Patents

Literature

80results about How to "Increase fluid flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

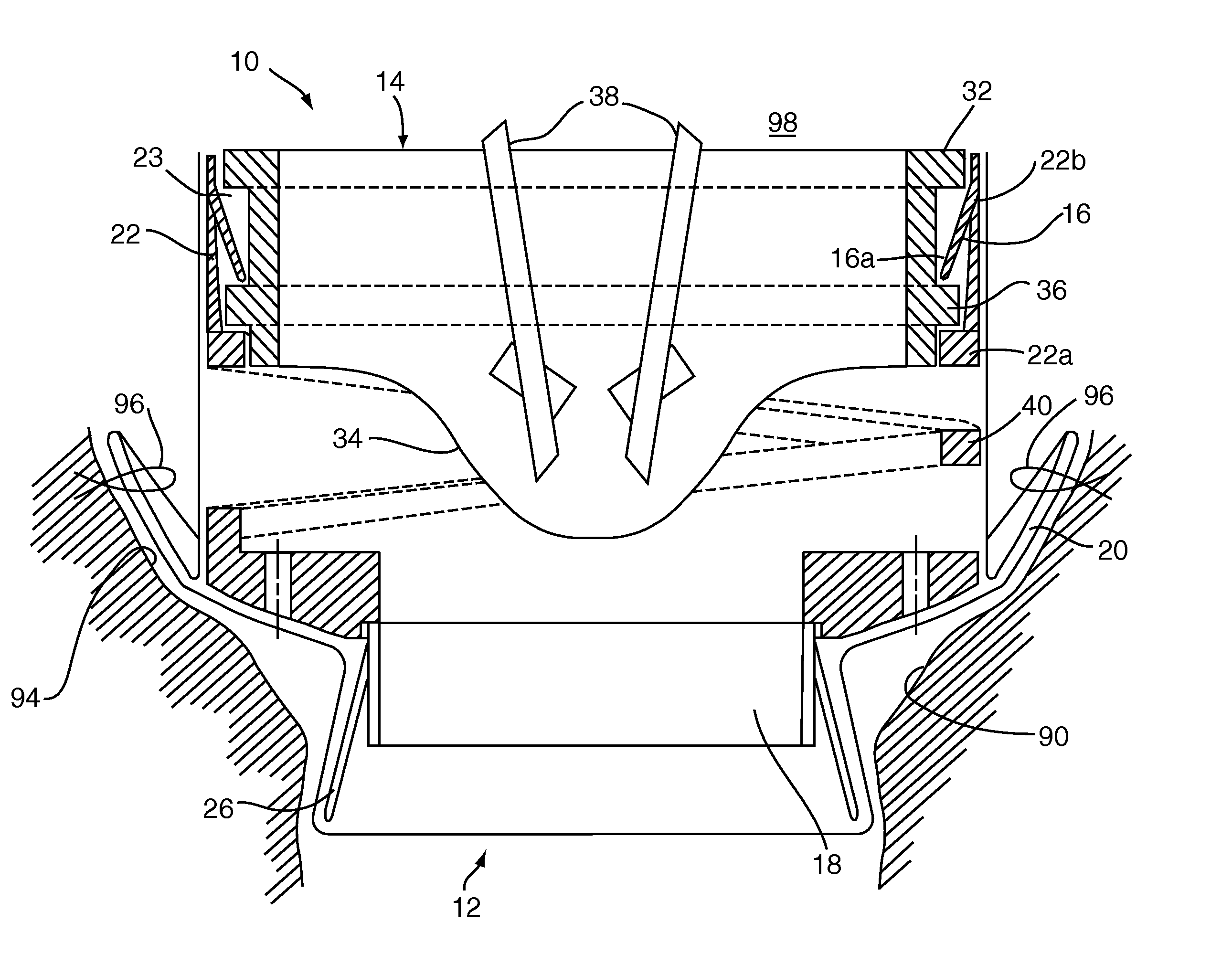

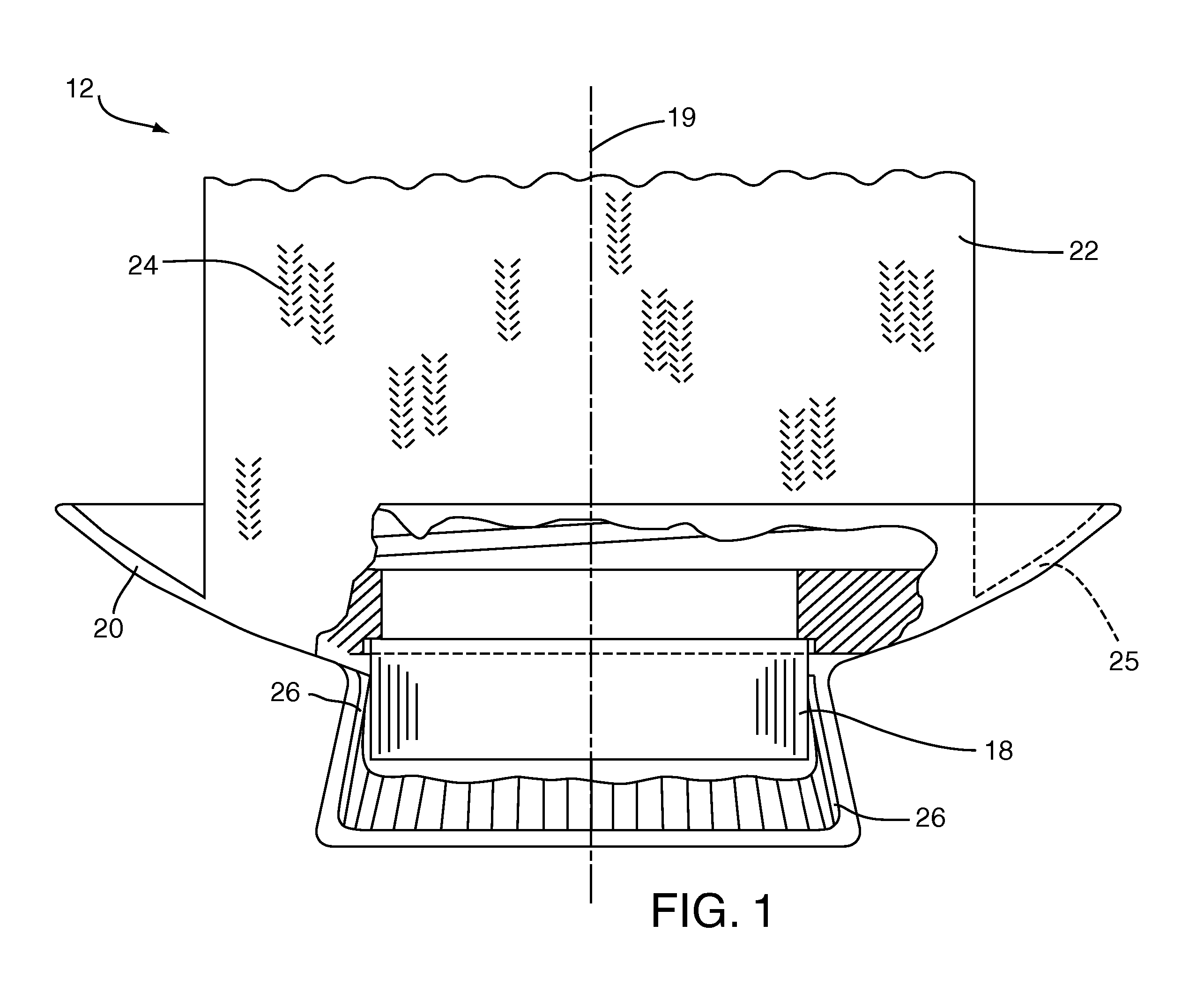

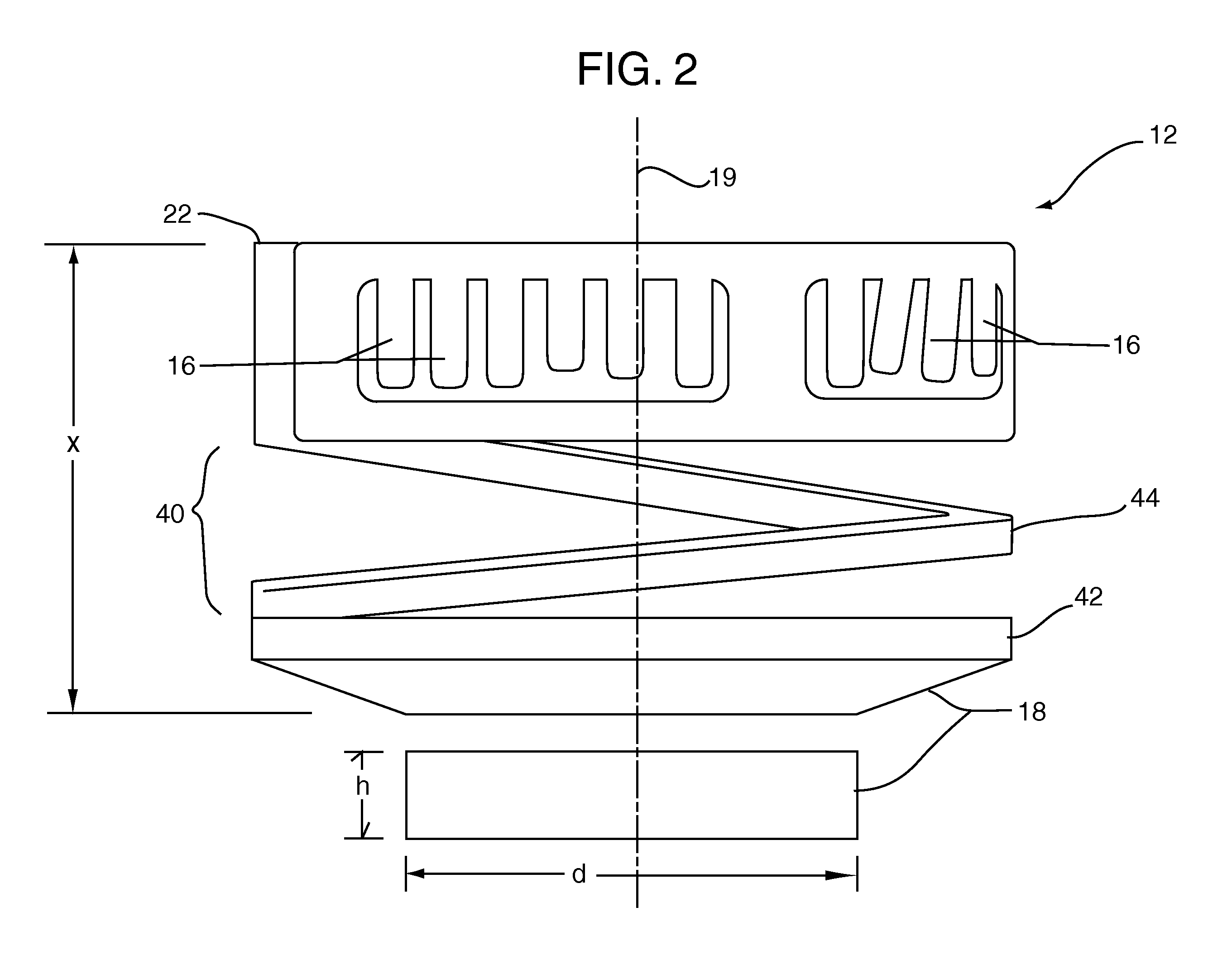

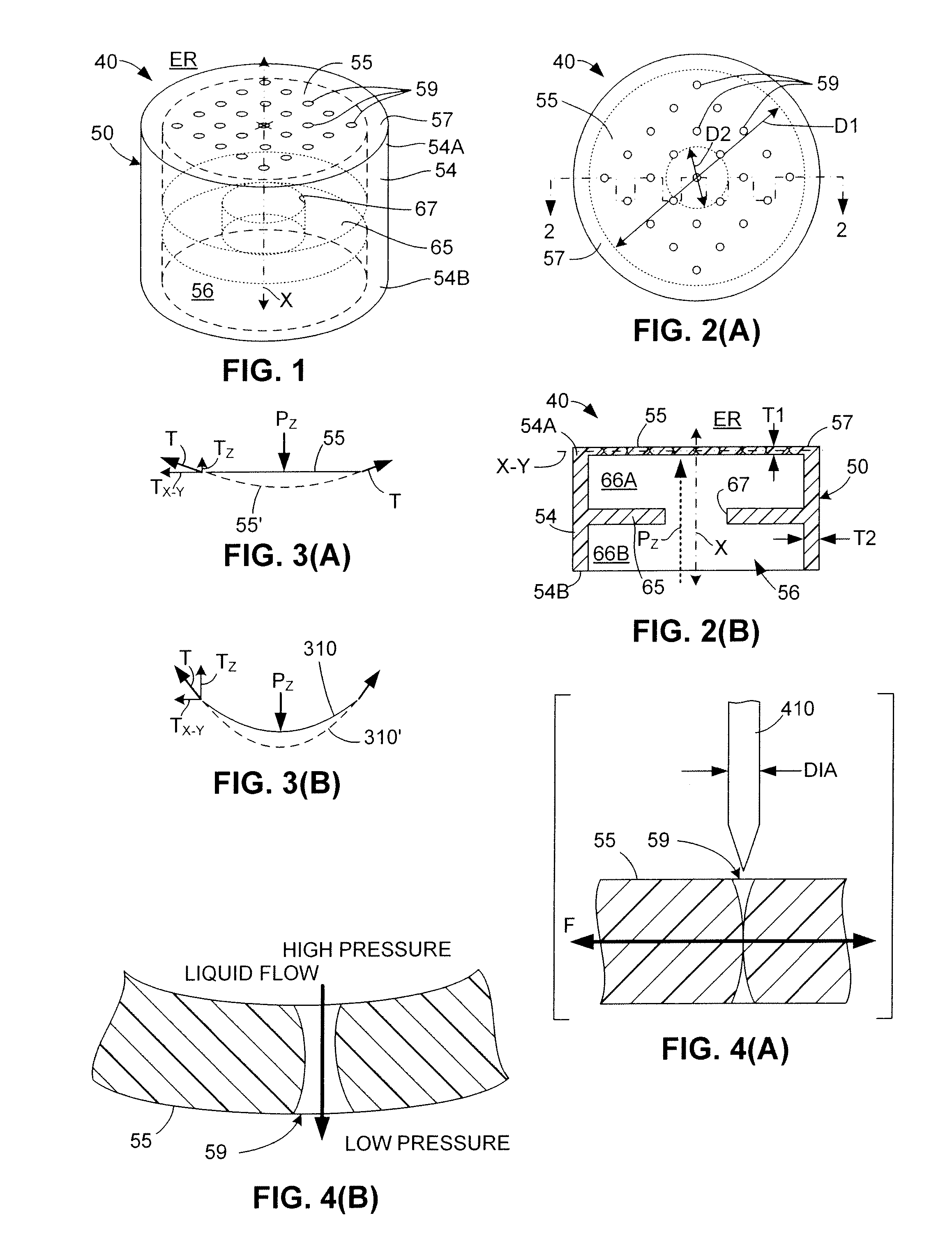

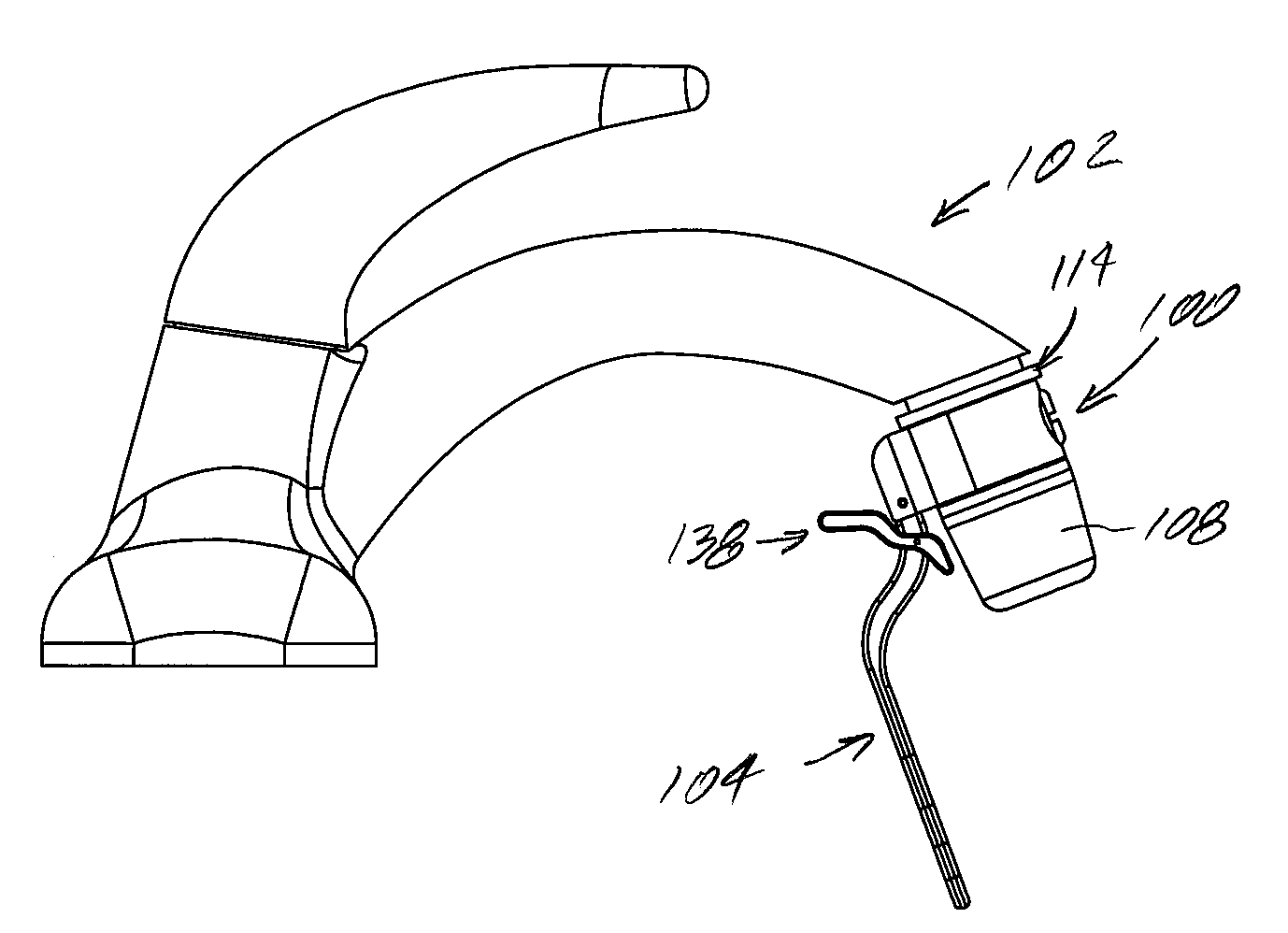

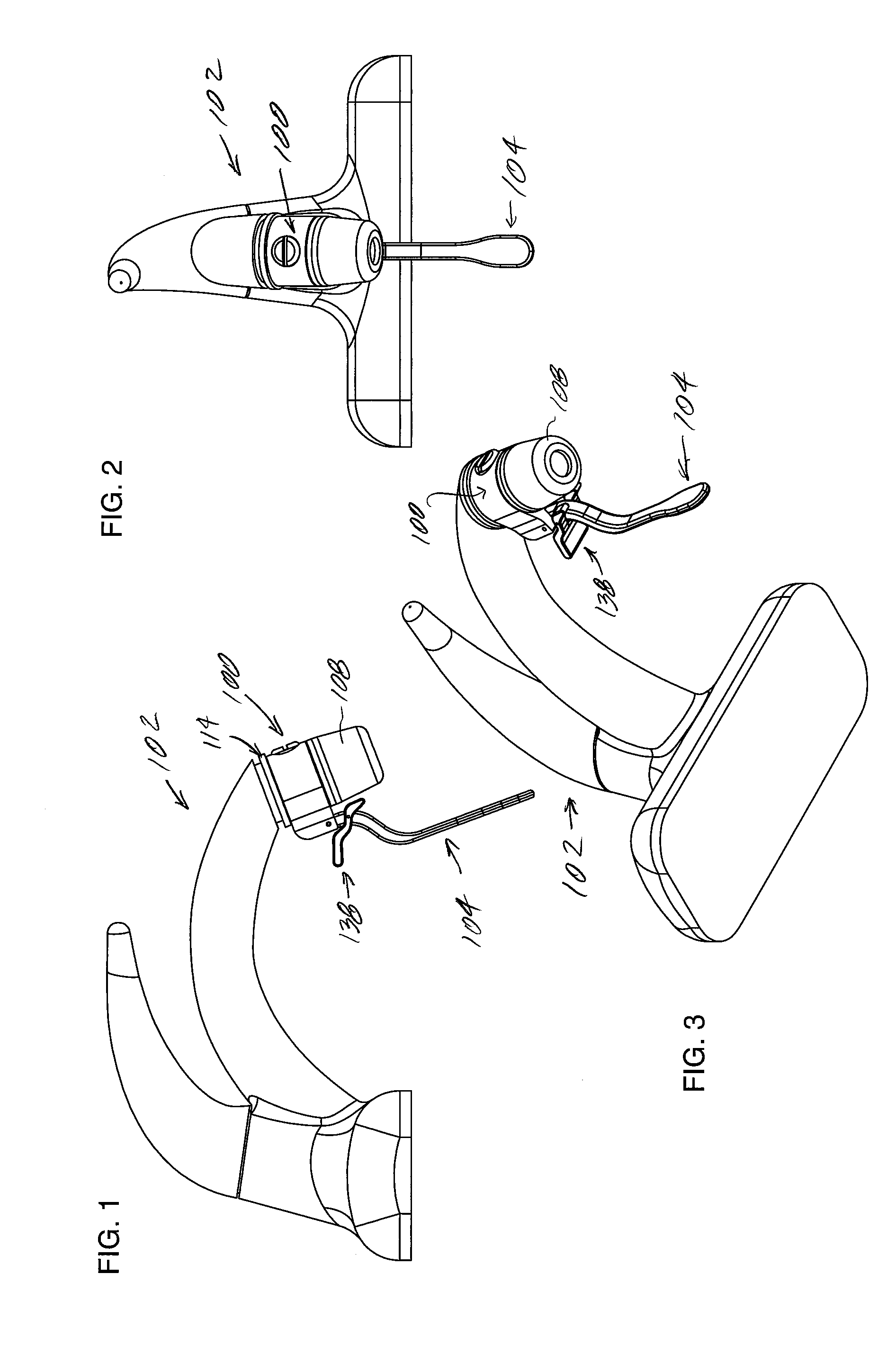

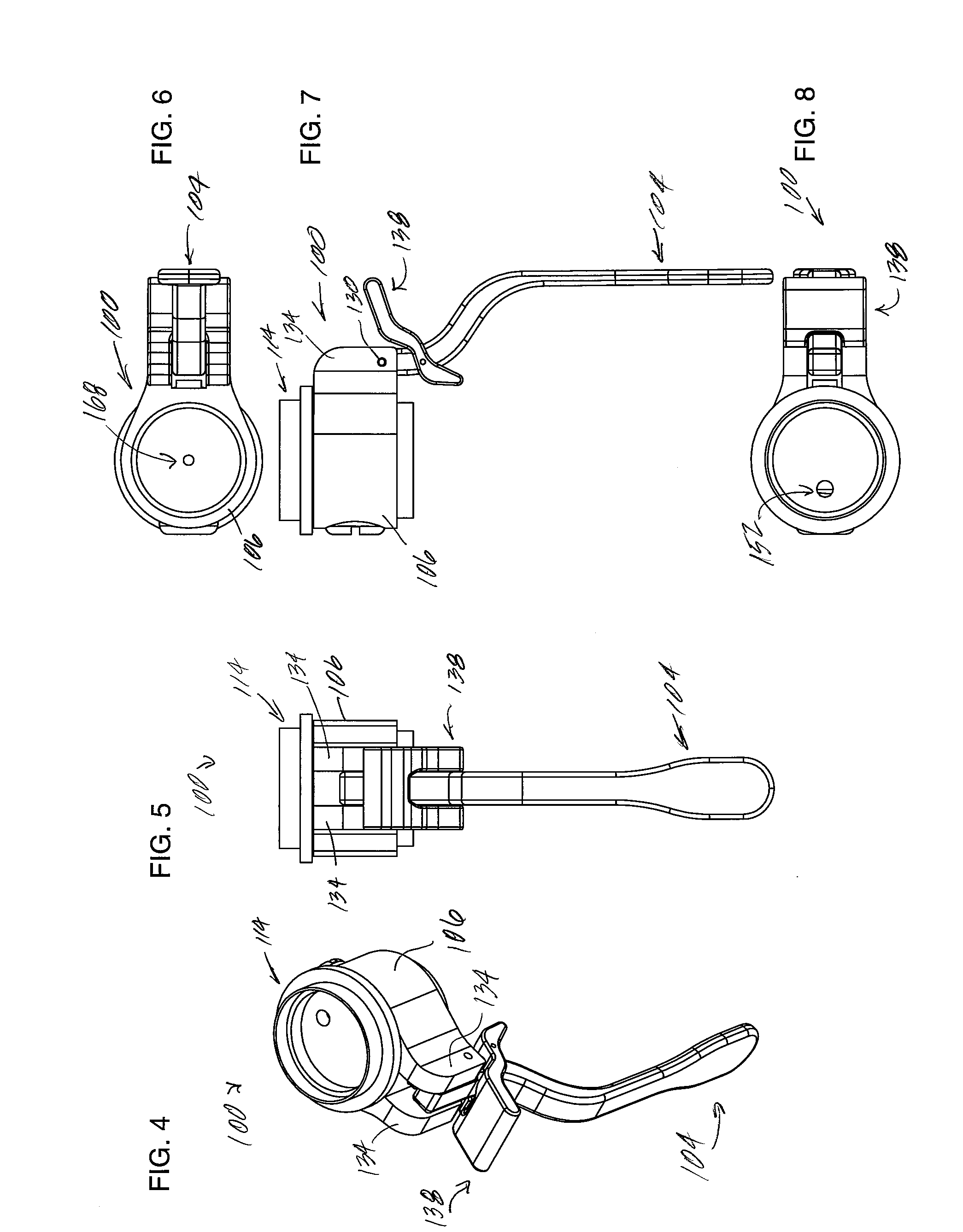

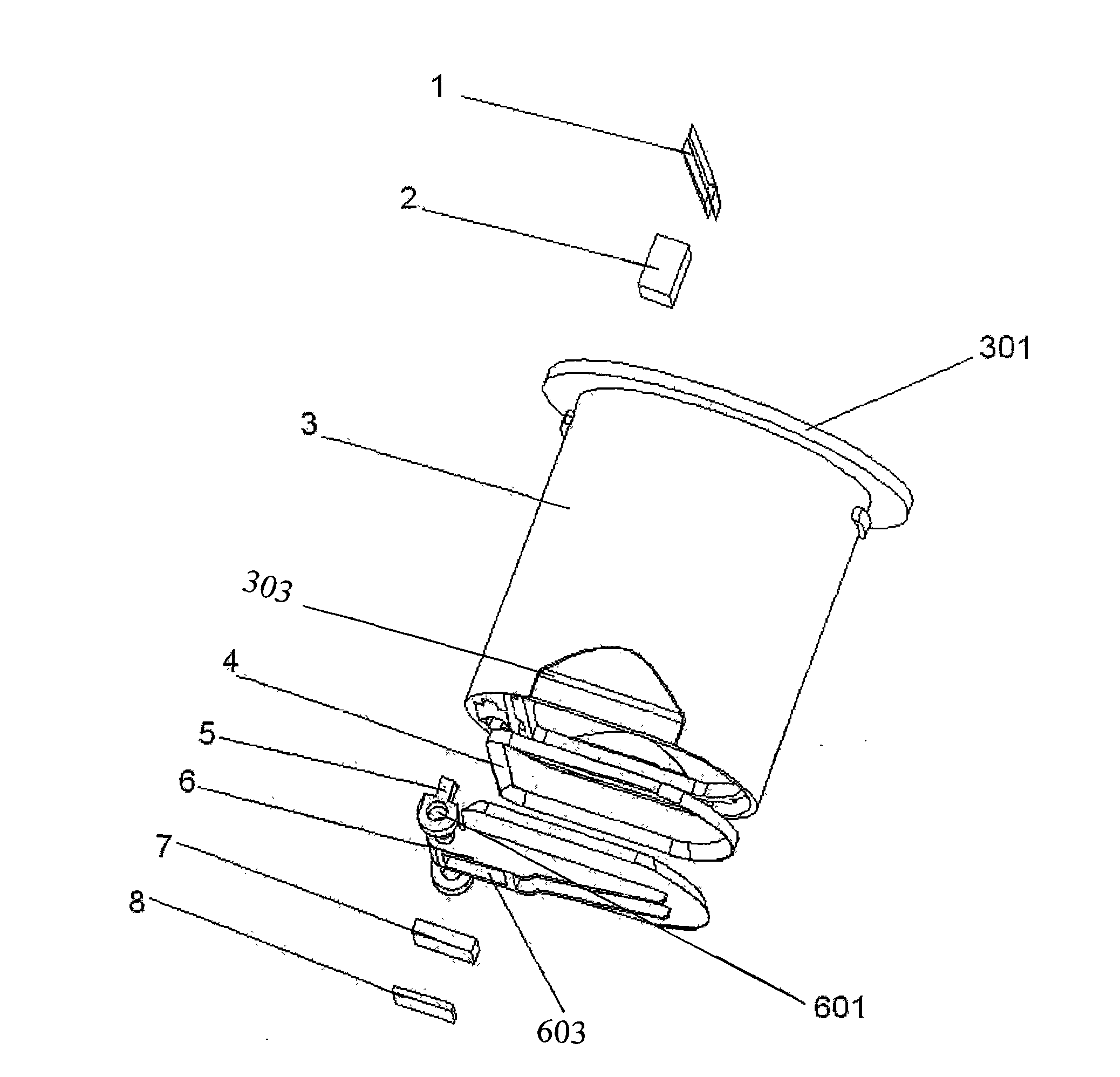

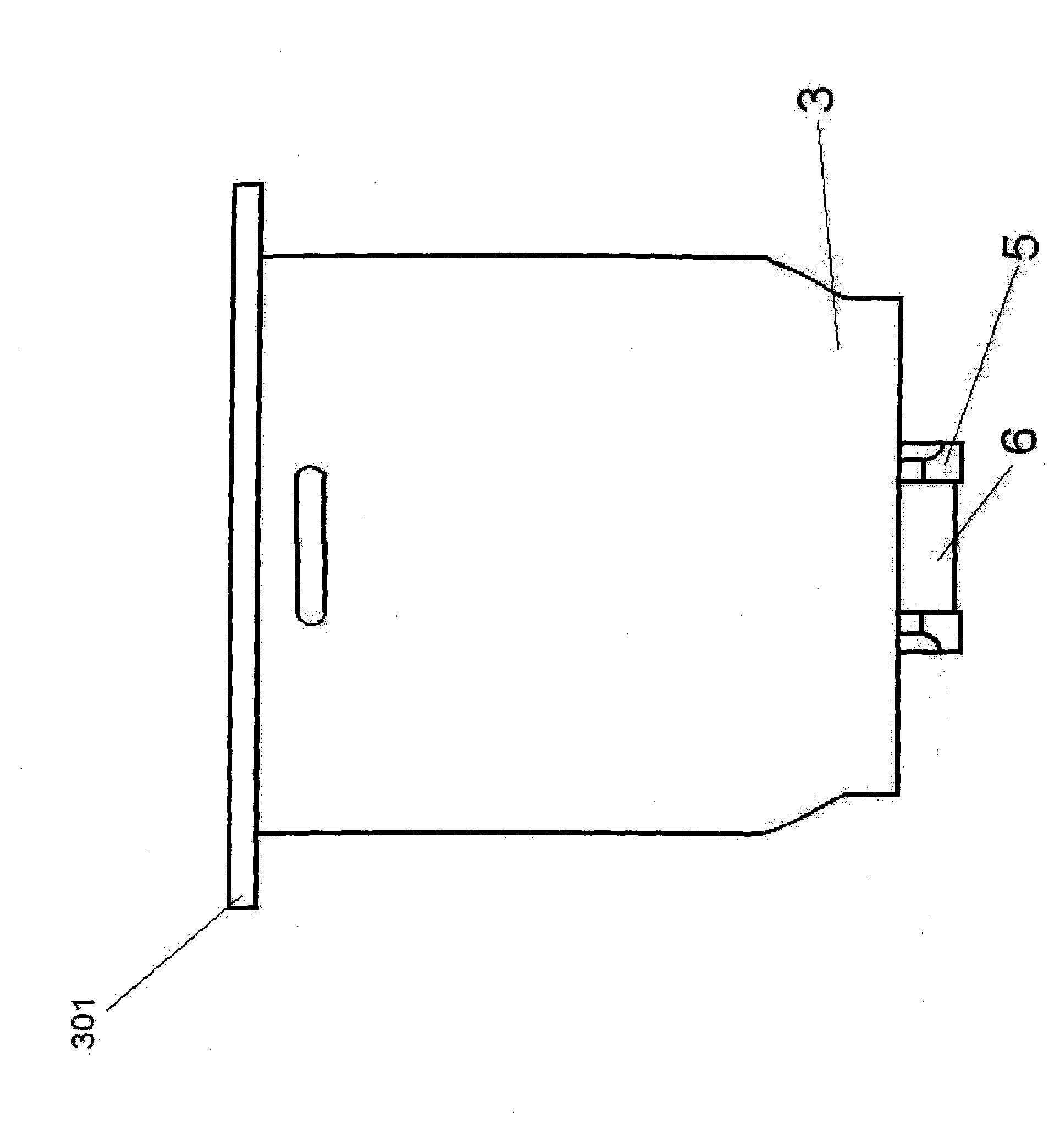

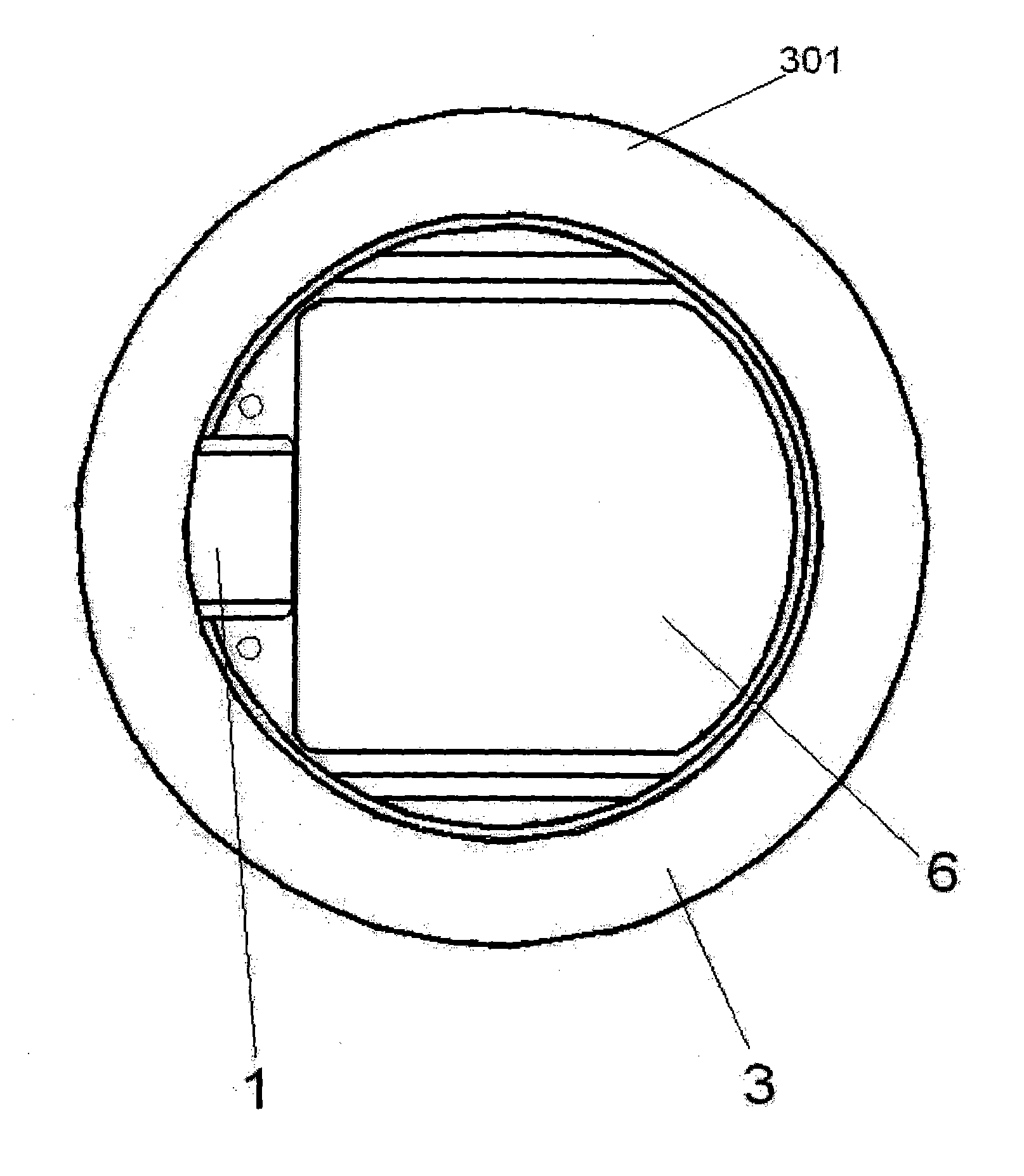

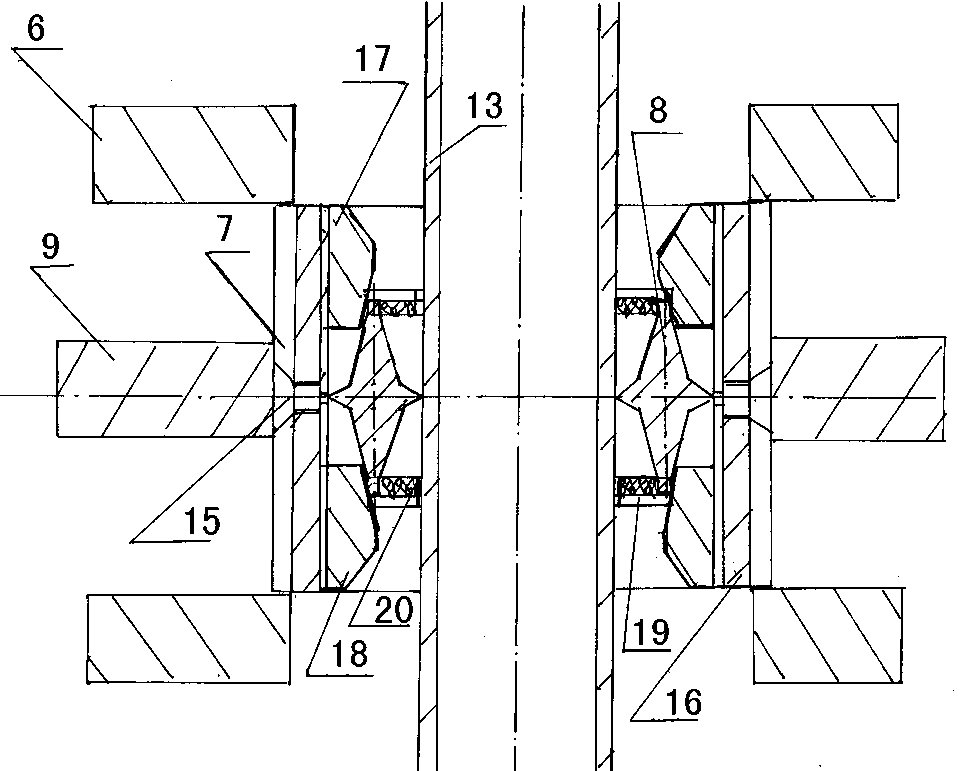

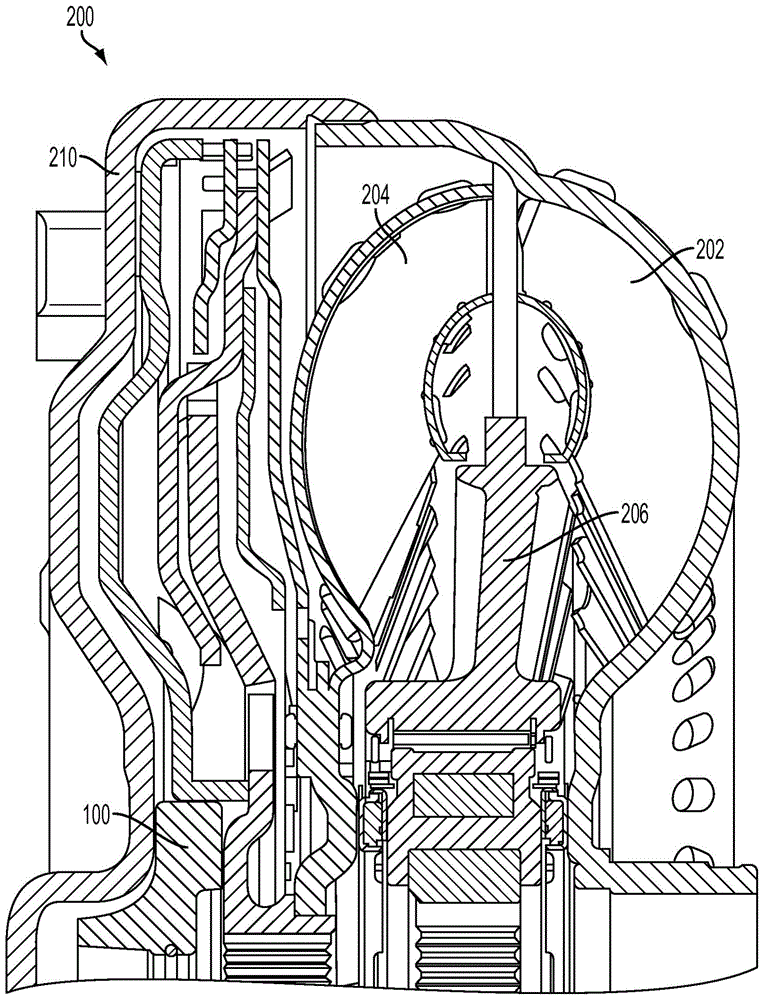

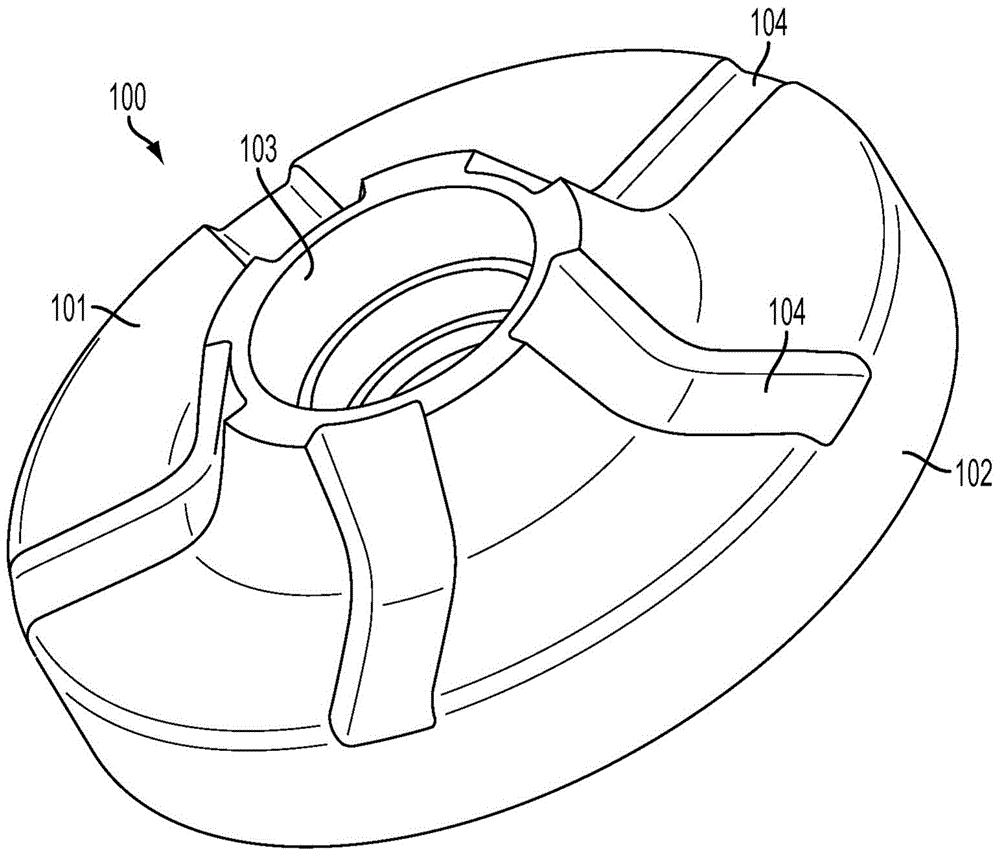

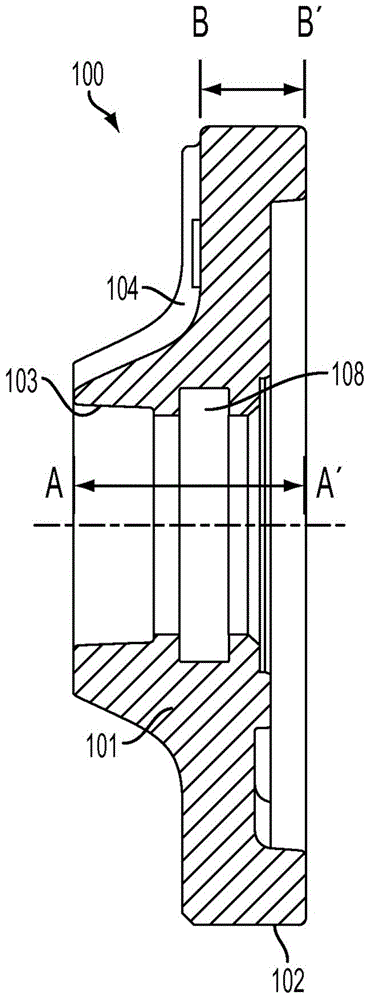

Gasket with spring collar for prosthetic heart valves and methods for making and using them

ActiveUS20070179604A1Increase fluid flowEnhancing other performance characteristicHeart valvesBioprosthetic valveProsthesis

A heart valve prostheses includes an annular member implantable within a biological annulus, a collar extending upwardly from the annular member, and a sewing ring extending from the annular member. A spring structure couples the collar to the annular member and biases the collar to align with the annular member at a predetermined distance above the annular member. During use, the prosthesis is introduced into a biological annulus, and fasteners are directed through the sewing ring into surrounding tissue to secure the prosthesis with the annular member within the biological annulus. A mechanical or bioprosthetic valve is introduced and coupled to the collar, e.g., using tabs or other connectors on the collar. The spring structure allows the collar to be directed towards the annular member and / or folded inwardly, e.g., to facilitate accessing the sewing ring to deliver fasteners.

Owner:MEDTRONIC INC

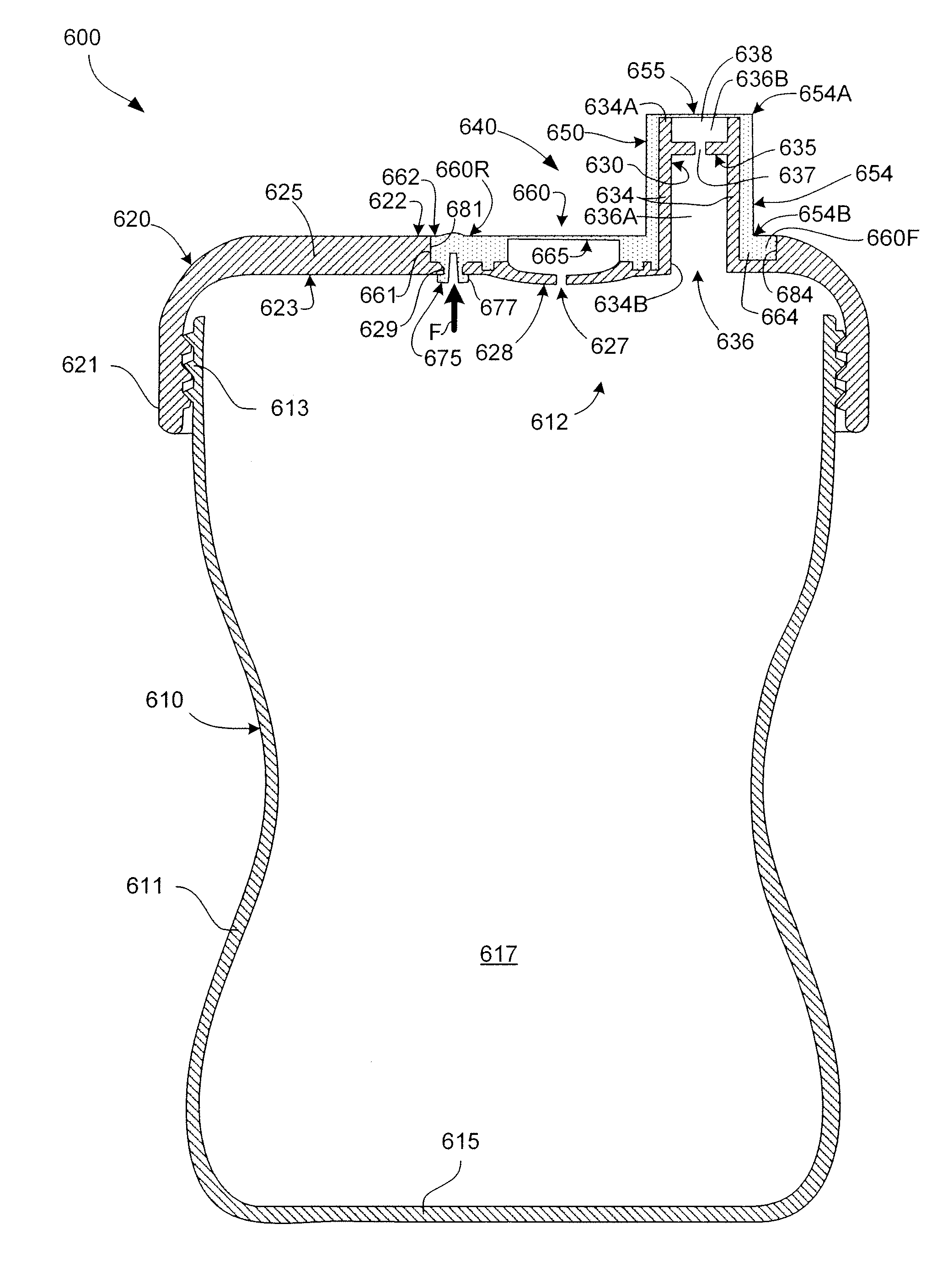

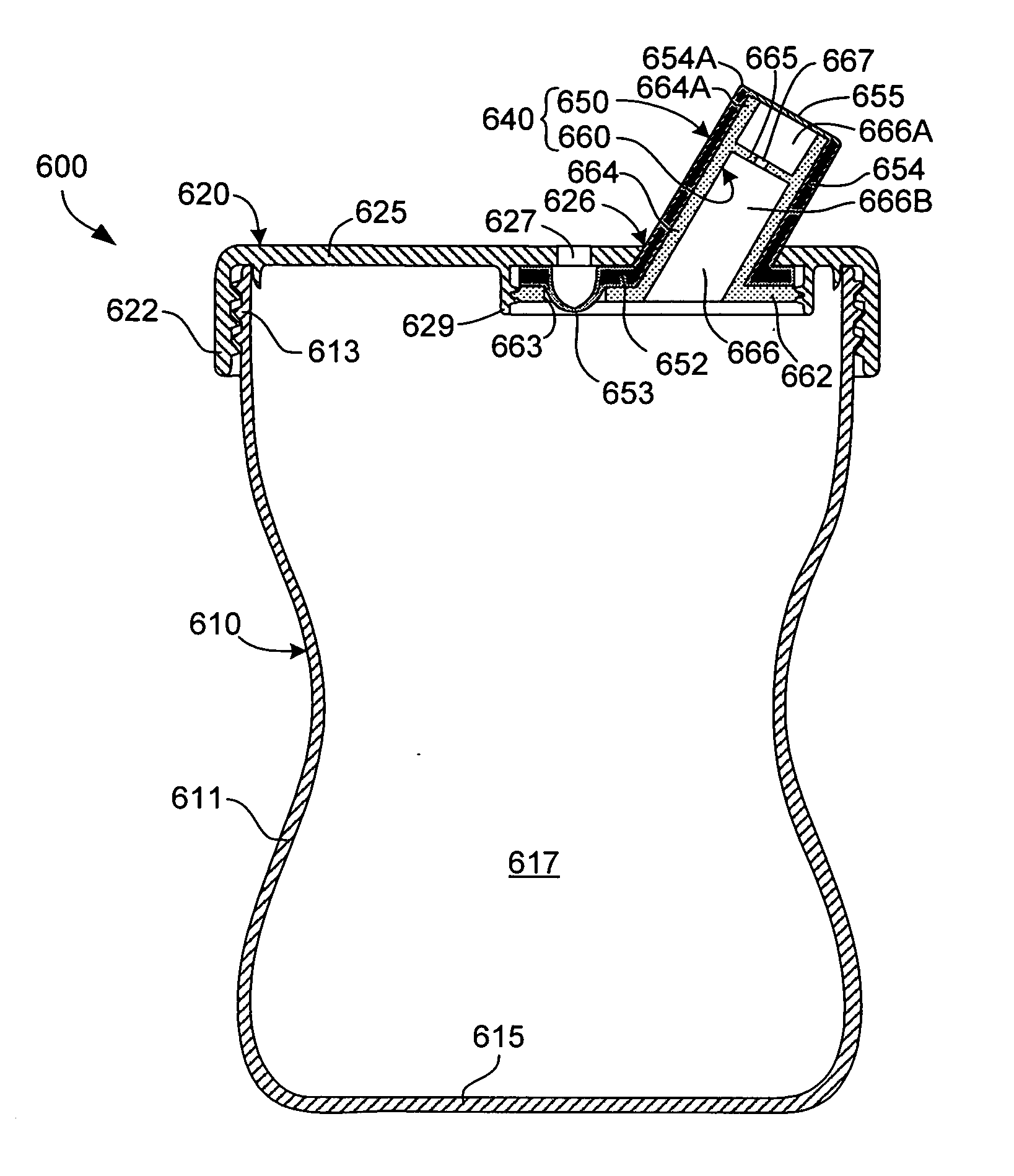

Beverage Container With Integral Flow Control Member Having Vent And Outlet Pinhole Membranes And Safety Button

InactiveUS20070051727A1Minimize liquid pressureControl pressureClosuresDrinking vesselsDifferential pressureEngineering

A non-spill beverage container includes a cap having a tube-like spout and a baffle mounted inside the spout, and a flow control member having a spout (first) membrane supported over the spout opening. A vent (second) membrane that is disposed adjacent to the spout and is supported over a vent opening defined in the cap. The spout and vent membranes are punctured to form multiple, substantially round pinholes that remain closed to prevent fluid flow under normal atmospheric conditions, and open to facilitate fluid flow under an applied pressure differential (e.g., when sucked on by a child). The baffle limits the differential pressure applied to the spout membrane when the container is not in use. The flow control member can only be removed from the cap by removing the cap from the container body and pressing a flexible safety button from an inside surface of the cap.

Owner:MEDELA HLDG AG

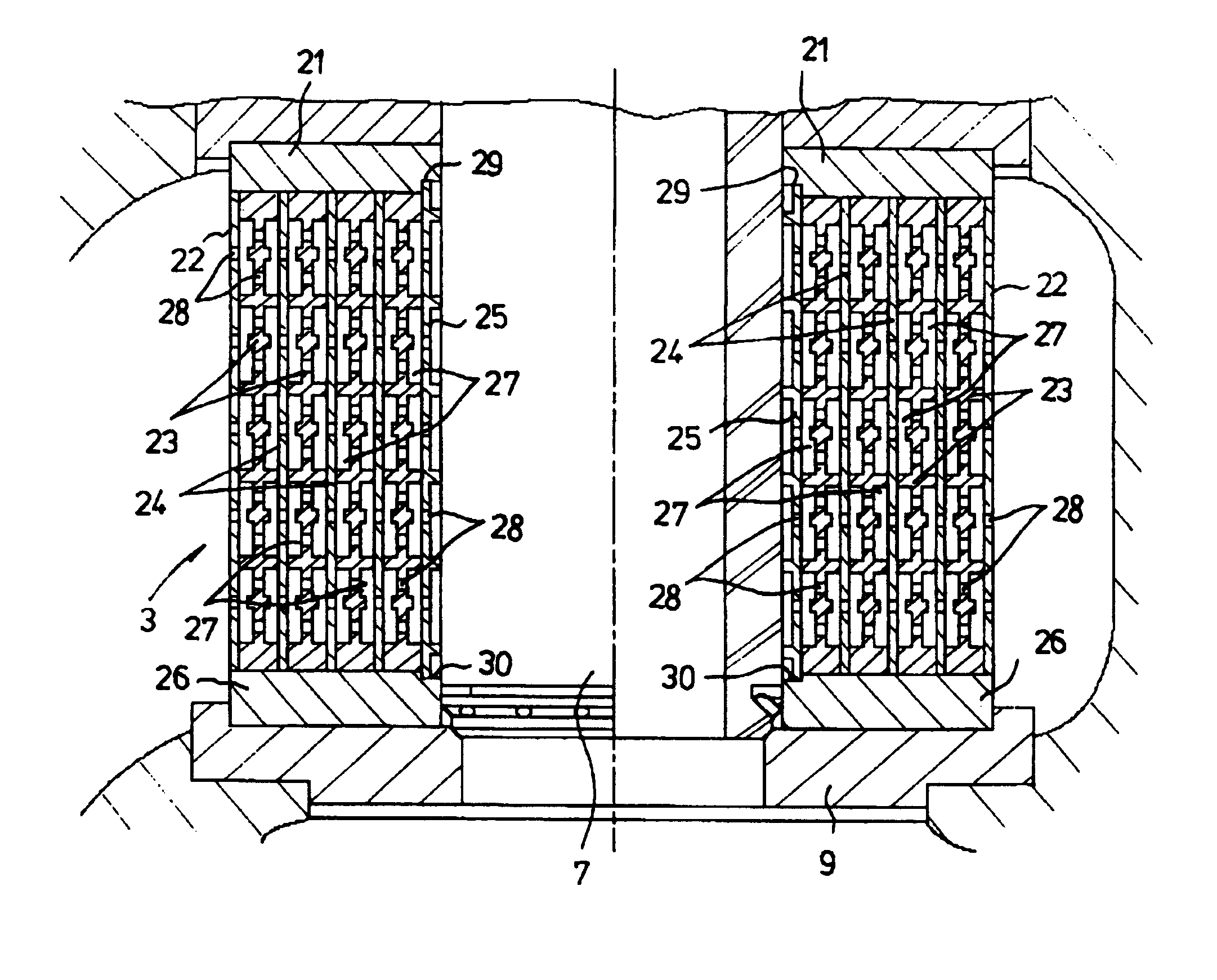

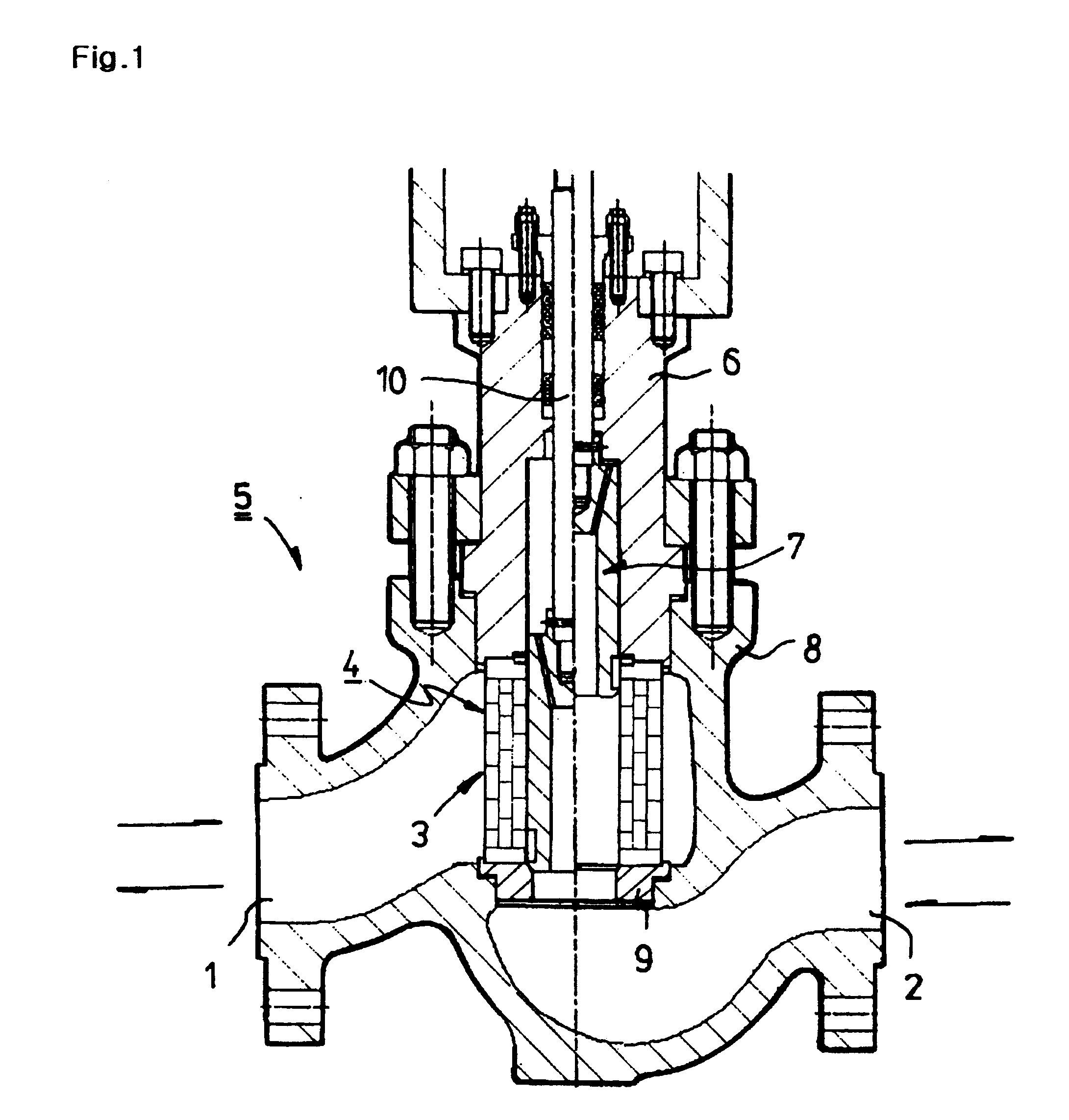

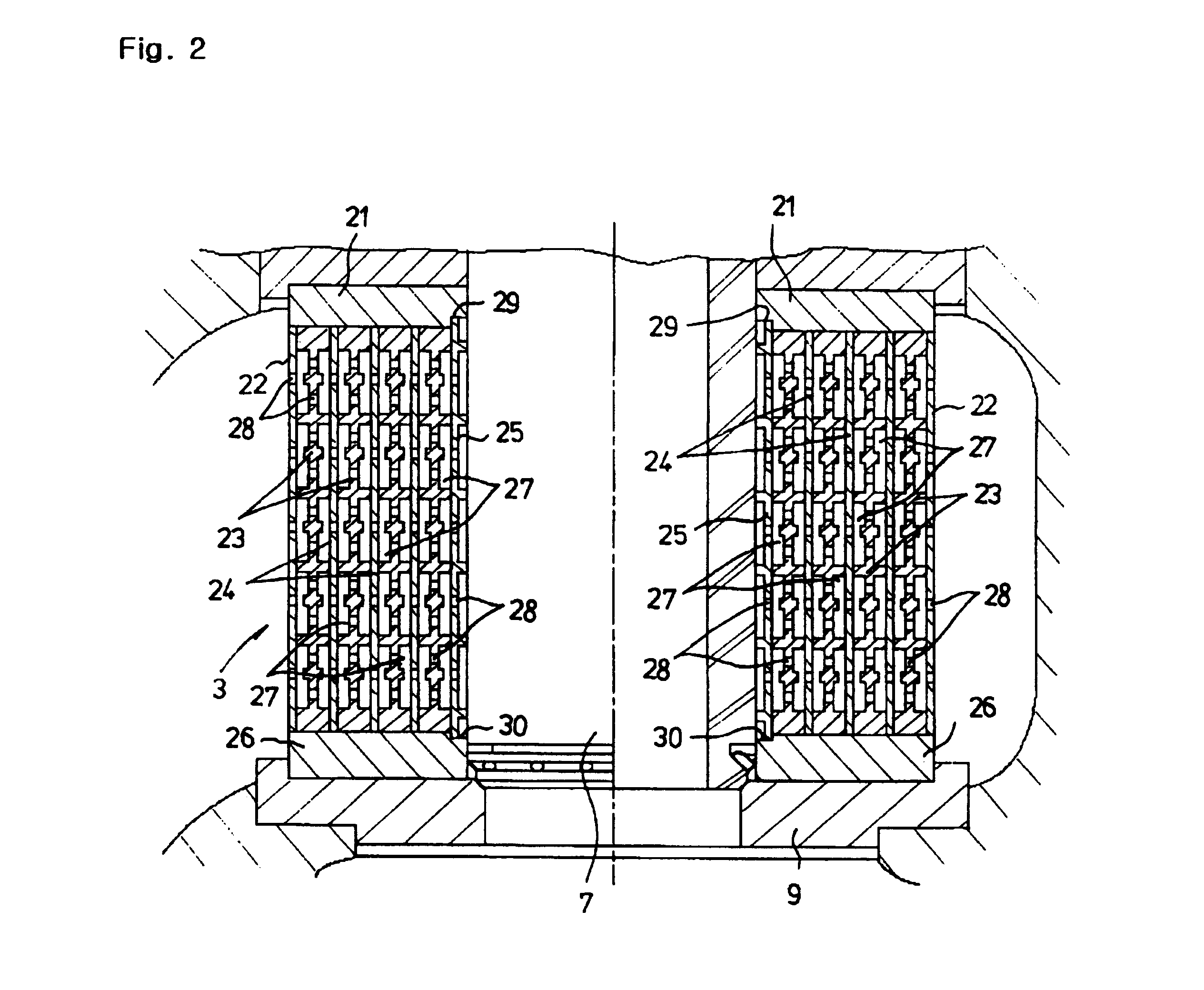

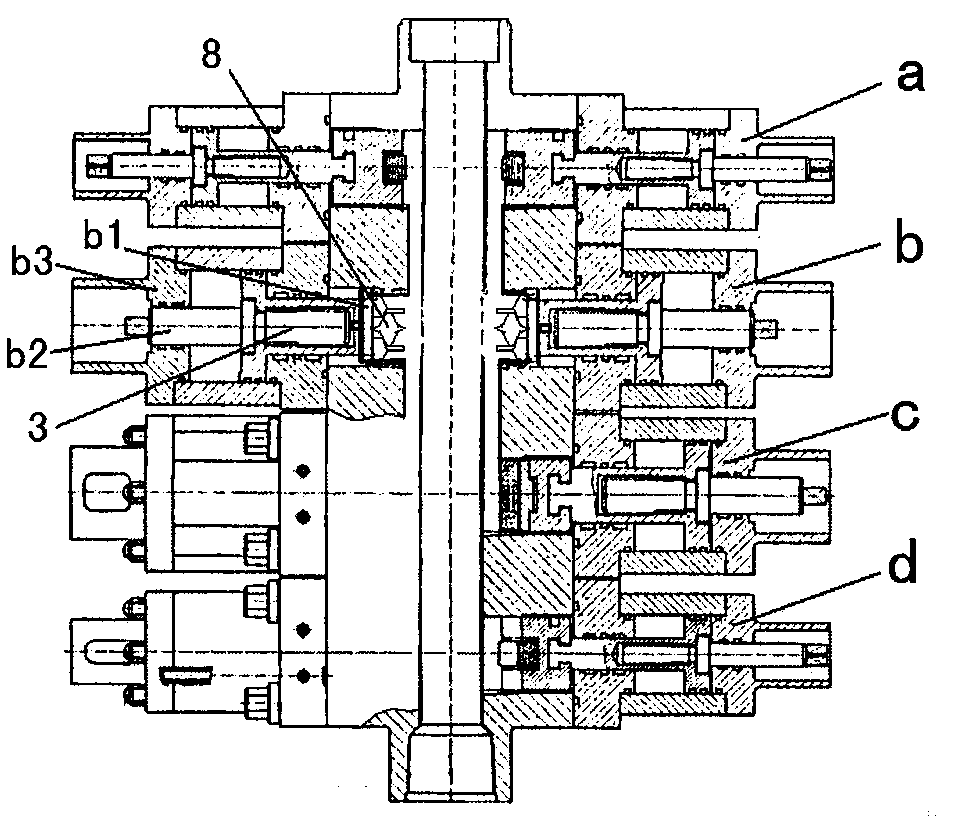

Control valve trim for high-pressure fluid flow

InactiveUS6394134B1Increase fluid flowIncrease volumeValve members for absorbing fluid energyPipe elementsHigh pressureCavitation

Disclosed is a fluid flowing control device of a valve having fluid flowing paths which are made in more sophisticated configuration and by controlling the velocity of the fluid by the maximal use of available volume thereof, to thereby prevent to a maximal extent the generation of cavitation, flashing, blocking by foreign materials, and the damage of internal parts. The device includes a cage having an inside cylinder which is closely contacted with a plug, an outside cylinder which forms a plurality of holes in axial and radius directions, respectively, a first internal cylinder which forms a plurality of concave / convex grooves having rectangular sectional elbows with recess in an axial direction, a second internal cylinder which forms a plurality of holes in axial and radial directions, and upper and lower supporting plates for closely coupling the inside and outside cylinders with the first and second internal cylinders on the top and bottom ends thereof; the plug forming a sealing portion and an opening / closing portion which are in contact with a seat, on the leading end of the lower portion thereof, to thereby open / close the seat and control the fluid flow, while being moved in the inside of the cage; and the seat being in internal-contact with the plug.

Owner:KWON KAB JU

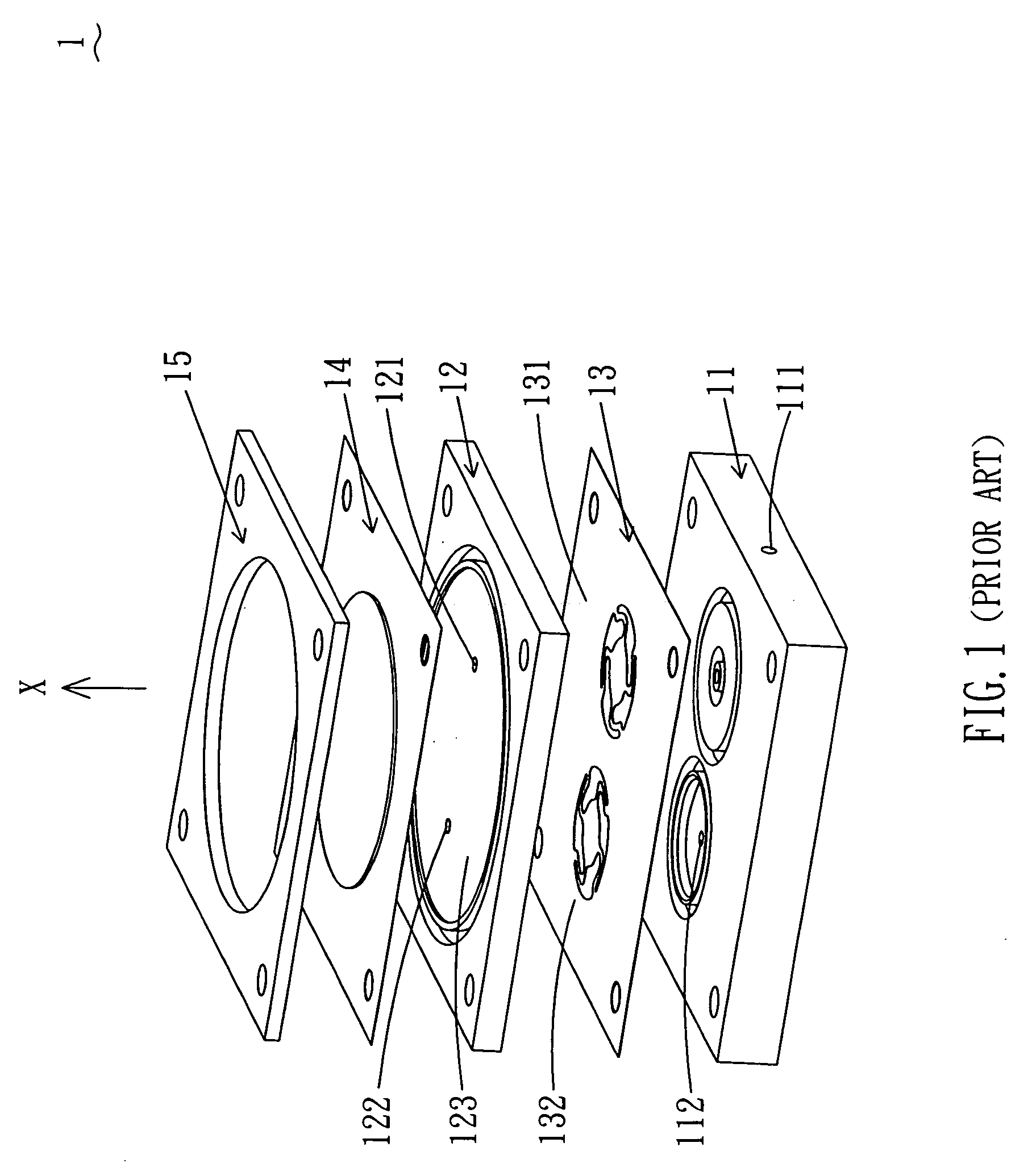

Non-spill container with flow control structure including baffle and elastic membrane having normally-closed pinholes

InactiveUS20060261064A1Reduced characteristicsControl pressureClosuresDrinking vesselsDifferential pressureEngineering

Owner:INSTA MIX INC SUBSIDIARY A DBA UMIX +1

Flow control element including elastic membrane with pinholes

InactiveUS6991122B2Increase fluid flowRealize automatic adjustmentClosuresBottlesEngineeringControl valves

A flow control element (e.g., a baby bottle nipple or a child sippy cup flow control valve) that includes a tube-like wall section defining a flow channel, and a substantially flat membrane supported by the wall section such that membrane impedes flow through the flow channel to an external region. The membrane punctured to form multiple, substantially round pinholes arranged in a two-dimensional pattern that remain closed to prevent fluid flow under normal atmospheric conditions, and open and to facilitate fluid flow rate through the membrane under an applied pressure differential (e.g., when sucked on by a child). The wall section has a greater rigidity than the membrane (which is formed from a relatively highly elastic material). Different sized pinholes are produced using different sized pins, thereby facilitating different flow rates in response to different applied pressure differentials. The pinholes are generated while stretching the membrane in a radial direction.

Owner:MEDELA HLDG AG

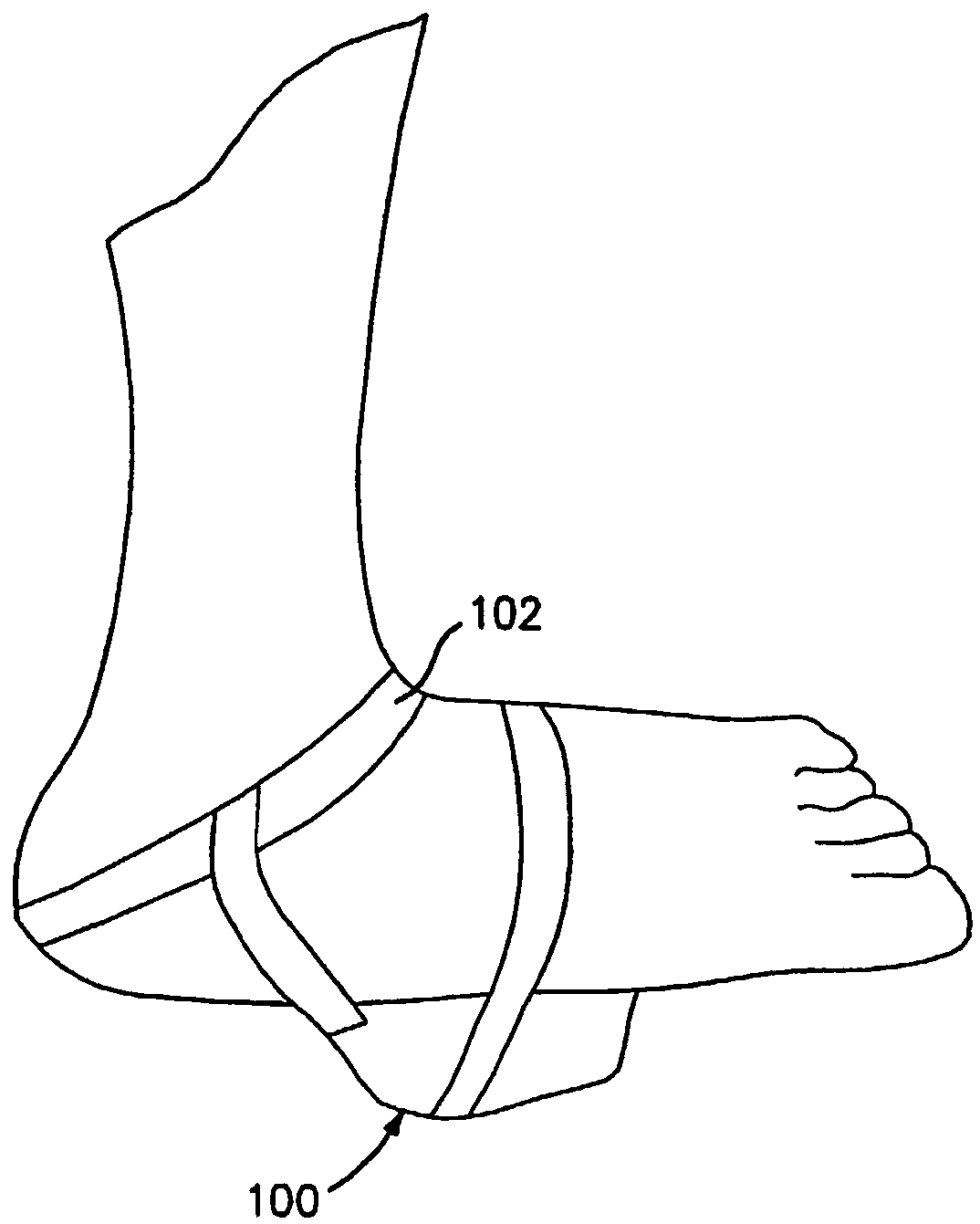

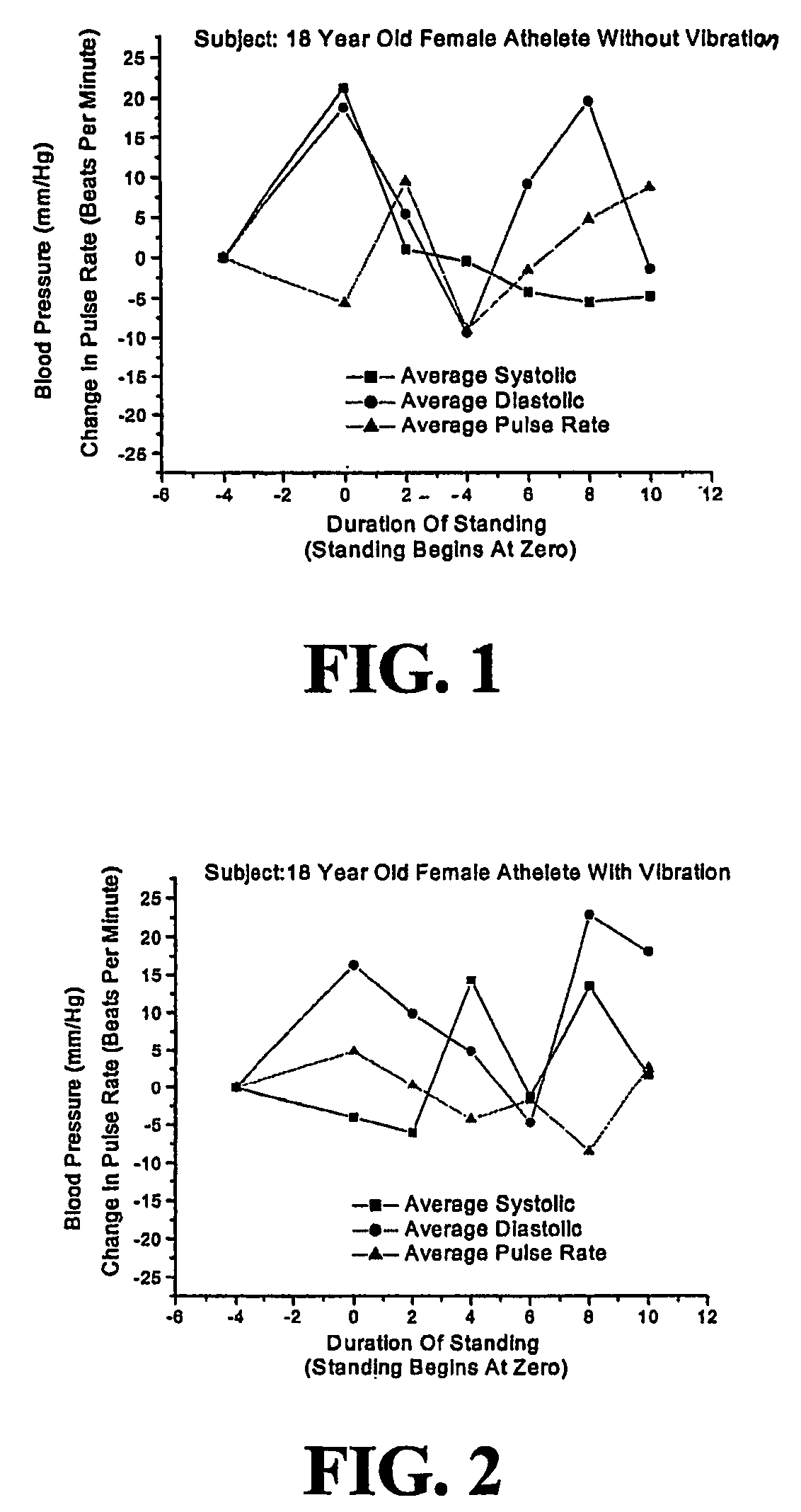

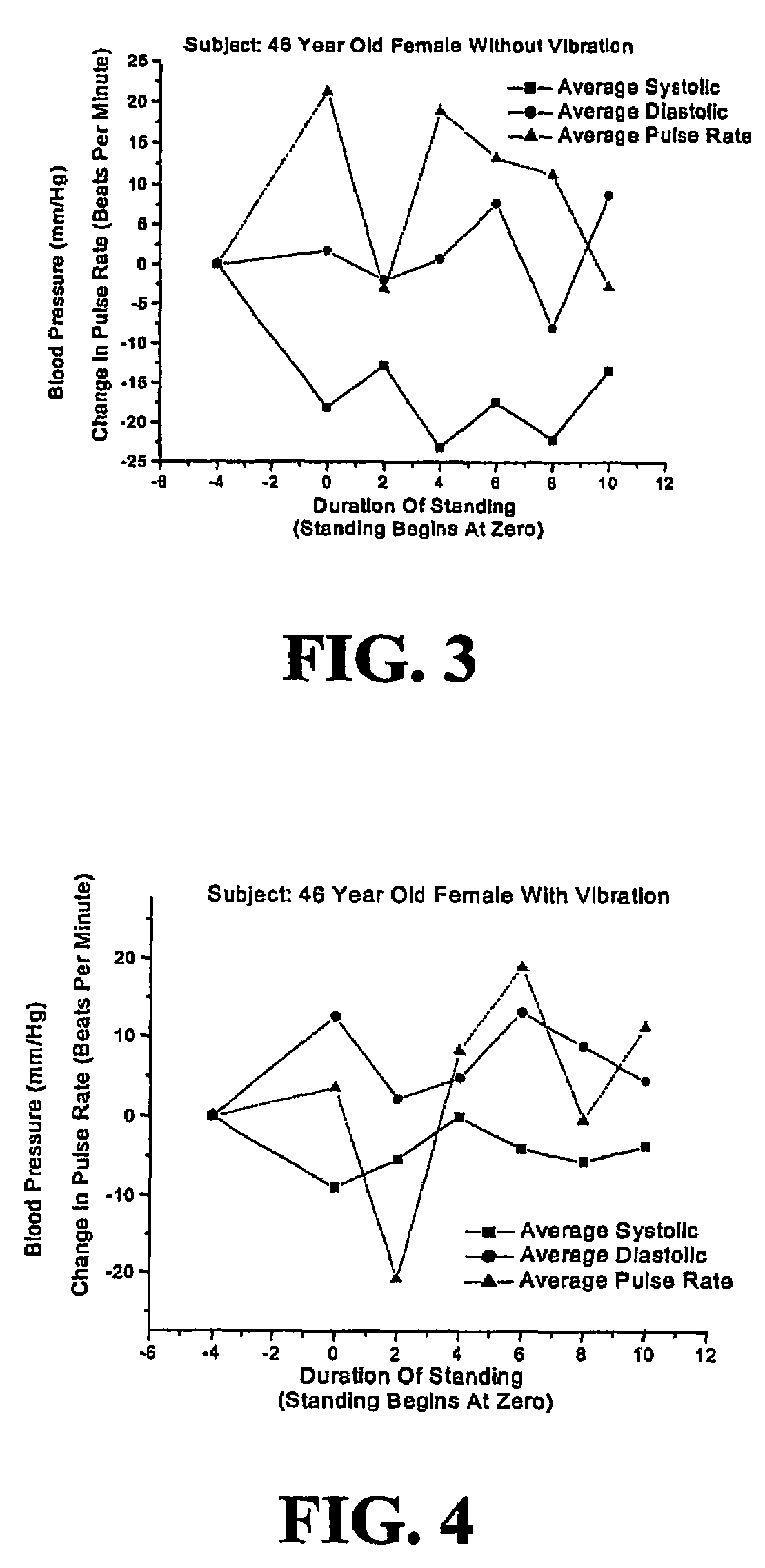

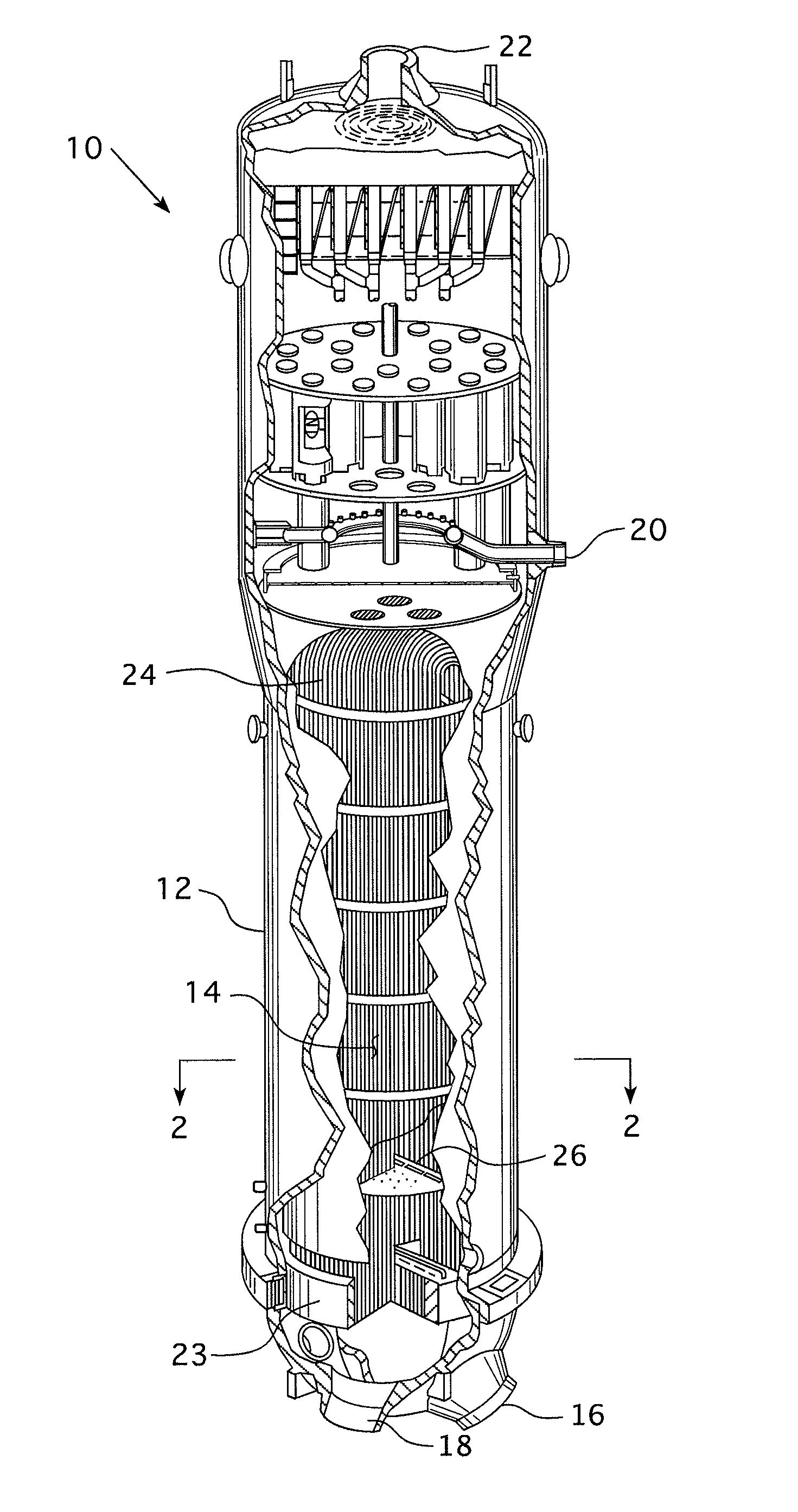

Non-invasive method and apparatus for treating orthostatic hypotension

InactiveUS7402144B2Reduce the impactIncrease blood flowElectrotherapyDiagnosticsPhysical medicine and rehabilitationNon invasive

A non-invasive method and apparatus are provided for treating orthostatic hypotension and for reducing the effects caused there from. An increase in blood and fluid flow in the lower extremities is achieved by vibrating the lower body of the individual at a frequency in the range of 10-120 Hz. The apparatus includes a strap for being secured to a body part of the individual's lower extremities, e.g., the sole of one's foot, and a displacement sensor which senses any movement of the body part. The displacement sensor continuously sends signals to a processor of the apparatus which indicate whether there was any movement of the body part. If the displacement sensor did not sense any substantial movement of the body part for a predetermined period of time the processor sends a signal to a vibrating mechanism. The signal activates the vibrating mechanism causing vibration of the body part for increasing blood and fluid flow in the lower extremities. The vibrating mechanism causes vibration for a predetermined period of time.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

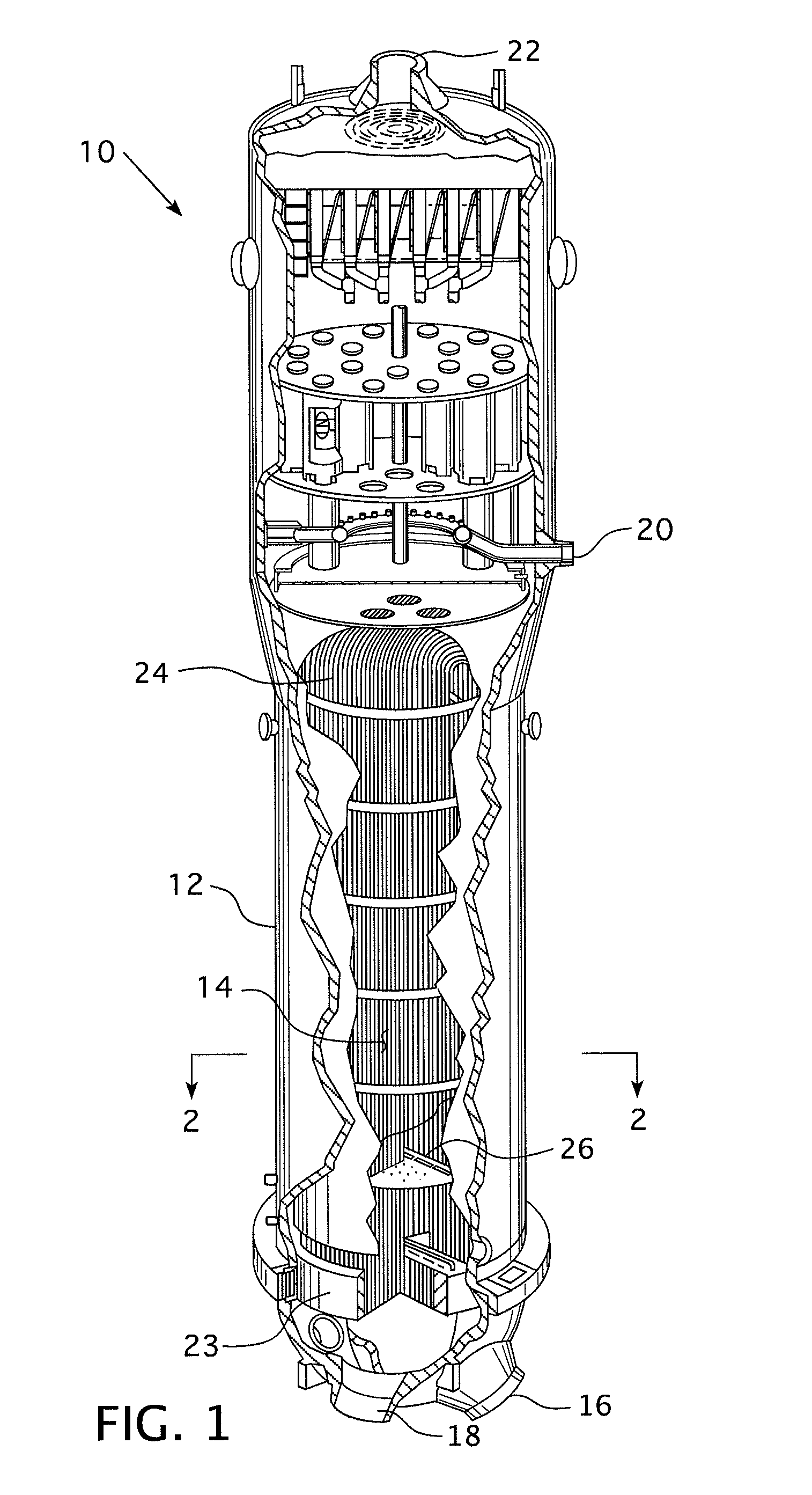

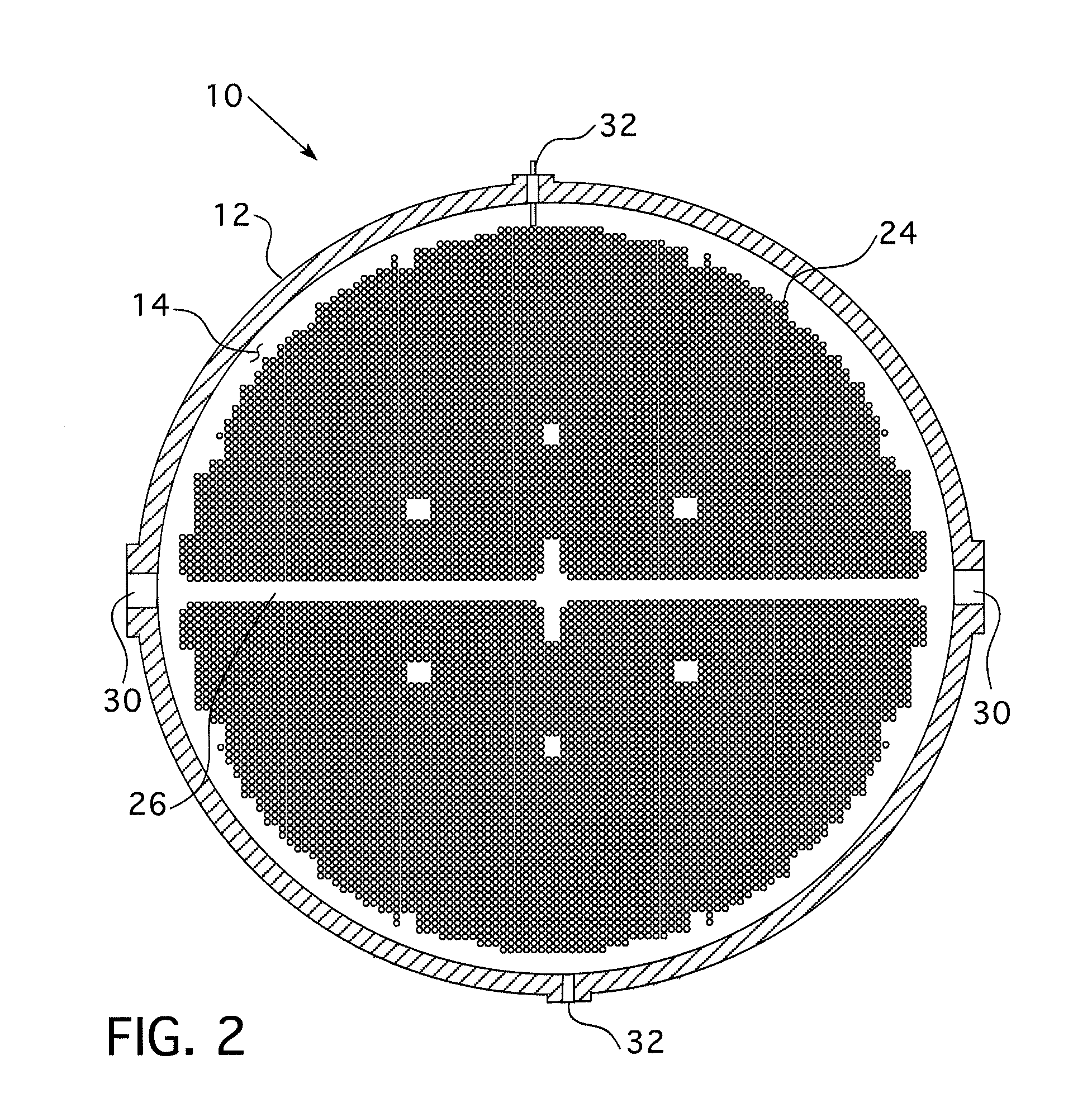

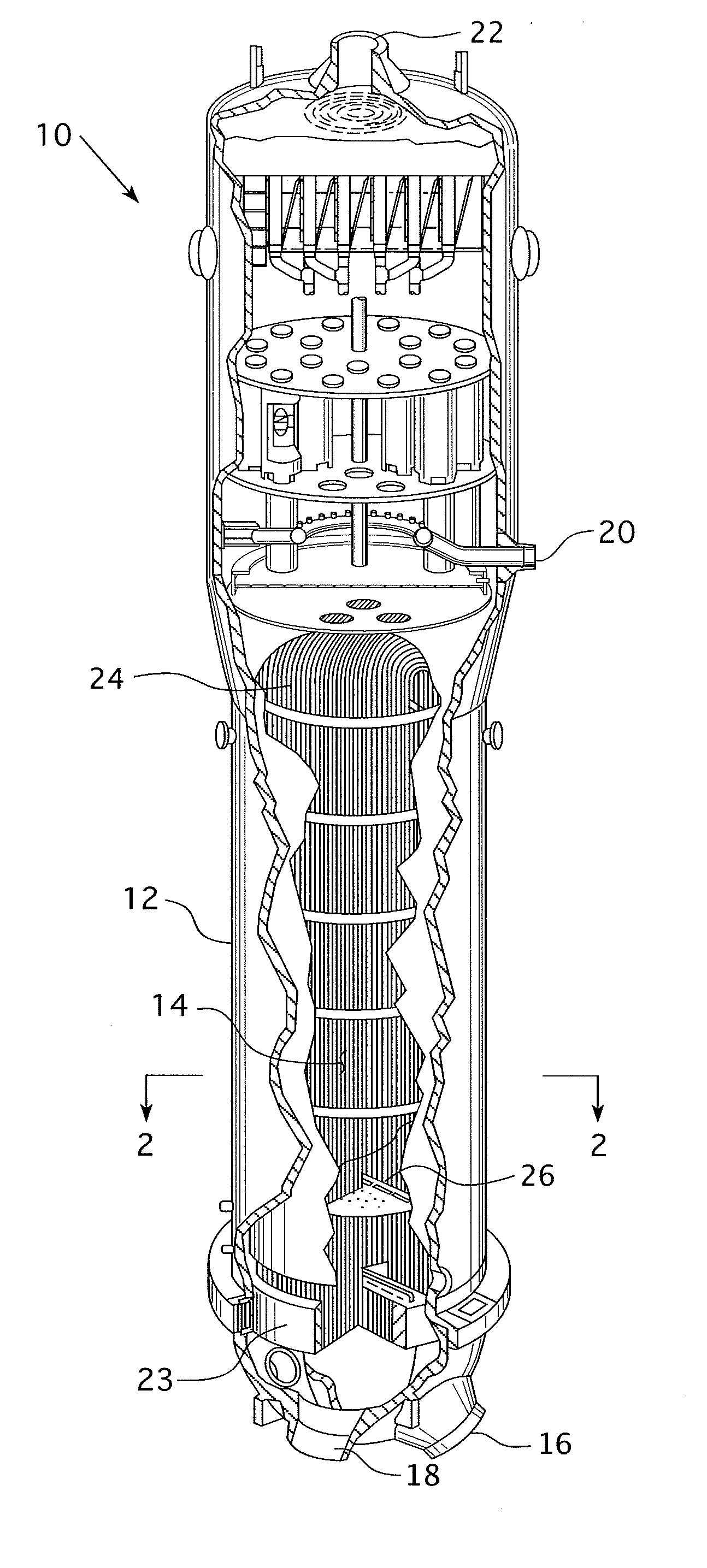

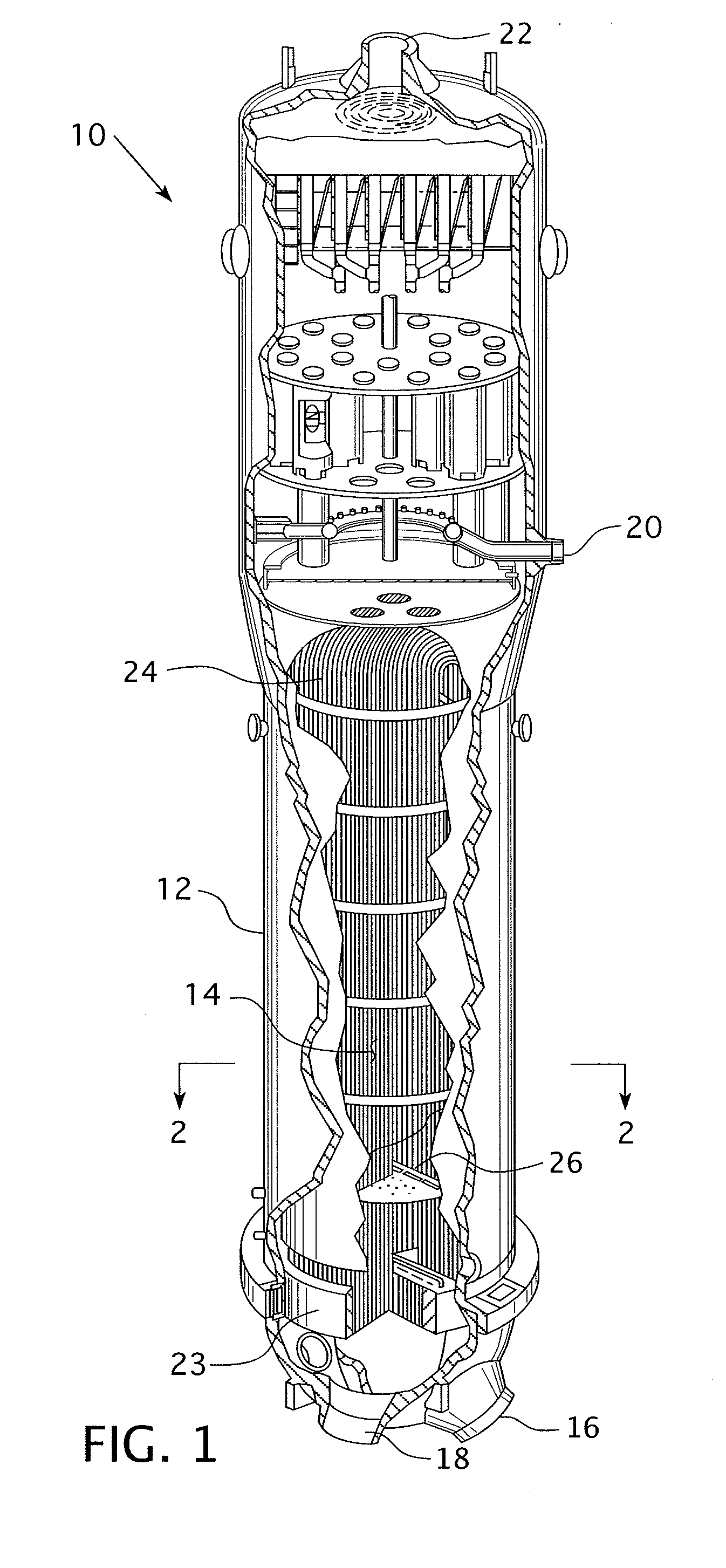

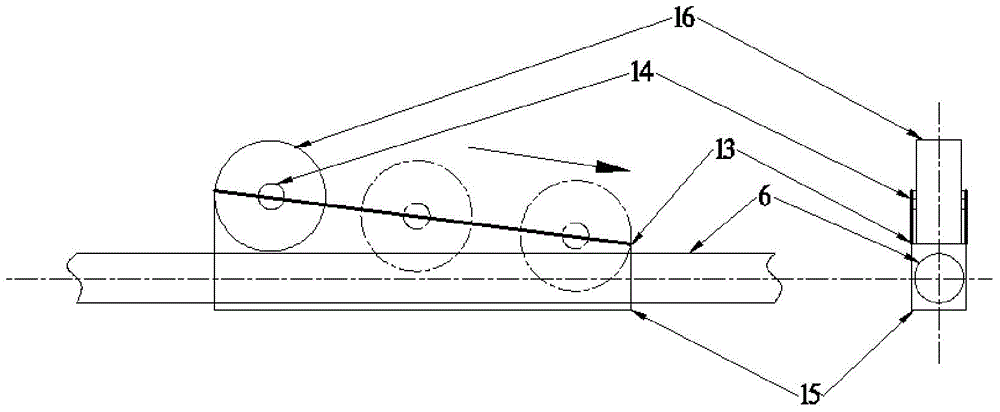

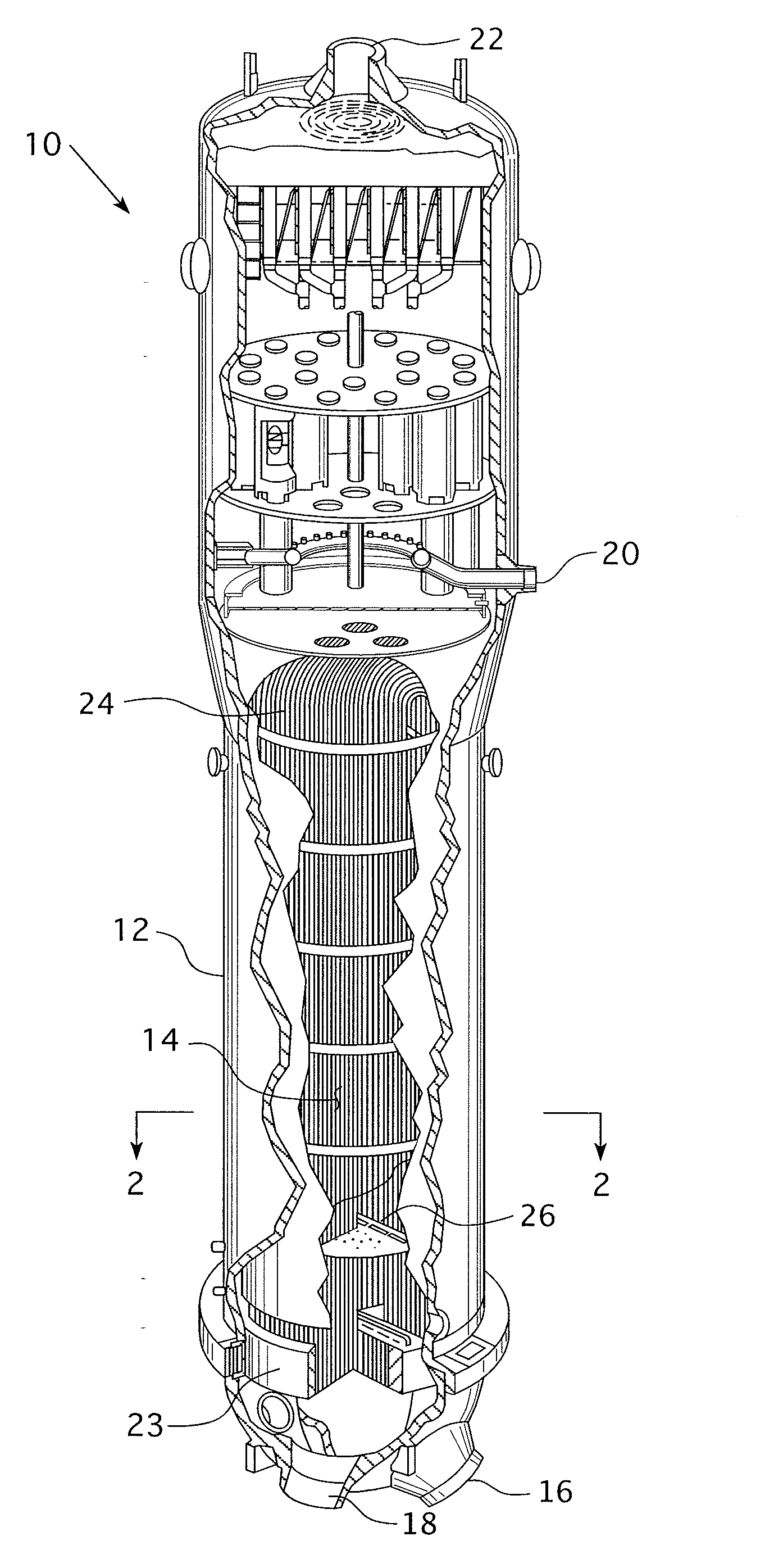

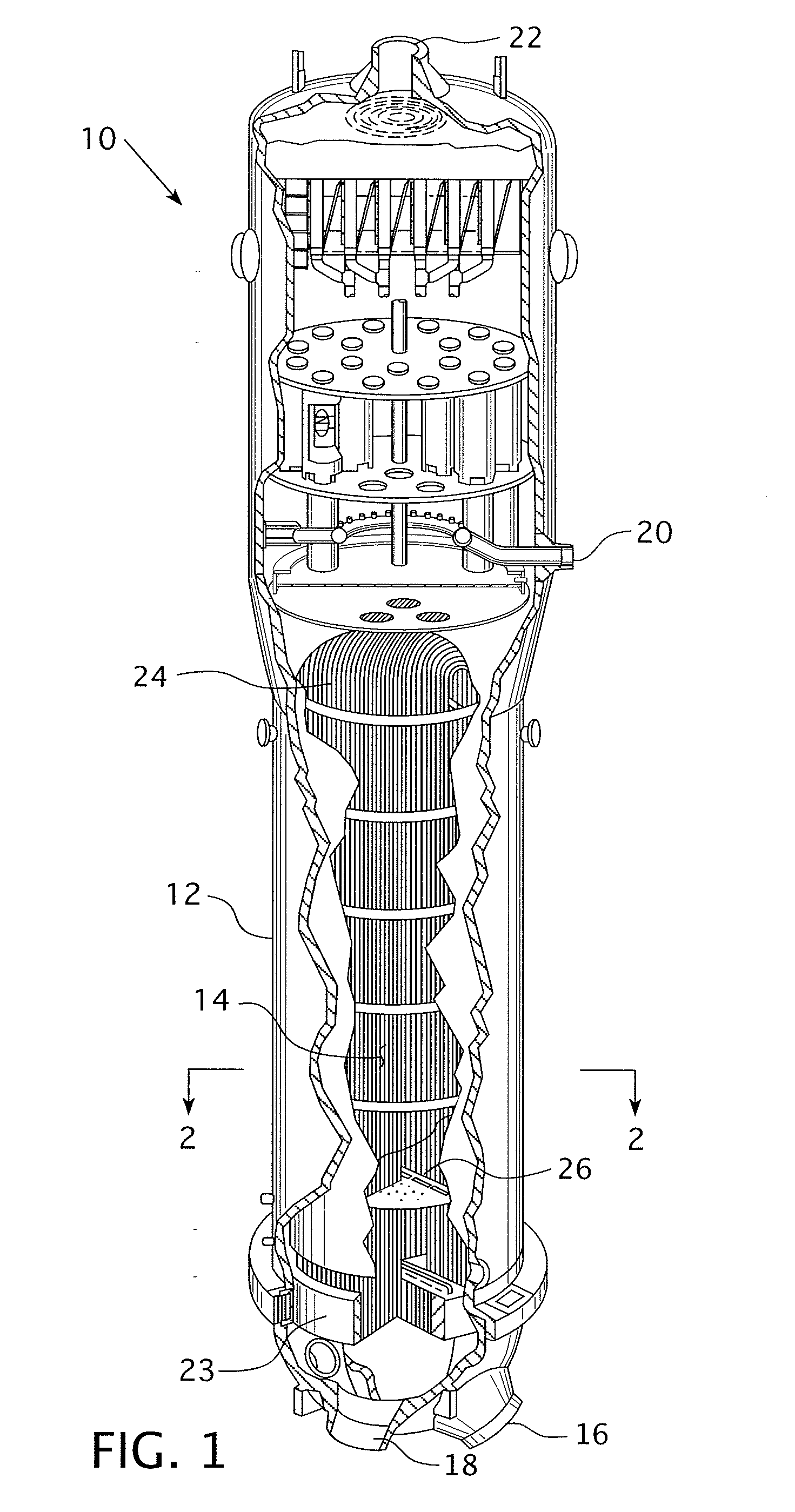

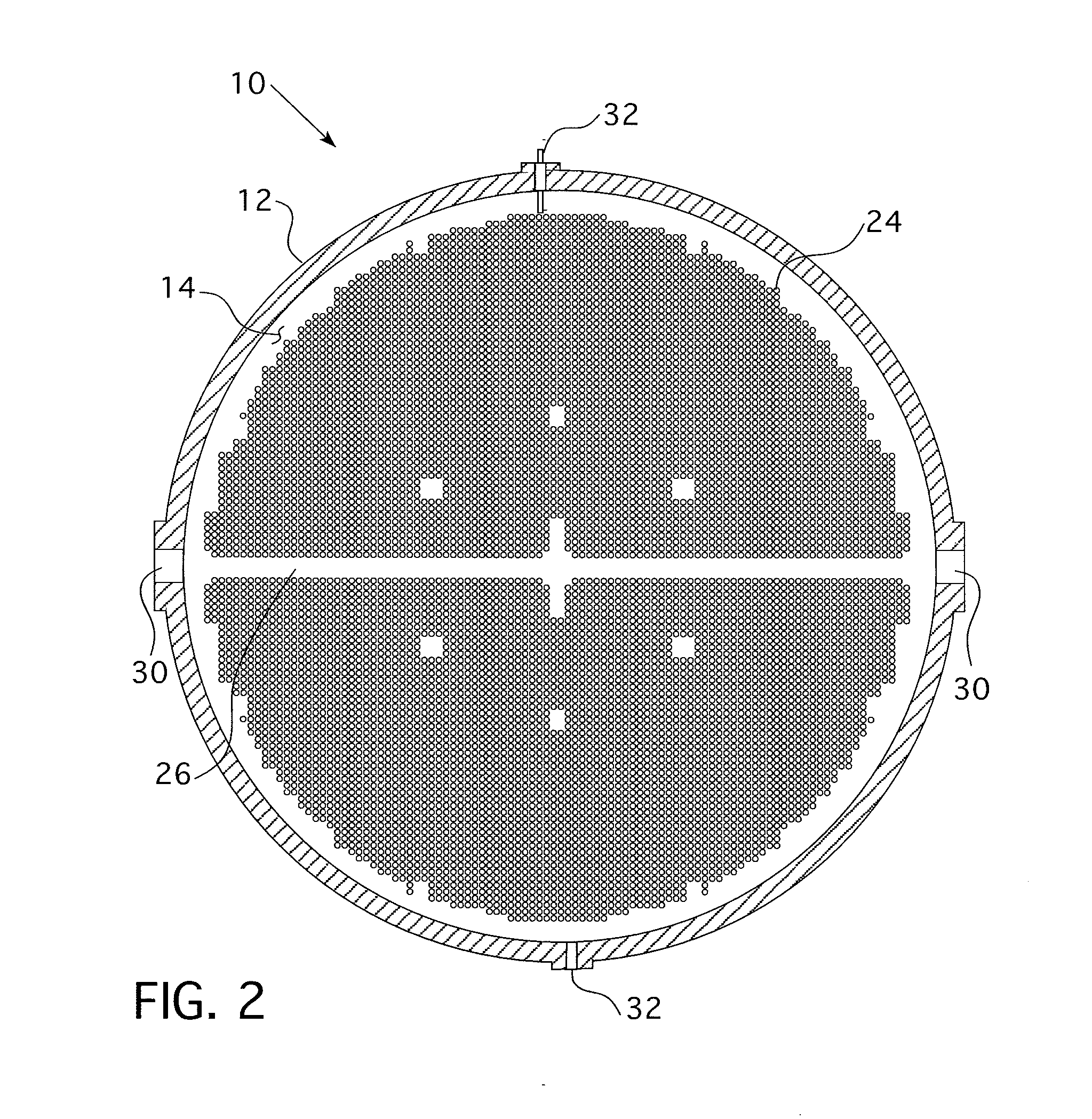

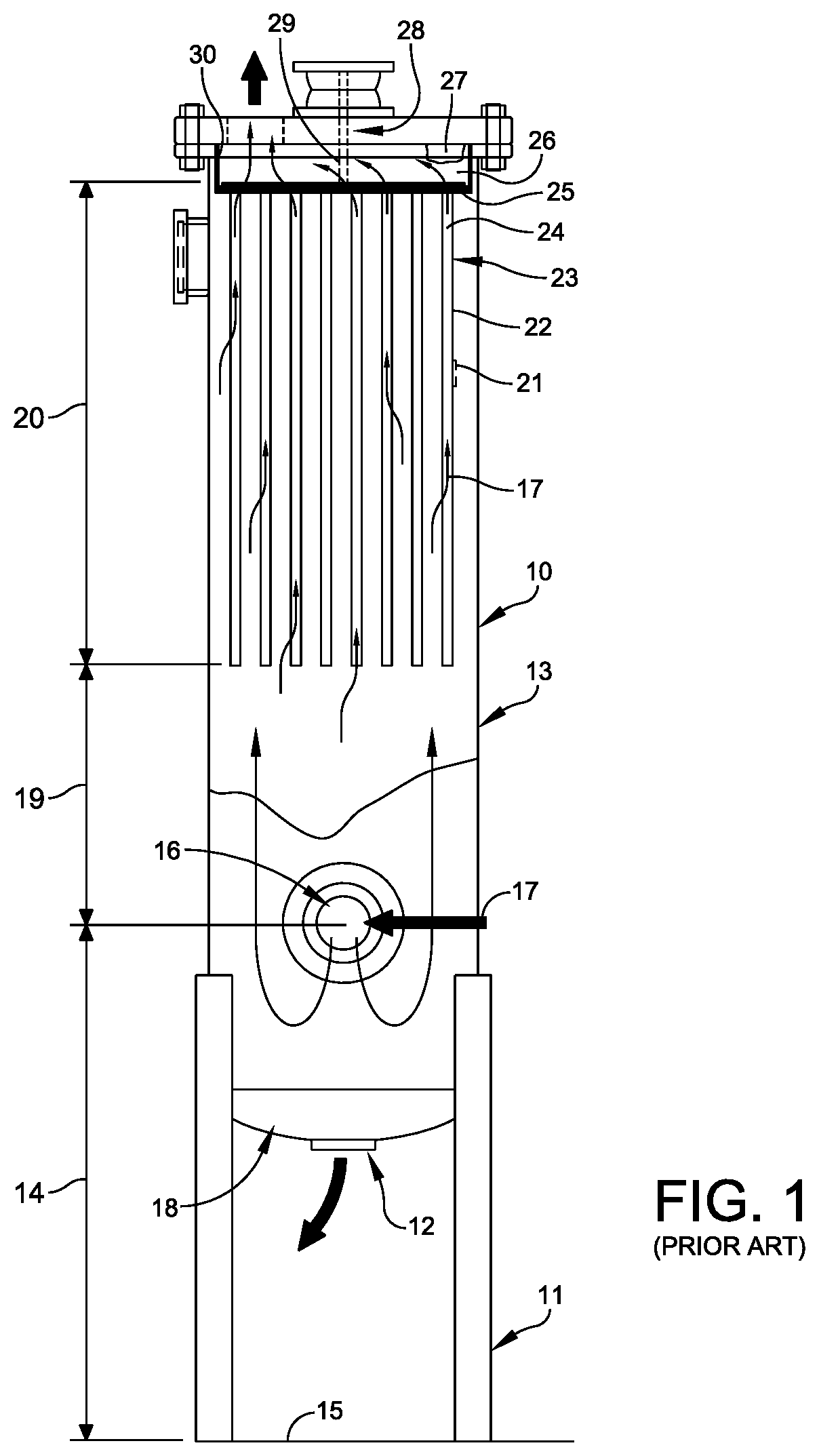

Minature sludge lance apparatus

ActiveUS20110079186A1Shorten the timeReduce doseBoiler cleaning apparatusMachines/enginesNuclear reactorSludge

A miniature sludge lance for a steam generator in a pressurized water nuclear reactor is provided. The sludge lance is structured to enter the steam generator via an inspection opening and has a body sufficiently thin to fit between adjacent tubes. The sludge lance rail has at least two types of nozzle assemblies that may be attached thereto. One nozzle assembly rotates and another nozzle assembly translates in a vertical direction. A drive assembly, a mounting assembly, an oscillation assembly, and flow straighteners are also provided.

Owner:WESTINGHOUSE ELECTRIC CORP

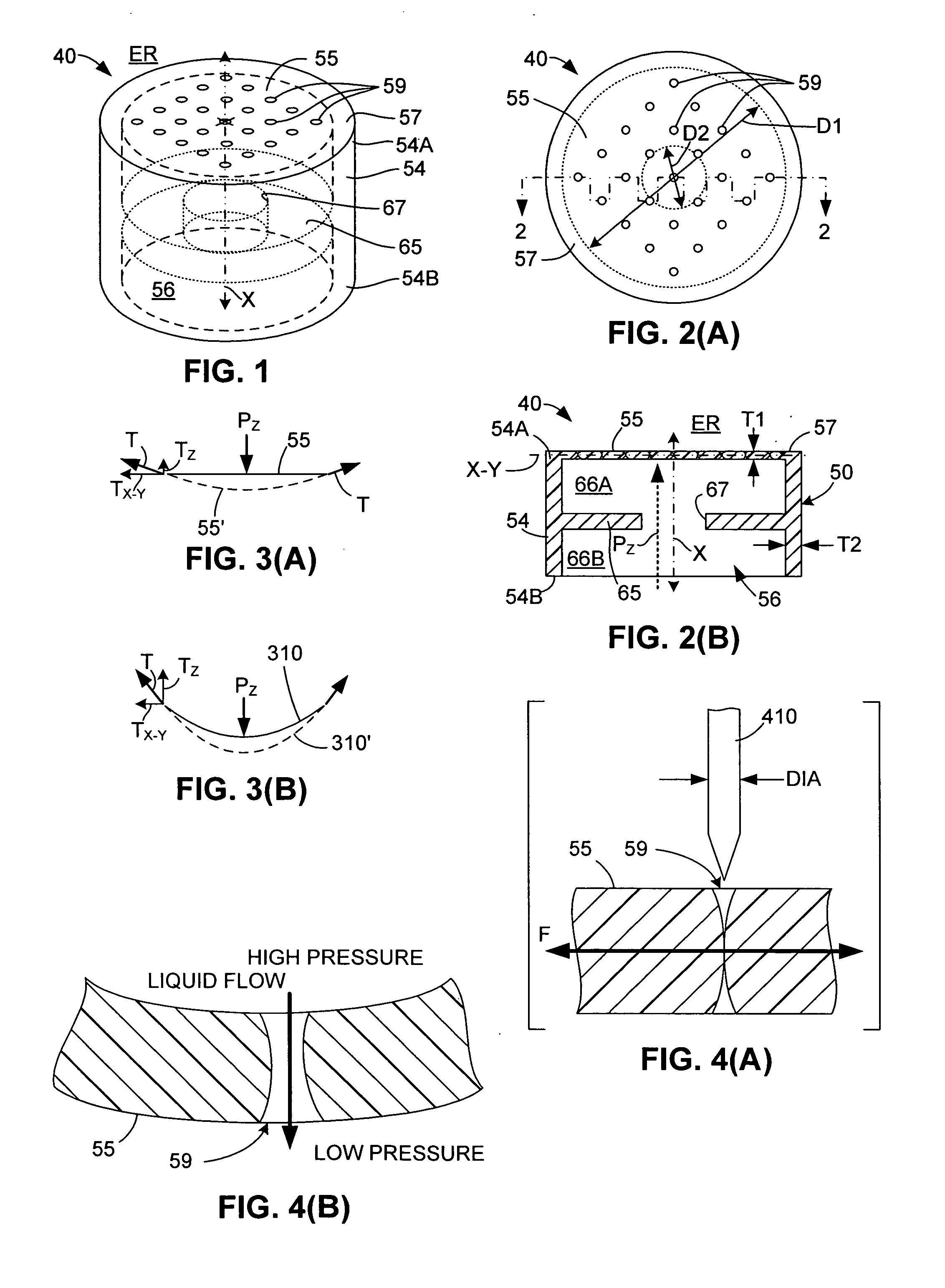

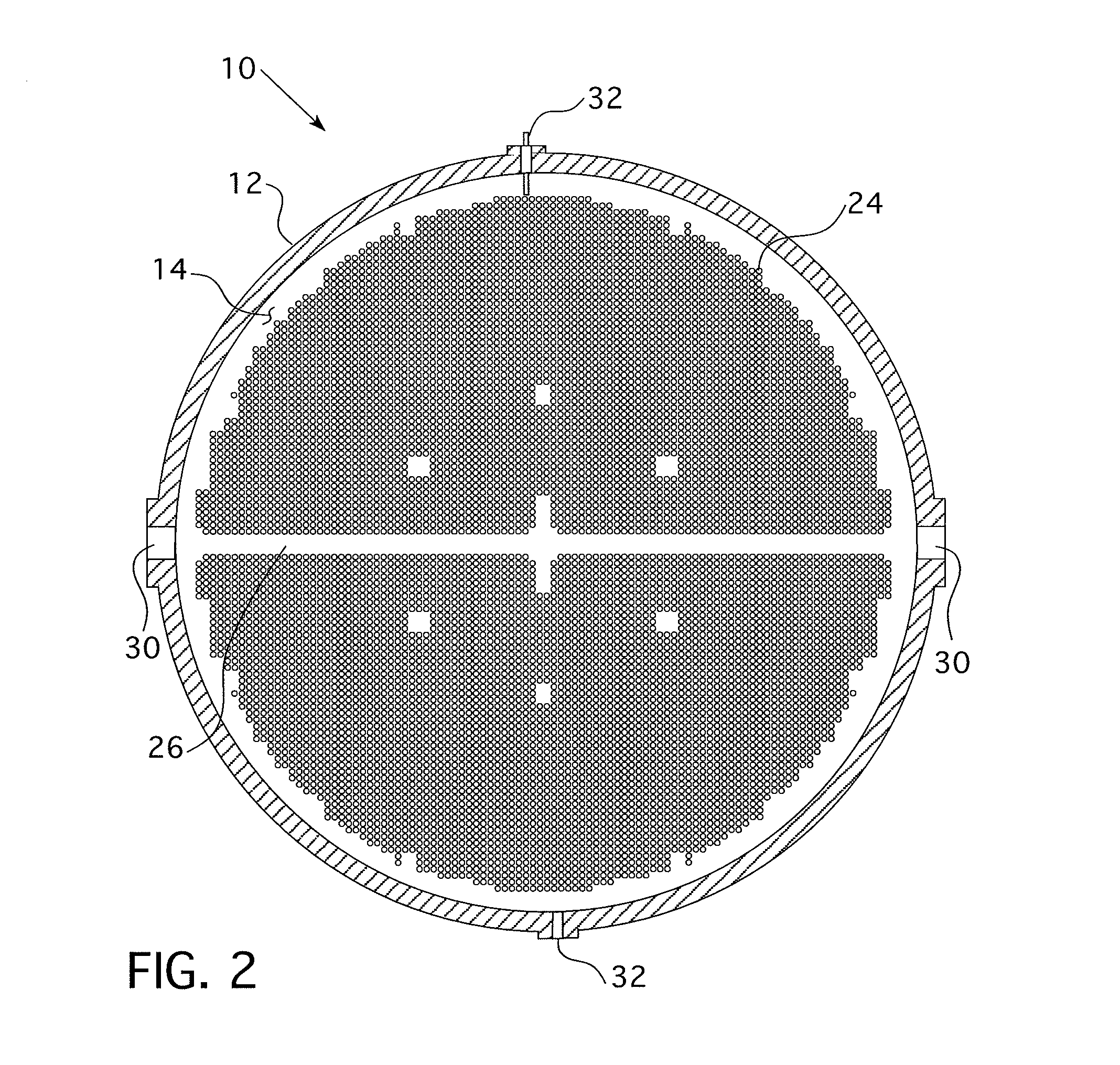

Abrasive tools having a permeable structure

ActiveUS7722691B2Improve performanceHighly porous and permeable structurePigmenting treatmentOther chemical processesThree dimensional shapeAgglomerate

Owner:SAINT GOBAIN ABRASIVES INC

Flow Valve For Example for Faucets

InactiveUS20100252115A1No longer be movedIncrease fluid flowOperating means/releasing devices for valvesServomotor componentsInlet flowStreamflow

A flow valve for faucets such as kitchen and bathroom faucets includes an inlet and outlet and a transverse valve mechanism where a valve element moves toward and away from a valve seat at least partly transverse to incoming inlet flow and / or outgoing outlet flow.

Owner:BASSOLS LUIS

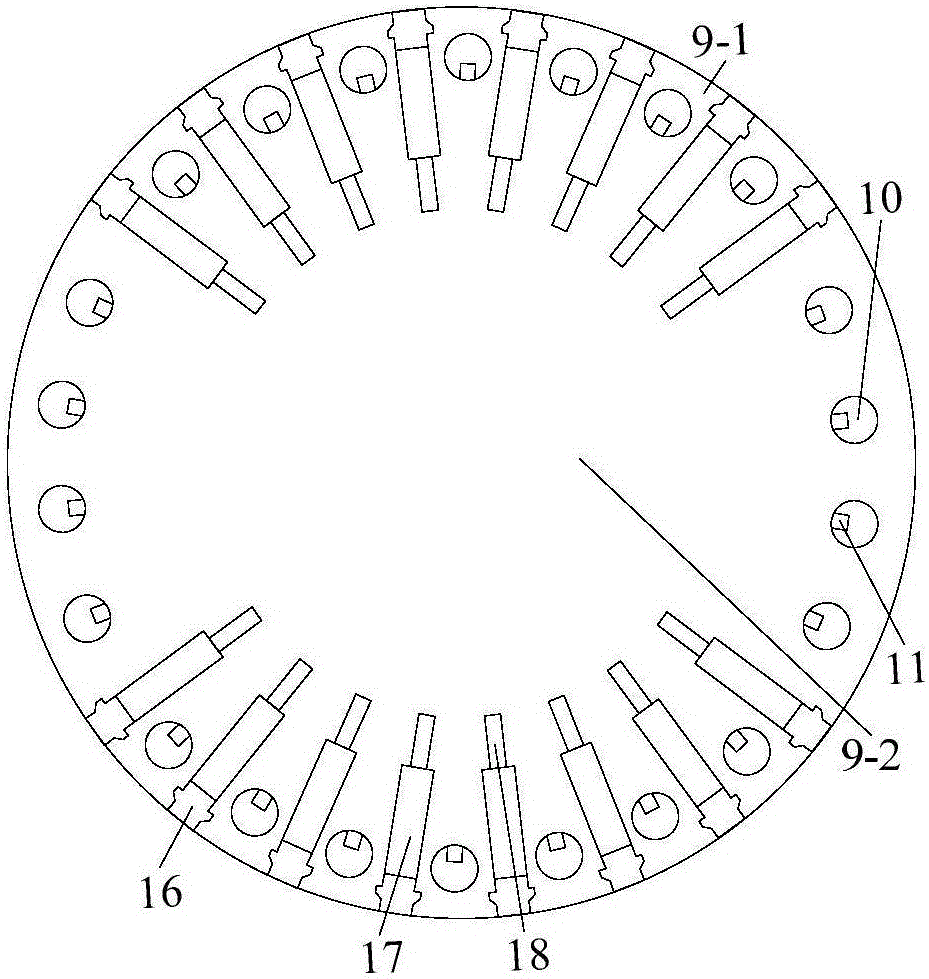

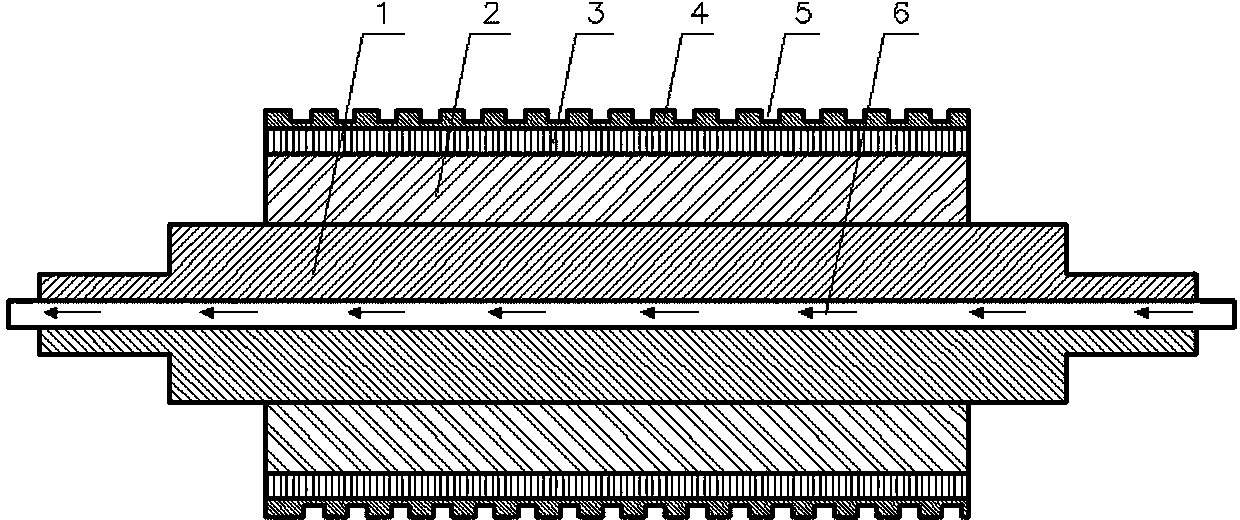

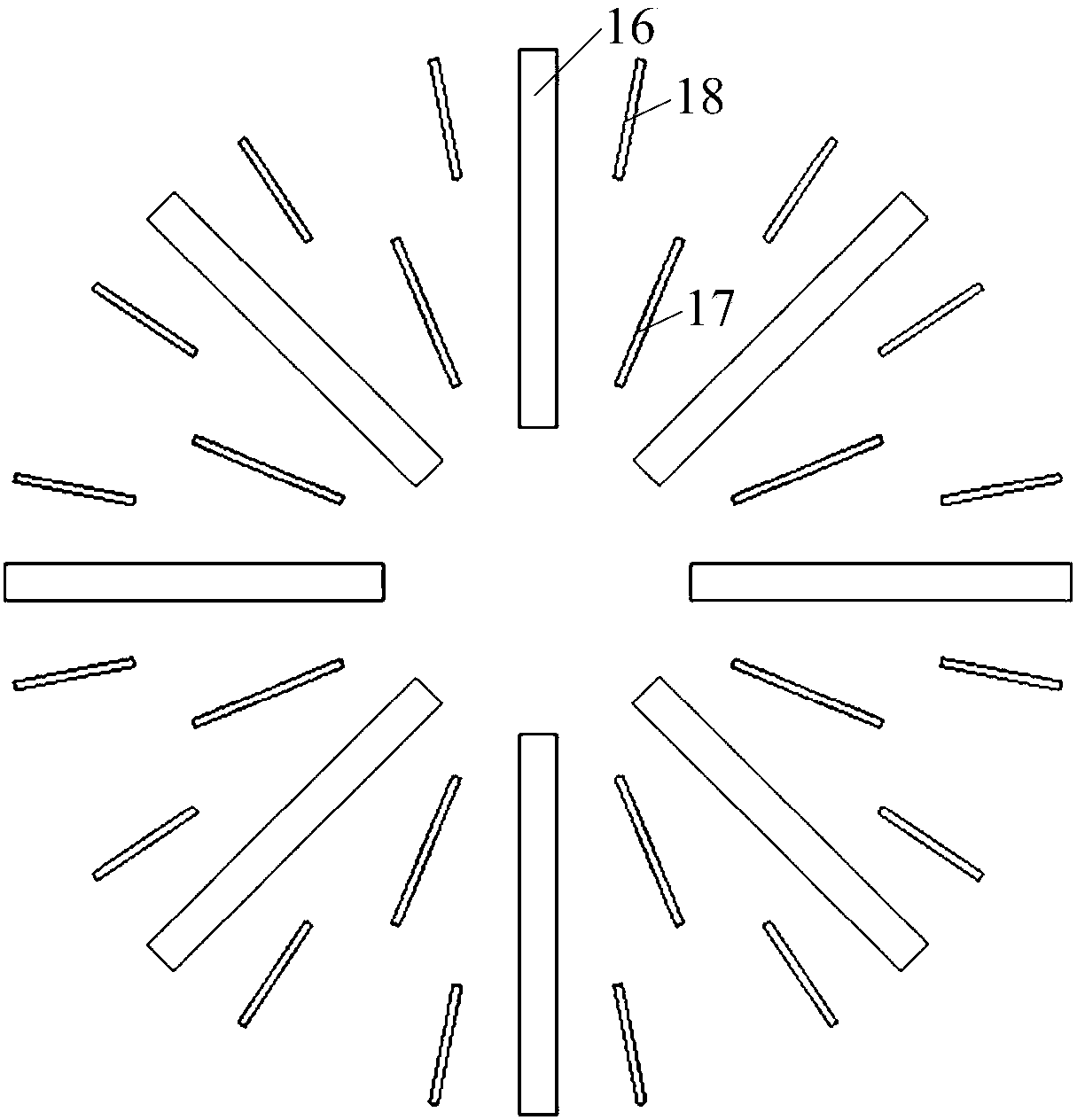

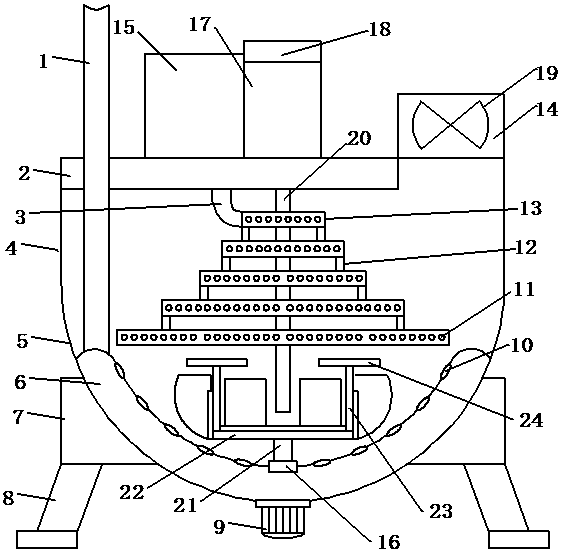

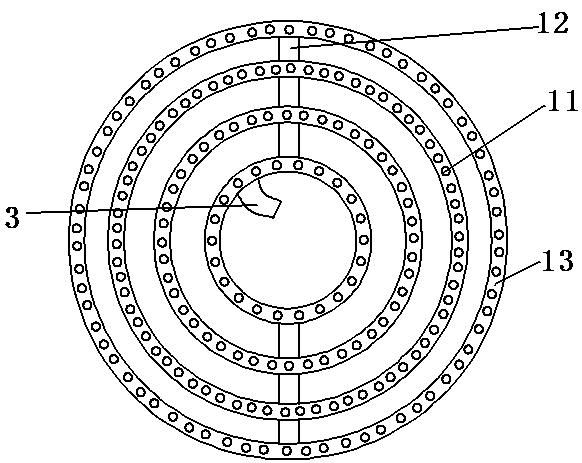

Turbonator cooling system provided with water cooling stator and inner fan type rotor

ActiveCN106026450AEfficient take awayReduce the temperatureMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringFan blade

The invention discloses a turbonator cooling system provided with a water cooling stator and an inner fan type rotor and relates to a field of motors. According to the invention, by adding an in-stator loop type water channel and an out-of-stator loop type water channel at a tooth top part and a yoke back part of an iron core segment of the stator respectively, arranging a rotor axial ventilating duct in rotor teeth and arranging rotor self-cooling fan blades in the rotor axial ventilating duct, the heat dissipation capability of a rotor area and a stator area is enhanced effectively, the utilization rate of cooling fluid in the turbonator is improved, the highest temperature of the stator area and the stator area are reduced substantially and the capability of safe and stable operation of the turbonator is improved.

Owner:HARBIN UNIV OF SCI & TECH

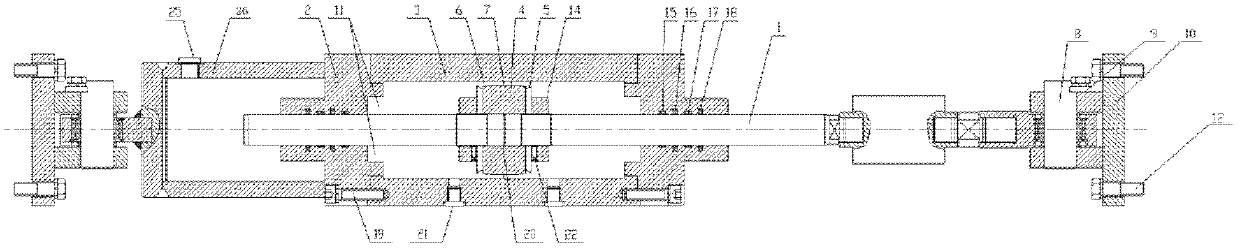

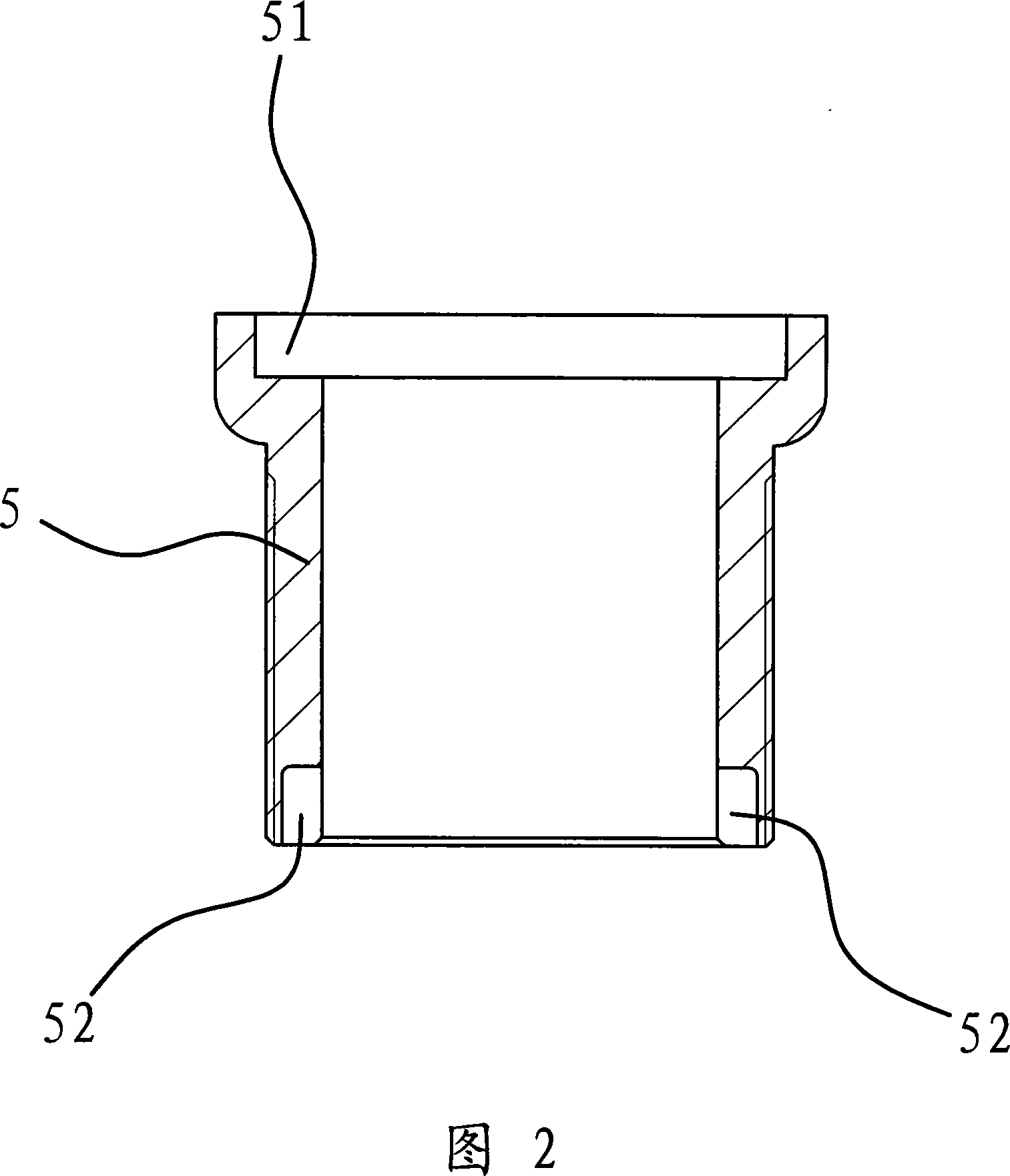

Viscous damper to passively adjust high energy consuming clearances

InactiveCN102606665AEnsure safetyAccelerate heat dissipation by conductionSpringsLiquid based dampersHigh energySoft metal

The invention relates to a viscous damper to passively adjust high energy consuming clearances, belonging to the technical field of engineering vibration reduction. The viscous damper comprises a piston rod, a cylinder head, a cylinder barrel and a piston head; a damping gap is formed between the piston head and the cylinder barrel to form a main fluid channel; an annular soft metal valve is arranged on the piston head, the gap between the annular soft metal valve and the cylinder barrel is formed to be a smallest gap through which the fluid passes; both sides of the piston head are provided with guide round disks. The viscous damper has the characteristics of stable damping force under the complex working condition, resistance of big impact load, simple structure and the like.

Owner:BEIJING UNIV OF TECH

Automatic magnetic check valve

The invention relates to an automatic magnetic check valve, which comprises a cover body, an upper magnet, a valve body, a shaft seat, a valve, a lower magnet and a sealing ring, wherein the shaft seat is arranged on one side of the bottom of the valve body; the valve is hinged on the shaft seat; the upper magnet is arranged on the valve body; the lower magnet is arranged on the valve; the sealing ring is arranged between the valve and the valve body; and the upper magnet and the lower magnet are in a Z-plane asymmetric structure. When asymmetric magnets attract each other, an Fx component force not equal to zero is generated, the consistency of the repeated opening / closing action of the valve is greatly improved under the action of the Fx, and the valve is closed to be accurately attracted and sealed; the valve body has a high flow structure, so that an effective area of fluid flowing through the valve body is greatly improved; the valve body is hardly wound with hair and cotton and is cleaning-free; the valve can realize 90-degree opening in a circular pipeline, the drainage is not hindered and the flow velocity is high; and the overflow of sewage is prevented, polluted air, insects and cockroaches are prevented. The check valve is conveniently arranged at a sewage pipeline to replace the conventional water return bend, is suitable for sewage drainage, and is also suitable for other fluid pipelines with one-way flow requirement.

Owner:张成

Miniature sludge lance apparatus

ActiveUS20110180021A1Shorten the timeReduce doseBoiler cleaning apparatusMachines/enginesNuclear reactorSludge

A miniature sludge lance for a steam generator in a pressurized water nuclear reactor is provided. The sludge lance is structured to enter the steam generator via an inspection opening and has a body sufficiently thin to fit between adjacent tubes. The sludge lance rail has at least two types of nozzle assemblies that may be attached thereto. One nozzle assembly rotates and another nozzle assembly translates in a vertical direction. A drive assembly, a mounting assembly, an oscillation assembly, and flow straighteners are also provided.

Owner:WESTINGHOUSE ELECTRIC CORP

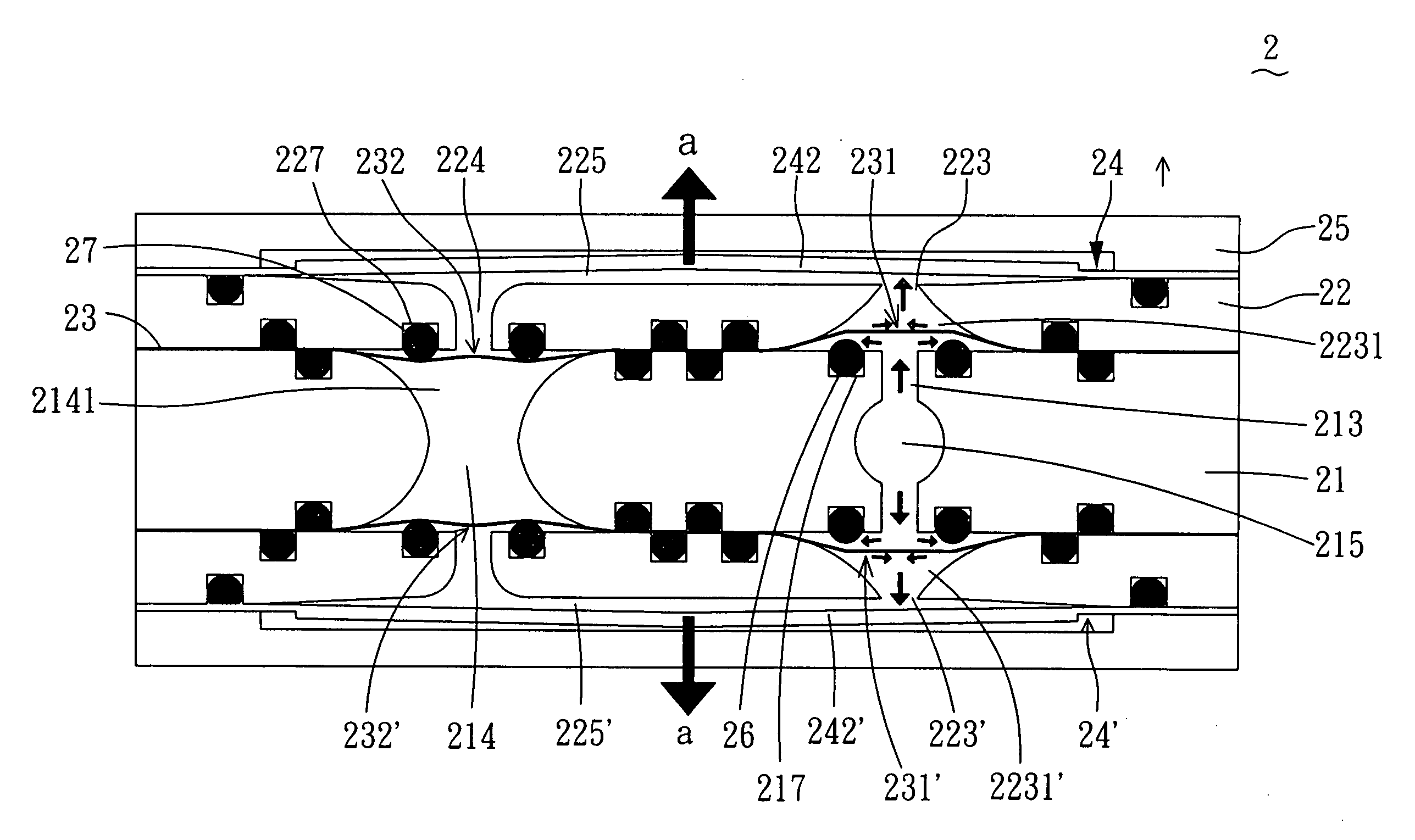

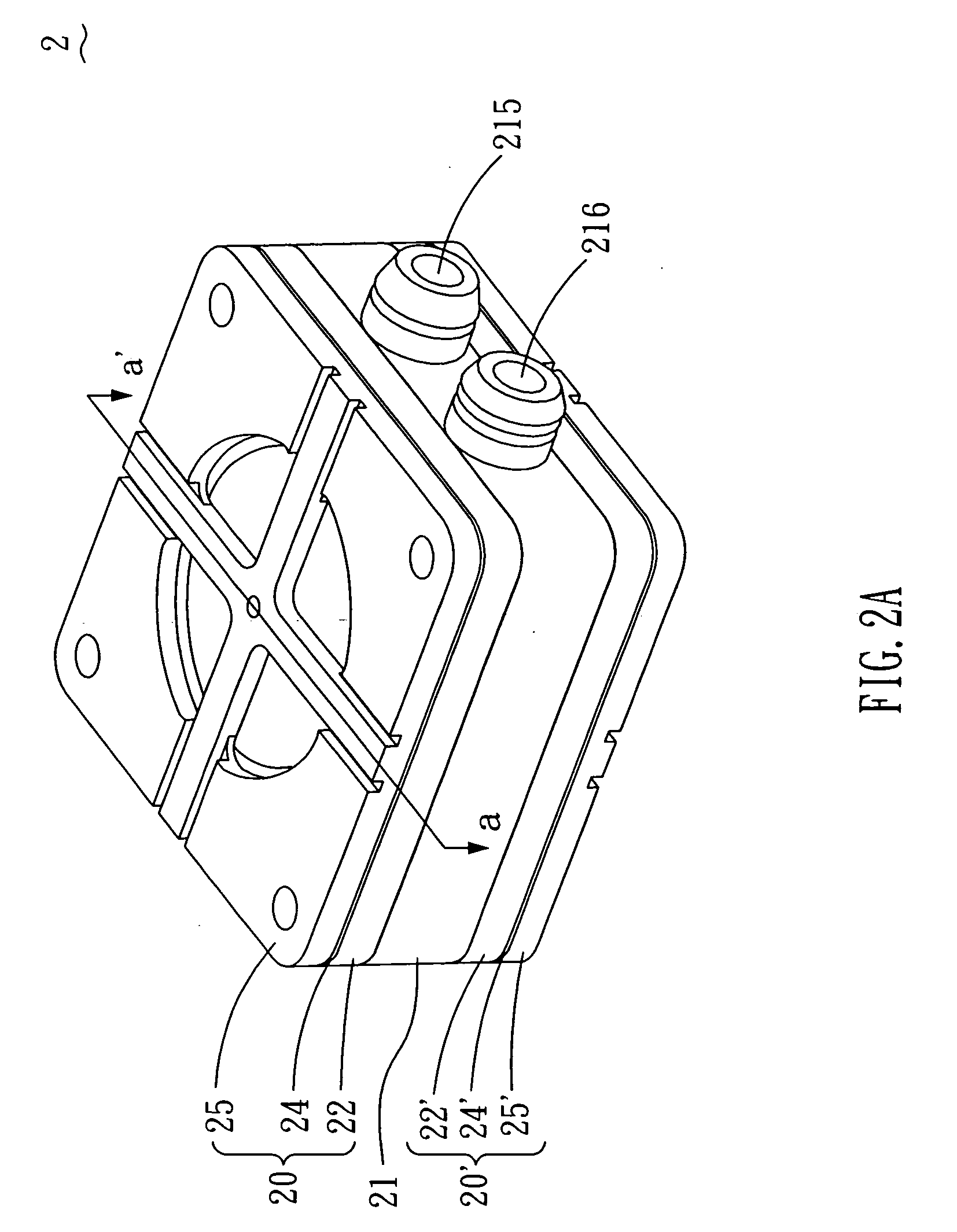

Dual-cavity fluid conveying apparatus

InactiveUS20090242061A1Increase fluid flowLarge volumePositive displacement pump componentsCircuit elementsEngineeringVALVE PORT

Owner:MICROJET TECH

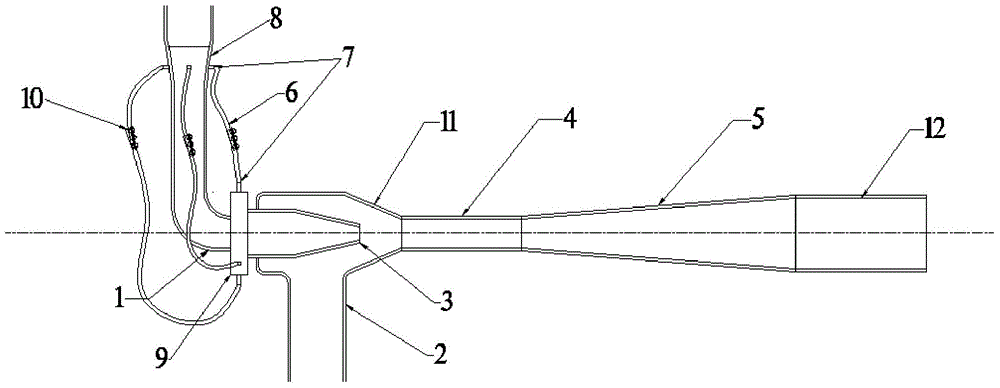

Spiral-flow type jet pump

ActiveCN104895852AIncrease fluid flowImprove efficiencyJet pumpsMachines/enginesOperating pointEngineering

The invention relates to a spiral-flow type jet pump. The jet pump comprises a water inlet pipe, a spiral flow generator, a nozzle, a throat pipe, a water suction pipe, a diffusion pipe and a water outlet pipe. The jet pump is sequentially provided with the water inlet pipe, the spiral flow generator, the nozzle, the water suction pipe, the throat pipe, the diffusion pipe and the water outlet pipe from left to right. An adjustable type spiral flow generating device is arranged in front of the nozzle of the jet pump, and the incoming flow of the water inlet pipe is divided into a plurality of strands and enters the position close to the nozzle in the symmetrically-tangent direction so as to form a vortex, the flow of sucked liquid is accordingly increased, and the efficiency of the jet pump is improved. The spiral-flow type jet pump is simple in structure, easy to mount and low in cost. According to different working conditions of the jet pump, different spiral flow intensities can be adjusted, so that an optimal operating point is obtained.

Owner:JIANGSU UNIV

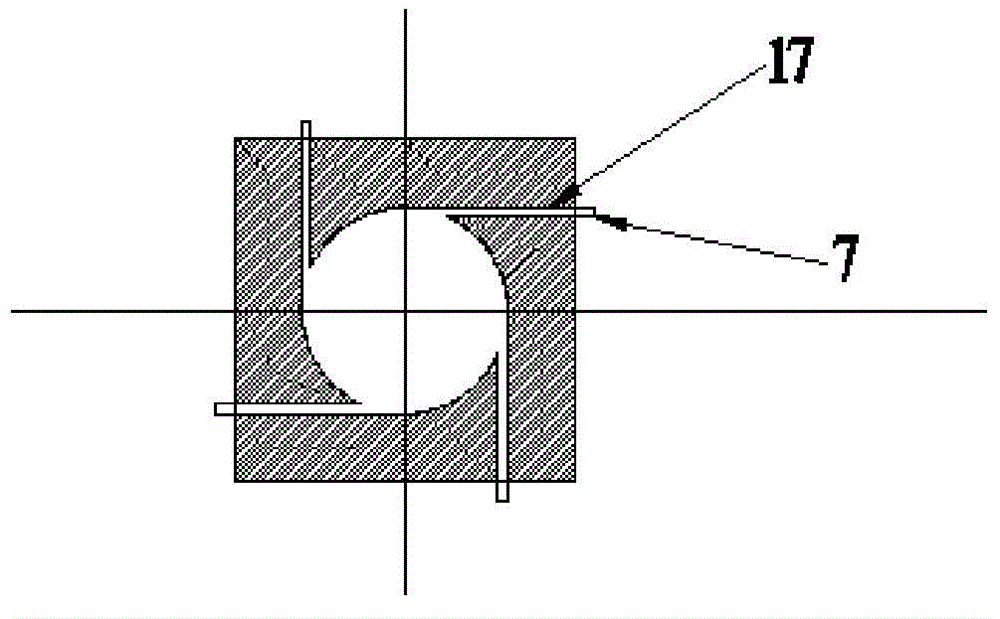

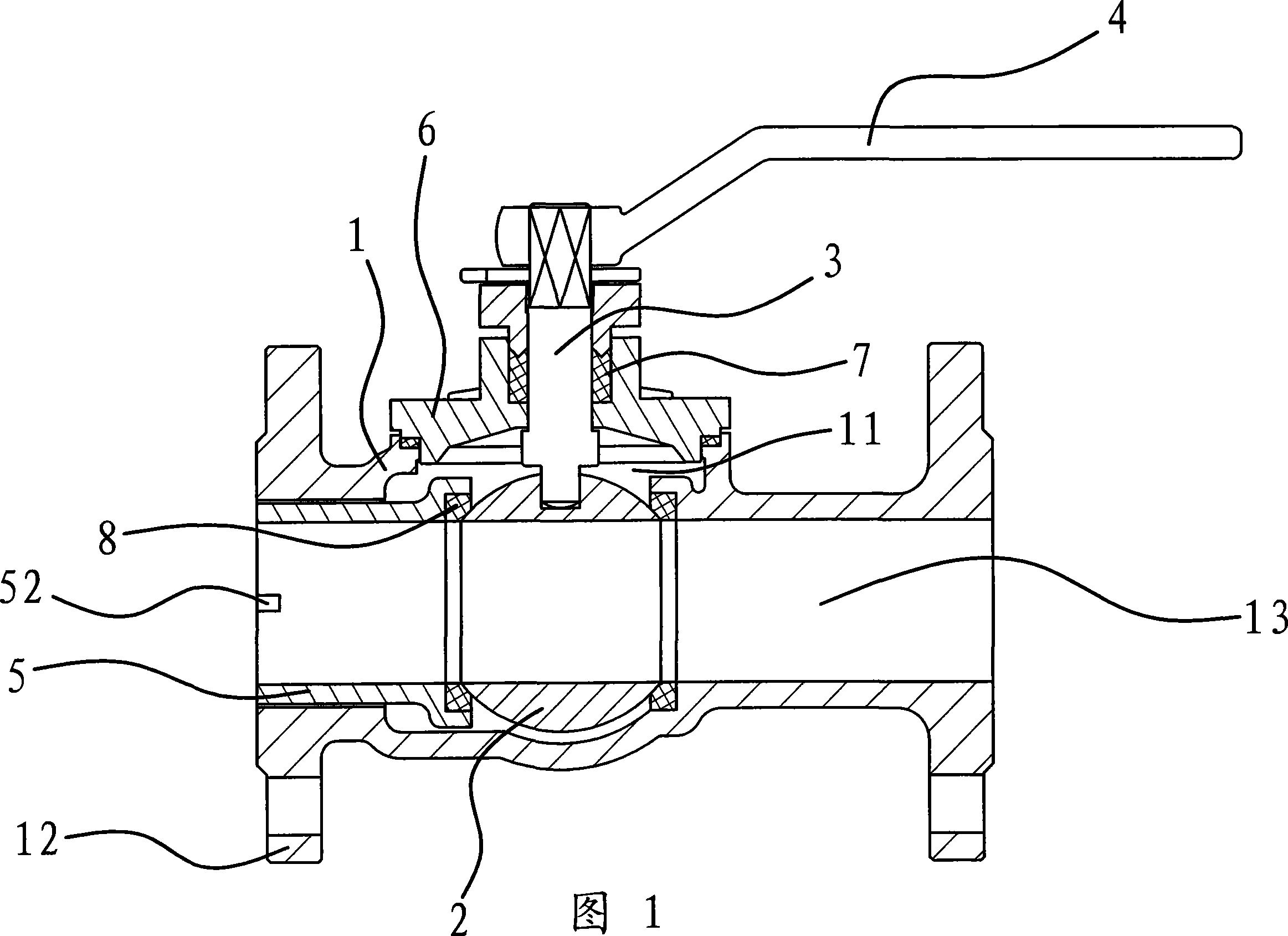

Integral whole-through diameter ball valve

The present invention provides an integral whole path ball valve which belongs to mechanical technique field and solves the problem that the existing flange type ball valve is small in flux and bad in safety. The integral whole path ball valve includes a valve body, a valve core, a valve spindle and a handle, the valve core is mounted in the valve body. The valve spindle passes through the valve body with inner end connected to the valve core and the outer end connected to the handle. The valve body is still disposed with a cylinder shape regulation valve seat which is connected to the valve body by screw and is abutted to the valve core. The valve body is an integral structure, and is disposed with a mounting hole on its top, the diameter of the mounting hole is larger than the outer diameter of the valve core, a press cover is disposed at the mounting hole and is connected to the valve body, and the valve spindle passes through the press cover. The integral whole path ball valve is simple in structure, low in cost, and can be adapted to various large flux pipe systems.

Owner:浙江鹏飞阀门有限公司 +1

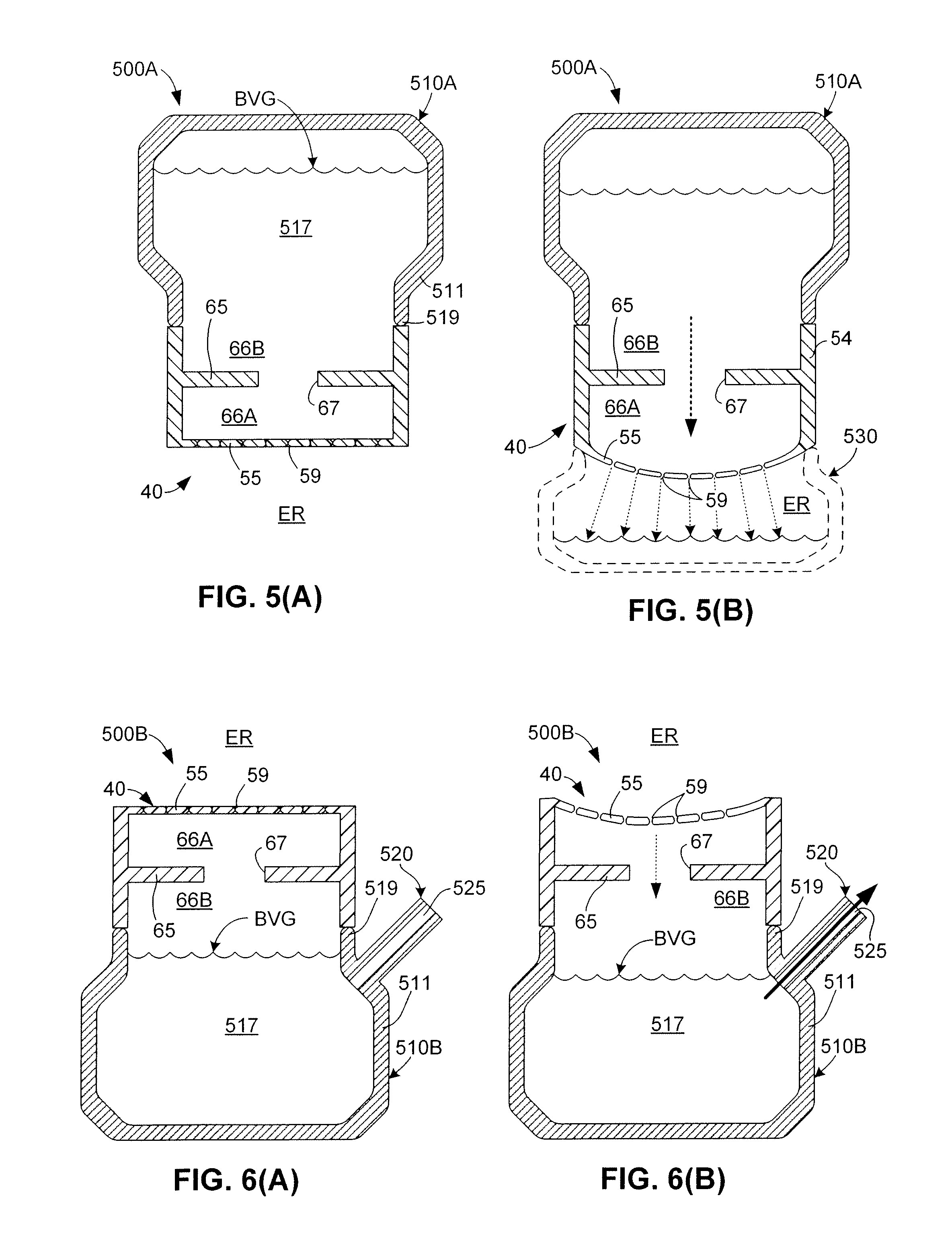

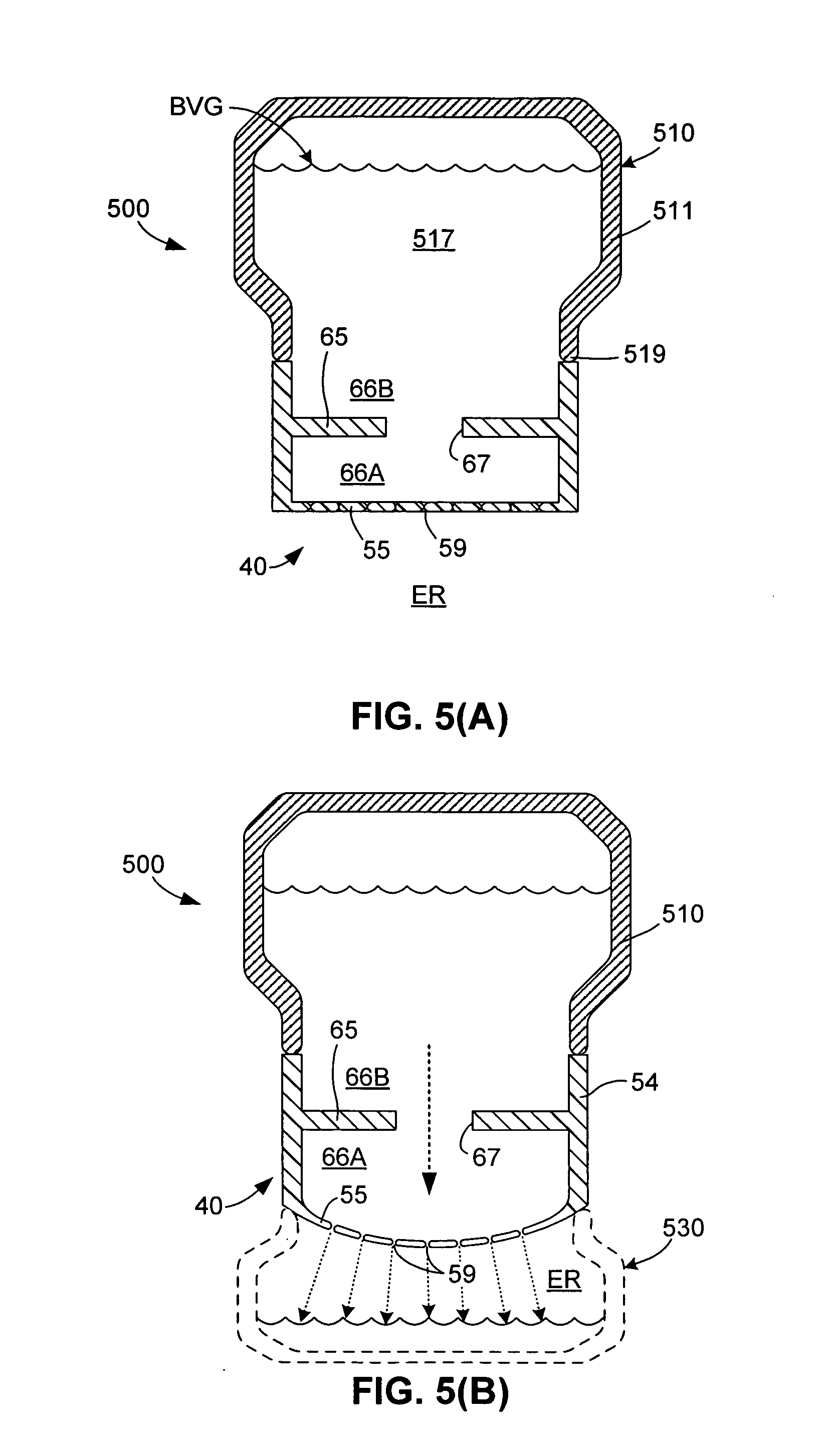

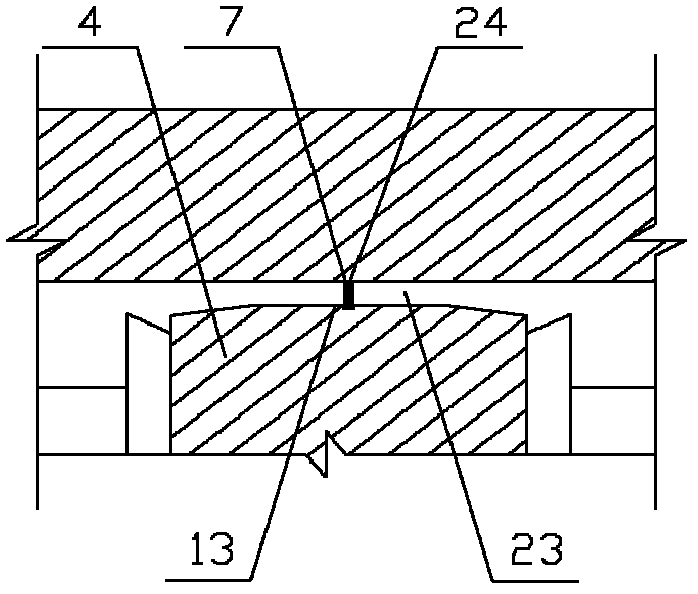

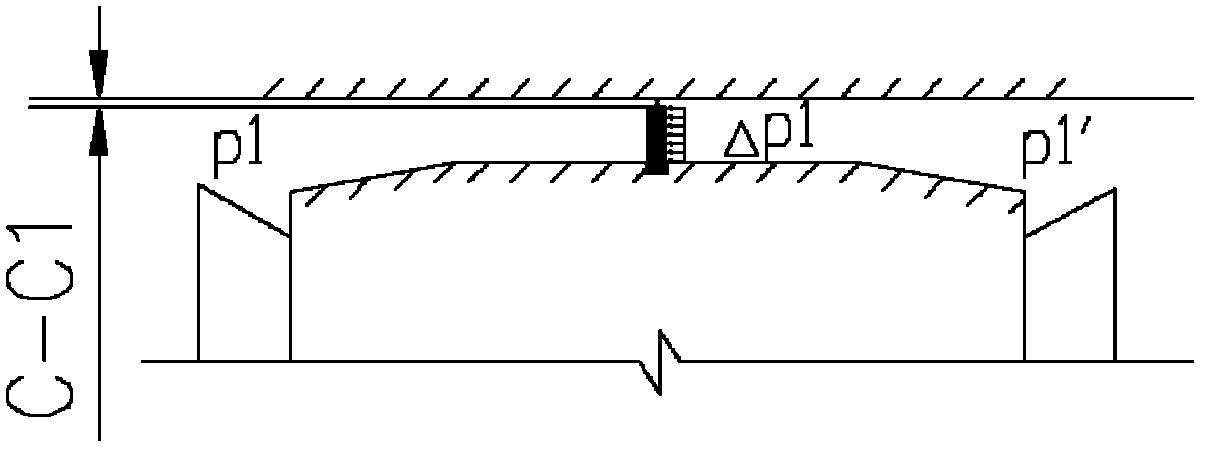

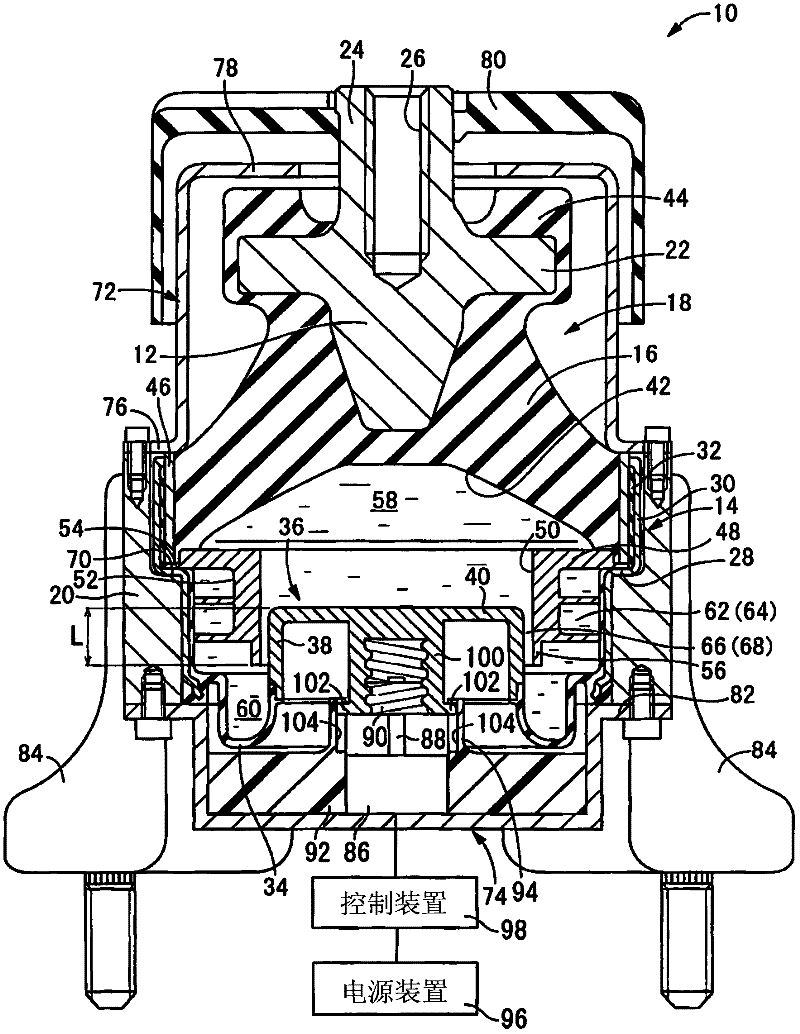

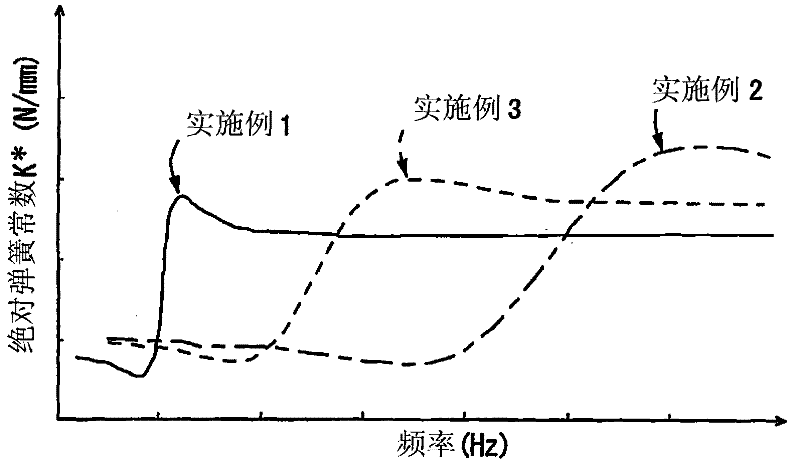

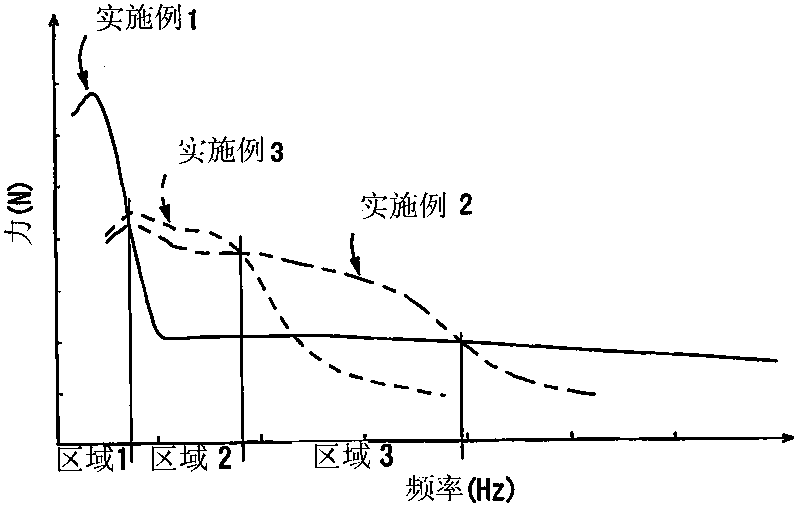

Fluid-filled vibration damping device

ActiveCN102245927AIncrease fluid flowControl internal pressureSpringsShock absorbersRelative pressureMechanical engineering

Disclosed is a fluid-filled vibration damping device that is provided with a first liquid chamber and a second liquid chamber, inside each of which is sealed a non-compressible fluid, and to which relative pressure fluctuations are applied when vibration is input. An orifice passageway that connects the first and second liquid chambers to each other is also provided. The device is able to achieve effective vibration damping effects against multiple kinds of vibrations of differing frequencies with greater reliability and durability. Modification of the tuning frequency of the orifice passageway (68) is accomplished by adjusting how far the inner orifice member (36) enters into the outer orifice member (48) to modify the length of the orifice passageway (68).

Owner:SUMITOMO RIKO CO LTD

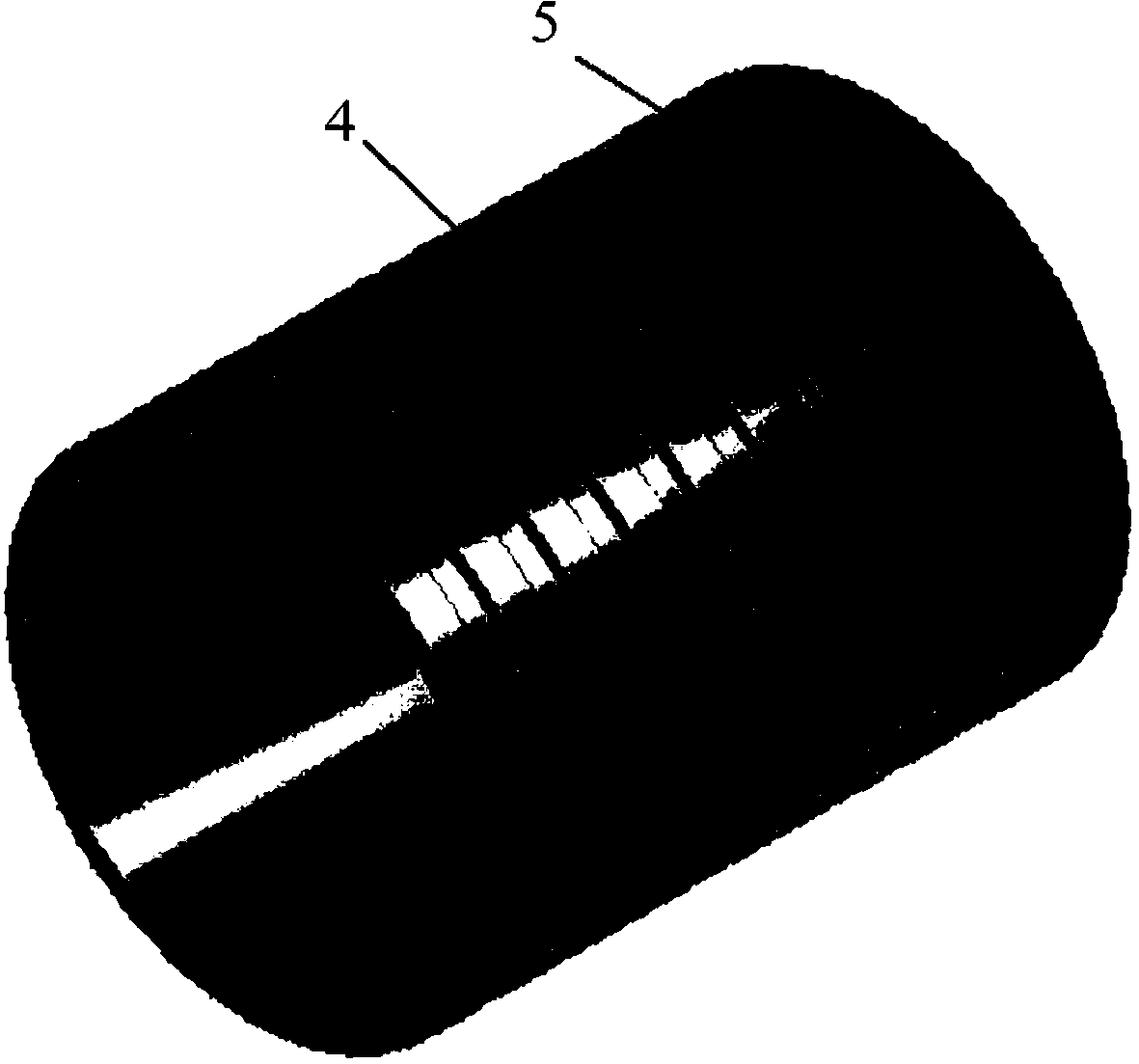

Rotor of high-speed permanent magnet motor

InactiveCN104377859AReduce eddy current lossReduce the temperatureMagnetic circuit rotating partsInterference fitElectric machinery

The invention discloses a rotor of a high-speed permanent magnet motor. The rotor of the high-speed permanent magnet motor comprises a rotary shaft, a rotor core, a permanent magnet, a rotor cooling channel and a protective sleeve, wherein the rotor cooling channel is formed in the center of the rotary shaft; cooling media like water or oil are led into the cooling channel; the protective sleeve is a semi-magnetic permeable alloy protective sleeve. Spiral grooves are evenly formed in the outer surface of the protective sleeve. The rotor of the high-speed permanent magnet motor is a surface-mounting type permanent magnet, and the protective sleeve is in interference fit with the permanent magnet. The rotor core can be made of low-loss silicon steel sheet materials and can also be made of carbon steel materials, and when the rotor core is made of carbon steel materials, the rotor core and the rotary shaft are of an integrated structure. The phenomenon that as a permanent magnet is subjected to severe magnetism loss and even irreversible demagnetization under high temperature, a motor cannot operate reliably is avoided.

Owner:SHENYANG POLYTECHNIC UNIV

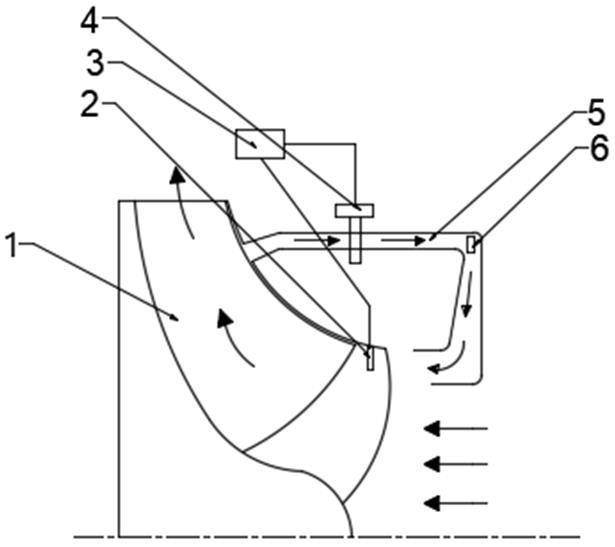

Self-circulation cavitation-preventing machine box suitable for centrifugal/mixed-flow type water pump

A self-circulation cavitation-preventing machine box suitable for a centrifugal / mixed-flow type water pump is characterized in that a backflow channel which guides high-pressure fluid on the rear portion of a water pump impeller into an inlet of the water pump is formed in the machine box so that the pressure intensity of the inlet of the water pump can be increased, and the pressure intensity ofthe fluid in the inlet of the water pump can be higher than the corresponding vaporization pressure to prevent vaporization from happening. An inlet of the backflow channel is formed in the rear portion of the water pump impeller, and an outlet of the backflow channel is formed in the inlet of the water pump. A temperature and pressure sensor is installed in the inlet of the water pump and used for detecting the pressure and the temperature of the fluid in the inlet to determine whether the pressure is equal to the saturated vapor pressure corresponding to the current water temperature or not.A valve is arranged in the backflow channel. According to the self-circulation cavitation-preventing machine box suitable for the centrifugal / mixed-flow type water pump, a backflow device is used, the high-pressure fluid on the rear portion of the impeller is jetted to the inlet of the water pump again through the backflow device, the pressure of the inlet of the water pump is improved, the phenomenon that the pressure of the fluid is equal to the vaporization pressure is avoided, the generation of vapor bubbles is avoided, and the influence of cavitation is fundamentally avoided.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

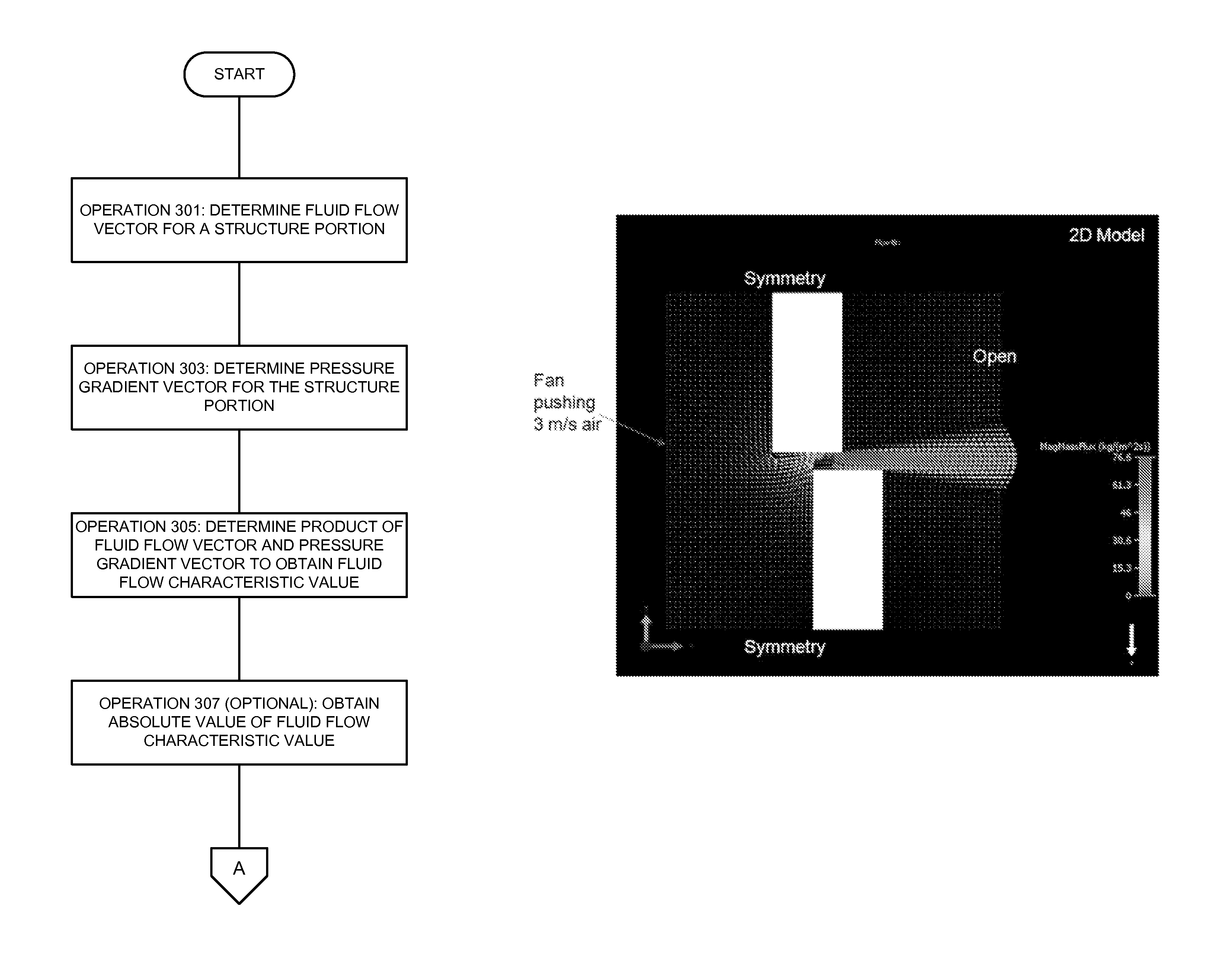

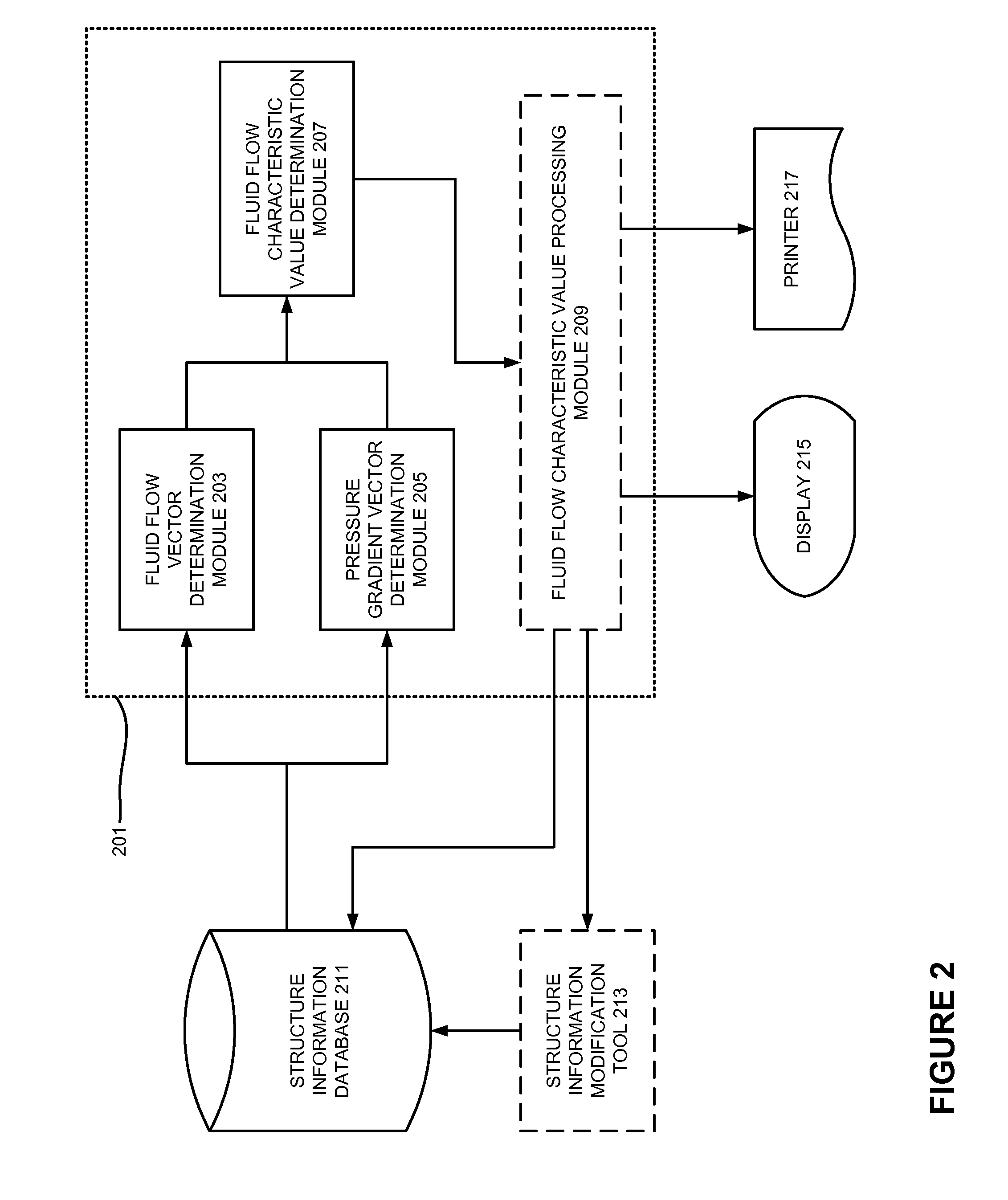

Identification of fluid flow bottlenecks

ActiveUS8688414B2Lower overall pressure dropSimple designVolume flow proportion measurementComputation using non-denominational number representationEnvironmental geologyEngineering

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

Minature sludge lance apparatus

ActiveUS20110180022A1Shorten the timeReduce doseBoiler cleaning apparatusMachines/enginesNuclear reactorSludge

A miniature sludge lance for a steam generator in a pressurized water nuclear reactor is provided. The sludge lance is structured to enter the steam generator via an inspection opening and has a body sufficiently thin to fit between adjacent tubes. The sludge lance rail has at least two types of nozzle assemblies that may be attached thereto. One nozzle assembly rotates and another nozzle assembly translates in a vertical direction. A drive assembly, a mounting assembly, an oscillation assembly, and flow straighteners are also provided.

Owner:WESTINGHOUSE ELECTRIC CORP

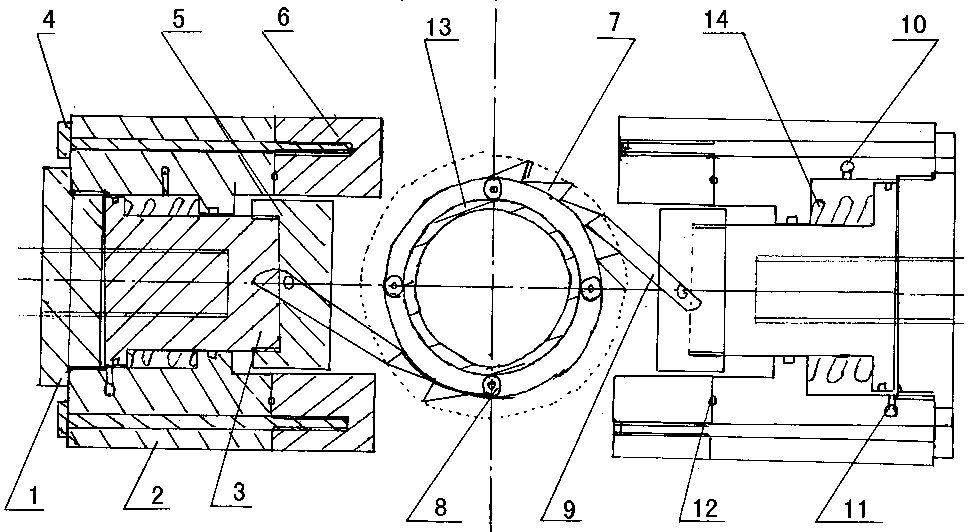

Circular shear device for coiled tubing four-flashboard blowout preventer

The invention relates to a circular shear device for a coiled tubing four-flashboard blowout preventer. According to the technical scheme, the circular shear device for the coiled tubing four-flashboard blowout preventer comprises a hydraulic power device, a ratchet thrust stick and a ratchet cutter device. The hydraulic power device is movably connected with the ratchet thrust stick. The hydraulic power device forms circular motion in a rotating mode by the ratchet thrust stick hitting against the ratchet cutter device and simultaneously, a positive-rotating downward-propelling body is drivento move down by the accelerated speed of impacting and a negative-rotating upward-propelling body is driven to move up and then a cutter squeezes and cuts coiled tubing in the horizontal direction. Annular cutting of the coiled tubing is realized finally and a round cutting section is formed. The circular shear device for the coiled tubing four-flashboard blowout preventer has the beneficial effects that the cutting section of the coiled tubing is of a circular structure in the narrow space of a shear ram by remoulding the shear ram of the coiled tubing four-flashboard blowout preventer, thedeformation condition of an existing notch is avoided, and therefore the resistance of mining liquid or gas is reduced and the oil recovery efficiency or gas production efficiency is improved during operation.

Owner:宋协翠

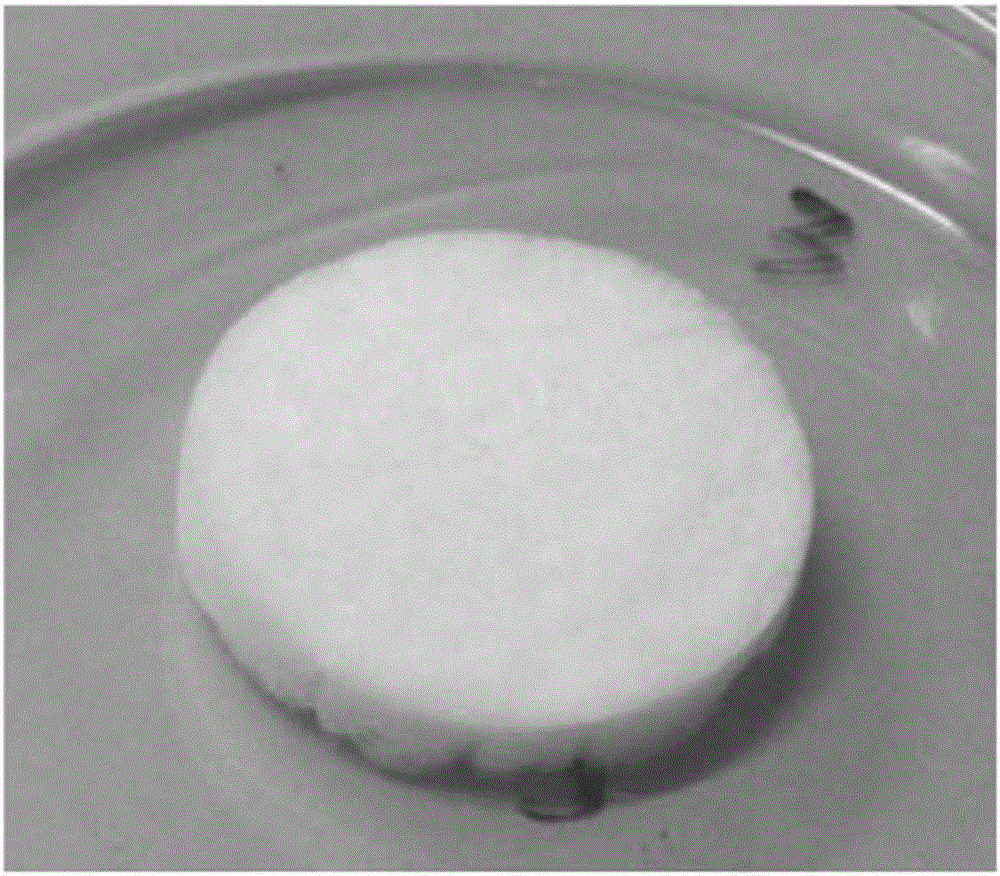

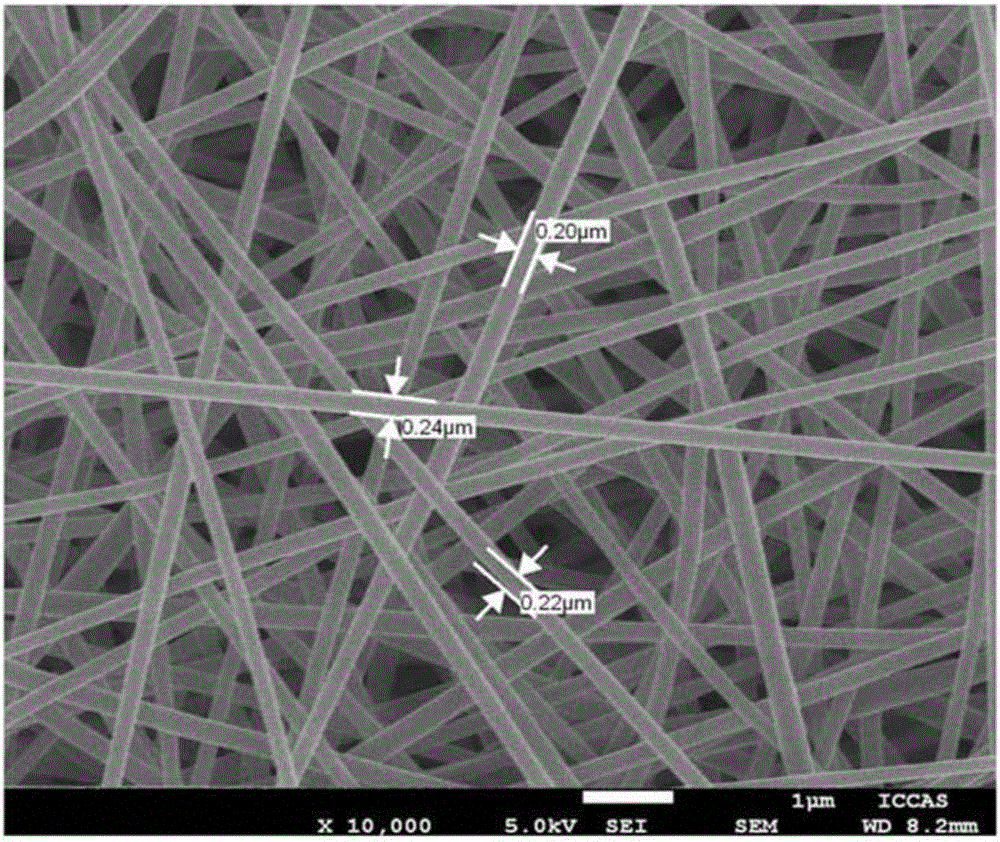

Preparation method of multi-stage pore-size distribution material

ActiveCN105734718AControl pore size distributionRegulation densityPhysical treatmentMonocomponent polyesters artificial filamentMaterials preparationFiber

The invention belongs to the field of material preparation, and particularly relates to a preparation method of a multi-stage pore-size distribution material. The preparation method comprises the following steps: firstly, preparing functional fibers, wherein chemical groups are arranged on the surfaces of the functional fibers; then, homogenizing the functional fibers to obtain homogenized functional fibers; performing crosslinking treatment on the homogenized functional fibers to obtain the multi-stage pore-size distribution material. The multi-stage pore-size distribution material prepared in the invention has multi-stage pore-size distribution, good adsorption properties, good flexibility and processibility, simple processes, high universality and low equipment requirements, can be subjected to industrial production, and has broad application prospects in many fields.

Owner:UNIV OF SCI & TECH BEIJING

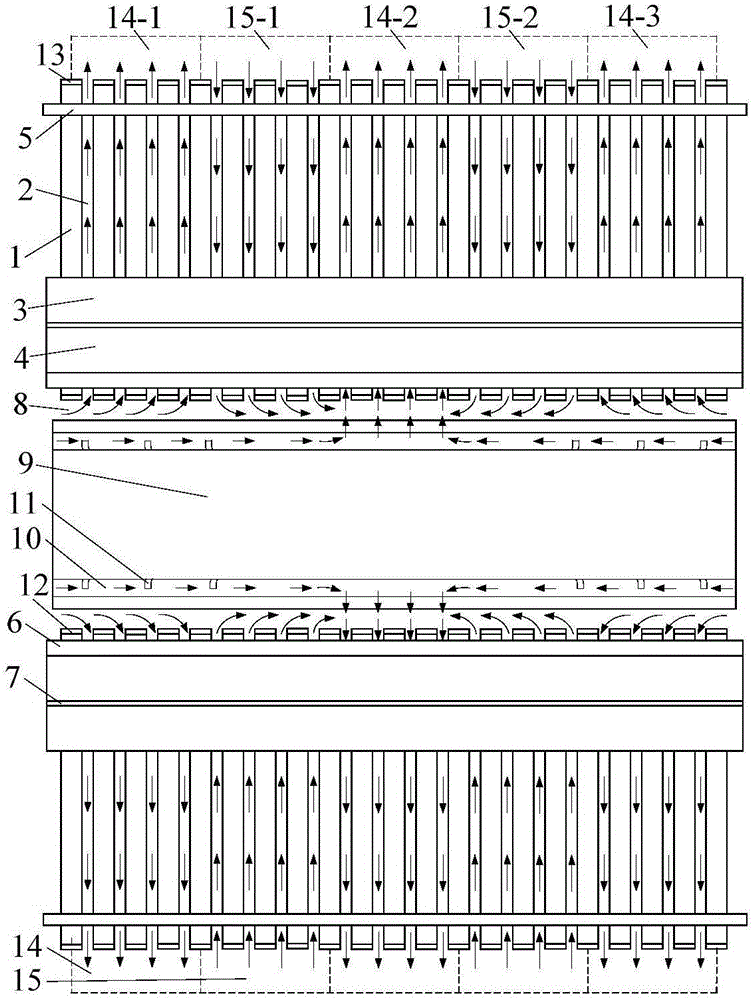

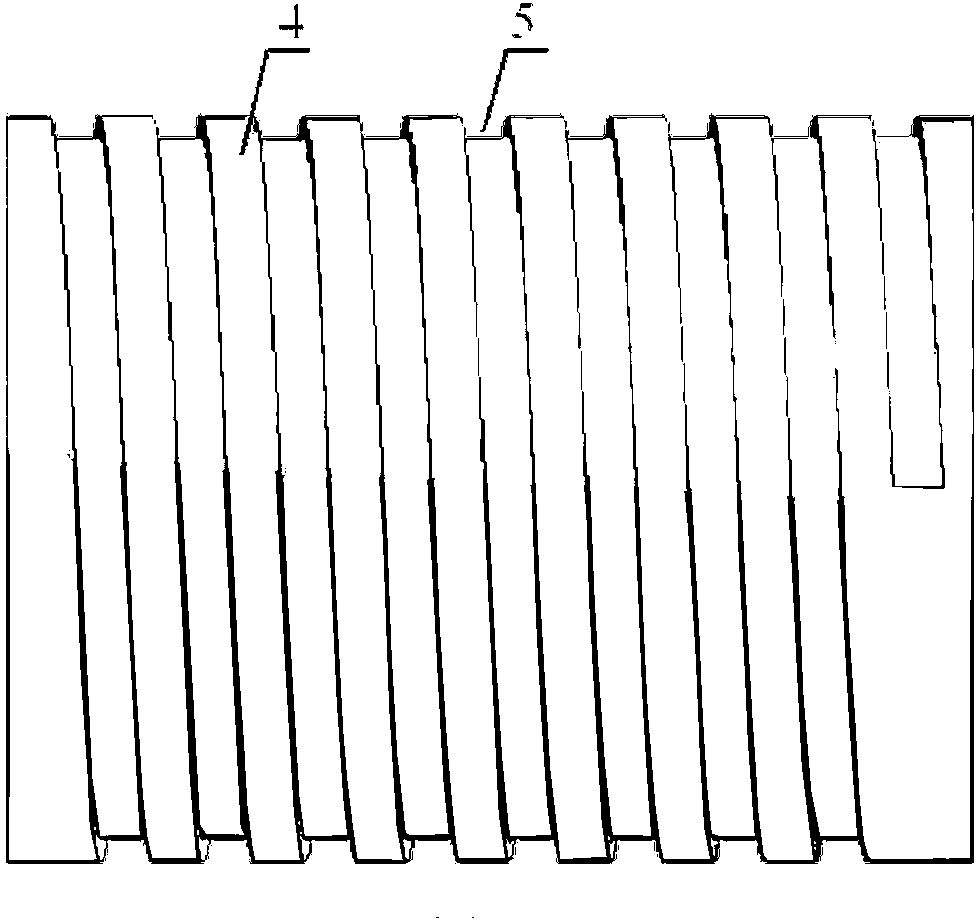

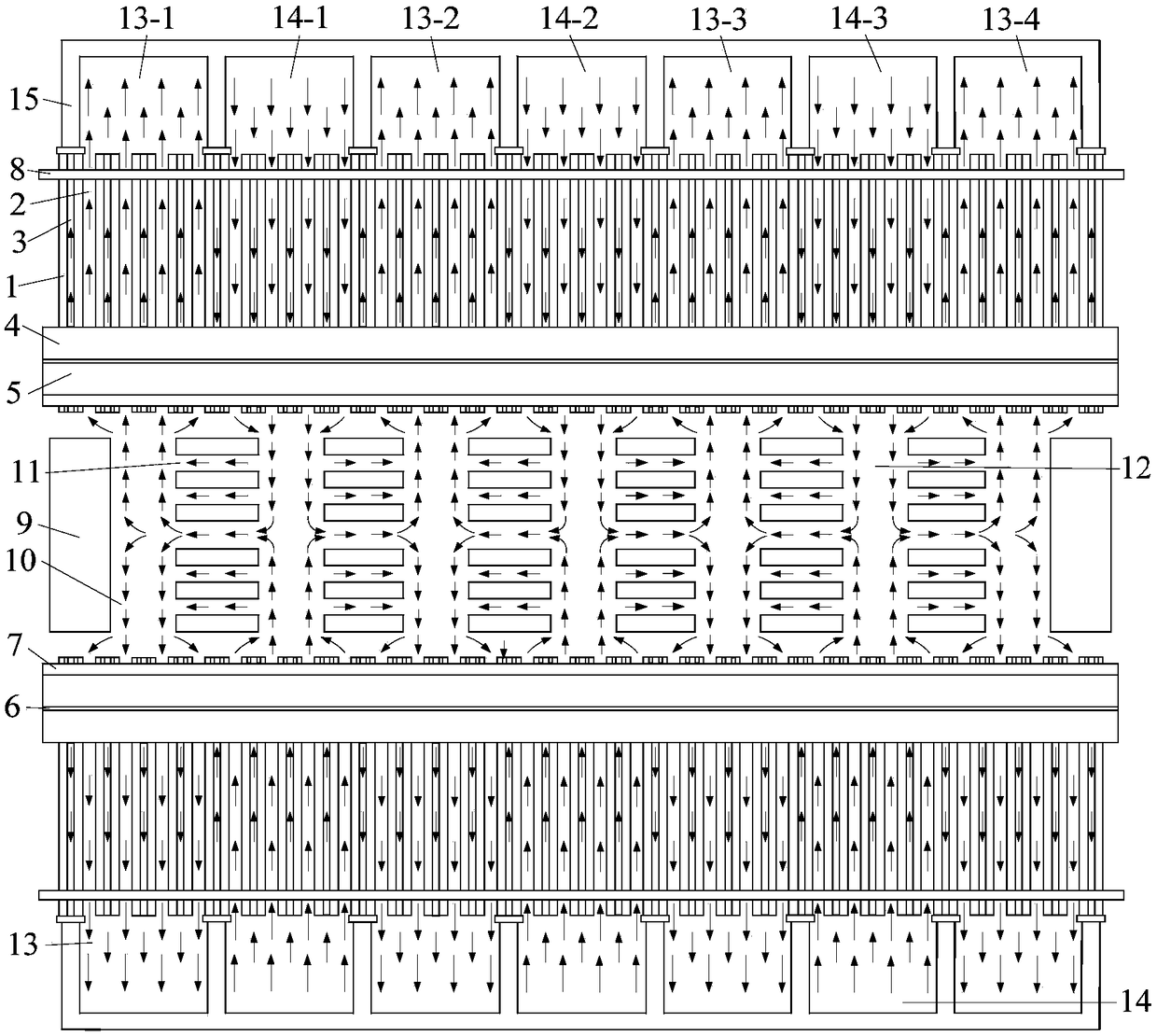

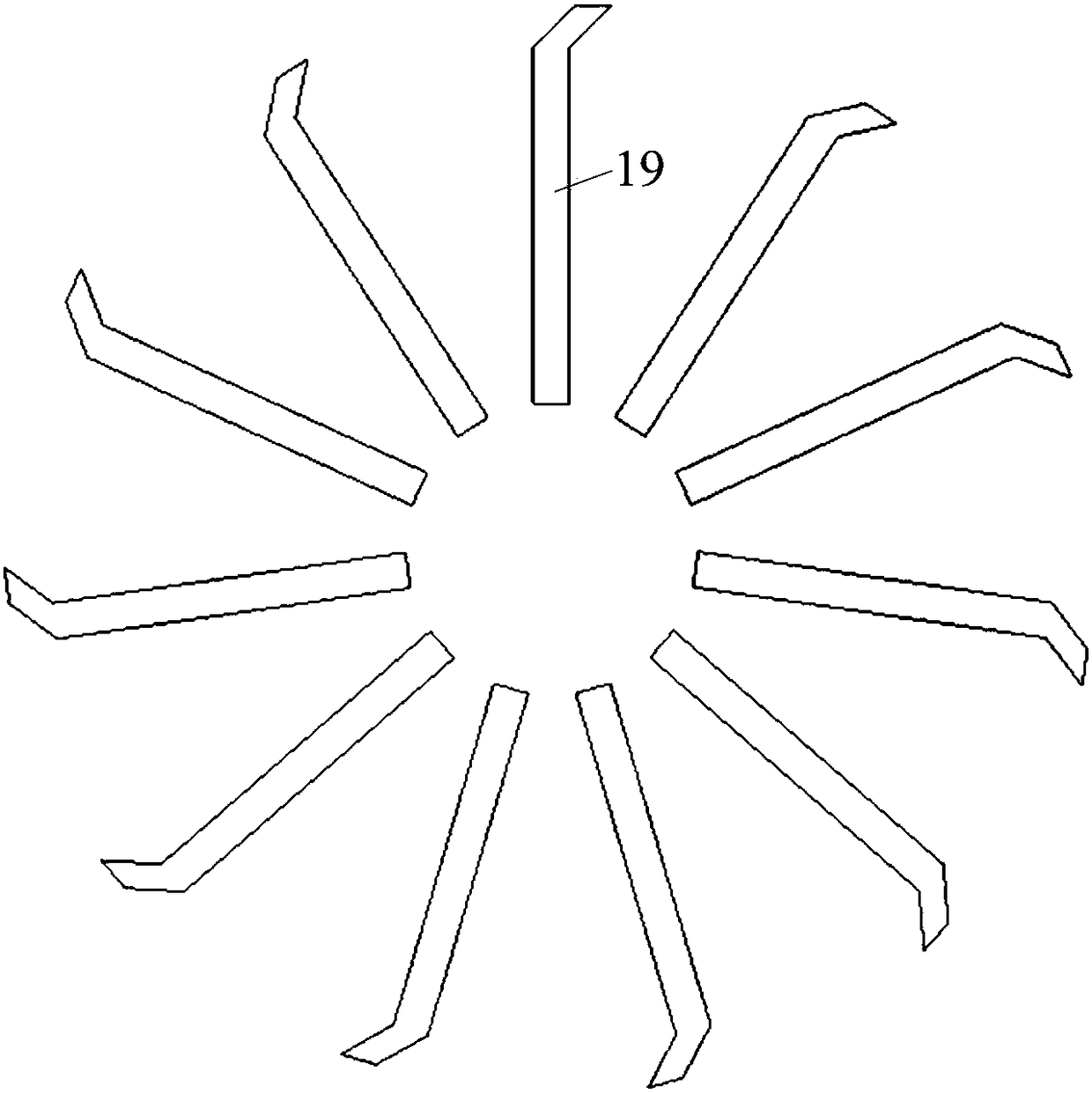

Forced pressure-in-draw-out type turbogenerator ventilation cooling system with multi-wind path interleaving

ActiveCN108566001AIncrease temperatureHigh heat dissipation coefficientMagnetic circuit rotating partsMagnetic circuit stationary partsCold airElectric machinery

The invention discloses a forced pressure-in-draw-out type turbogenerator ventilation cooling system with multi-wind path interleaving, which relates to the field of electric machinery. In order to solve the problem of high temperature of a stator iron core, a stator winding and a rotor iron core in an existing turbogenerator, a 'Y'-shaped stator internal air channel is formed in the stator iron core, a stator radial ventilation groove is reserved between the stator iron cores, the stator region is alternately divided into a stator hot air area and a stator cold air area along the axial direction, and the stator iron core is arranged in the stator base; the rotor area is alternately divided into a rotor hot air area and a rotor cold air area along the axial direction, the rotor hot air area and the rotor cold air area are connected through the axial ventilation holes of the rotor, a throw away type fan blade, a rotor first-stage pressurizing fan blade and a rotor second-stage pressurizing fan blade are arranged in the rotor hot air area, a rotor suction fan blade is arranged in the rotor cold air area. The turbine generator has the advantages that the cooling effect of the components of the turbogenerator is enhanced, the structure is simple, and the realization is convenient.

Owner:HARBIN UNIV OF SCI & TECH

Industrial waste gas treatment device

InactiveCN109012038APrevent leakageFully absorbedUsing liquid separation agentPulp and paper industryToxic industrial waste

The invention discloses an industrial waste gas treatment device, which comprises an intake pipe, a washing bucket, a barrel wall, a top cover, a cavity, a first through hole, a motor, a rotating shaft and a first stirring rod. Connecting rods are respectively connected above two sides of the first stirring rod. A second stirring rod is fixedly connected above the connecting rod. A water pump is also connected above the top cover. A drain pipe and a liquid suction pipe are in through connection with the water pump. A filter cartridge is also connected between the liquid suction pipe and the water pump. The top of the filter cartridge is connected with a filter cartridge cover. The bottom of the liquid suction pipe extends into the washing bucket. A plurality of annular tubes arranged one above the other are connected below the drain pipe, and two adjacent annular tubes are communicated with each other through two connecting pipes. The diameters of the annular tubes are sequentially increased from top to bottom. The annular tubes are provided with a plurality of second through holes. The top of the top cover is connected to an exhaust funnel, inside which an exhaust fan is connected. The deficiencies in the prior art can be improved, and the device of the invention has a better exhaust gas washing effect.

Owner:杨明超

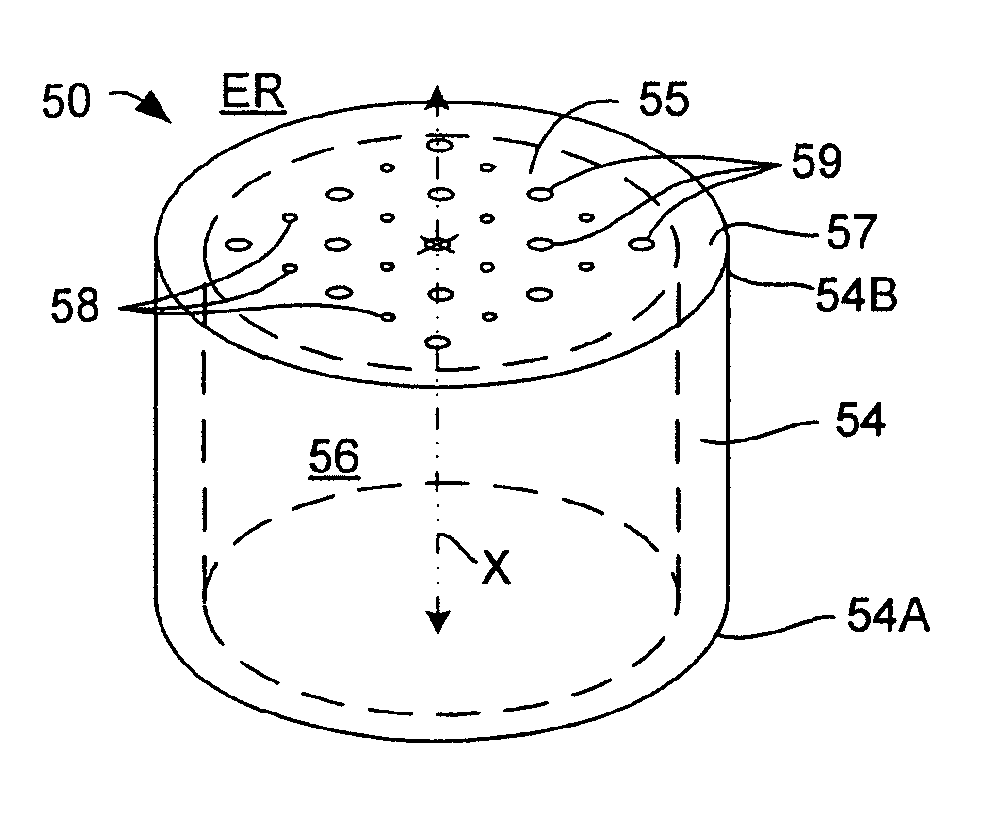

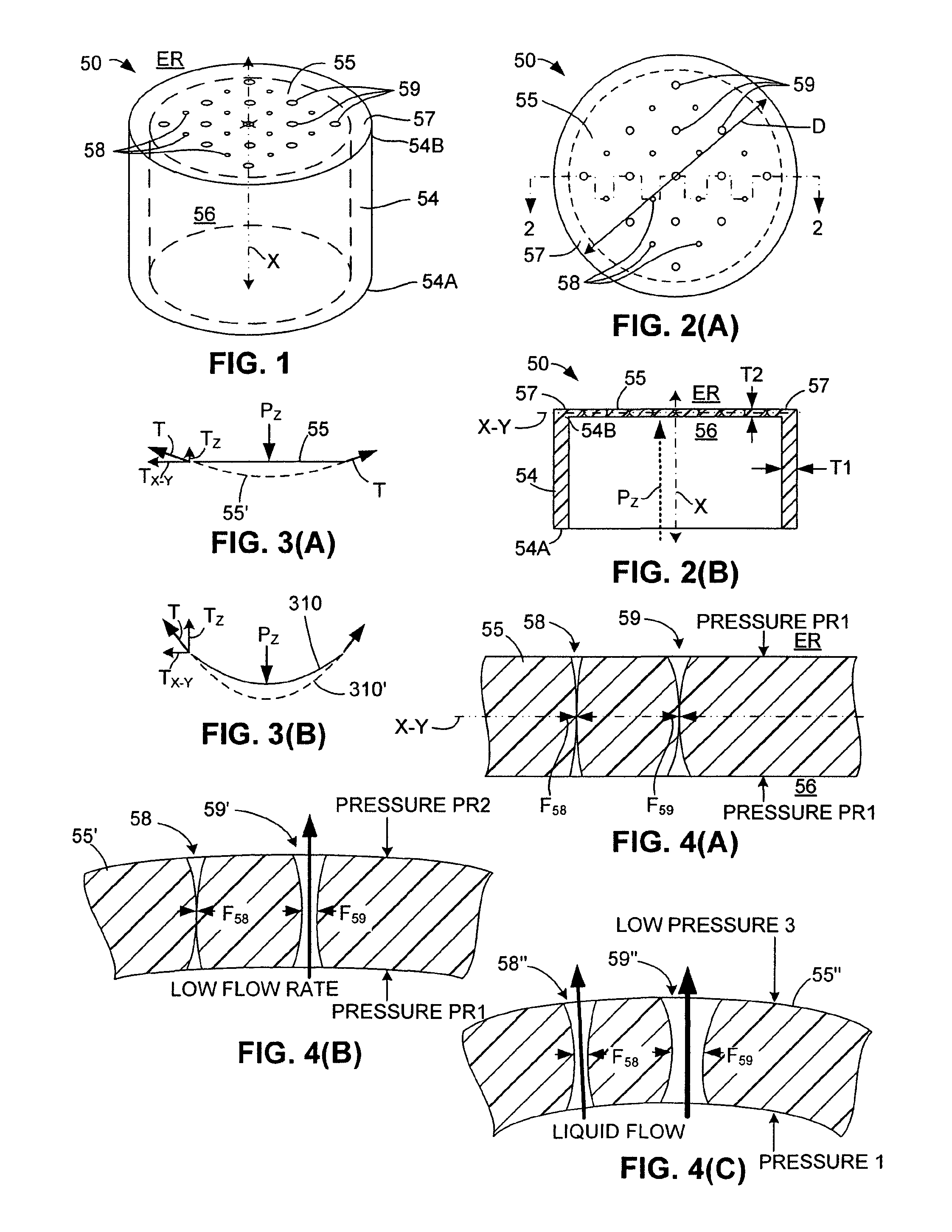

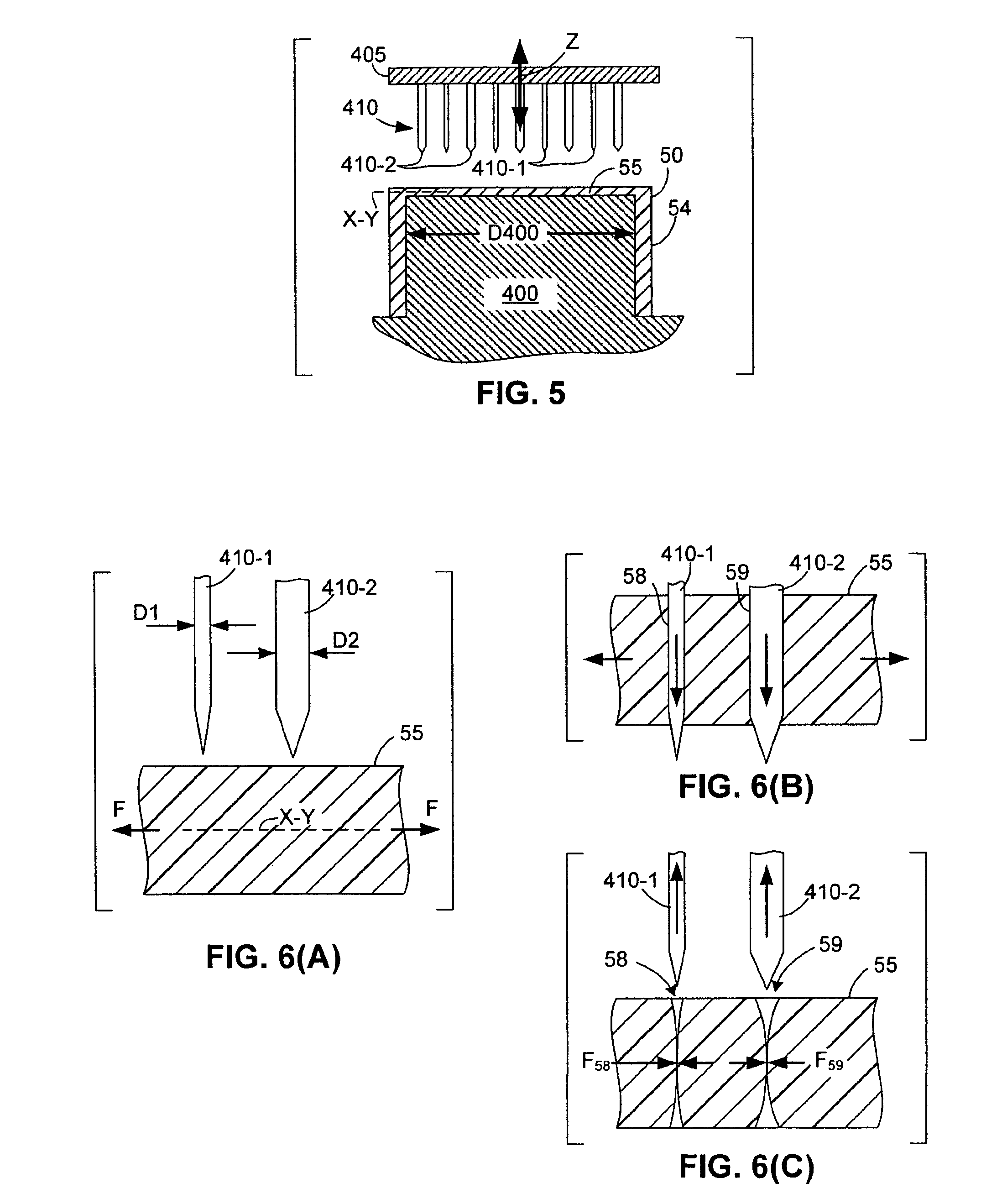

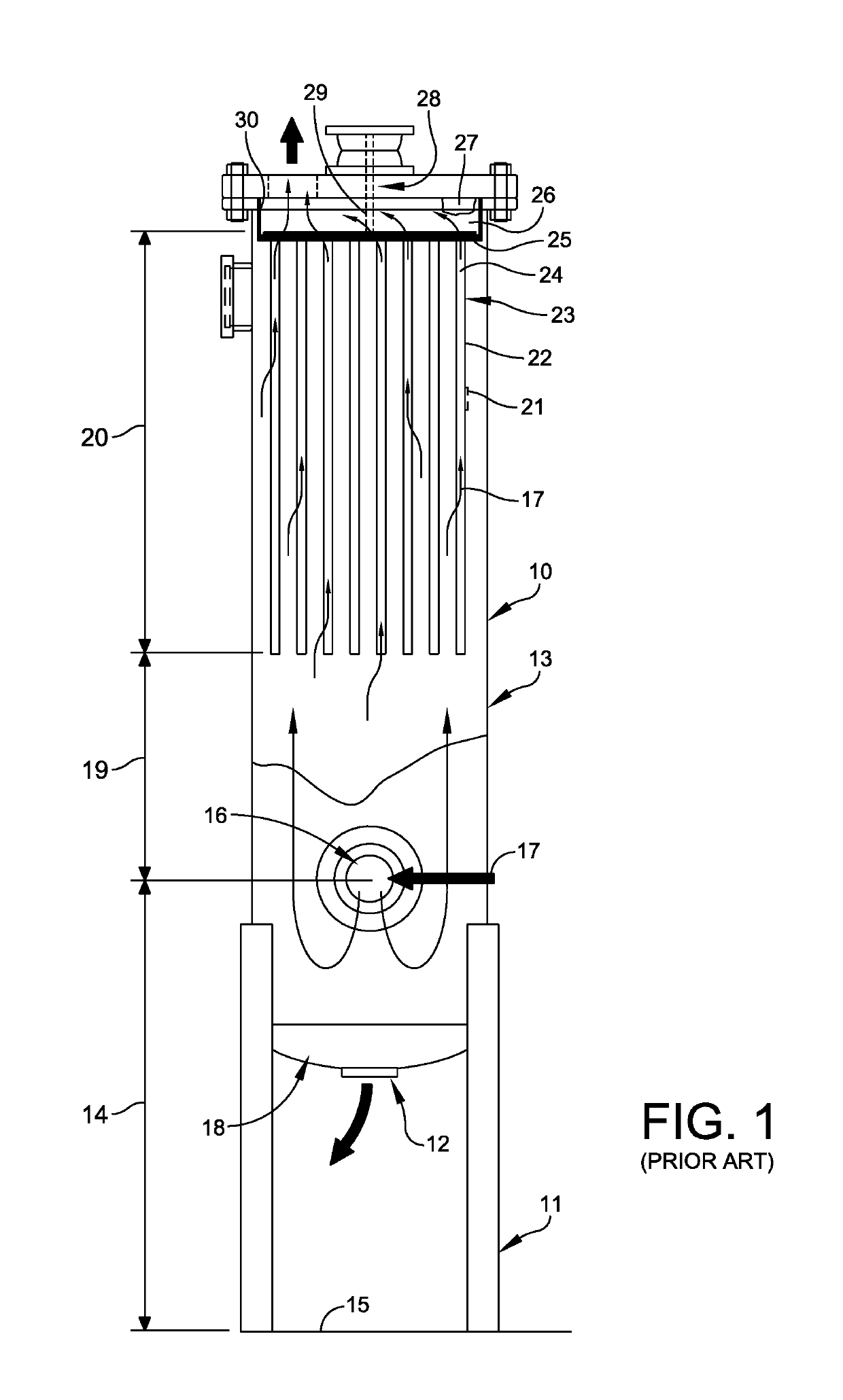

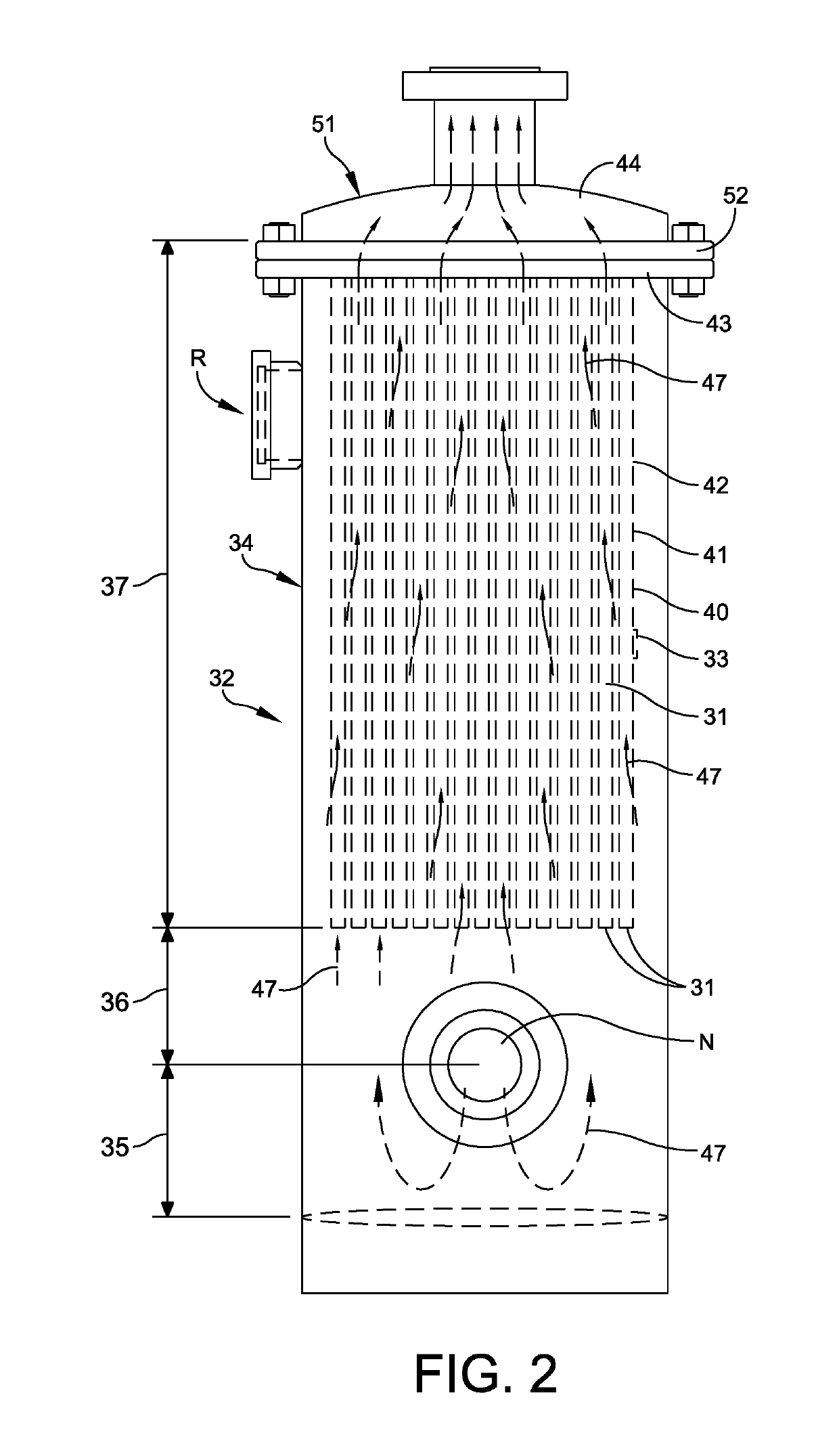

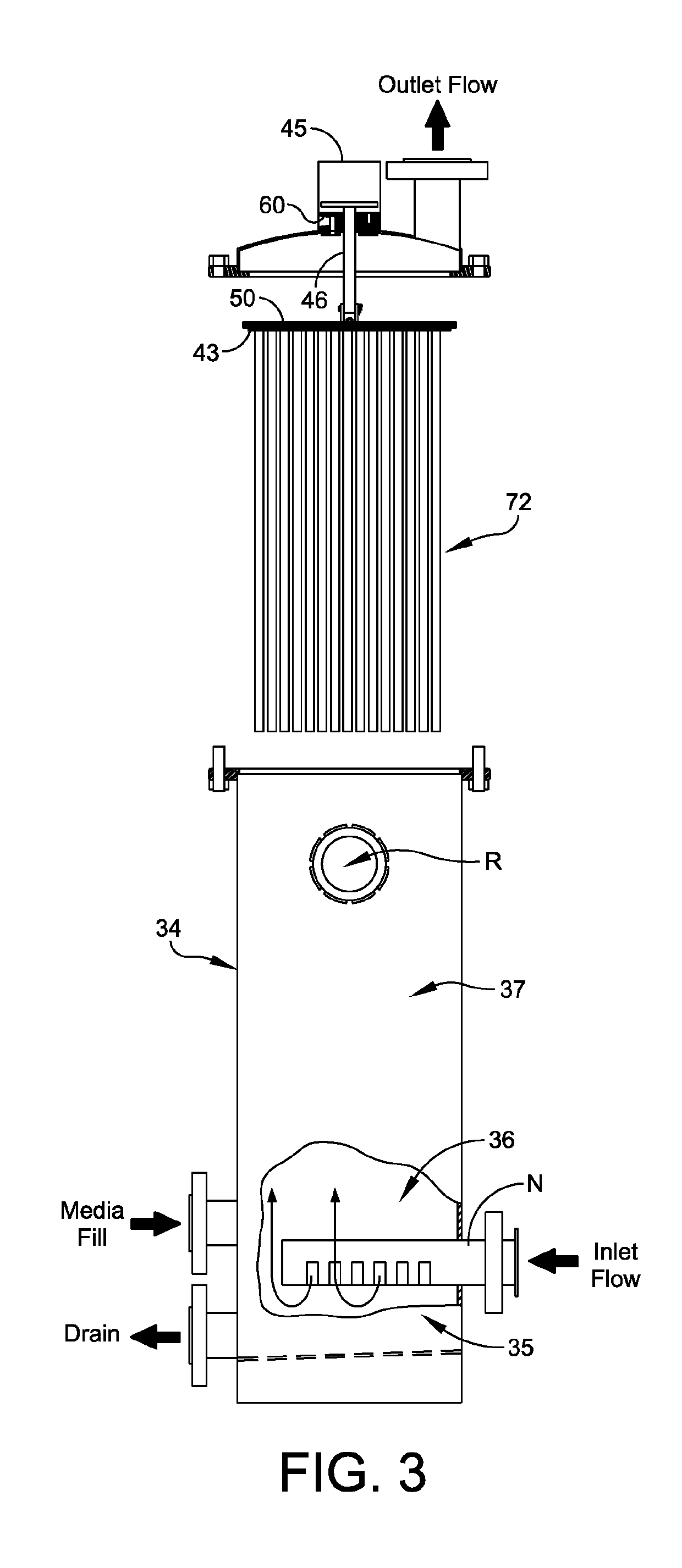

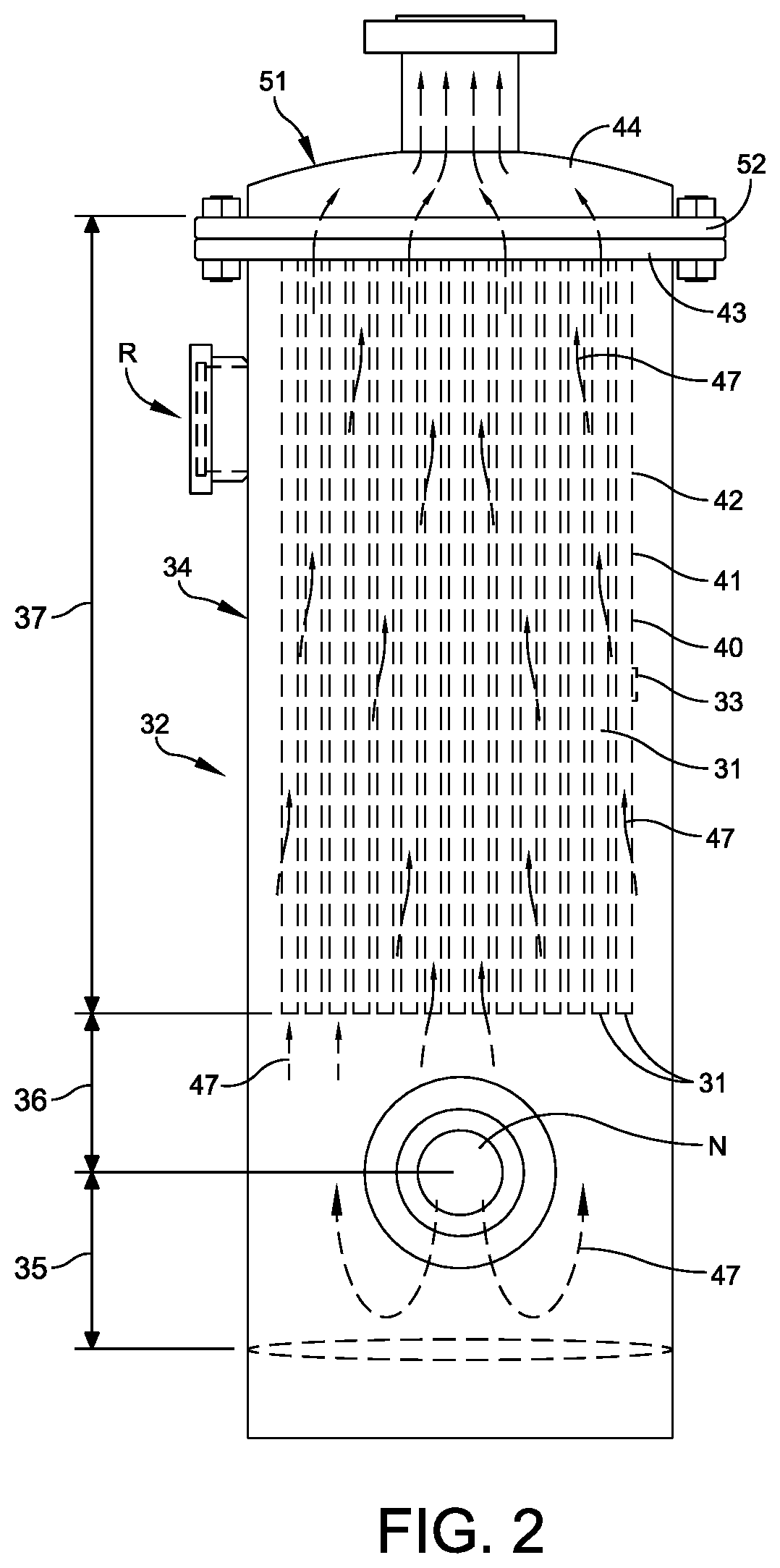

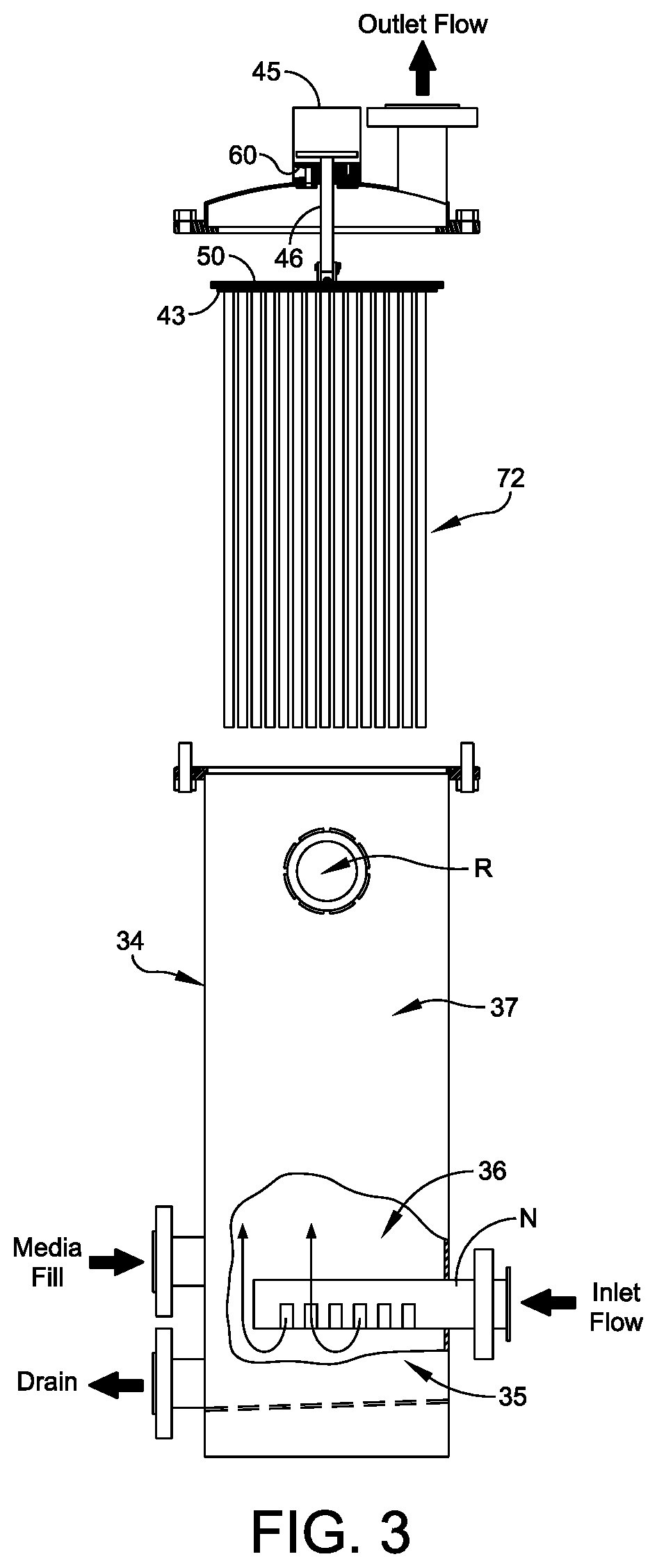

Regenerative media filtration

ActiveUS20190291028A1Increase fluid flowReduced footprintMembrane filtersStationary filtering element filtersParticulatesFiltration

A regenerative filter that includes a filter housing having inlet and outlet zones; a fluid path provided between the inlet and outlet zones; a plurality of filter elements each having an outer surface filter media applied thereto and functioning to filter particulate or contaminants from the fluid path; and a tube sheet that is supported across the filter housing, that is disposed just before the outlet zone and that provides the support for the plurality of filter elements. The plurality of filter elements are disposed in an array and includes bridging members or elements that connect between adjacent filter elements, and that forms with the filter elements, a closed interstitial space between adjacent filter elements for liquid flow; a nanoscale barrier on interior surfaces, including that of the regenerative media itself, providing a mechanism to disrupt the cell wall of microscopic viruses and organisms.

Owner:BLUE SKIES GLOBAL LLC

Regenerative media filtration

PendingUS20210331098A1Increase fluid flowReduced footprintMembrane filtersLoose filtering material filtersFilter mediaEngineering

A regenerative filter that includes a filter housing having inlet and outlet zones; a fluid path provided between the inlet and outlet zones; a plurality of filter elements each having an outer surface filter media applied thereto and functioning to filter particulate or contaminants from the fluid path; and a tube sheet that is supported across the filter housing, that is disposed just before the outlet zone and that provides the support for the plurality of filter elements. The plurality of filter elements are disposed in an array and includes bridging members or elements that connect between adjacent filter elements, and that forms with the filter elements, a closed interstitial space between adjacent filter elements for liquid flow; a nanoscale barrier on interior surfaces, including that of the regenerative media itself, providing a mechanism to disrupt the cell wall of microscopic viruses and organisms.

Owner:BLUE SKIES GLOBAL LLC

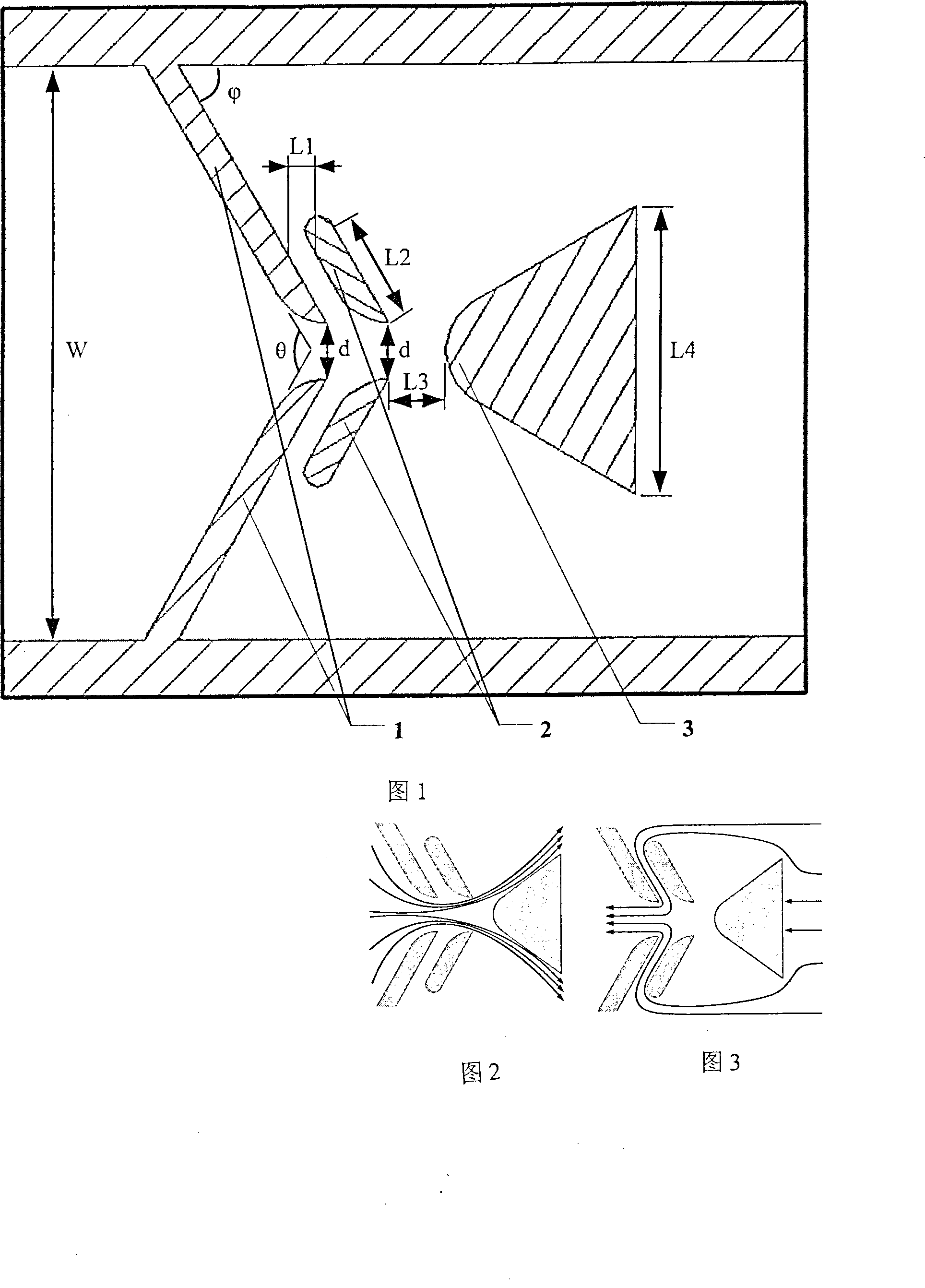

Three-rib type micro pneumatic valve

The invention relates to a three-rib type minisize air-operated valve for controlling the flow direction and the flow of liquid. The structure is that a first level rib, a second level rib and a third level rib are arranged in the order from left to right to form the three-rib type minisize air-operated valve, wherein the first level rib is constituted by an upper part and a lower part which are symmetrical, and is positioned on the left end of the minisize valve. The second level rib is constituted by an upper part and a lower part which are symmetrical, and is positioned on the right side of the first level rib, and the second level rib is parallel with the first level rib, and the left apical angle of the third level rib is located on the right end of the minisize valve. The invention has the advantages that the three-rib type minisize air-operated valve controls counter flow through a novel fluid dynamics principle, the flow difference between forward direction and negative direction is increased, the fluid flow quantity transferred by a minisize ejector such as a micro pump is significantly increased, and the efficiency is increased to four times of a dynamic passive valve, and the invention has high reliability, long service life, easy processing, and low costs. The invention provides a micro flow system control device which has favorable comprehensive performance for military or civil places comprising the fields of aviation, space fight, medical treatment and automobile and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

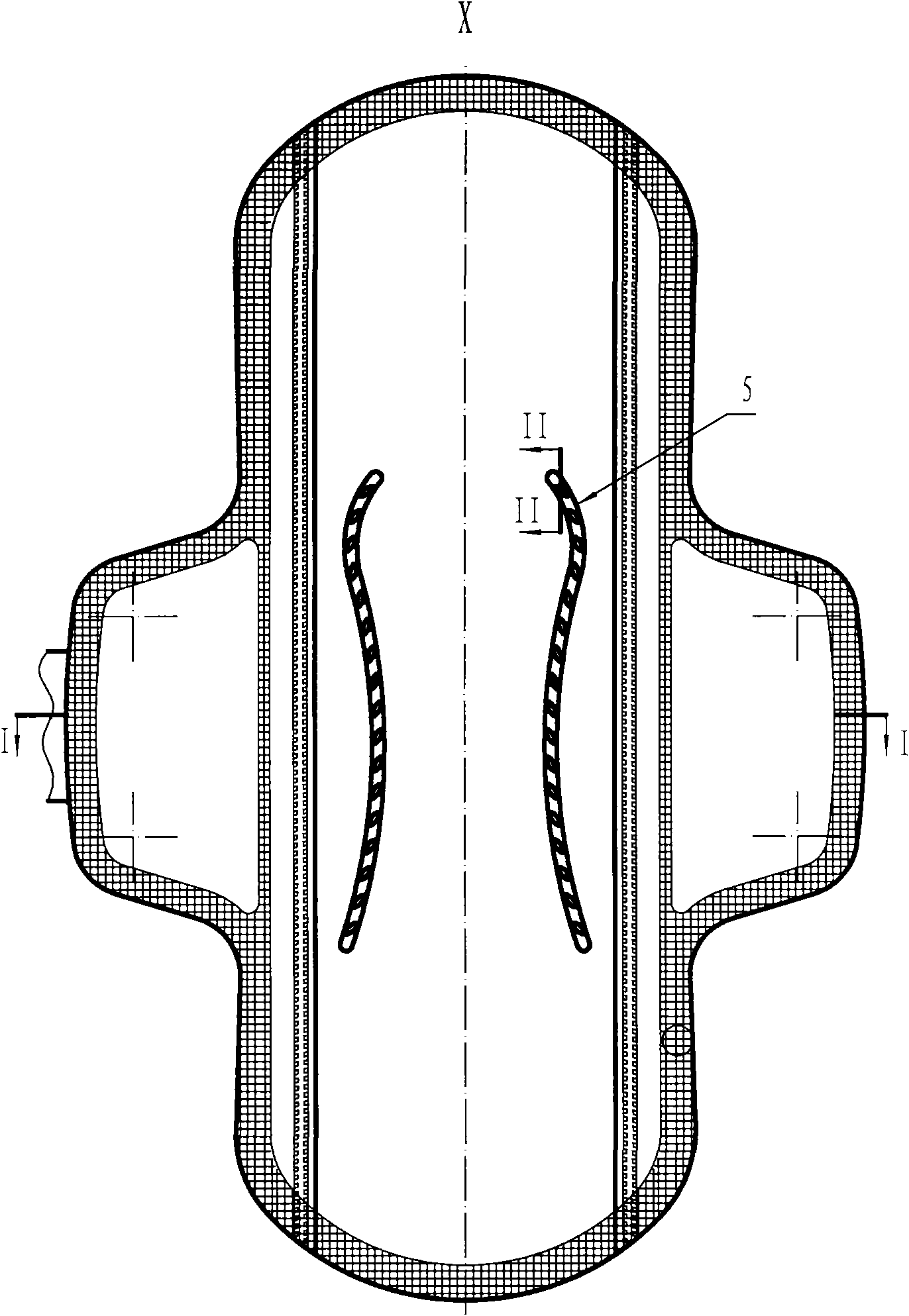

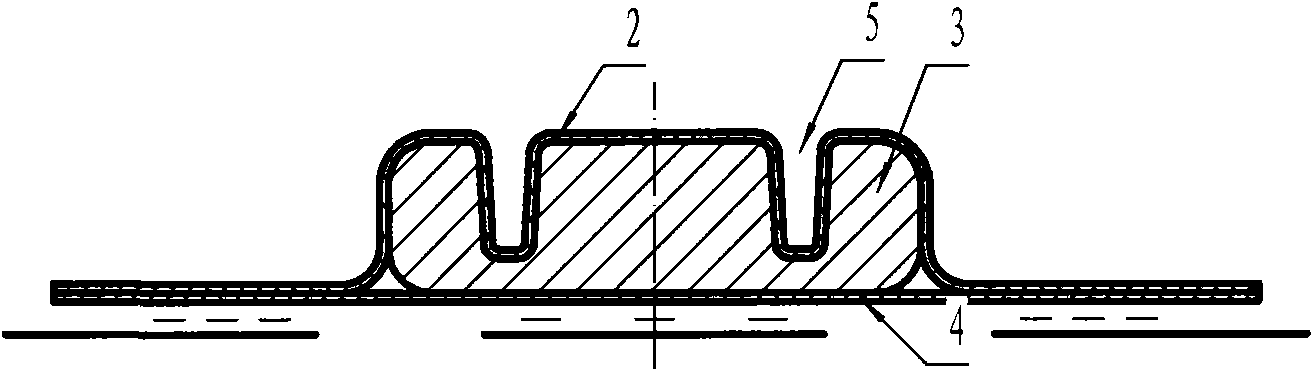

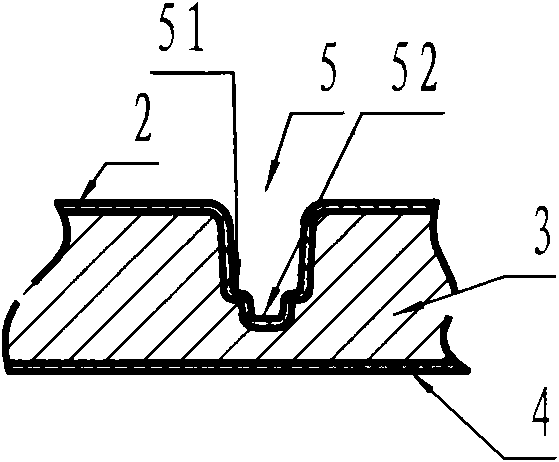

Moisture absorbing article

ActiveCN101623226AIncrease fluid flowThe absorption area is reducedSanitary towelsBaby linensSurface layerEllipse

The invention provides a moisture absorbing article, which is formed by a surface layer which can be penetrated by liquid, a bottom layer which cannot be penetrated by the liquid, and an absorption core between the surface layer and the bottom layer. The moisture absorbing article is provided with a slot, and is characterized in that high compression parts and low compression parts are arranged in the slot, wherein the high compression parts are of geometric figures in regular or irregular shapes, and the geometric figures are arranged in order along the slot; and the geometric figures of the high compression parts in the slot can be linear figures or non-linear figures, such as roundness, ellipse and key slot shapes. The average density of the slot is less than 0.7g / cm<3>; the density of the compression part in the slot is more than the average density of the slot; and density of the high compression part is more than that of the low compression part.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Thrust washer and torque converter containing the same

InactiveCN104919217AIncrease fluid flowWide entry areaRotary clutchesFluid gearingsControl theoryTorque converter

A thrust washer for a torque converter, the thrust washer having a curved front surface with a plurality of grooves for increasing fluid flow between the inner diameter and the outer diameter of the thrust washer. This increased fluid flow reduces the buildup of back pressure within the torque converter enabling better operation thereof.

Owner:FCA US

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com