Micro-polarizing film array used for acquiring full-polarization parameters and production method and application thereof

A micro-polarizer array, micro-polarizer technology, applied in polarizing elements, optics, instruments, etc., can solve the problems of reduced imaging quality, complex array structure, etc., and achieve excellent linear and circular polarization detection capabilities, good polarization transmission. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

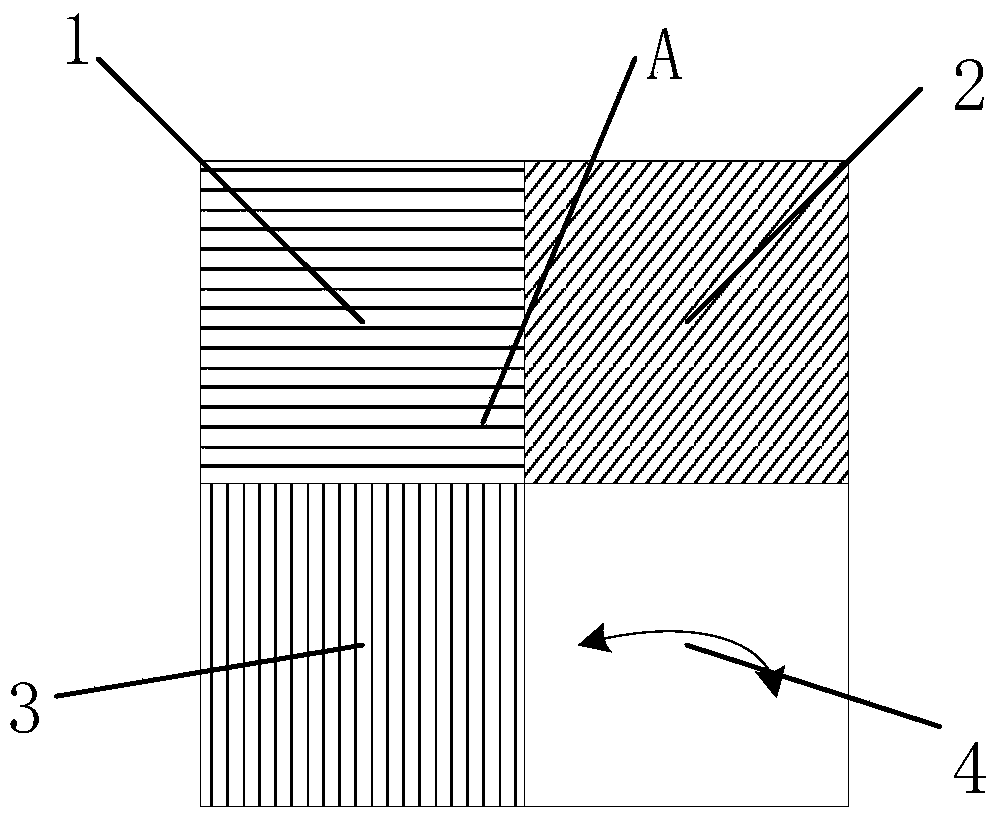

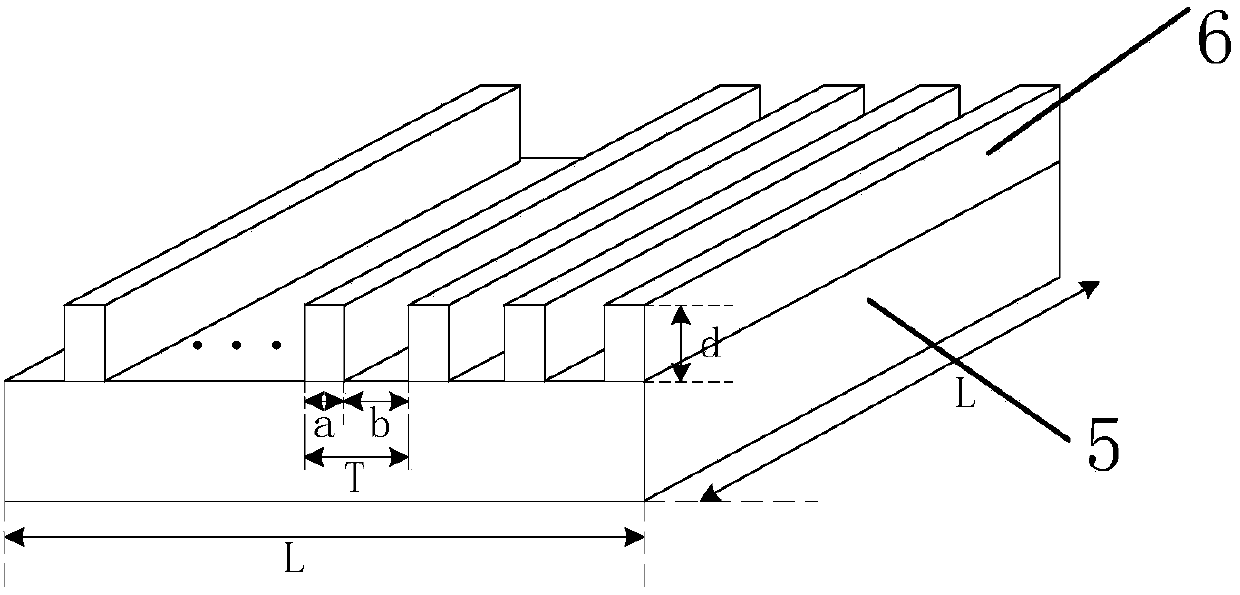

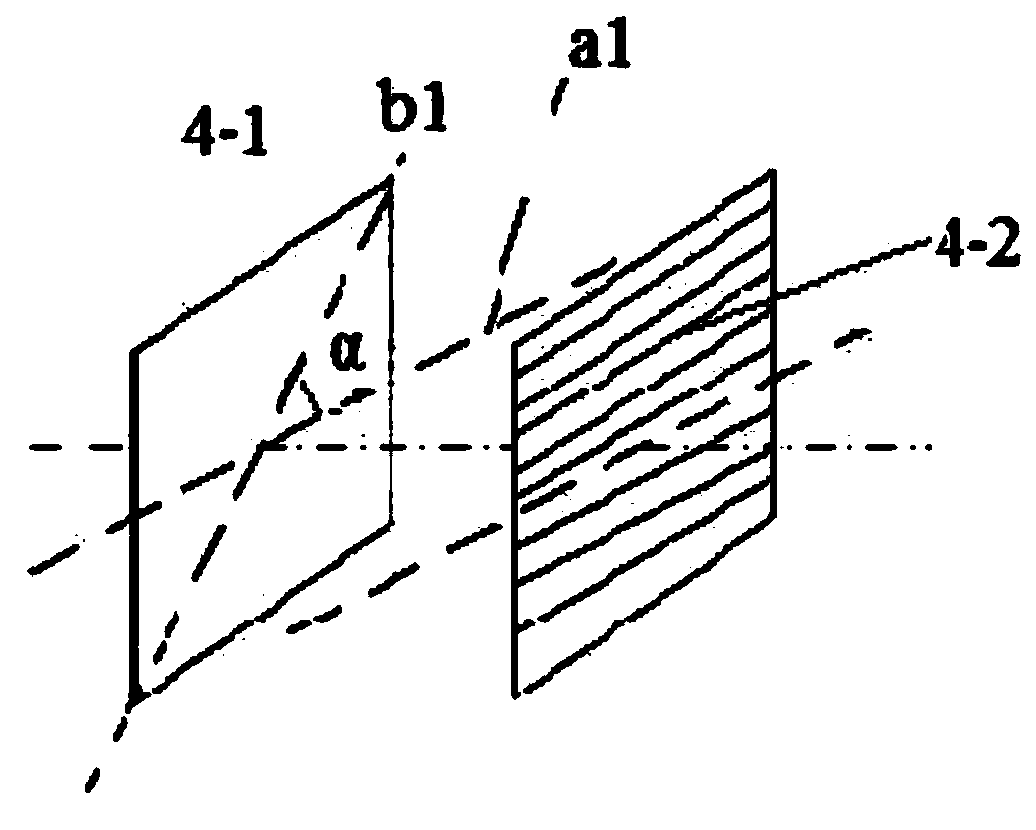

[0041] Such as figure 1 , 2 As shown in and 3, a micro-polarizer array for obtaining full polarization parameters of the present invention includes a plurality of micro-polarizer units A with a size of 2×2, and each micro-polarizer unit A includes 0° polarizers 1, 45° polarizer 2, 90° polarizer 3 and circular polarizer 4, 0° polarizer 1 and 45° polarizer 2 are adjacent and in the same row, 90° polarizer 3 and circular polarizer 4 are adjacent and Located in the same row, the 0° polarizer 1 is adjacent to the 90° polarizer 3 and located in the same column, and the 45° polarizer 2 is adjacent to the circular polarizer 4 and located in the same column. The 0° polarizer 1, the 45° polarizer 2 and the 90° polarizer 3 are sub-wavelength grating structure polarizers, including a transparent substrate 5 and a grating 6, the grating 6 is arranged on the substrate 5, and the grating 6 includes protrusions and the groove, the surface layer of the protrusion is coated with a metal layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com