Patents

Literature

365 results about "Particulate flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

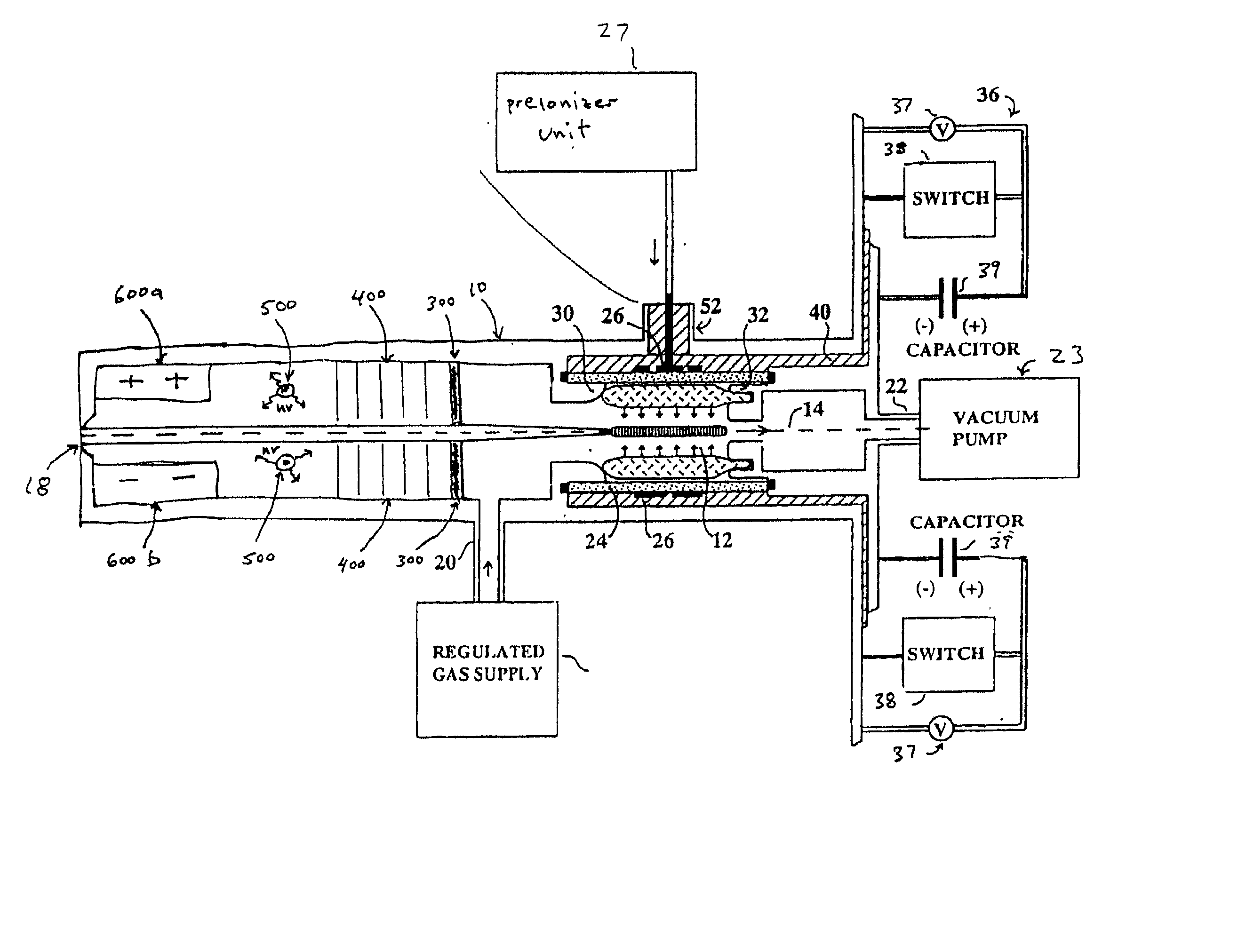

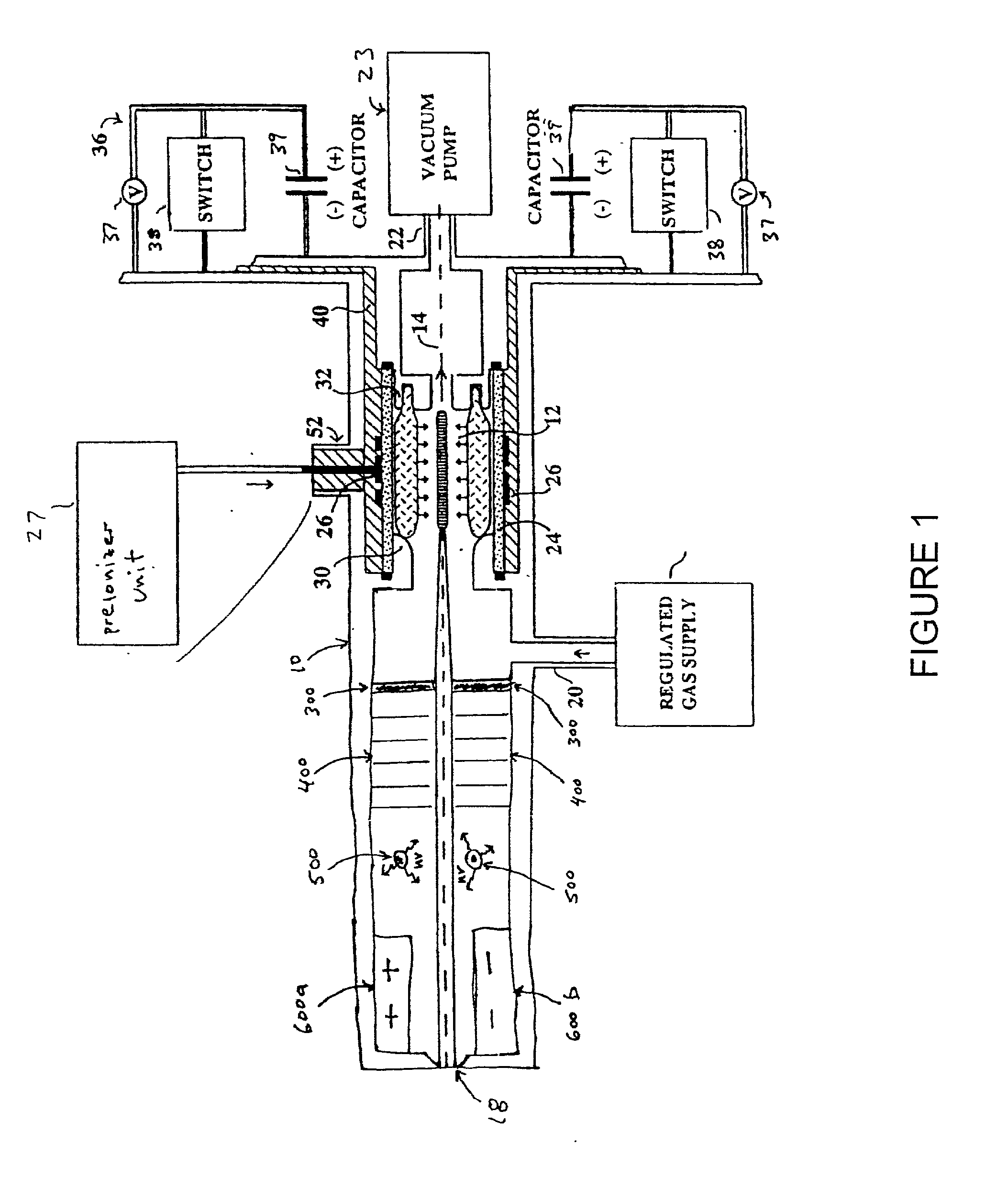

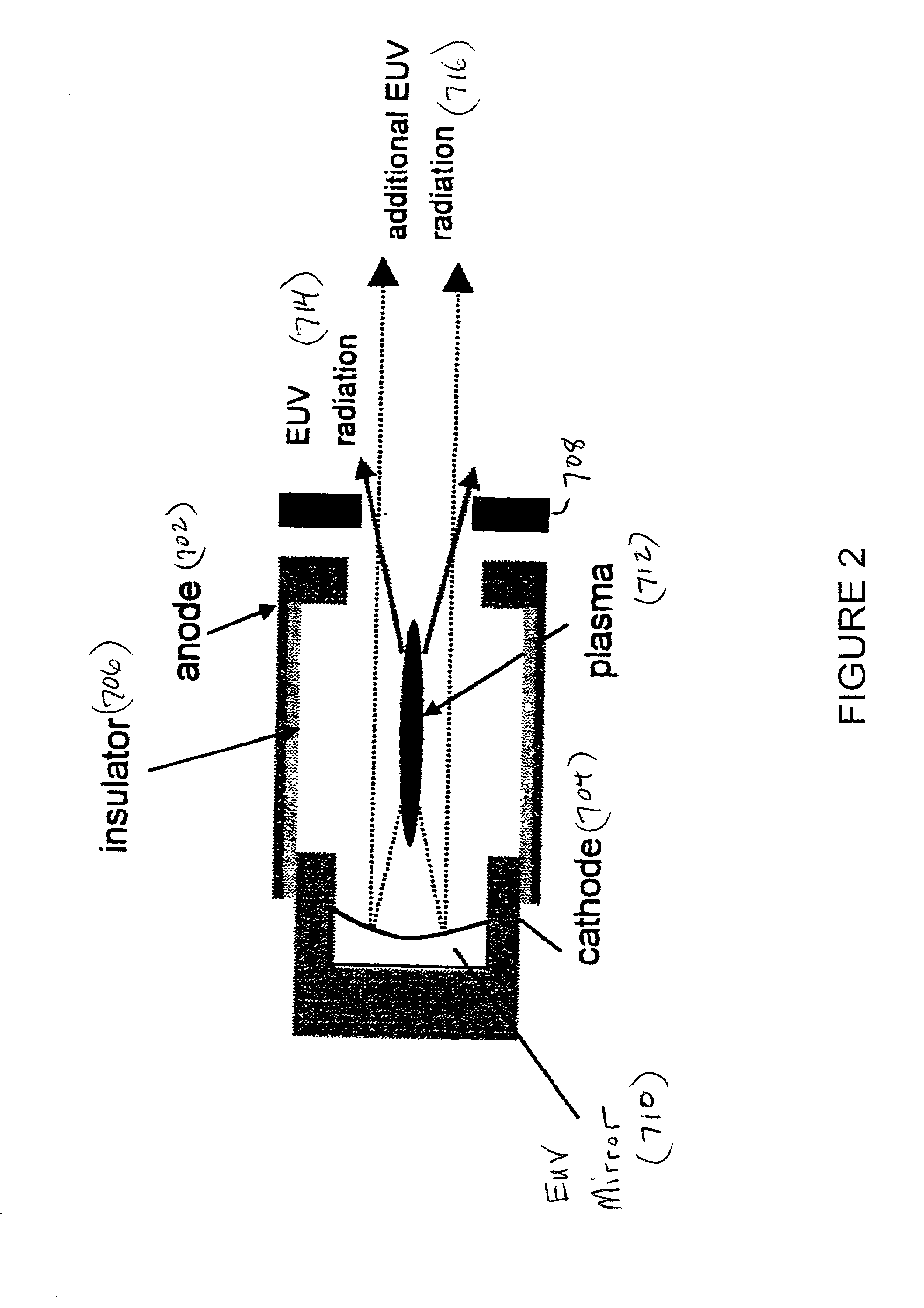

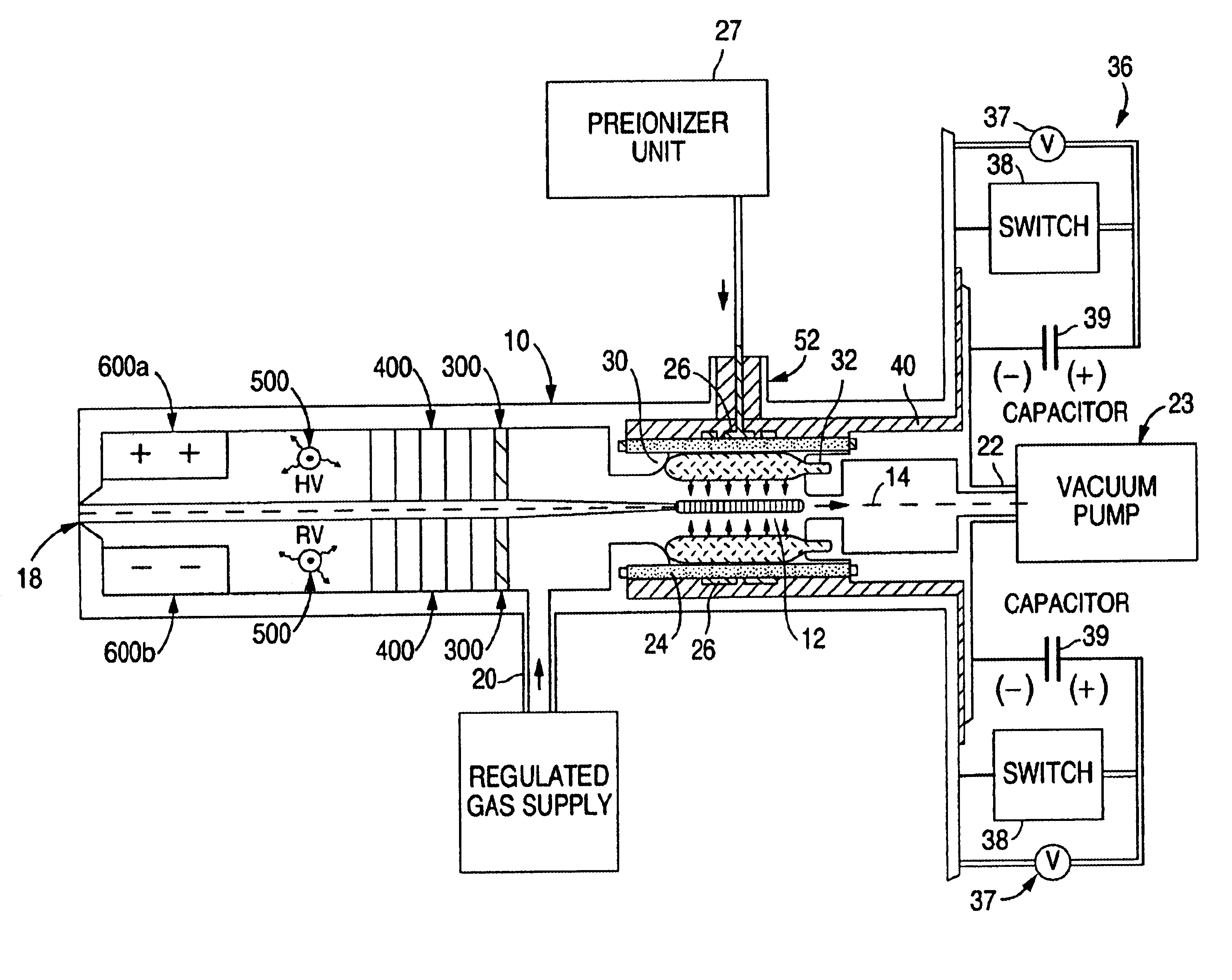

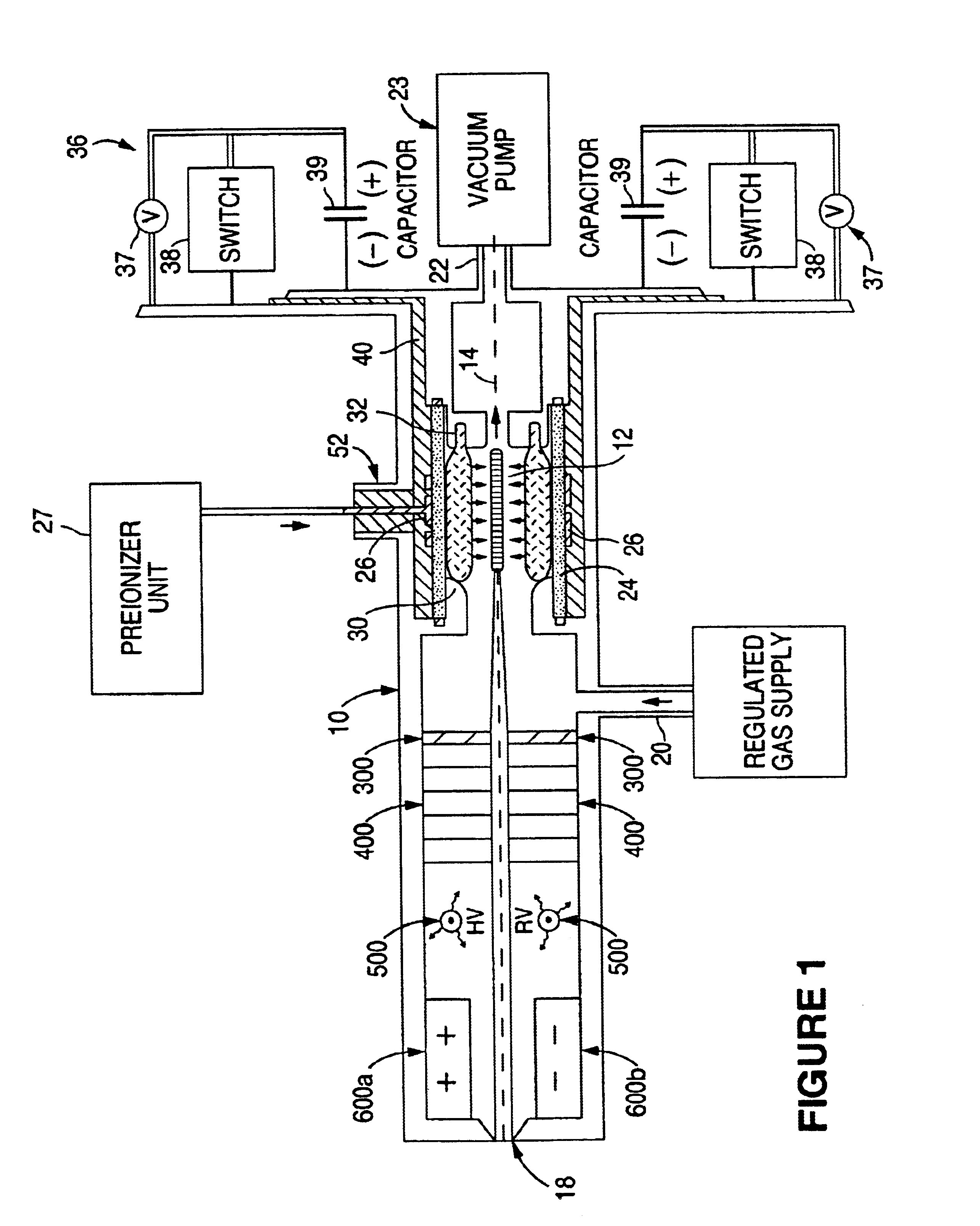

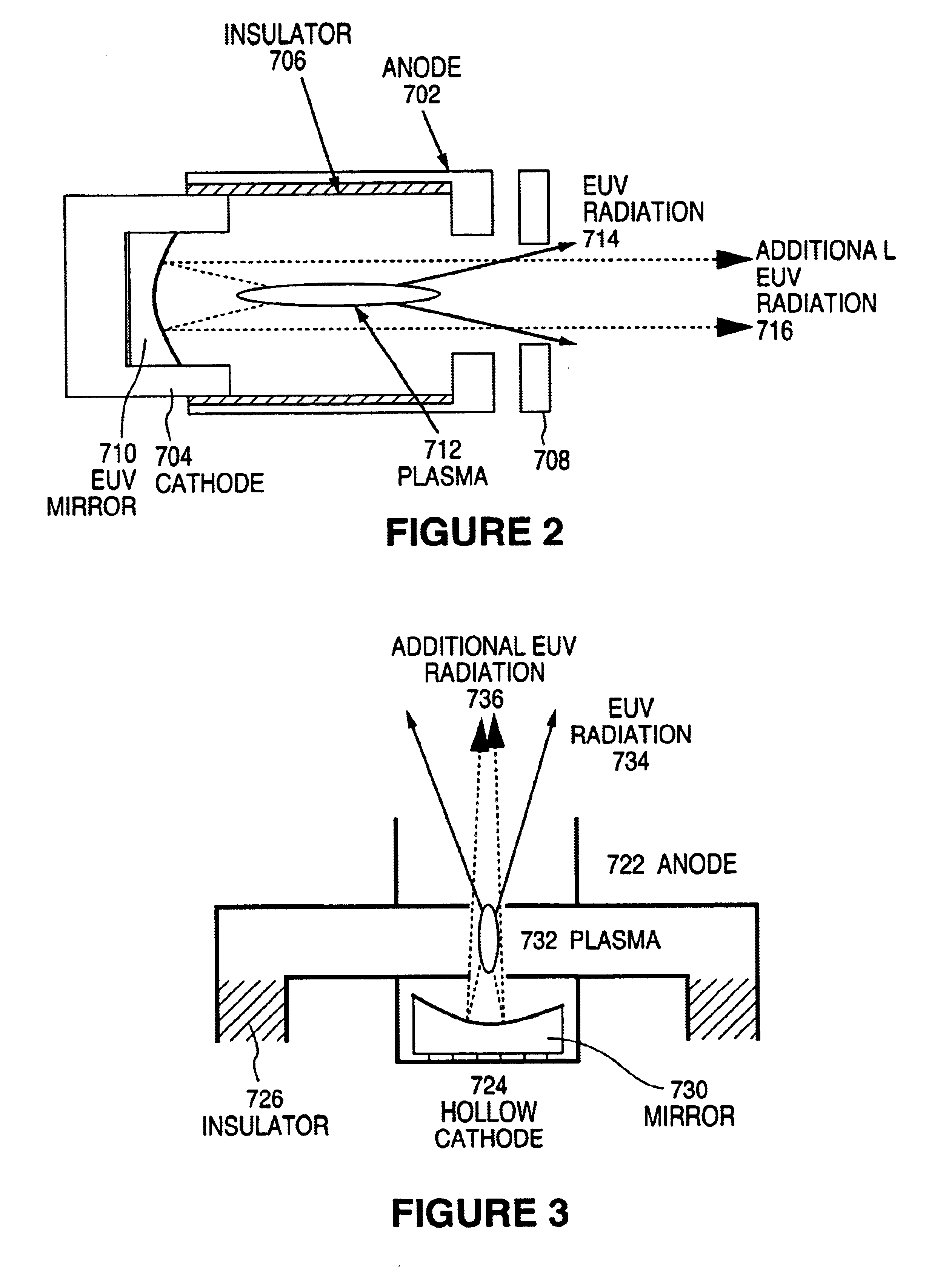

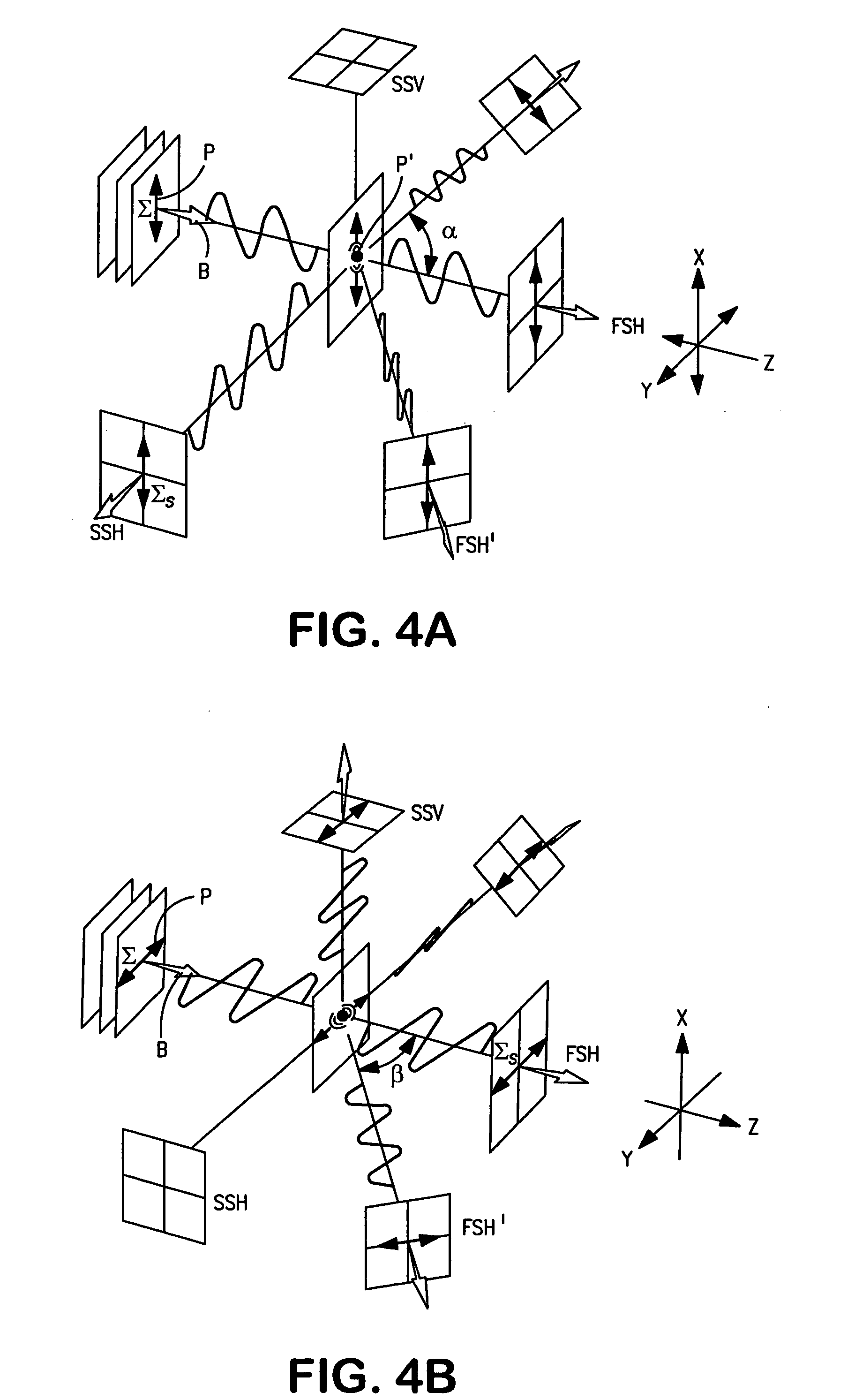

Method and apparatus for generating high output power gas discharge based source of extreme ultraviolet radiation and/or soft x-rays

InactiveUS20020168049A1Avoid reflectionsReduce reflectionRadiation/particle handlingNanoinformaticsSoft x rayUltraviolet radiation

An EUV photon source includes a plasma chamber filled with a gas mixture, multiple electrodes within the plasma chamber defining a plasma region and a central axis, a power supply circuit connected to the electrodes for delivering a main pulse to the electrodes for energizing the plasma around the central axis to produce an EUV beam output along the central axis, and a preionizer for ionizing the gas mixture in preparing to form a dense plasma around the central axis upon application of the main pulse from the power supply circuit to the electrodes. The EUV source preferably includes an ionizing unit and precipitator for collecting contaminant particulates from the output beam path. A set of baffles may be disposed along the beam path outside of the pinch region to diffuse gaseous and contaminant particulate flow emanating from the pinch region and to absorb or reflect acoustic waves emanating from the pinch region away from the pinch region. A clipping aperture, preferably formed of ceramic and / or Al2O3, for at least partially defining an acceptance angle of the EUV beam. The power supply circuit may generates the main pulse and a relatively low energy prepulse for homogenizing the preionized plasma prior to the main pulse. A multi-layer EUV mirror is preferably disposed opposite a beam output side of the pinch region for reflecting radiation along the central axis for output along the beam path of the EUV beam. The EUV mirror preferably has a curved contour for substantially collimating or focusing the reflected radiation. In particular, the EUV mirror may preferably have a hyperbolic contour.

Owner:USHIO DENKI KK

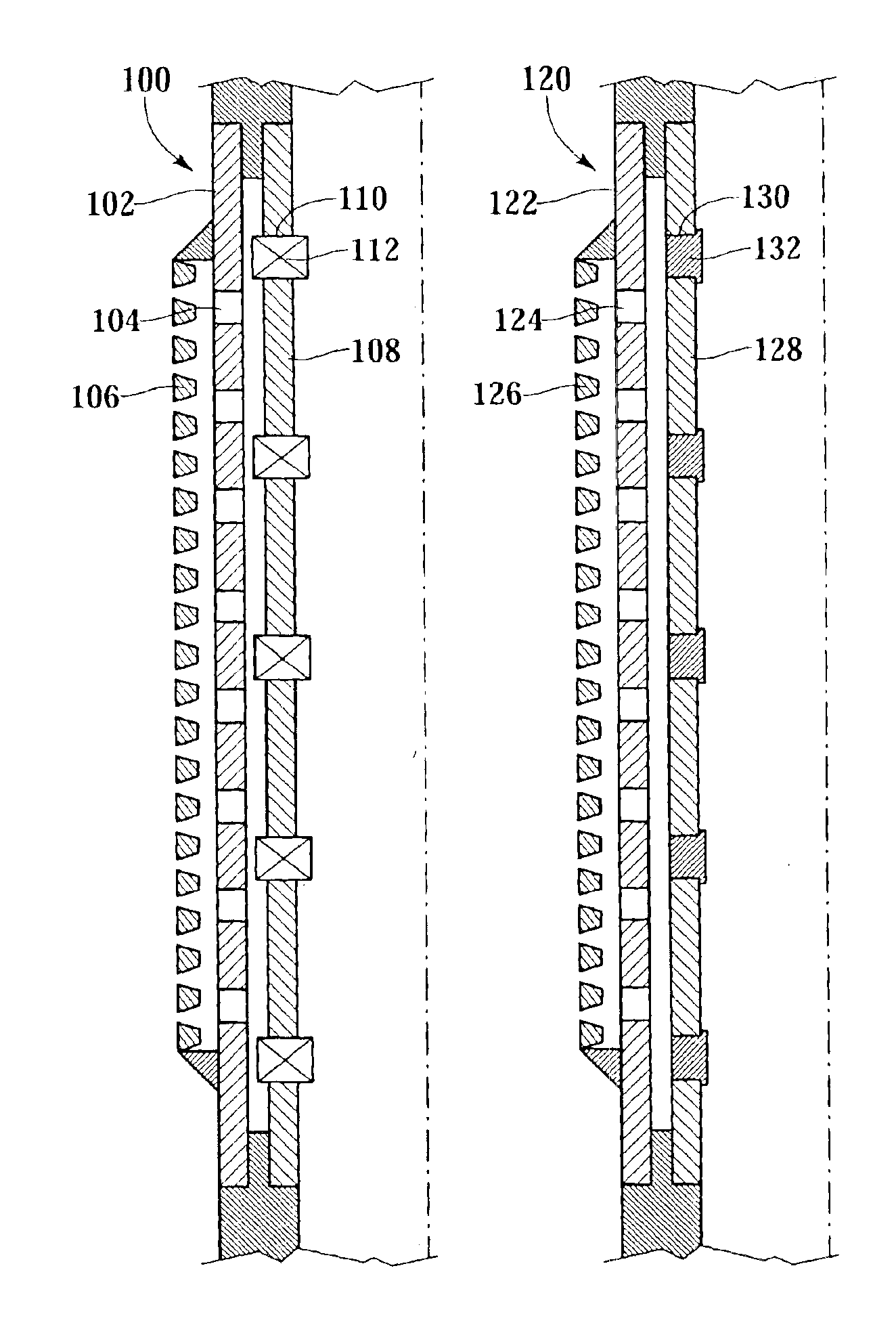

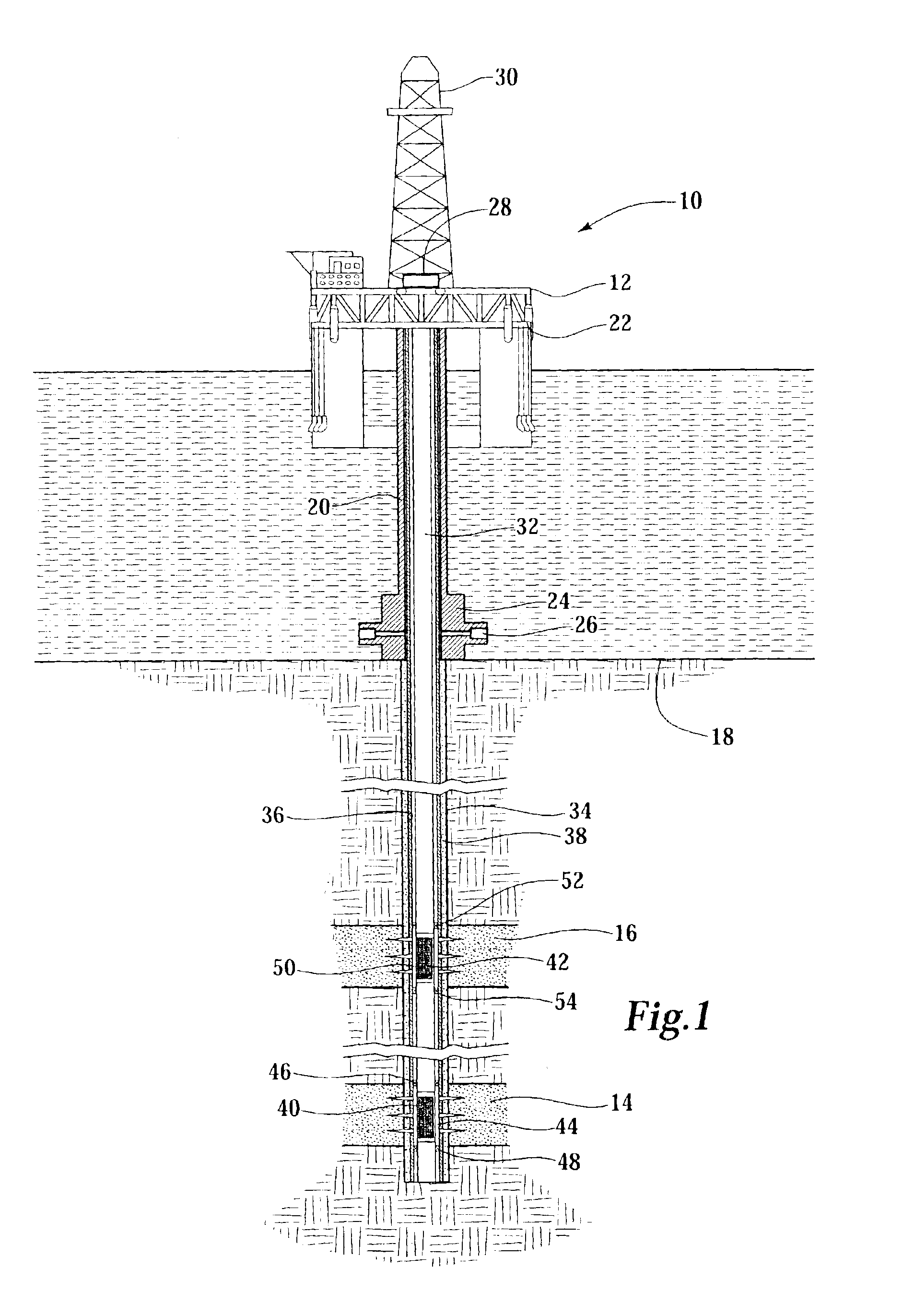

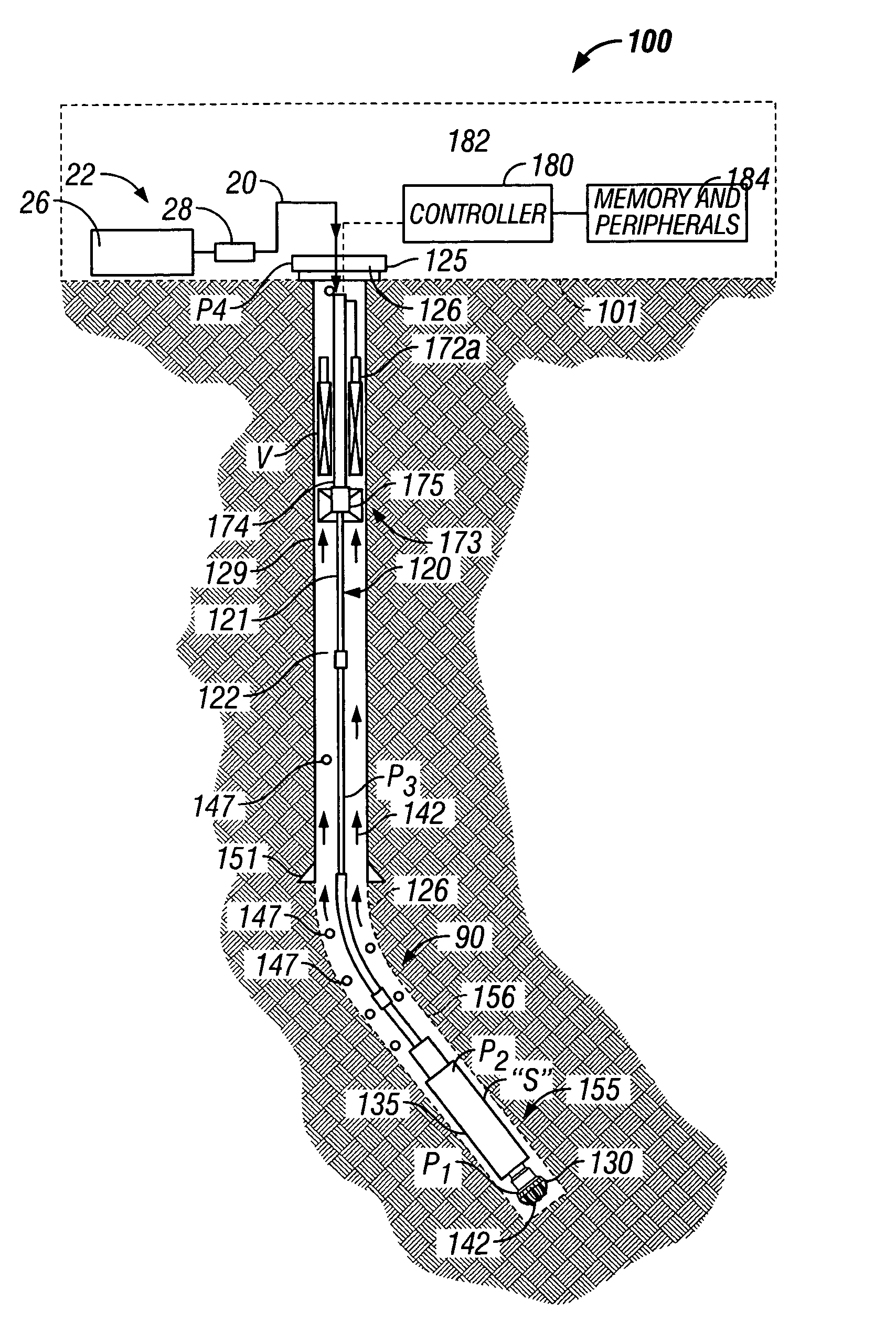

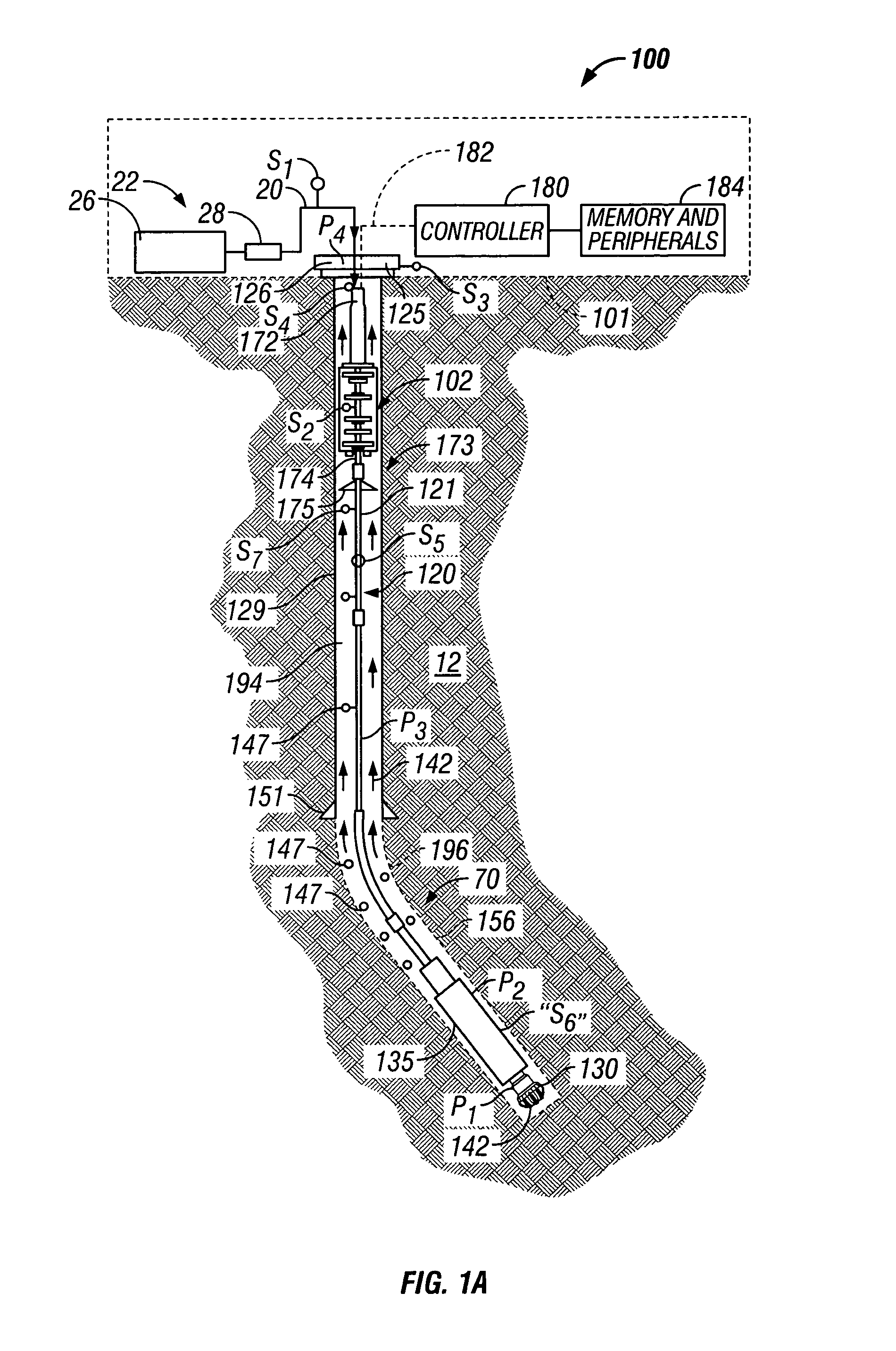

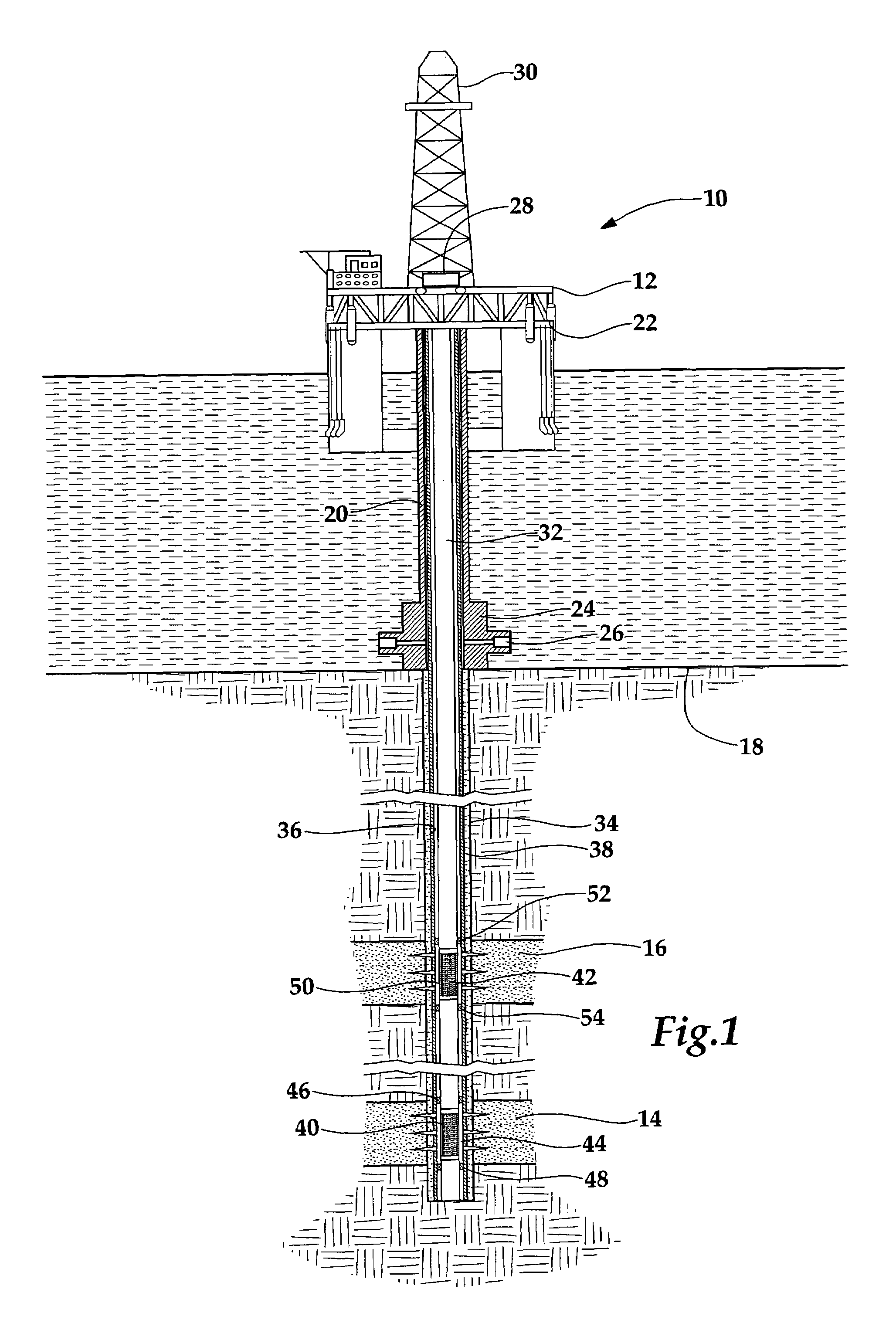

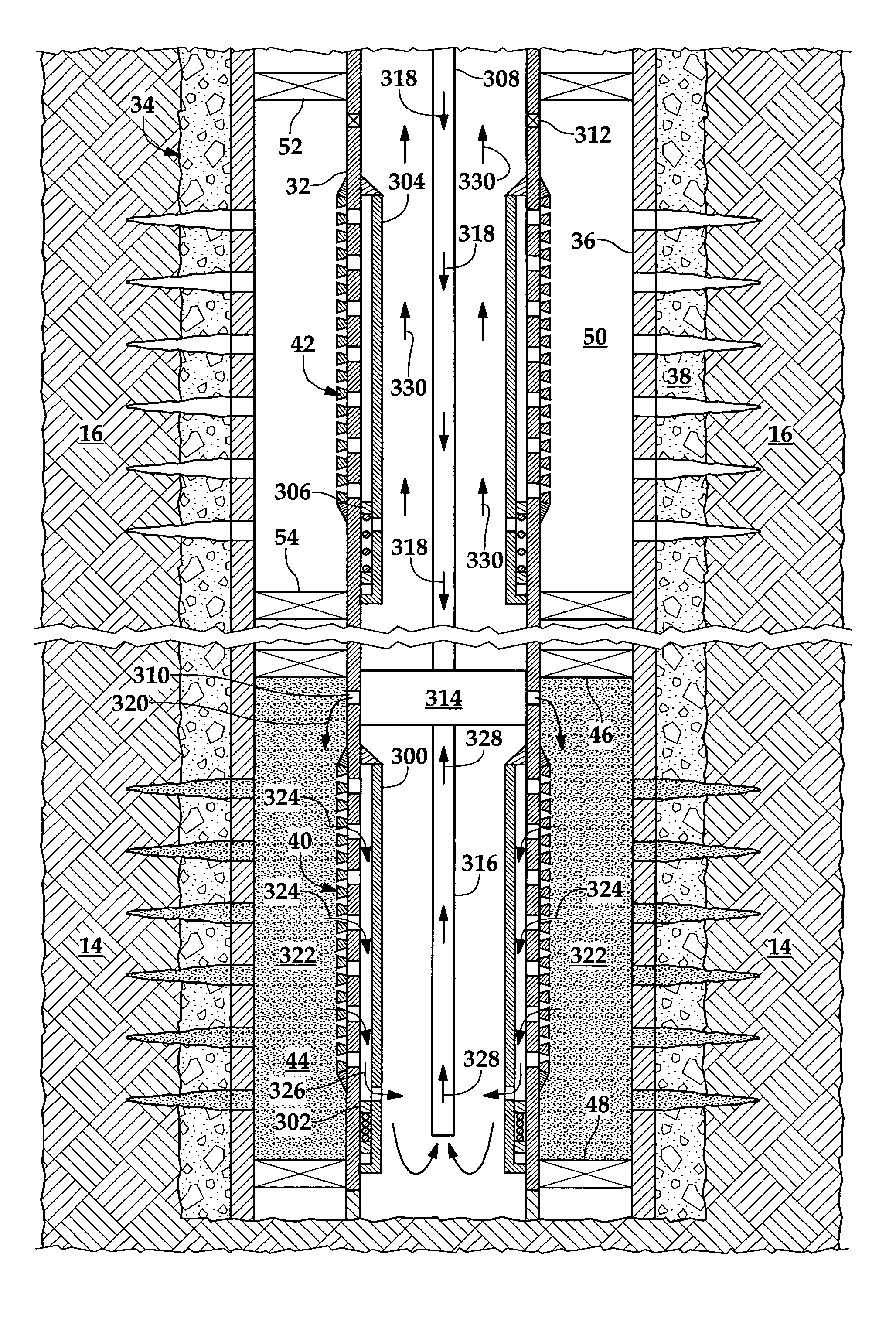

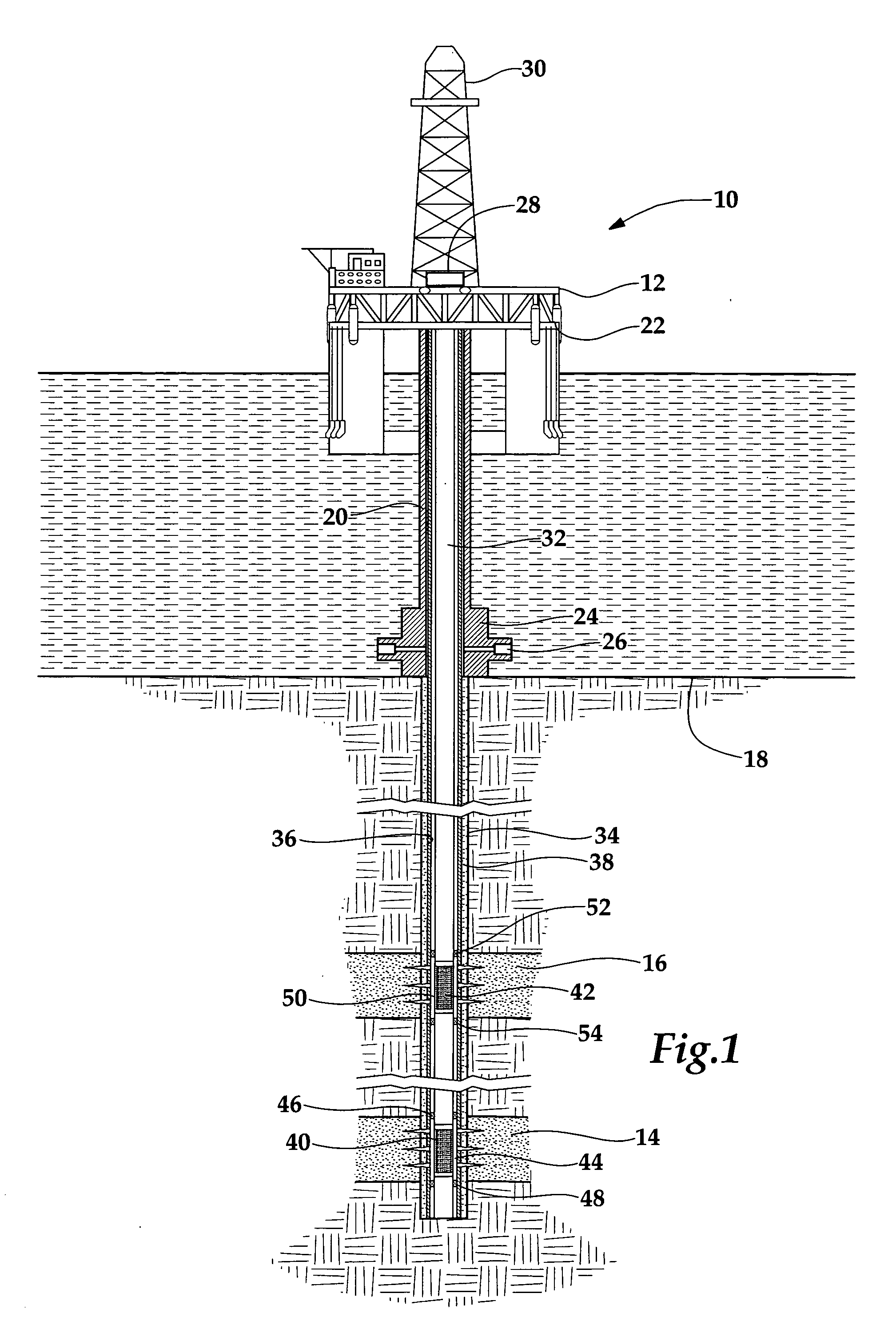

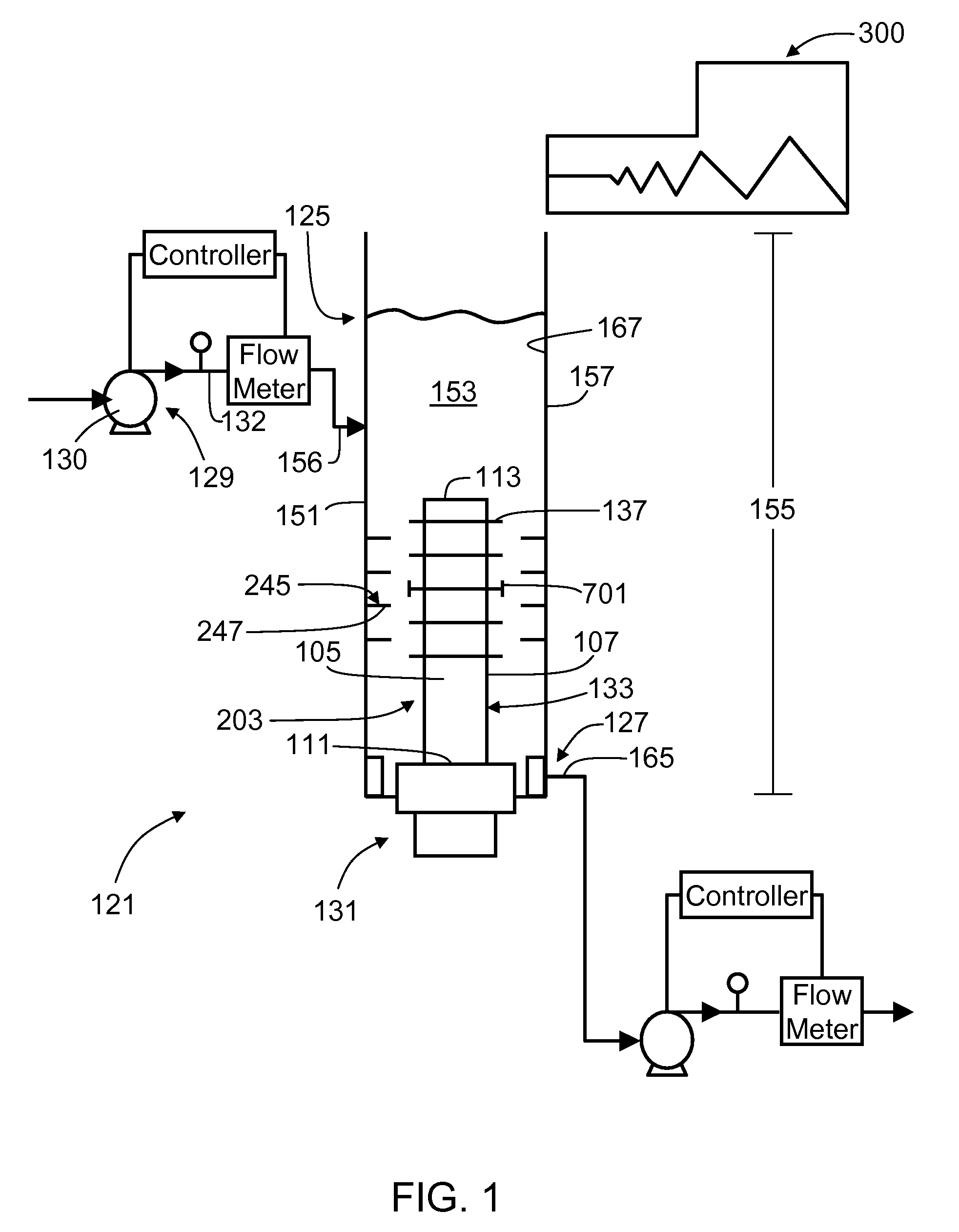

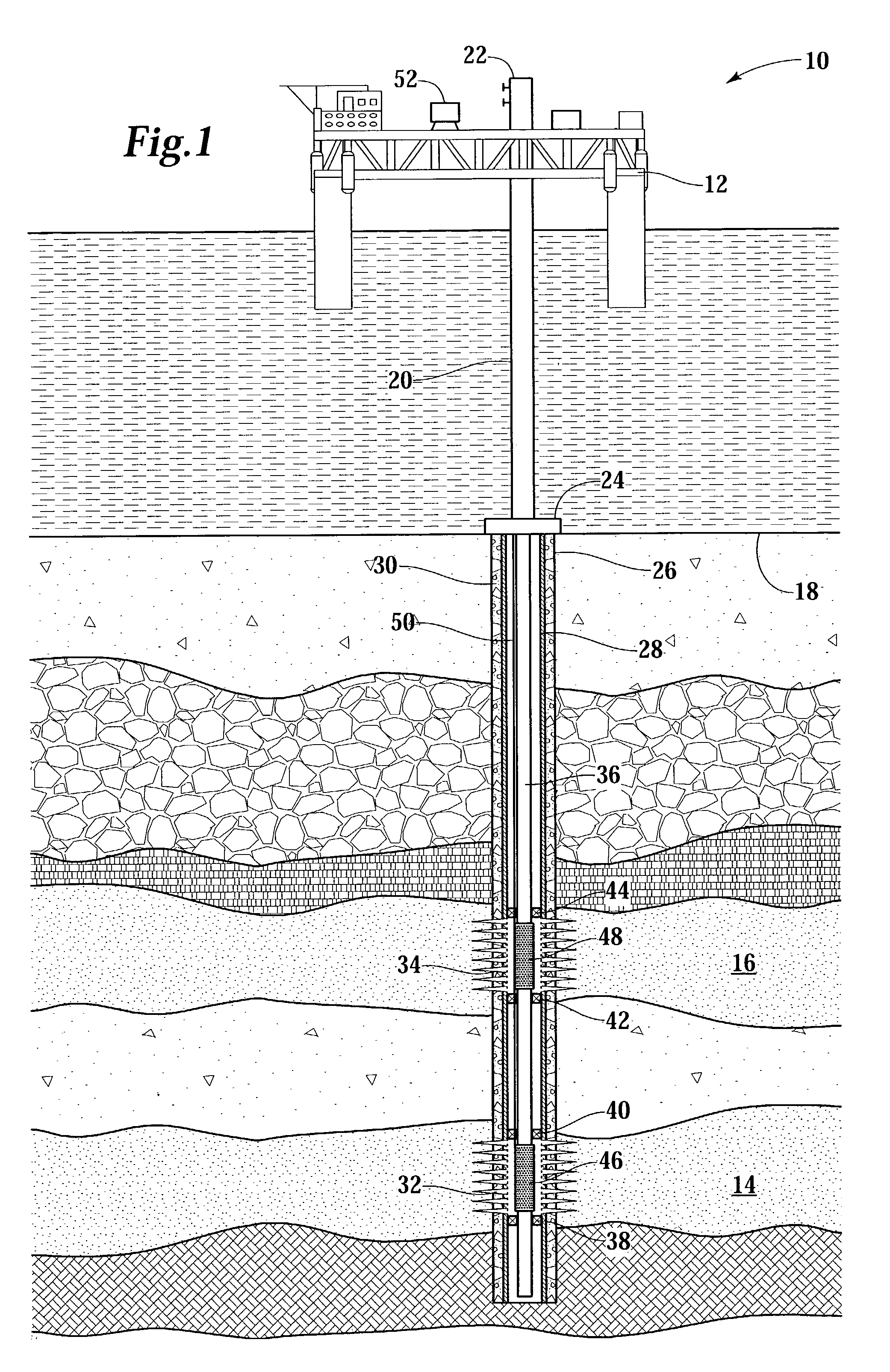

Sand control screen assembly having an internal isolation member and treatment method using the same

InactiveUS6886634B2Avoid flowAvoid lostFluid removalDrinking water installationParticulate flowFilter media

A sand control screen assembly (80) that is positionable within a wellbore comprises a base pipe (82) having at least one opening (84) that allows fluid flow therethrough and a filter medium (86) positioned about the exterior of the base pipe (82) that selectively allows fluid flow therethrough and prevents particulate flow of a predetermined size therethrough. An internal isolation member (88) that has at least one opening (90) is positioned within the base pipe (82). A one-way valve (92) is operably associated with the opening (90) of the internal isolation member (88). The one-way valve (92) controls the flow of fluid through the opening (90) of the internal isolation member (88) such that fluid flow is prevented from the interior to the exterior of the sand control screen assembly (80) but is allowed from the exterior to the interior of the sand control screen assembly (80).

Owner:HALLIBURTON ENERGY SERVICES INC

Method and apparatus for generating high output power gas discharge based source of extreme ultraviolet radiation and/or soft x-rays

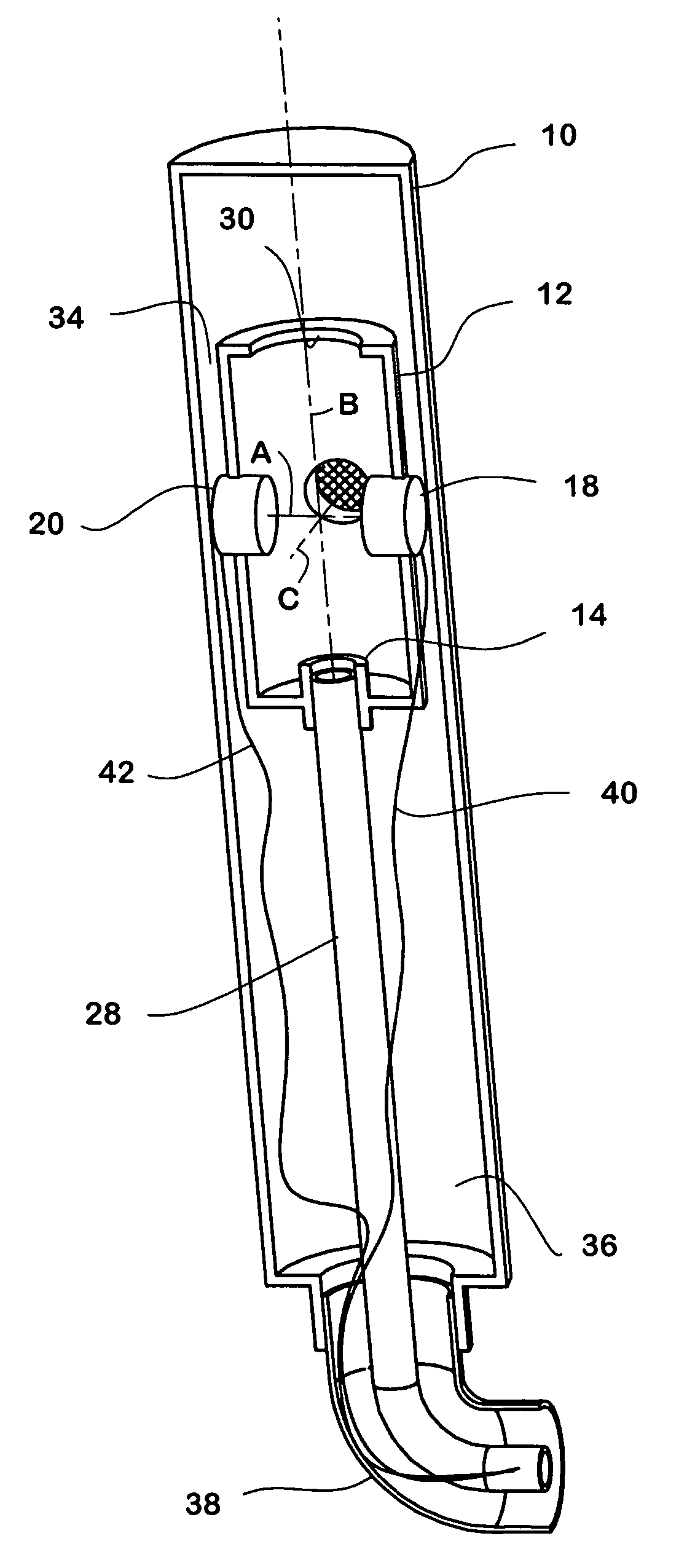

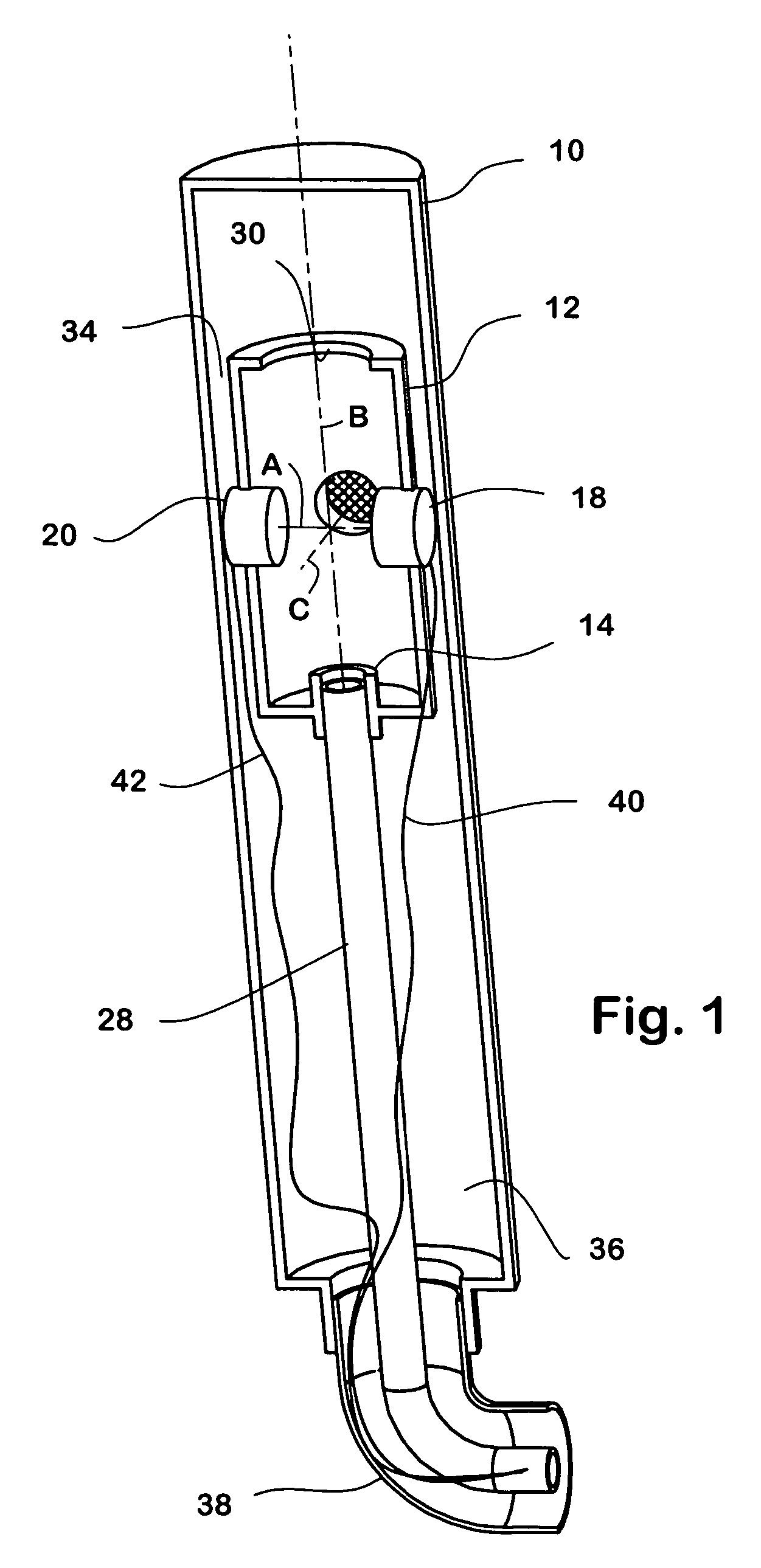

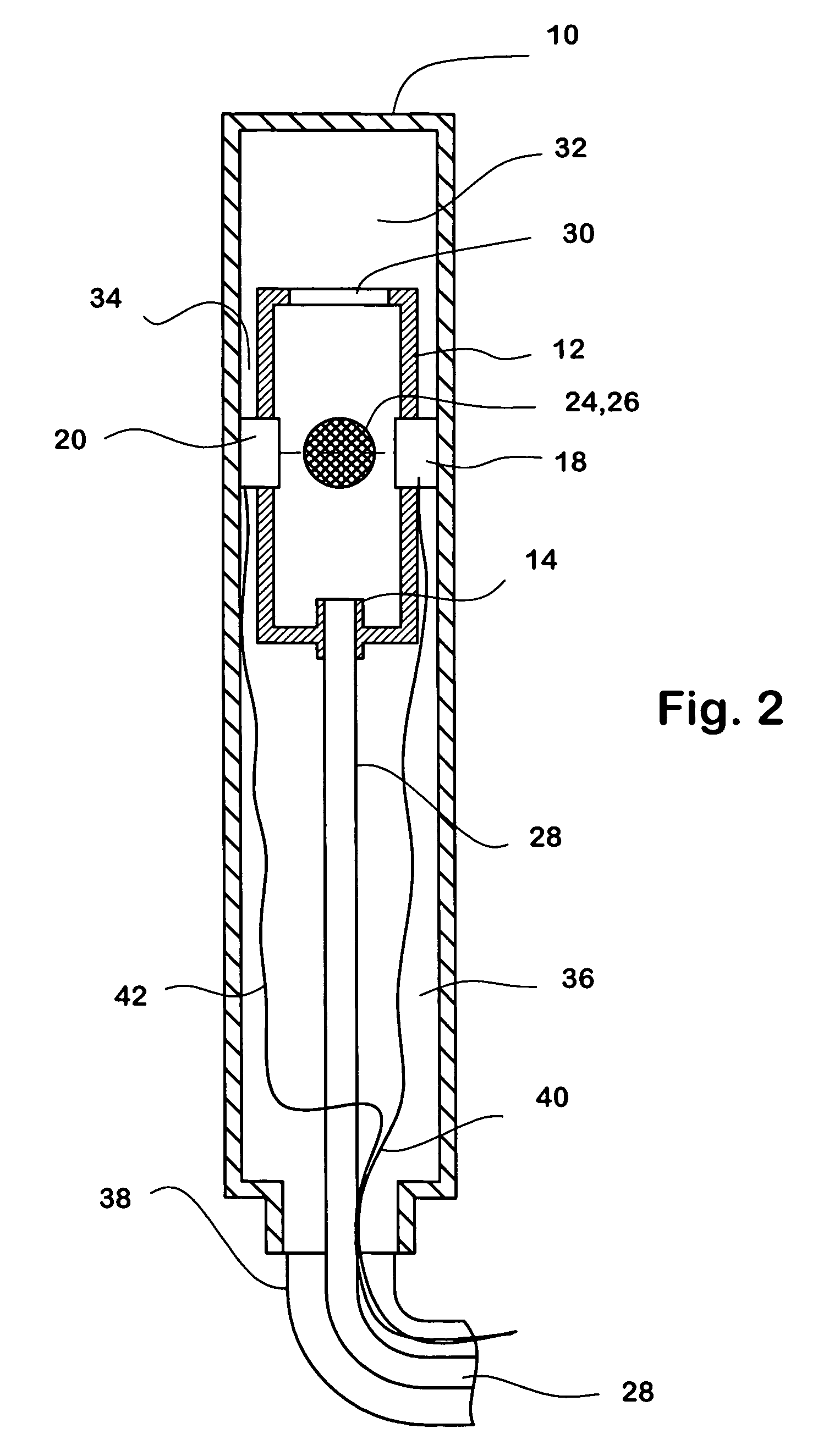

InactiveUS6804327B2Reduce impactPreventing electrode burnoutRadiation/particle handlingNanoinformaticsSoft x rayLight beam

The method and system herein pertain to an EUV photon source which includes a plasma chamber filled with a gas mixture, multiple electrodes within the plasma chamber defining a plasma region and a central axis, a power supply circuit connected to the electrodes for delivering a main pulse to the electrodes for energizing the plasma around the central axis to produce an EUV beam. The system can also include a preionizer for ionizing the gas mixture in preparing to form a dense plasma around the central axis upon application of the main pulse from the power supply circuit to the electrodes. A set of baffles may be disposed along the beam path outside of the pinch region to diffuse gaseous and contaminant particulate flow emanating from the pinch region and to absorb or reflect acoustic waves emanating from the pinch region away from the pinch region.

Owner:USHIO DENKI KK

Downhole cutting mill

InactiveUS6981561B2Eliminate needCertain applicationConstructionsBorehole drivesParticle flowBiomedical engineering

A downhole device processes particles entrained in a drilling fluid returning up a wellbore. In one embodiment, the device includes a housing having at least one cutting surface formed in a chamber of a housing. A cutting head disposed in the chamber crushes or comminutes the particles entrained in the drilling fluid to a predetermined size. The device is disposed in the wellbore and processes the entrained particles before they enter a selected wellbore device such as a pump. In certain embodiments, the housing has at least two chambers, wherein the entrained particles are reduced to a first predetermined size in the first chamber, a second predetermined size in the second chamber, etc. Also, the housing can include an operator that generates an energy field that reduces the size of the particles entrained in the drilling fluid to a first predetermined size when the particles flow through the energy field.

Owner:BAKER HUGHES INC

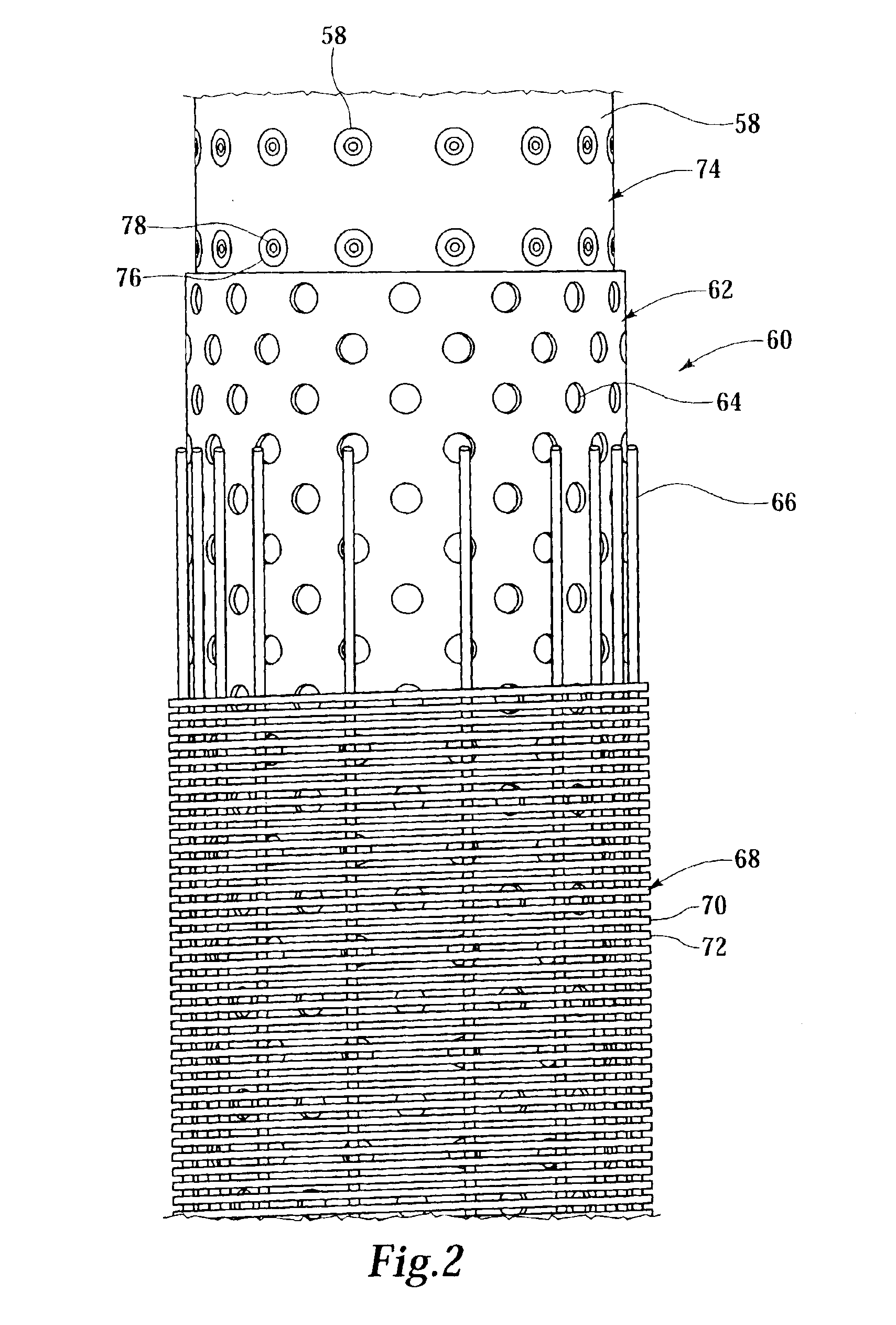

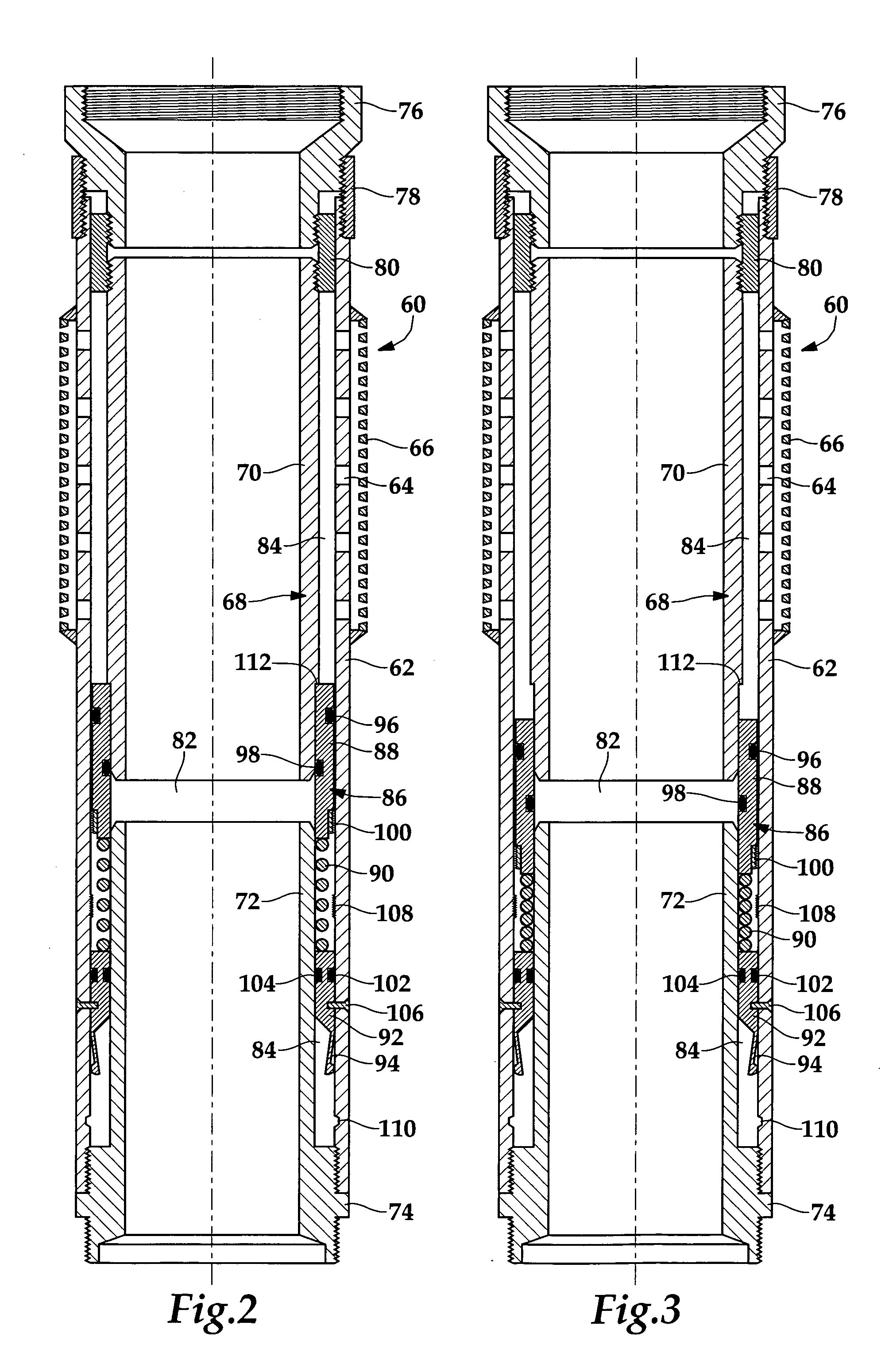

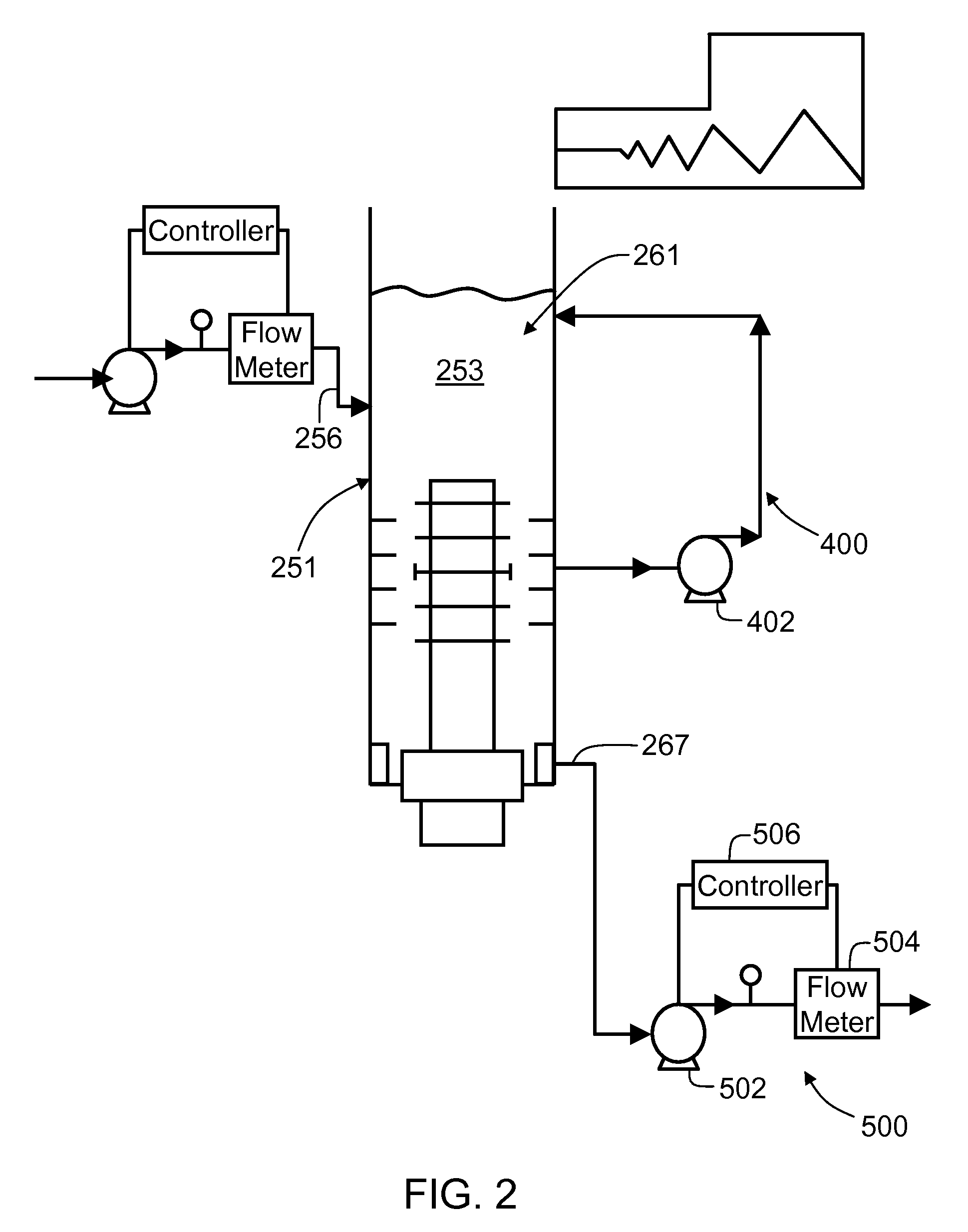

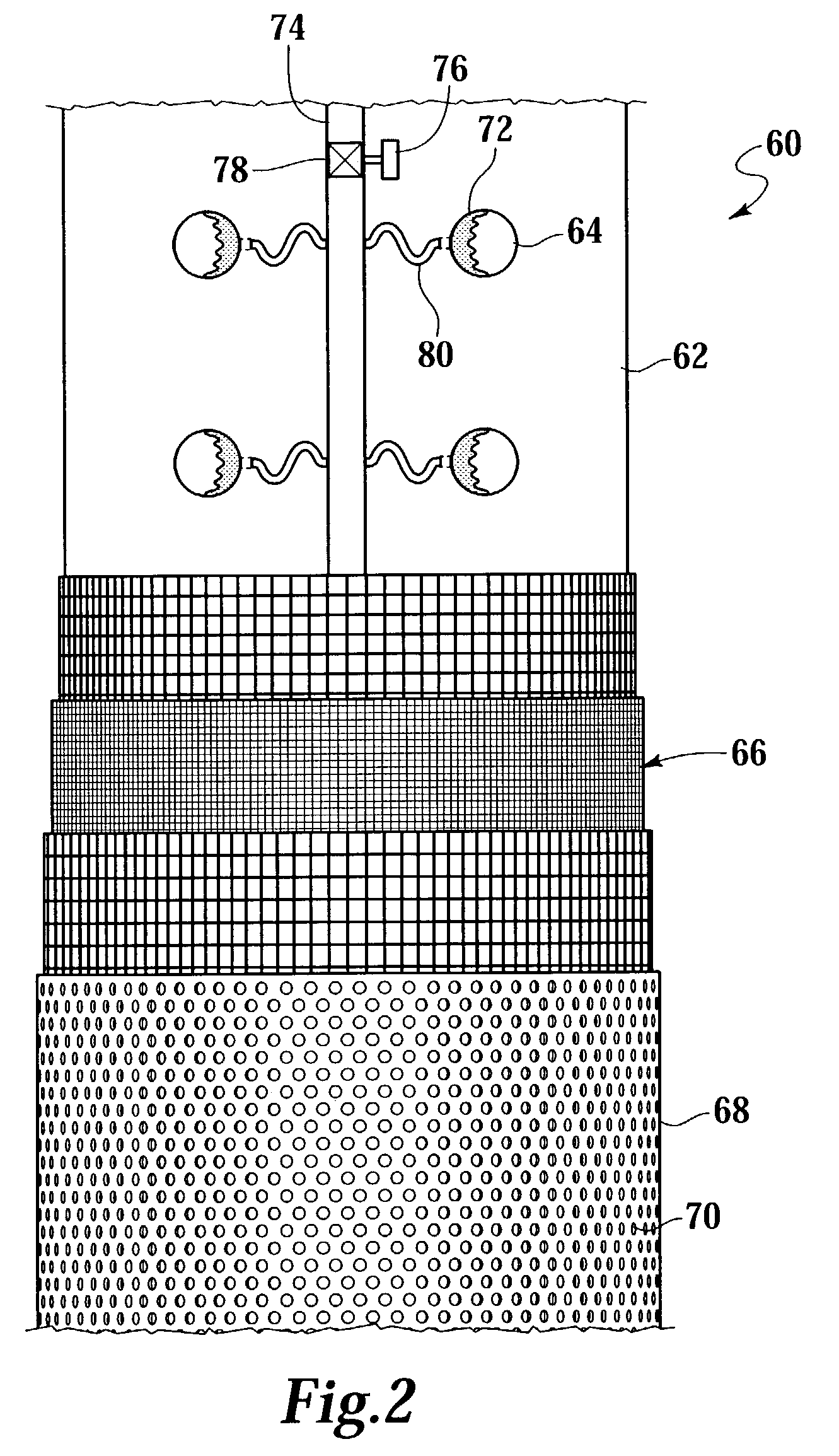

Sand control screen assembly having fluid loss control capability and method for use of same

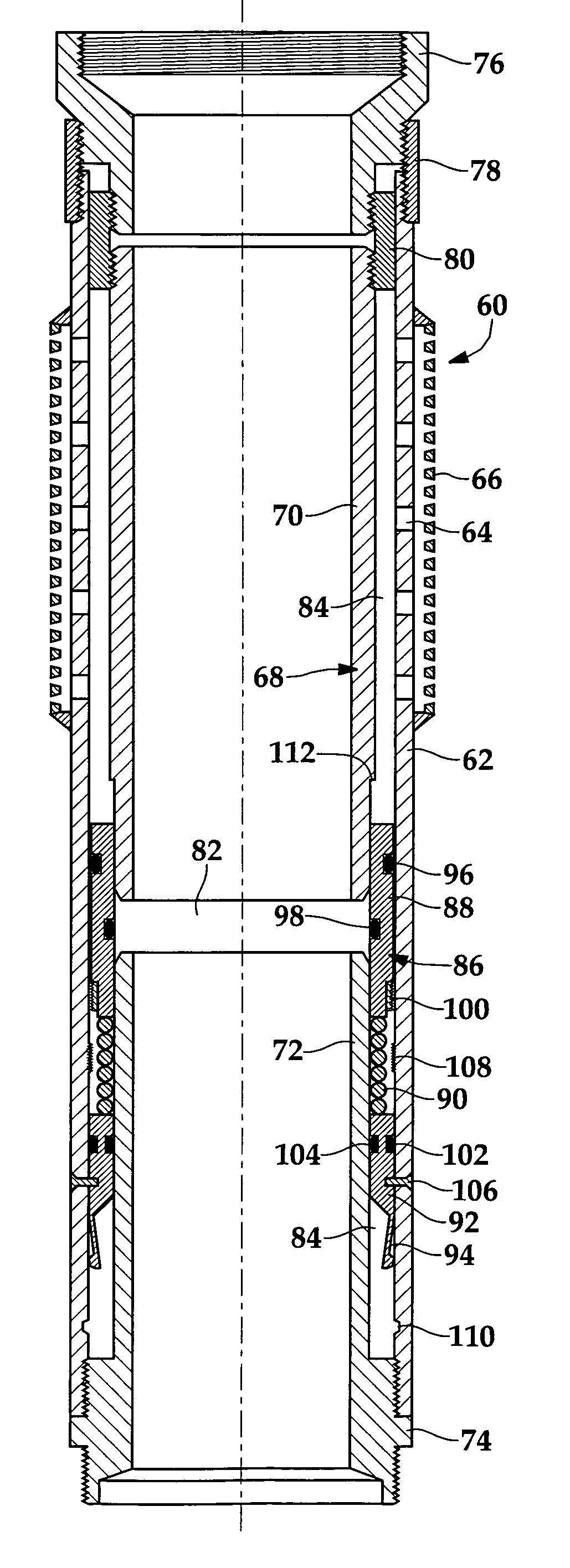

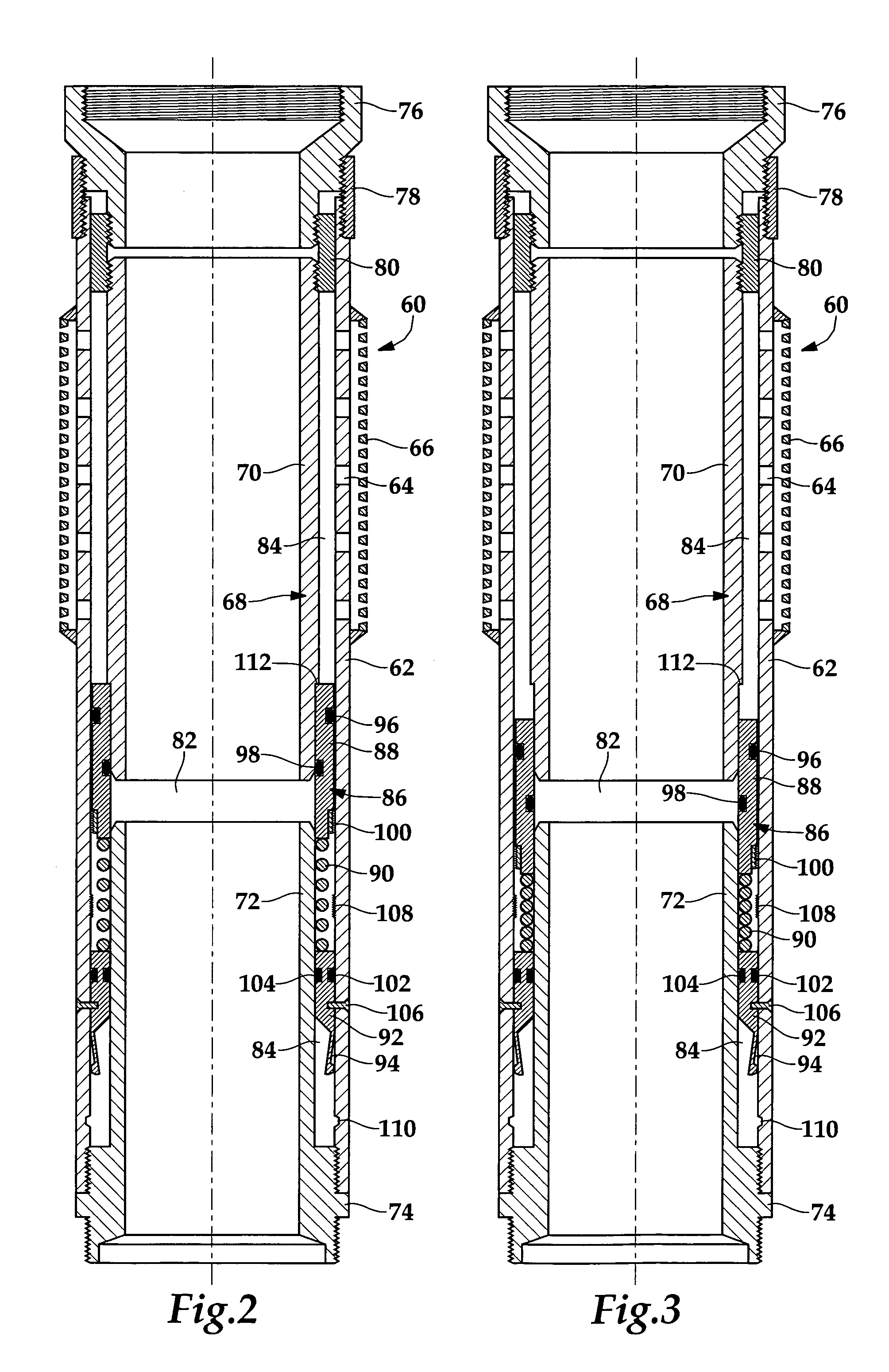

A sand control screen assembly (60) that is positionable within a wellbore includes a base pipe (62) having at least one opening (64) that allows fluid flow therethrough and a filter medium (66) positioned exteriorly of the base pipe (62) that selectively allows fluid flow therethrough and prevents particulate flow of a predetermined size therethrough. An isolation member (68) is positioned interiorly of the base pipe (62) forming an annulus (84) therewith. A one-way valve (86) is slidably operable within the annulus (84). The one-way valve (86) controls the flow of fluid through sand control screen assembly (60) such that fluid flow is selectively prevented from the interior to the exterior of the sand control screen assembly (60) but is allowed from the exterior to the interior of the sand control screen assembly (60).

Owner:HALLIBURTON ENERGY SERVICES INC

Sand control screen assembly having fluid loss control capability and method for use of same

InactiveUS20060042795A1Avoid lostAvoid flowFluid removalWell/borehole valve arrangementsFilter mediaParticulate flow

A sand control screen assembly (60) that is positionable within a wellbore includes a base pipe (62) having at least one opening (64) that allows fluid flow therethrough and a filter medium (66) positioned exteriorly of the base pipe (62) that selectively allows fluid flow therethrough and prevents particulate flow of a predetermined size therethrough. An isolation member (68) is positioned interiorly of the base pipe (62) forming an annulus (84) therewith. A one-way valve (86) is slidably operable within the annulus (84). The one-way valve (86) controls the flow of fluid through sand control screen assembly (60) such that fluid flow is selectively prevented from the interior to the exterior of the sand control screen assembly (60) but is allowed from the exterior to the interior of the sand control screen assembly (60).

Owner:HALLIBURTON ENERGY SERVICES INC

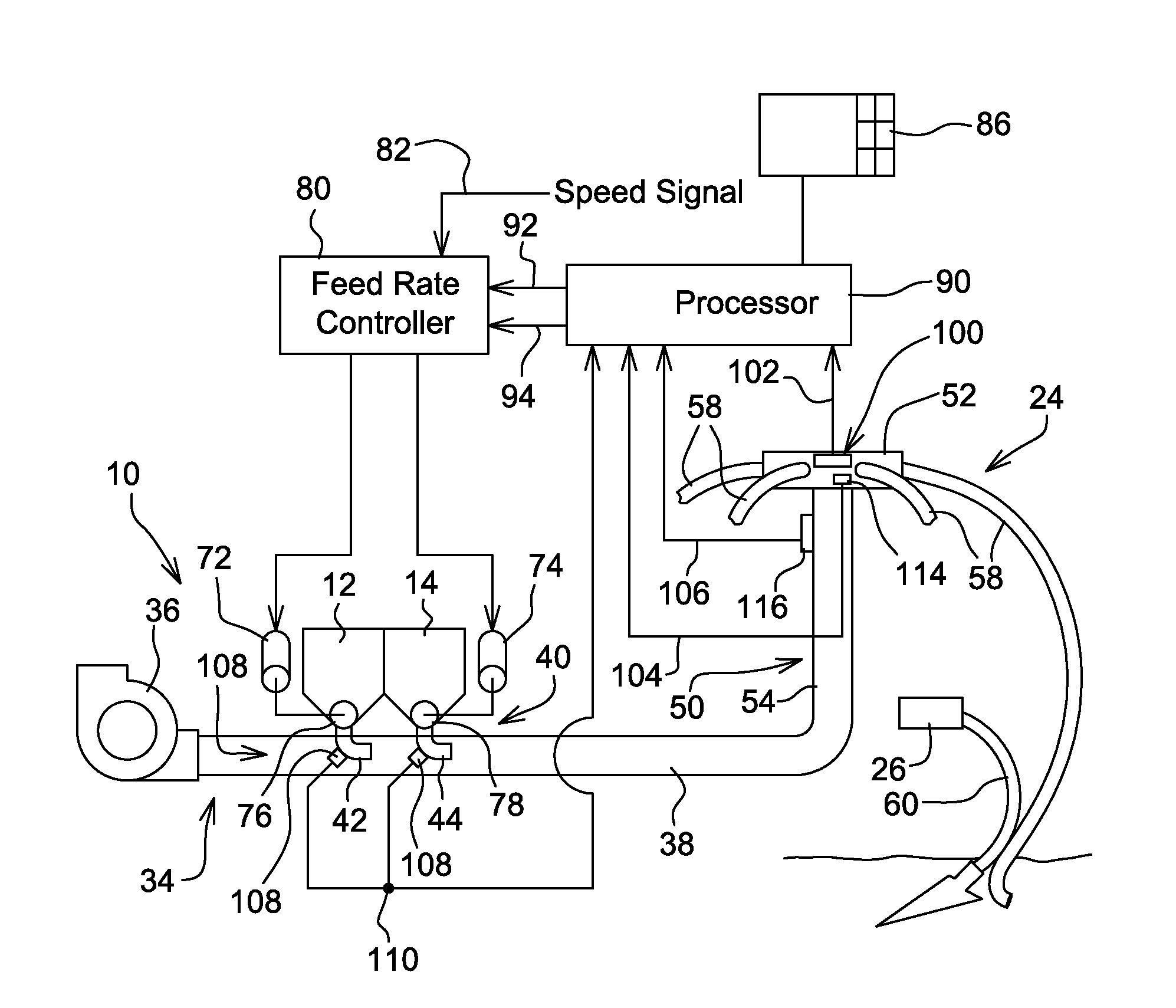

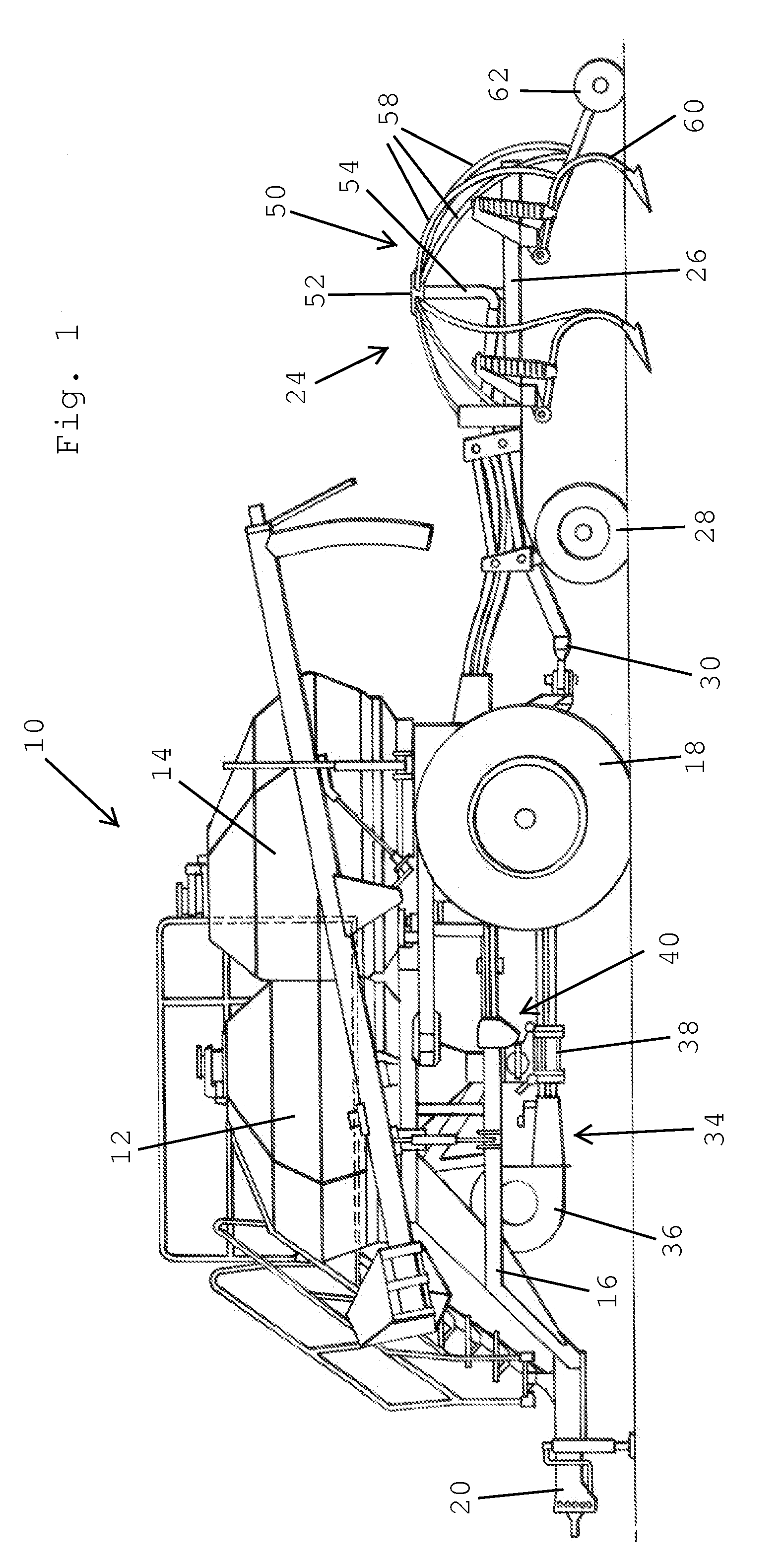

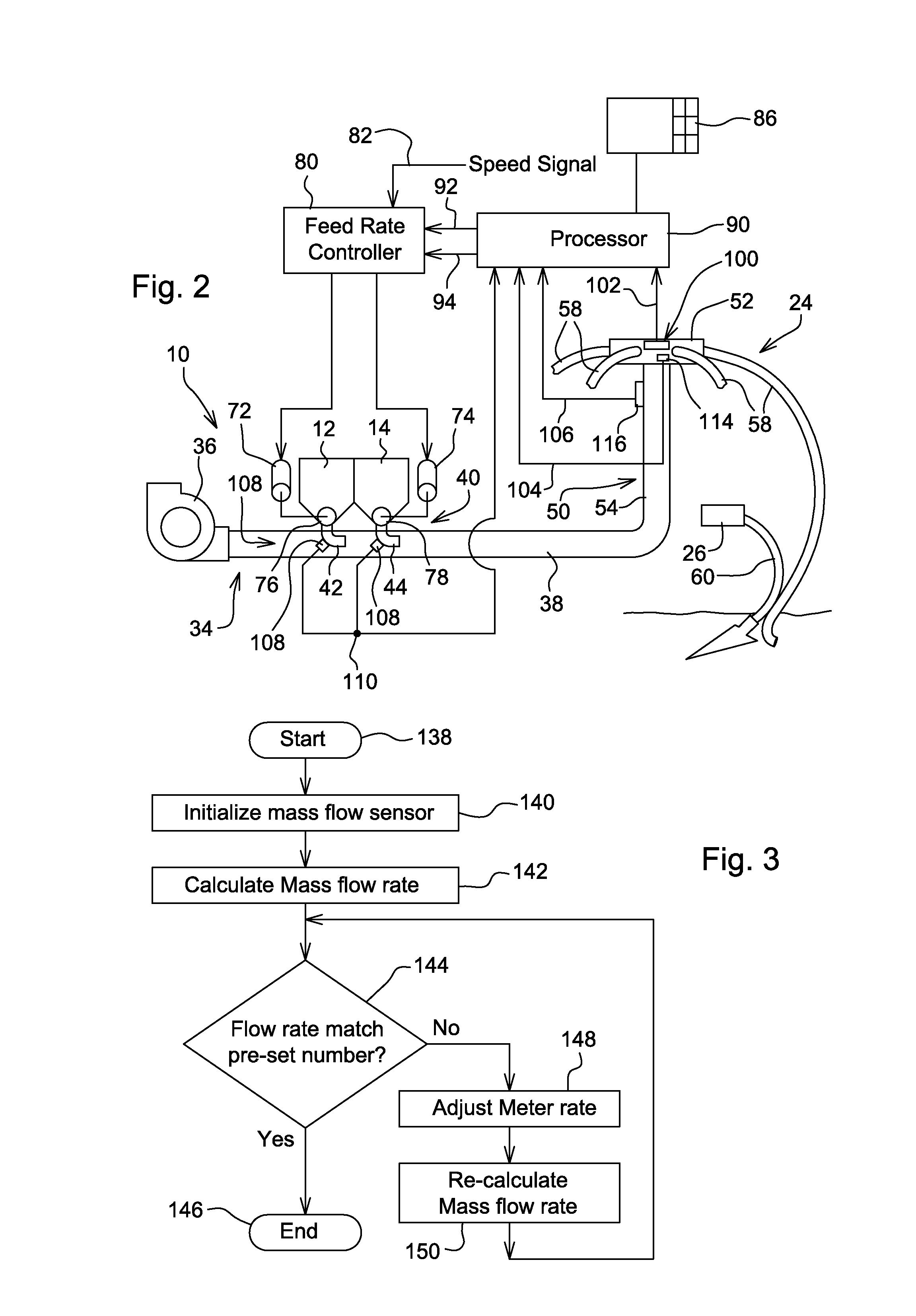

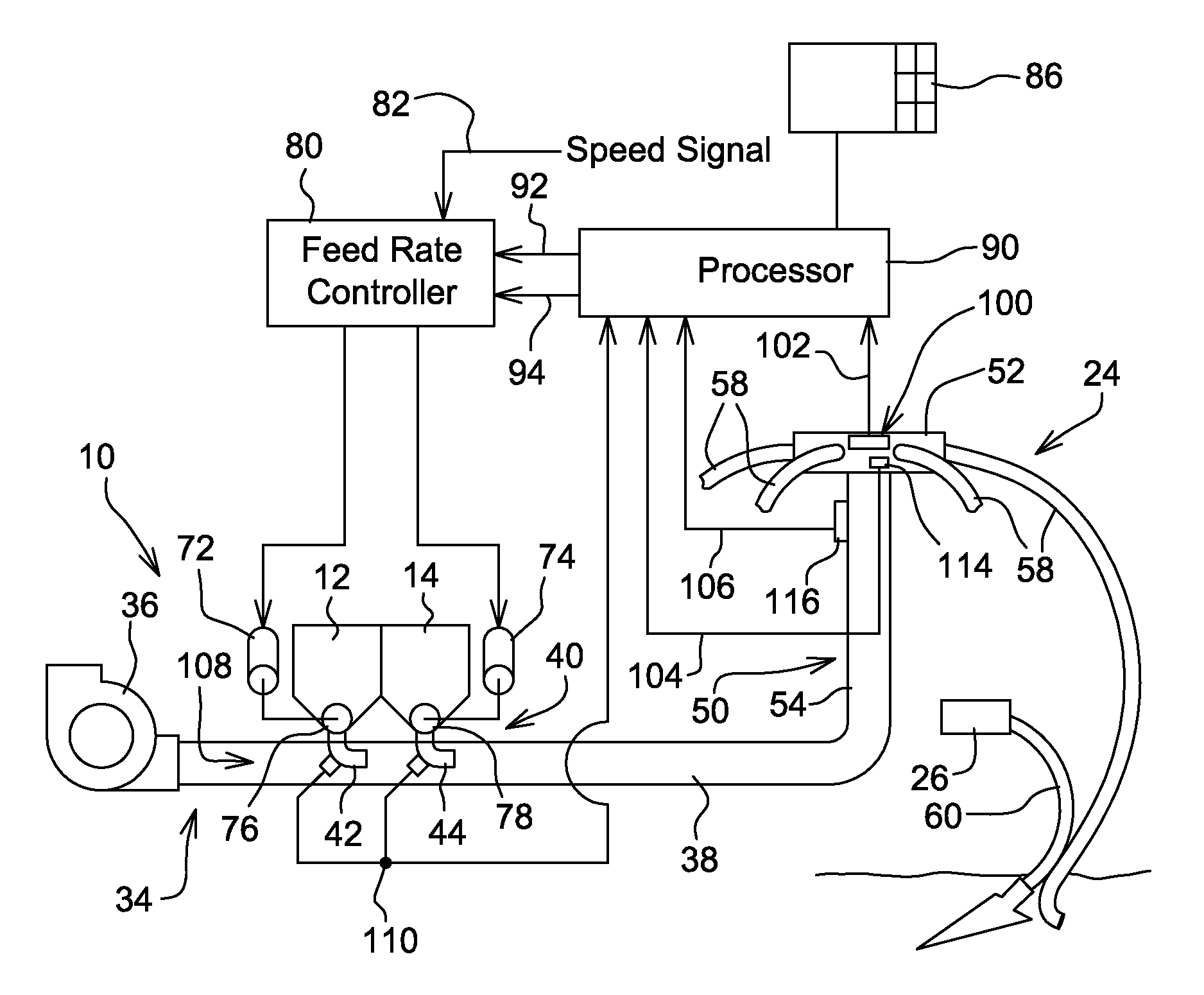

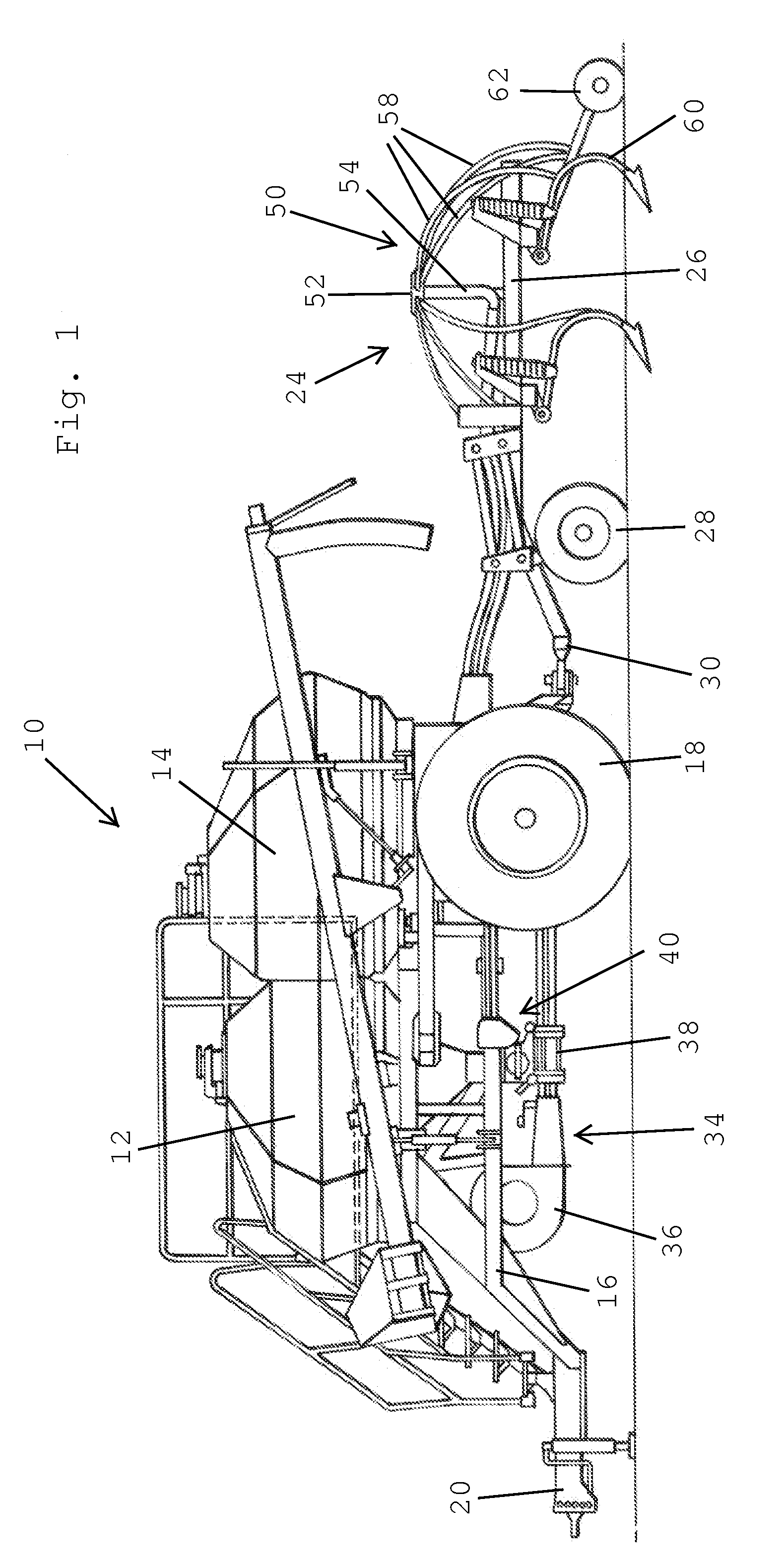

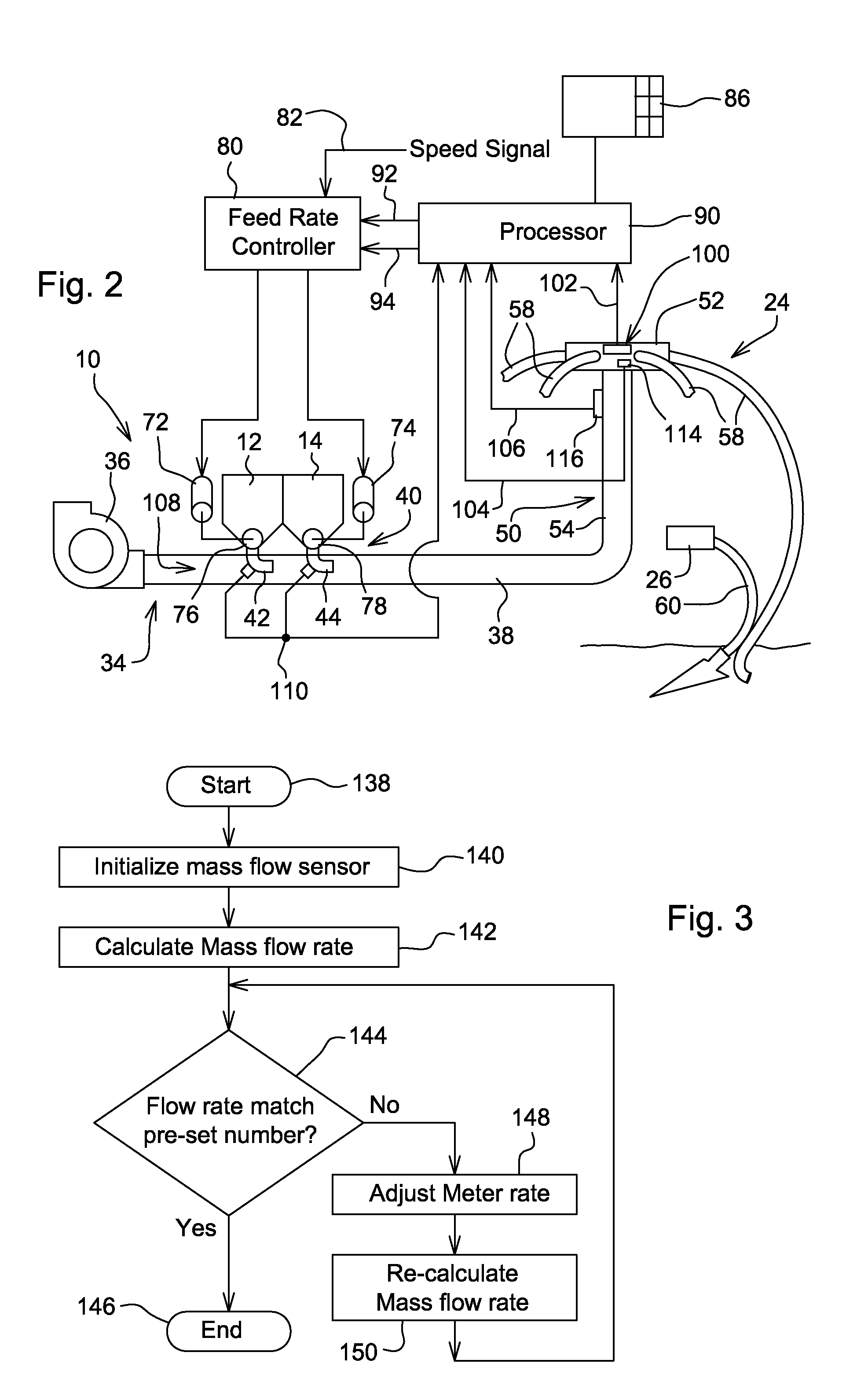

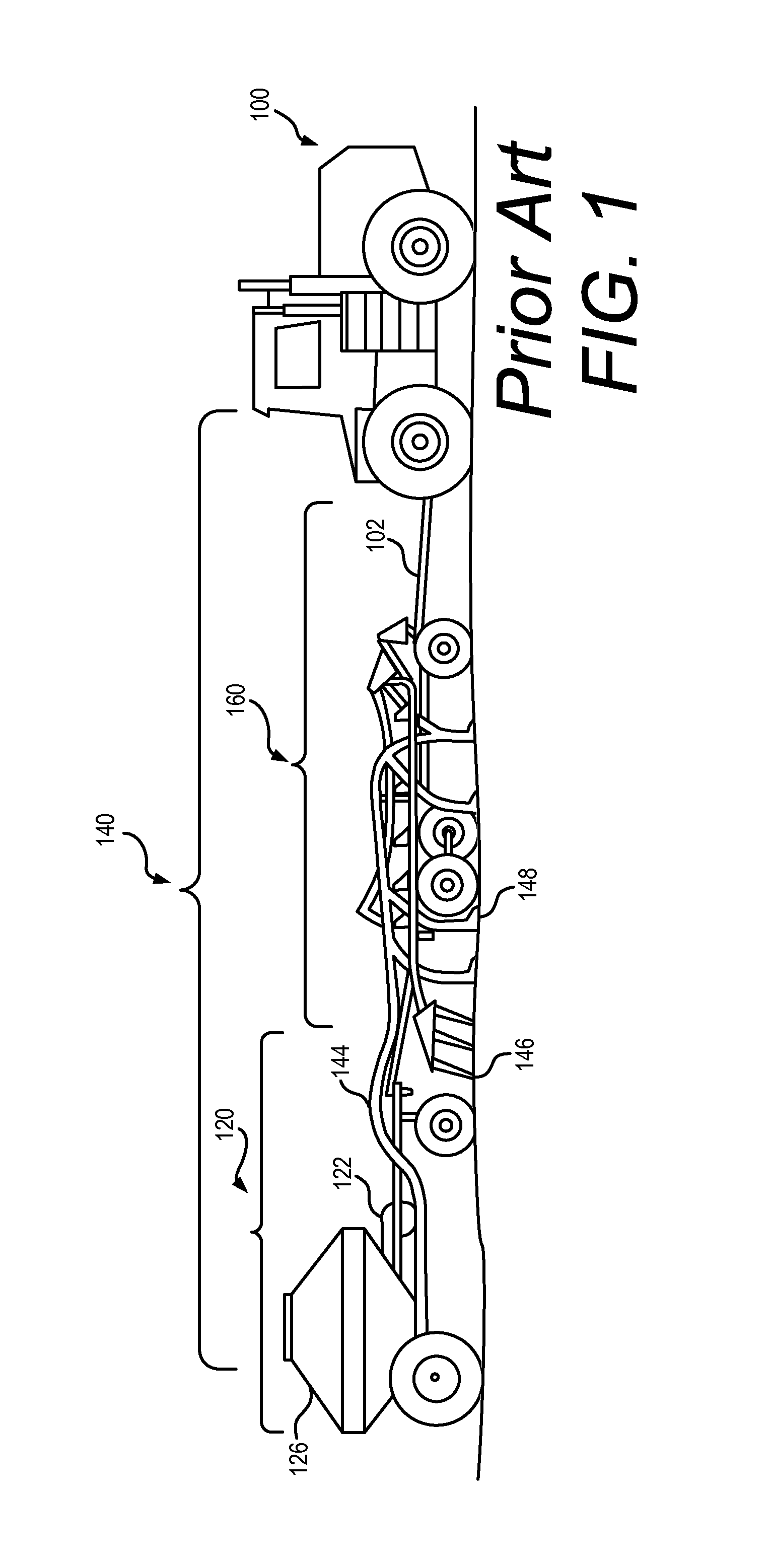

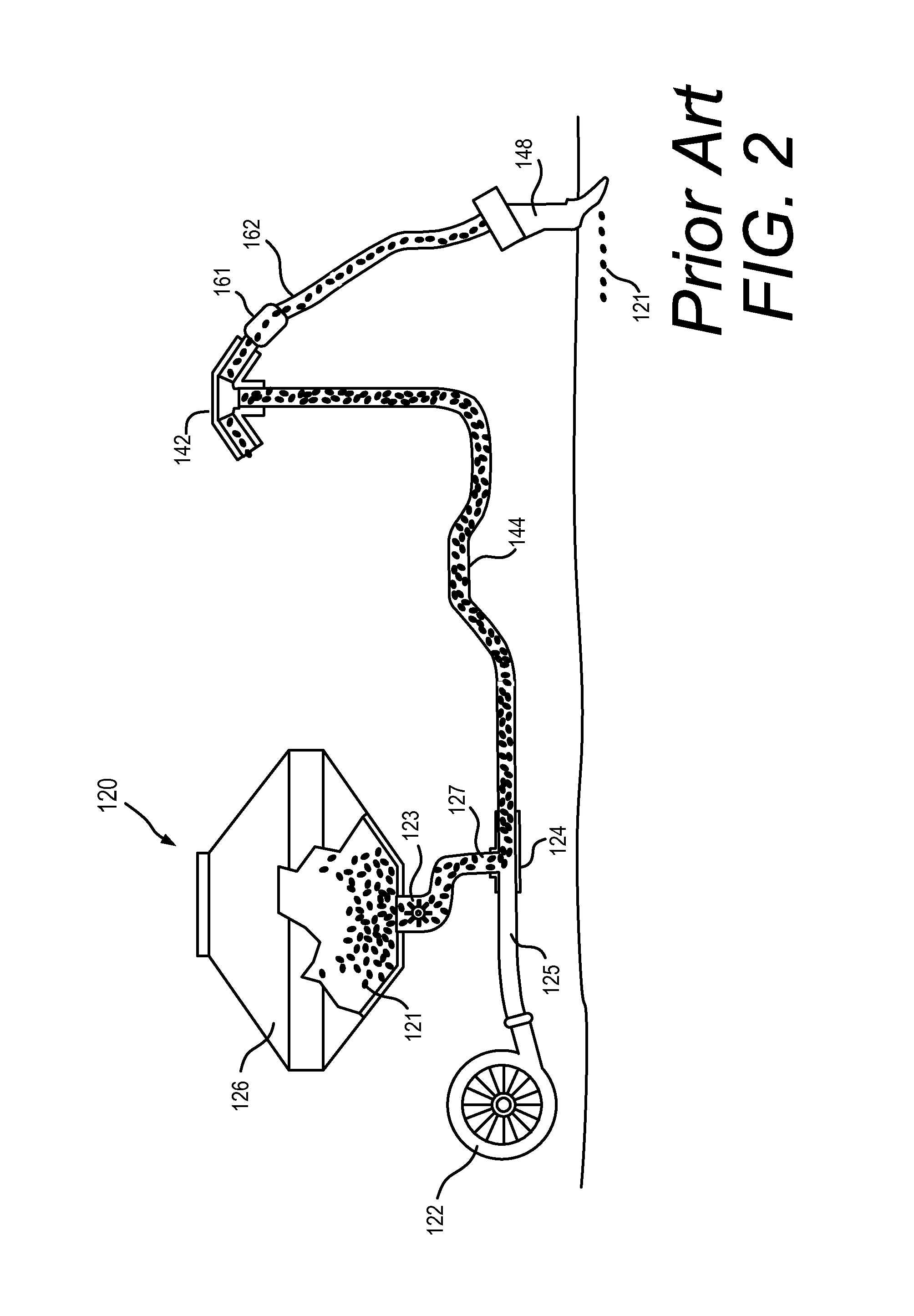

Particulate flow sensing for an agricultural implement

ActiveUS8504310B2Reduce delaysMore accurate seeding and fertilizing ratesFlow propertiesSowingAir velocityEngineering

Owner:DEERE & CO

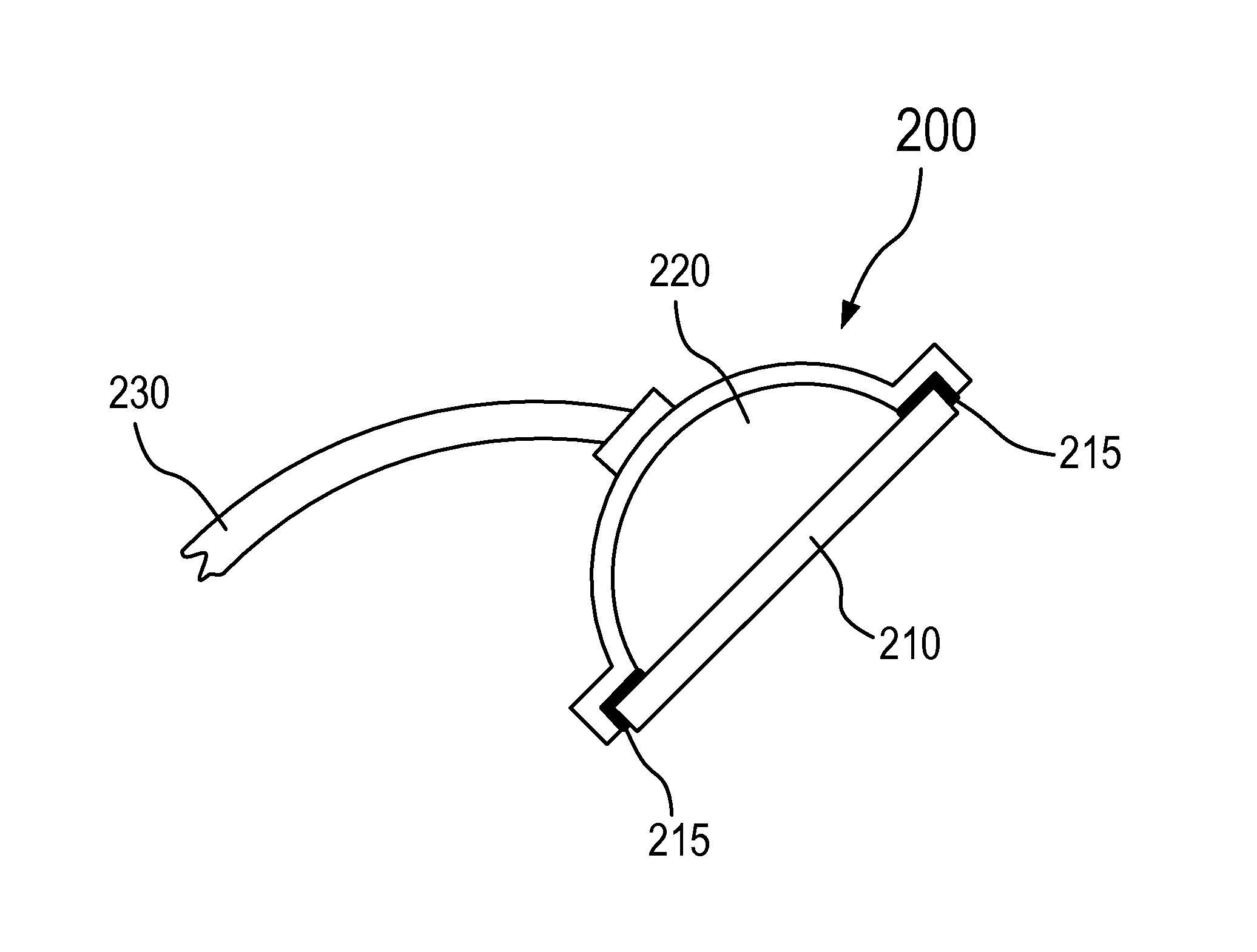

Cleaning assembly for use in fluid filtration systems

ActiveUS20120010063A1Easy to useEasy to disassembleWater/sewage treatment by centrifugal separationSemi-permeable membranesFluid filtrationFluid bearing

Cleaning assemblies and particulate tolerant fluid bearings that are particularly well suited for use in centrifugal separation enhanced filtration devices are described. In one aspect of the invention, at least one bearing is arranged to carry a circulating cleaning assembly such that the cleaning assembly can rotate around a filter membrane during filtering operation of the filtration device. The bearing is preferably arranged to maintain the circulating cleaning assembly in a substantially coaxial alignment with the filter membrane and in a substantially stable longitudinal position relative to the filter membrane as the circulating cleaning assembly is rotated around the filter membrane. In another aspect of the invention a variety of particulate tolerant bearings are described.

Owner:ACCELERATED FILTRATION INC

Particulate flow sensing for an agricultural implement

ActiveUS20110035163A1Reduce delaysMore accurate seeding and fertilizing ratesFlow propertiesSowingAir velocityEngineering

An impact sensor is located in a distribution tower which divides the seed and / or nutrient flow into individual rows, and a second sensor provides a compensation signal dependent upon one or more variables such as the velocity of the air in the conveying system, implement vibrations. As the seed / fertilizer bounces off of the impact sensor and flows into the individual row air streams, the impact sensor provides a force signal to a processor which calculates the total particulate mass flow rate from the force signal and the air velocity signal. To determine individual seed and fertilizer rates, a rate controller temporarily changes the metering rate of one of the materials, and the processor then calculates the desired information from the mass flow change and meter speed change. Another embodiment includes seed sensor structure at the meter output for achieving or confirming accuracy.

Owner:DEERE & CO

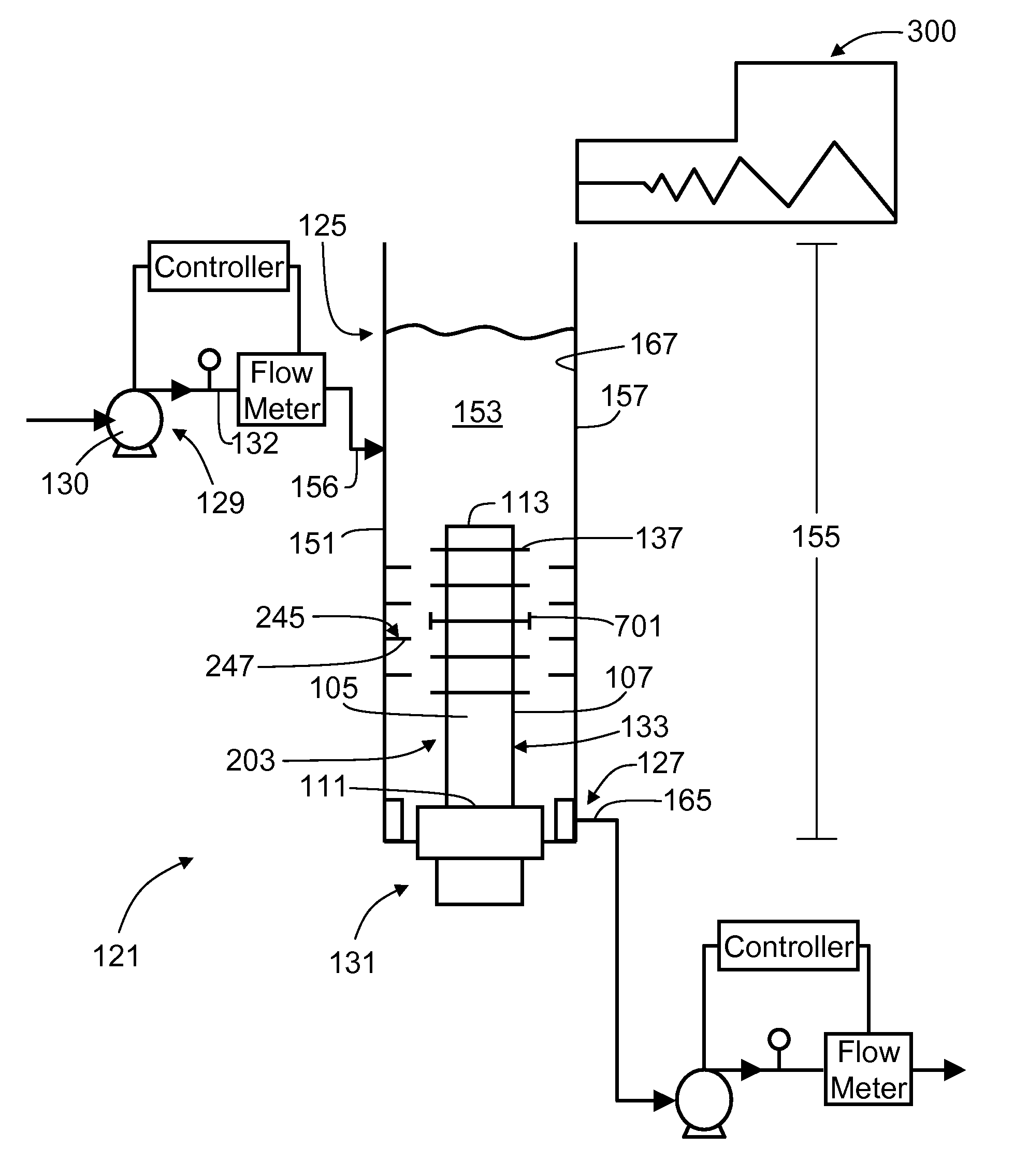

Ultrasonic treatment chamber for particle dispersion into formulations

ActiveUS20090168591A1Shaking/oscillating/vibrating mixersFlow mixersUltrasonic cavitationDynamic motion

An ultrasonic mixing system having a particulate dispensing system to dispense particulates into a treatment chamber and the treatment chamber in which particulates can be mixed with one or more formulations is disclosed. Specifically, the treatment chamber has an elongate housing through which a formulation and particulates flow longitudinally from an inlet port to an outlet port thereof. An elongate ultrasonic waveguide assembly extends within the housing and is operable at a predetermined ultrasonic frequency to ultrasonically energize the formulation and particulates within the housing. An elongate ultrasonic horn of the waveguide assembly is disposed at least in part intermediate the inlet and outlet ports, and has a plurality of discrete agitating members in contact with and extending transversely outward from the horn intermediate the inlet and outlet ports in longitudinally spaced relationship with each other. The horn and agitating members are constructed and arranged for dynamic motion of the agitating members relative to the horn at the predetermined frequency and to operate in an ultrasonic cavitation mode of the agitating members corresponding to the predetermined frequency and the formulation and particulates being mixed in the chamber.

Owner:KIMBERLY-CLARK WORLDWIDE INC

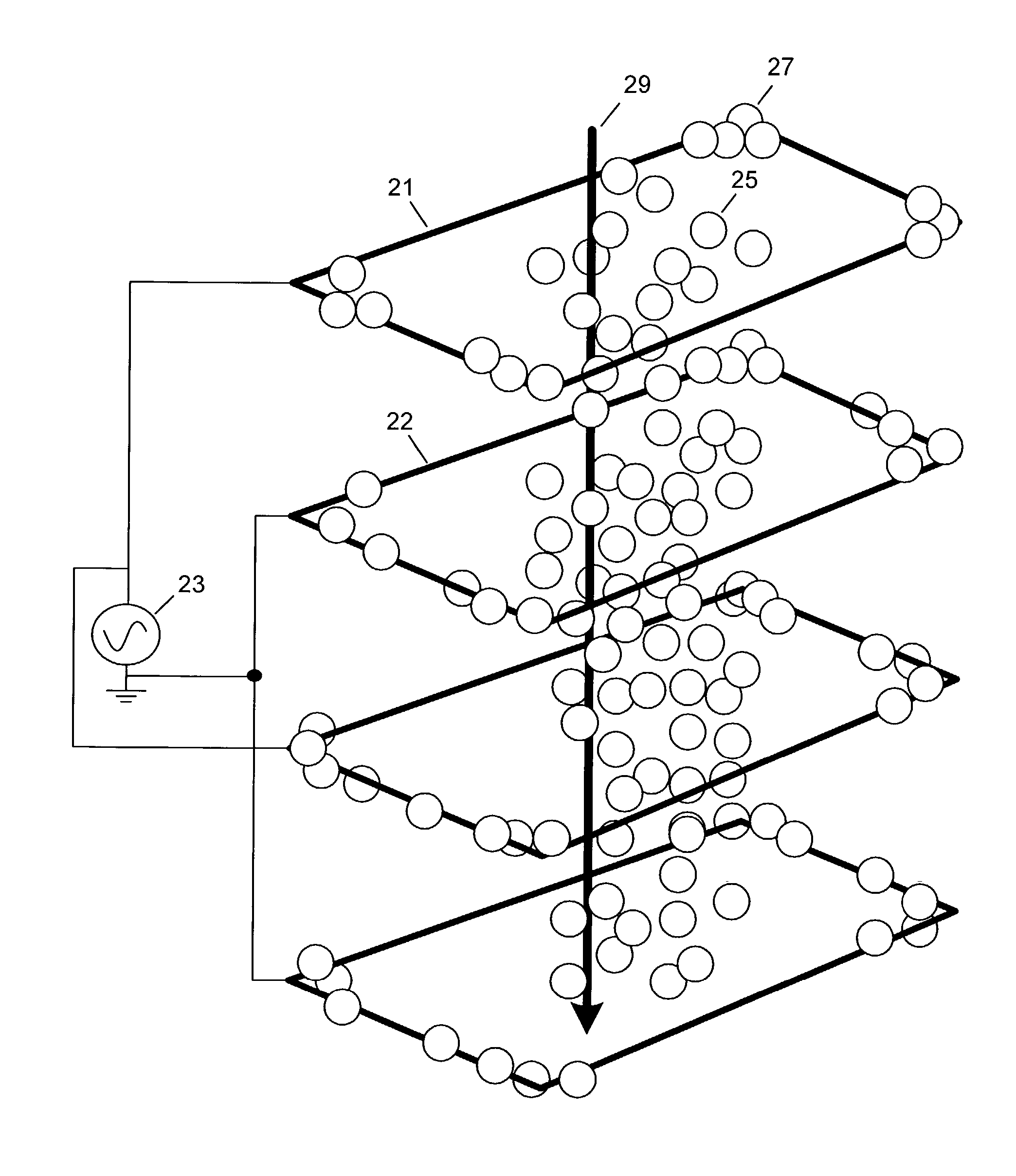

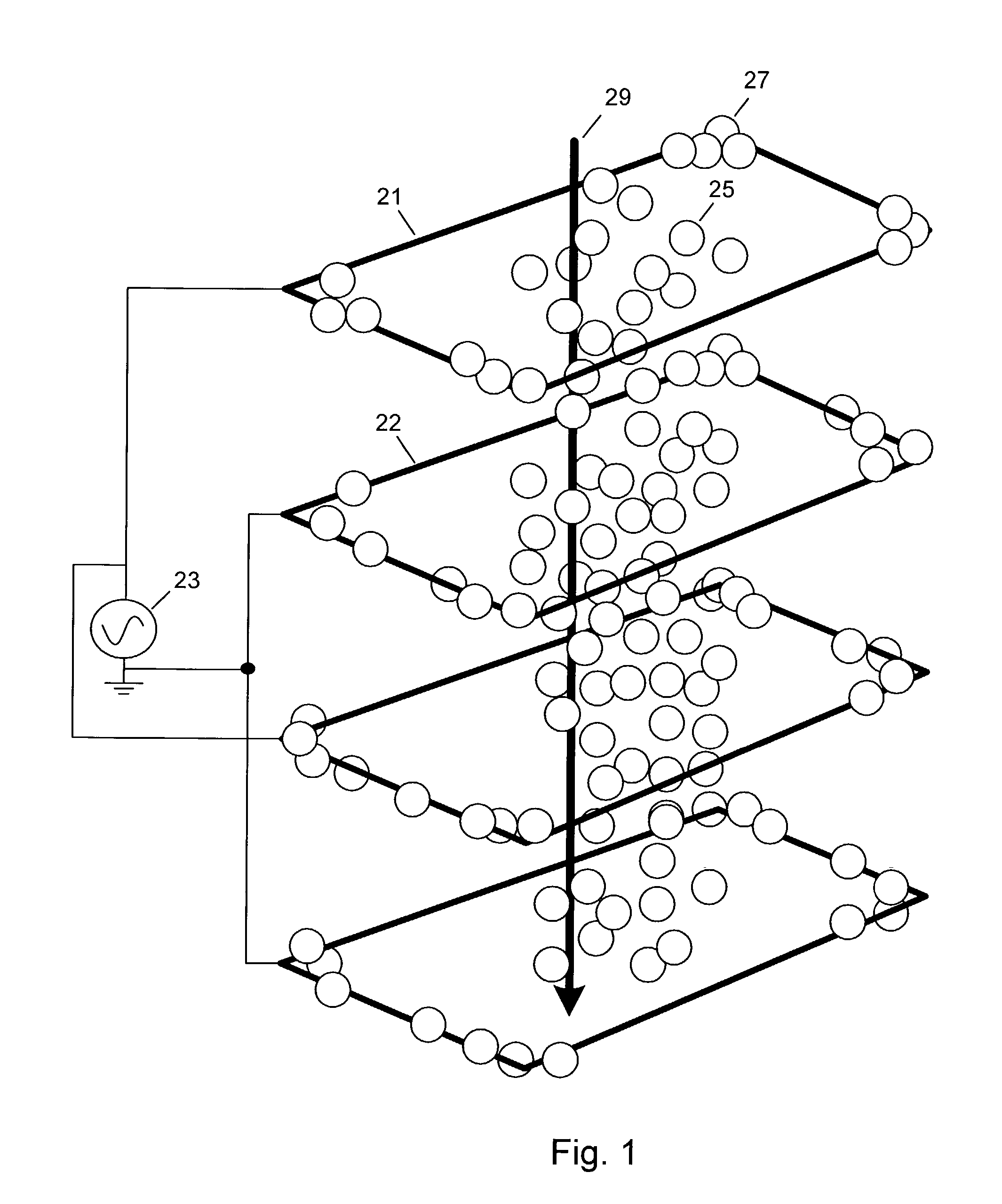

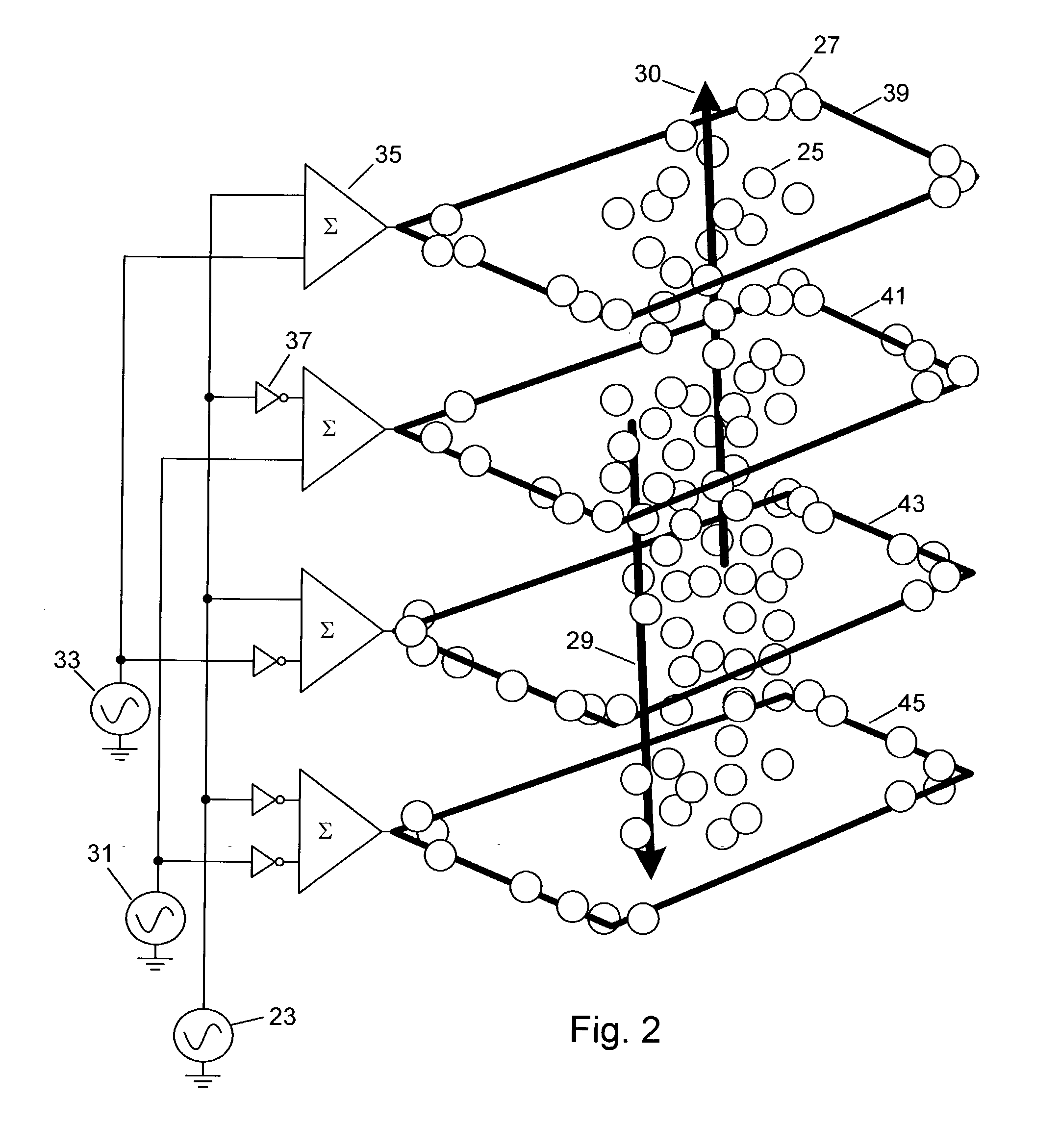

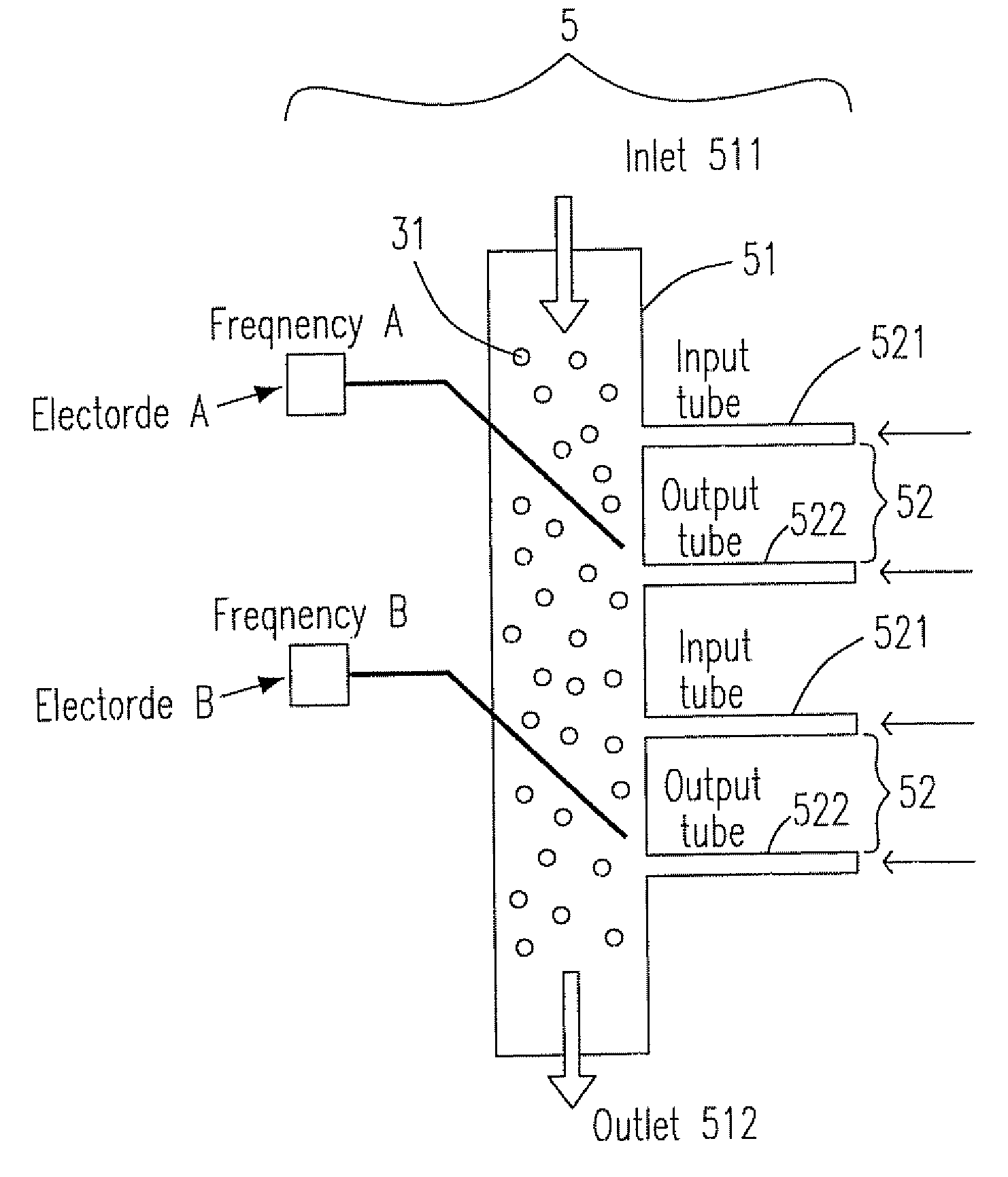

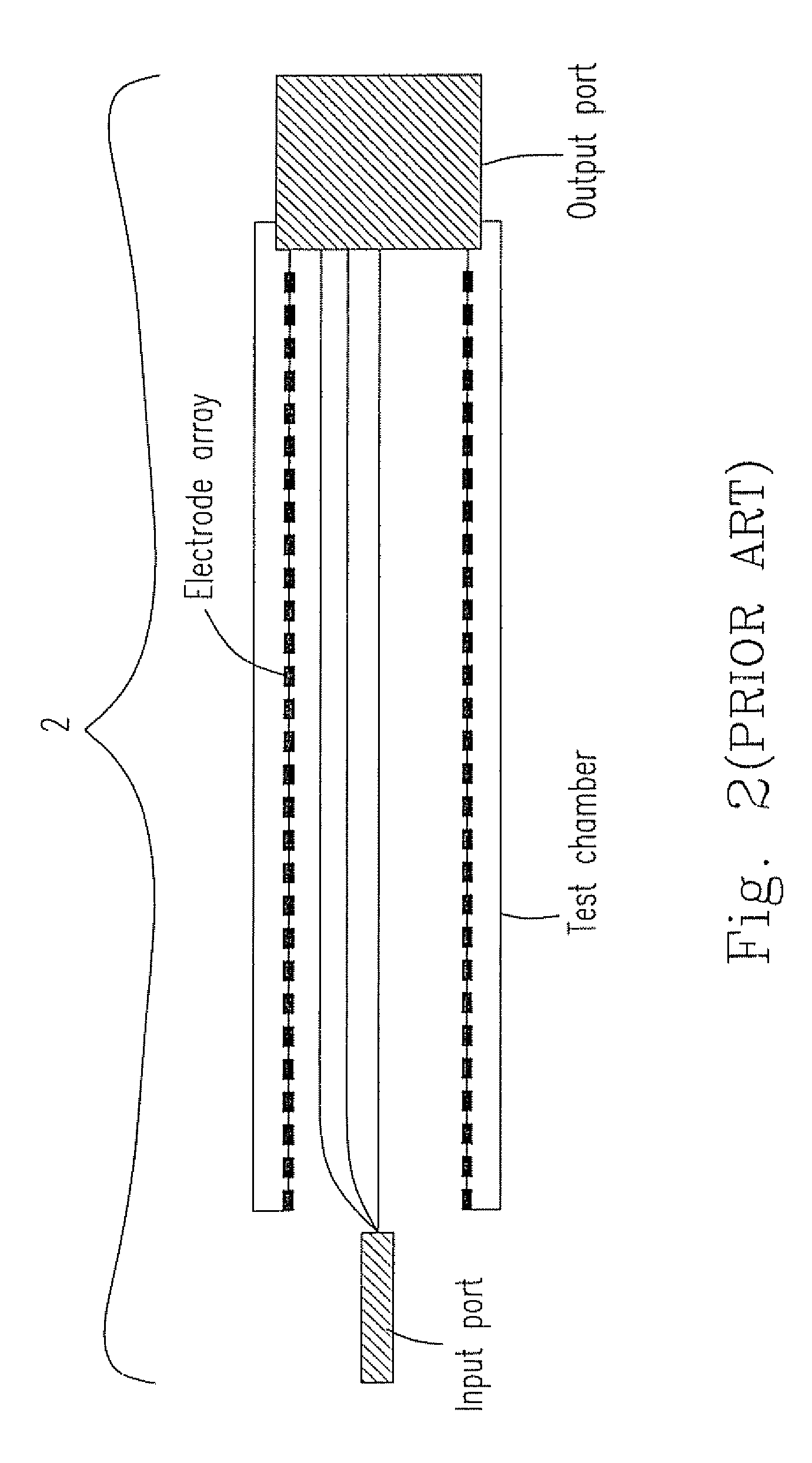

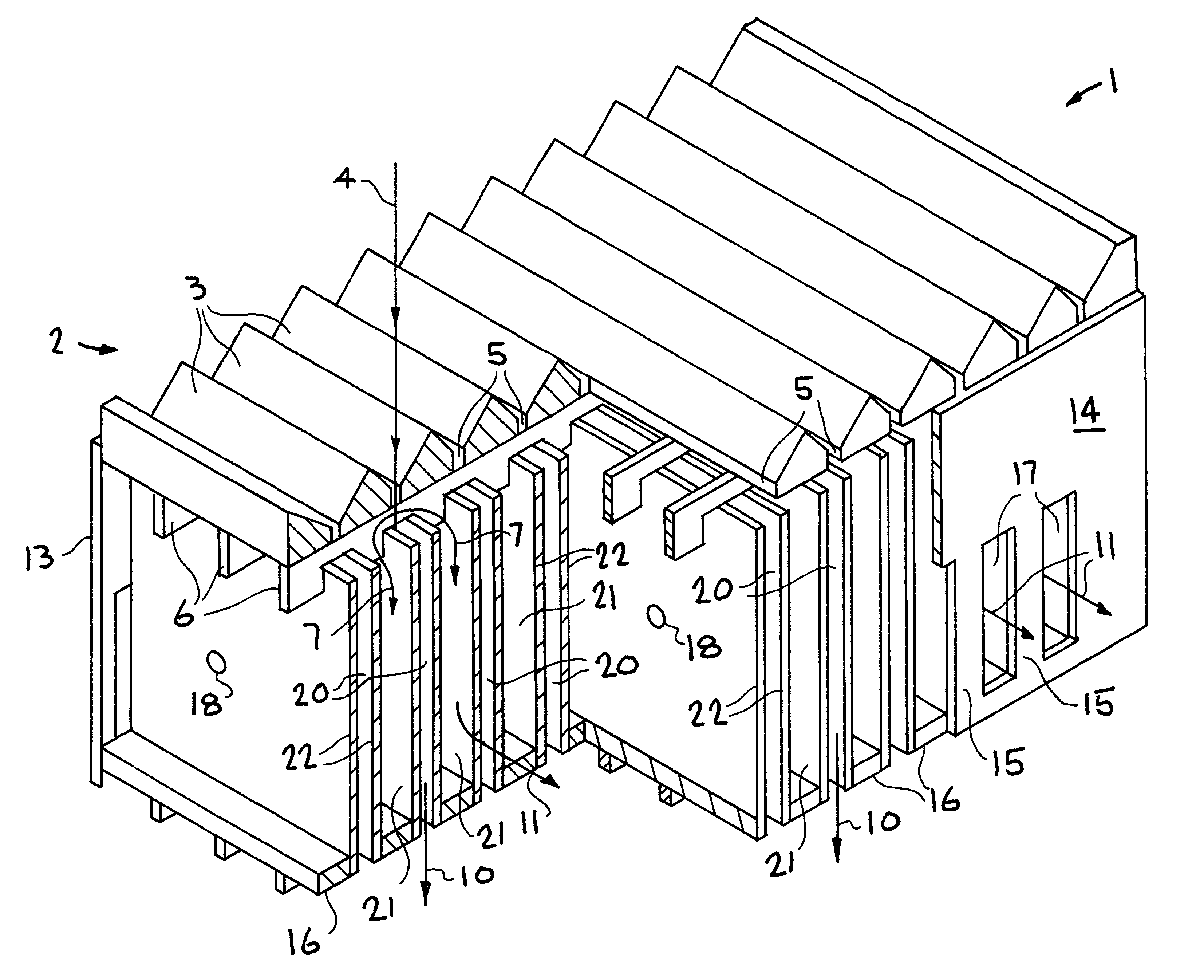

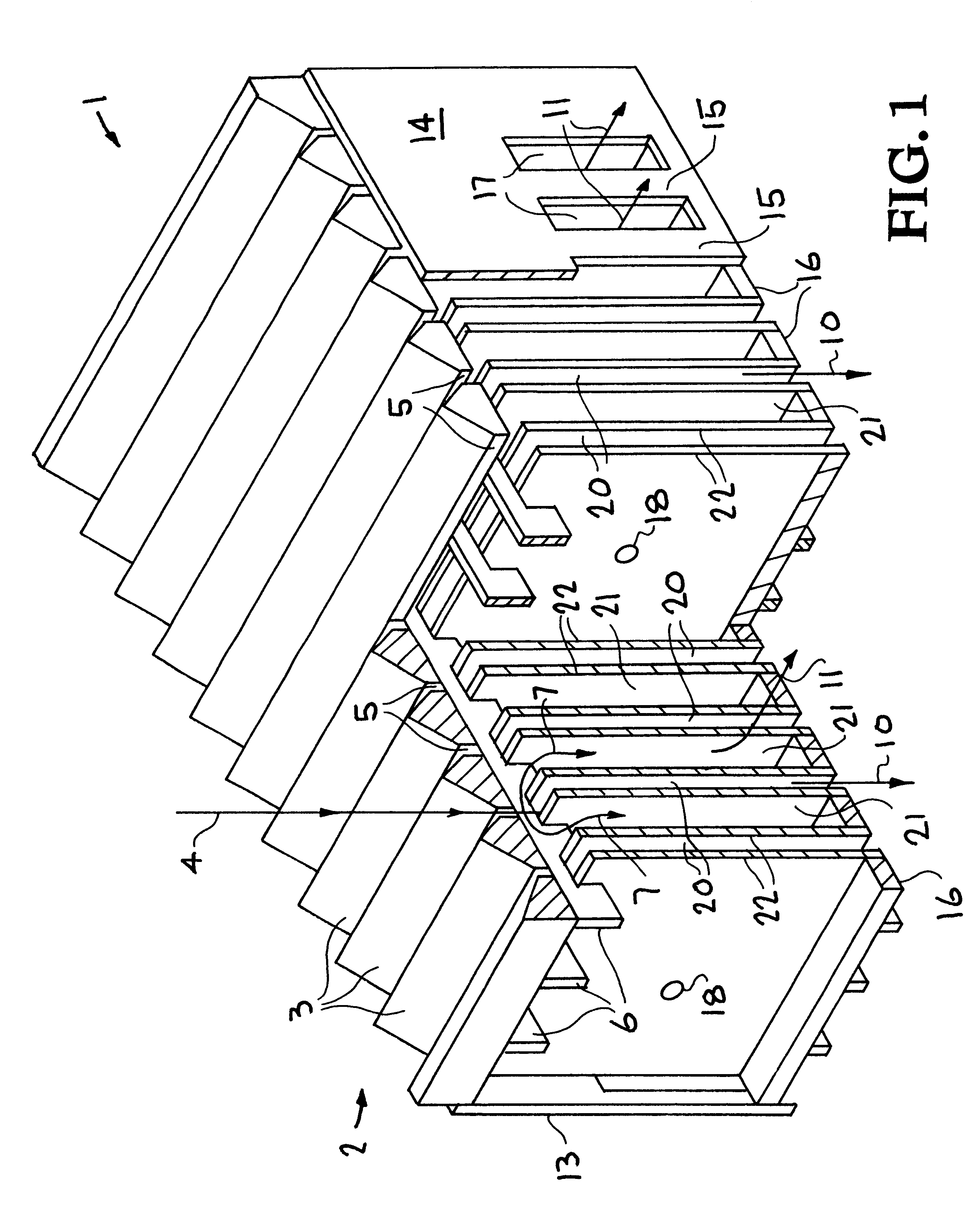

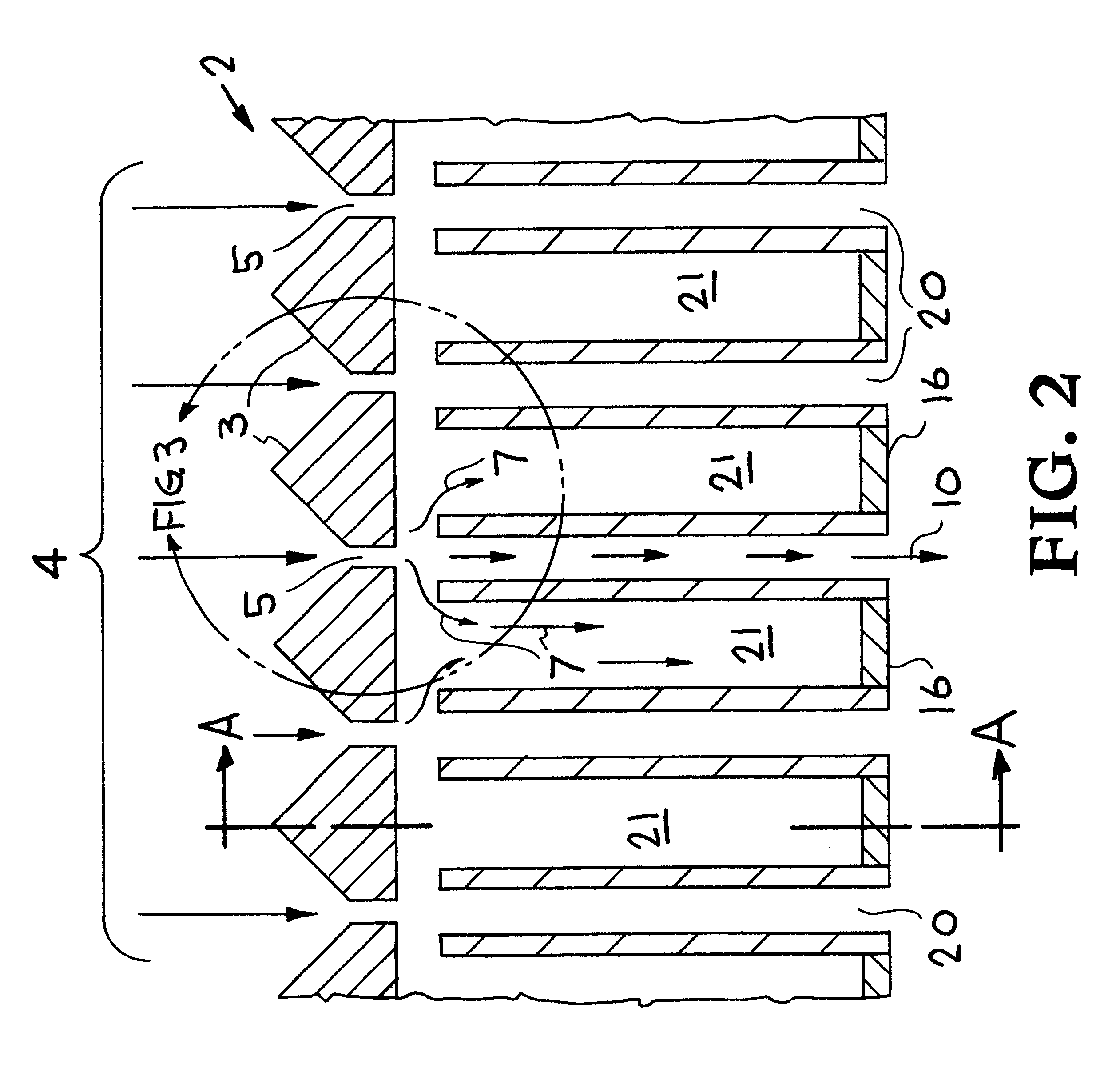

Separation of particles using multiple conductive layers

InactiveUS20040011652A1Increase the number of samplesSludge treatmentElectrostatic separatorsSignal generatorCondensed matter physics

An apparatus is disclosed which separates particles with different dielectric properties. The apparatus restricts the flow of some particles (27) through a three dimensional array of conductive layers (21) (22) while allowing other particles (25) to flow through. The separation process is controlled by electrical signal generators (23) that are connected to the conductive layers.

Owner:BRESSLER VINCENT EDWARD

Air seeder monitoring and equalization system using acoustic sensors

ActiveUS8950260B2Ensure efficient flowReduce complexityVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesElectricitySeeder

Owner:INTELLIGENT AGRI SOLUTIONS LLC

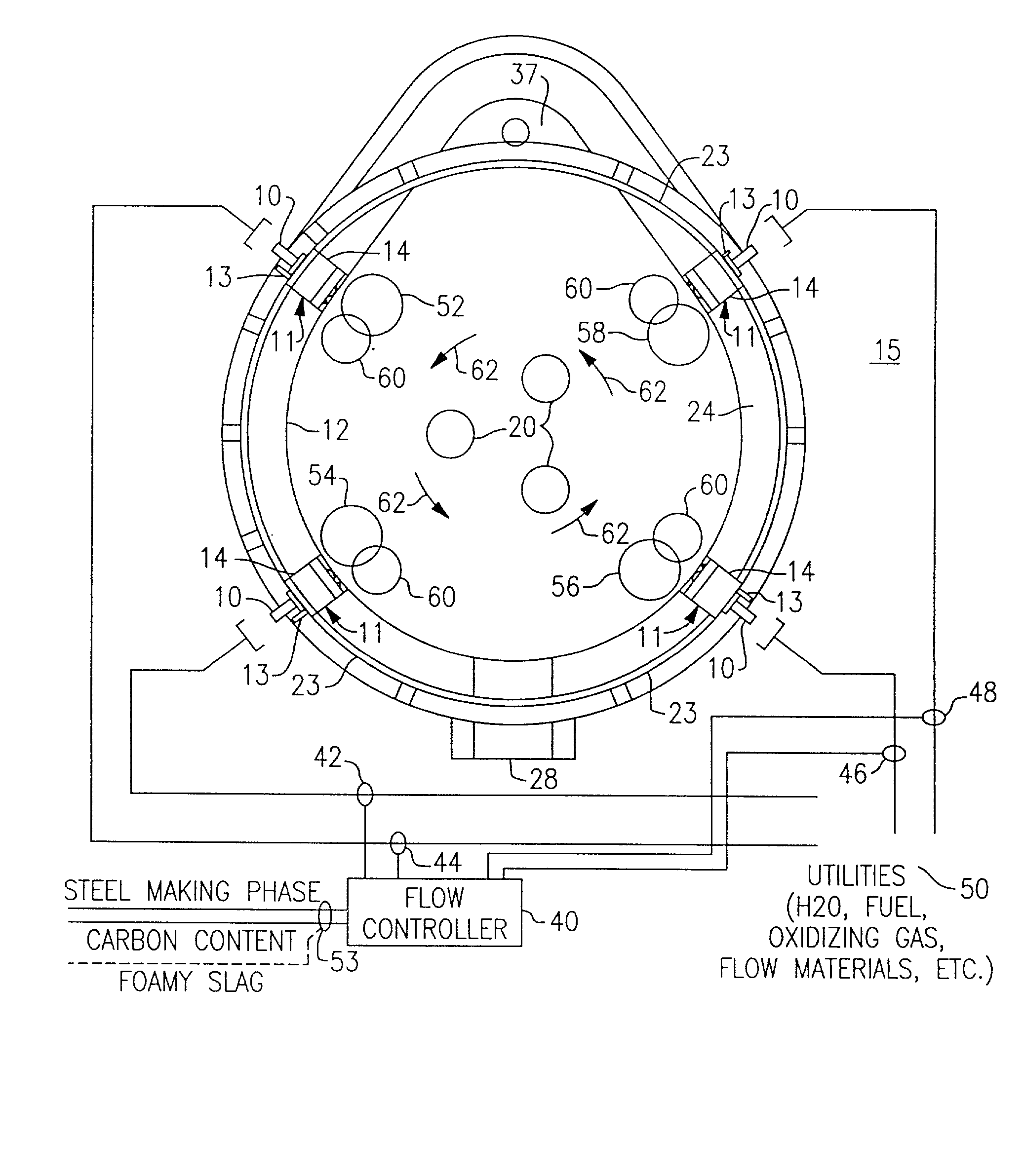

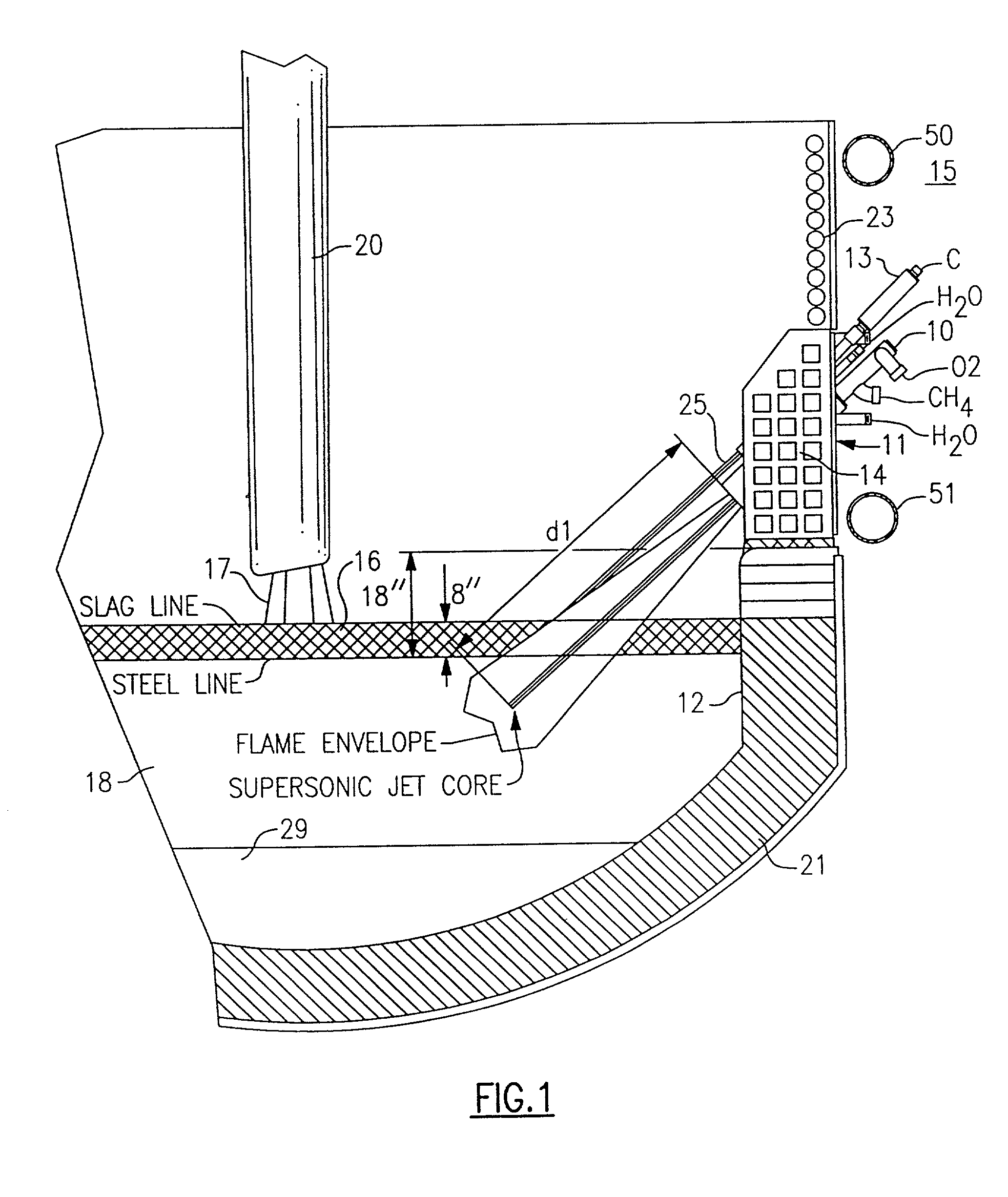

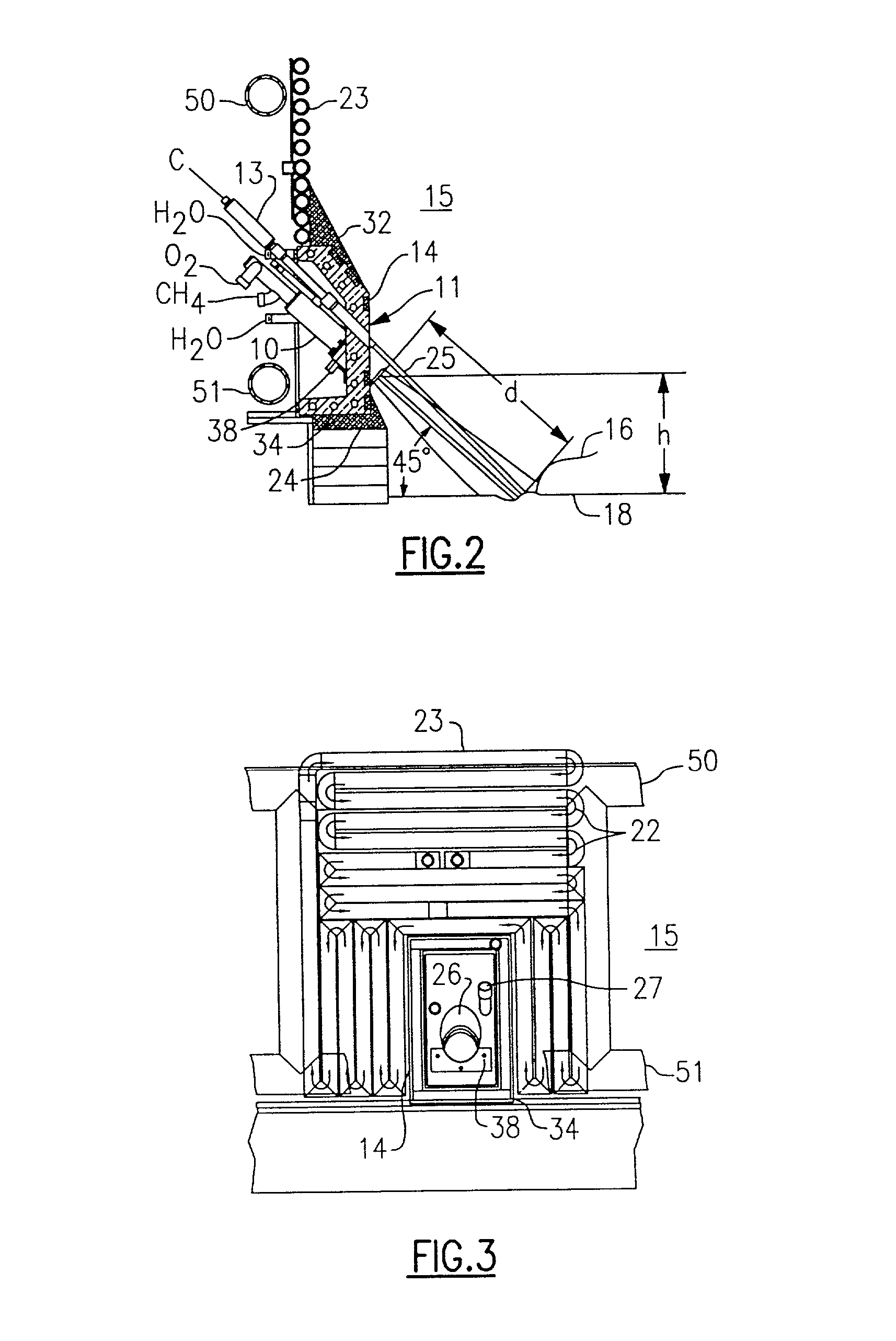

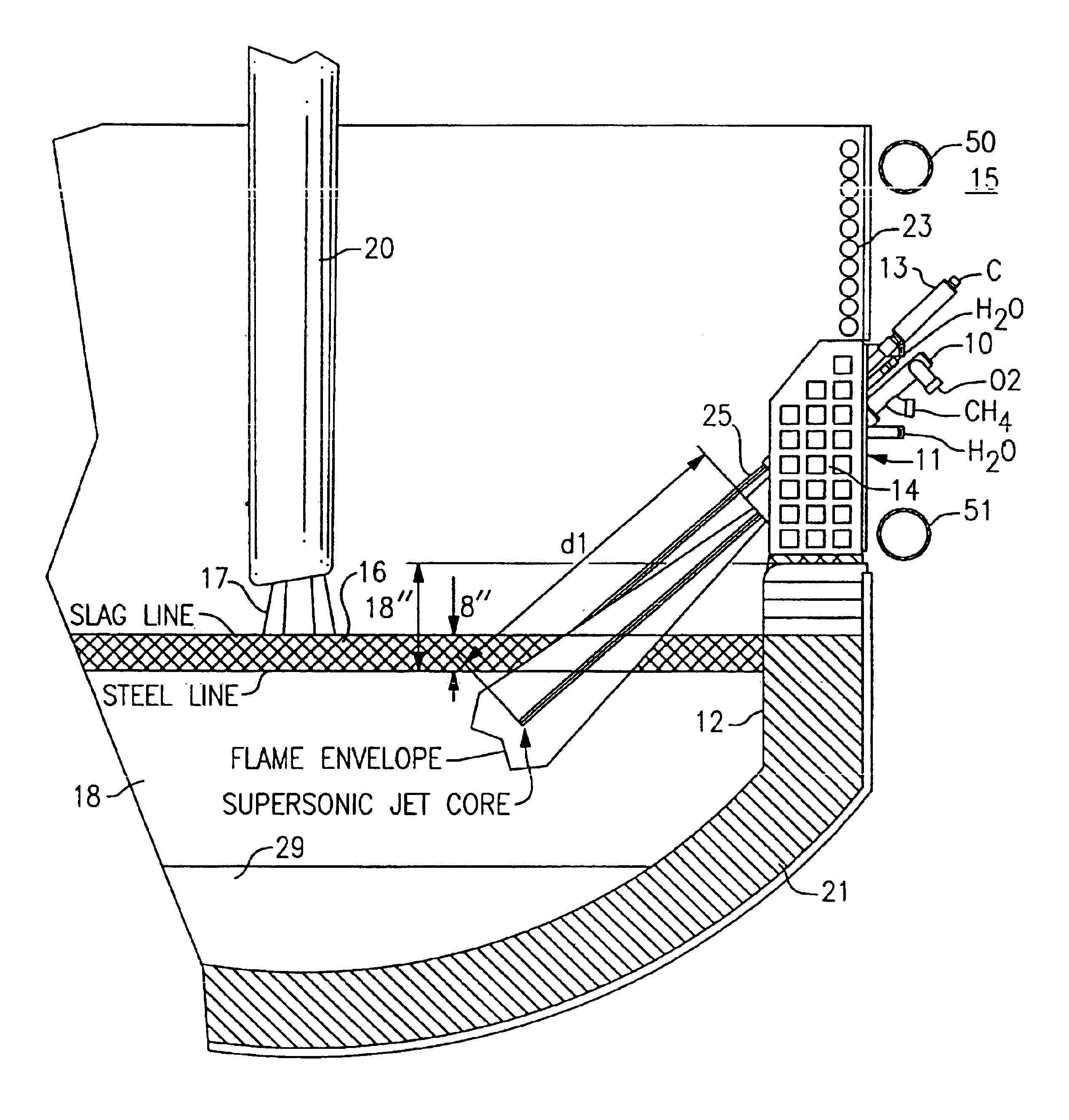

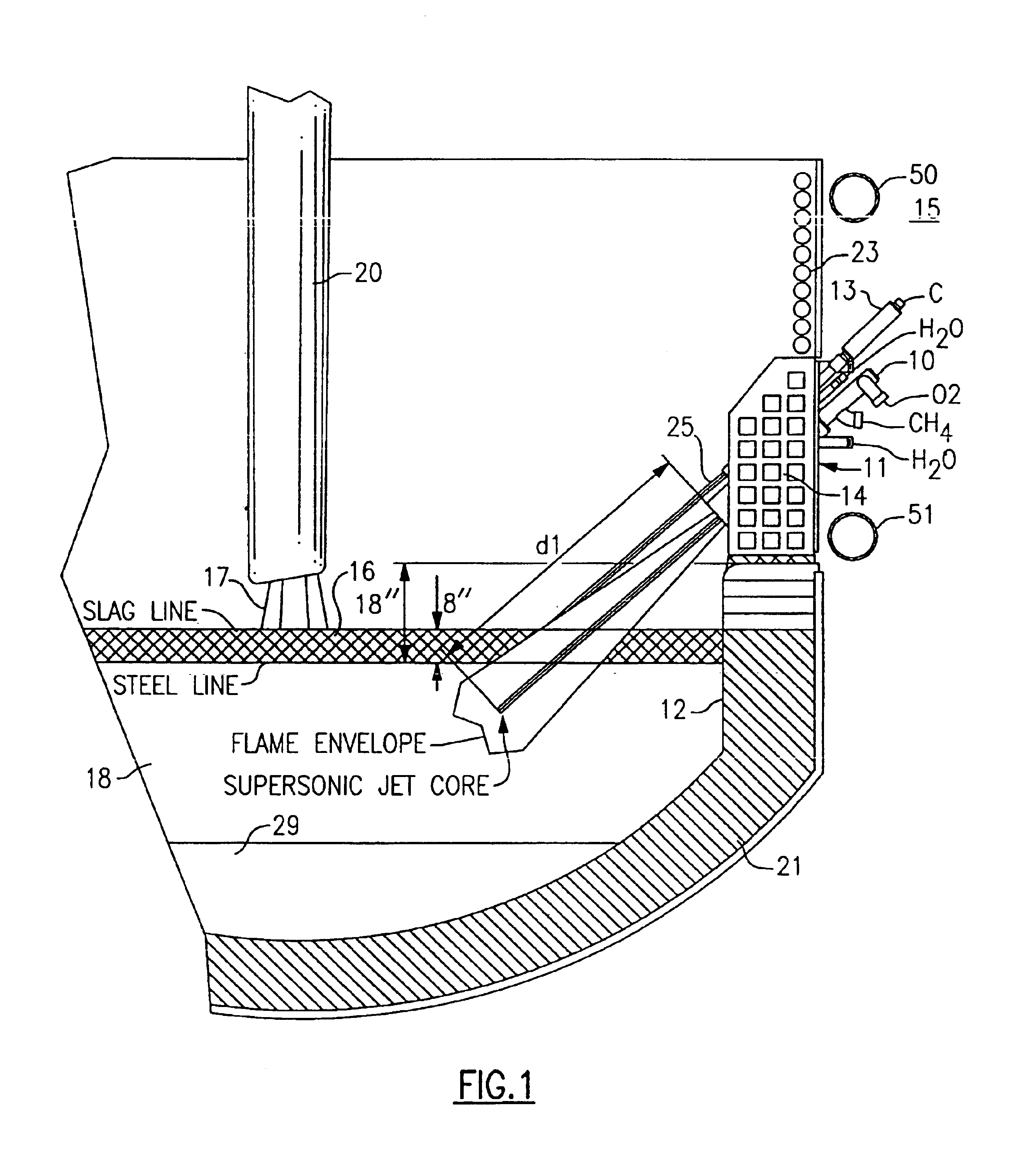

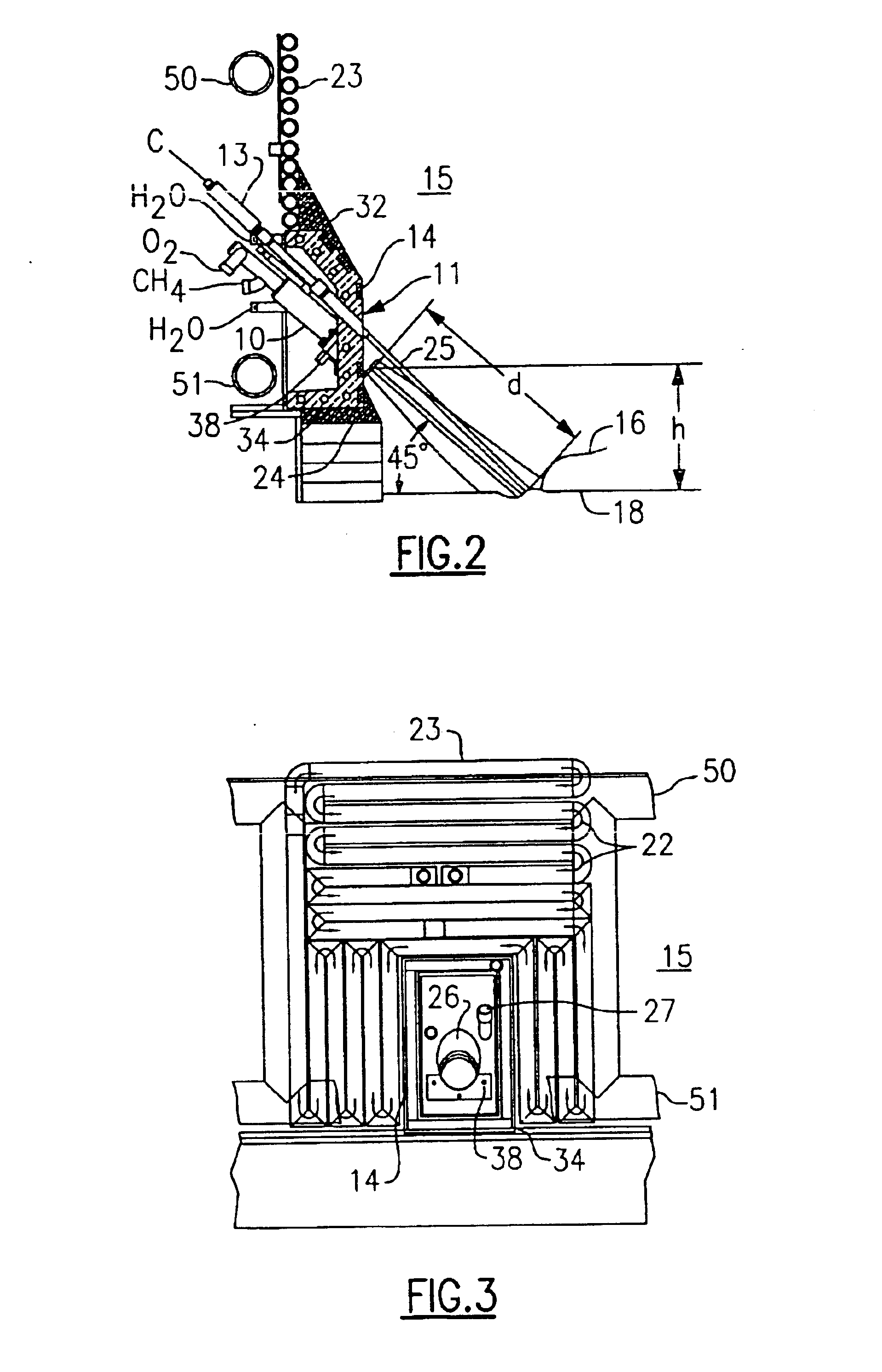

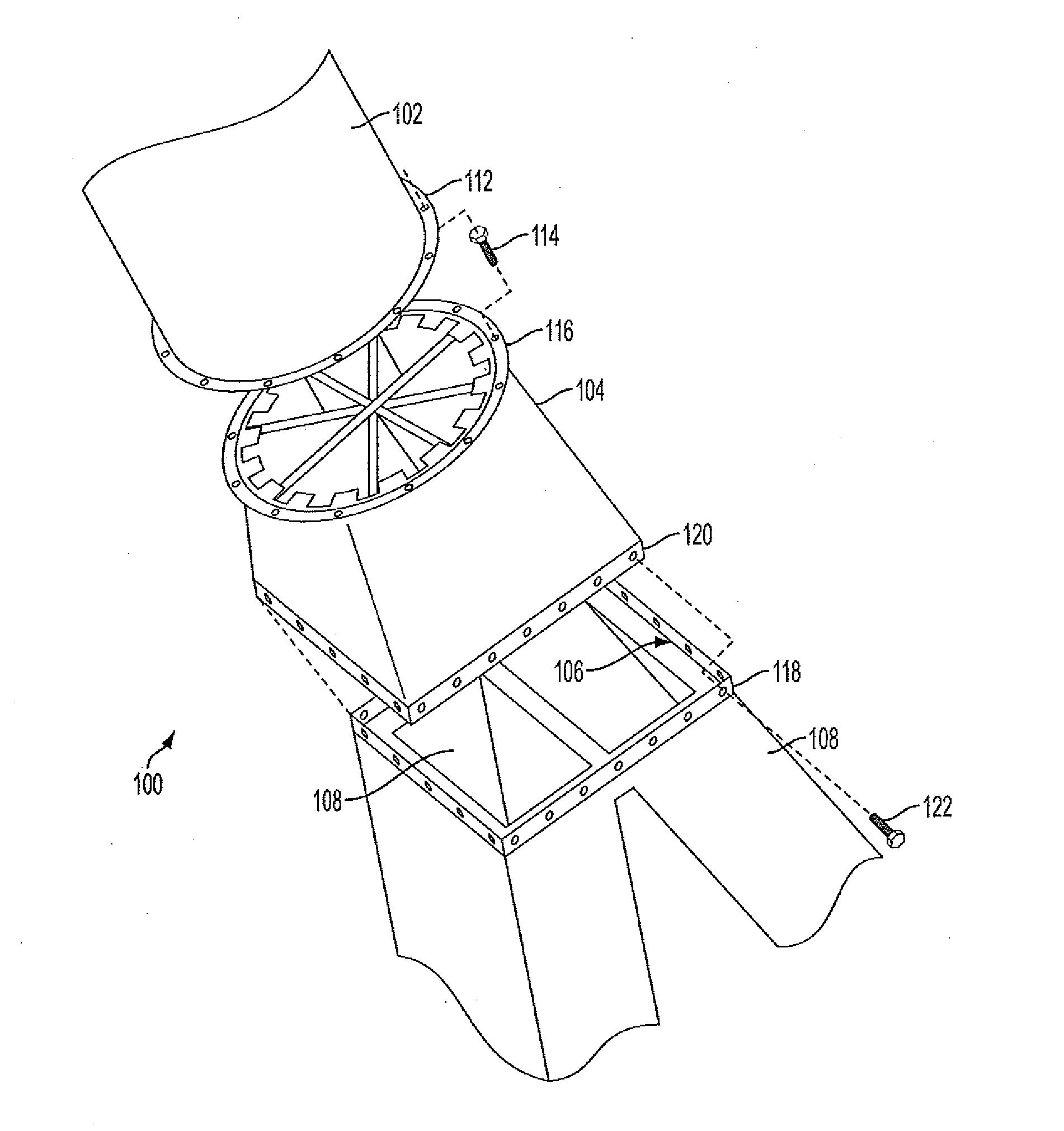

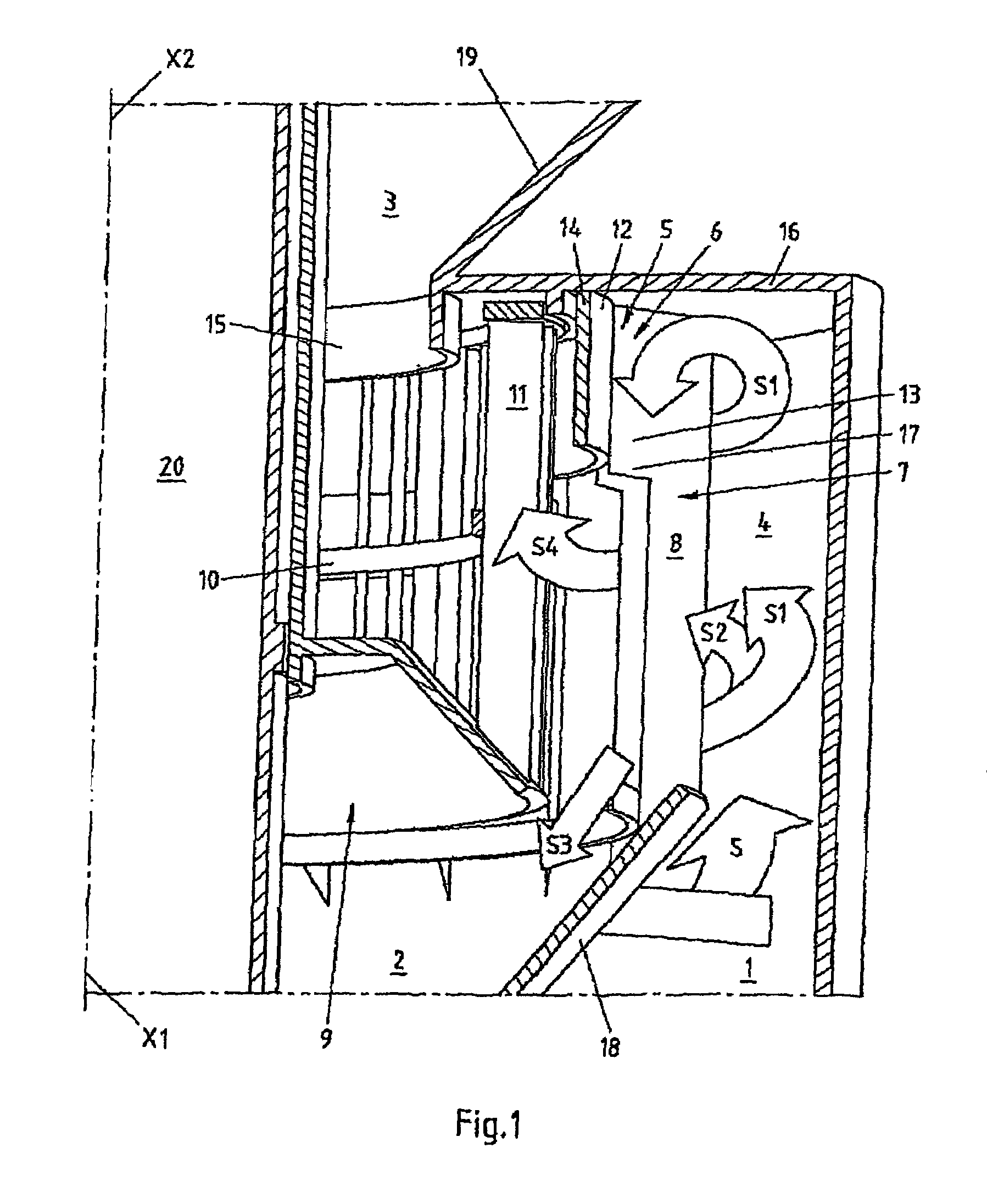

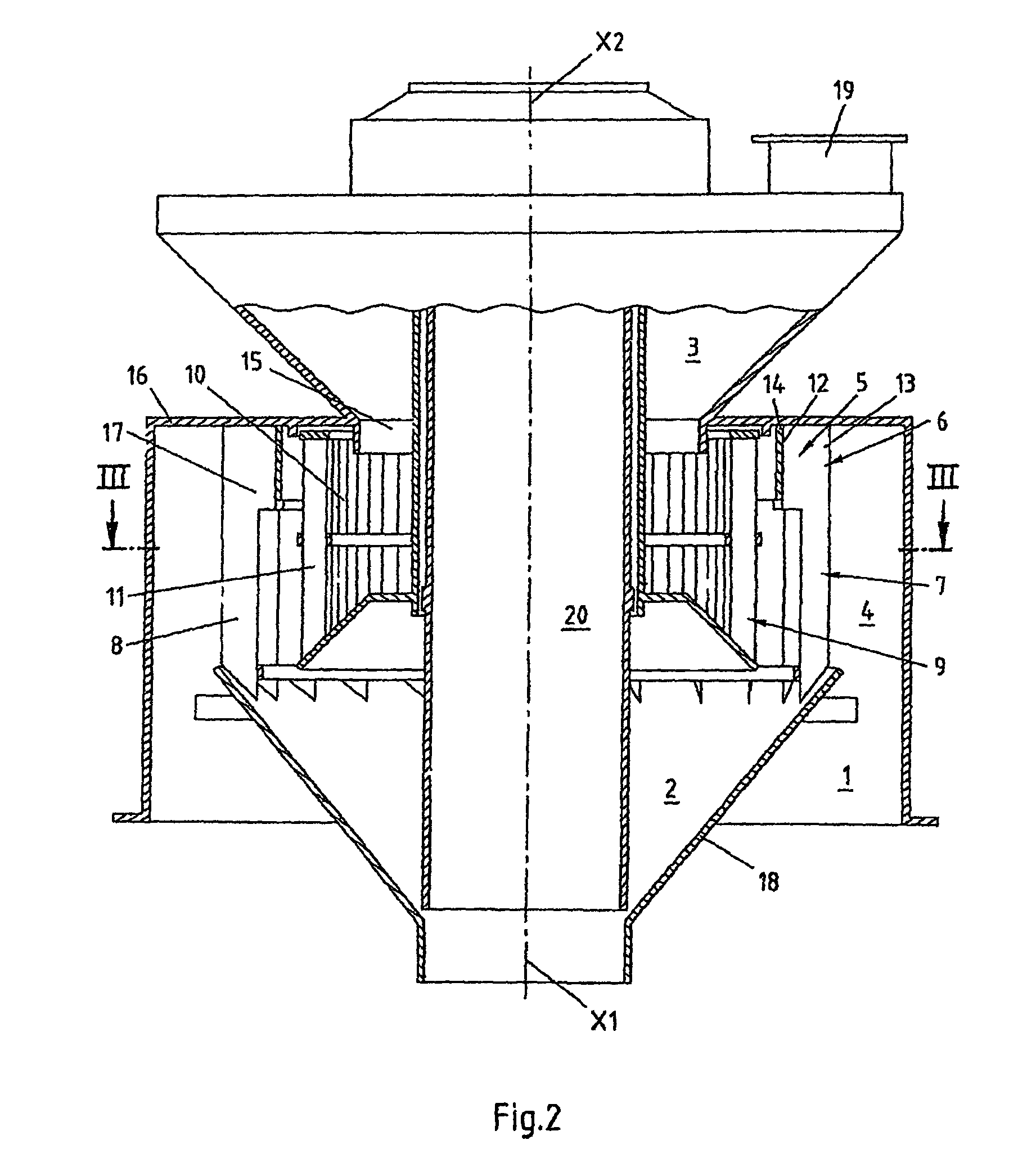

Method for particulate introduction for metal furnaces

InactiveUS20030000338A1Processing duration reducedReduce the amount of solutionElectric discharge heatingFurnace cooling arrangementsElectric arc furnaceSlag

A method and an apparatus for advantageously introducing a flame, a high velocity oxidizing gas, and a high velocity particulate flow into a furnace for metal melting, refining and processing, for example, steel making in an electric arc furnace. The steel making process of an electric arc furnace is made more efficient by shortening the time of the scrap melting phase, introducing a more effective high velocity oxidizing gas stream into the process sooner to decarburize the melted metal and introducing a more effective particulate injection to reduce FeO, form or foam slag and / or recarburize. Improved efficiency is obtained by mounting a fixed burner / lance and carbon injector lower and closer to the hot face of the furnace refractory at an effective injection angle. This mounting technique shortens the distance that the flame of the burner has to melt through scrap to clear a path to the molten metal, and shortens the distance the high velocity oxygen and high velocity particulates travel to the slag-metal interface. One method includes supplying a plurality of oxidizing reaction zones with the high velocity oxidizing gas to decarburize the melted metal and a plurality of particulate reaction zones with high velocity flows of particulate carbon for reducing FeO and / or forming foamy slag. The particulate reaction zones are located on the downstream side of the oxidizing gas reaction zones so as to minimize any effect of the reduction reaction on the decarburization reaction and to recover a part of the hot FeO produced in the oxidizing gas reaction zones.

Owner:PROCESS TECH INT

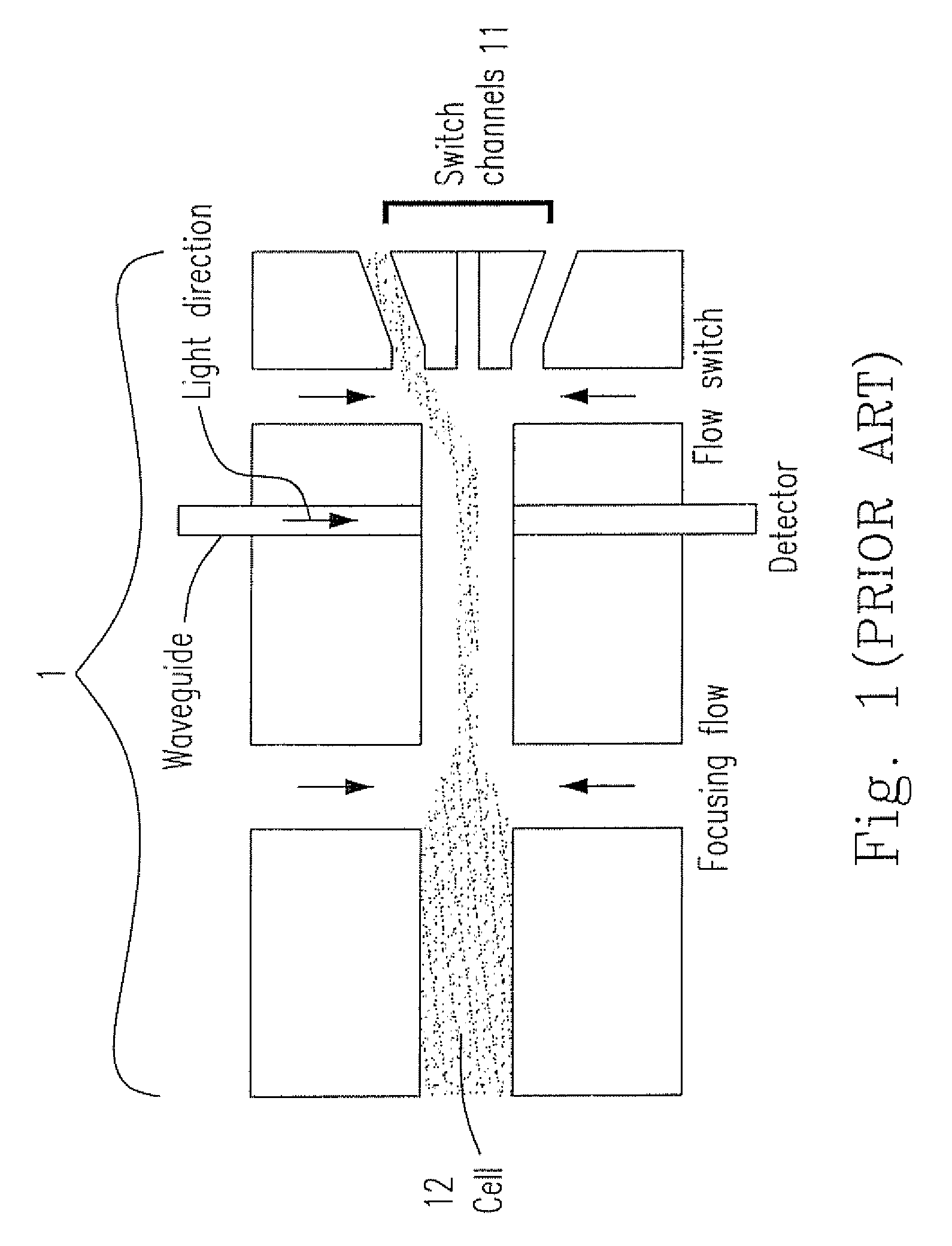

Multi-sample microfluidic dielectrophoresis separating device and method thereof

A microfluidic dielecttrophoresis separating device is provided. The microfluidic dielectrophoresis separating device includes a primary passage, at least a secondary passage and at least an electrode assembly. The primary passage has a primary flow containing a plurality of particulates flowing therein. The secondary passage has an input path and an output path and is connected with the primary passage. The electrode assembly generates a dielectrophoresis force to drive a specific one of the particulates into the output path.

Owner:IND TECH RES INST

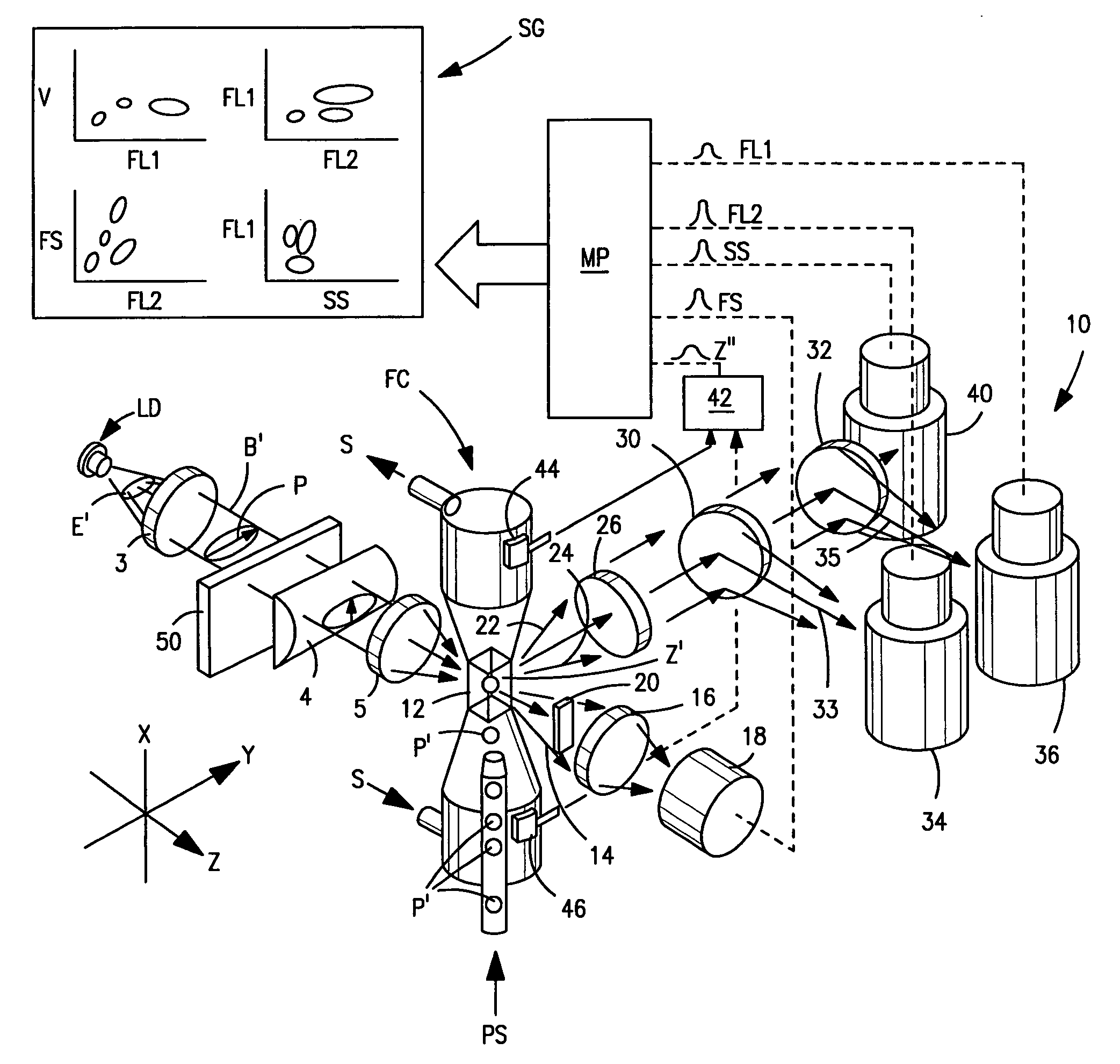

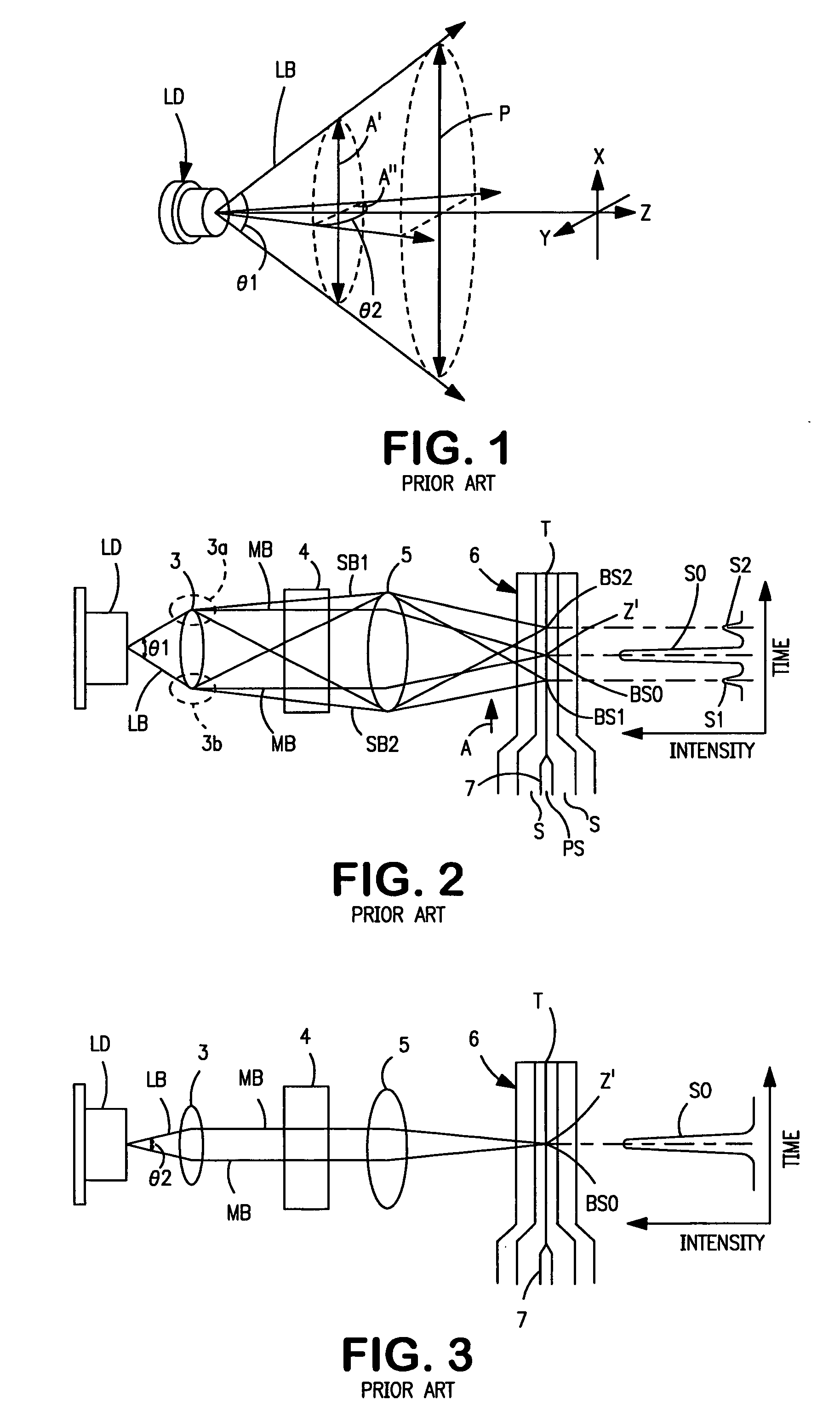

Flow cytometer for differentiating small particles in suspension

Owner:BECKMAN COULTER INC

Low pressure drop, multi-slit virtual impactor

InactiveUS6402817B1Increase fluid flowLower overall pressure dropWithdrawing sample devicesDispersed particle separationParticle flowEngineering

Fluid flow is directed into a multiplicity of slit nozzles positioned so that the fluid flow is directed into a gap between the nozzles and (a) a number of receiving chambers and (b) a number of exhaust chambers. The nozzles and chambers are select so that the fluid flow will be separated into a first particle flow component with larger and a second particle flow component with the smaller particles.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Method for particulate introduction for metal furnaces

InactiveUS6805724B2Processing duration reducedReduce the amount of solutionElectric discharge heatingFurnace cooling arrangementsElectric arc furnaceSlag

A method and an apparatus for advantageously introducing a flame, a high velocity oxidizing gas, and a high velocity particulate flow into a furnace for metal melting, refining and processing, for example, steel making in an electric arc furnace. The steel making process of an electric arc furnace is made more efficient by shortening the time of the scrap melting phase, introducing a more effective high velocity oxidizing gas stream into the process sooner to decarburize the melted metal and introducing a more effective particulate injection to reduce FeO, form or foam slag and / or recarburize. Improved efficiency is obtained by mounting a fixed burner / lance and carbon injector lower and closer to the hot face of the furnace refractory at an effective injection angle. This mounting technique shortens the distance that the flame of the burner has to melt through scrap to clear a path to the molten metal, and shortens the distance the high velocity oxygen and high velocity particulates travel to the slag-metal interface. One method includes supplying a plurality of oxidizing reaction zones with the high velocity oxidizing gas to decarburize the melted metal and a plurality of particulate reaction zones with high velocity flows of particulate carbon for reducing FeO and / or forming foamy slag. The particulate reaction zones are located on the downstream side of the oxidizing gas reaction zones so as to minimize any effect of the reduction reaction on the decarburization reaction and to recover a part of the hot FeO produced in the oxidizing gas reaction zones.

Owner:PROCESS TECH INT

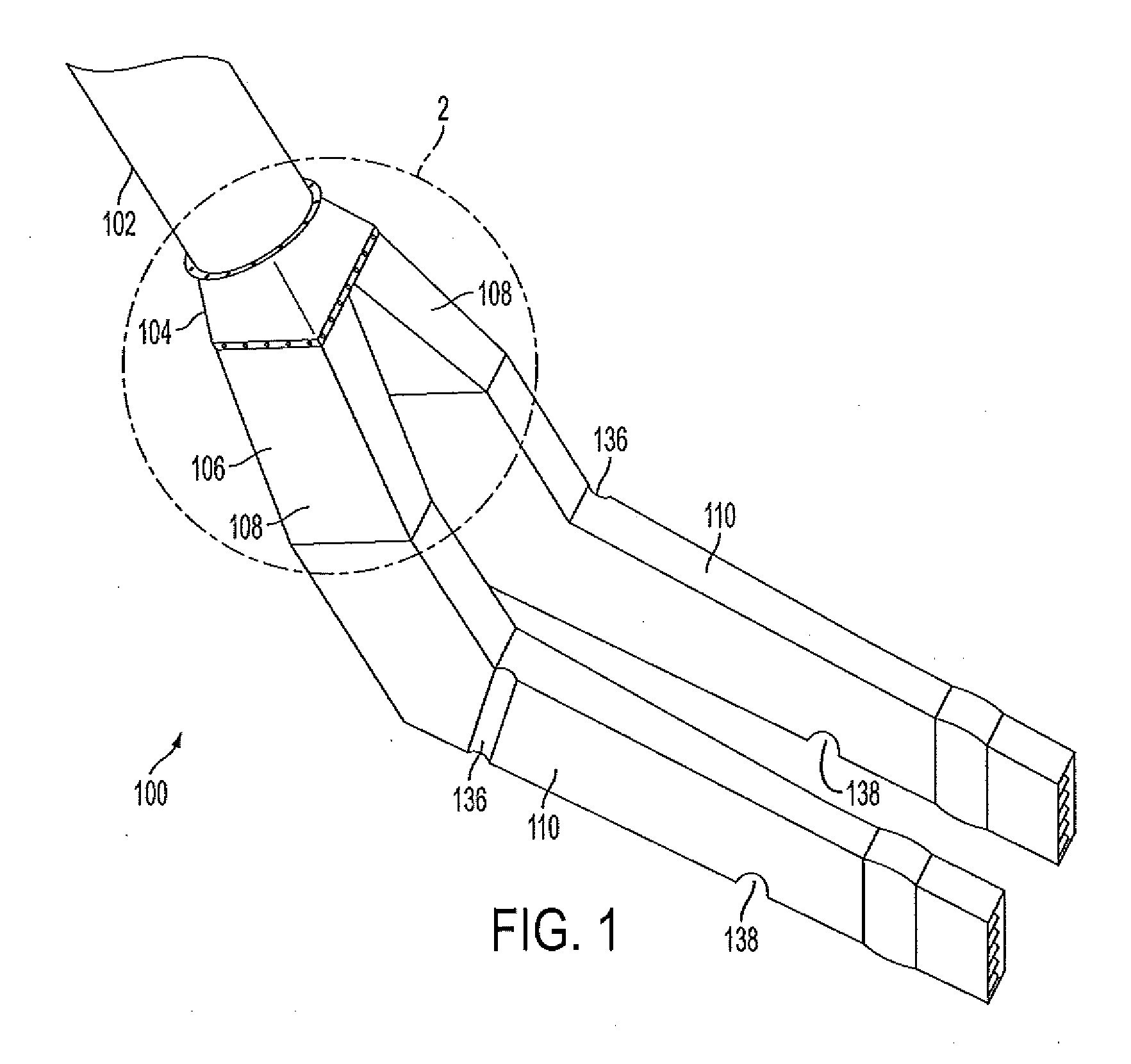

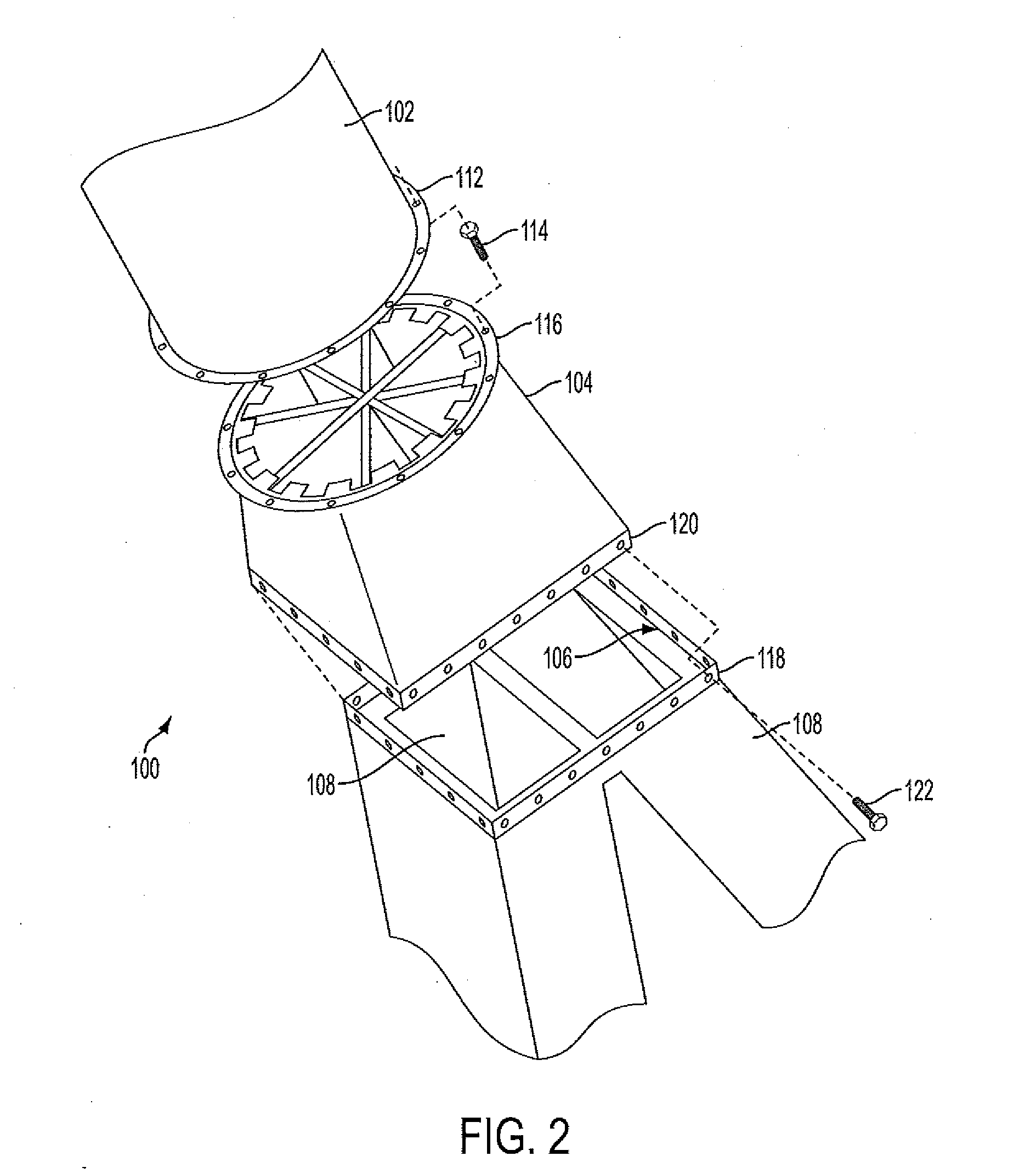

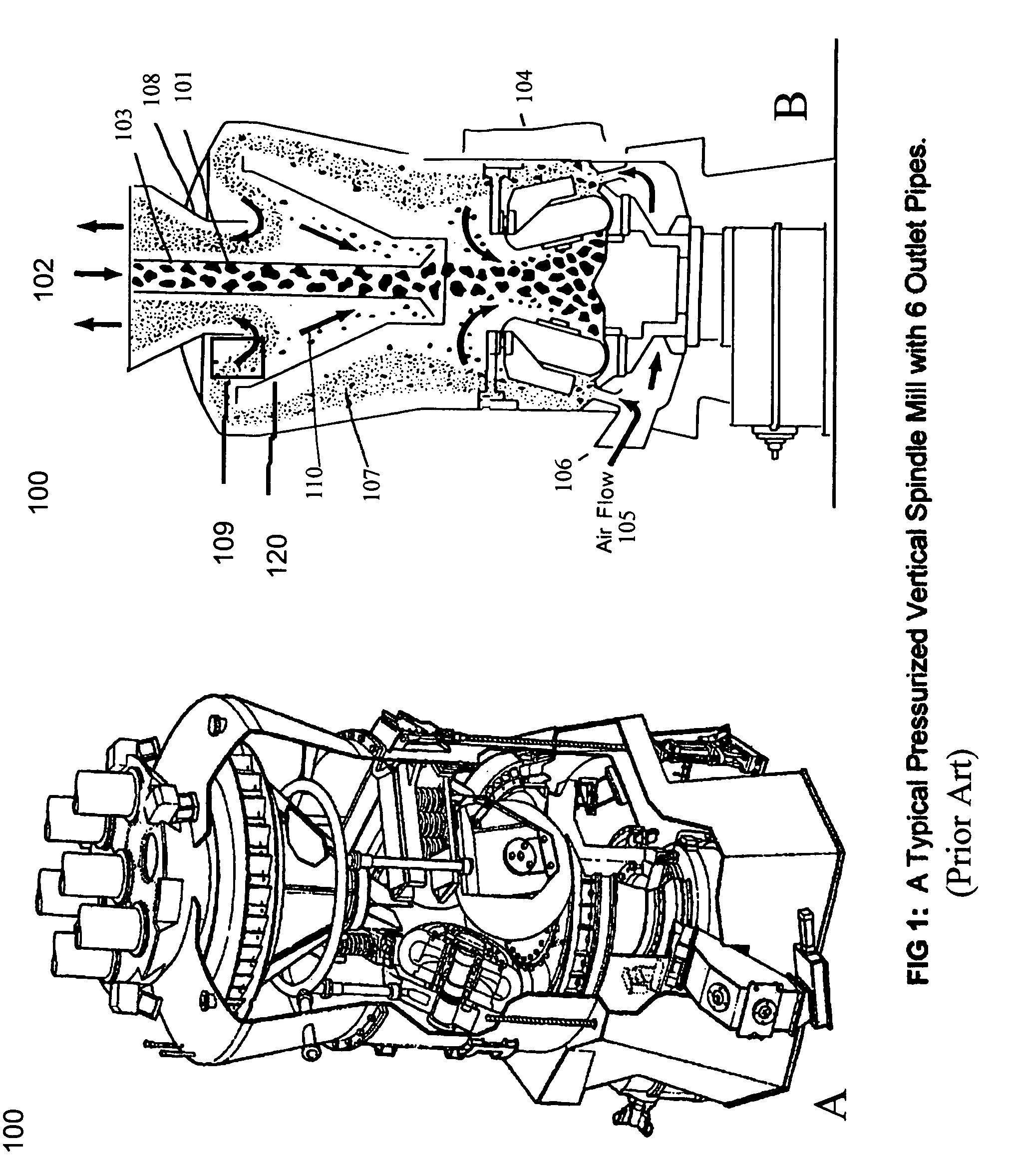

Coal flow balancing devices

InactiveUS20120186501A1Reduce unevennessImprove uniformityFuel feeding arrangementsBulk conveyorsParticle flowSolid particle

A flow splitter distributes solid particles flowing in a fluid, such as coal particles flowing in air, through a piping system. The flow splitter includes a divider housing having an inlet configured to connect to an upstream pipe and having an outlet configured to connect to a plurality of downstream pipes, e.g., by way of a divider head. A divider body is mounted within the divider housing. A plurality of divider vanes is included, each extending from the divider body to the divider housing. The divider housing, divider body, and divider vanes are configured and adapted to reduce non-uniformity in particle concentration from the inlet and to supply a substantially equal particle flow from the outlet to each of the downstream pipes.

Owner:BABCOCK POWER SERVICES

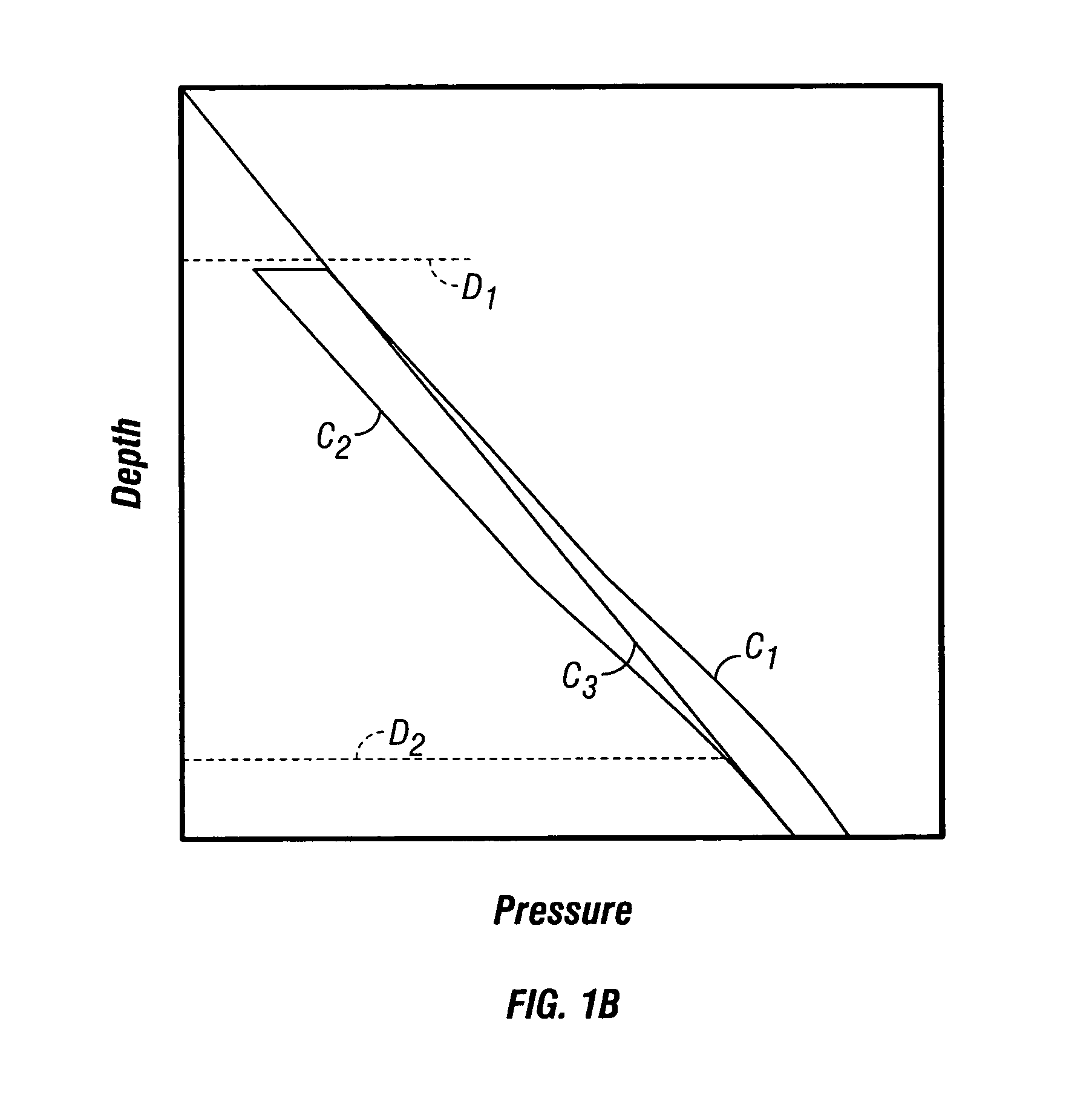

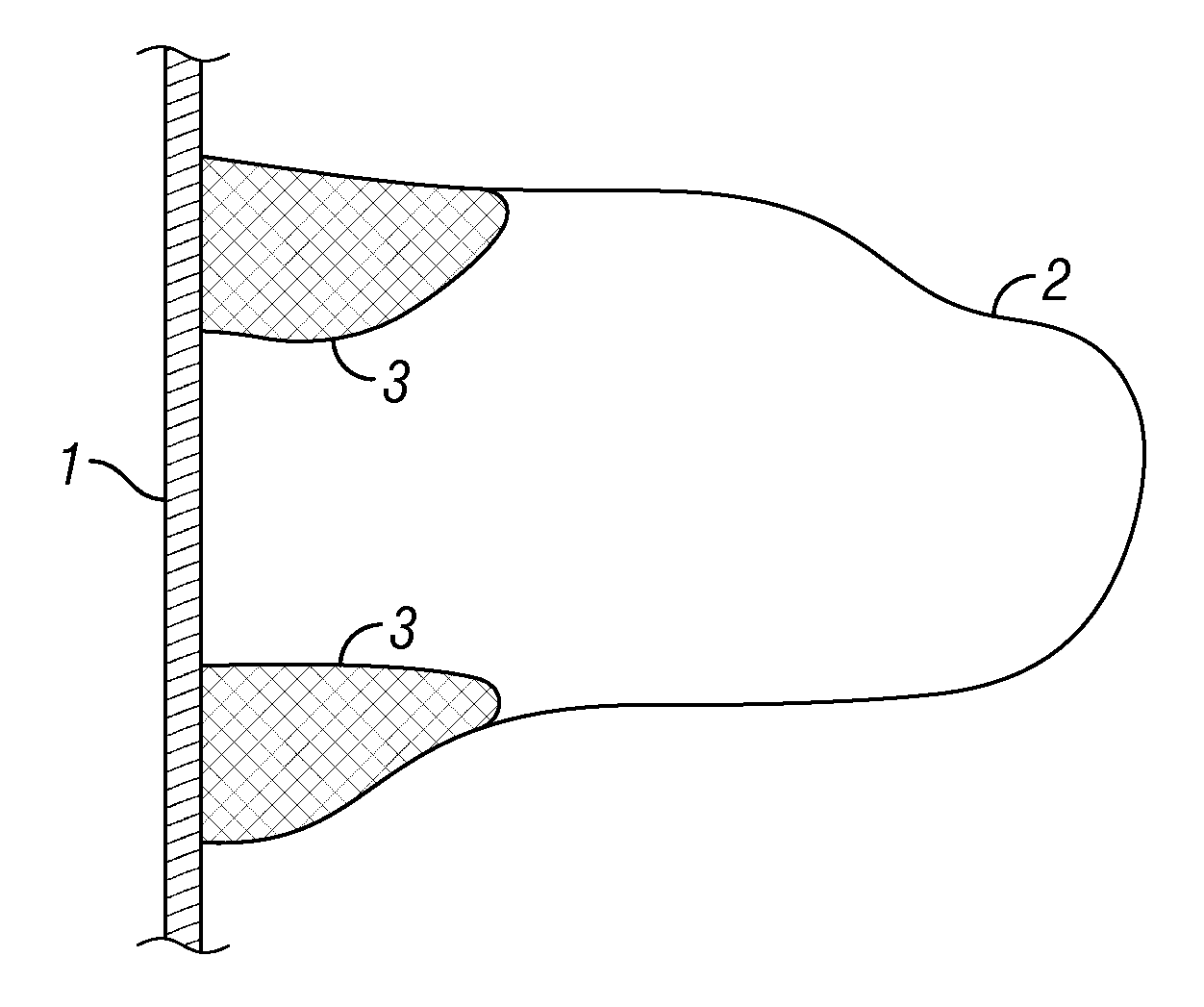

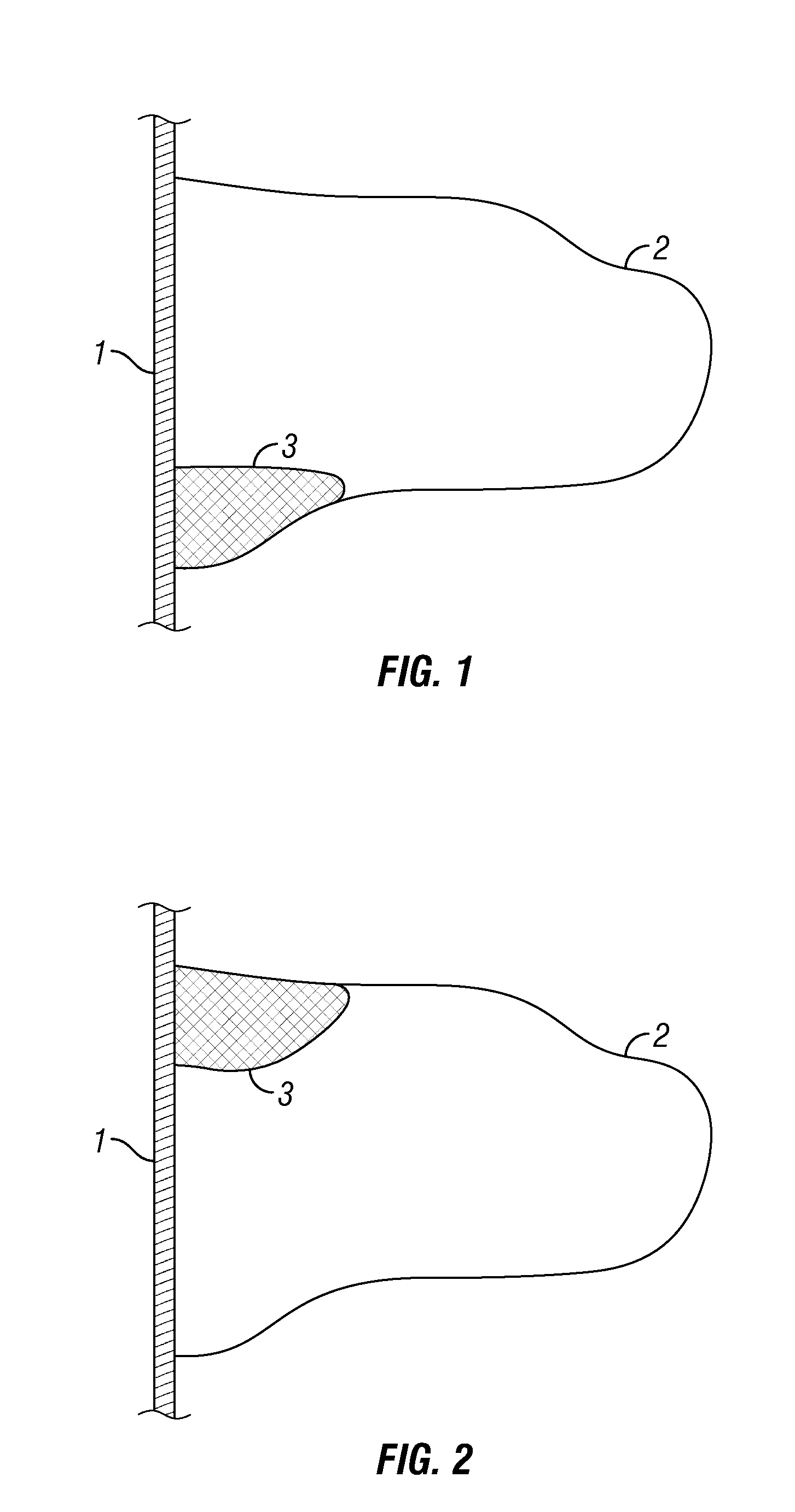

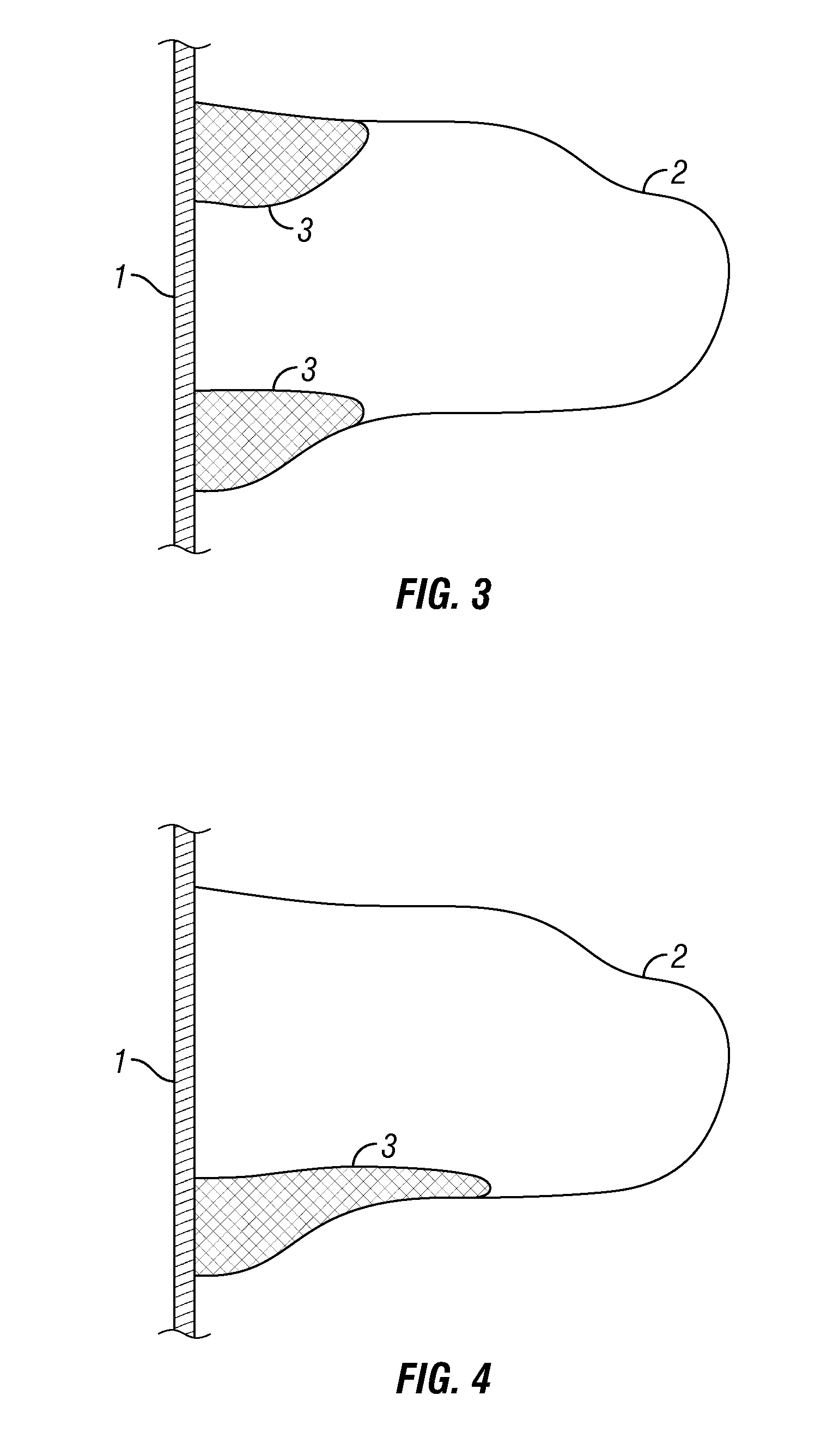

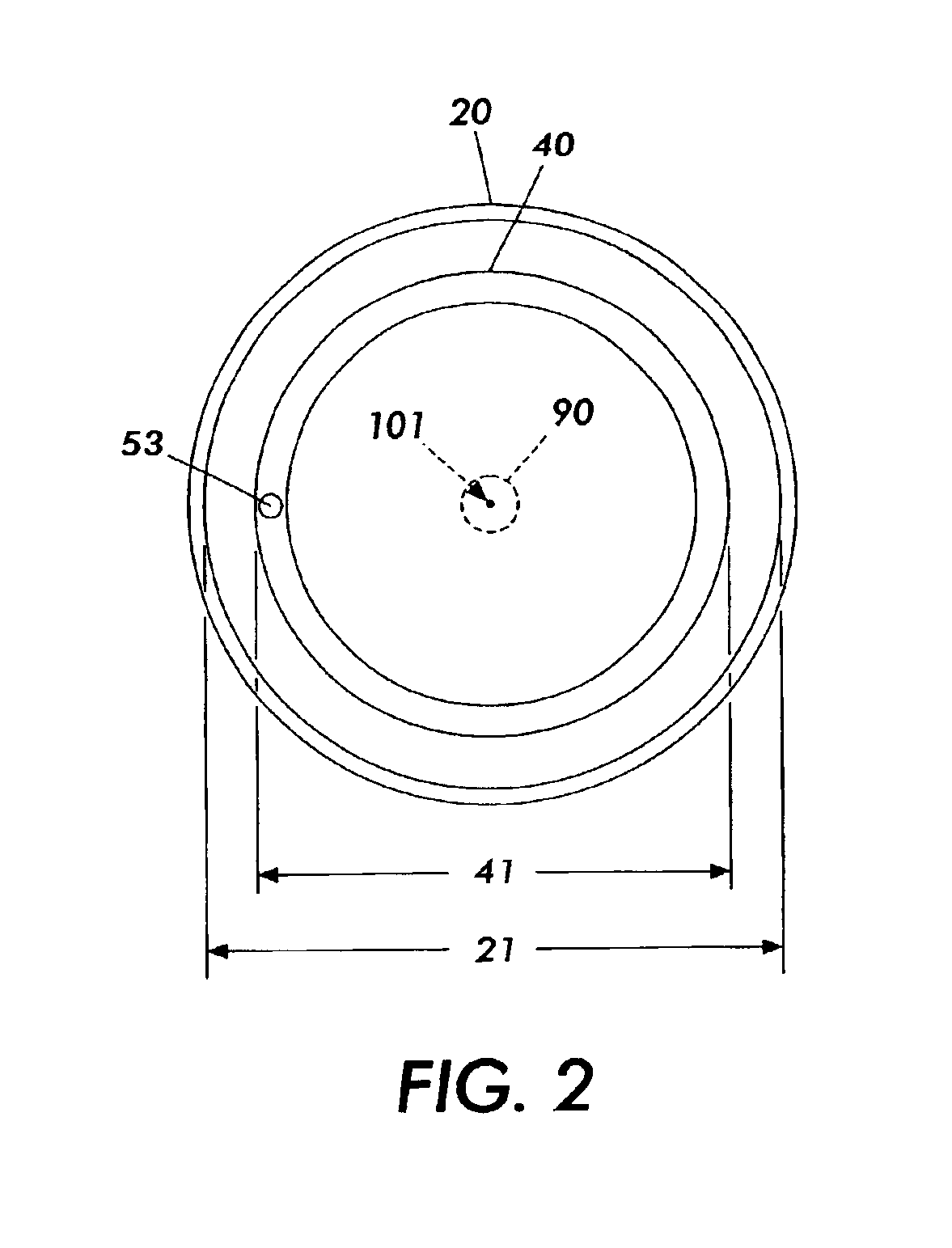

Hydraulic fracture height growth control

A method is given for creating a fracture, in a subterranean formation, that has a fluid flow barrier at the top, at the bottom, or at both the top and the bottom. The method is applied before or during a conventional hydraulic fracturing treatment and is used to limit undesired vertical growth of a fracture out of the productive zone. A lower-viscosity pad fluid is used to initiate the fracture; a higher-viscosity fluid containing barrier particles is then injected; a lower-viscosity particle-free fluid is then injected to promote settling (or rising) of the barrier particles and to finger through the slug of barrier particles and cut it into an upper and lower portion. If the barrier is to be at the bottom of the fracture, the barrier particles are denser than the fluids; if the barrier is to be at the top of the fracture, the barrier particles are less dense than the fluids. Optionally, between the barrier transport stage and the subsequent lower-viscosity stage, there may be a stage of a higher viscosity particle-free fluid that pushes the barrier particles farther into the fracture. To provide both upper and lower particles in one treatment, the pad stage may be of higher-viscosity, or the barrier particles may include particles less dense than, and more dense than, the fluid.

Owner:SCHLUMBERGER TECH CORP

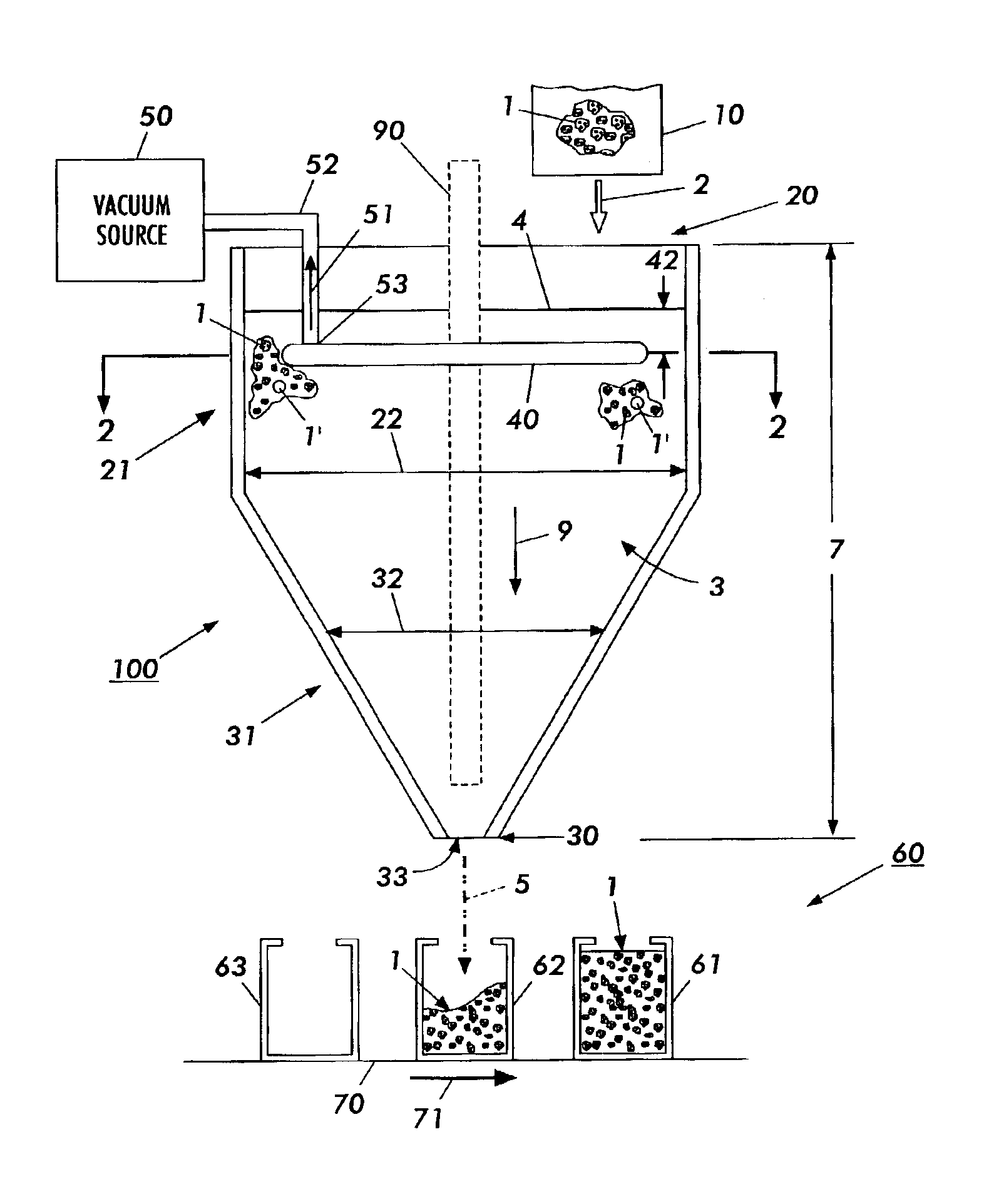

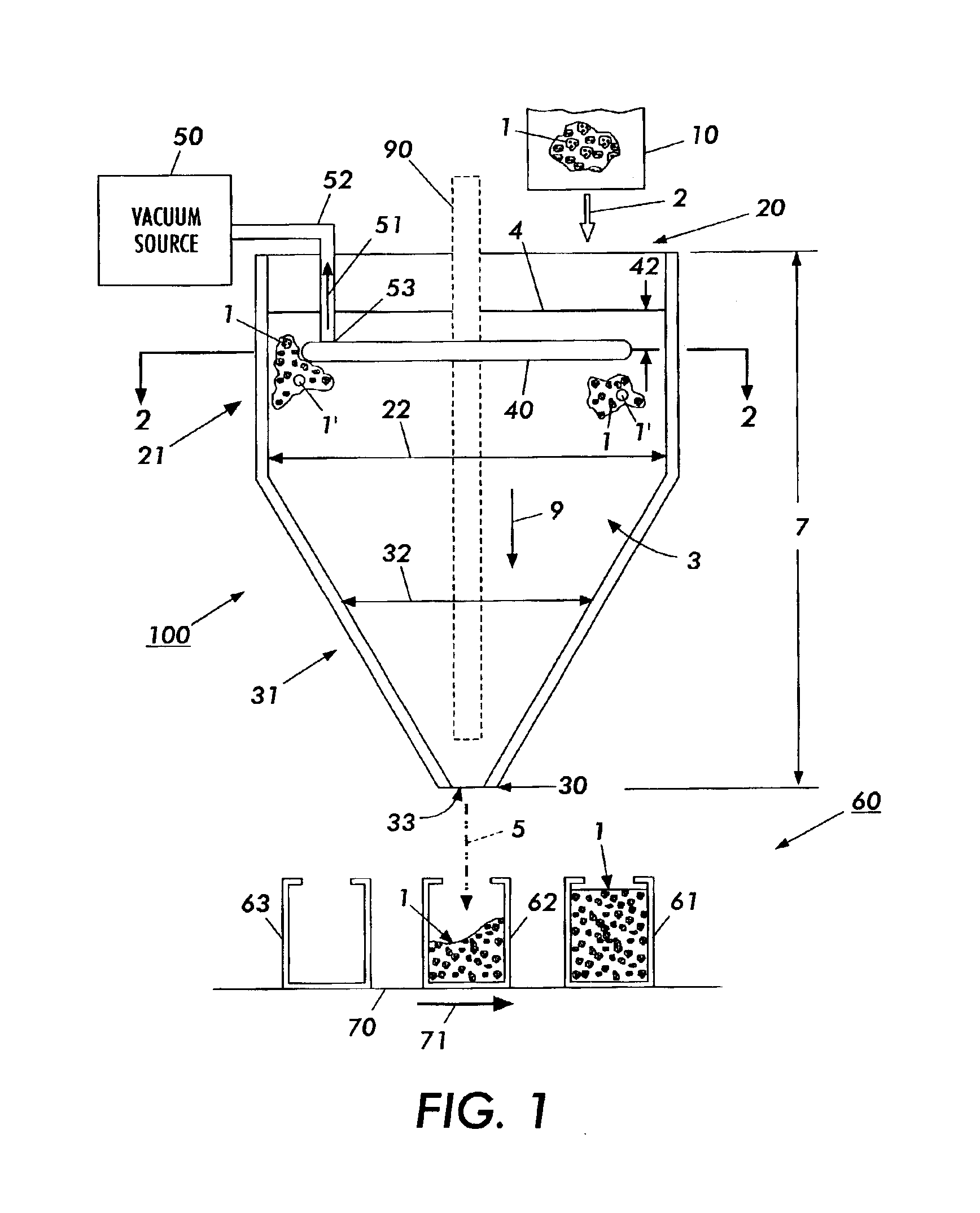

Method of dispensing particles, a particle filling line, and apparatus for dispensing particles

A particle filling line comprises a vertical conduit that is arranged to dispense particles to one or more containers that are disposed on an included movable conveyor belt. The conduit includes a conduit hollow, a conduit top and a conduit bottom that defines an outlet. Particles supplied to the conduit top flow through the outlet to fill the containers. The conduit is filled with particles. The particles include a particle spacing air. The particle spacing air is reduced by means of a porous tube that is fixed in the conduit hollow and coupled to a vacuum source. After reducing the particle spacing air, the particles flow through the outlet to be received in the containers.

Owner:XEROX CORP

Particulate flow detection microphone

Owner:SCHWARTZ DAVID M

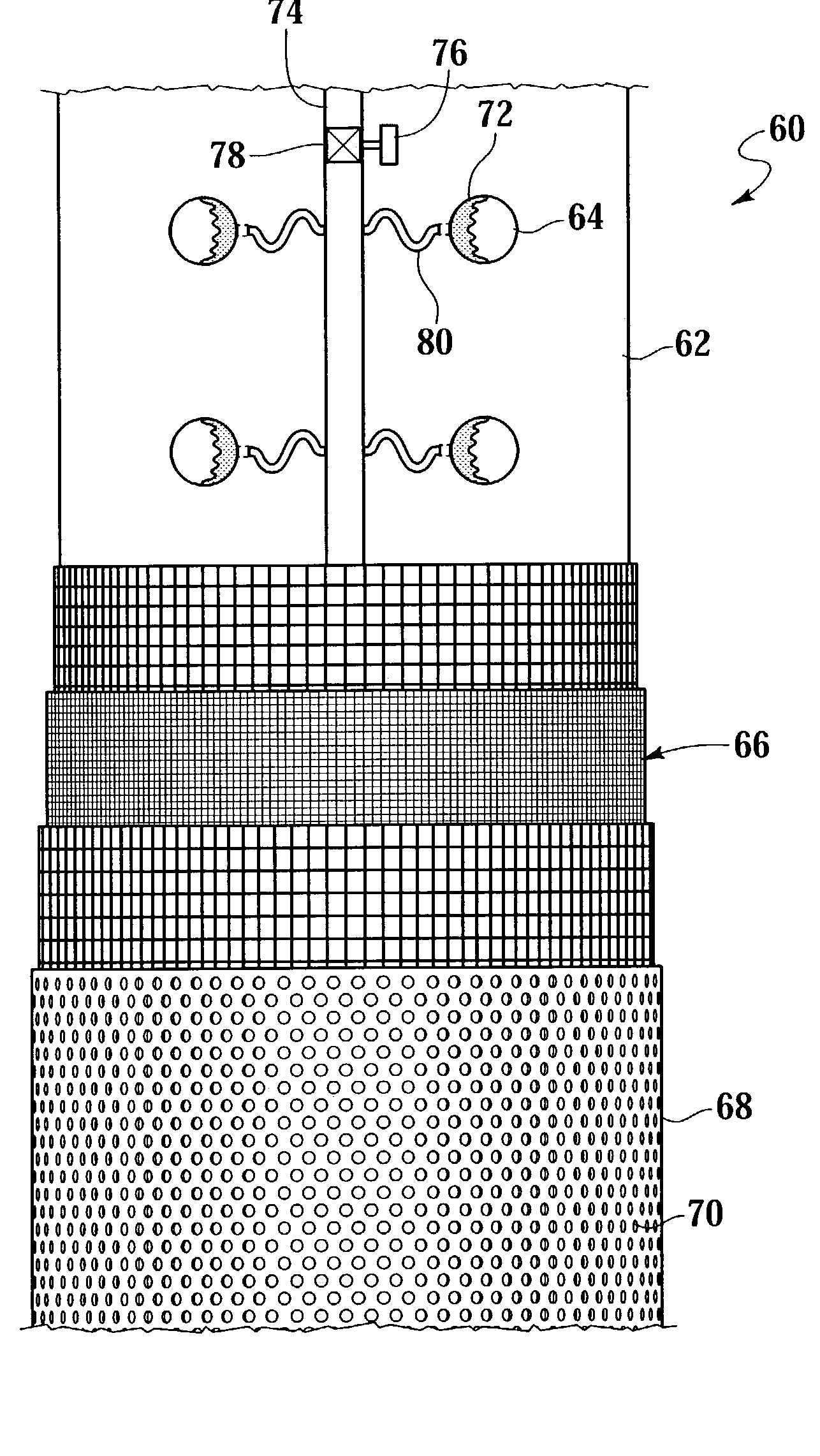

Expandable sand control screen assembly having fluid flow control capabilities and method for use of same

InactiveUS6994170B2Not difficult and expensive to manufactureAvoid flowSurveyDrilling rodsFilter mediaEngineering

A sand control screen assembly (60) comprises a base pipe (62) having at least one opening (64) that allows fluid flow therethrough and a filter medium (66) positioned about the exterior of the base pipe (62) that allows fluid flow therethrough and prevents particulate flow therethrough. An inflatable seal member (72) is disposed within the at least one opening (64) of the base pipe (62) and controls fluid flow through the at least one opening (64). An inflation fluid source (74) is in fluid communication with the inflatable seal member (72) and provides an inflation fluid to the inflatable seal member (72) to selectively urge the inflatable seal member (72) into sealing engagement with the at least one opening (64).

Owner:HALLIBURTON ENERGY SERVICES INC

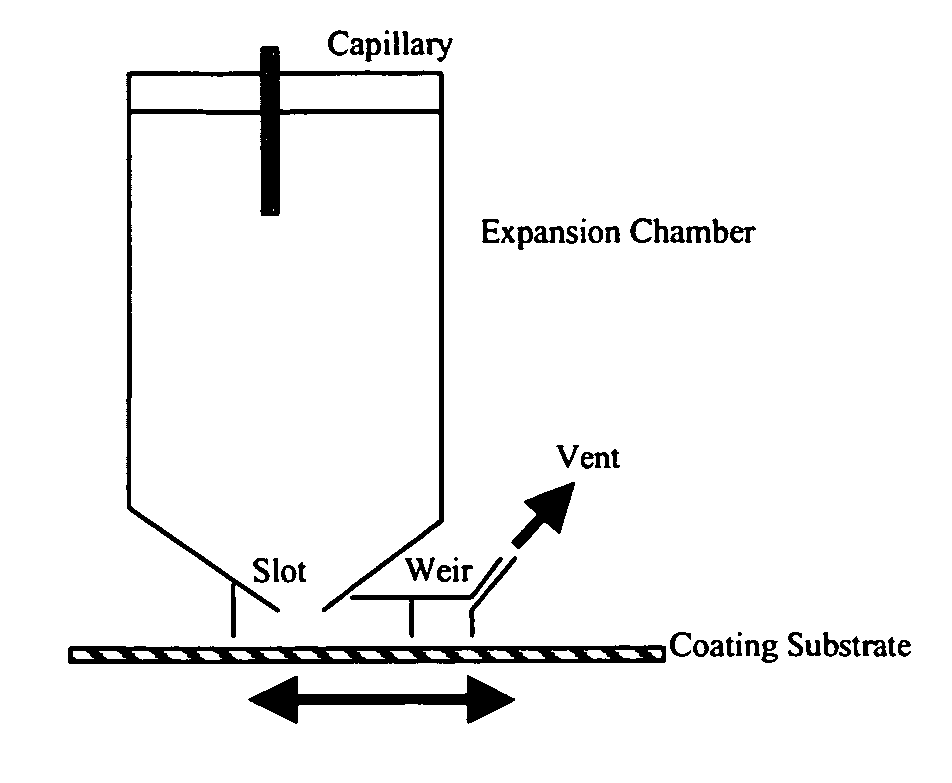

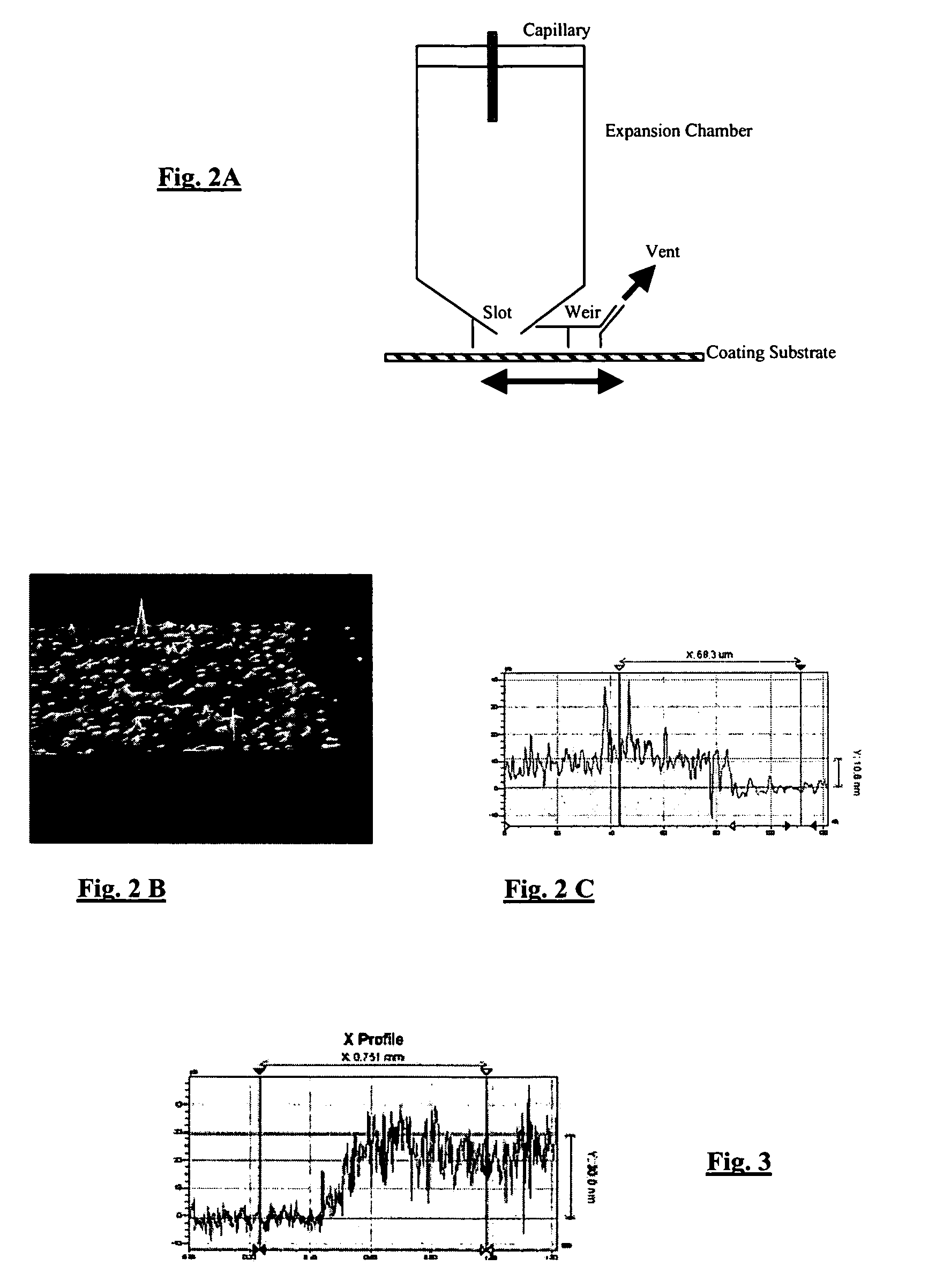

Process for the deposition of uniform layer of particulate material

InactiveUS20050221018A1High speedImprove capacityElectric shock equipmentsPretreated surfacesSolventSolubility

A process for the deposition of particulate material of a desired substance on a surface includes: (i) charging a particle formation vessel with a compressed fluid; (ii) introducing into the particle formation vessel a first feed stream comprising a solvent and the desired substance dissolved therein and a second feed stream comprising the compressed fluid, wherein the desired substance is less soluble in the compressed fluid relative to its solubility in the solvent and the solvent is soluble in the compressed fluid, and wherein the first feed stream is dispersed in the compressed fluid, allowing extraction of the solvent into the compressed fluid and precipitation of particles of the desired substance; (iii) exhausting compressed fluid, solvent and the desired substance from the particle formation vessel at a rate substantially equal to the rate of addition of such components to the vessel in step (ii) through a restrictive passage to a lower pressure whereby the compressed fluid is transformed to a gaseous state and a flow of particles of the desired substance is formed; and (iv) exposing a receiver surface to the exhausted flow of particles of the desired substance and depositing a uniform layer of particles on the receiver surface.

Owner:EASTMAN KODAK CO

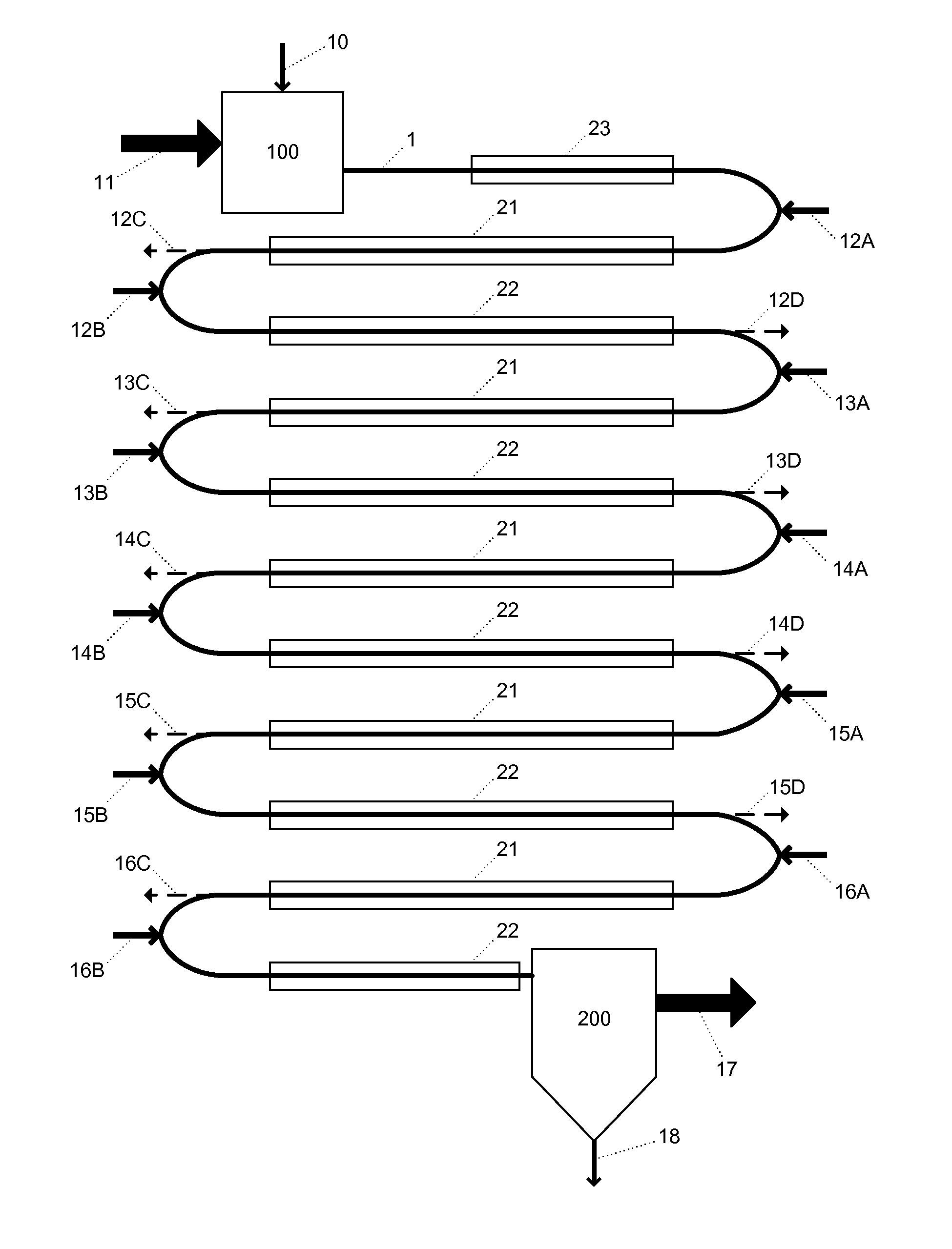

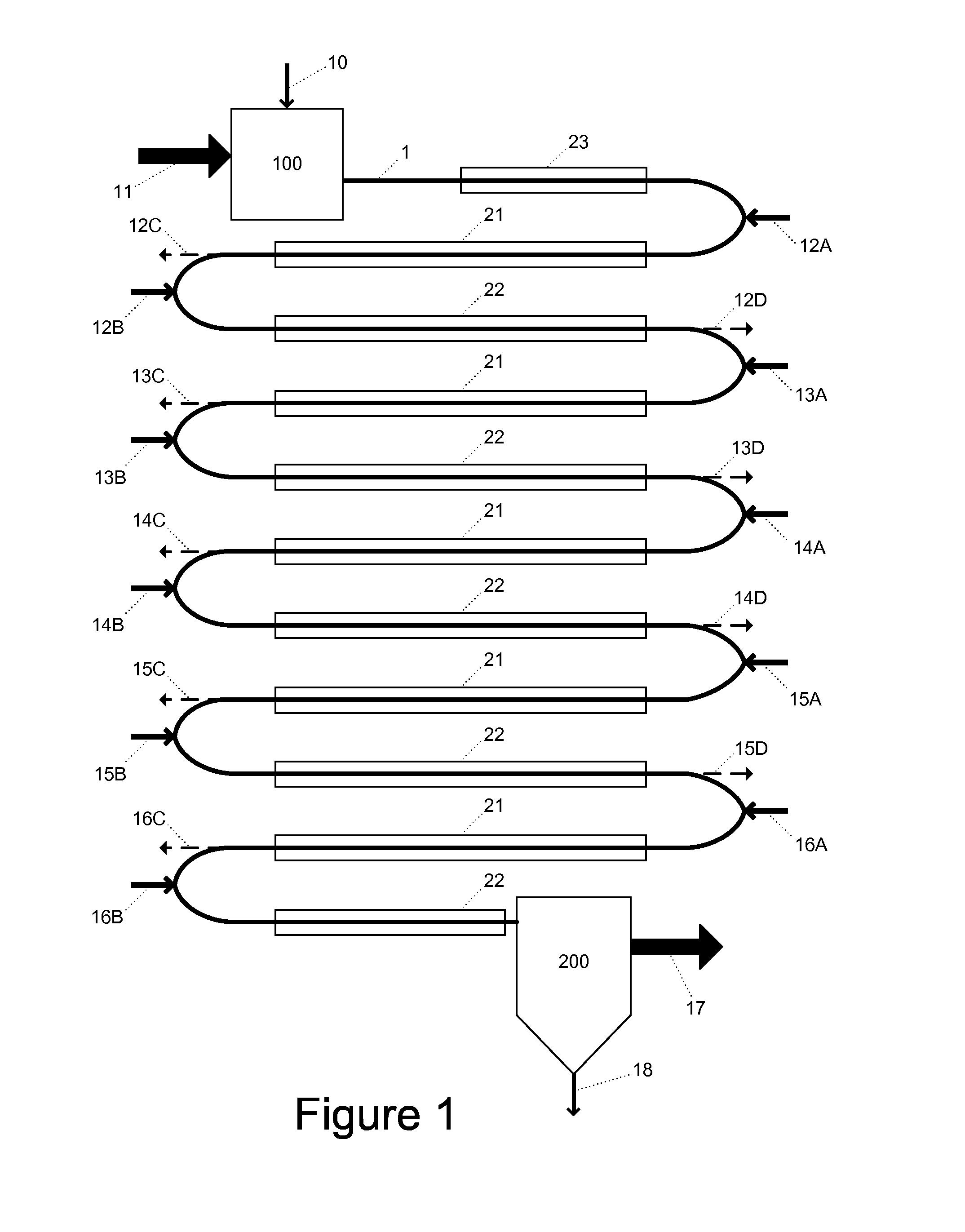

Apparatus and process for atomic or molecular layer deposition onto particles during pneumatic transport

ActiveUS20120009343A1Liquid surface applicatorsChemical vapor deposition coatingParticle flowInjection point

The invention provides a process for depositing a coating onto particles being pneumatically transported in a tube. The process comprising the steps of providing a tube having an inlet opening and an outlet opening; feeding a carrier gas entraining particles into the tube at or near the inlet opening of the tube to create a particle flow through the tube; and injecting a first self-terminating reactant into the tube via at least one injection point downstream from the inlet opening of the tube for reaction with the particles in the particle flow. The process is suitable for atomic layer deposition and molecular layer deposition. An apparatus for carrying out the process is also disclosed.

Owner:TECH UNIV DELFT

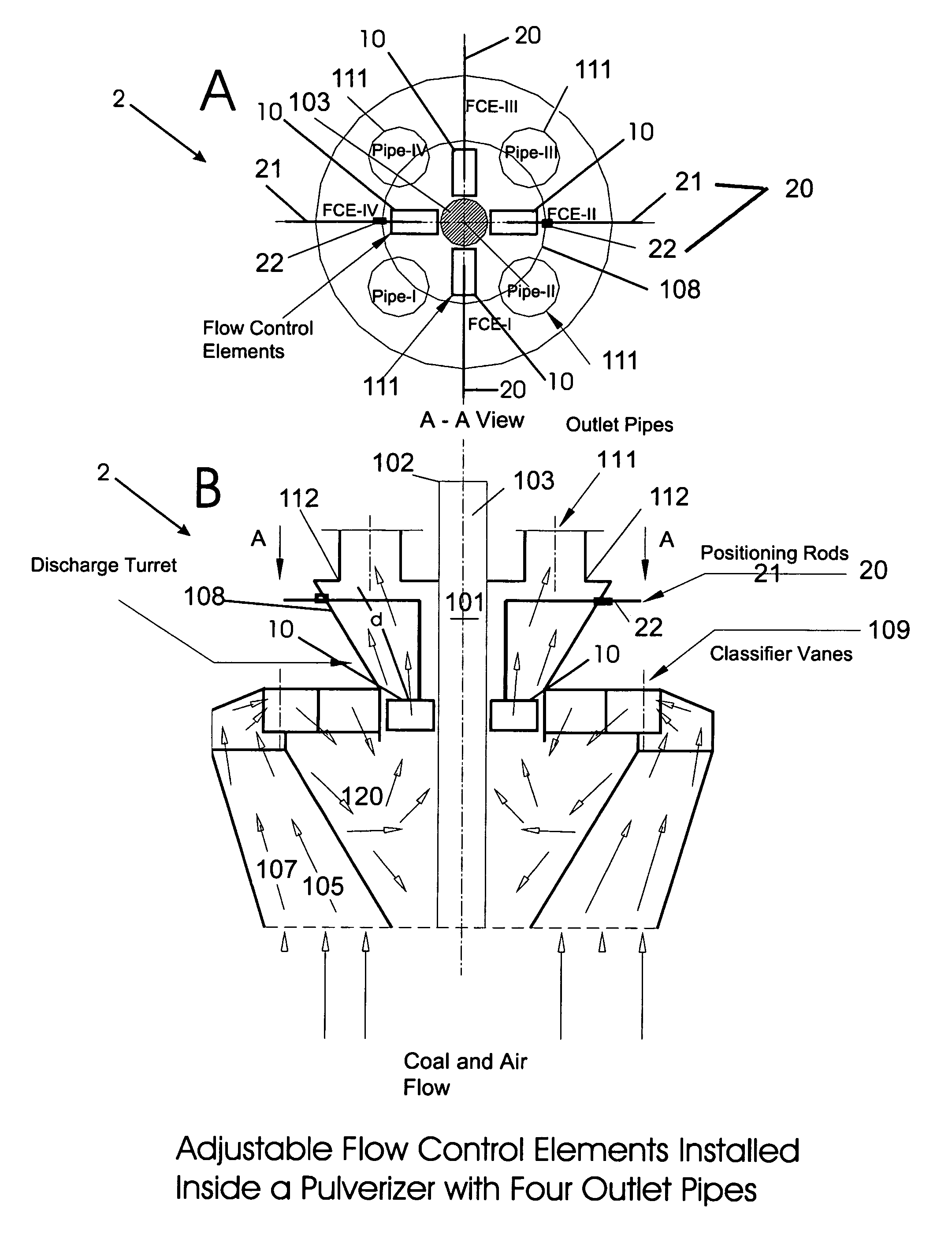

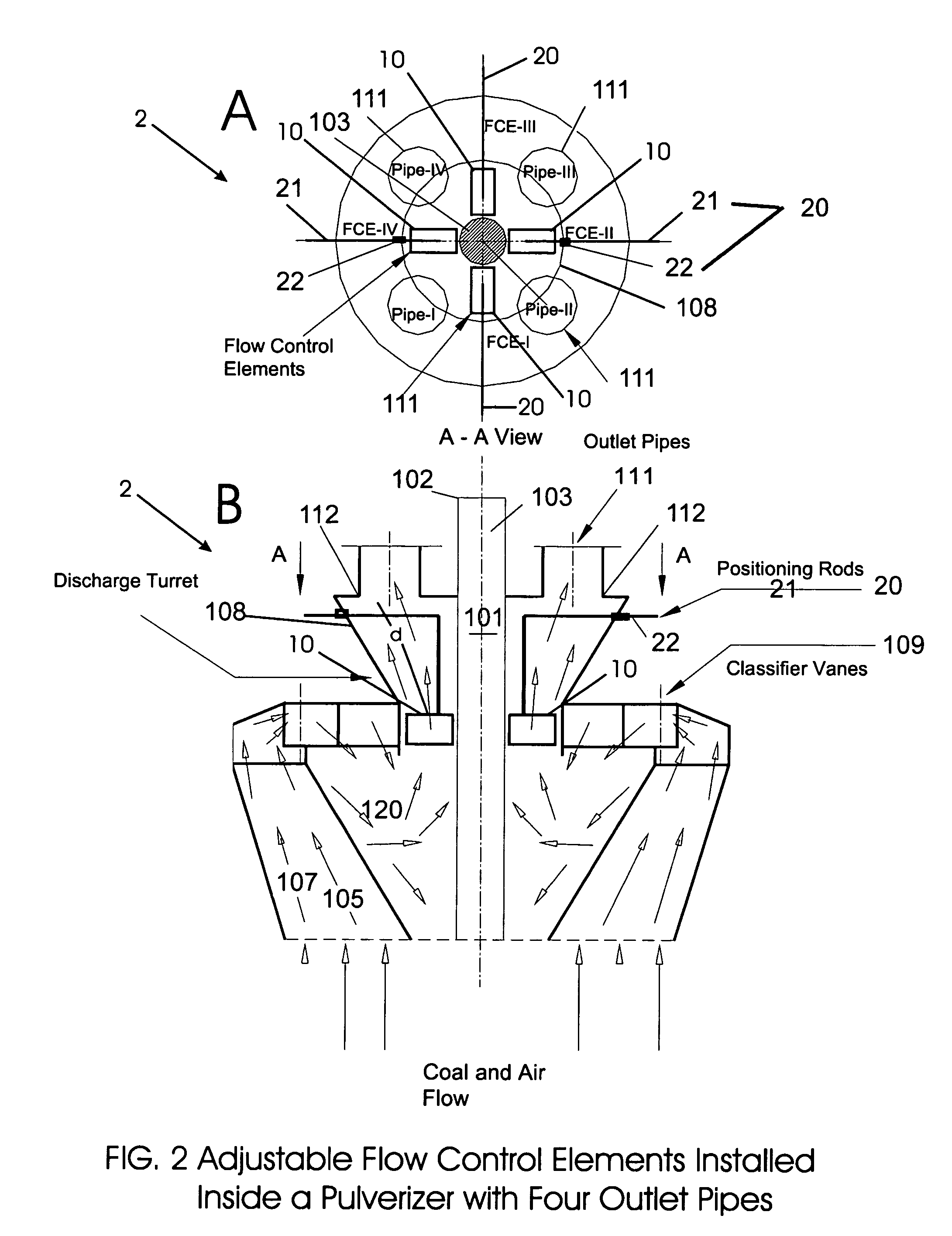

On-line control of coal flow

InactiveUS6966508B2Improve combustion efficiencyImprove performanceGas current separationGrain treatmentsCombustionEngineering

A system for balancing and controlling the distribution of pulverized coal into multiple equal diameter outlet pipes of coal pulverizers for improving boiler performance. The device includes a plurality of flow control elements, one flow control element for each outlet pipe, all positioned a pre-determined distance upstream of the outlet pipes. Each flow control element is mounted on an independent adjustment mechanism and is thereby adjustable in position relative its corresponding outlet pipe to selectively vary the wake of the downstream coal particulate flow relative to primary air flow. The method of the present invention is practiced by monitoring coal particulate flow at the outlet pipes relative to primary air flow or individual flame characteristics, and then compensating for noted imbalances by selectively adjusting the flow control elements, thereby balancing and controlling the distribution of coal and improving combustion efficiency.

Owner:LEVY EDWARD KENNETH +2

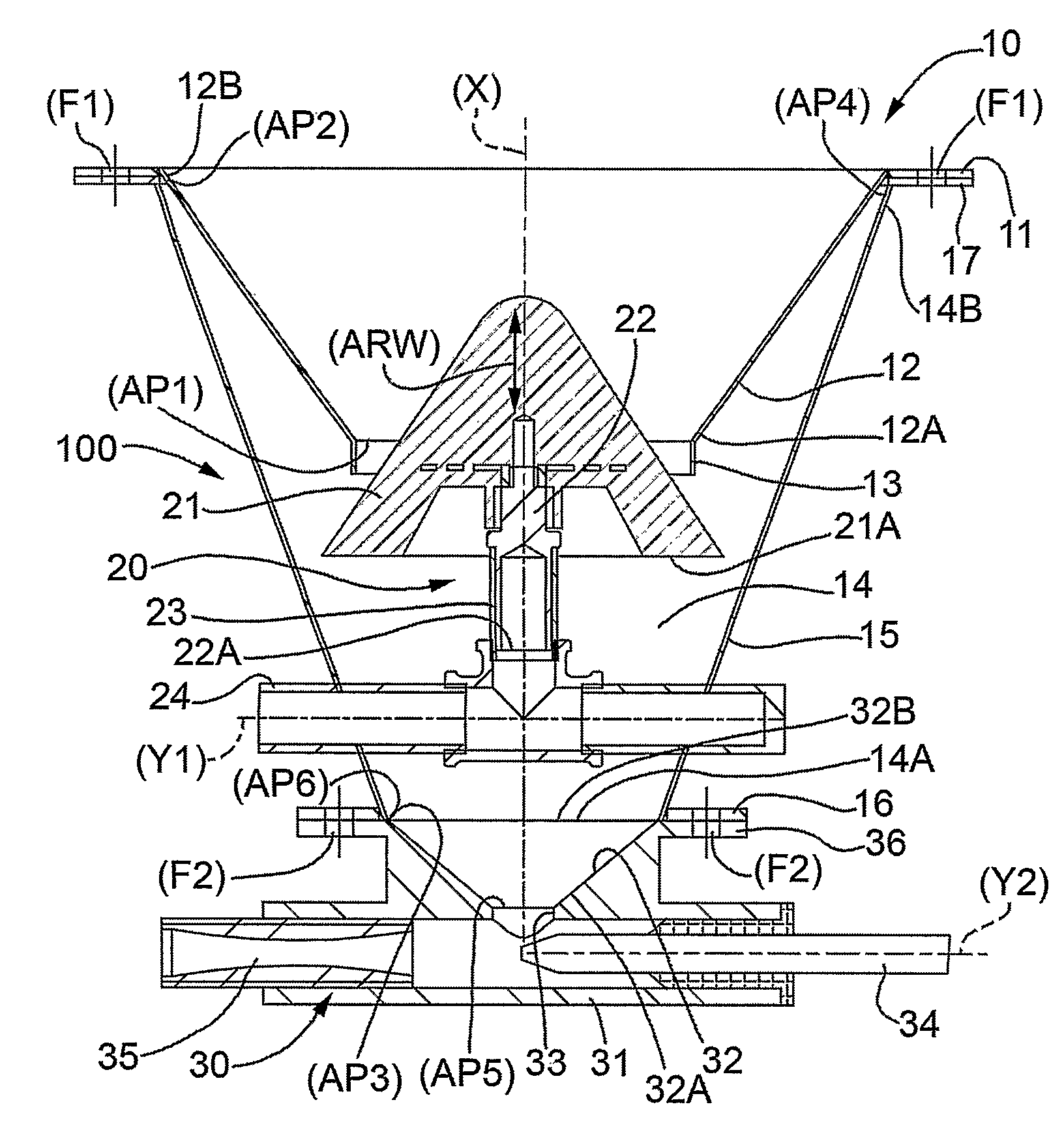

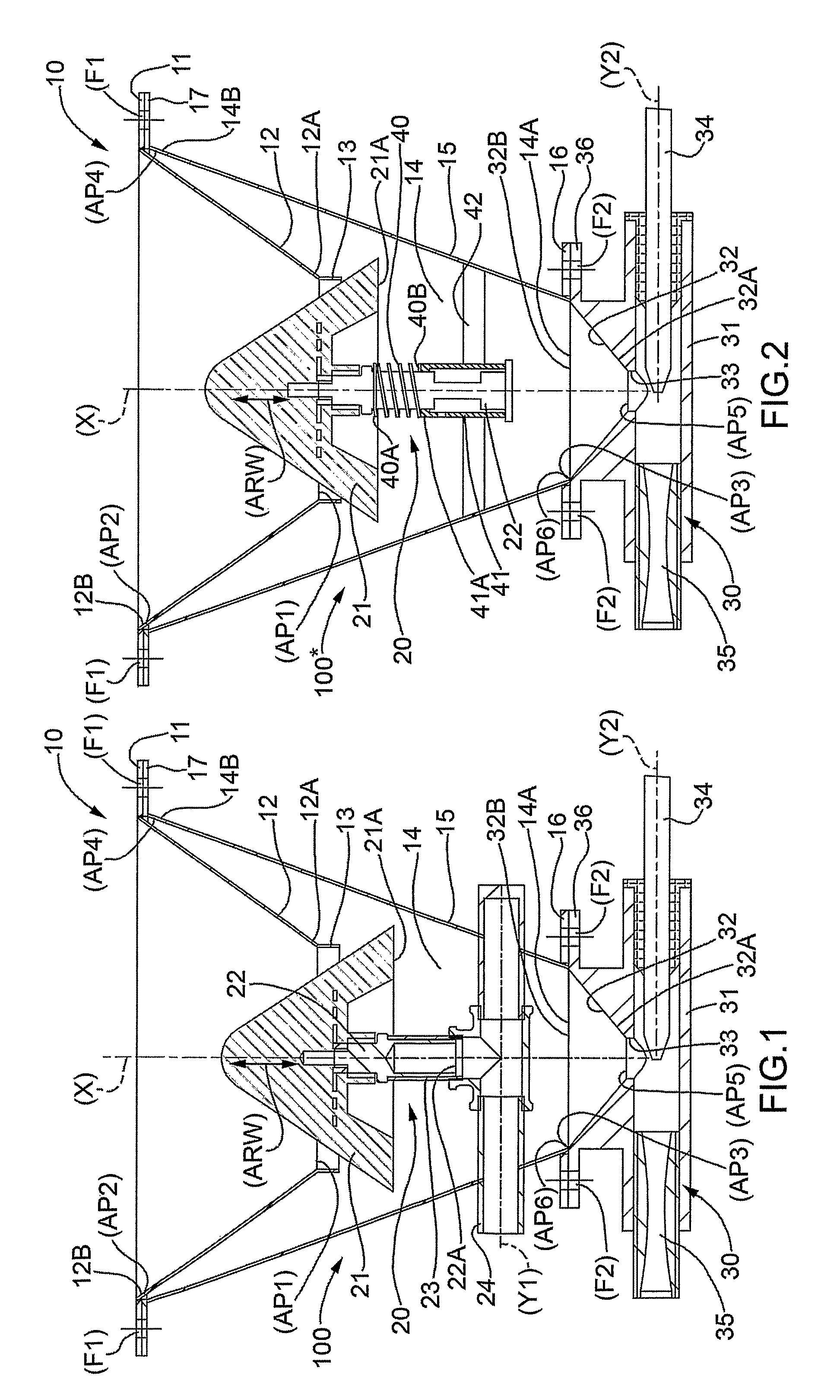

Apparatus and related method for the recovery and the pneumatic transportation of dust coming from a filtration system

ActiveUS9126772B2Easy and economical to produceDispersed particle filtrationBulk conveyorsParticulatesWindow shutter

An apparatus and related method for the recovery and the pneumatic transportation of dust coming from a filtration system provided with a particulate collection hopper. The apparatus comprises:an intermediate chamber for the passage of the particulate towards the evacuation means; andshutting means for a bottom opening (AP1) of said hopper. The apparatus is characterized in that the shutting means comprise, in turn, a shutter moved according to an arrow (ARW) by the action of intermittent pressurized air that flows in a control conduit forming part of said shutting means. Furthermore, the evacuation means comprise elements, specifically a nozzle aligned with a Venturi, to produce a pressure drop in the intermediate chamber.

Owner:WAM IND

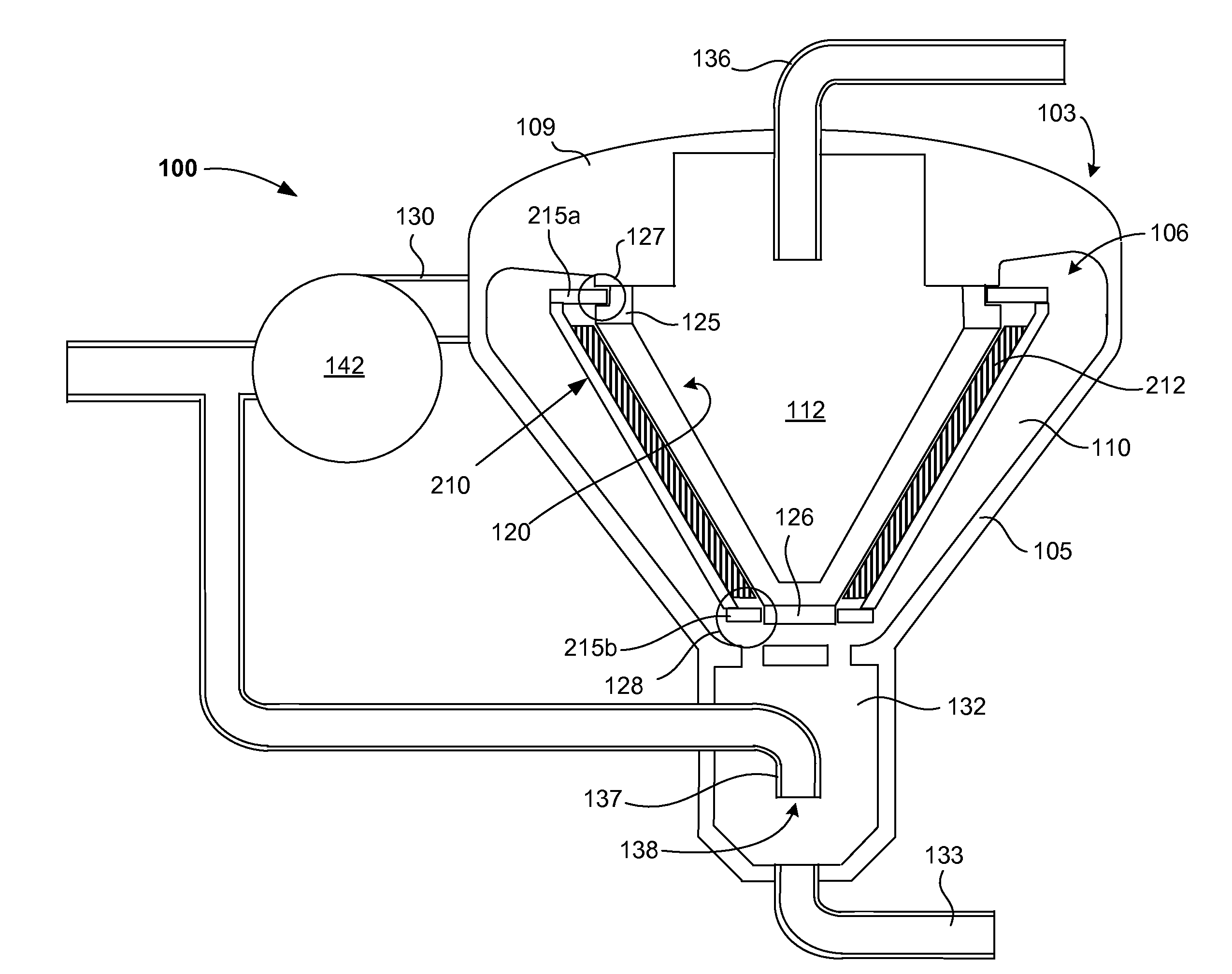

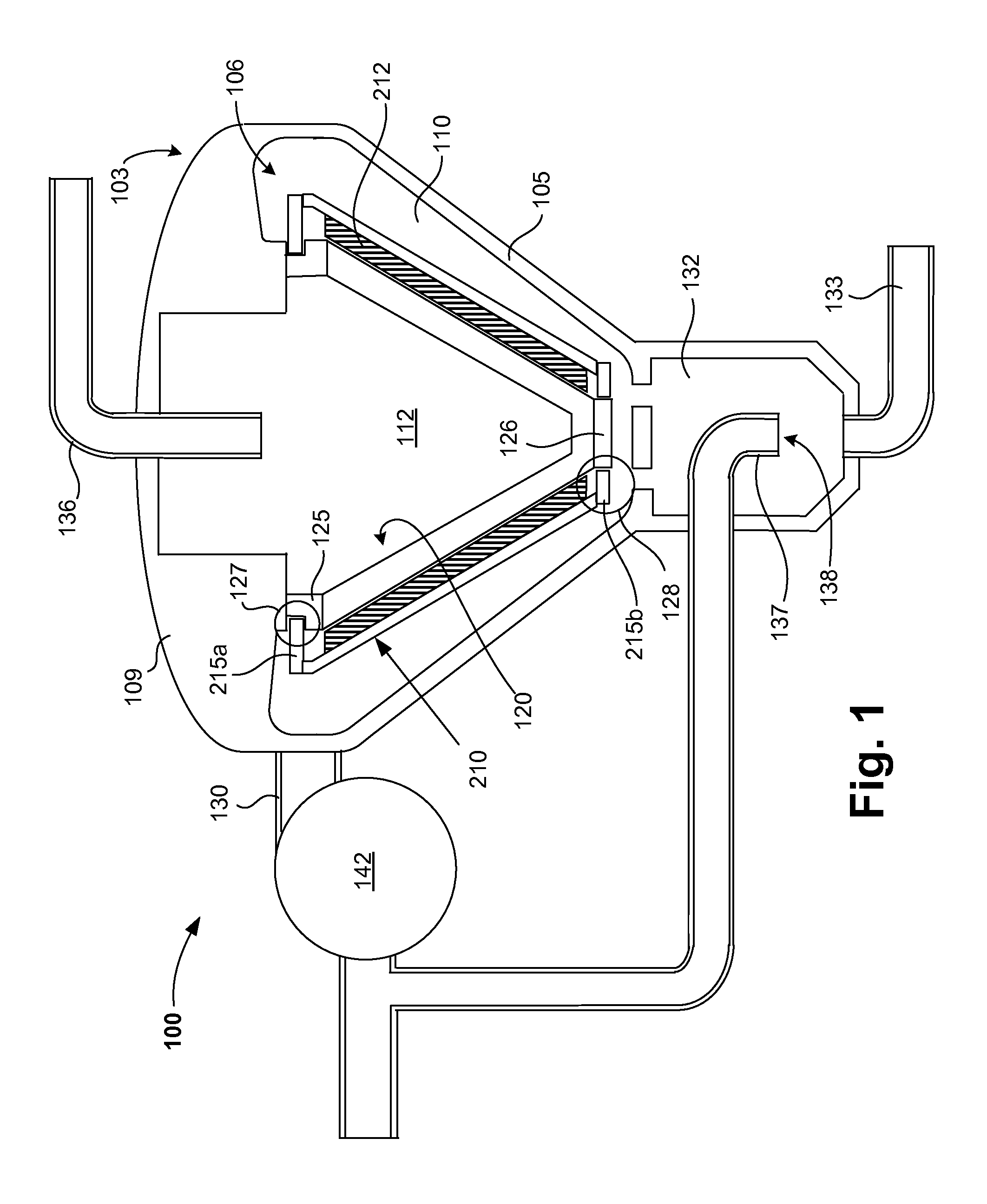

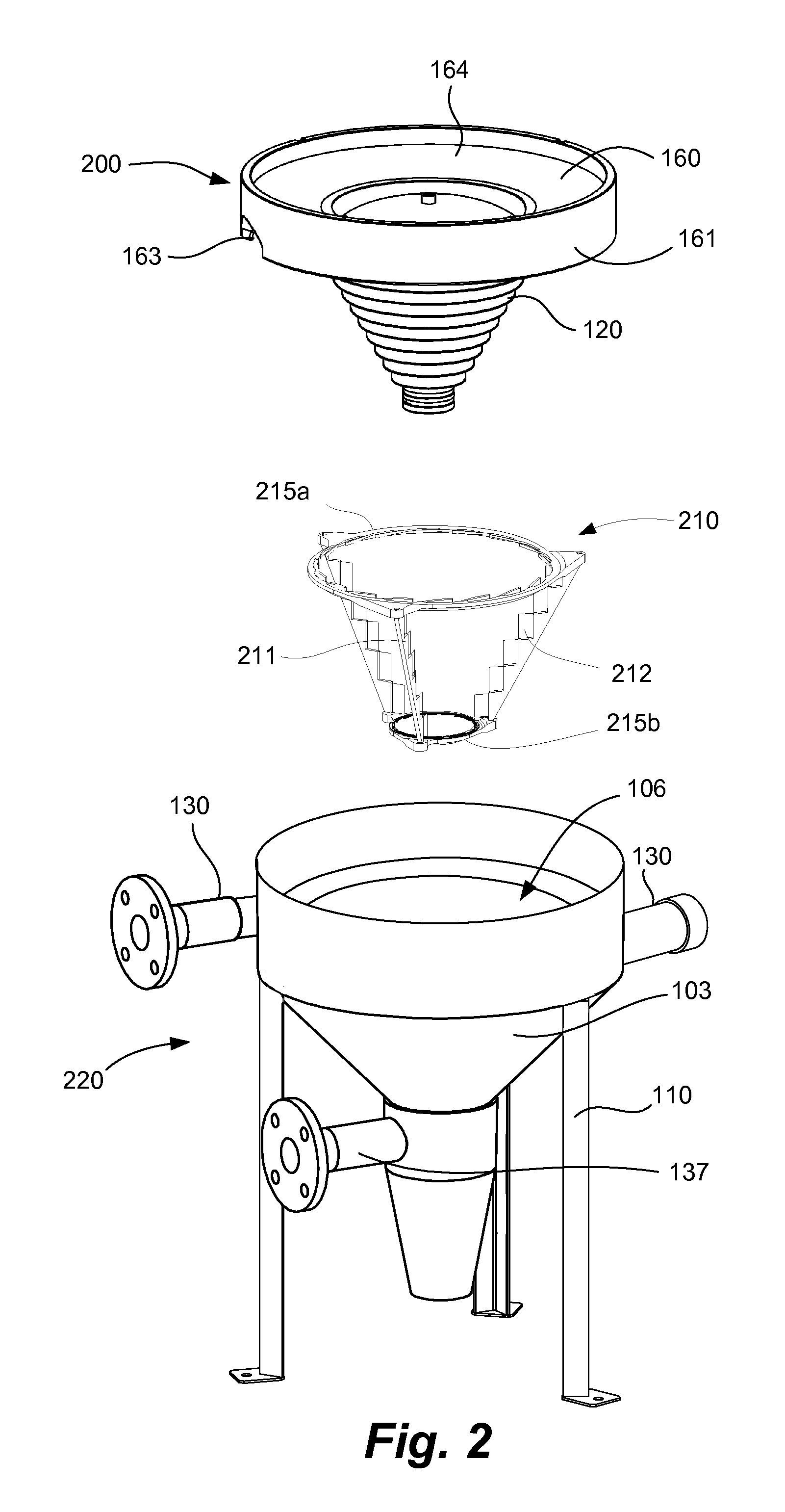

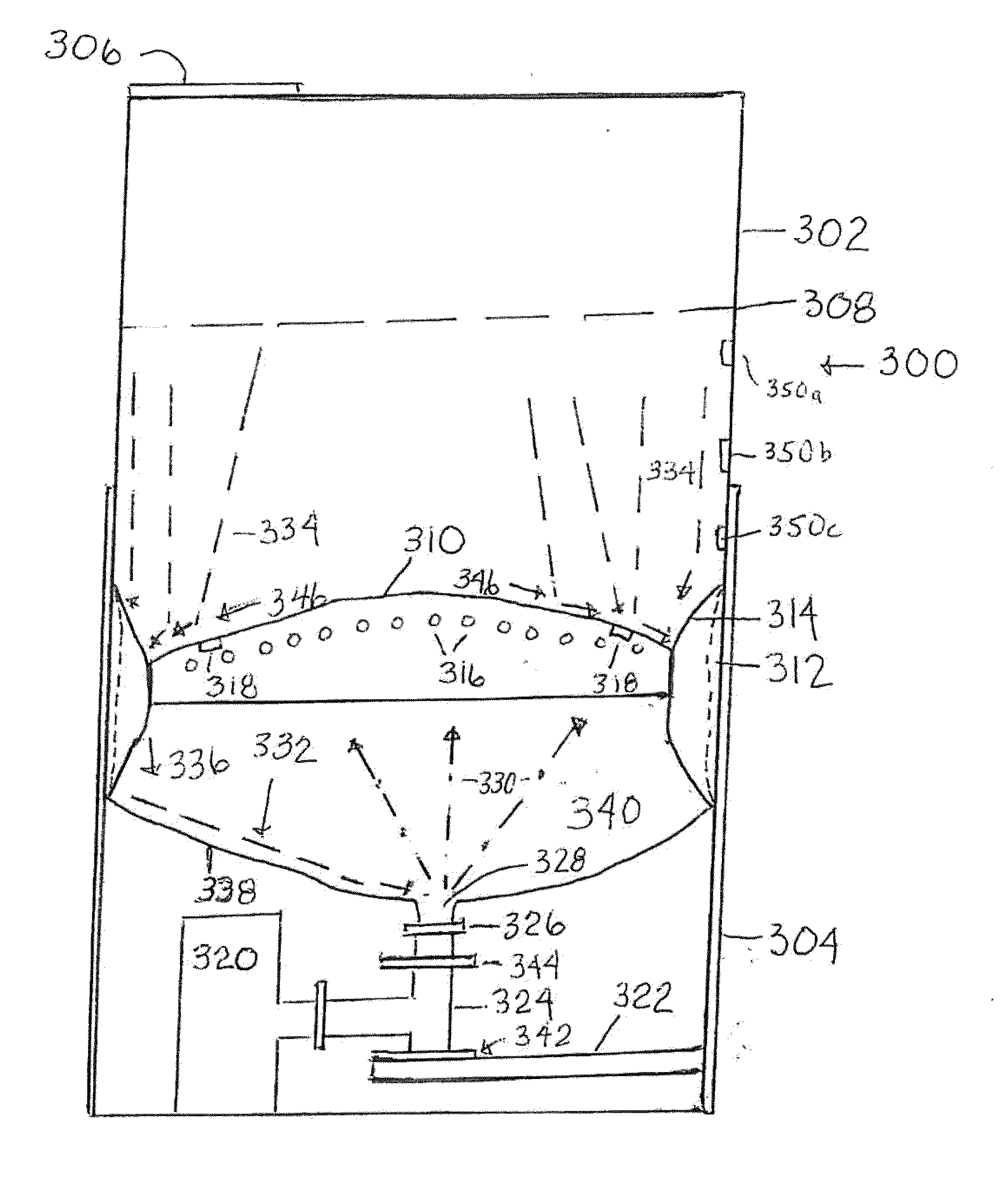

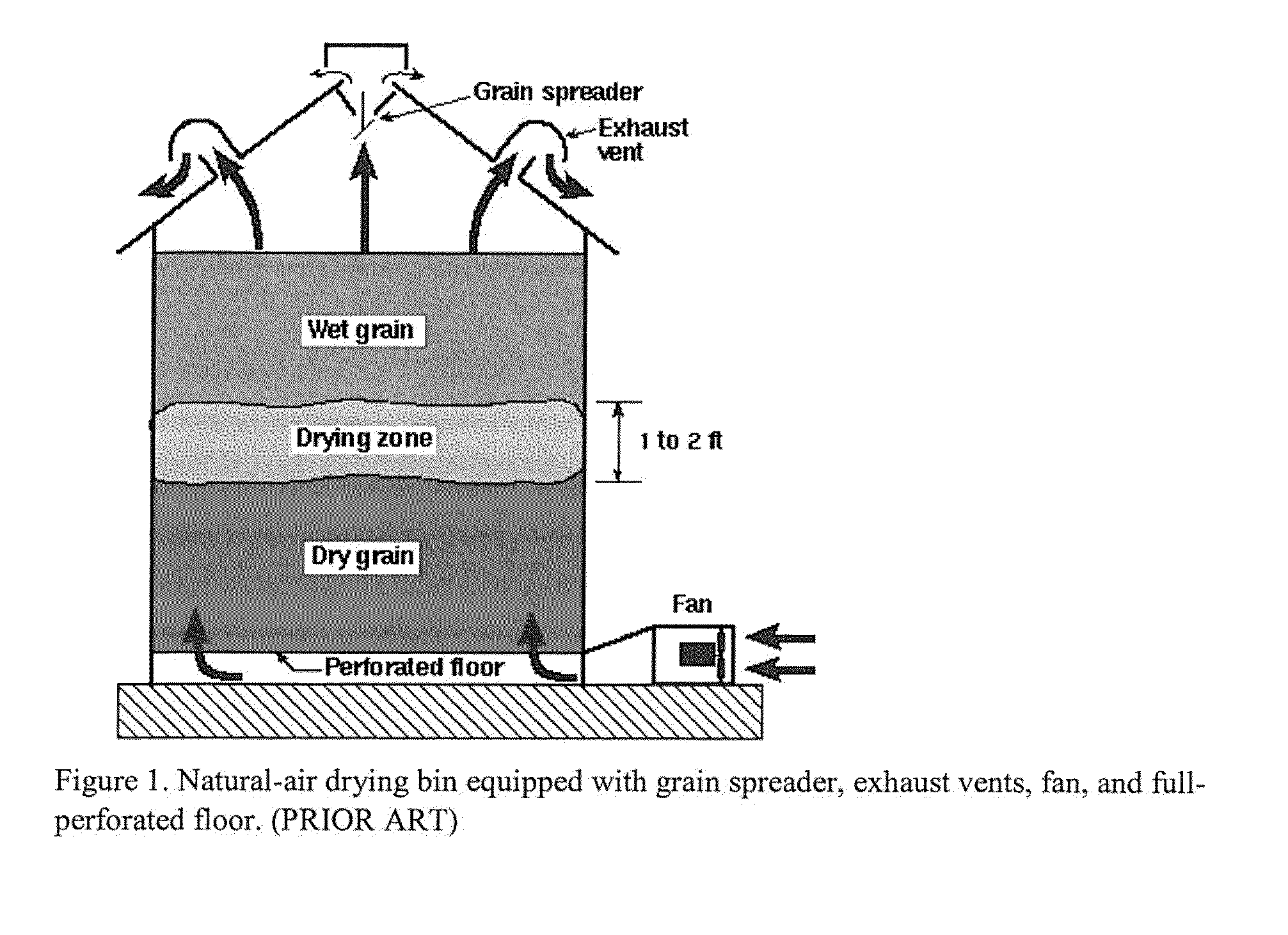

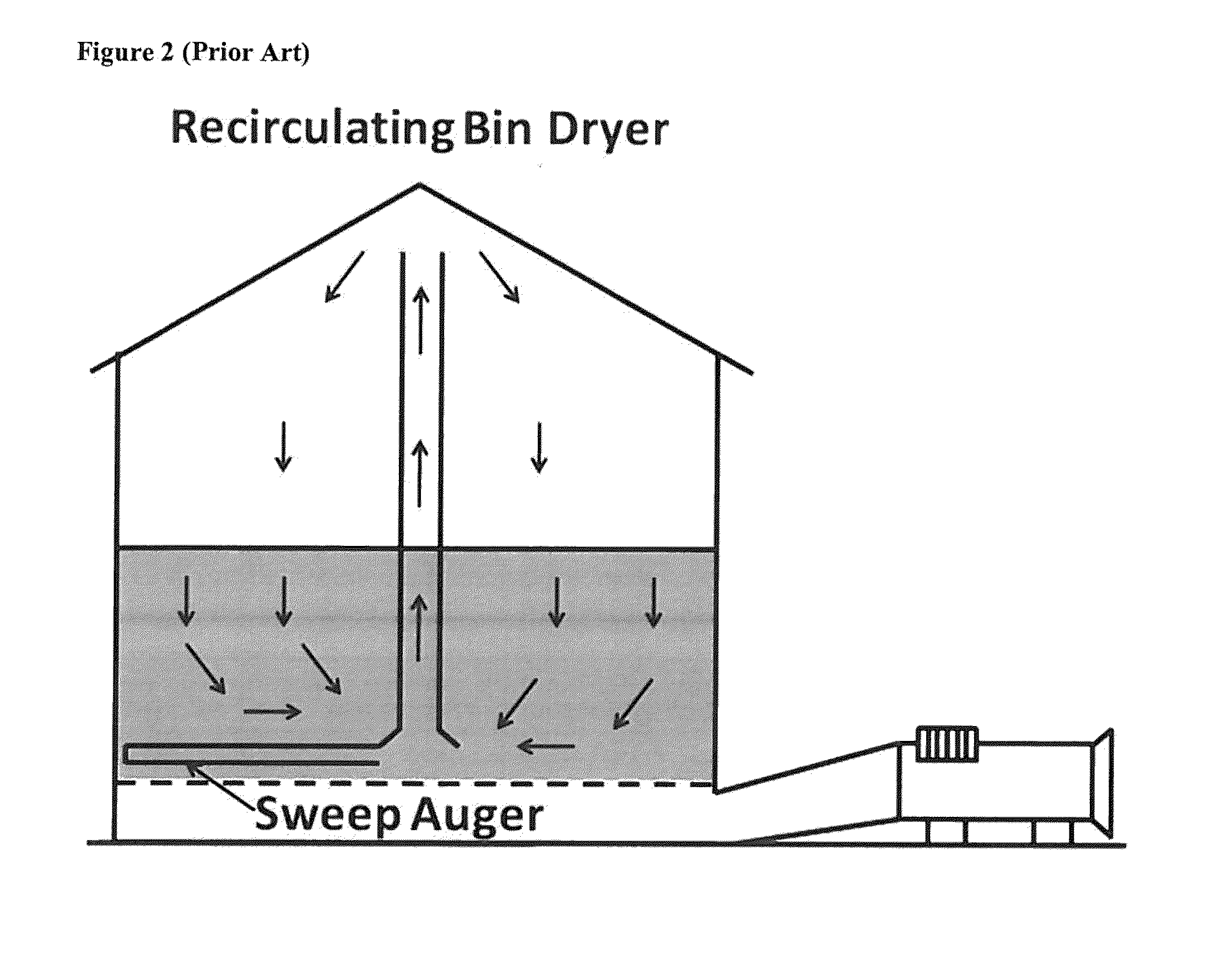

Bin system and method of regulating particulate flow from bins

InactiveUS20150345863A1Drying solid materials with heatDrying solid materials without heatEngineeringParticulate flow

A bin and method of use for containment and delivery of particulate materials has:a) a housing;b) a particulate materials support plate within the housing, the support plate having a porous structure allowing air flow therethrough;c) the support plate having a central area elevated away from the bottom of the housing and surrounding sides;d) an air flow area between the bottom of the housing and the support plate;e) a particle drop region surrounding the sides of the support plate; andf) a sealing and opening component within the particle drop region that seals and opens a particle drop path between the support plate and the side walls of the housing.The sealing and opening component has an expanded position when sealing the particle drop region and is in a retracted position when opening the particle drop region to particulate material passage.

Owner:OGARY GREGORY HOWARD

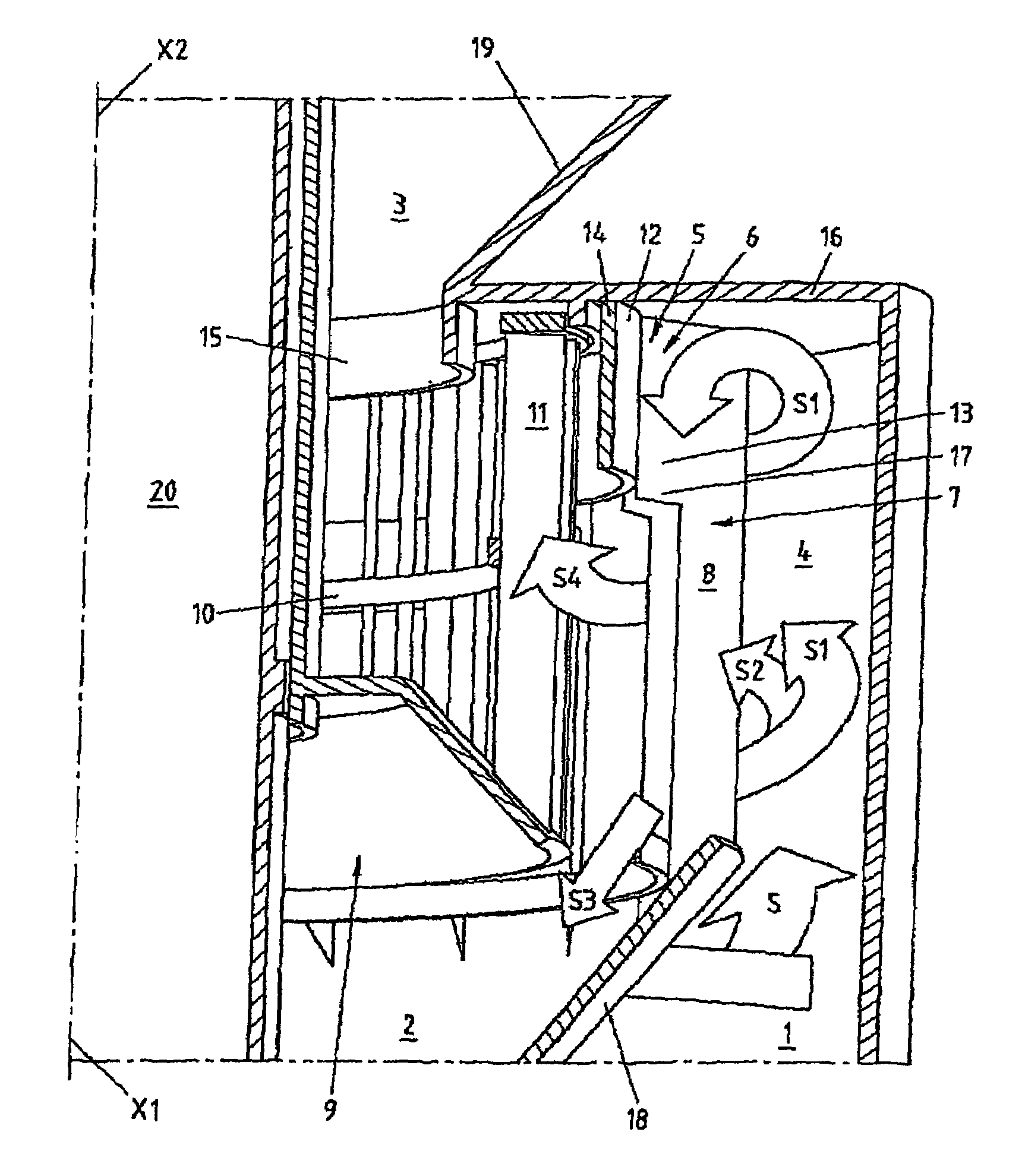

Centrifugal separator

ActiveUS8033399B2Improve clarityReduce loadReversed direction vortexGas current separationInlet channelEngineering

Disclosed is a centrifugal separator with an inlet channel for a flow containing coarse and fine particles, a first outlet channel for a flow containing predominantly coarse particles, a second outlet channel for a flow containing predominantly fine particles and a separator chamber with at least one separator device, wherein the separator chamber connects the inlet channel to the first outlet channel and the second outlet channel, and wherein the inlet channel, the separator channel and the two outlet channels form a flow path. To improve the degree of efficiency, as a first separator device, one or more separator pockets are arranged in the separator chamber, which project into the flow path. Also disclosed is a corresponding method for the separation of a flow containing coarse and fine particles.

Owner:BABCOCK BORSIG STEINMUELLER GMBH

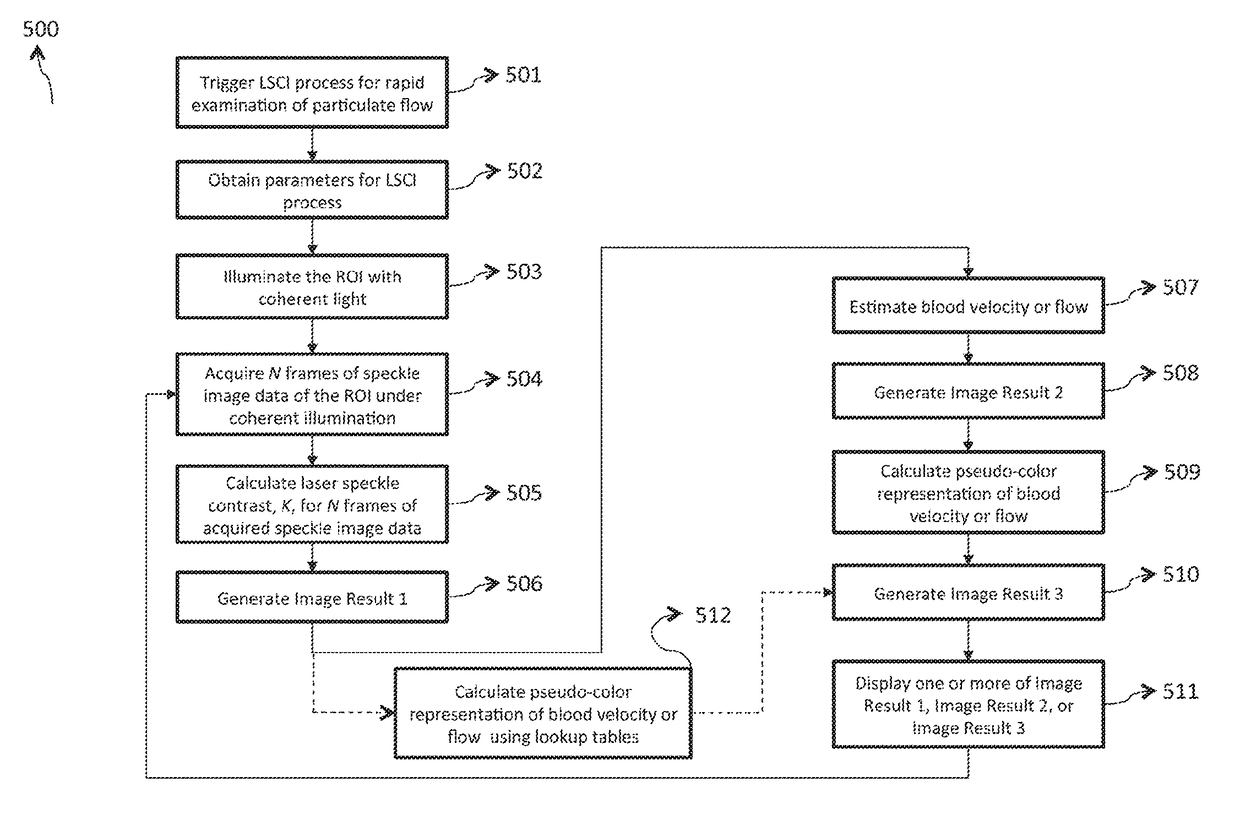

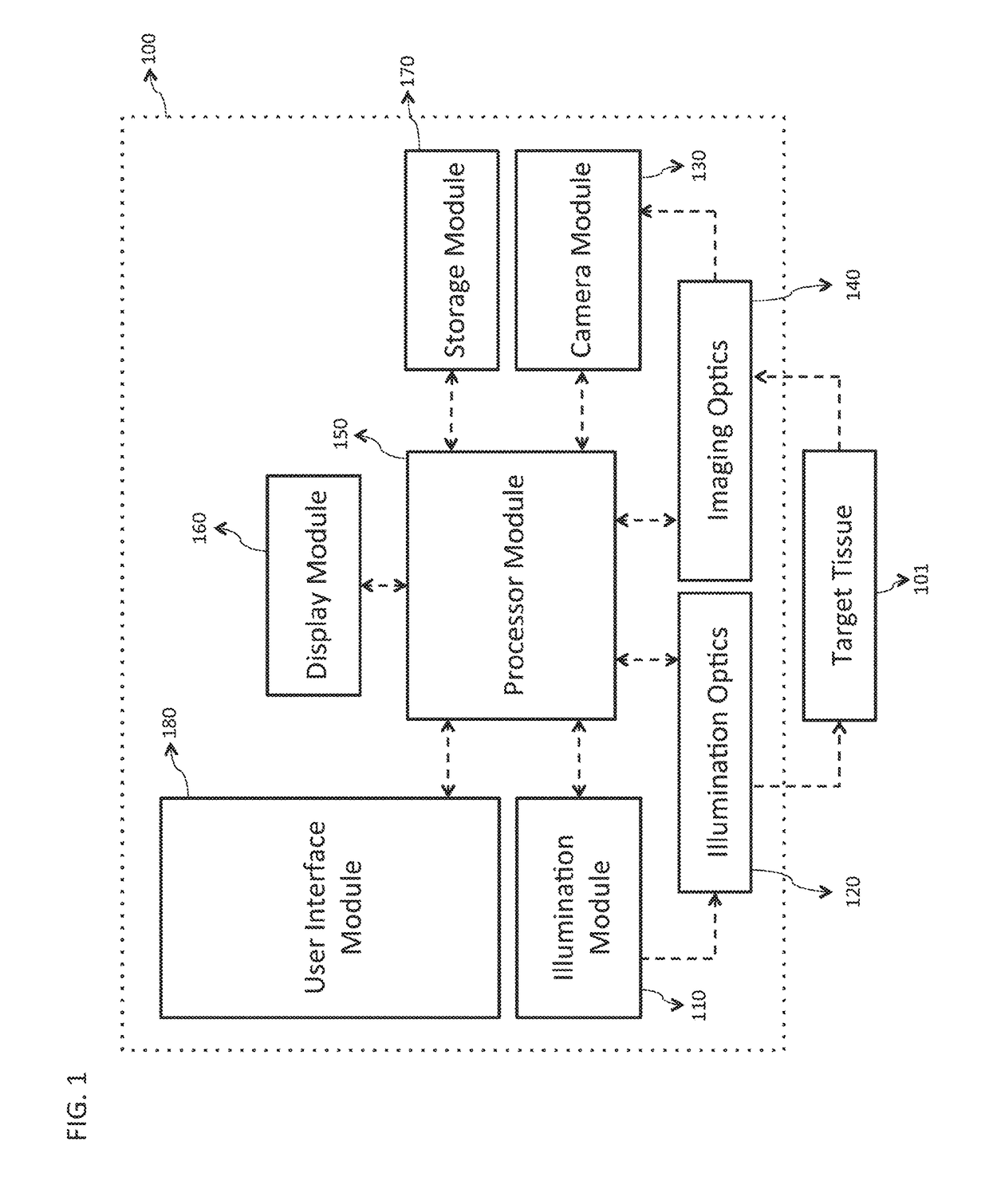

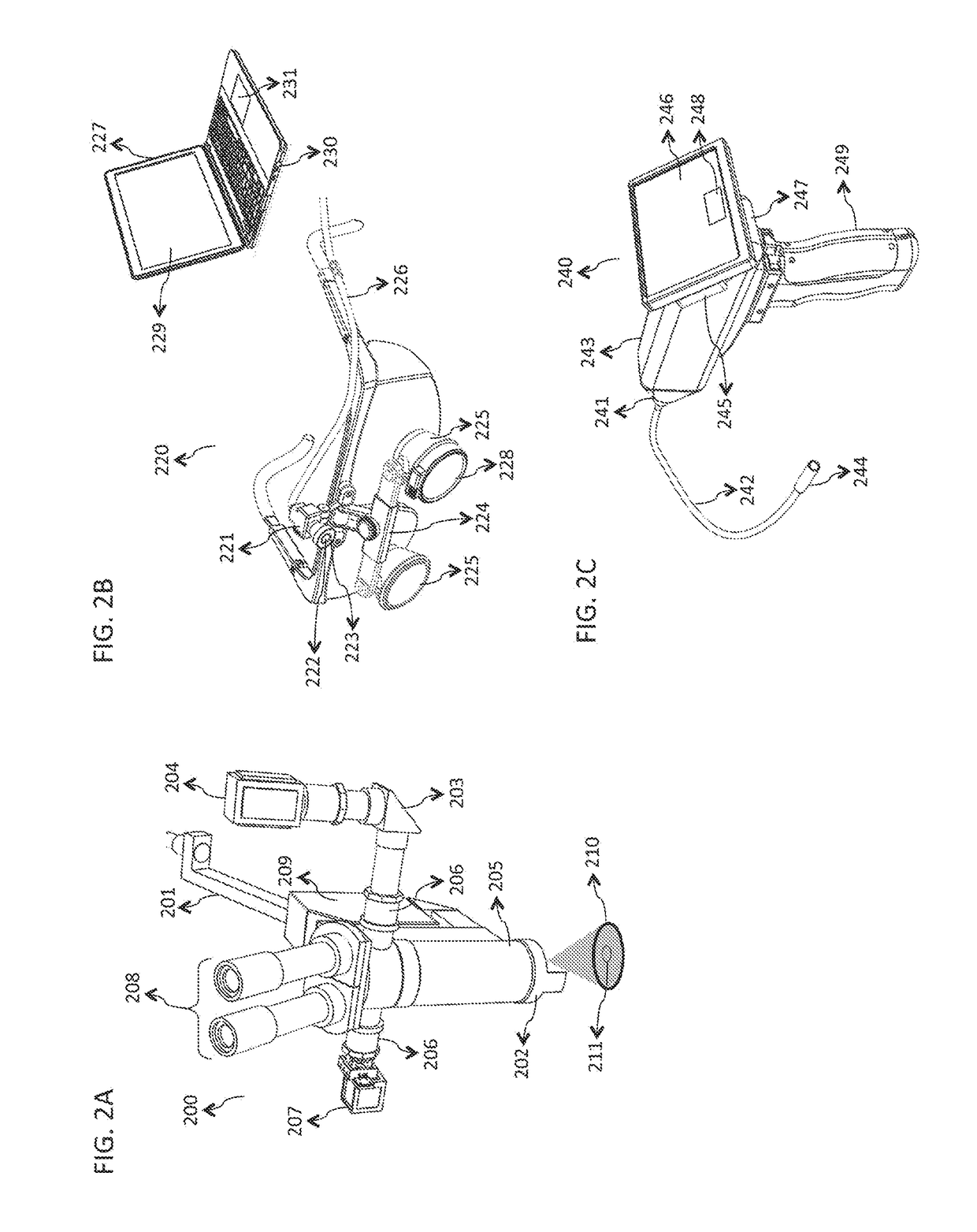

System and method for rapid examination of vasculature and particulate flow using laser speckle contrast imaging

Examination of the structure and function of blood vessels is an important means of monitoring the health of a subject. Such examination can be important for disease diagnoses, monitoring specific physiologies over the short- or long-term, and scientific research. This disclosure describes technology and various embodiments of a system and method for imaging blood vessels and the intra-vessel blood flow, using at least laser speckle contrast imaging, with high speed so as to provide a rapid estimate of vessel-related or blood flow-related parameters.

Owner:VASOPTIC MEDICAL

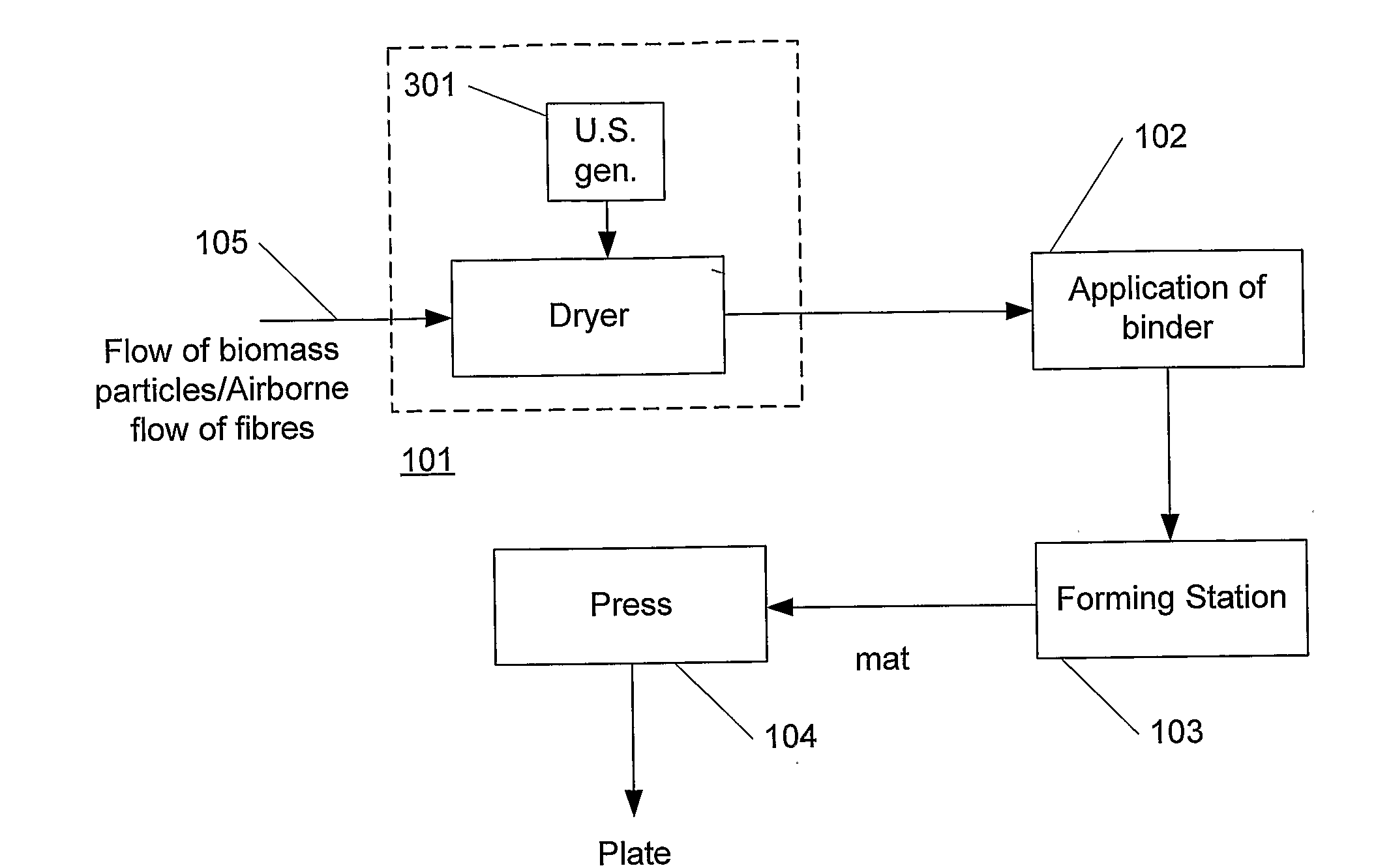

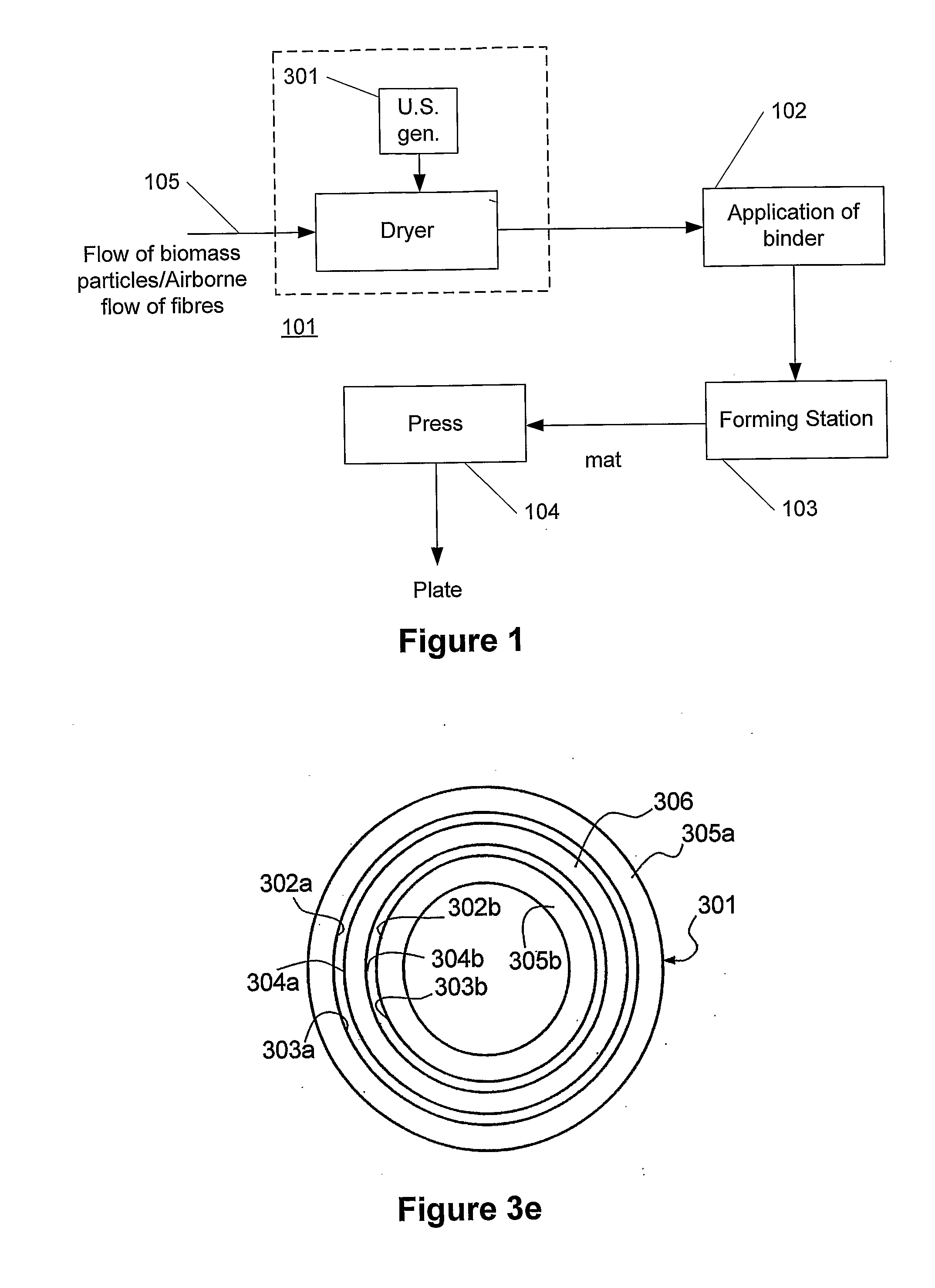

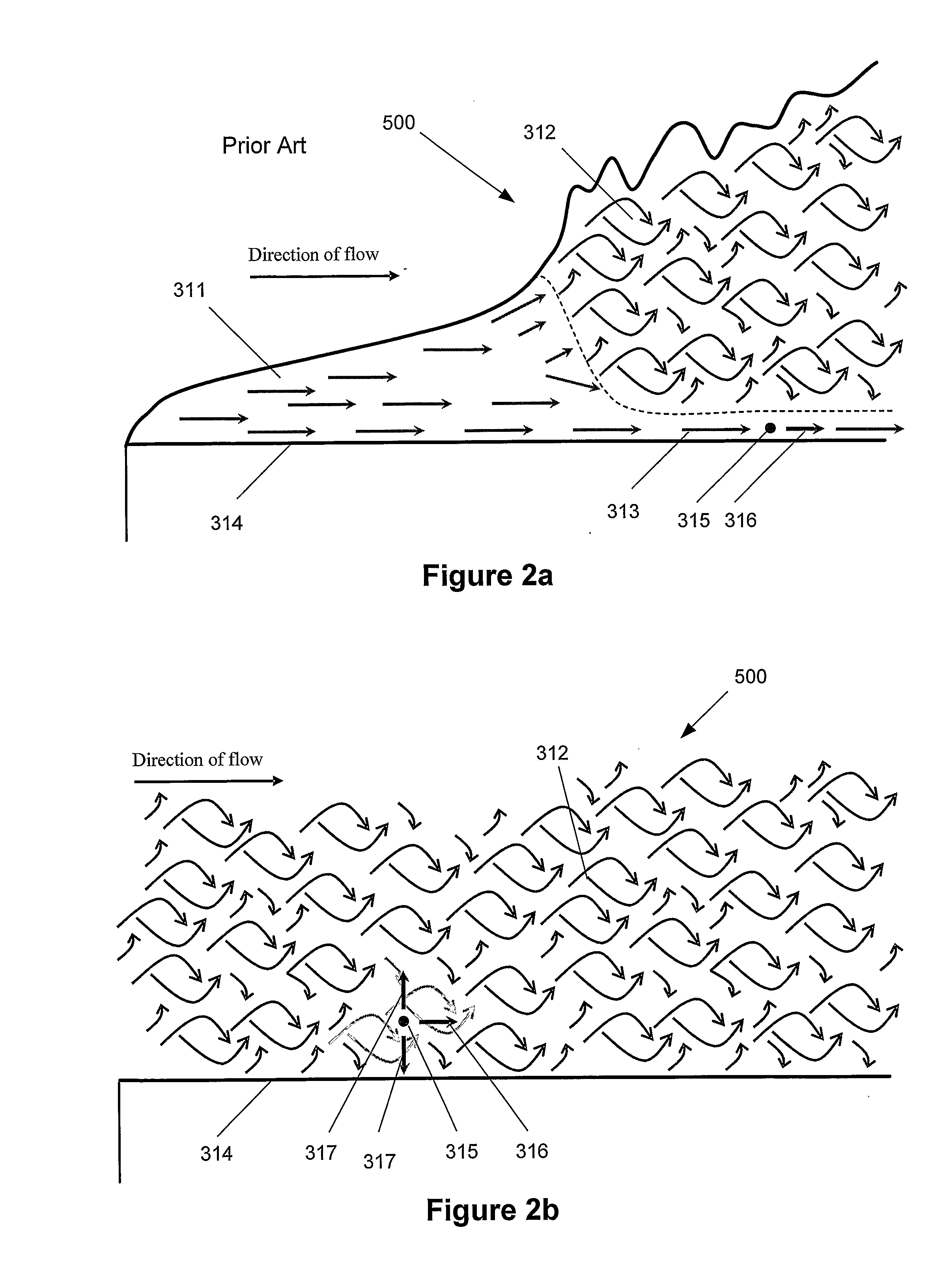

Method And Device For Drying A Flow Of Biomass Particles

InactiveUS20090007931A1Efficient dryingEfficient processDrying solid materials with heatDrying solid materials without heatWood fibreProcess engineering

A method and a system to be used in the process of manufacturing plates, such as fibreboards, particleboards and the like boards, where the raw material in the form of biomass particles, such as wood fibres or wood particles of various size and shape are dried from its natural moisture content to a moisture content suitable to be applied with a thermosetting binder and be spread onto a movable forming belt to form a mat, and where said mat by means of a hot press is compressed into the desired thickness of the finished plate and the thermosetting binder is hardened. According to the invention, the drying process of the biomass particles is facilitated by the use of ultrasound to remove the sub-layer of air at the surface of the particles and thus to intensify the transport of heat energy into the particles and the transport of moisture from the particles.

Owner:FORCE TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com