Patents

Literature

605results about How to "Increase subcooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

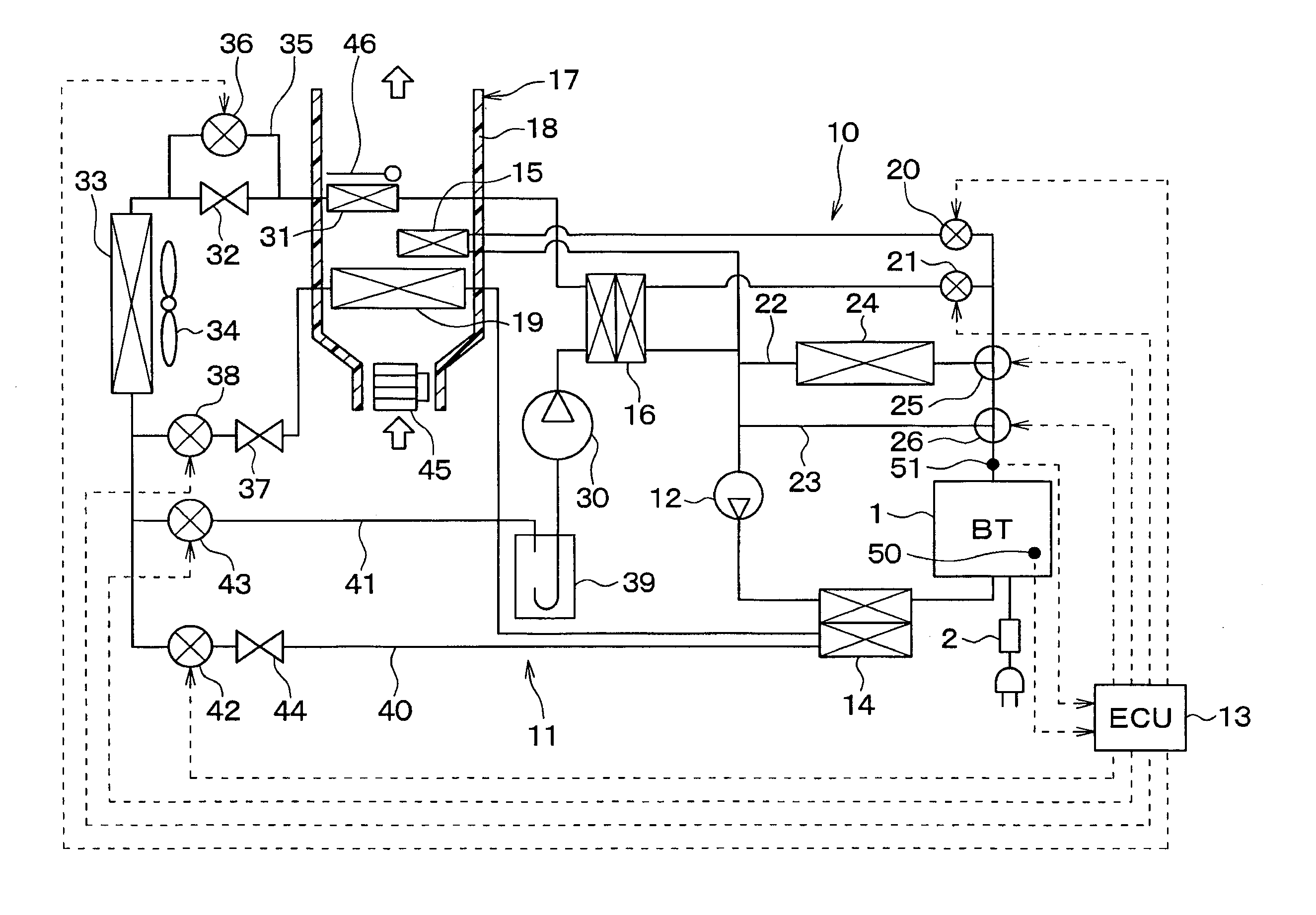

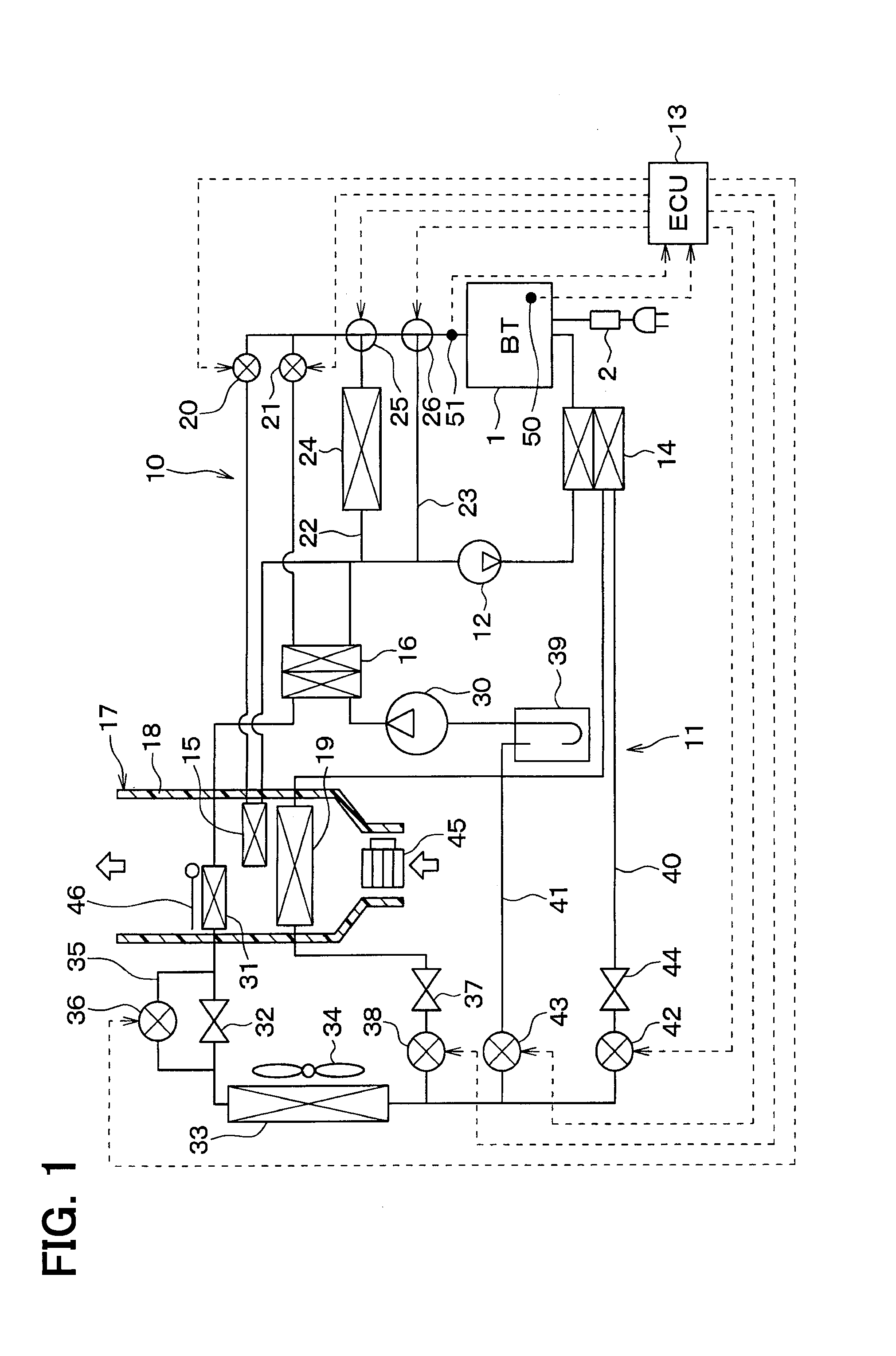

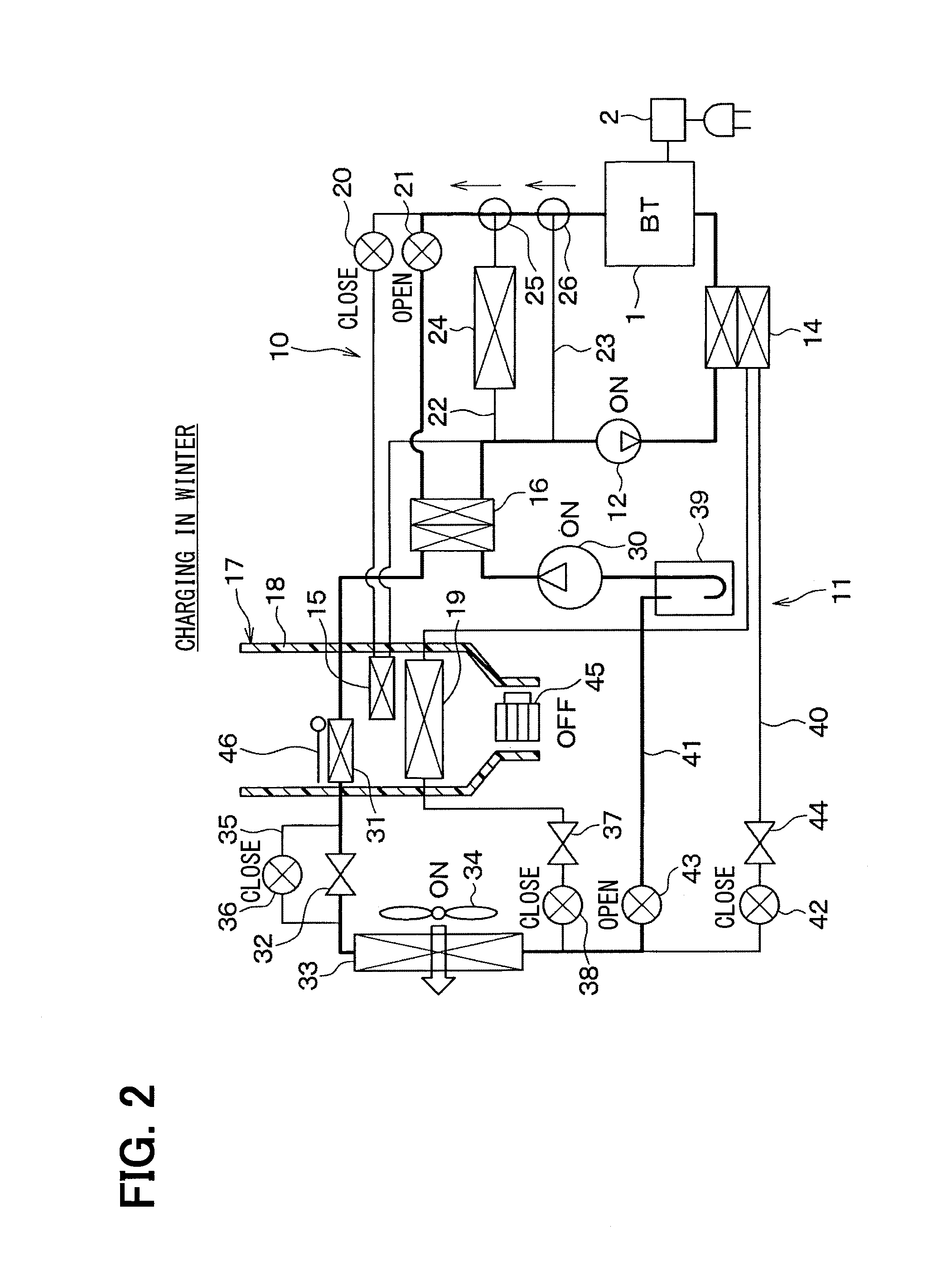

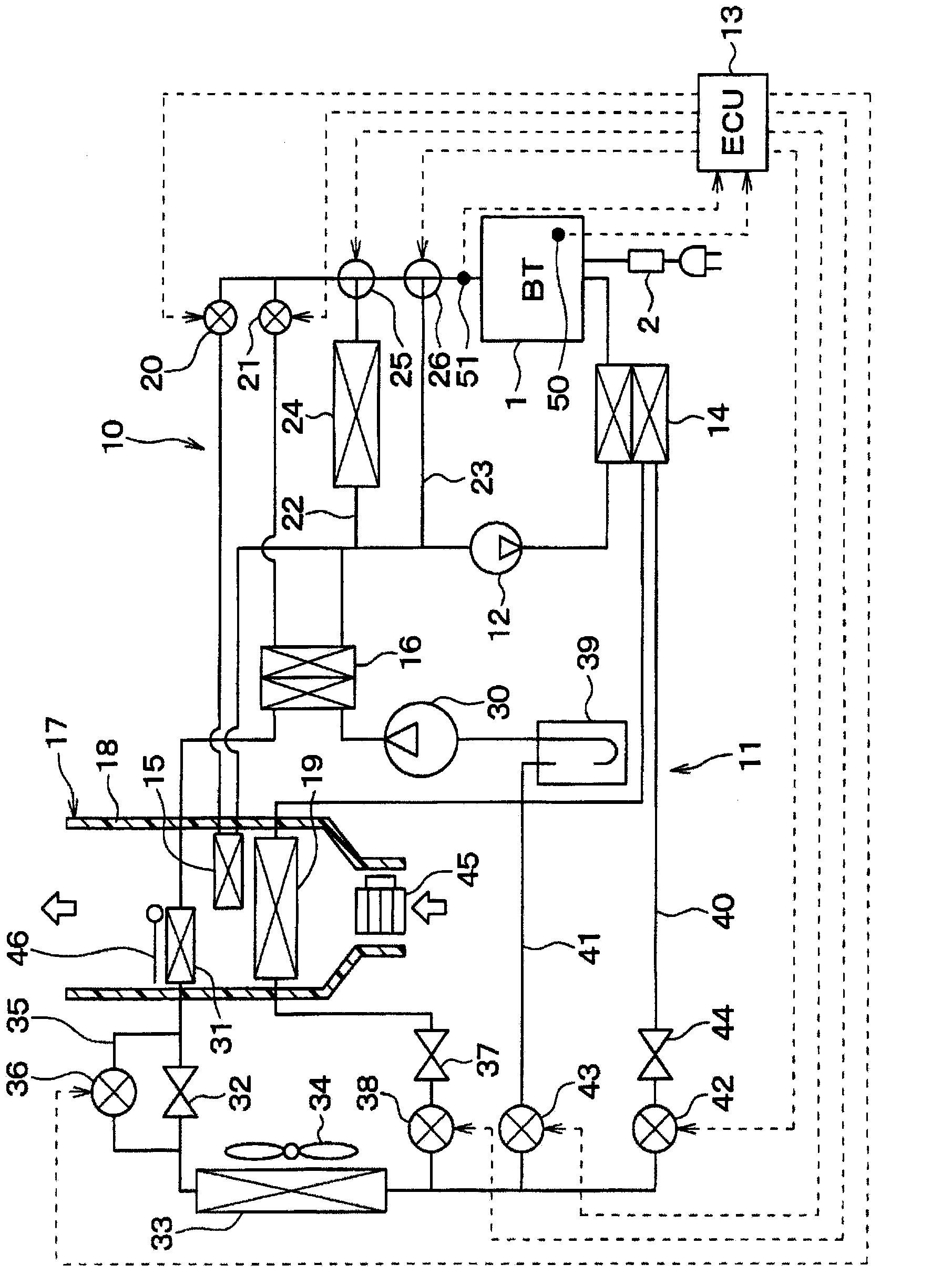

Vehicle temperature control apparatus and in-vehicle thermal system

InactiveUS20140041826A1Increase subcoolingImprove efficiencyTemperatue controlPower to auxillary motorsTemperature controlIn vehicle

A vehicle temperature control apparatus for controlling temperature of a temperature control object, which is at least one of inside air of a vehicle compartment and a vehicle component, includes a heat capacitive element capable of storing heat, a refrigeration cycle in which heat is absorbed from a low temperature side and is dissipated to a high temperature side, a heat exchanger that causes the heat capacitive element to exchange heat with refrigerant of the refrigeration cycle, and a heat dissipation portion which dissipates heat in the refrigerant of the refrigeration cycle to the temperature control object. Thus, a temperature control by using the heat capacitive element can be effectively performed.

Owner:DENSO CORP

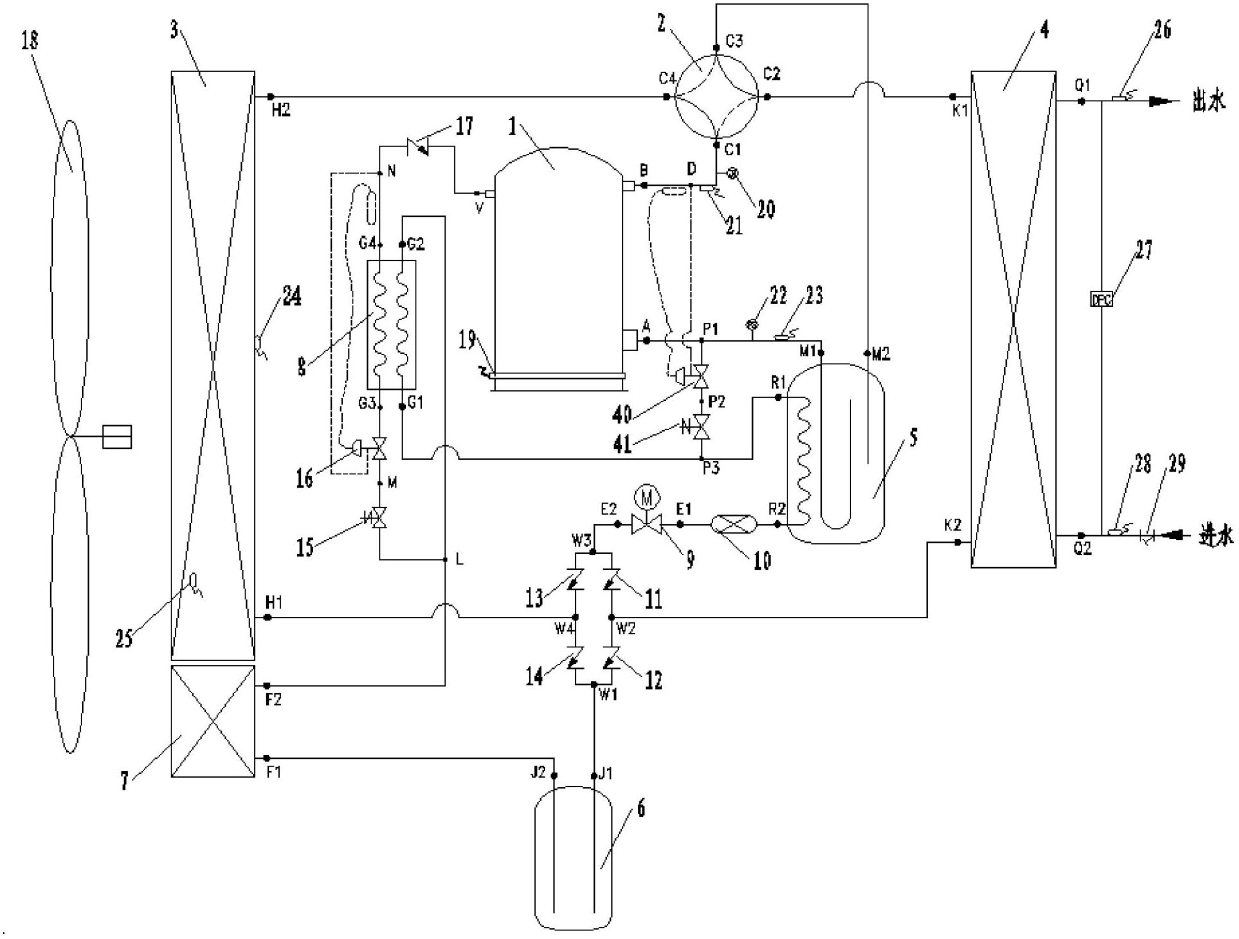

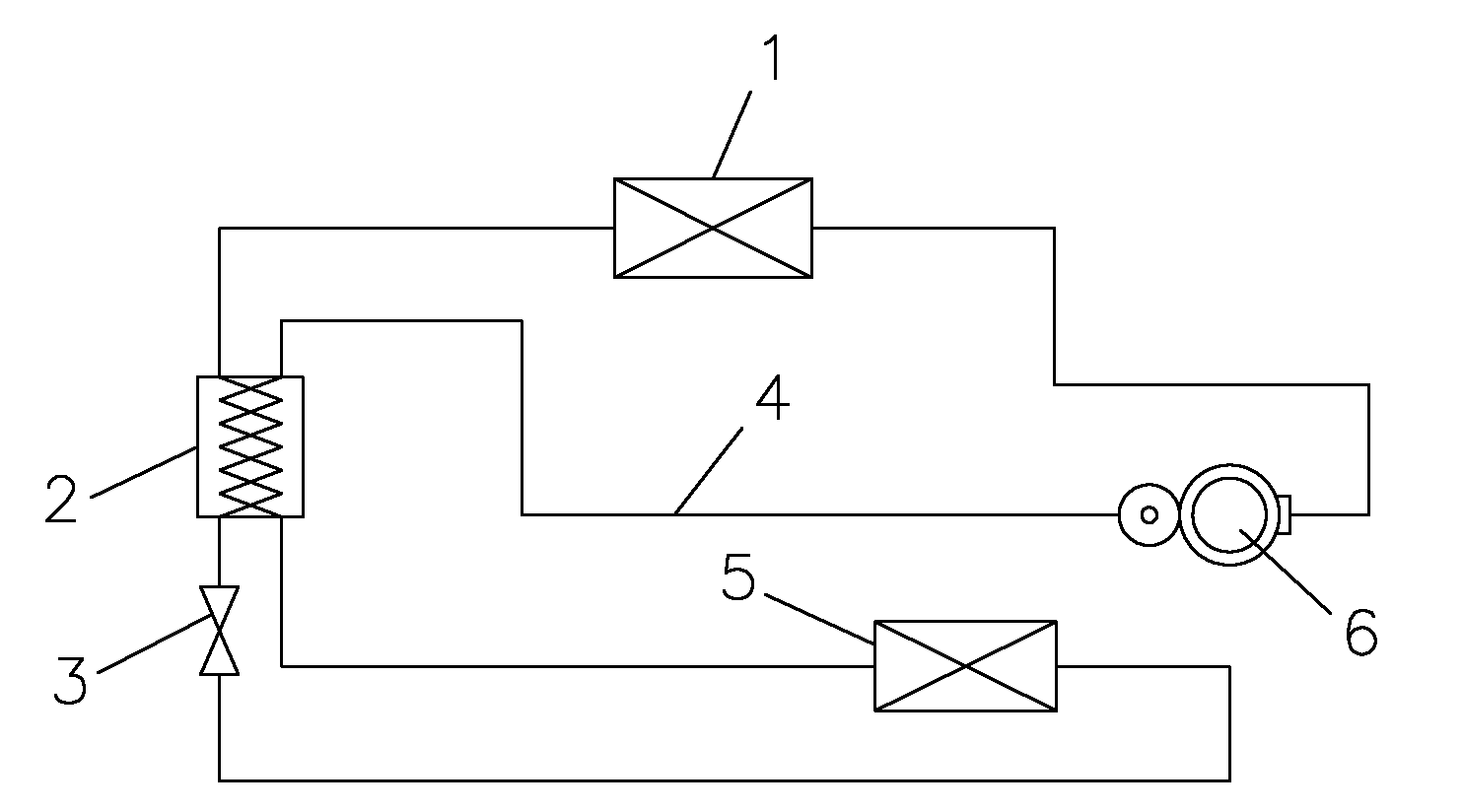

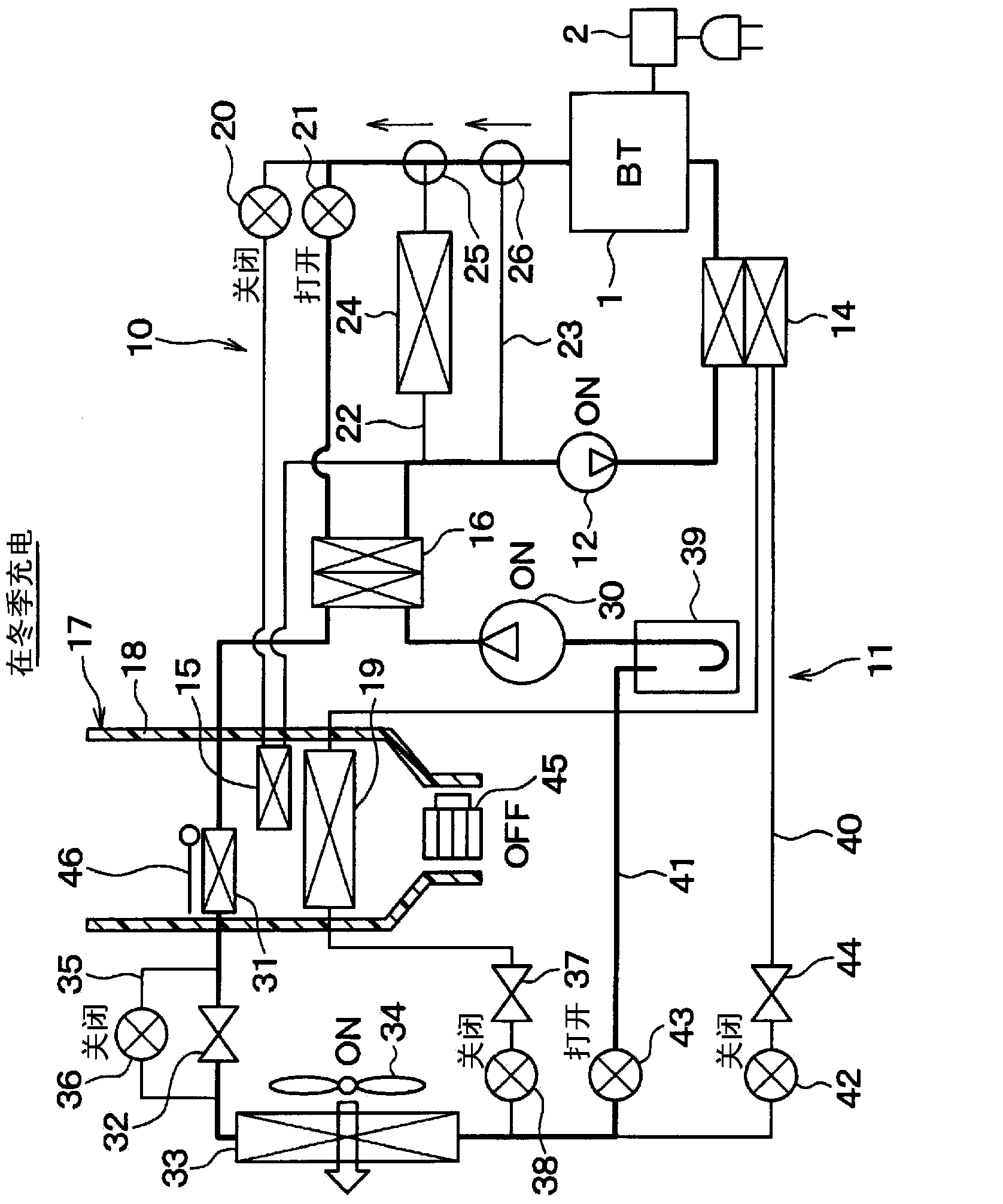

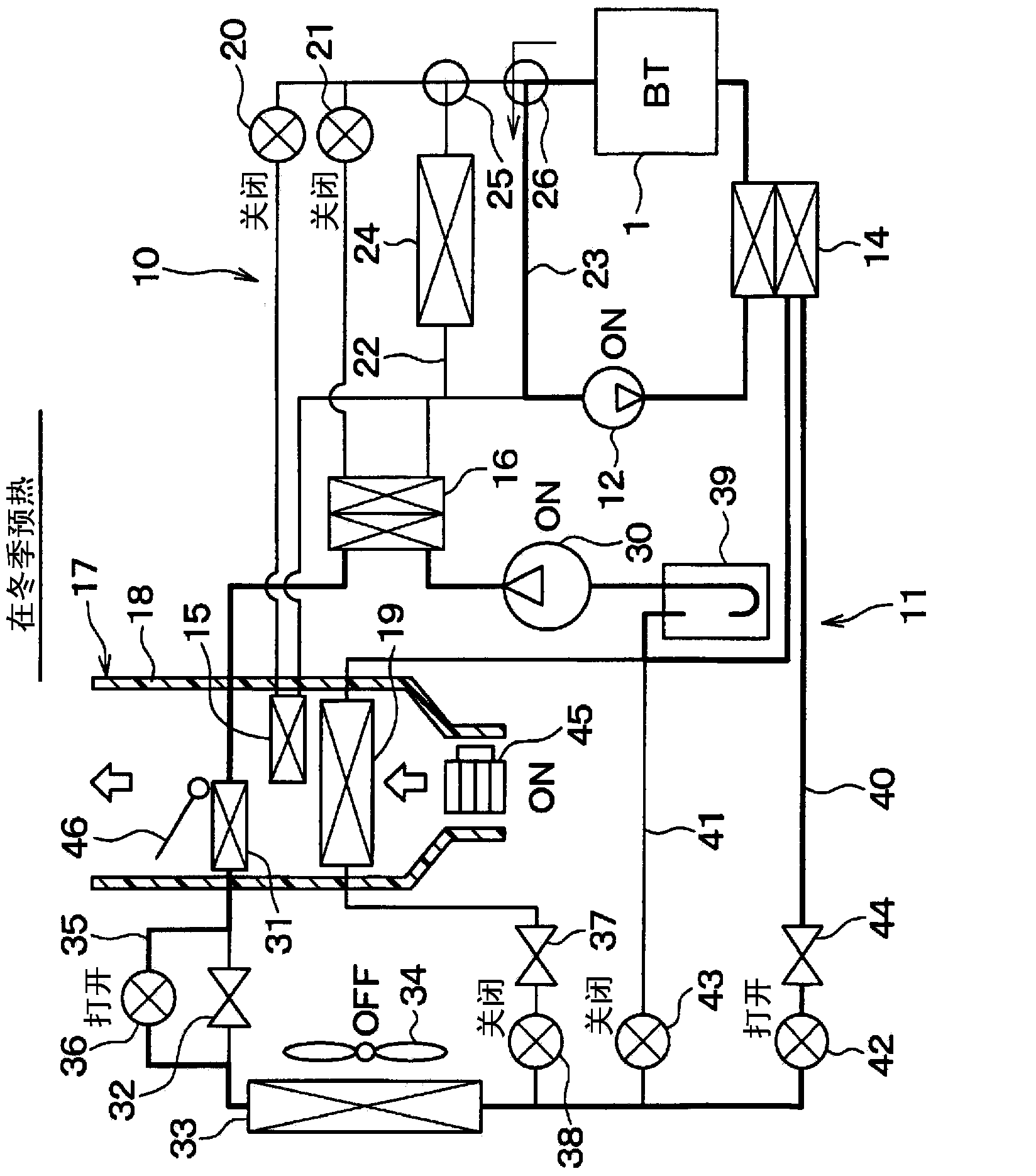

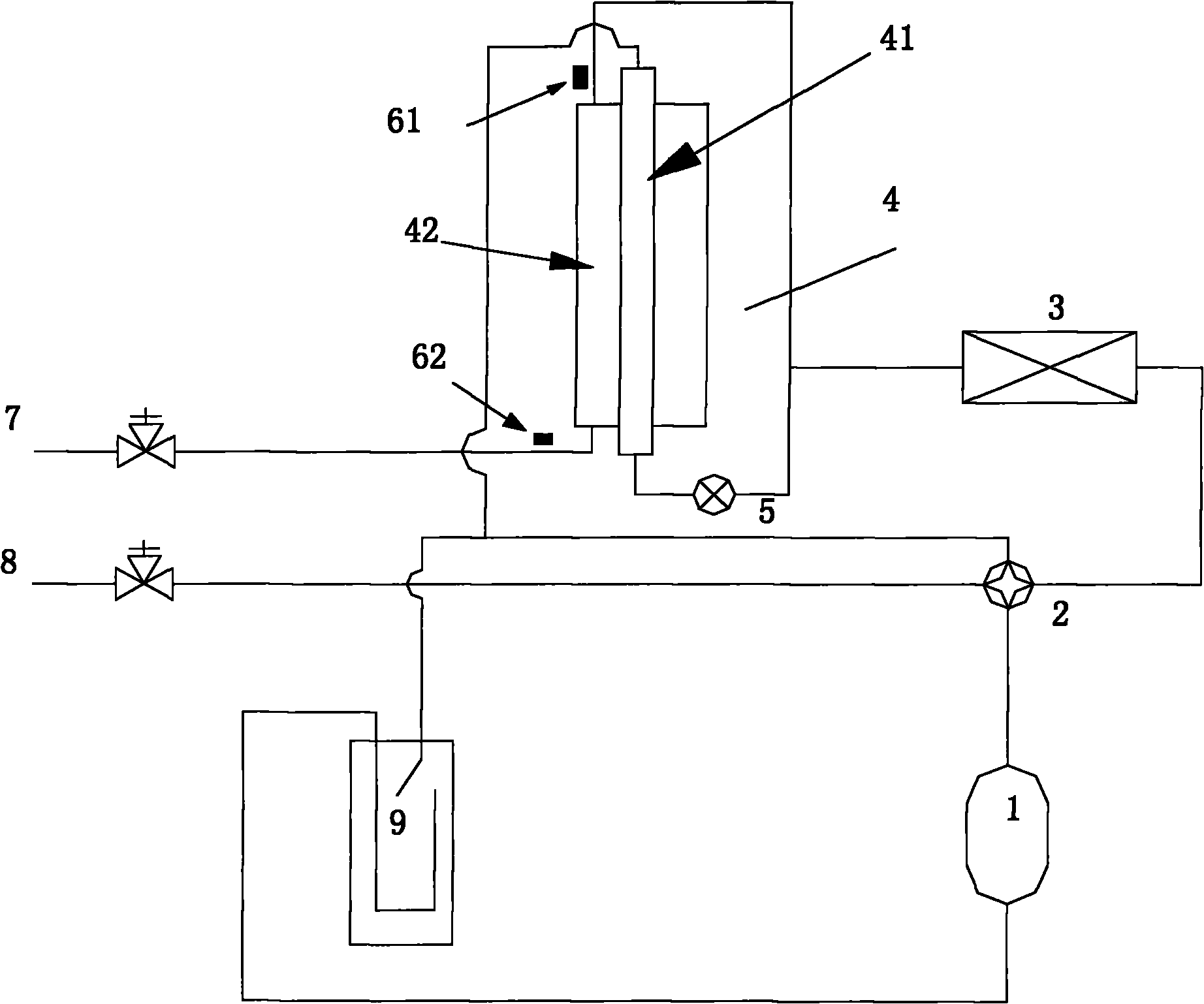

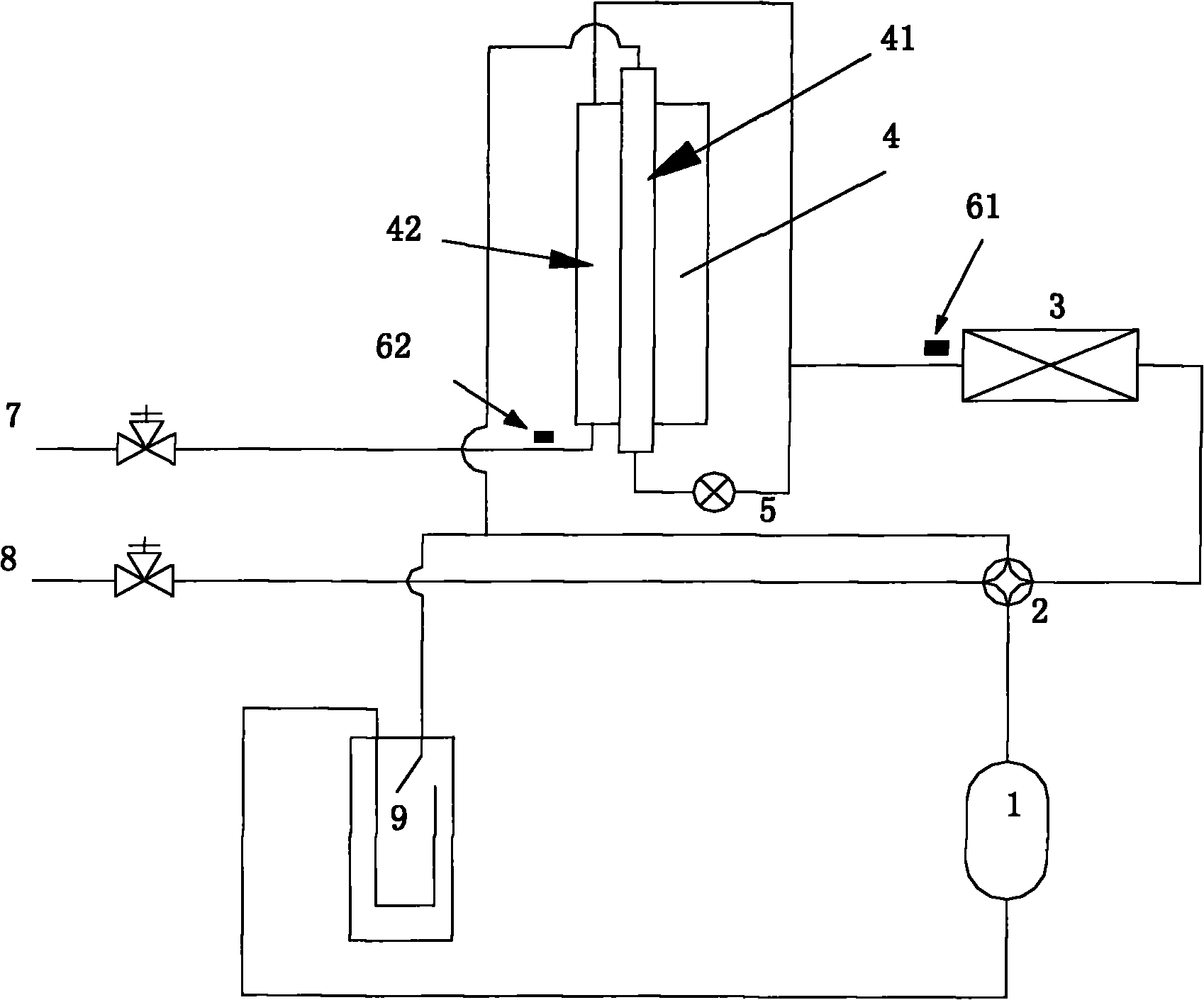

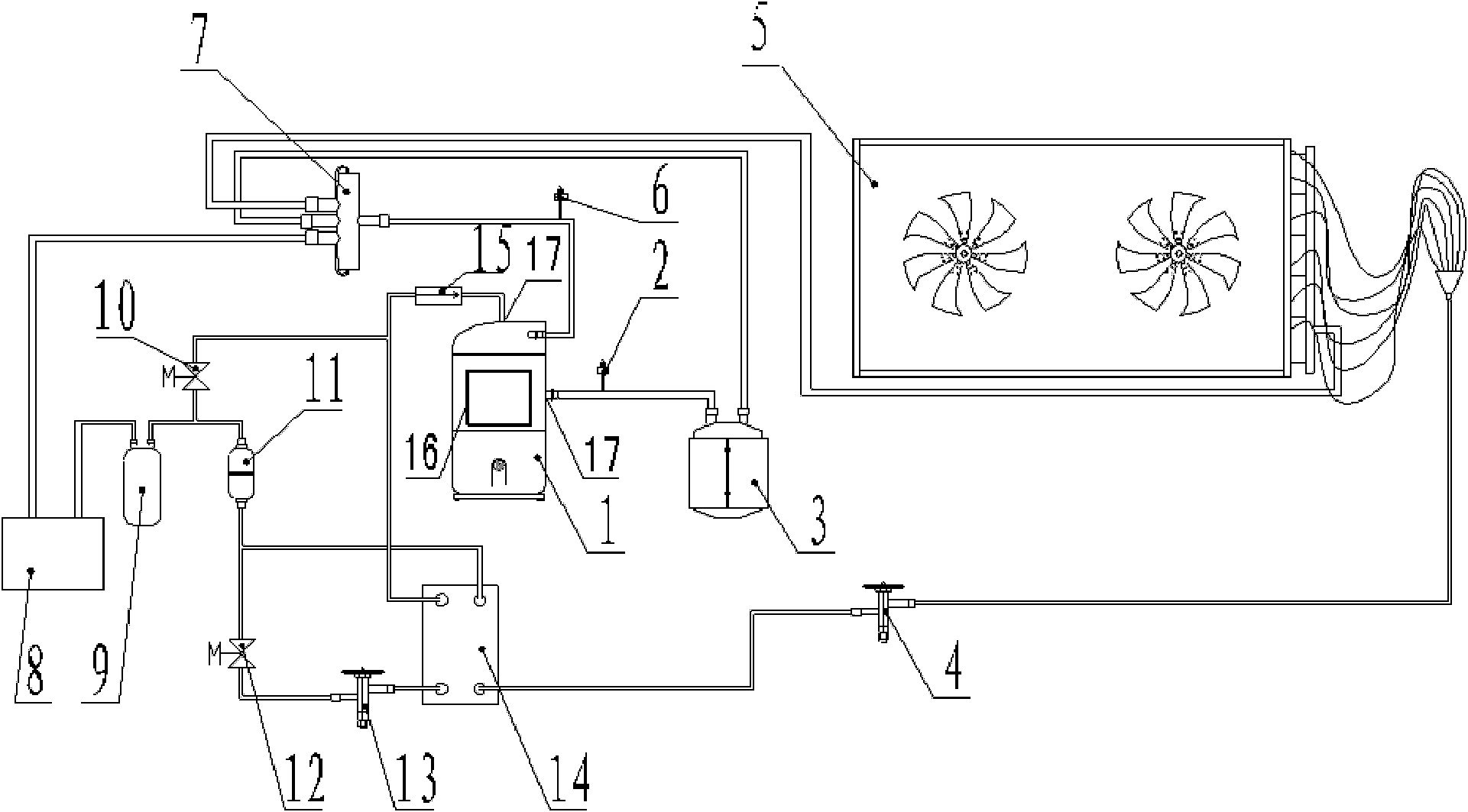

Air-cooled heat pump air conditioner

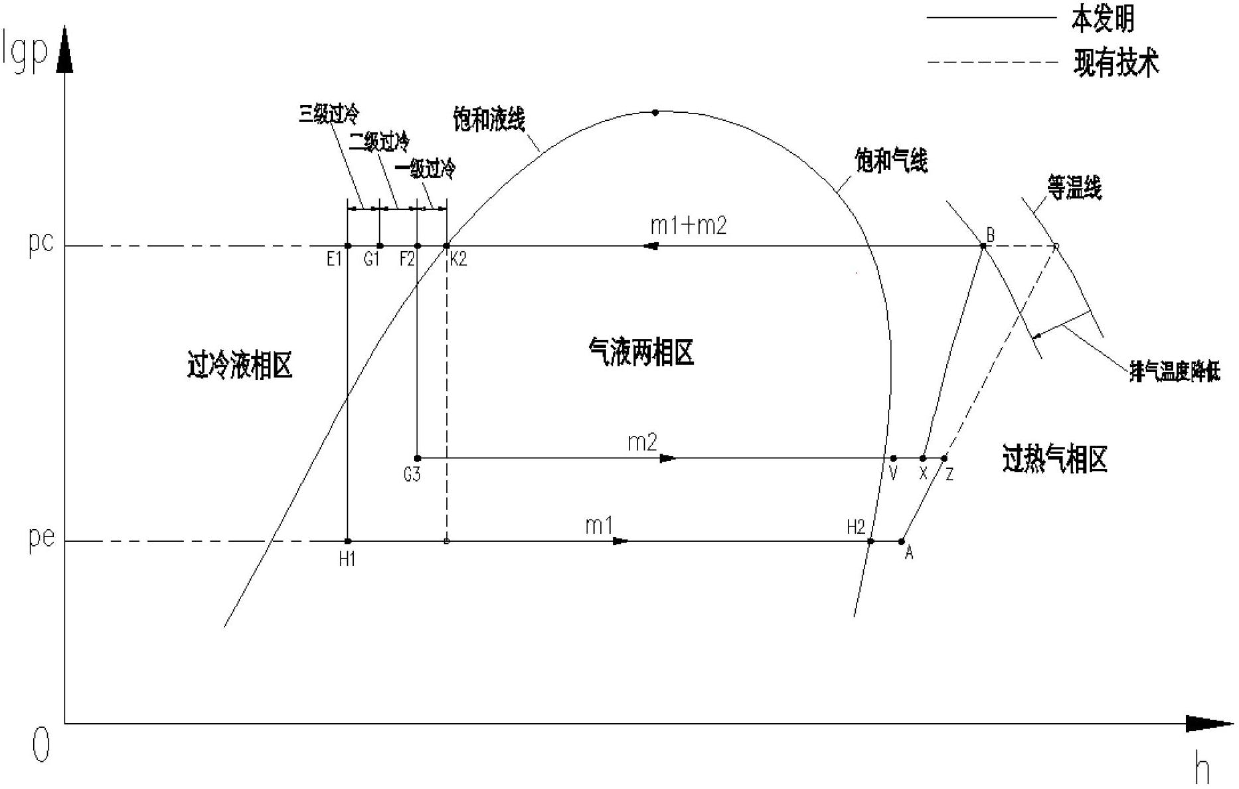

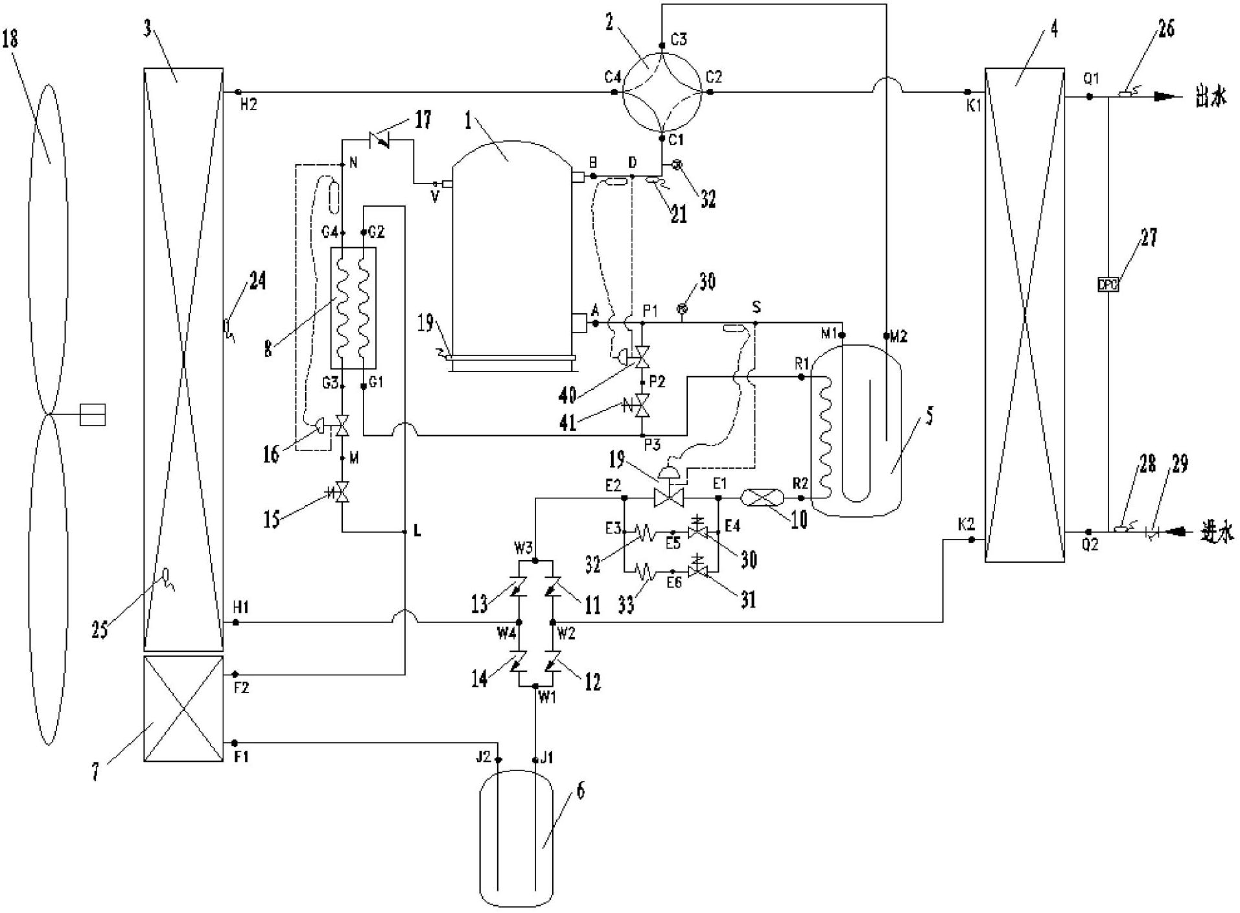

InactiveCN102679609AIncrease subcoolingLow heat recovery functionSubcoolersFluid circulation arrangementLiquid lineVapor–liquid separator

The invention discloses an air-cooled heat pump air conditioner which comprises a compressor, an outdoor coil, a heat exchanger, a main liquid line and supercooling devices, wherein the supercooling devices comprise two or three of a supercooling coil, an economizer and a liquid-vapor separator with a supercooling function, the supercooling devices are arranged on the main liquid line, and liquid state refrigerants which circulate in the main liquid line can achieve repeatedly the supercooling through the supercooling devices. According to the air-cooled heat pump air conditioner, the performance of cooling / heating circulation of the air-cooled heat pump air conditioner is effectively improved, so that the air-cooled heat pump air conditioner is stable and reliable in operation and energy saving in a low-temperature environment.

Owner:四川同达博尔置业有限公司

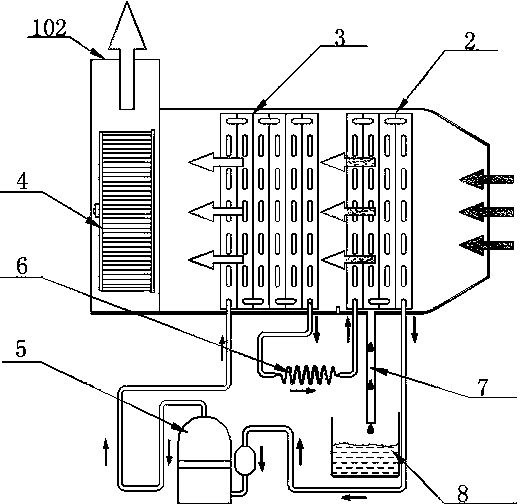

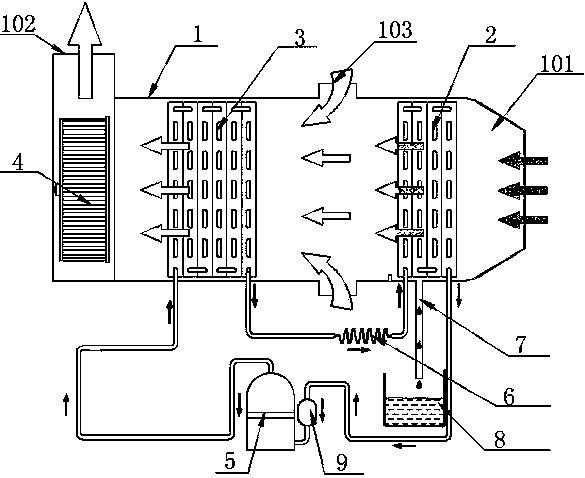

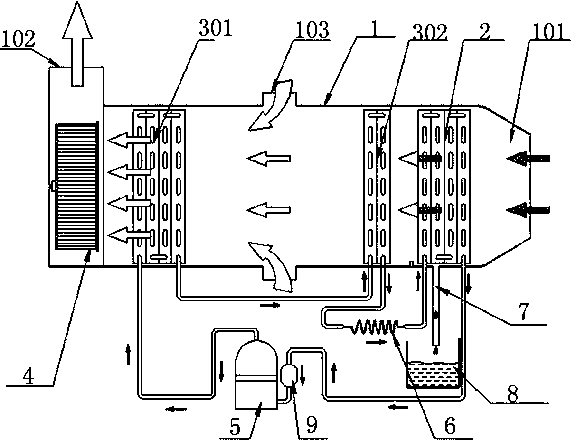

Low-condensing-pressure deep supercooling efficient dehumidifier

ActiveCN104019574AReduce condensing pressureReduce power consumptionCompression machines with several condensersBusiness efficiencyThermal bridge

The invention provides a low-condensing-pressure deep supercooling efficient dehumidifier. The low-condensing-pressure deep supercooling efficient dehumidifier comprises an air flue, a first draught fan and a refrigerating and dehumidifying system. The refrigerating and dehumidifying system comprises an evaporator, a first condenser, a second condenser, a compressor and a throttling device. According to the low-condensing-pressure deep supercooling efficient dehumidifier, a bypass airflow channel is additionally arranged in the air flue between the first condenser and the second condenser, so that the ventilation quantity of the first condenser is increased, and the condensing pressure of refrigerating fluid gas in the condensers is reduced; the first condenser is used for heat release and cooling of a sensible heat portion of the overheated refrigerating fluid gas and heat release, condensation and liquefaction of the refrigerating fluid gas, and the second condenser is used for cooling and supercooling of refrigerating fluid; since a finned thermal bridge between the first condenser and the second condenser is disconnected, the supercooling degree of the refrigerating fluid at the tail end of the second condenser is improved, the vaporization ratio of the refrigerating fluid in the throttling device can be lowered, the evaporation and heat absorption capacity of the refrigerating fluid in the evaporator is improved, and the energy efficiency ratio of the dehumidifier is increased substantially.

Owner:HANGZHOU PREAIR ELECTRICAL APPLIANCE IND

Heat pump air conditioner system

InactiveCN104613665AIncrease heat transfer temperature differenceDelay performance decayMechanical apparatusFluid circulation arrangementVapor–liquid separatorSolenoid valve

The invention discloses a heat pump air conditioner system. The heat pump air conditioner system comprises a compressor, an indoor heat exchanger, a first throttling device, an economizer, a second throttling device, an outdoor heat exchanger, a gas-liquid separator and an enhanced vapor injection refrigerating / heating circulating loop partially or totally composed in a third throttling device. The heat pump air conditioner system further comprises a first solenoid valve and a second solenoid valve. A connector of an auxiliary loop of the economizer and a vapor injection opening of the compressor is further communicated with an inlet of the gas-liquid separator through a pipe. The first solenoid valve is arranged on a connection pipe between the auxiliary loop of the economizer and an inlet of the gas-liquid separator. The second solenoid valve is arranged on a connection pipe between the auxiliary loop of the economizer and the vapor injection opening of the compressor. By means of the heat pump air conditioner system, the heat exchange temperature difference between the gas side and the liquid side of the economizer is increased, and higher heat exchange efficiency is achieved; the condensate depression of the system is improved in the refrigerating operating process, and capacity attenuation of unit long piping in the mounting process is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

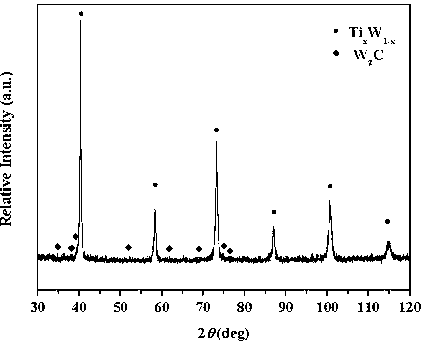

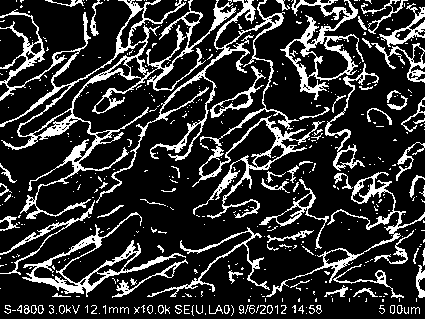

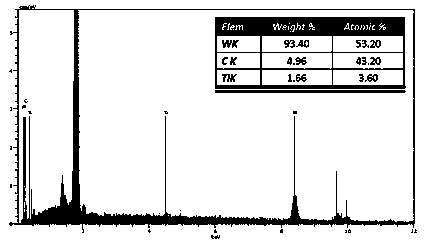

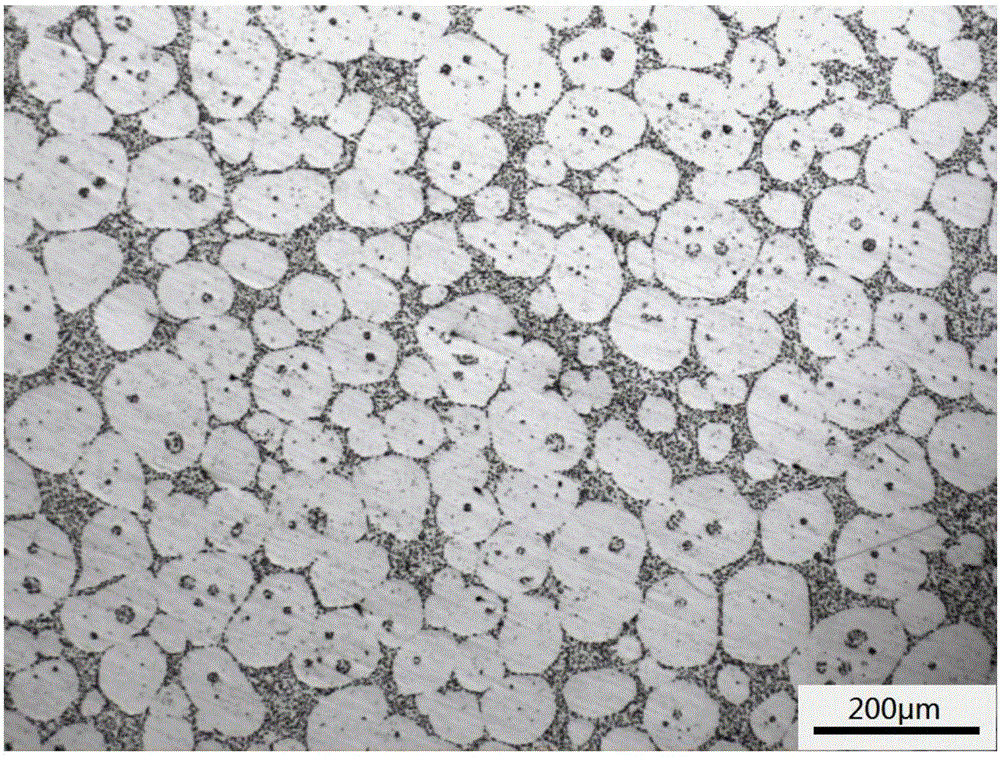

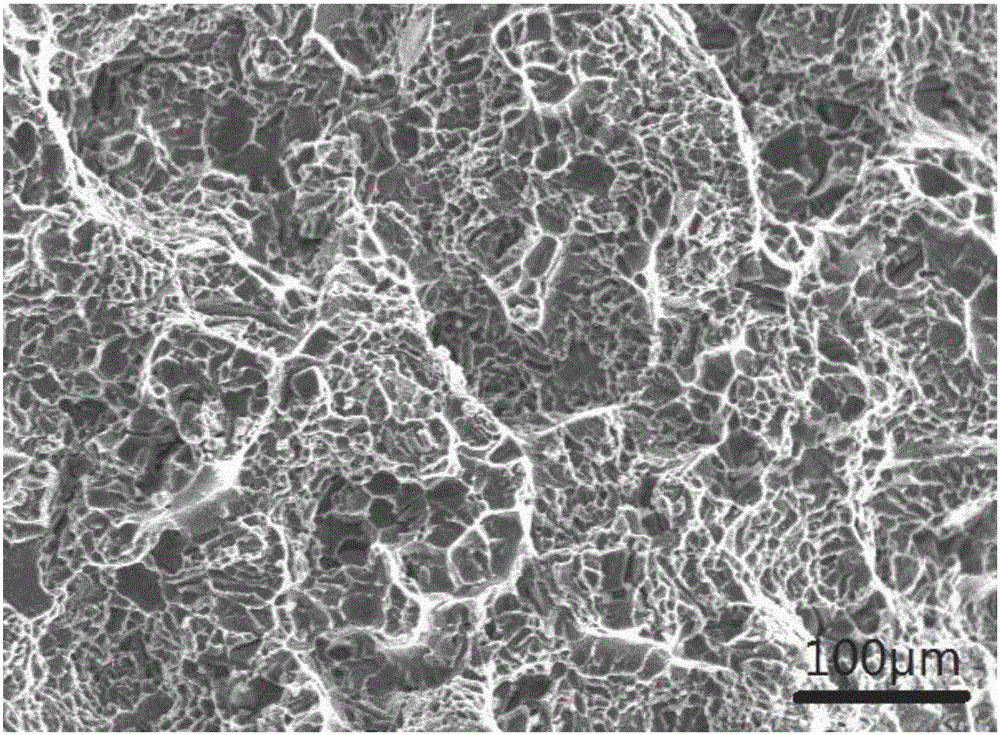

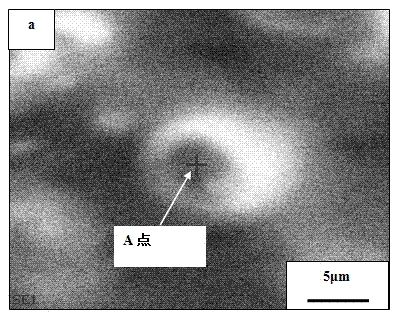

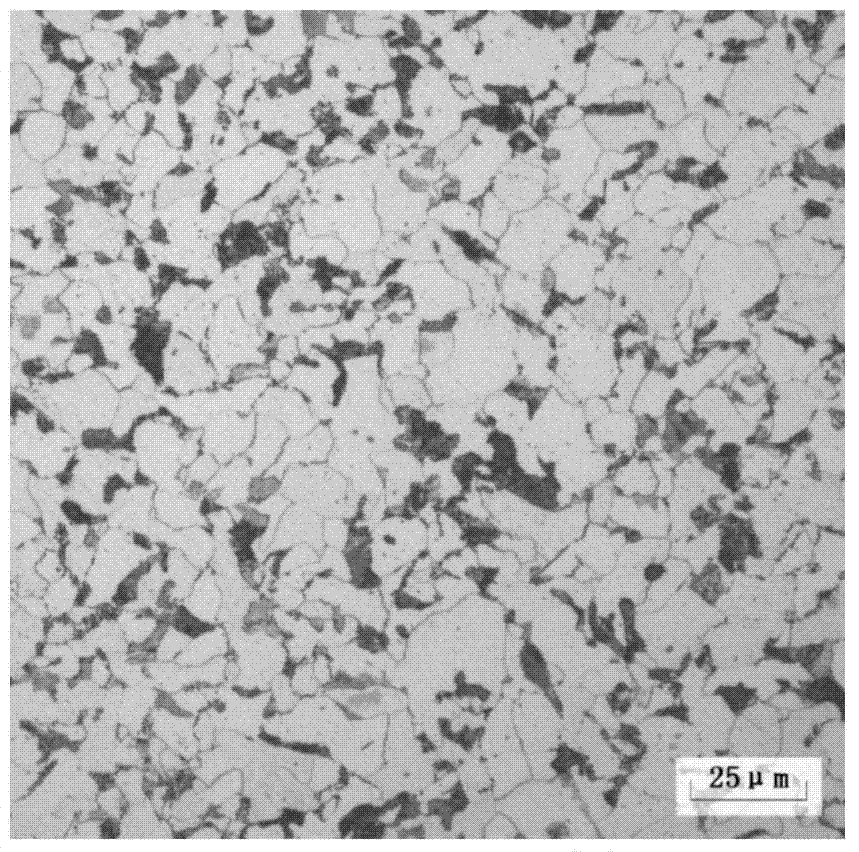

Method for preparing solid solution toughened wolfram-base composite material through laser rapid forming

InactiveCN103074532AImprove microstructureImprove performanceIncreasing energy efficiencySelective laser meltingHigh energy

The invention belongs to the technical field of laser rapid forming, and particularly relates to preparation of a solid solution toughened wolfram-base composite material. A preparation method of the solid solution toughened wolfram-base composite material is as follows: original mixed powder comprises W (wolfram) powder and TiC powder, wherein the TiC powder is 1-1.5wt percent of the total content; and the mixed powder is ball-milled in a high-energy mechanical ball mill for 30-45 h, and then the TiC / W composite material is formed by using a selective laser melting process. The parameters of the adopted laser process are as follows: the powder-bed depth is 50-60 Mum, the laser spot diameter is 200-210 Mum, the laser power is 120-140 W, the laser scanning rate is 100-300 mm / s, and the laser scanning interval is 120-140 Mum. According to the invention, the solid solution toughened wolfram-base composite material is successfully prepared through the method that combines high-energy mechanical ball milling and the selective laser melting process, and the fragility of W material is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

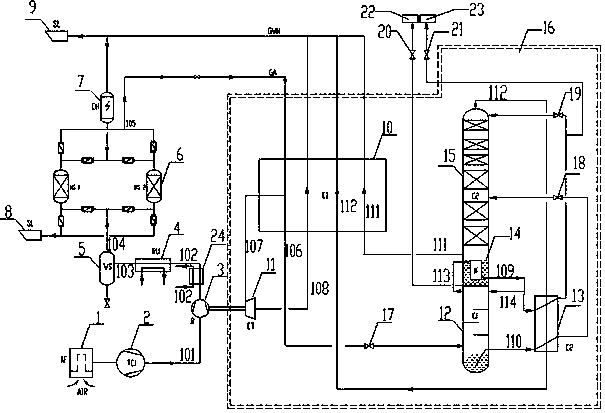

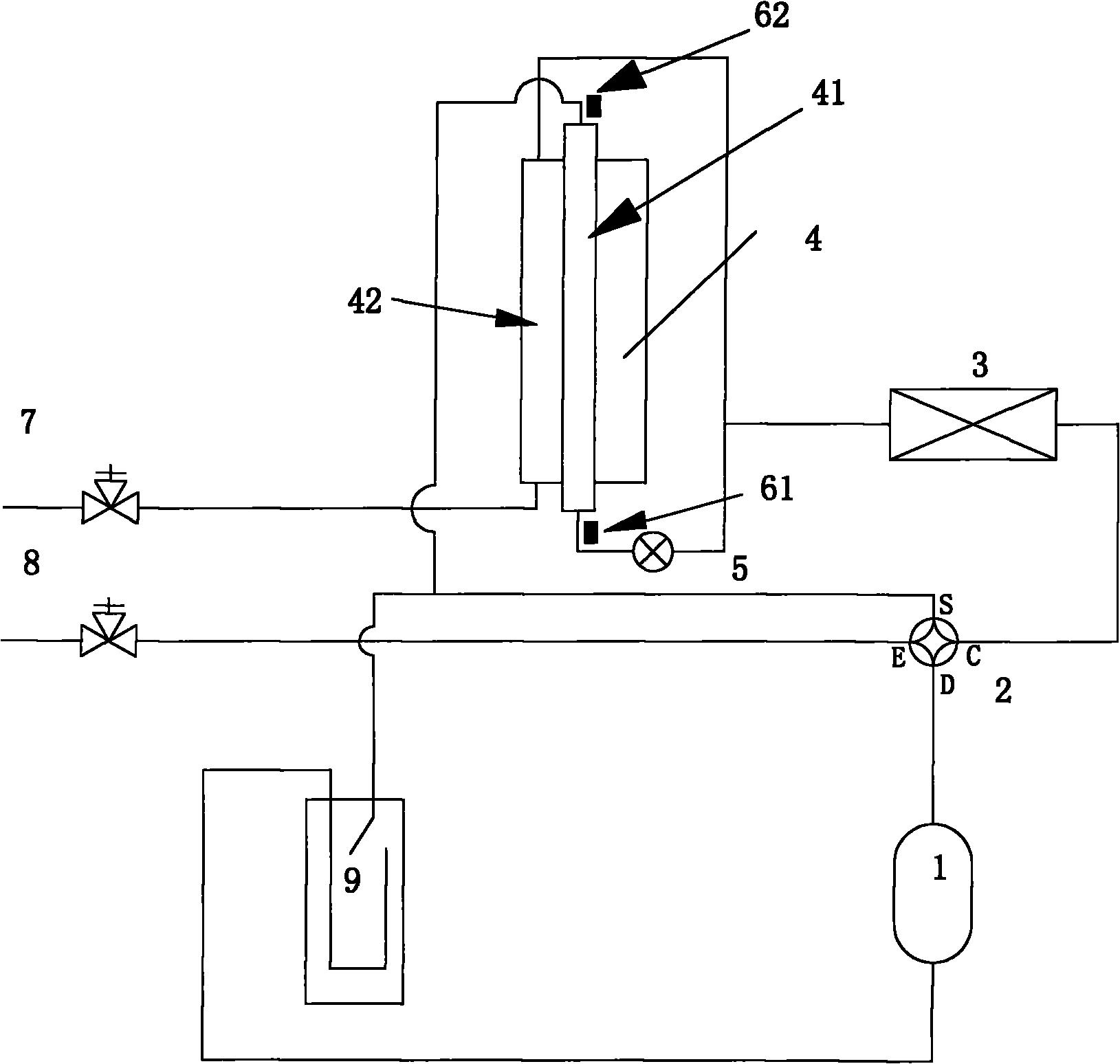

Liquid oxygen and liquid nitrogen preparation device and method

InactiveCN104061757AIncrease subcoolingReduce gasification lossSolidificationLiquefactionAir filterEngineering

The invention relates to a liquid oxygen and liquid nitrogen preparation device and method. The device comprises a self-cleaning air filter, an air compressor, a cold air unit, a separator, a molecular sieve adsorber, a main heat exchanger, a lower tower, an upper tower, a subcooler and an expander. The raw material of the device is air. The air passes through the self-cleaning air filter, the air compressor, the supercharging end of the expander, the cold air unit and the molecular sieve adsorber in sequence and then enters a cold box; after passing through the main heat exchanger, a part of the air is pumped out of the lower middle portion of the main heat exchanger and enters the expanding end of the turbo expander for adiabatic expansion; expanded air is reheated by the main heat exchanger and then sent out of the cold box; the remaining air is cooled to a liquefaction point, goes out of the main heat exchanger and enters the lower tower for rectification. A liquid oxygen product is pumped out of the bottom of the lower tower and then conveyed to a liquid oxygen storage tank; a liquid nitrogen product is pumped out of the main cold liquid nitrogen side and then conveyed to a liquid nitrogen storage tank. According to the liquid oxygen and liquid nitrogen preparation device and method, operation is simple in the technological process, the extraction rate is high, energy consumption is low, and meanwhile equipment investment cost is low.

Owner:KAIFENG AIR SEPARATION GROUP

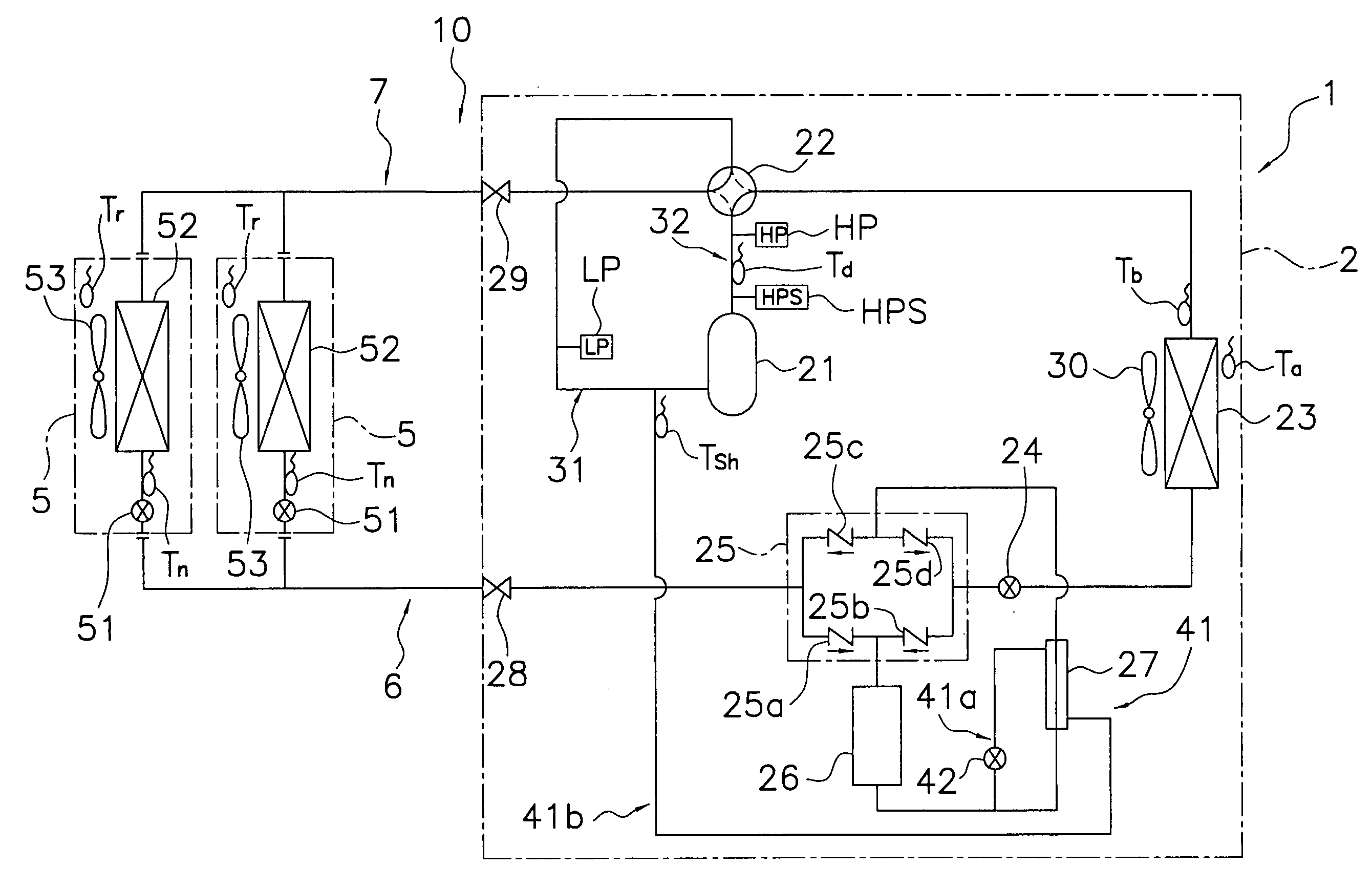

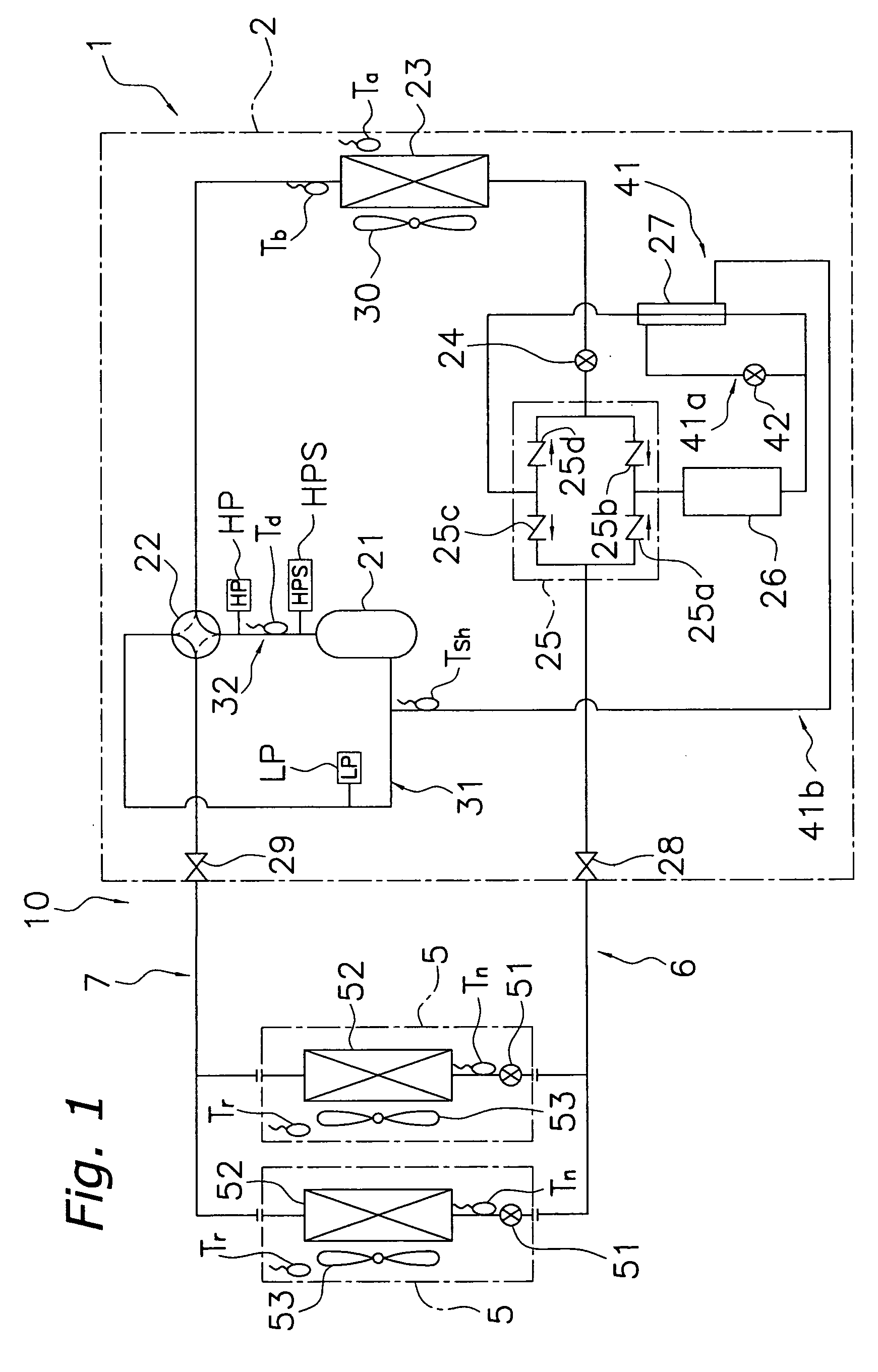

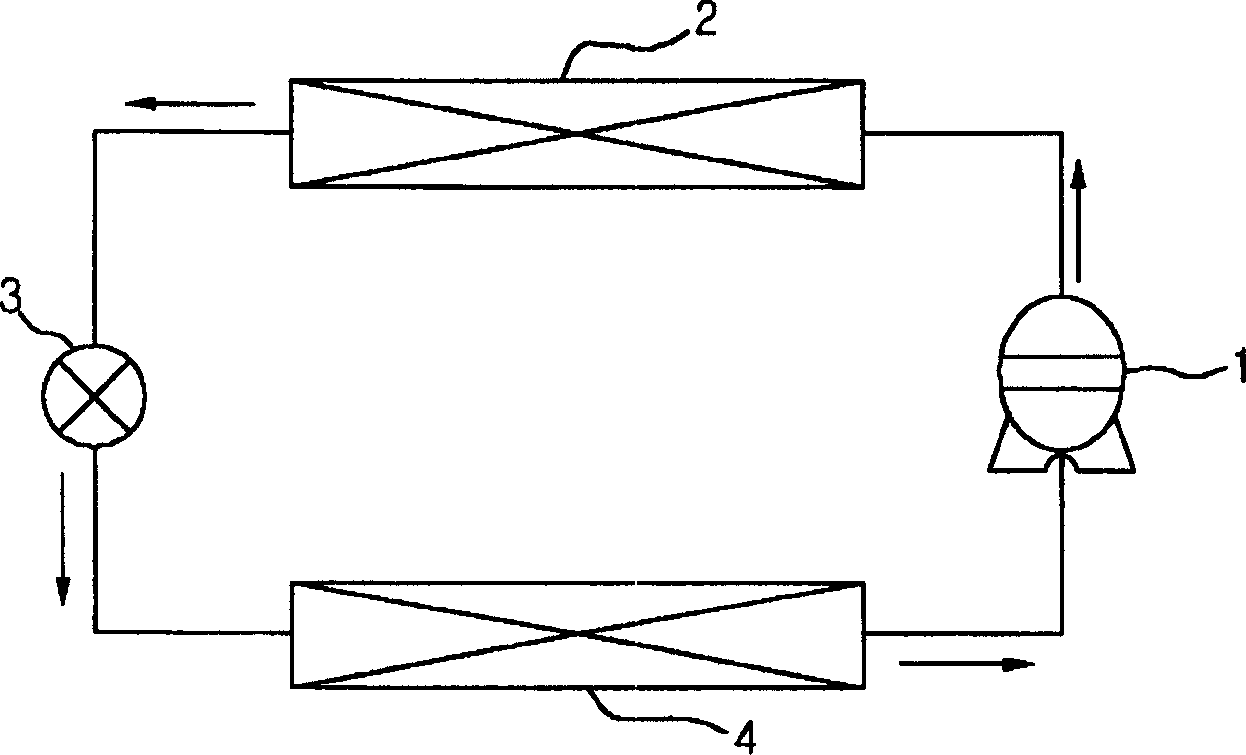

Freezer apparatus

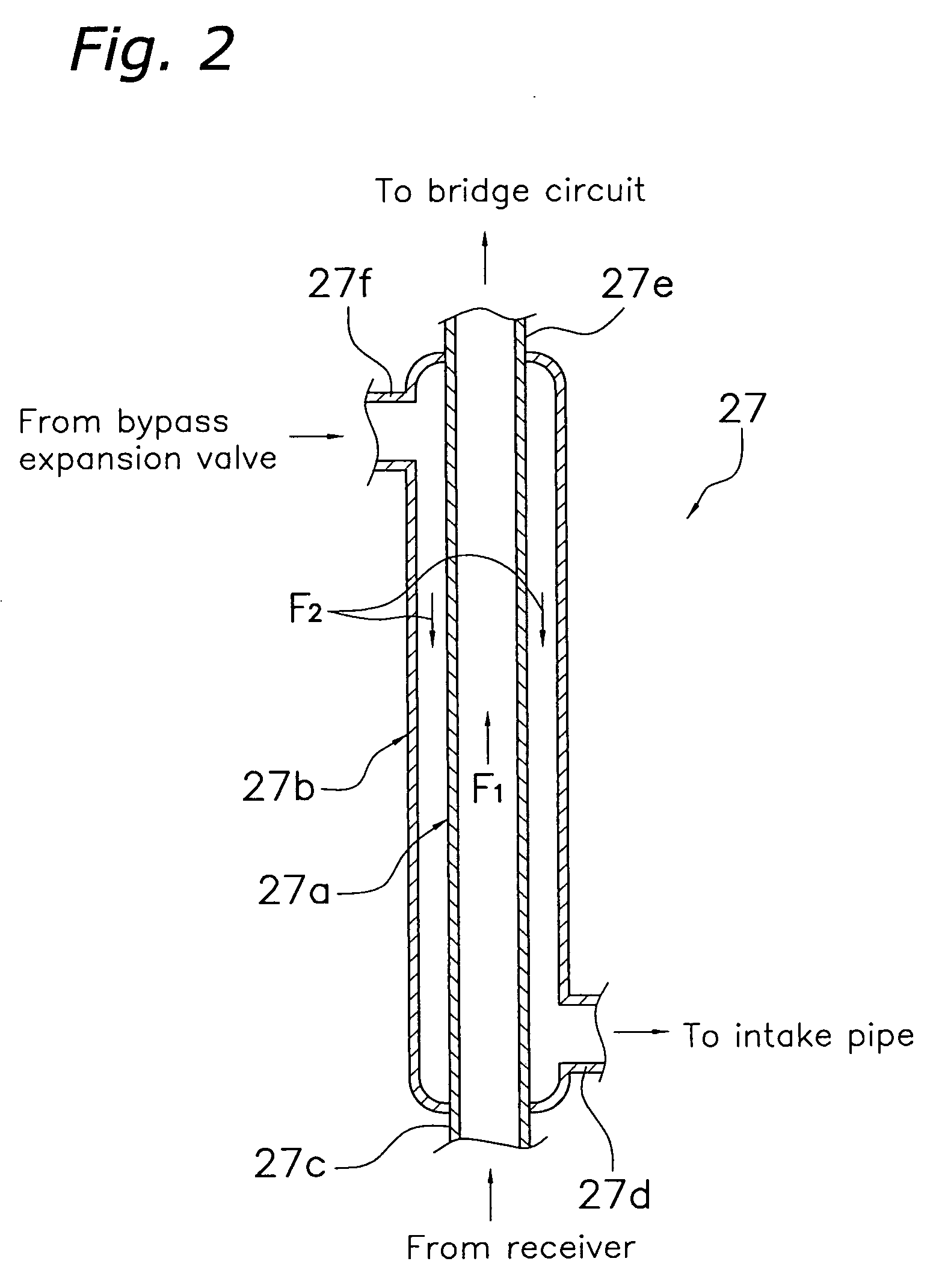

ActiveUS20060048539A1Increase flow rateIncrease subcoolingCompression machines with non-reversible cycleFluid circulation arrangementEngineeringRefrigeration

A refrigeration system to increase the subcooling degree of refrigerant flowing through a main refrigerant circuit is provided. The refrigeration system is configured such that a portion of the refrigerant flowing through the main refrigerant circuit can be made to bypass the remainder of the main refrigerant circuit in a bypass refrigerant circuit so as to be returned to the intake side of a compressor and to be used to cool the refrigerant flowing through the main refrigerant circuit to a subcooled state.

Owner:DAIKIN IND LTD

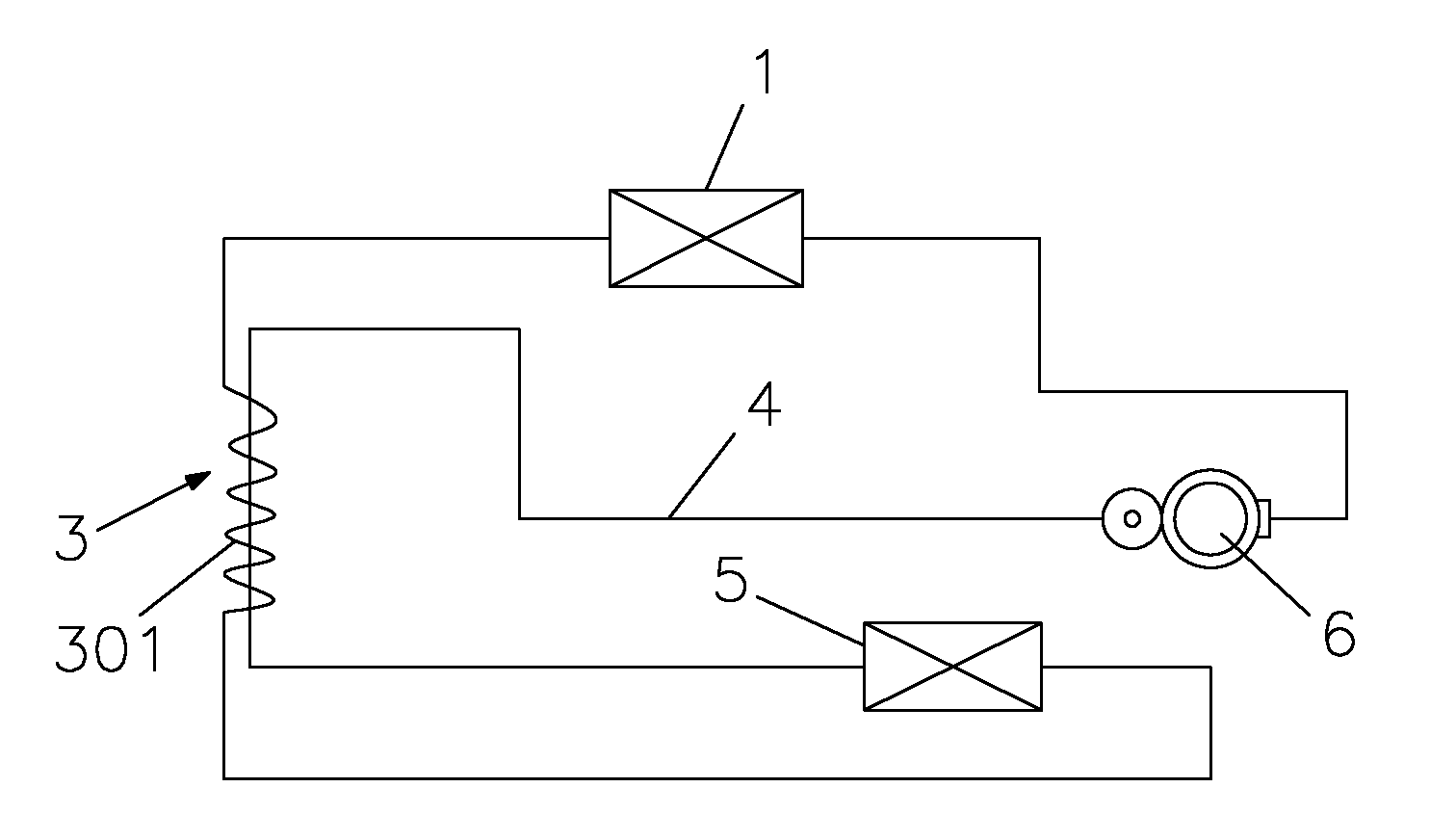

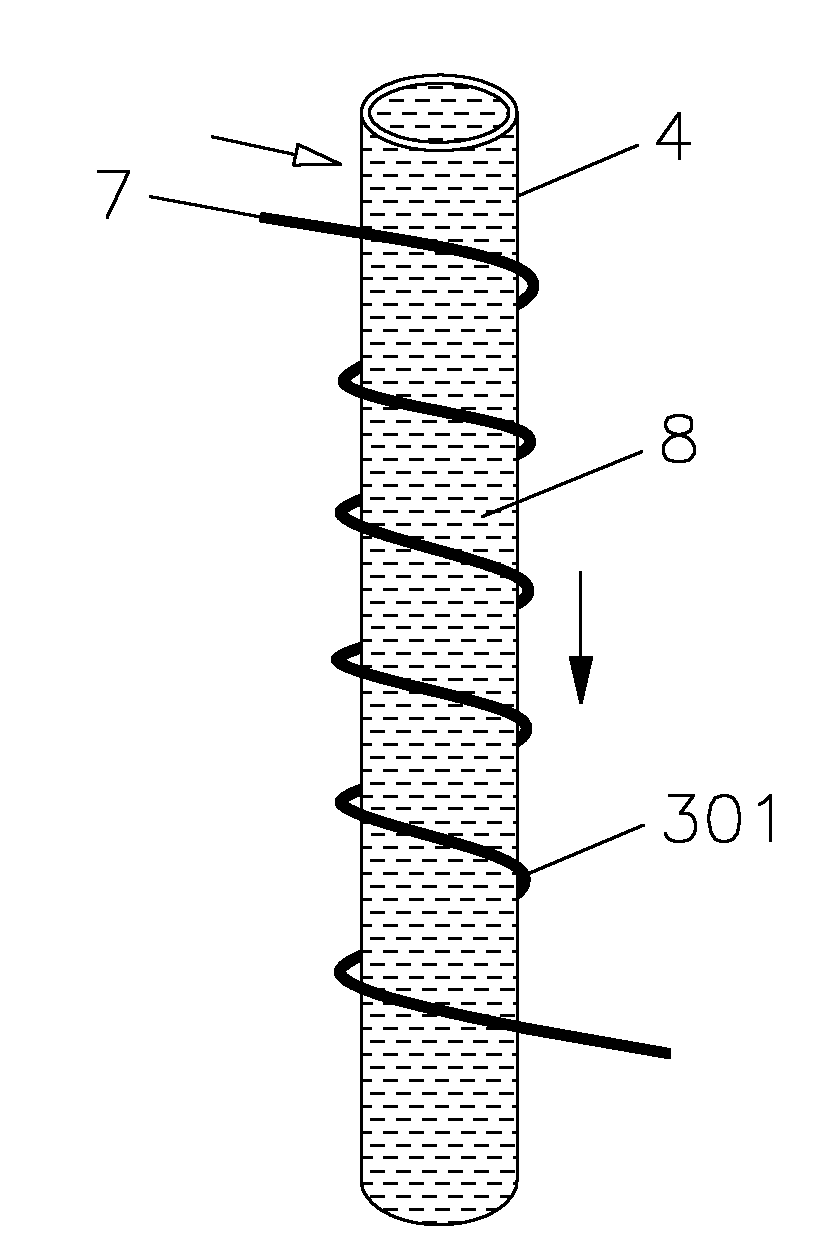

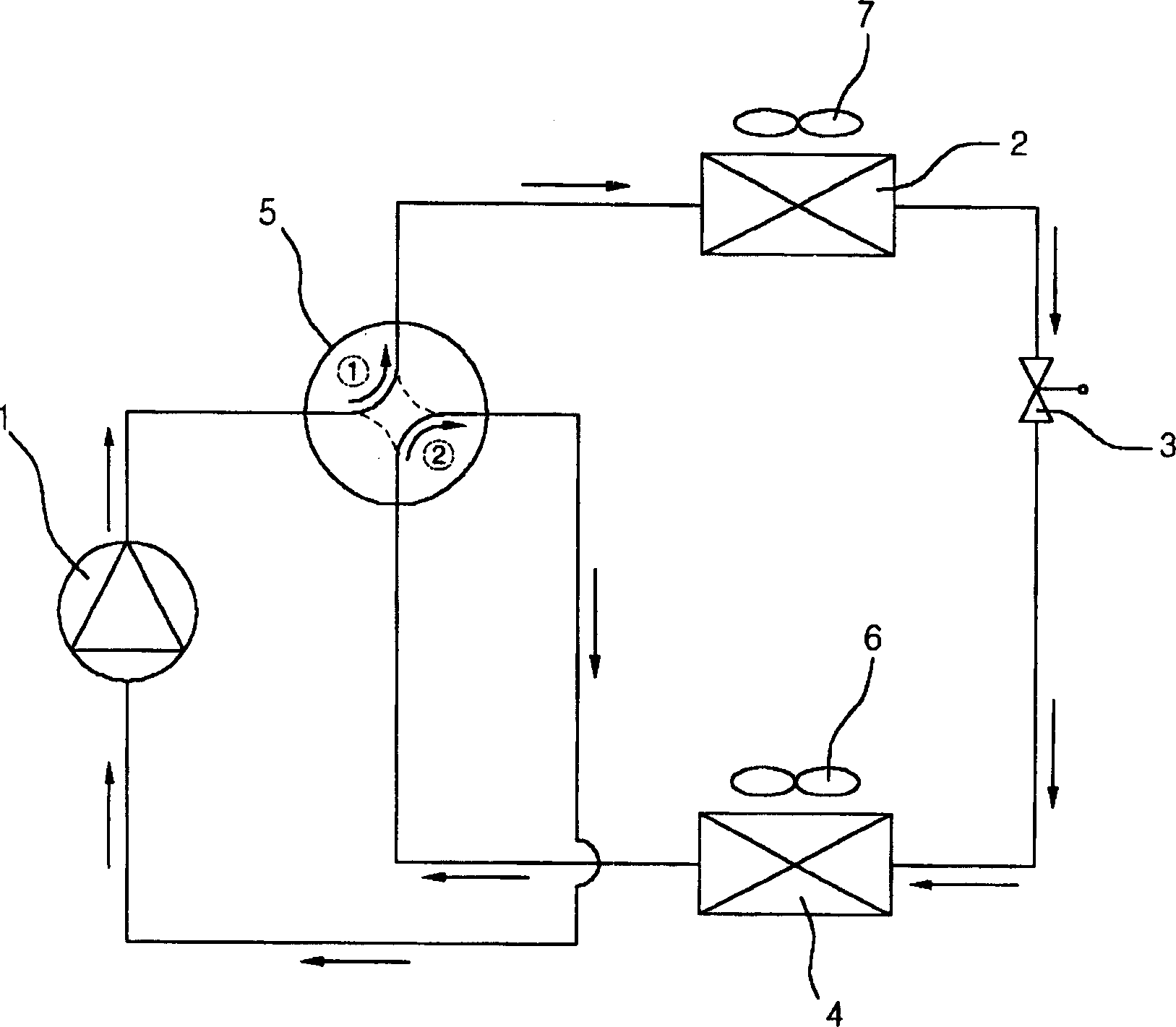

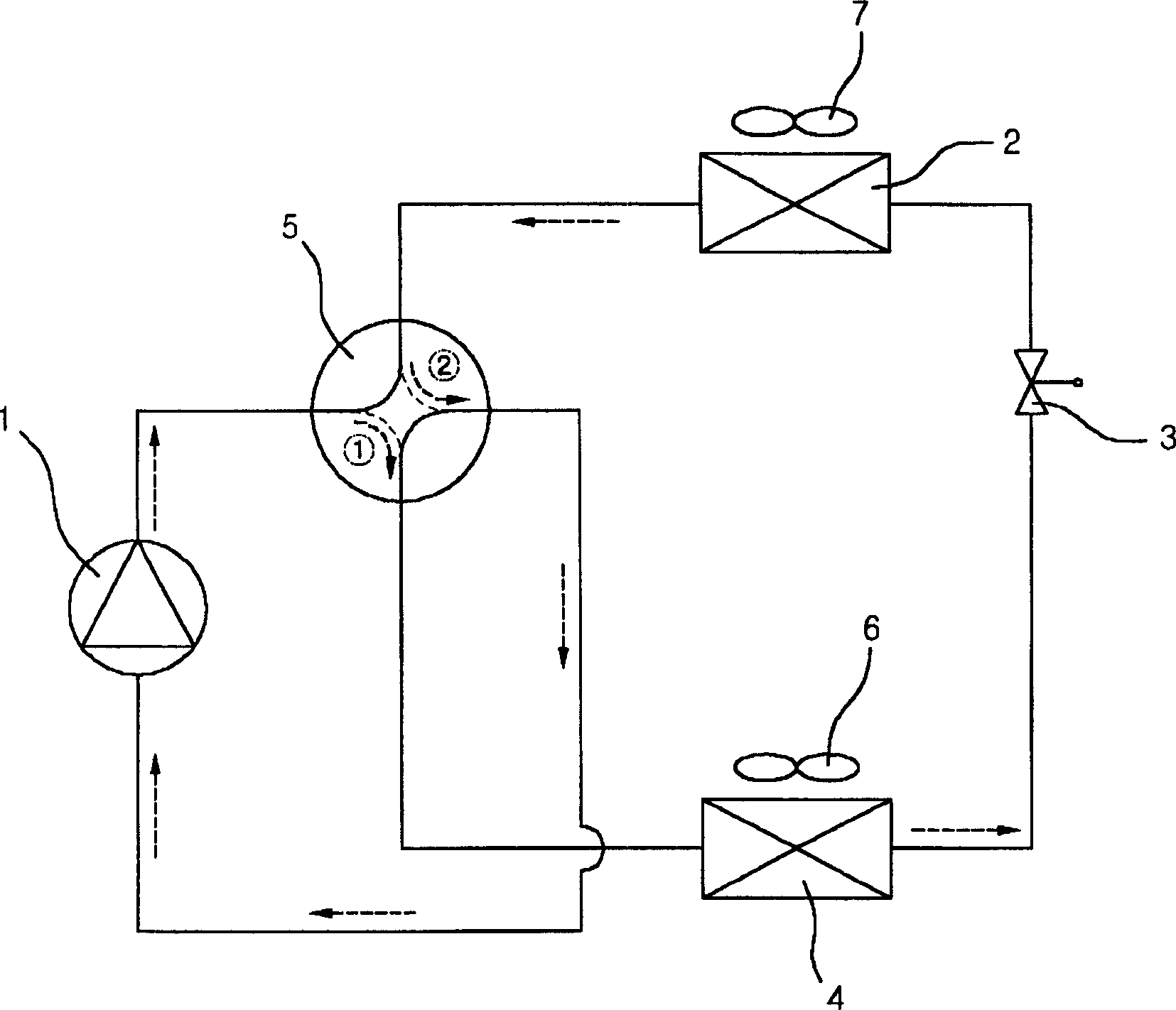

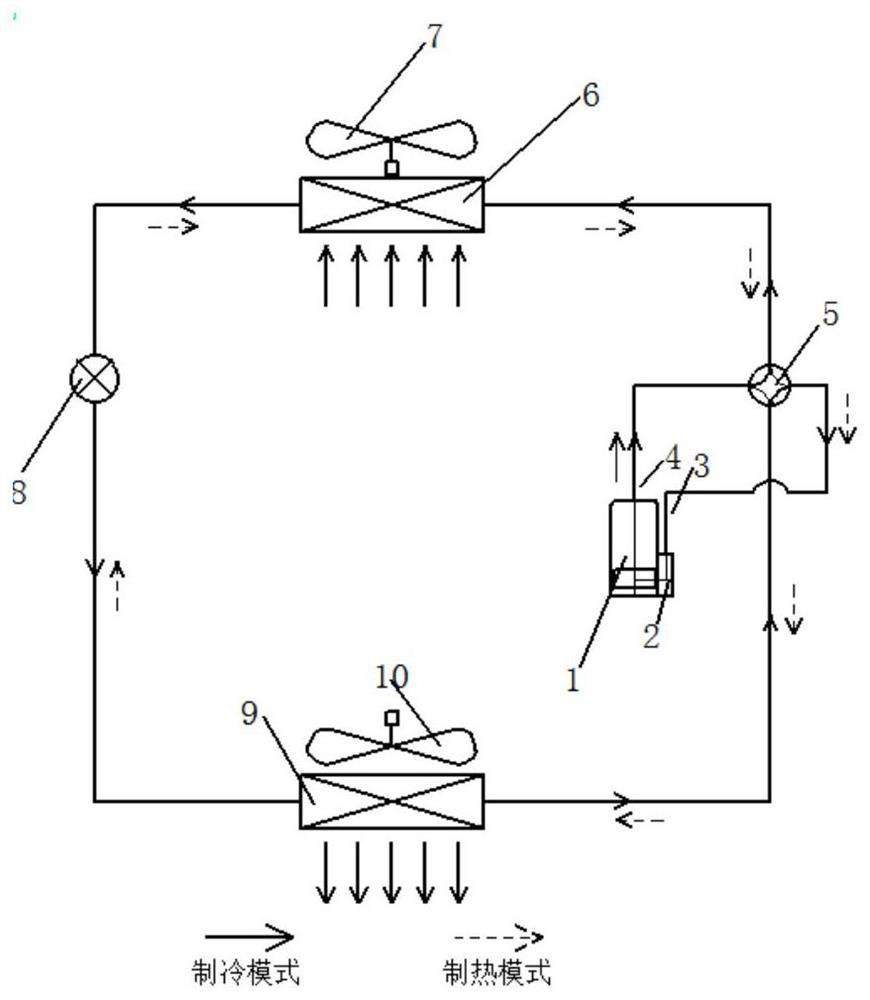

Backheating method and backheating structure for heat pump air conditioner

InactiveCN101979938AReduce the temperatureReduce vaporizationHeat recovery systemsFluid circulation arrangementEvaporationEngineering

The invention discloses a backheating method and a backheating structure for a heat pump air conditioner, which can improve the performance of the air conditioner. The backheating structure comprises heat exchangers A and B, a compressor, and a throttling element connected between the heat exchangers A and B, wherein the heat exchanger B is connected with the compressor by an air suction pipe of the compressor; and a higher-temperature coolant in the throttling element performs heat exchange with a lower-temperature coolant in the air suction pipe of the compressor. In the backheating method and the backheating structure, the temperature of the coolant in the throttling element can be reduced by performing backheating in a throttling process, thereby retarding the evaporation of the coolant and the change of the dryness of the coolant, making more stable the flow regime of the coolant and reducing inevitable loss; and the dryness of the coolant at an outlet of the throttling element is reduced, namely, the degree of subcooling of the air conditioner is increased, so the cooling capacity of the air conditioner can be improved. The backheating method and the backheating structure for the heat pump air conditioner can improve the cooling or heating performance of the heat pump air conditioner; and the backheating structure is simplified to a certain extent so as to be convenient to manufacture and save the cost.

Owner:四川长虹空调有限公司

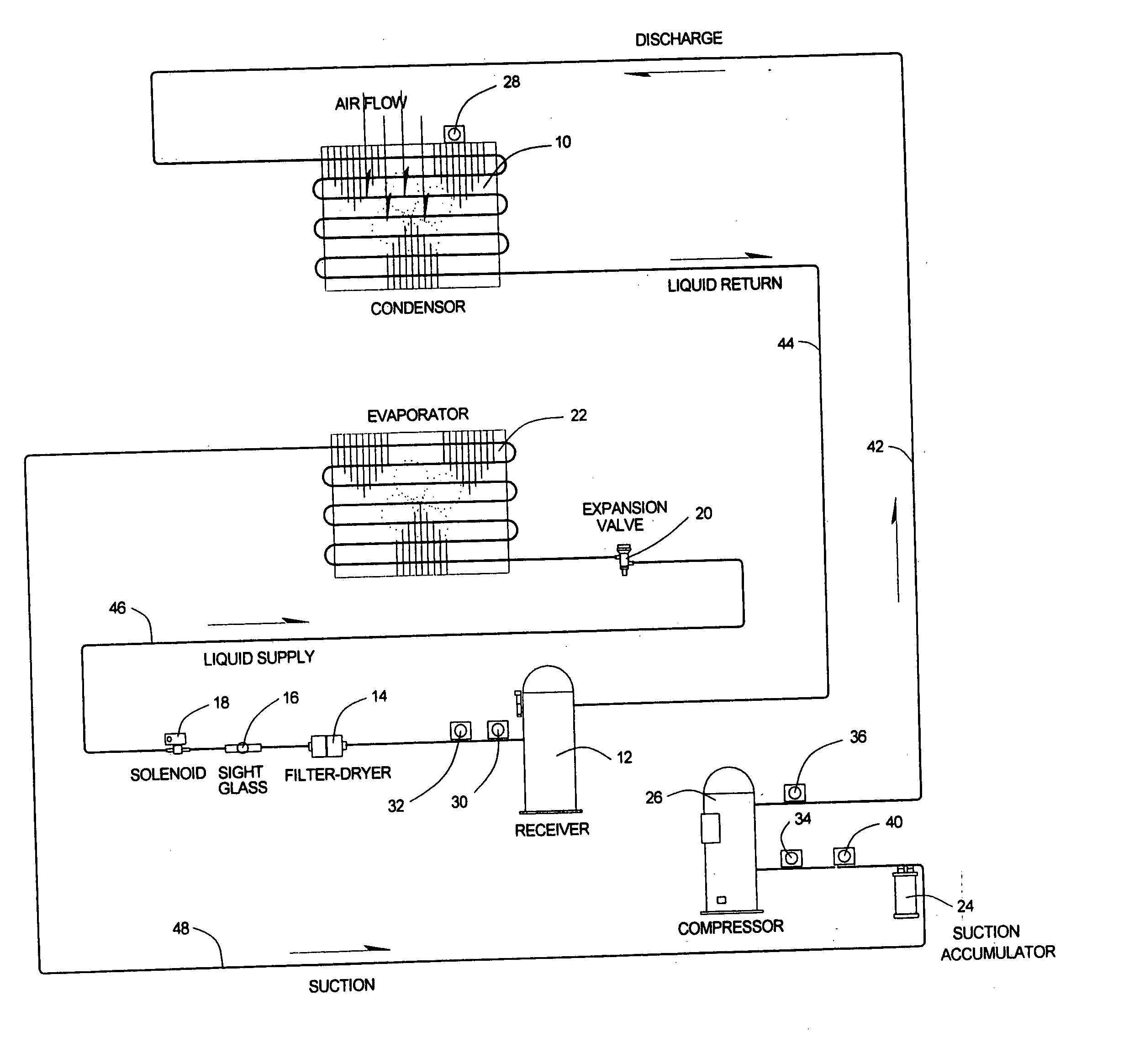

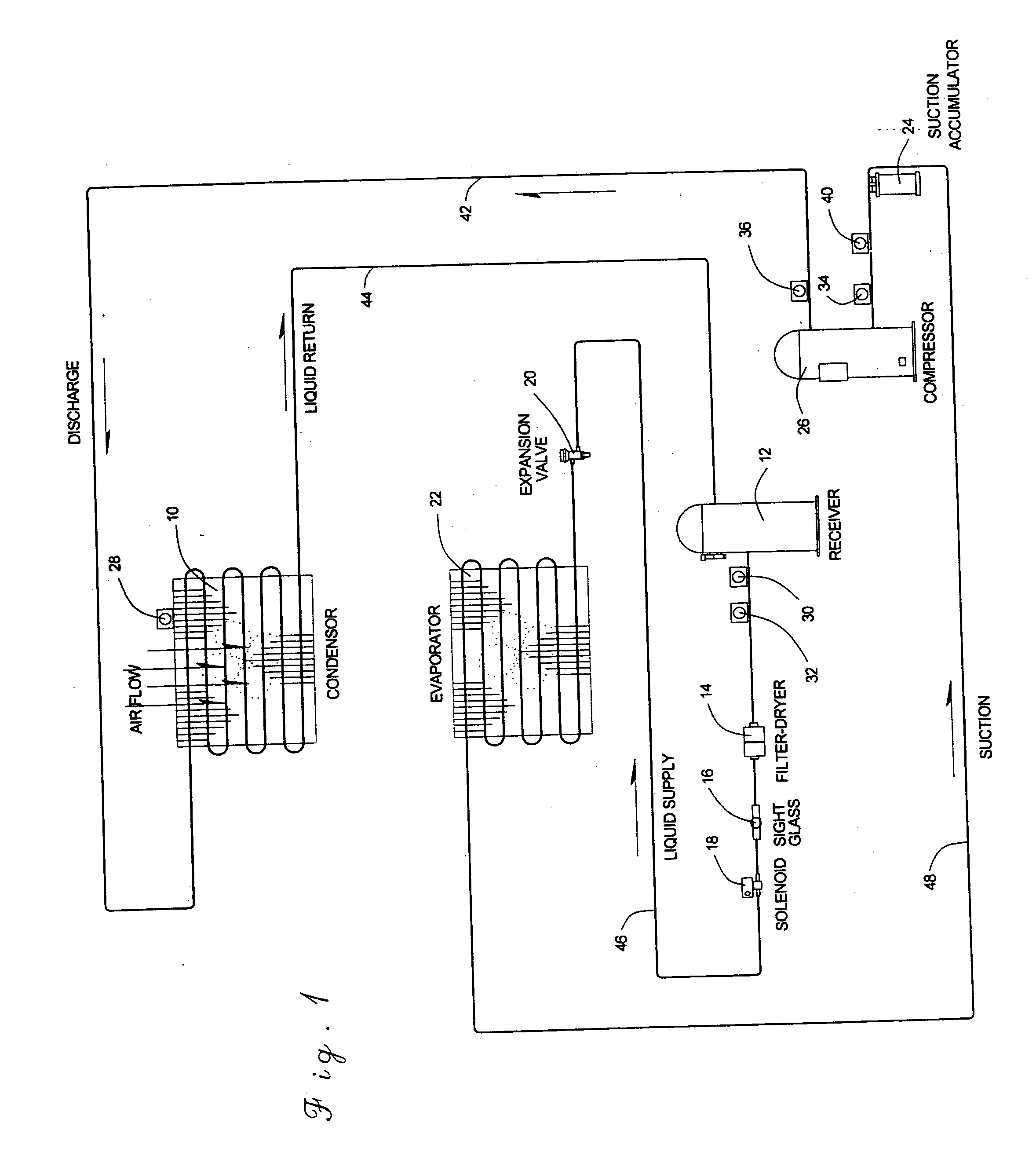

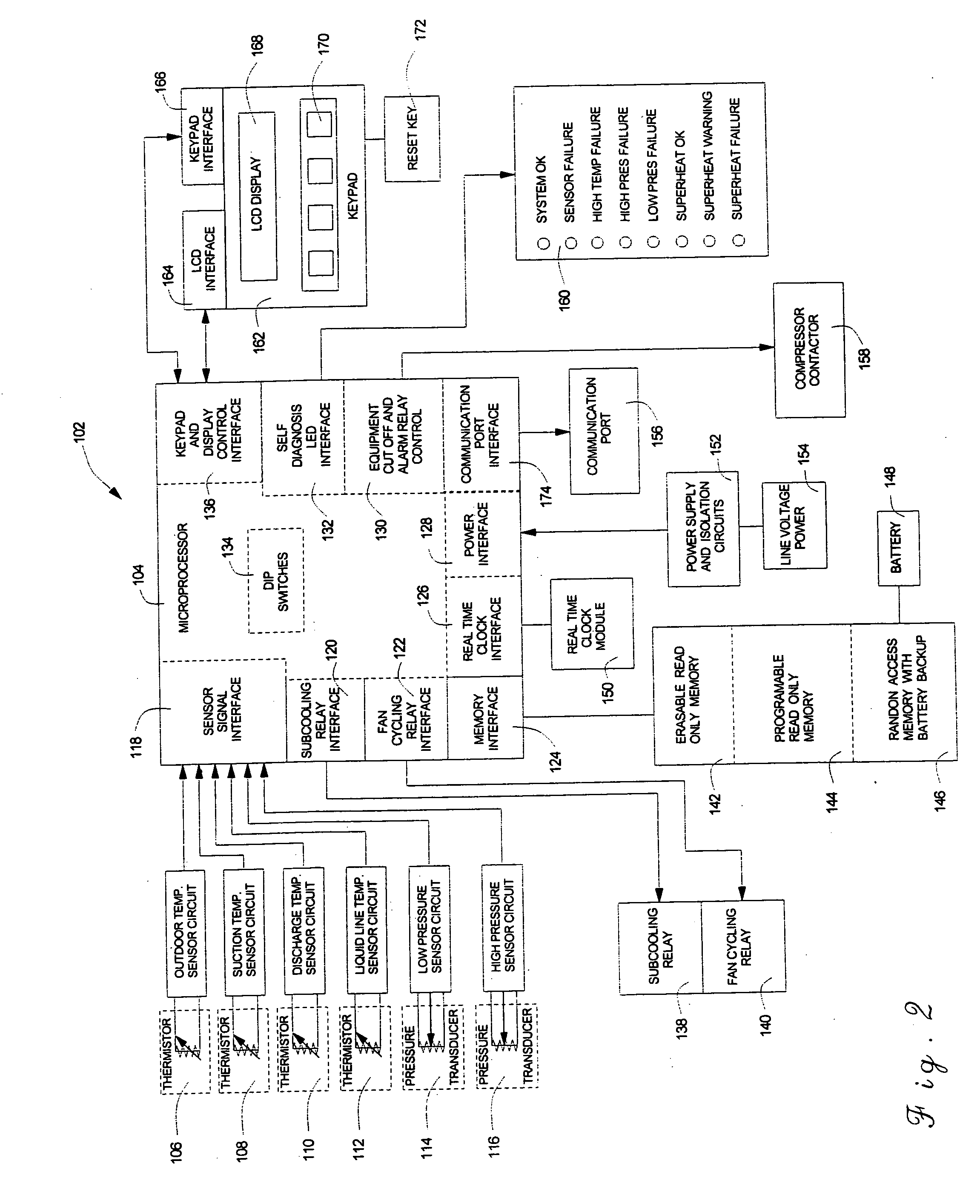

Refrigeration mechanical diagnostic protection and control device

InactiveUS20060075771A1Improve system efficiencyIncrease subcoolingCompression machines with non-reversible cycleEvaporators/condensersService personnelMonitoring system

In vapor compression refrigeration systems a mechanism and method are provided for protecting a compressor from failures related to lack of superheat, loss of lubricating oil and other system malfunctions. Also provided is a mean of monitoring system conditions and providing service personnel with a quick manner of diagnosing problems.

Owner:TRACEY GEORGE R JR +2

Vehicle temperature adjusting apparatus, and vehicle-mounted thermal system

InactiveCN103492204AImprove efficiencySave energyPower to auxillary motorsVehicular energy storageTemperature controlEngineering

A vehicle temperature adjusting apparatus for adjusting at least one of the air inside a vehicle compartment and a constituent component of a vehicle as an object for temperature adjustment is provided with: a heat capacity element (1) capable of storing heat; a refrigeration cycle (11) for absorbing heat from a low temperature side and dissipating heat on a high temperature side; heat exchanger units (14, 16) for exchanging the heat stored in the heat capacity element with a refrigerant of the refrigeration cycle (11); and heat imparting units (19, 31) for imparting the heat retained by the refrigerant of the refrigeration cycle (11) to the object for temperature adjustment. Thus, temperature adjustment can be performed effectively by using the heat capacity element.

Owner:DENSO CORP

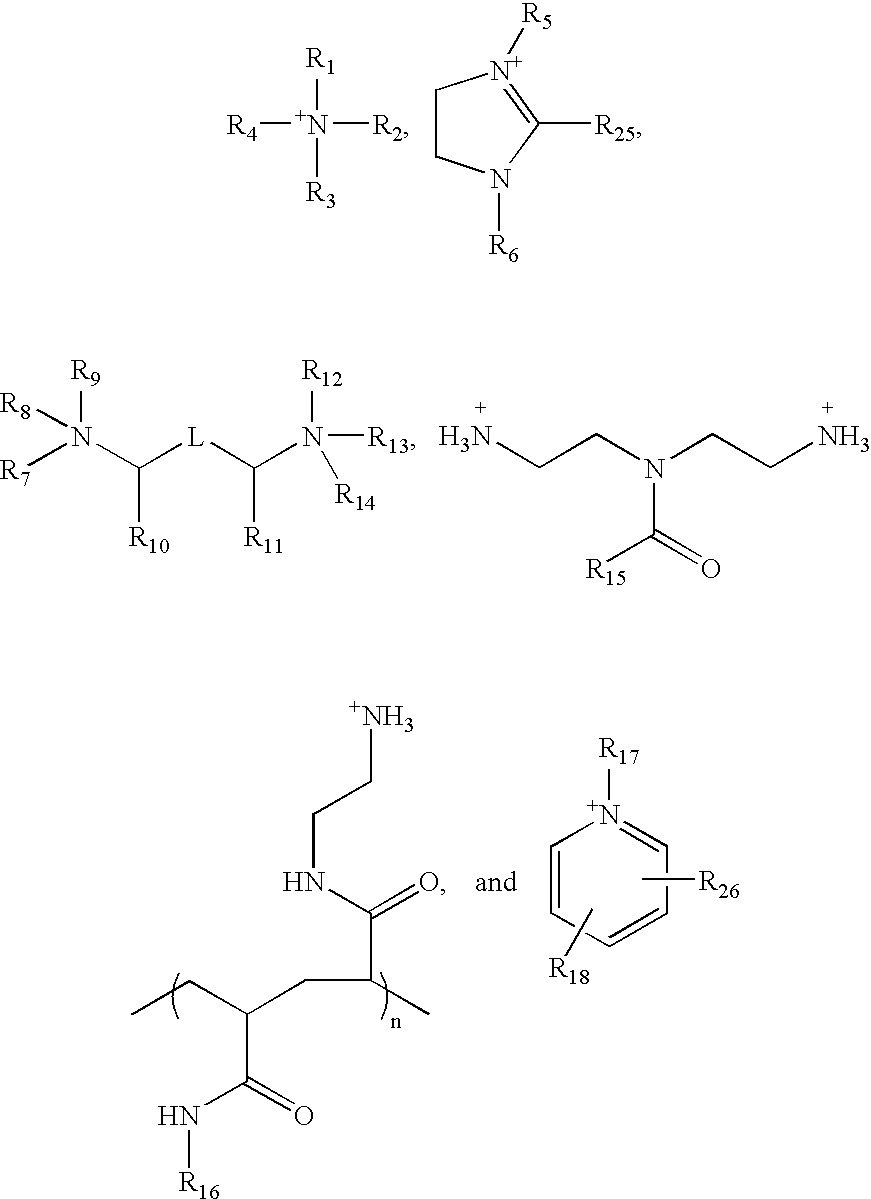

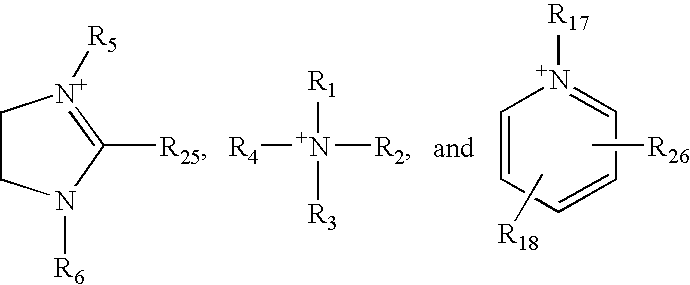

Ion pair amphiphiles as hydrate inhibitors

InactiveUS20080064611A1Enhanced inhibitory effectImprove liquidityGaseous fuelsFluid removalAmphiphileIon pairs

Owner:ECOLAB USA INC

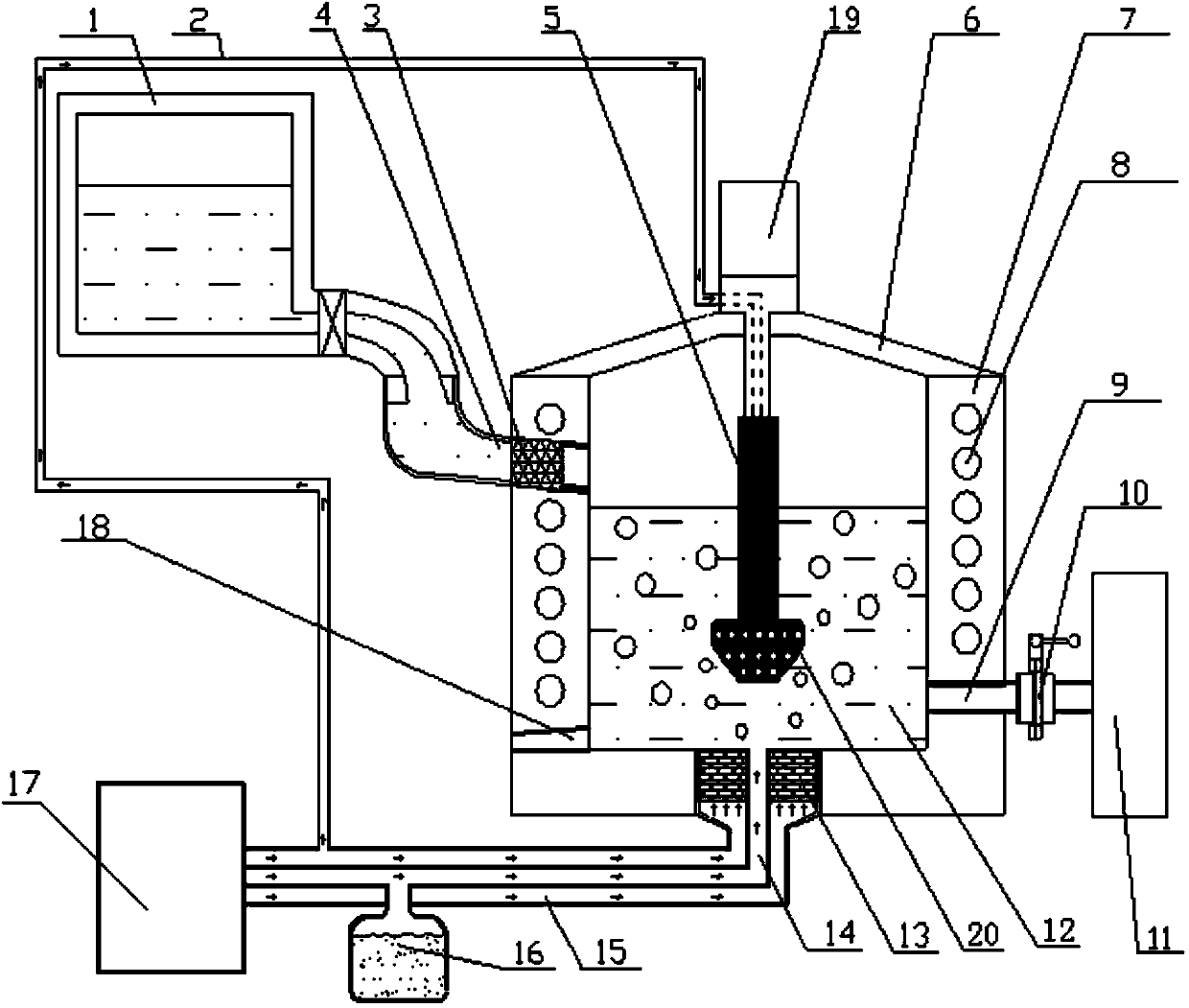

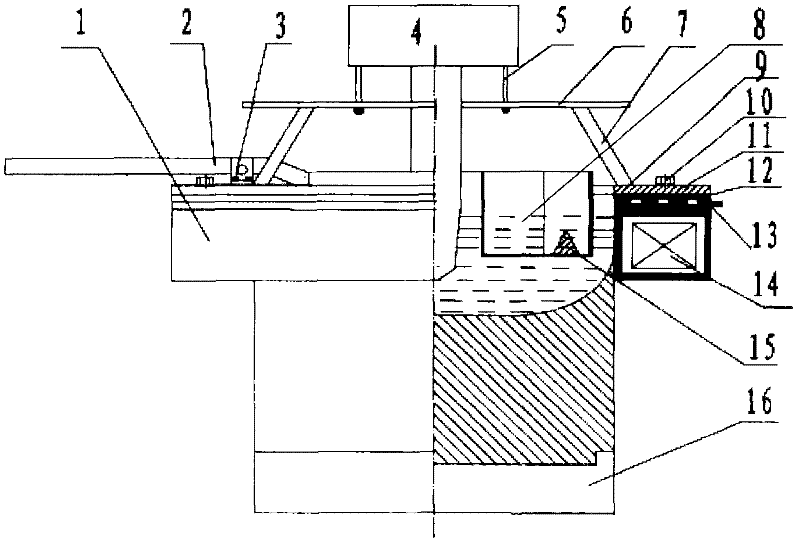

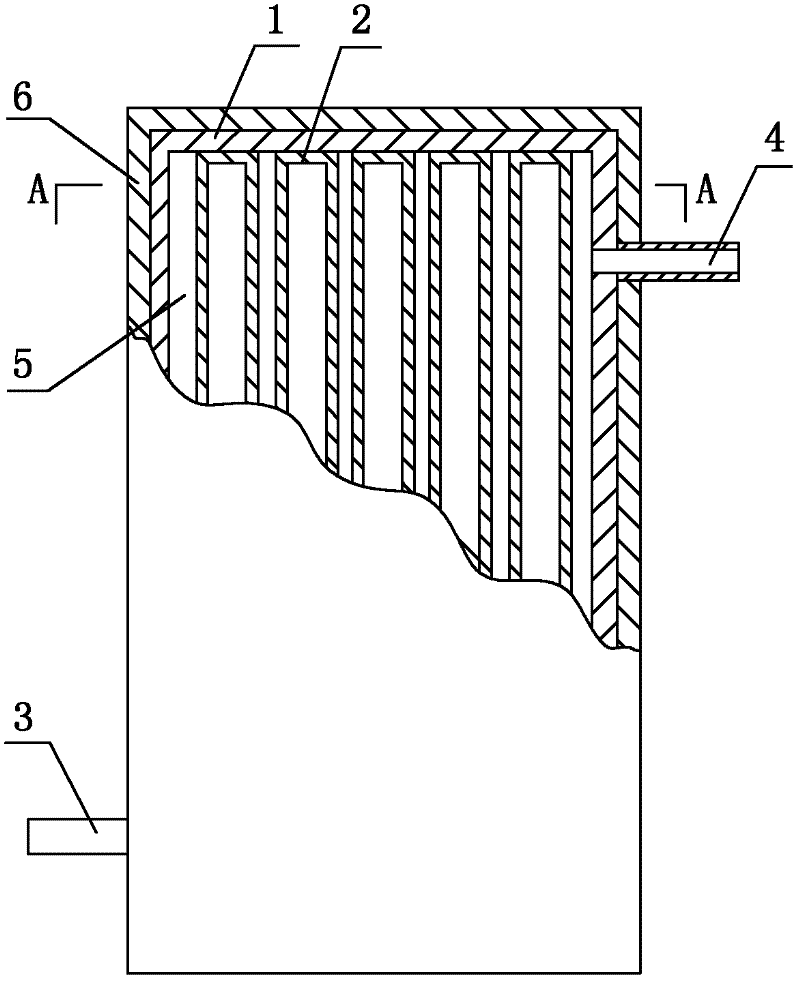

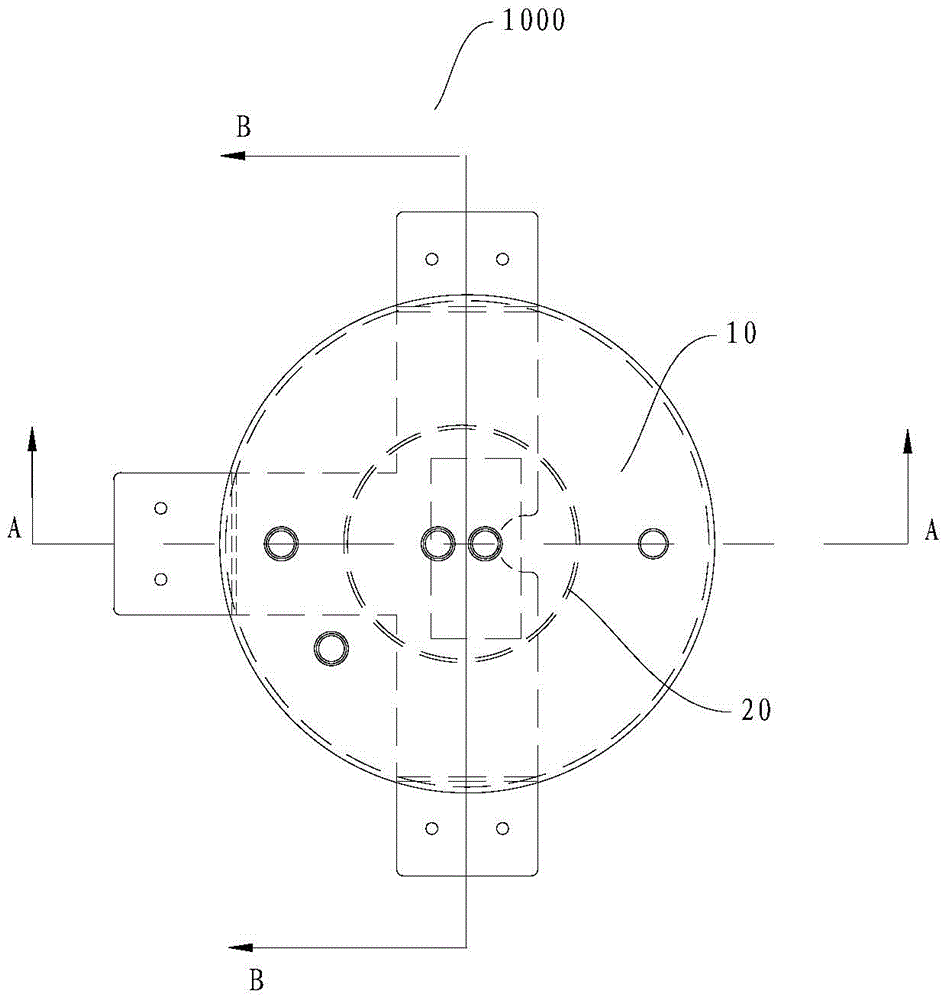

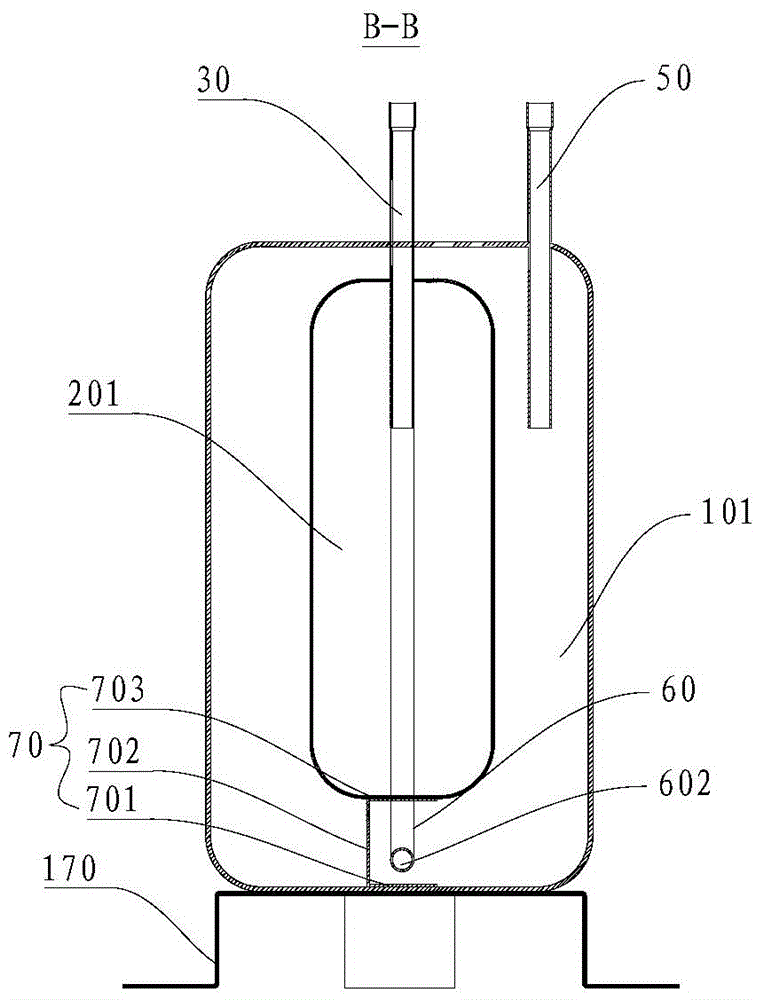

Manufacturing device for light alloy or light metal semi-solid slurry and manufacturing method

The invention discloses a manufacturing device for light alloy or light metal semi-solid slurry and a method for manufacturing the semi-solid slurry through the device. The manufacturing device for the light alloy or light metal semi-solid slurry comprises a smelting furnace, a runner, a mechanical stirring device, an inert gas stirring device, a powder spray device and a heating device. The semi-solid slurry manufacturing device reasonable in structure is designed, continuity for manufacturing the semi-solid slurry is good, and products can be cast industrially and continuously in a large scale by applying a semi-solid pressure casting or squeeze casting forming method. According to the manufacturing method for the semi-solid slurry, efficiency for manufacturing the light alloy or light metal semi-solid slurry is high, energy consumption is less, cost is low, and the manufactured semi-solid slurry cannot generate oxide inclusions, and is even in organization and excellent in quality.

Owner:机械科学研究总院(将乐)半固态技术研究所有限公司

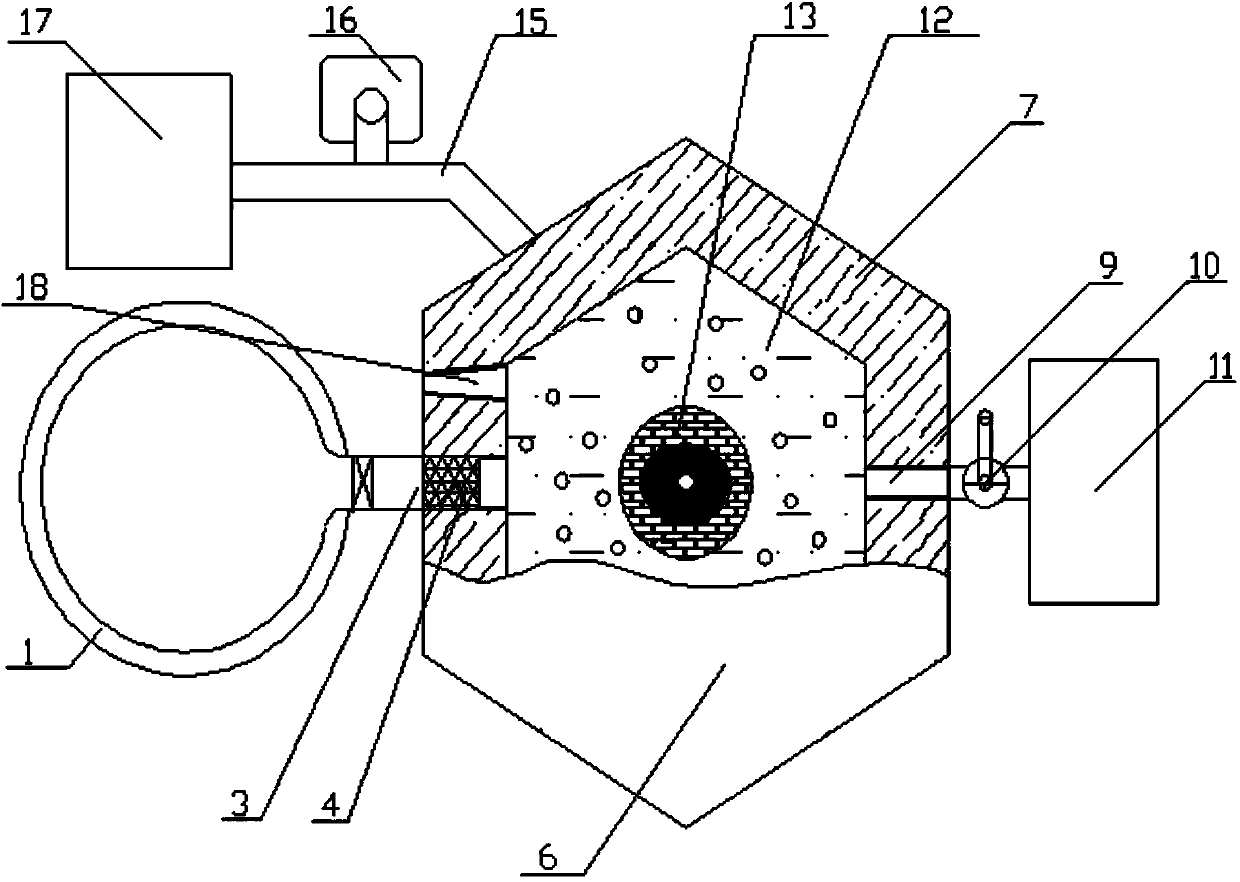

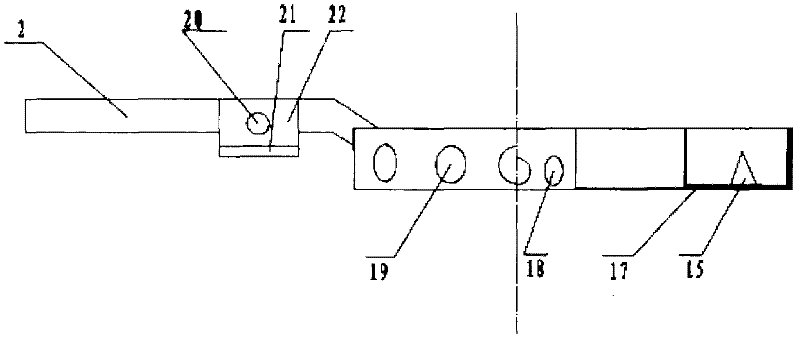

Device and process for internal and external cooling continuous casting of magnesium alloy and aluminum alloy ingot blanks

InactiveCN102430732AQuality improvementIncreased cooling rate in the middleIngot castingContinuous casting

The invention discloses continuous casting equipment and a continuous casting method for magnesium alloy and aluminum alloy ingot blanks. The continuous casting equipment comprises a mold and a dummy ingot block, a liquid level control lever, an internal cooling device, an oil way lubricating system and a split plate are further arranged in the continuous casting equipment, the internal cooling device comprises an internal cooling core pipe, an internal cooling head, a water inlet pipe, a sealing ring, a vibration head, an eccentric wheel, a variable-speed motor, a shell, a water outlet pipe,a spring and the like, the eccentric wheel is driven by the variable-speed motor, the upper end of the vibration head is connected with the eccentric wheel, the lower end of the vibration head and the upper end of the internal cooling head are fixedly connected into a whole and placed in a slide way defined by an upper plate and a lower plate, and the water inlet pipe is communicated with the internal cooling core pipe, an inner cavity of the internal cooling head and the water outlet pipe. When the continuous casting equipment for the magnesium alloy and aluminum alloy ingot blanks is operated, the internal cooling head of the internal cooling device is placed in the middle of a cast ingot to cool the center of the cast ingot, and accordingly, the quality of the center of the cast ingot is improved remarkably.

Owner:NORTHEASTERN UNIV

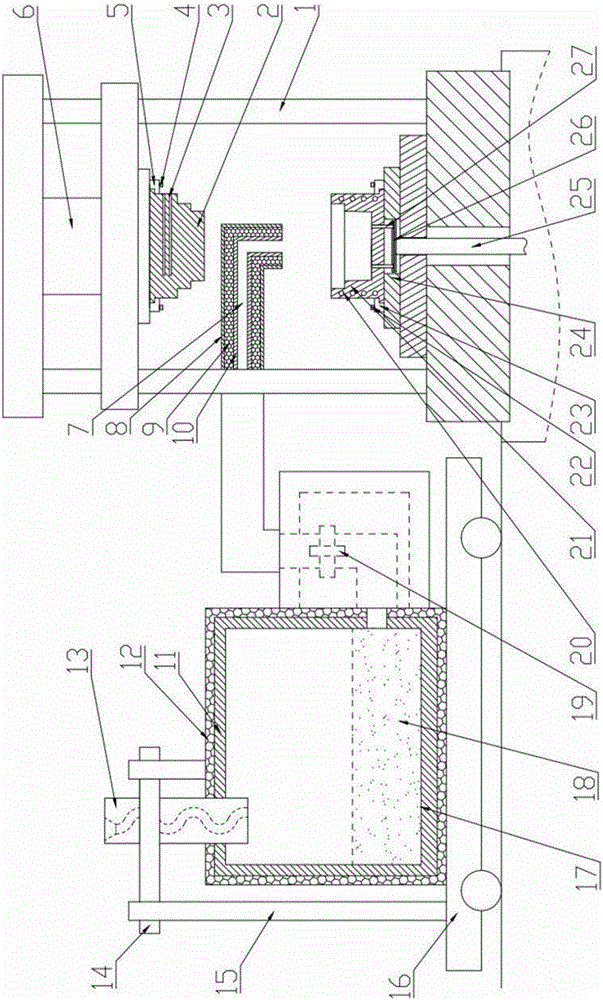

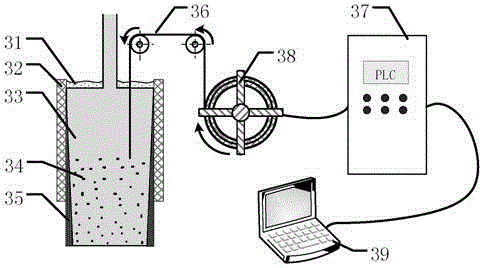

Semi-solid squeezing casting method and system for aluminum alloy

The invention relates to a semi-solid squeezing casting method and system for aluminum alloy and belongs to the technical field of preparation and application of nonferrous materials. The method comprises the following steps that firstly, an aluminum alloy block is cut into aluminum alloy pieces, the aluminum alloy pieces are wrapped with aluminum foil correspondingly, and then the wrapped aluminum alloy pieces are preheated; the preheated aluminum alloy pieces are smelted, so that molten aluminum alloy is obtained; the molten aluminum alloy is poured into a heat preservation device for heat preservation via a sprue with a bent channel or an inverted conical channel, and semi-solid aluminum alloy slurry is obtained; the semi-solid aluminum alloy slurry is poured into a heat preservation squeezing mold to be subjected to squeezing molding treatment; and finally, pressure application continues after the squeezing molding treatment is completed, then a casting is jacked out and subjected to air cooling, and an semi-solid aluminum alloy squeezed casting is obtained. According to the preparation method, the advanced process is achieved, procedures are precise, data are accurate and full, and after heat treatment of the prepared semi-solid aluminum alloy squeezed casting, the hardness of the casting can be up to 82.9 HB and the tensile strength of the casting can be up to 279 Mpa.

Owner:ZHONGBEI UNIV

Air conditioner comprising heat exchanger and means for switching cooling cycle

InactiveCN1590927AIncrease subcoolingImprove refrigerant flow characteristicsCompression machines with non-reversible cycleSpace heating and ventilation detailsCounter flowEngineering

The present invention relates to an air conditioner capable of performing heat exchange of refrigerant and cooling and heating operations. According to the invention, a dual-tube heat exchanger is disposed at the entrance of a compressor and a means for switching a cooling cycle is installed between an outdoor heat exchanger including a condenser and an indoor heat exchanger including an evaporator so that in an air conditioning mode, heat change between mid-temperature, high-pressure liquid refrigerant at the exit of the condenser and low-temperature, low-pressure superheated refrigerant at the exit of the evaporator is performed more effectively and as a result of this, super heating of the liquid refrigerant at the exit of the condenser is increased, refrigerant flow characteristics of an expansion unit are improved, and enthalpy at the entrance side of the evaporator is reduced, causing a greater enthalpy difference at the entrance and exit of the evaporator and improving air conditioning capacity overall. Moreover, the heat exchanger of the present invention has a dual tube structure and uses a counter flow or parallel flow for performing heat exchange.

Owner:LG ELECTRONICS INC

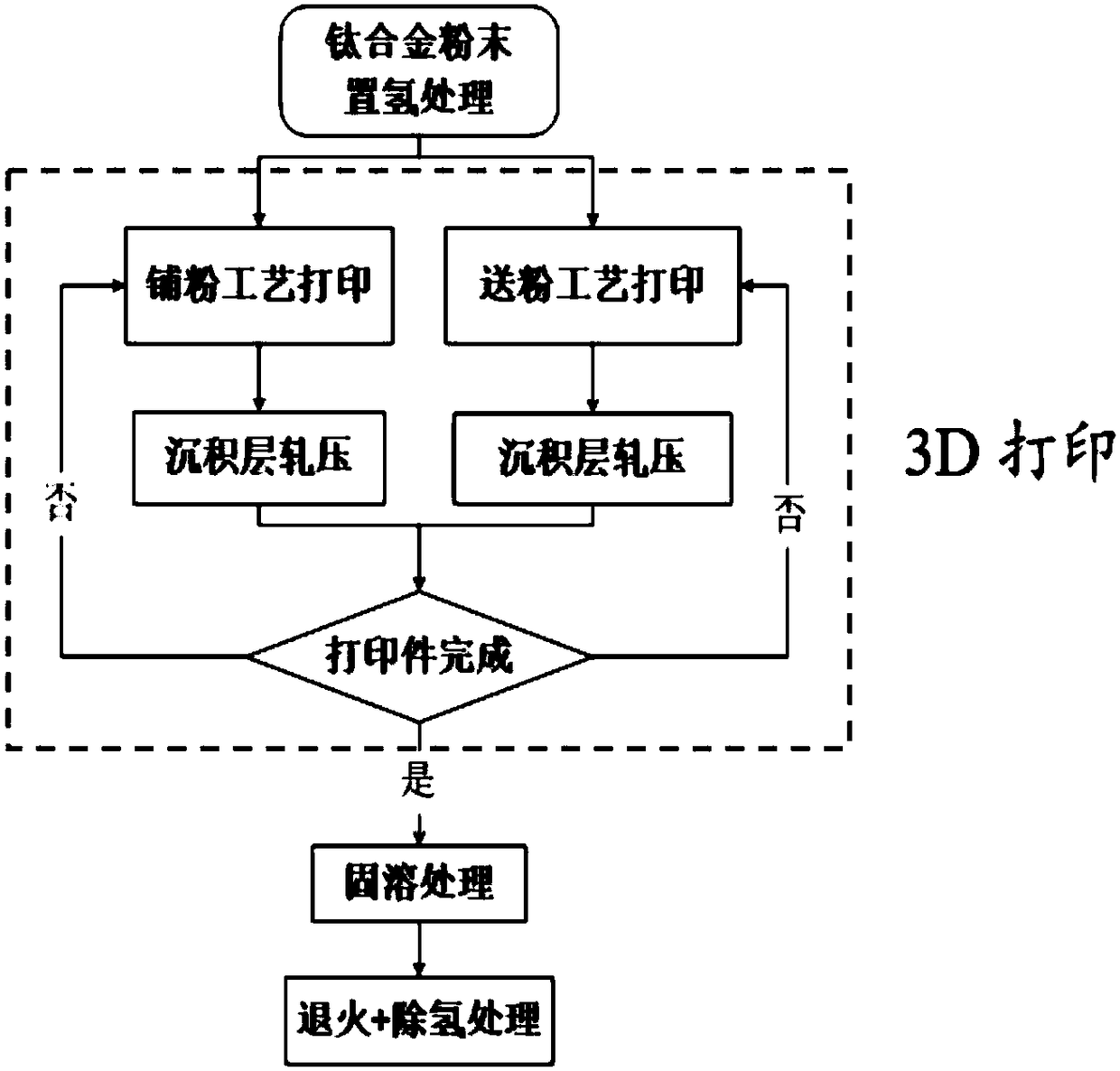

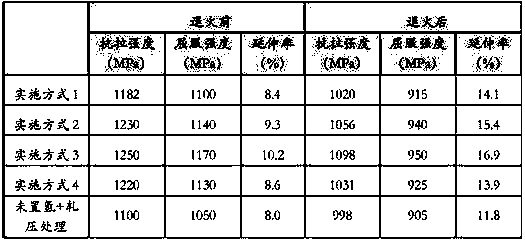

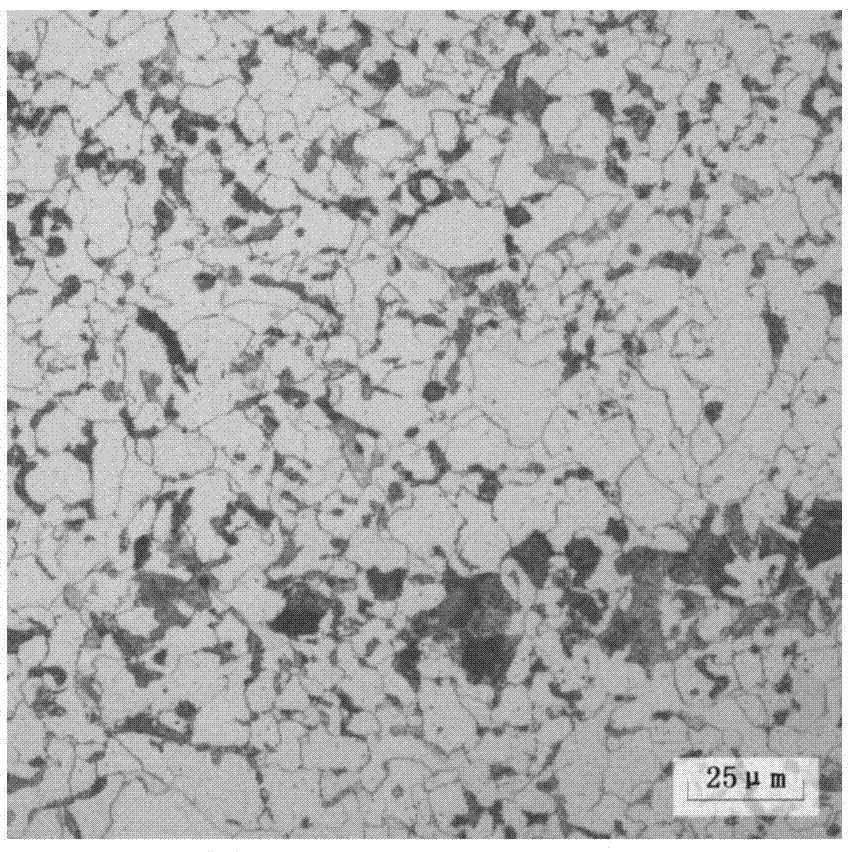

Hydrogen treatment roll compacting compound technology for improving additive manufacturing titanium alloy structure

ActiveCN108580884AFacilitated DiffusionIncrease subcoolingAdditive manufacturing apparatusTransportation and packagingCyclic processChemical composition

The invention provides a hydrogen treatment roll compacting compound technology for improving an additive manufacturing titanium alloy structure. The hydrogen treatment roll compacting compound technology for improving the additive manufacturing titanium alloy structure comprises the steps of during an additive manufacturing process, carrying out hydrogen treatment on titanium alloy powder, and roll compacting a printing piece layer by layer, so that the printing piece with structure being refined is prepared through a circulation process of printing-roll compacting-printing-roll compacting; and finally removing temporary alloying element hydrogen through vacuum annealing, so that the change of chemical components of a final material is avoided. During the process, the printing piece structure is refined and improved by utilizing hydrogen and the dislocation defects are increased by roll compacting at the same time, so that the capability of nucleation is reduced, the nucleation rate is improved, and the aims of refining grains and improving the structure without changing the alloy components are achieved.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

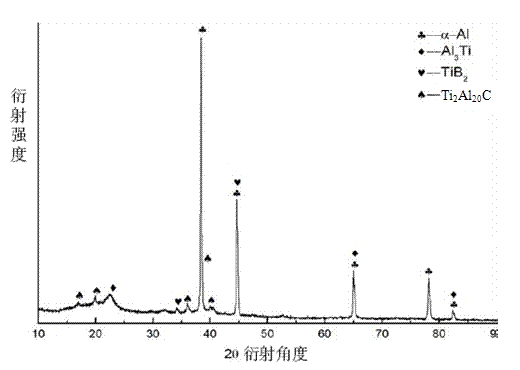

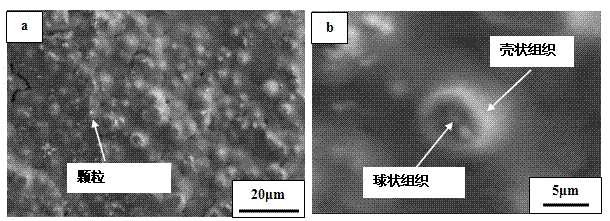

Multiphase nano ceramic particle reinforced Al-based composite material and laser 3D printing forming method thereof

The invention discloses a multiphase nano ceramic particle reinforced Al-based composite material and a laser 3D printing forming method thereof. AlSiMg powder with a purity of 99.9% and above and a particle size of 15-30 mu m is selected as a composite material base of the Al-based composite material; a powder composition with a purity of 99.9% or above and a particle size of 10-100 mu m is selected as a reinforced phase of the Al-based composite material, and the powder composition comprises Al2O3, SiO2, TiN and TiC, ZnO and Y2O3; after the two kinds of powder are mixed, the obtained mixture is sequentially subjected to high-temperature calcining synthesis, ball-milling and 3D printing forming, so that a required 3D block can be processed. The Al-based composite material obtained according to the invention has uniformly refined microscopic structures and excellent mechanical properties, and in comparison with the performance levels of traditional casting or powder metallurgy products of corresponding materials, the comprehensive mechanical properties of the Al-based composite material are increased by 25% or above.

Owner:JIANGSU SILAIMU INTELLIGENT TECH CO LTD

Preparation method of superfine crystal inoculating agent for aluminum alloy grain refinement

The invention provides a preparation method of a superfine crystal inoculating agent for aluminum alloy grain refinement and relates to aluminum-based alloy and is a method for preparing nano-crystalline Al-Ti-B-Re thin-strip intermediate alloy by a rapid solidification technology of metal, wherein the method comprises steps as follows: proportioning 5-5.4% of Ti, 1-1.04% of B, 1-1.2% of Ce, 0.05-0.2% of La and the balance of Al according to determined ingredients; weighing raw materials Al-5Ti-1B intermediate alloy and lanthanum cerium alloy to proportion the materials; melting in vacuum to obtain blocky Al-5Ti-1B-1Re intermediate alloy; carrying out rapid solidification to obtain the superfine crystal inoculating agent for the aluminum alloy grain refinement, wherein the superfine crystal inoculating agent is the nano-crystalline Al-5Ti-1B-1Re intermediate alloy. With the adoption of the method provided by the invention, adverse impact of needlelike TiAl3 on the matrix structure is eliminated, nucleating particles TiAl3 with thinner size and more dispersed distribution are obtained, and superfine nucleating particles are realized.

Owner:HEBEI UNIV OF TECH

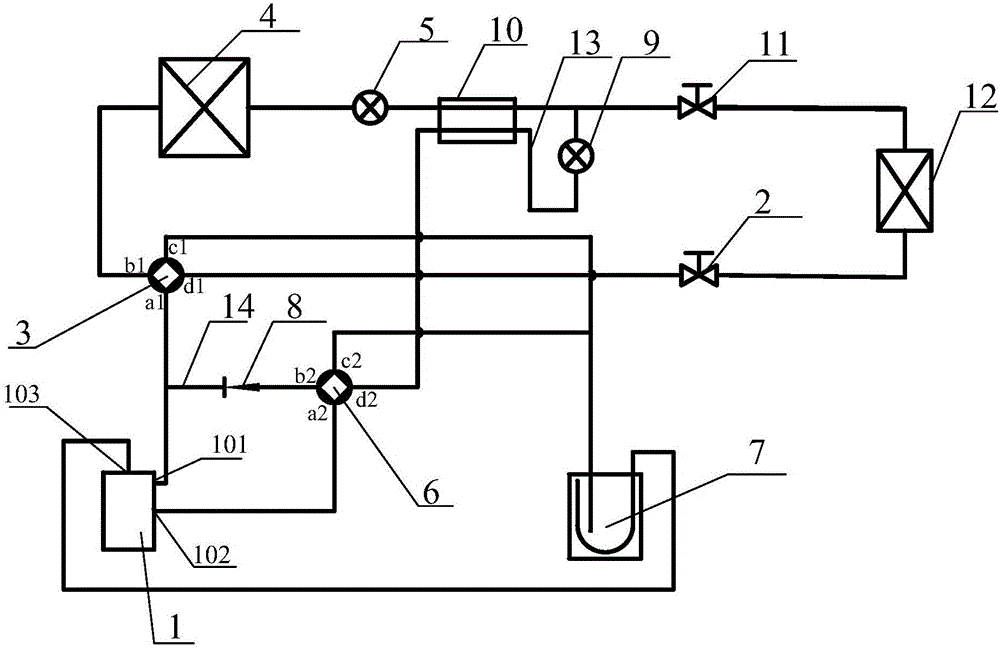

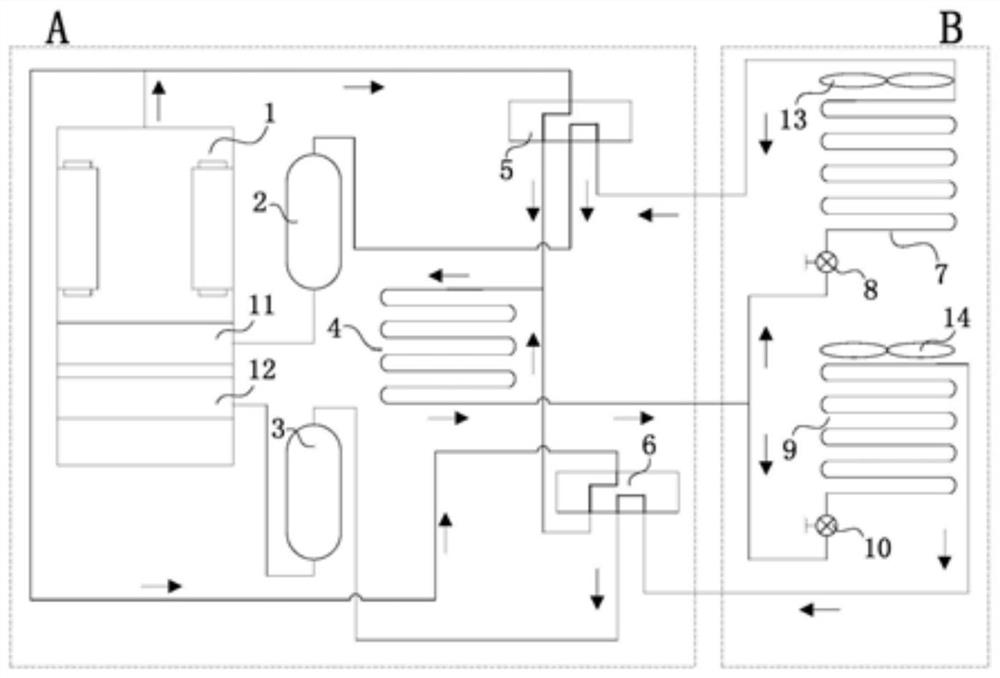

Multi-split air-conditioning system and supercooling and enhanced vapor injection method thereof

InactiveCN105004090ATo achieve the purpose of supercoolingSimple structureMechanical apparatusSubcoolersFour-way valveVapor–liquid separator

The invention relates to a multi-split air-conditioning system and a supercooling and enhanced vapor injection method thereof. The multi-split air-conditioning system comprises a compressor, an outdoor side heat exchanger, an indoor unit heat exchanger, a gas-liquid separator, an intermediate heat exchanger, a first four-way valve and a second four-way valve which are connected through pipelines. As the second four-way valve, a first branch circuit and the intermediate heat exchanger are arranged in the multi-split air-conditioning system, during cooling operation, the intermediate heat exchanger serves as a subcooler, a cooling medium flows in different directions through adjustment by the first branch circuit and the second four-way valve after passing through the intermediate heat exchanger, and accordingly, the cooling medium of the first branch circuit cools down a main-circuit cooling medium to achieve the supercooling purpose; and during heating operation, the intermediate heat exchanger serves as an economizer, the cooling medium passes through the first branch circuit and the second four-way valve after passing through the indoor unit heat exchanger, and then is sprayed into a medium-pressure cavity of the compressor through a jet orifice to supply a medium-pressure gaseous cooling medium for the compressor. The structure is simple and the supercooling and enhanced vapor injection purposes are better achieved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

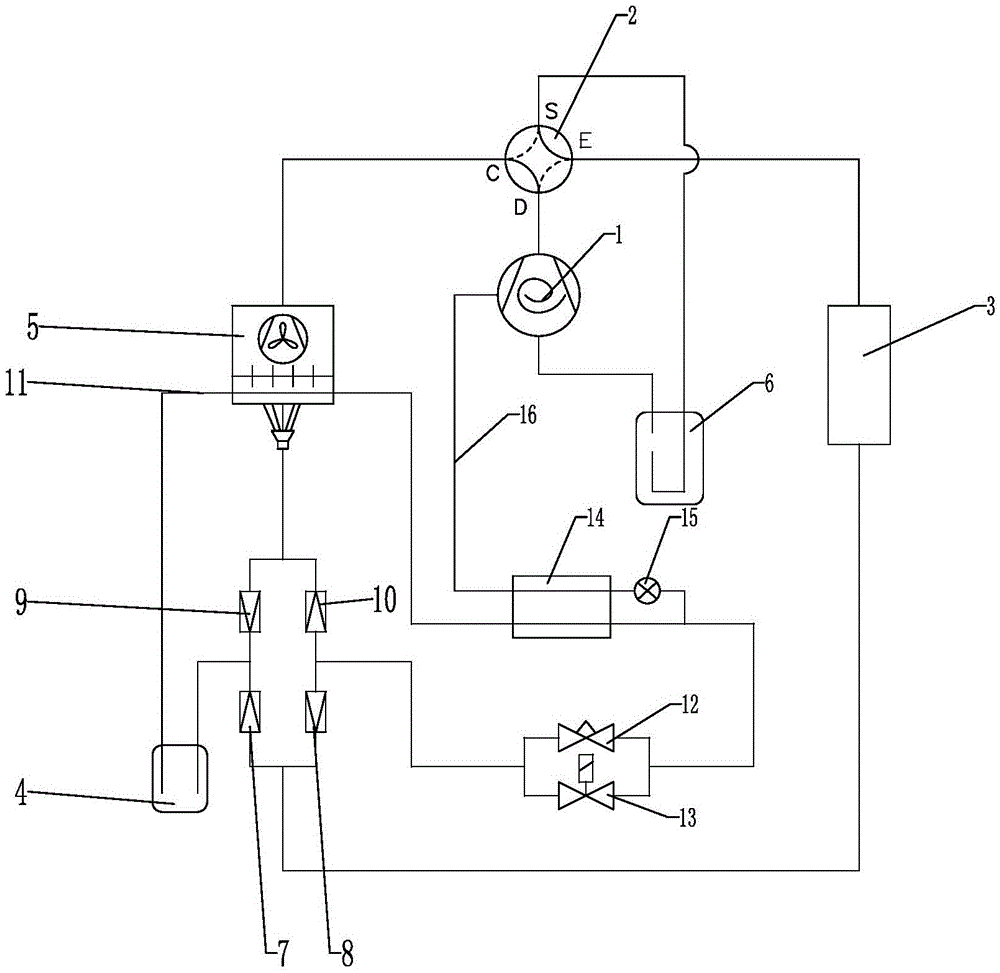

Low-environment-temperature air source heat pump system with undercooling loop

InactiveCN105157270AIncrease circulation flowIncrease subcoolingMechanical apparatusCorrosion preventionHigh humidityEngineering

The invention belongs to the technical field of air source heat pump systems, relates to an air source heat pump refrigerating system, in particular to a low-environment-temperature air source heat pump system with an undercooling loop. The low-environment-temperature air source heat pump system comprises a main loop, an auxiliary loop, the undercooling loop and a one-way valve assembly. A first outlet of an air-supplying enthalpy-adding compressor is connected with a first port of a four-way reversing valve. A second port of the four-way reversing valve is connected with a first port of an indoor heat exchanger. A second port of the indoor heat exchanger is connected with the inlet end of the one-way valve assembly. According to the low-environment-temperature air source heat pump system, the main loop, the auxiliary loop and the undercooling loop are combined in an optimization manner, so that the circular flow of the refrigerating system in the air source heat pump low-temperature environment is increased; high-temperature refrigerant is introduced into the bottom of an outdoor heat exchanger, so that the bottom temperature of the outdoor heat exchanger is always higher than zero in the low-temperature environment, the bottom of the heat exchanger will not freeze, condensate water and defrosting water of the outdoor heat exchanger can be discharged smoothly in winter, and the phenomenon that ice layers are accumulated, a unit cannot operate normally at the cold high-humidity environment is avoided.

Owner:WUXI TONGFANG ARTIFICIAL ENVIRONMENT

Air-conditioning system using sub-cooler and method for controlling refrigerant flow thereof

ActiveCN101886852AIncrease subcoolingEvenly distributedEfficient regulation technologiesSubcoolersComputer moduleEngineering

The invention provides an air-conditioning system using a sub-cooler and a method for controlling refrigerant flow thereof. The effect of the sub-cooler is exerted better by controlling the refrigerant flow on the low-pressure side of the sub-cooler so as to ensure that proper refrigerant is provided for cyclic operation when the system runs, improve the running efficiency and prolong the service life of a unit and ensure the using effect of a user. The air-conditioning system comprises a first sensor and a second sensor; the first sensor and the second sensor are arranged at different positions of a refrigerating system circulating passage; a controller comprises an operation result module and an output module; the operation result module calculates the refrigerant flow according to the data acquired by the first sensor and the second sensor, and converts the refrigerant flow into opening instruction of an electronic expansion valve; and the output module controls the opening of the electronic expansion valve according to the opening instruction of the electronic expansion valve.

Owner:GREE ELECTRIC APPLIANCES INC

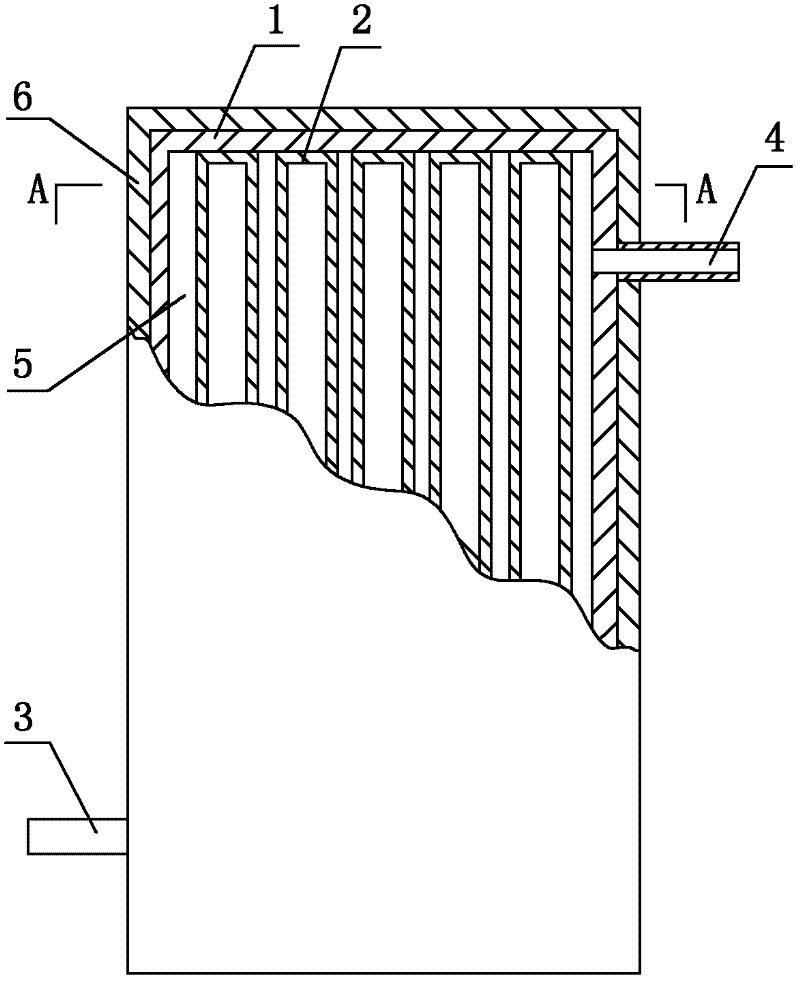

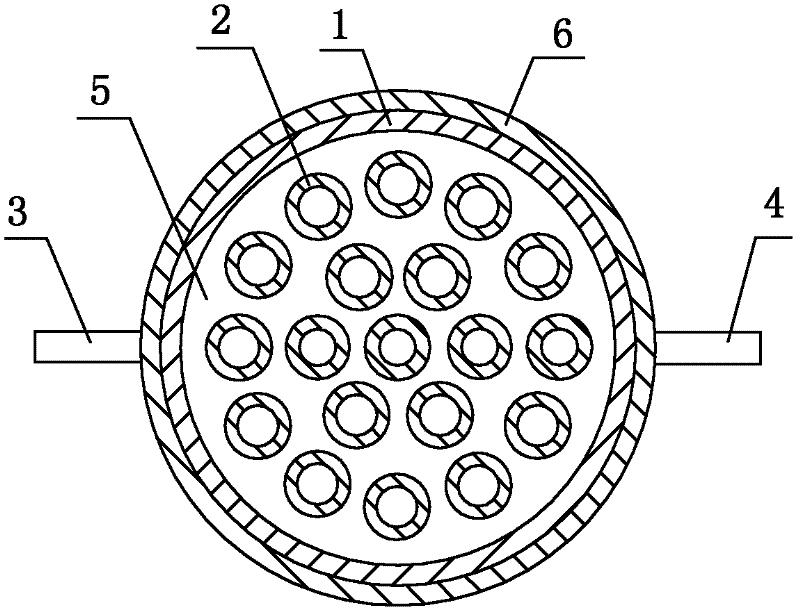

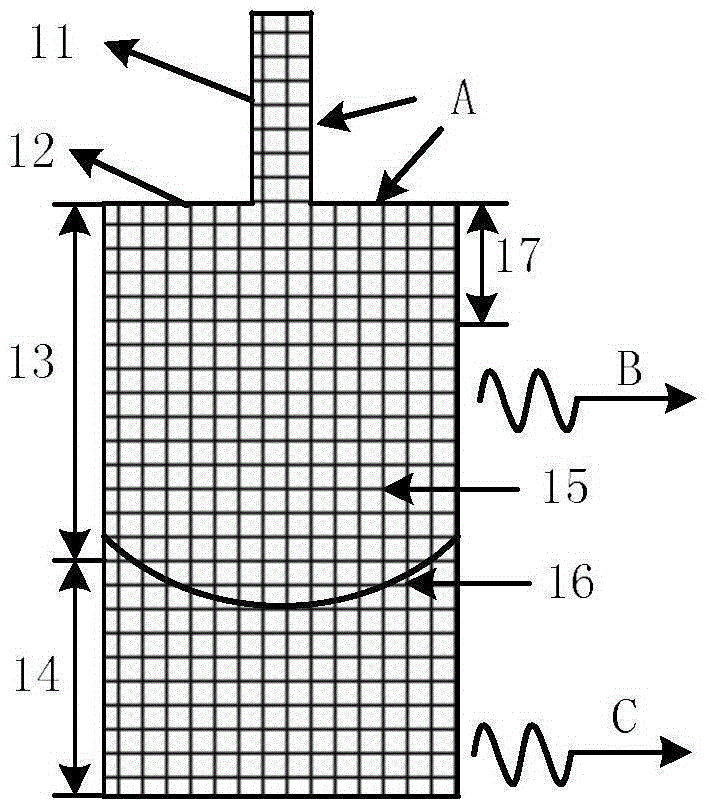

Fused salt phase change heat storage device applied to solar air conditioner

InactiveCN102252545AImprove heat transfer efficiencyGuarantee safety and reliabilityHeat storage plantsEnergy storageHeat conductingHeat storage material

The invention relates to a fused salt phase change heat storage device applied to a solar air conditioner. The fused salt phase change heat storage device applied to the solar air conditioner is characterized by comprising a heat storage chamber box, heat storage material accommodating pipelines, a heat storage material and heat conducting oil; a heat storage space is formed in the heat storage chamber box, the heat storage chamber box is provided with an oil inlet and an oil outlet, the oil inlet and the oil outlet are communicated with the heat storage space respectively, 2 to 200 heat storage material accommodating pipelines are arranged in the heat storage space of the heat storage chamber box, the heat storage material accommodating pipelines are fixed with the heat storage chamber box, and the heat storage material is filled in the heat storage material accommodating pipelines; and a heat transfer medium between the outer walls of the heat storage material accommodating pipelines and the inner wall of the heat storage chamber box is the heat conducting oil. The fused salt phase change heat storage device has the characteristics of simple structure, safety, reliability and high heat exchange efficiency.

Owner:WUHAN UNIV OF TECH

420MPa normalizing super-thick steel plate, and preparation method thereof

The invention discloses a 420MPa normalizing super-thick steel plate, and a preparation method thereof. The 420MPa normalizing super-thick steel plate comprises following chemical components, by mass, 0.14 to 0.16% of C, 0.30 to 0.40% of Si, 1.0 to 1.60% of Mn, 0.015 to 0.025% of Als, 0.005 to 0.025% of Nb, 0.065 to 0.10% of V, 0.010 to 0.02% of Ti, 0.2 to 0.45% of Ni, 0.05 to 0.30% of Cu, P less than 0.01% , S less than 0.005%, and the balance Fe and unavoidable impurities. The preparation method comprises following steps: continuous casting steel slab, which contains the above chemical components and possesses a thickness of 400mm, is subjected to two stages of rolling without water cooling, is discharged rapidly, and is subjected to stacking slow-cooling for 72h or more; and after steel plate shot blasting, the steel plate is obtained by normalizing plus accelerated cooling heat treatment process. The normalizing 100-120mm steel plate prepared by the preparation method possesses excellent strength and toughness; yield strength is more than 420MPa; and the normalizing 100 -120mm steel plate can be used for preparation of key force support elements of buildings, bridges and tower structures with large span frameworks.

Owner:SHOUGANG CORPORATION

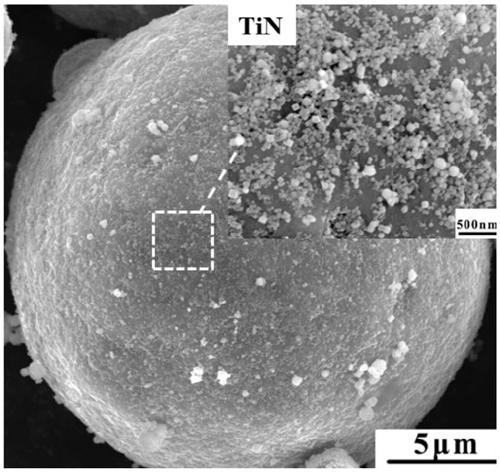

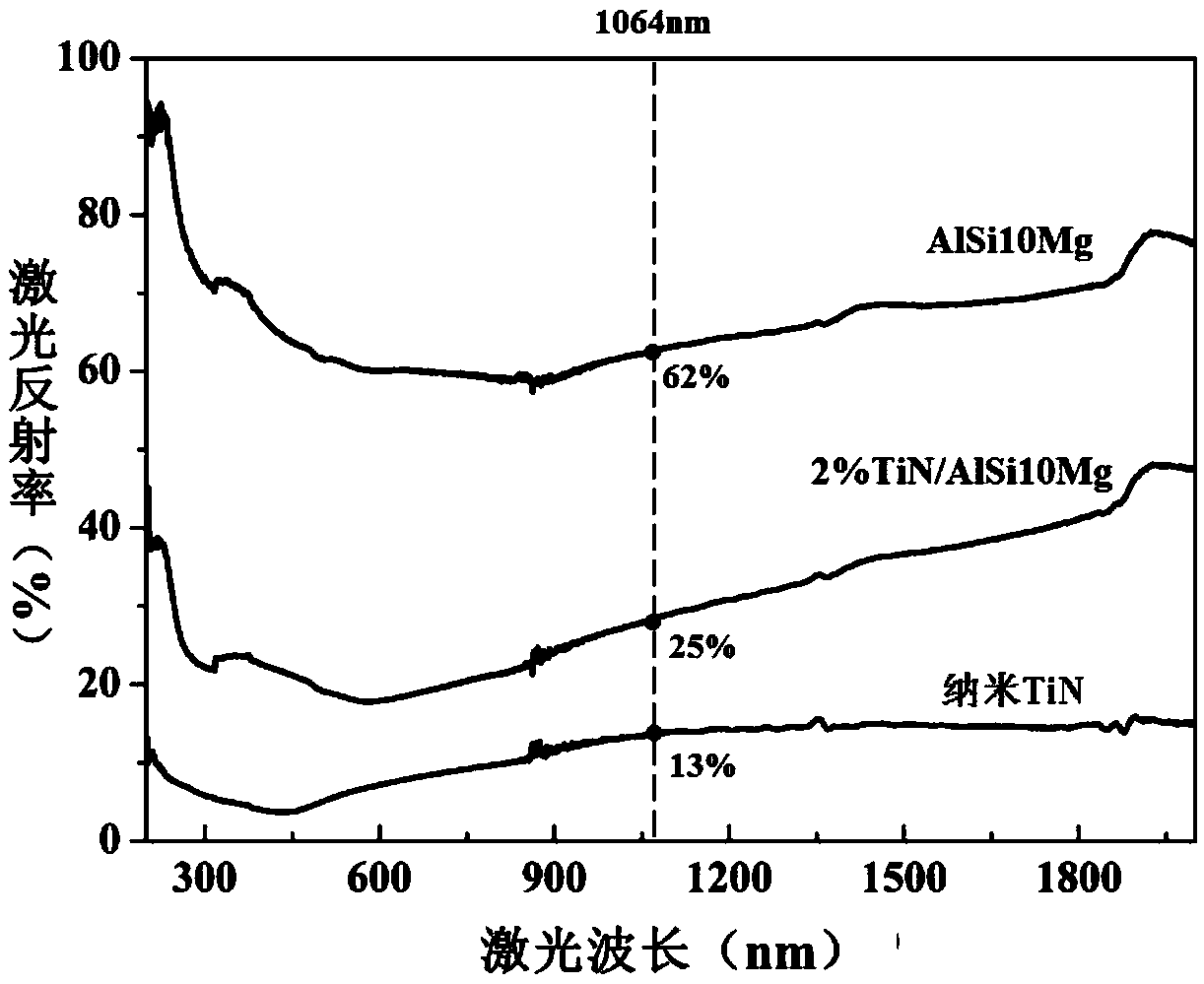

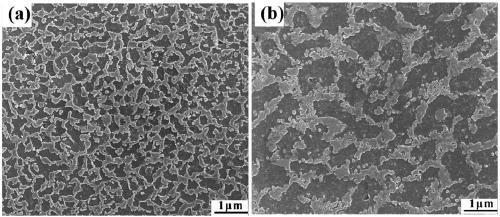

TiN/Al-based material composite powder and laser 3D printing forming method thereof

ActiveCN109317661AGood thermal stabilityStrong absorption capacityAdditive manufacturing apparatusIncreasing energy efficiencyAluminum matrix compositesAbsorption rate

The invention belongs to the field of aluminum-based composite materials, and discloses TiN / Al-based material composite powder and a laser 3D printing forming method thereof. The composite powder comprises matrix powder and reinforced phase particles, the matrix powder is AlSi10Mg powder, the reinforced phase particles are nano TiN ceramic particles, the nano TiN ceramic particles are evenly distributed on the surface of the AlSi10Mg powder, the mass fraction of the matrix powder, namely the AlSi10Mg powder is 90%-99%, and the mass fraction of the reinforced phase particles, namely the TiN particles is 1%-10%. The nano TiN ceramic particles are adopted as reinforced phases, the surface of the Al-based powder is coated with the nano TiN ceramic particles, the laser absorption rate of the composite powder is increased, the printing forming performance at low power is improved, and therefore the production cost is reduced. The reinforced phases still keep nano structures after laser processing, refined crystalline strengthening is generated, and the hardness and tensile strength of the material are improved.

Owner:SOUTH CHINA UNIV OF TECH +1

High-strength aluminum alloy material formed through metamorphism of salt hexafluorosilicate

The invention discloses a high-strength aluminum alloy material formed through metamorphism of salt hexafluorosilicate. The high-strength aluminum alloy material formed through the metamorphism of the salt hexafluorosilicate comprises, by weight, 2.6-3.2% of Cu, 0.45-0.7% of Mn, 2.0-2.4% of Mg, not more than 0.1% of Zn, not more than 0.15% of Ti, not more than 0.3% of Si, and not more than 0.3% of Fe. Salt hexafluorosilicate alterant accounts for 0.1-1.0% of the total furnace burden, and the rest is Al and unavoidable trace impurities, and the trace impurities comprise, by weight, not more than 0.05% of a single and not more than 0.10% of a total. The high-strength aluminum alloy material formed through the metamorphism of the salt hexafluorosilicate is good in metamorphism refining effect, can purify a furnace body, and is high in strength.

Owner:GUIZHOU ACAD OF SCI

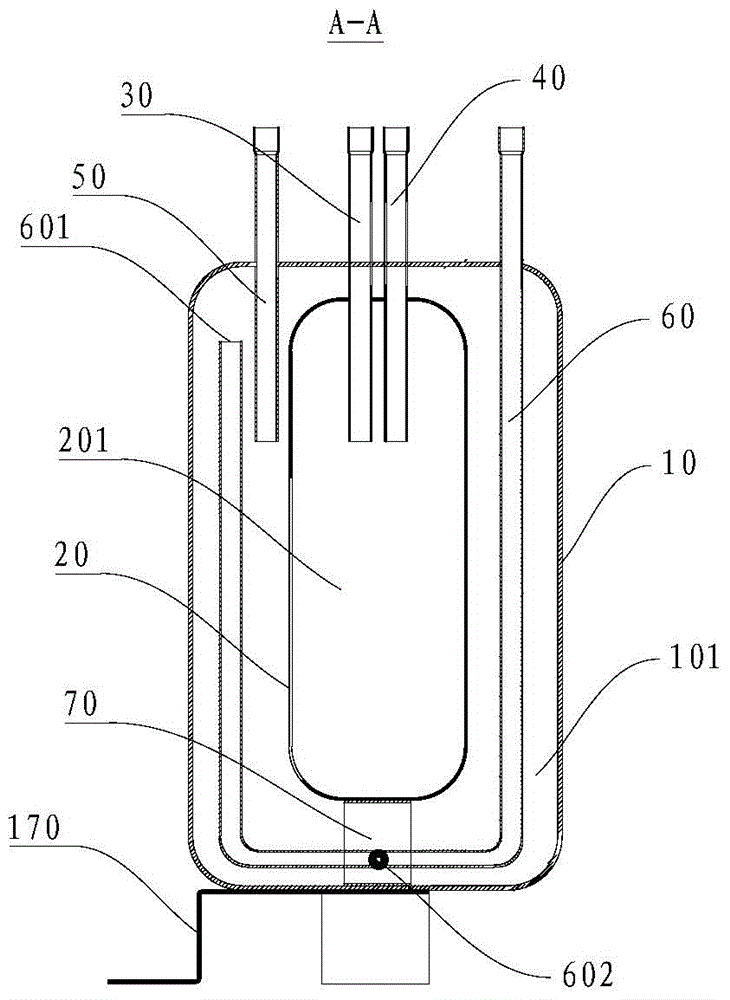

Liquid storage tank and multi-connected air conditioner provided with same

InactiveCN104634011AImprove reliabilityExtended service lifeRefrigeration componentsSuper coolingLiquid storage tank

The invention discloses a liquid storage tank and a multi-connected air conditioner provided with the liquid storage tank. The liquid storage tank comprises a low-pressure tank body, a high-pressure tank body, a first connecting pipe, a second connecting pipe, a third connecting pipe and a fourth connecting pipe. The first connecting pipe and the second connecting pipe extend into the high-pressure tank body, and the third connecting pipe and the fourth connecting pipe extend into the low-pressure tank body. The high-pressure tank body is partially or integrally placed in the low-pressure tank body, or the low-pressure tank body is partially or integrally placed in the high-pressure tank body. According to the liquid storage tank, a high-temperature refrigerant in the high-pressure tank body exchanges heat with a low-temperature and low-pressure refrigerant in the low-pressure tank body, and therefore the purpose of exchanging the heat by utilizing the refrigerating capacity of the low-temperature and low-pressure refrigerant is achieved; in this way, the super-cooling degree of the refrigerant in the high-pressure tank body can be effectively enhanced, and the occupied space of the liquid storage tank is reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

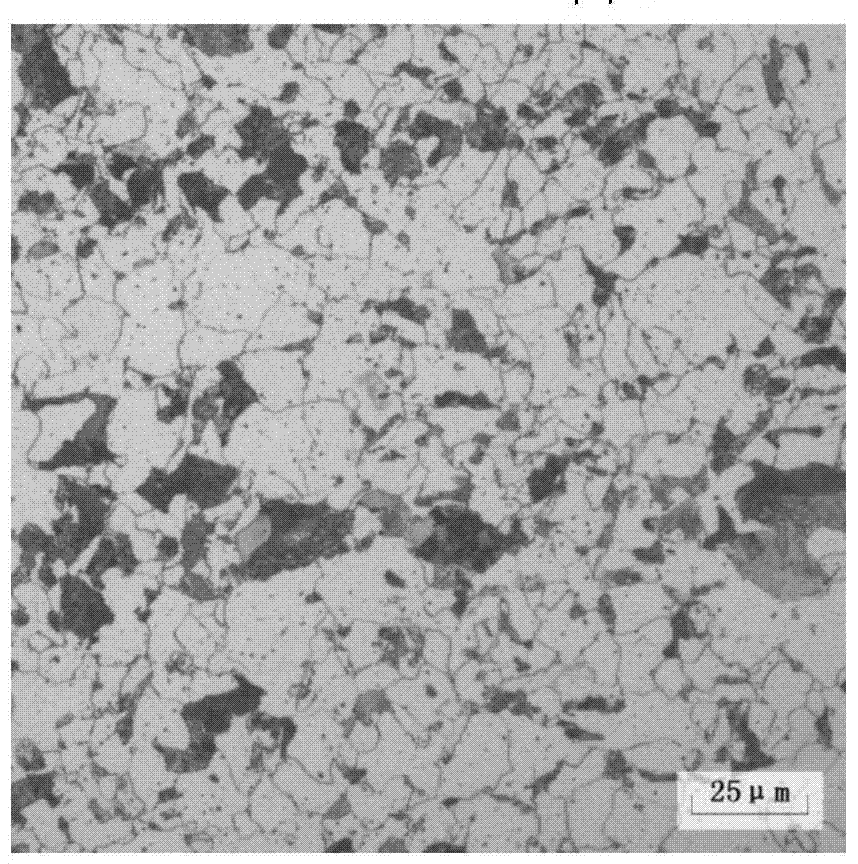

Core-covered wire fed by steel continuous casting crystallizer and method for dynamically controlling wire feeding process

The invention discloses a core-covered wire fed by a steel continuous casting crystallizer and a method for dynamically controlling a wire feeding process, and belongs to the field of iron and steel metallurgy continuous casting production. The core-covered wire fed by the steel continuous casting crystallizer consists of an outer shell and an inner core. The method for dynamically controlling the core-covered wire fed by the steel continuous casting crystallizer comprises the following steps: (1) establishing a database of the optimal wire feeding speed of the crystallizer; (2) retrieving the optimal wire feeding speed of a wire feeder from a database; (3) obtaining a speed deviation value; (4) judging whether the speed deviation value delta is zero or not; (5) dynamically controlling the wire feeding speed. During a continuous casting production process, the superheat degree of molten steel and the casting speed of a casting machine are affected by the rhythm of production, and process parameters change time after time; according to the method, the wire feeding speed can be adjusted dynamically in real time according to the continuous casting process parameters, so that the molten steel can be promoted to achieve great supercooling degree to increase liquid phase core grain nucleation, refine crystal grain size, and improve a feeding behaviour of a two-phase area; therefore, the purposes of reducing centre segregation and loosening of a casting blank and stabilizing the internal quality of the casting blank are achieved.

Owner:NORTHEASTERN UNIV

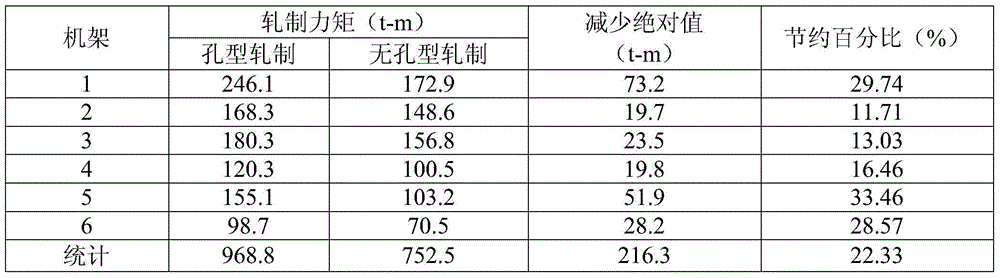

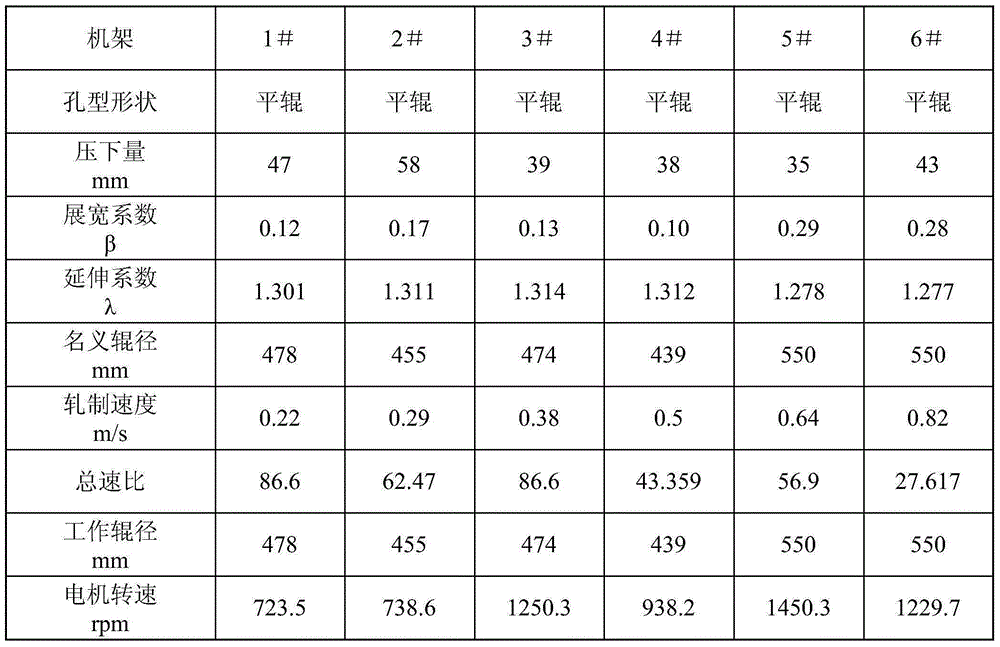

Production process for grooveless rolling of 82B wire rod by high-speed wire mill

ActiveCN104084421ASharedReduce reservesWork treatment devicesMetal rolling arrangementsWire rodEconomic benefits

The invention belongs to the technical field of rod wire deformation processes in metallurgical industry and particularly relates to a production process for grooveless rolling of an 82B wire rod by a high-speed wire mill. The production process aims that special equipment is not required, the processing cost is low, industrialized production is easy to realize, the steel off-square problem of a grooveless rolling production process is solved, the production accident rate is greatly reduced, the product quality is improved, and the economic benefit is increased. The production process adopts the technical scheme as follows: the production process comprises the following steps: (1) heating a 82B steel billet; (2) rolling by a grooveless flat-roll rough rolling unit, wherein in the rolling process, the extension coefficient of each pass is controlled from 1.20 to 1.45, the broadening coefficient ranges from 0.10 to 0.65, and the running speed of the steel billet ranges from 0.20 m / s to 1.04 m / s; (3) entering an intermediate rolling unit and a pre-finishing unit in sequence for rolling; (4) rolling by a finishing unit; (5) cooling by water and entering a wire-feeding machine to obtain the wire rod; (6) cooling by air, winding and transporting, and finally packaging and warehousing to obtain the finished high-speed 82B wire rod.

Owner:西安盛日机电科技有限公司

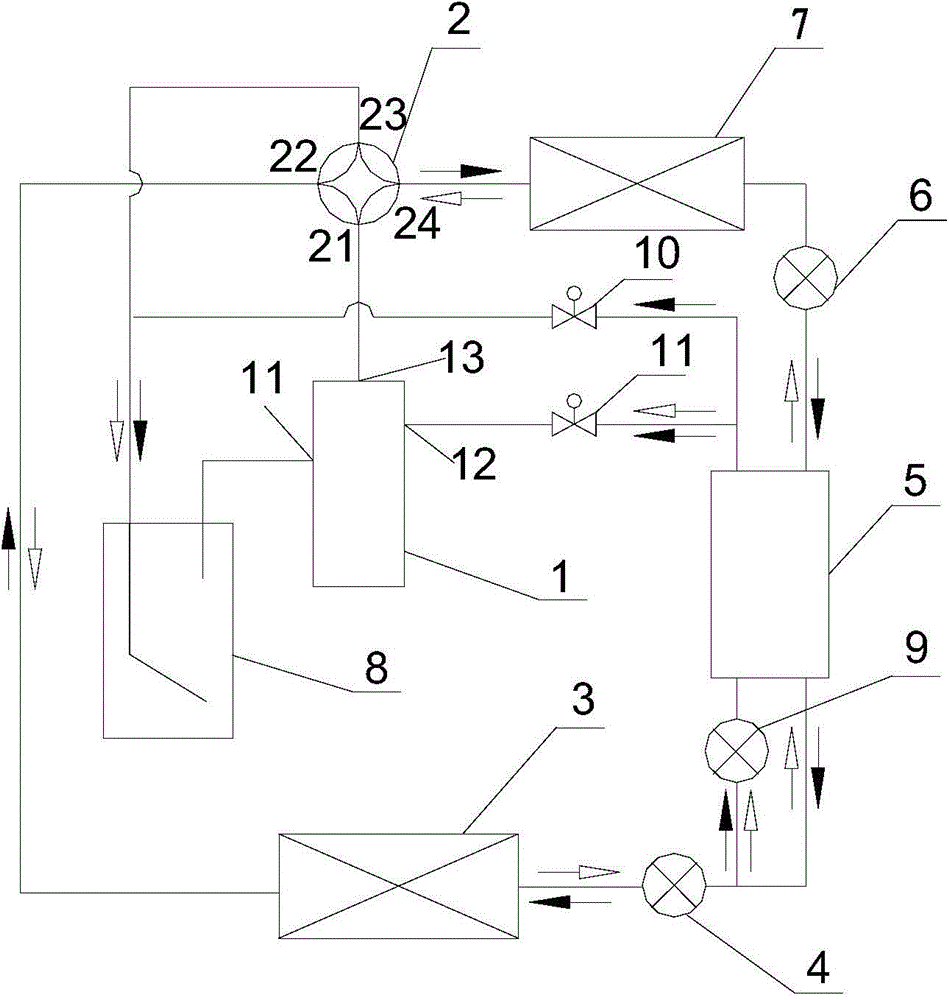

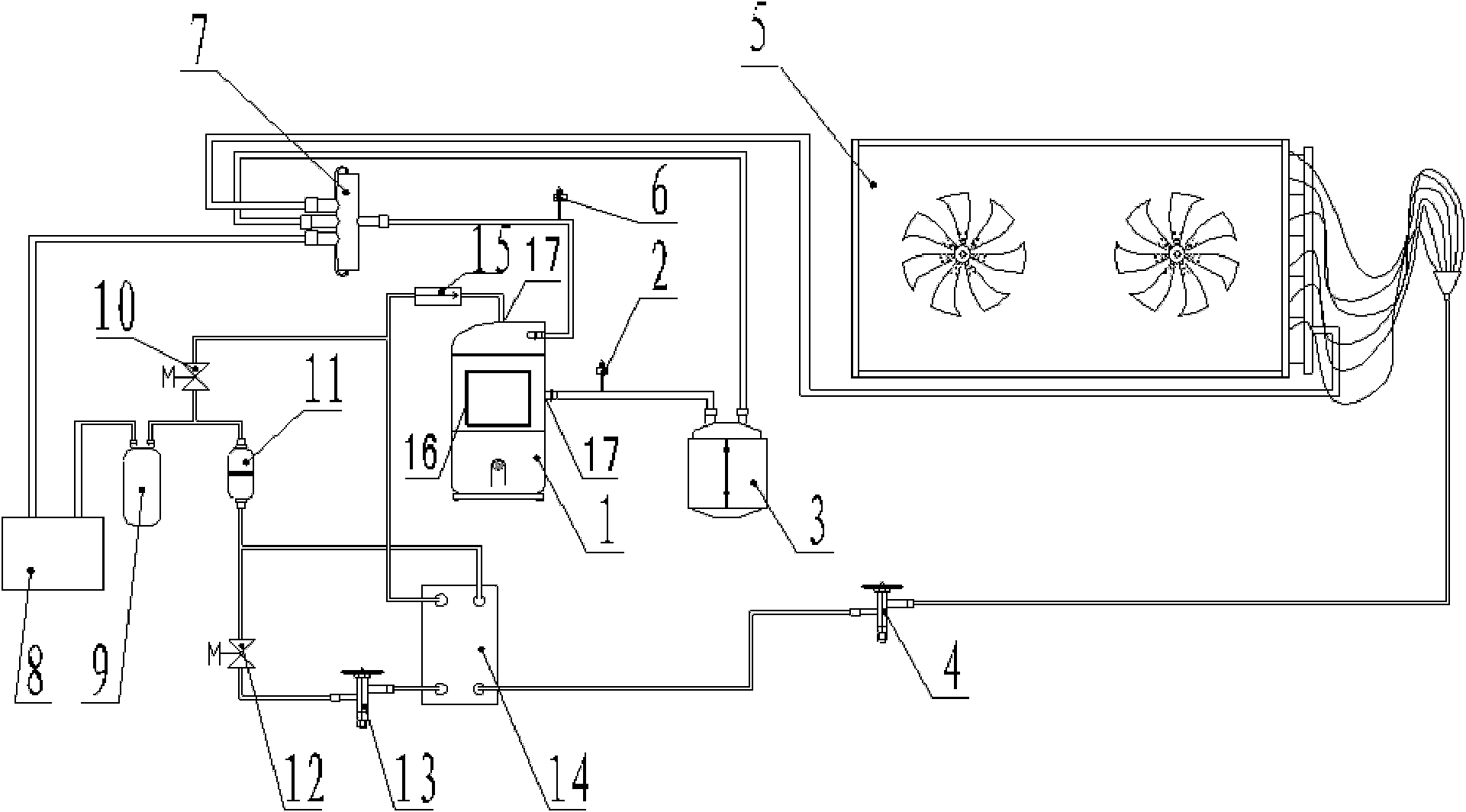

Ultralow temperature air source heat pump hot-water machine

InactiveCN101957060AReduce exhaust temperatureIncrease heat transferFluid heatersFluid circulation arrangementBusiness efficiencyThermal energy

The invention relates to a ultralow temperature air source heat pump hot-water machine, which comprises a compression engine(1),a air-side heat exchanger (5) and a hot-water-side heat exchanger(8) which are connected by pipeline; the compression engine(1) is internally provided with a cavity(16), one side of the compression engine(1) is provided with an air-supplement port. The heat pump hot-water machine further comprises an air-supply return circuit, a refrigerating circuit and an auxiliary air-supply return circuit. The heat pump hot-water machine can work in the ultralow temperature work environment, and has low delivery temperature, improves the conversion of thermal energy effect and the system energy efficiency ratio, and is favor of energy saving and environmental protection.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

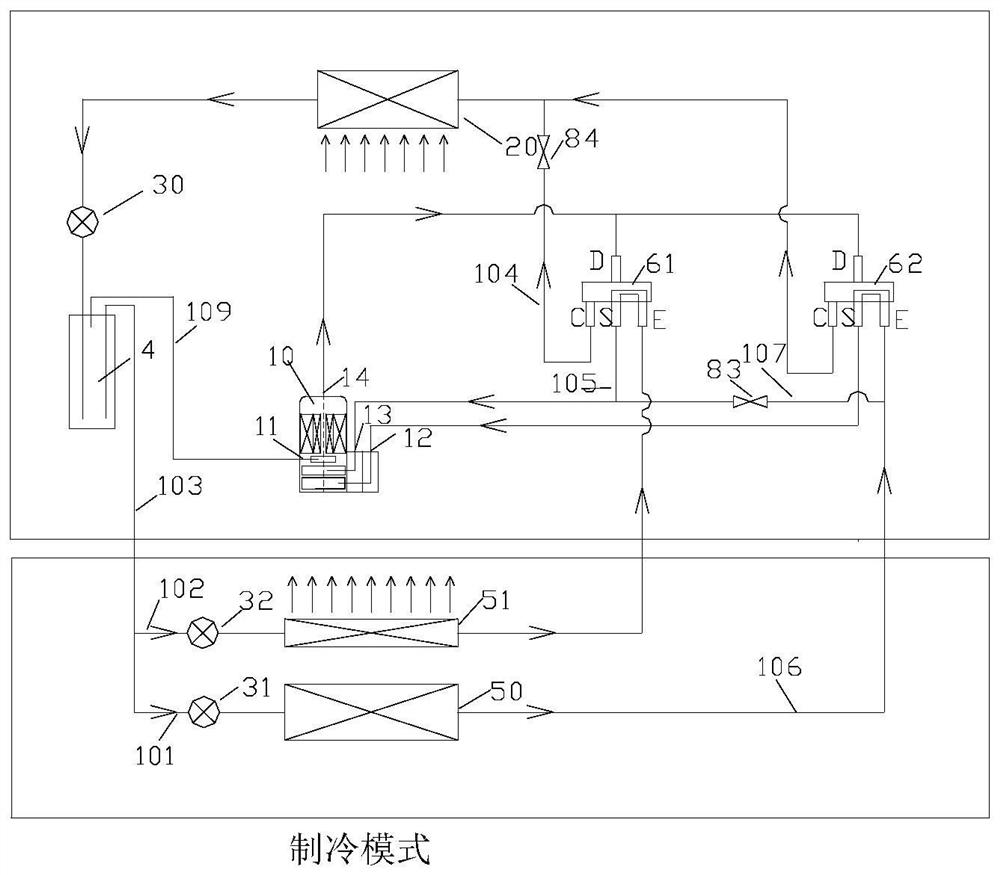

Air conditioning system and control method thereof

PendingCN111780254AIncrease subcoolingImprove indoor comfortMechanical apparatusFluid circulation arrangementAir conditioningRefrigeration

The invention provides an air conditioning system and a control method thereof. The air conditioning system comprises a compressor, a first indoor heat exchanger and a second indoor heat exchanger; the air conditioner further comprises a valve set structure, and through switching control of the valve set structure, in the refrigeration mode, the indoor first heat exchanger communicates with an airsuction port of the compressor, and the indoor second heat exchanger communicates with the air suction port of the compressor; in the heating mode, the indoor first heat exchanger communicates with an exhaust port of the compressor, and the indoor second heat exchanger communicates with the exhaust port of the compressor; in the reheating dehumidification mode, the indoor first heat exchanger communicates with the air suction port of the compressor, and the indoor second heat exchanger communicates with the exhaust port of the compressor; and air flow can sequentially flow through the indoorfirst heat exchanger and the indoor second heat exchanger to complete heat exchange. According to the air conditioning system, the leeward side heat exchanger can be converted into the reheating heatexchanger under the control of the valve when the air conditioning system operates in the dehumidification mode in the transition season, so that the air supply temperature when the air conditioning system operates in the dehumidification mode is increased, the condensation temperature is reduced, the supercooling degree of the outlet of a condenser is increased, and the system energy efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com