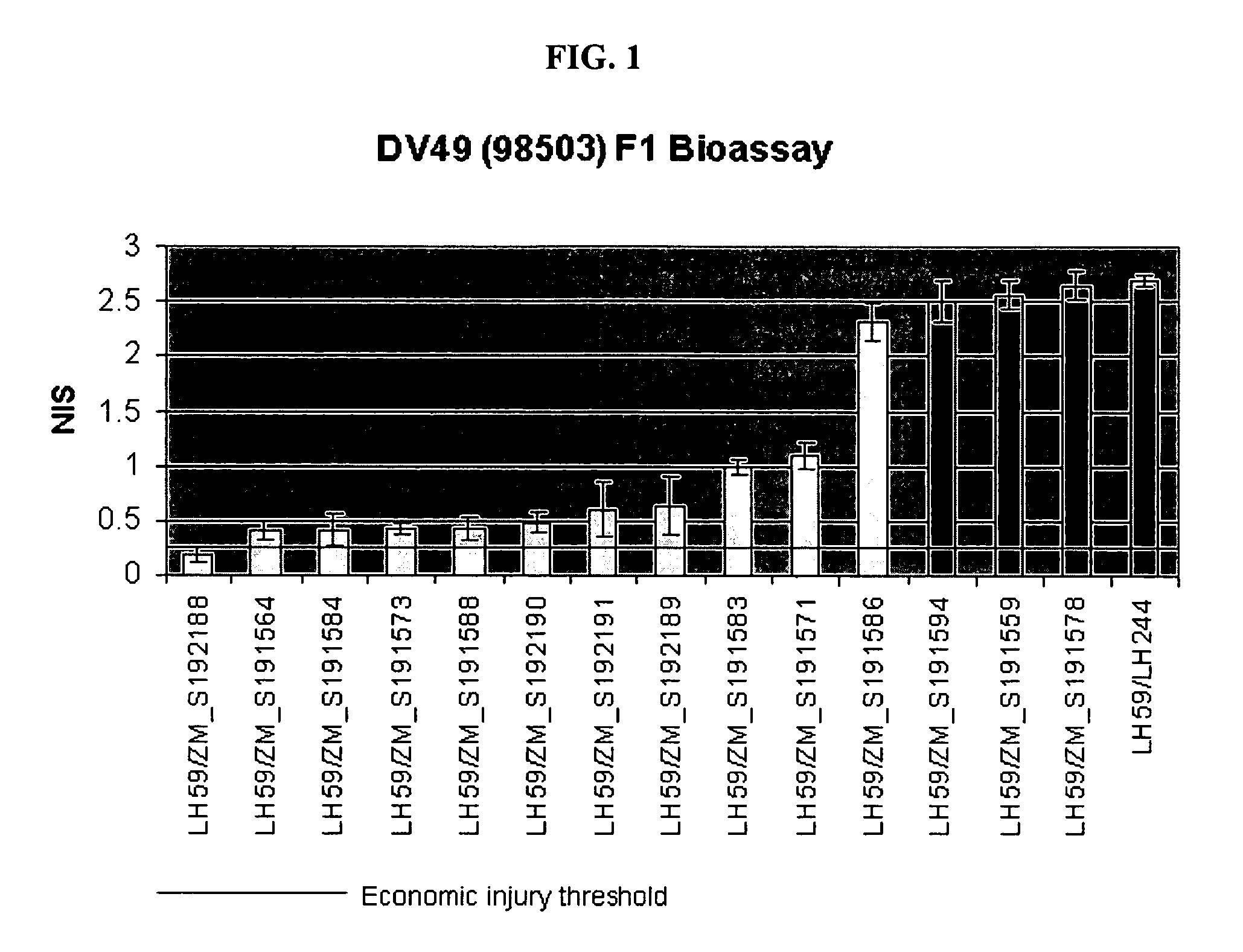

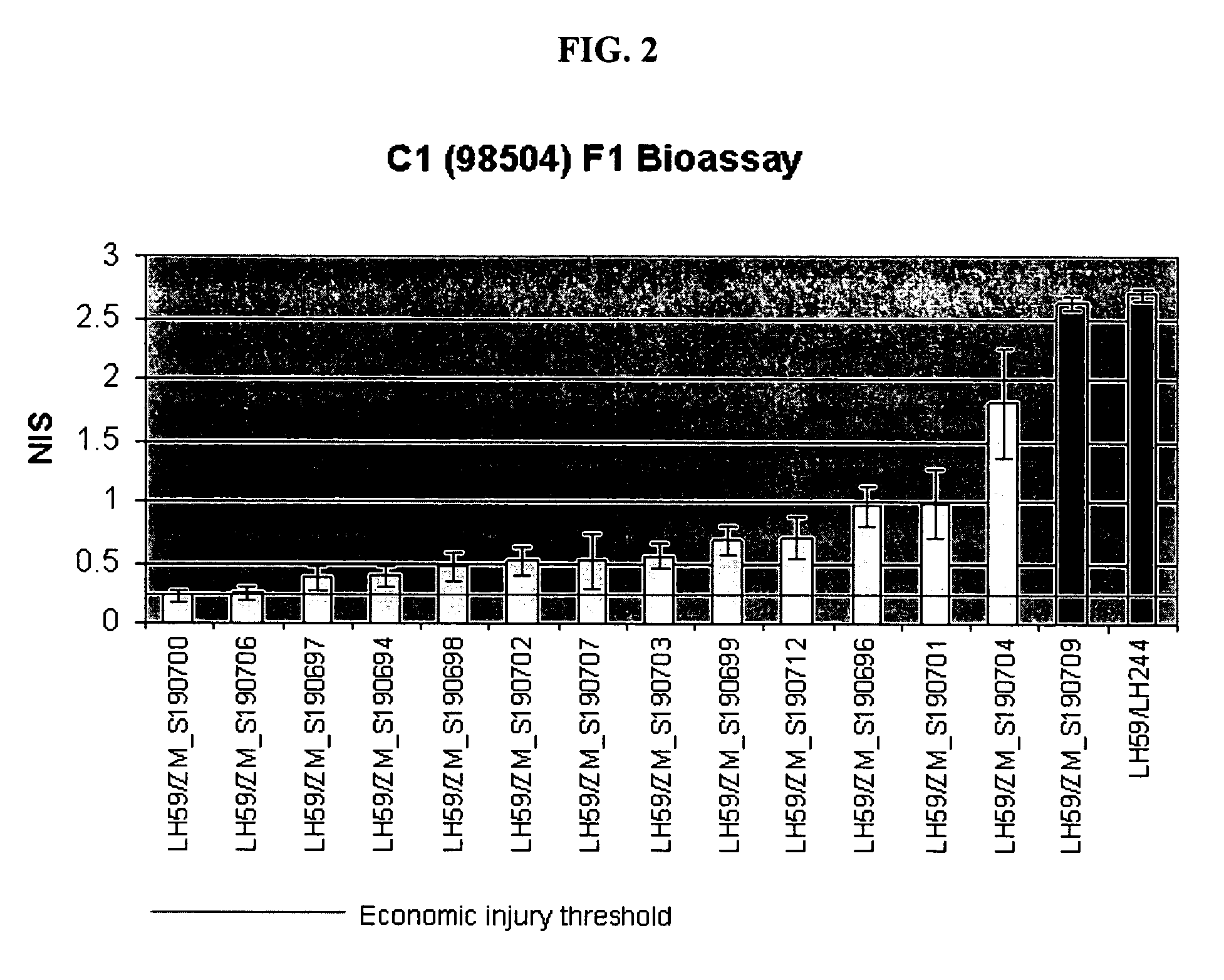

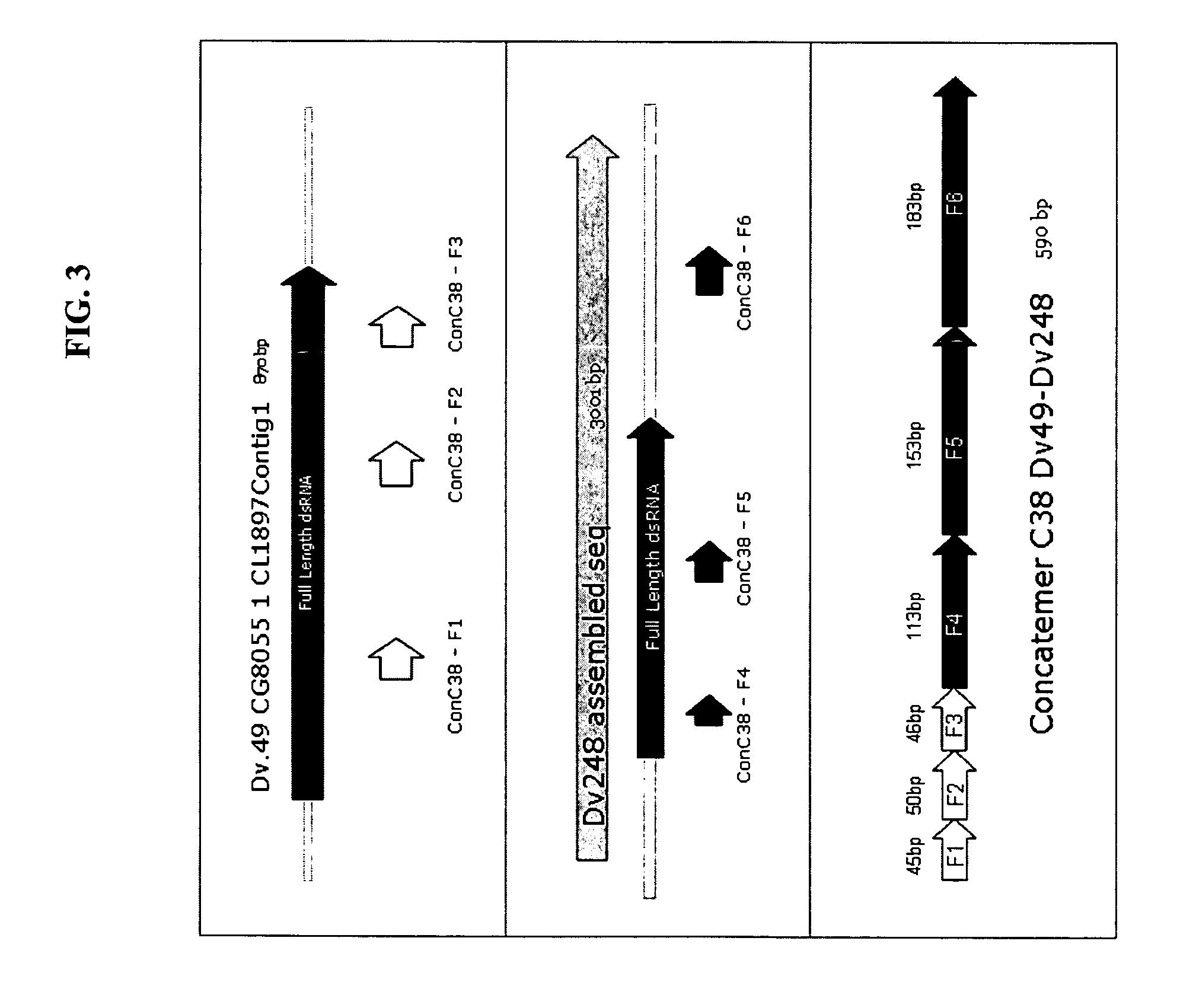

Compositions and methods for control of insect infestations in plants

InactiveUS20060021087A1Limiting and eliminating invertebrateInhibit expressionBiocideSugar derivativesInvertebrateOrganism

The present invention is directed to controlling pest infestation by inhibiting one or more biological functions in an invertebrate pest. The invention discloses methods and compositions for use in controlling pest infestation by feeding one or more different recombinant double stranded RNA molecules to the pest in order to achieve a reduction in pest infestation through suppression of gene expression. The invention is also directed to methods for making transgenic plants that express the double stranded RNA molecules, and to particular combinations of transgenic pesticidal agents for use in protecting plants from pest infestation.

Owner:MONSANTO TECH LLC

Methods for genetic control of insect infestations in plants and compositions thereof

ActiveUS20070124836A1Inhibit expressionReduced expression levelSugar derivativesClimate change adaptationBiotechnologyDouble strand

The present invention relates to control of pest infestation by inhibiting one or more biological functions. The invention provides methods and compositions for such control. By feeding one or more recombinant double stranded RNA molecules provided by the invention to the pest, a reduction in pest infestation is obtained through suppression of gene expression. The invention is also directed to methods for making transgenic plants that express the double stranded RNA molecules, and to particular combinations of transgenic pesticidal agents for use in protecting plants from pest infestation.

Owner:MONSANTO TECH LLC

Methods for genetic control of insect infestations in plants and compositions thereof

ActiveUS7943819B2Reduced expression levelLow effective doseSugar derivativesClimate change adaptationGMO PlantsDouble stranded rna

Owner:MONSANTO TECH LLC

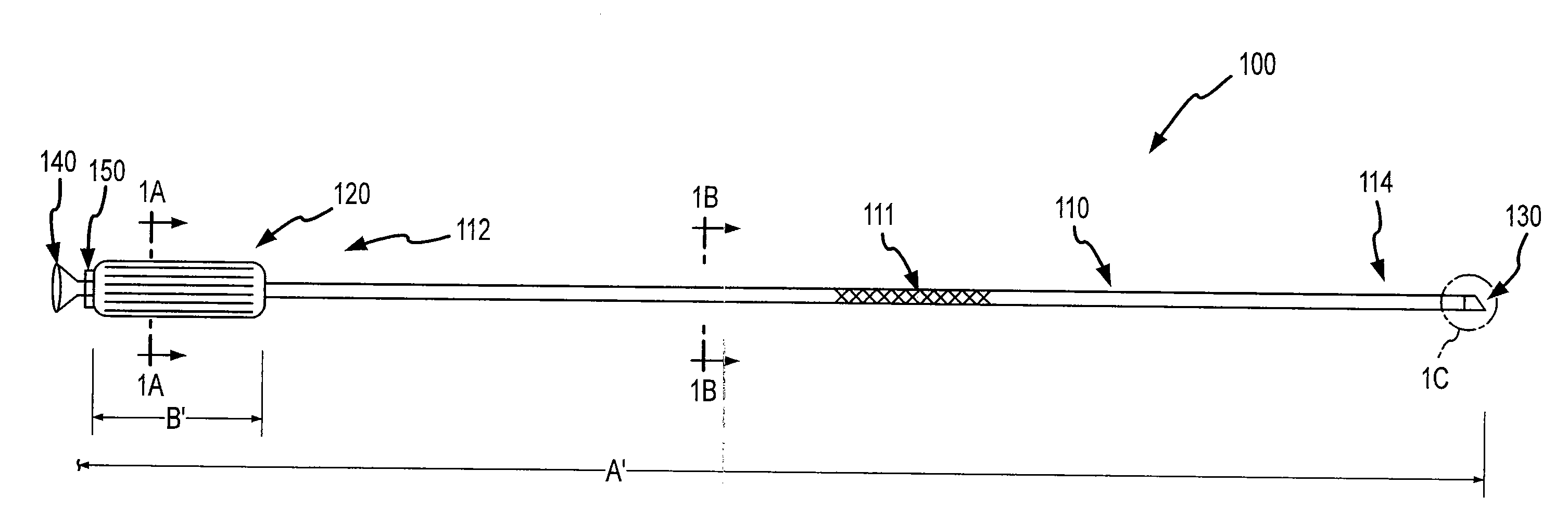

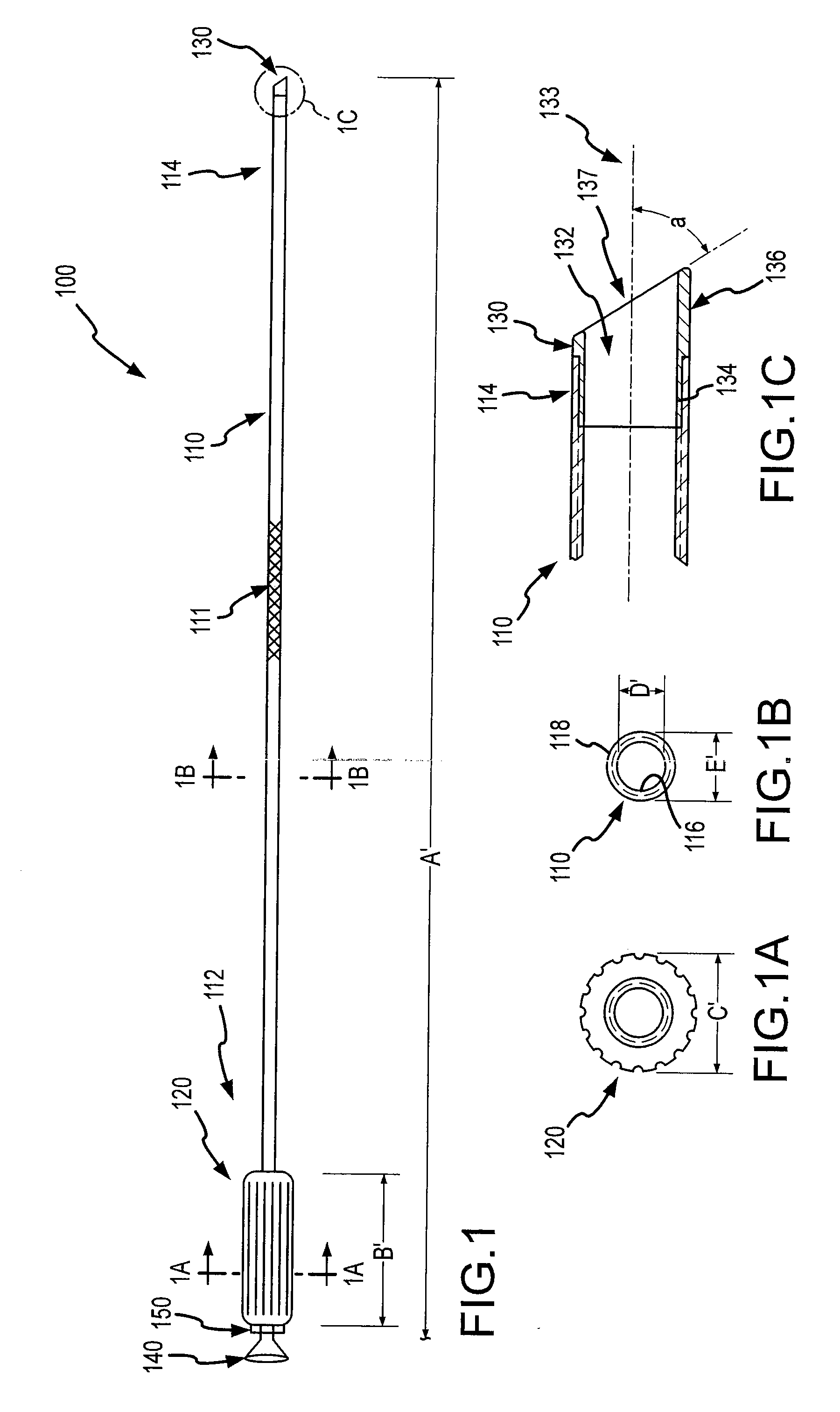

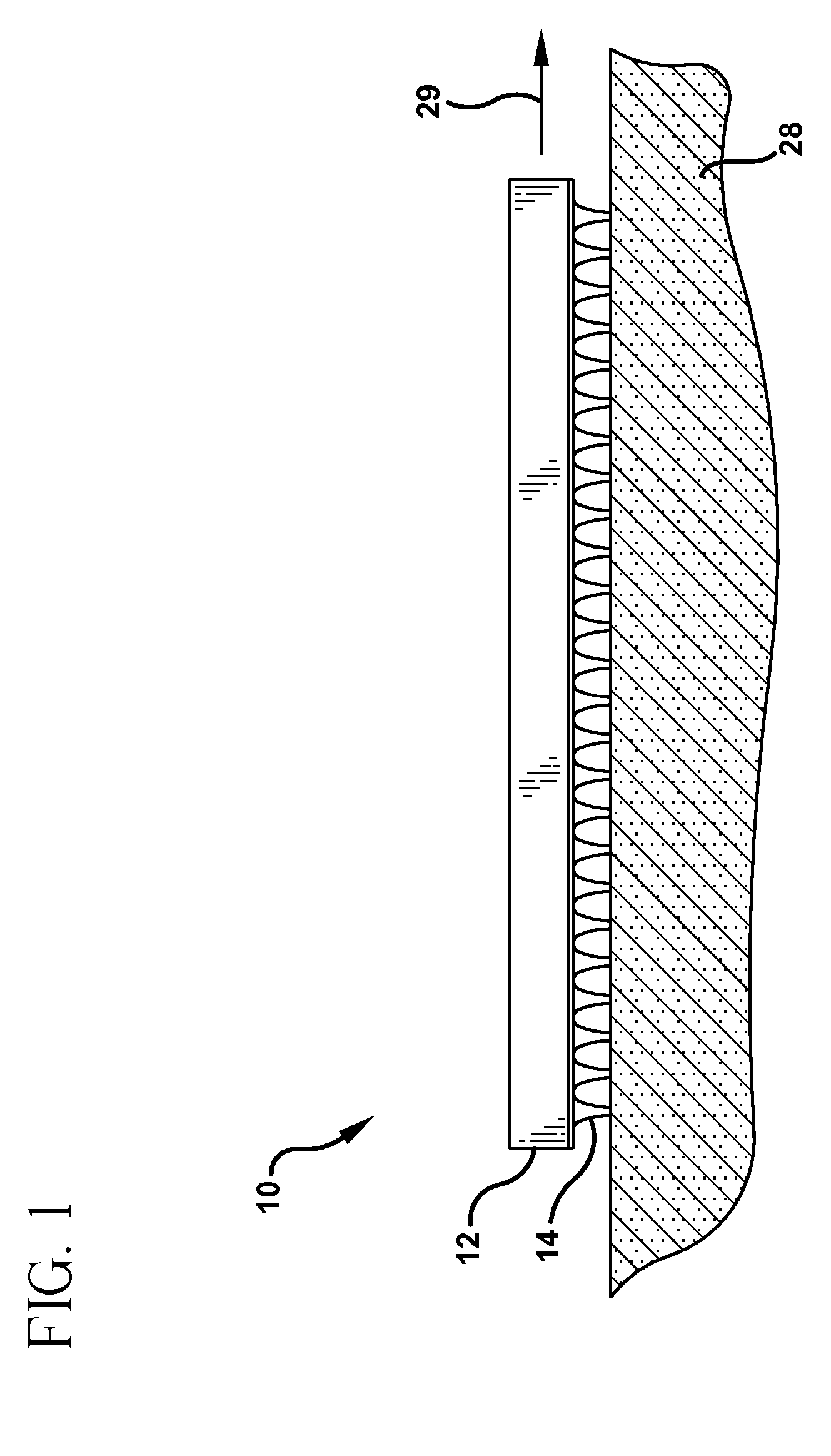

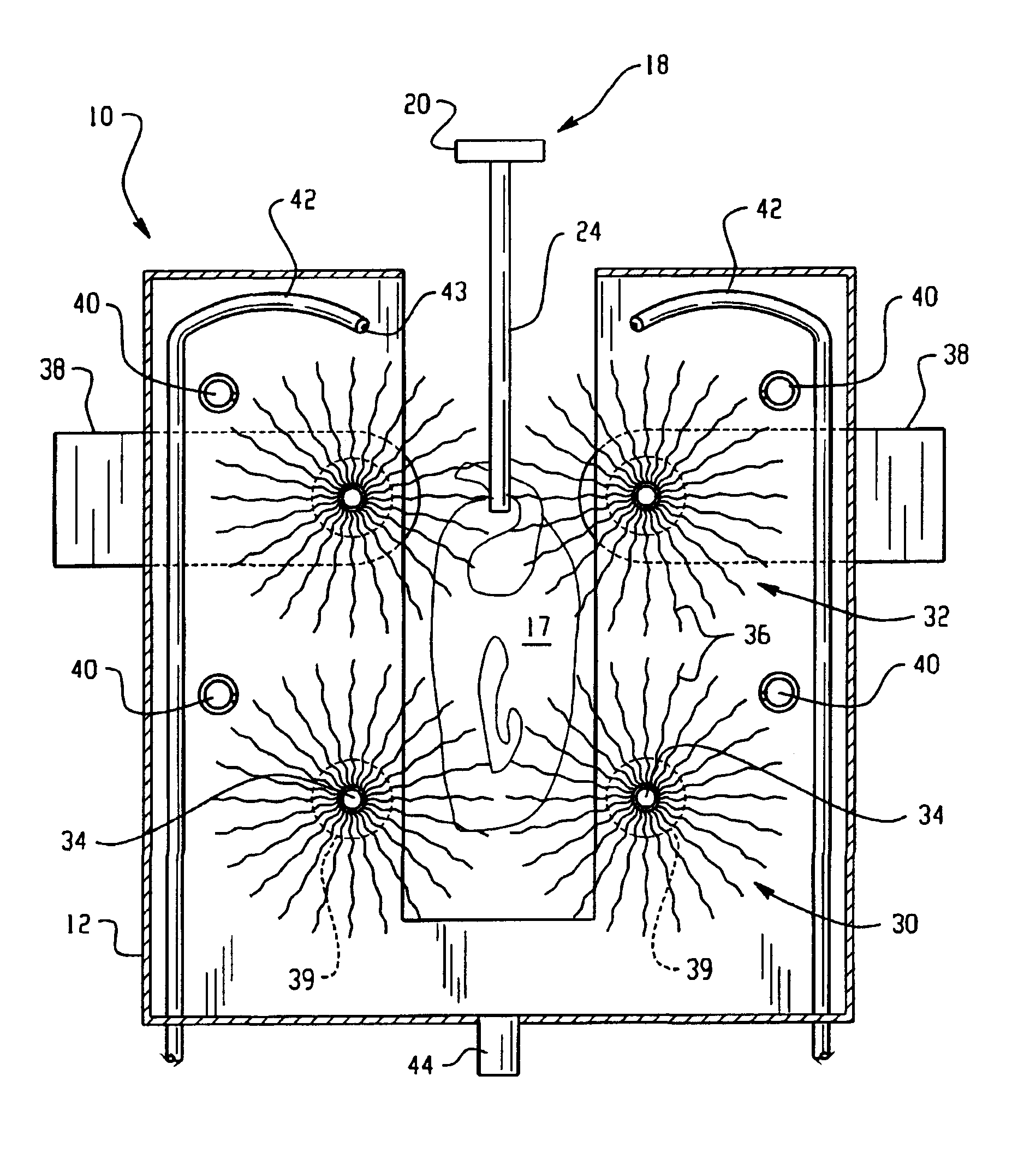

Tissue Separating Systems and Methods

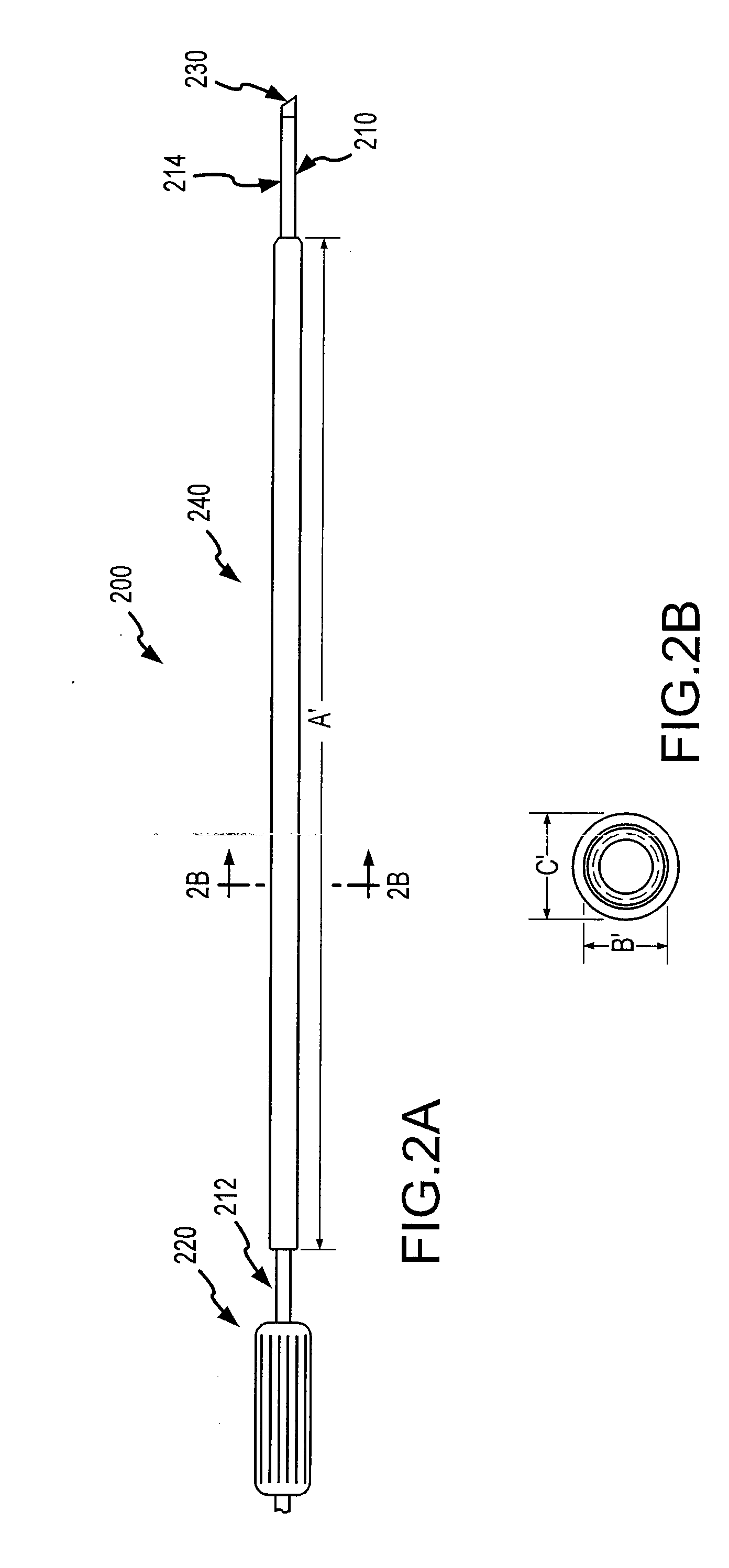

ActiveUS20080154296A1Smooth connectionReduce morbidityTransvascular endocardial electrodesBlunt dissectorsEngineeringBiomedical engineering

Systems and methods for separating an object such as a pacing lead from a patient tissue involve a flexible and torqueable shaft having an internal lumen sized to receive the object, and a hard separating mechanism for separating the object from the tissue. Typically the shaft and separating mechanism are advanced along or toward the object, and the separating mechanism is contacted with the tissue. The shaft is rotated to effect separation between the object and the tissue. The systems and methods are well suited for use in cardiac pacing or defibrillator lead explant procedures.

Owner:SPECTRANETICS

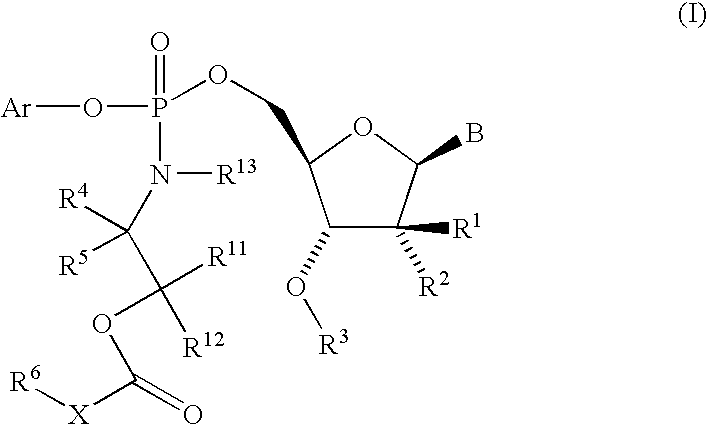

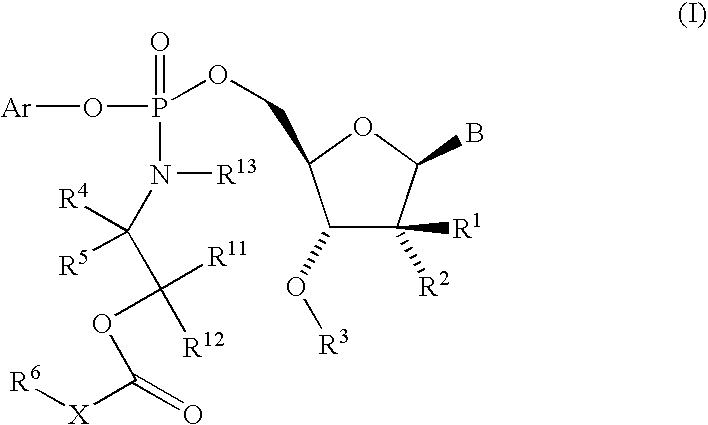

Nucleoside aryl phosphoramidates for the treatment of RNA-dependent RNA viral infection

InactiveUS7879815B2Effective penetrationLess susceptibleBiocideSugar derivativesHepatitis c viralPhosphoramidate

Owner:MSD ITAL +1

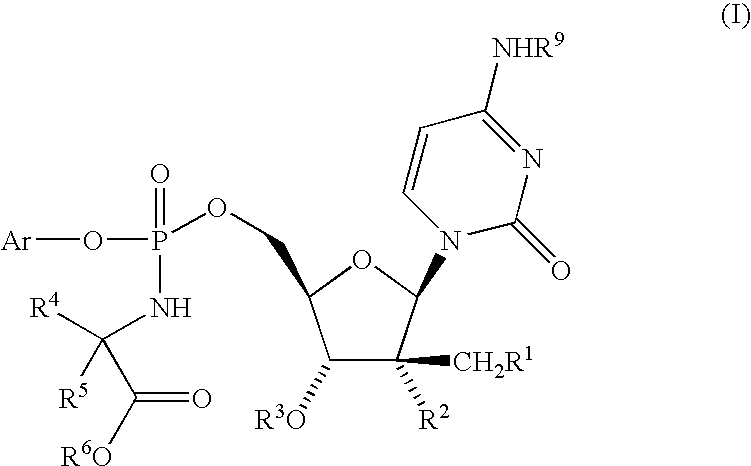

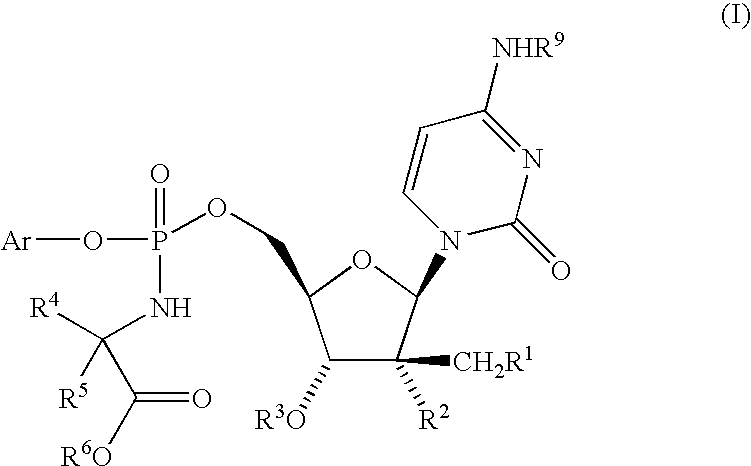

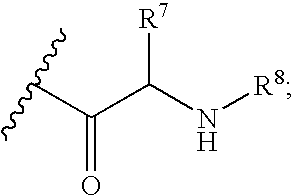

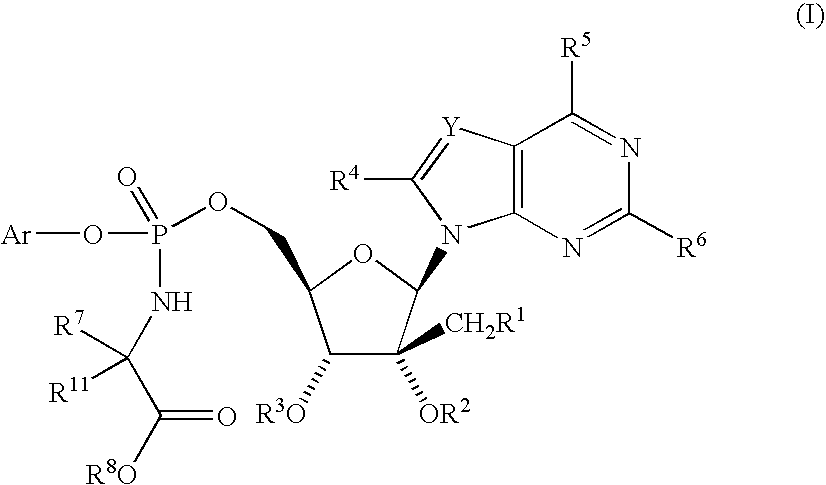

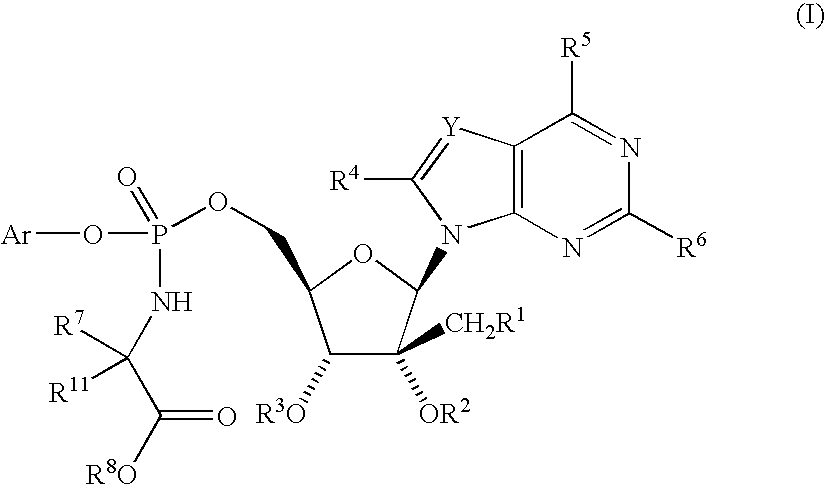

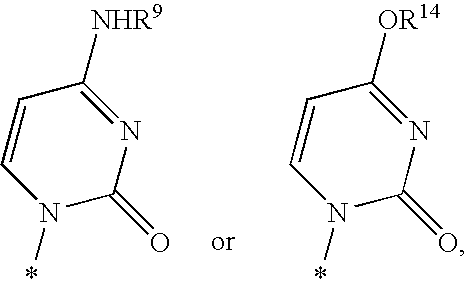

Nucleoside Aryl Phosphoramidates for the Treatment of Rna-Dependent Rna Viral Infection

InactiveUS20070265222A1Efficient cell penetrationWider therapeutic indexBiocideSugar derivativesRNA-dependent RNA polymerasePhosphoramidate

The present invention provides nucleoside aryl phosphoramidates which are precursors to inhibitors of RNA-dependent RNA viral polymerase. These compounds are precursors to inhibitors of RNA-dependent RNA viral replication and are useful for the treatment of RNA-dependent RNA viral infection. They are particularly useful as precursors to inhibitors of hepatitis C virus (HCV) NS5B polymerase, as precursors to inhibitors of HCV replication, and / or for the treatment of hepatitis C infection. The invention also describes pharmaceutical compositions containing such nucleoside aryl phosphoramidates alone or in combination with other agents active against RNA-dependent RNA viral infection, in particular HCV infection. Also disclosed are methods of inhibiting RNA-dependent RNA polymerase, inhibiting RNA-dependent RNA viral replication, and / or treating RNA-dependent RNA viral infection with the nucleoside aryl phosphoramidates of the present invention.

Owner:MERCK SHARP & DOHME CORP

Sprayable compositions comprising a combination of pharmaceutical actives and an oily phase

InactiveUS20050281749A1Good acceptability and toleranceChemically stableBiocideAerosol deliveryDermatological disordersOil phase

Sprayable, anhydrous and physically / chemically stable dermatological / pharmaceutical compositions, well suited for the treatment of a variety of dermatological disorders, notably psoriasis, contain: a) a therapeutically effective amount of a solubilized corticoid, notably dissolved clobetasol propionate; b) a therapeutically effective amount of a solubilized vitamin D derivative, notably dissolved calcitriol; and c) an oily phase which comprises one or more oils; formulated into d), a sprayable and topically applicable, dermatologically / pharmaceutically acceptable vehicle therefor.

Owner:GALDERMA SA

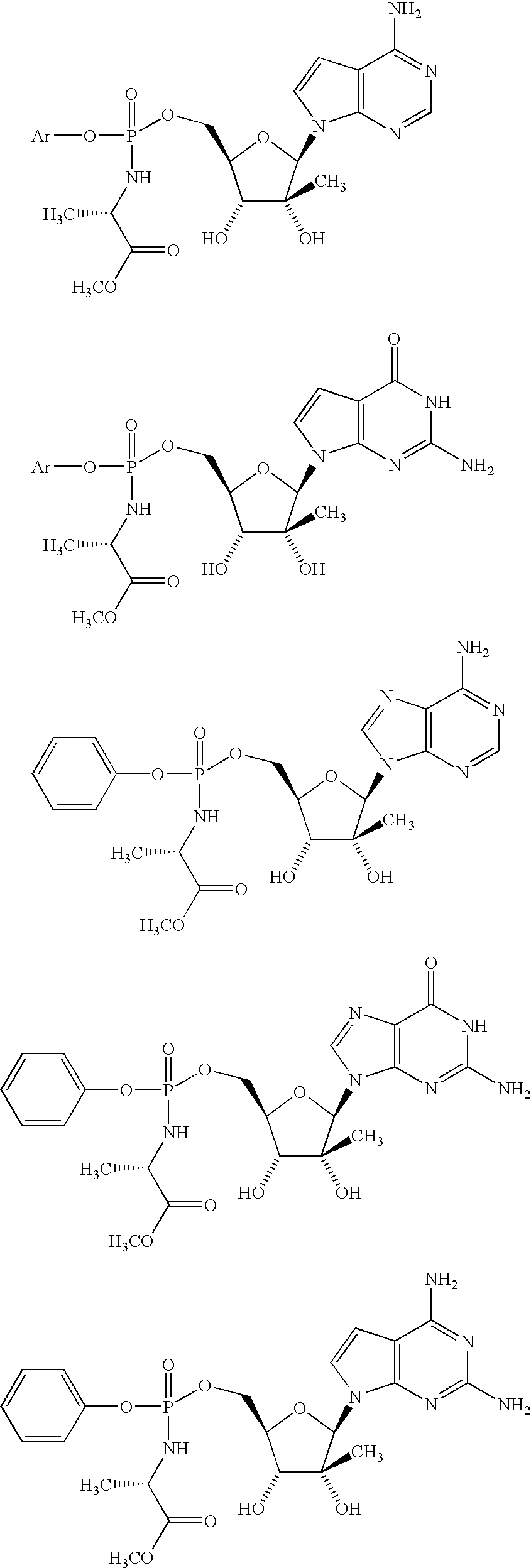

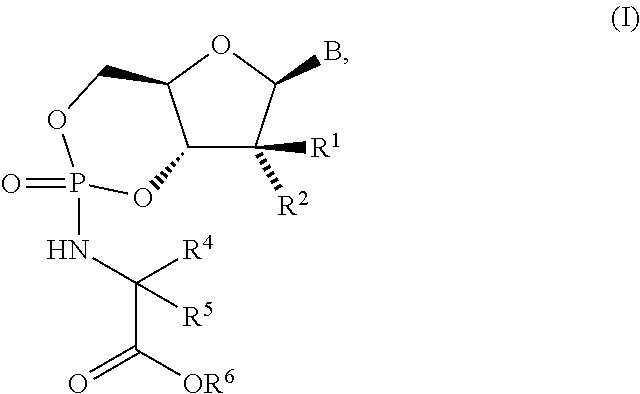

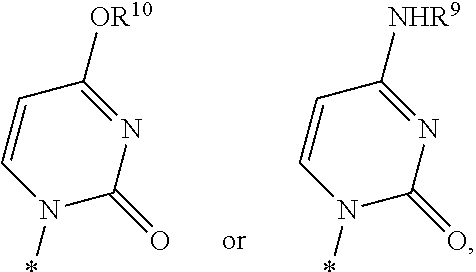

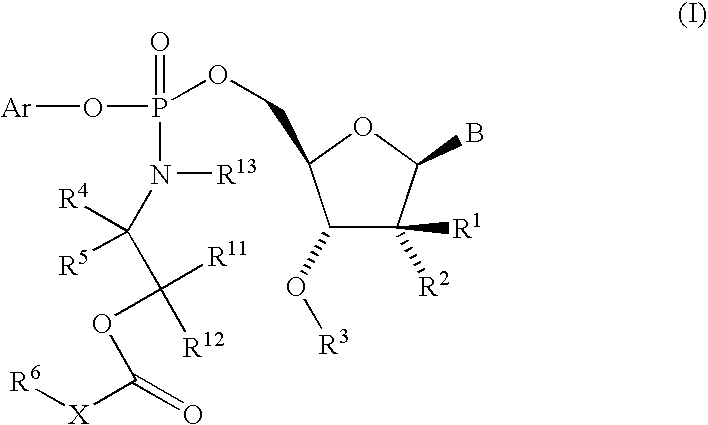

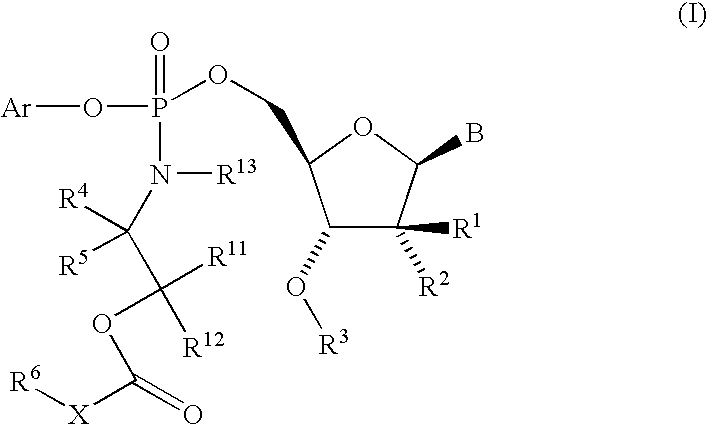

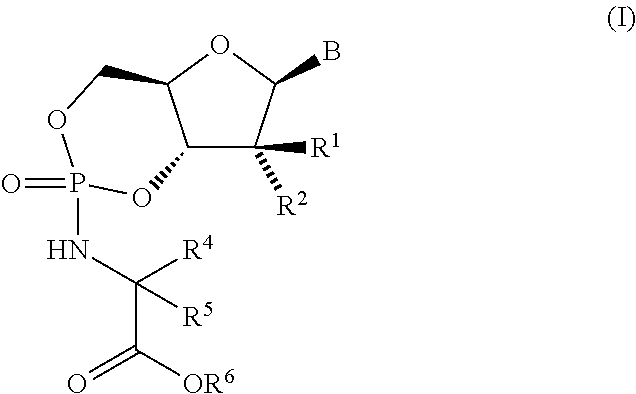

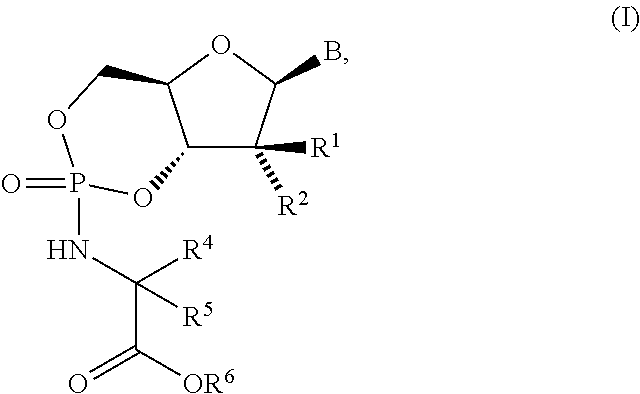

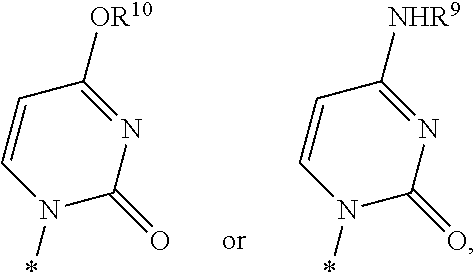

Nucleoside cyclic phosphoramidates for the treatment of RNA-dependent RNA viral infection

ActiveUS8148349B2Effective penetrationLess susceptibleBiocideSugar derivativesRNA Virus InfectionsRNA-dependent RNA polymerase

The present invention provides nucleoside cyclic phosphoramidates of formula (I), pharmaceutical compositions comprising the compounds of formula (I) and methods of inhibiting RNA-dependent RNA polymerase, inhibiting RNA-dependent RNA viral replication, and / or treating RNA-dependent RNA viral infection using the compounds of formula (I).

Owner:MSD ITAL +1

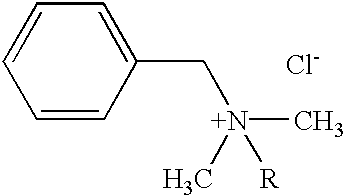

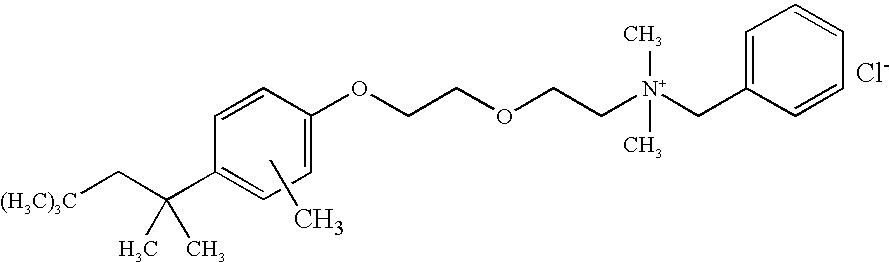

Anti-infective compositions for treating disordered tissue such as cold sores

The present invention relates to the treatment of disordered epithelial tissues such as cold sores and other complications resulting from disorders such as herpes, and the like. The invention relates to the use of an anti-infective and / or antimicrobial active agent in a carrier, with vigorous agitation of the disordered epithelial tissue for topical treatment thereof under such conditions sufficient to achieve clinically discernable improvement of the disordered epithelial tissue. The preferred anti-infective and / or antimicrobial active agent is an organohalide such as a quaternary ammonium compound, preferably benzalkonium chloride. The inventive method may be used also in connection with a preferred applicator configuration.

Owner:CHURCH & DWIGHT CO INC

Nucleoside aryl phosphoramidates for the treatment of RNA-dependent RNA viral infection

ActiveUS20100035835A1Efficient cell penetrationWider therapeutic indexBiocideSugar derivativesPolymerase LStructural formula

The present invention provides nucleoside aryl phosphoramidates of structural formula (I) which are precursors to inhibitors of RNA-dependent RNA viral polymerase. These compounds are precursors to inhibitors of RNA-dependent RNA viral replication and are useful for the treatment of RNA-dependent RNA viral infection. They are particularly useful as precursors to inhibitors of hepatitis C virus (HCV) NS5B polymerase, as precursors to inhibitors of HCV replication, and / or for the treatment of hepatitis C infection. The invention also describes pharmaceutical compositions containing such nucleoside aryl phosphoramidates alone or in combination with other agents active against RNA-dependent RNA viral infection, in particular HCV infection. Also disclosed are methods of inhibiting RNA-dependent RNA polymerase, inhibiting RNA-dependent RNA viral replication, and / or treating RNA-dependent RNA viral infection with the nucleoside aryl phosphoramidates of the present invention.

Owner:MSD ITAL +1

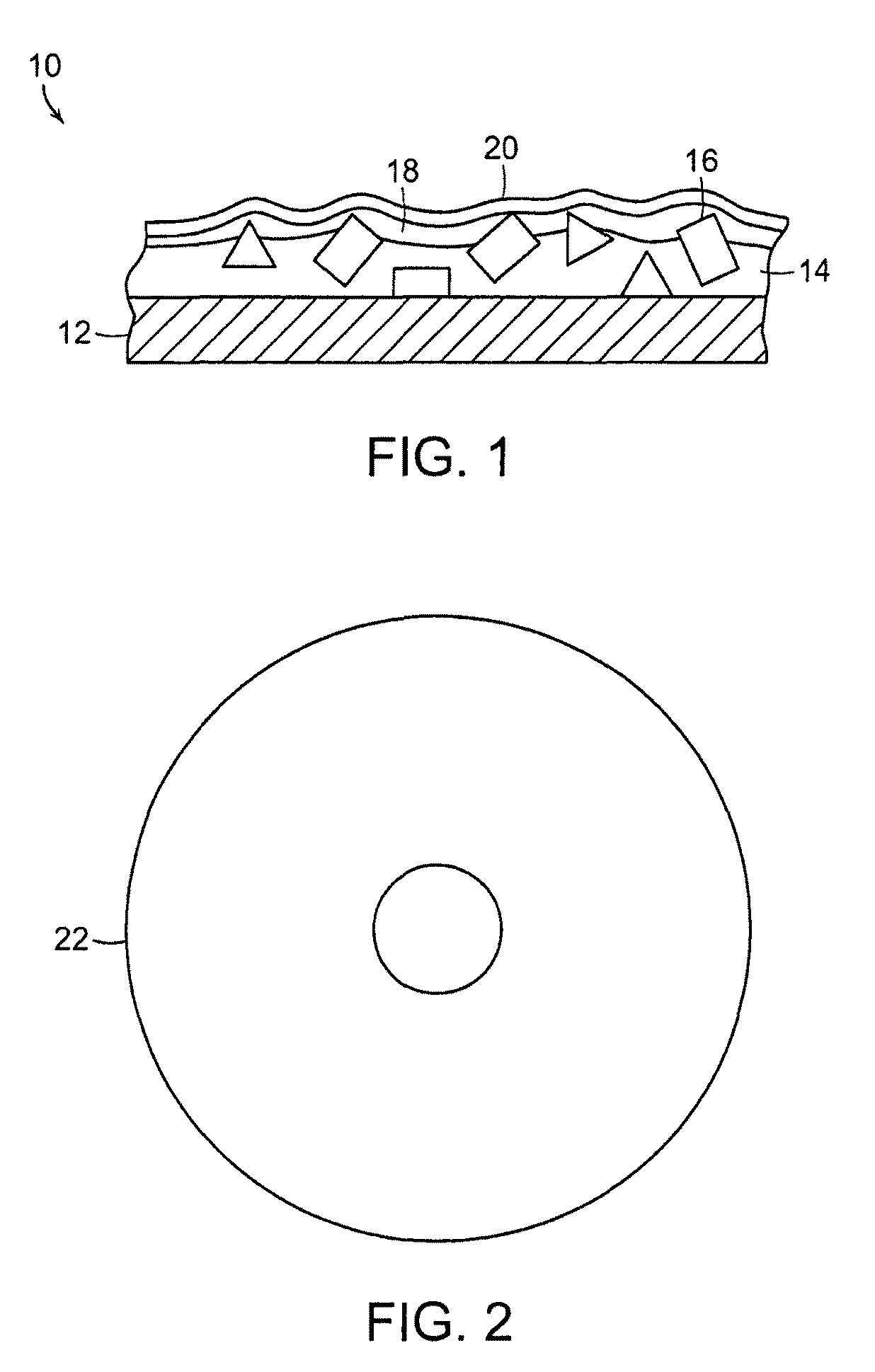

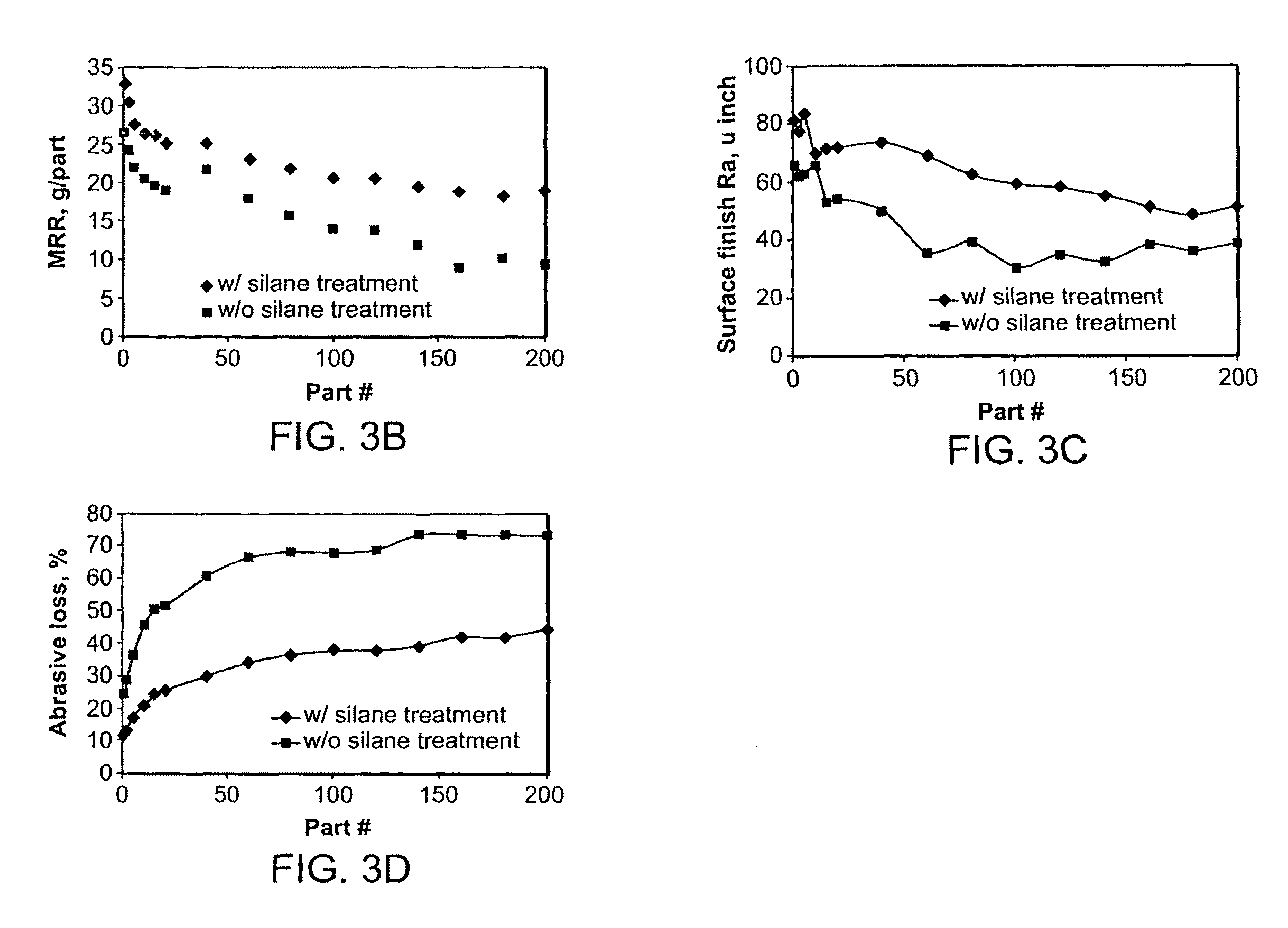

Hydrophilic and hydrophobic silane surface modification of abrasive grains

ActiveUS8021449B2Effective penetrationReduce penetrationPigmenting treatmentOther chemical processesSilanesSurface modification

Owner:SAINT GOBAIN ABRASIVES INC +1

Nucleoside aryl phosphoramidates for the treatment of RNA-dependent RNA viral infection

ActiveUS8071568B2Effective penetrationLess susceptibleBiocideSugar derivativesPolymerase LPhosphoramidate

The present invention provides nucleoside aryl phosphoramidates of structural formula (I) which are precursors to inhibitors of RNA-dependent RNA viral polymerase. These compounds are precursors to inhibitors of RNA-dependent RNA viral replication and are useful for the treatment of RNA-dependent RNA viral infection. They are particularly useful as precursors to inhibitors of hepatitis C virus (HCV) NS5B polymerase, as precursors to inhibitors of HCV replication, and / or for the treatment of hepatitis C infection. The invention also describes pharmaceutical compositions containing such nucleoside aryl phosphoramidates alone or in combination with other agents active against RNA-dependent RNA viral infection, in particular HCV infection. Also disclosed are methods of inhibiting RNA-dependent RNA polymerase, inhibiting RNA-dependent RNA viral replication, and / or treating RNA-dependent RNA viral infection with the nucleoside aryl phosphoramidates of the present invention. (I)

Owner:MSD ITAL +1

Compositions and Methods for Control of Insect Infestations in Plants

ActiveUS20080214443A1Inhibit expressionLower Level RequirementsBiocideOrganic active ingredientsDouble strandDouble stranded rna

The present invention is directed to controlling pest infestation by inhibiting one or more biological functions in an invertebrate pest. The invention discloses methods and compositions for use in controlling pest infestation by feeding one or more different recombinant double stranded RNA molecules to the pest in order to achieve a reduction in pest infestation through suppression of gene expression. The invention is also directed to methods for making transgenic plants that express the double stranded RNA molecules, and to particular combinations of transgenic pesticidal agents for use in protecting plants from pest infestation.

Owner:MONSANTO TECH LLC

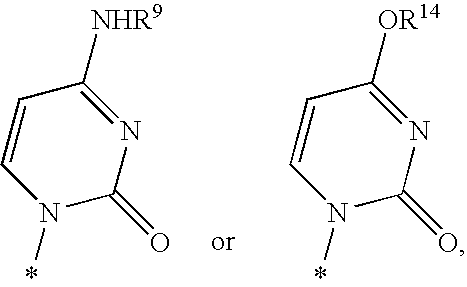

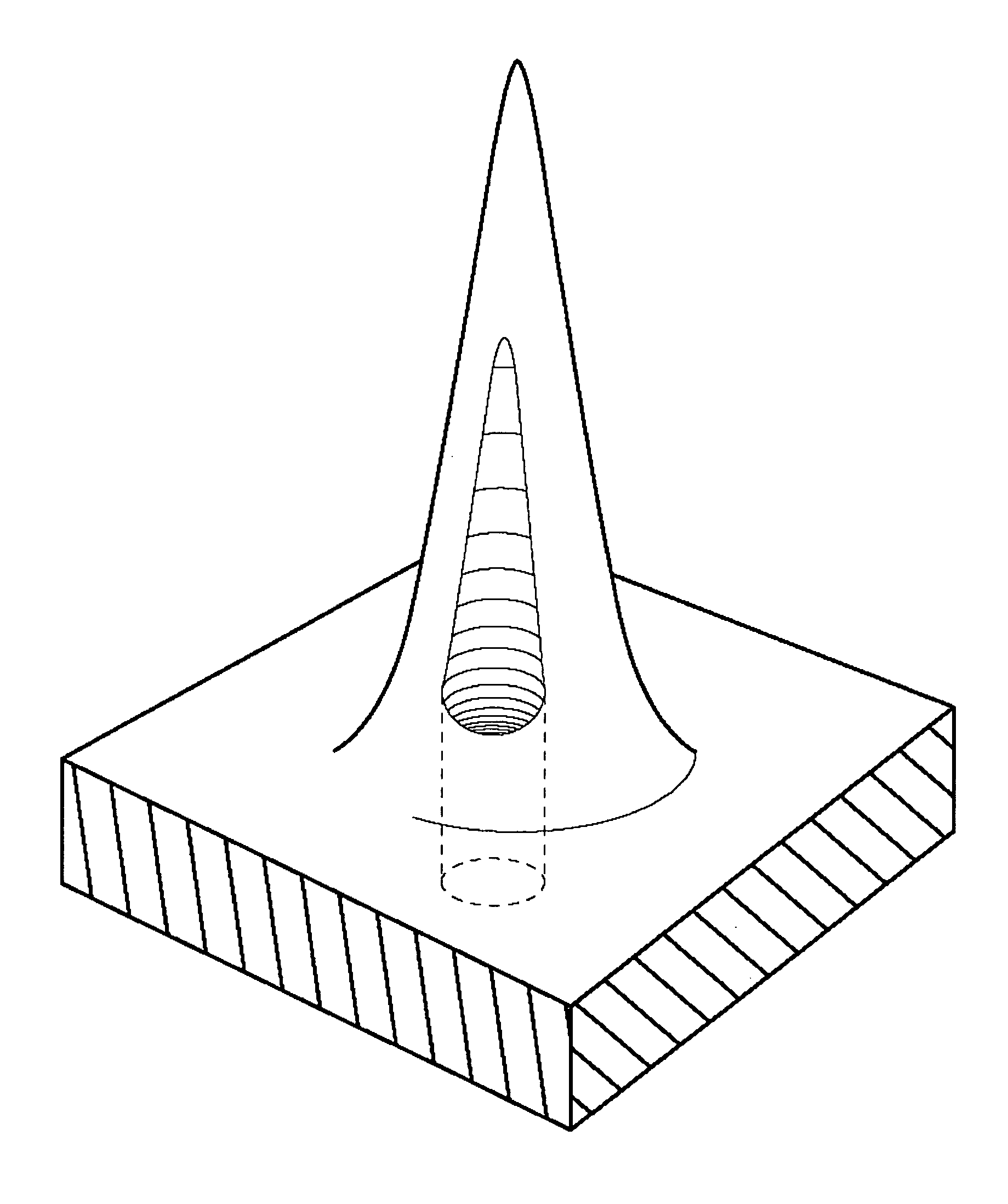

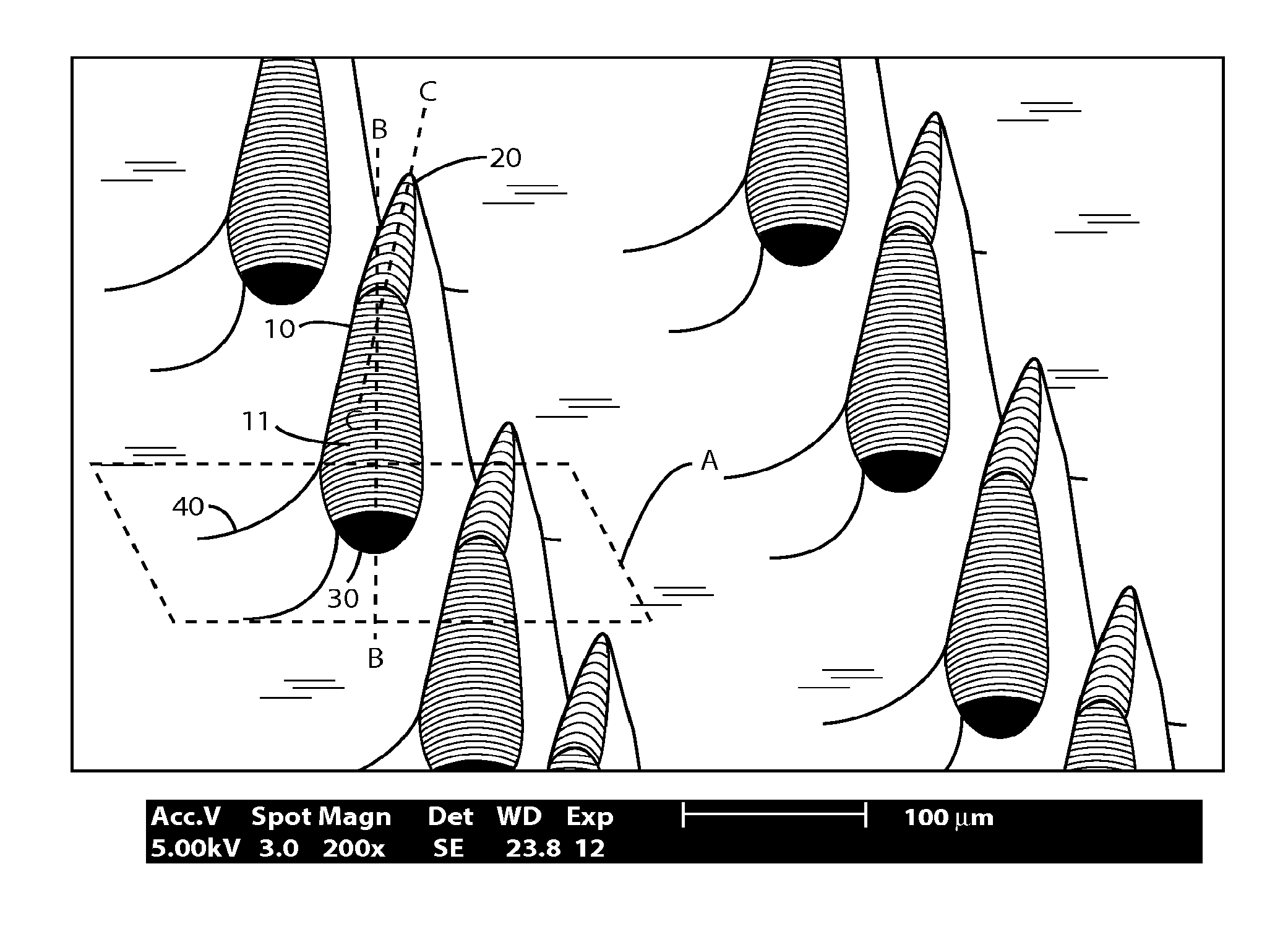

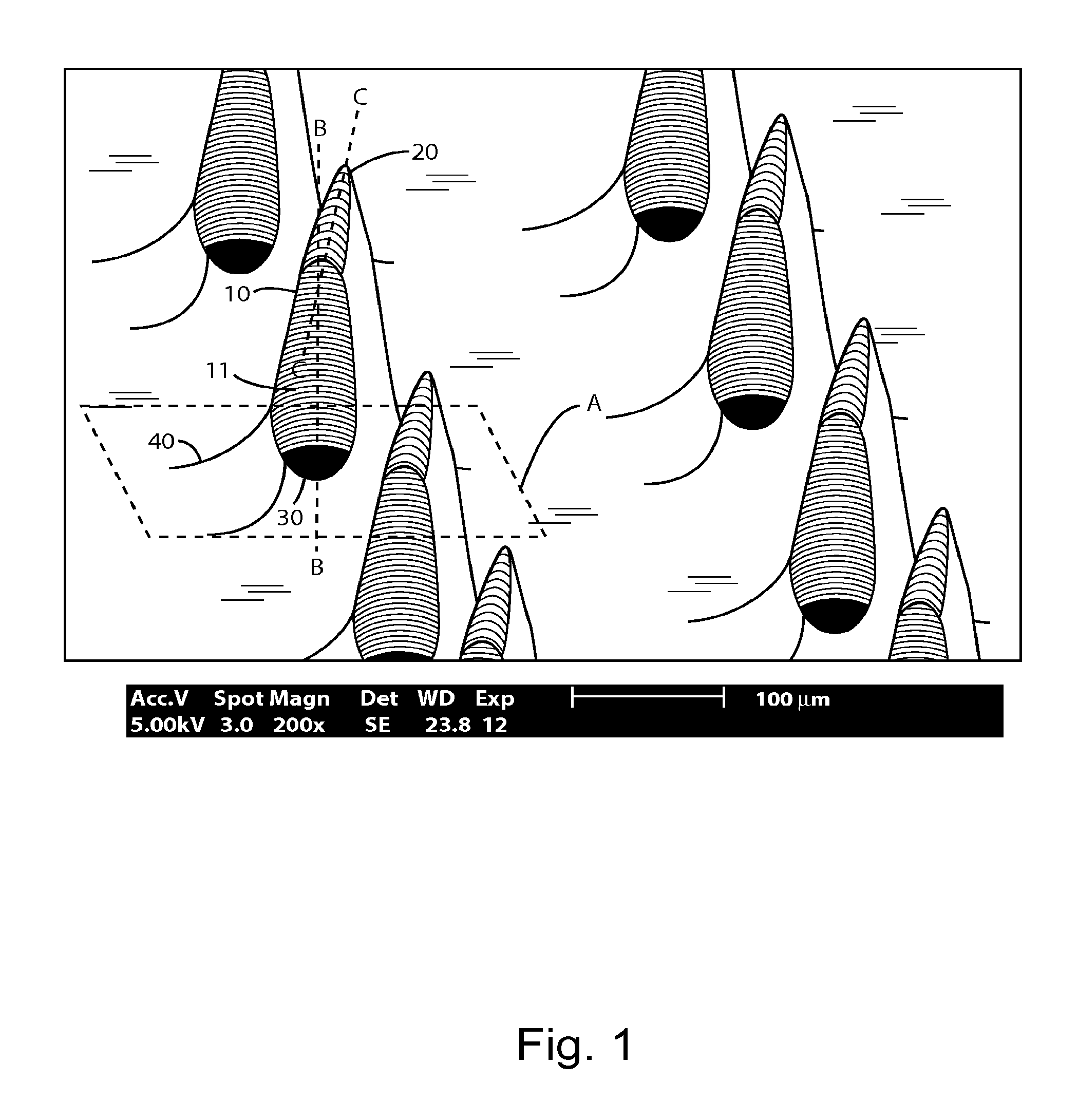

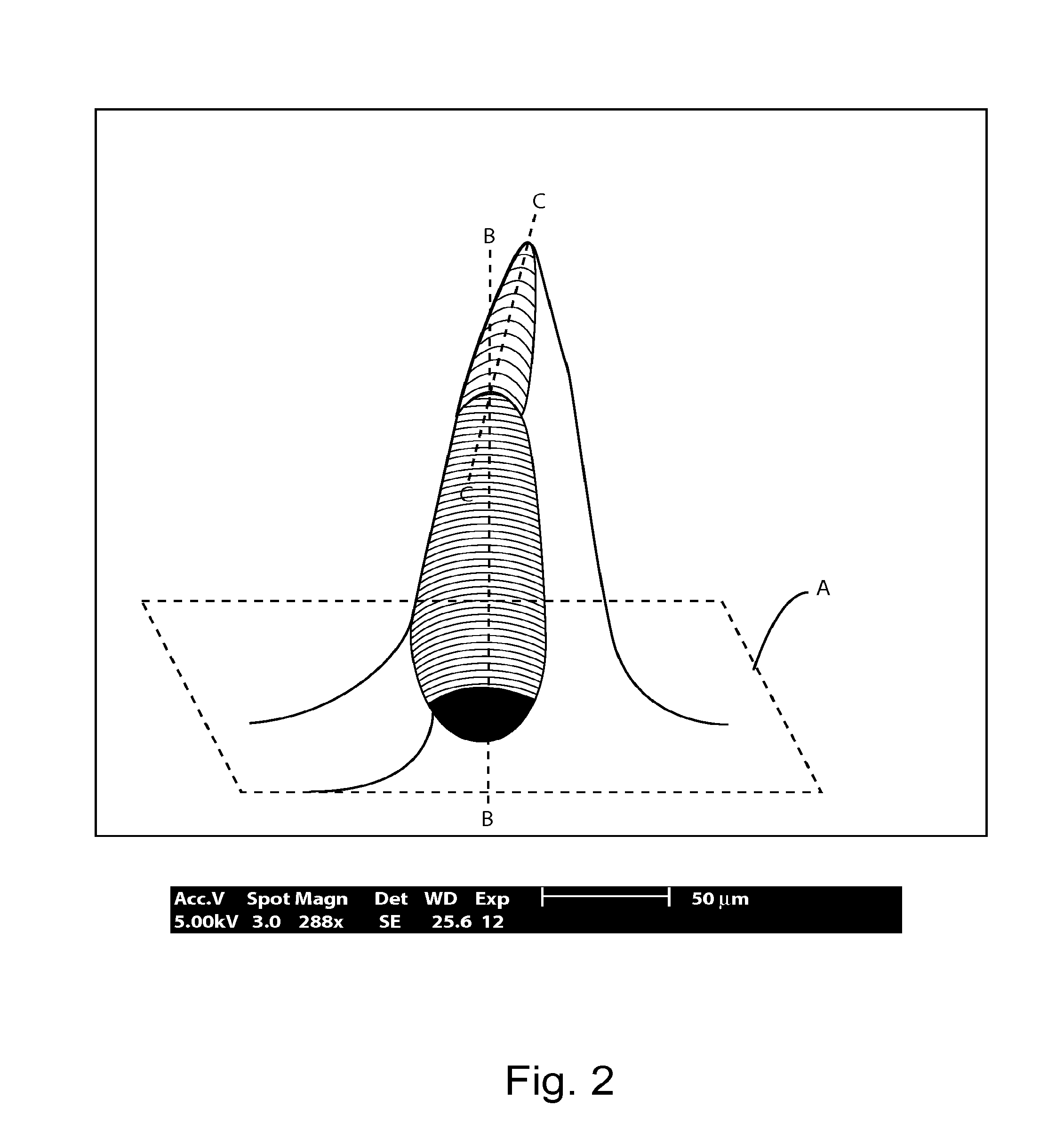

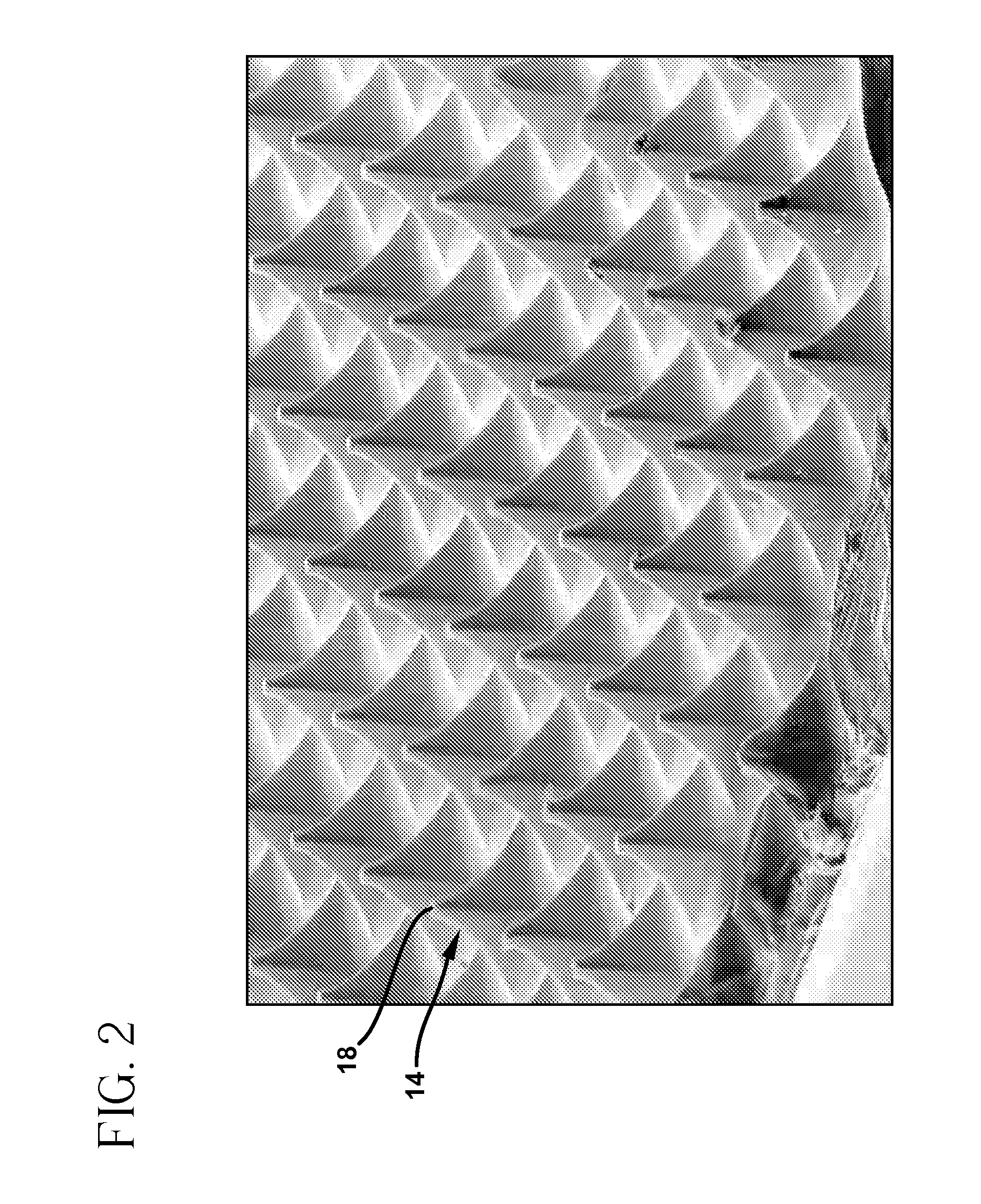

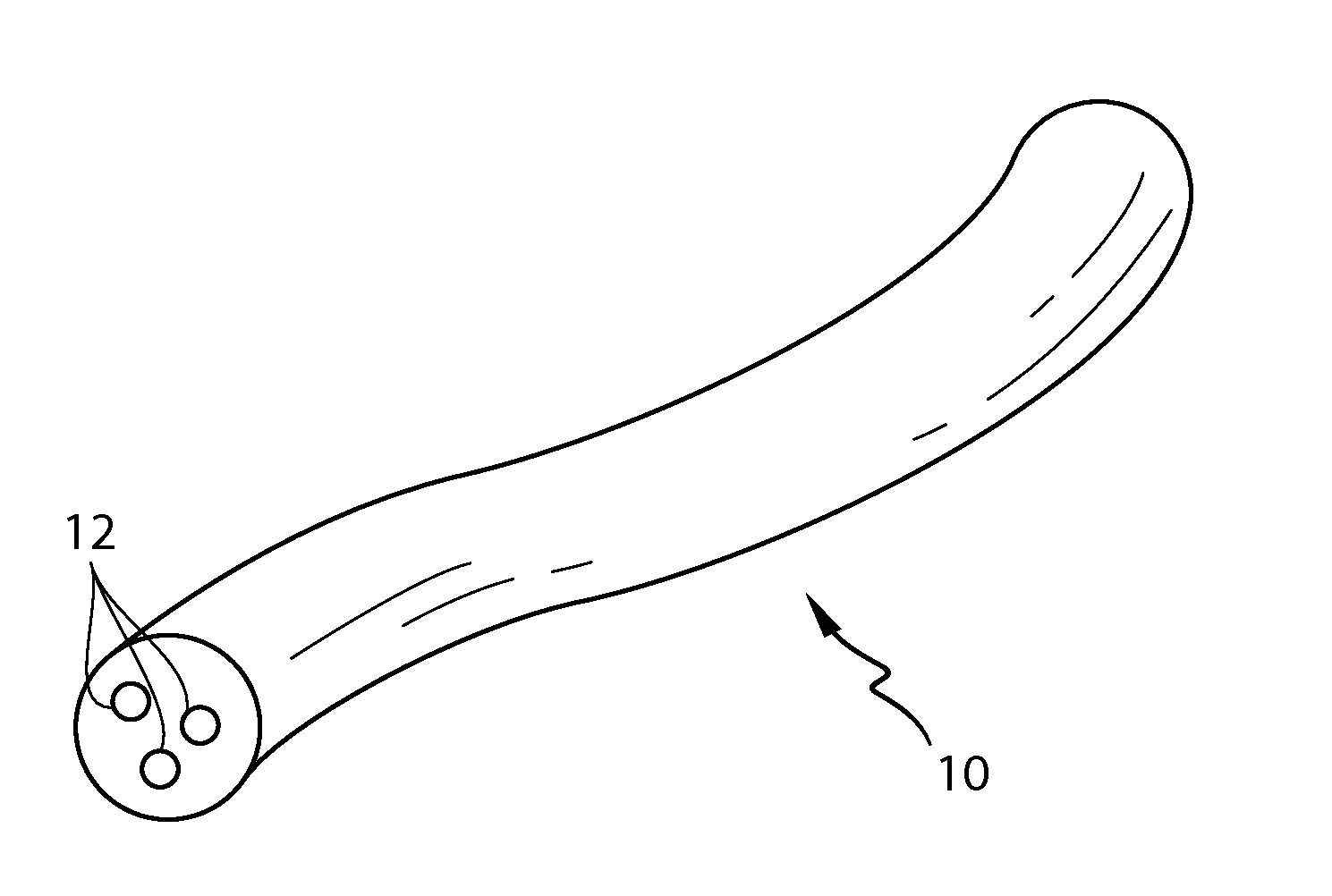

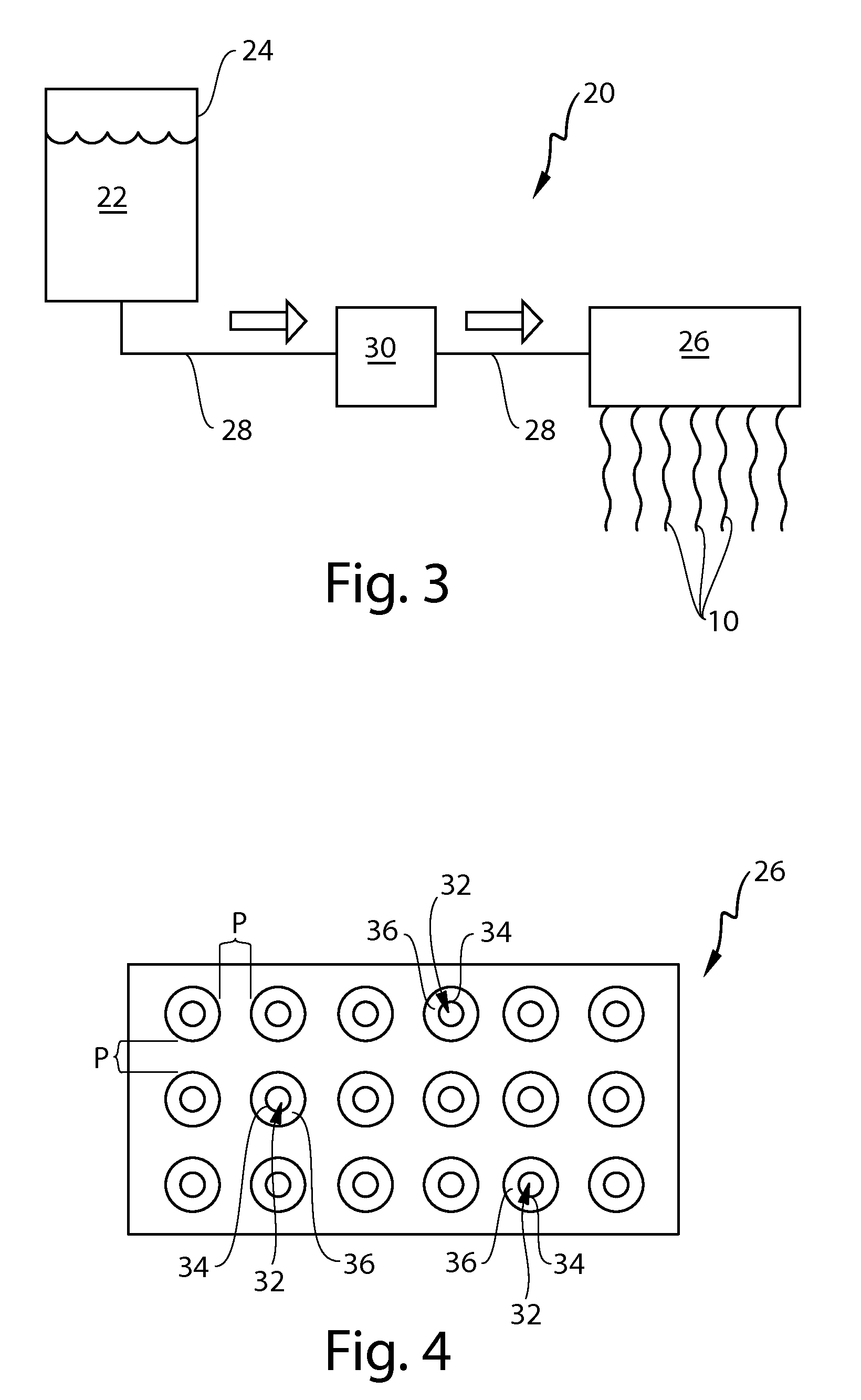

Method and/or apparatus for puncturing a surface for extraction, in situ analysis, and/or substance delivery using microneedles

InactiveUS20050171480A1Accurate sensor readingPainless and easy sensor applicationDecorative surface effectsMicroneedlesGlucose polymersD-Glucose

A method and apparatus for puncturing a surface for extraction, in situ monitoring, and / or substance delivery uses microneedles with improved properties. Applications include easy to handle glucose monitoring using a group of hollow out-of-plane silicon microneedles to sample substances in interstitial fluid from the epidermal skin layer.

Owner:RGT UNIV OF CALIFORNIA

Method and/or apparatus for puncturing a surface for extraction, in situ analysis, and/or substance delivery using microneedles

InactiveUS7753888B2OptimizationEffective penetrationDecorative surface effectsMicroneedlesGlucose polymersD-Glucose

A method and apparatus for puncturing a surface for extraction, in situ monitoring, and / or substance delivery uses microneedles with improved properties. Applications include easy to handle glucose monitoring using a group of hollow out-of-plane silicon microneedles to sample substances in interstitial fluid from the epidermal skin layer.

Owner:RGT UNIV OF CALIFORNIA

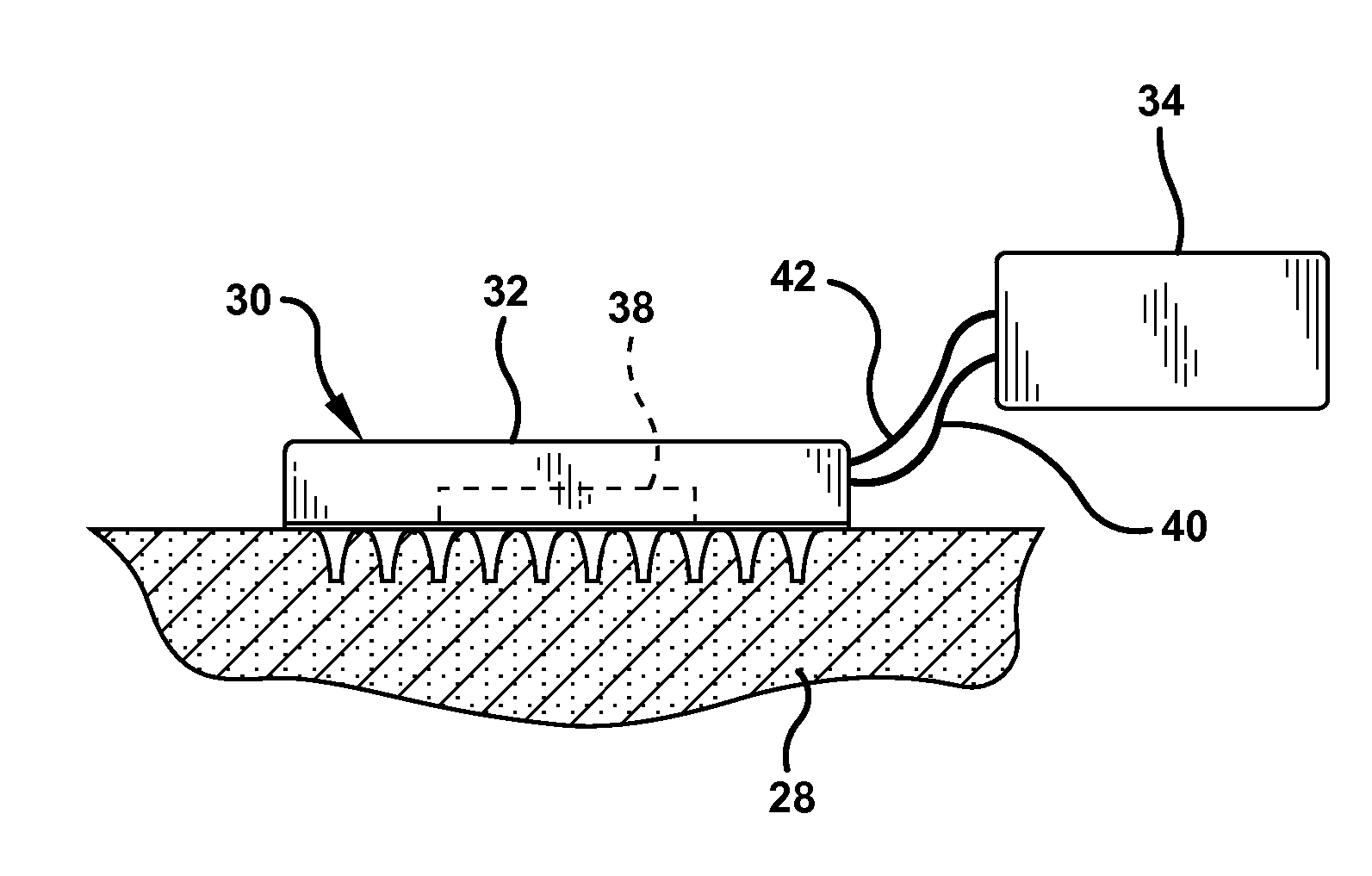

Method and device for abrading skin

InactiveUS20060264893A1Effective penetrationMinimal irritationElectrotherapyMicroneedlesIrritationStratum corneum

A device includes a plurality of microneedles for abrading the stratum corneum of the skin to form a plurality of grooves in the tissue having a controlled depth and width. The microneedles have a length of about 5-250 microns and generally about 5-200 microns. The device is rubbed over the skin to prepare an abraded site after which a transdermal delivery or sampling device is applied to the abraded delivery site. The abrasion increases the permeability of the skin and the rate of delivery and extraction of a substance without pain or irritation to the patient.

Owner:BECTON DICKINSON & CO

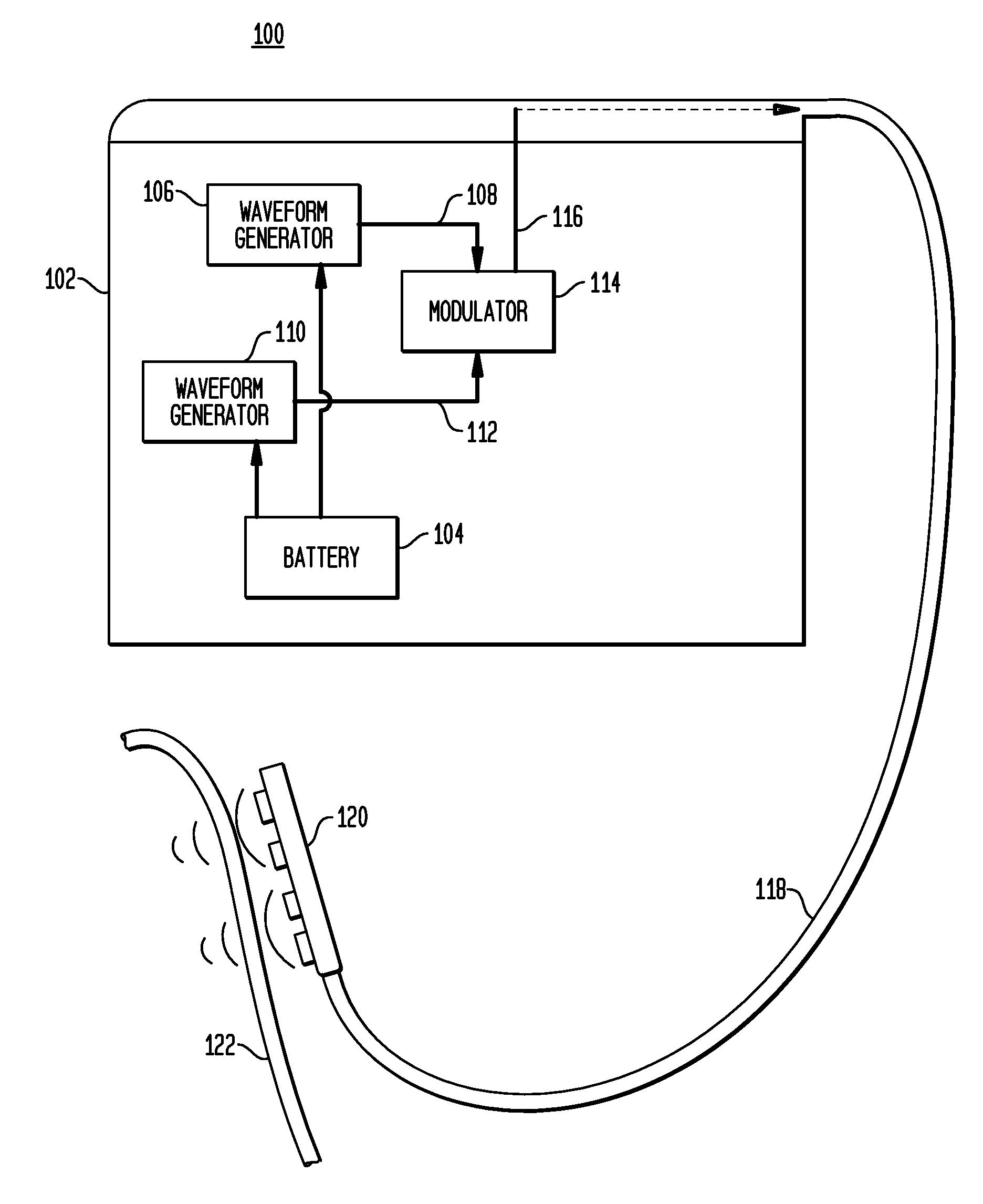

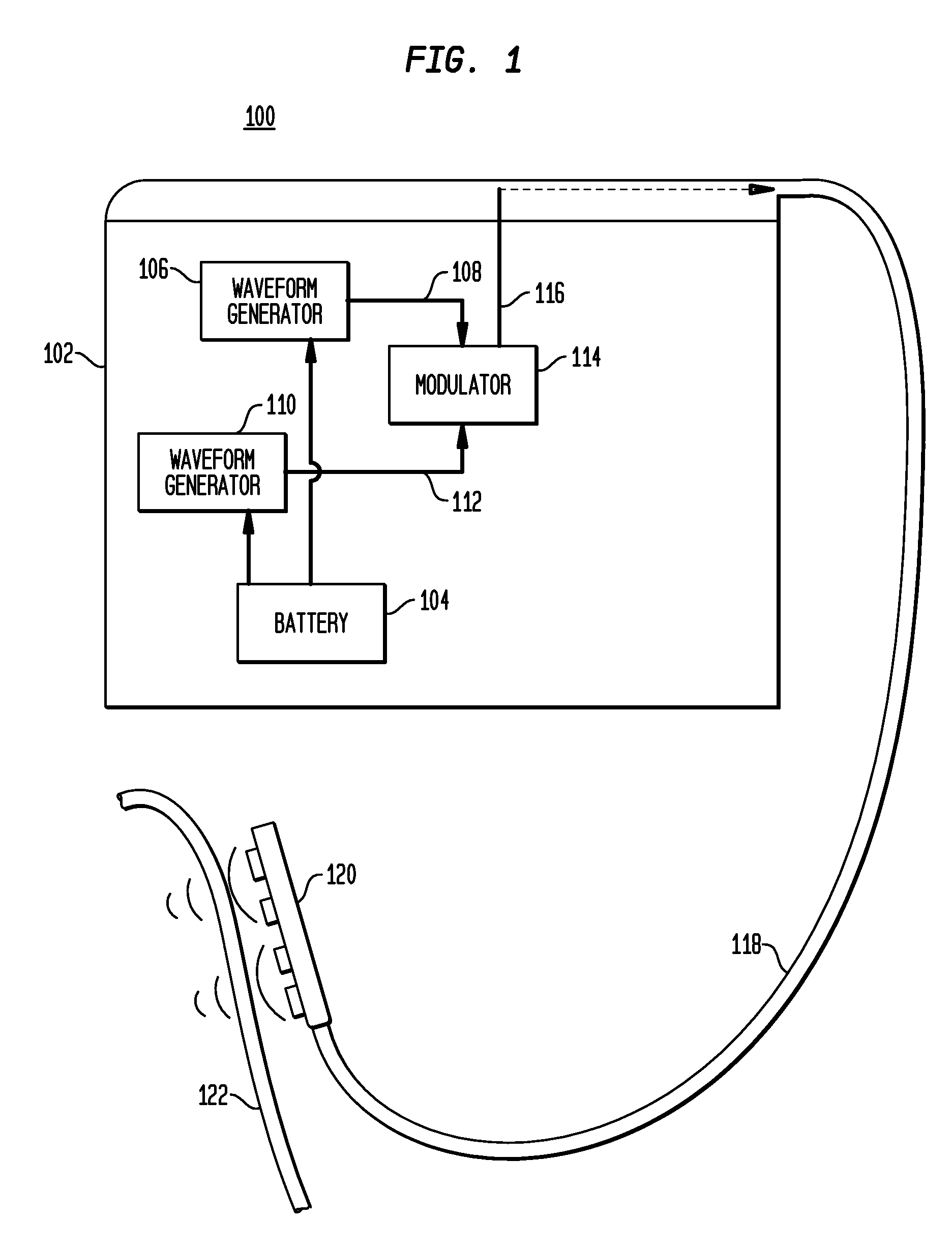

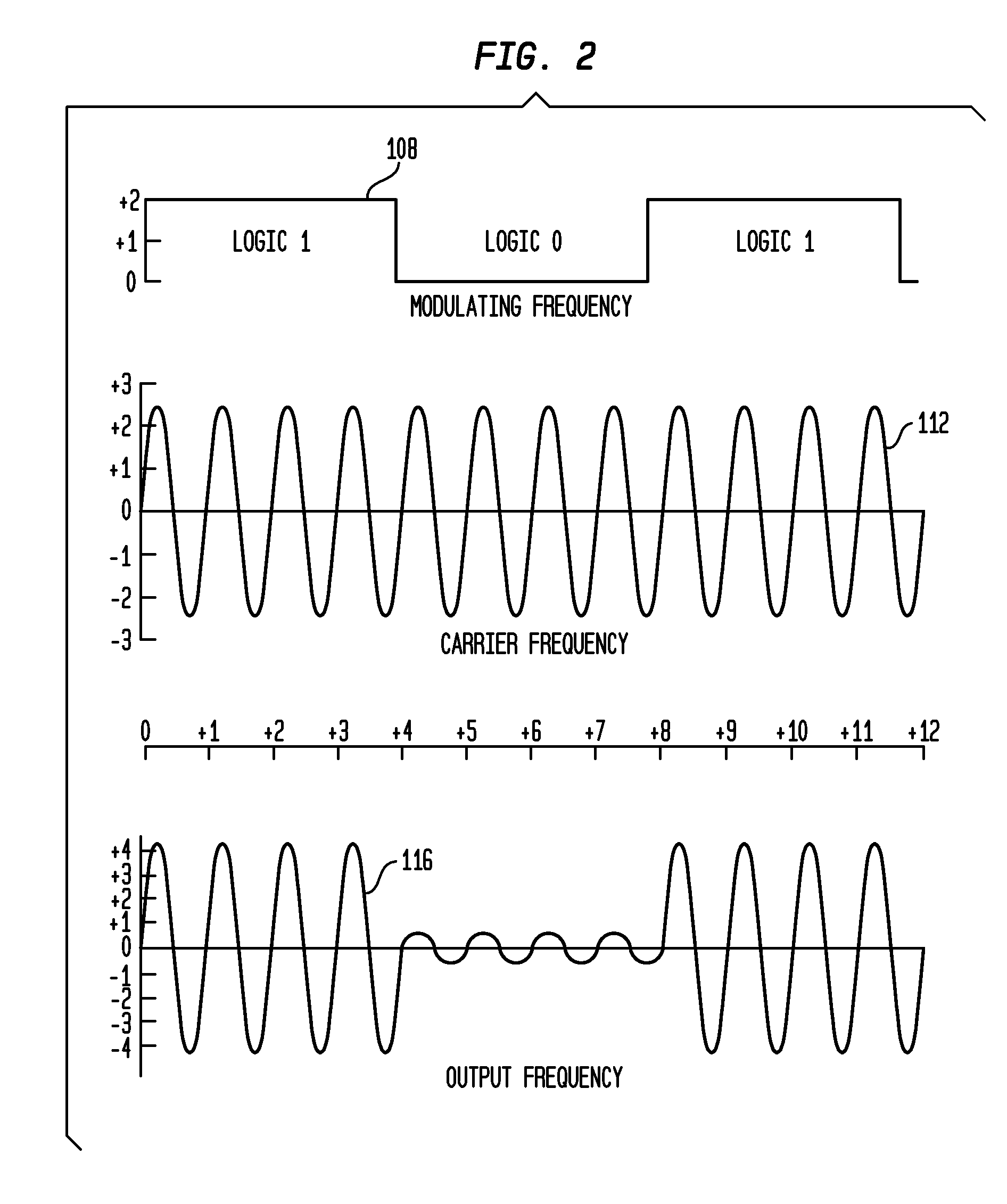

Implantable pulse generators and methods for selective nerve stimulation

ActiveUS20090093858A1Consumes less battery powerLong operationHeart stimulatorsDigestive electrodesPulse envelopeCarrier signal

An Implantable Pulse Generator (IPG) includes a surgically implantable housing, a battery, a first waveform generator, a second waveform generator, a modulator, and electrodes. The IPG produces a pulse envelope, a carrier waveform, and a modulated waveform. The pulse envelope is a low frequency waveform with specific pulse width, amplitude and shape to selectively stimulate a target nerve or body part. The carrier waveform is a high frequency waveform with properties such as amplitude, frequency and the like chosen so as to overcome tissue impedance and the stimulation threshold of the target nerve. The modulated waveform is the waveform obtained by modulating the carrier waveform by the pulse envelope.

Owner:ETHICON INC

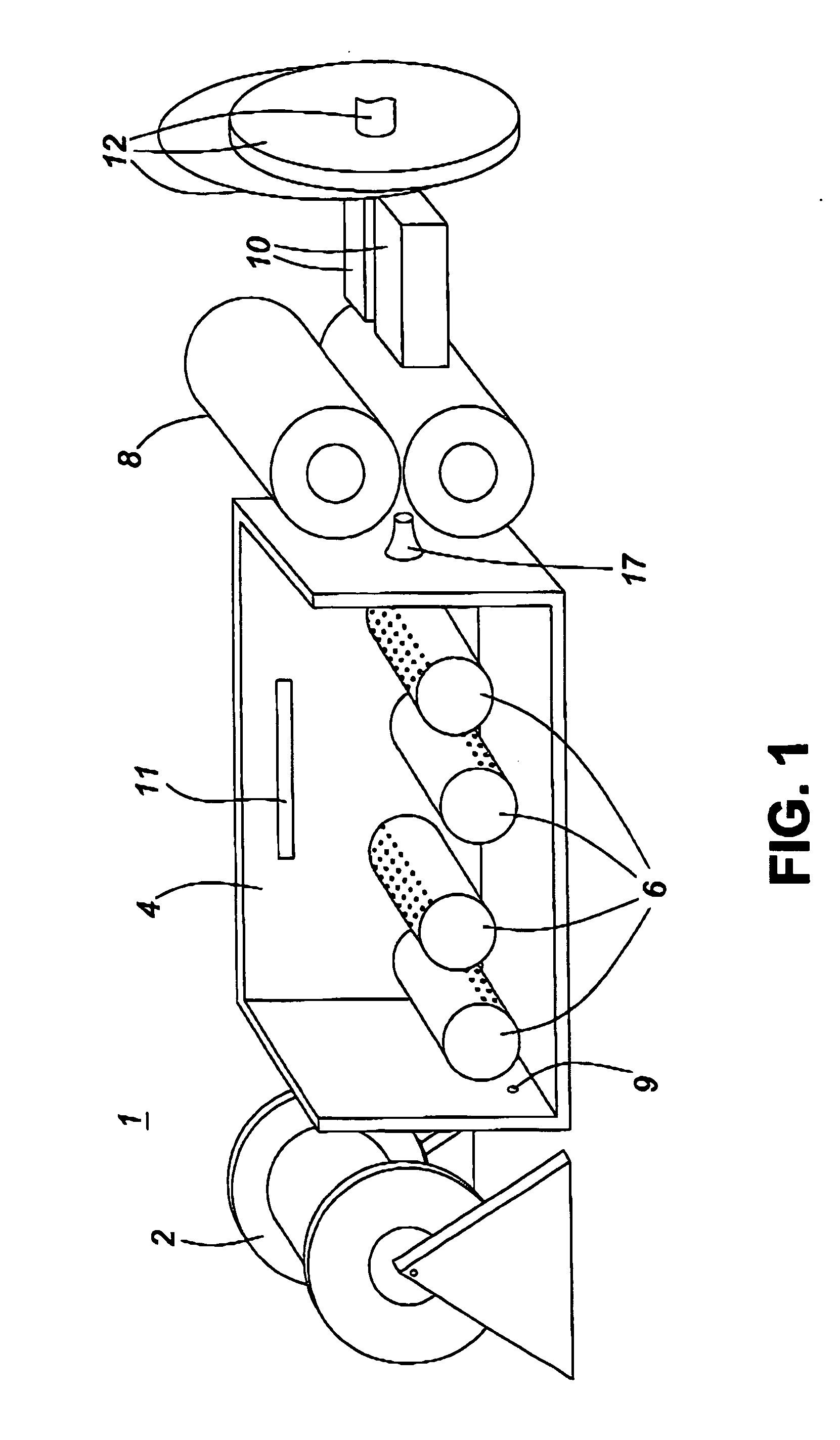

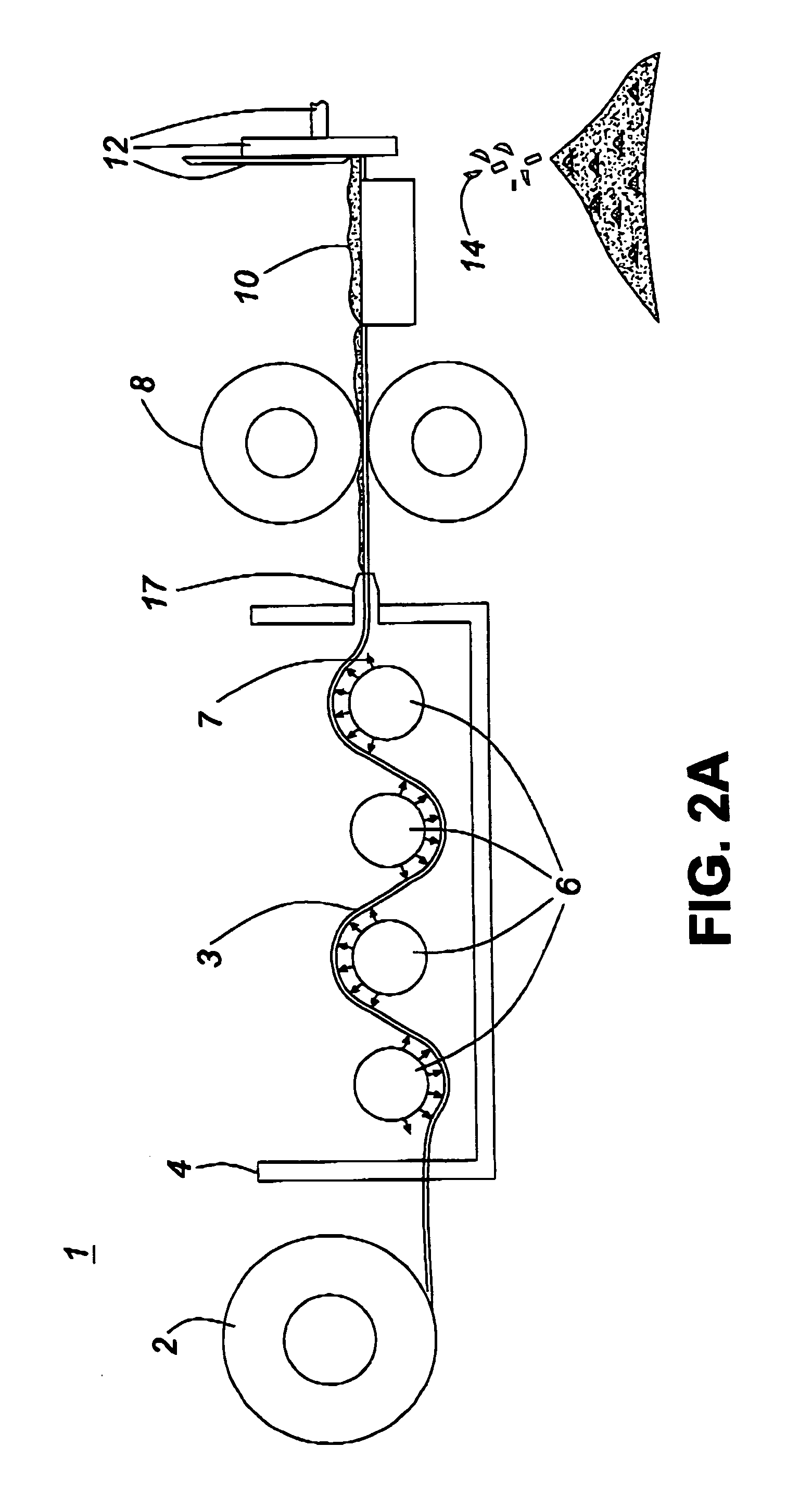

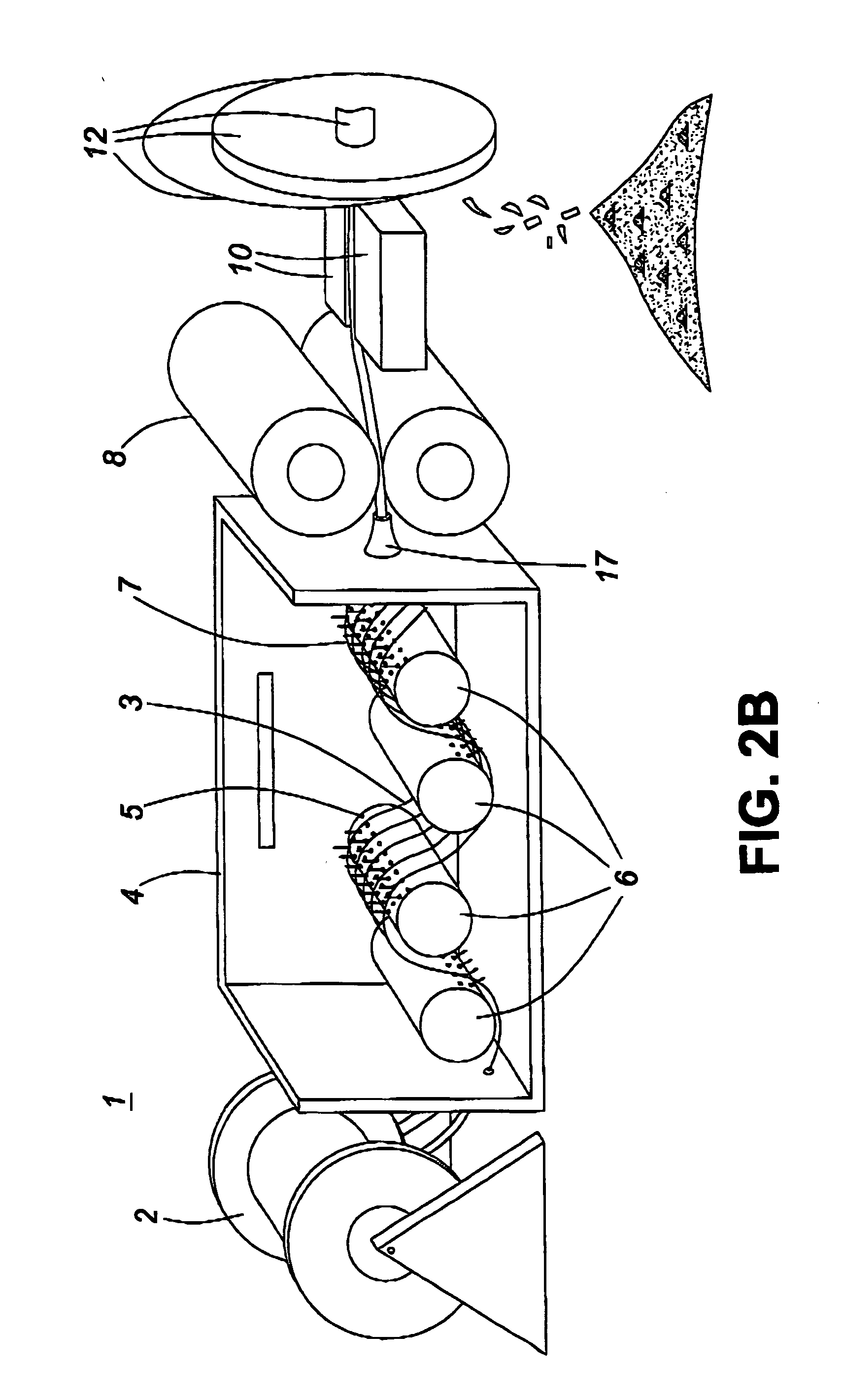

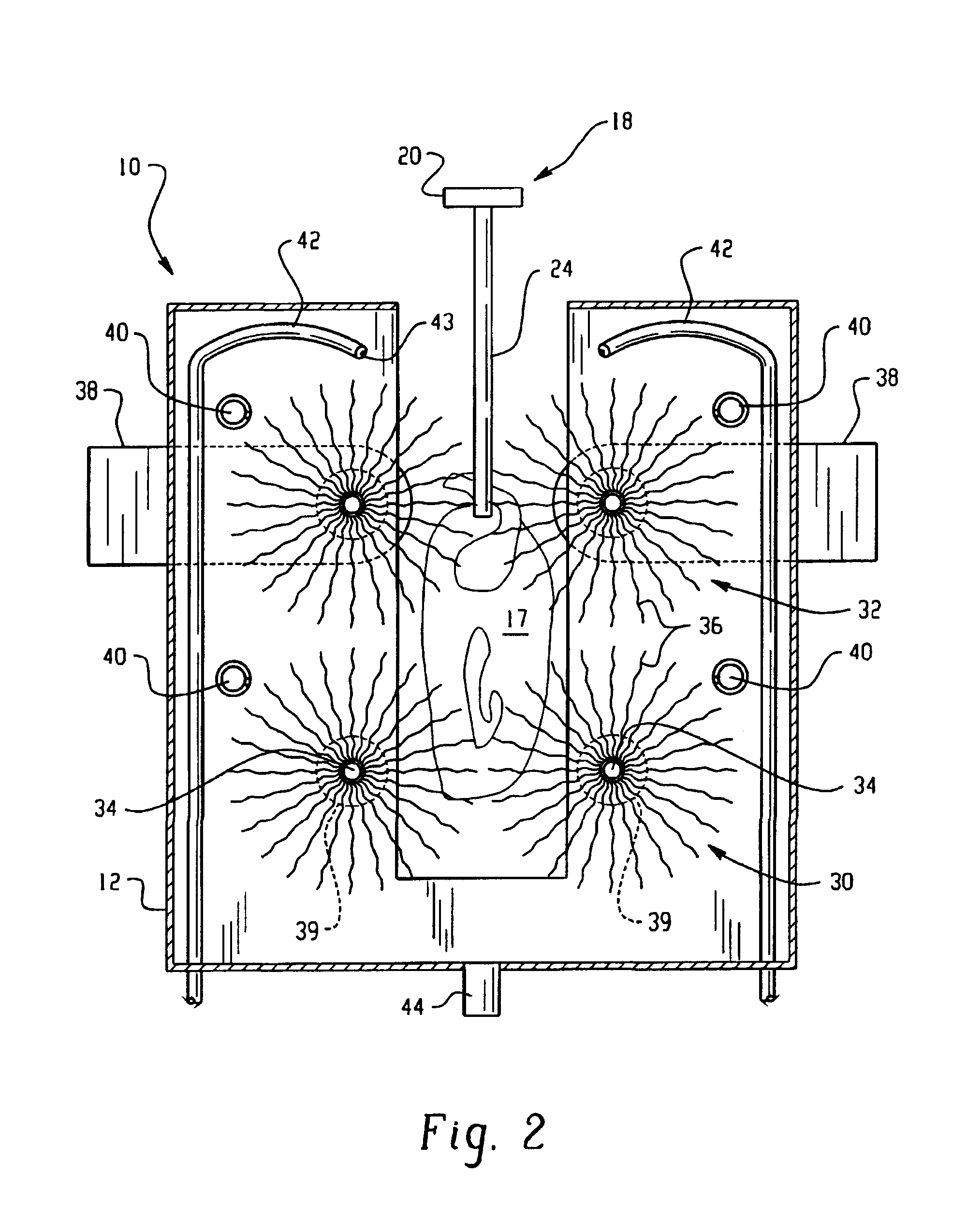

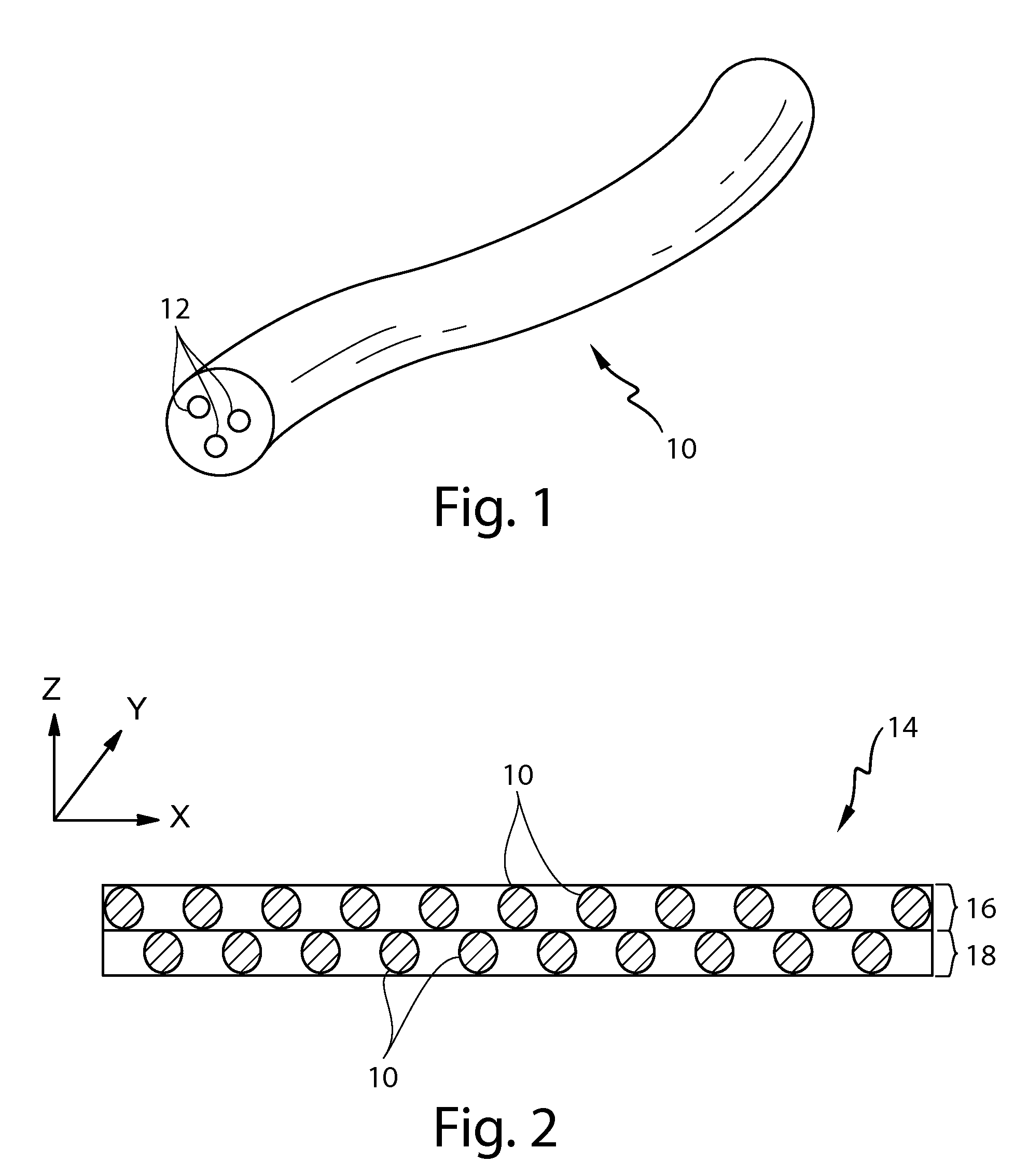

Method and apparatus for fabrication of polymer-coated fibers

InactiveUS20050221085A1Uniform coverageAvoid damageLiquid surface applicatorsFibre chemical featuresThermoplasticPolymer science

The present invention discloses the fabrication of polymer-coated, coated fiber composites, hybrid composites and a method and apparatus for fabricating the same. The invention provides for the maximum spraying and coating of a roving of coated fibers with molten polymer streams without making physical contact with a solid media, thus simultaneously preventing the fiber surface from getting damaged and stripping off the coating. When metal-coated fiber is used the invention improves the electromagnetic shielding properties of any subsequent product made from the inventive composite. The method and apparatus of the present invention uses sets of nozzle-type sprayers having multiple orifices to enable the thermoplastic or thermoset polymer to penetrate more efficiently into the fiber bundle, thereby providing a more uniform coverage of all fibers. The hybrid composites can consist of two or more types of reinforcements and one or more type of matrix polymer.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

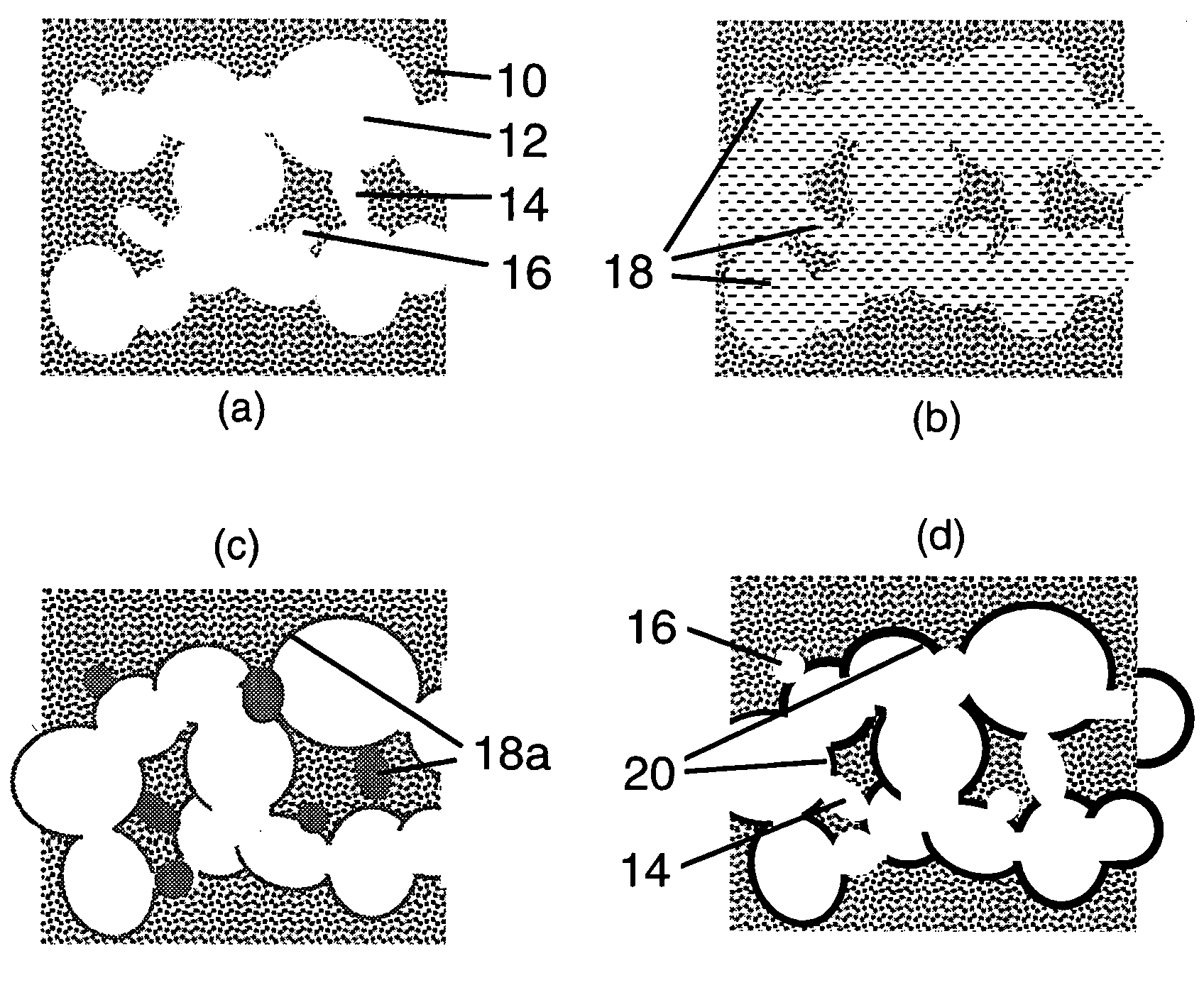

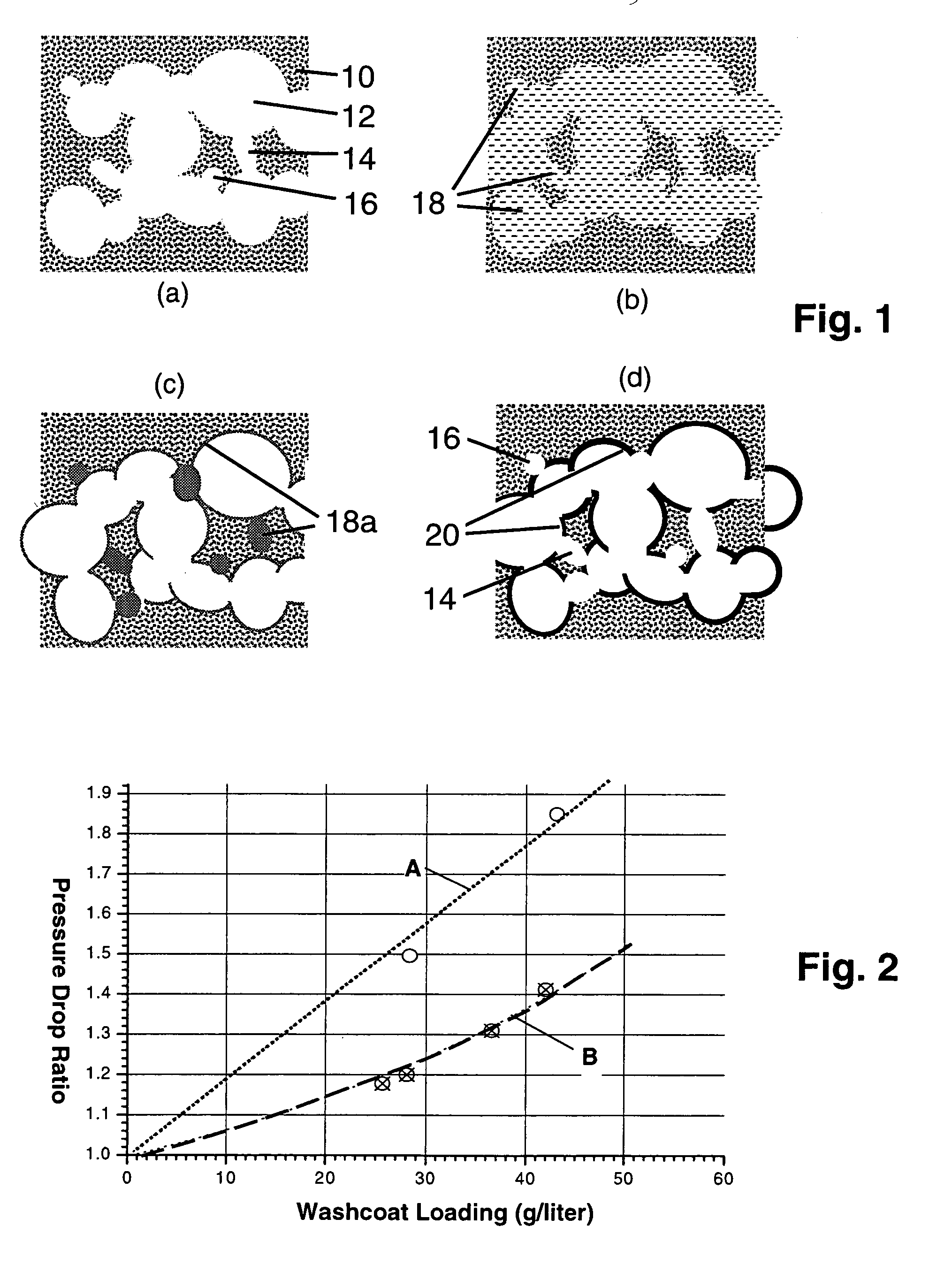

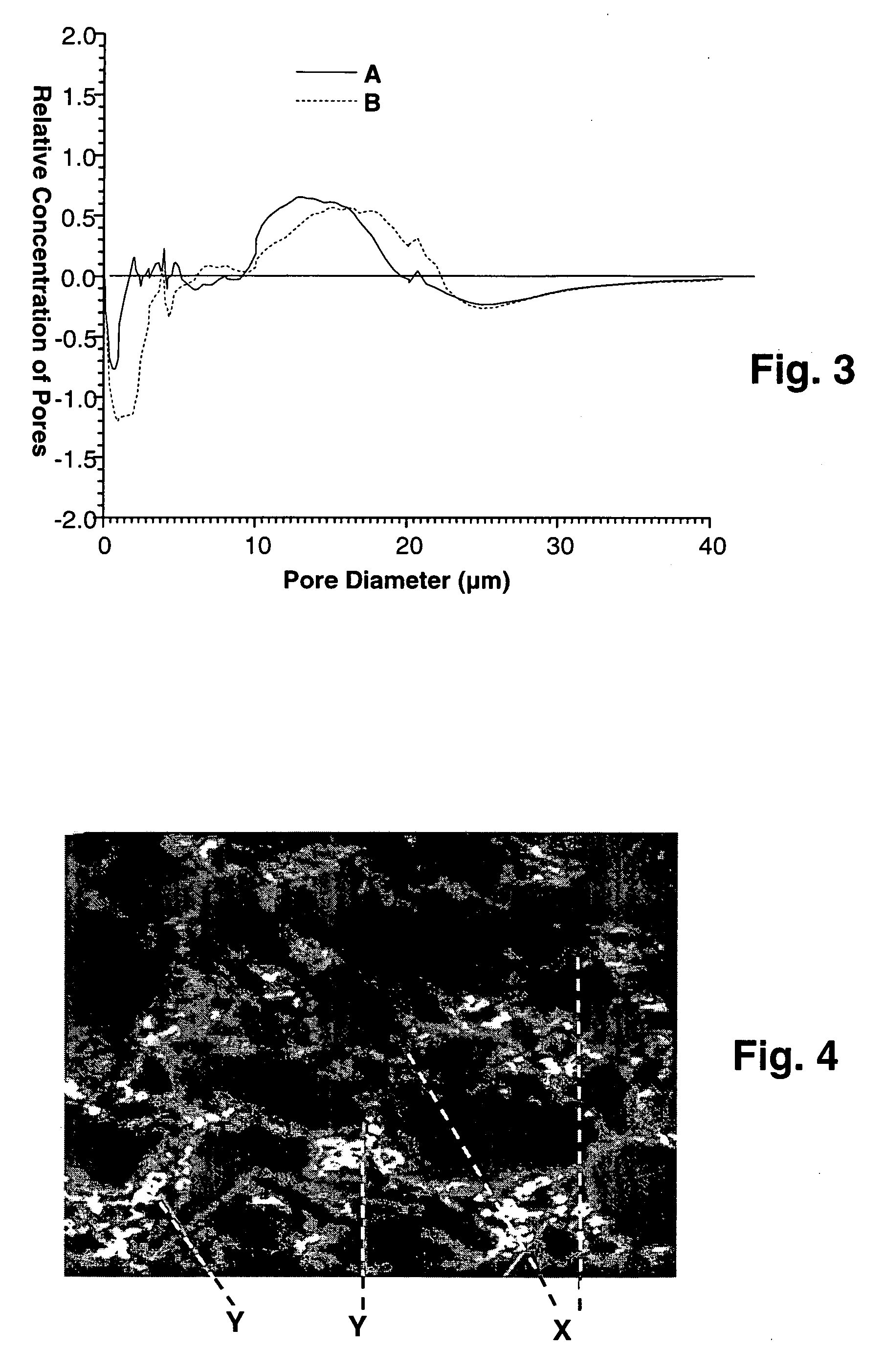

Porous ceramic filters with catalyst coatings

ActiveUS20050191480A1Effective penetrationExtensive cross-linking of the polymerLayered productsCatalyst activation/preparationCross-linkBiological activation

Porous ceramic catalyst supports or filters to be provided with catalyst coatings via oxide washcoating processes are pre-coated with cross-linked polymer barrier layers to prevent washcoat nanoparticle intrusion into the microcracked and / or microporous surfaces of the ceramics, the barrier coatings being formed by thermally cross-linking hydrocarbon polymers that are vaporizable at moderate washcoat stabilization or catalyst activation temperatures and being preferentially

Owner:CORNING INC

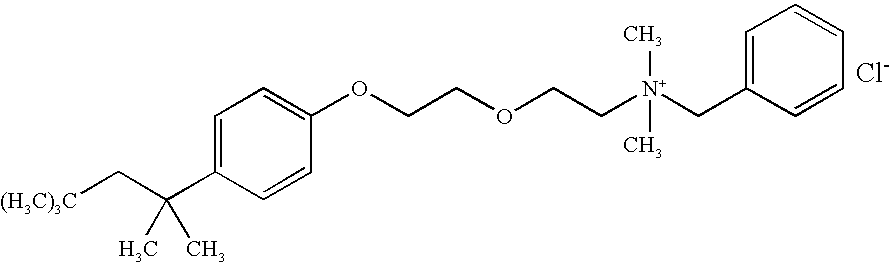

Protective agents for wood

InactiveUS6464764B1Effective penetrationLong-term stabilityBiocideNitro compound active ingredientsWater basedAmmonium compounds

Solvent-free coating materials and treating agents used as water-based wood or material protective agents containing emulsifiable binding agents, quaternary ammonium compounds and optional additional active agents. The wood or material protective agents are non-flammable and enable a uniform distribution of the binding agent and the quaternary ammonium compounds in the substrates. As a result, the quaternary ammonium compounds function as a dissolving mediator for the binding agents which are dispersed in water without opacifying effects and are used as a biocide. The agents can additionally absorb water-insoluble organic biocides without impairing the homogeneity or stability of the formulation of the homogeneity of the distribution in the substrate.

Owner:LONZA AG

Nucleoside cyclic phosphoramidates for the treatment of RNA-dependent RNA viral infection

ActiveUS20100022468A1Efficient cell penetrationWider therapeutic indexBiocideSugar derivativesRNA-dependent RNA polymerasePolymerase L

The present invention provides nucleoside cyclic phosphoramidates of structural formula (I) which are precursors to inhibitors of RNA-dependent RNA viral polymerase. These compounds are precursors to inhibitors of RNA-dependent RNA viral replication and are useful for the treatment of RNA-dependent RNA viral infection. They are particularly useful as pre-cursors to inhibitors of hepatitis C virus (HCV) NS5B polymerase, as precursors to inhibitors of HCV replication, and / or for the treatment of hepatitis C infection. The invention also describes pharmaceutical compositions containing such nucleoside cyclic phosphoramidates alone or in combination with other agents active against RNA-dependent RNA viral infection, in particular HCV infection. Also disclosed are methods of inhibiting RNA-dependent RNA polymerase, inhibiting RNA-dependent RNA viral replication, and / or treating RNA-dependent RNA viral infection with the nucleoside cyclic phosphoramidates of the present invention.

Owner:MSD ITAL +1

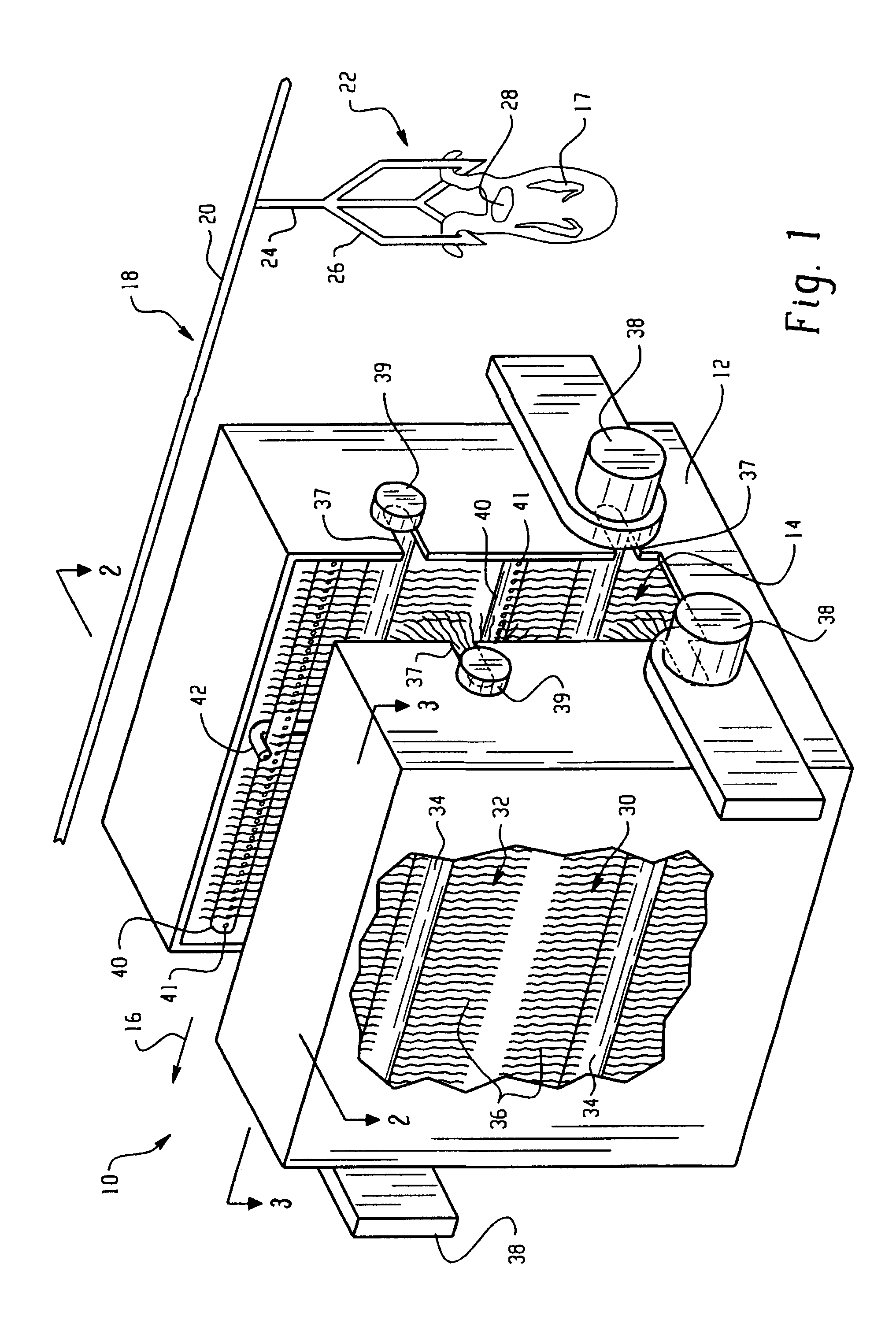

Post-evisceration process and apparatus

InactiveUS6733379B2Preventing line holdupsMinimize cross-contaminationFish washing/descalingPoultry cleaning/disinfectionDead bodyAbdominal evisceration

A process and apparatus for removing or reducing the levels of pathogenic bacteria present on an eviscerated carcass. The process includes introducing the eviscerated carcass to a cleaning apparatus. The cleaning apparatus generally includes a housing structure having an entrance and an exit. Disposed within the housing structure is a rotating brush assembly and a spray assembly. The brushing assembly provides brushing and massaging actions to the surfaces of the carcass whereas the spraying assembly simultaneously directs a cleaning solution onto the surfaces of the carcass.

Owner:RHONDIA INC

Soluble Fibrous Structures and Methods for Making Same

InactiveUS20160101204A1Improve solubilityRapid propagation rateInorganic/elemental detergent compounding agentsCosmetic preparationsActive agentFiber structure

Soluble fibrous structures and more particularly soluble fibrous structures that contain one or more fibrous elements, such as filaments, having one or more fibrous element-forming materials and one or more active agents present within the fibrous elements, wherein the fibrous structure exhibits improved dissolution properties compared to known soluble fibrous structures, and method for making such improved fibrous structures are provided.

Owner:THE PROCTER & GAMBLE COMPANY

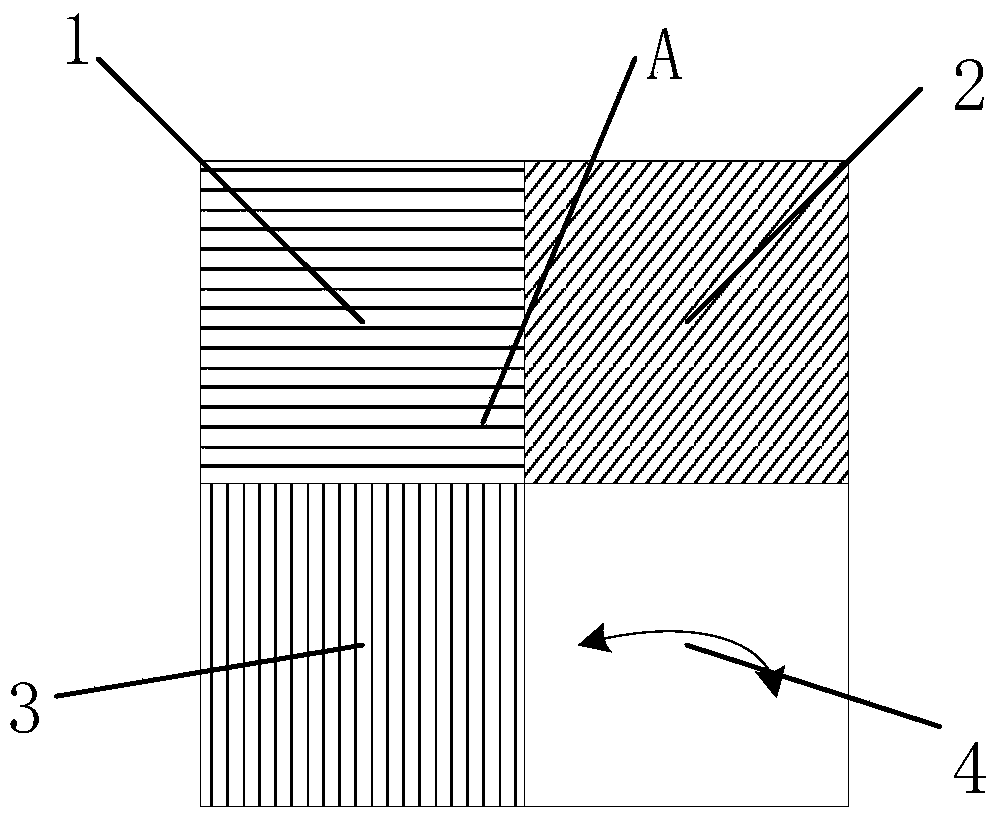

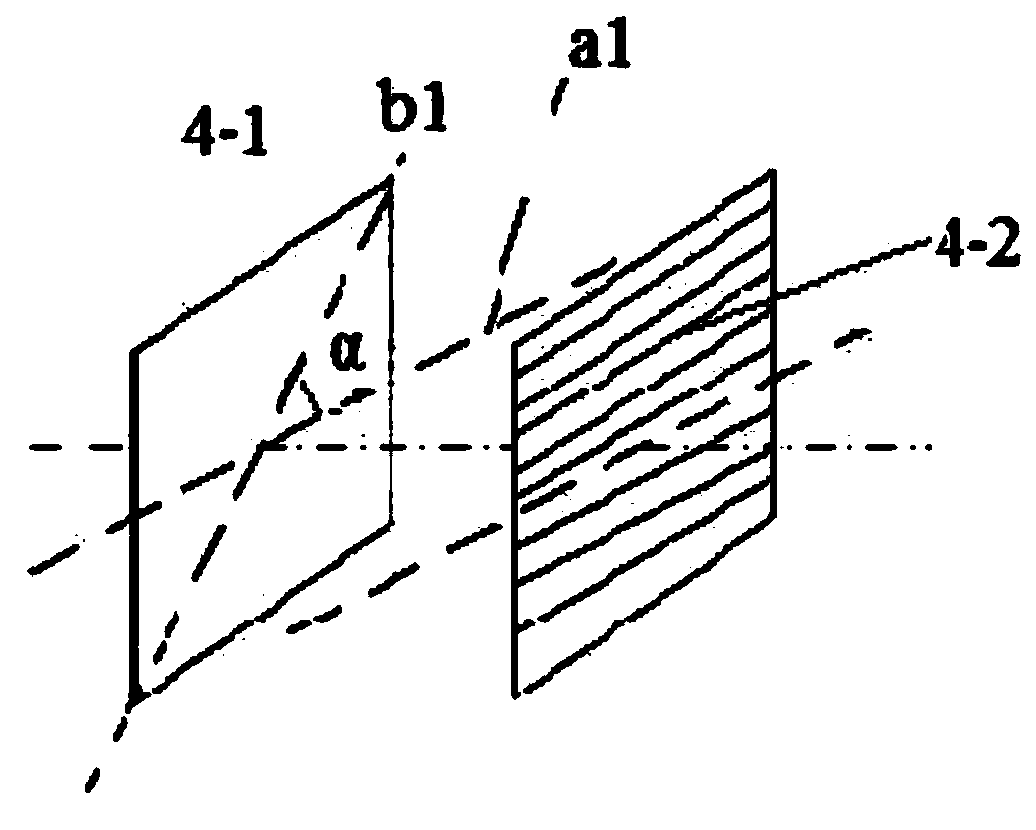

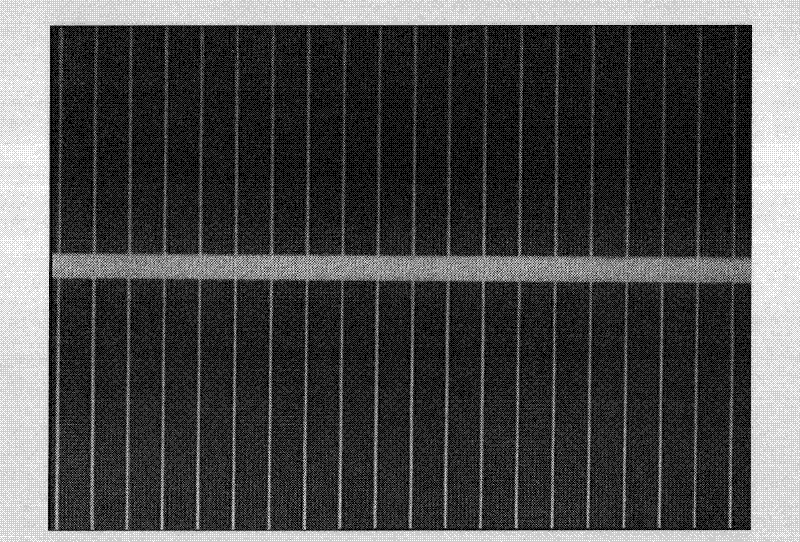

Micro-polarizing film array used for acquiring full-polarization parameters and production method and application thereof

InactiveCN104216135AGood polarized light transmission performanceExcellent line deviationPolarising elementsTransmittancePolarizer

The invention discloses a micro-polarizing film array used for acquiring full-polarization parameters and a production method and application thereof. The micro-polarizing film comprises a plurality of micro-polarizing film units with size of 2*2. Each micro-polarizing film unit comprises a micro-polarizing film of 0 degree, a micro-polarizing film of 45 degrees, a circular micro-polarizing film and a micro-polarizing film of 90 degrees which are closely integrated on the same plane and further sequentially disposed from the top left corner in a clockwise manner. The micro-polarizing film array is easy to produce and high in polarizing light transmittance performance and integration level.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

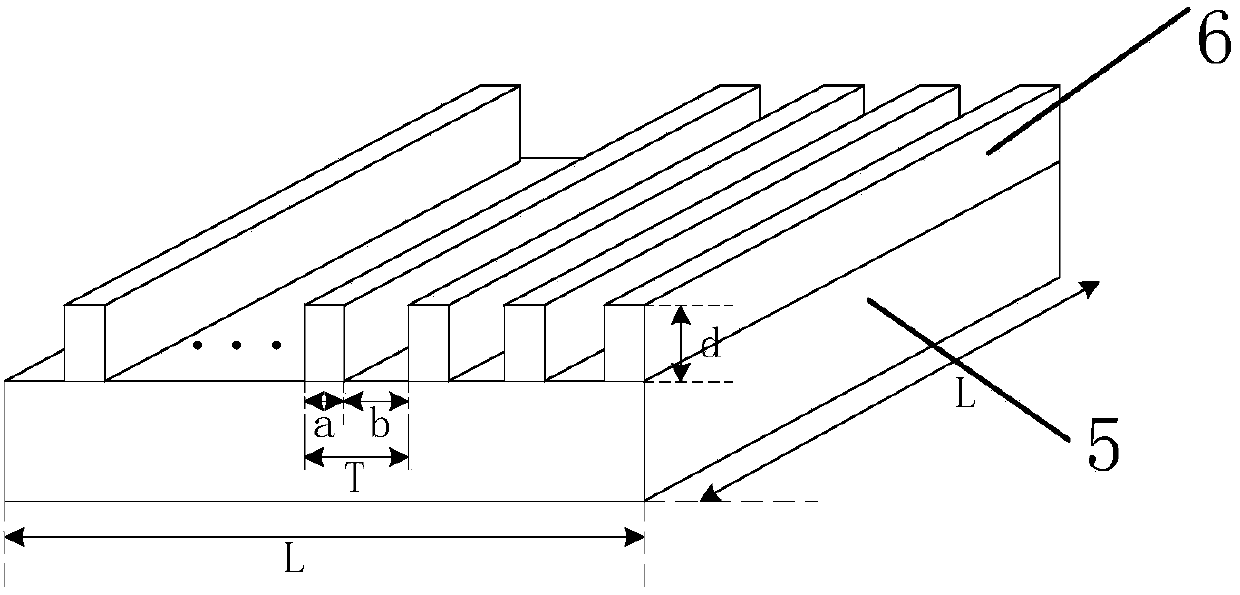

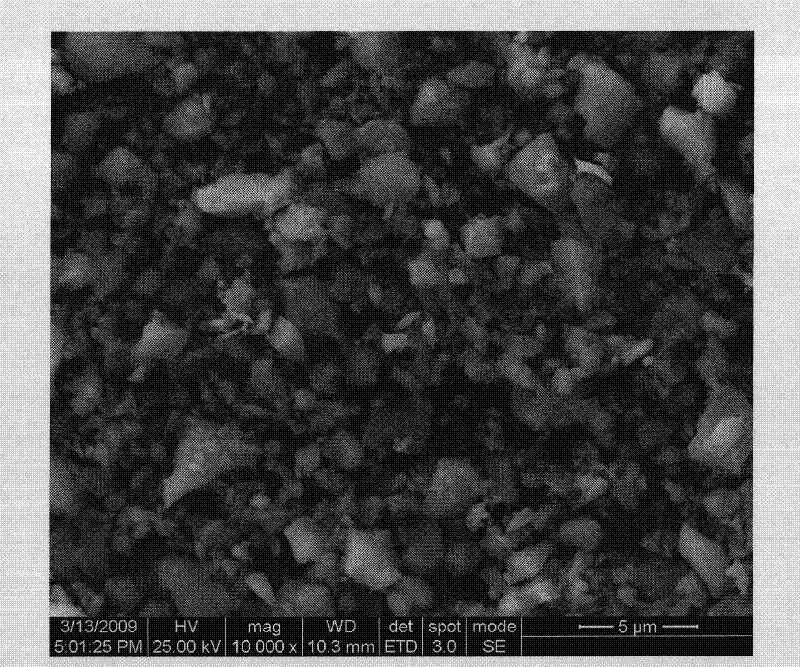

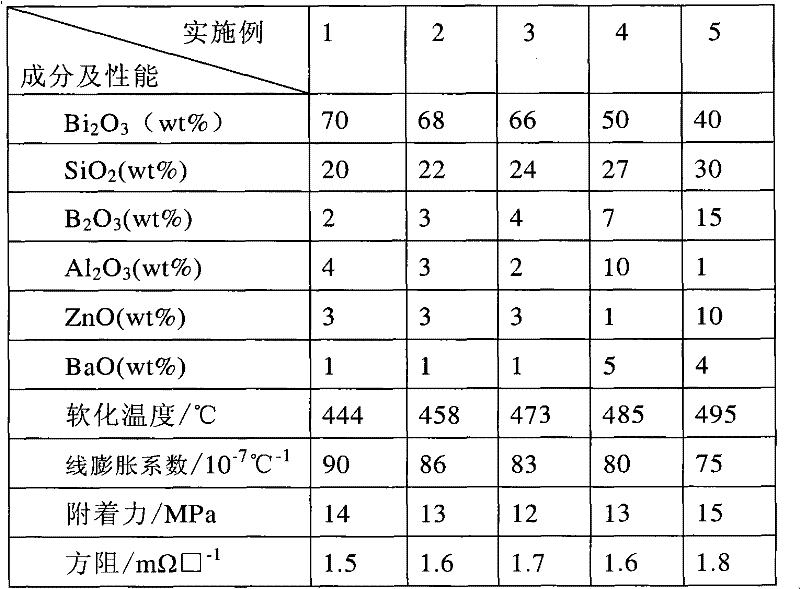

Lead-free glass powder, preparation method thereof, silver paste containing glass powder and crystal silicon solar cell manufactured by using silver paste

InactiveCN102126829AImprove adhesionStrong adhesionNon-conductive material with dispersed conductive materialSemiconductor devicesSilver pasteScreen printing

The invention discloses lead-free glass powder, a preparation method thereof, silver paste containing the glass powder and a crystal silicon solar cell manufactured by using the silver paste. The lead-free glass powder comprises the following components in percentage by weight: 20-30 percent of SiO2, 2-15 percent of B2O3, 40-70 percent of Bi2O3, 1-10 percent of ZnO, 1-10 percent of Al2O3 and 1-5 percent of BaO. The preparation method comprises the following steps of: (1) weighing the components for preparing a mixture; (2) putting the mixture into a crucible for melting; (3) performing water quenching on molten glass; (4) drying; (5) smashing the mixture into powder by planetary ball milling; and (6) screening. The needed silver paste is prepared from the lead-free glass powder, silver powder, an additive and an organic carrier. A solar panel front face electrode and a grid line are manufactured by performing screen printing and sintering on conductive silver paste on a cell substrate, so that the needed solar cell is obtained. The lead-free glass powder has low melting temperature, low softening temperature and low linear expansion factor.

Owner:湖南威能新材料科技有限公司

Chinese medicinal herbs for treating spur and its preparation

InactiveCN1939491AEffective cureEffective penetrationHeavy metal active ingredientsSkeletal disorderMedicinal herbsMedicinal herb

A Chinese medicine for treating osteophyte, rheumatic or rheumatoid arthritis, osteoarthritis, ischias, lumbar intervertebral disc protrusion, periomethritis, etc includes the enterior-applied pills prepared from 46 Chinese-medicinal materials and the exterior-applied ointment prepared from 54 Chinese-medicinal materials.

Owner:夏书桂

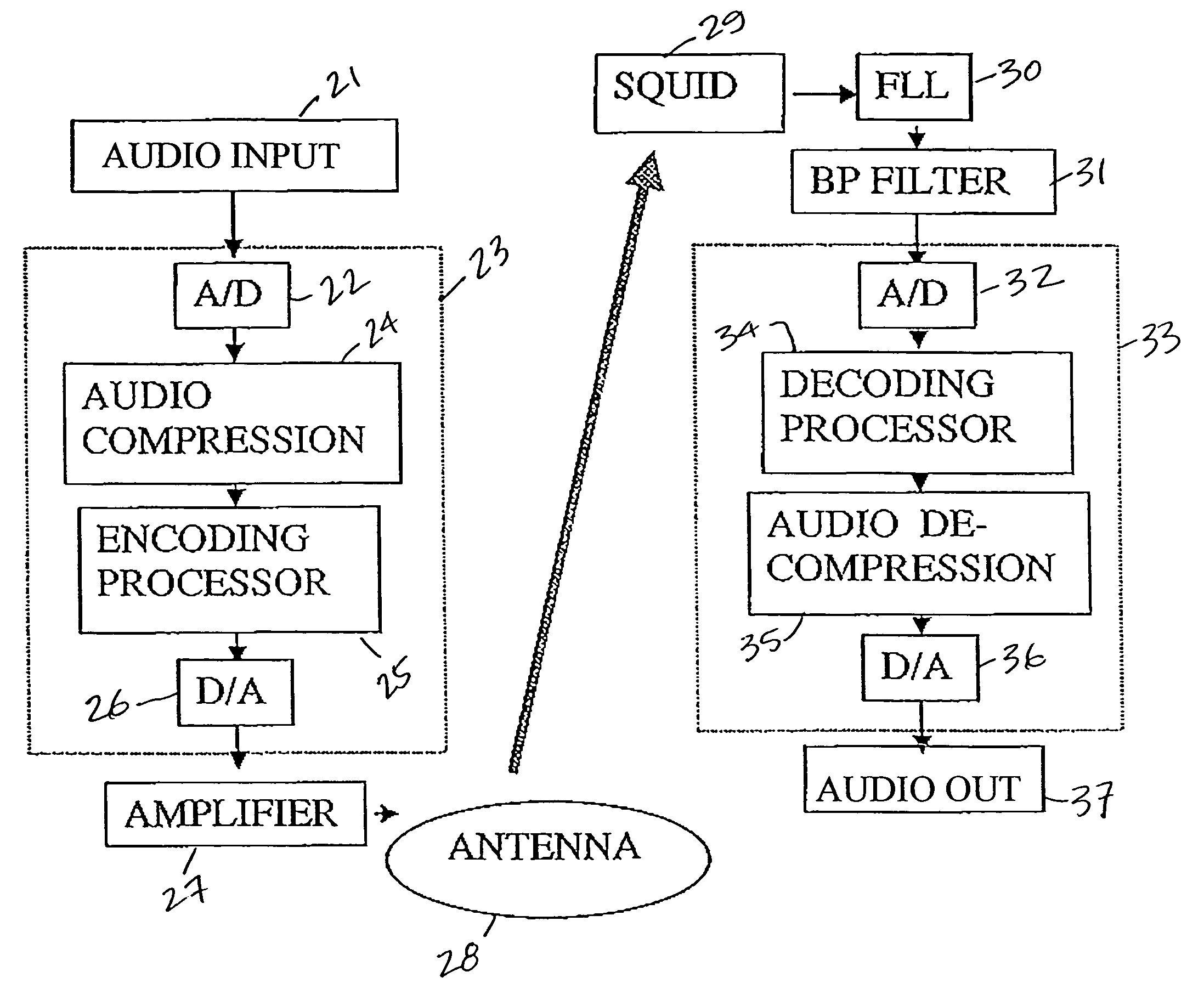

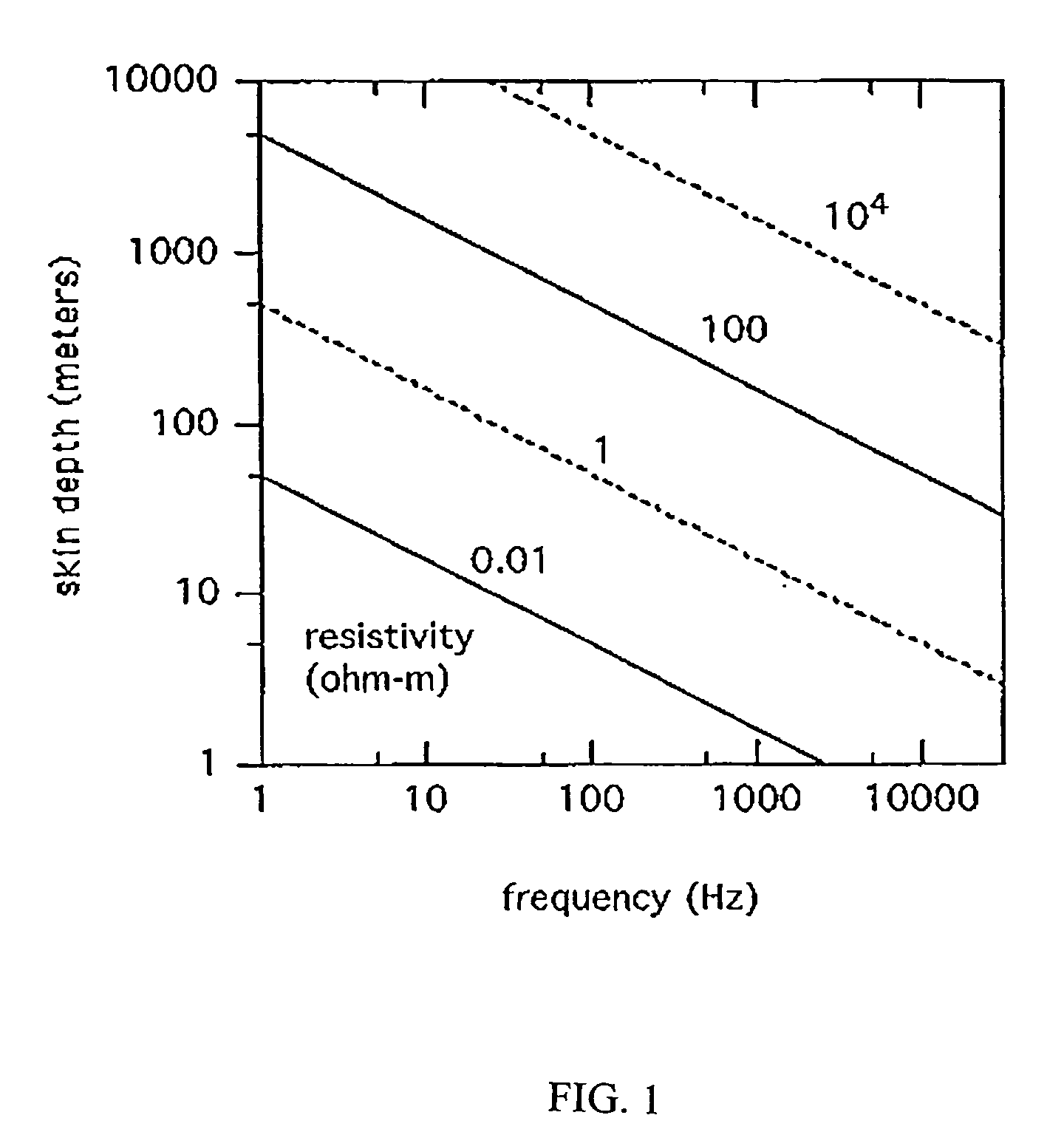

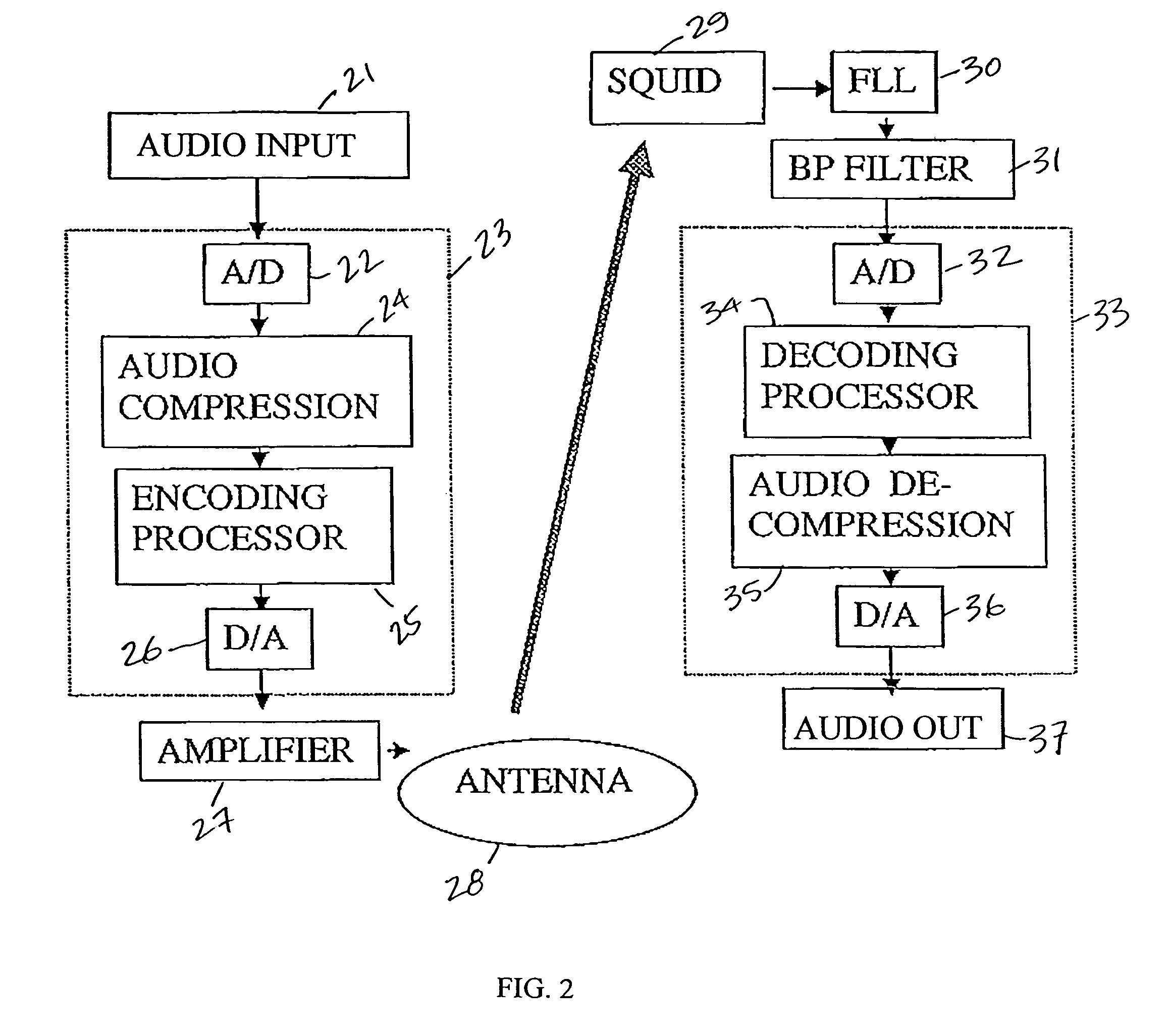

Through-the-earth radio

InactiveUS7043204B2Effective penetrationEffective distanceModulated-carrier systemsSubstation equipmentDigital-to-analog converterAnalog to information converter

A method and apparatus for effective through-the-earth communication involves a signal input device connected to a transmitter operating at a predetermined frequency sufficiently low to effectively penetrate useful distances through-the earth, and having an analog to digital converter receiving the signal input and passing the signal input to a data compression circuit that is connected to an encoding processor, the encoding processor output being provided to a digital to analog converter. An amplifier receives the analog output from the digital to analog converter for amplifying said analog output and outputting said analog output to an antenna. A receiver having an antenna receives the analog output passes the analog signal to a band pass filter whose output is connected to an analog to digital converter that provides a digital signal to a decoding processor whose output is connected to an data decompressor, the data decompressor providing a decompressed digital signal to a digital to analog converter. An audio output device receives the analog output form the digital to analog converter for producing audible output.

Owner:LOS ALAMOS NATIONAL SECURITY

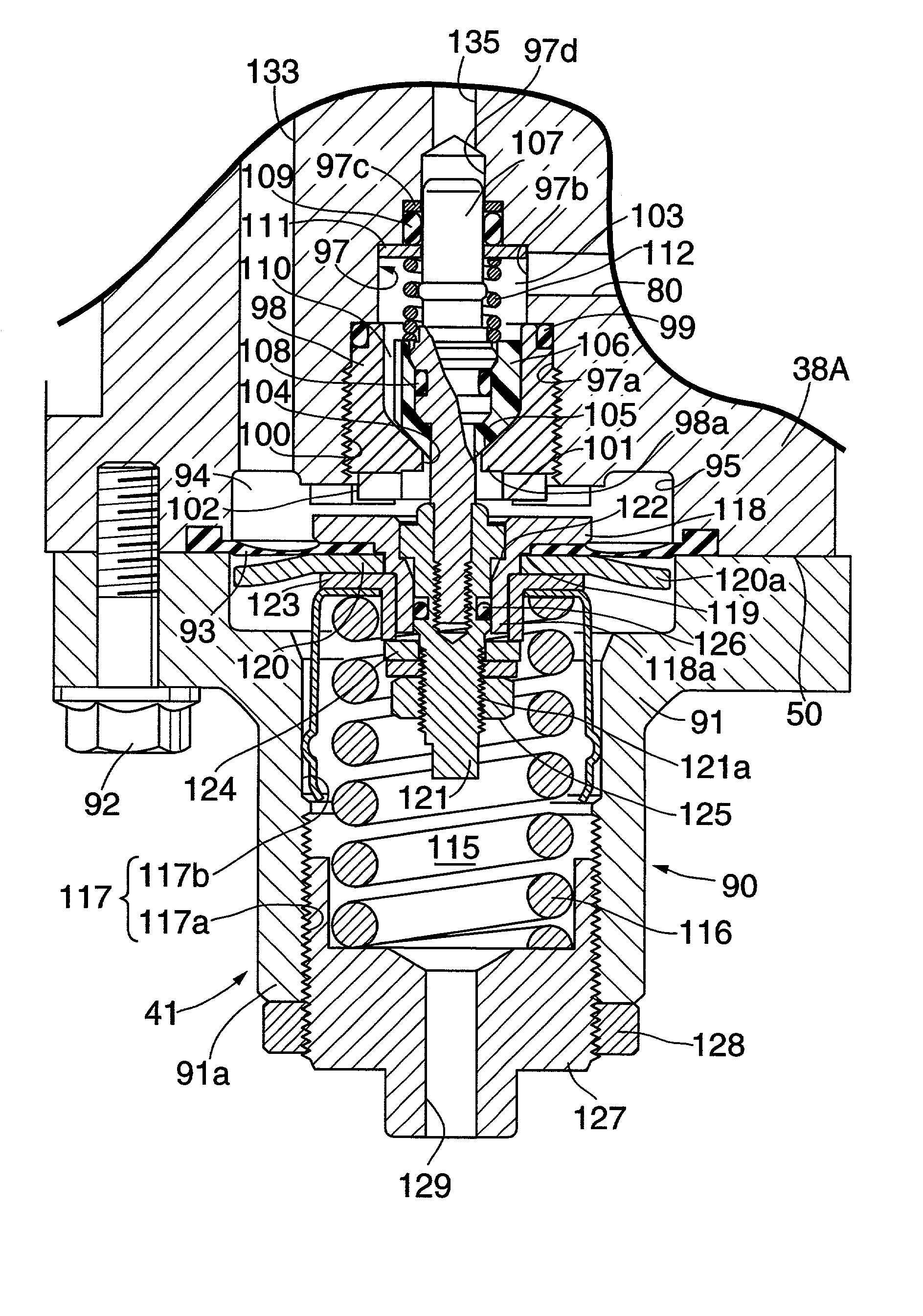

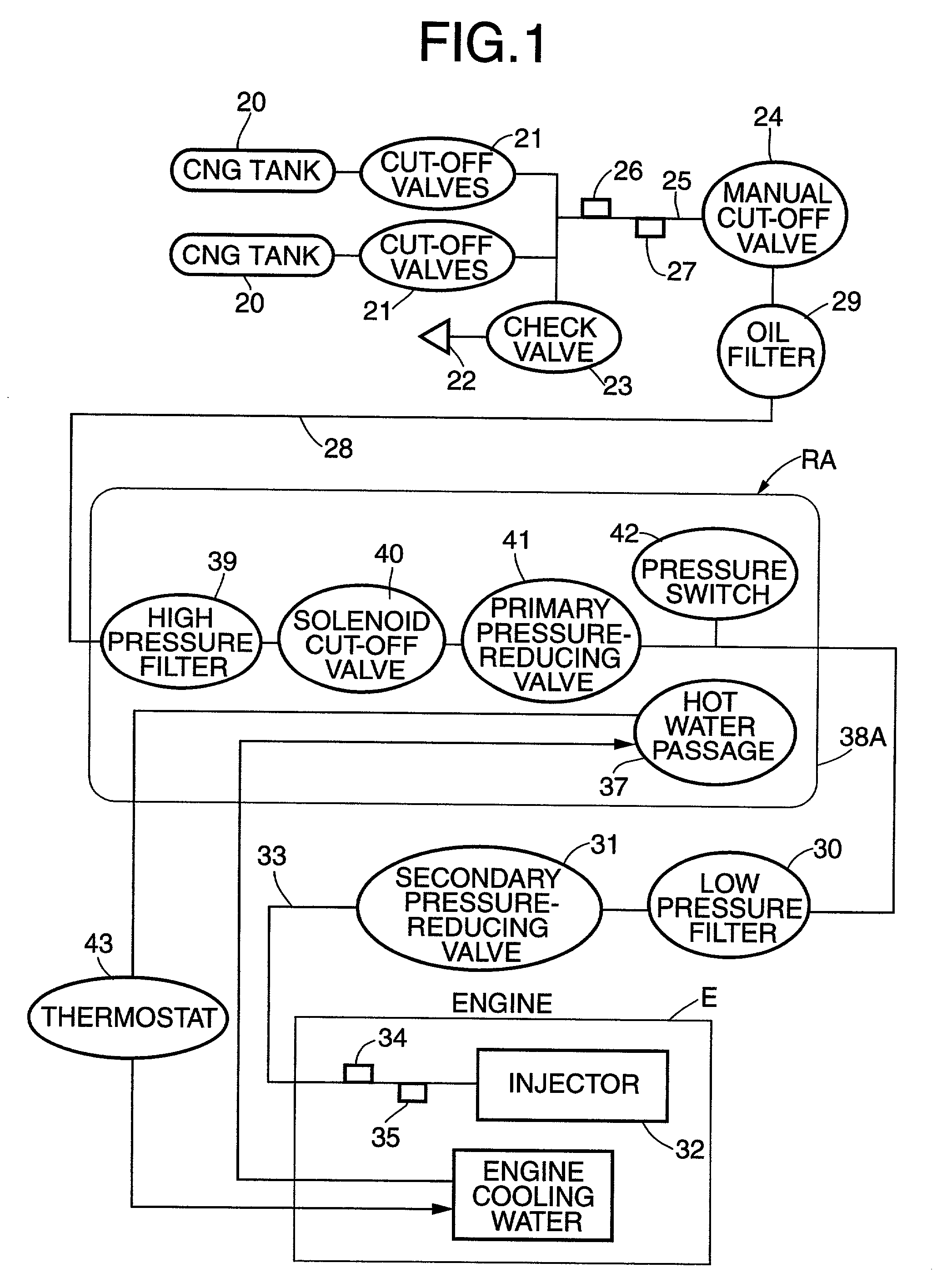

Gas pressure-reducing valve

InactiveUS20020083980A1Simple structureHigh precisionOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringPressure - action

A gas pressure-reducing valve includes a pressure-reducing chamber for generating a gas pressure that acts on one surface of a diaphragm, a valve body that can sit on a valve seat having in its central part a valve hole communicating with the pressure-reducing chamber, and a spring biasing the diaphragm in a direction that detaches the valve body from the valve seat. A valve housing is formed by conjoining a body, a partition, and a cover. The partition forms the pressure-reducing chamber between itself and the body and forms a pressure action chamber between itself and the diaphragm. The cover forms the spring chamber between itself and the other surface of the diaphragm and has the peripheral edge of the diaphragm clamped between itself and the partition. The partition has a through hole for allowing the valve stem to run through in an airtight and axially slidable manner and a communicating hole for providing communication between the pressure action chamber and the pressure-reducing chamber. The structure of the body can thus be simplified thereby enhancing the machining precision, and the diameter of the pressure-reducing chamber can be determined regardless of the diameter of the diaphragm.

Owner:KEIHIN CORP

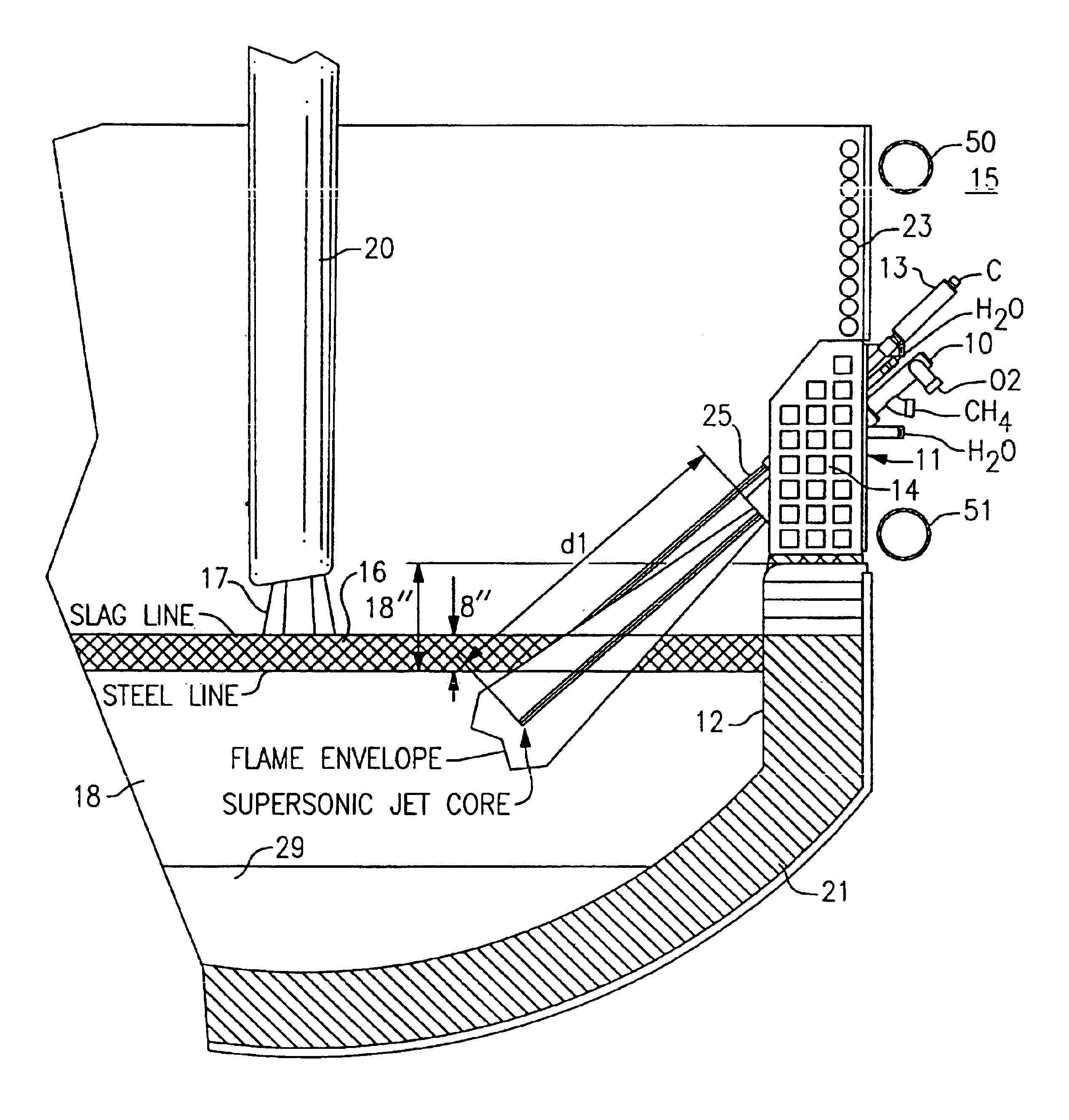

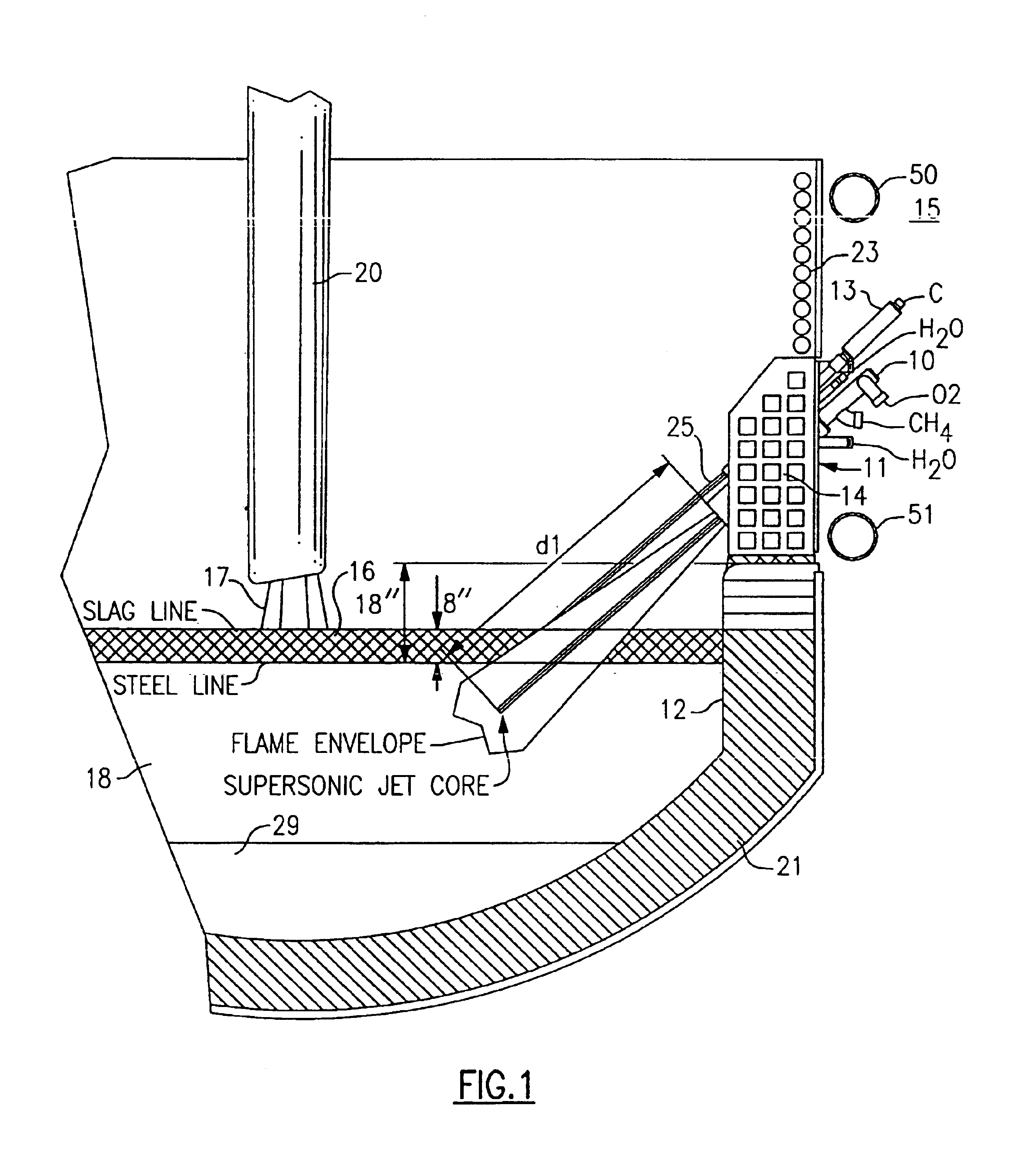

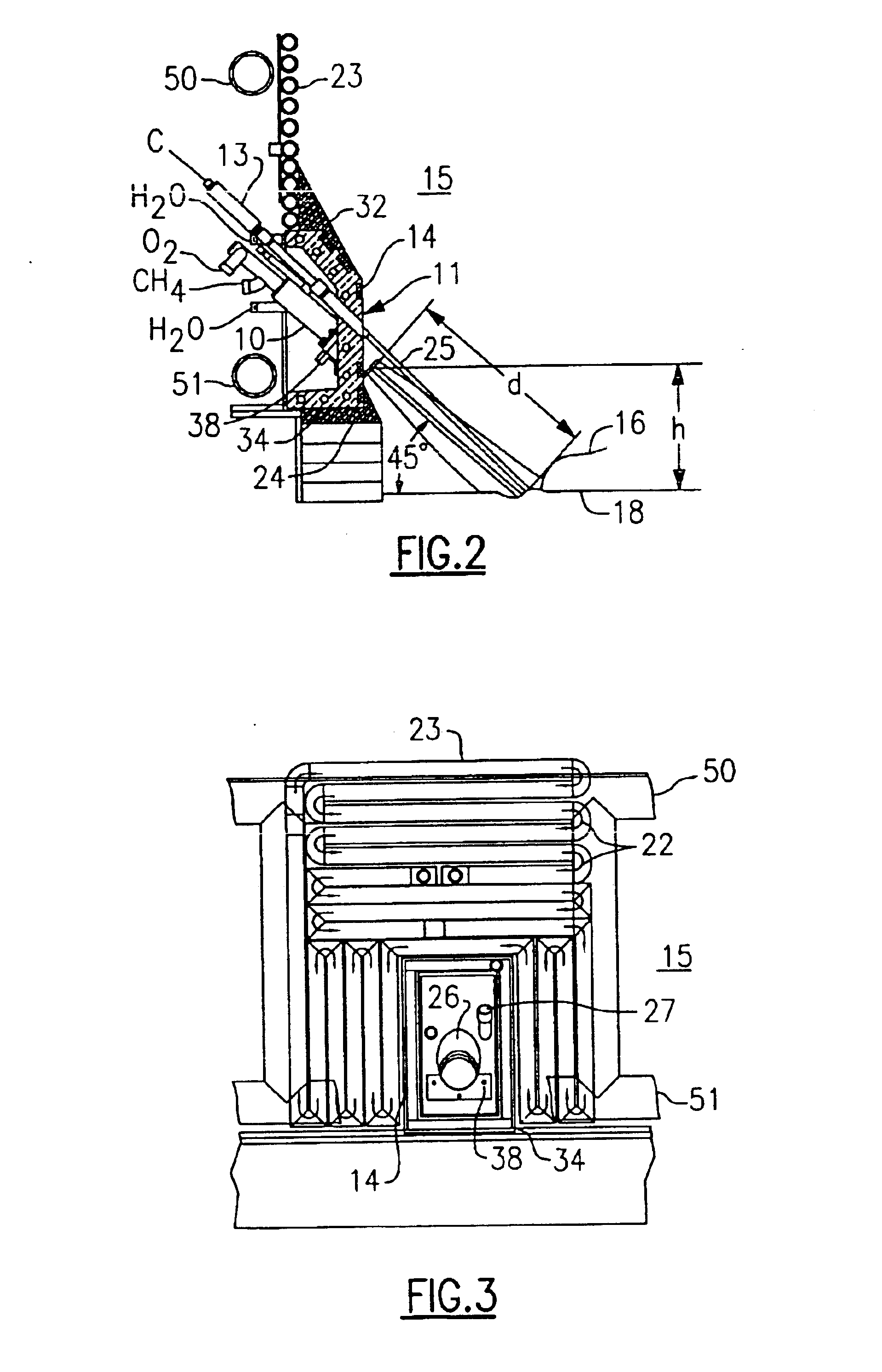

Method for particulate introduction for metal furnaces

InactiveUS6805724B2Processing duration reducedReduce the amount of solutionElectric discharge heatingFurnace cooling arrangementsElectric arc furnaceSlag

A method and an apparatus for advantageously introducing a flame, a high velocity oxidizing gas, and a high velocity particulate flow into a furnace for metal melting, refining and processing, for example, steel making in an electric arc furnace. The steel making process of an electric arc furnace is made more efficient by shortening the time of the scrap melting phase, introducing a more effective high velocity oxidizing gas stream into the process sooner to decarburize the melted metal and introducing a more effective particulate injection to reduce FeO, form or foam slag and / or recarburize. Improved efficiency is obtained by mounting a fixed burner / lance and carbon injector lower and closer to the hot face of the furnace refractory at an effective injection angle. This mounting technique shortens the distance that the flame of the burner has to melt through scrap to clear a path to the molten metal, and shortens the distance the high velocity oxygen and high velocity particulates travel to the slag-metal interface. One method includes supplying a plurality of oxidizing reaction zones with the high velocity oxidizing gas to decarburize the melted metal and a plurality of particulate reaction zones with high velocity flows of particulate carbon for reducing FeO and / or forming foamy slag. The particulate reaction zones are located on the downstream side of the oxidizing gas reaction zones so as to minimize any effect of the reduction reaction on the decarburization reaction and to recover a part of the hot FeO produced in the oxidizing gas reaction zones.

Owner:PROCESS TECH INT

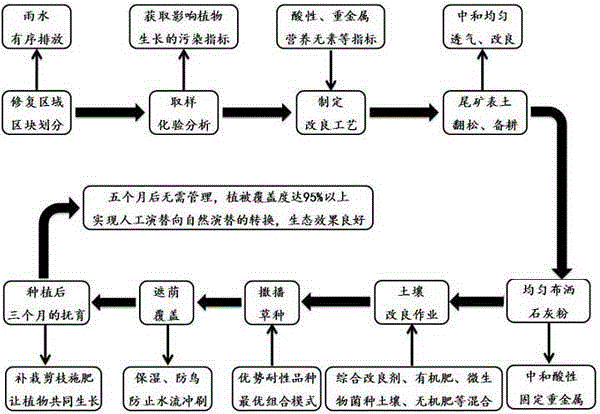

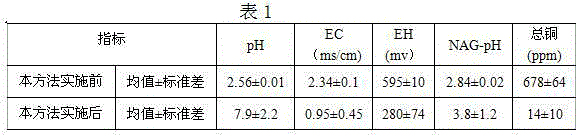

Method for recovering vegetation on strong-acid tailing waste land without soil

ActiveCN104624620AGood water solubilityEffective penetrationContaminated soil reclamationHorticultureRevegetationAcid water

The invention discloses a method for recovering vegetation on a strong-acid tailing waste land without soil. The method is characterized by comprising the following steps: A. performing early-stage preparations, and draining off water; B. changing the pH value of the land; C. culturing the fertility of the tailing waste land; D. screening and culturing plant varieties; and F. managing transplanted seedlings. The method has the advantages that by adopting the method for recovering the vegetation without soil, disturbance to the tailing land is reduced, and the purposes that water can be drained off, the influence of acid water to the vegetation can be alleviated, the heavy metals can be stabilized, and the living environment of plants is improved are achieved. In addition, according to the method, the cost is low, the effect taking is rapid, the effect is good and the operability is high.

Owner:CHINA NERIN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com