Patents

Literature

64results about How to "No drip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

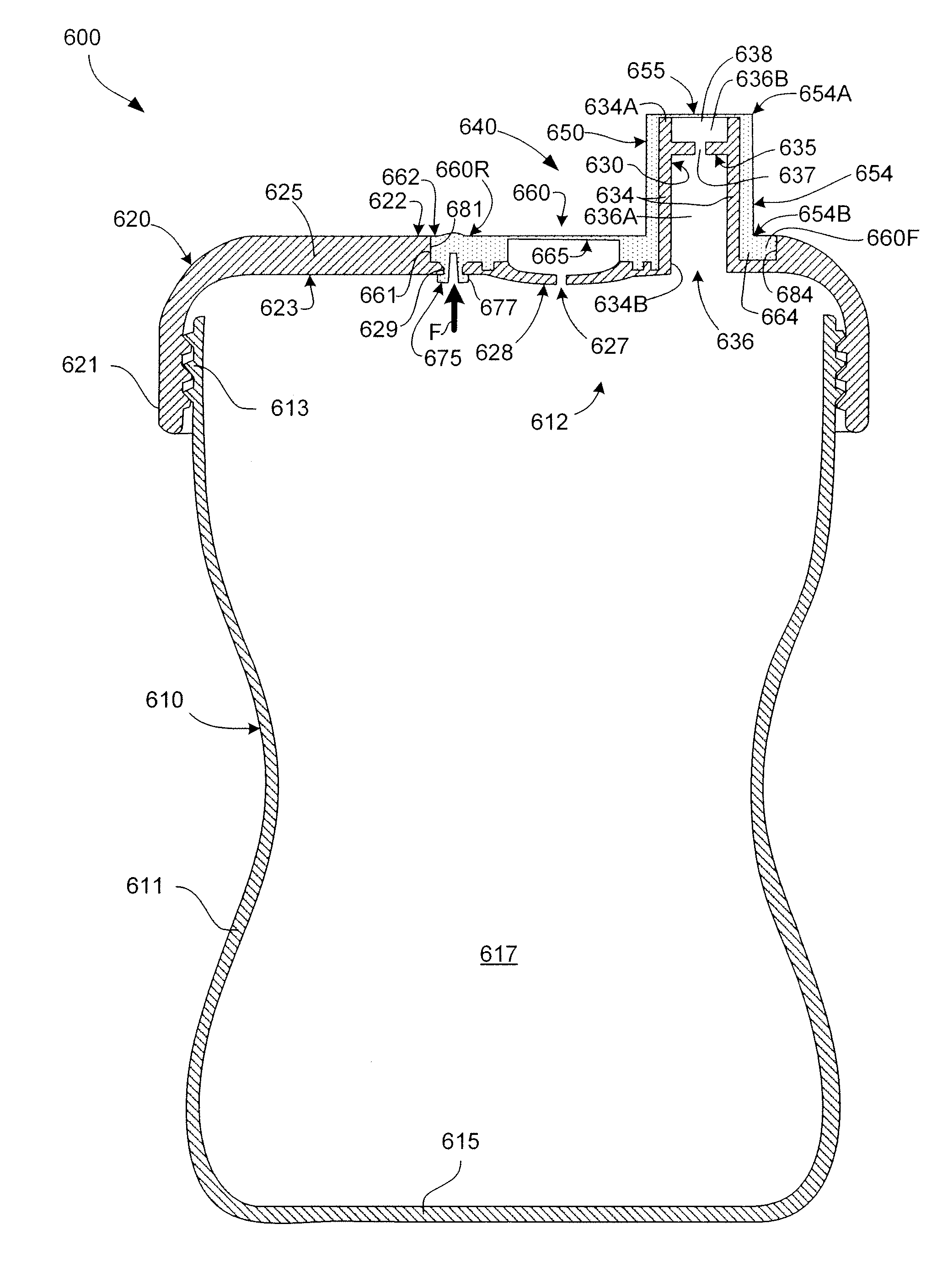

Beverage Container With Integral Flow Control Member Having Vent And Outlet Pinhole Membranes And Safety Button

InactiveUS20070051727A1Minimize liquid pressureControl pressureClosuresDrinking vesselsDifferential pressureEngineering

A non-spill beverage container includes a cap having a tube-like spout and a baffle mounted inside the spout, and a flow control member having a spout (first) membrane supported over the spout opening. A vent (second) membrane that is disposed adjacent to the spout and is supported over a vent opening defined in the cap. The spout and vent membranes are punctured to form multiple, substantially round pinholes that remain closed to prevent fluid flow under normal atmospheric conditions, and open to facilitate fluid flow under an applied pressure differential (e.g., when sucked on by a child). The baffle limits the differential pressure applied to the spout membrane when the container is not in use. The flow control member can only be removed from the cap by removing the cap from the container body and pressing a flexible safety button from an inside surface of the cap.

Owner:MEDELA HLDG AG

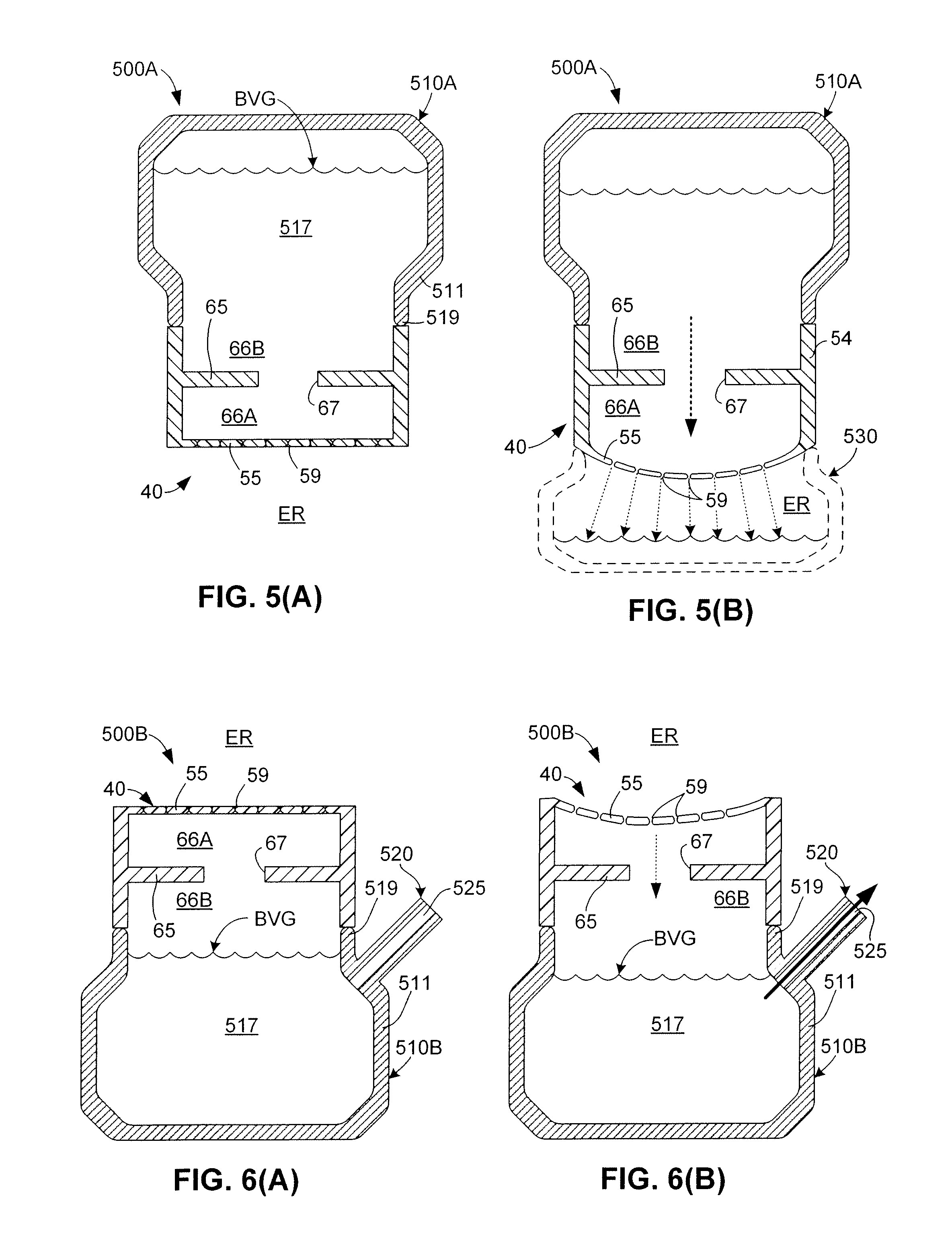

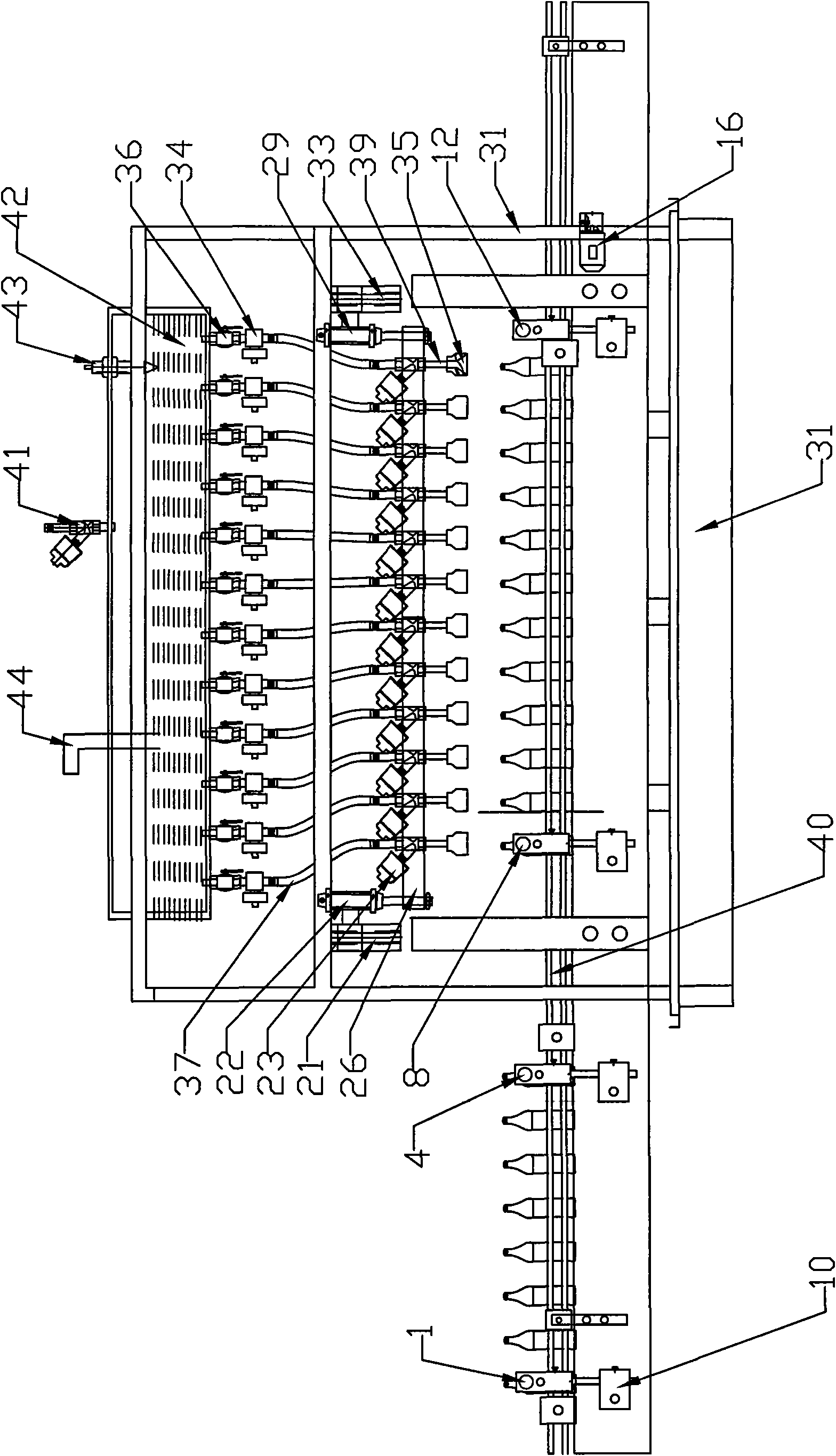

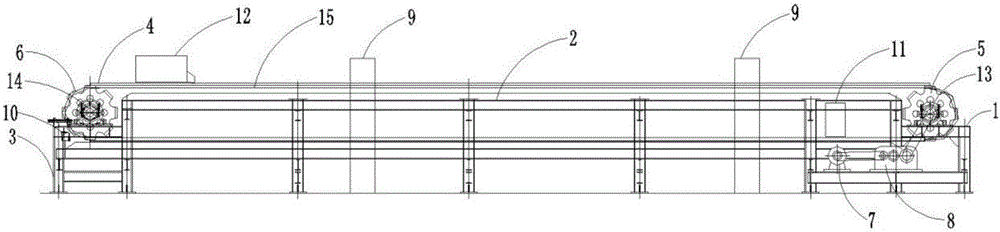

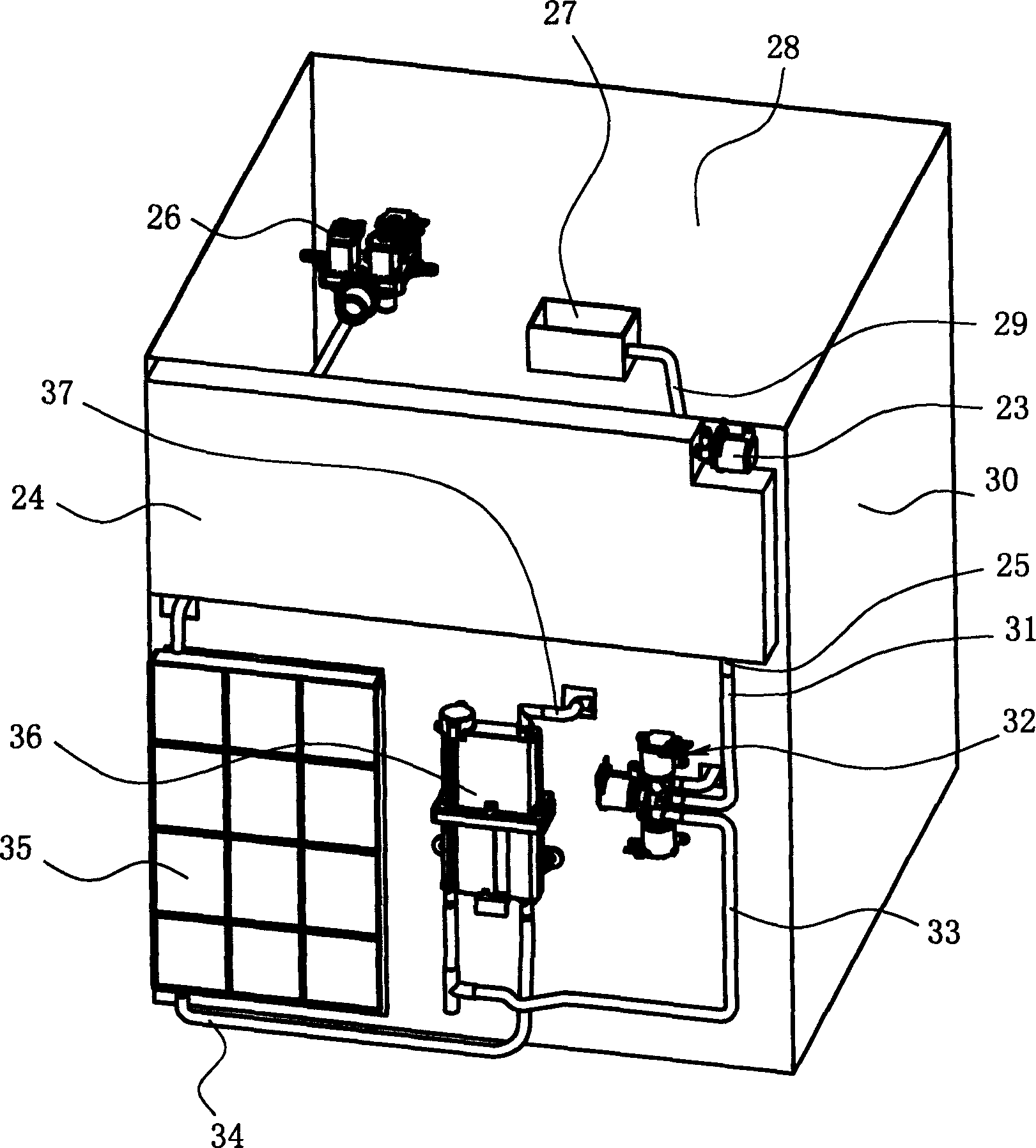

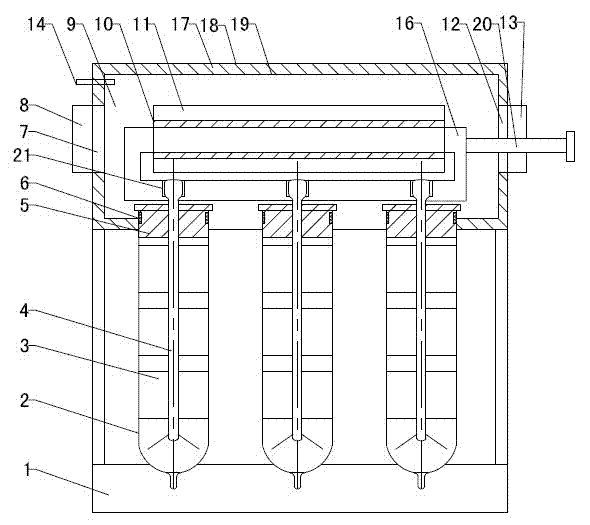

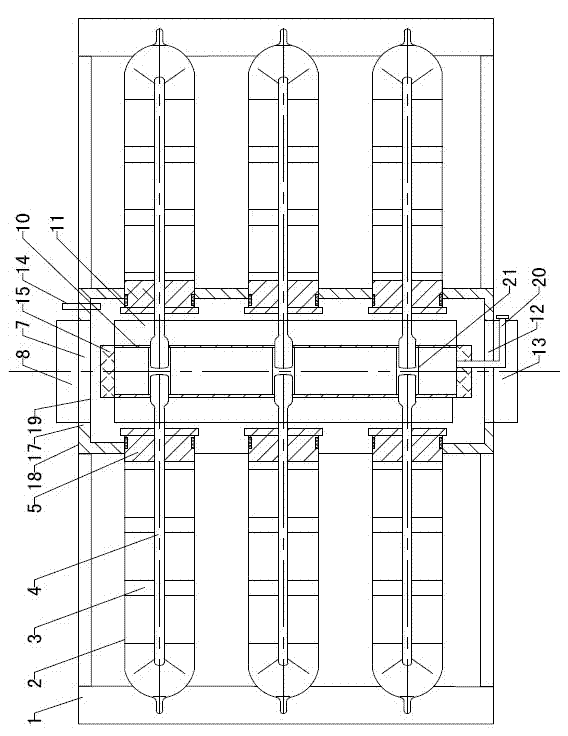

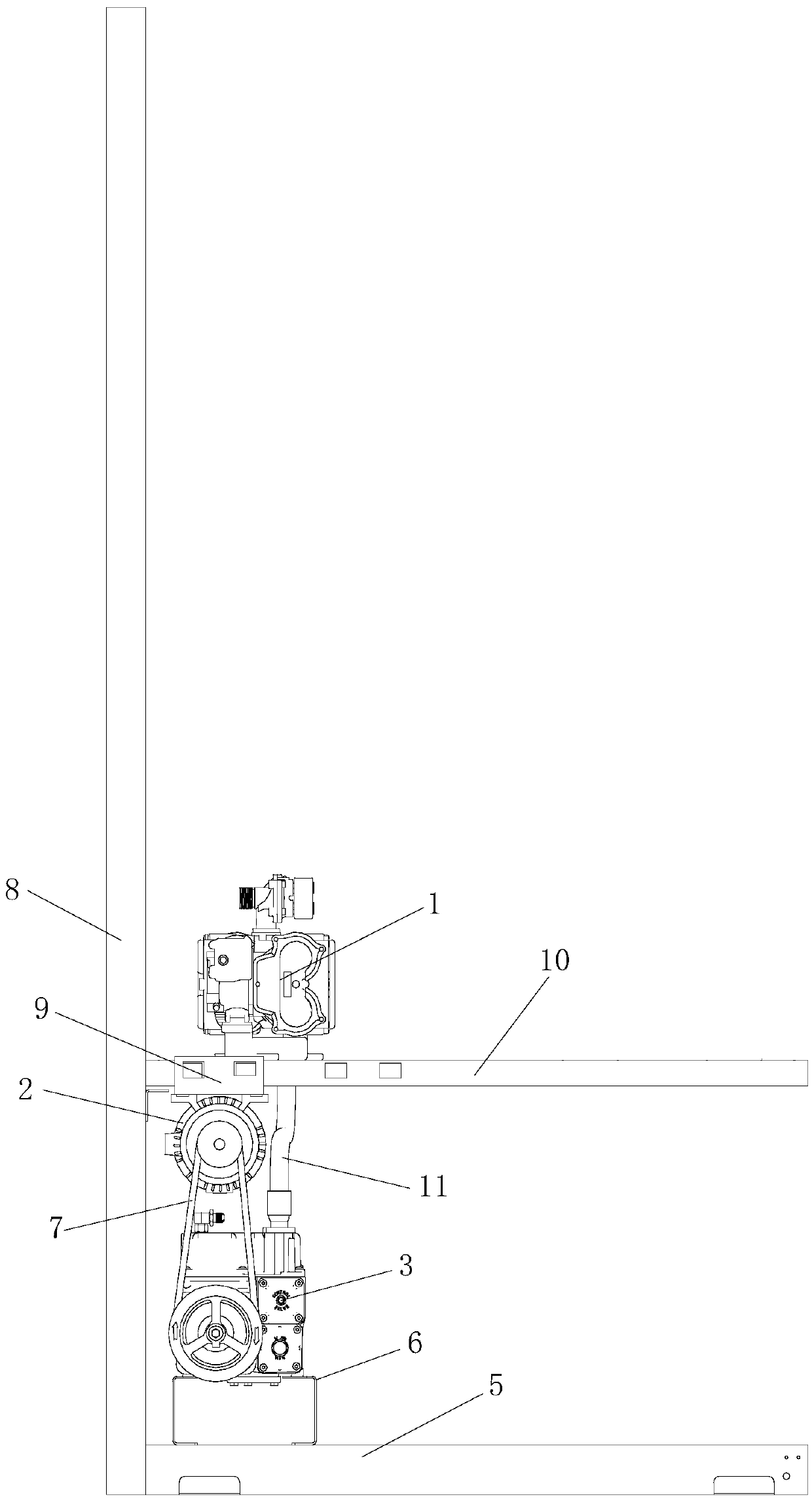

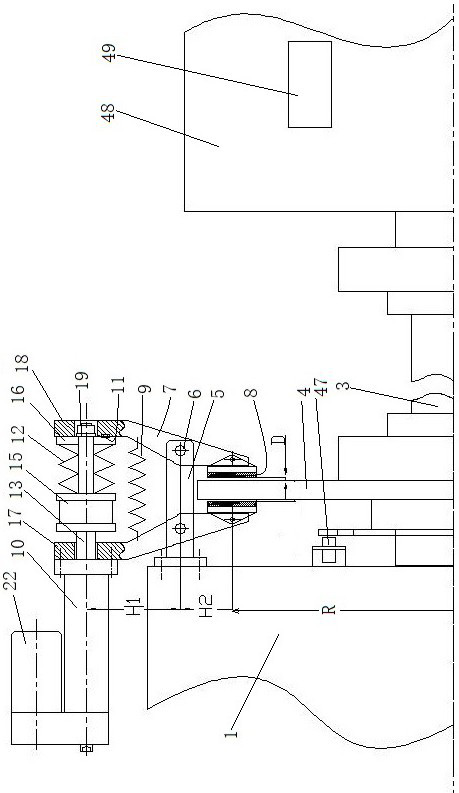

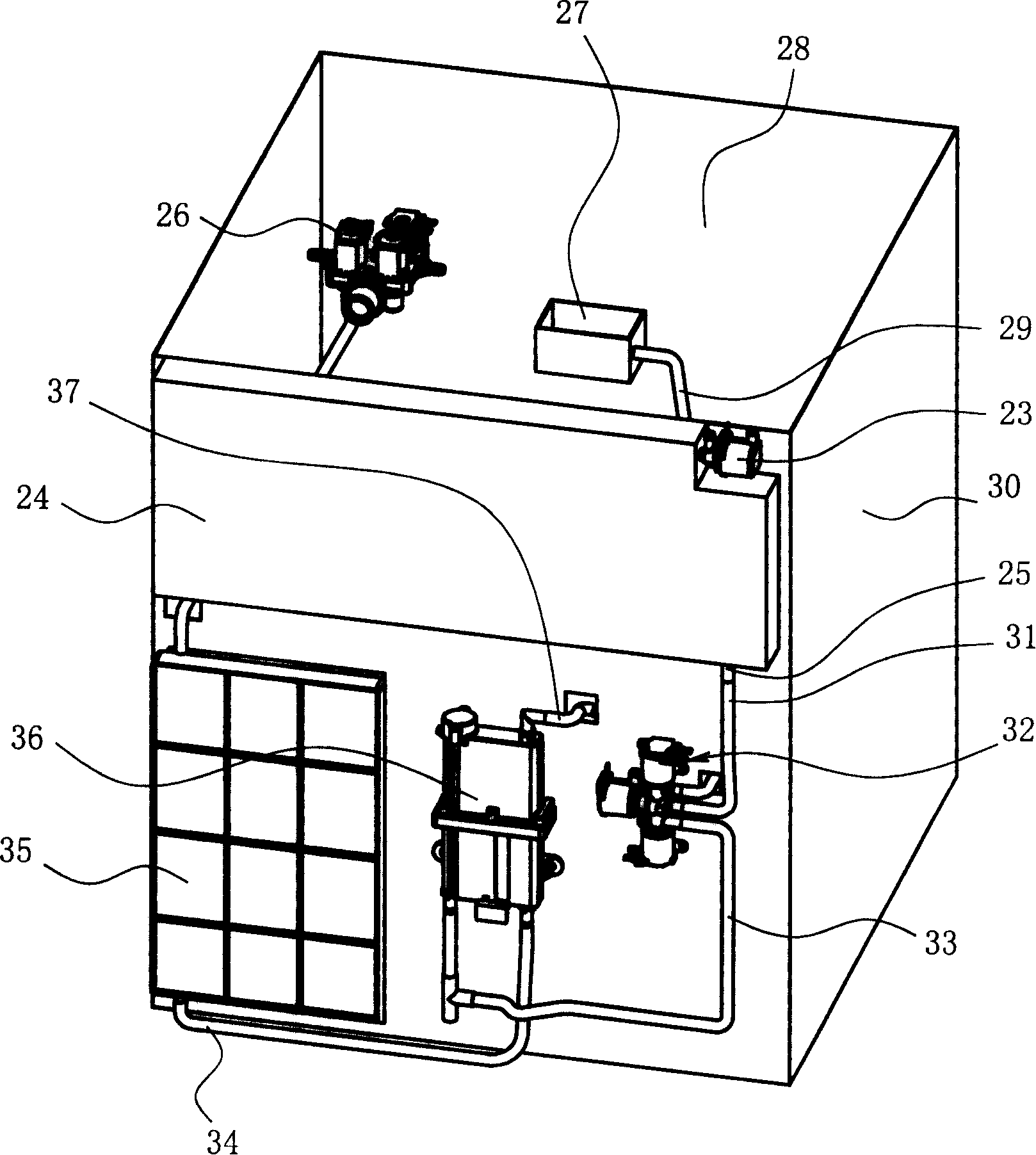

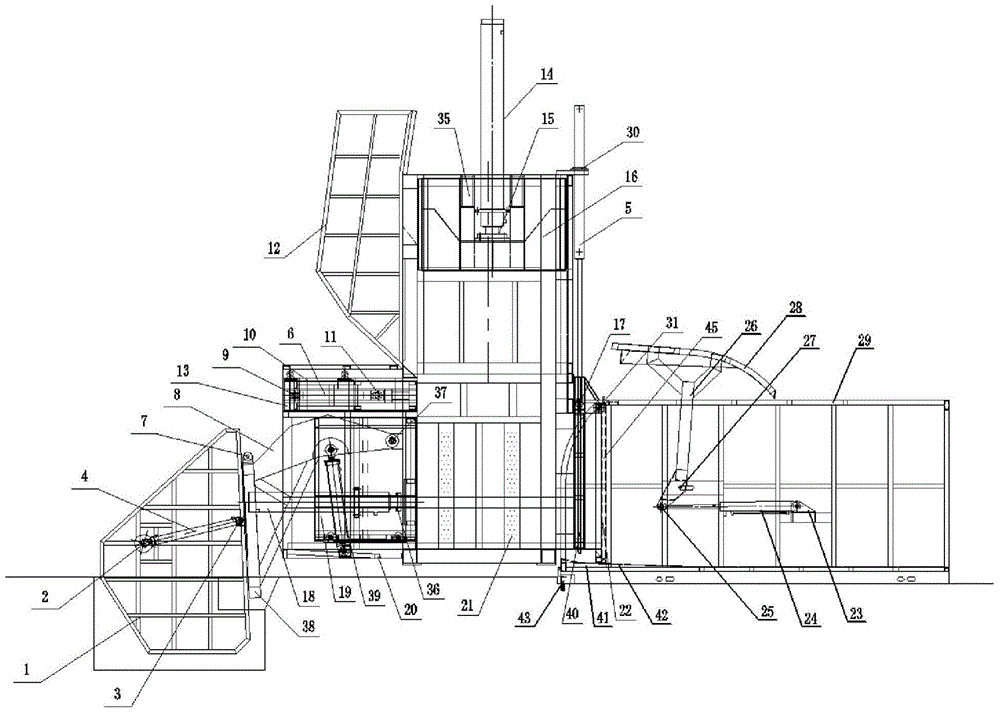

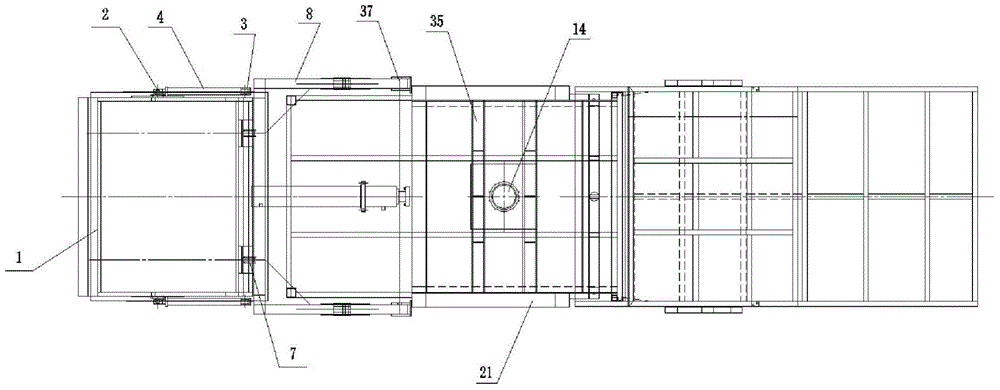

Three-row double-wire linear filling machine

InactiveCN101618845AShorten the intervalImprove filling efficiencyLiquid fillingAbnormal shapedEngineering

The invention discloses a three-row double-wire linear filling machine, comprising a frame. A bottle finishing and bottle conveying device and a liquid filling device are arranged on the frame, the bottle finishing and bottle conveying device comprises three rows of conveyer belts arranged in parallel, line exchanging devices are arranged between the three rows of conveyer belts, the bottle body can be continuously filled by carrying out line exchange on the bottle body, thereby overcoming the defect that the feeding of bottle needs to be waited when filling the bottle body by a traditional filling machine, shortening interval time between fed bottles and improving filling efficiency; the filling machine has the advantages of reasonable structure, high degree of automation, high precision, no drop leak, no discharge, simple capacity set, no bottle piling, strong applicability to abnormal shapes and high stability.

Owner:李真中

Technological method for upwardly continuously casting, rolling, drawing and producing copper alloy tubes

The invention provides a technological method for upwardly and continuously casting, rolling, drawing and producing copper alloy tubes. The technological method comprises the following steps: melting copper alloy raw materials according to a content proportion; further homogenizing the contents of an undercurrent passing by a standing chamber; keeping the temperature of the undercurrent by a maintaining furnace; cooling the undercurrent by a crystallizer to enter a tractor; upwardly drawing and continuously casting copper alloy tube blanks; then rolling the copper alloy tube blanks by a rolling mill; and drawing finished products of copper alloy tubes by a drawing mill. The technological method simplifies a traditional technological process in a new once-forming technology and has little investment, small occupation of land, low energy consumption, high efficiency, high rolling yield, little pollution and low cost, thereby being an advanced technological method with a certain market competitiveness.

Owner:高玉树

Hand-washing-free disinfecting gel and preparation method thereof

InactiveCN107669619AEfficient killingQuick killHydroxy compound active ingredientsAerosol deliveryTriclosanAlcohol

The invention discloses hand-washing-free disinfecting gel which includes, by weight parts, 45-78 parts of alcohol, 7-15 parts of n-propyl ethanol, 0.02-0.08 part of triclosan, 16-40 parts of deionized water, 0.2-0.8 part of thickening agent and 0.3-1.1 parts of neutralizer. The invention further discloses a method for preparing the hand-washing-free disinfecting gel. The method includes the stepsthat thickener powder is slowly dispersed on the surface of the deionized water and soaked for 40 to 60 h until the thickener powder is completely dissolved; the ethanol is used to dissolve the triclosan to make a triclosan ethanol solution; the ethanol, the n-propyl ethanol and the triclosan ethanol solution are mixed evenly, the thickener solution obtained in the first step is added, the deionized water is added, and uniform mixing is performed; the neutralizer is added to adjust the pH to 5-7, and the hand-washing-free disinfecting gel is obtained. The obtained hand-washing-free disinfecting gel has the advantages of being stable in performance, performing disinfection efficiently and quickly and being free of washing, refreshing and non-sticky.

Owner:蚌埠科卫消毒药剂有限公司

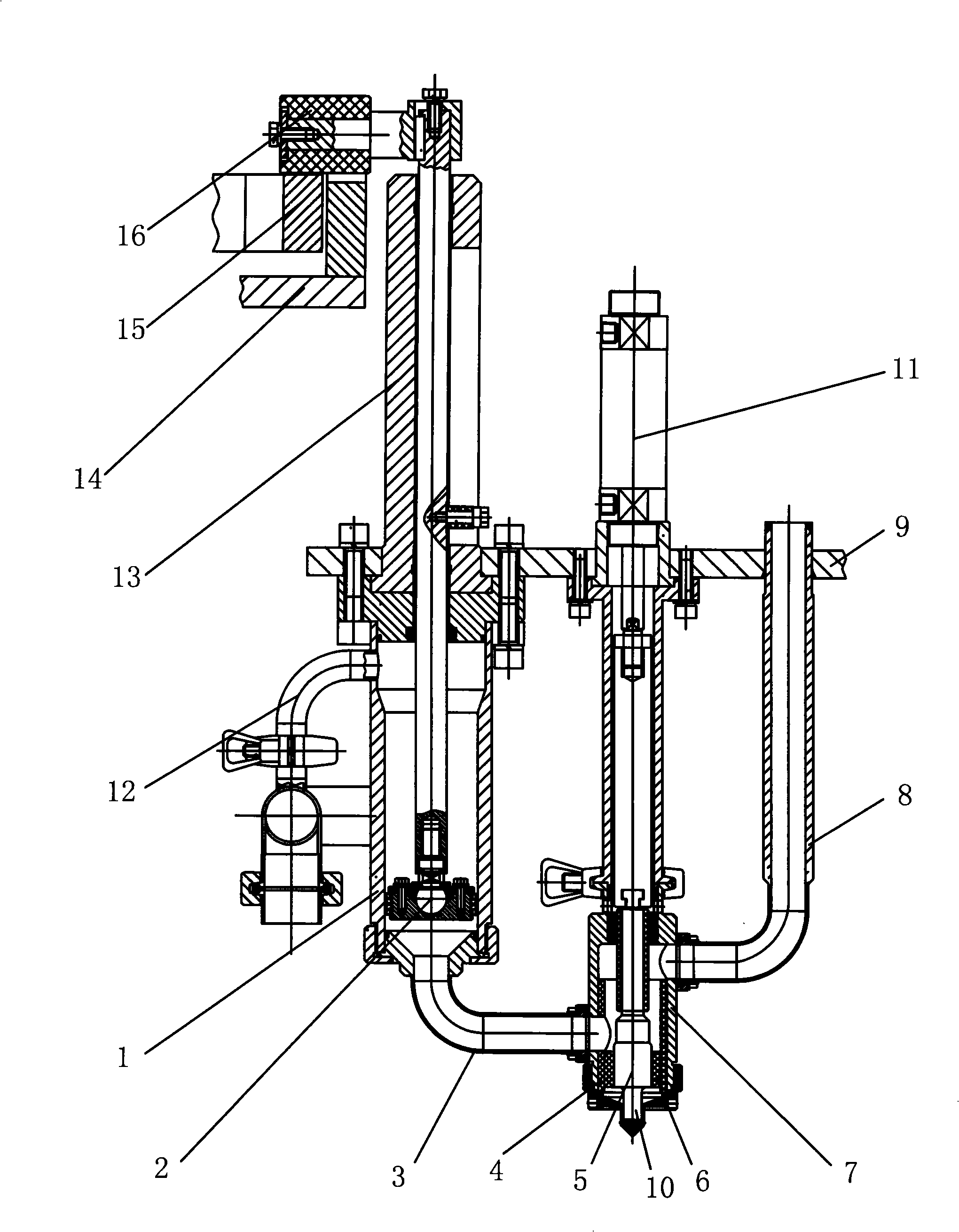

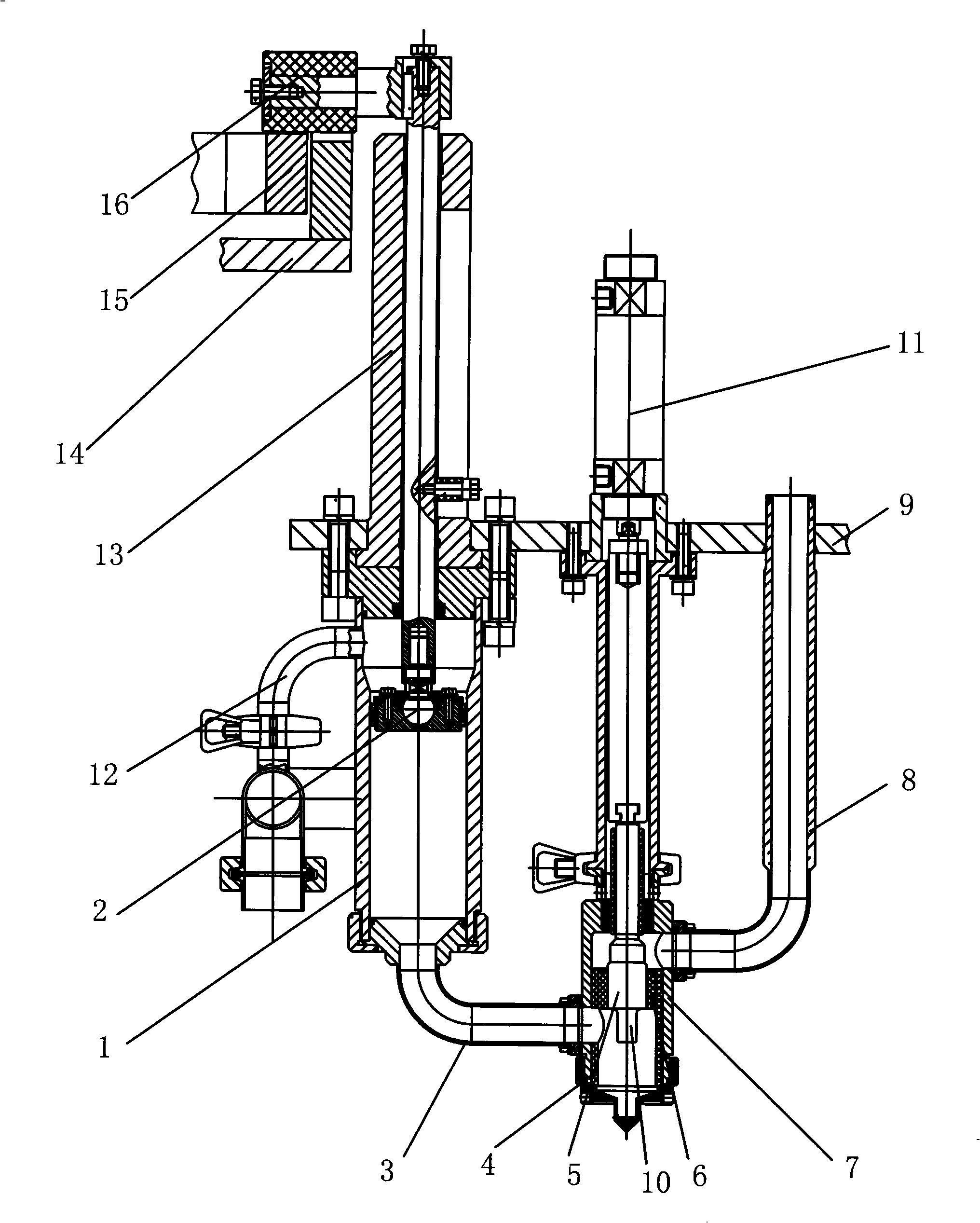

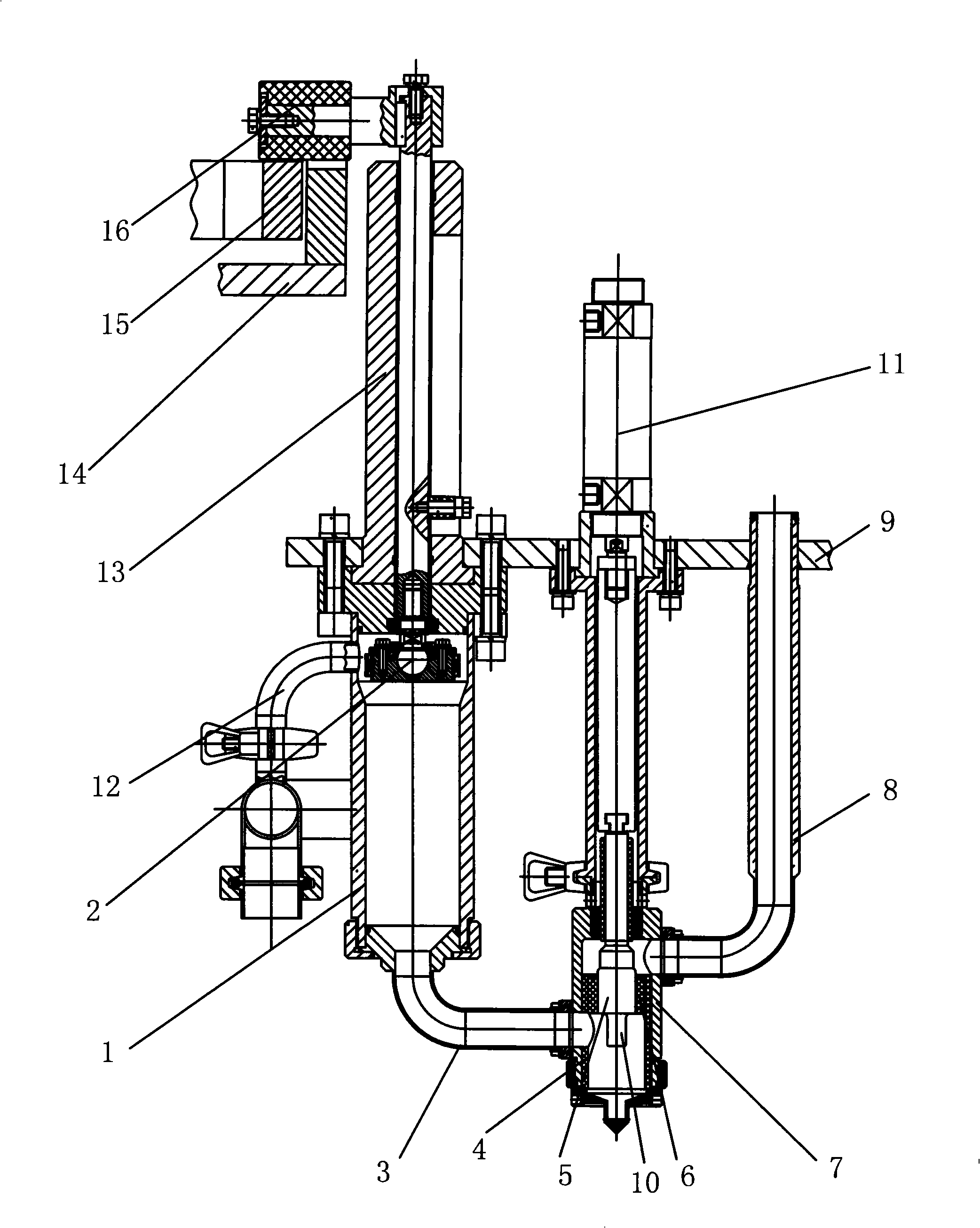

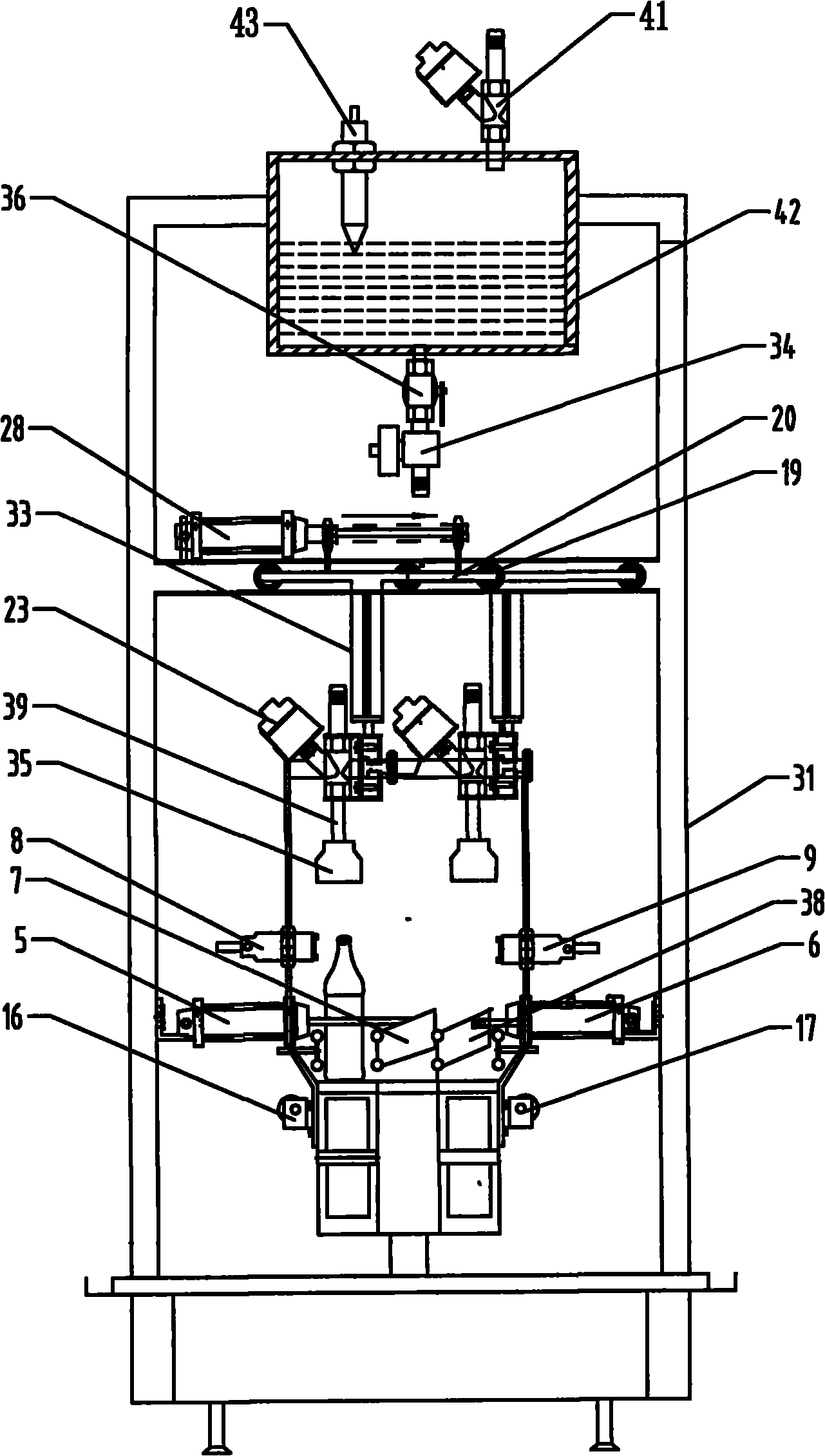

Filling device of filling machine

InactiveCN101348226ANo residual mediumAvoid affecting the pass rateLiquid bottlingEngineeringMechanical engineering

The invention discloses a filling device for a filling machine, having a structure that the filling device comprises a quantity cylinder body, connecting pipes, a switch valve and a valve core. The structure has the main points that an inner piston is arranged inside the quantity determining cylinder body; a first power mechanism is arranged above the inner piston; a first connecting pipe is arranged below the quantity determining cylinder body; the quantity determining cylinder body is communicated with the inside of the first connecting pipe; the other end of the connecting pipe is connected with the switch valve, and is communicated with a hole arranged on one side of the switch valve; the valve core is arranged inside the switch valve; the upper end of the valve core is provided with a second power mechanism; the other side of the switch valve is connected with a second connecting pipe; the other end of the second connecting pipe is connected with a material cylinder of the filling machine; and a filling valve adopts the rising height of the inner piston to realize the quantity. As the size of the filling valve is fixed, the rising height of the filling valve is the same, the capacity is not changed, and the quantity is accurate.

Owner:宁波市永宏机械有限公司

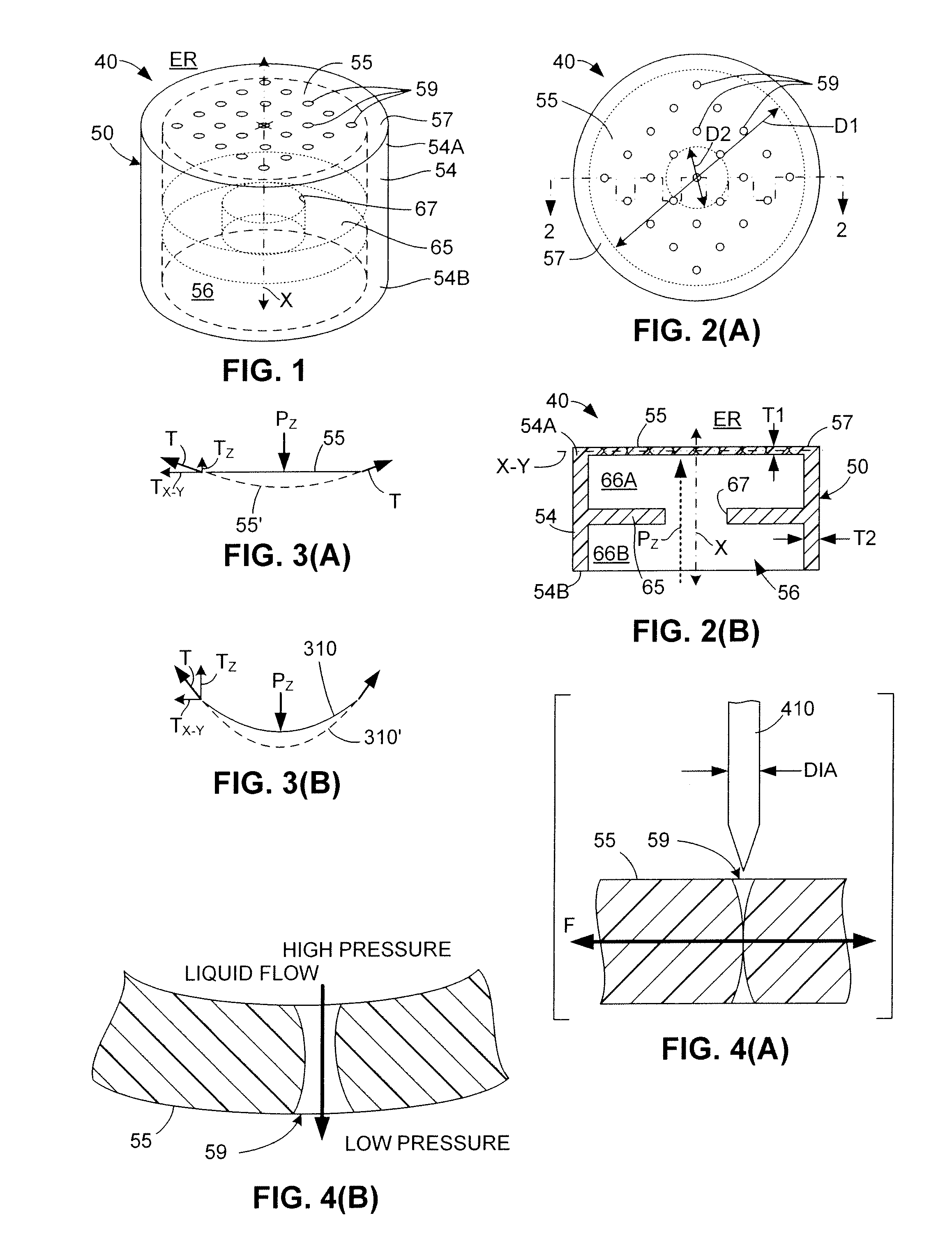

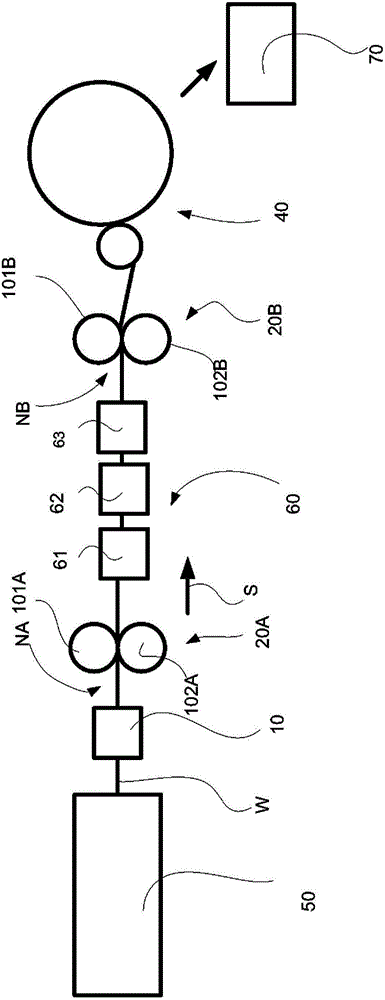

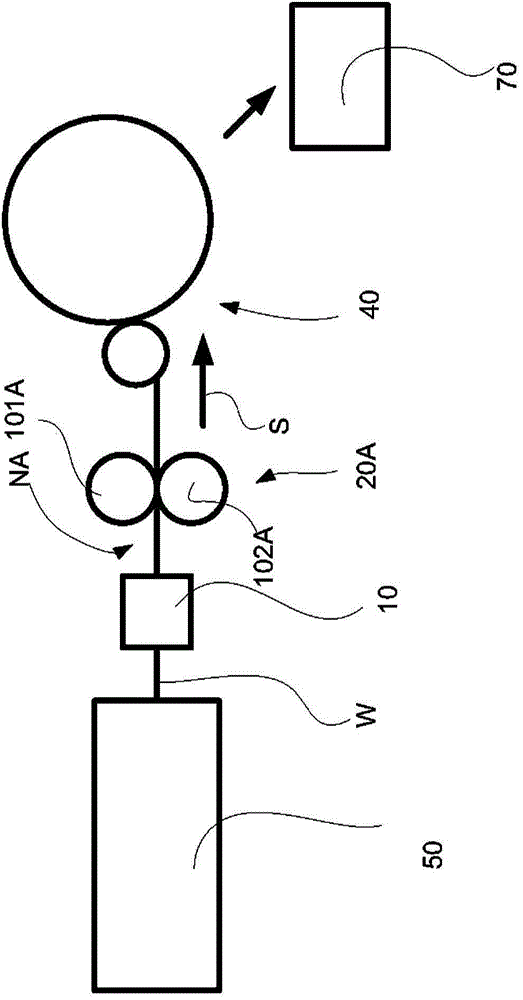

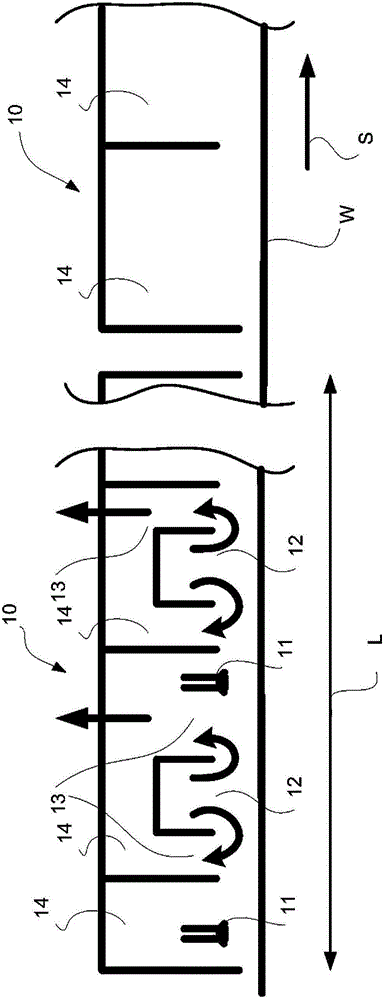

Method for producing fiber webs and production line for producing fiber webs

The invention relates to a method for producing a fiber web (W), in which method the fiber web (W) is calendered in at least one calendering nip (NA) of a calender (20A). The fiber web (W) is cooled at least partially by moisturizing evaporating cooling by a moisturizing evaporating cooling unit (10) before the fiber web is calendered and that the moisture is absorbed during 10 - 500 ms. The invention also relates to a production line for producing fiber webs (W), which comprises at least a calender (20A) with at least one calendering nip (NA). The production line for fiber webs, in particular for board webs, comprises a fiber web machine (50), in particular a board machine, which comprises a head box, a wire section, a press section and a drying section, and at least one moisturizing evaporating cooling module (10), a hard nip calender (20A) with a thermo roll, which has surface temperature at least 120 °C, and a reel-up (40).

Owner:VALMET TECH OY

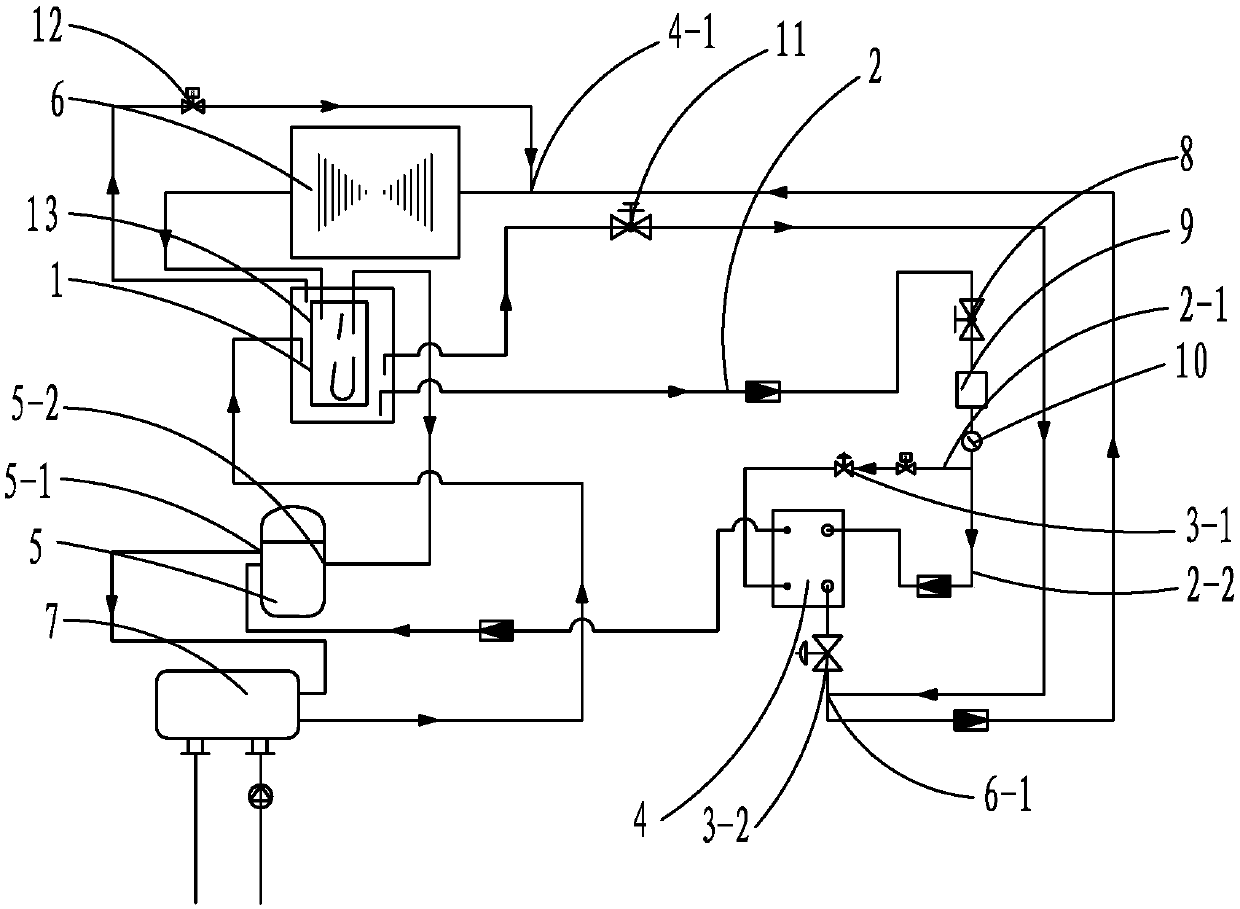

Energy-saving defrosting system of air source heat pump and control method for energy-saving defrosting system

ActiveCN107560253AIncrease subcoolingLess power consumptionMechanical apparatusHeat pumpsSuper coolingEvaporation

The invention belongs to refrigerating equipment, and particularly relates to an energy-saving defrosting system of an air source heat pump. The energy-saving defrosting system for the air source heatpump comprises a three-in-one defrosting gas-separating liquid accumulator, wherein one side of the three-in-one defrosting gas-separating liquid accumulator is connected with a first pipeline whichis divided into two branches; refrigerant in the three-in-one defrosting gas-separating liquid accumulator performs heat exchange twice to generate super-cooling and proper over-heating, so that a refrigerant enthalpy value in a cycle is increased, and maximal freezing capacity can be performed during evaporation; meanwhile, it is guaranteed that the phenomenon that liquid flows back into a compressor to cause liquid compression is avoided; the sense of value is increased, aesthetic sense of the whole machine is improved, and phenomena of dripping, getting moldy and smelly and polluting the surrounding environment are avoided; and gas and a liquid path are simultaneously defrosted, so that the air source heat pump also can normally operate at an extremely low temperature, it is guaranteedthat the unit normally operates without affecting efficiency of the unit, and the defrosting effect is more complete.

Owner:ZHEJIANG QINGFENG REFRIGERATION EQUIP MFG

Method for treating urban domestic sludge by using earthworms

InactiveCN102153260ANo dripSolve difficult worldwide problemsClimate change adaptationExcrement fertilisersVermicompostSludge

The invention provides a method for treating urban domestic sludge by using earthworms. The method comprises the following steps of: collecting the sludge to earthworm production trays; putting the earthworms on the sludge surfaces in the earthworm production trays; conveying the earthworm production trays to a production plant, and stacking the earthworm production trays on a tray rack; placing the earthworm production trays in the production plant for 1 to 2 days; putting dry cow dung into the earthworm production trays, and performing trapping collection on the earthworms; and transferring the mixture of the earthworm excretion and the cow dung to a solar drying shed, and drying the mixture. After the urban sludge is converted into the earthworm excretion by using the earthworms, the earthworm excretion can be used as the nutrient soil of parks or the garbage coverage soil of garbage landfills, so that the method is environmentally-friendly, has low cost and is beneficial to solution to the worldwide problem of difficulty in treating the urban domestic sludge.

Owner:刘波

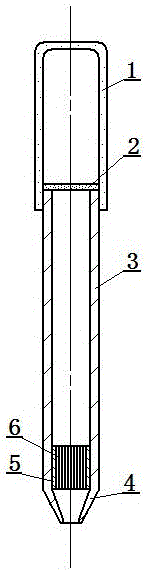

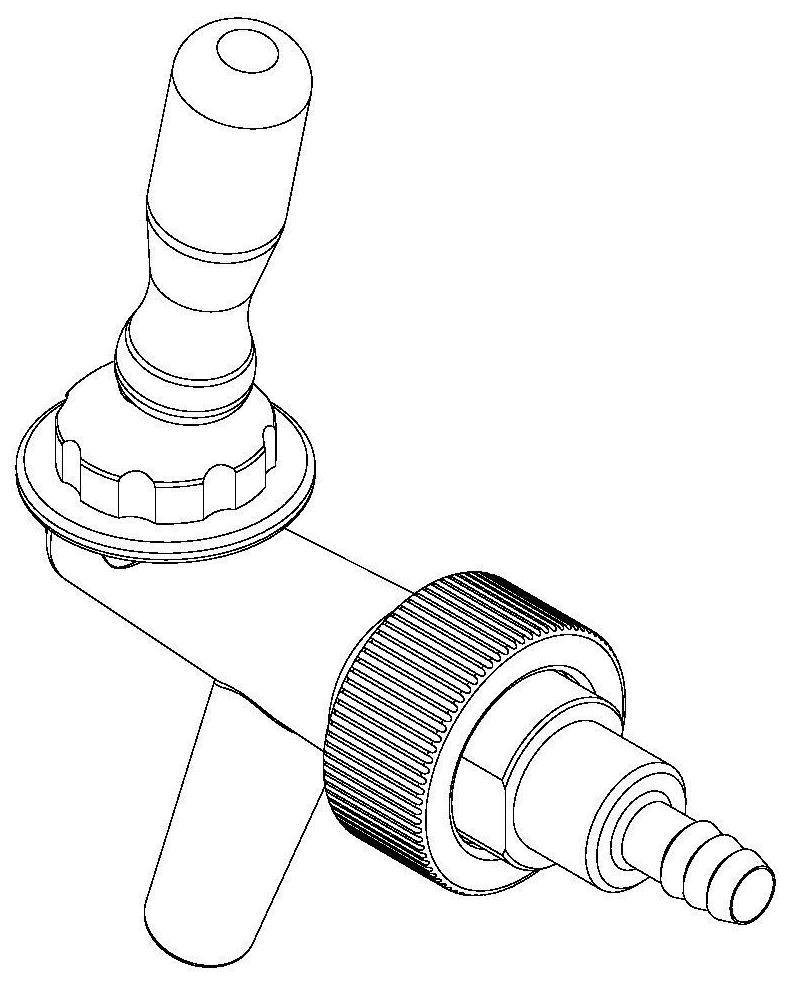

Transfer pipette capable of preventing liquid leakage

The invention discloses a transfer pipette capable of preventing liquid leakage. The transfer pipette comprises an air bag and a cylindrical sucker. The outer diameter end of the upper portion of the cylindrical sucker is movably sleeved with the air bag. A conical suction head of an integrated structure is arranged at the lower end of the cylindrical sucker. The transfer pipette is mainly characterized in that a circular waterproof and dustproof breathable film is arranged at the top end of the cylindrical sucker, and the circular waterproof and dustproof breathable film and the top end of the cylindrical sucker are adhesively fixed through high adhesive; a transparent cylinder is arranged at the lower portion inside the cylindrical sucker, the outer diameter end of the cylinder makes tight contact with the inner diameter of the cylindrical sucker, and capillary tubes are evenly distributed in the axial direction of the cylinder. According to the transfer pipette, air between the air bag and the cylindrical sucker is kept smooth, meanwhile, the phenomenon that liquid is sucked into the air bag in the liquid suction process is avoided, and the transfer pipette is convenient to clean; liquid will not be leaked from an opening in the bottom of the conical suction head when transferred from one container to another container.

Owner:罗丽秀

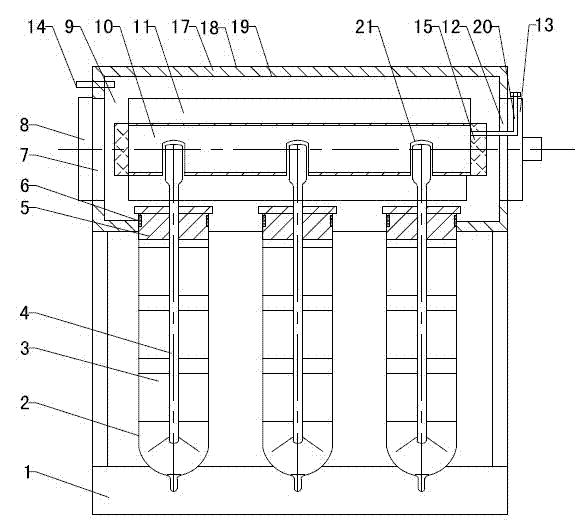

Continuous casting machine

InactiveCN105855527AGet rid of manual crushingReduce labor costsMolten metal conveying equipmentsEconomic benefitsSprocket

The invention provides a continuous casting machine, and belongs to metallurgical equipment. The continuous casting machine comprises a machine head frame, a machine body frame, a machine tail frame, a die, machine head transmission chain wheels, a machine head transmission main shaft, a machine tail transmission chain wheel, a machine tail transmission shaft, a motor, a speed reducer, a transmission chain, cooling devices, a die releasing agent spraying device, a die releasing device and a casting port, wherein the machine head frame, the machine body frame and the machine tail frame are all of rectangular steel frame structures and are sequentially integrally fixedly connected; bearing blocks which are assembled to the machine head transmission main shaft are mounted at two sides of the machine head frame; the machine head transmission chain wheels are mounted at two ends of the machine head transmission main shaft. The continuous casting machine is simple in structure; all components can be independently dismounted and replaced, so that the convenience of maintenance is ensued, a plurality of problems caused by manual breaking can be completely solved, and as a result, huge economic benefits can be brought to metallurgical enterprises.

Owner:宁夏铸源机械制造有限公司

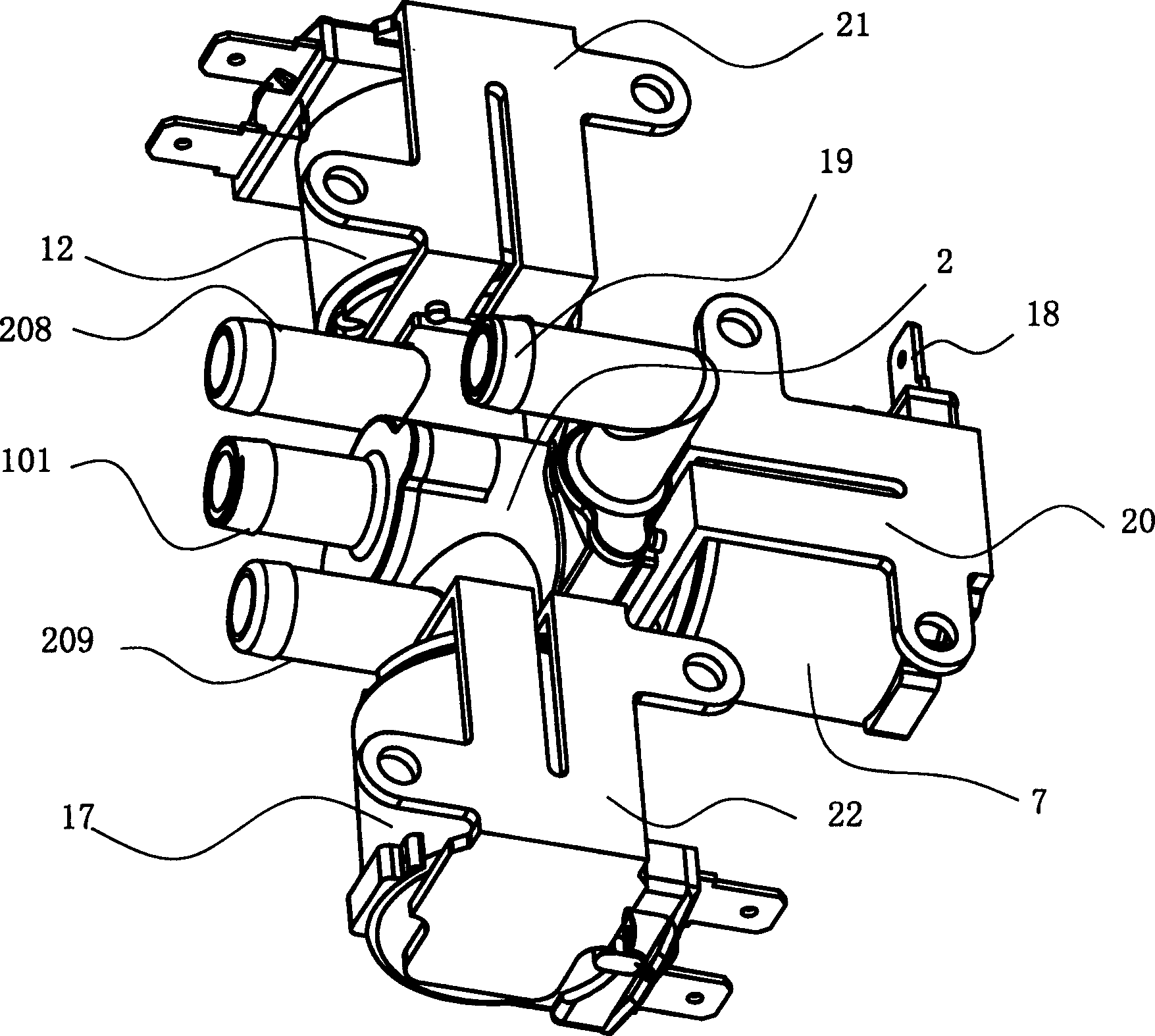

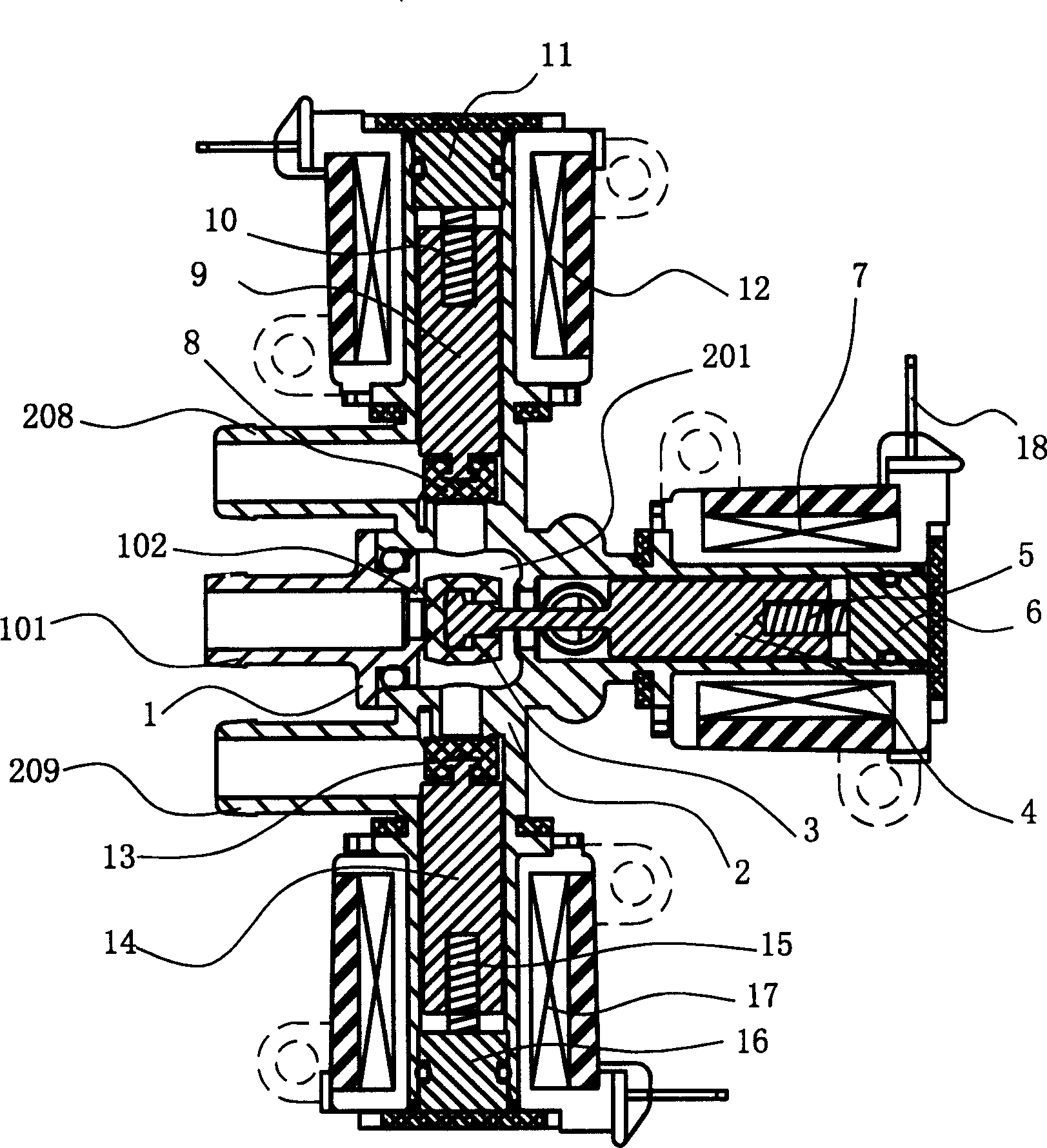

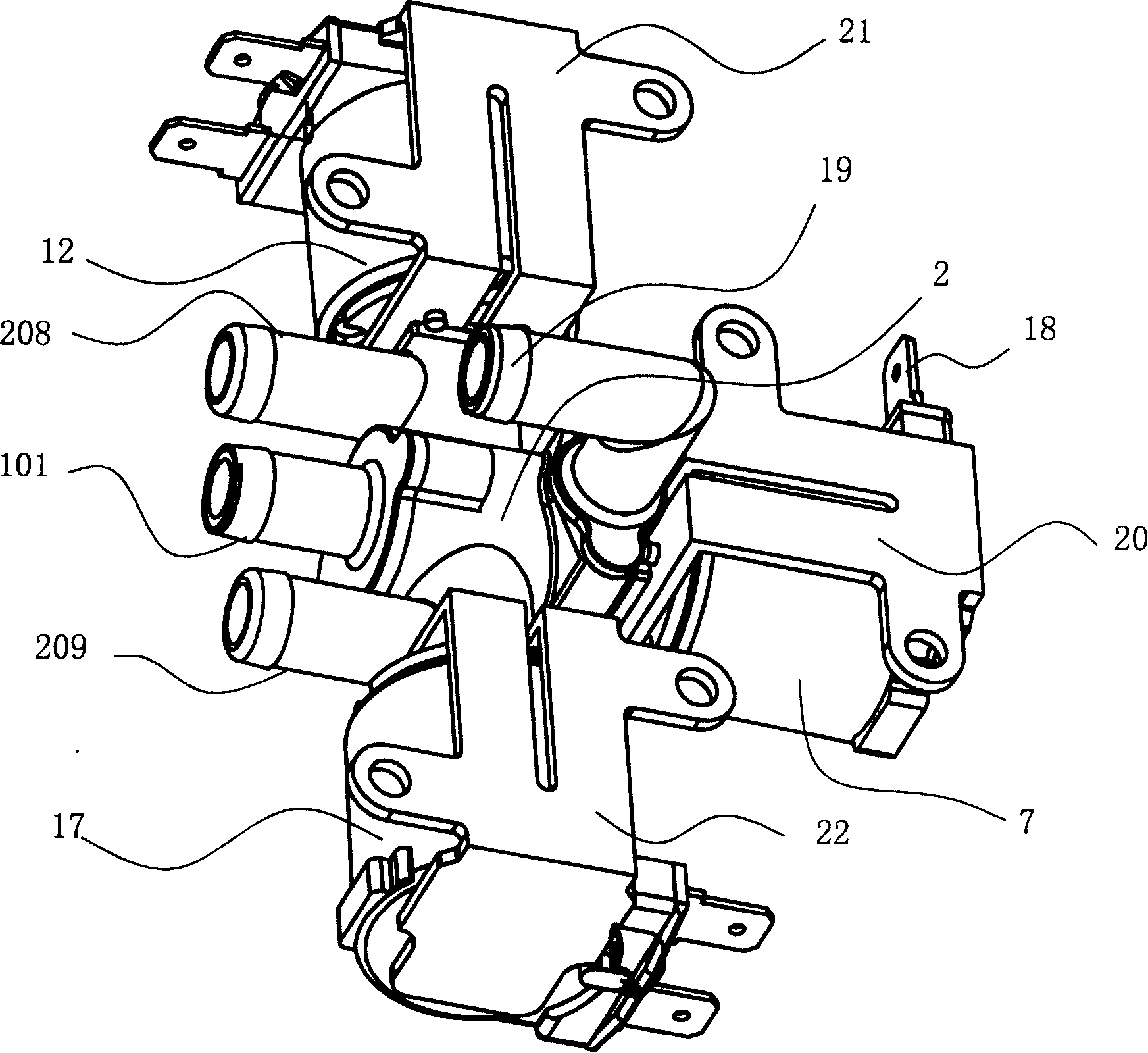

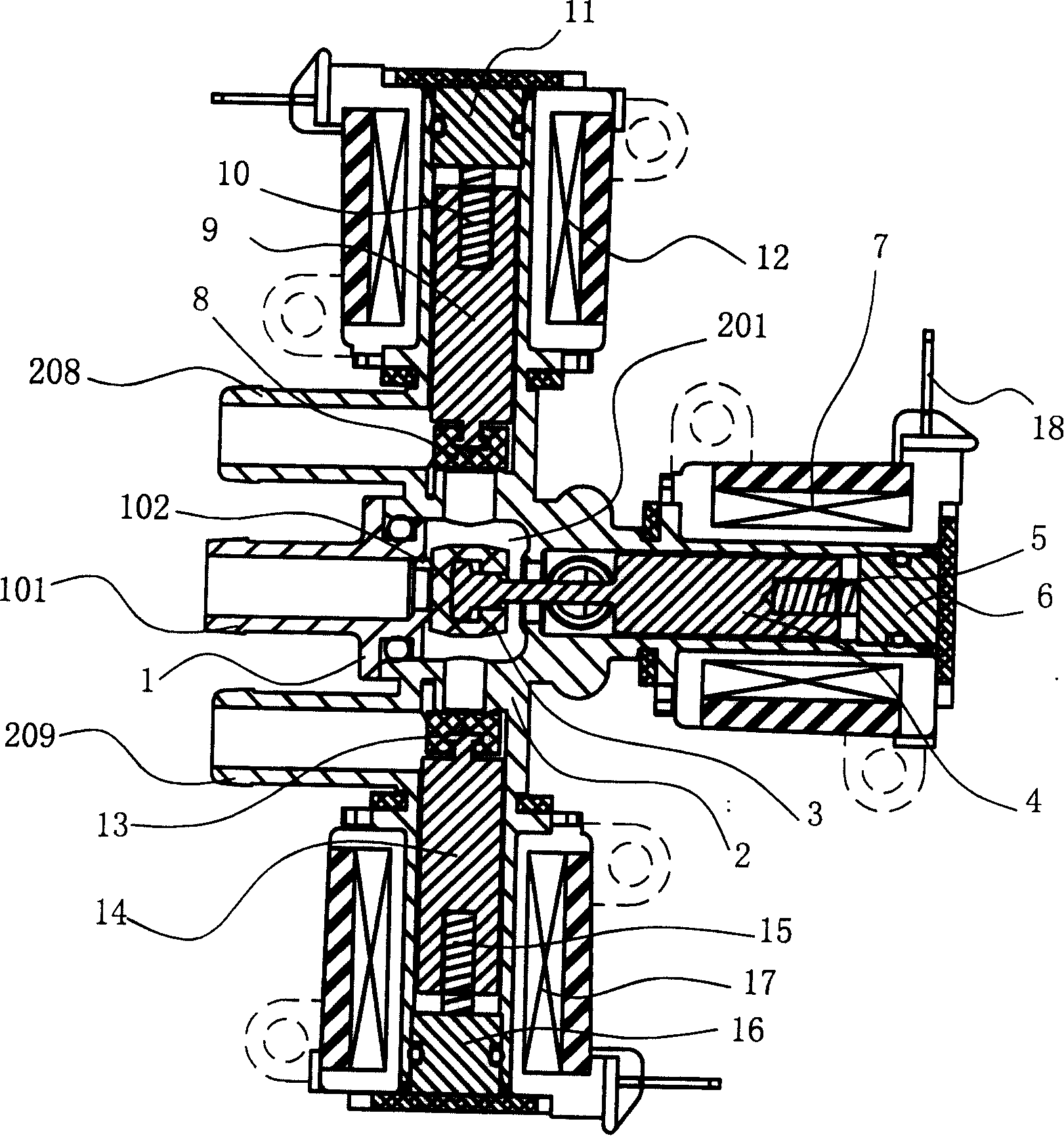

Electrical washing machine with electrobath being installed

InactiveCN1600972AImprove delivery accuracyShorter run timeOther washing machinesWater/sewage treatmentEngineeringControl circuit

A loading electrolytic tank of electric washer sets solenoid water supply valve, electrolytic tank, square switching valve and detegent container with air absorption valve on body box for releasing detergent accurately. It is featured as connecting said devices with duct and supplying power to then with control circuit.

Owner:HANGZHOU KAMBAYASHI ELECTRONICS

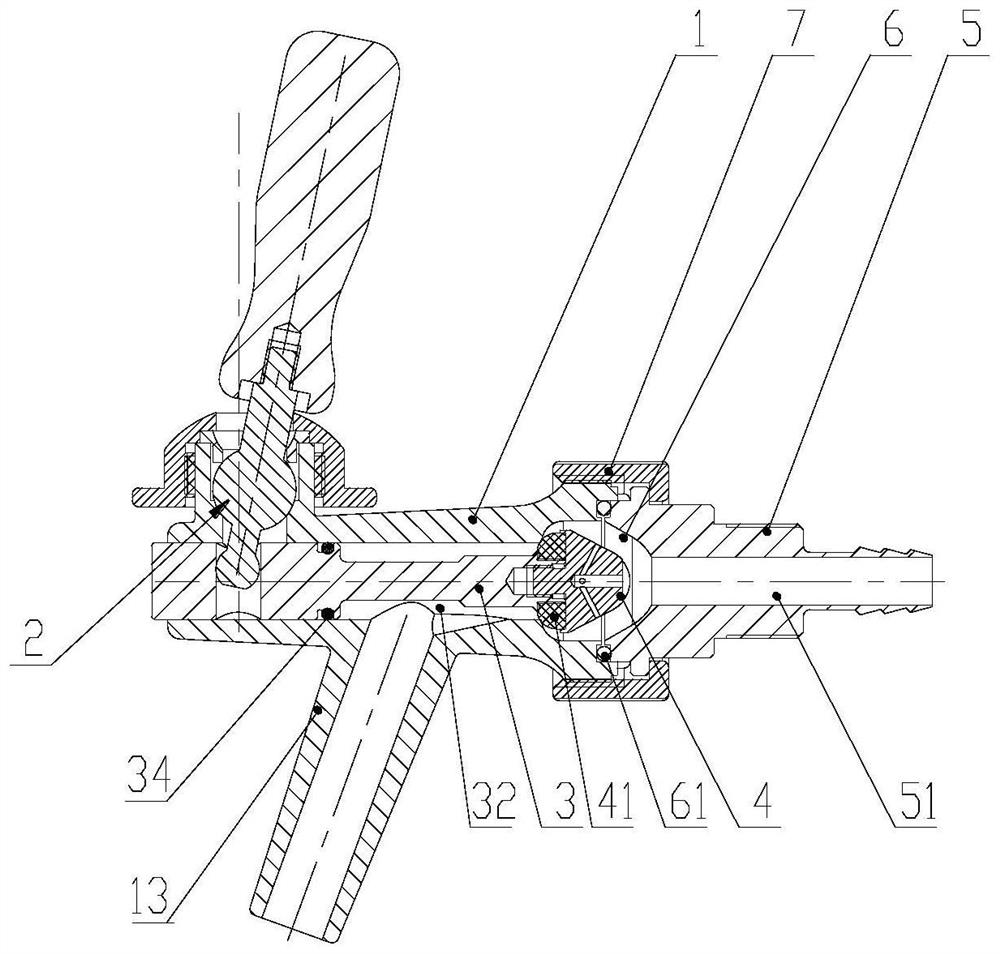

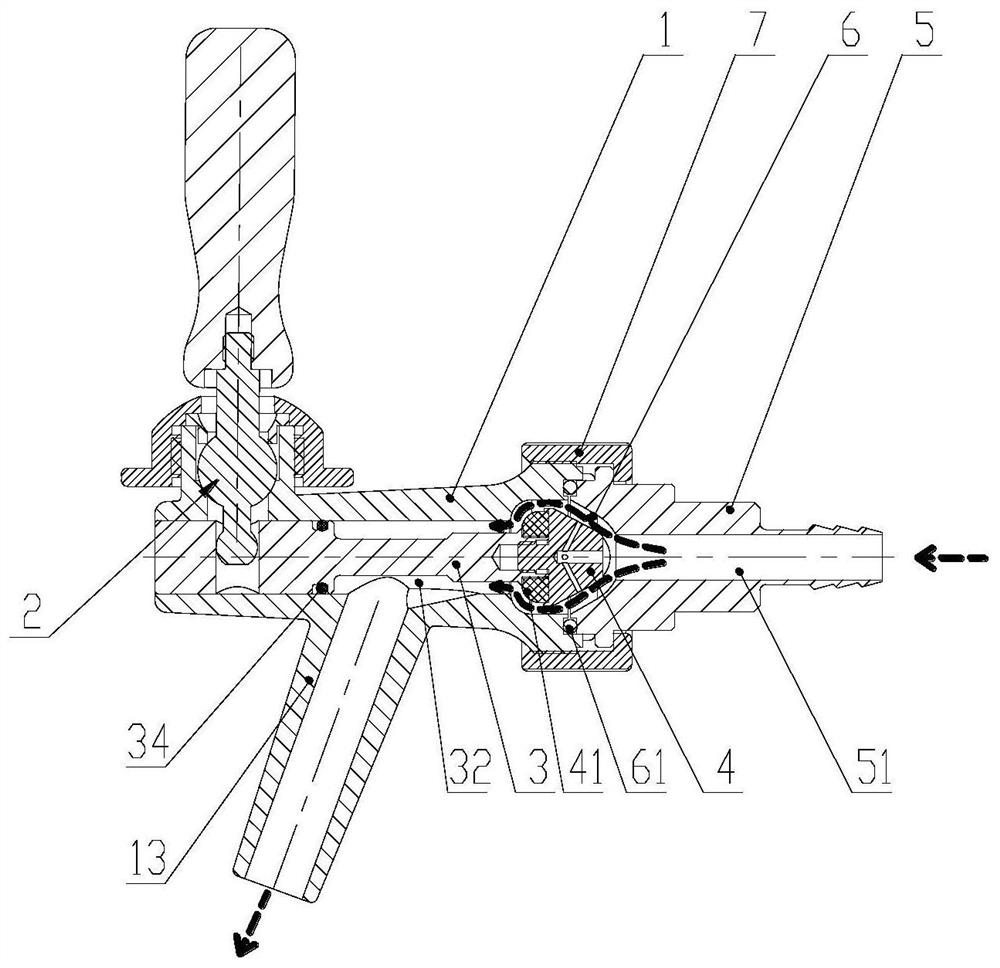

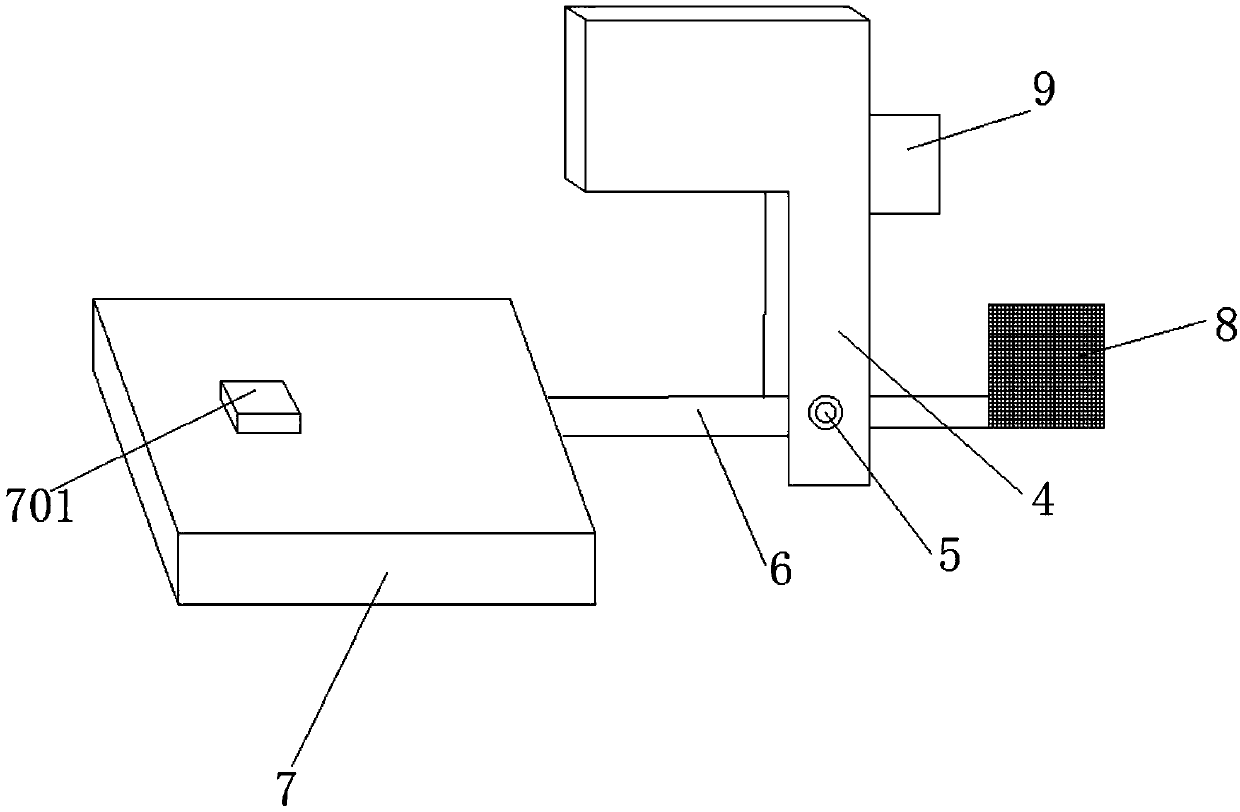

Beer outlet valve of beer machine

PendingCN111734836AImprove hygieneHygienic long-lastingOperating means/releasing devices for valvesLiquid dispensingReciprocating motionMouthfeel

The invention discloses a beer outlet valve of a beer machine, and relates to the field of liquid filling equipment. The beer outlet valve of the beer machine is simple in structure, convenient to useand good in user experience, and can keep long-acting cleanness and sanitation through quick and efficient single cleaning. The beer outlet valve comprises a valve body 1, a poking rod 2 and a valverod 3, wherein a valve rod hole 11 matched with the valve rod 3 is formed in the valve body 1; a beer outlet pipe 13 communicating with the valve rod hole 11 is arranged at the bottom of the valve body 1; a flowing channel 32 is formed in the side wall of the valve rod 3; and the poking rod 2 is poked to drive the valve rod 3 to perform a reciprocating motion in the valve rod hole 11. The beer outlet valve further comprises a valve base 5 fixedly connected to one side of the valve body 1; an accommodating space 6 is formed between the valve rod hole 11 and an inlet hole 51; a valve element 4 fixedly connected with the valve rod 3 is arranged in the accommodating space 6; and a bubble exciting channel is formed in the valve element 4. The beer outlet valve prevents the problems of flavor mixing and influence on the taste, and can keep long-acting cleanness and sanitation.

Owner:宁波鲜啤三十公里科技有限公司

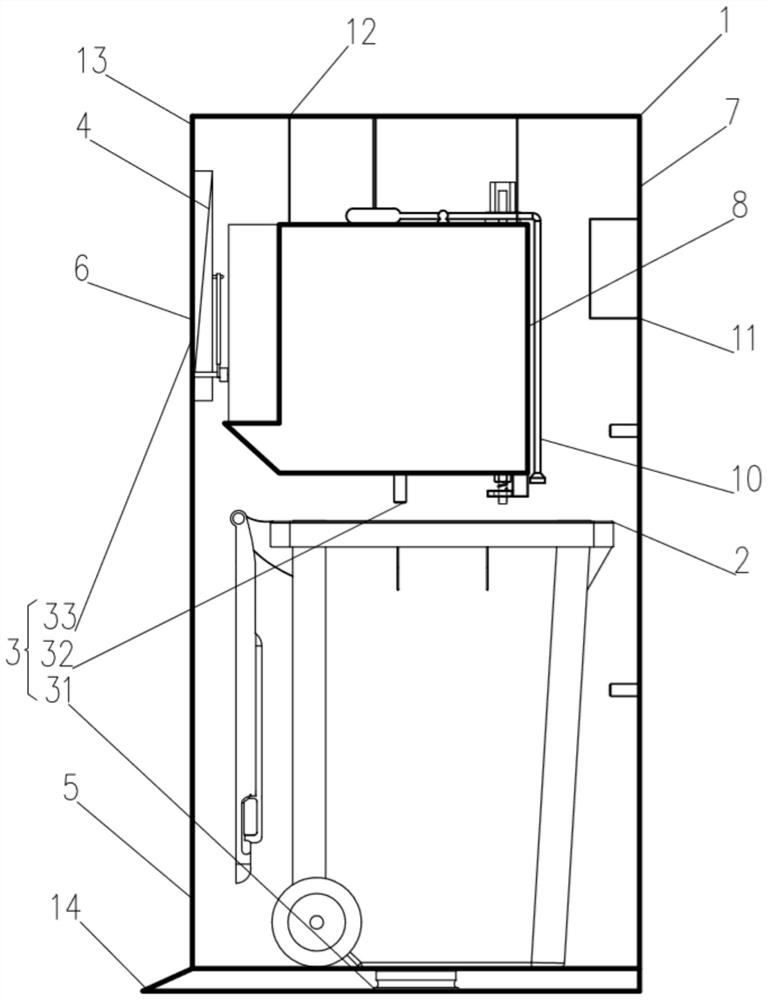

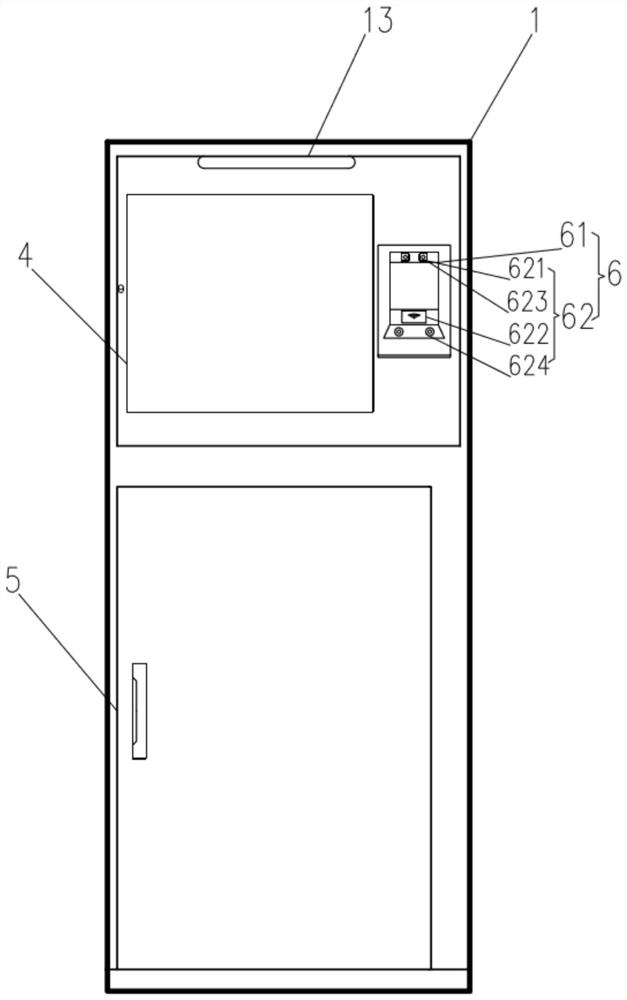

Bag-breaking, cleaning and throwing garbage can for wet garbage and using method

PendingCN112875089AReduce deliveryEasy to put inRefuse receptaclesProcess engineeringEnvironmental engineering

The invention discloses a bag-breaking, cleaning and throwing garbage can for wet garbage and a using method, and aims to solve the problems that sealing cannot be achieved in the wet garbage throwing process, and the throwing process is affected by odor diffusion of wet garbage in a can in the prior art. The garbage can comprises a can body and a garbage can, an intelligent weighing module is arranged at the bottom of the can body, the garbage can is located on the intelligent weighing module, and a throwing opening and a user information recognition module are arranged in front of the can body. A wet garbage throwing device, an odor monitoring early warning and atomization spraying deodorization module and a main controller are arranged in the can body, an access hole is formed in the rear face of the can body, and the wet garbage throwing device is located above the garbage can. According to the method, bag-breaking, cleaning and throwing of wet garbage can be achieved, it is guaranteed that odor in the can is isolated, garbage in the can is blocked, and leakage of percolate is avoided. The process is clean and convenient, the weight and height of garbage in the garbage can can be monitored in real time, the functions of intelligent odor monitoring and early warning and atomization spraying deodorization are achieved, the odor of wet garbage in the garbage can can be intelligently monitored, intelligent spraying is achieved, and cleaning and energy saving are achieved.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method for conductive paste

InactiveCN102522155AGood electrical conductivityWell protected and lubricatedNon-conductive material with dispersed conductive materialCable/conductor manufactureLubricationLithium

The invention discloses a preparation method for conductive paste. The method comprises the following steps of: grinding various waste carbon brushes into powder; screening the ground carbon brush powder; and well mixing the carbon brush powder and high temperature resistant lithium grease according to the proportion of 3:1, stirring and blending the mixture to obtain the conductive paste. The shortcoming of high cost of conductive paste on the market is overcome. The conductive paste can be prepared only by grinding the various waste carbon brushes into the powder and then uniformly stirring the powder and the high temperature resistant lithium grease according to a certain proportion. The waste carbon brushes with high electrical conductivity are excellent conductive materials, and can be collected anywhere; the high temperature resistant lithium grease has a good protection and lubrication function for contact parts of equipment; and therefore, the conductive paste prepared from the two raw materials has a good effect. By the method, waste is turned into wealth, and the conductive paste with high performance is prepared from the raw materials which are low in cost and readily available by a simple preparation process.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Wood structure reinforcing process based on vacuum negative-pressure method

A wood structure reinforcement process based on the vacuum negative pressure method is to apply sealant around the area of the wood structure to be reinforced, then spread glass fiber cloth, polyester release cloth and diversion vinyl mesh cloth in sequence; then lay vacuum bags , set the resin injection port and exhaust port, turn on the vacuum pump to evacuate, when the vinyl resin in the resin container is full of the vacuum bag, let the internal resin fully infiltrate the fiber, after the vinyl resin is fully cured, tear off the polyester release cloth and complete reinforcement. The invention realizes the reinforcement of the wood structure with the fiber-reinforced composite material cloth through the flow and penetration of the vinyl resin. The fiber-reinforced composite material cloth for reinforcing the wood structure by this method can control the number of fiber layers according to the needs, and can better fit the reinforcement surface , suitable for the reinforcement of complex curved wood structures, the biggest advantage is that it can be integrally formed without glue dripping, its process is simple, easy to operate, no environmental pollution, low cost, and the interface mechanical properties of the reinforced wood structure are excellent.

Owner:EAST CHINA JIAOTONG UNIVERSITY

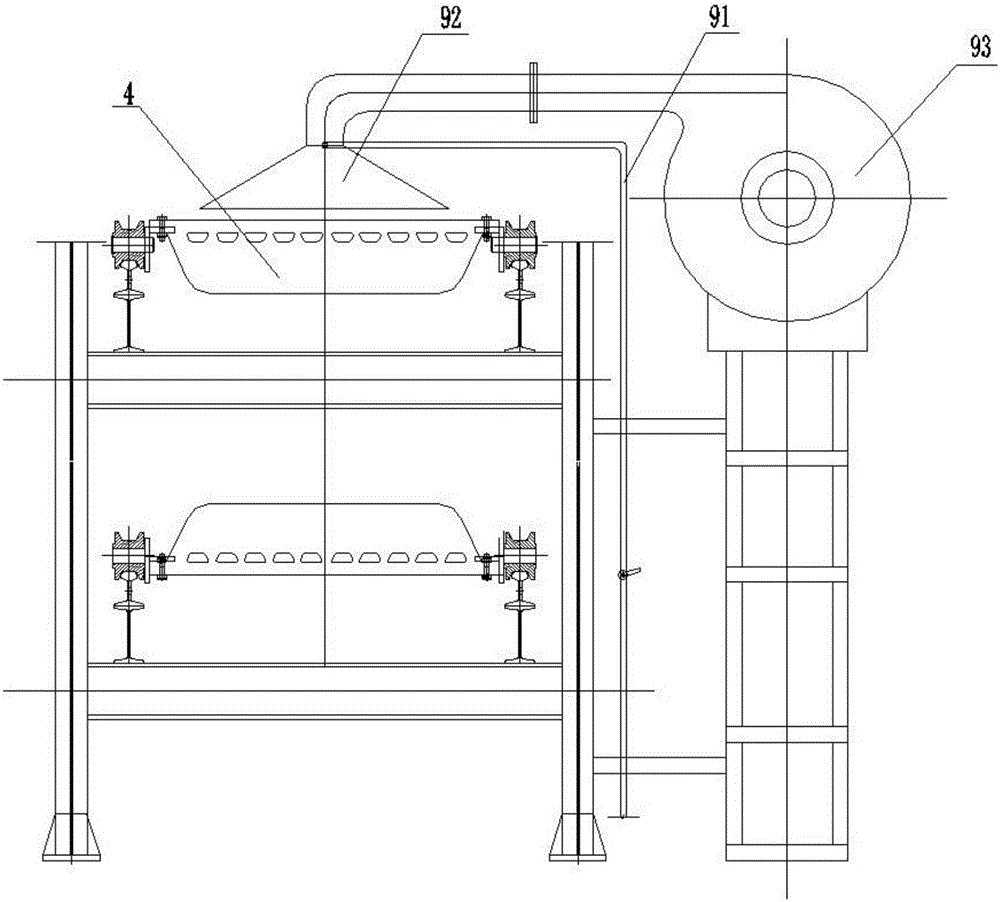

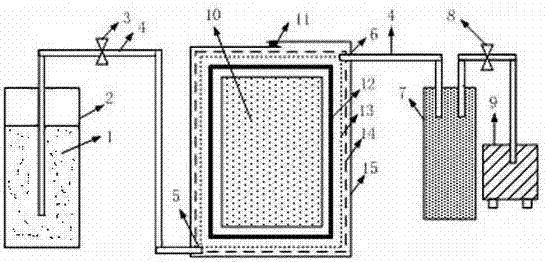

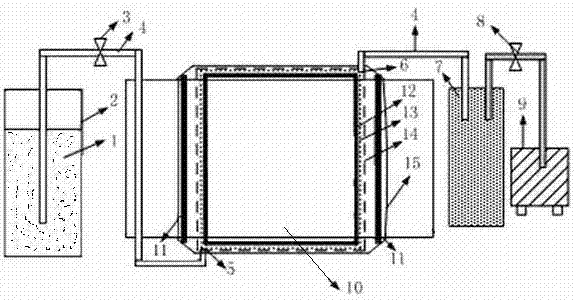

Solar vacuum glass heat collecting tube air heat collector

ActiveCN103175314BIncrease profitFast heat transferSolar heating energySolar heat devicesThermal energyHeat transmission

The invention provides a solar vacuum glass heat collecting tube air heat collector, belongs to the field of solar air heating equipment, and particularly relates to a device which uses a solar vacuum glass heat collecting tube and a metal thermal tube which are combined for air heating and heat collecting. The solar vacuum glass heat collecting tube air heat collector is characterized in that a fan radiator (10) is arranged inside an air heat collecting chamber (9), the air heat collecting chamber (9) is connected with a condensing end at the top end of the metal thermal tube (4) through the fin radiator (10), and radiating fins (11) which are distributed in a radiating shape mode are arranged on the outer peripheral ring of the fin radiator (10). The solar vacuum glass heat collecting tube air heat collector has the advantages of being high in heat transmission speed, high in solar heat energy utilization ratio, good in sealing effect and the like.

Owner:泰州市华驰不锈钢制品有限公司

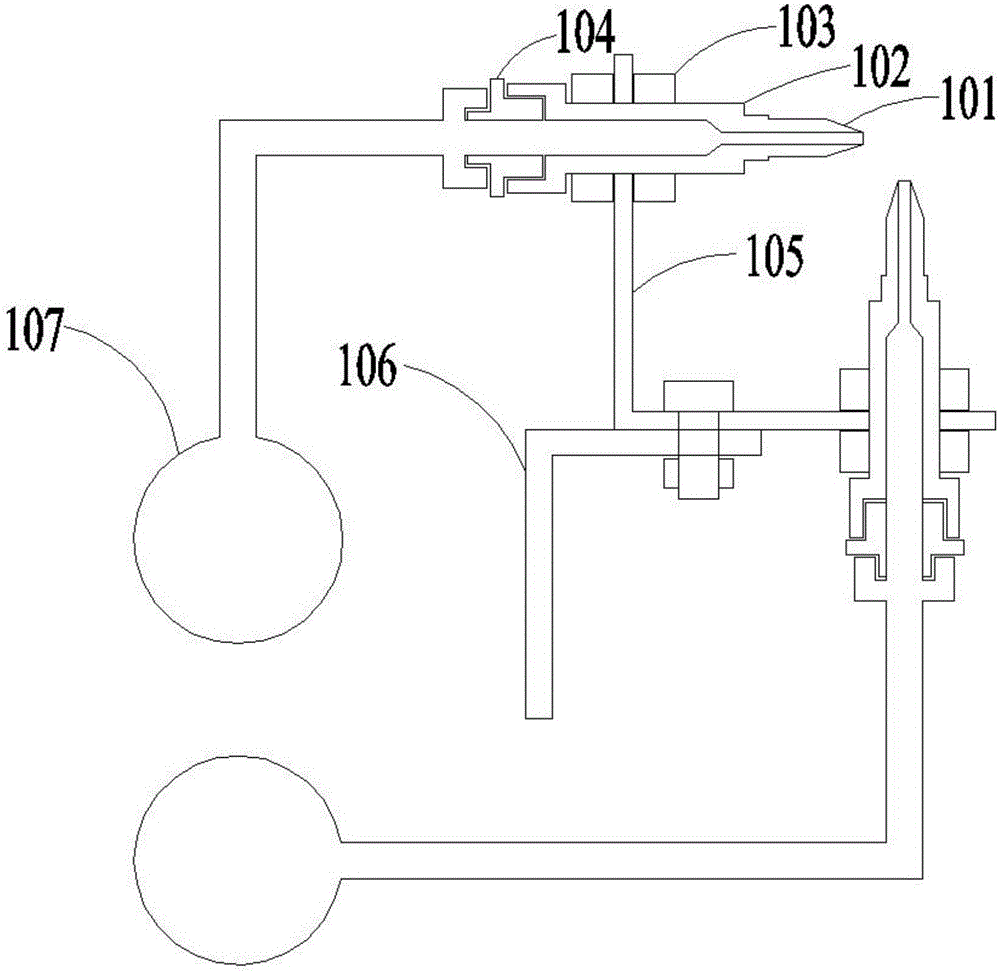

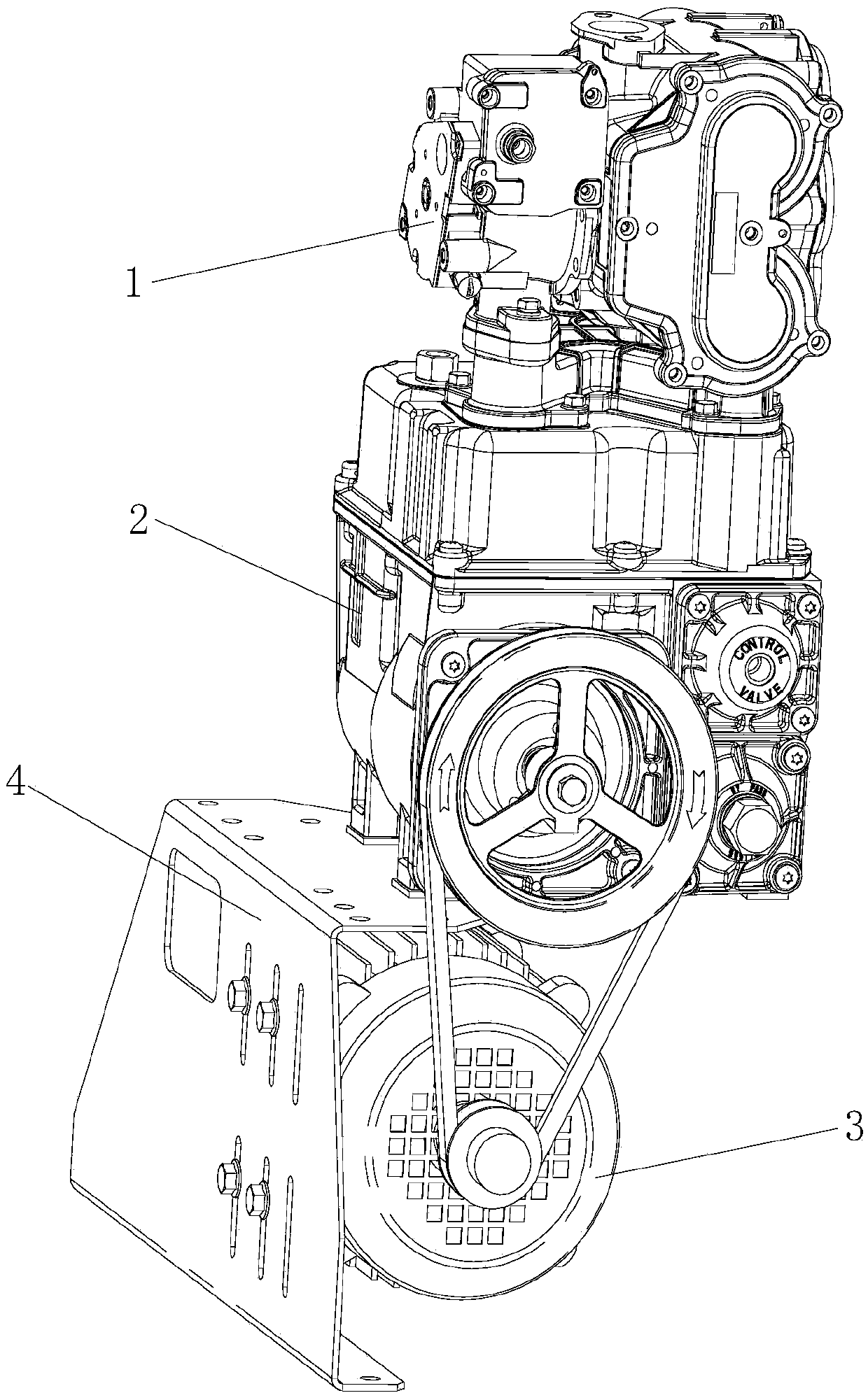

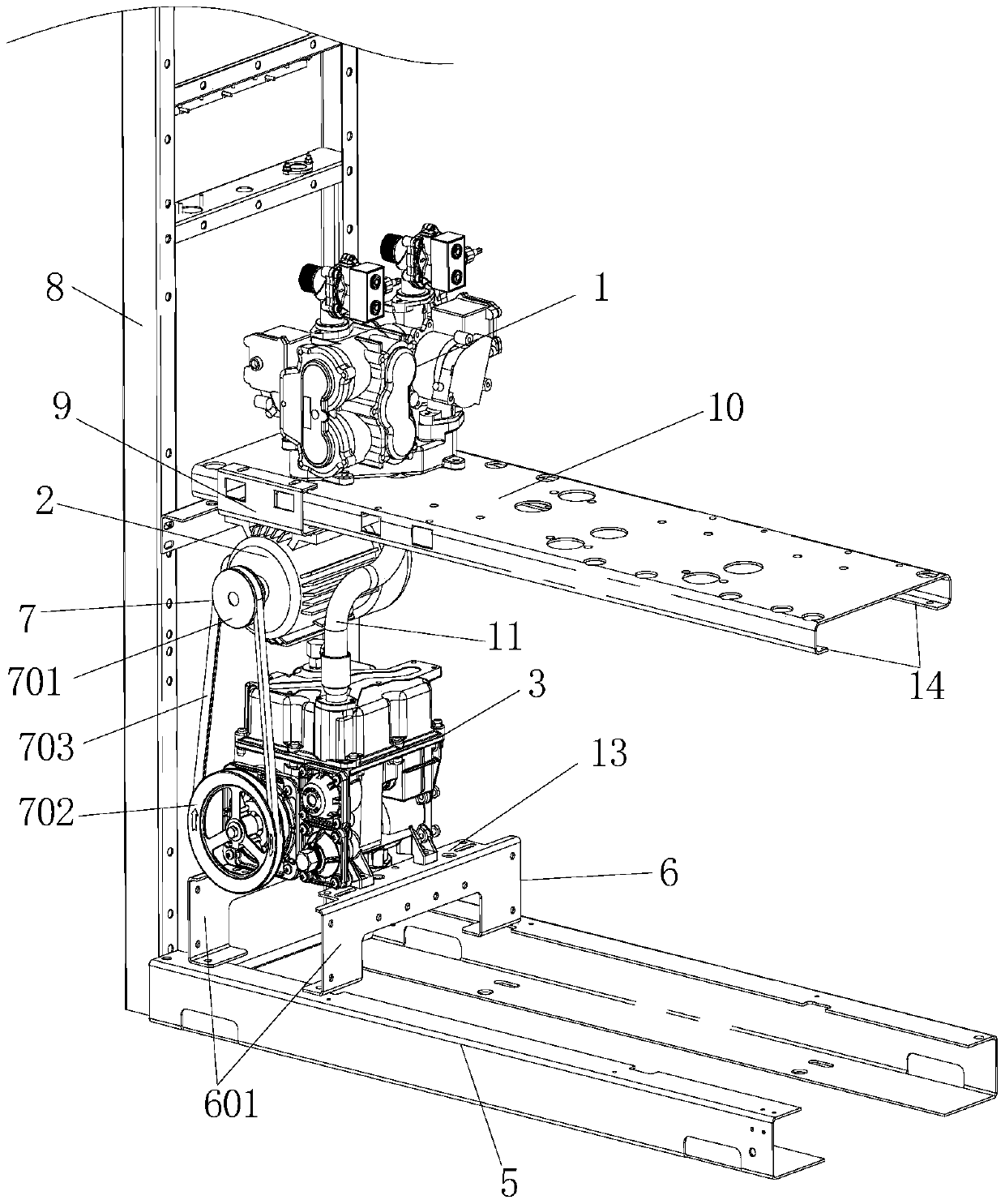

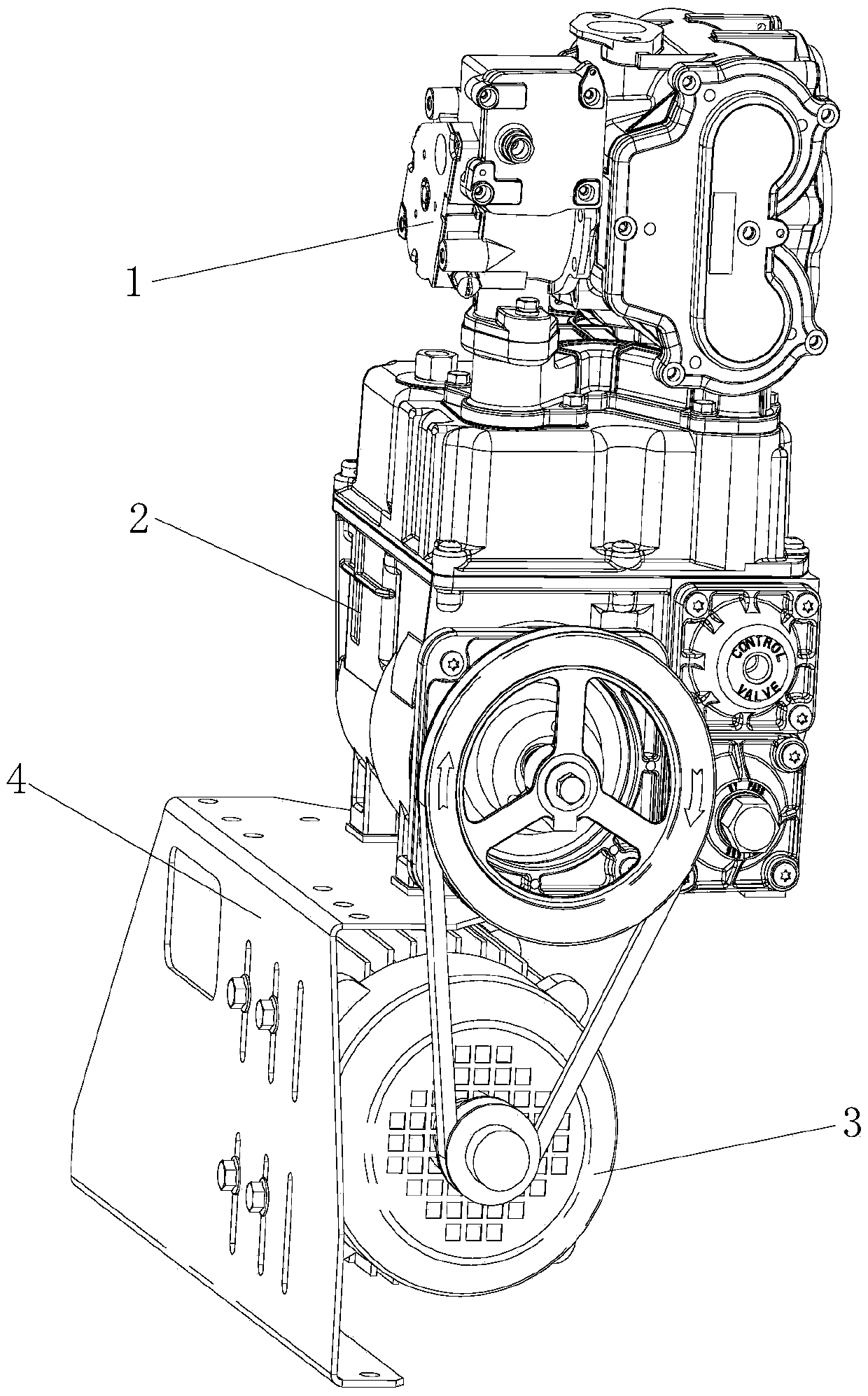

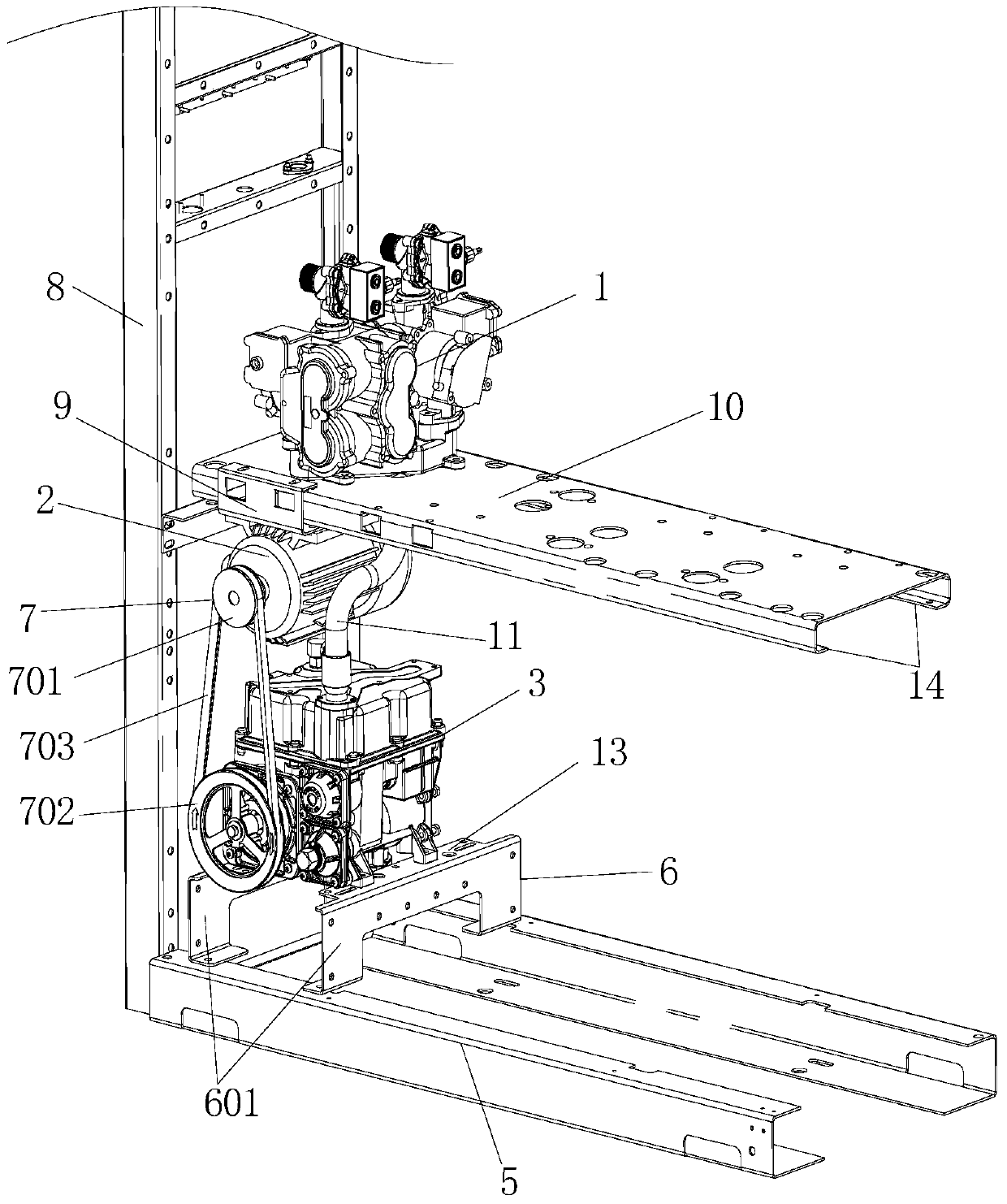

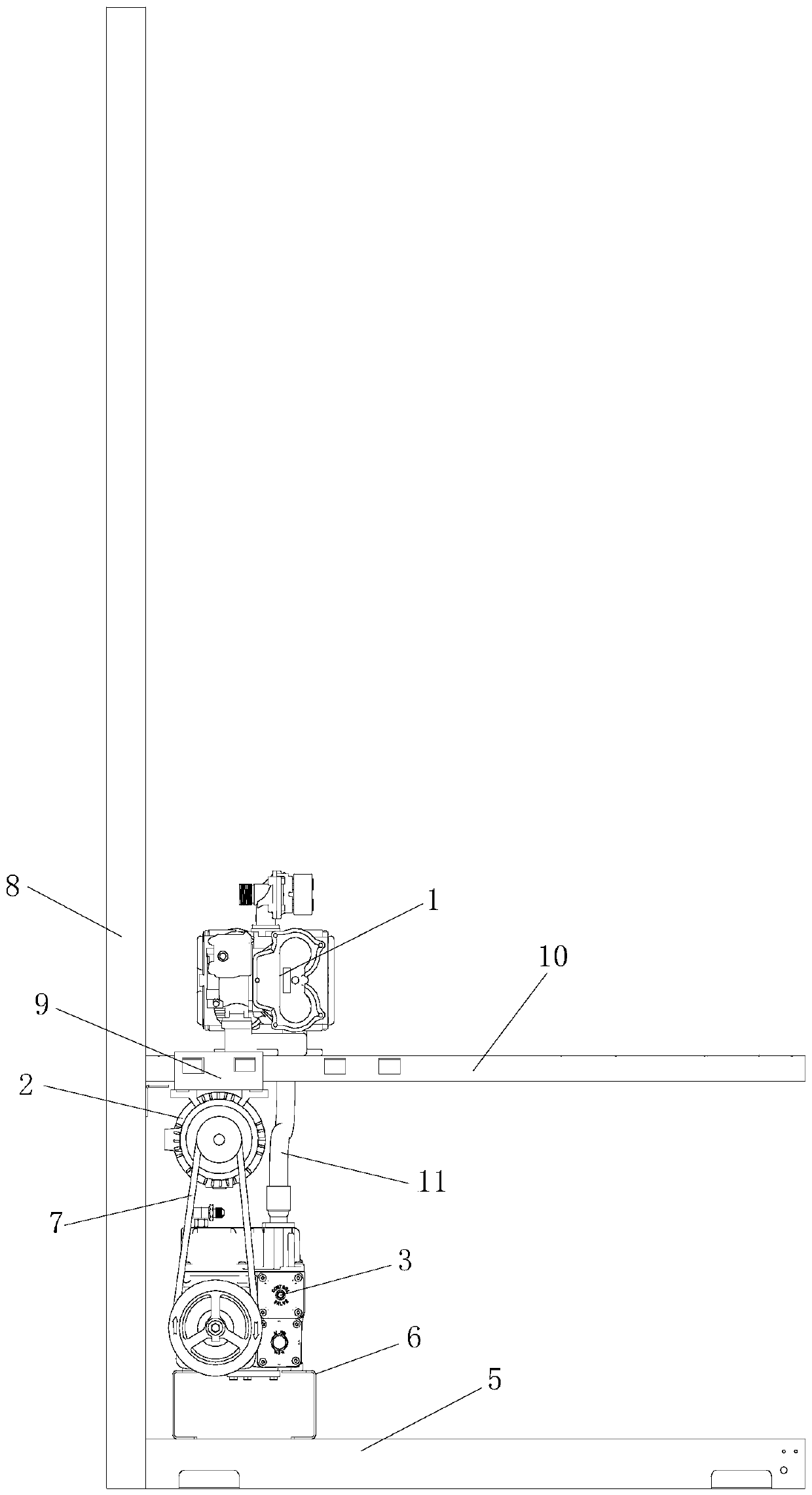

Hydraulic system of oiling machine

ActiveCN105502272AImprove convenienceGuaranteed reliabilityLiquid transferring devicesPulp and paper industry

The invention discloses a hydraulic system of an oiling machine. The hydraulic system comprises a flow meter, a motor, a pump, a supporting frame and a base, wherein the flow meter is connected with the pump; the motor is connected with the pump through a transmission mechanism; the pump is mounted on the base through the supporting frame. The hydraulic system further comprises a stand column, a connection frame, a supporting plate and an oil outlet pipe, wherein the lower end of the stand column is fixed on the base; one end of the supporting plate is fixed on a side wall of the stand column; the motor is mounted on the lower side of the supporting plate through the connection frame and the flow meter is mounted on the upper surface of the supporting plate; the pump is connected with the flow meter through the oil outlet pipe; and the pump, the motor and the flow meter are sequentially distributed from bottom to top. According to the hydraulic system of the oiling machine, provided by the invention, the flow meter, the motor and the pump are mounted in a splitting manner, so that the convenience of installation and maintenance is improved. Meanwhile, the motor is not inclined due to an acting force generated by the working of the pump and the working reliability is improved.

Owner:TOKHEIM HENGSHAN TECH GUANGZHOU

Braking system for fan blade rotating shaft of wind generating set

ActiveCN113719409ASimple structureNo dripWind motor controlMachines/enginesStructural engineeringFan blade

The invention relates to a braking system for a fan blade rotating shaft of a wind generating set. The braking system comprises a gear box, the fan blade rotating shaft rotationally connected to the gear box, a brake disc arranged on the fan blade rotating shaft, a support and two scissor arms with the middles hinged to the support through pin shafts, the two scissor arms are distributed on the two axial sides of the brake disc, one end of each scissor arm is provided with a friction plate used for being matched with the brake disc, the other end of each scissor arm enables the corresponding friction plate to be connected to an electric push rod of the brake disc in a butt-joint mode by driving the scissor arm to rotate with the corresponding pin shaft as the axis, and the support is fixedly connected with the gear box. The first purpose of the invention is to provide a wind generating set fan blade rotating shaft brake which does not generate oil leakage information, and the problem of oil leakage caused by an oil pressure type brake in the prior art is solved.

Owner:JIAXING NANYANG POLYTECHNIC INST

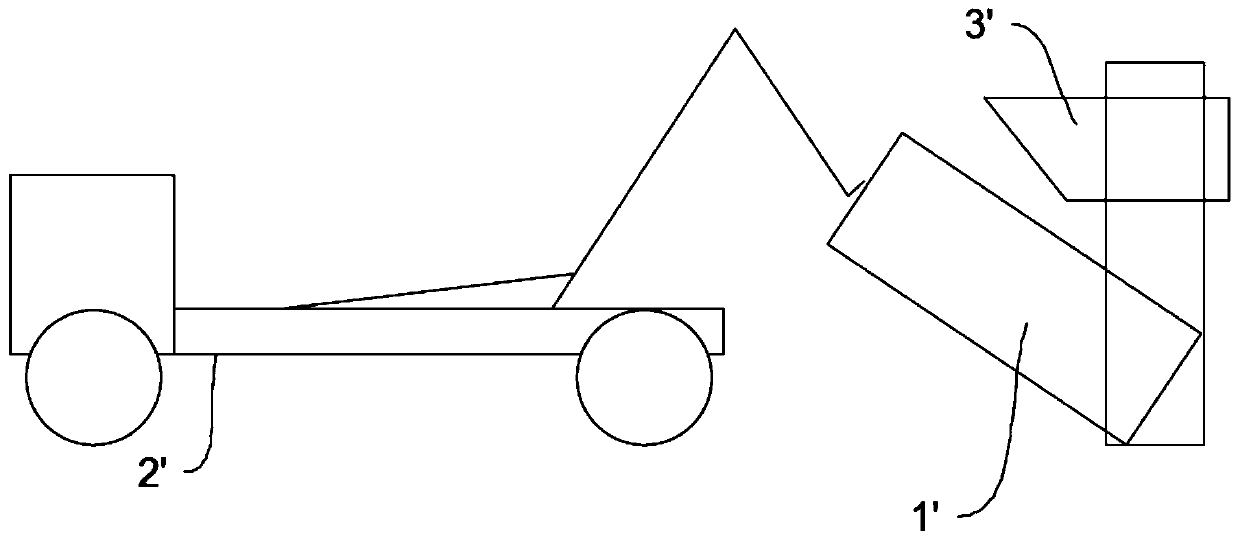

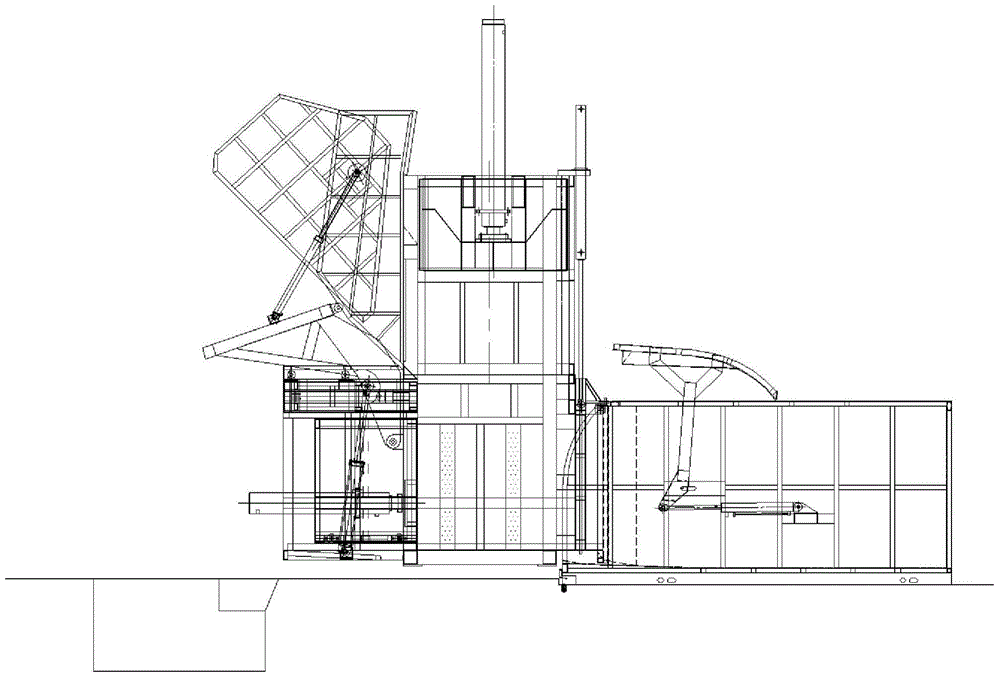

Movable garbage compression box and boxing method thereof

ActiveCN102167207BBody weight reductionHigh energy consumptionRefuse vehiclesPressesLight equipmentElectrical control

The invention relates to the technical field of garbage compression boxes, in particular to a movable garbage compression box and a boxing method thereof. The compression box is characterized in that: a movable lifting device and a compression head are of a split structure; the movable lifting device is connected with the front end of the compression head; power units of a hydraulic power system and an electric control system are arranged on the movable lifting device; each power unit is connected with a hydraulic quick joint; the hydraulic quick joint is detachably connected with a compression part hydraulic system; the movable lifting device comprises a walking mechanism, a lifting mechanism and an electrical appliance control button; the compression head has a totally-enclosed structure; the back part of the compression head is connected with the front part of a charging box; and the compression head and the charging box are of an integrated structure. Compared with the prior art, the movable garbage compression box has the advantages of light equipment, small floor area, low energy consumption, large compression volume reduction capability, energy conservation, environmental friendliness, easiness of cleaning, no residual of garbage or percolate, high durability and long service life.

Owner:SHANGHAI LOEP PRIVATE VEHICLES CO LTD

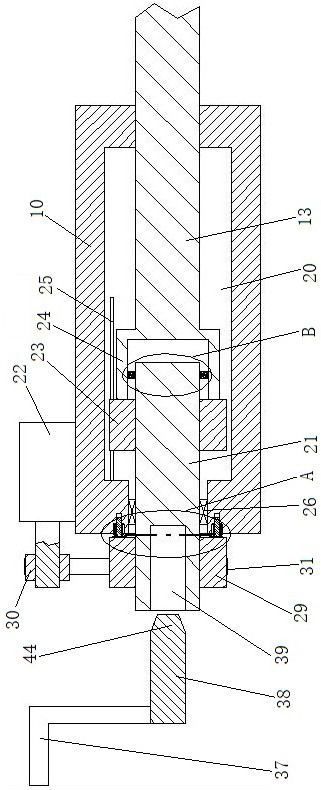

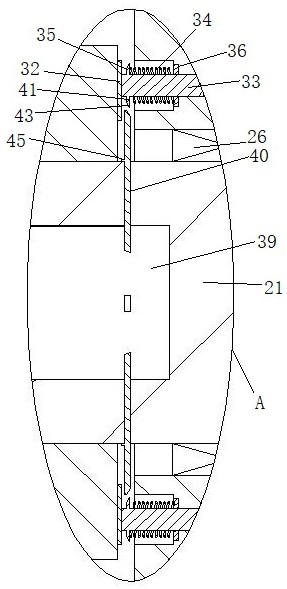

Filling nozzle of liquid filling machine

The invention discloses a filling nozzle of a liquid filling machine. The filling nozzle comprises a filling nozzle end and a filling head which are connected. A first support device and a second support device are arranged on the outer wall of the filling head. The first support device is connected with a first axle which is connected with a rotatable first balancing rod. The two ends of the first balancing rod are connected with a first baffle and a first iron block respectively. The second support device is connected with a second axle which is connected with a rotatable second balancing rod. The two ends of the second balancing rod are connected with a second baffle and a second iron block respectively. The first baffle and the second baffle are located at the bottom of the filling head. By means of the filling nozzle, it can be avoided that rapid-outflow liquid is splashed out of a packaging object when a packaging object opening pipe is filled with the liquid, and meanwhile the liquid dropping phenomenon can be avoided.

Owner:湖北永进药业股份有限公司

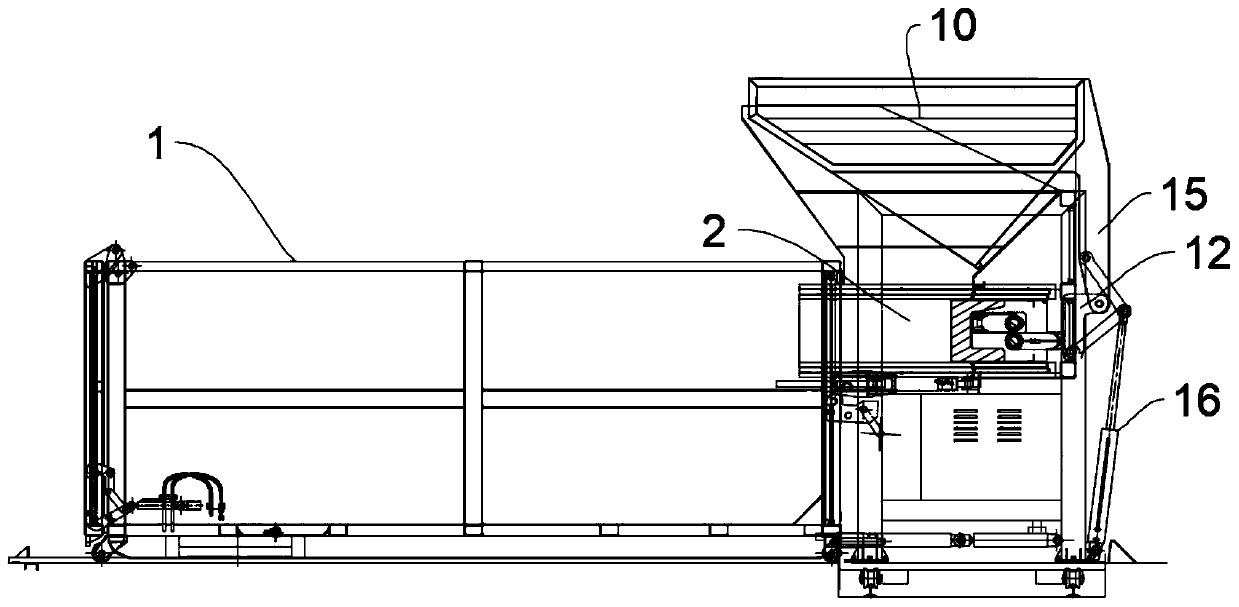

Garbage compression station

PendingCN111470227AEasy dockingEasy to removeRefuse transferringStorage devicesComputer hardwareEngineering

The invention relates to the technical field of garbage compression equipment, and discloses a garbage compression device and a garbage compression station. The garbage compression device comprises afeeding mechanism and a push-pull box mechanism, wherein the feeding mechanism comprises a push head stock bin for feeding materials into a box body, the push-pull box mechanism comprises a box body guide rail extending towards the feeding mechanism and a driving device for driving the box body to horizontally move along the box body guide rail so as to enable a feeding hole of the box body to bebutted with the push head stock bin. According to the garbage compression device and the garbage compression station, the effective height needed by butt joint of the box bodies of the garbage stationis reduced, the current situation that the space height of the garbage station is limited can be better adapted, large size utilization space and feasibility are provided for transformation of an existing garbage station, a double-station or multi-station operation mode of one machine with one box or two boxes or multiple boxes is adopted, use is more reasonable and convenient, the utilization rate is higher, and the garbage treatment efficiency is higher.

Owner:重庆捌拾玖度环保科技有限公司

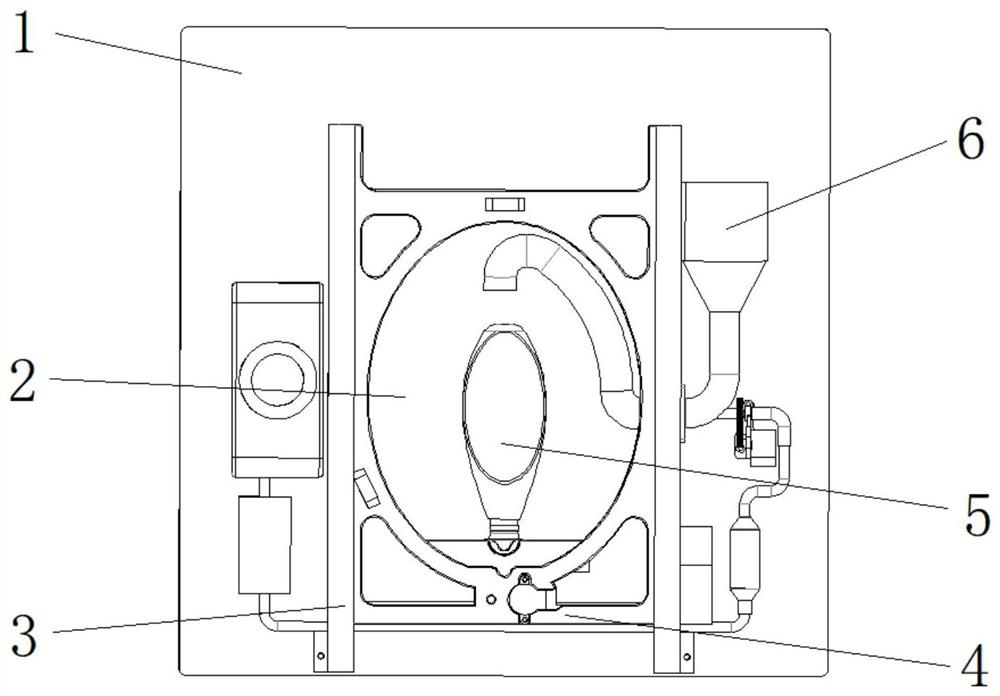

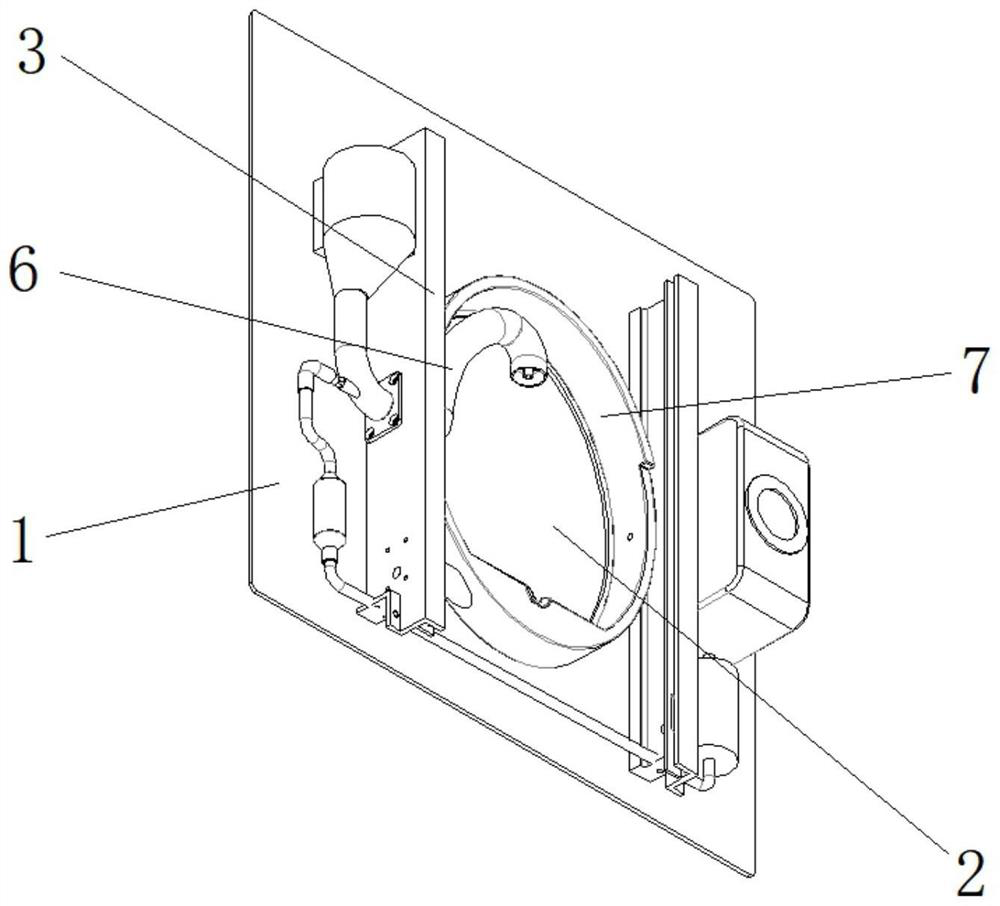

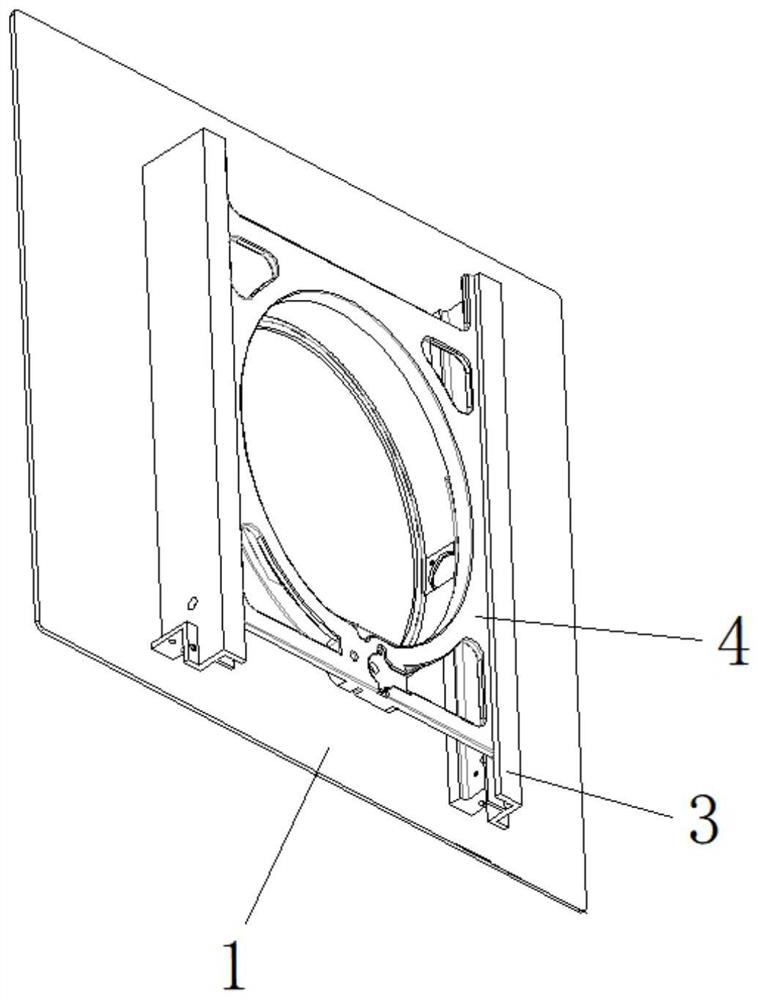

Intelligent pedestal pan applied to wheelchair and nursing bed (chair)

ActiveCN113287963ARealize automatic cleaning functionRealize functionWheelchairs/patient conveyanceBathroom coversWheelchairDrive shaft

The invention discloses an intelligent pedestal pan applied to a wheelchair and a nursing bed (chair). The intelligent pedestal pan comprises a base, a defecation opening and sliding rails, the defecation opening is formed in the base, the sliding rails are installed at the positions, located on the two sides of the defecation opening, of one end of the base, and defecation bag transmission structures are arranged in the sliding rails. By arranging the defecation bag transmission structures, the shifting piece and the packer, a binding belt at an opening in the top end of a disposable defecation bag can be tightened and fixed, operation of a first driving motor can drive a transmission shaft to rotate, an excrement bag disc is indirectly driven to slide along a groove in a sliding rail, and the disposable defecation bag is fed into the bottom end of adefecation opening; meanwhile, the packer can pull the binding belt and tighten the bag opening of the disposable defecation bag, the disposable defecation bag is a disposable degradable special plastic defecation bag, automatic packing is conducted after defecation is finished, the defecation bag is automatically pushed out of the pedestal pan, a series of dirty and odorous activities such as defecation treatment and container cleaning after defecation are omitted, contact is avoided in the whole process, and the pedestal pan is very worry-saving.

Owner:吉世斌

A kind of fast-drying alcohol-based spray casting coating and its spraying method

The invention discloses a quickly dried alcohol based spraying casting coating and a spraying method thereof. The quickly dried alcohol based spraying casting coating comprises the following components in parts by weight: 60-65 parts of fire resistant powder material, 3-4 parts of suspension agent, 15-20 parts of low boiling point solvent, 15-20 parts of medium boiling point solvent, 1-2 parts of bonding agent and 1 part of assistant. The quickly dried alcohol based spraying casting coating can fully meet the spraying usage requirement; according to different castings, different fire resistant materials are used so as to meet the production requirements of different castings.

Owner:杨俊新

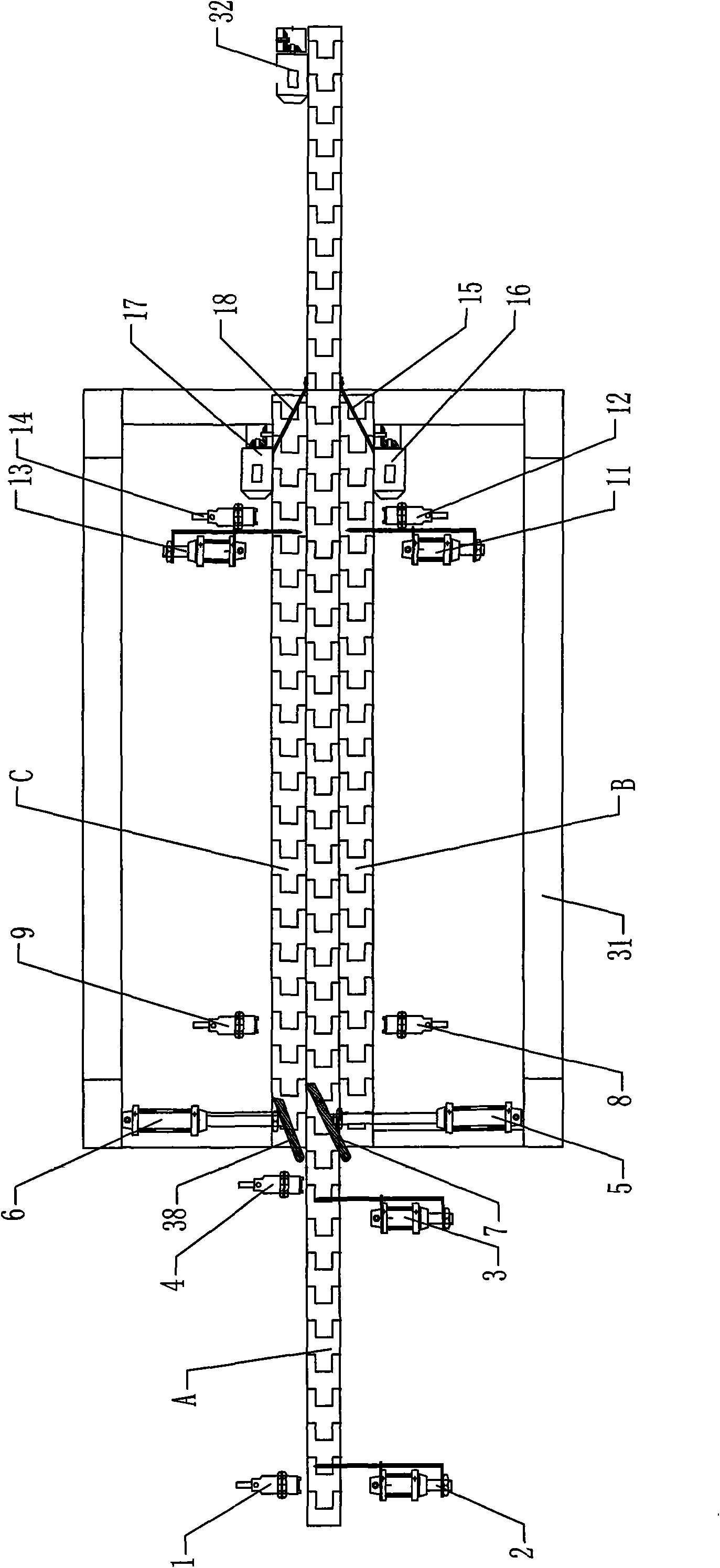

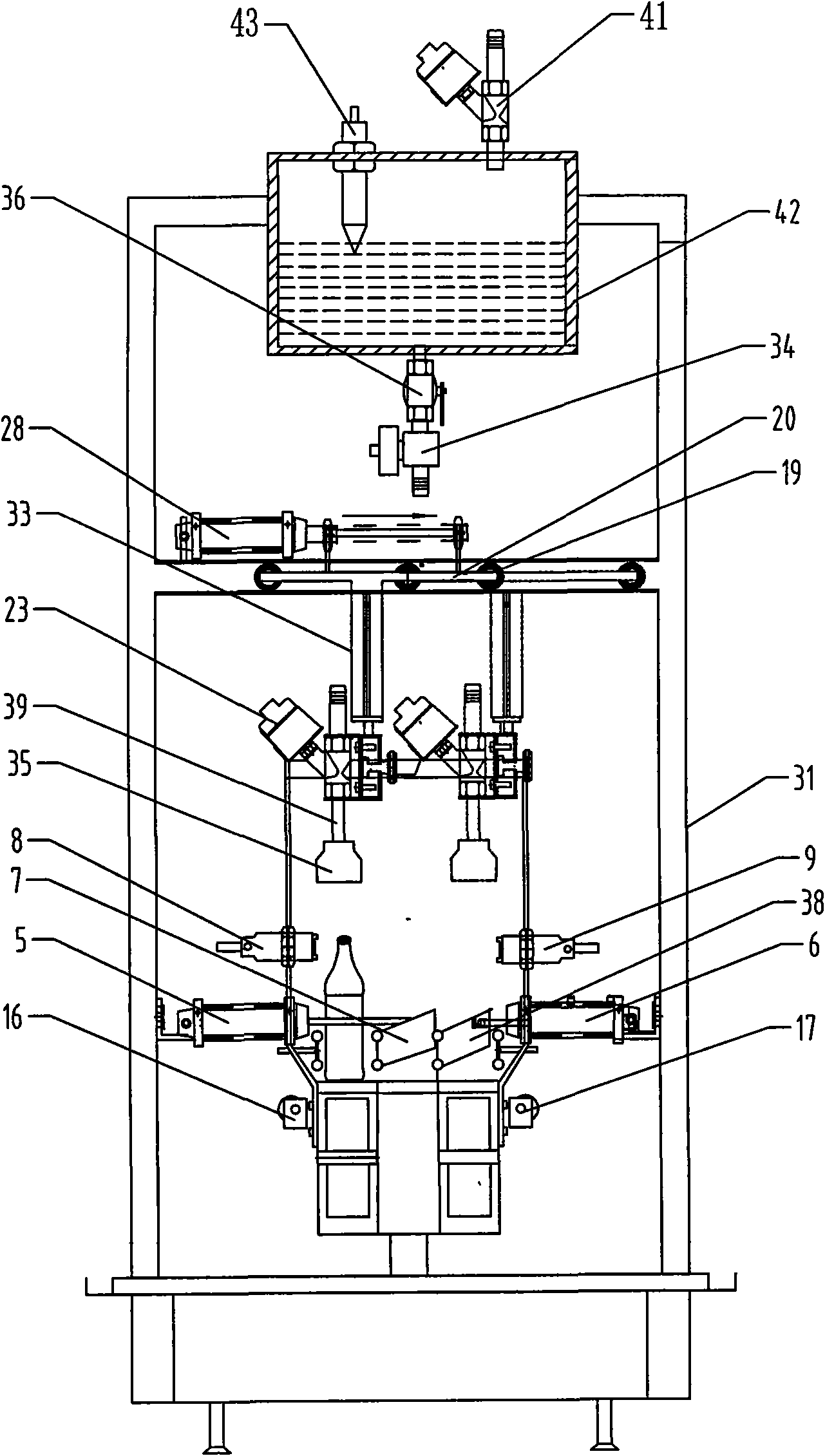

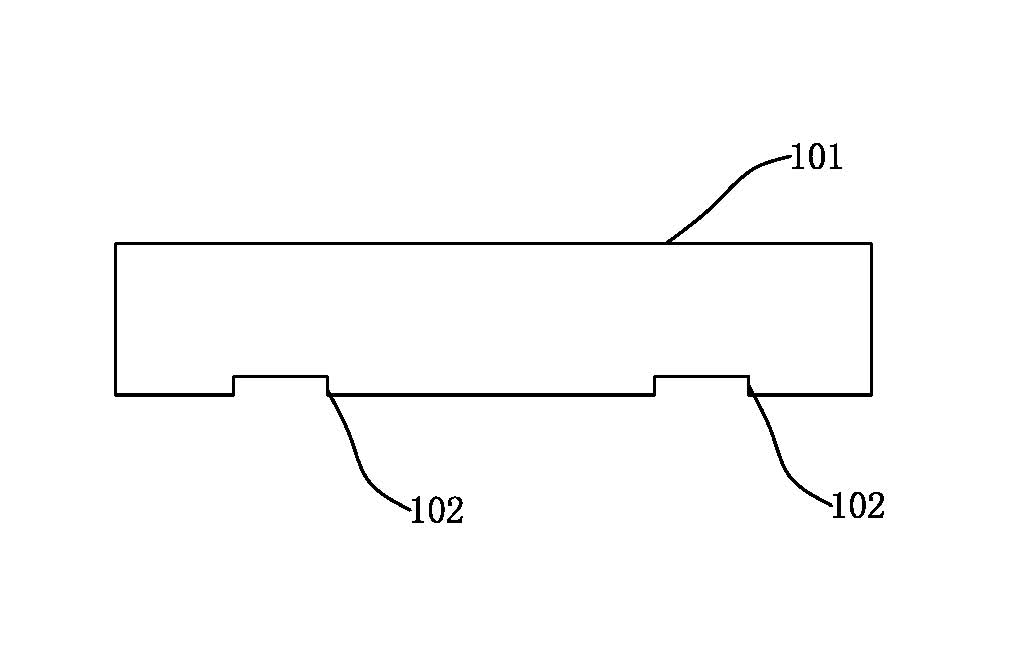

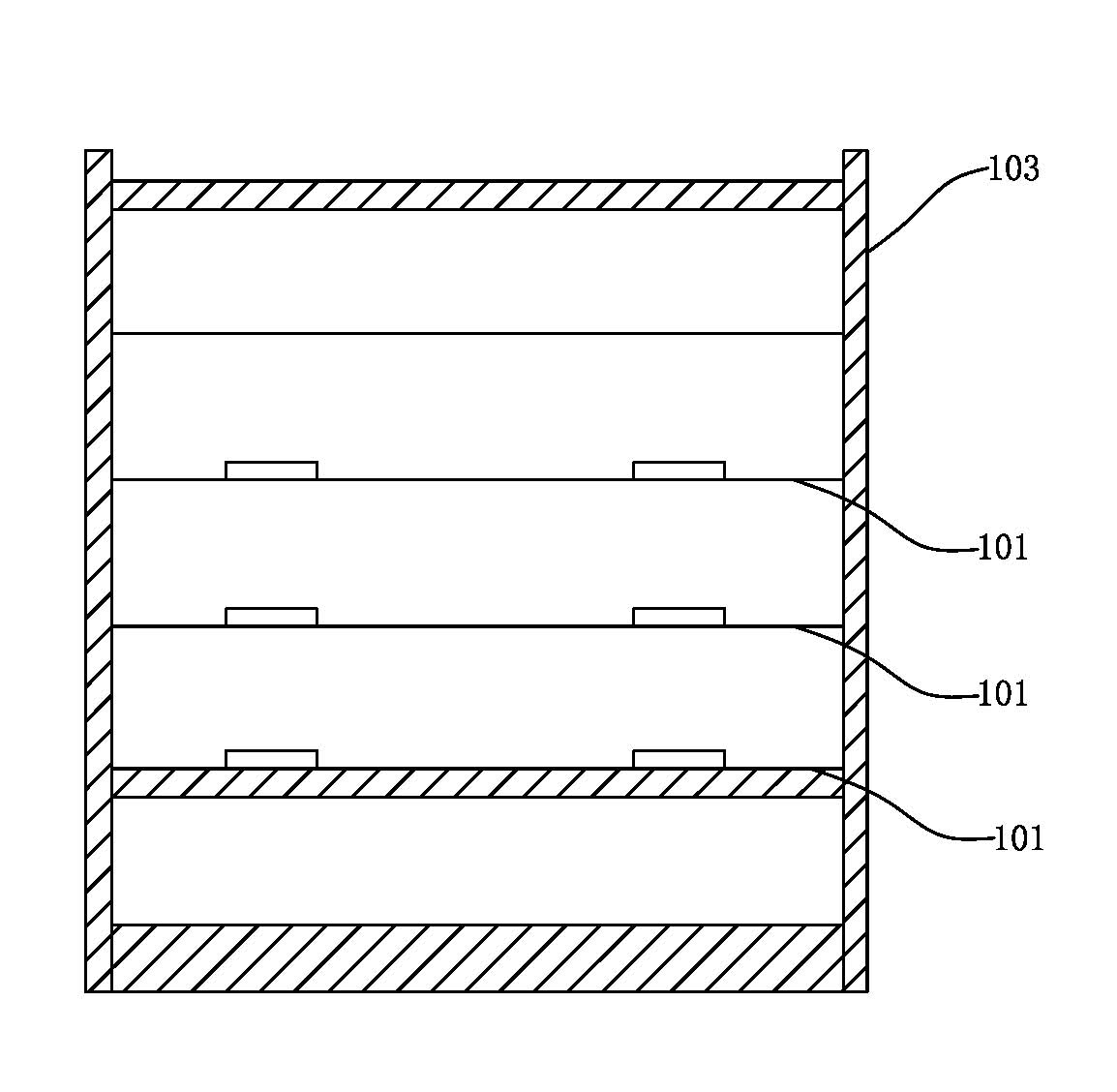

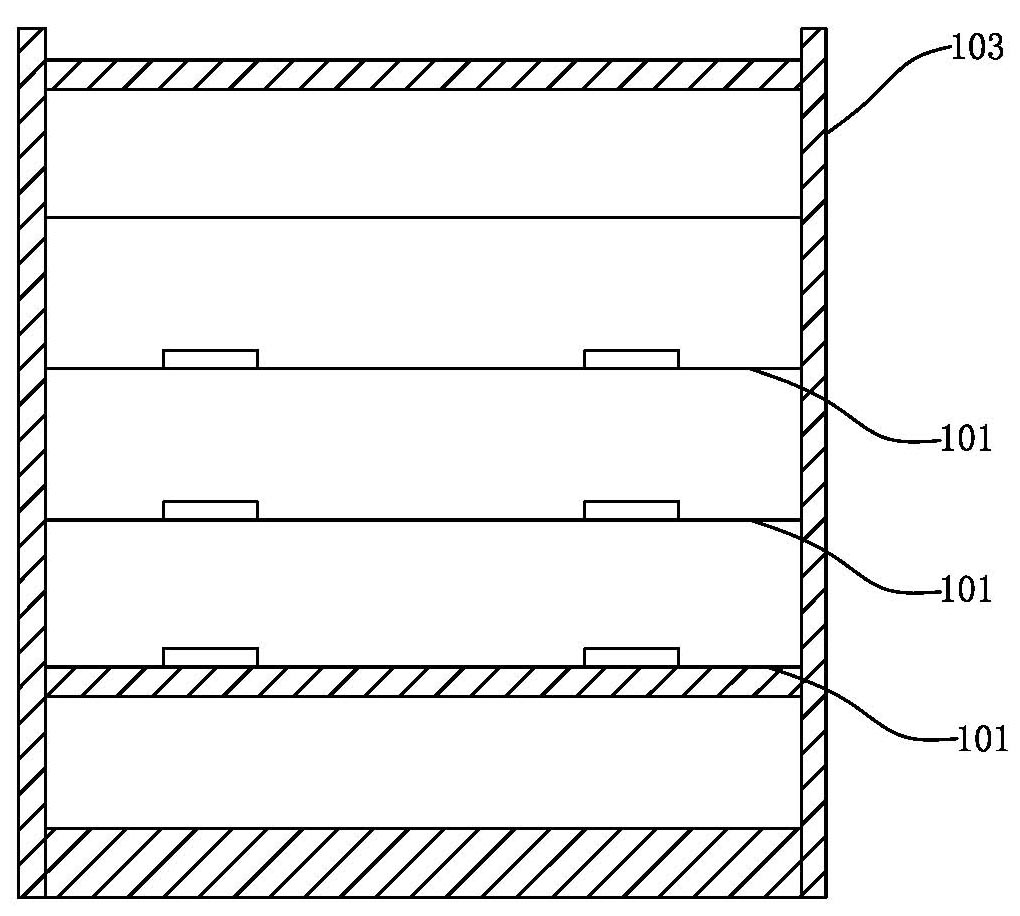

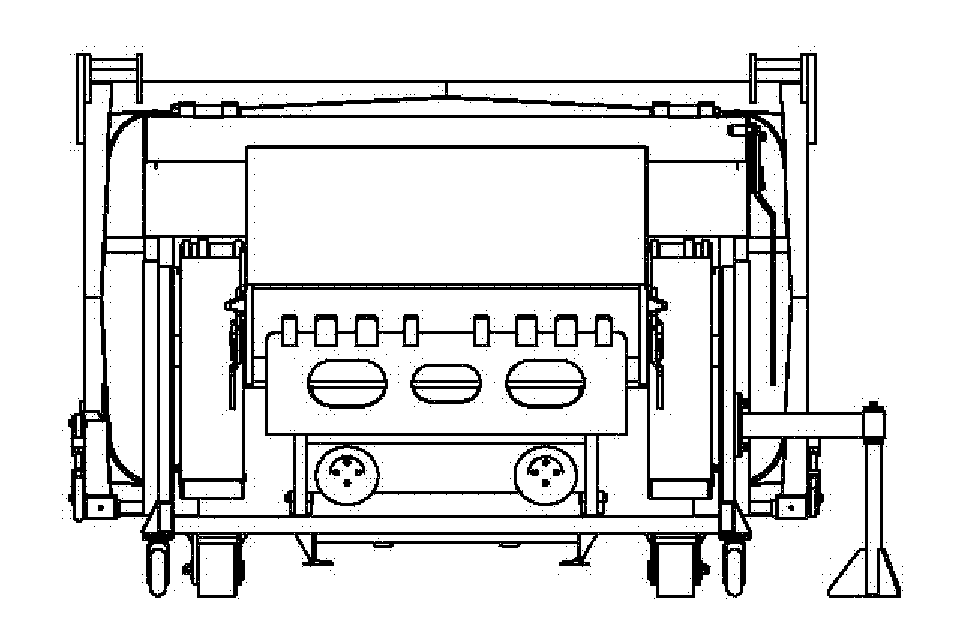

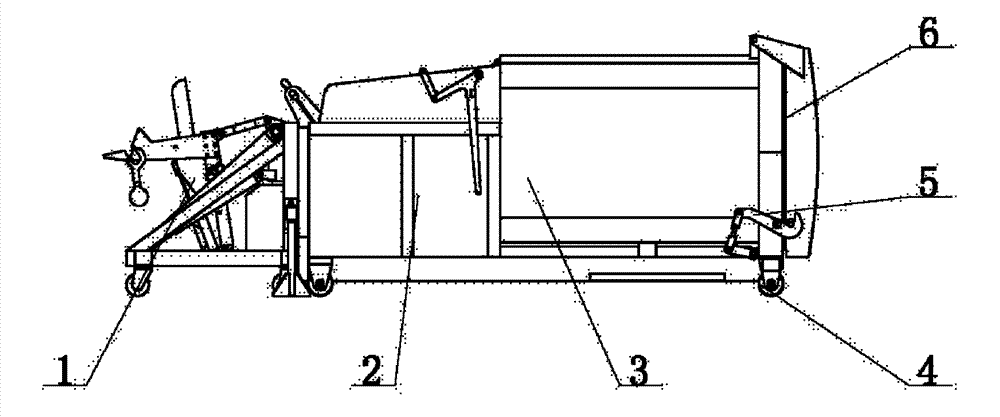

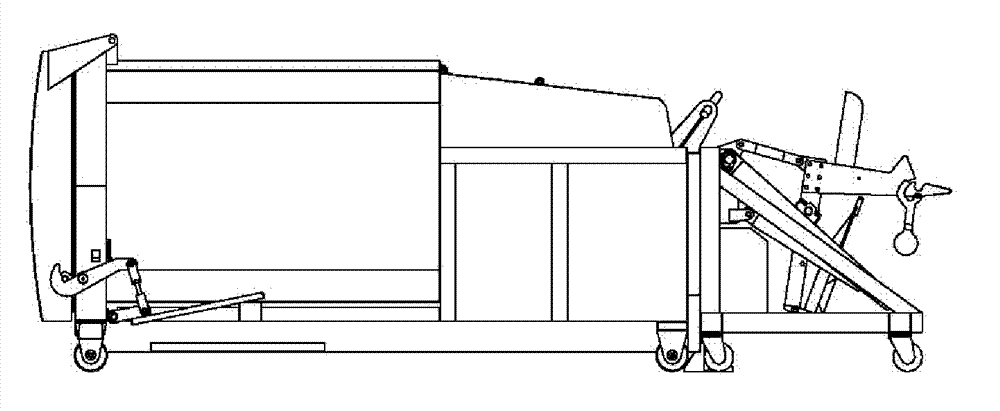

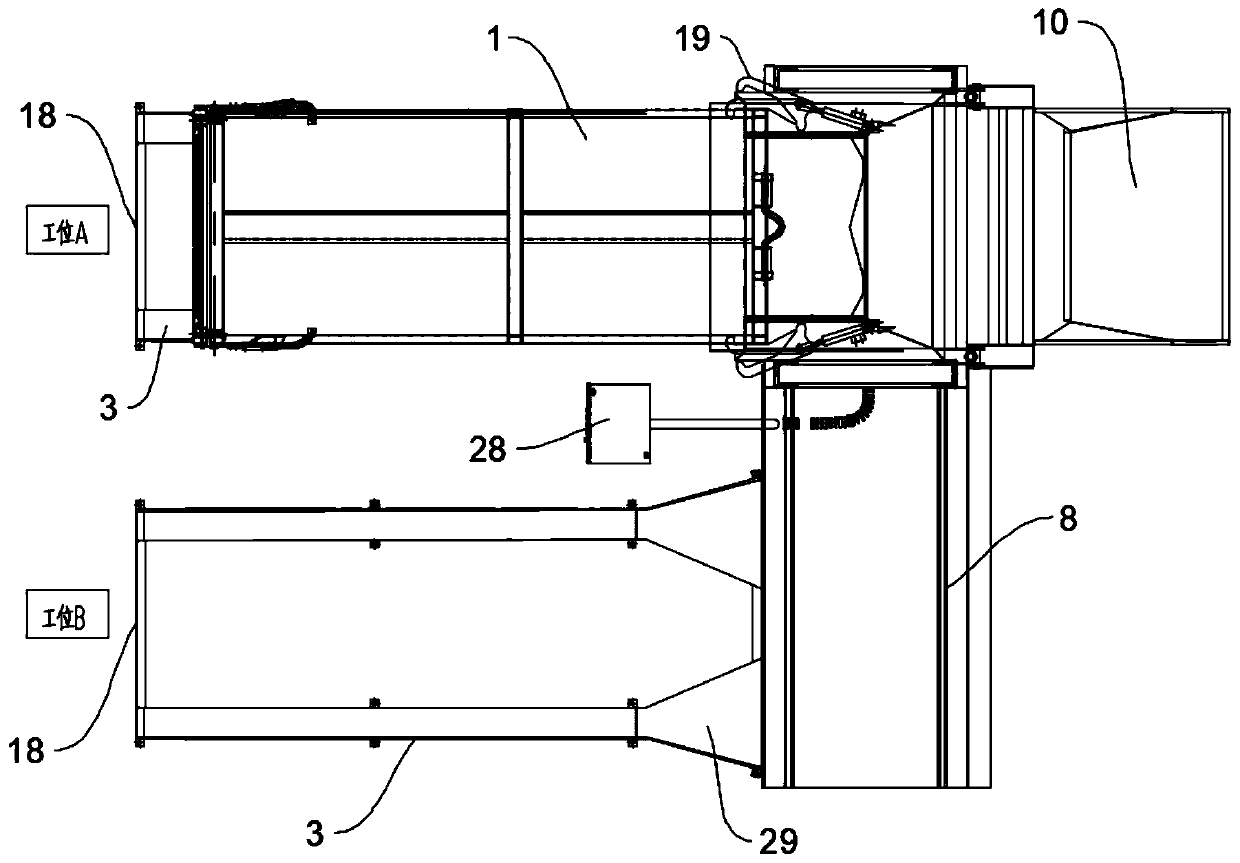

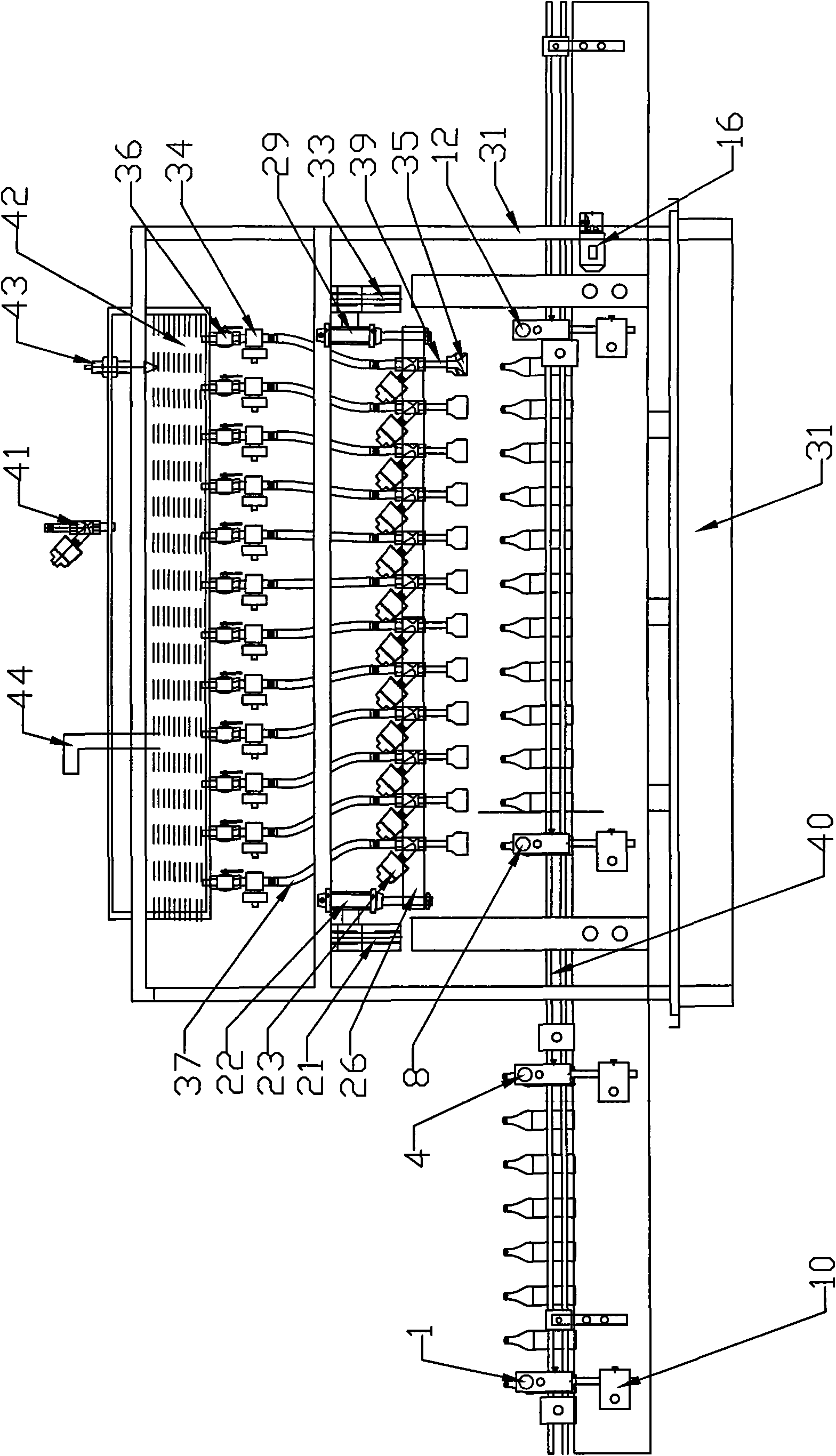

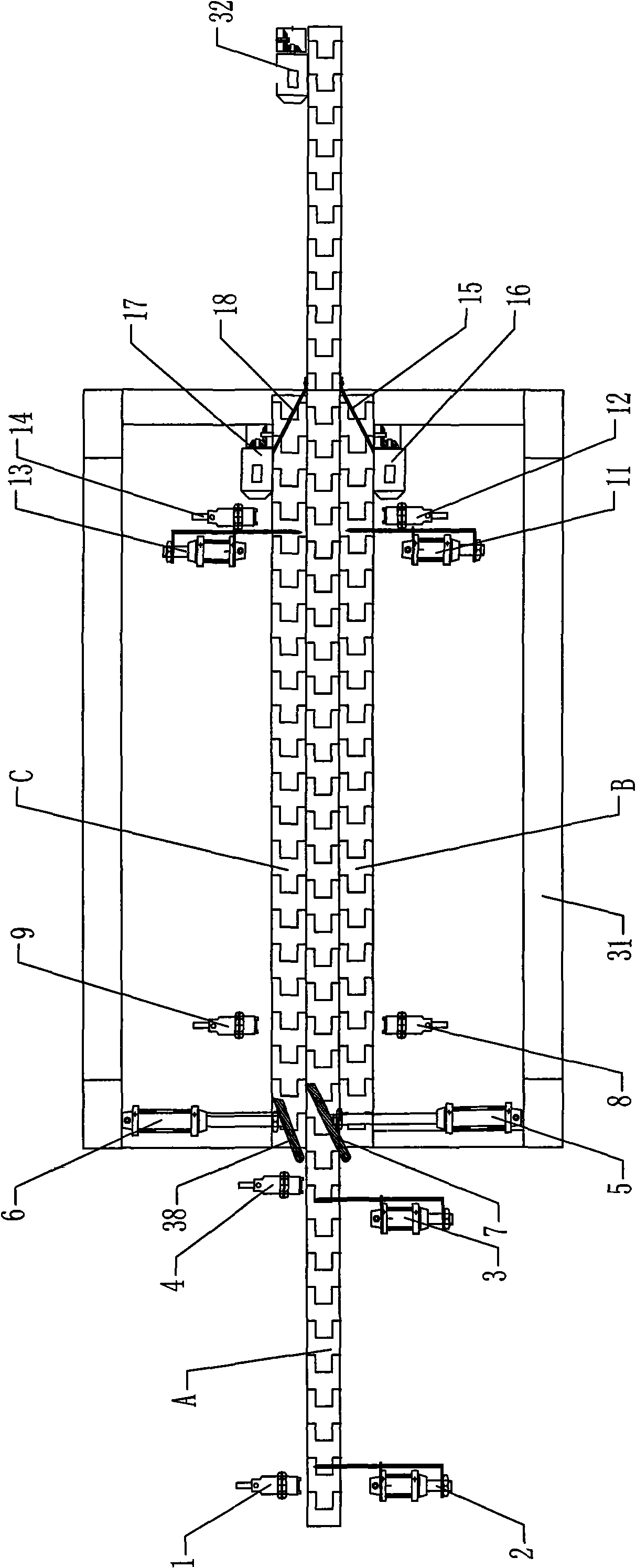

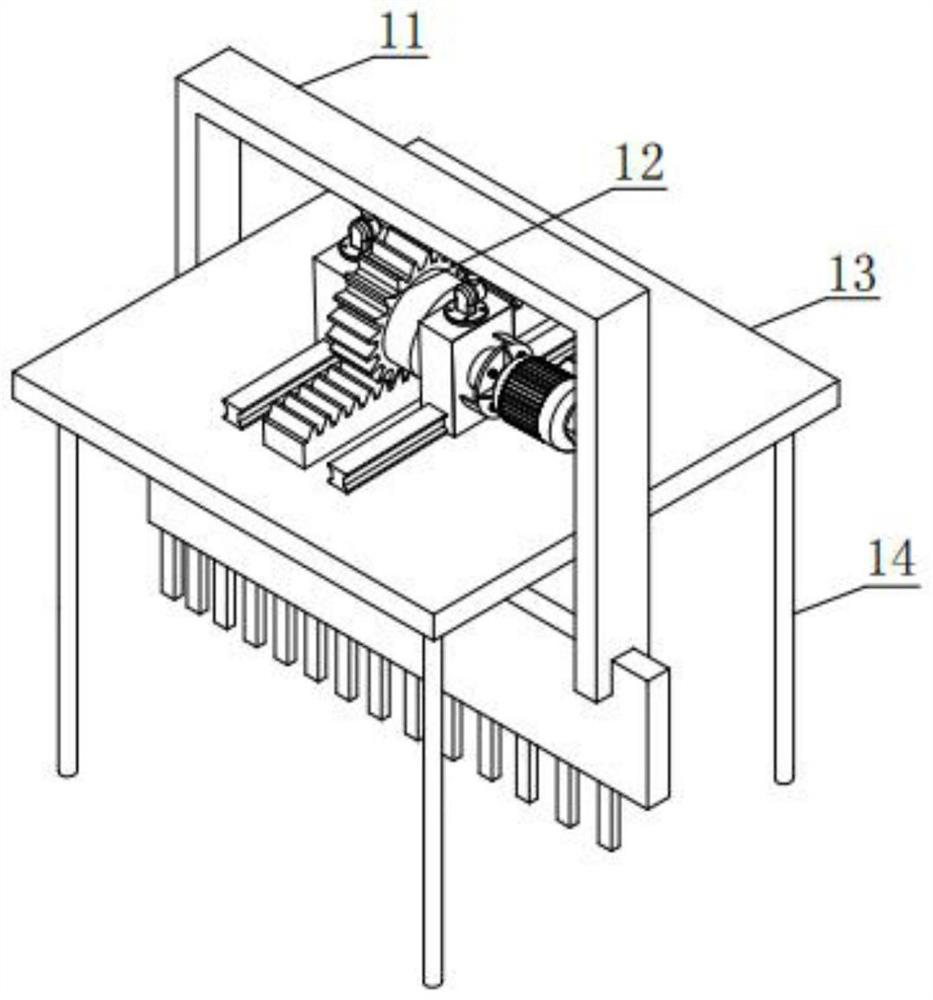

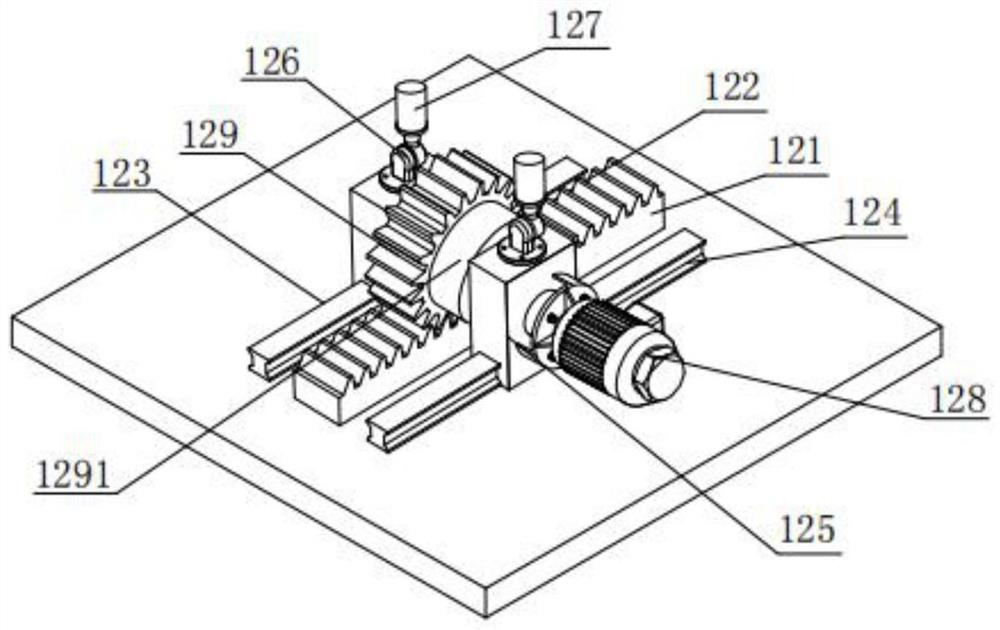

Three-row double-wire linear filling machine

InactiveCN101618845BOvercome the disadvantage of needing to wait for the bottle to enterShorten the intervalLiquid fillingAbnormal shapesEngineering

The invention discloses a three-row double-wire linear filling machine, comprising a frame. A bottle finishing and bottle conveying device and a liquid filling device are arranged on the frame, the bottle finishing and bottle conveying device comprises three rows of conveyer belts arranged in parallel, line exchanging devices are arranged between the three rows of conveyer belts, the bottle body can be continuously filled by carrying out line exchange on the bottle body, thereby overcoming the defect that the feeding of bottle needs to be waited when filling the bottle body by a traditional filling machine, shortening interval time between fed bottles and improving filling efficiency; the filling machine has the advantages of reasonable structure, high degree of automation, high precision, no drop leak, no discharge, simple capacity set, no bottle piling, strong applicability to abnormal shapes and high stability.

Owner:李真中

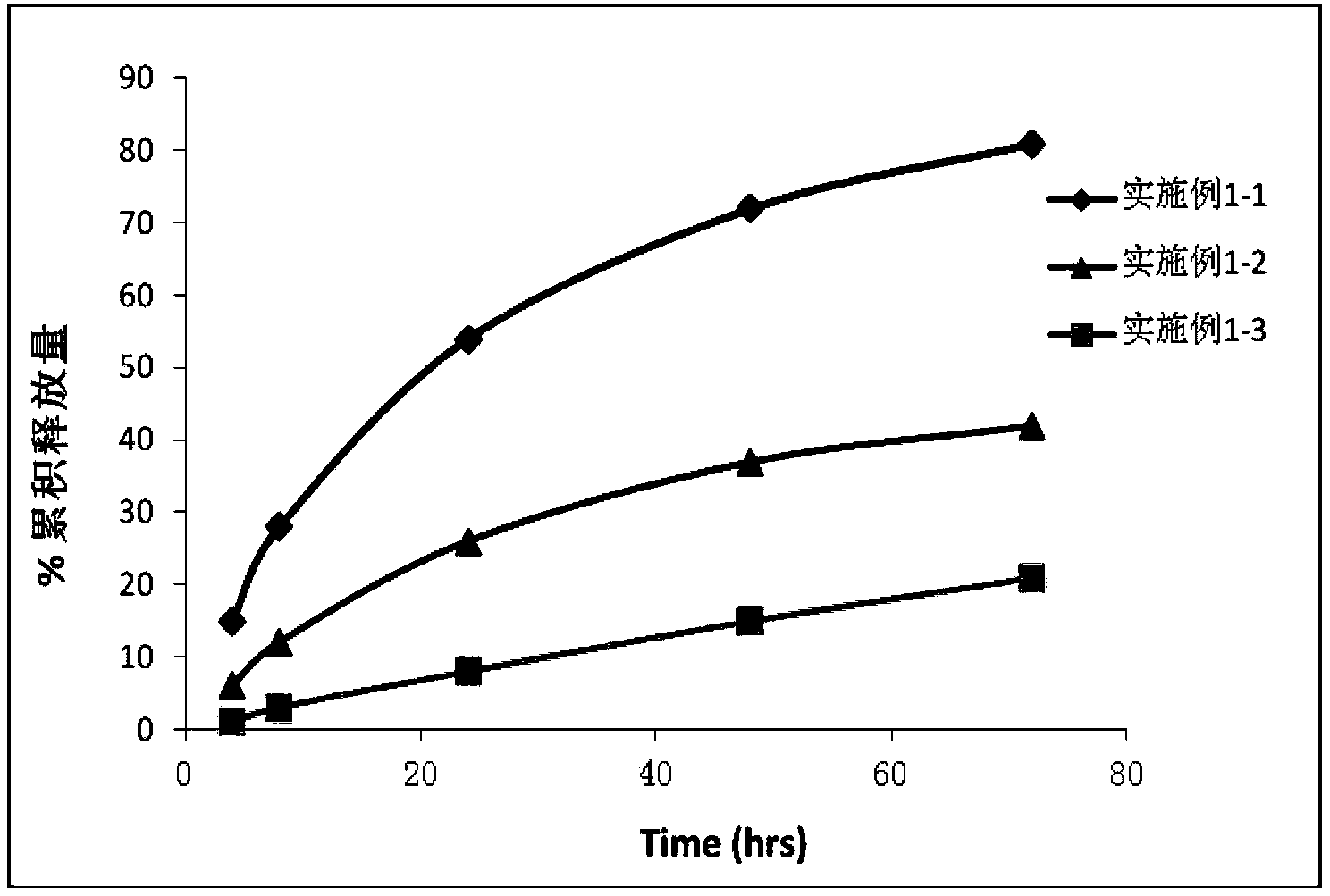

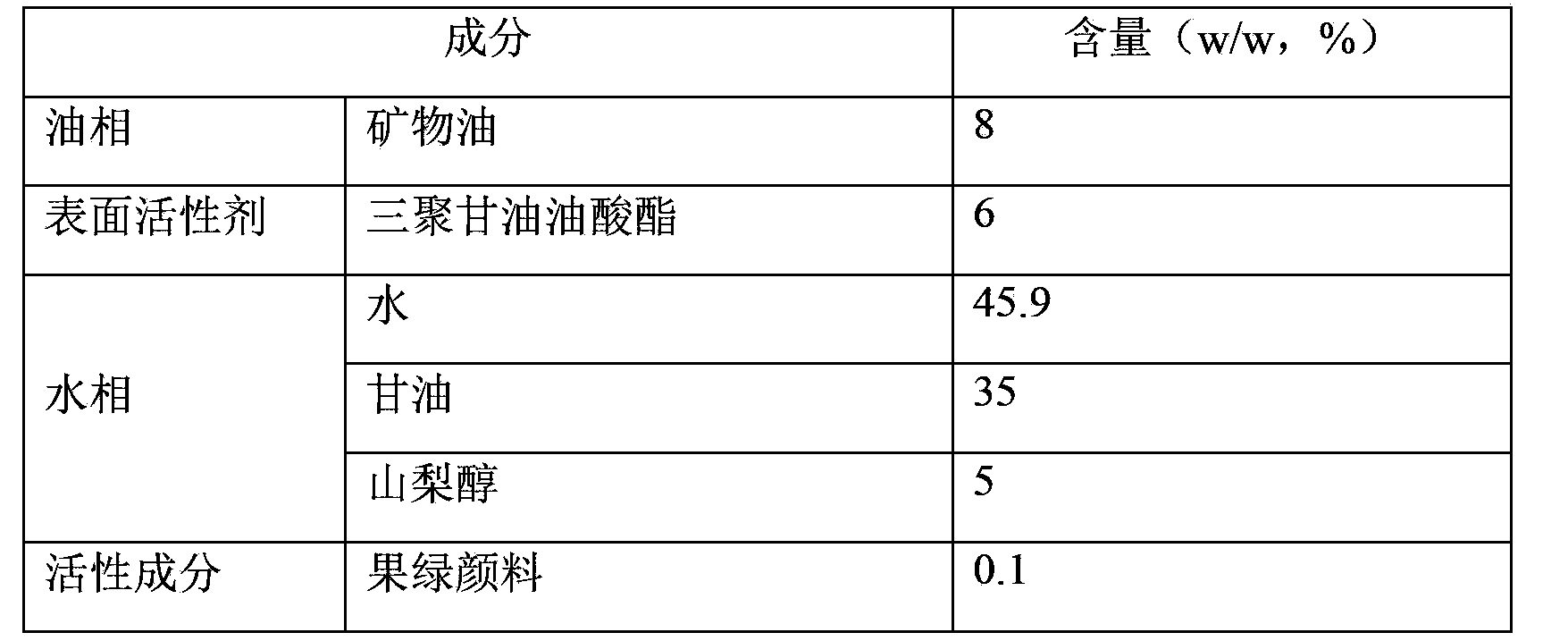

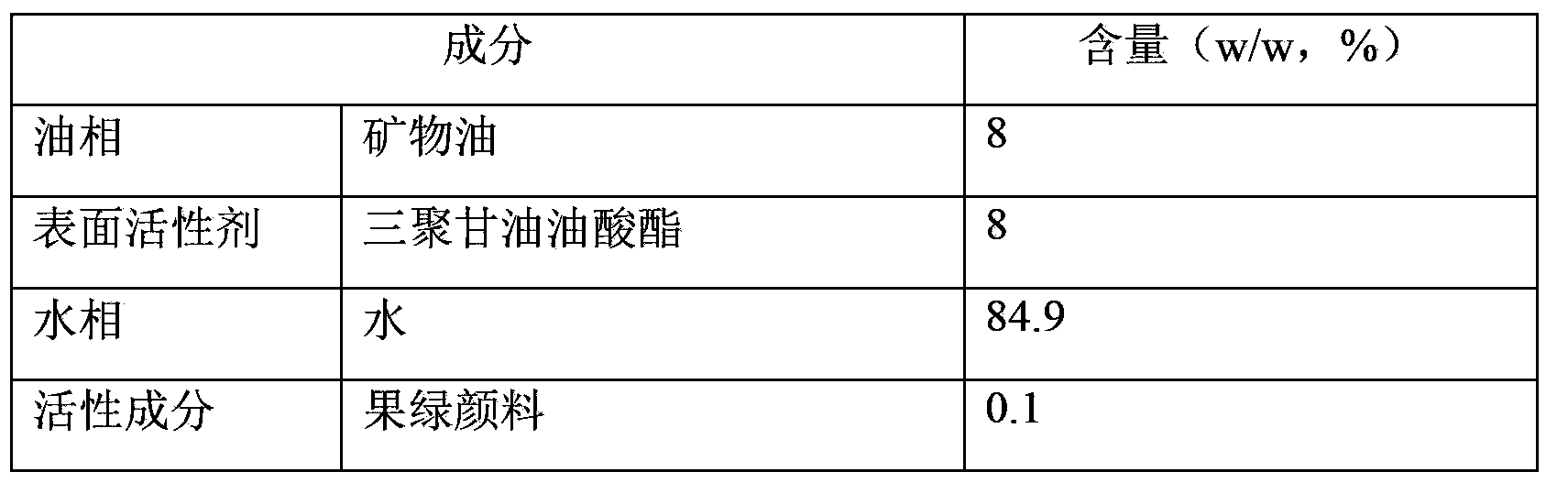

Expandable biological adhesive sustained and controlled release preparation for preventing and curing oral diseases and preparation method thereof

ActiveCN102641236BFully contactedGood bioadhesionAerosol deliveryDigestive systemOral diseaseAdhesive

The invention discloses an expandable biological adhesive sustained and controlled release preparation for preventing and curing oral diseases, which consists of a water phase, a surfactant and an oil phase. Active ingredients for preventing and curing the oral diseases exist in the water phase and / or the oil phase, wherein the water phase is an inner phase, the oil phase is an outer phase, the boundary of the water phase and the oil phase is constructed and maintained by the surfactant, and the water phase and the oil phase are in a uniform and fully osculatory state. The invention also discloses a preparation method of the biological adhesive sustained and controlled release preparation. Through the preparation, a drug sustained and controlled release mode is formed, a product is lasting and effective, the frequency of usage of the product is reduced, the compliance of the product is increased, and the use cost is reduced; and the release preparation exists at drug administration target positions in a plastic physical form, so that the active ingredients in the product effectively cover the drug administration target positions, even the drug administration target positions with complex physiological structures, such as teeth in an oral cavity and periodontal pocket between gingivae.

Owner:PIVOT PHARMA TECH SHANGHAI

Electrical washing machine with electrobath being installed

InactiveCN100381631CImprove delivery accuracyShorter run timeOther washing machinesWater/sewage treatmentEngineeringControl circuit

A loading electrolytic tank of electric washer sets solenoid water supply valve, electrolytic tank, square switching valve and detegent container with air absorption valve on body box for releasing detergent accurately. It is featured as connecting said devices with duct and supplying power to then with control circuit.

Owner:HANGZHOU KAMBAYASHI ELECTRONICS

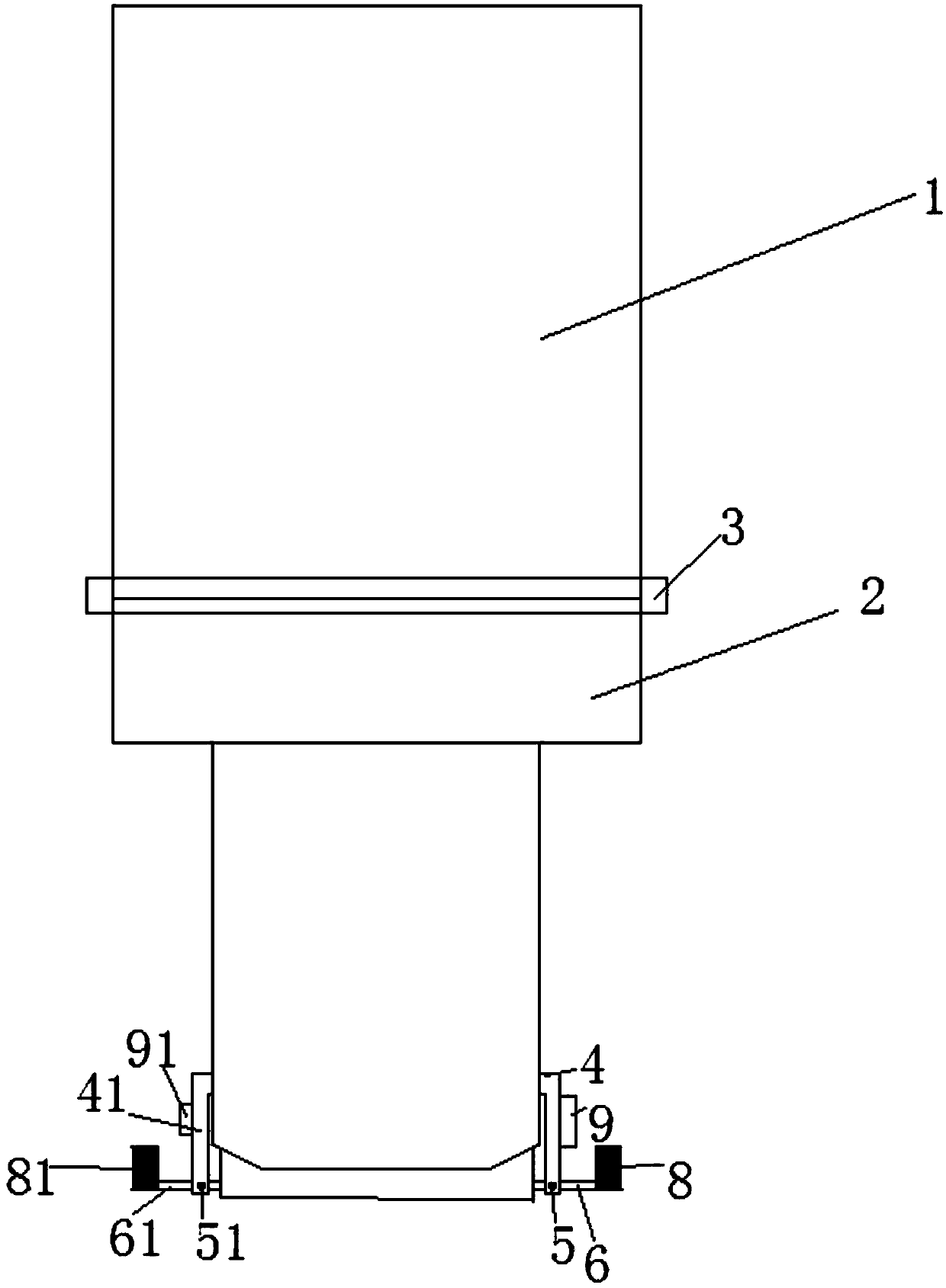

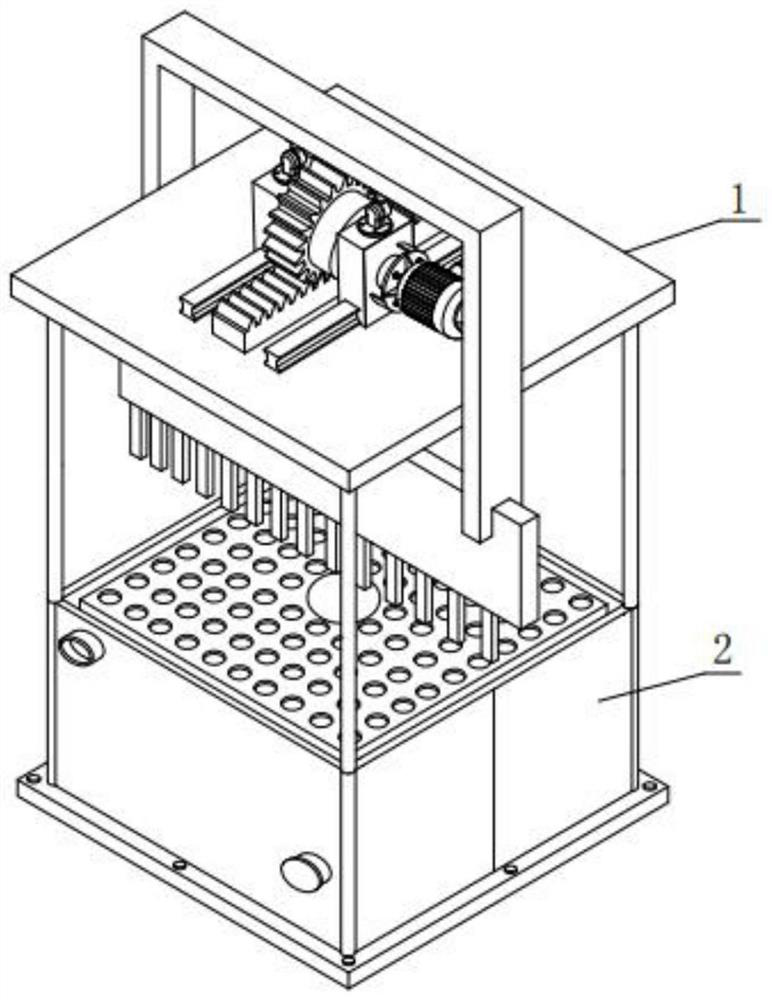

Storable type pollution-free waste briquetting machine

InactiveCN103407714BReduce drippingNo dripRefuse transferringStorage devicesProcess engineeringMechanical engineering

The invention discloses a storable type pollution-free waste briquetting machine. The storable type pollution-free waste briquetting machine comprises a molding box, a pushing box, a leveling box and a storage box, and is characterized in that a stress beam is installed above the molding box, a vertical pressure oil cylinder connected with a vertical pressure plate frame which can extend into the molding box is installed on the stress beam, the pushing box is installed in front of the molding box, a pushing oil cylinder connected with a pushing plate frame which can extend into the molding box is installed in the pushing box, the leveling box is installed on the pushing box, a leveling oil cylinder connected with a leveling plate frame which can extend into the molding box is installed in the leveling box, a hopper which can be used for pushing a lifting arm to ascend and descend through a lifting oil cylinder and is connected to a hopper bracket is installed in front of the pushing box, the hopper is turned through a turning oil cylinder installed on the hopper bracket, and a discharging gate which can be used for pushing waste blocks from the molding box to the storage box through the discharging gate is installed behind the molding box. Due to the matched large-capacity storage box, the storage capacity is greatly increased, and the phenomenon of queuing of small collecting vehicles cannot occur when a waste transport vehicle does not arrive.

Owner:FUZHOU GUANGHUI ENVIRONMENTAL PROTECTION SANITARYEQUIP

Surface passivation treatment device and treatment process for wind driven generator blade

ActiveCN114438484AEfficient separationKeep the compoundCleaning using toolsMetallic material coating processesWind drivenElectric machine

The invention discloses a surface passivation treatment device and process for a wind driven generator blade, relates to the technical field of passivation treatment, and aims to solve the problem of surface passivation of the wind driven generator blade. According to the surface passivation treatment device and process for the wind driven generator blade, the microwave rod effectively separates some organic matter components from the wind driven generator blade when the wind driven generator blade is soaked under the action of an electromagnetic field, and the original compound state of the wind driven generator blade can be kept; a sealing ring can effectively guarantee that liquid in the passivation box does not leak when the lifting device ascends and descends, a movable motor drives a gear to reciprocate on teeth, a sweeper can reciprocate, a cleaning brush can clean impurities on the passivated wind driven generator blade, the qualified rate after delivery is guaranteed, and the passivating efficiency of the wind driven generator blade is improved. The steel plate ascends or descends in the passivation box, and pickling passivation liquid and rinsing liquid can be injected into the passivation box, so that the blade of the wind driven generator can be passivated more perfectly.

Owner:连云港苏运新能源科技有限公司

Hydraulic system of a fuel dispenser

ActiveCN105502272BImprove convenienceGuaranteed reliabilityLiquid transferring devicesPulp and paper industry

The invention discloses a hydraulic system of an oiling machine. The hydraulic system comprises a flow meter, a motor, a pump, a supporting frame and a base, wherein the flow meter is connected with the pump; the motor is connected with the pump through a transmission mechanism; the pump is mounted on the base through the supporting frame. The hydraulic system further comprises a stand column, a connection frame, a supporting plate and an oil outlet pipe, wherein the lower end of the stand column is fixed on the base; one end of the supporting plate is fixed on a side wall of the stand column; the motor is mounted on the lower side of the supporting plate through the connection frame and the flow meter is mounted on the upper surface of the supporting plate; the pump is connected with the flow meter through the oil outlet pipe; and the pump, the motor and the flow meter are sequentially distributed from bottom to top. According to the hydraulic system of the oiling machine, provided by the invention, the flow meter, the motor and the pump are mounted in a splitting manner, so that the convenience of installation and maintenance is improved. Meanwhile, the motor is not inclined due to an acting force generated by the working of the pump and the working reliability is improved.

Owner:TOKHEIM HENGSHAN TECH GUANGZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com