Patents

Literature

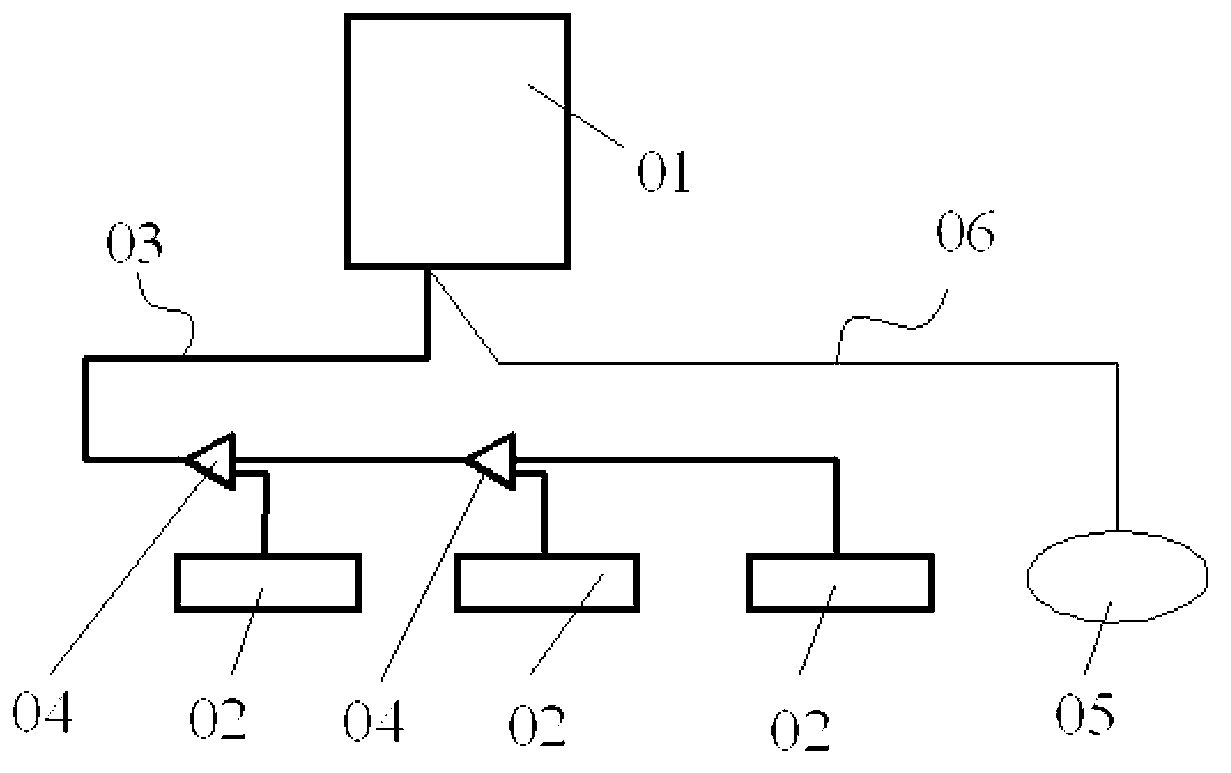

849results about How to "Reduce exhaust temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Advanced heat recovery and energy conversion systems for power generation and pollution emissions reduction, and methods of using same

ActiveUS6964168B1Reduce exhaust temperatureSteam engine plantsCombined combustion mitigationWorking fluidEngineering

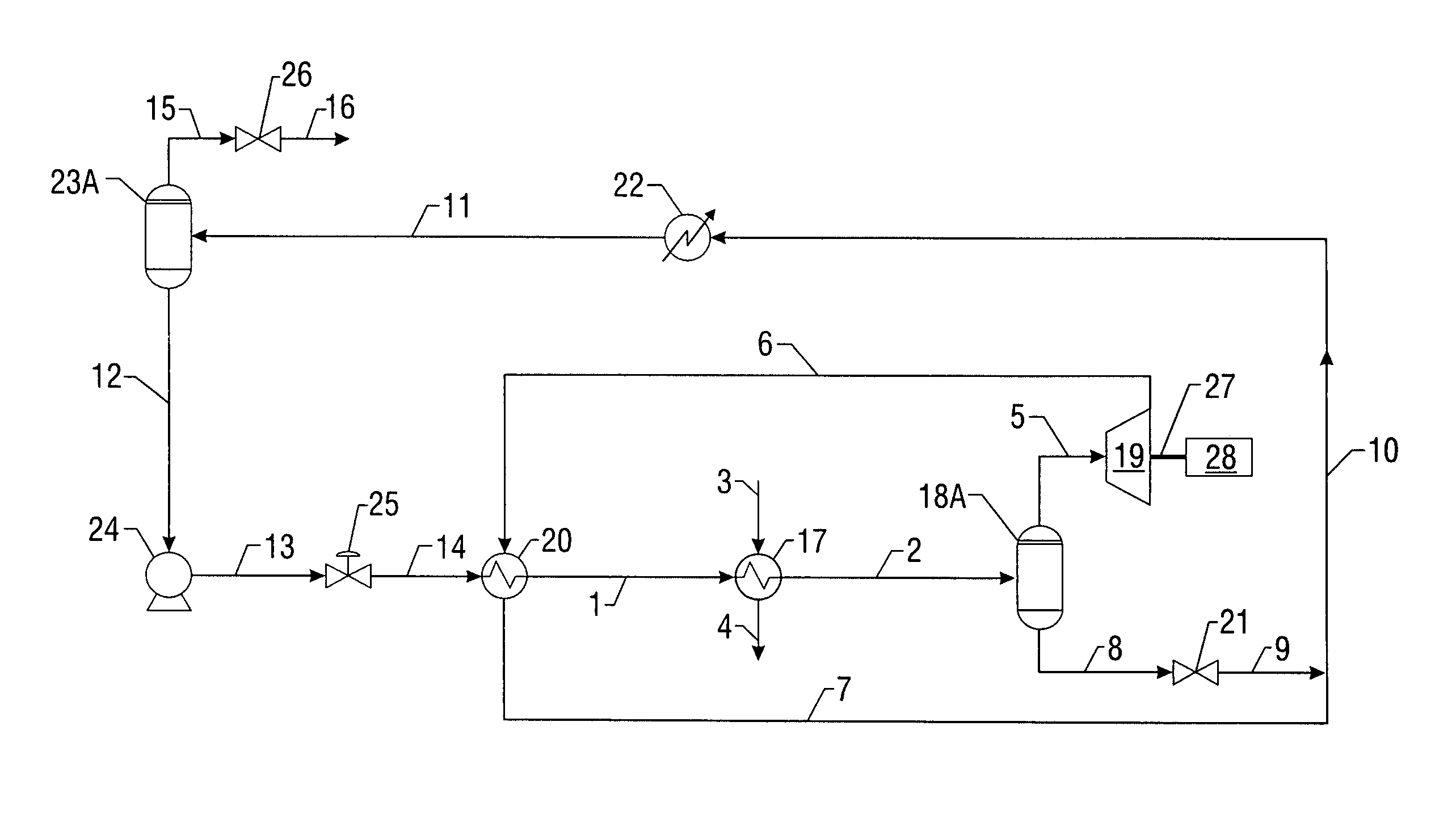

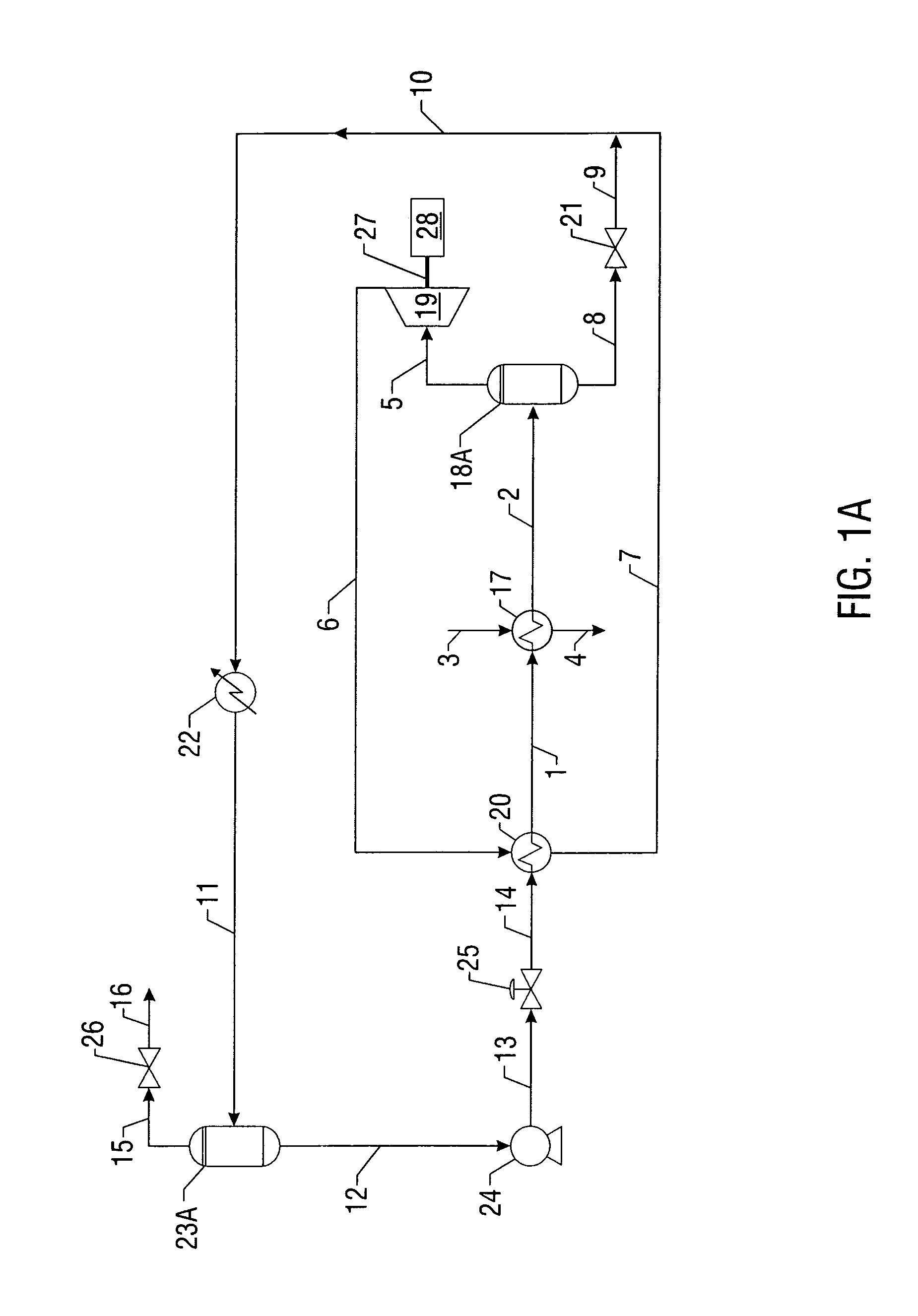

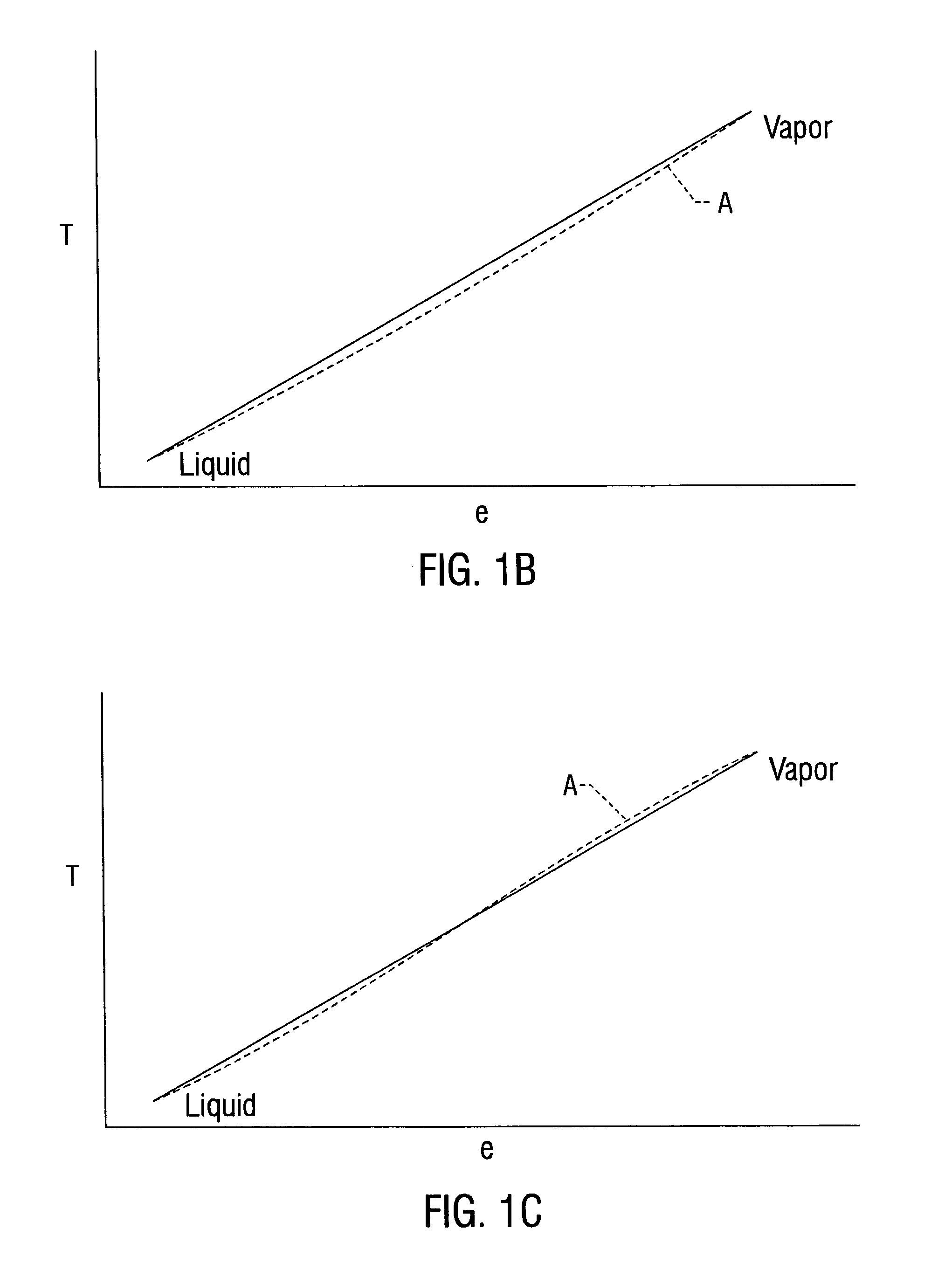

Disclosed herein are various systems and methods for producing mechanical power from a heat source. In various illustrative examples, the system may include a heat recovery heat exchanger, a turbine, an economizer heat exchanger, a condenser heat exchanger, and a liquid circulating pump, etc. In other embodiments, a desuperheater may be employed. In one illustrative embodiment, the system comprises a first heat exchanger adapted to receive a fluid from a heat source and a working fluid, wherein, when the working fluid is passed through the first heat exchanger, the working fluid is converted to a vapor via heat transfer with the fluid from the heat source, at least one turbine adapted to receive the vapor, and an economizer heat exchanger adapted to receive exhaust vapor from the turbine and the working fluid, wherein a temperature of the working fluid is adapted to be increased via heat transfer with the exhaust vapor from the turbine prior to the introduction of the working fluid into the first heat exchanger. The system further comprises a condenser heat exchanger that is adapted to receive the exhaust vapor from the turbine after the exhaust vapor has passed through the economizer heat exchanger and a cooling fluid, wherein a temperature of the exhaust vapor is reduced via heat transfer with the cooling fluid, and a pump that is adapted to circulate the working fluid to the economizer heat exchanger.

Owner:TAS ENERGY +1

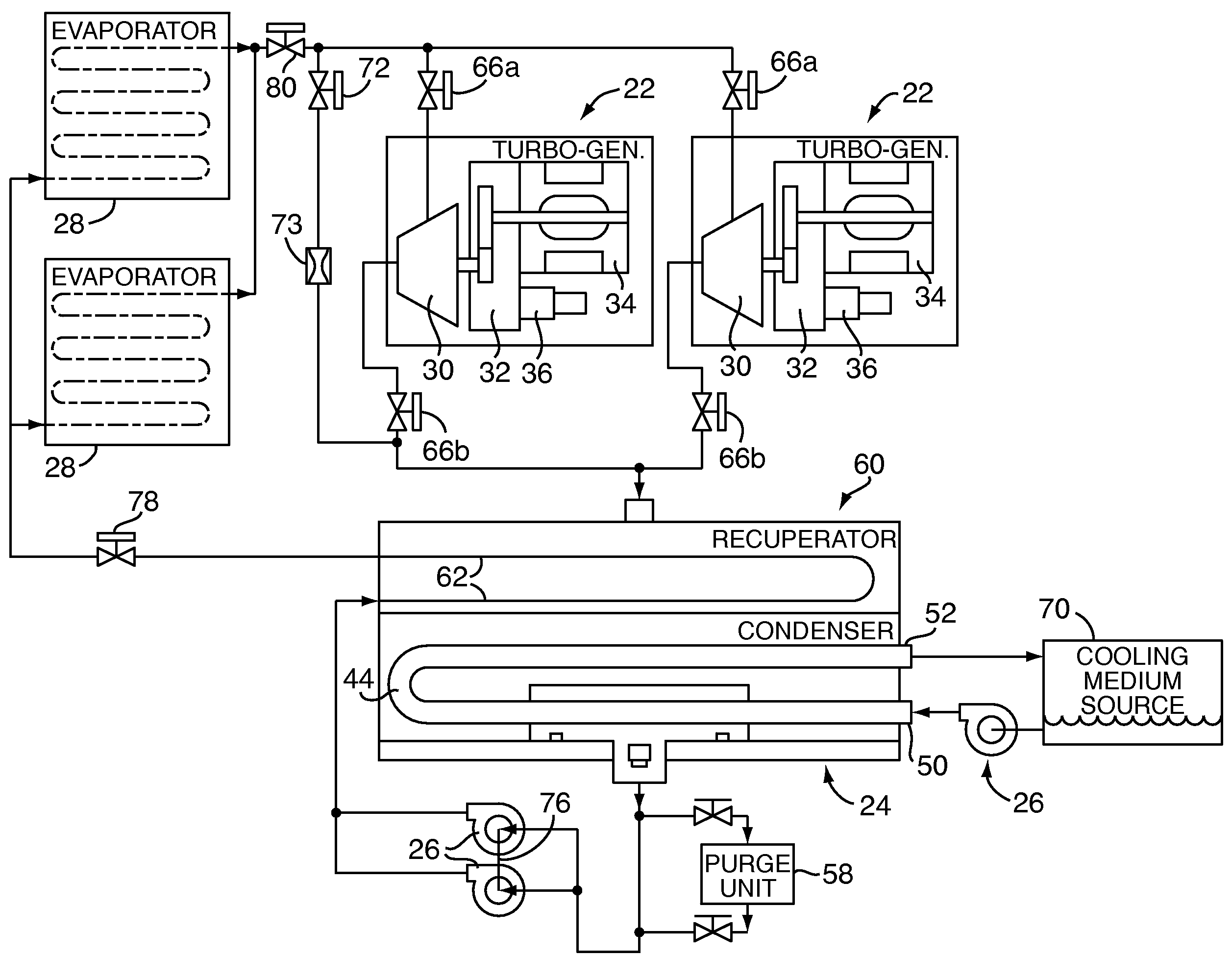

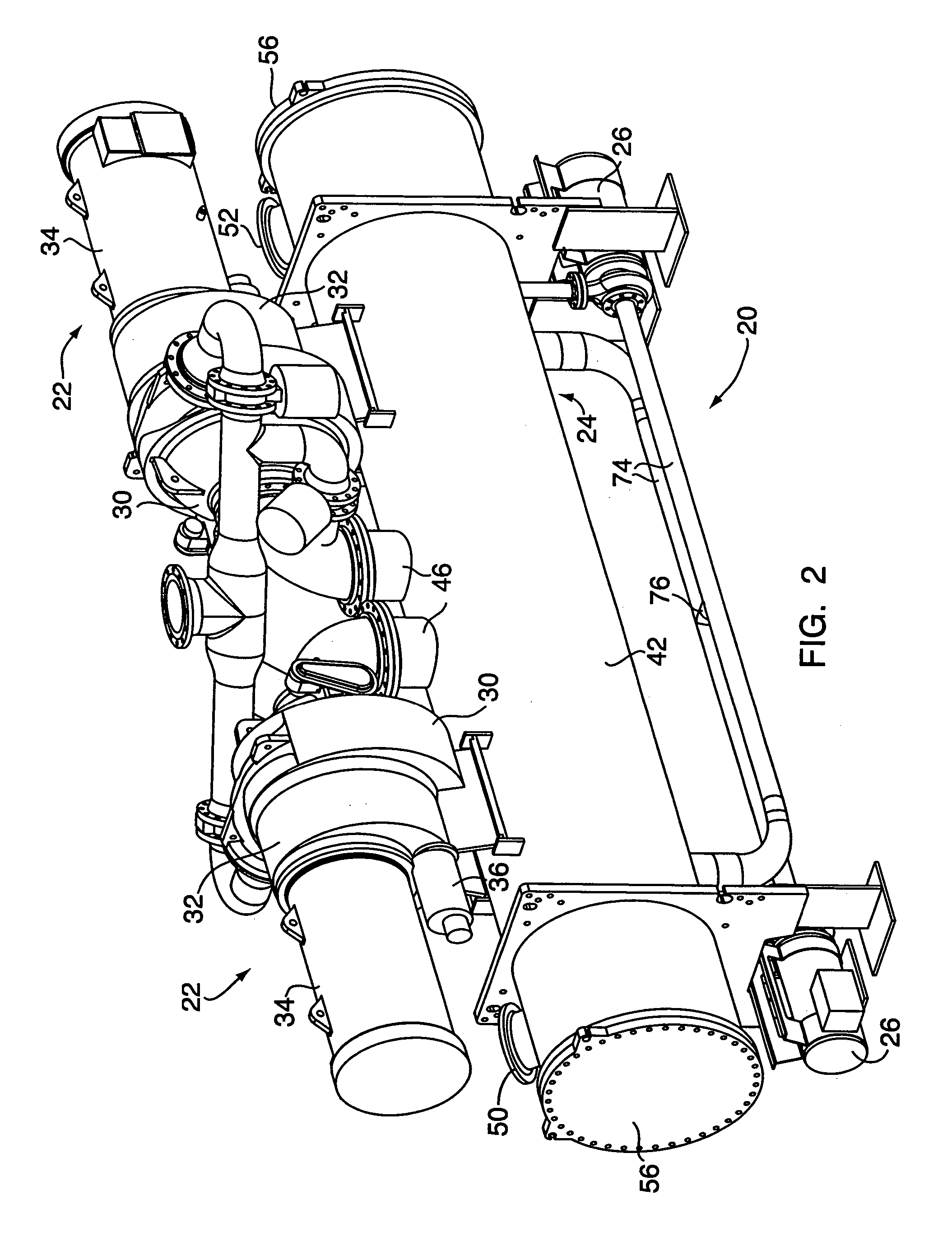

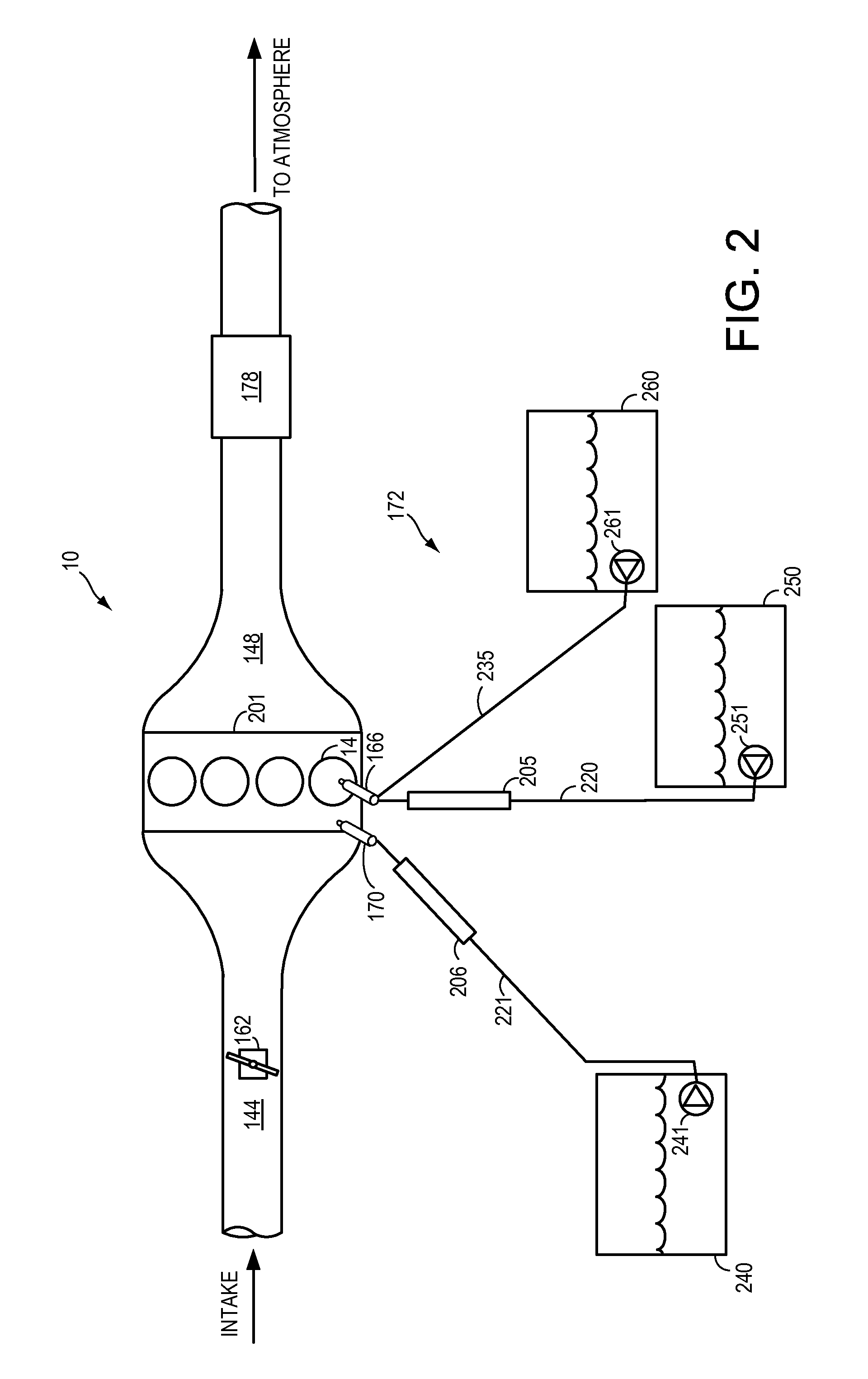

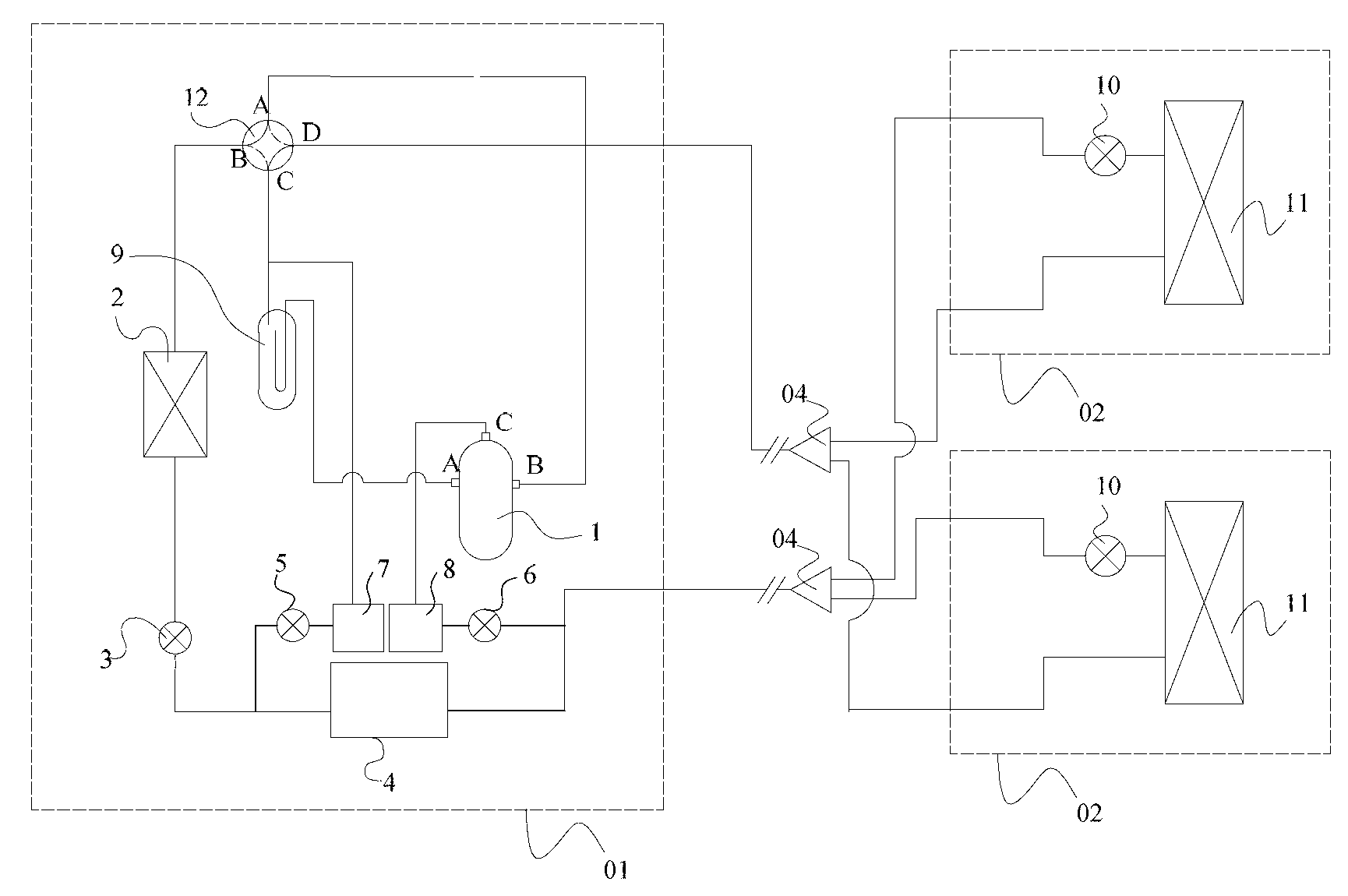

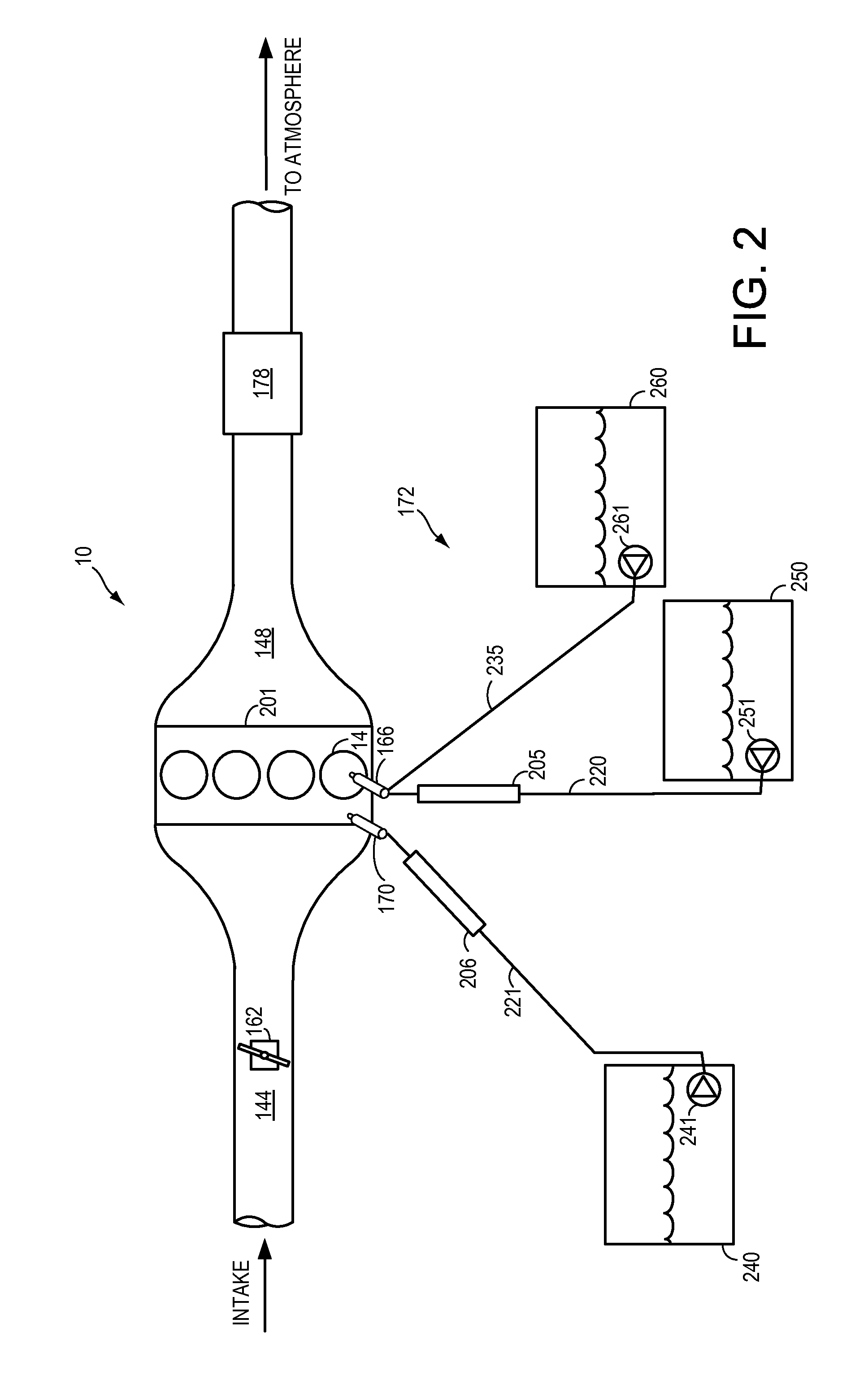

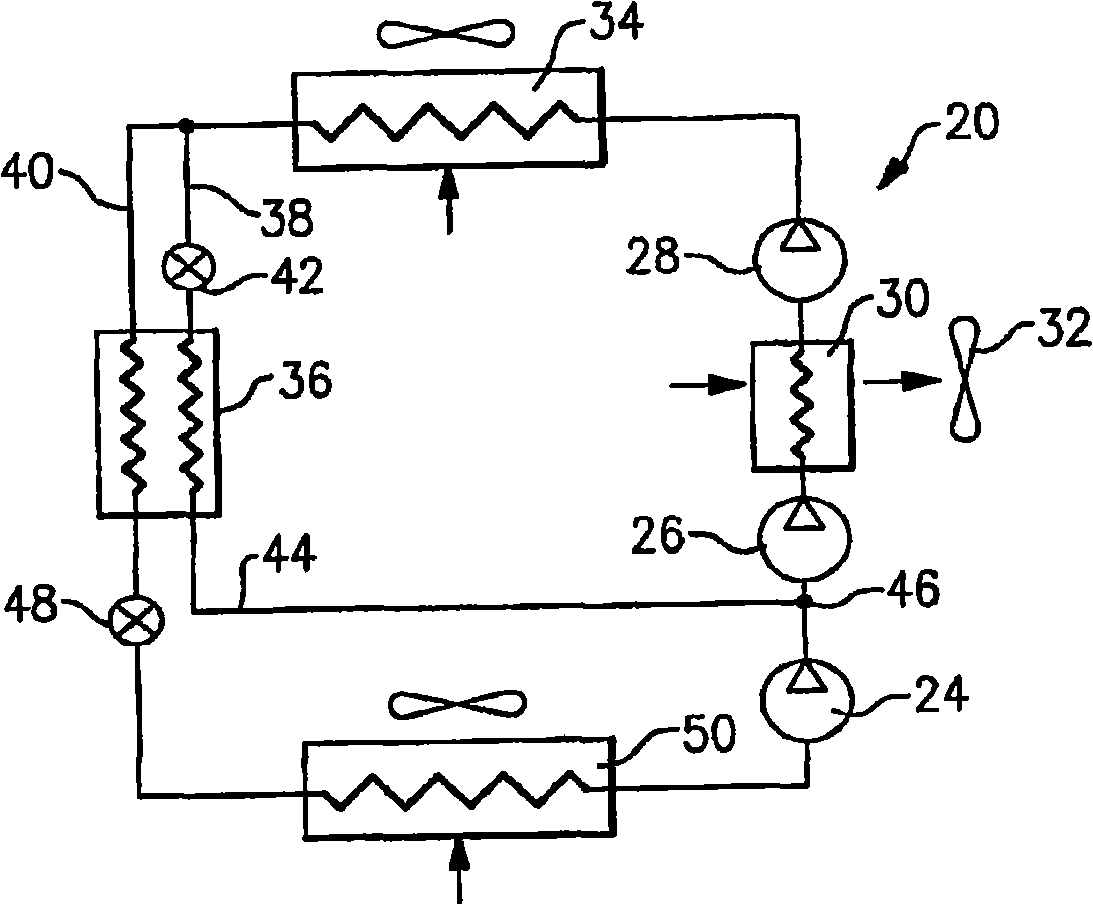

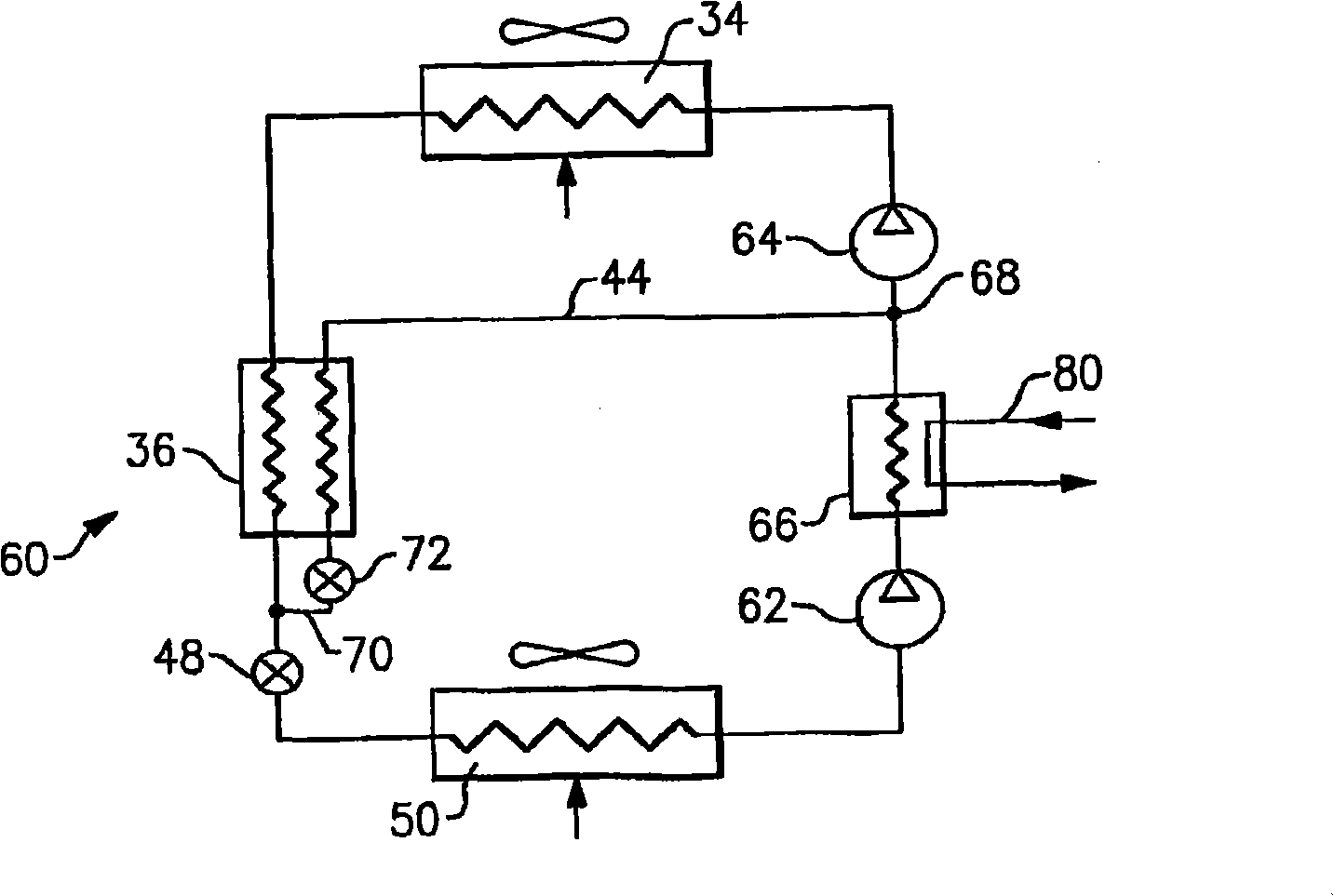

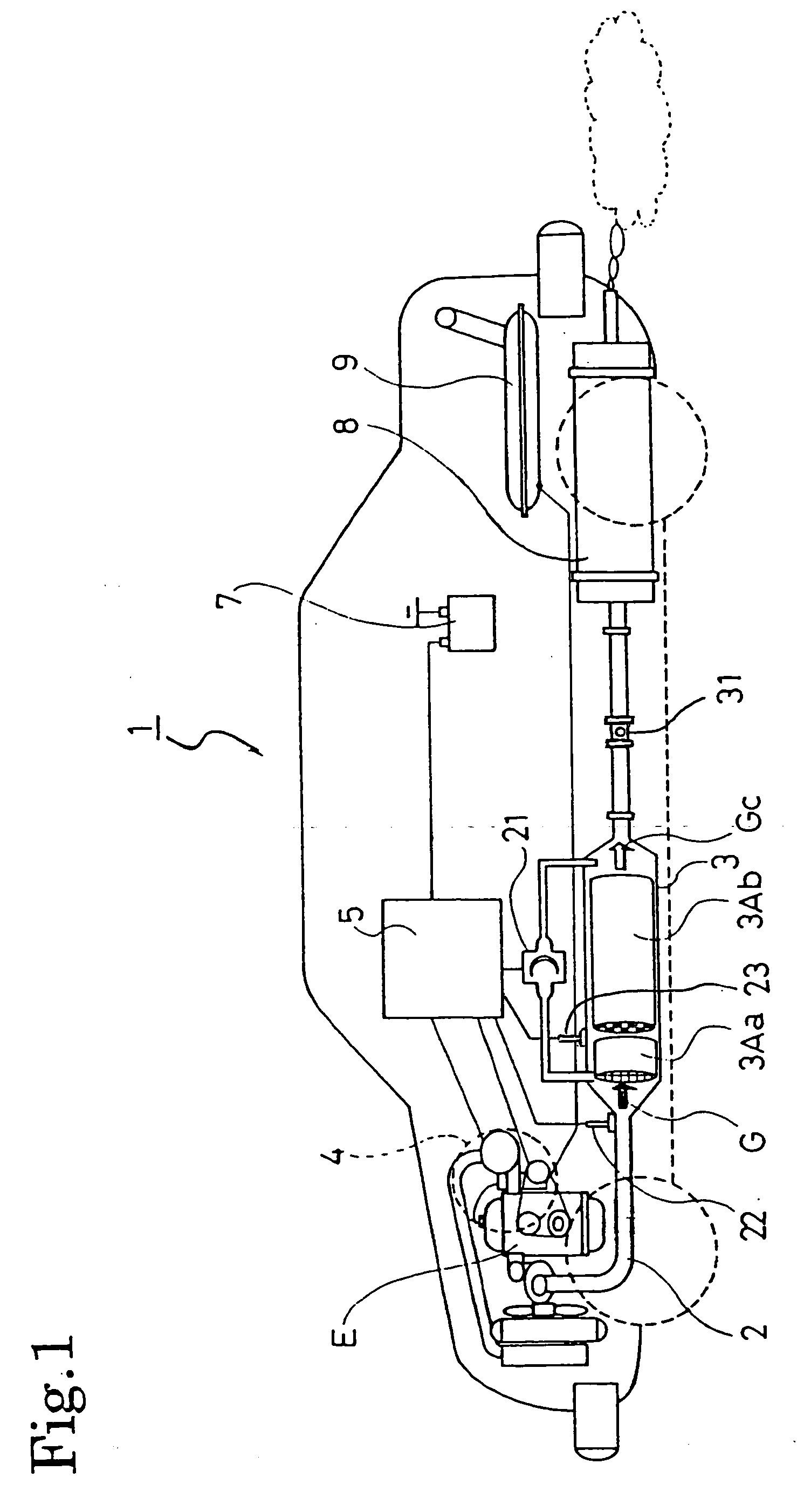

Rankine cycle device having multiple turbo-generators

A method for generating power, comprising the steps of: a) providing a Rankine Cycle device that includes a plurality of turbo-generators, each including a turbine coupled with an electrical generator, and at least one of each of an evaporator, a condenser, and a refrigerant feed pump; b) disposing the one or more evaporators within an exhaust duct of a power plant of a marine vessel; c) operating the power plant; and d) selectively pumping refrigerant through the Rankine Cycle device.

Owner:NANJING TICA AIR CONDITIONING CO LTD +1

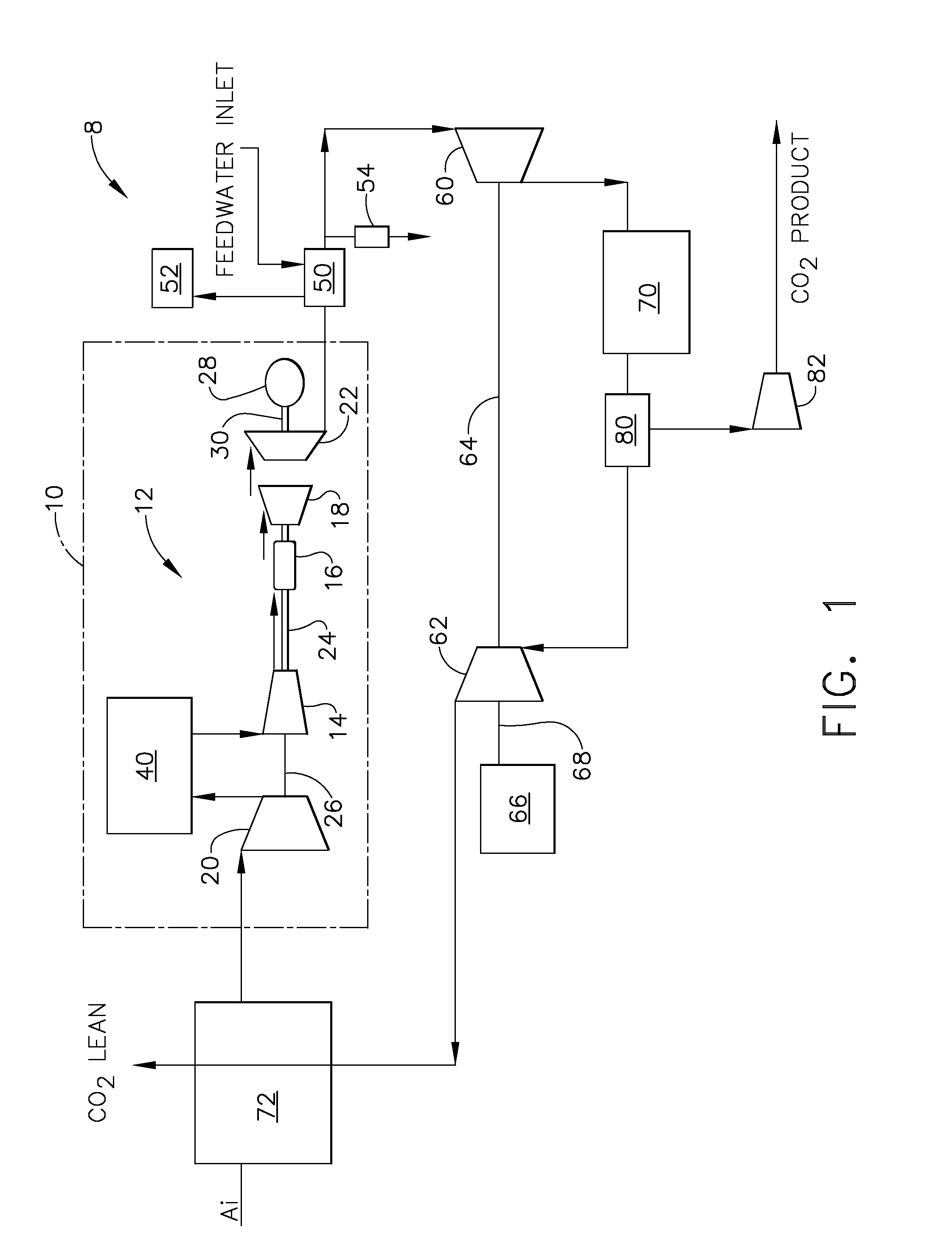

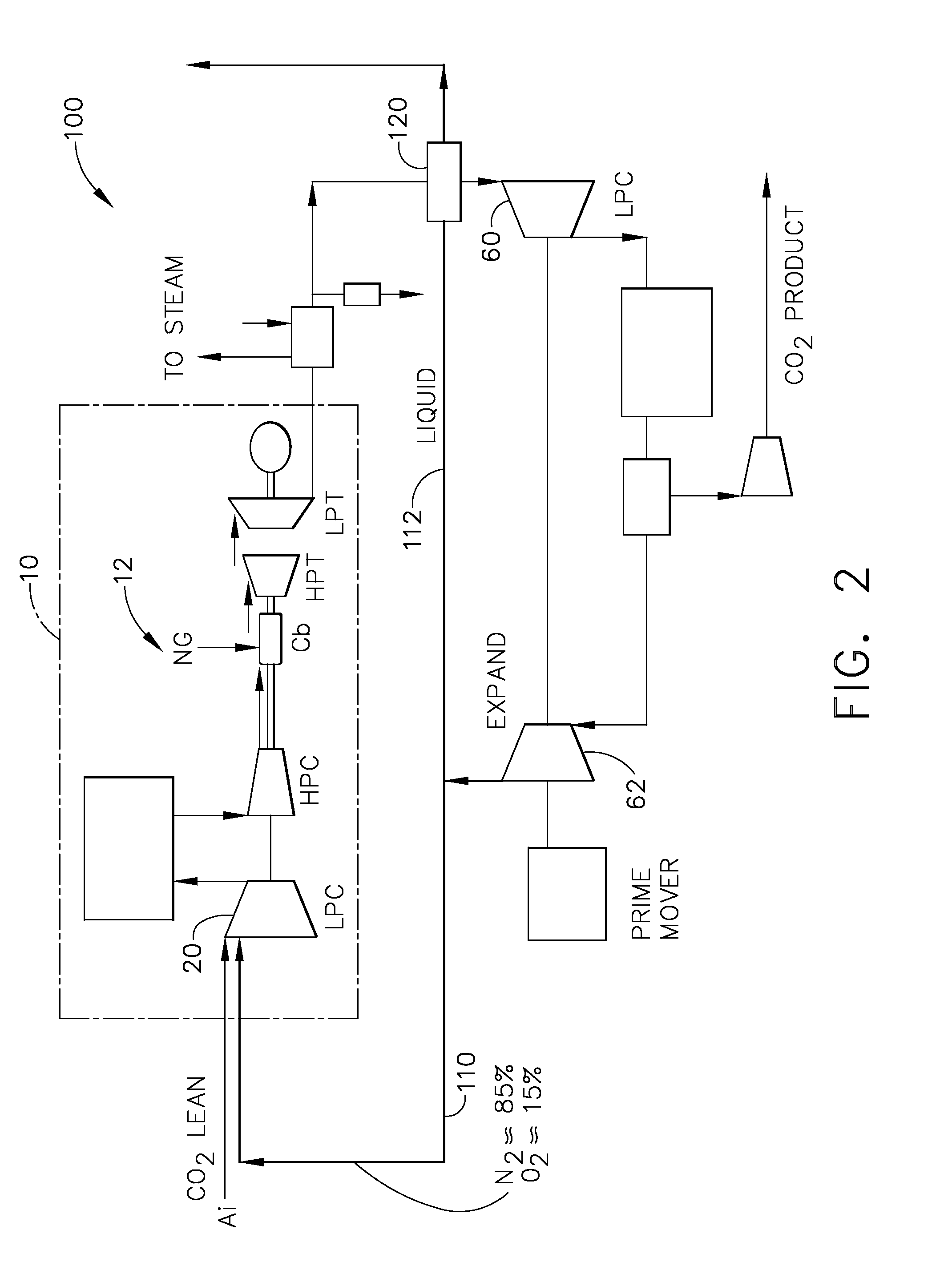

Method and system for reducing power plant emissions

InactiveUS7942008B2Increase exhaust pressureReduce exhaust temperatureGas treatmentGas turbine plantsPower stationTurbine

Owner:GENERAL ELECTRIC CO

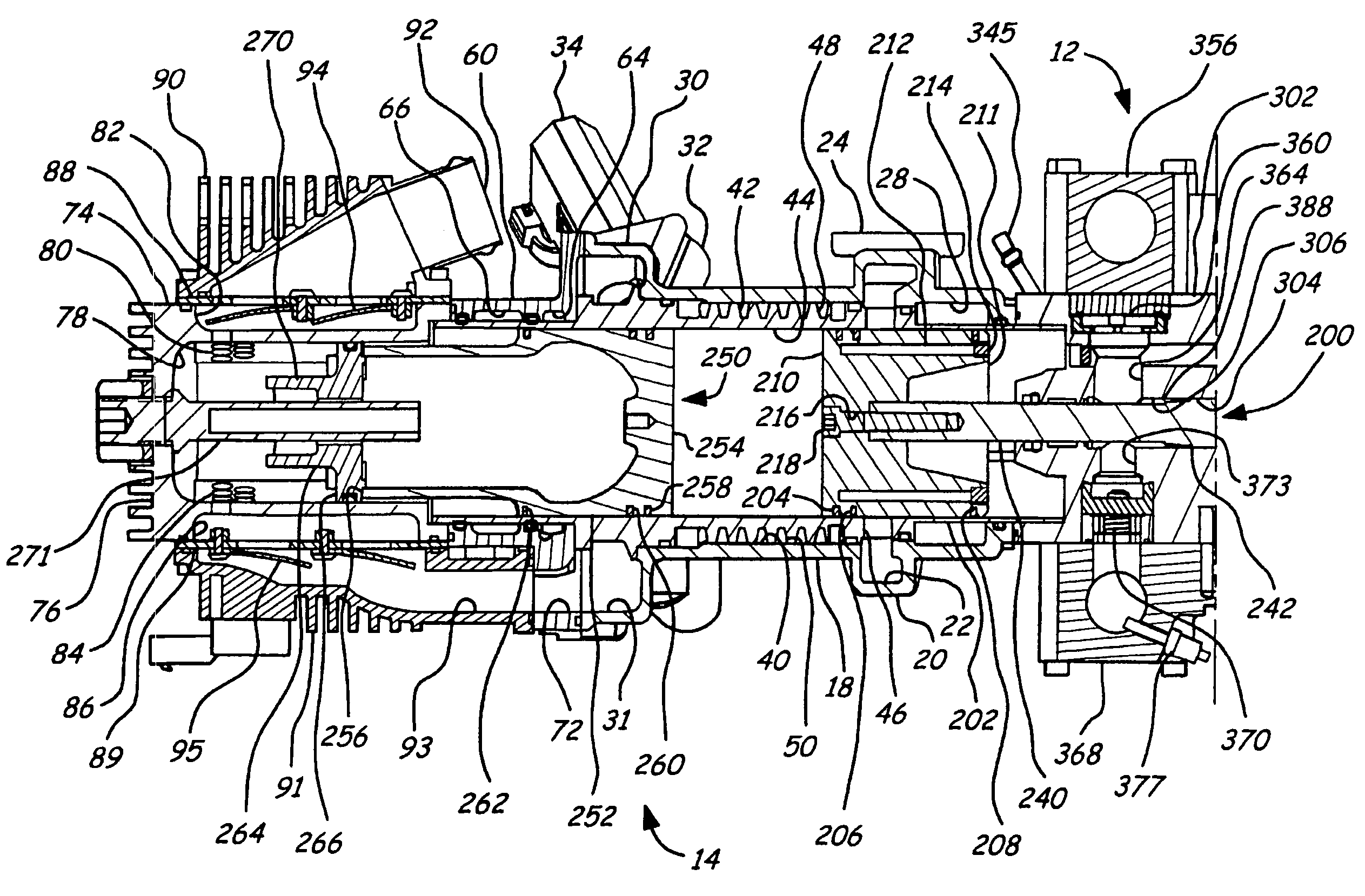

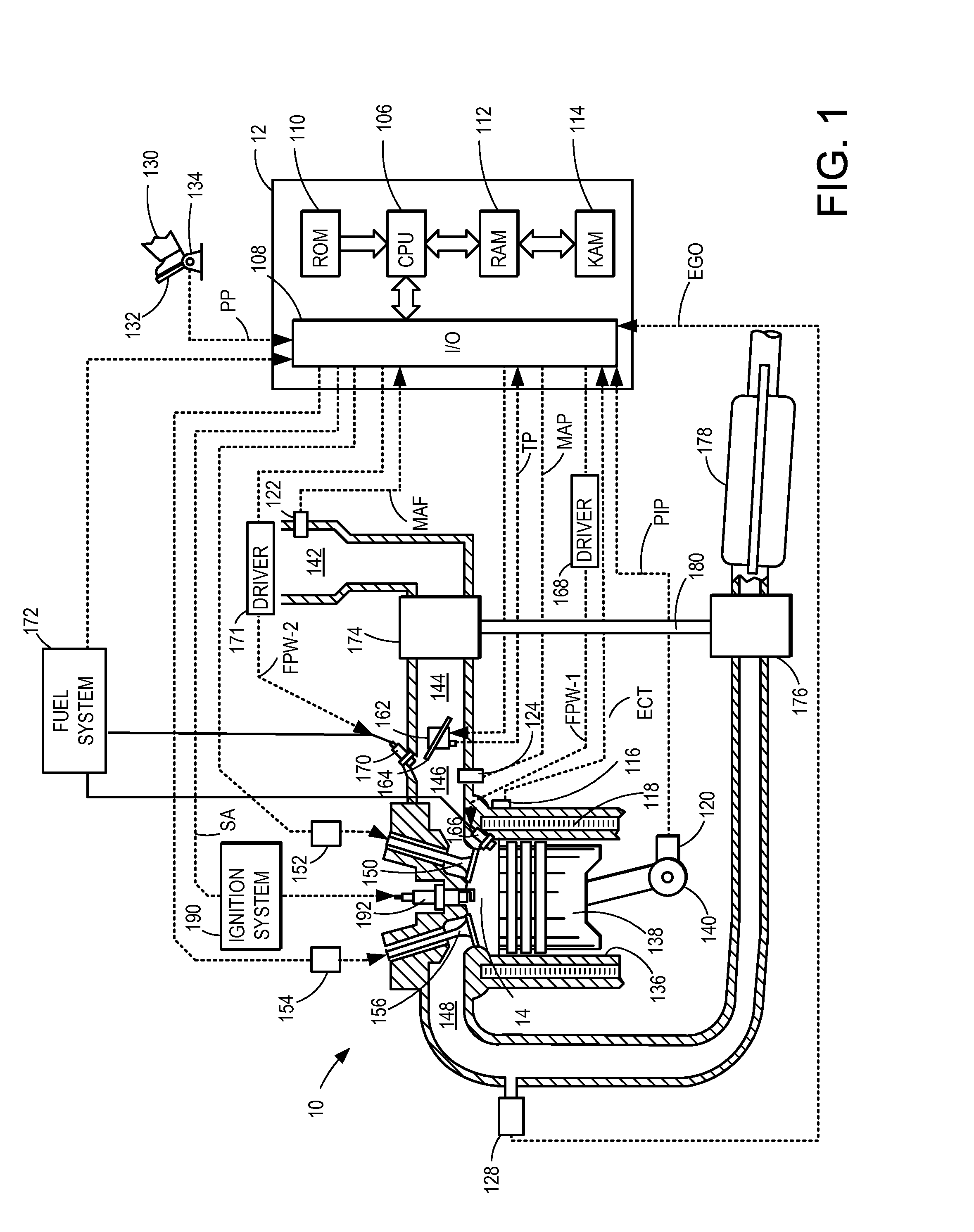

Air charging system for an opposed piston opposed cylinder free piston engine

InactiveUS6957632B1Avoid less frictionEfficient chargingElectrical controlInternal combustion piston enginesFree-piston enginePump chamber

A free piston engine is configured with a pair of opposed engine cylinders located on opposite sides of a fluid pumping assembly. An inner piston assembly includes a pair of inner pistons, one each operatively located in a respective one of the engine cylinders, with a push rod connected between the inner pistons. The push rod extends through an inner pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. An outer piston assembly includes a pair of pistons, one each operatively located in a respective one of the engine cylinders, with at least one pull rod connected between the outer pistons. The pull rod extends through an outer pumping chamber in the fluid pumping assembly and forms a fluid plunger within this chamber. Each outer piston cooperates with an integrated scavenge pump in order to compress the charge air, thus significantly increasing the air charge density into the engine cylinders for each stroke of the engine.

Owner:FORD GLOBAL TECH LLC

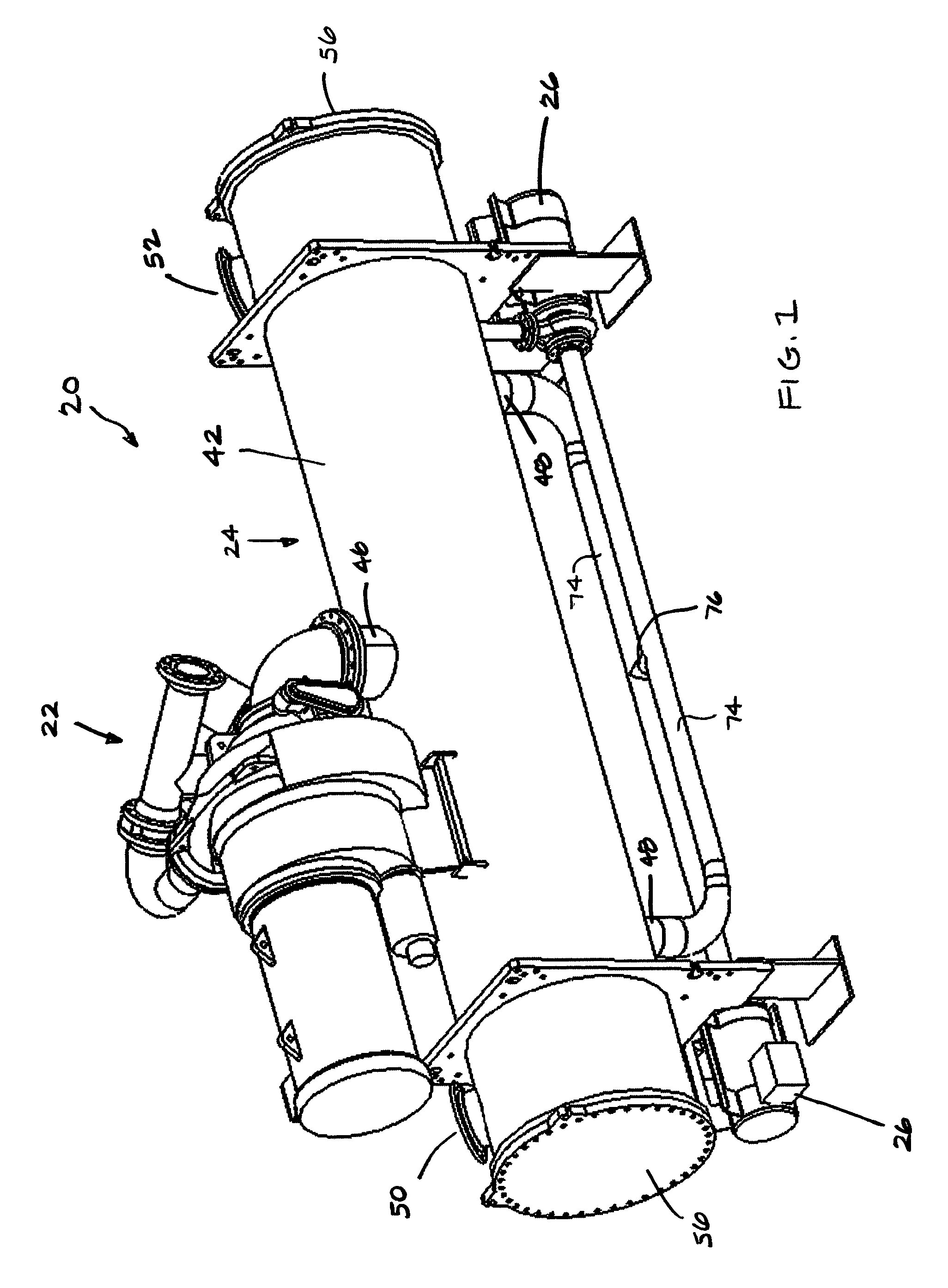

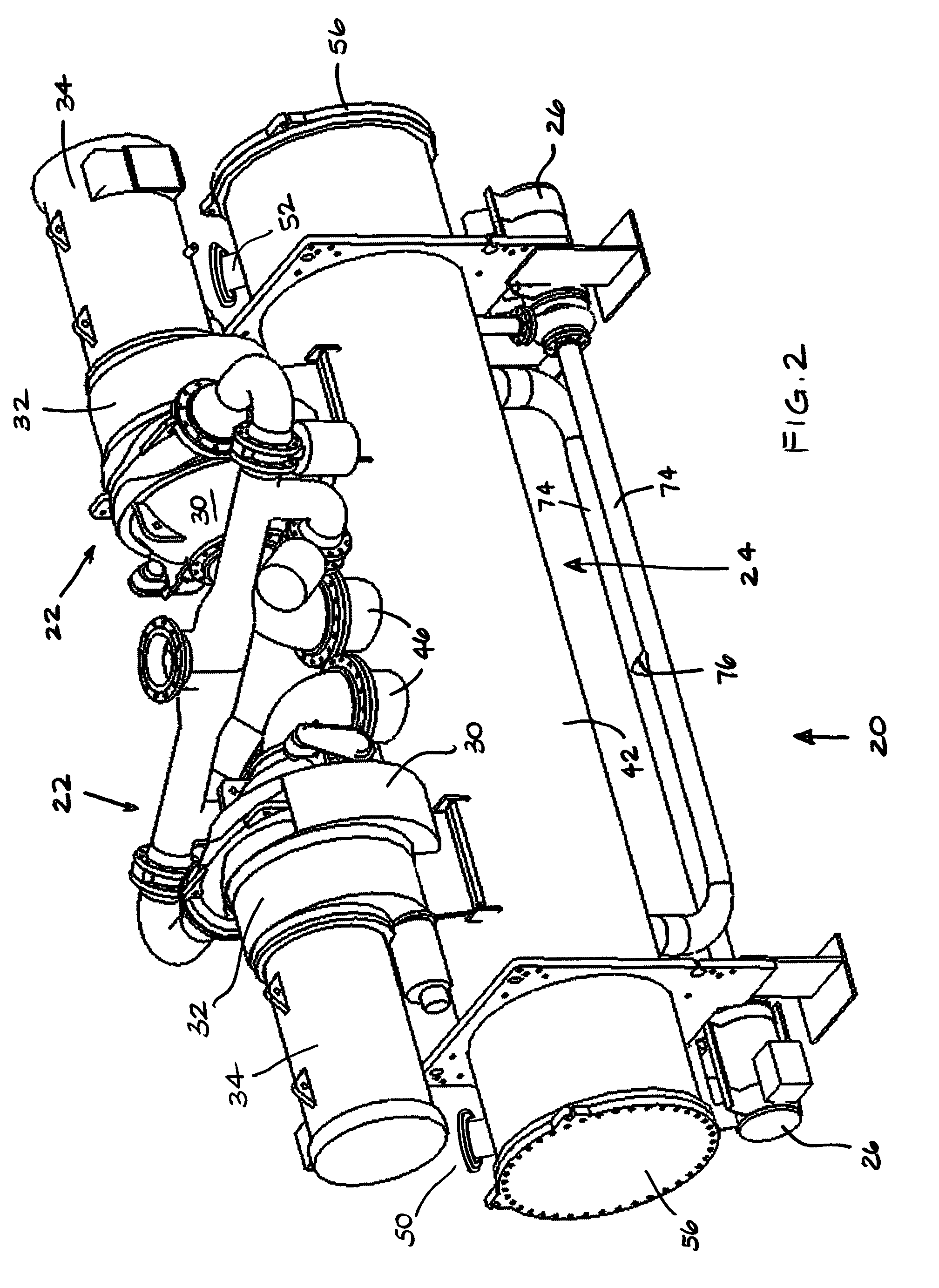

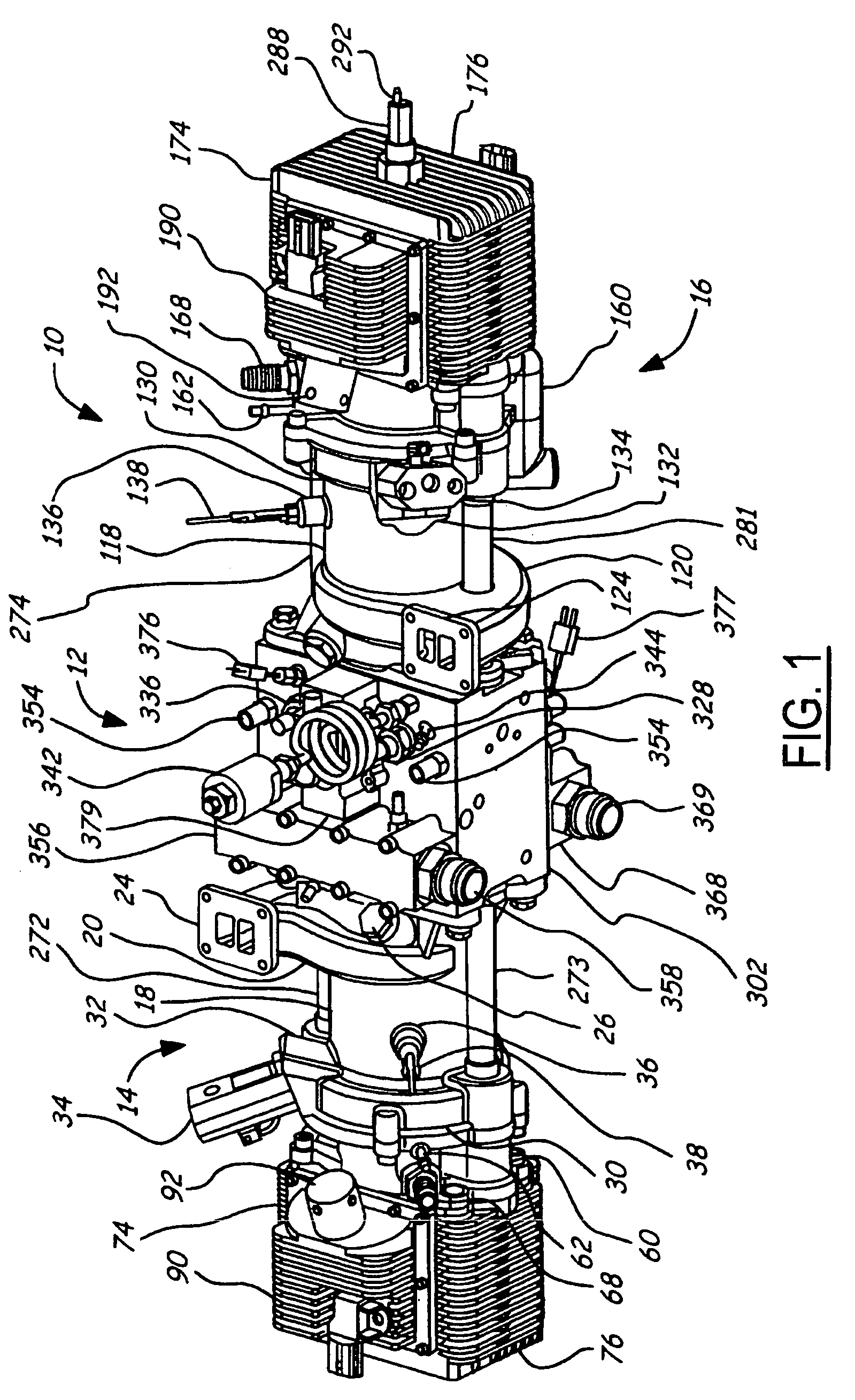

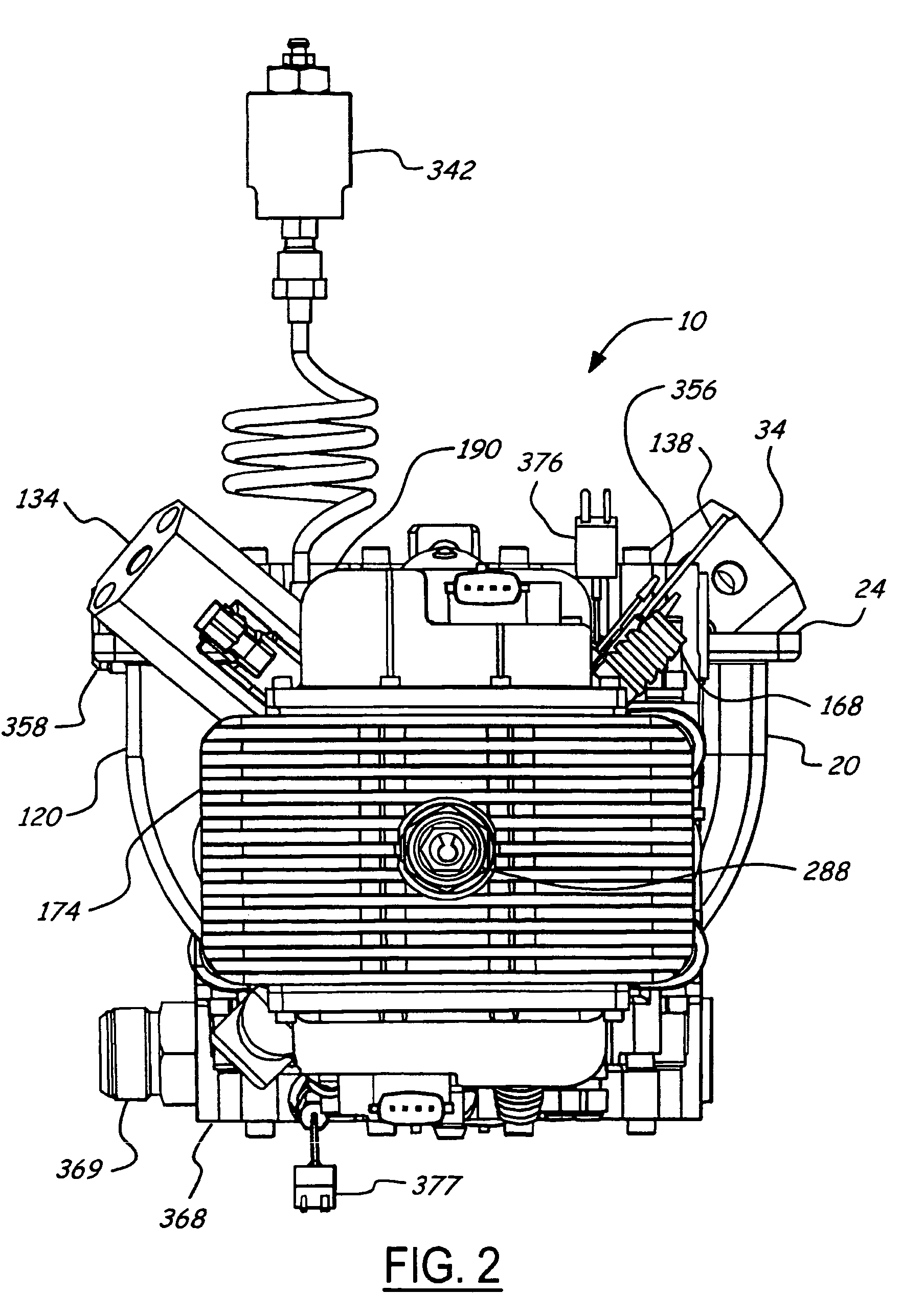

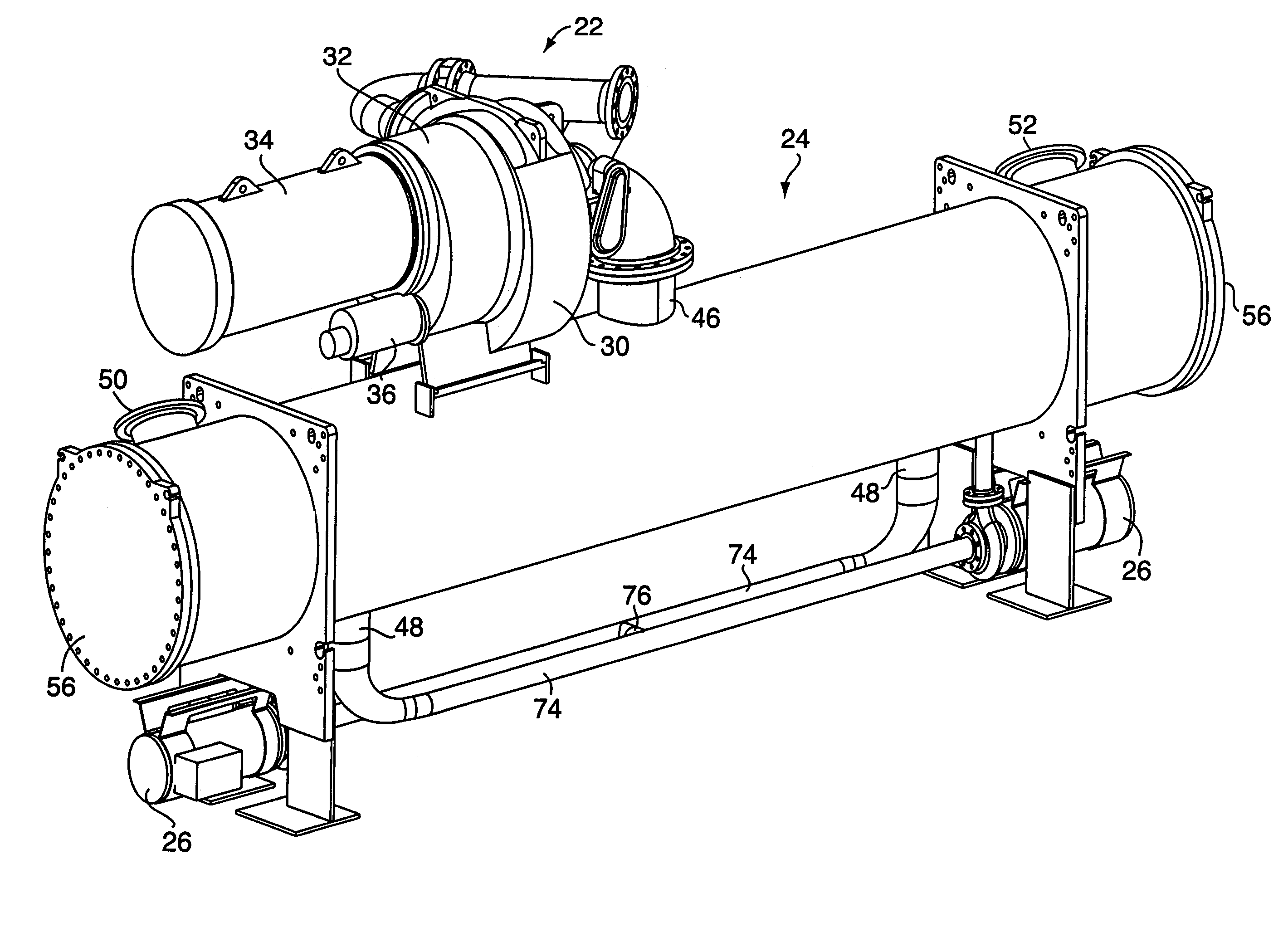

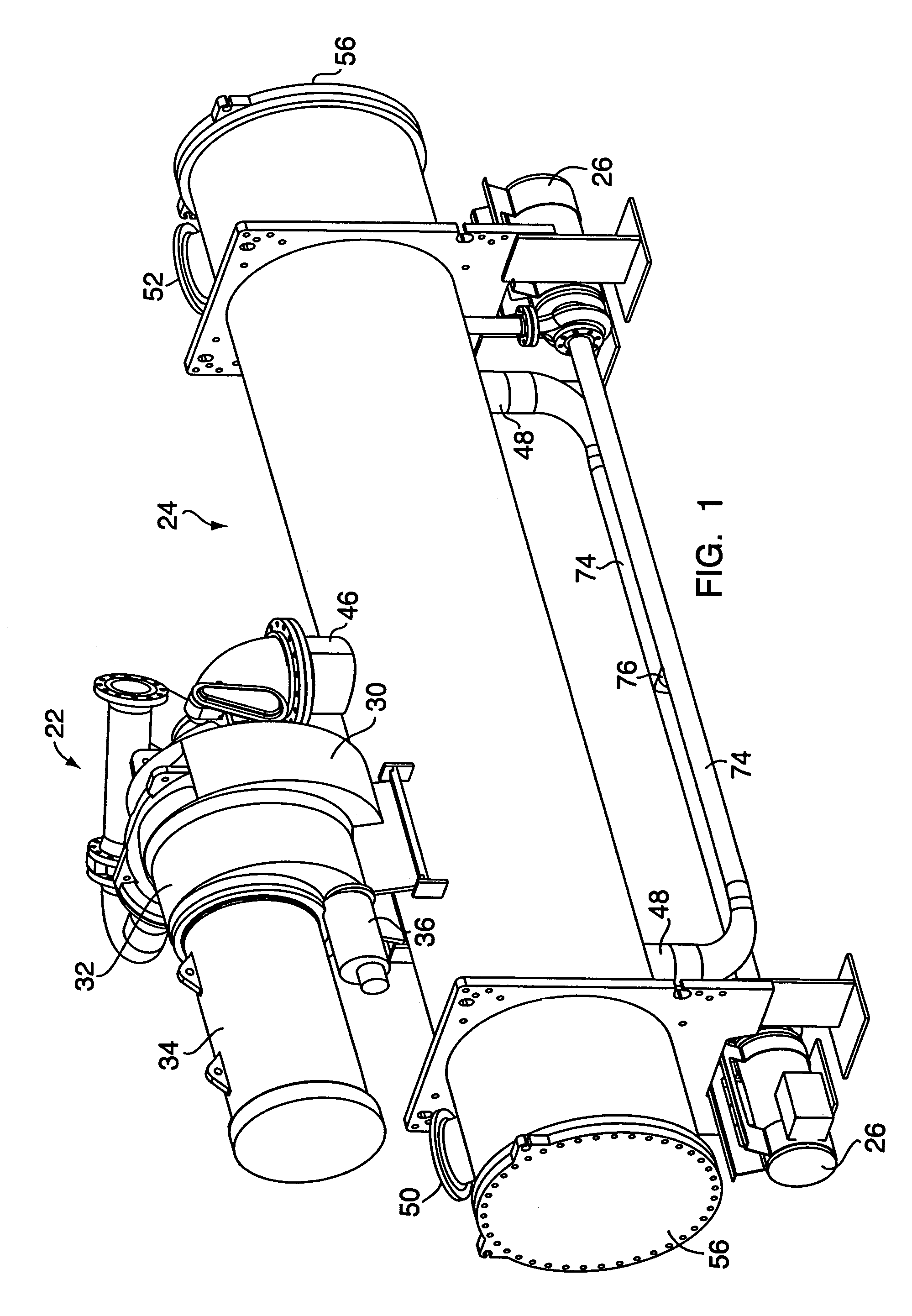

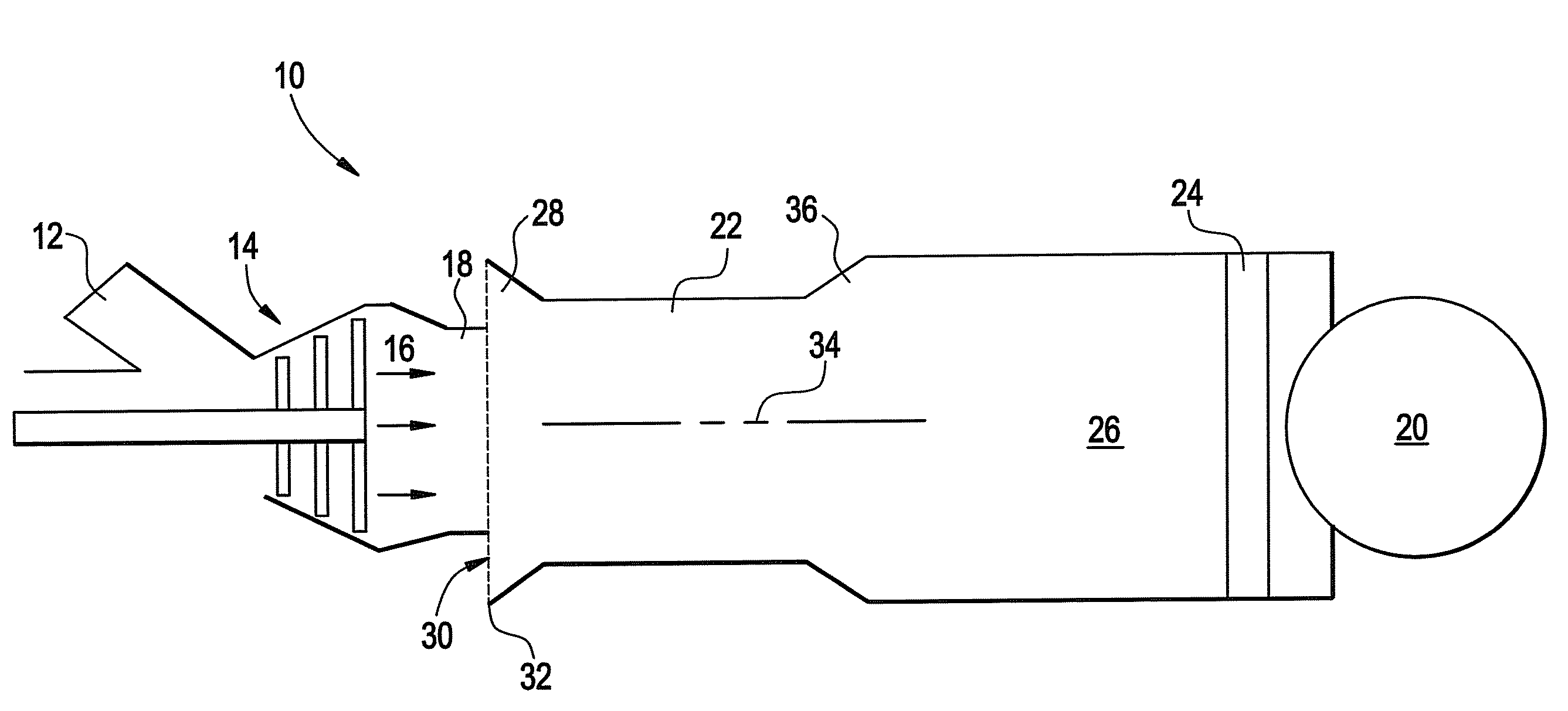

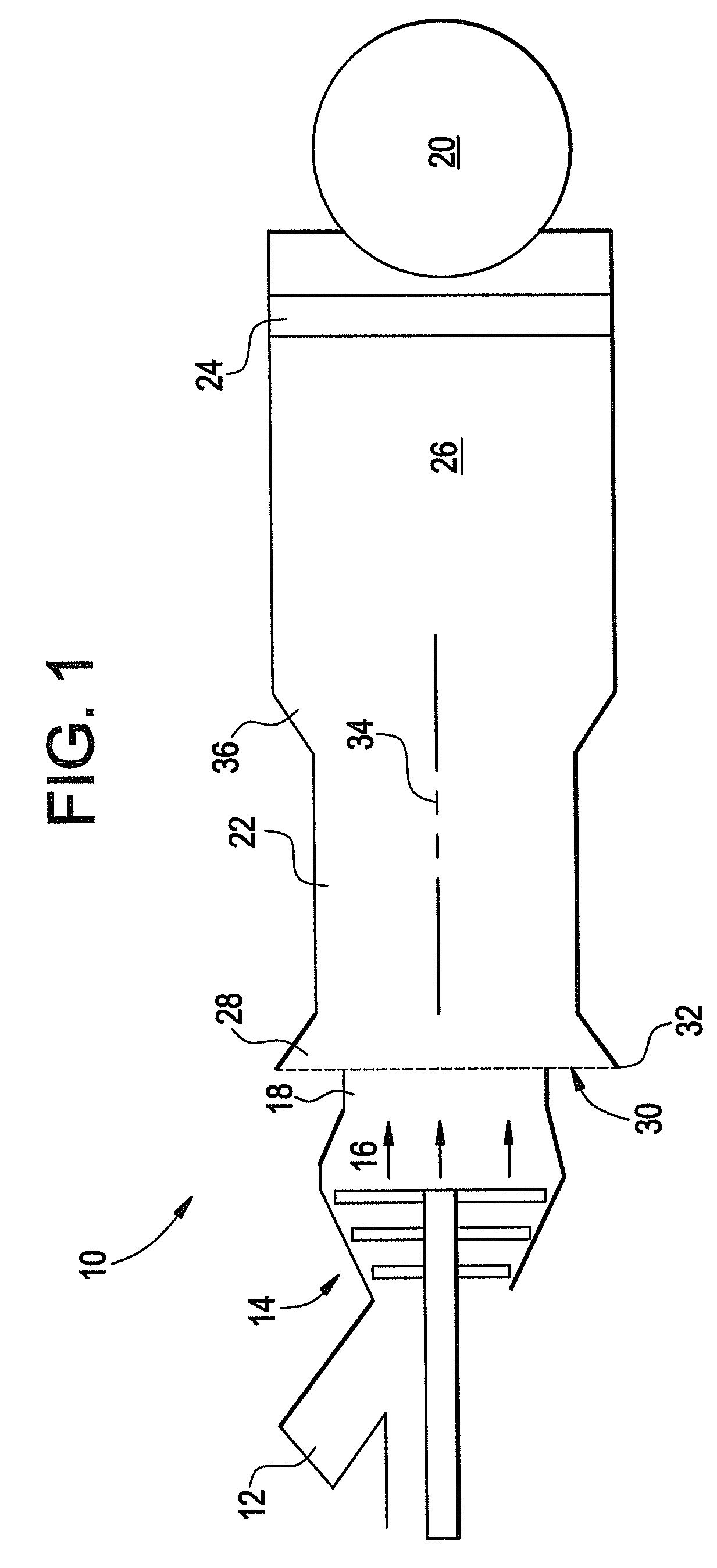

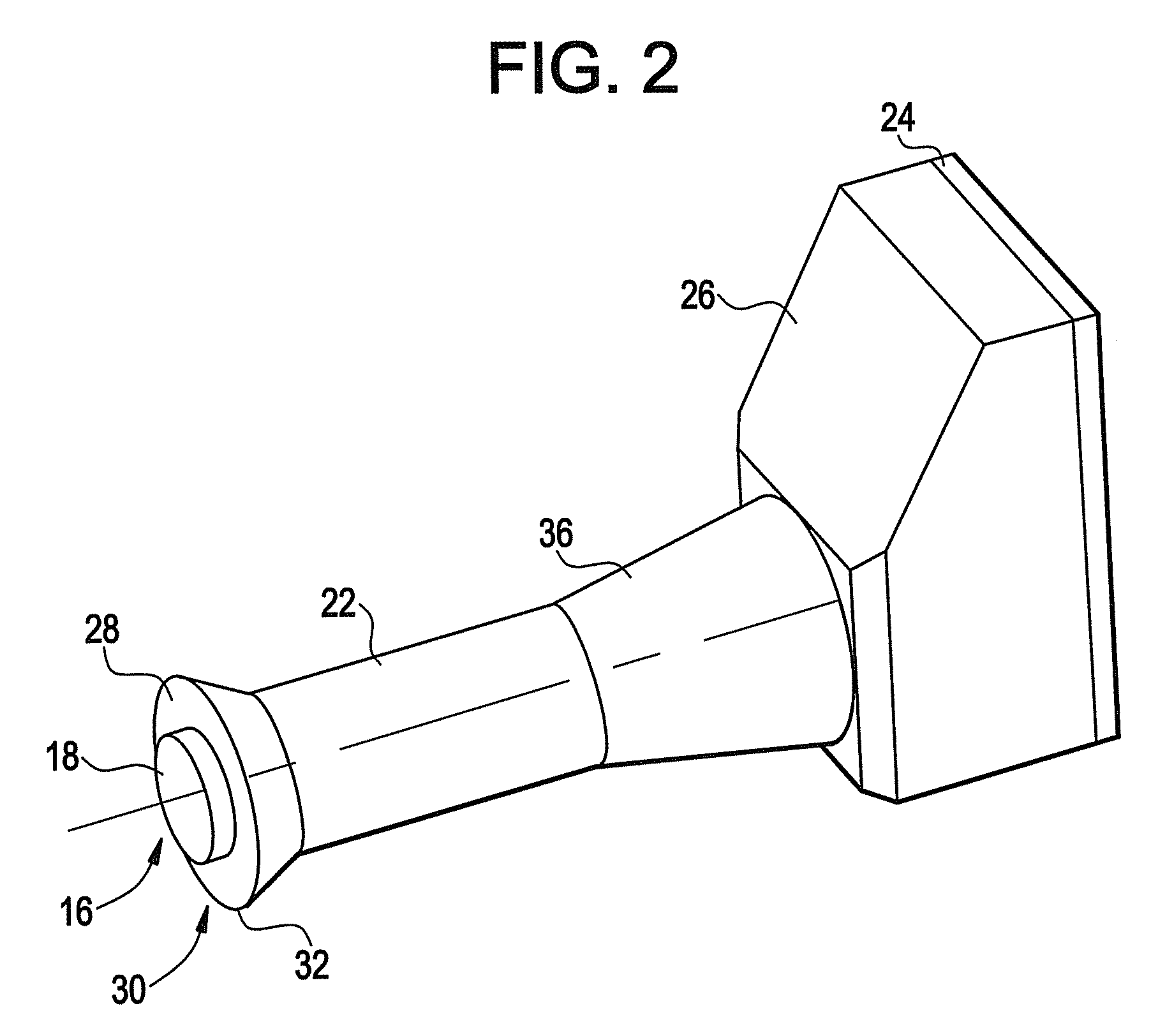

Method and apparatus for decreasing marine vessel power plant exhaust temperature

InactiveUS7121906B2Reduce exhaust temperatureReduce signalingDefensive equipmentLiquid coolingPower stationEngineering

According to the present invention, a method and apparatus for generating power aboard a marine vessel is provided. The method comprises the steps of: (a) providing a Rankine Cycle device that includes at least one of each of an evaporator, a turbo-generator that includes a turbine coupled with an electrical generator, a condenser, and a refrigerant feed pump; (b) disposing the one or more evaporators within an exhaust duct of a power plant of the marine vessel; (c) operating the power plant; and (d) selectively pumping refrigerant through the Rankine Cycle device, wherein refrigerant exiting the evaporator powers the turbine, which in turn powers the generator to produce power.

Owner:CARRIER CORP

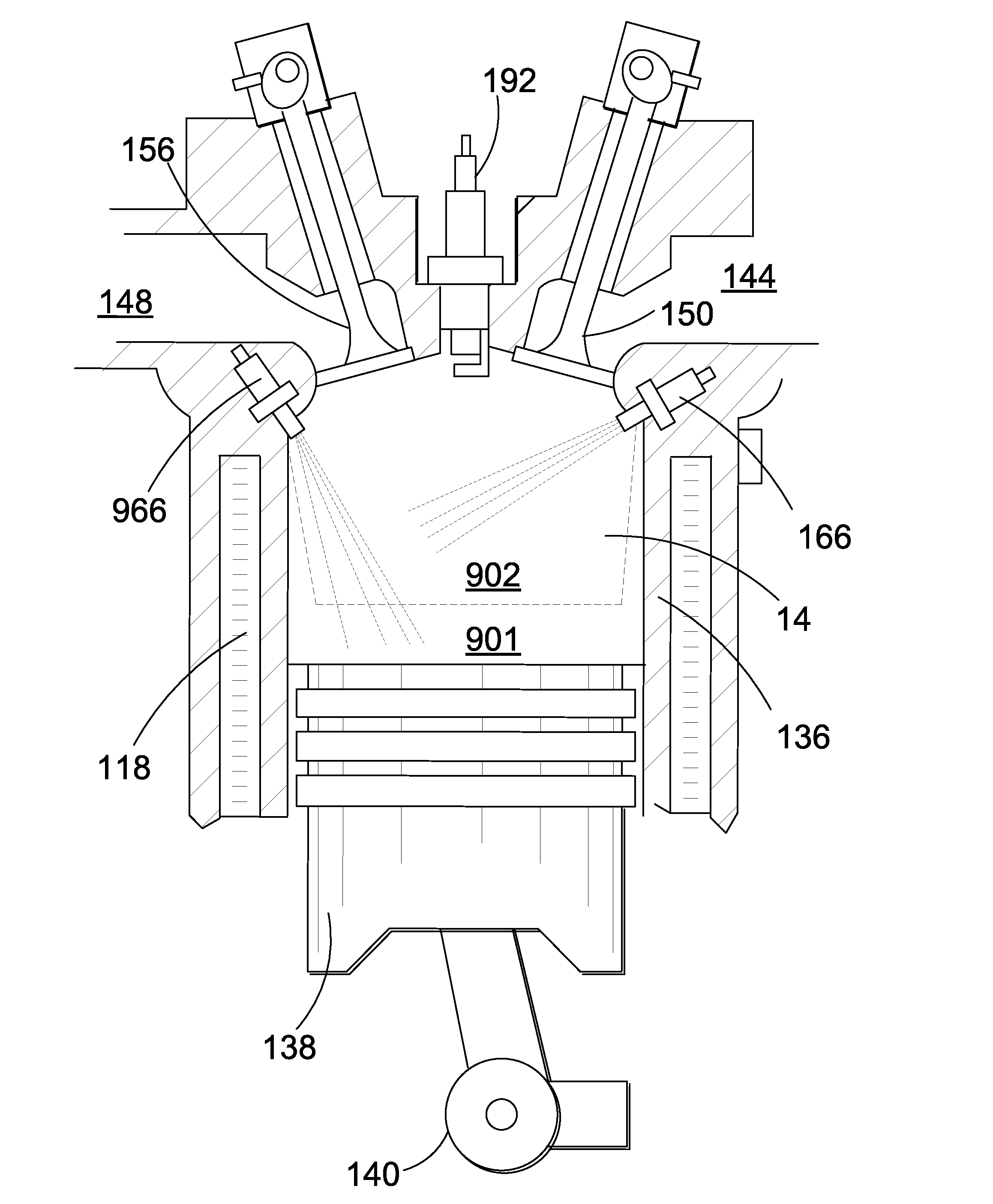

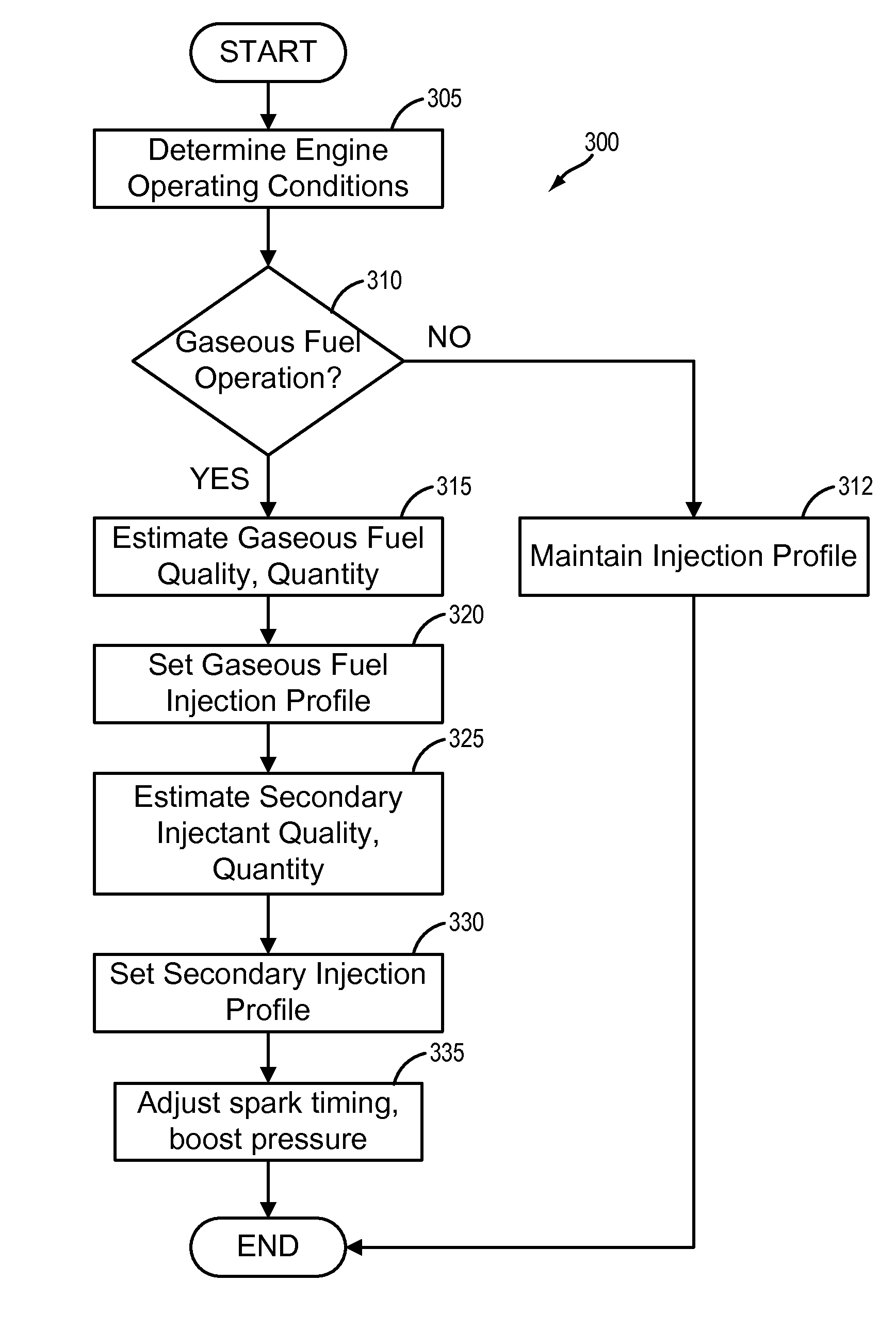

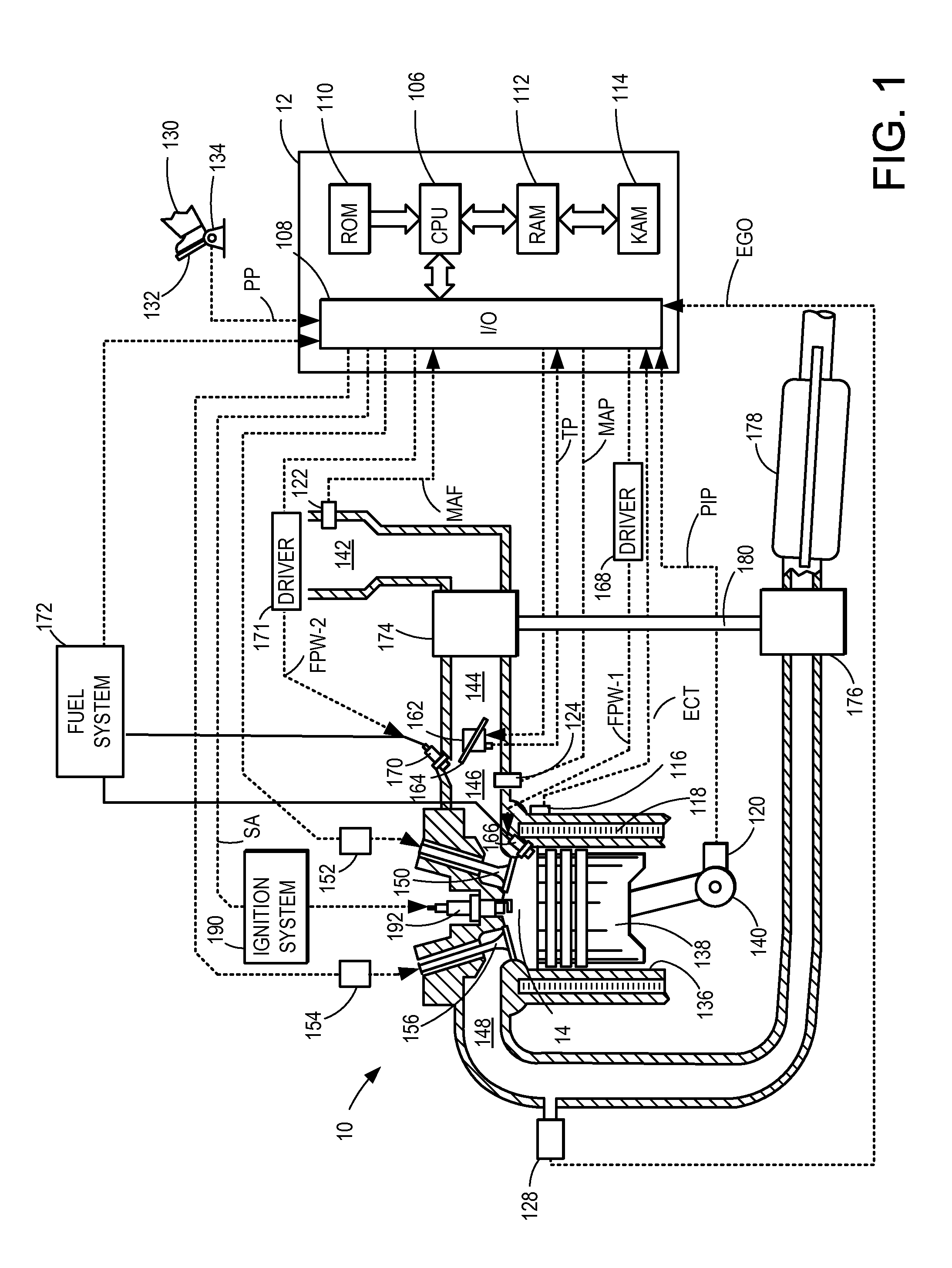

Direct injection of diluents or secondary fuels in gaseous fuel engines

ActiveUS20140331970A1Reduce exhaust emissionsHigh priceInternal combustion piston enginesExhaust gas recirculationCombustionDiluent

A method for operating an engine, comprising port injecting a first quantity of a first gaseous fuel in a cylinder cycle and direct injecting a second quantity of a secondary injectant in the cylinder cycle as a function of a desired air-to-fuel ratio (AFR), the desired AFR based on a temperature of an engine cylinder valve. The desired AFR may be outside the AFR range available during natural gas combustion alone and thus allows for cooler engine operation.

Owner:FORD GLOBAL TECH LLC

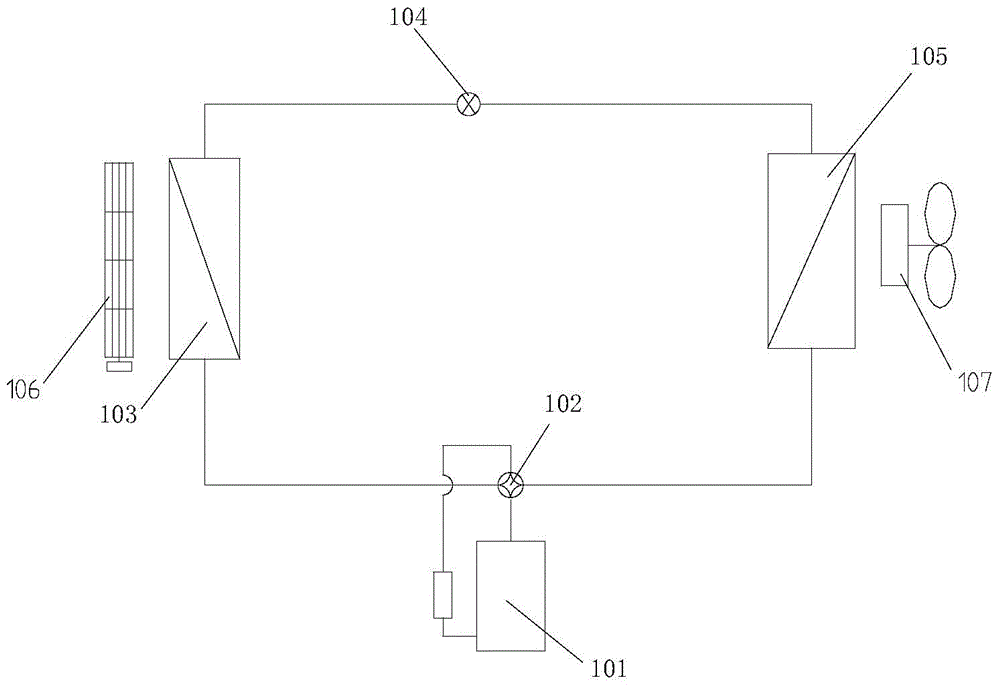

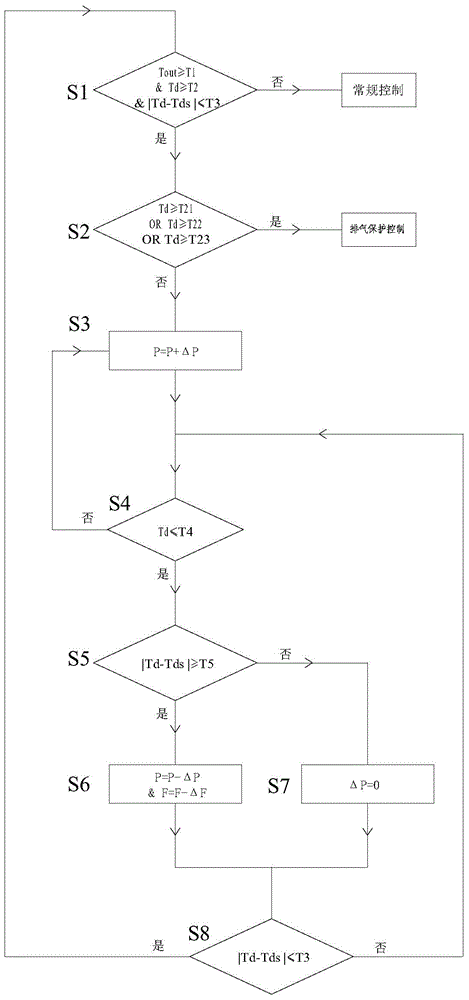

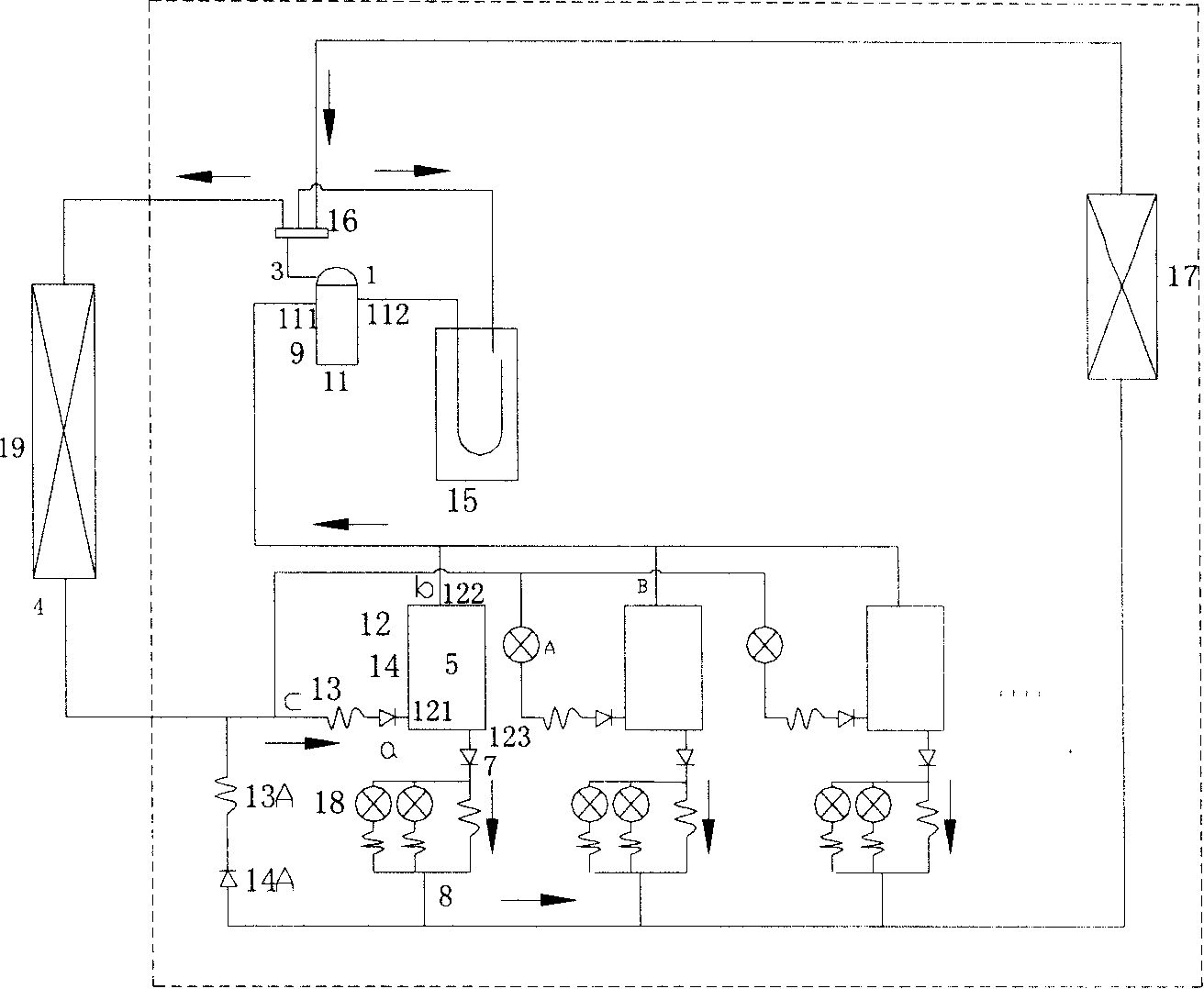

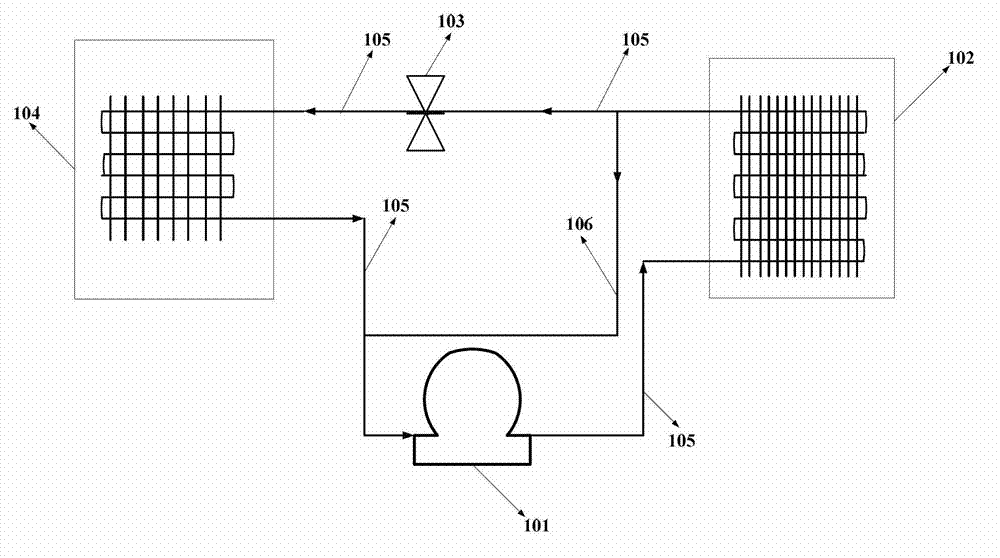

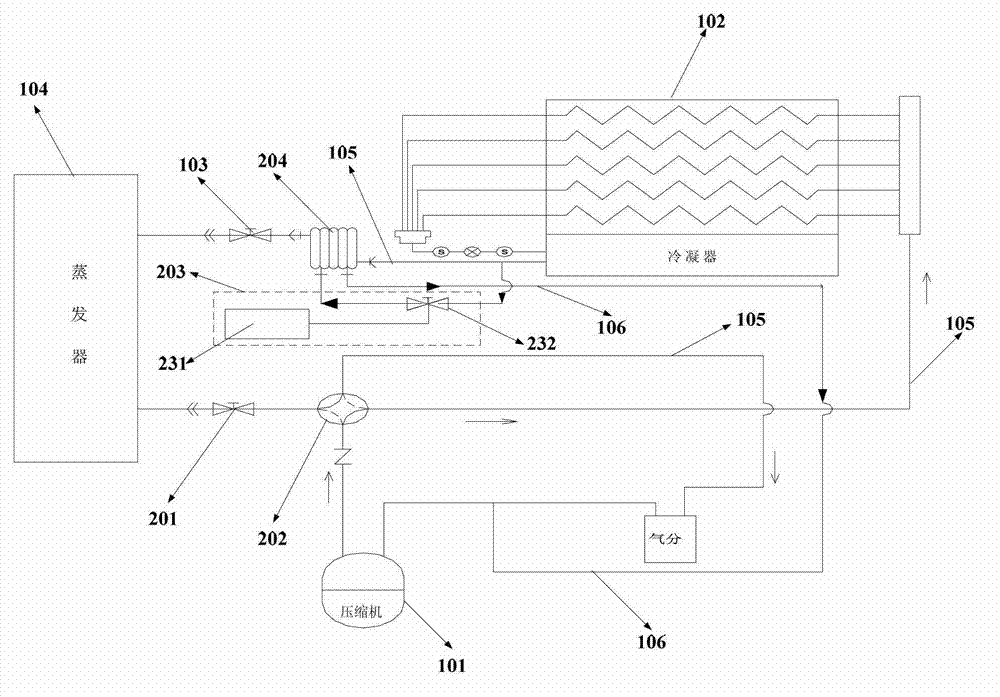

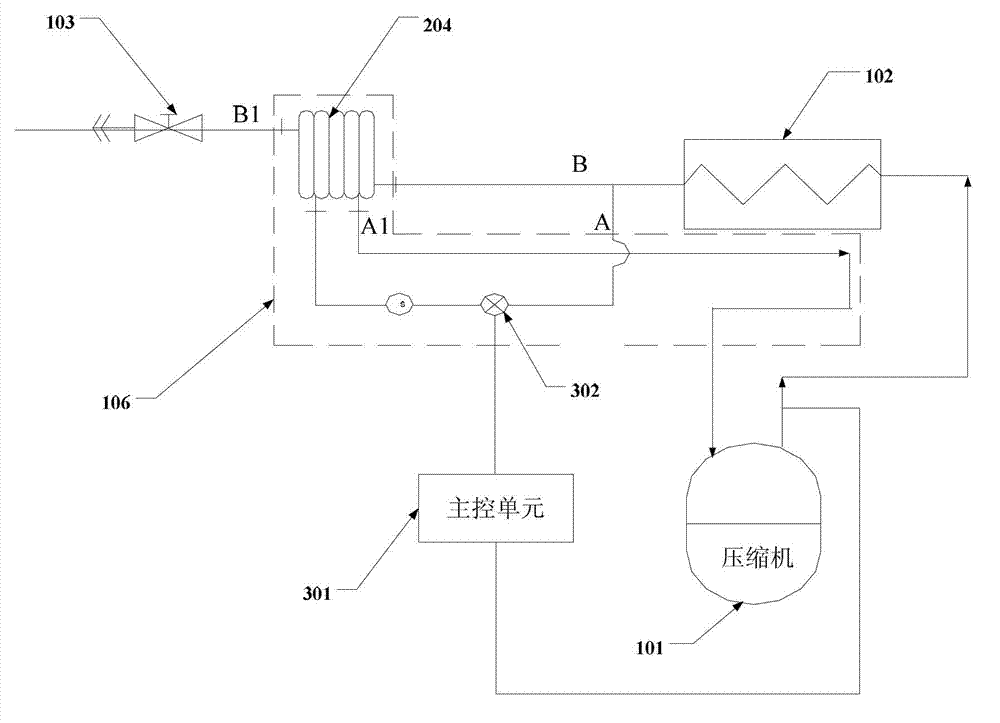

Control method for electronic expansion valve of refrigerating system and refrigerating system

ActiveCN104964498ALarge openingReduce exhaust temperatureMechanical apparatusFluid circulation arrangementEngineeringElectronic expansion valve

The invention provides a control method for an electronic expansion valve of a refrigerating system. The method comprises the steps that firstly, whether the current work condition belongs to the high-temperature work condition or not is judged according to the outdoor environment temperature Tout and the exhaust temperature Td of a compressor, if yes, the third step is executed, and if not, conventional control is executed; thirdly, the aperture P of the electronic expansion valve is increased. According to the control method, compressor frequency reducing even protection shutdown and other situations of the refrigerating system due to the overhigh exhaust temperature under the high temperature work condition can be effectively prevented, and normal and reliable running of the compressor is achieved. The invention further relates to the refrigerating system.

Owner:GREE ELECTRIC APPLIANCES INC

Frequency conversion control method for heat pump water heater

The invention relates to a frequency conversion control method for a heat pump water heater. The frequency conversion control method for the heat pump water heater is characterized by comprising the following steps of: performing frequency conversion control on a compressor of the heat pump water heater; performing frequency conversion control on a throttle mechanism of the heat pump water heater; performing frequency conversion control on a defrosting mechanism of the heat pump water heater; and performing frequency conversion control on an exhaust temperature of the heat pump water heater. The frequency conversion control method for the heat pump water heater has the advantages of high heating speed, few start-stop times, small temperature fluctuation of a water tank and energy conservation. At a high ambient temperature, the frequency of the compressor can be reduced and the circulating flow quantity of a system can be reduced, so that the suction pressure is reduced and the stable operation of the compressor is guaranteed. At a low ambient temperature, the circulating flow quantity of the system is increased by increasing the frequency of the compressor and the opening degree of an electronic expansion valve, the exhaust temperature is reduced and the compression ratio is reduced, so that the compressor can operate stably. In the defrosting process, the defrosting time is greatly shortened by increasing the circulating flow quantity of the system; and the frost can be removed completely, without the problem that the frost is accumulated into ice.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

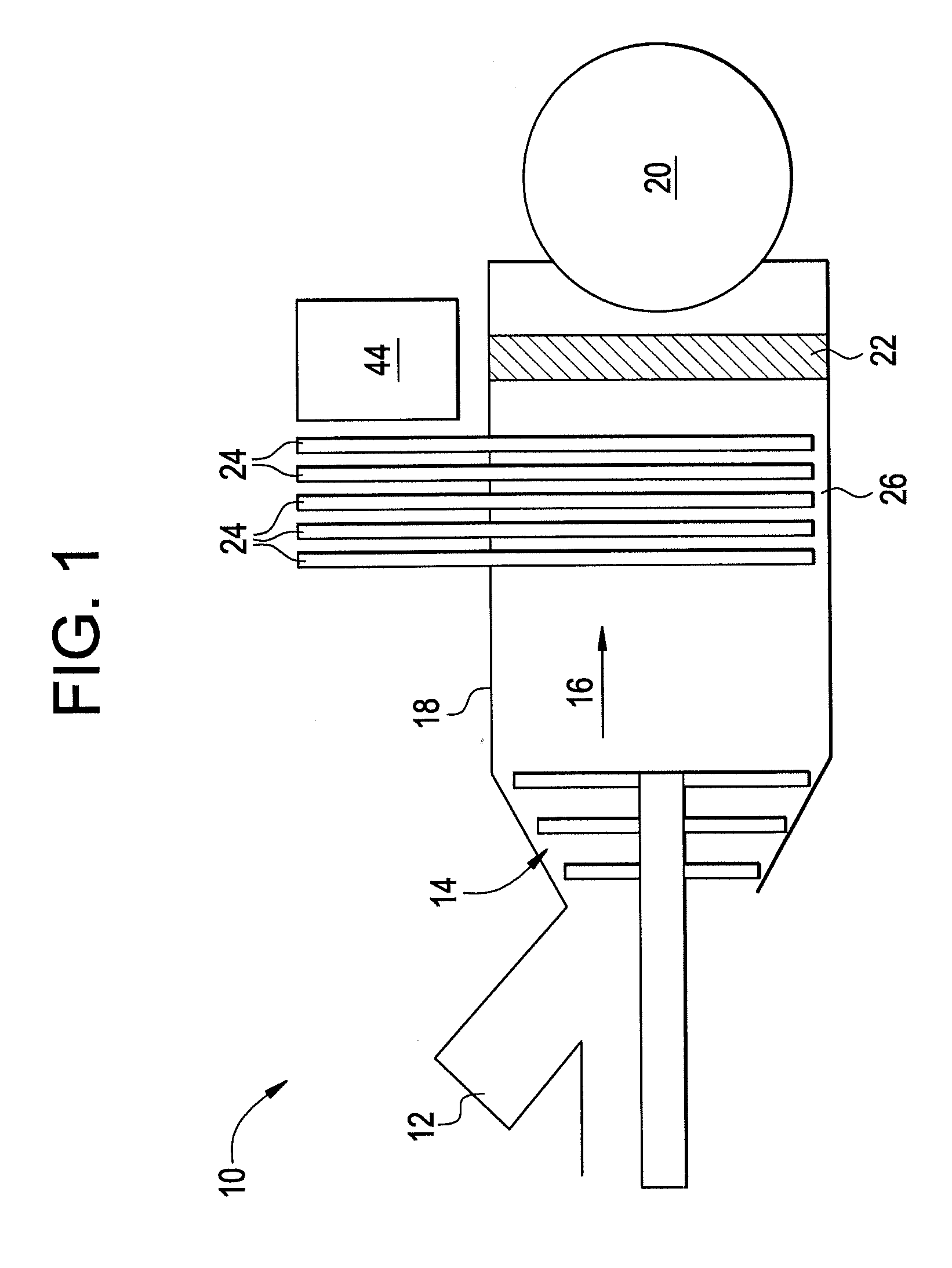

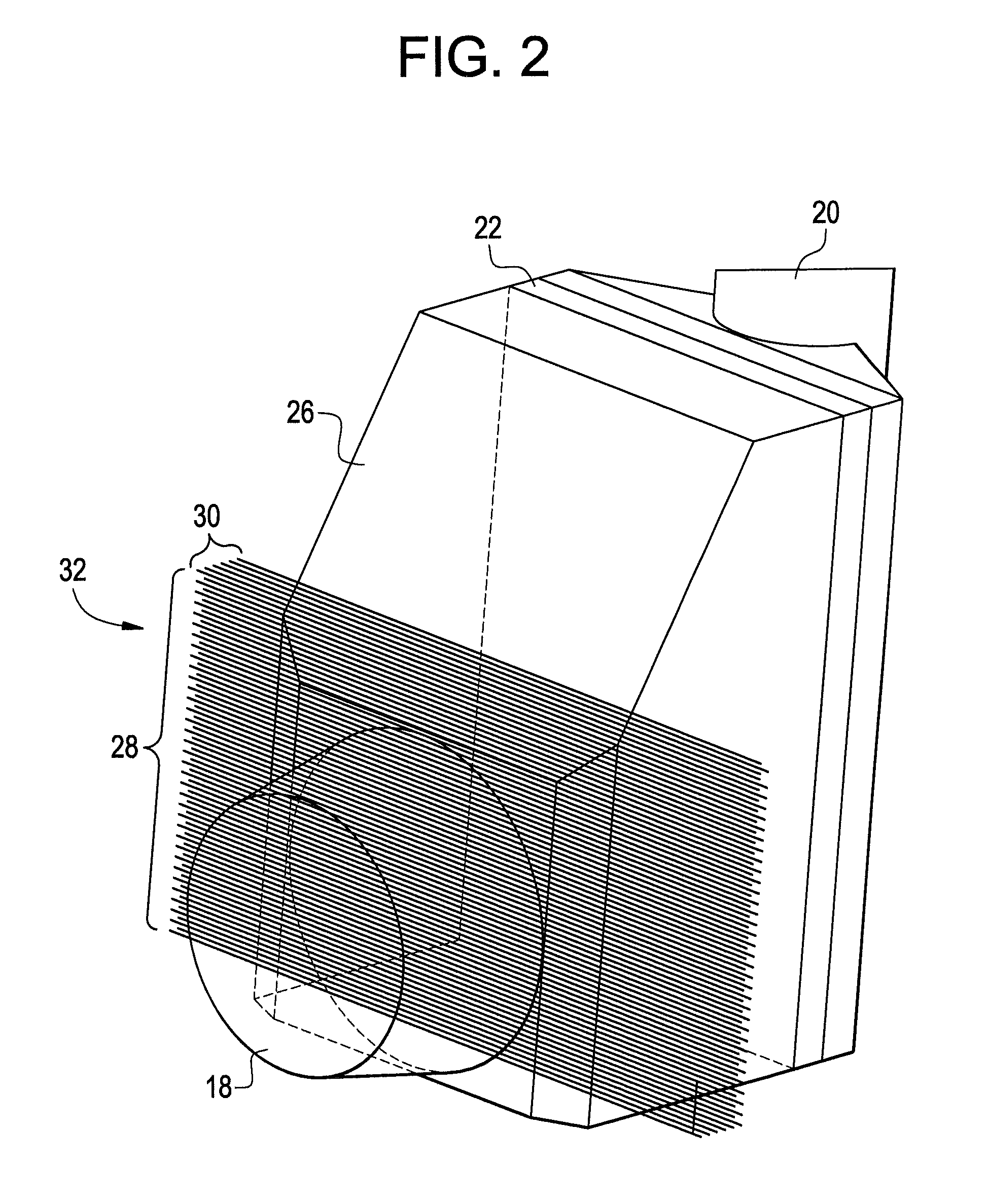

Apparatus and method for cooling turbomachine exhaust gas

InactiveUS8186152B2Improve efficiencyReduce pressureTurbine/propulsion fuel supply systemsEngine manufactureExhaust fumesAmbient air

Disclosed is a turbomachine including at least one exhaust pathway along which exhaust is directed and released to ambient and at least one exhaust processor capable of removing regulated substances from the exhaust. One or more ambient air inlets are located at the at least one exhaust pathway upstream of the at least one exhaust processor. The at least one exhaust pathway is configured such that ambient air is capable of being urged into the at least one exhaust pathway through the one or more ambient air inlets by an acceleration of the exhaust along the at least one exhaust pathway. The ambient air urged into the at least one exhaust pathway reduces a temperature of the exhaust to increase effectiveness of the at least one exhaust processor. Further disclosed is a method for releasing turbomachine exhaust to ambient.

Owner:GENERAL ELECTRIC CO

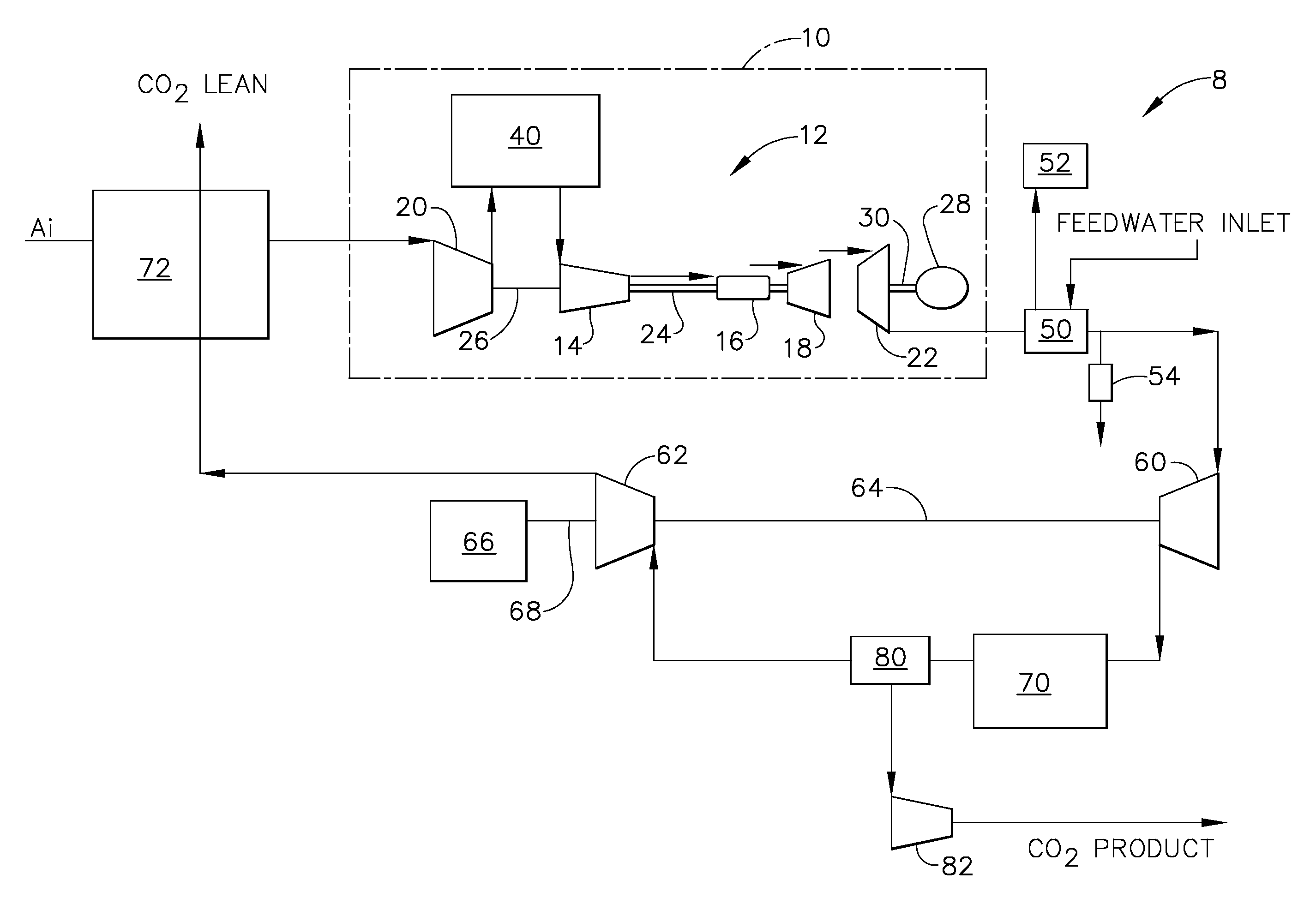

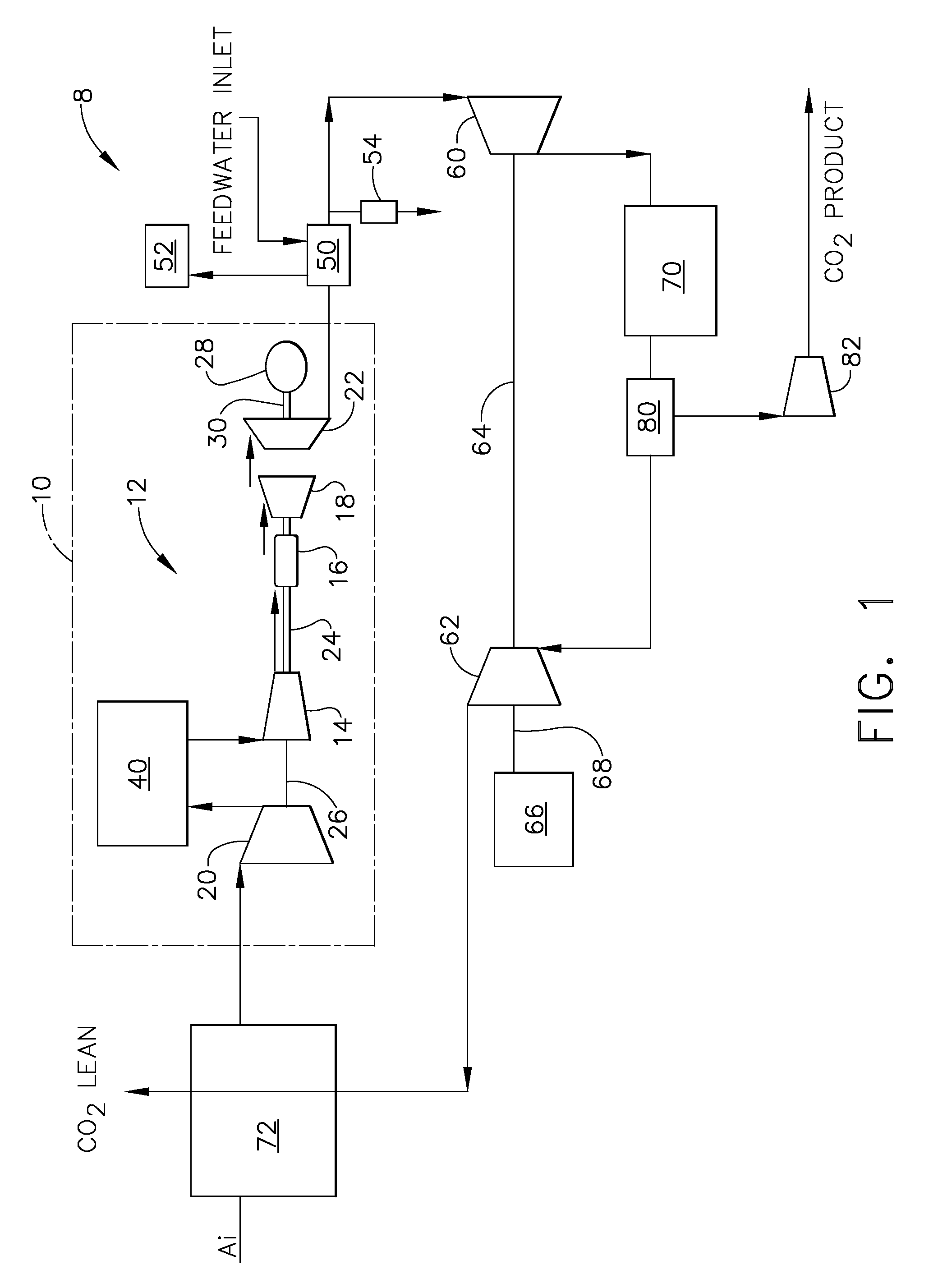

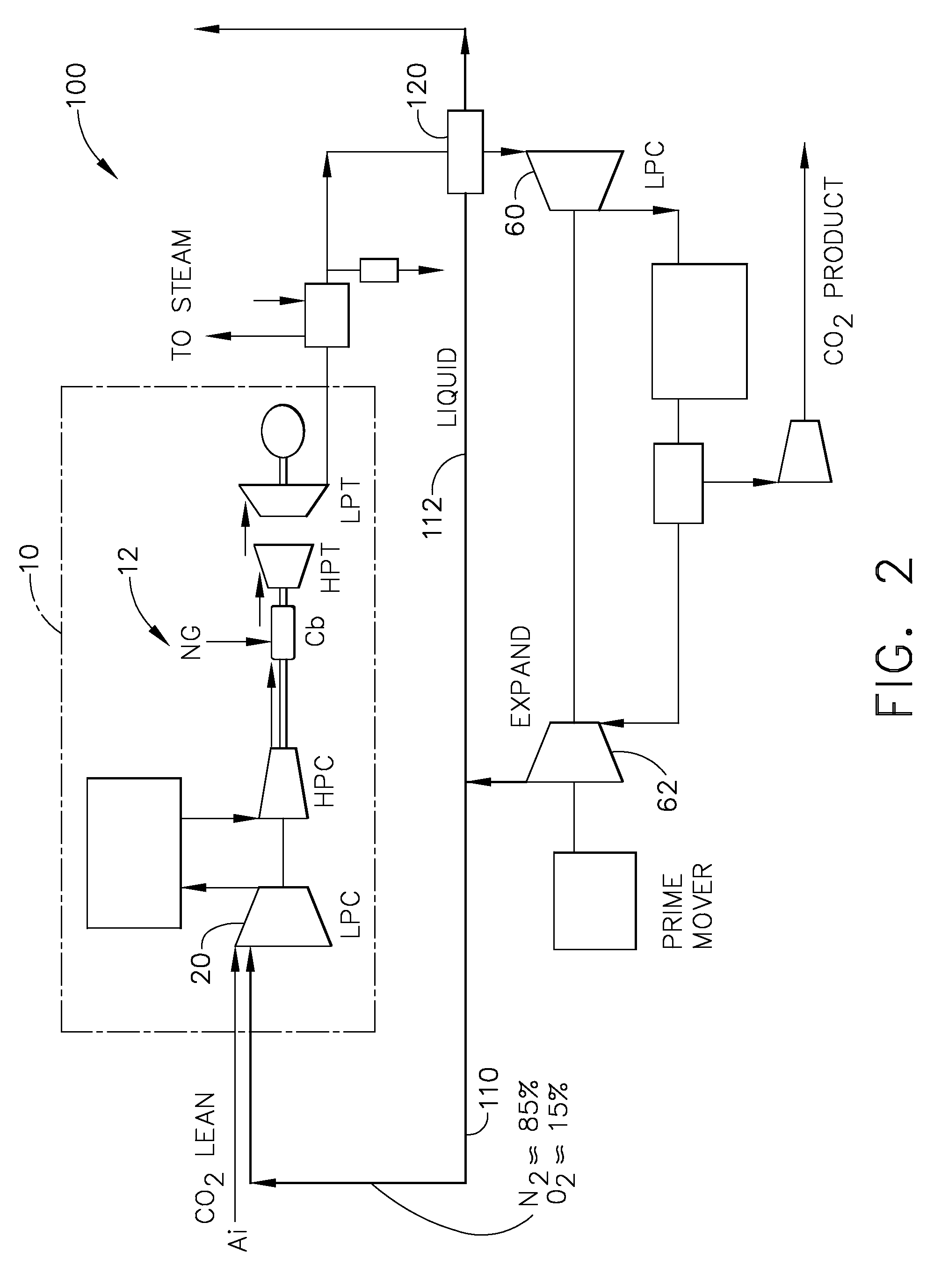

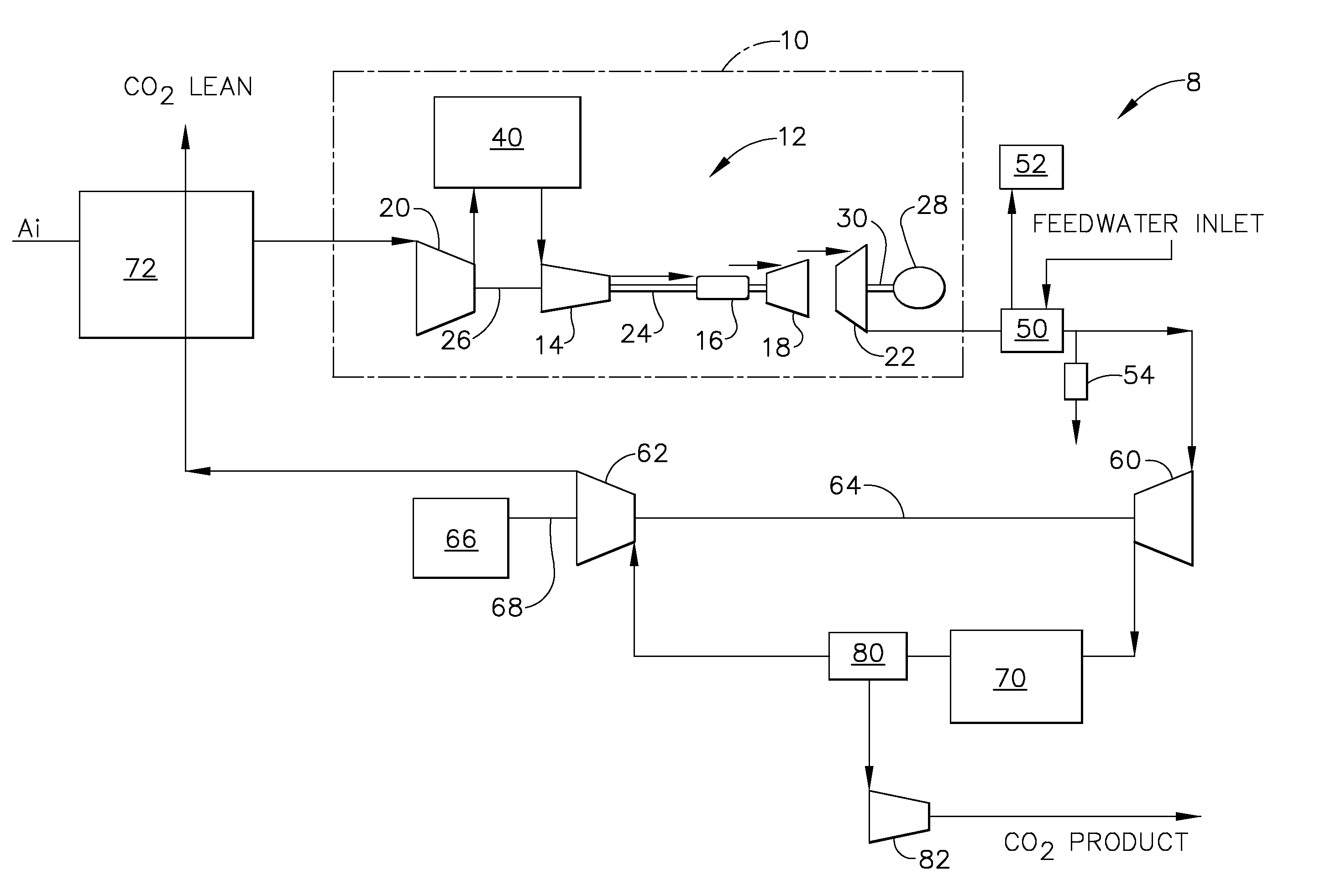

Method and system for reducing power plant emissions

InactiveUS20080083226A1Increase exhaust pressureReduce exhaust temperatureGas treatmentGas turbine plantsPower stationTurbine

A method for operating a power plant to facilitate reducing emissions, wherein the power plant includes a gas turbine engine assembly and a carbon dioxide (CO2) separator. The method includes increasing an operating pressure of exhaust gas discharged from the gas turbine engine assembly, separating substantially all the CO2 entrained within the gas turbine engine utilizing the CO2 separator to produce a CO2 lean airstream, reducing the operating temperature of the CO2 lean airstream, and utilizing the cooled CO2 lean airstream to facilitate reducing an operating temperature of air entering the gas turbine engine assembly.

Owner:GENERAL ELECTRIC CO

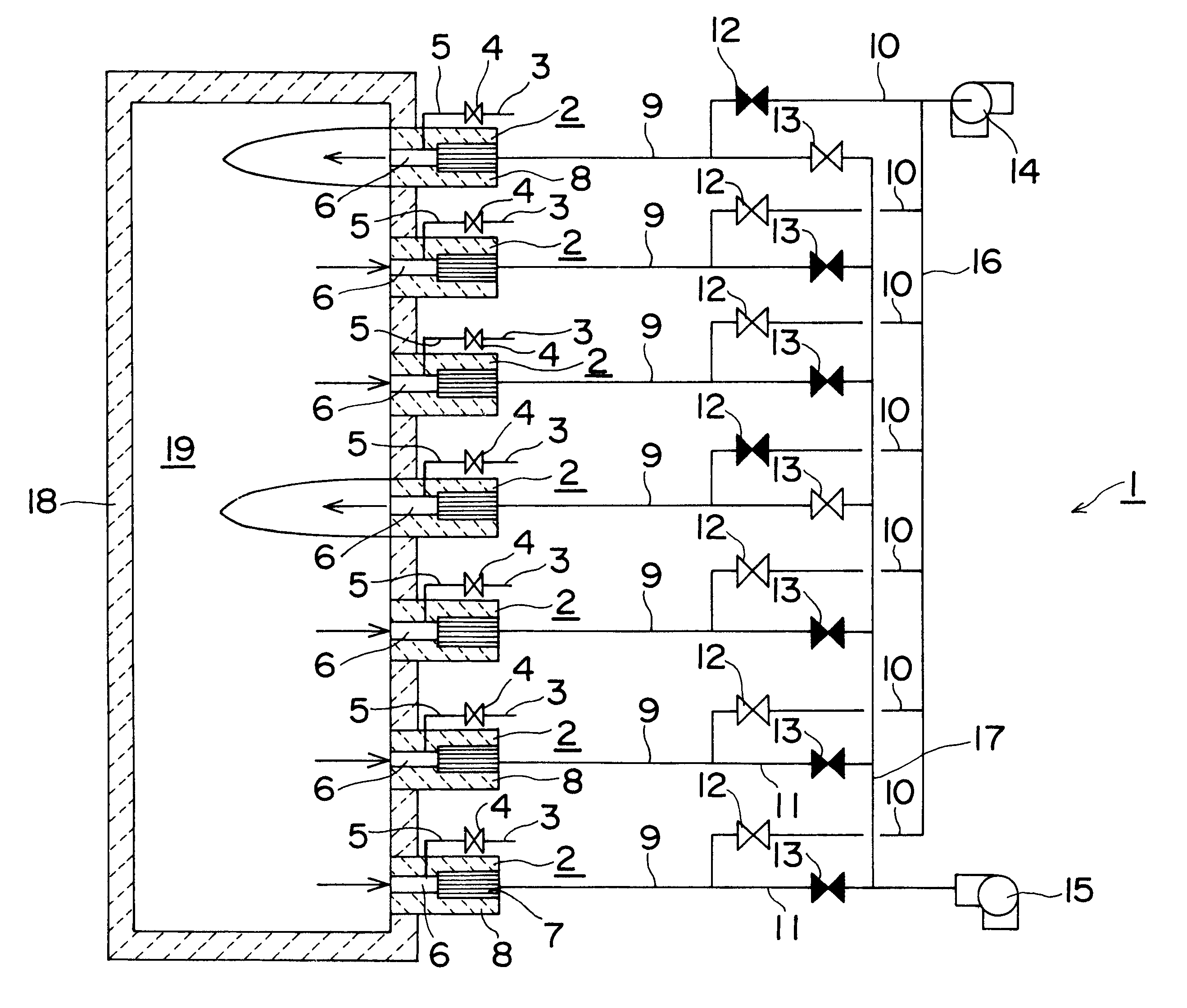

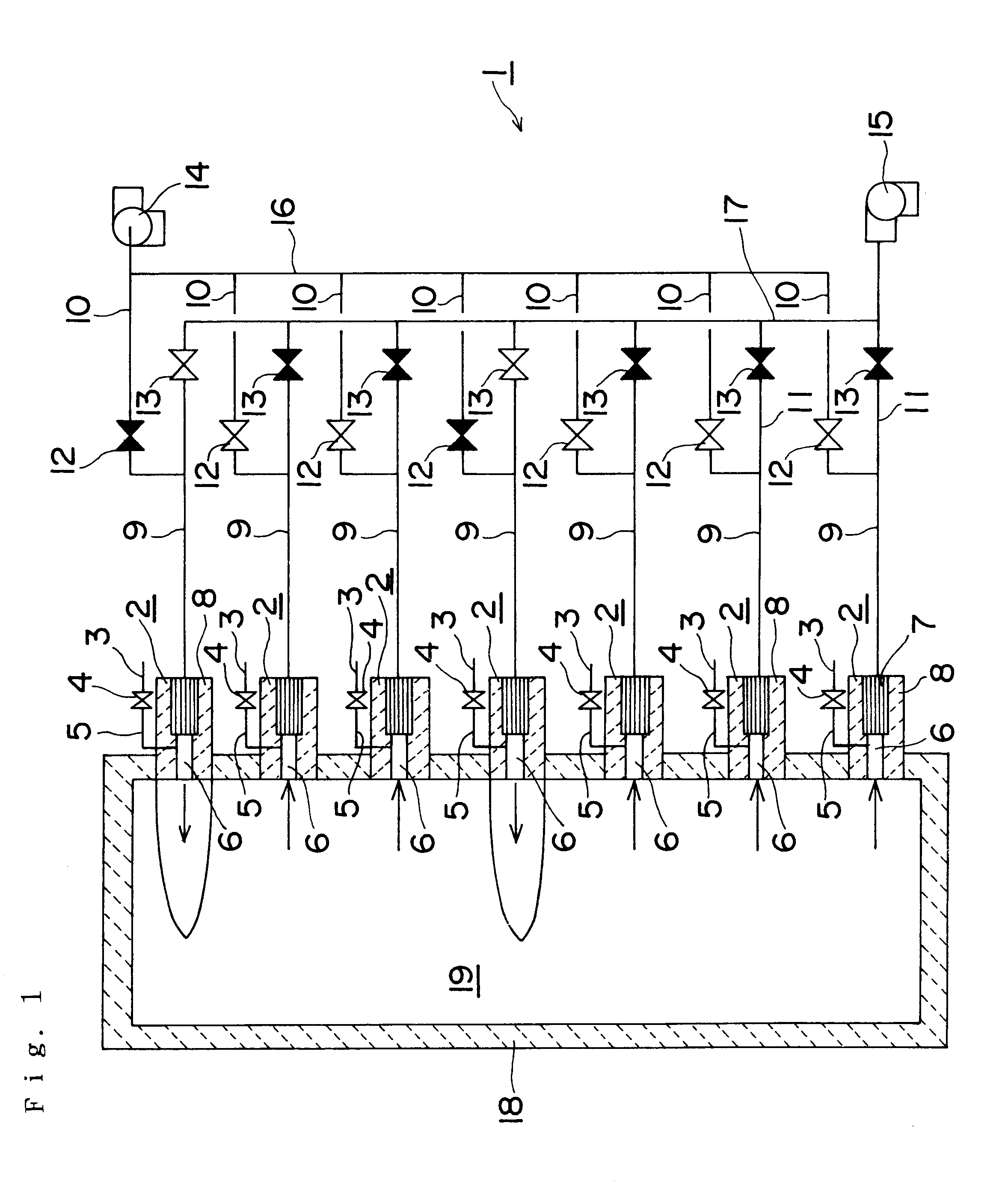

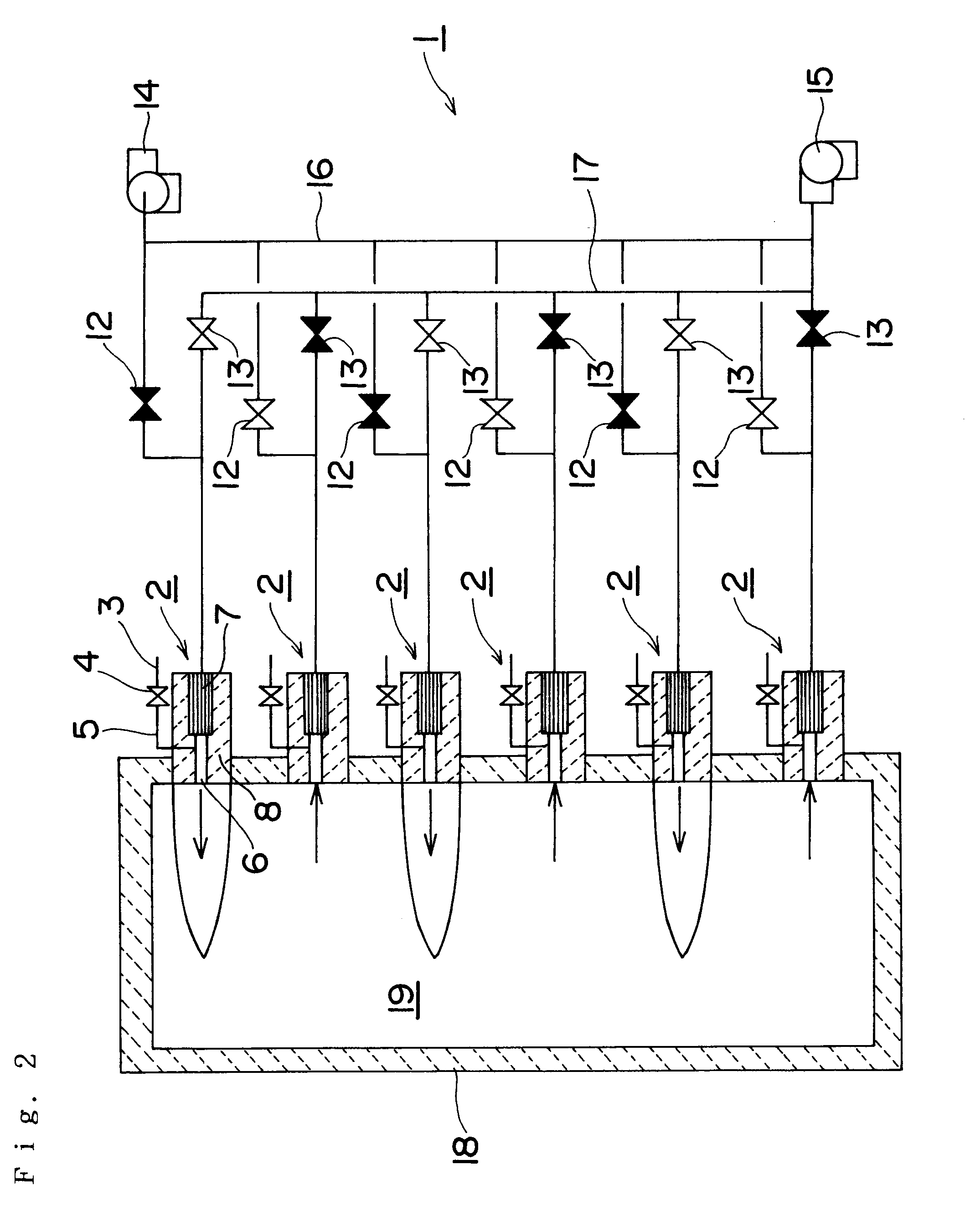

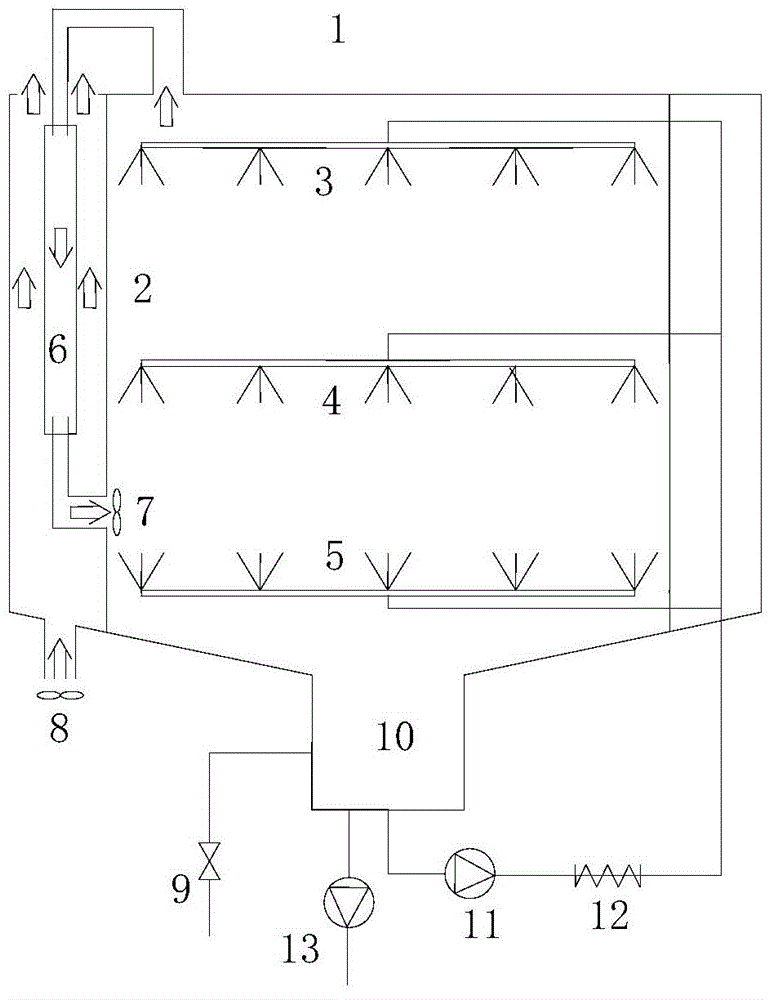

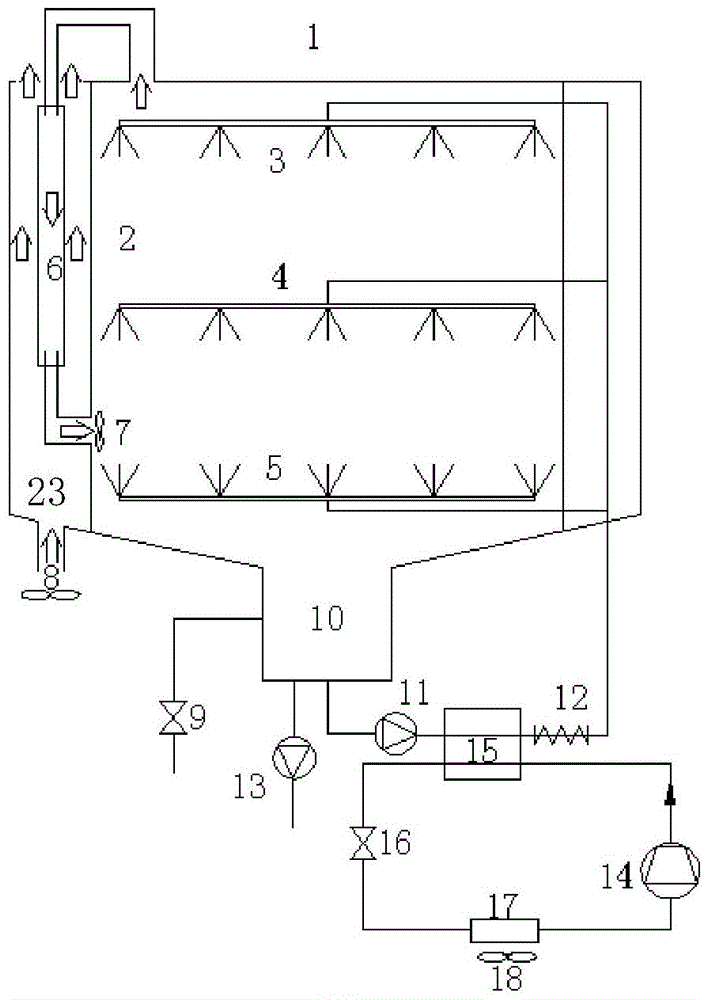

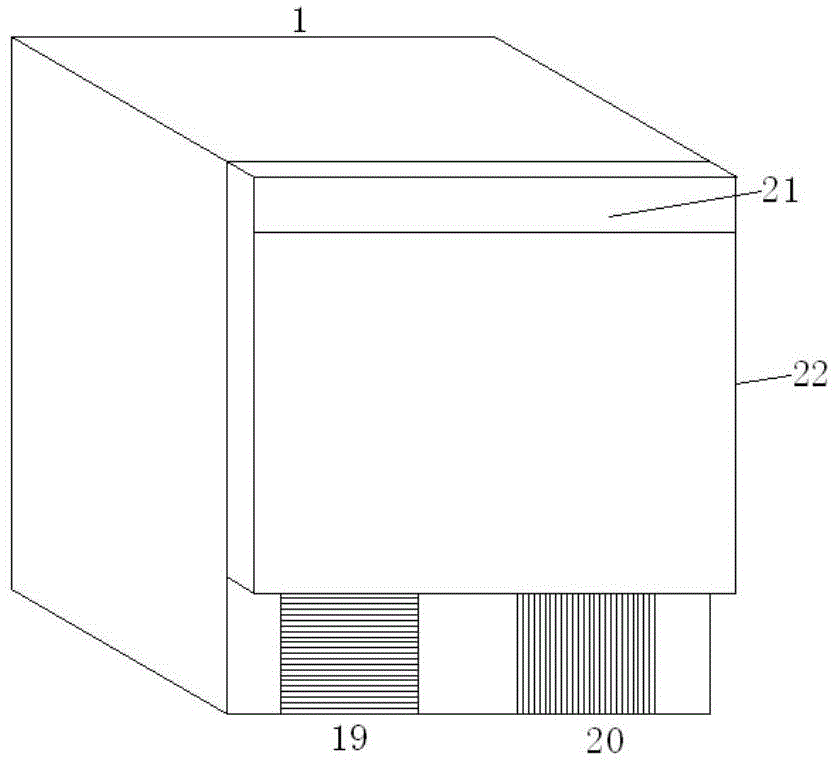

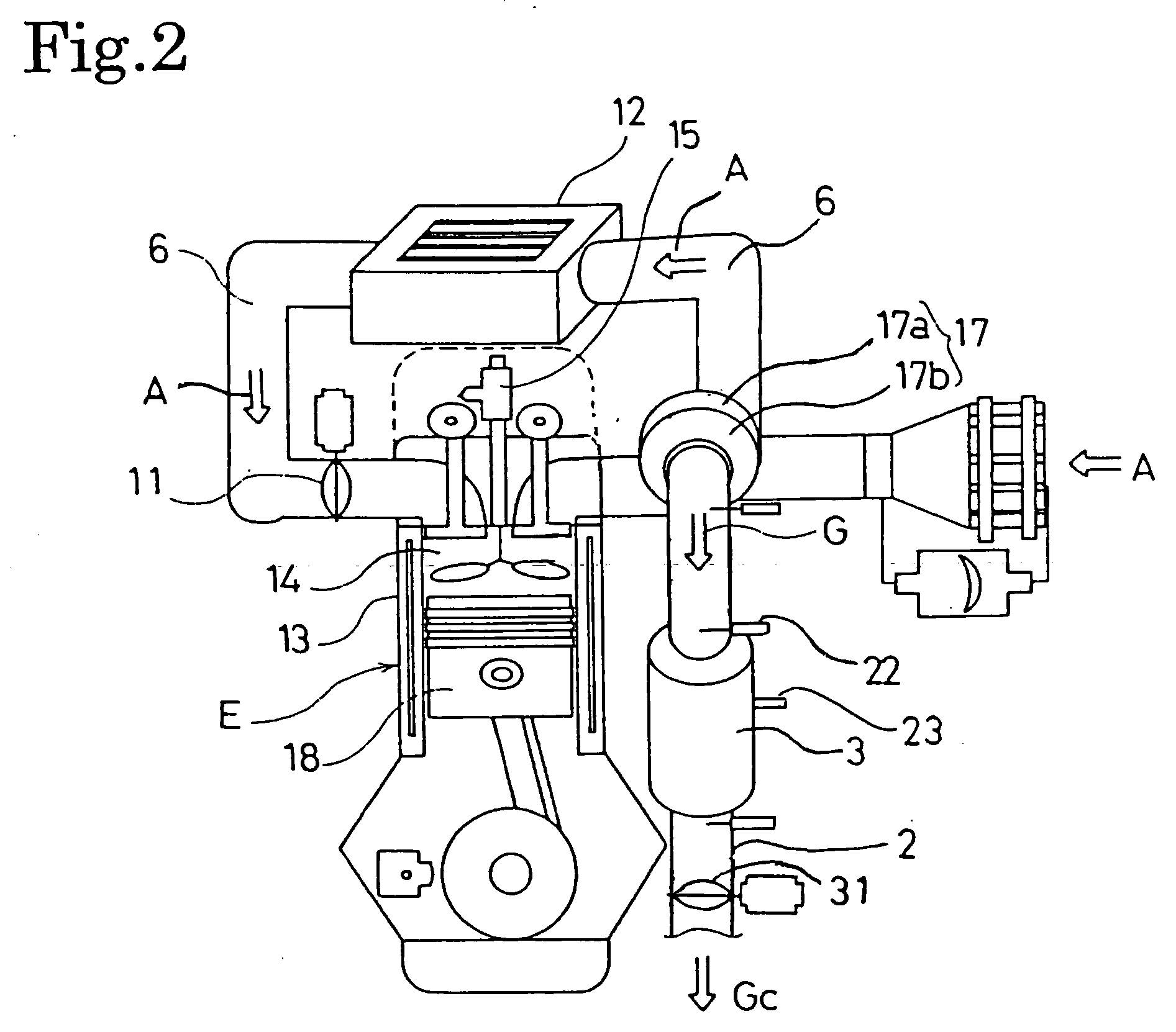

Inter-switching heat accumulating regenerative burner system

InactiveUS6234789B1Reduce rateImprove heat transfer performanceBurnersDomestic stoves or rangesCombustion systemProcess engineering

The present invention provides an alternate changeover regenerative burner system suitable for use as a heat source for an industrial furnace and the like where re-increase in temperature is relatively-often carried out; an alternate changeover regenerative burner constituted by a burner 2 having a regenerator 7 and air supply / exhaust switching mechanisms 12 and 13 for switching connection with an air supply system 17 and an exhaust system 16 of the burner 2 is regarded as a module unit; and three or more units of the alternate changeover regenerative burner constitute a combustion system 1; a ratio of the number of the burners 2 performing combustion and the number of the burners 2 being stopped is variable; and combustion is controlled in such a manner that all the units sequentially repeat alternate regenerative combustion with the units forming no fixed pairs. According to the present invention, a flow velocity of air injected from a burner throat can be variable irrespective of a quantity of combustion; the flow velocity of air emitted from the burner throat can be maintained high even if the operation is carried out with a quantity of combustion lower than the burner capacity; and a non-stationary flame can be formed in a wider range.

Owner:NIPPON FURNACE KOGYO KAISHA LTD

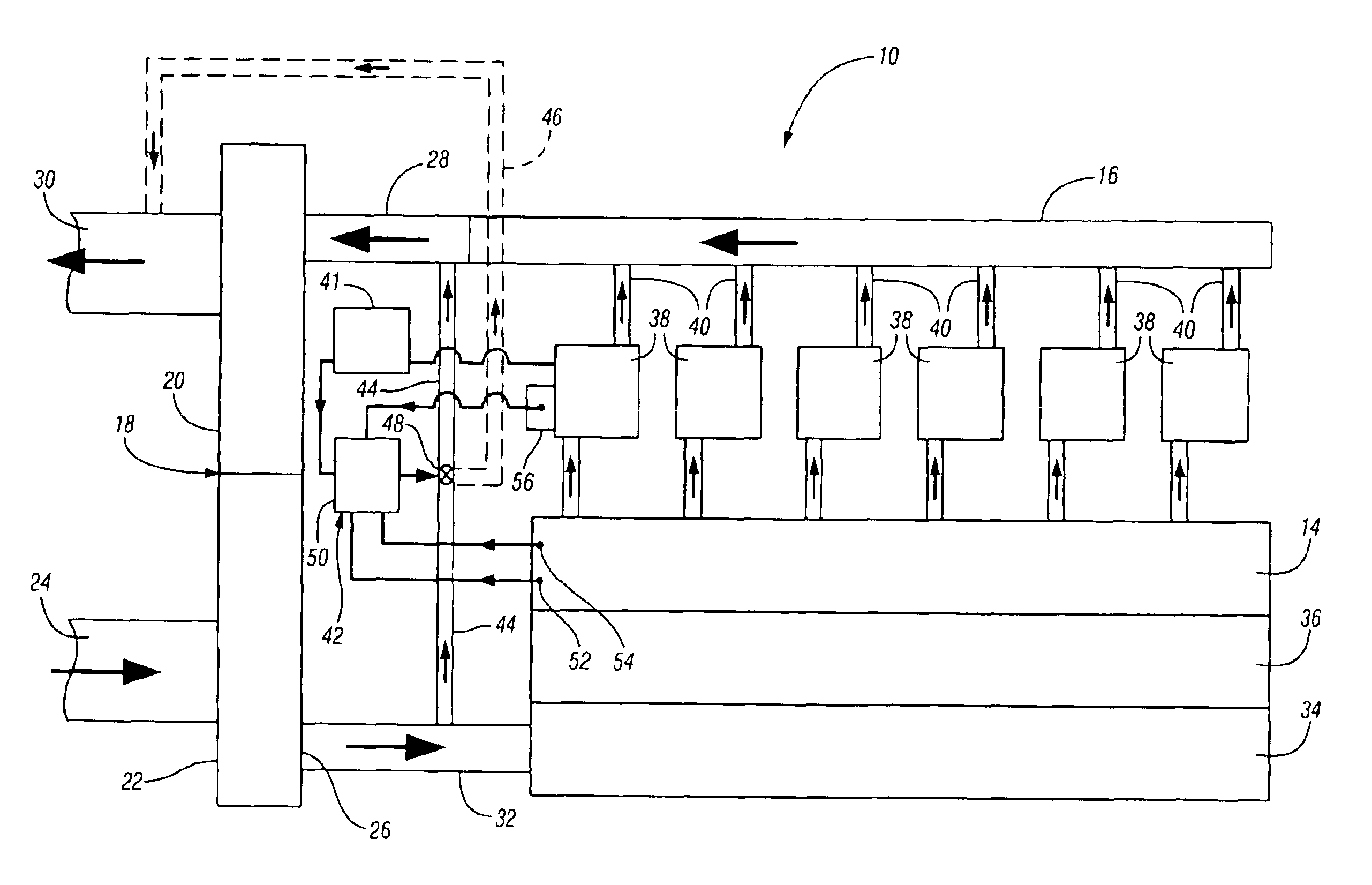

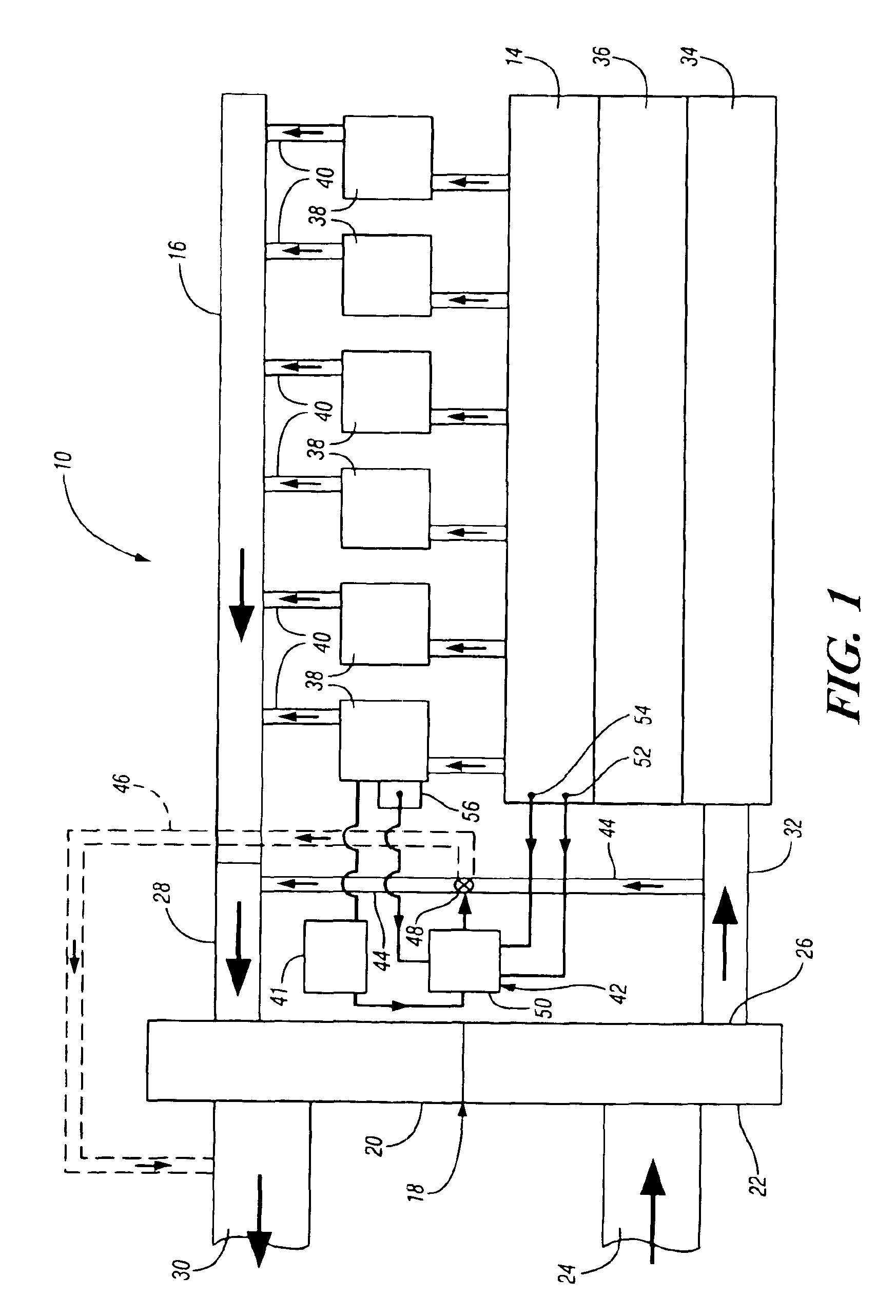

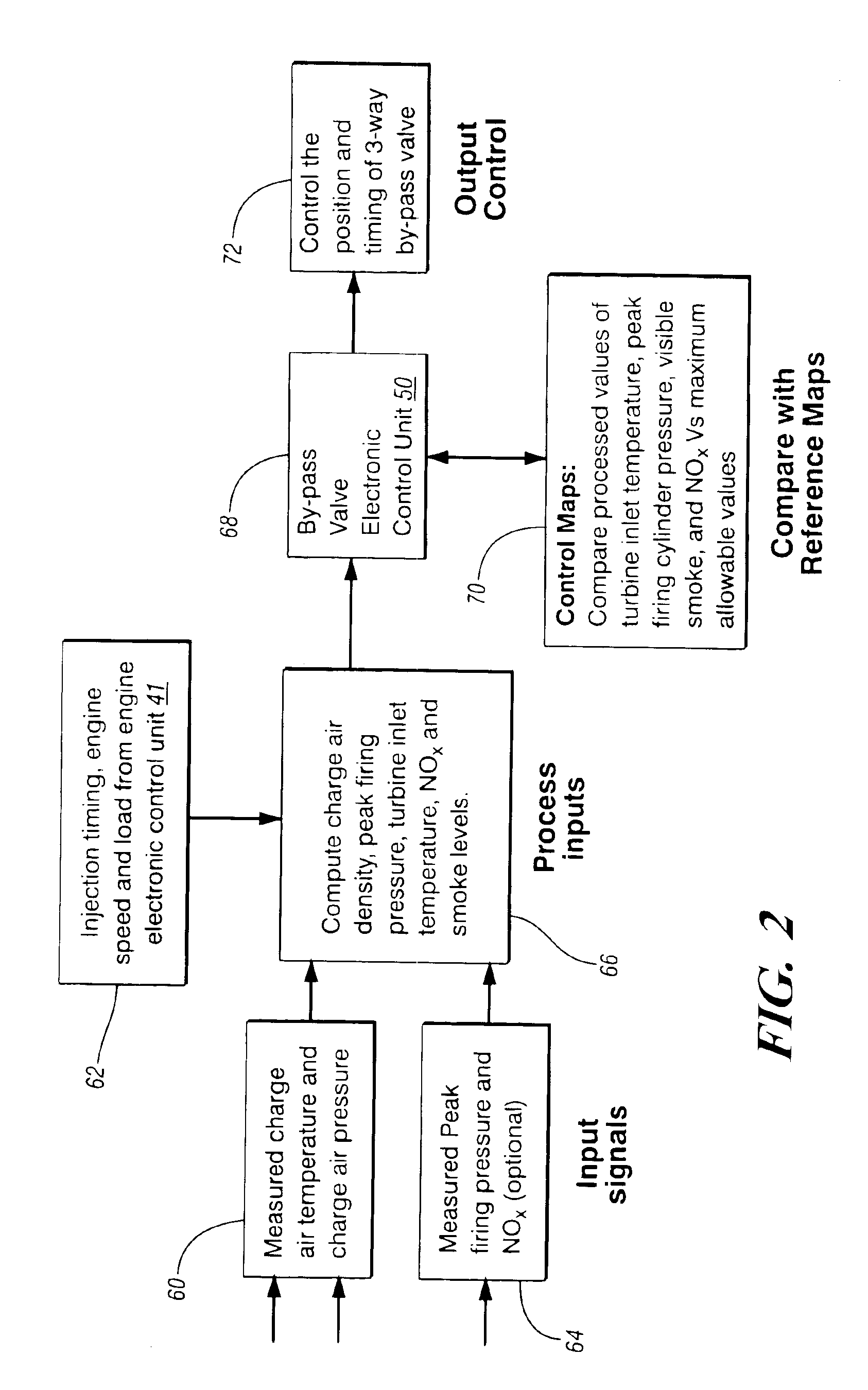

Method for engine condition control with turbocompressor controllable bypass

InactiveUS6912852B2Fast dynamic responseHigh pressureInternal combustion piston enginesEngine controllersTurbochargerExhaust fumes

A system for a turbocharged internal combustion engine includes an engine having a charge inlet connected to the compressor outlet and an exhaust outlet connected to the turbine inlet for driving the turbocharger with hot exhaust gas and supplying compressed air to the engine for combustion. A bypass duct connects the compressor outlet to the turbine inlet for diverting a portion of the compressed air around the engine to the turbine inlet or exhaust. A control device selectively controls the diversion of air. An operating method for the system involves controlling peak cylinder firing pressure and / or maximum turbine inlet temperature, optionally with exhaust NOx and smoke in order to limit these variables to acceptable limits with a minimum of operational limitations.

Owner:ELECTRO-MOTIVE DIESEL

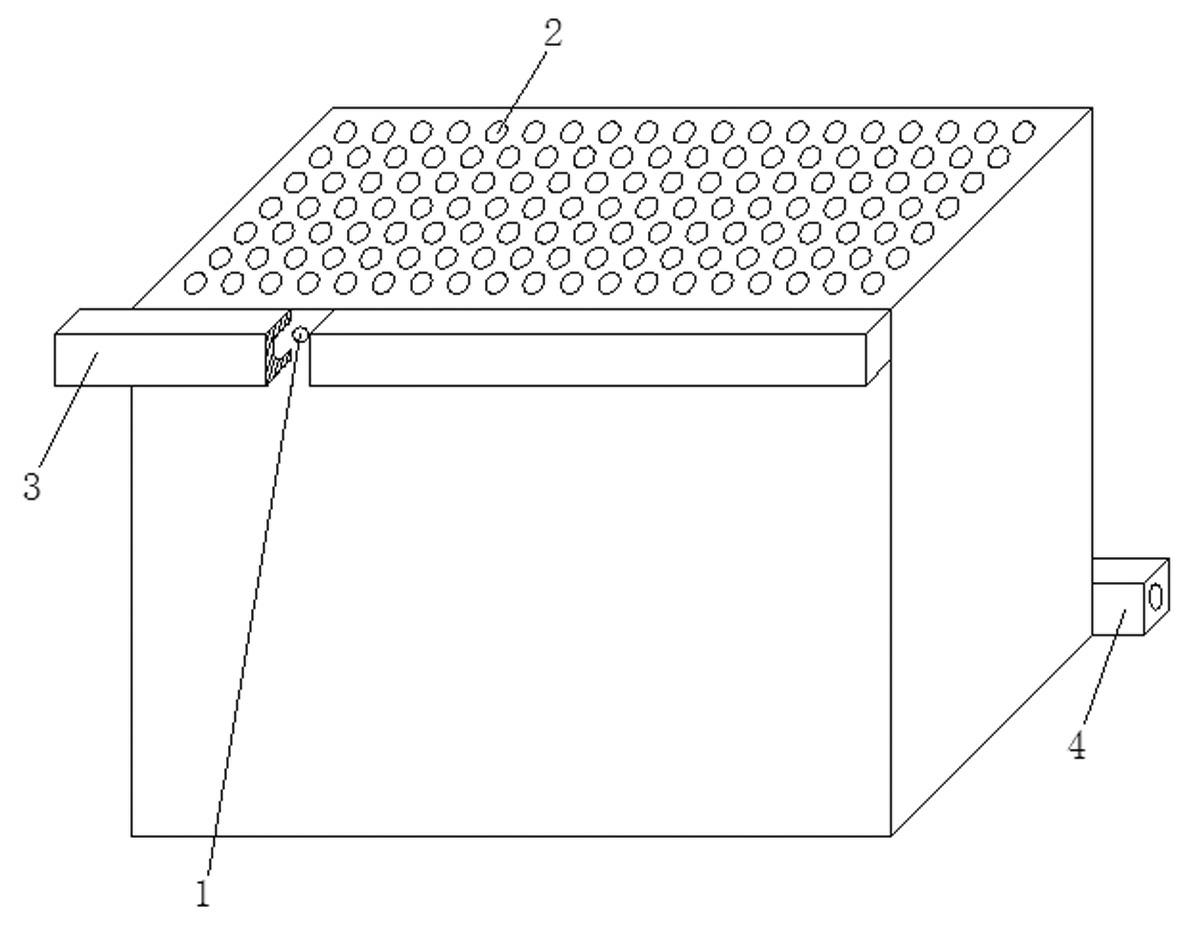

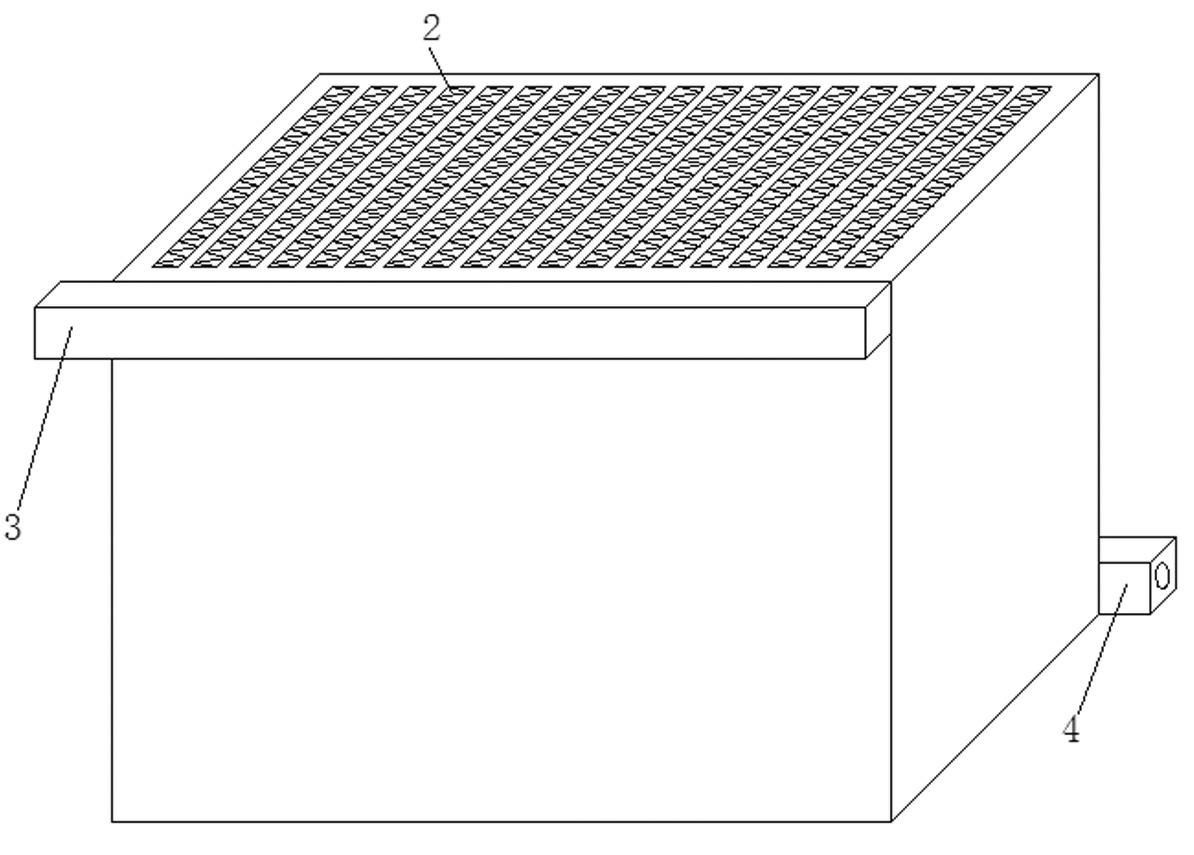

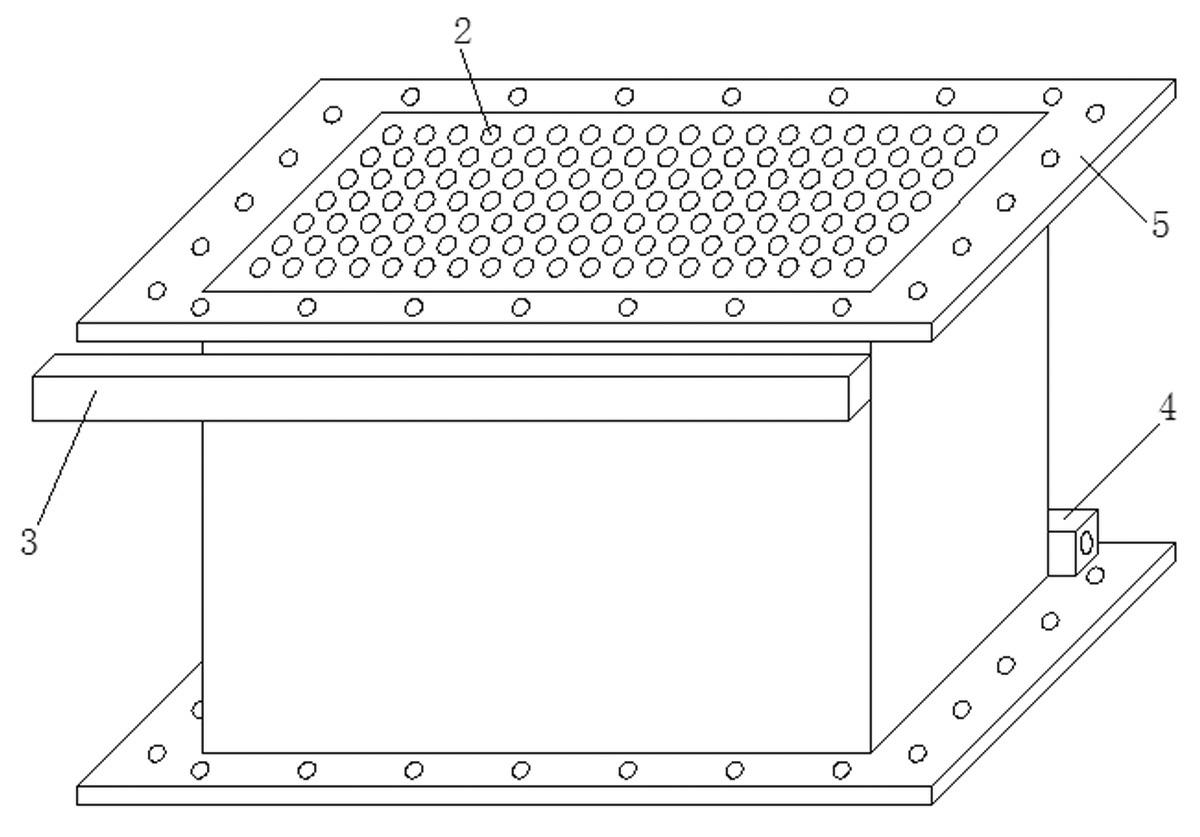

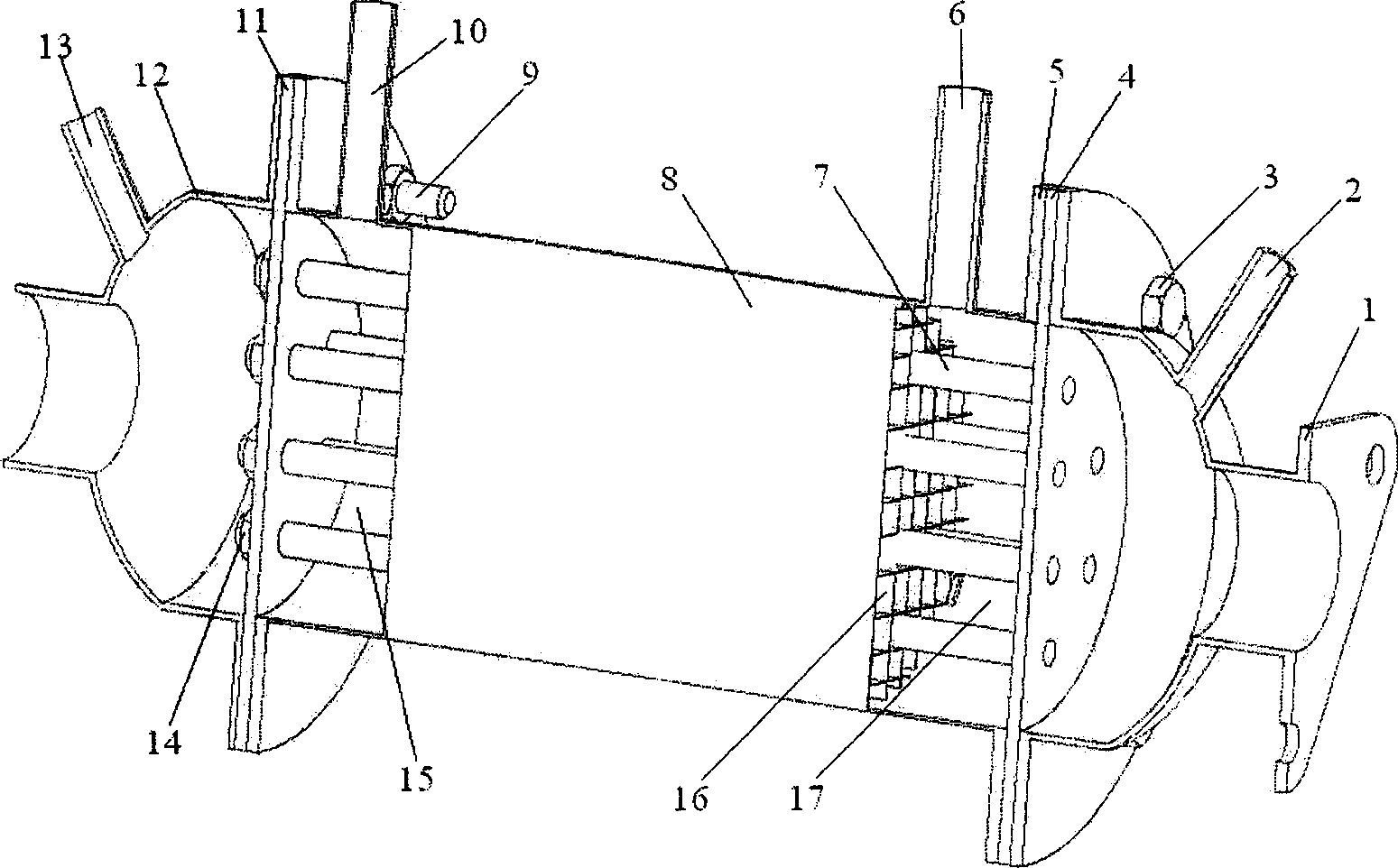

Pure-countercurrent cellular plate-pin heat exchanger and combination thereof

ActiveCN102589328AImprove efficiencyReduce exhaust temperatureStationary plate conduit assembliesEngineeringStreamflow

The invention discloses a pure-countercurrent cellular plate-pin heat exchanger and a combination thereof. The heat exchanger comprises a cellular heat exchange unit body, a flow channels A and flow channels B which are for different fluids are arranged in the cellular heat exchange unit body and staggered in a way that the planes wherein the flow channels A and flow channels B are located are parallel, one end of each flow channel B is provided with a fluid inlet and the other end of each flow channel B is provided with a fluid outlet, each flow channel A comprises a longitudinal flow channel parallel to the flow channels B, one end of each longitudinal flow channel is connected with an inlet on the upper left of heat exchange unit body through transverse distributive channels, and the other end of each longitudinal flow channel is connected with an outlet on the lower right of heat exchange unit body through transverse converge channels. The invention further provides a combination of the pure-countercurrent cellular plate-pin heat exchanger. The pure-countercurrent cellular plate-pin heat exchanger and the combination thereof are simple in structure, low in production cost, low in resistance, high in processing flow and high in heat exchange efficiency, and uniform distribution can be realized.

Owner:JIANGSU TONGSHENG HEAT EXCHANGER

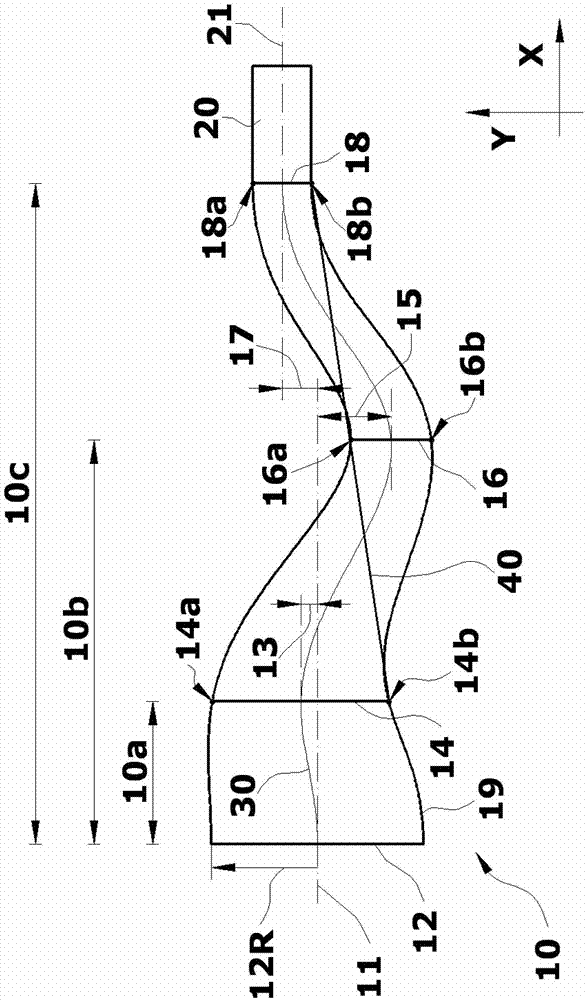

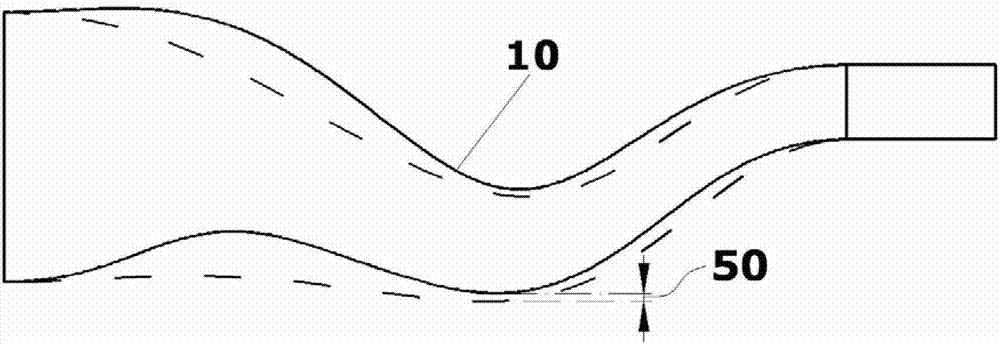

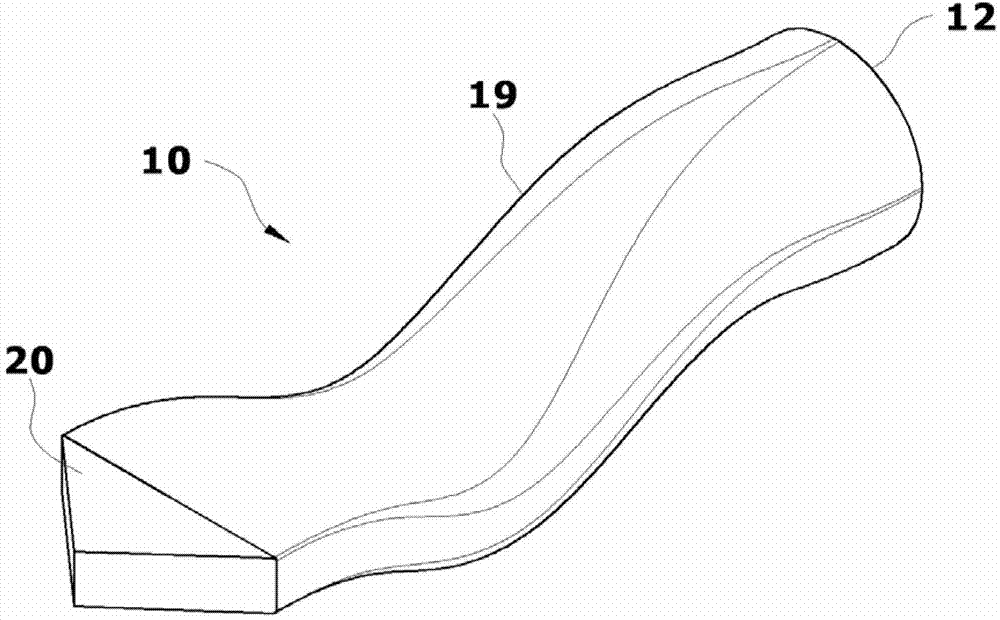

Stealth exhaust system

ActiveCN102926888AImprove adaptabilityImprove infrared stealth performancePower plant exhaust arrangementsJet propulsion plantsThroatRadar

The invention relates to an exhaust system applied to an air vehicle, in particular to a stealth exhaust system. A cross-section shape of a throat of a spray pipe is designed to a non-round shape with an aspect ratio greater than 1, so that mixing of high-temperature exhaust airflow of an engine and ambient air is strengthened, the exhaust temperature is reduced, and an infrared stealth property of the exhaust system is improved. Central lines of the stealth exhaust system are three longitudinal S-bent curves, and the bent central lines can enable sidewalls of the spray pipe to shield high-temperature components of the engine, therefore, the infrared stealth property of the exhaust system can be improved; and simultaneously, the bent central lines can also cause radar waves going into the stealth exhaust system from the rear to difficultly generate backward waves, therefore, a radar stealth property of the exhaust system can be improved. Properties of the exhaust system are considered while the stealth properties are ensured, so that a requirement of the stealth exhaust system on the layout space is reduced, and adaptability of the stealth exhaust system is strengthened.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

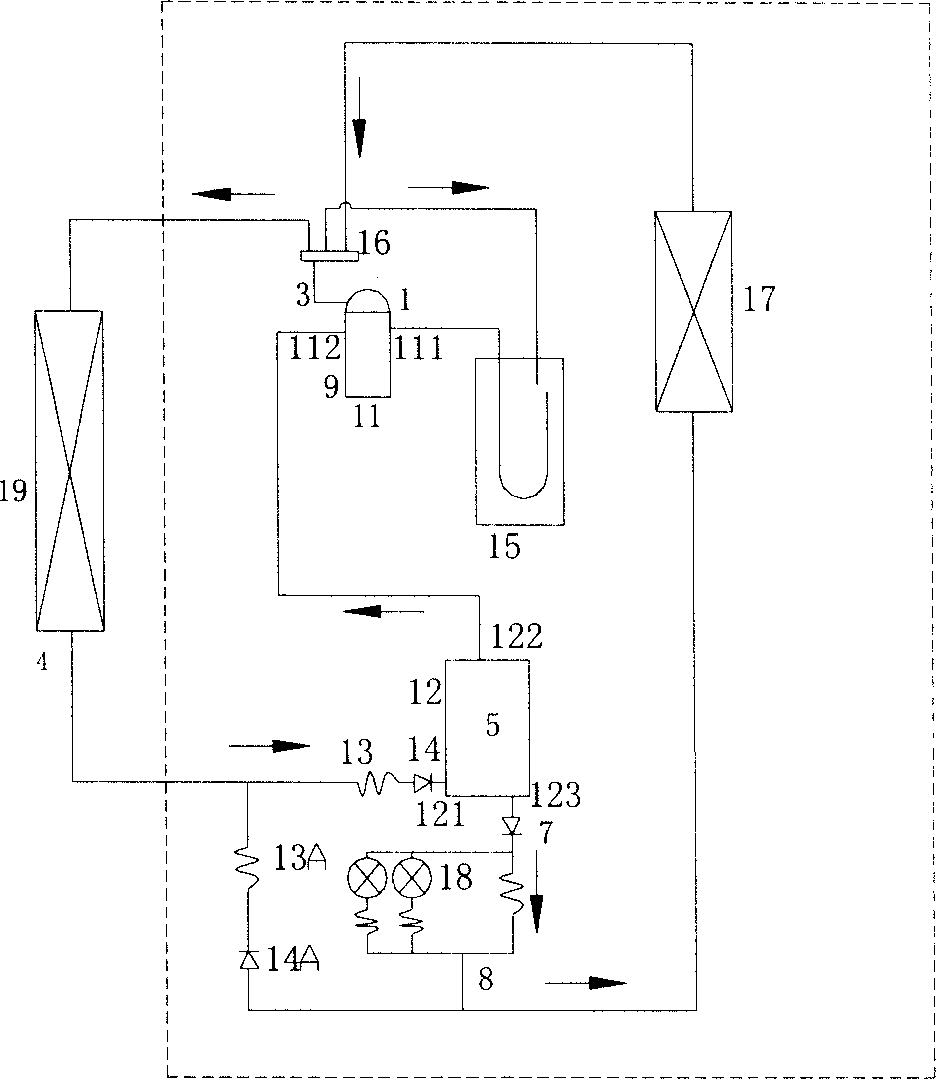

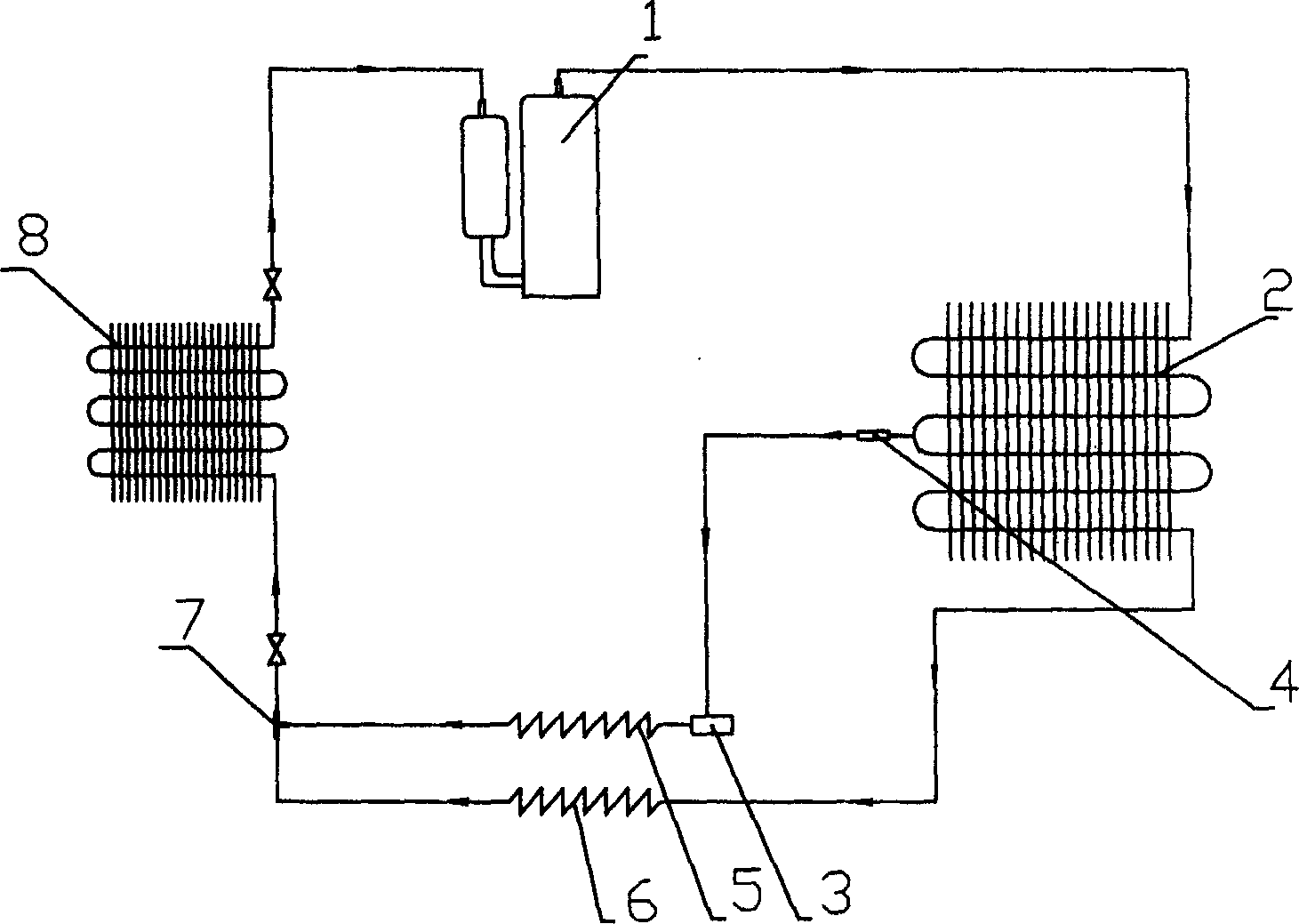

Super low temperature heat pump air conditioner system

ActiveCN101165438AOvercoming the problem of serious attenuation of heating heatGuaranteed uptimeCompression machines with reversible cycleFour-way valveBusiness efficiency

This invention relates to a super low temperature heat pump air conditioner system which has good heating effect even under outdoor super low temperature working state. The system includes compressor, main throttling component, indoor external heat exchanger, gas-liquid separator, four-way valve and electromagnetic valve. Each part is connected through pipeline. The system also has a flash evaporator groupware. One outlet of the flash evaporator groupware connects to the air absorbing opening of compressor through pipeline. This invention uses enhanced air jet scroll compressor and steam spraying system. When heating under low temperature working state, the flash evaporator is used to spray refrigerant. It makes the compressor absorb more refrigerant. It fulfills quasi-double stages compression. The heating quantity and energy-efficiency ratio are increased. It can also keep low compression ratio and exhausting temperature. The air conditioner can work steady.

Owner:GREE ELECTRIC APPLIANCES INC

Methanol catalytically reforming hydrogen producing apparatus utilizing afterheat of internal combustion engine and its control method

InactiveCN1887691AImprove conversion rateHigh hydrogen production rateHydrogenHydrogenExternal combustion engine

The present invention relates to internal combustion engine afterheat utilizing technology, and is especially methanol catalytically reforming hydrogen producing apparatus utilizing afterheat of internal combustion engine and its control method. The apparatus includes mainly methanol aqua gasifying cavities in the front part, middle part and back part of the reformer casing, catalytically reacting cavity and reformed gas product cavity. In the middle part inside the reformer casing, there are porous honeycomb ceramic with inside catalytically reacting cavity; and the inner wall of the catalytically reacting cavity has set honeycomb pores with reforming catalyst coated to the inner wall. One heat exchange pipe penetrates the porous honeycomb ceramic axially. The present invention has integrated heat exchange pipe and porous honeycomb ceramic, and possesses compact structure, high heat exchange efficiency, high hydrogen rate and other advantages.

Owner:BEIJING UNIV OF TECH

Cold-region used multi-connected heat pump system and control method thereof

ActiveCN103175344AReduce the temperatureTo overcome the shortcomings of large flow pressure lossMechanical apparatusHeat pumpsEngineeringRefrigeration

The invention discloses a cold-region used multi-connected heat pump system and a control method of the multi-connected heat pump system. The multi-connected heat pump system comprises a first refrigerant branch and a second refrigerant branch. The first refrigerant branch is connected between a first heat exchanger and a compressor of a main refrigerant loop in a crossed mode. A control unit controls the main refrigerant loop and when the main refrigerant loop is in refrigeration working condition, and the first refrigerant branch splits refrigerant flowing out the first heat exchanger; split refrigerant exchanges heat with the refrigerant flowed into a second heat exchanger after the split refrigerant is throttled and depressurized in the first refrigerant branch, the temperature of the refrigerant flowed into a second heat exchanger is decreased, and then the split refrigerant flows back to the main refrigerant loop to enter the compressor. The second refrigerant branch is connected between the second heat exchanger and a compressor of a main refrigerant loop in a crossed mode. The second refrigerant branch splits refrigerant flowing out the second heat exchanger. Split refrigerant exchanges heat with the refrigerant flowed into the main refrigerant loop after the split refrigerant is throttled and depressurized in the second refrigerant branch, and then the split refrigerant turns into gaseous refrigerant and is injected into the compressor to decrease the temperature of refrigerant vapor in the compressor.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Direct injection of diluents or secondary fuels in gaseous fuel engines

InactiveUS20140331668A1Reduce exhaust emissionsHigh priceInternal combustion piston enginesNon-fuel substance addition to fuelDiluentExhaust gas recirculation

An engine system, comprising a first gaseous fuel source with a first gaseous fuel located therein coupled to one or more engine cylinders and an exhaust gas recirculation (EGR) system with a reform catalyst located therein, the reform catalyst reforming natural gas into a gas with a wider AFR operating range. The engine may thus operate at an AFR that may be outside of that available during natural gas combustion alone to allow for cooler engine operation.

Owner:FORD GLOBAL TECH LLC

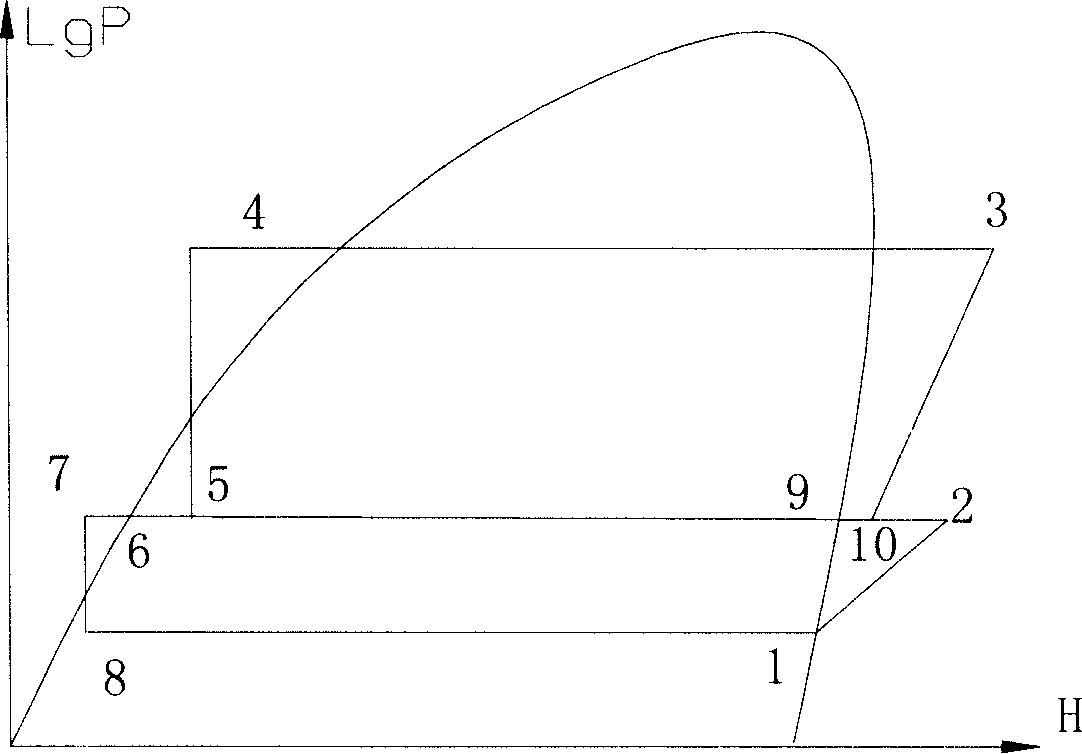

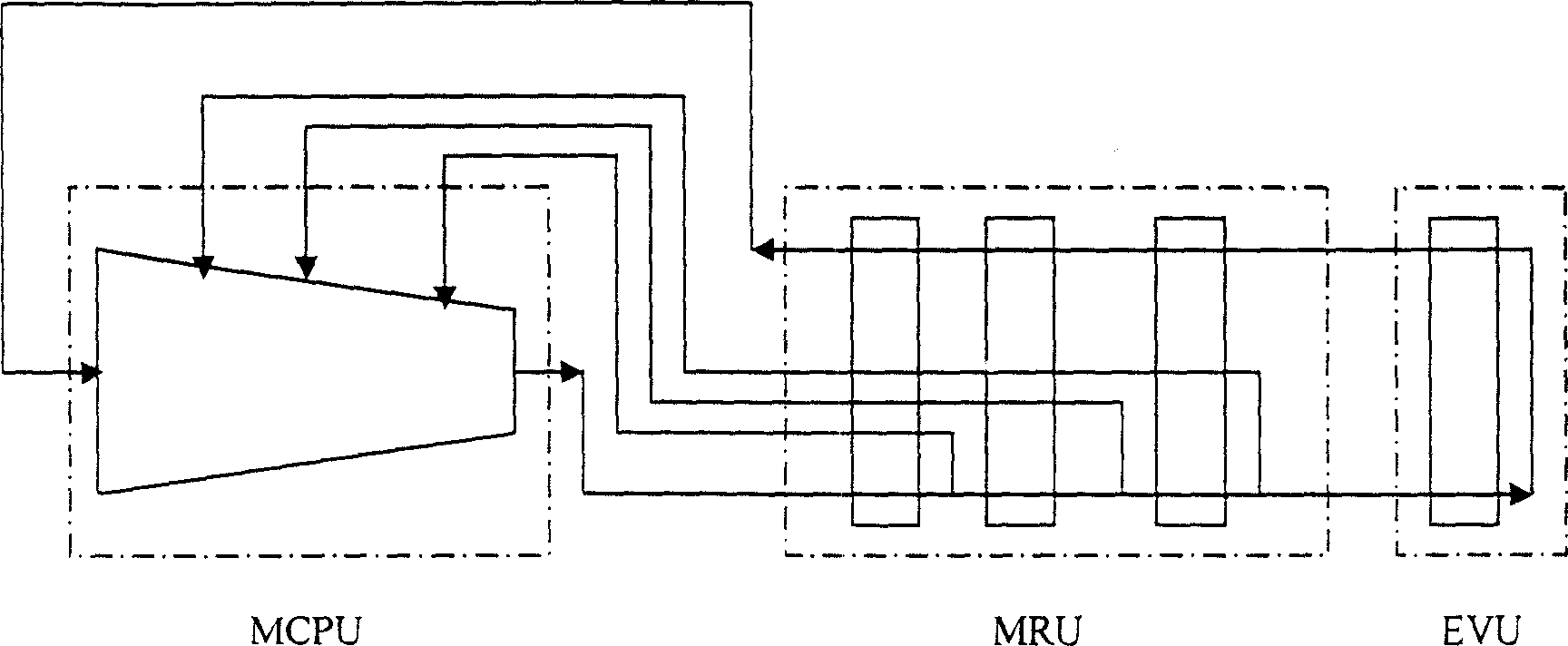

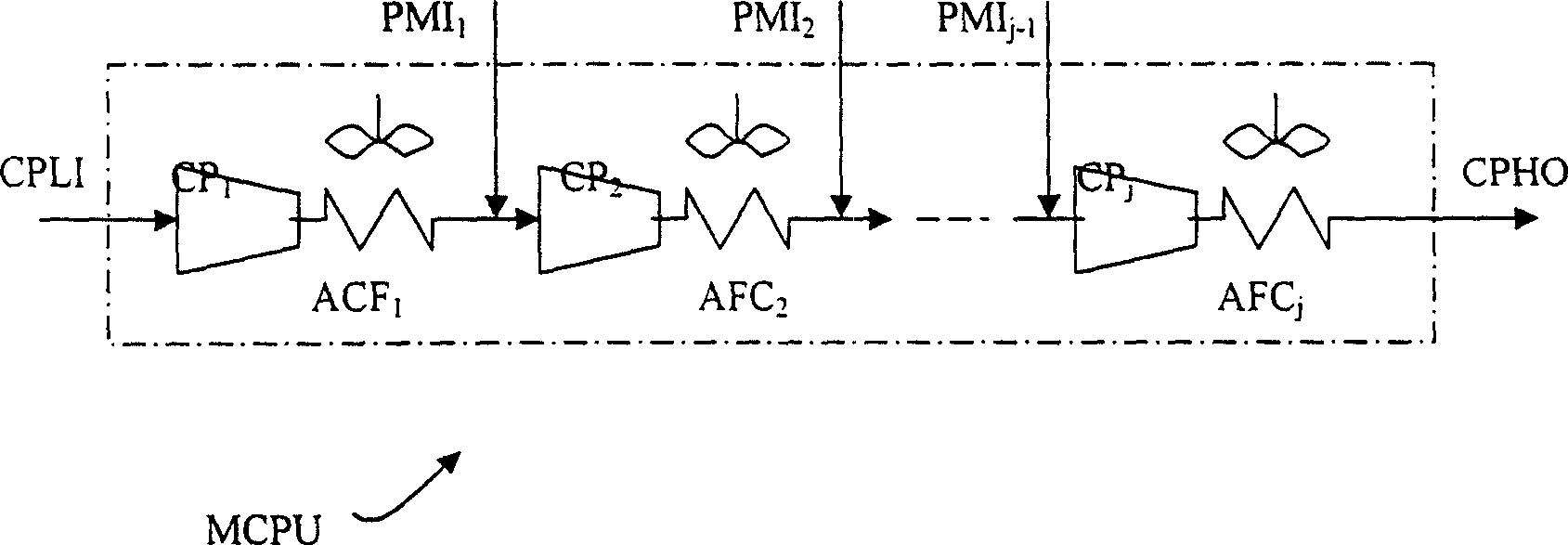

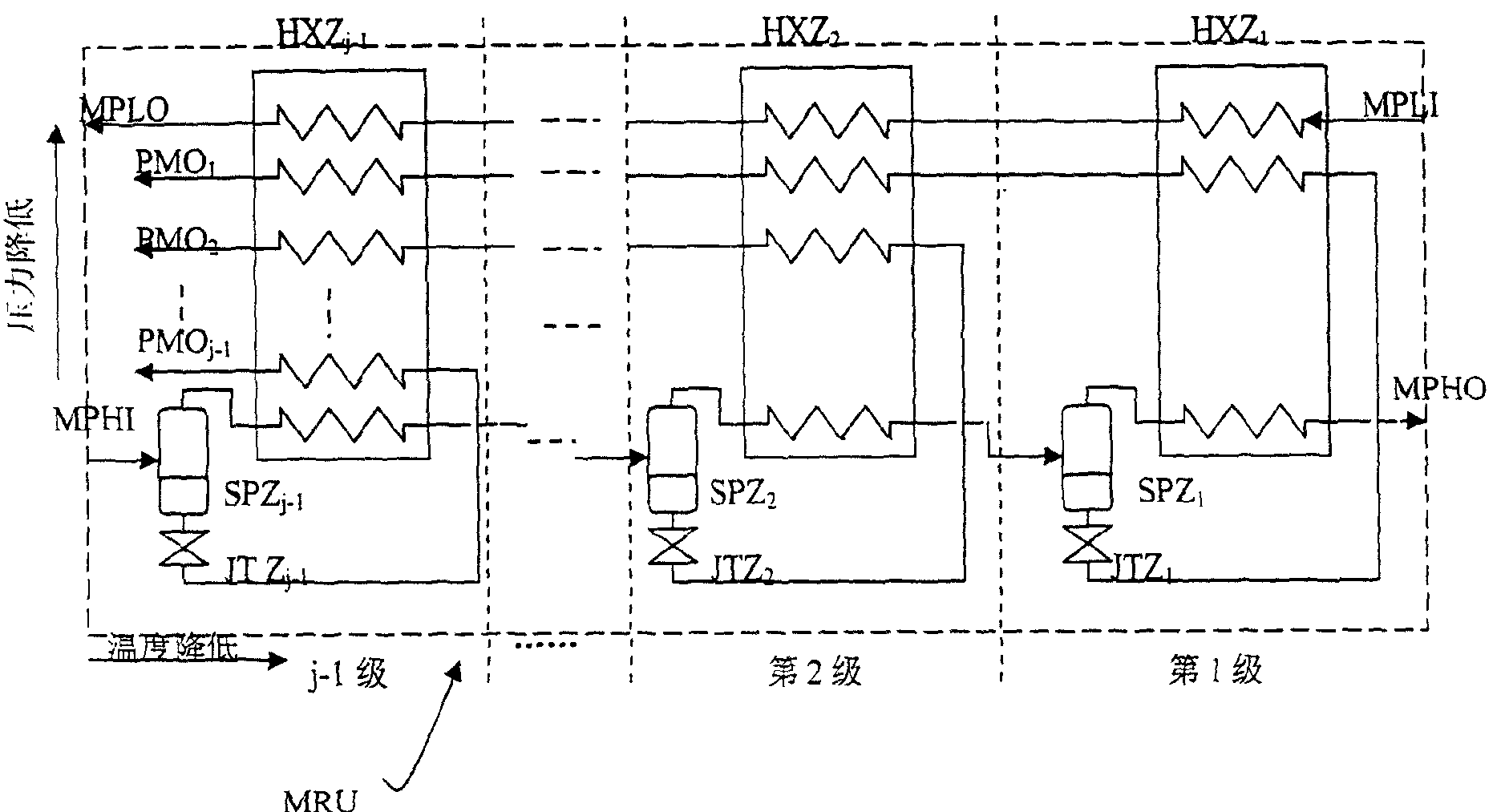

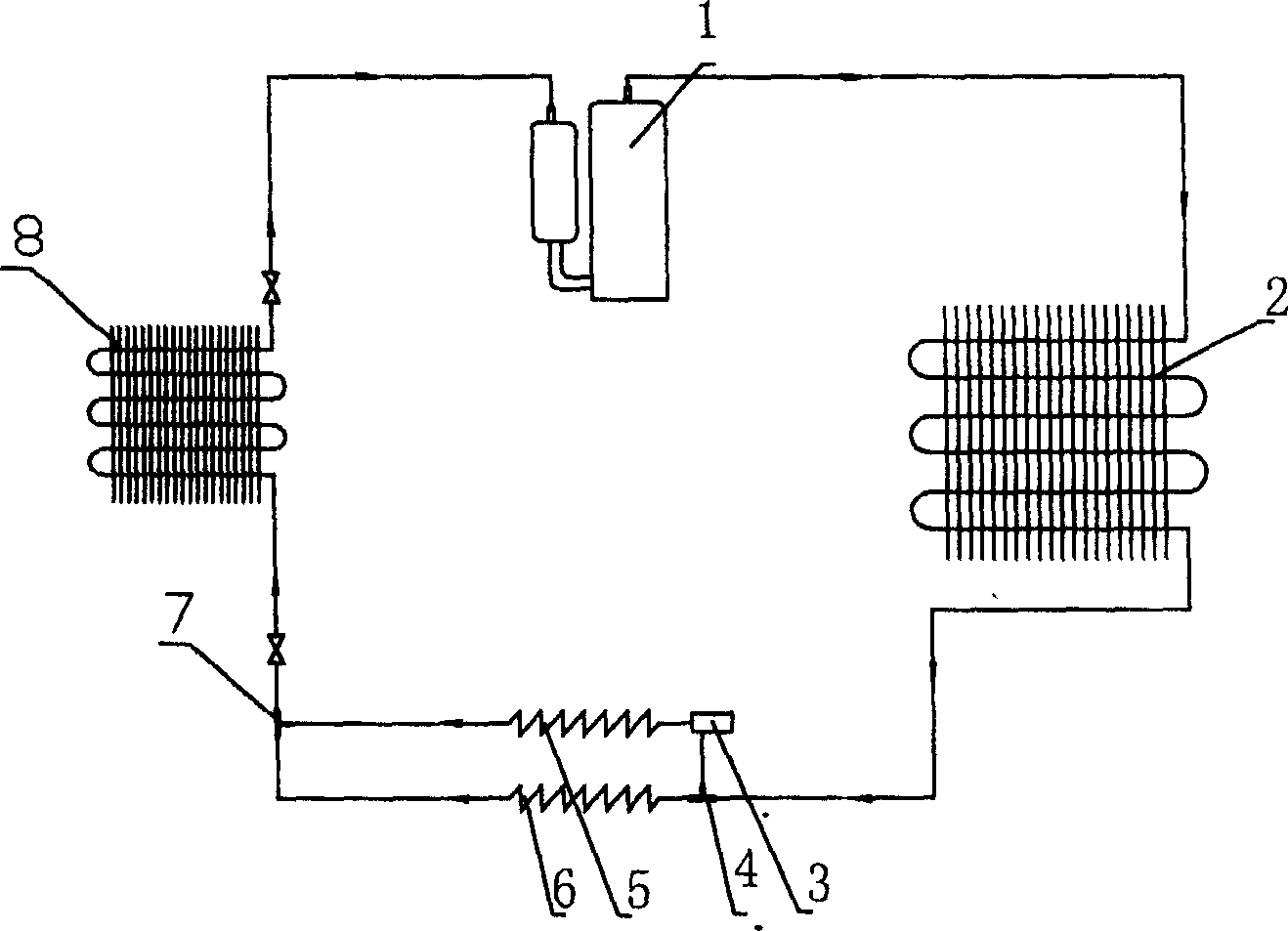

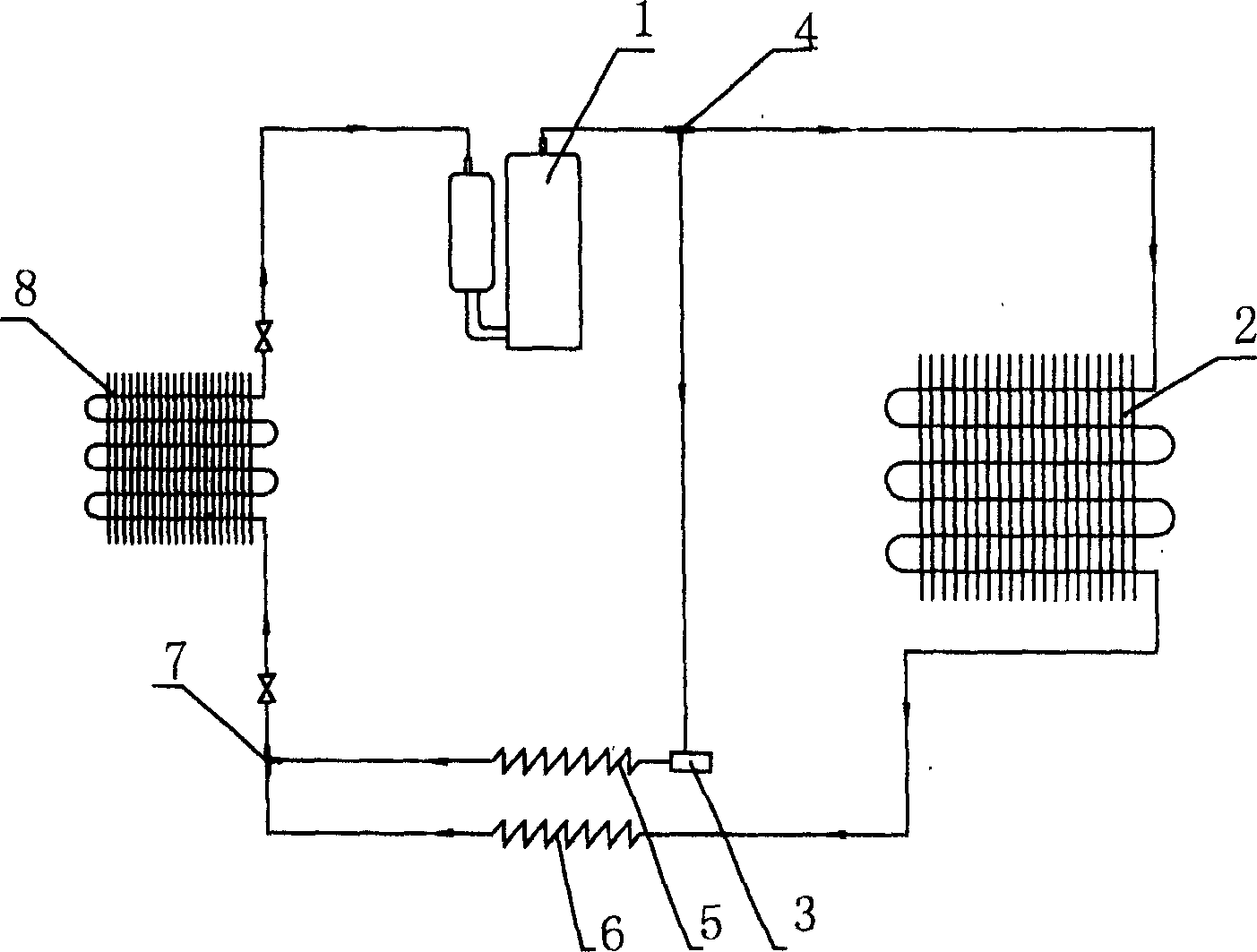

Multiple pressure grade mixed working medium cryogenic throttling refrigeration system

ActiveCN1683844AHigh thermal efficiencyGood throttling effectSolidificationLiquefactionProduct gasEngineering

The multiple pressure stage mixed work medium cryogenic throttling refrigeration system consists of several stages of compressor set unit MCPU, back heating pre-cooling unit MRU and evaporator unit EVU. The connection mode includes connecting the high pressure outlet of MCPU to the high pressure inlet of MRU, connecting the low pressure inlet of MCPU to the low pressure outlet one MRU, connecting the high pressure outlet operate MRU to the inlet of EVU, and connecting the outlet of EVU to the low pressure inlet of MRU. The present invention adopts high efficiency multiple-element mixed work medium. The refrigeration system has lowered irreversible loss of compression and back heating process thermodynamically, reduced loss in the practical flow and heat exchange process, and thus high thermodynamic efficiency, and is especially suitable for large and middle scale low temperature refrigerating and gas liquefying fields.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

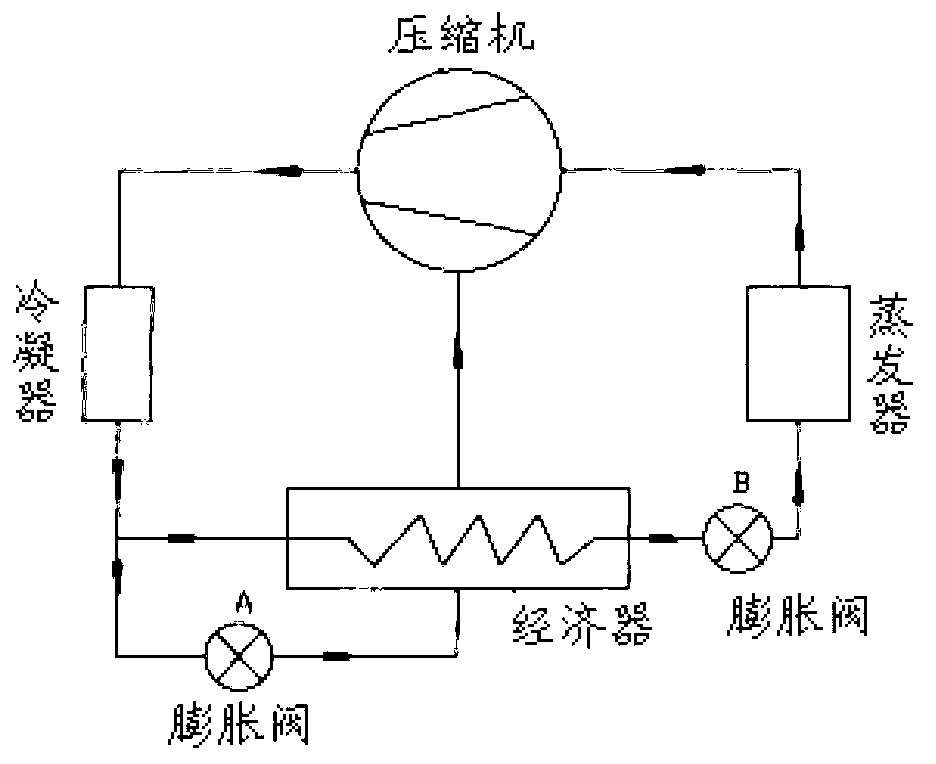

Refrigerant system with economizer, intercooler and multi-stage compressor

InactiveCN101568769AImprove dehumidification effectHigh cooling potentialCompression machines with non-reversible cycleRefrigeration componentsIntercoolerEngineering

A refrigerant system is provided with a multi-stage compression system. An intercooler is positioned between at least two compression stages to cool a refrigerant, by heat transfer interaction with a secondary fluid, after it has been compressed in the lower compression stages to some intermediate pressure. The intercooler enhances refrigerant system performance, improves compressor reliability, and extends operational envelope. Further, at least one economizer circuit is incorporated into the refrigerant system that returns the economized refrigerant flow at the location between at least two compression stages.

Owner:CARRIER CORP

Berry can and processing method thereof

The invention relates to a new can processing method which is applicable to a berry raw material and a berry can processed through the method, and the can processing method is characterized in that the tissue improvement method in line with the characteristics of berry is adopted, a calcium preparation and the sugar impregnation are combined for treatment so as to increase the strength of the skin part and pulp part of the berry, and the complete and due taste of fruit granules can be maintained during the follow-up heat treatment process; a formula with special flavor and nutritional attributes is utilized for the preparation of canned soup, thereby greatly improving the health-care and beautifying effects of the product; according to the actual nutritional requirement of the berry raw material, a safe thermal sterilization way is adopted, the thermal degasification temperature and sterilization temperature in the traditional process are reduced by about 10 DEG C, the nutritional value and sensory quality of the product are better protected, the natural taste of the berry raw material is maintained, energy is saved, and the can processing method can be maturely applied to berry can products and is applicable to actual situations of the majority of can food production enterprises.

Owner:丹东美比食品有限公司

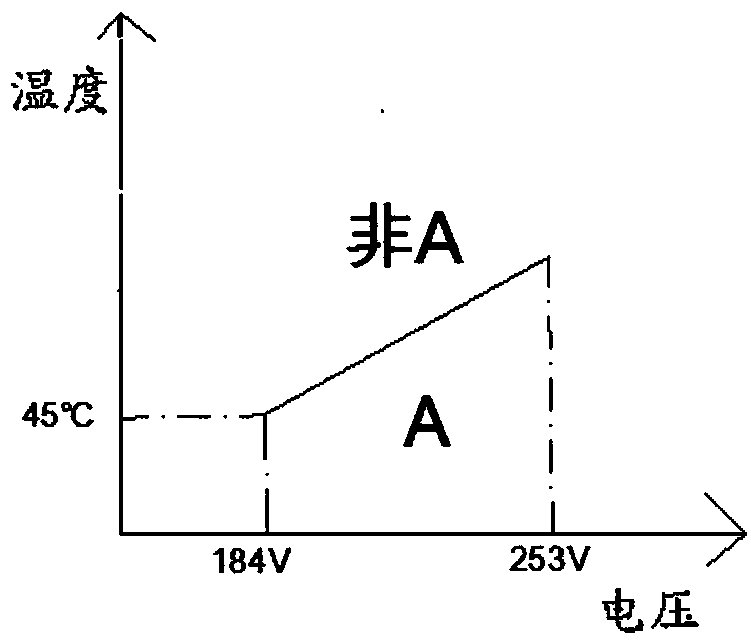

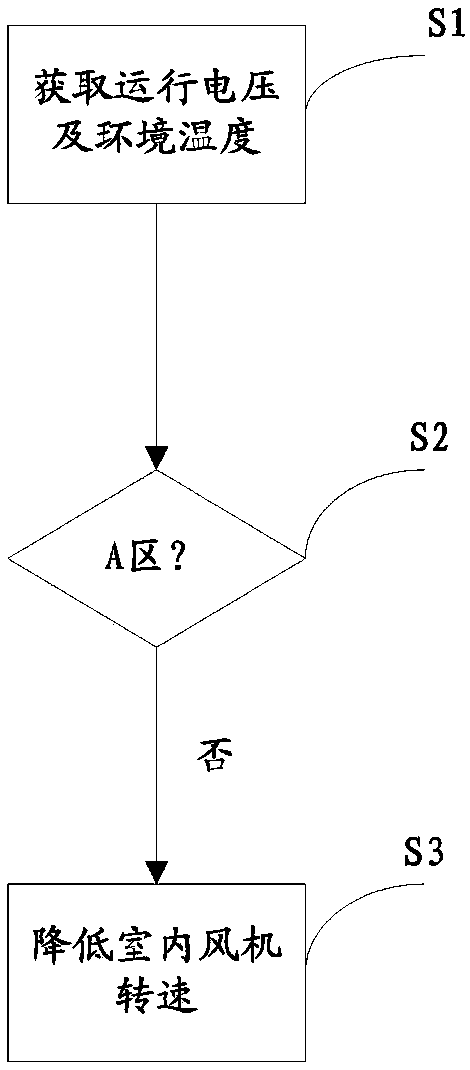

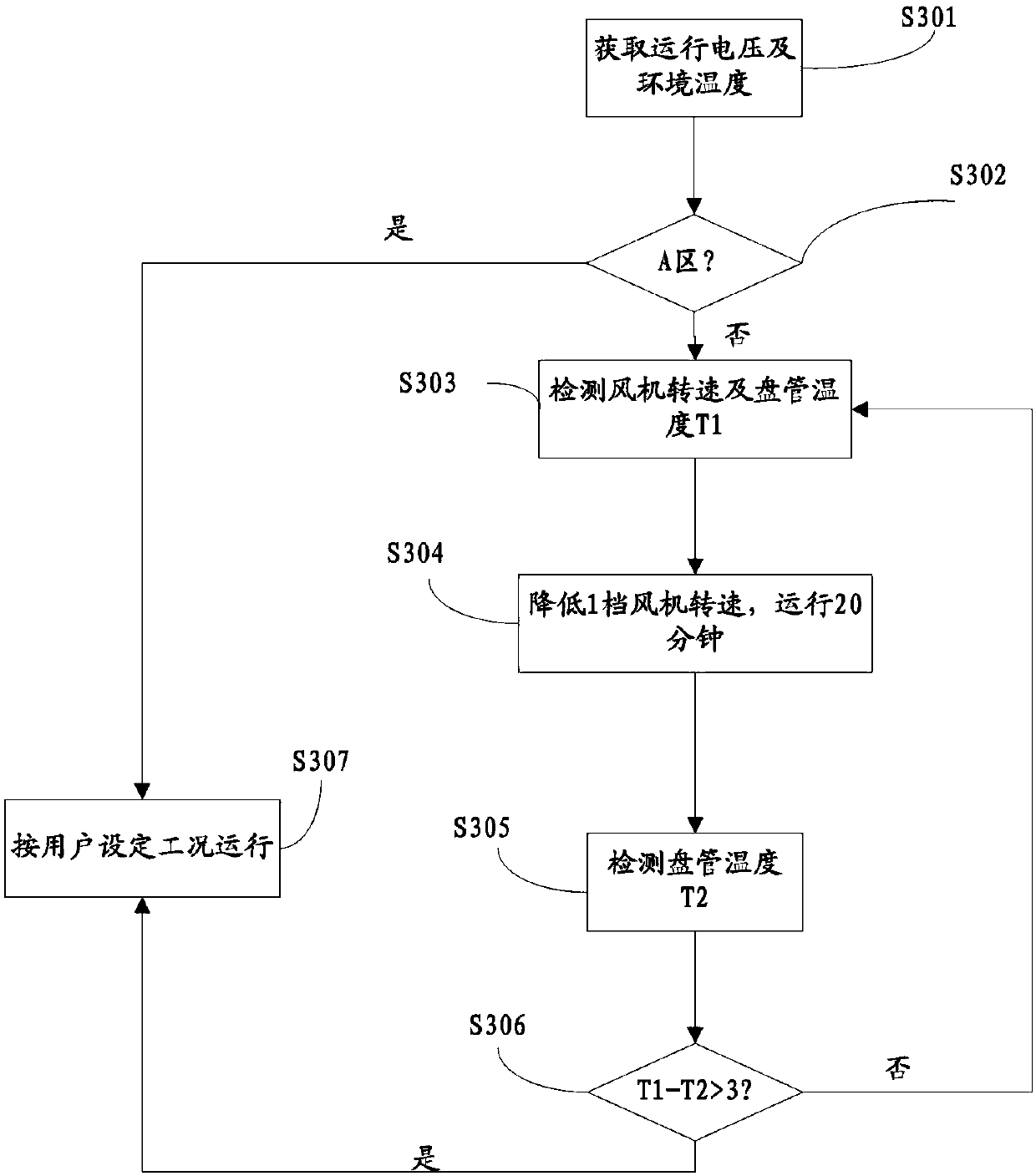

Protection control method and device for air conditioner

ActiveCN107747790AShort maintenance periodAvoid actionMechanical apparatusSpace heating and ventilation safety systemsLow voltageControl theory

The invention discloses a protection control method for an air conditioner, and belongs to the technical field of air conditioners. The method comprises the following steps: acquiring a running voltage of the air conditioner and an environment temperature; and when the running voltage and the environment temperature are out of a set area, lowering the rotational speed of an indoor fan. The invention further discloses a protection control device for an air conditioner. The invention solves the problem that a compressor of a fixed-frequency air conditioner is liable to stop due to the action ofan overload protector of the compressor in a high-temperature and low-voltage environment.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

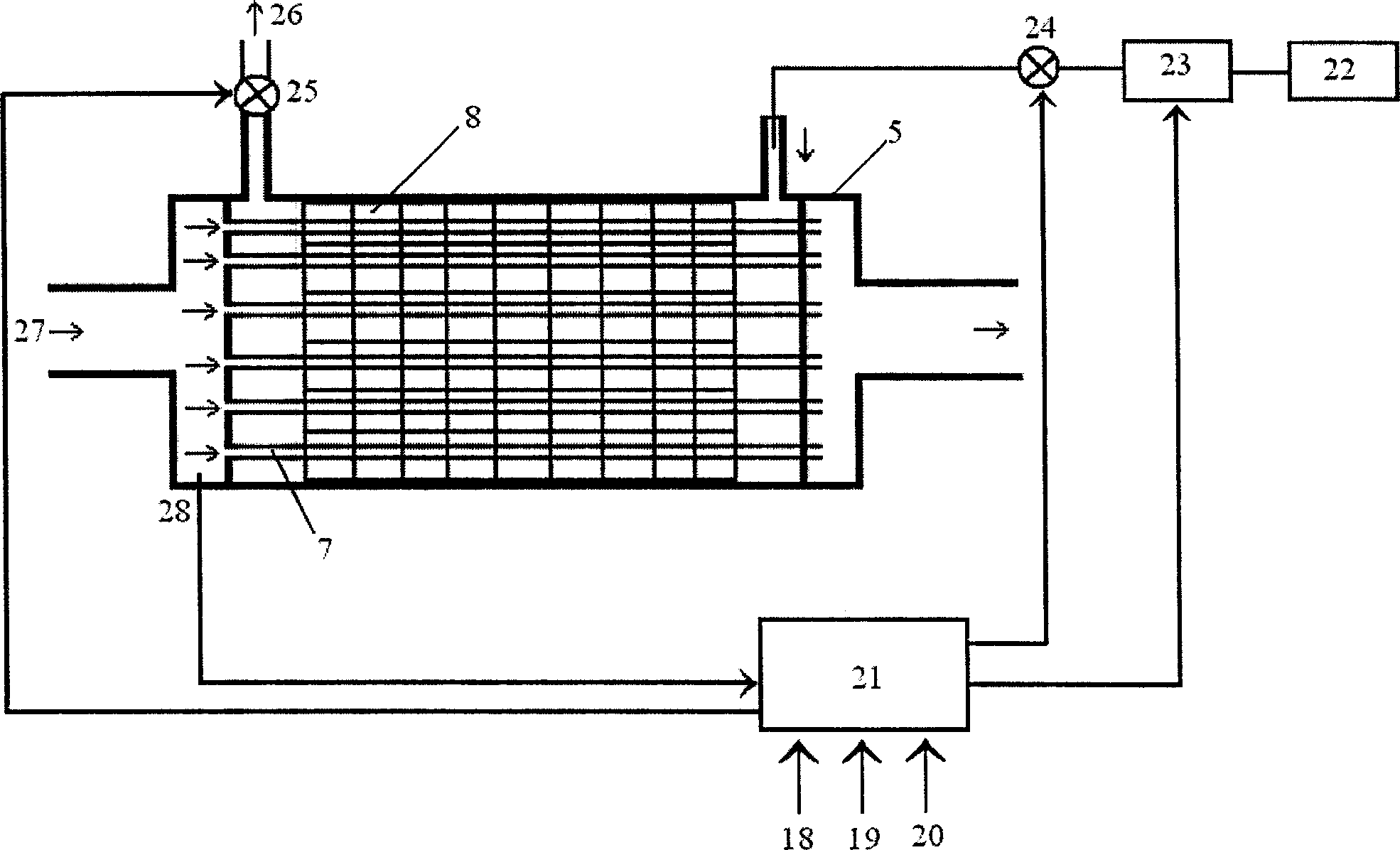

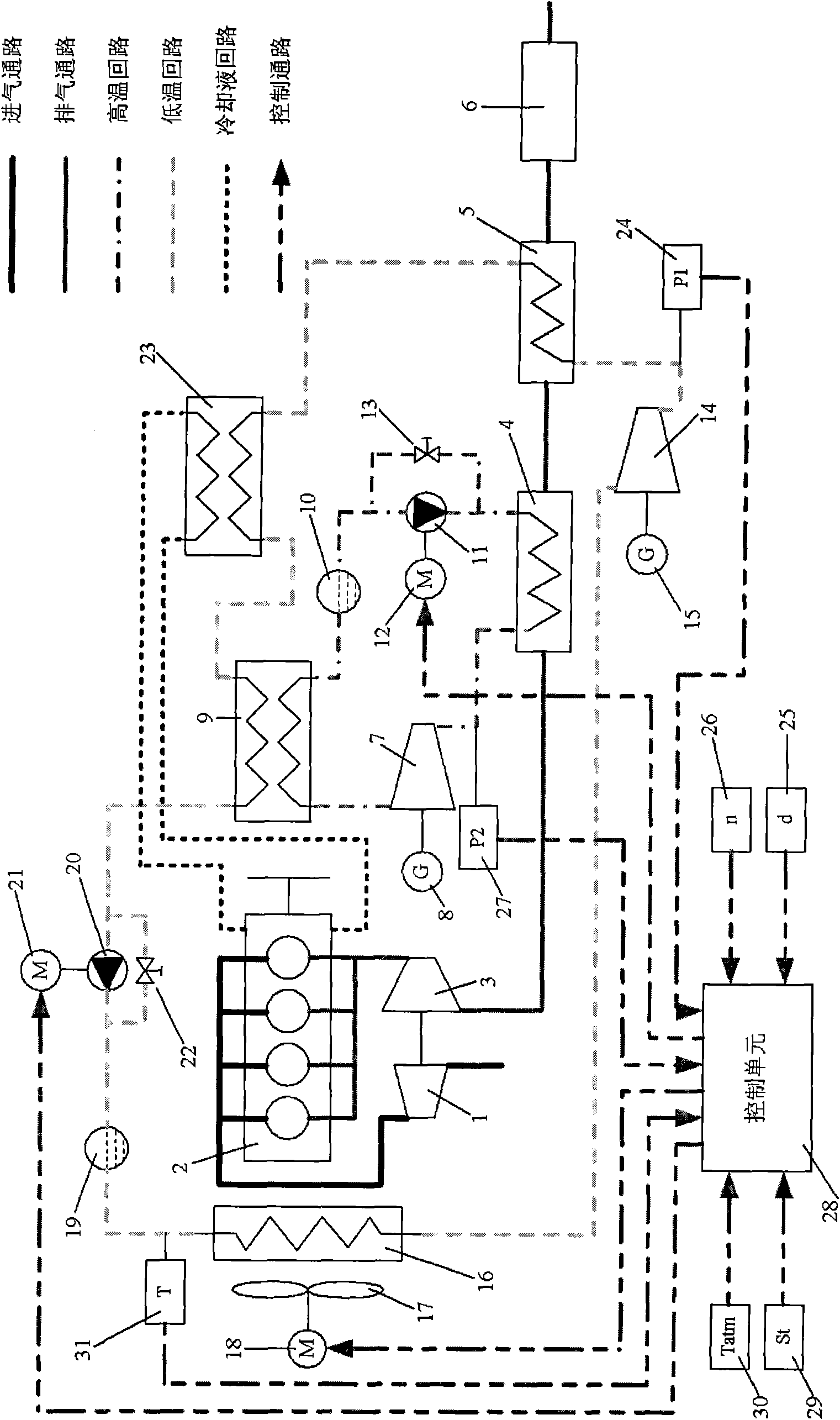

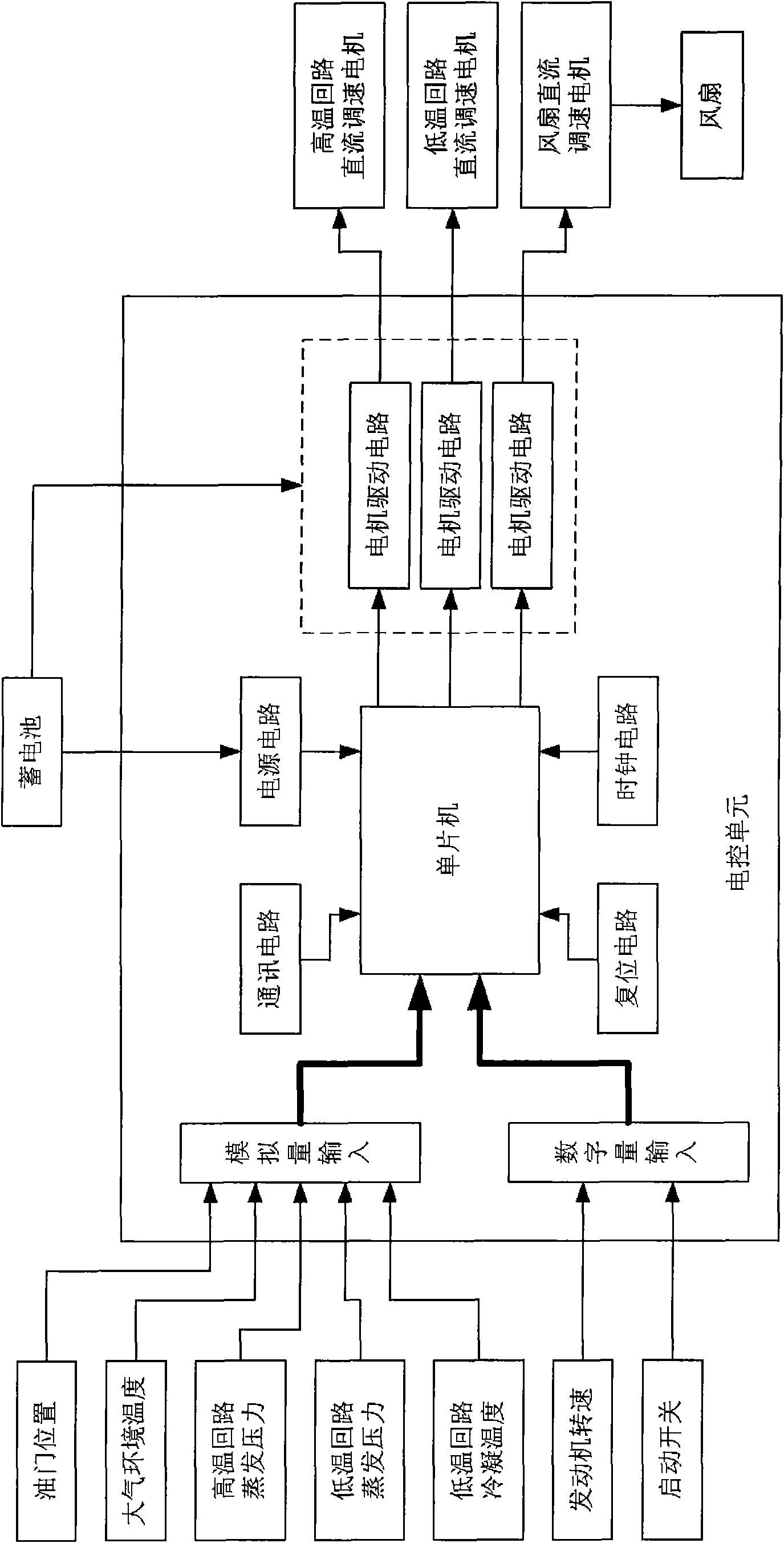

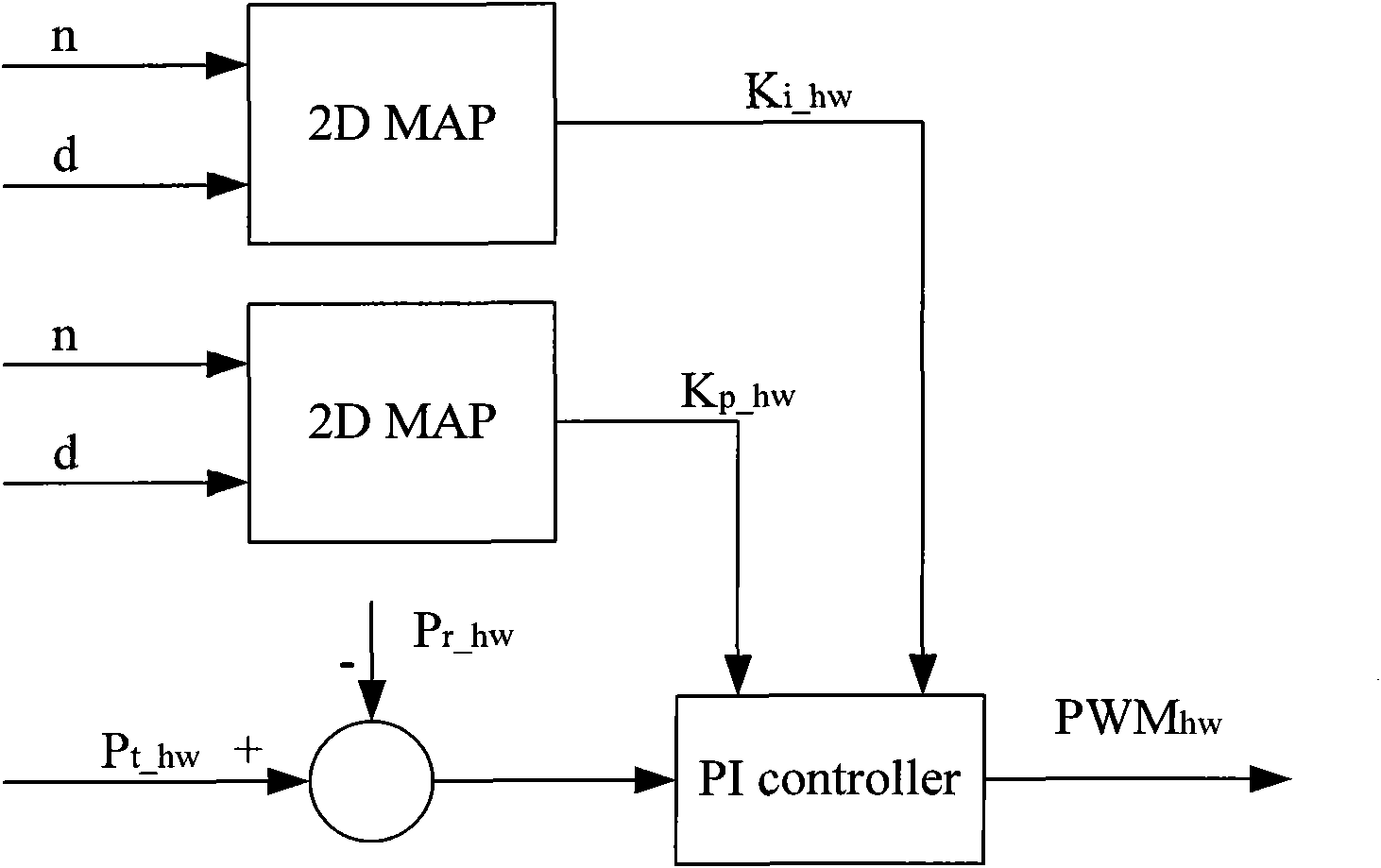

Control system and method for generating power by waste heat of diesel engine

InactiveCN102003229AHigh output useful workImprove useful workInternal combustion piston enginesEngine componentsClosed loop feedbackOrganic Rankine cycle

The invention provides a control system and method for generating power by waste heat of vehicle diesel engine, wherein the control method comprises the following steps: converting the waste heat which is taken away by the exhaust of a diesel engine to an available power by using an organic rankine cycle with a high-temperature circuit of close-loop feedback control, outputting the available power, converting the waste heat which is taken away by the cold solution of the diesel engine to an available power by using an organic rankine cycle with a low-temperature circuit of close-loop feedback control, outputting the available power and driving the electric generator generate electricity; the flow rate of working medium is controlled by regulating the revolution speed of a motor, and a pressure regulation valve of high-temperature circuit is connected to the working medium of the high-temperature circuit in parallel so as to limit the supreme evaporating pressure and control the flow rate of the cold air which is flown through a condenser and to regulate condensation temperature of the low-temperature circuit. The control system for generating power by waste heat is used for judging the working condition of the engine by collecting the revolution speed of the engine and the position signal of the accelerator pedal, accurately regulating flow rates of the working mediums of high-temperature circuit and low-temperature circuit, fully utilizing the waste heat of diesel engine, improving the thermal efficiency of the diesel engine and simultaneously reducing the harm of exhaust of the diesel engine to the environment.

Owner:BEIJING UNIV OF TECH

Heat pump type tableware washer and control method thereof

ActiveCN105476584AImprove energy efficiencyFast heatingTableware washing/rinsing machine detailsFluid circulation arrangementDecreased energyEngineering

The invention provides a heat pump type tableware washer and a control method thereof. The washer is added with a heat pump device comprising a compressor, a condenser, a throttle device, an evaporator and an evaporator fan. The condenser is disposed on a line where a circulating water pump is located; a heating heat-exchange passage is also disposed between a housing and a treatment chamber, the evaporator and the evaporator fan of the heat pump device are received in the heating heat-exchange passage, and both an air inlet and an air outlet of the heating heat-exchange passage are arranged in the front of the housing. The heat pump device provides hot water in a washing stage, decreasing energy consumption; both the air inlet and the air outlet are arranged in the front of a body, enabling air to circulate more smoothly, avoiding the problem that unsmooth air circulation in a cupboard where the washer is mounted may cause poor heat dissipation of a chamber of the compressor; a guarantee is given to both timely discharge of heat of the chamber of the compressor and reduction of exhaust temperature, thus prolonging life of the compressor.

Owner:HANGZHOU SANHUA RES INST CO LTD

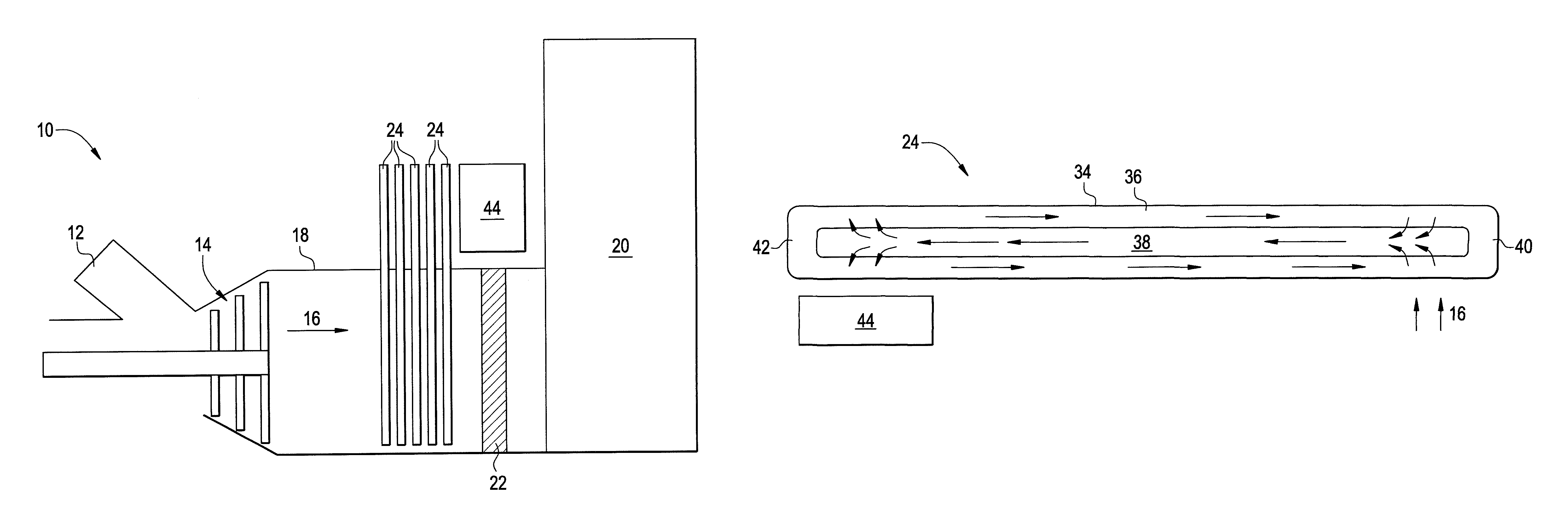

Heat pipe for removing thermal energy from exhaust gas

InactiveUS8596073B2Reduce exhaust temperatureImprove efficiencyInternal combustion piston enginesExhaust apparatusThermal energyExhaust fumes

Disclosed is a turbomachine including at least one exhaust pathway along which exhaust is directed and released, and at least one exhaust processor capable of removing regulated substances from the exhaust. A plurality of heat pipes are disposed at least partially in the exhaust pathway upstream of the at least one exhaust processor. The plurality of heat pipes are capable of transferring thermal energy from the exhaust to the plurality of heat pipes thus reducing a temperature of the exhaust to increase effectiveness of the at least one exhaust processor. A method for releasing turbomachine exhaust includes urging turbomachine exhaust along at least one exhaust pathway and flowing the exhaust past a plurality of heat pipes. Thermal energy is transferred from the exhaust to the plurality of heat pipes thus reducing a temperature of the exhaust.

Owner:GENERAL ELECTRIC CO

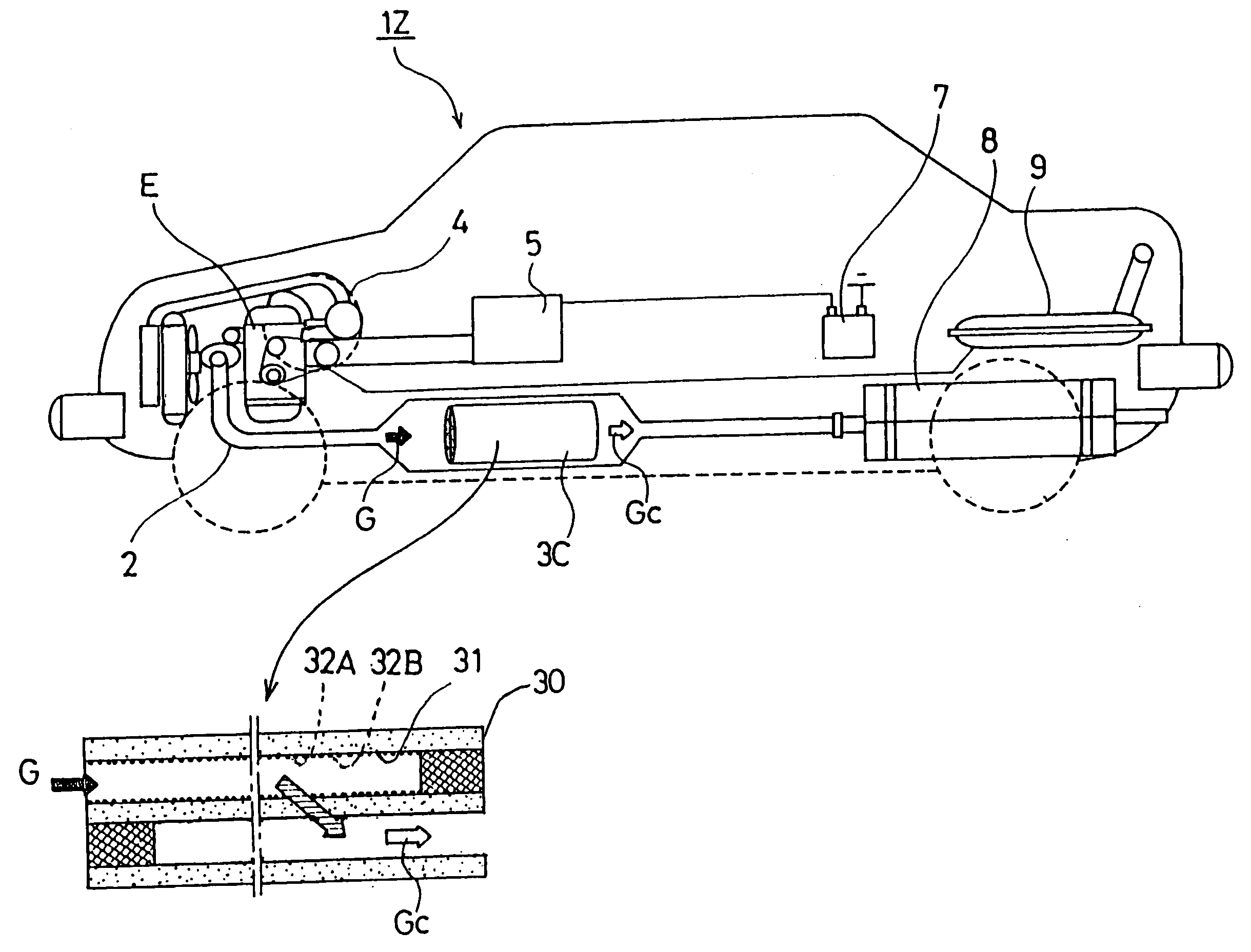

Exhaust gas cleaning system

ActiveUS20060201144A1Improve fuel efficiencyReduce exhaust temperatureElectrical controlInternal combustion piston enginesLower limitCombustion

An exhaust gas purifying system causes less torque fluctuation and is capable of preventing the occurrence of white smoke in a regeneration control operation for regenerating a continuous regeneration DPF 3. When the continuous regeneration DPF 3 with an oxidation catalyst 3Aa on the upstream side of a filter 3Ab is controlled to regenerate, an exhaust throttle valve 31 provided in an exhaust passage 2 is closed and a delay multi-step injection control is performed to increase the temperature of the exhaust gas if an exhaust temperature T1 at the inlet of the oxidation catalyst 3Aa is less than the activation temperature Ta of the oxidation catalyst. After the exhaust temperature T1 at the inlet of the oxidation catalyst 3Aa has risen to the activation temperature Ta of the oxidation catalyst or higher, the exhaust throttle valve 31 is opened in a stepwise or continuous manner so that the exhaust temperature T2 at the inlet of the filter 3Ab rises to a lower limit temperature of PM forced combustion Tb1 or higher.

Owner:ISUZU MOTORS LTD

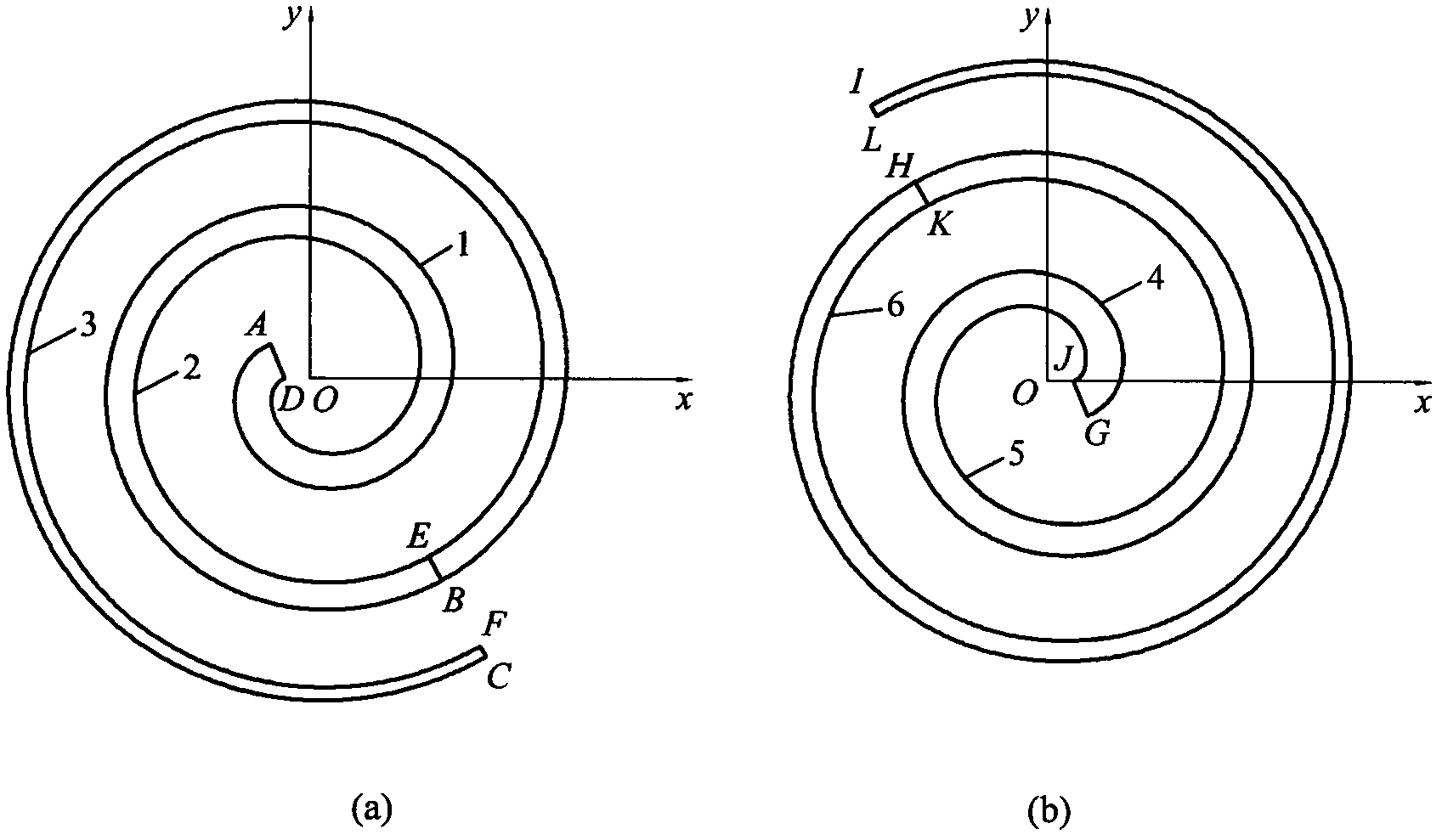

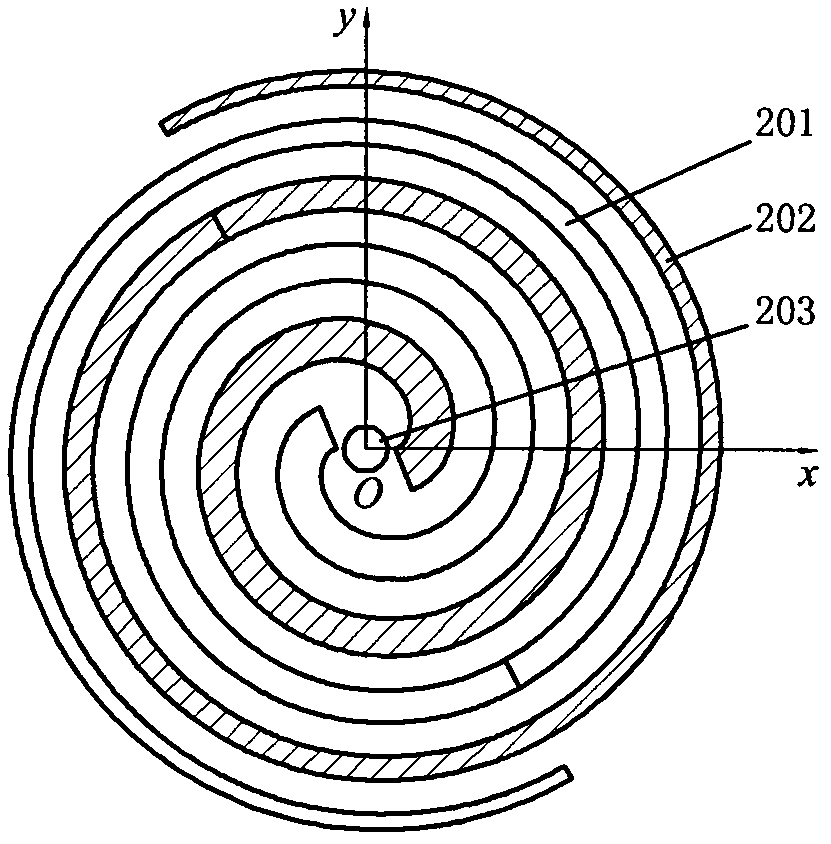

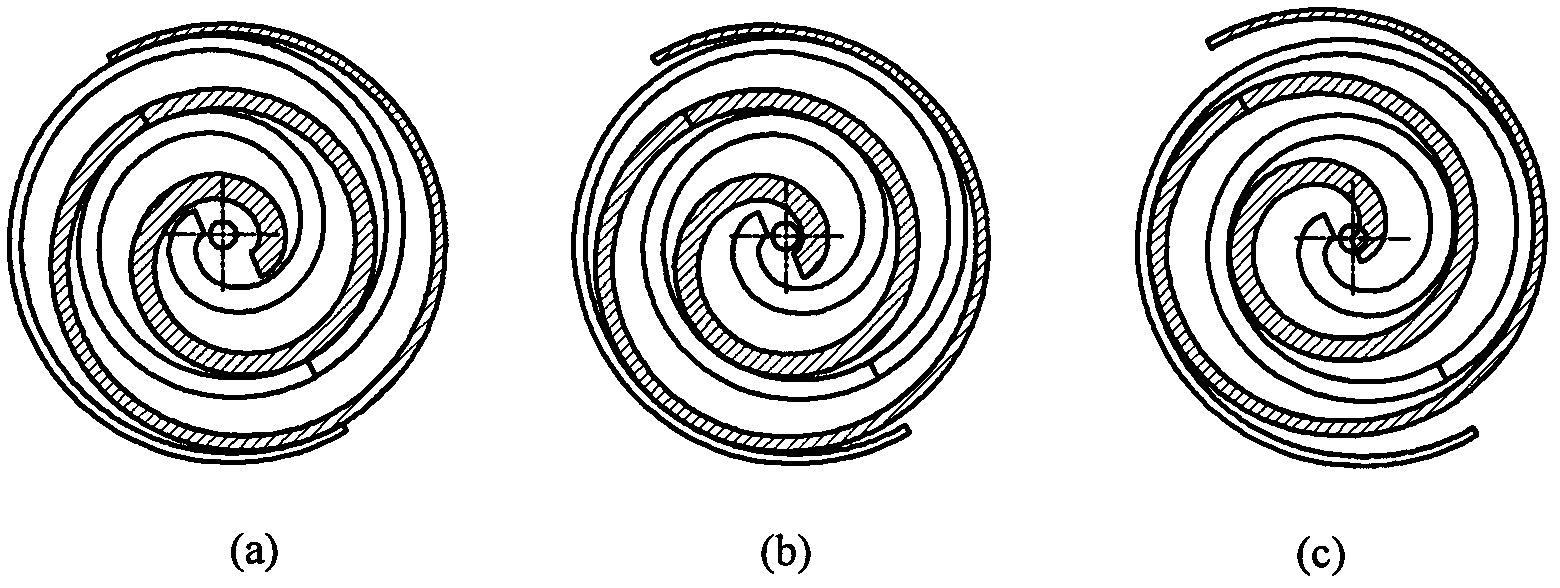

Scroll wrap profile of liquid-injected scroll compressor

InactiveCN103047135AStrong enoughExtended service lifeRotary piston pumpsRotary piston liquid enginesInvoluteEngineering

The invention relates to a scroll wrap profile of a liquid-injected scroll compressor. Outer profiles of a static scroll wrap and a dynamic scroll wrap are composed of a section of a variable diameter base circle involute, and the inner profiles of the static scroll wrap and the dynamic scroll wrap are composed by smoothly connecting a variable diameter base circle involute at a center part and normal equidistant curves of the variable diameter base circle involute of the outer ring. The scroll wrap refers to a scroll wrap with compression chamber variational meshing clearance and the wall thickness of the scroll wrap changing gradually. The meshing part close to a central air outlet of the compression chamber is provided with the meshing clearance which forms a pressure unloading channel to the air outlet with small clearance internal leakage, so that the problems of surge pressure in the compression chamber or liquid impacting which are produced by incompressible liquid with relatively large spraying volume. The meshing point of a suction cavity formed by the scroll wrap has no meshing clearance, so that the suction cavity is completely isolated from the compression chamber; at the same time, the wall thickness of the scroll wrap changes thinner gradually from the center to the outer ring, so that the central part of the scroll wrap has enough strength; and the wall thickness at the outer ring of the scroll wrap is relatively thin, so that area utilization rate of a scroll plate is effectively increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

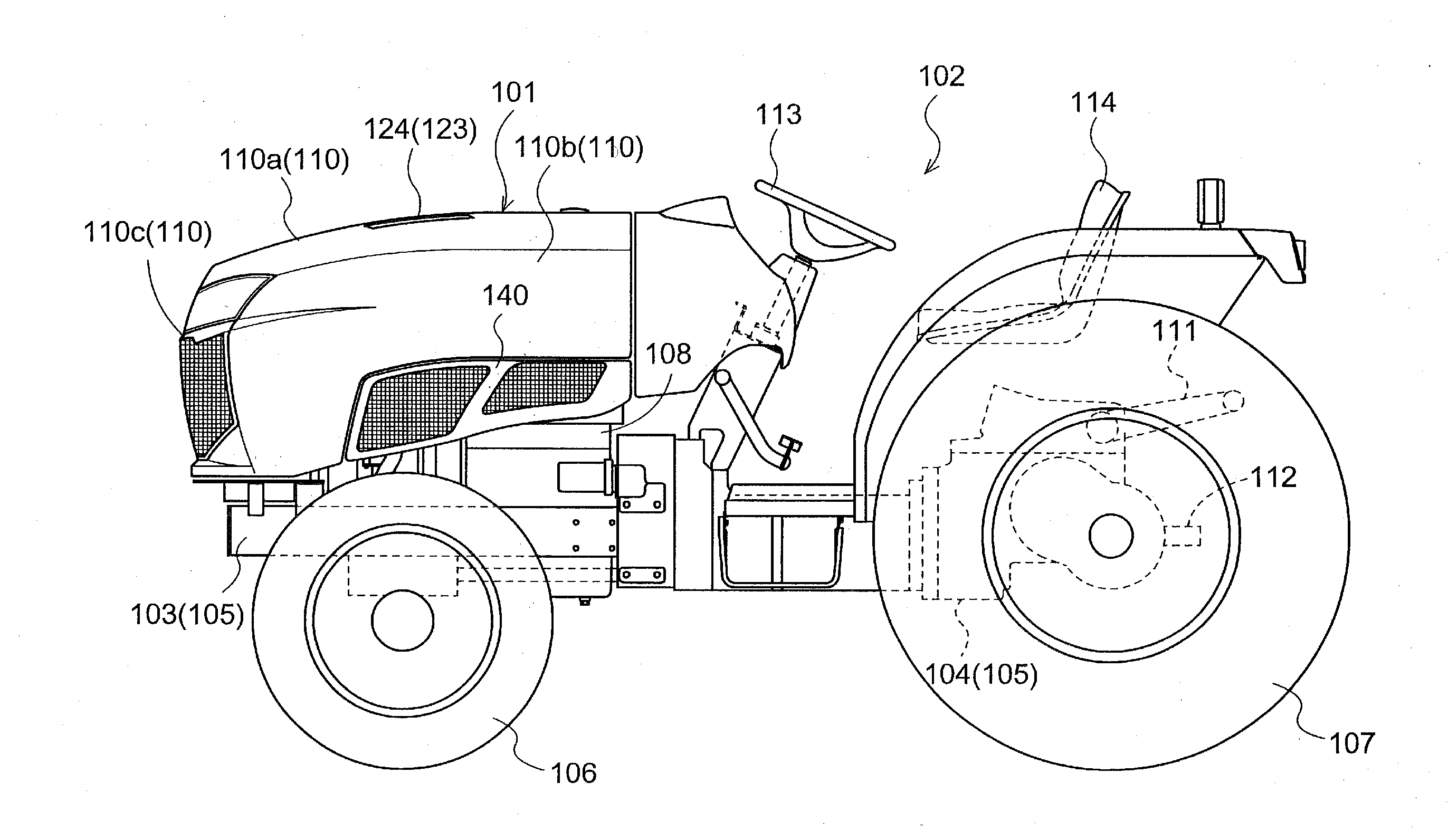

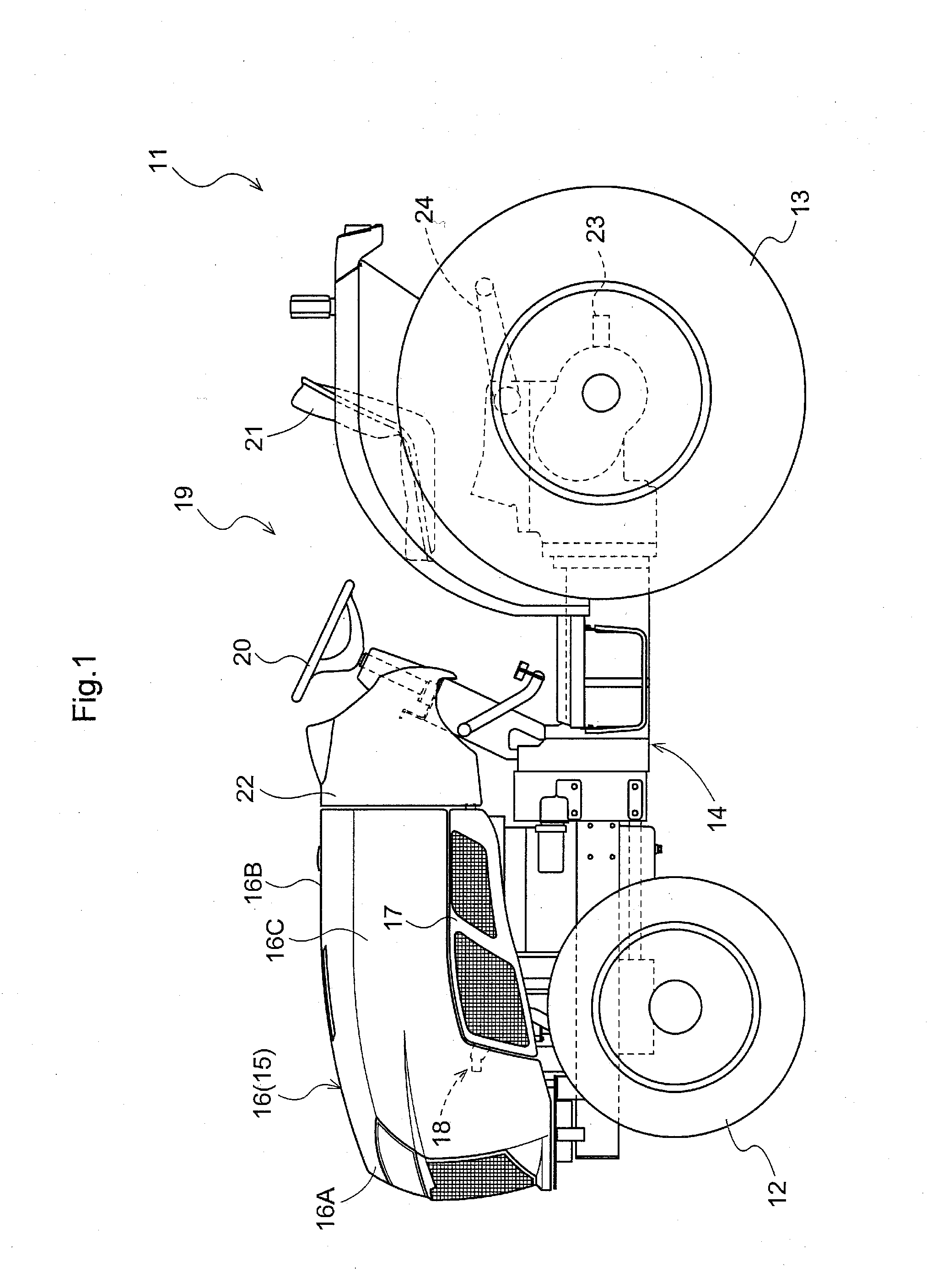

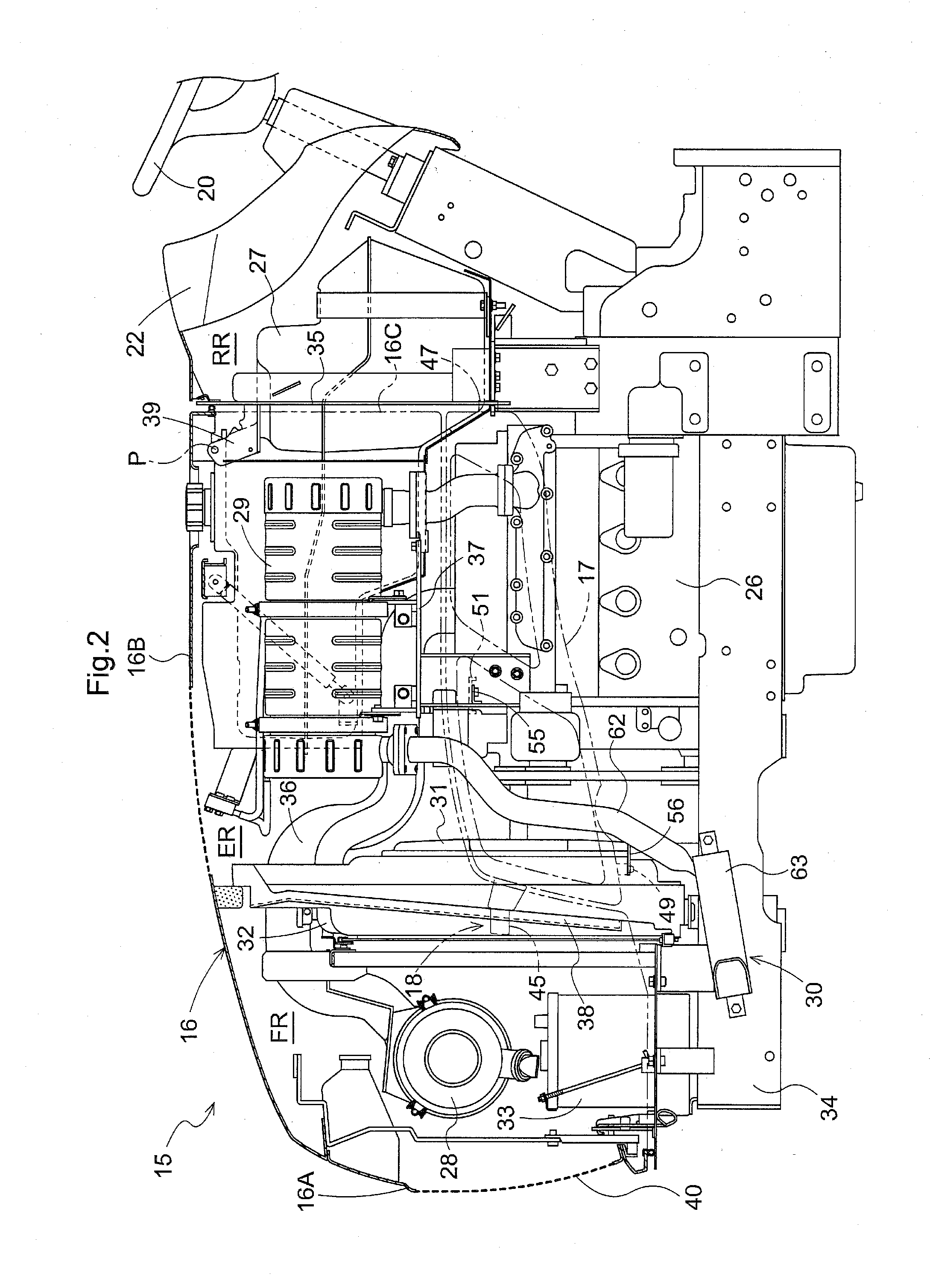

Working Vehicle

ActiveUS20140251713A1Increase temperatureLower exhaust gas temperatureSuperstructure subunitsVehiclesEngineeringMechanical engineering

A working vehicle includes a traveling machine assembly, a drive unit, a bonnet configured to cover the drive unit, and a cover provided below the bonnet and configured to be removably attached to the traveling machine assembly, including a main body portion extending in a longitudinal direction of the traveling machine assembly, a first male engagement portion provided at a front end portion of the main body portion, a second male engagement portion provided at a rear end portion of the main body portion, and a third male engagement portion provided at a lower end portion of the main body portion.

Owner:KUBOTA LTD

Air conditioner used in high-temperature environment and control method

InactiveCN102889641AGuaranteed cooling efficiencyGuarantee job stabilitySpace heating and ventilation safety systemsSpace heating and ventilation control systemsEngineeringRefrigerant

The invention discloses an air conditioner used in a high-temperature environment and a control method. The air conditioner comprises a compressor, a condenser, a first throttling valve, an evaporator, a refrigerant circulating pipe and a liquid refrigerant spraying loop pipe, wherein the compressor, the condenser, the first throttling valve and the evaporator are sequentially connected with one another end to end through a refrigerant circulating pipe, so that a closed refrigerant circulating channel is formed; one end of the liquid refrigerant spraying loop pipe is communicated with a refrigerant circulating pipe between the condenser and the throttling valve; and the other end of the liquid refrigerant spraying loop pipe is communicated with a refrigerant circulating pipe between the evaporator and the compressor. The liquid refrigerant spraying loop pipe is used for mixing liquid refrigerant flowing from the condenser with gas refrigerant evaporated by the evaporator so as to reduce the air suction temperature of the compressor. Along with reduction of the air suction temperature of the compressor, the temperature of a motor in the compressor is reduced, the air exhaust temperature of the compressor is also reduced, so that the compressor can stably work in the high-temperature environment, and the refrigerating efficiency of the air conditioner is greatly improved.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

High temperature self-adaption separated air conditioners

InactiveCN1645016AImprove flow coefficientHigh trafficMechanical apparatusSpace heating and ventilation safety systemsDecreased pressureHigh pressure

A high temperature self-adapting air conditioner comprises a refrigerating circle which is composed by a compressor, a condenser, main capillary, an evaporator. The refrigerating circle is parallel connected by a subsidiary throttle sidecut which is composed by a filter, an unloading valve and subsidiary capillary. Due to the subsidiary throttle sidecut, upon the side condenser's pressure exceeds the safety limit, the unloading valve opens and the subsidiary sidecut got through; then the flux index of the capillary will be increased, refrigerant flux will be increased; then lower down the pressure of the condenser; then the compressor will be protected for a continuous running.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com