Patents

Literature

330 results about "Decreased pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

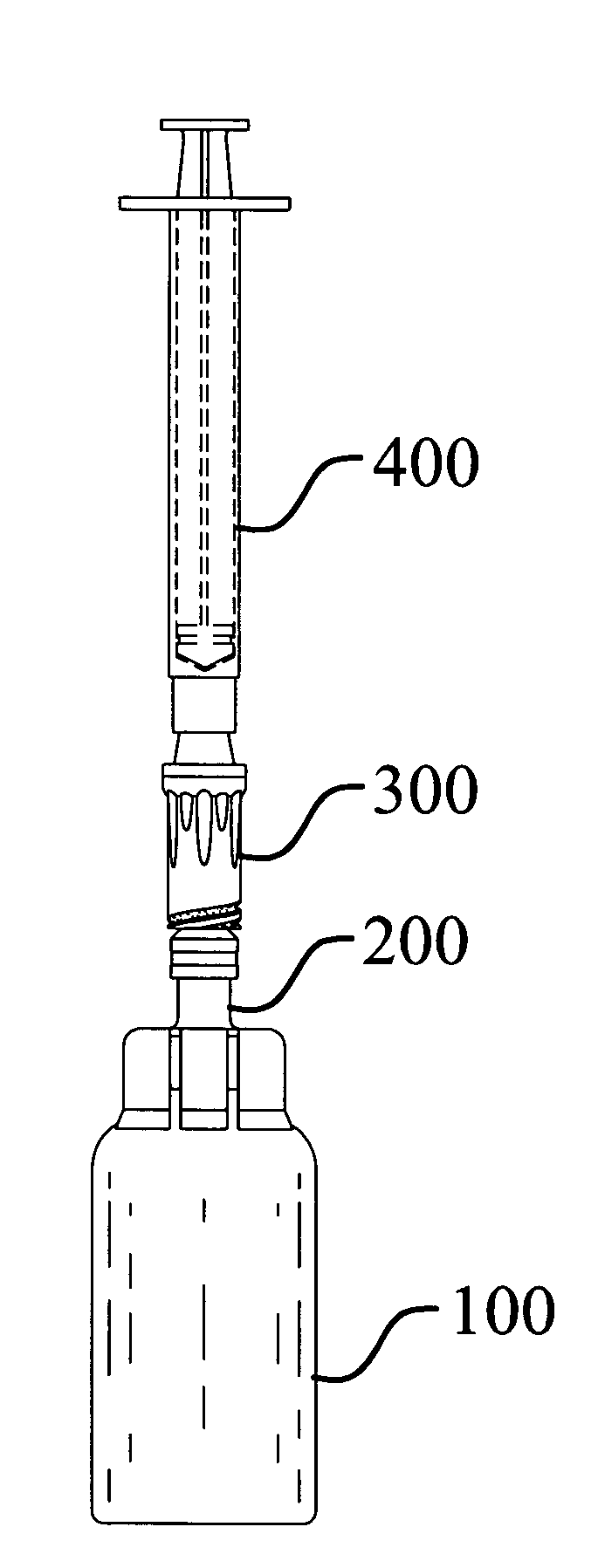

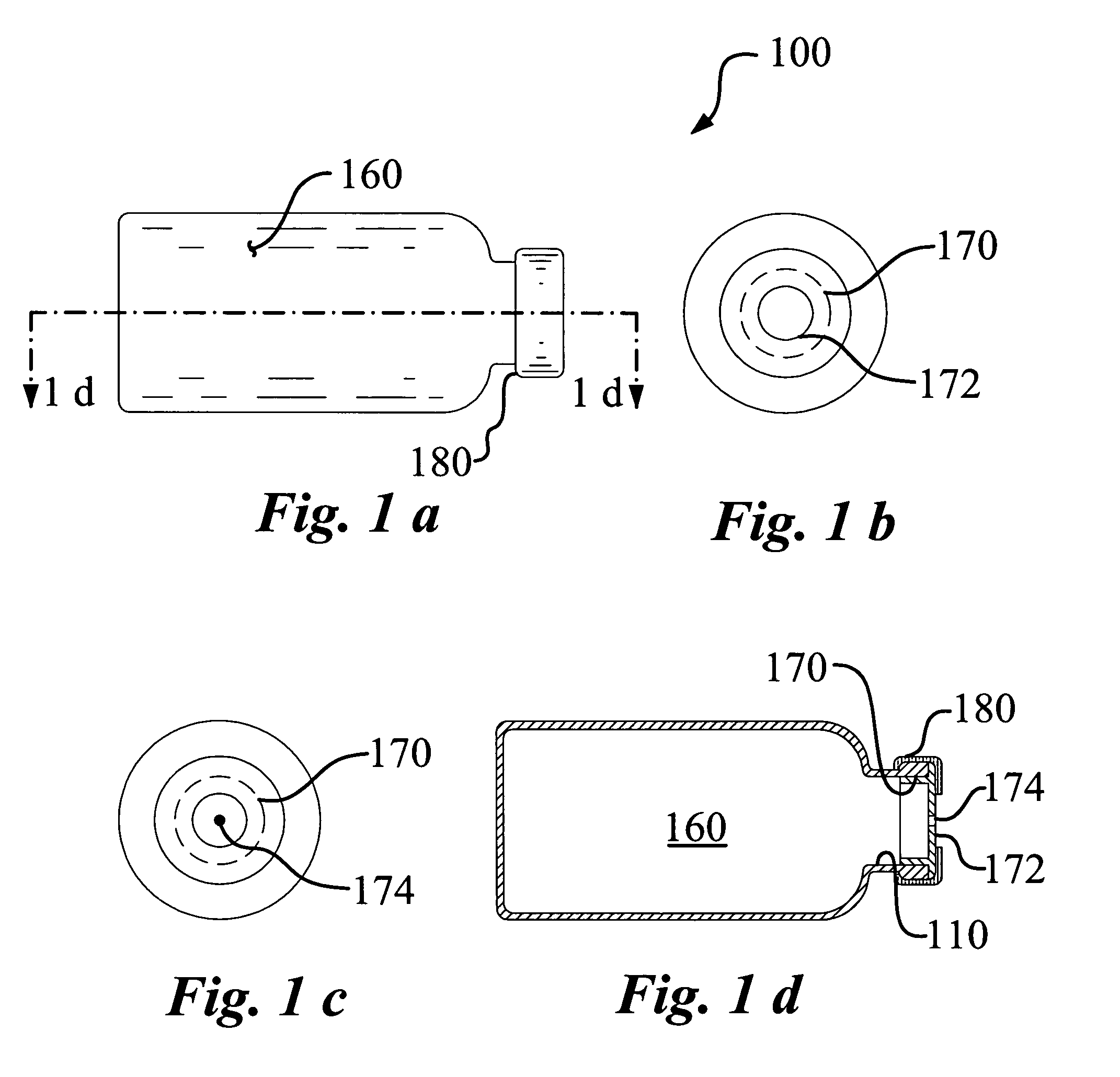

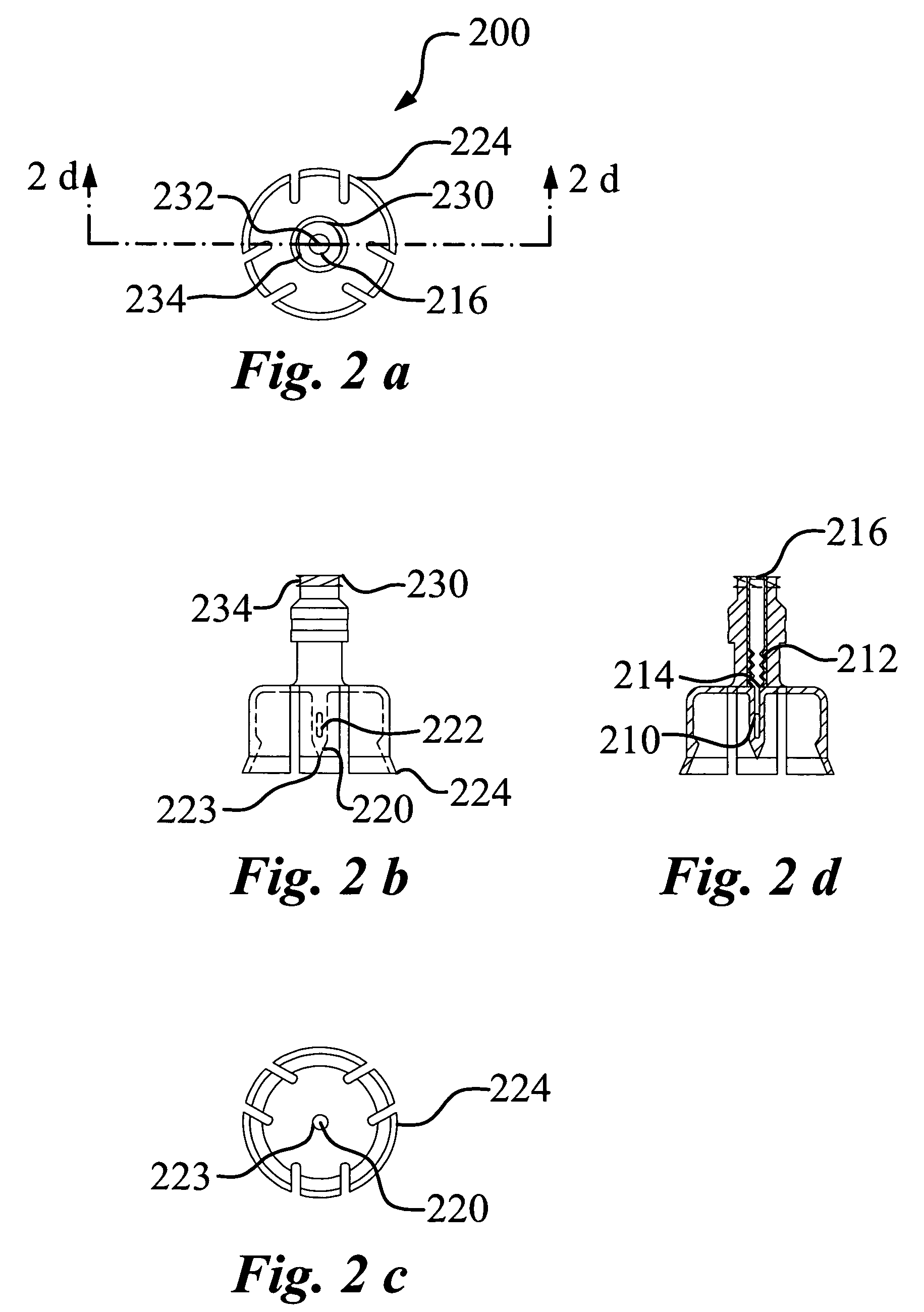

Method and apparatus for the handling of a radiopharmaceutical fluid

An apparatus for the handling of hazardous fluids includes a collection vessel, a collection vessel connector, a dose control connector, a unit dose container, a delivery control connector, and a delivery site access device. The collection vessel contains the fluid prior to dispensing, the unit dose container contains a predetermined amount of the fluid for dispensing, the delivery site access device provides access to an intended delivery site, and the connector attaches pieces of the apparatus to one another. The method of the invention allows needle-free connections to be made for the apparatus, using a predetermined arrangement of the pieces of the apparatus, and in one embodiment, employs deformable elastomeric valves capable of creating a decreased pressure at a valve surface, so that upon closure of said valves, a fluid on the surface on the valves is withdrawn within the connector.

Owner:CARDINAL HEALTH INC

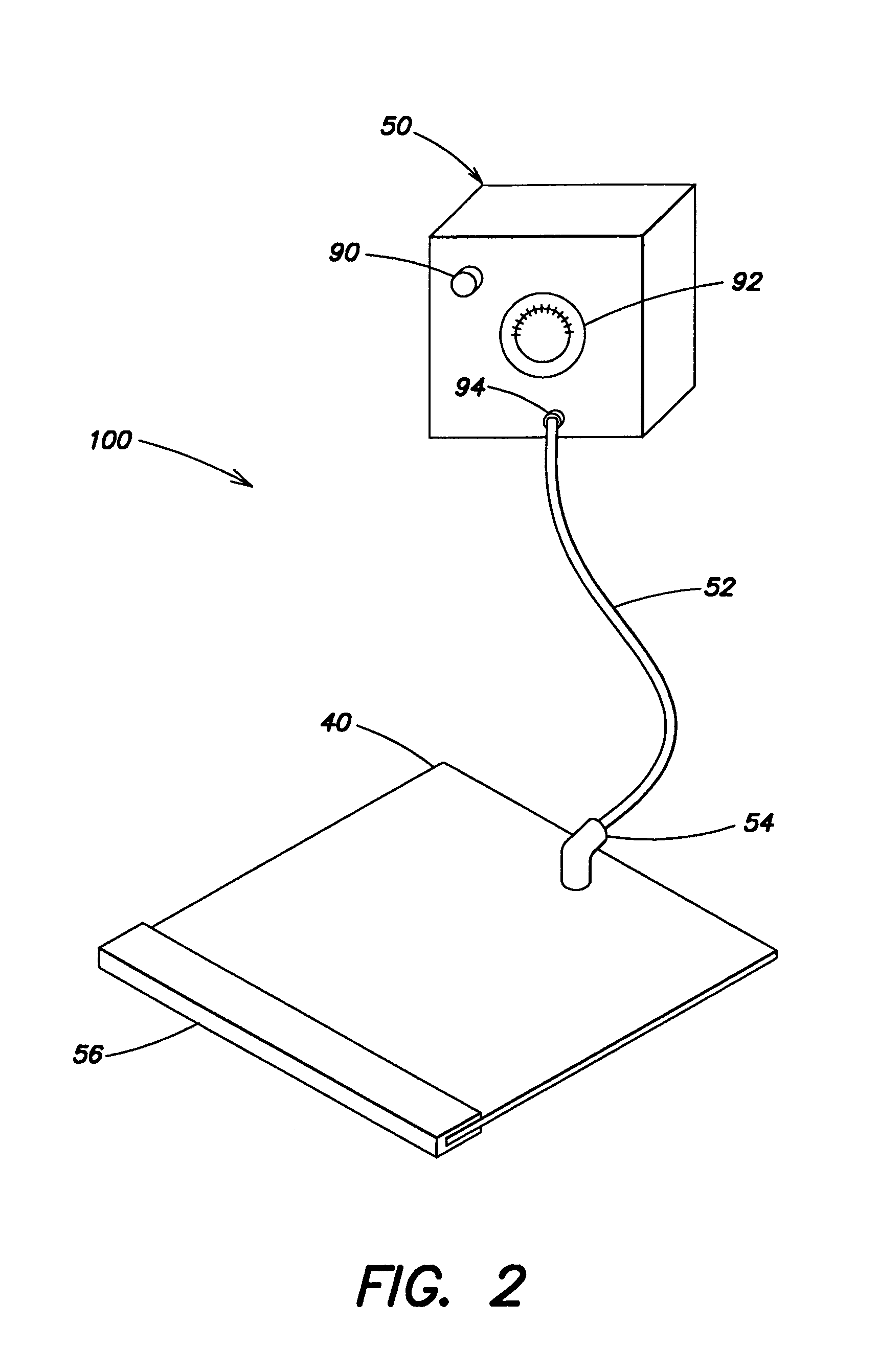

Sensor equilibration and calibration system and method

InactiveUS6993954B1Ease of evacuationWeighing apparatus testing/calibrationFluid pressure measurementDecreased pressureEngineering

Owner:TEKSCAN

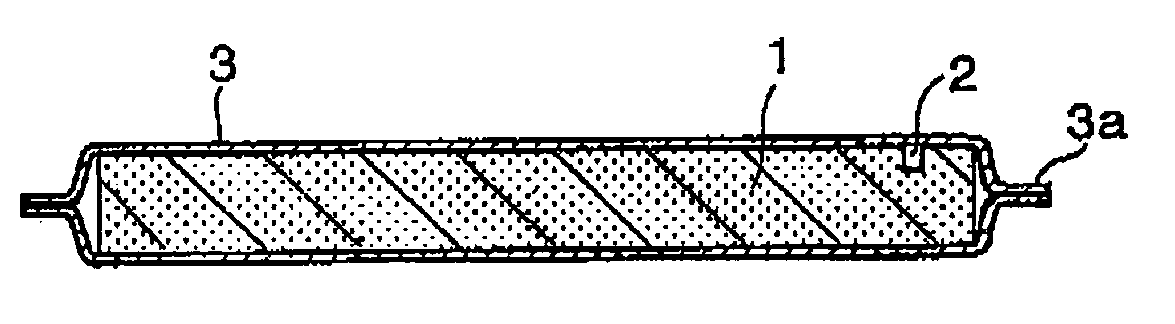

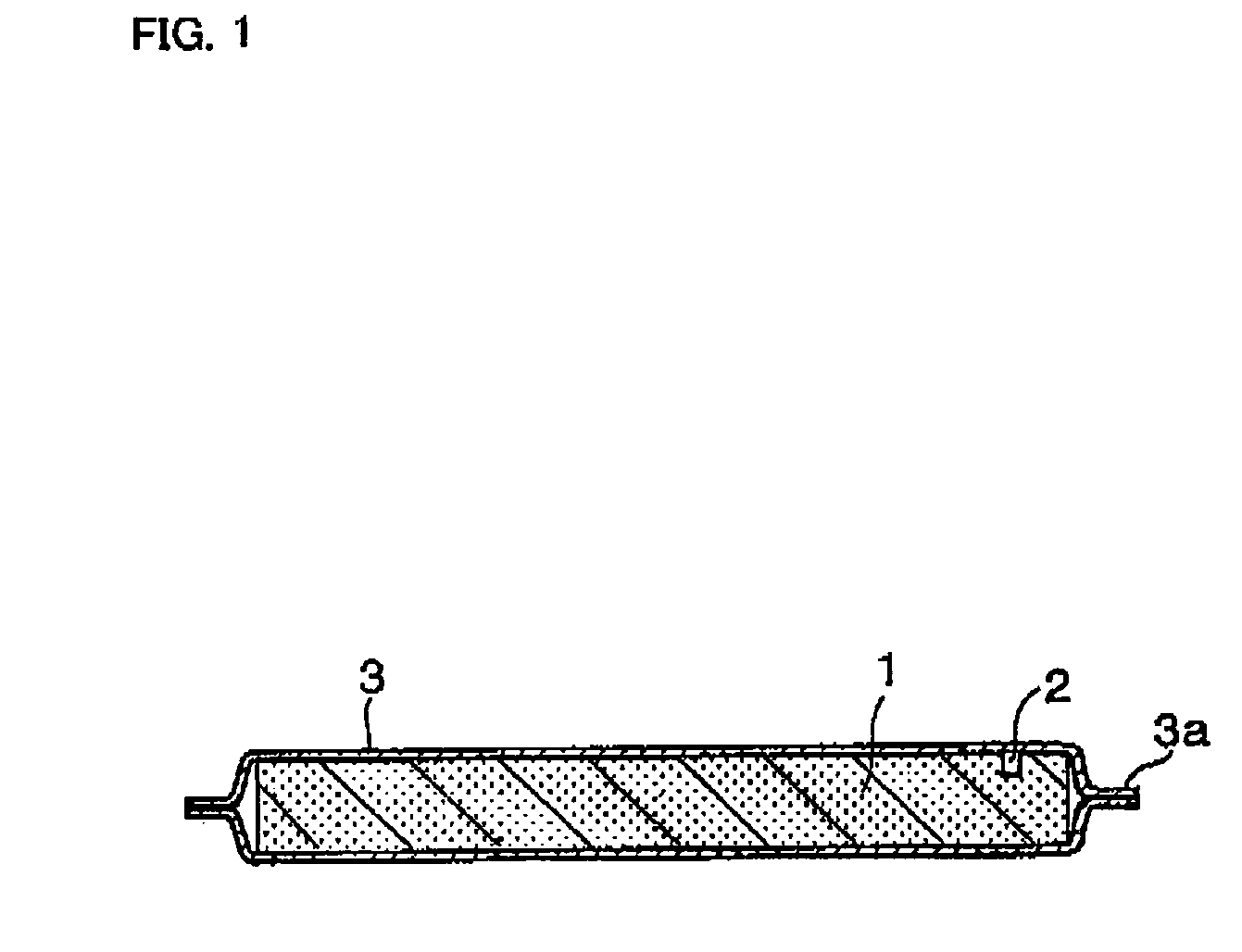

Vacuum heat insulating material and manufacturing method therefor

InactiveUS20040253406A1Improve performanceLow thermal conductivityThermal insulationDomestic cooling apparatusSorbentDecreased pressure

Provided is a vacuum heat insulating material, using inorganic fibers as a core material, high in heat insulating performance (low in thermal conductivity), capable of maintaining the heat insulating performance for a long period, free of defects such as projections and depressions on a large scale on a surface thereof, short in manufacturing time and advantageous in terms of cost; and a manufacturing method therefor. A vacuum heat insulating material of the present invention is of a construction in which a core material 1 and a gas adsorbent 2 are housed in a bag 3 made from a gas barrier film and the interior thereof is reduced in internal pressure thereof and air-tightly sealed, wherein the core material 1 is a molded product obtained by coating a binder B on inorganic fibers having an average fiber diameter in the range of from 3 to 5 mum at a coating amount in the range of from 0.5 to 1.5 wt % relative to the fibers and heat pressing the inorganic fibers, or a laminate fabricated by stacking two or more sheets of the molded product.

Owner:ASAHI FIBER GLASS CO LTD

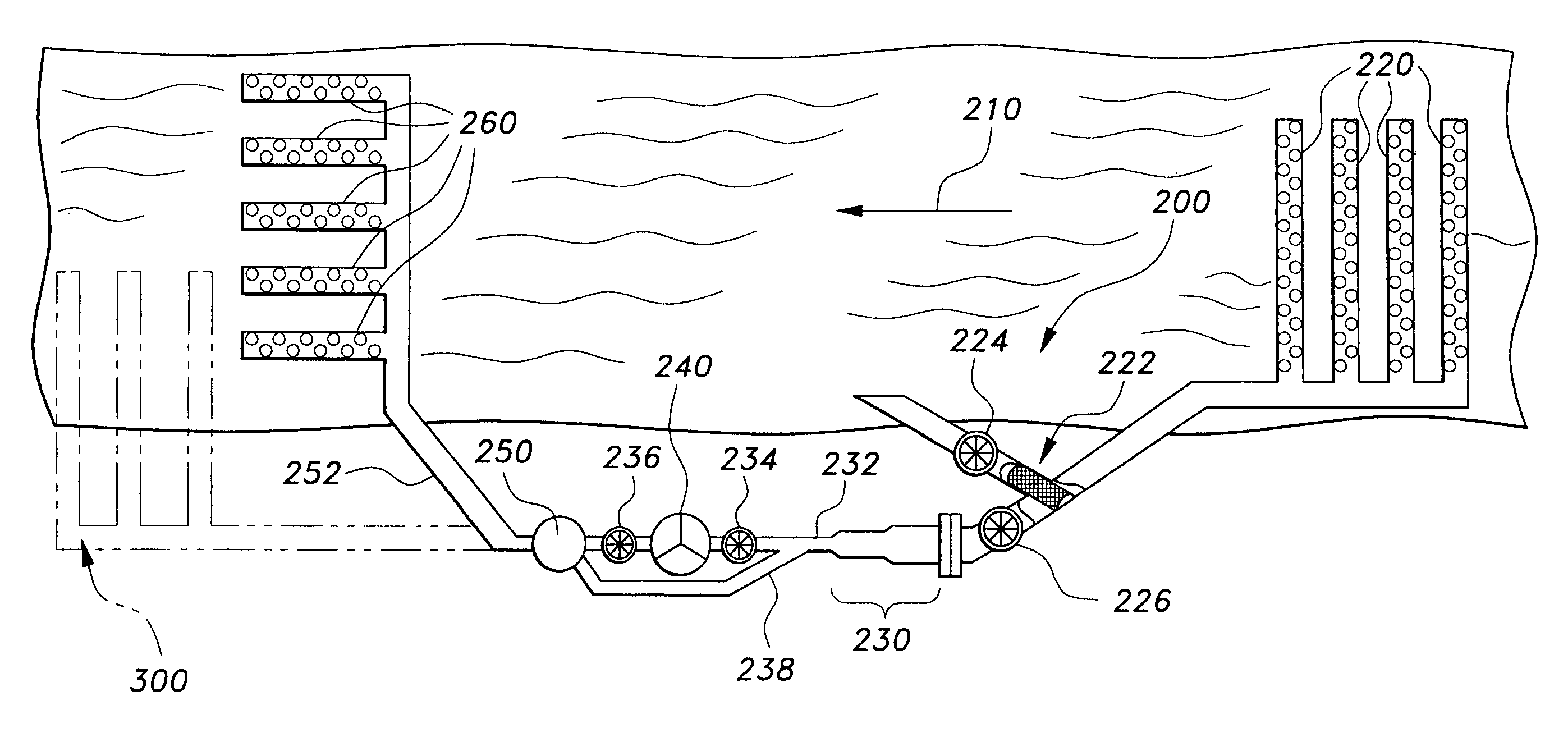

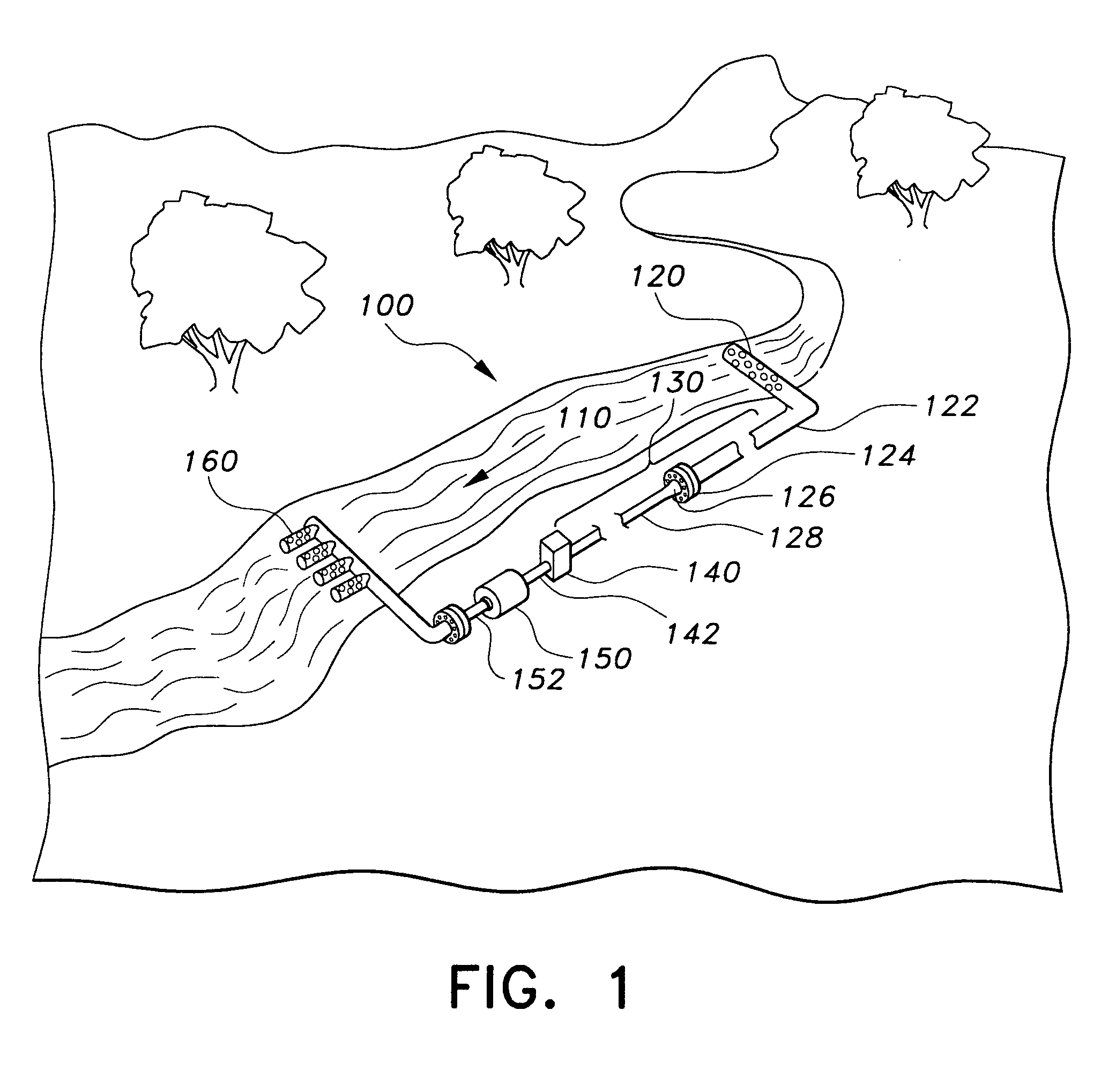

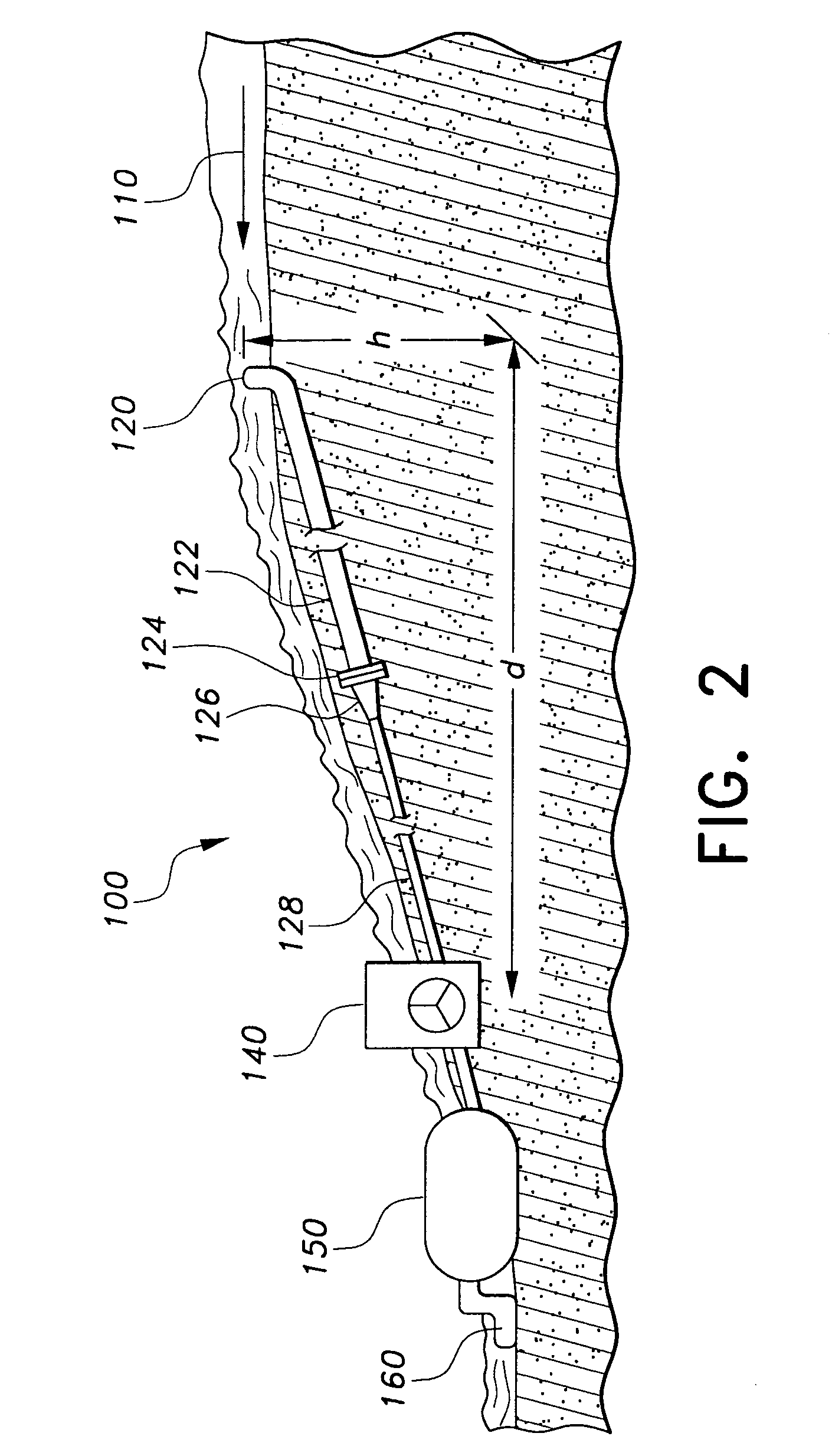

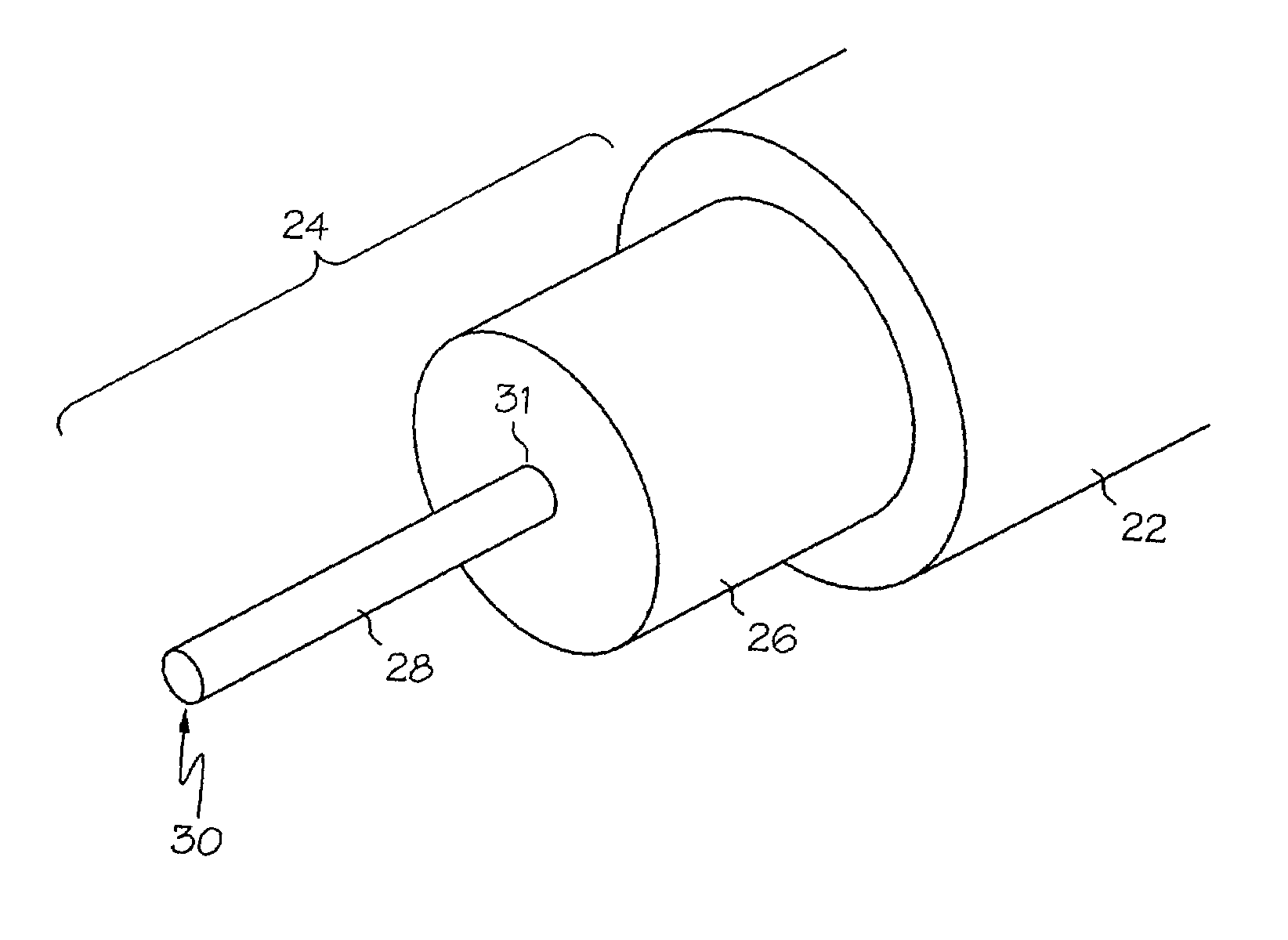

Method and apparatus for generating hydro-electric power

ActiveUS7084521B1Small sizeSmoother power generationMachines/enginesEngine componentsElectricityElectric power system

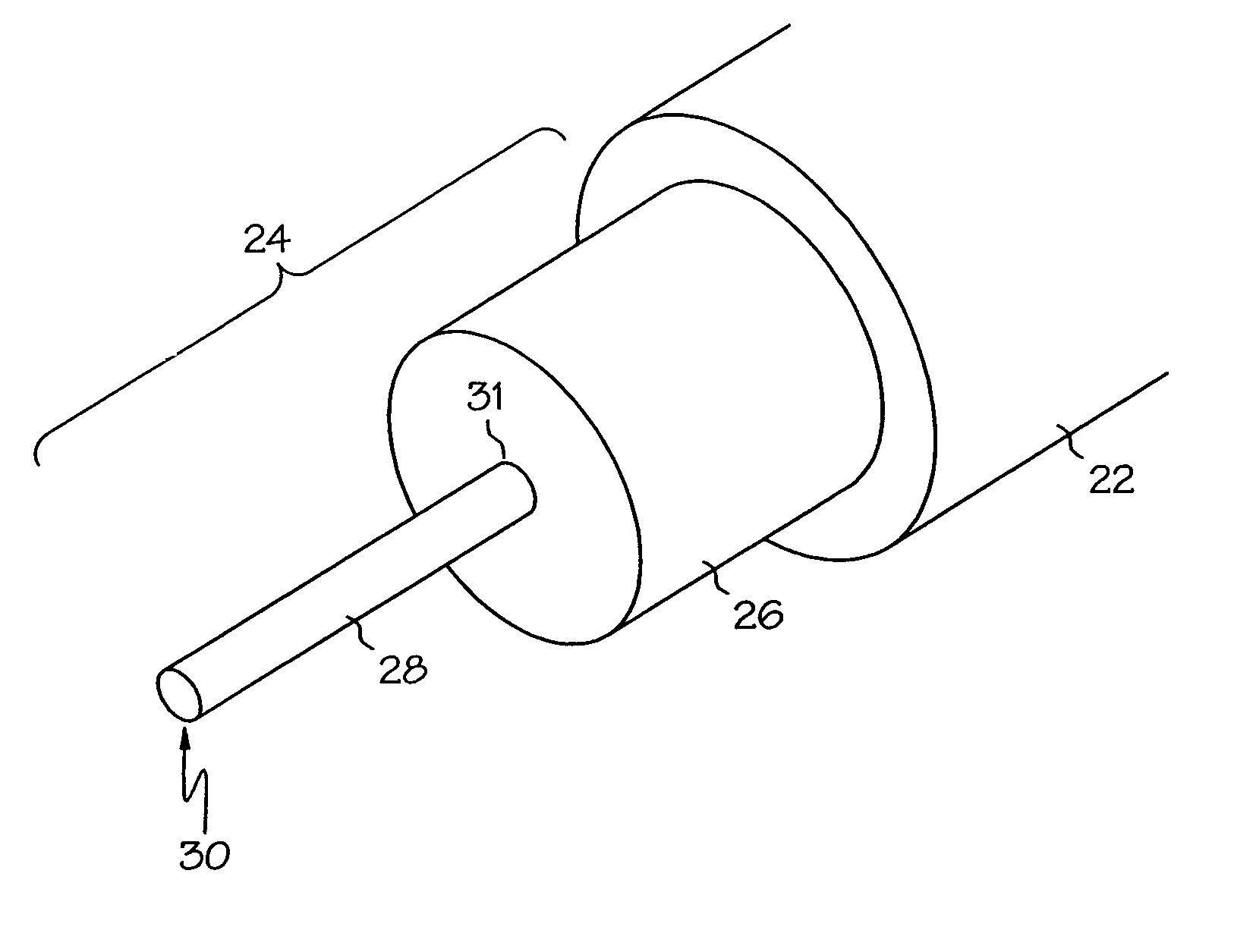

A hydroelectric power generating method and / or apparatus provides one or more inlet pipes perpendicular to a flow of water in a stream or river. The inlet pipes have a length and plural apertures along the length of the at least one inlet pipe. A feedline and a turbine generator combination are interconnected with the inlet pipes. One or more outlet pipes are interconnected with the feedline and the turbine generator combination. The outlet pipes have an elevation lower than the inlet pipe. A flow of water passes through the inlet pipes, the feedline, the turbine generator combination, and the outlet pipes, and generates electricity from the flow of water passing through the turbine generator combination. The hydroelectric power generating method also provides a pressure dissipation device that causes a reduction in the pressure of the water so that the water can be released safely back into the stream or river.

Owner:MARTIN GERALD G

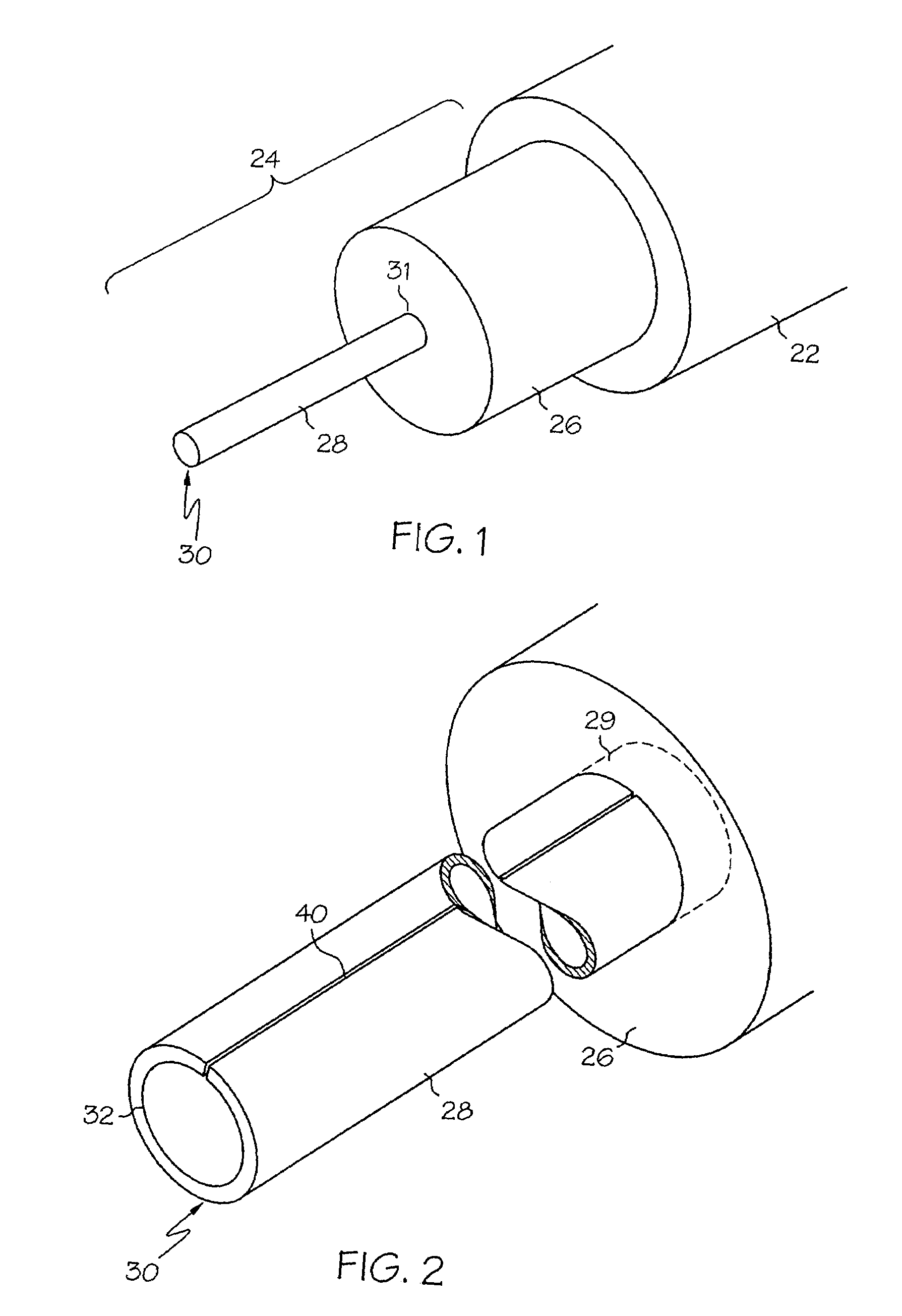

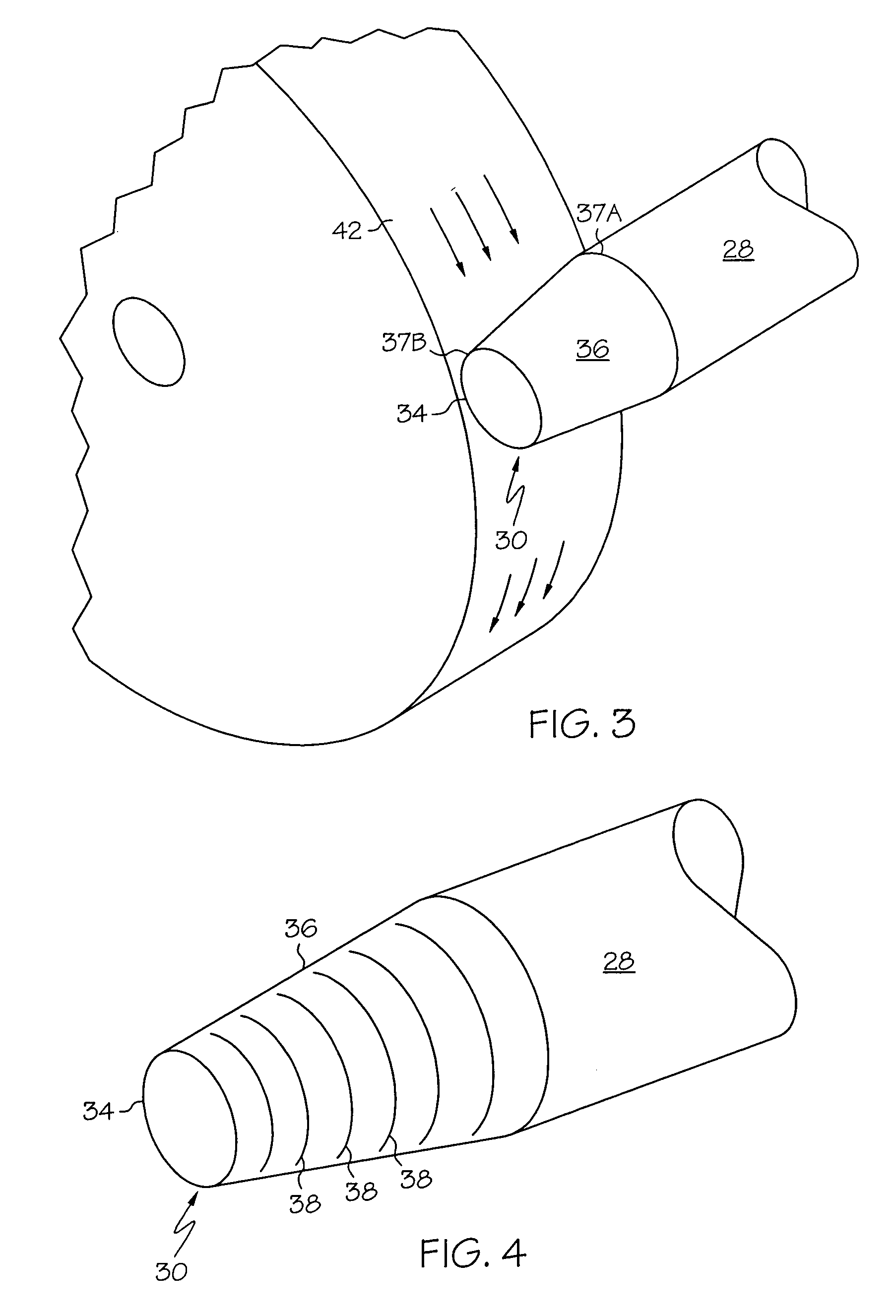

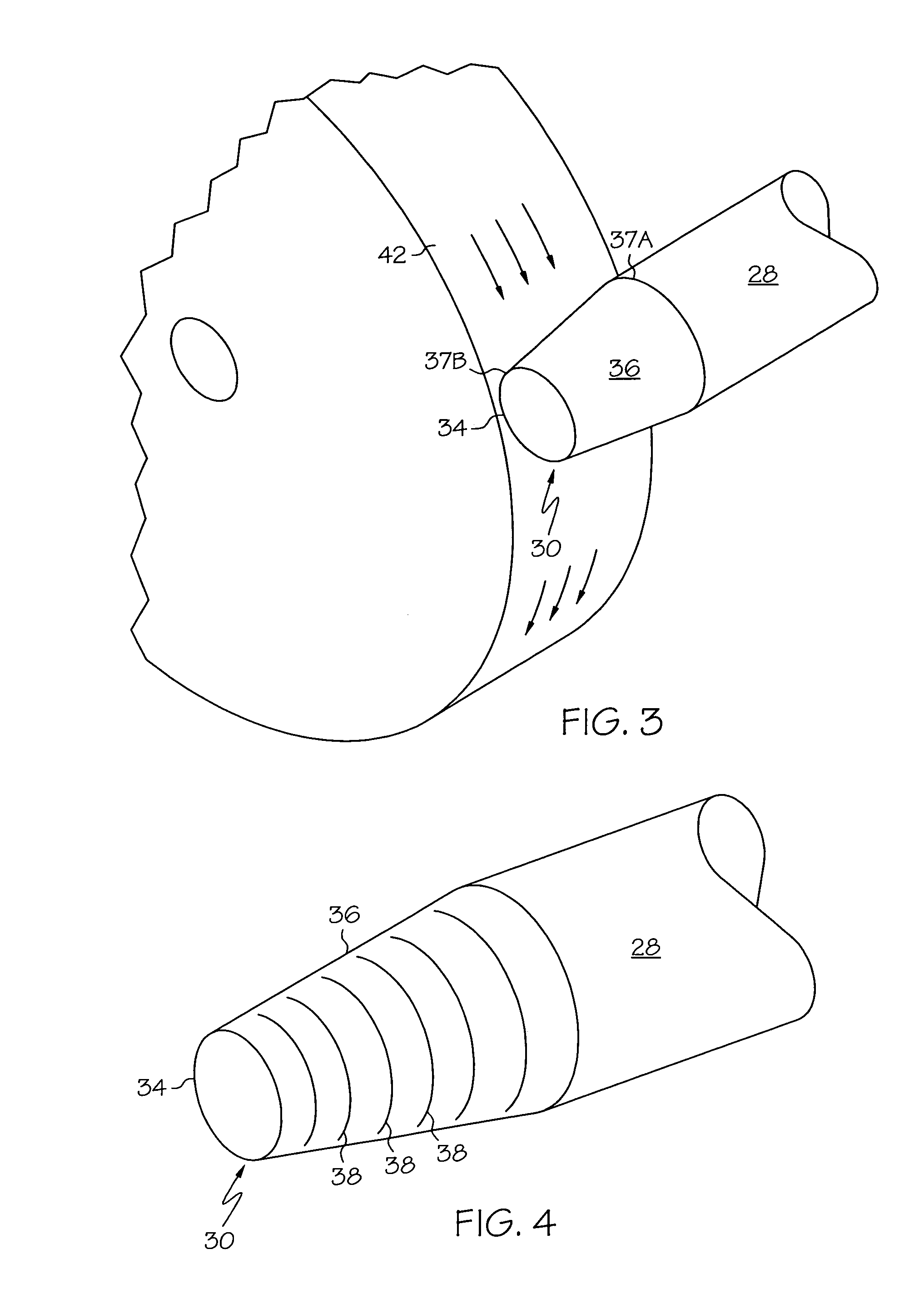

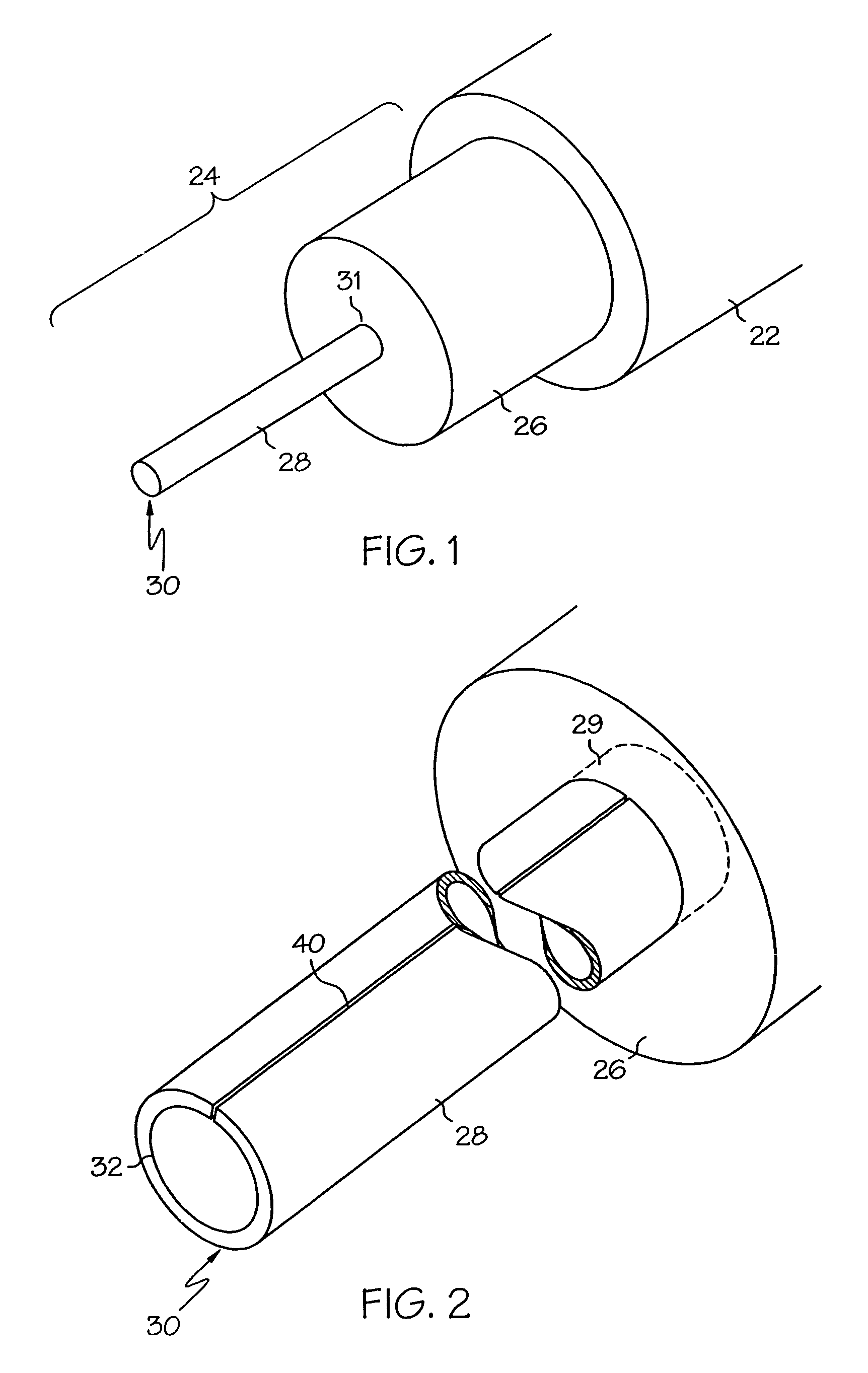

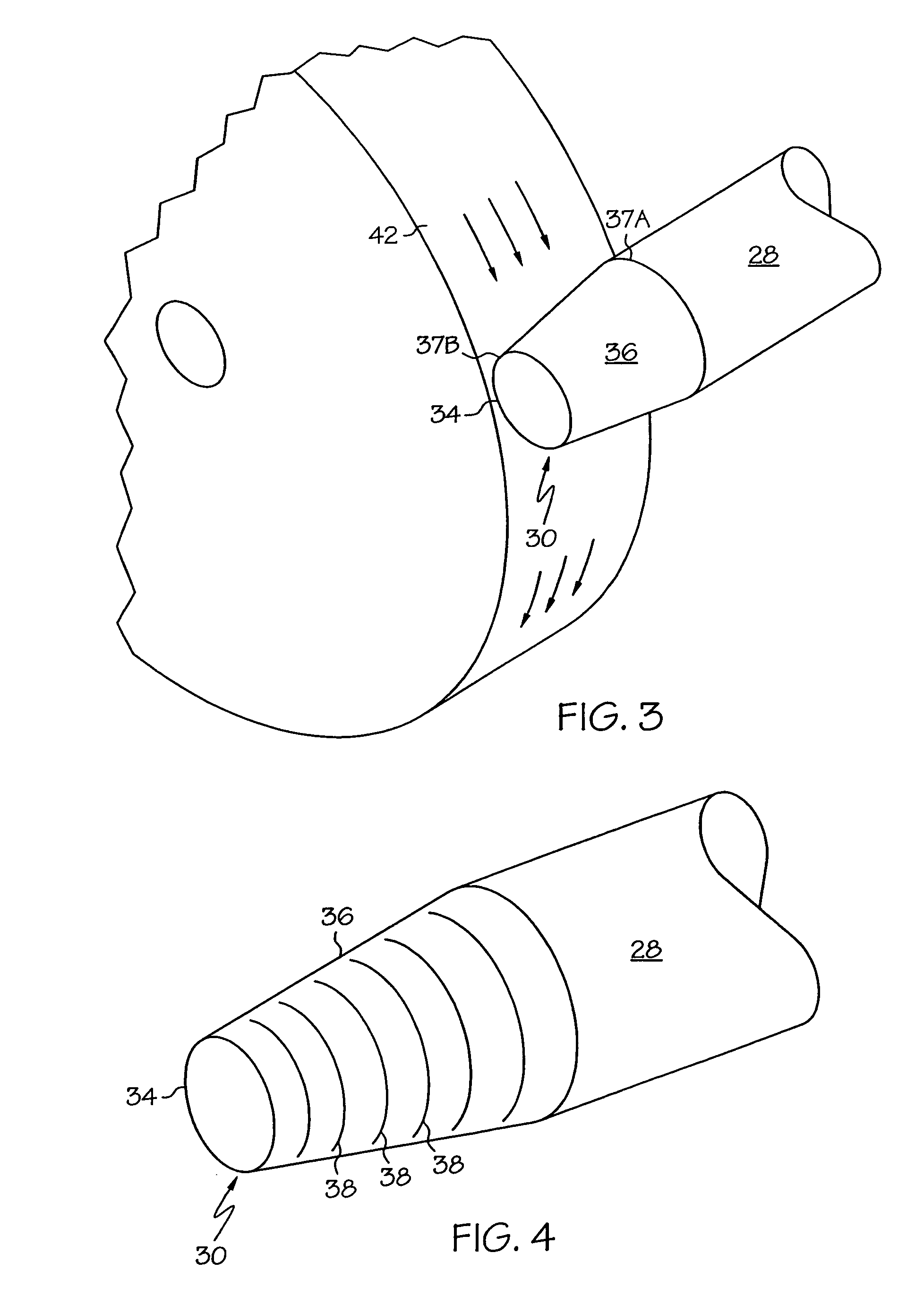

Fluid dispense tips

InactiveUS6981664B1Further-reduced surface tensionIncreased dispensing precision capabilityLiquid surface applicatorsClosuresDecreased pressureBiomedical engineering

A fluid dispense tip includes a bevel at an opening to reduce the amount of surface tension, or “land”, at the opening. The bevel is formed by grinding in a longitudinal direction such that any tooling scars resulting from the grinding operation are likewise longitudinally oriented, further reducing the amount of surface tension in the tip, thereby leading to heightened dispensing accuracy. The tip may be machined from stock as a unitary piece, to increase its lifetime, and may be formed with a bore of a relatively large diameter that is tapered down to a smaller diameter near the tip opening, to allow for delivery of fluid through the tip body at a decreased pressure. The tip may optionally be formed with a Luer™-style fitting on the body, such that the tip is compatible with pumps that utilize such a fitting.

Owner:DL TECH

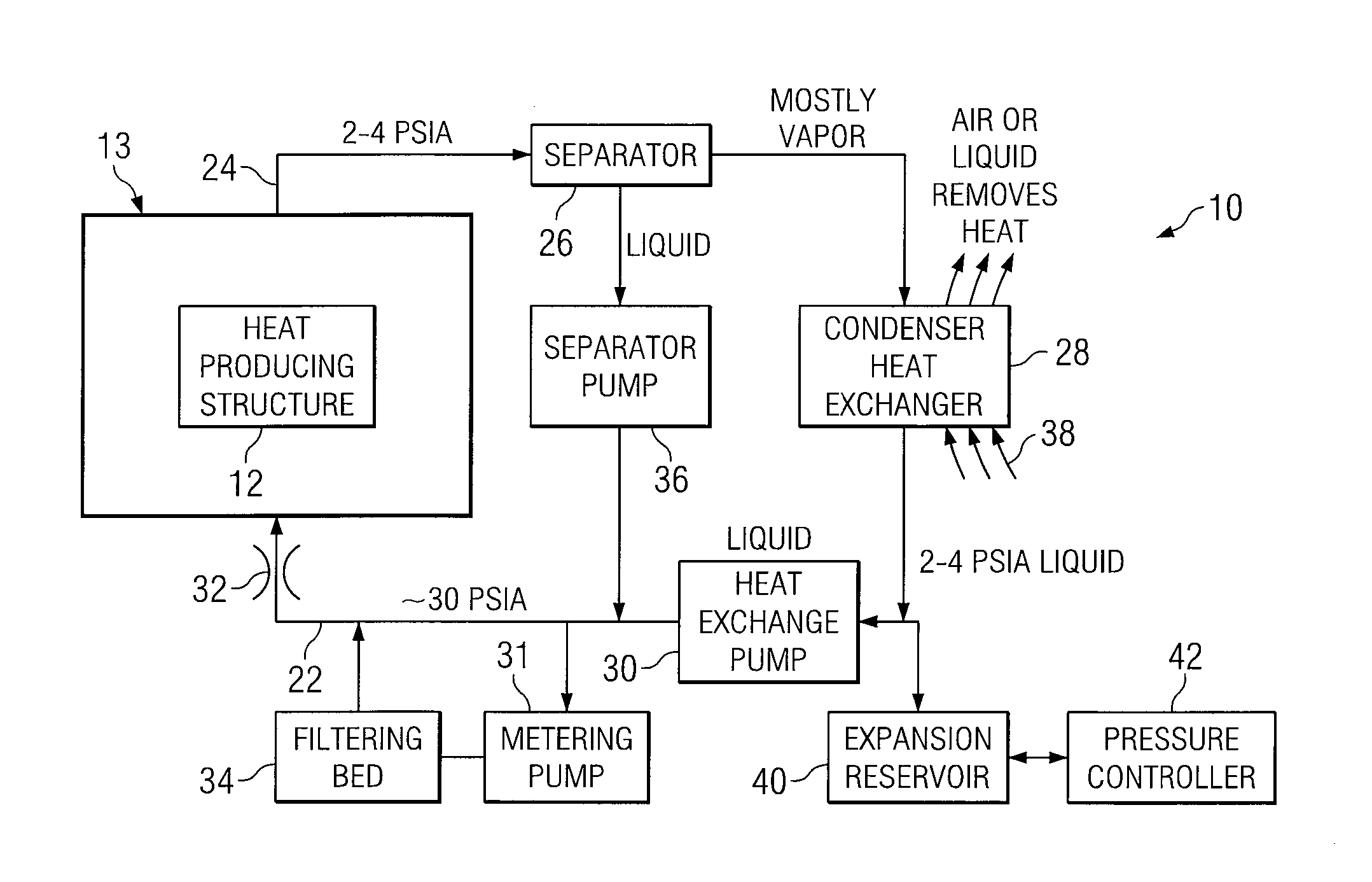

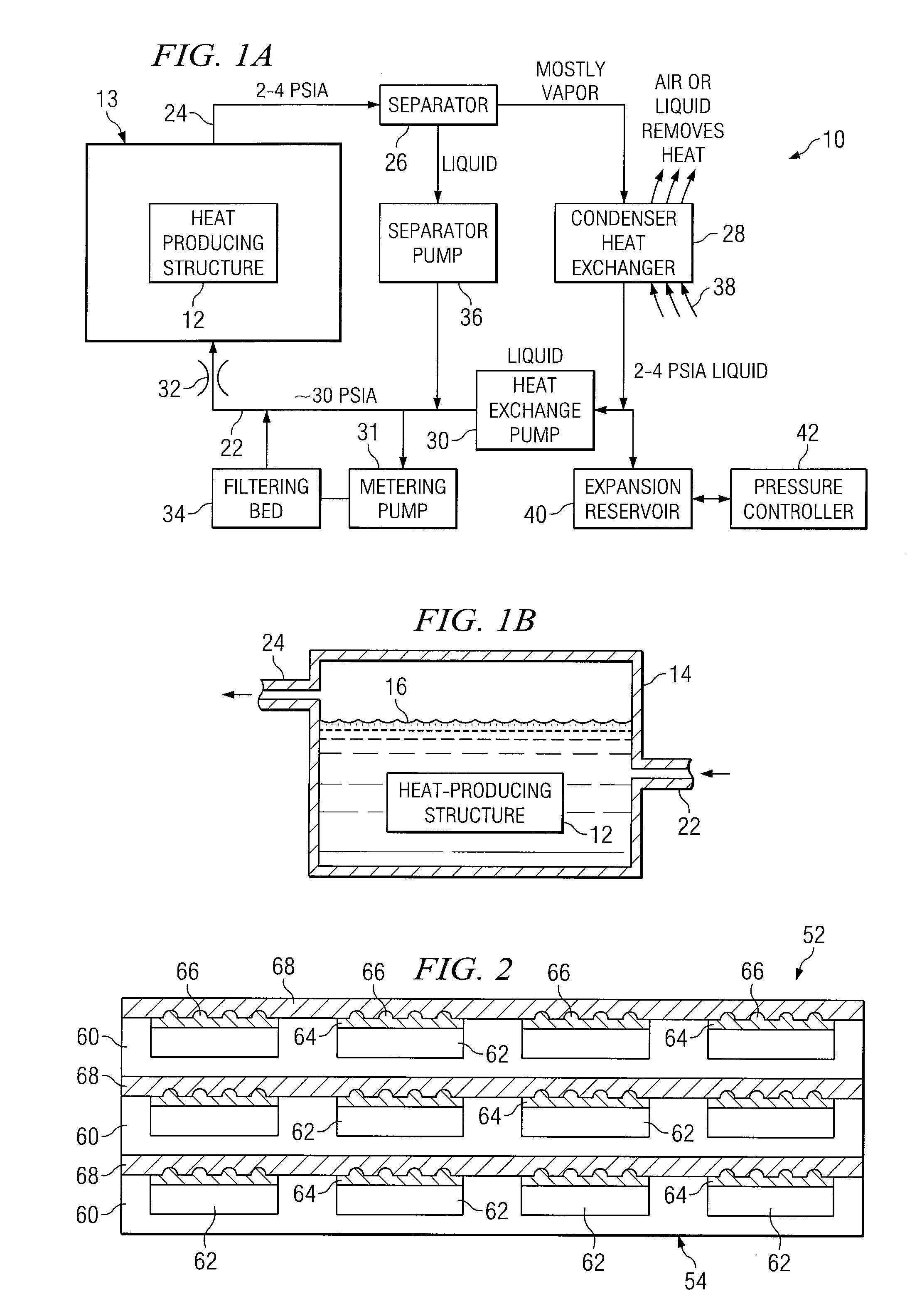

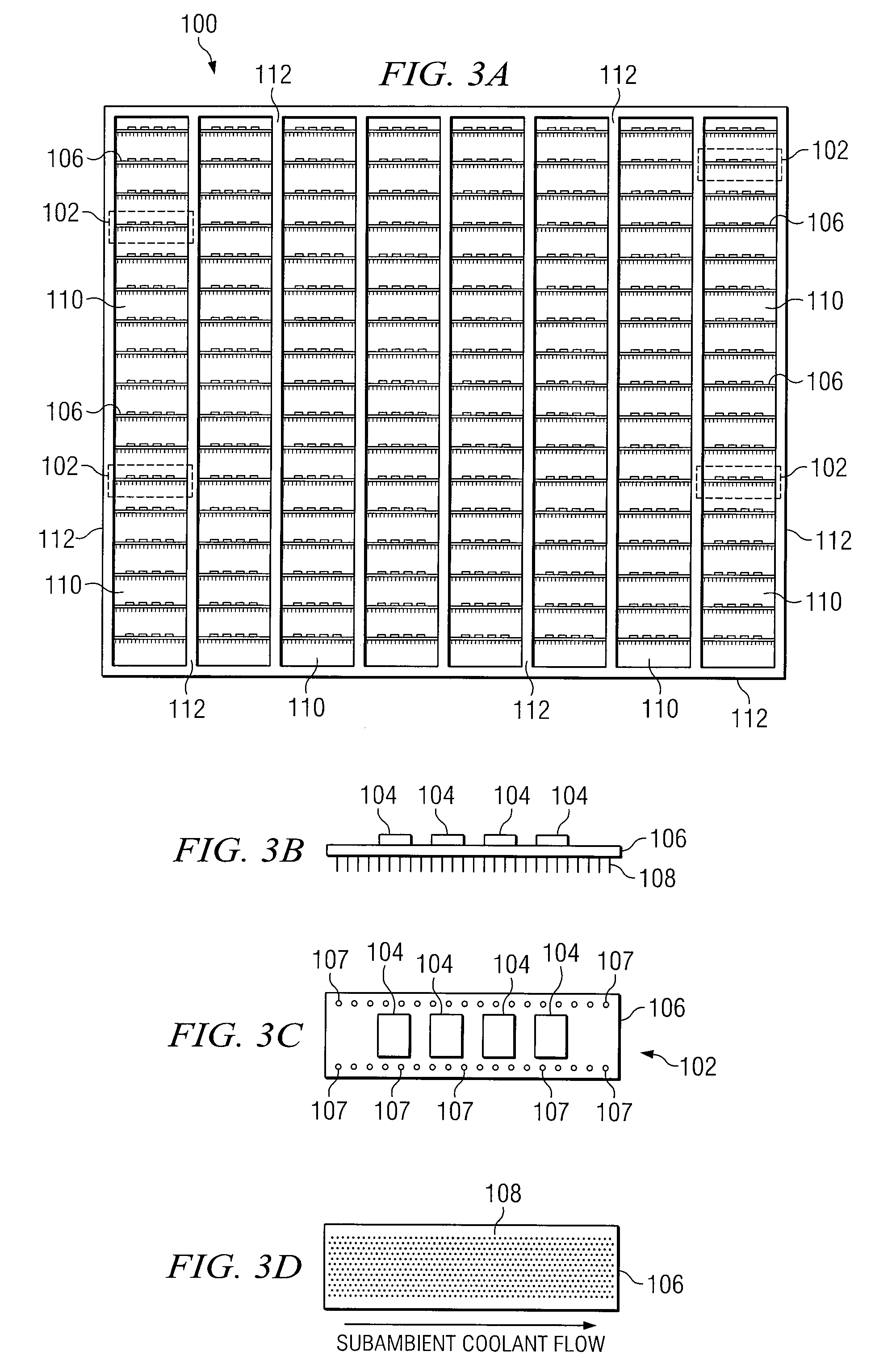

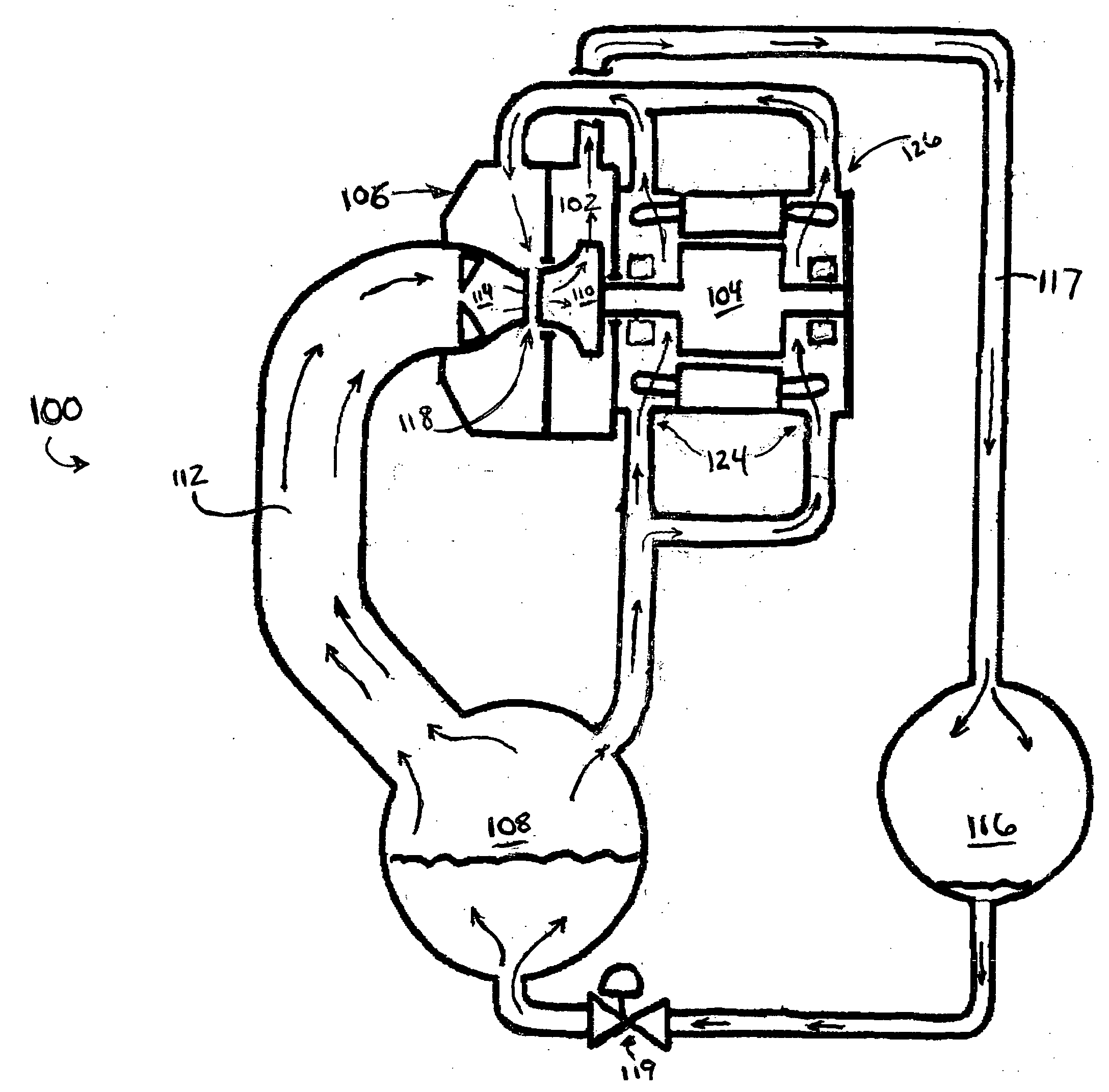

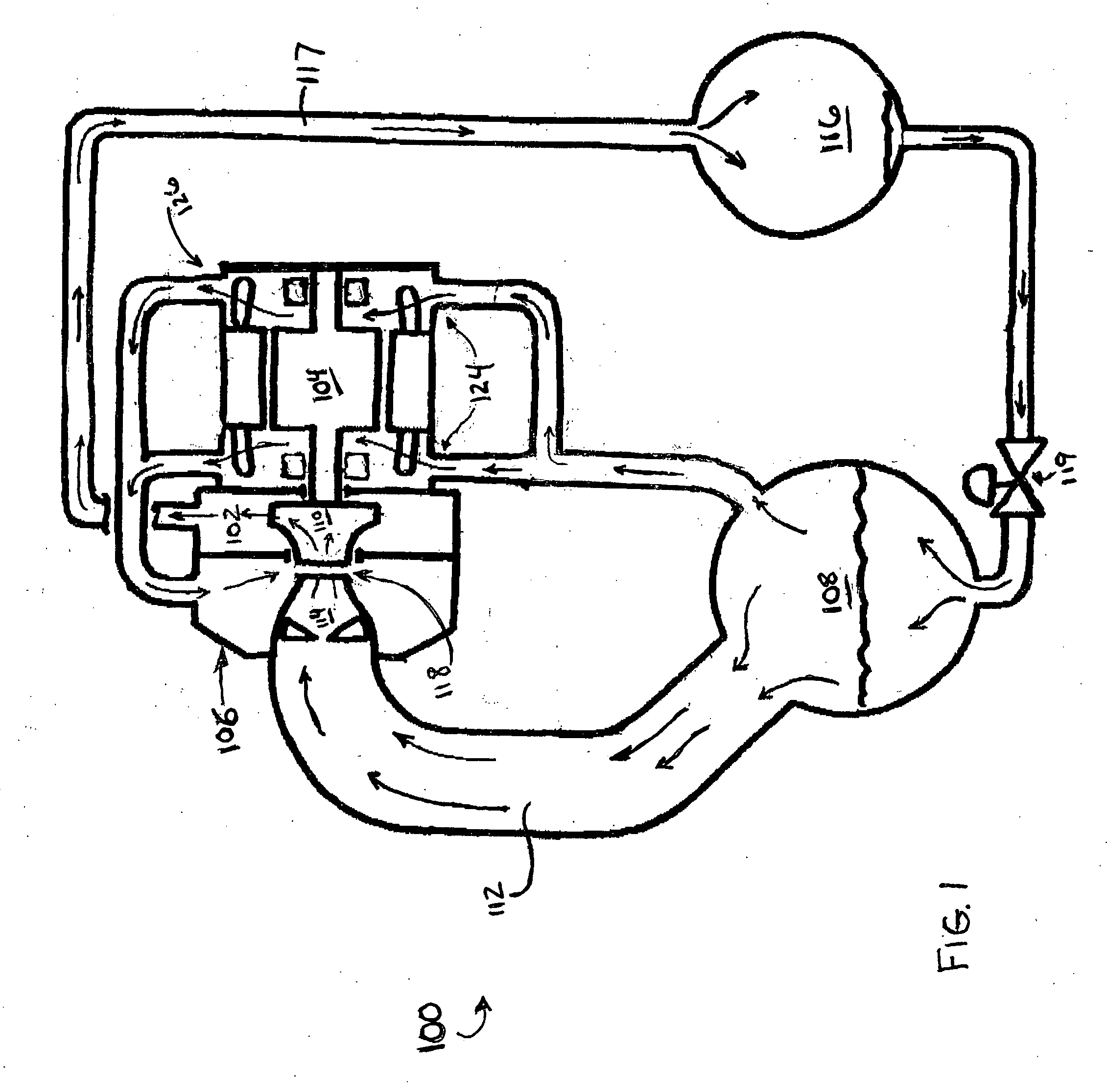

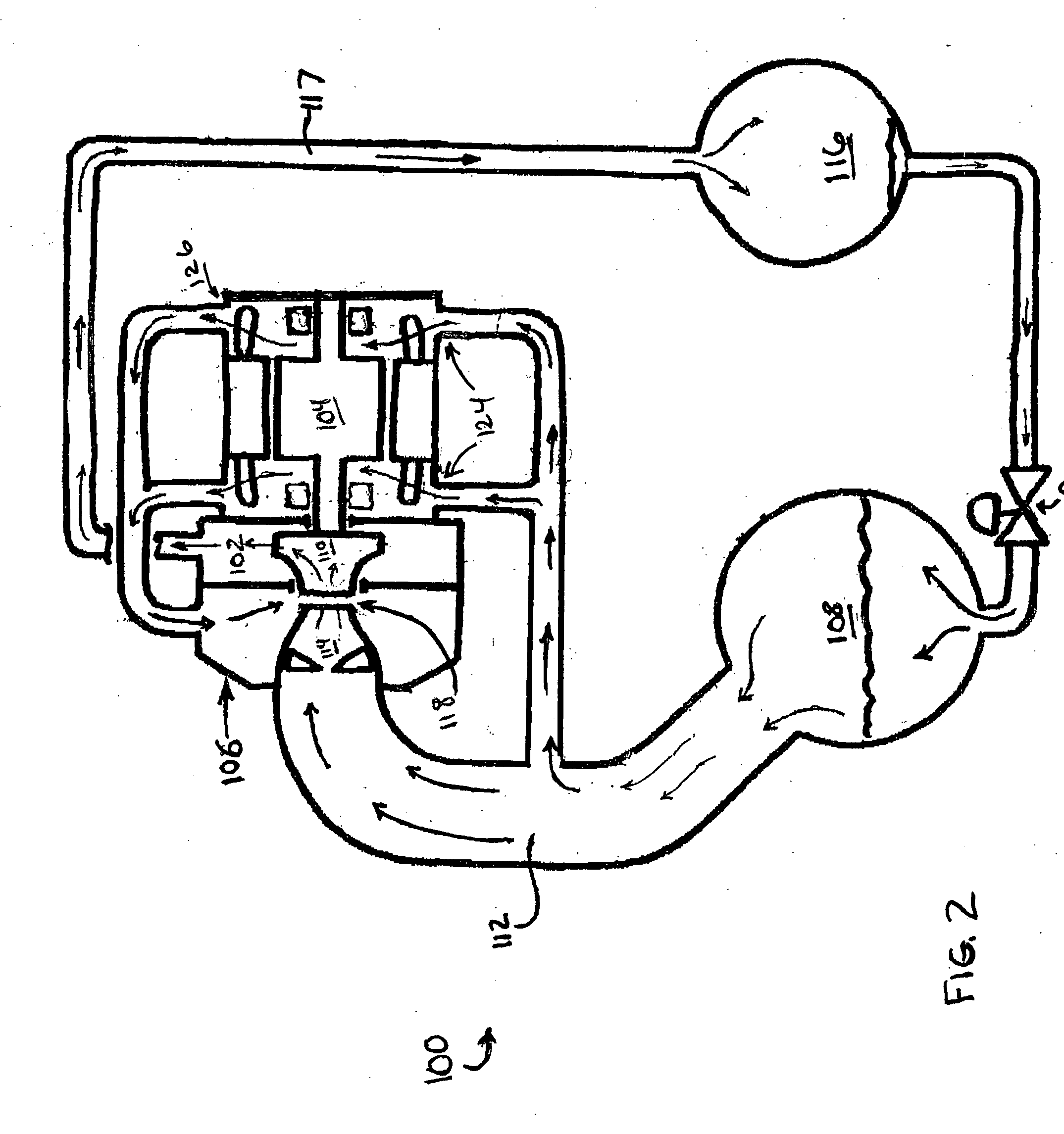

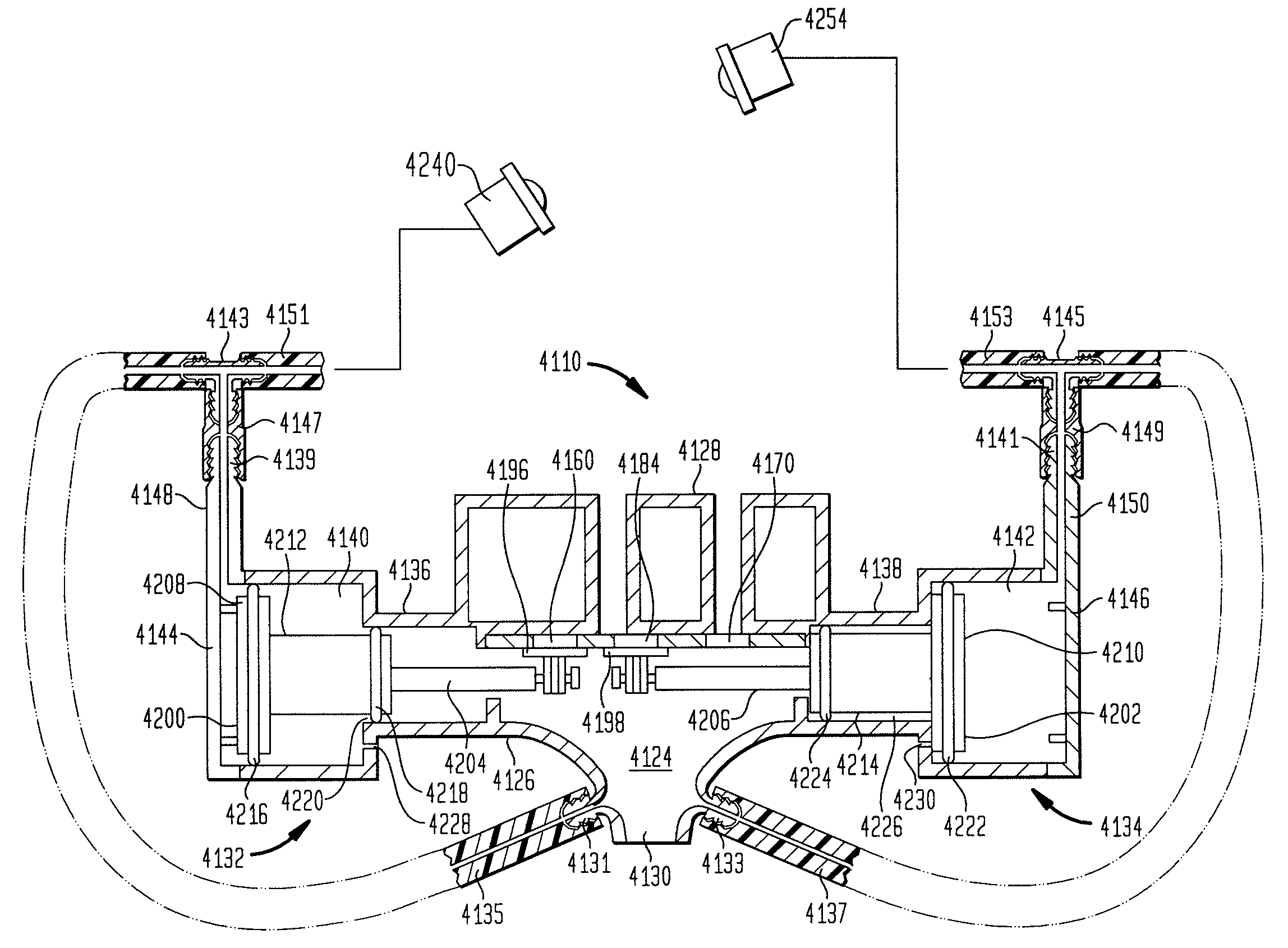

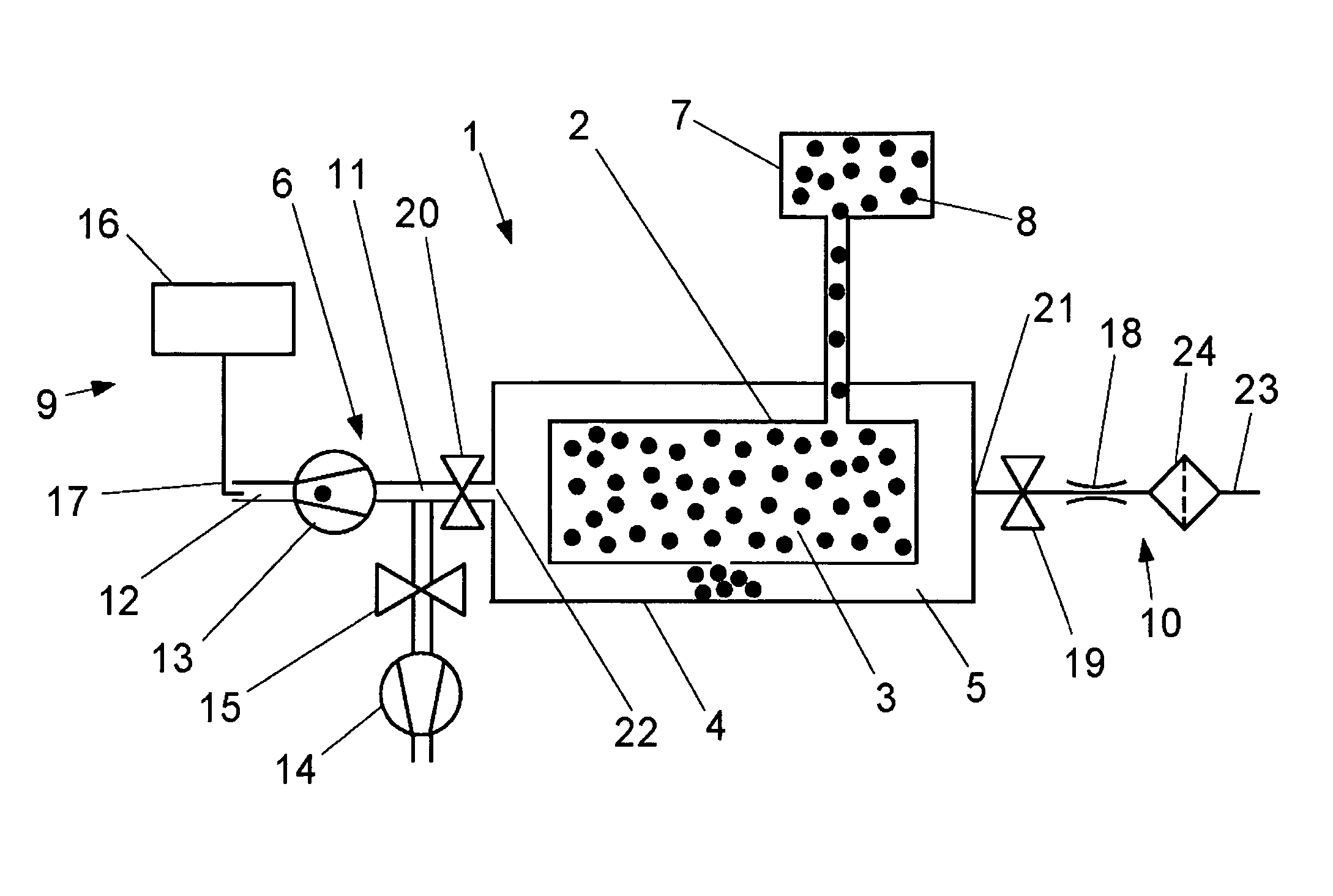

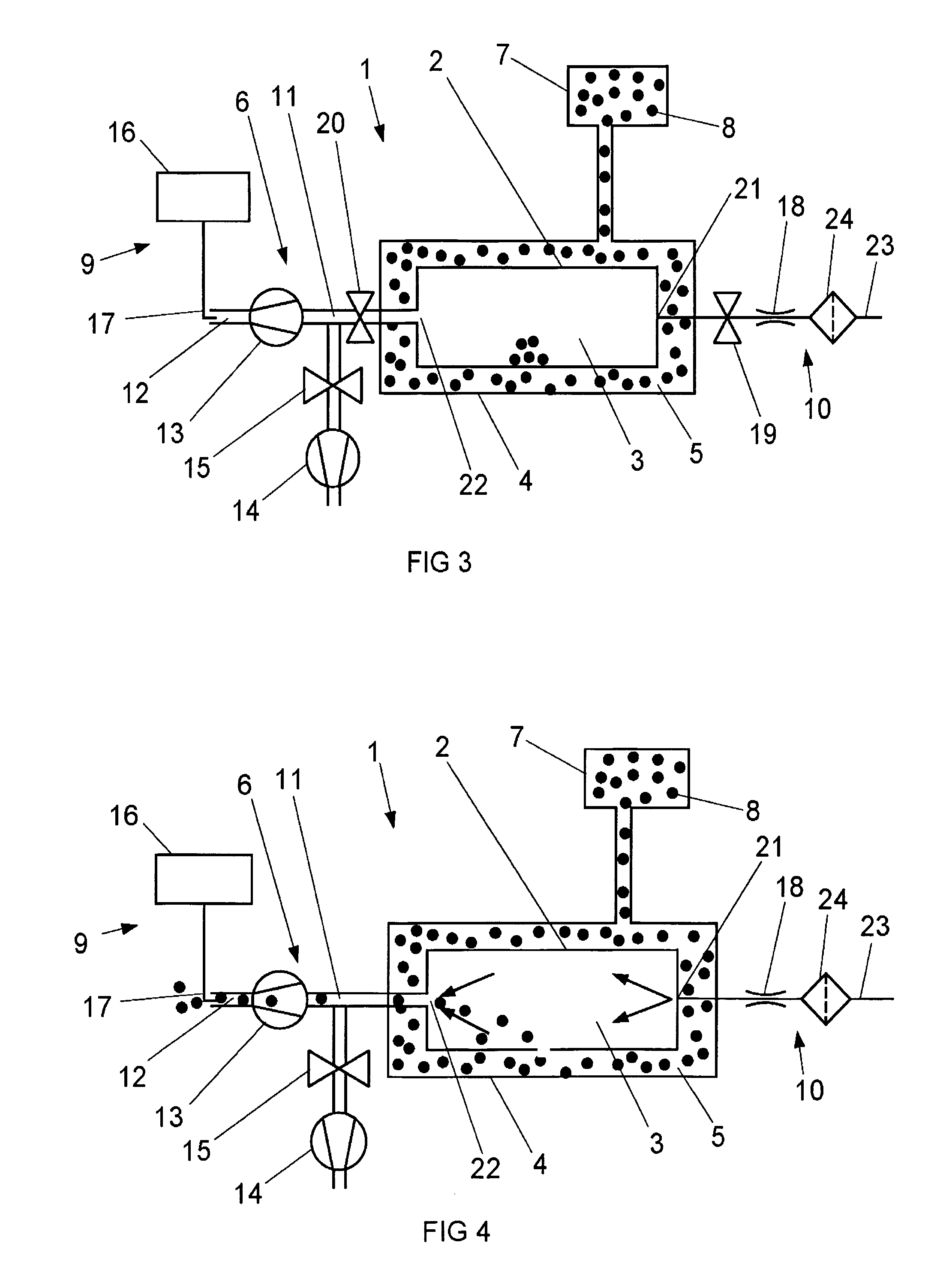

Method and Apparatus for Cooling Electronics with a Coolant at a Subambient Pressure

ActiveUS20070263356A1Large amount of removalSolid-state devicesIndirect heat exchangersBoiling pointAmbient pressure

According to one embodiment of the invention, a method is provided for cooling heat-generating structure disposed in an environment having an ambient pressure. The heat-generating structure includes electronics. The method includes providing a coolant, reducing a pressure of the coolant to a subambient pressure at which the coolant has a boiling temperature less than a temperature of the heat-generating structure, and bringing the heat-generating structure and the coolant at the subambient pressure into contact with one another, so that the coolant boils and vaporizes to thereby absorb heat from the heat-generating structure. In a more particular embodiment the coolant is either pure water or pure methanol with an electrical resistivity level of greater than one million Ohms-cm. Further, in another particular embodiment the method includes filtering the coolant to maintain its purity above a particular level.

Owner:RAYTHEON CO

System and method for cooling a compressor motor

ActiveUS20050284173A1Improvement in motor coolingExcellent motor coolingCompressorPump componentsDecreased pressureAir compressor

Apparatus and methods are provided for cooling motors used to drive gas and air compressors. In particular, the cooling of hermetic and semi-hermetic motors is accomplished by a gas sweep using a gas source located in the low-pressure side of a gas compression circuit. The gas sweep is provided by the creation of a pressure reduction at the compressor inlet sufficient to draw uncompressed gas through a motor housing, across the motor, and out of the housing for return to the suction assembly. The pressure reduction is created by means provided in the suction assembly, such as a nozzle and gap assembly, or alternatively a venturi, located upstream of the compressor inlet. Additional motor cooling can be provided by circulating liquid or another cooling fluid through a cooling jacket in the motor housing portion adjacent the motor.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

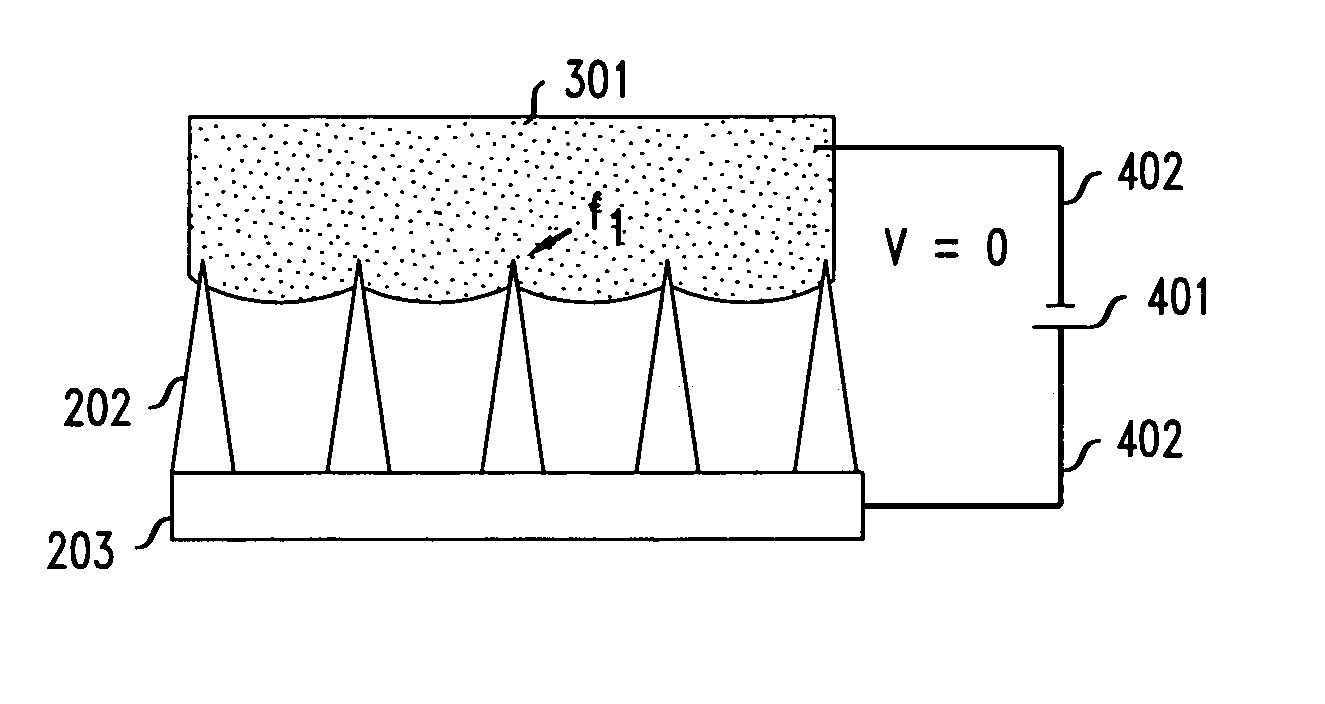

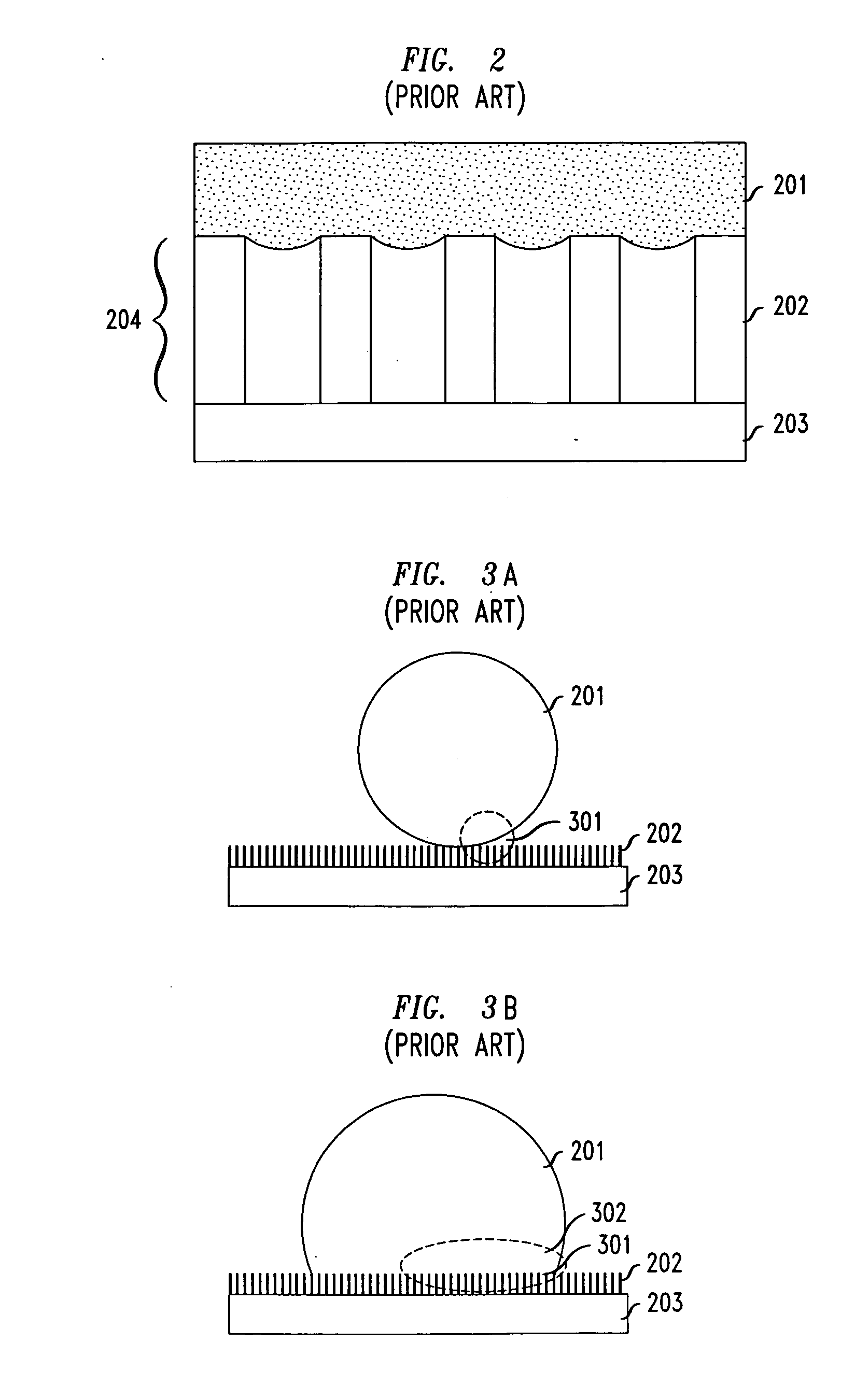

Method and apparatus for controlling the flow resistance of a fluid on nanostructured or microstructured surfaces

ActiveUS20050069458A1Low flow resistanceIncrease pressureFixed microstructural devicesOffensive equipmentDecreased pressureEngineering

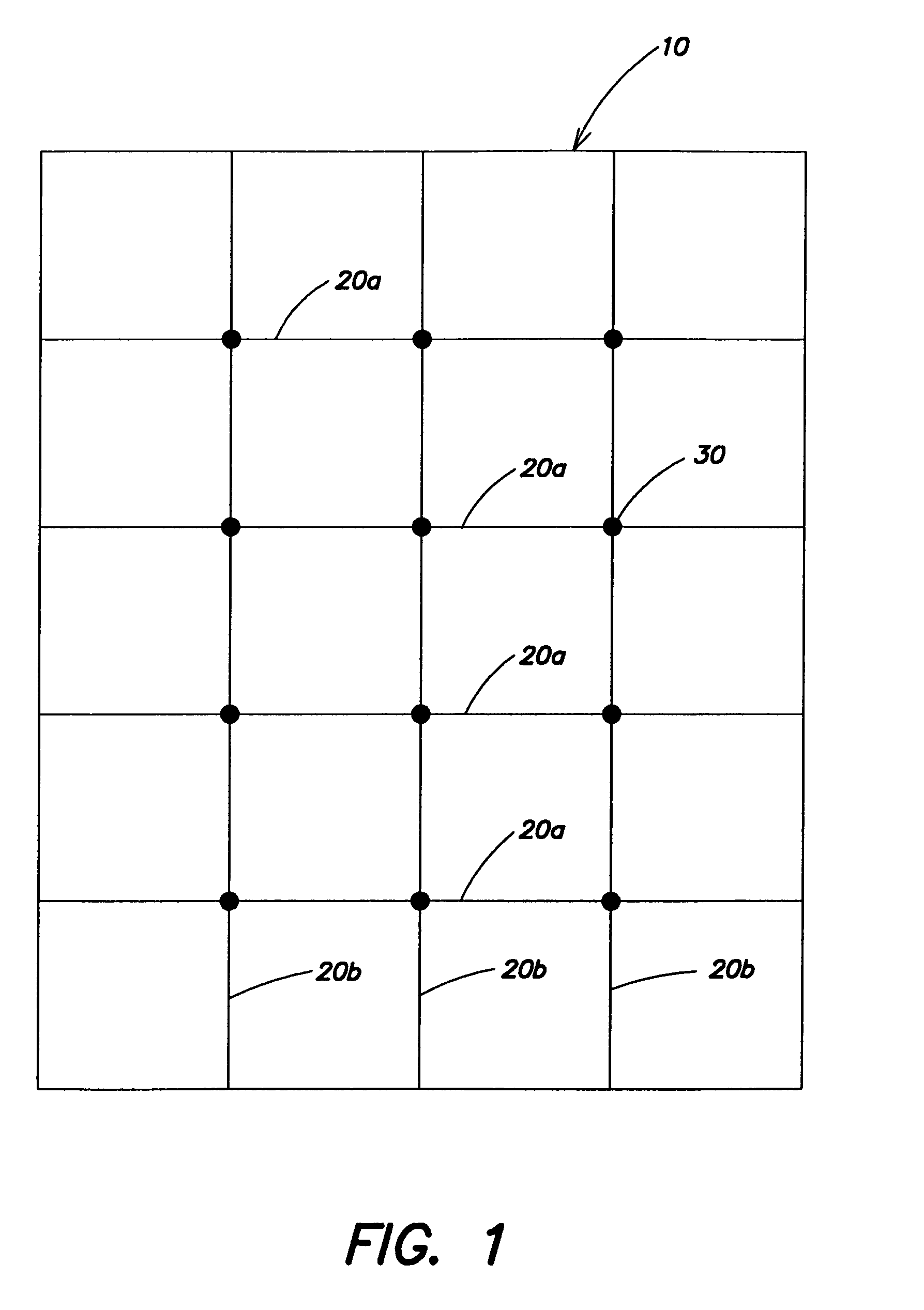

A method and apparatus is disclosed wherein the flow resistance of a droplet disposed on a nanostructured or microstructured surface is controlled. A closed-cell feature is used in a way such that, when the pressure of at least a first fluid within one or more of the cells of said surface is decreased to or below a desired level, a droplet disposed on that surface is caused to at least partially penetrate the surface. In another illustrative embodiment, the pressure within one or more of the cells is increased to or above a desired level in a way such that the droplet of liquid is returned at least partially to its original, unpenetrated position. In yet another embodiment, a closed-cell structure feature pattern is used to prevent penetration of the nanostructured or microstructured surface, even when the pressure of the fluid disposed on the surface is relatively high.

Owner:ALCATEL LUCENT SAS

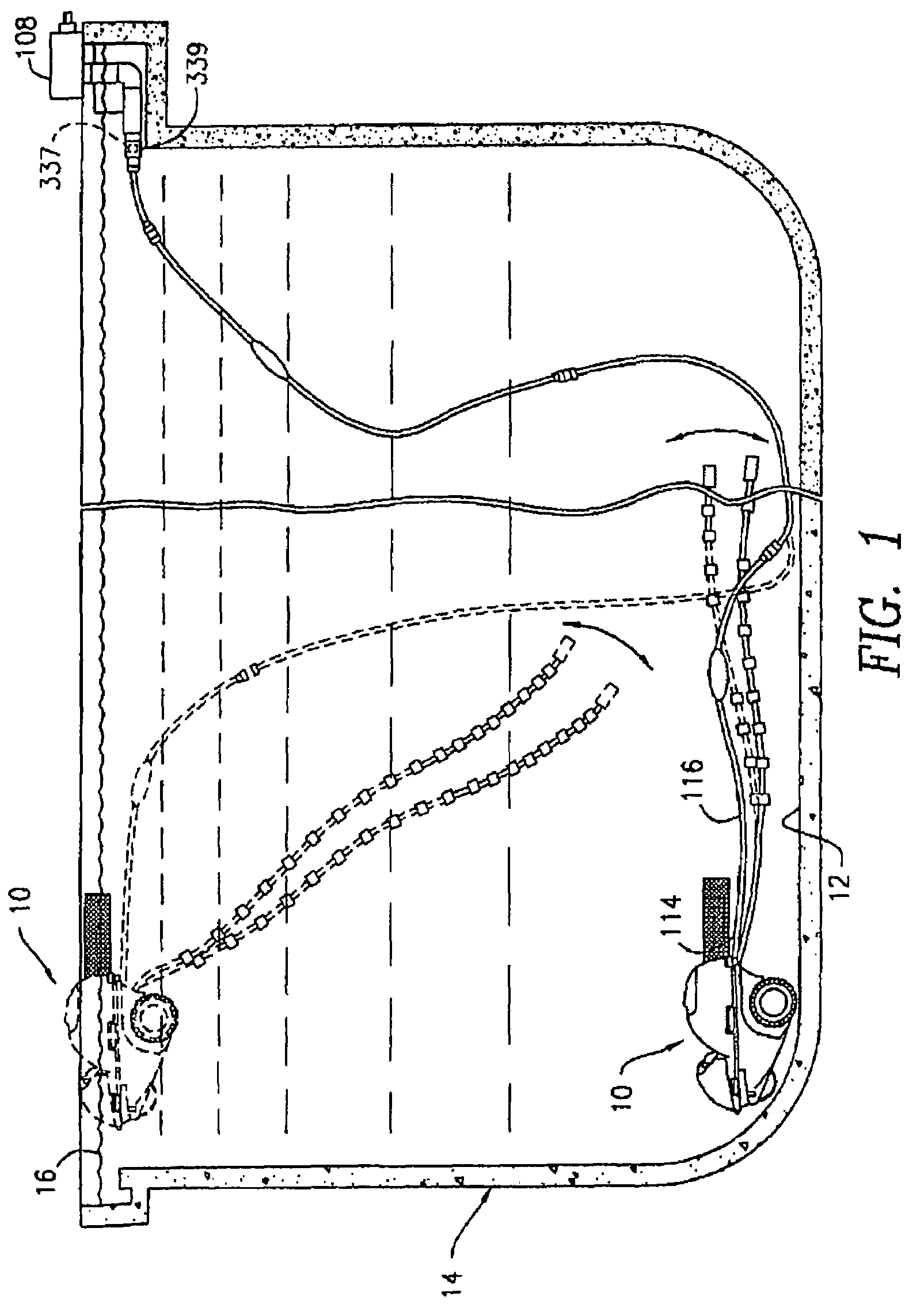

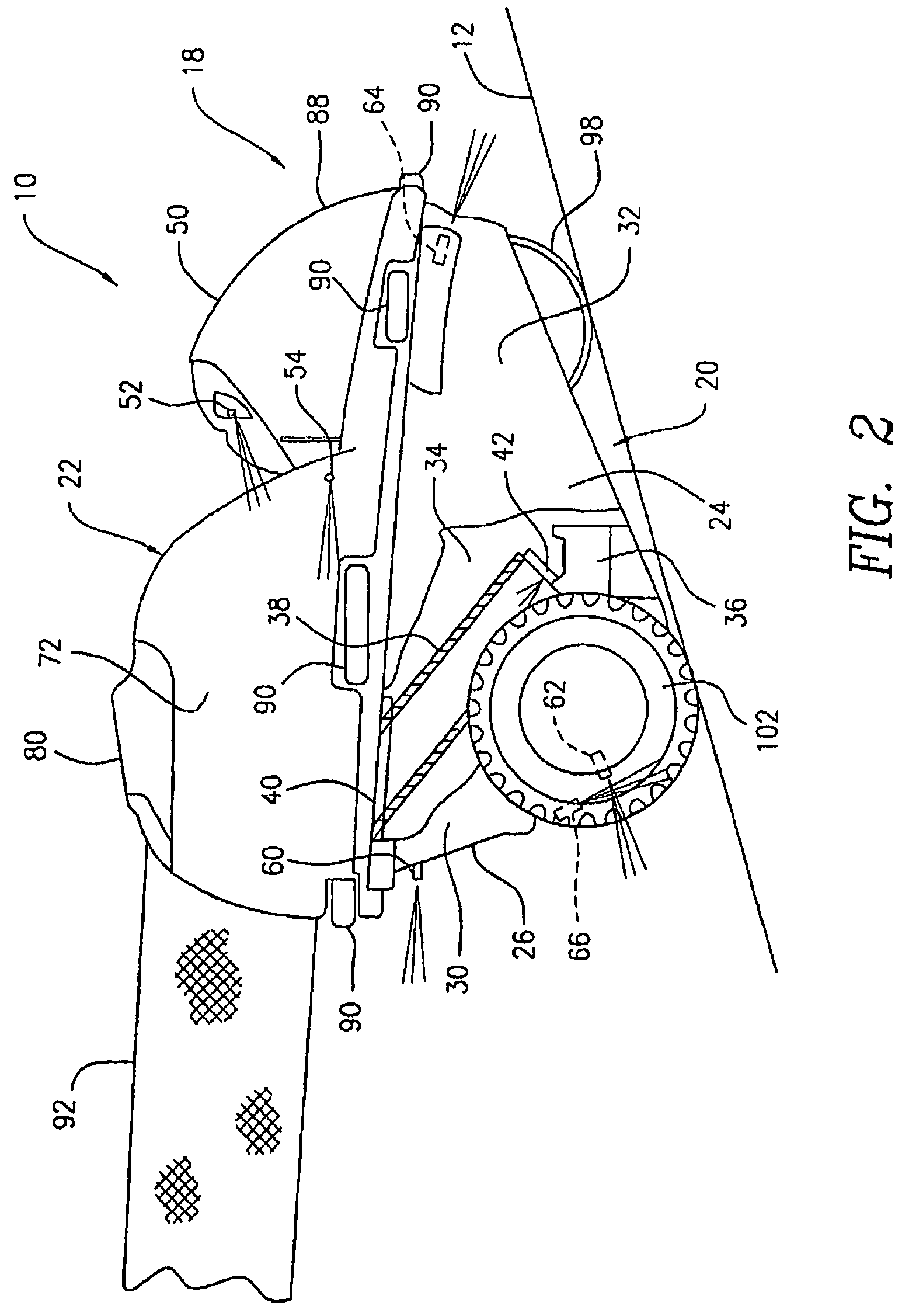

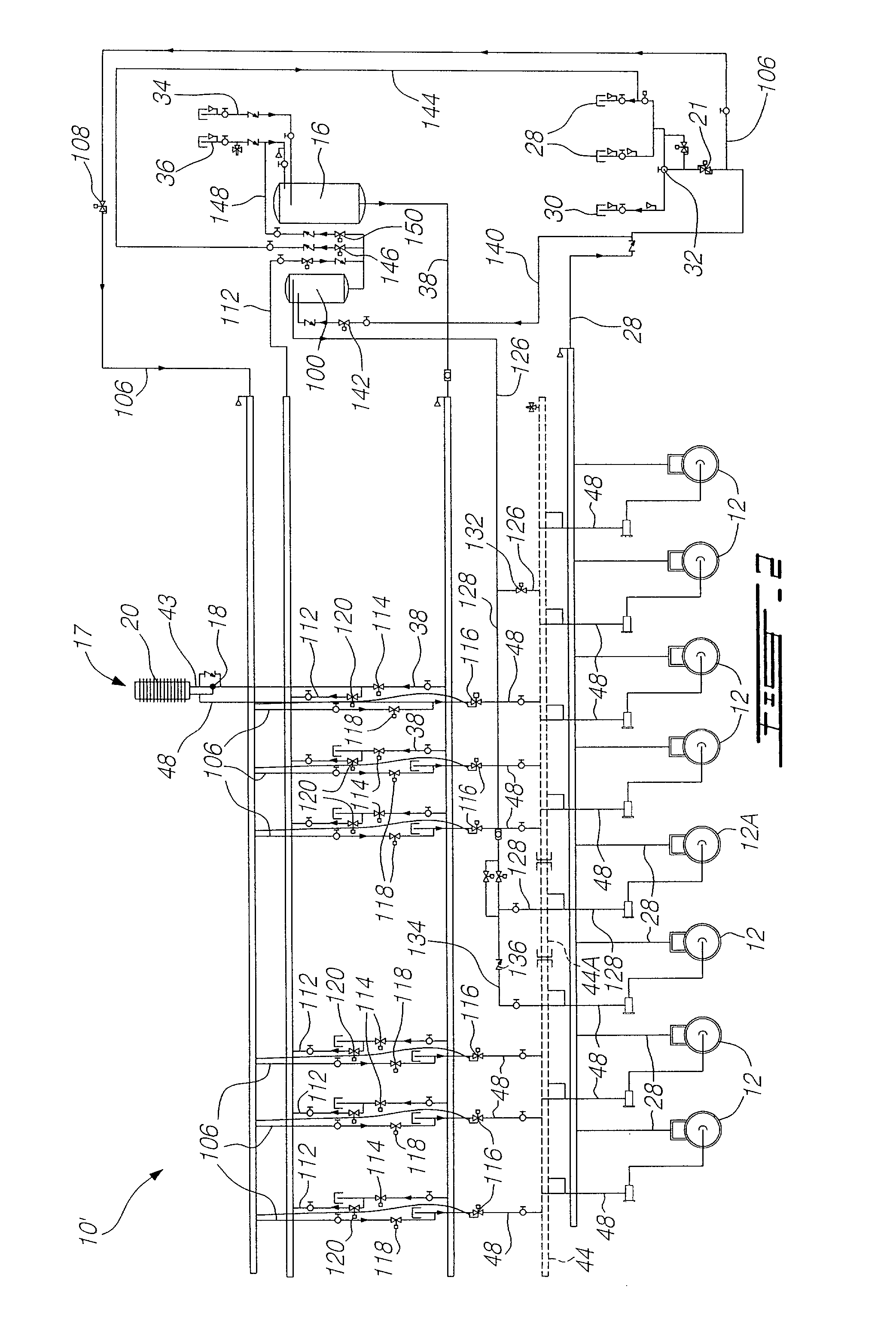

Fluid distribution system for a swimming pool cleaning apparatus

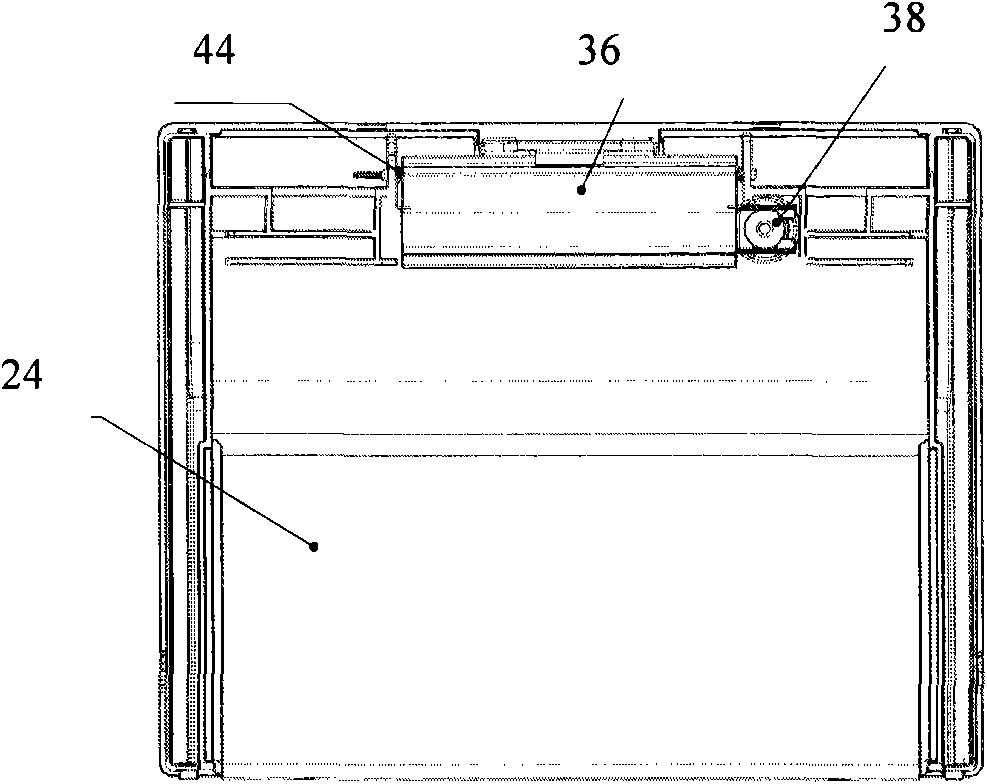

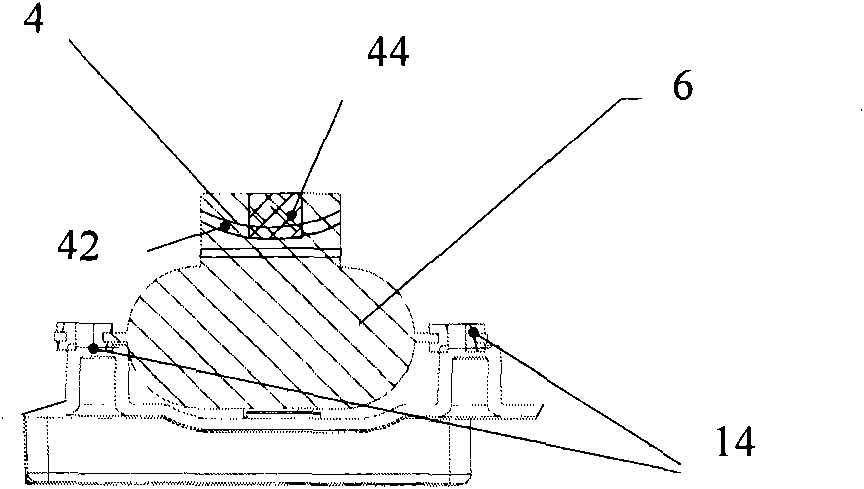

InactiveUS7677268B2Diaphragm valvesOperating means/releasing devices for valvesDistribution systemDecreased pressure

A fluid distribution system for controlling the operation of a swimming pool cleaning device includes a housing having an inlet for receiving a supply of pressurized fluid, a plurality of outlet openings and a valve chamber between the inlet and outlet openings. The housing has at least one compound cylinder having two portions with different bore diameters for slideably accommodating therein a mating stepped piston. Each portion of the compound cylinder fluidly communicates with pressurized water in the valve chamber via associated fluid pathways. The larger cylinder is vented by a relief valve actuated by a fluid driven cam that periodically opens and closes the relief valve. When the relief valve is closed, the pressure within the large cylinder pushes the piston to a first position which effects the opened / closed status of a port, e.g., allowing one of the outlets to communicate with the pressurized water in the valve chamber. When the relief valve is opened, the pressure within the larger cylinder is reduced, allowing the pressure in the smaller cylinder to push the piston to a second position which effects the opened / closed status of the port and / or opens another port to allow the pressurized fluid to be discharged through another outlet.

Owner:HAYWARD IND INC

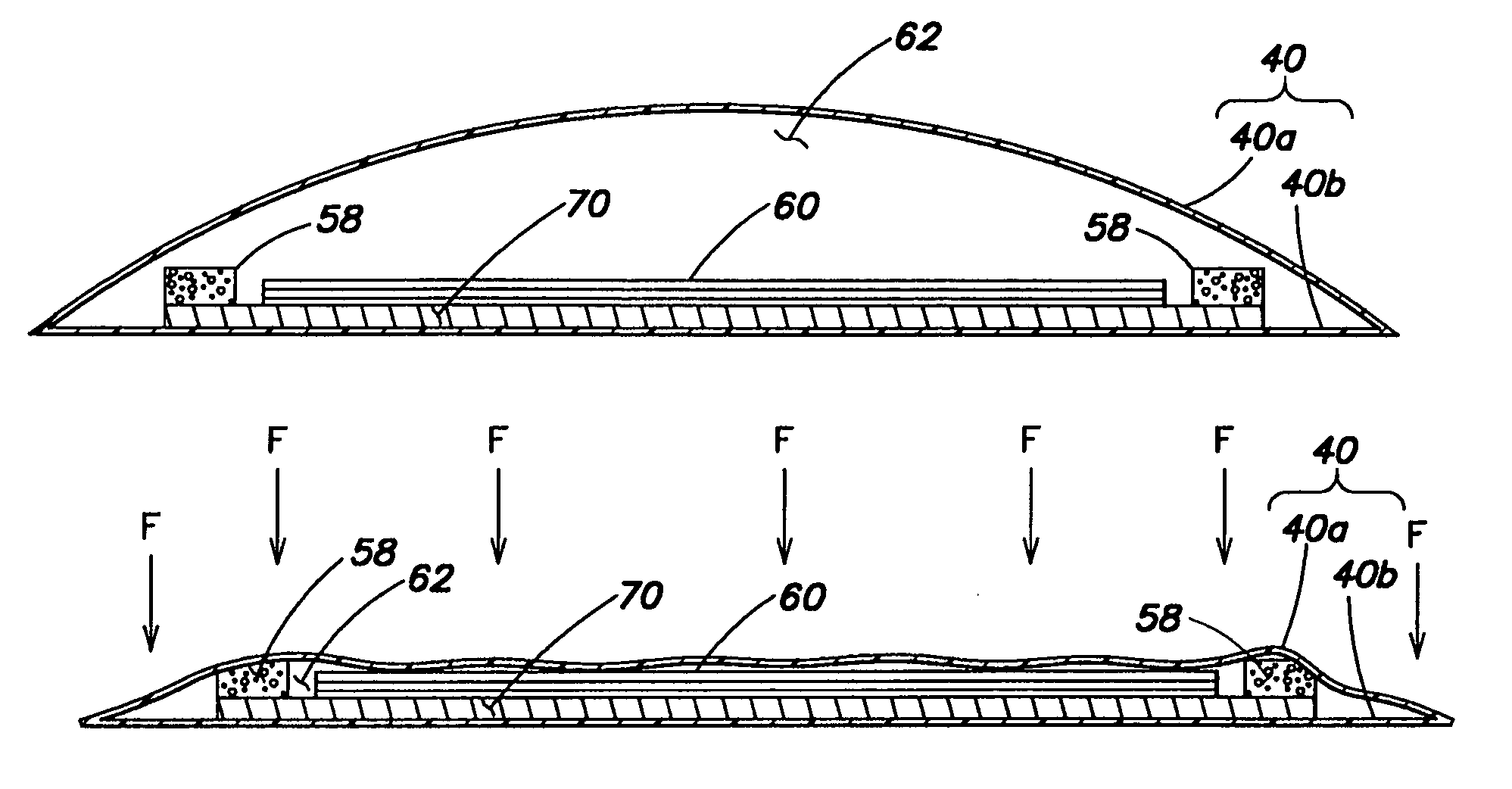

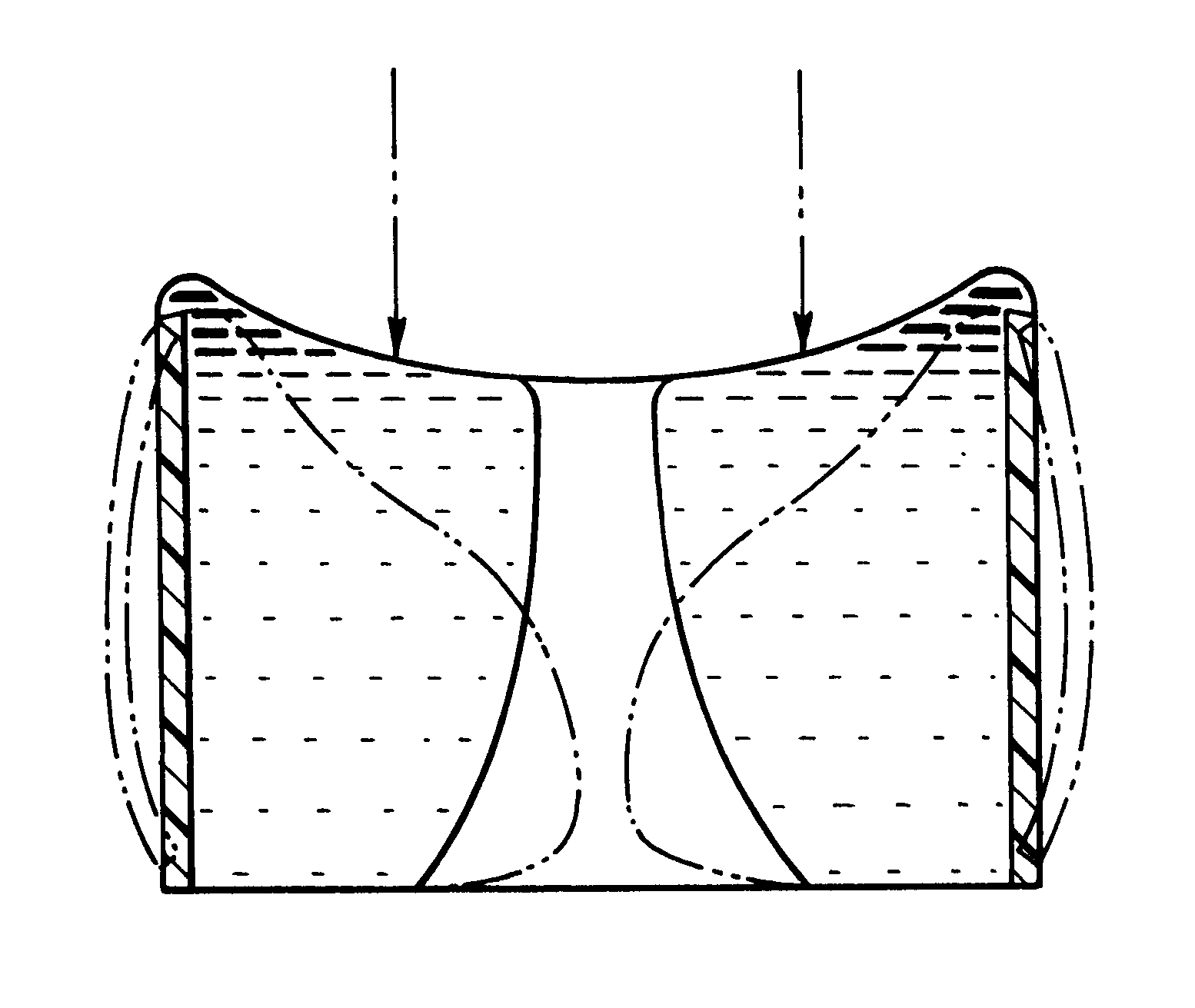

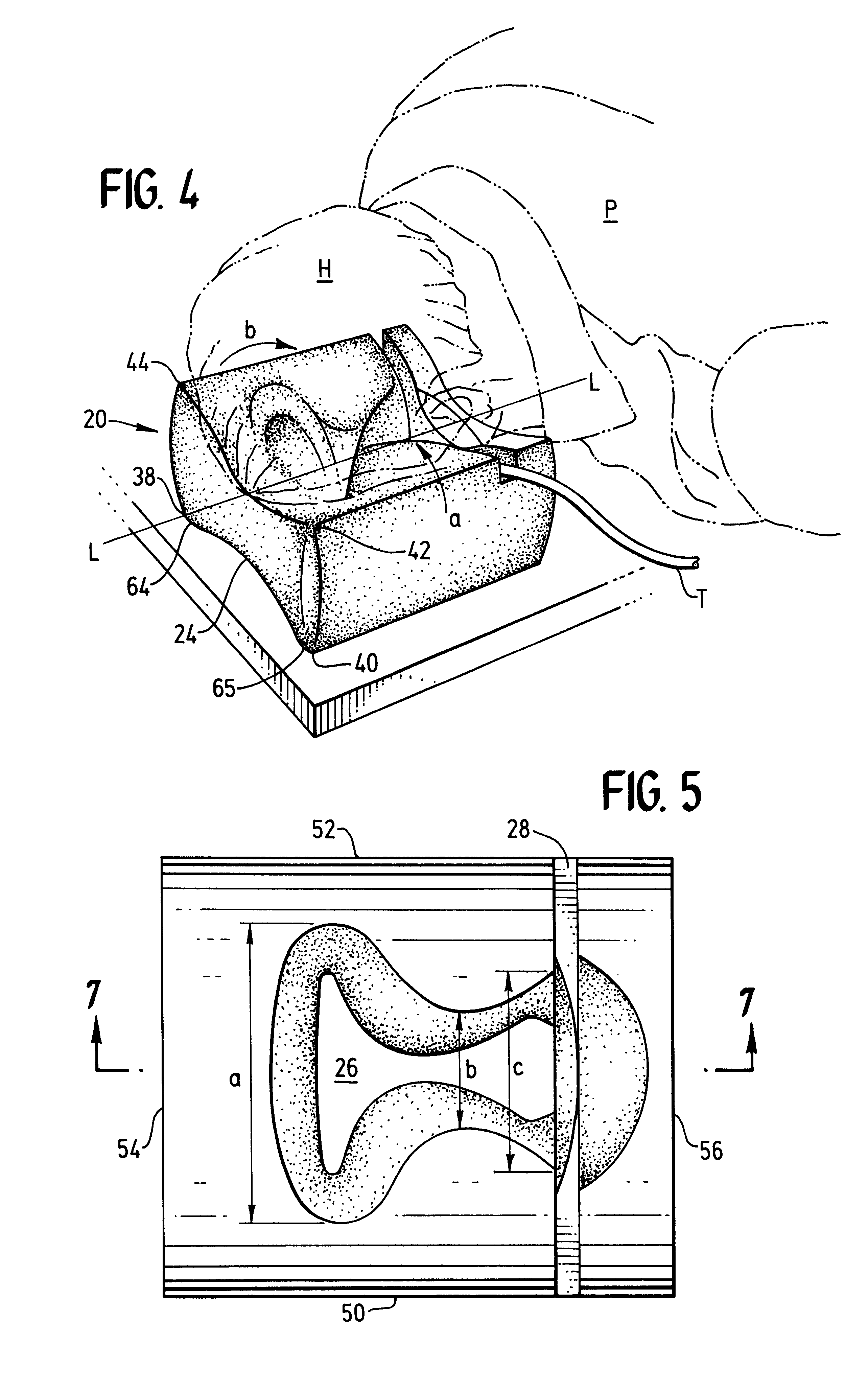

Surgical face support

InactiveUS6561194B2Relief of pressure to the areasRelieve stressEar treatmentOperating chairsNoseProne position

The present invention provides a face support device specifically for the purpose of facilitating surgery on humans in the prone position providing for the complete relief of pressure to the areas of the eyes, ears, nose, and mouth of a patient. The face support has a concave curved upper portion, a concave lower surface and a central opening for avoiding pressure on the eyes, nose and lips of the patient, while providing for increased support with decreased pressure and skin shear experienced by the patient's face in contact with the face support.

Owner:WARSAW ORTHOPEDIC INC

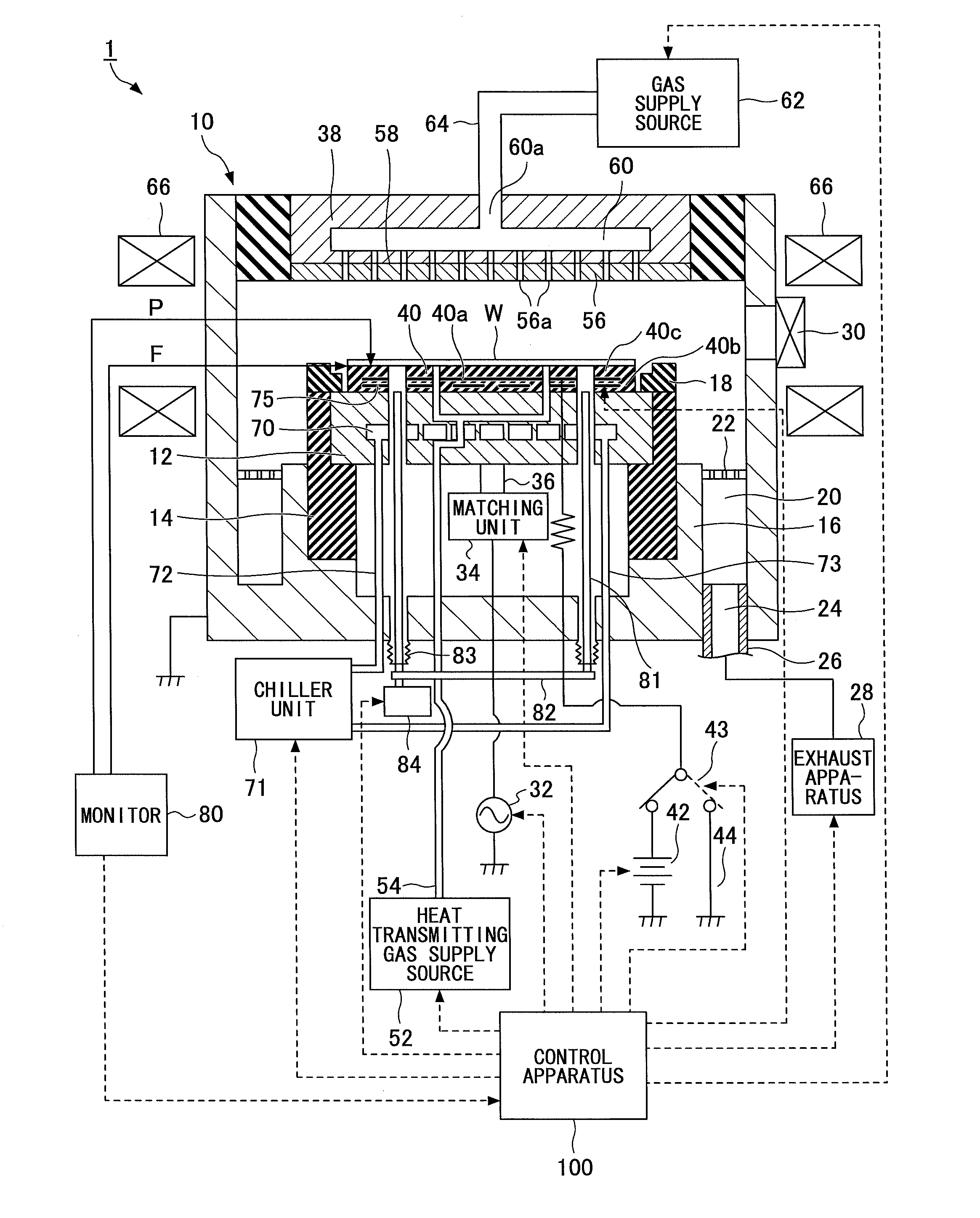

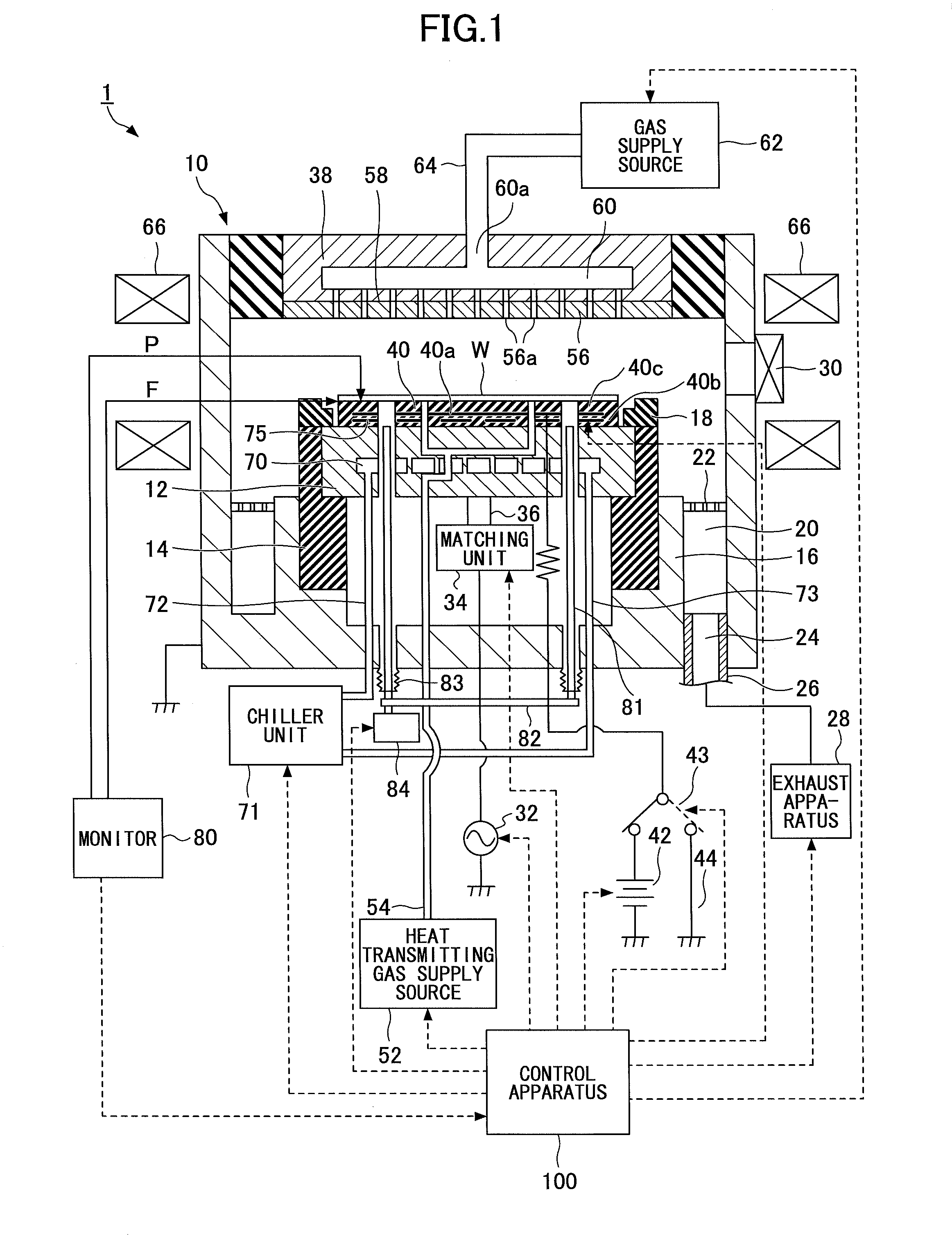

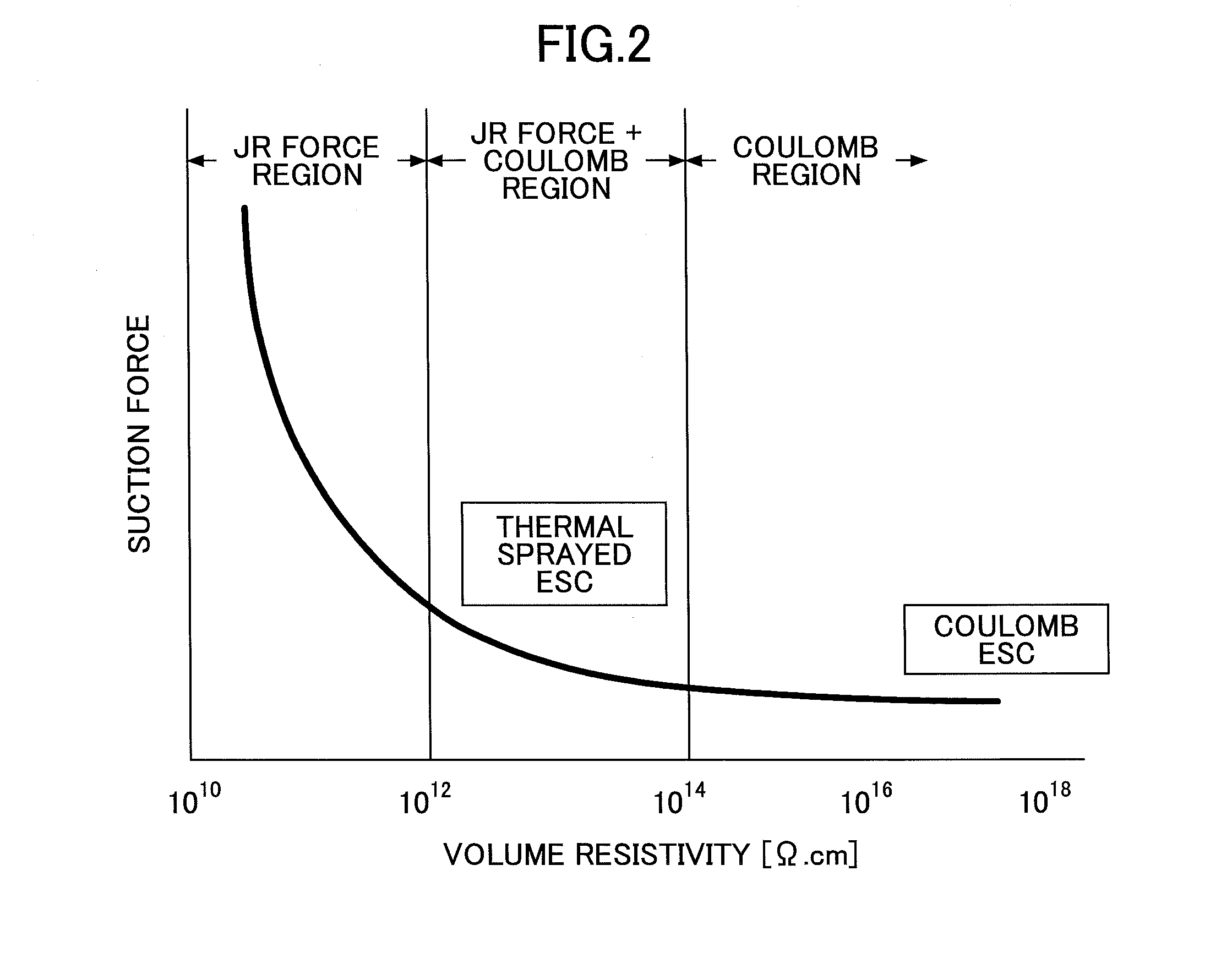

Dechuck control method and plasma processing apparatus

ActiveUS20130153147A1Reduce pressureElectric discharge tubesSemiconductor/solid-state device manufacturingDecreased pressureElectrical polarity

A dechuck control method includes performing a discharge process by introducing an inert gas into a processing chamber and maintaining the pressure within the processing chamber at a first pressure; monitoring the pressure of a heat transmitting gas supplied to the processing object rear face and / or the leakage flow rate of the heat transmitting gas; obtaining the amount and polarity of the residual electric charge of the electrostatic chuck surface and applying a voltage for supplying an electric charge that is of the same amount as the residual electric charge but of the opposite polarity to a chuck electrode; evacuating the inert gas from the processing chamber while applying the voltage to the chuck electrode and reducing the pressure within the processing chamber to a second pressure; and turning off the voltage applied to the electrostatic chuck and dechucking the processing object from the electrostatic chuck.

Owner:TOKYO ELECTRON LTD

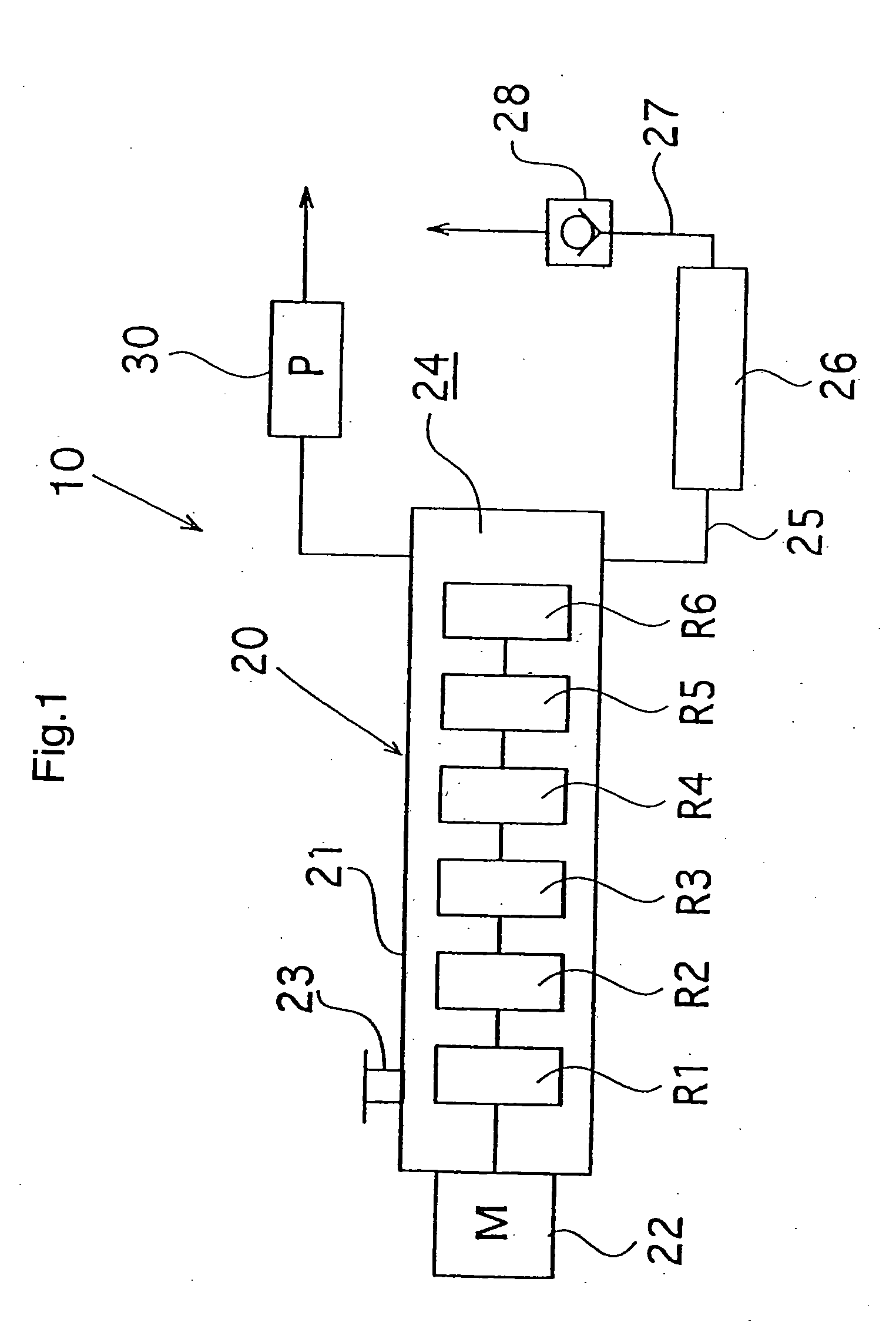

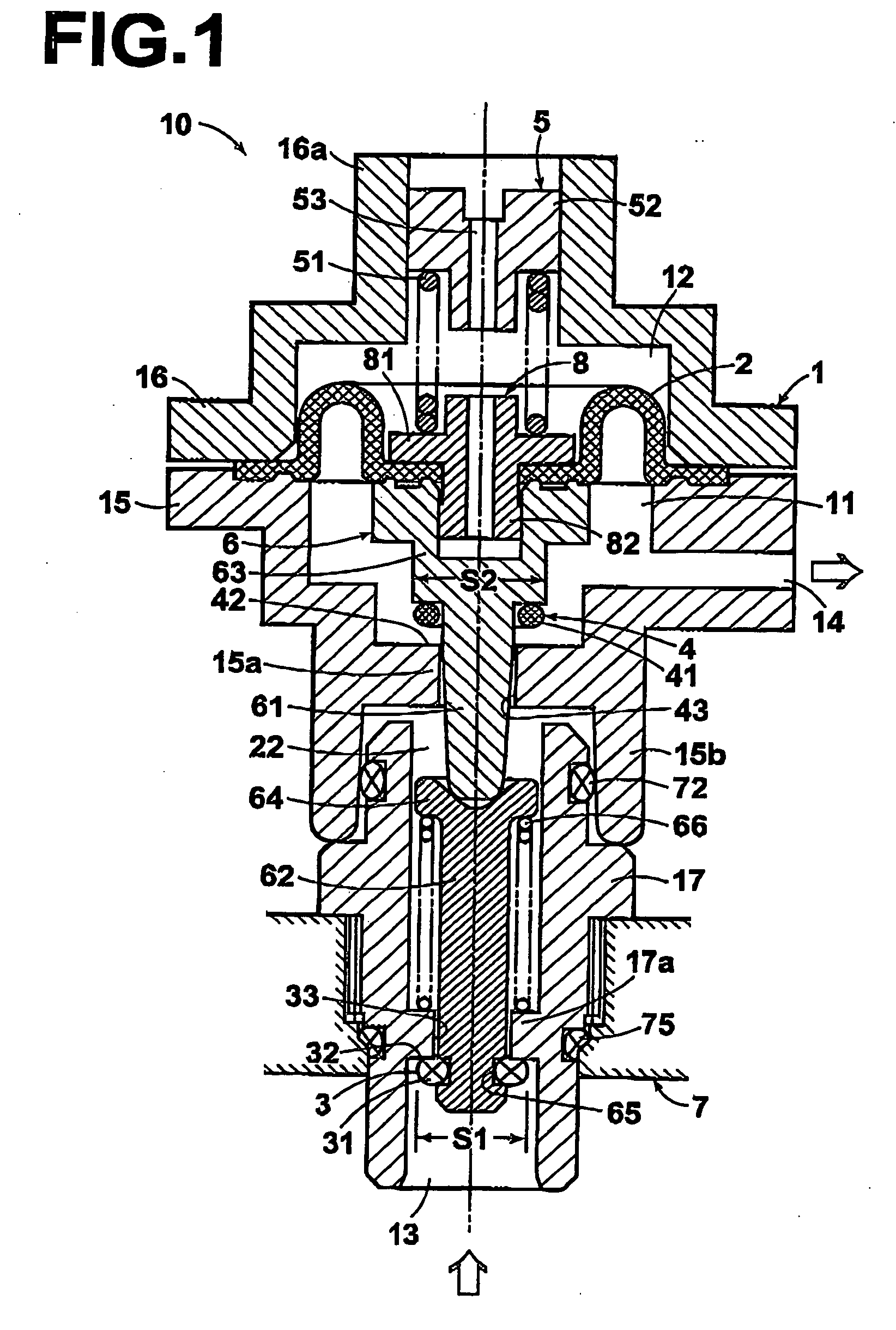

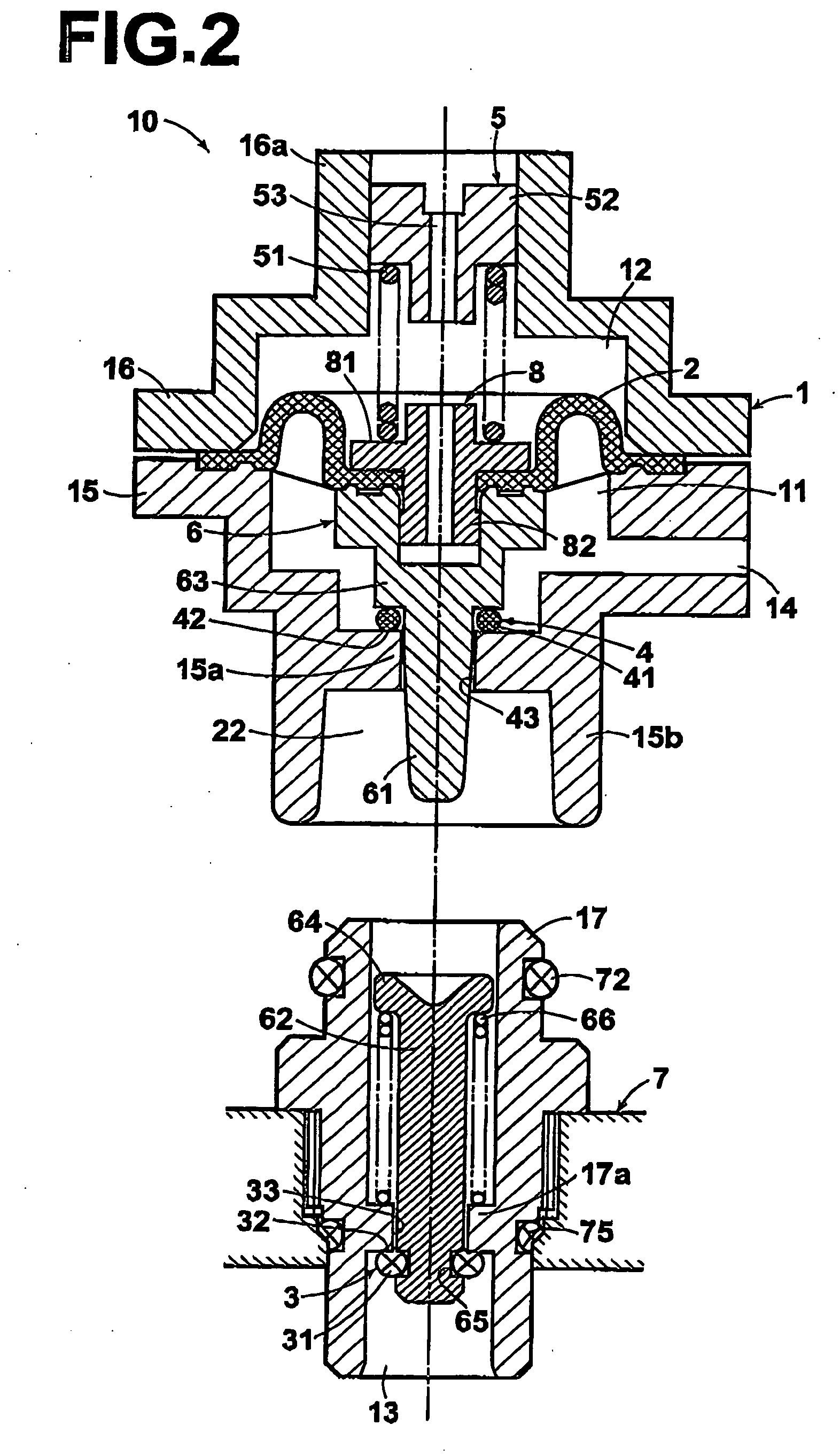

Vacuum exhaust apparatus and drive method of vacuum apparatus

InactiveUS20040173312A1Rotary/oscillating piston combinations for elastic fluidsPump componentsDecreased pressureIntermediate stage

Pairs of rotors (R1, R2, R3, R4, R5 and R6) driven rotationally by a motor (22) are disposed in the body (21) of a main pump (20) comprising a multistage Roots dry vacuum pump. A suction opening (23) communicating with the rotor chamber of the rotor R1 is provided in the upper wall portion at the left end of the body (21). A delivery section (24) communicating with the delivery side of the rotor chamber of rotor R6 on the final stage is coupled to an exhaust pipe (25) and is provided with a silencer (26) and further coupled to a check valve (28) through a pipe (27). The check valve (28) has its forward direction toward the atmospheric side. The delivery section (24), or a delivery section (24') at the side intermediate stage, is coupled to an auxiliary pump (30) having an exhaust capacity smaller than that of the main pump (20). When the motor (22) is driven, gas exhausted through rotation of the rotors (R1-R6) is carried sequentially to the downstream side from the rotor chambers and a vacuum processing chamber coupled to the suction opening (23) is exhausted. The delivery section (24) on the final stage is exhausted by driving the auxiliary pump (30), and the pressure is reduced. Consequently, the burden of the exhaust action on the rotor (R6) on the final stage or the rotor (R5) on the intermediate stage is lessened, and the power consumption of the motor (22) can be reduced significantly as compared with the prior art.

Owner:ULVAC INC

System and method for determining the leakproofness of an object

A system and a method for determining the leakproofness of an object having a first cavity. The system includes a closed chamber having a second cavity arranged to envelope the object, an evacuator for lowering the pressure inside one of the cavities, a supply for supplying a tracer gas into the one of the cavities rendered the higher pressure, a detector sensitive to the tracer gas and an introducer for introducing a transport gas into the one of the cavities rendered the lower pressure. Furthermore, the evacuator is arranged to compress arriving gas to the ambient pressure of the chamber and to communicate with the detecting means, which is suited for operation at the ambient pressure of the chamber. The tracer gas is hydrogen.

Owner:INFICON AB

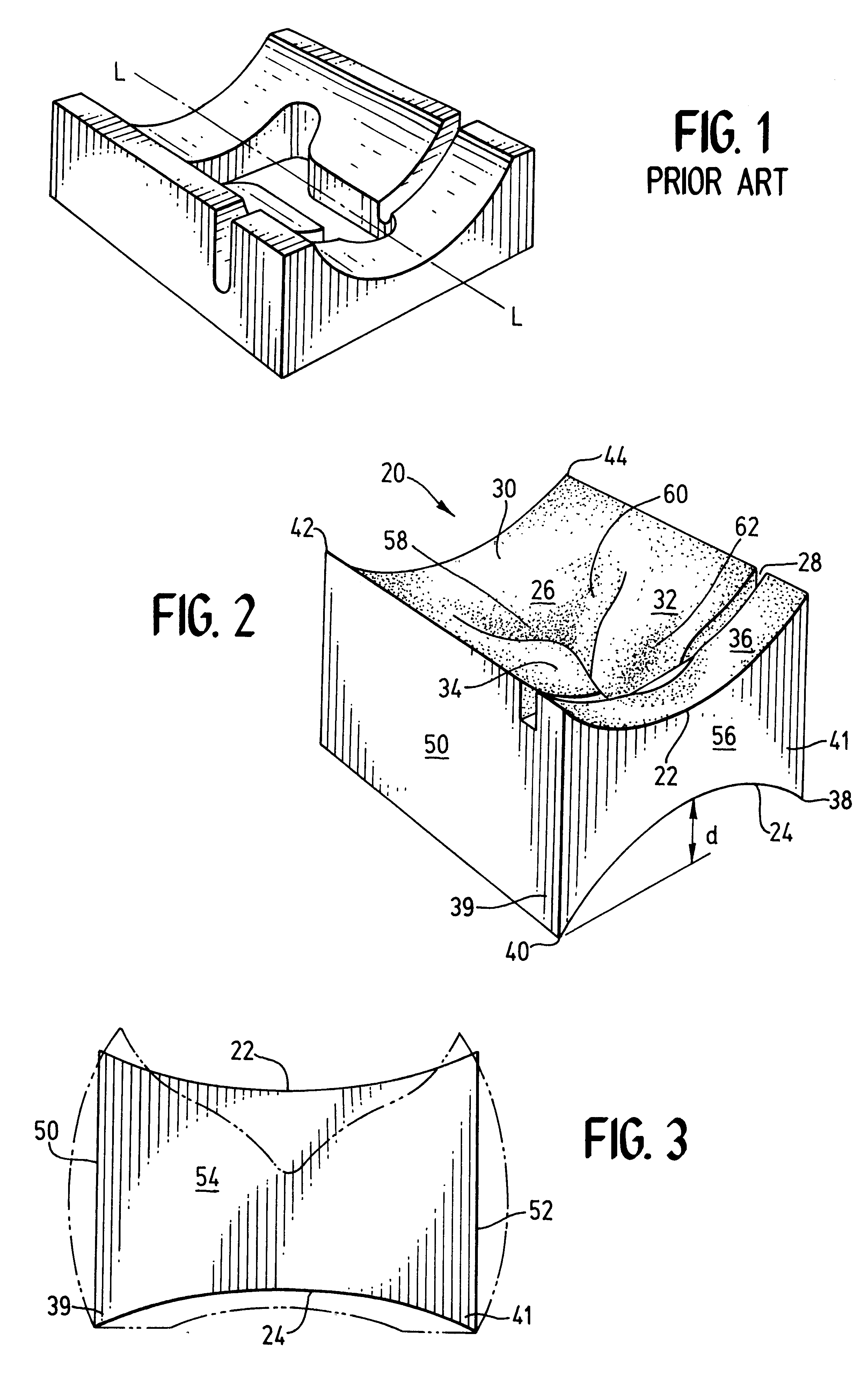

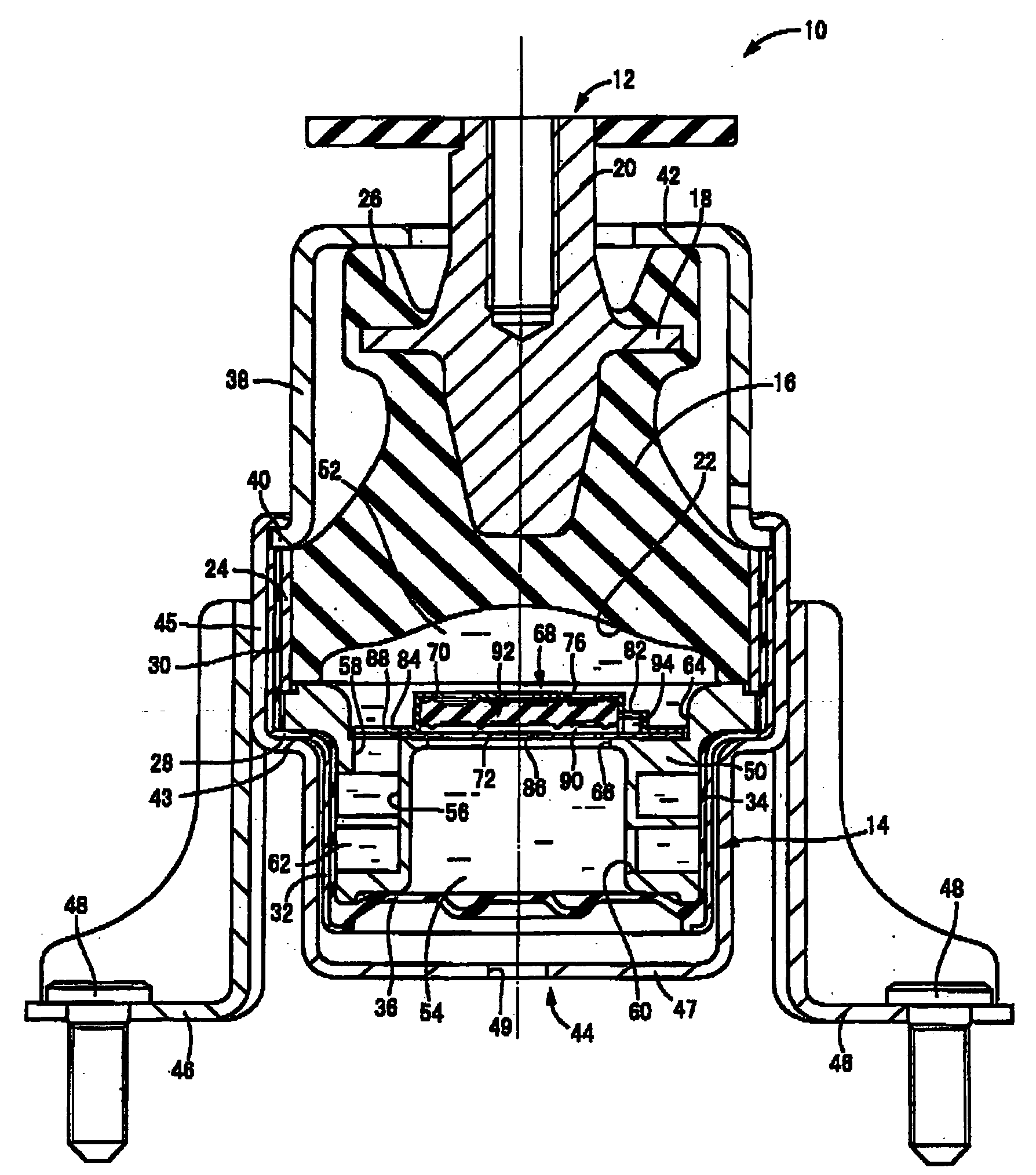

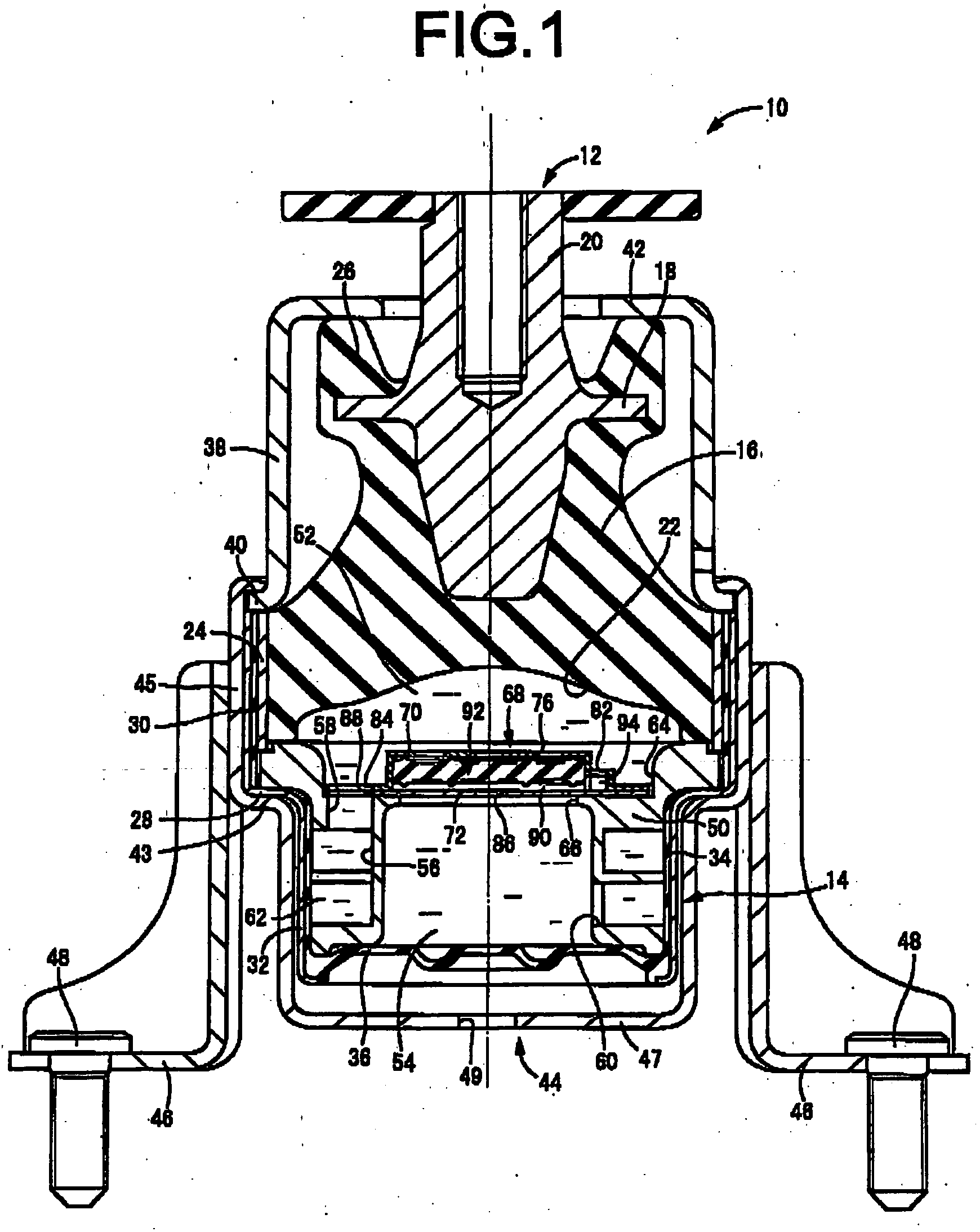

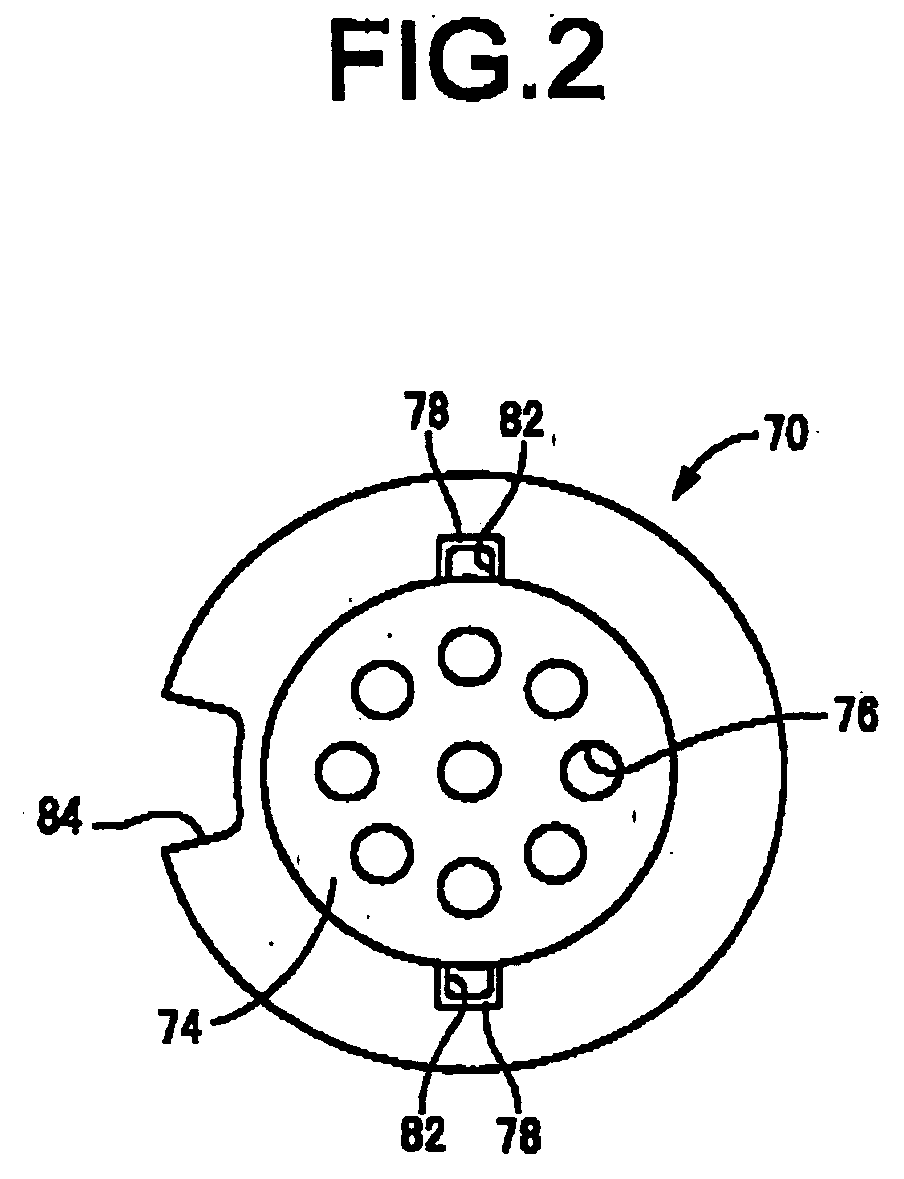

Fluid-filled vibration damping device

InactiveUS20050206056A1Improve shock absorptionEasy constructionMachine framesLiquid springsElastomerDecreased pressure

A fluid-filled vibration damping device including: an elastic body connecting a first and a second mounting member, defining a pressure receiving chamber undergoing pressure fluctuation during input of vibration; an equilibrium chamber defined by a flexible layer for permitting its volume change; an orifice passage connecting the pressure receiving chamber and equilibrium chamber; a movable member; and a short passage for connecting two chambers with a length smaller than that of the orifice passage. When pressure in the pressure-receiving chamber increases, the movable member is displaced or deformed toward to close the equilibrium-chamber-side opening of the short passage to have the short passage substantially closed, while when pressure in the pressure-receiving chamber decreases, the movable member is displaced or deformed to have the short passage operative.

Owner:SUMITOMO RIKO CO LTD

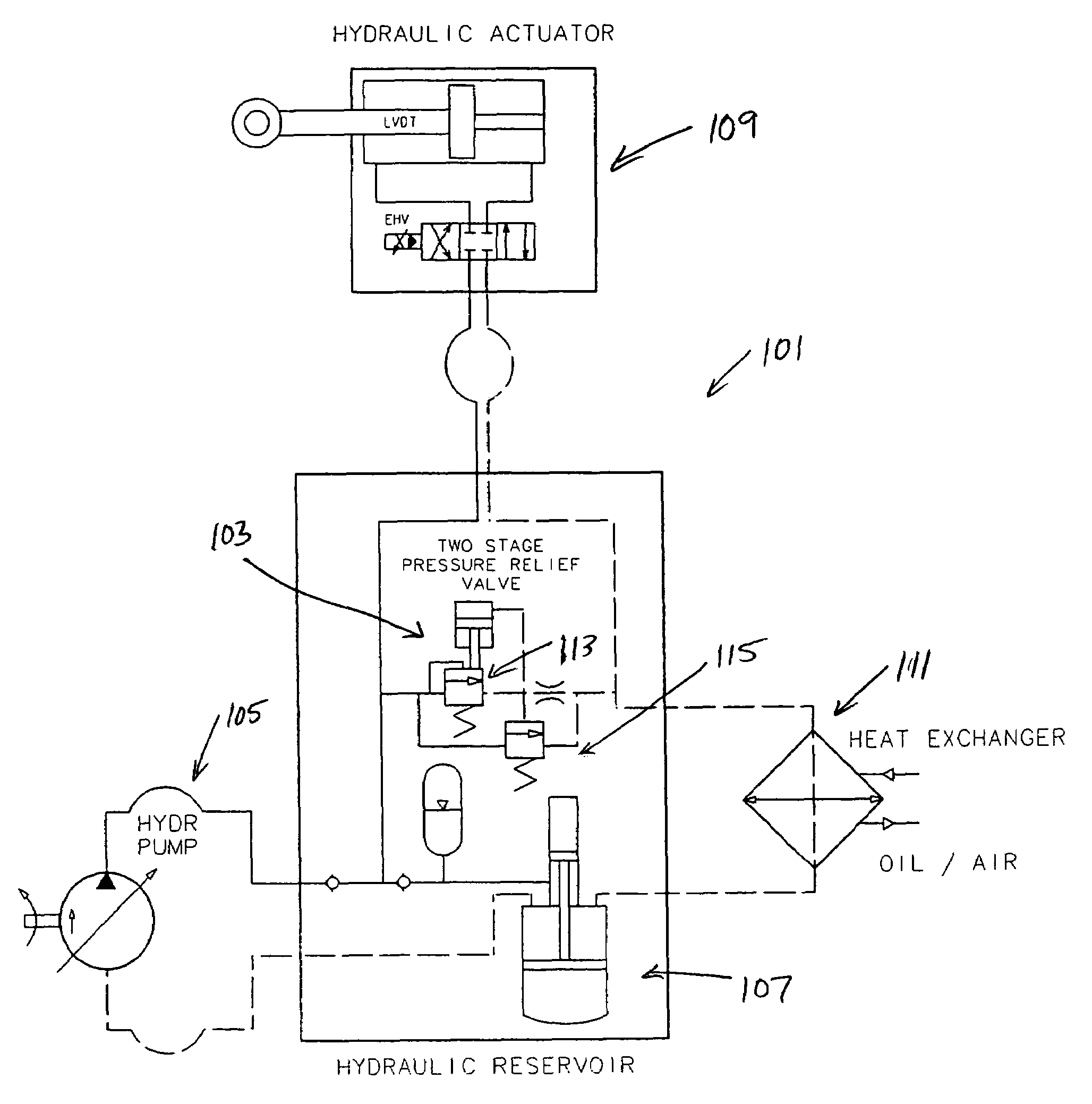

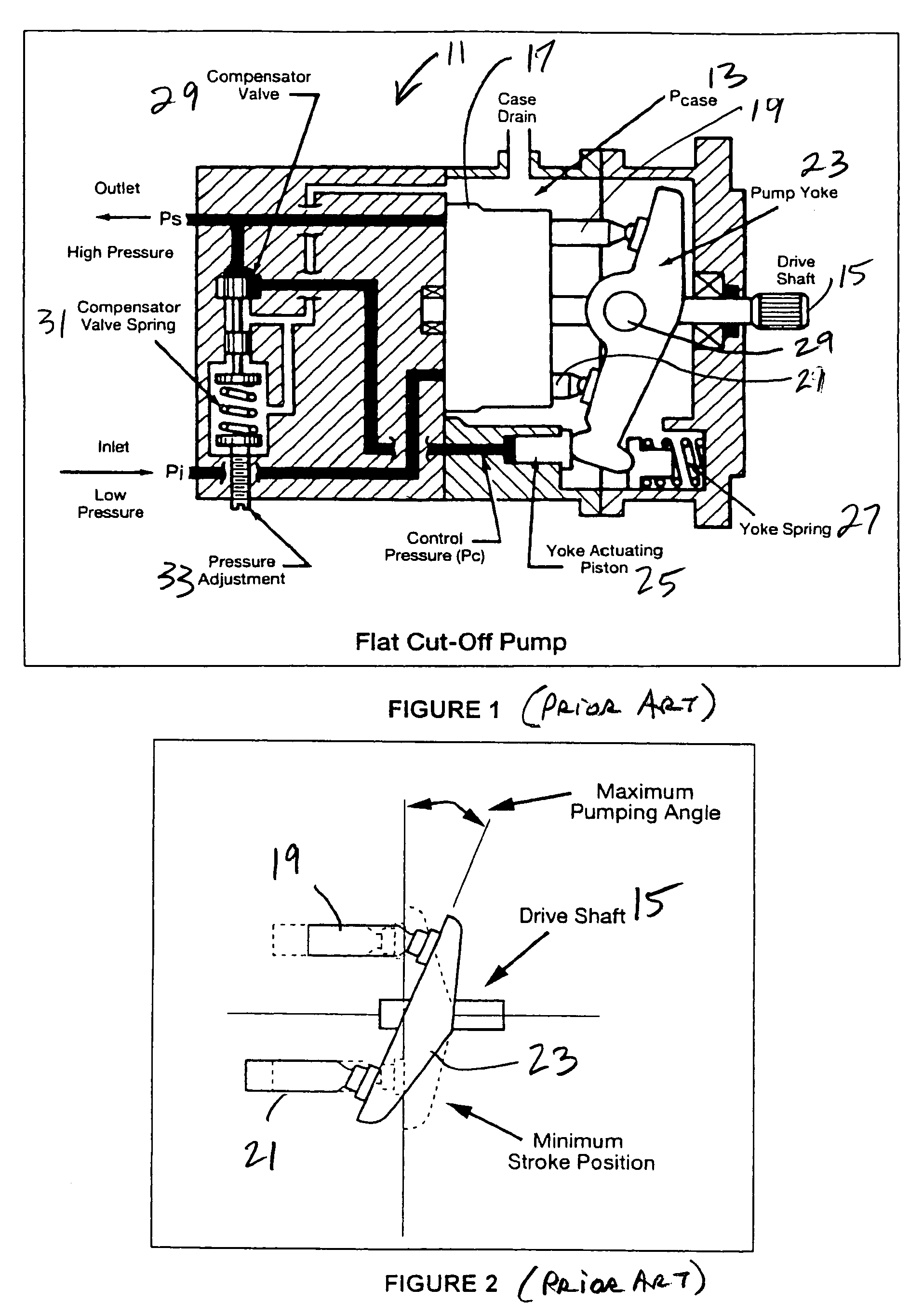

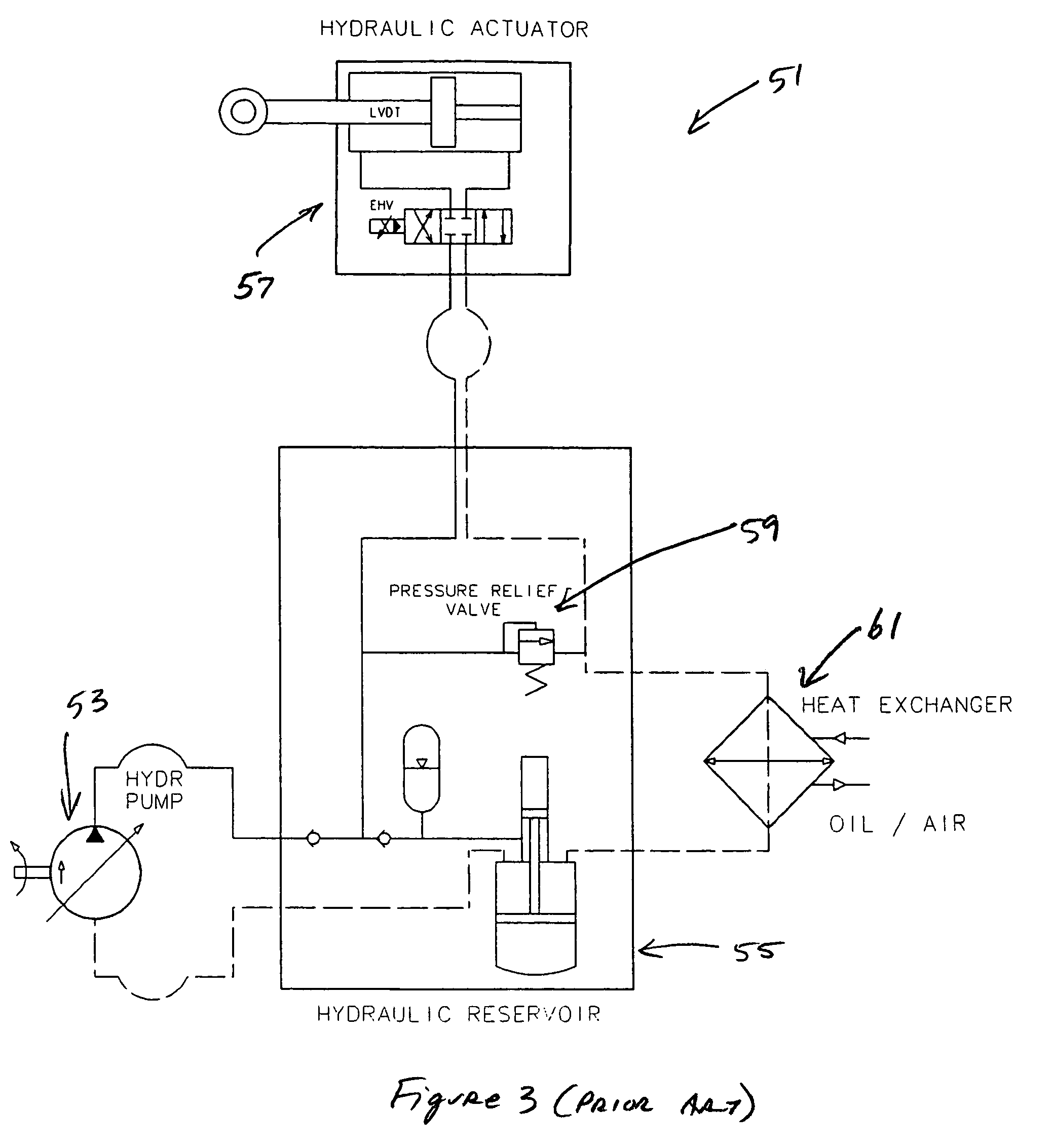

Two-stage pressure relief valve

ActiveUS7165950B2More reliableLess expensiveFluid-pressure actuator safetyServomotor componentsDecreased pressureSystem pressure

A two-stage pressure relief valve for use with hydraulic systems is disclosed. The two-stage pressure relief valve has a first stage that relieves increases in hydraulic system pressure over the normal operating pressure and up to a selected threshold pressure level, and a second stage that brings the hydraulic system pressure down to a selected reduced operating pressure that is below the normal operating pressure in response to increases in the operating pressure over the threshold pressure level.

Owner:BELL HELICOPTER TEXTRON INC

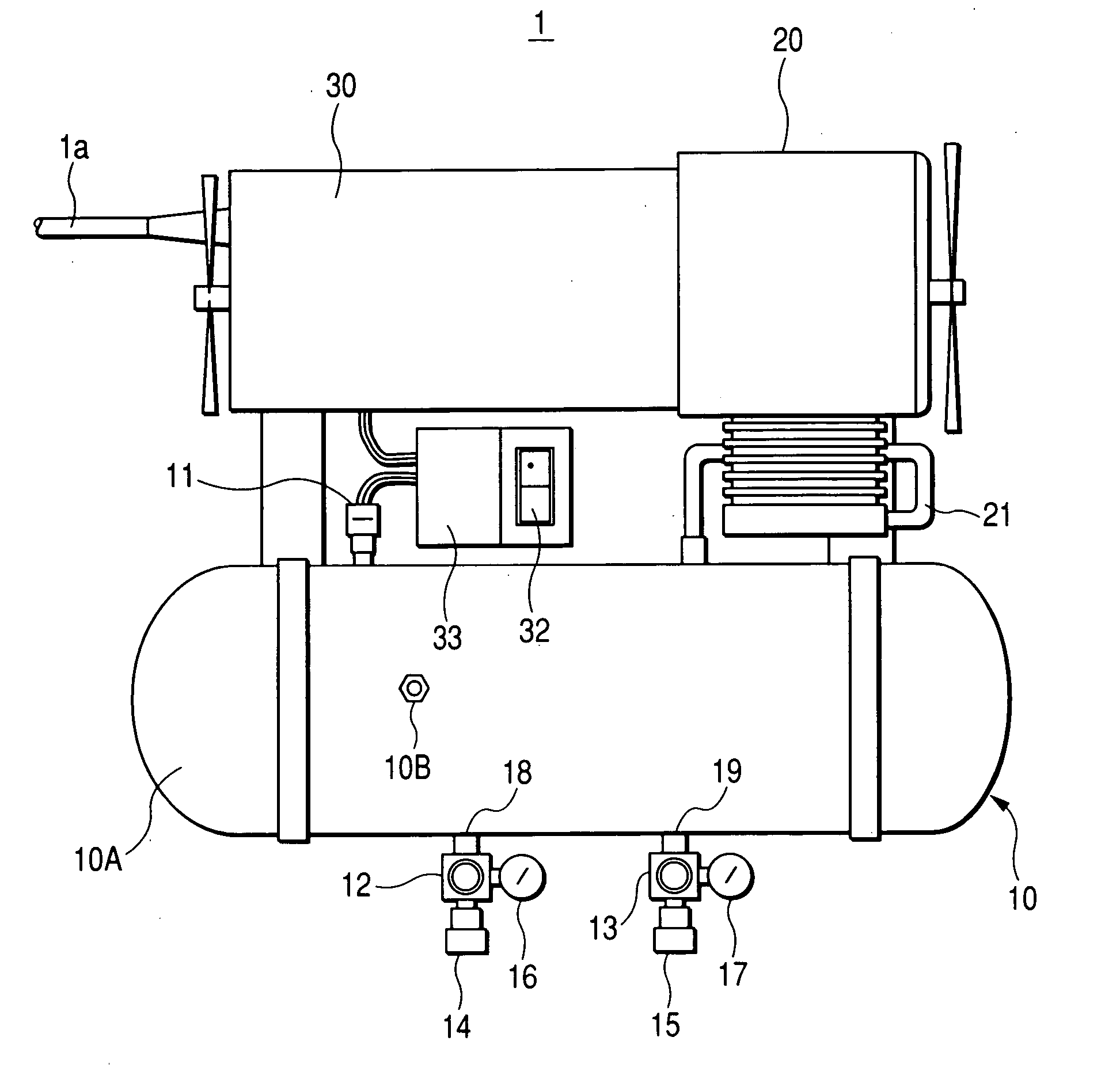

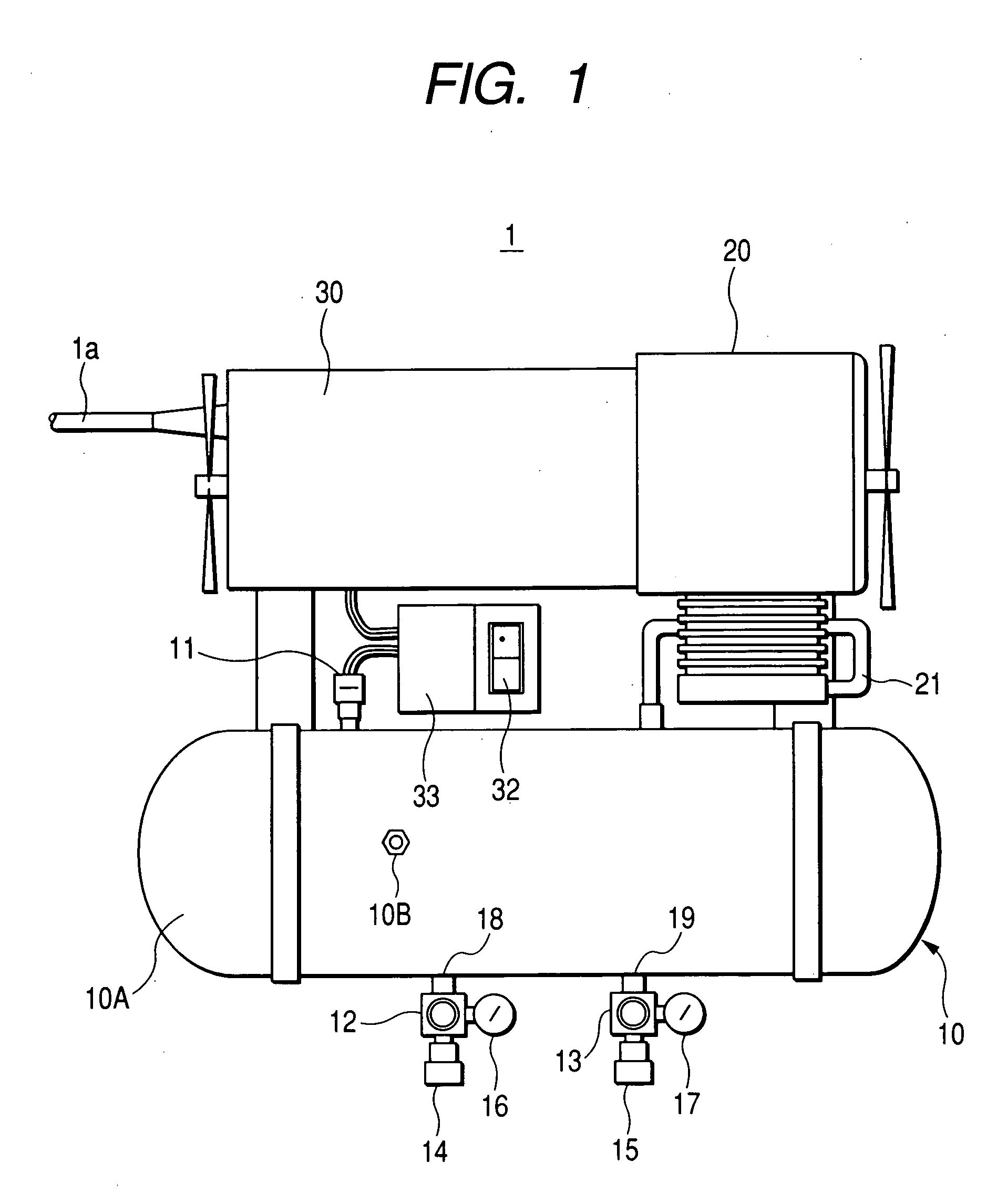

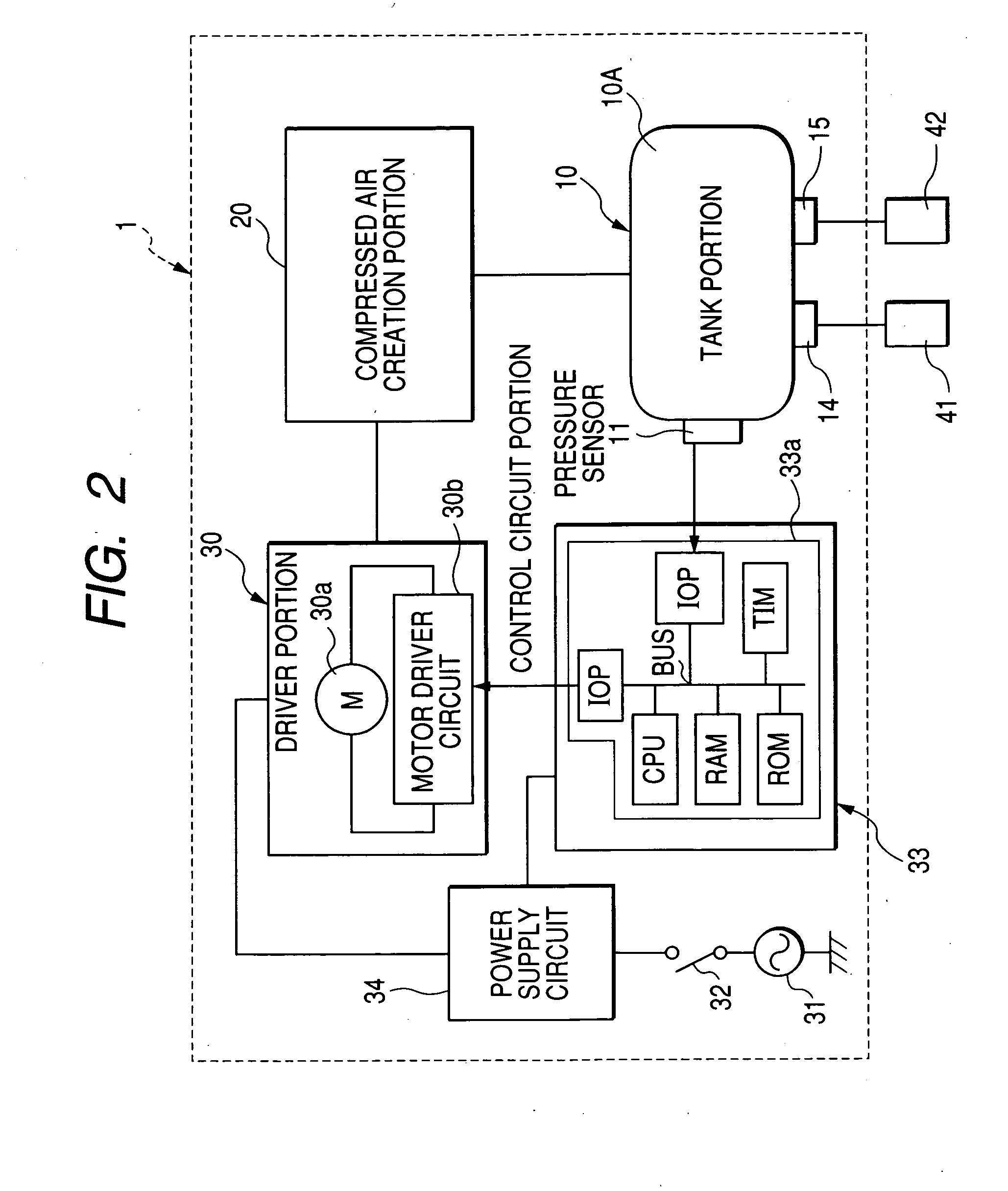

Air compressor

InactiveUS20060110258A1Increase internal pressureFrictional forcePump controlPositive-displacement liquid enginesDecreased pressureEngineering

A control circuit portion in an air compressor finds the rate of decrease of pressure inside a tank portion when a motor is at rest relative to the time based on a detection signal from a pressure sensor. Where the rate of decrease of pressure is greater than a given value, the motor is started without waiting for the pressure inside the tank to decrease to a motor restart pressure value, the pressure inside the tank portion rises to a given motor stop pressure value and the motor is then controlled to come to a stop. Where the rate of decrease of pressure is less than the given value, the motor is started when the pressure inside the tank has decreased to the motor restart pressure value. After the start of the motor, the motor is controlled such that it comes to a stop when the pressure inside the tank portion increases to a given value lower than the motor stop pressure value.

Owner:KOKI HLDG CO LTD

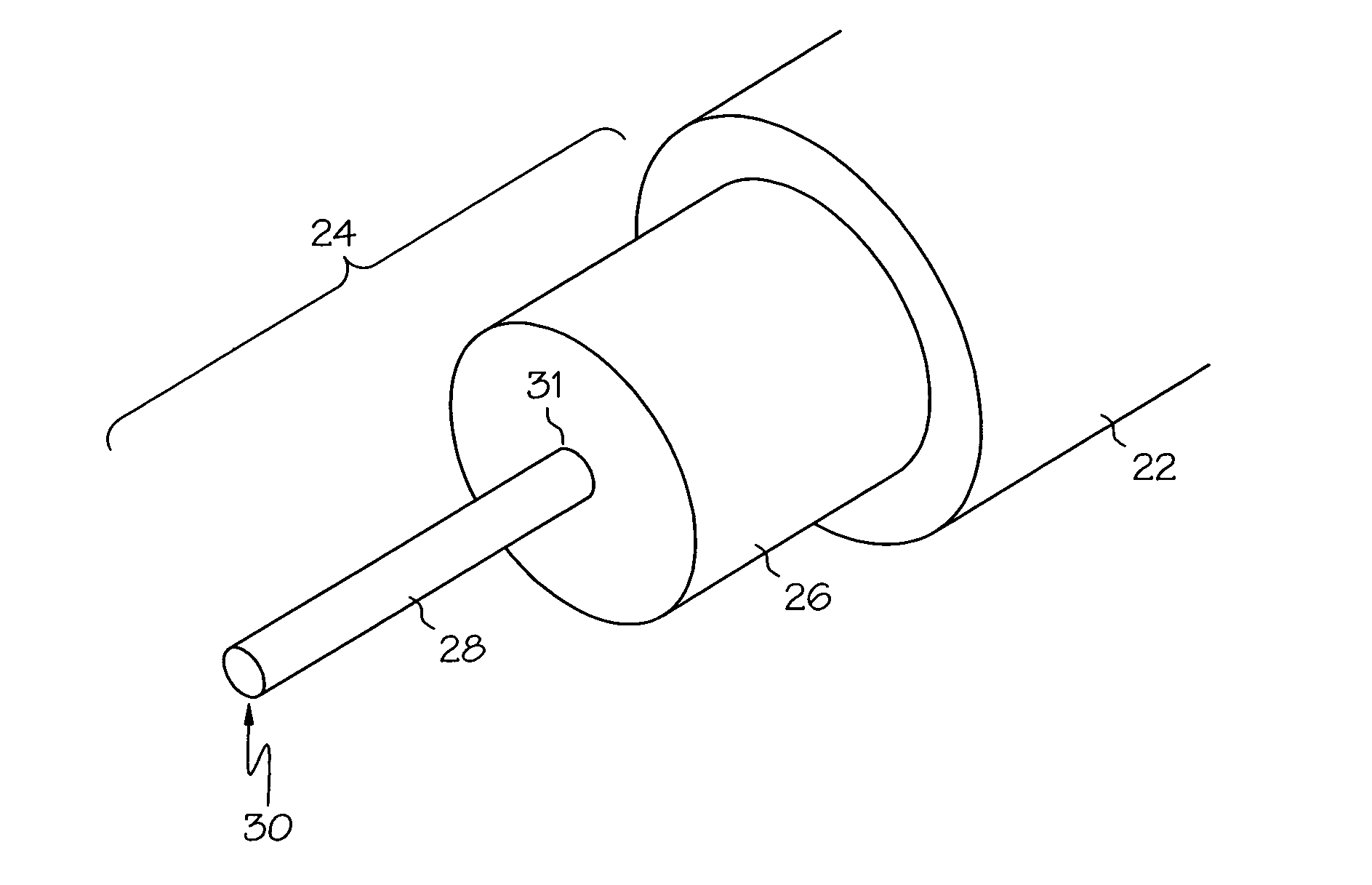

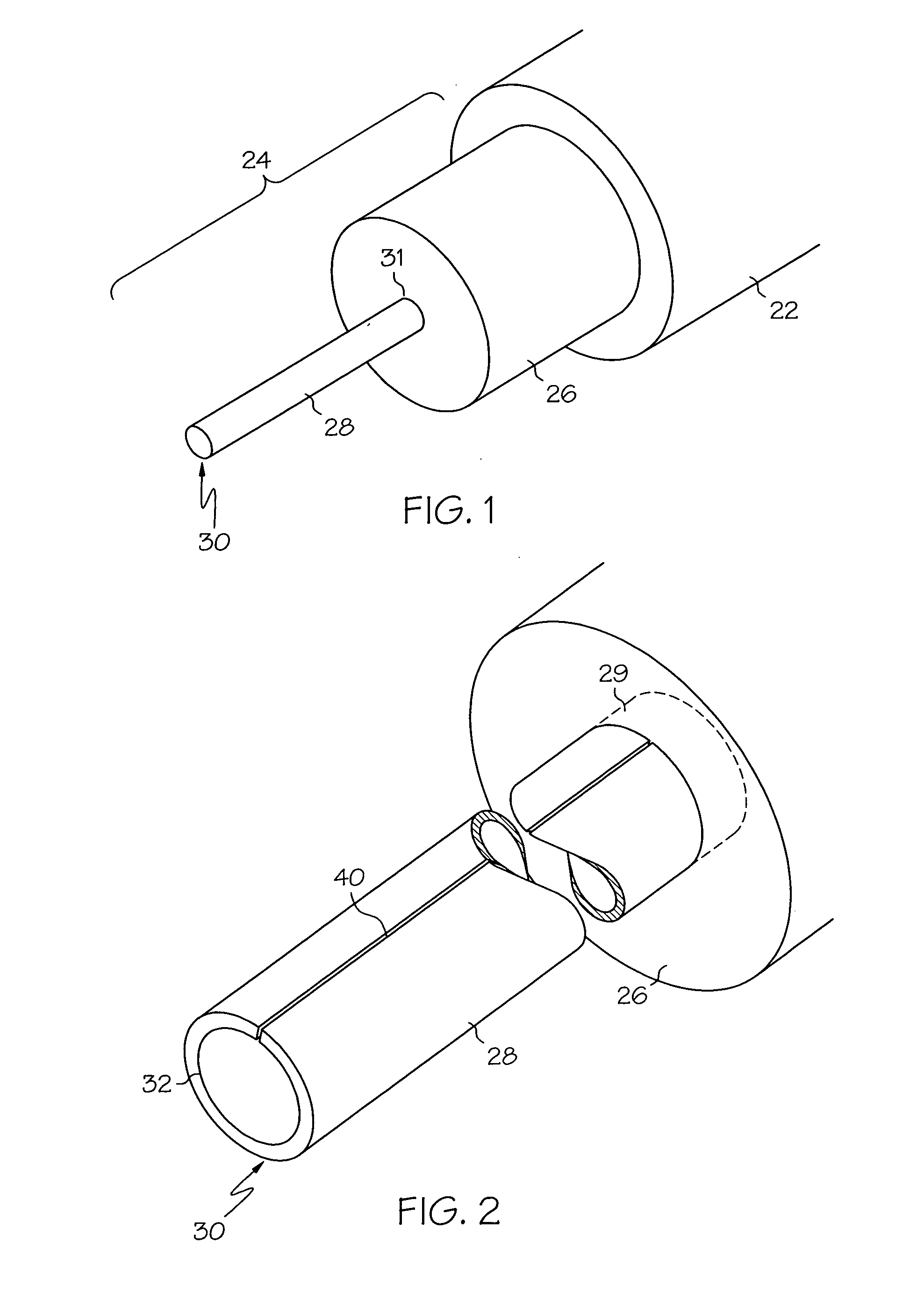

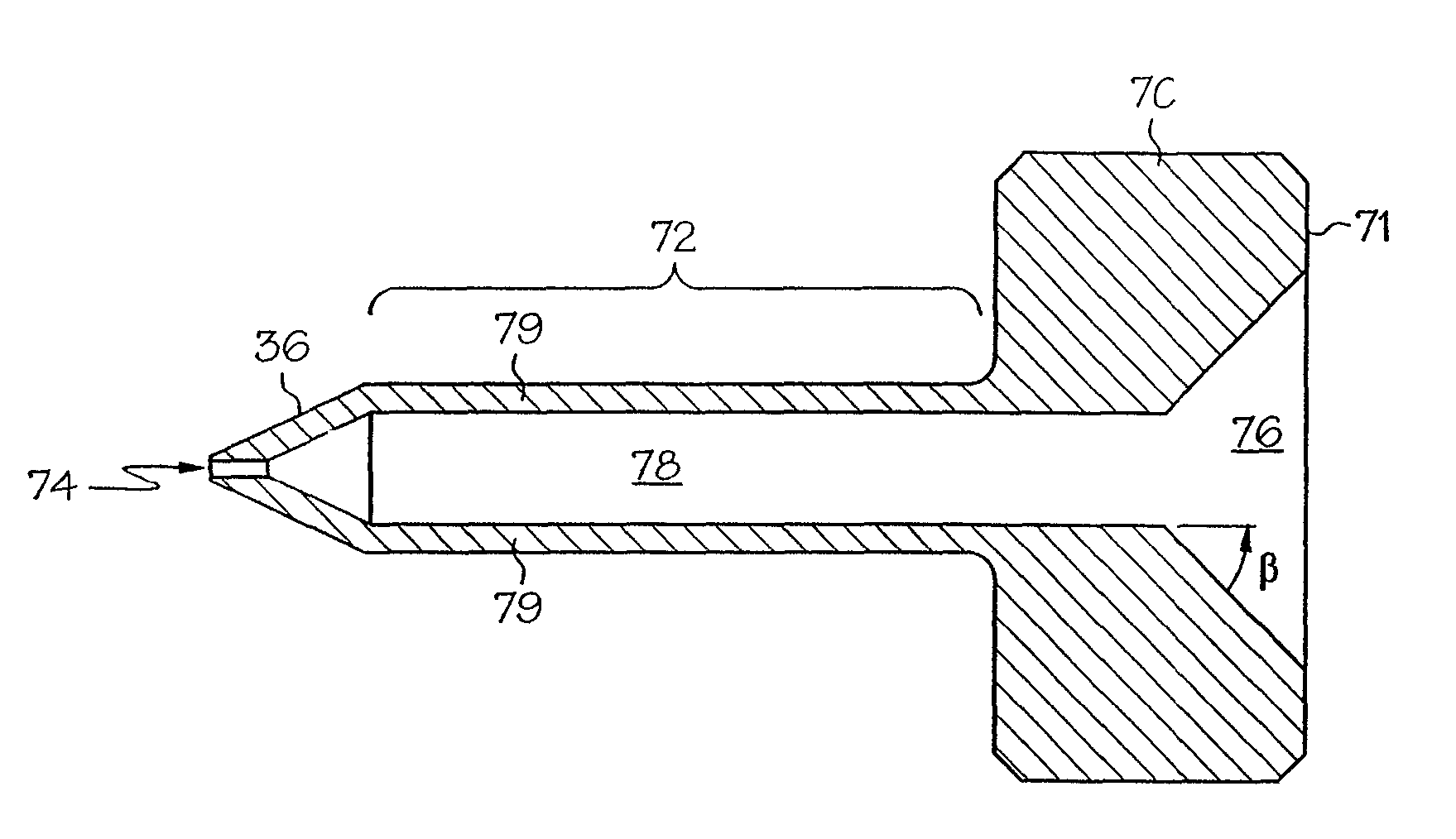

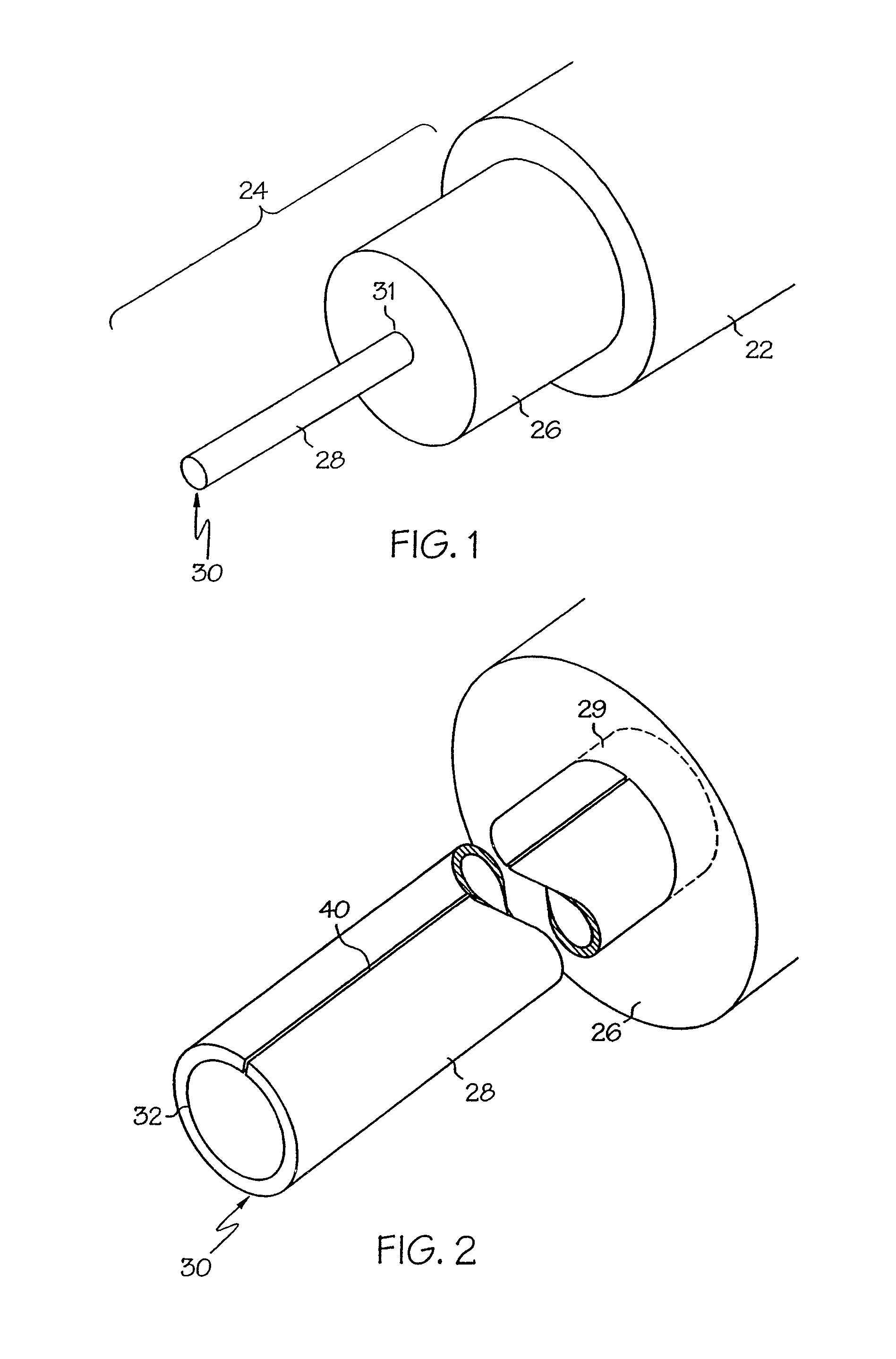

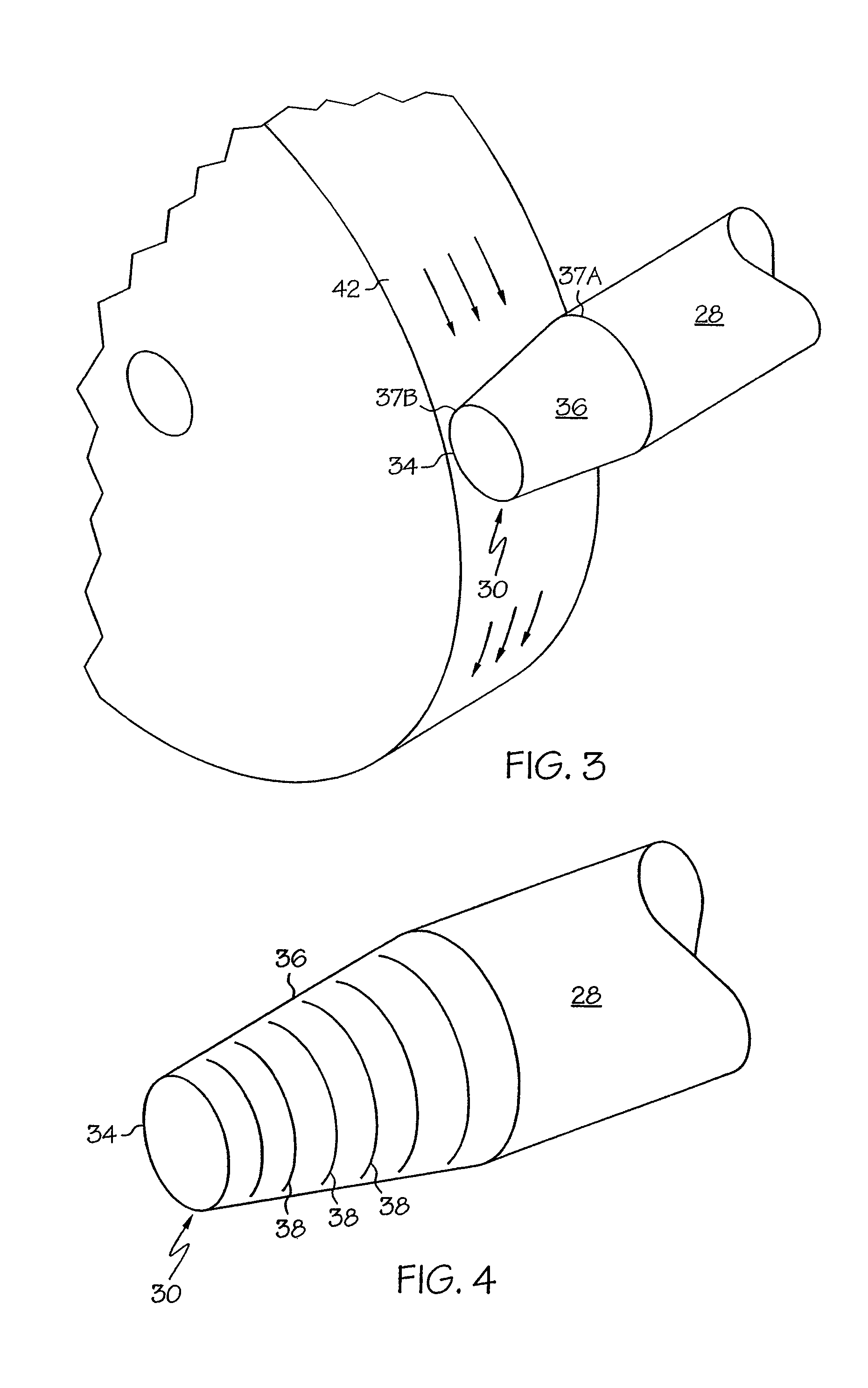

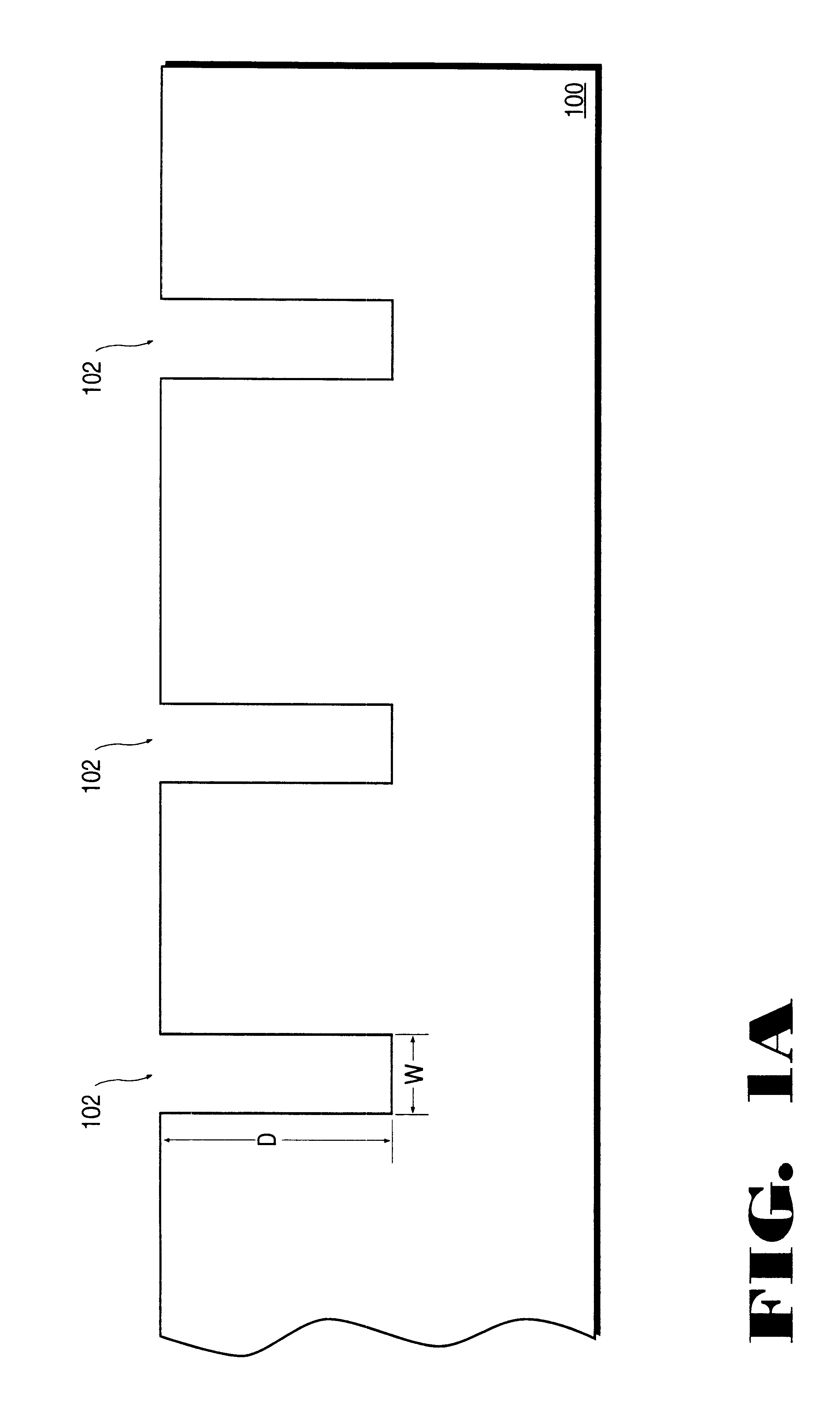

Fluid dispense tips

InactiveUS6896202B1Prevent buildupExtended service lifeLiquid surface applicatorsSpray nozzlesDecreased pressureEngineering

A fluid dispense tip includes a bevel at an opening to reduce the amount of surface tension, or “land”, at the opening. The bevel is formed by grinding in a longitudinal direction such that any tooling scars resulting from the grinding operation are likewise longitudinally oriented, further reducing the amount of surface tension in the tip, thereby leading to heightened dispensing accuracy. The tip may be machined from stock as a unitary piece, to increase its lifetime, and may be formed with a bore of a relatively large diameter that is tapered down to a smaller diameter near the tip opening, to allow for delivery of fluid through the tip body at a decreased pressure. A cleaning tool may be provided for removing residual material from the inner surfaces of the tip. A removable liner sleeve may be provided within the bore to reduce the effective inner diameter of the dispense tip.

Owner:DL TECH

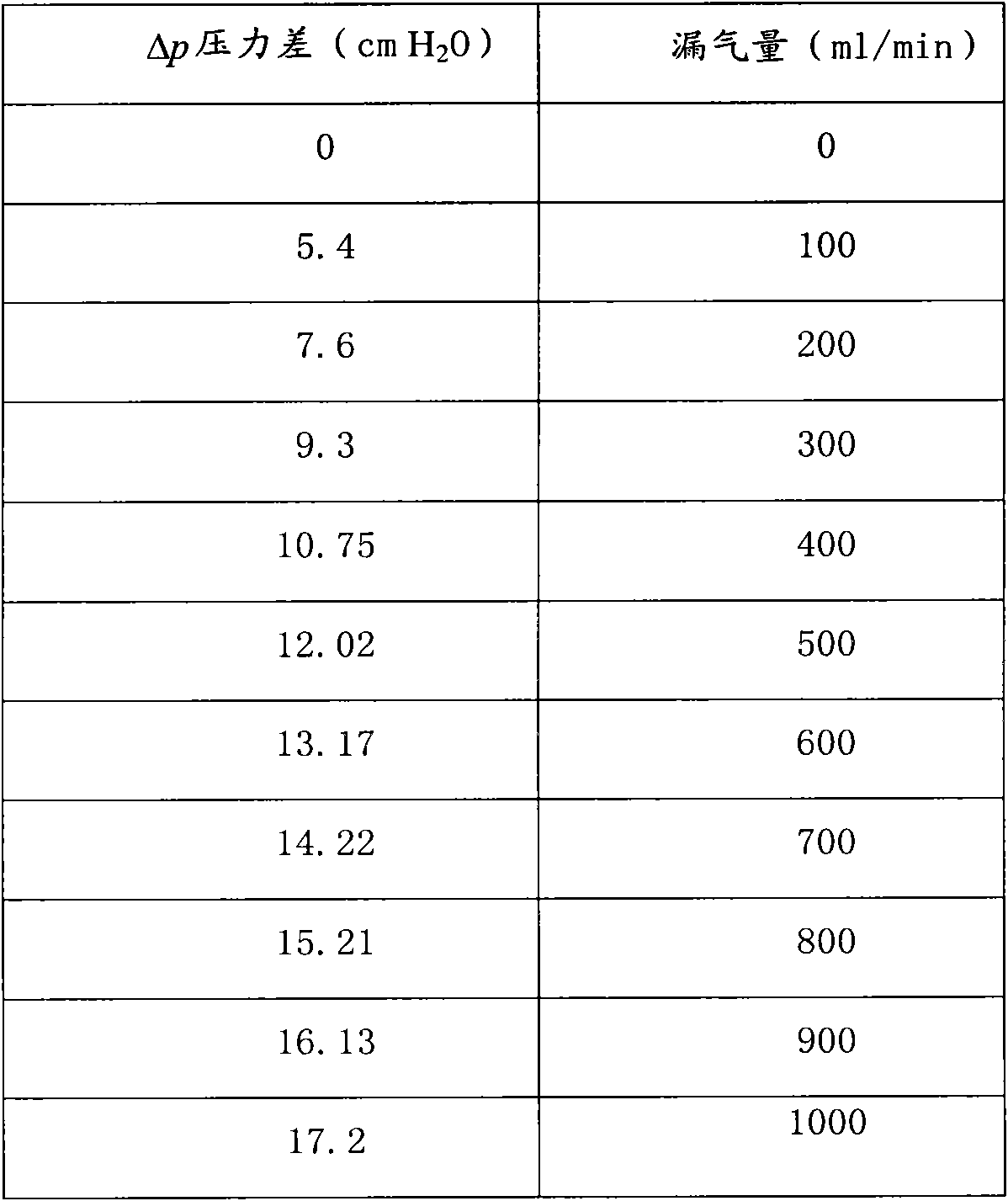

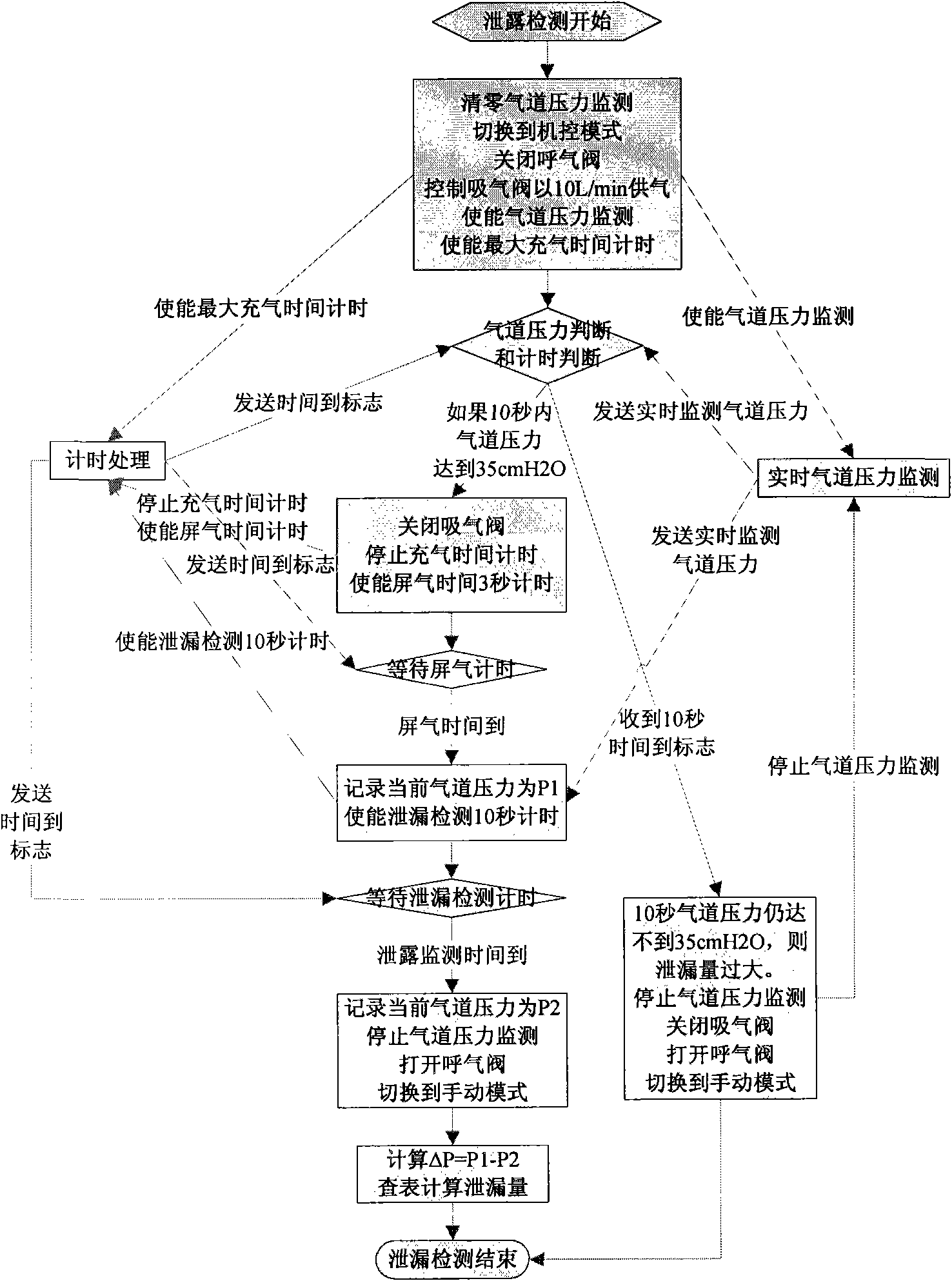

Method for leak detection of anesthesia machine system

InactiveCN101592547AHigh precisionAccurate detectionRespiratorsMeasurement of fluid loss/gain rateInternal pressureDecreased pressure

The invention provides a method for the leak detection of an anesthesia machine system. The method comprises the following steps that: each gas passage of the anesthesia machine system, which is communicated with outside, is closed, and the anesthesia machine system becomes a closed containing cavity; an inspiratory valve is opened, the anesthesia machine system is inflated, and simultaneously, a pressure sensor of the gas passages is utilized to monitor the internal pressure of the anesthesia machine system at real time; when the internal pressure of the anesthesia machine system reaches a preset value, the inspiratory valve is closed, and inflation is stopped; the current internal pressure of the anesthesia machine system is detected; the internal pressure of the anesthesia machine system is detected again after a preset time; the decreased pressure difference of the internal pressure of the anesthesia machine system is calculated; and a corresponding data table of the pressure difference and the leak quantity is looked up according to the pressure difference, and the leak quantity leaked by the anesthesia machine system is calculated. The method can accurately detect the gas leak quantity leaked by the anesthesia machine system, and can enhance the moisture control and the monitoring accuracy of the anesthesia machine simultaneously.

Owner:BEIJING AEONMED

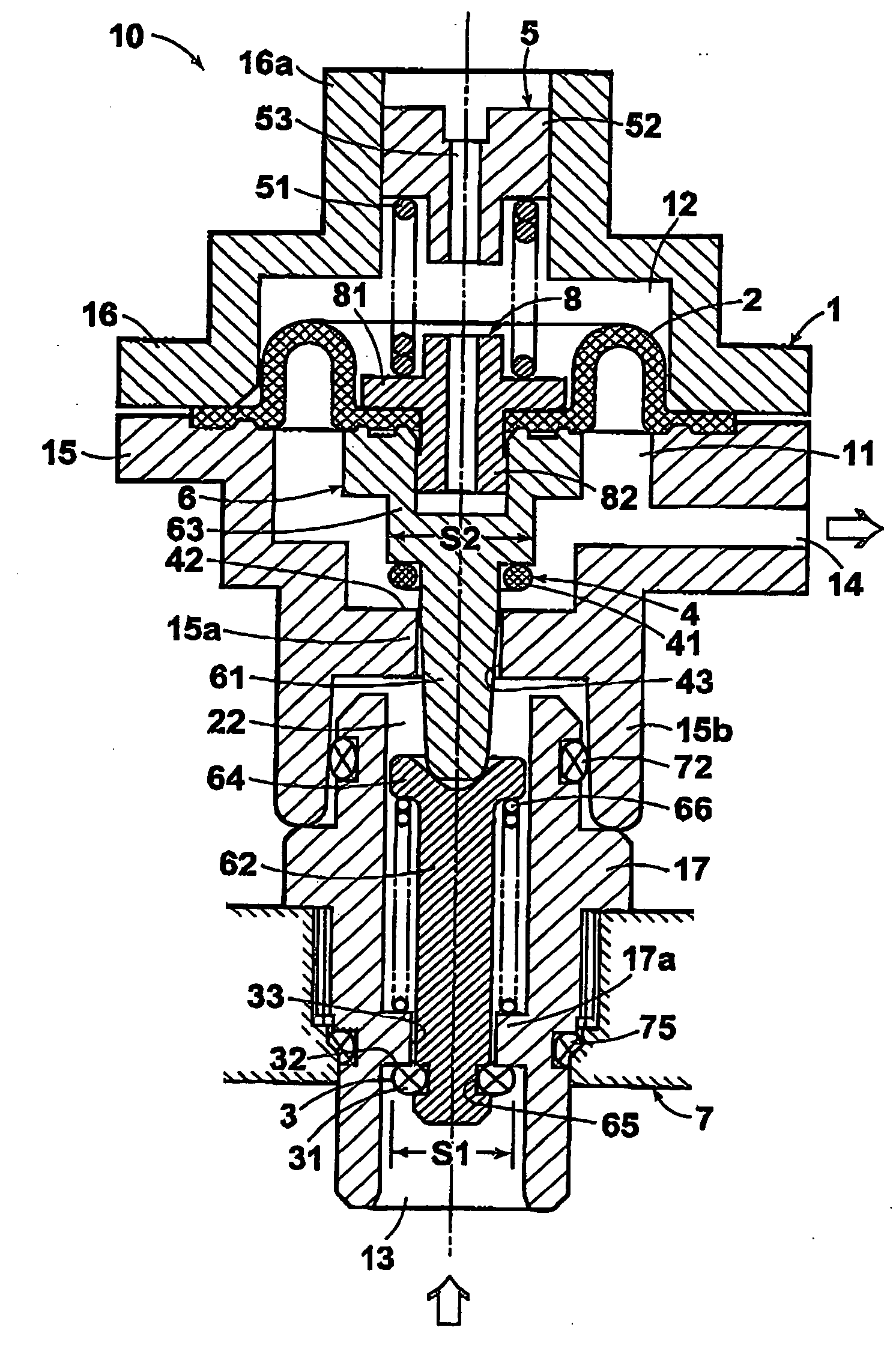

Pressure regulator

InactiveUS20050263189A1Simple structureOptimization mechanismOperating means/releasing devices for valvesFluid pressure control without auxillary powerDecreased pressureEngineering

A pressure regulator include a fluid introducing port; a primary regulating valve for reducing the primary pressure to a secondary pressure; a pressure regulating chamber receiving the fluid from the first pressure regulating valve; a diaphragm which is being displaced in response to the secondary pressure; a shift for drivingly connecting the diaphragm and the primary regulating valve; a pressure-setting section for adjusting a displacement magnitude of the diaphragm; and a discharging port through which the fluid of secondary pressure is discharged. The shaft includes a secondary regulating valve operatively associated with the primary regulating valve so as to further regulate the fluid from the primary regulating valve by opening-closing operations in reverse to those of the primary regulating valve. Hence, the pressure regulation characteristic of the secondary regulating valve against the fluctuations in the primary pressure become reverse to that of the primary regulating valve.

Owner:TOKAI

Two-phase flow injector replacing refrigerator throttling element

InactiveCN1776324AImprove efficiencyCompression machinesLiquid spraying apparatusMixed flowDecreased pressure

Injector in two-phase flow includes step motor, adjustable valve body, nozzle, case of injector, adaptor of injection liquid, air intake cavity, mixing chamber and pressure expansion chamber etc. In nozzle, refrigerant agent is quickened up continuously so as to reduce pressure in the air intake cavity. Thus, gaseous refrigerant agent from evaporator is injected to the air intake cavity. Then, gaseous refrigerant agent and liquid in main flow from condenser are mixed in the mixing chamber. Pressure expansion is carried out in pressure expansion chamber, and mixed flow outflows from case of injector. Mixing liquid in main flow with injection liquid is carried out under approximate equi-pressure. The pressure expansion chamber is designed based on theory of equal flow of momentum rate so as to raise efficiency of injector. Features are: few moving parts, raised efficiency of system about 5úÑ-20úÑ.

Owner:YORK WUXI AIR CONDITIONING & REFRIGERATION CO LTD

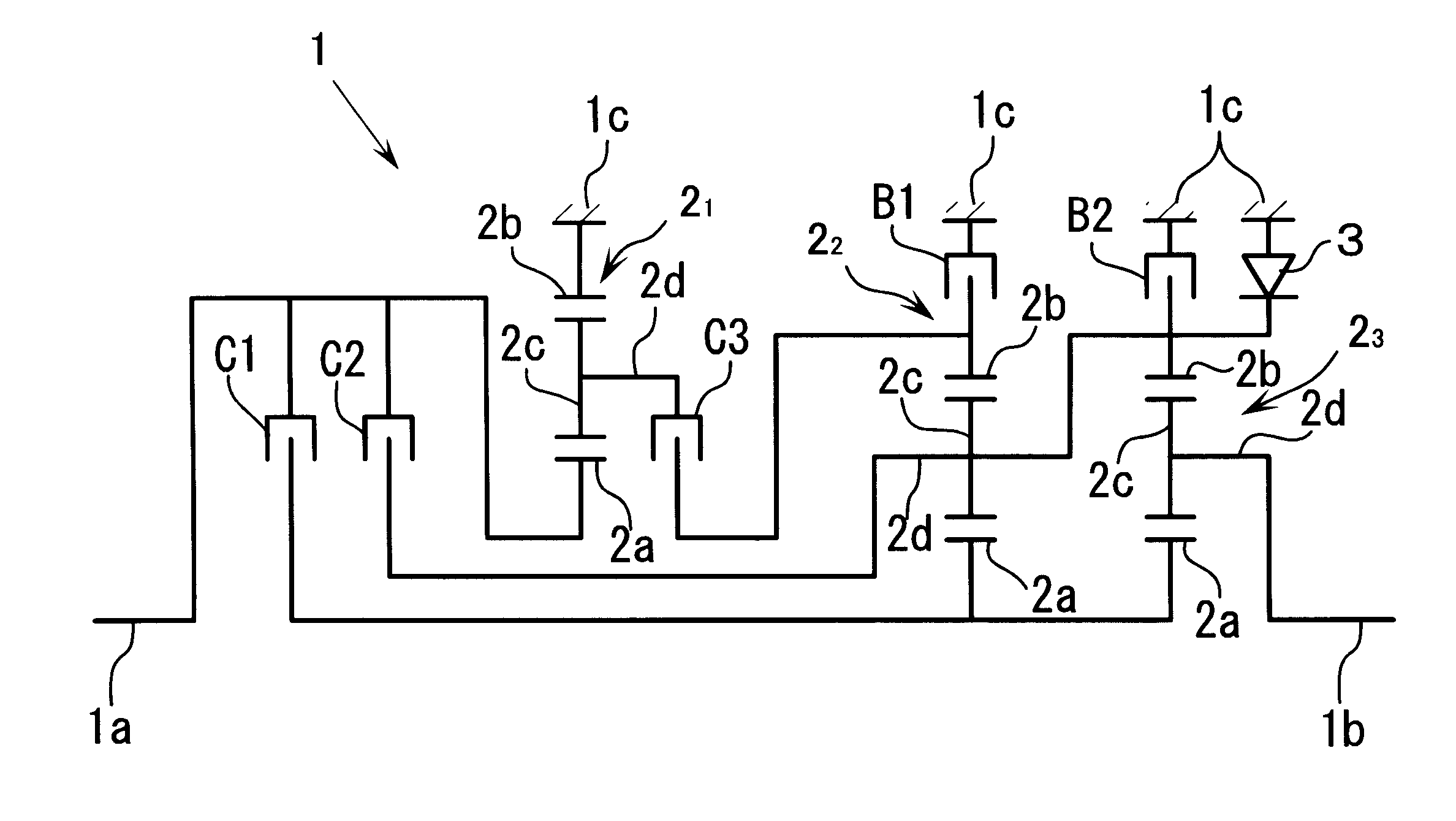

Vacuum preservation device, refrigerator and control method of vacuum preservation device

InactiveCN101948029AInhibit deteriorationTo meet the demand for extended storage timeLighting and heating apparatusPackaging under vacuum/special atmosphereTime extensionDecreased pressure

The invention provides a vacuum preservation device. The vacuum preservation device is provided with a vacuum preservation container, a vacuum pump and a pressure switch, wherein the vacuum pump is used for vacuumizing the vacuum preservation container; and the pressure switch is fixed on the vacuum pump and turns on and turns off the vacuum pump repeatedly to keep the pressure in the vacuum preservation container in a preset pressure range. The invention also provides a refrigerator provided with the vacuum preservation device. Furthermore, the invention provides a control method of the vacuum preservation device. The control method comprises the following steps of: selecting a vacuum preservation mode; starting to vacuumize; in the process of vacuumizing, turning off the vacuum pump by the pressure switch when the pressure in the vacuum preservation container is reduced to a first pressure value; and after the vacuum pump is turned off, feeding a startup signal back by the pressure switch to return to the step of vacuumizing and repeating the steps when the pressure in the vacuum preservation container is increased to a second pressure value. According to the vacuum preservation device, the refrigerator and the control method of the vacuum preservation device, the requirement on the extension of storage time under a low-oxygen vacuum environment of users is met, and the cost is reduced.

Owner:HAIER GRP CORP +1

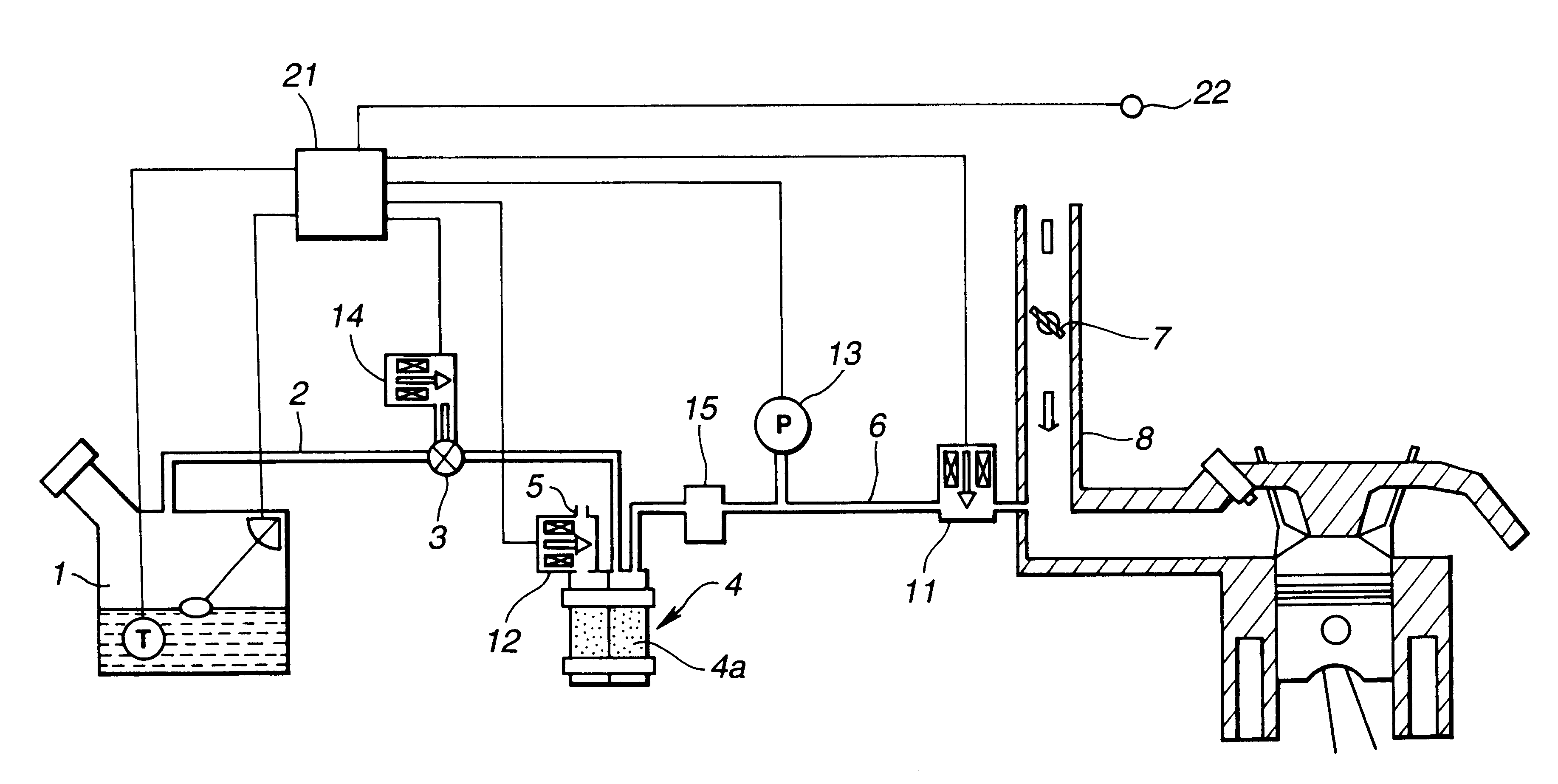

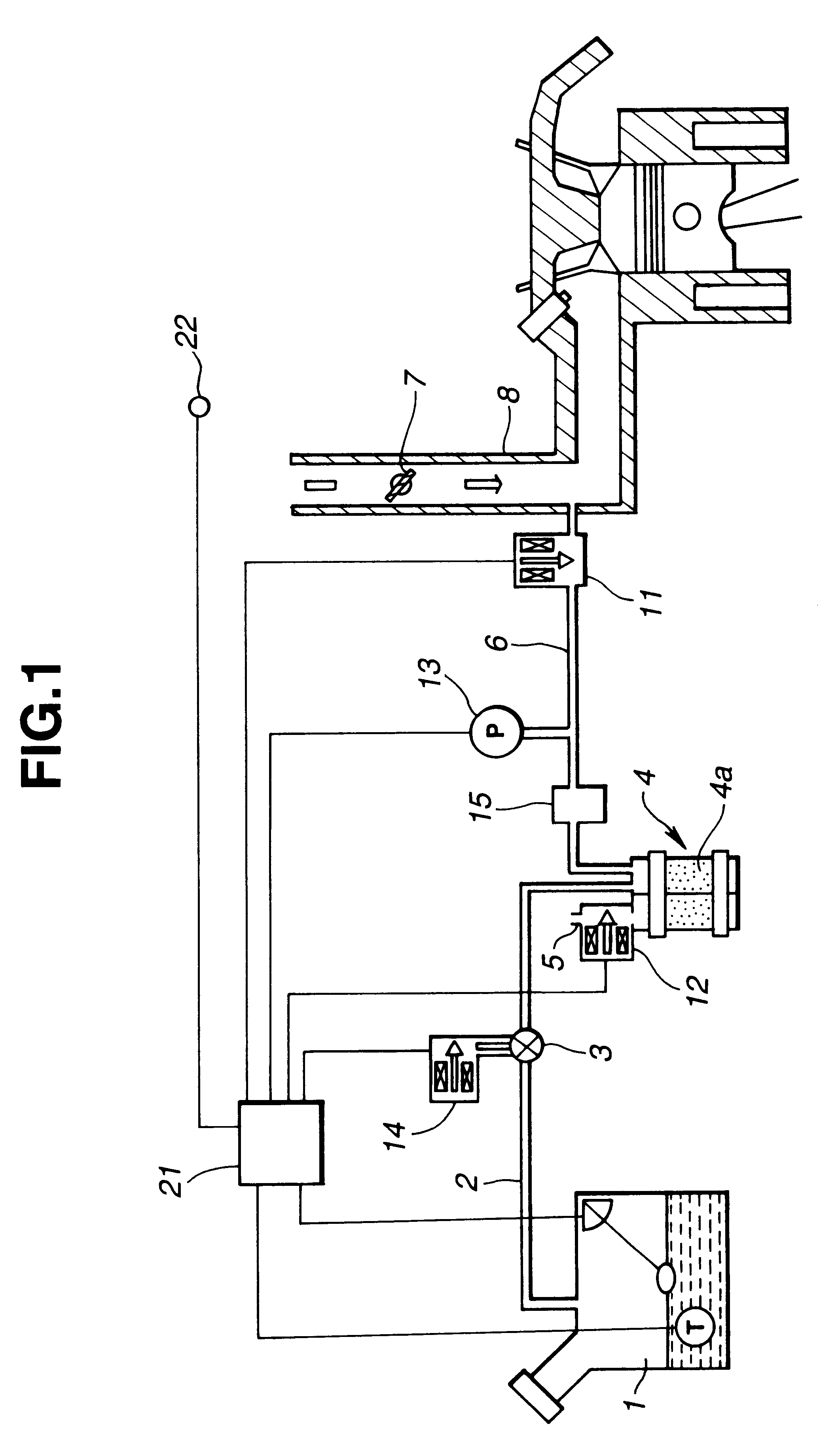

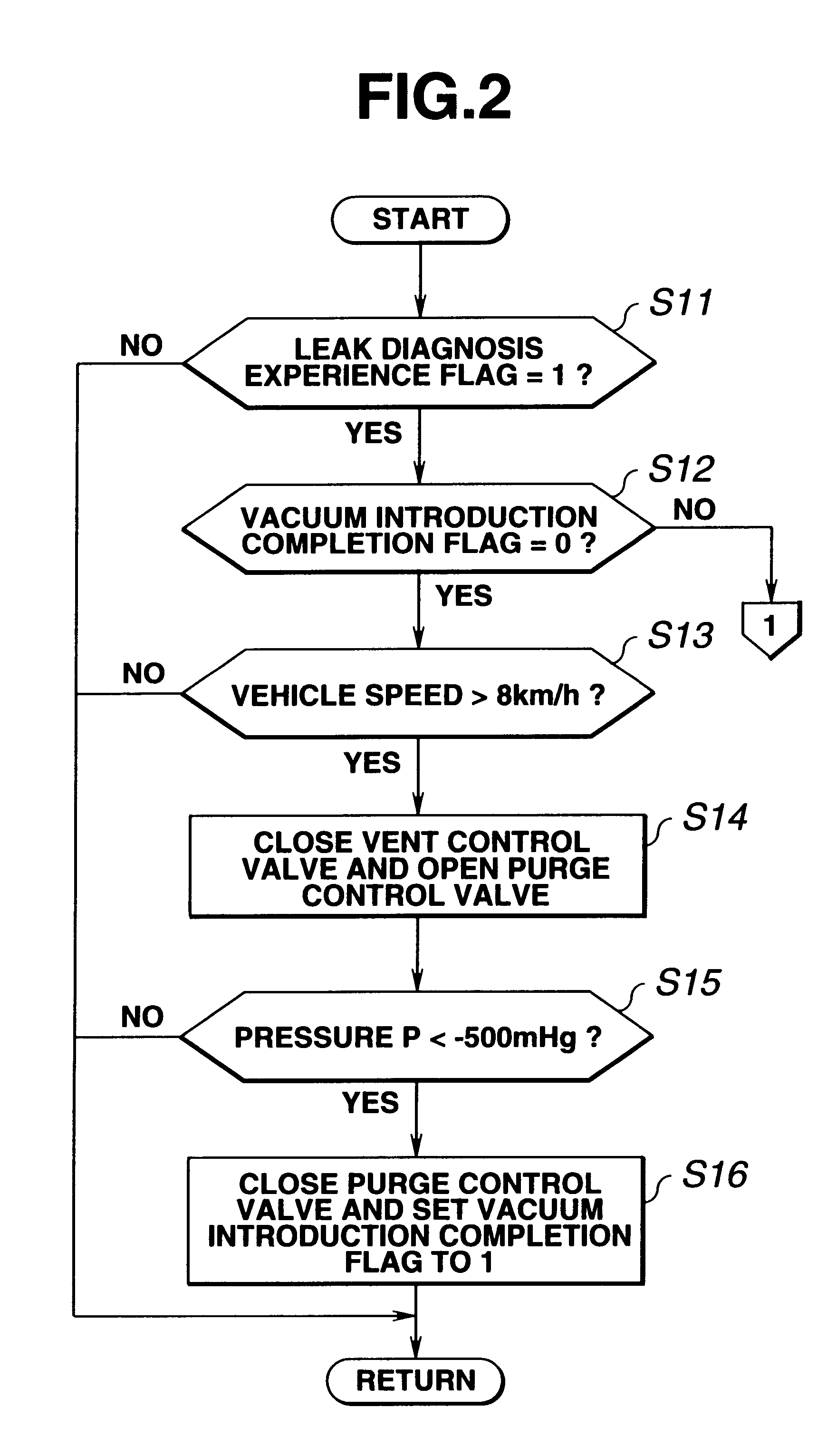

Evaporative emission control system for internal combustion engine

InactiveUS6220230B1Measurement of fluid loss/gain rateElectrical controlExternal combustion engineControl system

An evaporative emission control system is provided which includes a bypass valve, purge control valve and a vent control valve. To make a leak diagnosis, firstly the vent control valve is closed while the purge control valve is opened, whereby to negatively pressurize the inside of a fuel vapor conduit portion extending from the bypass valve to an intake pipe side. After the pressure in the fuel vapor conduit portion from the bypass valve to the intake pipe is reduced to a predetermined value, the purge control valve is closed. Then, the bypass valve is opened, and after lapse of a predetermined time from the opening of the bypass valve a variation of pressure in a conduit extending from the fuel tank to the purge control valve is asured. Based on the variation of pressure, a leak diagnosis is made. By this, the evaporative emission control system can prevent the fuel vapor in the fuel tank from being drawn into the intake pipe during reduction of pressure in the conduit and thus causing unstable operation of an engine.

Owner:NISSAN MOTOR CO LTD

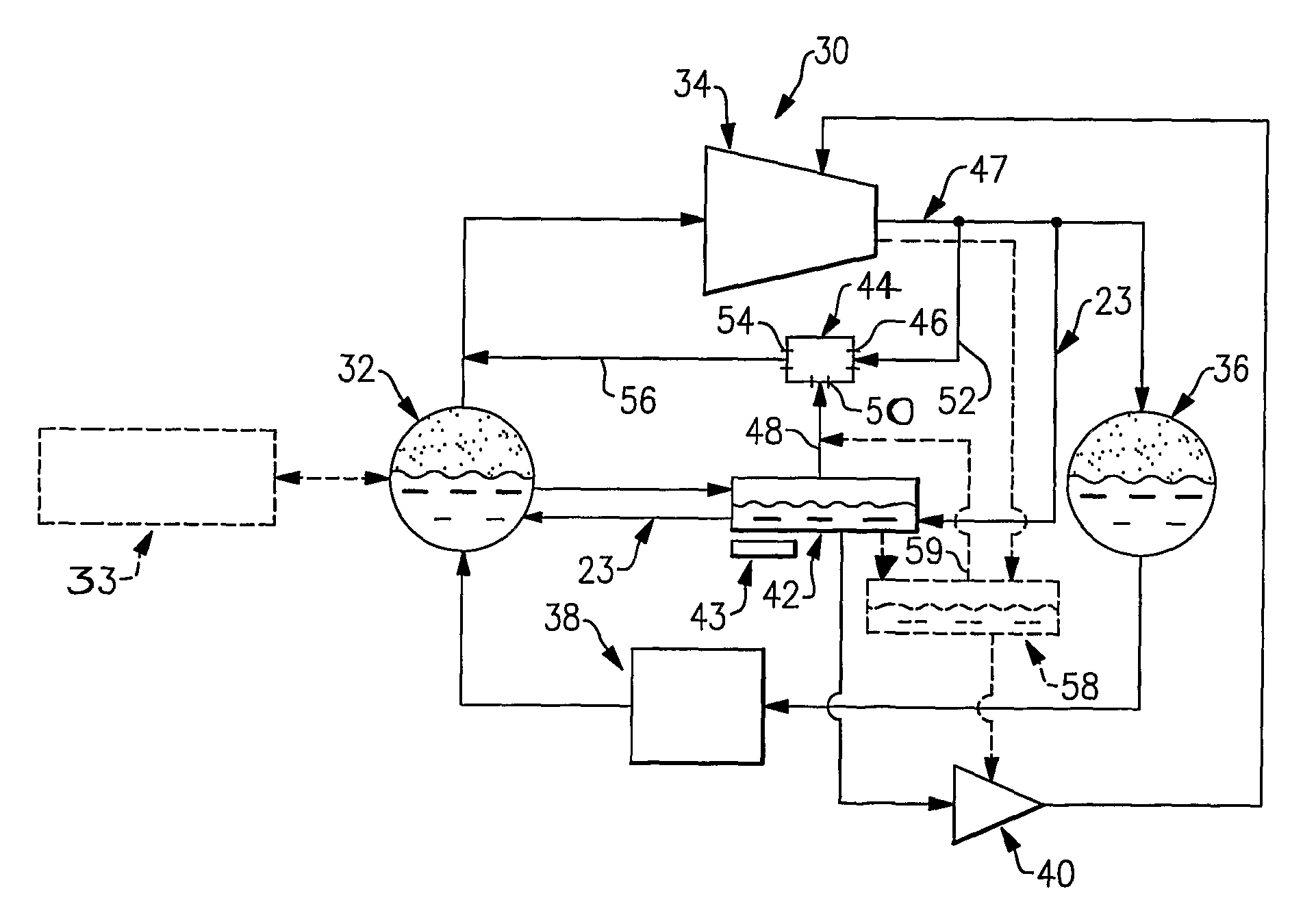

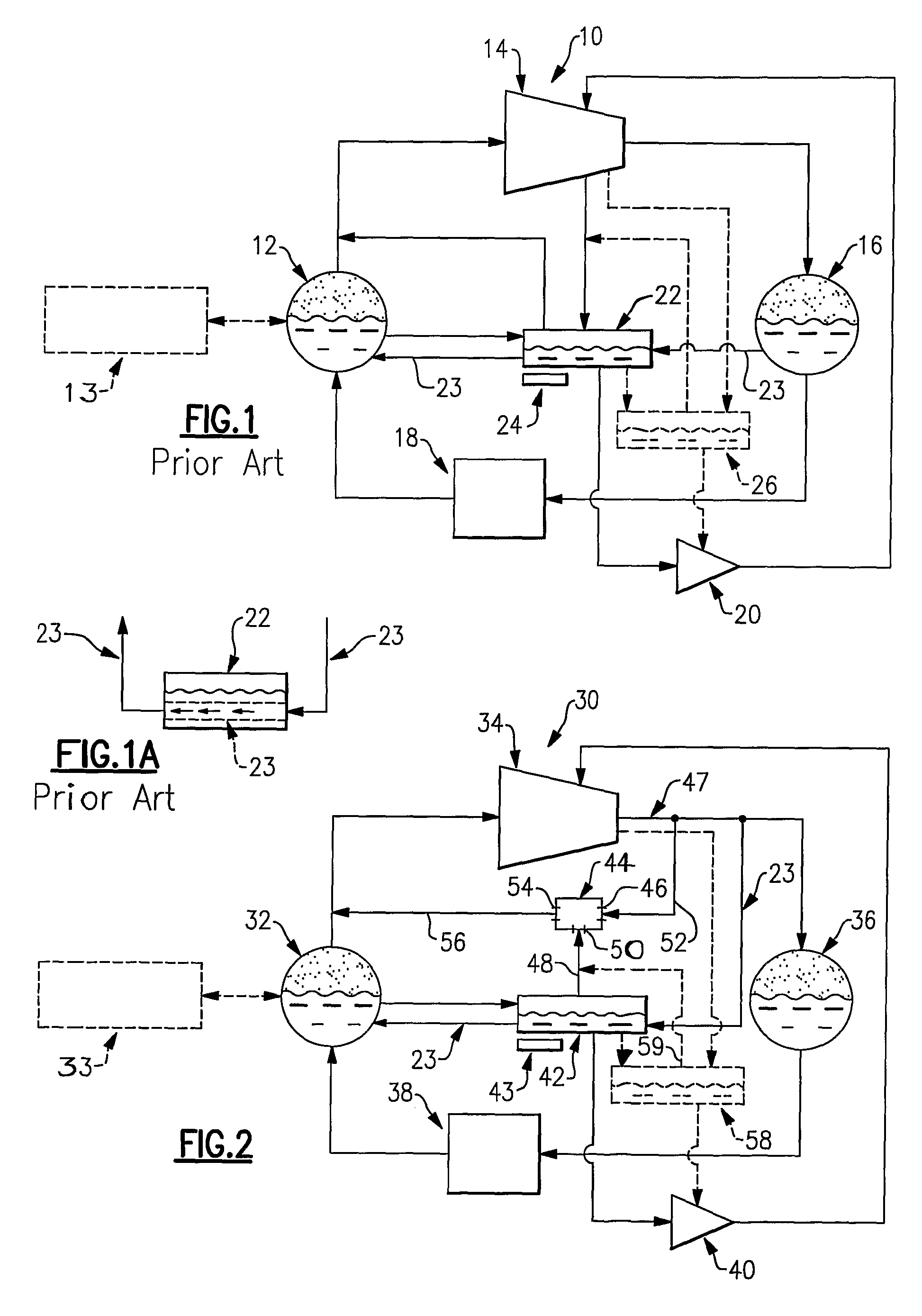

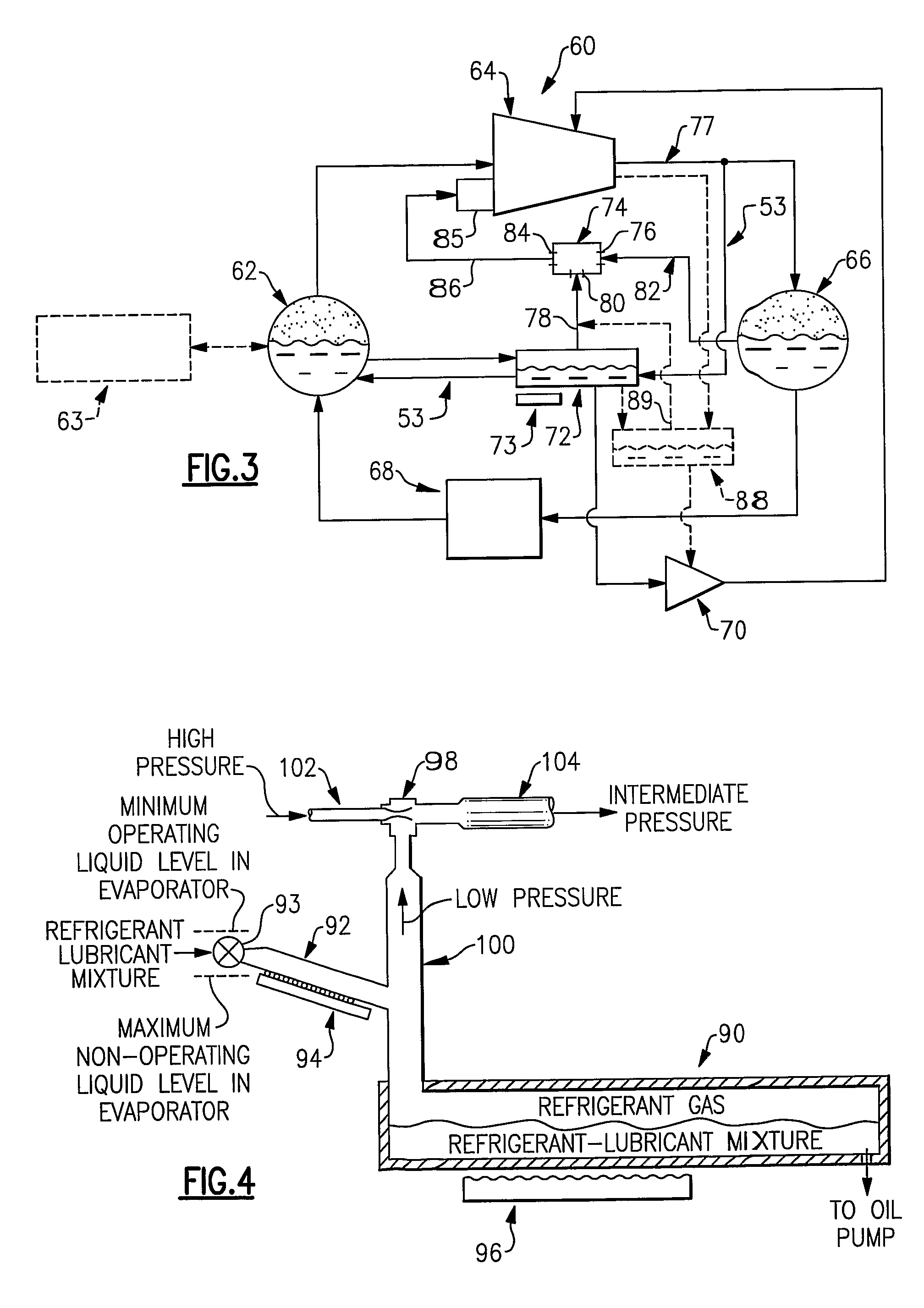

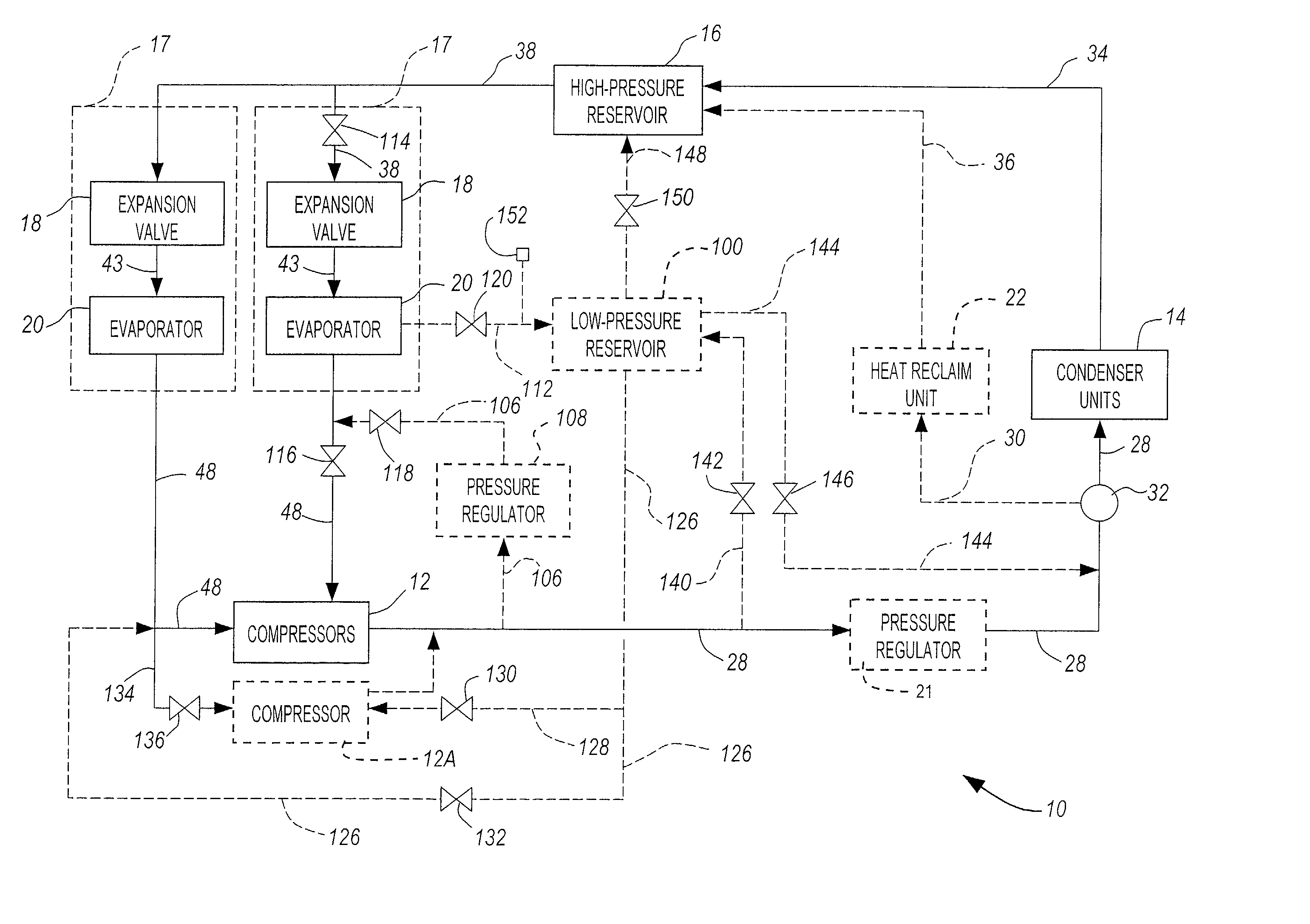

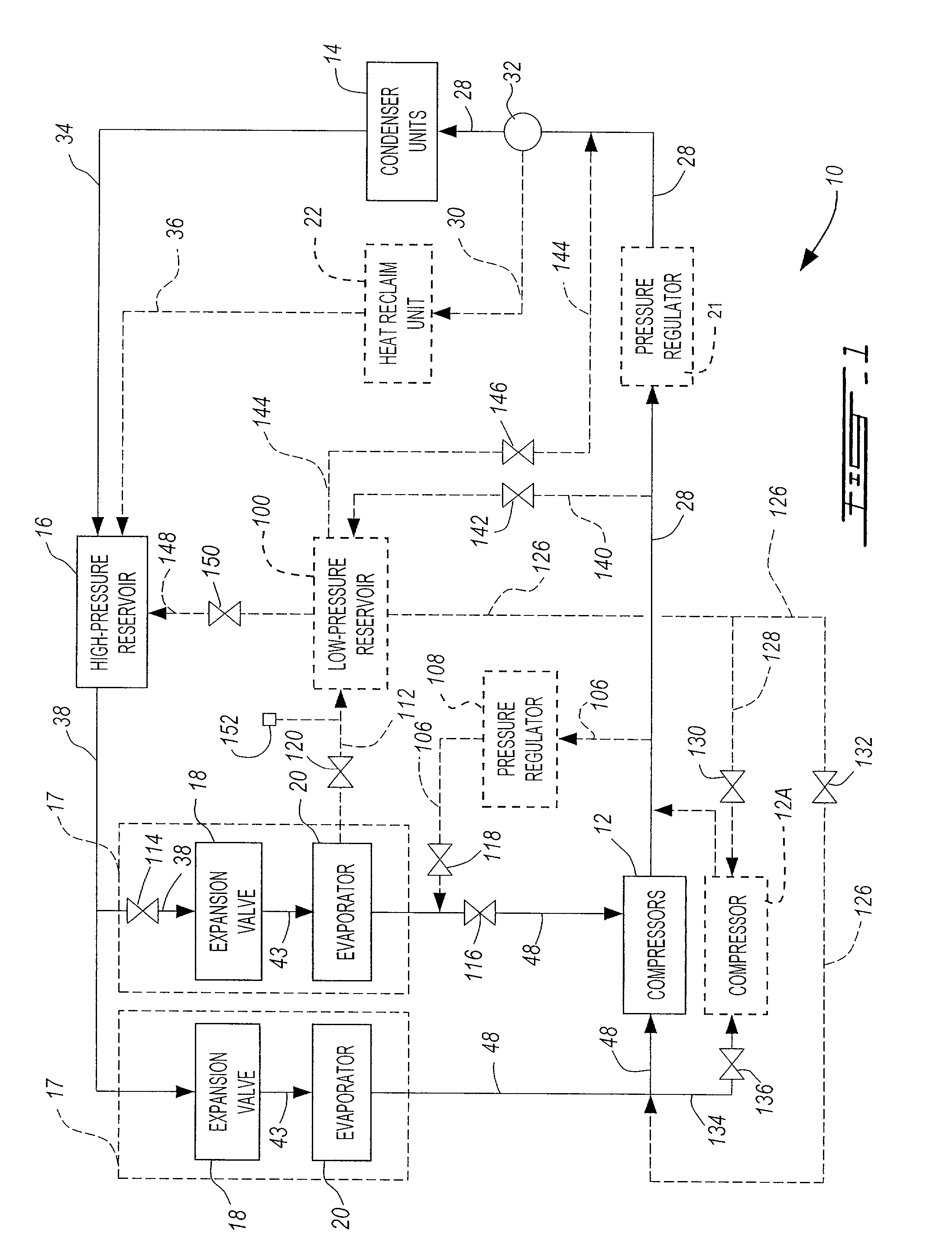

De-Gassing Lubrication Reclamation System

ActiveUS20080210601A1Reduce pressureCompressorCompression machines with non-reversible cycleGas lubricationDecreased pressure

A vapor compression system (10), also known as a chiller, includes a refrigeration loop and a lubrication loop. The lubrication loop includes a lubrication reclamation system that further includes a still (42) and an ejector (44) to reduce a pressure in the still (42). The ejector (44) includes an input portion (46), an output portion 54 and a vent portion (50). The input portion (46), the output portion (54) and the vent portion (50) are in fluid communication with one another. The vent portion (50) of the ejector (44) is positioned in a vent line (48) associated with the still (42). The still (42) primarily contains a mixture of liquid refrigerant and lubricant. The input portion (46) of the ejector receives liquid or gas at a high pressure and expels the liquid or gas through the output portion (54) at an intermediate pressure. As the input fluid at a high pressure flows through the ejector (44), a low pressure is created at the vent portion (50). The reduction in pressure in the vent portion (50) causes a suction pressure within the vent portion (50) associated with the still (44), resulting in a portion of the liquid refrigerant vaporizing, leaving a higher viscosity lubricant.

Owner:CARRIER CORP

Fluid dispense tips

InactiveUS7207498B1Surface tensionCorrection capabilityLiquid surface applicatorsWatering devicesDecreased pressureBiomedical engineering

A fluid dispense tip includes a bevel at an opening to reduce the amount of surface tension, or “land”, at the opening. The bevel is formed by grinding in a longitudinal direction such that any tooling scars resulting from the grinding operation are likewise longitudinally oriented, further reducing the amount of surface tension in the tip, thereby leading to heightened dispensing accuracy. The tip may be machined from stock as a unitary piece, to increase its lifetime, and may be formed with a bore of a relatively large diameter that is tapered down to a smaller diameter near the tip opening, to allow for delivery of fluid through the tip body at a decreased pressure. A cleaning tool may be provided for removing residual material from the inner surfaces of the tip. A removable liner sleeve may be provided within the bore to reduce the effective inner diameter of the dispense tip.

Owner:DL TECH

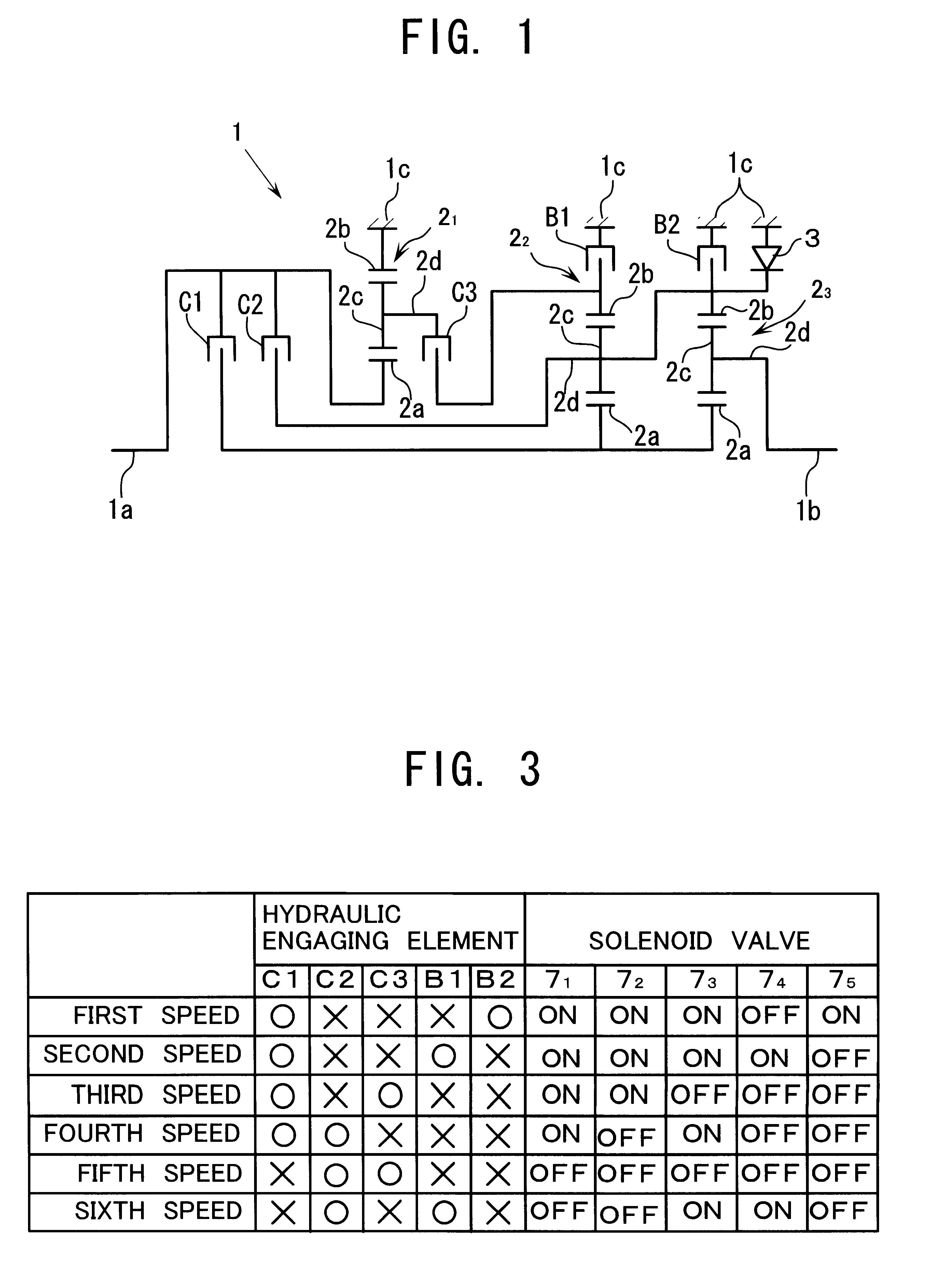

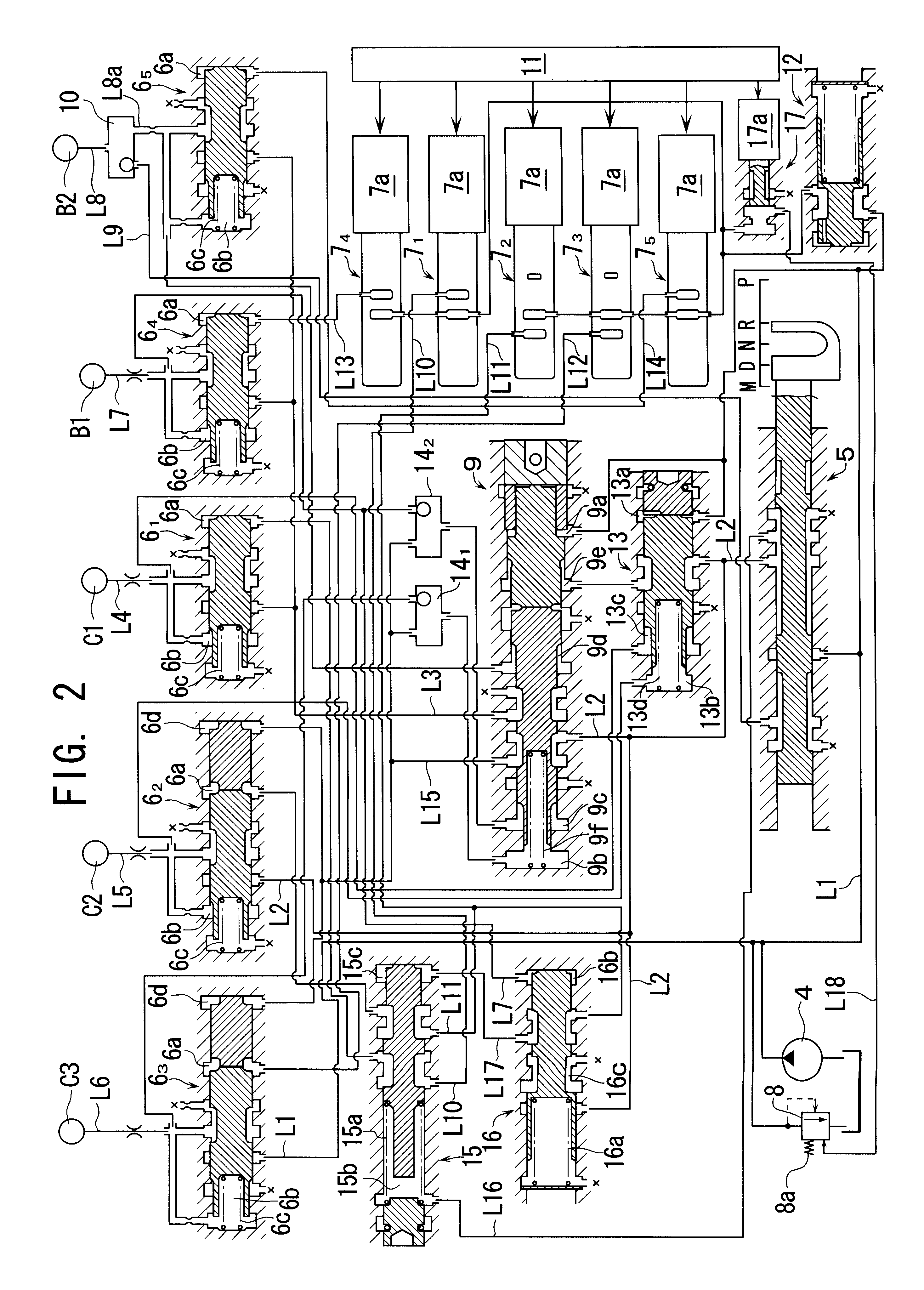

Control apparatus for automatic transmission of vehicle

InactiveUS6315692B1Improve toughnessHigh frequencyGearing controlFluid gearingsForeign matterAutomatic transmission

In a control apparatus for that automatic transmission of a vehicle which is provided with speed-change solenoid valves for regulating the hydraulic oil pressures in the hydraulic engaging elements through speed-change control valves corresponding to the hydraulic engaging elements, cleaning work to remove foreign matter in the solenoid valves is performed by varying the opening degree of the speed-change solenoid valves during running of the vehicle without affecting the hydraulic oil pressures in the hydraulic engaging elements. At the time of a line pressure control mode in which the line pressure is reduced below a maximum set pressure, the opening degree of the speed-change solenoid valve is varied within a range in which there is outputted a signal pressure higher than a minimum signal pressure required to fully open a speed-change control valve which corresponds to the hydraulic engaging element of the then-established speed transmission train.

Owner:HONDA MOTOR CO LTD

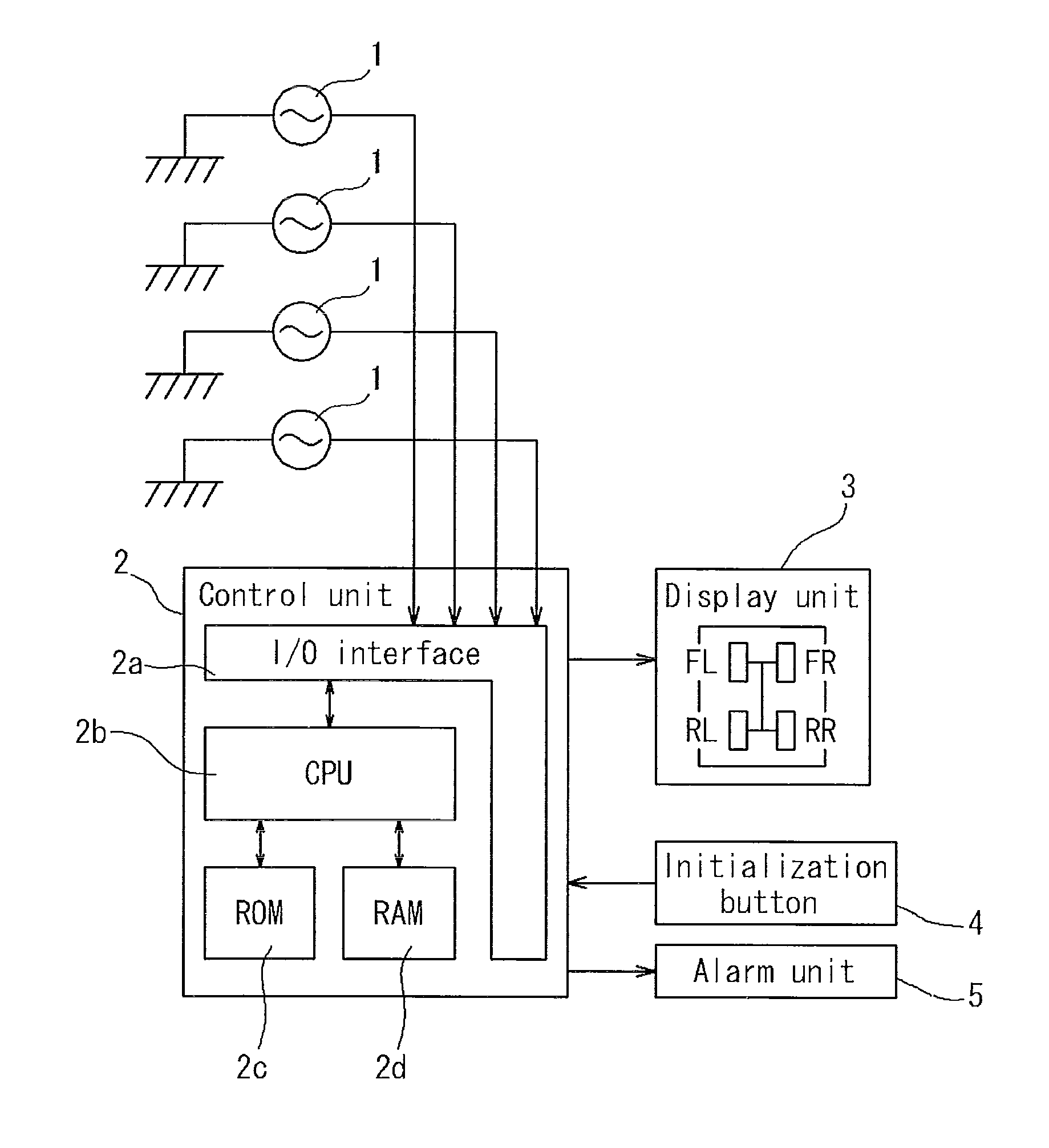

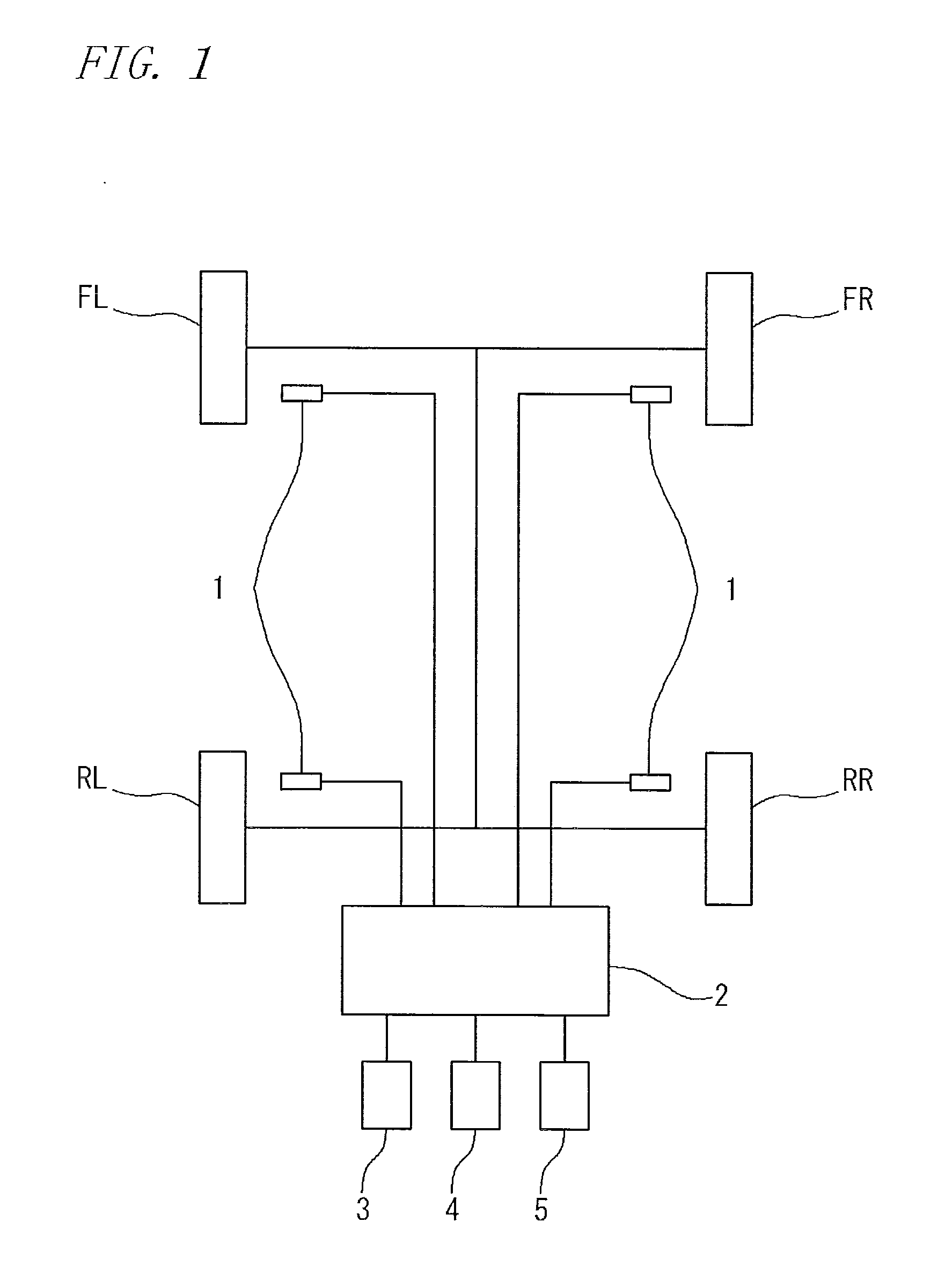

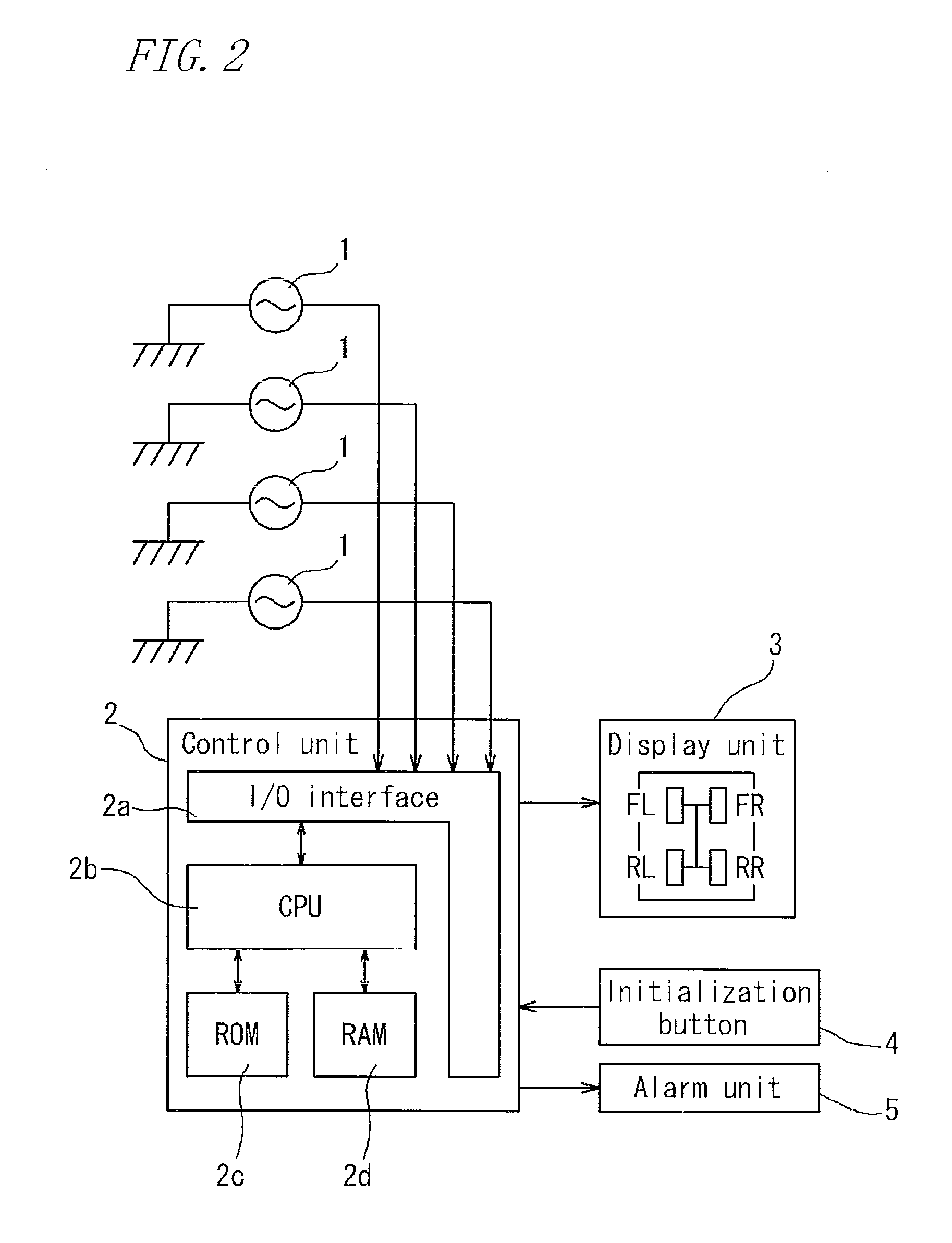

Apparatus, method, and program for detecting rotation speed information, and apparatus, method, and, program for detecting tire having decreased pressure

ActiveUS20100217542A1Accurate calculationReduce pressureInflated body pressure measurementDigital data processing detailsTime informationGear wheel

A rotation speed information detection apparatus, including: a wheel sensor for detecting passage of teeth of a gear provided in association with tires of a vehicle; a number-of-teeth calculation means for calculating the number of teeth of the gear passed per a sampling cycle set in advance; and a wheel speed calculation means for regularly calculating rotation speed information of the tire with using the number of teeth calculated. The number-of-teeth calculation means is configured to use a ratio between time information at the point and a remaining time until the time at which the next sampling cycle is started is reached to thereby calculate the number of remaining teeth to calculate the number of teeth passed during the sampling cycle. The wheel speed calculation means is configured to calculate tire rotation speed information based on an interval between neighboring teeth in the gear, the number of teeth passed during the sampling cycle, the number of remaining teeth calculated by the number-of-teeth-calculation means, and the sampling cycle.

Owner:SUMITOMO RUBBER IND LTD

Fluid dispense tips

InactiveUS7744022B1Surface tensionCorrection capabilityLiquid surface applicatorsSpray nozzlesDecreased pressureBiomedical engineering

Owner:DL TECH

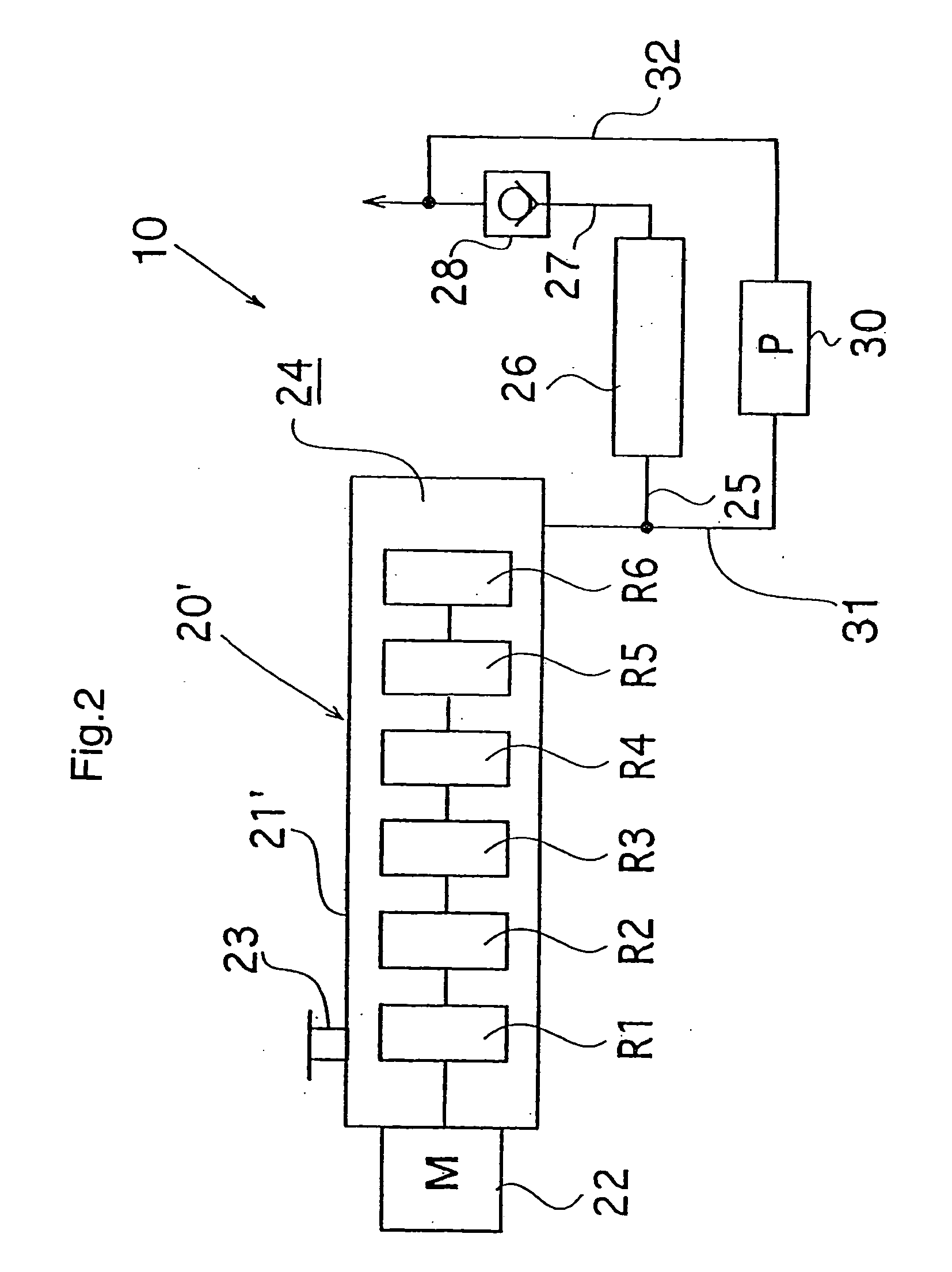

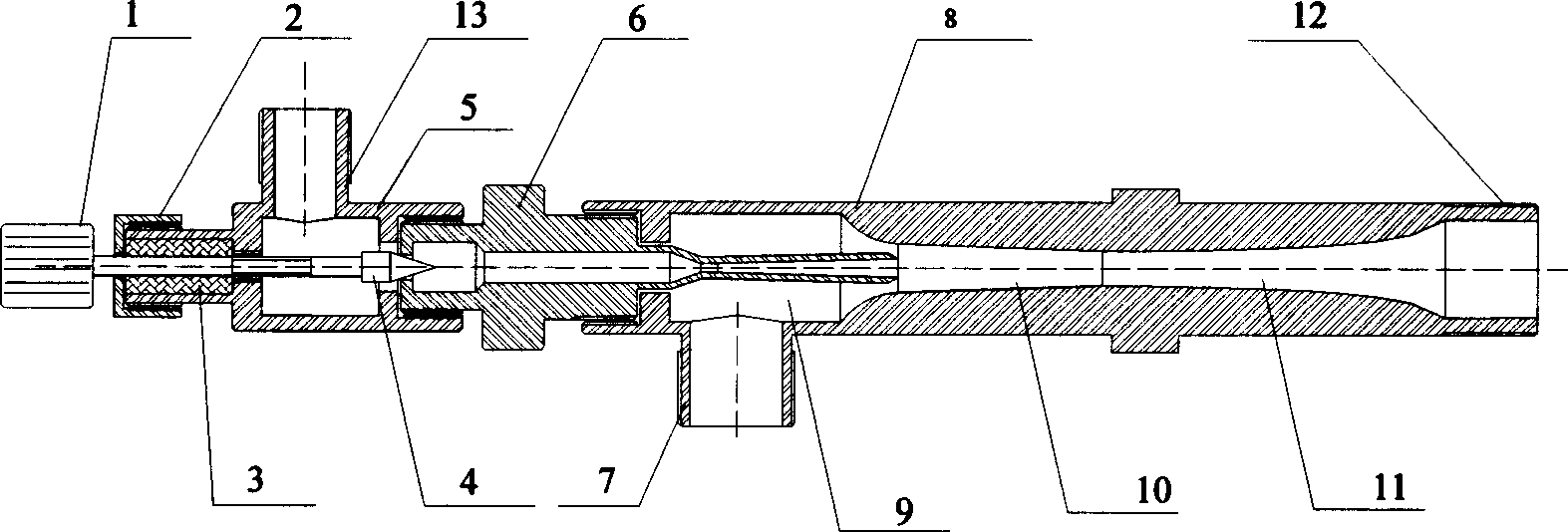

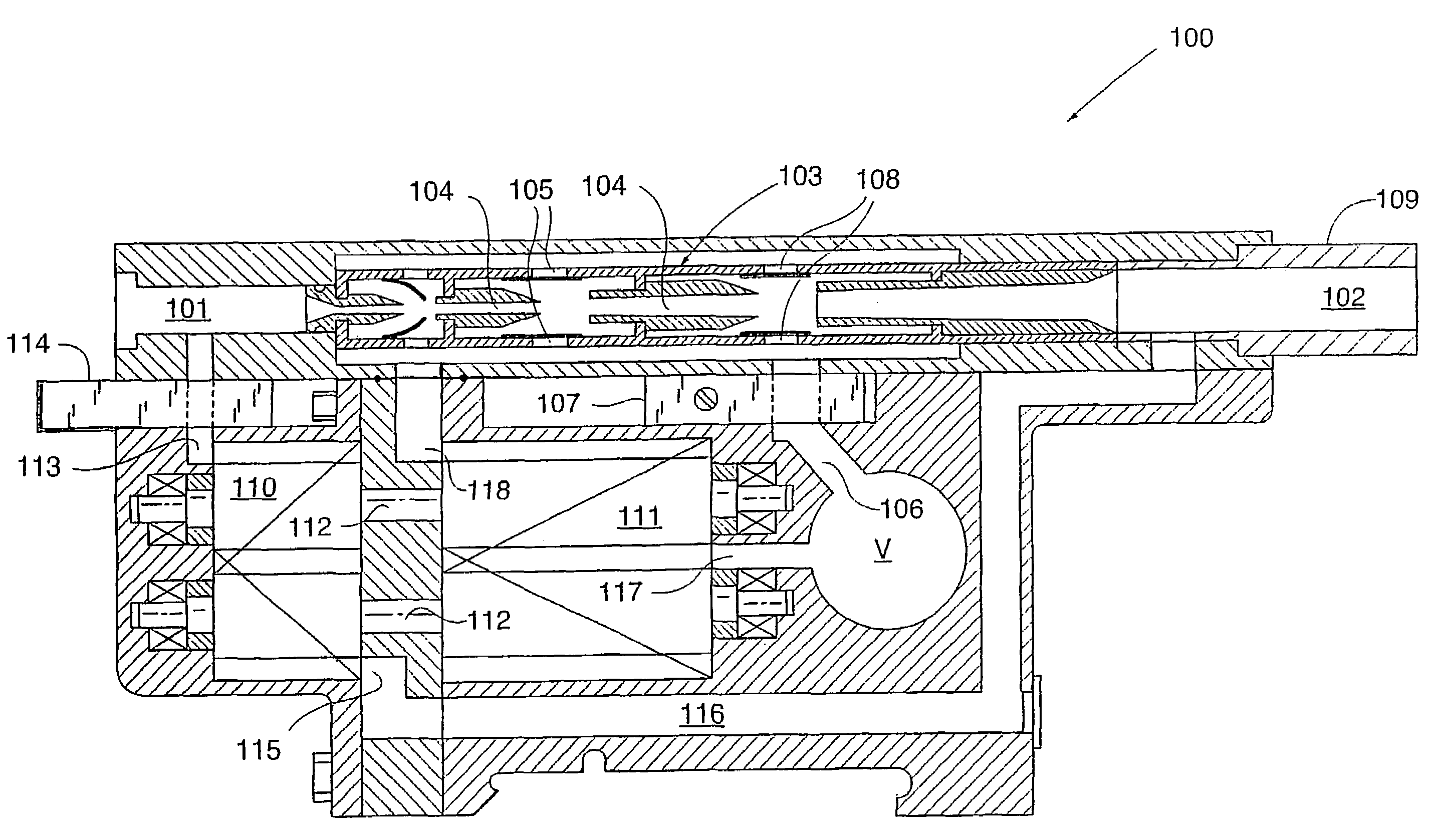

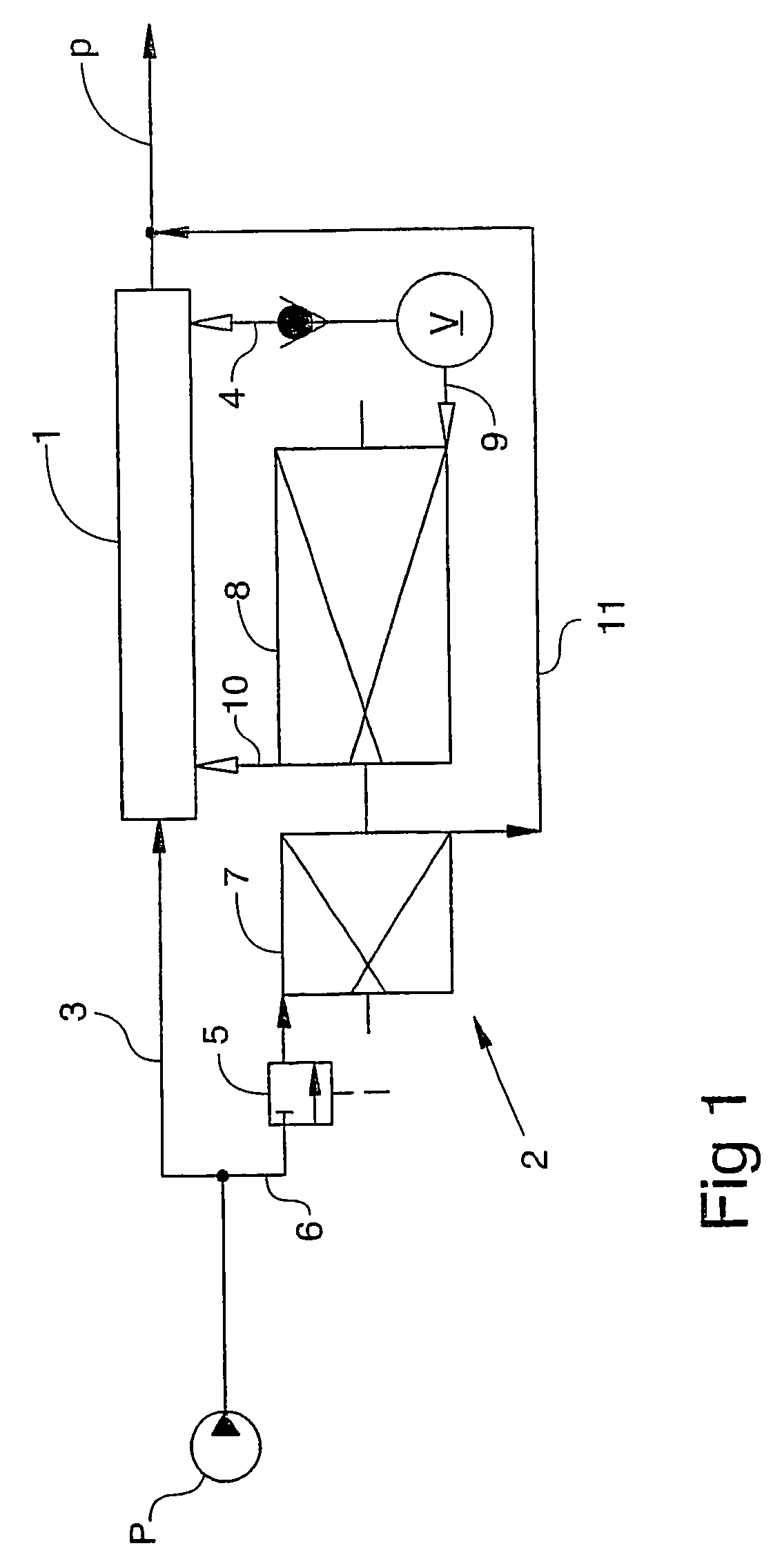

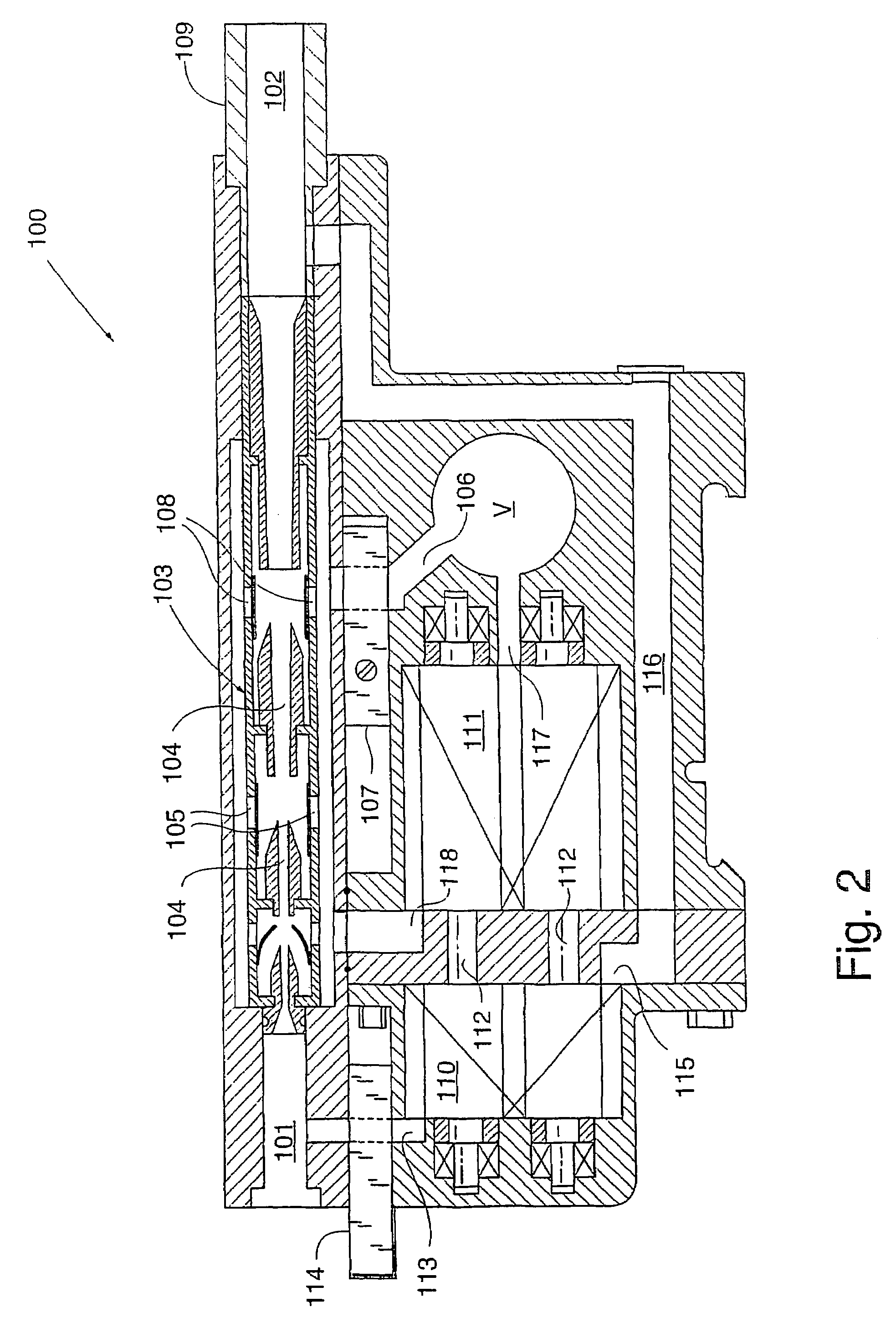

Vacuum pump and method for generating sub-pressure

InactiveUS7452191B2Rotary/oscillating piston combinations for elastic fluidsJet pumpsDecreased pressureVacuum pump

According to the invention, a vacuum pump is disclosed comprising a screw-rotor pump having a compression section (8) and an expansion section (7), and wherein a discharge (10) from the compression section communicates with at least one ejector (1) for discharge of compressed gas through the ejector, and wherein the expansion section (7) is connectable via a first valve means (5), to a drive-gas source (P) for operating the screw,-rotor pump and the ejector in parallel. Also, a method for providing sub-pressure to an industrial process is disclosed wherein at least one ejector (1) is used initially to reduce the pressure to a predetermined lower level, from where the pressure is further reduced by means of a screw-rotor pump (7, 8) that is arranged to operate through, and in parallel with the ejector.

Owner:PIAB

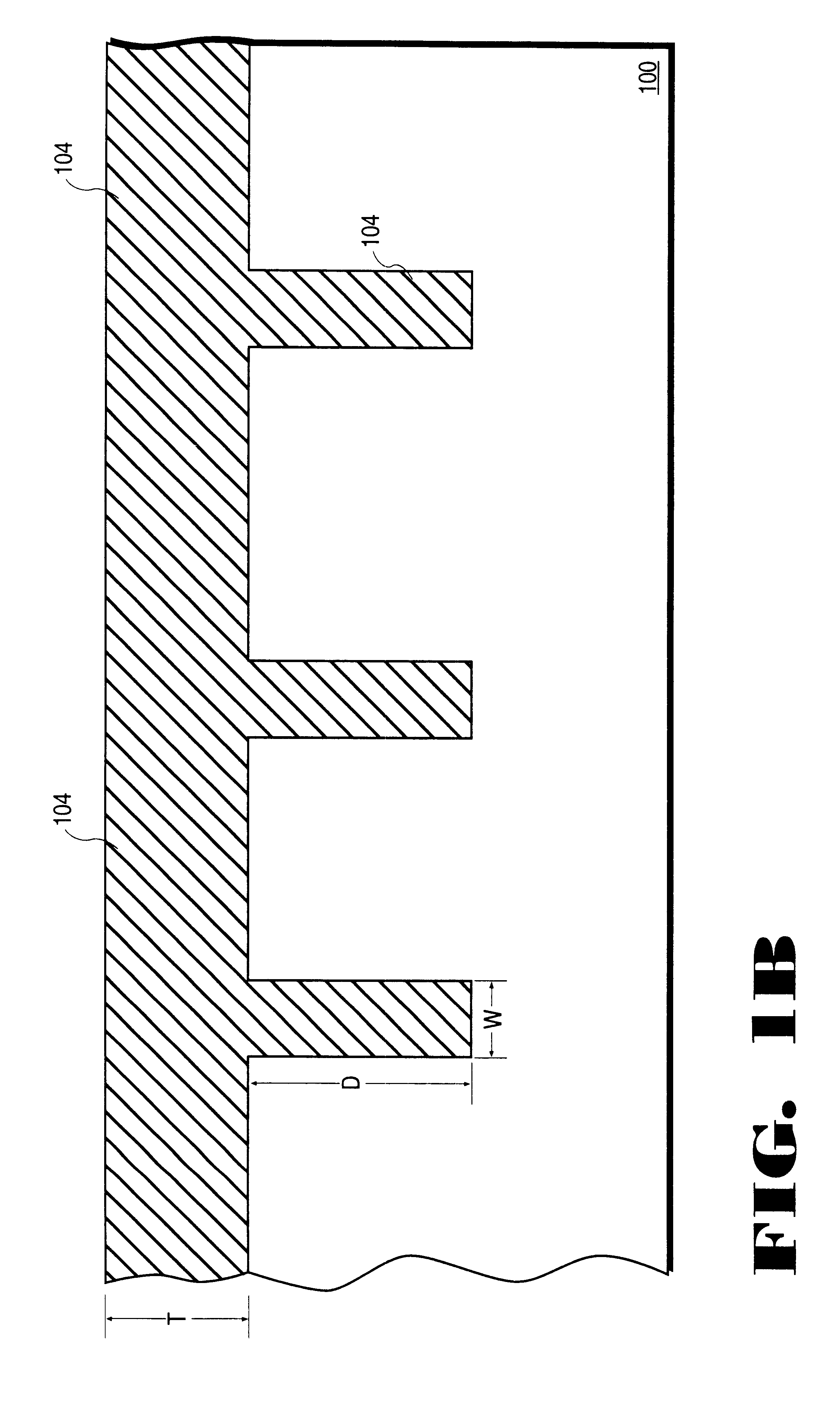

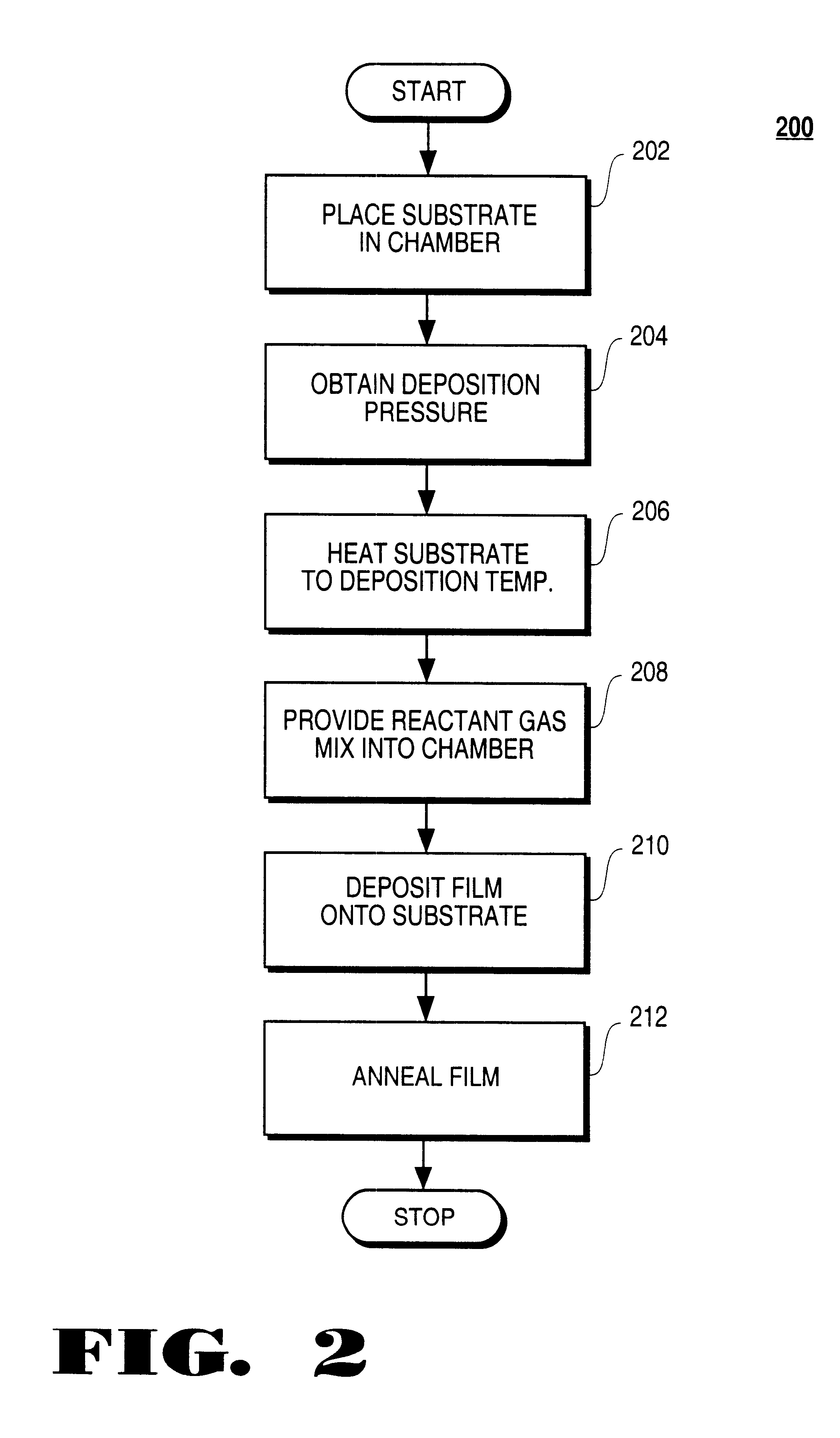

Method and apparatus for forming insitu boron doped polycrystalline and amorphous silicon films

InactiveUS6410090B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDeposition temperatureDecreased pressure

A method and apparatus for depositing a boron insitu doped amorphous or polycrystalline silicon film on a substrate. According to the present invention, a substrate is placed into deposition chamber. A reactant gas mix comprising a silicon source gas, boron source gas, and a carrier gas is fed into the deposition chamber. The carrier gas is fed into the deposition chamber at a rate so that the residence of the carrier gas in the deposition chamber is less then or equal to 3 seconds or alternatively has a velocity of at least 4 inches / sec. In another embodiment of forming a boron doped amorphous for polycrystalline silicon film a substrate is placed into a deposition chamber. The substrate is heated to a deposition temperature between 580-750° C. and the chamber pressure reduced to a deposition pressure of less than or equal to 50 torr. A silicon source gas is fed into the deposition at a rate to provide a silicon source gas partial pressure of between 1-5 torr. Additionally, a boron source gas is fed into the deposition chamber at a rate to provide a boron gas partial pressure of between 0.005-0.05 torr.

Owner:APPLIED MATERIALS INC

High-speed defrost refrigeration system

InactiveUS20040003601A1Increase speedReduce stressCompression machines with several evaporatorsCorrosion preventionLiquid stateDecreased pressure

A defrost refrigeration system having a main refrigeration system and comprising a first line extending from a compressing stage to an evaporator stage and adapted to receive refrigerant in high-pressure gas state from the compressing stage. A first pressure reducing device on the first line is provided for reducing a pressure of the refrigerant in the high-pressure gas state to a second low-pressure gas state. Valves are provided for stopping a flow of the refrigerant in a first low-pressure liquid state from a condensing stage to evaporators of the evaporator stage and directing a flow of the refrigerant in the second low-pressure gas state to release heat to defrost the evaporators and thereby changing phase at least partially to a second low-pressure liquid state. A second line is provided for directing the refrigerant having released heat to the compressing stage, the condensing stage or the evaporator stage.

Owner:DUBE SERGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com